Patents

Literature

1132results about How to "Easy to drill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

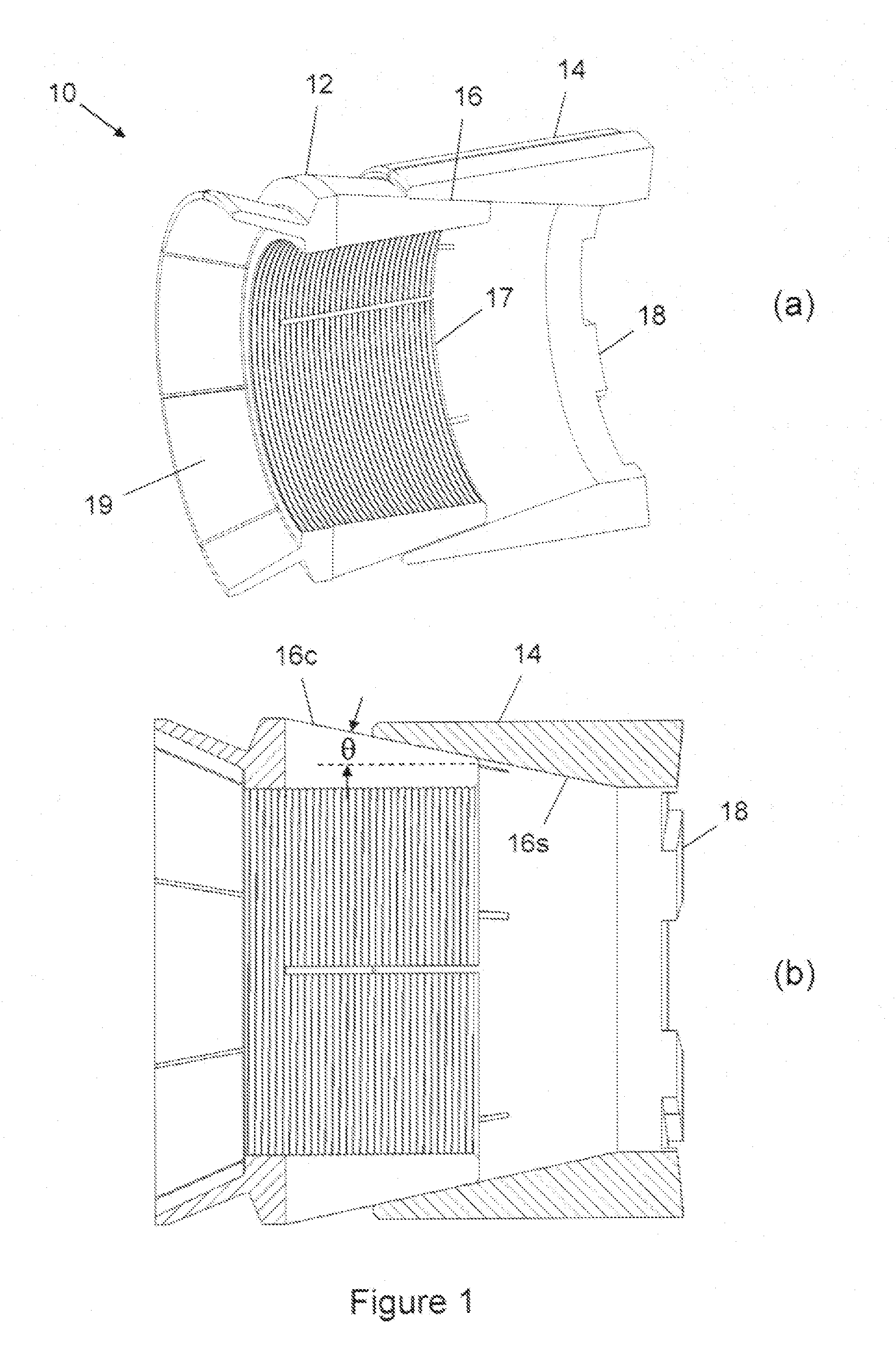

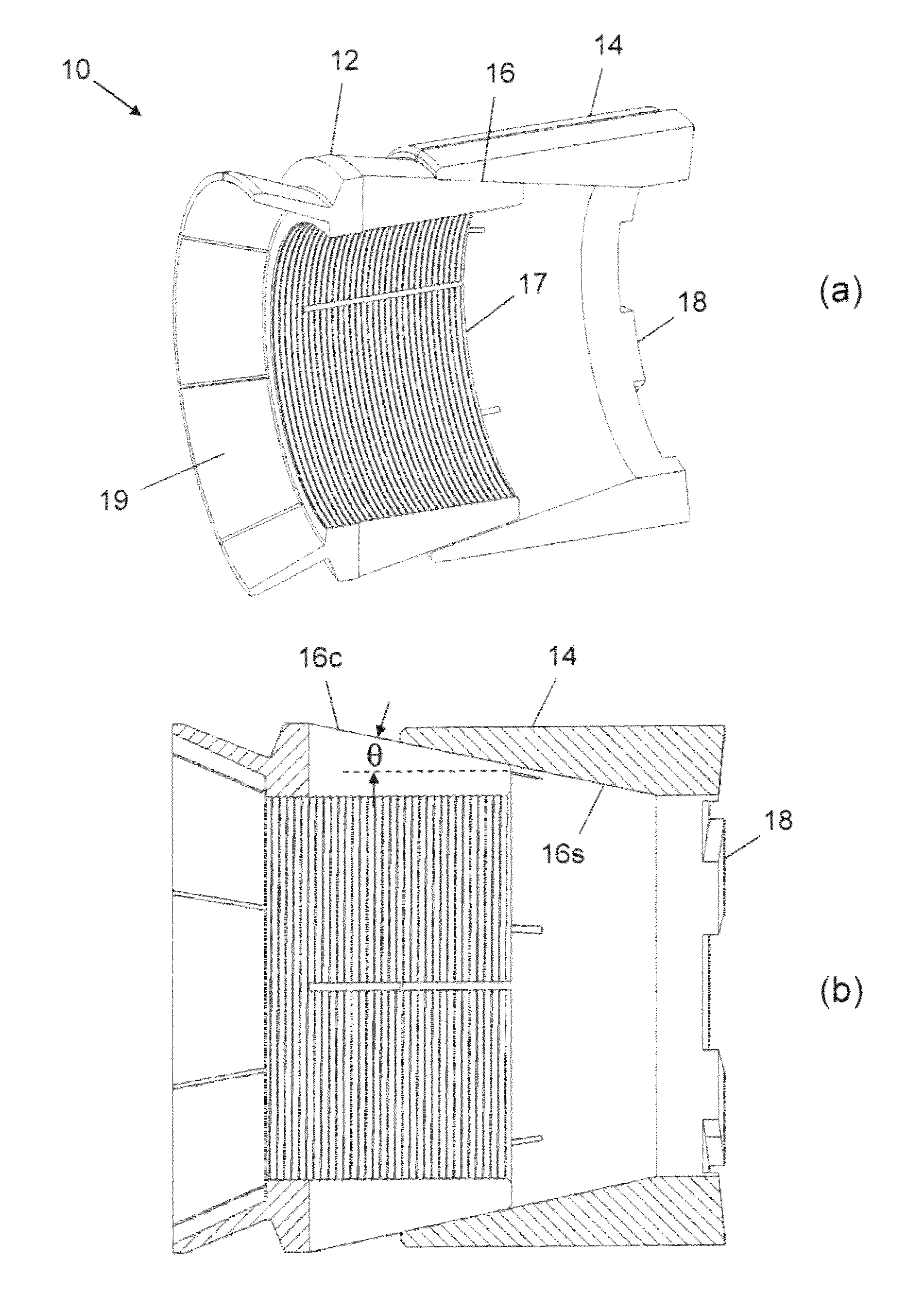

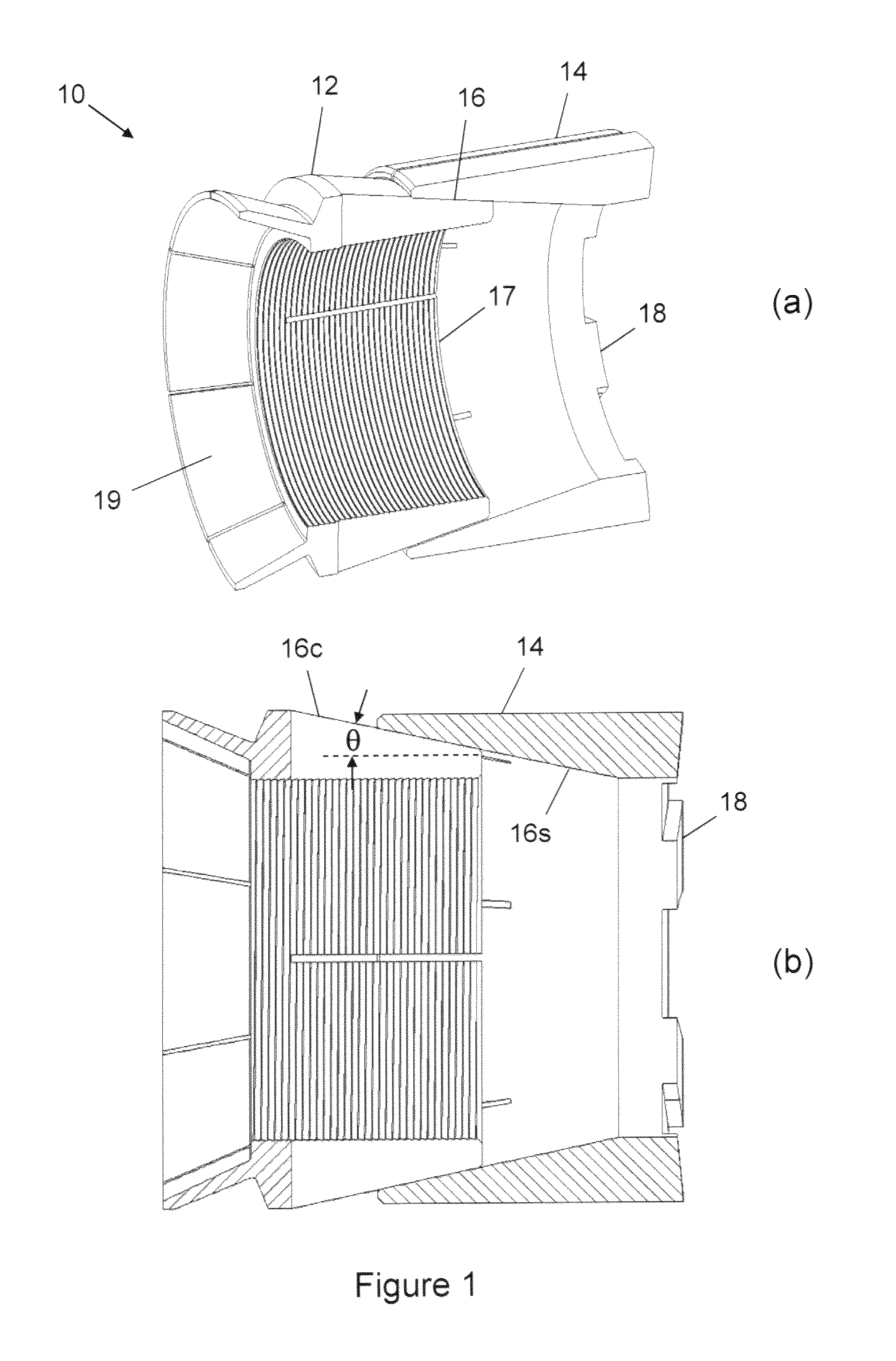

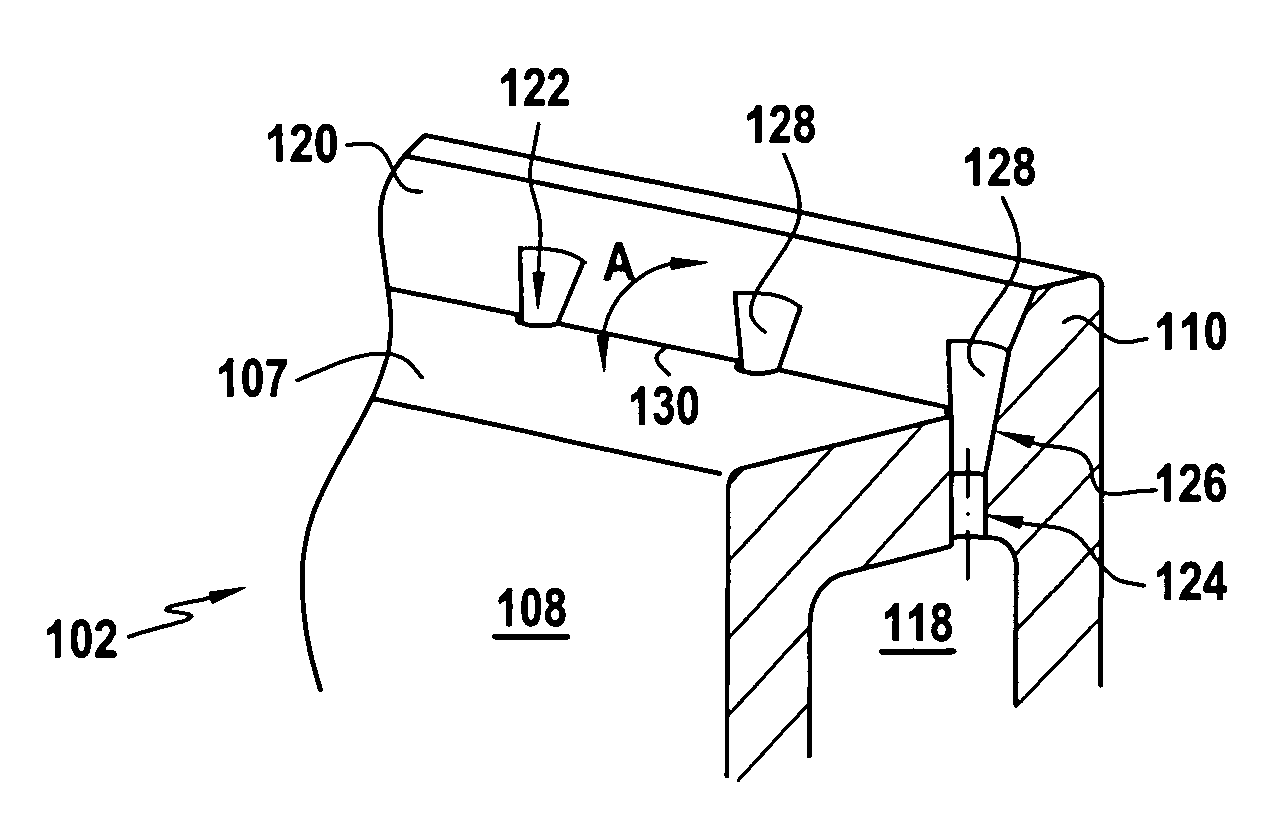

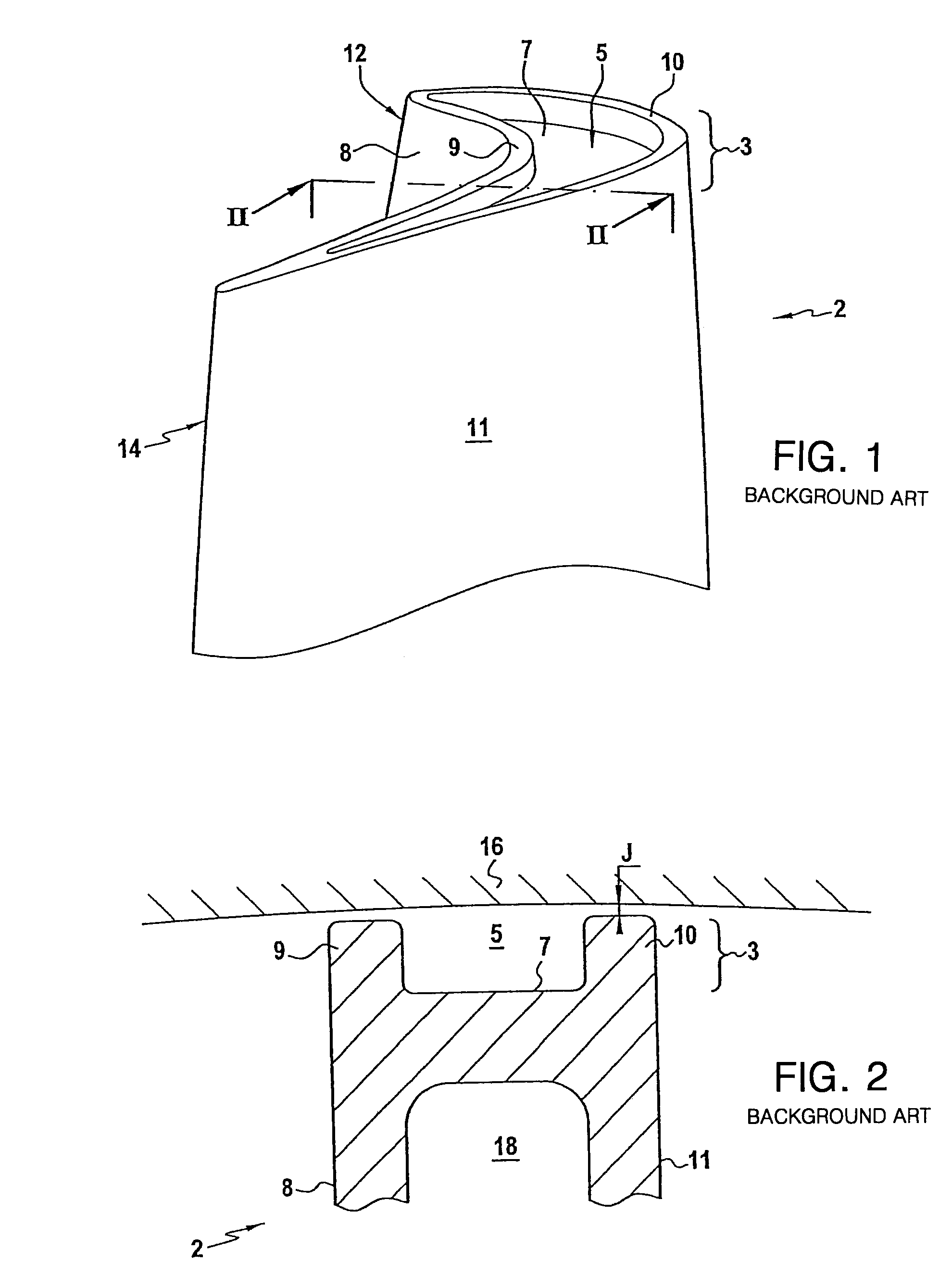

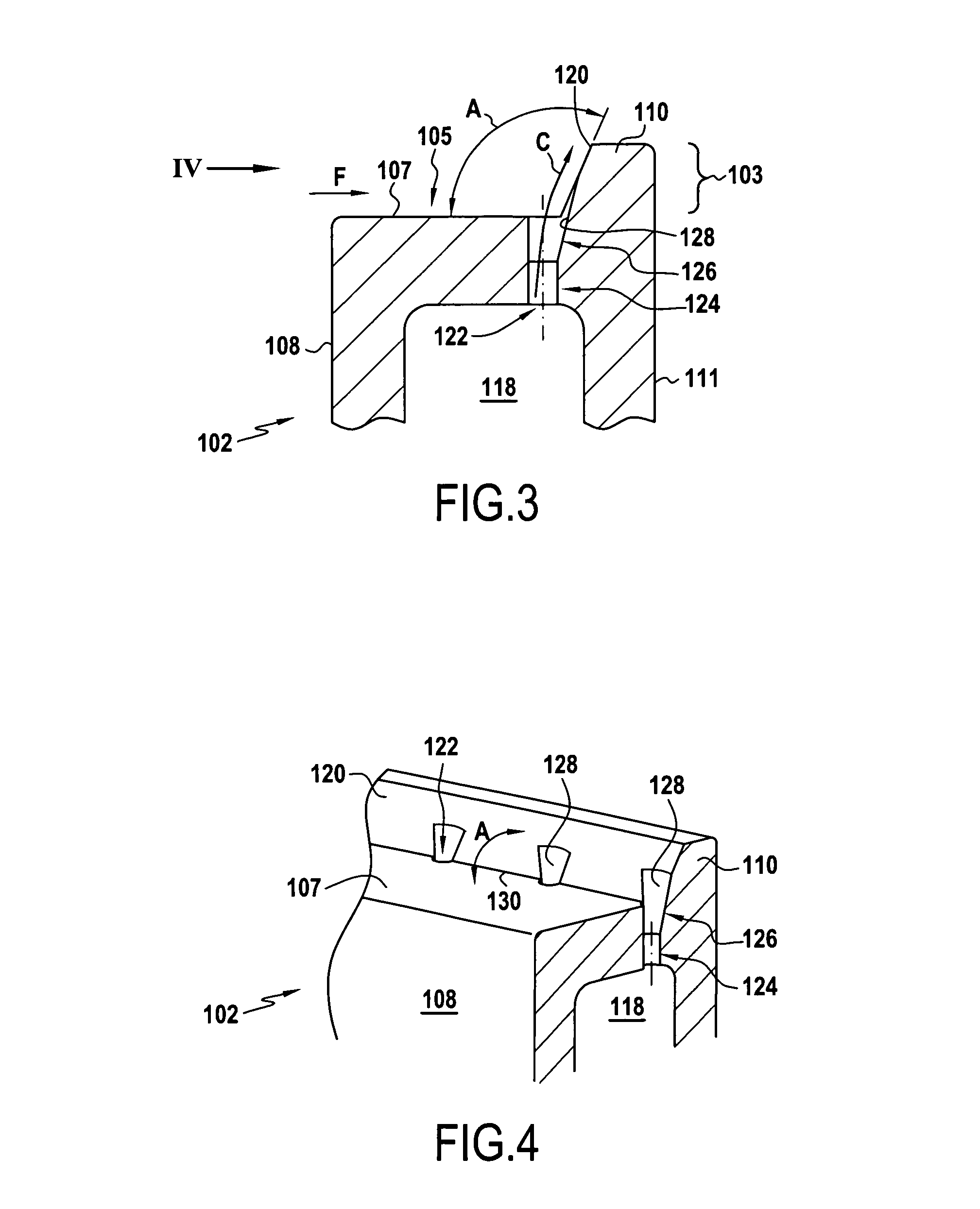

Non-Damaging Slips and Drillable Bridge Plug

ActiveUS20100276159A1Easily drillablePrevent from rotateFluid removalSealing/packingSmooth surfaceDuctile materials

A non-damaging slip assembly includes slips having grit on a smooth surface, the slips preferably made from a ductile material, such that the slips do not cause damage to the wall of a tubular when the slips are set. The slips fail under tensile force during setting. The cone used to expand the slips may have slits that narrow during setting of the slips. The slip assembly may be used to anchor a variety or devices inside a tubular. A drillable, non-damaging bridge plug using the non-damaging slip assembly has a threaded mandrel holding the cone by threads inside the cone. When the slips are set, the slits in the cone narrow such that threads in the cone do not allow rotation of the slips as they are drilled. The bridge plug can be drilled by a PDC bit without damaging the tubular.

