Patents

Literature

37342results about How to "Reduce vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

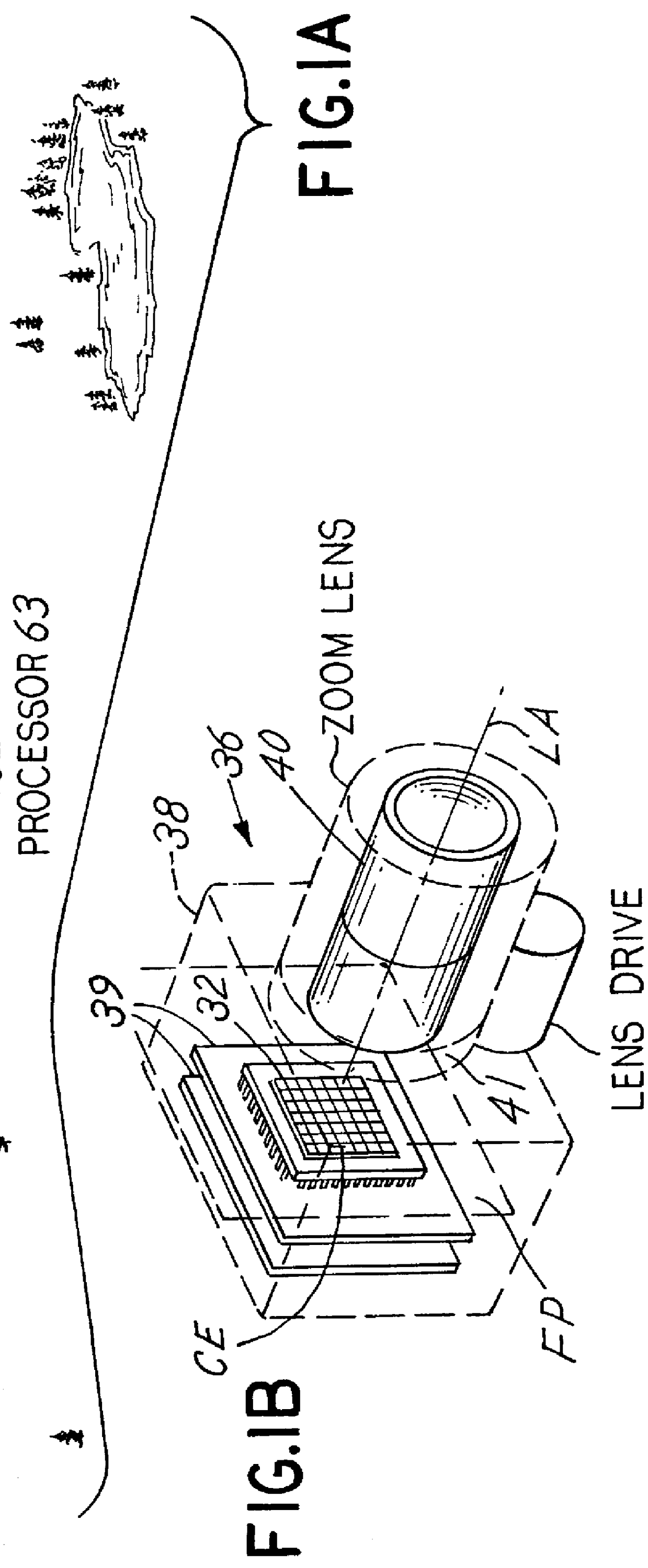

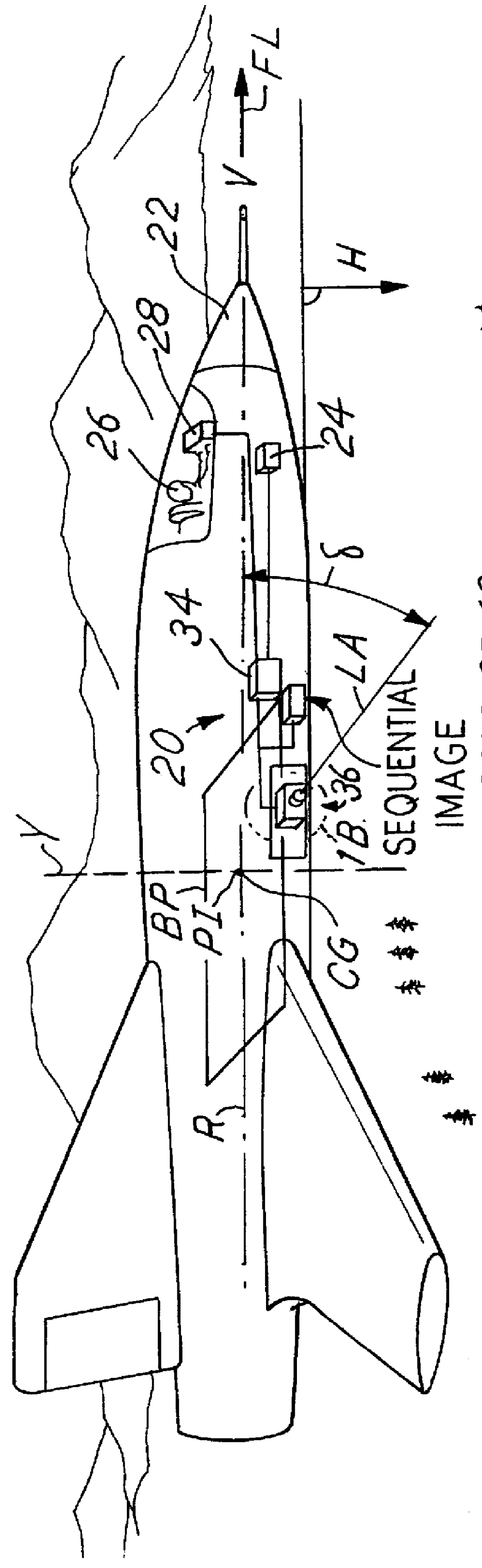

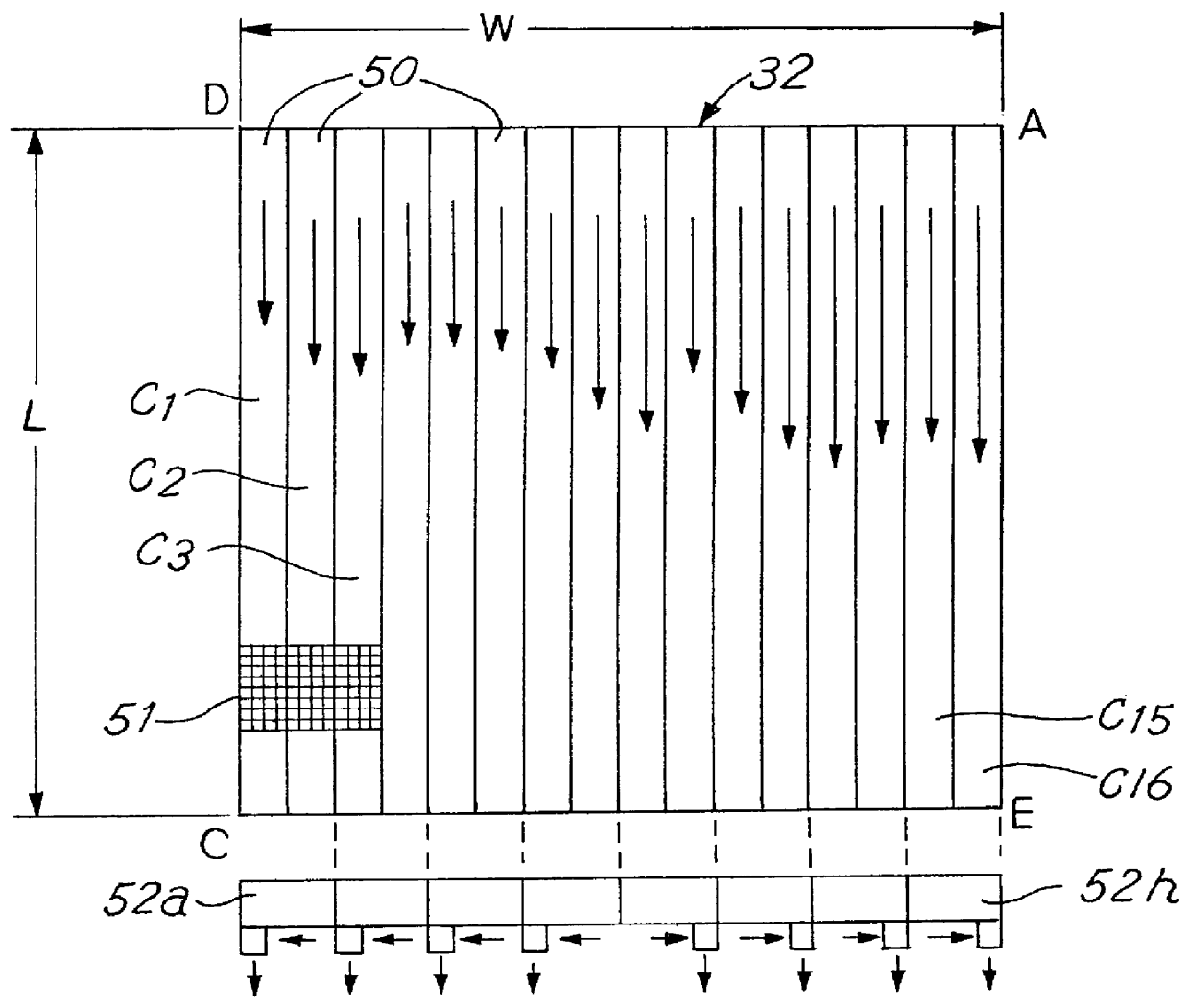

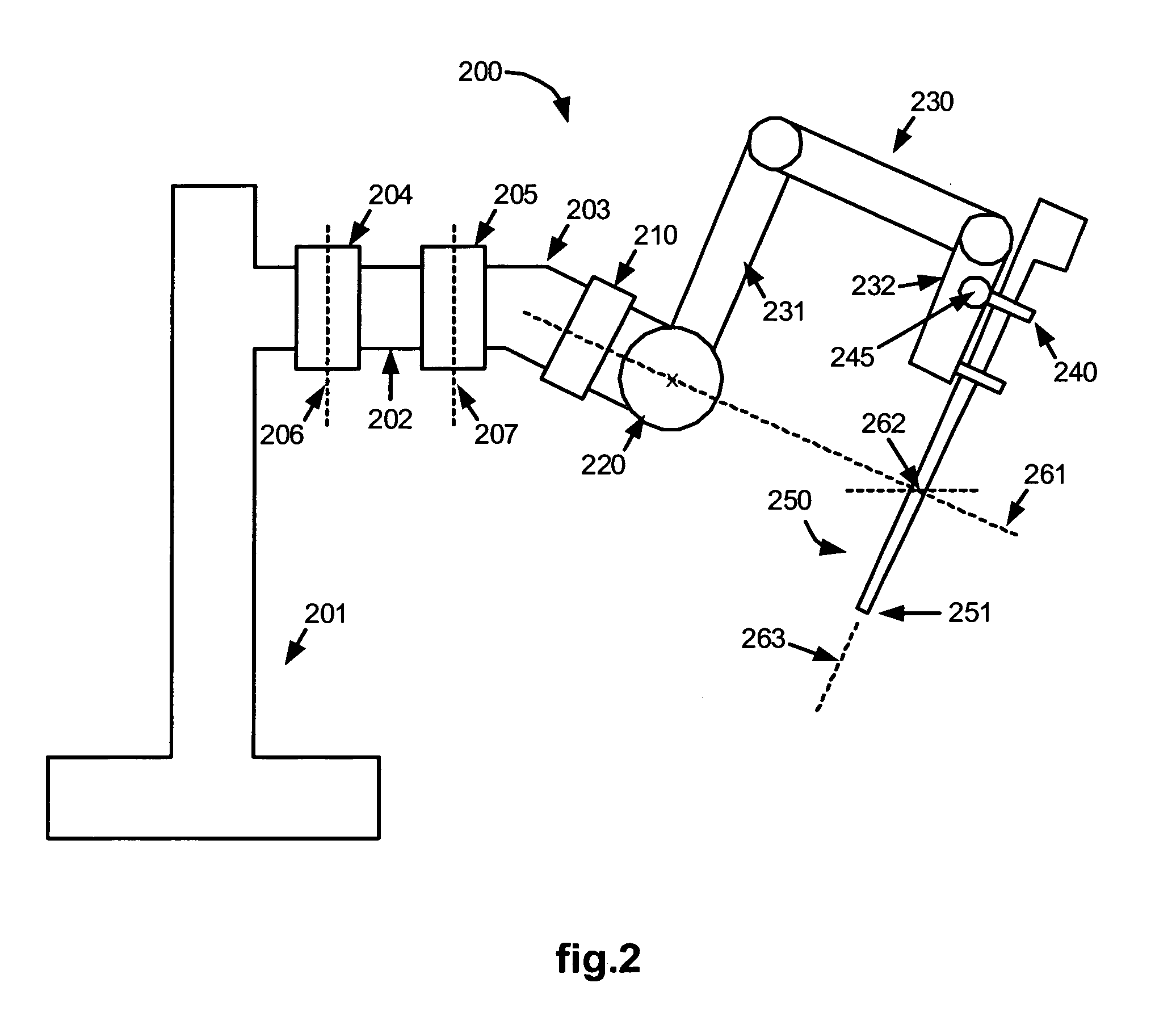

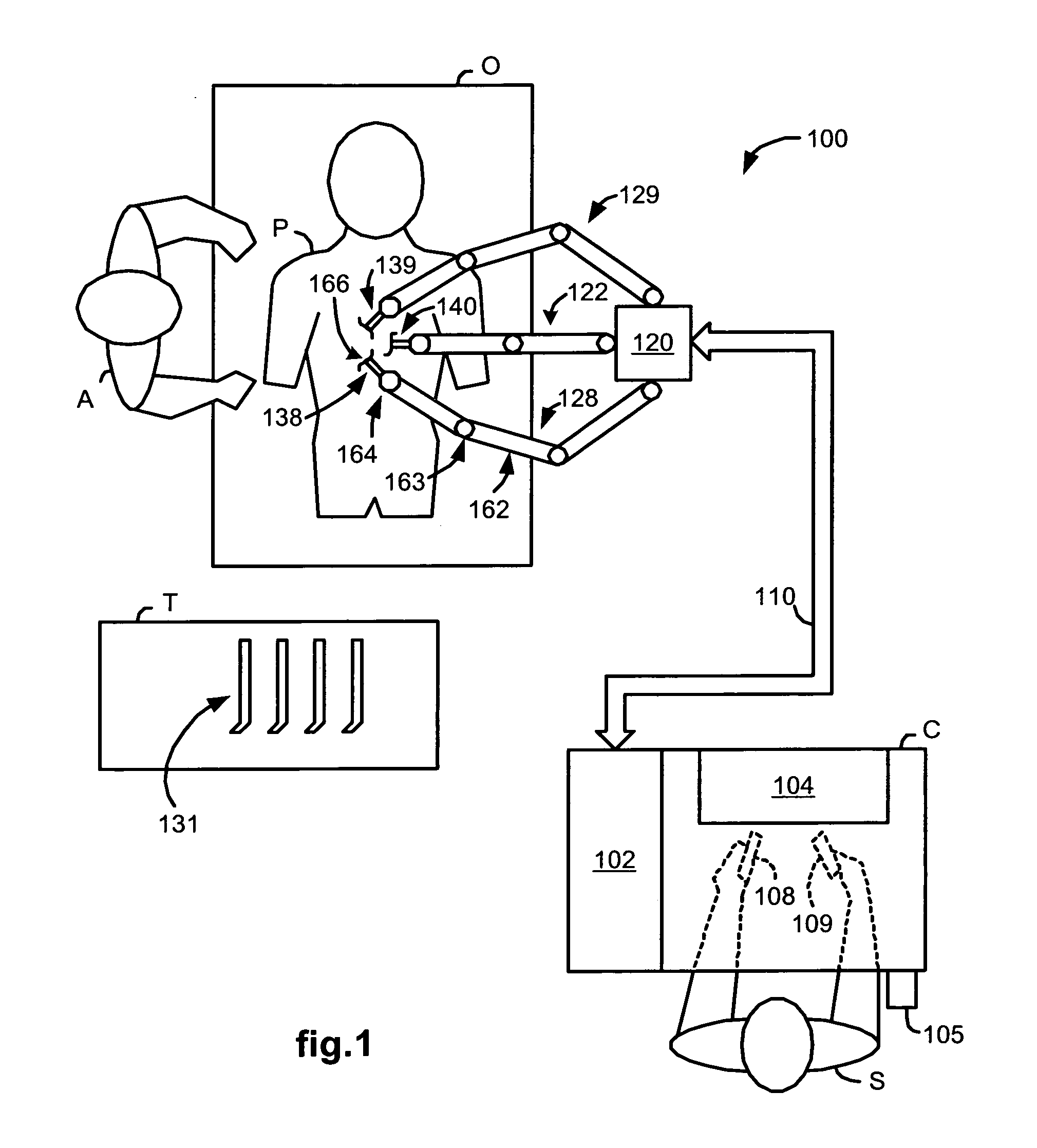

Autonomous electro-optical framing camera system with constant ground resolution, unmanned airborne vehicle therefor, and methods of use

InactiveUS6130705AReduce vibrationIncrease flexibilityTelevision system detailsOptical rangefindersCamera imageImage resolution

An aerial reconnaissance system generates imagery of a scene that meets resolution or field of view objectives automatically and autonomously. In one embodiment, a passive method of automatically calculating range to the target from a sequence of airborne reconnaissance camera images is used. Range information is use for controlling the adjustment of a zoom lens to yield frame-to-frame target imagery that has a desired, e.g., constant, ground resolution or field of view at the center of the image despite rapid and significant aircraft altitude and attitude changes. Image to image digital correlation is used to determine the displacement of the target at the focal plane. Camera frame rate and aircraft INS / GPS information is used to accurately determine the frame to frame distance (baseline). The calculated range to target is then used to drive a zoom lens servo mechanism to the proper focal length to yield the desired resolution or field of view for the next image. The method may be performed based on parameters other than range, such as aircraft height and stand off distance.

Owner:THE BF GOODRICH CO

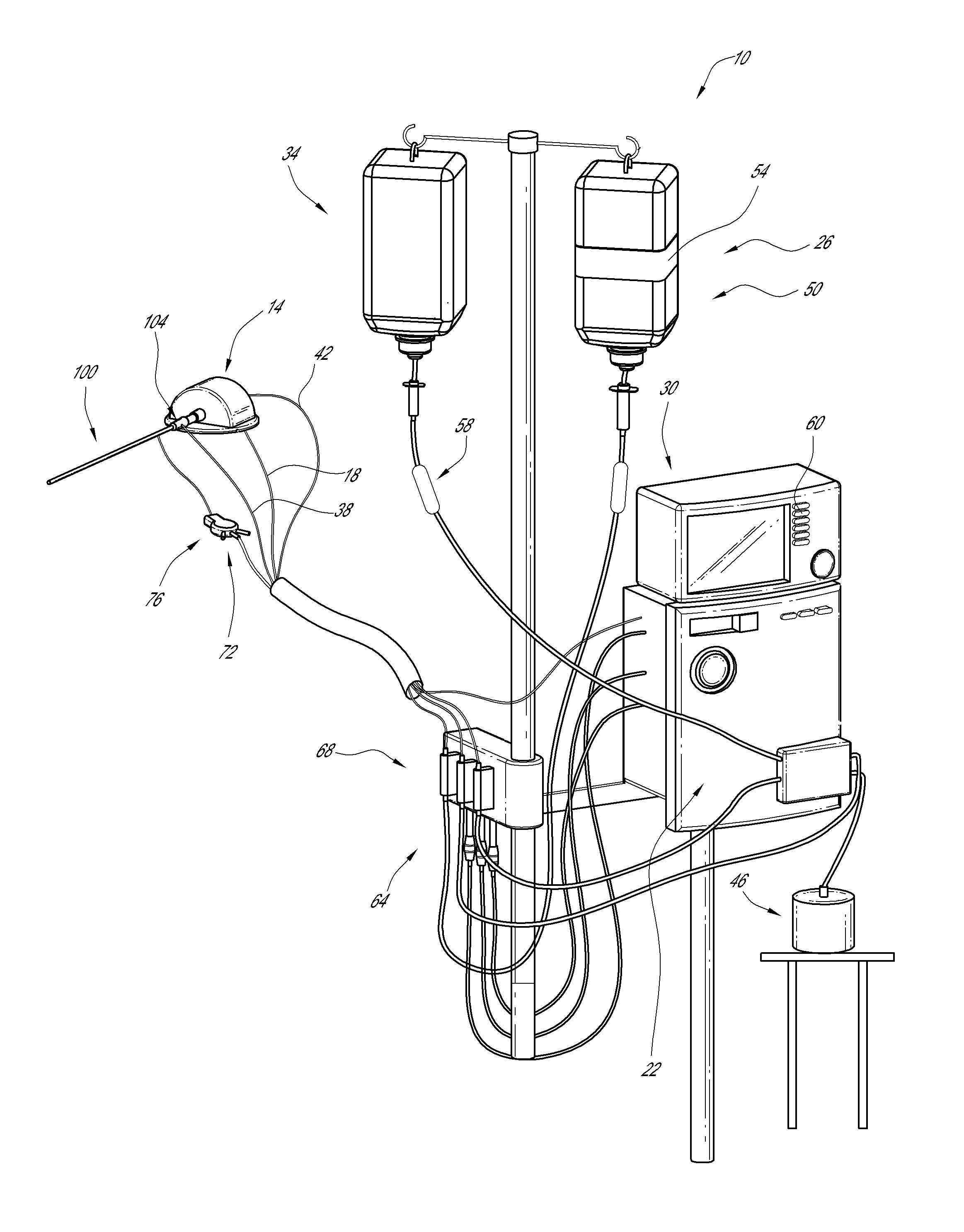

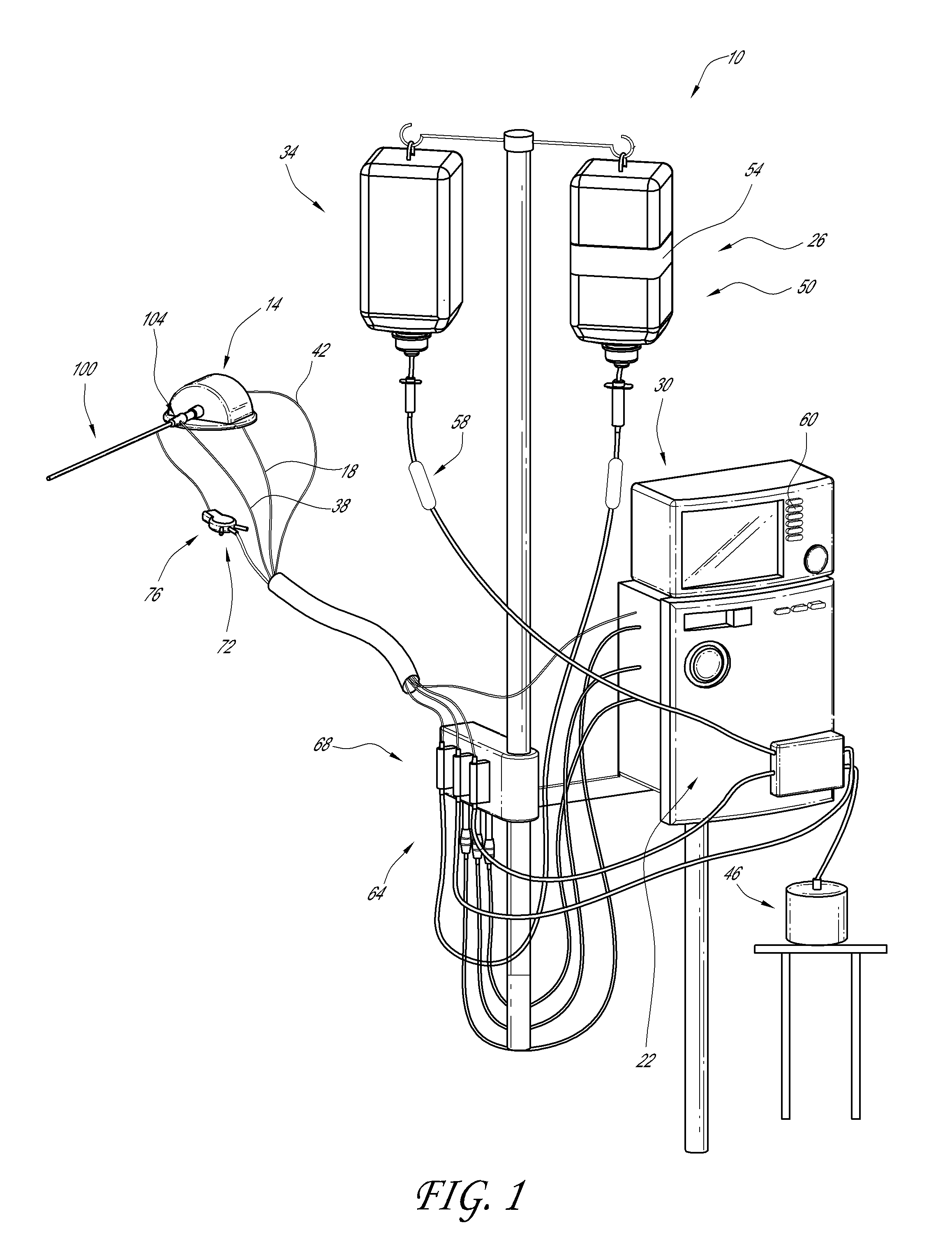

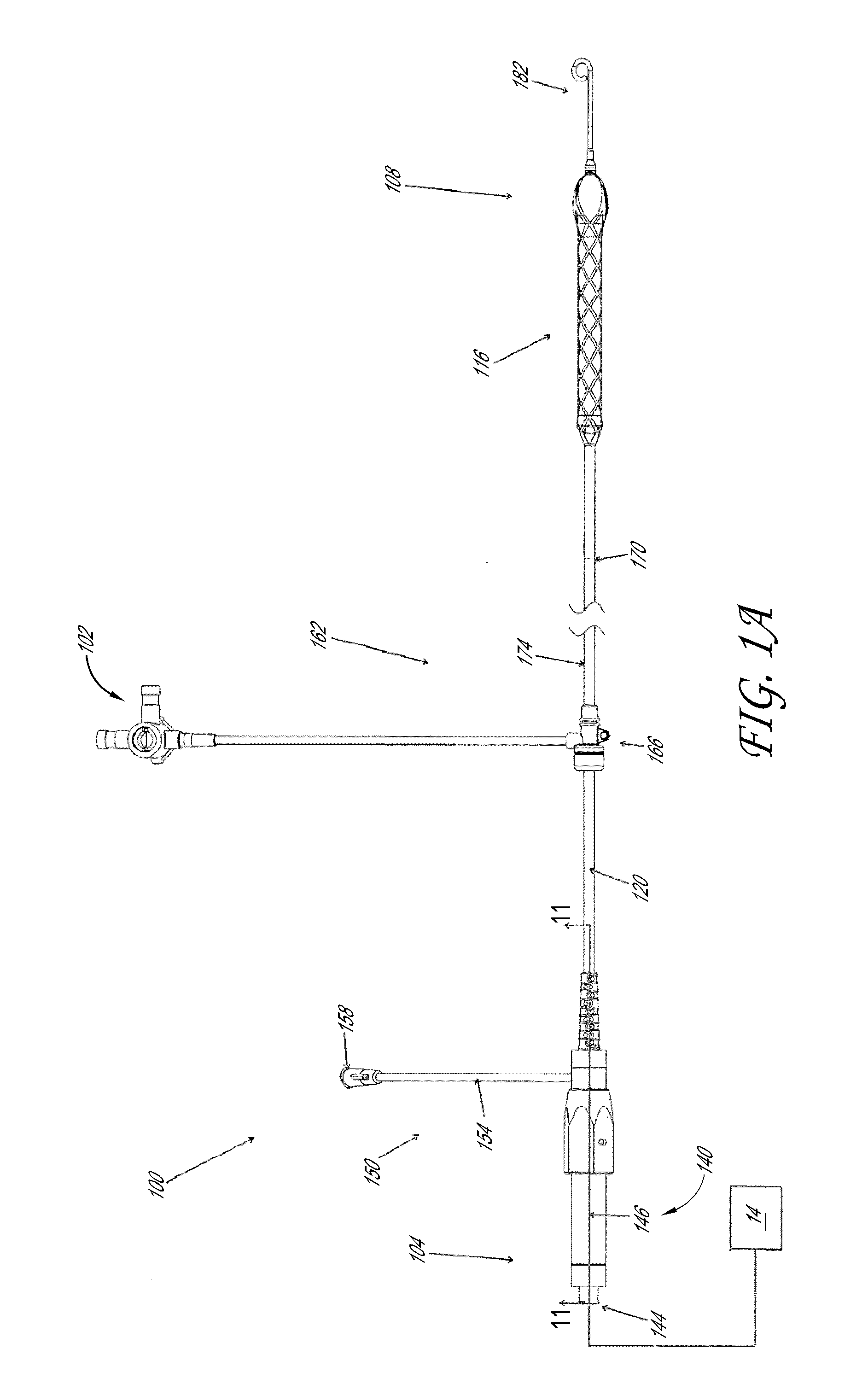

Impeller housing for percutaneous heart pump

Disclosed herein are heart pumps that include a catheter assembly and that can be applied percutaneously. Some embodiments include a locking device that prevents components of the catheter assembly from being separated when in use. The catheter assembly can include an expandable tip. In some embodiments, the catheter assembly includes a housing having a wall structure, a portion of which can have a bulbuous shape or can be deformable. In other embodiments, the housing can be configured to reduce fluttering or deflection of the housing and / or to maintain a gap between the housing and an impeller blade disposed therein.

Owner:PENN STATE RES FOUND +1

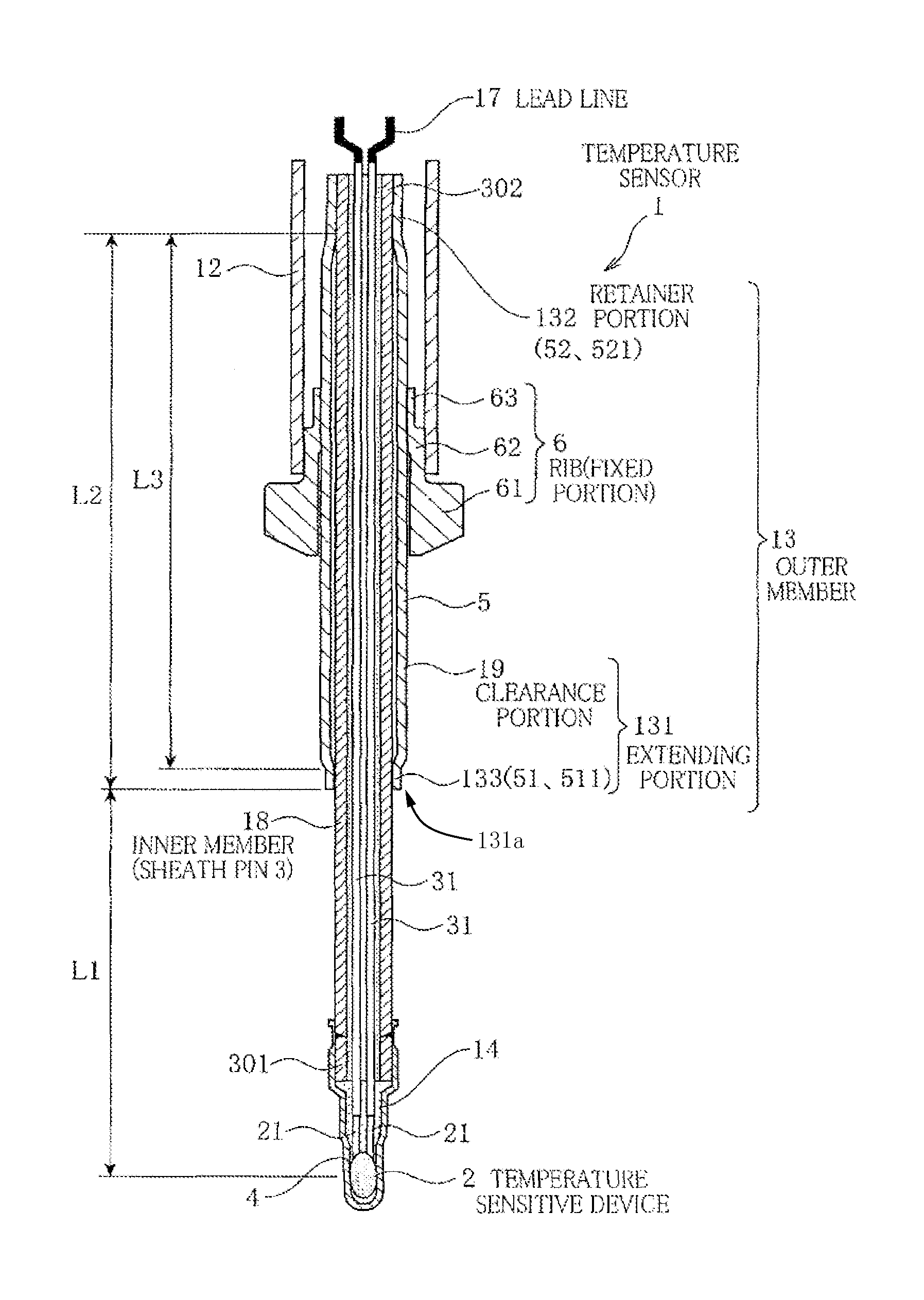

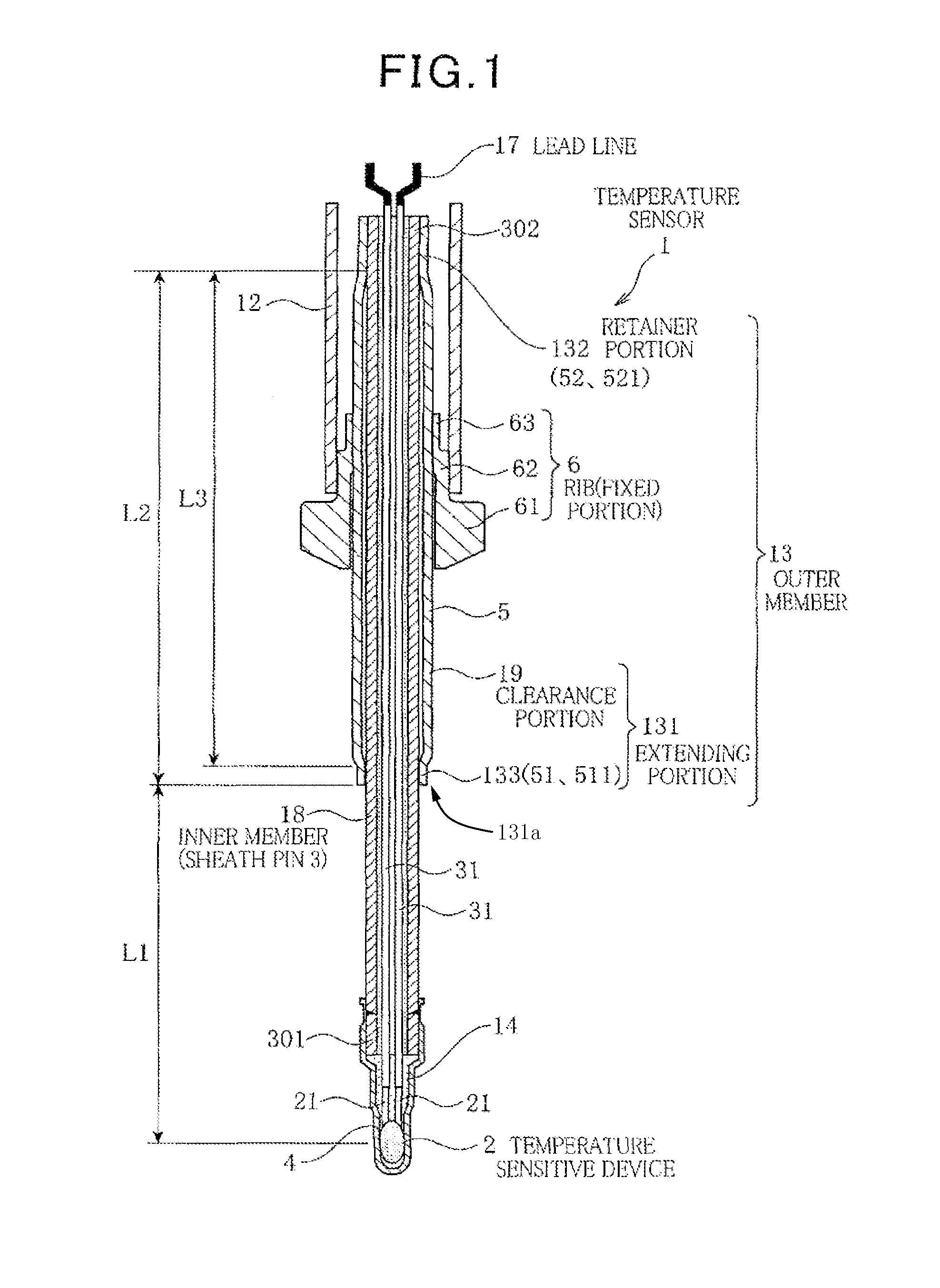

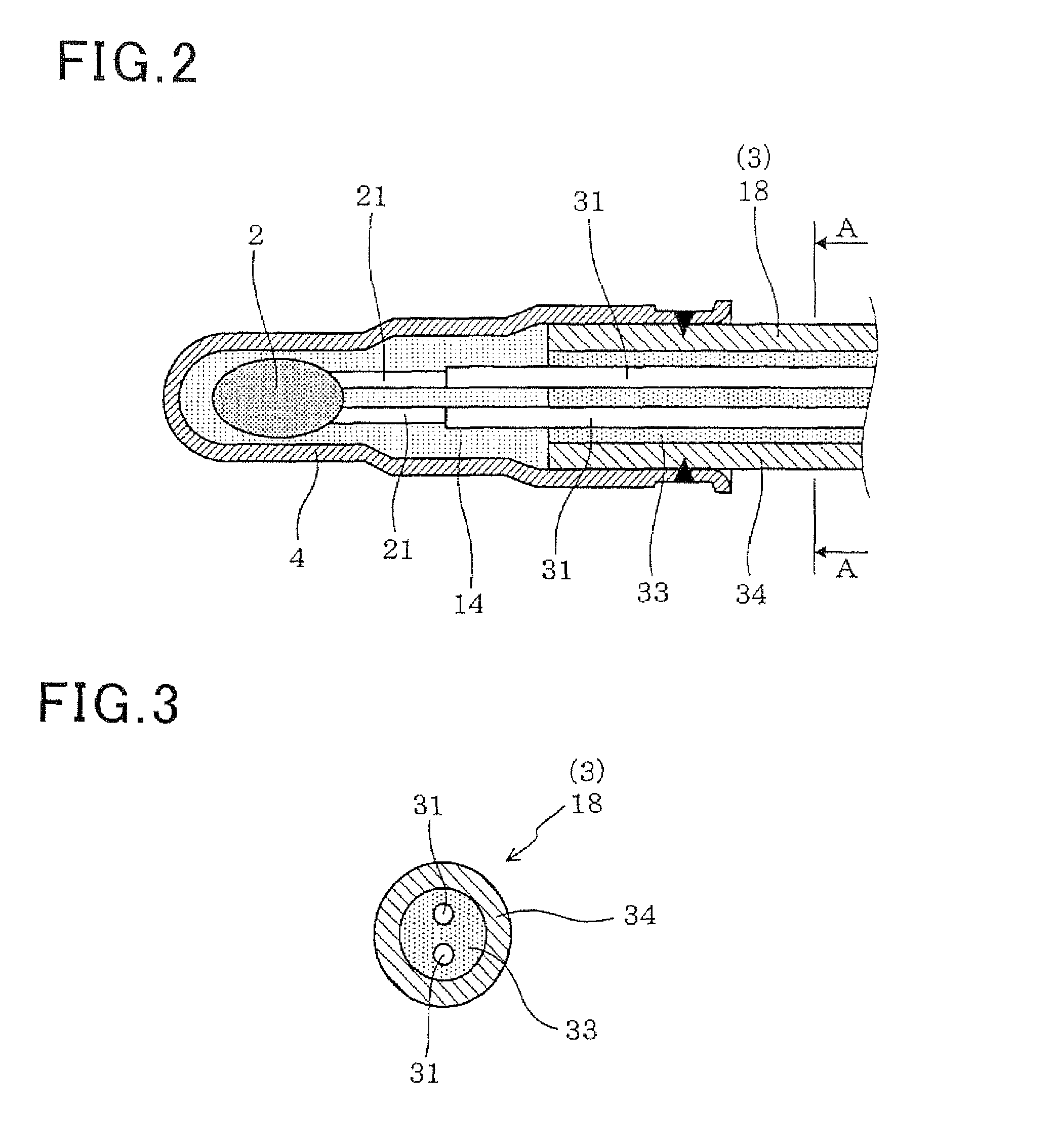

Temperature sensor

ActiveUS8864375B2Reduce vibrationReduce the overall heightThermometer detailsTemperature measurement in motorsInternal combustion engineExhaust pipe

The temperature sensor 1 is equipped with a temperature sensitive device 2 to be disposed inside an exhaust pipe of an internal combustion engine, signal lines 31 connected at a top end side to the temperature sensitive device 2 and at a rear end side to leads for connection with an external circuit, an inner member 18 having a sheath pin 3 in which the signal lines 31 are disposed, and an outer member 13 disposed to cover at least a portion of an outer periphery of the inner member 18. The outer member 13 includes a fixed portion (rib 6) to be fixed to an upper wall of the exhaust pipe, a retainer portion 132 retaining the inner member 18, and an extending portion 131 formed closer to a top end side than the retainer portion 132. The extending portion 131 includes a clearance portion 19 disposed so as to have an air gap between itself and the inner member 18 and a front interference portion 133 disposed in a condition that a maximum air gap between the front interference portion 133 and the inner member 18 in a radius direction is 0.2 mm or less.

