Patents

Literature

996 results about "Plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

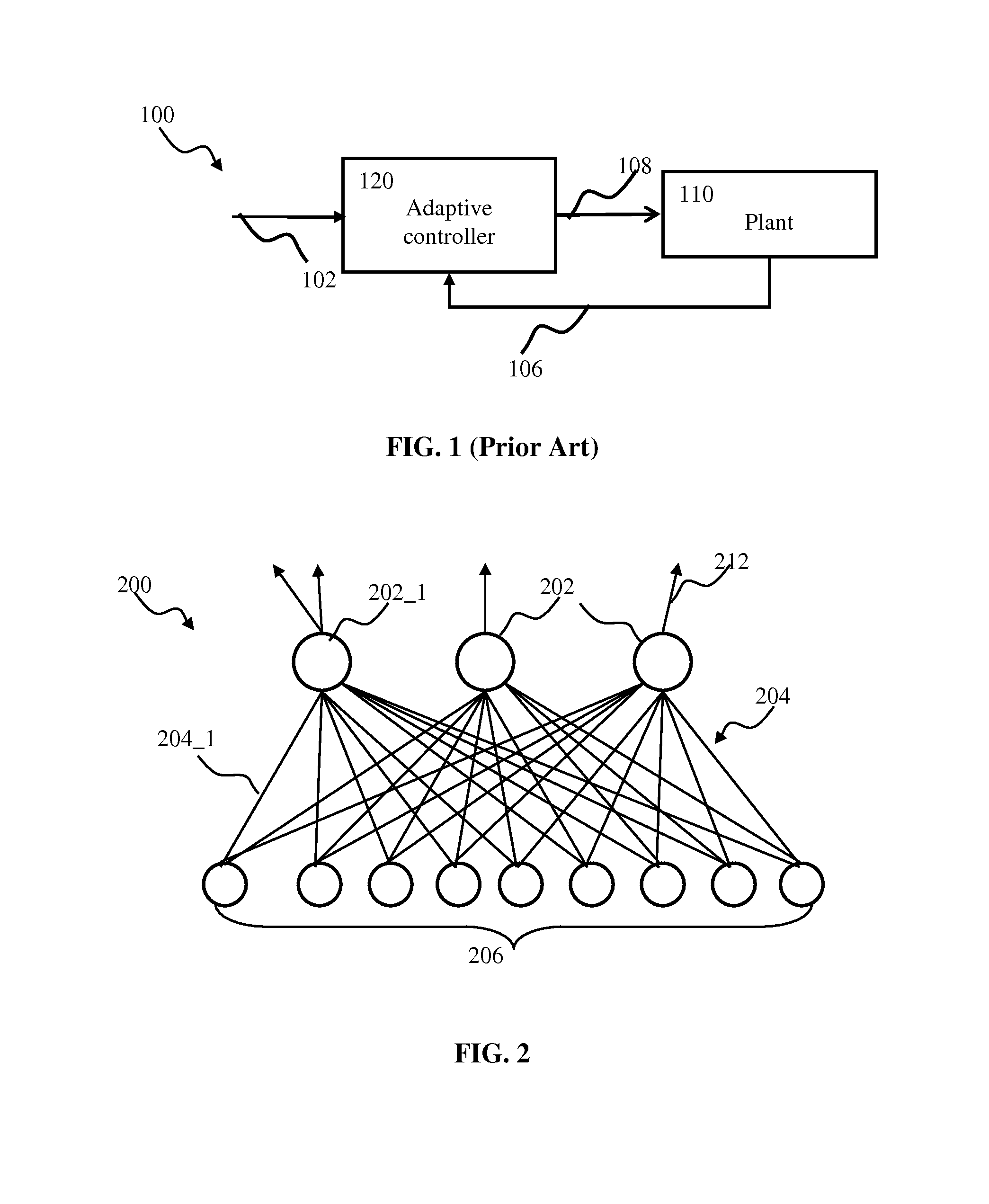

A plant in control theory is the combination of process and actuator. A plant is often referred to with a transfer function (commonly in the s-domain) which indicates the relation between an input signal and the output signal of a system without feedback, commonly determined by physical properties of the system. An example would be an actuator with its transfer of the input of the actuator to its physical displacement. In a system with feedback, the plant still has the same transfer function, but a control unit and a feedback loop (with their respective transfer functions) are added to the system.

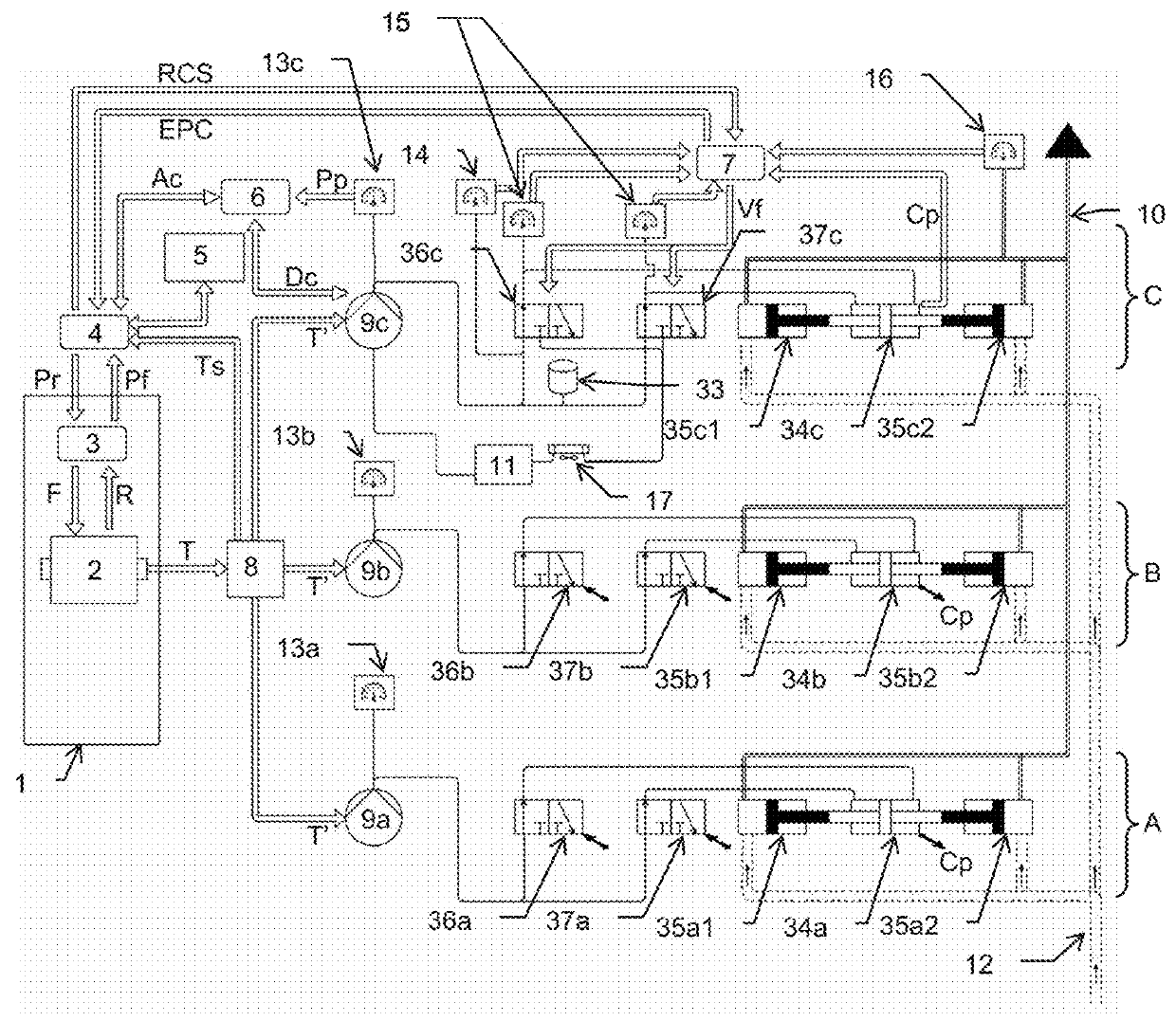

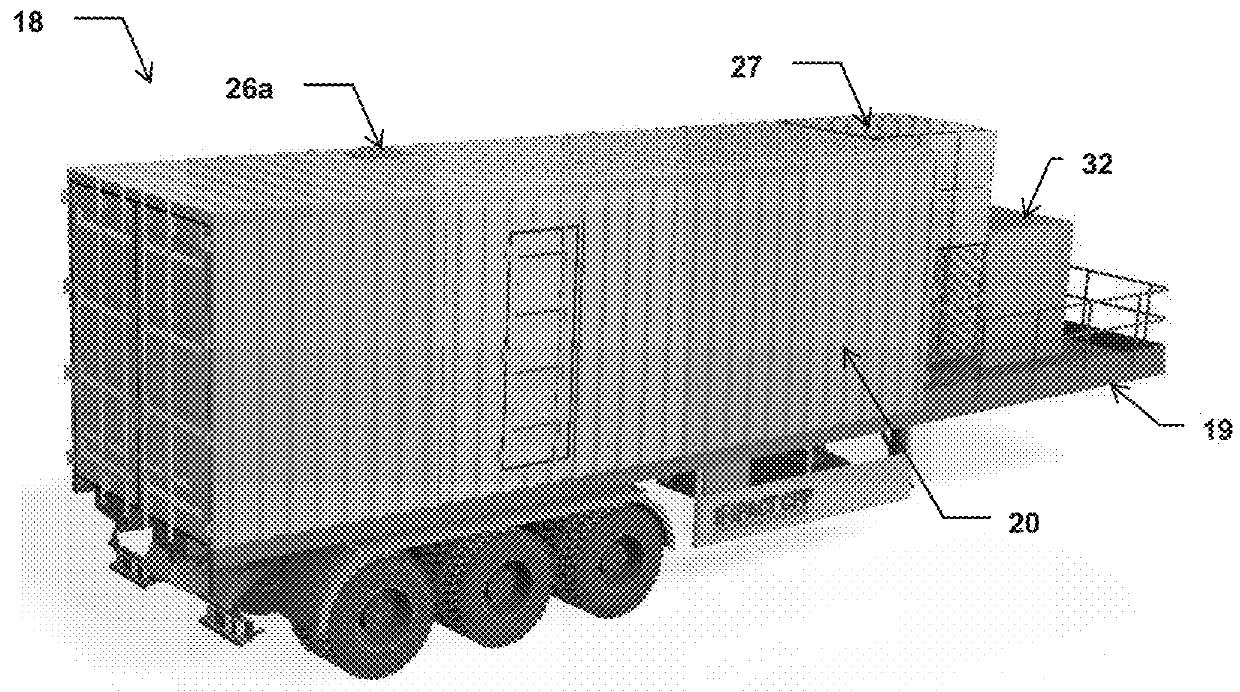

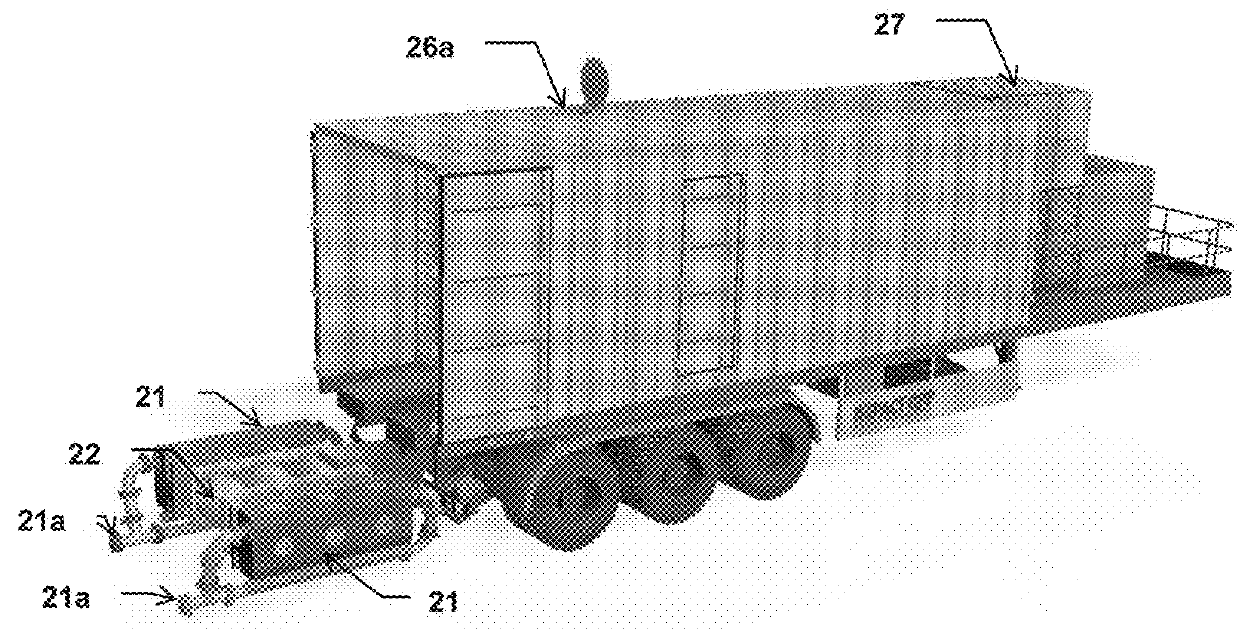

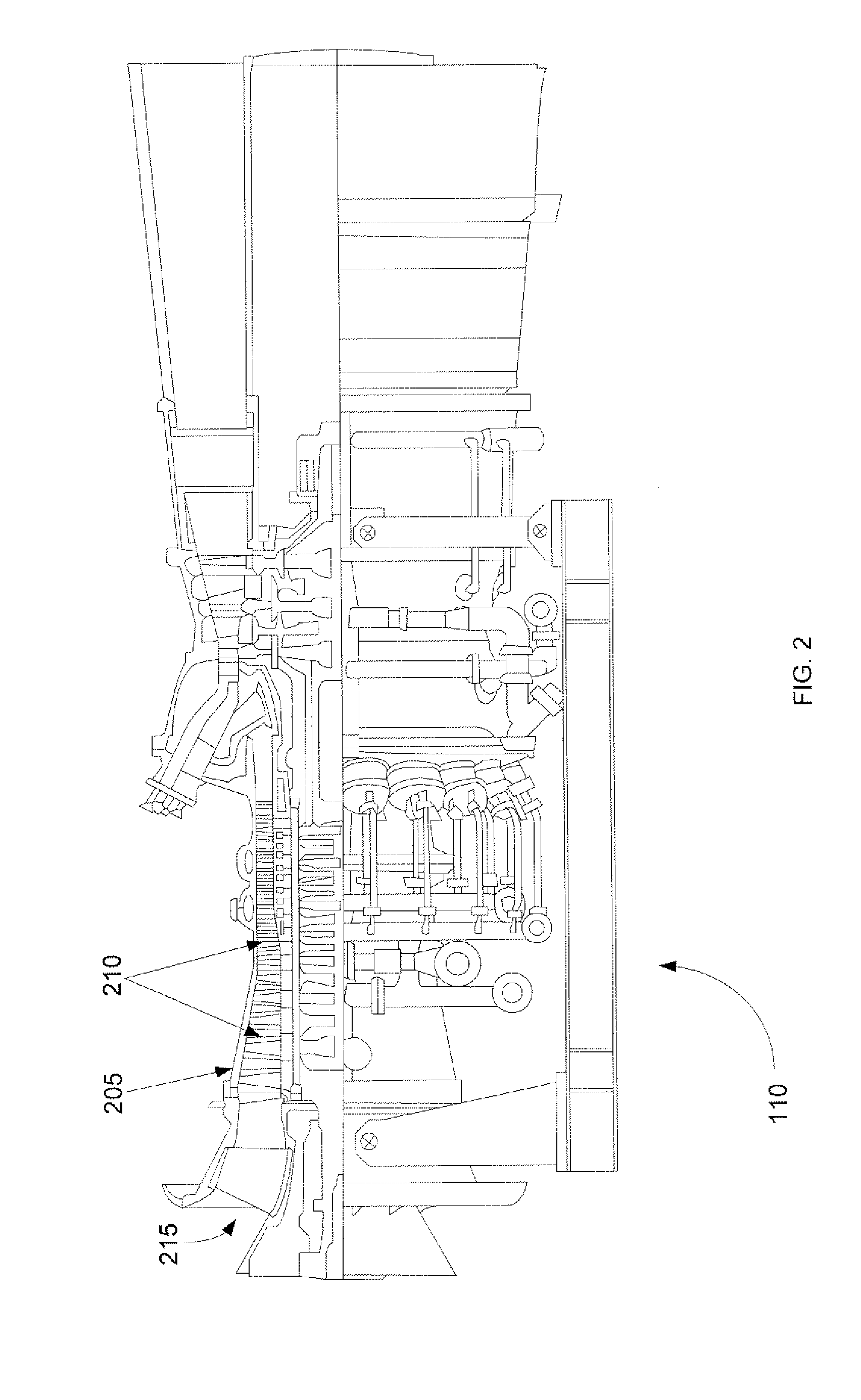

Plant for controlling delivery of pressurized fluid in a conduit, and a method of controlling a prime mover

A plant for delivering a fluid in a conduit (10) comprises a prime mover (2), for example a gas turbine, which is configured to drive one or more fluid delivery systems (34a-c, 35a1-c1, 35a2-c2) for delivering a fluid in the conduit (10). A first sensor (16) is configured for sensing pressure variations in the pipe (10) and is connected to a first controller (7). The first controller (7) is configured to provide control signals to control valves (36a-c, 37a-c) for at least one fluid delivery system and to a control system (4, 3) for the prime mover (2). One or more hydraulic pumps (9a-c) are configured to operate the fluid delivery systems and are driven by the prime mover, whereby interaction between the hydraulic pumps and the prime mover is controlled based on sensed pressure in the pipe (10).

Owner:IMPACT SOLUTIONS AS

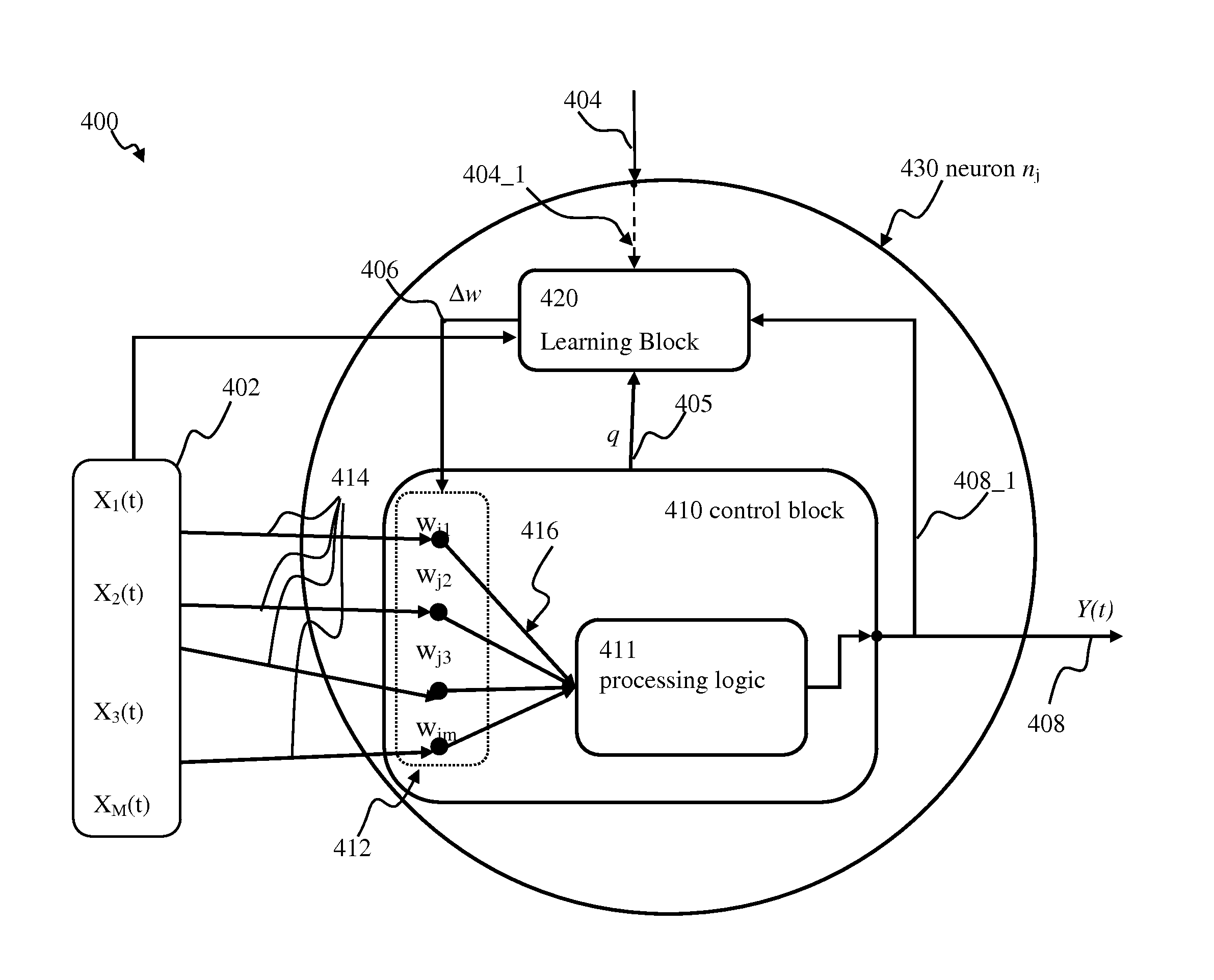

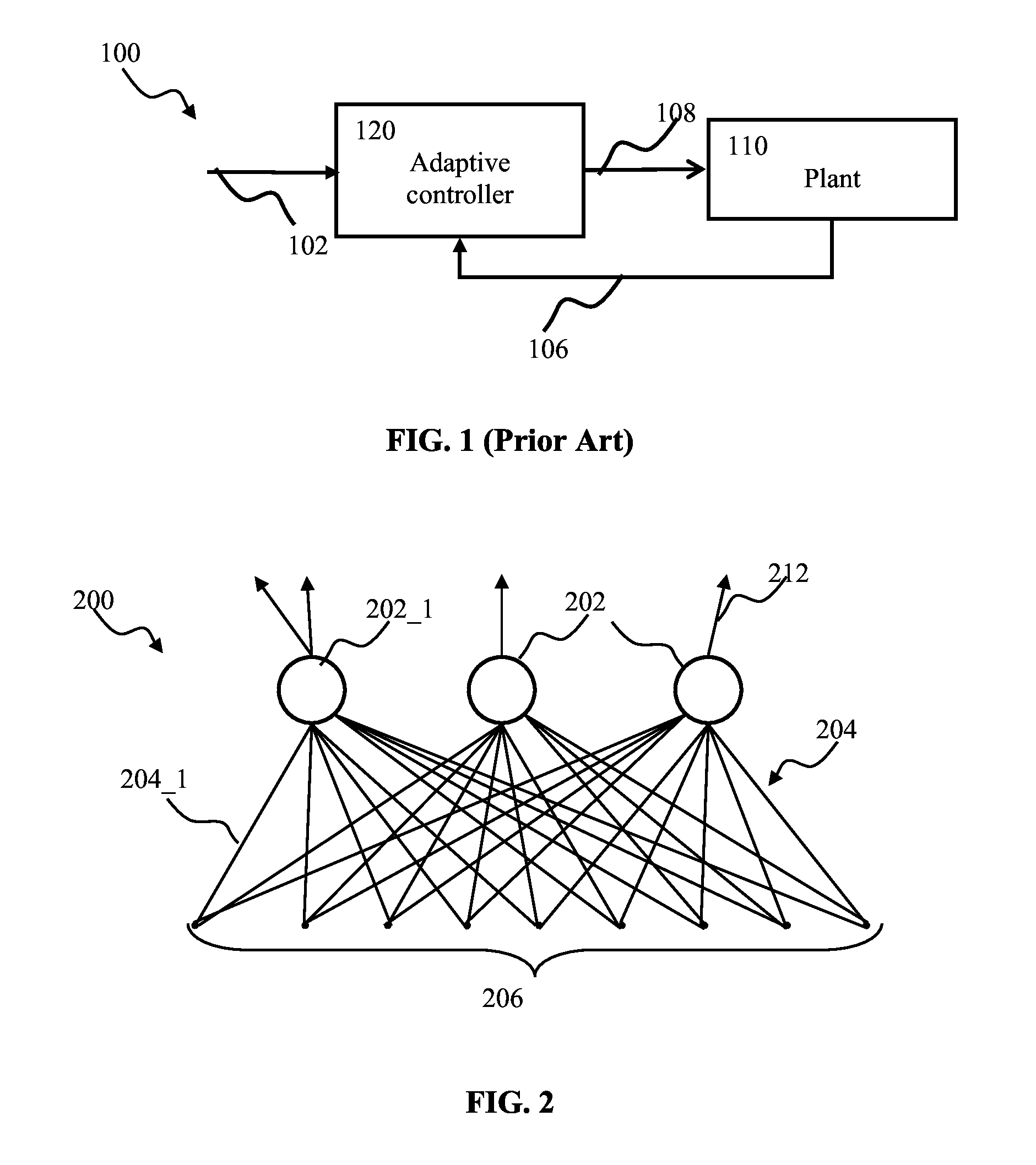

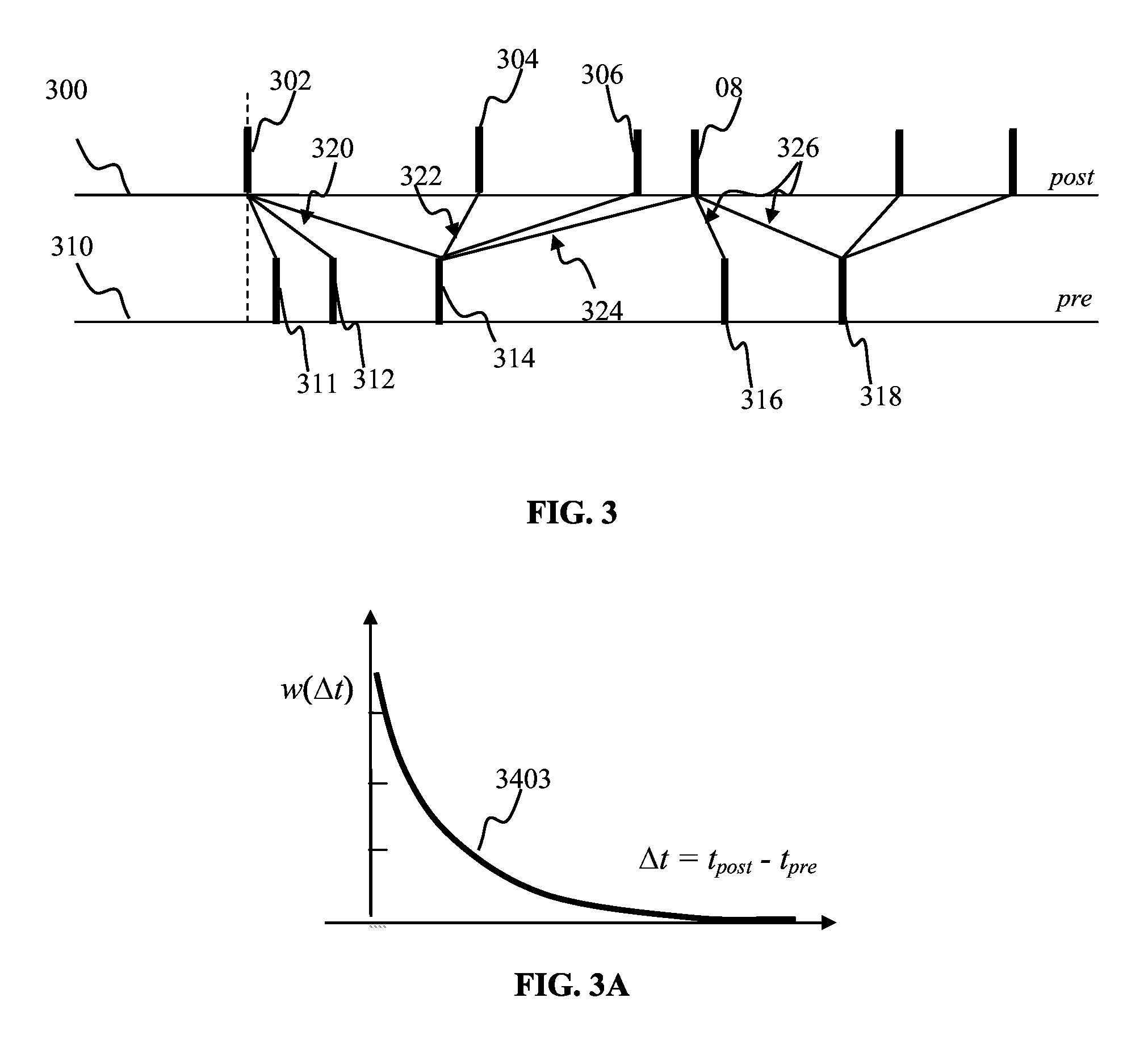

Spiking neuron network adaptive control apparatus and methods

ActiveUS20140081895A1Minimizing distance measureSmooth connectionDigital computer detailsNeural architecturesNeuron networkSpiking neural network

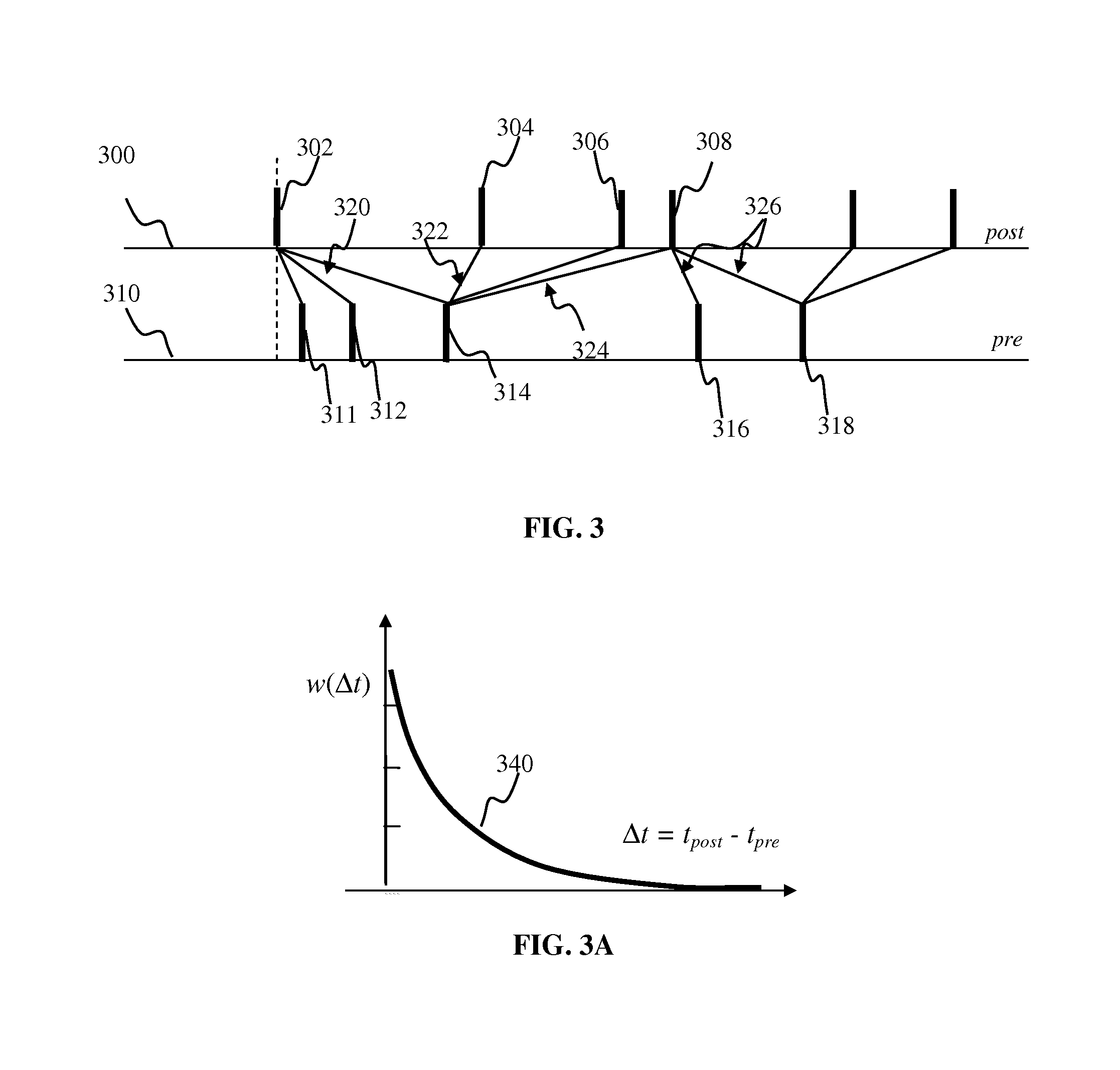

Adaptive controller apparatus of a plant may be implemented. The controller may comprise an encoder block and a control block. The encoder may utilize basis function kernel expansion technique to encode an arbitrary combination of inputs into spike output. The controller may comprise spiking neuron network operable according to reinforcement learning process. The network may receive the encoder output via a plurality of plastic connections. The process may be configured to adaptively modify connection weights in order to maximize process performance, associated with a target outcome. The relevant features of the input may be identified and used for enabling the controlled plant to achieve the target outcome.

Owner:BRAIN CORP

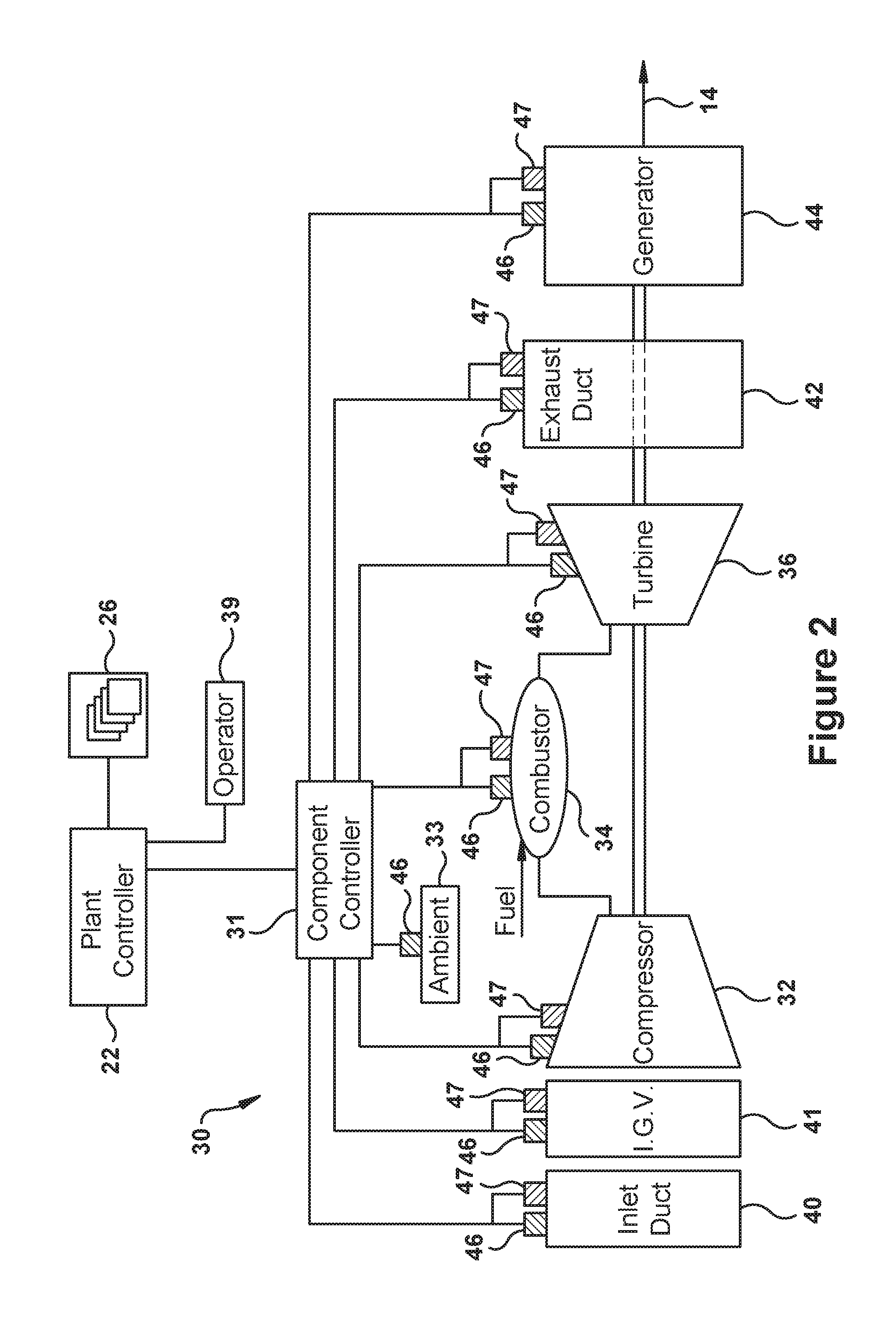

Methods and systems for enhancing operation of power plant generating units and systems

ActiveUS20160281607A1Programme controlTurbine/propulsion engine ignitionPower stationControl engineering

A method for controlling and enhancing a startup operation for a combined cycle power block (block) having at least one gas turbine and at least one steam turbine, wherein operating parameters define performance and operational characteristics for the startup operation, the method comprising: receiving measured operating parameters from a plurality of reference blocks and, for each of the plurality of reference blocks, a plurality of types of the startup operations; given the measured operating parameters, developing one or more reference transfer functions between two of the measured operating parameters; receiving measured operating parameters from the startup operation of a target block; given the measured operating parameters from the target block, developing one or more transfer functions for the target block between two of the operating parameters; selecting one of the reference transfer functions; and normalizing the transfer function of the target block per the selected reference transfer function.