Owner:INNOVEX DOWNHOLE SOLUTIONS INC

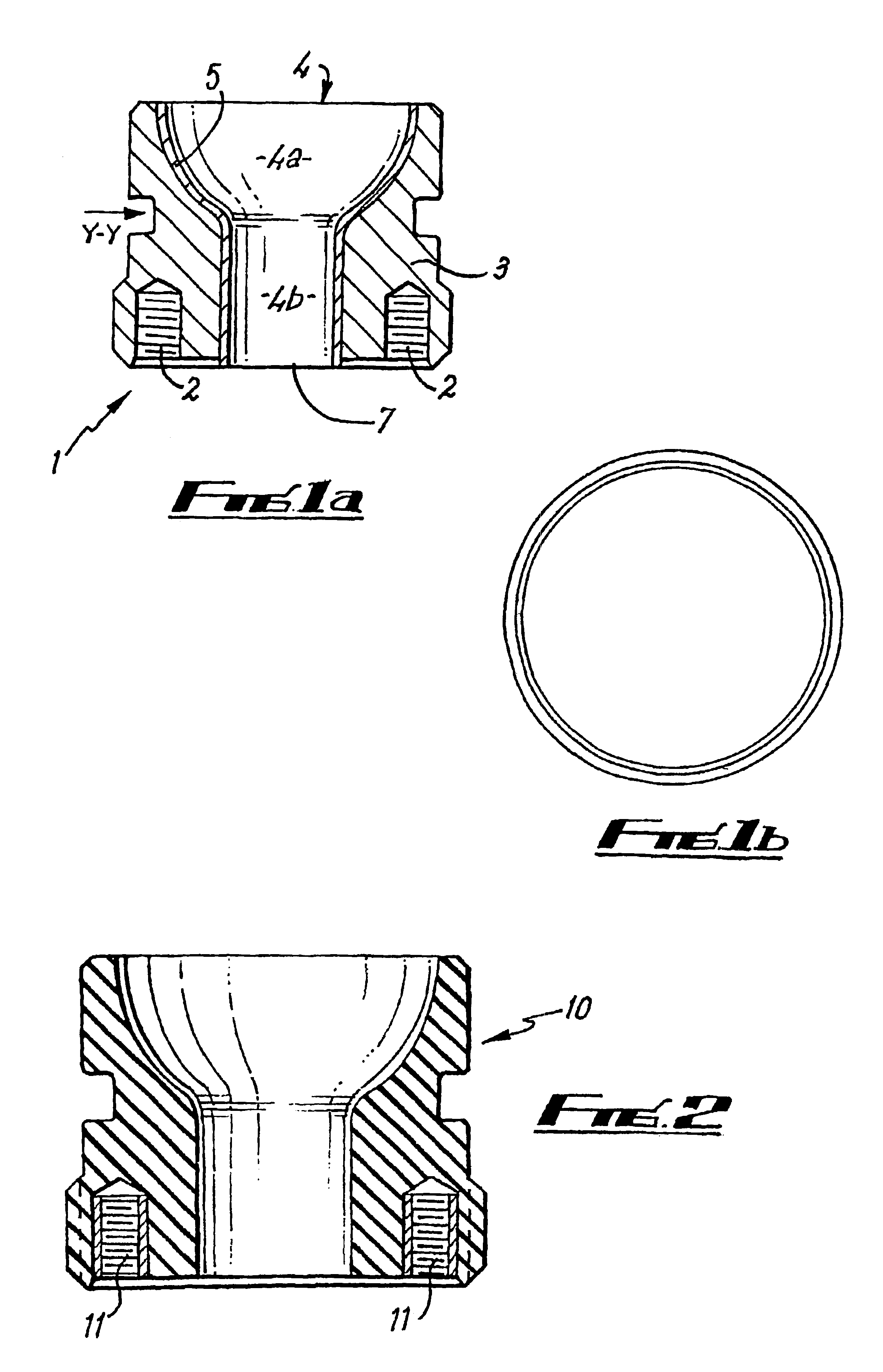

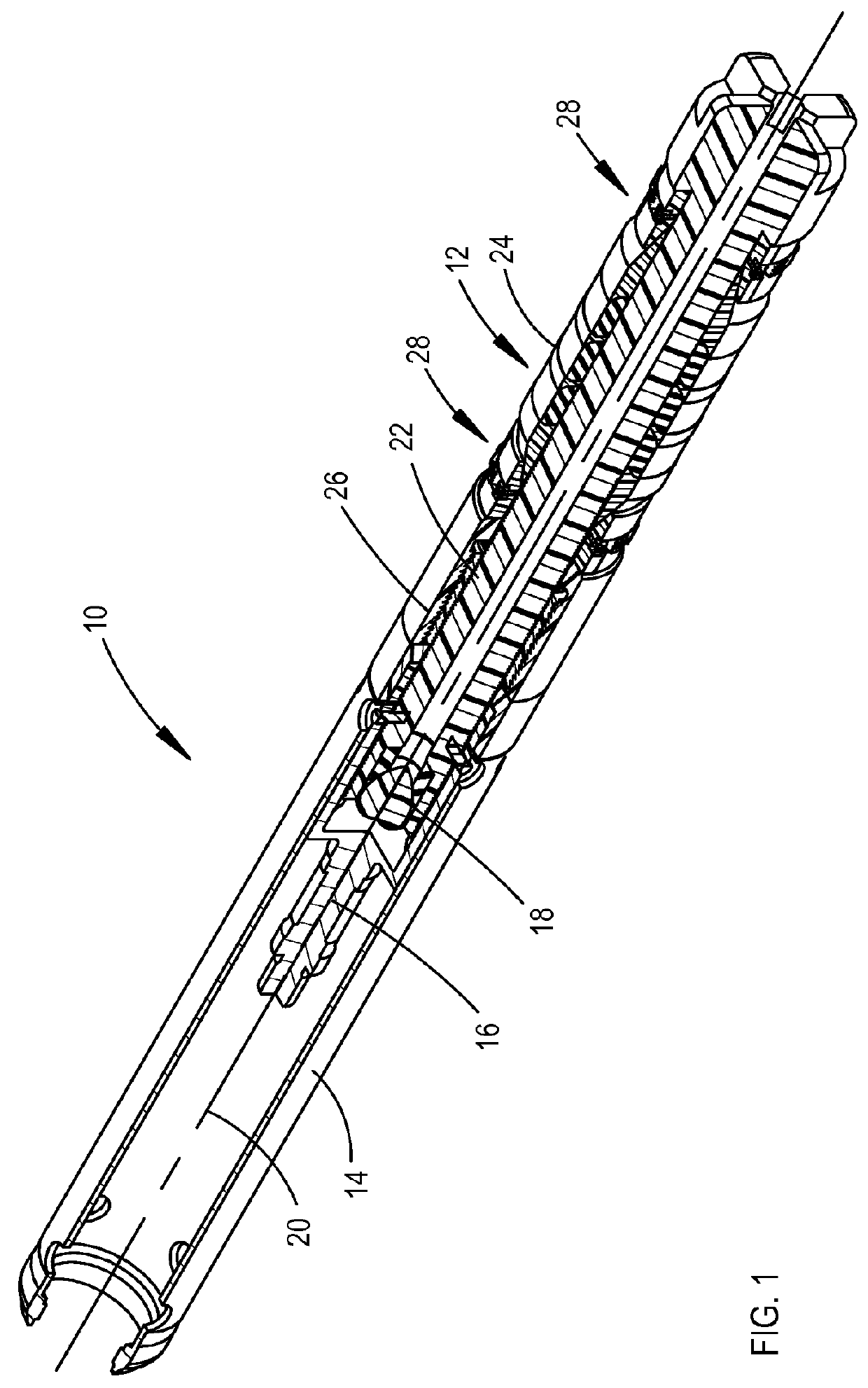

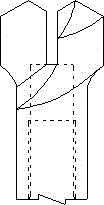

Drillable drill bit nozzle

InactiveUS6848517B2Thin structureImprove corrosion resistanceDrill bitsDrilling rodsHigh resistanceRubber material

A drill bit nozzle providing a through bore for the passage of drilling fluid through a drill bit. The nozzle is made of a material or materials which can be drilled through by standard well bore drilling equipment. The material(s) are selected to provide a surface to the through bore which has a relatively high resistance to erosion to withstand the abrasive and corrosive impact of jetted drilling fluid. Embodiments are described using a hard chrome / copper combination and a single rubber material.

Owner:WEATHERFORD TECH HLDG LLC

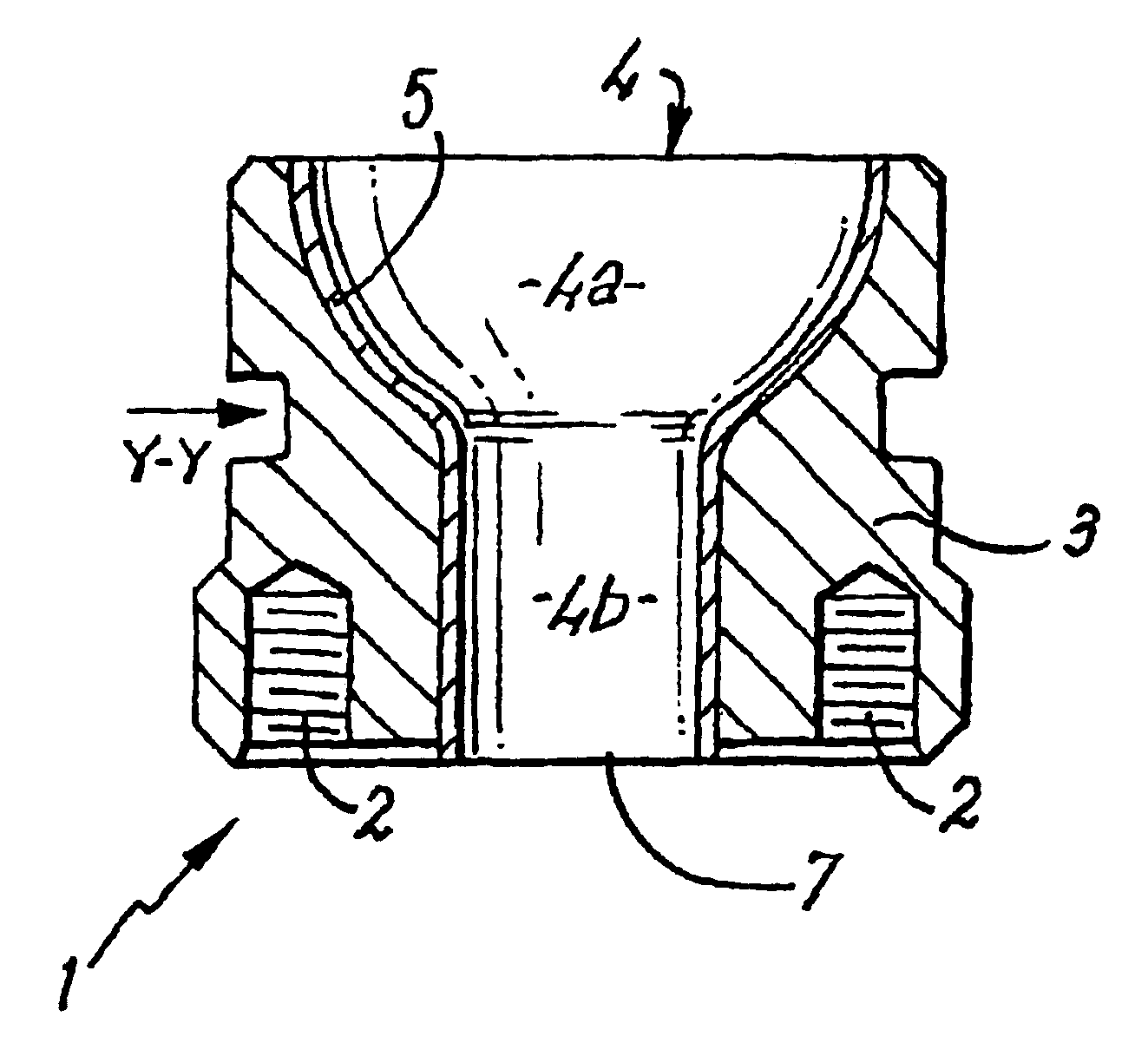

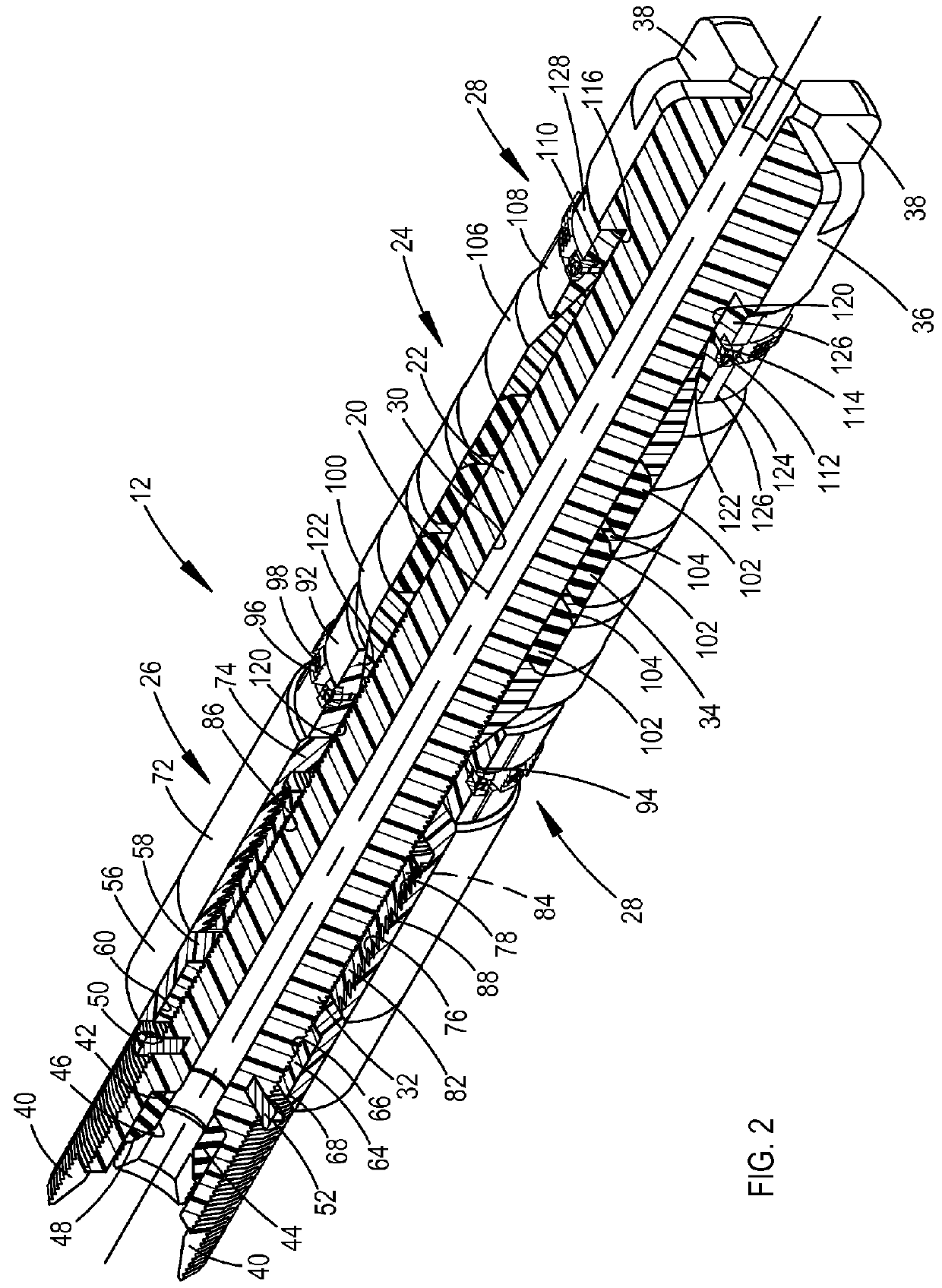

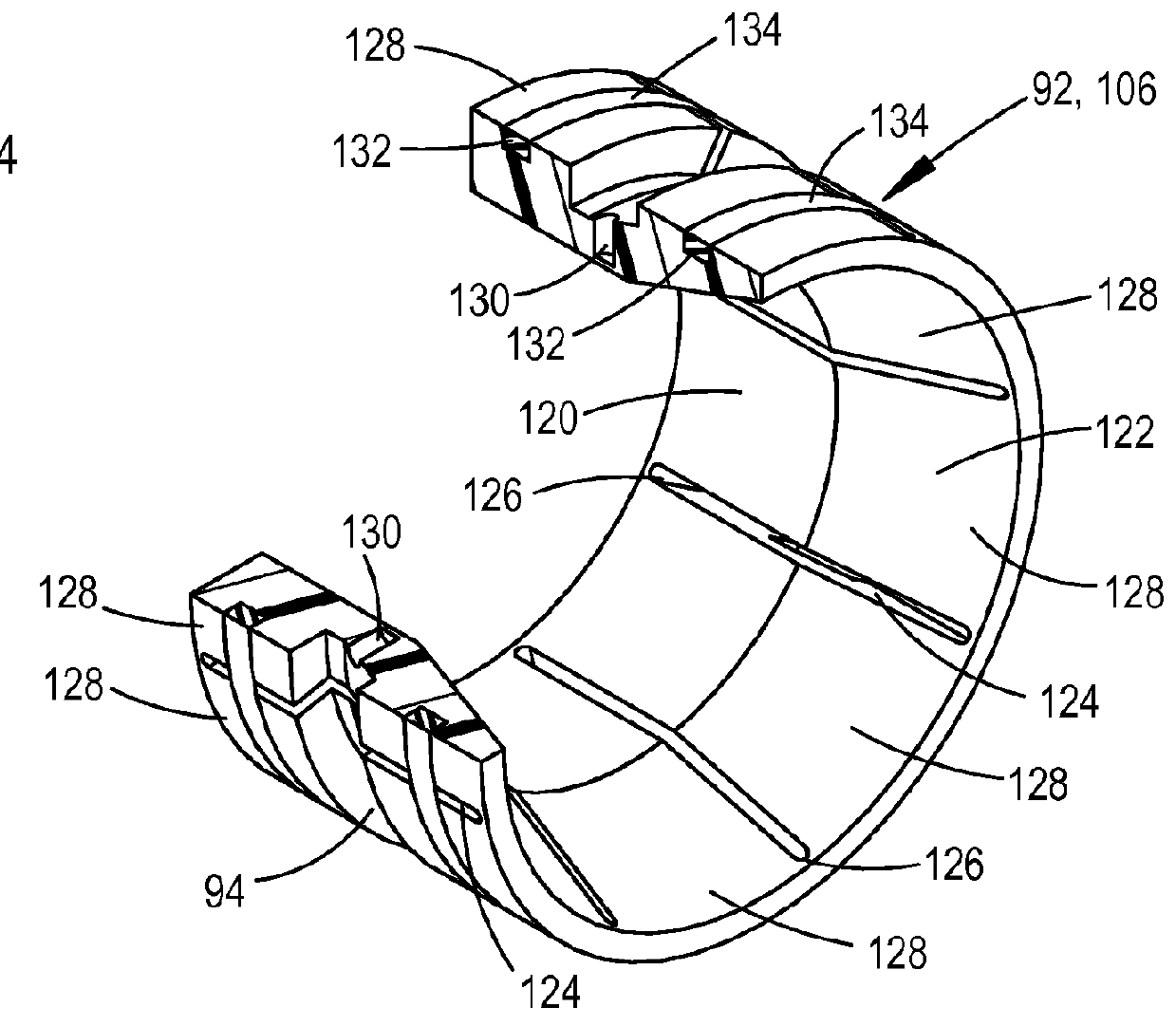

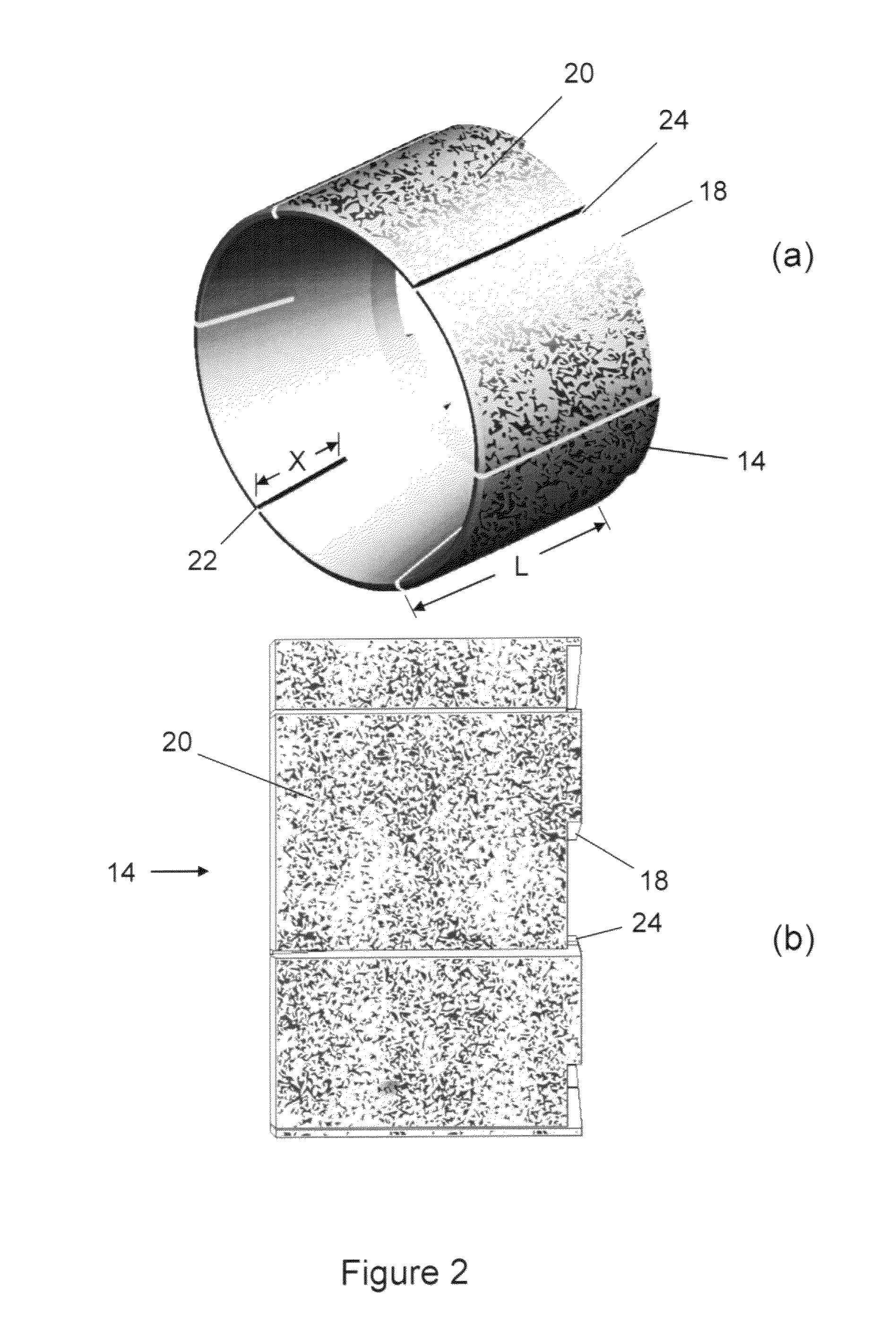

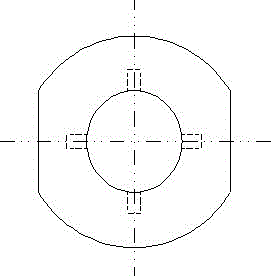

Composite frac plug

InactiveUS8887818B1Easy to drillPrevent movementFluid removalSealing/packingEngineeringComposite polymer

A composite frac plug (12) is formed of composite polymer materials, except for shear pins (52) and anchor cleats (96, 112) which are formed of metal. The composite materials provide for easy drilling of the frac plug (12) at the end of 5 fracturing operations. The frac plug (12) has an elastomeric ball seat (44) which sealing engages with a frac ball (18). A ratchet lock assembly (26) has a split ratchet ring (82) which moves over the mandrel (22) in a downward direction only, and prevents movement of the mandrel (22) downward within the ratchet ring (92). An anchor assembly (28) has slip bodies (92, 108) which are segmented and separately urge anchor cleats (96, 112) into 10 the interior surface of a well casing (136).

