Patents

Literature

2024 results about "Combined cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

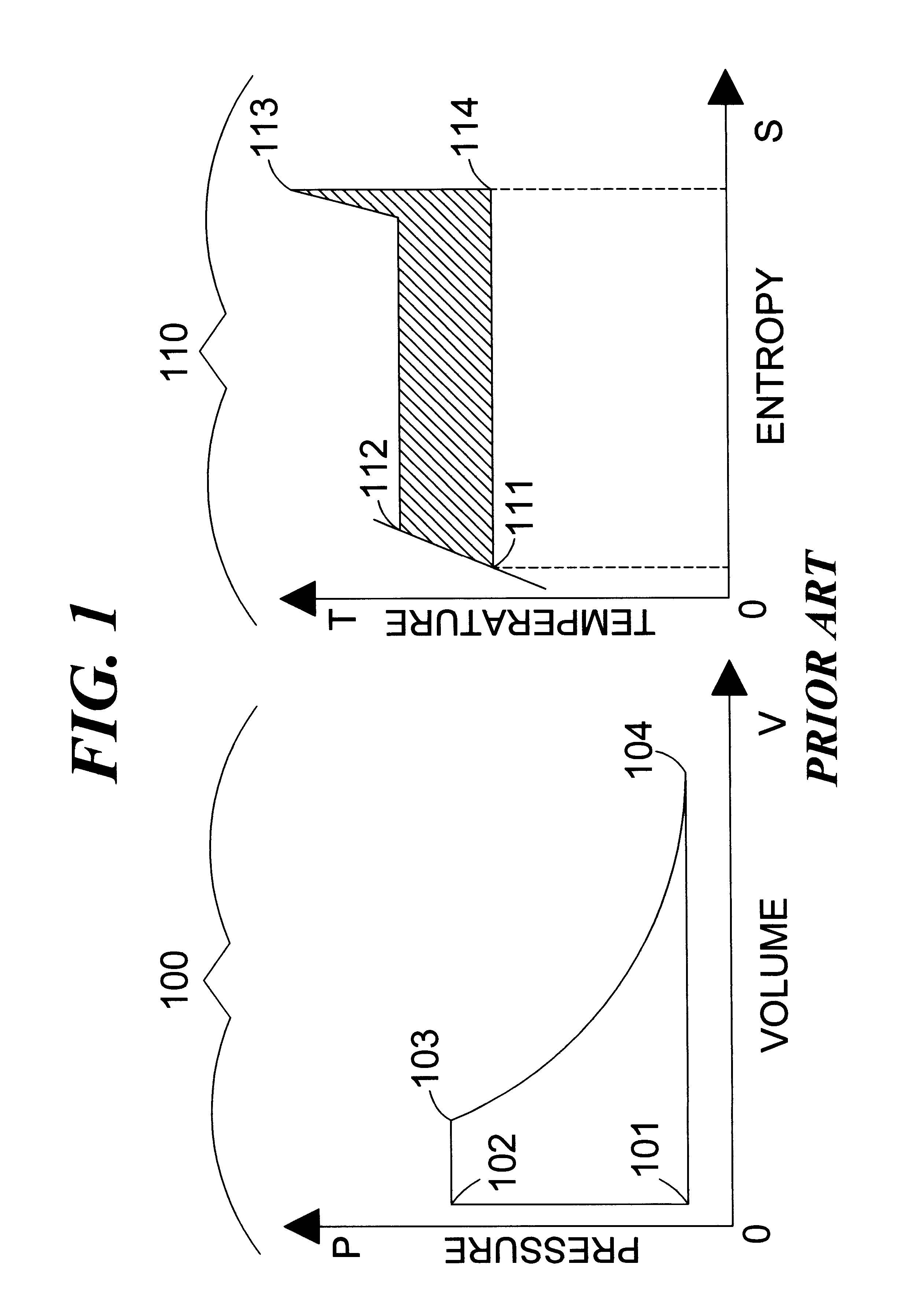

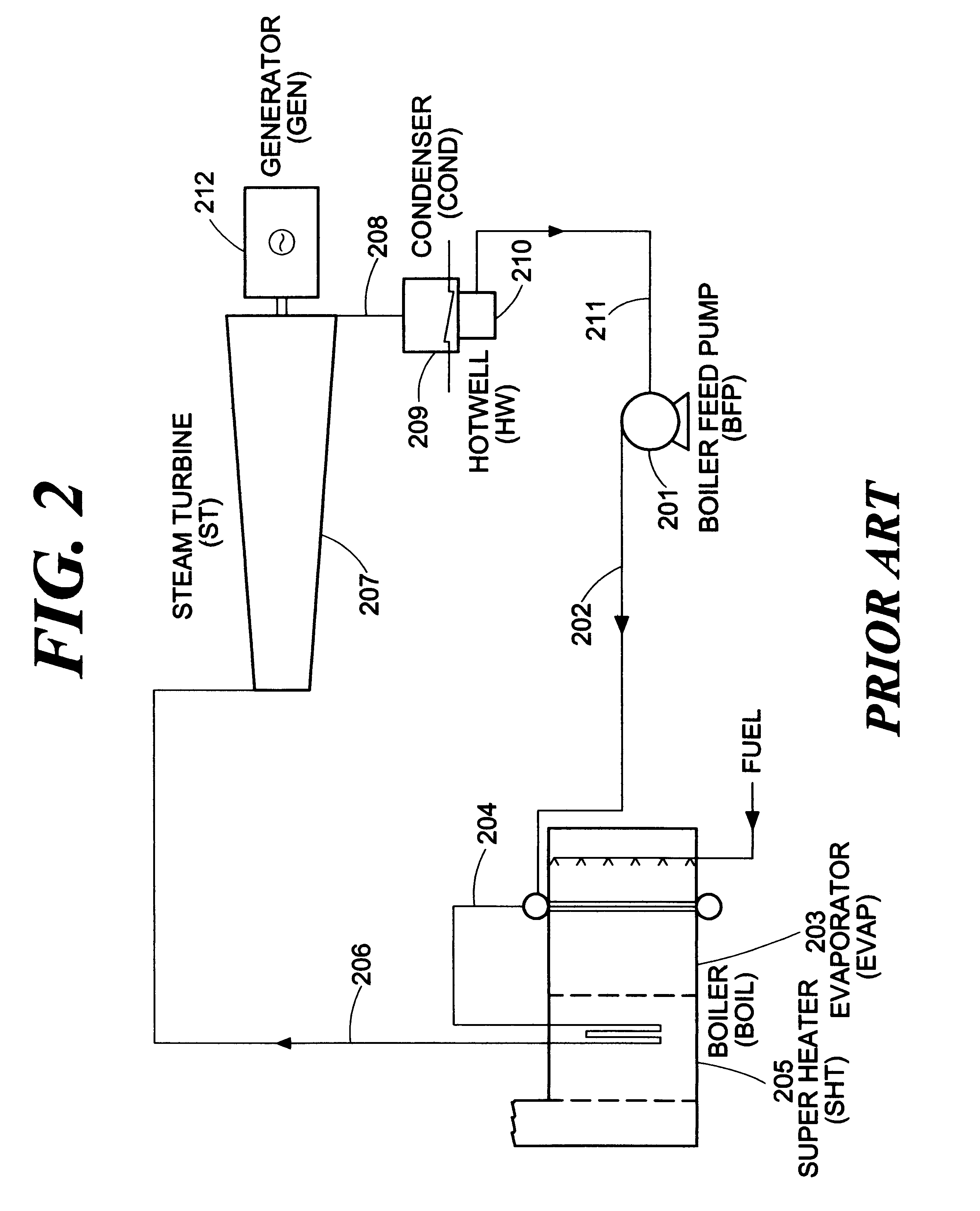

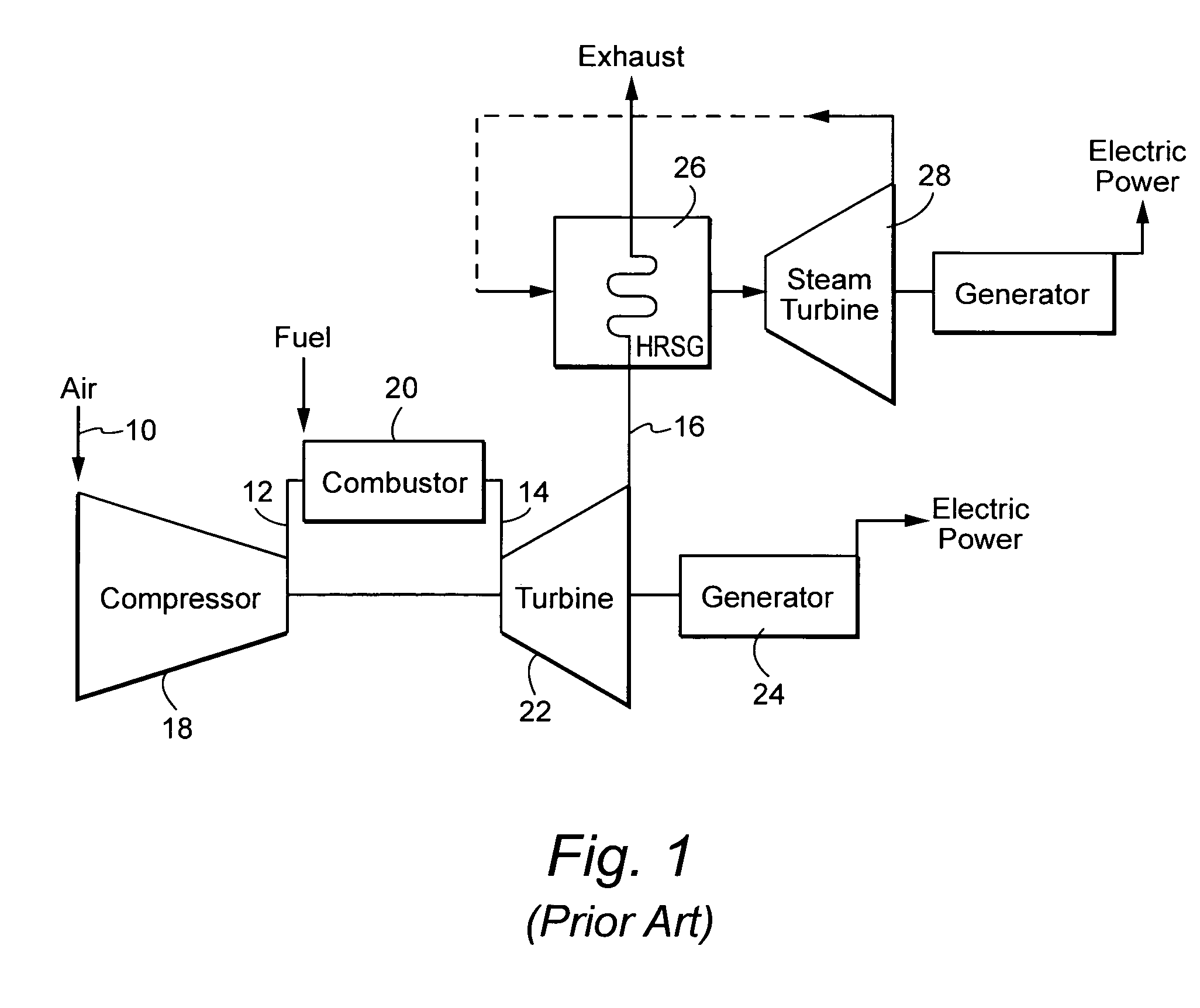

In electric power generation a combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy to drive electrical generators. The principle is that after completing its cycle (in the first engine), the temperature of the working fluid in the system is still high enough that a second subsequent heat engine extracts energy from the heat that the first engine produced. By generating electricity from multiple streams of work, the overall net efficiency of the system may be increased by 50–60%. That is, from an overall efficiency of say 34% (simple cycle), to possibly an overall efficiency of 62% (combined cycle), 84% of theoretical efficiency (Carnot cycle)

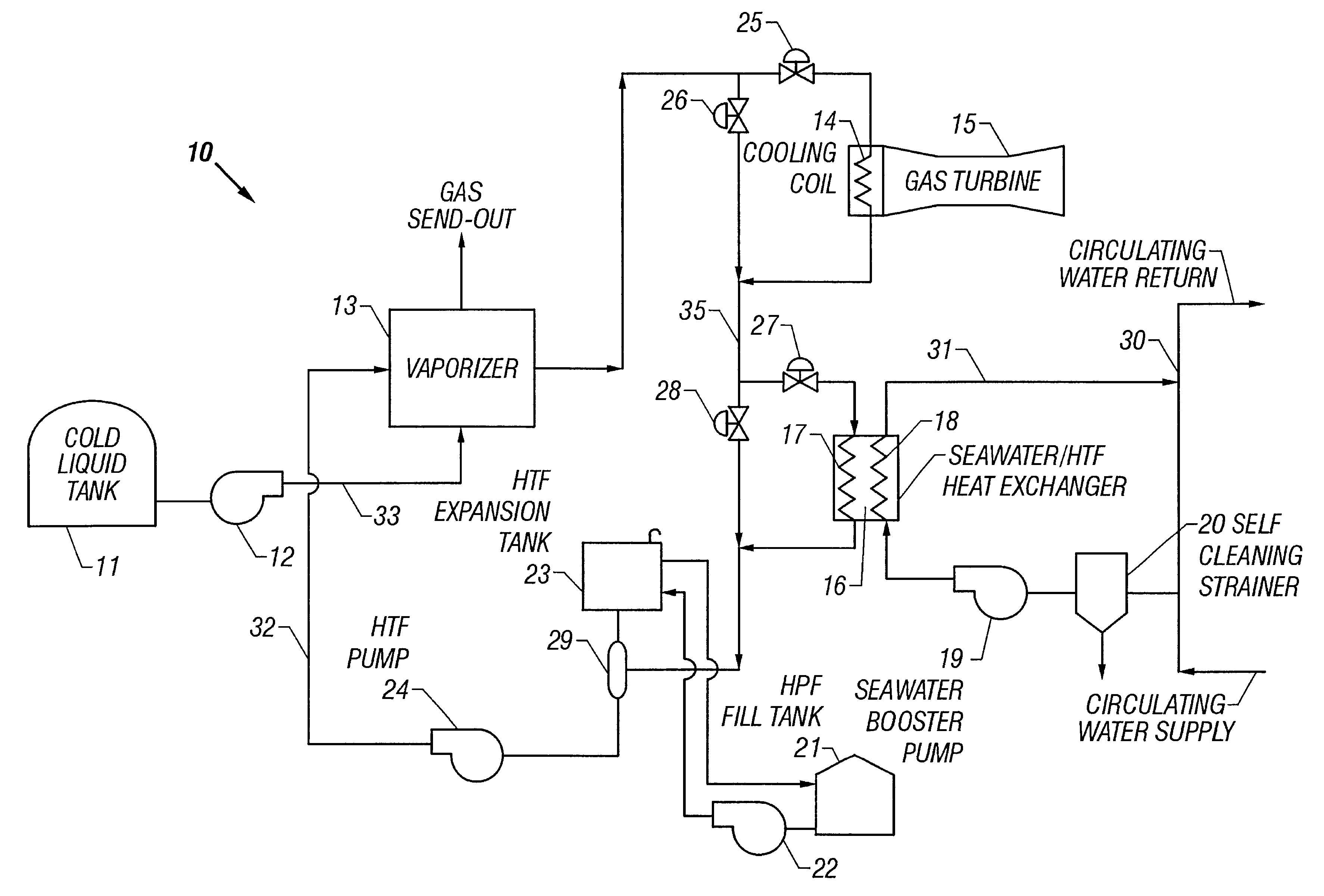

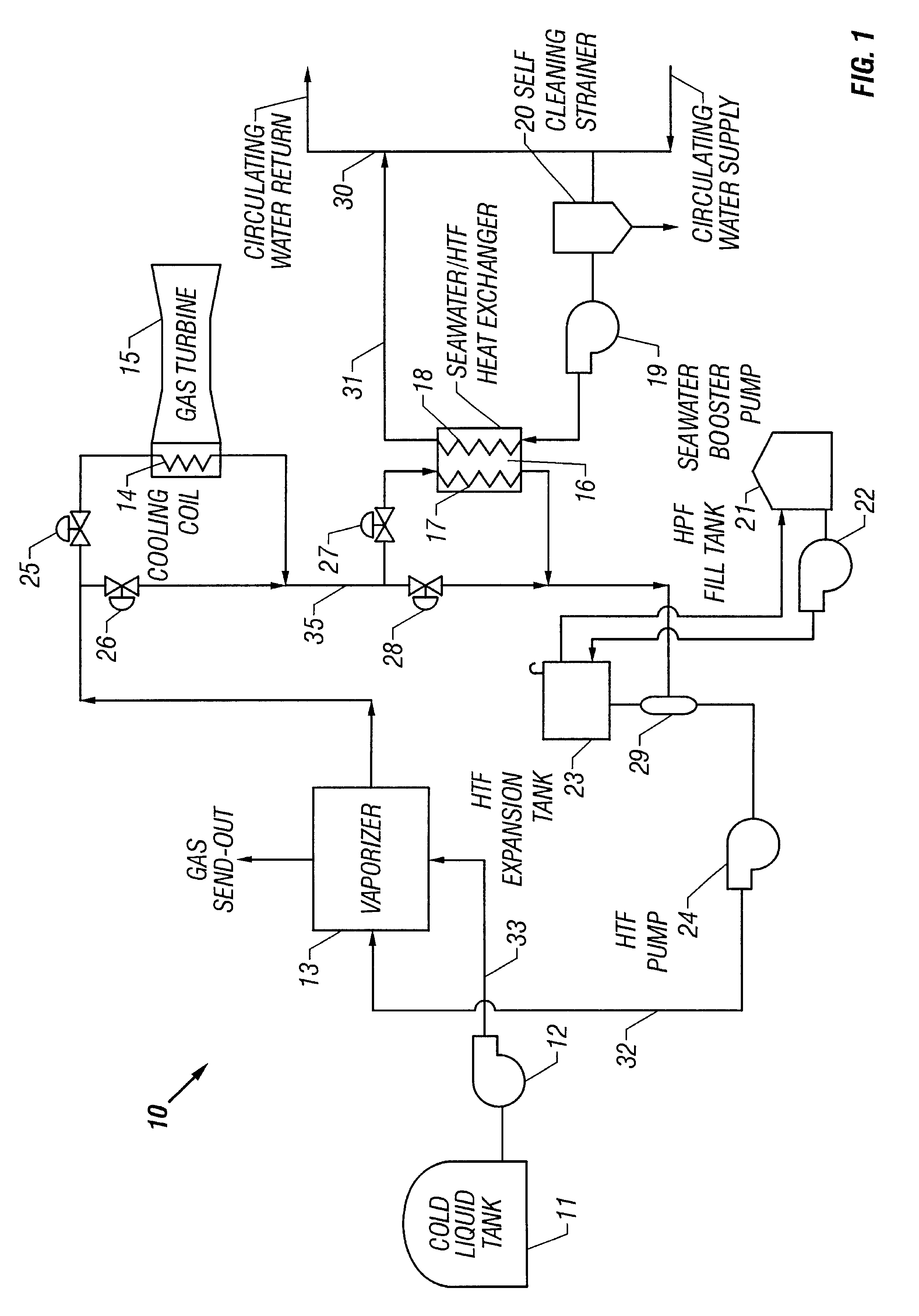

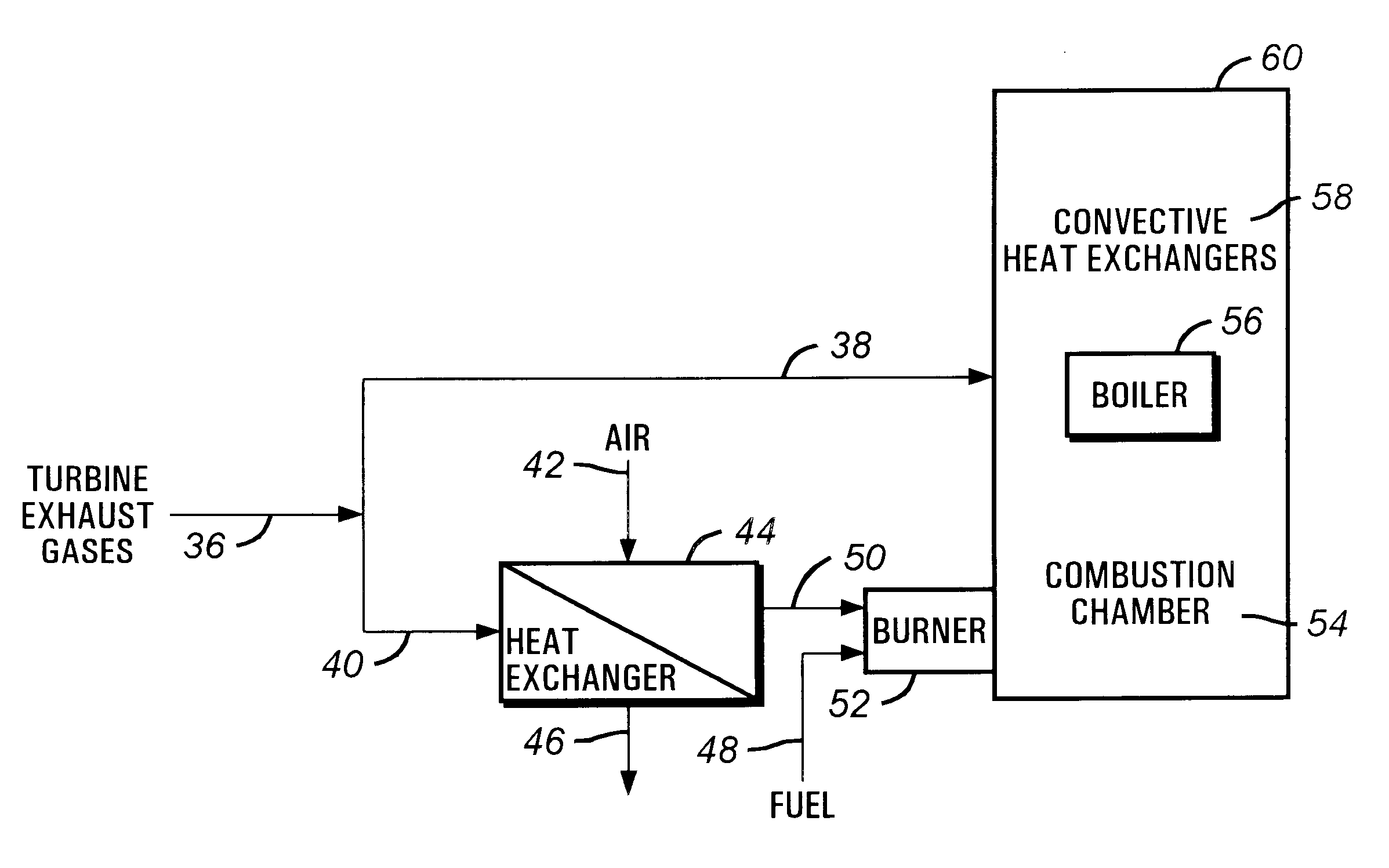

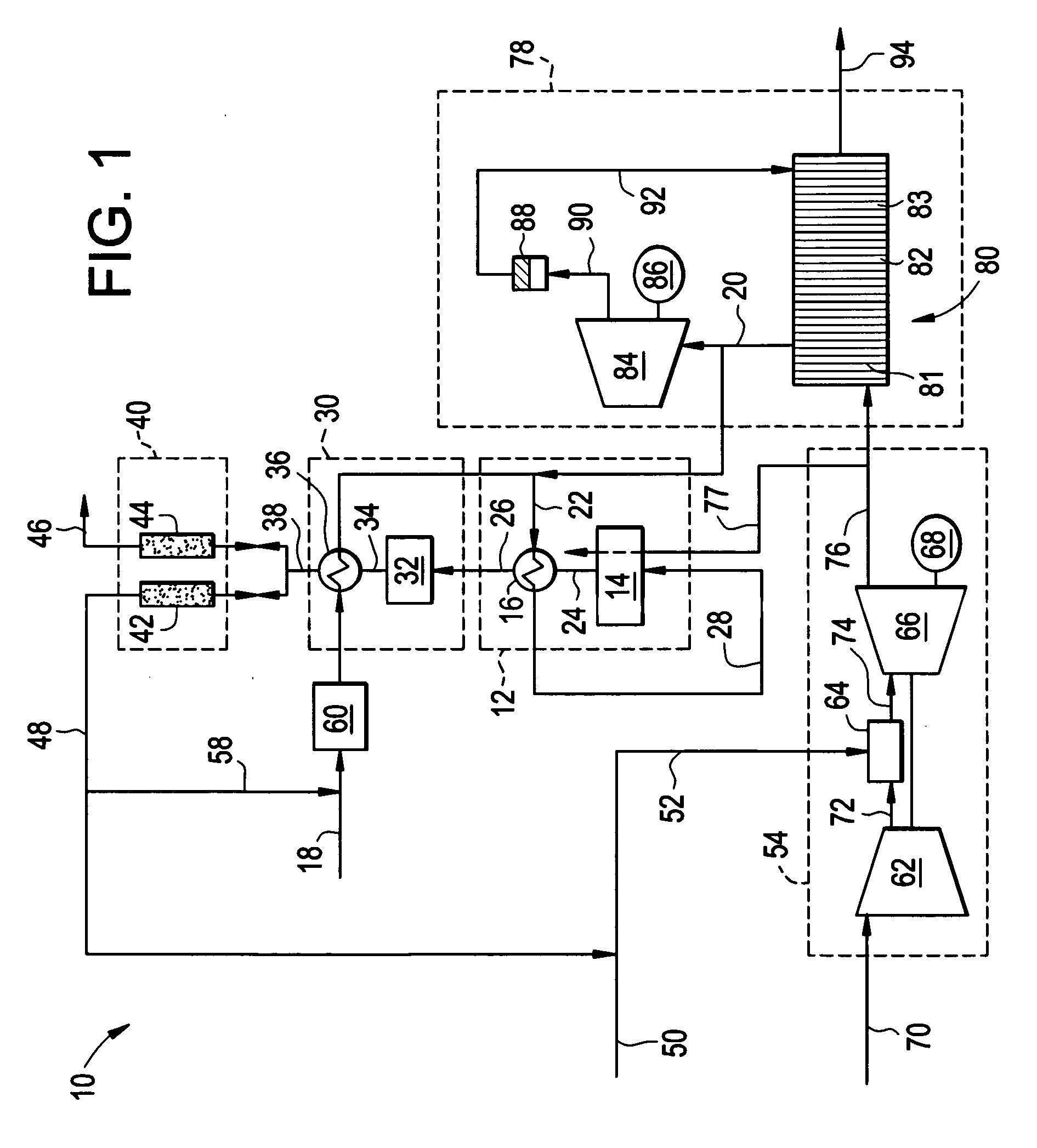

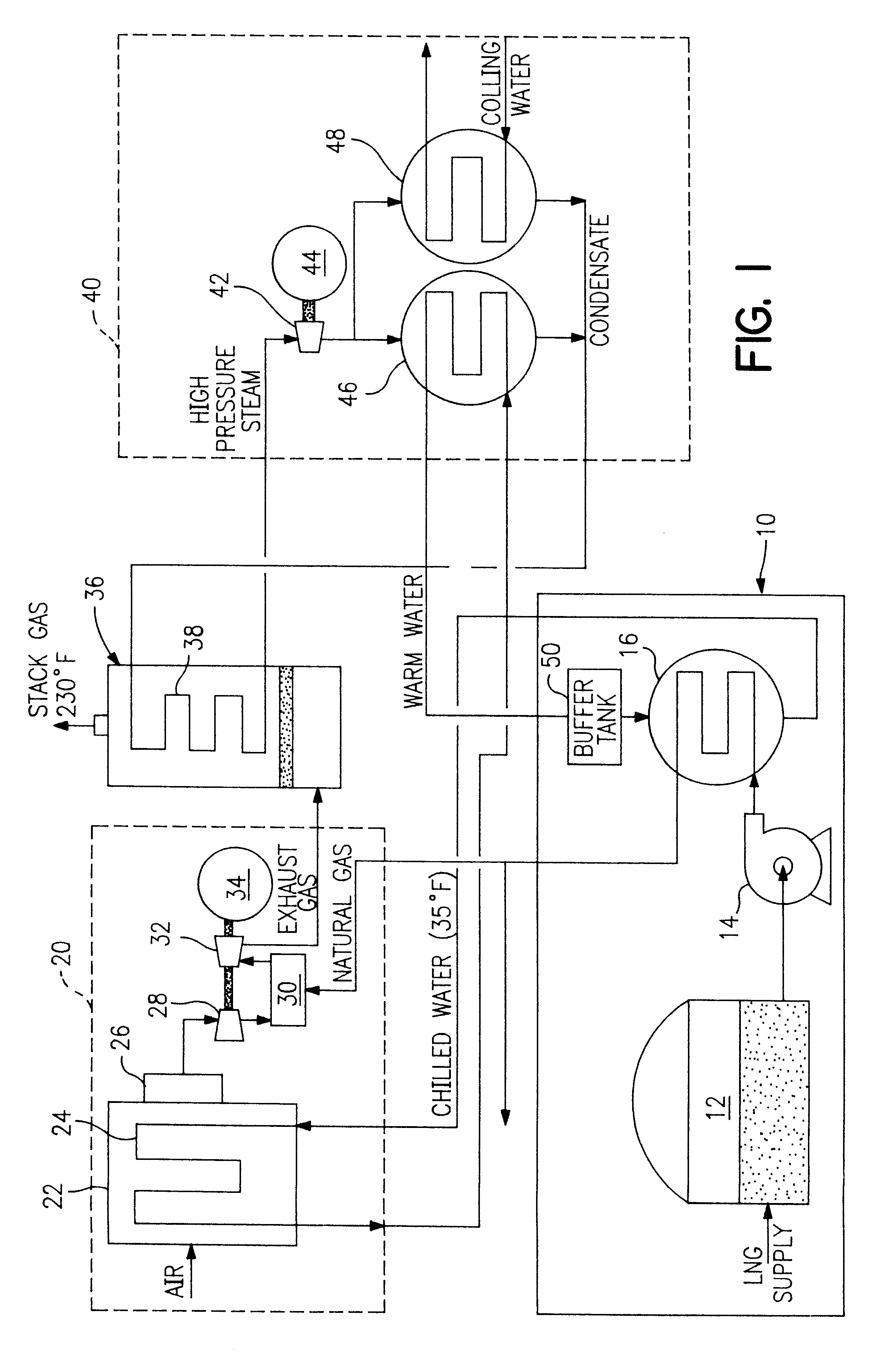

Method and apparatus for vaporizing liquid natural gas in a combined cycle power plant

