Patents

Literature

4075 results about "Monitoring and control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

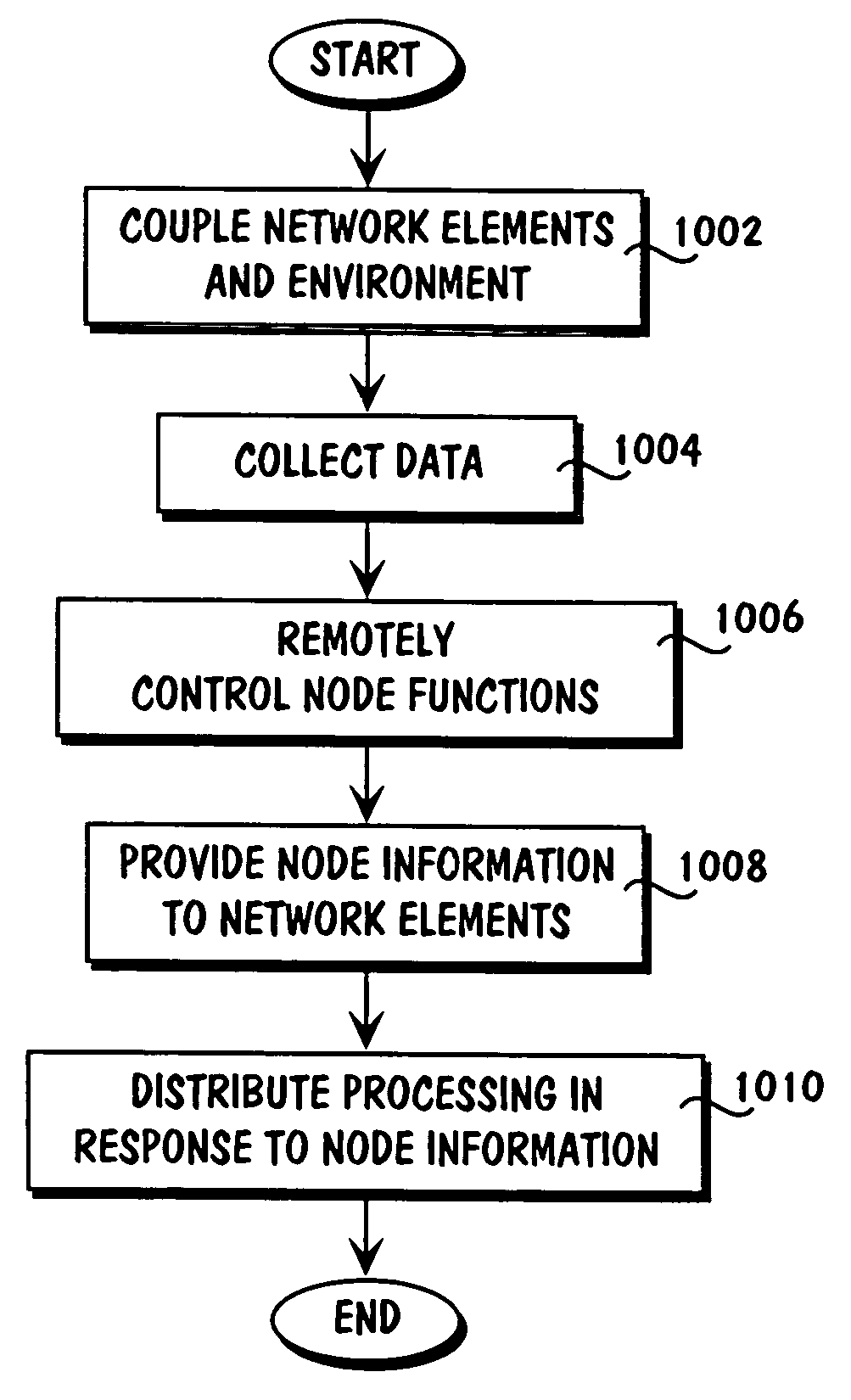

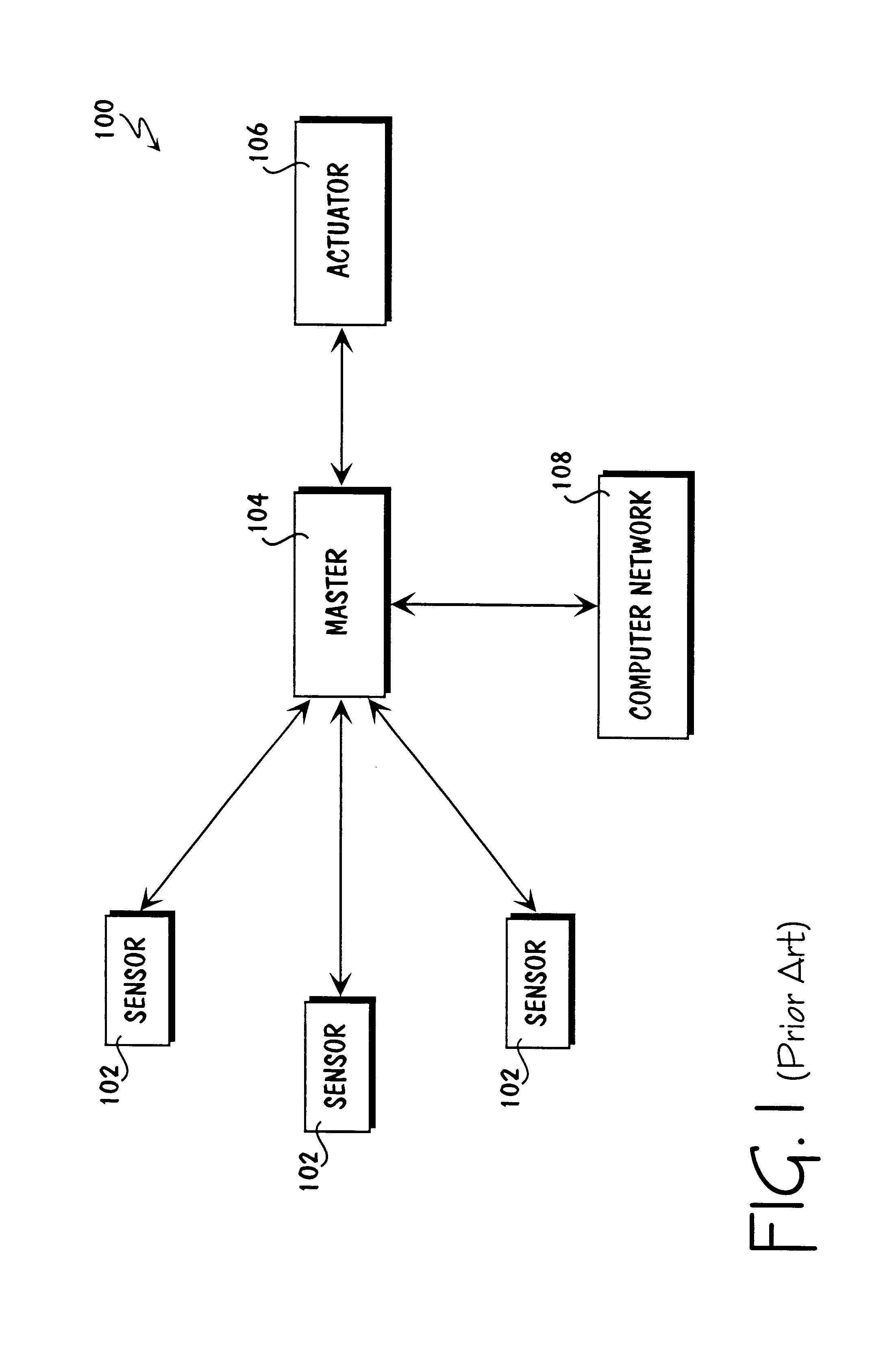

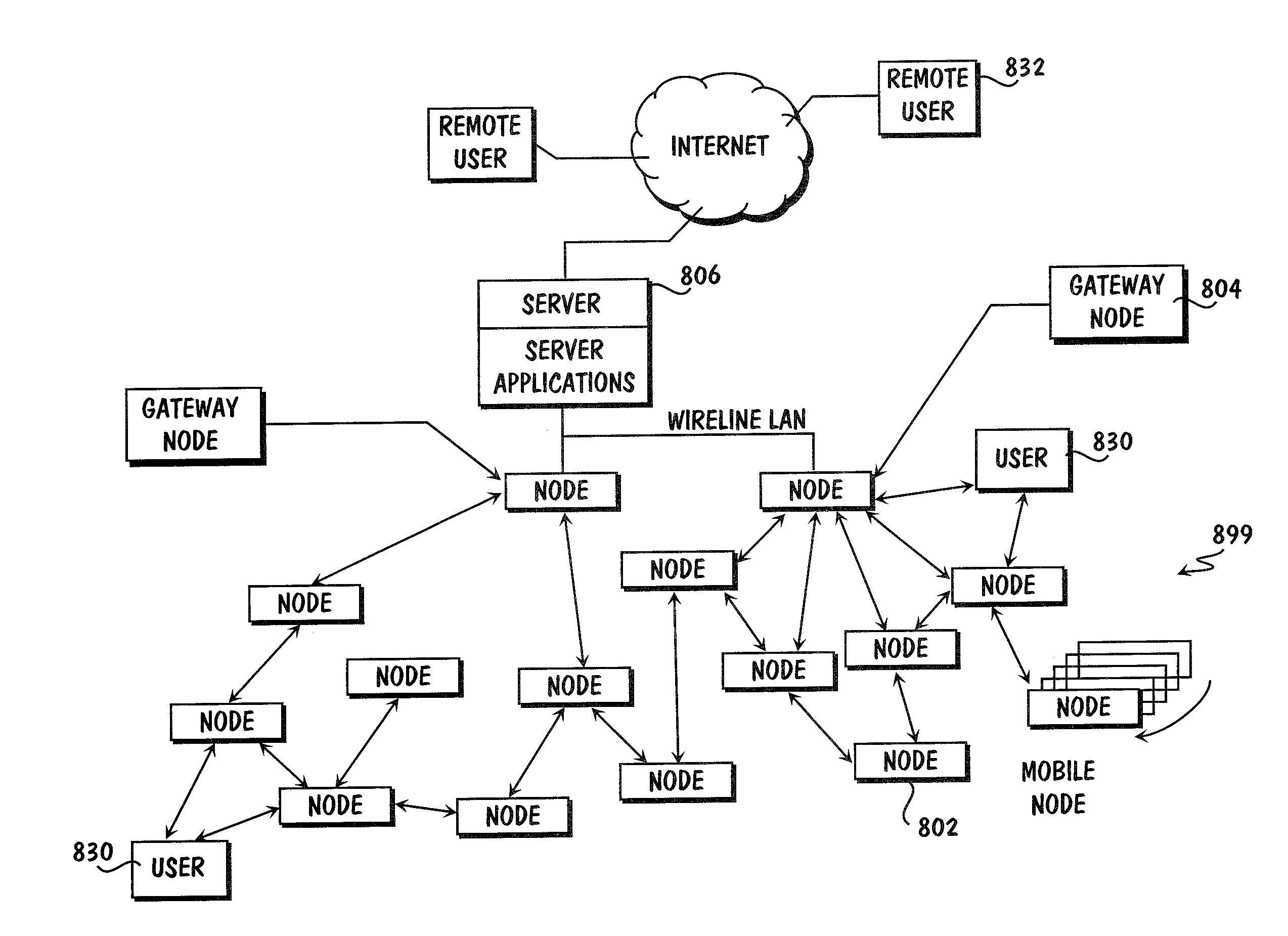

Method for collecting and processing data using internetworked wireless integrated network sensors (WINS)

InactiveUS7020701B1High reliability accessEasy to operateEnergy efficient ICTPower managementReconfigurabilityMonitoring and control

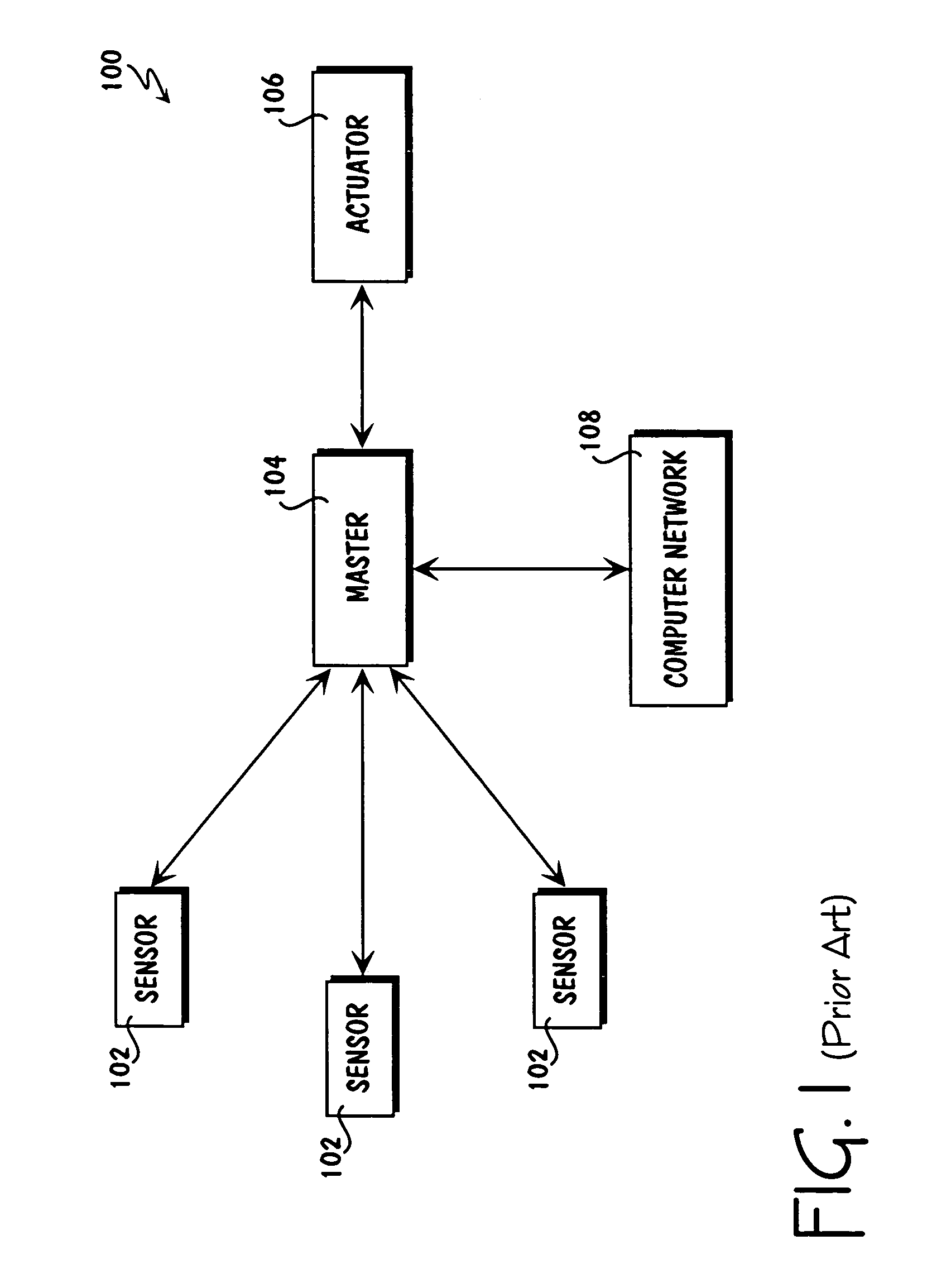

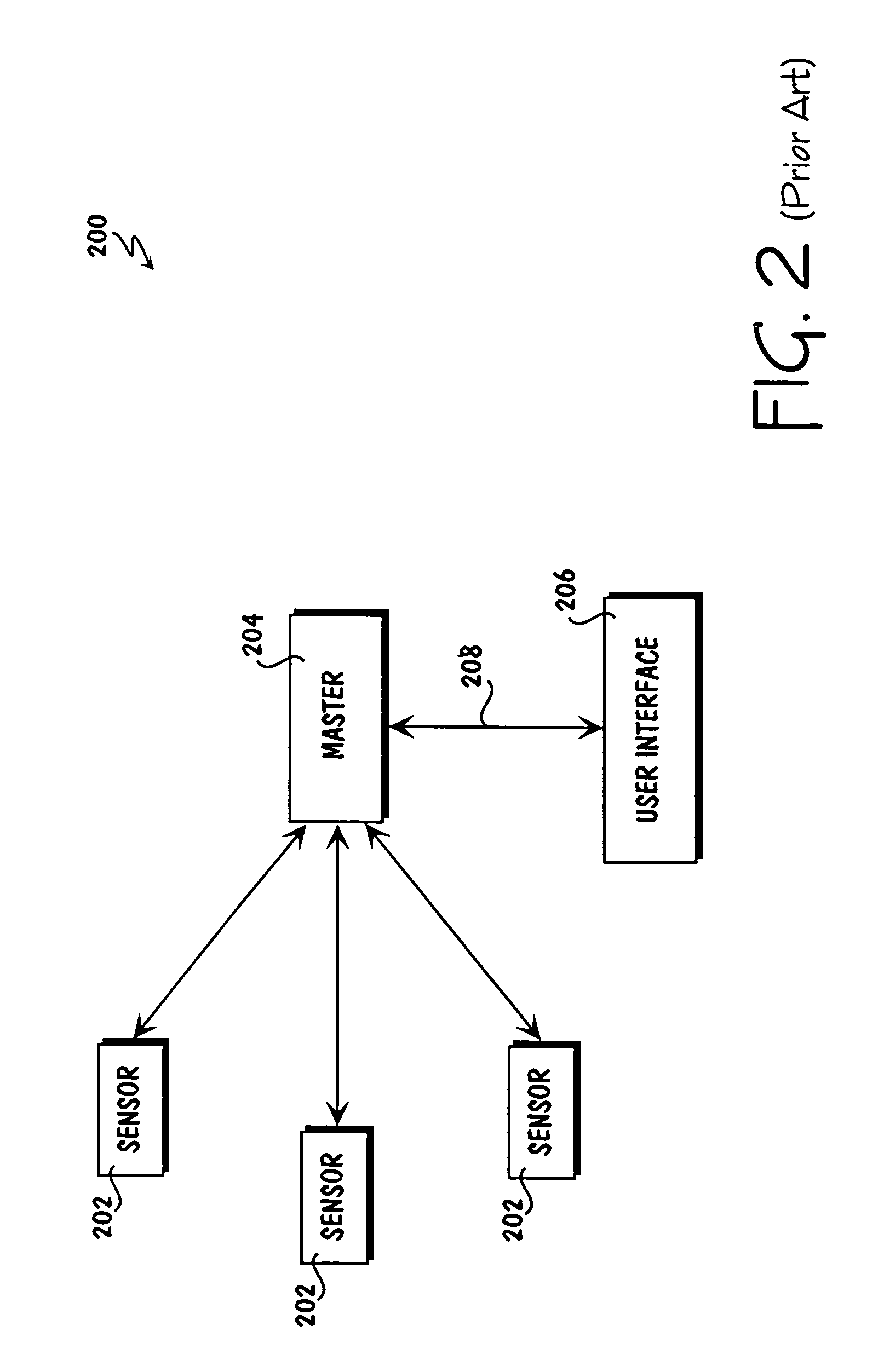

The Wireless Integrated Network Sensor Next Generation (WINS NG) nodes provide distributed network and Internet access to sensors, controls, and processors that are deeply embedded in equipment, facilities, and the environment. The WINS NG network is a new monitoring and control capability for applications in transportation, manufacturing, health care, environmental monitoring, and safety and security. The WINS NG nodes combine microsensor technology, low power distributed signal processing, low power computation, and low power, low cost wireless and / or wired networking capability in a compact system. The WINS NG networks provide sensing, local control, remote reconfigurability, and embedded intelligent systems in structures, materials, and environments.

Owner:INTELLECTUAL VENTURES I LLC

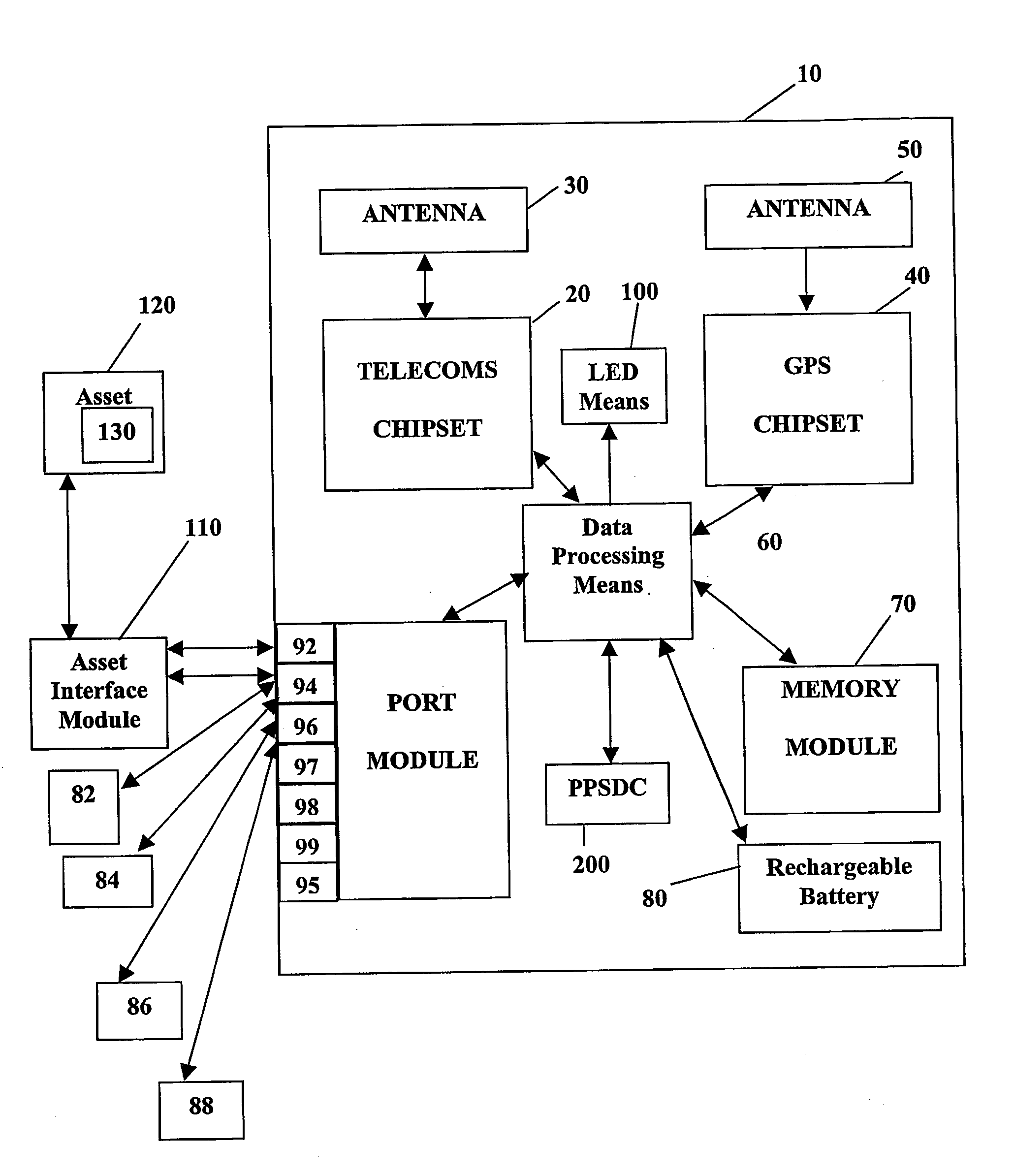

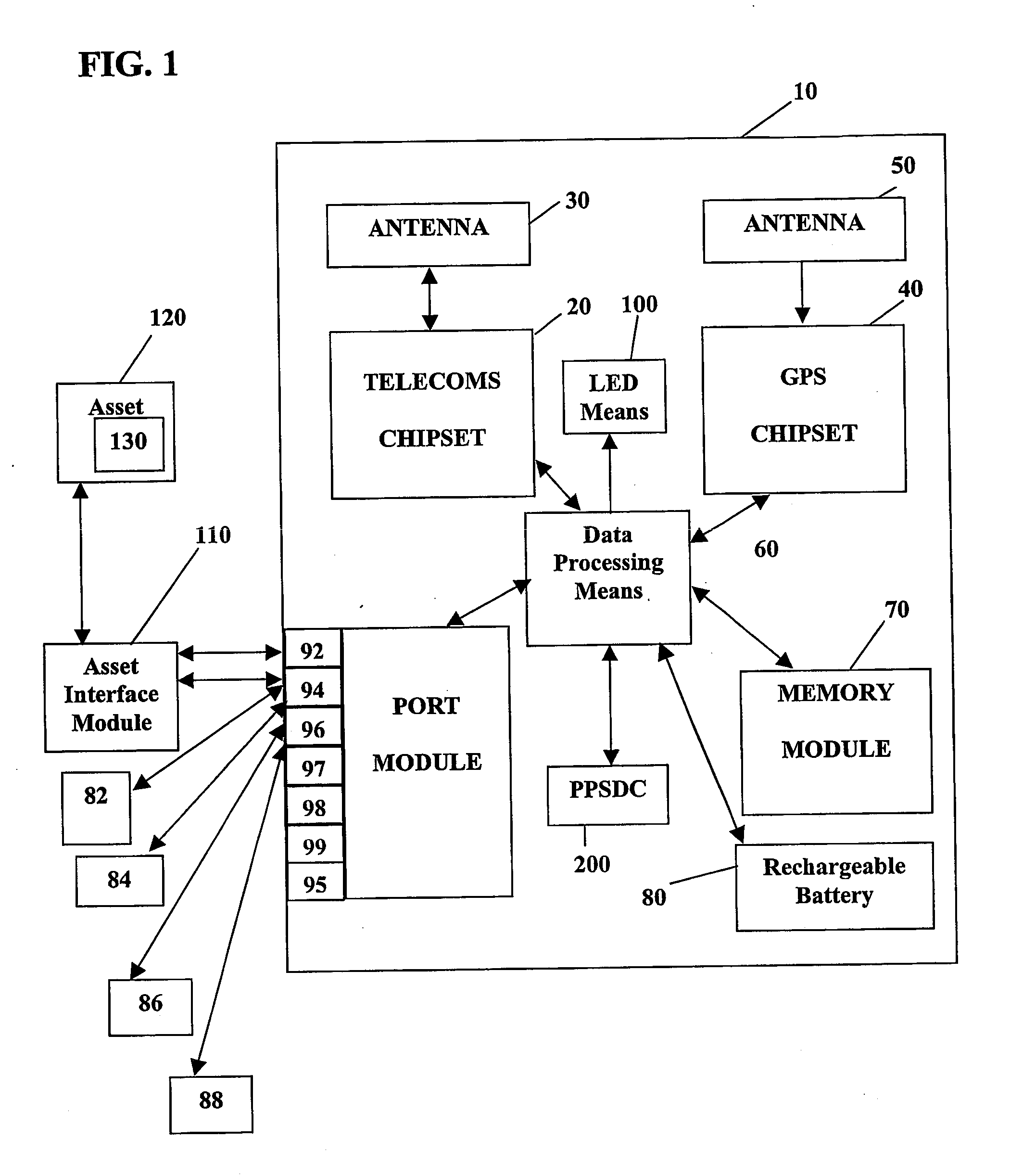

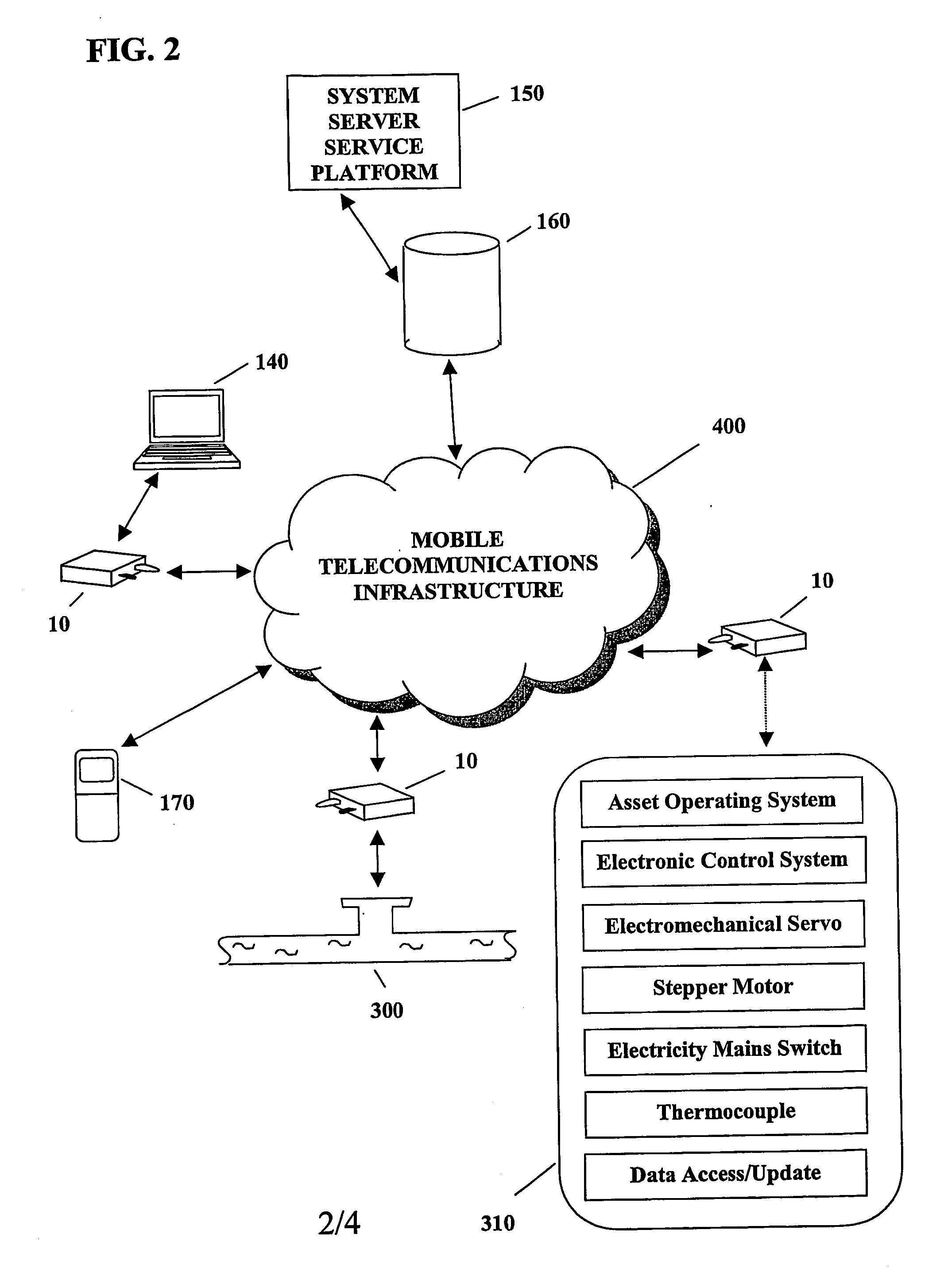

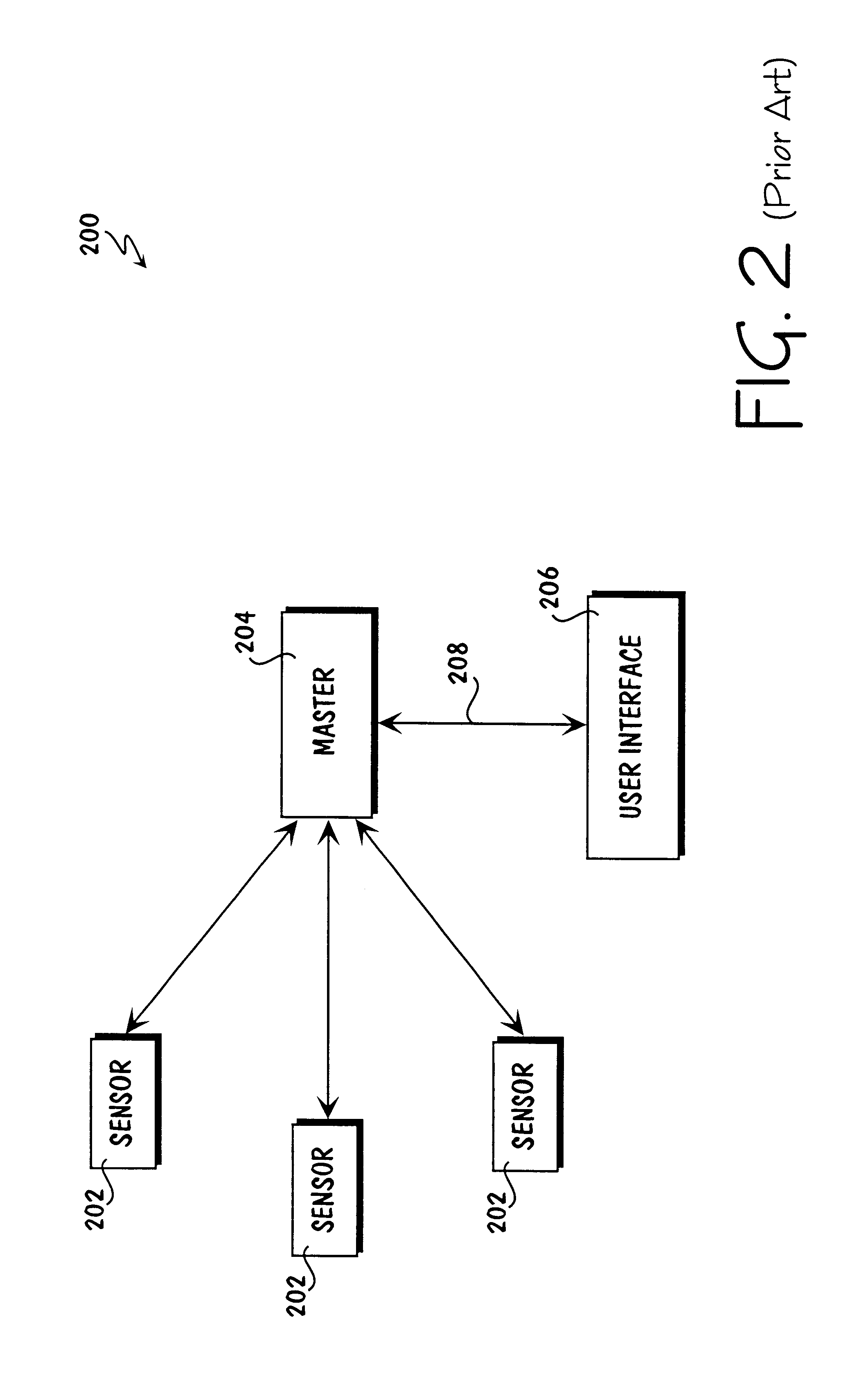

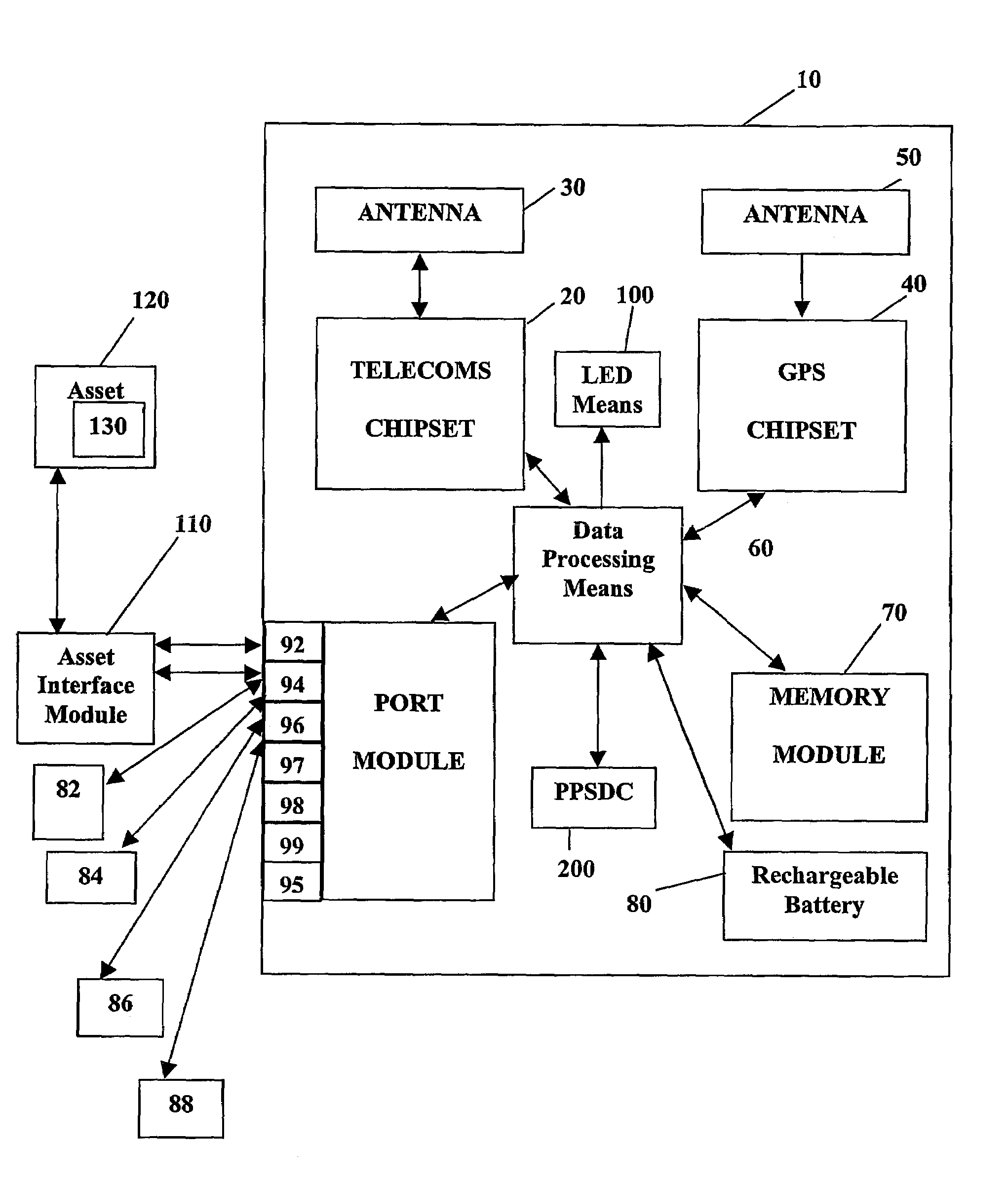

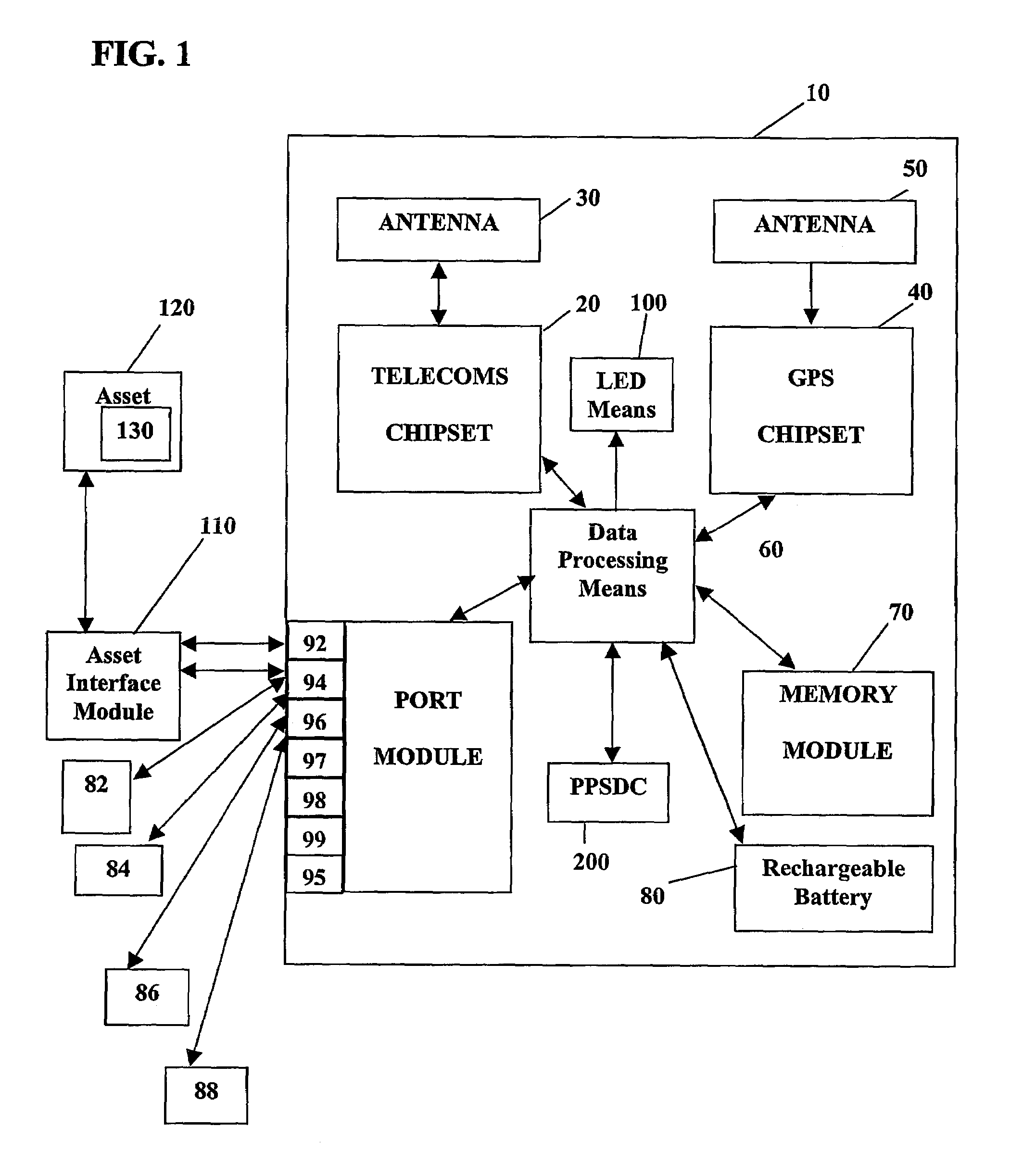

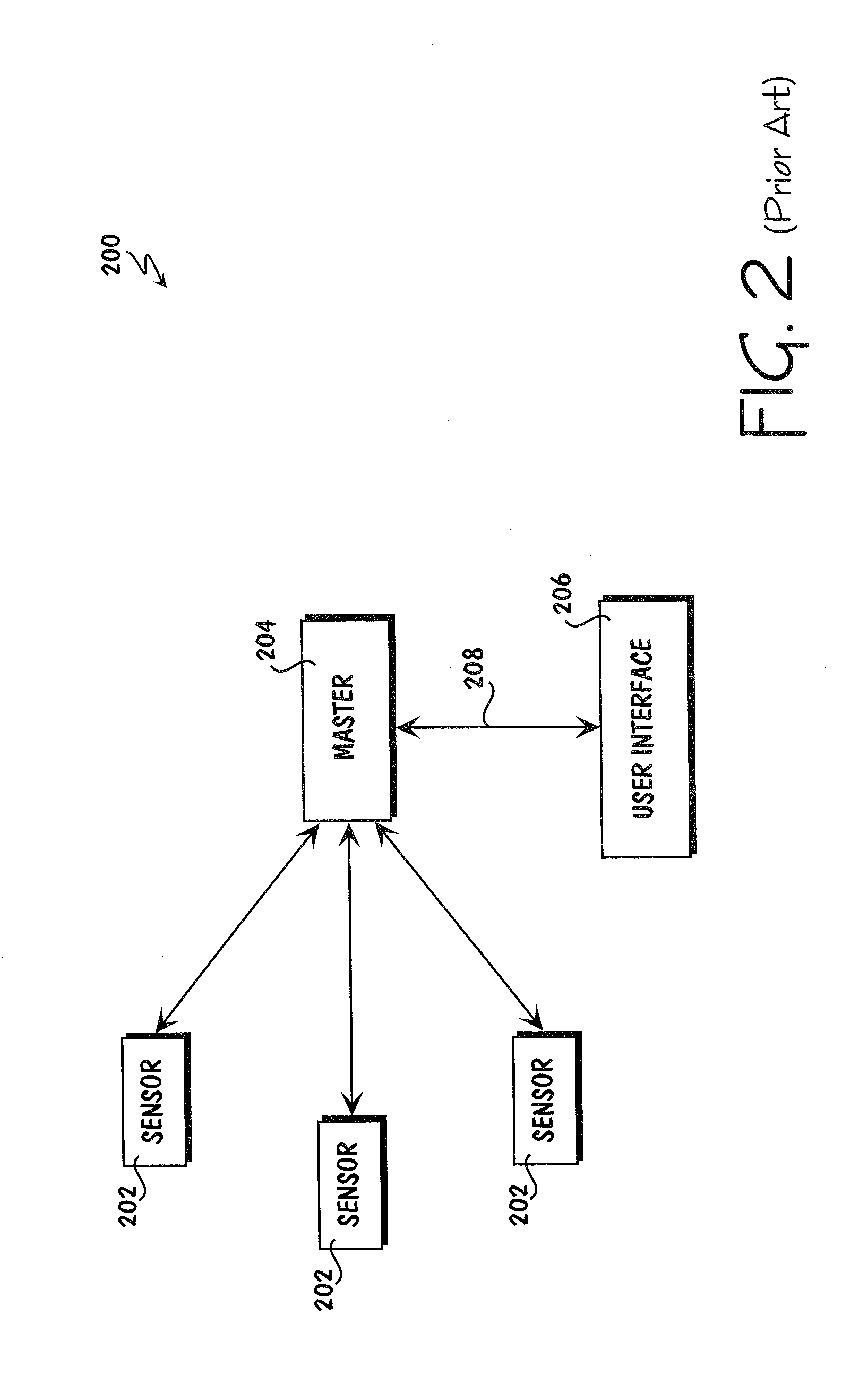

System and method for monitoring and control of wireless modules linked to assets

A system and method for remote asset management is described which can provide the basis for a diverse product group including an improved remote location monitoring system, a means for communicating with and for monitoring the status and or location of a plurality of diverse assets, as well as the means for communicating with said assets for the purpose of modifying the operational status of one or more of said assets according to one or more stored data parameters such as location, use, battery power, and such like. The remote asset management system comprise a wireless module, which is associated with at least one of the plurality of assets and which is interfaced with the operating system of said asset and or with an electromechanical control means, which may control one or more features of the operation of said assets. A supporting network-based, or internet-based service platform controls and manages the status of each of the plurality of assets, either automatically, or in response to received messages from fixed or wireless communication devices, and which is capable of selectively communicating data to said assets for changing the operational status of said assets according to pre-programmed conditions.