Owner:OSO PERFORATING LLC

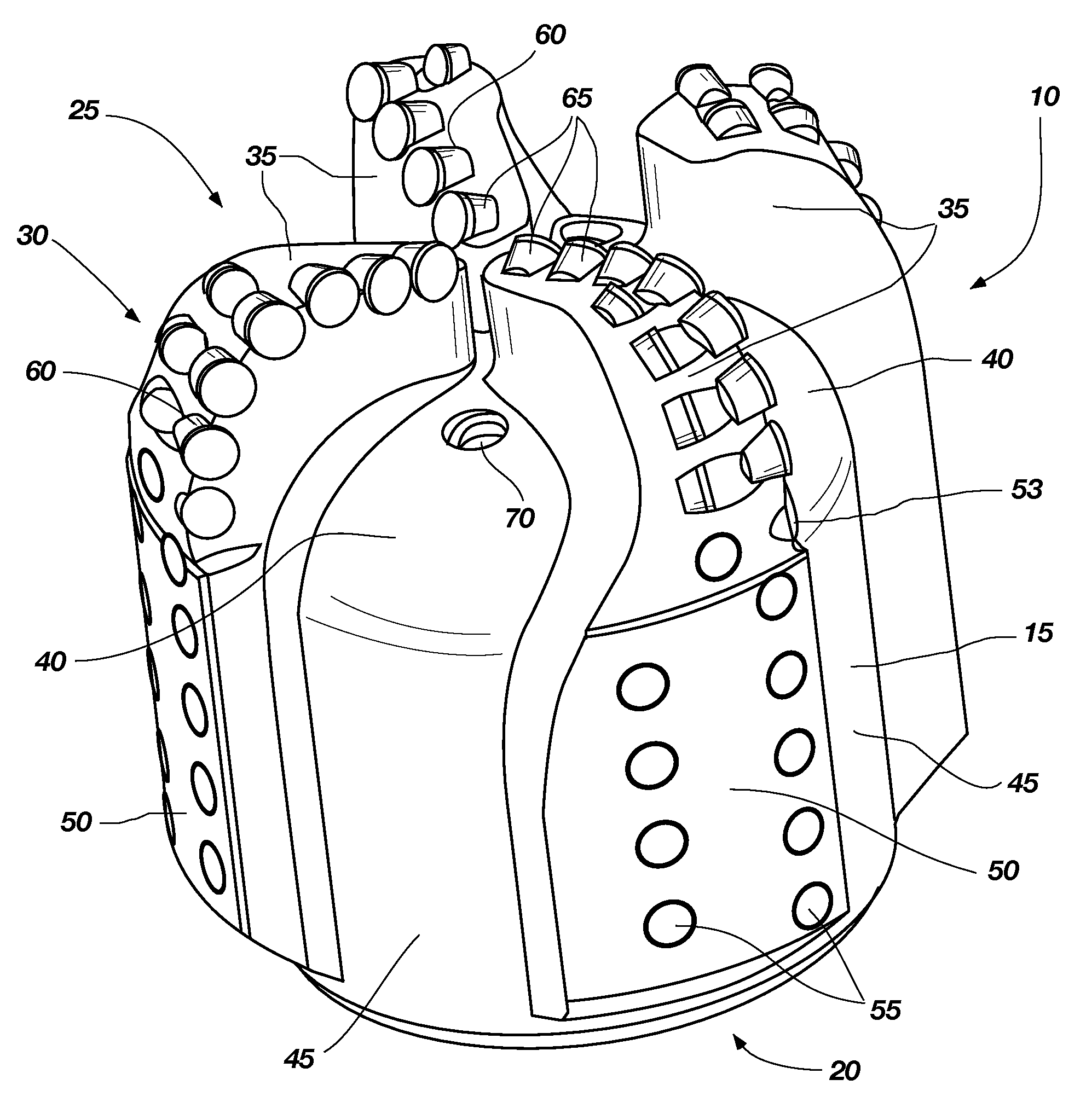

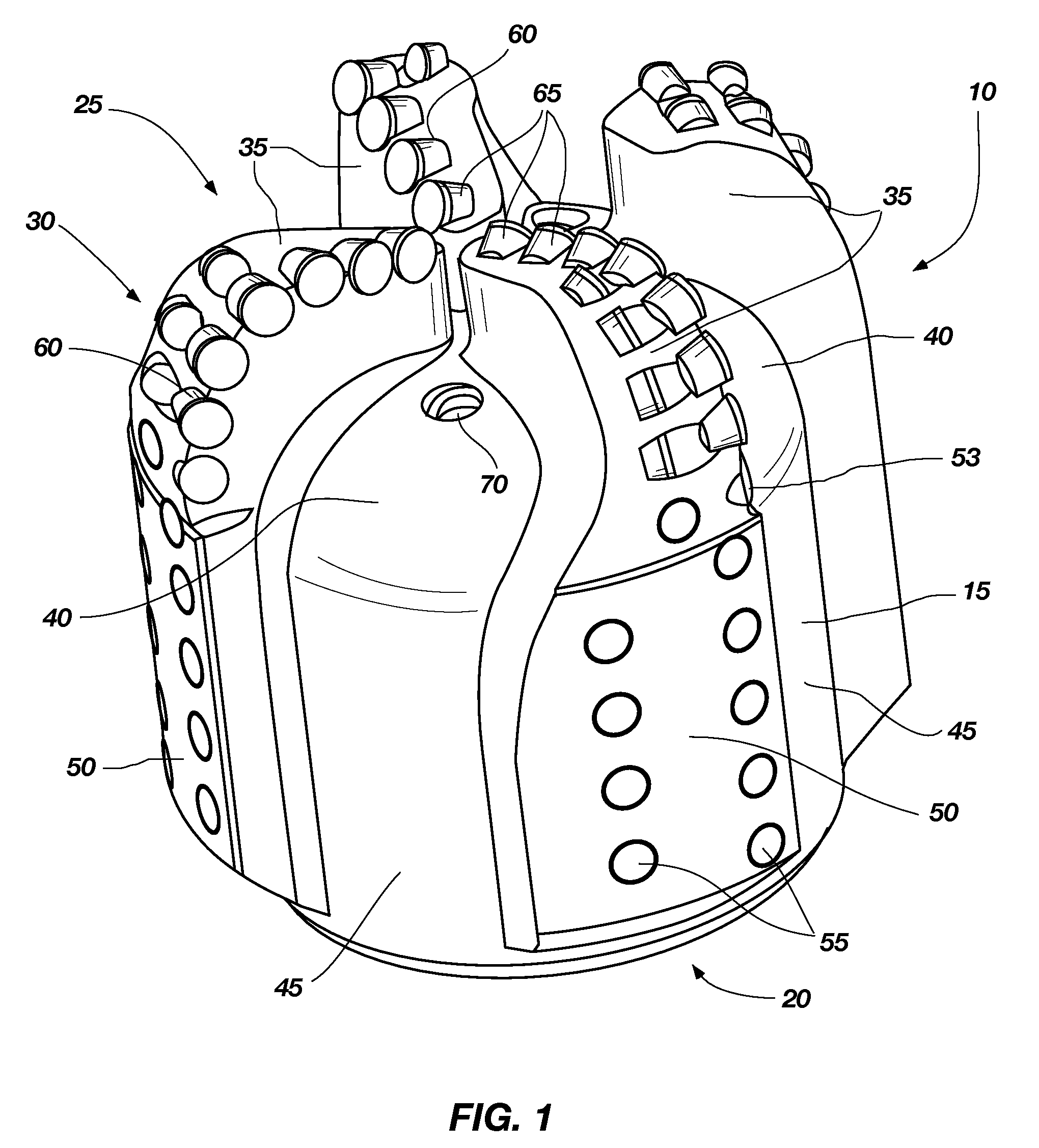

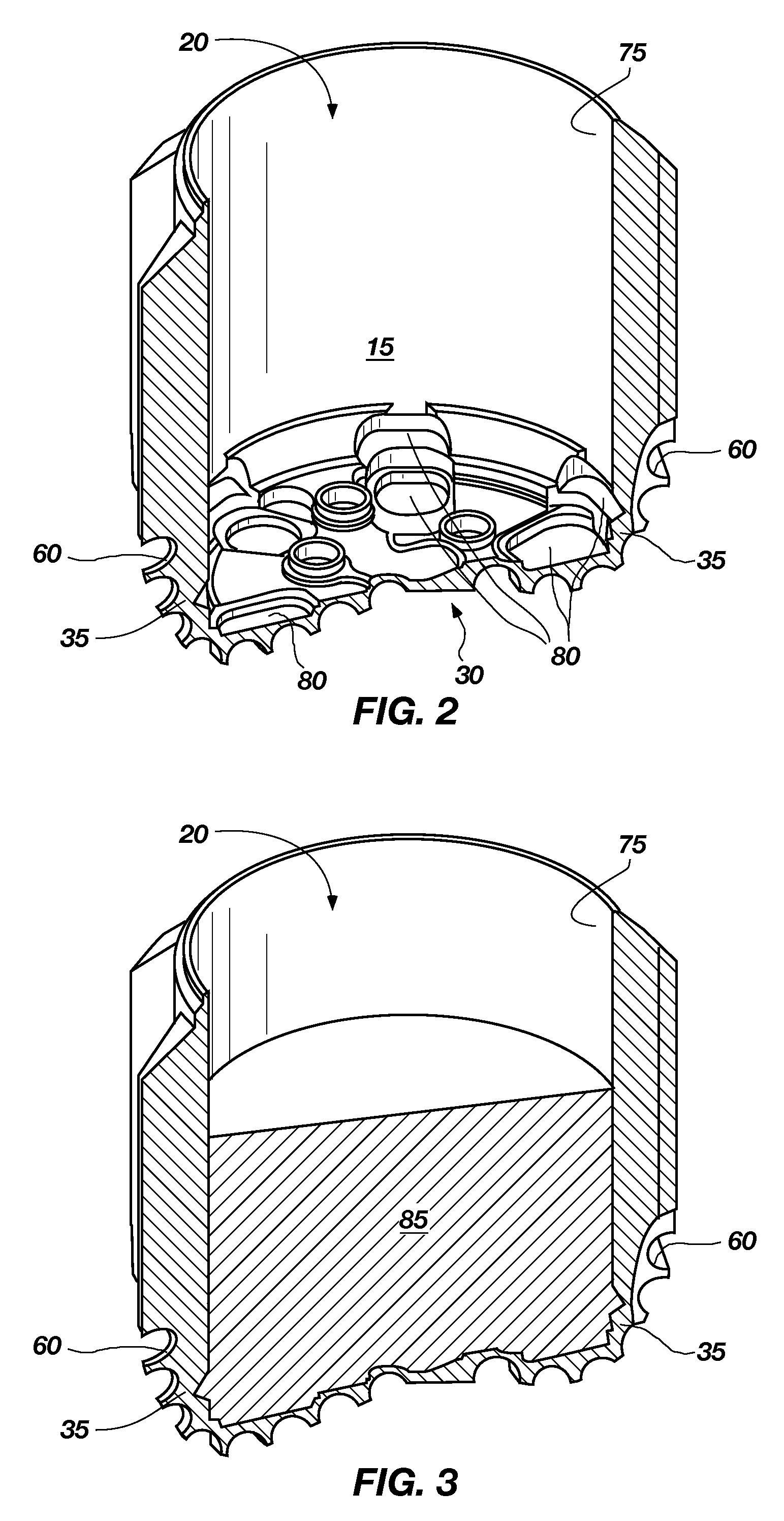

Earth-boring tools attachable to a casing string and methods for their manufacture

Casing bits include a crown having a substantially hollow interior. The bit crown has blades over a face portion thereof, the blades including a plurality of cutting elements attached thereto. The bit crown further includes a composite inlay positioned at least within the substantially hollow interior. Casing bits also include case hardened outer surfaces radially outside the drill-out region. Casing bits further include short-substrate cutting elements. Methods of forming a casing bit are also disclosed.

Owner:BAKER HUGHES INC

Method for decreasing lost circulation during well operation

ActiveUS6976537B1Reduce circulation lossIncrease in sizeLiquid/gas jet drillingFluid removalLost circulationPolymer

A method is provided for reducing lost circulation when aqueous, oil, or synthetic based drilling fluid is used. The method includes injecting two fluids into the well bore and lost circulation zone. The first fluid is an aqueous liquid containing at least one polymer capable of absorbing water in an alkaline environment. The aqueous liquid has a pH that inhibits at least one polymer from absorbing water. The second fluid contains a hardening composition in a base fluid having a pH sufficient to increase the pH in situ to allow at least one polymer to absorb water and expand with the absorbed water and substantially increase in size to close off the lost circulation zone and allow the hardening composition to create a plug in the well bore and set up.

Owner:TURBO CHEM INT

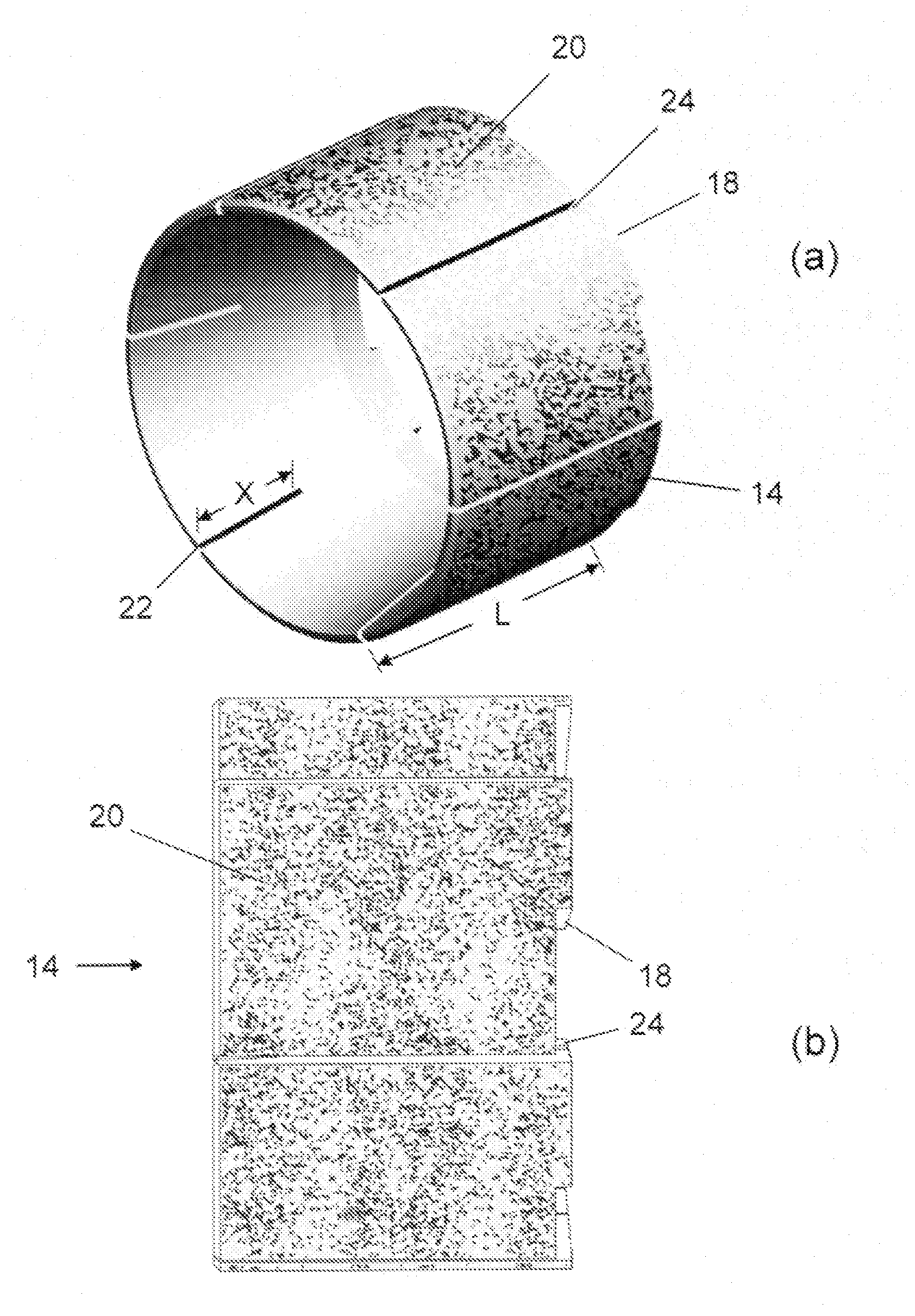

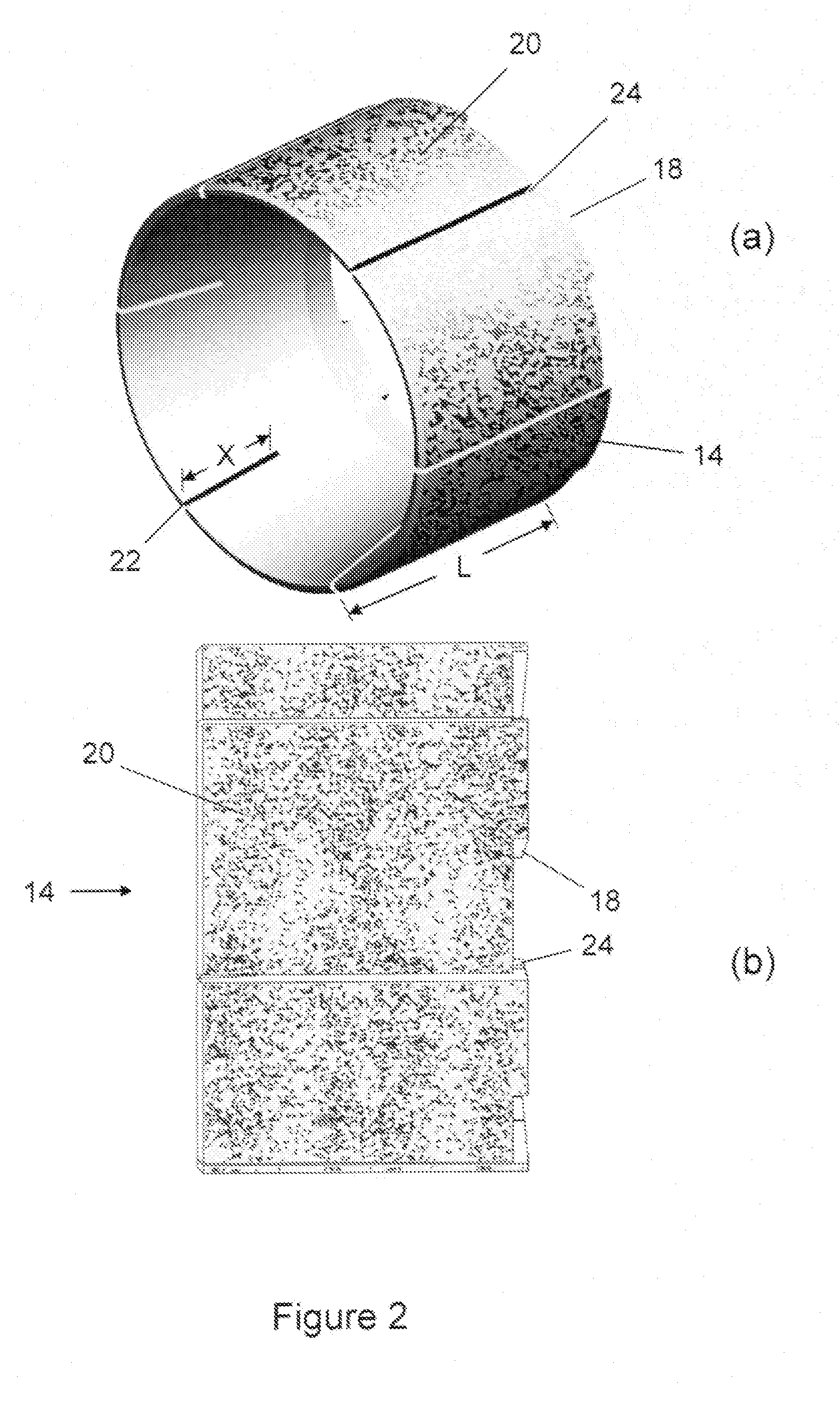

Non-damaging slips and drillable bridge plug

ActiveUS8579024B2Easy to drillPrevent rotationFluid removalSealing/packingNon destructiveMechanical engineering

A non-damaging slip assembly includes slips having grit on a smooth surface, the slips preferably made from a ductile material, such that the slips do not cause damage to the wall of a tubular when the slips are set. The slips fail under tensile force during setting. The cone used to expand the slips may have slits that narrow during setting of the slips. The slip assembly may be used to anchor a variety or devices inside a tubular. A drillable, non-damaging bridge plug using the non-damaging slip assembly has a threaded mandrel holding the cone by threads inside the cone. When the slips are set, the slits in the cone narrow such that threads in the cone do not allow rotation of the slips as they are drilled. The bridge plug can be drilled by a PDC bit without damaging the tubular.

Owner:INNOVEX DOWNHOLE SOLUTIONS INC

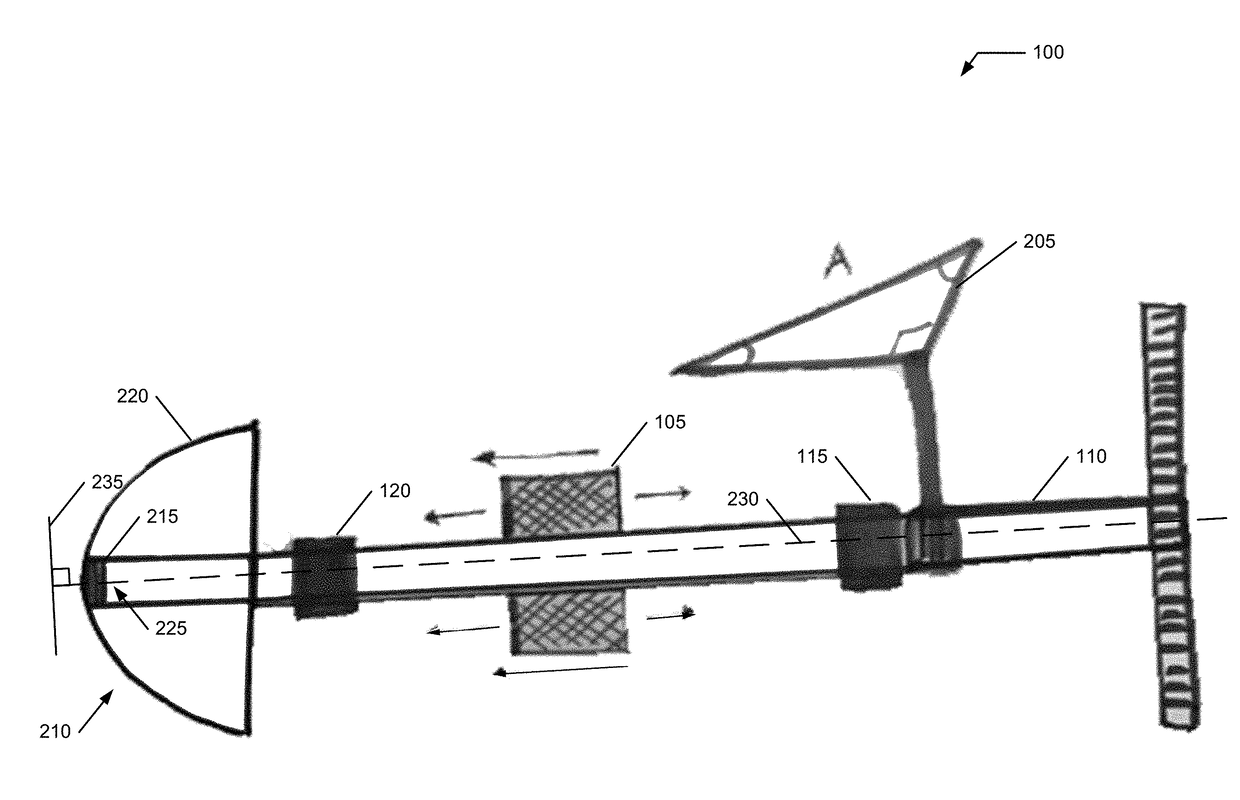

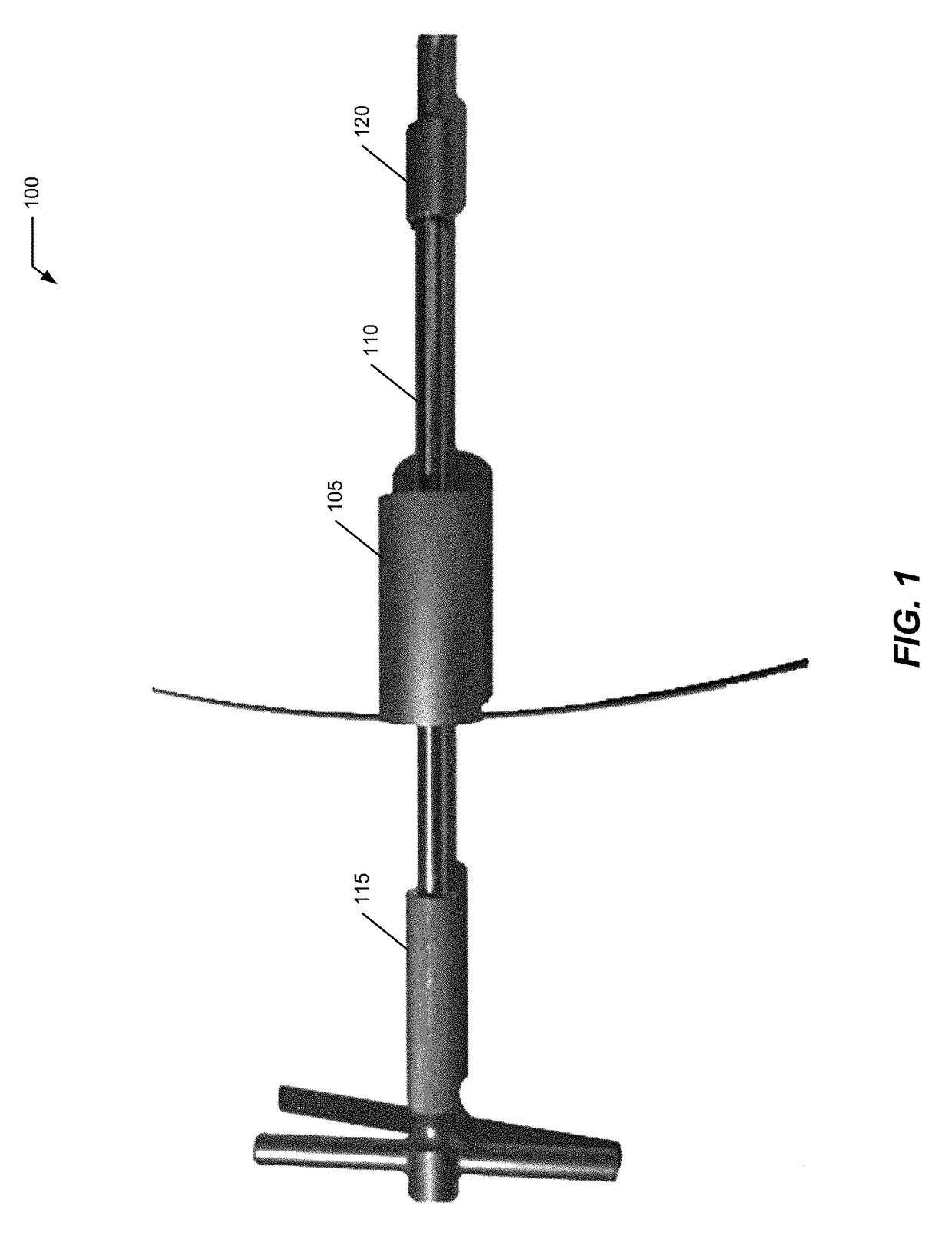

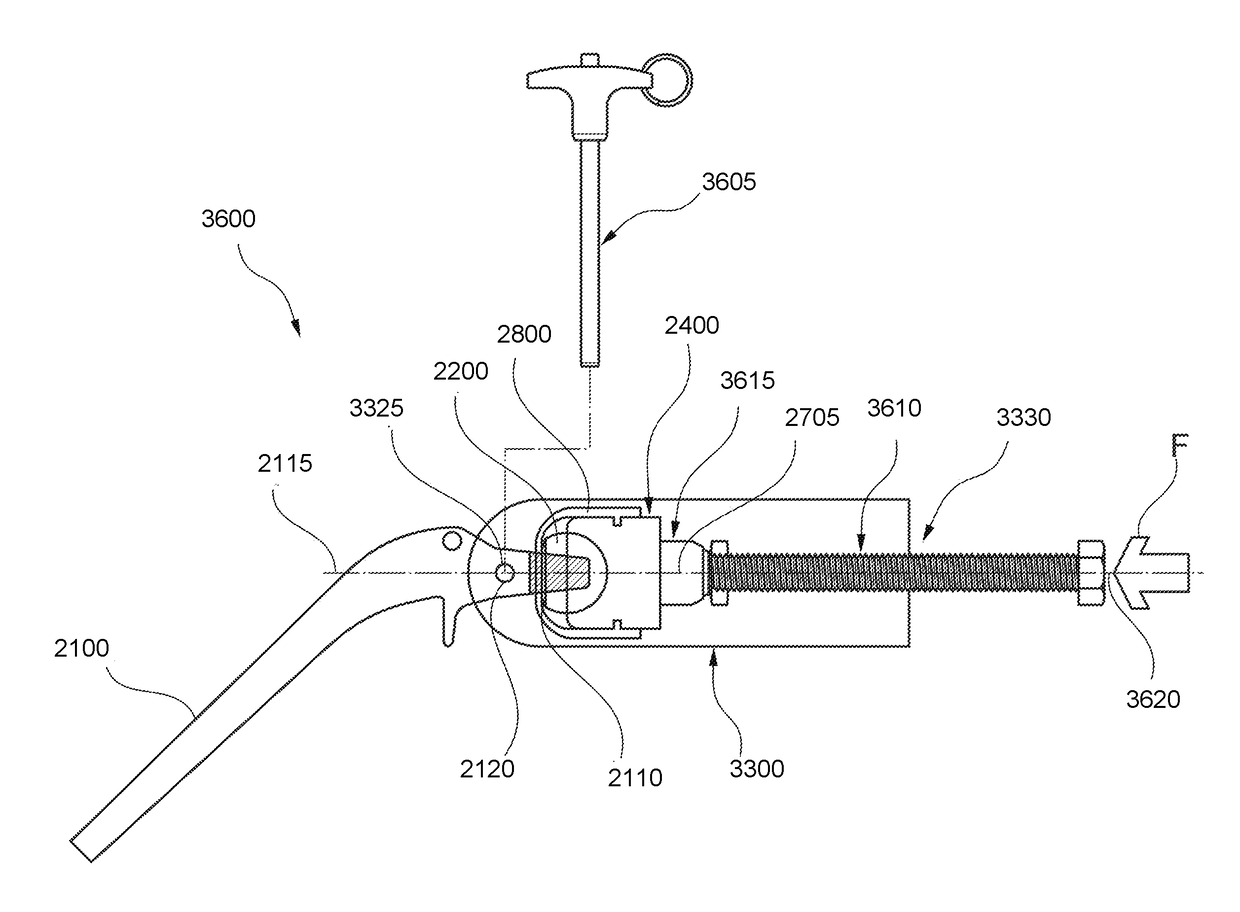

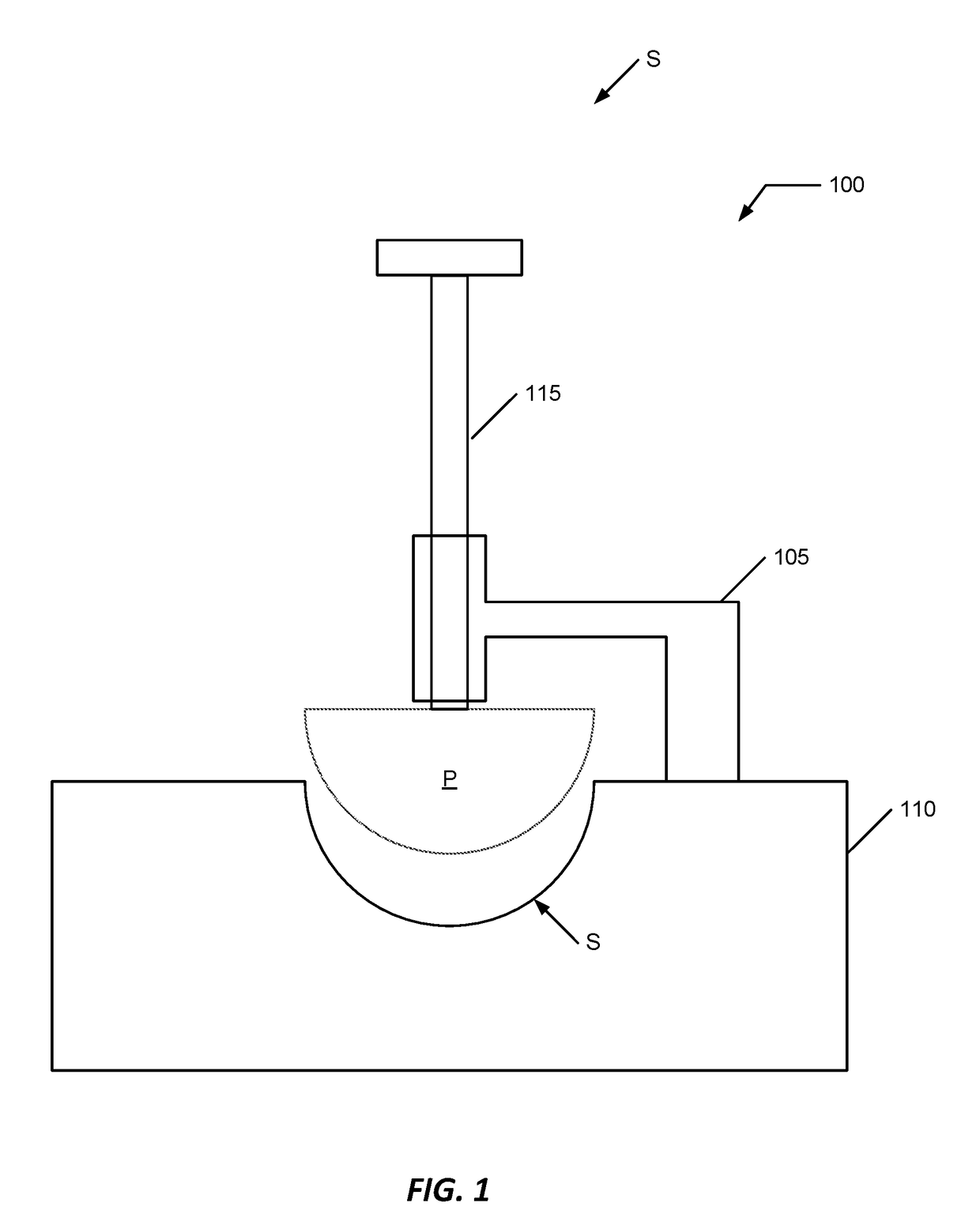

Bone preparation apparatus and method

ActiveUS20170196705A1Assembly precisionImprove site preparationJoint implantsFemoral headsProsthesisPower tool

A system and method for improving installation of a prosthesis. Devices include prosthesis installation tools, prosthesis assembly tools, site preparation systems, and improved power tools used in implant site preparation.