InactiveUS6367258B1Turbine/propulsion engine coolingTurbine/propulsion fuel heatingPower stationProcess engineering

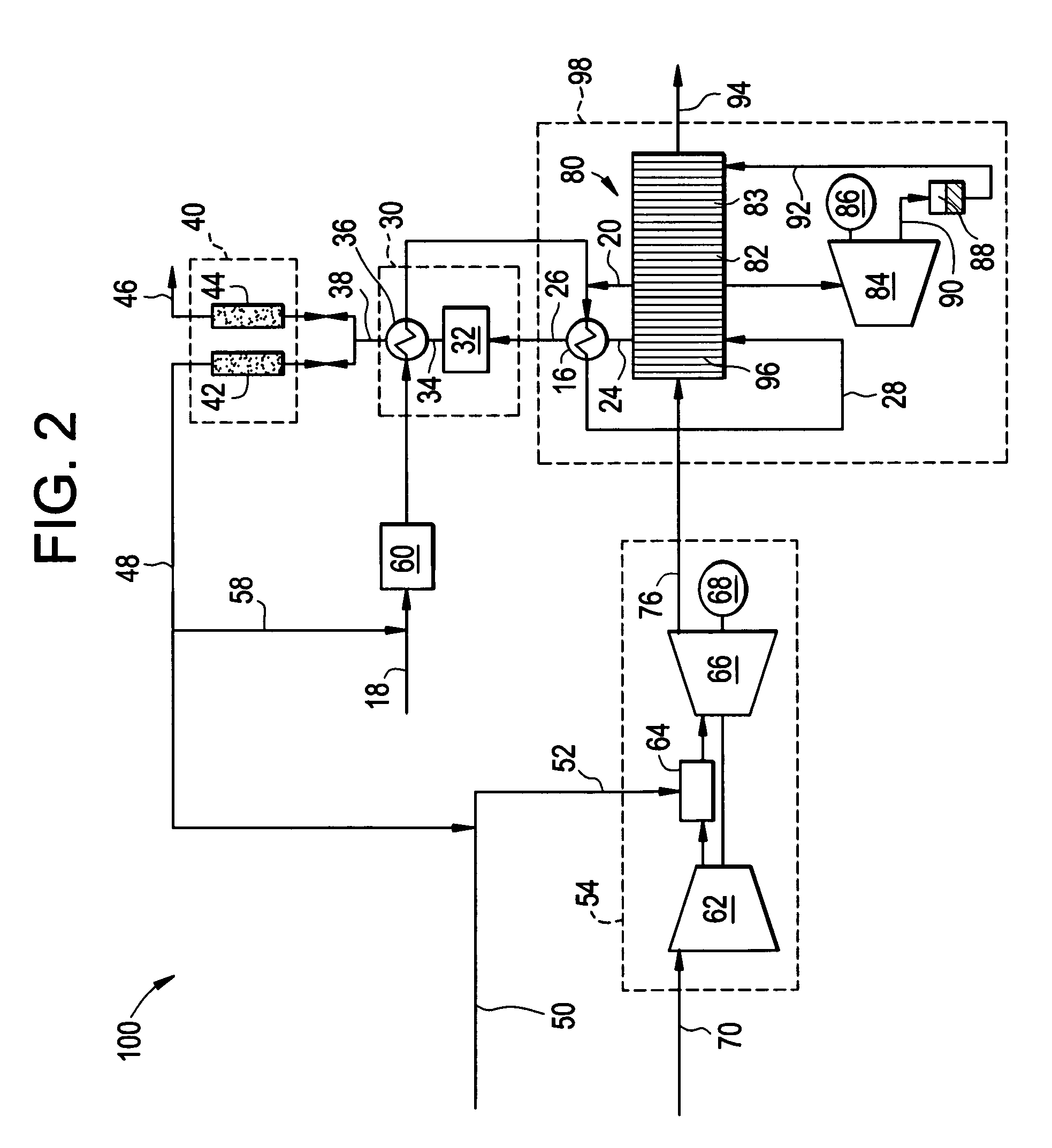

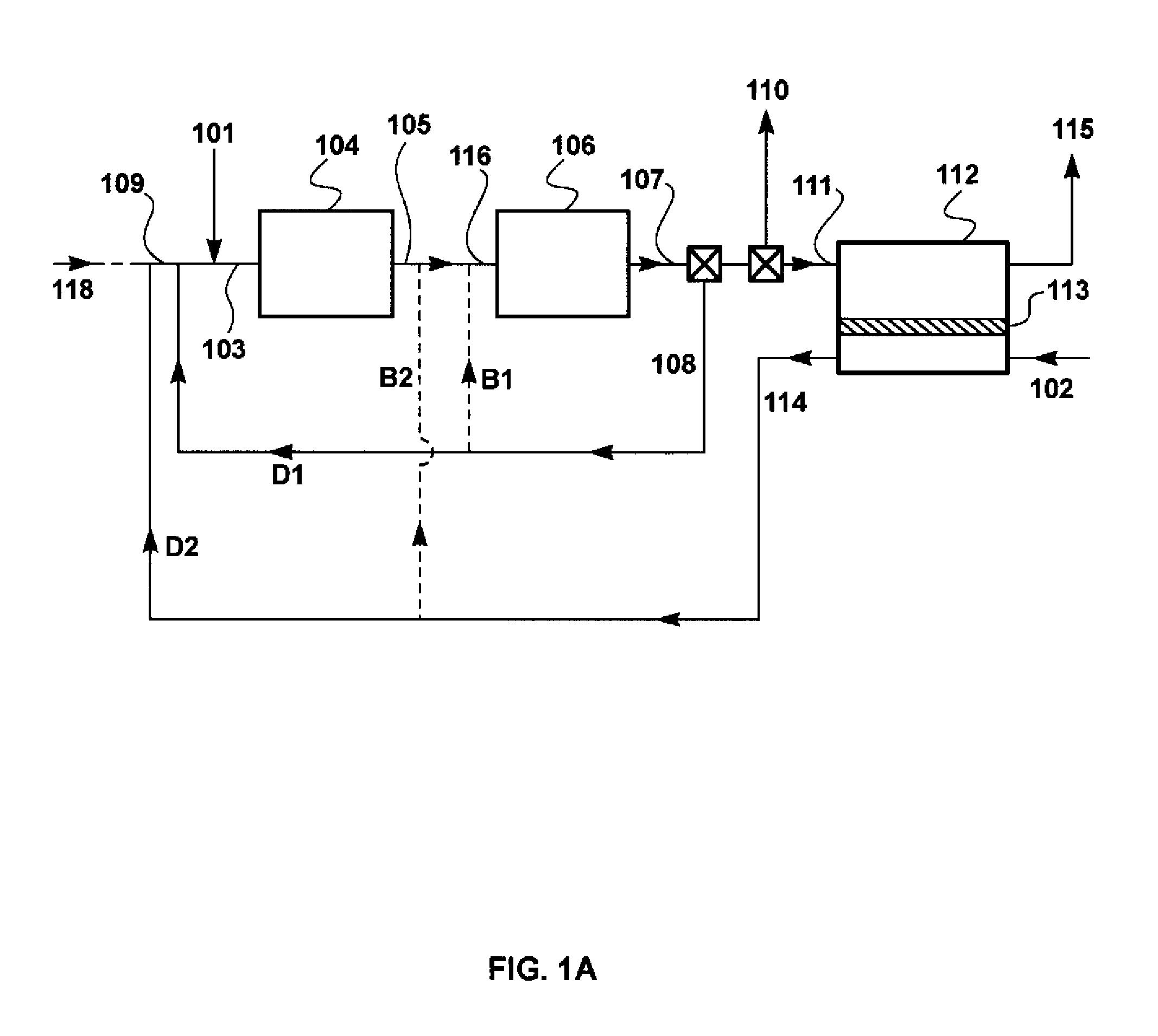

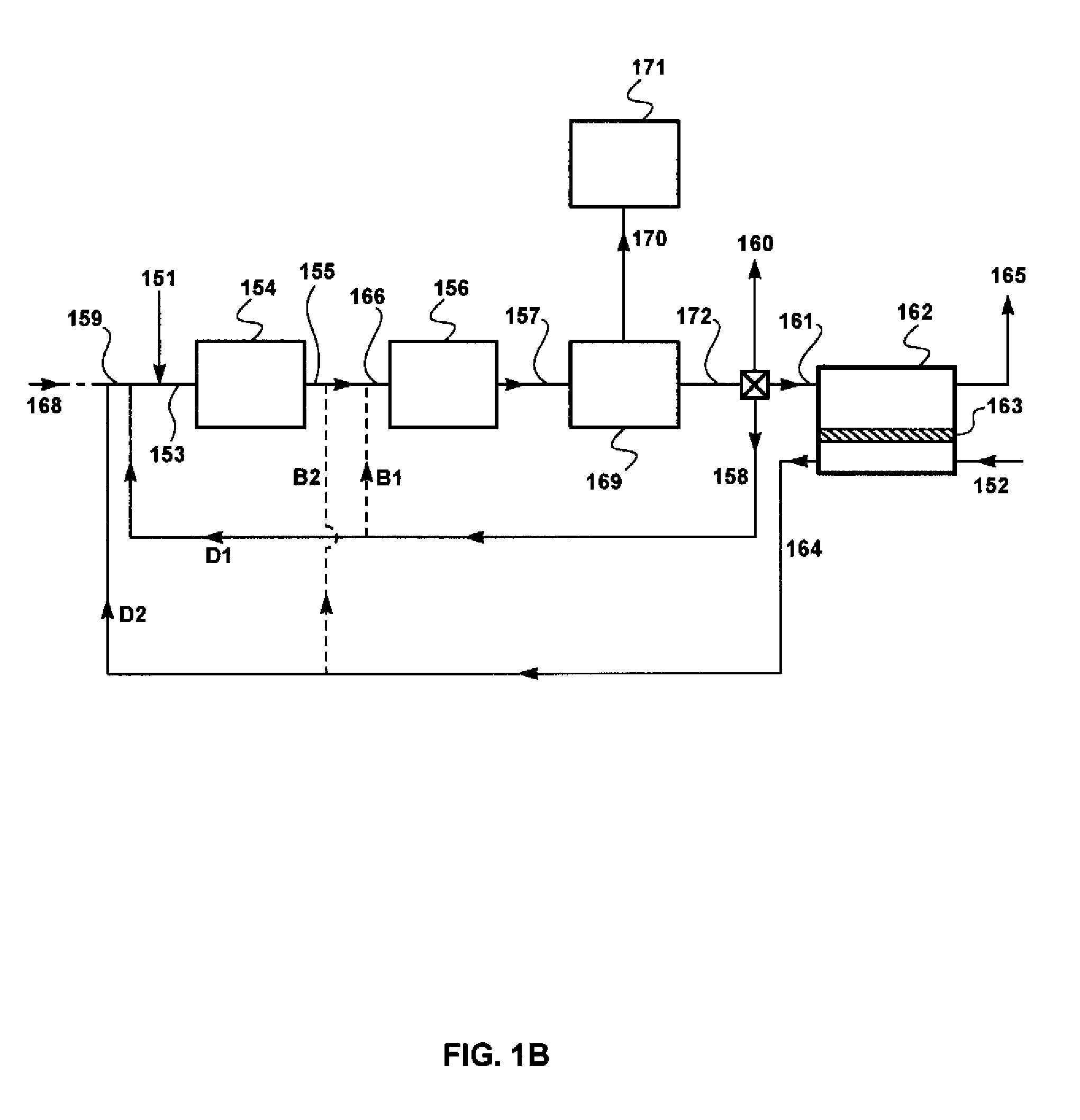

A method and apparatus for increasing the efficiency of a combined cycle generation plant by assisting the vaporization of cold liquid including liquefied natural gas ("LNG") or liquefied petroleum gas (LPG) in a combined cycle power plant. Cold liquid vaporization is assisted by circulating a warm heat transfer fluid to transfer heat to a LNG / LPG vaporizer. The heat transfer fluid is chilled by LNG / LPG cold liquid vaporization and warmed by heat from a gas turbine. The heat transfer fluid absorbs heat from the air intake of a gas turbine and from a secondary heat transfer fluid circulating in a combined cycle power plant. Chilling the gas turbine air intake densifies the air and increases the gas turbine output. Chilling the steam condenser cooling water increases steam turbine output. The effects of chill recovery is higher output and better efficiency of the combined cycle plant.