Owner:DENSO CORP

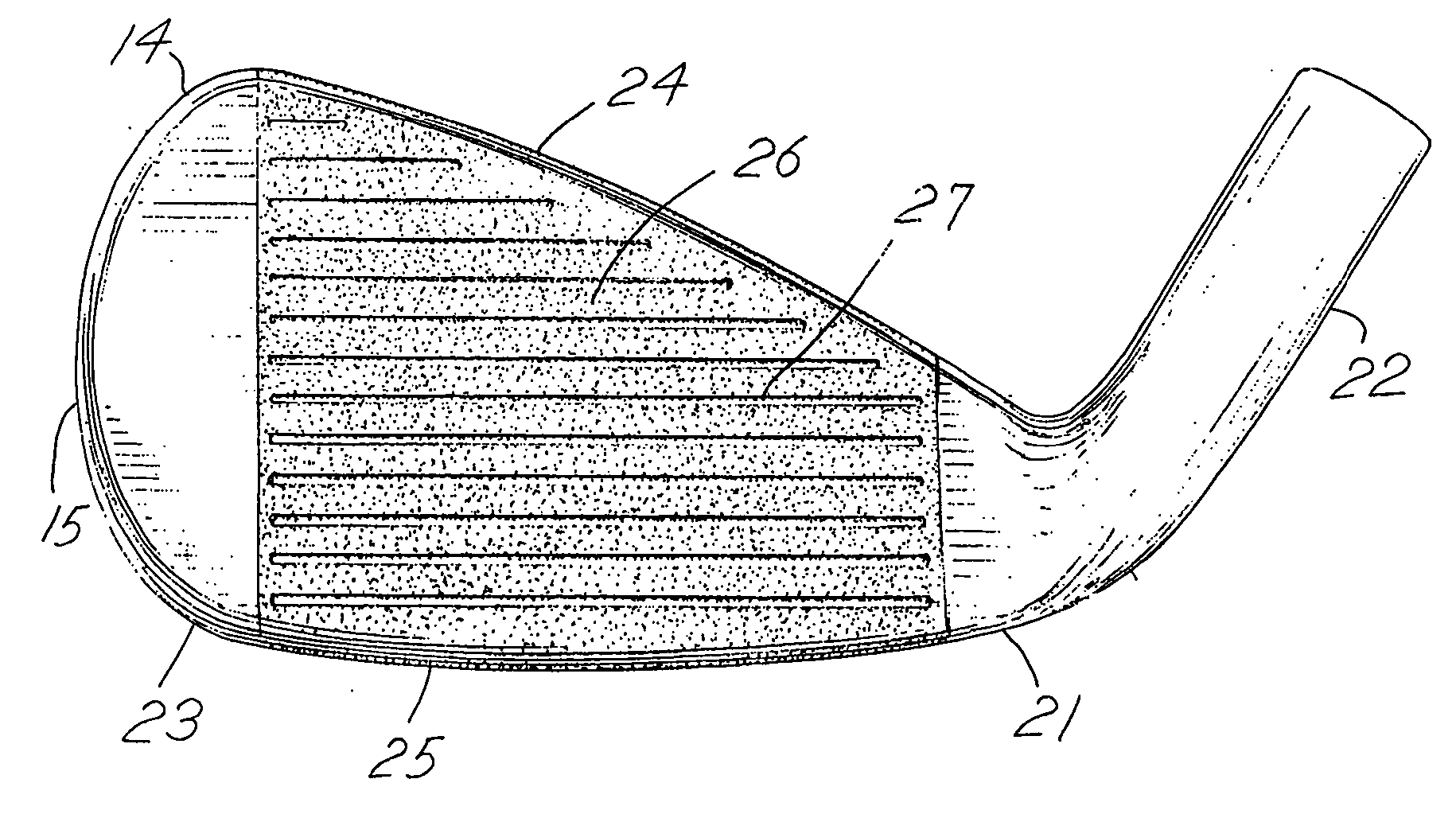

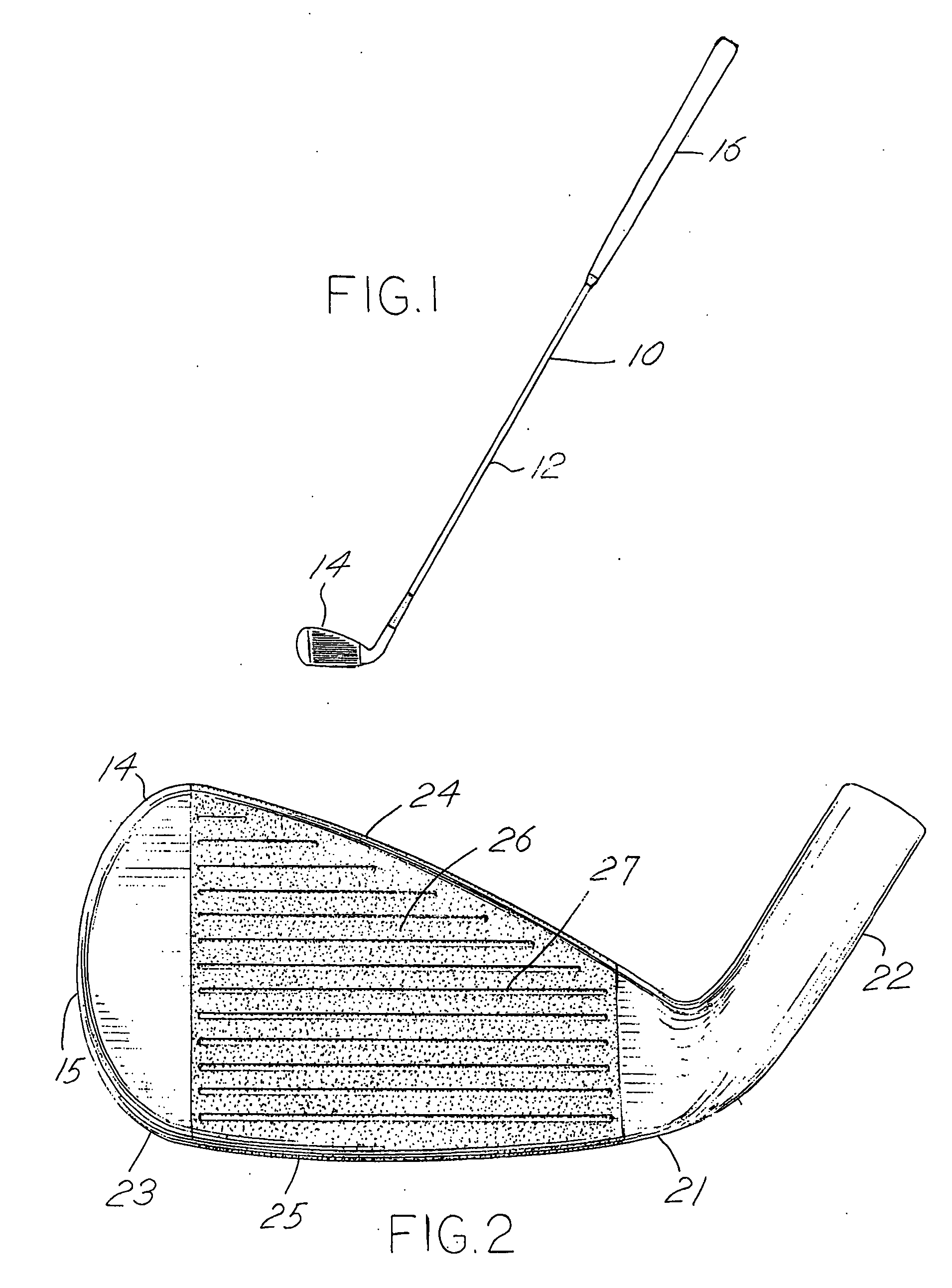

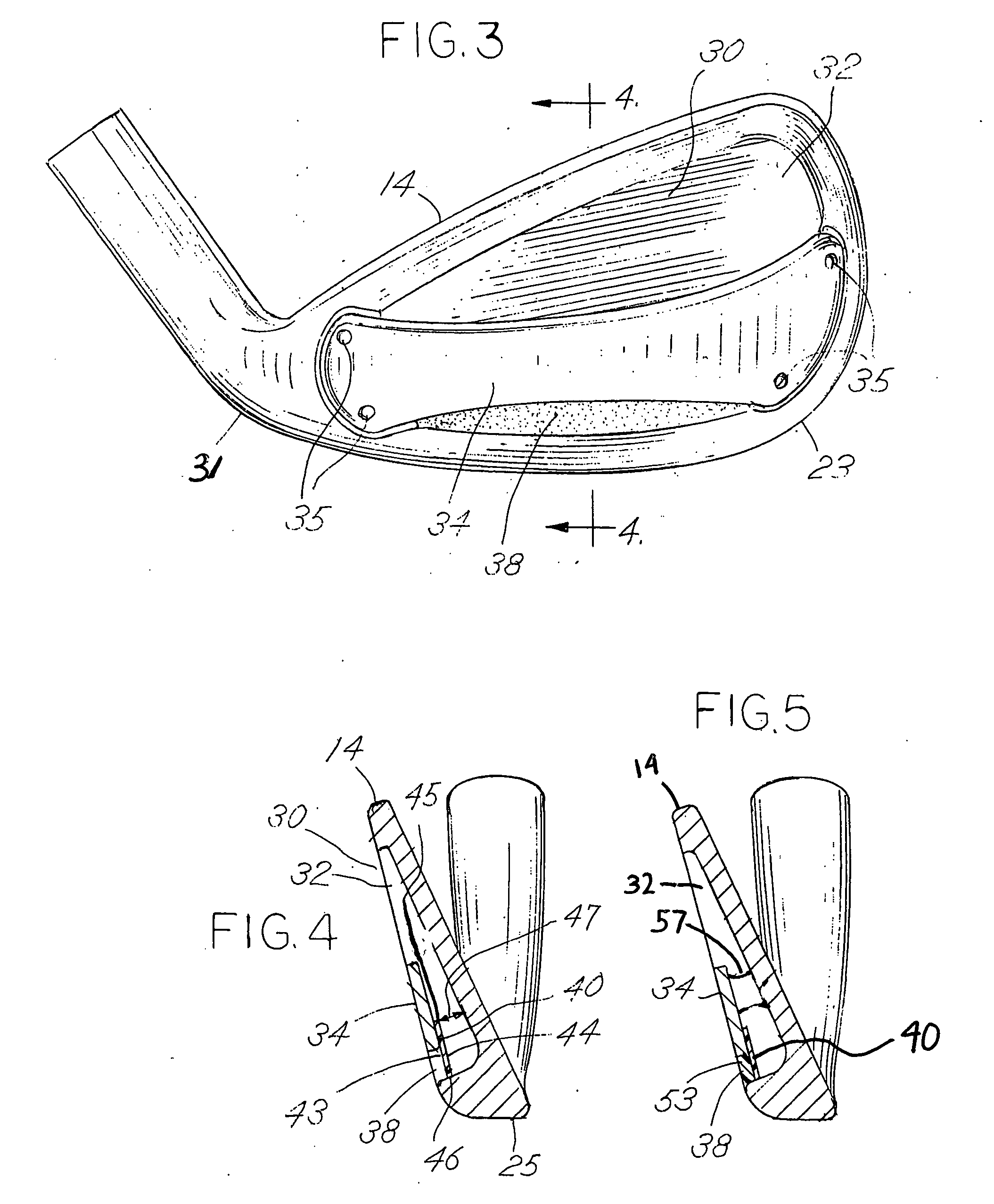

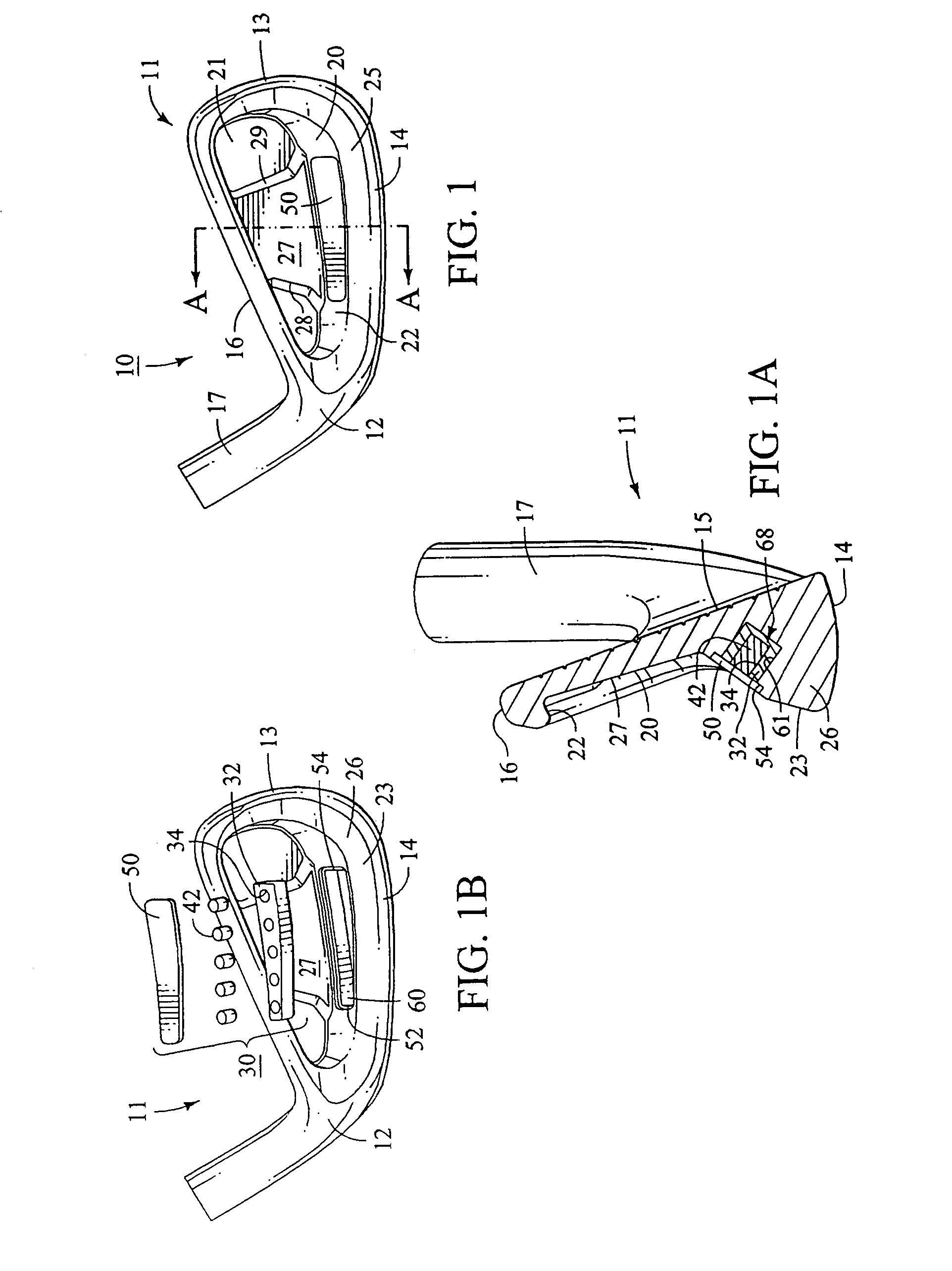

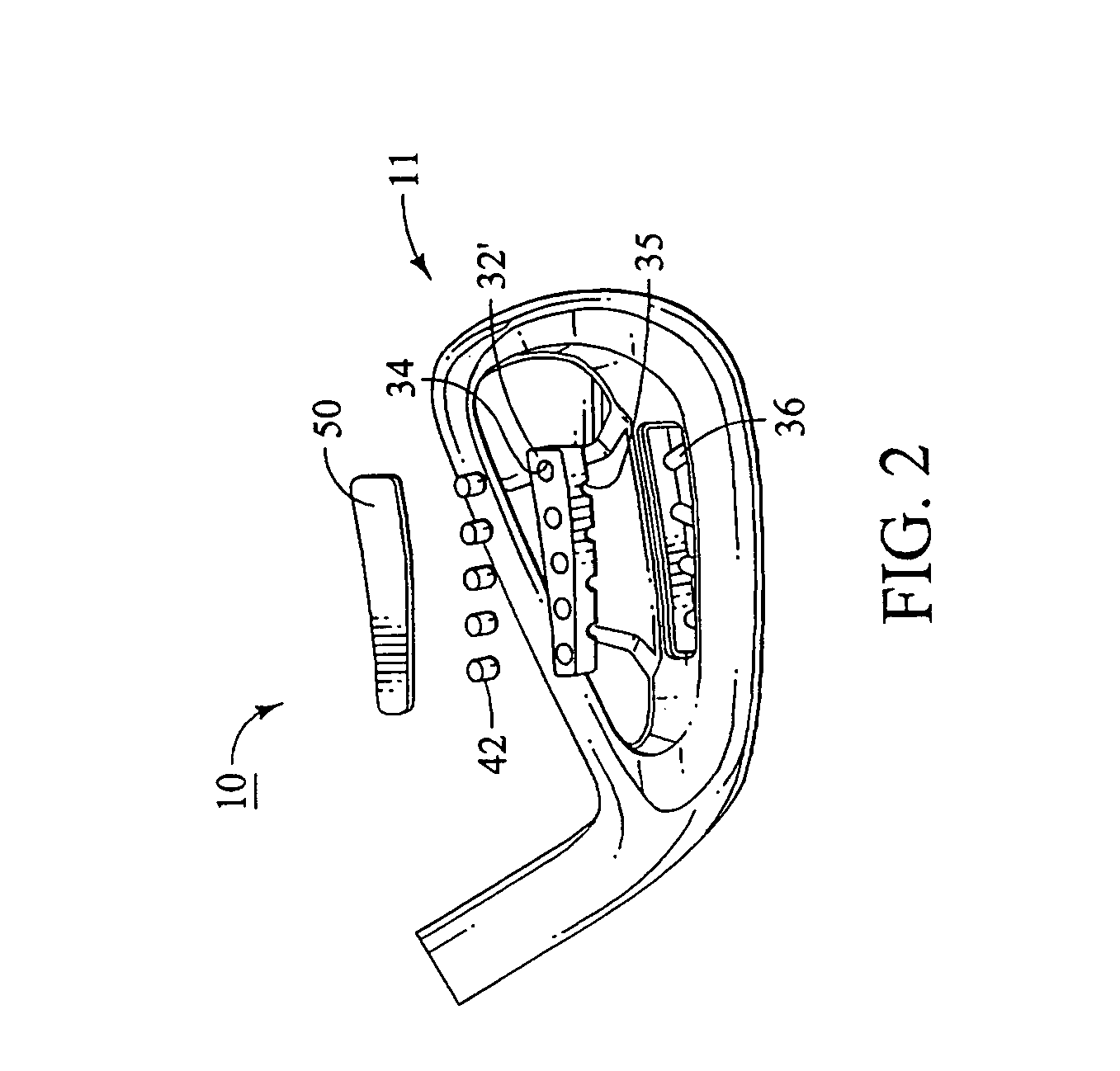

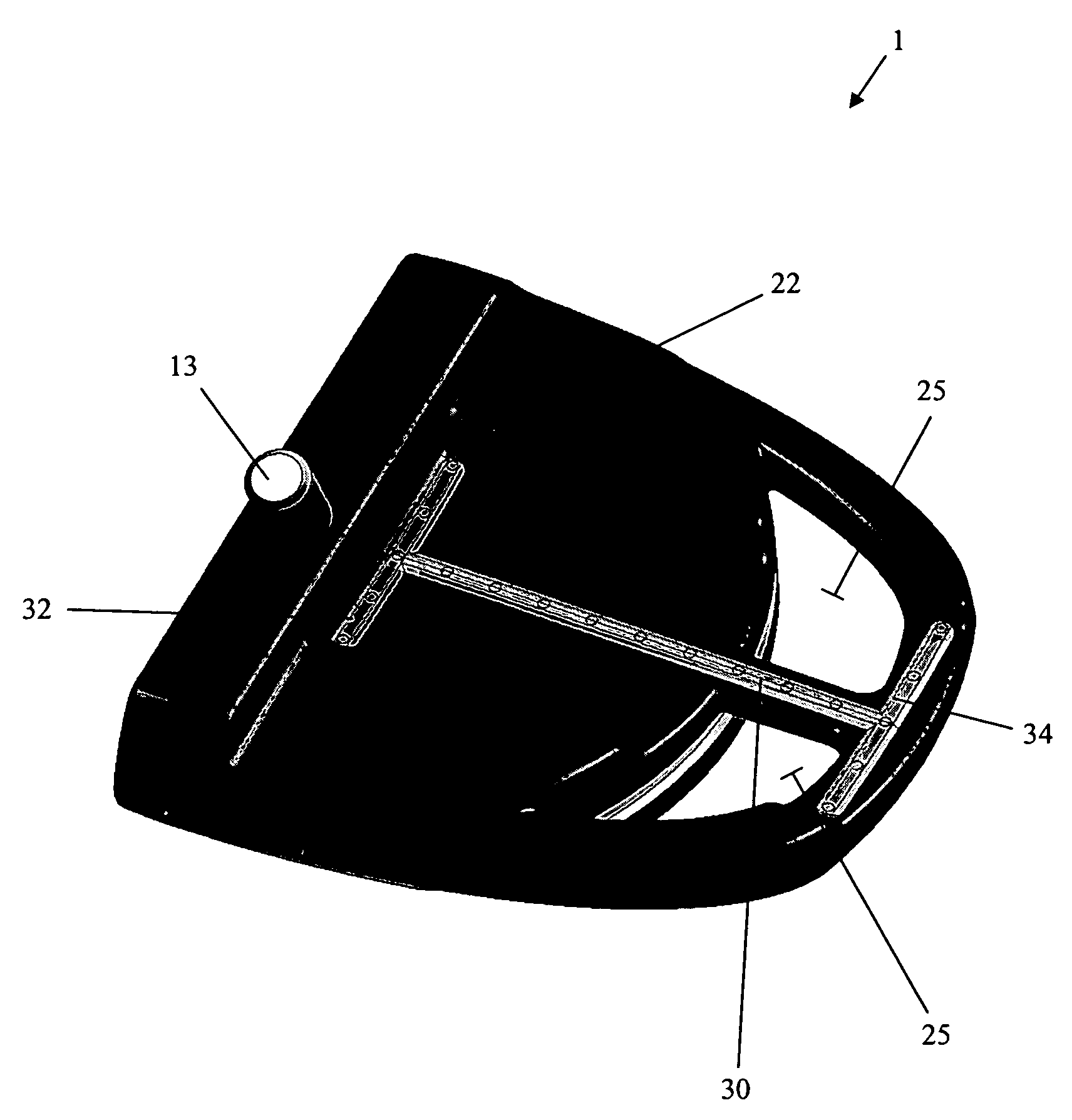

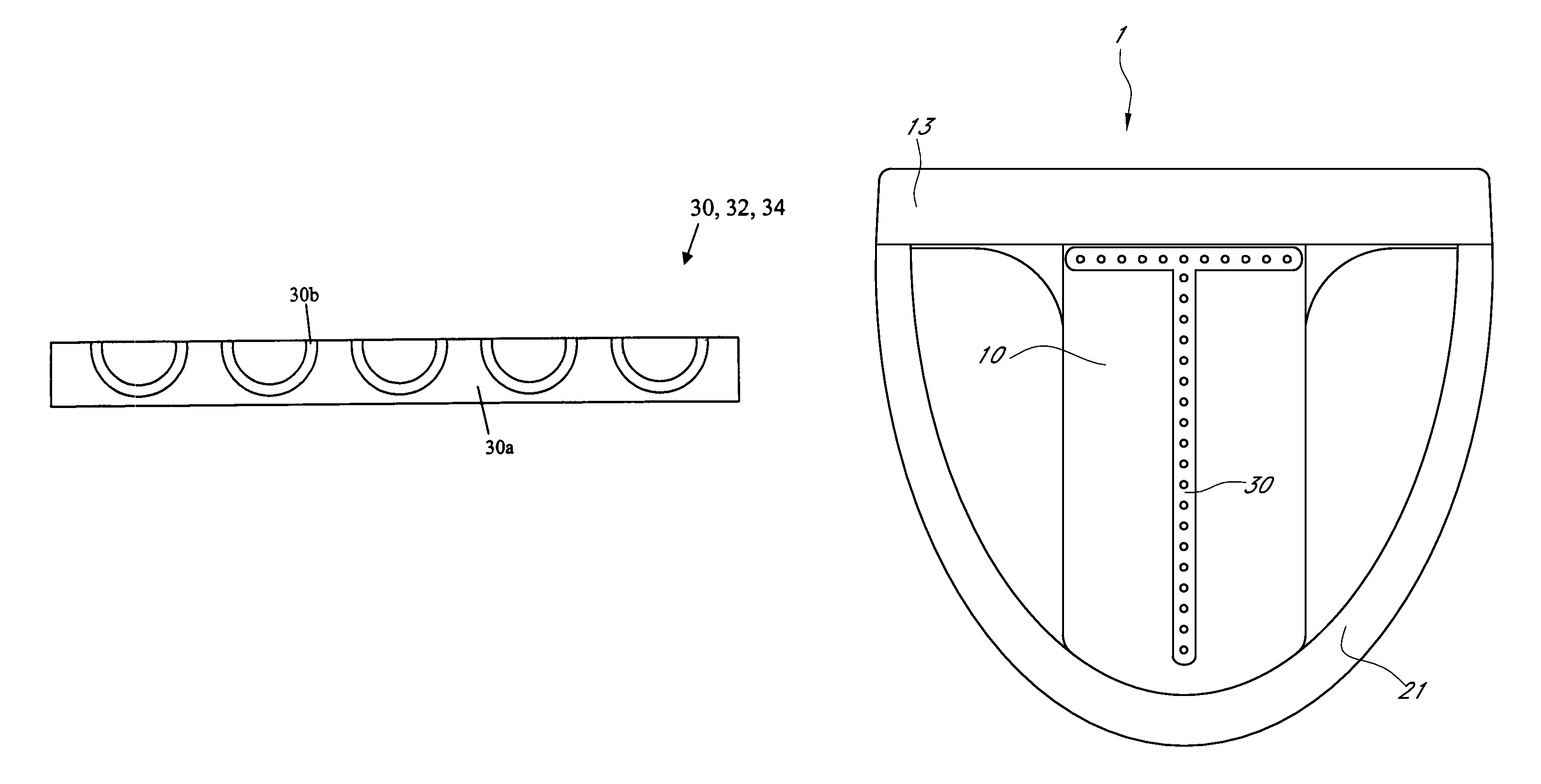

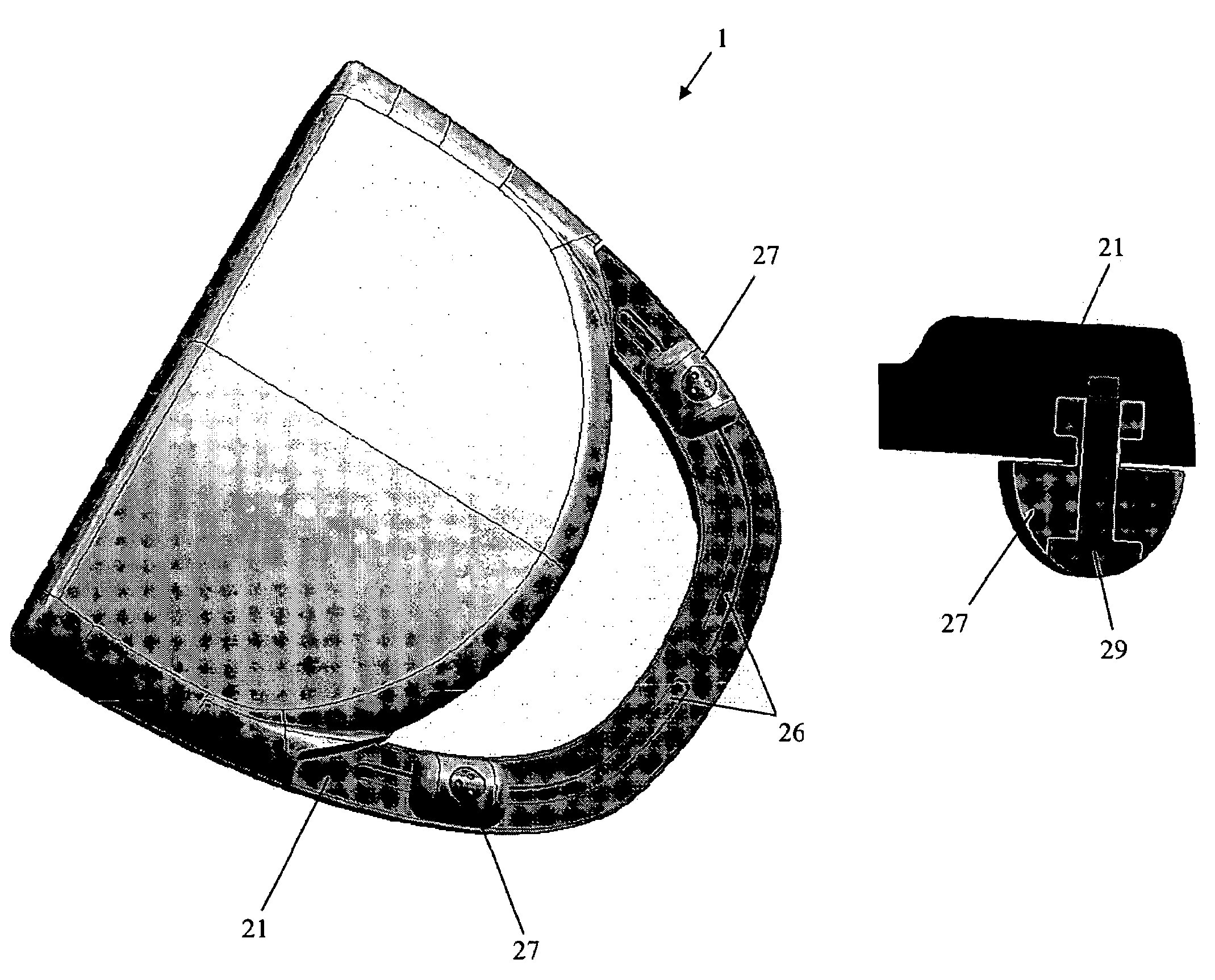

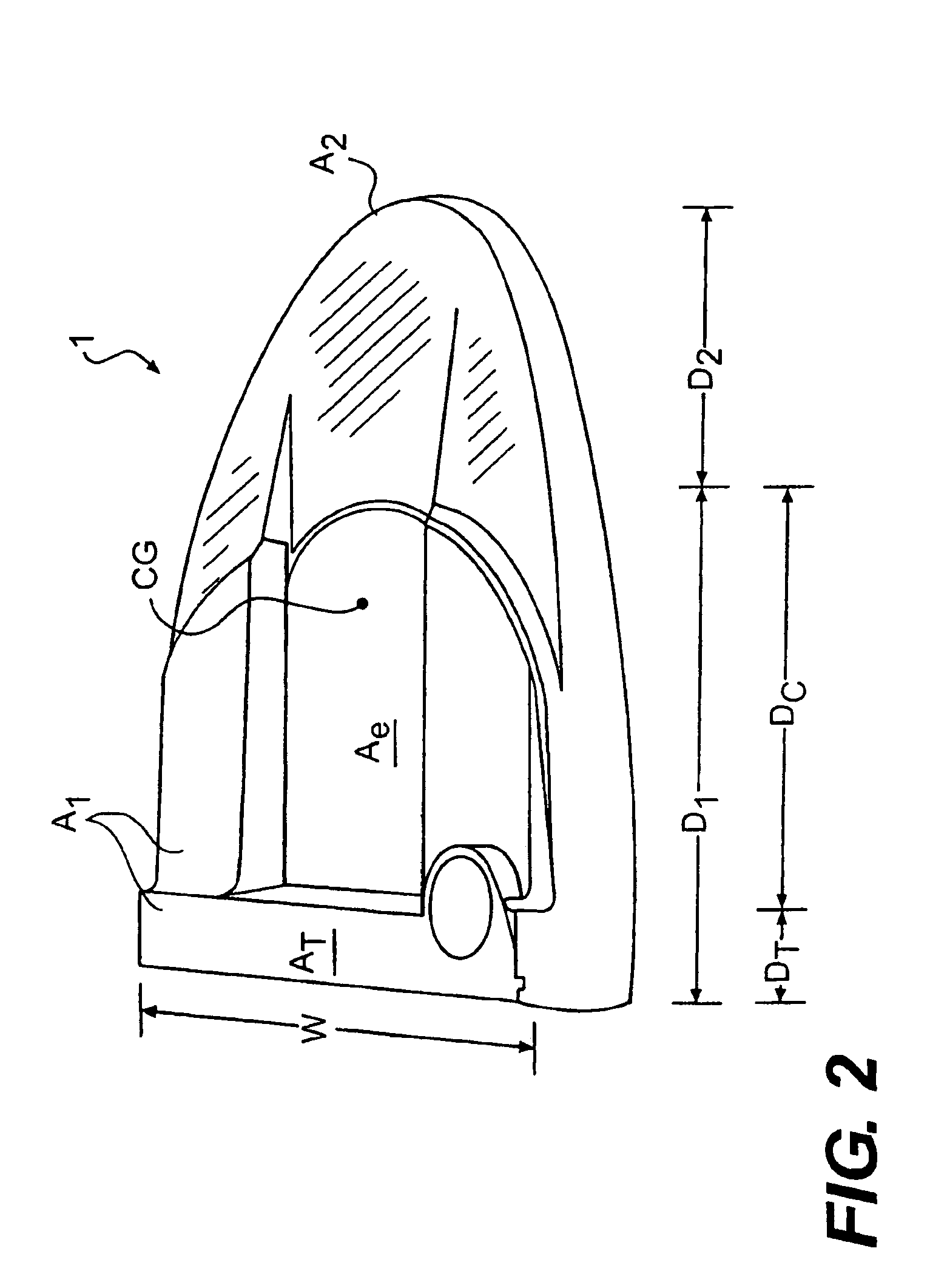

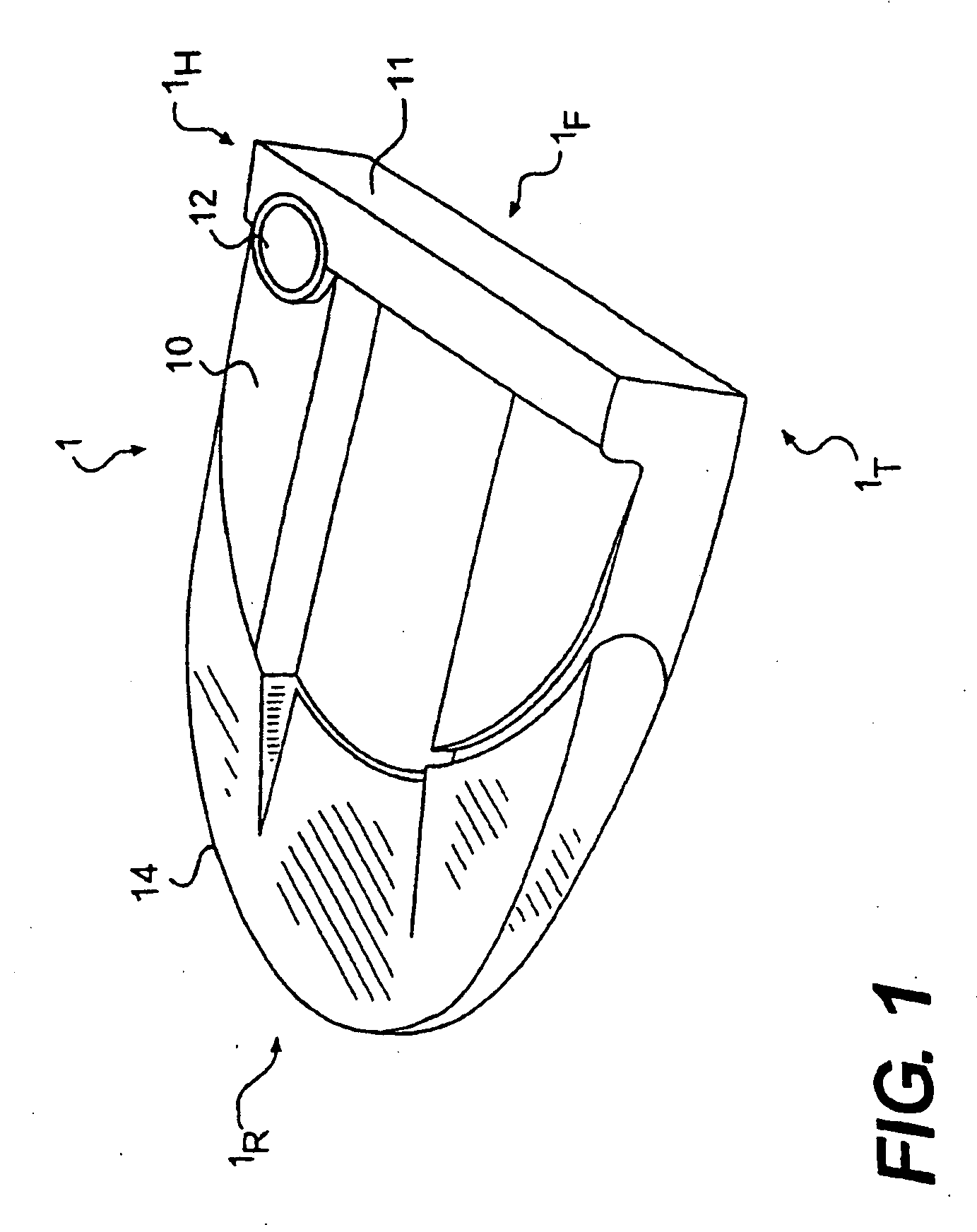

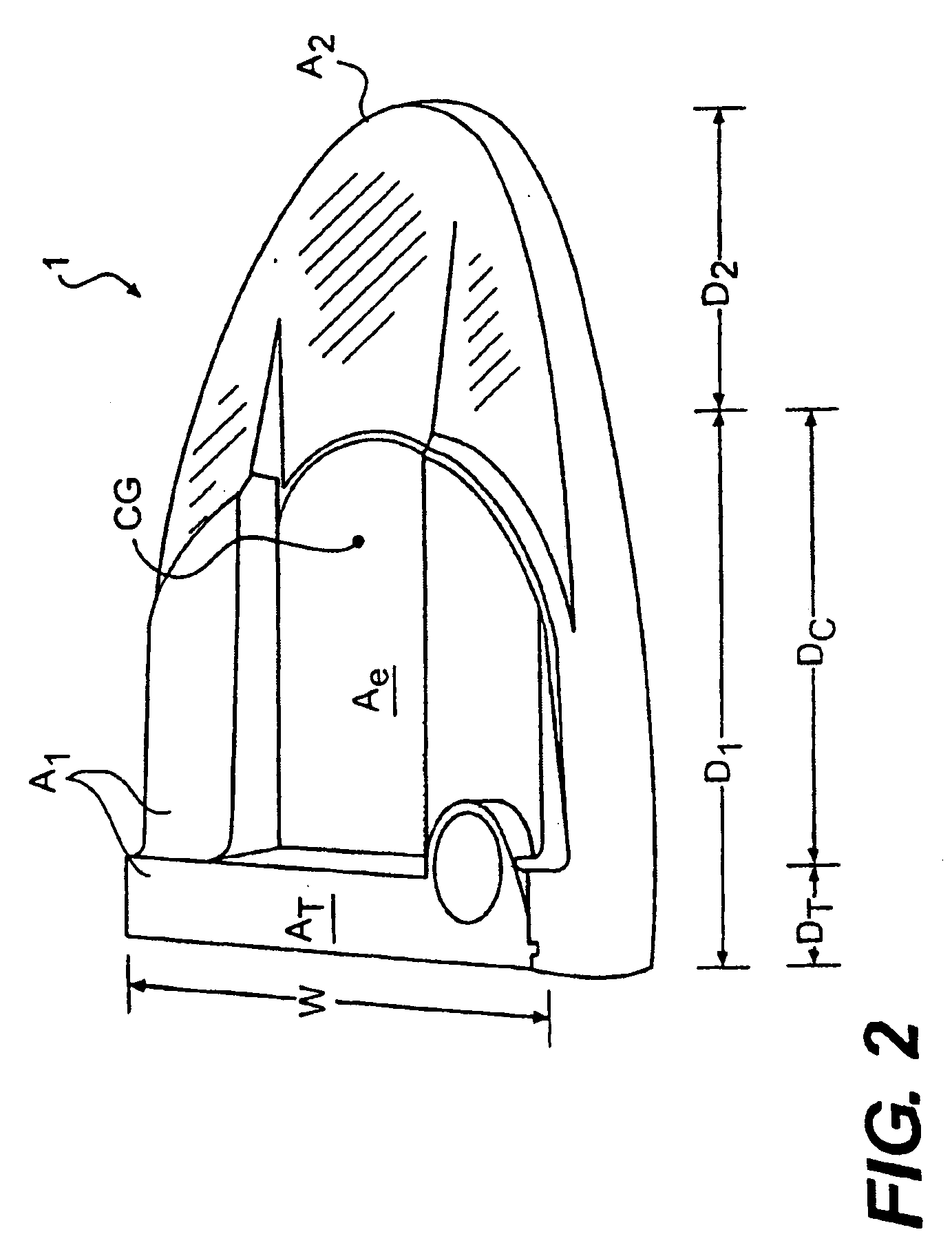

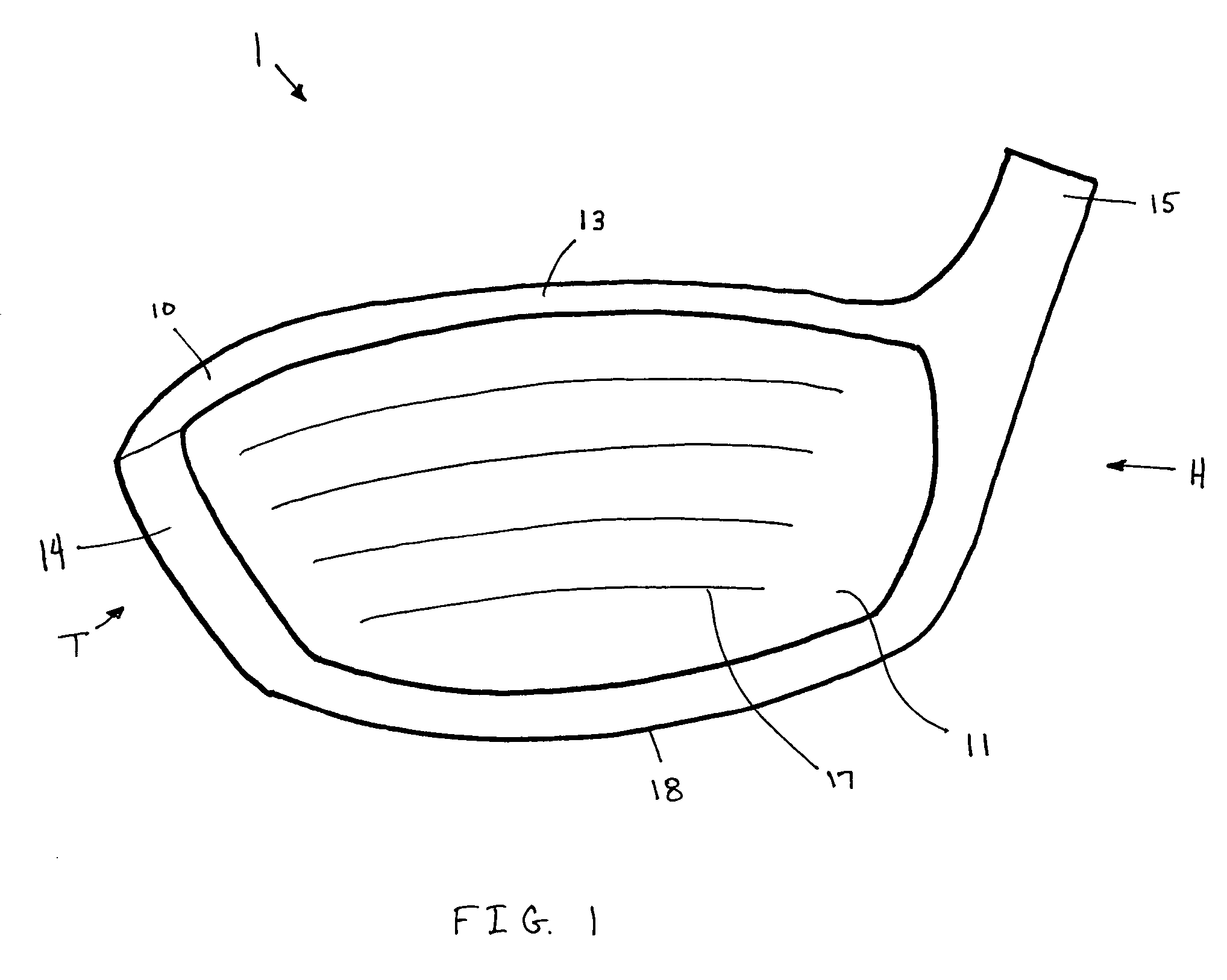

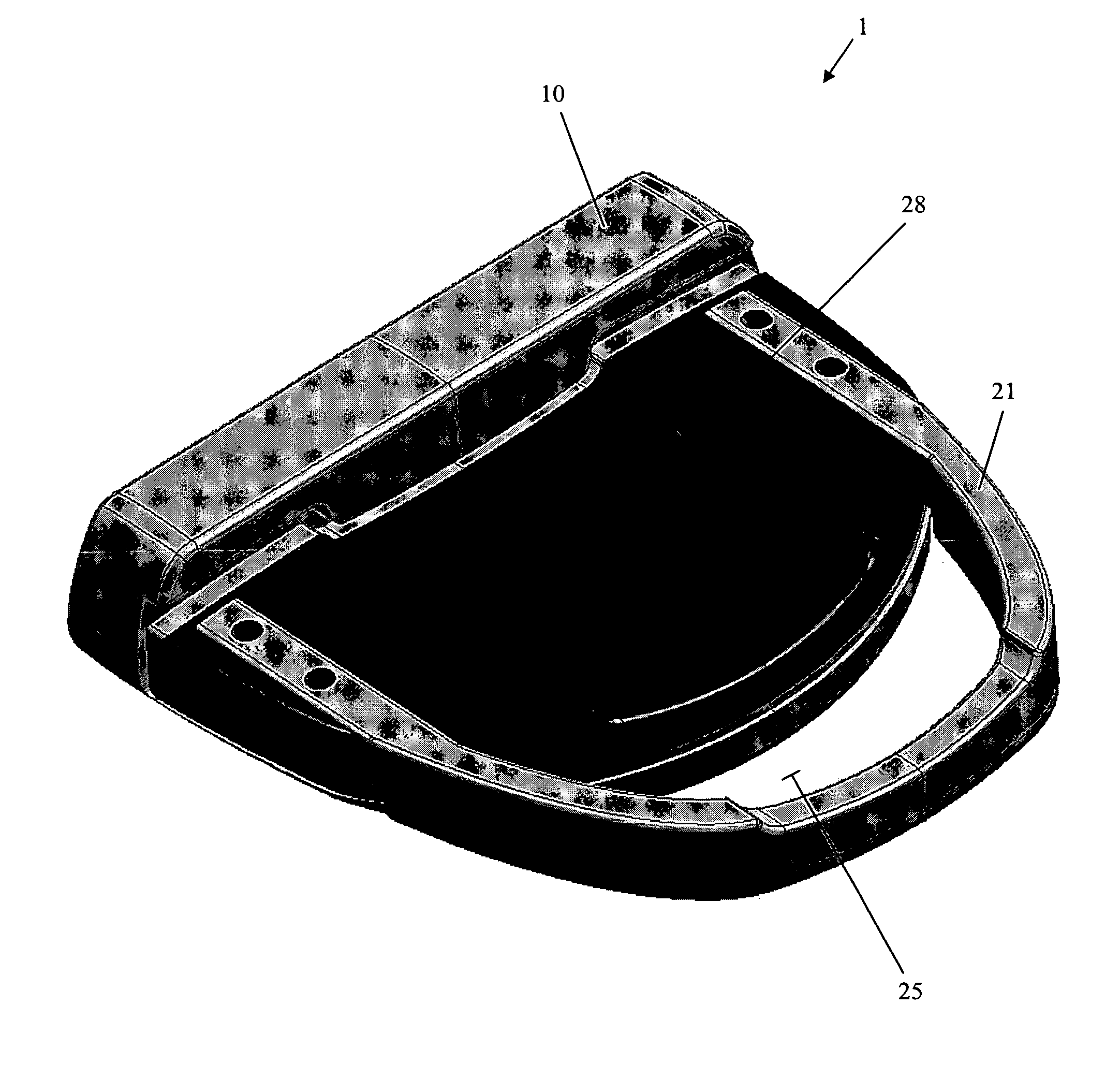

Golf club head having a bridge member and a damping element

A cavity back golf club head having a bridge member and a damping element is disclosed. The bridge member extends across a first rear cavity connecting a heel and a toe of the golf club head to control the trajectory of a golf ball. For the longer iron clubs, a damping element extends from the sole portion of the cavity back golf club head to the bridge member to define a second cavity to further influence the trajectory of the golf ball. For the shorter iron clubs, the damping element extends from the top portion of the cavity back golf club head to the bridge member. The damping element may reduce the vibration and sound of the golf club head upon impact with a golf ball.

Owner:KARSTEN MFG CORP

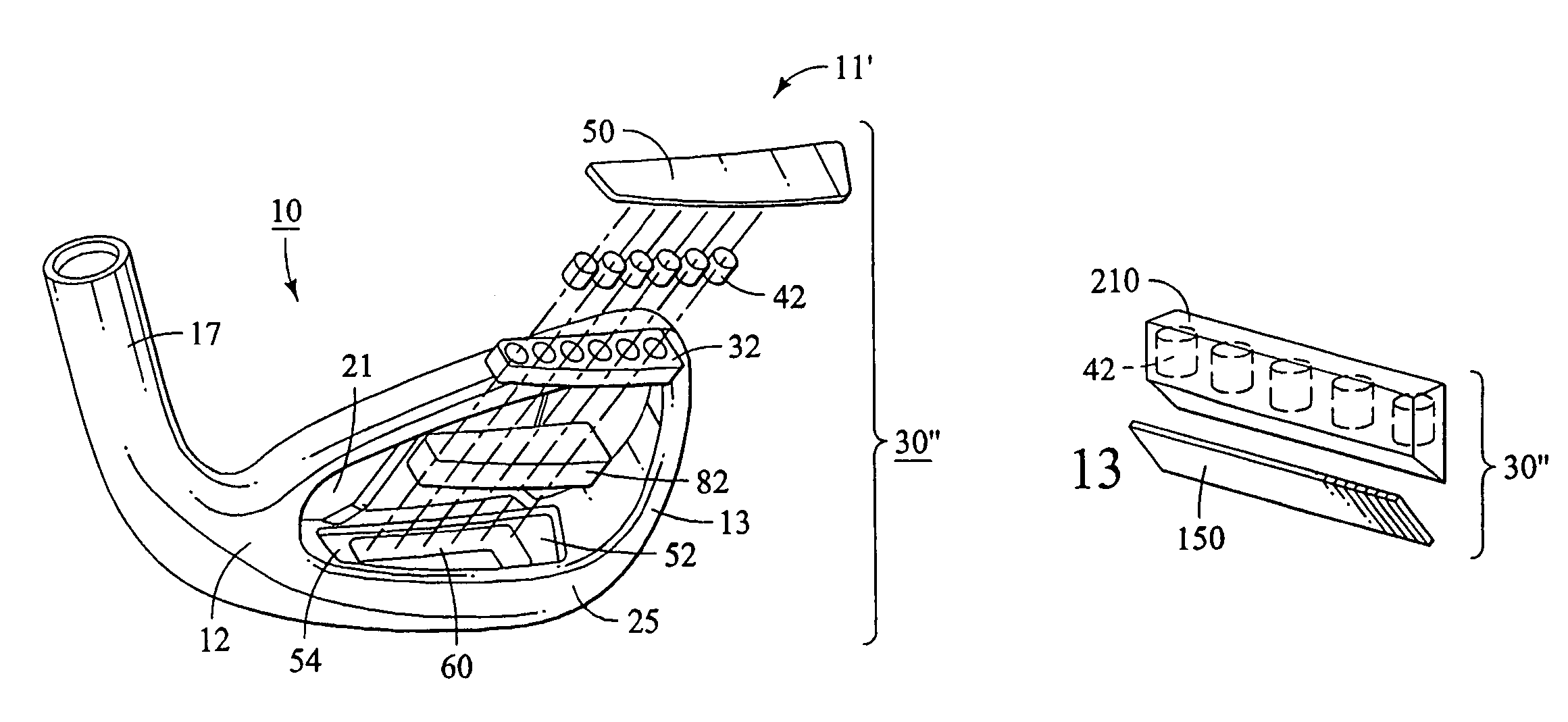

Golf club head

InactiveUS7083530B2Feel goodReduce stiffnessThermal switch detailsGolf clubsGolf BallBiomedical engineering

An iron-type golf club head is disclosed that comprises a striking face, a heel, a toe and a sole bar, wherein a recess is formed in the sole bar. A cartridge comprised of a first material at least partially disposed the sole recess, and at least one pin, comprised of a second material coupled to the cartridge. The first material has a modulus of elasticity that are less than that of the second material.

Owner:TAYLOR MADE GOLF

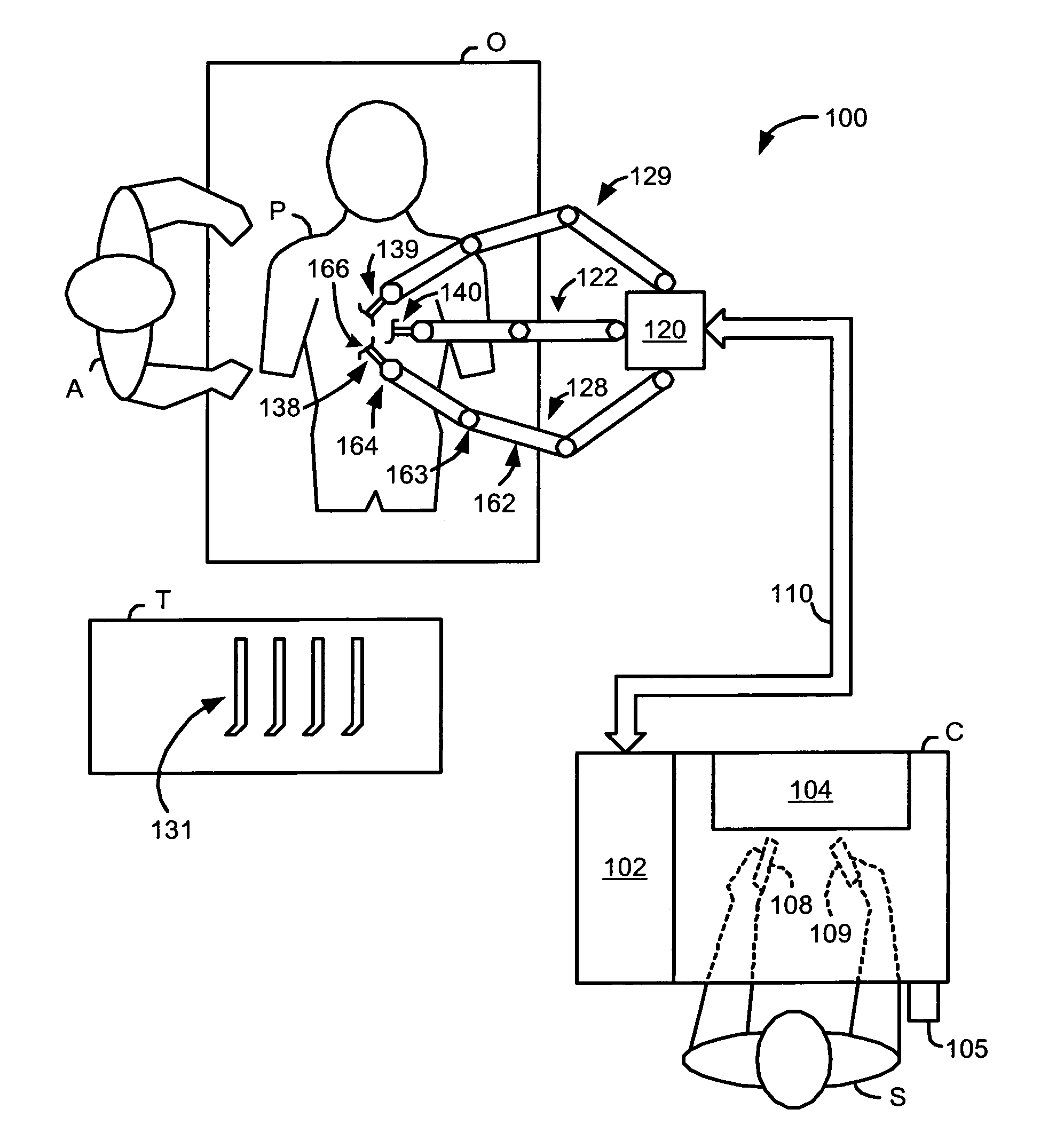

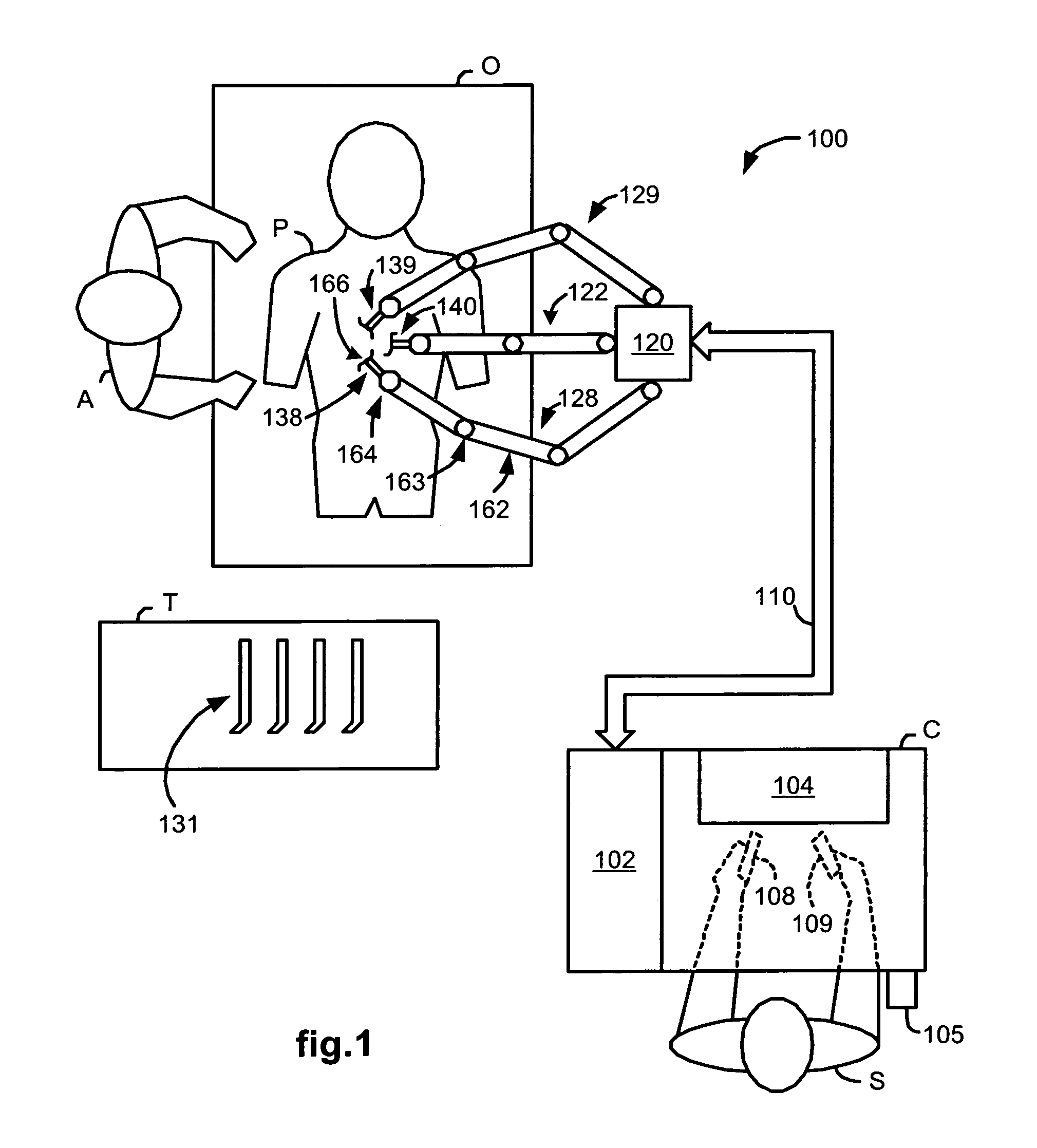

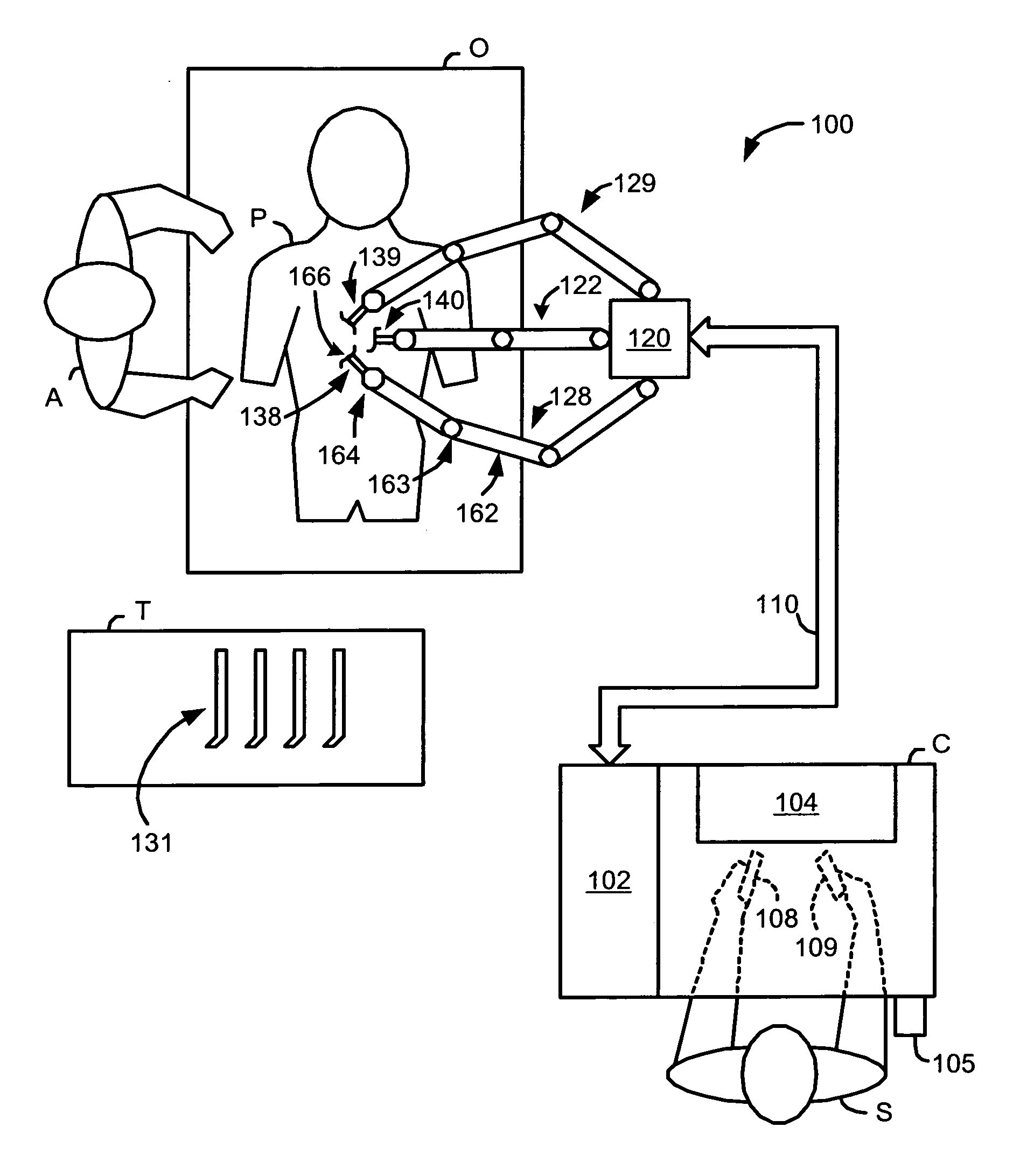

Robotic surgical system with joint motion controller adapted to reduce instrument tip vibrations