Owner:M2M SOLUTIONS

Method and apparatus for internetworked wireless integrated network sensor (WINS) nodes

InactiveUS6859831B1Ease real-time operating system issueImprove adaptabilitySpecific access rightsAnti-theft devicesReconfigurabilityMonitoring and control

The Wireless Integrated Network Sensor Next Generation (WINS NG) nodes provide distributed network and Internet access to sensors, controls, and processors that are deeply embedded in equipment, facilities, and the environment. The WINS NG network is a new monitoring and control capability for applications in transportation, manufacturing, health care, environmental monitoring, and safety and security. The WINS NG nodes combine microsensor technology, low power distributed signal processing, low power computation, and low power, low cost wireless and / or wired networking capability in a compact system. The WINS NG networks provide sensing, local control, remote reconfigurability, and embedded intelligent systems in structures, materials, and environments.

Owner:INTELLECTUAL VENTURES I LLC

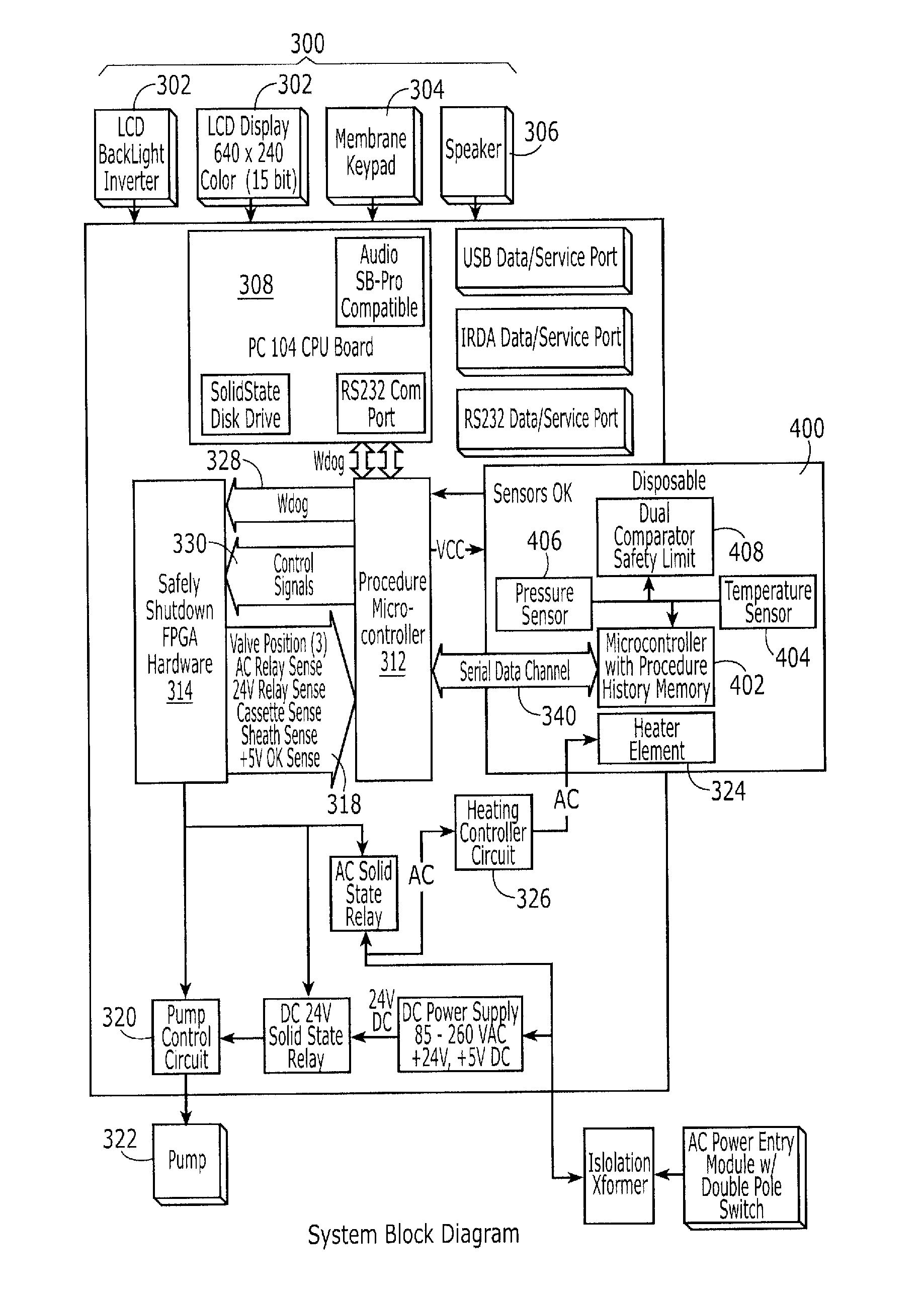

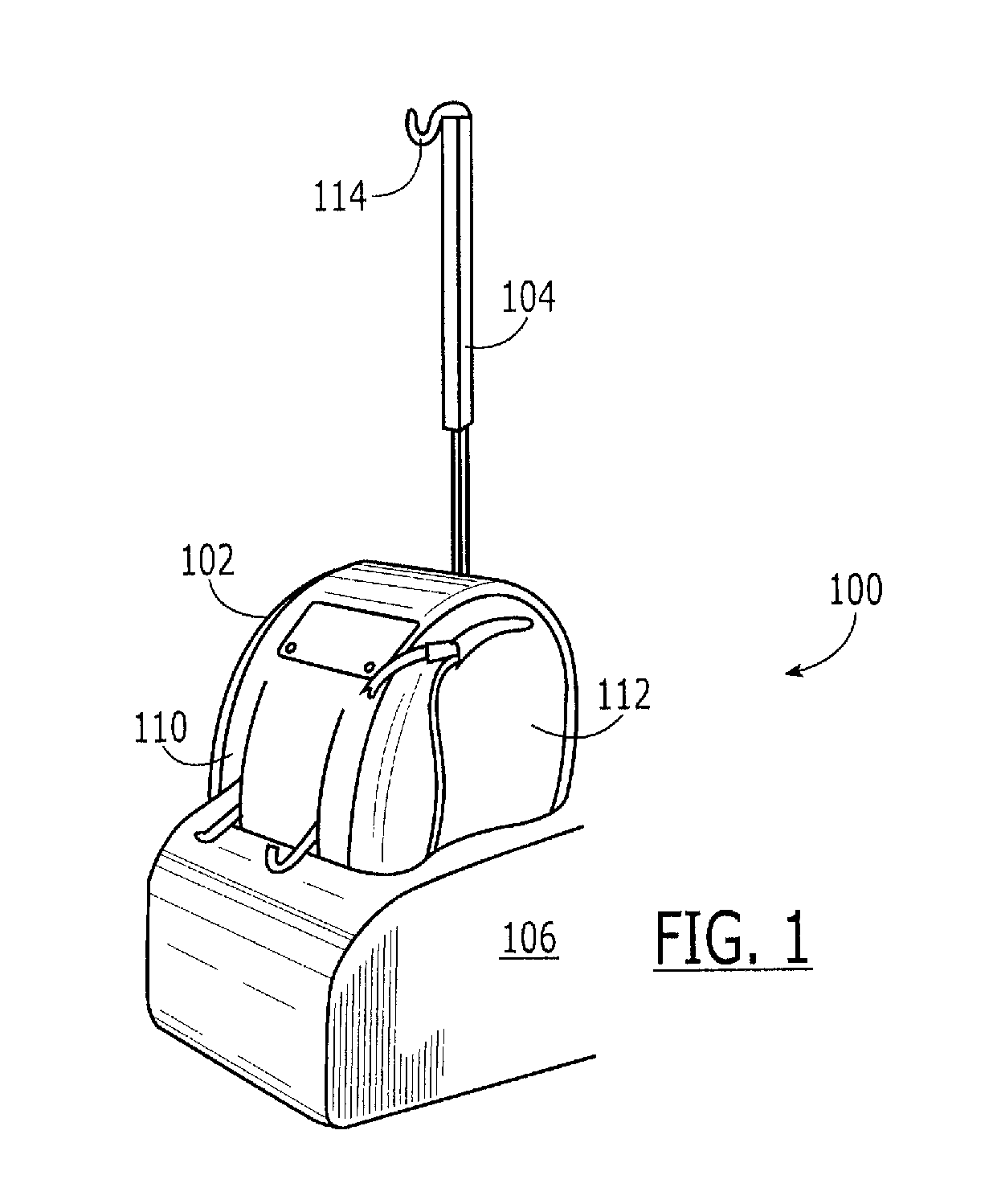

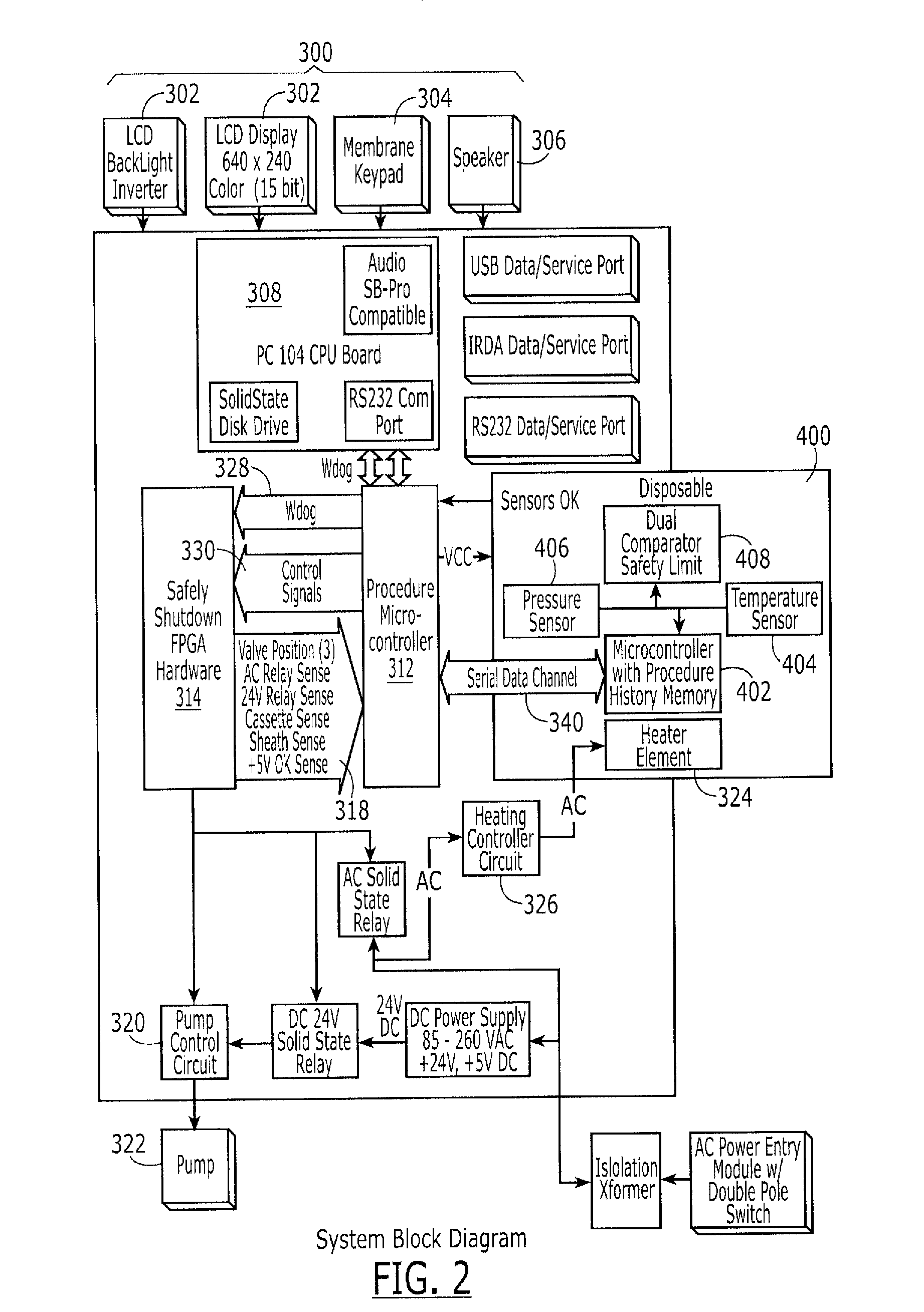

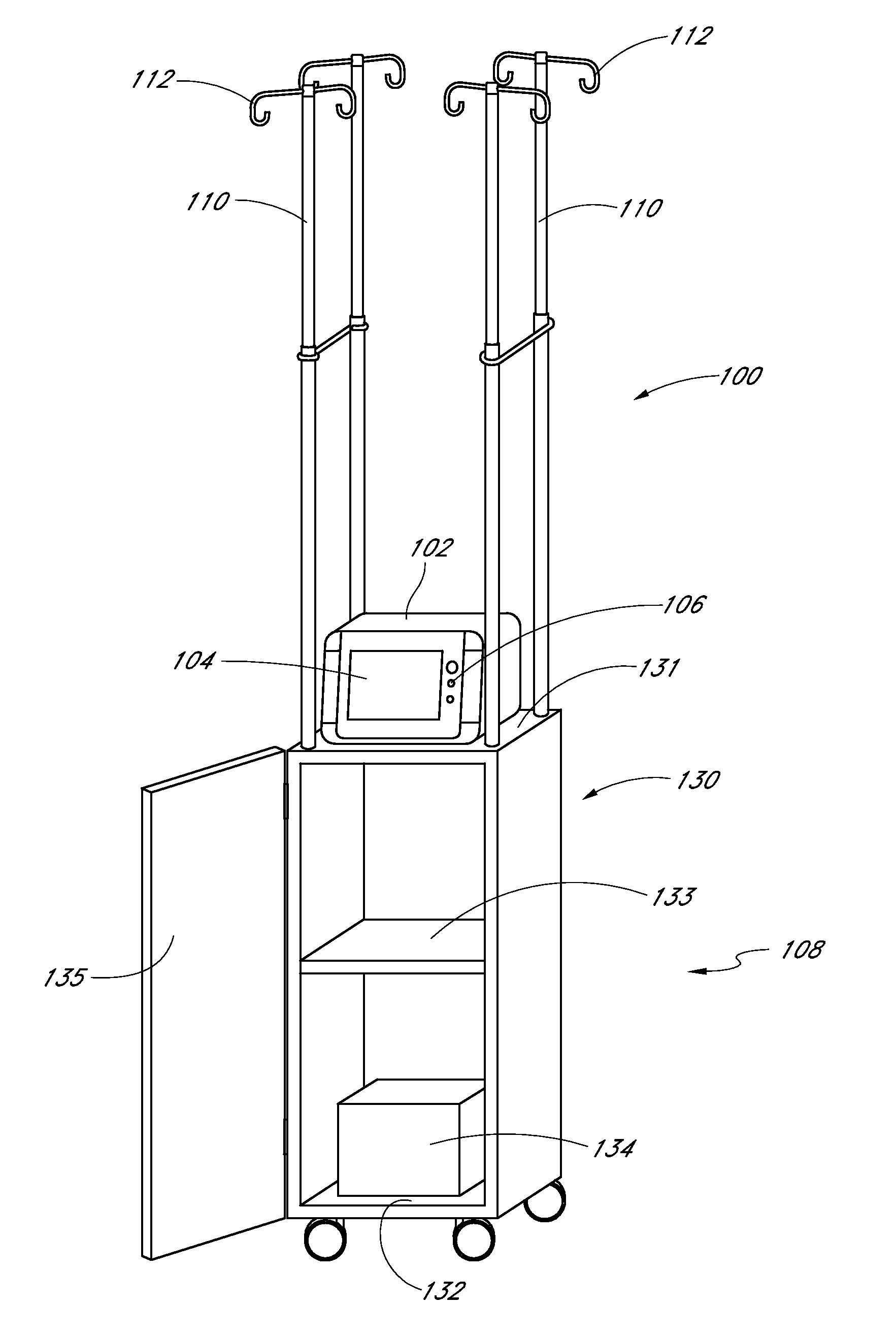

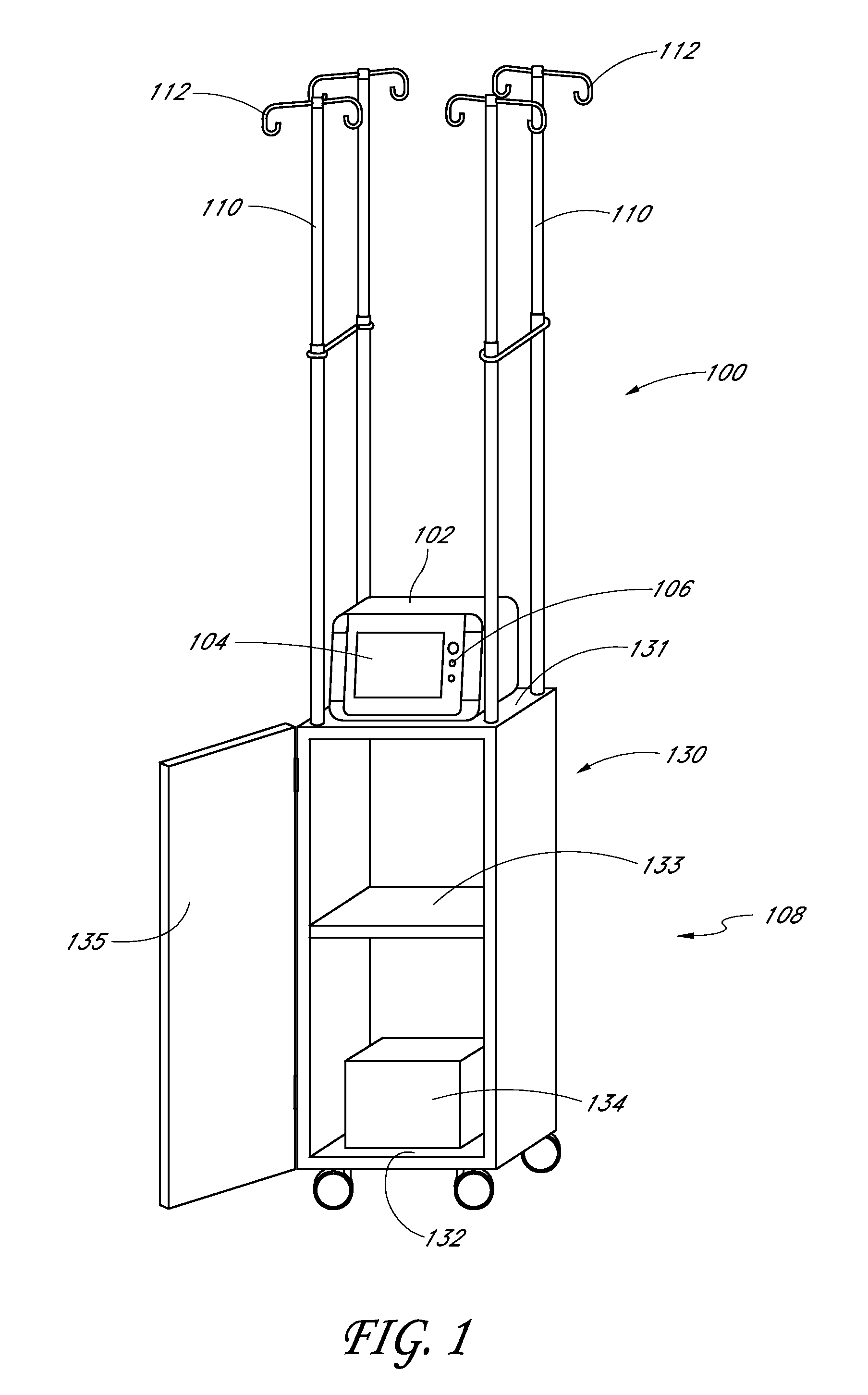

Device for circulating heated fluid

ActiveUS8226635B2Controlling energy of instrumentSurgical instruments for heatingMonitoring and controlEmbedded system

A system for ablating tissue includes a reusable control unit including a processor monitoring and controlling ablation and a control interface receiving input to and output from the processor in combination with a disposable procedure set releasably connectable to the control unit to couple to the control interface for communication with the processor.

Owner:MINERVA SURGICAL

System and method for monitoring and control of wireless modules linked to assets

InactiveUS7027808B2Wireless commuication servicesElectric/magnetic detectionOperational systemComputer module

A system and method for remote asset management is described which can provide the basis for a diverse product group including an improved remote location monitoring system, a means for communicating with and for monitoring the status and or location of a plurality of diverse assets, as well as the means for communicating with said assets for the purpose of modifying the operational status of one or more of said assets according to one or more stored data parameters such as location, use, battery power, and such like. The remote asset management system comprises a wireless module, which is associated with at least one of the plurality of asset and which is interfaced with the operating system of said assert and or with an electromechanical control means, which may control one or more features of the operation of said assets. A supporting network-based, or internet-based service platform, controls and manages the status of each of the plurality of assets, either automatically, or in response to received messages from fixed or wireless communication devices, and which is capable of selectively communicating data to said assets for changing the operational status of said assets according to pre-programmed conditions.

Owner:M2M SOLUTIONS

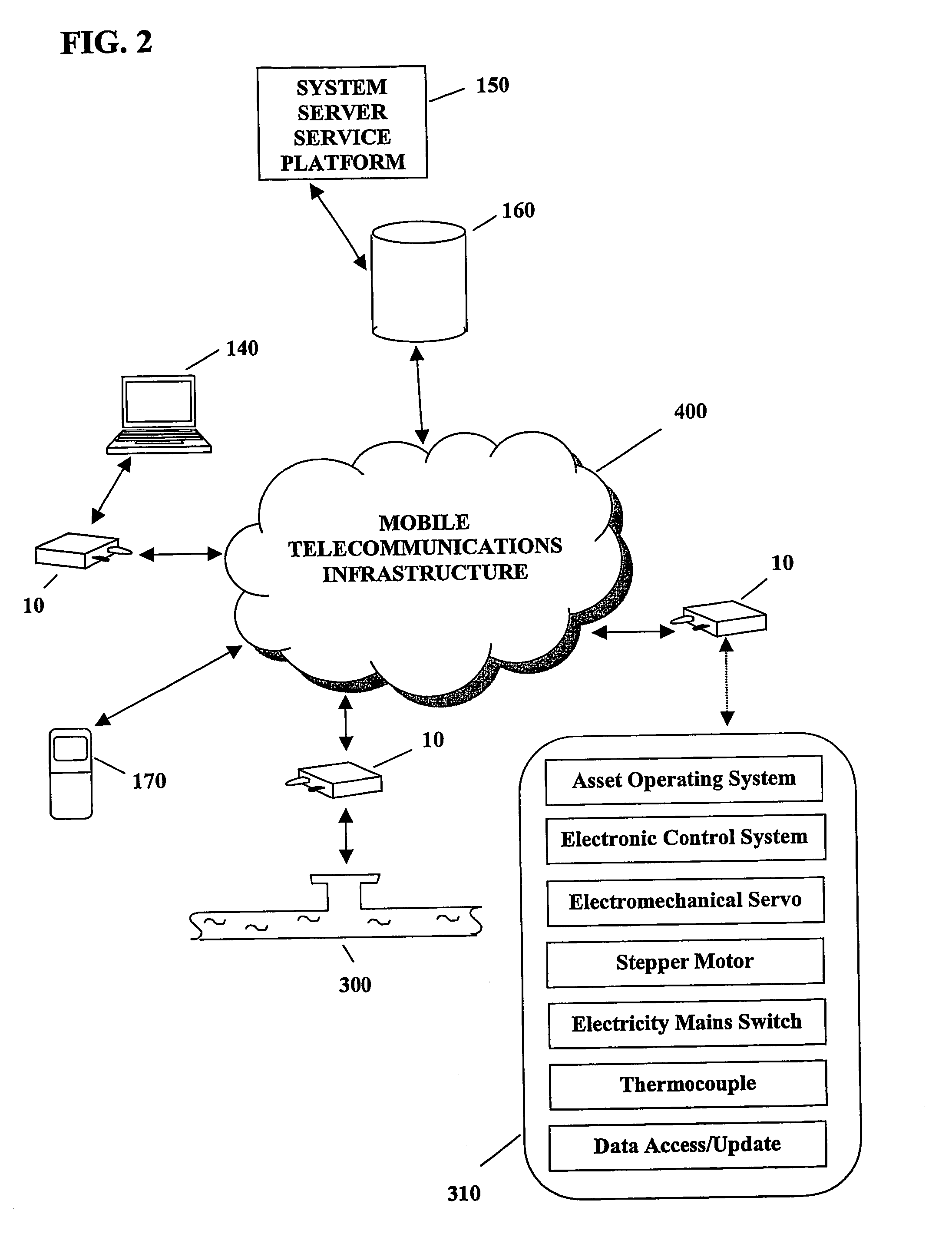

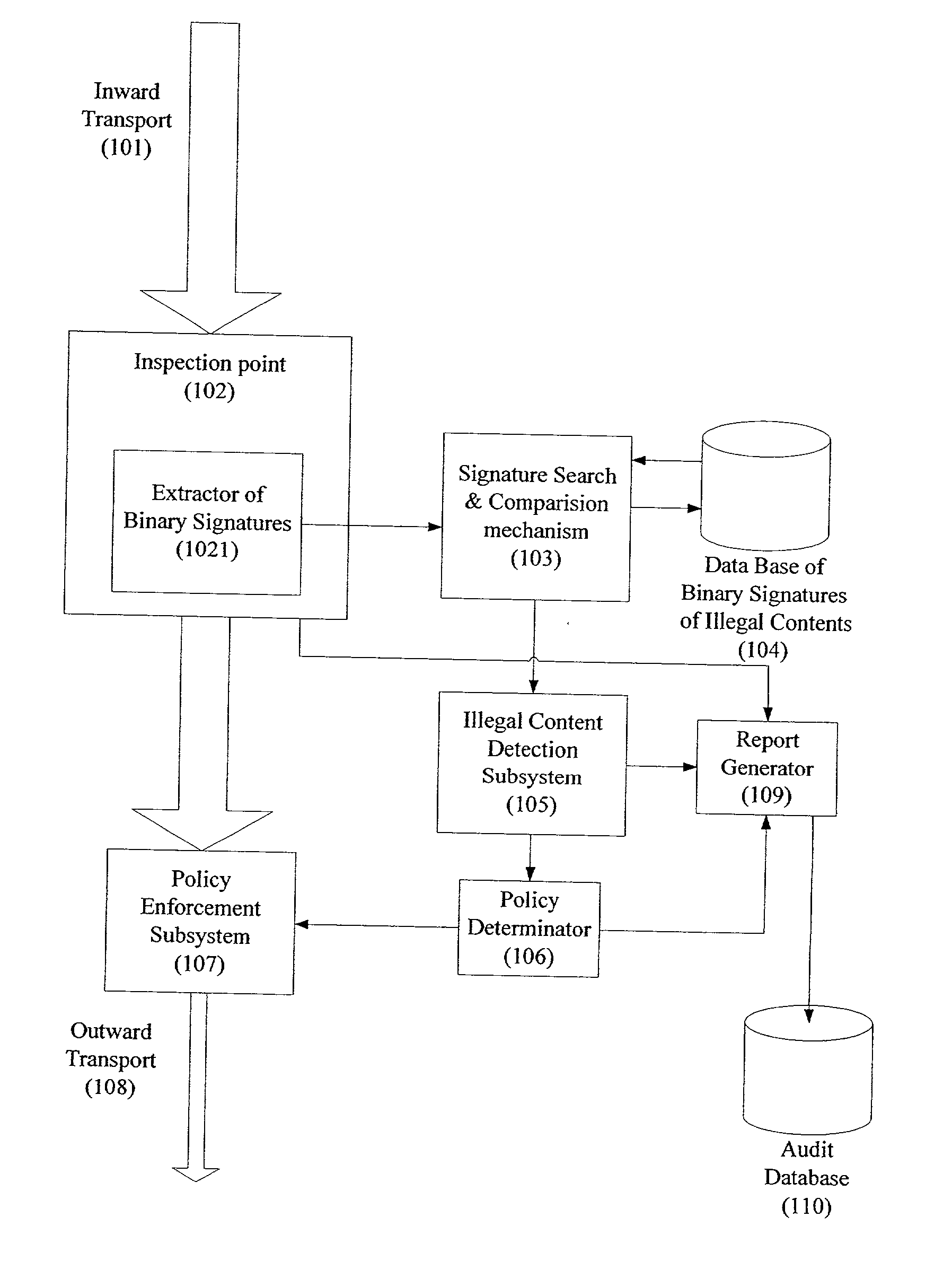

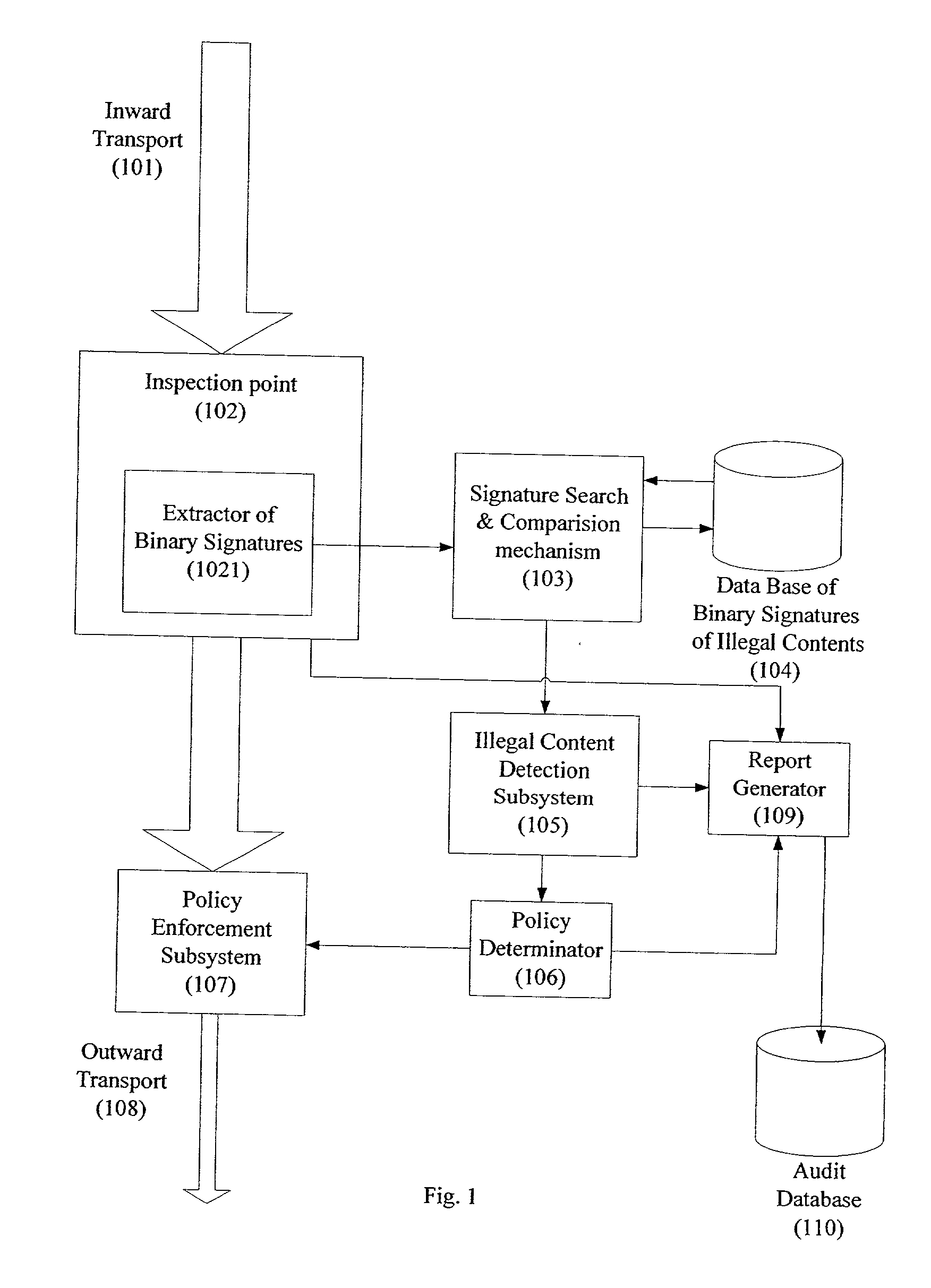

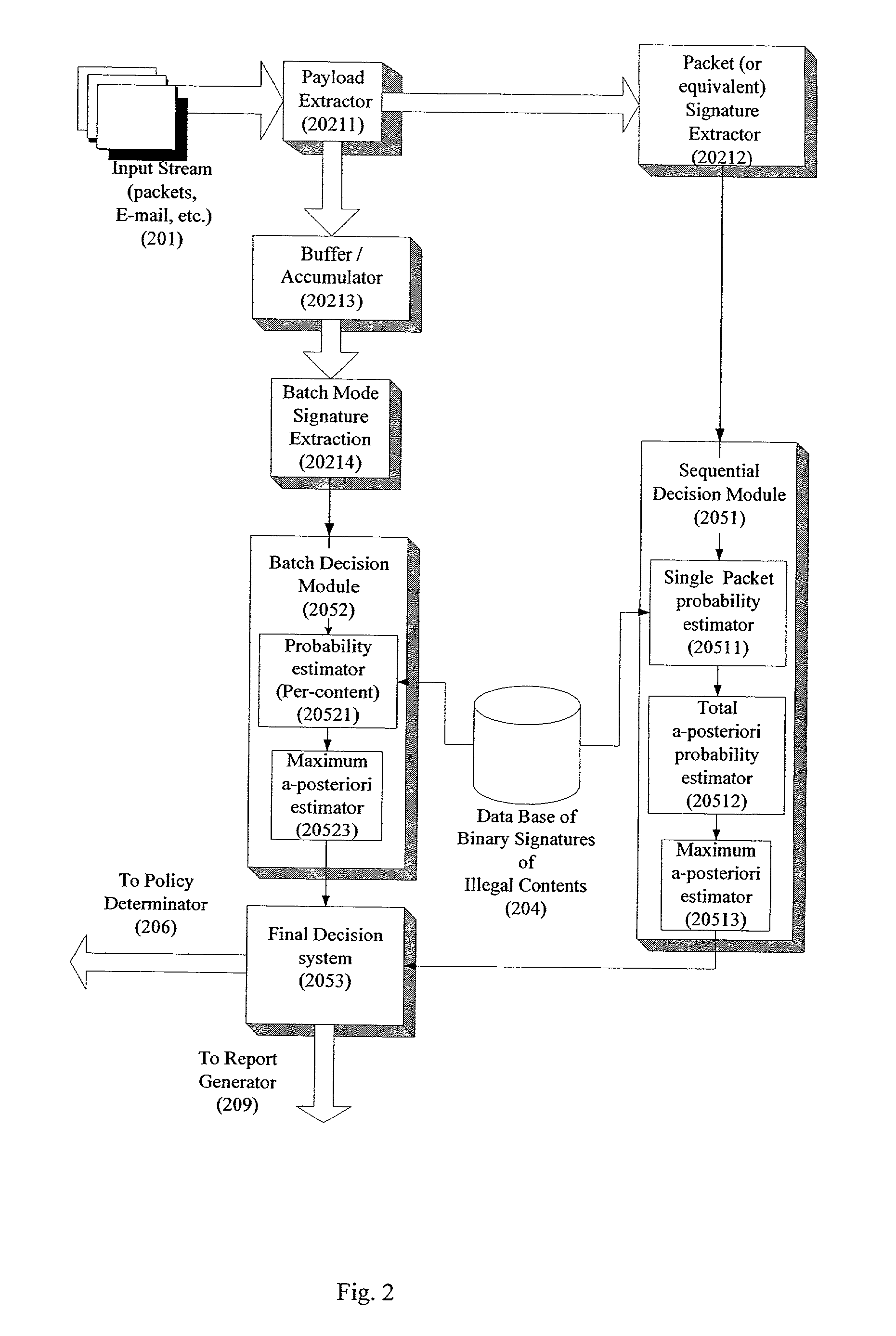

System and method for monitoring unauthorized transport of digital content

ActiveUS20020129140A1Reduce decreaseAttenuation bandwidthMemory loss protectionError detection/correctionDigital contentNumber content

A system for network content monitoring and control, comprising: a transport data monitor, connectable to a point in a network, for monitoring data being transported past said point, a signature extractor, associated with said transport data monitor, for extracting a derivation of said data, said derivation being indicative of content of said payload, a database of preobtained signatures of content whose movements it is desired to monitor, and a comparator for comparing said derivation with said preobtained signatures, thereby to determine whether said payload comprises any of said content whose movements it is desired to monitor. The monitoring result may be used in bandwidth control on the network to restrict transport of the content it is desired to control.