Owner:BECHTEL CORP

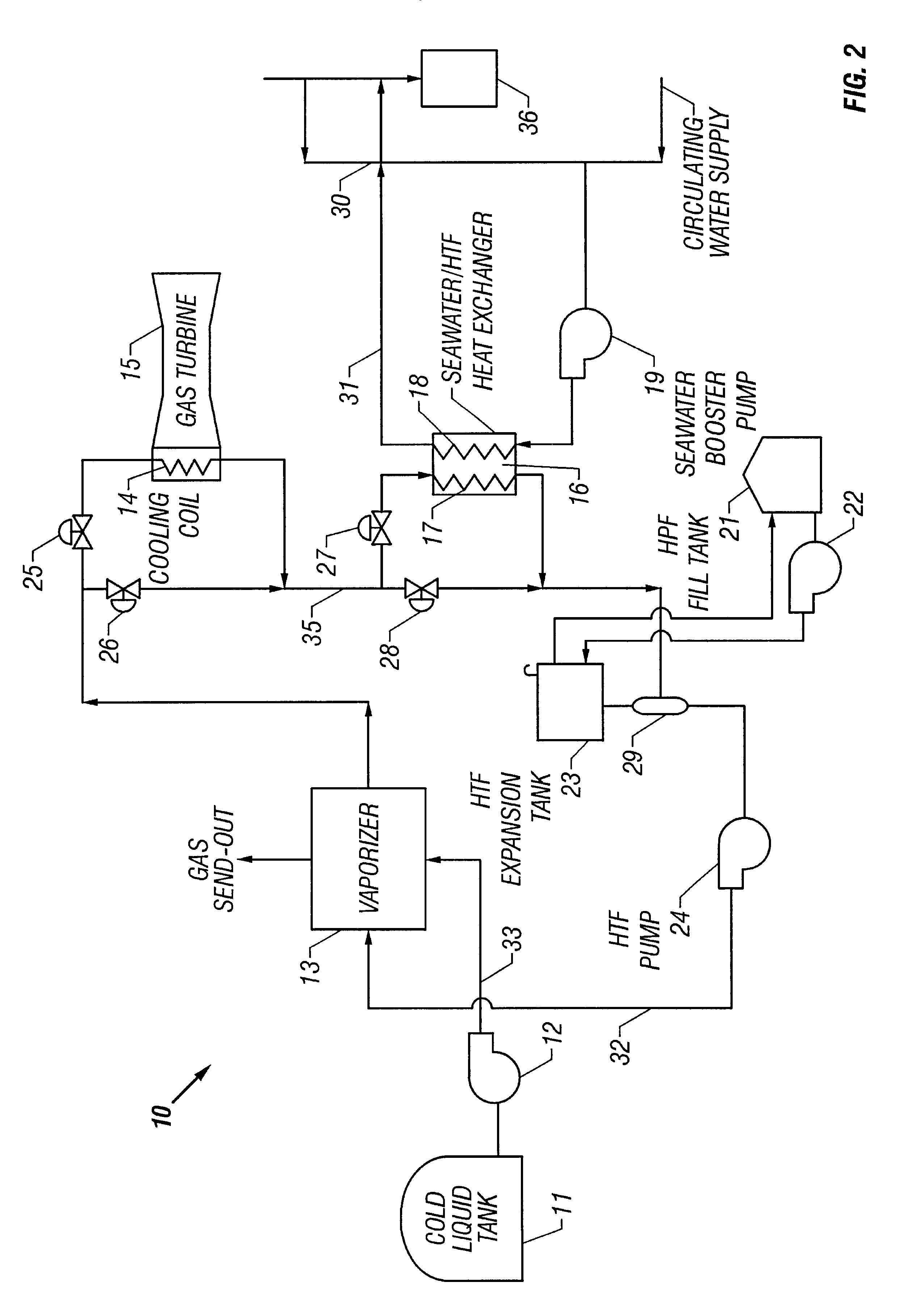

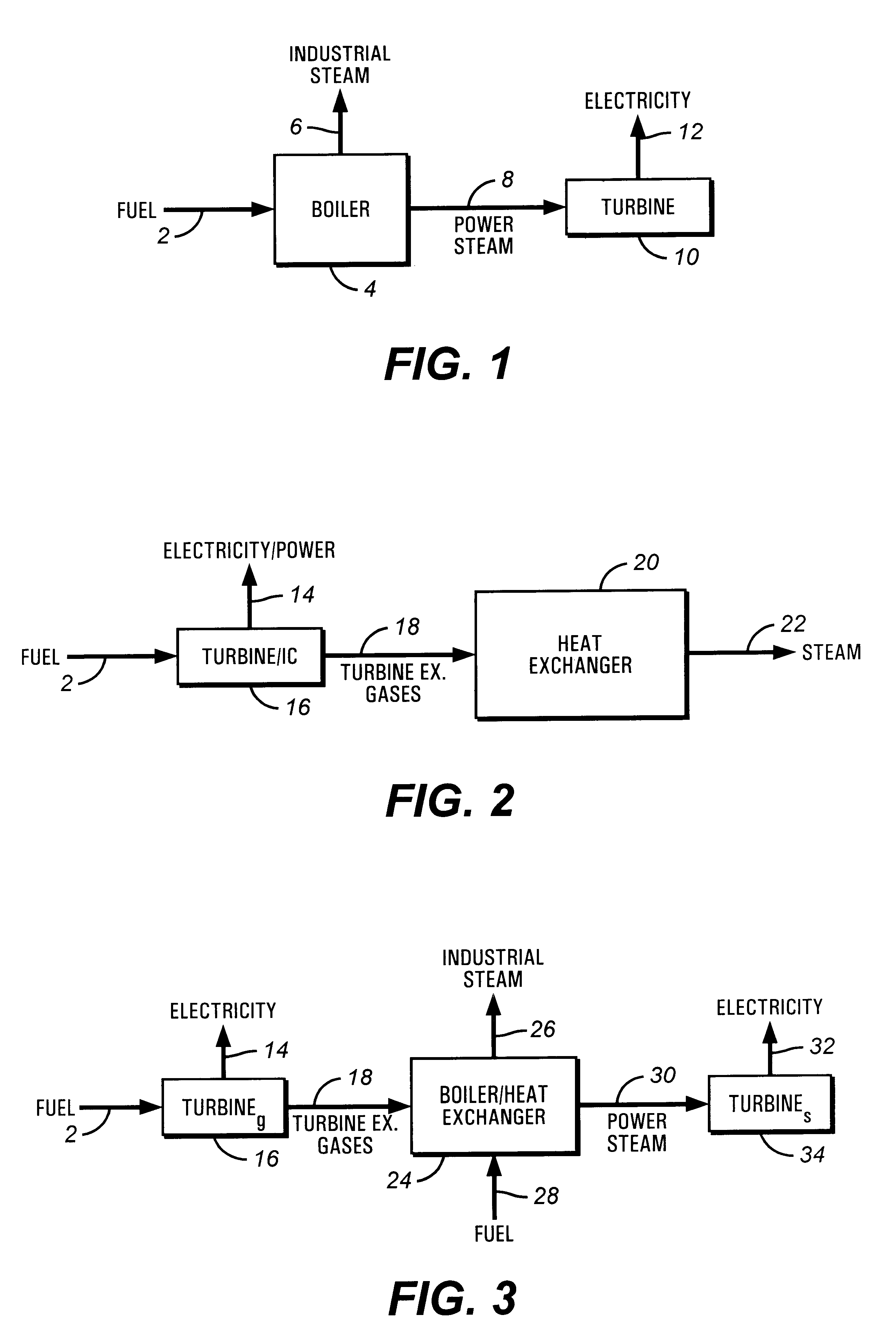

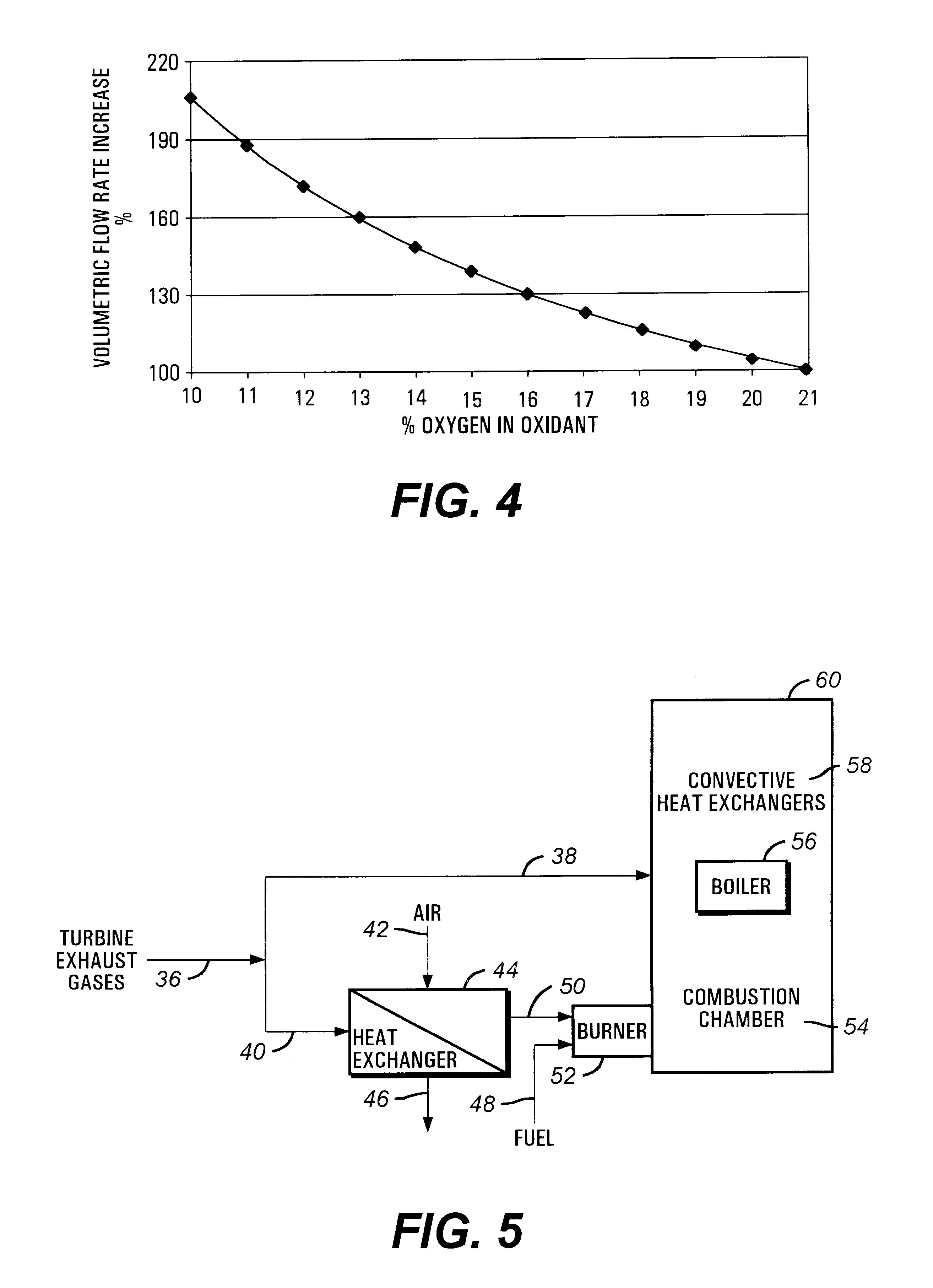

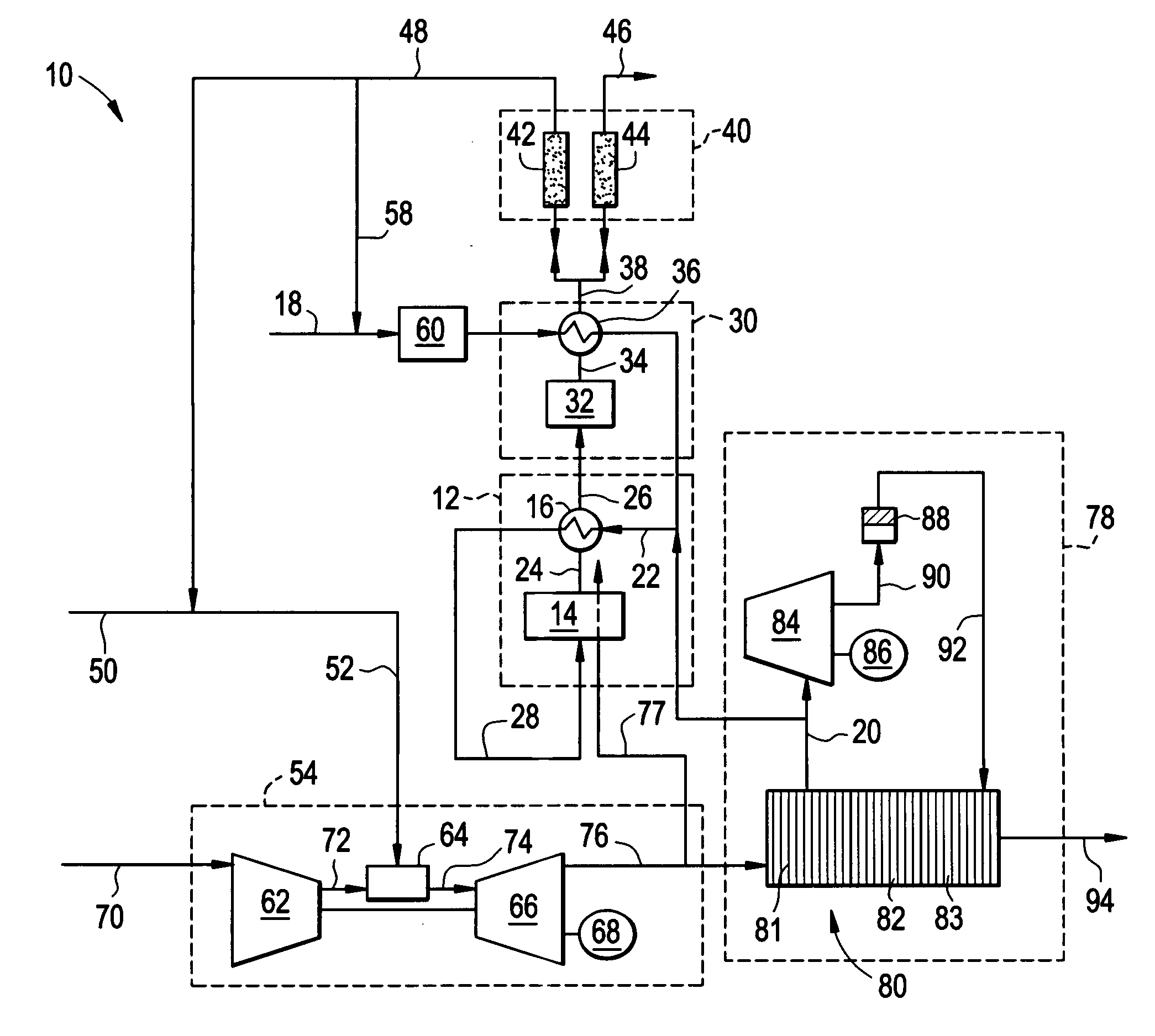

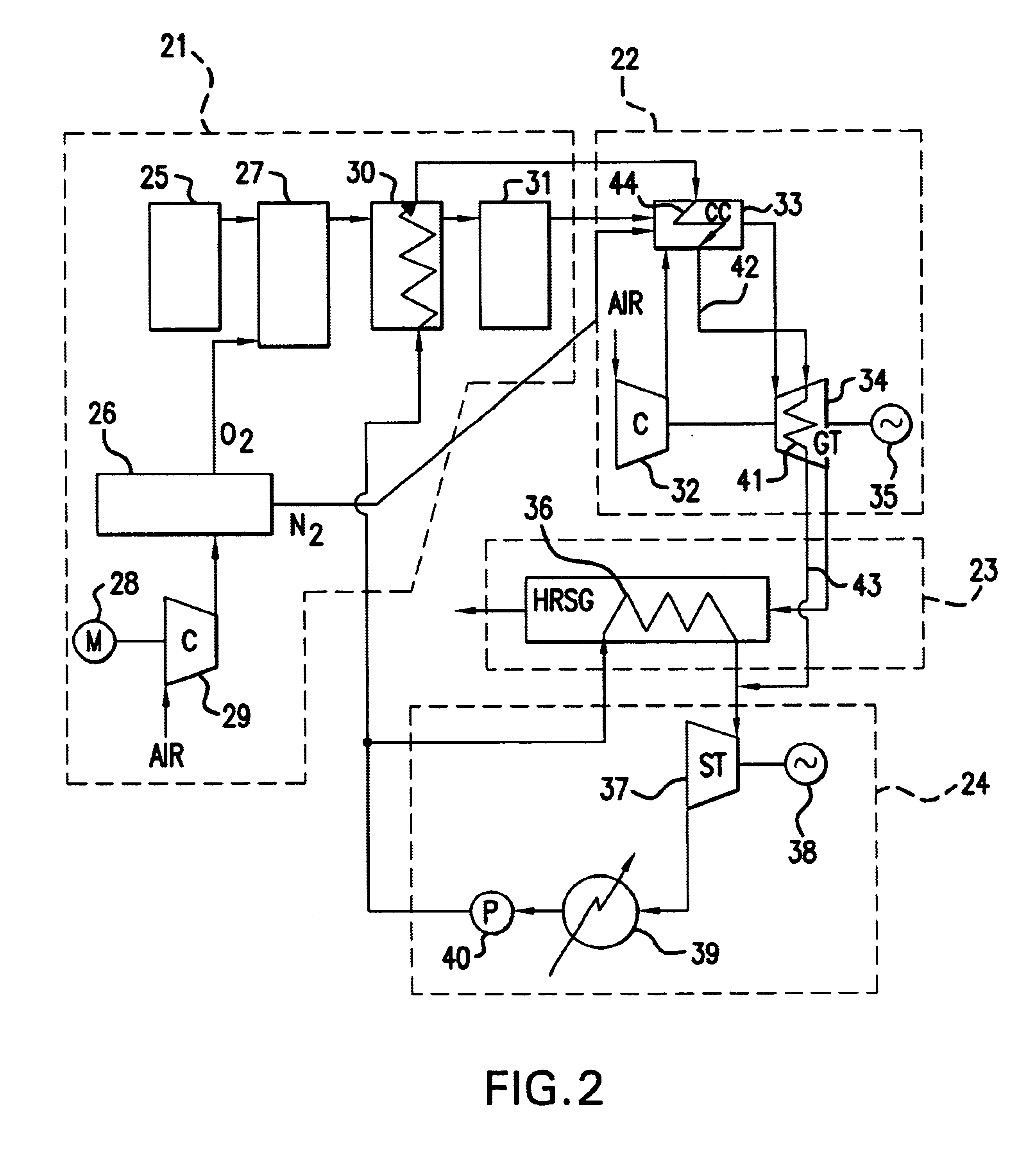

Oxidant control in co-generation installations

InactiveUS6247315B1Steam regenerationIndirect carbon-dioxide mitigationControl system designCogeneration

This invention is related to so-called combined cycle co-generation installations, and it addresses present concerns of the industry. Among these, combustion stability, corrosion (due to large water content in the flue gases), large heat transfer areas, and the like. In some embodiments, an additional heat exchanger is added to heat combustion air with a portion of the exhaust gases resulting from an engine, preferably a gas turbine. As a result, the efficiency of the cycle will improve, the oxidant will be enriched by above 50% oxygen, the combustion process will be enhanced, and the dimensions of the boiler may be reduced. It is considered that the combustion air will require between 10% and 80% of the total flue gas volume, more preferably between 20% and 40%. This is the portion of the flue gases sent through the heat exchanger. A control system designed to optimize the flow of the different streams is also presented. Other inventive embodiments forego heat exchanges in lieu of precise control of two flows of exhaust gas, with preferred addition of additional oxidant to the boiler bumers.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

Reforming system for combined cycle plant with partial CO2 capture

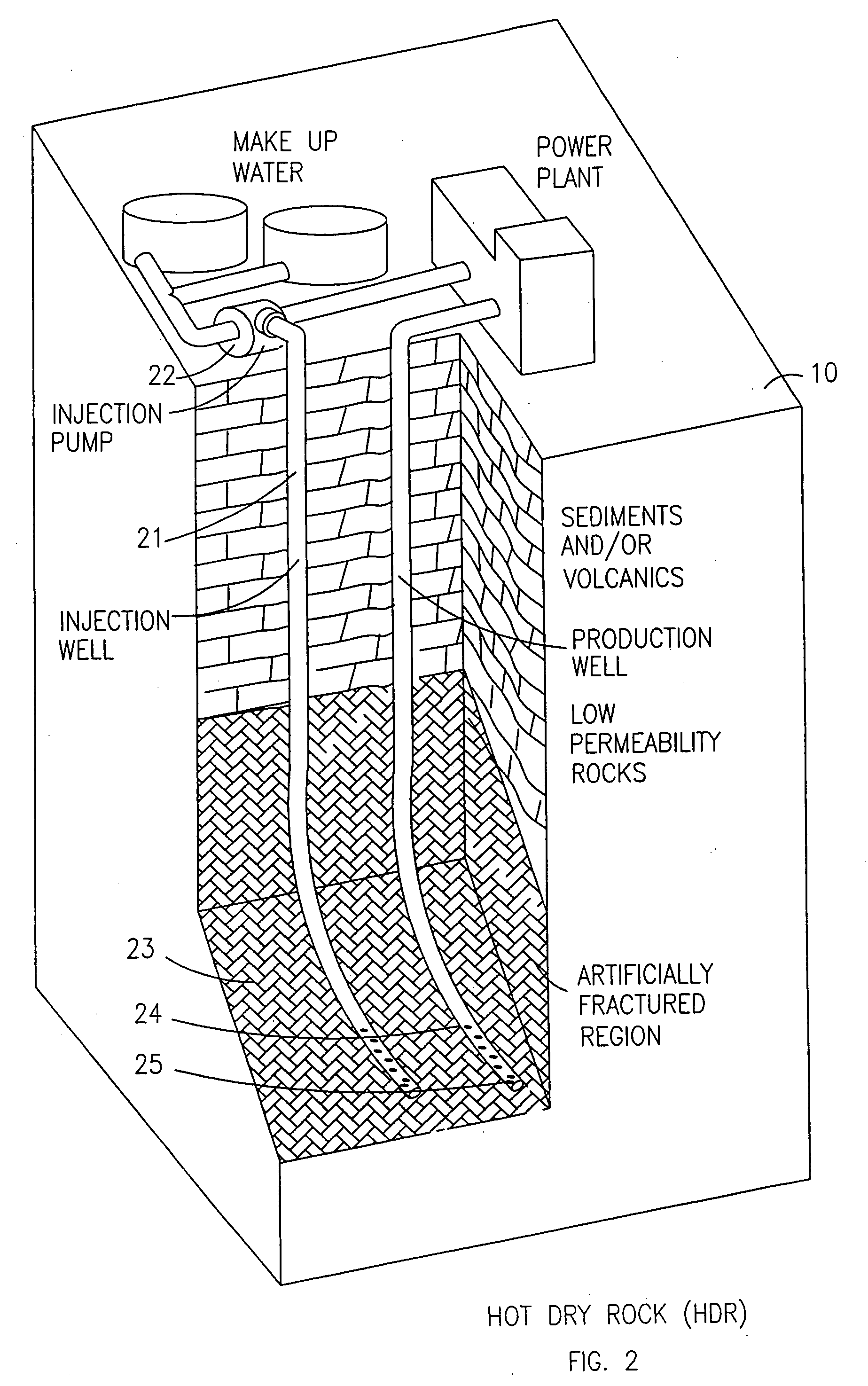

A combined cycle system includes, a pre-steam-methane-reformer operating at a temperature of less than about 800 degrees Celsius to reform a mixed fuel stream to generate a first reformate stream, a water-gas-shift reactor to convert carbon monoxide in the first reformate stream to carbon dioxide and form a second reformate stream, a carbon dioxide removal unit for removing carbon dioxide from the second reformate stream and form a carbon dioxide stream and a third reformate stream; wherein less than about 50 percent of the carbon contained in the mixed fuel stream is recovered as carbon dioxide by the removal unit, a gas turbine unit for generating power and an exhaust stream, and a steam generator unit configured to receive the exhaust stream, wherein the heat of the exhaust stream is transferred to a water stream to generate the steam for the mixed fuel stream and for a steam turbine.

Owner:GENERAL ELECTRIC CO

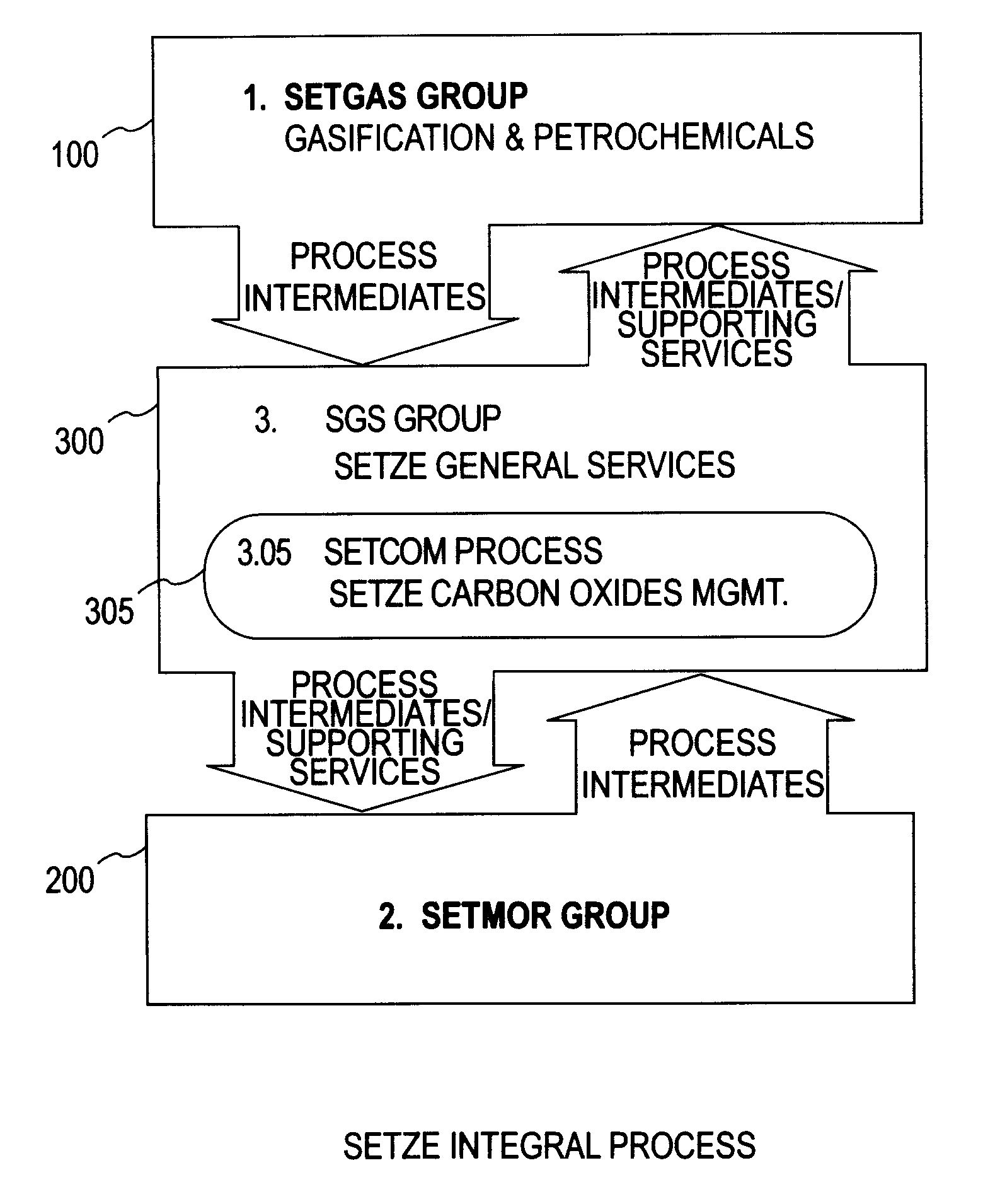

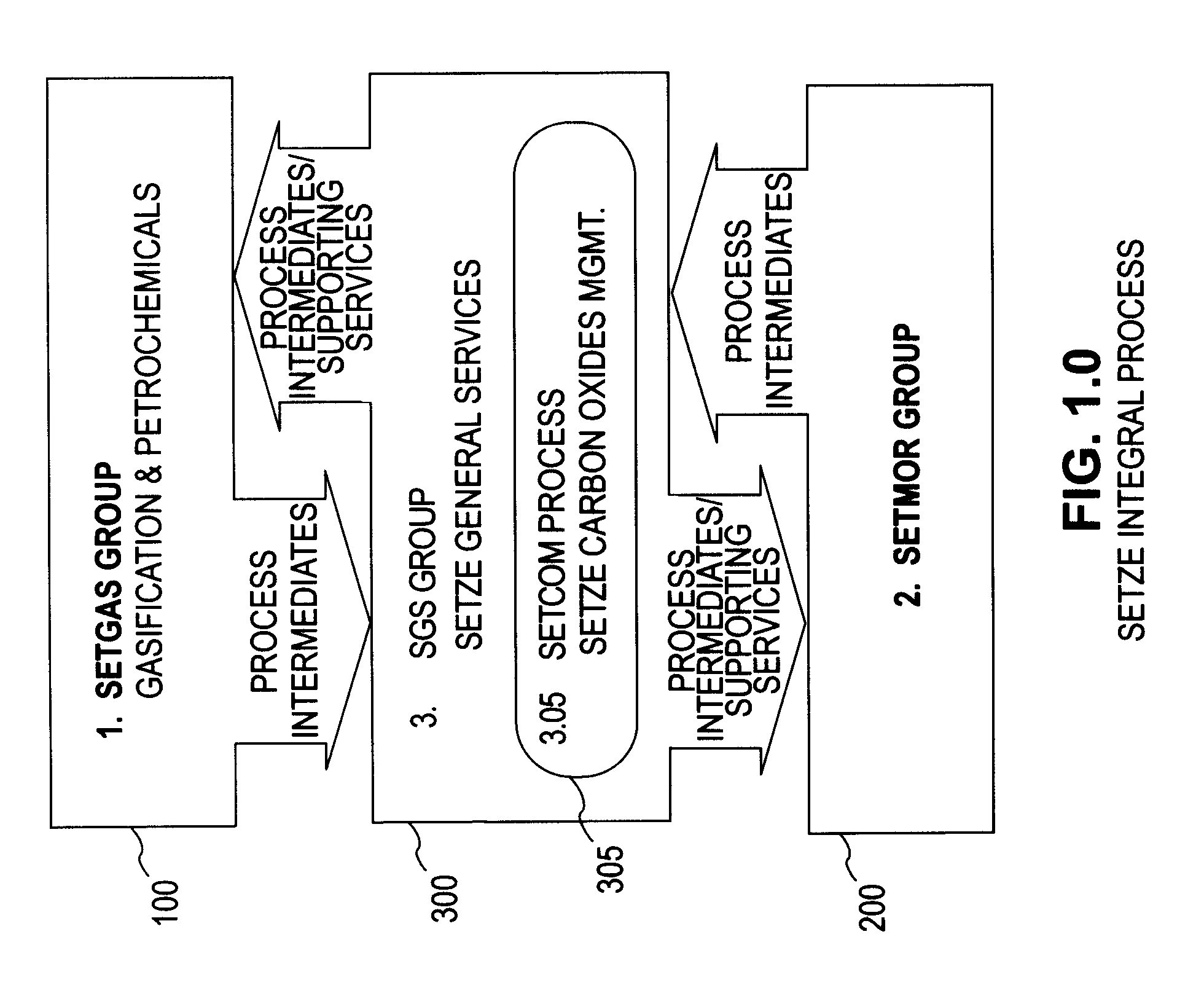

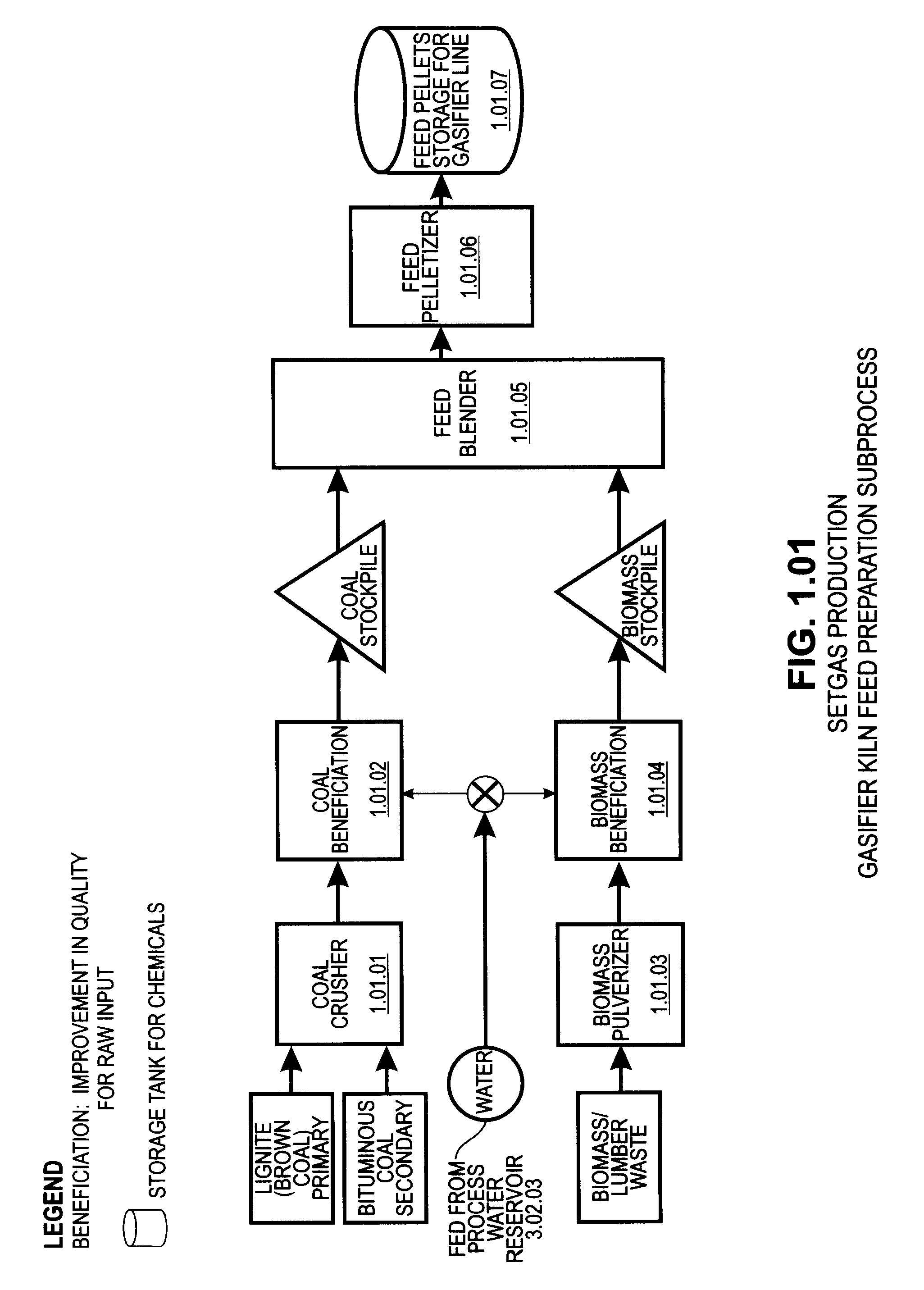

Zero emission gasification, power generation, carbon oxides management and metallurgical reduction processes, apparatus, systems, and integration thereof

ActiveUS7674443B1Improvement in individual technology componentEnhances economic performanceUsing liquid separation agentBiofuelsCyclonic separationOxygen

A system involving a two-step gasification of a carbonaceous source to produce bulk hydrogen that avoids the early formation of CO2 and obviates the traditional water gas shift (WGSR) step, carbochlorination of a metallic ore the production of metals found in the ore that utilizes carbon monoxide as an oxygen sink, rather than the traditional coke, and carbon oxides management that eliminates major impediments to emission-neutral power generation and the reduction of major metals. The gasification uses a rotary kiln reactor and gas-gas cyclonic separation process to separate synthesis gas into purified hydrogen and purified carbon monoxide. Purified bulk carbon monoxide issued in metallurgical reduction, and purified bulk hydrogen as fuel for an emission-neutral hydrogen combined cycle (HCC) turbine power generation station. The carbochlorination is integrated with: a) the concurrent separation and purification of all metal-chlorides (metchlors) and capture of CO2 for passage to the carbon oxides management system; b) the direct reduction of metchlors to nanoscale metallurgical powders and / or to dendritically-shaped particles, including metchlor reduction for the ultrahigh-performance semiconductor metals of the III-V group; and, c) the reforming of metal-oxides with improved crystalline structure from metchlors. The carbon oxides management collects, stores and directs to points of usage, carbon oxides that arise in various processes of the integrated system, and captures carbon monoxide for process enhancement and economic uses and captures carbon dioxide as a process intermediate and for economic uses.

