Patents

Literature

18990results about "Rotary/oscillating piston pump components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

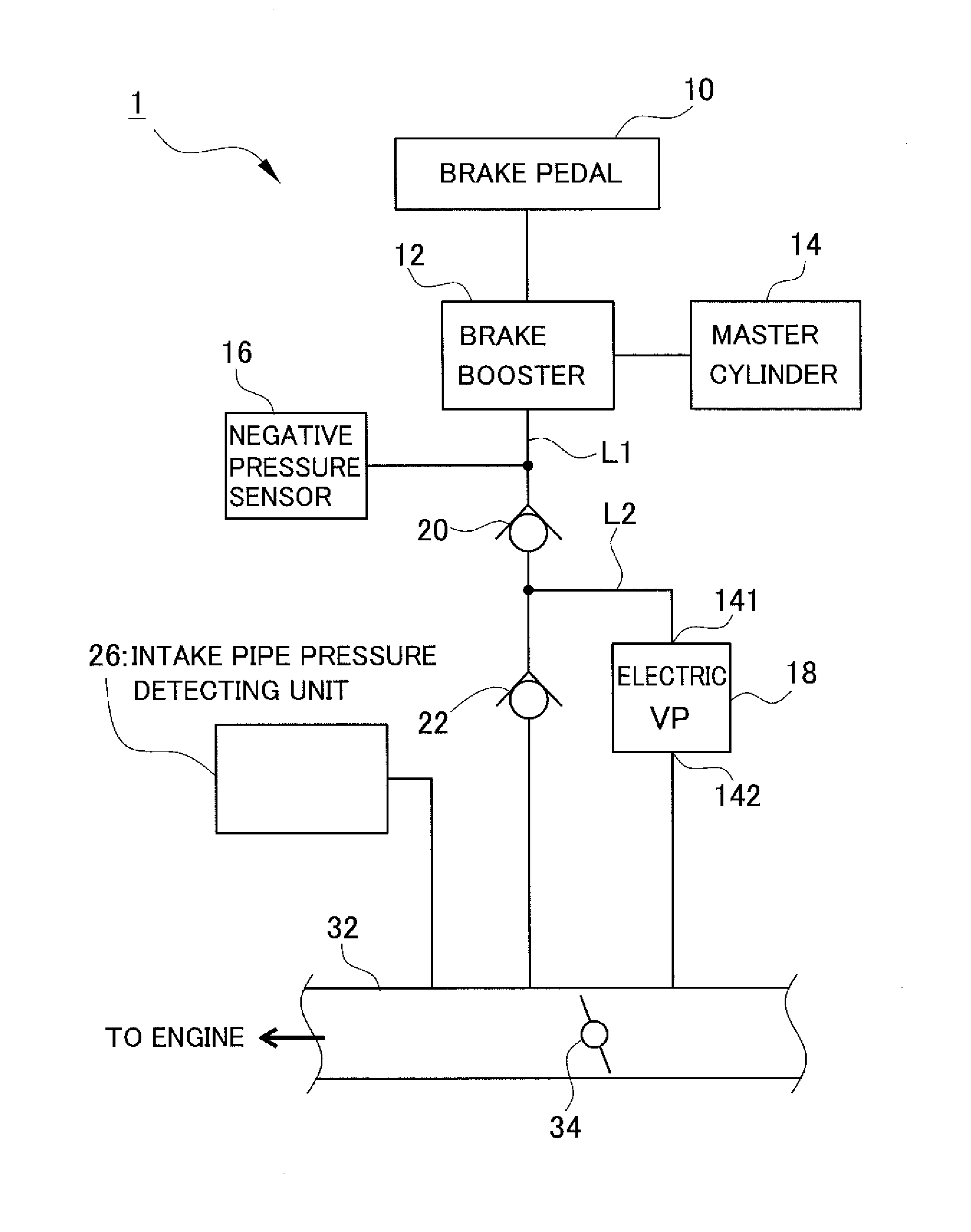

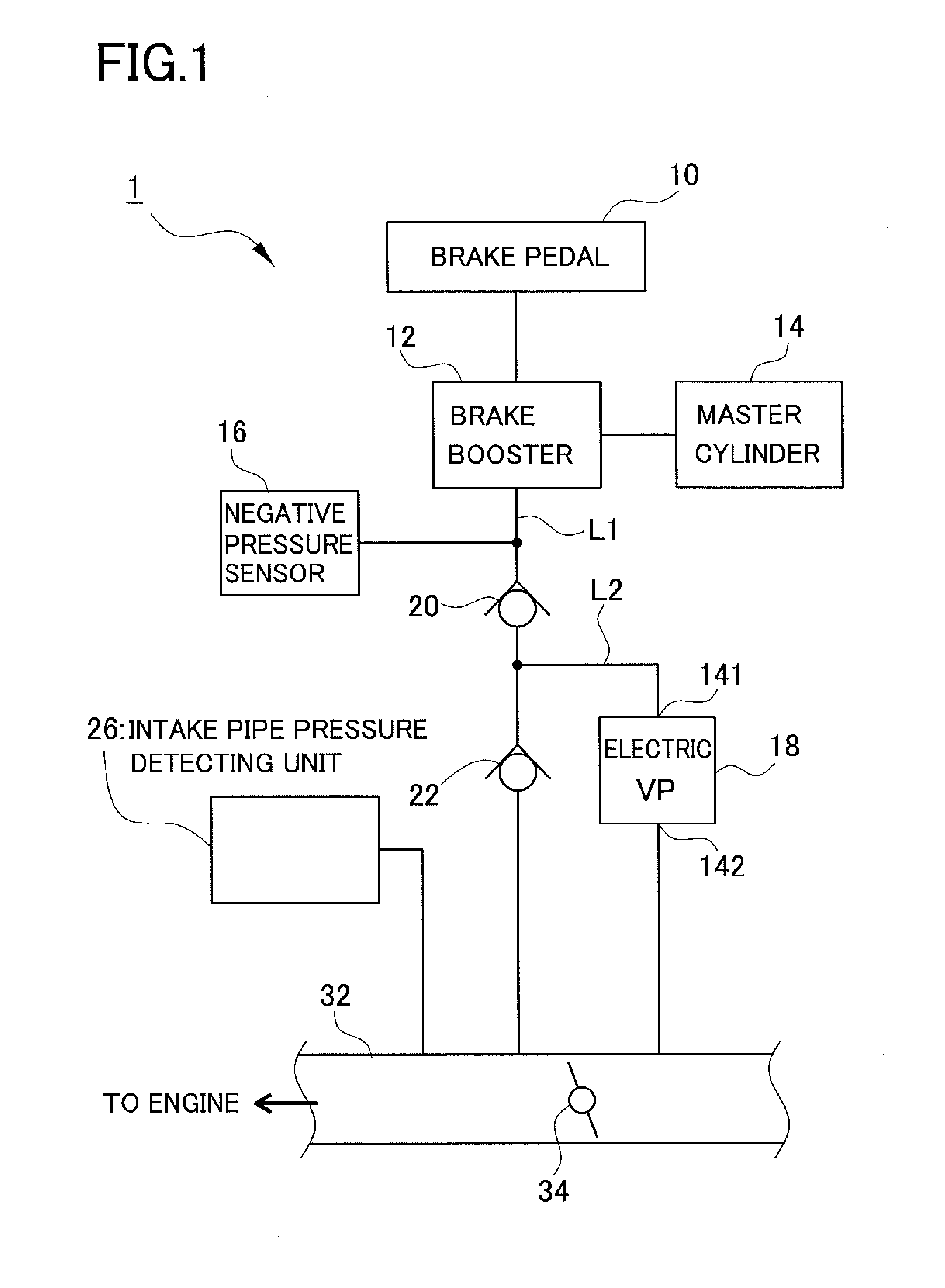

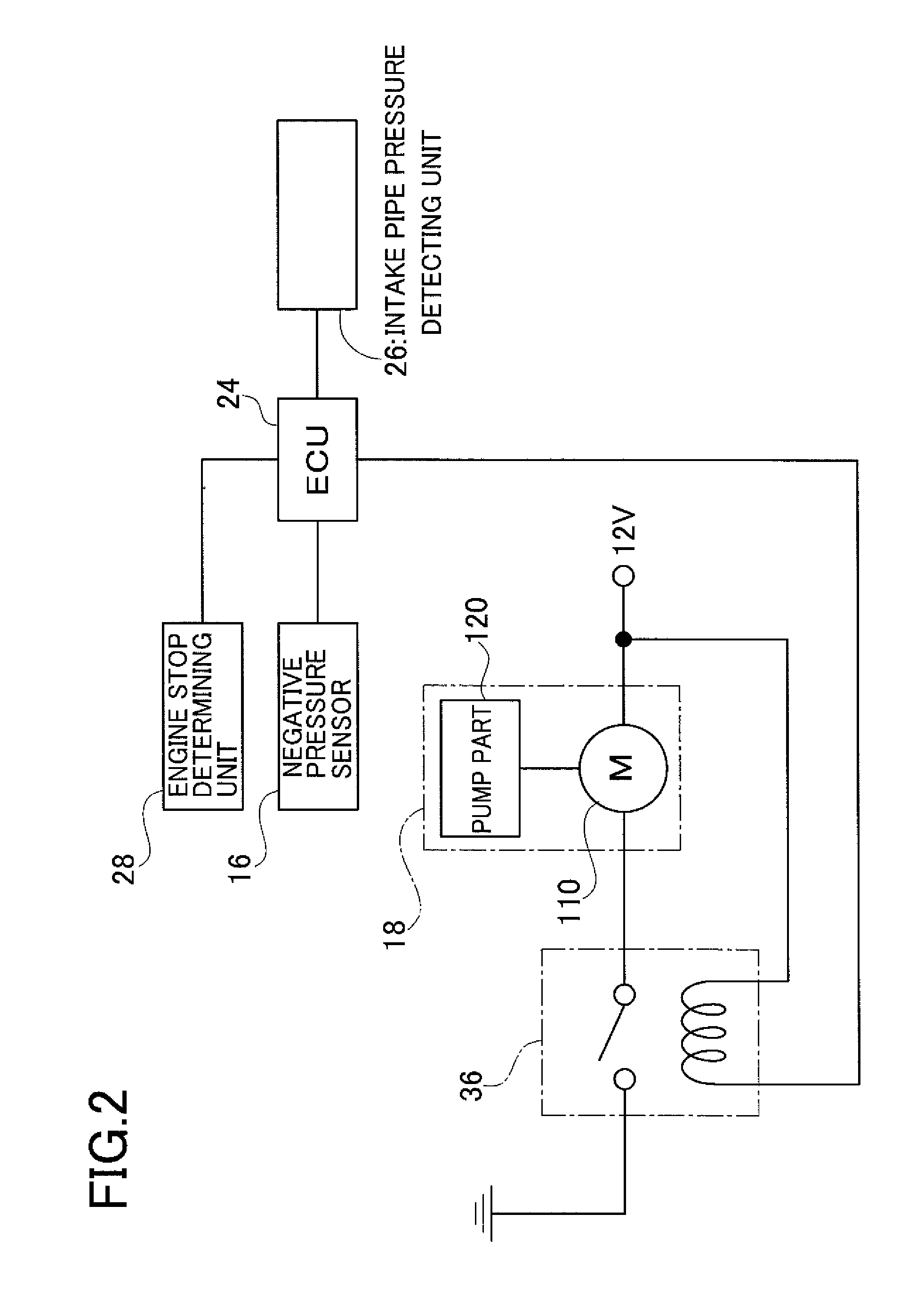

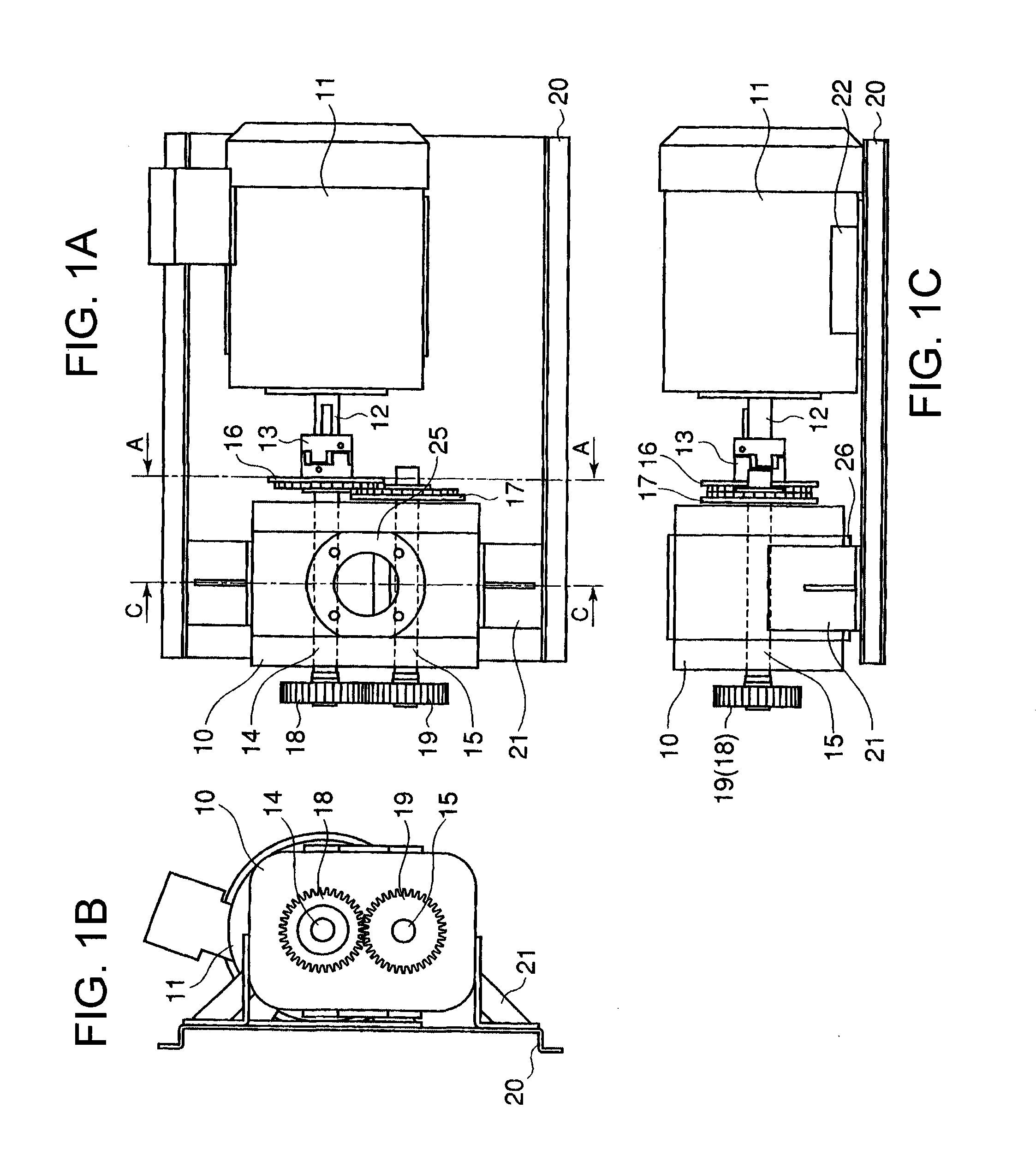

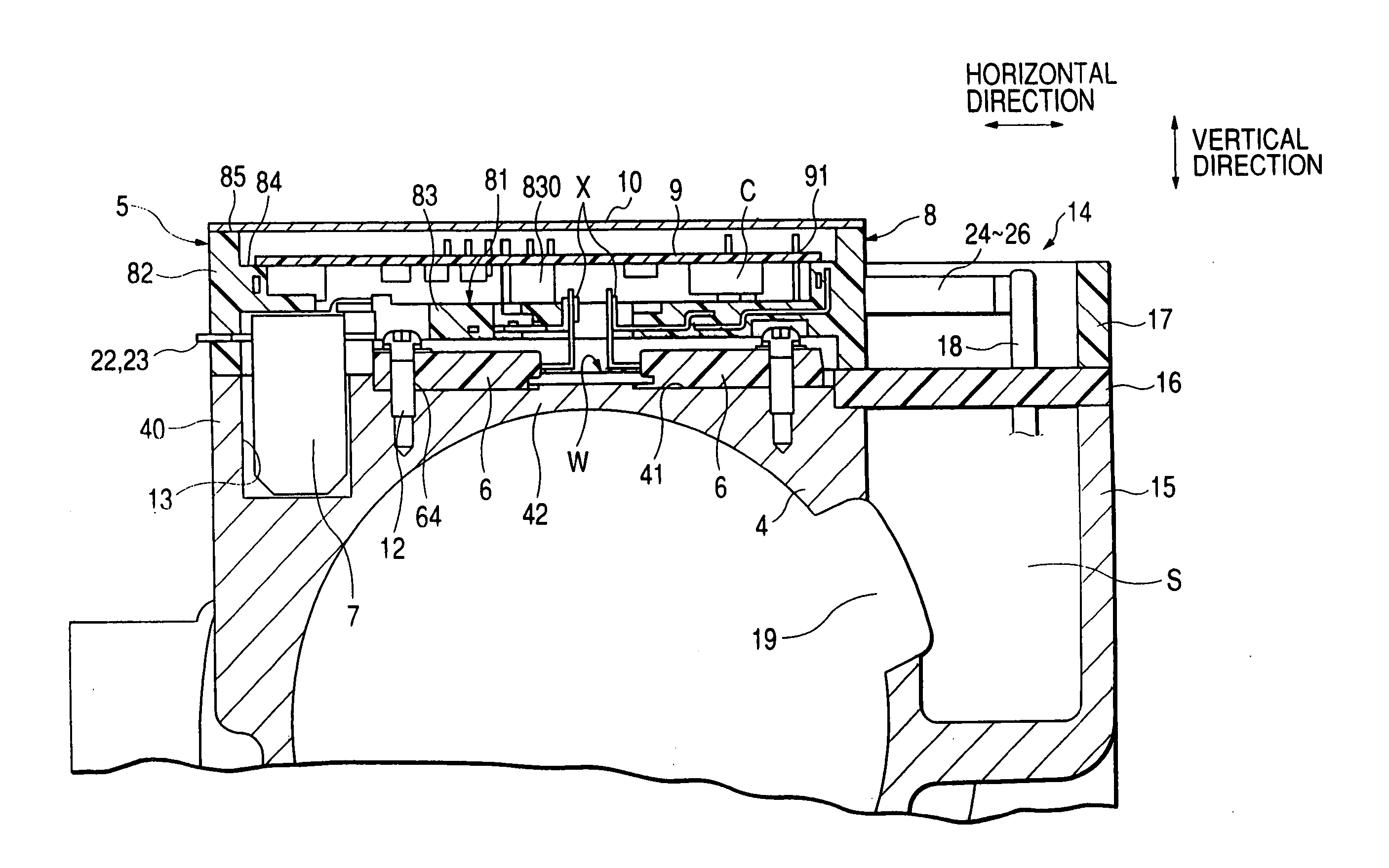

Electric vacuum pump

InactiveUS20140248167A1Small sizeImprove accuracyRotary piston pumpsRotary piston liquid enginesEngineeringVacuum pump

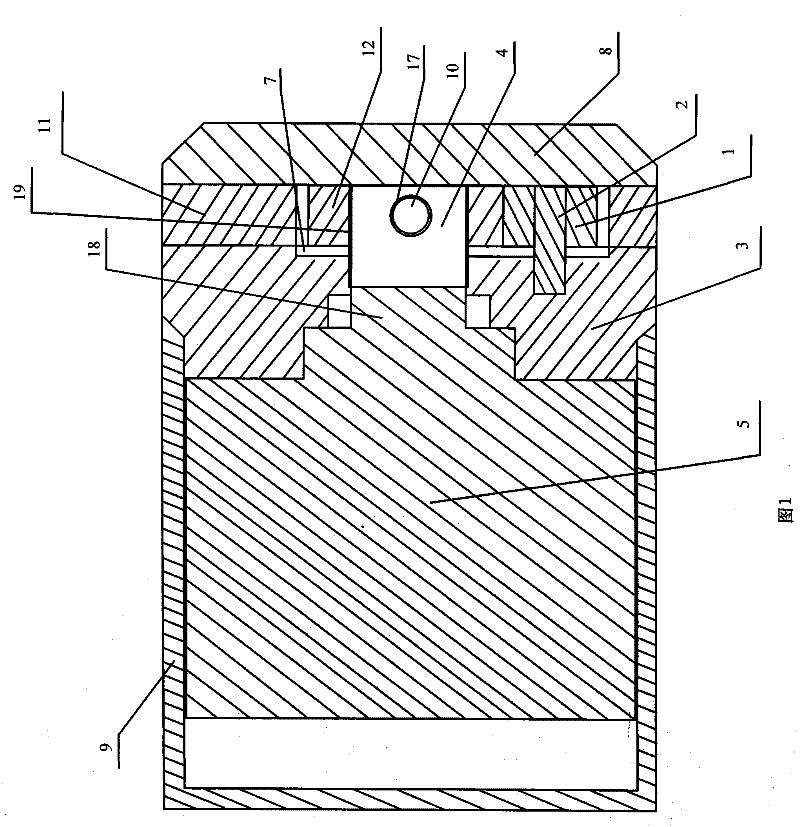

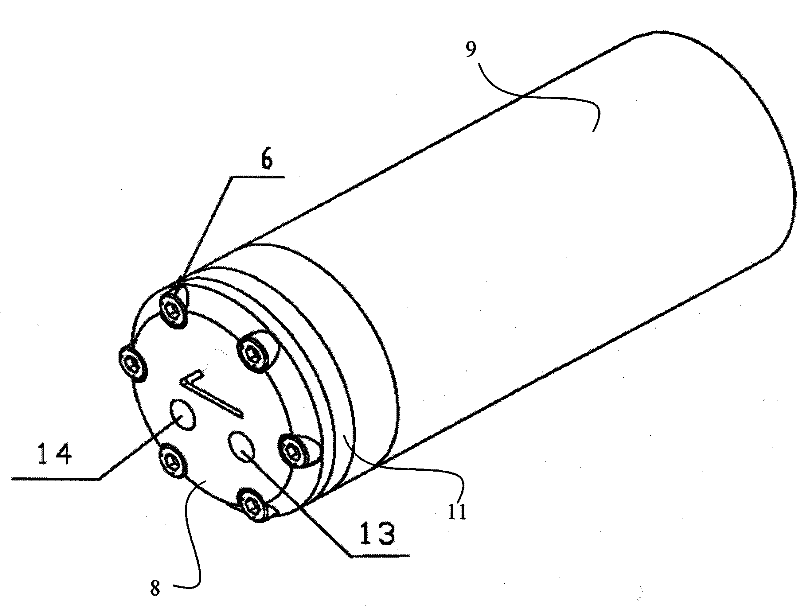

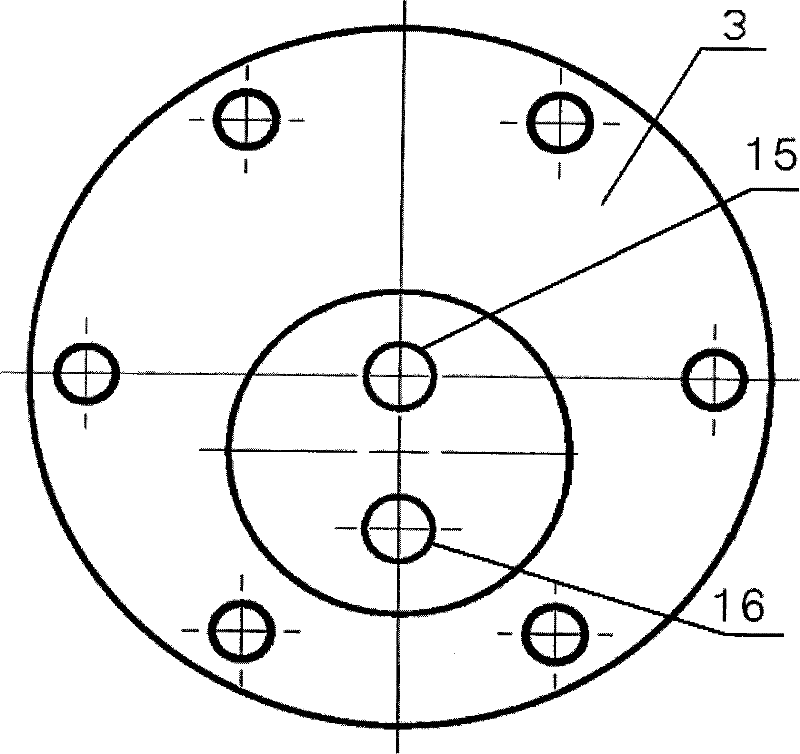

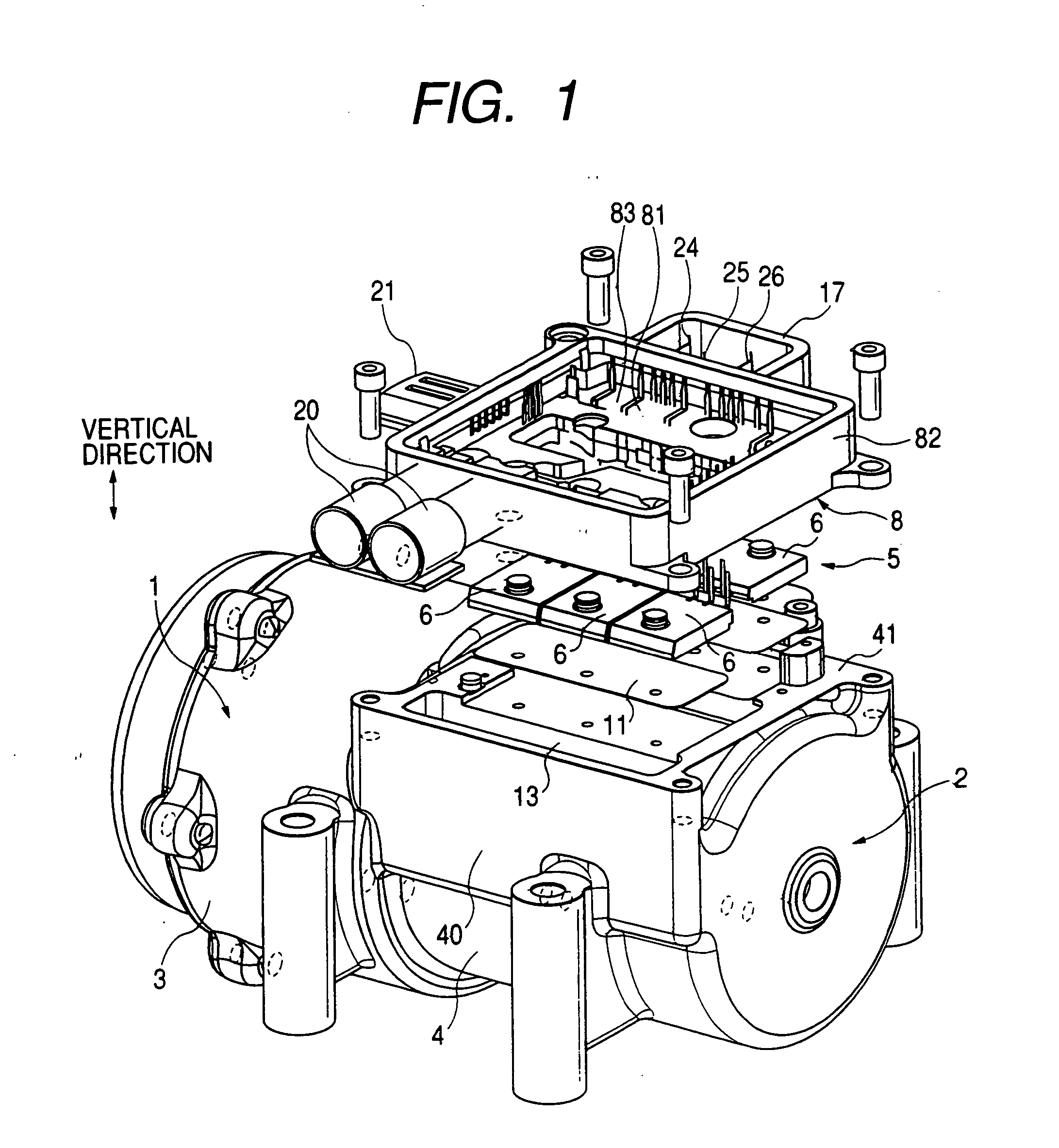

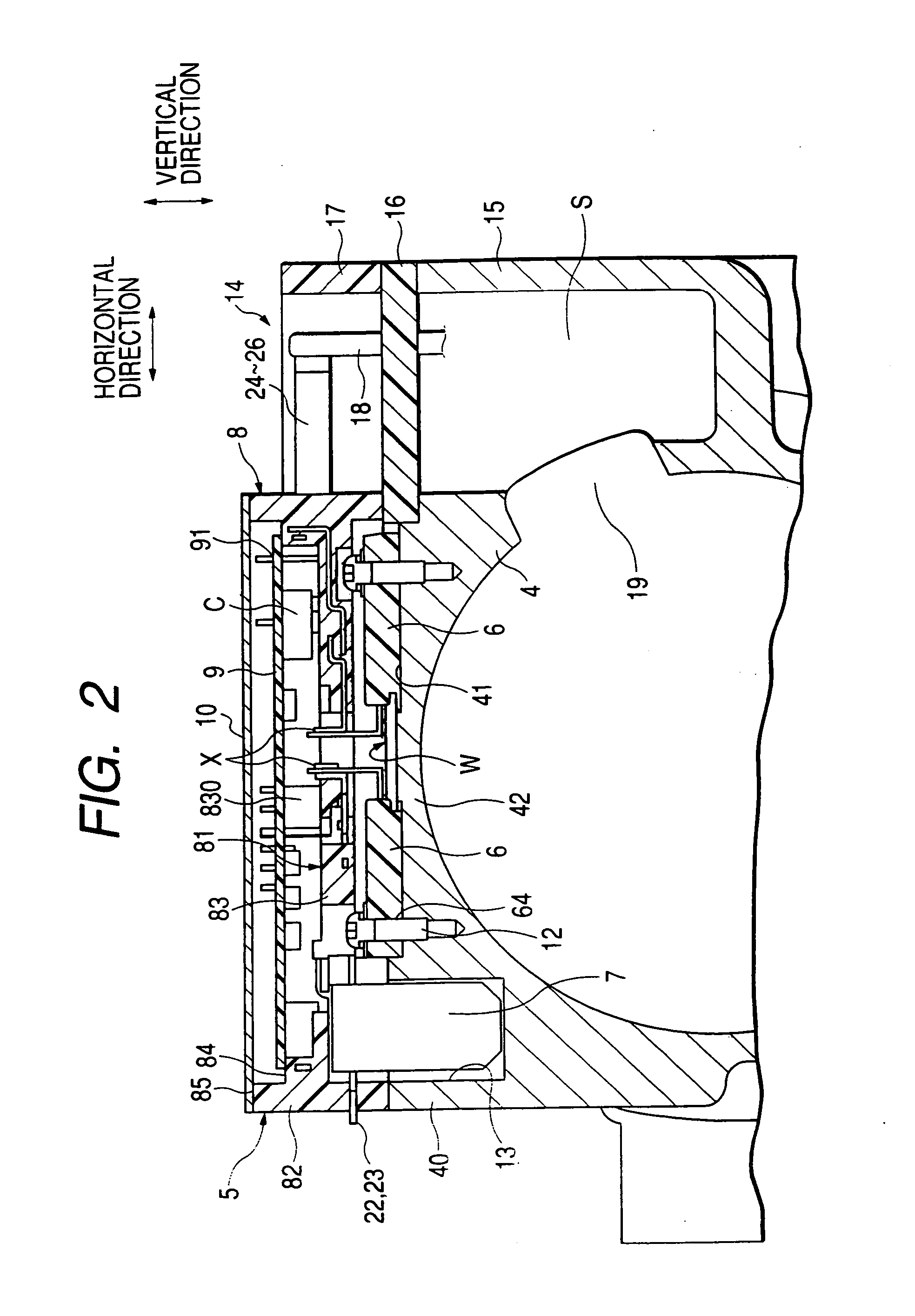

In an electric vacuum pump, a pump housing and a lower-end cover member respectively include positioning retainers respectively formed on outer peripheries of the pump housing and the lower-end cover member. A case includes positioning retainers each protruding inward from an inner peripheral surface of the case. The positioning retainers are in contact with the positioning protrusions, thereby positioning the pump housing and the lower-end cover member with respect to the case. The positioning protrusions are formed with screw holes.