ActiveUS7689320B2Reduce vibrationWithout jeopardizing control system stabilityProgramme-controlled manipulatorMechanical/radiation/invasive therapiesControl systemJoints movement

A robotic surgical system has a robot arm holding an instrument for performing a surgical procedure, and a control system for controlling movement of the arm and its instrument according to user manipulation of a master manipulator. The control system includes a filter in its forward path to attenuate master input commands that may cause instrument tip vibrations, and an inverse filter in a feedback path to the master manipulator configured so as to compensate for delay introduced by the forward path filter. To enhance control, master command and slave joint observers are also inserted in the control system to estimate slave joint position, velocity and acceleration commands using received slave joint position commands and torque feedbacks, and estimate actual slave joint positions, velocities and accelerations using sensed slave joint positions and commanded slave joint motor torques.

Owner:INTUITIVE SURGICAL OPERATIONS INC

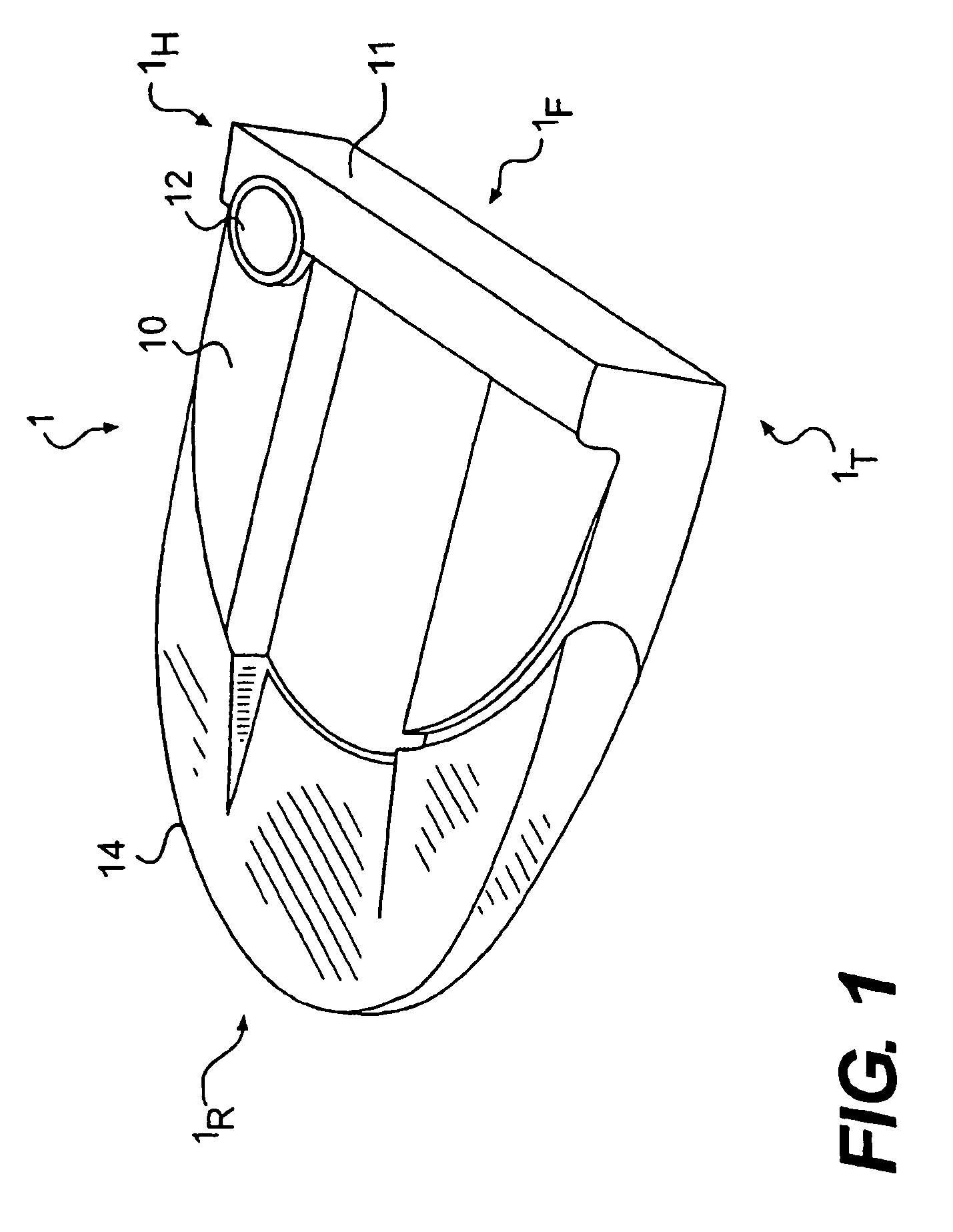

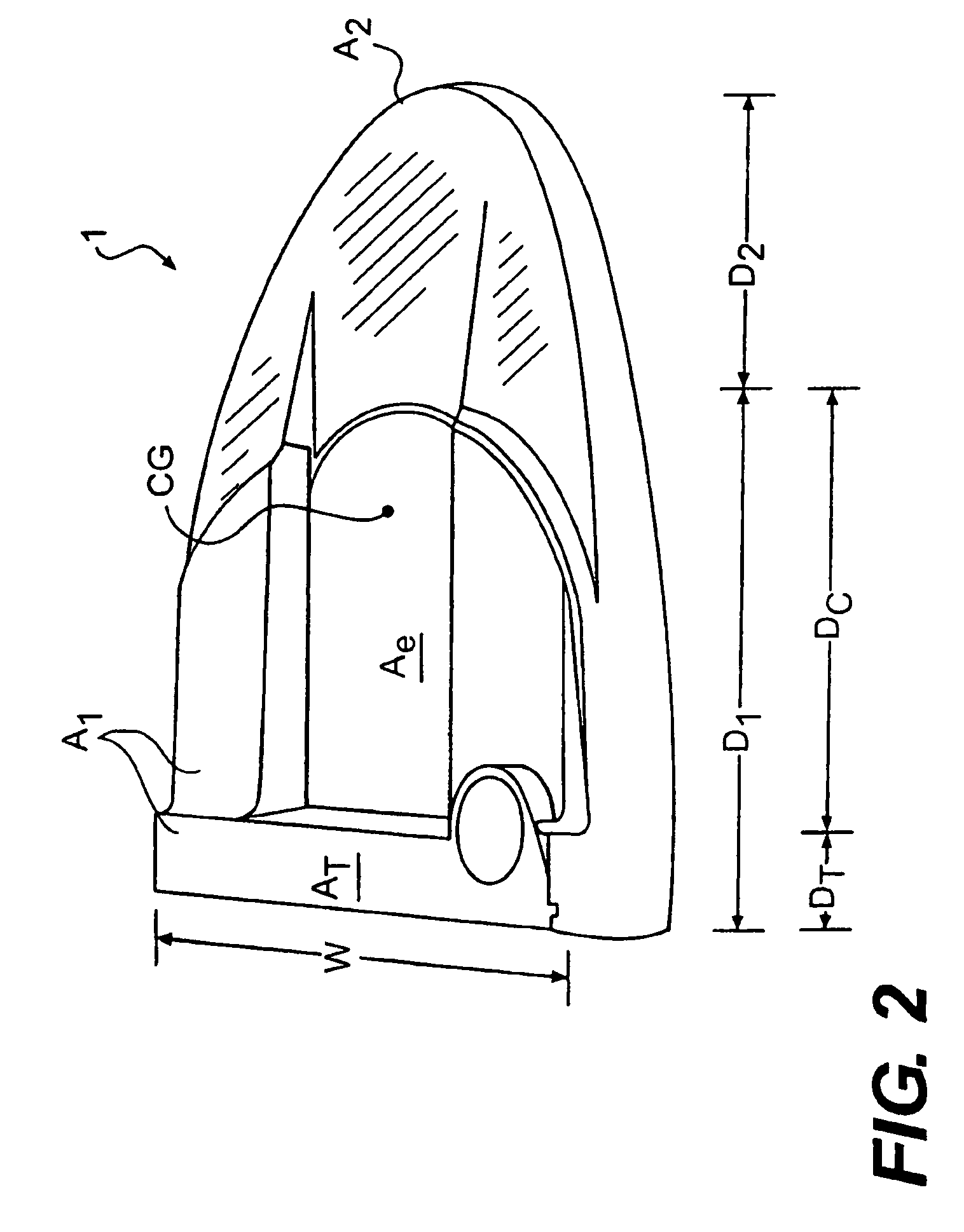

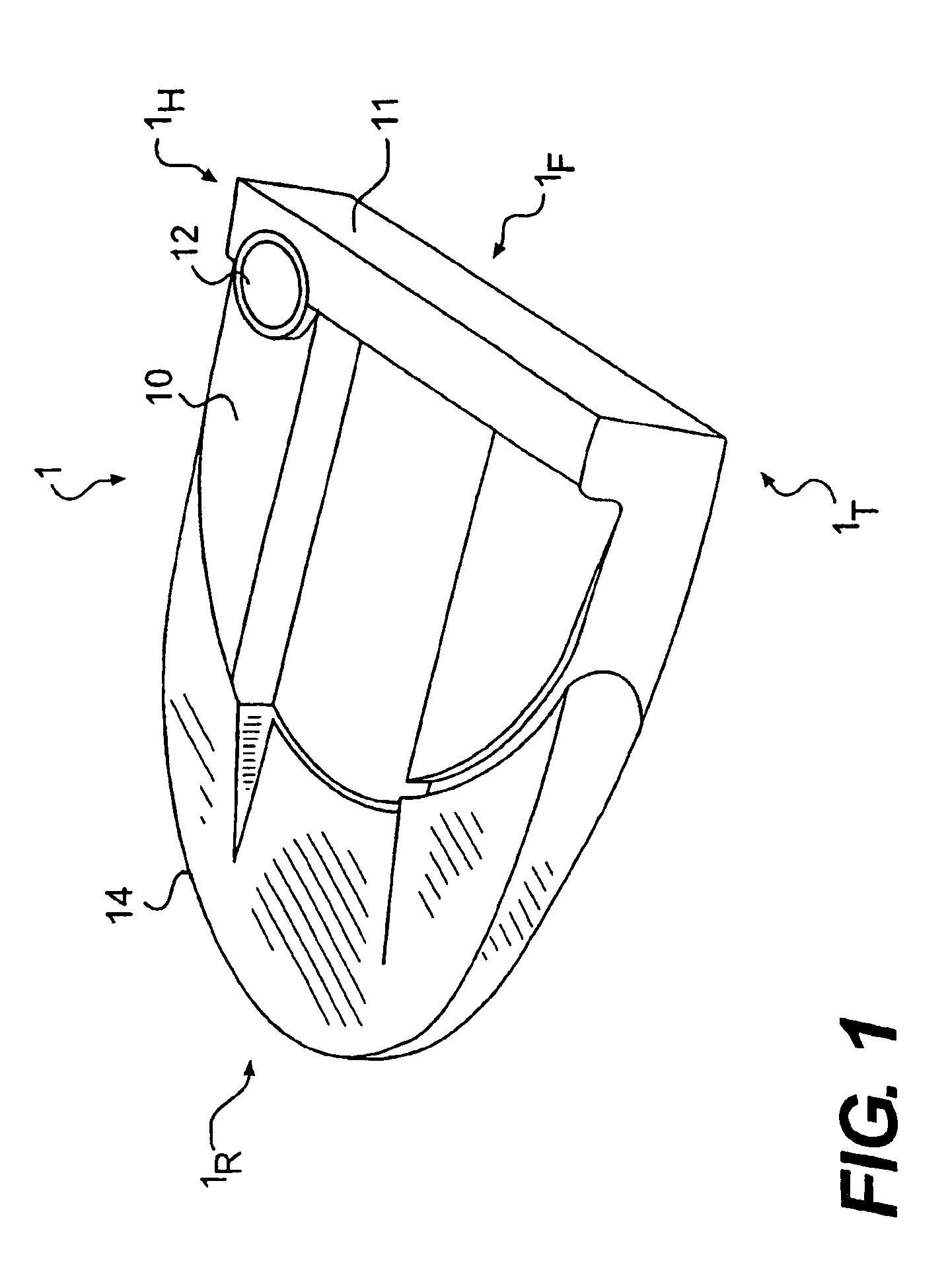

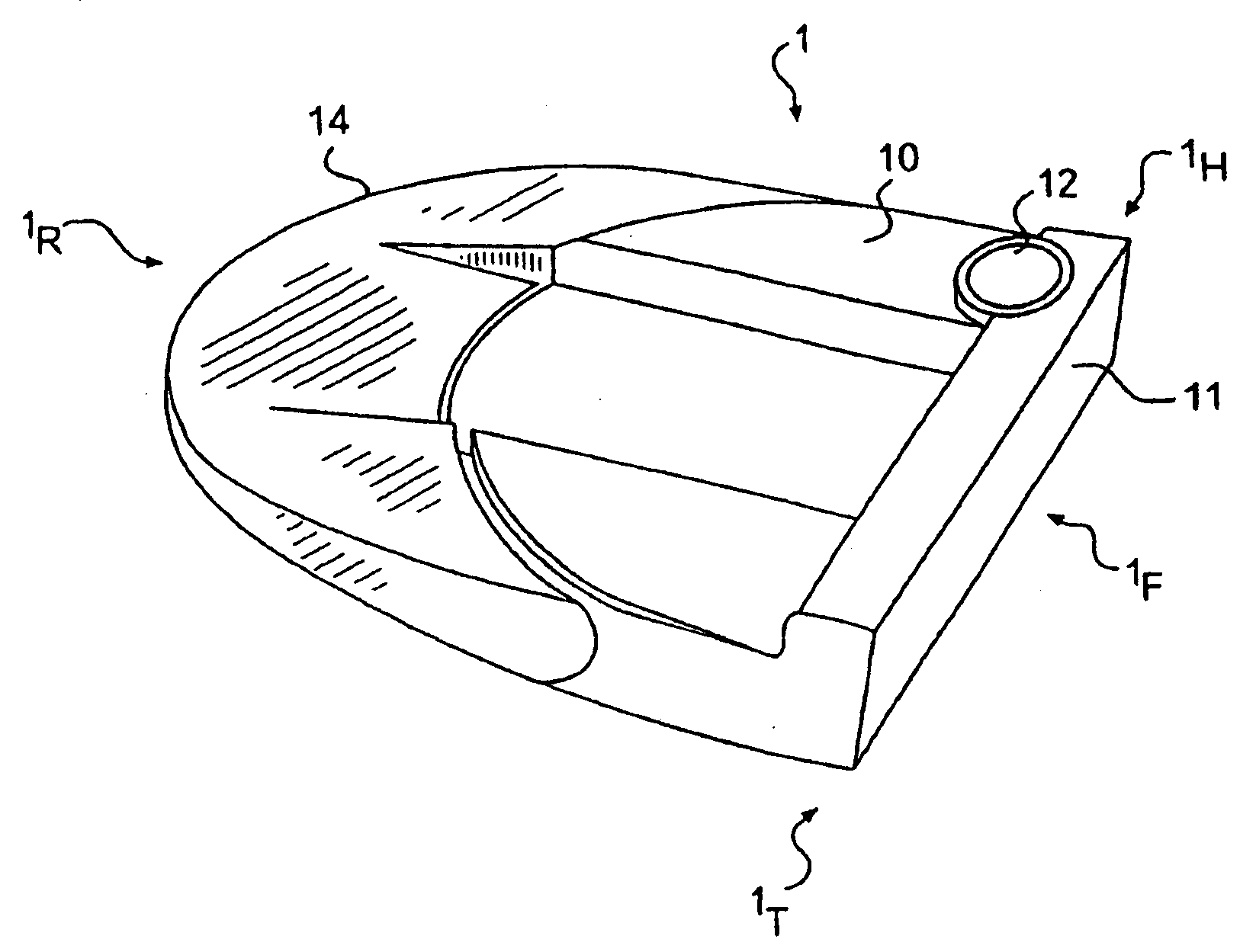

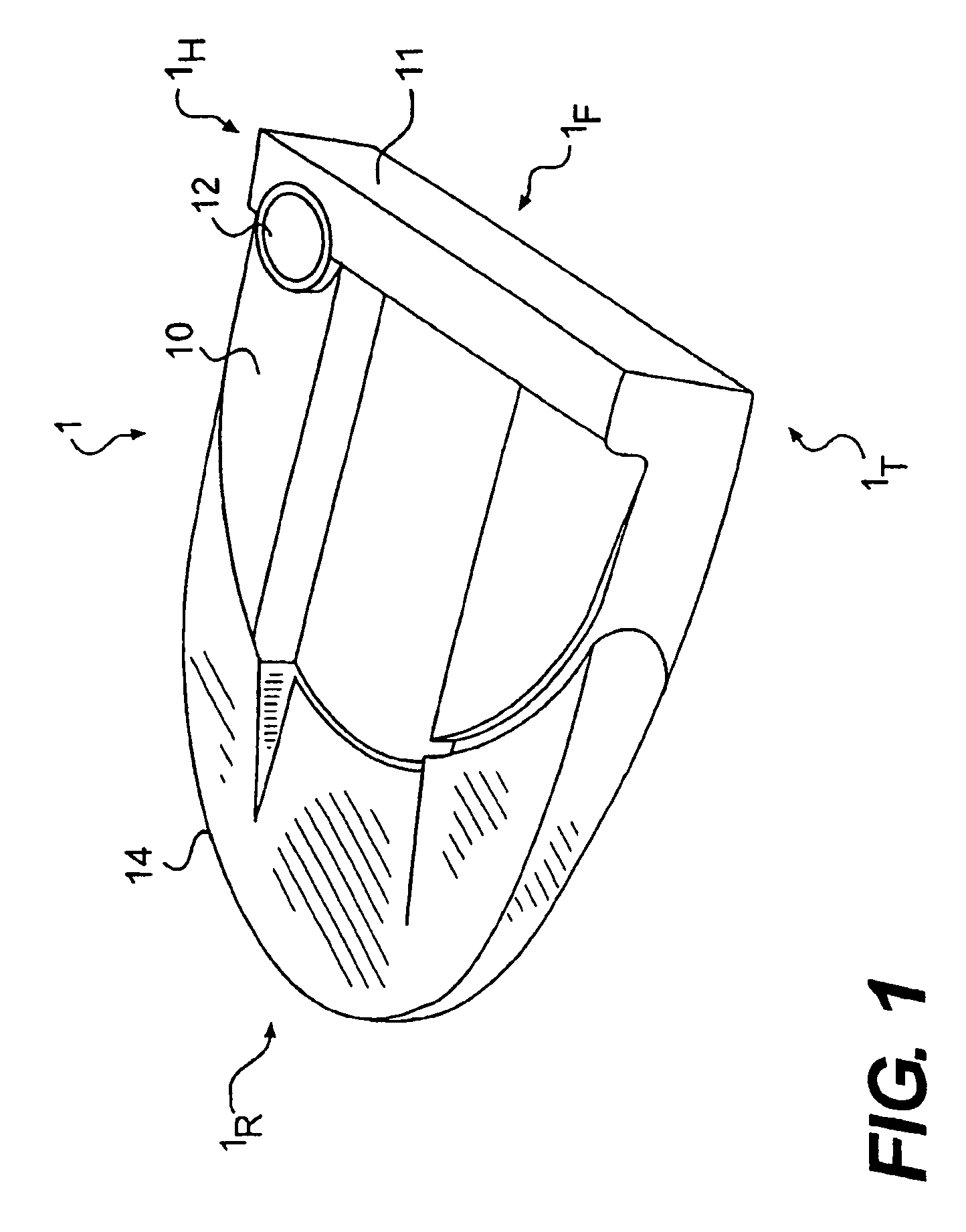

Golf club head with alignment system

A golf club head is disclosed. The golf club head includes a first body member and a second body member. The first body member includes a strike face and a top portion. The second body member is coupled to the first body member and extends away from the first body member in a direction opposite the strike face. At least a top portion of the second body member is camouflaged. A preferred method of camouflage is color differentiation, wherein the second body member is darker than the first body member. Specific color values and club head geometries are also disclosed and claimed. The club head may include a body member and a weight member such as a bar that extends rearward from the body member. A cover may be included to camouflage the weight member. A separate core member and high visibility sight lines may also be provided.