Owner:BEHZADI KAMBIZ

Prosthesis installation

ActiveUS20170196711A1Assembly precisionImprove site preparationJoint implantsFemoral headsProsthesisRelative motion

A system and method for improving installation of a prosthesis, particularly an acetabular cup. The system and method may include implementation of a constant velocity relative motion between a prosthesis and an installation site. For example, an installation system may be fixed relative to the installation site, with the prosthesis fixed into an initial position. The prosthesis is moved at constant speed (i.e., with minimal if any acceleration or applied impulses) relative to the installation site. That is, one or both of the prosthesis or the installation site may be in motion. Resistive forces to installation of a prosthesis may thus be reduced by maintaining the prosthesis constantly in motion relative to the installation site. Securing a processing / implanting tool directly to the installation site may offer advantages.

Owner:BEHZADI KAMBIZ

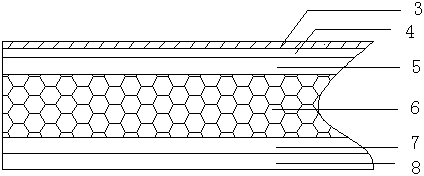

Copper clad laminate

InactiveUS6833198B2Easy to drillImproved hole processabilityLight absorption dielectricsExtrusion containersCopper foilLaser beams

There is provided a copper clad laminate which makes laser beam drilling extremely easy and is suitable for forming an interlayer connection microhole by improving a surface of its copper foil, which is to be used as the surface which a laser beam enters, in the production of printed circuit boards. Specifically, the copper clad laminate is such that it includes electrodeposited copper foil for use in the laser beam drilling and is characterized in that the matte side of the above electrodeposited copper foil is used as the surface which the laser beam enters.

Owner:JX NIPPON MINING& METALS CORP

Composition for decreasing lost circulation during well operation

InactiveUS20060079408A1Reduce circulationIncrease in sizeFluid removalFlushingLost circulationAbsorption of water

A method is provided for reducing lost circulation when aqueous, oil, or synthetic based drilling fluid is used. The method includes injecting two fluids into the well bore and lost circulation zone. The first fluid is an aqueous liquid containing at least one polymer capable of absorbing water in an alkaline environment. The aqueous liquid has a pH that inhibits at least one polymer from absorbing water. The second fluid contains a hardening composition in a base fluid having a pH sufficient to increase the pH in situ to allow at least one polymer to absorb water and expand with the absorbed water and substantially increase in size to close off the lost circulation zone and allow the hardening composition to create a plug in the well bore and set up.

Owner:TURBO CHEM INT

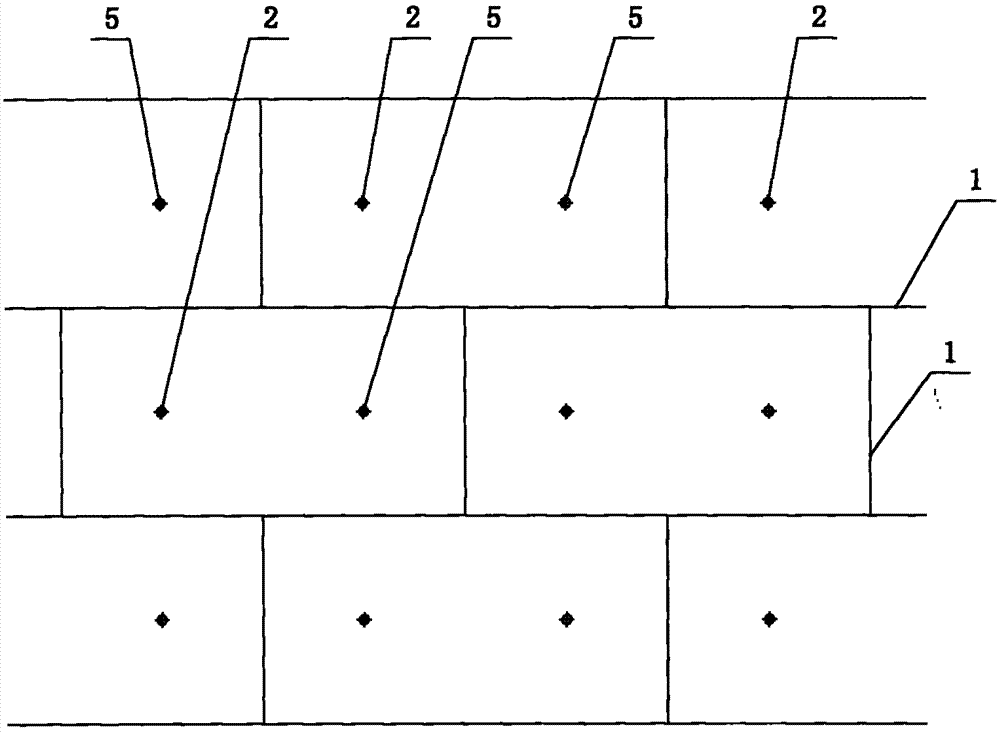

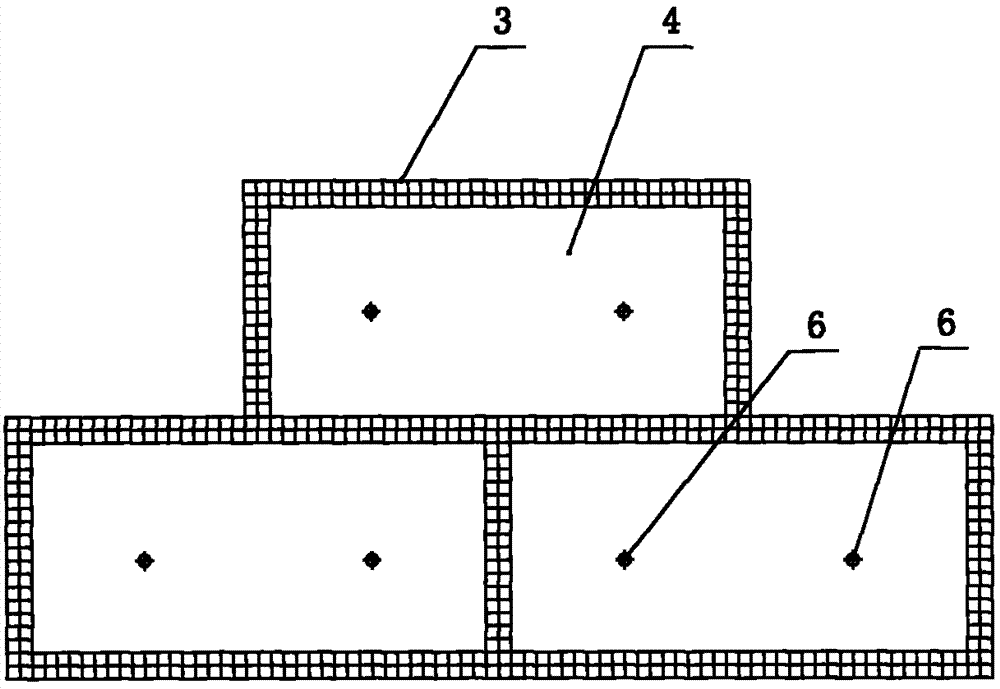

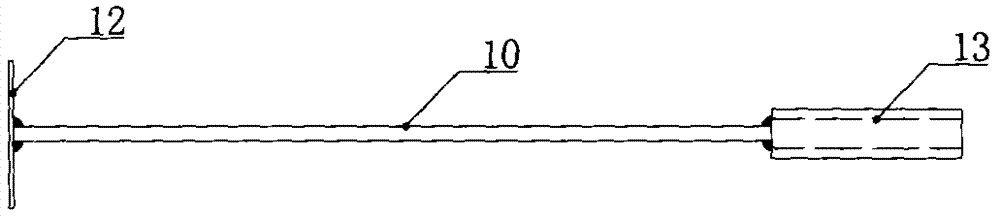

Soft and weak wall rock tunnel advance reinforced support construction method

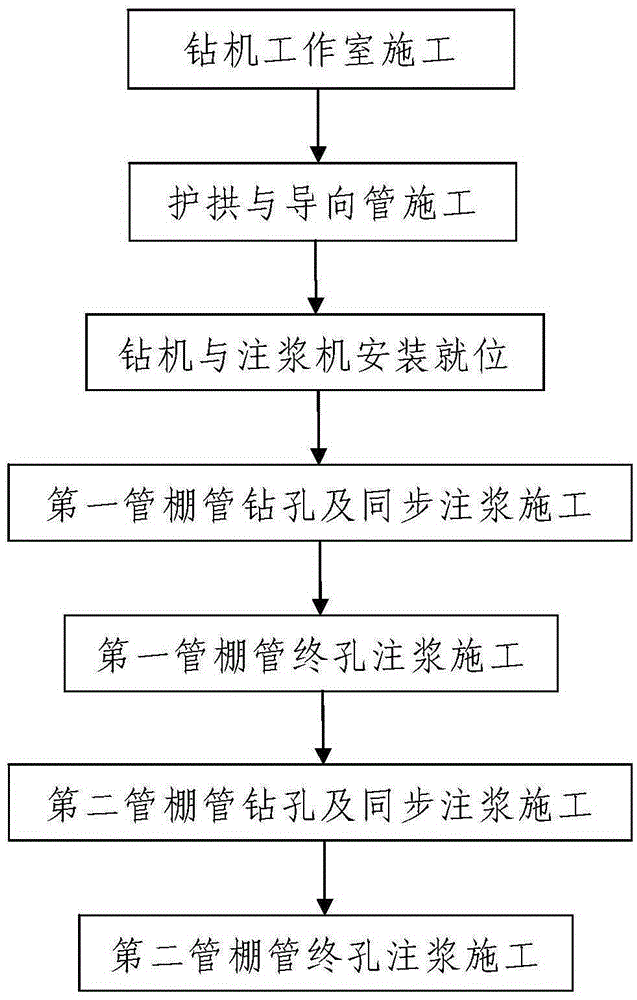

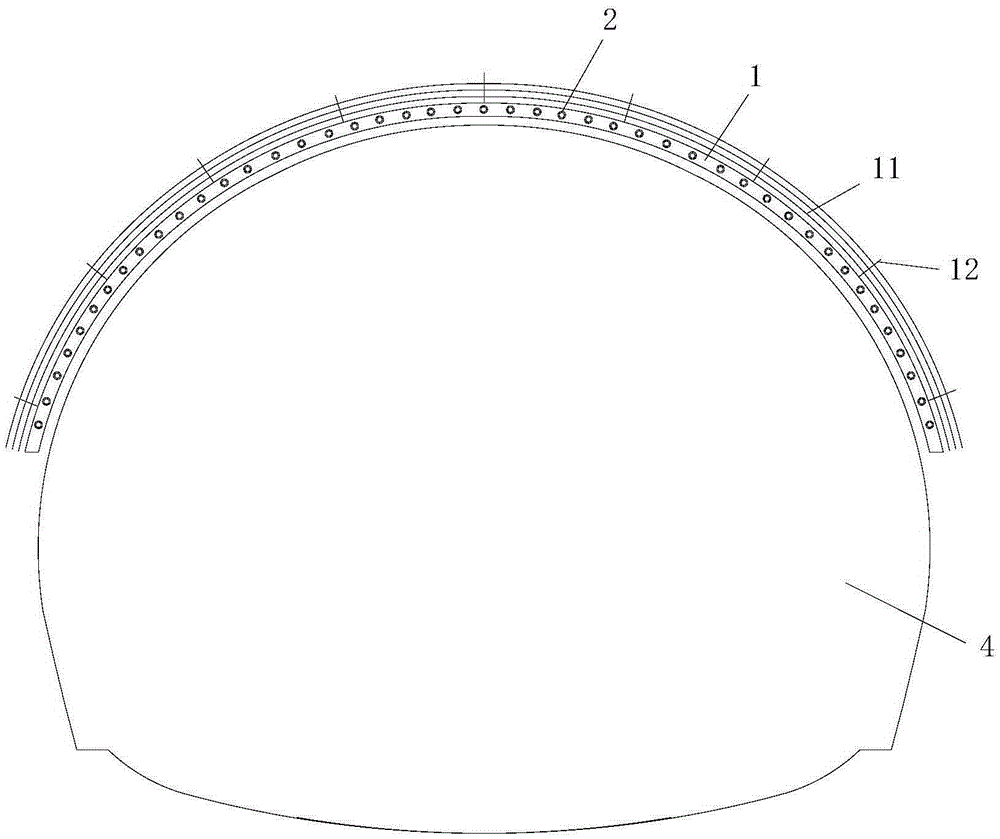

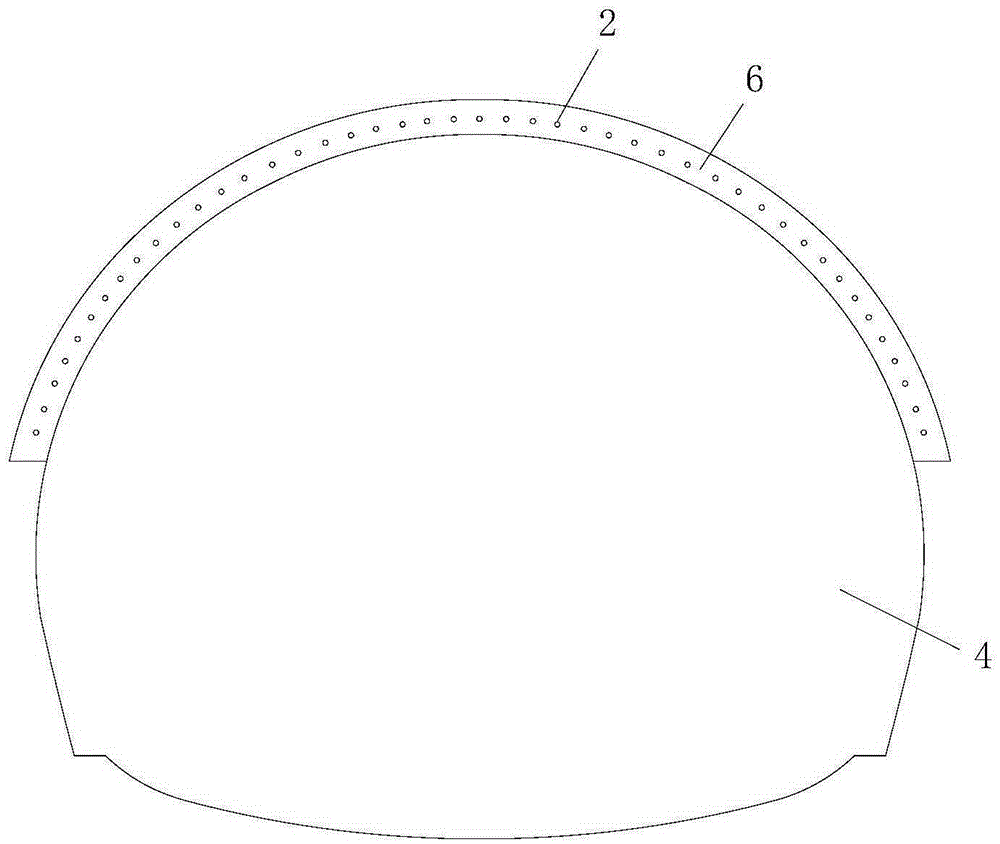

InactiveCN105298517AThe method steps are simpleEasy to implementUnderground chambersTunnel liningGuide tubeDrilling machines

The invention discloses a soft and weak wall rock tunnel advance reinforced support construction method. When a pipe roof advance support construction is carried out on one segment of the constructed tunnel, the construction method comprises the following steps: (1) support arch and guide pipe construction, wherein a plurality of guide tubes for carrying out guiding on a plurality of pipe roof pipes are arranged on a support arch; each pipe roof pipe comprises a pipe body and a drill bit; each pipe body is formed by splicing a plurality of pipe joints; each drill bit is coaxially arranged at the front end of the pipe body; the pipe joints are spiral steel pipes; the pipe roof pipes are first pipe roof pipes or second pipe roof pipes; and the first pipe roof pipes and the second pipe roof pipes are staggered; (2) drilling machine and slip casting machine installation and emplacement; (3) pipe roof advance support construction, which comprises the following processes: first pipe roof pipe drilling and synchronous grouting construction, final hole grouting construction of the first pipe roof pipes, second pipe roof pipe drilling and synchronous grouting construction and final hole grouting construction of the second pipe roof pipes. The method disclosed by the invention is simple in steps, reasonable in design, simple and convenient to construct and good in support effect; and the soft and weak wall rock tunnel advance reinforced support process can be simply, conveniently and quickly finished.