Owner:AISAN IND CO LTD

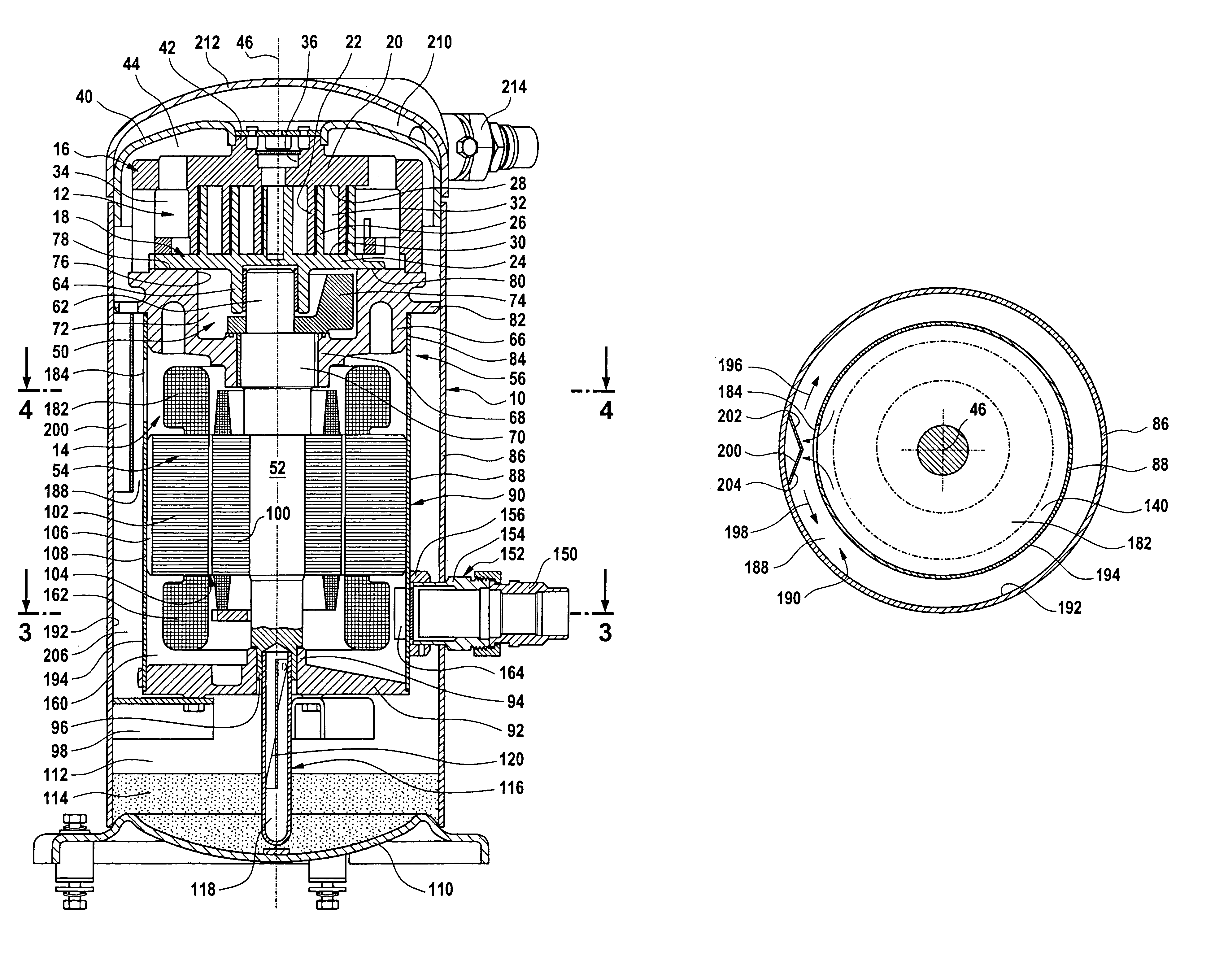

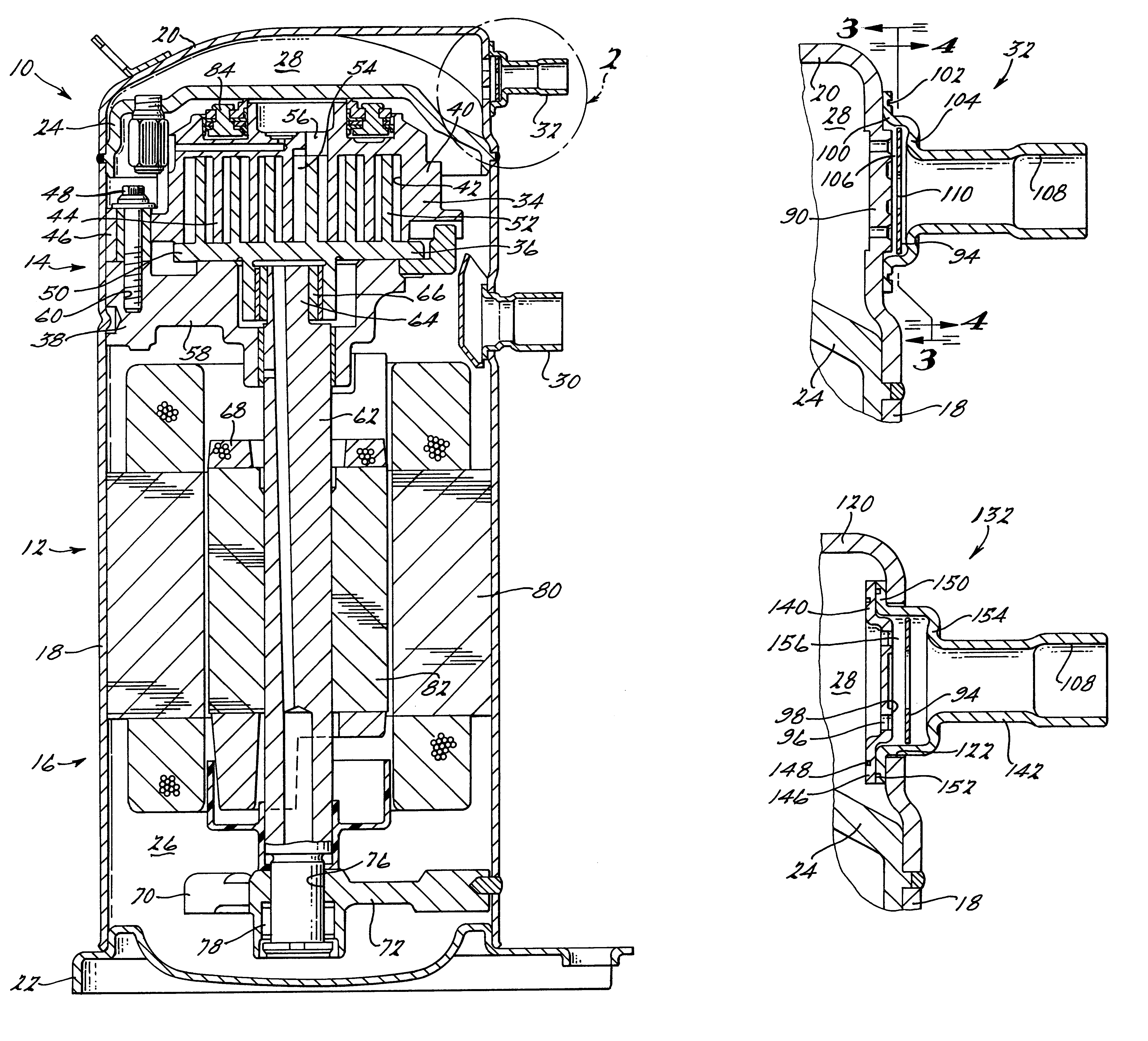

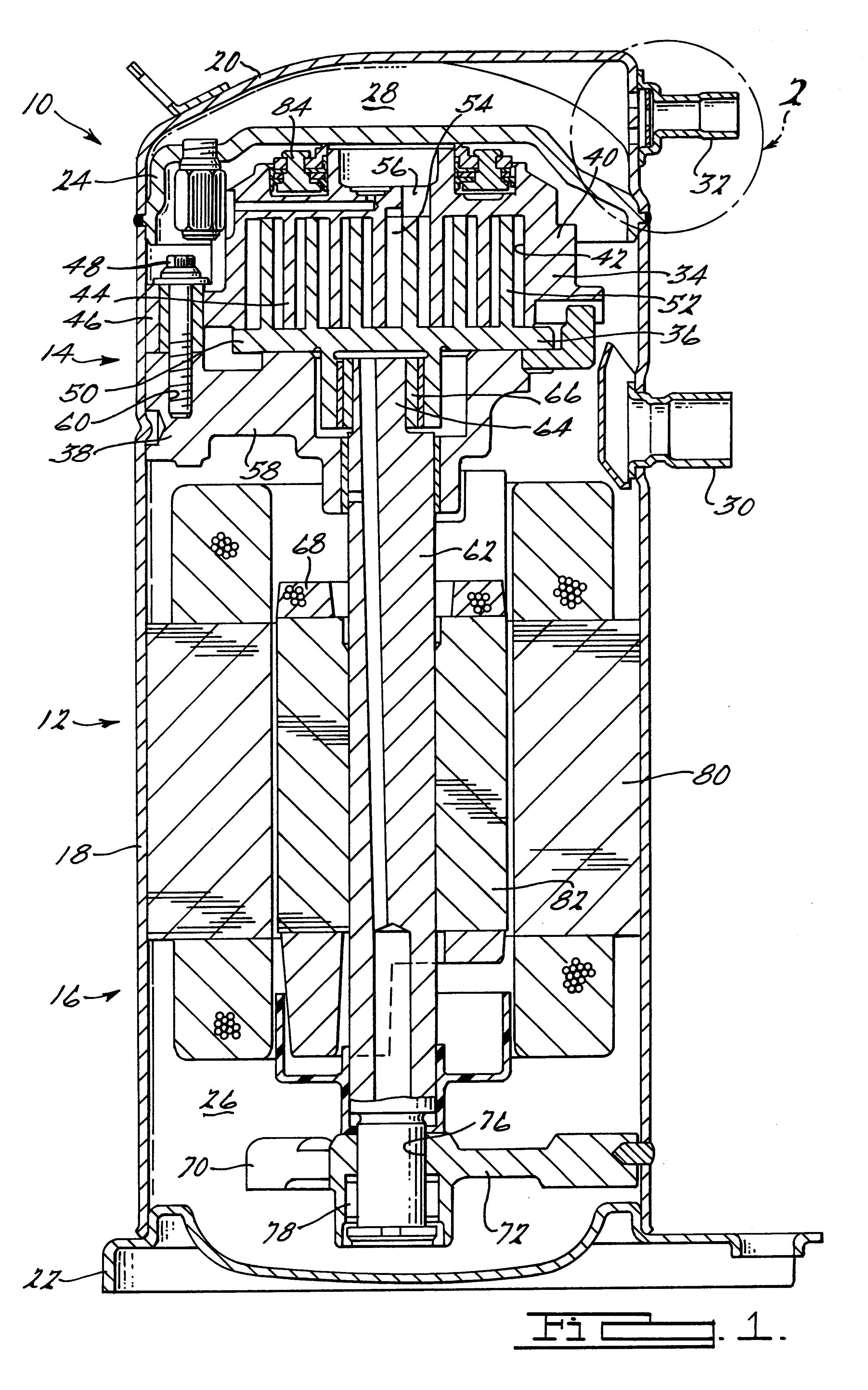

Compressor

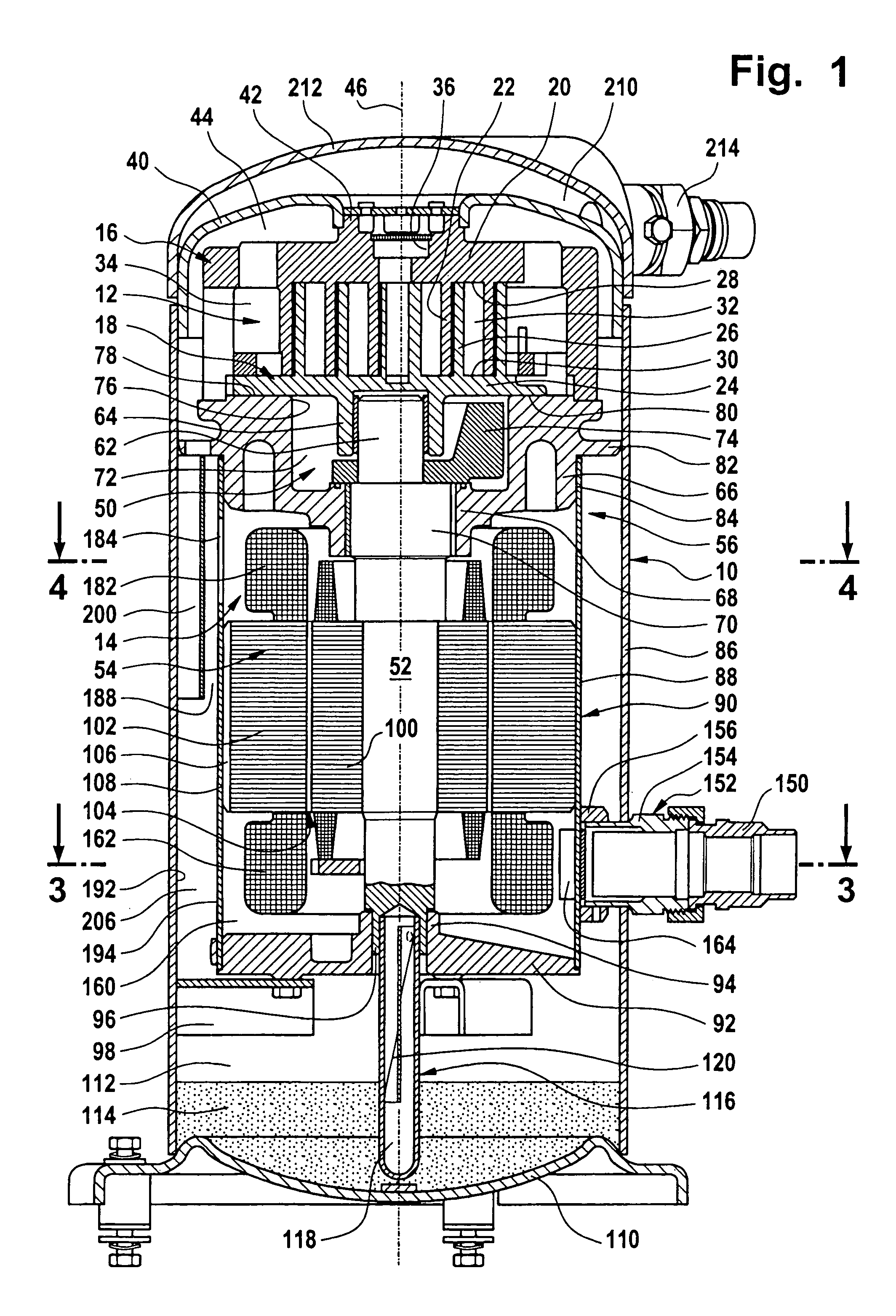

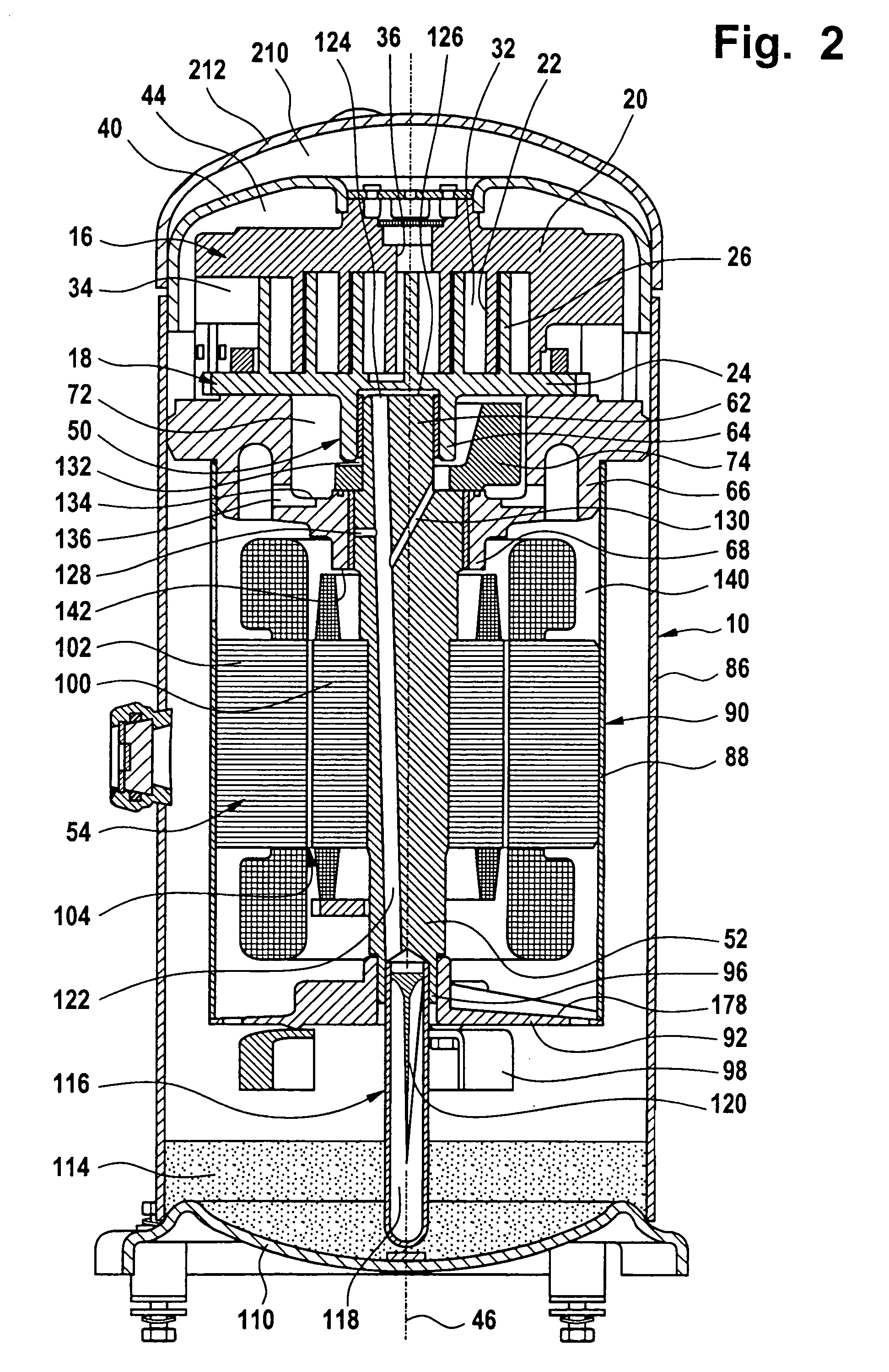

ActiveUS6960070B2Easy to fixPrecise alignmentRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDrive shaftEngineering

In order to improve a compressor for refrigerant, comprising an outer housing, a scroll compressor arranged in the outer housing and having a first compressor member arranged stationarily in the outer housing and a second compressor member which is movable relative to the first compressor member, the compressor members each having a base and first and second scroll ribs, respectively, which rise above the respective base and engage in one another such that the second compressor member is movable relative to the first compressor member on an orbital path about a central axis for the purpose of compressing the refrigerant, a drive unit for the second compressor member having an eccentric drive, a drive shaft, a drive motor arranged in a motor housing and having drawn-in refrigerant flowing around it as well as a bearing unit for the drive shaft which comprises a first bearing member connected to the outer housing, in such a manner that the refrigerant drawn in by the scroll compressor is free from lubricating oil to as great an extent as possible it is suggested that the refrigerant flow through an oil separator, which is arranged in the outer housing between this and the drive unit, after flowing around the drive motor and prior to entering the scroll compressor.

Owner:BITZER KUEHLMASCHINENBAU GMBH

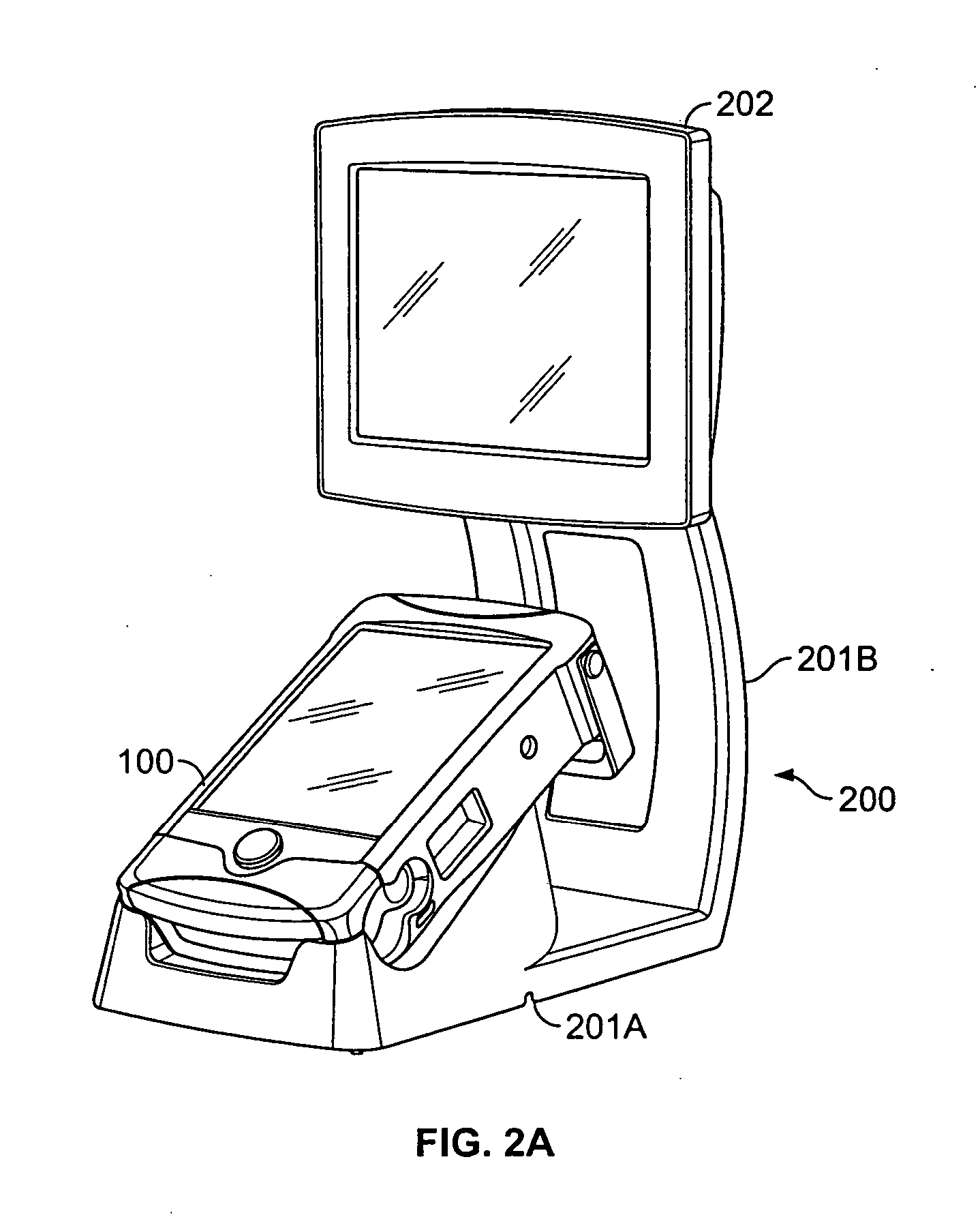

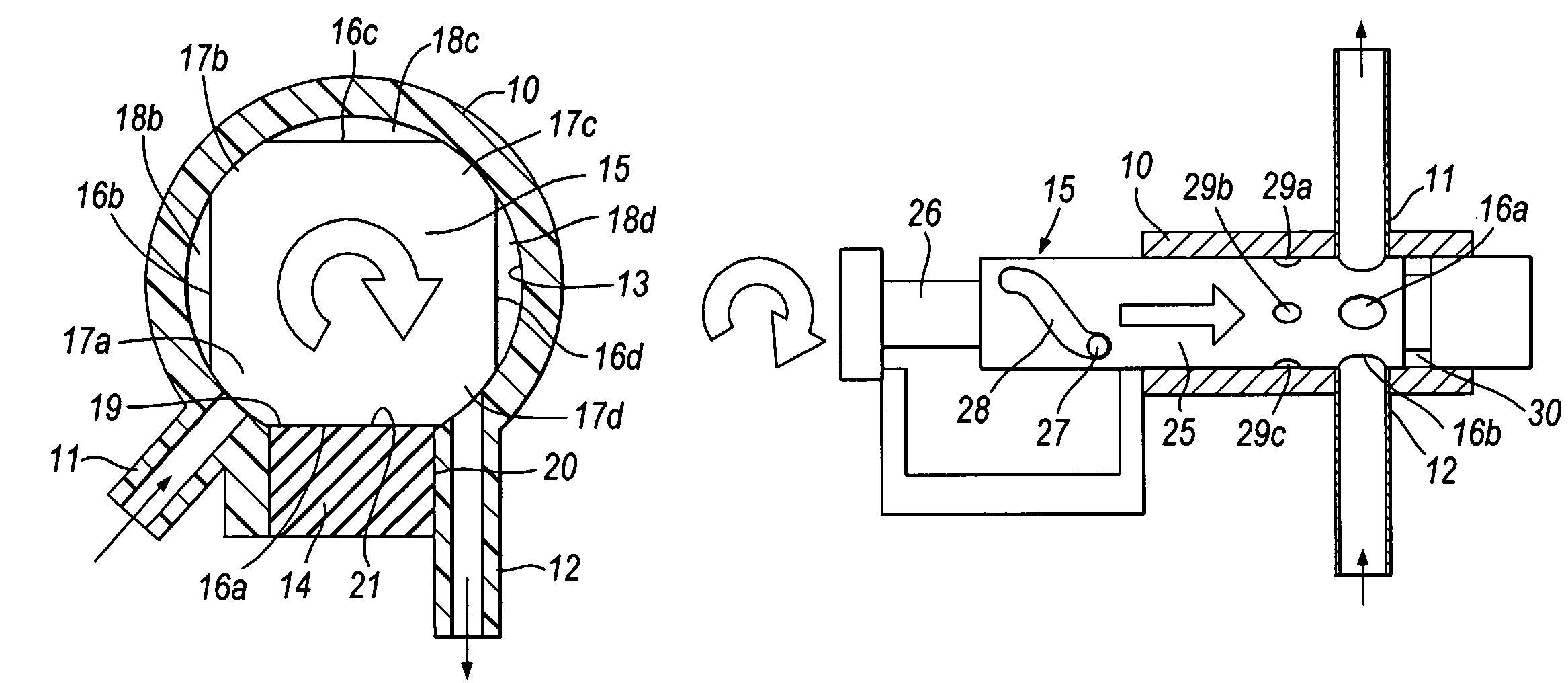

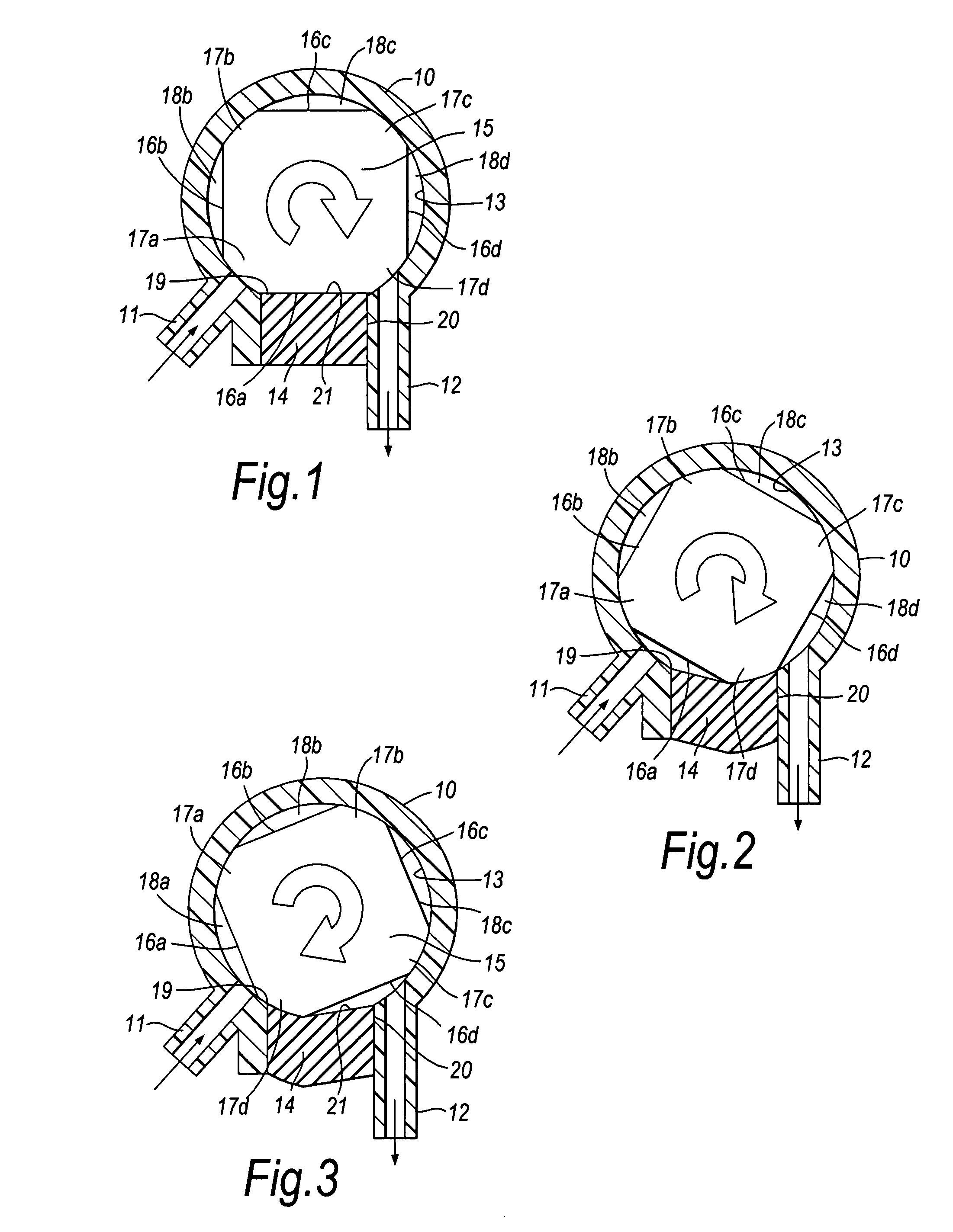

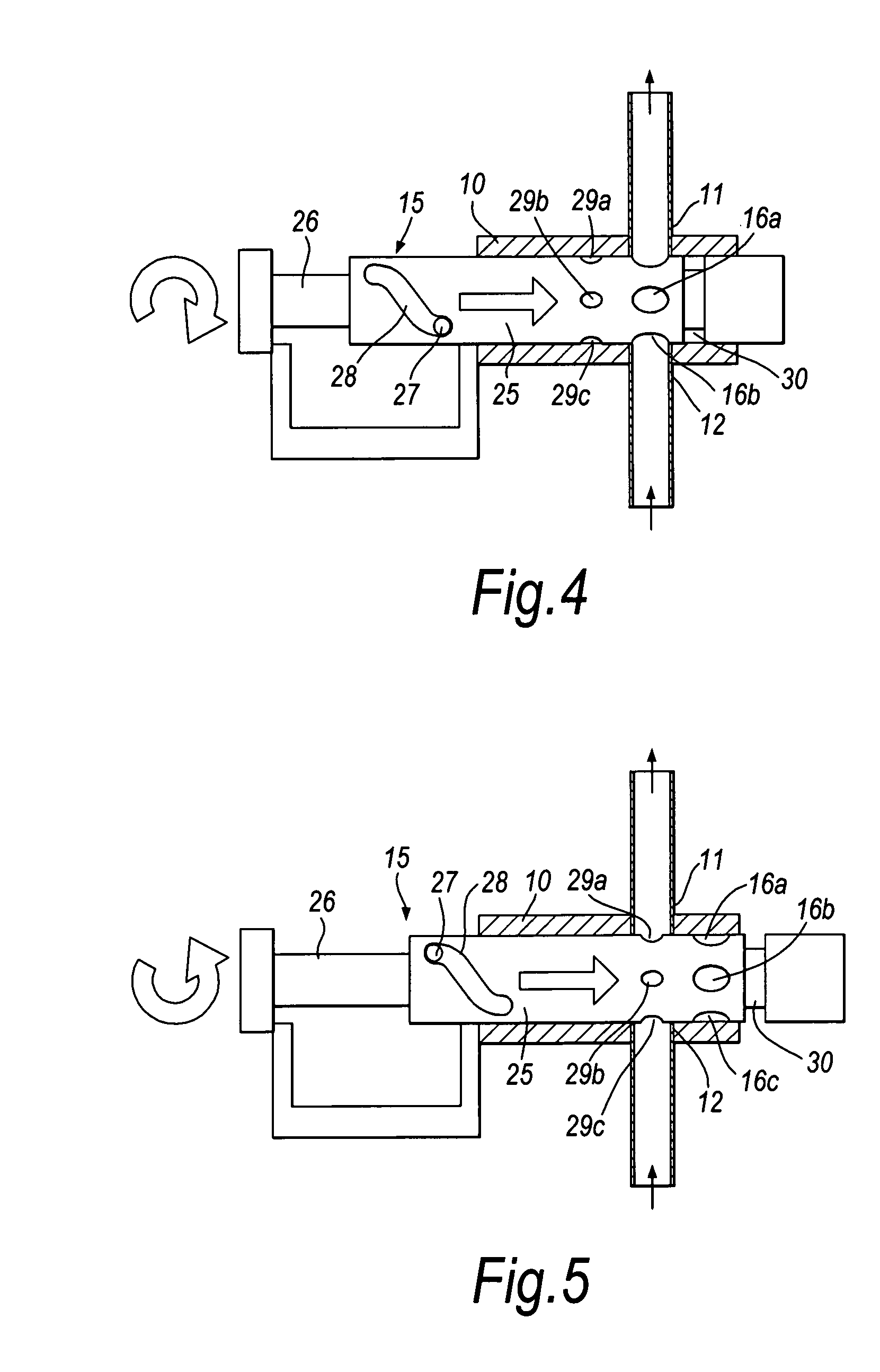

Portable ventilator system

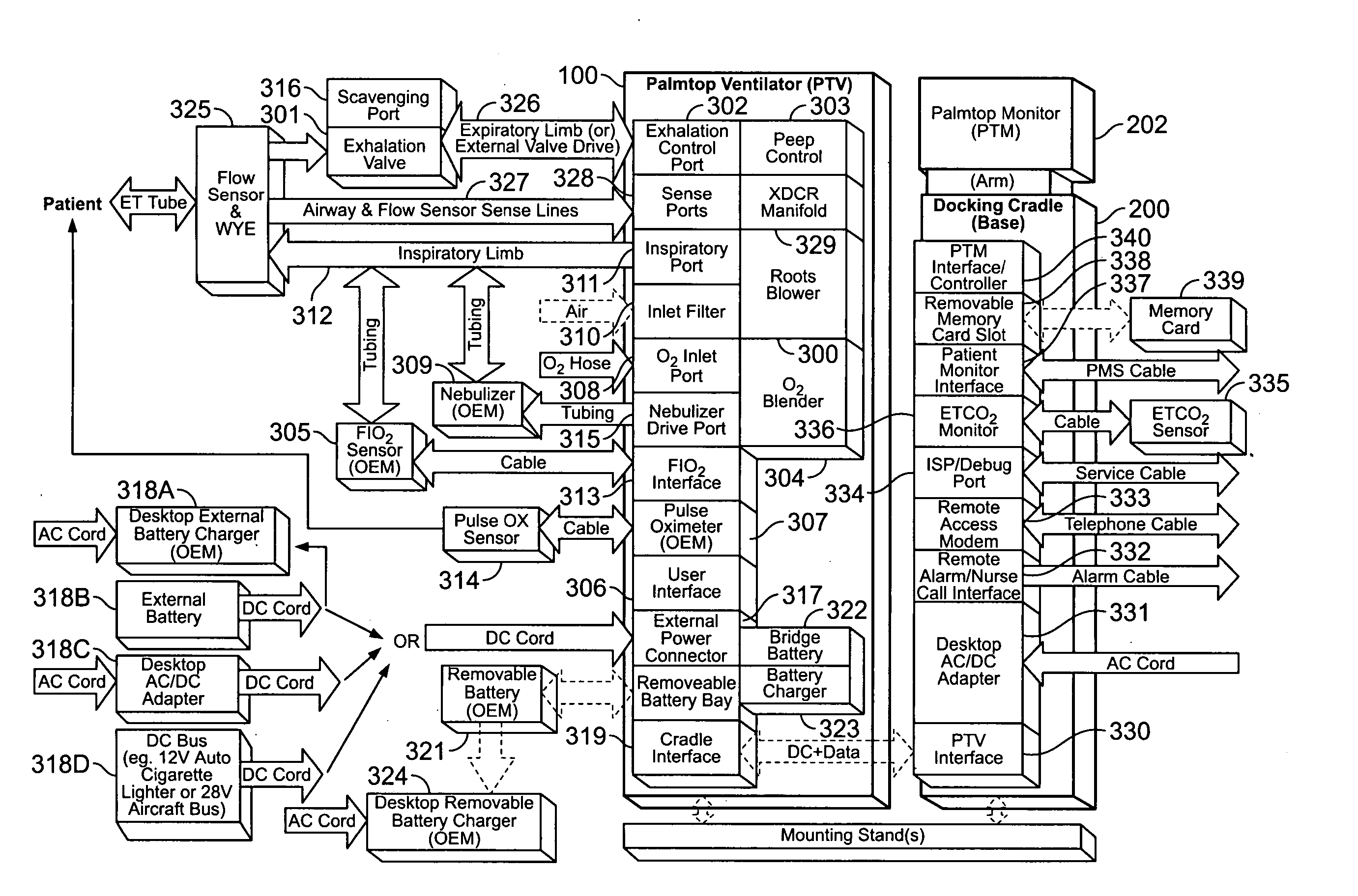

ActiveUS20050051168A1Reduce power consumptionSmall sizeMechanical/radiation/invasive therapiesPhysical therapyPortable ventilatorsEngineering

A portable ventilator uses a Roots-type blower as a compressor to reduce both the size and power consumption of the ventilator. Various functional aspects of the ventilator are delegated to multiple subassemblies having dedicated controllers and software that interact with a ventilator processor to provide user interface functions, exhalation control and flow control servos, and monitoring of patient status. The ventilator overcomes noise problems through the use of noise reducing pressure compensating orifices on the Roots blower housing and multiple baffling chambers. The ventilator is configured with a highly portable form factor, and may be used as a stand-alone device or as a docked device having a docking cradle with enhanced interface and monitoring capabilities.

Owner:VYAIRE MEDICAL 203 INC

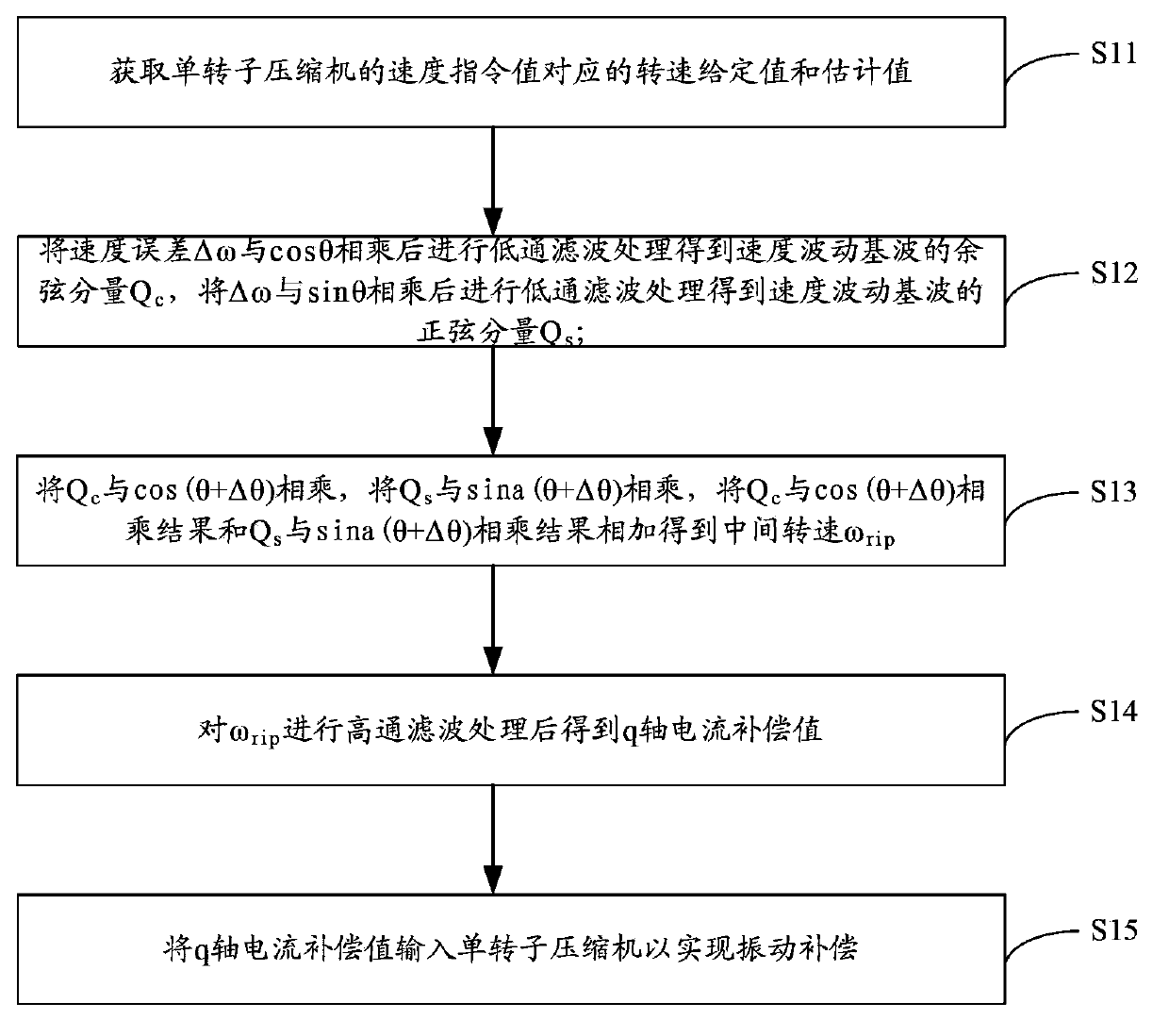

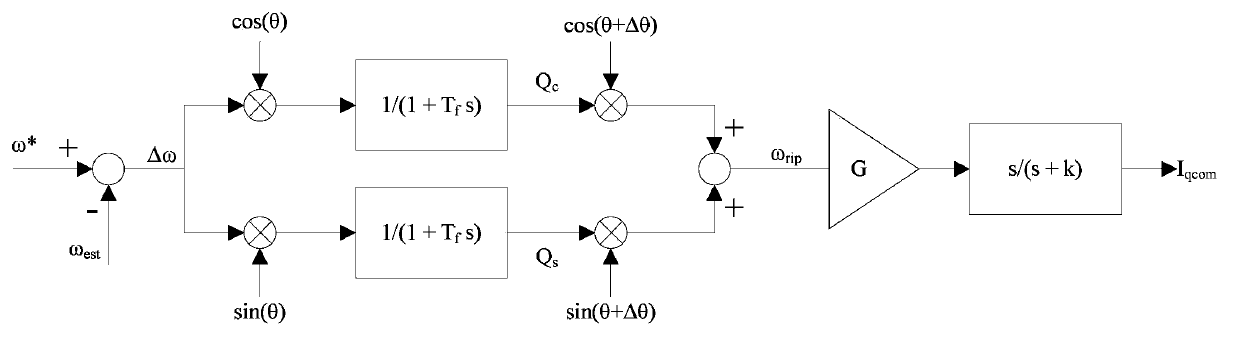

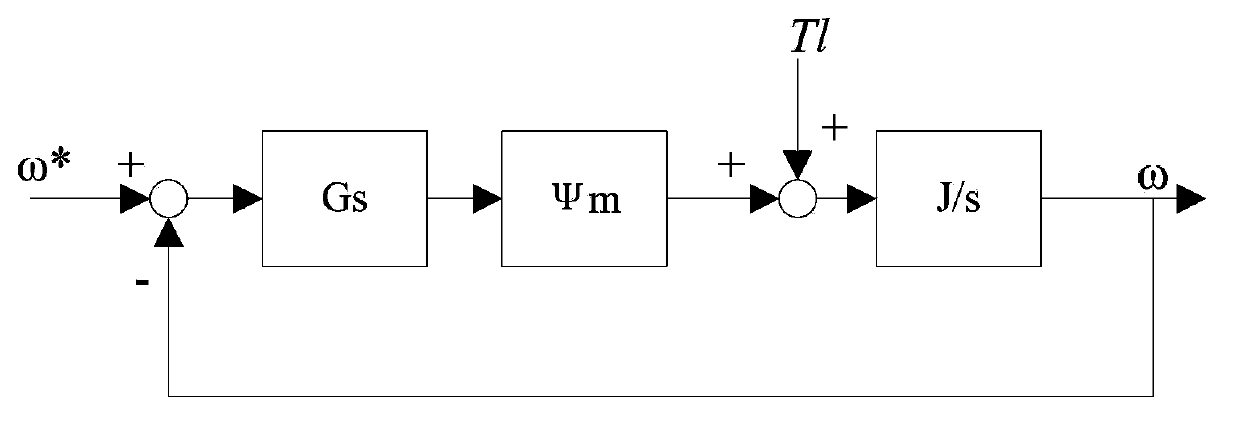

Vibration compensation method for single-rotor compressor and controller

ActiveCN103967794AReduce vibrationImprove noiseRotary/oscillating piston pump componentsLiquid fuel engine componentsVibration compensationHigh-pass filter

The invention is applicable to the technical field of household electrical appliances and provides a vibration compensation method for a single-rotor compressor and a controller. The method comprises the following steps: acquiring a rotating speed set value omega* and a rotating speed estimated value omega e corresponding to a speed command value; multiplying a speed error delta omega by cos theta, carrying out low pass filtering so as to obtain the cosine component Qc of a speed fluctuation fundamental wave, multiplying delta omega by sin theta and carrying out low pass filtering so as to obtain the sine component Qs of the speed fluctuation fundamental wave; multiplying Qc by cos (theta+delta theta), multiplying Qs by sin (theta+delta theta) and adding the result of multiplication of Qc by cos (theta+delta theta) and the result of multiplication of Qs by sin (theta+delta theta) together so as to obtain an intermediate rotating speed omega rip; subjecting omega rip to high pass filtering so as to obtain a q-shaft current compensation value; and inputting the q-shaft current compensation value into the single-rotor compressor to realize vibration compensation. With the technical scheme provided by the invention, the advantages of reduction in vibration of the single-rotor compressor and easy realization are obtained.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