Owner:DAVIS OLUMIJI B +1

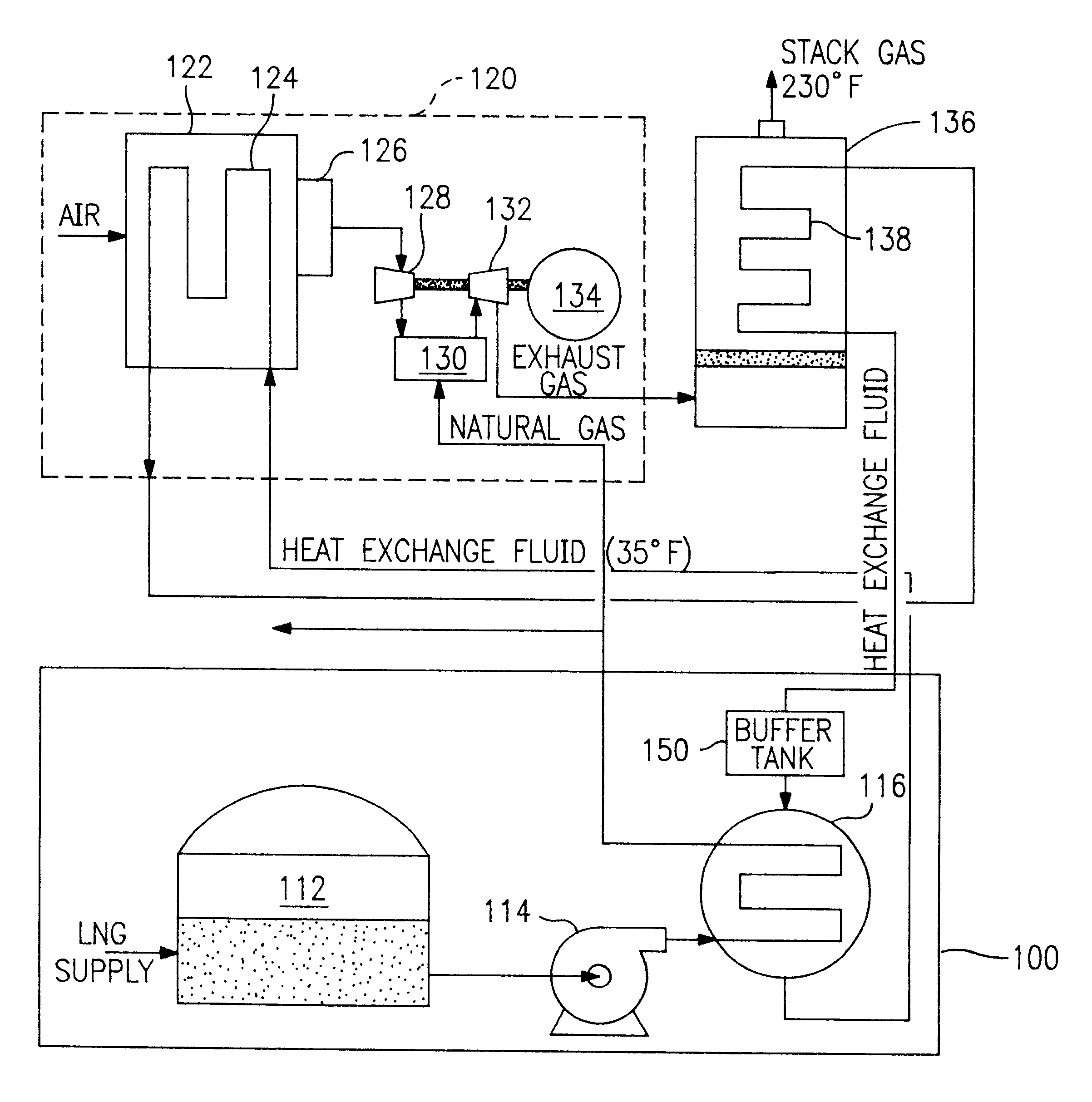

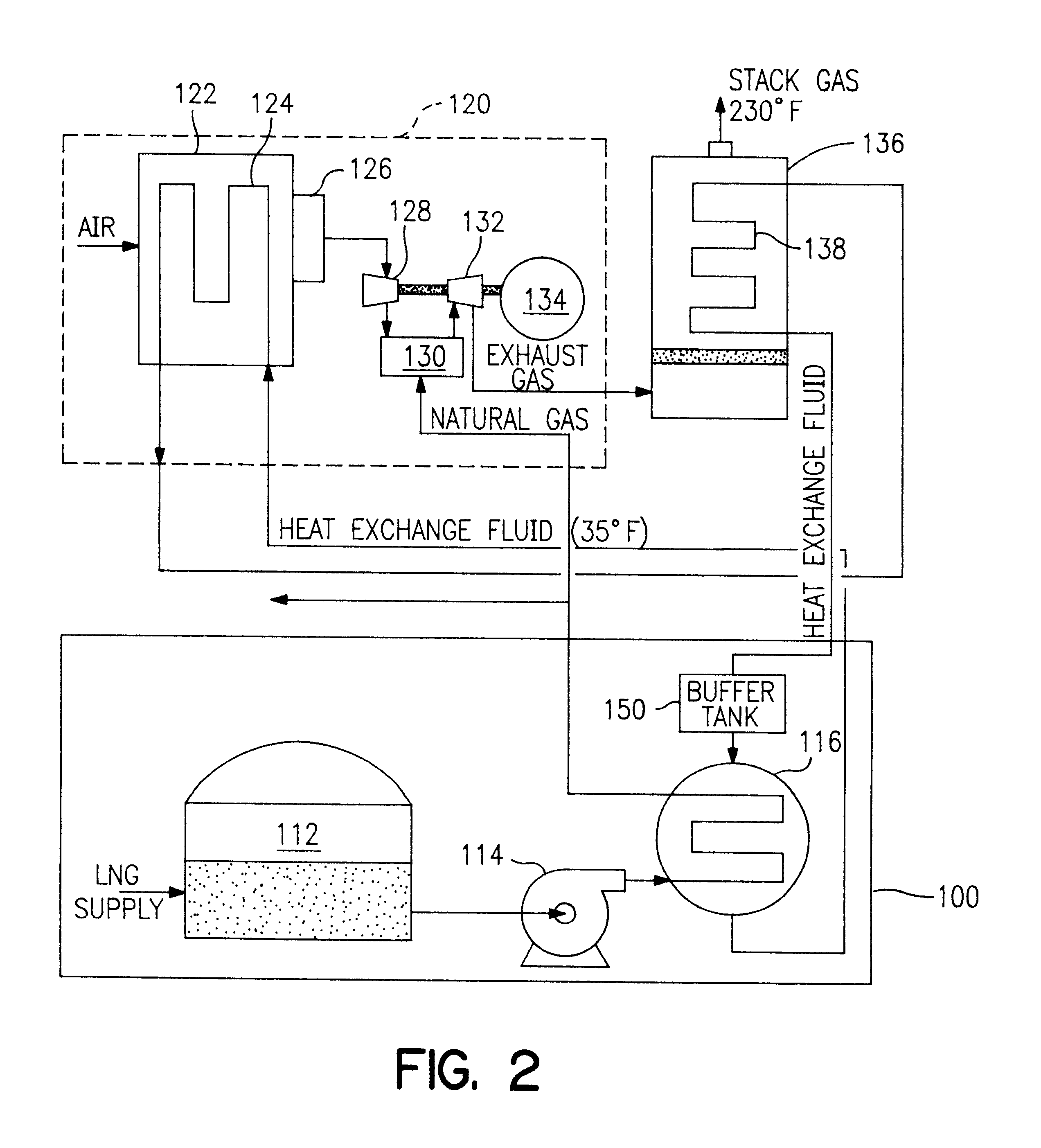

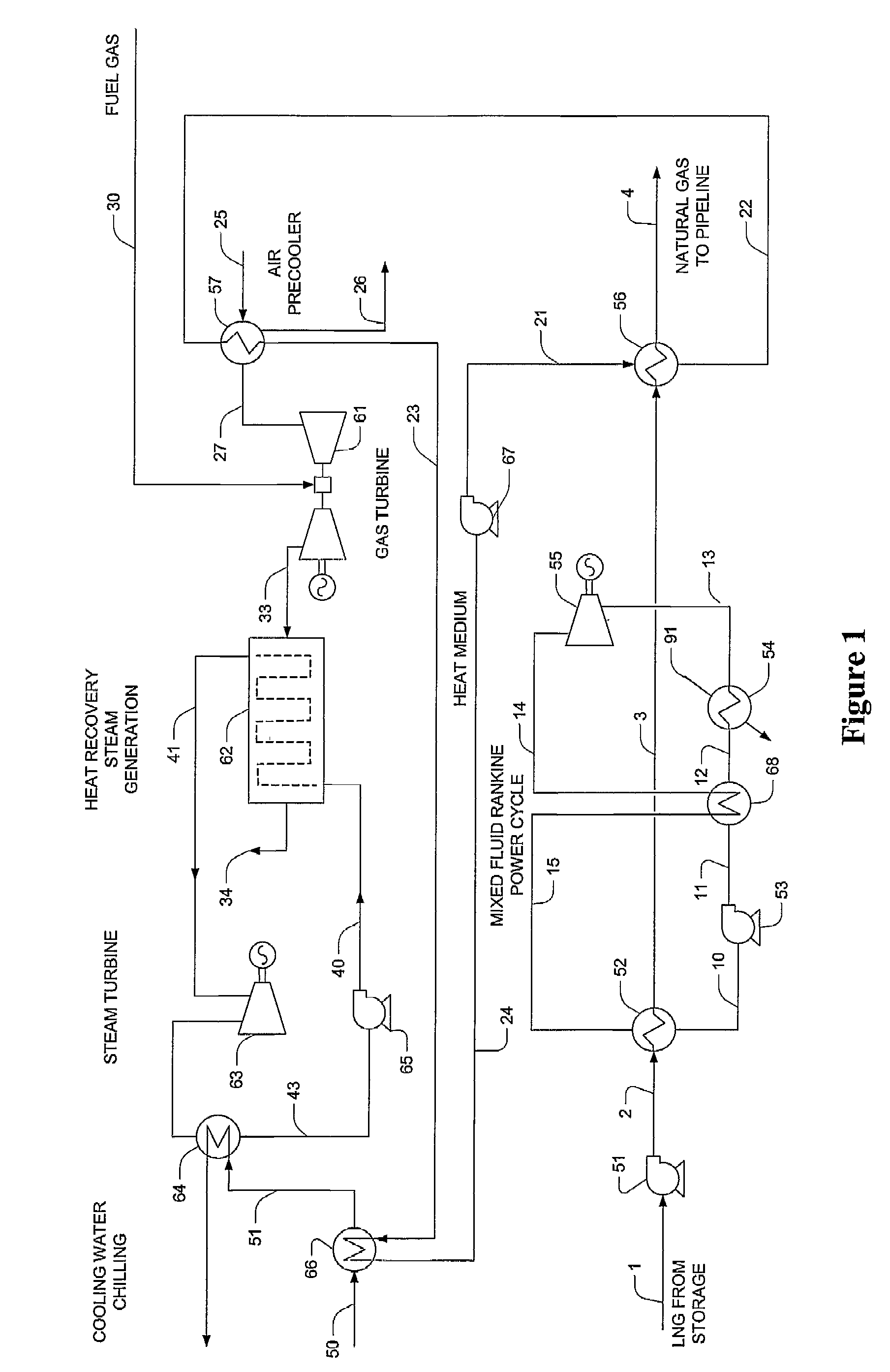

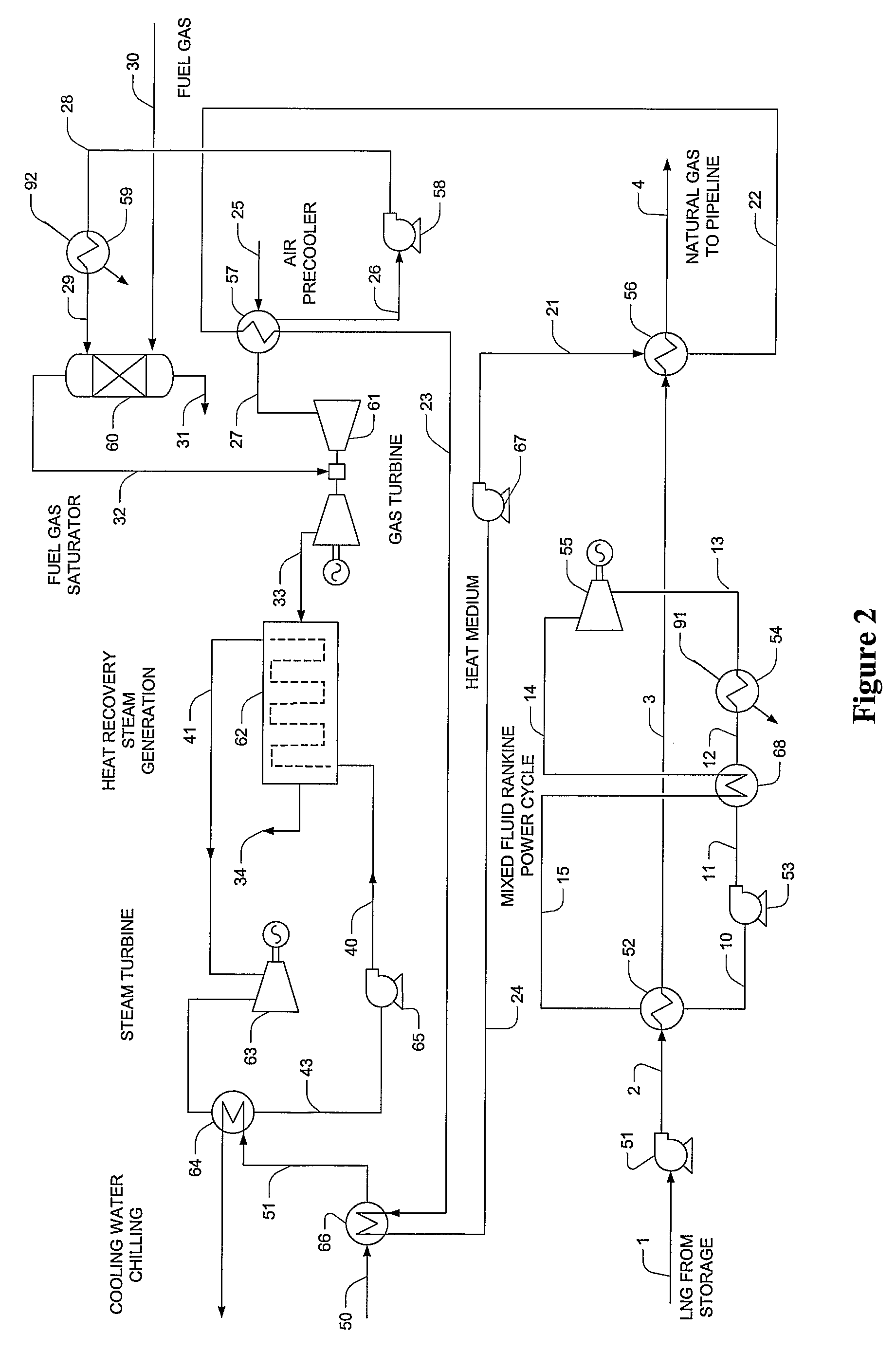

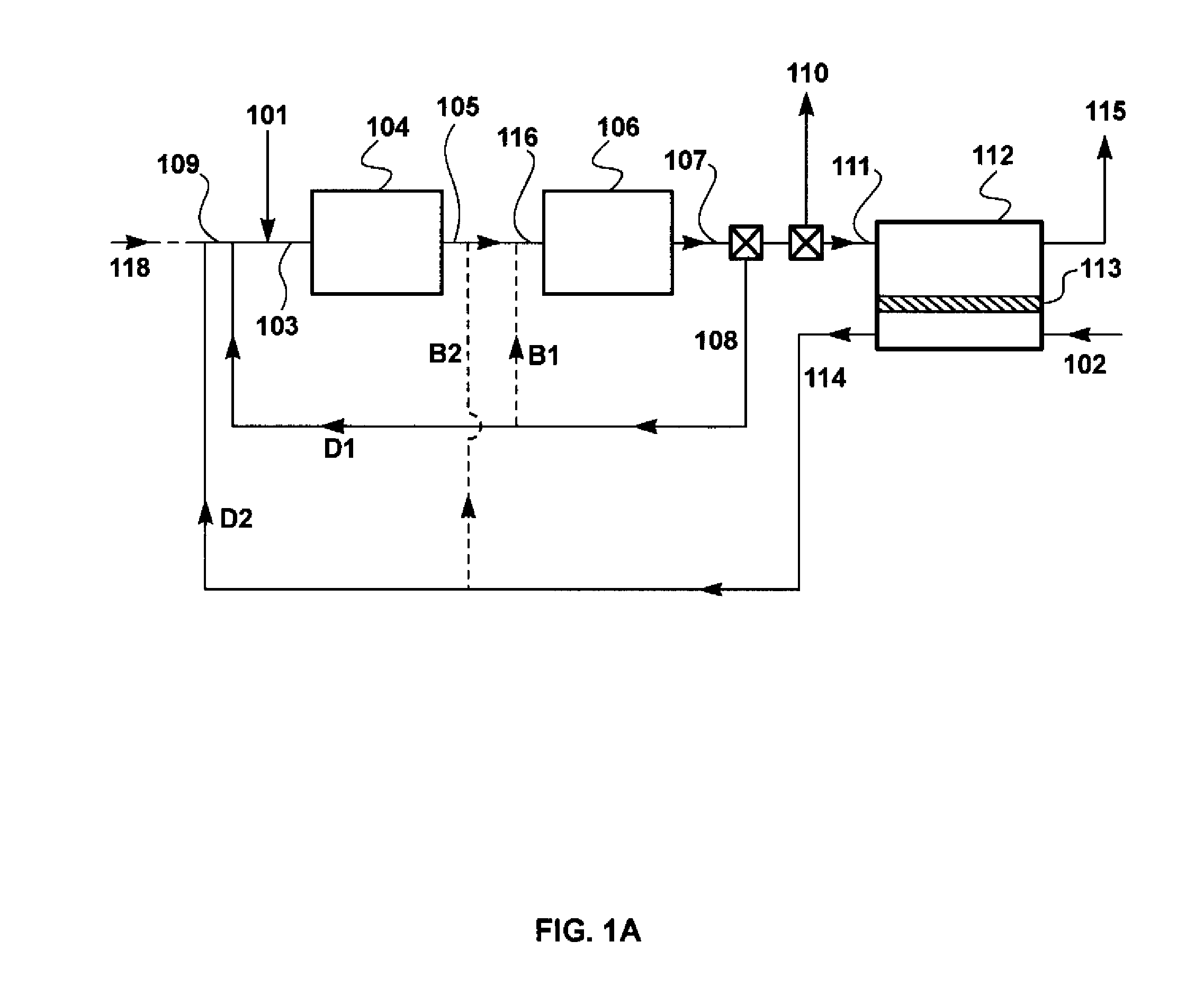

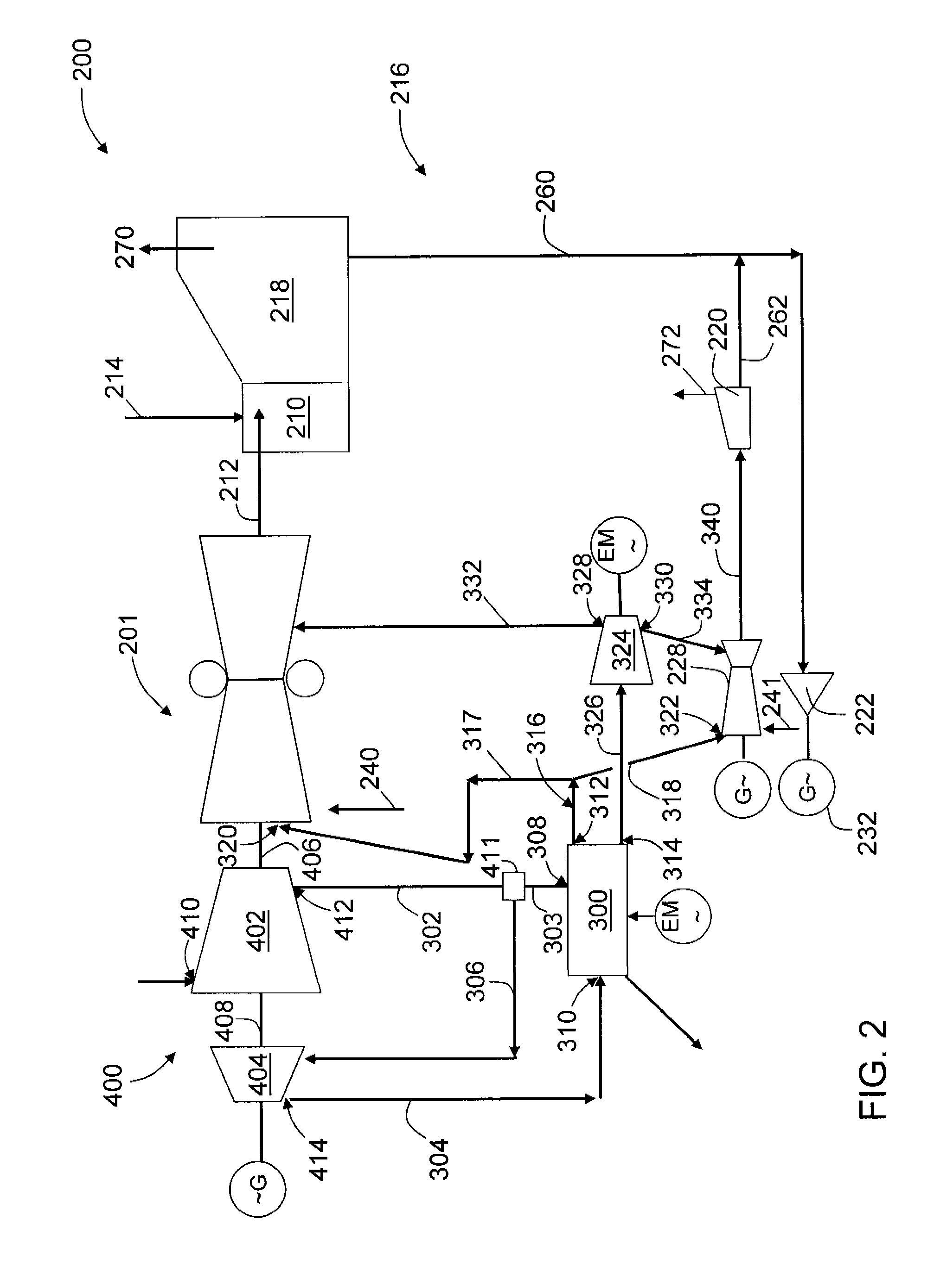

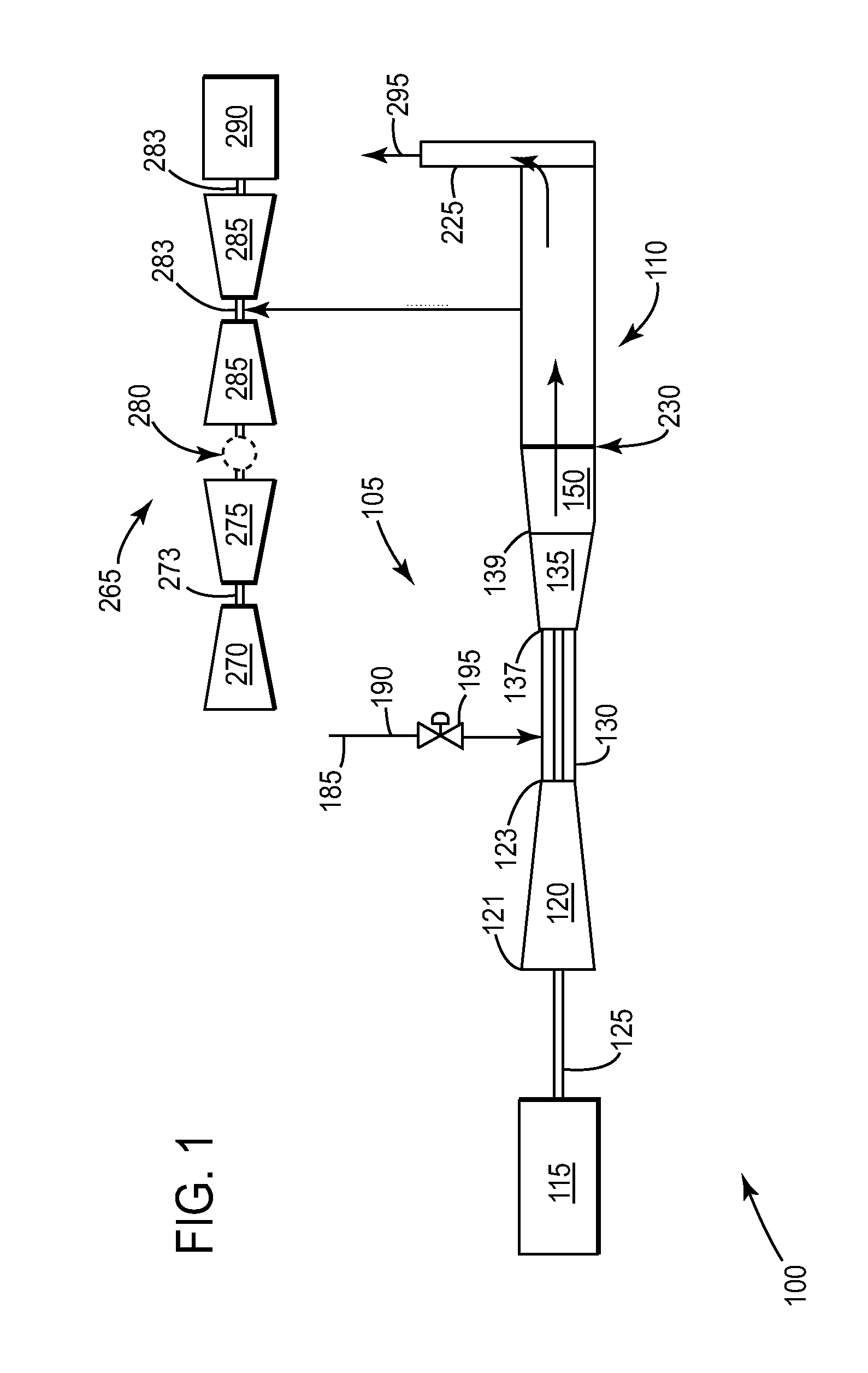

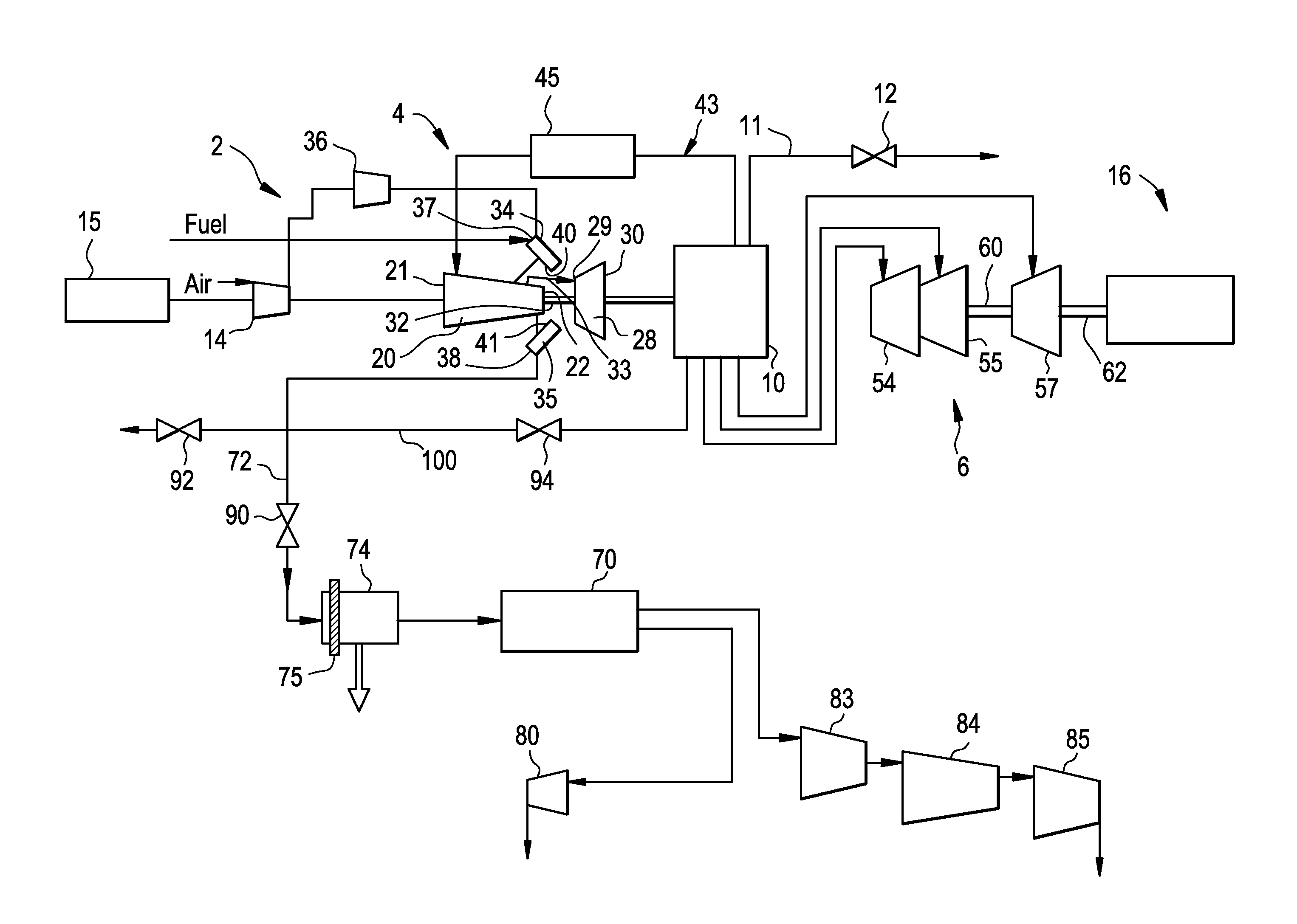

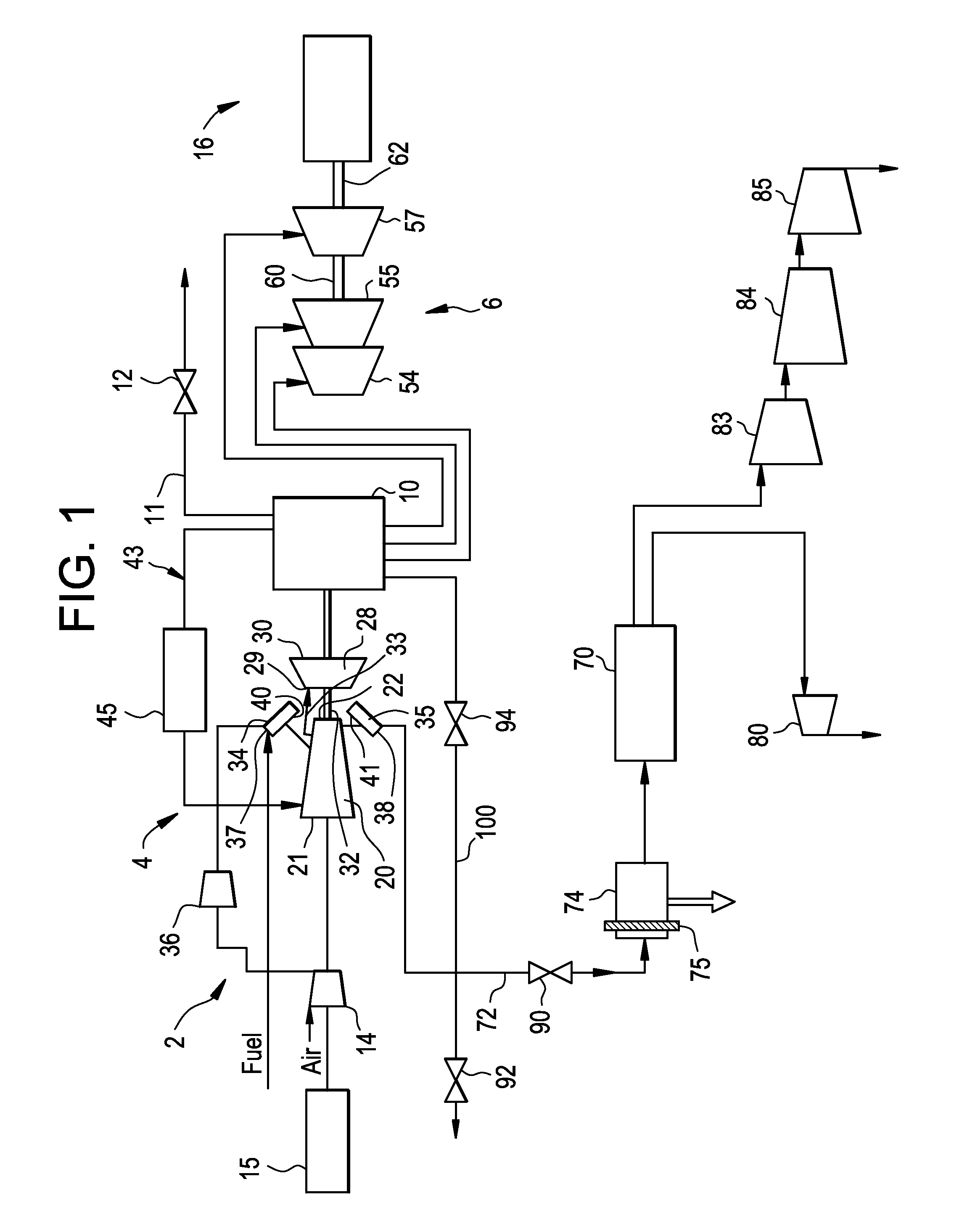

Liquified natural gas (LNG) fueled combined cycle power plant and a (LNG) fueled gas turbine plant

InactiveUS6374591B1Improve efficiencyParts are smallGas handling applicationsGas turbine plantsCombustion chamberPower station