Owner:中铁二十局集团第二工程有限公司

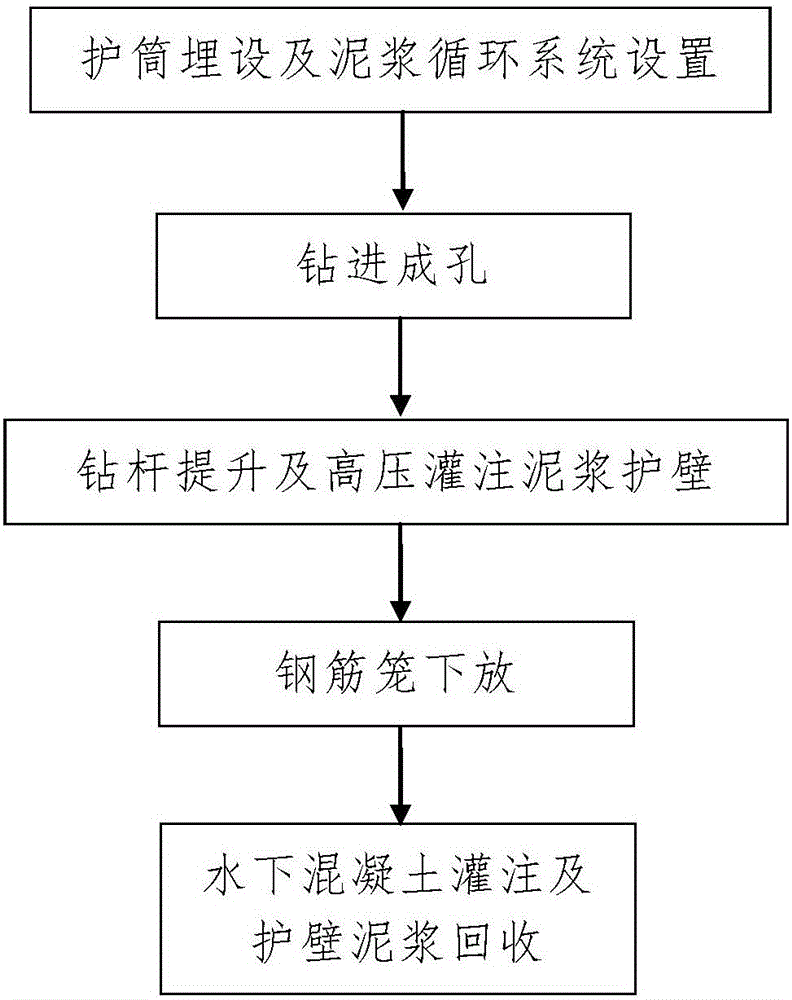

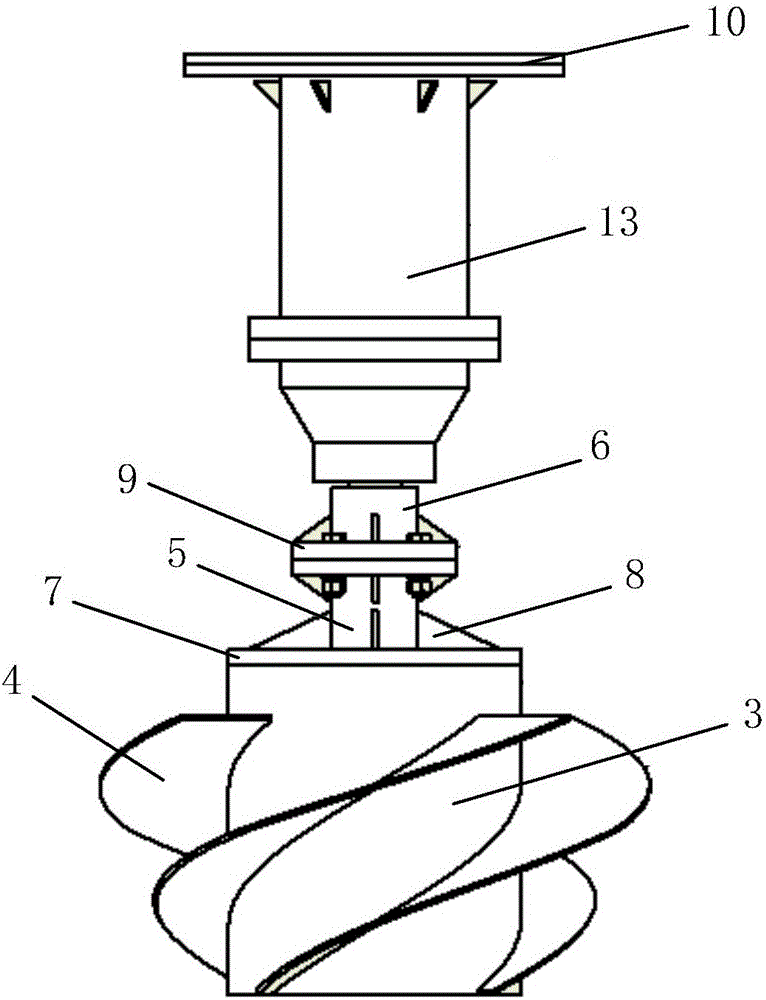

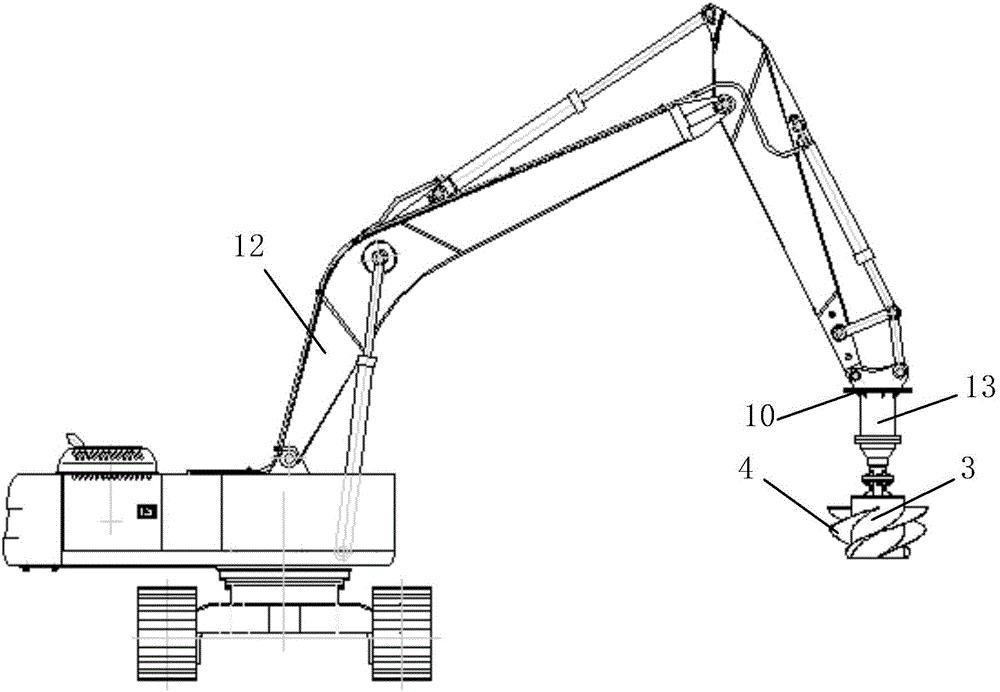

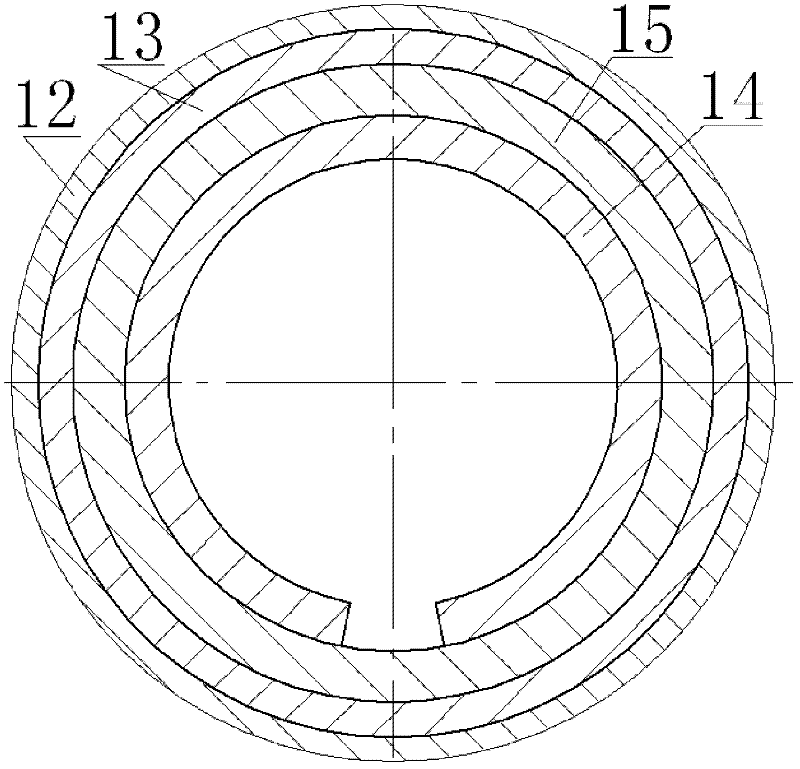

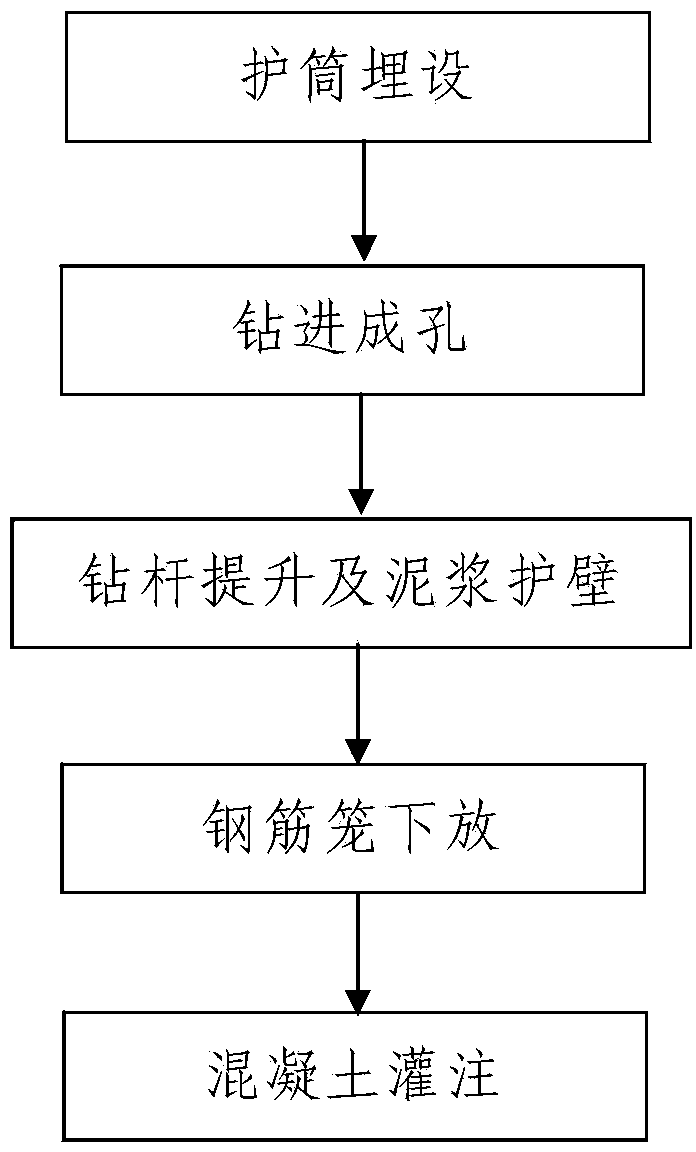

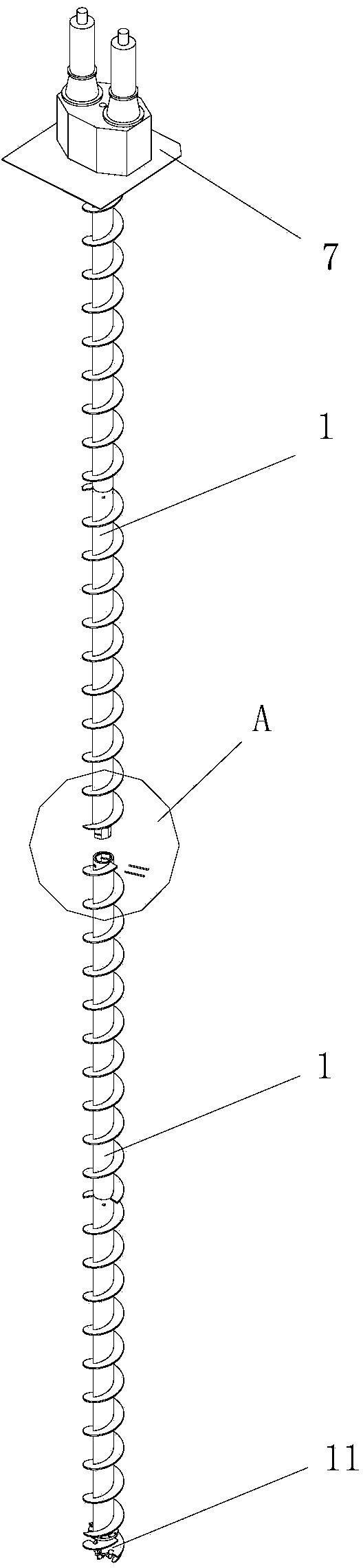

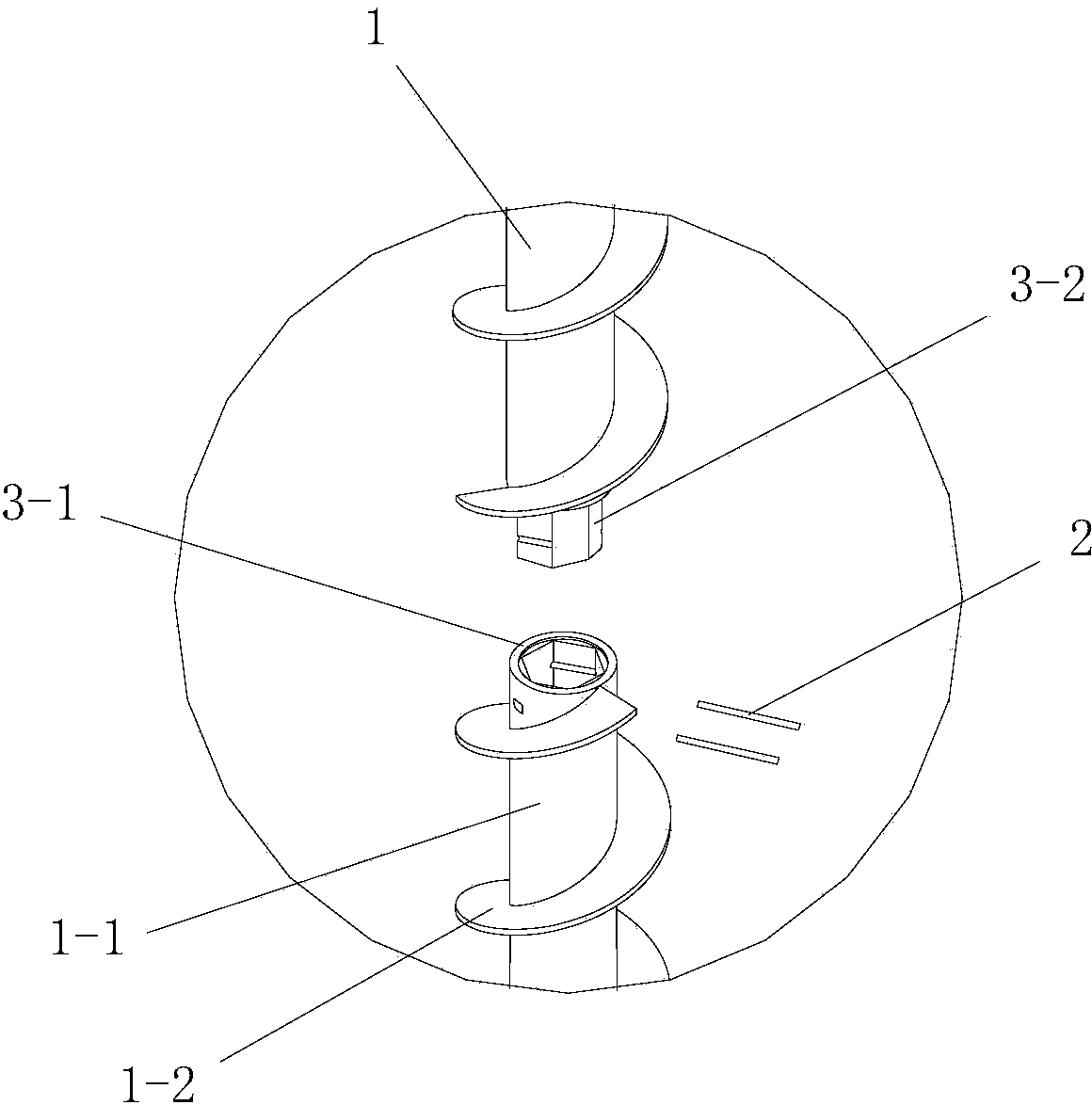

Long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall

ActiveCN106284313AReasonable structural designEasy to operateBulkheads/pilesDrilling machines and methodsUnderwaterHigh pressure

The invention discloses a long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall, comprising the steps of first, burying a protective barrel and setting a slurry circulating system that comprises a slurry storage tank and a slurry pumping device, with the upper portion of the protective barrel provided with an overflow hole; second, drilling to form a borehole; third, lifting a drill pipe, and casting a slurry breast wall under high pressure: lifting up the drill pipe, and continuously casting wall supporting slurry from bottom to top from the borehole bottom through the drill pipe by using the slurry pumping device; fourth, lowering a reinforcement cage; fifth, casting concrete underwater and recycling the wall supporting slurry, and recycling the wall supporting slurry discharged through the overflow hole to the slurry storage tank for backup. The method has simple steps, is easy to implement, has high hole-forming quality and good construction effect, and enables the construction of a long screw extrusion-socketed cast-in-place pile to be finished simply and quickly, and by casting the wall supporting slurry from bottom to top from the borehole bottom in a high-pressure casting manner, it is possible to effectively protect the wall and keep the borehole bottom clean with no deposit; the wall supporting slurry is reusable.

Owner:SHAANXI ZHUANGXIN CONSTR ENG +4

Variable-diameter fracturing valve

ActiveCN102337862AFull boreEasy to drillFluid removalWell/borehole valve arrangementsUpper jointEngineering

The invention relates to a variable-diameter fracturing valve, which is applied to modification construction of oil gas field fracturing. An upper pressure transmitting joint is fixed on the top of an upper pressure transmitting channel; an upper joint is provided with an axial fracturing channel, and an outer sliding sleeve and an inner sliding sleeve are arranged in the upper joint; the lower end of the upper joint is connected with a cylinder sleeve; an upper connecting cylinder is sleeved in the cylinder sleeve; a guide sleeve is sleeved in the upper connecting cylinder; the upper connecting cylinder is connected with the guide sleeve through a shearing pin; a supporting seat is in threaded connection with the upper connecting cylinder; the supporting seat is arranged in the upper connecting cylinder; a variable-diameter ball seat is arranged in the supporting seat; the cylinder sleeve is in threaded connection with a lower pressure transmitting body; the upper end of the lower pressure transmitting body is connected with a lower connecting cylinder; the lower pressure transmitting body is provided with a lower pressure transmitting channel, and the lower end of the lower pressure transmitting channel is provided with a lower pressure transmitting joint; and the lower end of the lower pressure transmitting body is connected with a lower joint. The variable-diameter fracturing valve has the effects that: the variable-diameter ball seat is drawn down sequentially to form a ball seat in the fracturing process; sealing balls with the same diameter are input repeatedly, and the fracturing valve is opened to sequentially complete fracturing repeatedly; and the variable-diameter fracturing valve is not limited by a borehole diameter and realizes unlimited section fracturing construction of laying down a row of pipe columns.

Owner:PETROCHINA CO LTD

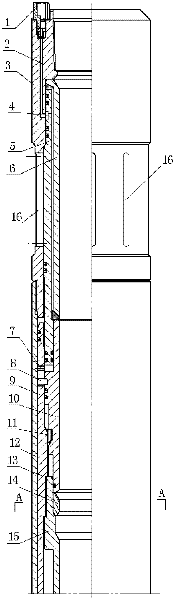

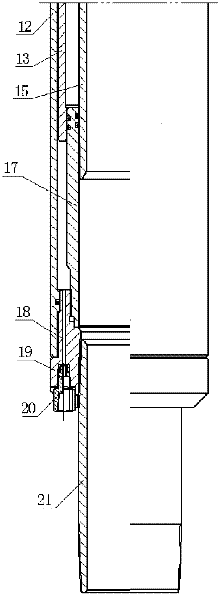

Construction technology for long-spiral cast-in-place pile extruded into rock

ActiveCN103850249AReasonable structural designEasy to operateDrilling rodsRotary drillingSlurryEngineering

The invention discloses a construction technology for a long-spiral cast-in-place pile extruded into rock. The construction technology comprises the following steps: 1) embedding a pile casing: embedding the pile casing in a pile position acquired by surveying and setting out; 2) drilling a hole: downward drilling by a long-spiral pile machine and acquiring a constructed and formed hole after drilling in place; 3) lifting a drill rod and protecting a wall with slurry: upward lifting the drill rod after drilling in place till taking the drill rod out of the formed hole, adopting a grouting device and pumping the wall-protecting slurry through the drill rod during the process of upward lifting the drill rod, and protecting the wall with the slurry for the formed hole; 4) putting down a reinforced bar cage; 5) grouting concrete: performing concrete grouting construction on the constructed long-spiral cast-in-place pile extruded into rock through a concrete pumping device and a grouting guide tube. The construction technology provided by the invention has the advantages of simple steps, convenience in realization, high hole quality, good construction effect and capability of effectively solving the problems of the present construction for the long-spiral cast-in-place pile extruded into rock that the hole wall is easy to collapse, the hole is repeatedly cleaned, the construction efficiency is low, and the like.

Owner:SHAANXI ZHUANGXIN CONSTR ENG

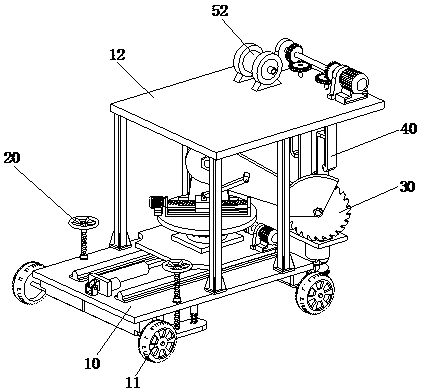

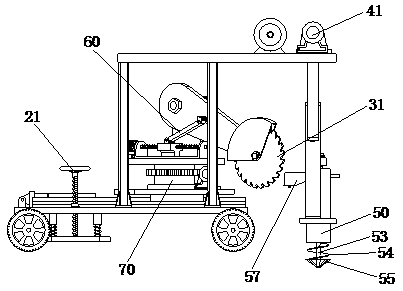

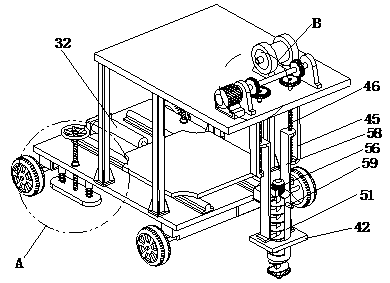

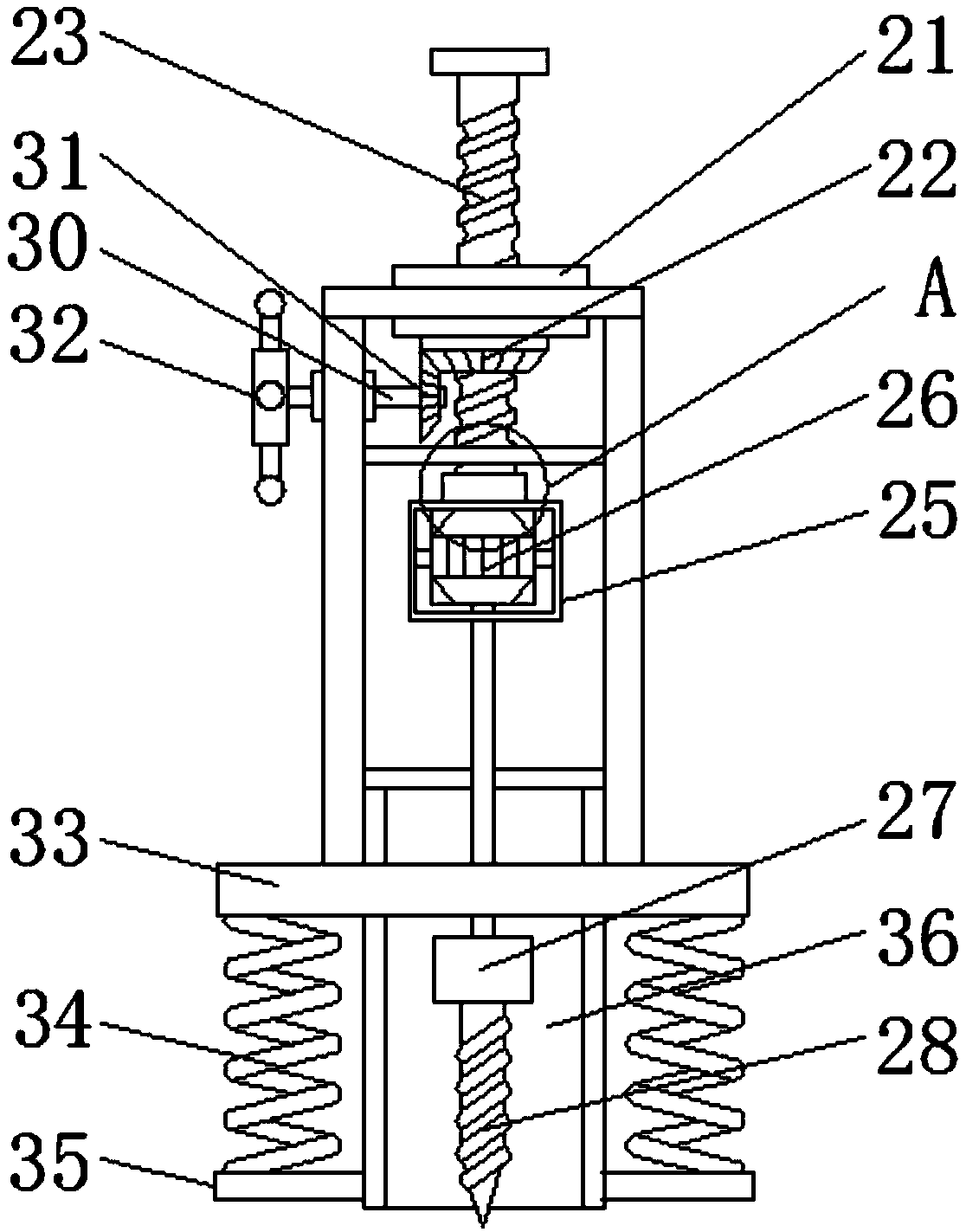

Sampling device for geotechnical exploration

InactiveCN110308010AAutomatic cuttingAutomatic crushing operationWithdrawing sample devicesDrive wheelSpiral blade

The invention discloses a sampling device for geotechnical exploration, and belongs to the technical field of geological exploration equipment. The sampling device comprises a base, a stabilizing mechanism, a rock cutting mechanism and a drilling and sampling mechanism; four driving wheels are arranged at the bottom of the base; a supporting frame is arranged on the top of the base; the drilling and sampling mechanism comprises a lifting assembly, a lifting plate and a drilling and sampling assembly; the drilling and sampling assembly comprises a sampling barrel and a connecting frame; a rotating shaft is arranged on the connecting frame; a spiral blade is arranged on the rotating shaft in a sleeved mode; and a drilling head is arranged at the bottom end of the rotating shaft in a sleevedmode. The sampling device has the beneficial effects that the lifting operation of the drilling and sampling assembly can be realized, and the sample can be conveyed to a material collecting hopper byvirtue of the drilling and sampling mechanism; the automatic cutting assembly can be used for cutting and crushing rock samples; and a rotary assembly can drive the automatic cutting assembly to rotate to a proper position, so that the interference of the automatic cutting assembly on the operation of the drilling and sampling mechanism is avoided.

Owner:胡立宇

Method for installing and connecting decoration and heat preservation combined plates on wall made of low-strength materials

InactiveCN103790322AImprove pull strengthHigh construction guarantee rateCovering/liningsEngineeringCement mortar

The invention belongs to a method for installing and connecting decoration and heat preservation combined plates on a wall made of low-strength materials. The method is characterized by including the steps of fixing a panel to the wall through expansion anchors, drilling a special anchor rod hole penetrating through a base wall, inserting a special anchor rod into the special anchor rod hole from the indoor side, enabling a polygonal cap of the special anchor rod to be sunken in a counter bore and closely attached to the bottom of the counter bore, and then enabling the counter bore to be flattened through cement mortar. The special anchor rod is composed of a pull rod and a screw, the polygonal cap is fixedly arranged at one end of the pull rod, and a long nut is fixedly arranged at the other end of the pull rod; when the pull rod is long enough and can be completely inserted into the special anchor rod hole from the indoor side, the tip at the long nut end of the pull rod can extend to be close to an opening of a prefabricated rivet hole of the plate. According to the method, safety and durability of the decoration and heat preservation combined plate installed and connected to the wall made of the low-strength materials are well achieved.

Owner:上海欧墅节能科技股份有限公司

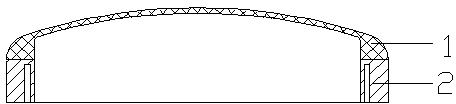

Combined antenna housing

The invention relates to an antenna housing and provided a combined antenna housing. The combined antenna housing comprises an arc-shaped housing body (1) and a steel base (2) in a hollow cylindrical structure, wherein the steel base (2) is located on the lower portion of the arc-shaped housing body (1), and the arc-shaped housing body is in a sandwiched composite structure. Compared with existing products, the combined antenna housing has the advantages of being good in electromagnetic permeability and high and low temperature shock resistance and capable of protecting antennas to be used in severe weather such as sand, high wind and humid rainy climate and in regions with large temperature differences.