Owner:COBRA GOLF

Golf club head with alignment system

Owner:COBRA GOLF

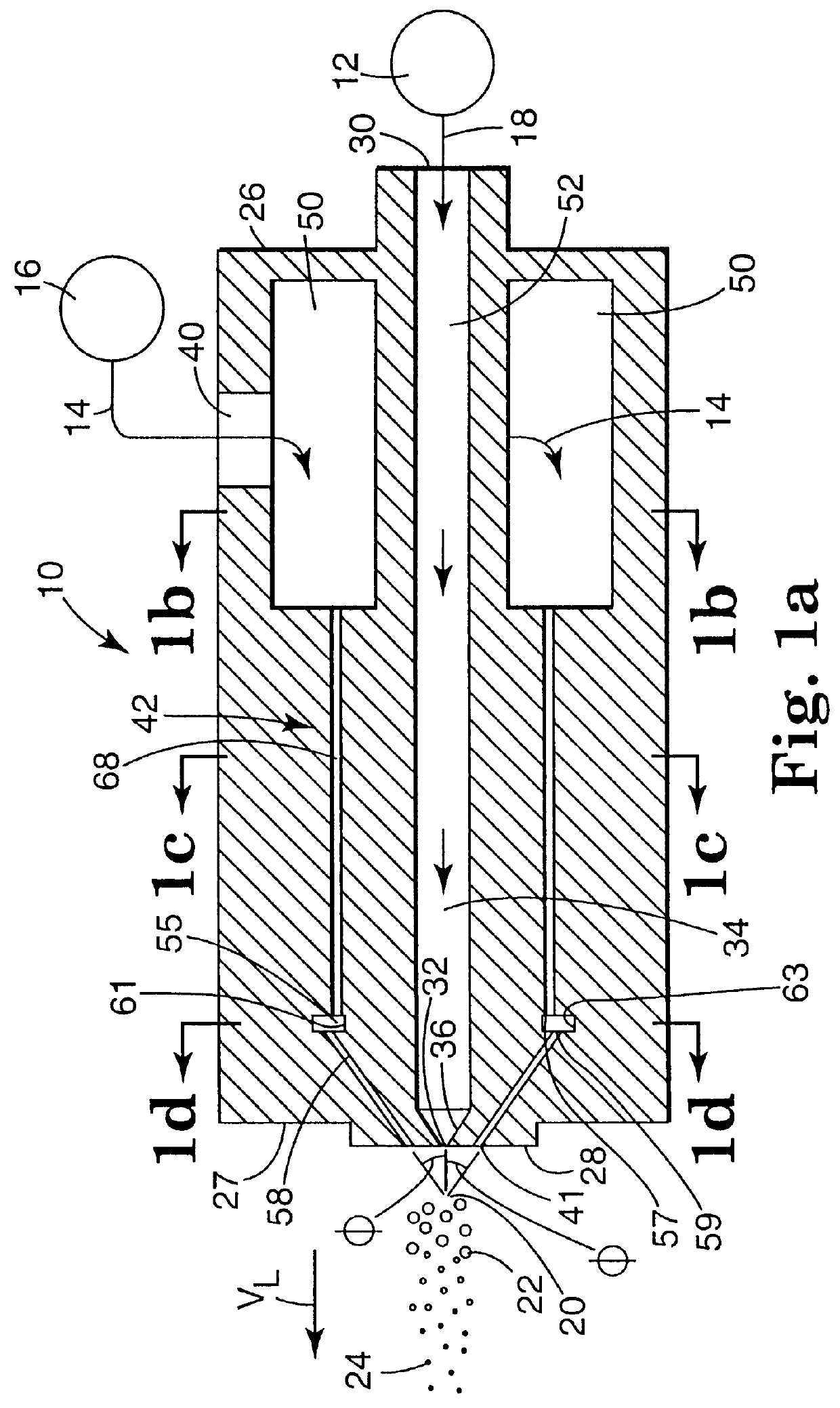

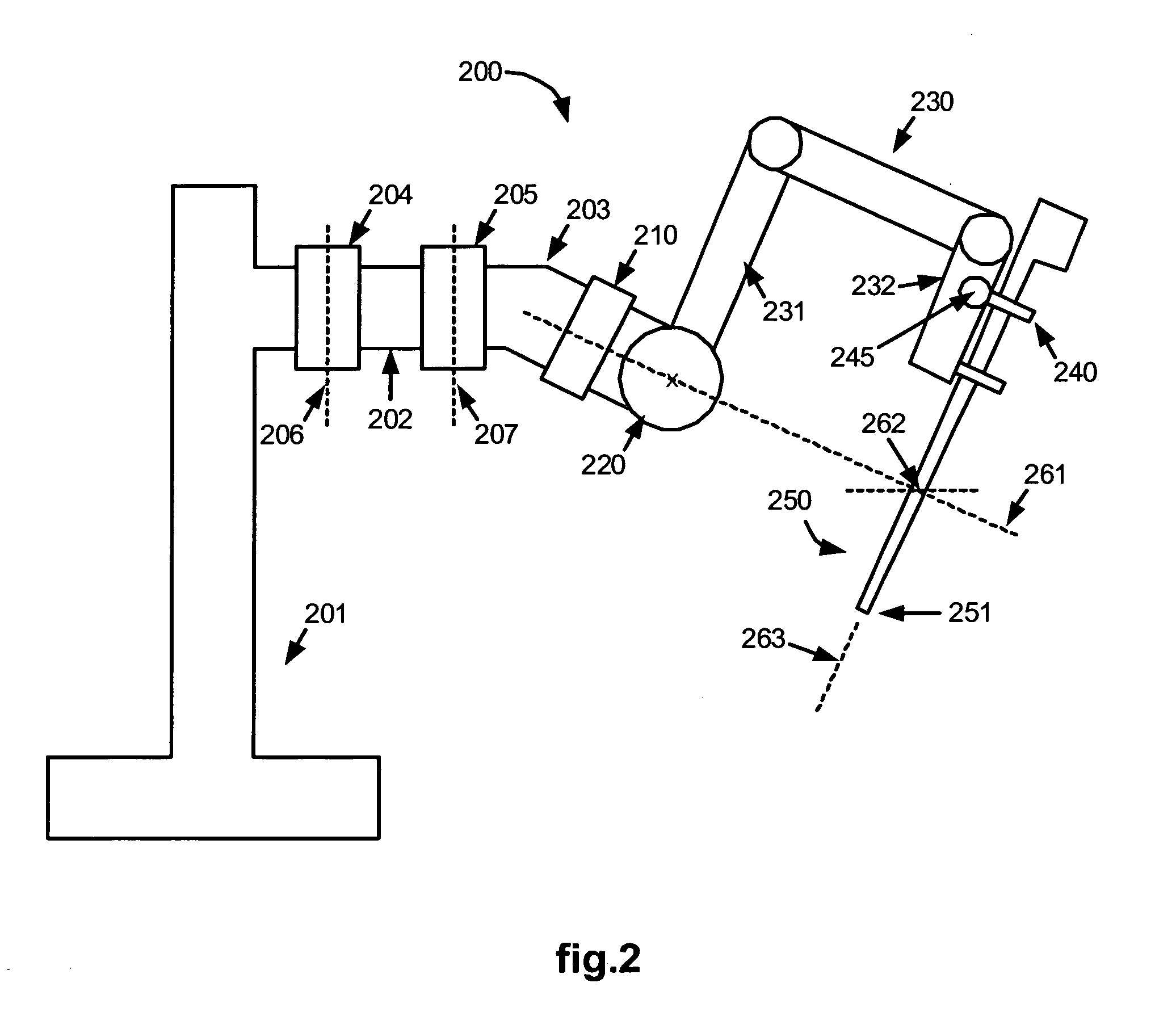

Apparatus and method of atomizing and vaporizing

InactiveUS6012647AMinimal slippageVaporization fastBurnersSpray nozzlesGas passingProcess engineering

Apparatus suitable for atomizing and vaporizing at least a first liquid by colliding at least one gas with the first liquid. The apparatus includes a gas inlet through which the gas enters the apparatus and a first liquid inlet through which the first liquid enters the apparatus. A discharge end of the apparatus includes at least one first liquid discharge outlet through which at least one stream of the first liquid is discharged from the apparatus. The discharge end also includes at least one gas discharge outlet through which at least one stream of gas is discharged from the apparatus to collide with and thereby atomize the discharged stream of the first liquid. A first liquid passageway interconnects the first liquid inlet with the first liquid discharge outlet. A gas passageway interconnects the gas inlet with the at least one gas discharge outlet. In one embodiment, the gas passageway comprises at least one gas chamber in thermal contact with an initial portion of the first liquid passageway such that a heated quantity of the gas in the chamber preheats the first liquid in the initial portion of the first liquid passageway. In alternative embodiments, the gas passageway includes a pressure dampening chamber allowing gas to be continuously discharged without pulsating.

Owner:3M INNOVATIVE PROPERTIES CO

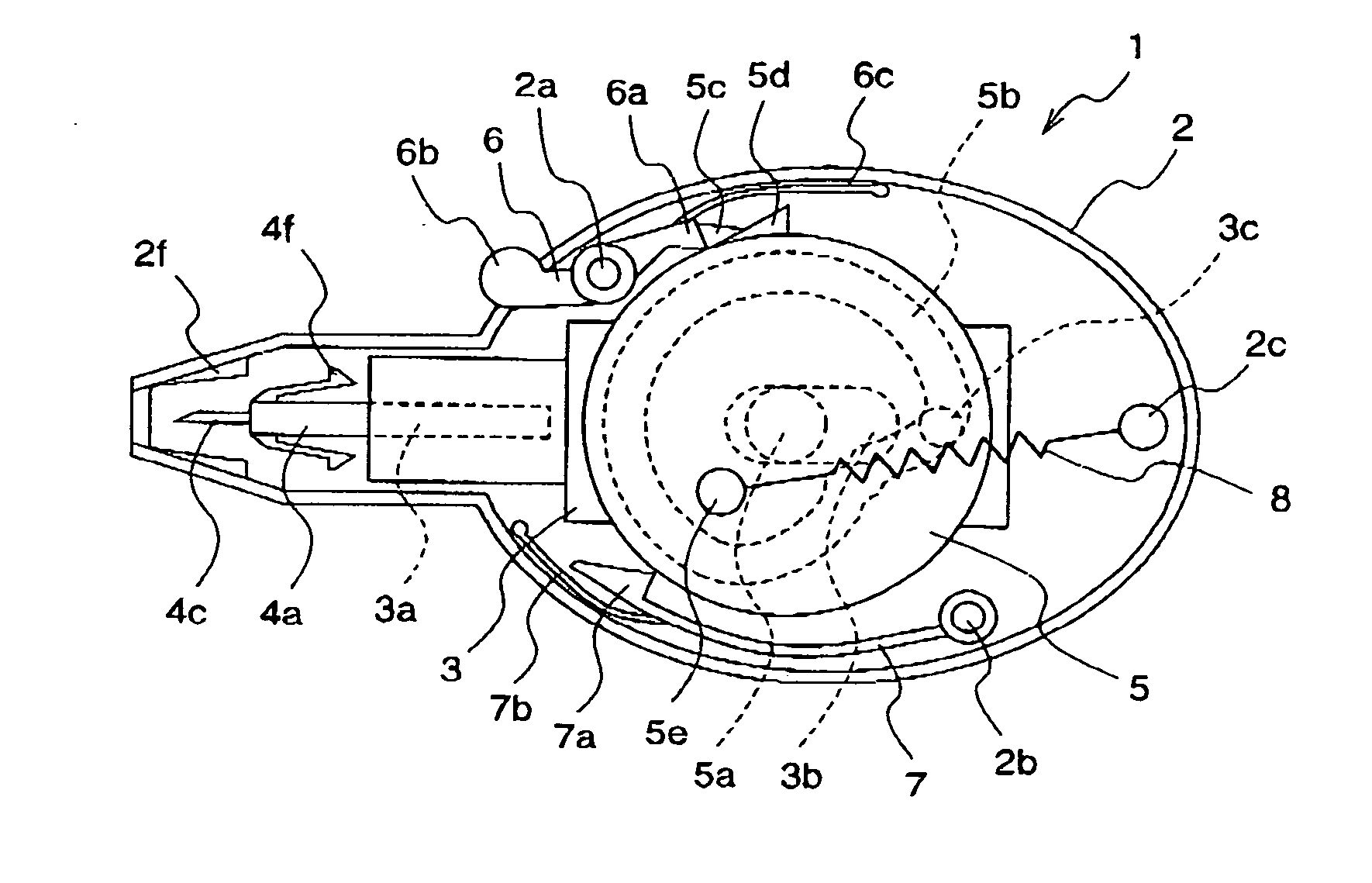

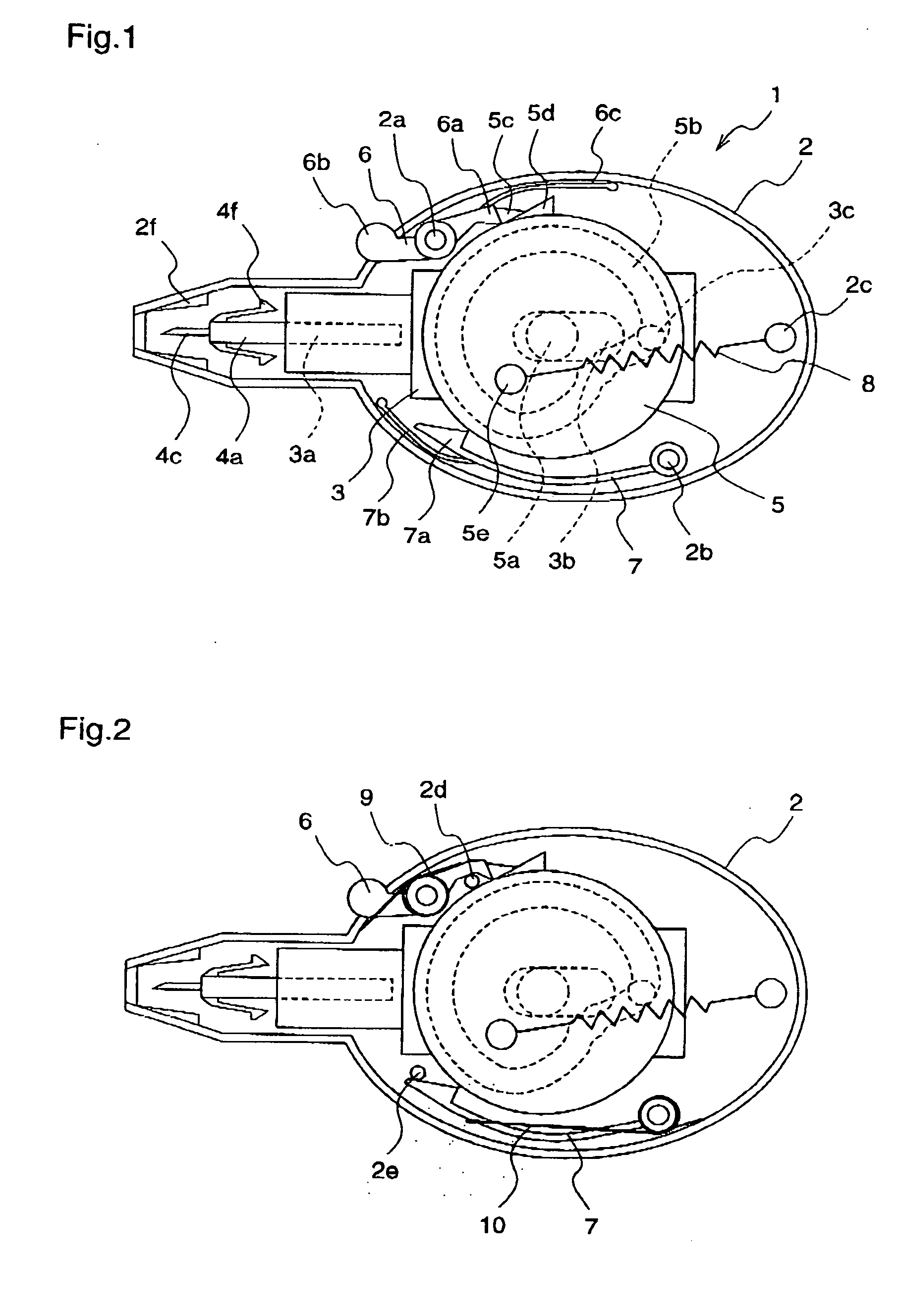

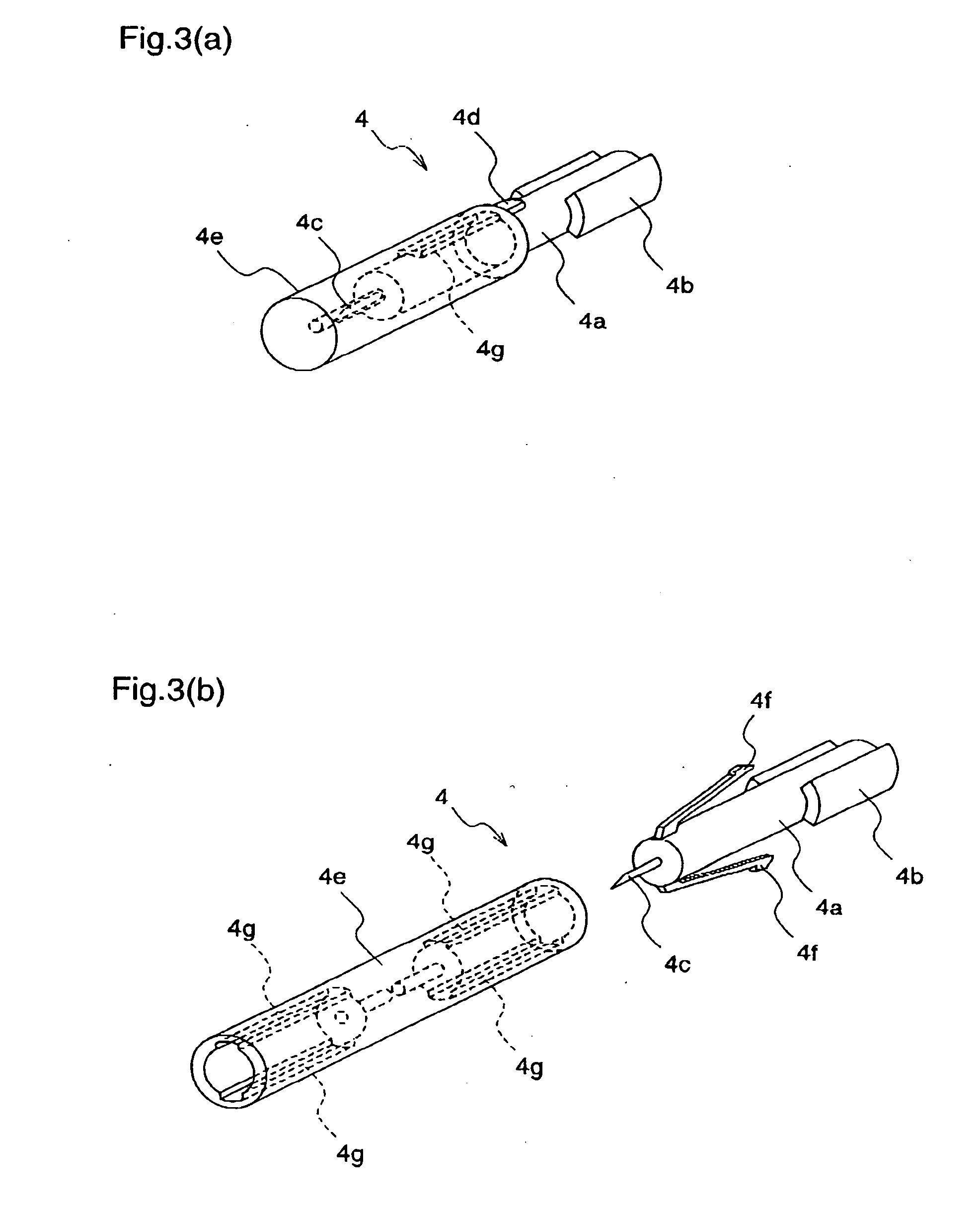

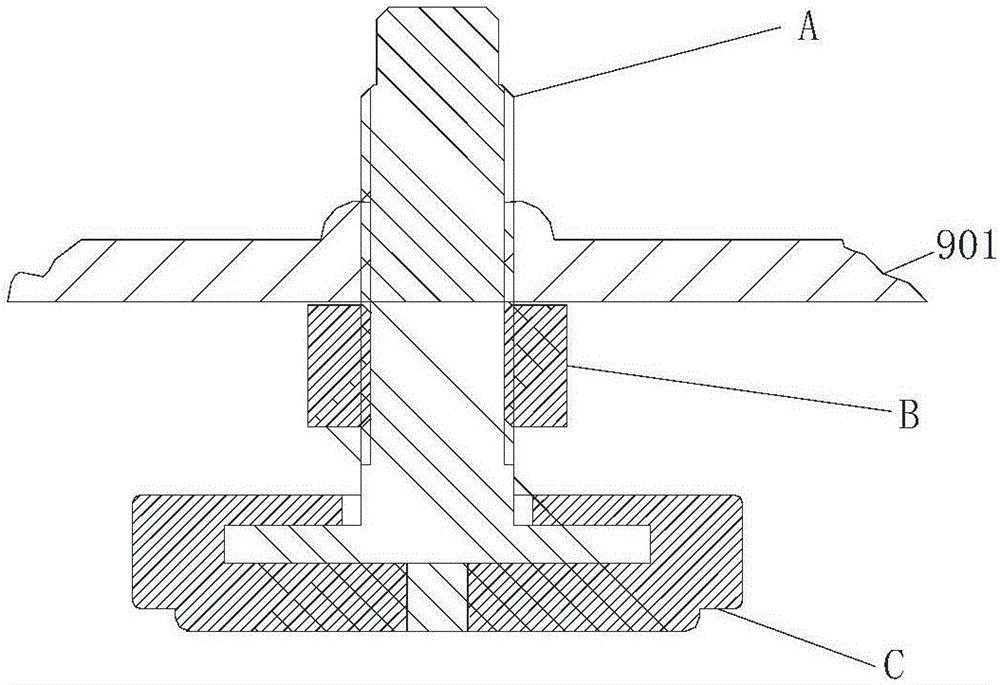

Lancet for blood collection and puncture needle unit

InactiveUS20050131441A1Safely discardedEasy to useSensorsBlood sampling devicesBlood collectionEngineering

A lancet comprises a slider having a puncture needle holding mechanism at its one end; a cam ring which has a continuous cam groove, is rotatable about a support shaft, and has a cam ring claw and an anti-return claw for restricting the rotation; a ring spring for applying a force to rotate the cam ring; a rotatable stopper arm for holding and releasing the rotation of the cam ring; and a rotatable ratchet for restricting the direction of rotation of the cam ring. A puncture needle unit comprises a puncture needle body which is integrally molded with a protrusion to be fitted to the lancet, a rotation stop rib, and a puncture needle; and a puncture needle cap which is lightly pressed into the puncture needle body.

Owner:PHC HLDG CORP

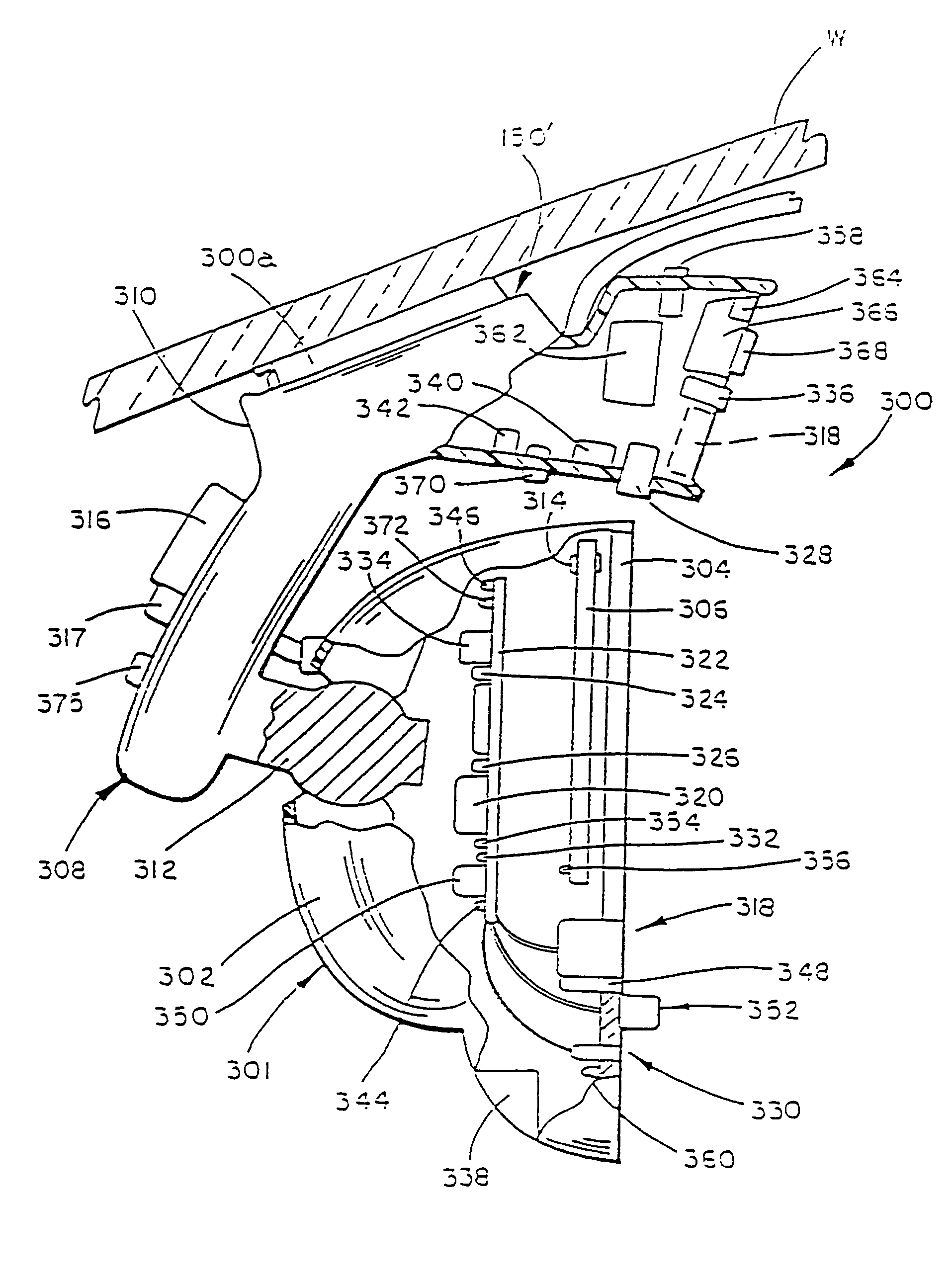

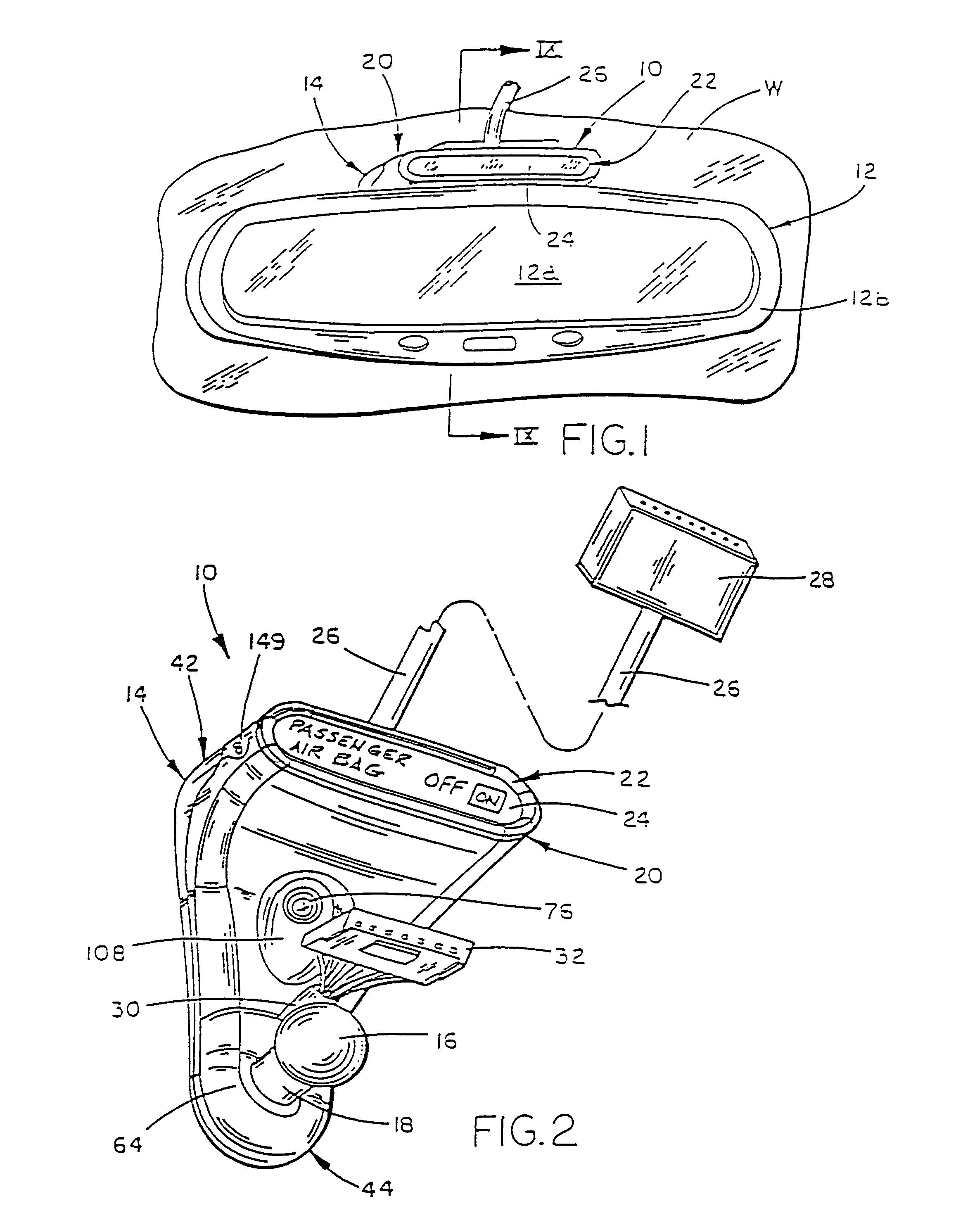

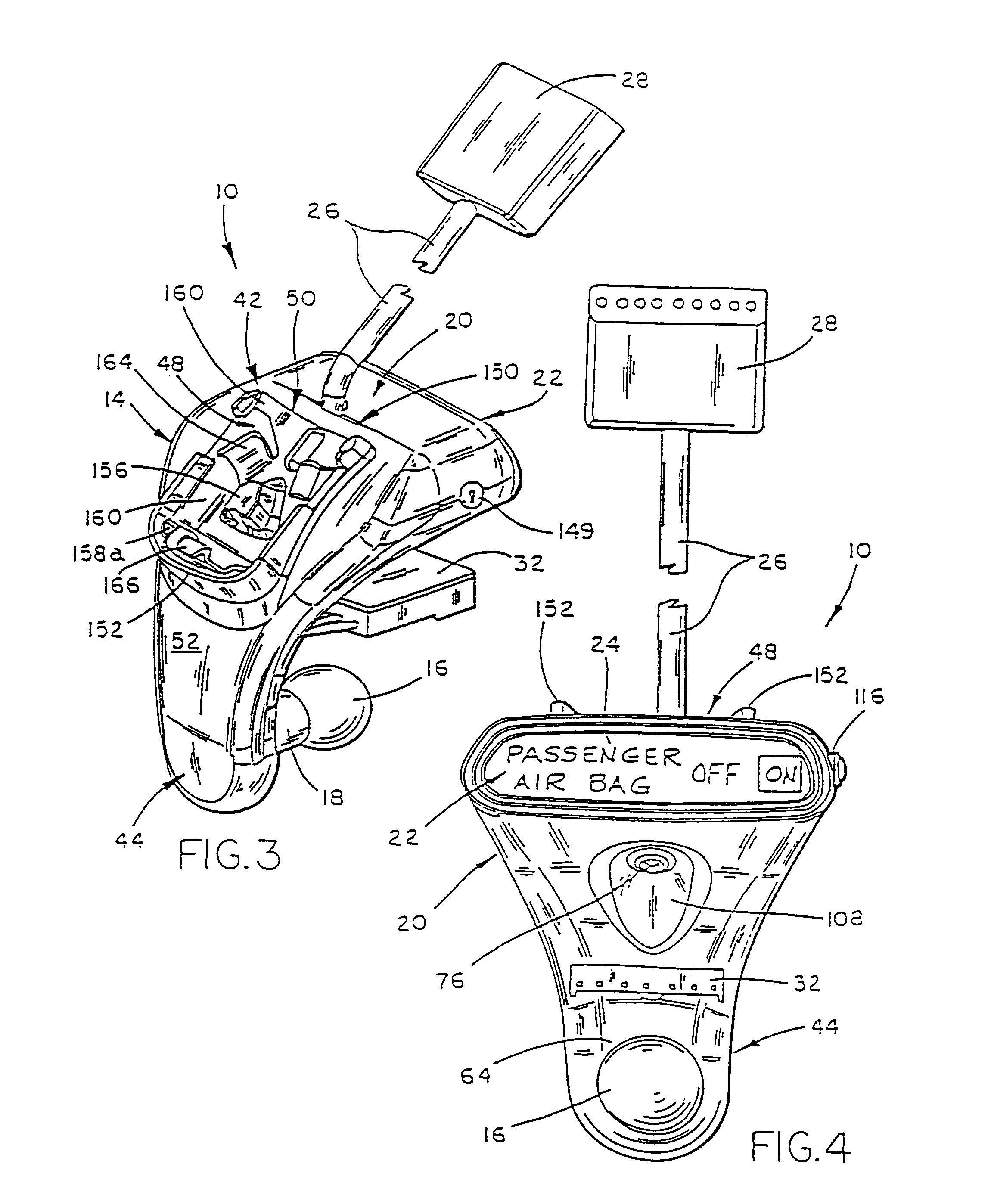

Rearview mirror assembly incorporating accessories

InactiveUS7012543B2Improve visibilityClosely positionedVehicle testingRegistering/indicating working of vehiclesEngineeringRear-view mirror

An interior rearview mirror system for use in a vehicle includes a mirror support assembly for attachment to the interior of a vehicle. The mirror support assembly comprises a first electronic accessory such as an imaging sensor. A reflective mirror element is disposed in a housing, the housing being pivotally adjustable about the mirror support assembly via a pivot element. The housing includes second and third electronic accessories at least partially controlled by a microprocessor. The mirror support assembly preferably includes a wire passageway for wires passing into the housing for the reflective mirror element. The second and third electronic accessories may be a headlamp controller and automatic dimming circuitry, or may be selected from a variety of other devices such as a garage door opener, an INTERNET interface, a video device, a trip computer, a light, or other items. The mirror assembly may also be in wireless communication with an external device.

