Method and apparatus for controlling the temperature of an electrically-heated discharge nozzle

a technology of discharge nozzle and temperature control, which is applied in the direction of electrical apparatus, pump components, printing, etc., can solve the problems of inefficiency of process, difficult use of shadow masks over large areas, and increasing coating of shadow masks, so as to avoid detection of failed sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

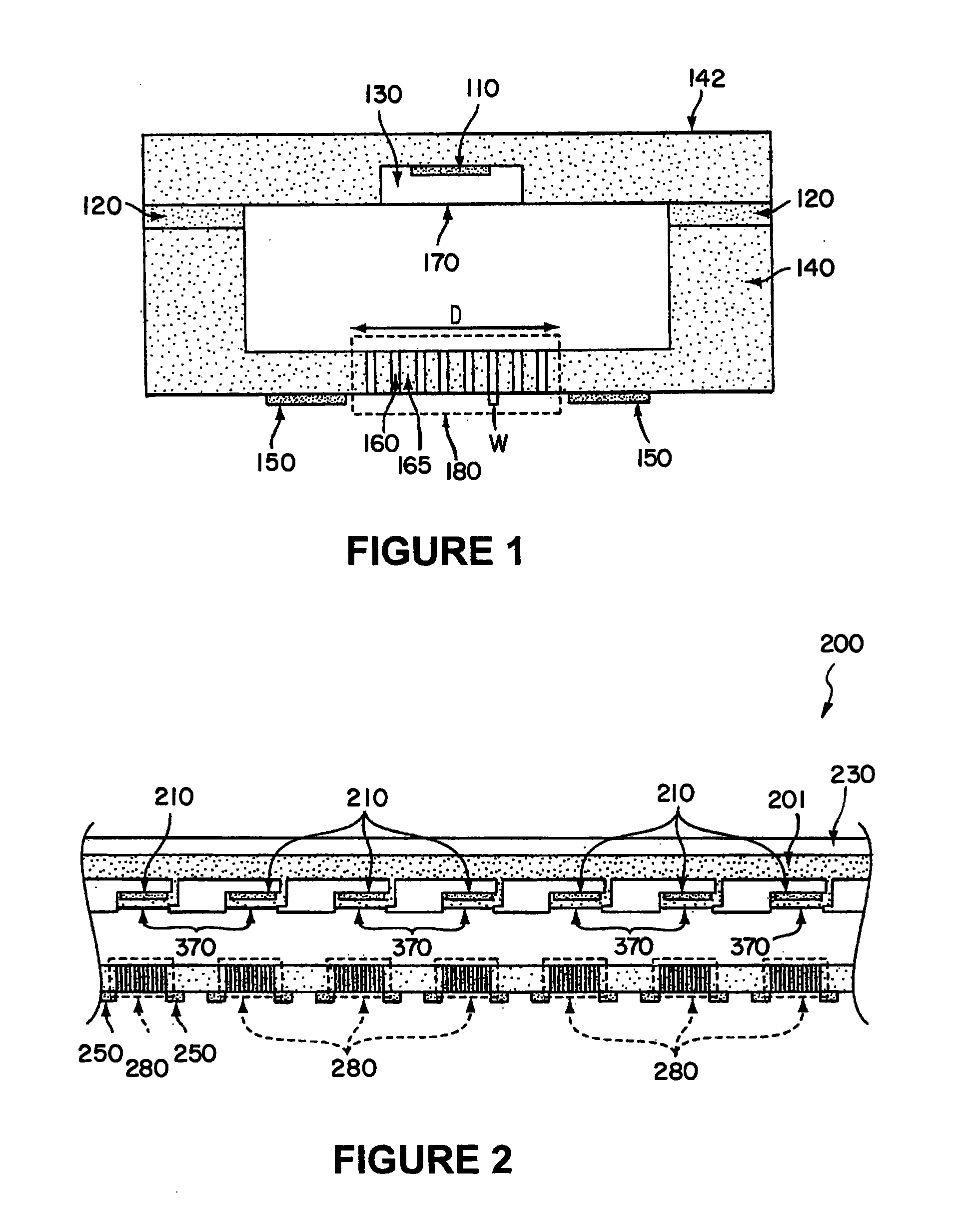

[0024]FIG. 1 is a schematic representation of an exemplary print-head having a thermal ink depositing mechanism according to one embodiment of the disclosure. The exemplary print-head of FIG. 1 includes chamber 130, orifice 170, nozzle 180, and micro-porous conduits 160. Chamber 130 receives ink in liquid form and communicates the ink from orifice 170 to discharge nozzle 180. The ink can comprise suspended or dissolved particles in a carrier liquid. These particles can comprise single molecules or atoms, or aggregations of molecules and / or atoms. The path between orifice 170 and discharge nozzle 180 defines a delivery path. In the embodiment of FIG. 1A, discharge nozzle 180 comprises conduits 160 separated by partitions 165. Conduits 160 may include micro-porous material therein. A surface of discharge nozzle 180 proximal to orifice 170 defines the inlet port to discharge nozzle 180 while the distal surface of discharge nozzle 180 defines the outlet port. A substrate (not shown) can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com