Owner:洛阳双瑞橡塑科技有限公司

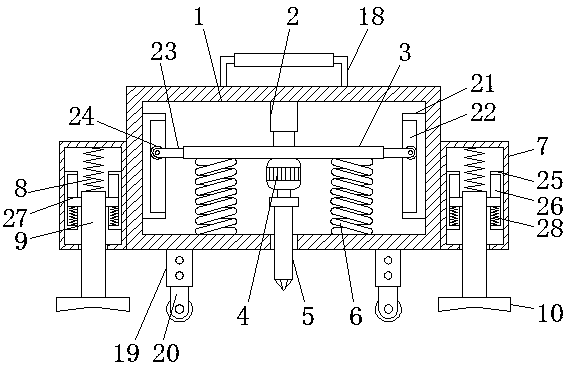

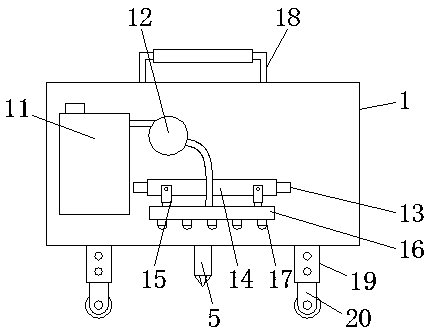

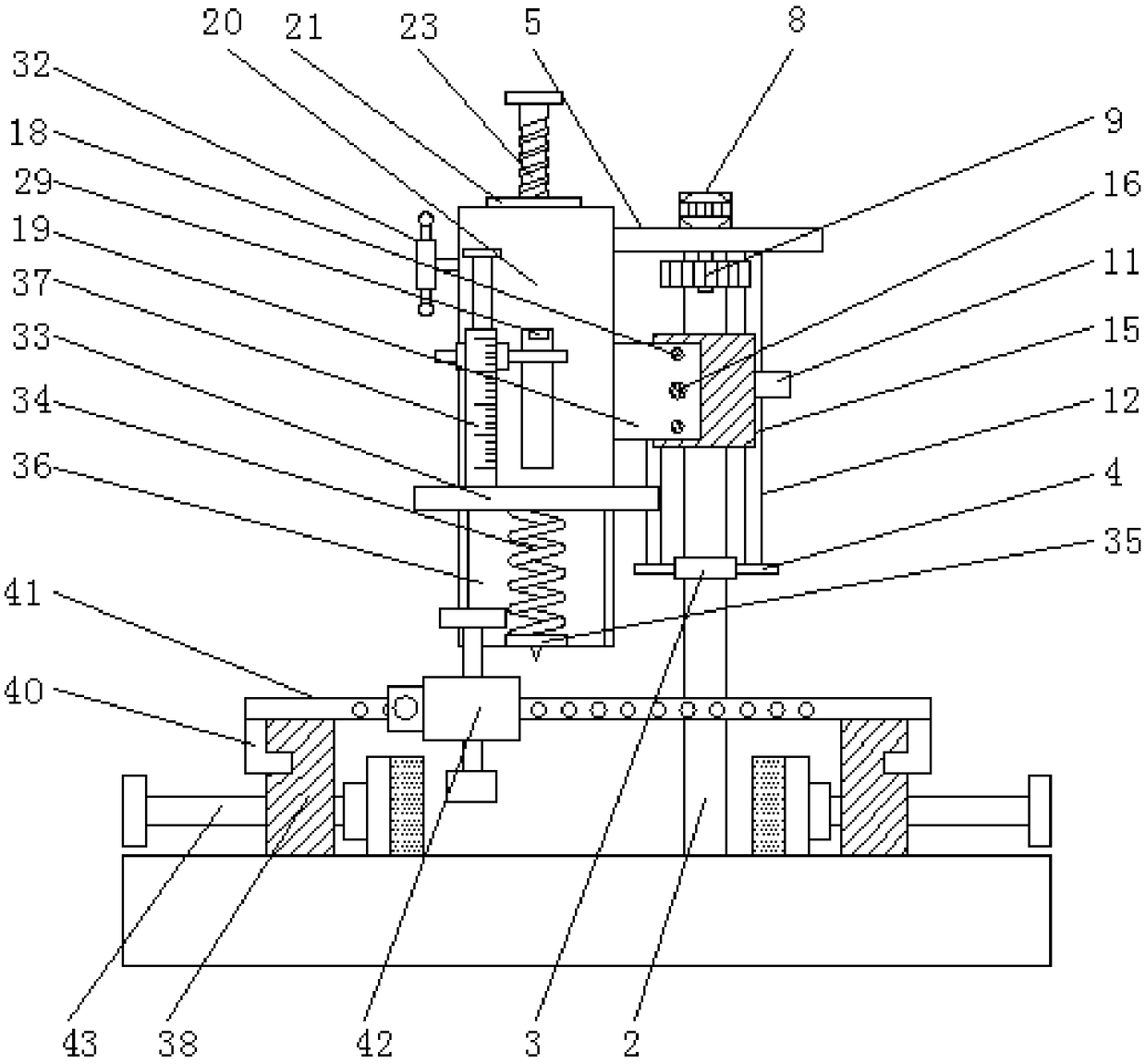

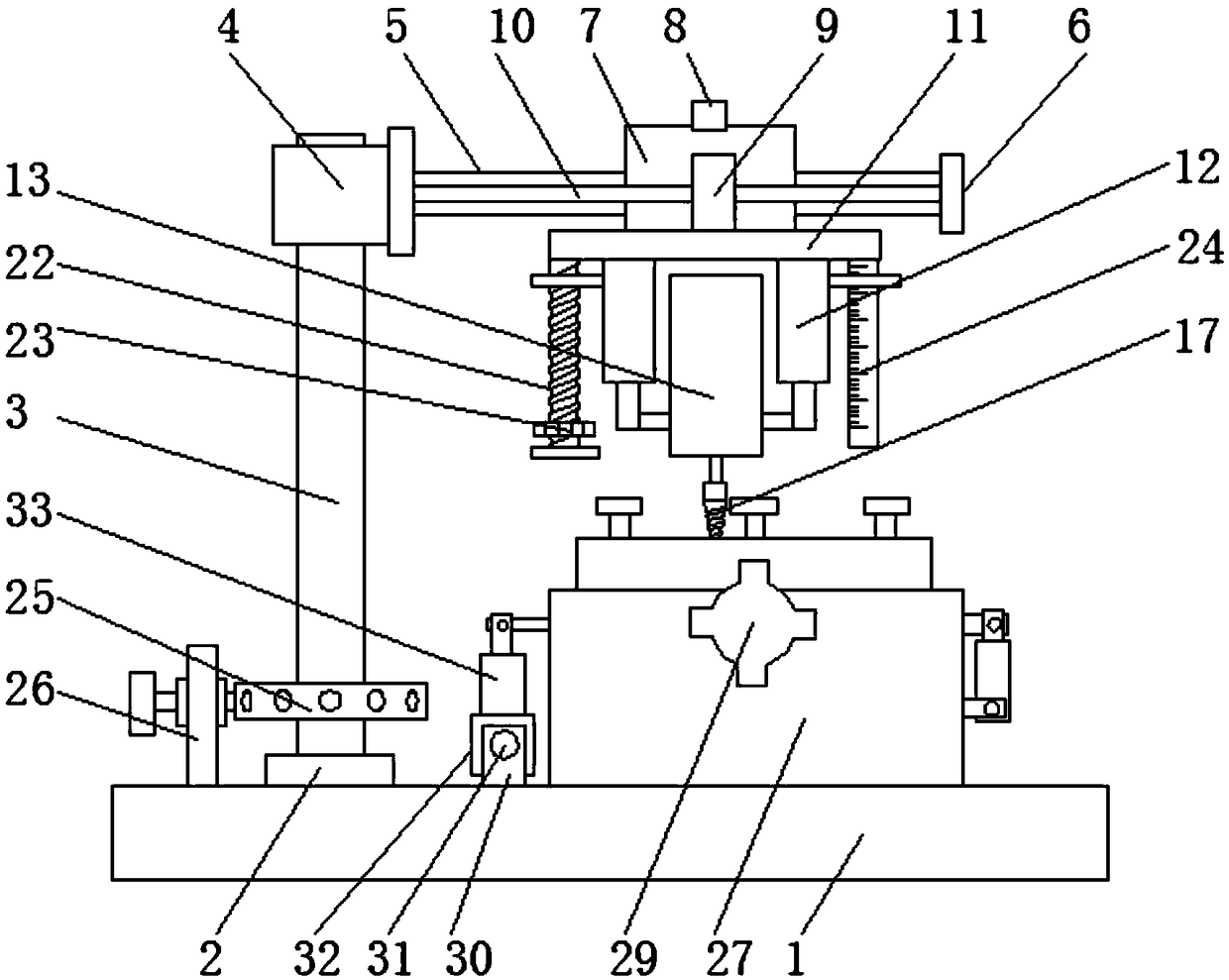

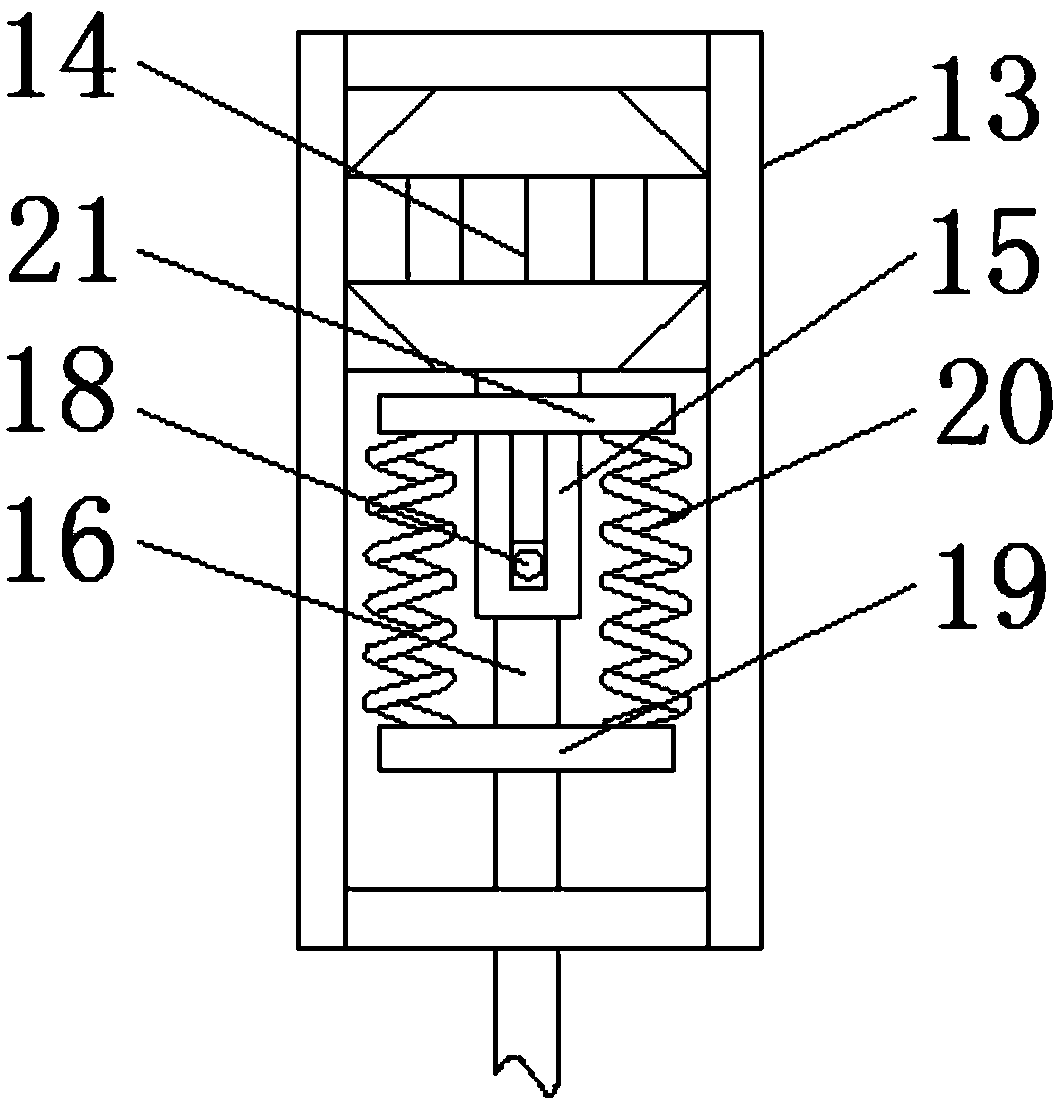

Drilling device for building construction

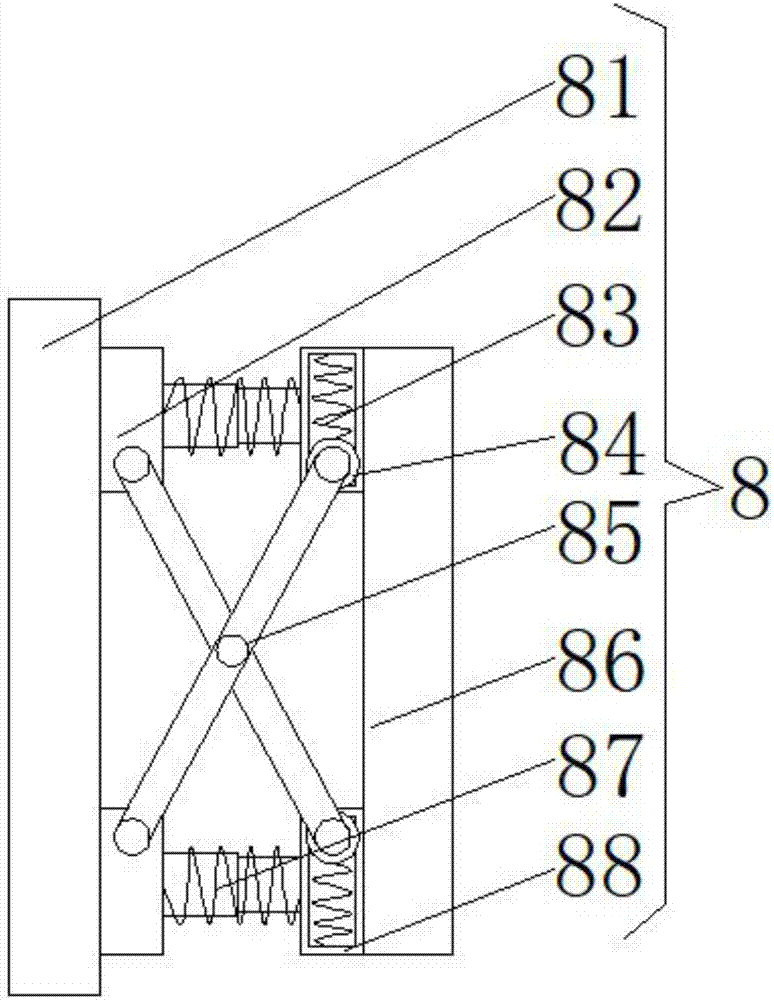

ActiveCN108505937AEasy to useReduce vibrationConstructionsDerricks/mastsFixed frameMaterial resources

The invention discloses a drilling device for building construction. The drilling device comprises a machine body, wherein a hydraulic telescopic rod is fixedly connected to the top of an inner cavityof the machine body, a moving plate is fixedly connected to the output end of the hydraulic telescopic rod, a motor is fixedly connected to the bottom of the moving plate, a drill bit is fixedly connected to the output shaft of the motor, and the bottom of the drill bit penetrates through the machine body and extends to the outside of the machine body. According to the drilling device, through the arrangement of the hydraulic telescopic rod, the moving plate, the motor, the drill bit, a first damping spring, a fixing frame, a second damping spring, a limiting rod and a placing plate, drillingoperation can be automatically carried out, vibration generated by drilling can be effectively reduced in the drilling process, and construction personnel can use conveniently, time and labor are saved, and at the same time, the problems that a traditional drilling device always drills manually, the drilling efficiency is low, manpower and material resources are wasted, vibration is generated inthe drilling operation at the same time, a drill bit is damaged in long-time operation, and the personal safety of users is endangered in serious cases are solved.

Owner:浙江众安建设集团有限公司

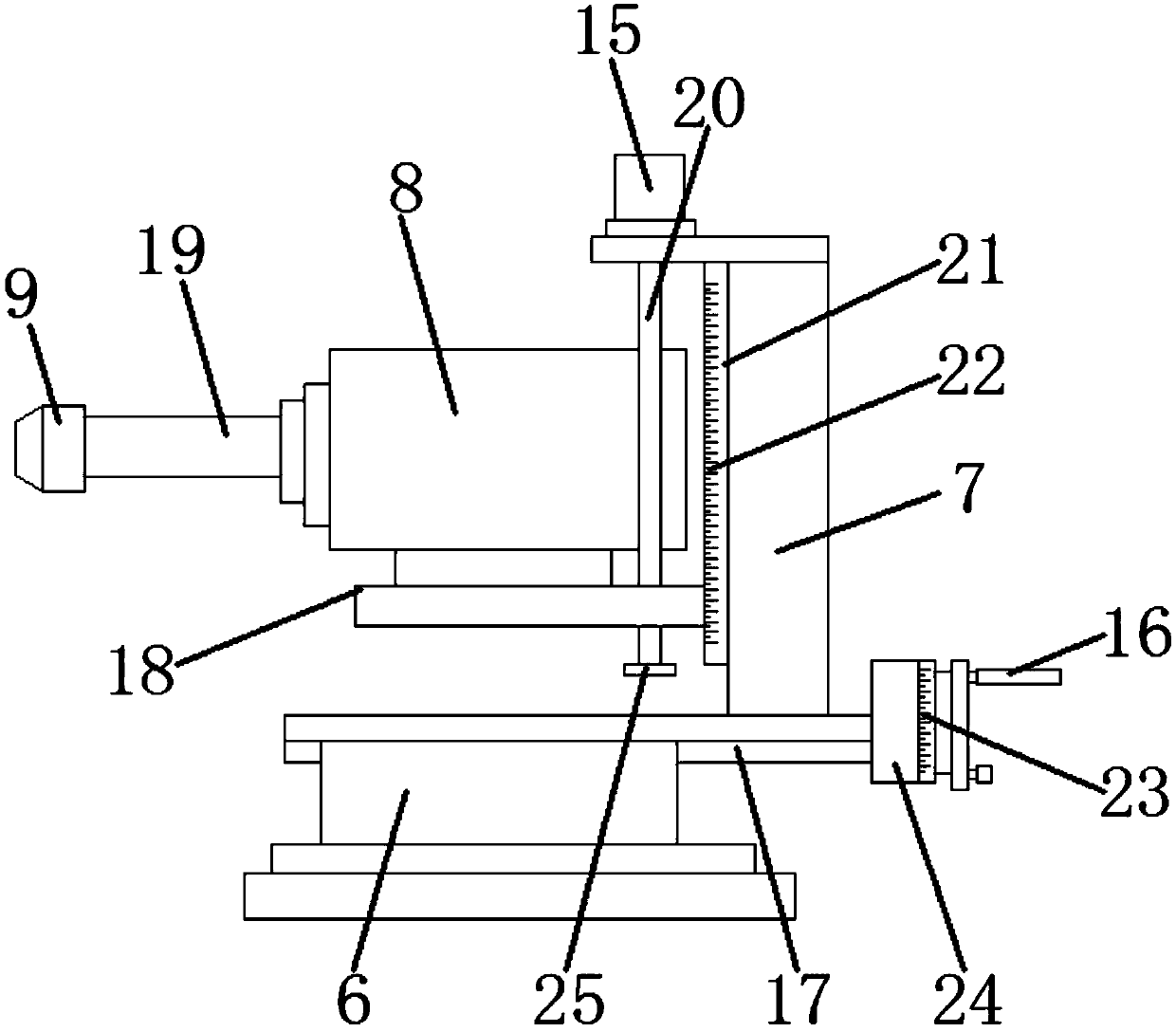

Stable drilling device used for computer mainframe case structure

InactiveCN107297521AQuality assuranceImprove drilling efficiencyPositioning apparatusBoring/drilling componentsEngineeringComputer case

Owner:合肥雷呈信息技术有限公司

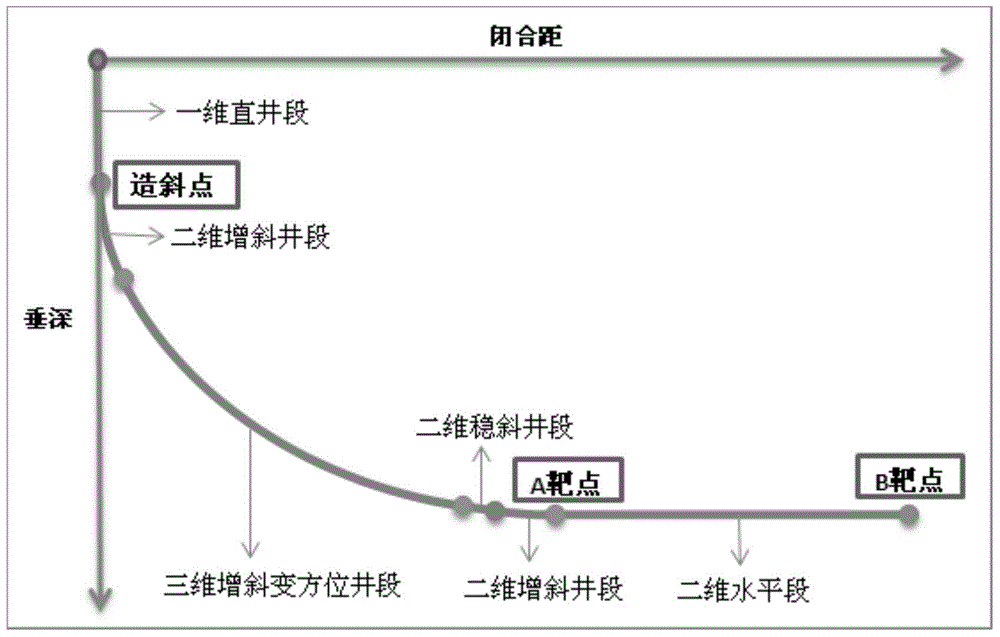

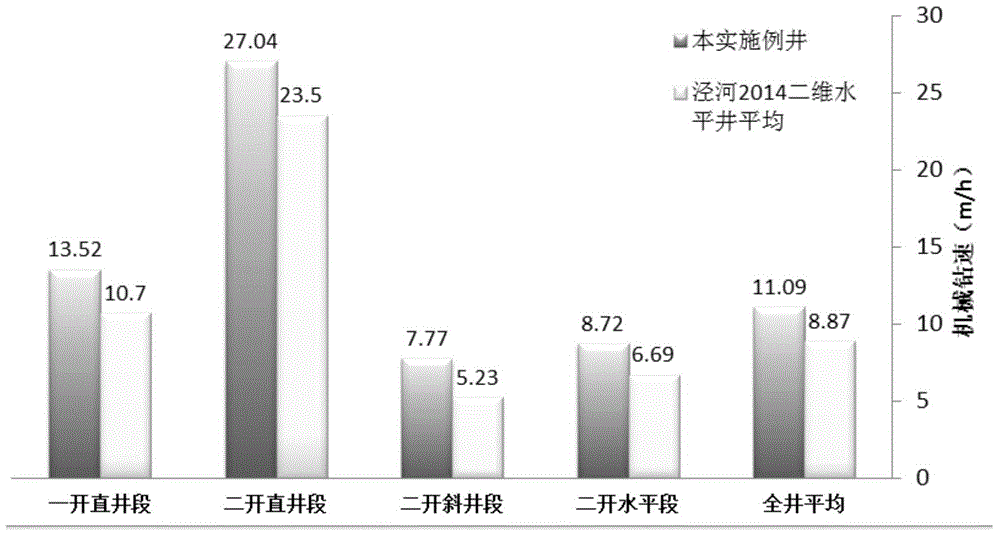

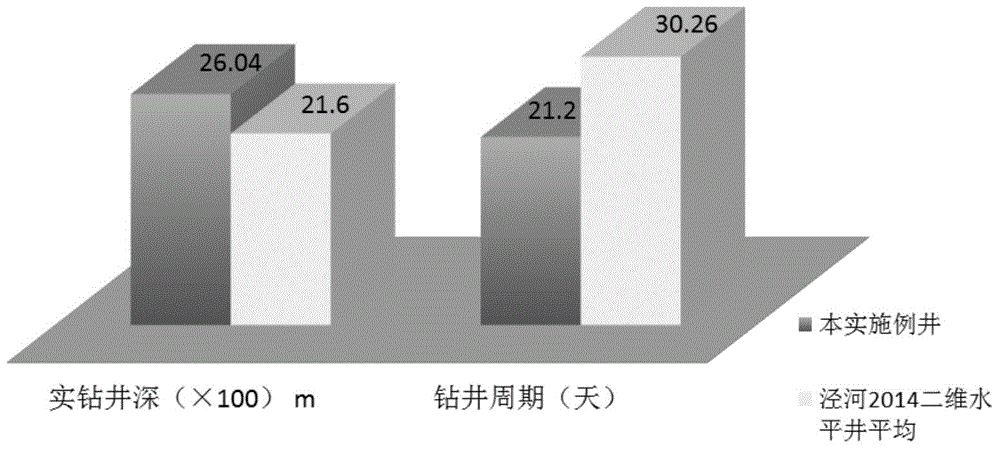

Three-dimensional (3D) horizontal well drilling construction method

ActiveCN104481398AAvoid timeAvoid construction workFluid removalDirectional drillingWell drillingPetroleum

The invention discloses a three-dimensional (3D) horizontal well drilling construction method, and belongs to the technical field of oil and gas well drilling. According to the method, a directional inclined well section is four sectioned; the 3D angle building variable-azimuth well section drilling build-up rate of a second section and the two-dimensional angle building variable-azimuth well section drilling build-up rates of a first section and a fourth section are identical, so that the technical shortages that tool build-up rates need to be adjusted usually for the reason that build-up rates in the traditional construction method are changed continuously and pulling out of a hole and drilling down are performed frequently are overcome; meanwhile, the angle building variable-azimuth well section turning direction tool face angle of the second section is a constant all the time, and the time and construction amount to put a tool face are saved. By the construction method disclosed by the invention, well drilling and directional construction are performed conveniently; the heterogeneous reservoir shooting probability is improved; the traditional drilling tool equipment is used, the construction time in the same case can be shorted by above 25%; the construction efficiency is greatly improved; the construction difficulty is reduced; the construction costs are reduced by above 17%; the costs are greatly reduced; the construction method is suitable for actual production.

Owner:CHINA PETROLEUM & CHEM CORP +1

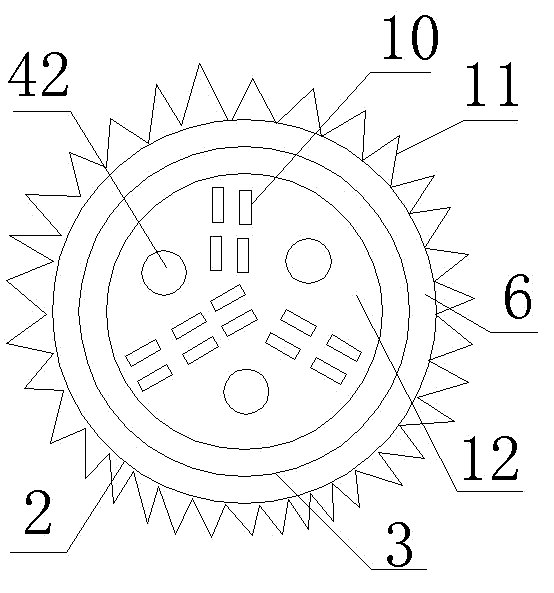

Device and method for drilling and forming hole in coal rock in structural belt

InactiveCN102230363APlay a cooling roleWon't clogDrill bitsDrilling rodsDrill bitPetroleum engineering

The invention discloses a device for drilling and forming a hole in coal rock in a structural belt. The device comprises a power device, a drilling rod mechanism and a water injection mechanism; the drilling rod mechanism comprises an external drilling rod; the external drilling rod comprises an external wall and an internal wall which are concentrically sleeved together; an external drilling rod cavity is formed between the external wall and the inner wall; a hollow internal drilling rod is concentrically sleeved in the inner wall; the external diameter of the inner drilling rod is smaller than the inner diameter of the inner wall so that an annular runner is formed between the internal drilling rod and the inner wall; the front end of the external drilling rod is provided with an annular external drilling head; the front end of the internal drilling rod is provided with a disc-shaped internal drilling head; the water injection mechanism comprises an internal drilling rod water injection device and an external drilling rod water injection device; and the power device is in transmission connection with the external drilling rod and the internal drilling rod by a transmission mechanism. By the device, the problems of easily-collapsed holes in the coal rock and difficulty in hole forming and gas drainage of a structural area can be solved, so that hole forming rate in the structural belt and around structural belt is improved, gas pre-drainage is effectively performed, and the safety of coal exploitation is further enhanced.