Owner:DONNELLY CORP

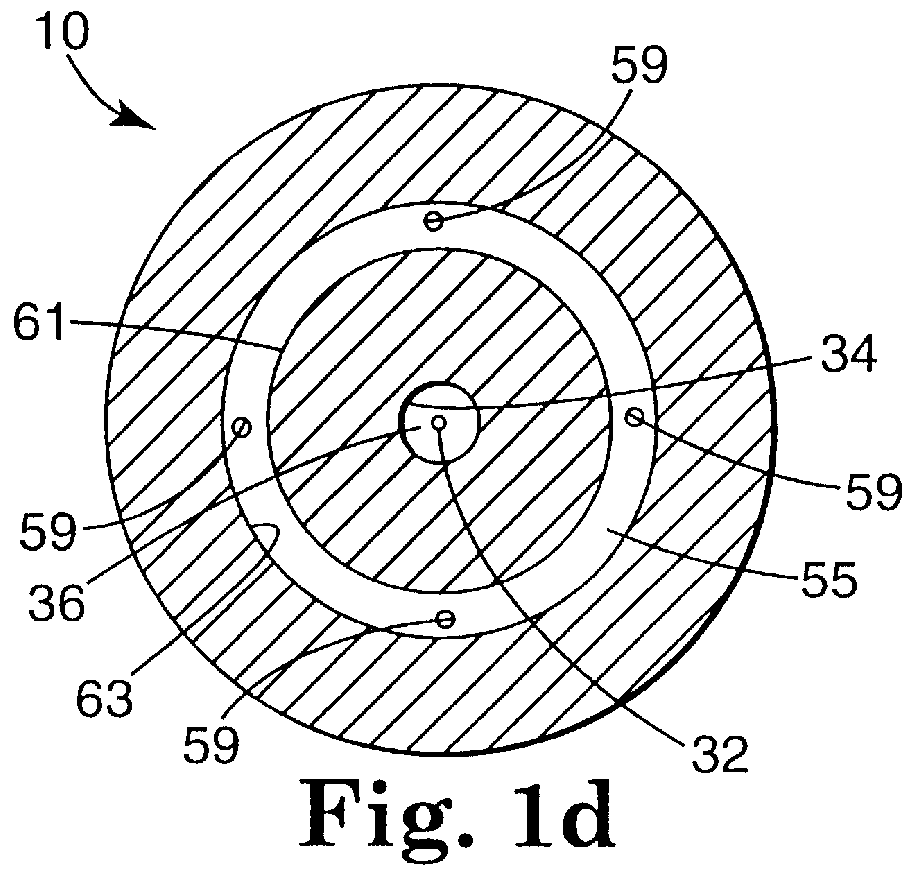

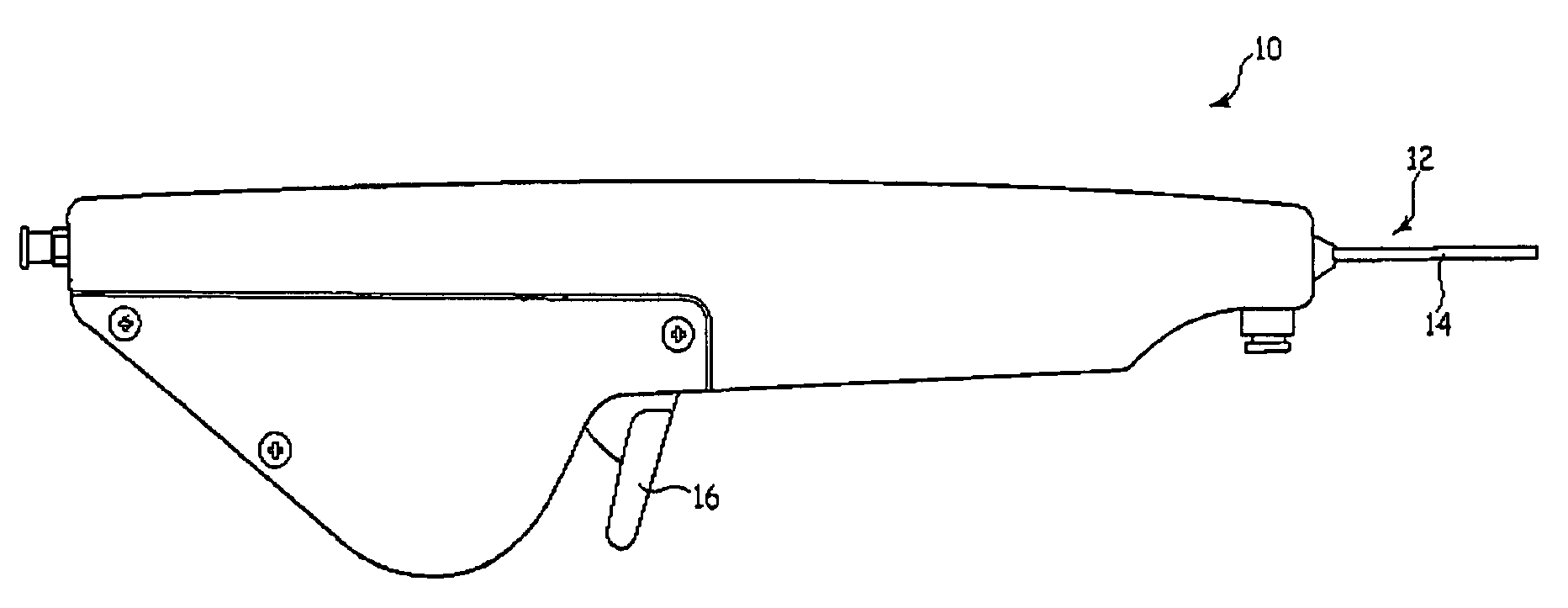

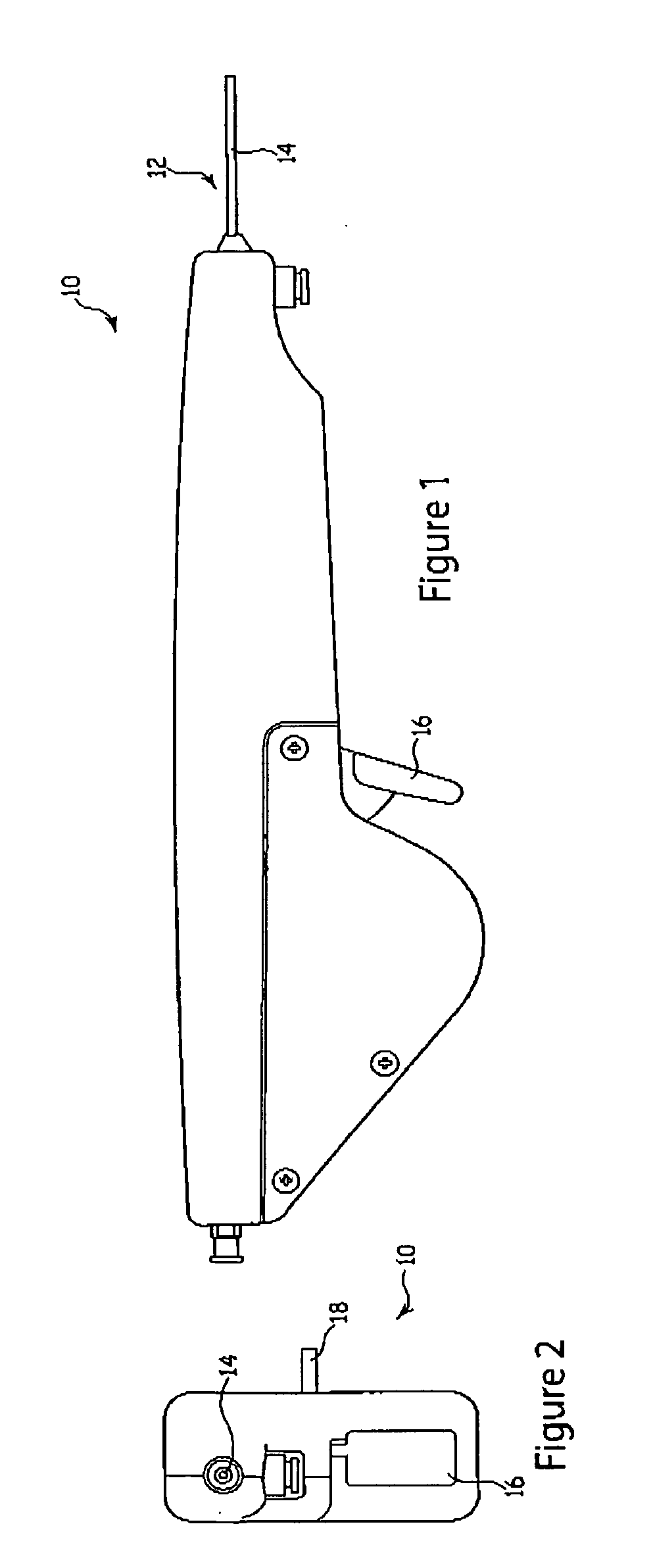

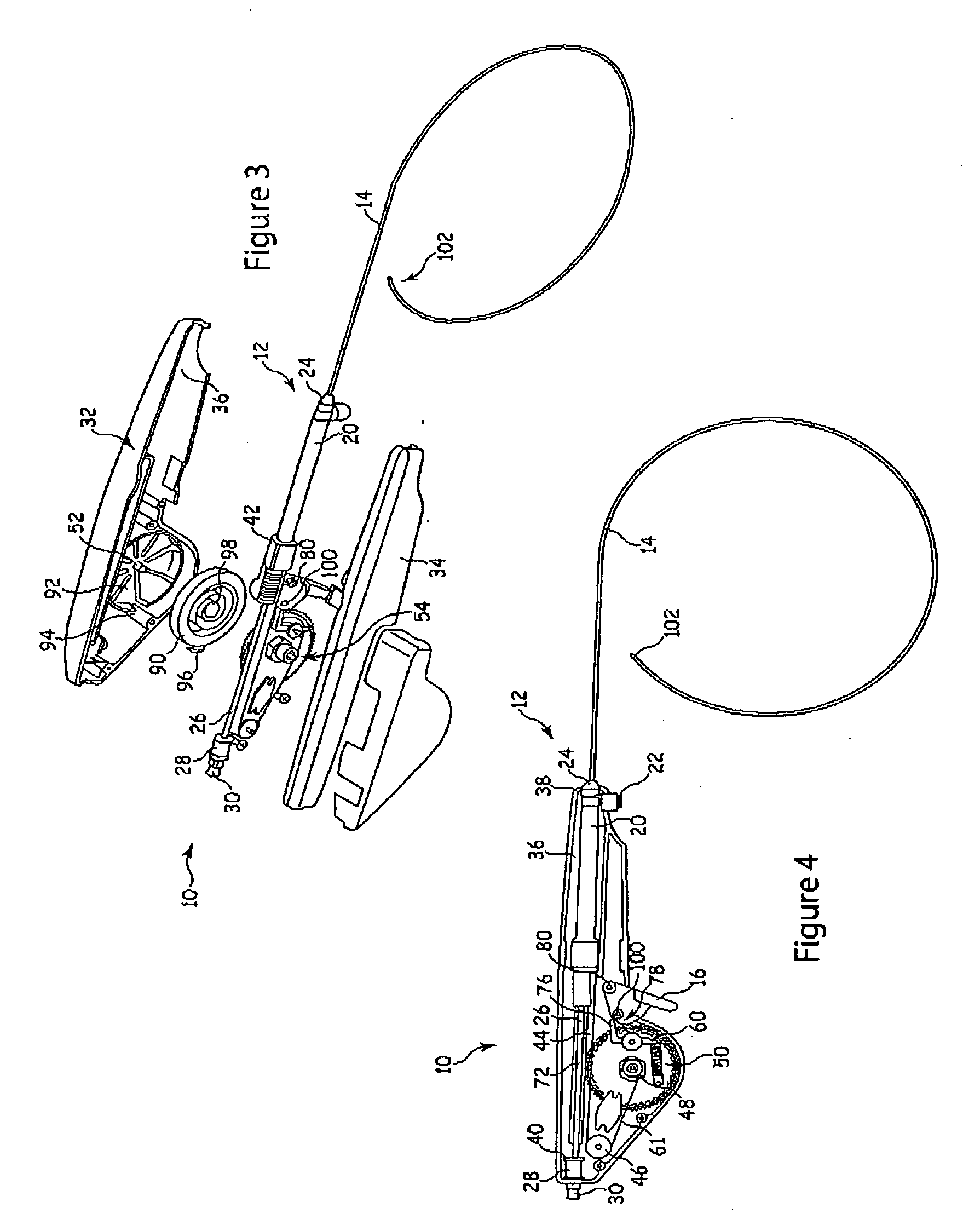

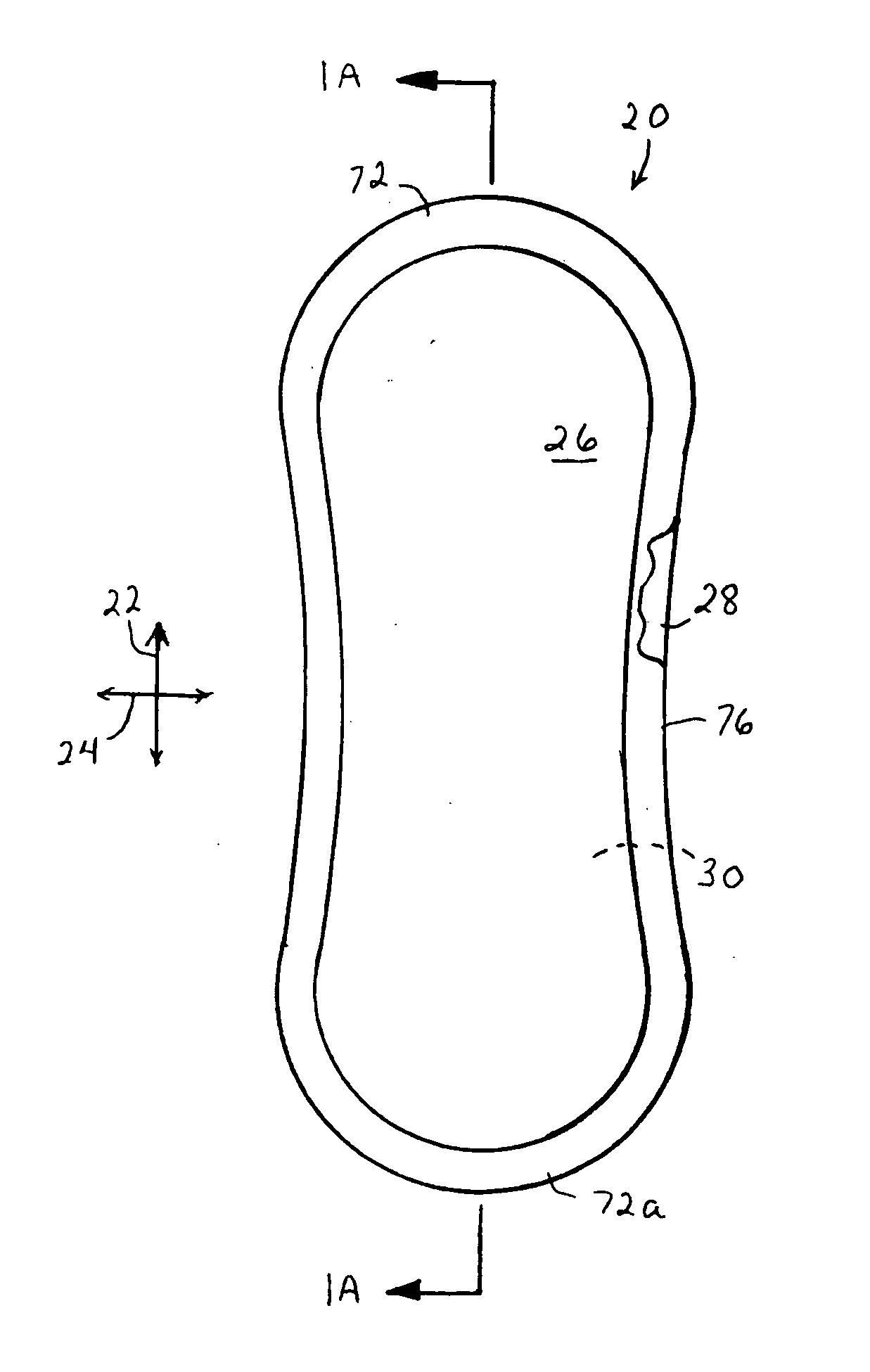

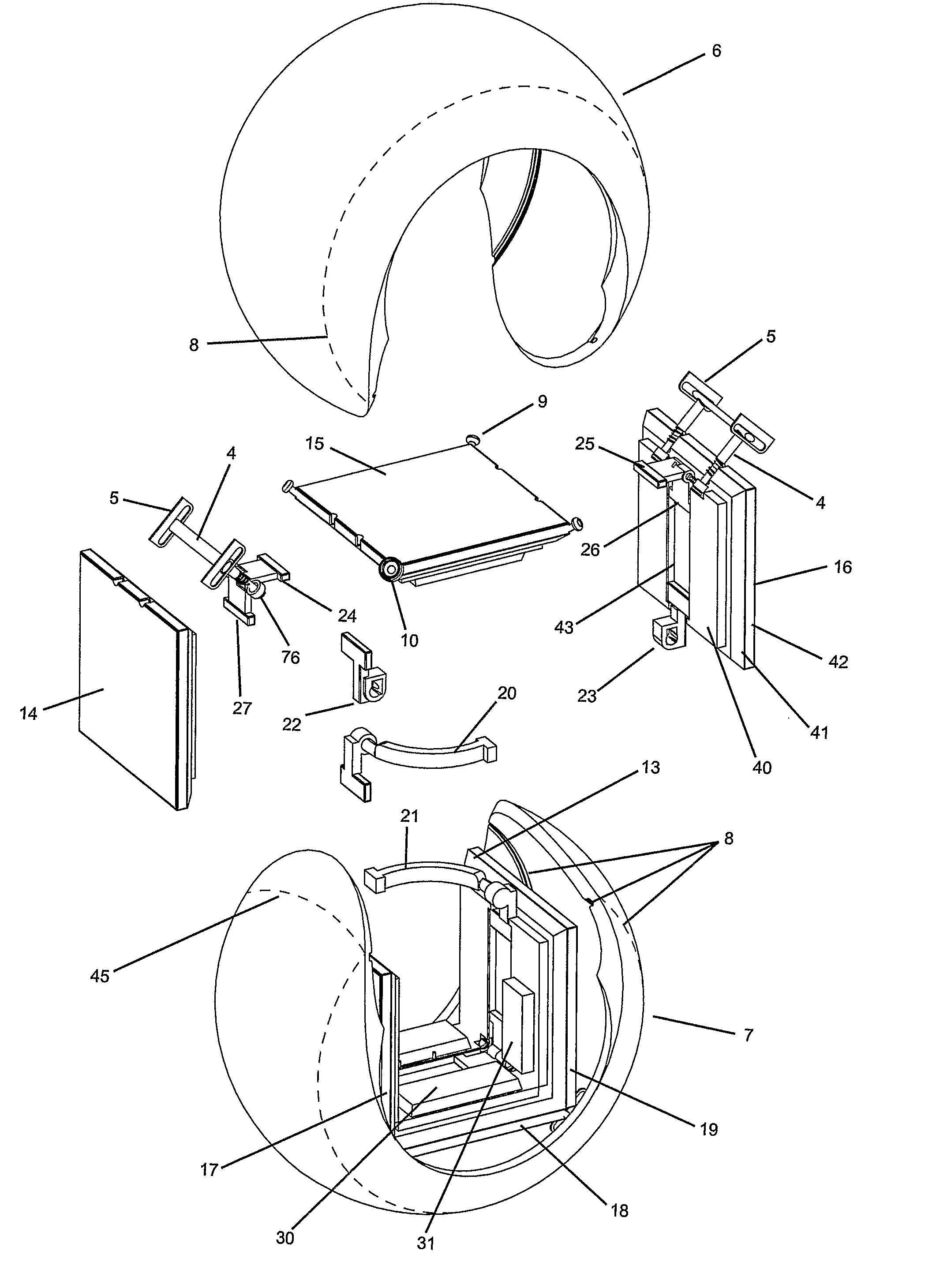

Deployment assembly and introducer

A deployment assembly (10) for an introducer used for introducing into a patient a stent or other device, the deployment assembly including a housing 30 carrying a sprung loaded (90) actuator (44, 50). The actuator includes a toothed wheel (50) carrying a spool (48) around which a retraction strap (44) can be wound. The strap (44) is coupled to a body member (26) of the introducer and through this to the outer sheath (14) thereof. A trigger (16) is provided for operating the actuator (44, 50). When the trigger (16) is pressed, the actuator winds, under the force produced by the spring (90), the strap (44) to thereby retract the outer sheath (14) so as to expose and then deploy the device carried on the introducer. The mechanism is such that a surgeon need not expend his own energy to retract the outer sheath (14) since this force is provided by the spring (90). Furthermore, the spring (90) acts in a plane other than that of the direction of retraction of the sheath (14), which minimises the risk of inadvertent movement of the introducer as the sheath (14) is being retracted.

Owner:COOK MEDICAL TECH LLC

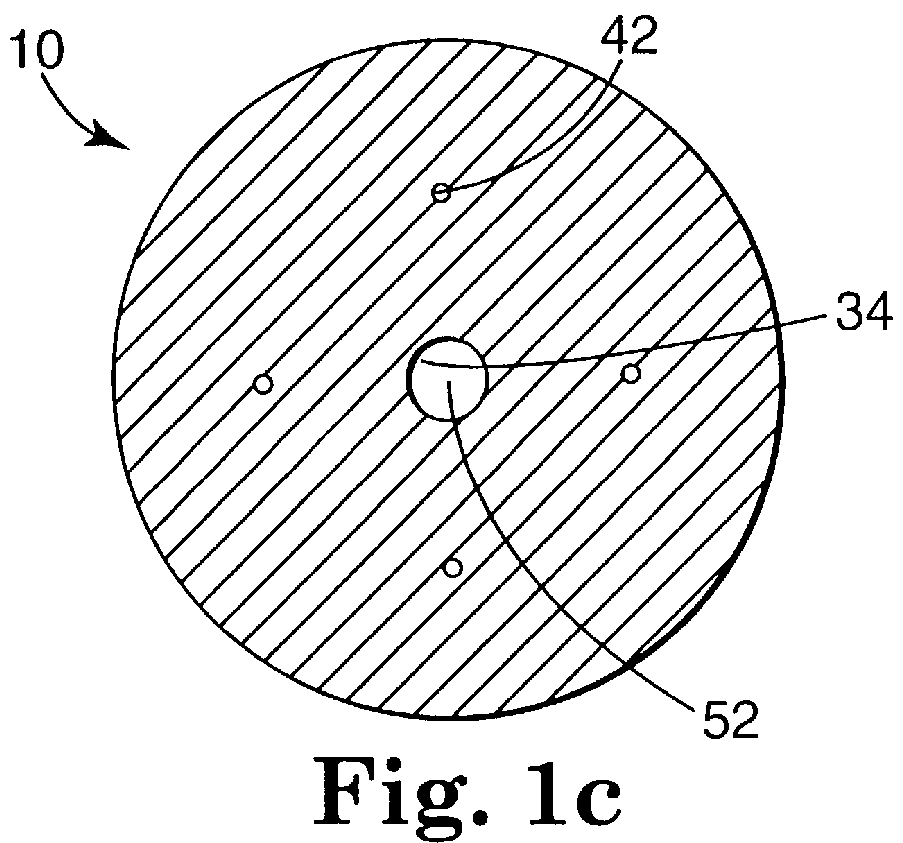

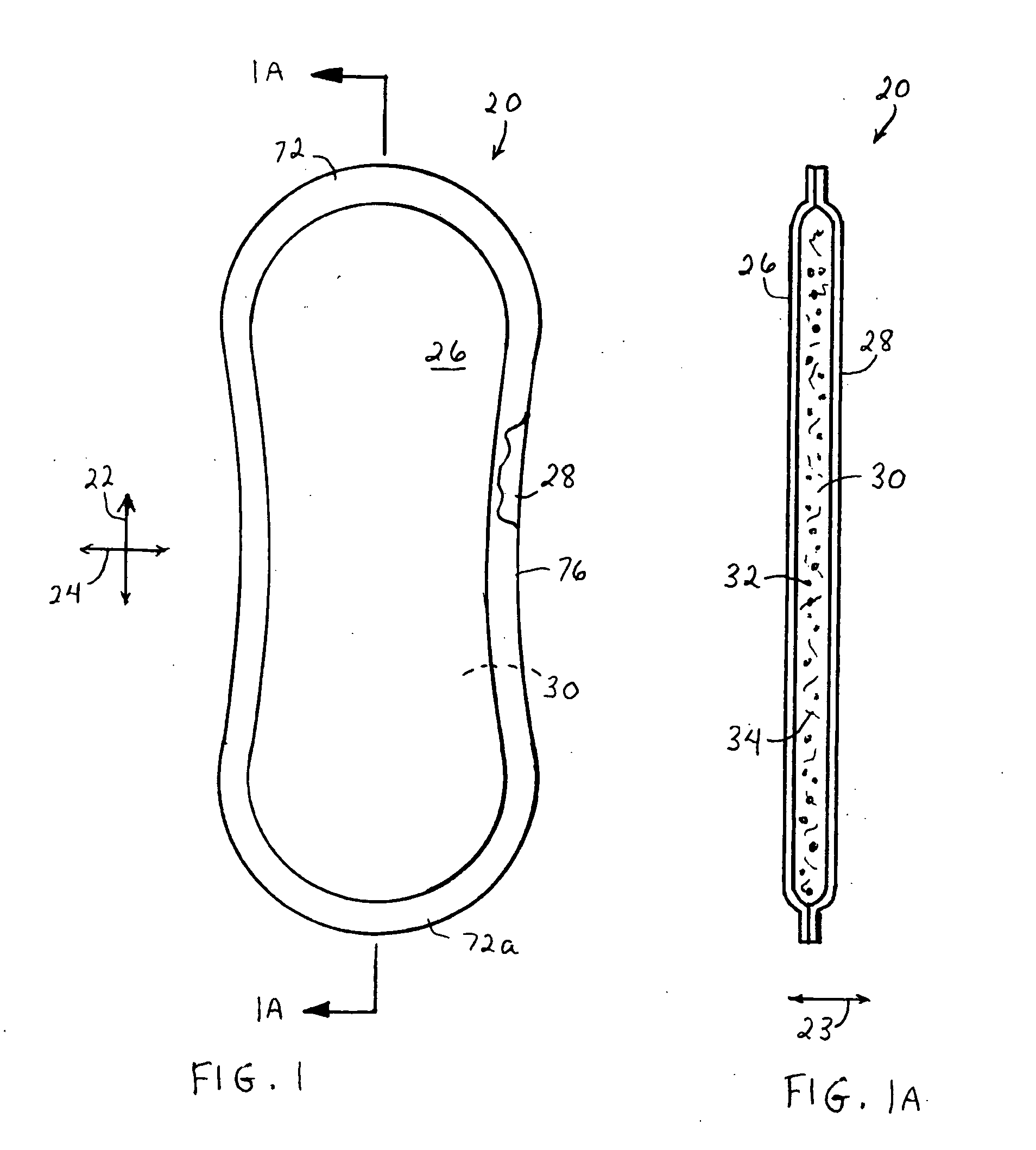

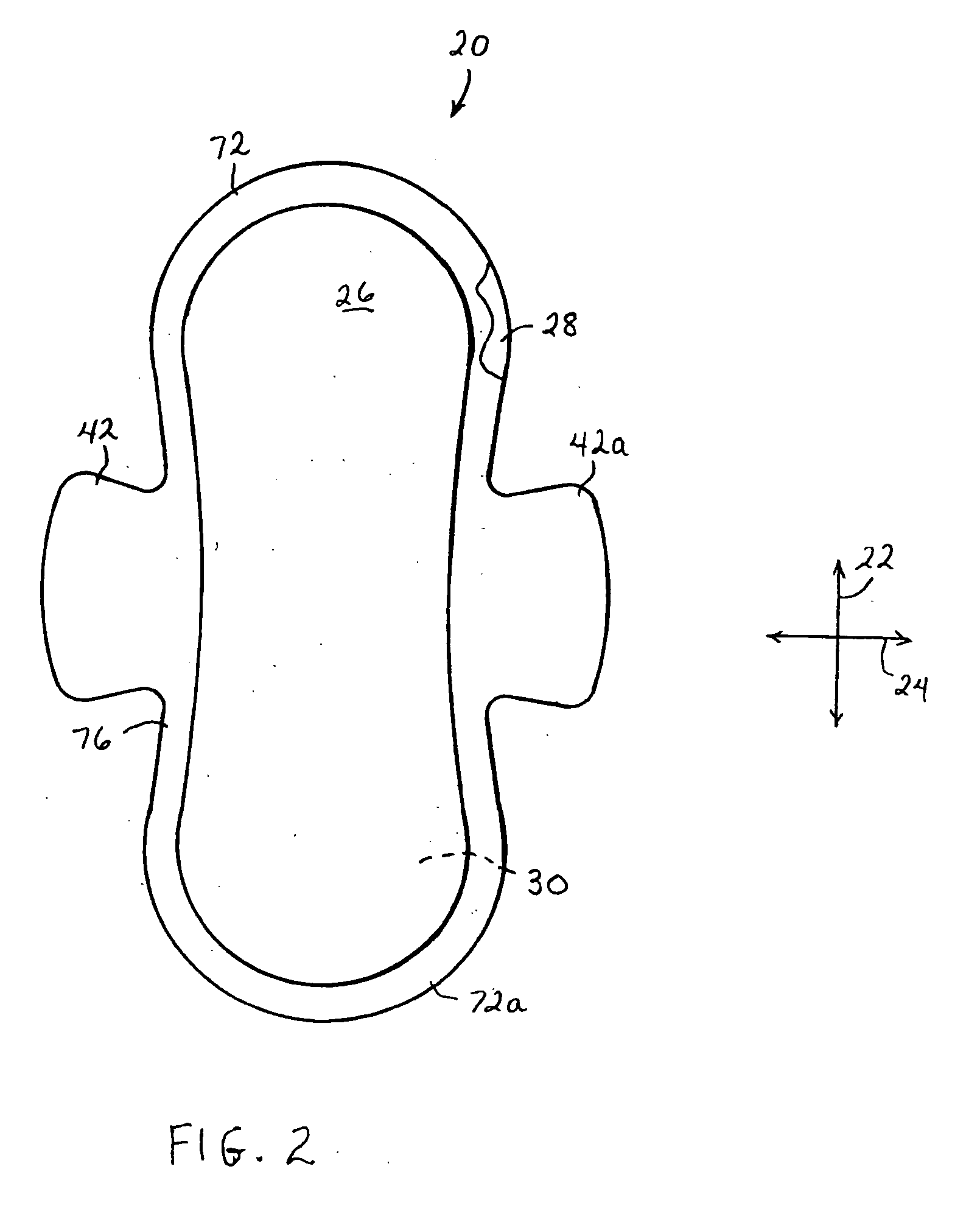

Stretchable absorbent composite with low superaborbent shake-out

InactiveUS20060004336A1Improve tensile propertiesReduce vibrationBaby linensCoatingsWater solubleFiber

An article comprises a stretchable absorbent composite (30) that includes a quantity of superabsorbent particles (32) which are operatively contained within a matrix of elastomeric polymer fibers (34). In particular aspects, the composite article can include at least about 60 wt % of the superabsorbent particles and not more than about 40 wt % of the elastomeric polymer fibers, based on a total weight of the composite. In other aspects, the composite article can provide a high stretchability. Additional aspects can provide a low shake-out. Particular configurations can, for example, provide a stretchability value of at least about 30%. Additional aspects can include a configuration that provides a shake-out value of not more than about 2%. In other aspects, the invention can provide a shake-out value of not more than about 1.2%. In further aspects, the absorbent composite can include superabsorbent particles having a coating of treatment-material that is thermally processible. Additional aspects can include a treatment-material which is water soluble.

Owner:KIMBERLY-CLARK WORLDWIDE INC

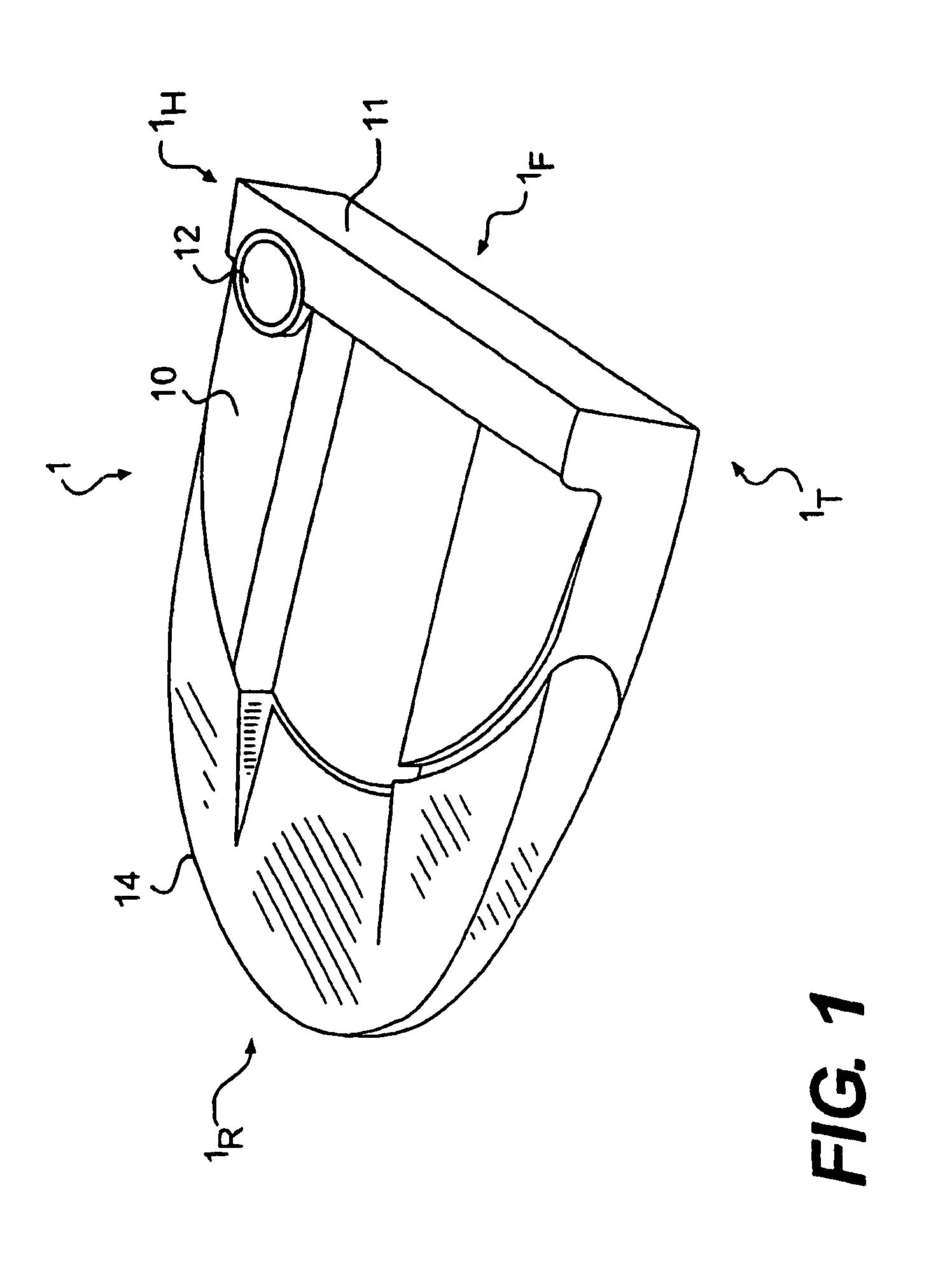

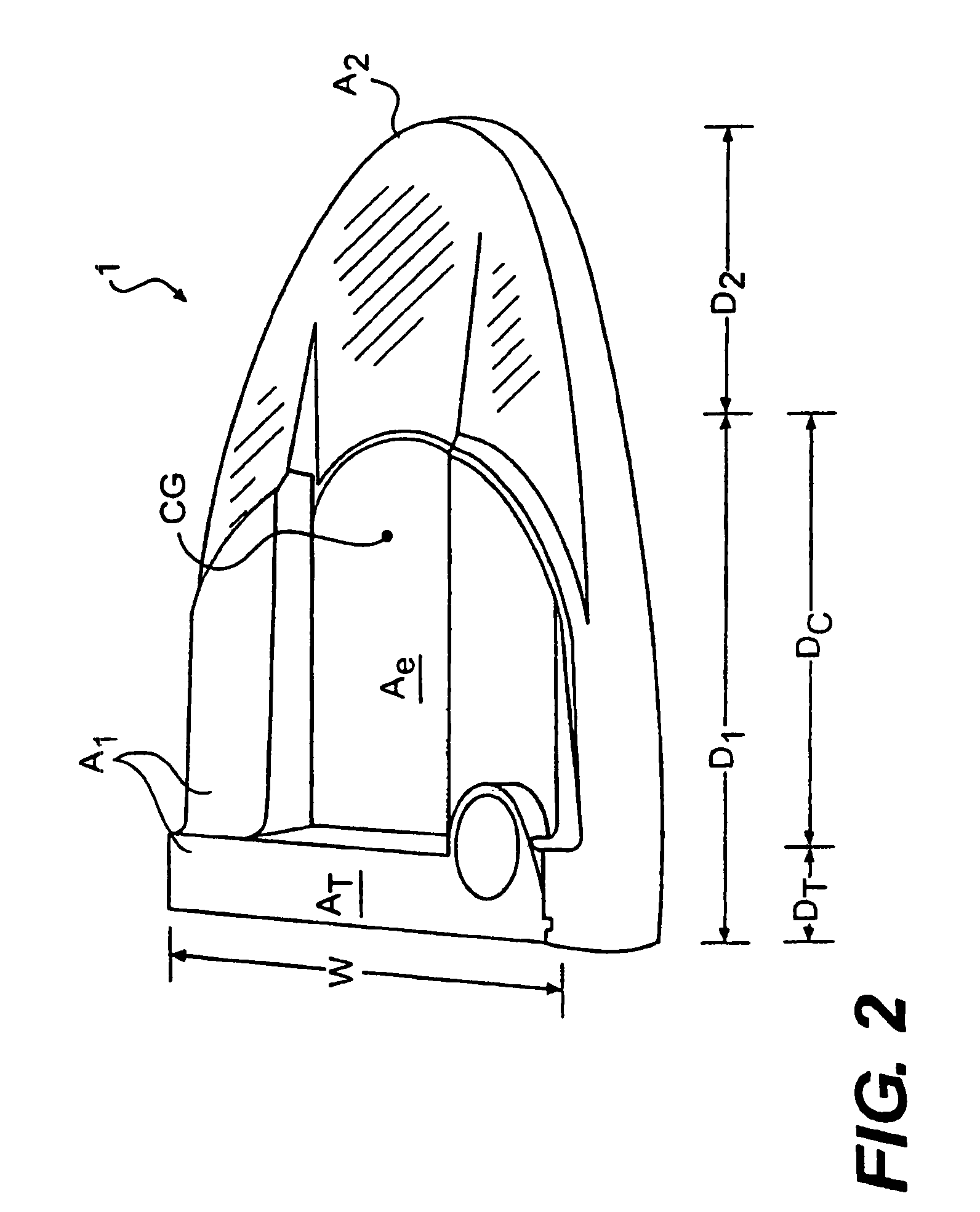

Golf club head with alignment system

A golf club head is disclosed. The golf club head includes a first body member and a second body member. The first body member includes a strike face and a top portion. The second body member is coupled to the first body member and extends away from the first body member in a direction opposite the strike face. At least a top portion of the second body member is camouflaged. A preferred method of camouflage is color differentiation, wherein the second body member is darker than the first body member. Specific color values and club head geometries are also disclosed and claimed. The club head may include a body member and a weight member such as a bar that extends rearward from the body member. A cover may be included to camouflage the weight member. A separate core member and high visibility sight lines may also be provided.

Owner:COBRA GOLF

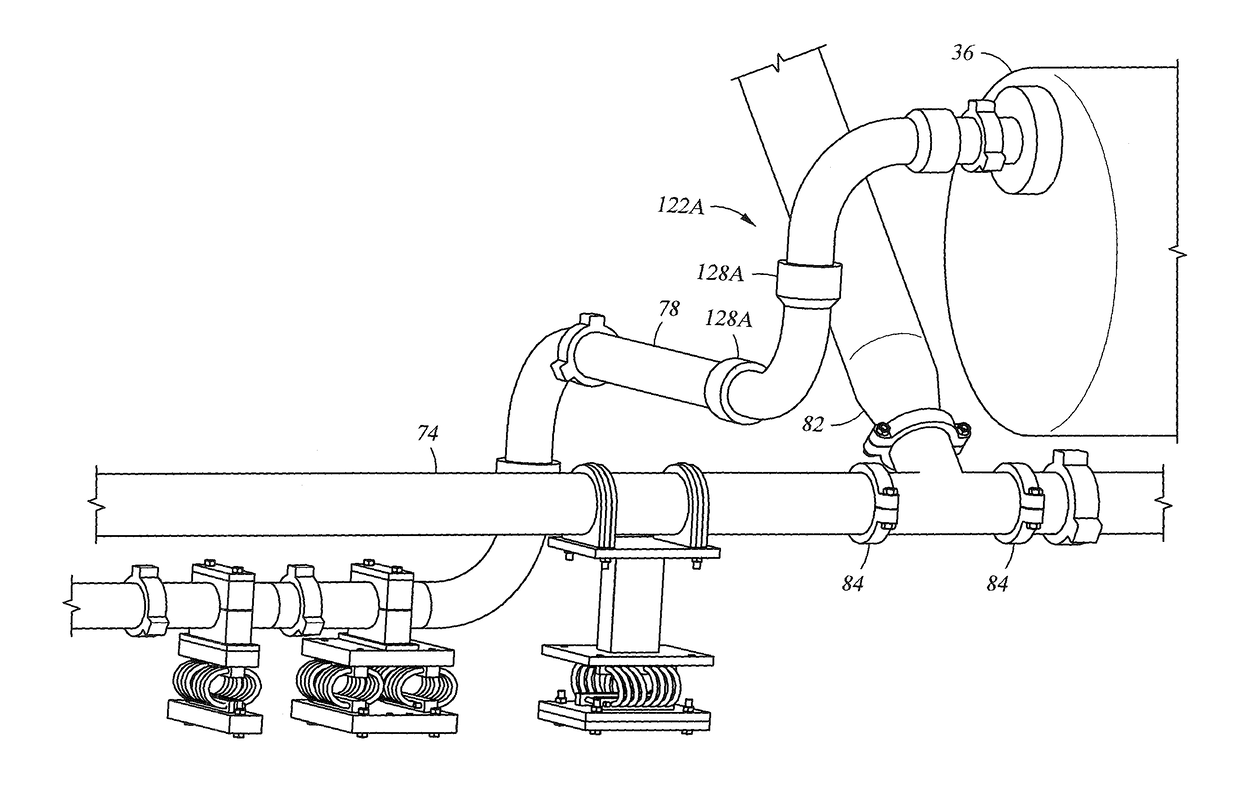

System for reducing vibrations in a pressure pumping fleet

ActiveUS10119381B2Vibration highReduce turbulenceAC motor controlPositive displacement pump componentsFracturing fluidHelical coil

An electrically powered hydraulic fracturing system having pumps for pressurizing fracturing fluid, piping for carrying fracturing fluid, and vibration reducing equipment for use with the piping. The vibration reducing equipment includes helical coils that support the piping. The coils are made of a wire rope made of strands of steel cable twisted together. Grooved fittings are provided on some piping connections, and which allow pivoting between adjacent fluid conveyance members. Swivel joints are strategically located in the piping which allow rotational flexing between adjacent sections of the piping; thereby attenuating vibration in the piping but without stressing the piping.

Owner:US WELL SERVICS LLC

Robotic surgical system with joint motion controller adapted to reduce instrument tip vibrations

ActiveUS20070142968A1Reduce vibrationWithout jeopardizing control system stabilityProgramme-controlled manipulatorMechanical/radiation/invasive therapiesJoints movementInstrumentation

A robotic surgical system has a robot arm holding an instrument for performing a surgical procedure, and a control system for controlling movement of the arm and its instrument according to user manipulation of a master manipulator. The control system includes a filter in its forward path to attenuate master input commands that may cause instrument tip vibrations, and an inverse filter in a feedback path to the master manipulator configured so as to compensate for delay introduced by the forward path filter. To enhance control, master command and slave joint observers are also inserted in the control system to estimate slave joint position, velocity and acceleration commands using received slave joint position commands and torque feedbacks, and estimate actual slave joint positions, velocities and accelerations using sensed slave joint positions and commanded slave joint motor torques.