Owner:GENERAL ELECTRIC CO

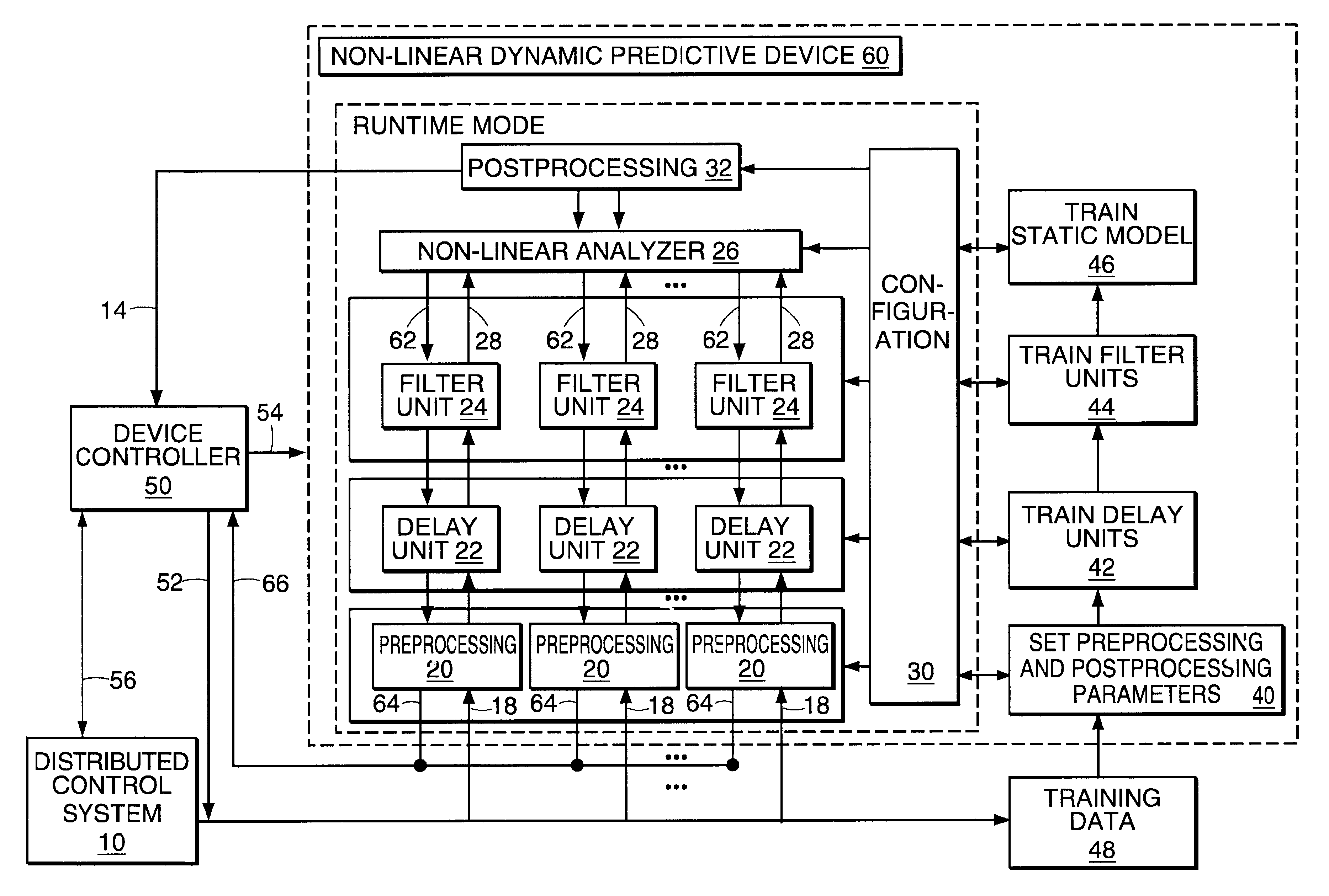

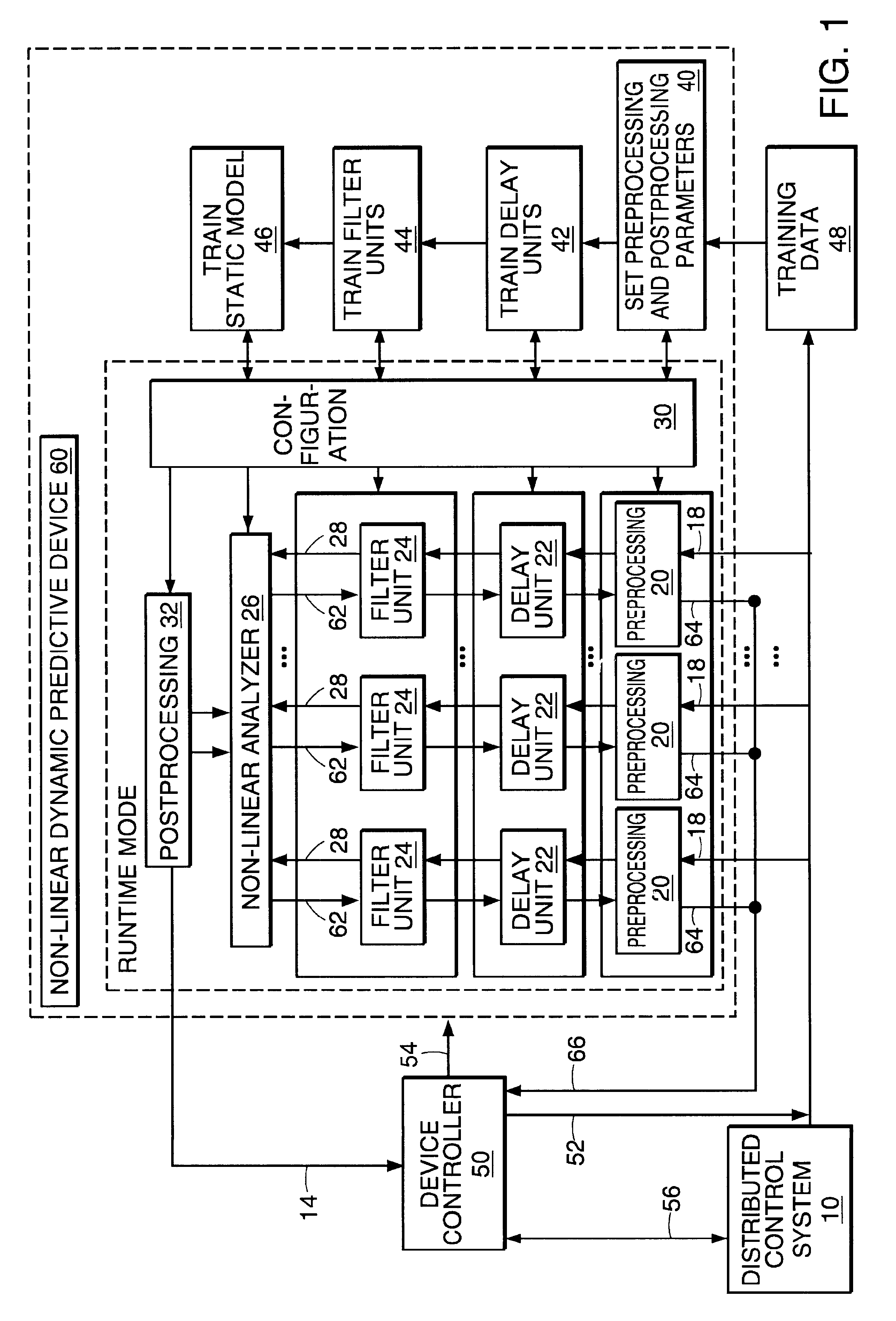

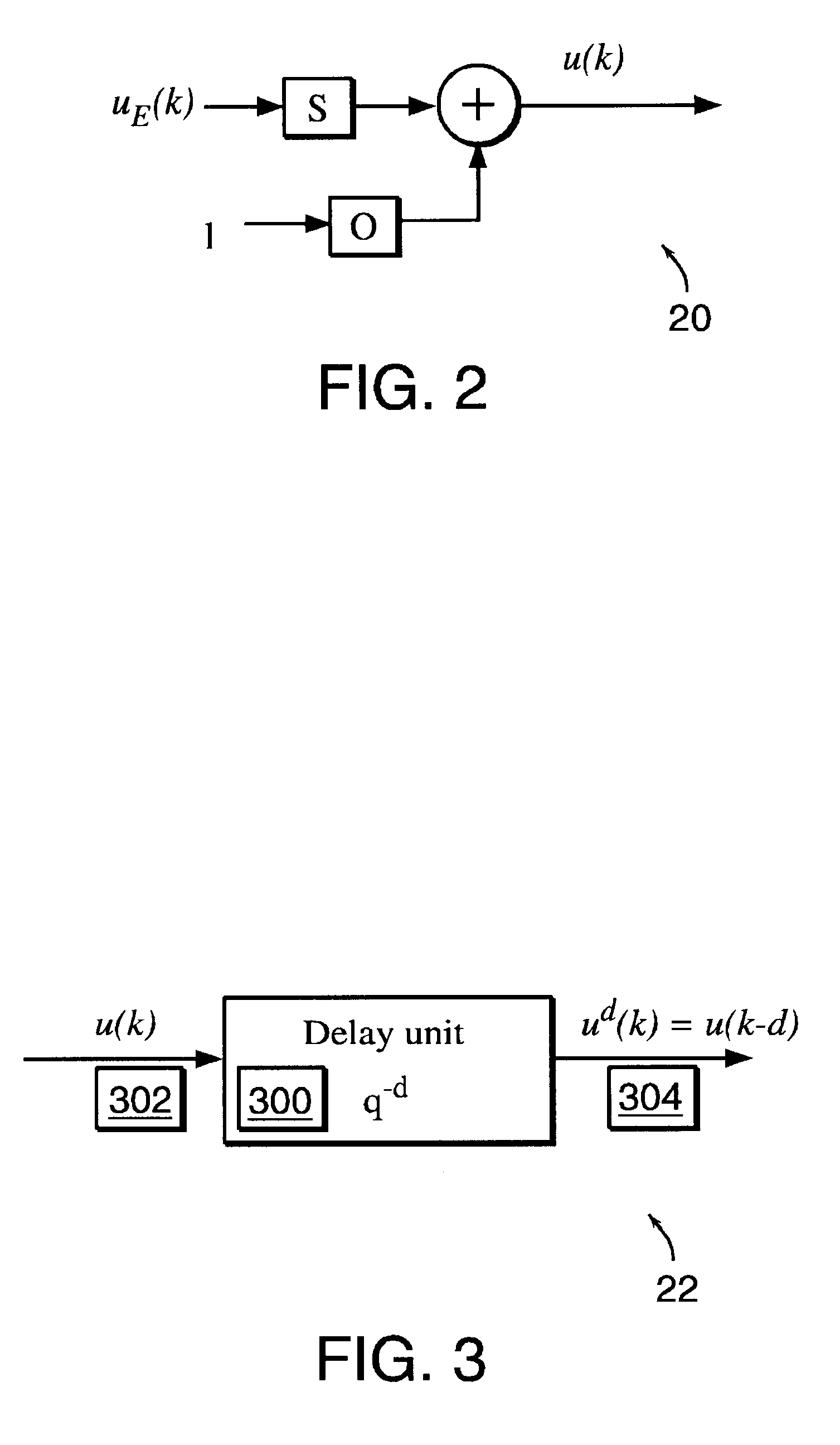

Non-linear dynamic predictive device

InactiveUS6453308B1Improve accuracyFast computerSimulator controlElectric testing/monitoringHorizonDead time

A non-linear dynamic predictive device (60) is disclosed which operates either in a configuration mode or in one of three runtime modes: prediction mode, horizon mode, or reverse horizon mode. An external device controller (50) sets the mode and determines the data source and the frequency of data. In prediction mode, the input data are such as might be received from a distributed control system (DCS) (10) as found in a manufacturing process; the device controller ensures that a contiguous stream of data from the DCS is provided to the predictive device at a synchronous discrete base sample time. In prediction mode, the device controller operates the predictive device once per base sample time and receives the output from the predictive device through path (14). In horizon mode and reverse horizon mode, the device controller operates the predictive device additionally many times during base sample time interval. In horizon mode, additional data is provided through path (52). In reverse horizon mode data is passed in a reverse direction through the device, utilizing information stored during horizon mode, and returned to the device controller through path (66). In the forward modes, the data are passed to a series of preprocessing units (20) which convert each input variable (18) from engineering units to normalized units. Each preprocessing unit feeds a delay unit (22) that time-aligns the input to take into account dead time effects such as pipeline transport delay. The output of each delay unit is passed to a dynamic filter unit (24). Each dynamic filter unit internally utilizes one or more feedback paths that are essential for representing the dynamic information in the process. The filter units themselves are configured into loosely coupled subfilters which are automatically set up during the configuration mode and allow the capability of practical operator override of the automatic configuration settings. The outputs (28) of the dynamic filter units are passed to a non-linear analyzer (26) which outputs a value in normalized units. The output of the analyzer is passed to a post-processing unit (32) that converts the output to engineering units. This output represents a prediction of the output of the modeled process. In reverse horizon mode, a value of 1 is presented at the output of the predictive device and data is passed through the device in a reverse flow to produce a set of outputs (64) at the input of the predictive device. These are returned to the device controller through path (66). The purpose of the reverse horizon mode is to provide essential information for process control and optimization. The precise operation of the predictive device is configured by a set of parameters. that are determined during the configuration mode and stored in a storage device (30). The configuration mode makes use of one or more files of training data (48) collected from the DCS during standard operation of the process, or through structured plant testing. The predictive device is trained in four phases (40, 42, 44, and 46) correspo

Owner:ASPENTECH CORP

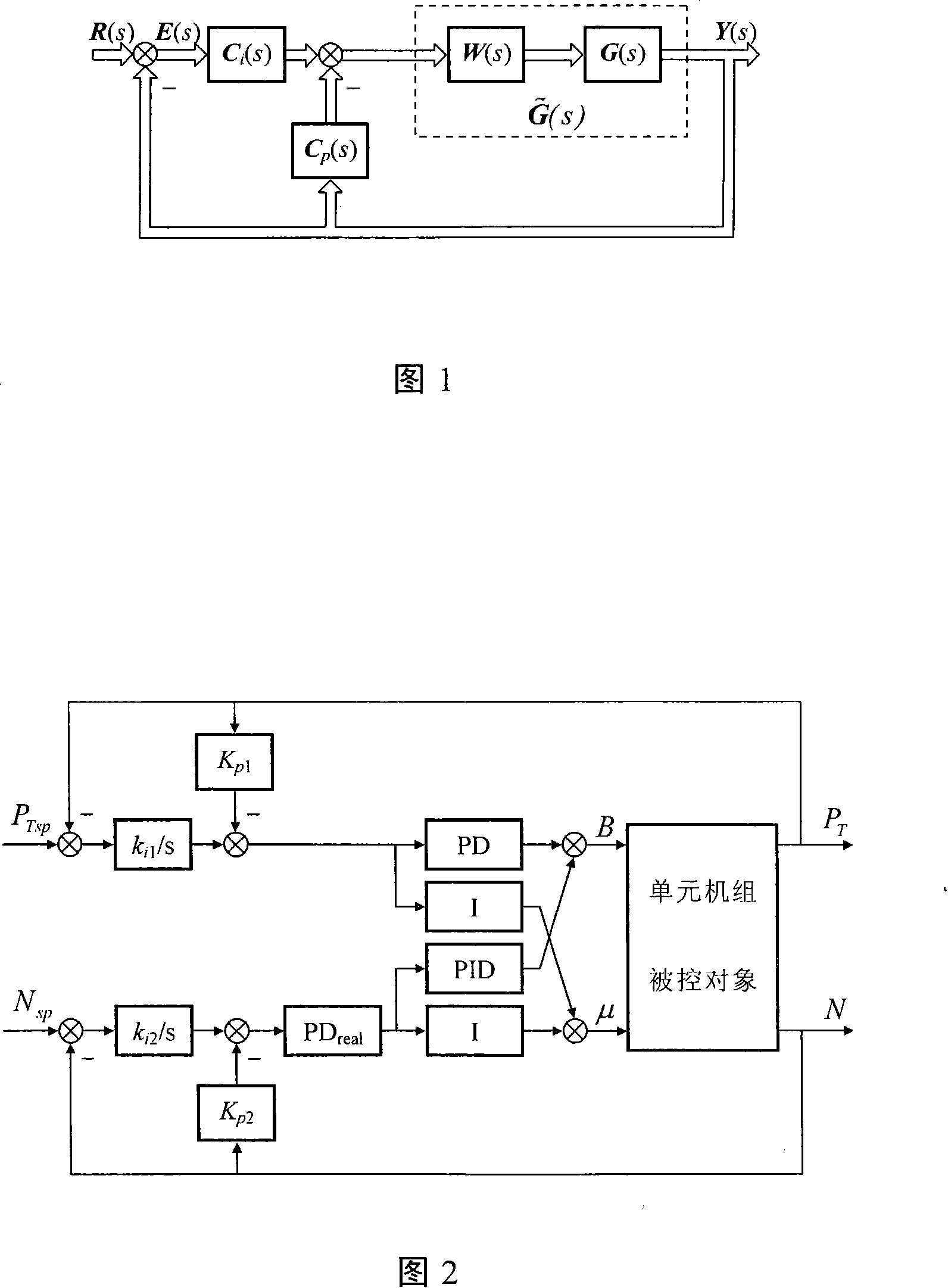

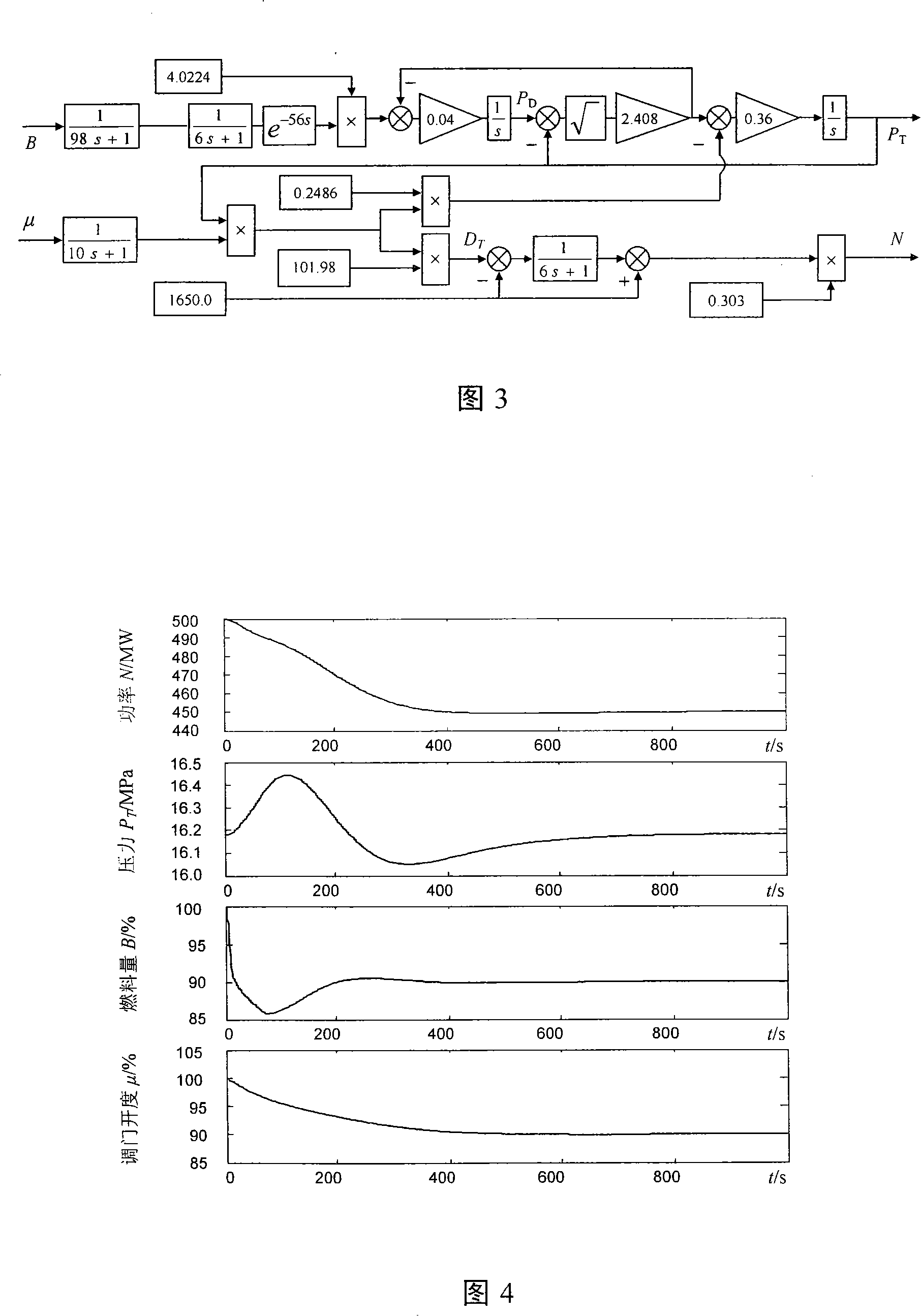

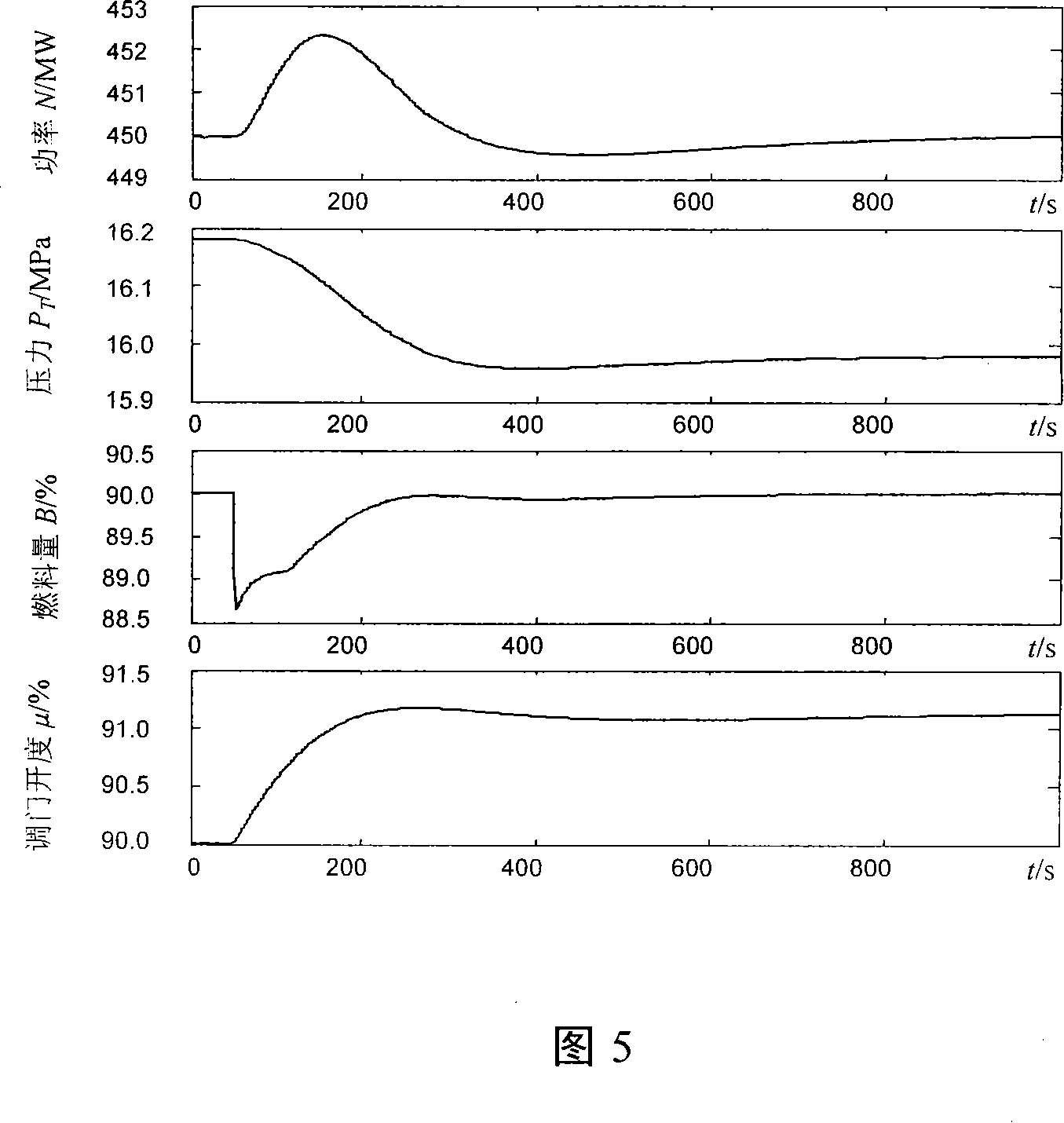

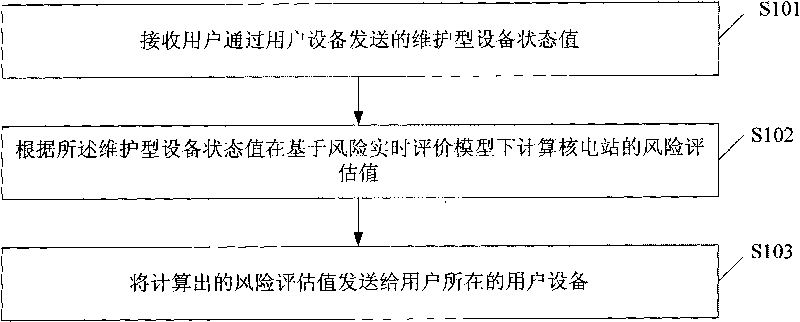

PID parameter setting method for monobloc generator group coordination and control system

InactiveCN101131571AEasy to tuneMeet performance index requirementsElectric generator controlAdaptive controlGroup coordinationMathematical model

This invention discloses a sort of method of the PID parameter setting of the coordinated control system of the cell-system generating set which belongs to this area of the control technique of the set. This method identifies the multivariable dynamic mathematic model of the unit plant according to the universal structural style. Used the series decoupling principle and the two-degree of freedom control structure the coordinated control system of the unit plant which has the PID form is thought out based this model, thereby the each setting step of the related parameter are get in this system by combining the theoretical derivation and the engineering test. This invention has this character in that the consecution is clear; the practicability is good, and it fits to engineering apply. The engineering technical personnel structures the corresponding coordinated control system expediently, and combines the engineering test aimed at the unit plant of various group, it sets out the related parameter of this system availably.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

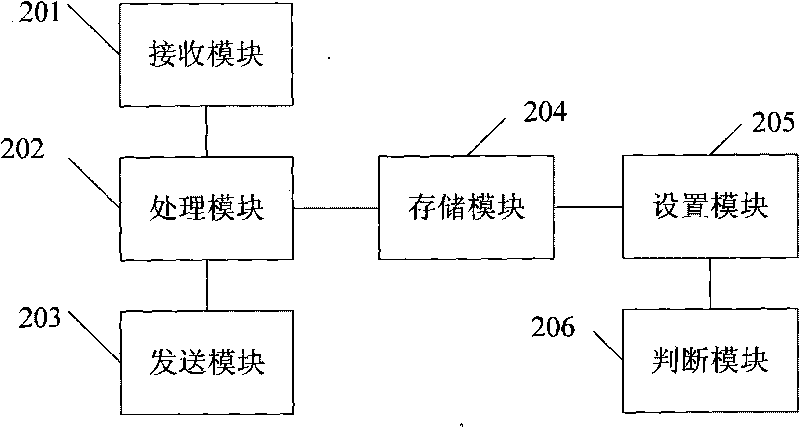

Method and device for evaluating risk of nuclear power station

ActiveCN101710400AGuaranteed correctnessGuaranteed accuracyForecastingInformation technology support systemNuclear engineeringNuclear power

The invention discloses a method for evaluating risk of nuclear power station, comprising the following steps: receiving the maintenance device state value transmitted by the user device, wherein the maintenance device is a power plant device to be regularly maintained by the user or regularly tested or a power plant device for evaluating risk value when something is wrong with the device, computing the risk evaluation value of the nuclear power station based on the risk real-time evaluation model according to the maintenance device state value, and transmitting the computed risk evaluation value to the user device where the user is. The invention further discloses a device for evaluating risk in real time. The embodiment of the invention is convenient for the operator to realize the riskcondition of the nuclear power station in real time.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +1

Real time asset optimization

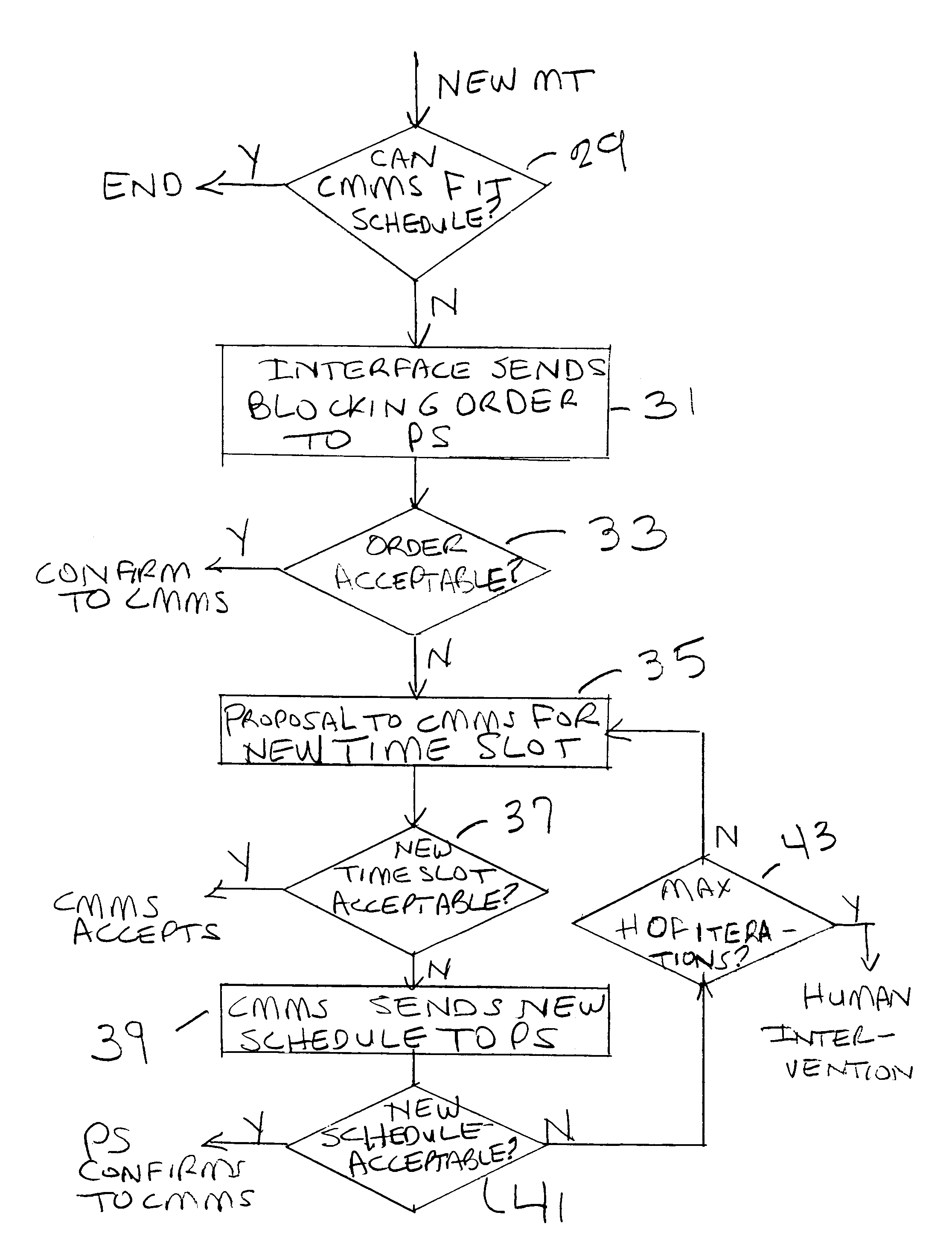

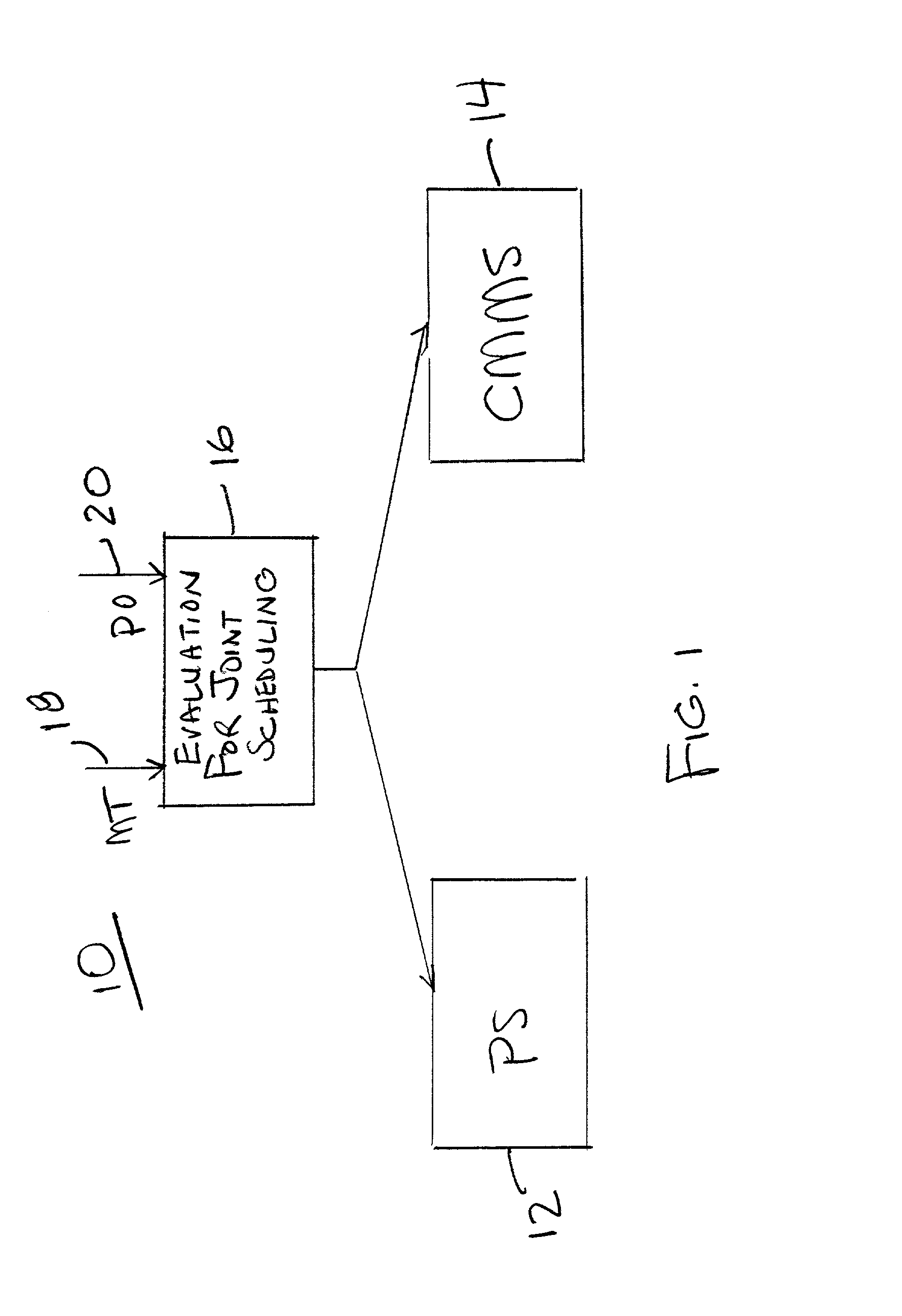

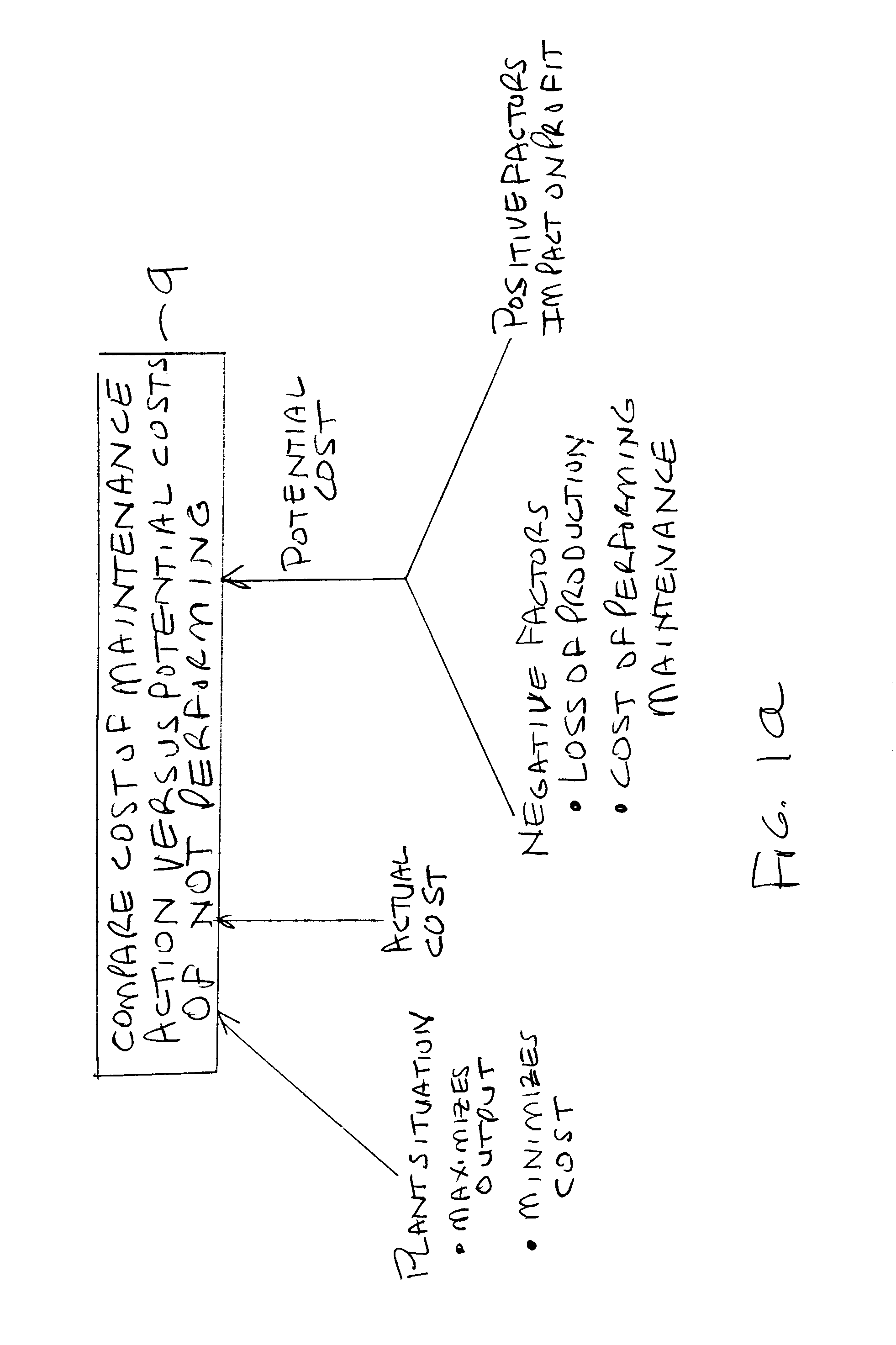

InactiveUS20030130755A1Technology managementResourcesComputerized maintenance management systemEngineering