Owner:HENAN POLYTECHNIC UNIV

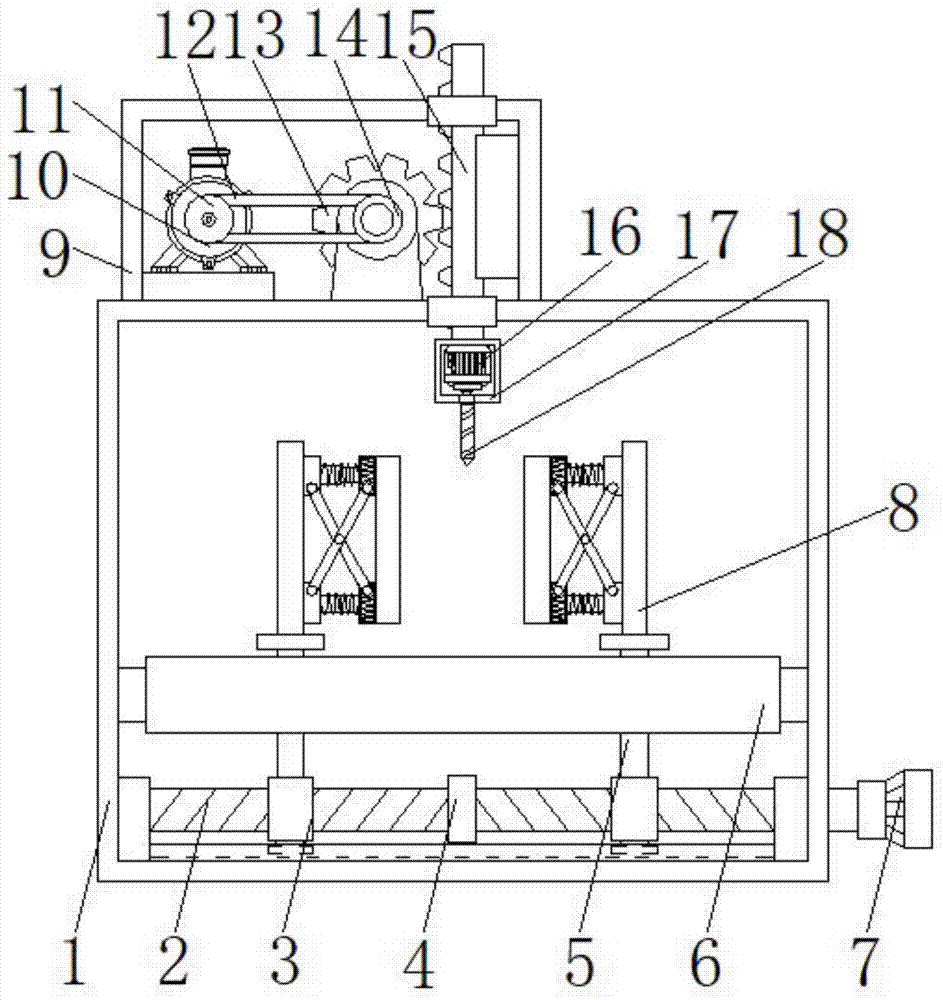

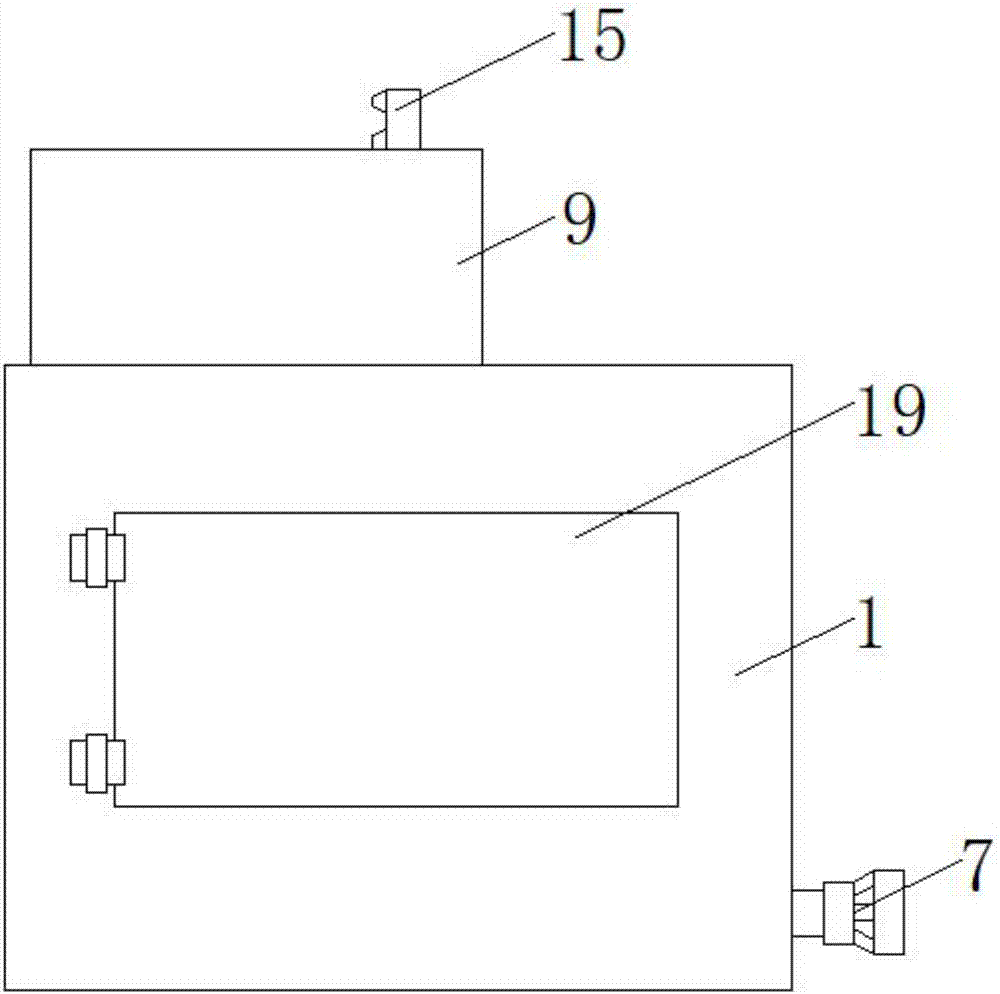

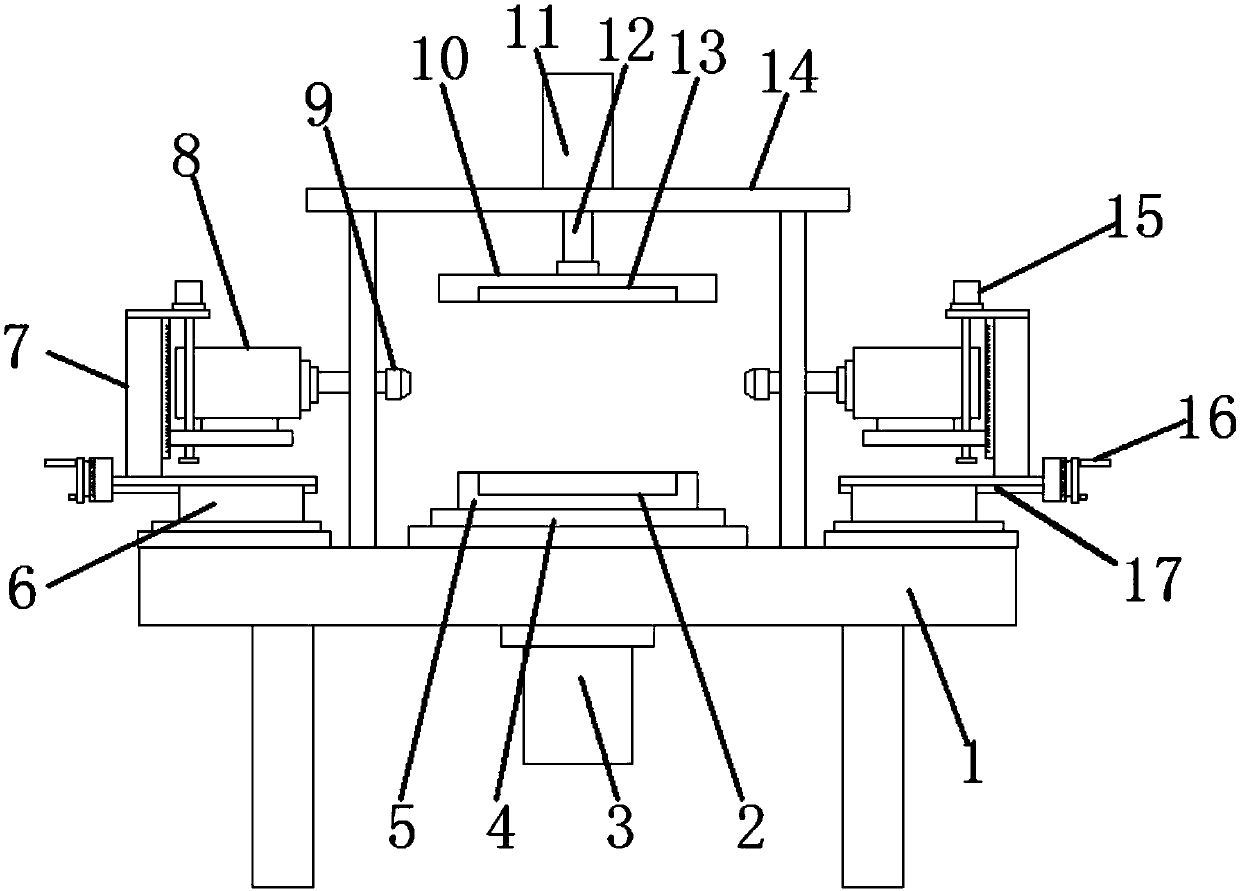

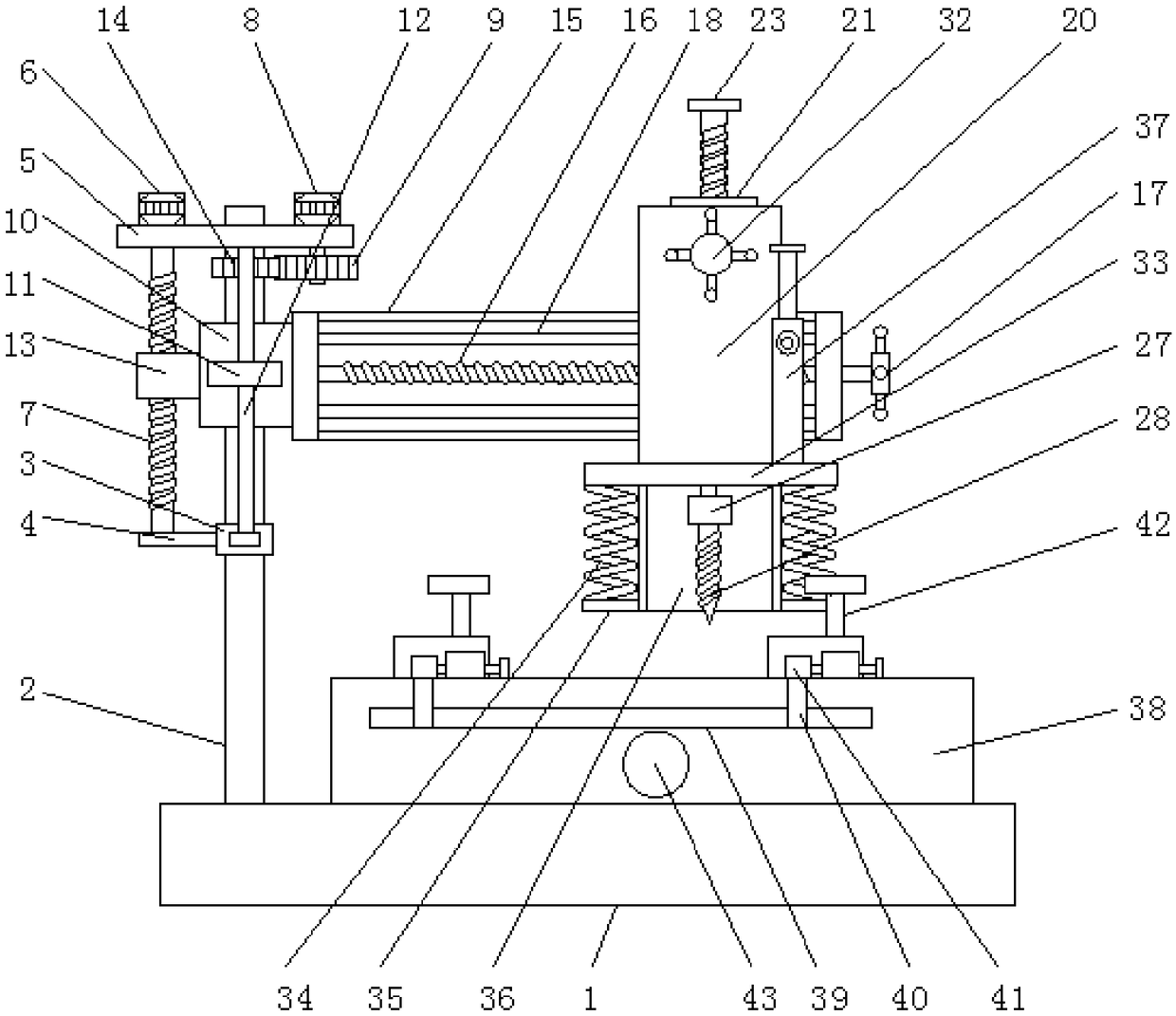

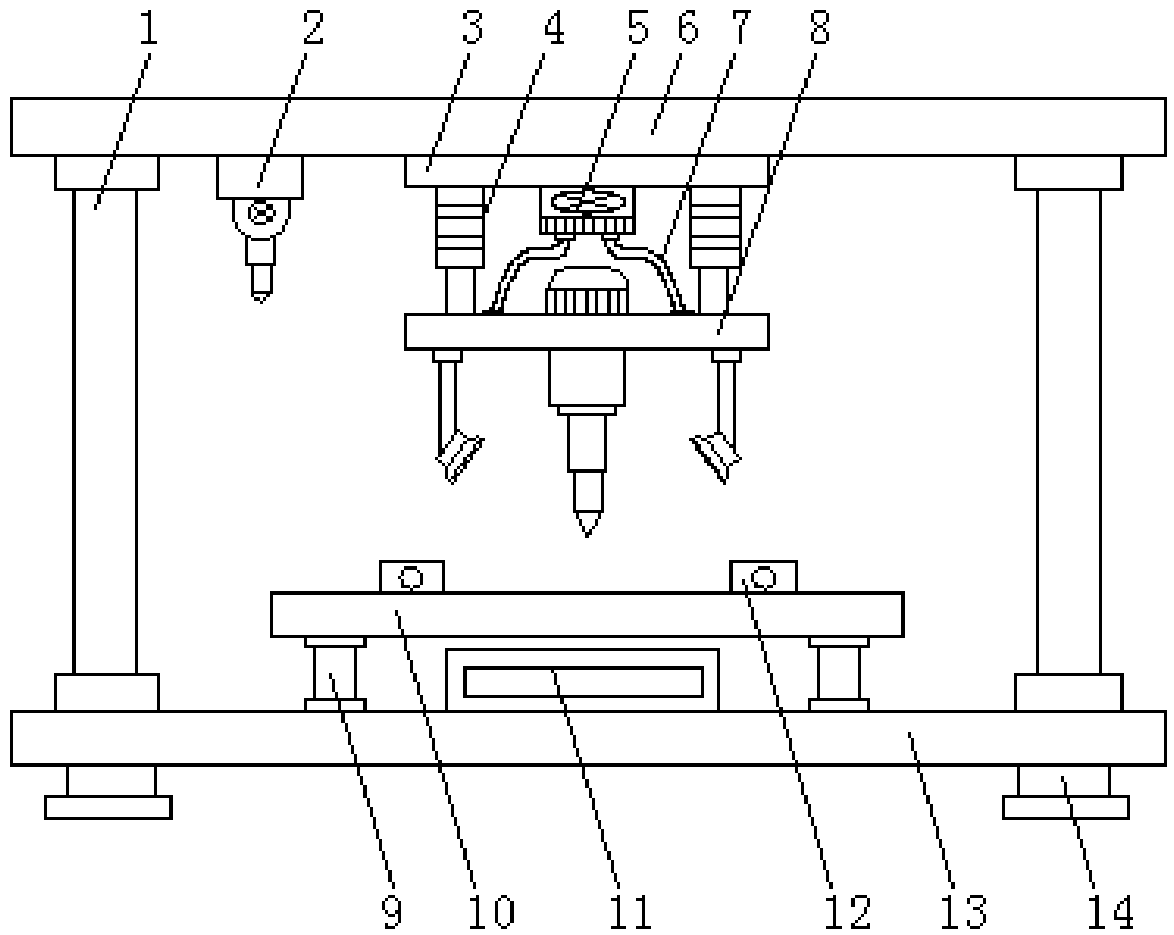

Rotating and clamping type drilling machine for workpieces

InactiveCN107649702AEasy to processEasy grippingPositioning apparatusMetal working apparatusHydraulic cylinderEngineering

The invention discloses a rotating and clamping type drilling machine for workpieces. The rotating and clamping type drilling machine comprises a worktable, a rotary plate, a clamping plate, transverse sliding rails and lifting plates. The upper end of the worktable is connected with a gantry. A hydraulic cylinder is mounted in the middle of the top end of the gantry. The hydraulic cylinder is connected with a piston rod. The bottom end of the piston rod is connected with the clamping plate. An upper clamping groove is formed in the bottom of the clamping plate. The rotary plate is arranged below the clamping plate. A transverse adjusting block is connected to one end of each transverse sliding rail. A lifting stand column is mounted on the upper side of each transverse adjusting block. Alifting sliding rail is arranged on the side face of each lifting stand column. The lifting plates are slidably arranged in the lifting sliding rails. A lifting screw penetrates through each lifting plate. A drilling motor is mounted on each lifting plate. The drilling motors are connected with drilling bits through drilling rods. By the adoption of the rotating and clamping type drilling machinefor the workpieces, workpiece clamping and direction switching are achieved conveniently, machining of the workpieces is facilitated, and no multi-time clamping fixing and changing of the direction isneeded; and in cooperation with horizontal movement of transverse adjusting blocks and vertical movement of the lifting plates, the drilling work of the drilling bits is facilitated, and the drillingefficiency and quality are improved.

Owner:NANCHANG INST OF TECH

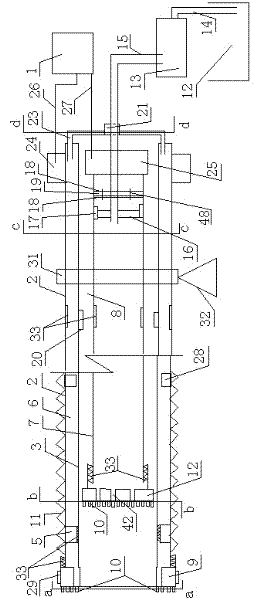

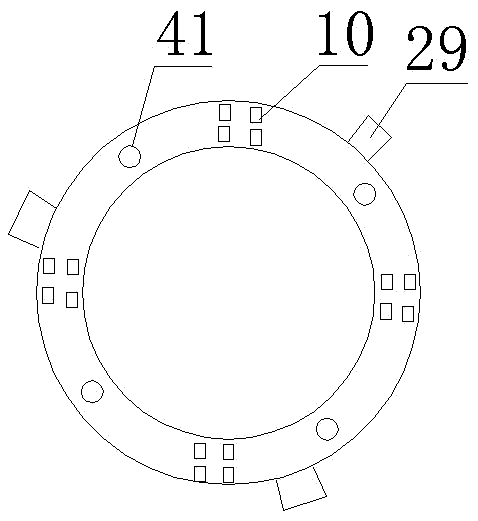

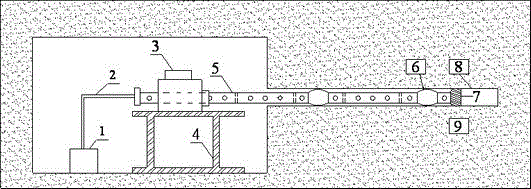

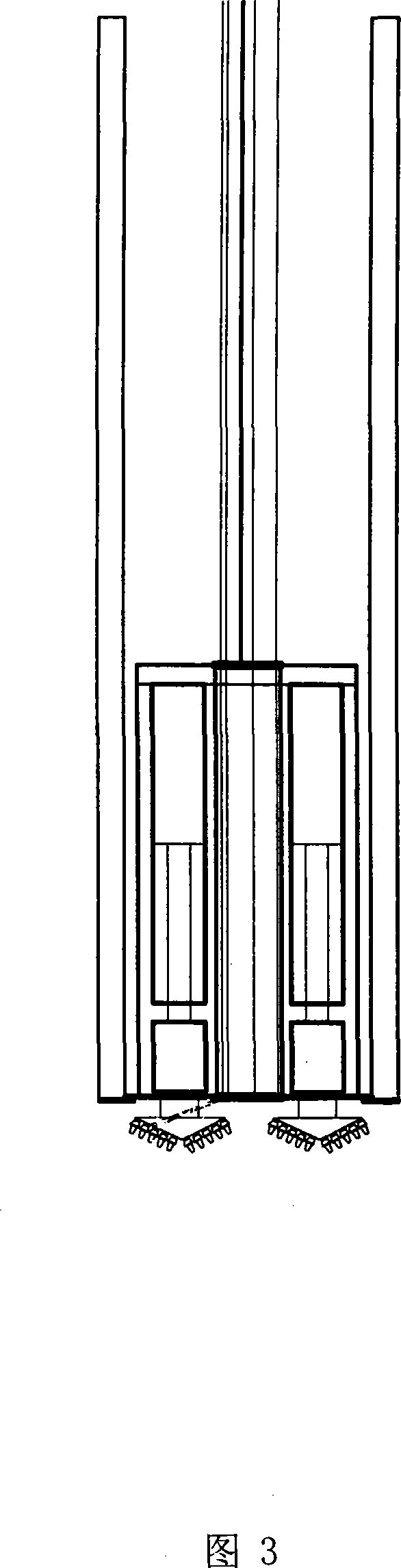

Multiple step type drilling and protecting integrated system and process for soft coal seam

ActiveCN102747953AEffective supportLarge diameterDrill bitsDirectional drillingWhole bodyAir compressor

The invention discloses a multiple step type drilling and protecting integrated system and a process for a soft coal seam. The system mainly comprises an air compressor, a high-pressure rubber hose, a hole protecting drilling machine, a rack, a hole protecting drilling rod, a guider and a simple drill. The process comprises the steps of firstly drilling a hole by using a common drilling rod and a common drill and pulling the common drilling rod and the common drill out of the hole after the hole is formed; then performing second drilling of the formed drill hole by using the hole protecting drilling rod and the simple drill in a matching mode, and simultaneously performing wind-power auxiliary slagging, when an end hole point is drilled, the hole protecting drilling rod is not withdrawn, the whole body is left inside the hole, and hole wall supporting and gas extraction functions are achieved; and finally pulling out and recycling the hole protecting drilling rod through the hole protecting driller after the gas extraction is completed. According to the system and the process, the process is unique, a hole protecting pipe can transmit high-pressure air and can extract gas, the coal dust discharging performance is strong, the hole protecting pipe moves forwards along the drill hole easily, the hole protecting pipe diameter is large, the hole protecting length is long, the problems that the soft coal seam is small in hole protecting pipe diameter and short in feeding distance are solved, and the system and the process are particularly suitable for soft high gas coal seams with a value of a sturdiness coefficient f, which ranges between 0.3 and 0.8.