Owner:FORCEPOINT LLC

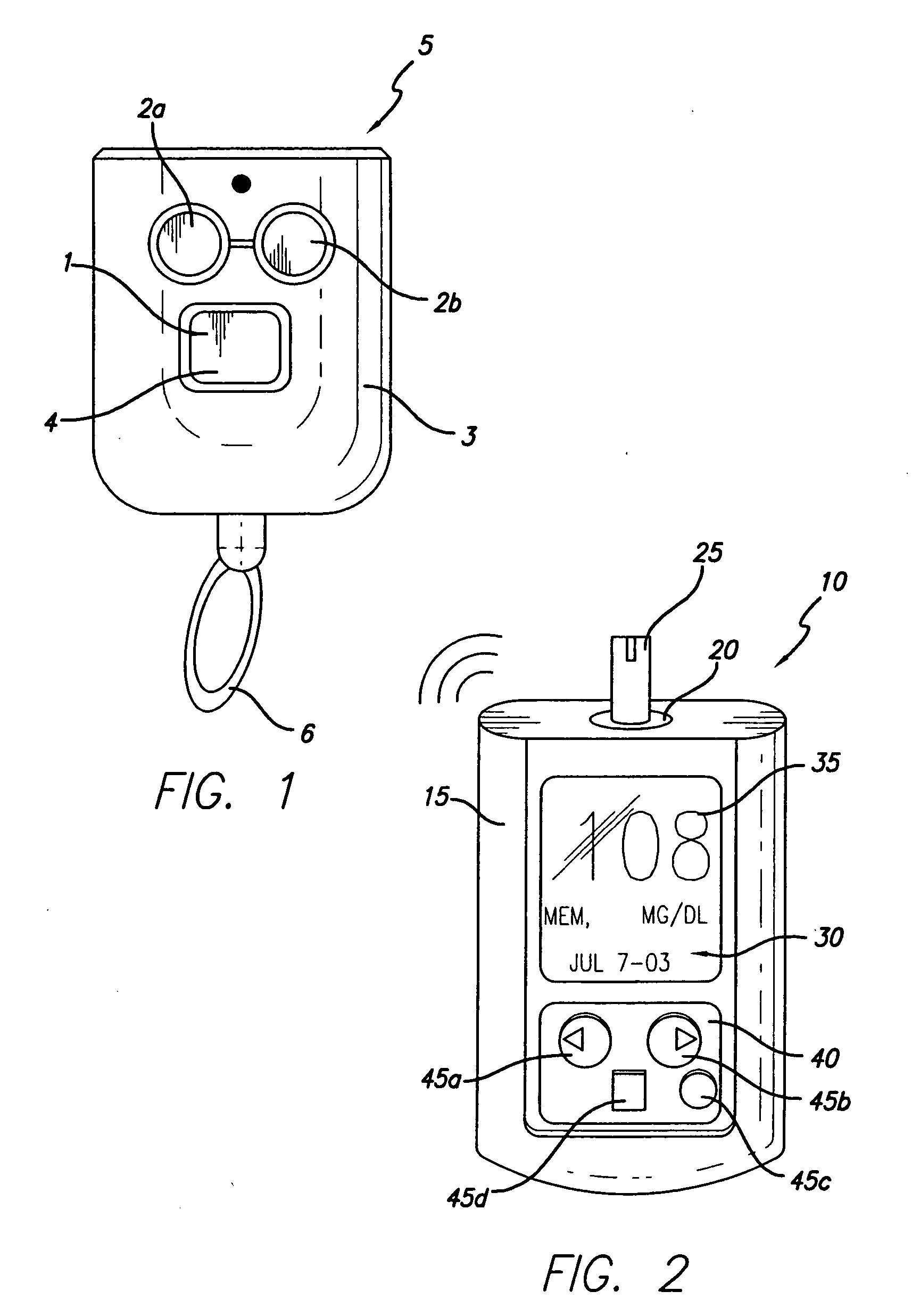

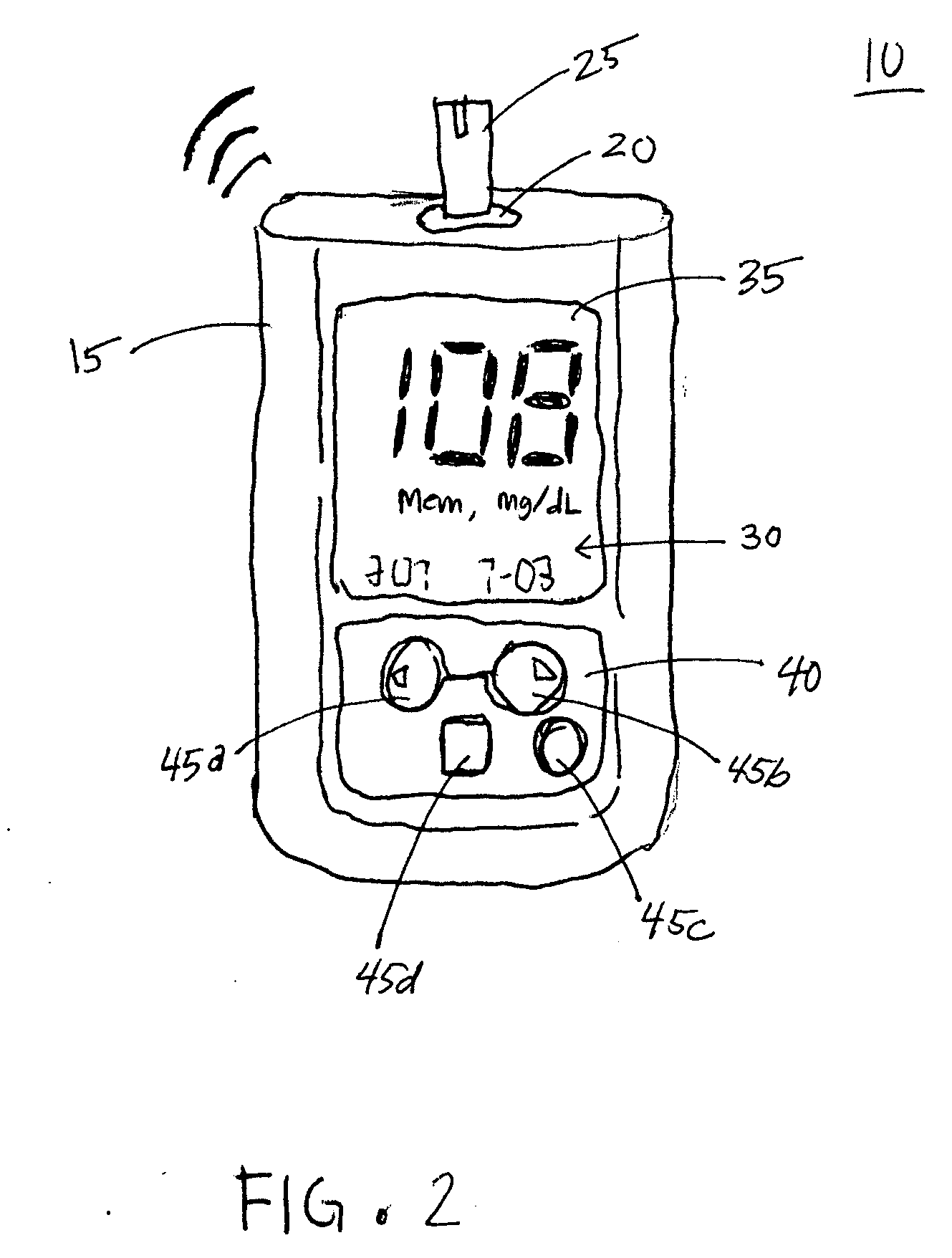

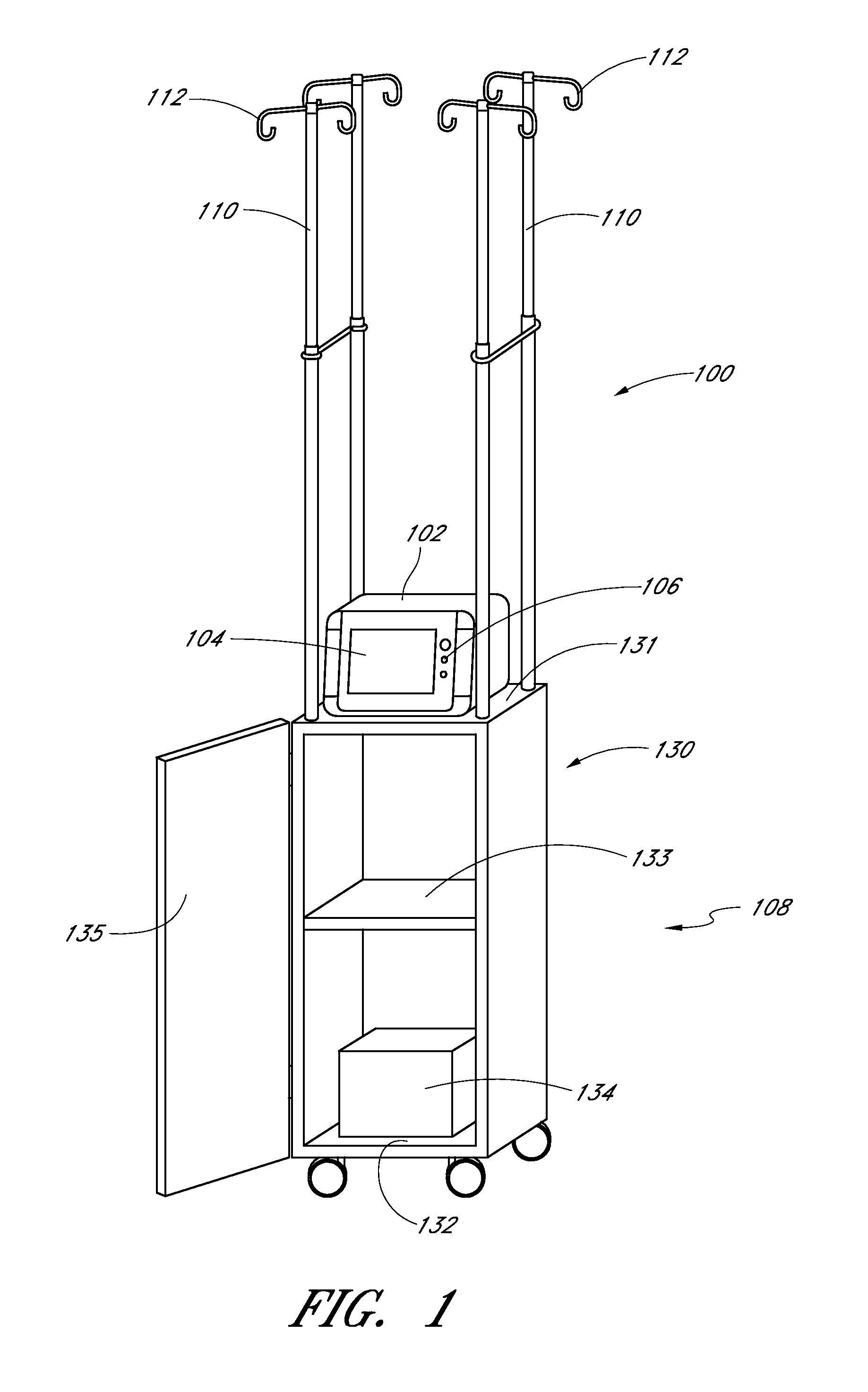

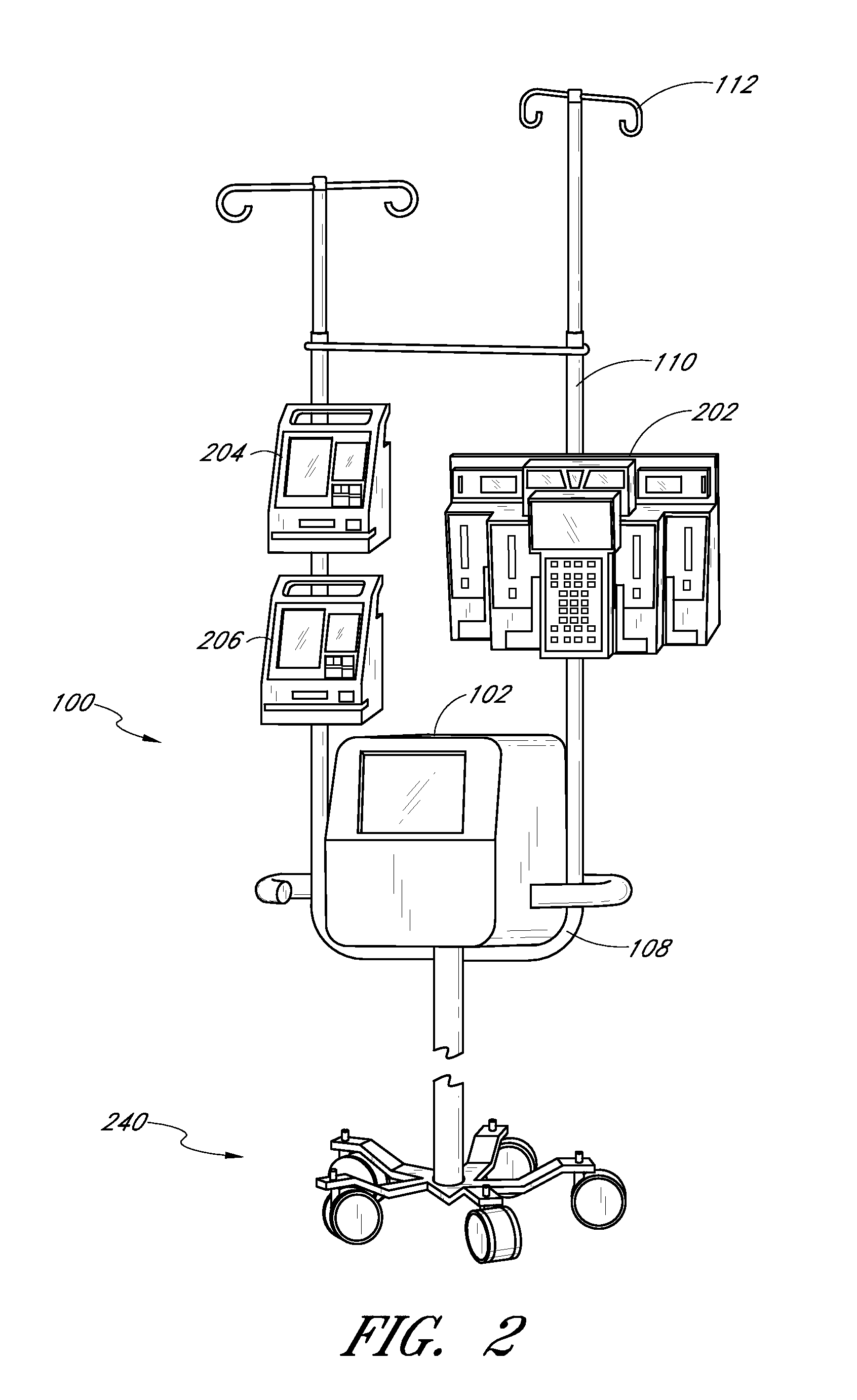

Watch controller for a medical device

InactiveUS20070093786A1Minimizes potential for errorEasy to watchMedical devicesPharmaceutical delivery mechanismCommunications systemMonitoring and control

An infusion system that includes a watch controller device and a communication system to transmit the communications from the watch controller device to an infusion device pump that controls delivery of fluids to the user's body. More particularly, these apparatuses and methods are for providing convenient monitoring and control of the infusion pump device in determining the appropriate amount of insulin to deliver.

Owner:MEDTRONIC MIMIMED INC

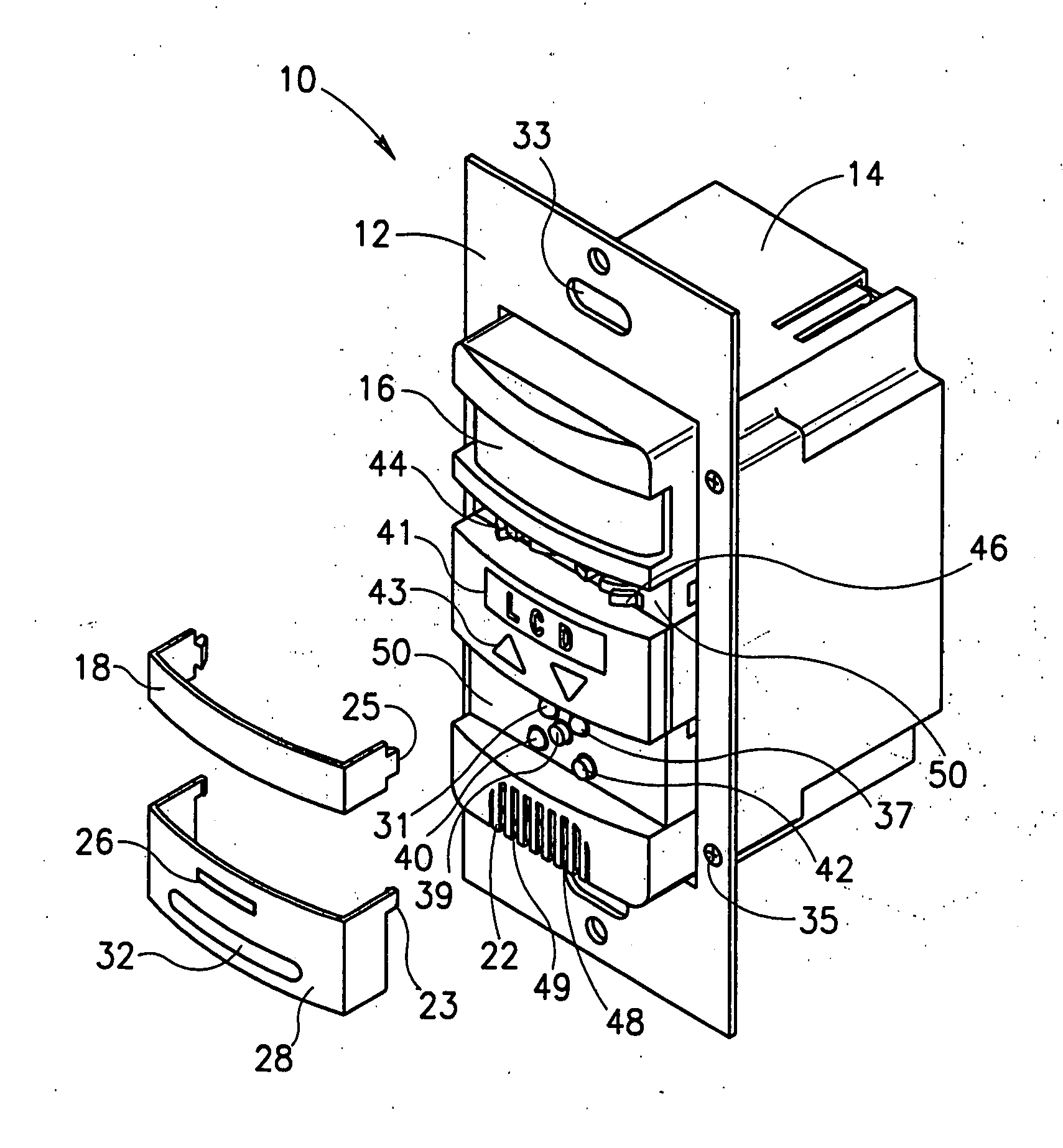

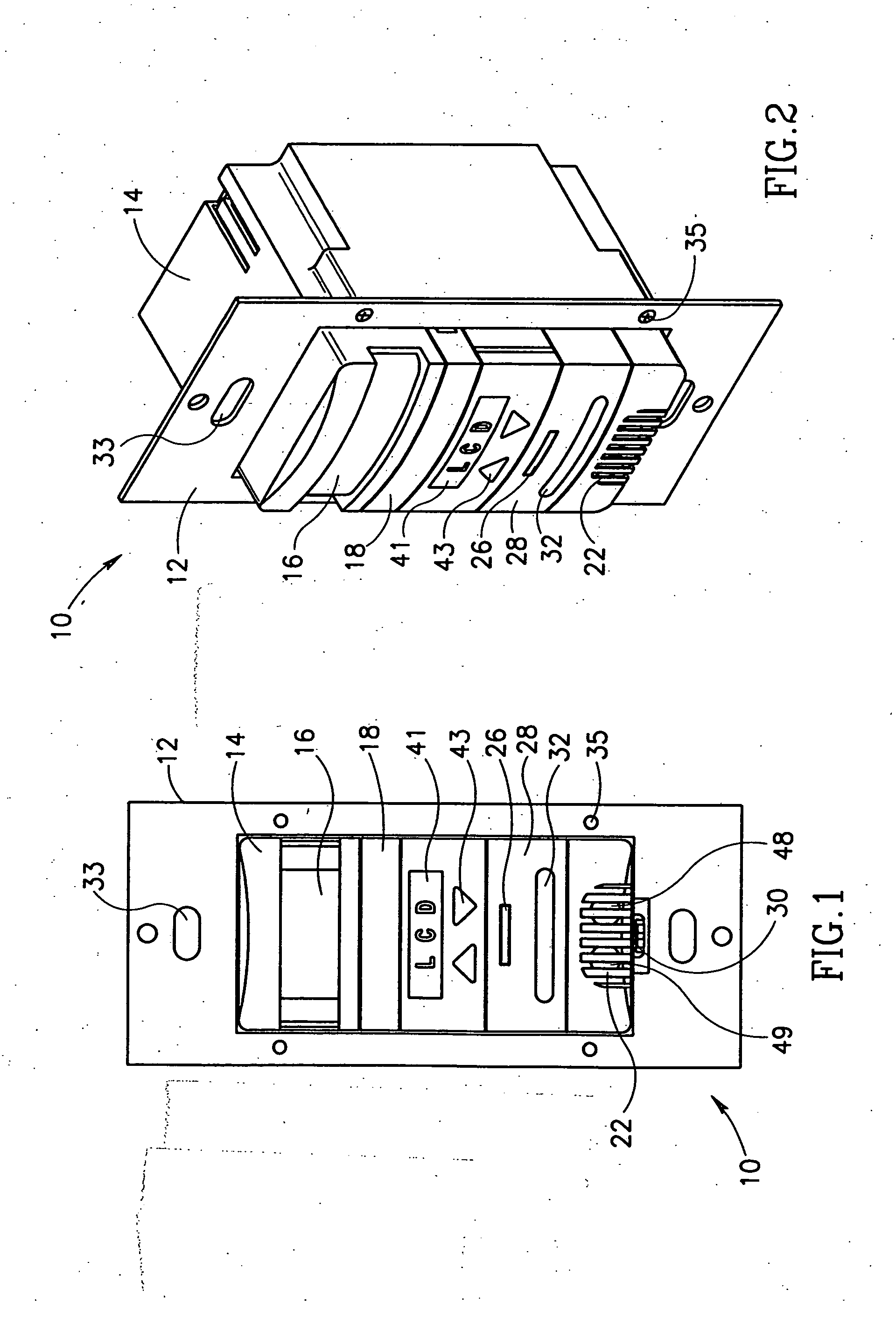

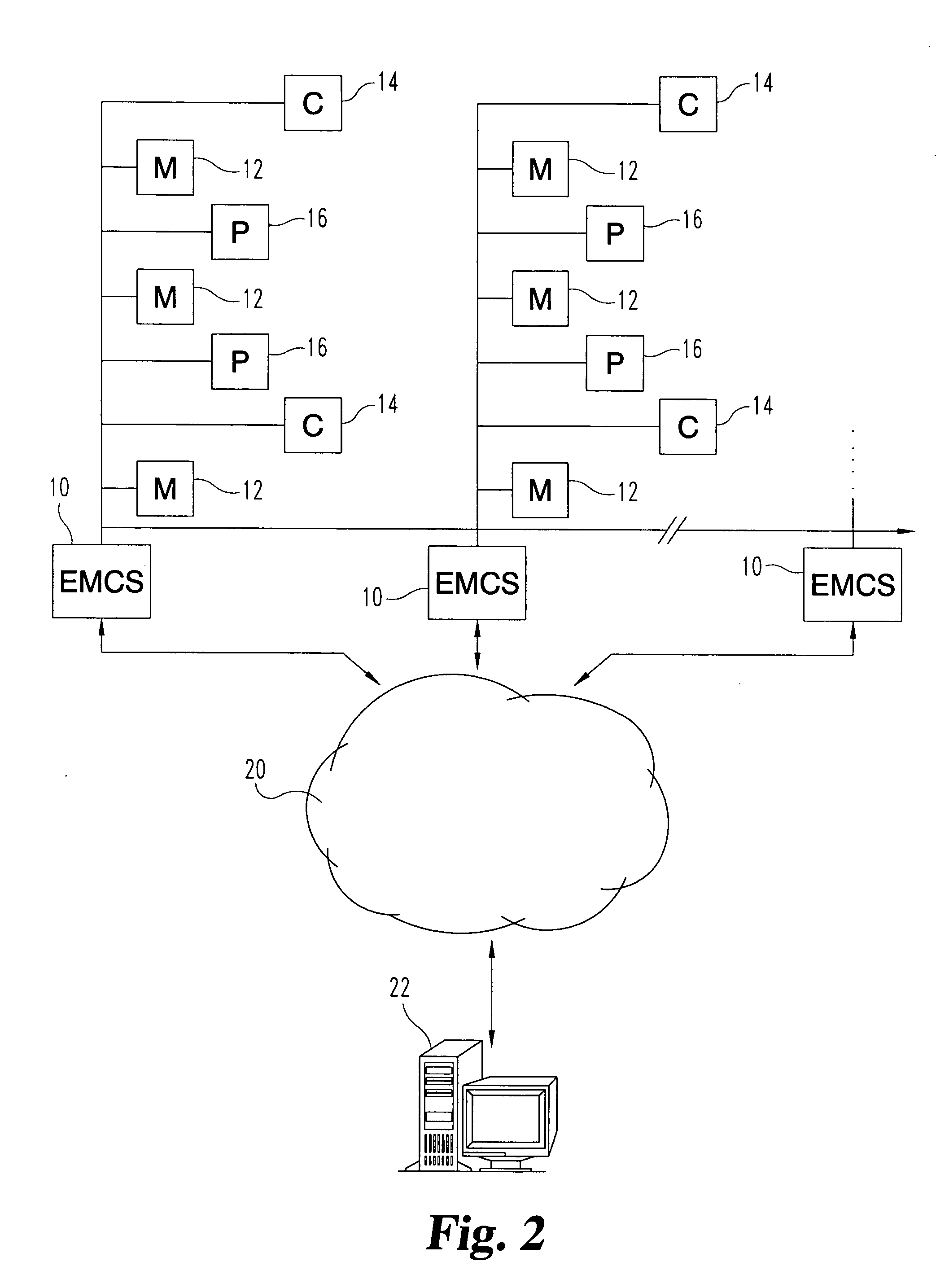

Network based multiple sensor and control device with temperature sensing and control

InactiveUS20050043907A1Minimize adverse effectsPartial latencyThermometer detailsElectric devicesMultiple sensorControl equipment

A multifunction sensor device which provides various transducer functions including means for performing temperature sensing, humidity sensing, ambient light sensing, motion detection, thermostat functions, switching functions, load switching and dimming functions, displaying actual and set temperature values, displaying time of day values and a means to put the device in an on, off or auto mode. The device has utility in environments such as that found in offices, schools, homes, industrial plants or any other type of automated facility in which sensors are utilized for energy monitoring and control, end user convenience or artificial or natural cooling, heating and HVAC control. The device can be used as a switch or dimmer, sensor or thermostat as well as to adjust and control all natural and artificial lighting, temperature and humidity devices. Key elements of the invention include overcoming the difficulty of mounting diverse sensors or transducers within the same device or housing; permitting these various sensors to exist in a single package that can be mounted to a wall in a substantially flush manner; and eliminating the requirement of an air flow channel in the device, thus minimizing any adverse effects on the motion detecting element or sensor as well as providing built in partial hysteresis. The device may include additional transducers or sensors and is constructed such that the temperature and humidity sensors are neither exposed to the flow of air in a room or area nor in an airflow channel whereby a chimney effect may occur. The device can transmit and receive real time data, relative data and actual discrete data in addition to switching and controlling loads locally or remotely. An embodiment utilizing airflow channels to direct air over the temperature and humidity sensors is also disclosed.

Owner:ECKEL DAVID P +2

Reprogrammable remote sensor monitoring system

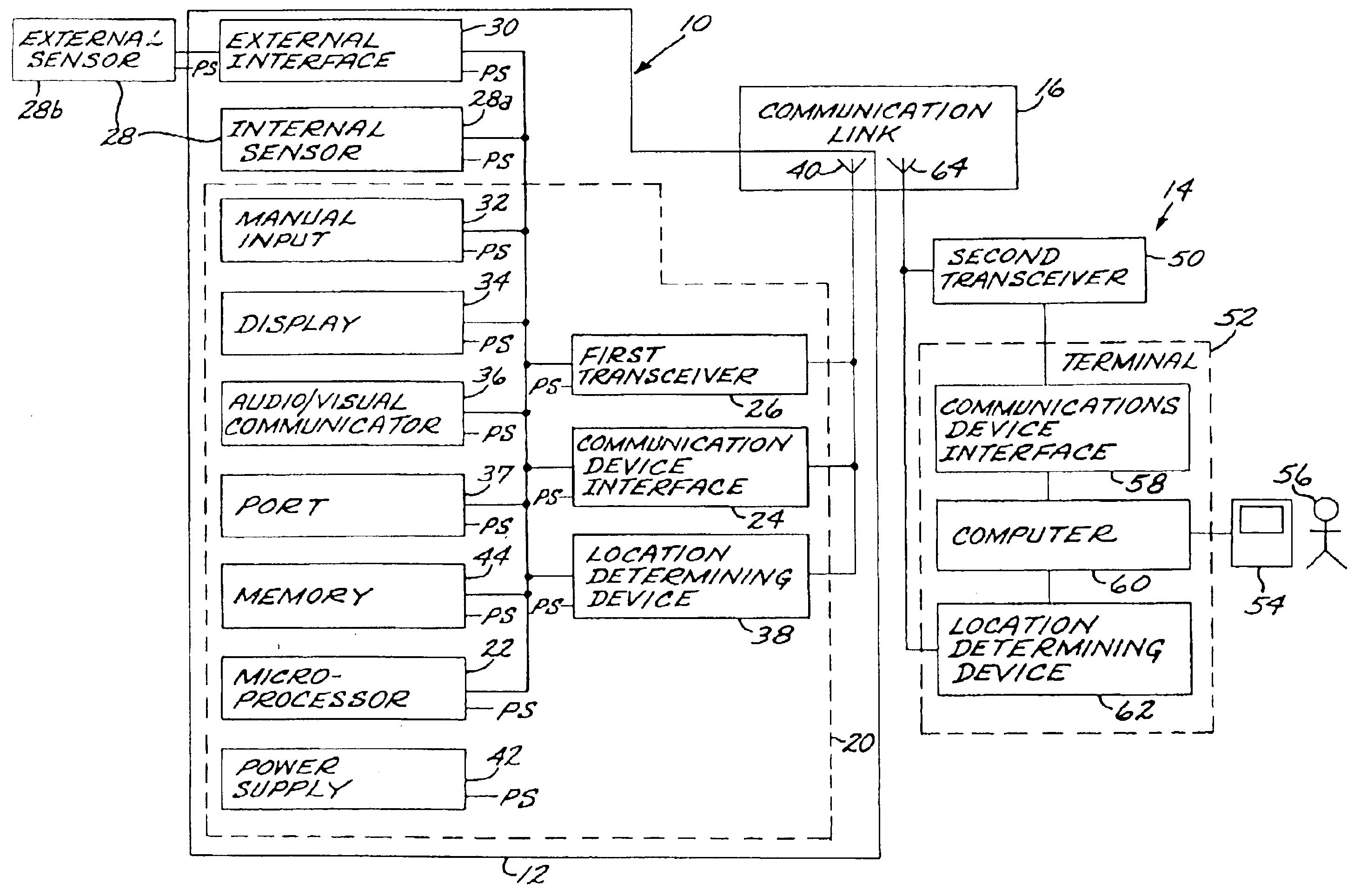

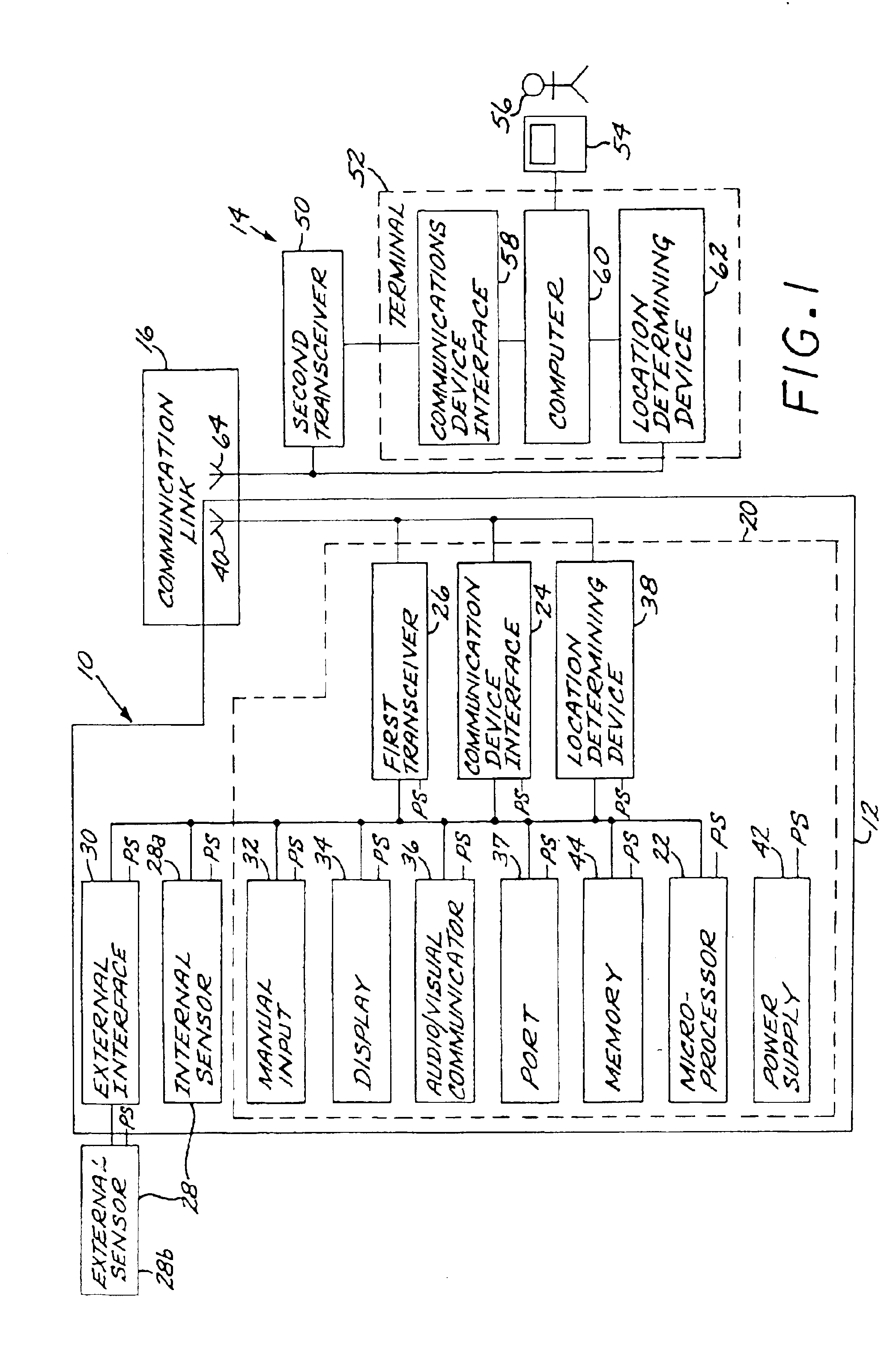

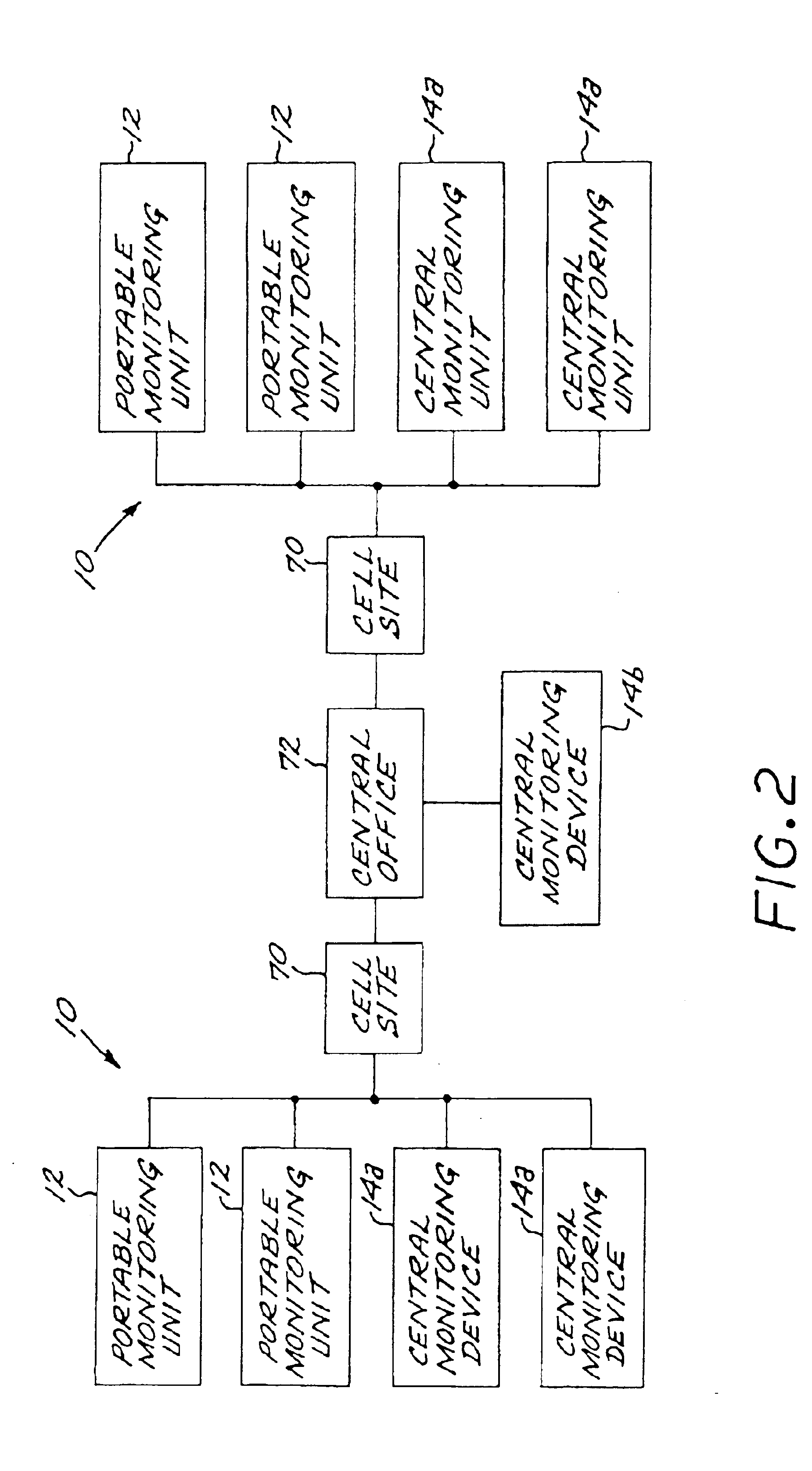

An automated, real-time, reprogrammable monitoring and control system for portable, remote sensors and subjects includes one or more portable monitoring units, each of the portable monitoring units having a sensor, a location-determining device, and a sensor interface unit. Each sensor interface unit is separately configured to monitor its sensor and to transmit that sensor's data, via a digital wireless communications network, to a central monitoring device. The portable unit is carried or worn by a person or animal, or affixed to an inanimate subject.

Owner:BRAEMAR MFG

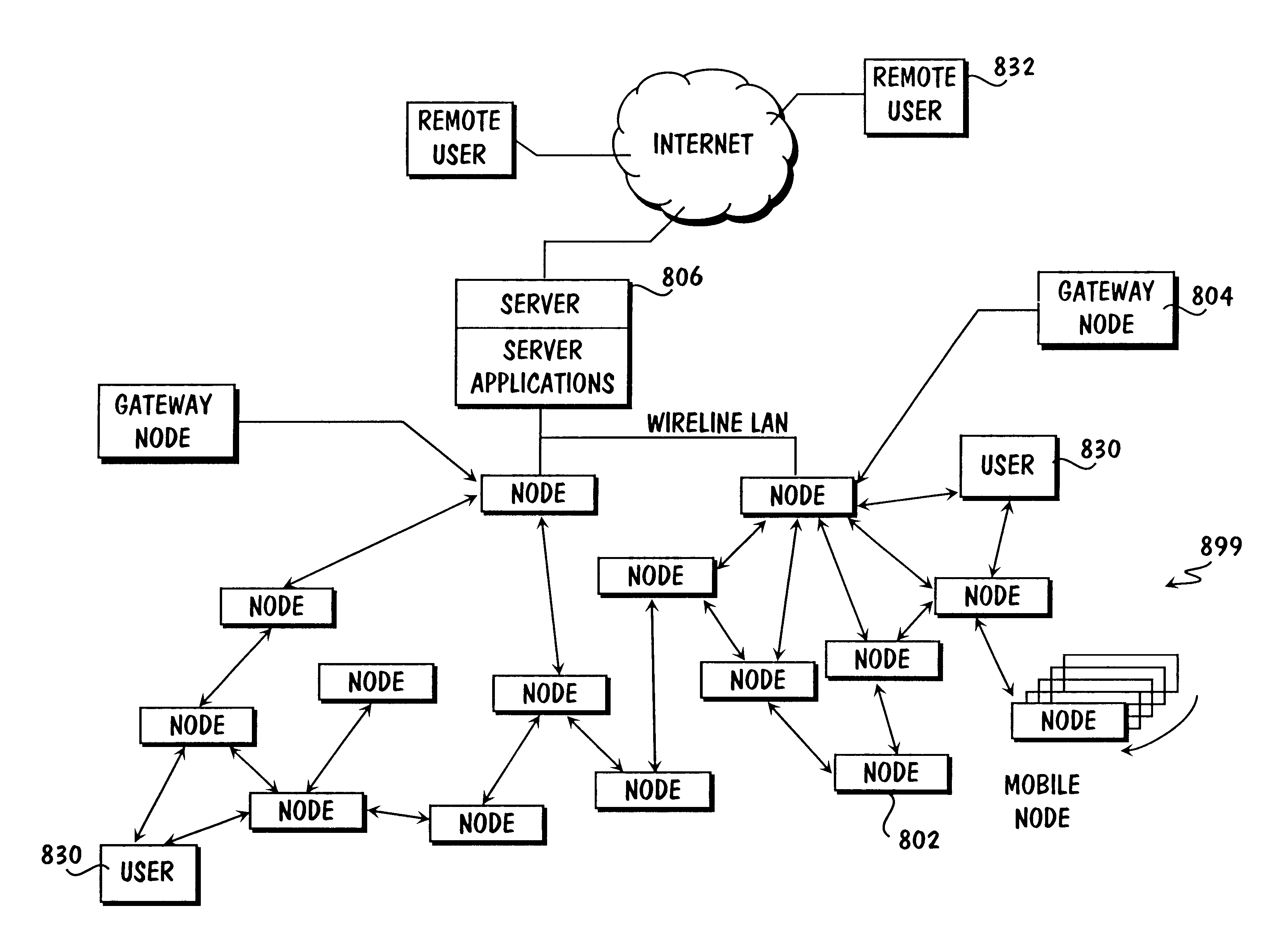

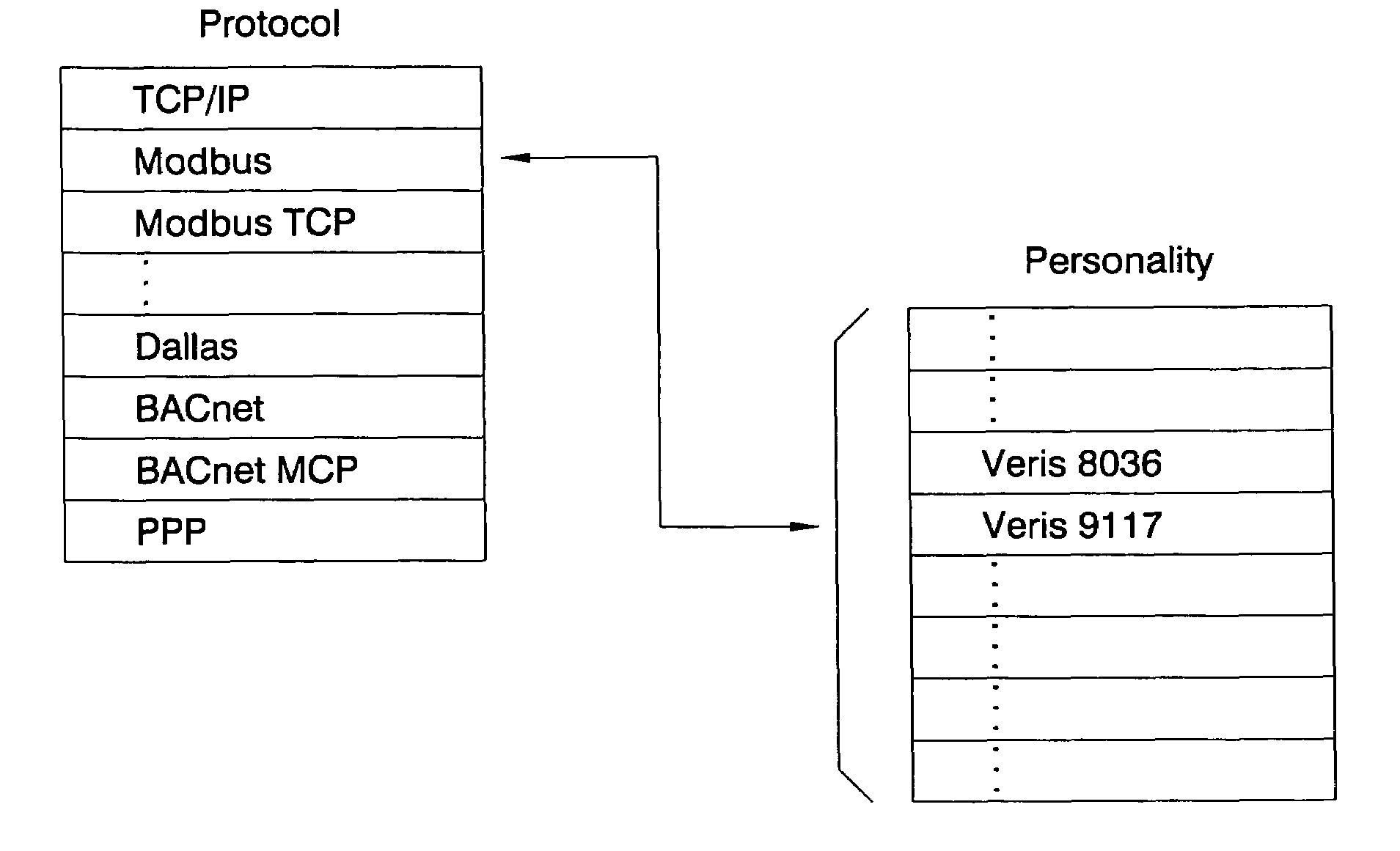

System and method for distributed facility management and operational control

ActiveUS7349761B1Programme controlSampled-variable control systemsControl systemEnvironmental control system

An environmental control system controls monitoring and operation of a multiplicity of disparate environmental control devices by determining an appropriate configuration for each control device and communicates corresponding monitoring and control commands to each device in accordance with its corresponding communication protocol over a selected I / O port. An operational instruction set includes a structural definition of an enterprise facility in which devices are defined by personality modules and communicate with a system host in accordance with a protocol defined in a protocol module. Facility implementation is defined by a node tree structure which collects suitable protocol nodes under a corresponding I / O interface port node. Device (personality) nodes are collected under corresponding protocol nodes, and data point nodes depend from their corresponding device nodes. Data points nodes are individually accessible by merely traversing the node tree using a URL-like notational structure, allowing off-site users to control and monitor environmental devices by issuing commands in the form of a URL.