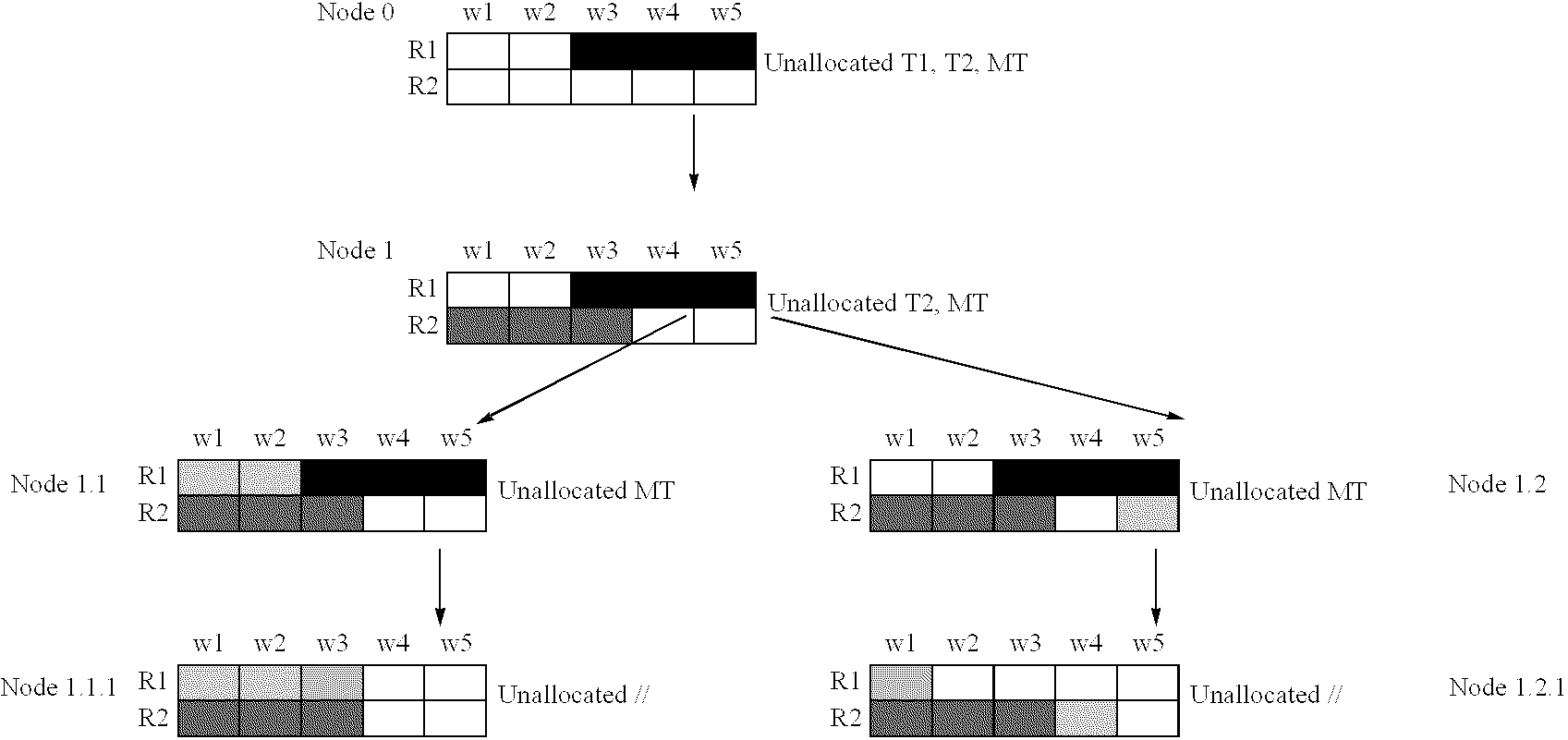

A technique to optimize both the production schedule and the maintenance of plant assets based on predetermined criteria which may be economic or otherwise. In one embodiment the technique receives at least one maintenance trigger (MT) and one production order and evaluates those inputs to propose one or more solutions for the joint scheduling of the asset maintenance and required plant production. In another embodiment a computerized maintenance management system (CMMS) acquires a new MT and proposes a new maintenance schedule. The technique transmits a blocking order to a production scheduling (PS) system for converting the maintenance request into a production schedule. In another embodiment, a CMMS acquires a new MT and asks for confirmation of a time slot to perform the maintenance action. The technique evaluates the priorities and finds based on the predetermined criteria the right time slot and communicates a request for that slot to the PS.

Owner:ABB INC +1

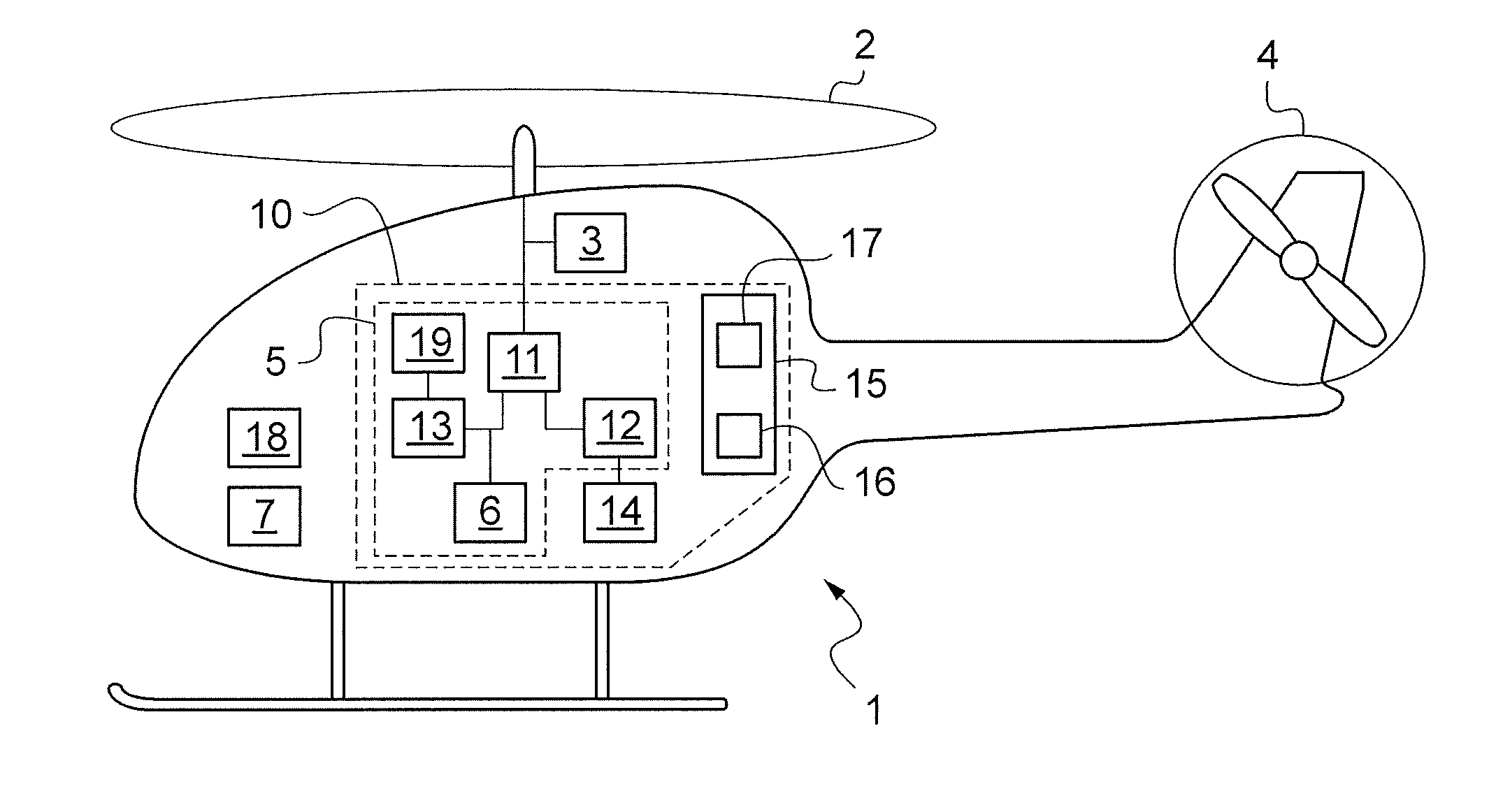

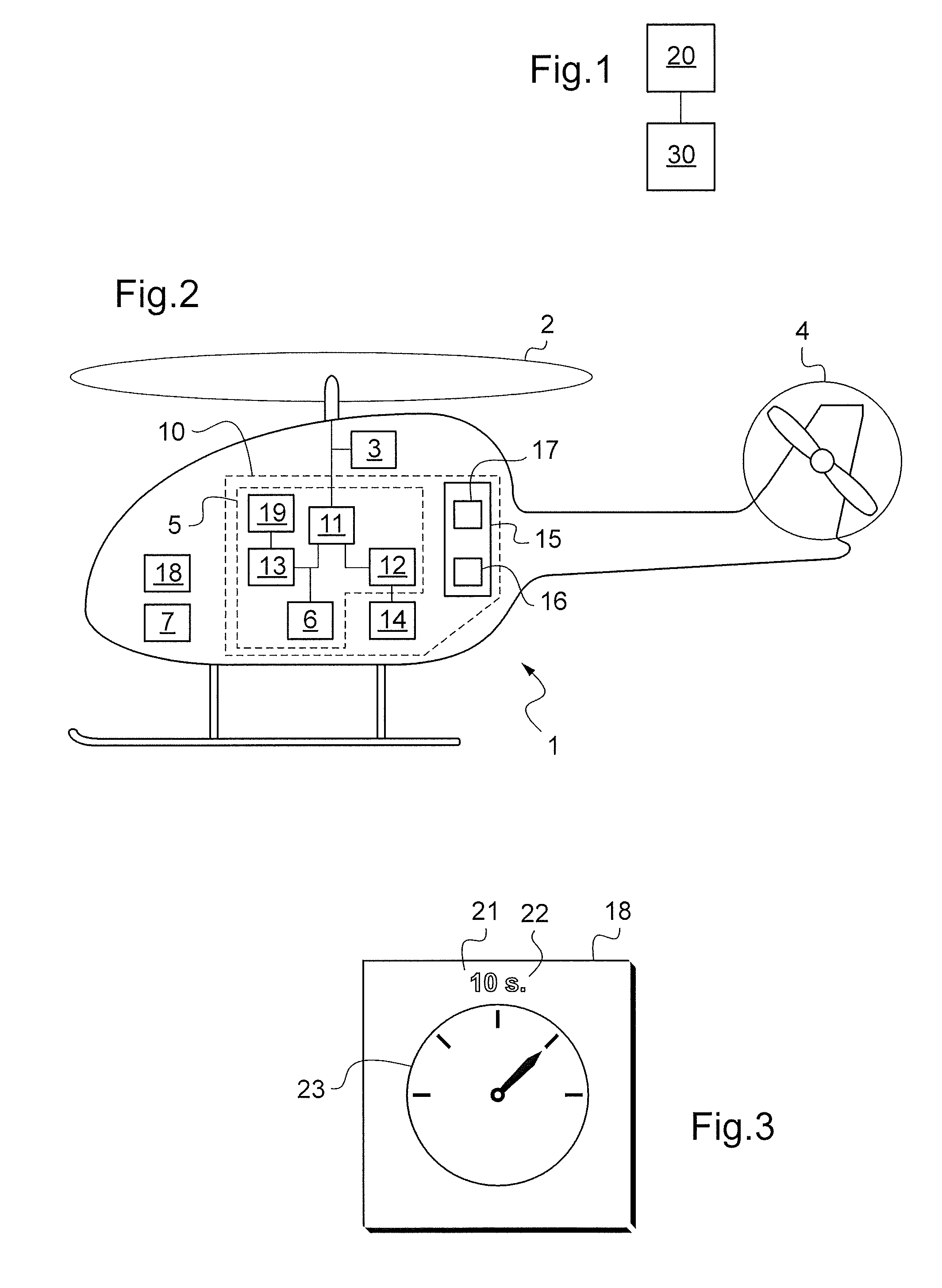

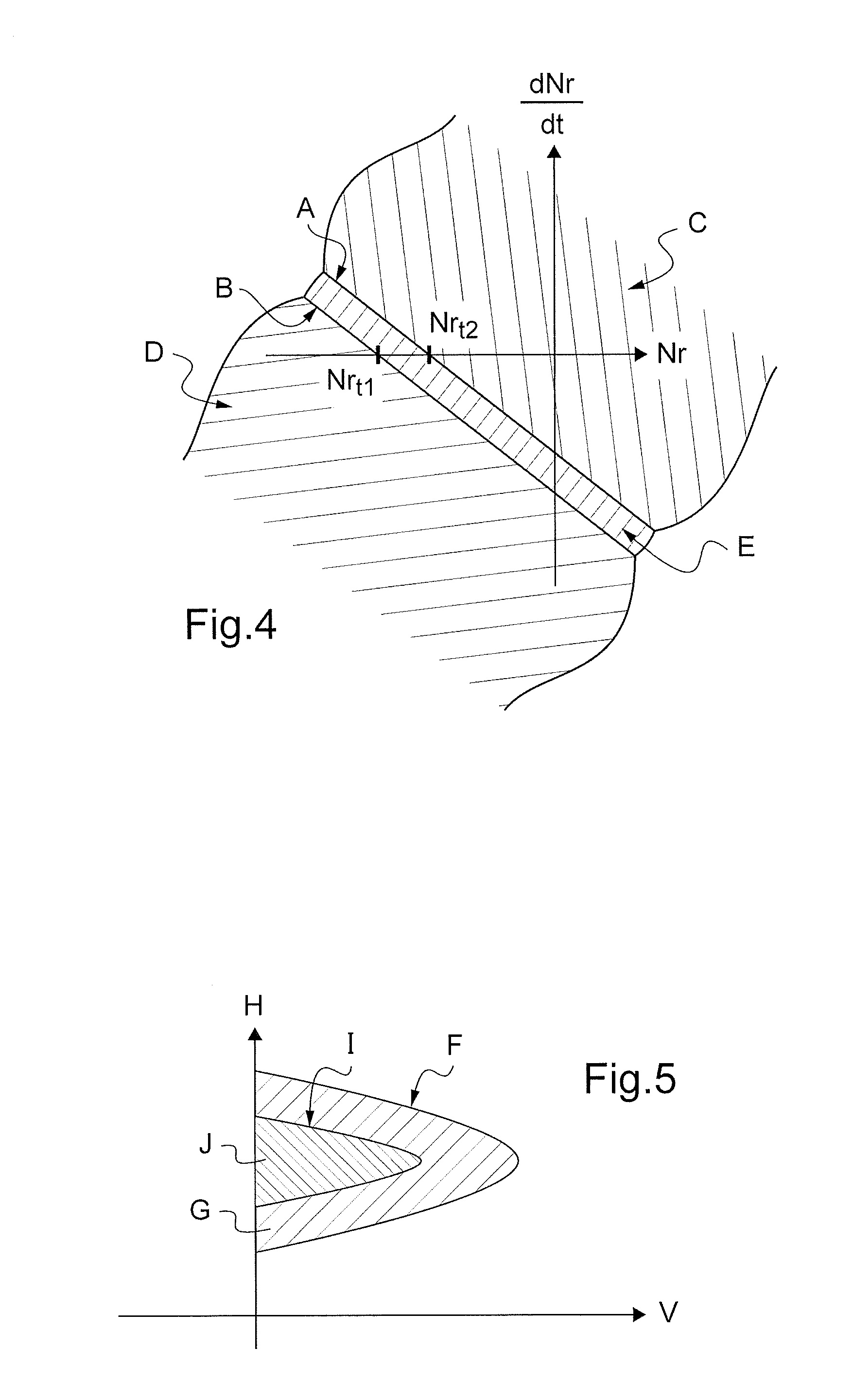

Method of assisting a pilot of a single-engined rotary wing aircraft during a stage of flight in autorotation

ActiveUS20140054411A1Safe handlingPropellersEfficient propulsion technologiesElectric machineRotary wing

A method of assisting a pilot of a single-engined rotary wing aircraft (1) during a stage of flight in autorotation, said aircraft (1) including a hybrid power plant having an engine (13), an electric machine (12), and a main gearbox (11). Said aircraft (1) also includes electrical energy storage means (14) and a main rotor (2) mechanically connected to said hybrid power plant (5). According to said method, while in flight, the operation of said engine (13) is monitored in order to detect a failure thereof, in particular by monitoring for a drop of power on said main rotor (2), and then in the event of a failure of said engine (13) being detected, said electric machine (12) is controlled to deliver auxiliary power We to said main rotor (2), thereby enabling the pilot of said aircraft (1) to be assisted in maneuvering said aircraft (1) during said stage of flight in autorotation following said failure.

Owner:EUROCOPTER

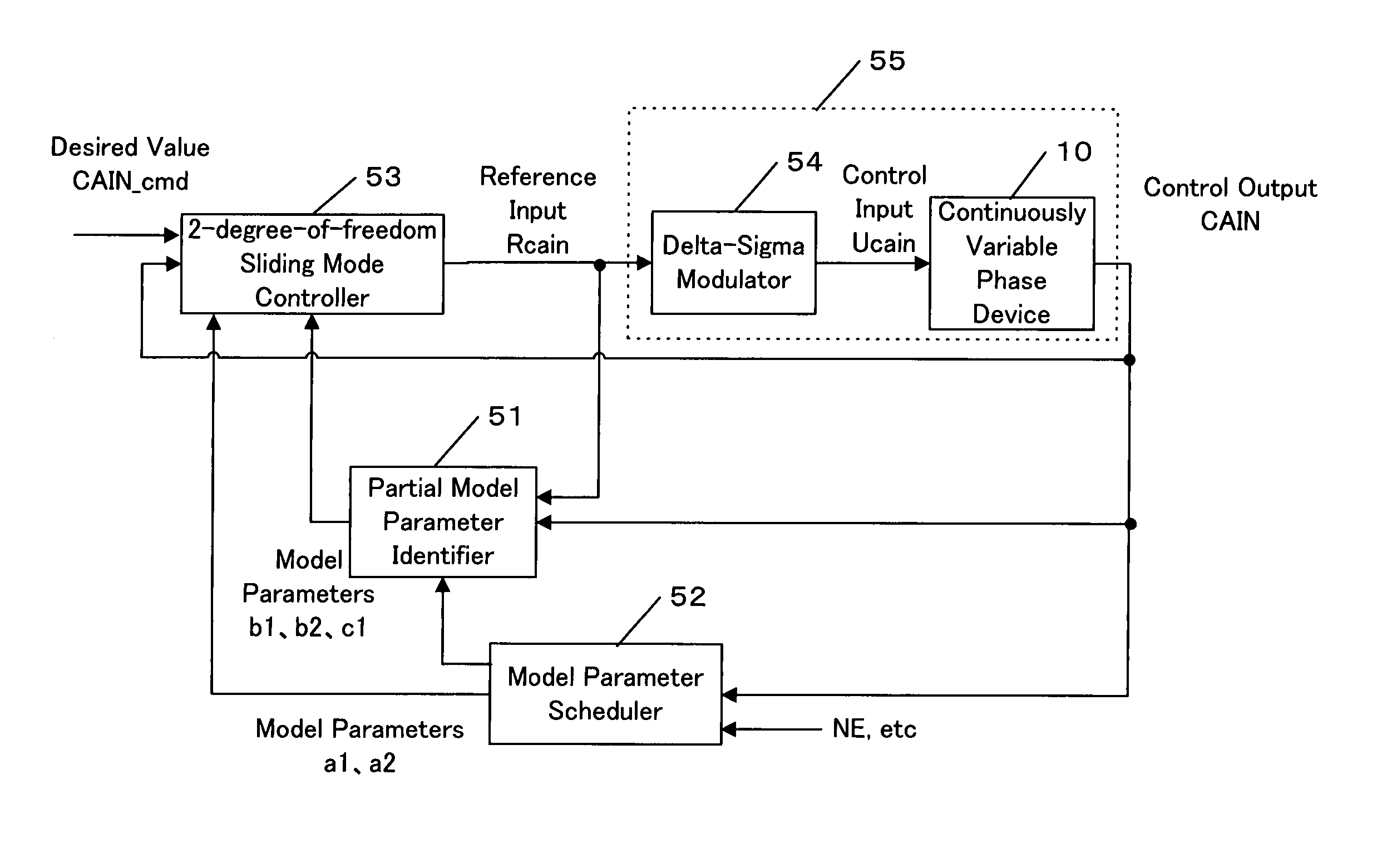

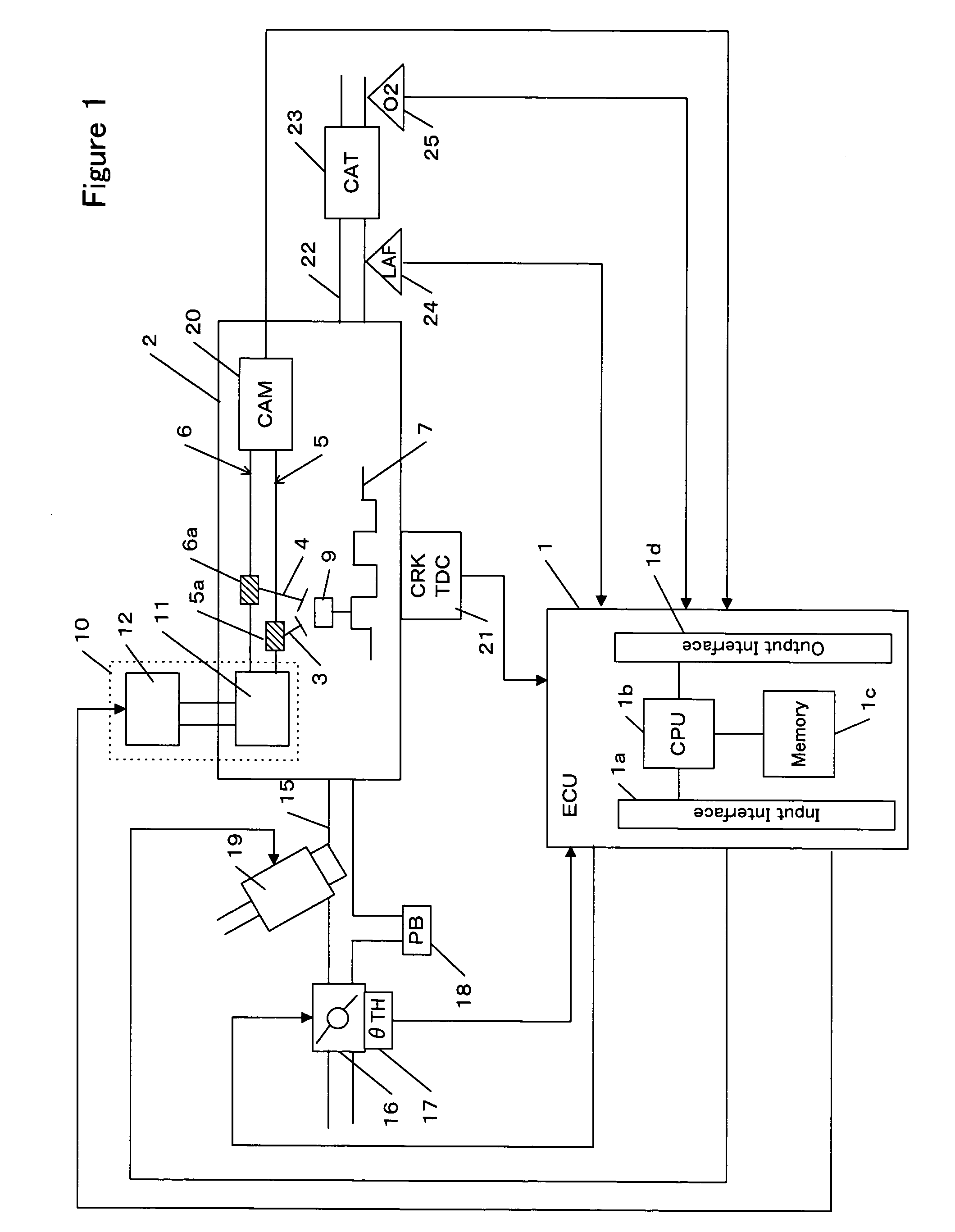

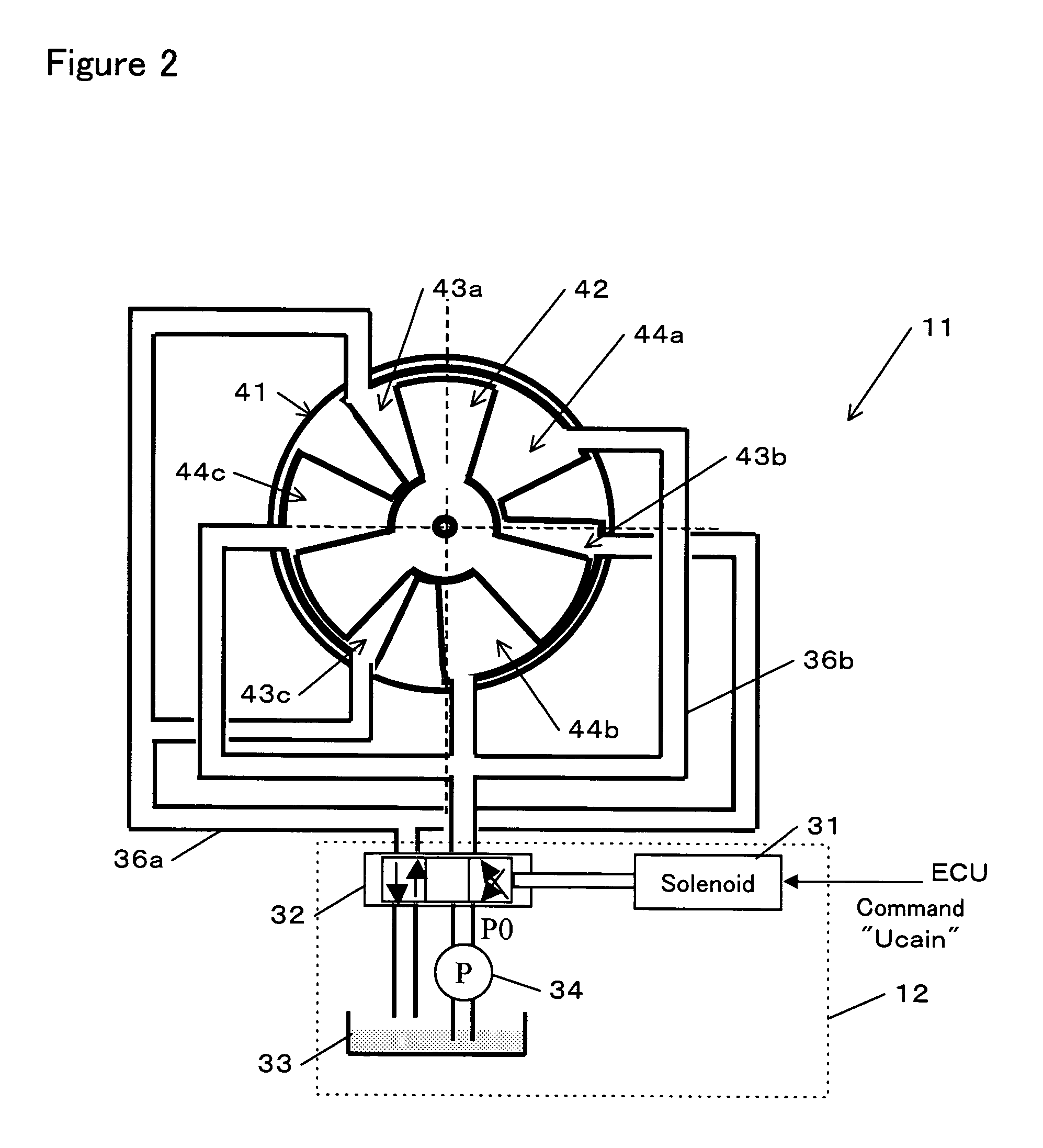

Control apparatus for controlling a plant by using a delta-sigma modulation

InactiveUS7058501B2Avoid vibrationSubstance reductionAnalogue computers for vehiclesHand manipulated computer devicesControl engineeringModel parameters

A control apparatus for controlling an object that is modeled using at least one model parameter is provided. The control apparatus comprises an identifier, a controller and a modulator. The identifier identifies the model parameter. The controller is coupled to the identifier and uses the model parameter to determine a reference input so that an output of the object converges to a desired value. The modulator is coupled to the controller and applies any one of a delta-sigma modulation algorithm, a sigma-delta modulation algorithm and a delta modulation algorithm to the reference input to determine an input into the object. The model parameter is identified based on the output of the object and the reference input. Since the identifier determines the model parameter based on the reference input, the model parameters is prevented from vibrating.

Owner:HONDA MOTOR CO LTD

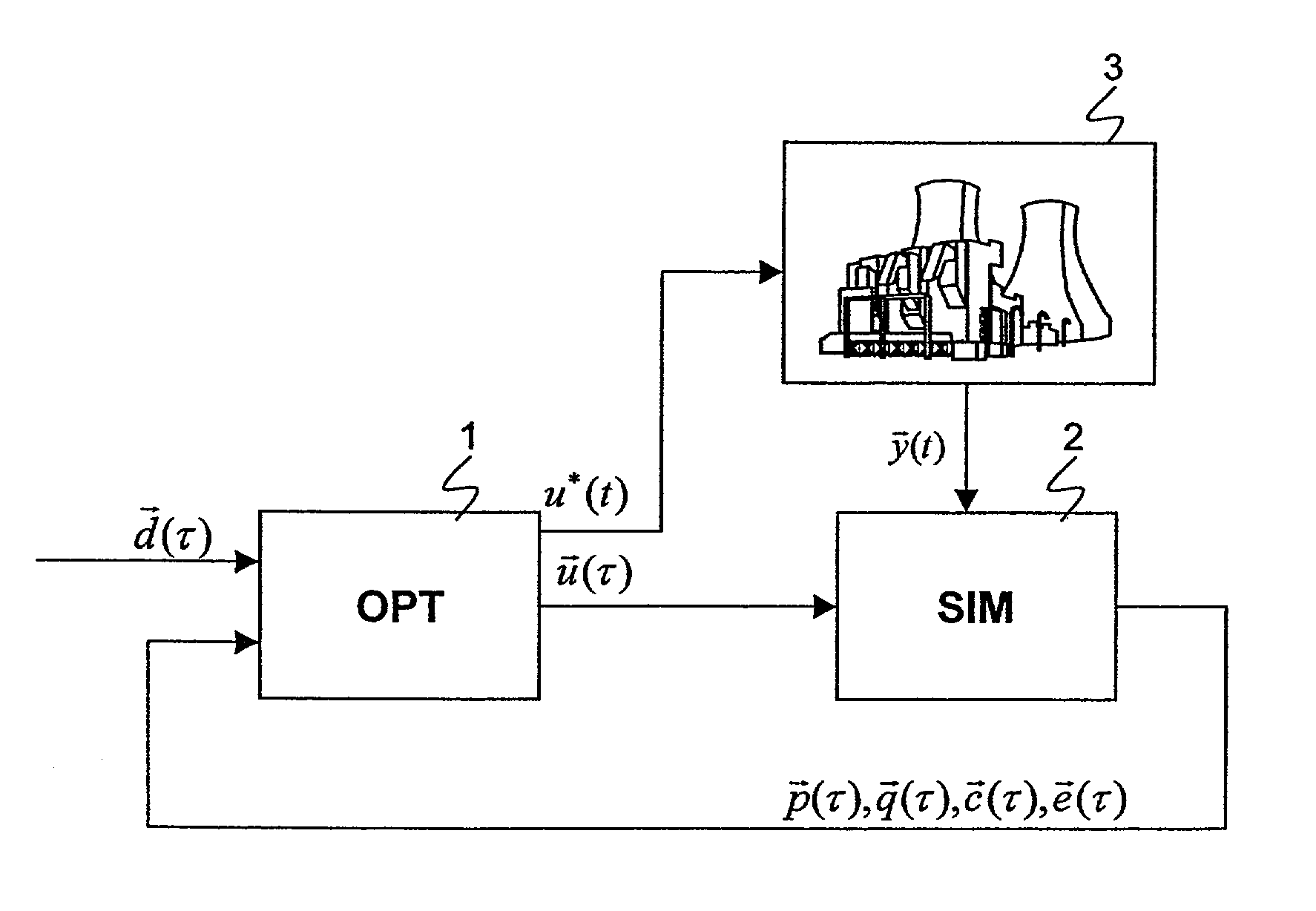

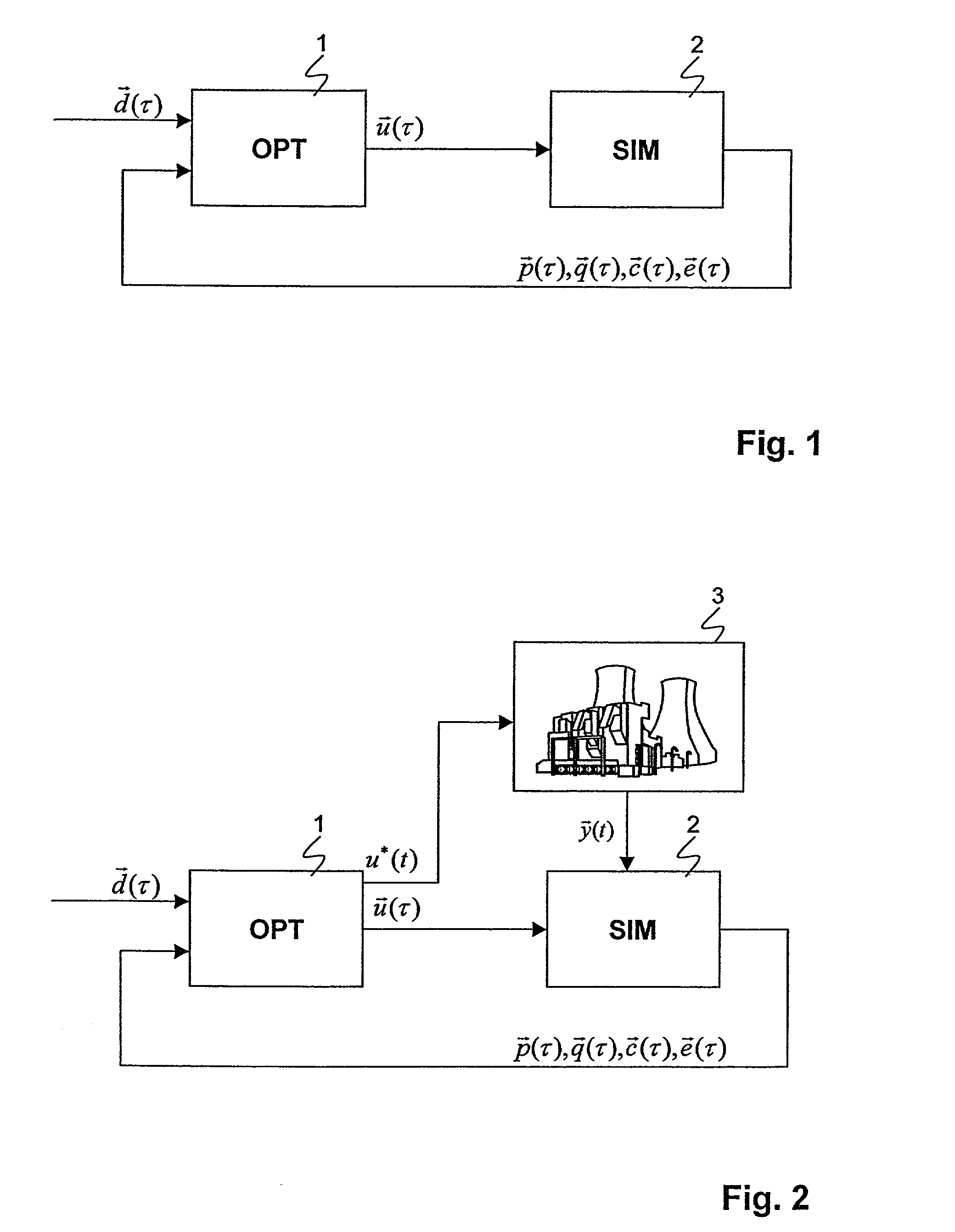

Optimizing plant control values of a power plant

InactiveUS7058552B2High maintenance and replacement costHigh maintenanceComputation using non-denominational number representationAdaptive controlProcess engineeringPower station

In a method and computer program product for optimizing power plant control values and a power plant optimizing system an optimization module (1) minimizes total plant operation costs while achieving predetermined required output values for produced power and process steam. This is done by, at a given time, determining future values of control values and simulating, in a simulation module (2), the behavior of the plant up to a given future time. Corresponding fuel costs and generated power are determined in the simulation, and incorporated in an objective function. The optimization module (1) minimizes the objective function by varying the control values. According to the invention, a rate of ageing of plant components is determined when simulating the future behavior of the plant, and the objective function to be minimized comprises said rate of ageing.