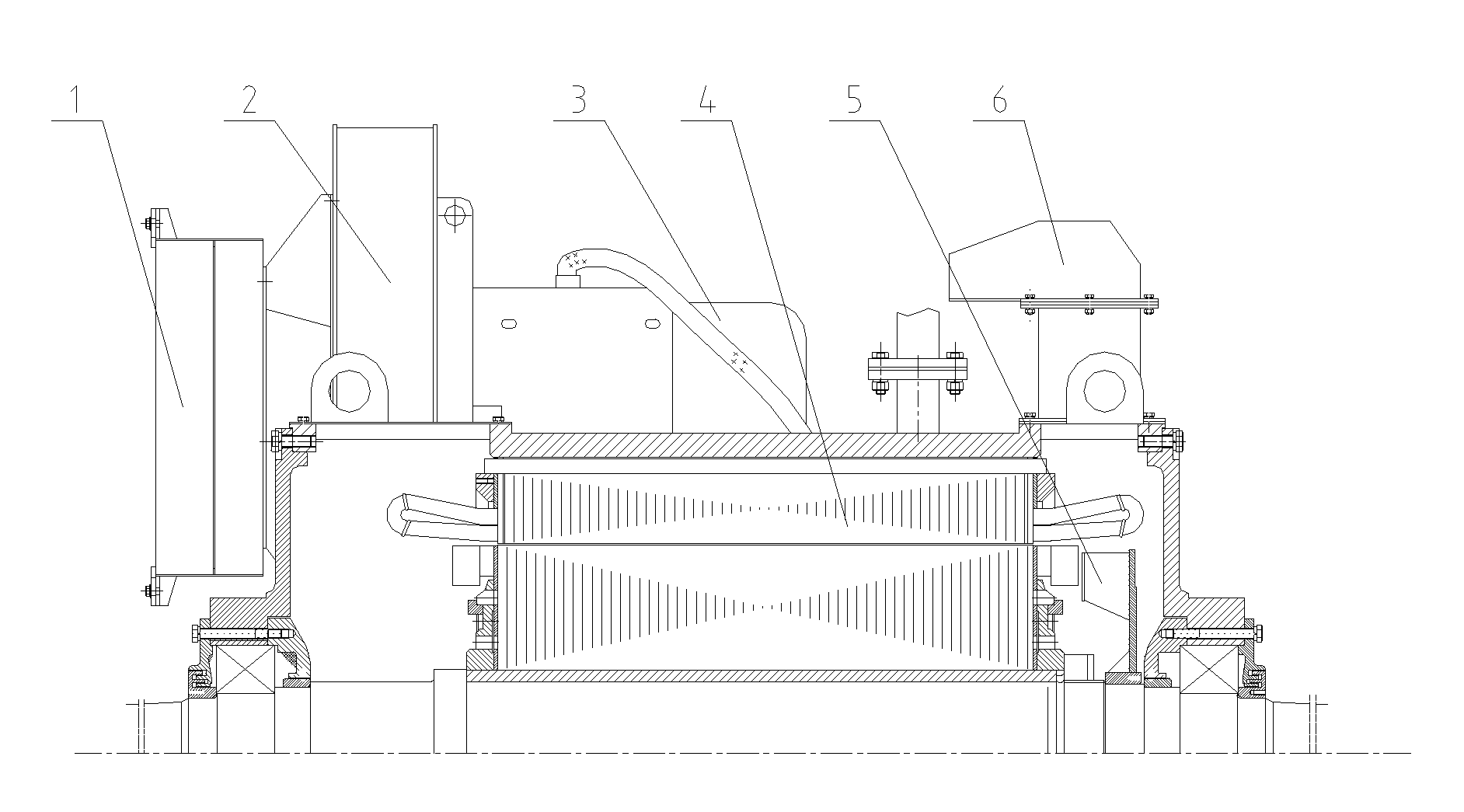

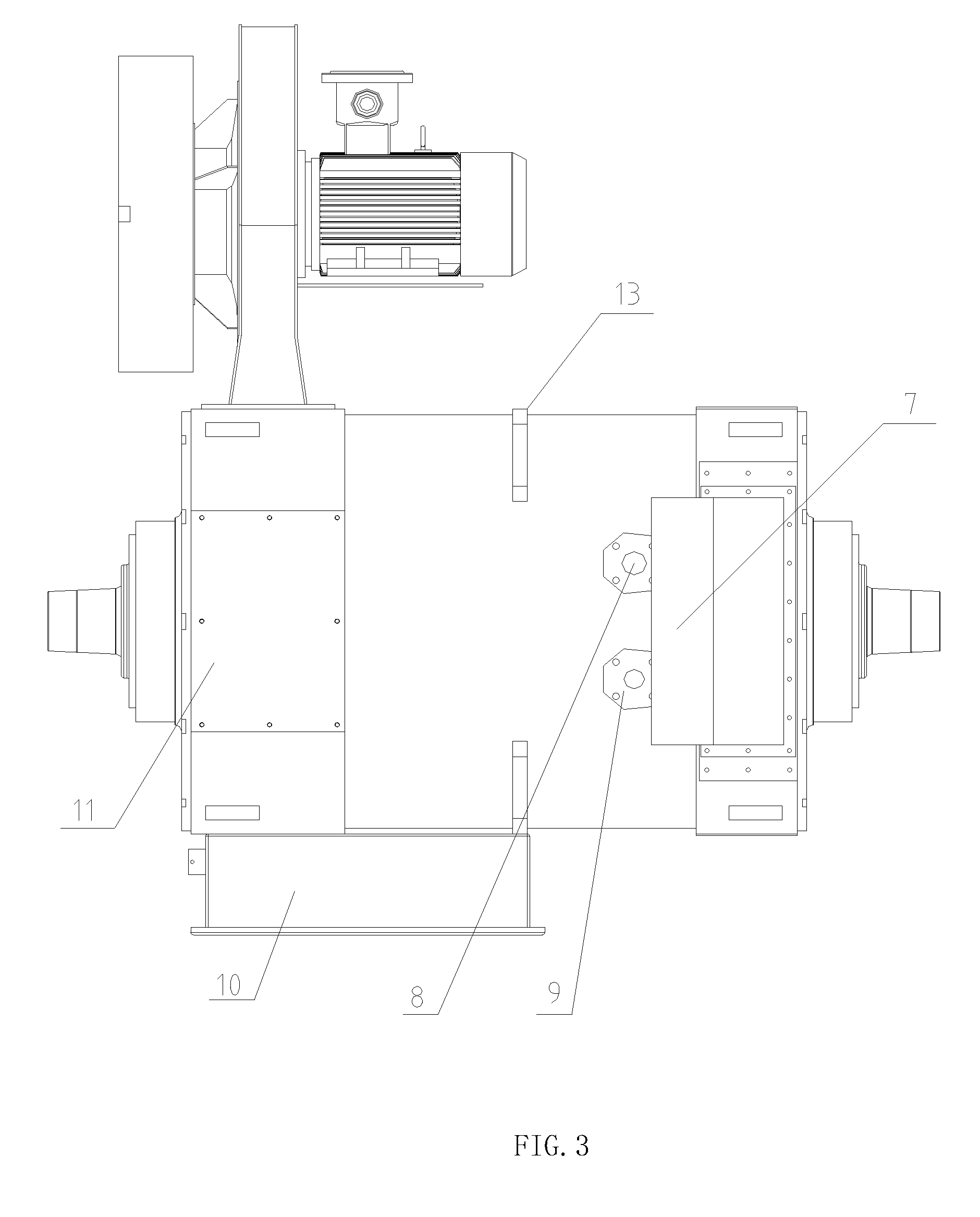

Fracturing Pump

InactiveUS20150078924A1Large single-machine powerWork at highPositive displacement pump componentsFlexible member pumpsEngineeringDiesel engine

The invention discloses a fracturing pump, comprising a cooling device and a control device, wherein a motor is connected on an shaft of the fracturing pump, the cooling device comprises an air-cooled device for cooling a rotor of the motor and a water-cooled device for cooling a stator of the motor, and the control device is connected with the motor and the cooling device, respectively. The fracturing pump in the invention adopts a structure directly driven by the motor, thus breaking the form of a transmission structure of a diesel engine of the conventional fracturing pump added with a transmission tank, simplifying the structure of the entire fracturing pump, reducing the apparatus mounted on a fracturing car, decreasing failure rate of the apparatus, and becoming more safe and reliable.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

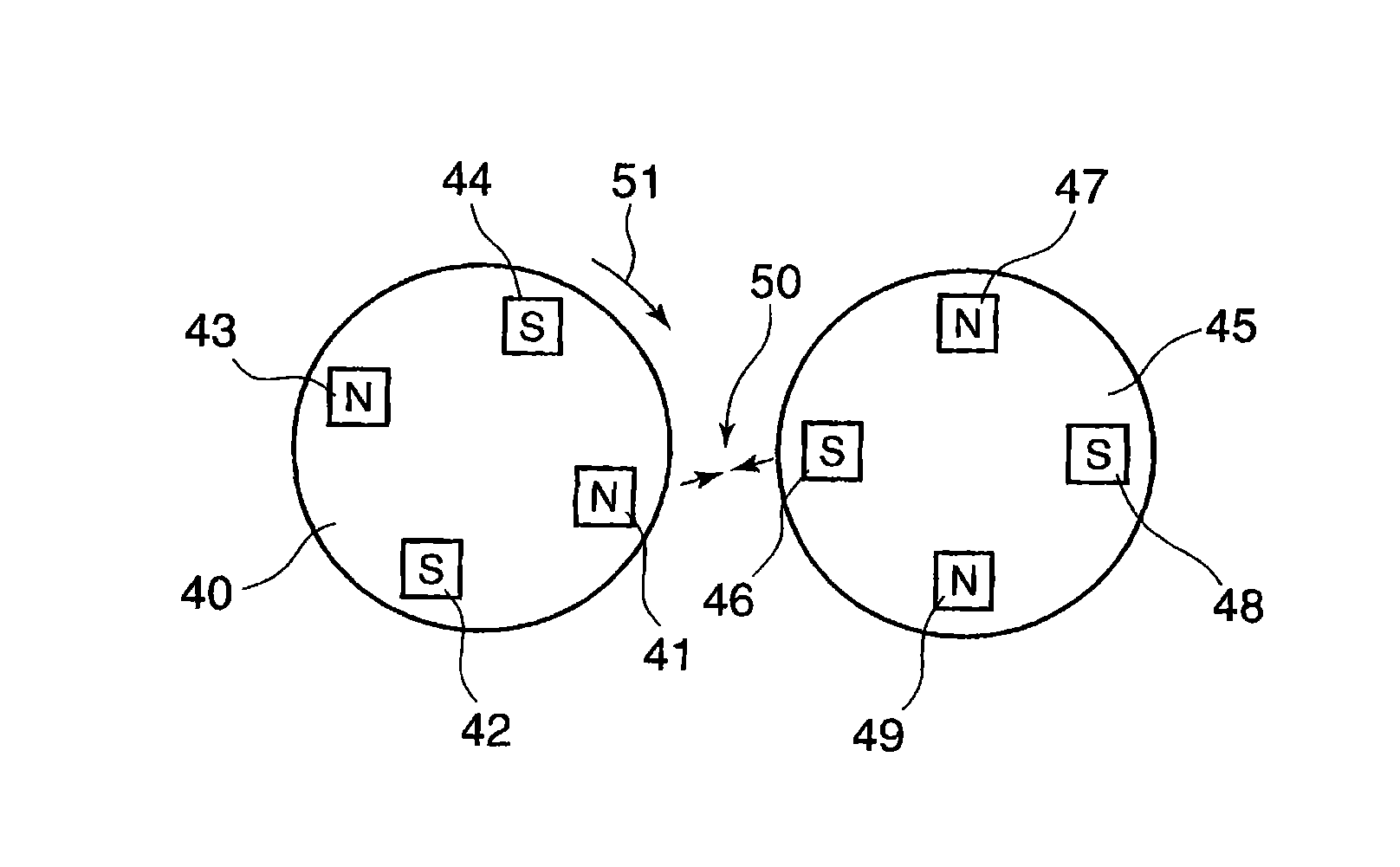

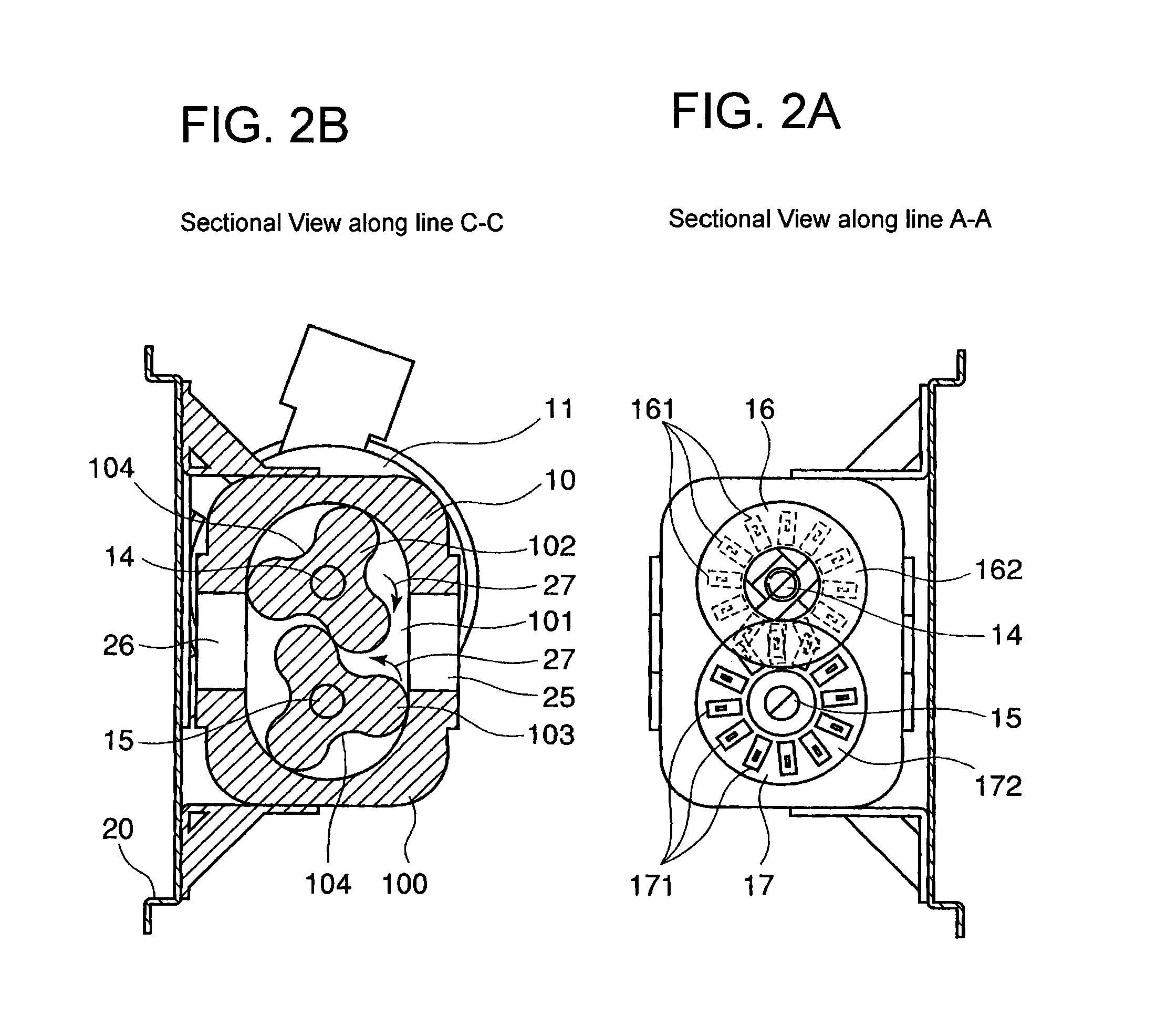

Drive transmission mechanism between two or more rotary shafts and oil-free fluid machine equipped with the mechanism

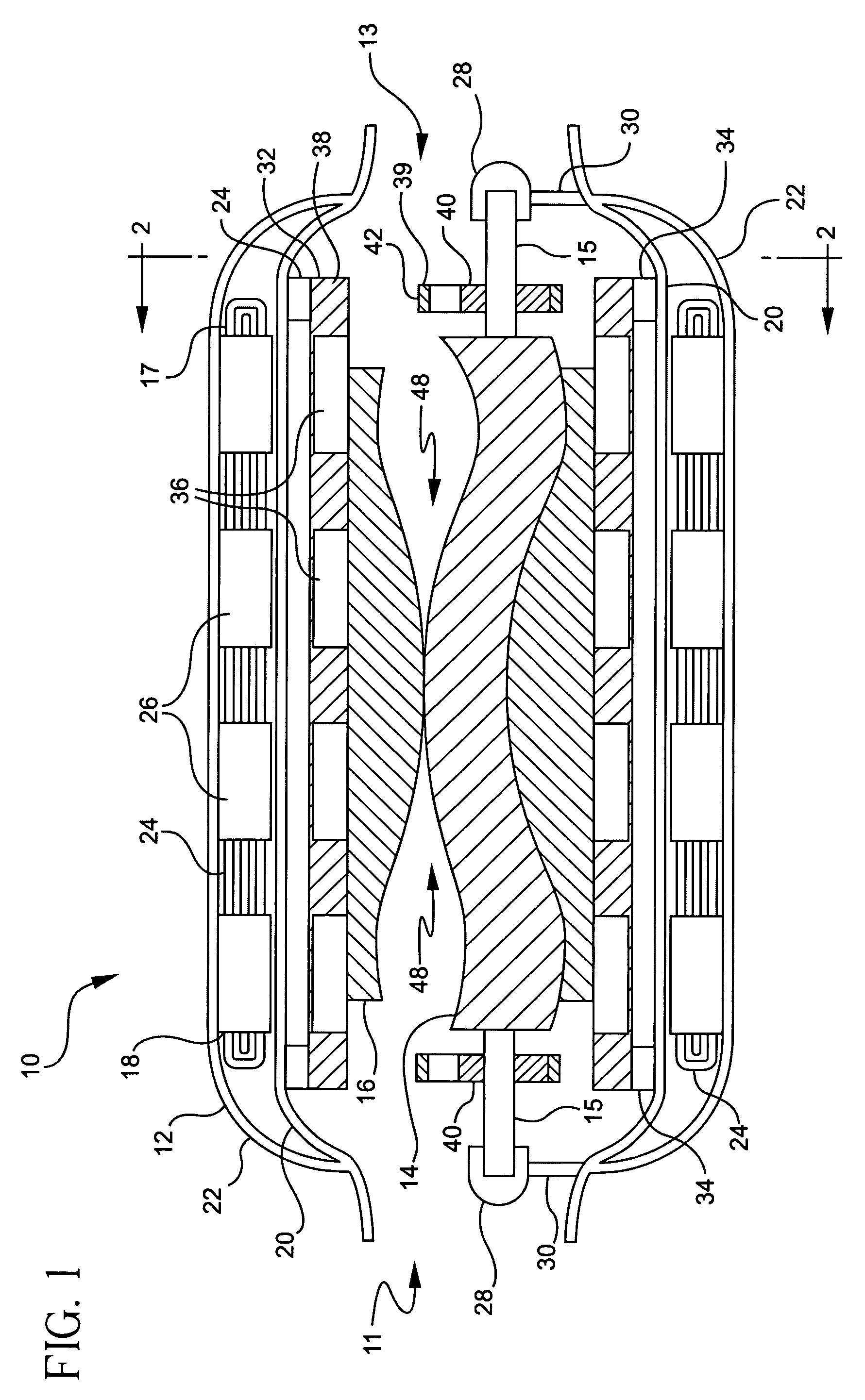

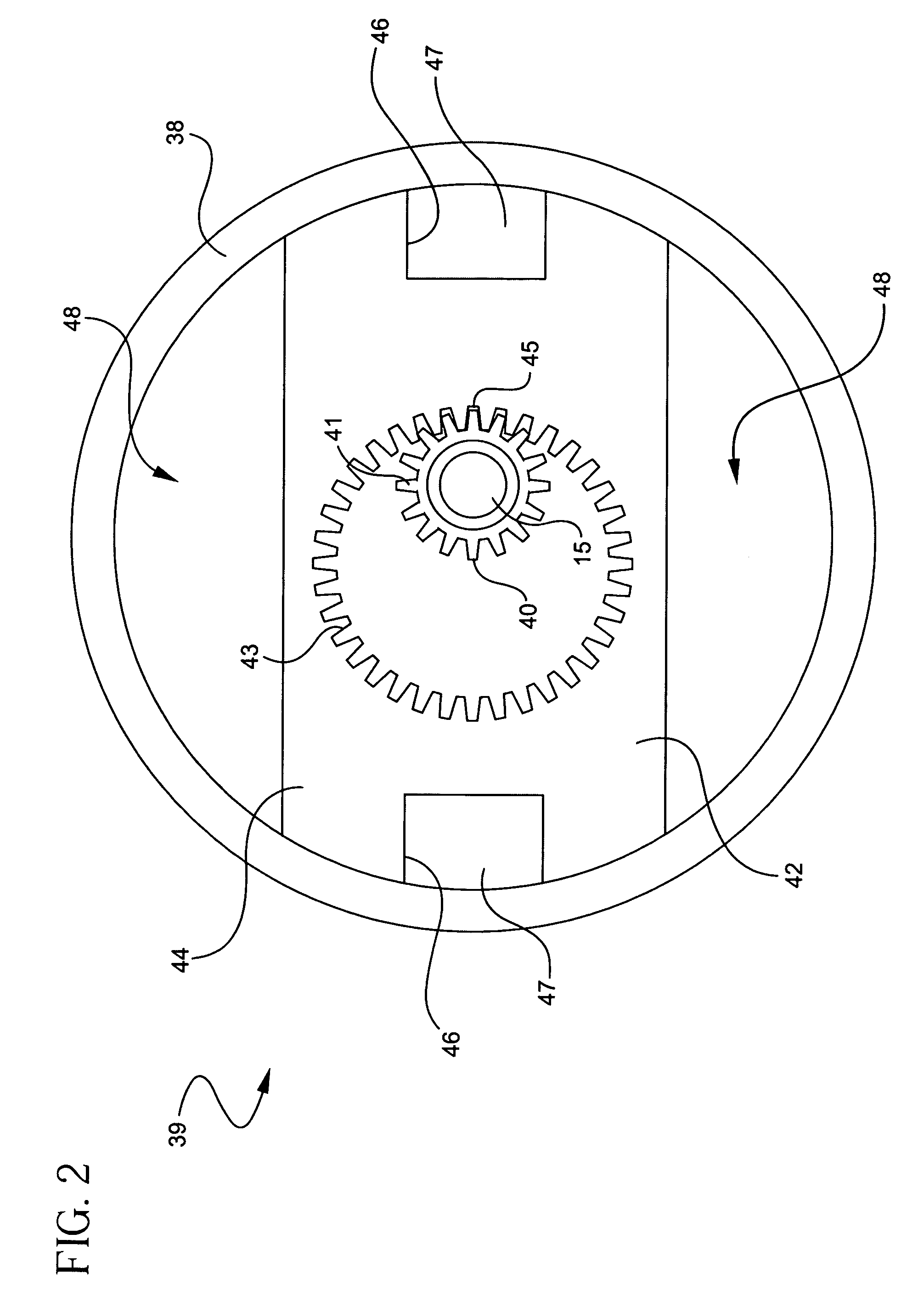

InactiveUS20080181804A1Reduced service lifeEliminate pollutionDynamo-electric brakes/clutchesEngine of counter-engagement typePlastic materialsOil free

A drive transmission mechanism for transmitting torque between two or more rotary shafts in synchronization with one another without need for lubrication thereby eliminating occurrence of oil contamination, and an oil-free fluid machine equipped with the mechanism, are provided. A magnetic drive disk 16 and a synchronization gear 18 are attached to a rotary shaft 14 connected to a drive motor 11, a magnetic drive disk 17 and a synchronization gear 19 is attached to a rotary shaft 15, torque transmission from the rotary shaft 14 to the rotary shaft 15 is carried out in two ways, via the magnetic drive disks 16, 17 and via the synchronization gears 18, 19, and at least one of the synchronization gears is made of plastic material. With the construction, torque transmit load between the rotary shafts via the synchronization gears is decreased, and a plastic gear or gears can be adopted for synchronization gears without reducing life of the gears without need for lubrication oil.

Owner:ANEST IWATA CORP

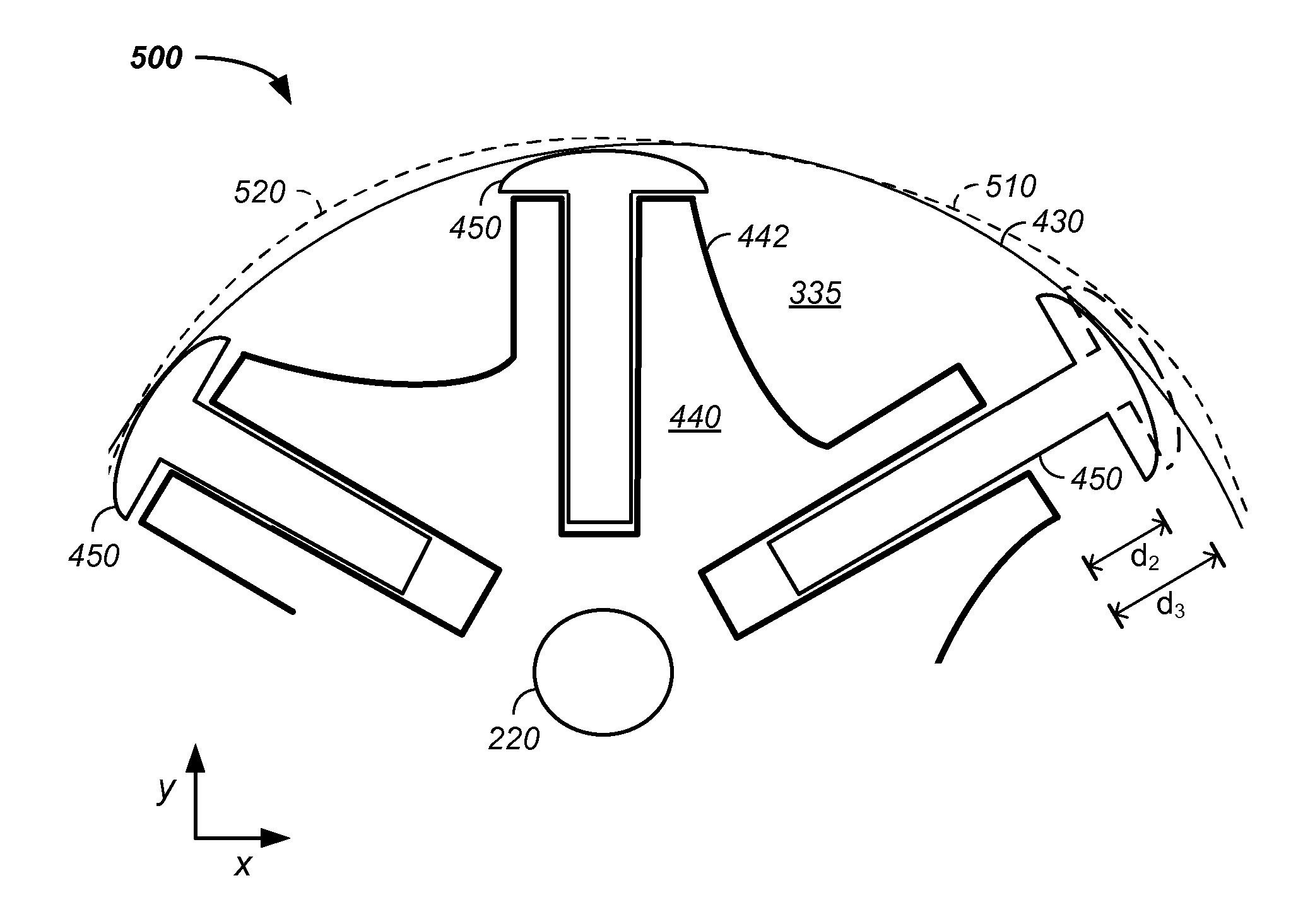

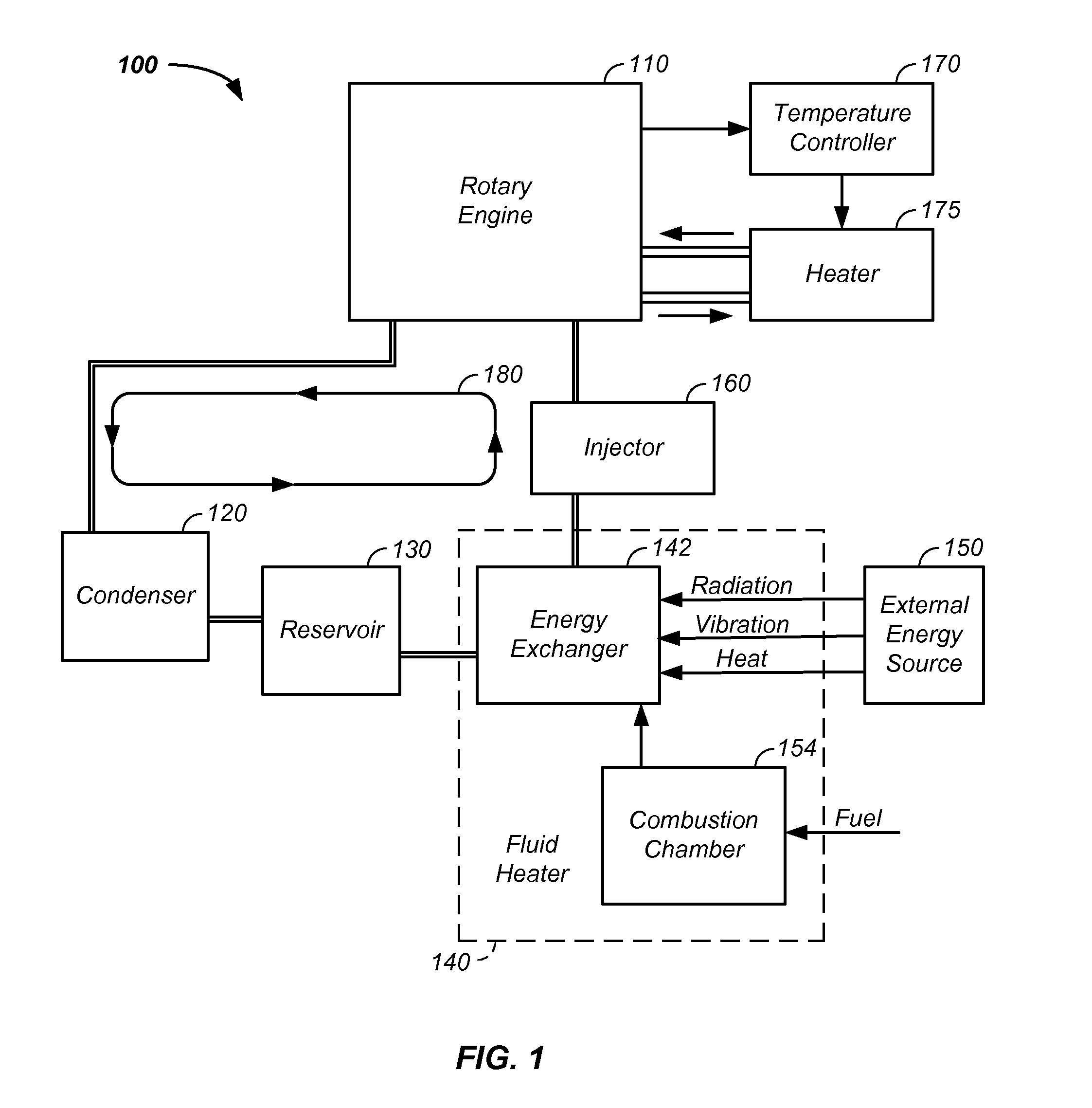

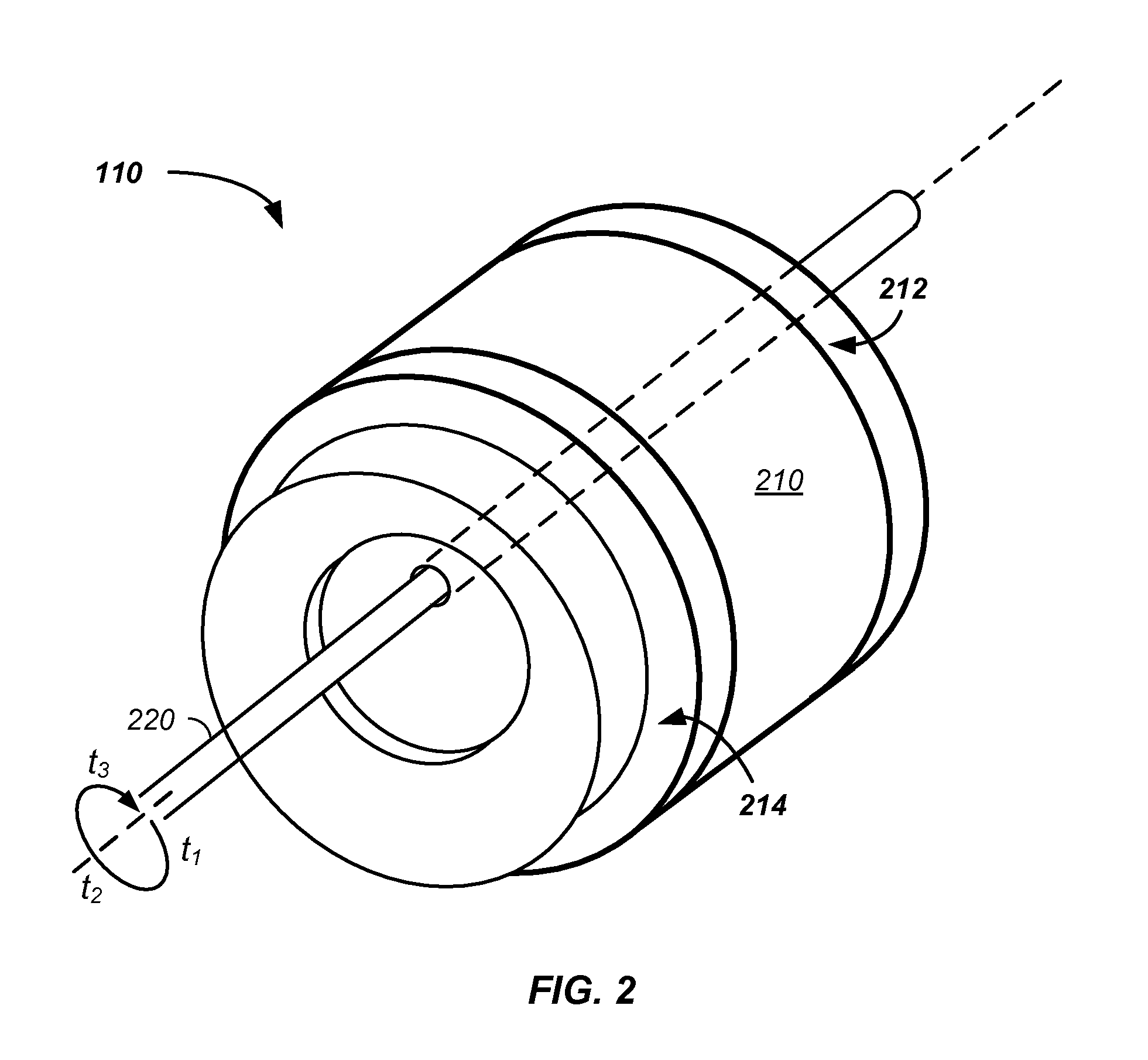

Rotary engine expansion chamber apparatus and method of operation therefor

ActiveUS8523547B2Internal combustion piston enginesOscillating piston enginesRotary engineExpansion chamber

Owner:PEKRUL MERTON W

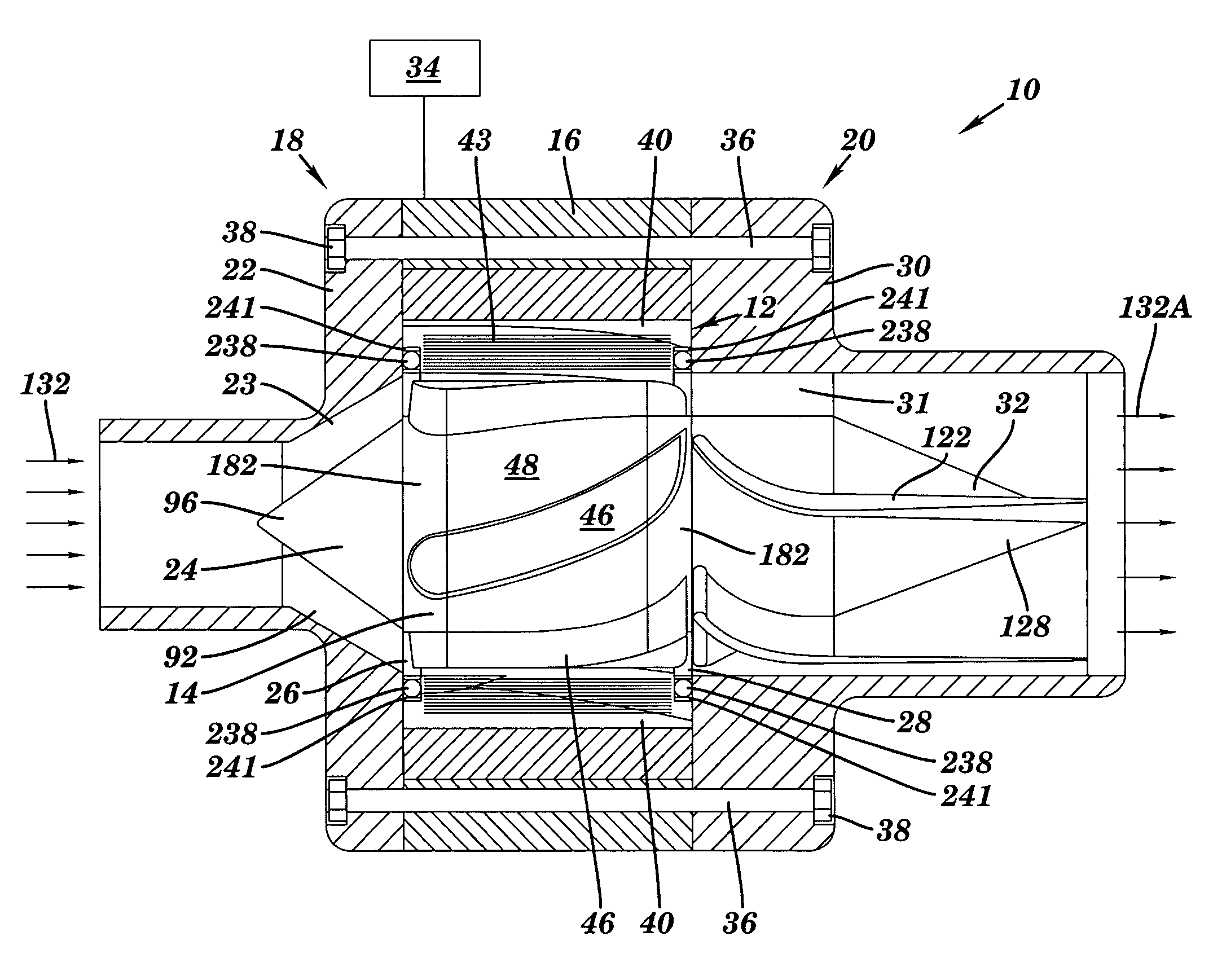

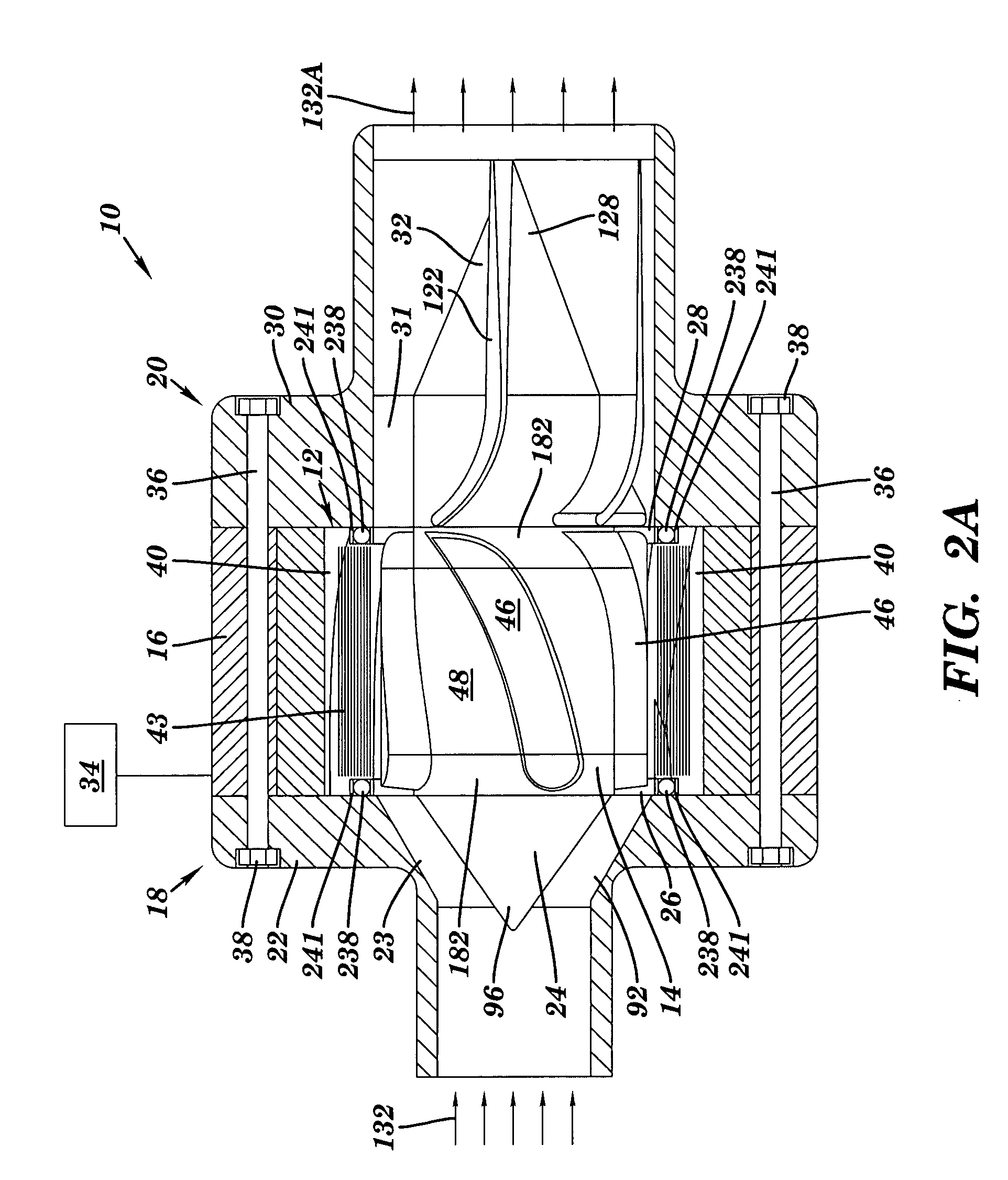

Fluid pump/generator with integrated motor and related stator and rotor and method of pumping fluid

InactiveUS7021905B2Small sizeReduce the number of partsGas turbine plantsRotary piston pumpsImpellerElectric machine