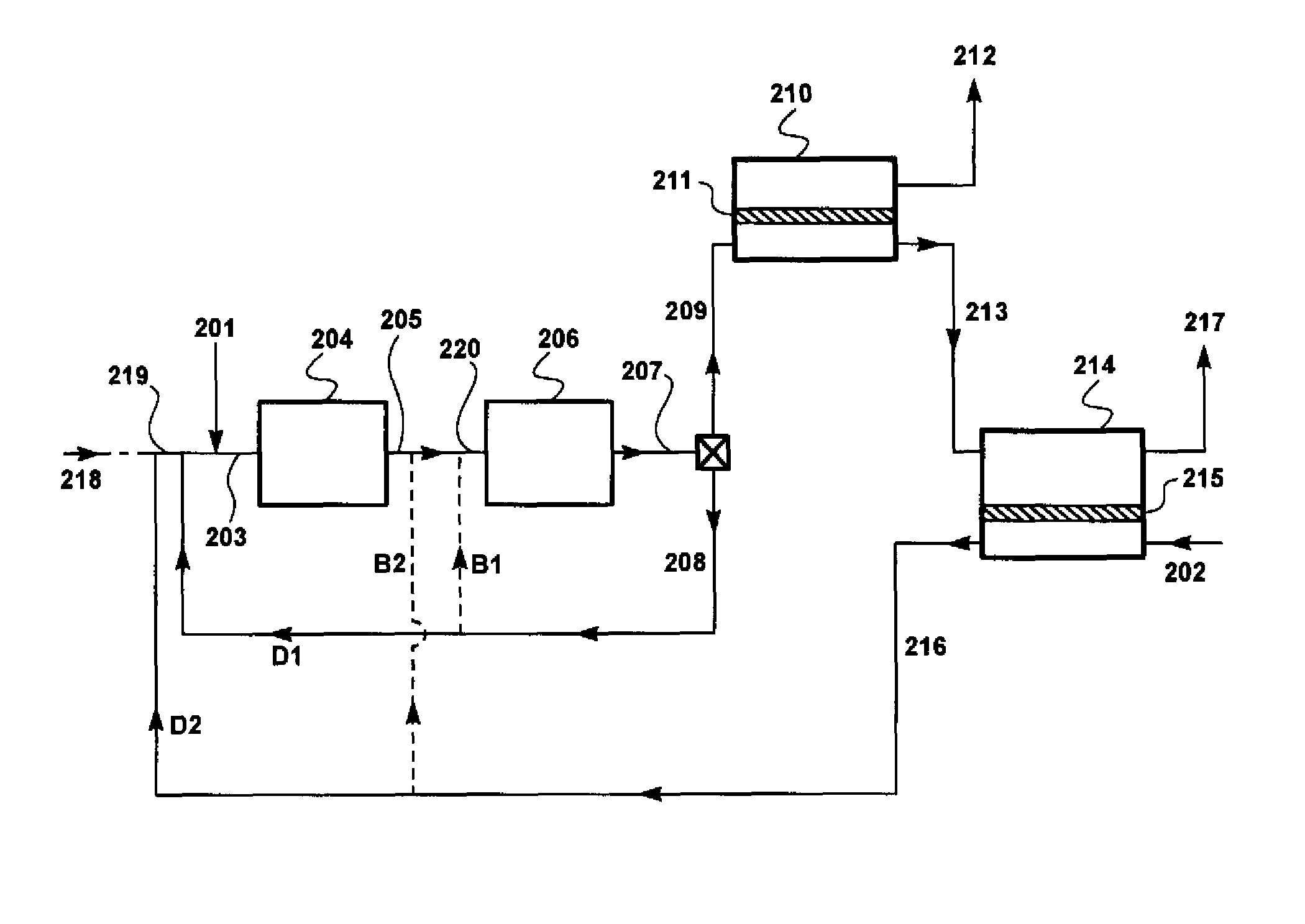

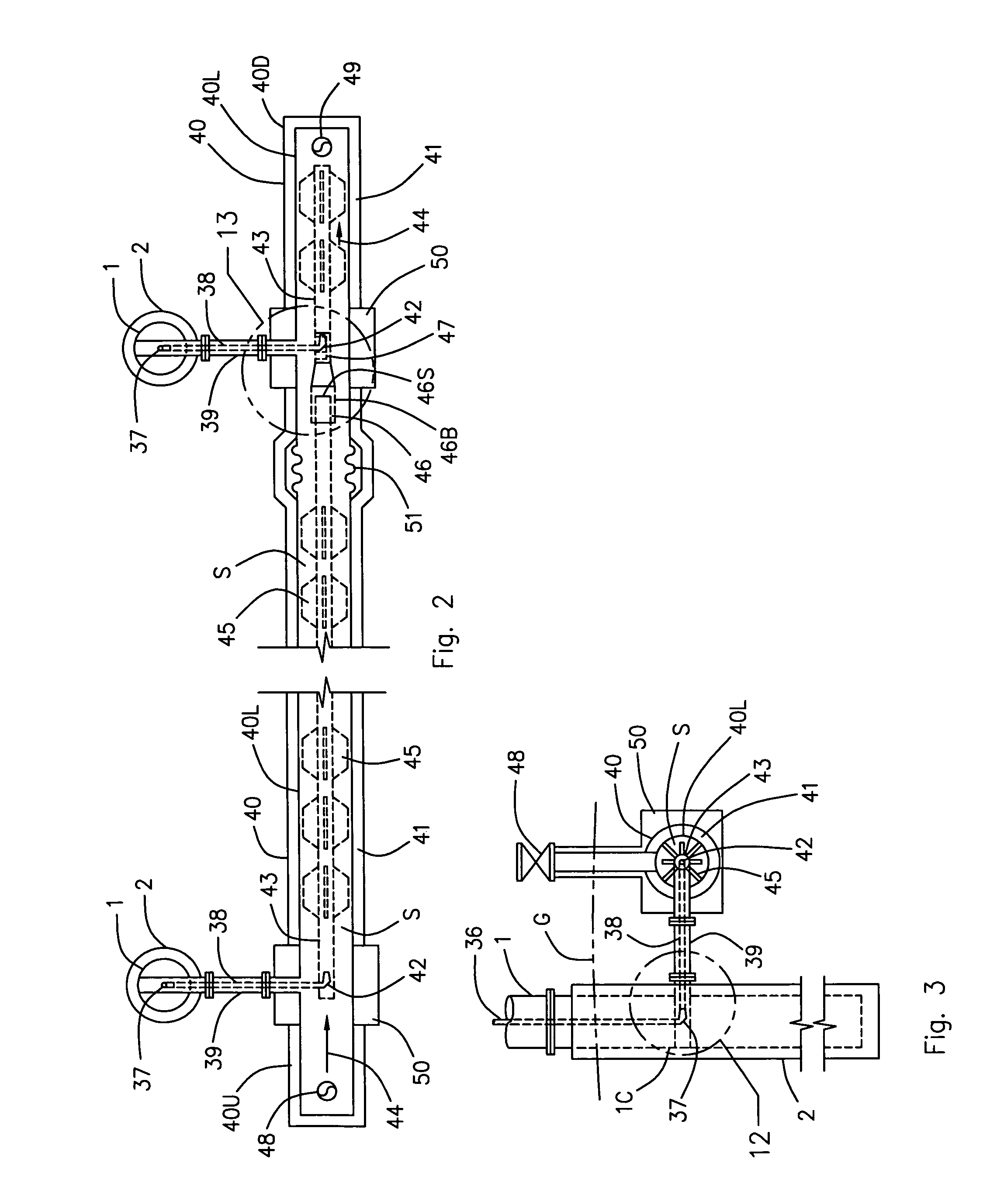

A process and system which improves the capacity and efficiency of a power plant. A LNG supply system fuels the plant. Gasified LNG in a combustor mixes with the air from an air compressor to provide the hot combustion gas for a gas turbine. The expanding LNG is used to chill a heat exchange fluid, e.g. water, which heat exchange fluid cools and densifies the intake air for the air compressor. Subsequently, the heat exchange fluid is used in another heat exchange step and is then re-chilled and recycled to cool and densify the intake air.