Owner:ABB RES LTD

Real time asset optimization

InactiveUS6999829B2Technology managementResourcesComputerized maintenance management systemTechnology assessment

A technique to optimize both the production schedule and the maintenance of plant assets based on predetermined criteria which may be economic or otherwise. In one embodiment the technique receives at least one maintenance trigger (MT) and one production order and evaluates those inputs to propose one or more solutions for the joint scheduling of the asset maintenance and required plant production. In another embodiment a computerized maintenance management system (CMMS) acquires a new MT and proposes a new maintenance schedule. The technique transmits a blocking order to a production scheduling (PS) system for converting the maintenance request into a production schedule. In another embodiment, a CMMS acquires a new MT and asks for confirmation of a time slot to perform the maintenance action. The technique evaluates the priorities and finds based on the predetermined criteria the right time slot and communicates a request for that slot to the PS.

Owner:ABB INC +1

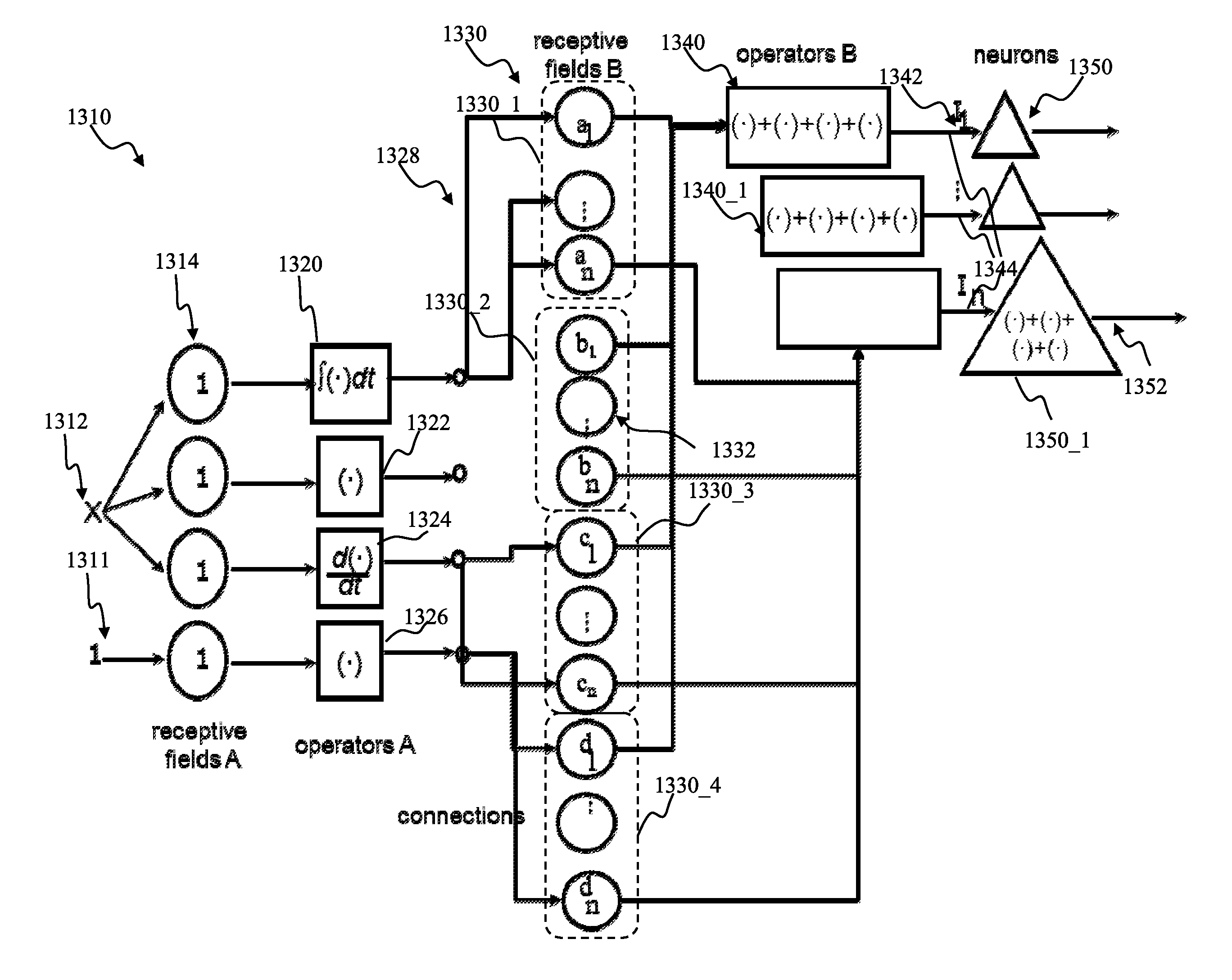

Proportional-integral-derivative controller effecting expansion kernels comprising a plurality of spiking neurons associated with a plurality of receptive fields

ActiveUS9082079B1Improve connection efficiencyEasy to measureDigital computer detailsNeural architecturesNeuron networkControl engineering

Adaptive proportional-integral-derivative controller apparatus of a plant may be implemented. The controller may comprise an encoder block utilizing basis function kernel expansion technique to encode an arbitrary combination of inputs into spike output. The basis function kernel may comprise one or more operators configured to manipulate basis components. The controller may comprise spiking neuron network operable according to reinforcement learning process. The network may receive the encoder output via a plurality of plastic connections. The process may be configured to adaptively modify connection weights in order to maximize process performance, associated with a target outcome. Features of the input may be identified and used for enabling the controlled plant to achieve the target outcome.

Owner:BRAIN CORP

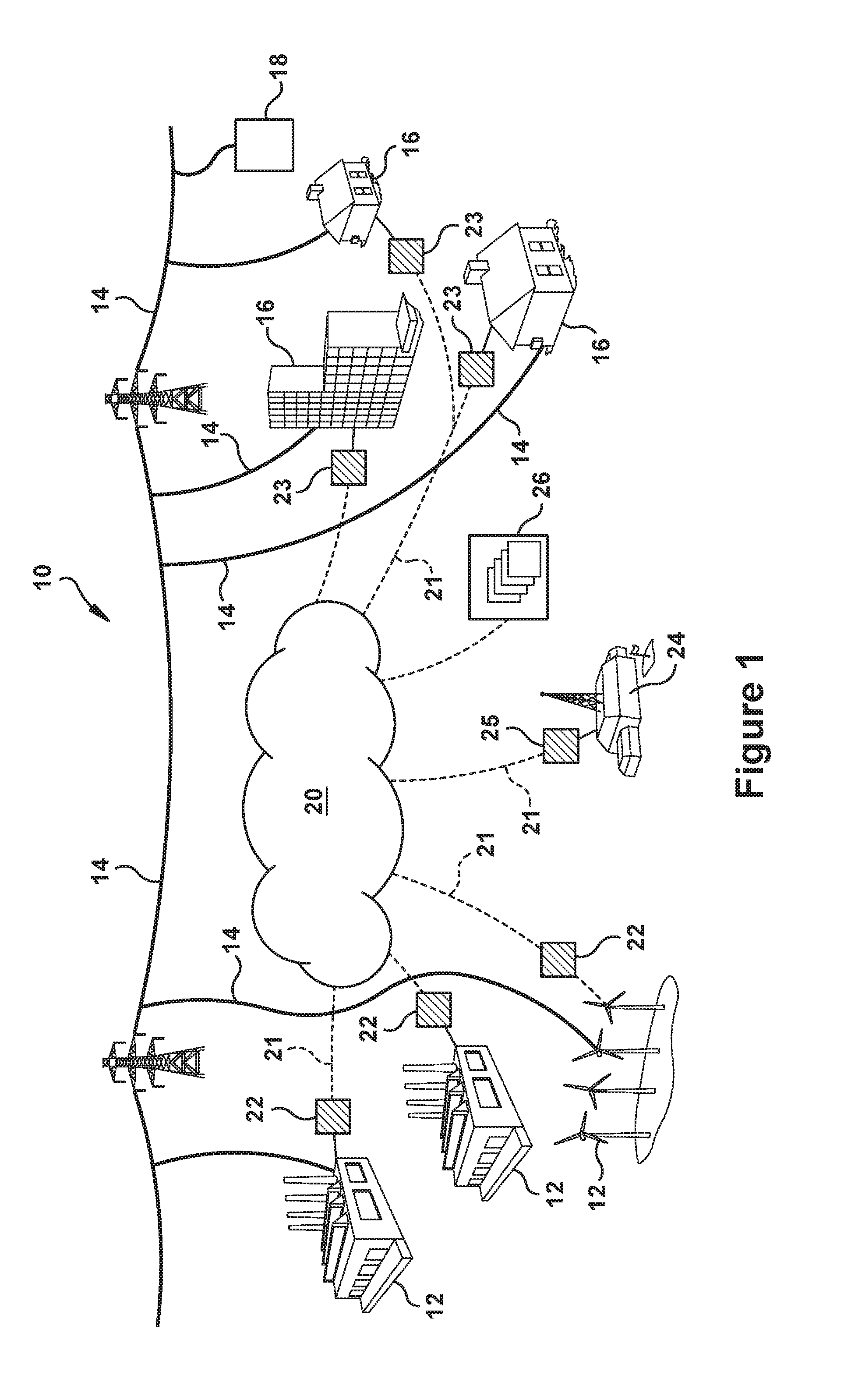

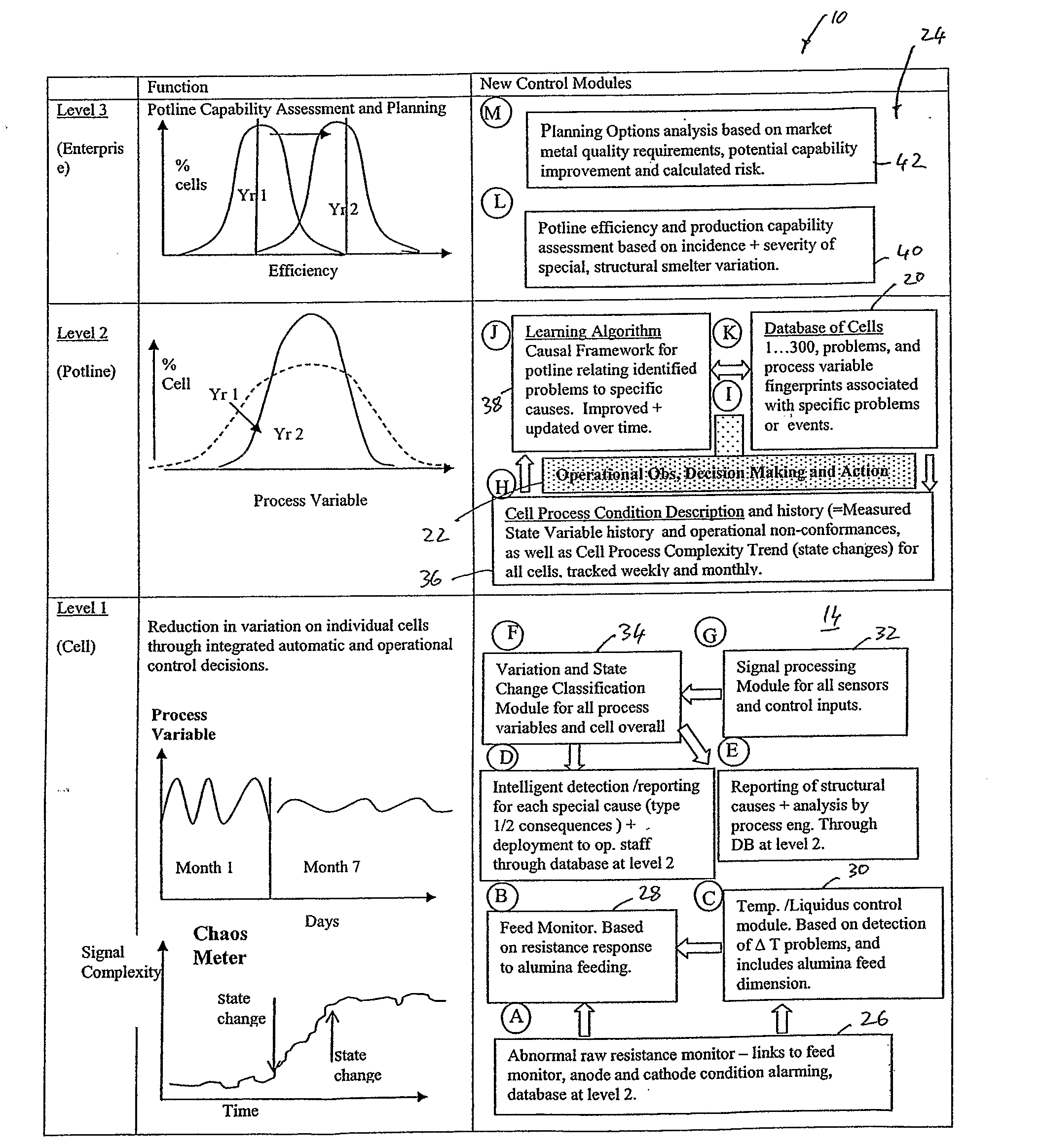

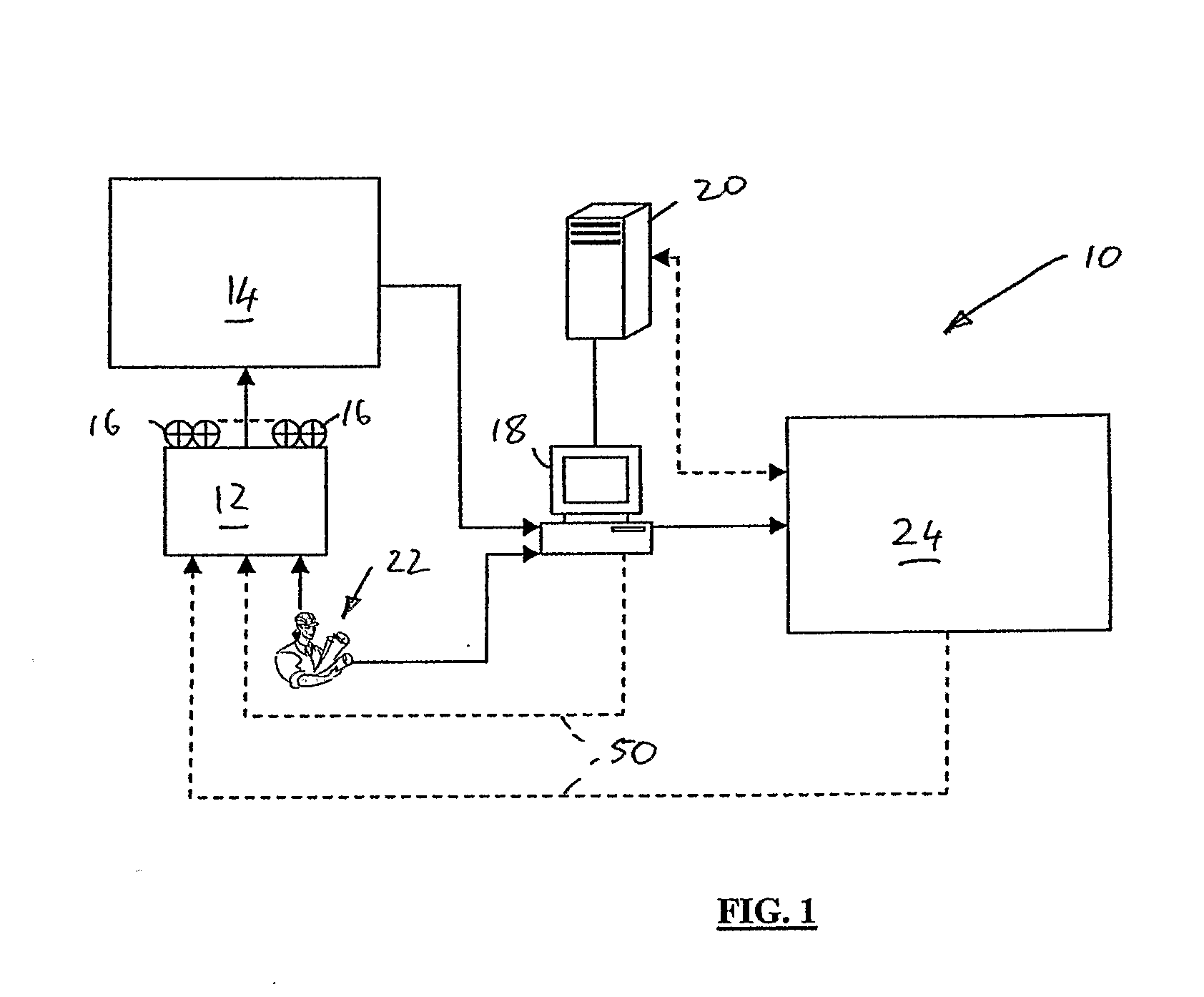

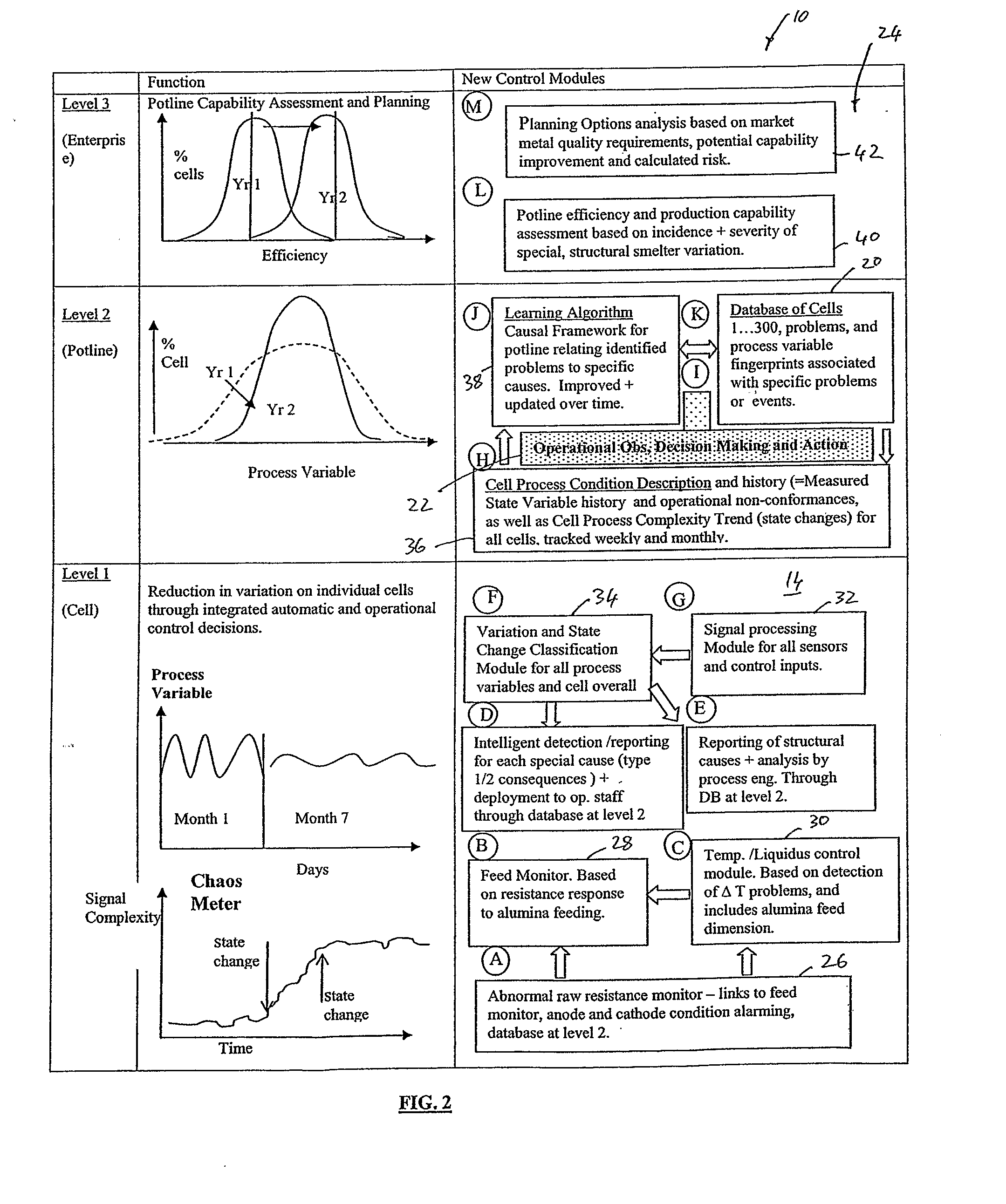

Process control of an industrial plant

ActiveUS20140316579A1Reduce variationExtension of timeSampled-variable control systemsComputer controlAutomatic controlProcess conditions

A system 10 for controlling an industrial plant 12 comprises automatic control equipment 14 comprising a plurality of measurement sensors 16 for sensing predetermined variables associated with components of the industrial plant 12. The sensors 16 generate measured data relating to operation of the components of the industrial plant 12. A database 20 contains operational data, including observational data, regarding the industrial plant 12. A processor 18 is in communication with the automatic control equipment 14 and the database 20 for receiving the measured data from the sensors 16 of the automatic control equipment 14 and the operational data from the database 20. The processor 18 manipulates the measured and operational data to provide an evolving description of a process condition of each component over time, along with output information relating to operational control of the industrial plant 12 and for updating the database 20.

Owner:AUCKLAND UNISERVICES LTD

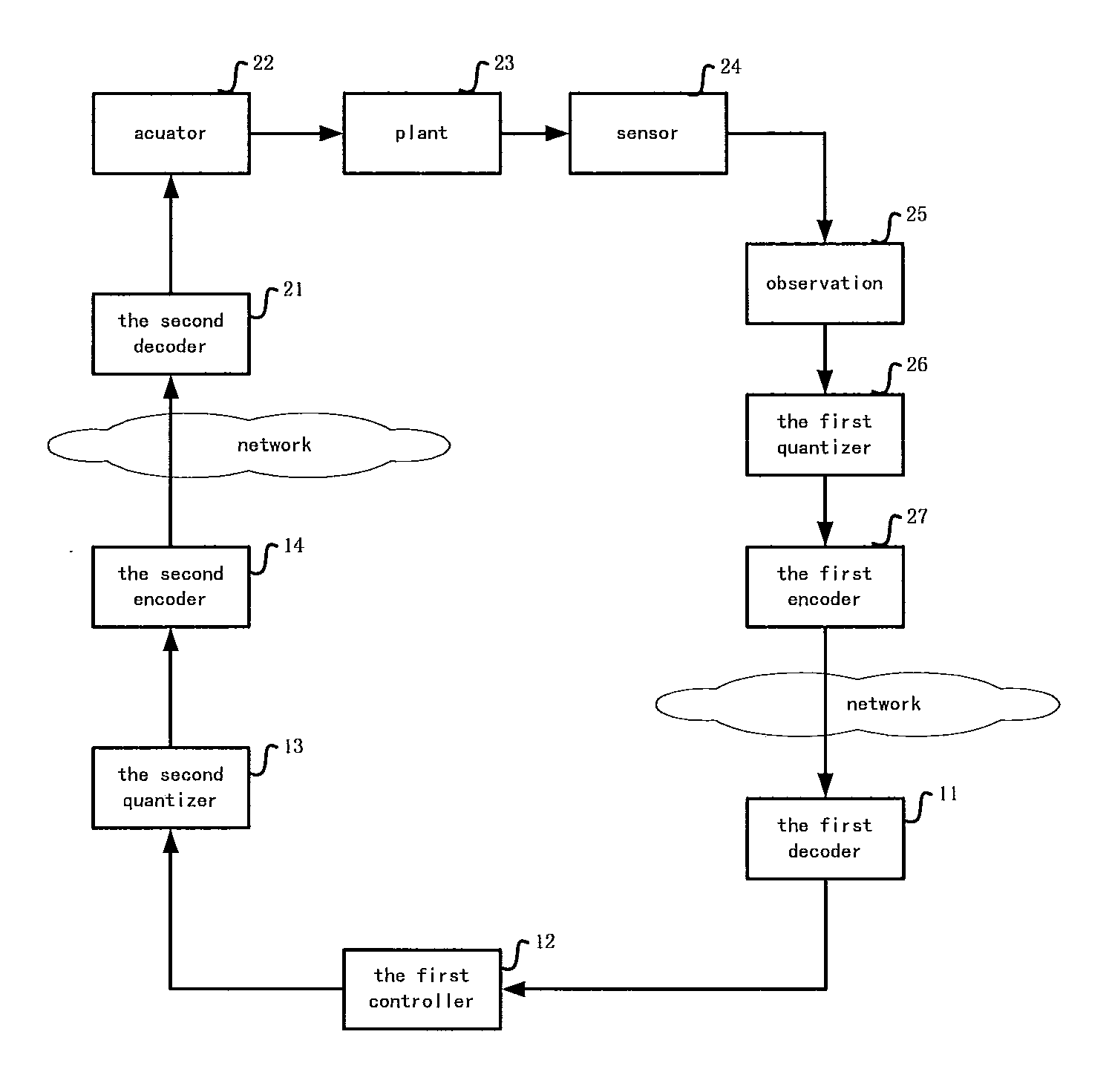

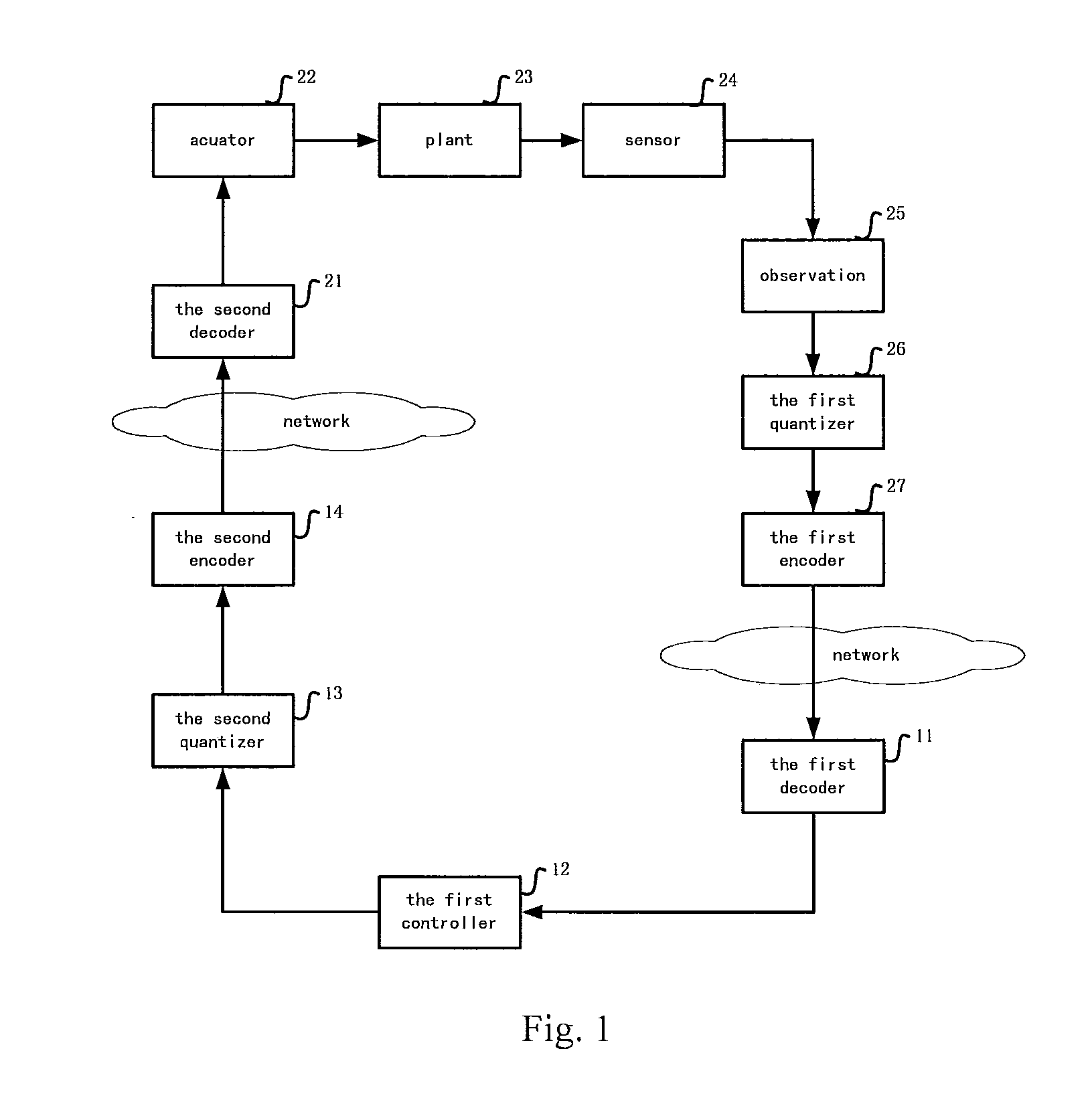

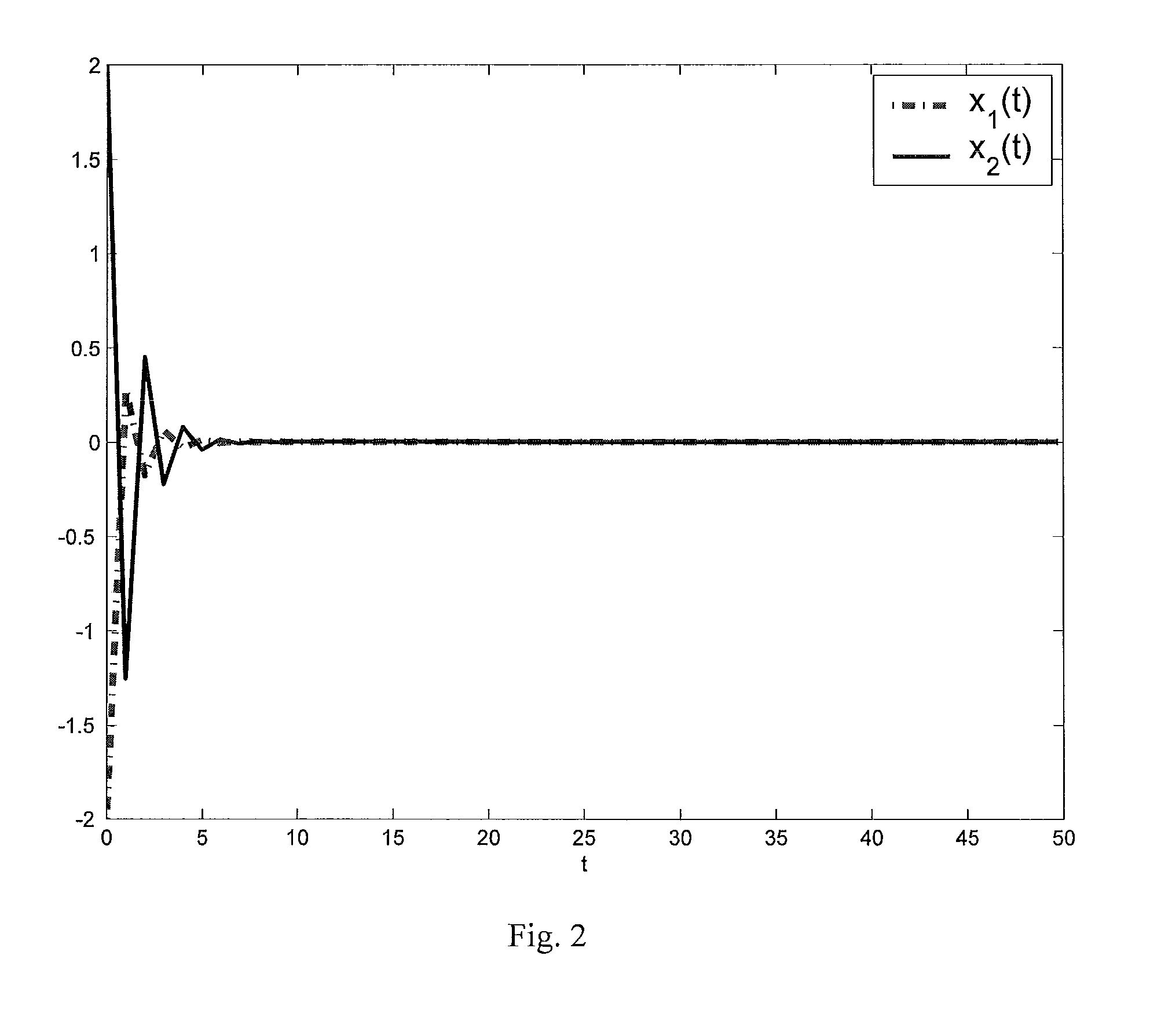

Method for real-time online control of hybrid nonlinear system

InactiveUS20120045013A1Guarantee asymptotic stabilitySimple structureModulated-carrier systemsComputer controlLoad capacityLinear system

The present invention provides a method for real-time online control of hybrid nonlinear system, characterized in that, it comprises the following steps: a. the current observational state of plant in the network is transmitted to first controller, where said first controller is used to provide real-time online control for plant, which guarantees the asymptotic stability of the controlled plant in the network; b. Said first controller obtains the current control output information according to the current observation state information; c. Giving said output control information to said controlled plant in the network as feedback, wherein said controlled plant in the network is nonlinear hybrid system. The present invention realizes the control of nonlinear hybrid system through network by providing control method with quantized controller to guarantee the asymptotic stability of the system. Especially, the load capacity of network will be greatly reduced by transmitting the observation information after being quantized.