Owner:ADVANCED ENERGY CONVERSION

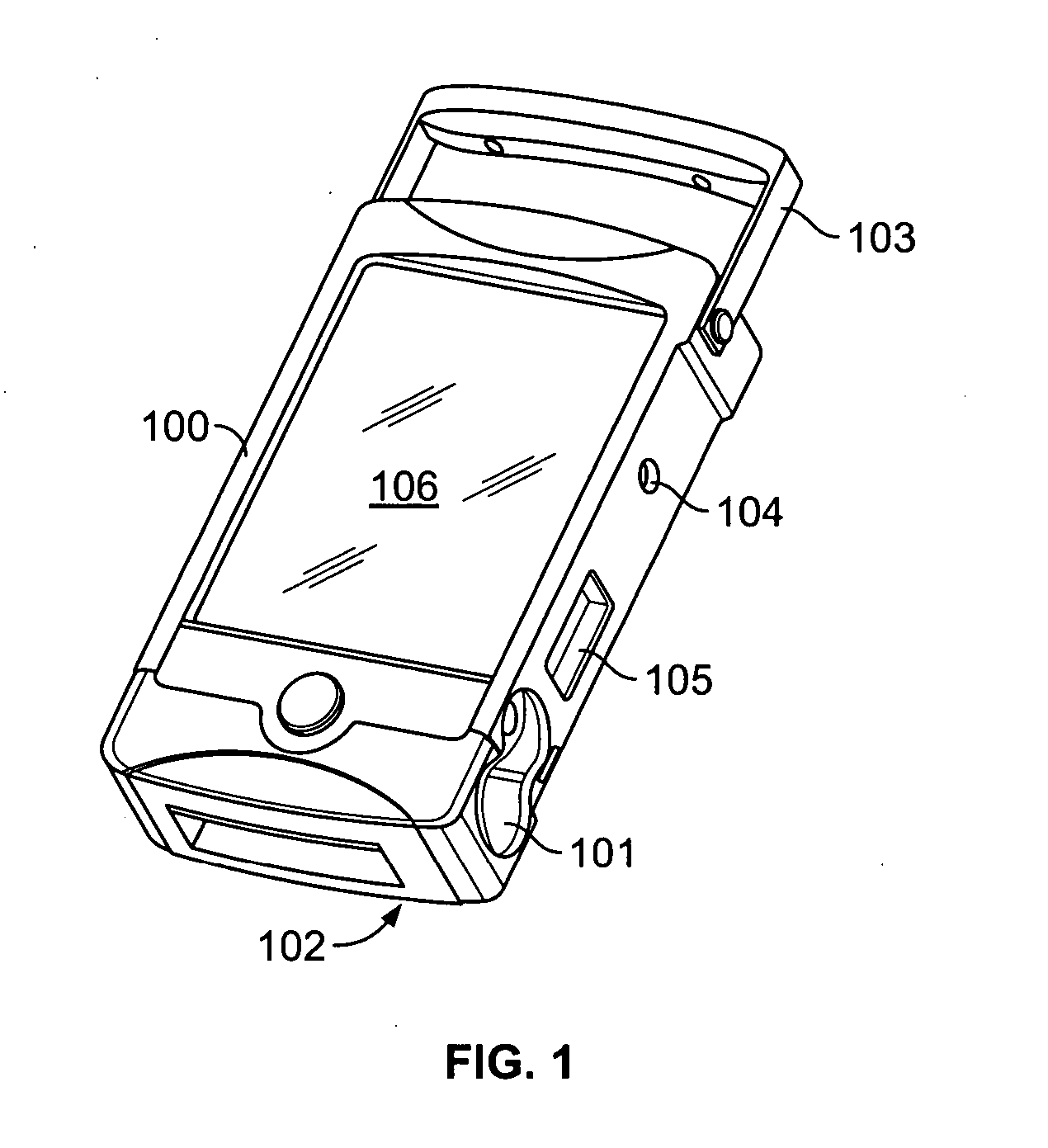

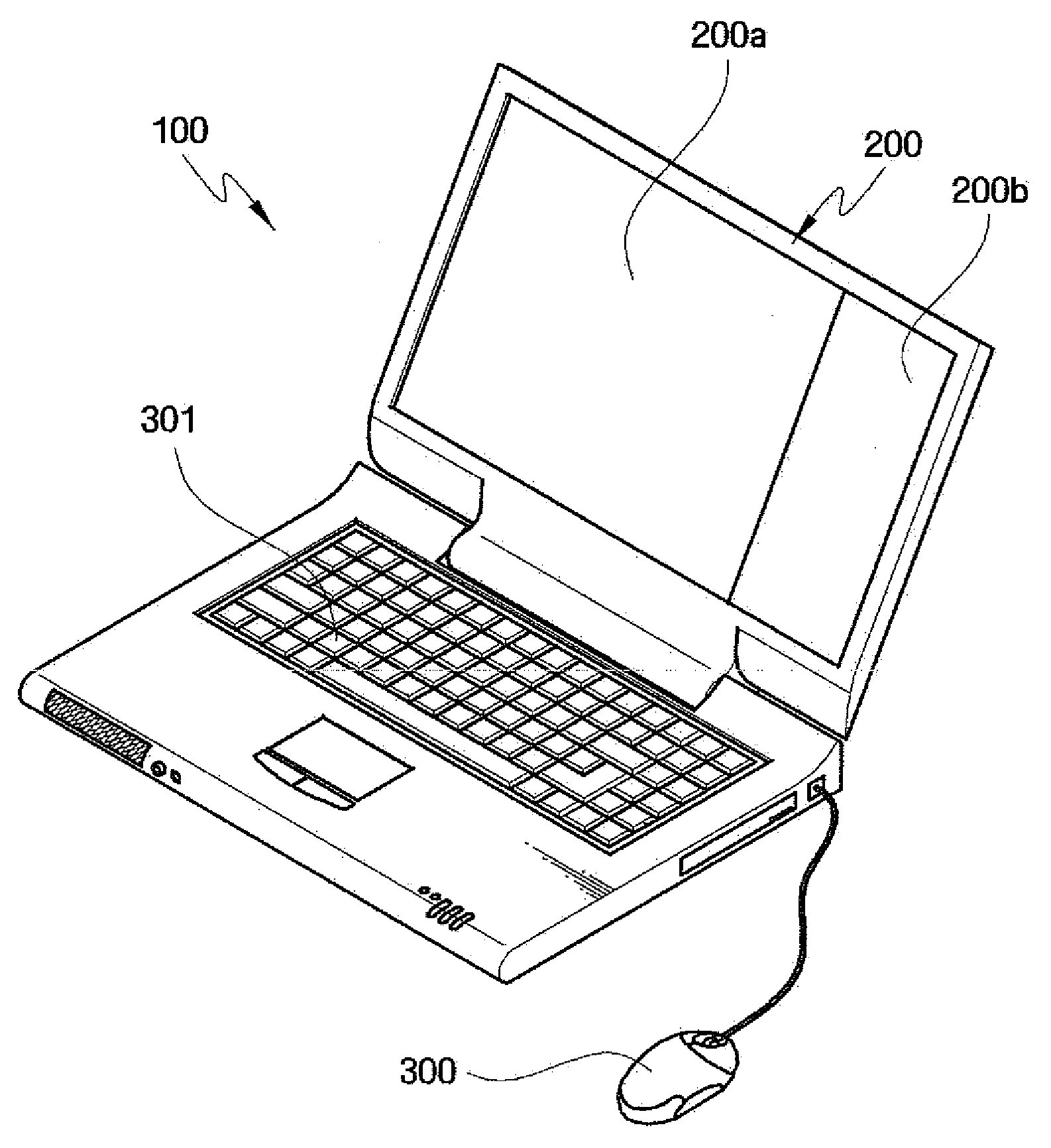

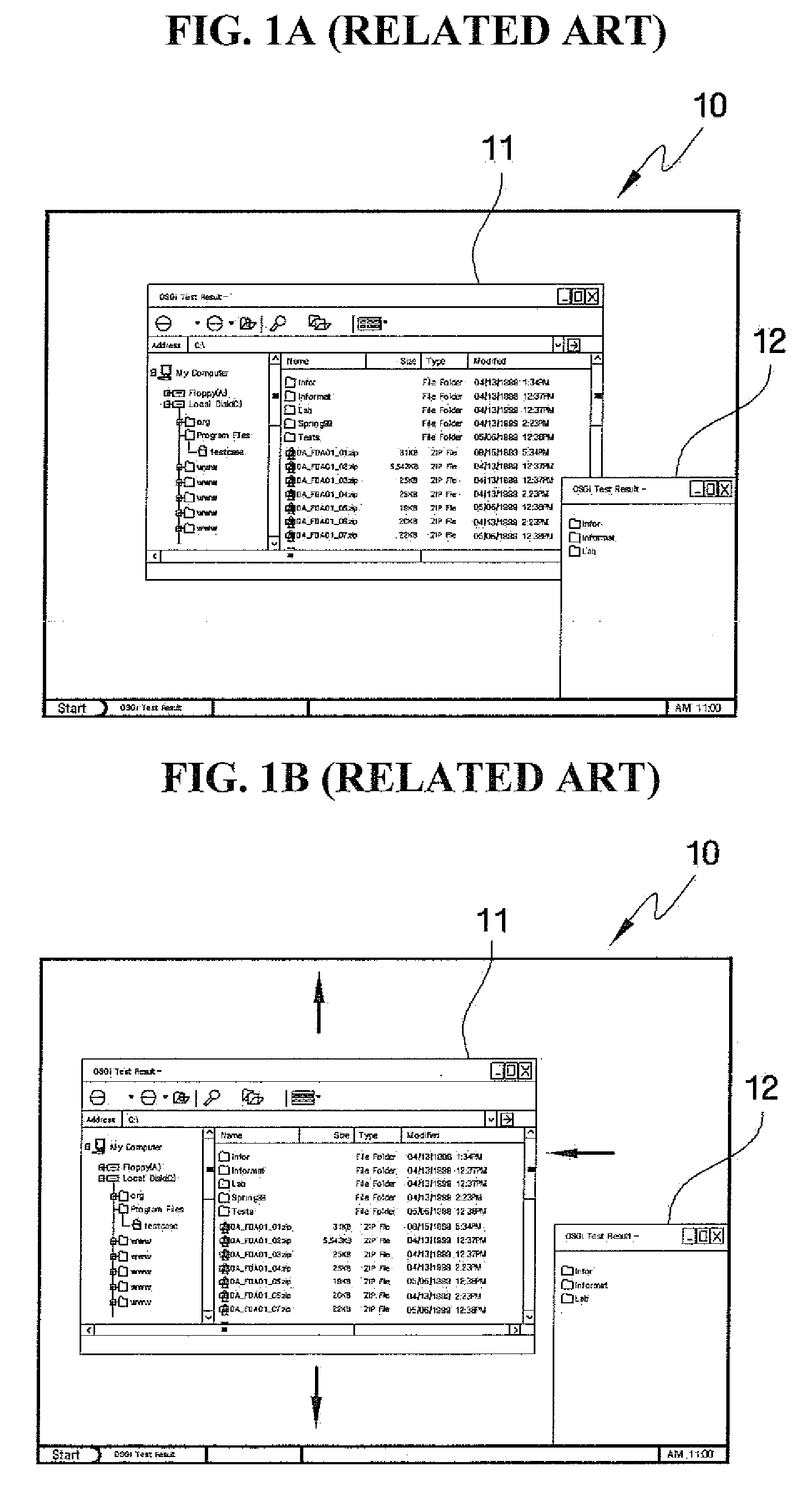

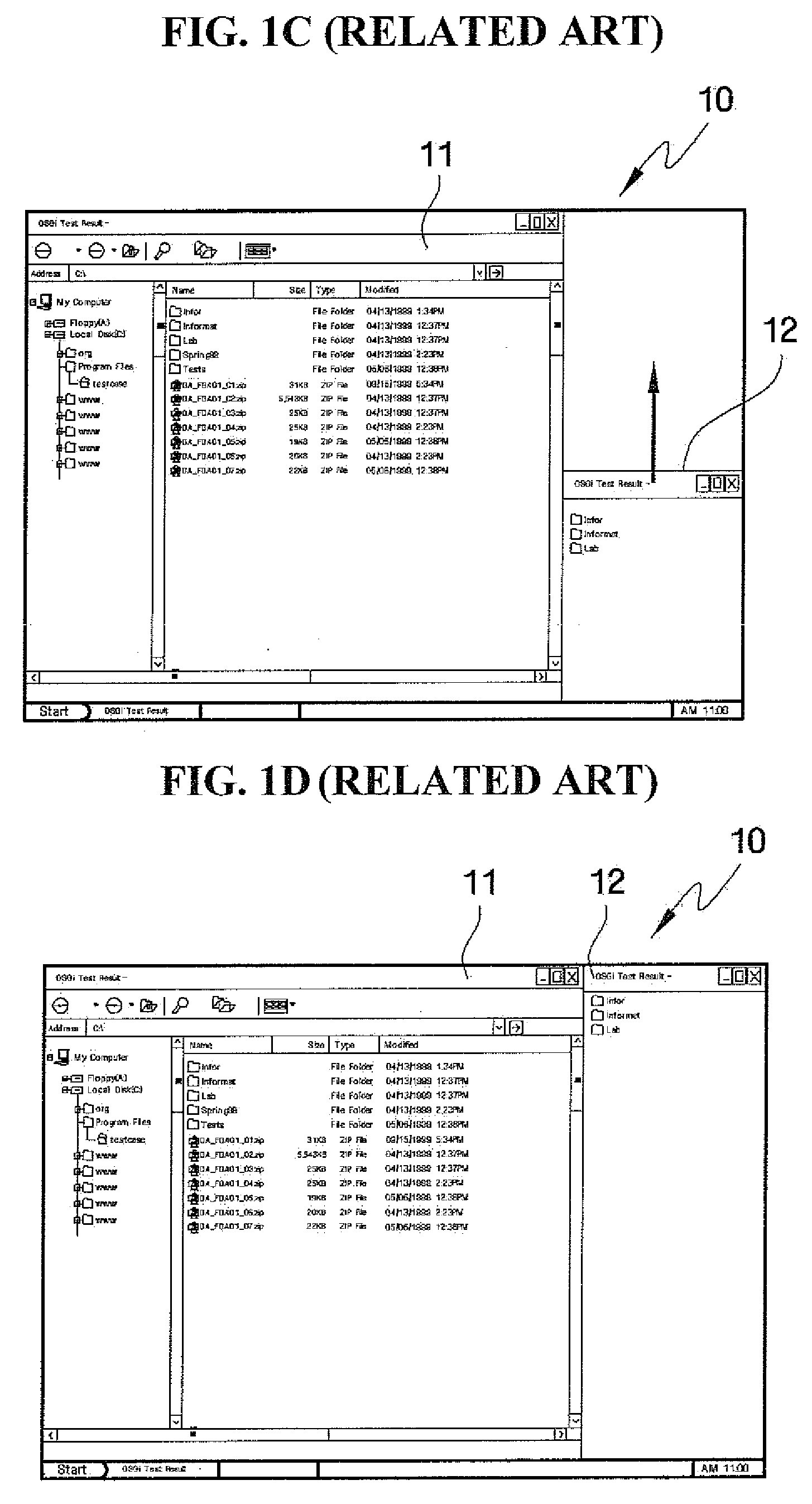

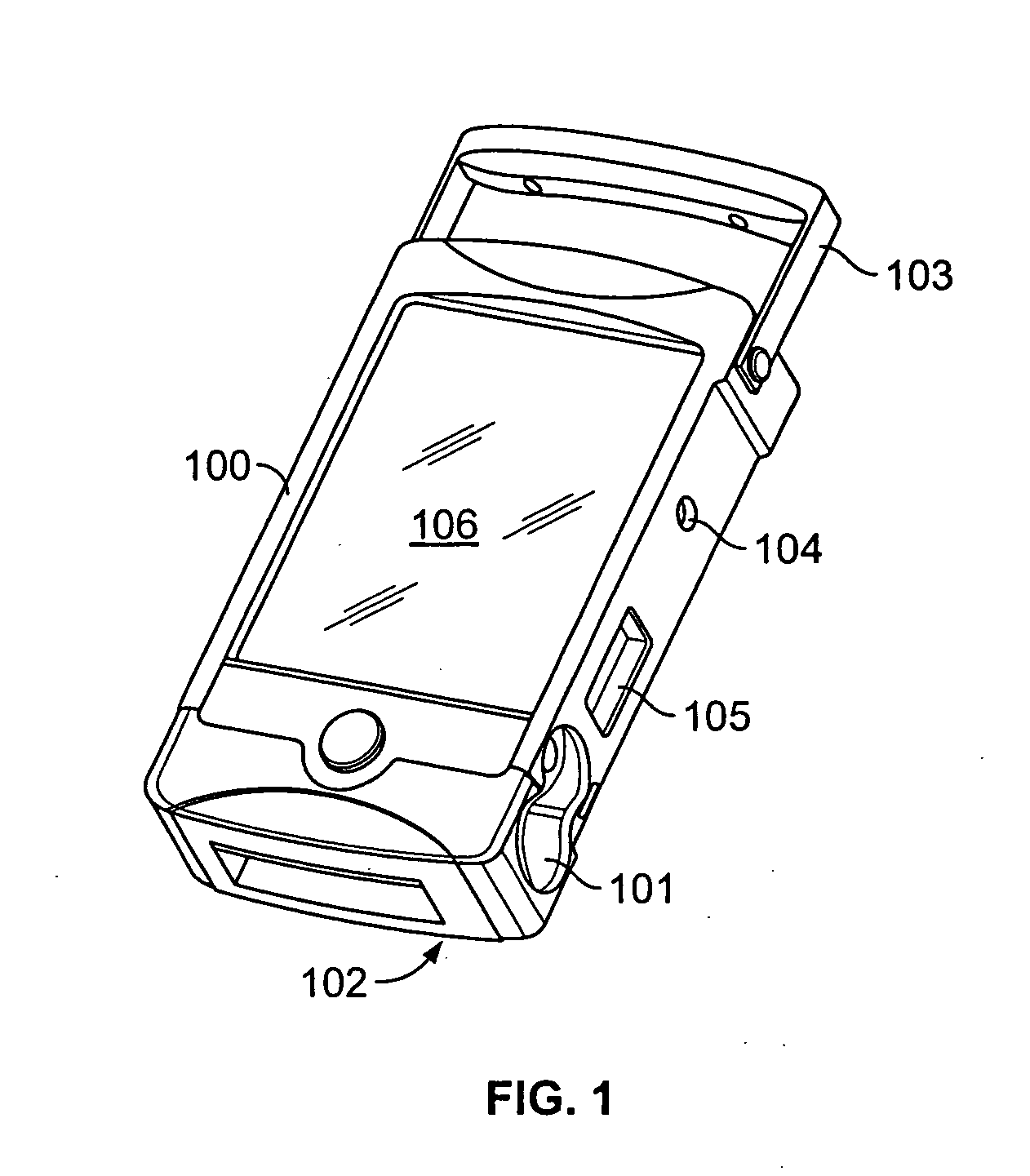

Apparatus and method for managing layout of a window

InactiveUS20070192726A1Easy to useRotary piston pumpsCathode-ray tube indicatorsComputer graphics (images)

An apparatus and method for managing the layout of a window is provided. The apparatus includes a display unit that displays the window on a screen; the screen is divided into a plurality of display areas; a pointer-position-checking unit that checks the coordinate position of a pointer moved by a user and determines the one display area corresponding to the position of the checked pointer; and a window-size-adjusting unit that moves the window to the one display area where the pointer is positioned and adjusts the size of the window in proportion to the size of the one display area.

Owner:SAMSUNG ELECTRONICS CO LTD

Overheat protection for fluid pump

InactiveUS6837688B2Avoid damageReduce stepsRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsPump headThreshold temperature

An apparatus for detecting the presence of an overheat condition in a fluid pump includes a pump head for receiving a fluid at a first pressure and outputting the fluid at a second pressure that is greater than the first pressure. A motor is positioned adjacent the pump head to drive the pump head to pressurize the fluid. A single overheat sensor senses an overheat condition in the pump head and an overheat condition in the motor. When a threshold temperature is sensed by the overheat sensor, a switch is activated to prevent operation of the motor. In one embodiment, the overheat sensor and switch are integral and may, for example, take the form of a bi-metal switch formed in the stator windings of the motor. In alternate embodiments, the overheat sensor and switch are separate.

Owner:STANDEX INT CORP

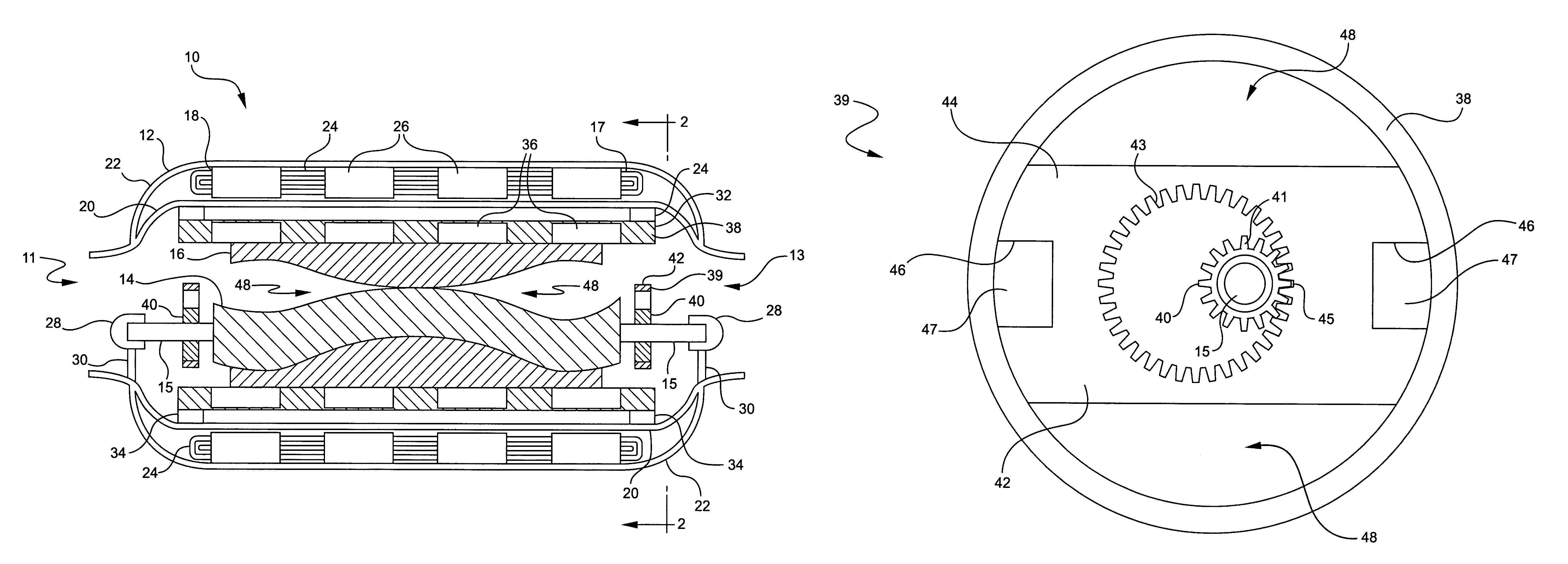

Direct drive linear flow blood pump

A ventricular assistive device (VAD) based on a progressive cavity pump includes a pump housing having an inlet and an outlet, a pump stator contained within the pump housing, a pump rotor rotatably disposed within the pump stator, a motor including a motor rotor contained within the pump housing and a direct drive means connected between the motor rotor and an axial shaft of the pump rotor for rotating the pump rotor. The motor rotates the motor rotor, which in turn rotates the pump rotor through the direct drive means. The rotation of the pump rotor within the pump stator forms a plurality of cavities that carry blood forward through the pump housing from the inlet to the outlet as the motor drives the direct drive means.

Owner:CHANG SHELDON

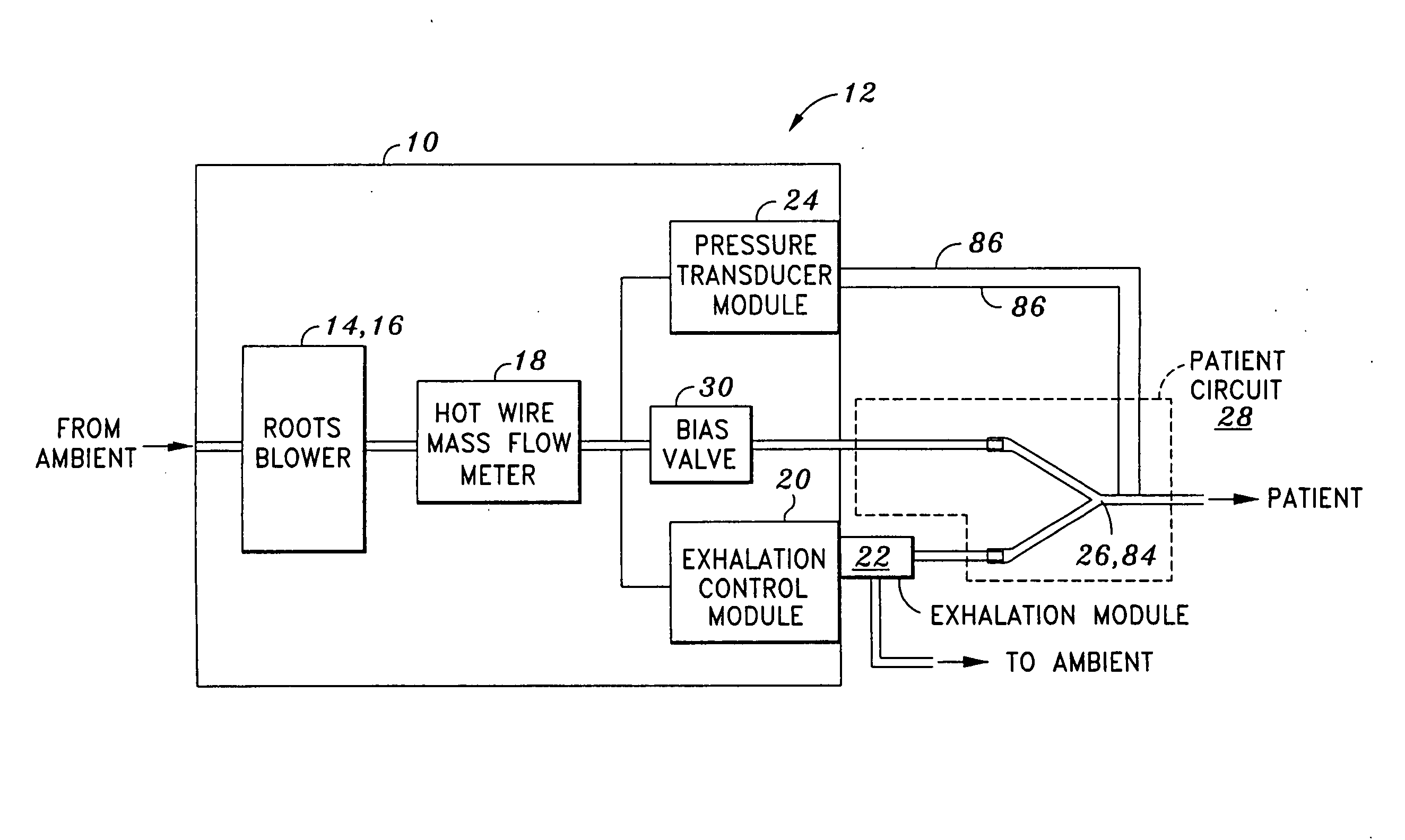

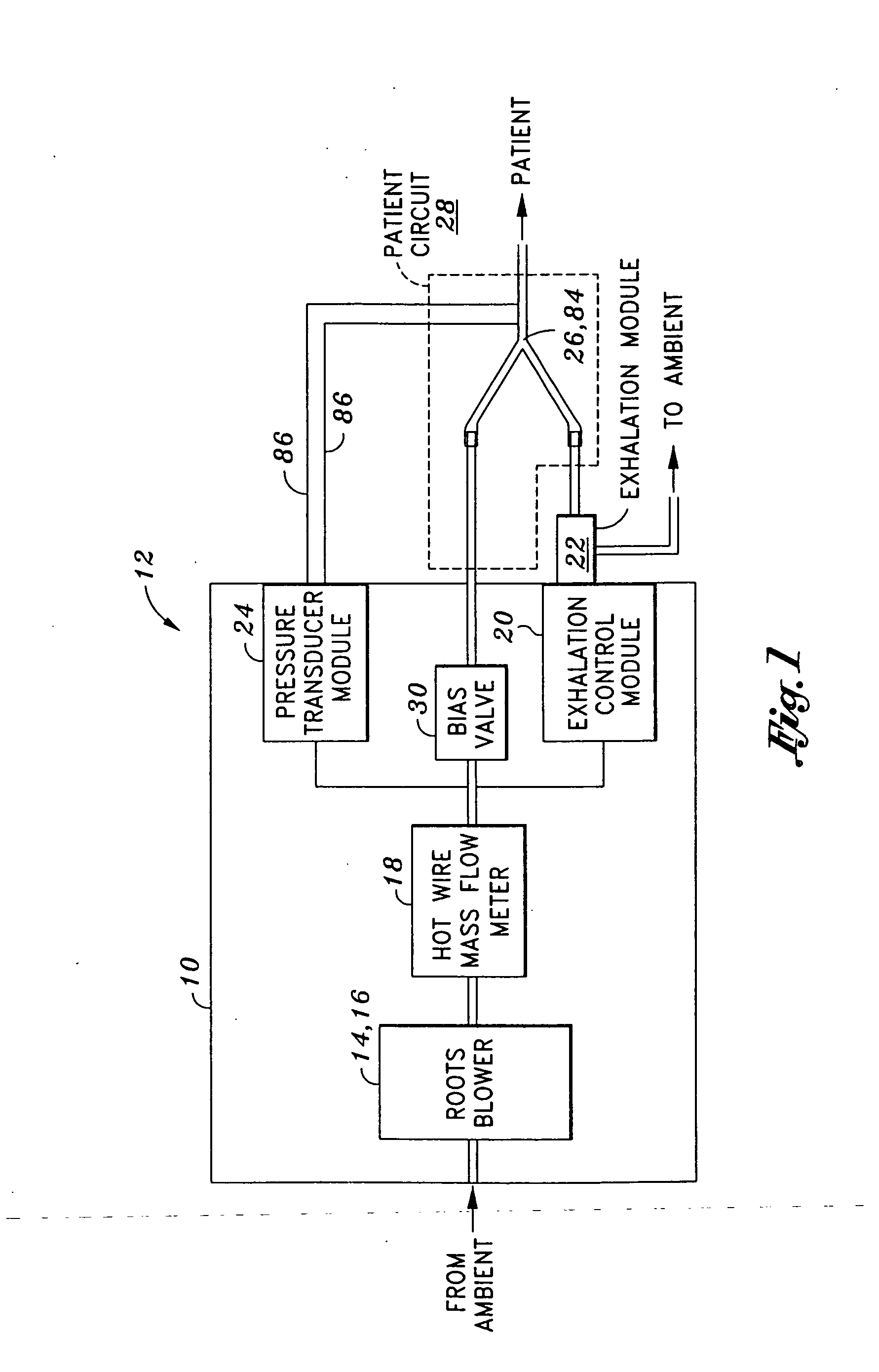

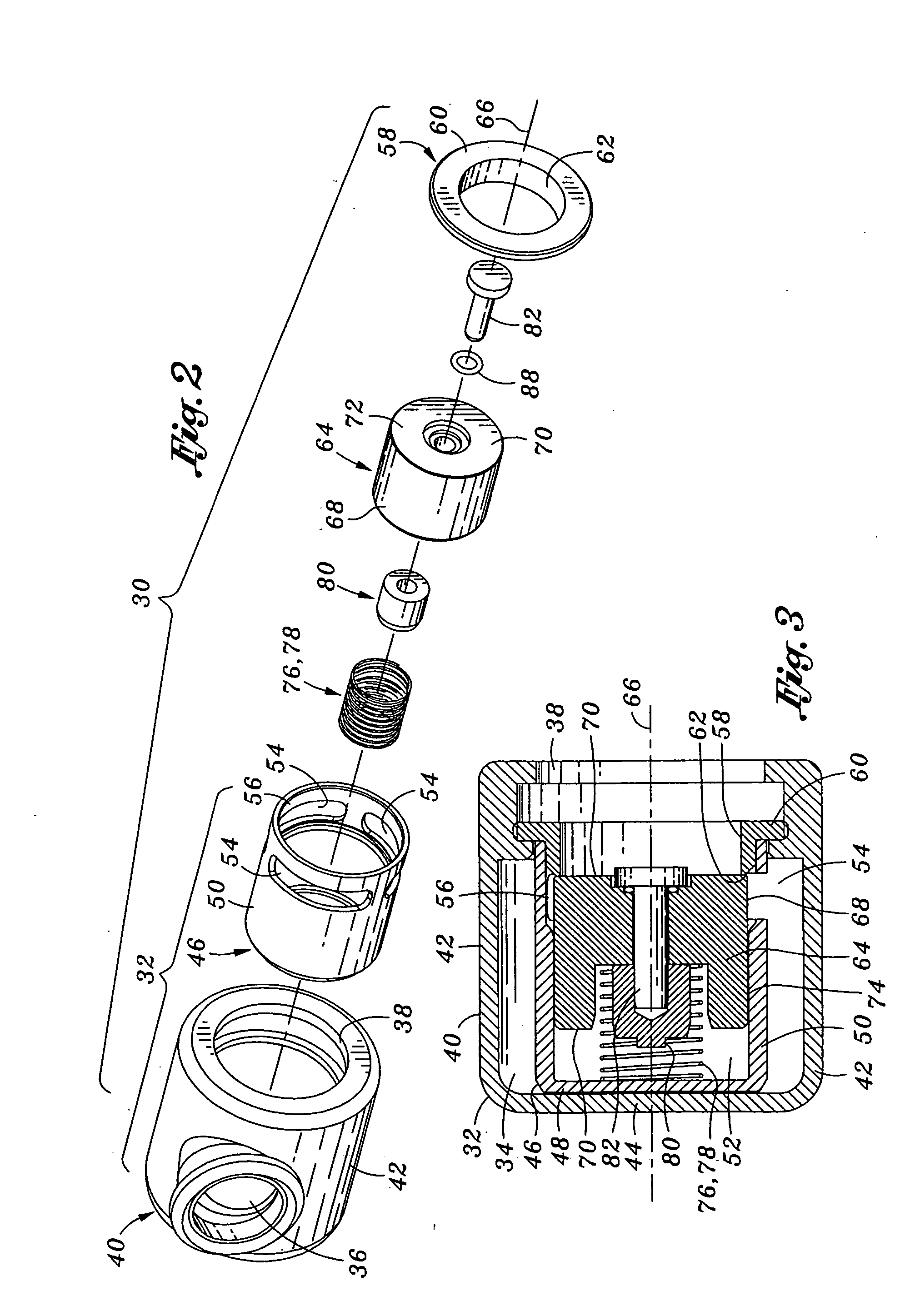

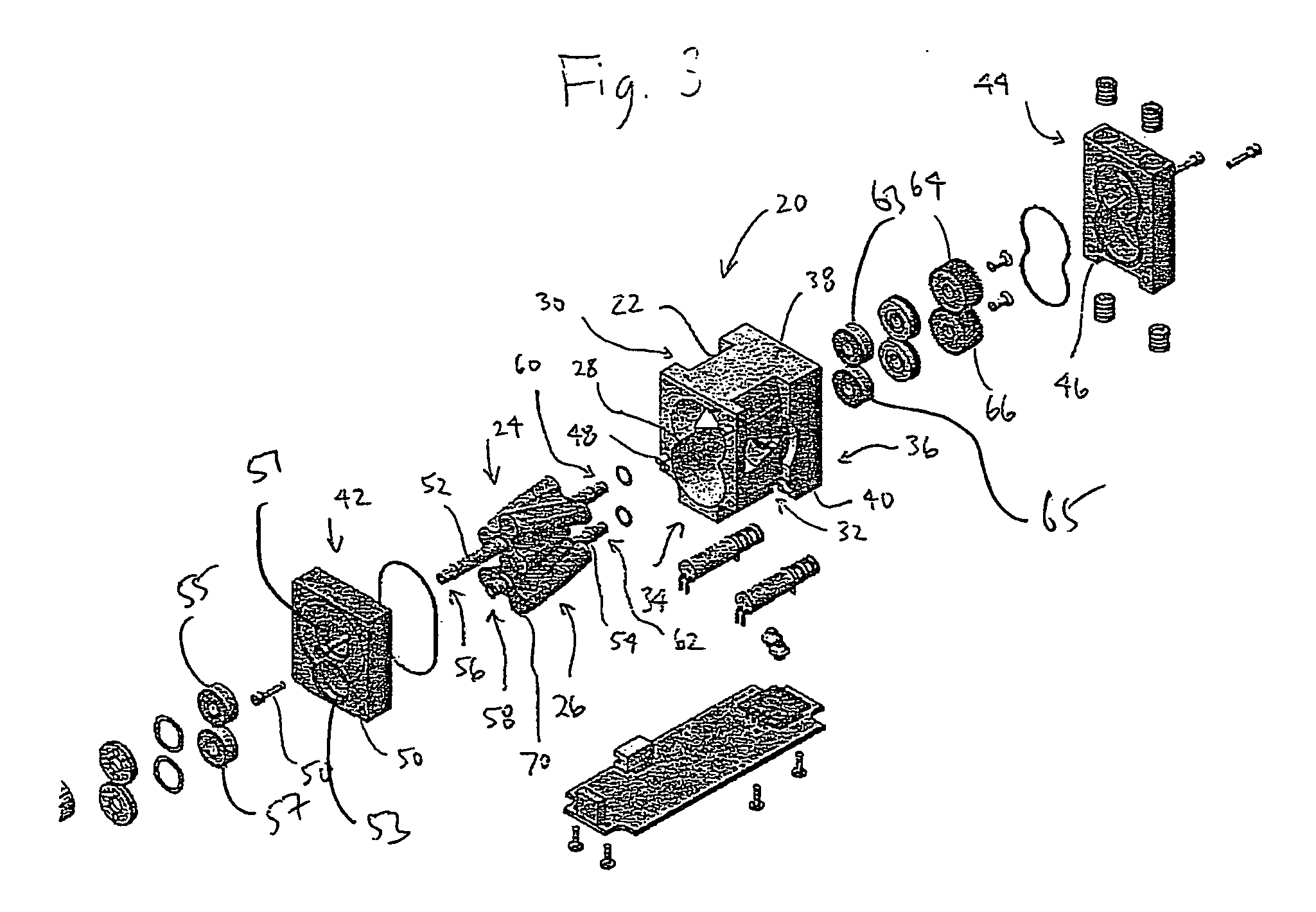

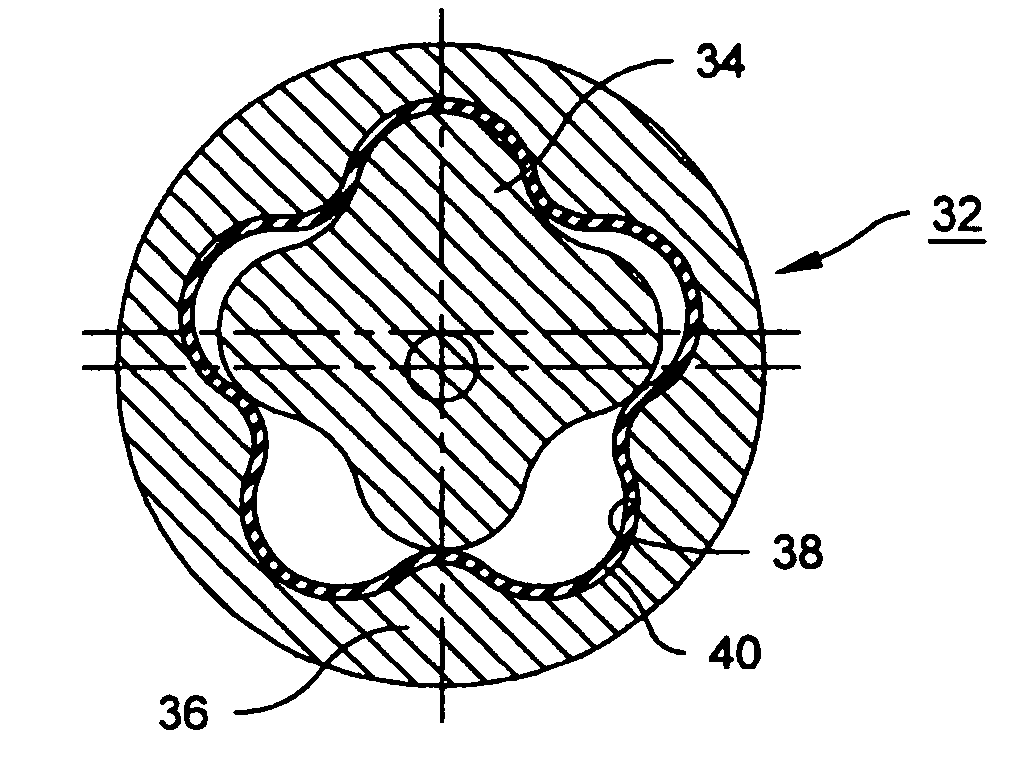

Mechanical ventilation system utilizing bias valve

ActiveUS20060249153A1Accurate measurementViscous dampingRespiratorsOperating means/releasing devices for valvesPositive pressureEngineering