Owner:CISCO TECH INC +1

Apparatus for internetworked wireless integrated network sensors (WINS)

InactiveUS20100148940A1High reliability accessEasy to operateAntenna supports/mountingsDigital computer detailsReconfigurabilityMonitoring and control

The Wireless Integrated Network Sensor Next Generation (WINS NG) nodes provide distributed network and Internet access to sensors, controls, and processors that are deeply embedded in equipment, facilities, and the environment. The WINS NG network is a new monitoring and control capability for applications in transportation, manufacturing, health care, environmental monitoring, and safety and security. The WINS NG nodes combine microsensor technology, low power distributed signal processing, low power computation, and low power, low cost wireless and / or wired networking capability in a compact system. The WINS NG networks provide sensing, local control, remote reconfigurability, and embedded intelligent systems in structures, materials, and environments.

Owner:INTELLECTUAL VENTURES I LLC

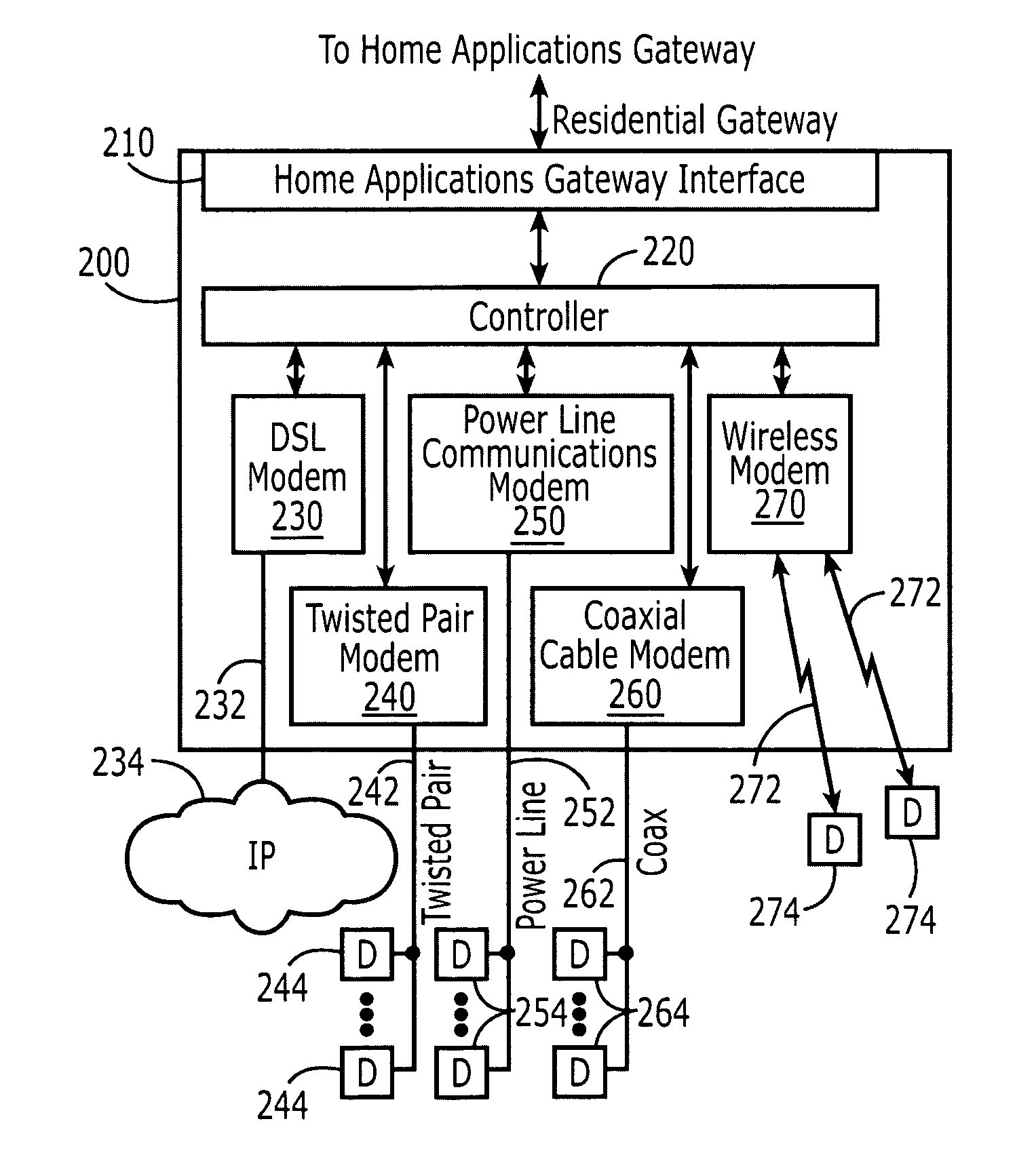

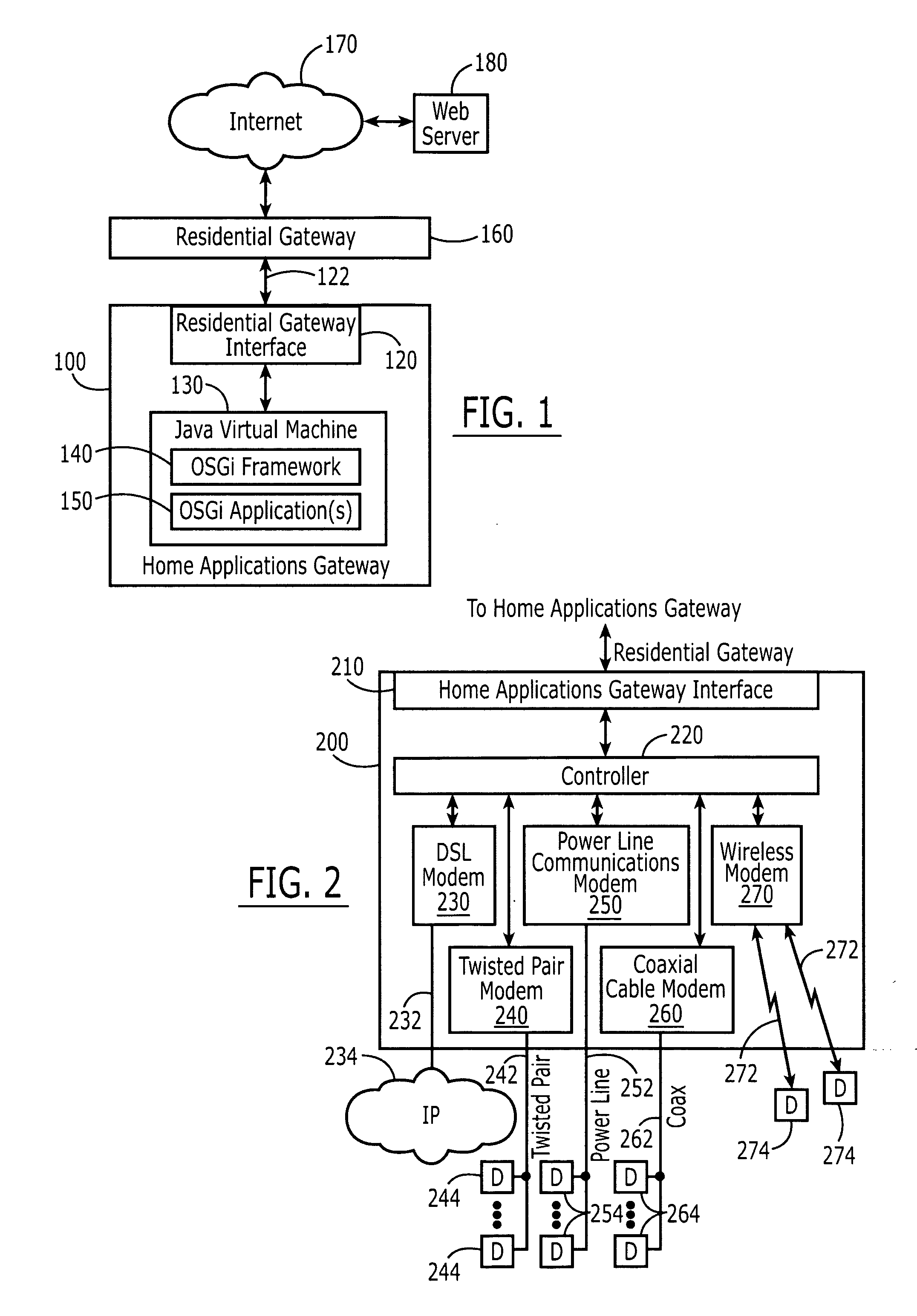

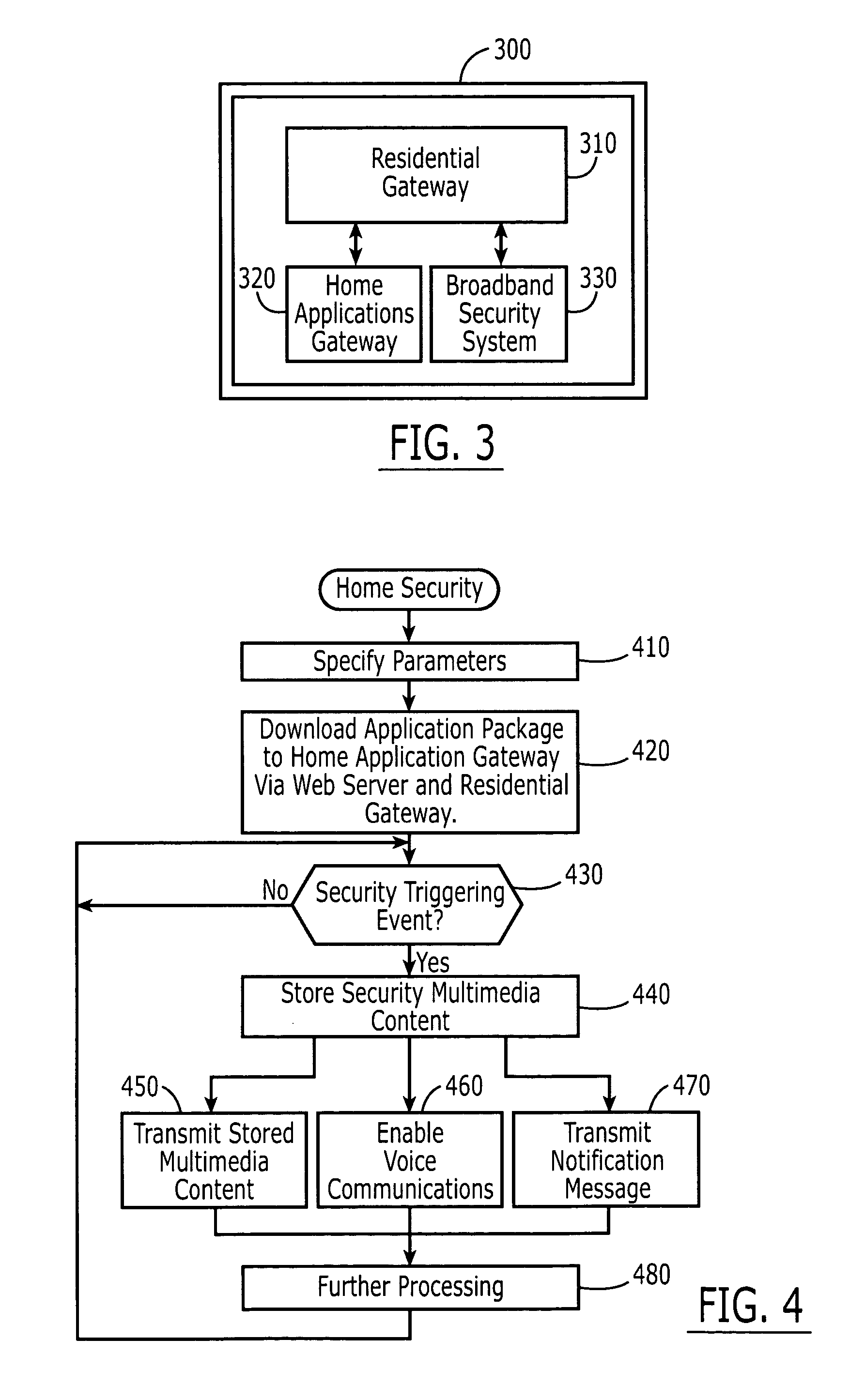

Broadband home applications gateway/residential gateway systems, methods and computer program products

A home applications gateway includes a residential gateway interface that is configured to connect to a residential gateway, and a Java Virtual Machine (JVM) that includes an Open Services Gateway initiative (OSGi) framework configured to execute OSGi Java applications that are downloaded and life cycle managed from a Web server through the residential gateway interface. The OSGi Java applications can include a video monitoring application that is configured to provide in-home and out-of-home access to Internet Protocol (IP)-based home video cameras and video files captured by the IP-based home video cameras, at a Web page. The OSGi Java applications can further include a lighting control application that is configured to control activation and deactivation of home lighting from the Web page. The OSGi Java applications can also include a home monitoring and control application that is configured to monitor home sensors and take action upon their activation.

Owner:BELLSOUTH INTPROP COR

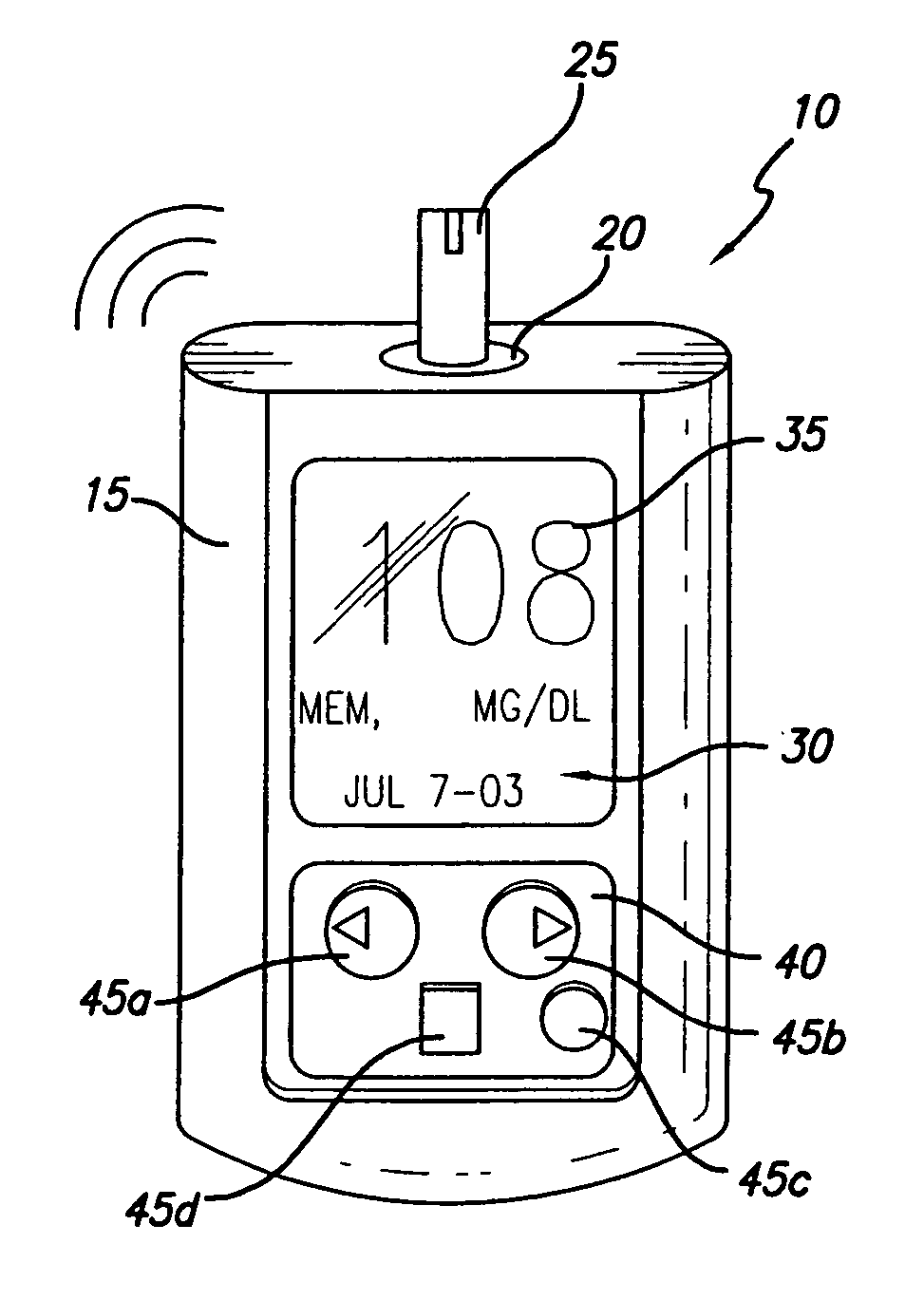

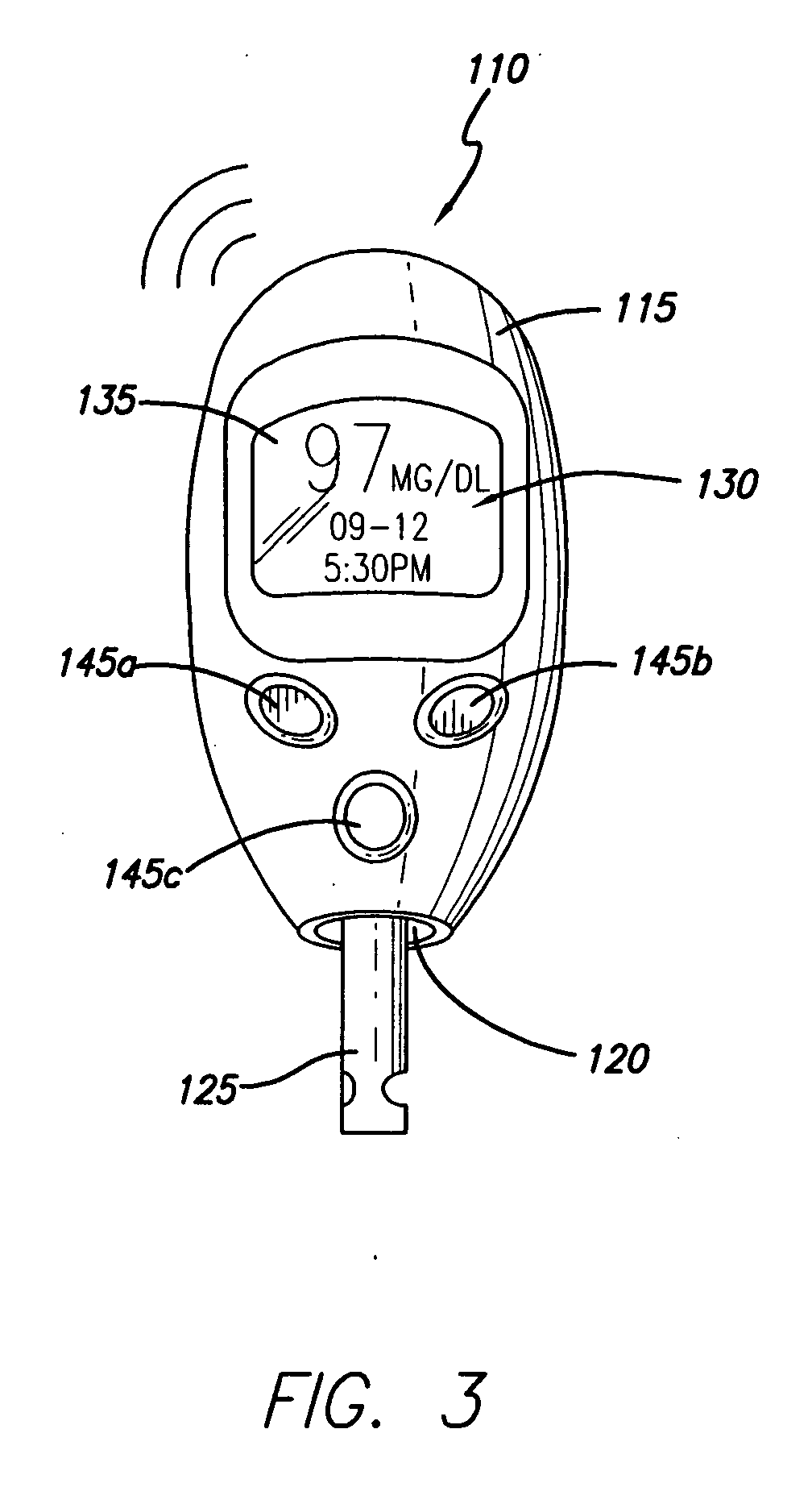

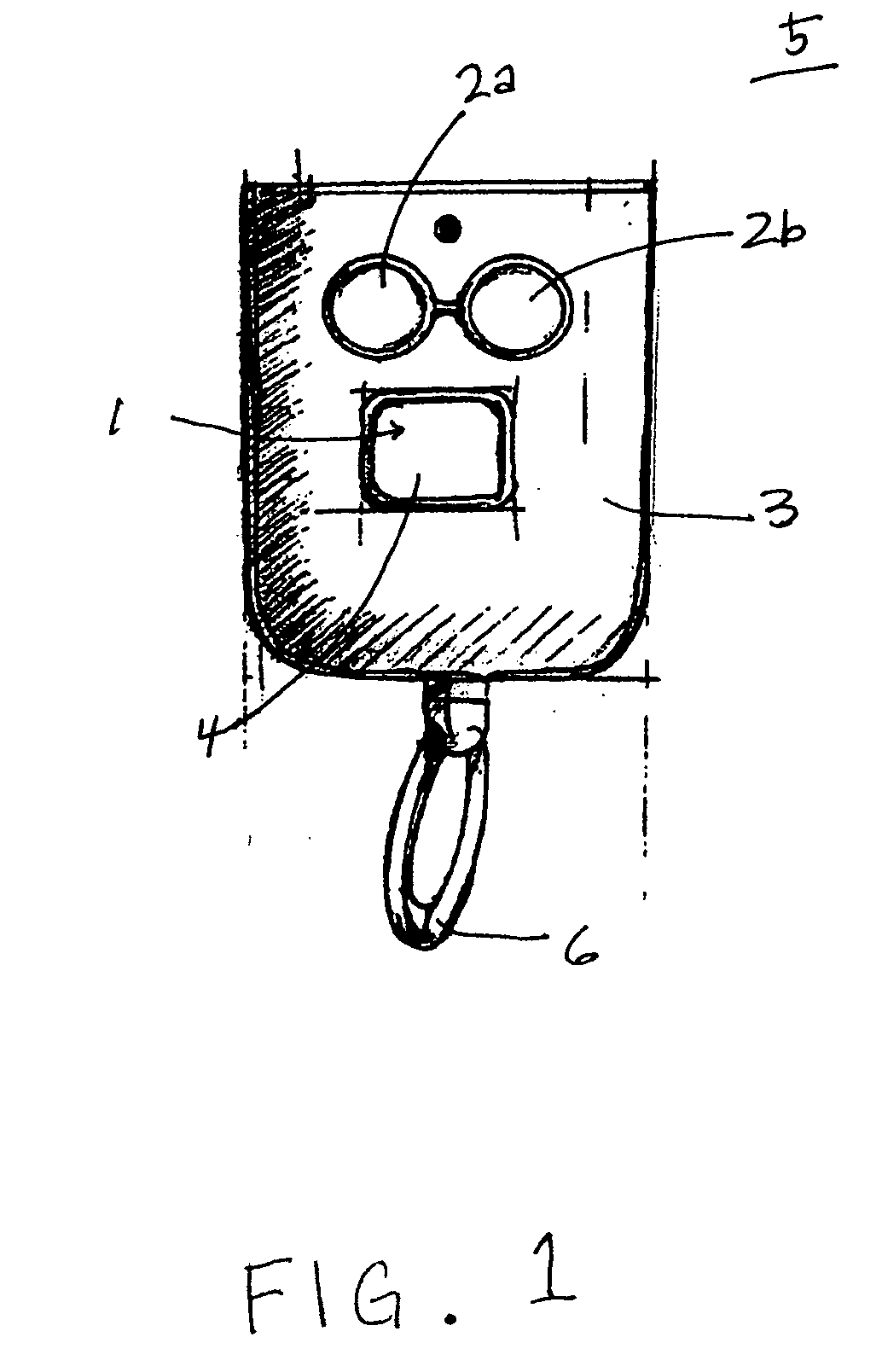

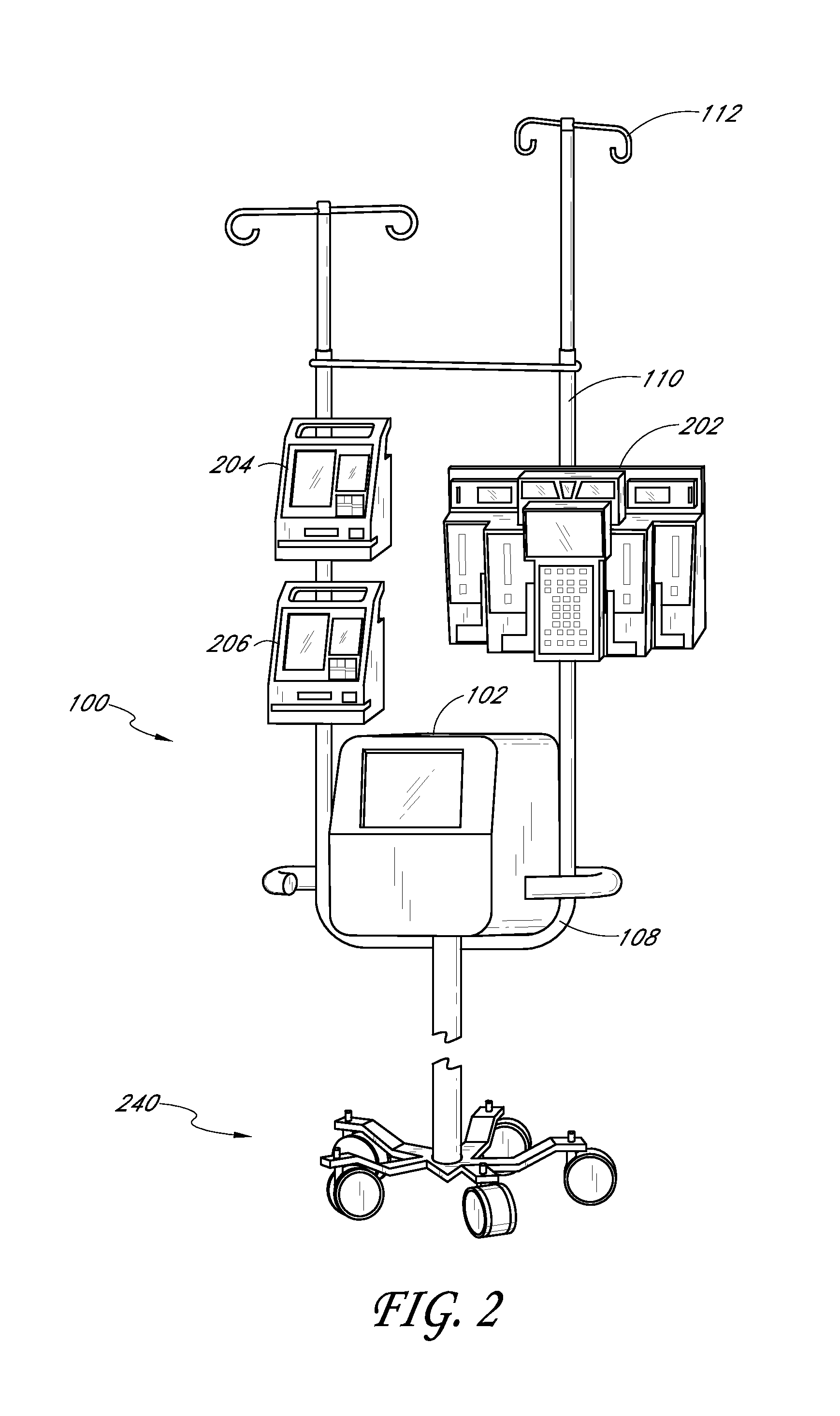

Controller device for an infusion pump

InactiveUS20070060869A1Avoid interferenceMinimizes potential for errorMedical devicesIntravenous devicesCommunications systemEngineering

An infusion system that includes a controller device and a communication system to transmit the communications from the controller device to an infusion device pump that controls delivery of fluids to the user's body. More particularly, these apparatuses and methods are for providing convenient monitoring and control of the infusion pump device in determining the appropriate amount of insulin to deliver.

Owner:MEDTRONIC MIMIMED INC

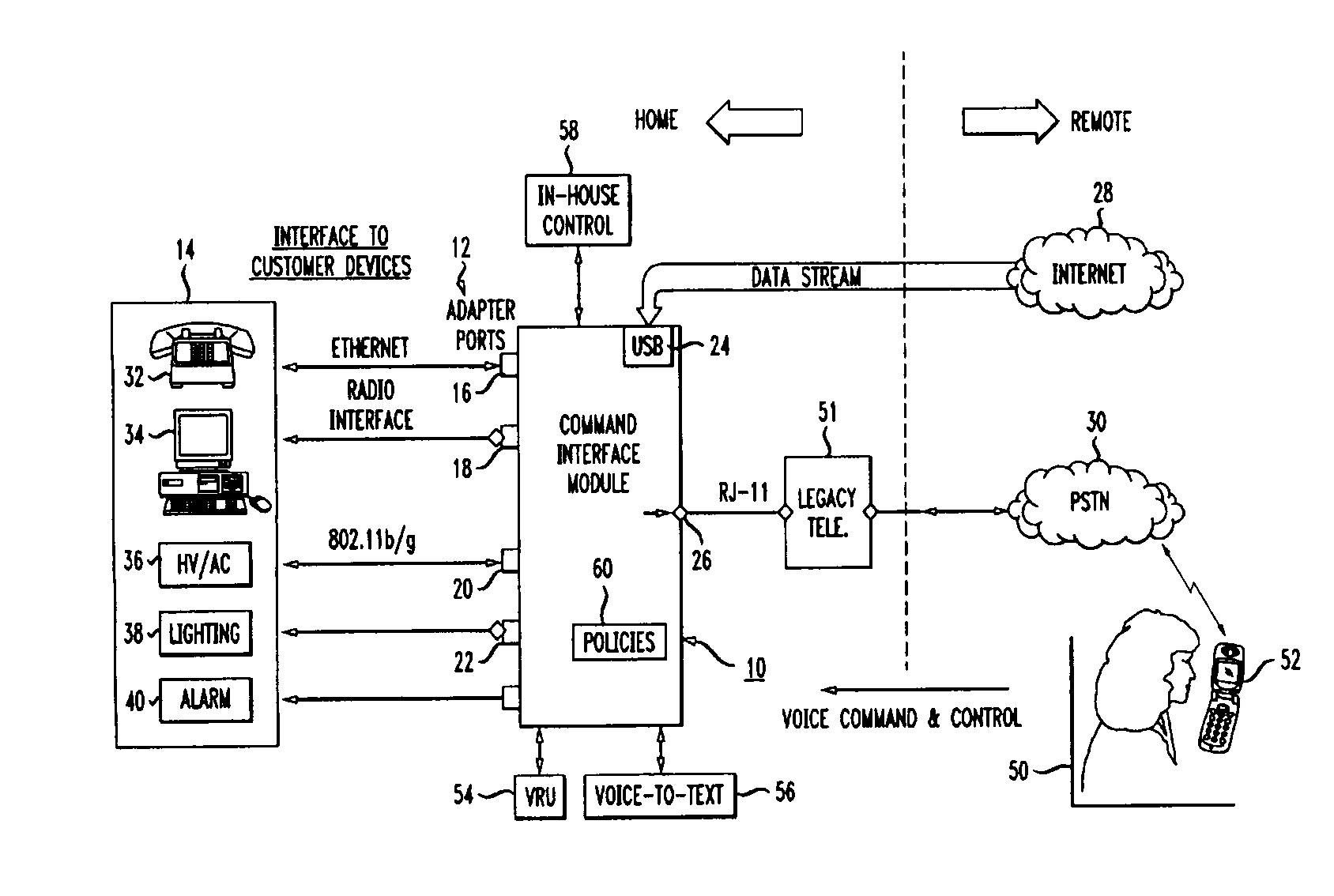

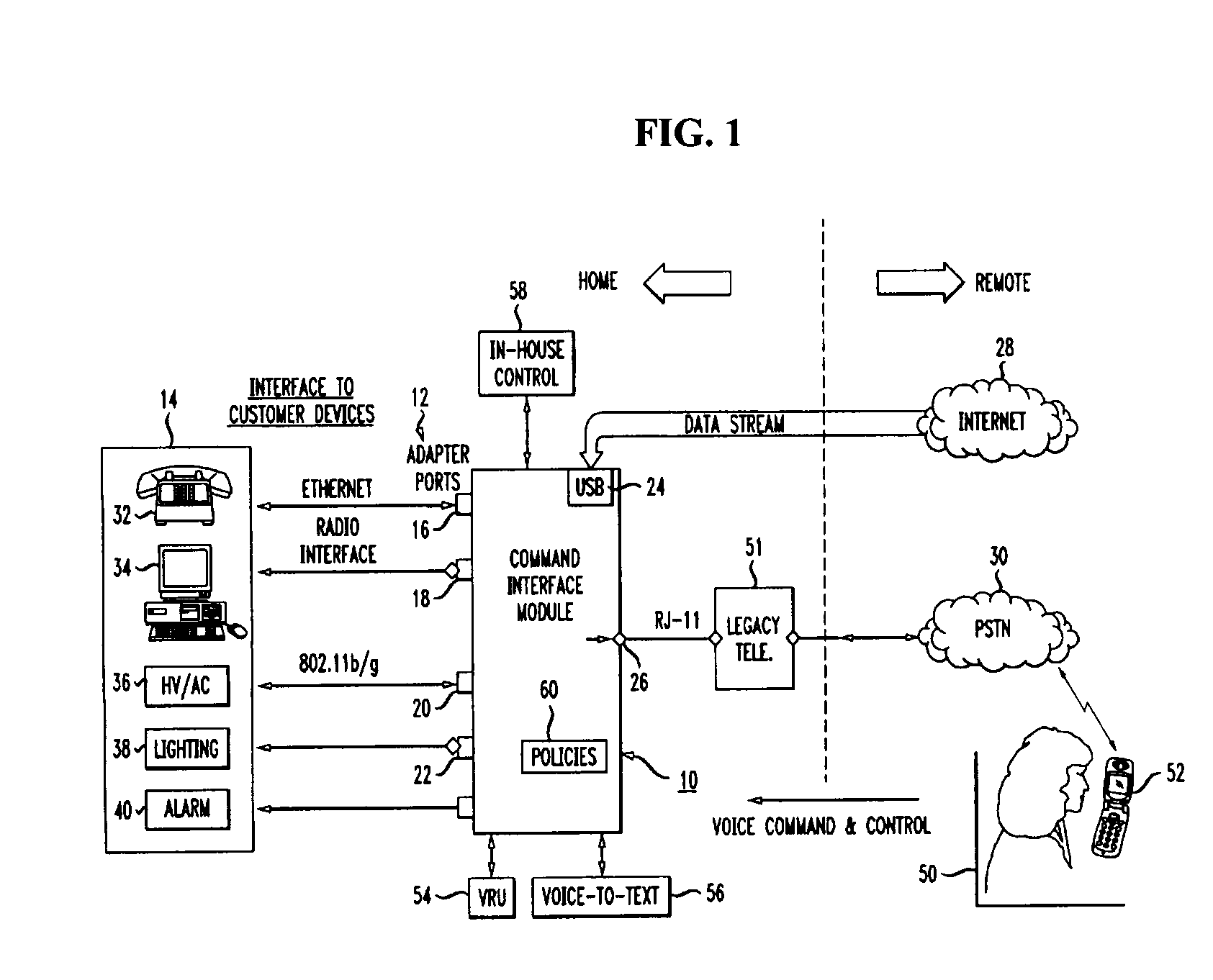

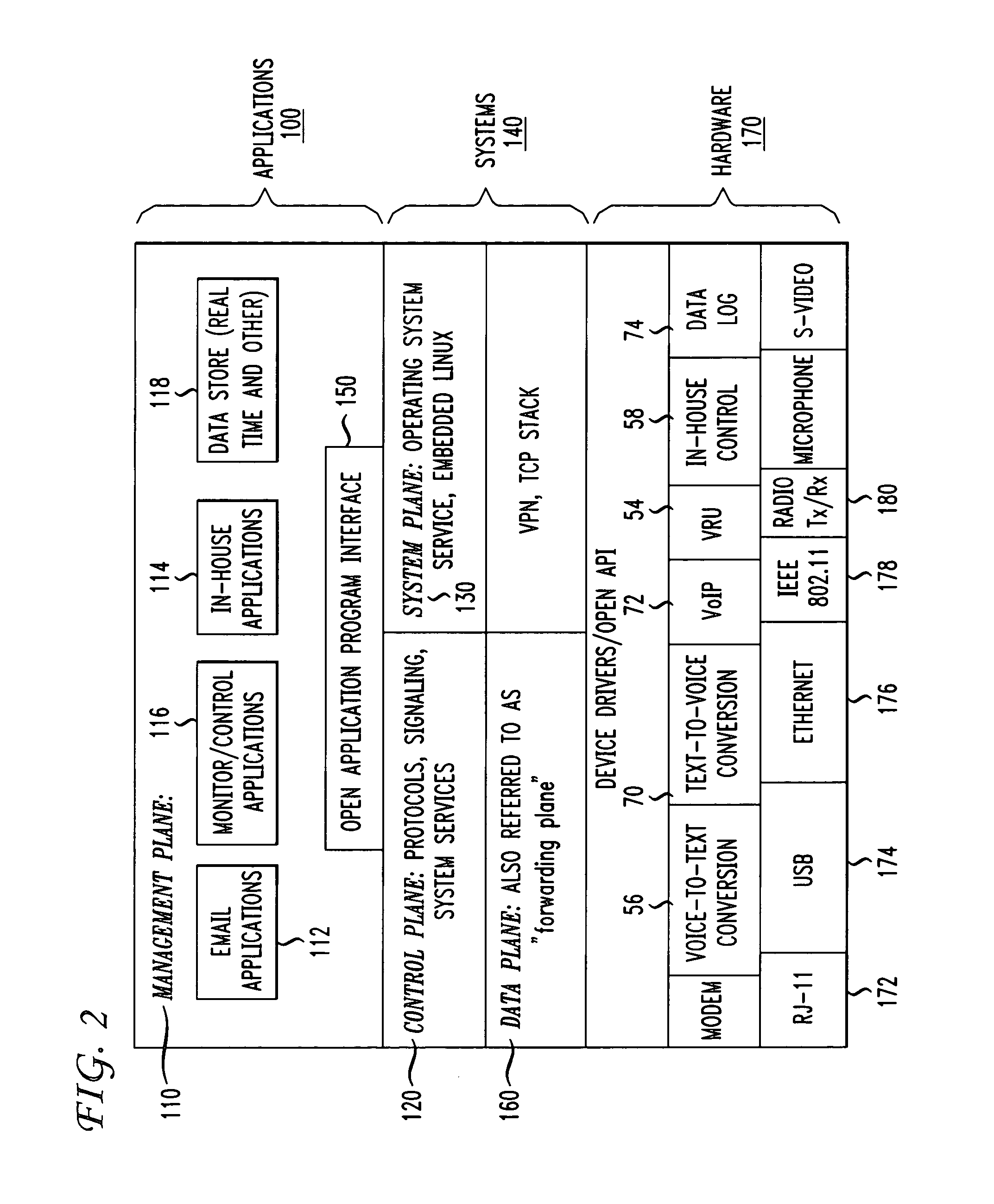

Home control, monitoring and communication system using remote voice commands

ActiveUS8654936B1Devices with voice recognitionAutomatic call-answering/message-recording/conversation-recordingCommunication interfaceCommunications system

A voice-activated command interface module for interacting with a plurality of home-based electronic devices so as to allow for a remotely-located home owner to communicate with, command and control various ones of the electronic devices. The module includes a plurality of communication ports, each communication port associated with a different type of communication interface for providing communications to and from the plurality of electronic devices. The module also includes a voice network communication port for receiving the voice commands from the home owner and a data network communication port for transmitting monitoring and control information between the plurality of electronic devices and the home owner. In operation, the command interface module is responsive to voice commands received from a remote user via an incoming telephone line (either data or voice). A voice recognition unit within the command interface module is utilized to translate the received voice signal into an “action / control” signal and then perform the desired activity.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