Owner:TONGJI UNIV

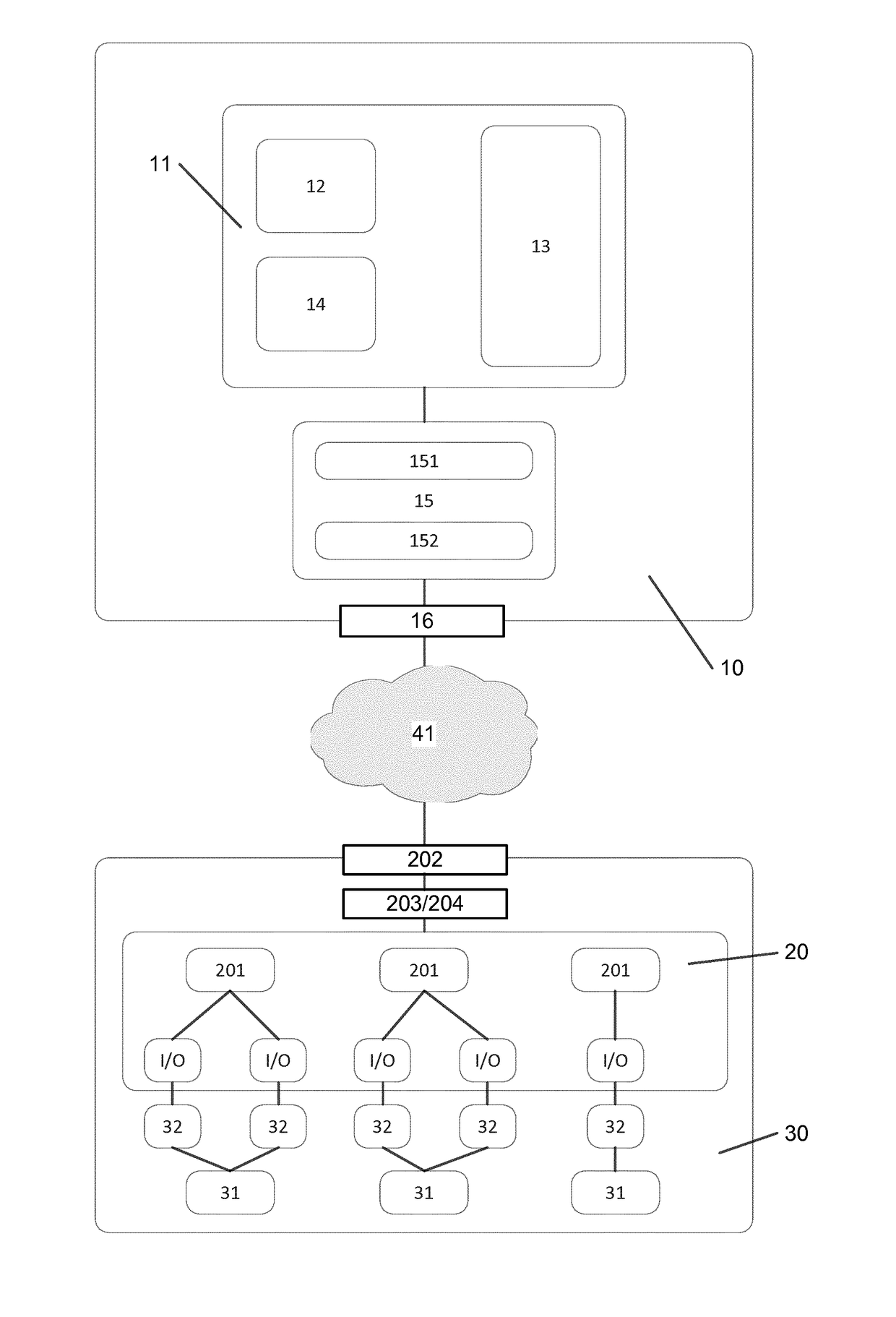

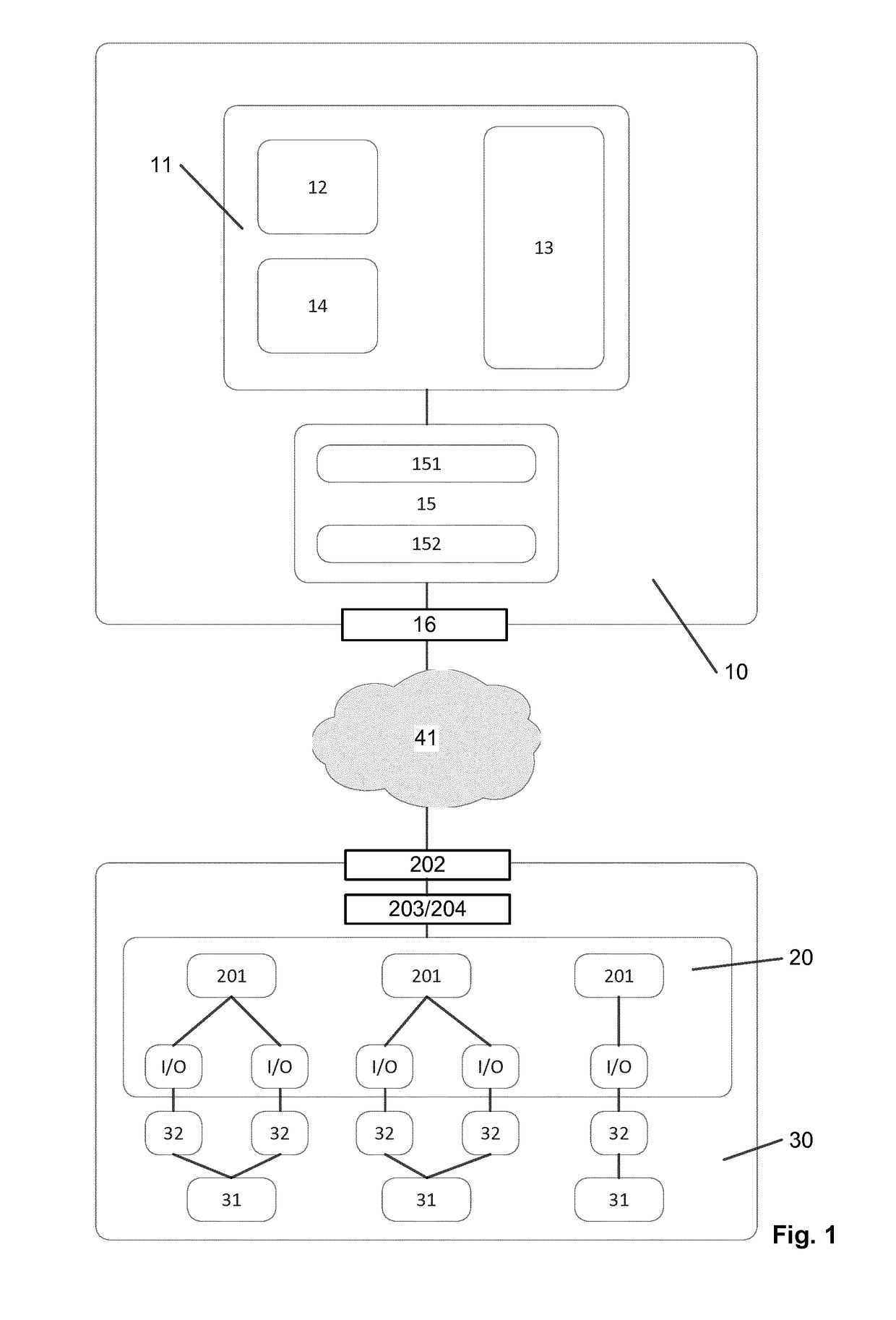

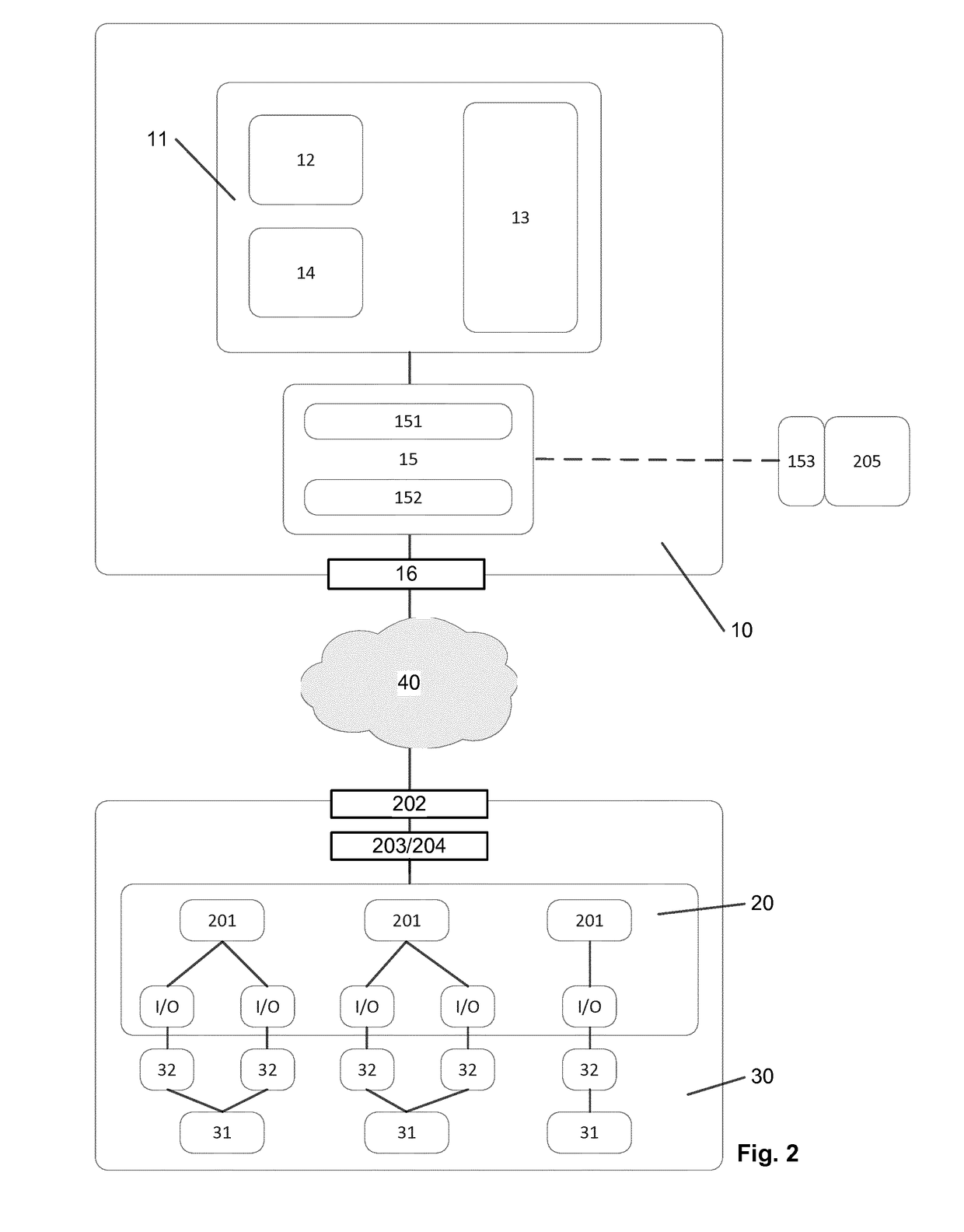

Method and system for process controlling of plants in an opc-ua based machine-to-machine network

ActiveUS20180088548A1Simple planEasy maintenanceTechnology managementBoiler controlBiotechnologyControl engineering

A method for process controlling of plants and plant control systems in an OPC UA based Machine-to-Machine (M2M) network is provided. A plant associated with the plant control system a plurality of interlocked elements of one or more operational units of the plant. The operation of an operational unit is controlled by the plant control system using the elements interlocked to the plant control system. The plant control system is accessible by an independent process control system in the Machine-to-Machine (M2M) network via one or more network interfaces, and wherein messages containing signaling data and steering commands are transmitted between the process control system and the plant control system.

Owner:BUEHLER AG

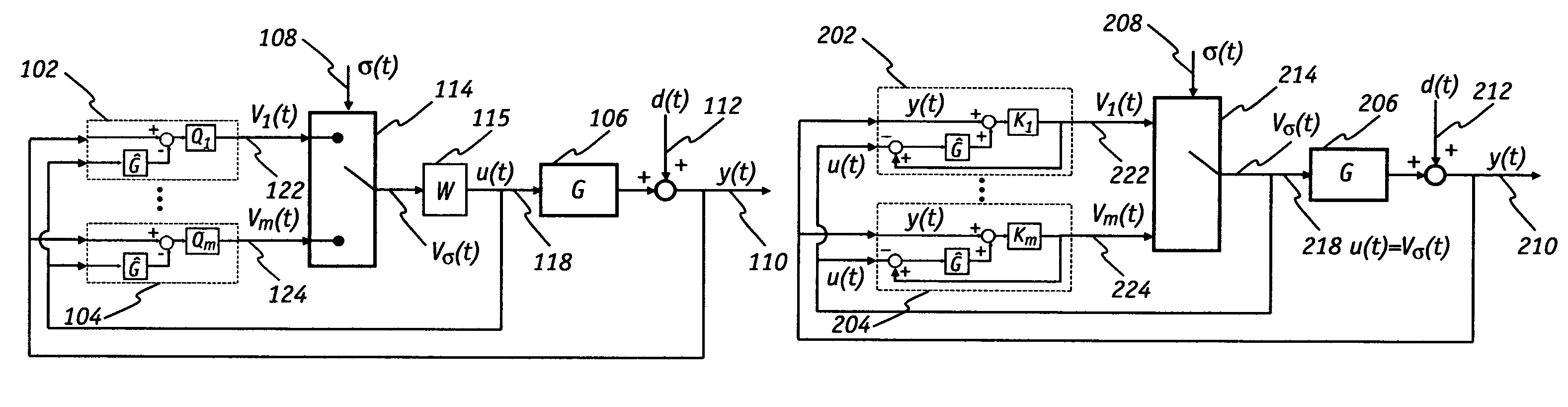

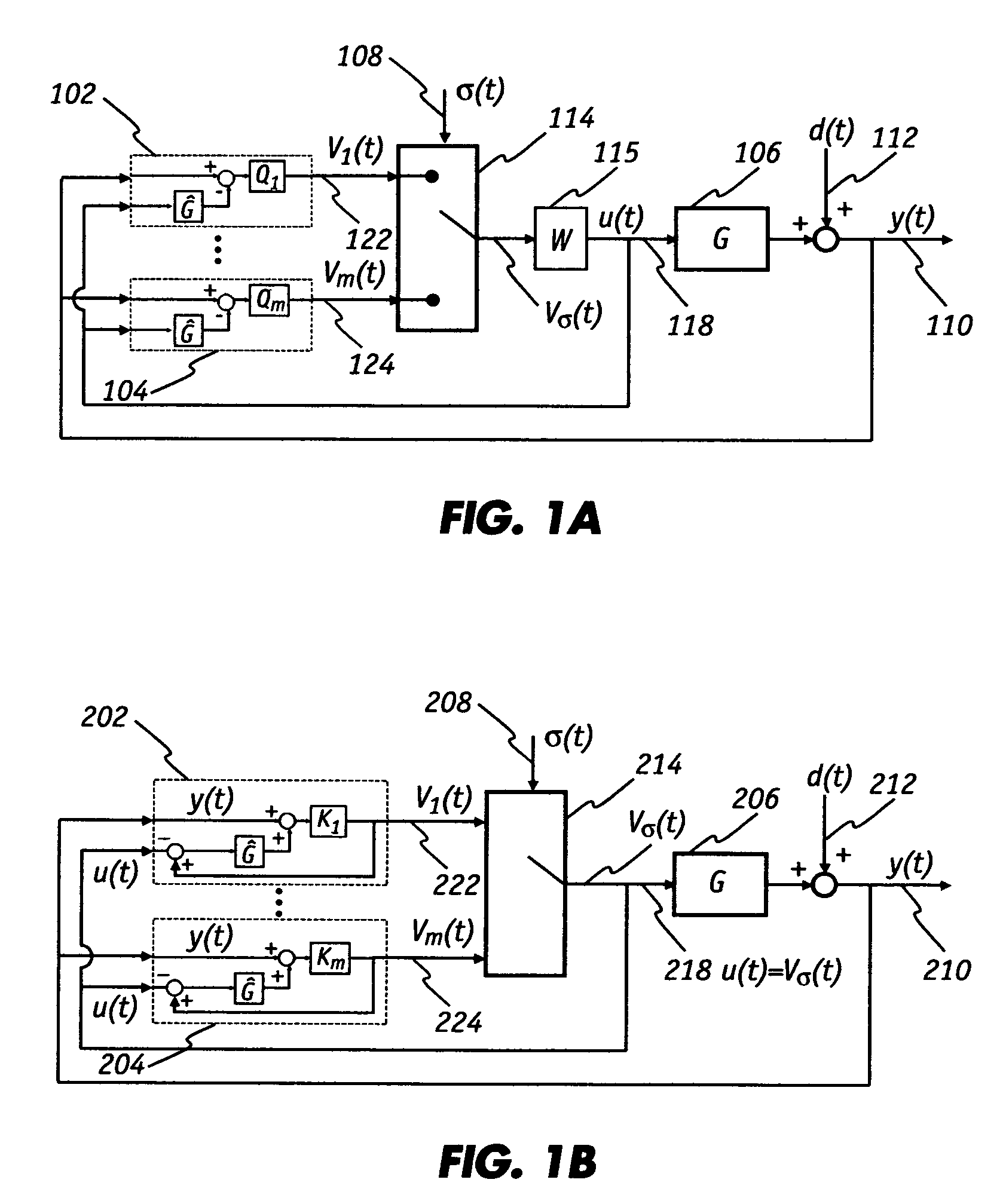

Technique for switching between controllers

ActiveUS7515975B2High-tension/heavy-dress switchesAir-break switchesControl engineeringComputer science

A controller design for switching between m linear multivariable controllers each of whom stabilizes a linear plant has been presented. A Youla-Kucera factorization was exploited in the interest of obtaining a closed-loop system that is exponentially stable for any switching signal σ(t) in the absence of plant model uncertainty. Robustness to practical model uncertainty was also considered and lower and upper bounds on the tolerable magnitude of unstructured additive plant uncertainty were presented. Numerical example demonstrated that the two controller degrees of freedom in the proposed controller design could be used to separately modify the closed-loop steady-state (with respect to σ(t)) performance and the switching transients.

Owner:HONEYWELL ASCA INC

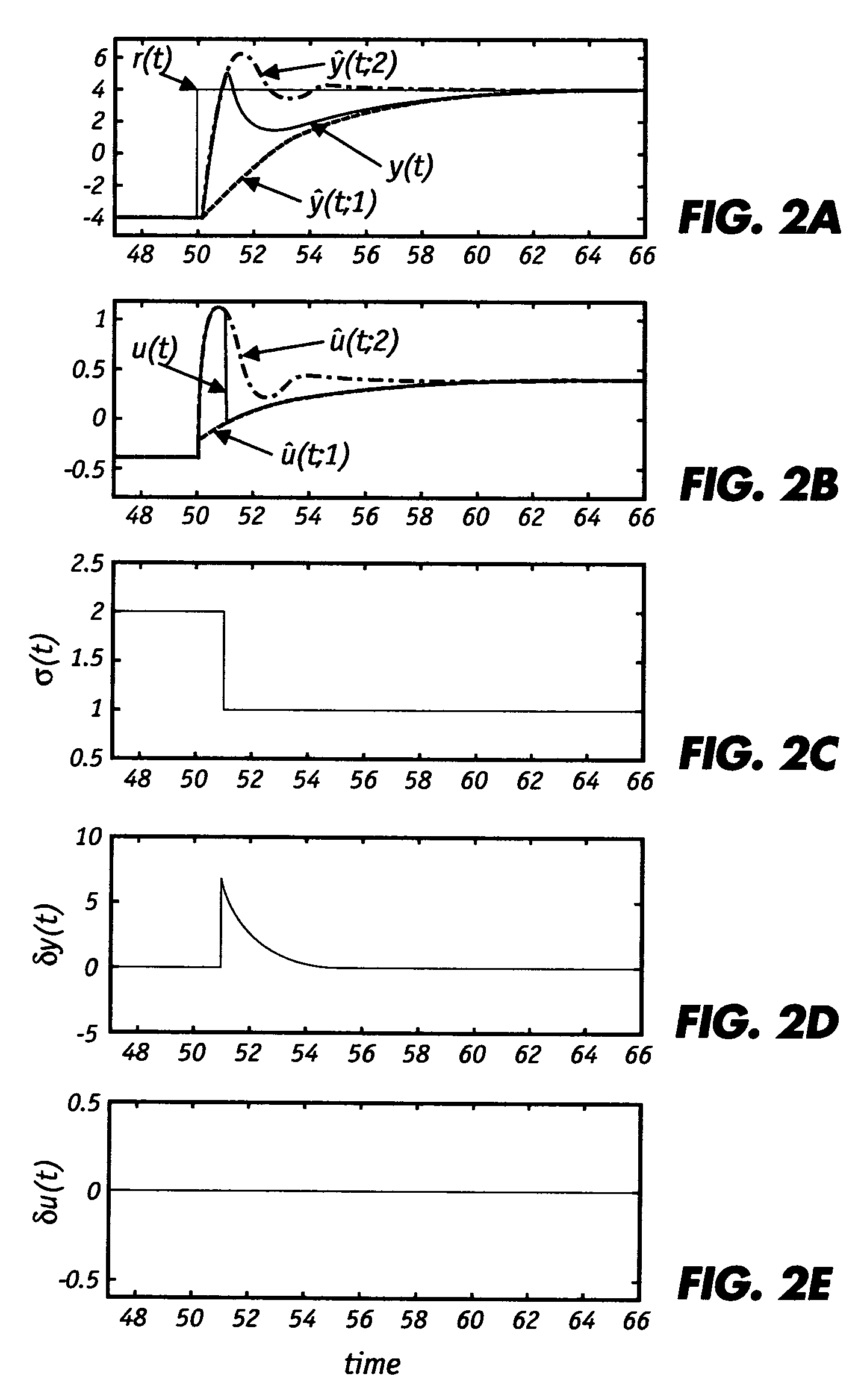

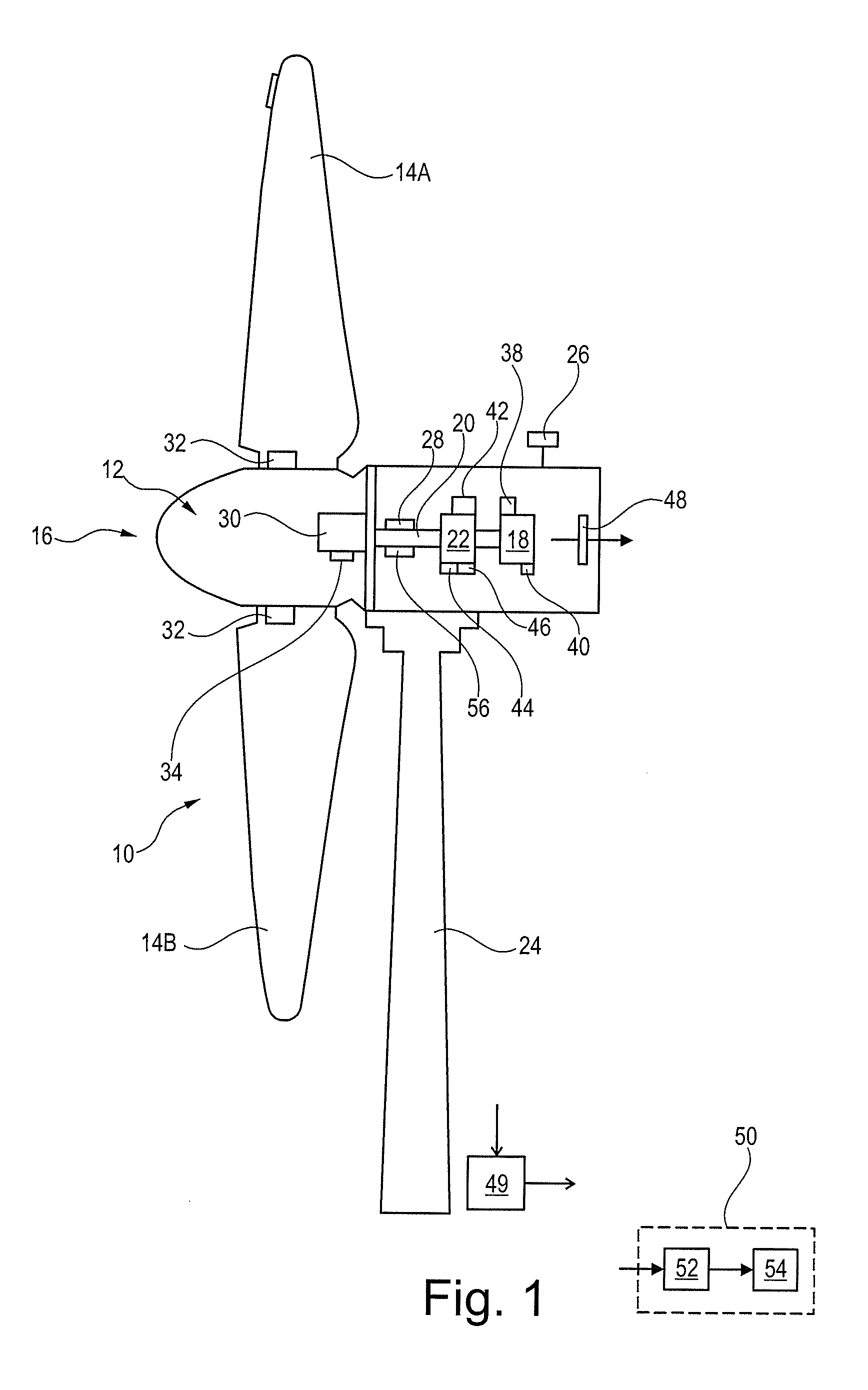

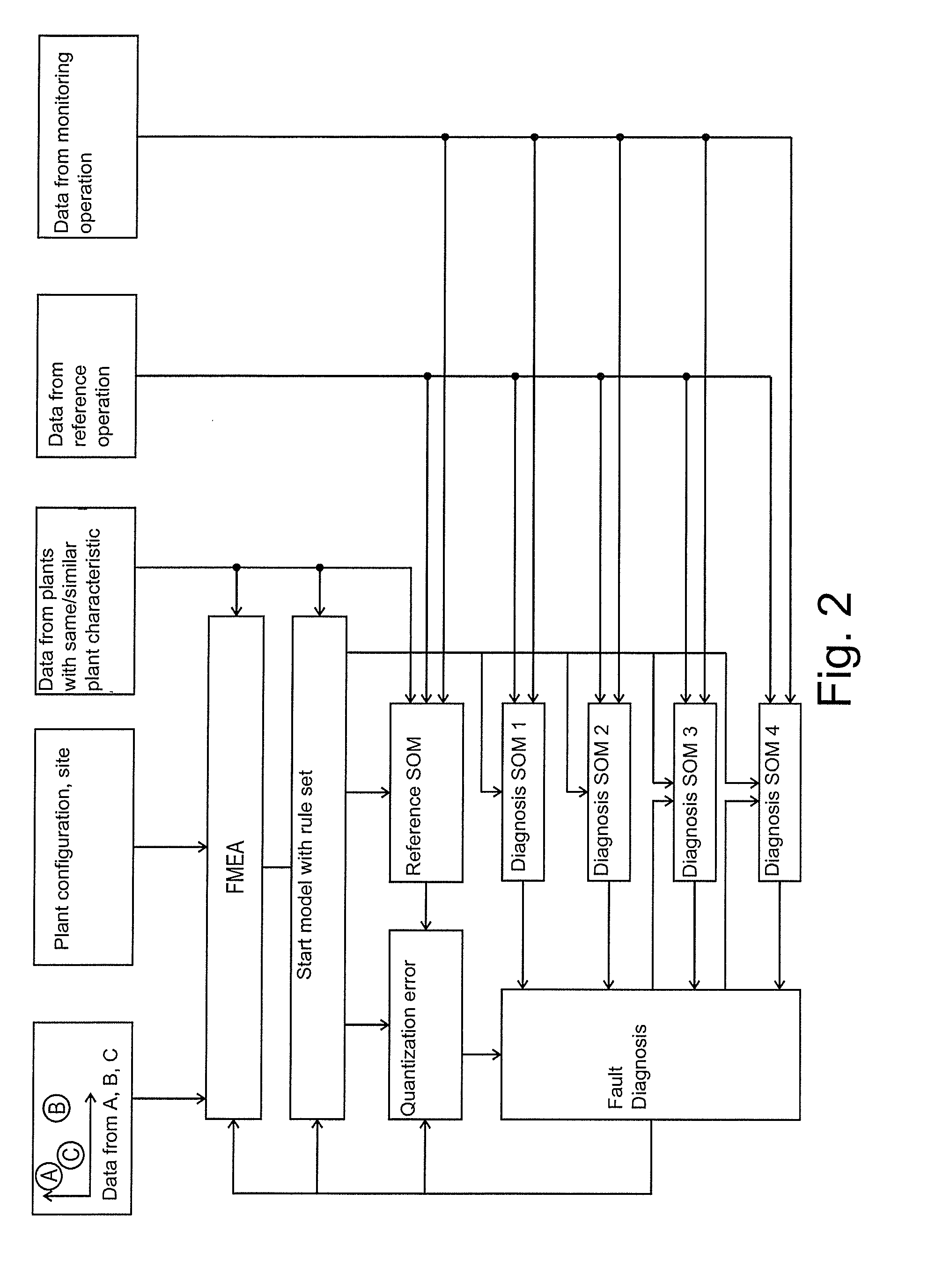

Method for monitoring of rotating machines

ActiveUS20140046881A1Efficiently and reliably recognizes fault stateEffective classificationProgramme controlTesting/monitoring control systemsPower stationComputer science

Method for monitoring of a wind power plant operated in variable operating states. Start sensor data is obtained in at least one basic operating state of the machine; based on the start sensor data, a starting model with a rule set for conducting the monitoring is set up, the rule set determining which parameters are to be monitored, in which manner and with which weighting and which sensor data are to be obtained and used for this purpose; a reference SOM is prepared using the rule set with sensor data selected using the rule set and obtained in a reference operating phase of the machine; during a monitoring operating phase, time characteristics of a quantization error of the sensor data selected using the rule set being tracked with respect to the reference SOM, troubleshooting being started if the quantization error meets a criterion which is dictated by the rule set.

Owner:PRUTECHNIK DIETER BUSCH AG

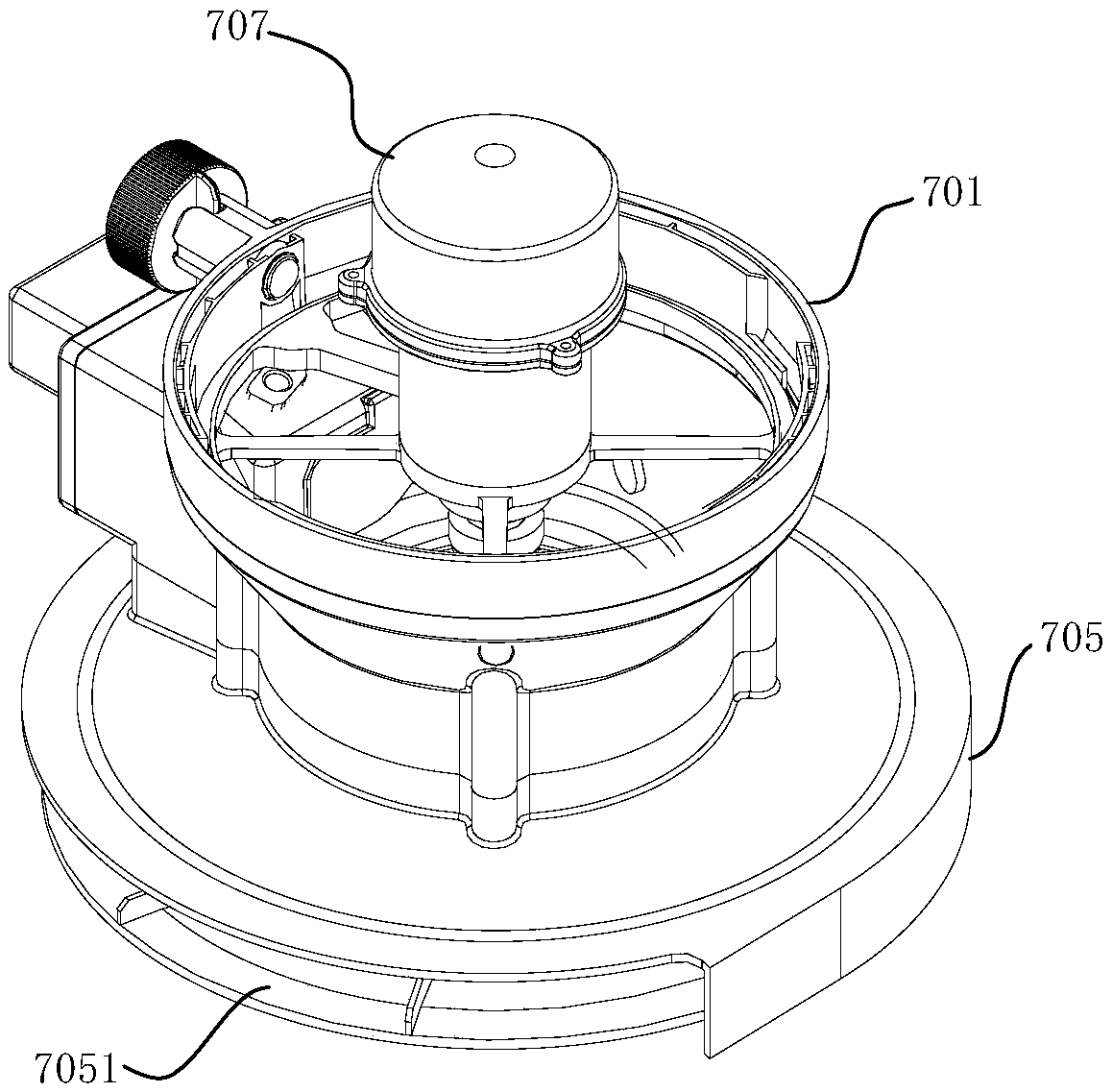

Intelligent hierarchical control method and control device for ore grinding in concentration plant

InactiveCN101950171AEasy to operateFlexible operationTotal factory controlProgramme total factory controlProcess equipmentProcess engineering

The invention relates to the technical field of ore grinding control in a concentration plant, in particular to an intelligent hierarchical control method and a control device for ore grinding in a concentration plant. The control method comprises the following program processes: controlling system initialization; judging whether ore feeding quantity control is implemented or not; implementing ore feeding quantity PID control; judging whether ore water feeding control is implemented or not; implementing the ore water feeding control; judging whether ore water discharging control is implemented or not; implementing the ore water discharging control; judging whether cyclone inlet pulp density and water replenishing cascade control is implemented or not; judging whether pump sump liquid level control is implemented or not; implementing the pump sump liquid level control; judging whether the ore grinding process is finished or not; finishing the ore grinding process; judging whether to return or not; and carrying out interconnected control on each processing device. The device comprises an upper computer, a lower computer, a detecting instrument and an executing mechanism. The invention enables the system to have the characteristics of high control accuracy, high regulating speed, strong interference resistance, stability, reliability and the like, accurately regulates the operating parameters in real time, and improves the working efficiency and the product quality of grinding classification.