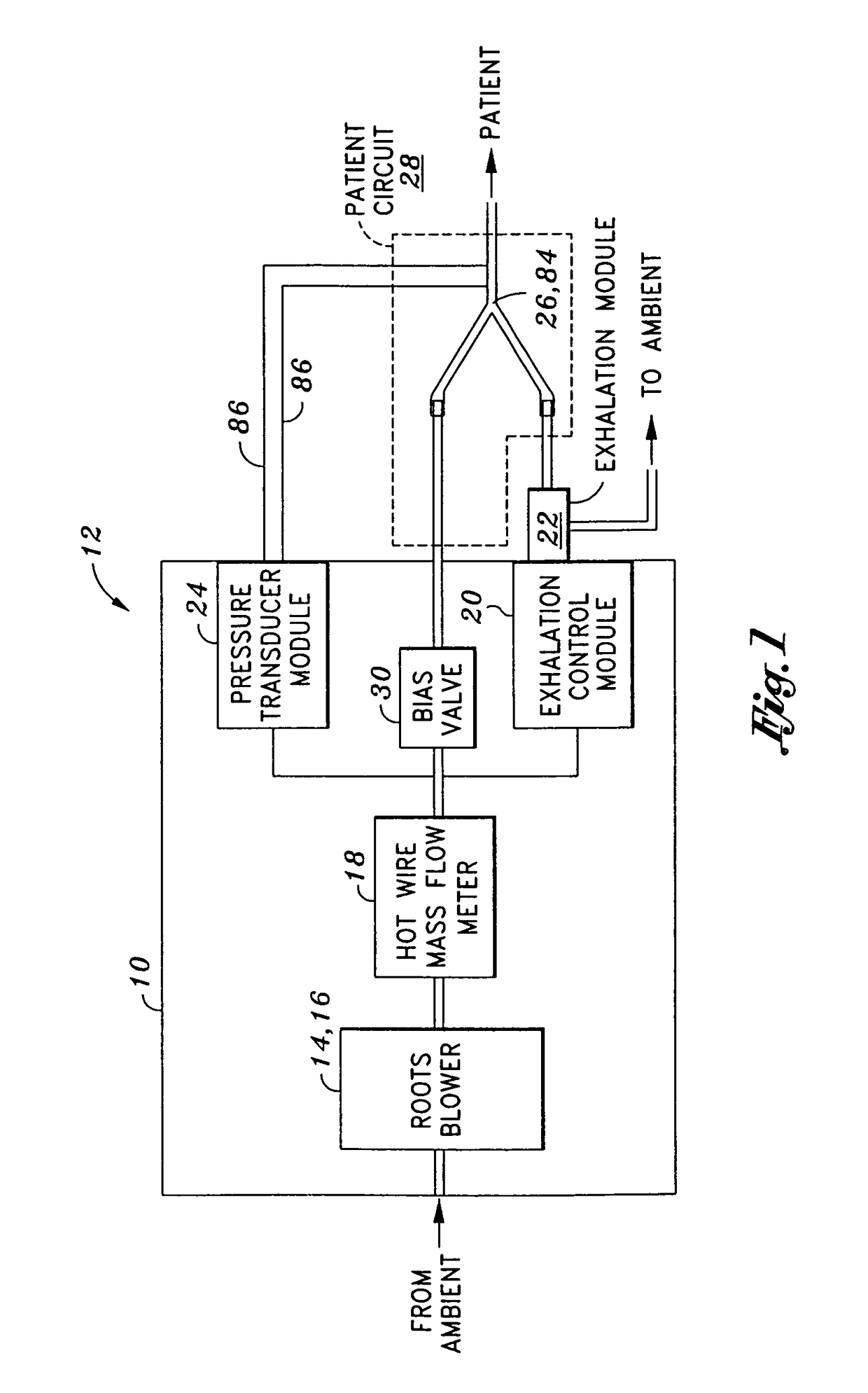

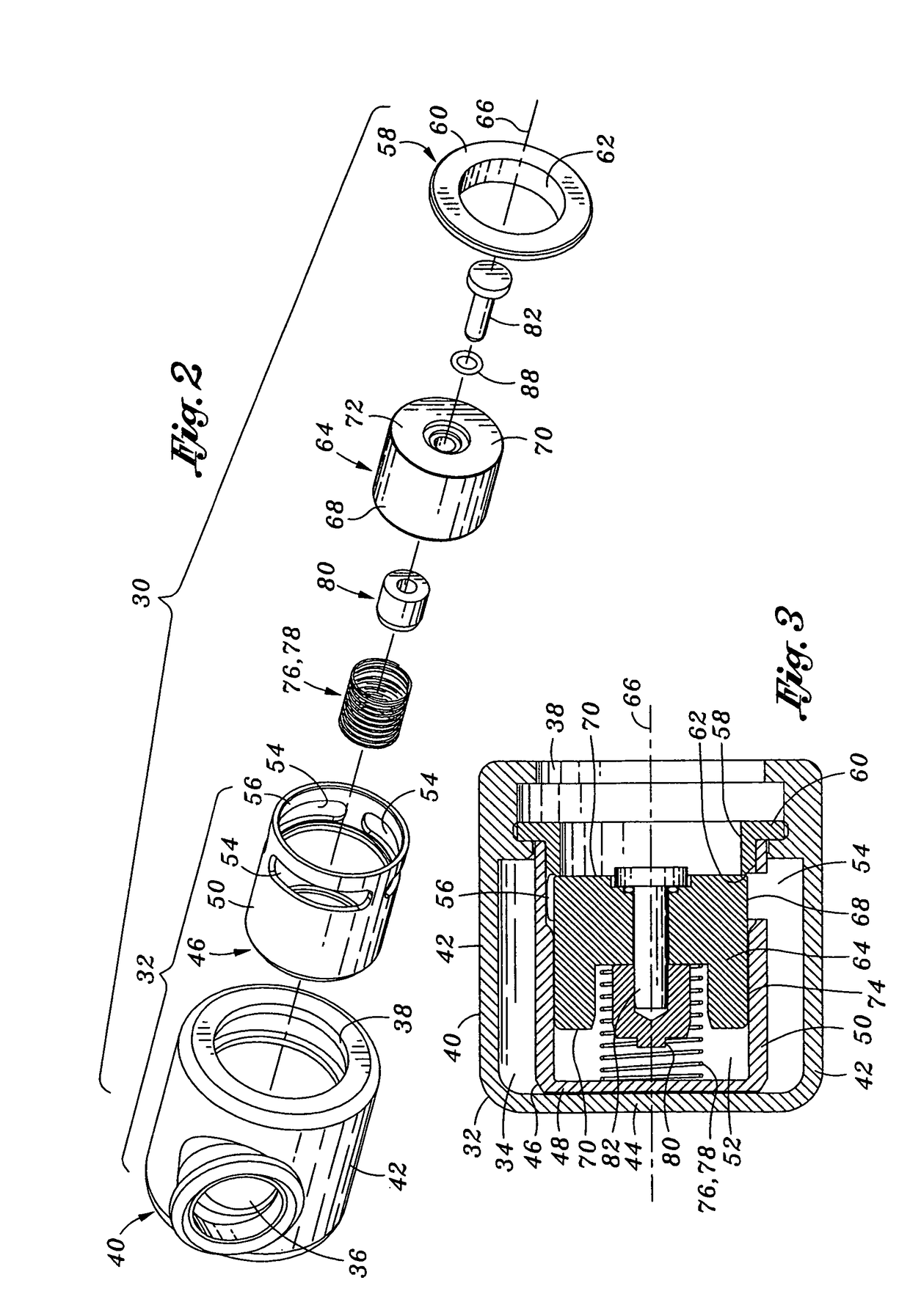

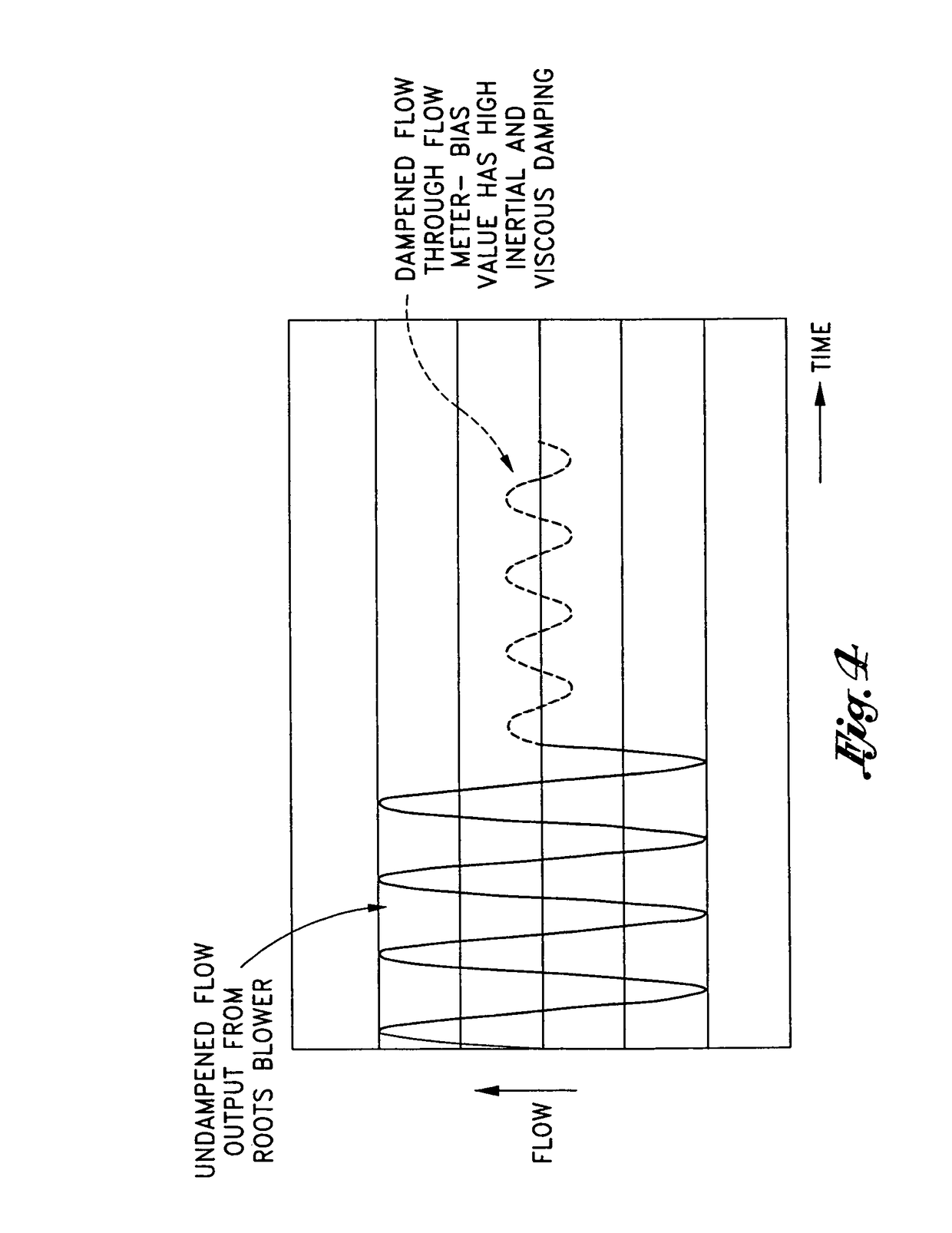

A portable mechanical ventilator having a Roots blower is configured to provide a desired gas flow and pressure to a patient circuit. The mechanical ventilator includes a flow meter operative to measure gas flow produced by the Roots blower and an exhalation control module configured to operate an exhalation valve connected to the patient circuit. A bias valve connected between the Roots blower and the patient circuit is specifically configured to generate a bias pressure relative to the patient circuit pressure at the exhalation control module. The bias valve is further configured to attenuate pulsating gas flow produced by the Roots blower such that gas flowing to the mass flow meter exhibits a substantially constant pressure characteristic. The bias pressure facilitates closing of the exhalation valve at the start of inspiration, regulates positive end expiratory pressure during exhalation, and purges sense lines via a pressure transducer module.

Owner:VYAIRE MEDICAL 203 INC

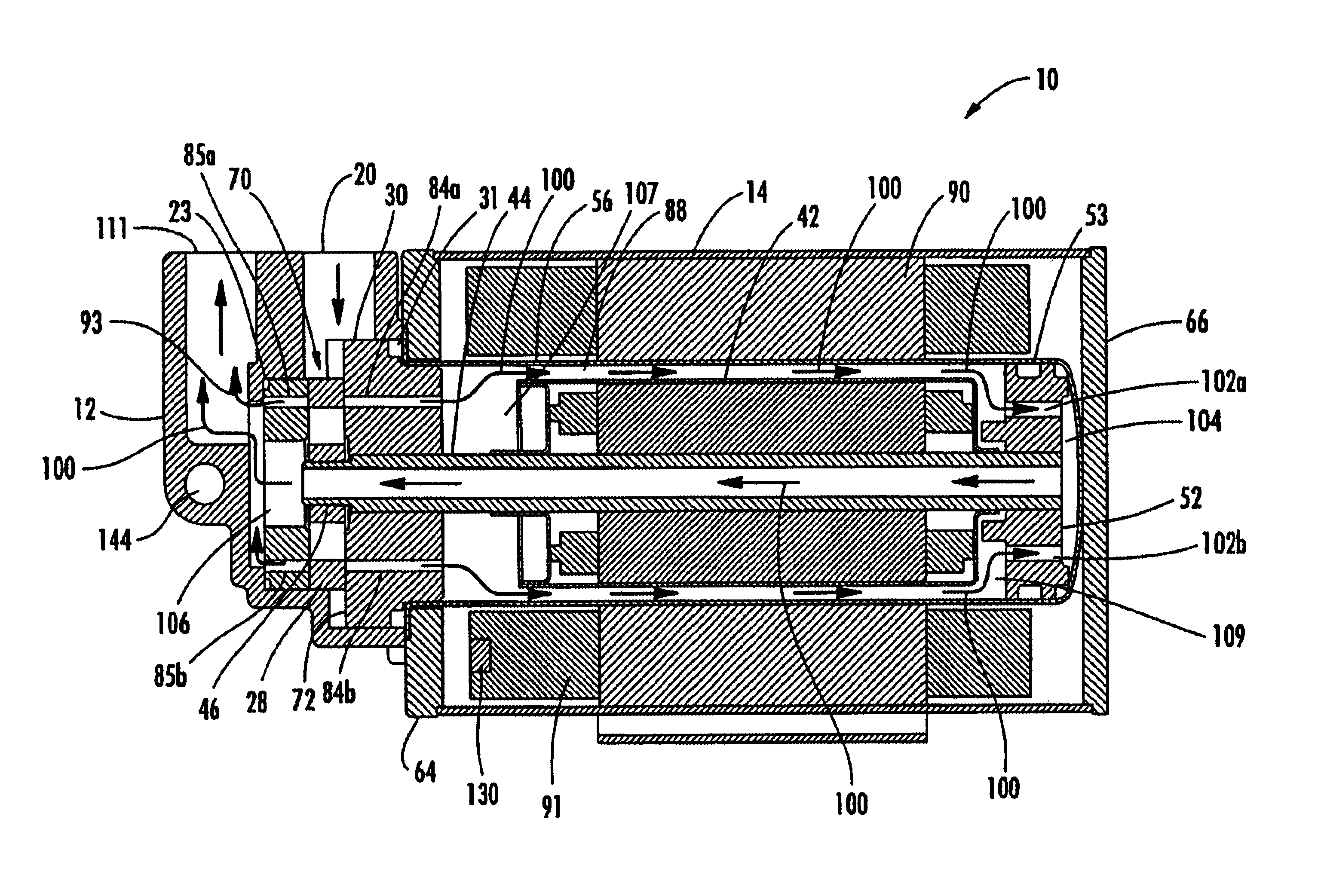

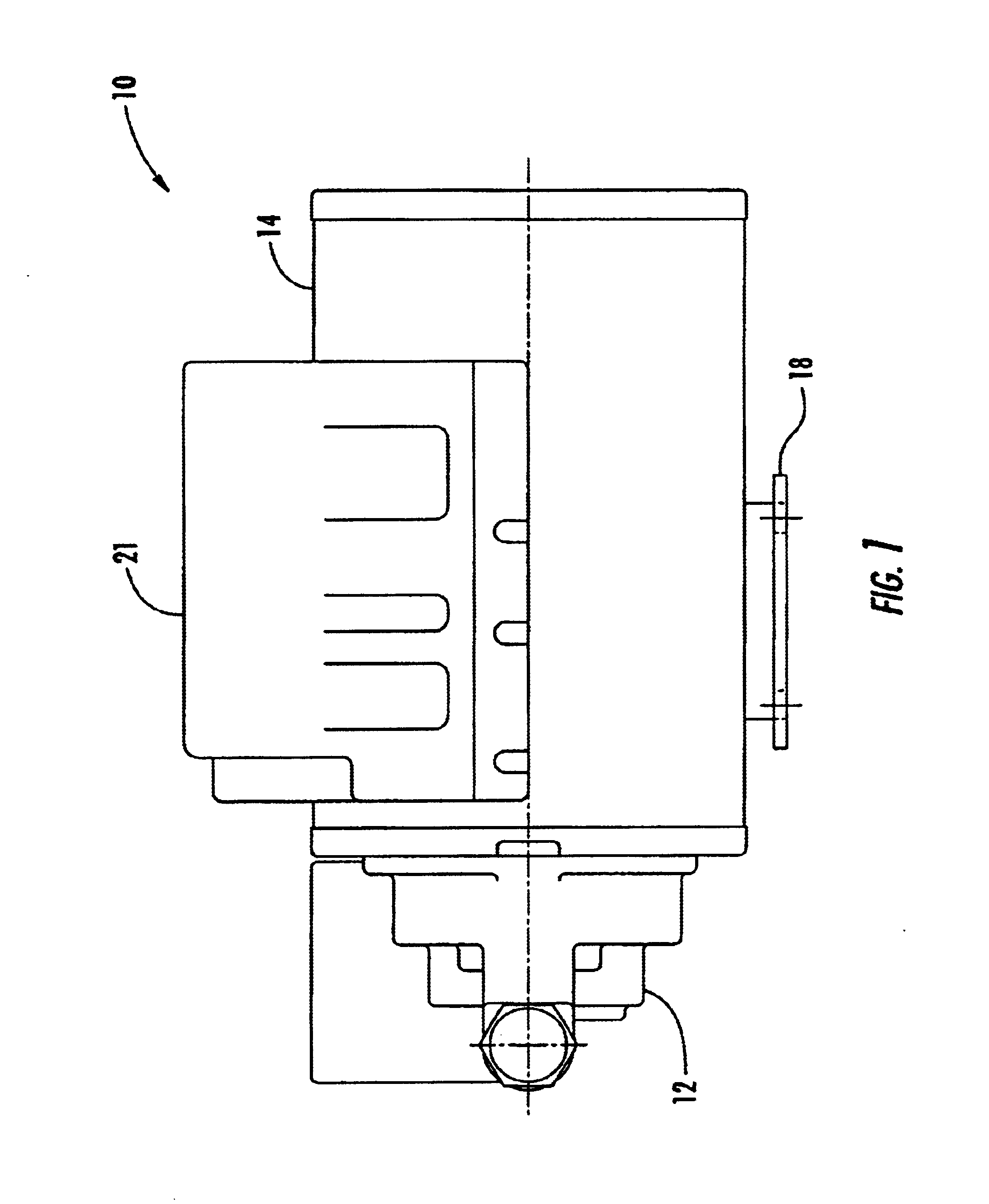

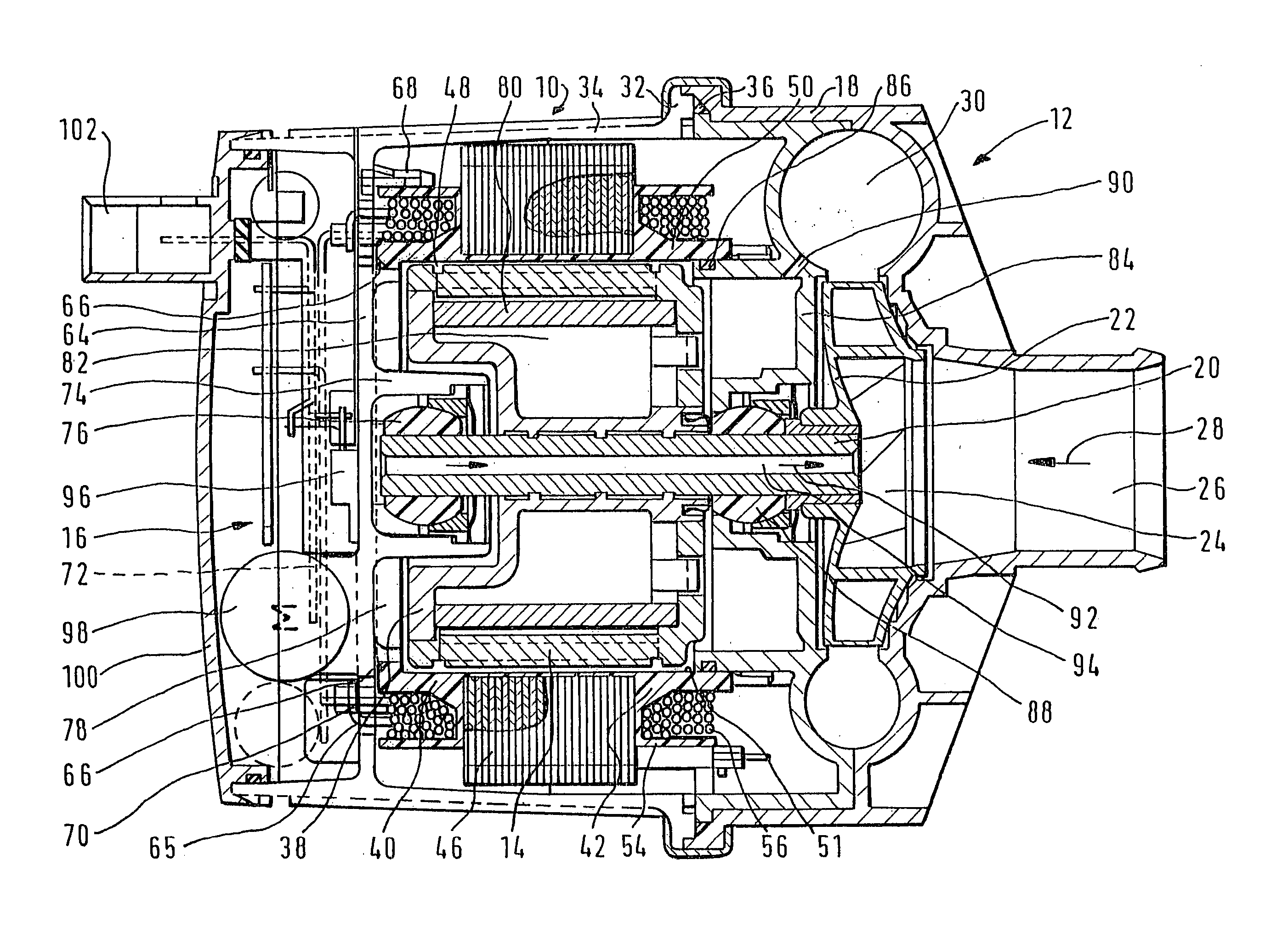

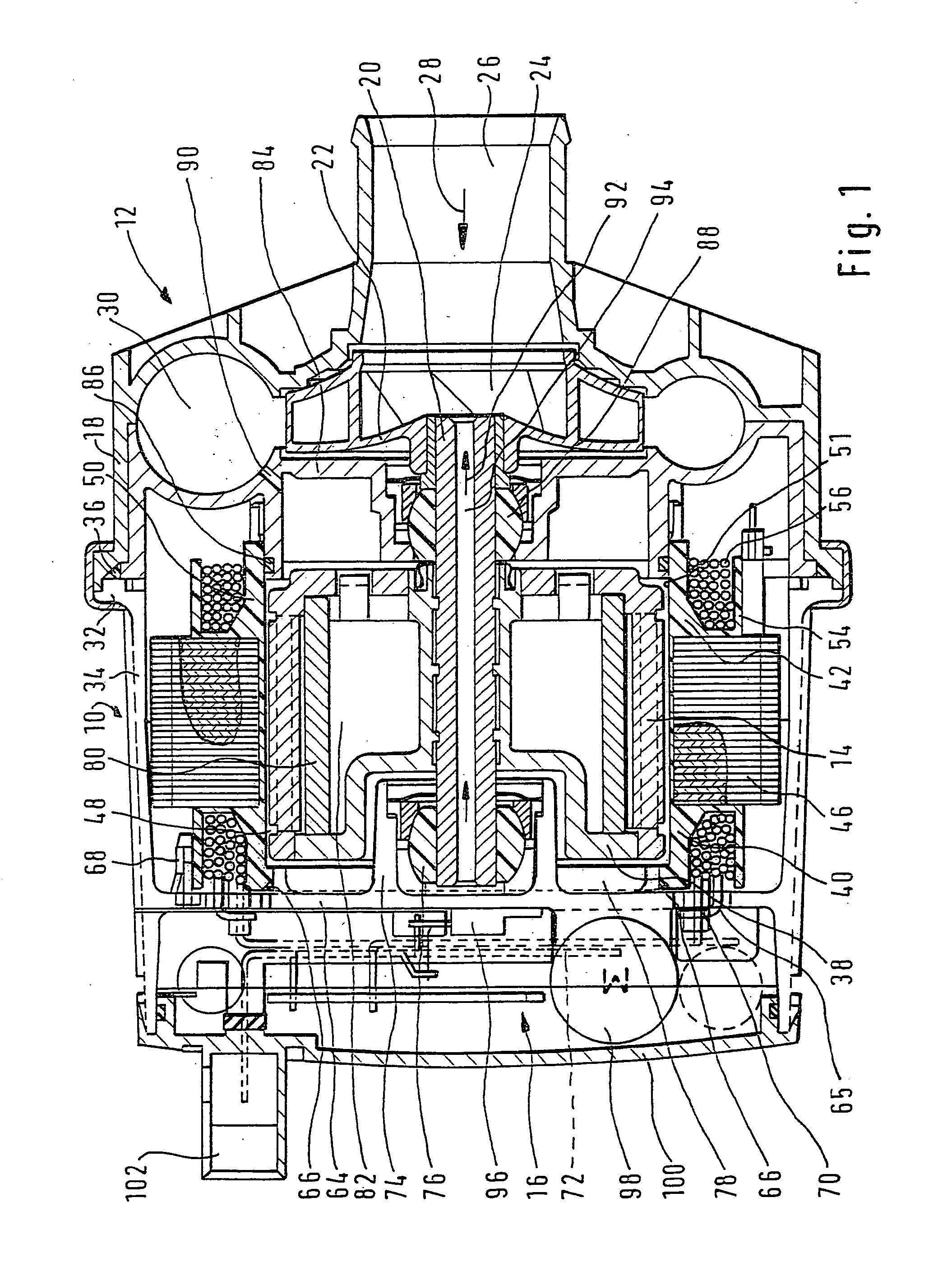

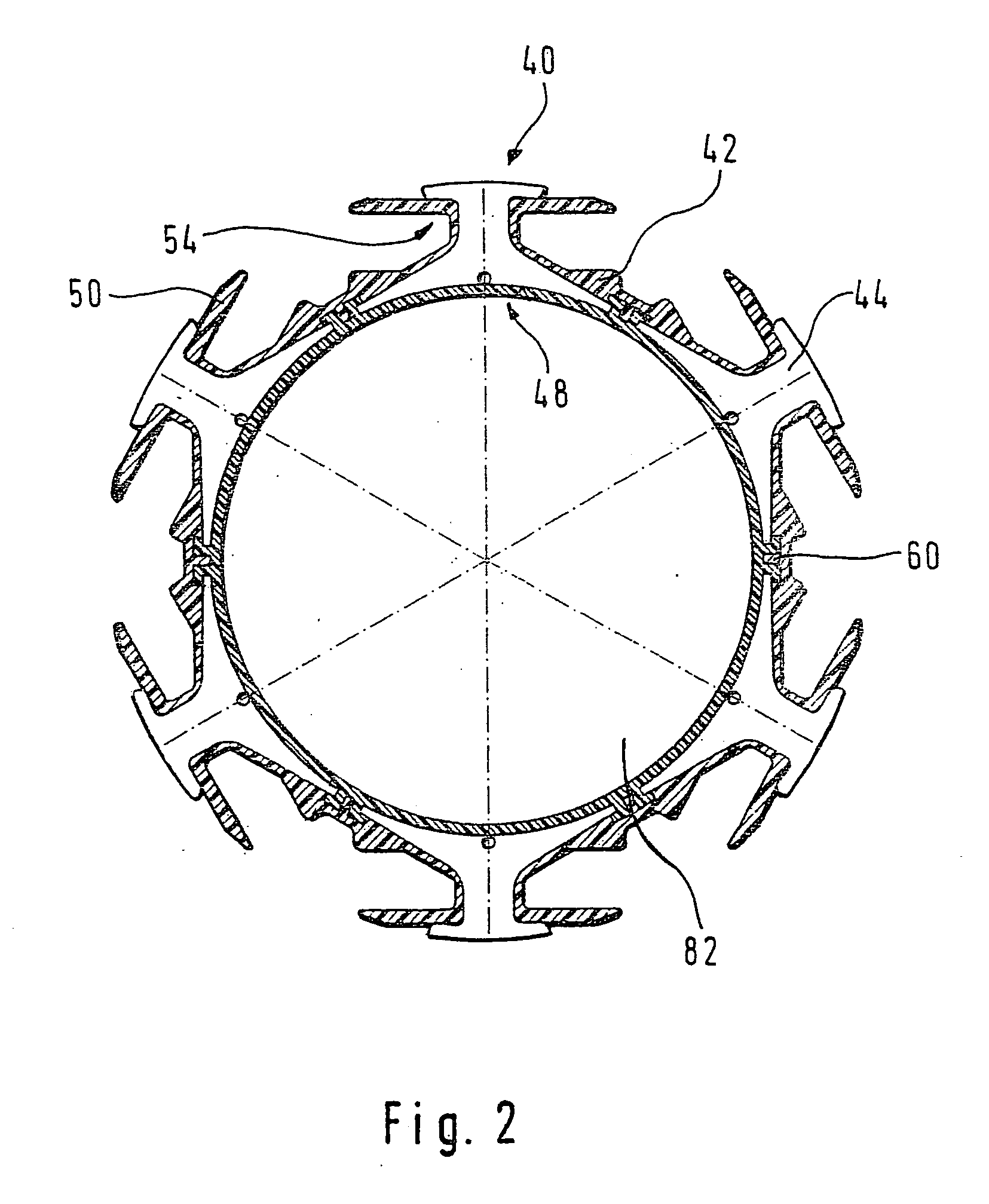

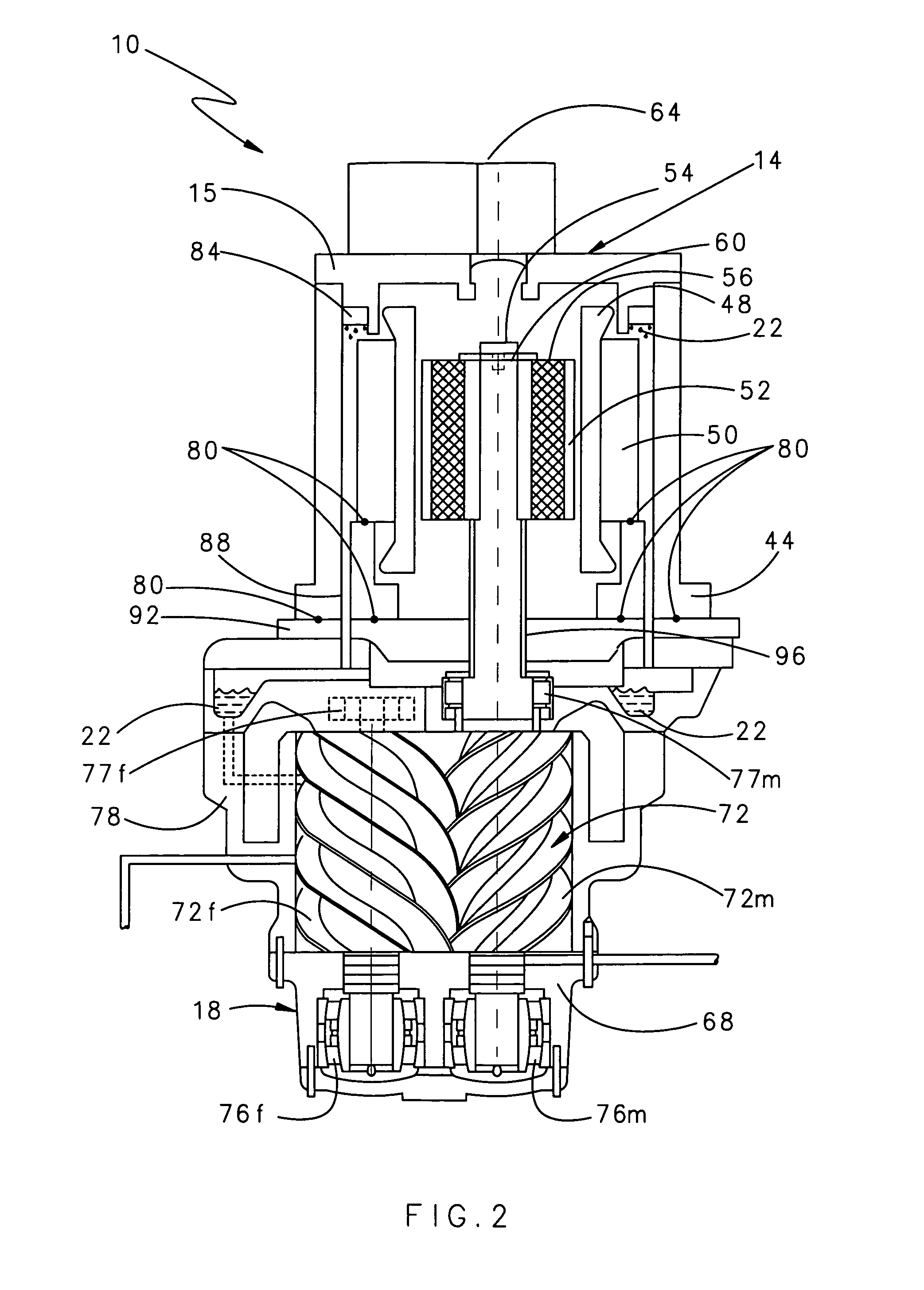

Pump driven by an electromotor and method for producing a pump of this type

The invention relates to a pump (10), having a pump head (12), which has a pump chamber (11), and having an electric motor (14), which drives the pump head (12) and has a stator (40) and a rotor (38), the rotor (38) being connected to the pump head (12) and being disposed in a rotor chamber (82) open toward the pump chamber (11). It is proposed that the stator (40) is disposed radially around the rotor chamber (82), and the rotor chamber (82) is sealed off from the pump chamber (11) by a sealing wall (51) belonging to the stator (40) and by at least one wall (64) of the pump housing (18).

Owner:ROBERT BOSCH GMBH

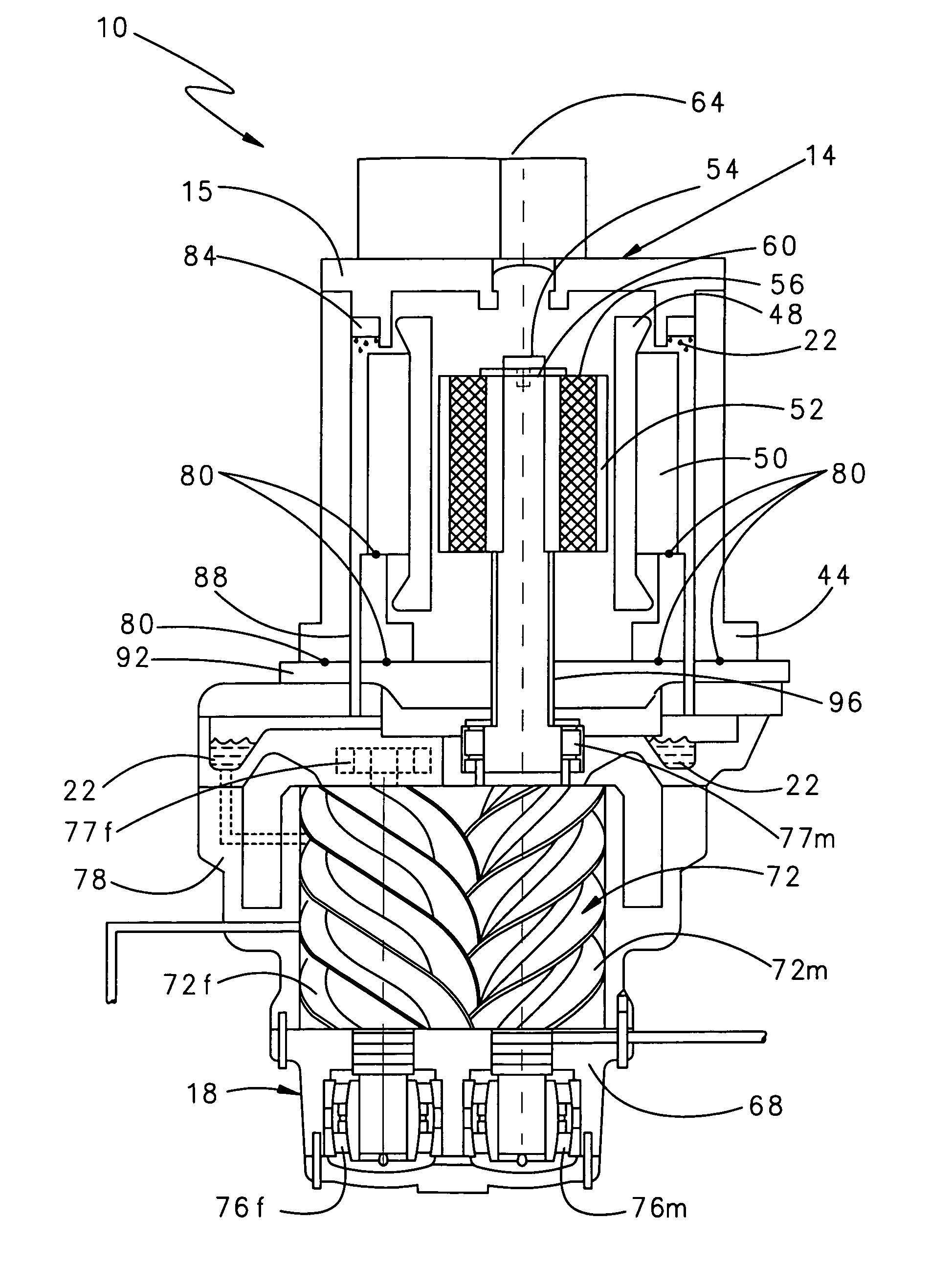

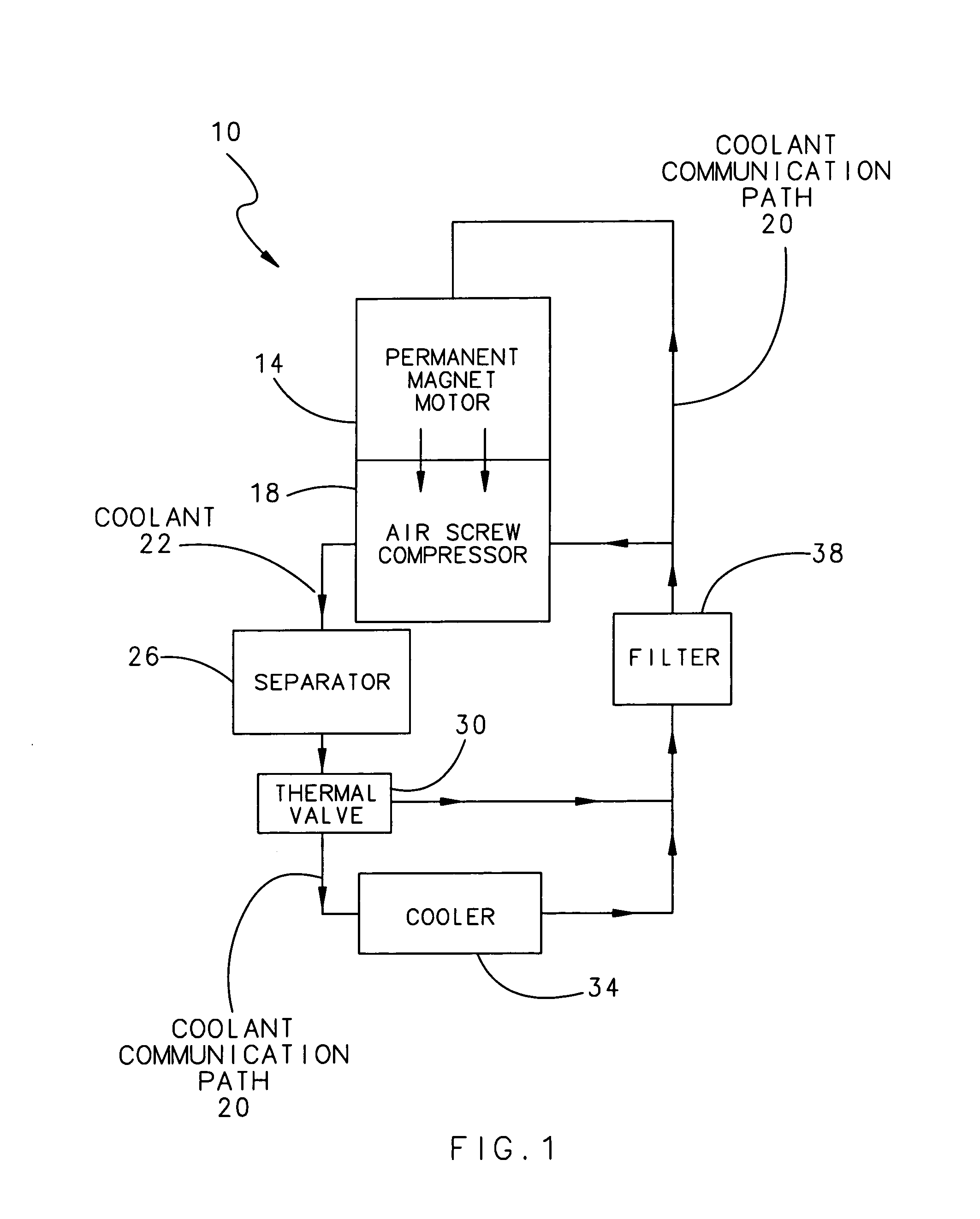

Lubricant cooled integrated motor/compressor design

InactiveUS20070241627A1Prevent overboard leakageThe process is compact and efficientRotary/oscillating piston combinations for elastic fluidsEngine of counter-engagement typePermanent magnet motorGear train

A compressor system according to the present invention utilizes direct rotational input from a permanent magnet motor to generate compressed air. The permanent magnet motor is mounted directly to an air screw compressor. The rotational input is provided by the permanent magnet motor to the air screw compressor without a gear train. The permanent magnet motor and associated variable speed drive controls the rotational speed of the permanent magnet motor and hence the screw compressor. Differing motors may selectively mount, and provide rotational input to, the air screw compressor.