Owner:INTUITIVE SURGICAL OPERATIONS INC

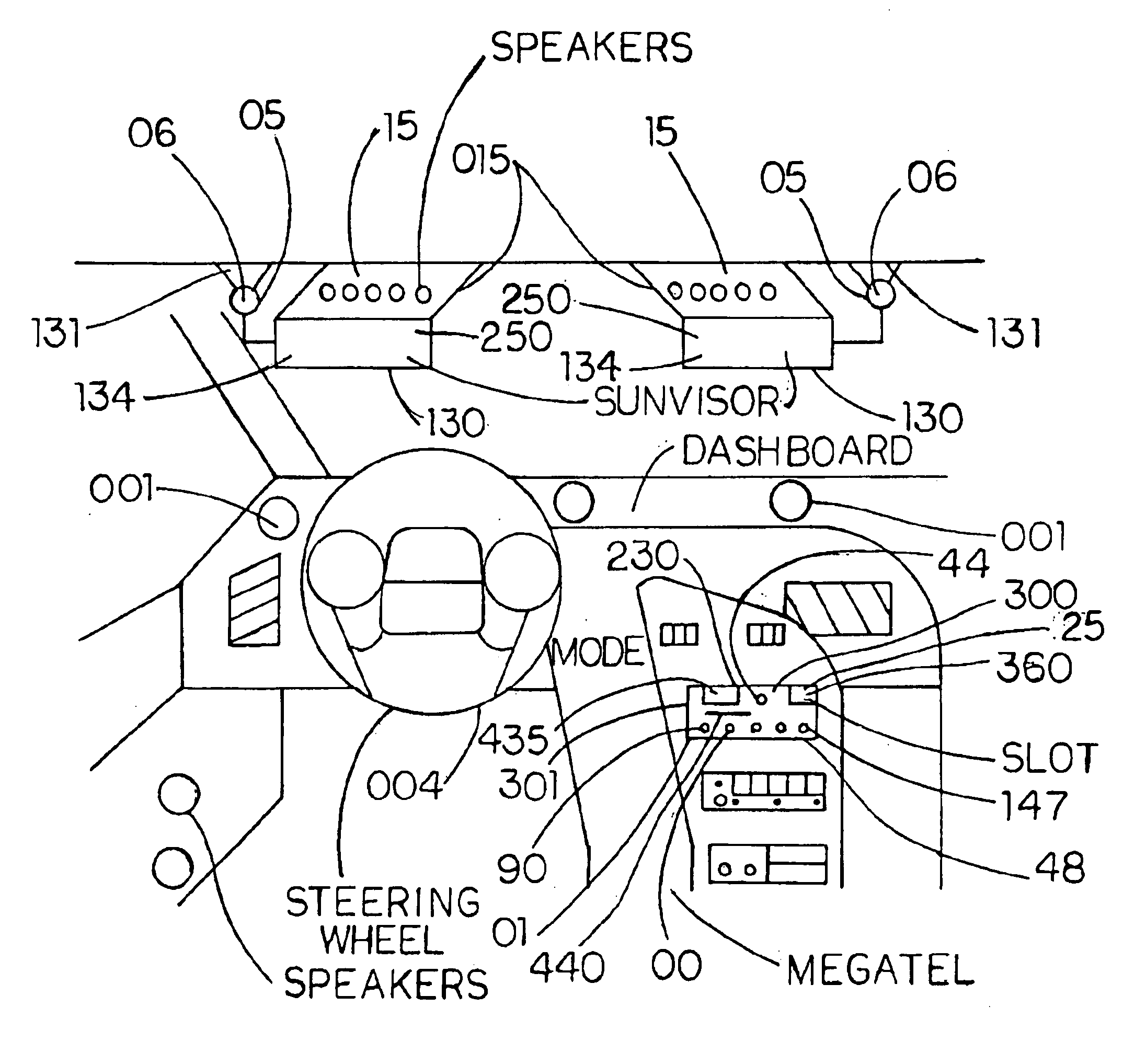

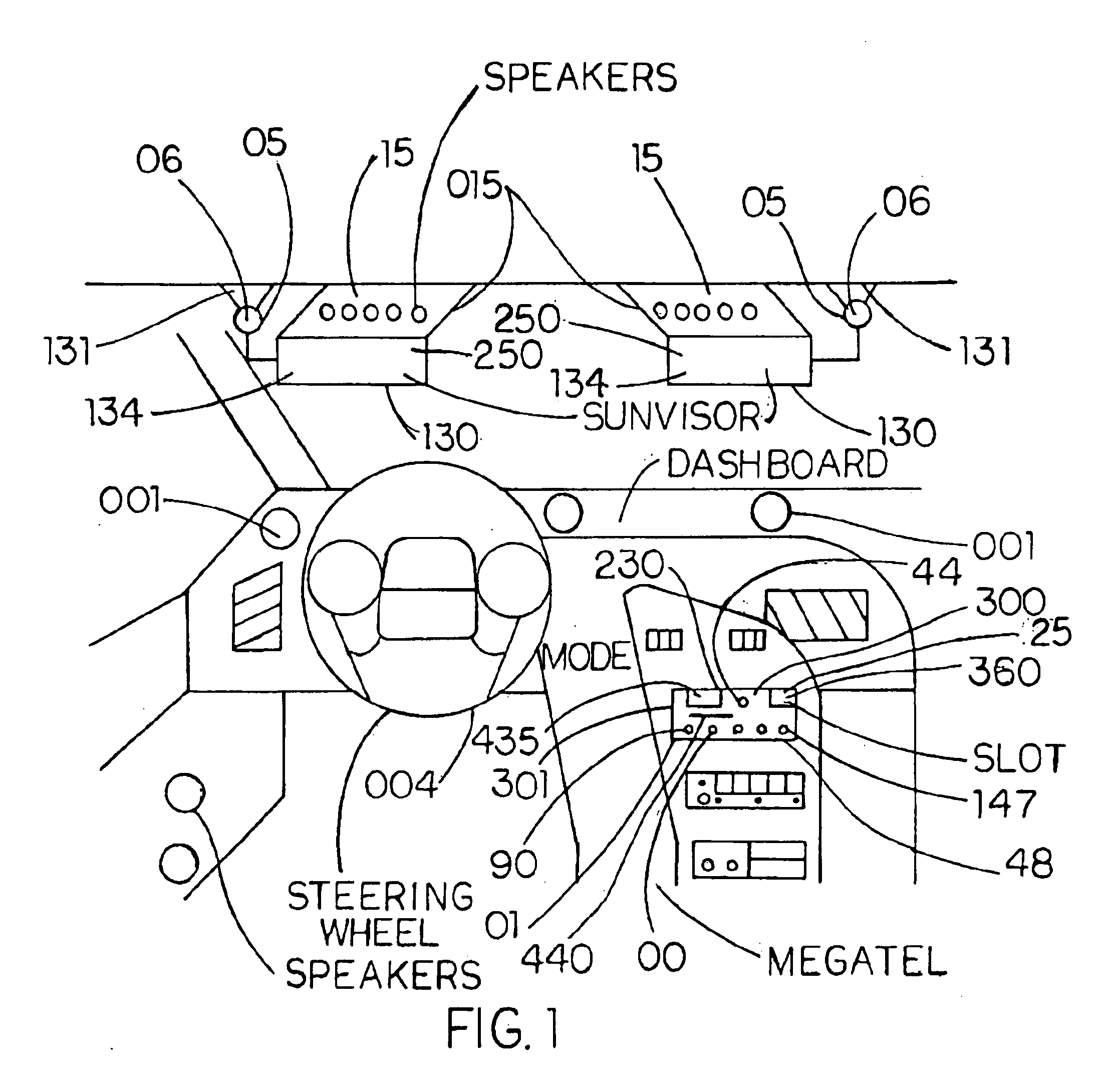

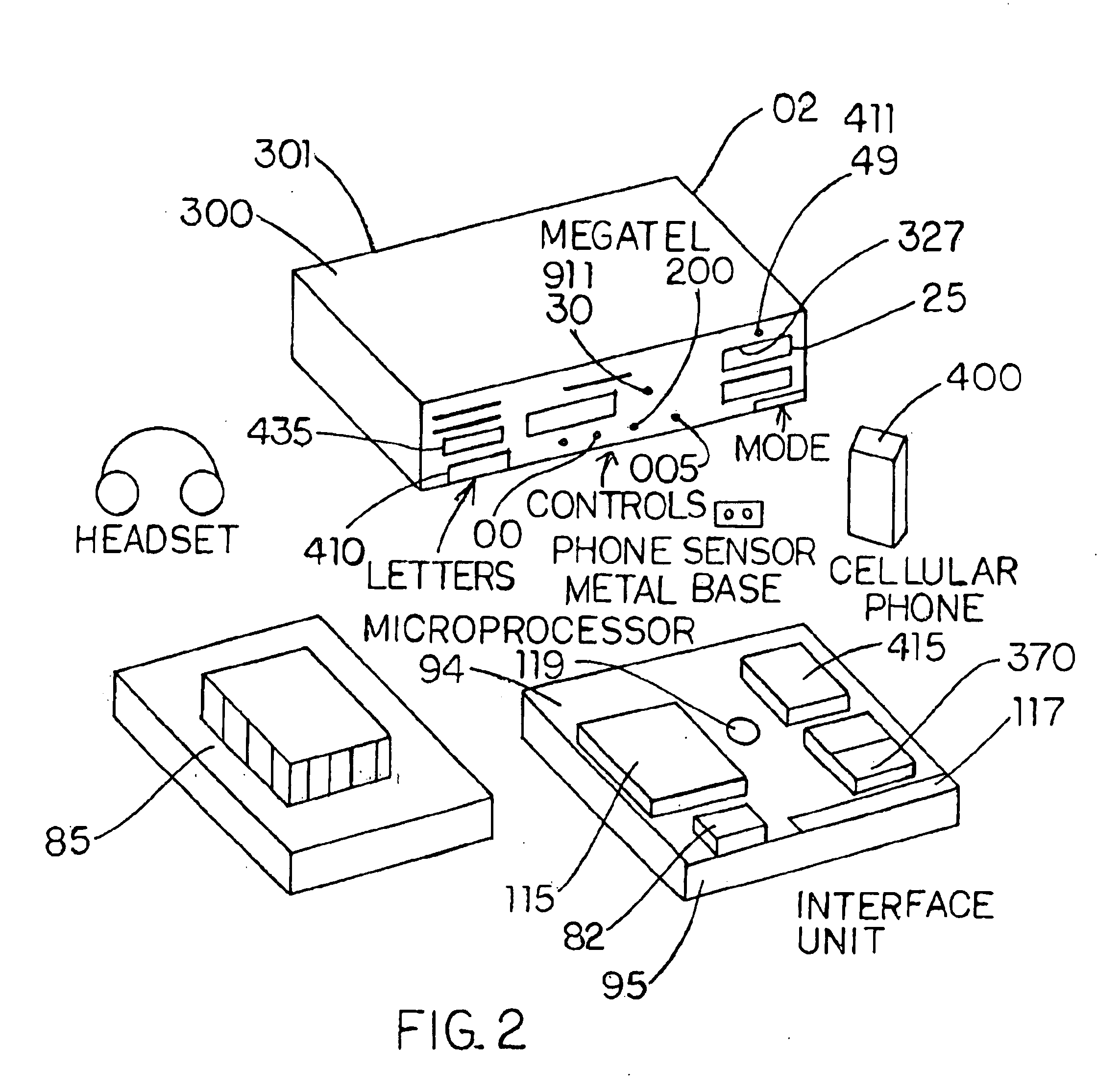

Megatel communication information system

InactiveUS6782240B1Reduction of pressure effectEnhanced informationSubstation speech amplifiersRadio transmissionThe InternetHands free

An entertainment device for vehicles adaptable to include various telecommunication and Internet applications, a sunviser monitoring screen for viewing, with an electronic screen protector for protecting the screen. The device, which is referred to as megatel, incorporates receivers and transmitters to enable cell phone and Internet transmission via the radio wave of an entertainment device radiated towards the antenna to the megatel body and output to the CPU. The signal to the CPU is controlled by the controller so that transmissions for the radio, the cell phone, and the Internet is separated and output to the monitoring screen and the speakers of the entertainment device so as to allow hands free communication while driving.

Owner:TABE JOSEPH A

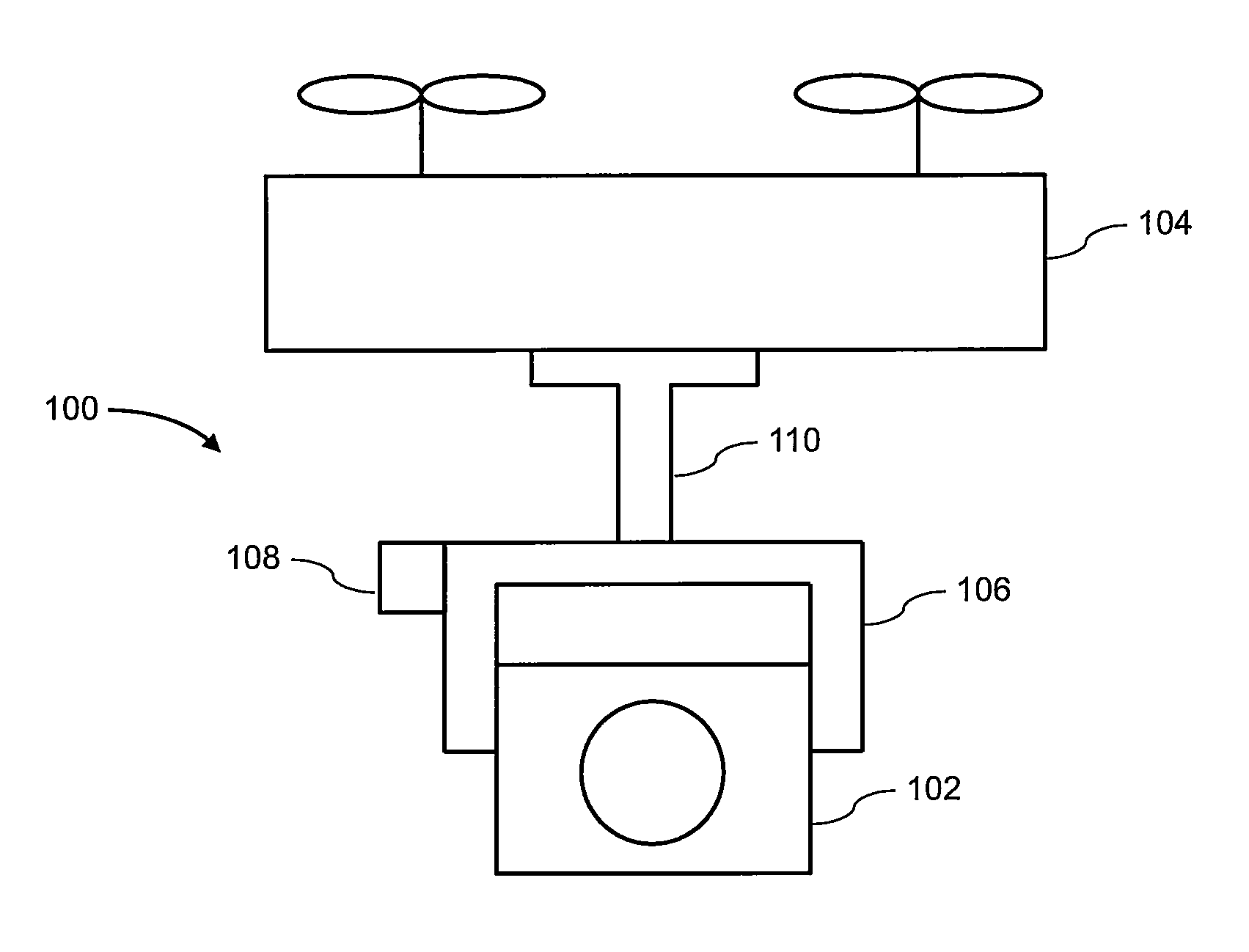

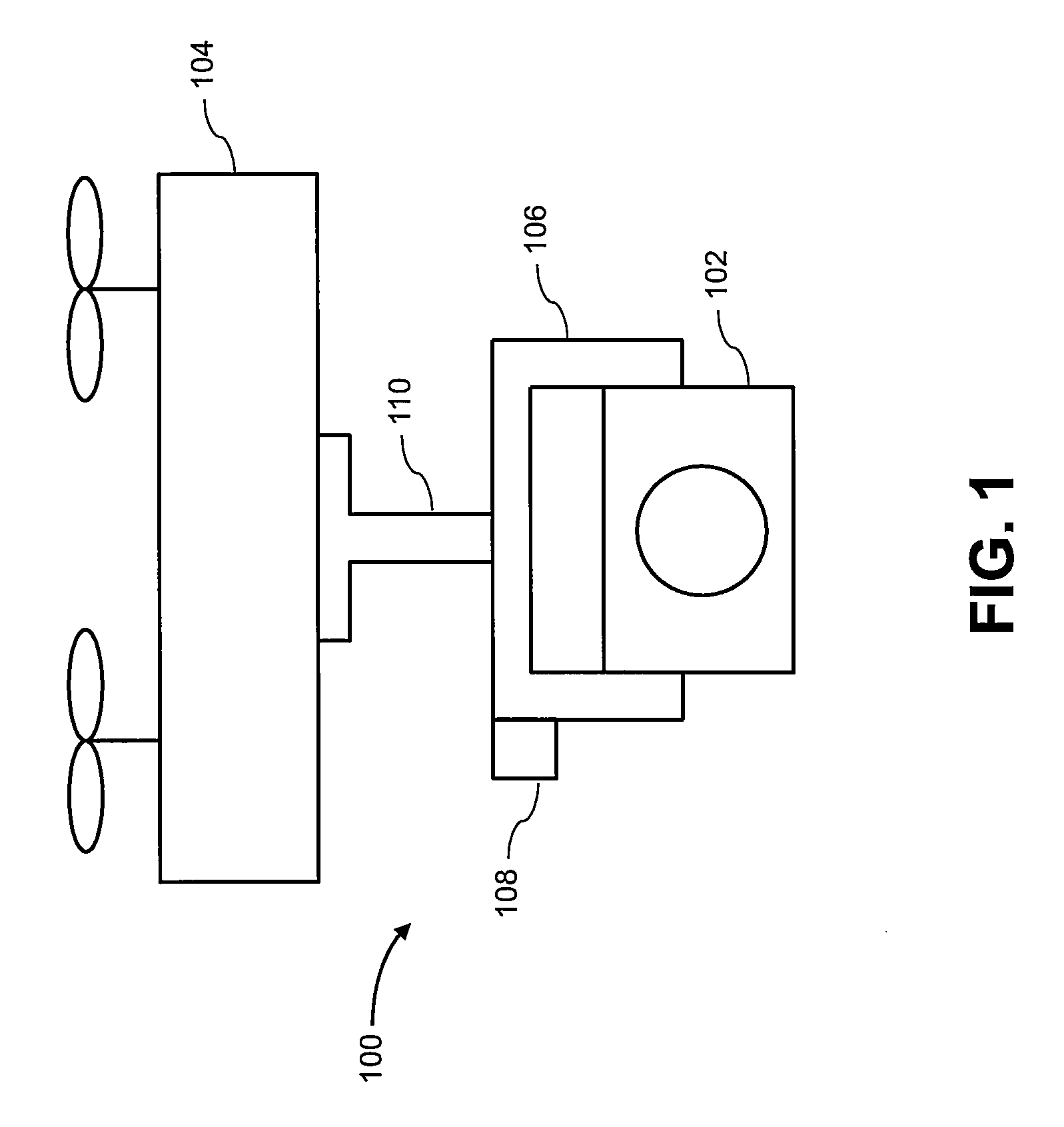

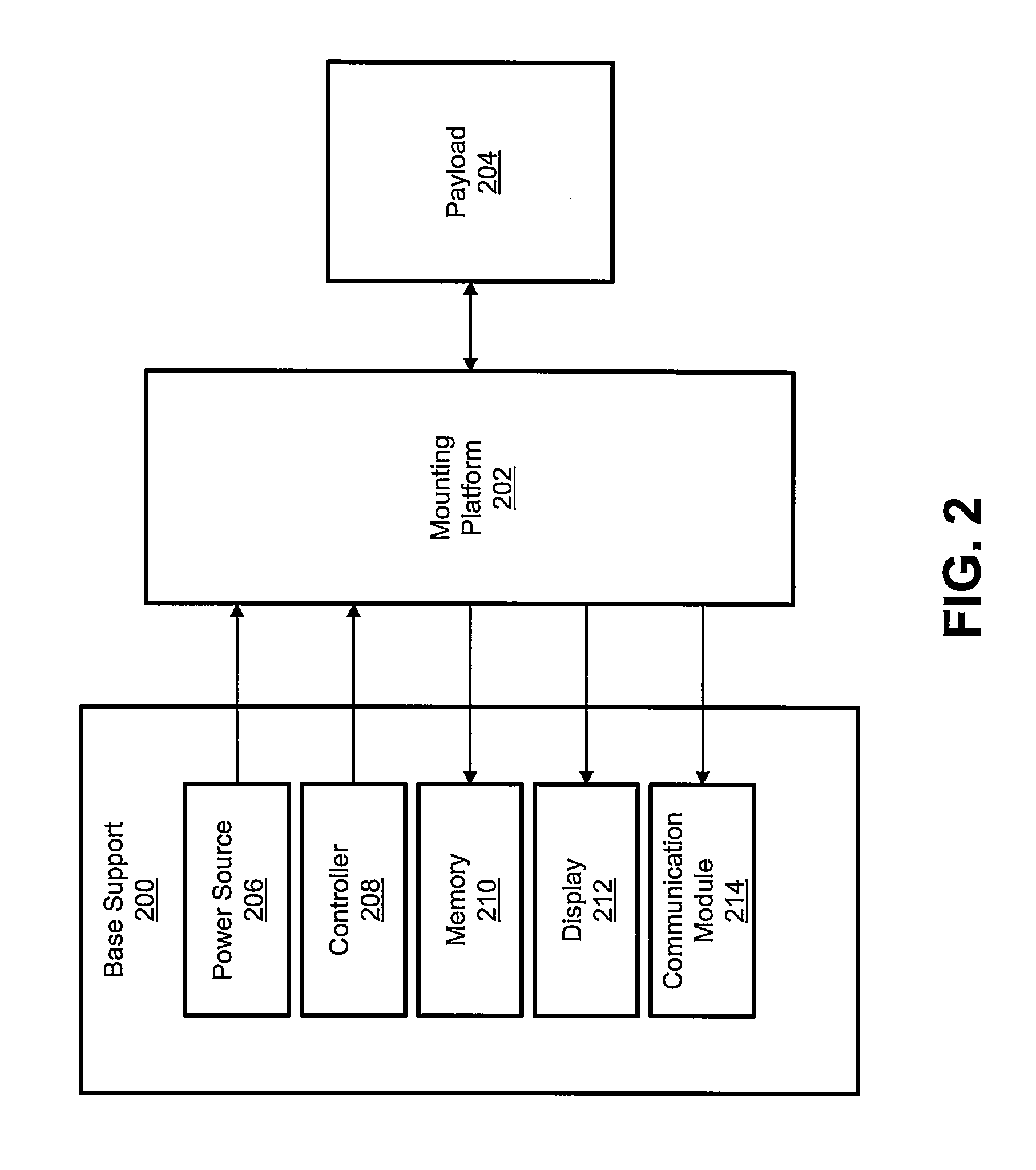

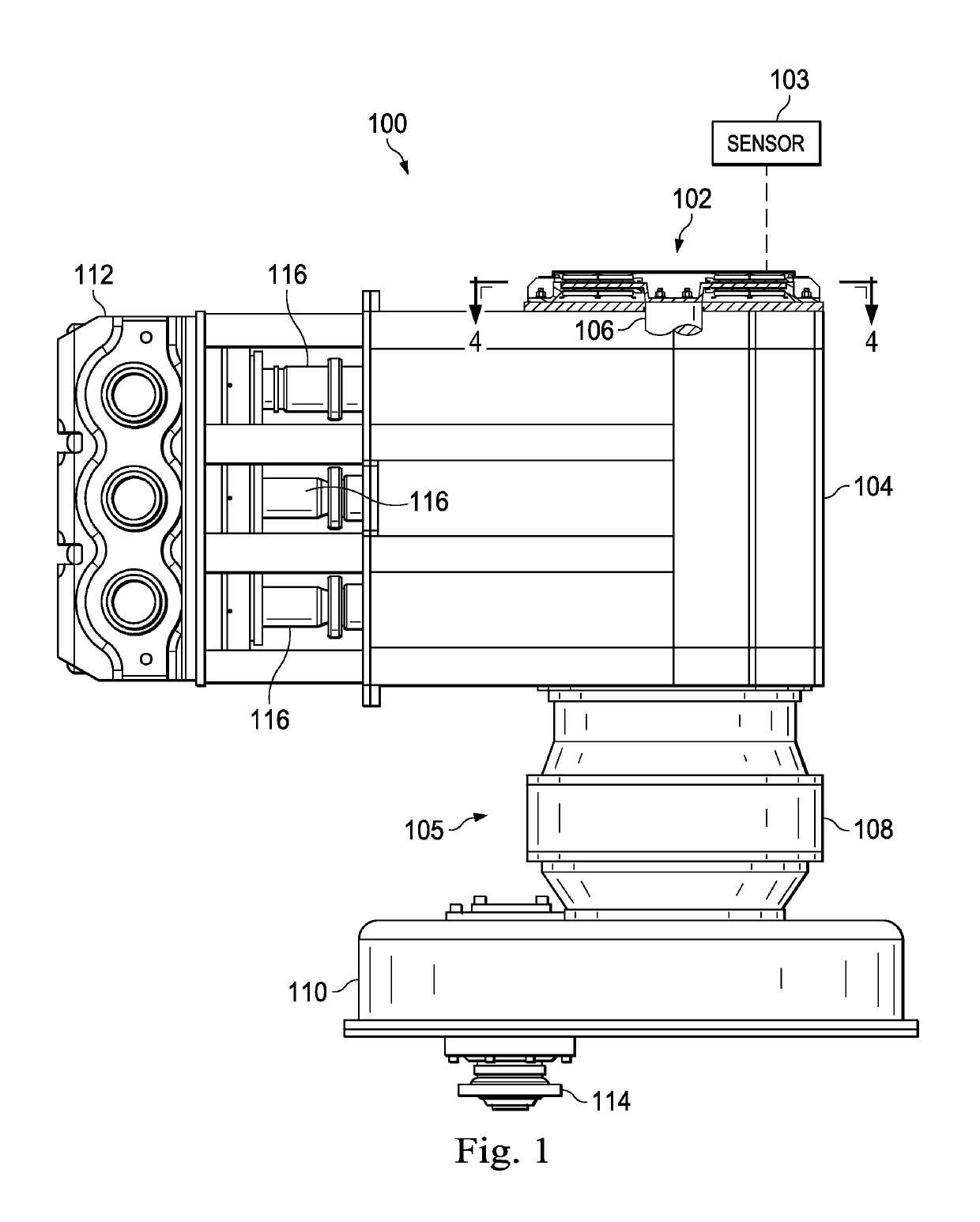

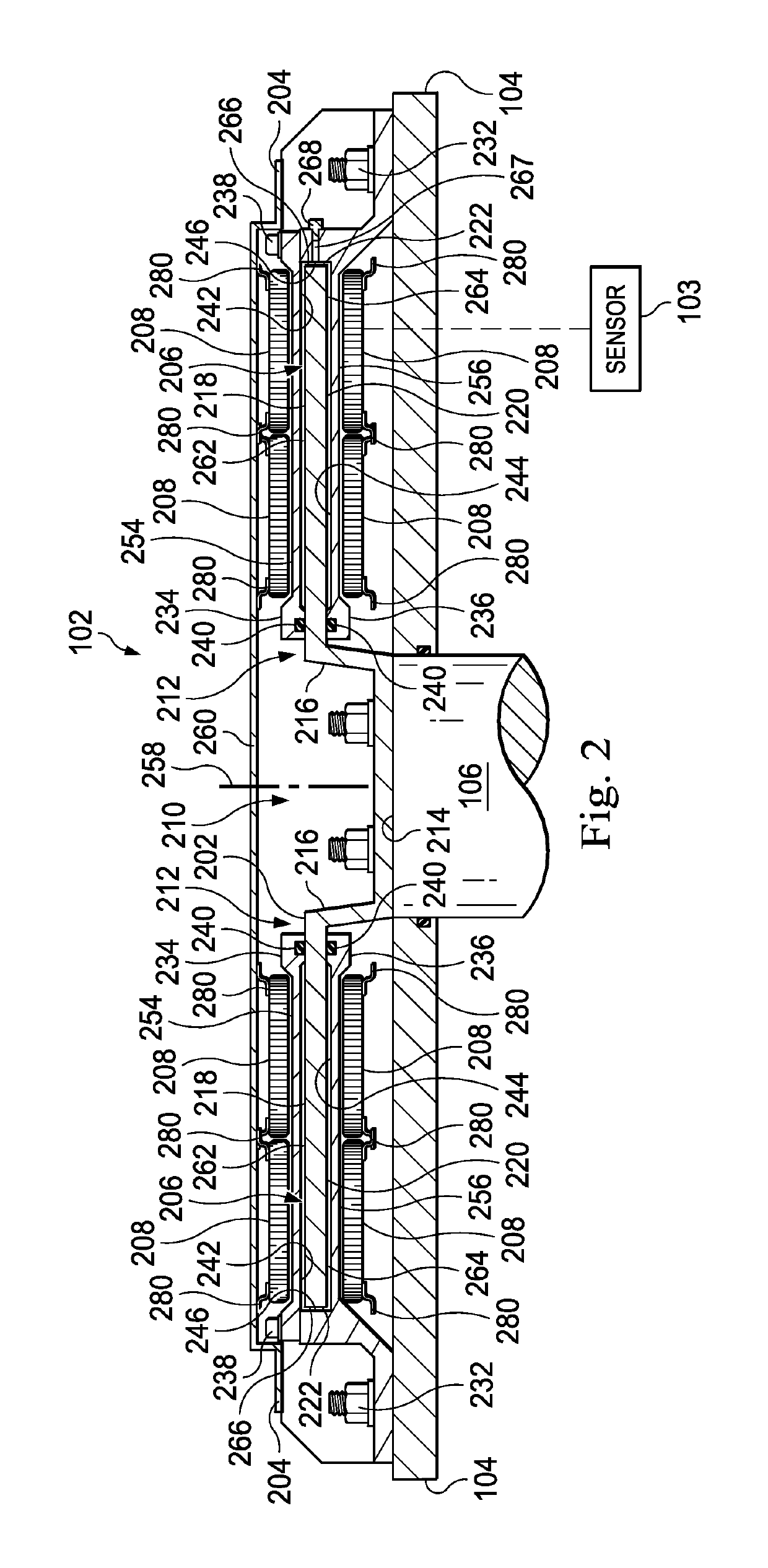

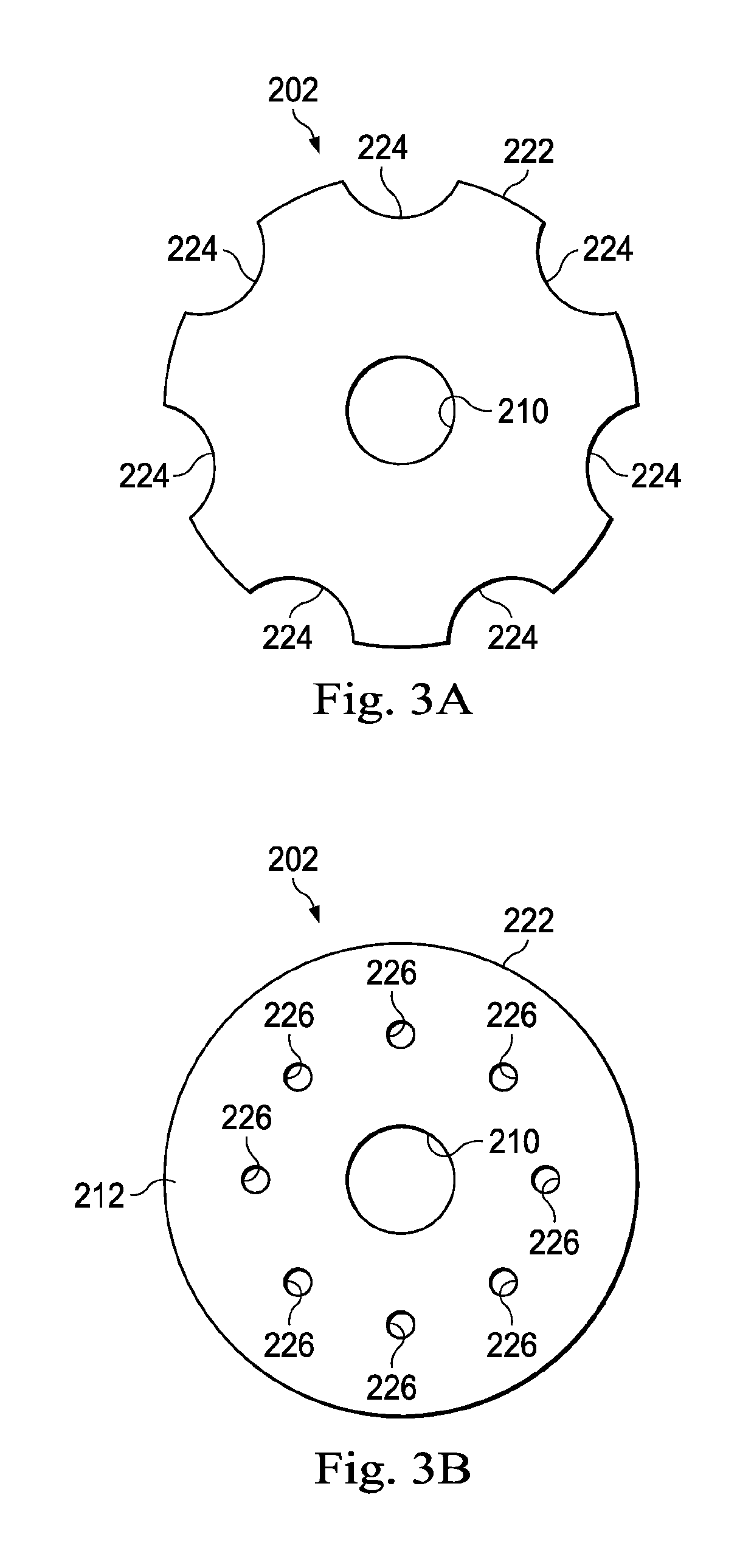

Interchangeable mounting platform

ActiveUS9280038B1Easy to optimizeImprove convenienceAircraft componentsTravelling carriersFlight vehicleSoftware engineering

A platform for interchangeably mounting a payload to a base support is provided. In one aspect, the platform comprises: a support assembly configured to be releasably coupled to a payload via a first coupling and configured to control a spatial disposition of the payload; and a mounting assembly configured to be releasably coupled via a second coupling to a plurality of types of base supports selected from at least two of the following: an aerial vehicle, a handheld support, or a base adapter mounted onto a movable object.