Owner:NORTHERN ENG & TECH CORP MCC

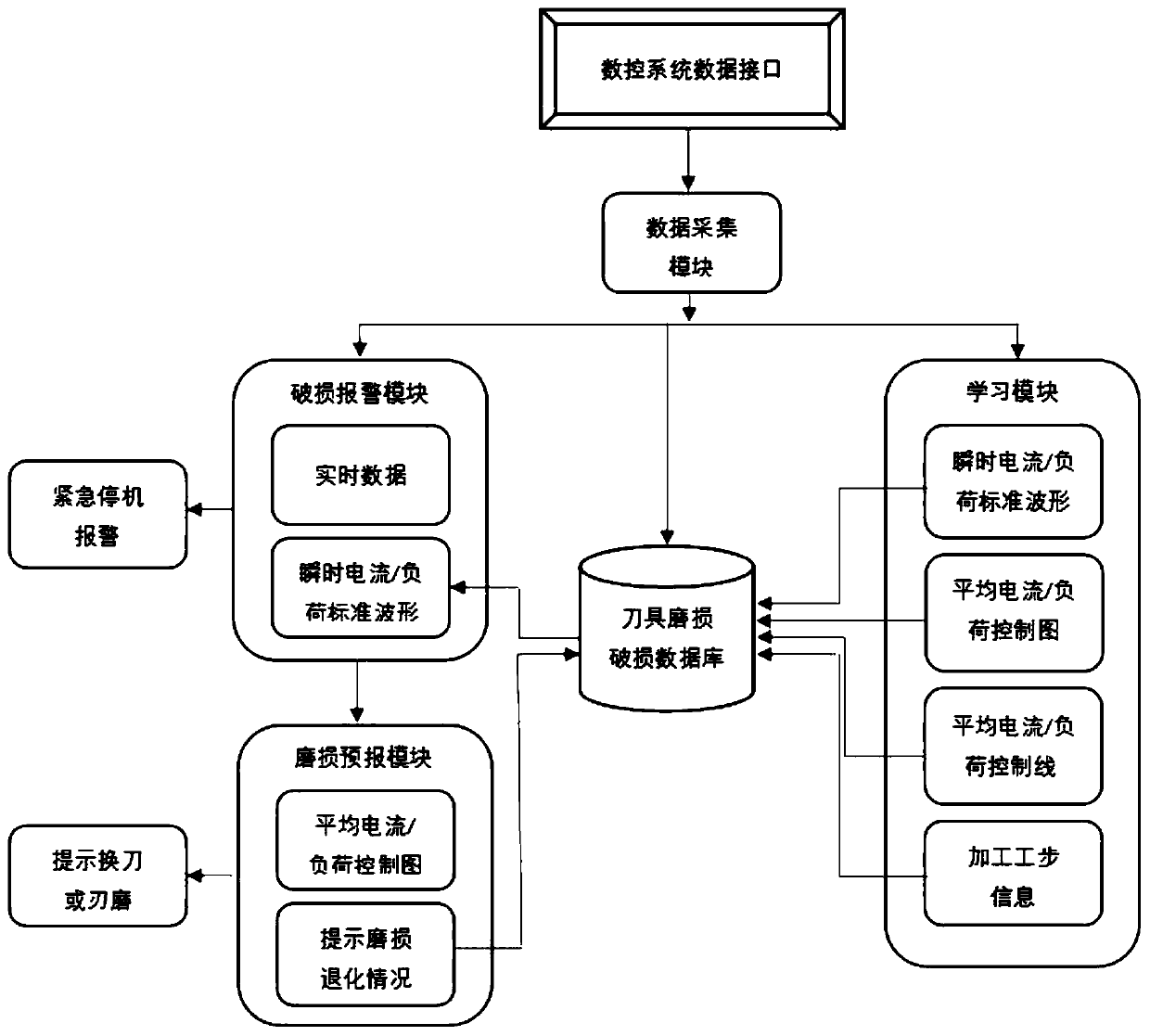

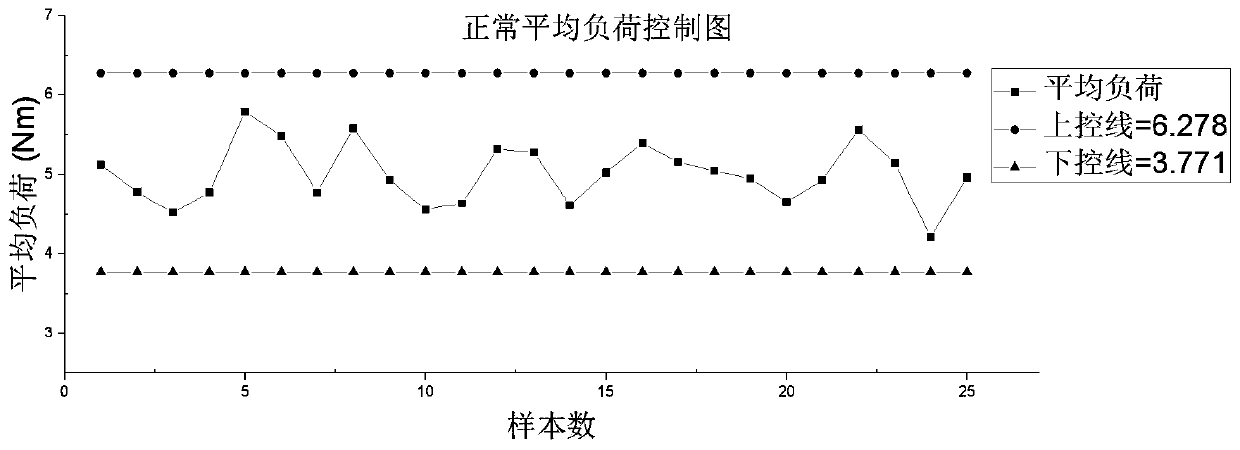

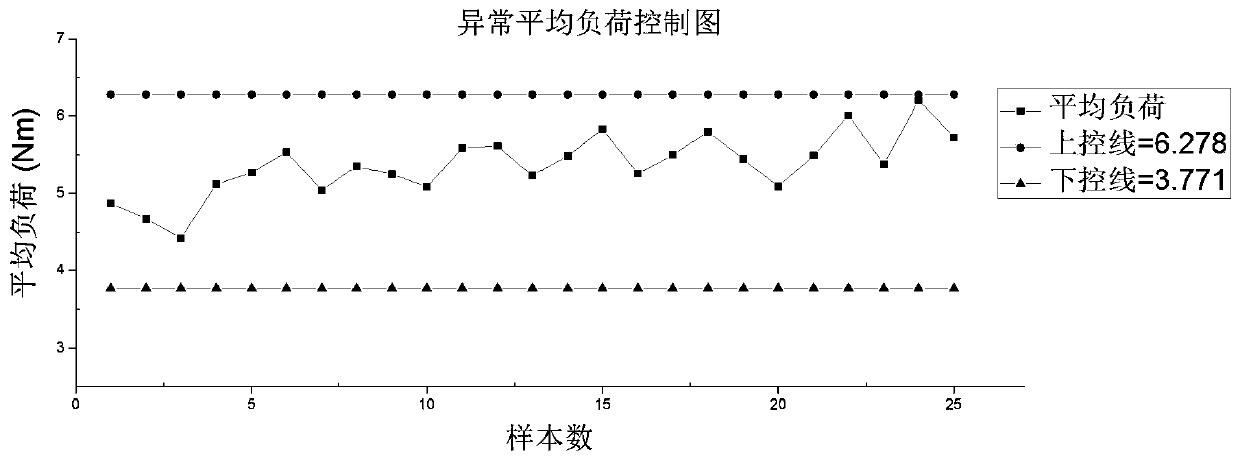

On-line monitoring method for cutter abrasion damage based on main shaft driving current and working step.

ActiveCN109909804ARealize breakage alarmExtended service lifeMeasurement/indication equipmentsAverage currentControl line

The invention discloses an on-line monitoring method for cutter abrasion damage based on main shaft driving current and working step. The method is made by the following steps that realizing communication with a numerical control system to obtain machining working step information, meanwhile, the driving current and the load of the main shaft are monitored, and on the basis of a normal cutter andabrasion damage cutter cutting torque difference analysis and statistical quality control principle. Control graph for drawing average current / load required by each working step processing, a control graph control line is reasonably formulated, the abrasion state of each working step is judged, and a tool changing or cutter edge grinding rule is formulated. According to the variation of instantaneous main shaft current or instantaneous load with the deviation from the instantaneous current / load in normal machining in each working step of machining, the cutter breakage is determined, the alarm signal is sent to inform the numerical control system to emergency shutdown so as to avoid the serious consequences of damaging the workpiece and the machine tool. According to the method, on onehand, the part rejection rate and the machine tool fault rate can be reduced, on the other hand, the service life of the cutter can be prolonged to the maximum extent, and the use cost of a plant cutter is reduced.

Owner:BEIJING UNIV OF TECH +1

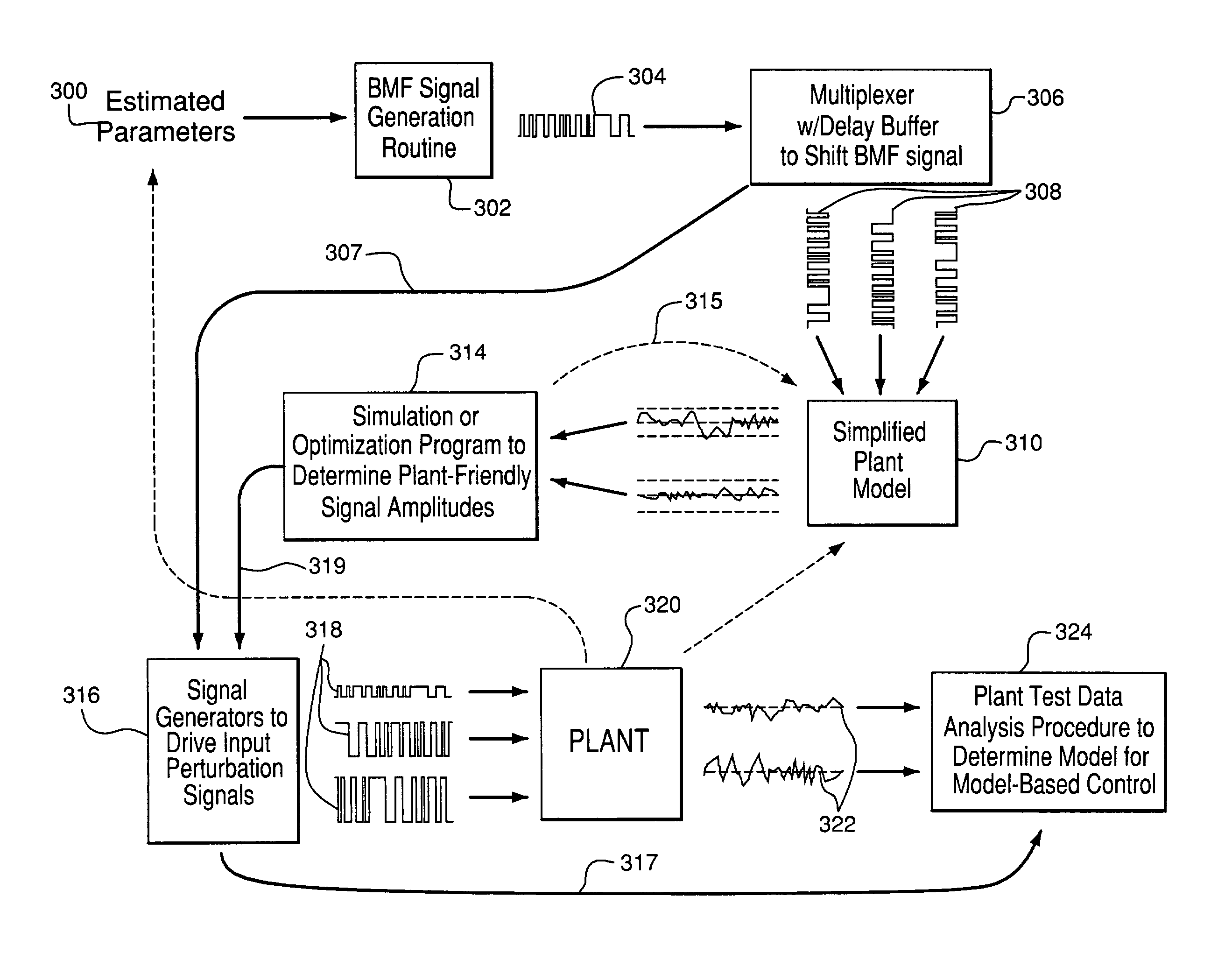

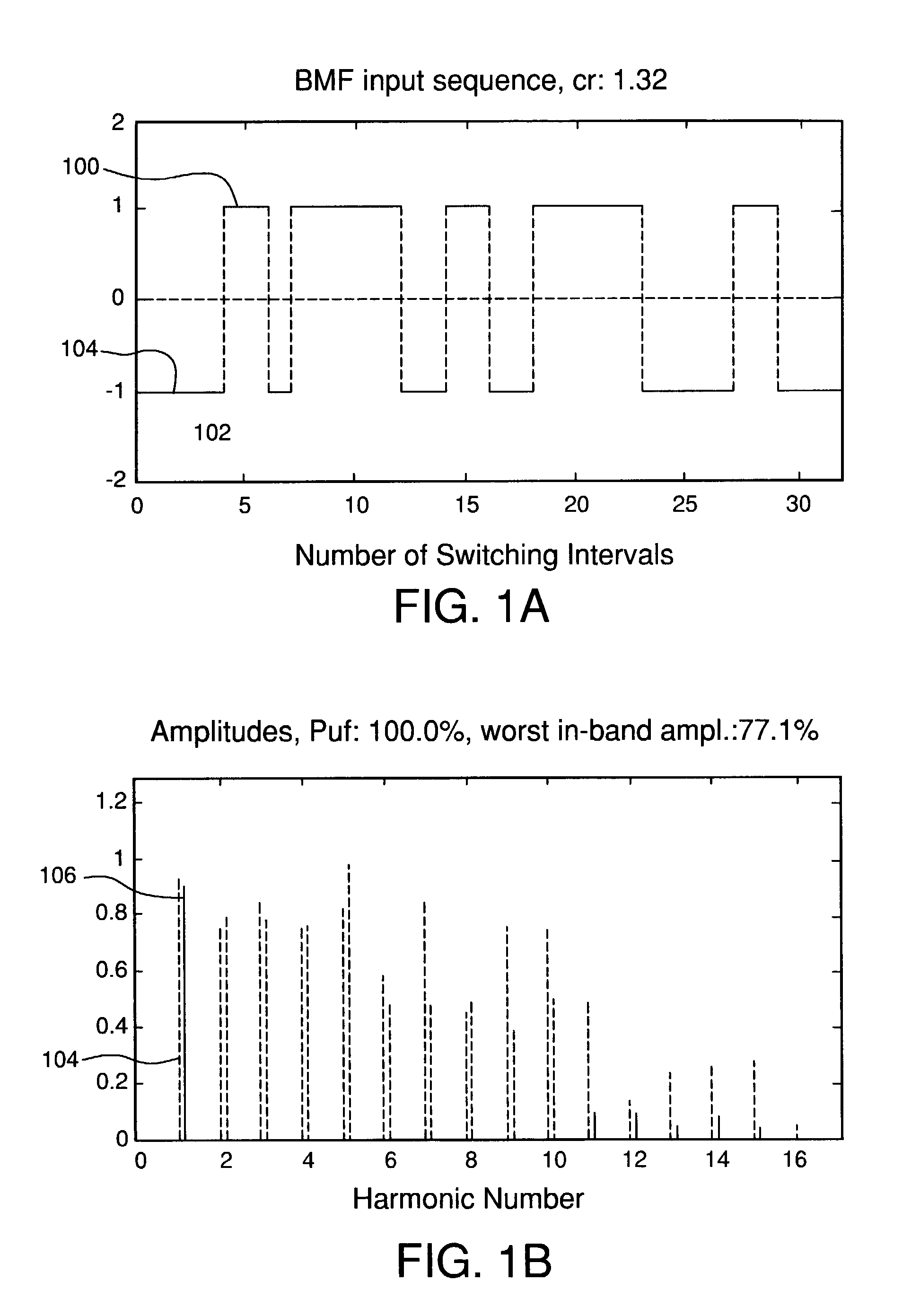

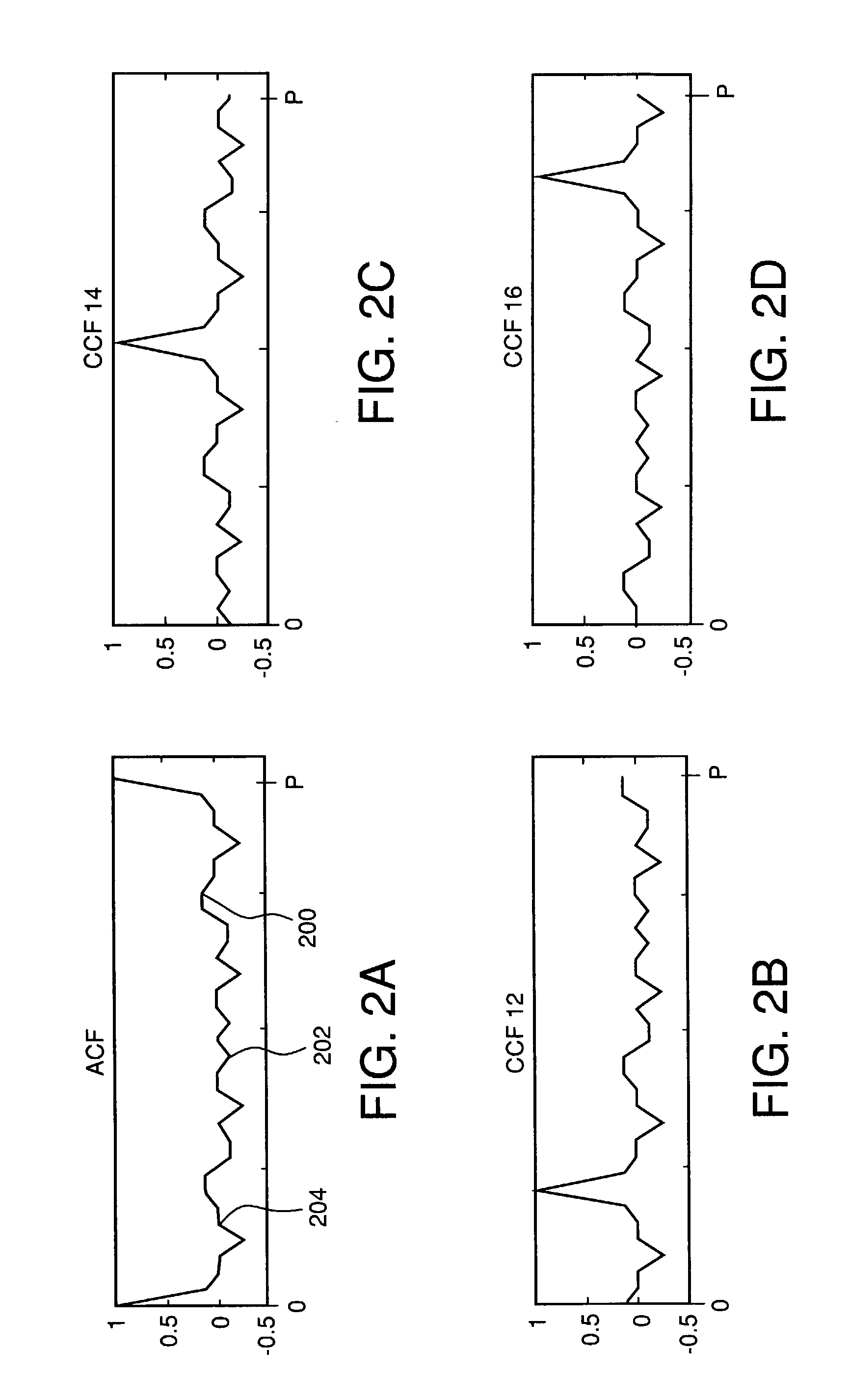

Fast plant test for model-based control

InactiveUS7194317B2Simple modelData processing applicationsElectronic circuit testingFrequency spectrumModel based controller

A method and apparatus for designing perturbation signals to excite a number of input variables of a system, in order to test that system for the purpose of obtaining models for the synthesis of a model-based controller. The method begins with providing input parameters of the system. A plurality of binary multi-frequency (BMF) signals are generated based on these input parameters and the frequency spectra of these BMF signals are calculated. One BMF signal is selected out of the set of BMF signals so that the frequency spectrum of the selected BMF signal most closely matches a desired frequency spectrum specified by the input parameters. The selected BMF signal is used as a first perturbation signal for testing the system. The selected BMF signal is also shifted by predetermined amounts of samples to create delayed copies of the original BMF signal to be used as additional perturbation signals.

Owner:AIR PROD & CHEM INC

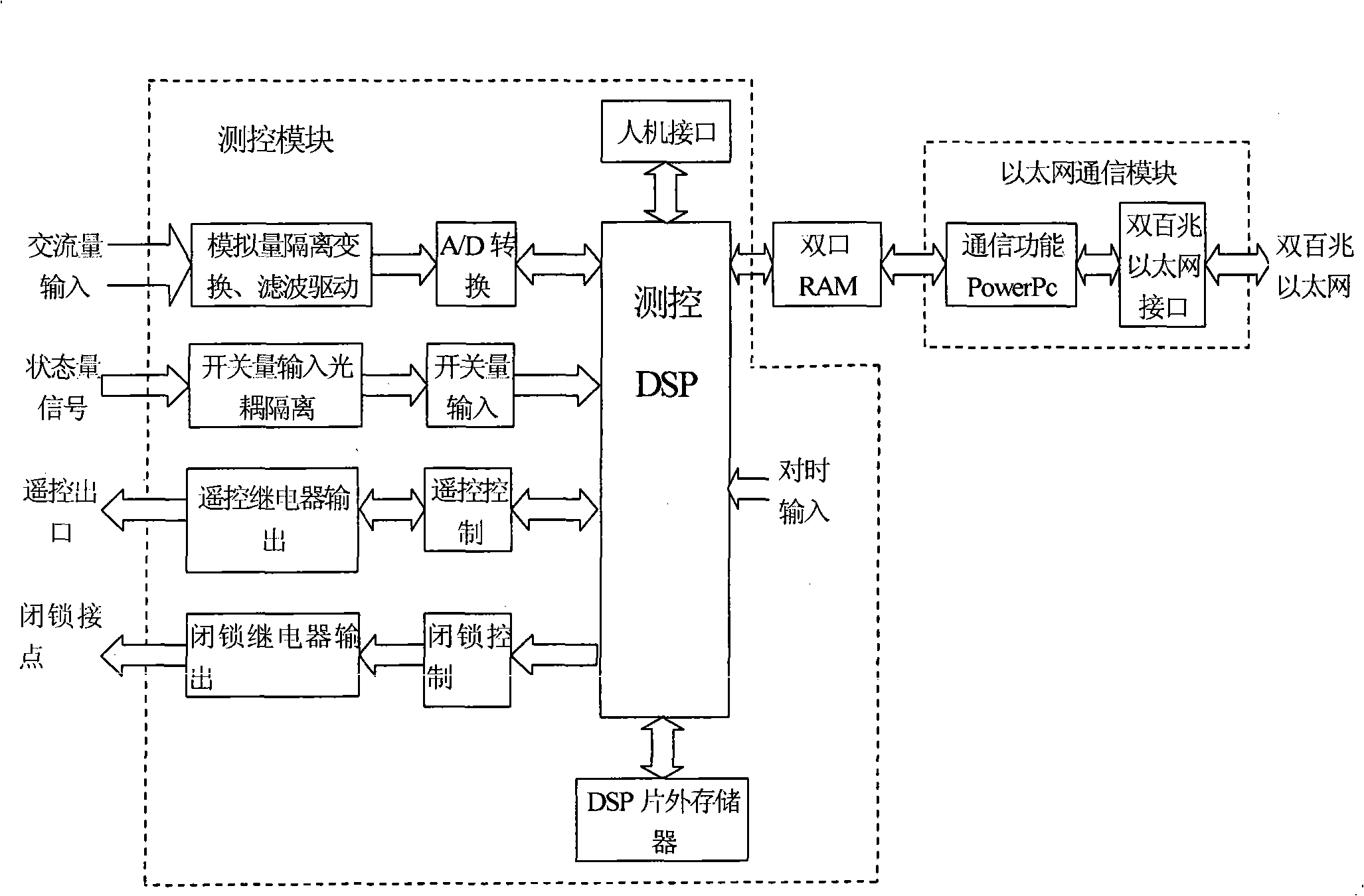

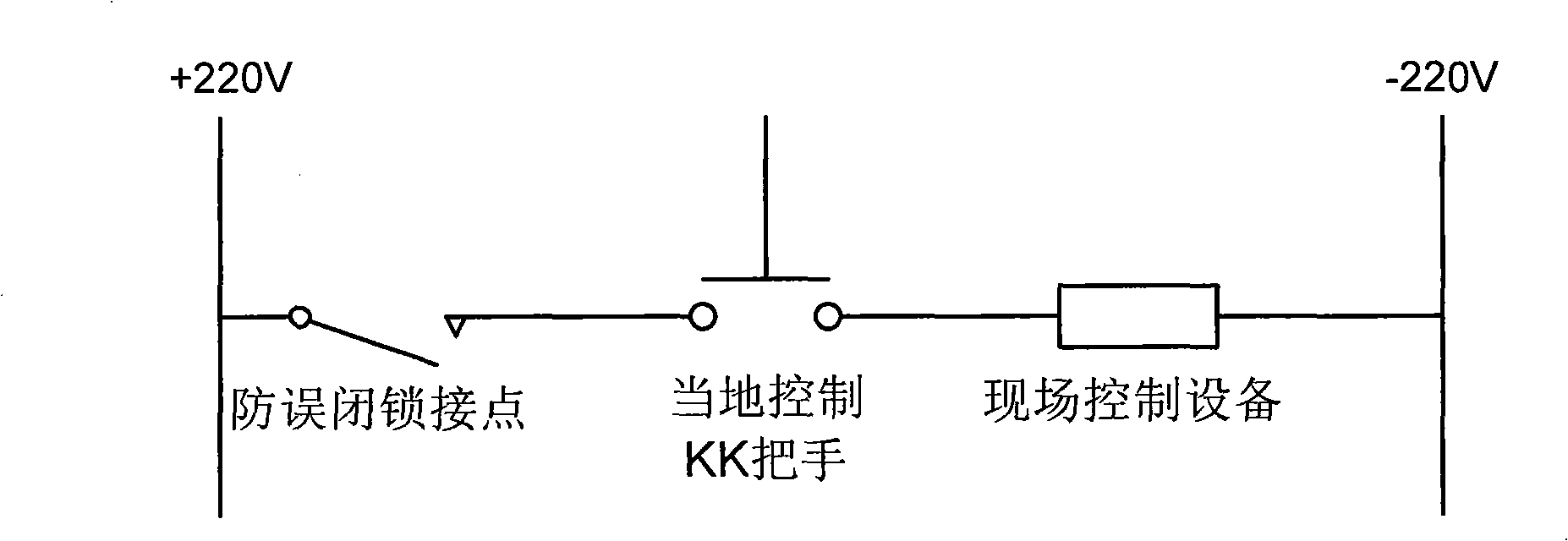

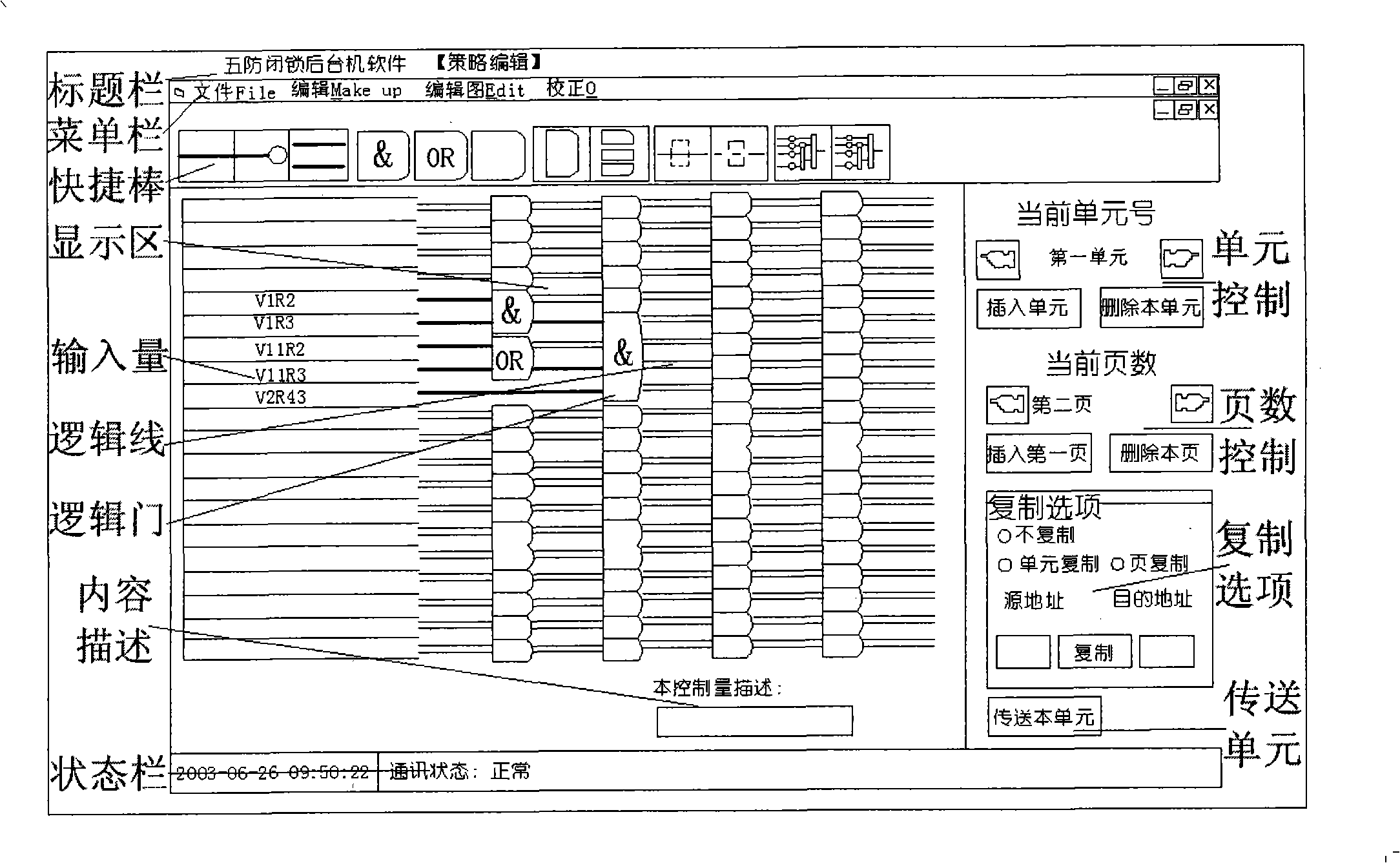

Technique for realizing transforming plant anti mis-closedown function in transforming plant observe and control apparatus

ActiveCN101257224AAvoid lossRealize anti-mislocking functionData processing applicationsCircuit arrangementsInformation sharingComputer science

The invention relates to a technique for realizing substation anti error-locking function in a substation measurement and control device which includes: the measurement and control device uses double-module structure; the measurement and control device connects with internet, UDP / IP agreement is used between various spacing layer for sharing information; anti error-locking logic is input and compiled through computer, and is download installed to the measurement and control device via internet; signal amount and electric amount of equipment state is used for processing anti error-locking logic judgement, and a hand-operation locking junction is added to each control object respectively. The technique uses spacing layer measurement and control device for realizing anti error-locking function, and realizes all remote operation and local hand-operation anti error-locking logic judgement, and prevents error protection; the technique also can classify message for preventing important message loss; anti error-locking logic using reversed Polish expression occurs less resource, has simple operation and is easy to calculation; remote operation and hand-operation are judged in advance, then locking is opened, thus, safety and correctness of operation can be ensured.

Owner:NARI TECH CO LTD +1

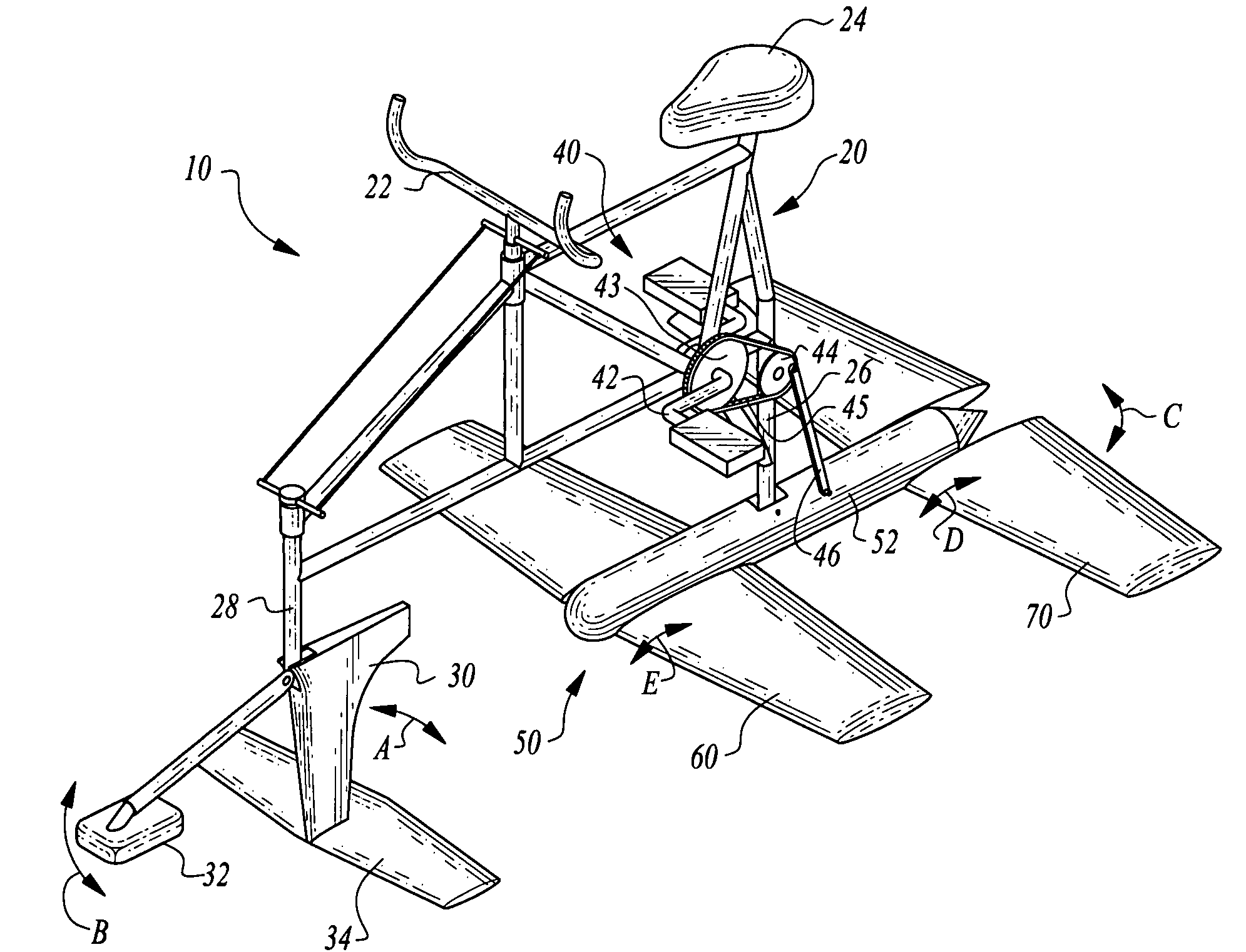

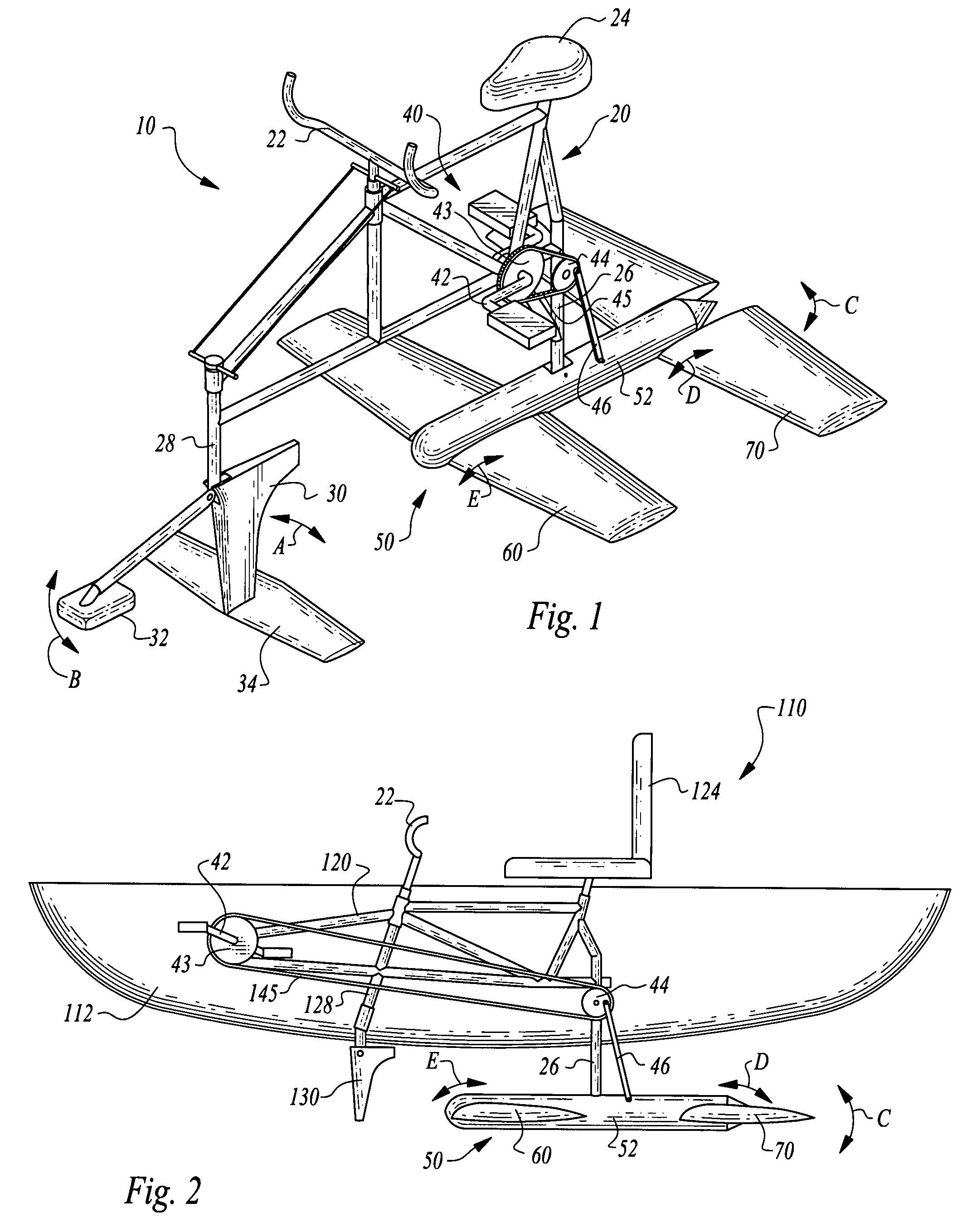

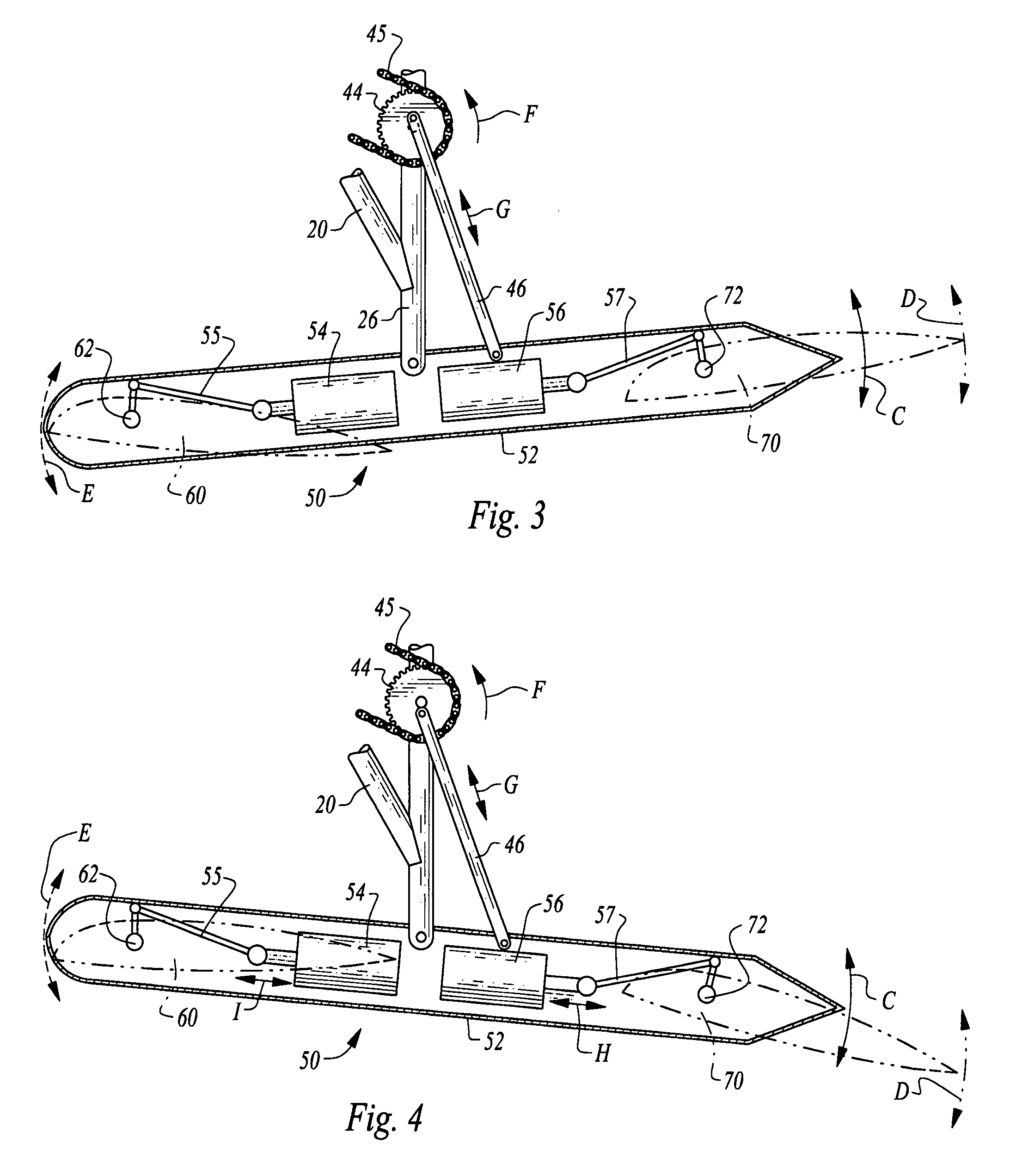

Human-powered flapping hydrofoil craft

InactiveUS7662004B1Easy to useHigh degreePropulsive elements of non-rotary typeMuscle power acting propulsive elementsNacelleClassical mechanics

A pair of foils are pivotably coupled to a nacelle. The nacelle is pivotably coupled to a mast extending down from to a frame and below a water surface. A push rod oscillates, causing the nacelle to experience a heaving motion, in turn causing the foils to flap up and down. The push rod is driven by a power plant such as a human rider. Angles of attack for the foils are actively controlled to optimize lift and propulsion forces provided by the foils to cause the water craft to move over the water. A steering fin is also provided for heading control of the water craft. A control system for separate angles of attack for the foil sends appropriate information to servo motors which cause the foils to rotate relative to the nacelle to achieve optimal angles of attack relative to the particular position of the nacelle at any given moment.