Owner:SUEZ LNG NA

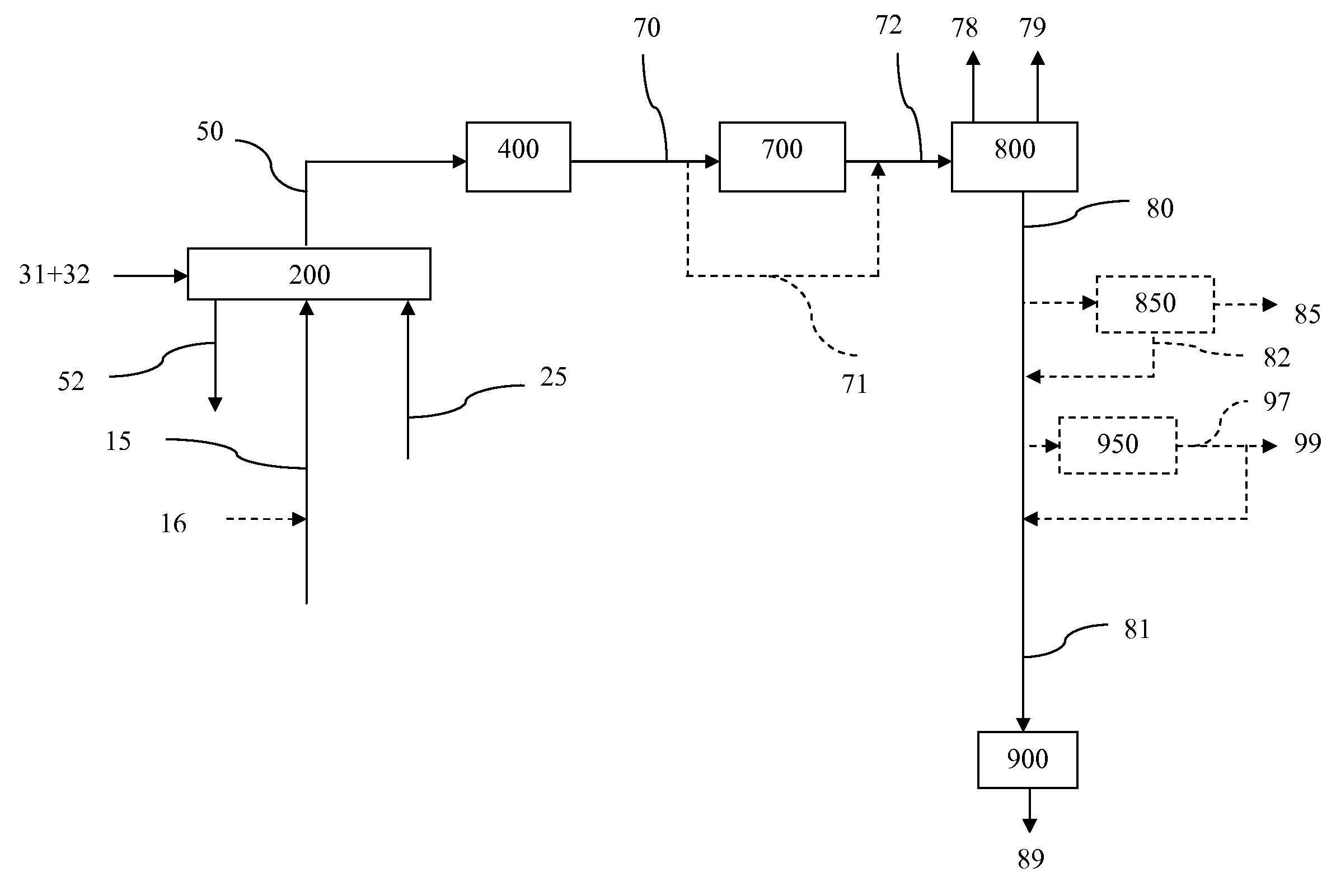

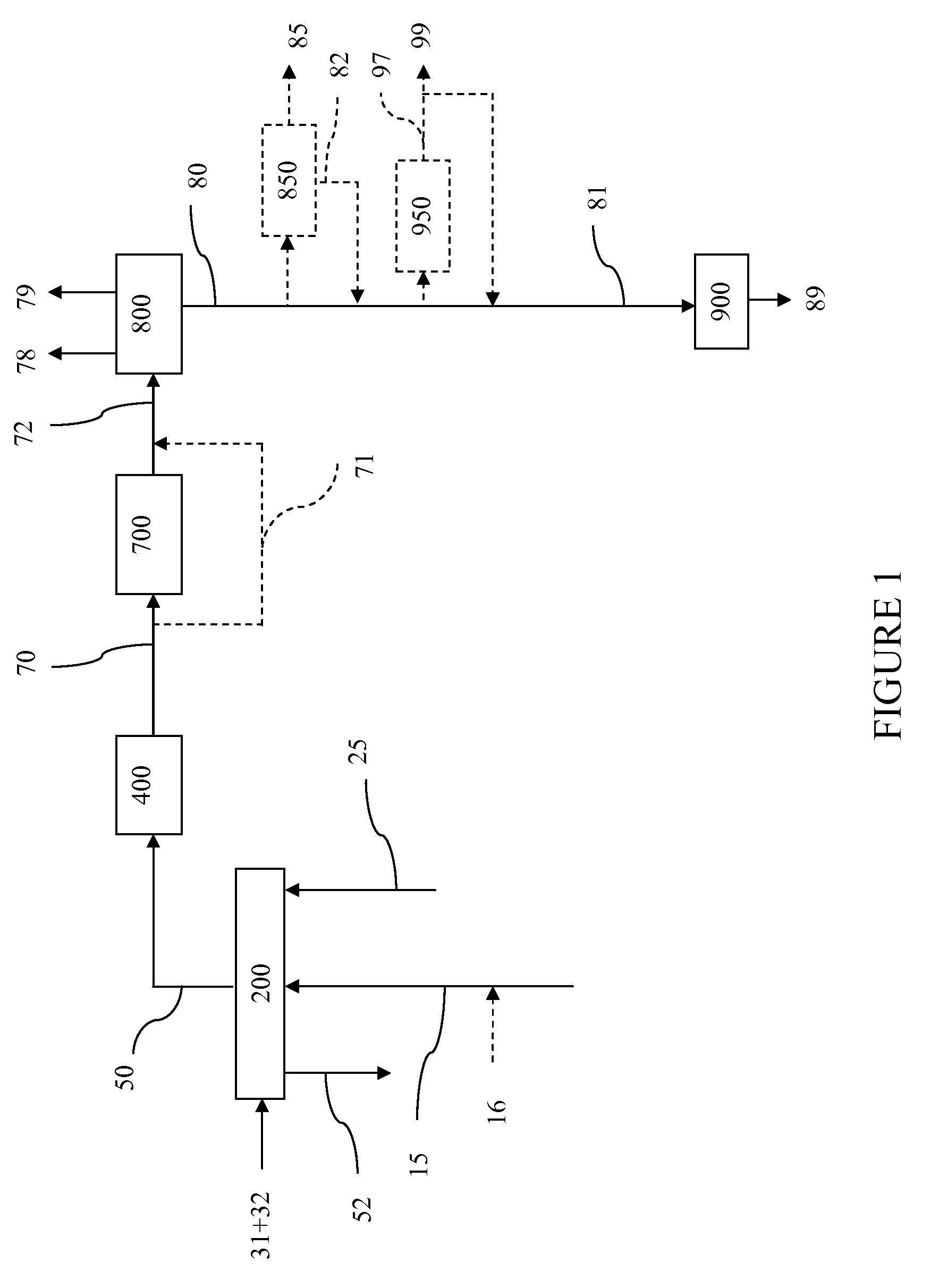

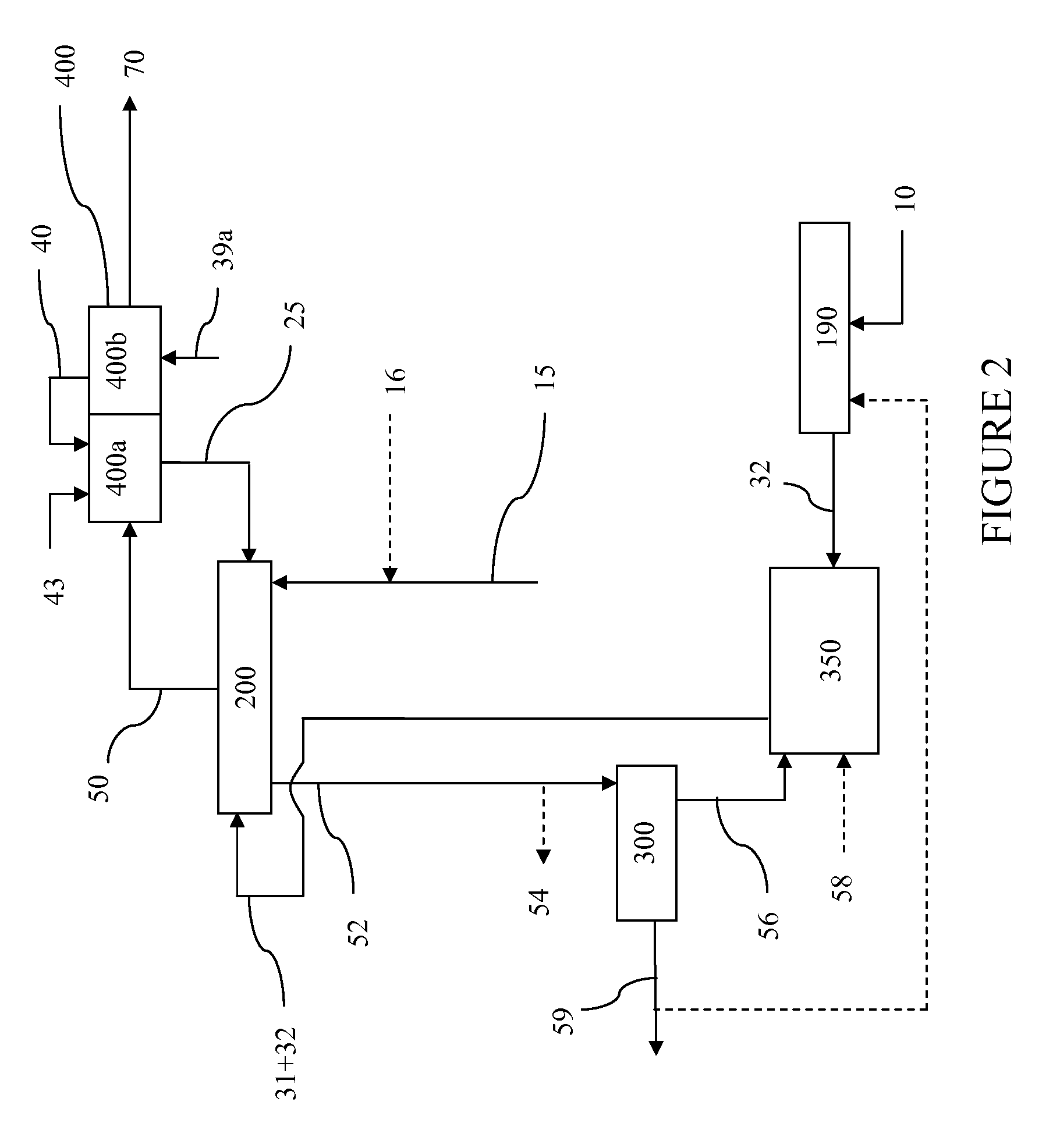

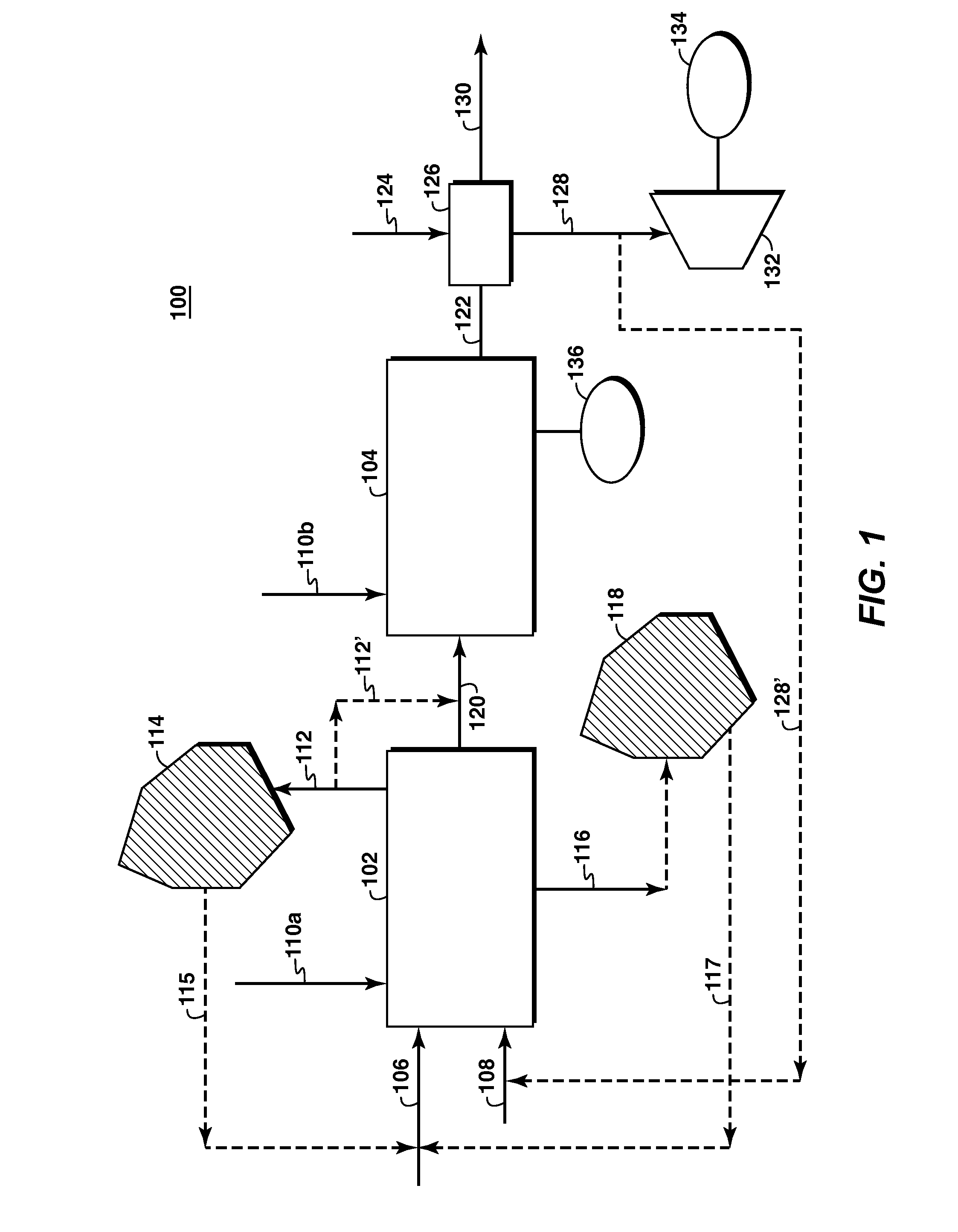

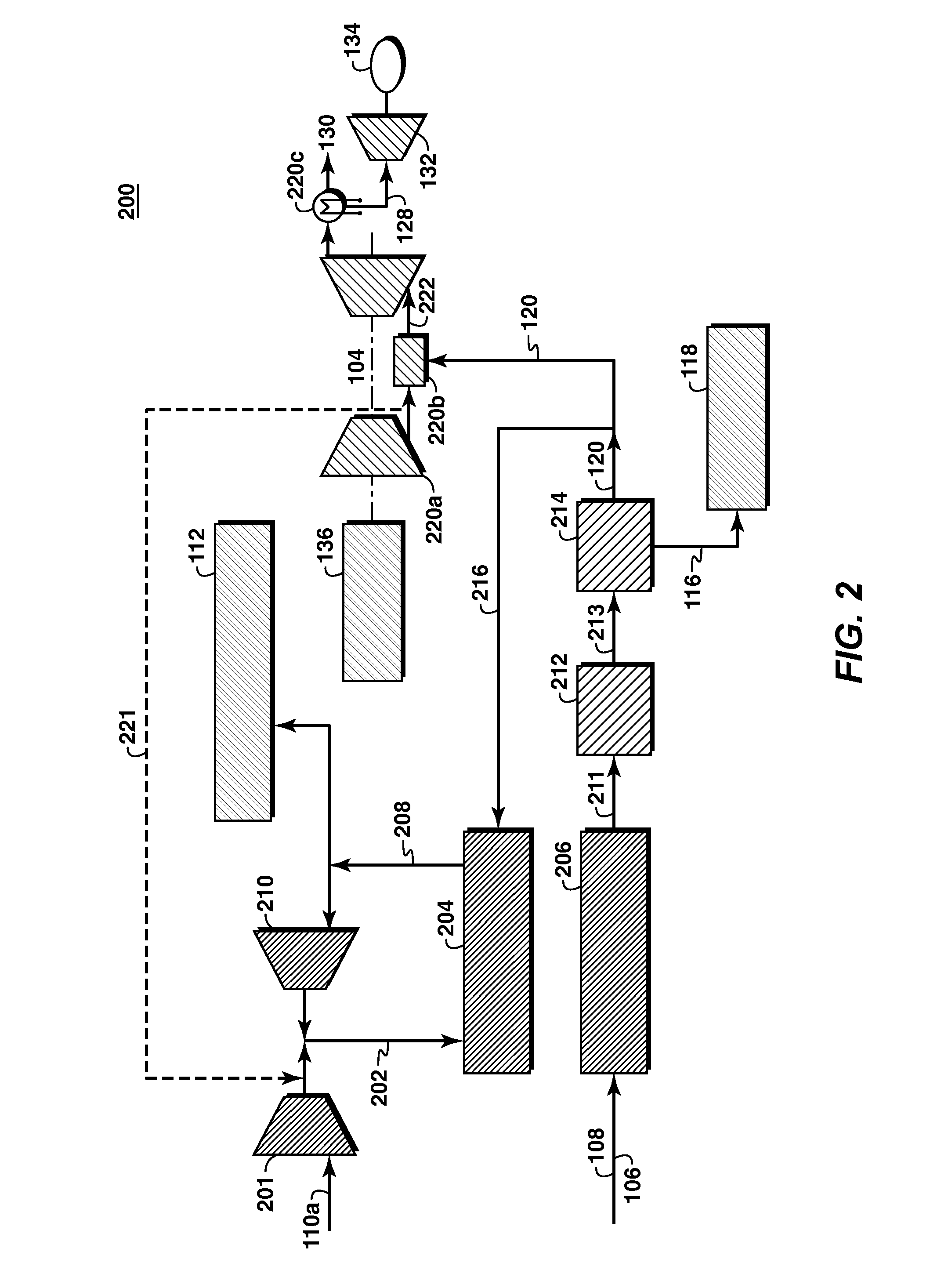

Methods and systems for enhancing operation of power plant generating units and systems

ActiveUS20160281607A1Programme controlTurbine/propulsion engine ignitionPower stationControl engineering

A method for controlling and enhancing a startup operation for a combined cycle power block (block) having at least one gas turbine and at least one steam turbine, wherein operating parameters define performance and operational characteristics for the startup operation, the method comprising: receiving measured operating parameters from a plurality of reference blocks and, for each of the plurality of reference blocks, a plurality of types of the startup operations; given the measured operating parameters, developing one or more reference transfer functions between two of the measured operating parameters; receiving measured operating parameters from the startup operation of a target block; given the measured operating parameters from the target block, developing one or more transfer functions for the target block between two of the operating parameters; selecting one of the reference transfer functions; and normalizing the transfer function of the target block per the selected reference transfer function.

Owner:GENERAL ELECTRIC CO

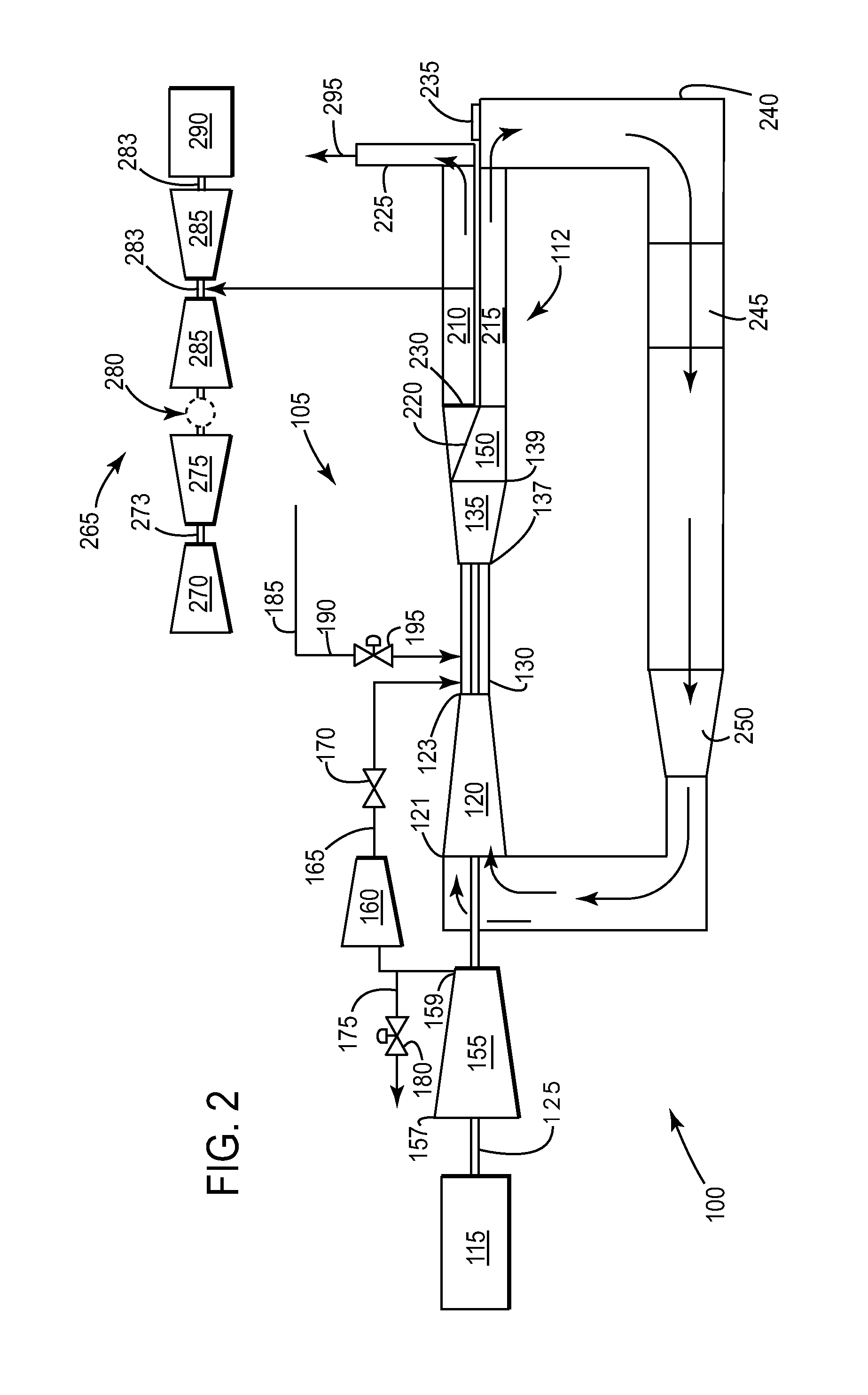

Integrated hydromethanation combined cycle process

InactiveUS20110062721A1Easy to understandCombustible gas catalytic treatmentHydrogen/synthetic gas productionHydrogenCombustible gas

The present invention relates to an integrated process for preparing combustible gaseous products via the hydromethanation of carbonaceous feedstocks in the presence of steam, carbon monoxide, hydrogen, a hydromethanation catalyst and optionally oxygen, and generating electrical power from those combustible gaseous products as well as a hydrogen and / or methane by-product stream.

Owner:SURE CHAMPION INVESTMENT LTD

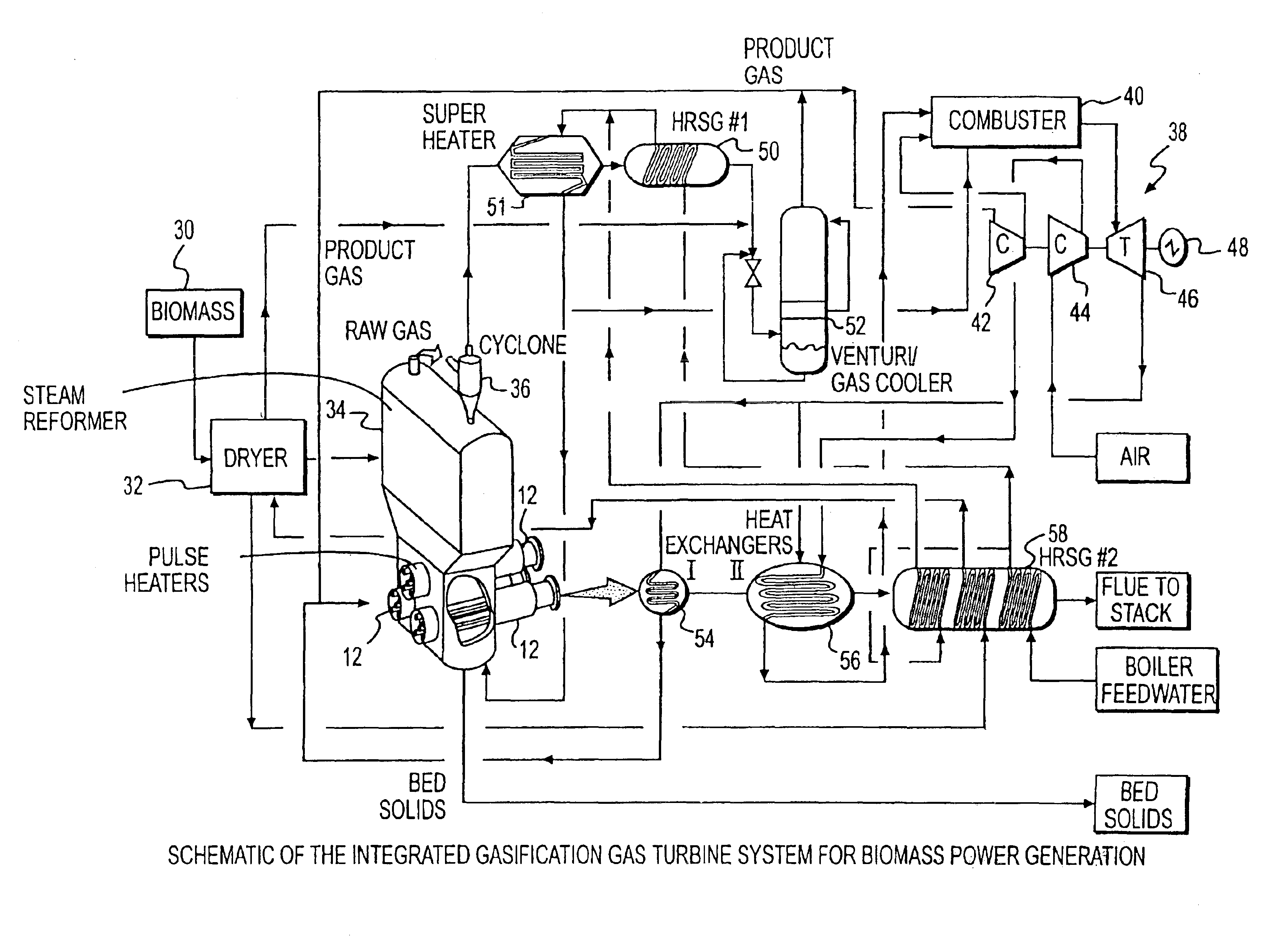

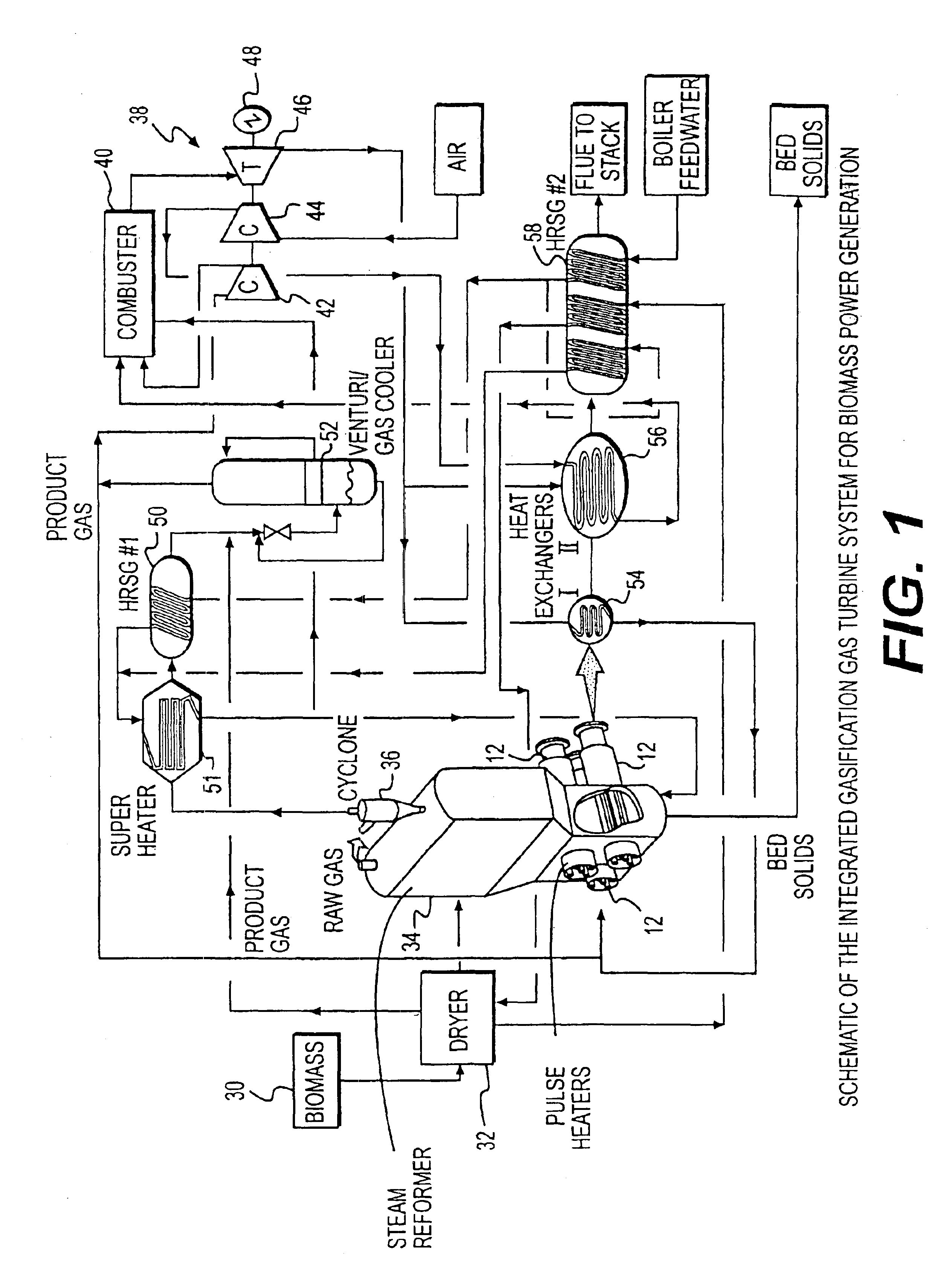

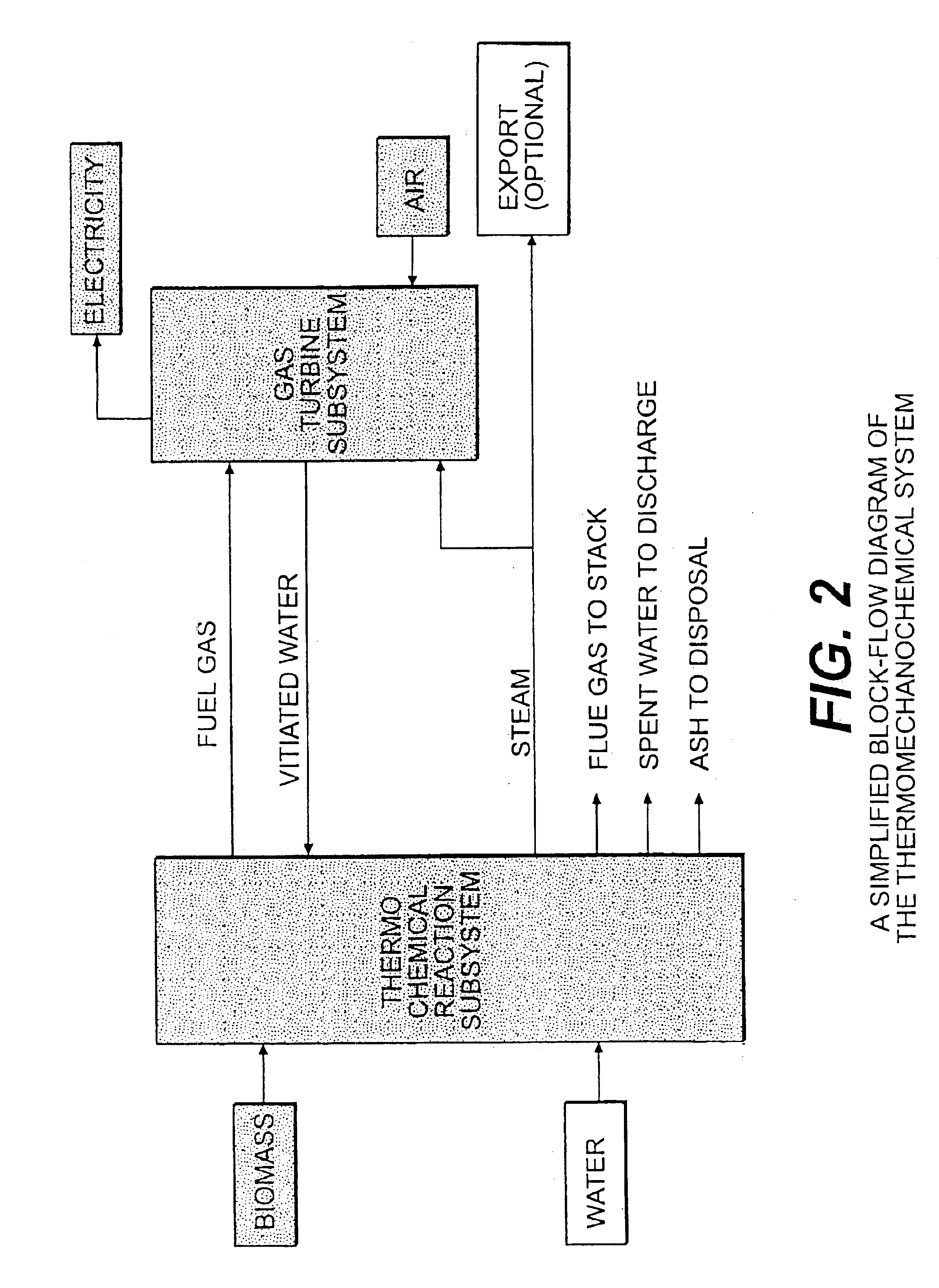

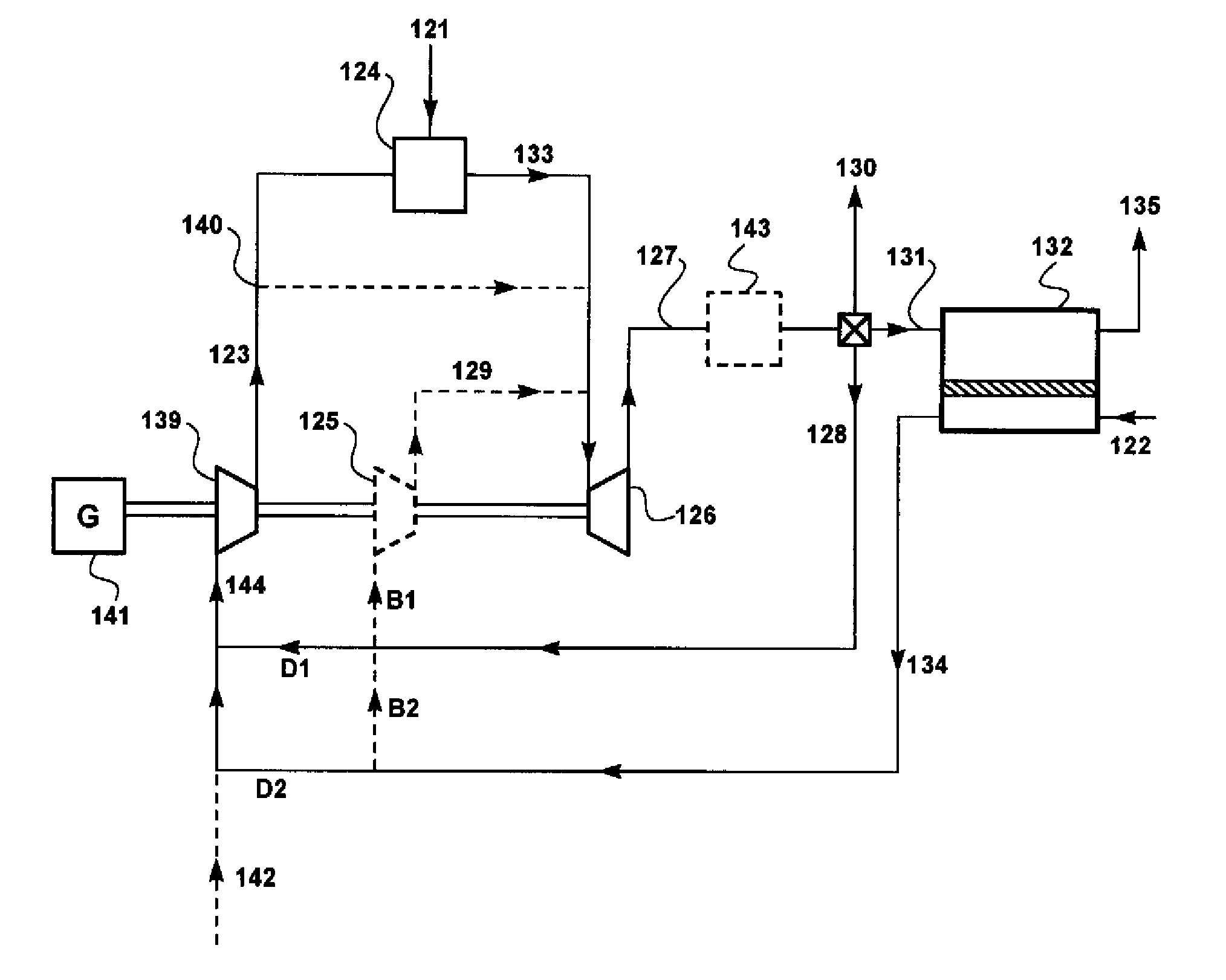

System integration of a steam reformer and gas turbine

A novel process and apparatus for power generation from biomass and other carbonaceous feedstocks are provided. The process integrates a pulse combustor steam reformer with a gas turbine to generate electricity such that (i) efficiency is higher than those of conventional and current advanced power systems, (ii) emissions are lower than those proposed in the new environmental regulations, and (iii) performance is comparable to that of combined cycle, even though a bottoming cycle is not included here. The pulse combustor steam reformer generates a hydrogen-rich, medium-Btu fuel gas that is fired in a gas turbine to generate electricity. The apparatus may be configured to produce only power or combined heat and power.