Owner:SULLAIR CORP

Portable ventilator system

InactiveUS20060213518A1Small sizeReduce power consumptionMechanical/radiation/invasive therapiesPhysical therapyPortable ventilatorsEngineering

A portable ventilator uses a Roots-type blower as a compressor to reduce both the size and power consumption of the ventilator. Various functional aspects of the ventilator are delegated to multiple subassemblies having dedicated controllers and software that interact with a ventilator processor to provide user interface functions, exhalation control and flow control servos, and monitoring of patient status. The ventilator overcomes noise problems through the use of noise reducing pressure compensating orifices on the Roots blower housing and multiple baffling chambers. The ventilator is configured with a highly portable form factor, and may be used as a stand-alone device or as a docked device having a docking cradle with enhanced interface and monitoring capabilities.

Owner:VYAIRE MEDICAL 203 INC

Gear pump for micro-miniature turbojet engine

ActiveCN101403382BReduce weightReduce leakageRotary piston pumpsRotary piston liquid enginesMicrocontrollerJet engine

The invention discloses a gear pump used for a microminiature turbo-jet engine, comprising a direct current motor, a pump body, an upper pump cover, a lower pump cover, a shell, a pair of driving and driven gears which are meshed and a driving shaft and a driven shaft. The driving gear is arranged on the driving shaft; the driven gear is arranged on the driven shaft and is aligned and meshed withthe driving gear; the lower pump cover is fixed on the direct current motor, the upper pump cover is connected to the lower pump cover and the plane of the pump body is pressed tightly and sealed so as to lead the structure to be simple; the shell is sleeved at the outside of the lower pump cover; the driving gear and the driving shaft adopt a method of combining clearance fit and a transmission pin to eliminate the installation error of an output shaft of the direct current motor; and an antifriction material is embedded at the positions on the lower pump cover and the upper pump cover corresponding to the driving gear and the driven gear so as to increase the reliability and durability of the gear pump. Most parts of the gear pump adopt aluminium alloy so as to reduce the weight furthest. The gear pump can control the rotating speed of the direct current motor by pulse-width modulation of a single-chip microcontroller and control the flow rate of the gear pump precisely.

Owner:北京领动国创科技有限公司

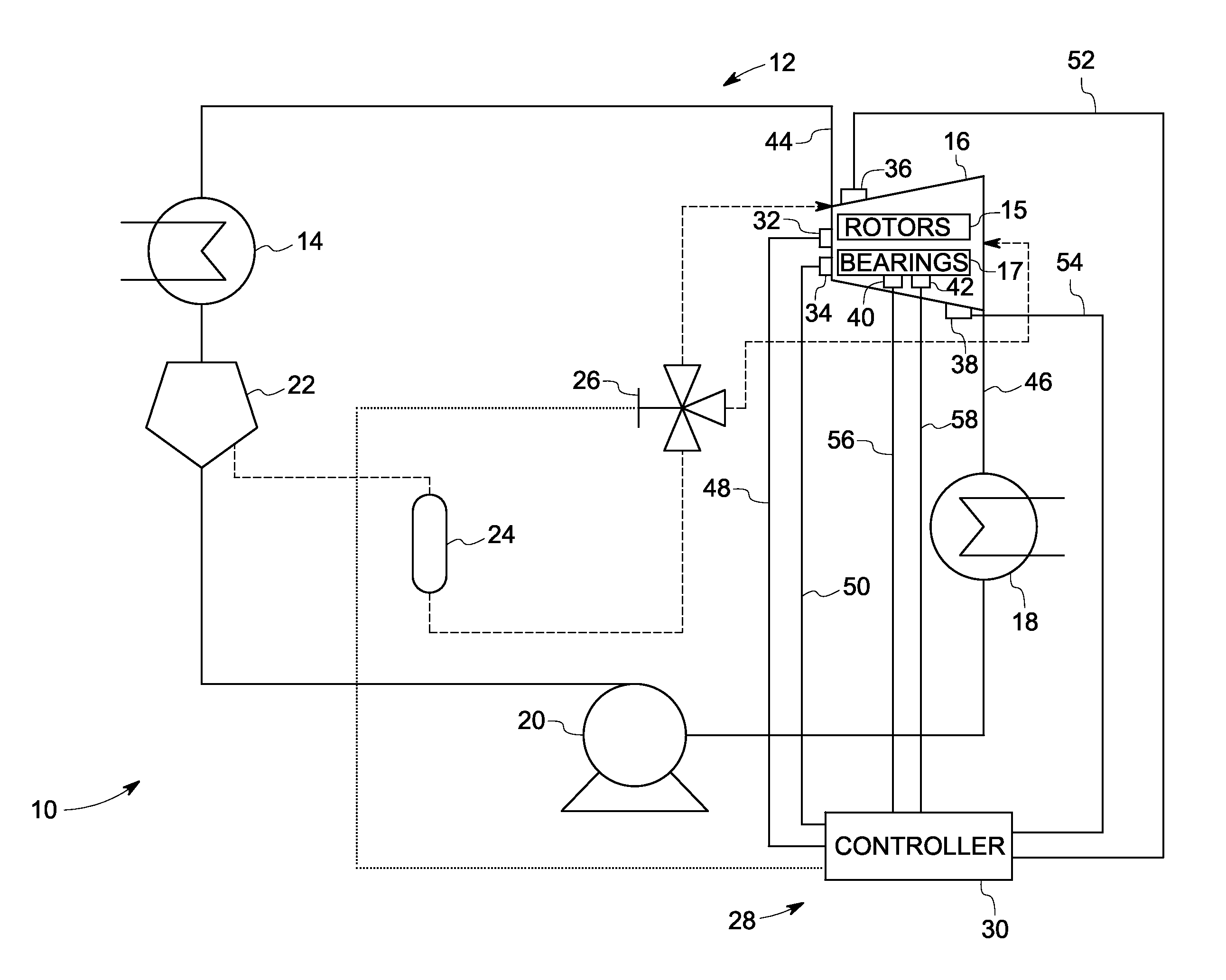

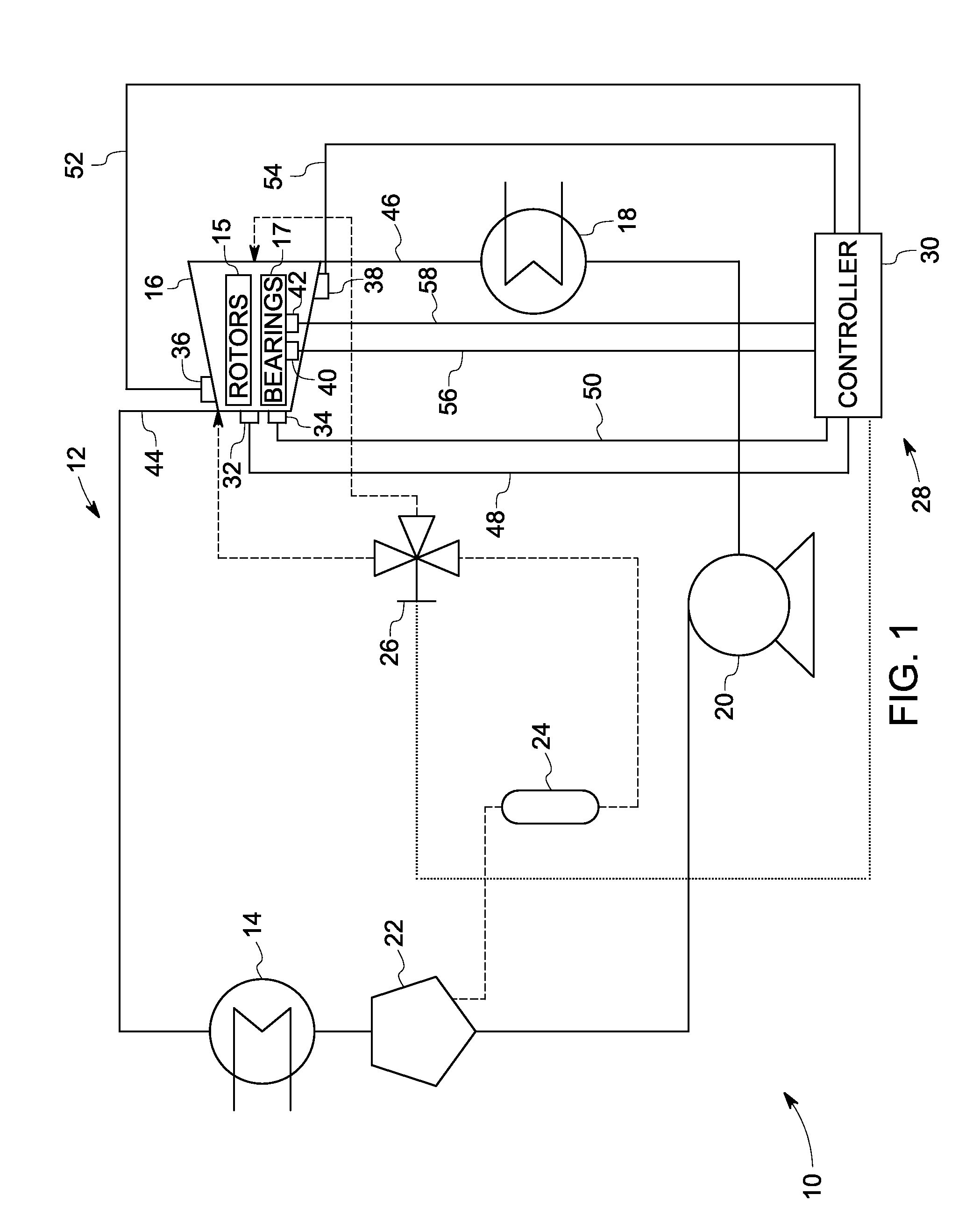

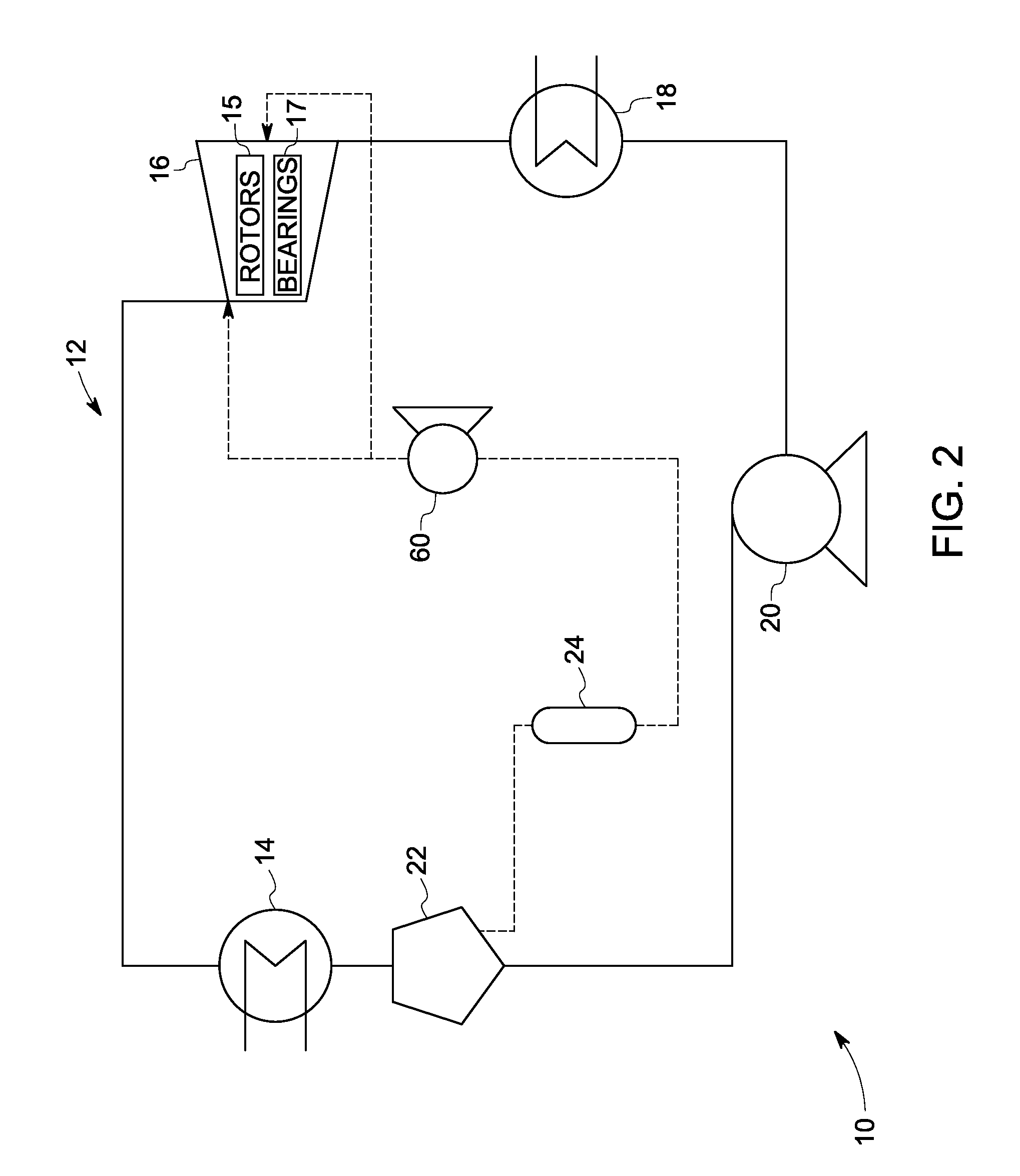

Method for lubricating screw expanders and system for controlling lubrication

A method for lubricating a screw expander includes condensing a mixture of working fluid and lubricant fed from the screw expander, through a condenser. At least a portion of the mixture of working fluid and lubricant fed from the condenser is pressurized from a first pressure to a second pressure through a pump. The method also includes separating the lubricant from the condensed working fluid of the at least portion of the mixture via a separator and feeding the lubricant to the screw expander; or separating the lubricant from the working fluid of the at least portion of the mixture via an evaporator and feeding the lubricant to the screw expander; or feeding the at least portion of the mixture of condensed working fluid and lubricant to the screw expander; or combinations thereof.

Owner:GENERAL ELECTRIC CO

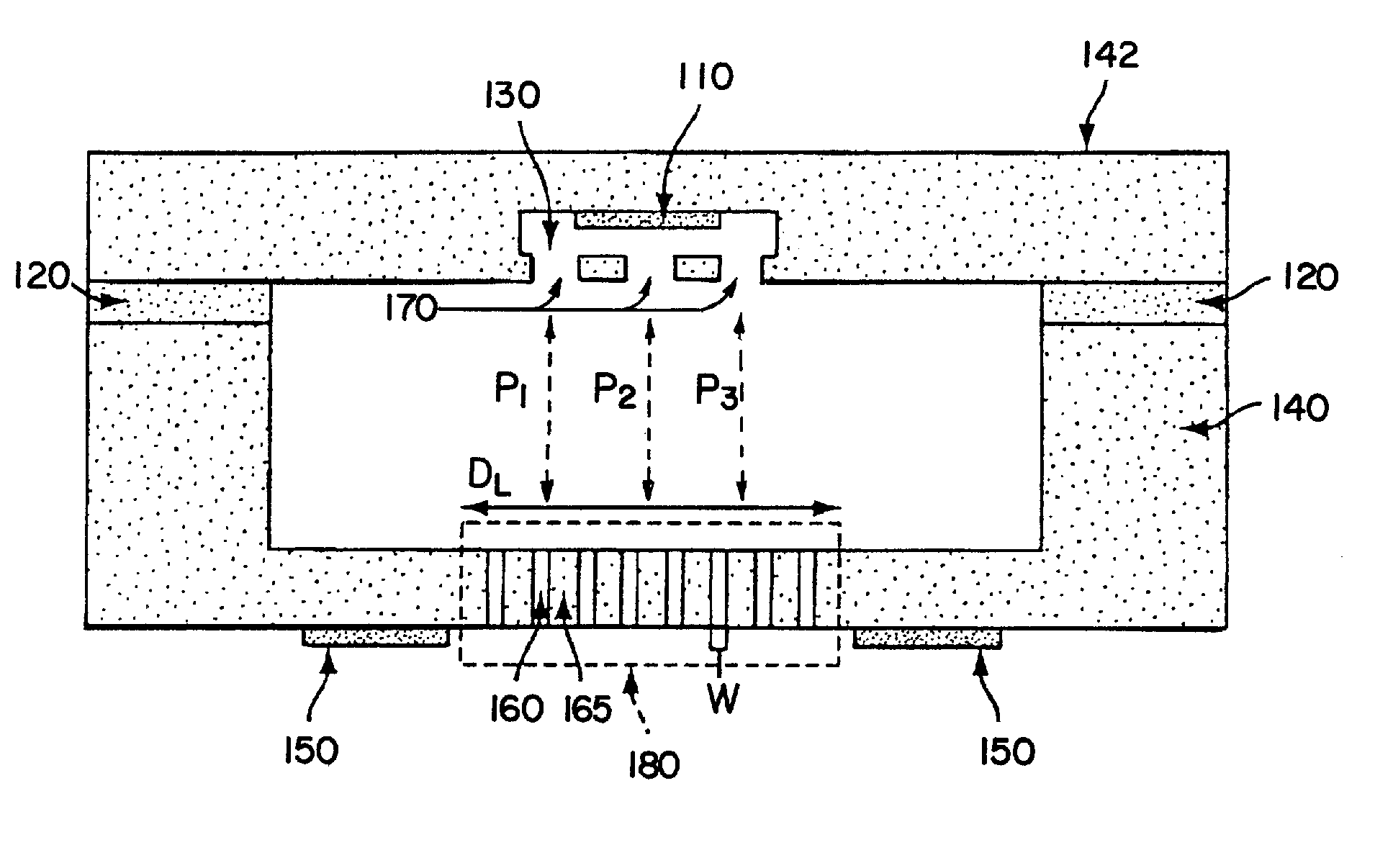

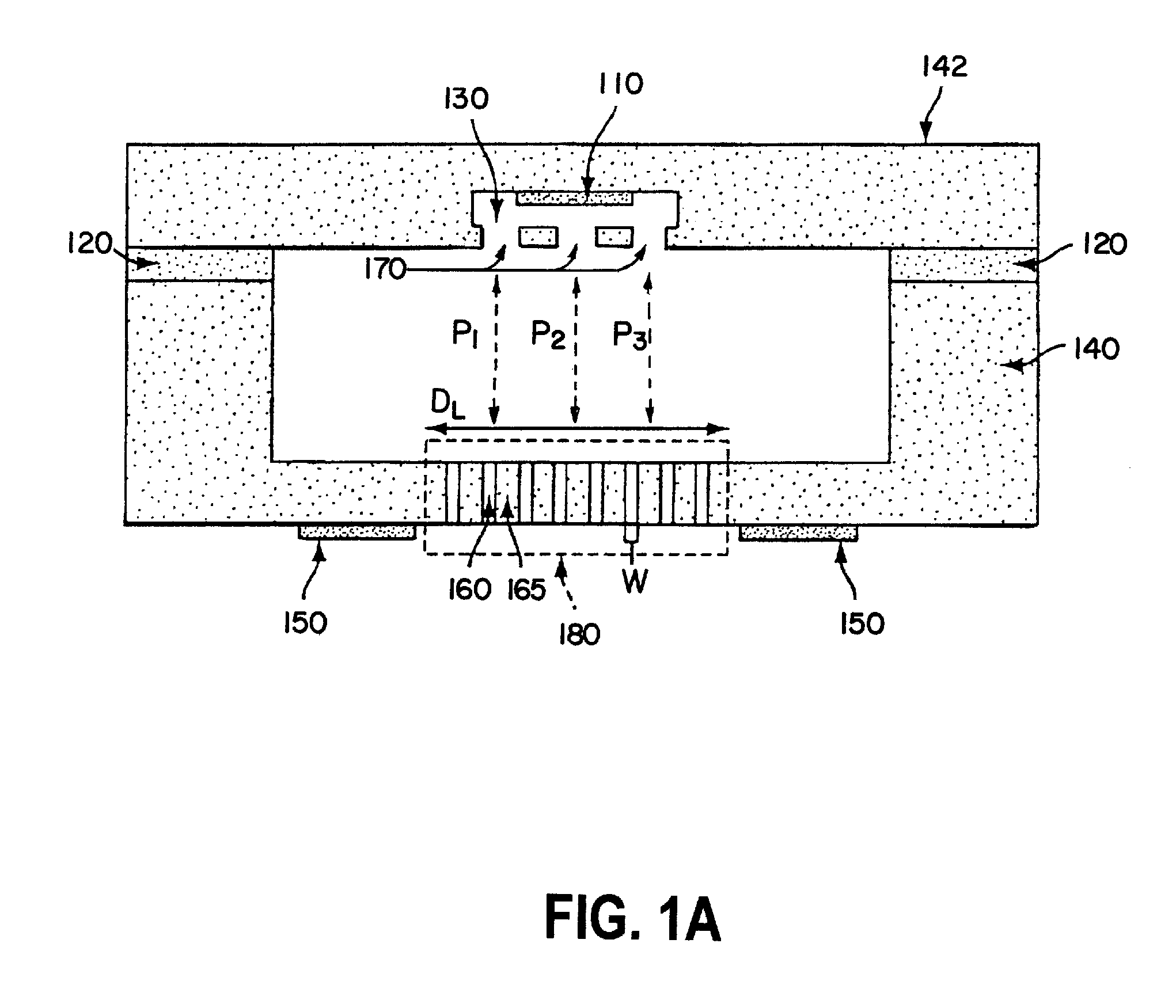

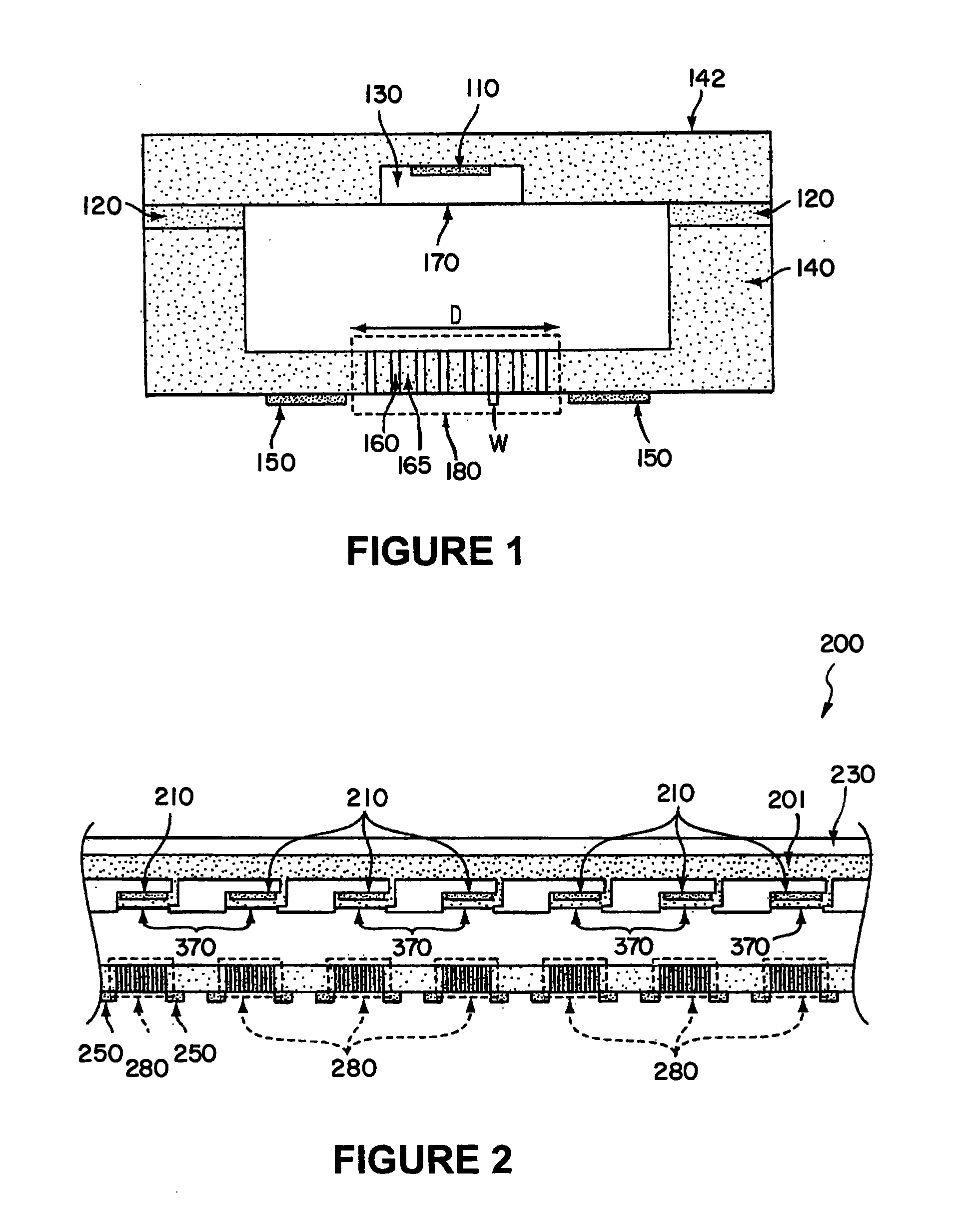

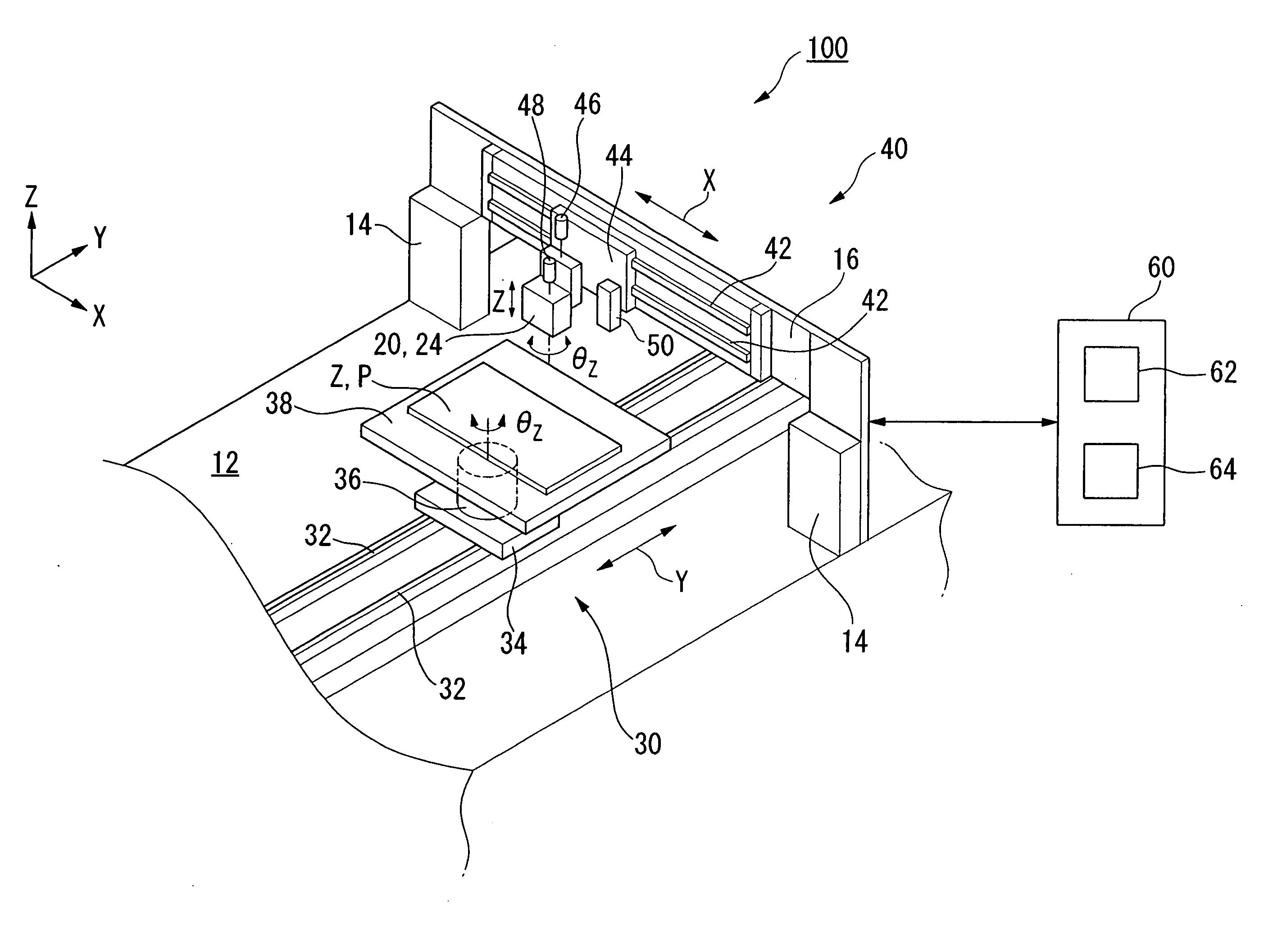

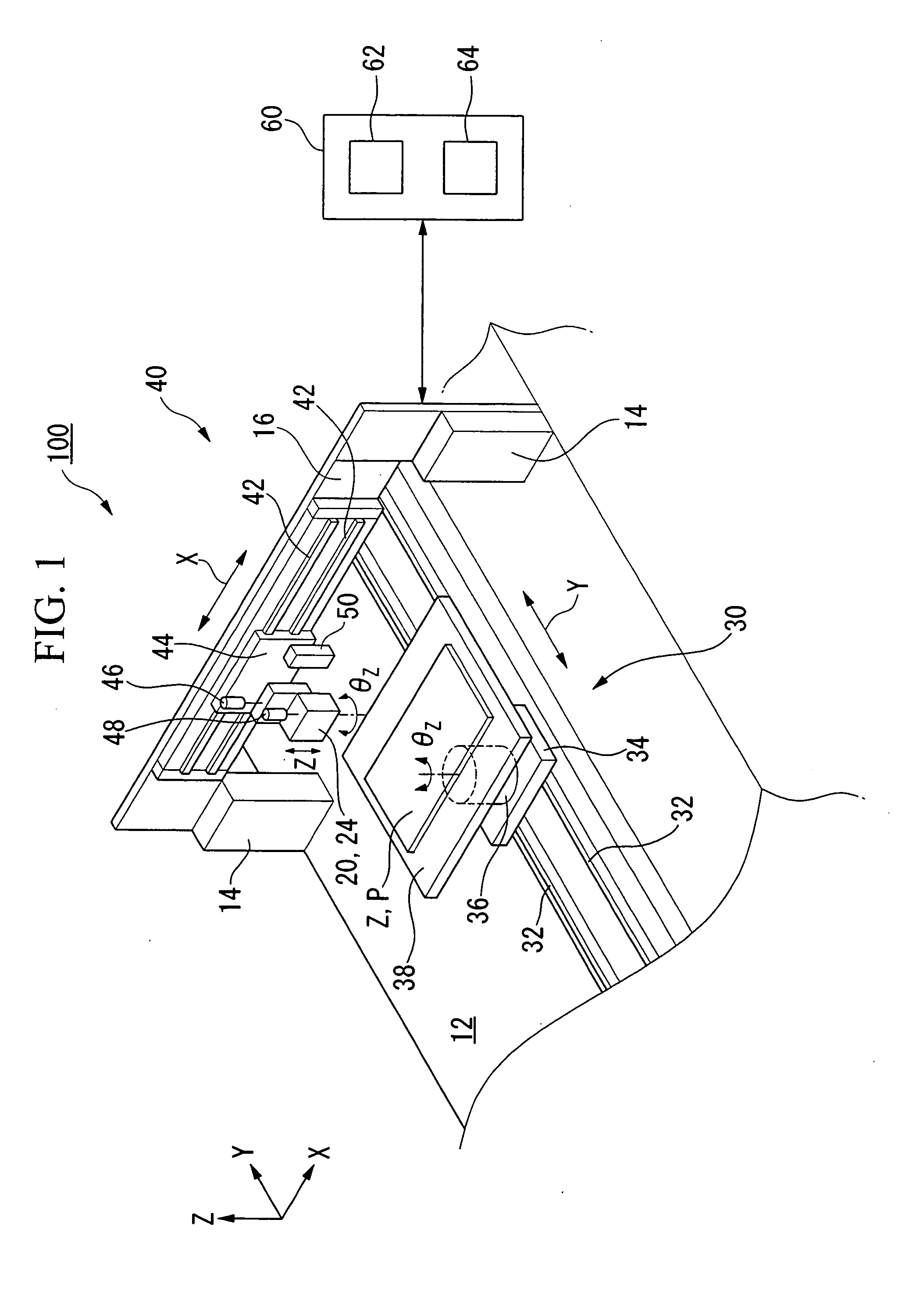

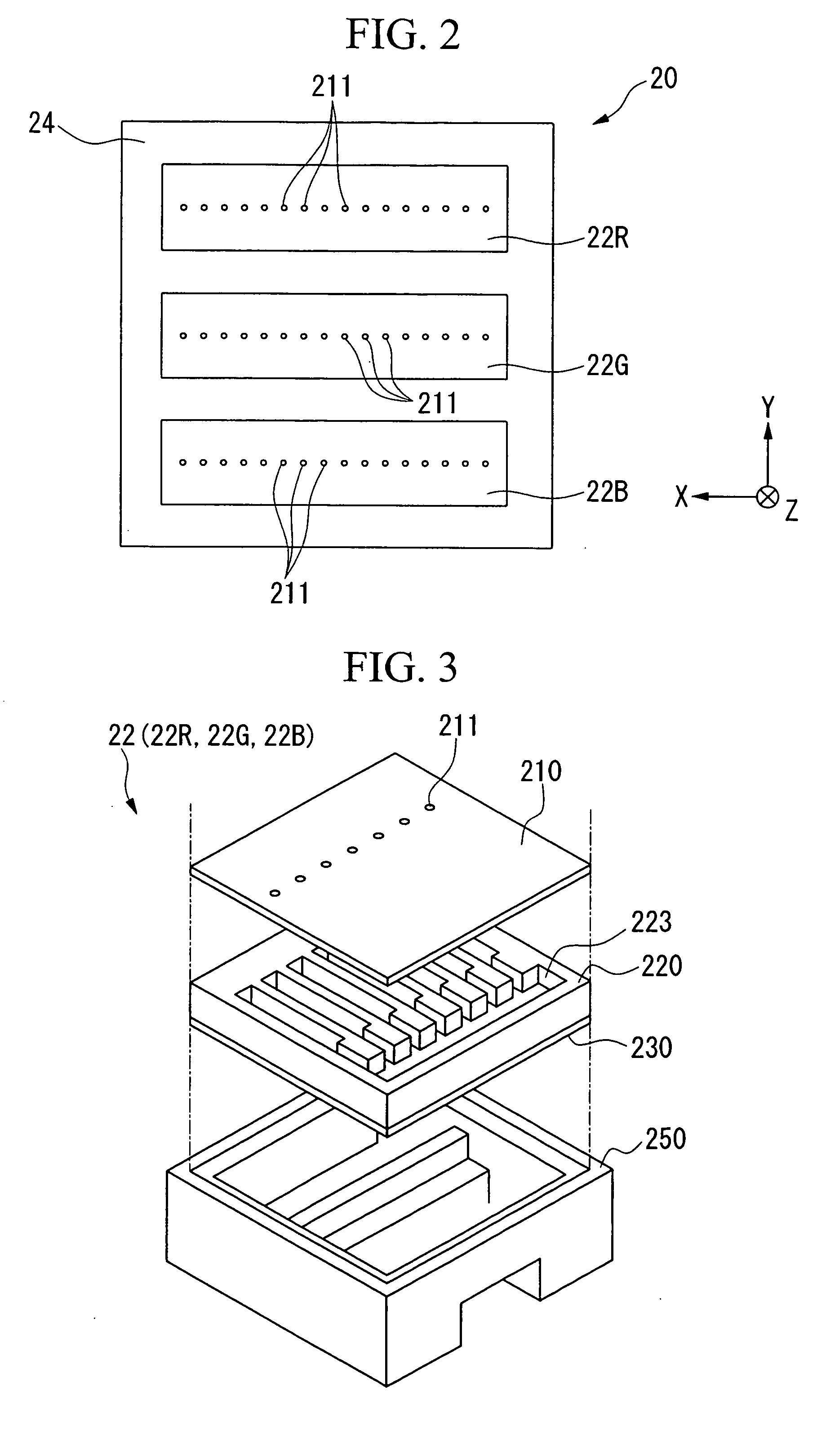

Rapid Ink-Charging Of A Dry Ink Discharge Nozzle

InactiveUS20100171780A1Sufficient materialSolid-state devicesMachines/enginesMulti materialSuspended particles

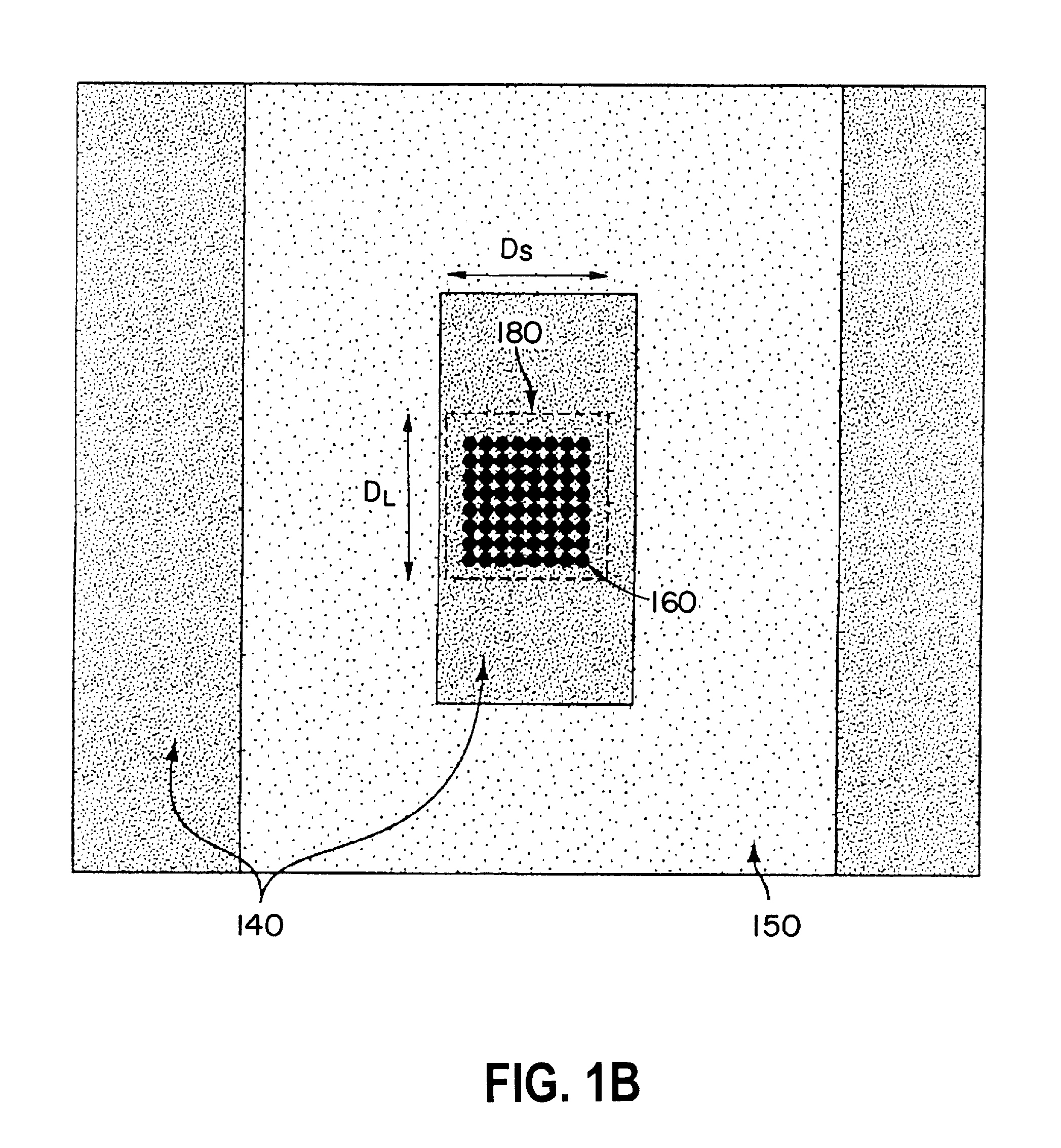

The present teachings relate to methods and apparatus for depositing one or more materials (e.g., one or more films, such as one or more solids) on one or more substrates, which may form part of an OLED or other type(s) of display. In some embodiments, the disclosure relates to apparatus and methods for depositing ink on one or more substrates. The apparatus can include, for example, one or more chambers for receiving ink, and plural orifices configured in the one or more chambers which are adapted for ejecting droplets of the ink; a discharge nozzle comprising an array of micro-pores (e.g., configured in a rectangular array), with each micro-pore having an inlet port and an outlet port, and the discharge nozzle receiving plural quantities (e.g., droplets) of ink from the chamber(s) via the orifices at the inlet ports and dispensing the ink from the outlet ports. The droplets of ink can be received at unique, spaced-apart locations on the inlet ports of the discharge nozzle. In some embodiments, a single liquid ink-holding chamber, which includes plural orifices (e.g., three), receives ink in liquid form having a plurality of suspended particles, and droplets of the ink are ejected substantially simultaneously from the chamber to respective, spaced-apart locations on the discharge nozzle; and the discharge nozzle evaporates the carrier liquid and deposits the solid particles on one or more substrates.