Owner:MARCH PHILIP A +3

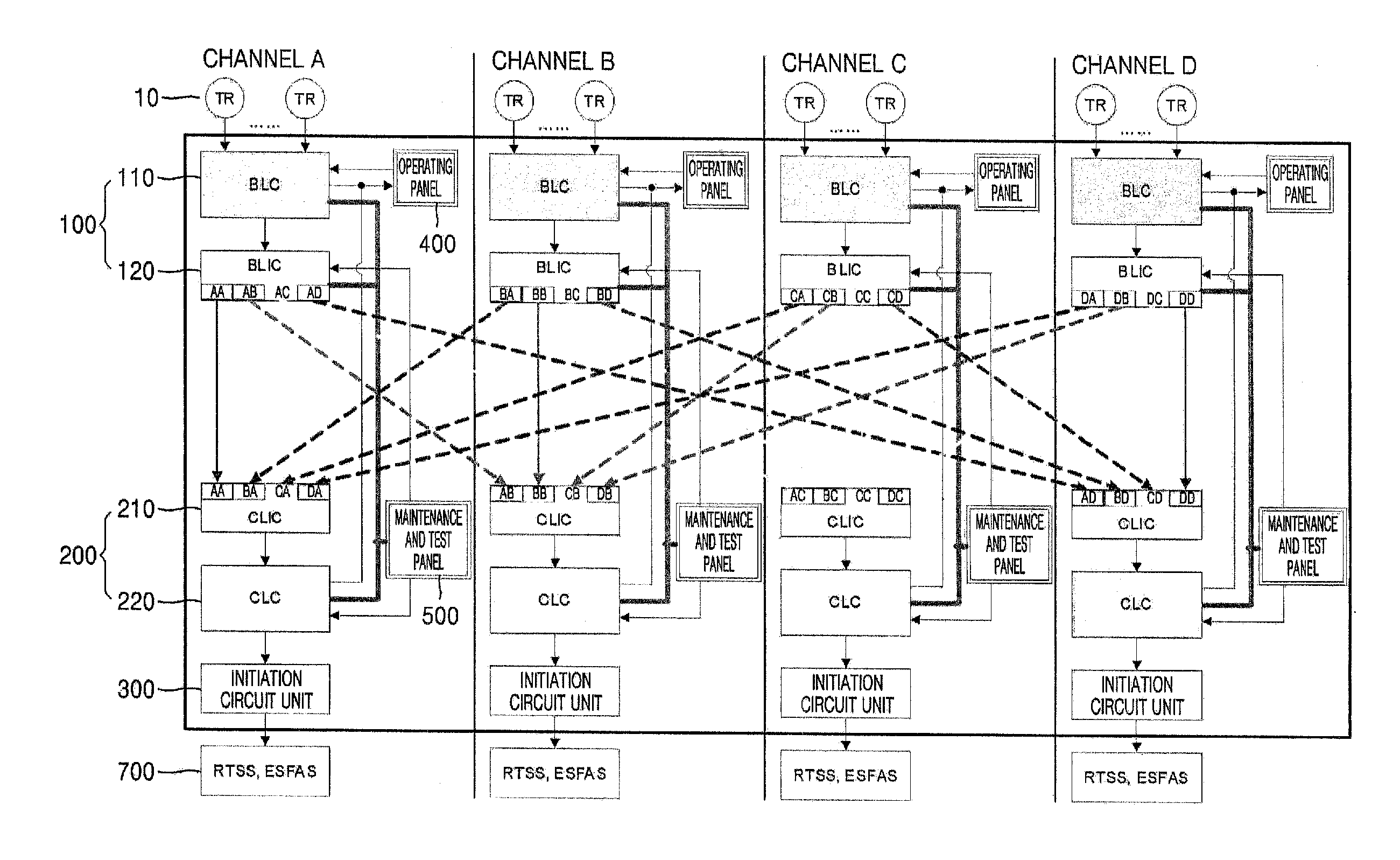

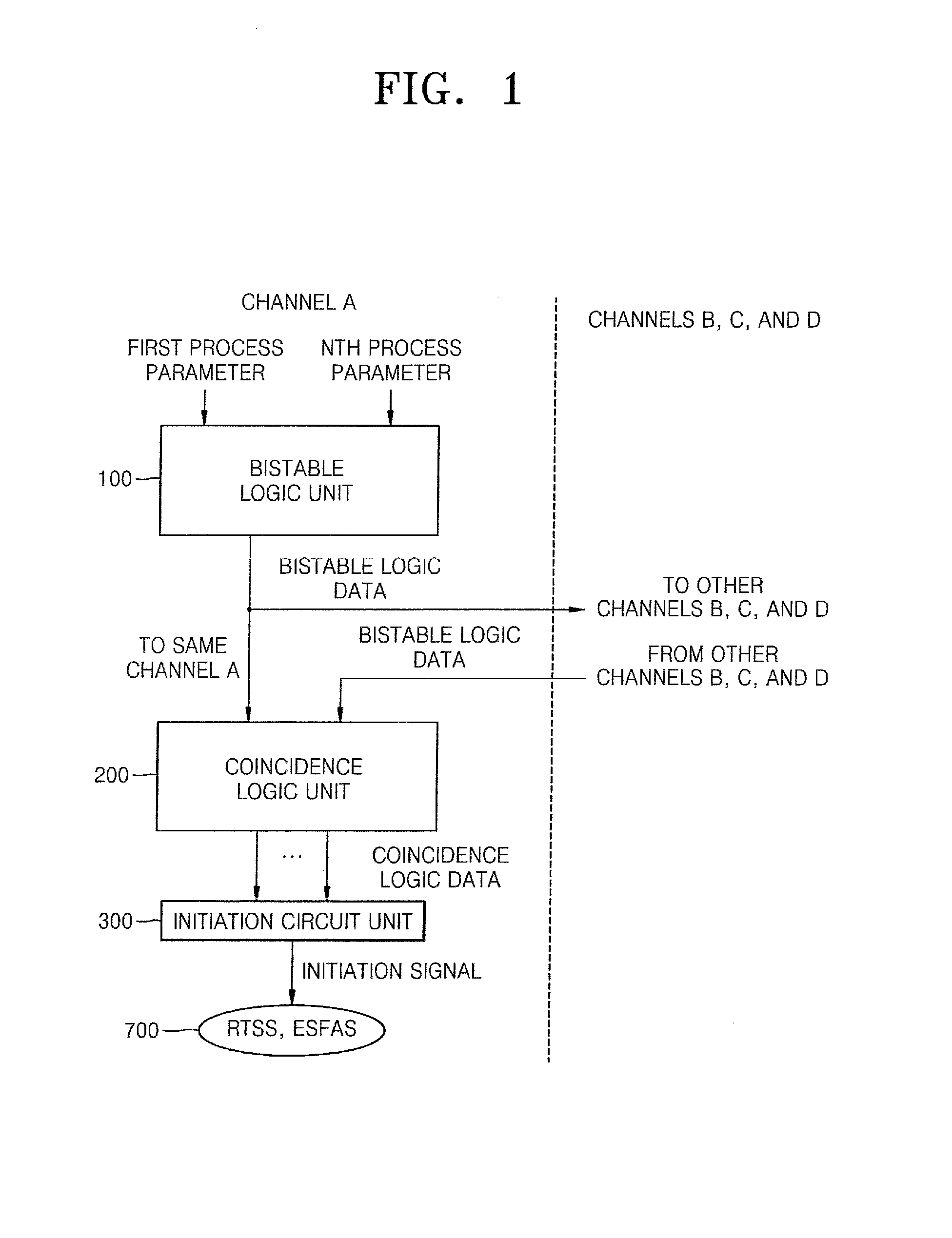

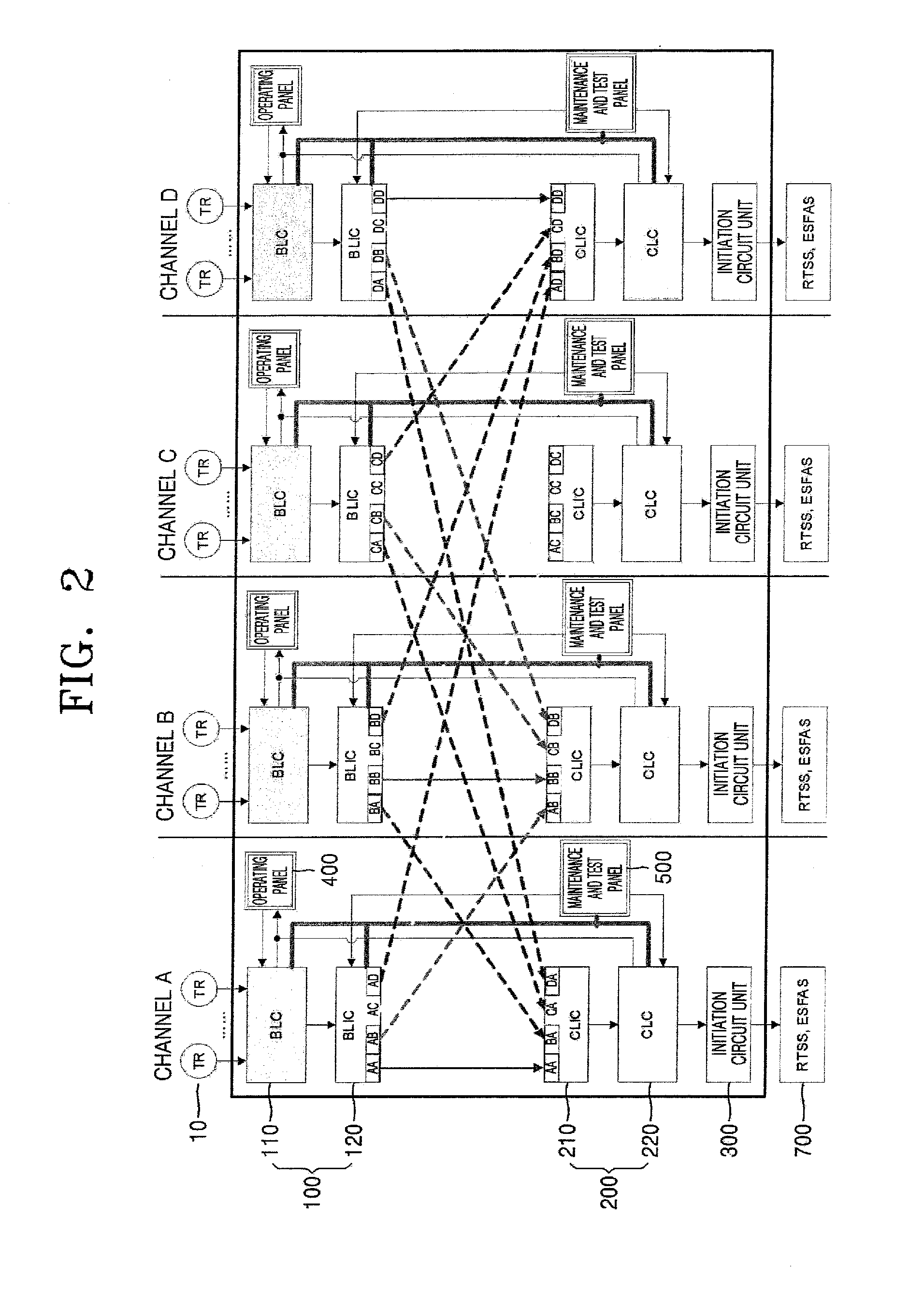

Plant protection system and method using field programmable gate array

InactiveUS20110202163A1Programme controlPower plant safety arrangementControl systemCommon mode failure

Provided is a plant protection system, which determines initiation of protective actions for the plant, and more particularly to the plant protection system including four channels which controls systems that shut down the plant or mitigate consequences of abnormal conditions of the plant by detecting non-permissible plant conditions with the result of bistable logic comparing process parameters with their setpoints assigned to each channel. Accordingly, common mode failure and cyber security vulnerability caused by software are removed since the system is composed of FPGA and other types of hardware without central processing units and software in determining the initiation of plant protective actions.

Owner:KOREA ELECTRIC POWER CORP

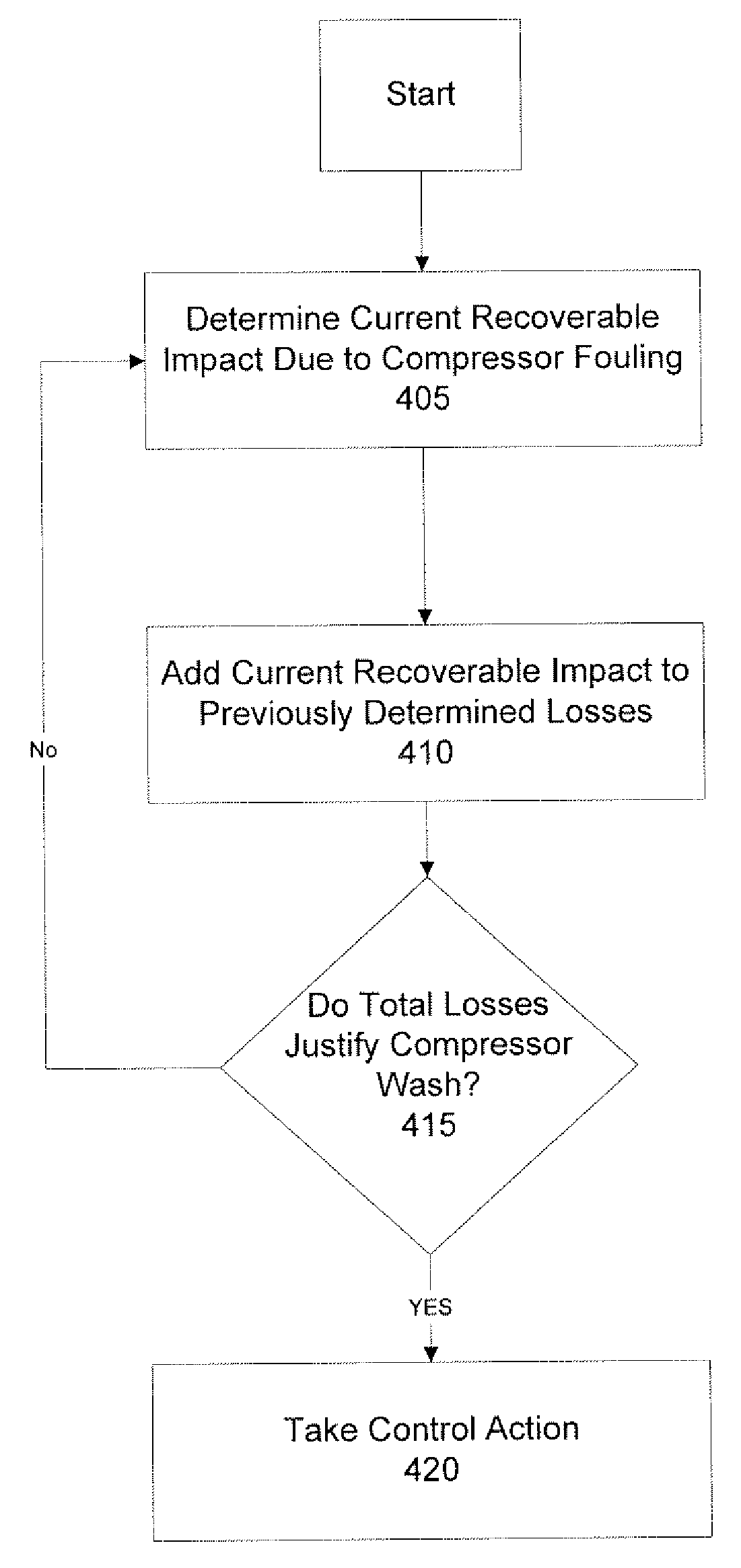

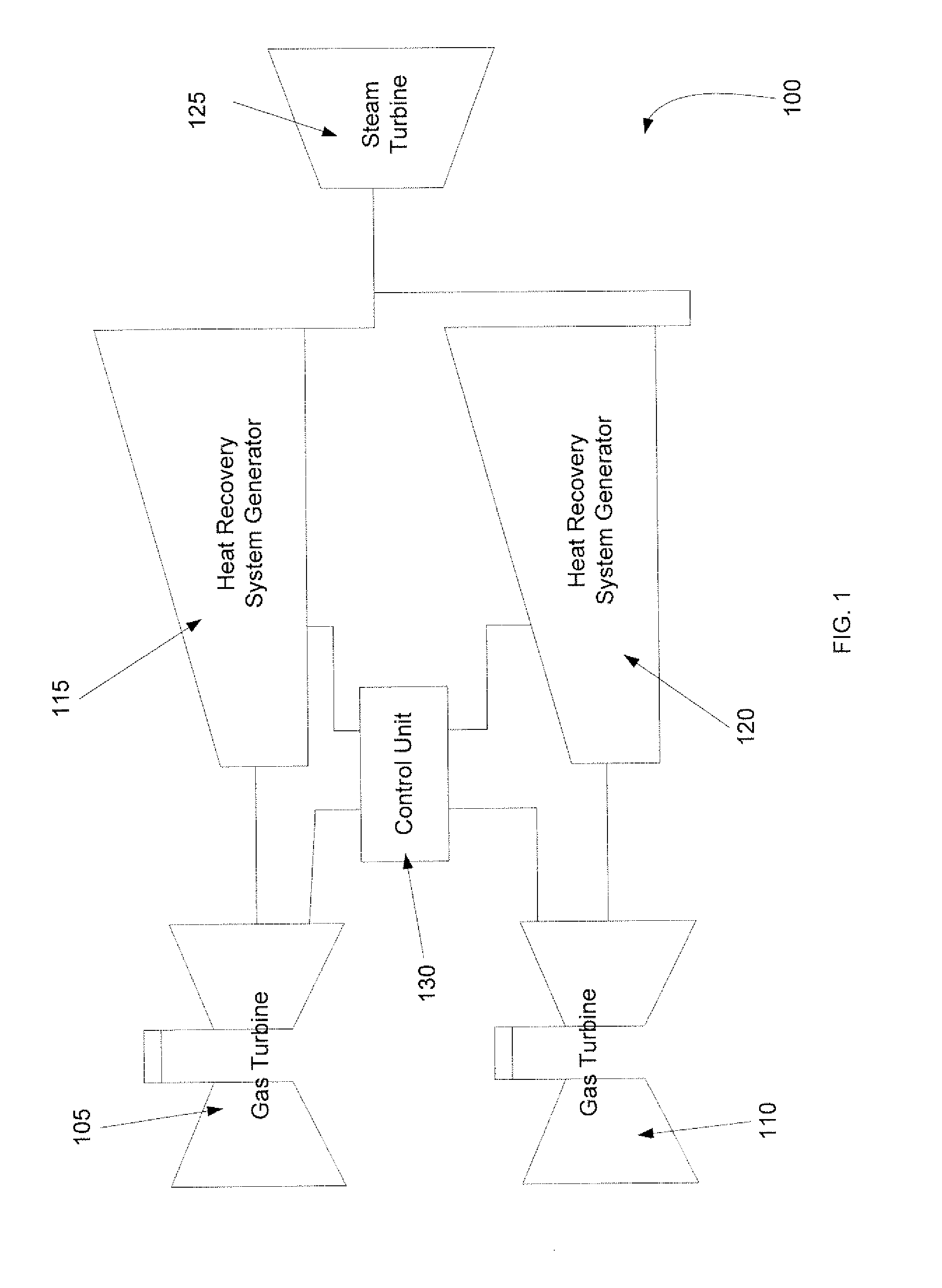

Methods and systems for estimating compressor fouling impact to combined cycle power plants

InactiveUS20080027616A1Wind motor controlDigital data processing detailsPower stationProcess engineering

A system and method for estimating the impact of compressor fouling in a combined cycle power block. The current performance of the combined cycle power block is determined and normalized to one or more reference conditions. A baseline performance of a gas turbine of the combined cycle power block is also determined. A predicted performance of the combined cycle power block is then determined by substituting the baseline performance of the gas turbine for the current performance of the gas turbine. A recoverable impact to the combined cycle power block due to compressor fouling is then determined by subtracting the normalized current performance from the predicted performance and a recoverable impact to the fuel consumption of the combined cycle power block is determined from the recoverable impact.

Owner:GENERAL ELECTRIC CO

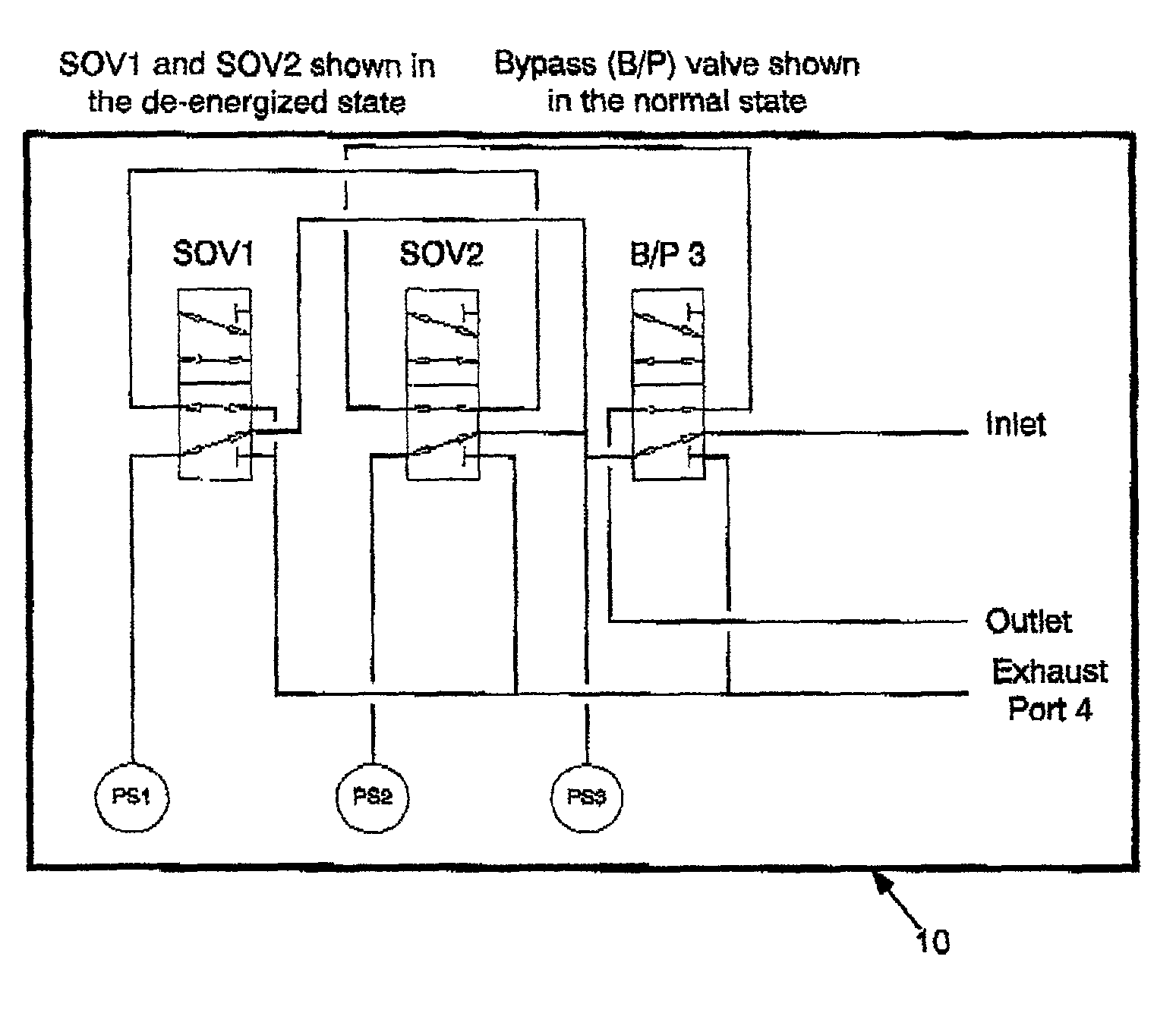

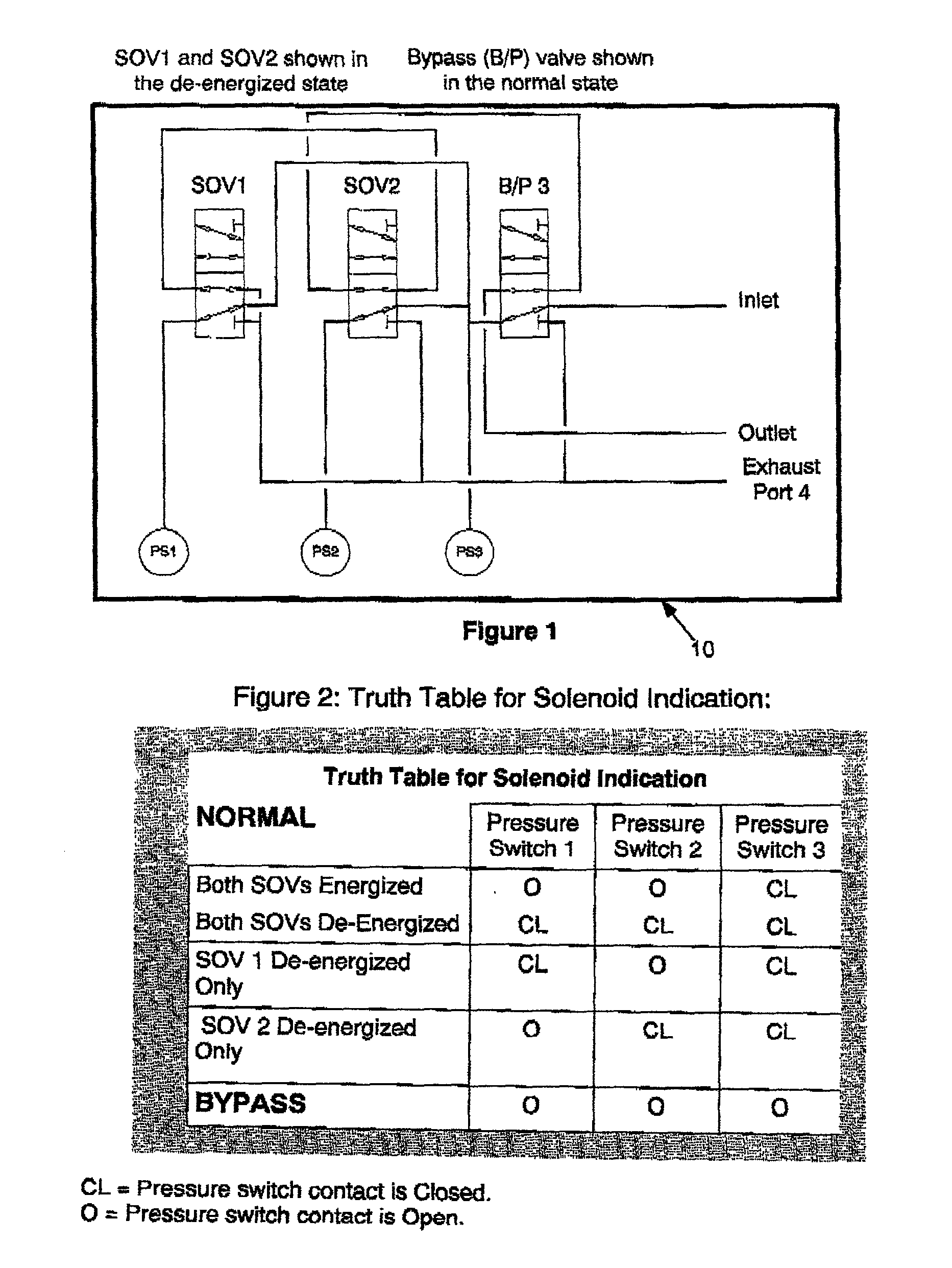

Variable function voting solenoid-operated valve apparatus and testing method therefor

InactiveUS20020091451A1Safety availabilityImprove system reliabilityTemperatue controlStatic/dynamic balance measurementSolenoid valveControl system

A variable function voting solenoid-operated valve apparatus is provided having both high safety availability and high plant reliability that does not require a plant system to be bypassed during testing. Also provided is a variable function voting solenoid-operated valve apparatus wherein initiation of a safety action will occur only if each of a pair of operatively associated solenoid-operated valves in the apparatus are actuated, and wherein either of the solenoid valves can singly default to a pre-designated safety action without inadvertently actuating the process valve and isolating or venting the process fluid. Also provided is a variable function voting solenoid-operated valve apparatus wherein either a "1 out of 1 with hot stand-by" operational mode or a "2 out of 2 with high diagnostics" operational mode may be selected by an operator using a logic control system depending on the technical requirements of a given plant environment. Also provided is a variable function voting solenoid-operated valve apparatus, wherein a plurality of pressure sensing devices are incorporated to detect failure of either of a pair of operatively associated solenoid-operated valves so as to prevent inadvertent initiation of a safety action, and wherein a bypass switch is provided to allow on-line maintenance of the device should one of the solenoid valves fail during operation or when a failure is detected during a testing cycle. Finally, a variable function voting solenoid-operated valve apparatus is provided, wherein diagnostic information on the performance of the safety action, a partial movement of the process valve can be executed to prove the process valve is capable of actuating to the safe state, can be ascertained with either operational mode using a logic control system depending on the technical requirements of a given plant environment.