Owner:THERMOCHEM RECOVERY INT

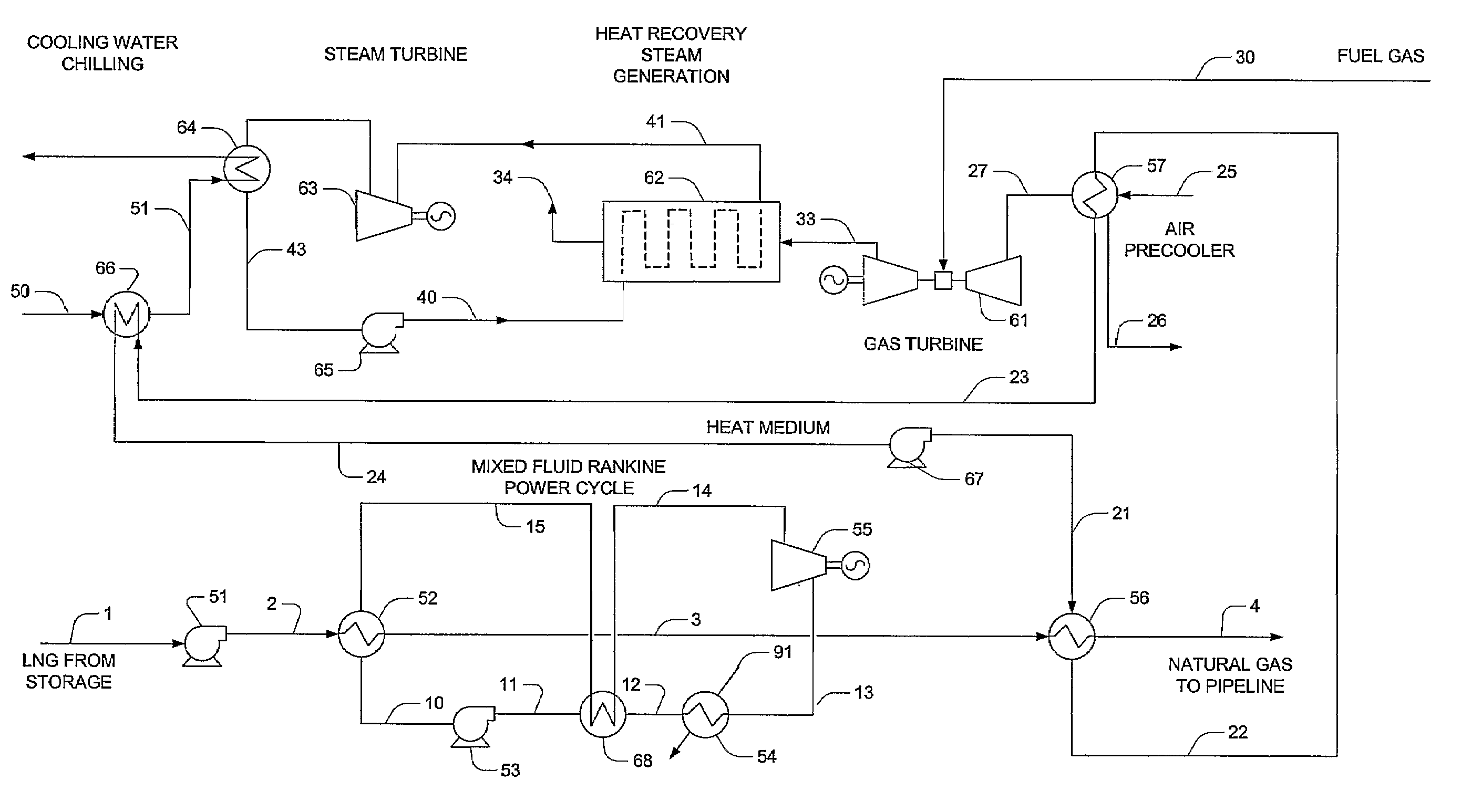

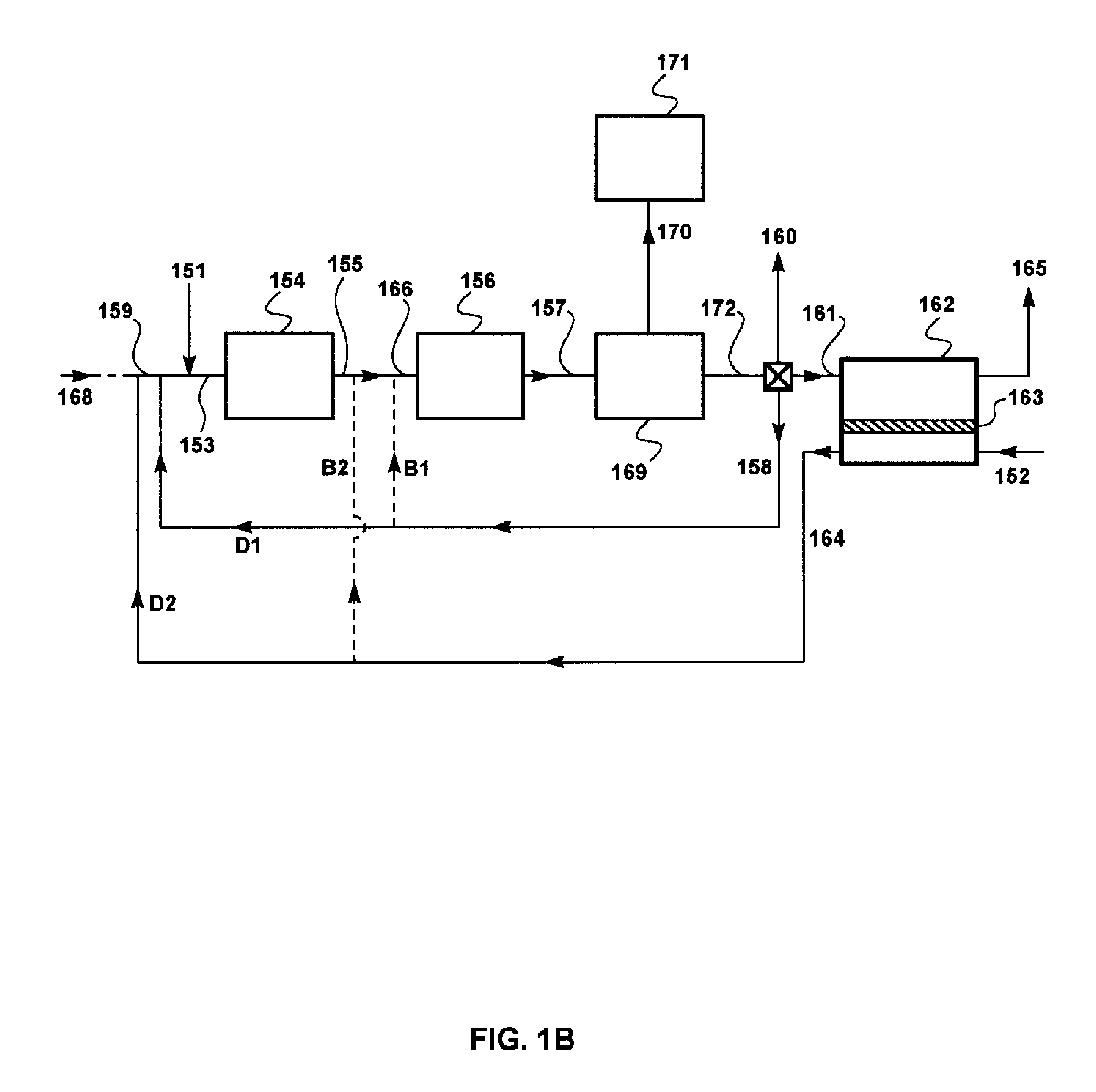

Configurations and methods for power generation with integrated LNG regasification

Owner:FLUOR TECH CORP

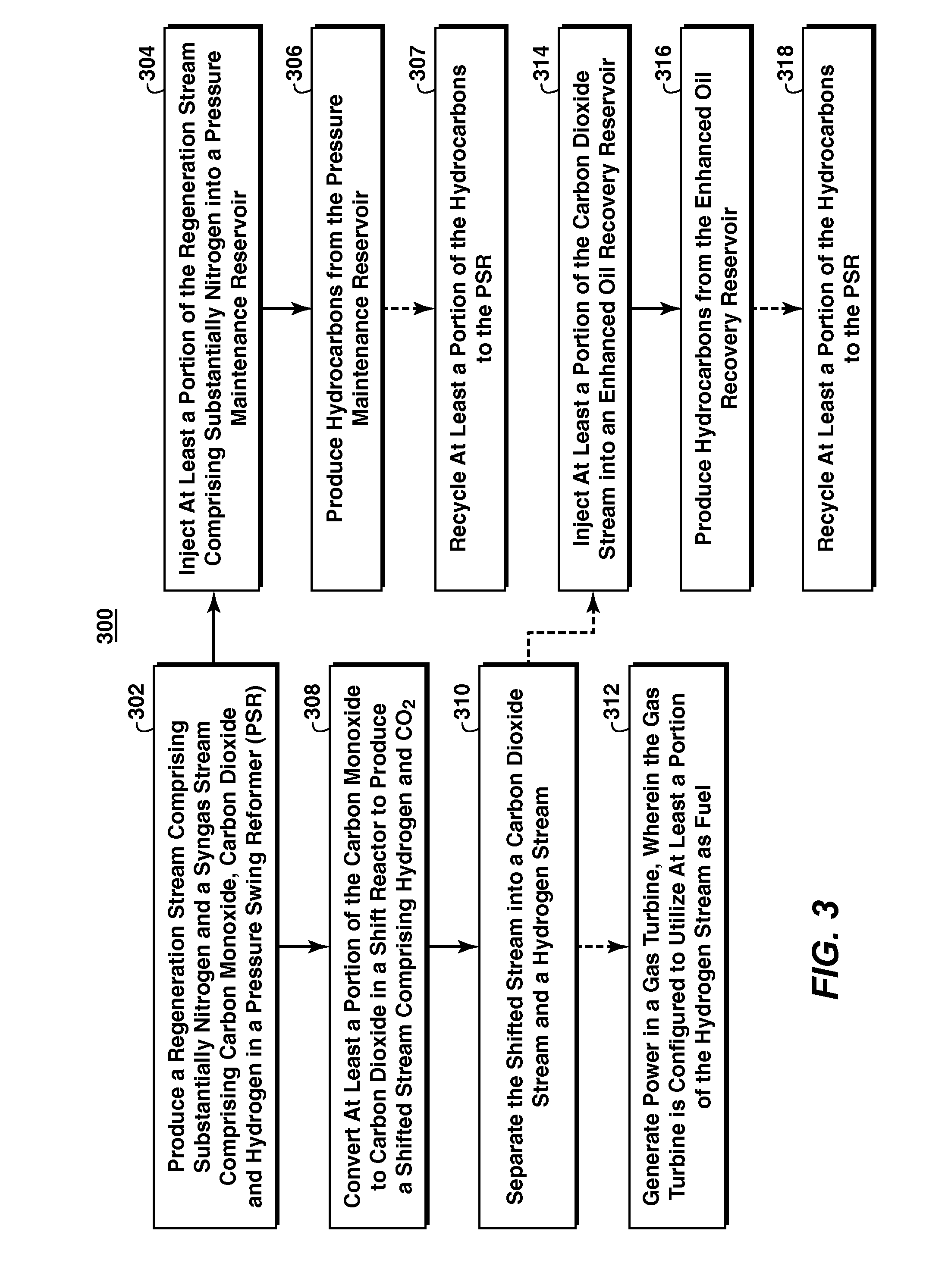

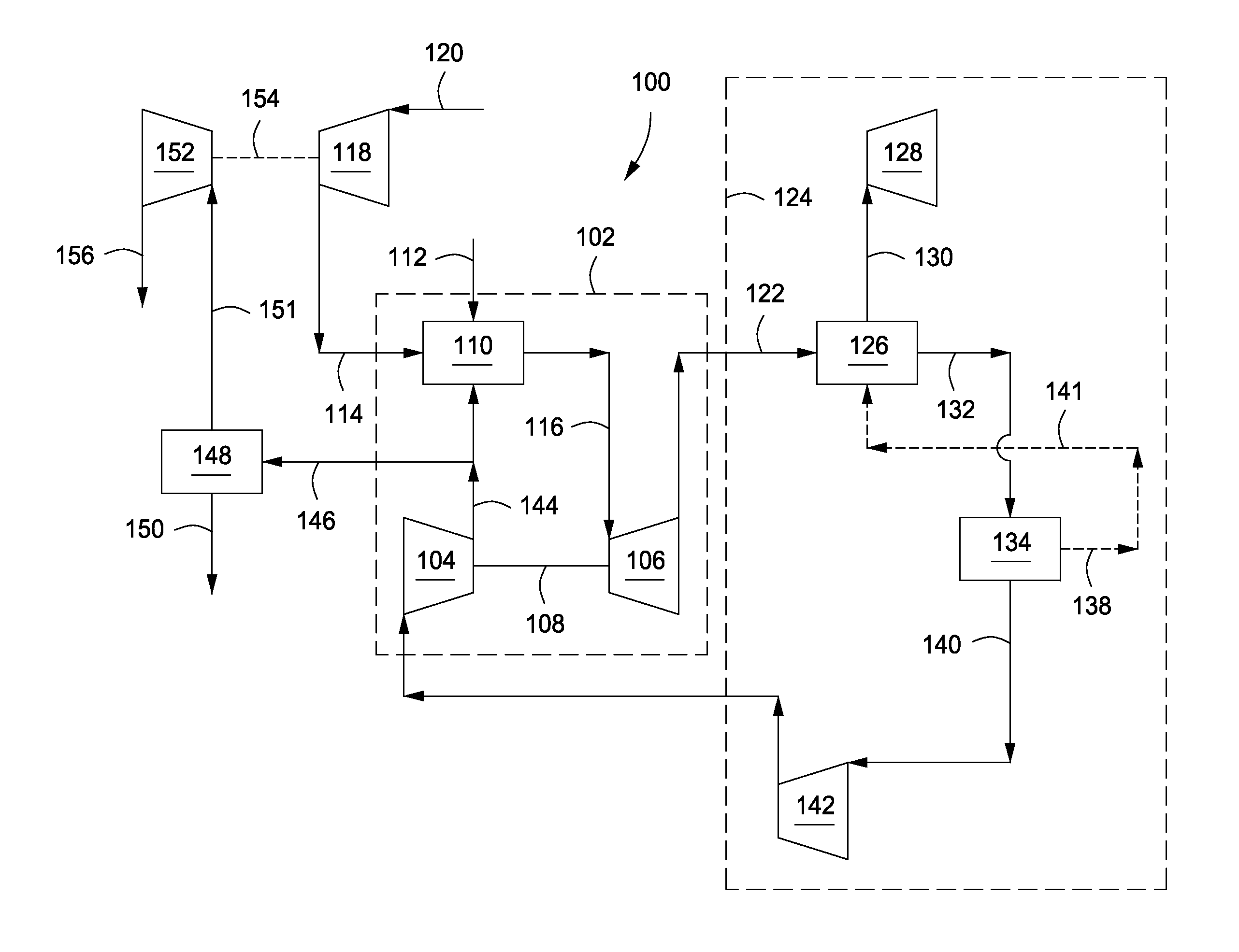

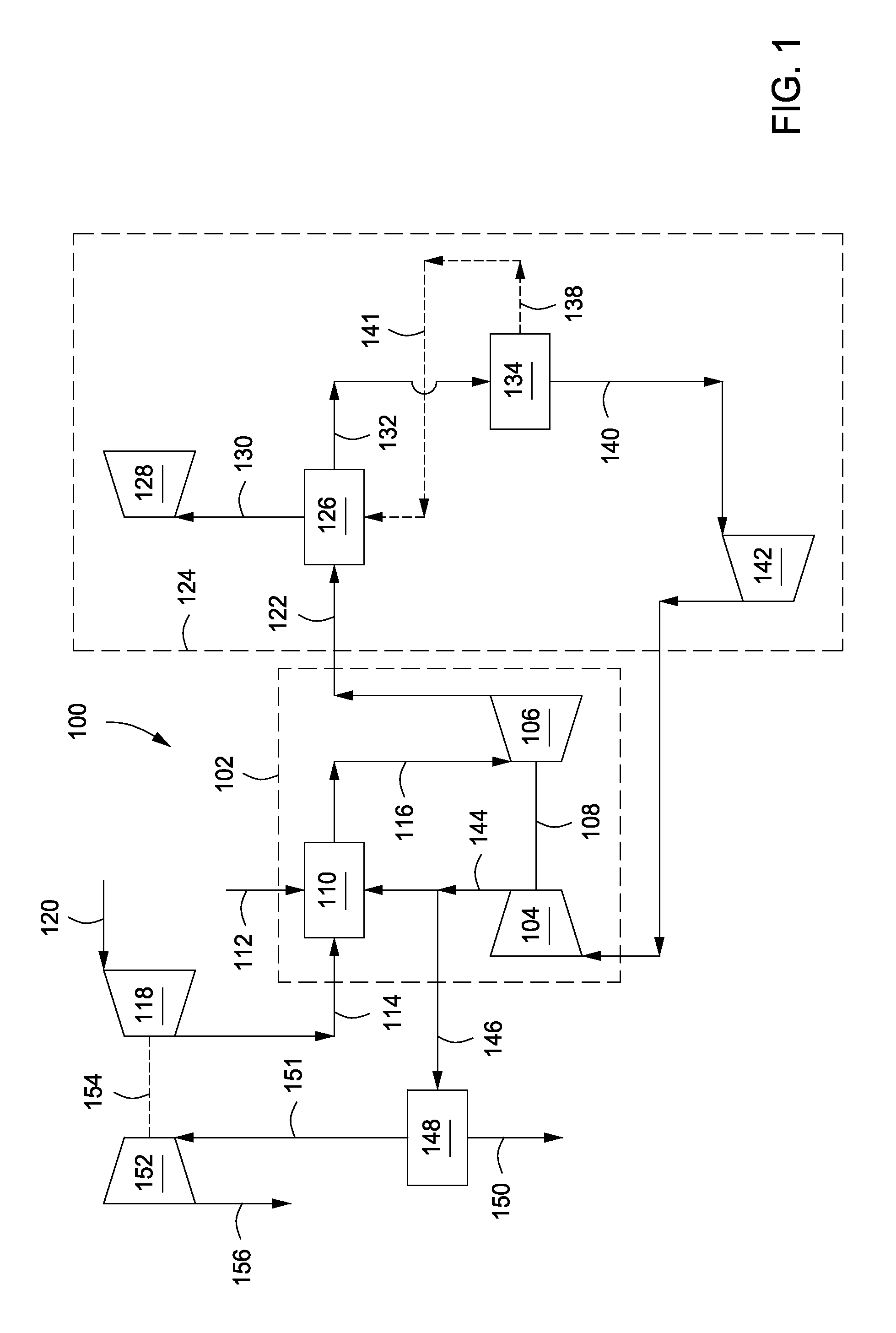

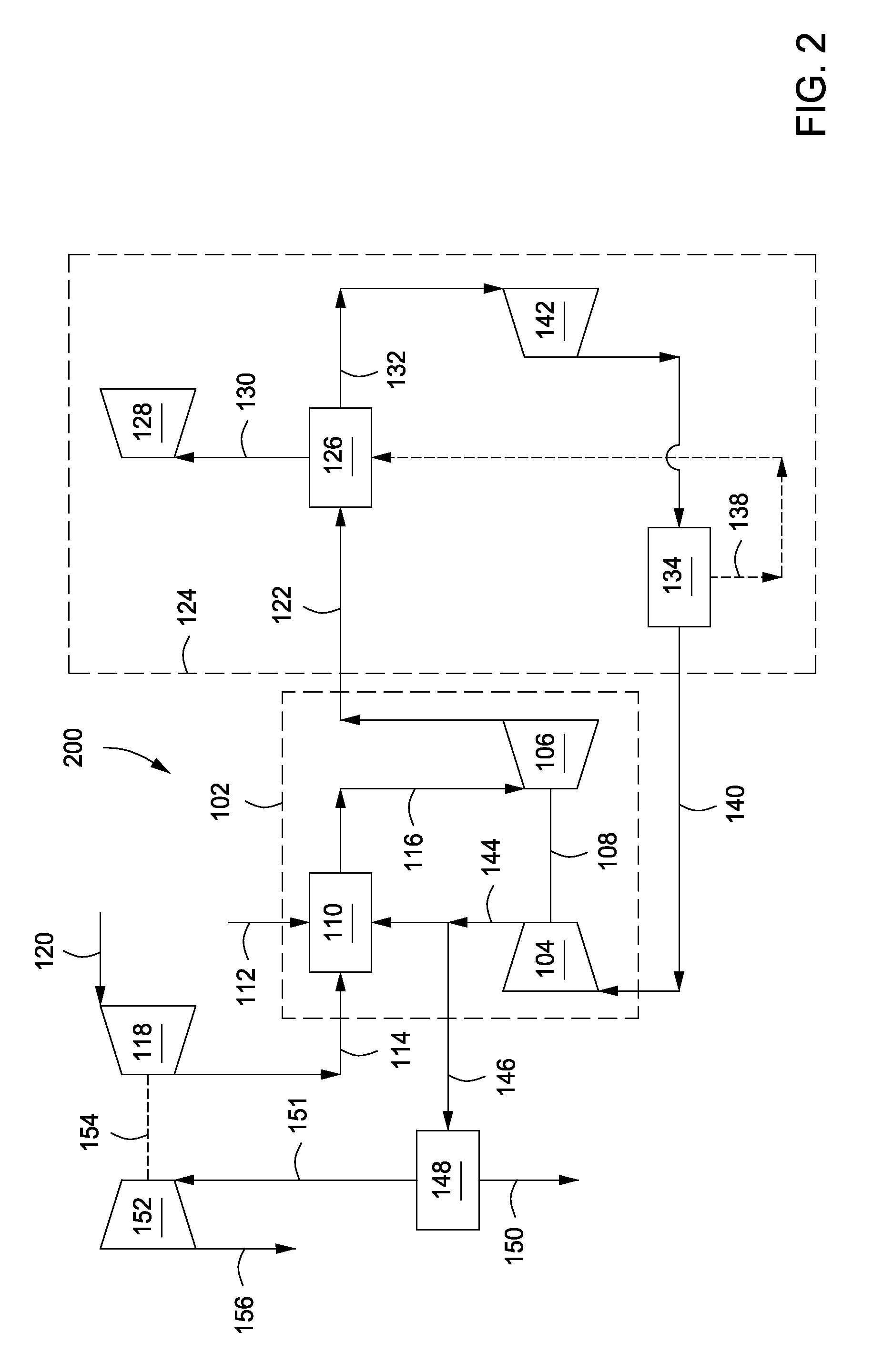

Low Emission Power Generation and Hydrocarbon Recovery Systems and Methods

Methods and systems for low emission power generation in hydrocarbon recovery processes are provided. One system includes integrated pressure maintenance and miscible flood systems with low emission power generation. The system may also include integration of a pressure swing reformer (PSR), air-blown auto-thermal reformer (ATR), or oxygen-blown ATR with a gas power turbine system, preferably a combined cycle gas power turbine system. Such systems may be employed to capture and utilize greenhouse gases (GHG) and generate power for use in hydrocarbon recovery operations.

Owner:EXXONMOBIL UPSTREAM RES CO

Low Emission Triple-Cycle Power Generation Systems and Methods

Methods and systems for low emission power generation in combined cycle power plants are provided. One system includes a gas turbine system that stoichiometrically combusts a fuel and an oxidant in the presence of a compressed recycle stream to provide mechanical power and a gaseous exhaust. The compressed recycle stream acts as a diluent to moderate the temperature of the combustion process. A boost compressor can boost the pressure of the gaseous exhaust before being compressed into the compressed recycle stream. A purge stream is tapped off from the compressed recycle stream and directed to a C02 separator which discharges C02 and a nitrogen-rich gas which can be expanded in a gas expander to generate additional mechanical power.

Owner:EXXONMOBIL UPSTREAM RES CO

Exhaust heat augmentation in a combined cycle power plant

InactiveUS20070130952A1Gas turbine plantsCombined combustion mitigationPower stationElectric generator