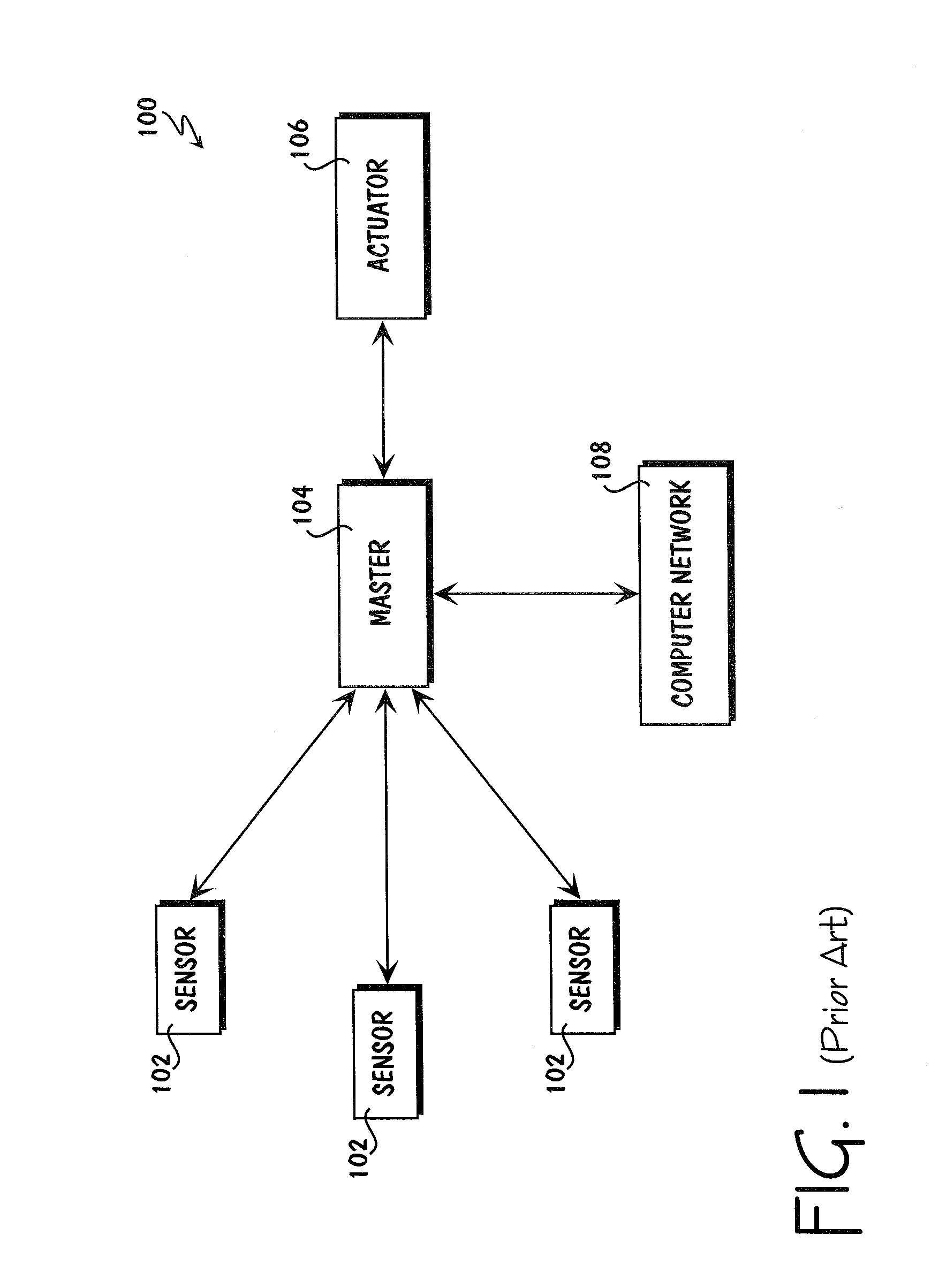

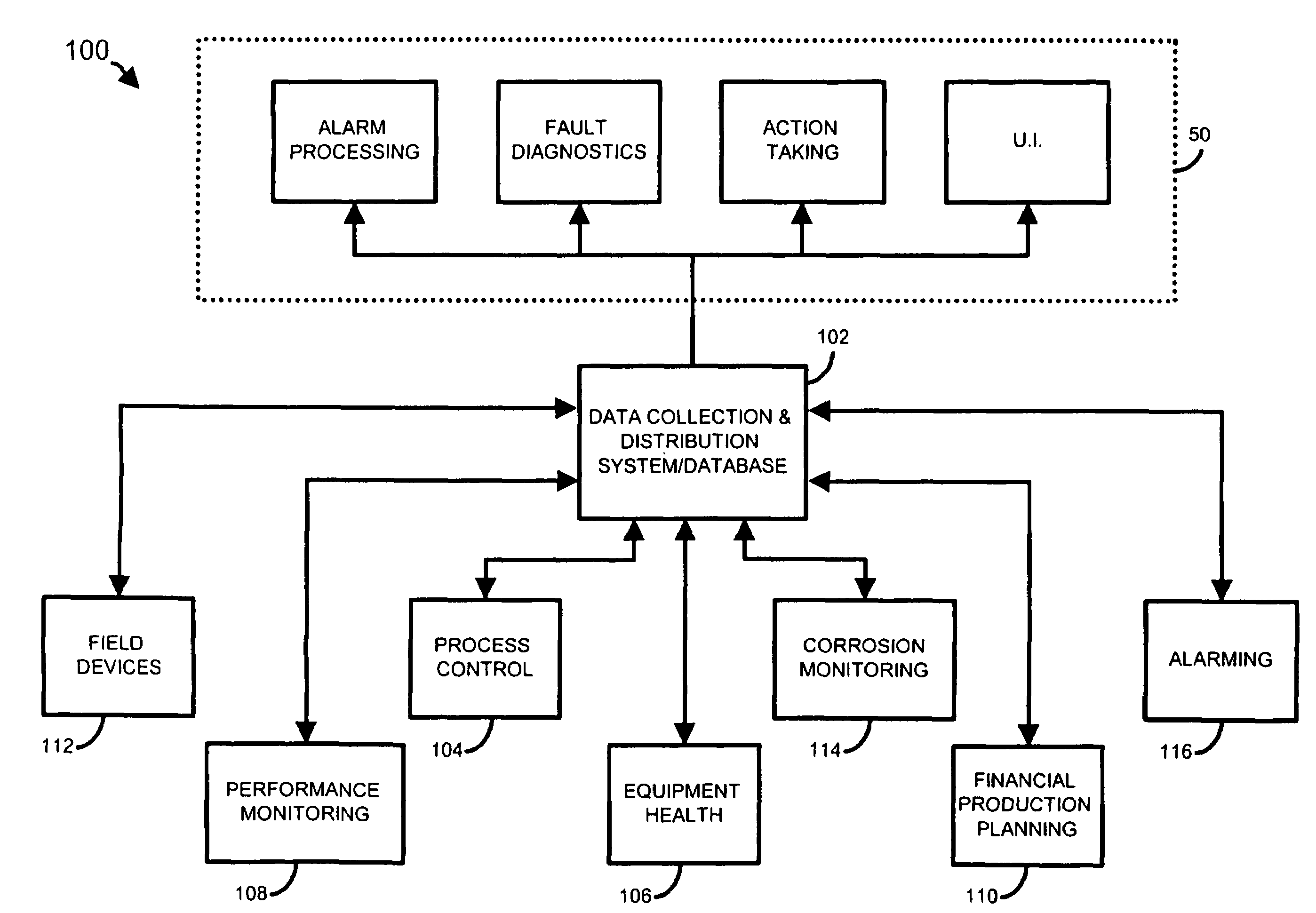

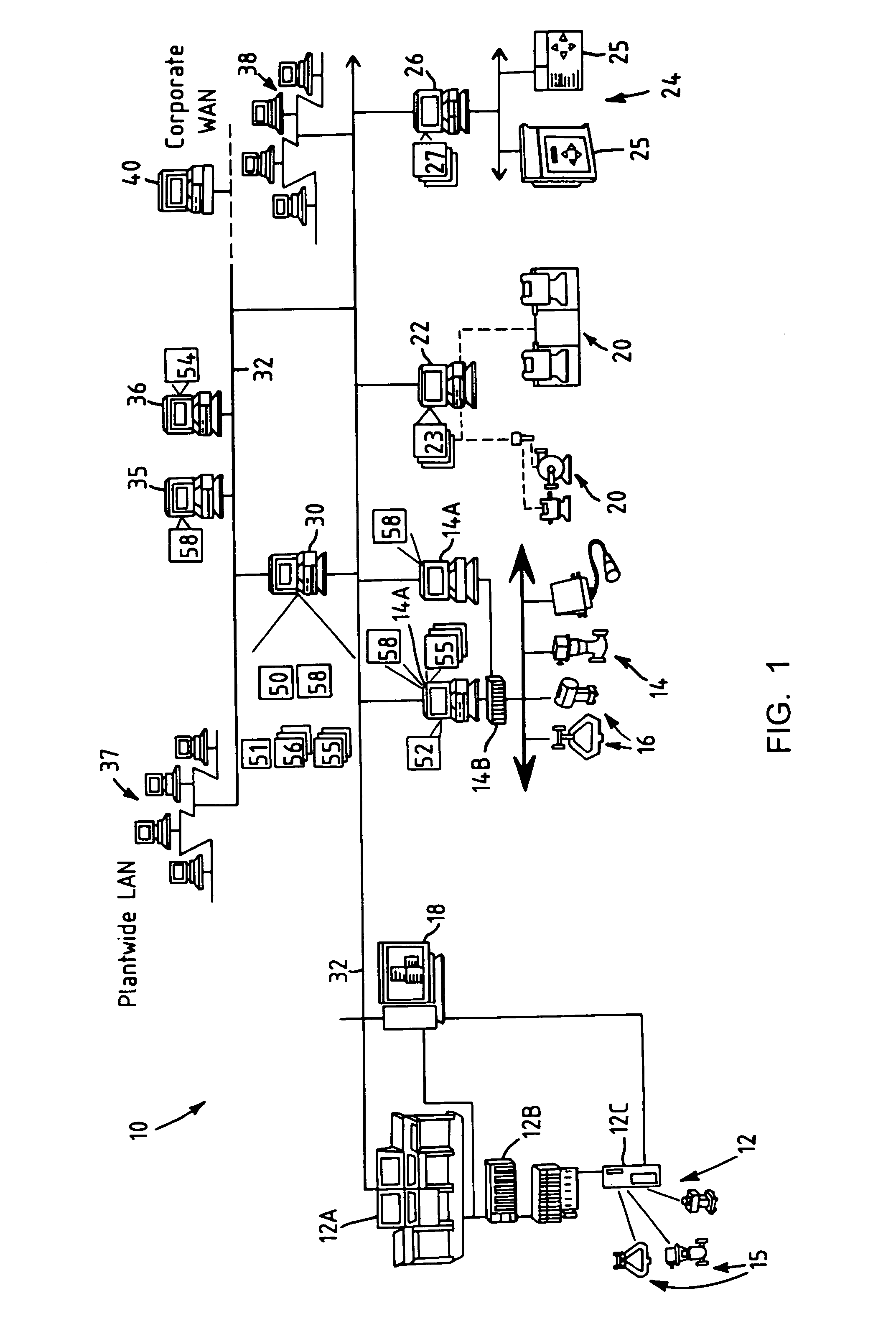

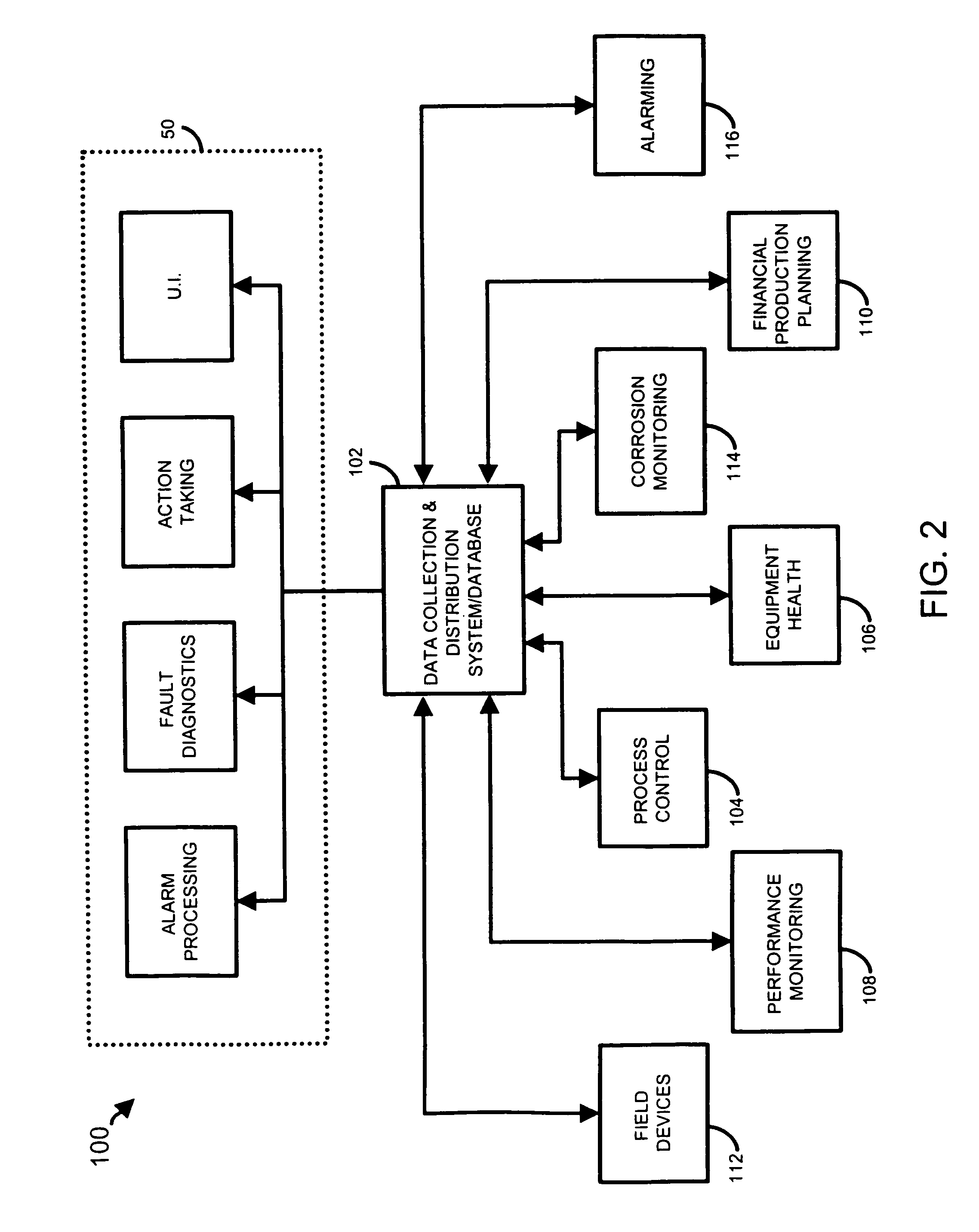

Method and apparatus for performing a function in a plant using process performance monitoring with process equipment monitoring and control

InactiveUS7206646B2Easy to operateBetter stateSafety arrangmentsCatalytic crackingProcess equipmentOptimal control

A process control system uses a data collection and distribution system and an asset utilization suite to collect data or information pertaining to the assets of a process plant from various sources or functional areas of the plant including, for example, the process control functional areas, the maintenance functional areas and the process performance monitoring functional areas. This data and information is manipulated in a coordinated manner by the data collection and distribution system and is redistributed to other applications where this it is used to perform overall better or more optimal control, maintenance and business activities. Information or data may be collected by maintenance functions pertaining to the health, variability, performance or utilization of a device, loop, unit, area, etc. and this information may then be sent to and displayed to a process operator or maintenance person to inform that person of a current or future problem. A user interface is provided that enables users to access and manipulate the expert engine to optimize plant operation or cause optimization of plant operation, to get information about the operation of the plant, etc. Furthermore, applications, such as work order generation applications may automatically generate work orders, parts or supplies orders, etc. based on events occurring within the plant.

Owner:FISHER-ROSEMOUNT SYST INC

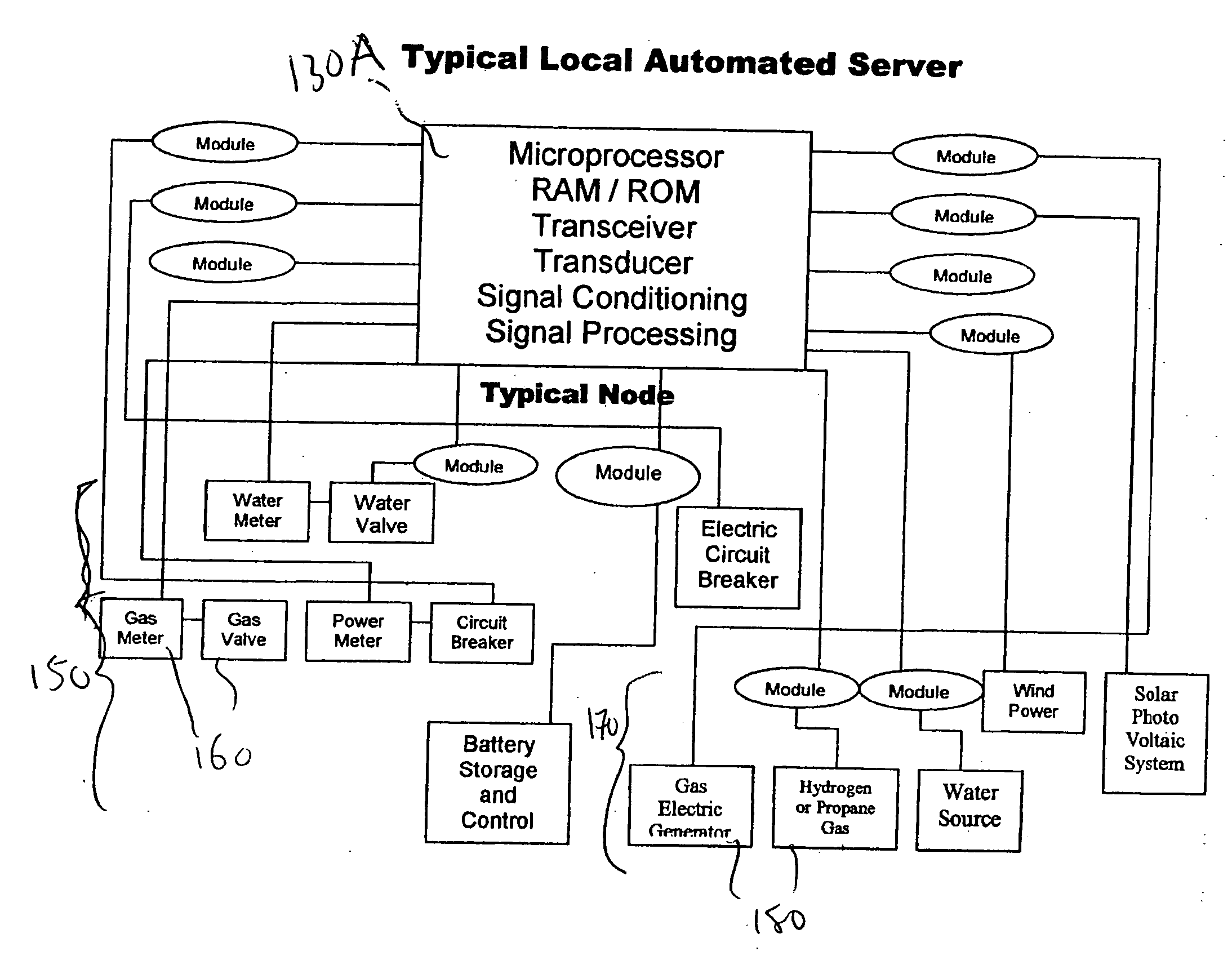

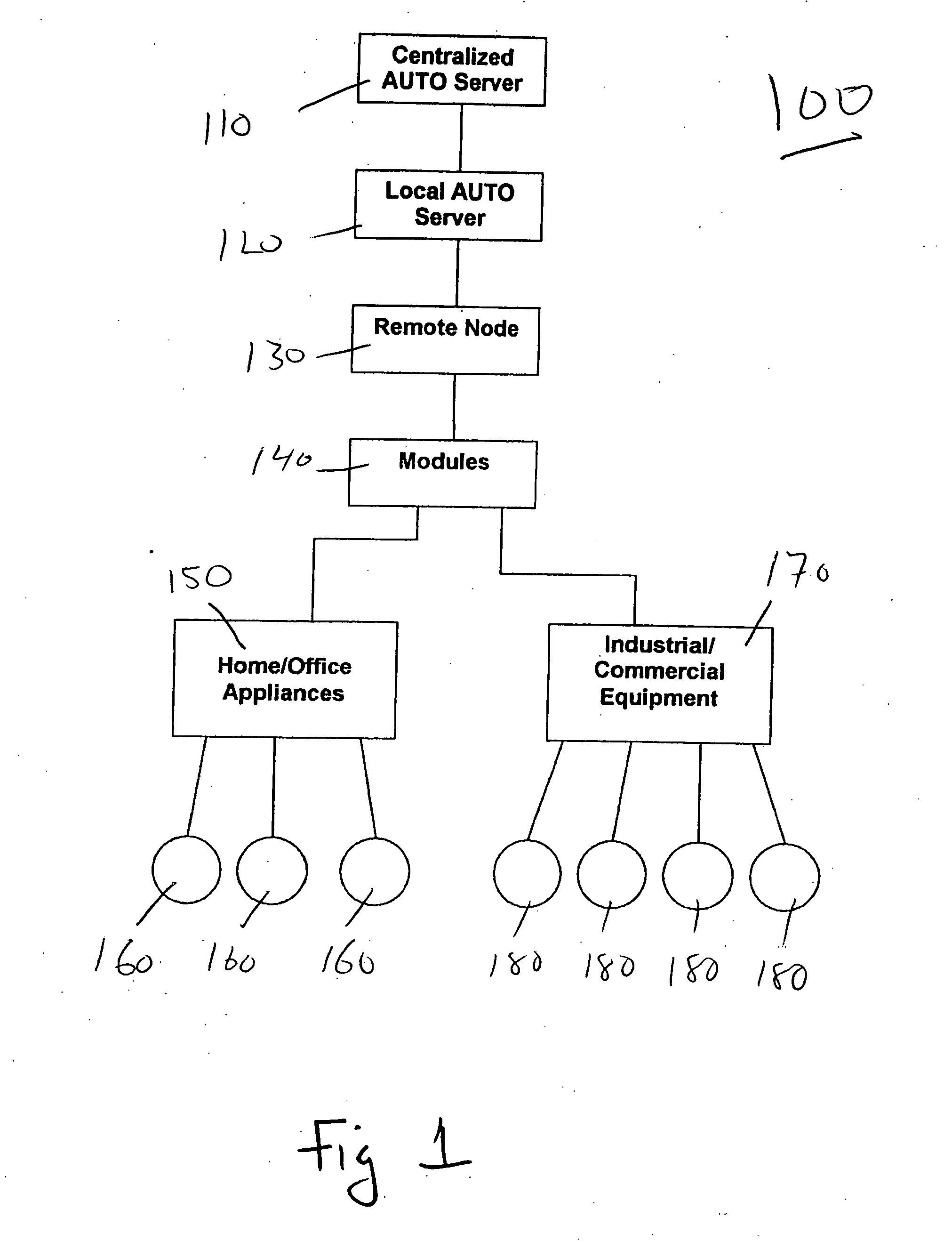

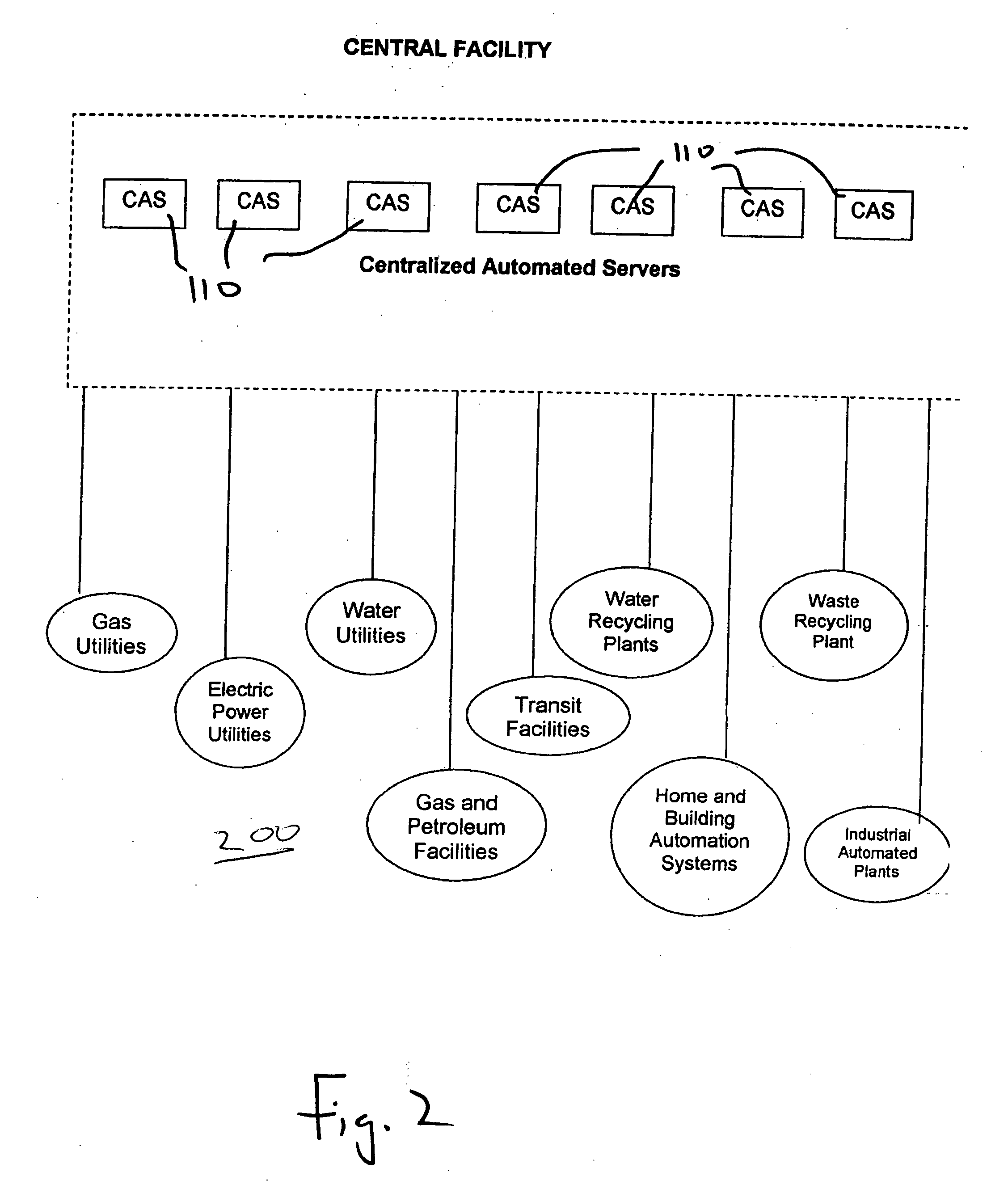

Remote meter monitoring and control system

InactiveUS20070063866A1Electric signal transmission systemsTariff metering apparatusMarine engineeringSCADA

An automated server based system for monitoring, reading, controlling as well as switching gases, liquids and electric power is provided for use in remote Automated Meter Reading (AMR) industry for water, gas and electric power utilities, Supervisory Control and Data Acquisition (SCADA); Security, Safety and Fire Alarm Systems (SSFA) and Home and Industrial Automation (HIA), in connection with appliances and equipment of all kinds.

Owner:ANDISA TECH

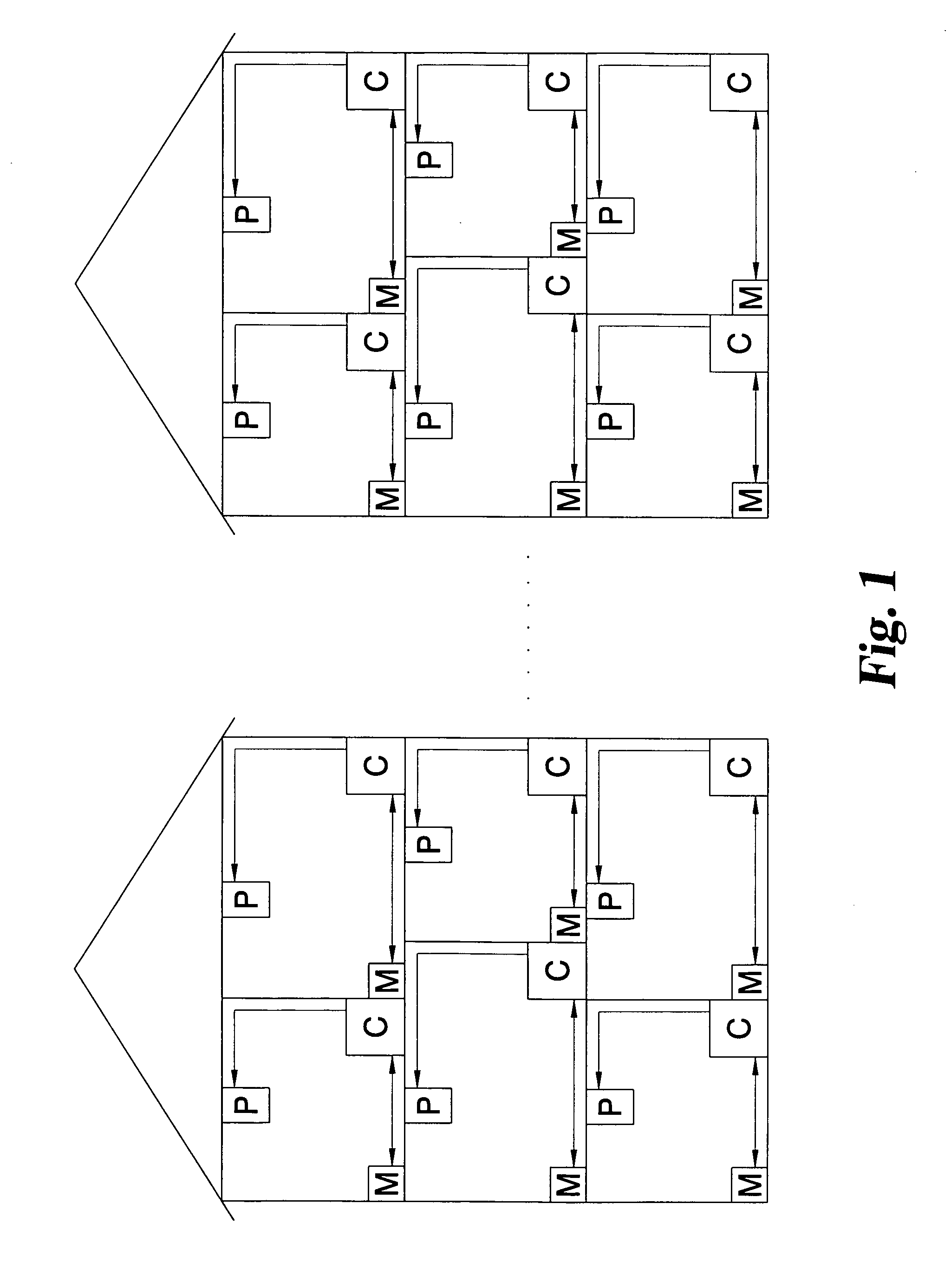

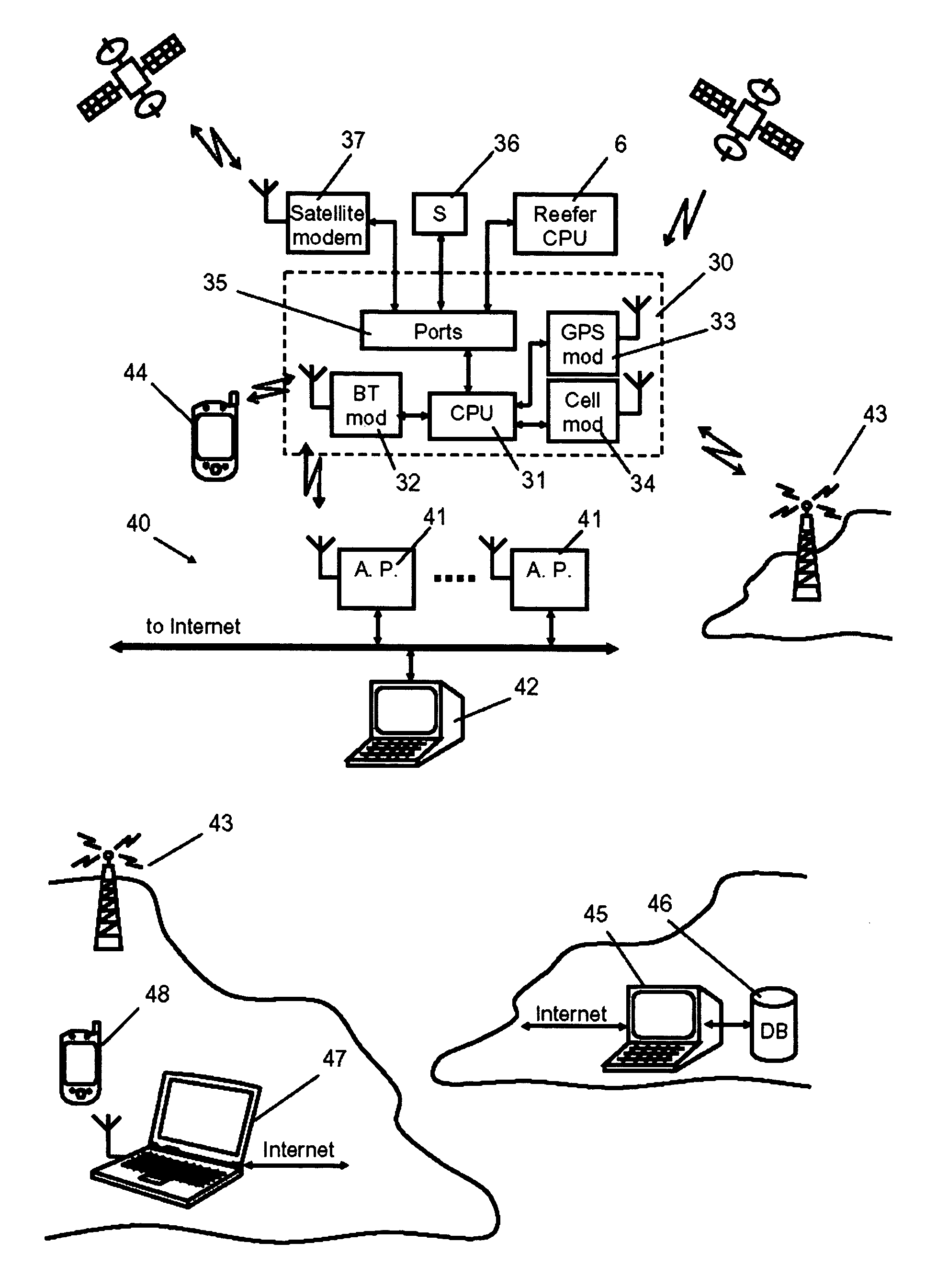

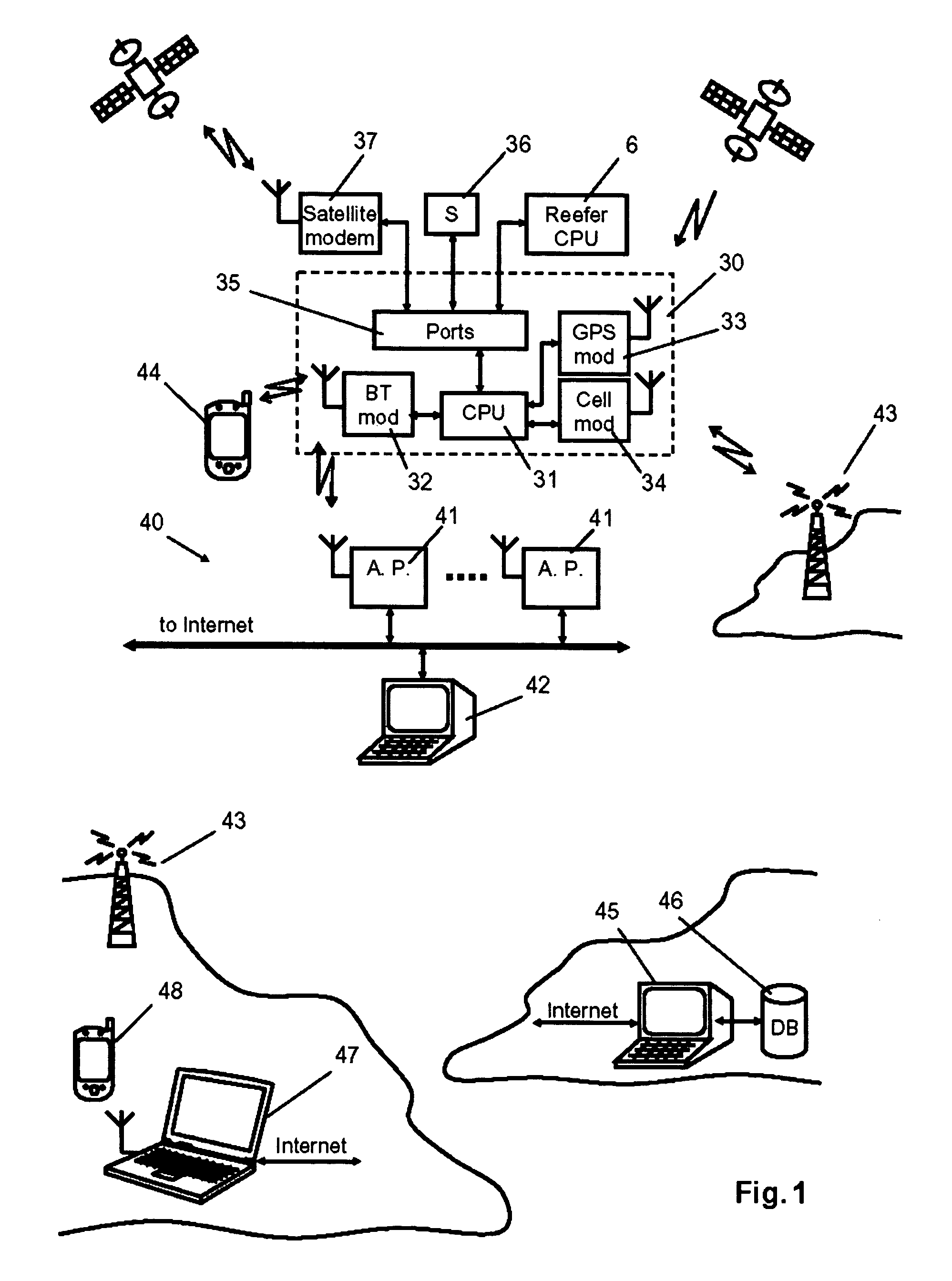

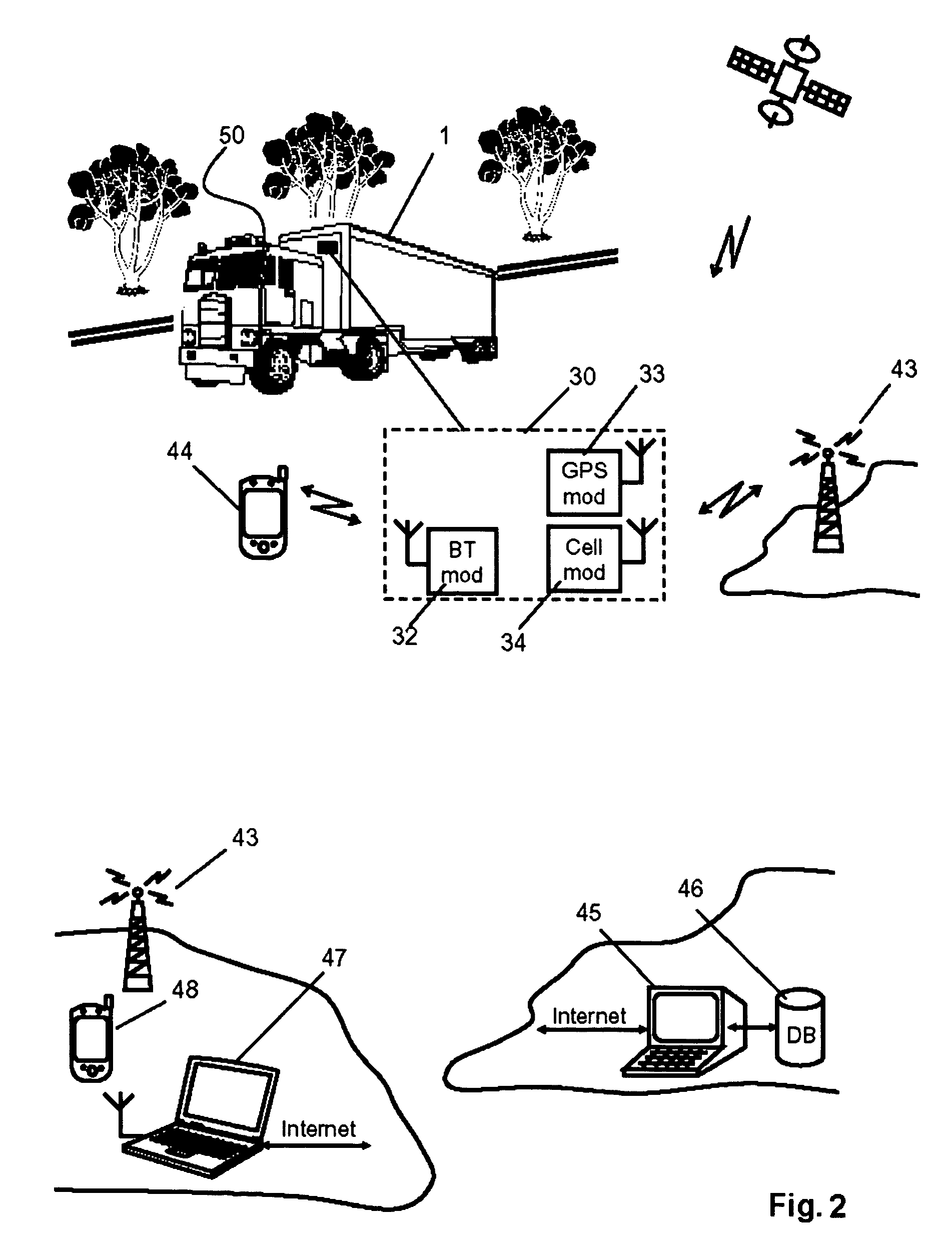

System for monitoring and control of transport containers

The invention comprises a unit and system for remote monitoring and controlling of various conditions in a container during cargo. The system includes a local wireless or cable (wired) network with a local station and access points positioned in the vicinity of location of containers, a remote central station connected with the Internet and a container-mounted means for monitoring and control of reefer equipment, each of which includes a processor (CPU) and a transceiver of wireless local communication, a GPS-receiver and a transceiver of cellular communication (with all of them being connected to the said processor). In addition the processor (CPU) of the device is connected to the controller of reefer equipment, while the transceiver of wireless local communication is made so that the creation of Personal Area Network (PAN) with mobile electronic devices (e.g., Notebook, Pocket PC, PDA) is possible, and establishment of wireless communication with a communication gateway of the said local network is also possible.