Owner:CHINA UNIV OF MINING & TECH

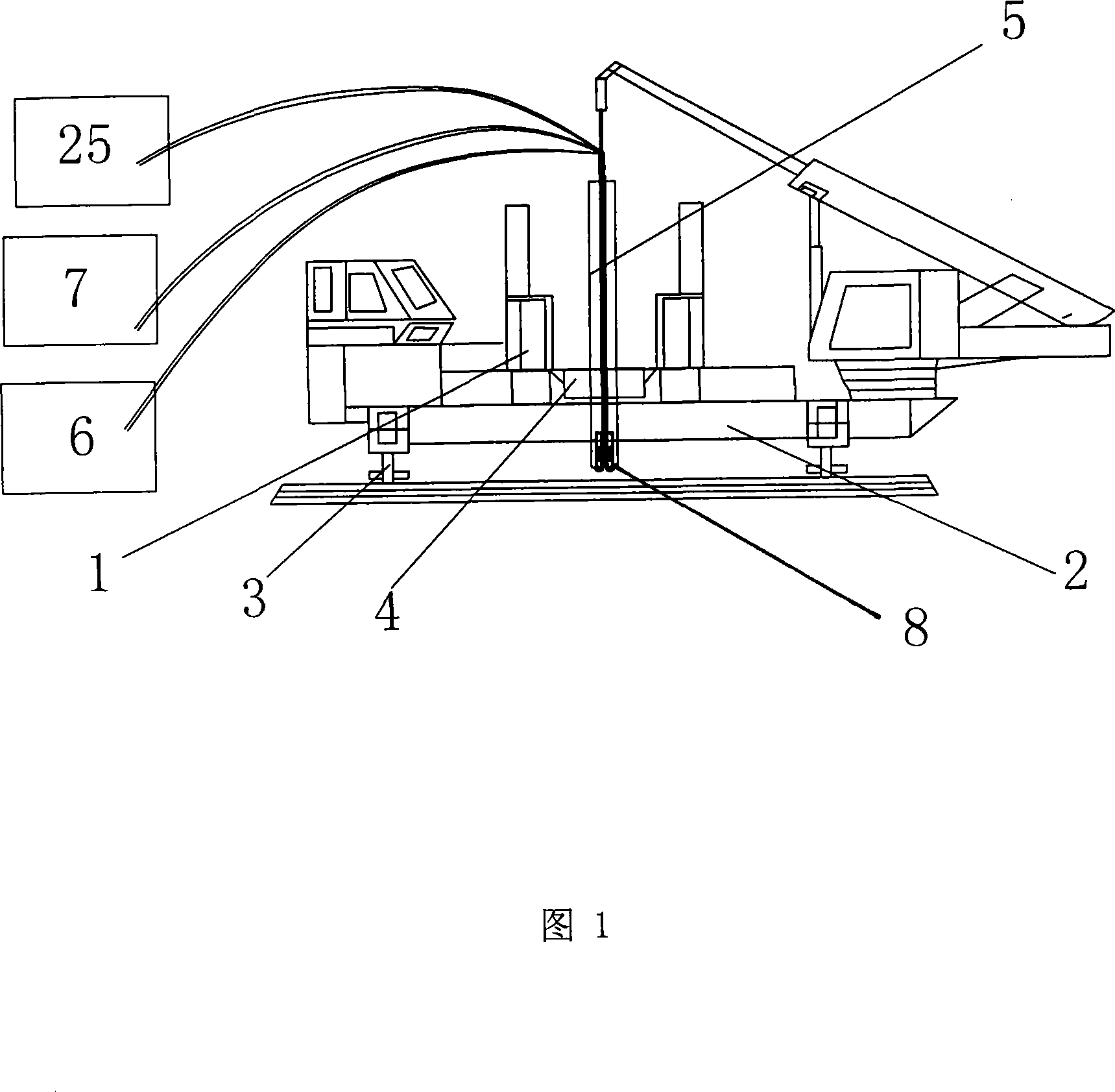

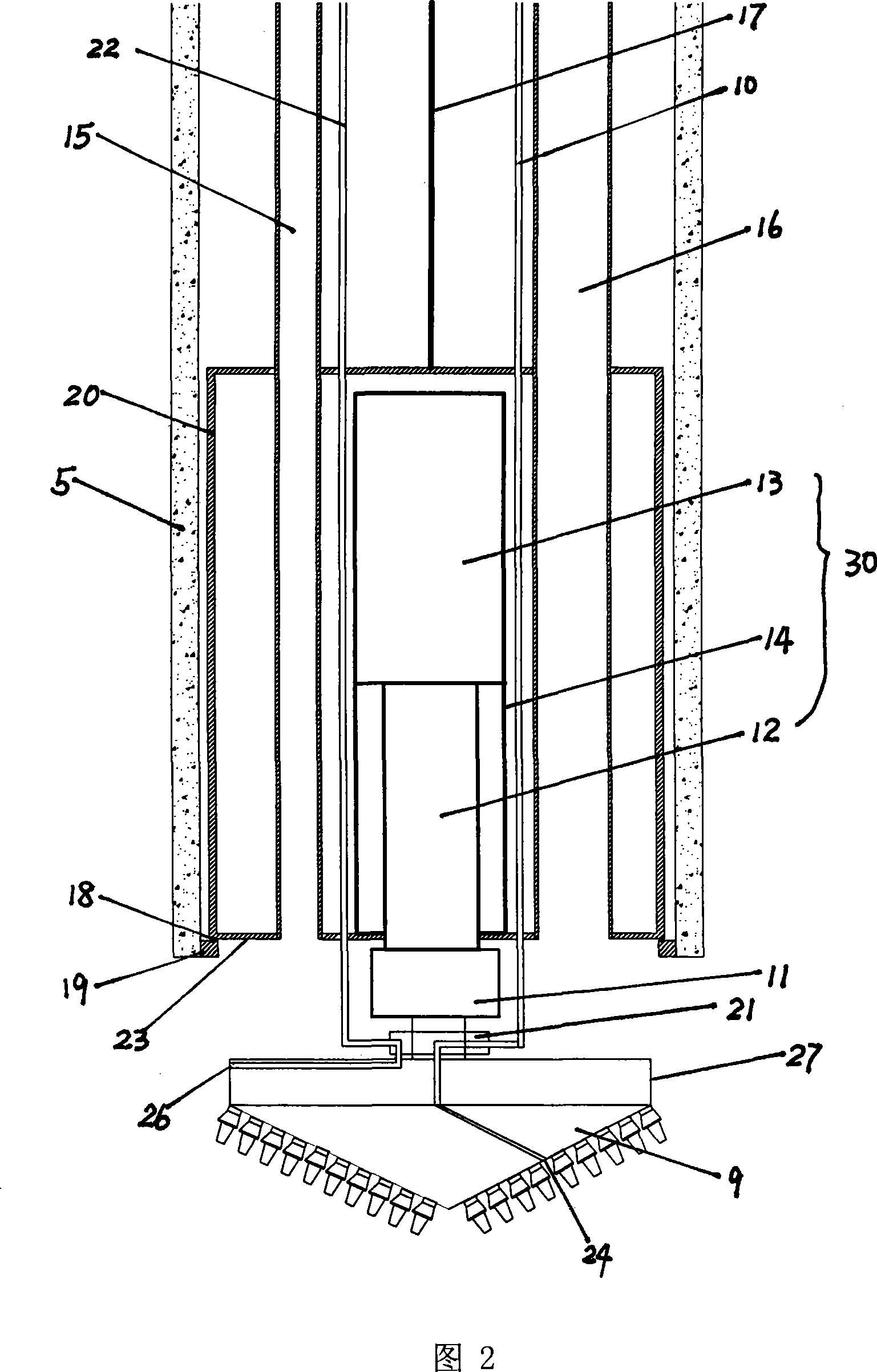

Construction machinery used for large diameter hollow pile and its construction method and use

InactiveCN101215836AReduce side frictionIncreased vertical bearing capacity of single pileBulkheads/pilesDrilling machines and methodsHigh pressureHigh load

The invention discloses a construction machine for hollow piles with large diameter and the construction method and usage, which comprises a drilling system, a pile pounding system, a drainage system which are integrated into one part. The pile forming method comprises: a high-spray drilling bit is arranged on a steel tube (a protection cylinder) or on the bottom of an inner hole of a pre-made tube pile for hole drilling and mud making; the mud is drained from a water joint or a drainage pipe; the protection cylinder or tube pile is pressed asynchronously or synchronously along with the drilling bit; during pile-sinking process, water mud is sprayed to the outer soil of the hole to solidify the surrounding soil of the pile and fill the gaps between the pile and surrounding soil of the pile; after the drilling bit reaches certain depth, the water mud is again sprayed to solidify surrounding soil of the pile; lifting the drilling bit; putting down reinforcement cage; casting concrete for piling. The invention is a construction method for foundation piles and drilling with large diameter, super long and high load, which especially provides convenient, labor-saving, rapid and economical equipment and method for marine pile driving.

Owner:雷玉华

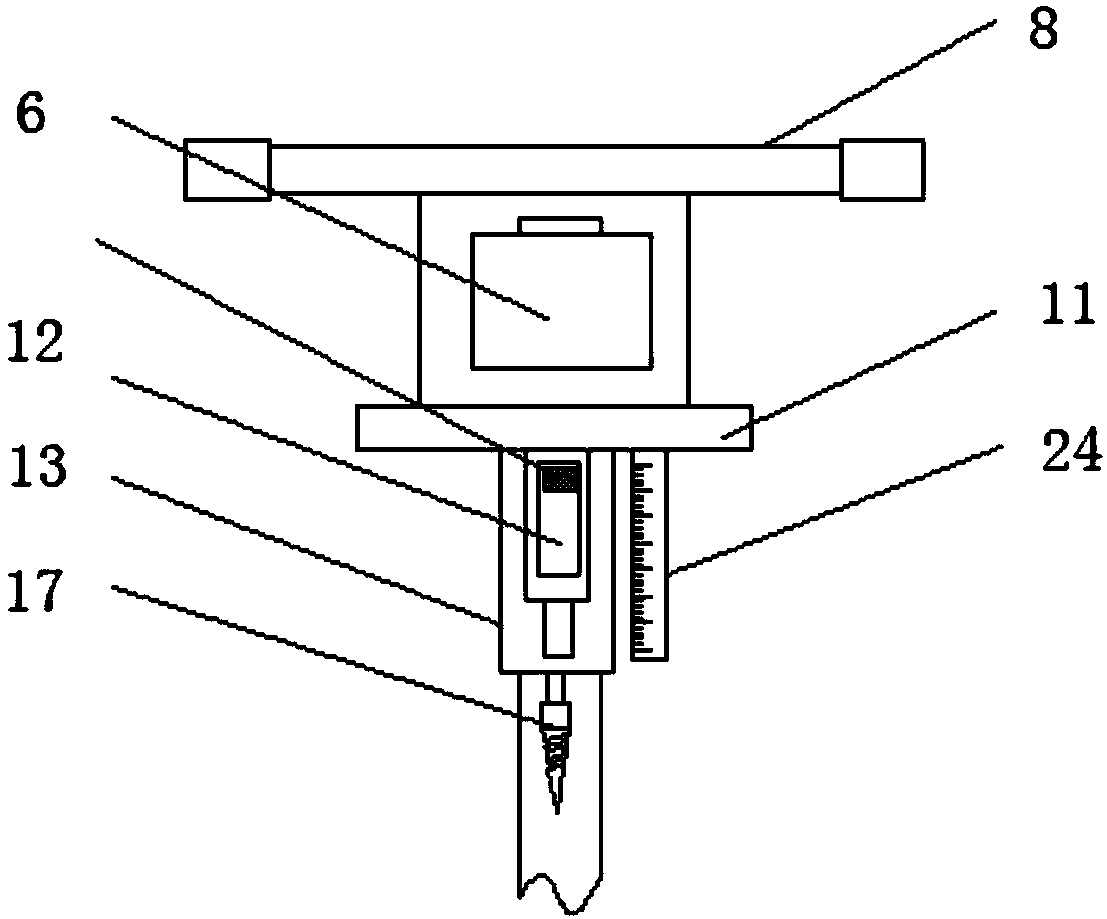

Hole drilling device having depth adjusting function

InactiveCN108296526ADepth adjustableQuality improvementFeeding apparatusPositioning apparatusElectric machineryDrive motor

The invention relates to the field of hole drilling devices and discloses a hole drilling device having the depth adjusting function. The hole drilling device having the depth adjusting function comprises a base. A supporting rod is fixedly installed on one side of the top of the base. A first bearing is fixedly arranged in the middle of the supporting rod in a sleeved manner. The front face, theback face and the side face of the first bearing are all fixedly connected with tow bars. The top of the supporting rod is movably connected with a rotating plate in a sleeved manner. One side of thetop of the rotating plate is fixedly provided with a first drive motor. The bottom end of an output shaft of the first drive motor is fixedly connected with a lead screw. According to the hole drilling device having the depth adjusting function, through downward movement of a following block, a following shaft is driven to move downwards, the following shaft is made to be located at the needed drilling depth according to scales on a fixing pipe, and through rotation of a nut, the following shaft is fixed by means of cooperation of a locating sleeve; during drilling, when a mark post makes contact with the following shaft, the hole drilling device reaches the needed drilling depth, and therefore the drilling depth is accurately controlled; and in this way, the quality of a machined device is improved, and the phenomenon that the hole drilling depth of the machined device do not meet a demand, so that waste is caused is avoided.

Owner:王华亮 +1

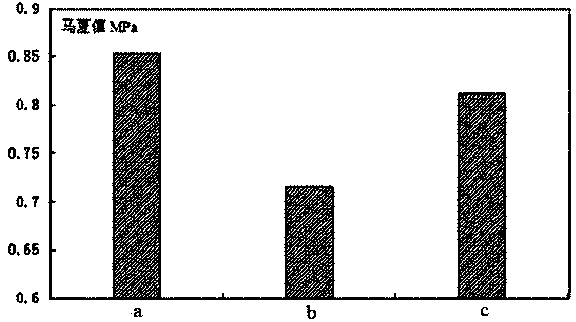

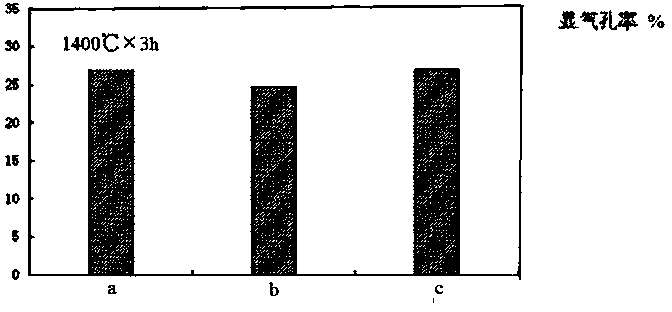

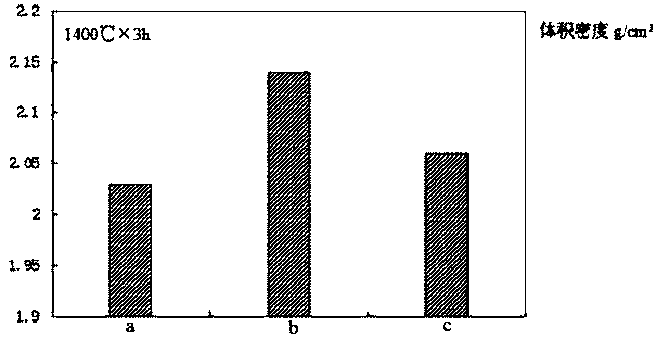

Environment-friendly anhydrous tamping plug and preparation method thereof

The invention relates to an environment-friendly anhydrous tamping plug and a preparation method thereof and belongs to the field of fireproof materials. The environment-friendly anhydrous tamping plug comprises the following components by weight: 15-20 parts of coke, 22-43 parts of bauxite, 0-10 parts of brown aluminum oxide, 20-25 parts of silicon carbide, 0-8 parts of silicon nitride, 0-3 parts of silicon metal, 10-15 parts of clay, 3-6 parts of sericite and 15-20 parts of a binding agent, wherein the total parts of all materials, except for the binding agent, is 100 parts; the binding agent is composed of the following raw materials in parts by weight: 20-60 parts of carbon-containing resin, 20-50 parts of vegetable fat, 10-40 parts of linear phenolic resin and 5-10 parts of carbon powder. The environment-friendly anhydrous tamping plug has the following advantages of (1) being low in harmful substance content and harmless to a human body; (2) being free of smoke dust and hardly affecting the environment; (3) meeting the use requirements of flushing and casting operation of a blast furnace.

Owner:渑池金华新材料有限公司

Metal plate drilling device

InactiveCN108284239AReduce processing efficiencyAvoid wastingPositioning apparatusMetal working apparatusPunchingEngineering

The invention relates to the field of drilling equipment, and discloses a metal plate drilling device. The metal plate drilling device comprises a base. An end face bearing is fixedly arranged on oneside of the top of the base. A supporting column is fixedly sleeved with the middle portion of the end face bearing. The top end of the supporting column is fixedly sleeved with a rotation block. A sliding rod is fixedly connected to the side face of the rotation block. The end, away from the rotation block, of the sliding rod is fixedly connected with a limiting baffle. According to the metal plate drilling device, a positioning nut rotates on a threaded rod, and the deepest punching position is determined in cooperation with the positions of a right side marker post and a dividing ruler. During punching, only a moving pipe needs to be downwards moved, a drill bit is driven to move downwards to conduct drilling till a left side marker post makes contact with the positioning nut, then drilling is conducted to the deepest position, accordingly, the situation that the metal plate depth cannot be accurately controlled, the metal plate drilling quality cannot meet the project requirement,consequently, raw materials are wasted, and the metal plate machining efficiency is reduced is avoided.

Owner:陈灵燕

Hollow turbomachine blade

ActiveUS7530788B2Easy to manufactureImprove cooling effectPropellersPump componentsLeading edgeTrailing edge

A hollow turbomachine blade including an internal cooling passage, an open cavity situated at the free end of the blade and defined by an end wall and the side wall of at least one rim which extends between the leading edge and the trailing edge of the blade, and at least one cooling channel connecting said internal cooling passage to said open cavity, said cooling channel opening out at the base of the rim and the wall of the rim forming an angle relative to said end wall that is obtuse, being strictly greater than 90°. An indentation may be formed in the wall of the rim at the outlet from said cooling channel. Said blade advantageously does not include a pressure rim.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Drilling equipment for machining

InactiveCN108405899AIncrease frictionEasy to operatePositioning apparatusMaintainance and safety accessoriesCouplingMachining

The invention discloses drilling equipment for machining. The drilling equipment includes a support plate and a top plate, a drilling platform is arranged on the support plate, and an opening is formed in the surface of the drilling platform. Positioning plates are arranged around the opening, screw push rods are arranged on the positioning plates, and clamping plates are arranged at the front ends of the screw push rods. A fixing plate is arranged on the bottom surface of the top plate, a blower is installed on the bottom surface of the fixing plate, and hydraulic telescopic rods are installed on the two sides of the blower. A connecting plate is arranged at the lower ends of the hydraulic telescopic rods, a motor is installed at the center of the upper end of the connecting plate, and arotating shaft is connected to the output end of the motor through a coupling. A drill bit frame is arranged at the bottom end of the rotating shaft, air outlet pipes are arranged on the two sides ofthe drill bit frame, and a laser lamp holder is installed at the lower end of a fixing block. The drilling equipment for machining is easy to operate and convenient to drill, the position of a plate to be punched can be located quickly through a laser lamp, drilling is precise, waste generated during drilling can be removed in time, and the working efficiency is improved greatly.

Owner:ZHEJIANG JUFENG WOOD IND

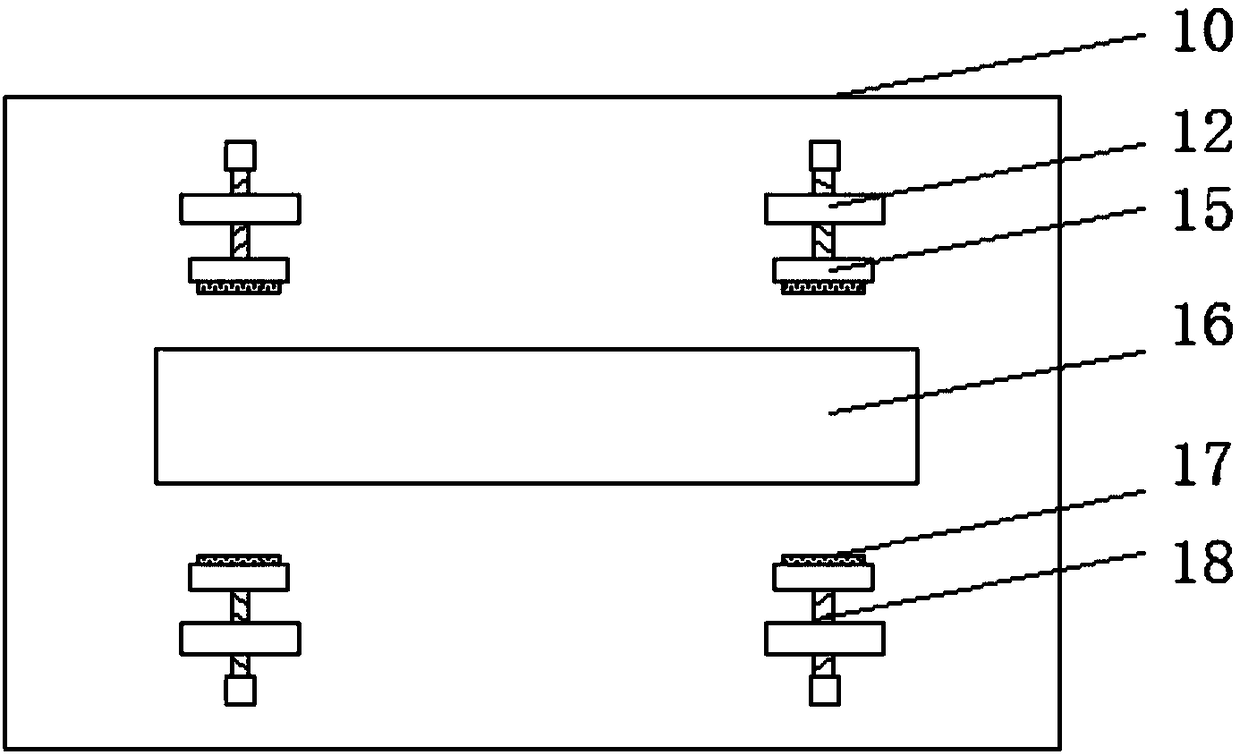

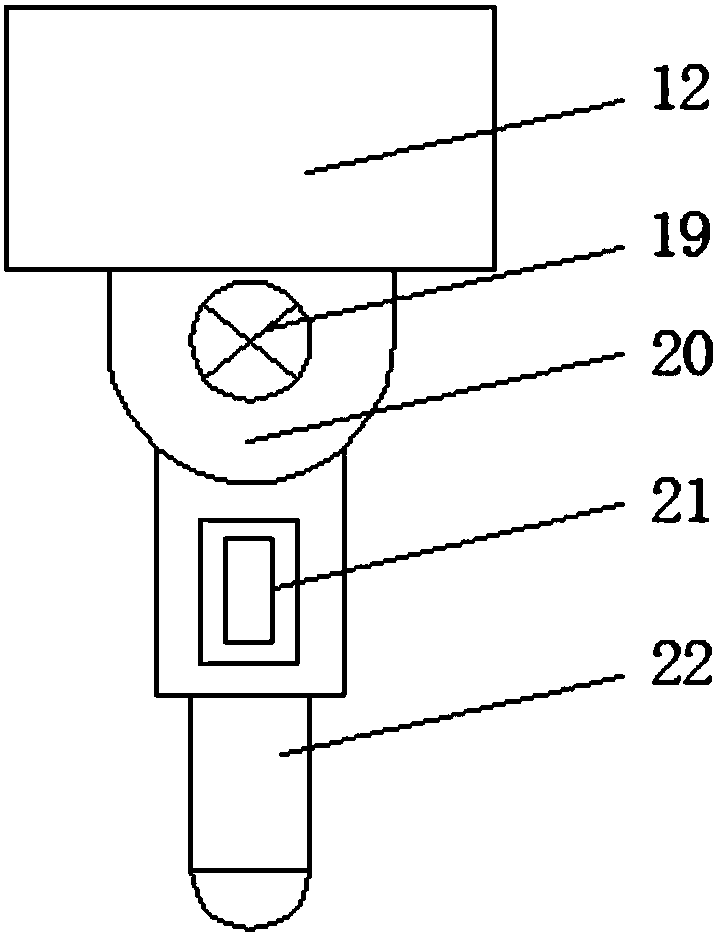

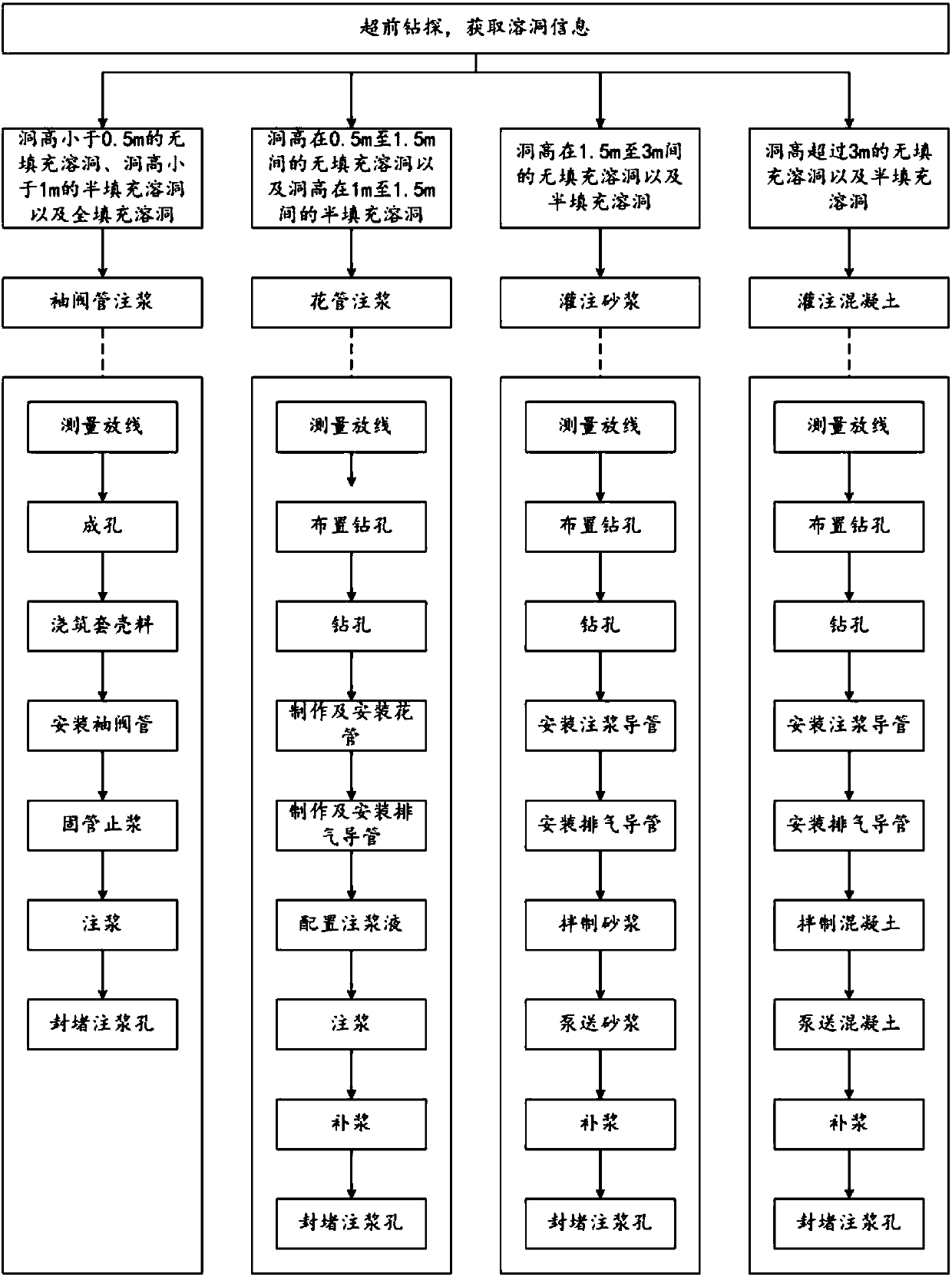

Karst cave treatment method applied to karst area cast-in-situ bored pile construction

The invention relates to a treatment method of karst caves with different sizes and types applied to karst area cast-in-situ bored pile construction. Firstly, the depths and the heights of the karst caves at pile positions are obtained by adopting an advance drilling technology; treatment is conducted on non-filled karst caves and semi-filled karst caves with the cave heights being higher than 3 mby adopting a concrete pouring method; treatment is conducted on non-filled karst caves and semi-filled karst caves with the cave heights being between 1.5 m and 3 m by adopting a mortar pouring method; treatment is conducted on non-filled karst caves with the cave heights being between 0.5 m and 1.5 m and semi-filled karst caves with the cave heights being between 1 m and 1.5 m by adopting a screen pipe grouting method; and treatment is conducted on non-filled karst caves with the cave heights being lower than 0.5 m and semi-filled karst caves and full-filled karst caves with the cave heights being lower than 1 m by adopting a sleeve valve pipe grouting method. The karst cave treatment method can conduct treatment on the different types of karst caves well.

Owner:CHINA FIRST METALLURGICAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com