Owner:KATEEVA

Mechanical ventilation system utilizing bias valve

ActiveUS8118024B2Small powerSmall sizeRespiratorsOperating means/releasing devices for valvesTransducerEngineering

A portable mechanical ventilator having a ROOTS® blower is configured to provide a desired gas flow and pressure to a patient circuit. The mechanical ventilator includes a flow meter operative to measure gas flow produced by the ROOTS® blower and an exhalation control module configured to operate an exhalation valve connected to the patient circuit. A bias valve connected between the ROOTS® blower and the patient circuit is specifically configured to generate a bias pressure relative to the patient circuit pressure at the exhalation control module. The bias valve is further configured to attenuate pulsating gas flow produced by the ROOTS® blower such that gas flowing to the mass flow meter exhibits a substantially constant pressure characteristic. The bias pressure facilitates closing of the exhalation valve at the start of inspiration, regulates positive end expiratory pressure during exhalation, and purges sense lines via a pressure transducer module.

Owner:VYAIRE MEDICAL 203 INC

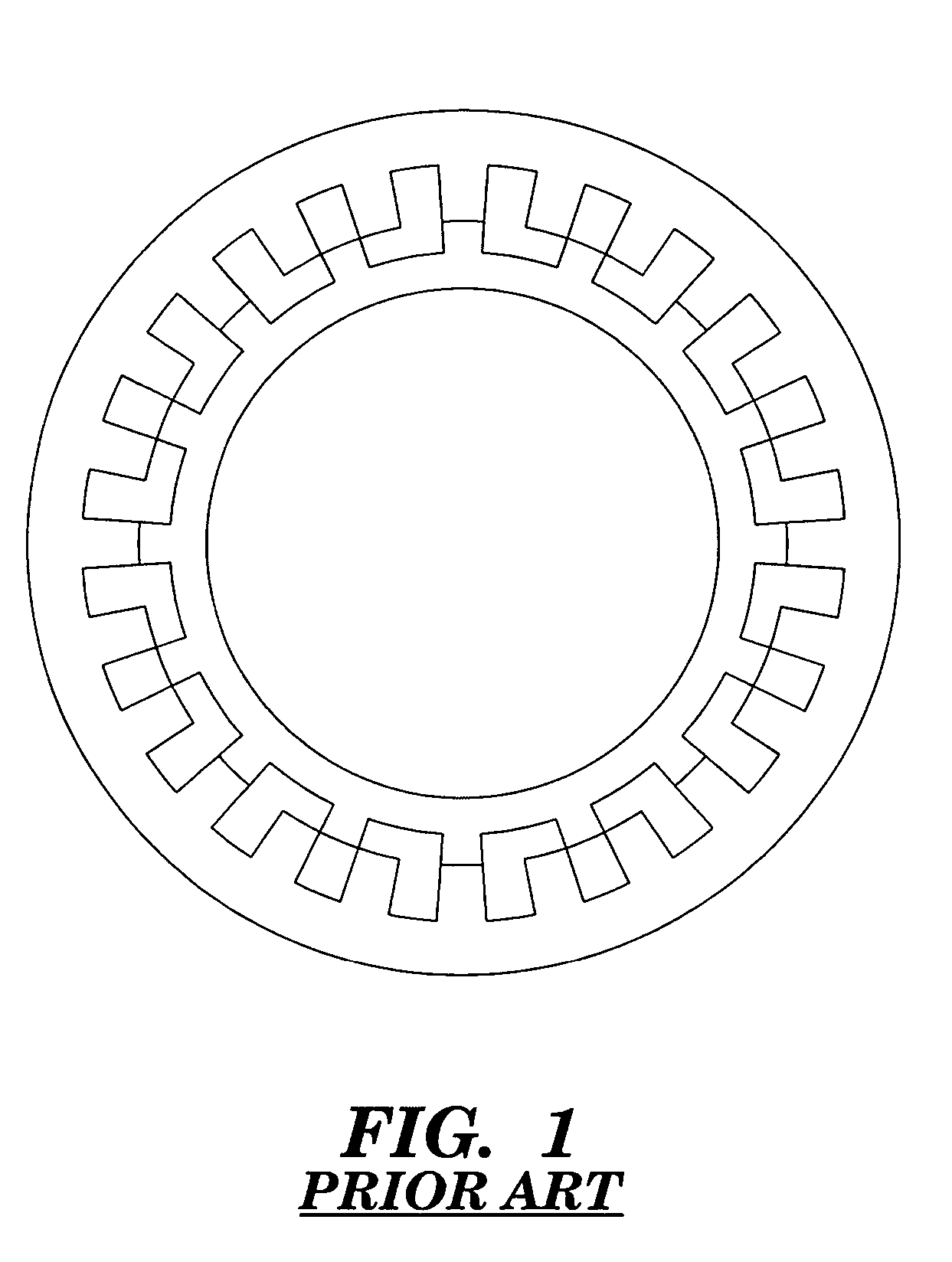

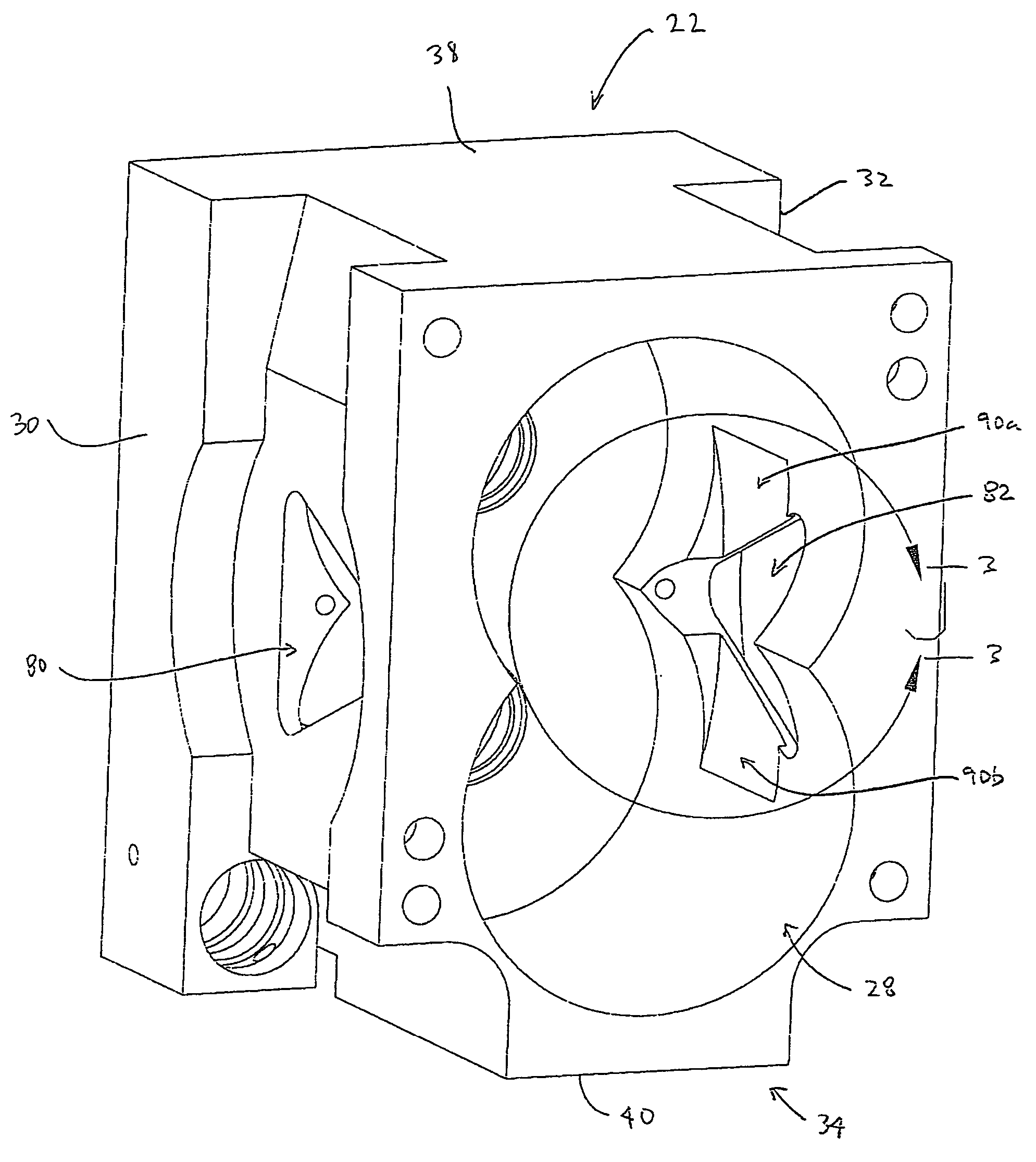

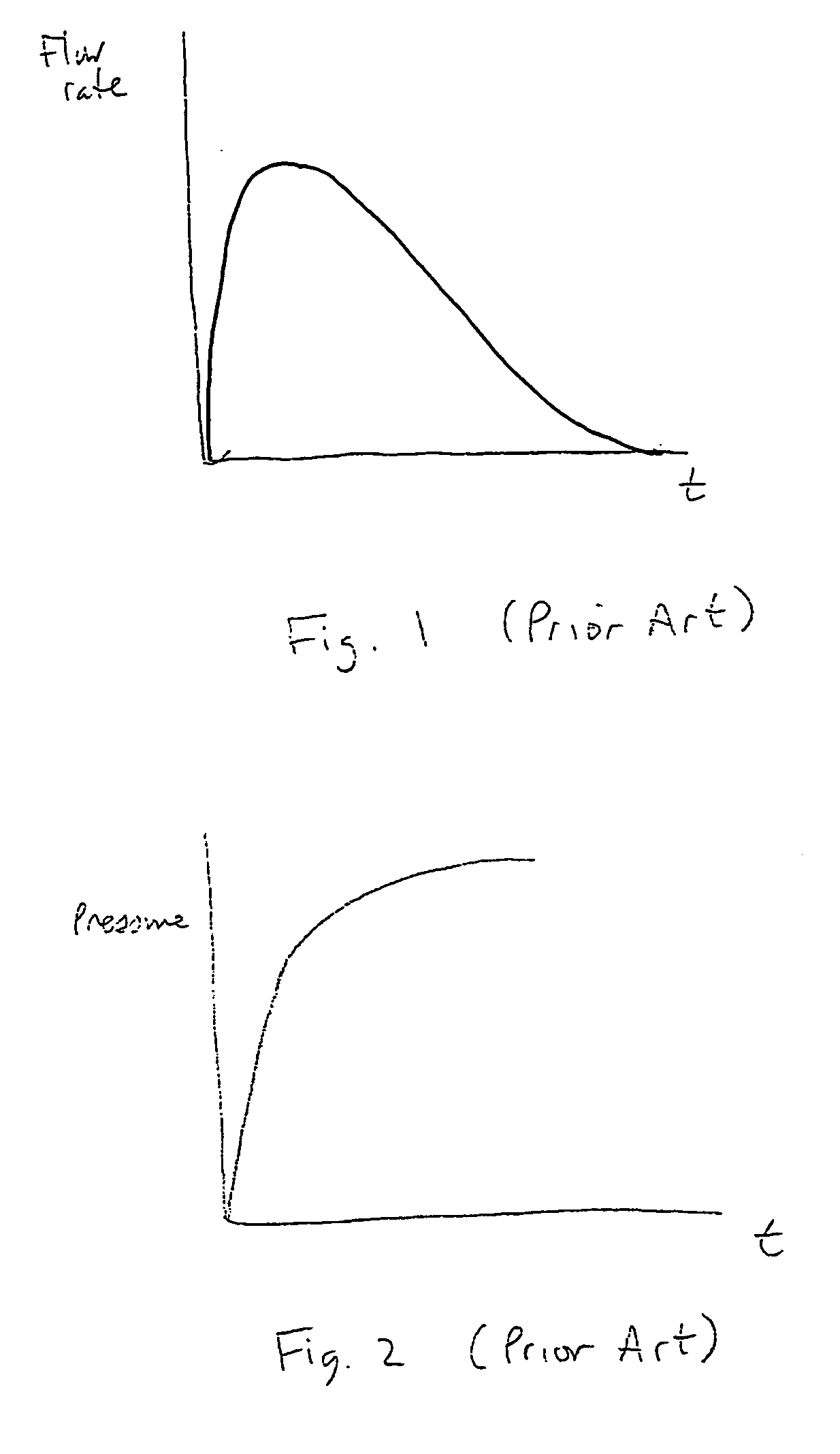

Method and apparatus for reducing noise in a roots-type blower

InactiveUS20050112013A1Reduce noisePhysical therapyEngine of counter-engagement typeNoise levelEngineering

A Roots-type blower comprises a housing defining a rotor chamber and an inlet and outlet to the rotor chamber. First and second rotors are mounted in the rotor chamber, each rotor defining a plurality of lobes, adjacent lobes and the housing cooperating to define gas transport chambers. The blower is configured so that a net flow rate of gas into a gas transport chamber is generally or approximately constant, whereby a change in gas pressure in the gas transport chamber is generally or approximately linear, as the gas transport chamber approaches the outlet. In one embodiment, this is accomplished by providing flow channels extending from the outlet towards the inlet, and from the inlet towards the outlet, corresponding to each rotor. The flow channels permit gas to flow from the high pressure outlet to a gas transport chamber and from the gas transport chamber to the low pressure inlet. The resulting amelioration of pressure spikes associated with flow back substantially reduces the operational noise level of the blower.

Owner:PULMONETIC SYST

Inverter-integrated motor for an automotive vehicle

InactiveUS20060064998A1Low sectionDomestic cooling apparatusSupports/enclosures/casingsPower switchingControl circuit

A bus-bar integrated plate and outer frame section, arranged into a double-deck structure and having numerous bus bars molded with a resin molding plate portion, is provided as a wiring for connecting power switching elements and a smoothing capacitor, fixed on an outer surface of a cylindrical wall of a motor housing, to a printed circuit board serving as a control circuit.

Owner:DENSO CORP

Discharge valve

InactiveUS6171084B1Easy to operateRaise the possibilityRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringValve seat

A compressor assembly includes a shell which defines a discharge chamber. A discharge valve assembly is attached to the shell in communication with the discharge chamber. The discharge valve assembly includes a stamped or coined valve seat, a drawn tubular element and a stamped valve member. The stamping, drawing and coining operations used to manufacture the discharge valve assembly significantly reduce the manufacturing costs for the discharge valve assembly.

Owner:EMERSON CLIMATE TECH INC

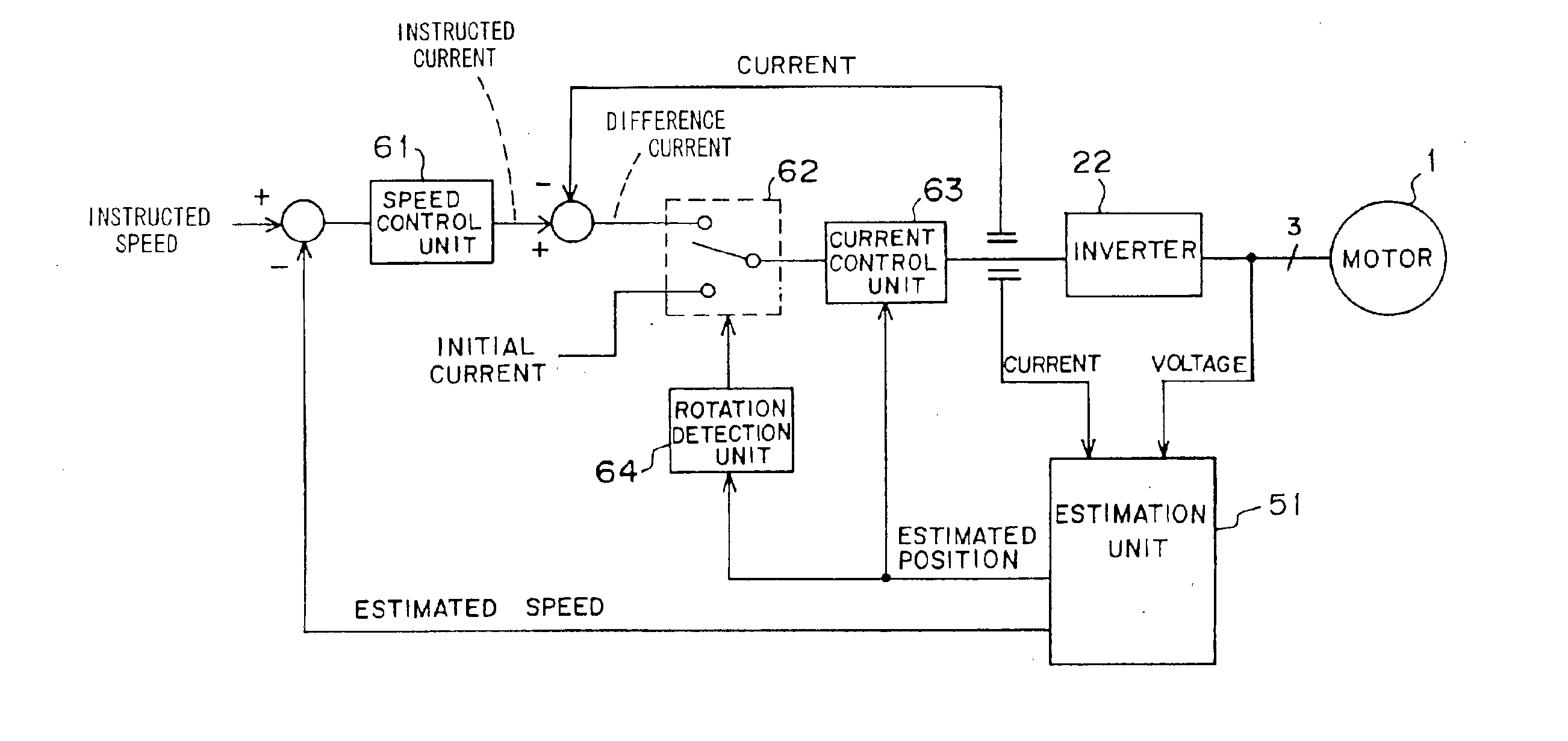

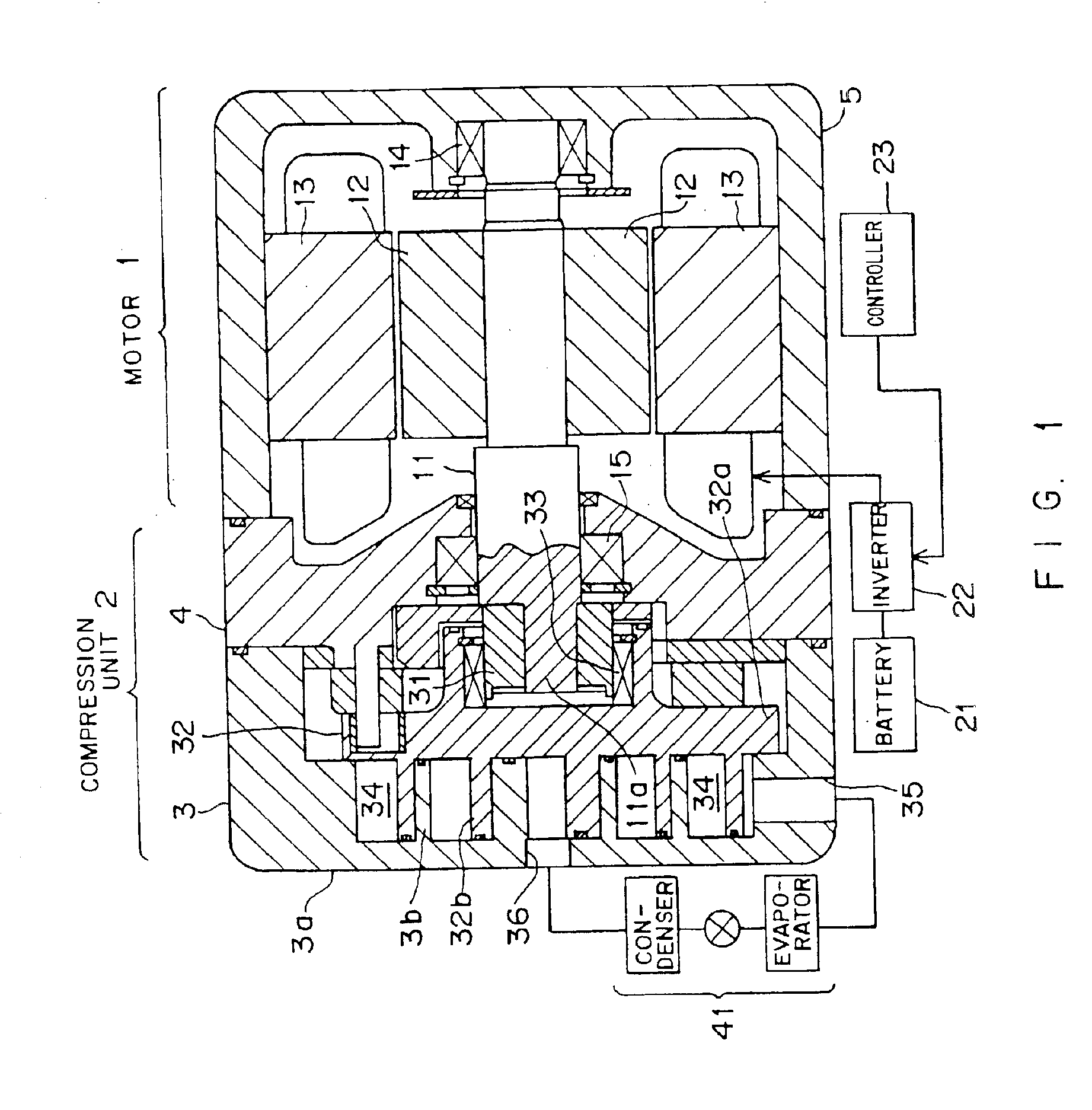

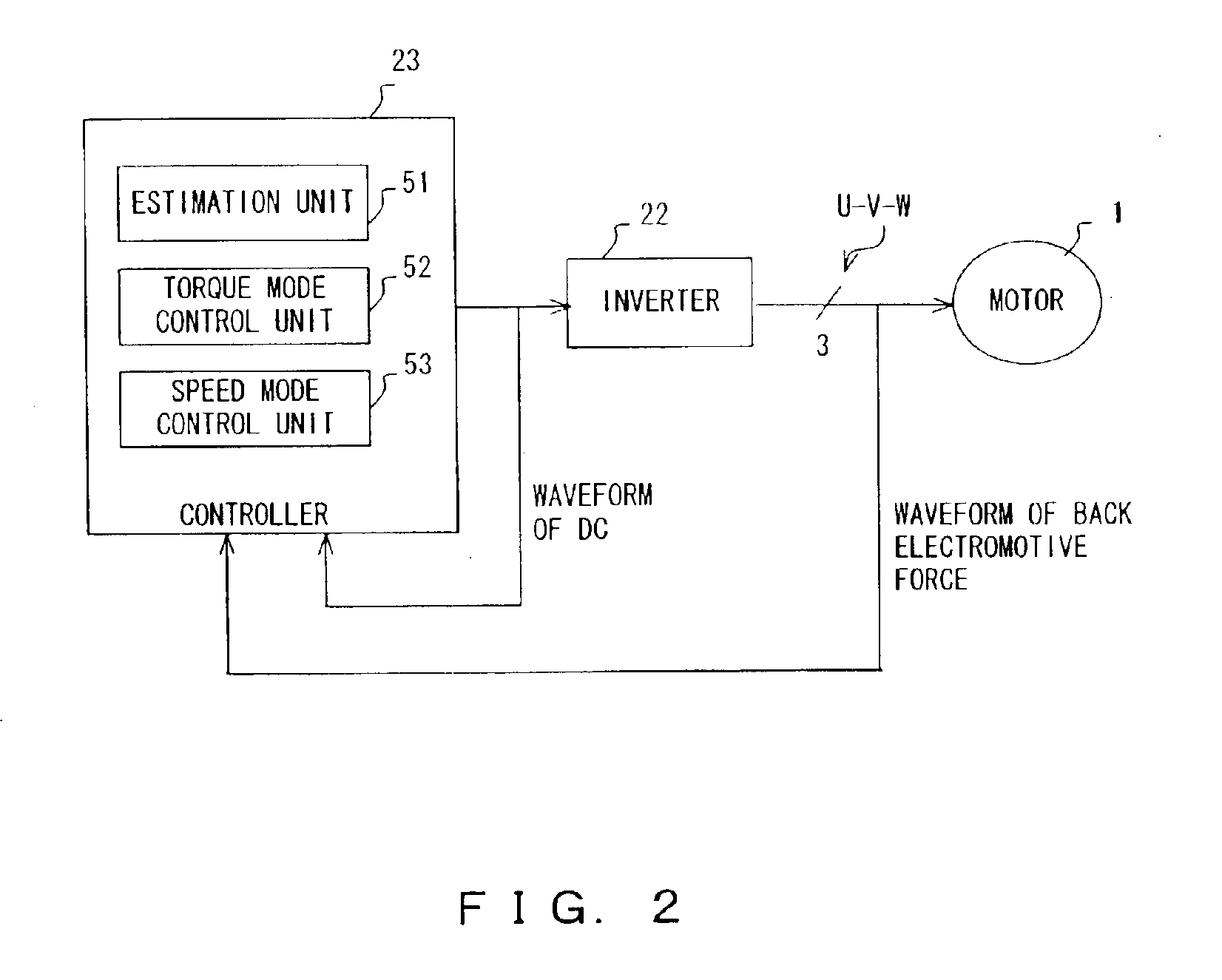

Electric compressor and control method therefor

InactiveUS6869272B2Efficient driveLight loadSingle motor speed/torque controlMotor parameterControl theoryInitial current

When an electric compressor is activated, initial current data is selected by a selector, and a motor is driven with the torque corresponding to the initial current data. When the motor is driven by a ½ turn, the selector selects current difference data. The current difference data corresponds to an instructed speed. After the switch of the selector, the motor is driven to rotate at the instructed speed.

Owner:TOYOTA IND CORP

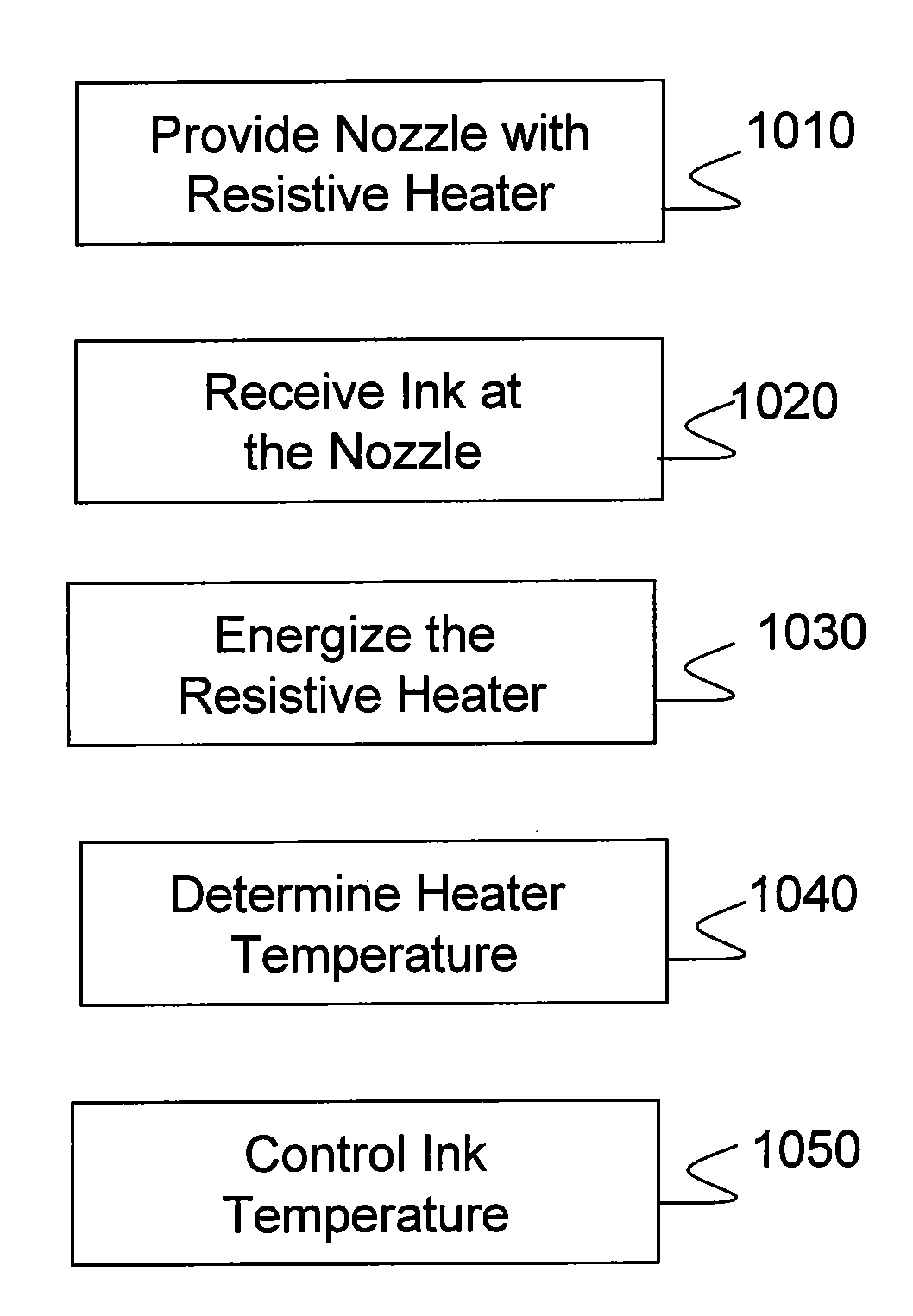

Method and apparatus for controlling the temperature of an electrically-heated discharge nozzle

InactiveUS20100188457A1Easy to identifySolid-state devicesMachines/enginesElectricityElectrical resistance and conductance

In an embodiment, the disclosure relates to a method and apparatus for fault monitoring and controlling operation of a discharge nozzle in a large array of discharge nozzles. An exemplary apparatus includes a thin, thermally conductive membrane, with an integrated thin-film electrical heater. When a fixed voltage is applied to the heater, and as the heater heats, the resistance of the heater will increase which will cause a concomitant decrease in the electrical current flowing through the heater. By measuring the resistance of the heater it can readily be determined whether the device is functioning properly.

Owner:MADIGAN CONNOR F +2

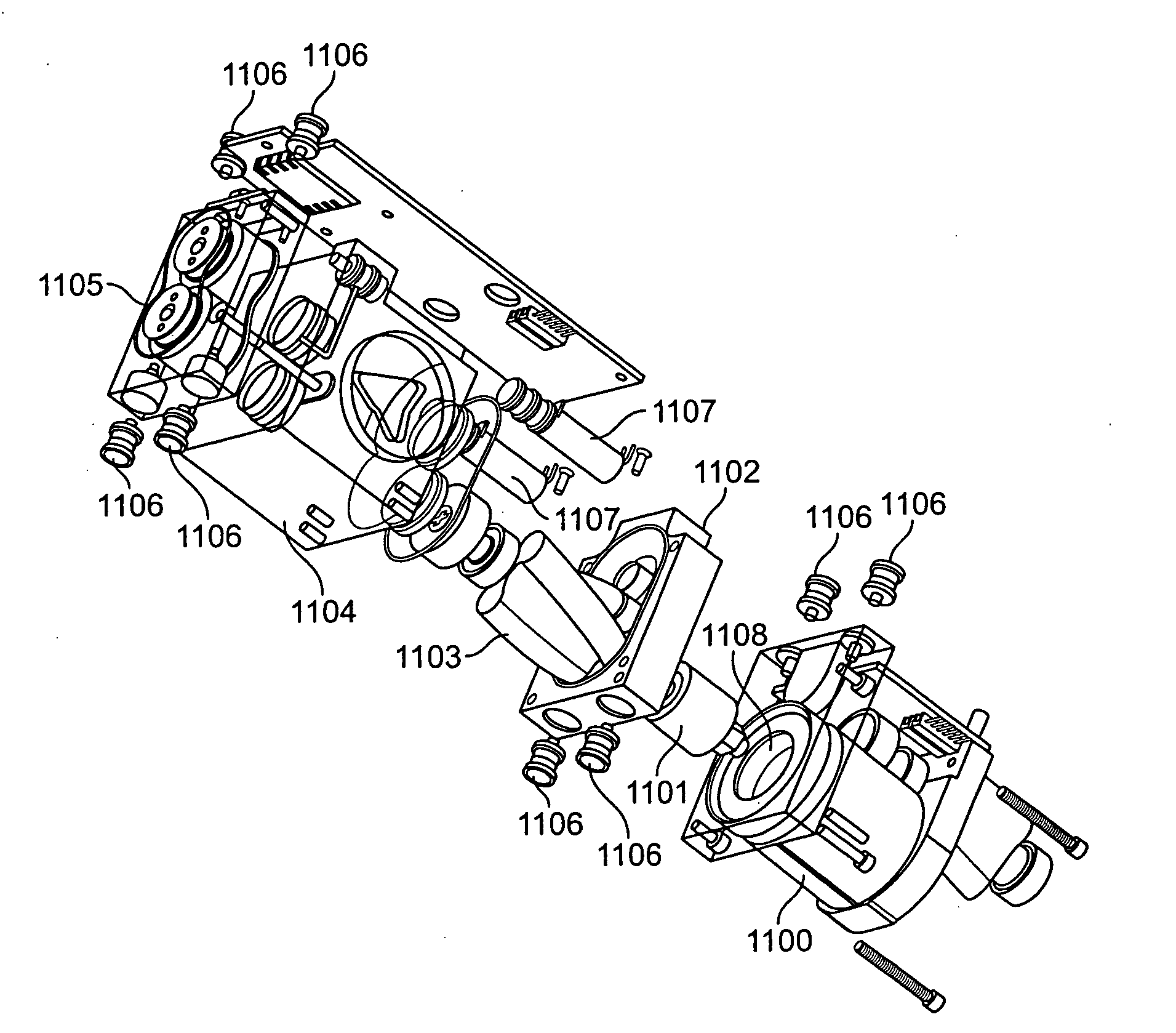

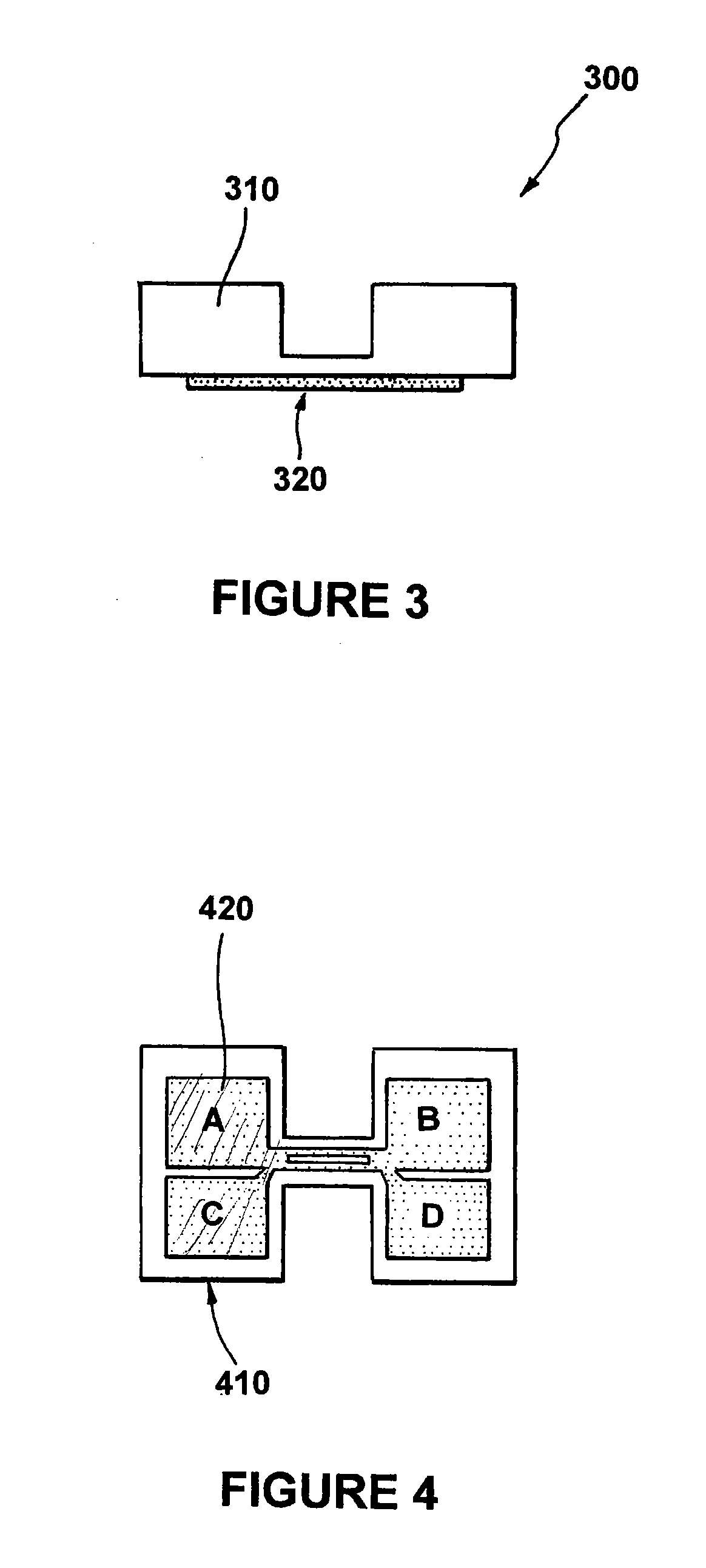

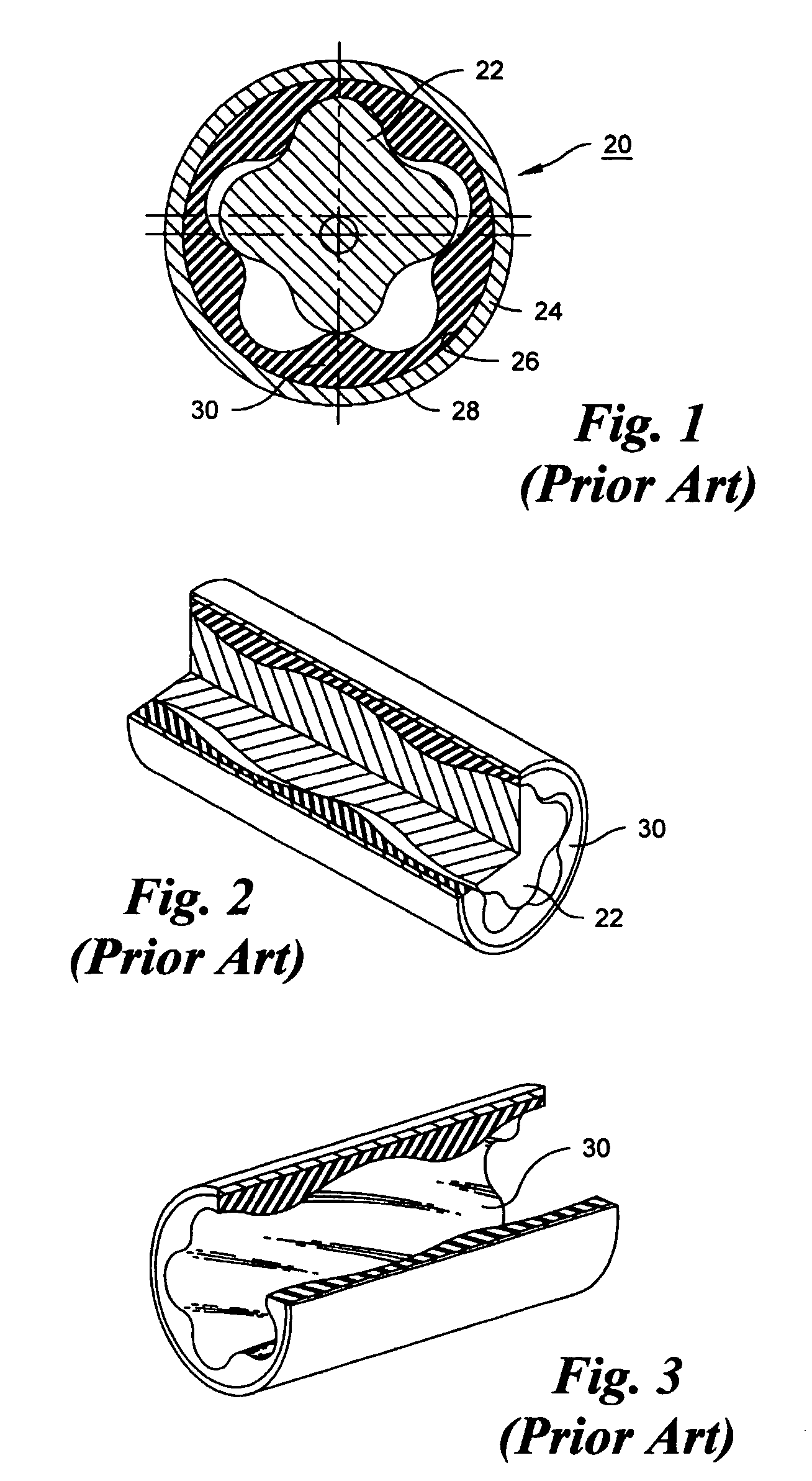

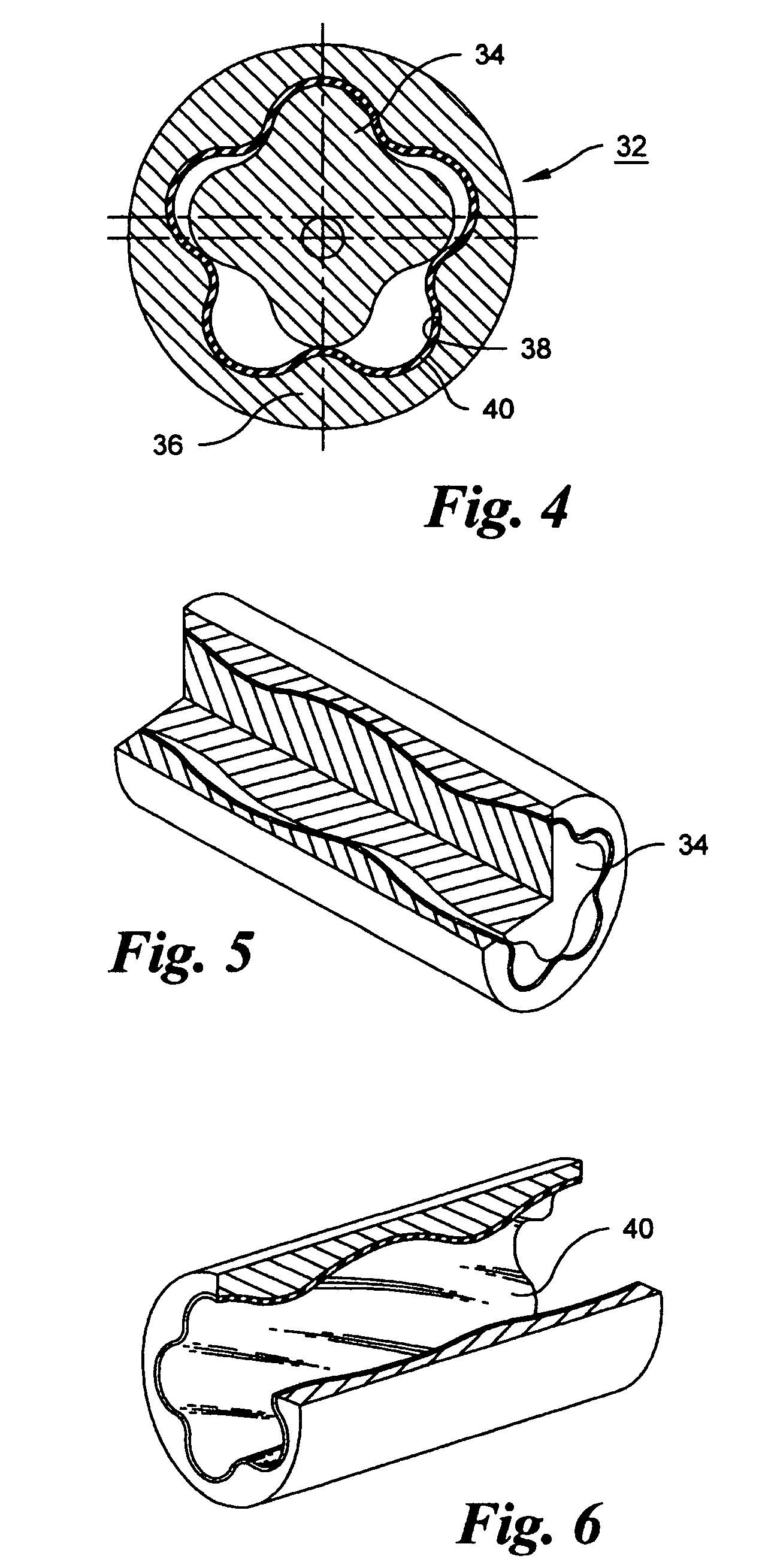

Progressive cavity pump/motor stator, and apparatus and method to manufacture same by electrochemical machining