Owner:WIRELESS DATA SOLUTIONS

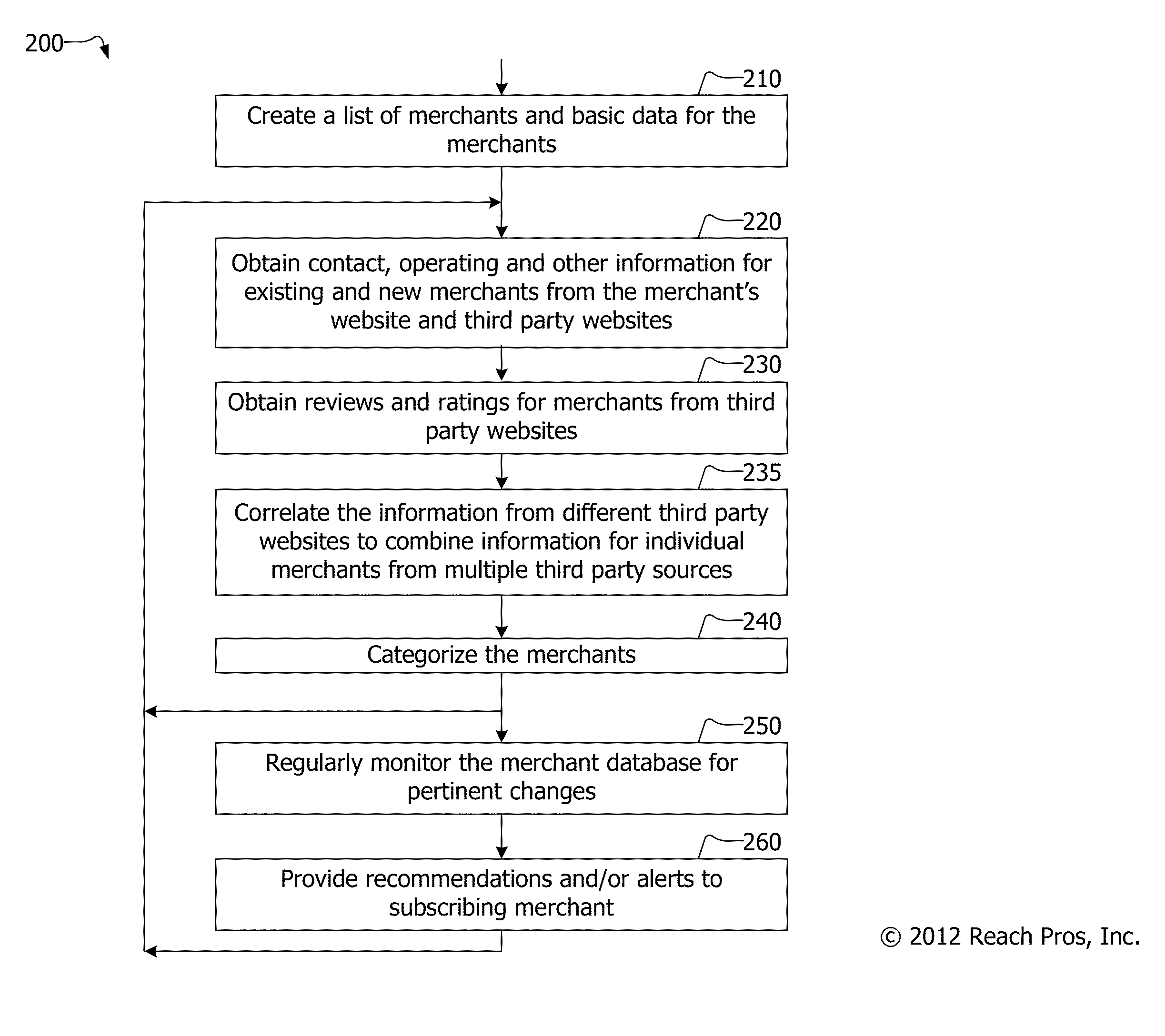

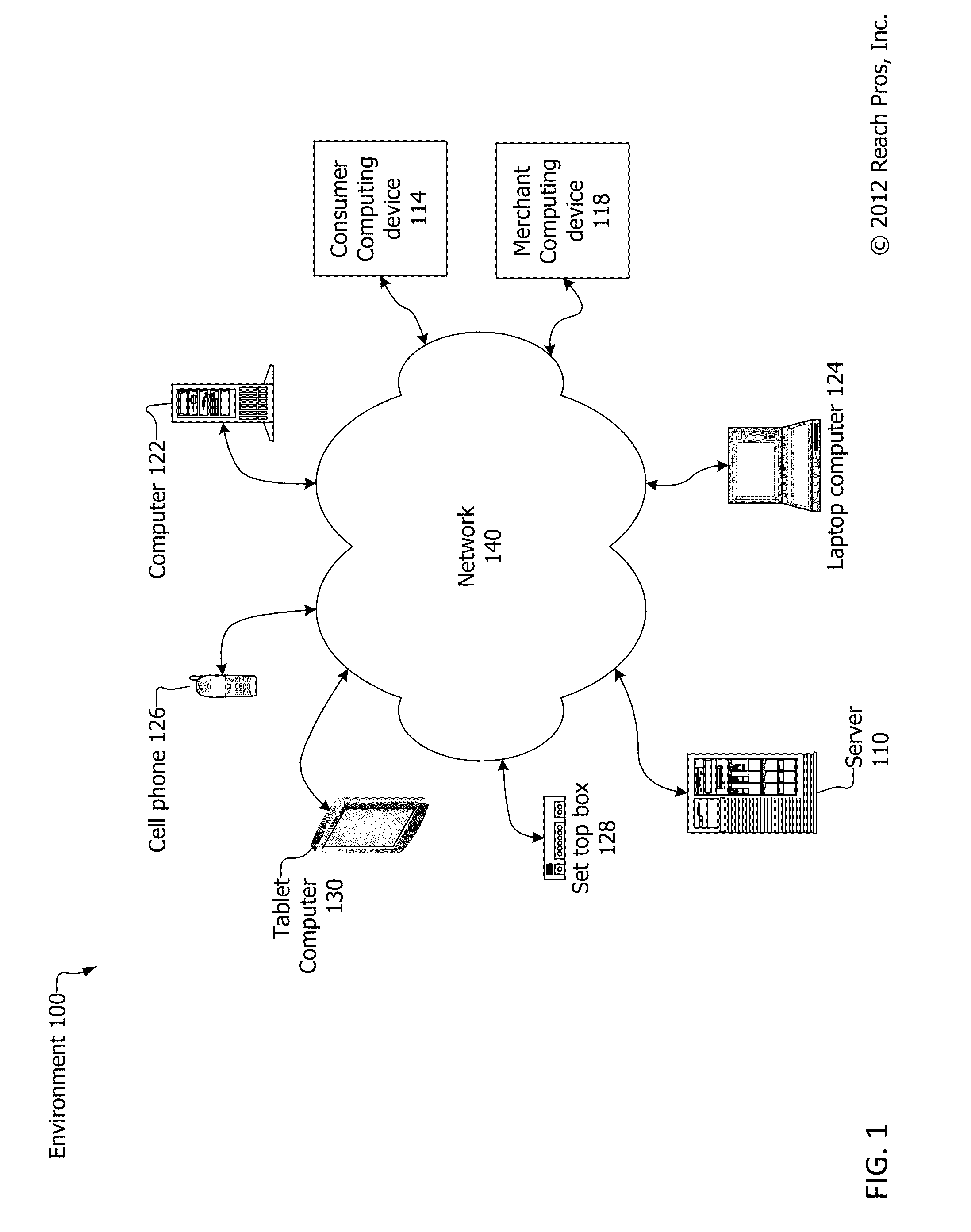

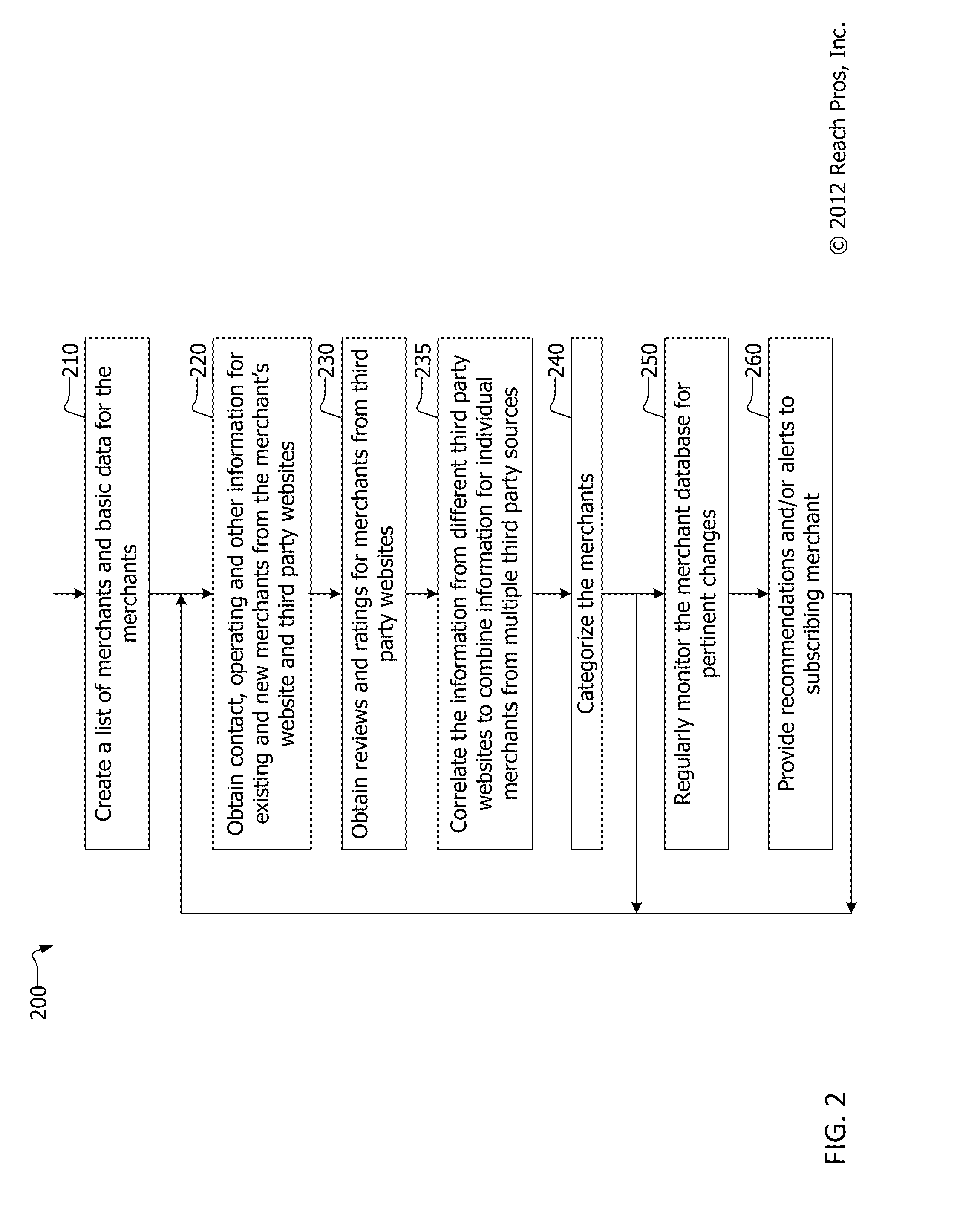

Online marketing, monitoring and control for merchants

Systems and methods of online marketing, monitoring and control for merchants are disclosed. Third party providers are crawled to obtain information about a plurality of merchants and correlate the merchant information to create a merchant database. Third party providers are monitored for merchant information, and information about the merchants is stored. Alerts are provided to subscribing merchants when an alert trigger is identified within the system or at a third party provider. The method allows the subscribing merchant to view and respond to reviews, view and maintain online listings, prepare and send consumer offers, and prepare and send communications to consumers, all directly from the system. The method allows the subscribing merchant to view information and analyses for competing merchants. An overall marketing score for merchants is prepared and displayed. The method may be performed on a server and accessed via an Internet browser and mobile device applications.

Owner:REACH PROS

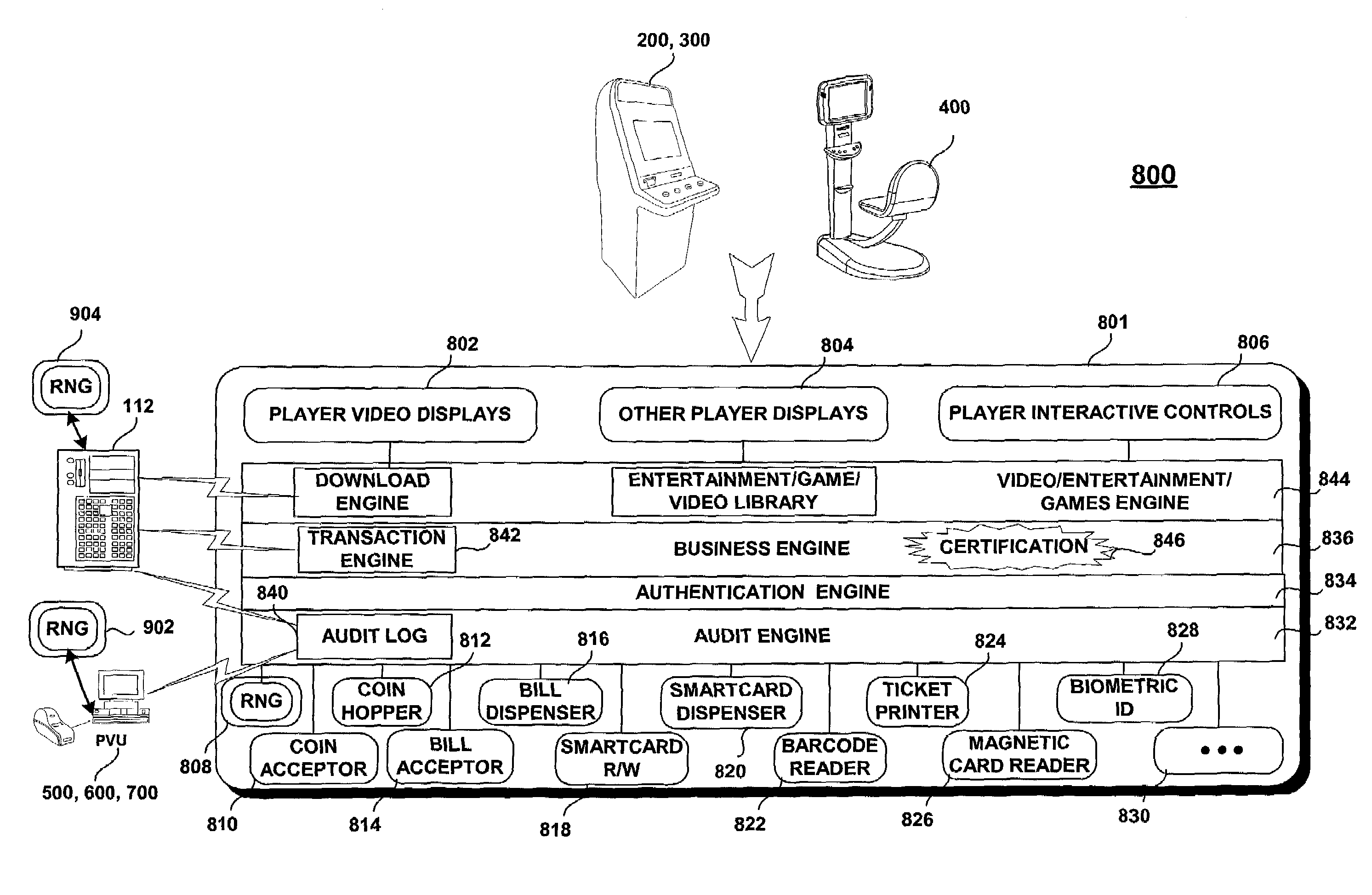

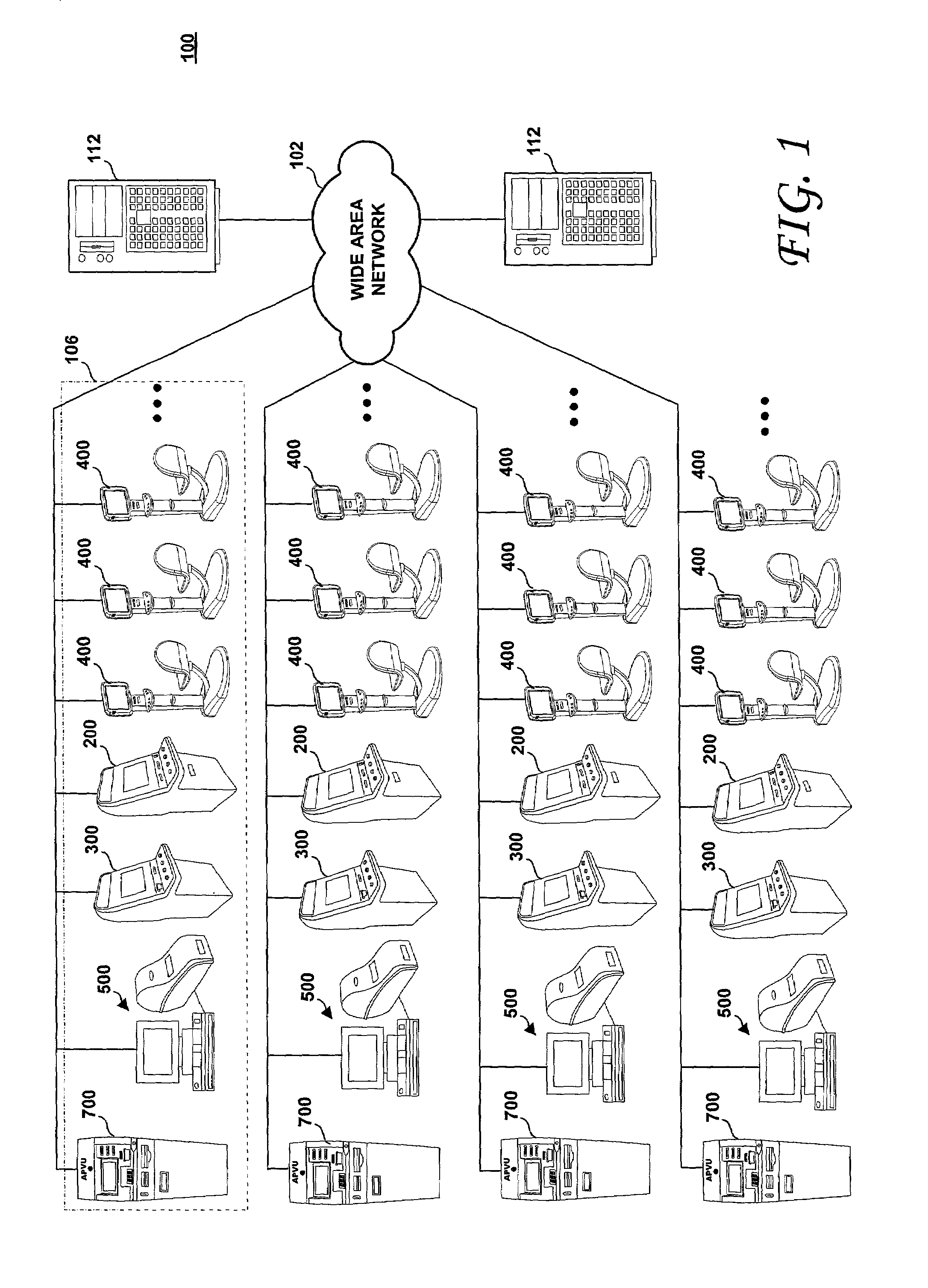

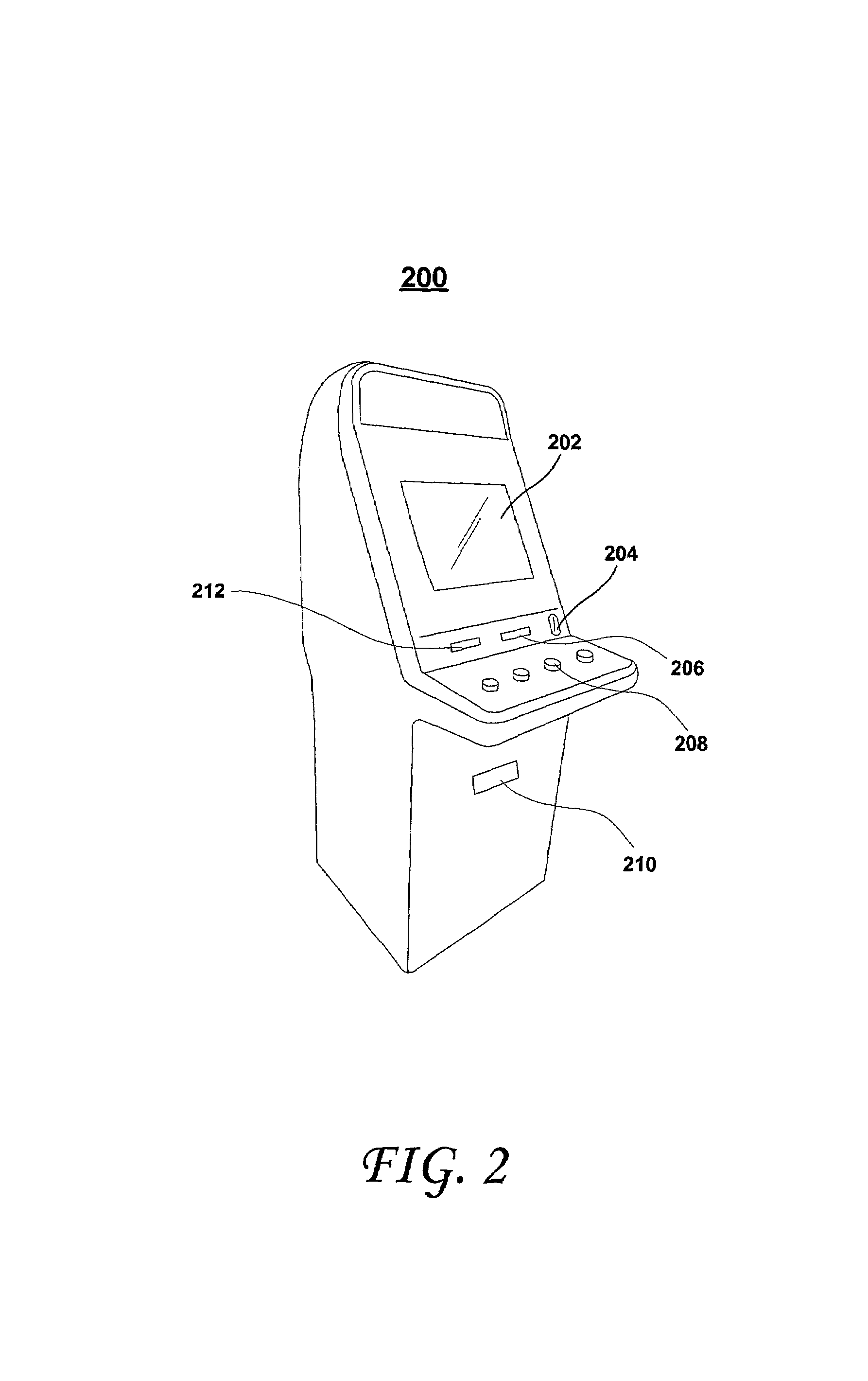

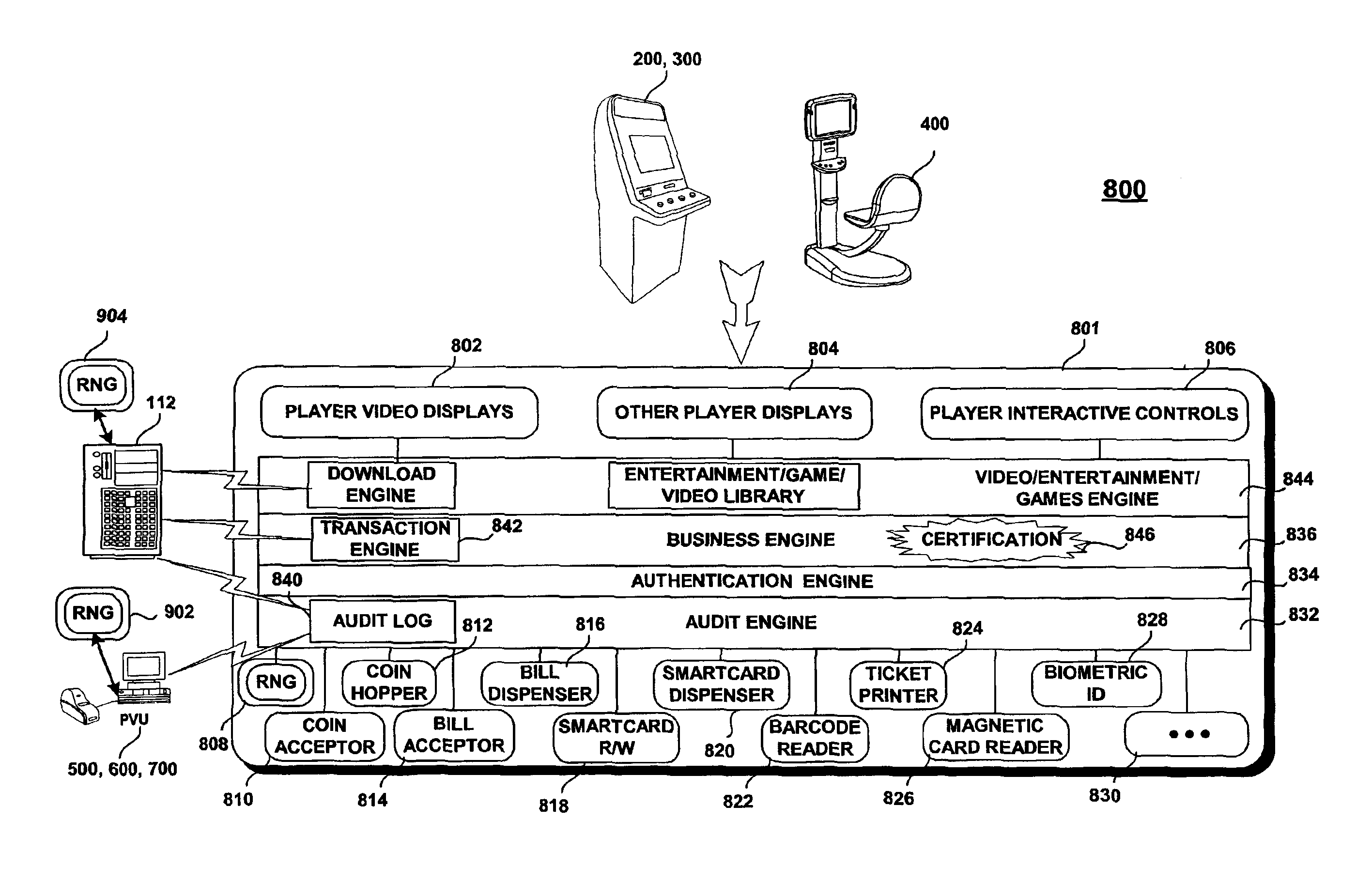

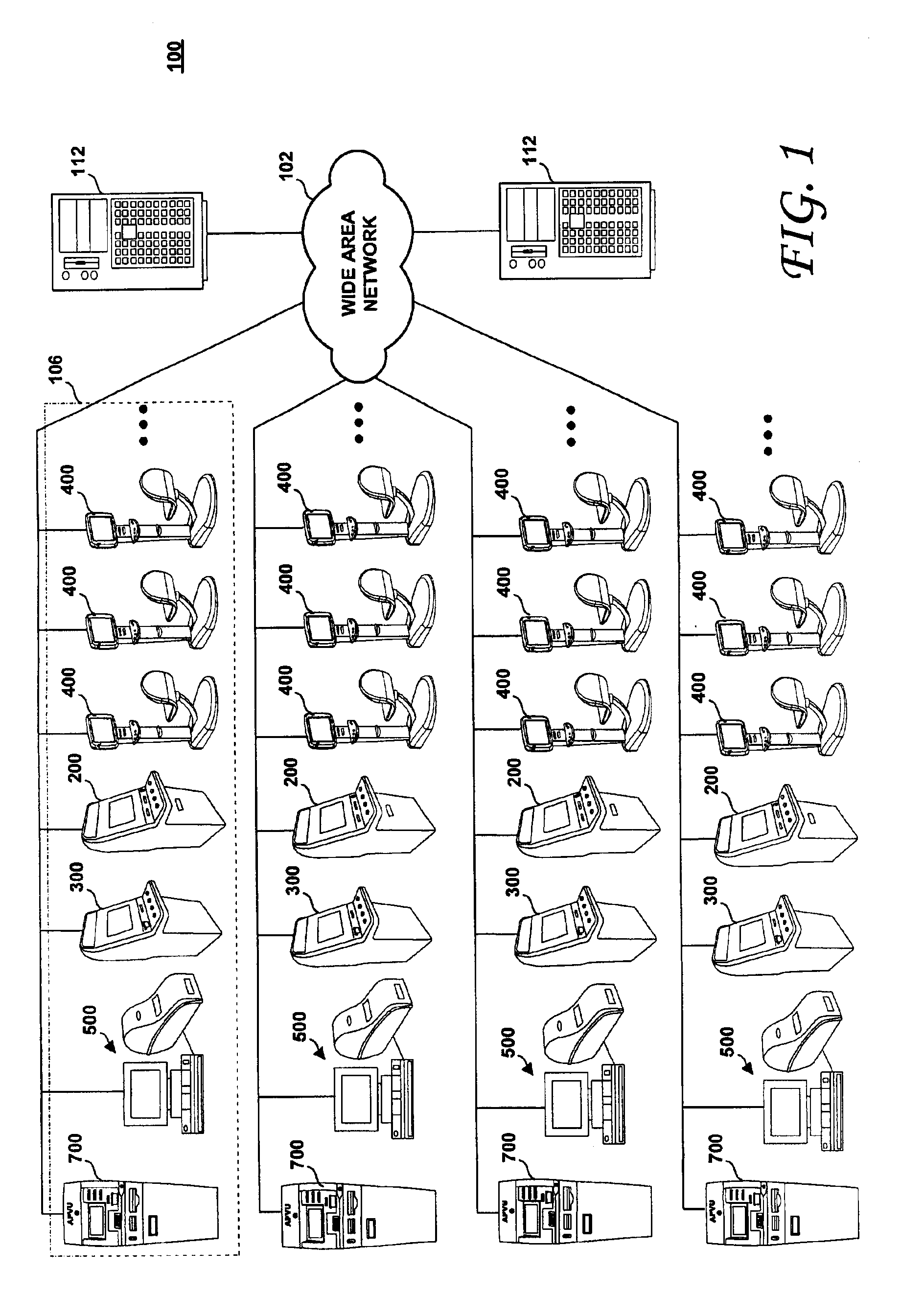

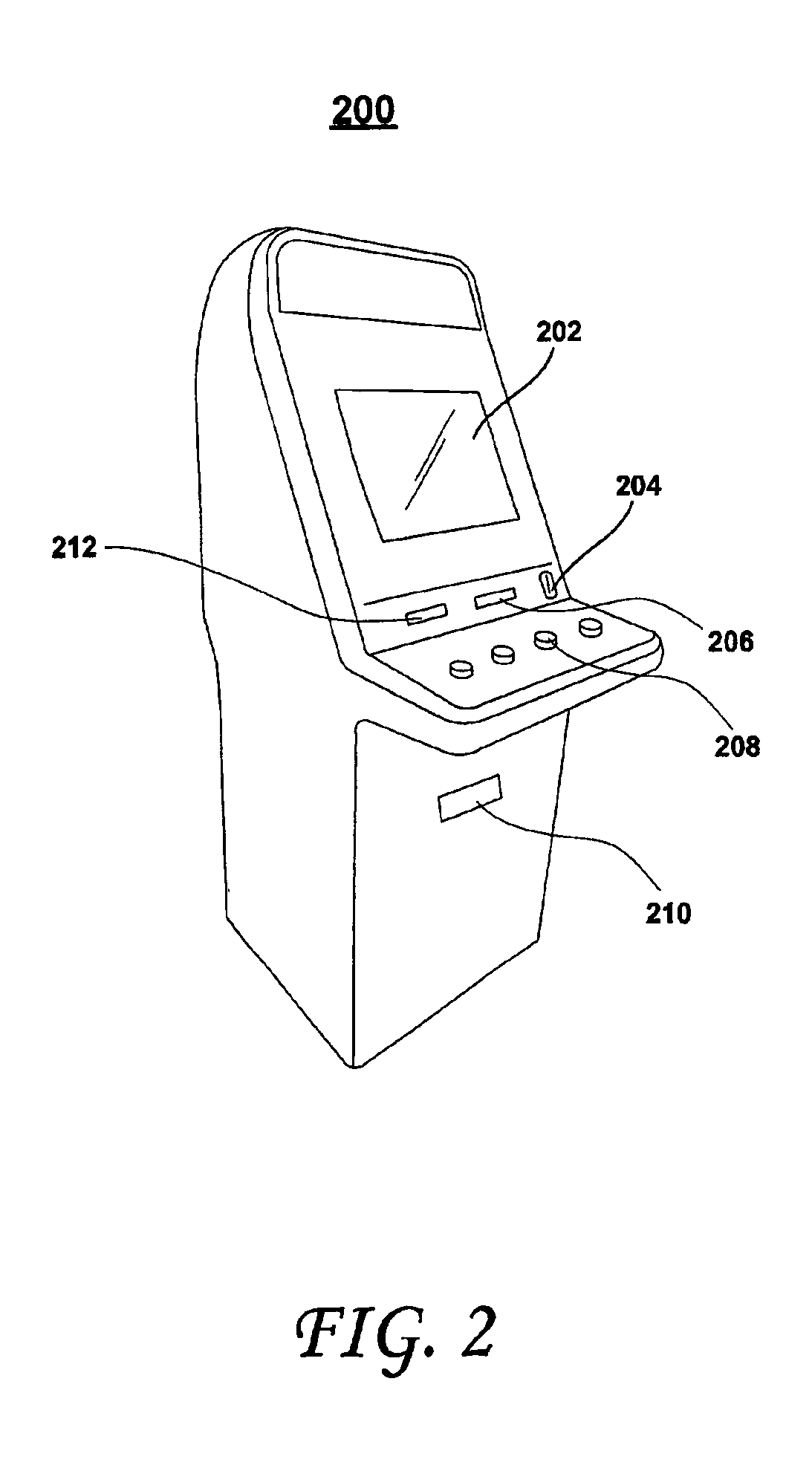

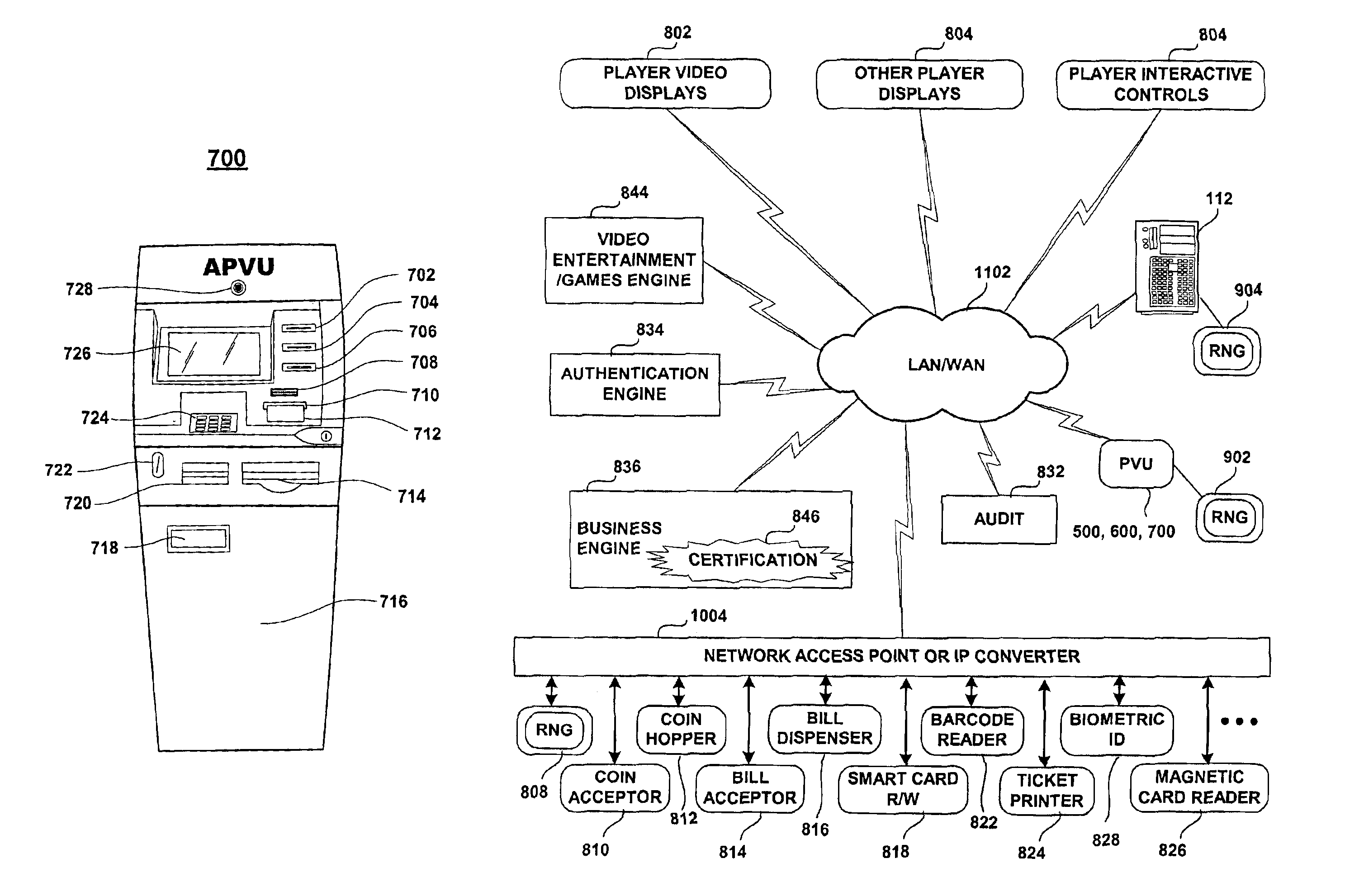

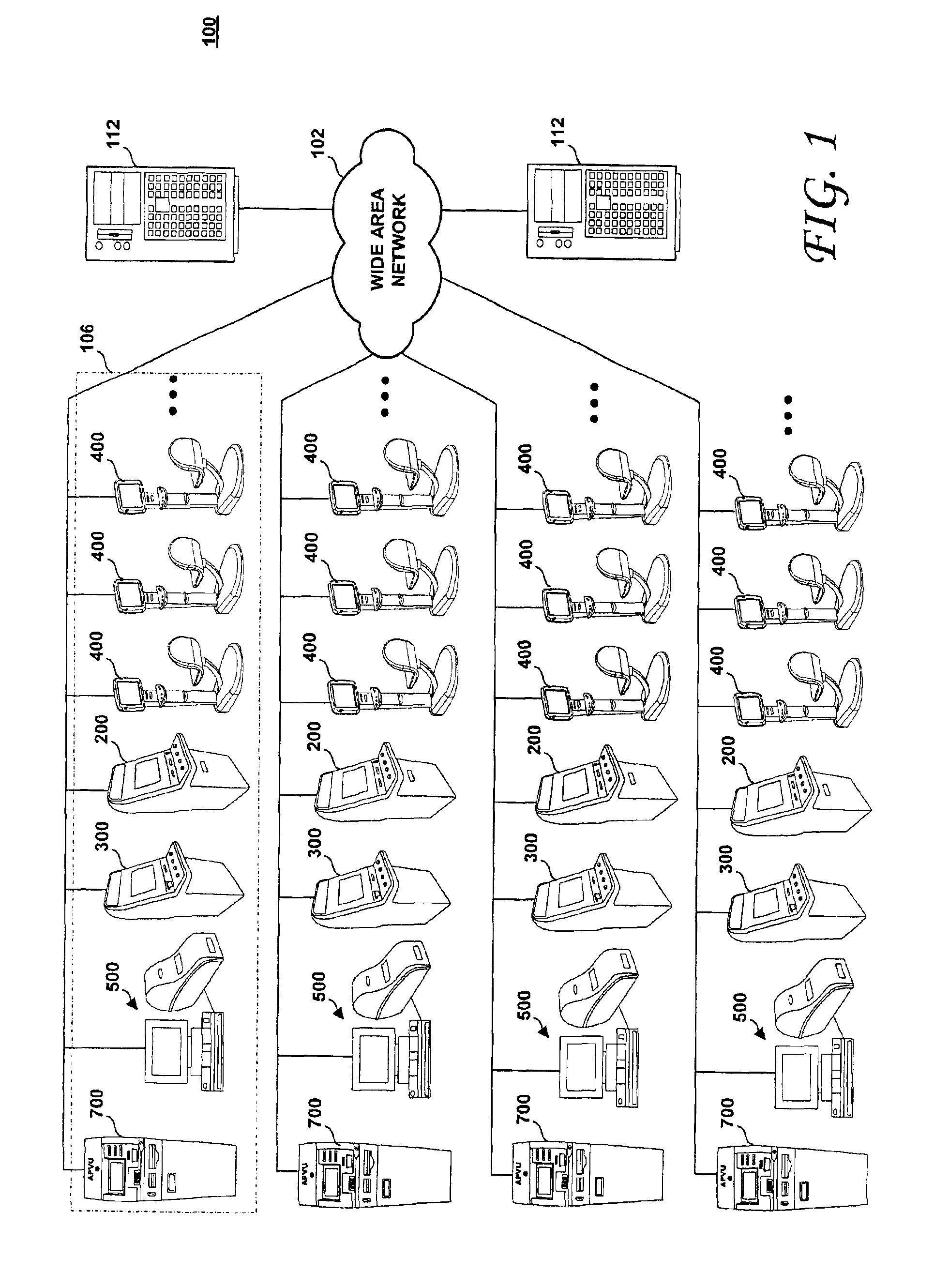

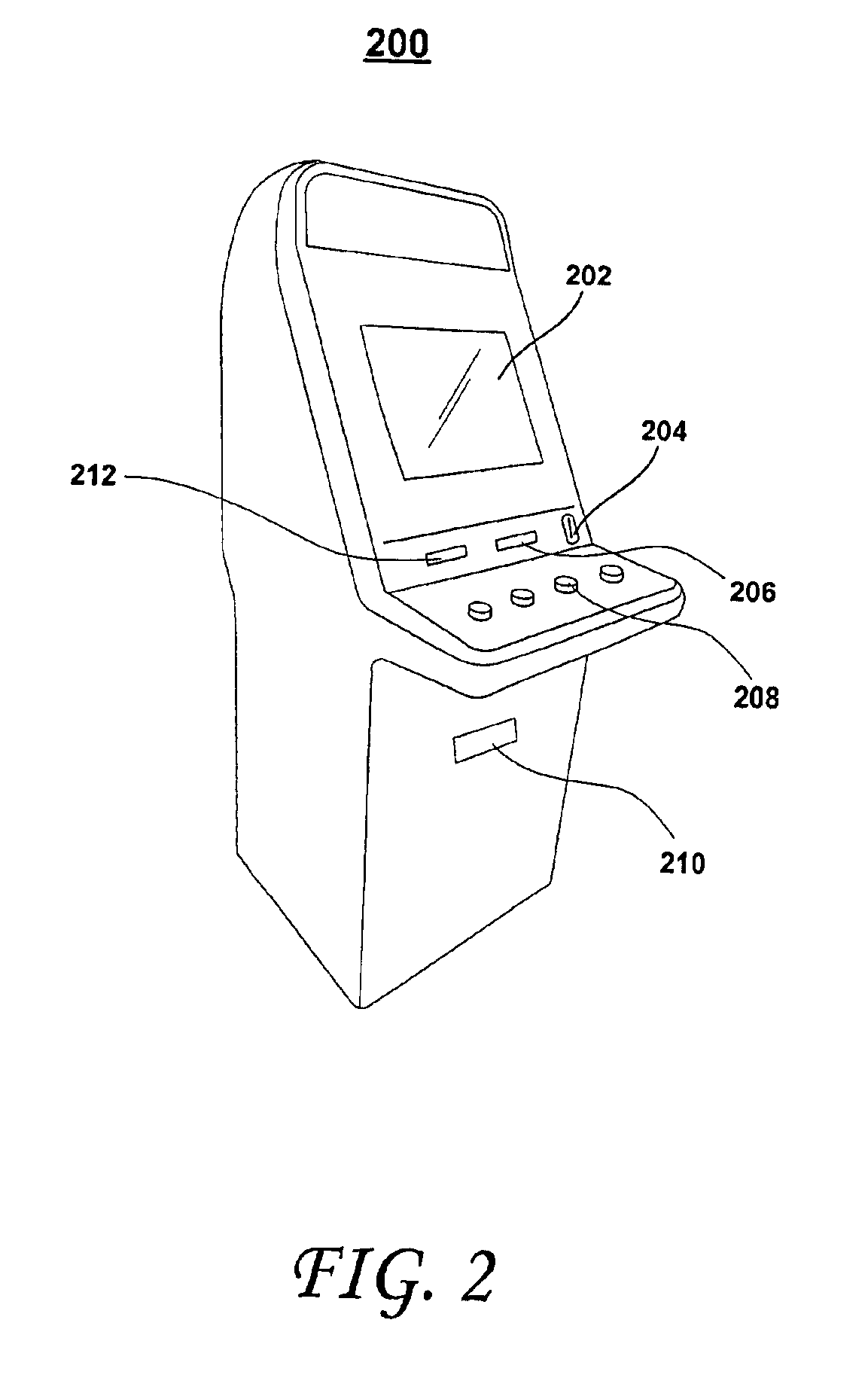

Modular entertainment and gaming systems configured to consume and provide network services

InactiveUS7297062B2Overcomes technical lagOvercomes security limitationElectric signal transmission systemsDigital data processing detailsModularityThe Internet

A secure and modular architecture for monitoring and controlling clusters of pay entertainment and gaming devices. The architecture allows flexible and secure use of state-of-the-art multimedia and Internet technologies to attract the younger player generation used to flashy and networked games. Cash or cash-less entertainment and gaming devices are supported.