Owner:SZ DJI TECH CO LTD

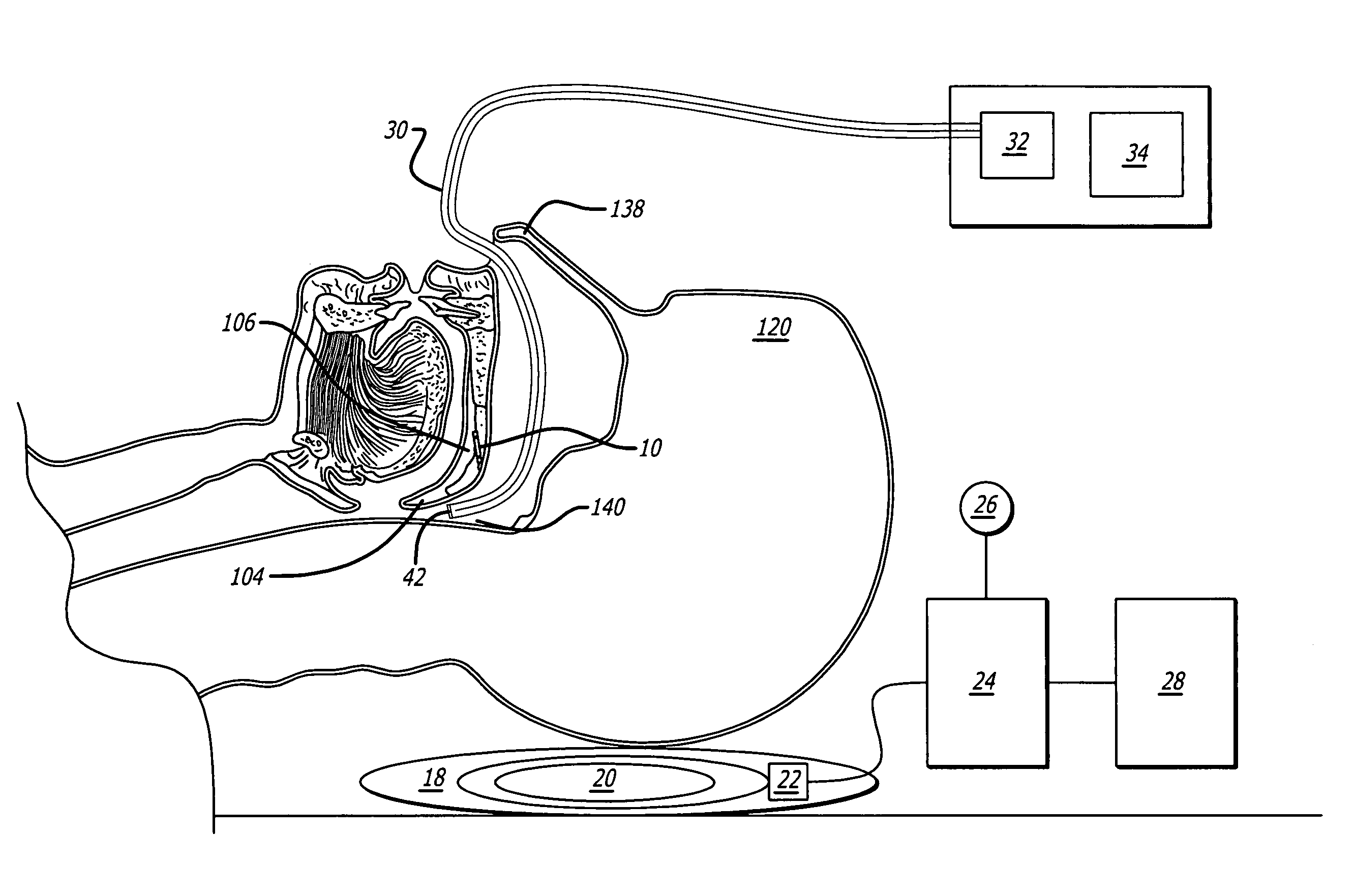

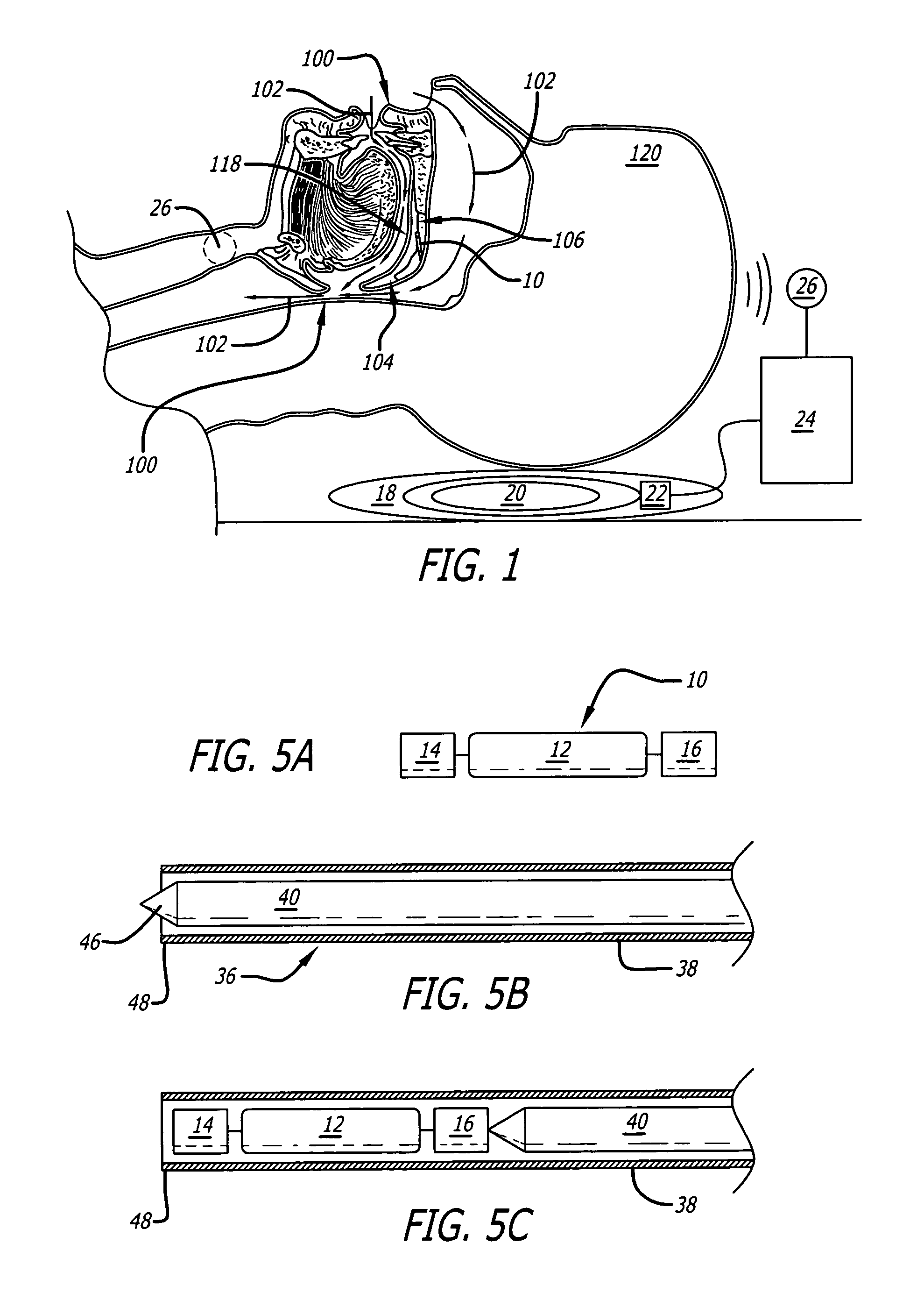

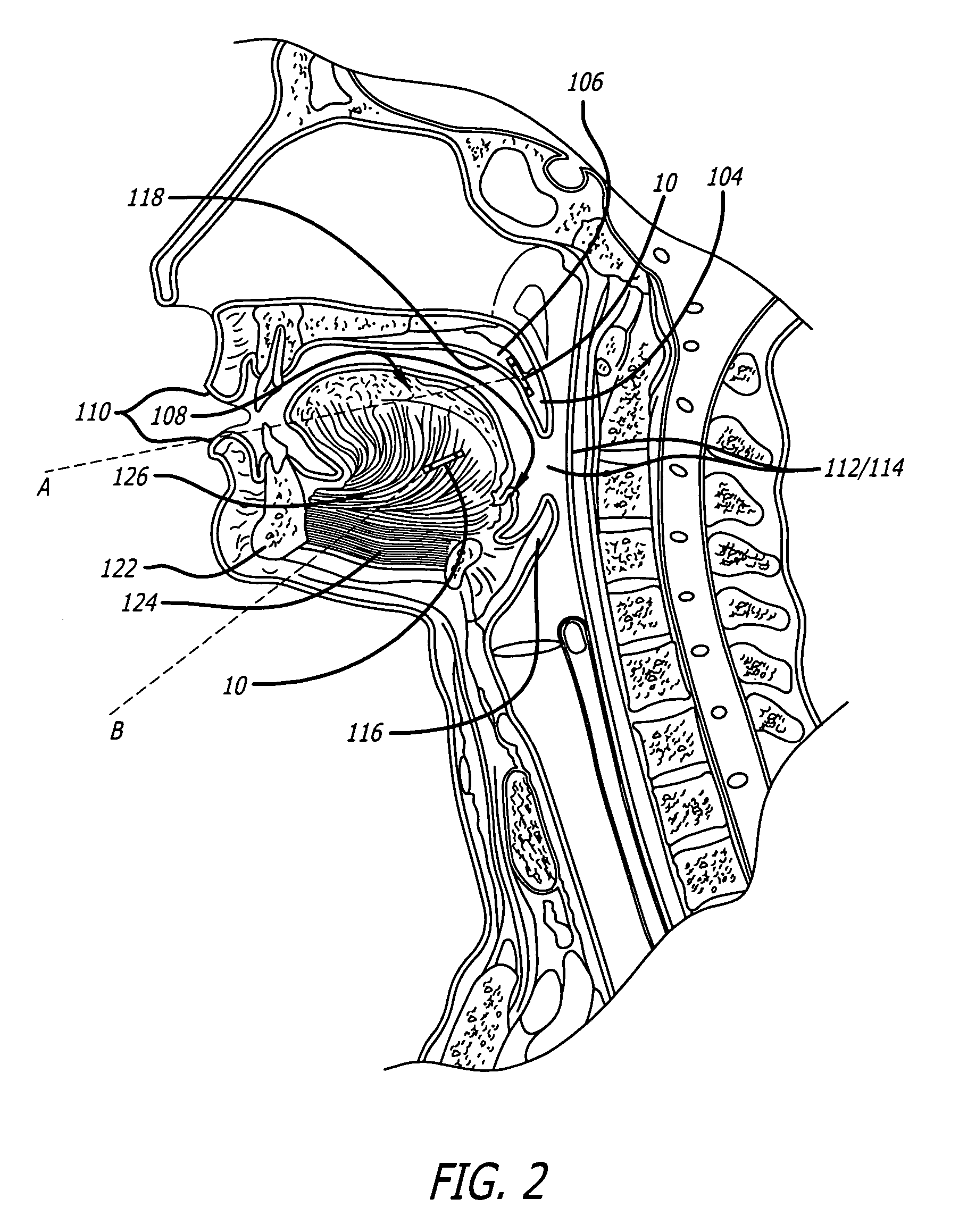

Treatments for snoring using injectable neuromuscular stimulators

InactiveUS7277749B2Reduce frequencyReduce severityImpression capsHeart defibrillatorsAnatomical structuresMuscle contraction

Many individuals generate excessively loud snoring during their sleep, often to the point where others cannot tolerate sleeping in the same room with them. Most cases of snoring are caused by excessive bulk and flaccidity of soft tissues of the palate and uvula that vibrate as air flows past them. These palate and uvula contain muscles whose contractions can stiffen and displace the soft tissues so that they do not vibrate. The invention provides electrical stimulation that causes the oropharyngeal muscles to contract during sleep using one or more microstimulators injected into or near these muscles or the nerves which innervate them. The invention also provides methods of determining the anatomical structures implicated in snoring and testing such locations for effective placement and stimulation of muscle contraction to decrease the frequency or magnitude of snoring.

Owner:ALFRED E MANN INST FOR BIOMEDICAL ENG AT THE UNIV OF SOUTHERN CALIFORNIA

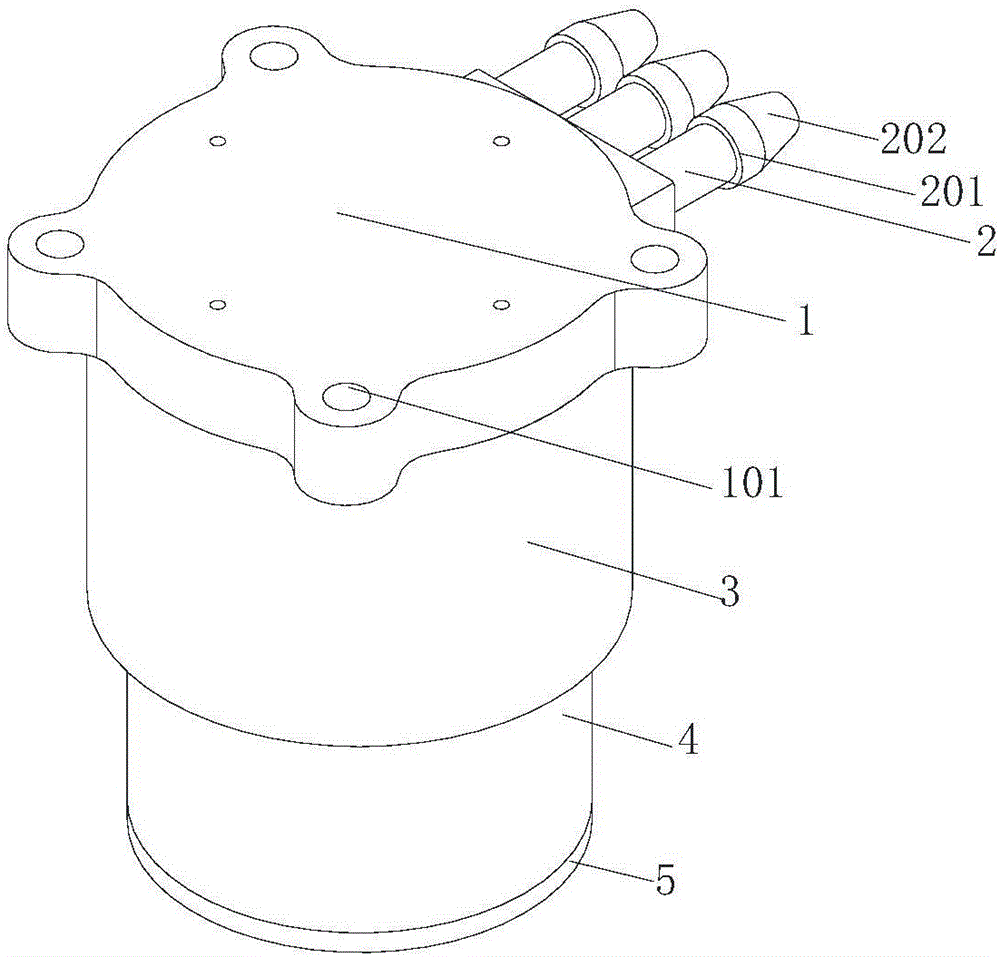

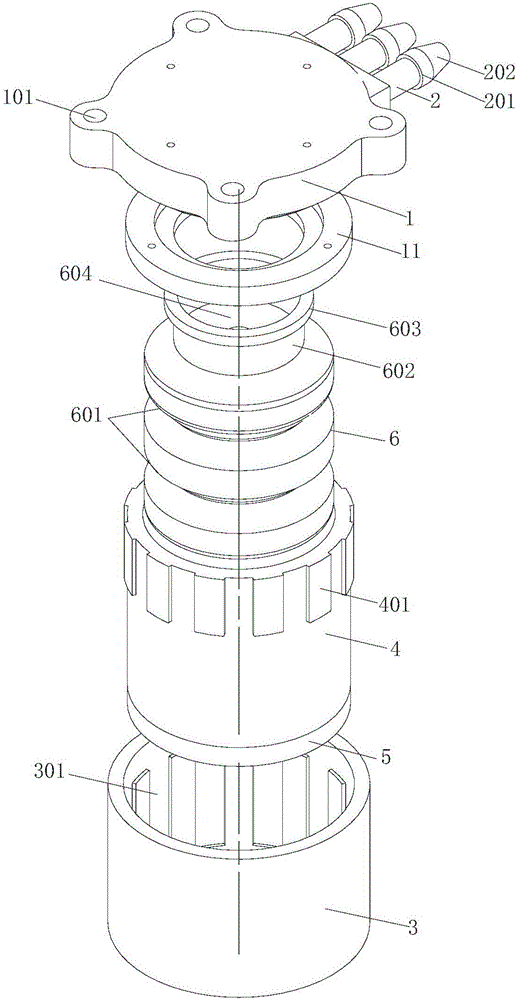

Washing machine feet with automatic levelling function and washing machine

ActiveCN105755757ALarge adjustment rangeEasy to adjustMachine framesOther washing machinesLaundry washing machineLiquid medium

The invention provides washing machine feet with an automatic levelling function and a washing machine. The bottom of the washing machine is provided with the multiple feet; each foot comprises a fixed part and a moving part, a hollow chamber is formed between each fixed part and the corresponding moving part, and each hollow chamber is filled with a hydraulic medium; every two related feet are mutually connected by a high-pressure oil pipe, so that the hollow chambers of the two feet are mutually communicated, or all the feet are respectively connected to a communicating device by high-pressure oil pipes, so that the hollow chambers of all the feet are mutually communicated; under the action of pressure, the hydraulic medium can flow among the mutually-communicated hollow chambers of the feet to enable the moving parts to stretch and retract, and automatic levelling is performed. The washing machine feet with the automatic levelling function has the advantages that according to a hydraulic principle, each foot is filled with the hydraulic medium, and is enabled to perform adaptive adjustment because of the fluidity of the hydraulic medium under different pressures, the hydraulic medium can flow among the feet, the adjustment range is bigger, and the effect is better.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Golf club head with alignment system

A golf club head is disclosed. The golf club head includes a first body member and a second body member. The first body member includes a strike face and a top portion. The second body member is coupled to the first body member and extends away from the first body member in a direction opposite the strike face. At least a top portion of the second body member is camouflaged. A preferred method of camouflage is color differentiation, wherein the second body member is darker than the first body member. Specific color values and club head geometries are also disclosed and claimed. The club head may include a body member and a weight member such as a bar that extends rearward from the body member. A cover may be included to camouflage the weight member. A separate core member and high visibility sight lines may also be provided. The club head may include a color alignment system wherein a top portion of the second body member comprises a transparent colored panel, and a bottom portion of the second body member comprises another transparent colored panel. The viewing of a third combination color to the golfer at address indicates proper alignment of the club head.

Owner:COBRA GOLF

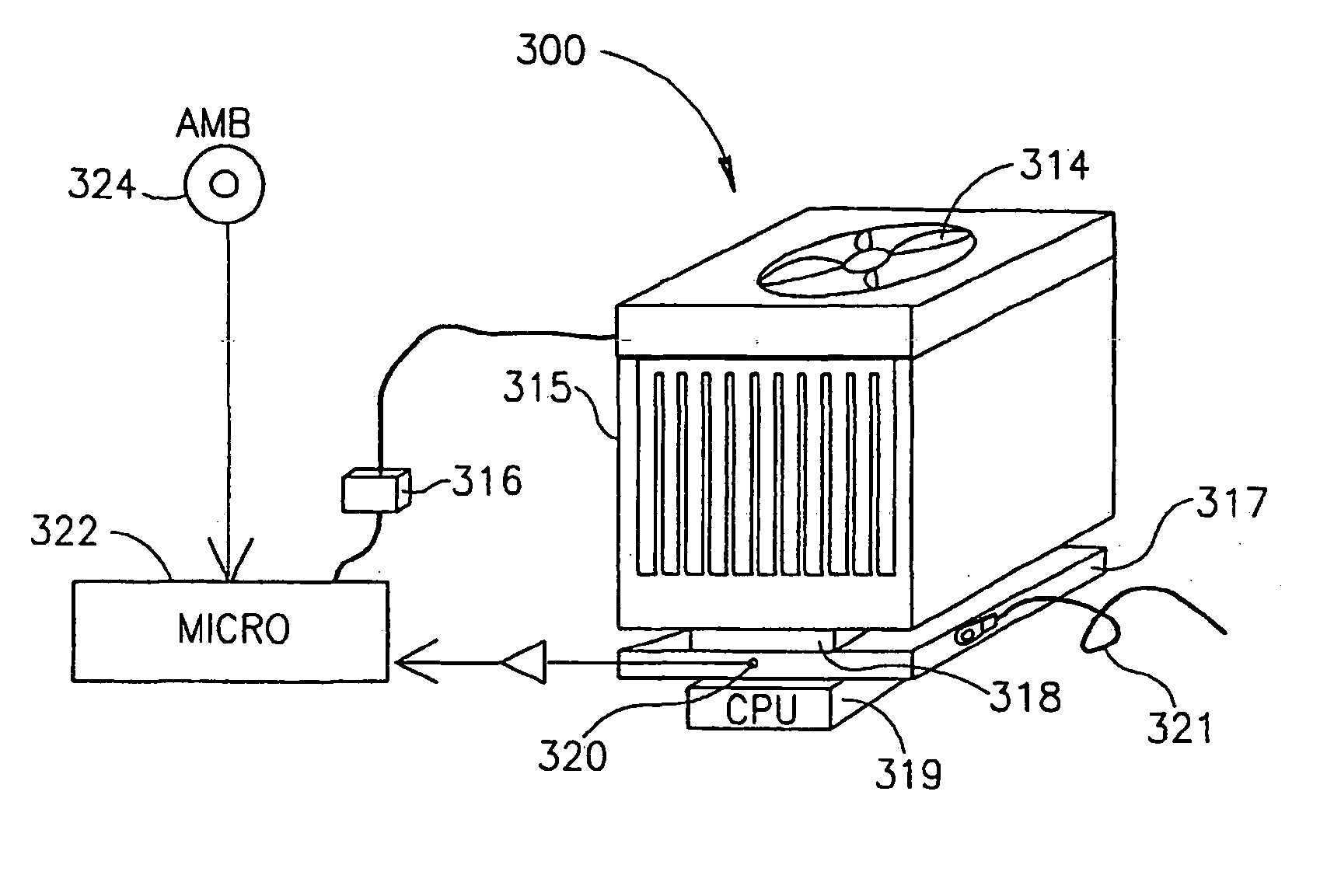

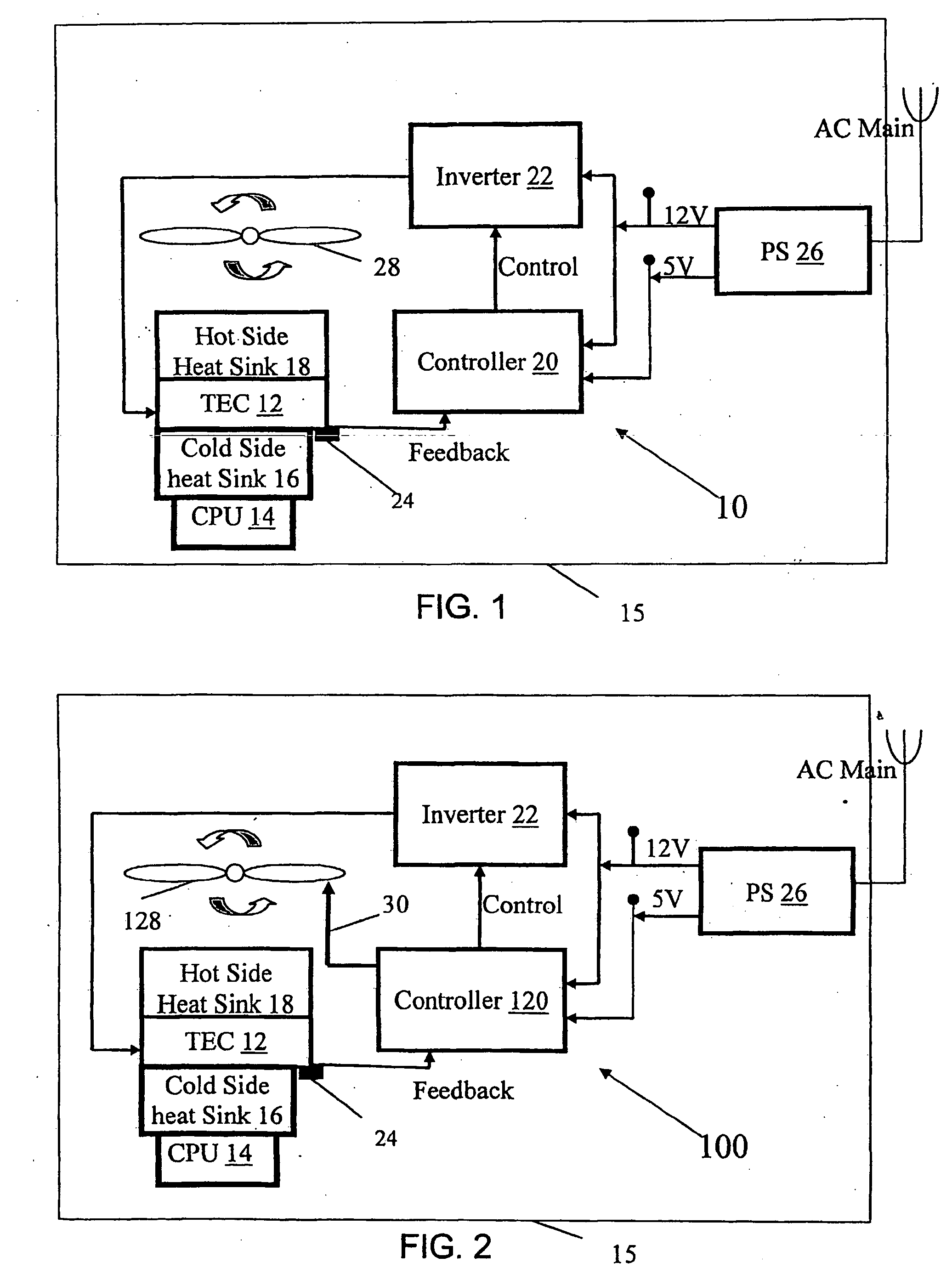

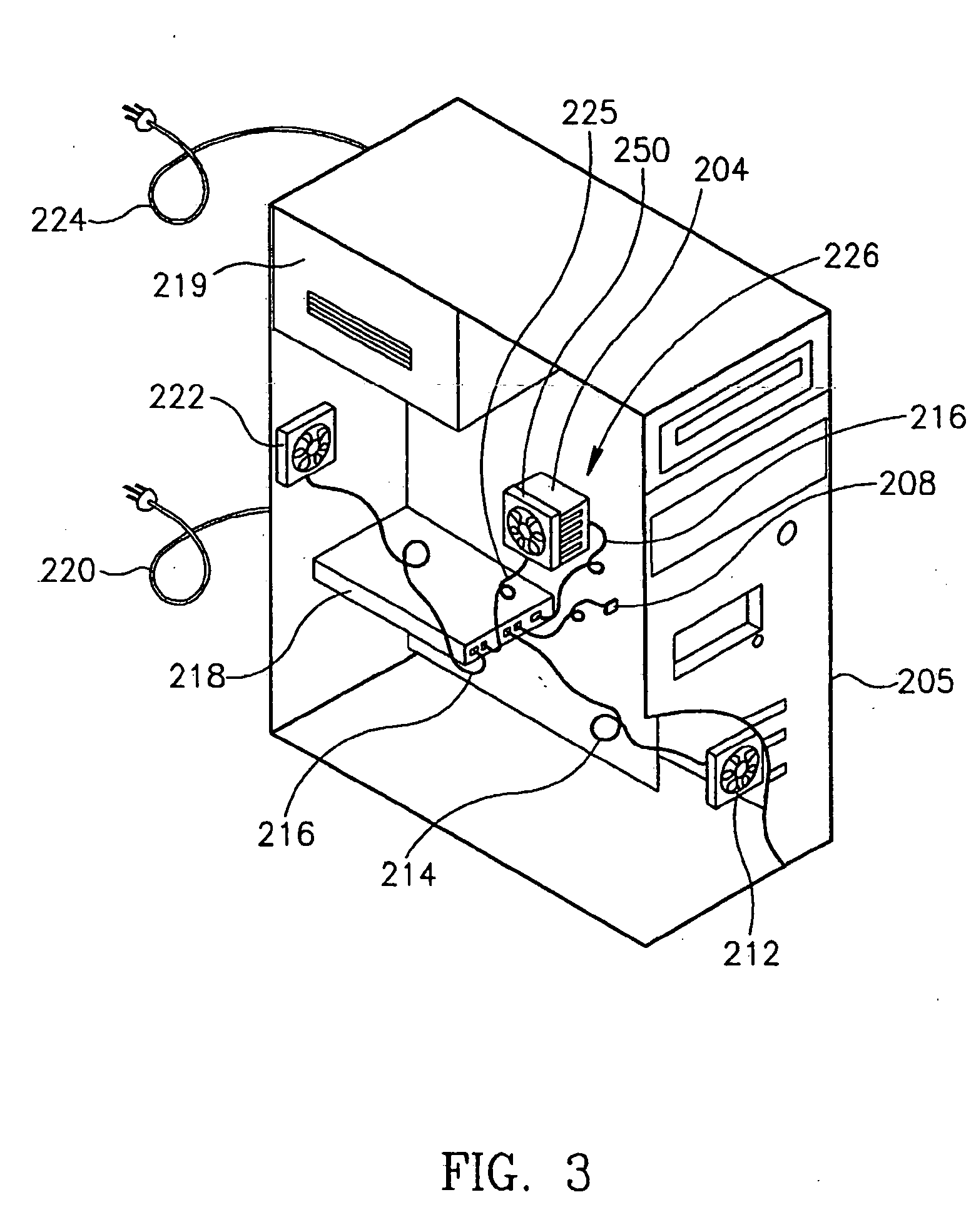

Quiet cooling system for a computer

InactiveUS20050174737A1Fan speed be lowReduce vibrationDigital data processing detailsCooling/ventilation/heating modificationsComputer caseCooling Units

A system for cooling a CPU of a computer within a computer case, the system being characterized by having low noise emission levels, the system comprising: a CPU-cooling unit including a thermoelectric component (TEC) couplable to mains for power supply; a cold side heat sink coupled to the TEC and in thermally conductive contact with the CPU; a hot side heat sink coupled to the TEC; a CPU fan attached to the hot side heat sink for pulling heated air from the hot side heat sink; and an electronic controller, a CPU temperature sensor coupled to the cold plate and to the electronic controller for sensing the temperature of the CPU and providing an indication thereof to the electronic controller; wherein the electronic controller is controllingly coupled to the CPU fan for varying fan speed in accordance with the sensed CPU temperature and with software algorithms.

Owner:ACTIVE COOL RES & DEV LTD

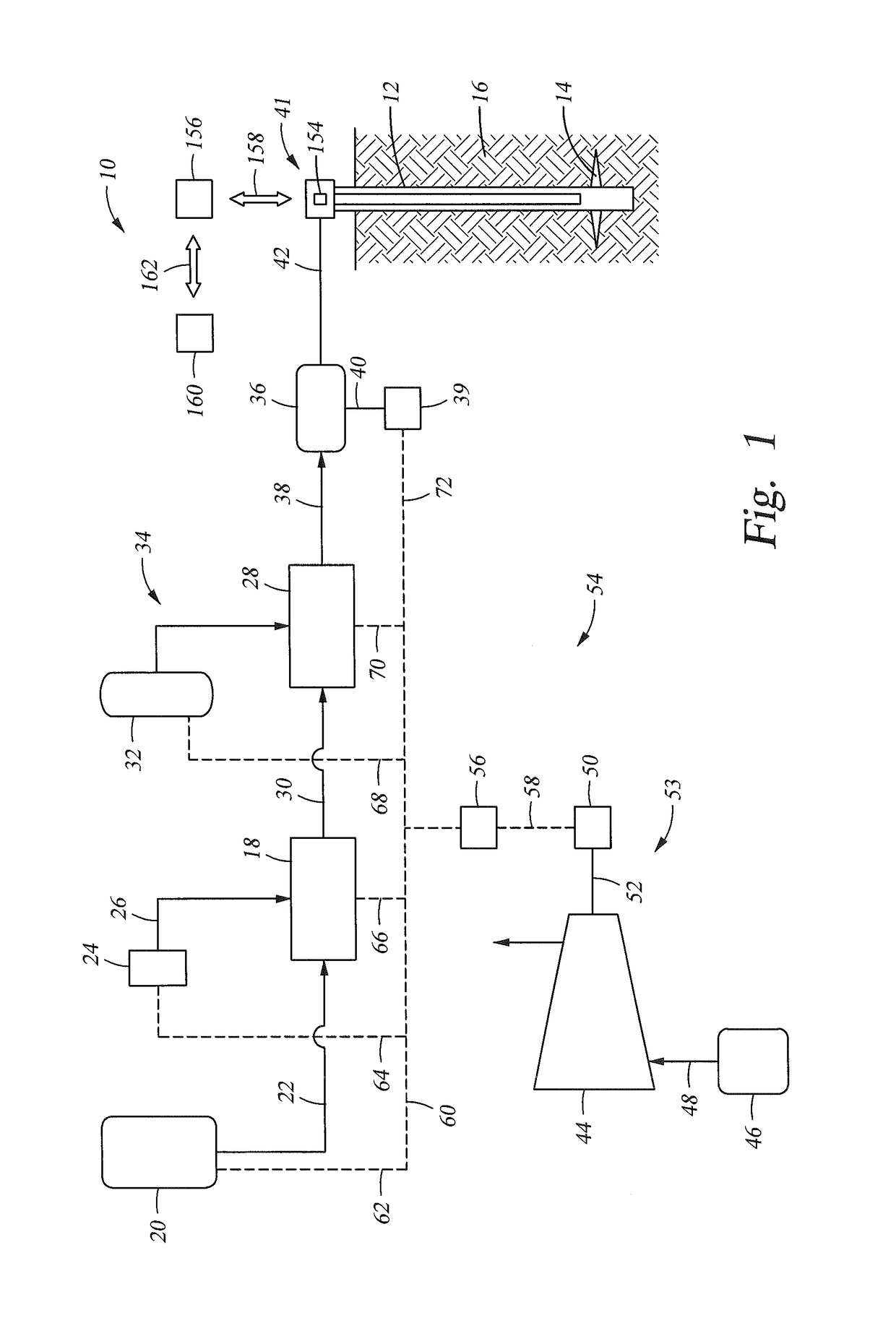

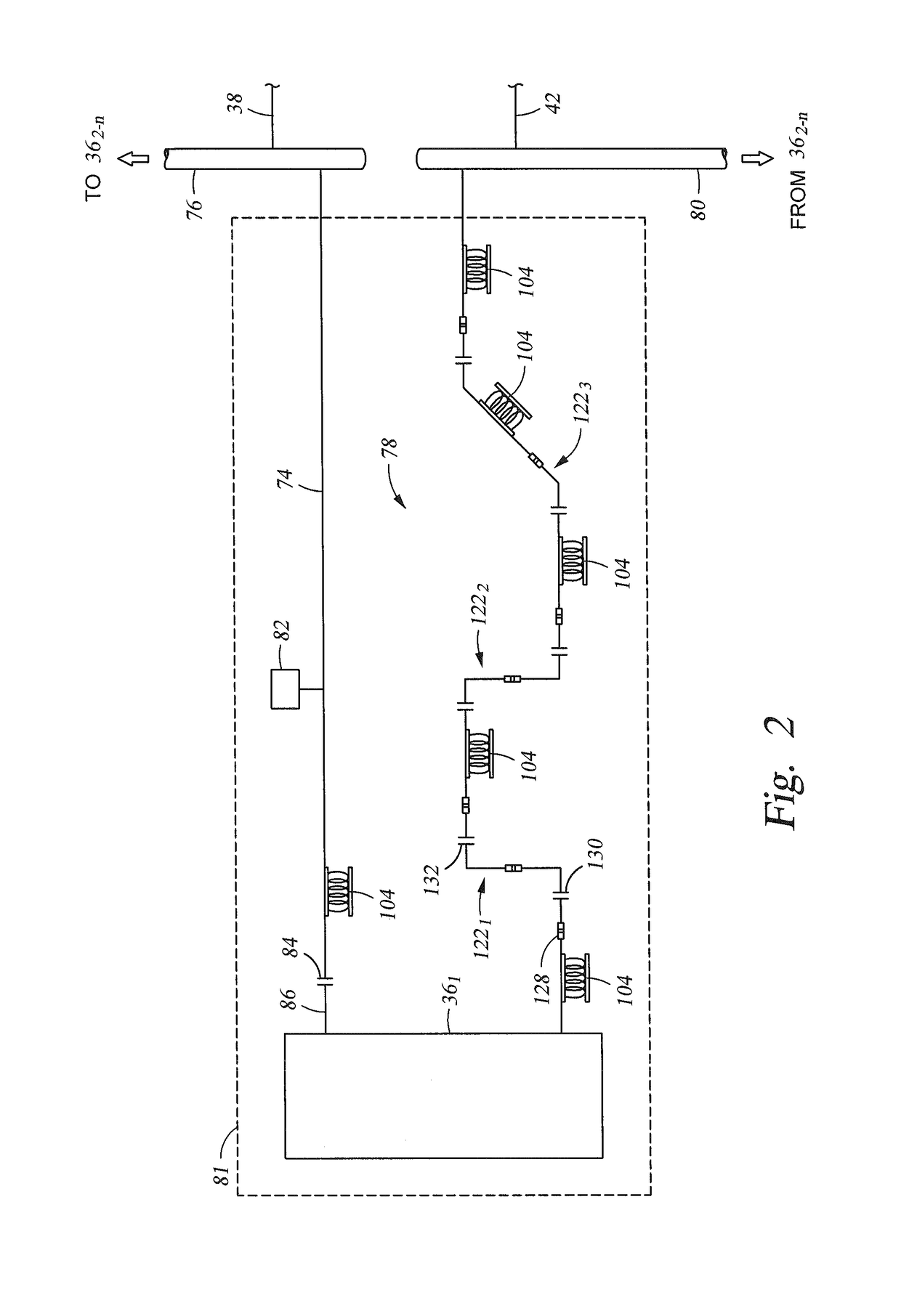

Pump drivetrain damper system and control systems and methods for same

ActiveUS10316832B2Reduce vibrationLiquid resistance brakesPositive displacement pump componentsControl signalDrivetrain