Owner:SIS TECH APPL

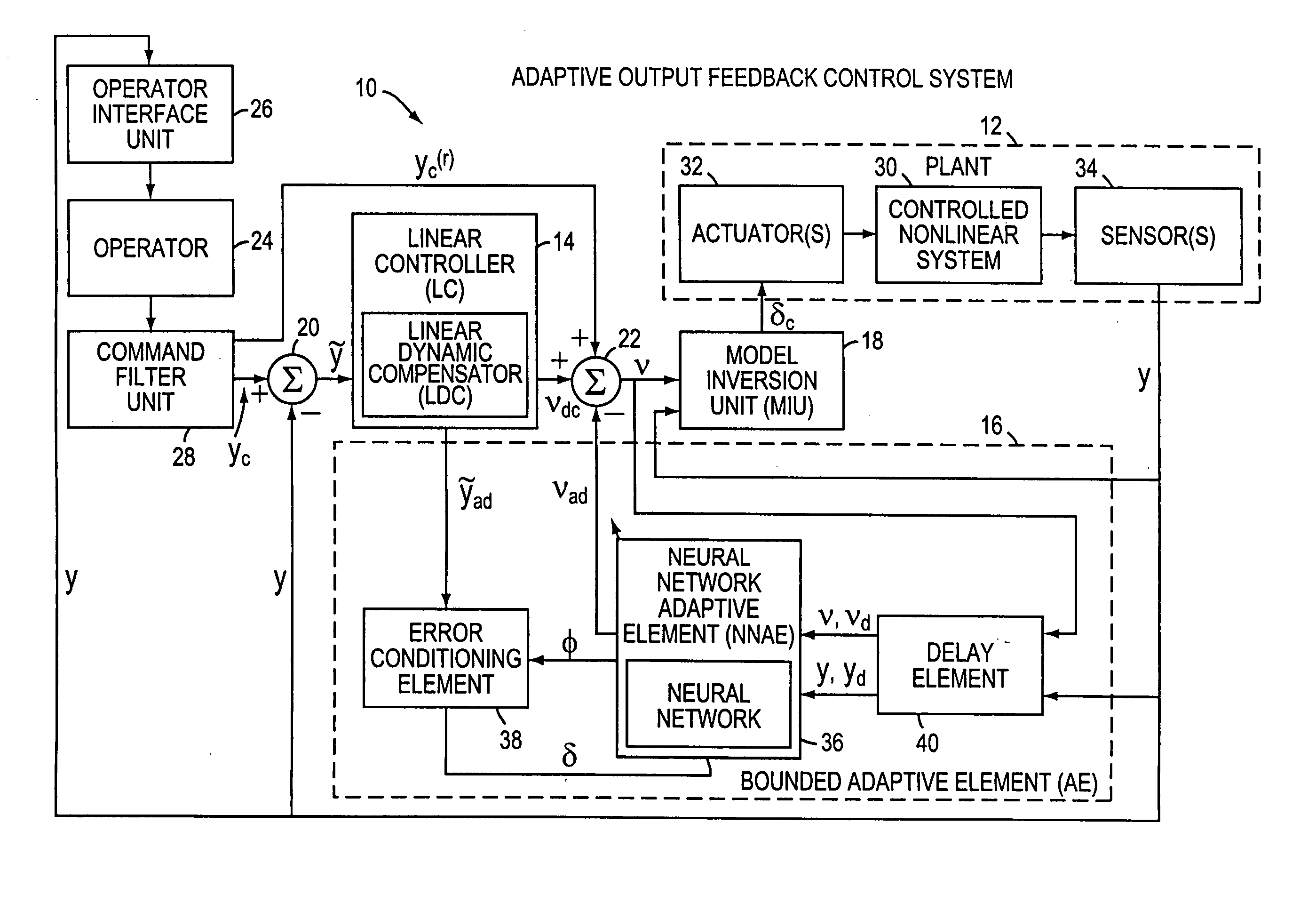

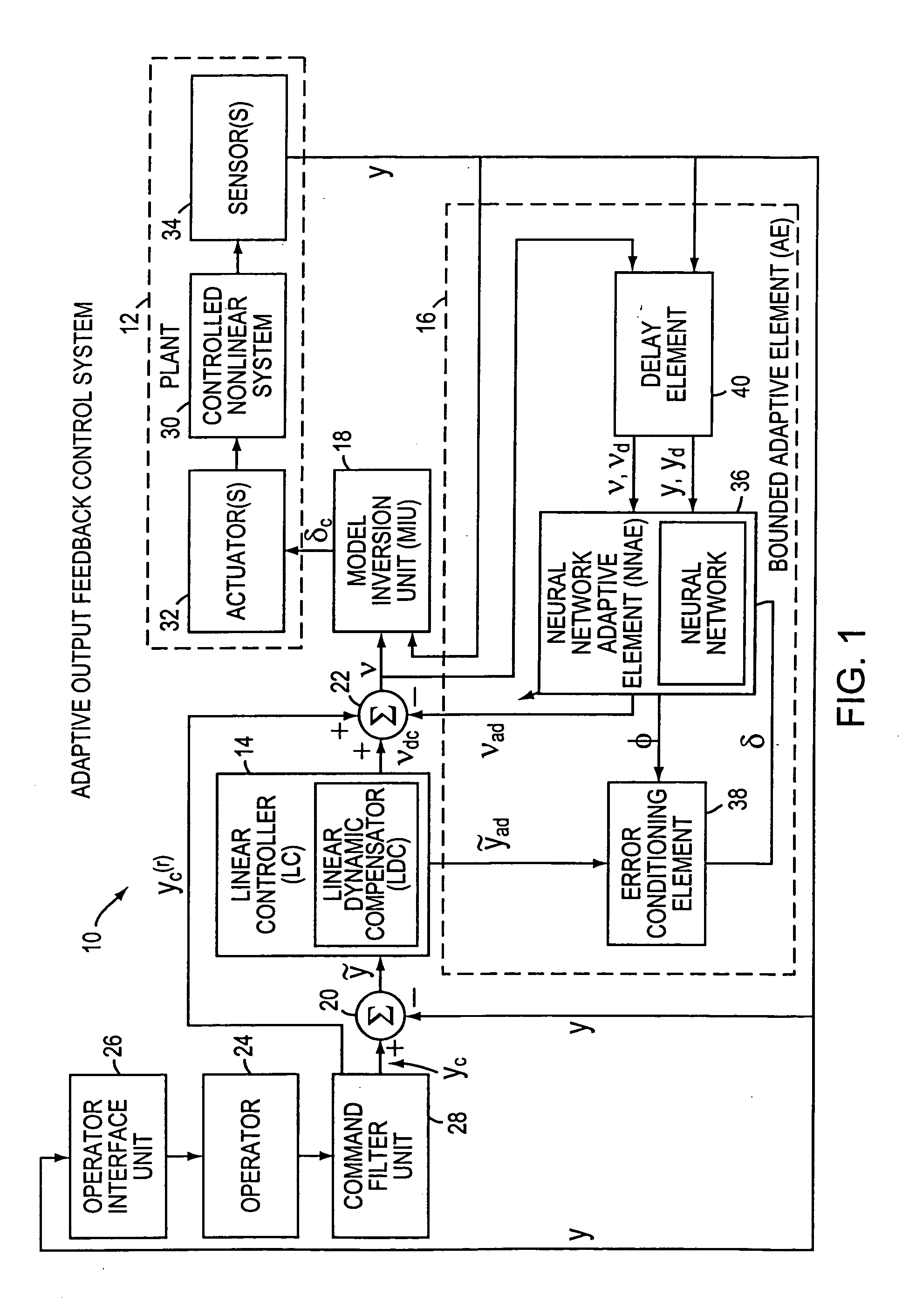

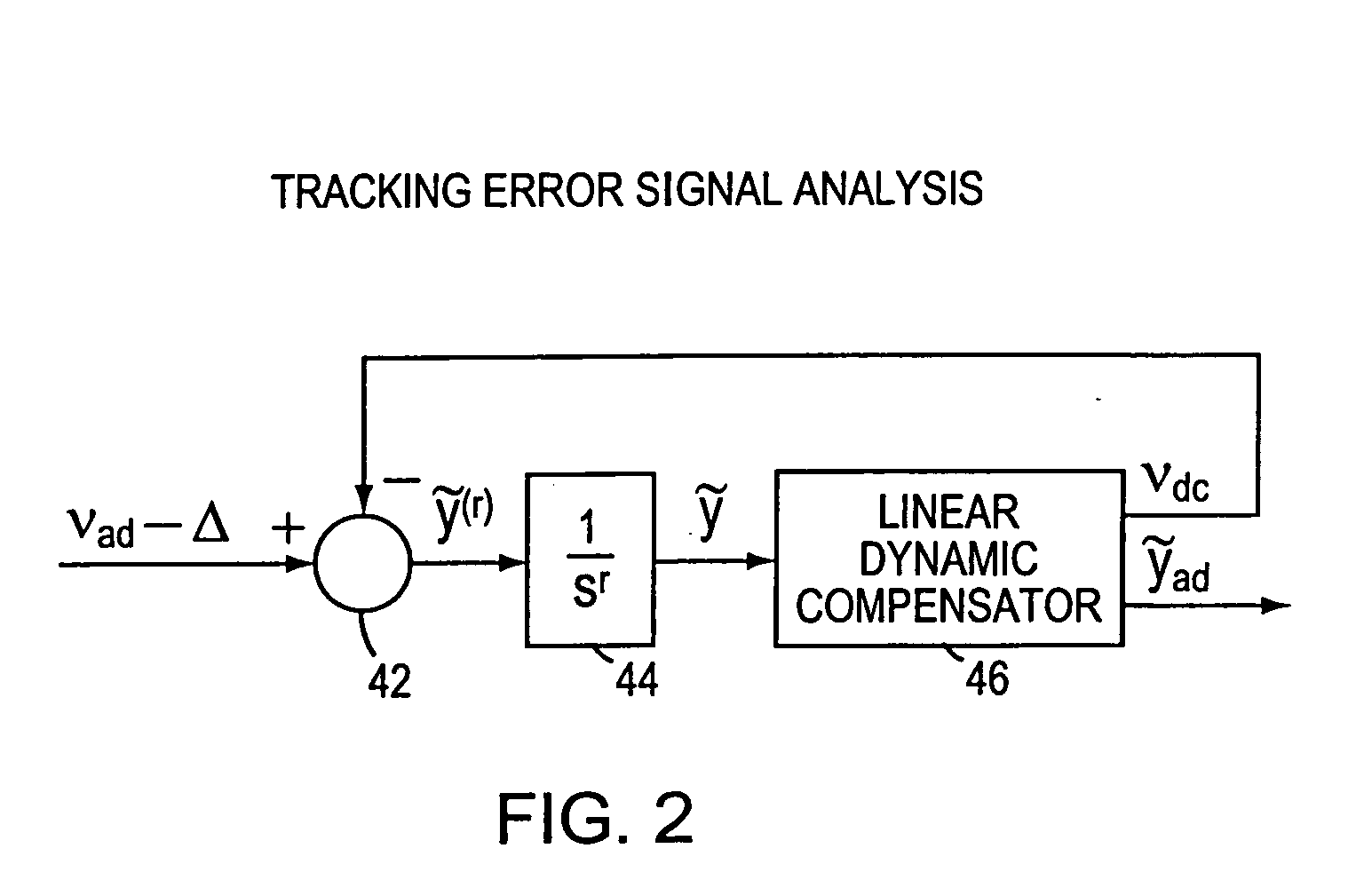

Adaptive control system having direct output feedback and related apparatuses and methods

An adaptive control system (ACS) uses direct output feedback to control a plant. The ACS uses direct adaptive output feedback control developed for highly uncertain nonlinear systems, that does not rely on state estimation. The approach is also applicable to systems of unknown, but bounded dimension, whose output has known, but otherwise arbitrary relative degree. This includes systems with both parameter uncertainty and unmodeled dynamics. The result is achieved by extending the universal function approximation property of linearly parameterized neural networks to model unknown system dynamics from input / output data. The network weight adaptation rule is derived from Lyapunov stability analysis, and guarantees that the adapted weight errors and the tracking error are bounded.

Owner:GEORGIA TECH RES CORP

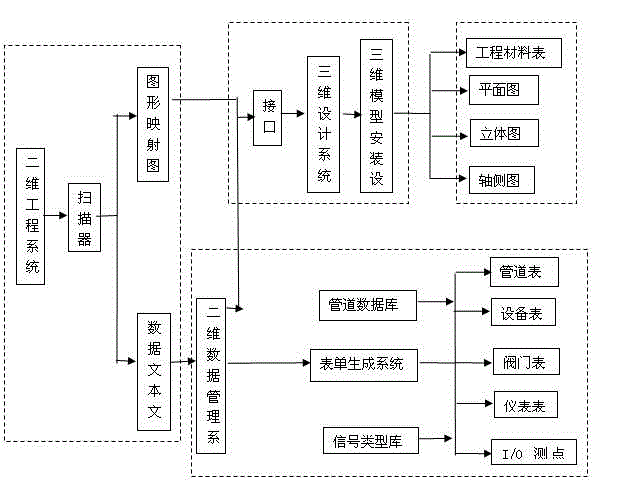

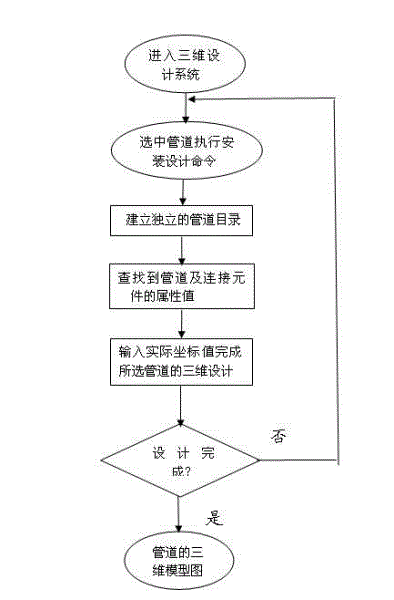

Method for automatically and designing pipeline of power plant

ActiveCN102622484AAutomate your designSave human effortSpecial data processing applicationsInformation technology support systemMaterial resourcesPlant

The invention discloses a method for automatically and designing a pipeline of a power plant, which is used for automatic design of the pipeline in power plant design. According to the method for automatically and designing the pipeline of the power plant, by taking a three-dimensional design system and a two-dimensional data management system as the basis and a two-dimensional engineering system diagram of the pipeline as a data source, under the support of the KKs coding technique and a related master control program, a three-dimensional model diagram of the pipeline is automatically designed and generated. The method for automatically and designing the pipeline of the power plant comprises an information acquisition step, a pipeline data generating step, a three-dimensional model design step and an outputting step. By adopting the technical scheme provided by the invention, the automatic design can be realized on the three-dimensional diagram of the pipeline, and thereby, manpower and material resources are saved, and moreover, the correctness is increased.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

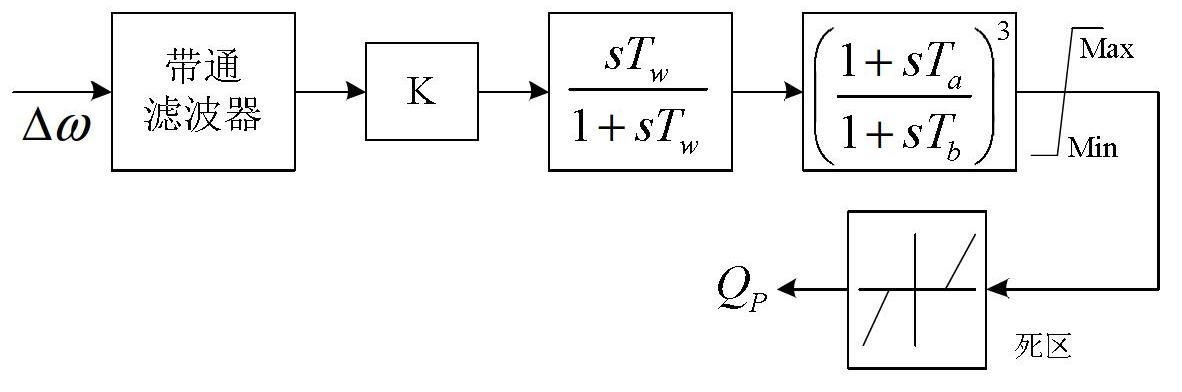

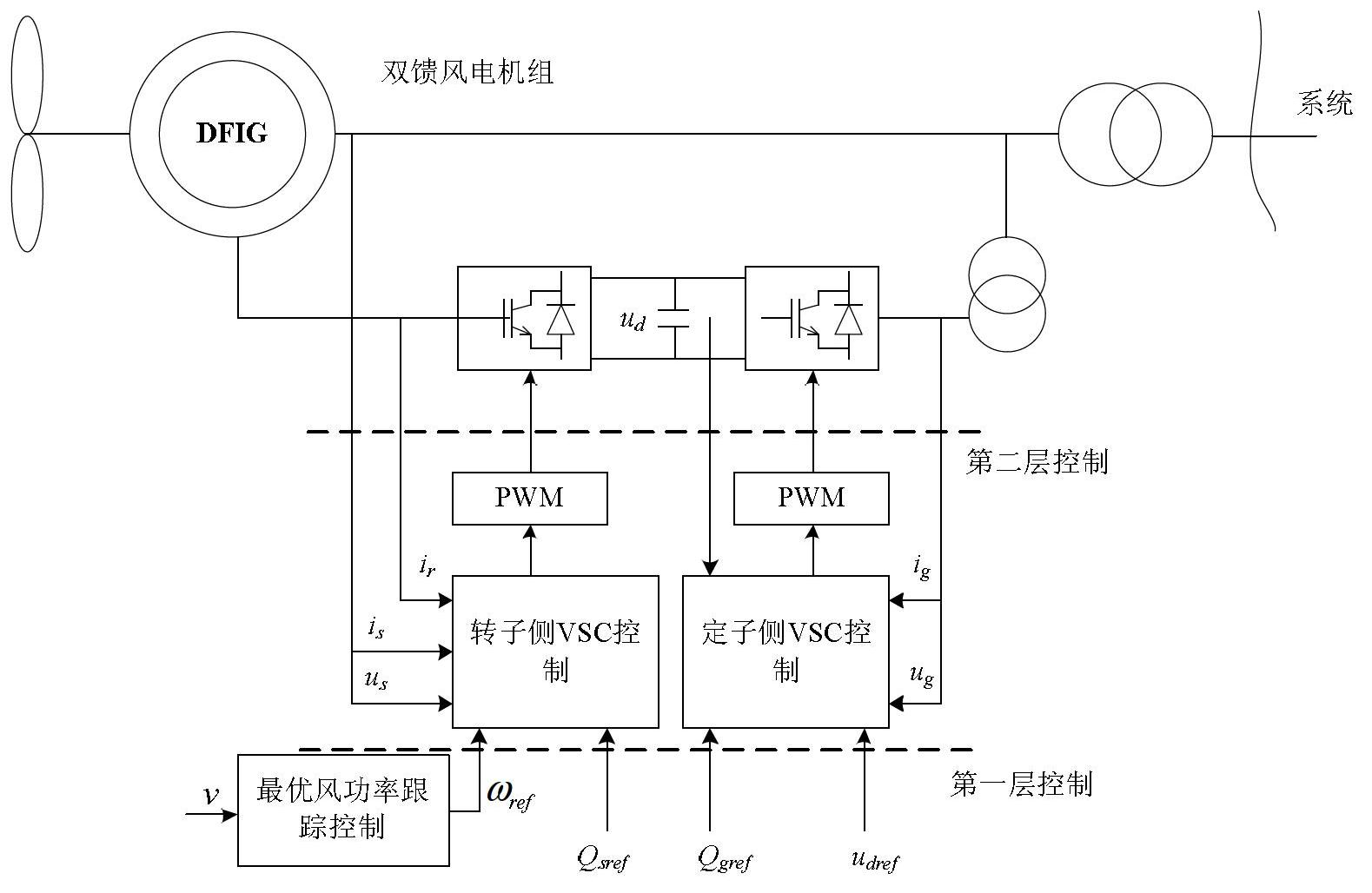

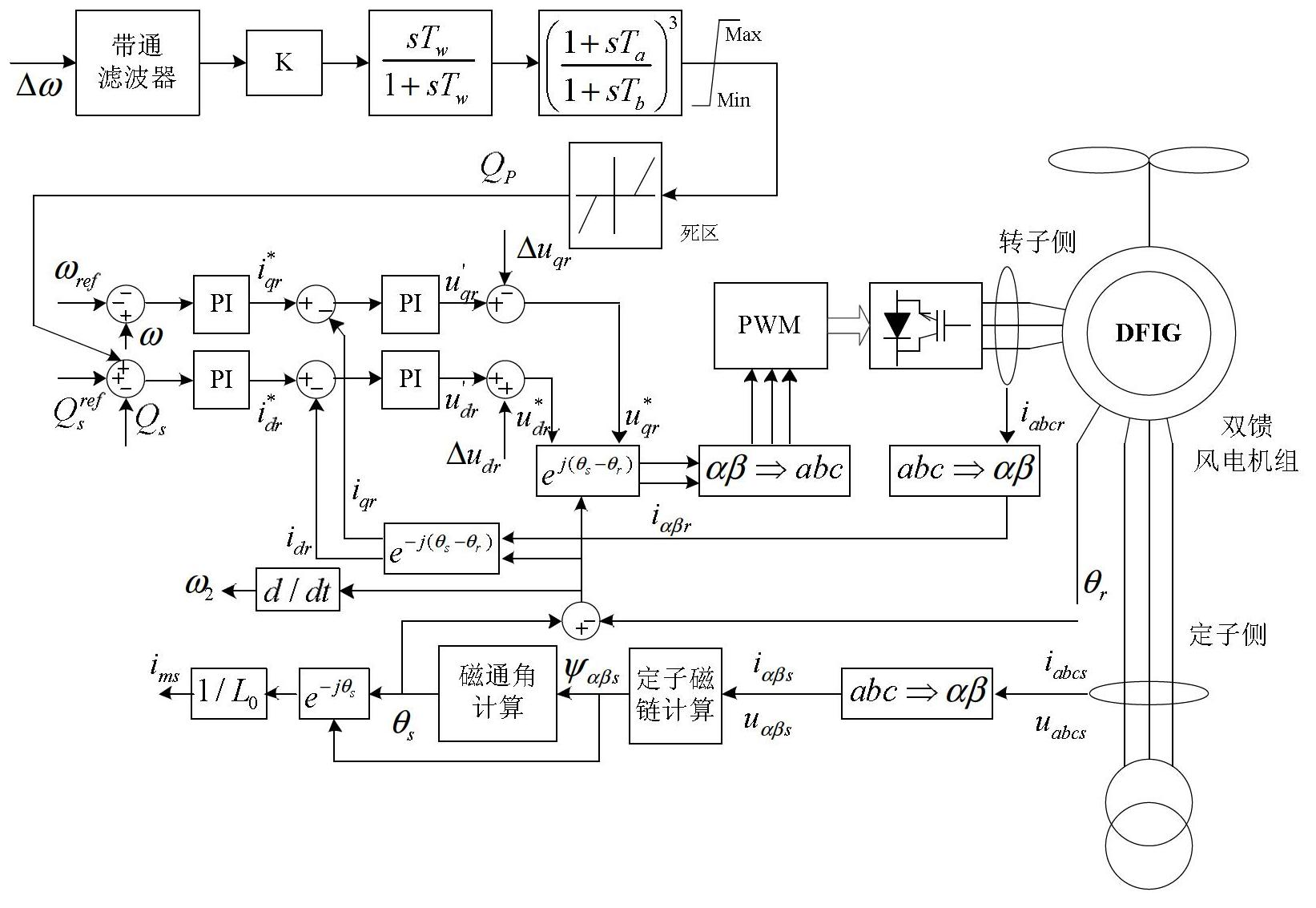

Method for improving sub-synchronous oscillation (SSO) damping of thermal power plant by utilizing fan supplementary controller

ActiveCN102684209AImproved Subsynchronous Oscillation Damping CharacteristicsEnhanced effect of subsynchronous oscillation dampingElectronic commutation motor controlVector control systemsCapacitanceNew energy

The invention belongs to the power system field and particularly relates to a method for improving the sub-synchronous oscillation (SSO) damping of a thermal power plant in a wind-thermal power series-compensation combined transmission system by utilizing a supplementary controller to modulate the reactive power output of a wind generation set. The method is based on the rotor current active and reactive decoupling control principle of a double-fed wind generation set, and introduces shafting rotational speed difference of a combined-transmission thermal power plant as the characteristic signal for designing a damping controller, and the output of the damping controller is modulation component under the control of rotor reactive power; and through the regulation on the reactive power of the wind generation set, the effect of enhancing the SSO damping of the combined-transmission thermal power plant is achieved. The invention is applicable to large-capacity wind-thermal power combined series capacitance compensation transmission occasions, so the SSO property of the thermal power plant can be improved, the electric power of a new energy resource is ensured to be transmitted safely, continuously and reliably, and the power system is also ensured to operate safely and stably.

Owner:CHINA ELECTRIC POWER RES INST +1

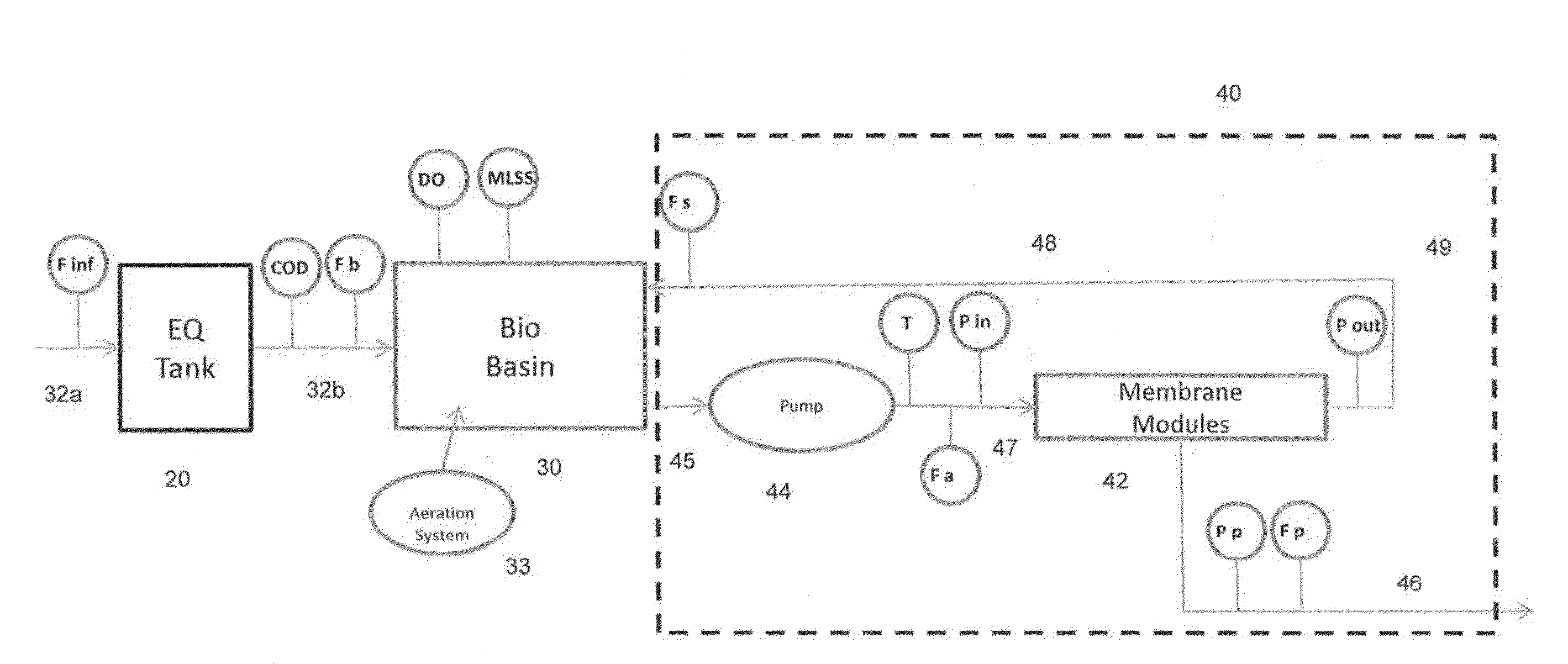

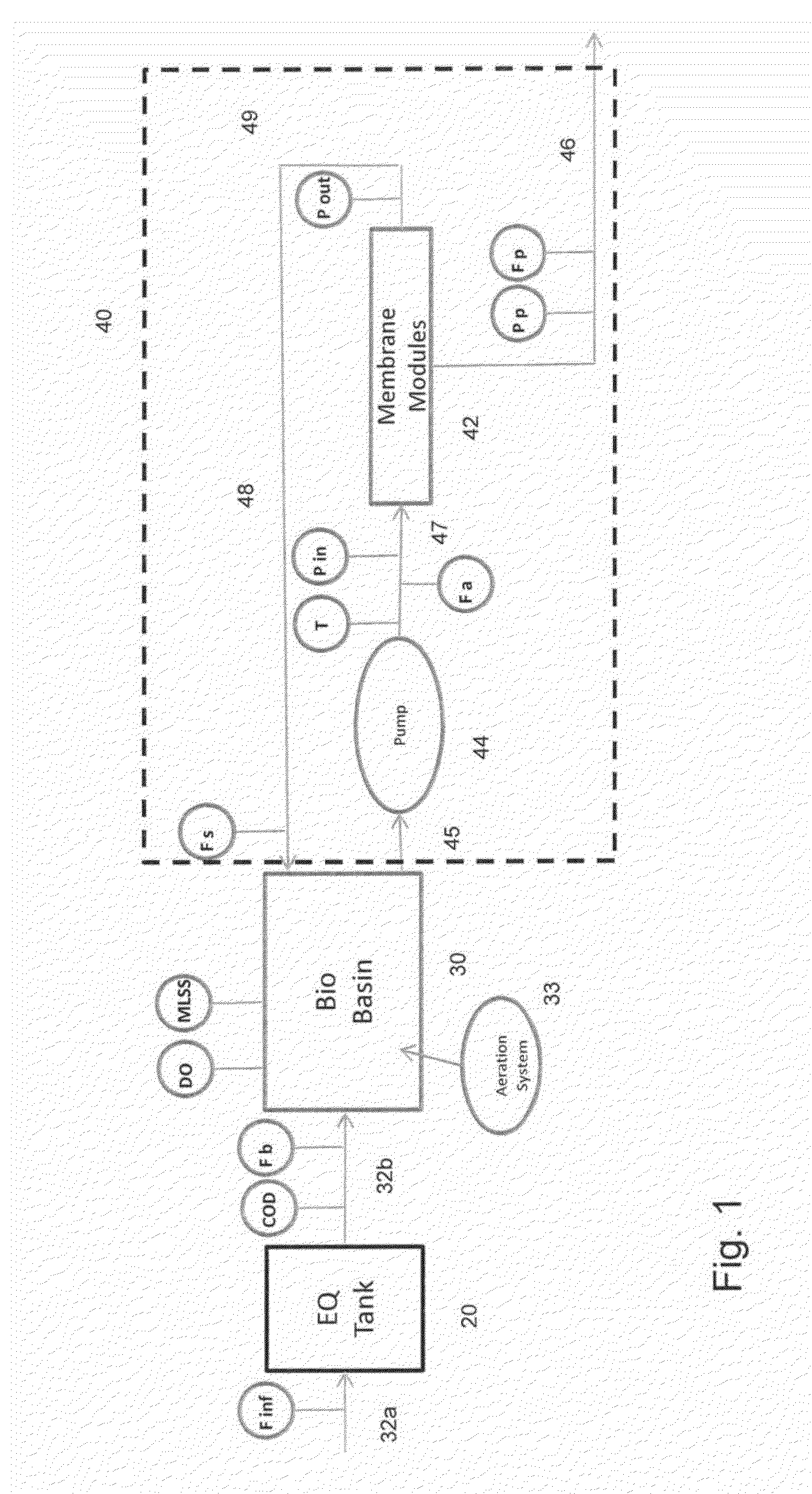

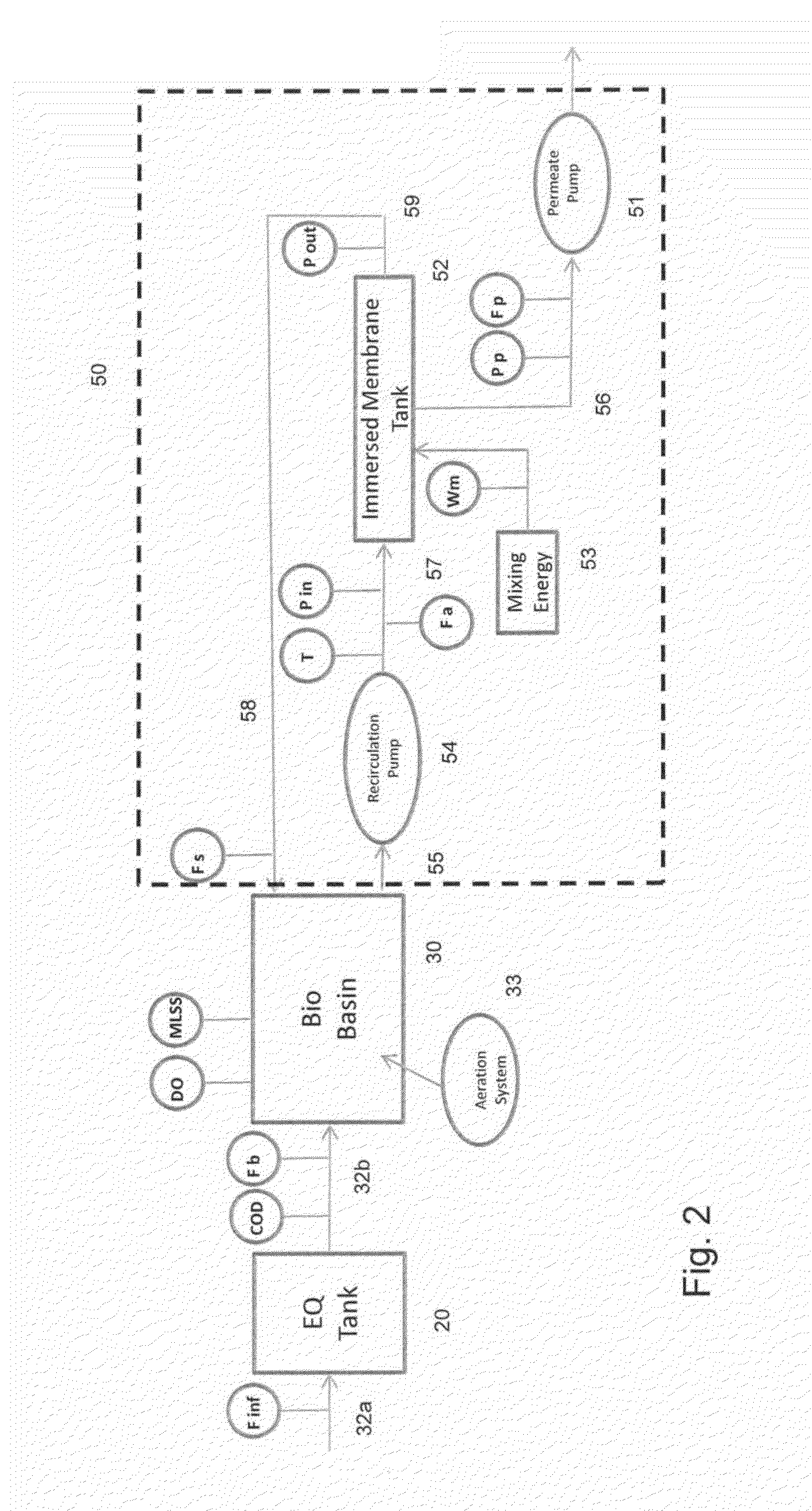

Advanced control system for wastewater treatment plants with membrane bioreactors

InactiveUS20130001142A1Semi-permeable membranesWater treatment parameter controlControl systemMembrane bioreactor

An advanced control system for a membrane bioreactor based wastewater treatment plant is disclosed. The disclosed control system comprises a membrane bioreactor (MBR) system and a microprocessor based controller that receives signals corresponding to selected measured MBR parameters and calculates or estimates one or more MBR calculated parameters including Membrane Conductivity (Fxc); and / or Oxygen Uptake Rate (OUR). The microprocessor based controller compares one or more calculated or estimated MBR parameters to prescribed setpoints or desired ranges and governs one or more pumps and valves in the MBR system to adjust the cleaning cycle the MBR system, the MBR flows in the MBR system, or the influent flow to the biological basin in response thereto.

Owner:PRAXAIR TECH INC

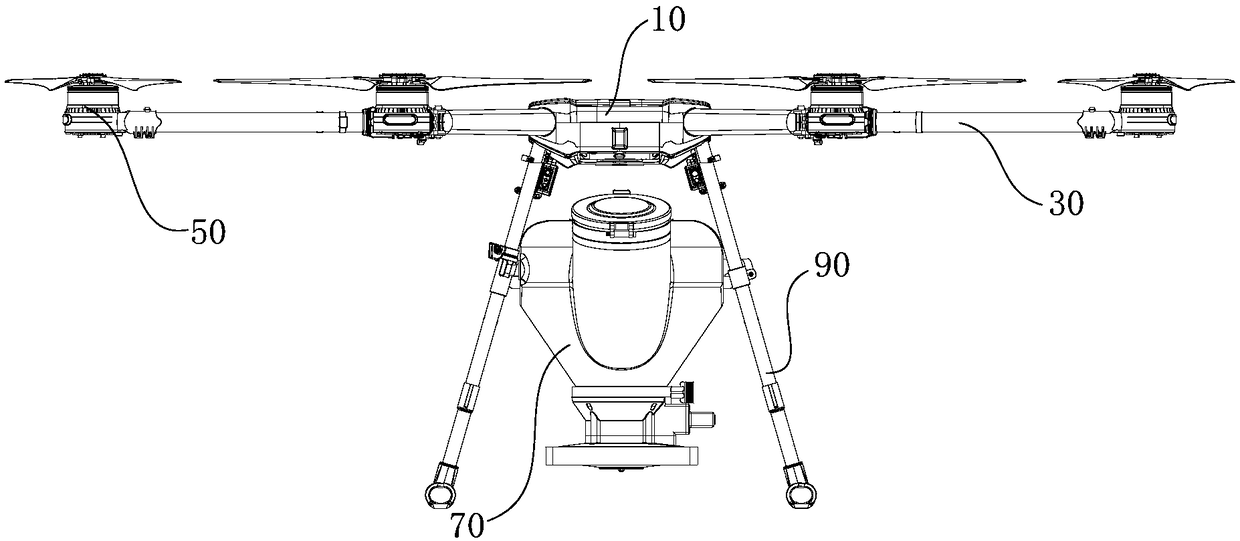

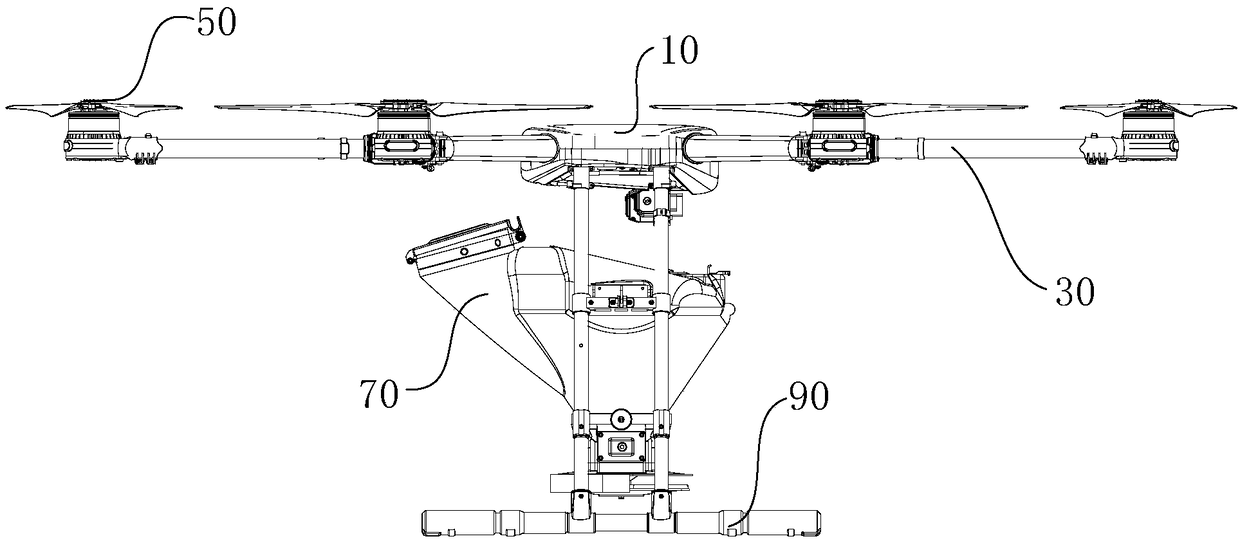

Sowing device and control method thereof, and plant protection unmanned aerial vehicle

ActiveCN109153452AEasy to grasp in timeAircraft componentsSpraying apparatusRemote controlEngineering

Provided is a control method of a sowing device. The method includes steps: obtaining a target openness and a real-time openness of a discharging port; determining whether the openness of the discharging port is abnormal according to a comparison result of the real-time openness and the target openness; and if yes, transmitting an alarm signal to a remote control device. According to the control method, the target openness and the real-time openness of the discharging port are obtained, whether the openness of the discharging port is abnormal can be determined through the comparison result ofthe target openness and the real-time openness, and the alarm signal is transmitted to the remote control device if the openness of the discharging port is abnormal so that a user can conveniently grasp information of the abnormal openness of the discharging port in time, target measures can be taken according to different conditions of abnormal openness, and the influence of the abnormal opennesson the sowing uniformity is avoided. The invention also provides a sowing device and a plant protection unmanned aerial vehicle.

Owner:SZ DJI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com