Owner:MUDALLA TECH INC THOITS LOVE HERSHBERGER & MCLEAN

Modular entertainment and gaming system configured for network boot, network application load and selective network computation farming

InactiveUS6908391B2Overcomes technical lagOvercomes security limitationApparatus for meter-controlled dispensingVideo gamesModularityThe Internet

A secure and modular architecture for monitoring and controlling clusters of pay entertainment and gaming devices. The architecture allows flexible and secure use of state-of-the-art multimedia and Internet technologies to attract the younger player generation used to flashy and networked games. Cash or cash-less entertainment and gaming devices are supported.

Owner:MUDALLA TECH INC THOITS LOVE HERSHBERGER & MCLEAN

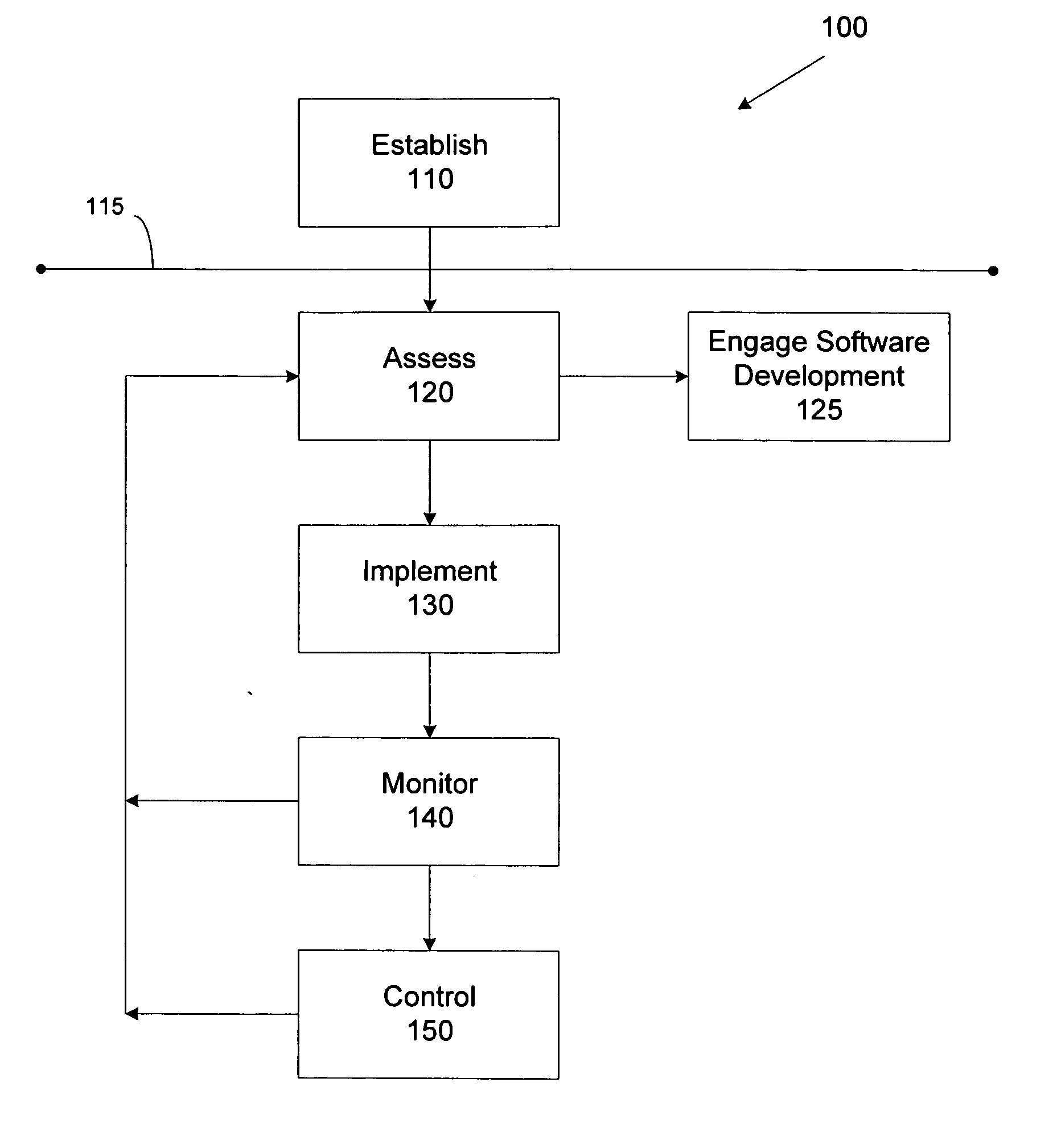

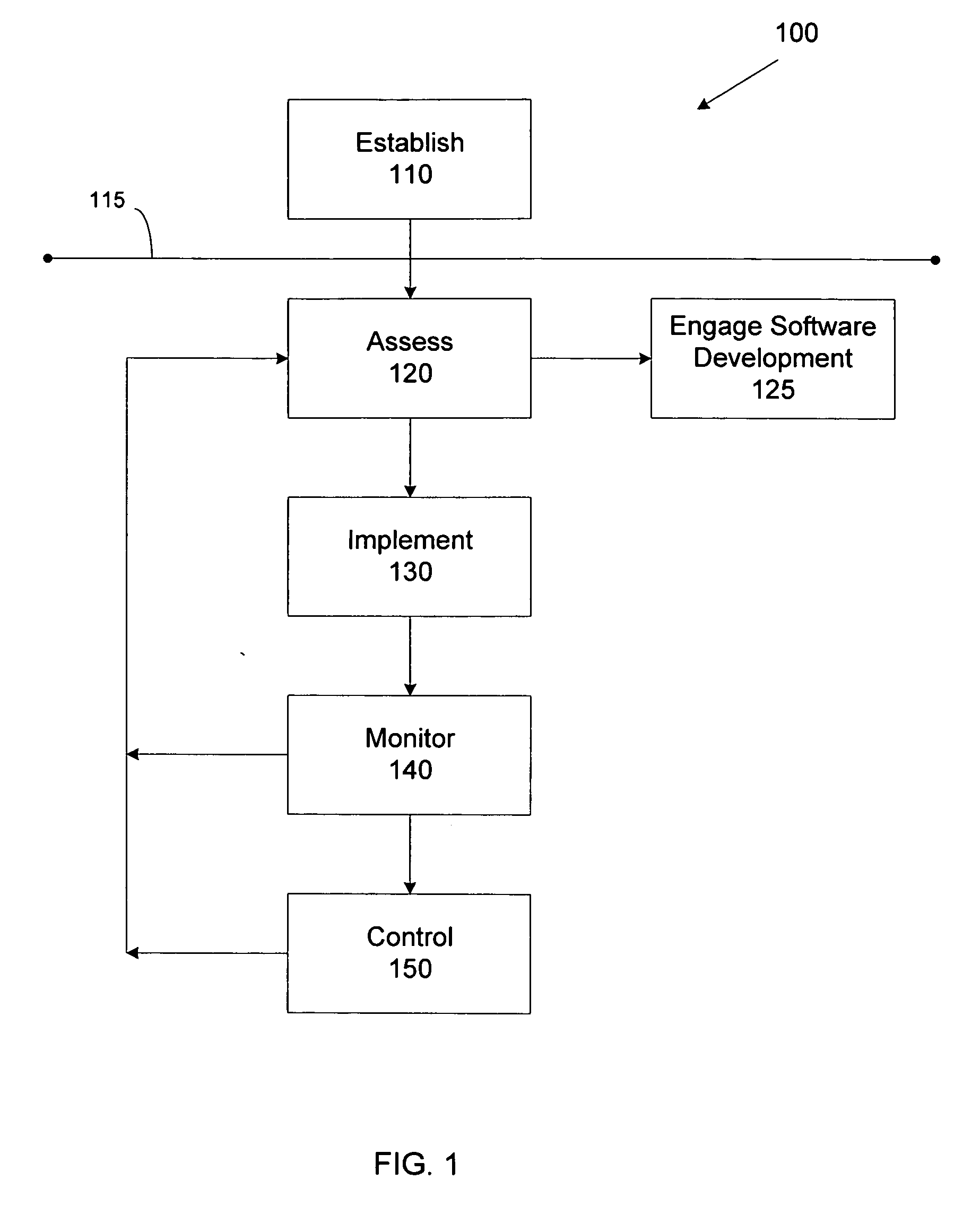

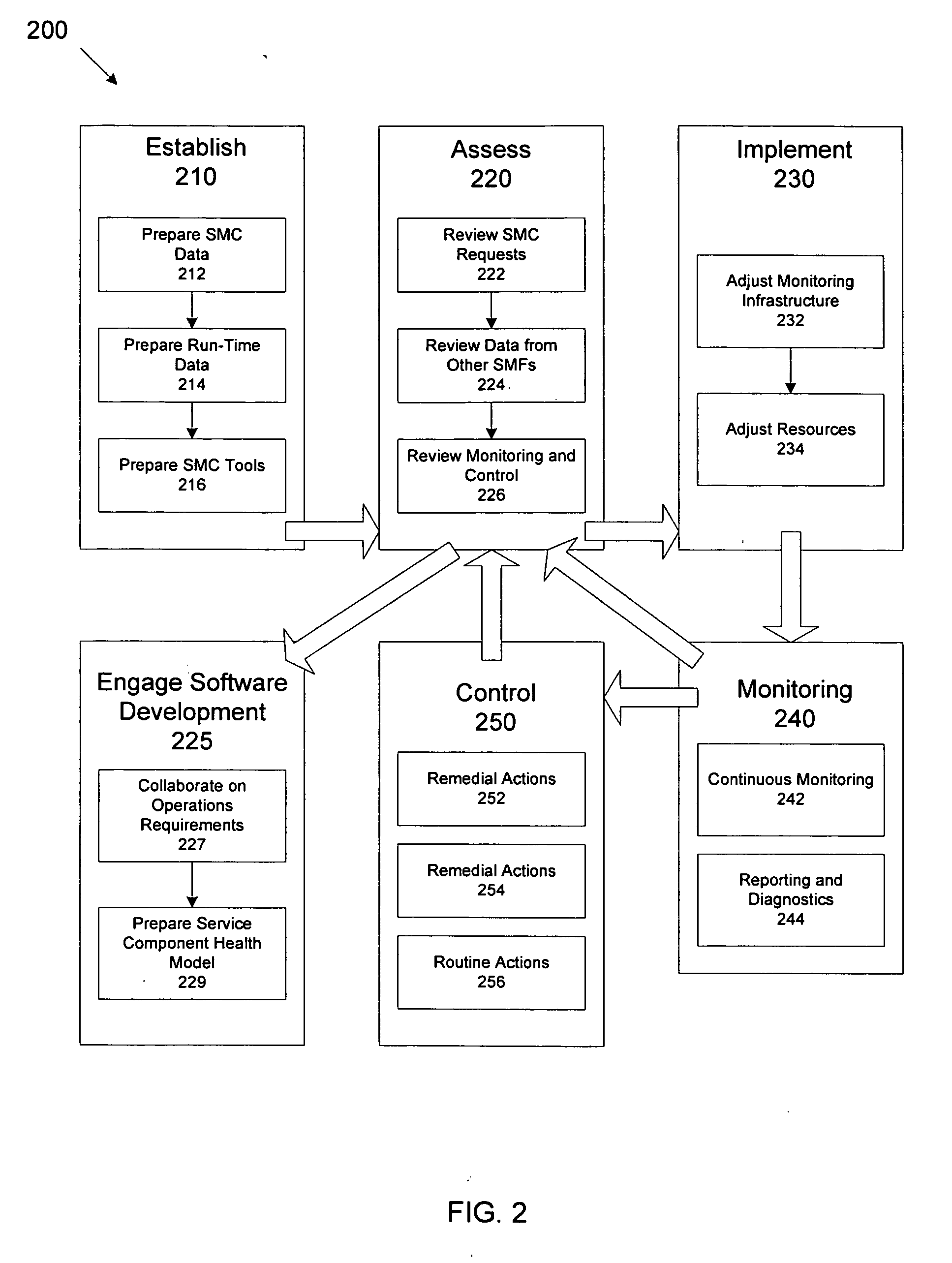

Methods for service monitoring and control

InactiveUS20060064486A1Improve performanceDigital computer detailsTransmissionMonitoring and controlGood practice

In one aspect, a method of instructing operators in a best practices implementation of a service monitoring and control (SMC) facility performing a plurality of functions in a computer system comprising a plurality of services to be monitored is provided. The method comprises an act of providing best practices instructions for the implementation of the SMC facility in a hierarchical manner so that the implementation of the SMC facility is described as comprising a plurality of top level activities to be performed during the operation of the SMC, with each of the plurality of top level activities being described as comprising at least one lower level sub-activity, the top level activities comprising, assessing performance of the SMC facility, in response to information learned during assessing the performance of the SMC facility, implementing at least one change in the SMC facility, monitoring the computer system with the changed SMC facility for an occurrence of at least one event, and automatically performing at least one control action in response to the occurrence of the at least one event. In another aspect, a top-level activity of collaborating with one or more developers is described, resulting in a change to at least one change to software executed on the computer system. In another aspect, at least a part of the effectiveness of an SMC facility is automatically assessed, and in response, one of the plurality of functions performed by the SMC facility is automatically changed.

Owner:MICROSOFT TECH LICENSING LLC

Modular entertainment and gaming system configured for processing raw biometric data and multimedia response by a remote server

InactiveUS6945870B2Overcomes technical lagOvercomes security limitationElectric signal transmission systemsDigital data processing detailsBiometric dataThe Internet

A secure and modular architecture for monitoring and controlling clusters of pay entertainment and gaming devices. The architecture allows flexible and secure use of state-of-the-art multimedia and Internet technologies to attract the younger player generation used to flashy and networked games. Cash or cash-less entertainment and gaming devices are supported.

Owner:MUDALLA TECH INC THOITS LOVE HERSHBERGER & MCLEAN

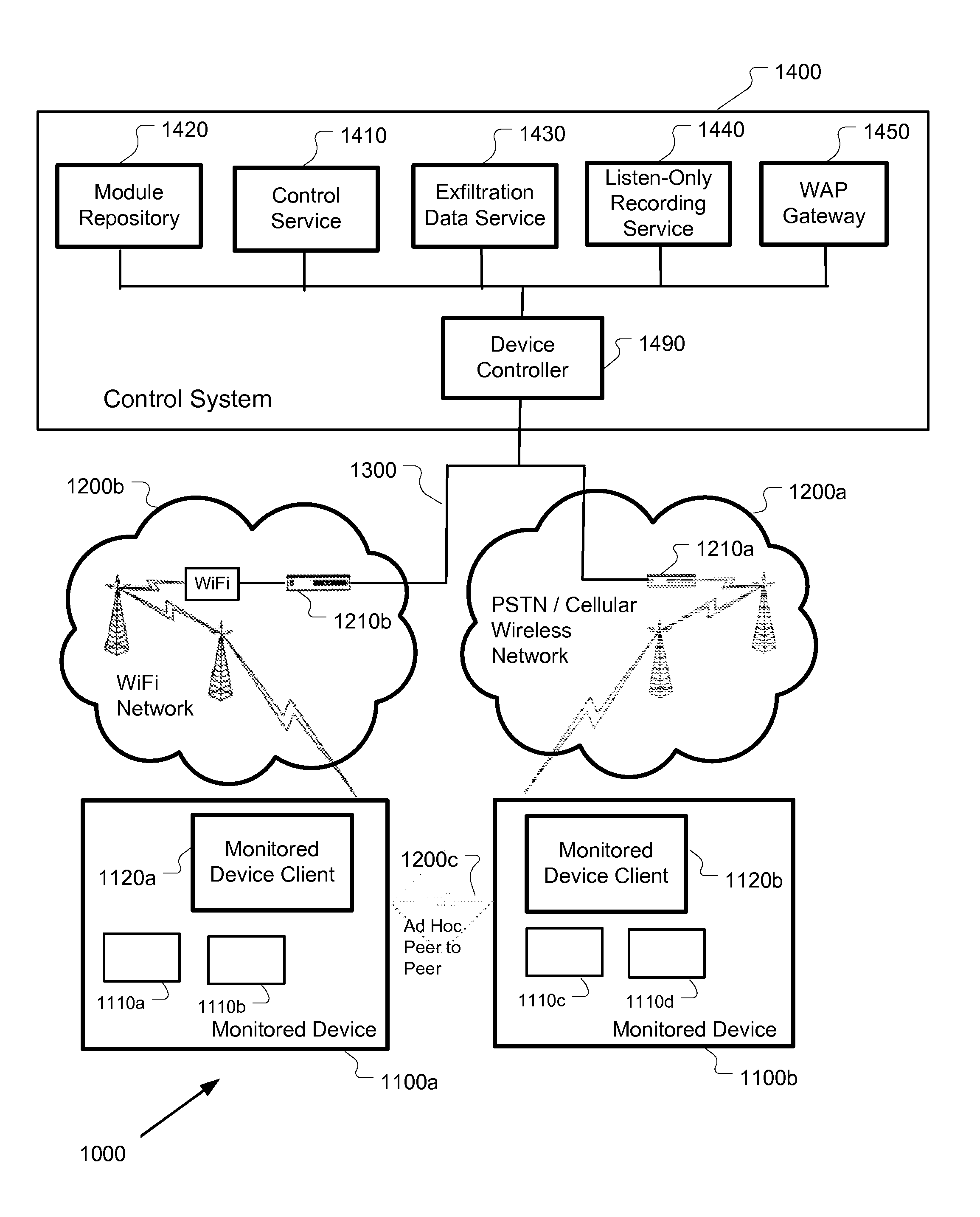

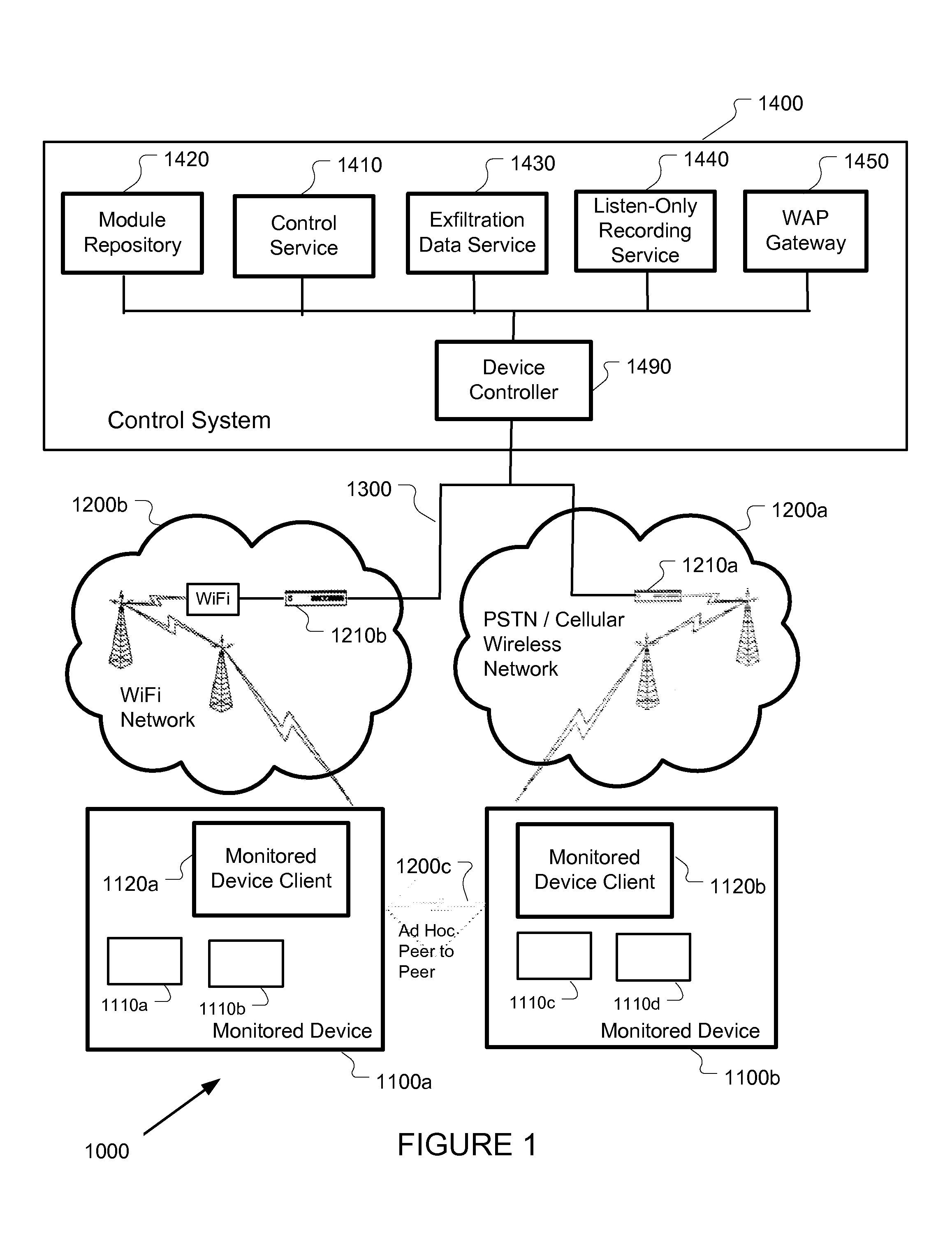

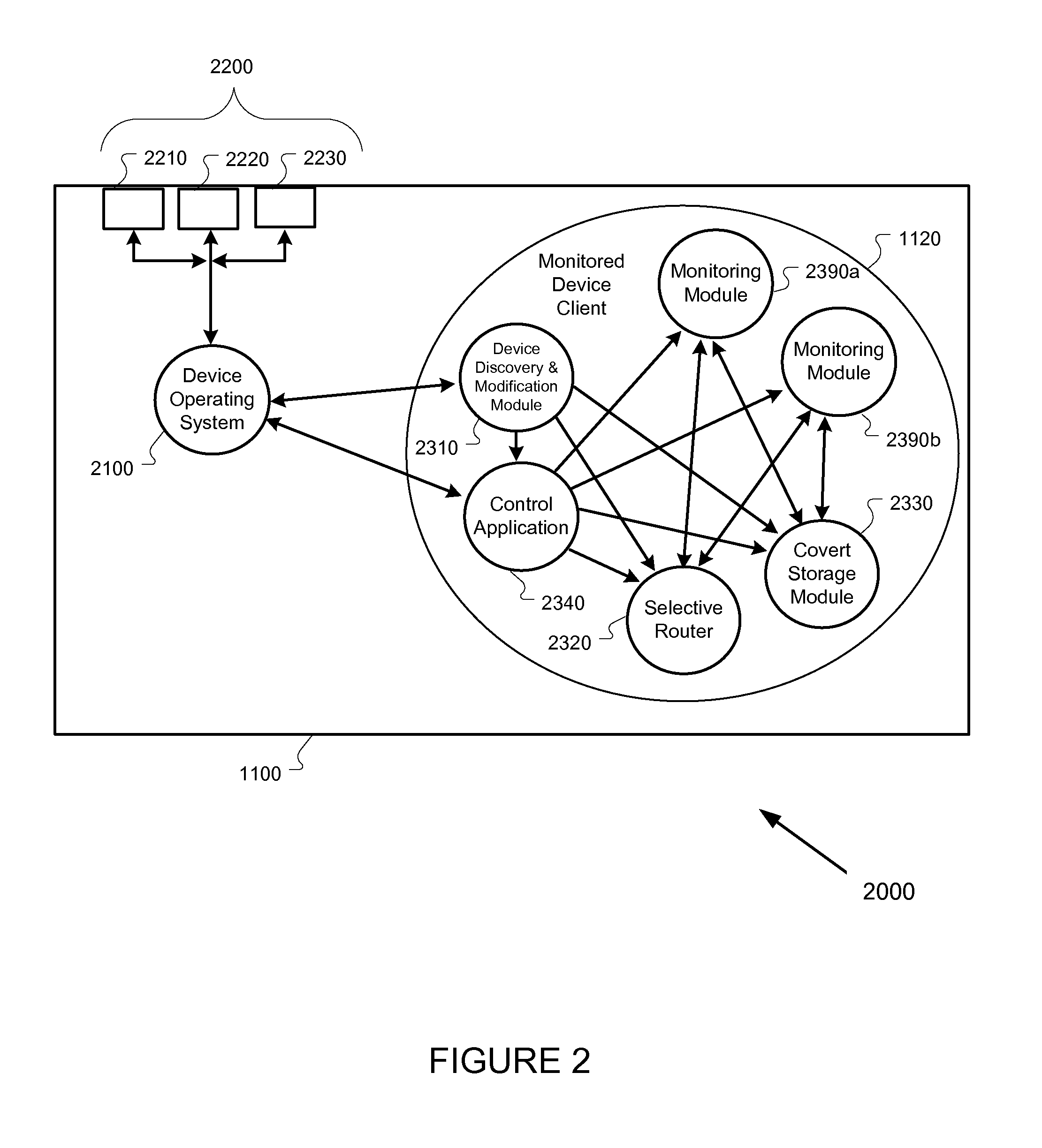

Mobile device monitoring and control system

Methods and apparatus, including computer program products, for surreptitiously installing, monitoring, and operating software on a remote computer controlled wireless communication device are described. One aspect includes a control system for communicating programming instructions and exchanging data with the remote computer controlled wireless communication device. The control system is configured to provide at least one element selected from the group consisting of: a computer implemented device controller; a module repository in electronic communication with the device controller; a control service in electronic communication with the device controller; an exfiltration data service in electronic communication with the device controller configured to receive, store, and manage data obtained surreptitiously from the remote computer controlled wireless communication device; a listen-only recording service in electronic communication with the device controller; and a WAP gateway in electronic communication with the remote computer controlled wireless communication device.

Owner:MANTECH ADVANCED SYST INT

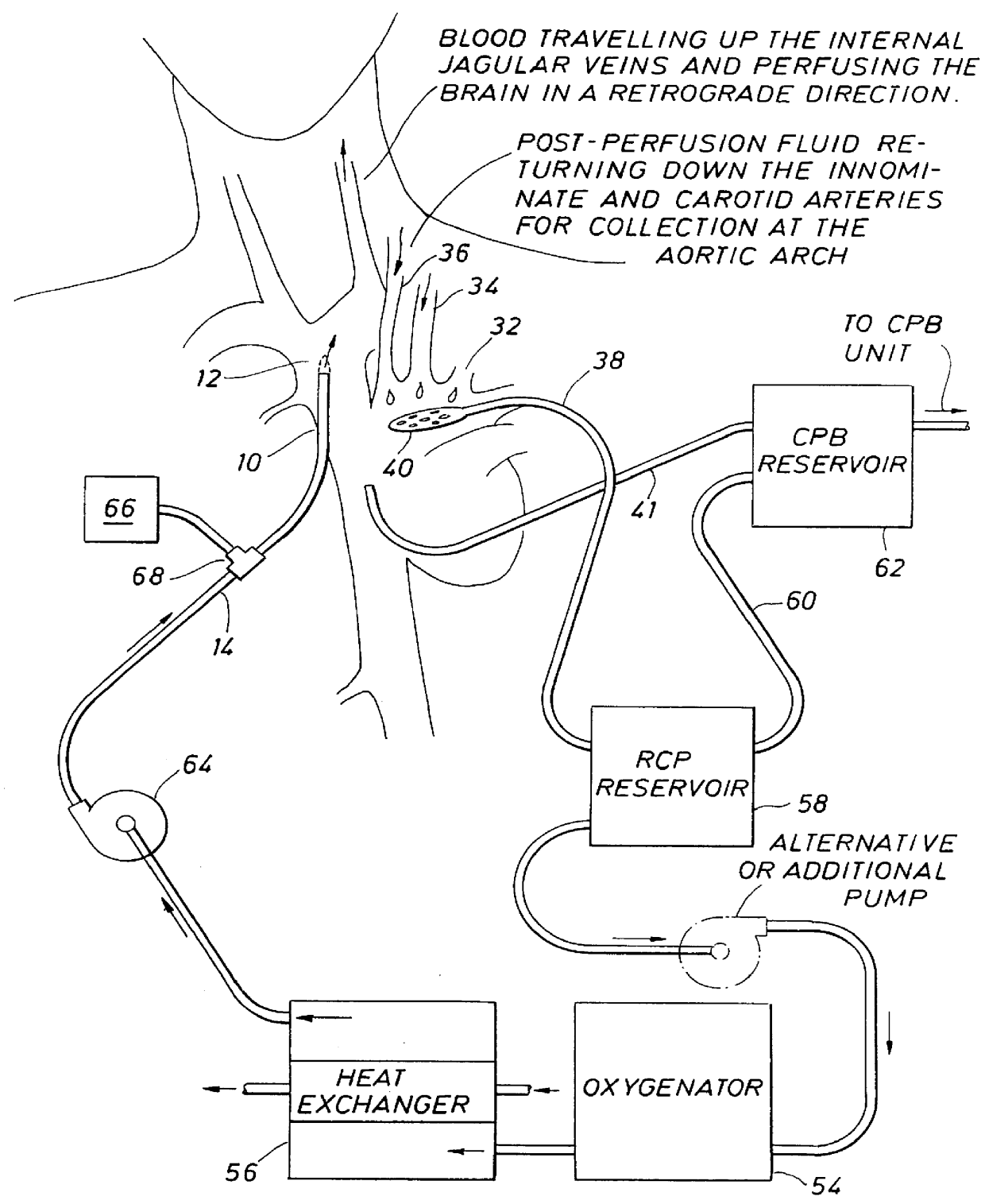

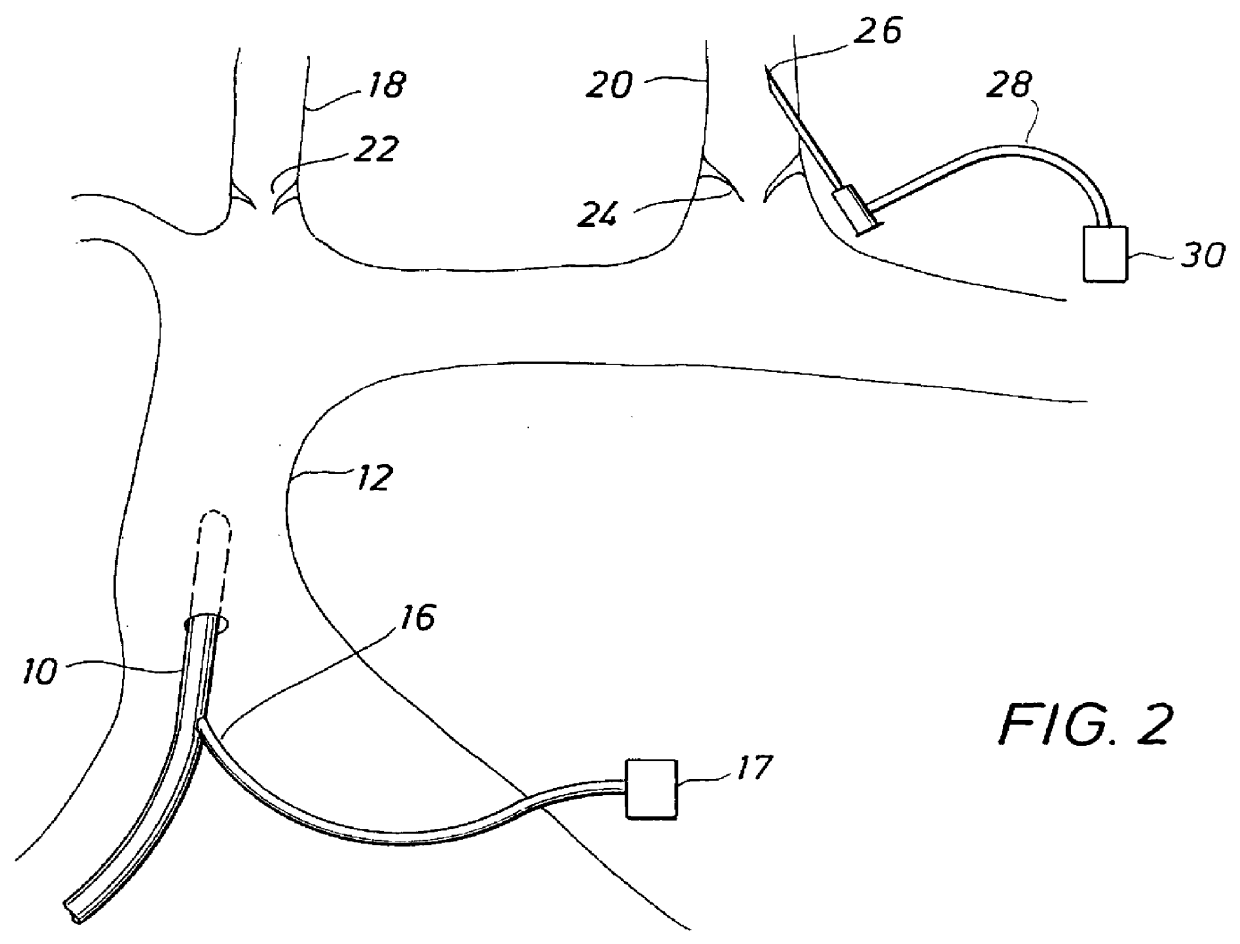

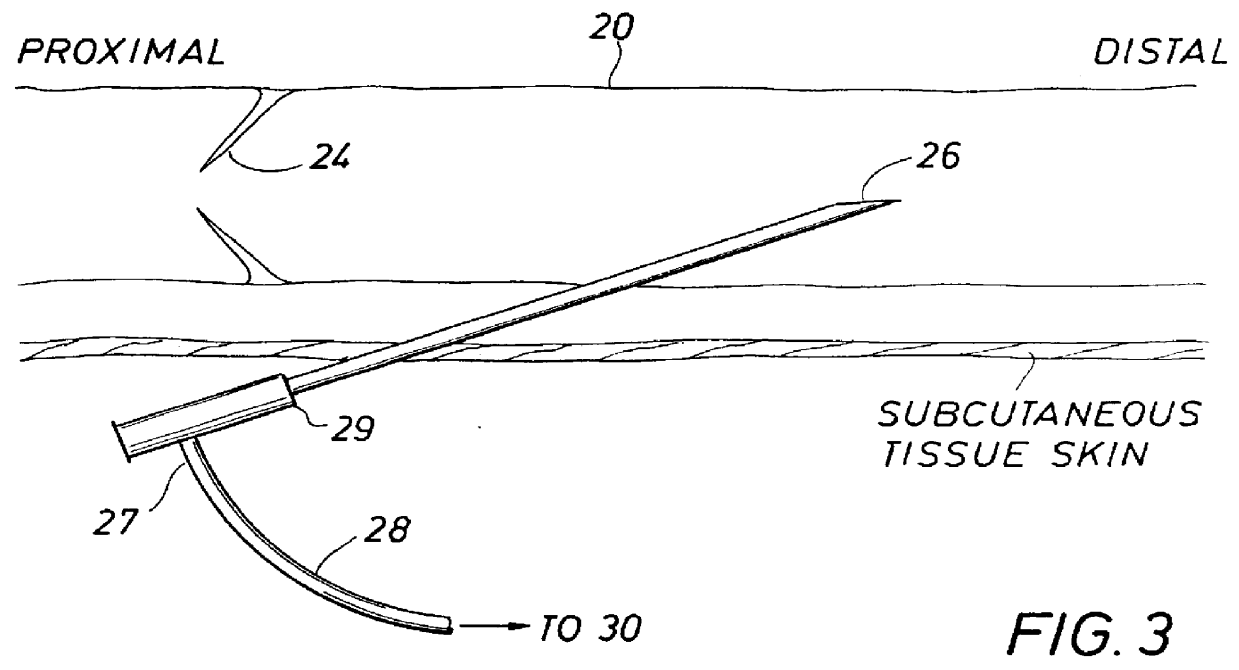

Retrograde perfusion monitoring and control system

InactiveUS6110139AOther blood circulation devicesDialysis systemsOrgan systemCardiopulmonary bypass time

Apparatus and methods for performing retrograde perfusion, especially during cardiopulmonary bypass operations, including dedicated pediatric scaled apparatus for retrograde perfusion of an adult human organ, organ system, or limb, especially the brain, employing small scale oxygenators and heat exchangers such as are designed for pediatric surgery; also including methods and apparatus for retrograde cerebral perfusion, using nonselective infravalvular cannulation of the superior vena cava, estimating the efficacy of cerebral perfusion by monitoring fluid flow across a valve of an internal jugular vein, modification of inflow pressure and administration of pharmacologic agents, and increasing fluid flow into a brain by occlusion of an inferior vena cava distal to its junction with an azygos vein.