Owner:SPM OIL & GAS INC

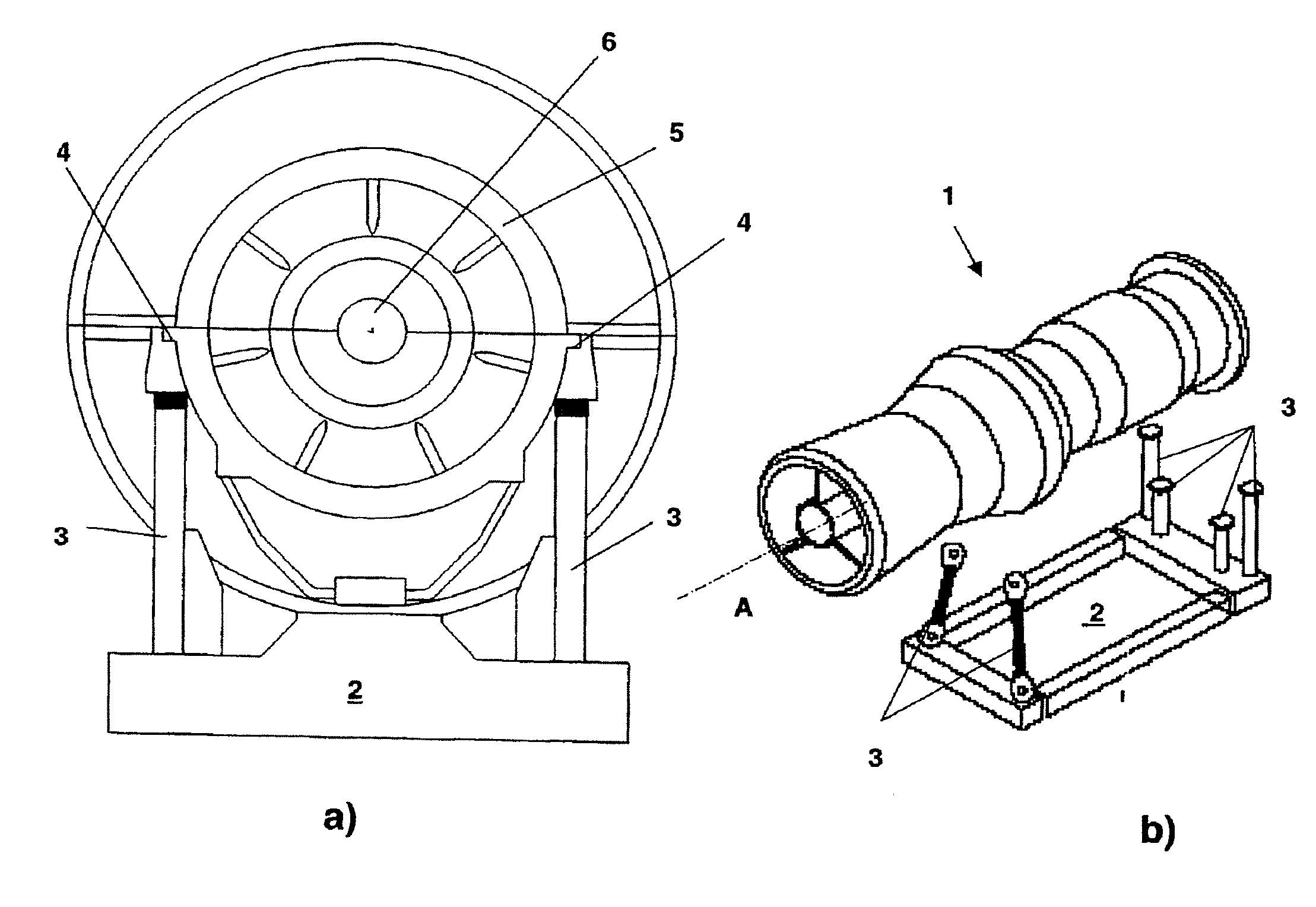

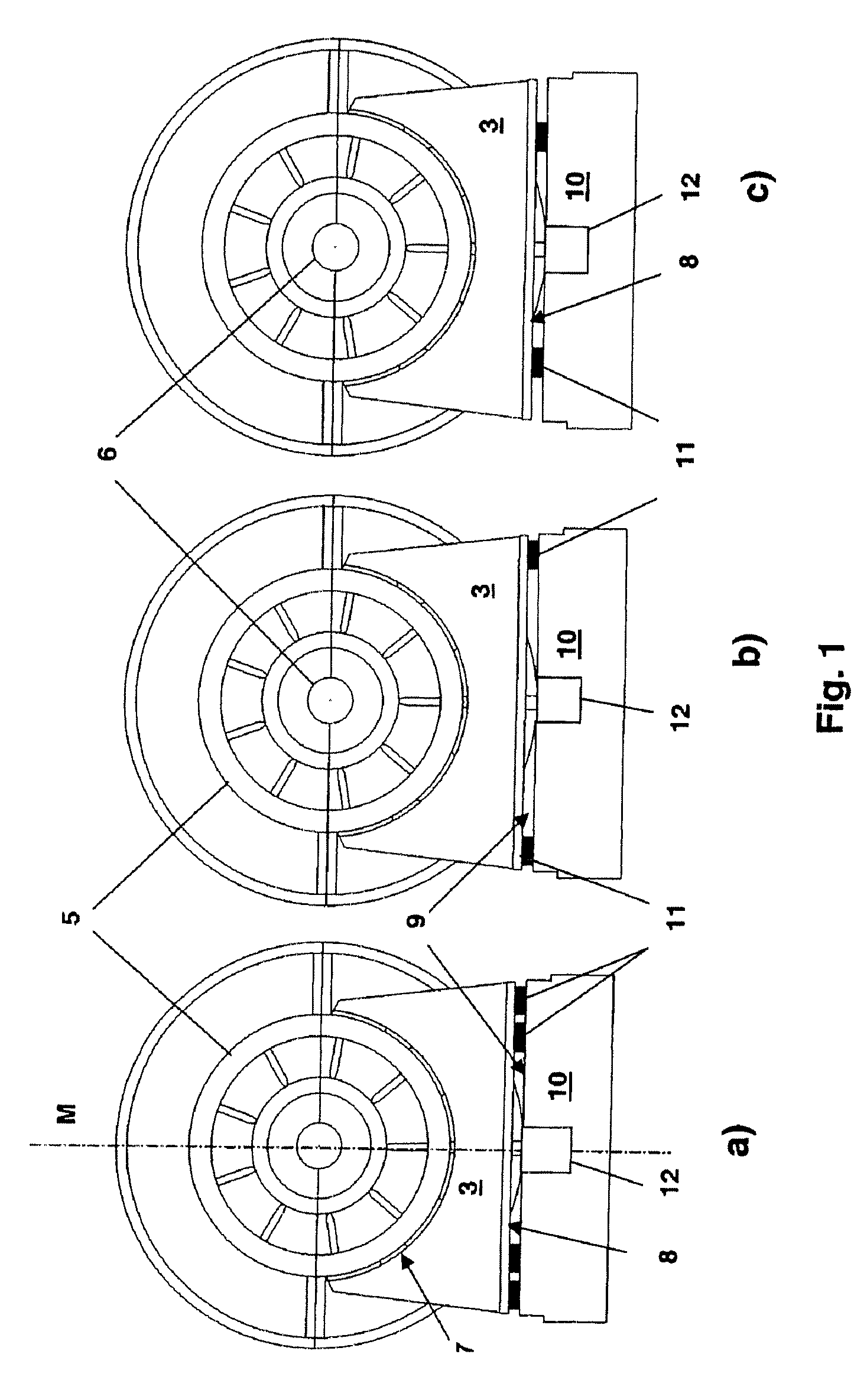

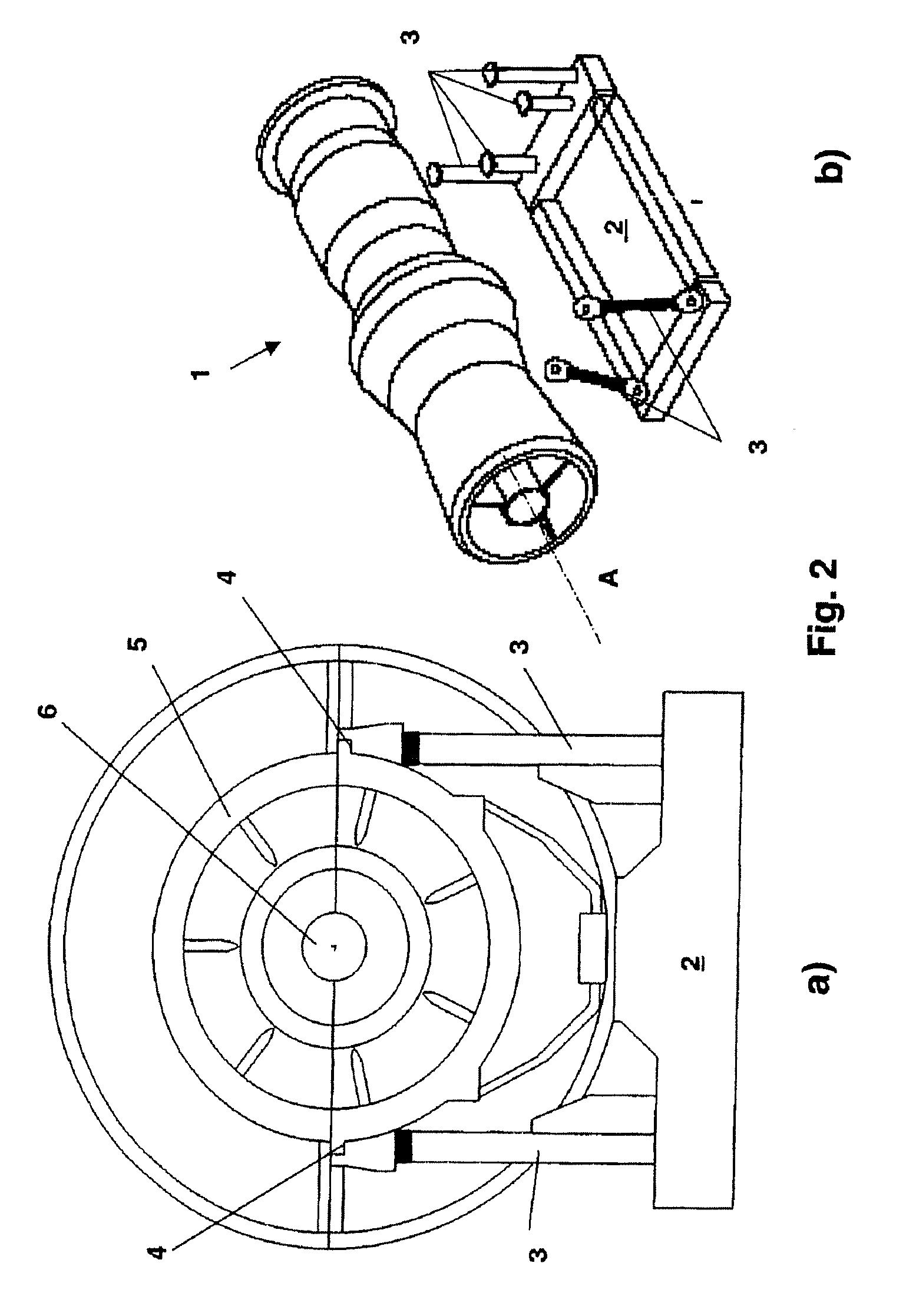

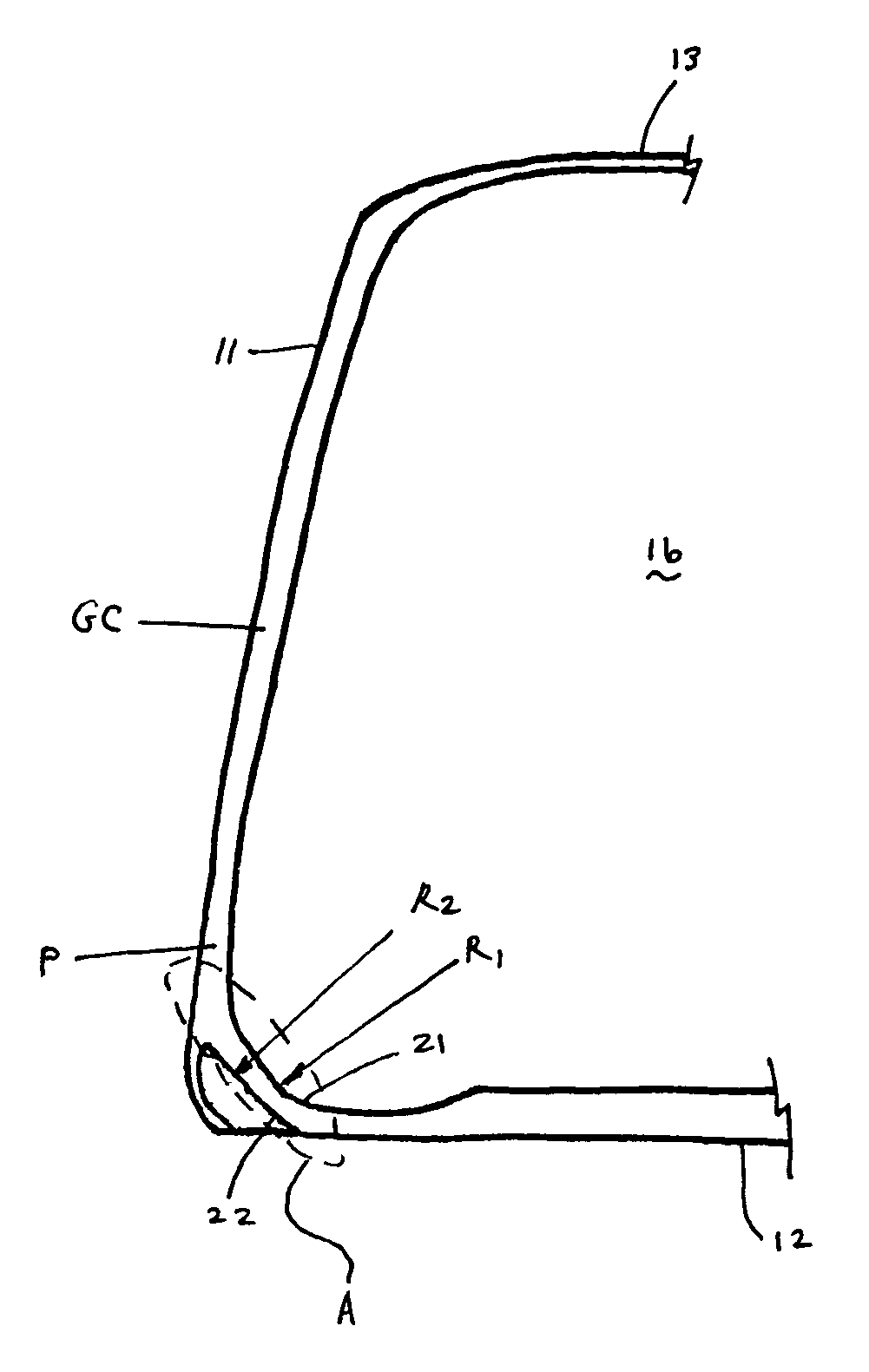

Device and method for mounting a turbine engine

InactiveUS20090064685A1Reduce vibrationVibration minimizationPortable framesPump componentsTurbineGas turbines

A device and a method for mounting a turbine engine, e.g., a gas turbine system, are described, in which a rotor unit is mounted to rotate inside a stationary external housing, having at least two supports for taking up the weight of the turbine engine, these supports being arranged at a spacing from one another in an axial longitudinal direction in relation to the external housing and at one side being articulated directly or indirectly on the external housing and at the other being supported directly or indirectly on a base frame. At least one support provides at least one support face which is supported exclusively in partial regions on at least two support plate elements. The at least one support face of the support is in operational engagement with the base frame by way of the support plate elements.

Owner:ANSALDO ENERGIA IP UK LTD

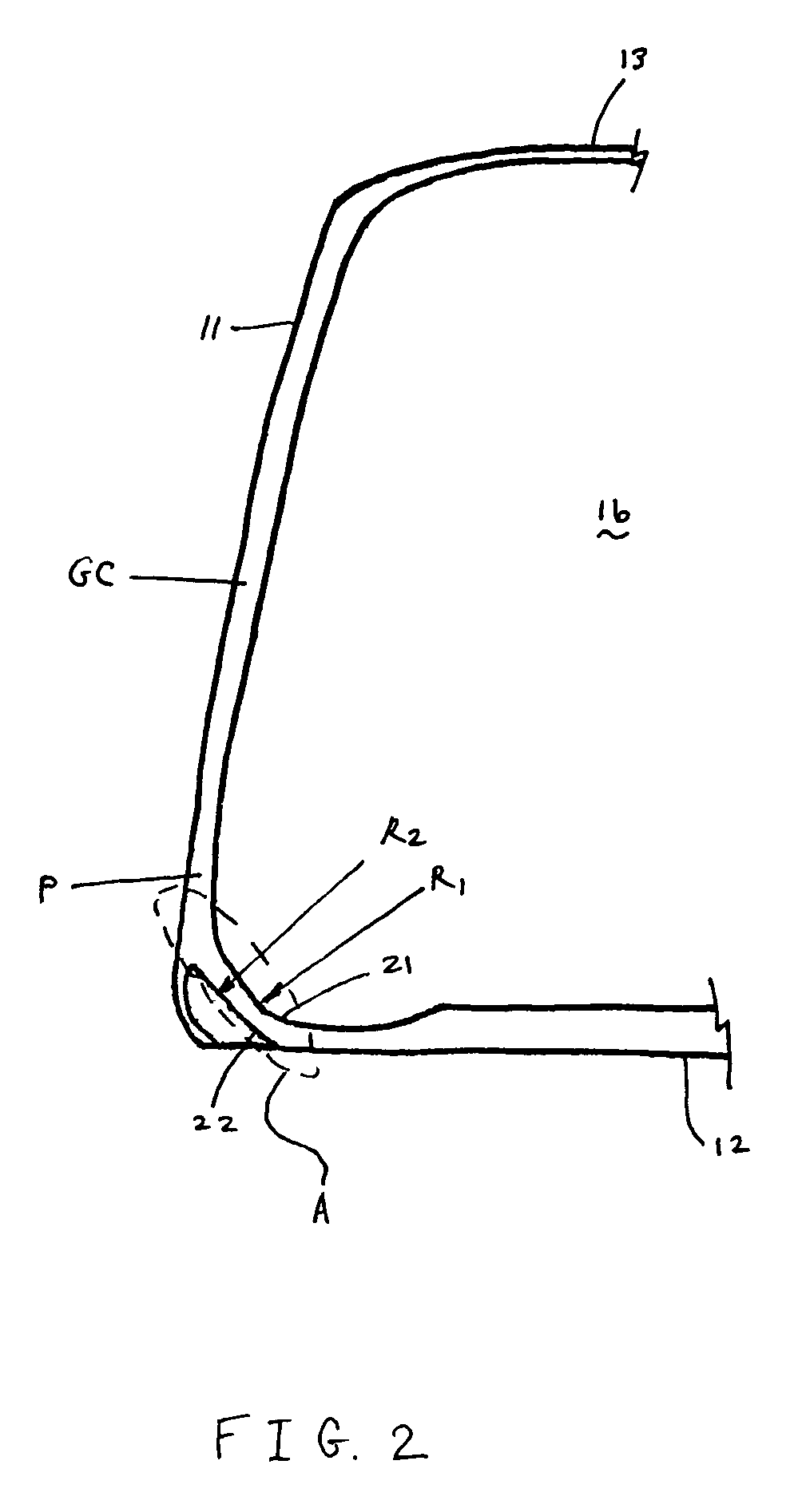

Hollow golf club

InactiveUS7396293B2Improve performanceMaintain structural integrityGolf clubsRacket sportsCoefficient of restitutionGolf Ball

A golf club with improved performance over a larger percentage of the strike face, including the lower extremities of the face, is disclosed and claimed. The club head has a coefficient of restitution that approaches substantial uniformity across the face. The golf club head includes a body having a face, a sole, a transition zone between the face and the sole. The transition zone has an internal surface and an external surface. Both the internal and external surfaces have radii of curvature greater than 0.2 inch. The transition zone transitions smoothly from the face, through the transition zone, to the sole. An extension may be provided adjacent the transition zone, cooperating with the transition zone to form a chamber. Dampening and / or weight inserts may be positioned within the chamber.

Owner:COBRA GOLF

Golf club head with alignment system

InactiveUS8096039B2Easy to controlMore forgivingMetal working apparatusGolf clubsVisibilityGolf Ball

A golf club head is disclosed. The golf club head includes a first body member and a second body member. The first body member includes a strike face and a top portion. The second body member is coupled to the first body member and extends away from the first body member in a direction opposite the strike face. At least a top portion of the second body member is camouflaged. A preferred method of camouflage is color differentiation, wherein the second body member is darker than the first body member. Specific color values and club head geometries are also disclosed and claimed. The club head may include a body member and a weight member such as a bar that extends rearward from the body member. A cover may be included to camouflage the weight member. A separate core member and high visibility sight lines may also be provided.

Owner:COBRA GOLF

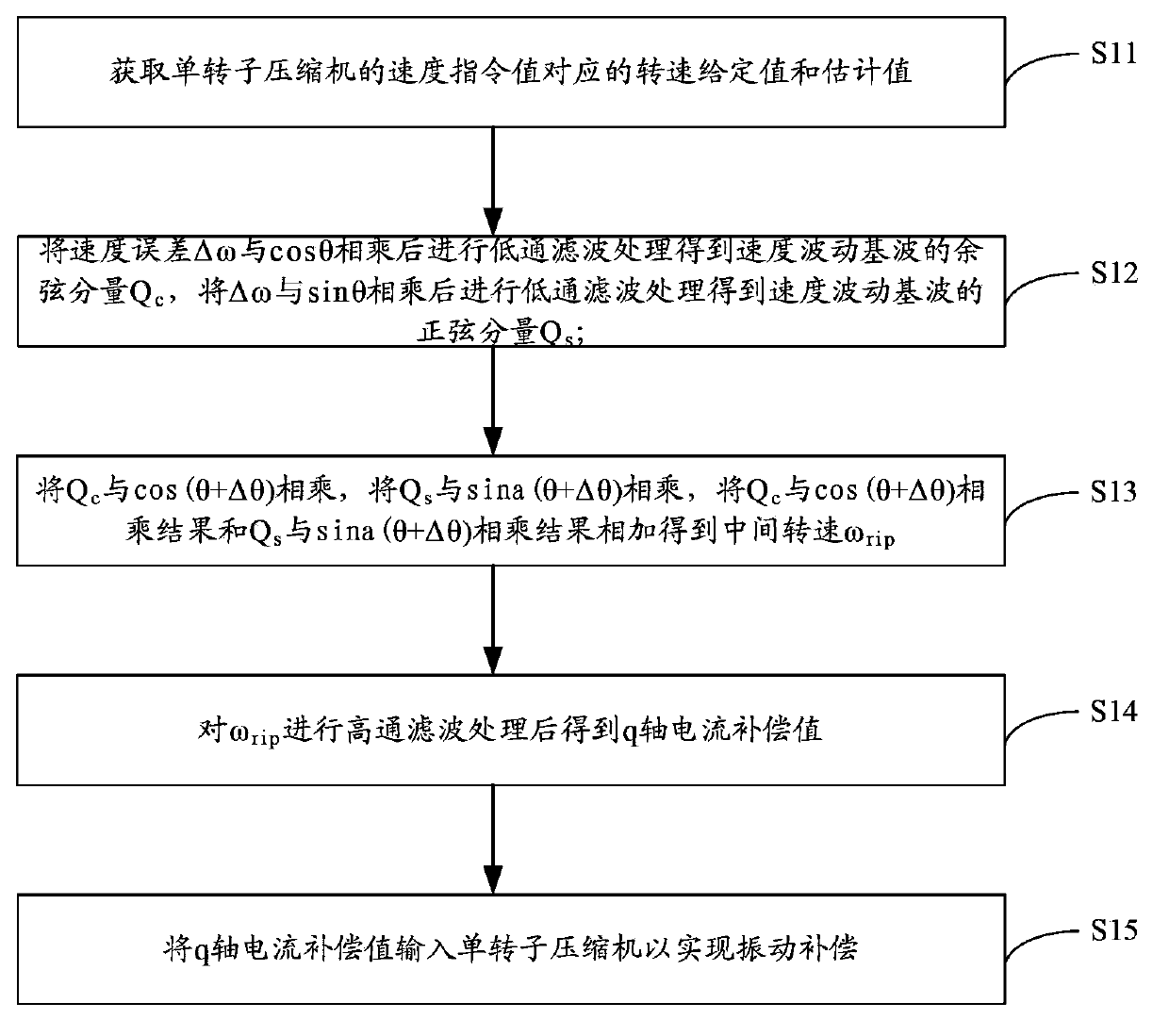

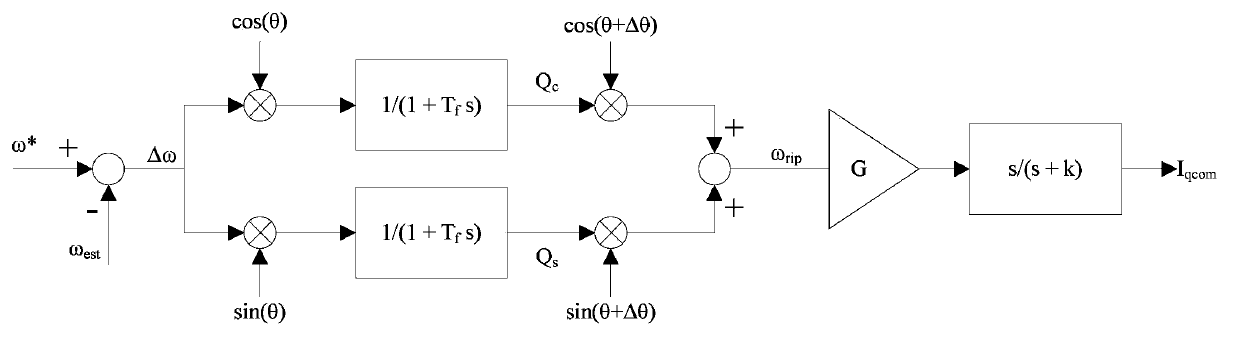

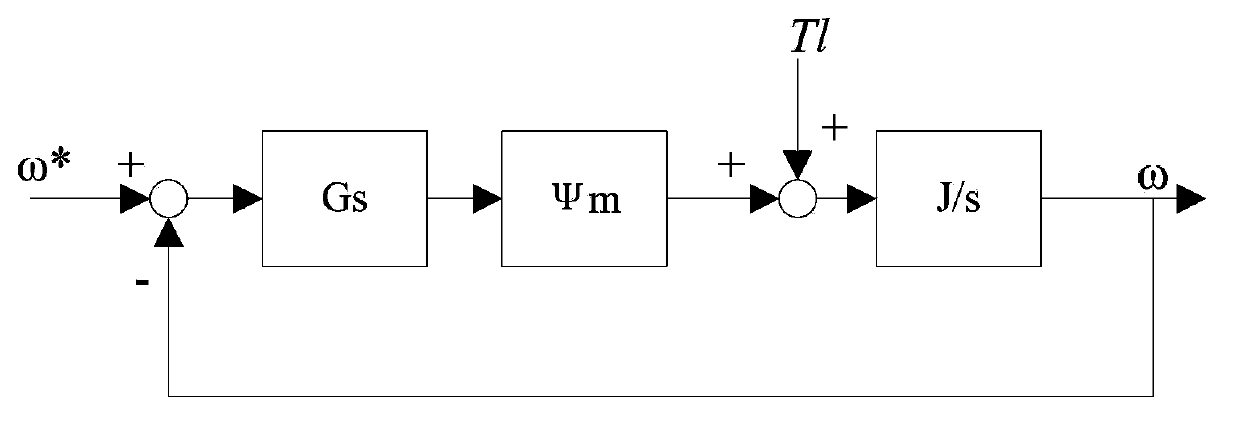

Vibration compensation method for single-rotor compressor and controller

ActiveCN103967794AReduce vibrationImprove noiseRotary/oscillating piston pump componentsLiquid fuel engine componentsVibration compensationHigh-pass filter

The invention is applicable to the technical field of household electrical appliances and provides a vibration compensation method for a single-rotor compressor and a controller. The method comprises the following steps: acquiring a rotating speed set value omega* and a rotating speed estimated value omega e corresponding to a speed command value; multiplying a speed error delta omega by cos theta, carrying out low pass filtering so as to obtain the cosine component Qc of a speed fluctuation fundamental wave, multiplying delta omega by sin theta and carrying out low pass filtering so as to obtain the sine component Qs of the speed fluctuation fundamental wave; multiplying Qc by cos (theta+delta theta), multiplying Qs by sin (theta+delta theta) and adding the result of multiplication of Qc by cos (theta+delta theta) and the result of multiplication of Qs by sin (theta+delta theta) together so as to obtain an intermediate rotating speed omega rip; subjecting omega rip to high pass filtering so as to obtain a q-shaft current compensation value; and inputting the q-shaft current compensation value into the single-rotor compressor to realize vibration compensation. With the technical scheme provided by the invention, the advantages of reduction in vibration of the single-rotor compressor and easy realization are obtained.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

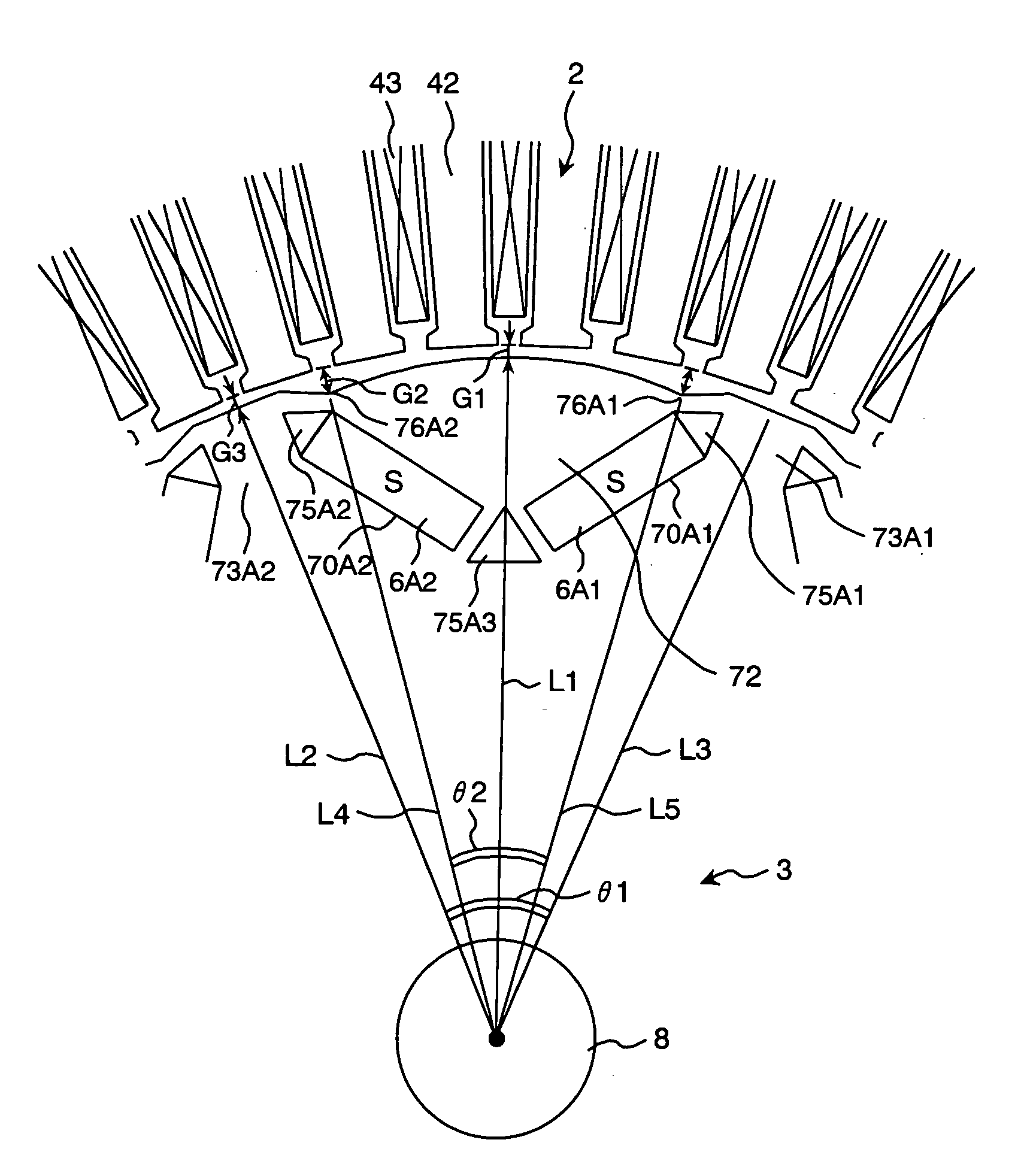

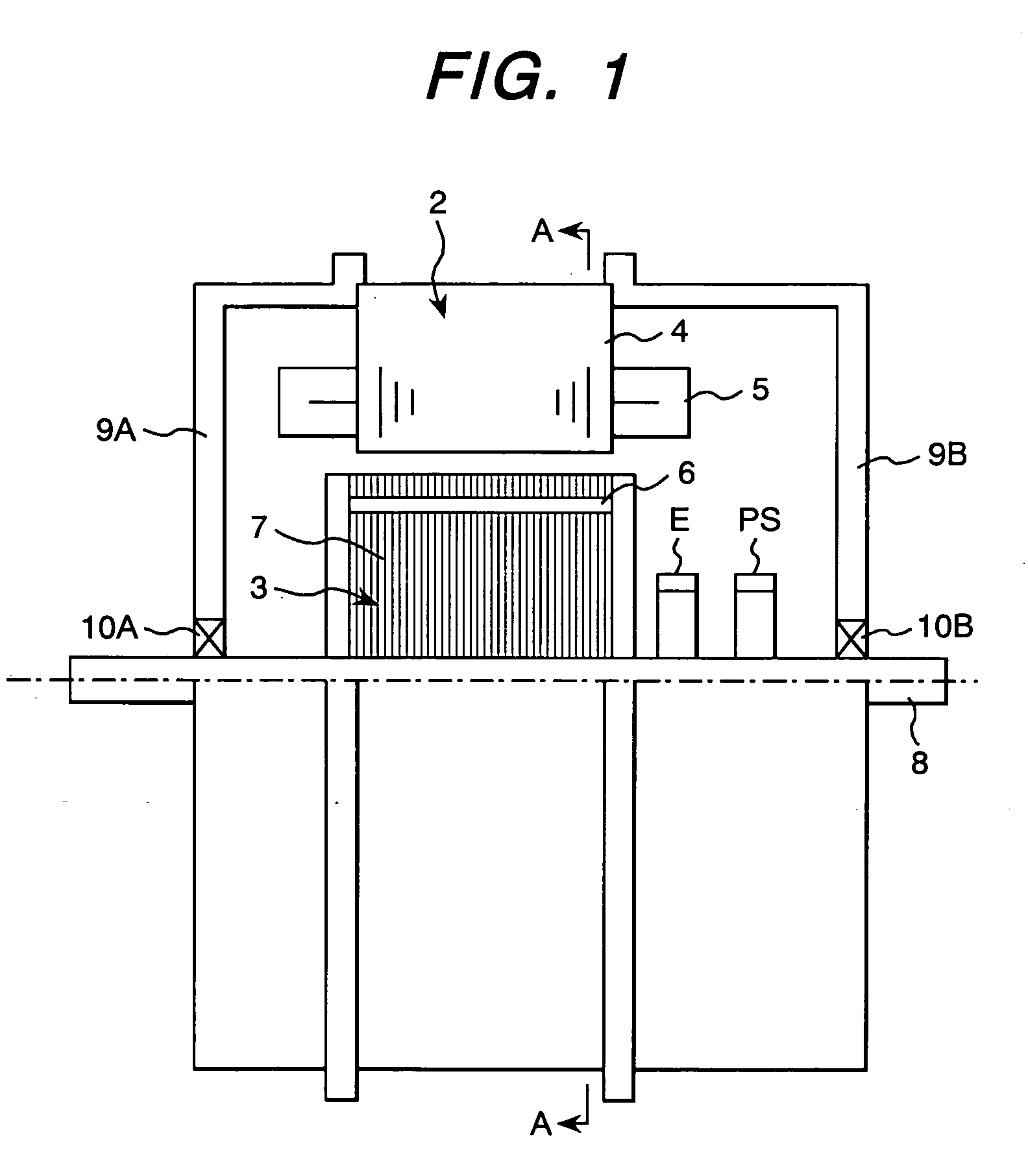

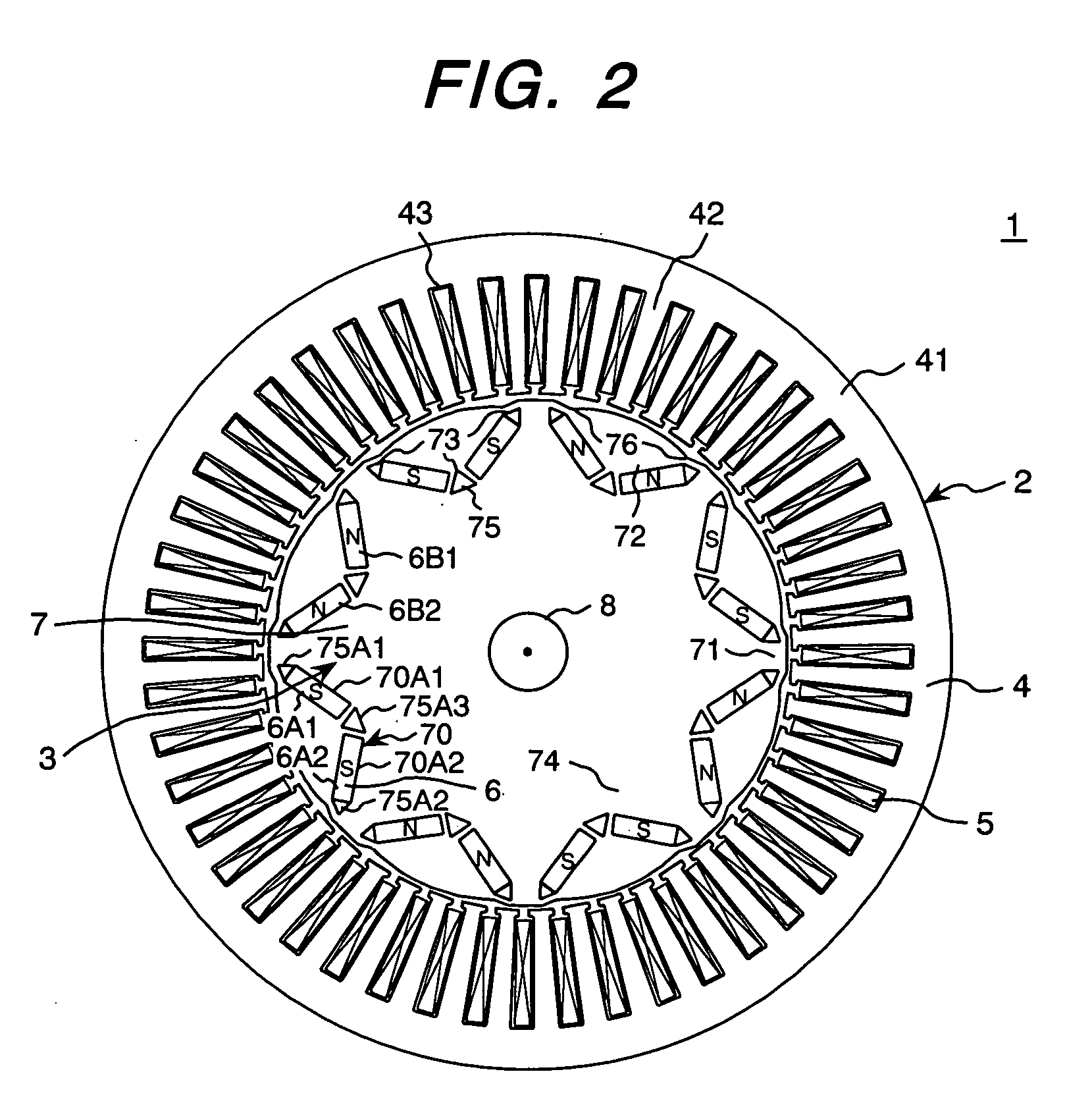

Permanent magnet rotating electric machine and electric car using the same

ActiveUS20050200223A1Reduce vibrationReduce noiseSpeed controllerMagnetic circuit rotating partsPhysicsElectric cars

A permanent magnet rotating electric machine comprises a stator having stator windings wound round a stator iron core and a permanent magnet rotor having a plurality of inserted permanent magnets in which the polarity is alternately arranged in the peripheral direction in the rotor iron core. The rotor iron core of the permanent magnets is composed of magnetic pole pieces, auxiliary magnetic poles, and a stator yoke, and furthermore has concavities formed on the air gap face of the magnetic pole pieces of the rotor iron core of the permanent magnets, gently tilting from the central part of the magnetic poles to the end thereof. In a permanent magnet rotating electric machine, effects of iron loss are reduced, and an electric car using highly efficient permanent magnet rotating electric machine are realized.

Owner:HITACHI ASTEMO LTD

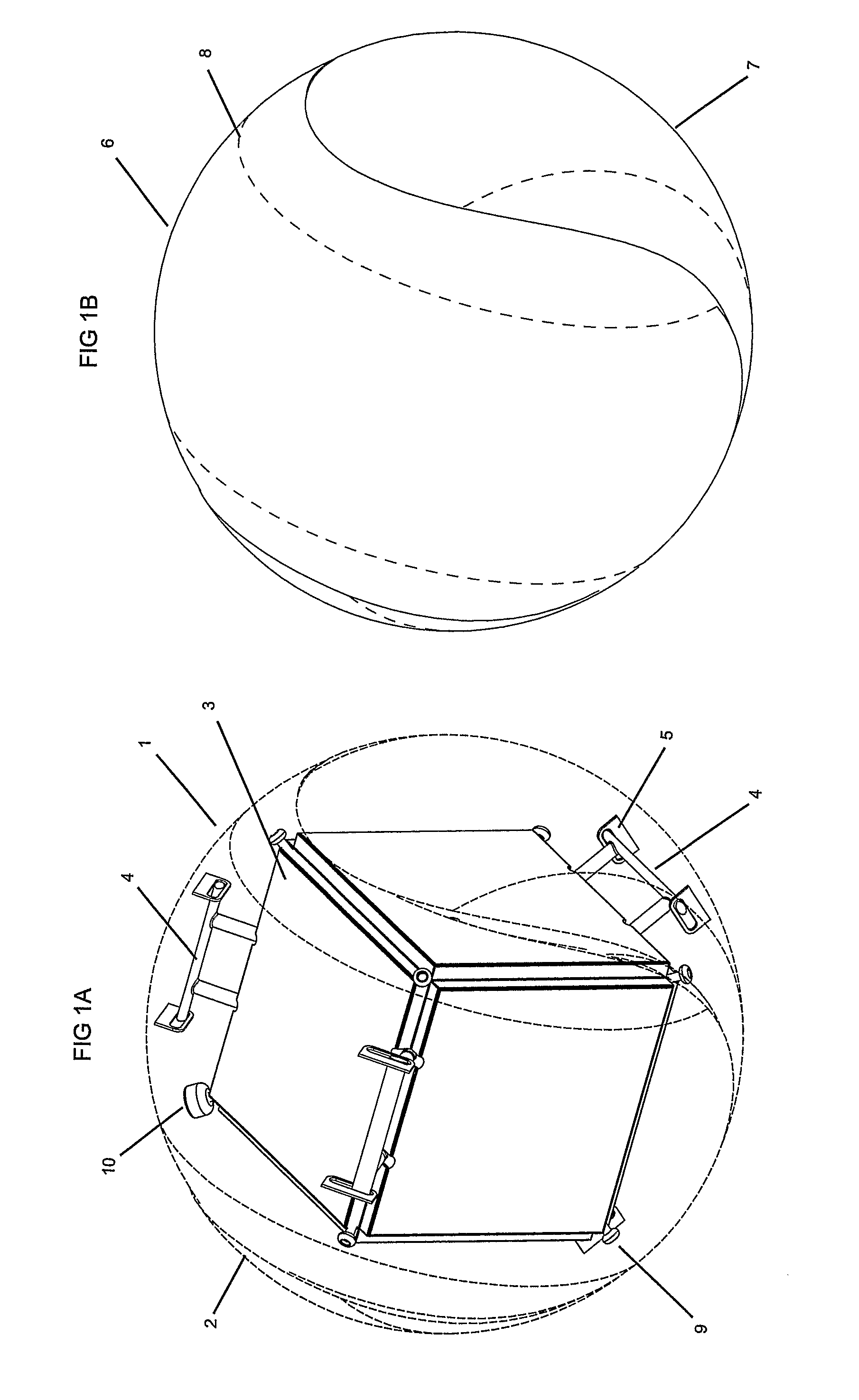

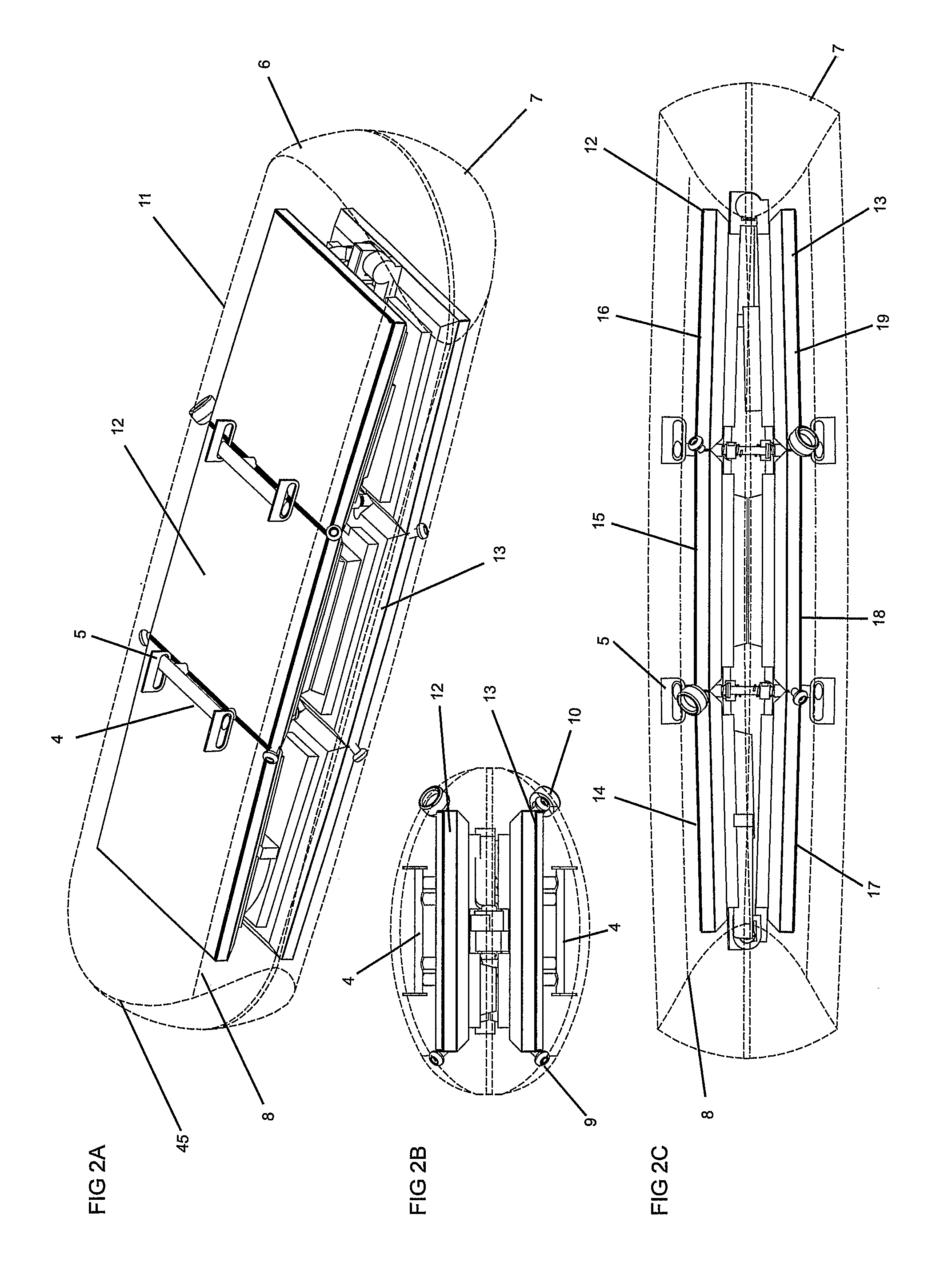

Spherical Display and Control Device

InactiveUS20070247439A1Rapid drill-downQuick selectionCathode-ray tube indicatorsDetails for portable computersGyroscopeDisplay device

A spherical display and control device, that is preferably collapsible between a spherical configuration and a collapsed generally cylindrical ellipsoid configuration, comprising a flexible transparent spherical surface sprung attached to a central hinged modular cube assembly that contains digital displays on outward faces, and circuitry, battery units and electronic modules on inward surfaces, where said sphere surface contains surface position sensing layers and said central cube contains gyroscopic and inertial sensing devices to provide spherical rotation, and physical displacement data for three dimensional control applications, where said displays preferably have curved polarizer lenses such that the overall device appears as a spherical display or are flat to form an overall Cuboid display or are combined with a flexible spherical display surfaces. The overall device being mechanically biased such that it is Bi-stable between the spherical and collapsed configuration via the action of pulling open and rotating the central cube halves.

Owner:DANIEL SIMON +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com