ActiveUS7192260B2Improve heat transfer performanceReduce adverse effectsElectrolysis componentsEngine of intermeshing engagement typeElastomerElectricity

Electrochemical machining is used to generate the helical lobe profiles of the stator of a progressive cavity pump or motor. A thin, elastomeric liner, of uniform thickness is bonded either to the interior of the stator, or to the exterior of the rotor. Where the elastomeric liner is to be bonded to the interior of the stator, bonding is improved by electrically etching the interior of the stator during the electrochemical machining process to produce a roughened surface.

Owner:LEHR PRECISION

Pump with conveying chamber formed in outer rotor surface

ActiveUS7674100B2Avoid flowEngine of arcuate-engagement typeRotary piston pumpsMechanical engineeringMedical treatment

Owner:QUANTEX ARC LTD

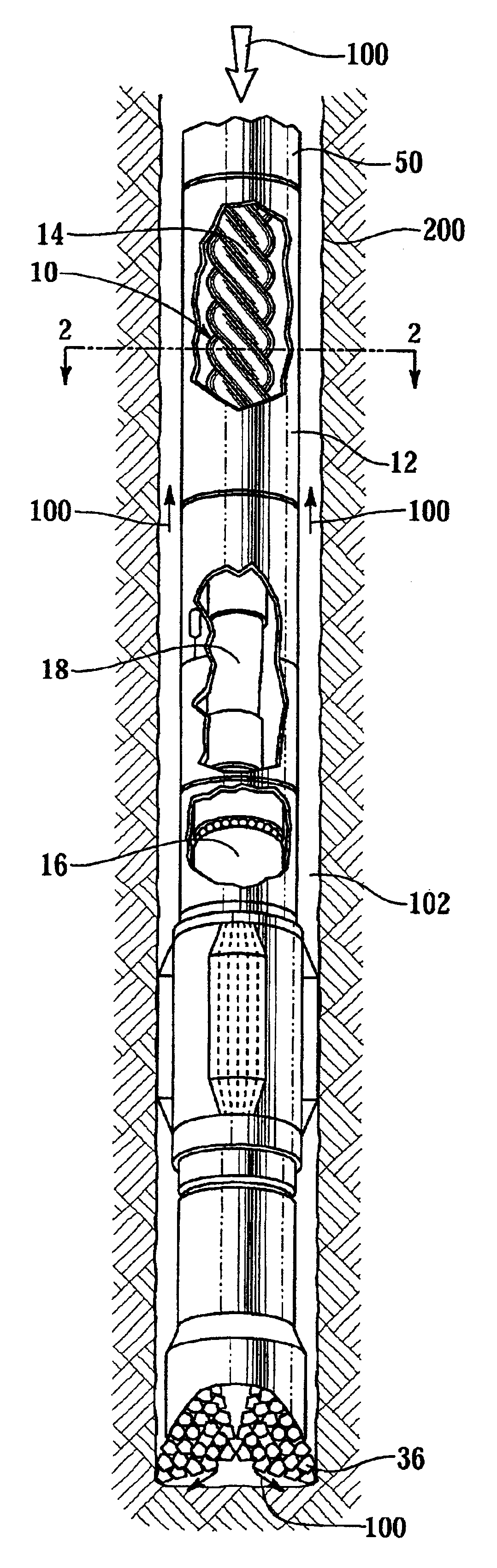

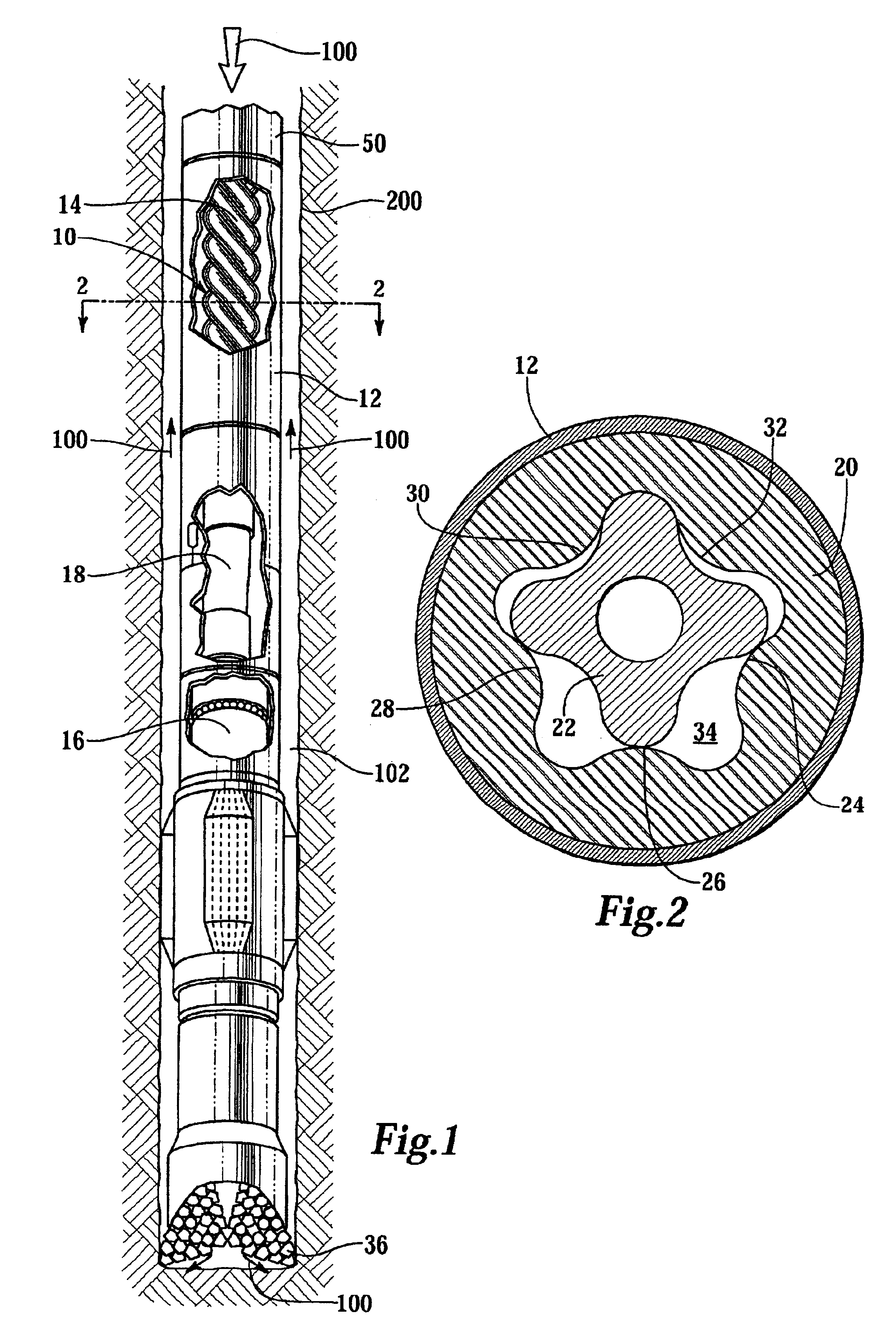

Stator for down hole drilling motor

InactiveUS6905319B2Reduced susceptibility to stator damageSufficient wear characteristicOscillating piston enginesEngine of intermeshing engagement typeDrill holePhysics

An improved down hole drilling motor suitable for drilling applications. The down hole drilling motor comprising a stator disposed in the tubular housing. The stator includes an internal cavity having one or more lobes. A rotor operatively positioned in the cavity of the stator is adapted to cooperate with the one or more lobes of the stator. The stator comprising a compound having improved manufacturing and performance characteristics.

Owner:HALLIBURTON ENERGY SERVICES INC

Method and apparatus for forming a pattern, device and electronic apparatus

ActiveUS20050177343A1Improve landing accuracyImprove accuracyElectric lighting sourcesSolid-state devicesEngineeringElectron

Owner:TOKYO ELECTRON LTD

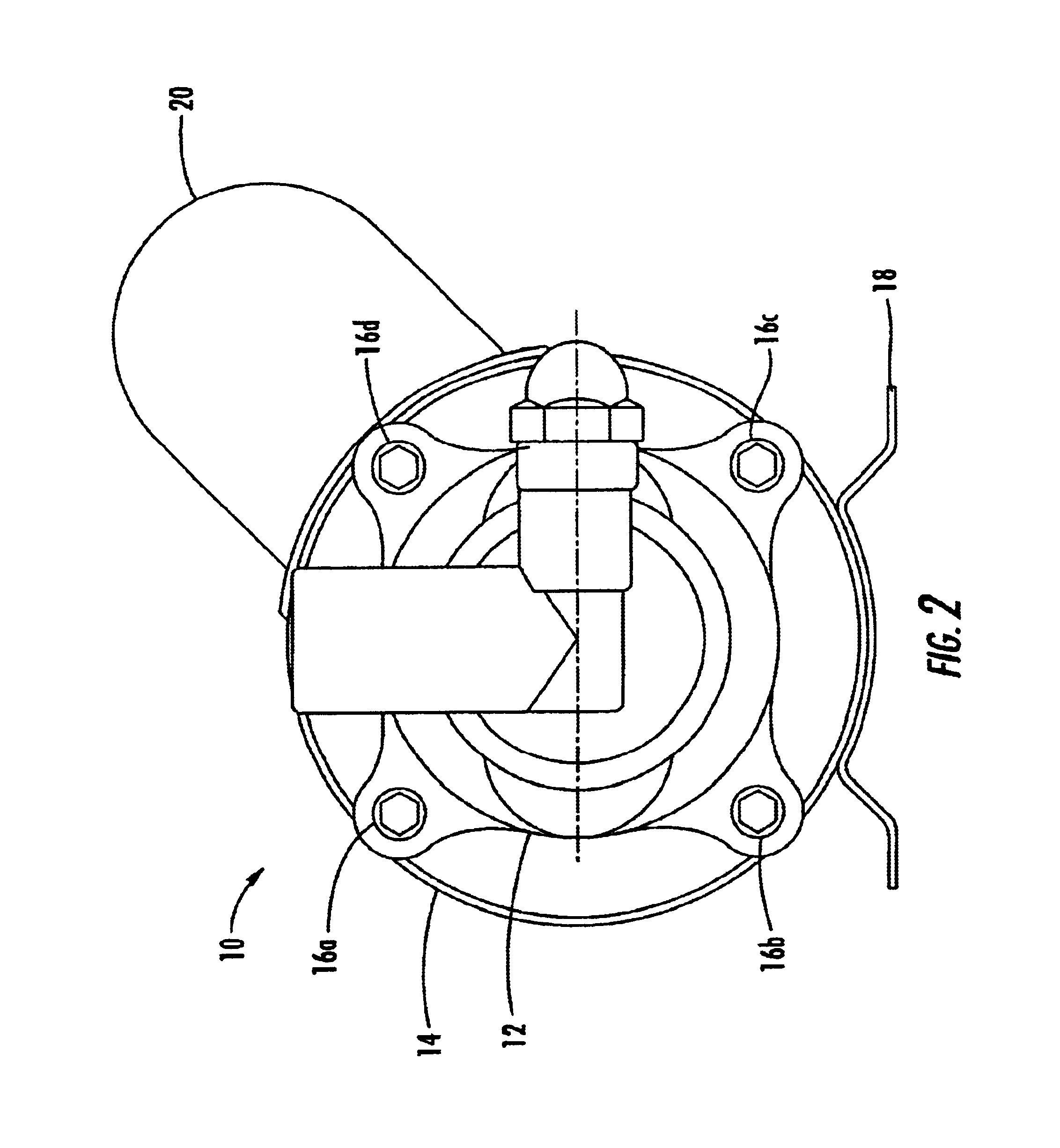

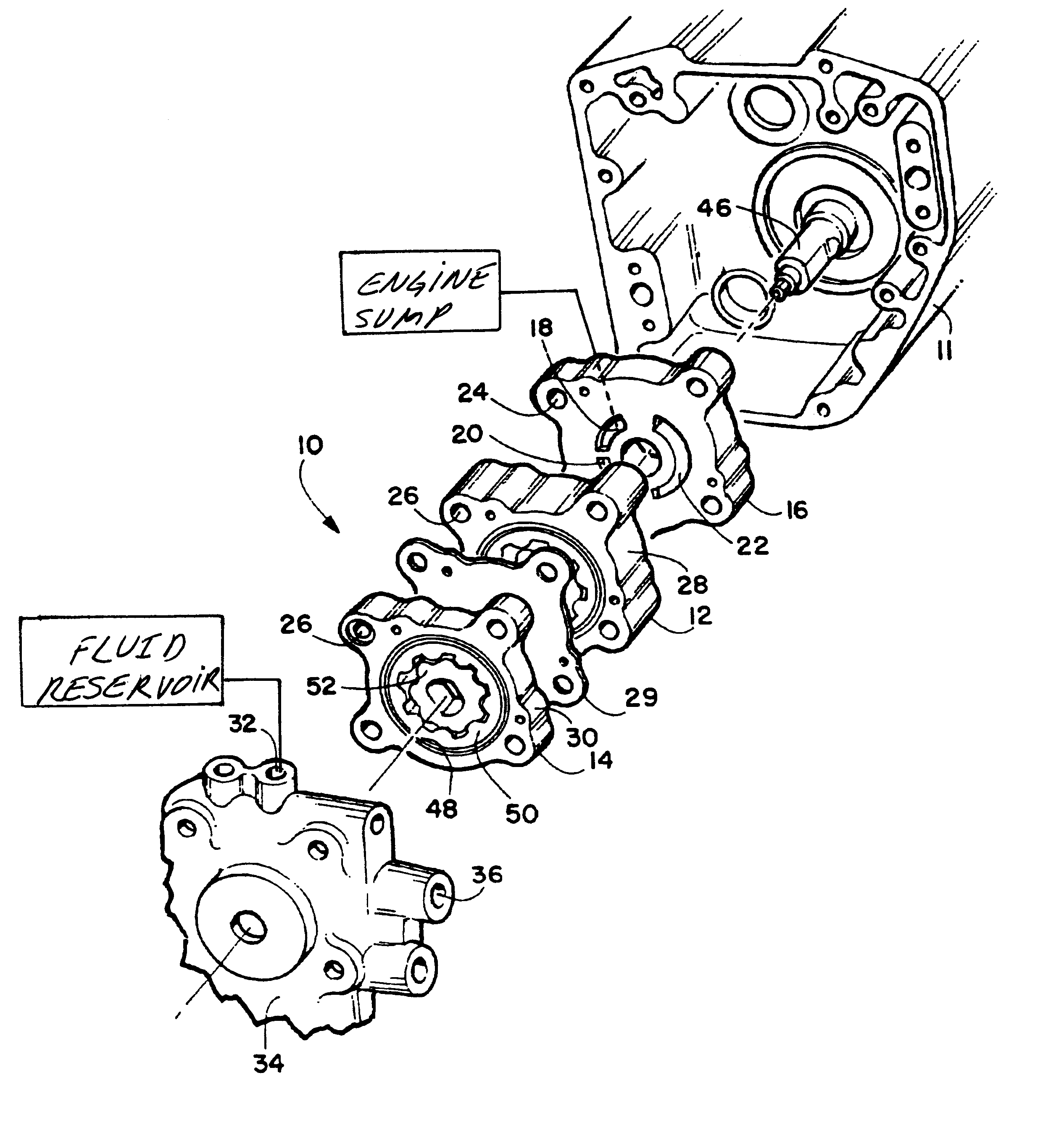

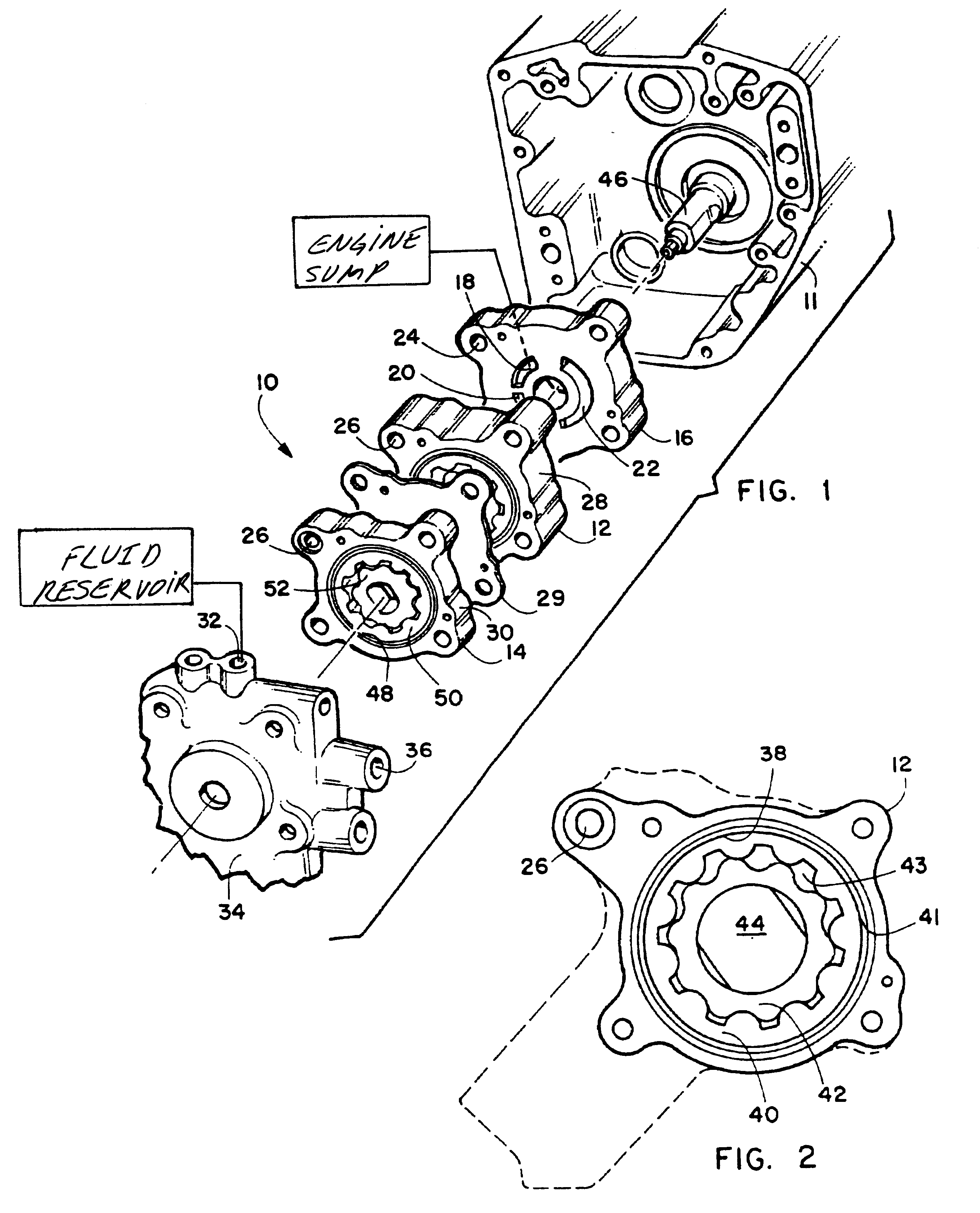

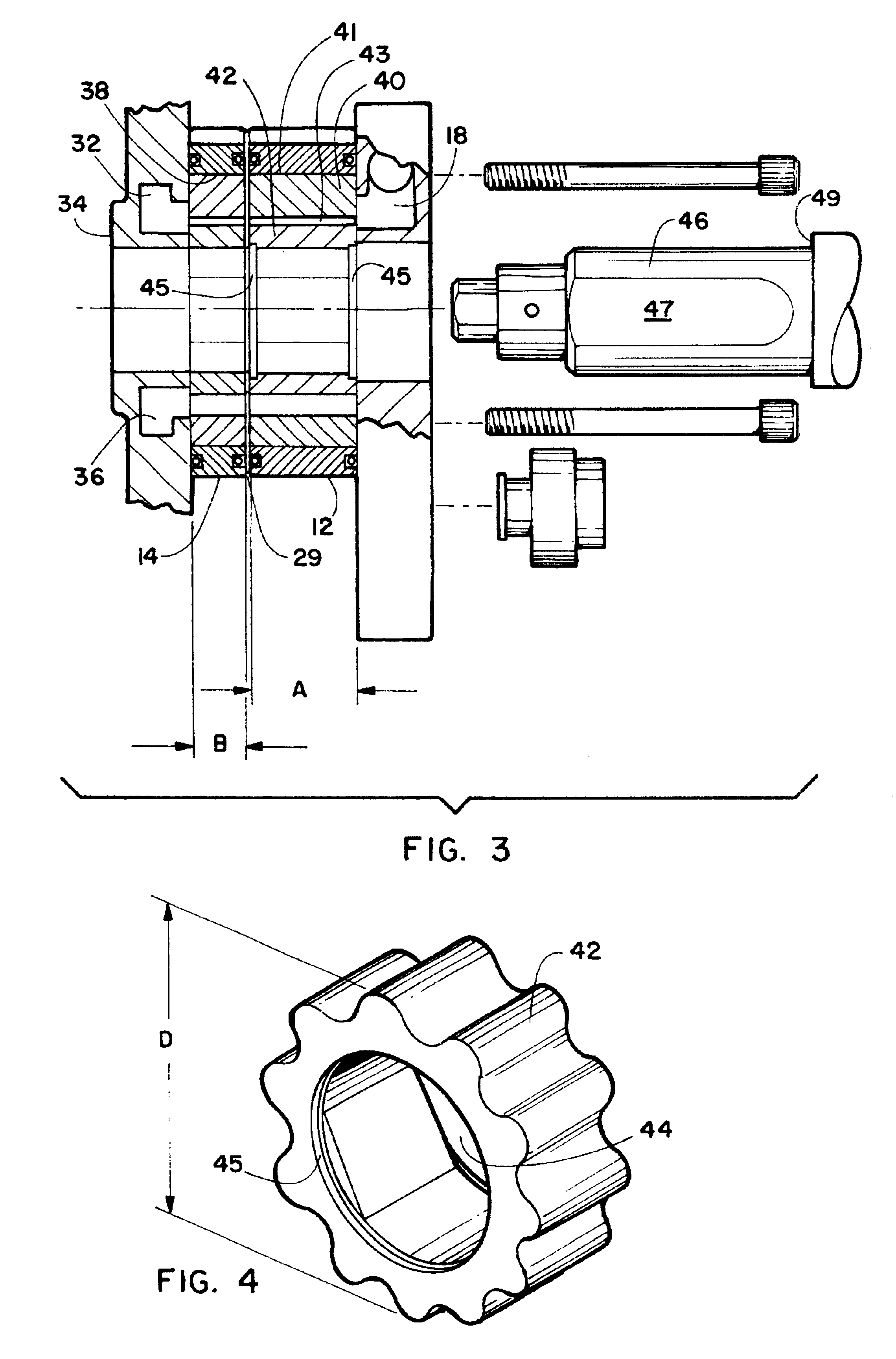

Oil pump

InactiveUS6679692B1Easy to replacePromote repairRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesFuel tankEngineering

A modular oil pump for use in combination with an internal combustion engine having a dry sump lubrication system. The device features a first gerotor pump having an intake port engageable in communication with at least one engine sump and having an discharge port engageable in sealed communication with a fluid reservoir for the dry sump system. A second gerotor pump, engageable in sealed communication with the fluid reservoir has a discharge port fluidly engageable with the engine lubrication system oil supply conduit. Both the first pump and second pump are assembled from separate housings, and cooperatively engaged inner and outer gears sized for rotation and in line mounting on the engine crankshaft inside a cavity in the housings. The volume pumping capacity of the first pump at a ratio to efficiently drain fluid and gas from the engine sumps and supply the reservoir with a constant supply of lubrication fluid. The device may be assembled from a kit having a plurality of different sized components to adjust the ratio of the pumping volume of the first pump to the second pump.

Owner:FEULING JAMES J

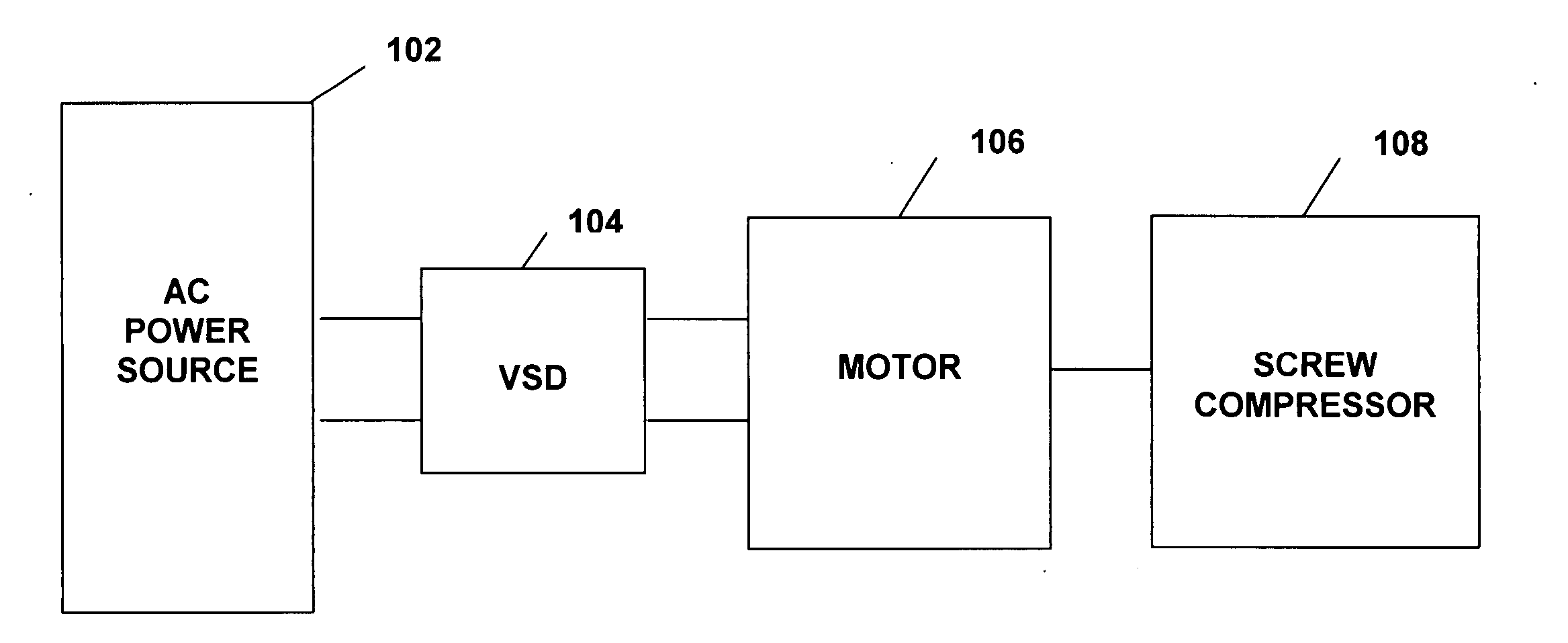

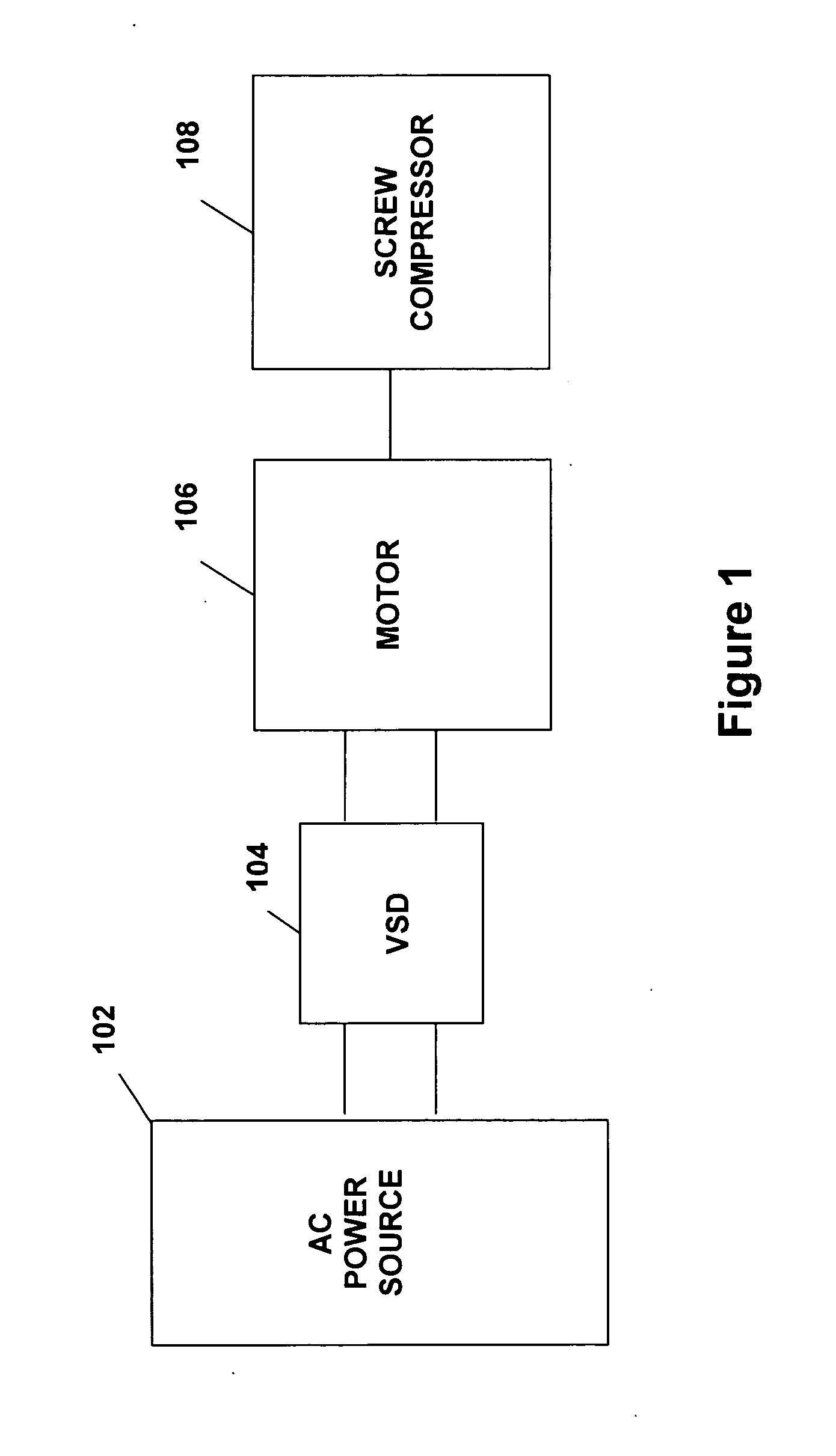

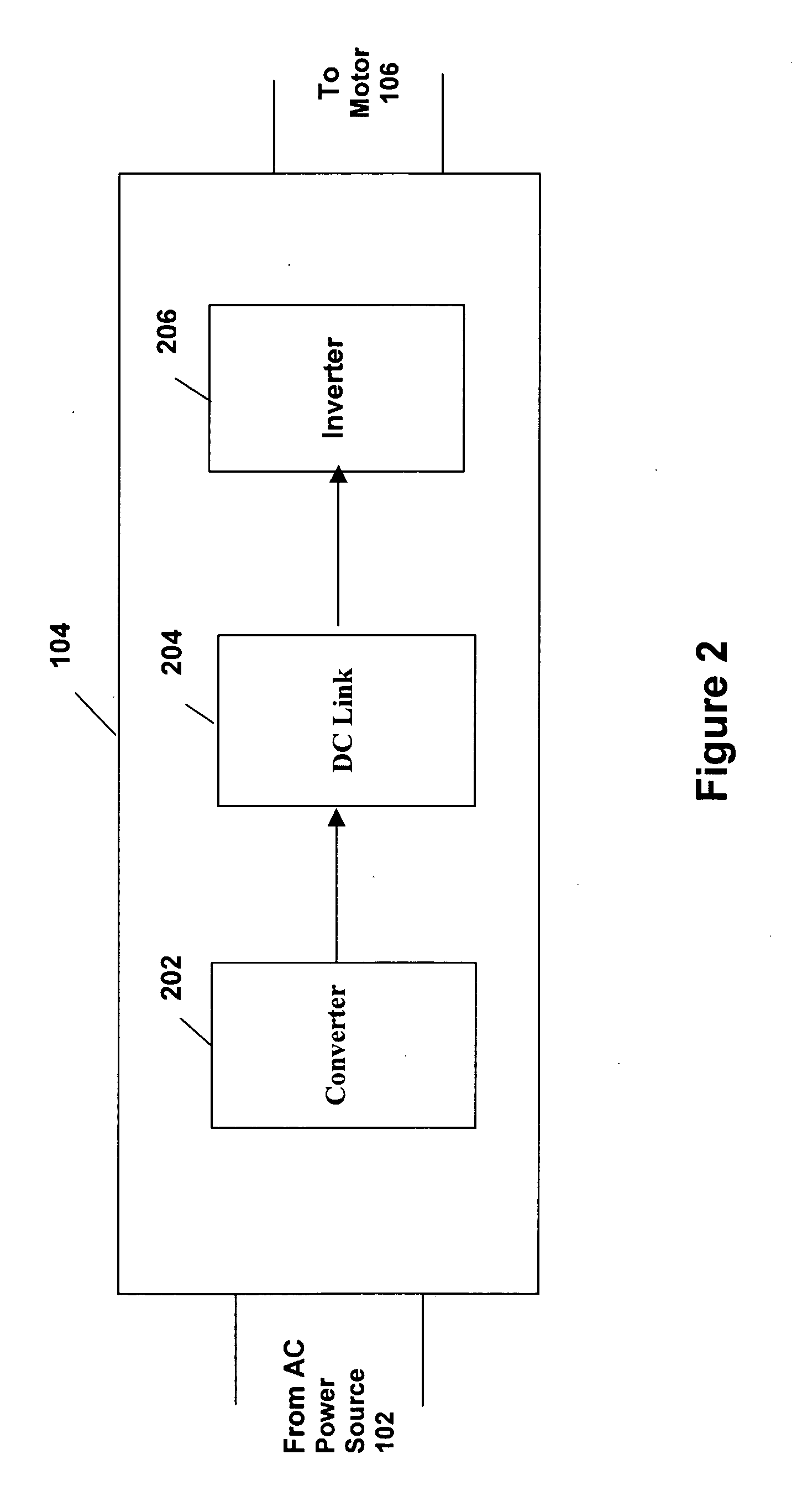

System and method for variable speed operation of a screw compressor

ActiveUS20050188708A1Efficient screw compressor operationReduce gas leakageAC motor controlRotary piston pumpsControl theoryOperating speed

A system and method are provided for variable speed operation of a screw compressor to obtain increased capacity and efficiency. The screw compressor is connected to an induction motor driven by a variable speed drive, wherein the screw compressor has a variable output capacity that is dependent on the output speed of the motor. To obtain increased capacity and efficiency, the screw compressor is operated at a speed greater than the screw compressor's rated speed and does not include a slide valve. The maximum operating speed of the screw compressor, which speed is greater than the rated speed, is related to the maximum operating speed of the motor when operated at a voltage and frequency provided by the variable speed drive that is greater than the motor's rated voltage and frequency in a constant flux or constant volts / Hz mode.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com