Owner:LOUBSER PAUL GERHARD

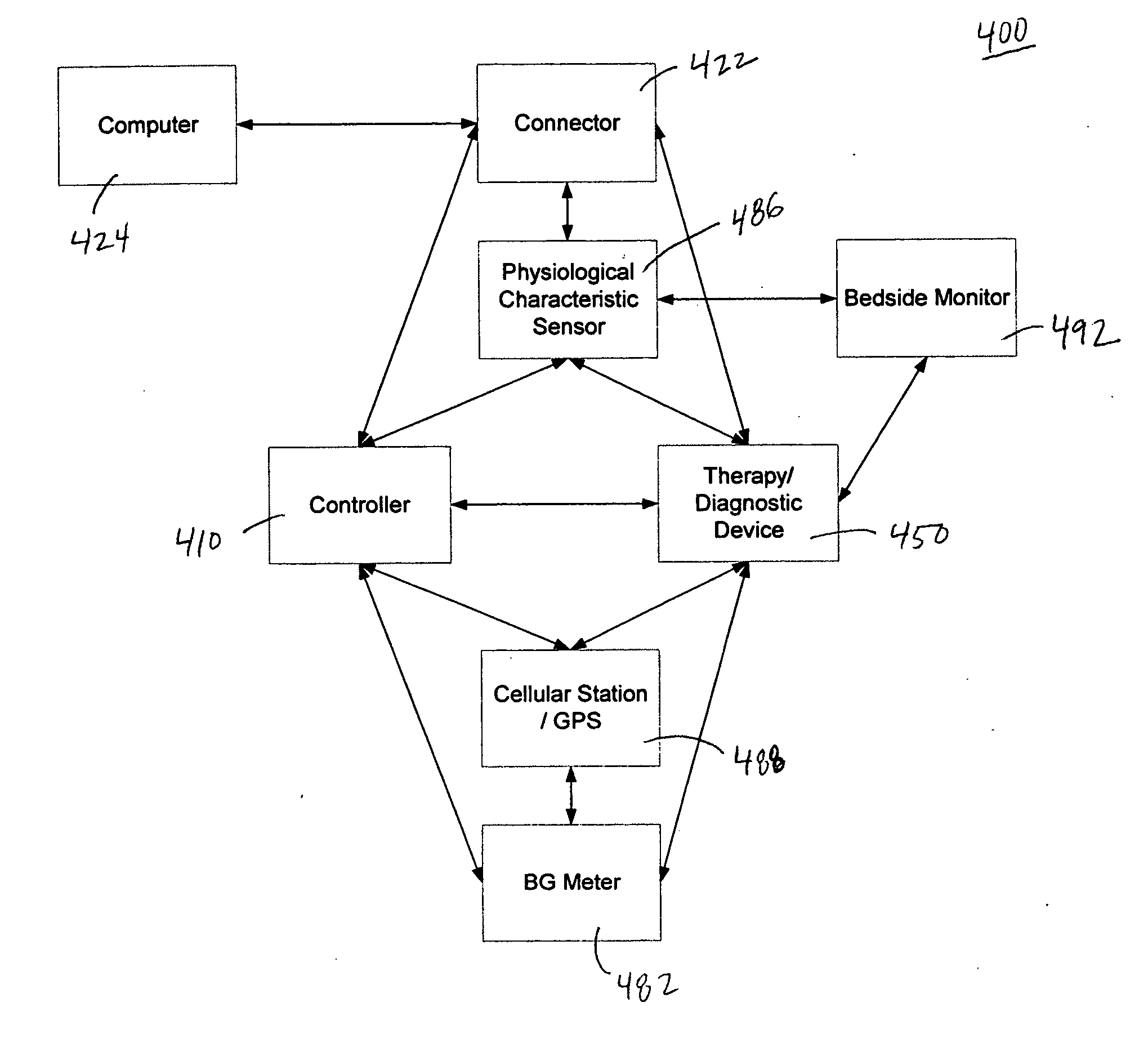

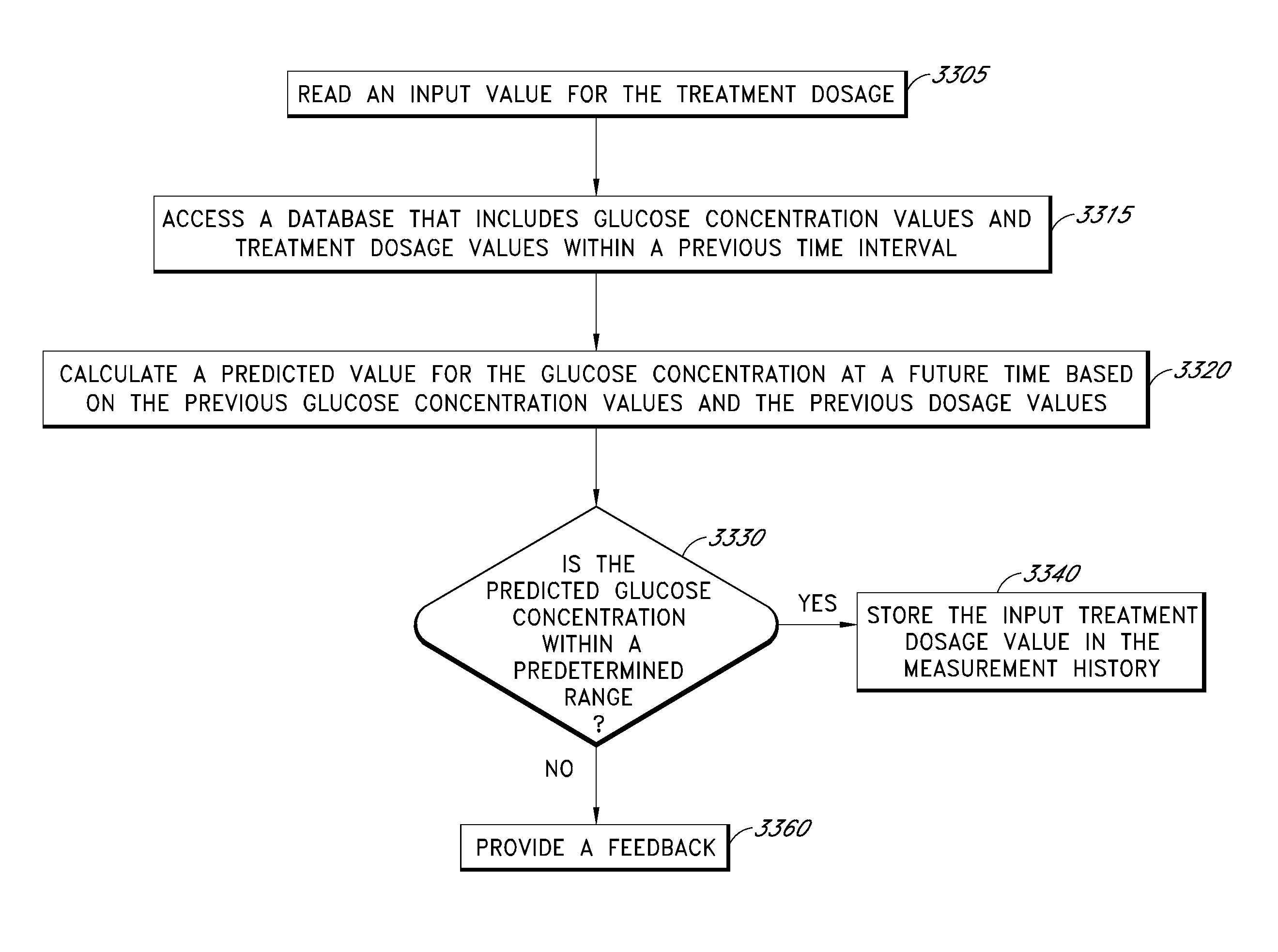

Fluid component analysis system and method for glucose monitoring and control

Owner:INSULET CORP +1

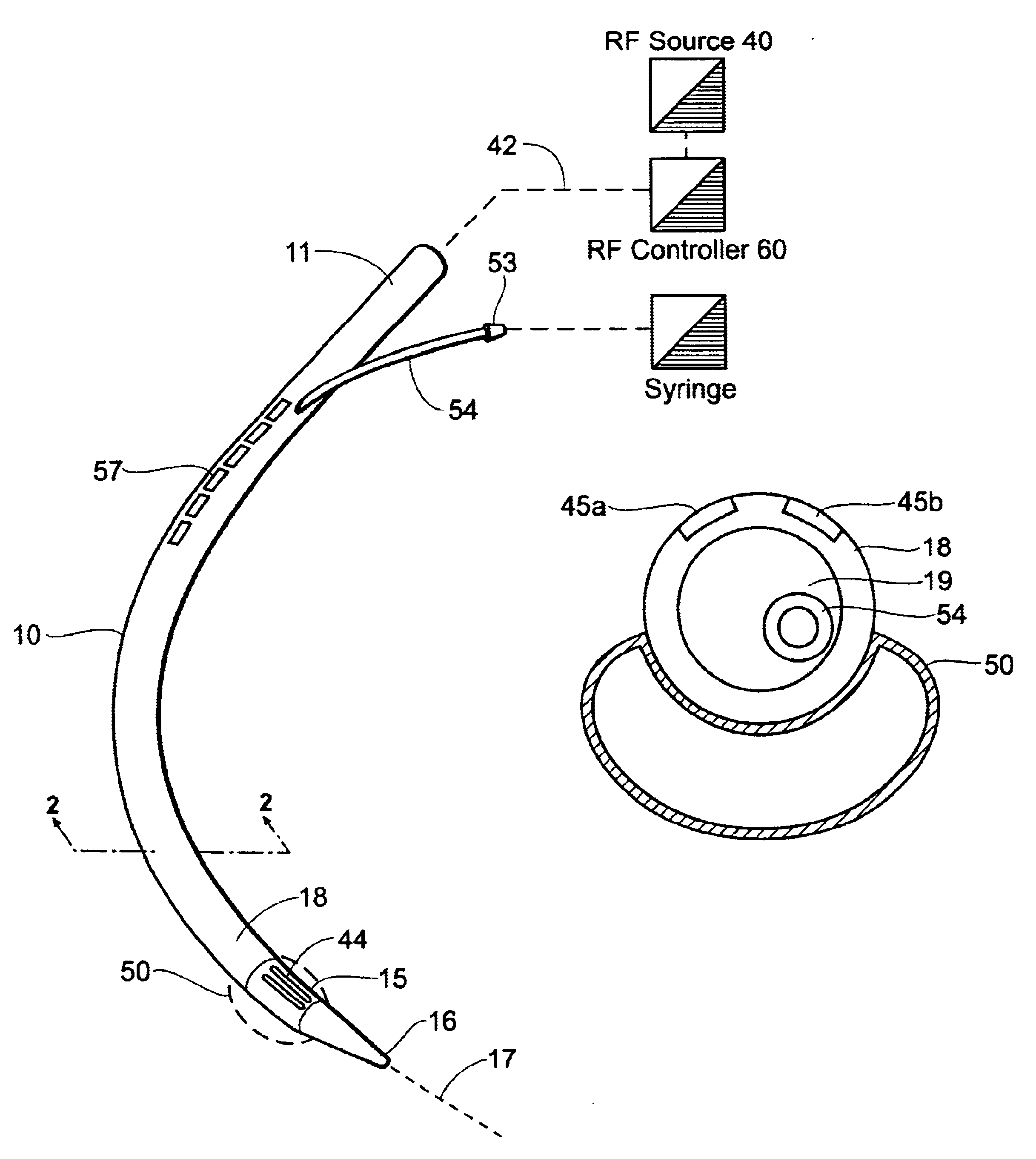

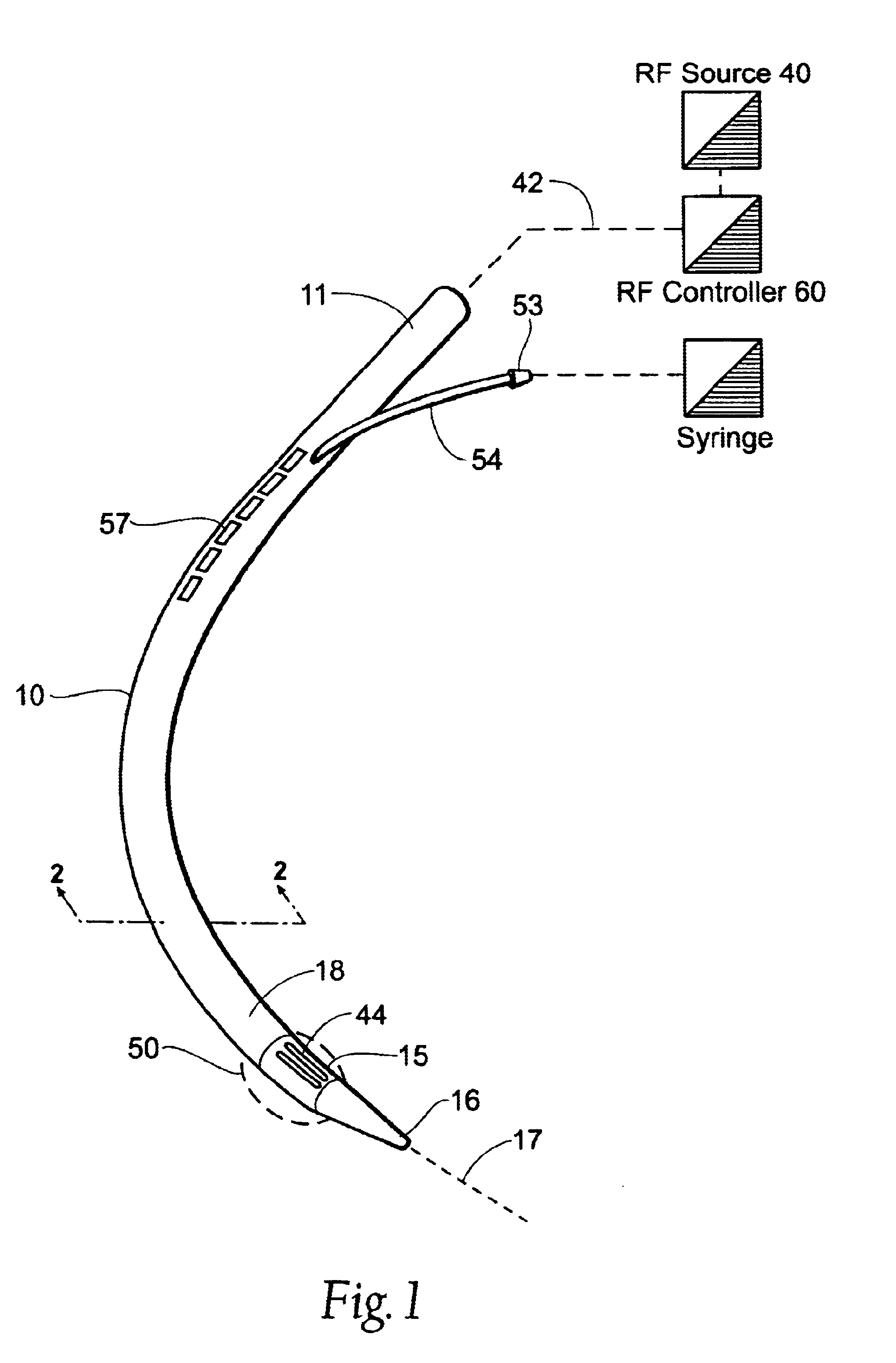

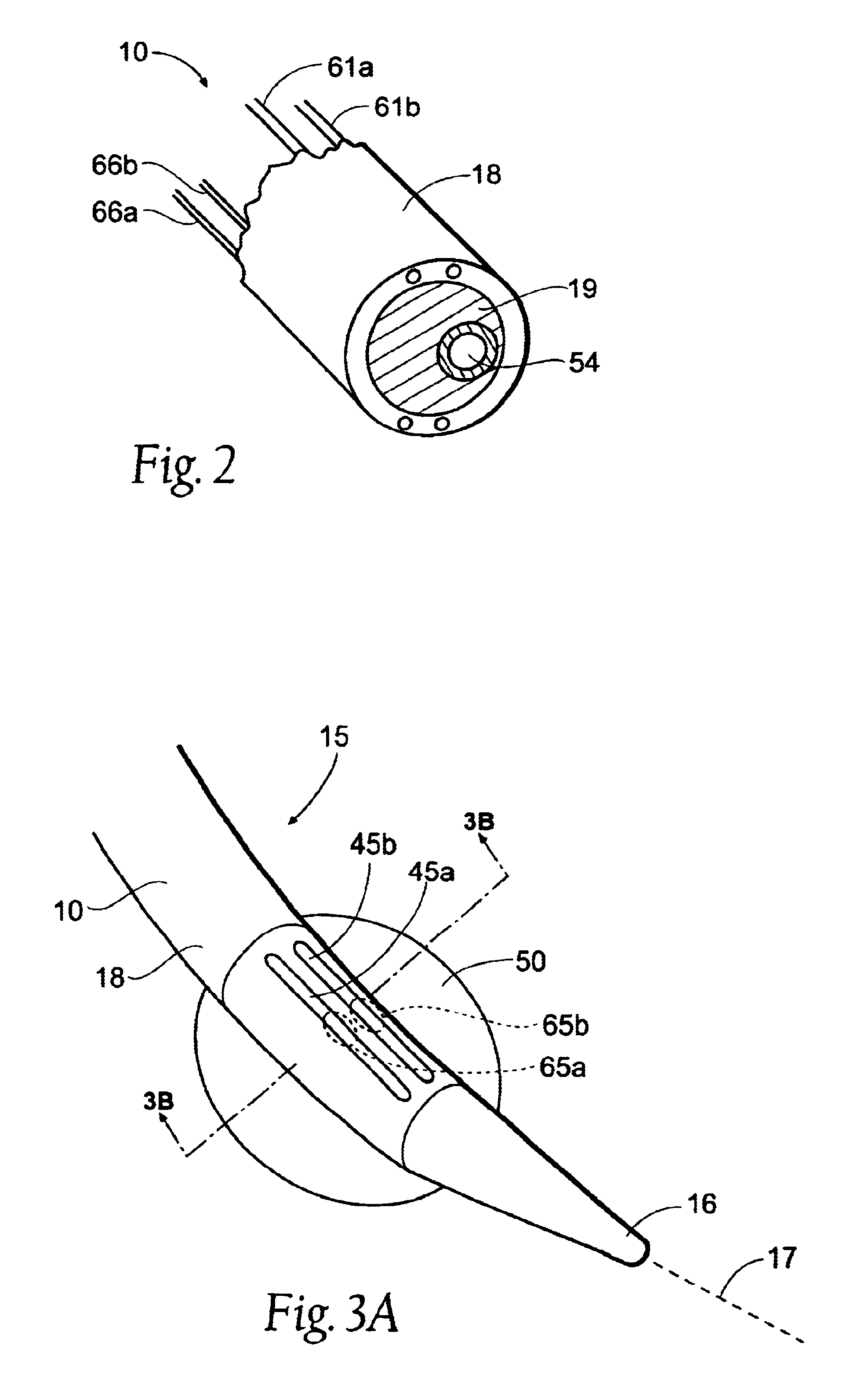

Surgical instruments for treating gastro-esophageal reflux

InactiveUS6740082B2Augment objectInexpensive and disposableElectrotherapyEndoscopesSensor arrayFiber

Instruments for thermally-mediated treatment of a patient's lower esophageal sphincter (LES) to induce an injury healing response to thereby populate the extracellular compartment of walls of the LES with collagen matrices to altere the biomechanics of the LES to provide an increased intra-esophageal pressure for preventing acid reflux. A preferred embodiment is a bougie-type device for trans-esophageal introduction that carries conductive electrodes for delivering Rf energy to walls of the LES (i) to induce the injury healing response or (ii) to "model" collagenous tissues of the LES by shrinking collagen fibers therein. Typically, an Rf source is connected to at least one conductive electrode that may be operated in a mono-polar or bi-polar fashion. A sensor array of individual sensors is provided in the working end. A computer controller is provided, which together with feedback circuitry, is capable of full process monitoring and control of: (i) power delivery; (ii) parameters of a selected therapeutic cycle, (iii) mono-polar or bi-polar energy delivery, and (iv) multiplexing of current flow between various paired electrodes. The controller can determine when the treatment is completed based on time, temperature, tissue impedance or any combination thereof.

Owner:MEDERI RF LLC

Fluid component analysis system and method for glucose monitoring and control

Disclosed are methods and apparatuses for determining analyte concentration in a sample such as bodily fluid. Systems and methods disclosed herein can also include a treatment dosing system to infuse or inject a treatment dose (e.g. insulin, dextrose, etc.) and provide glycemic control. The dose of the treatment drug may be based on the patient's calculated sensitivity to treatment dosing, for example. The dose of the treatment drug may be based on the concentration of the analyte or the average value for the concentration of the analyte and / or the rate of change of the value of the concentration of the analyte. Delivery of the treatment drug can be cut off if the determined analyte concentration indicates that continued delivery would be harmful to the patient.

Owner:OPTISCAN BIOMEDICAL +1

Filtration monitoring and control system

InactiveUS6077435AUseful controlAccurate CalibrationDispersed particle filtrationUltrafiltrationFouling indexFiltration

PCT No. PCT / AU96 / 00144 Sec. 371 Date Jan. 12, 1998 Sec. 102(e) Date Jan. 12, 1998 PCT Filed Mar. 15, 1996 PCT Pub. No. WO96 / 28236 PCT Pub. Date Sep. 19, 1996A method and apparatus for determining the fouling effect of a feedstream on a filter having known characteristics disclosed. The method comprises passing the feedstream through a filter (5) having known characteristics; determining the change in resistance to flow of the feedstream across the filter, either continuously or over a number of time intervals and from this data, calculating a feed fouling index (FFI) representative of the fouling characteristics of the feedstream with respect to the filter. A method and apparatus for monitoring the operation of a filtration system is also disclosed the method comprising sampling system parameter values at selected locations within the filtration system at a predetermined sampling rate; generating a parameter profile characteristic from the sampled parameter values at predetermined intervals of time; and analysing the parameter profile characteristic to determine correct operation of the filtration system. A further method and apparatus of monitoring and controlling a filtering system based on backwash efficiency is also disclosed, the method comprising determining resistance values of filtering elements used in the filtering system at predetermined times during the backwash cycle of the system by monitoring a number of operating parameters of the system; calculating a backwash efficiency value representative of the efficiency of the backwash cycle of the filtering system using the resistance values determined; and controlling the operation of the filtering system in dependence on the value of the backwash efficiency calculated.

Owner:EVOQUA WATER TECH LLC

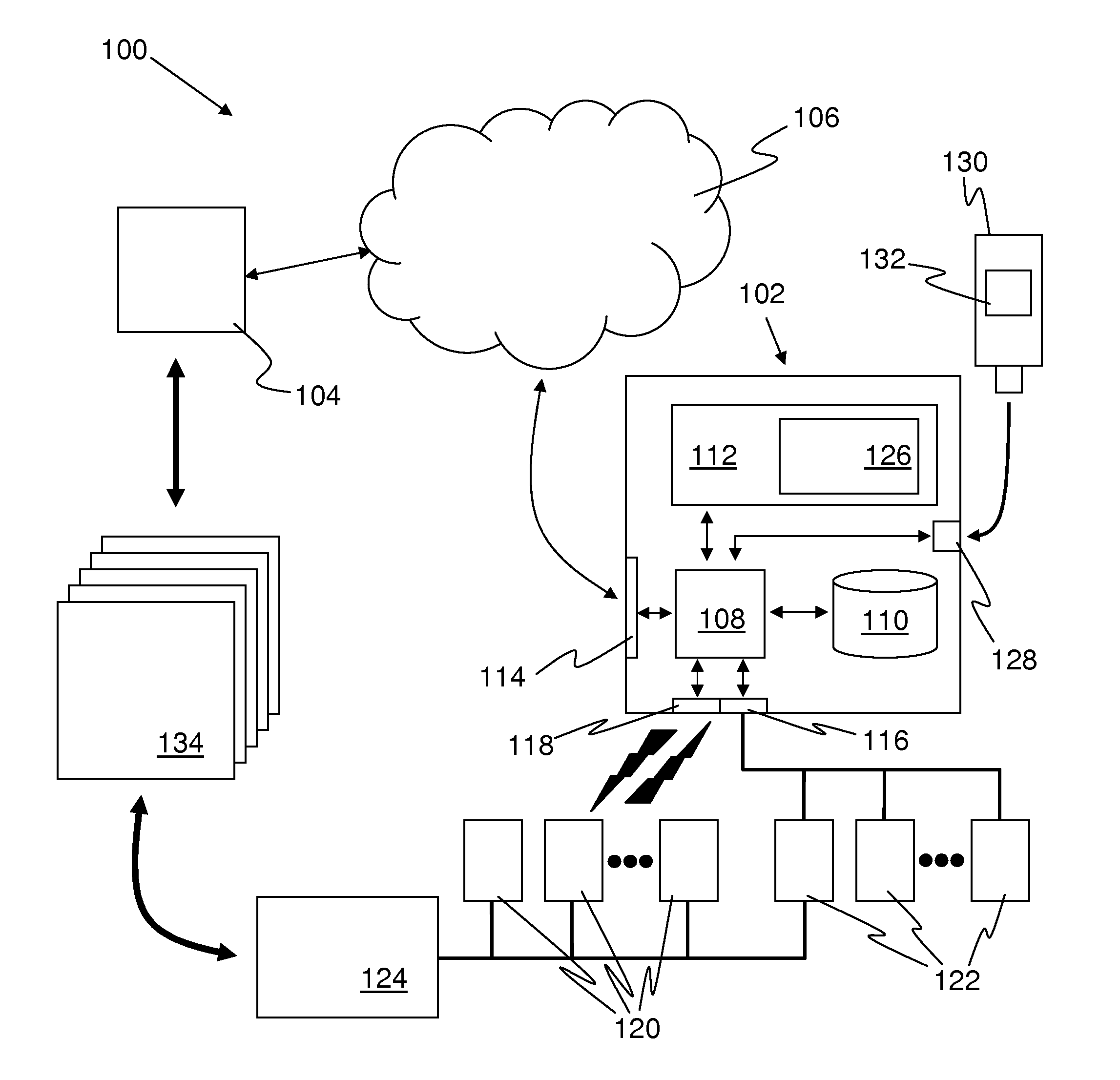

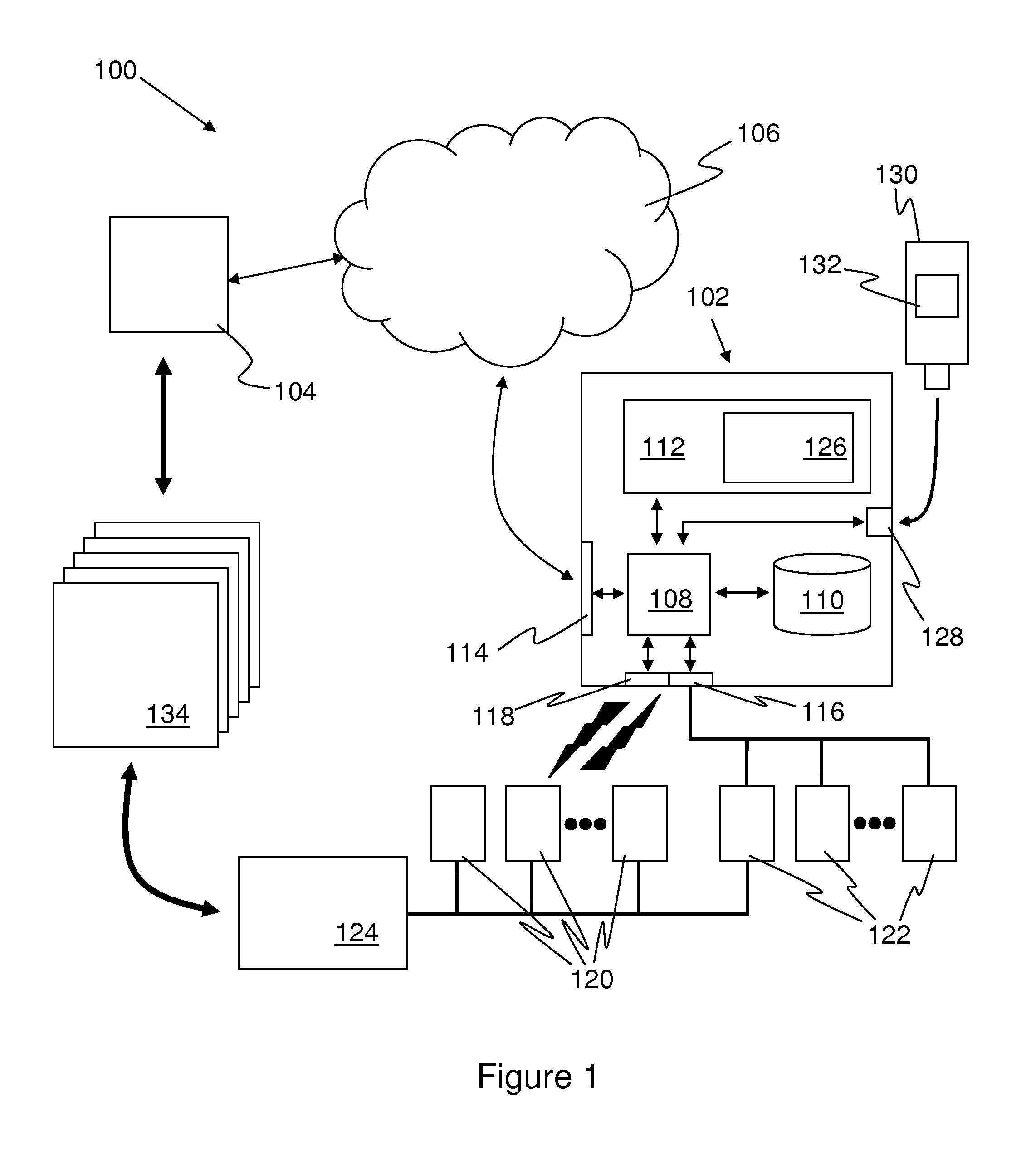

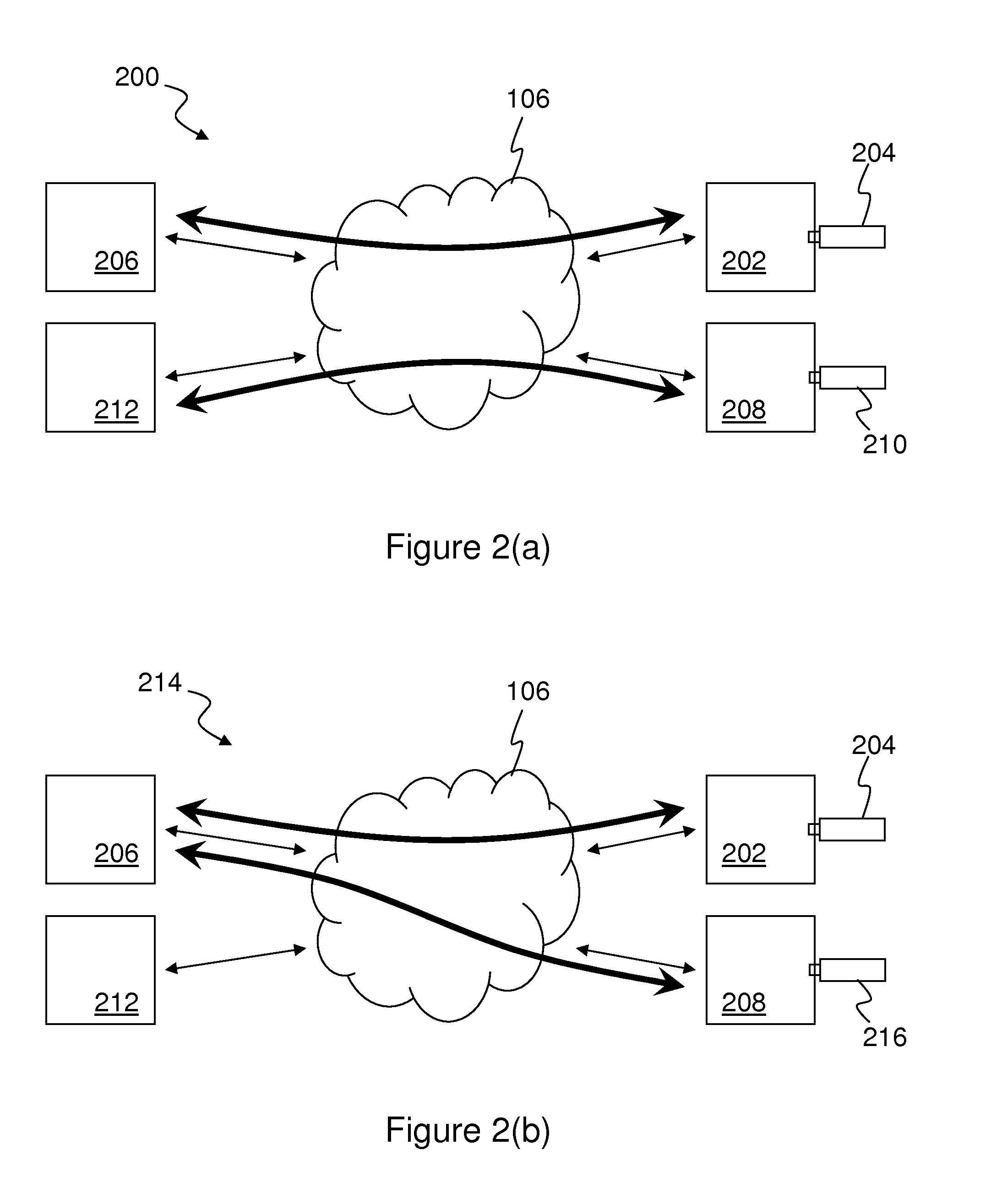

Energy service delivery platform

InactiveUS20130173807A1Low costMinimal ongoing maintenance requirementData processing applicationsDigital computer detailsElectronic accessCommunication interface

A resource management client apparatus (client, 102) comprises an interface to a wide area network (WAN, 106) facilitating connection to a resource management server (server, 104), and at least one communications interface (116, 118) to communicate with a plurality of associated resource monitoring and control devices (devices, 120, 122). A secure key interface (128) to receive an electronic access device (130) that securely stores information including at least a unique identifier, server connection data, and one or more encryption keys for encrypting information transmitted between the client (102) and the server (104). The client (102) establishes a connection to the server (104) via the WAN (106), using the server connection data stored in the electronic access device (130), receives status messages from the devices (120, 122), processes received status messages, and encrypts and transmits corresponding status information of the devices (120, 122) to the server (104) via the WAN (106). It receives and decrypts encrypted resource control information from the server (104) via the WAN (106). Furthermore, it processes received resource control information and transmits corresponding control messages to the devices (120, 122).

Owner:COMMONWEALTH SCI & IND RES ORG

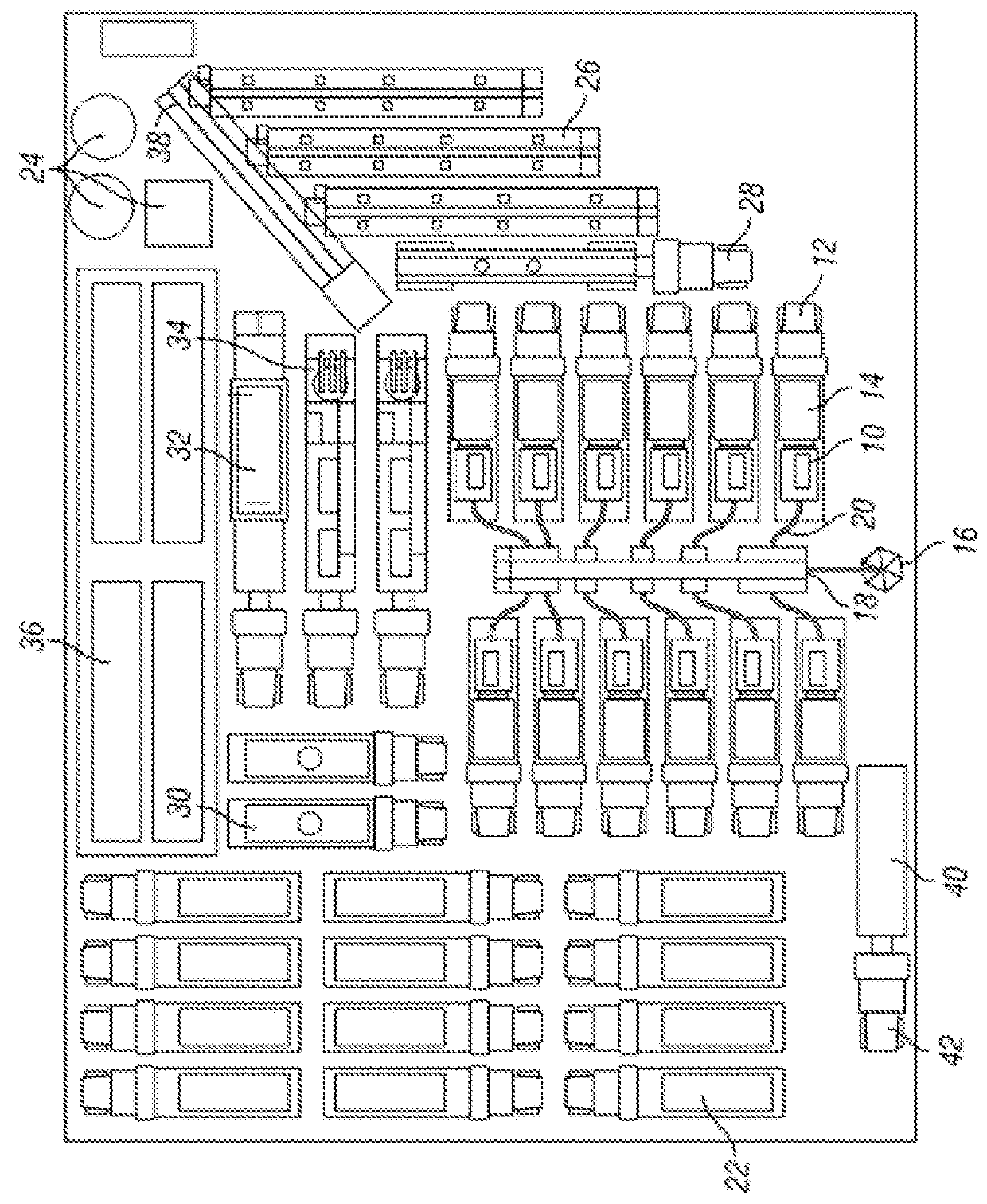

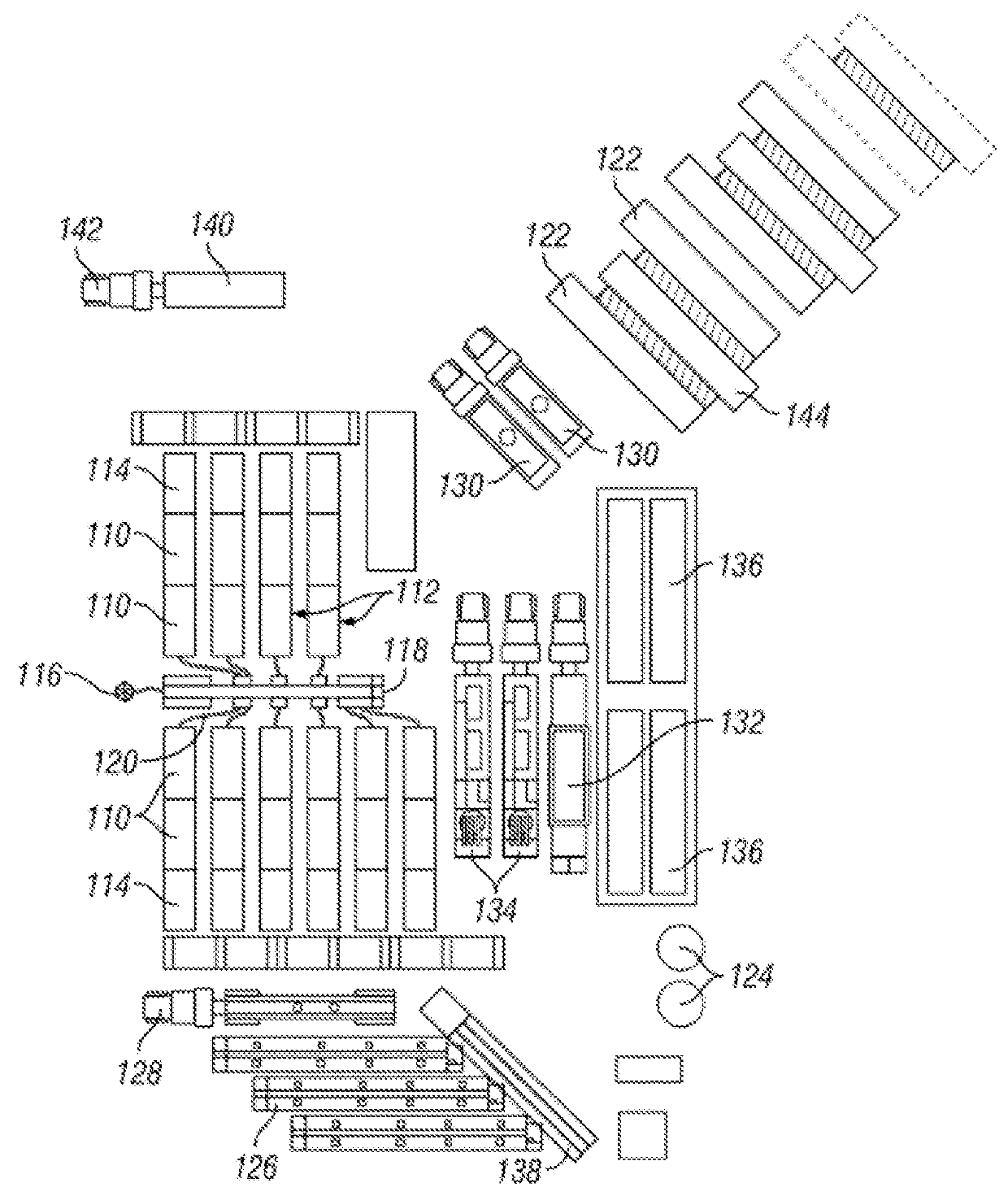

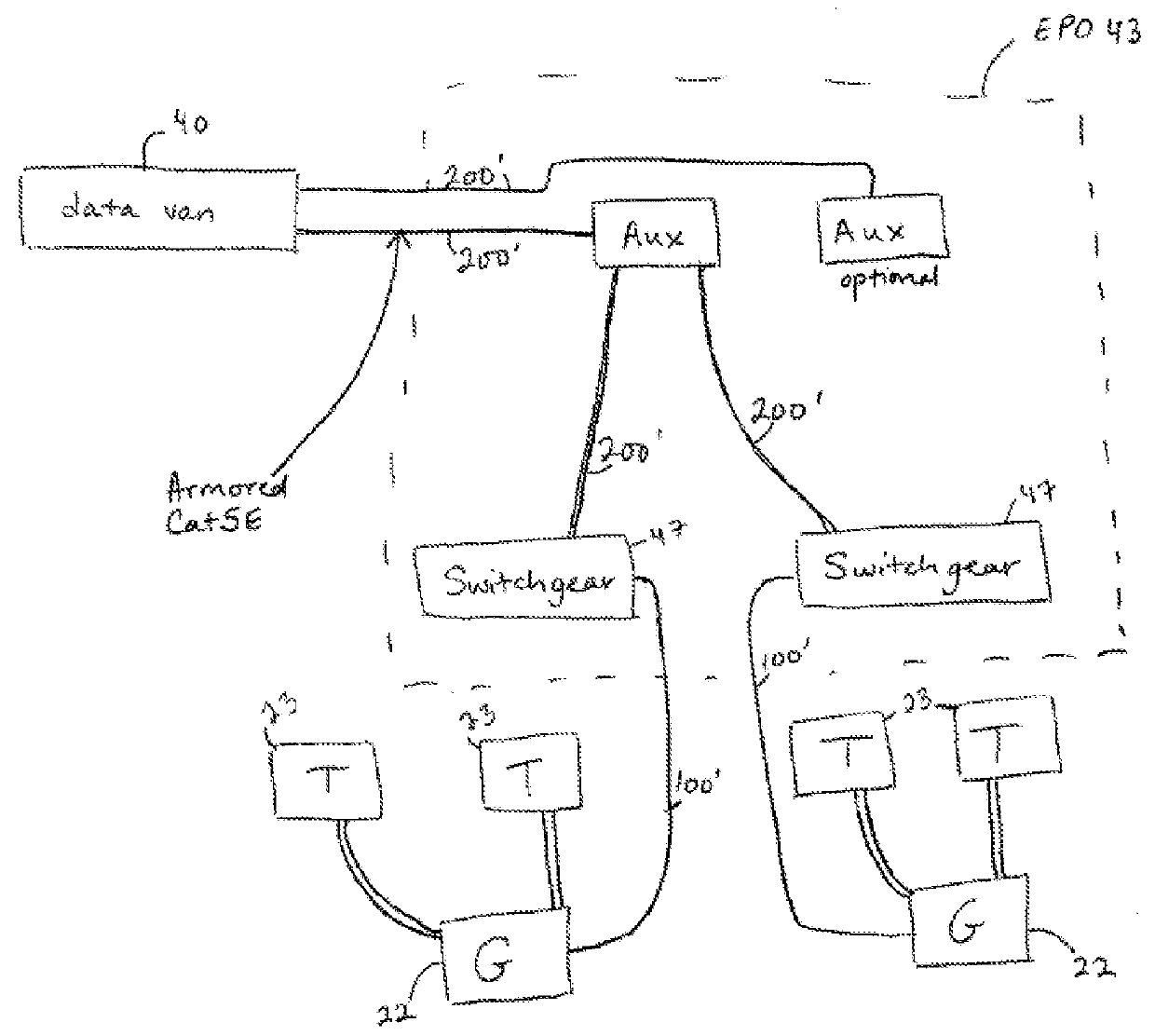

System for centralized monitoring and control of electric powered hydraulic fracturing fleet

A system and method are disclosed for centralized monitoring and control of a hydraulic fracturing operation. The system includes an electric powered fracturing fleet and a centralized control unit coupled to the electric powered fracturing fleet. The electric powered fracturing fleet can include a combination of one or more of: electric powered pumps, turbine generators, blenders, sand silos, chemical storage units, conveyor belts, manifold trailers, hydration units, variable frequency drives, switchgear, transformers, and compressors. The centralized control unit can be configured to monitor and / or control one or more operating characteristics of the electric powered fracturing fleet.

Owner:US WELL SERVICS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com