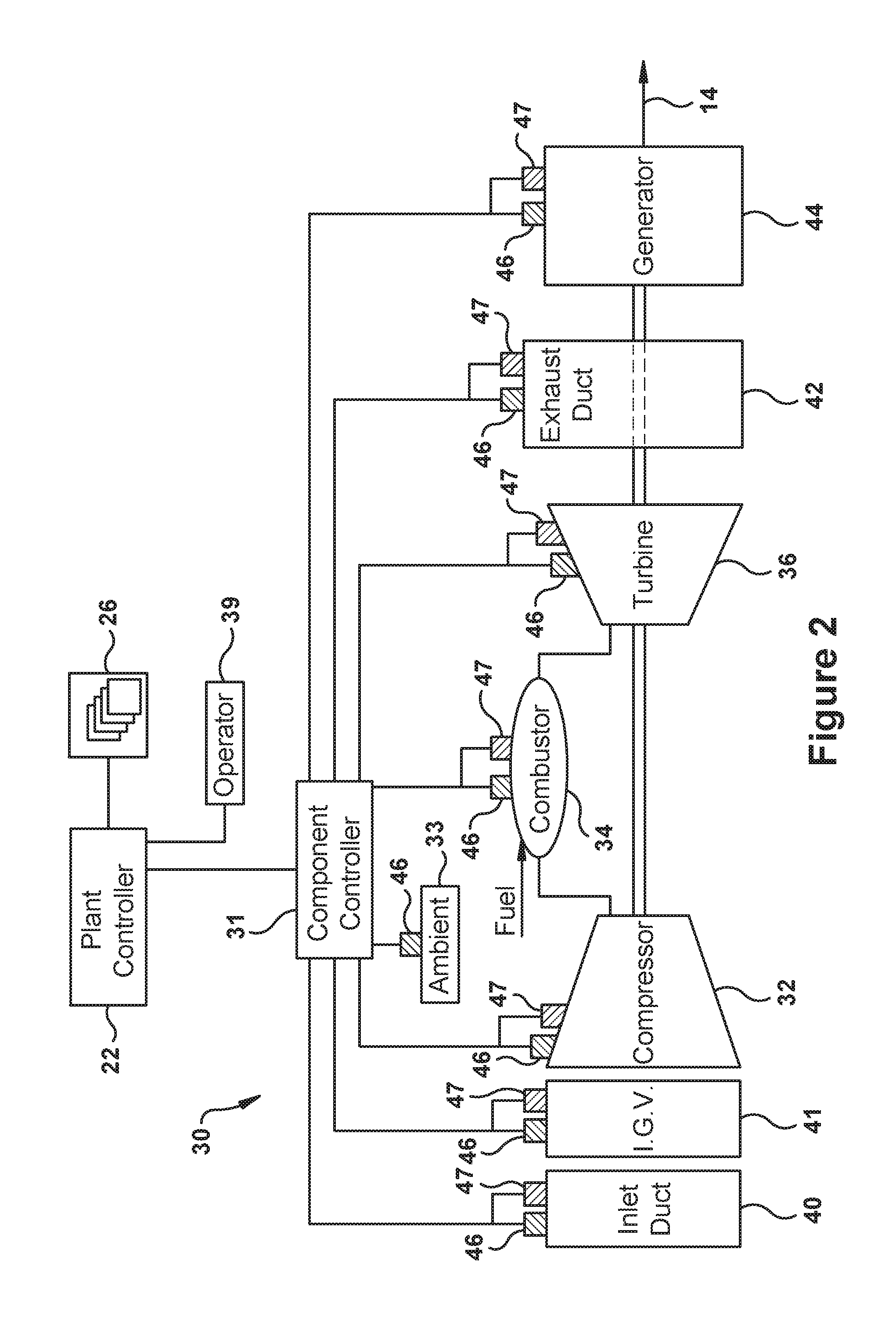

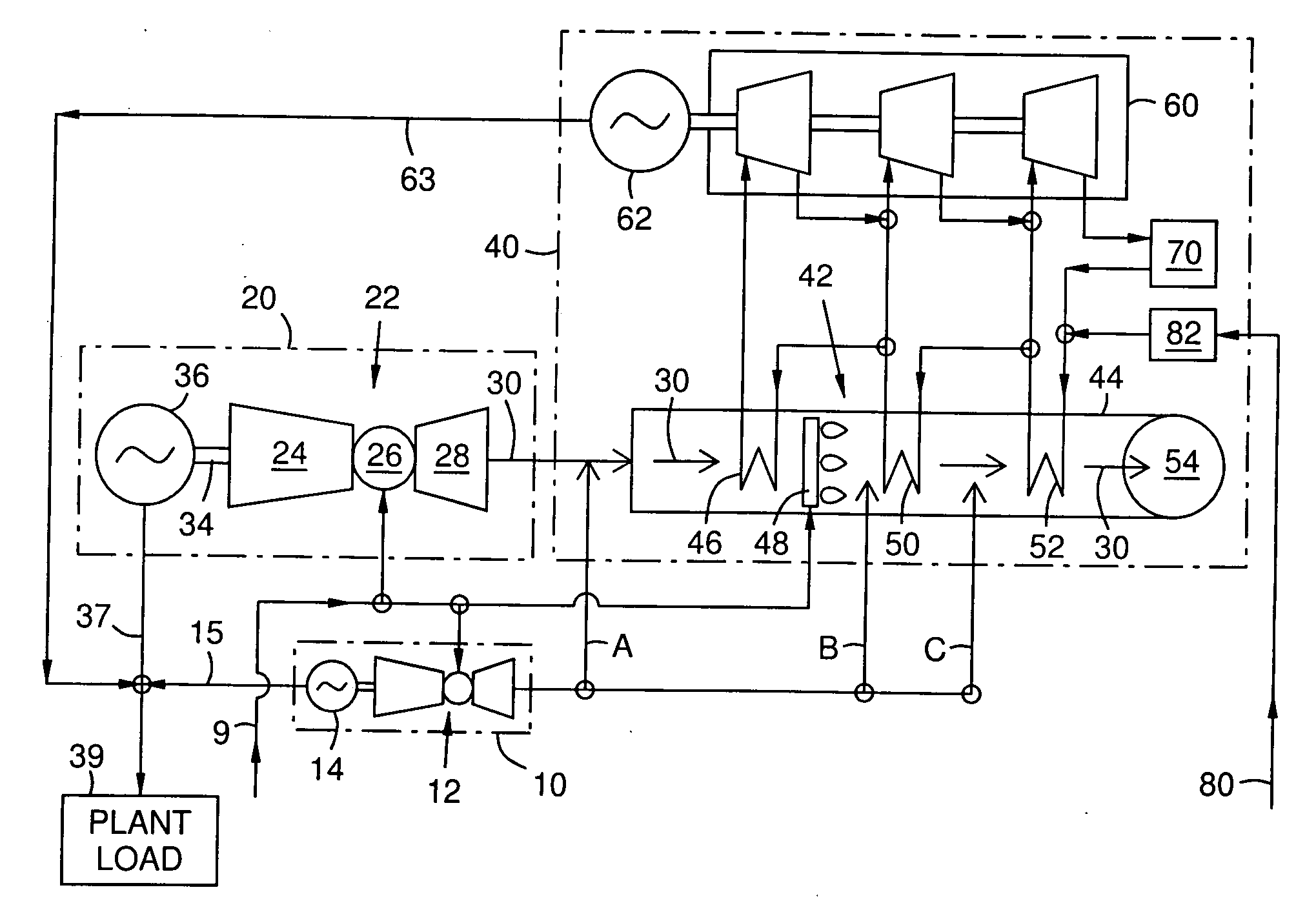

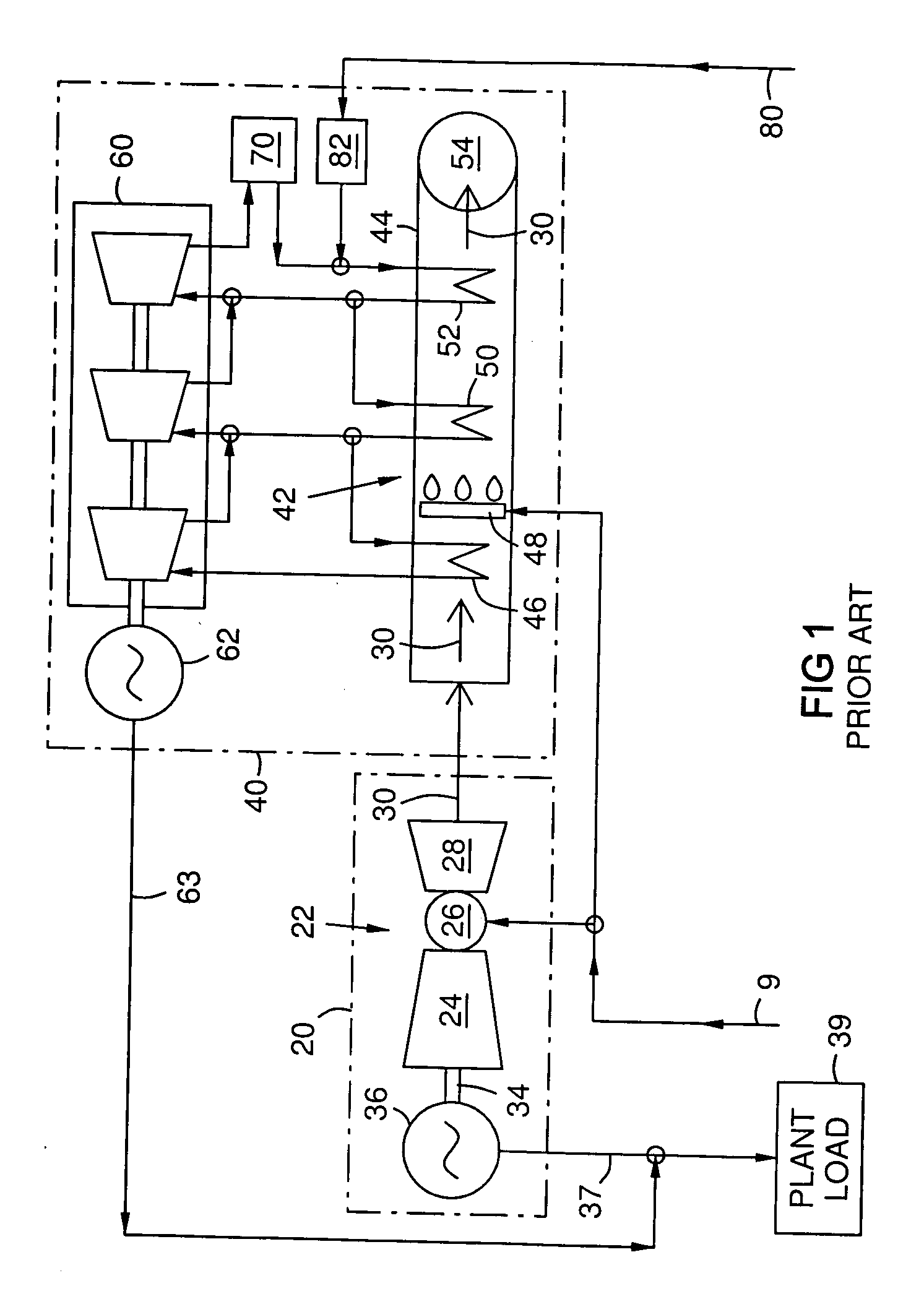

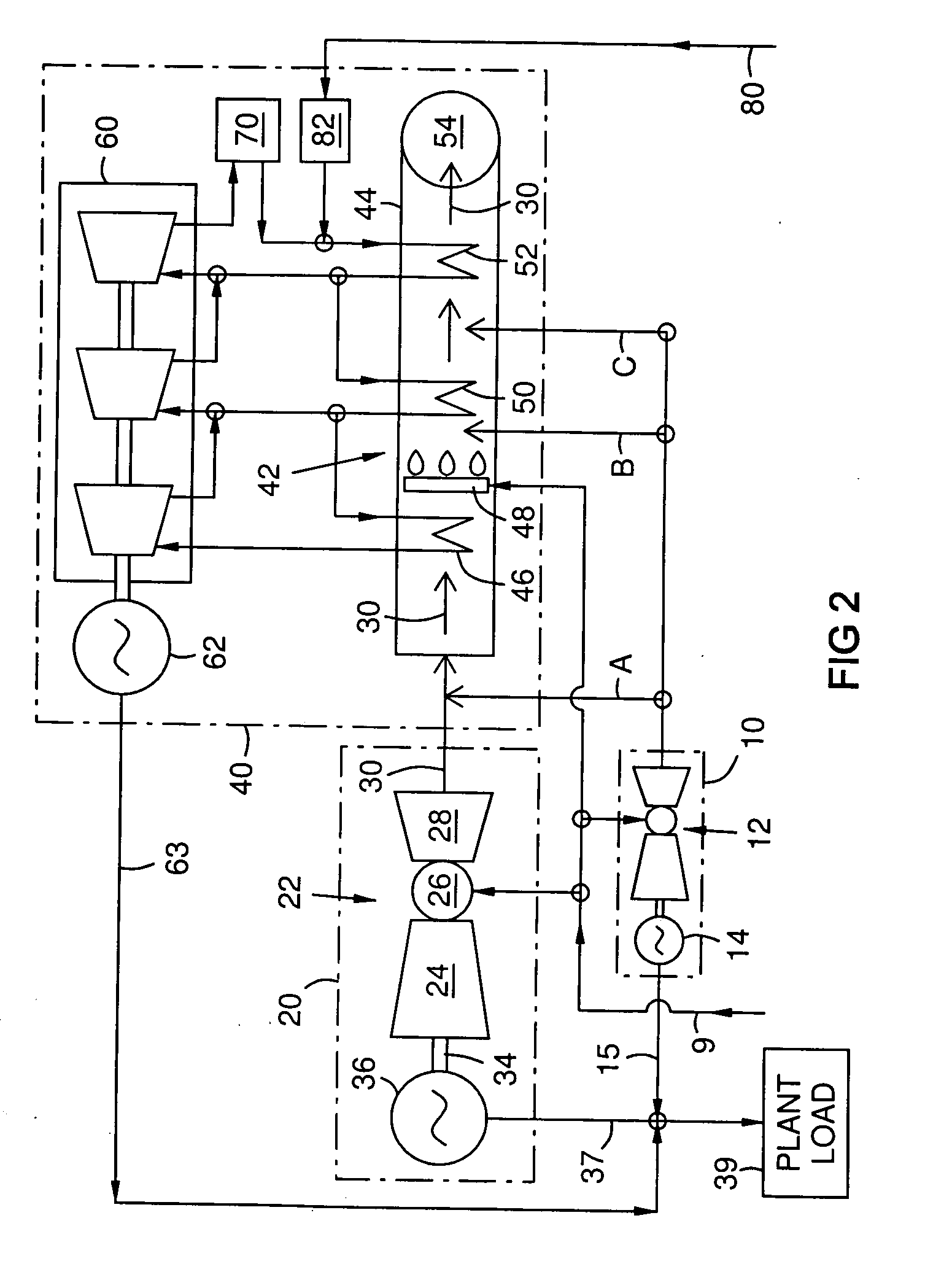

A method and system for augmenting the output of a combined cycle power plant having a base gas turbine (22) driving a generator (36) and a heat recovery steam generator (42) that recovers exhaust heat (30) from the base gas turbine (22) to drive a steam turbine (60). A complementary gas turbine engine (12) is added to the power plant to drive a complementary generator (14). The exhaust (A, B, C) of the complementary gas turbine (12) is merged into the flow path of exhaust gas (30) from the base gas turbine (22) upstream of a selected one or more heat exchangers (46, 50, 52) in the heat recovery steam generator (42). Such a complementary system (10) may be used together with supplemental duct burners (48) in a hybrid augmentation embodiment.

Owner:SIEMENS ENERGY INC

Power generation process with partial recycle of carbon dioxide

ActiveUS8220248B2Inexpensively separatedQuantity minimizationGas treatmentDispersed particle separationElectricityGeneration process

Disclosed herein is a power generation process in which a portion of the carbon dioxide generated by gaseous fuel combustion is recycled back to the power generation process, either pre-combustion, post-combustion, or both. The power generation process of the invention may be a combined cycle process or a traditional power generation process. The process utilizes sweep-based membrane separation.

Owner:MEMBRANE TECH & RES

High power density combined cycle power plant

InactiveUS6230480B1Reduce installation costsService degradationEnergy industryGas turbine plantsPower stationCogeneration

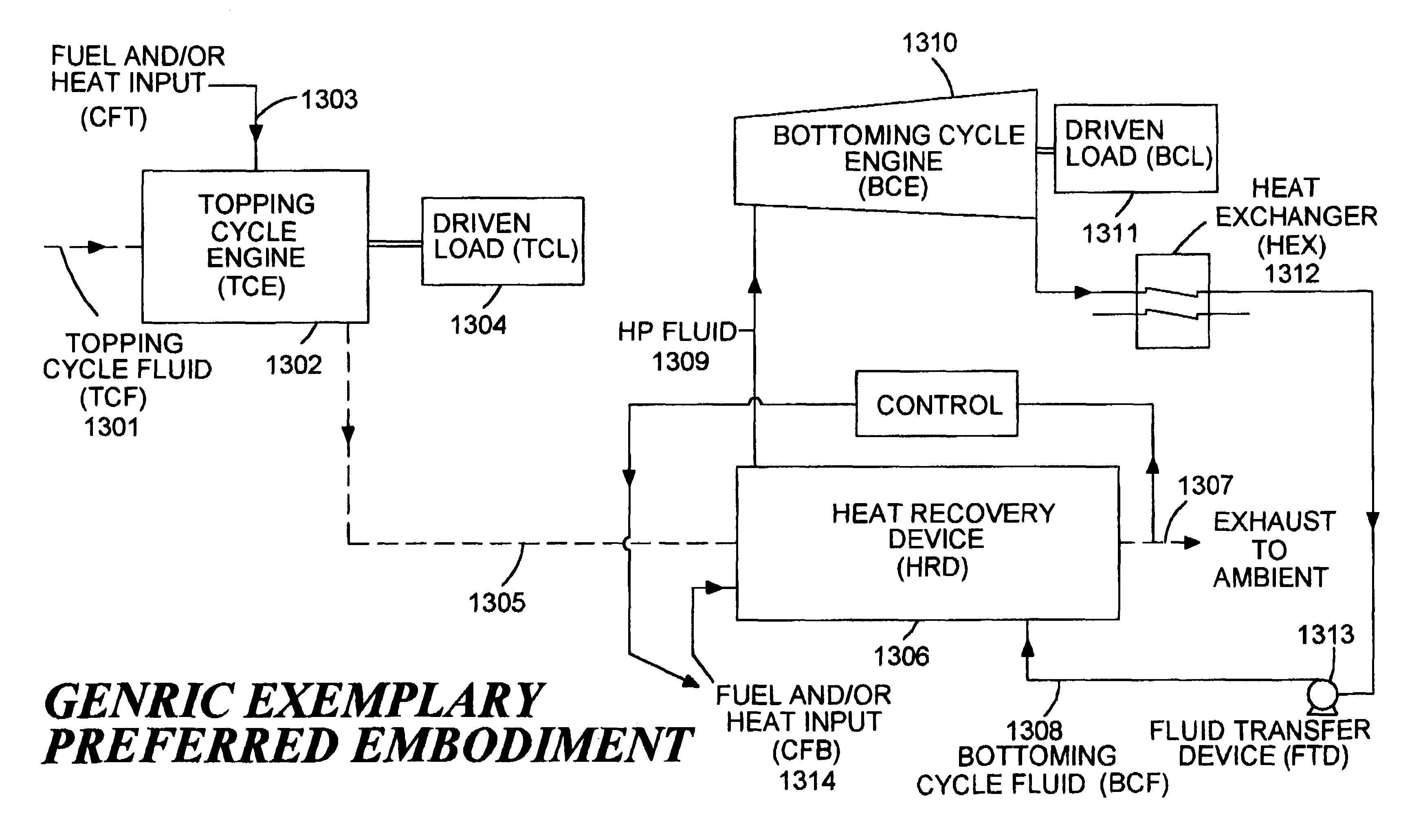

A system and method for increasing the specific output of a combined cycle power plant and providing flexibility in the power plant rating, both without a commensurate increase in the plant heat rate, is disclosed. The present invention demonstrates that the process of upgrading thermal efficiencies of combined cycles can often be accomplished through the strategic use of additional fuel and / or heat input. In particular, gas turbines that exhaust into HRSGs, can be supplemental fired to obtain much higher steam turbine outputs and greater overall plant ratings, but without a penalty on efficiency. This system and method by in large defines a high efficiency combined cycle power plant that is predominantly a Rankine (bottoming) cycle. Exemplary embodiments of the present invention include a load driven by a topping cycle engine (TCE), powered by a topping cycle fluid (TCF) which exhausts into a heat recovery device (HRD). The HRD is fired with a supplementary fuel or provided an additional heat source to produce more energetic and / or a larger quantity of the bottoming cycle fluid (BCF) which is used to power a bottoming cycle engine, (BCE) which drives a load (potentially the same load as the topping cycle engine). Energy contained in either the TCF or BCF is used to power the TCE and BCE respectively, but these fluids, and / or their respective engine exhausts, may also be used to support a wide variety of cogeneration applications.

Owner:ROLLINS III WILLIAM SCOTT

Gas turbine inlet conditioning system and method

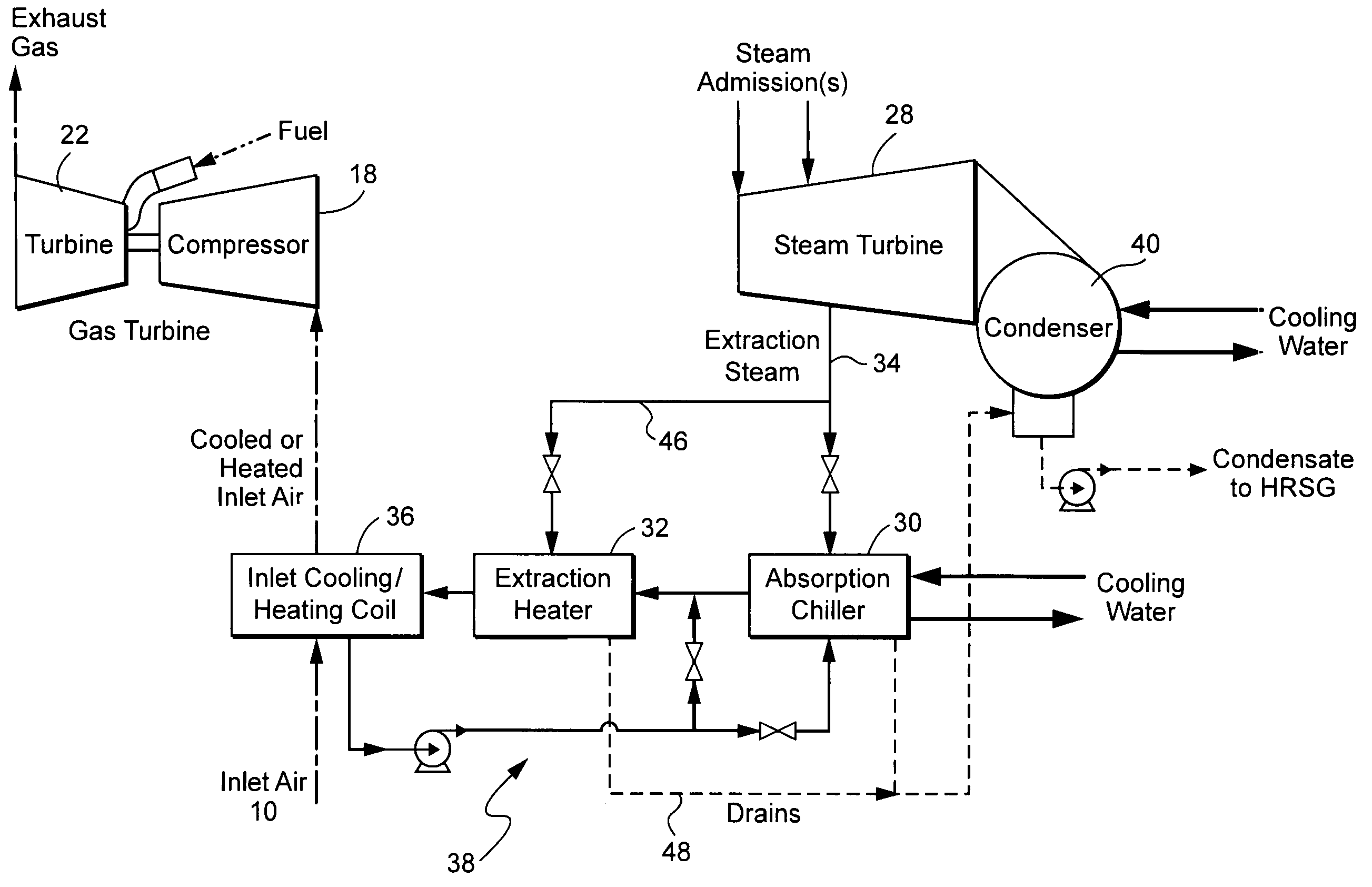

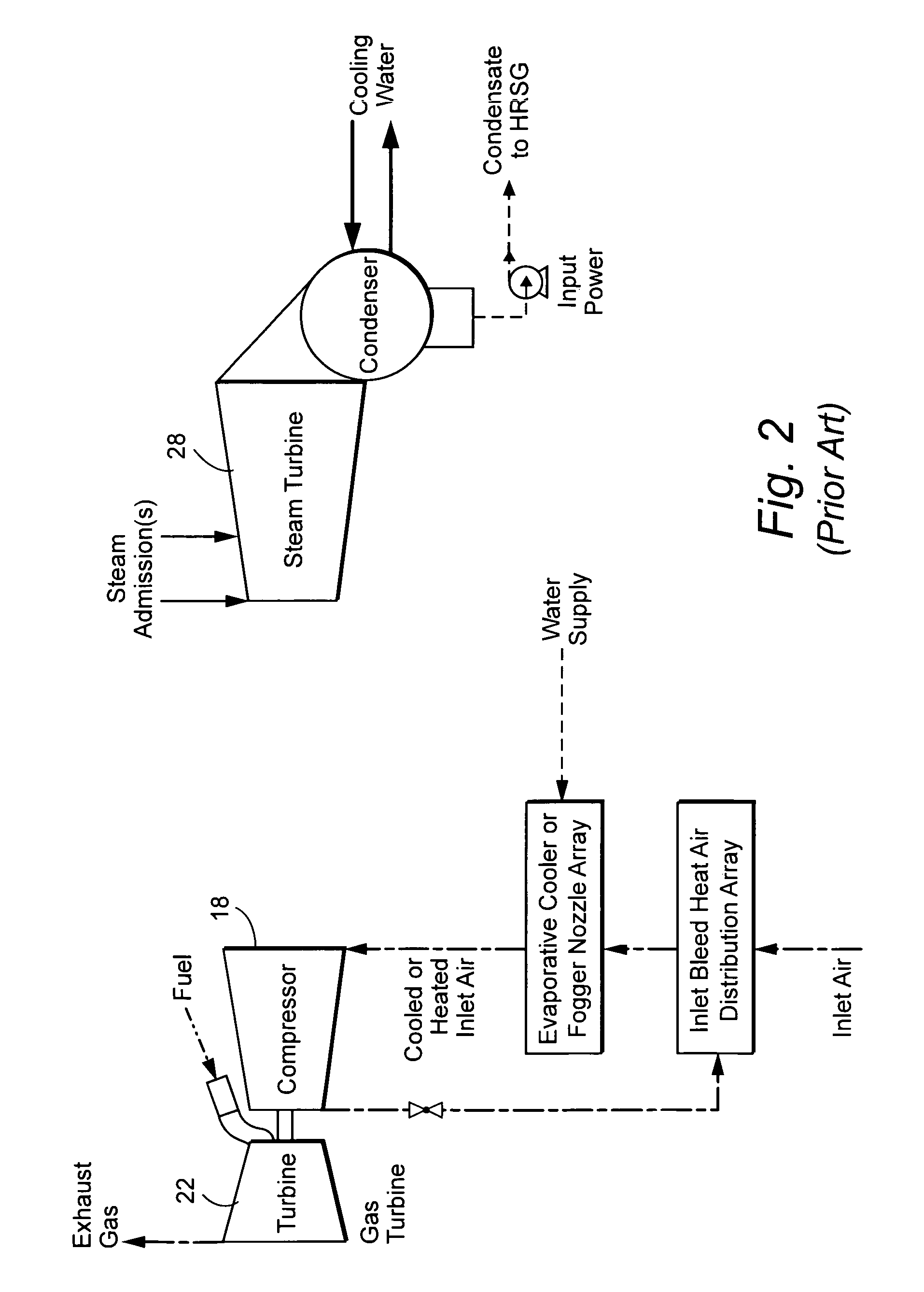

ActiveUS7644573B2Maximize efficiencyOutput maximizationGas turbine plantsSteam engine plantsSystems designEngineering

A system capable of both increasing warm day output and maintaining compressor operating margin across the ambient and load range of a gas turbine combined cycle installation. The proposed solution takes advantage of the fact that both goals can be satisfied by manipulation of compressor inlet air temperature. Specifically, the system is designed to heat inlet air as may be required to maintain safe compressor operating margin at low ambient air temperatures or when burning dilute fuels. In the alternative, the system is designed to cool inlet air on warm days.

Owner:GE INFRASTRUCTURE TECH INT LLC

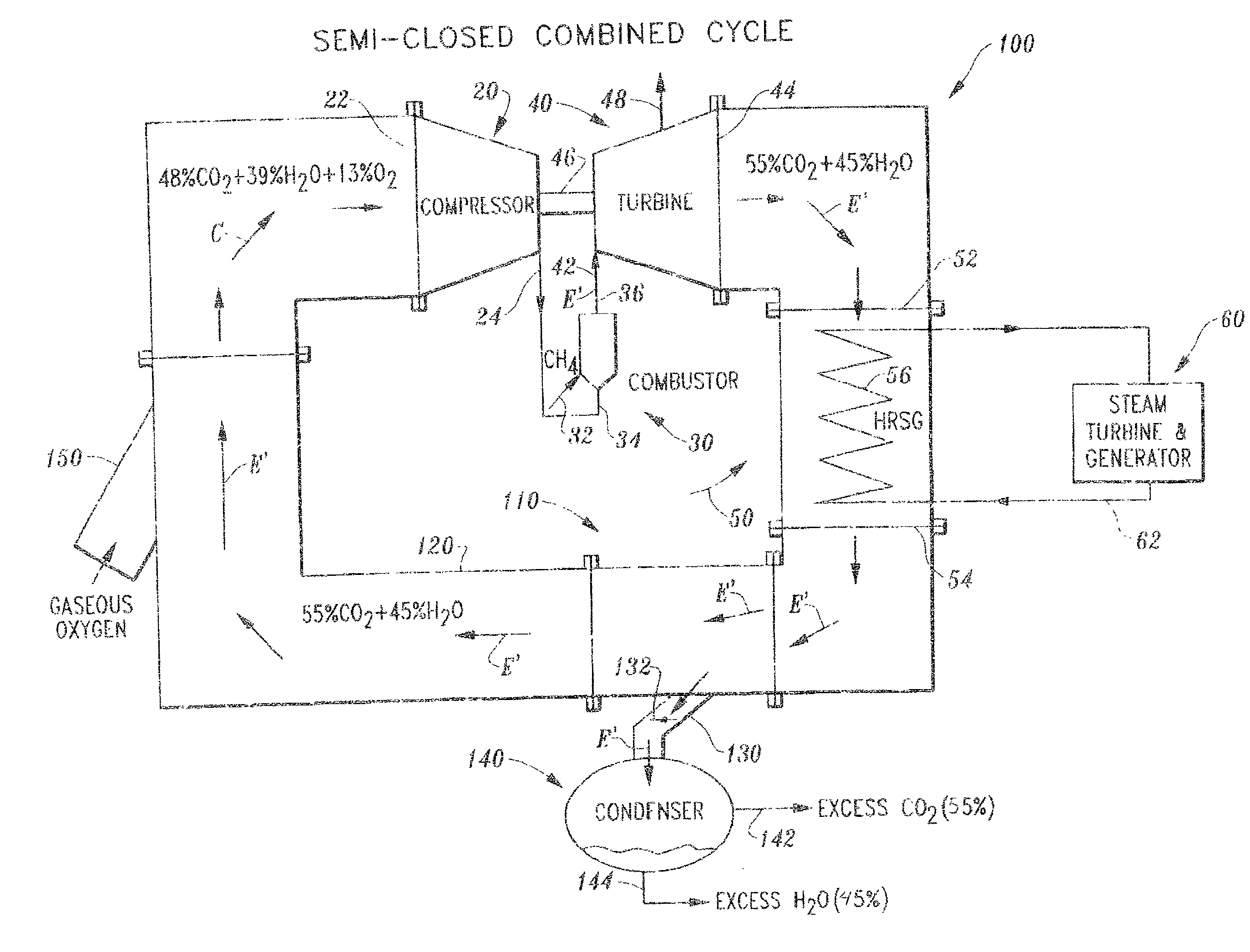

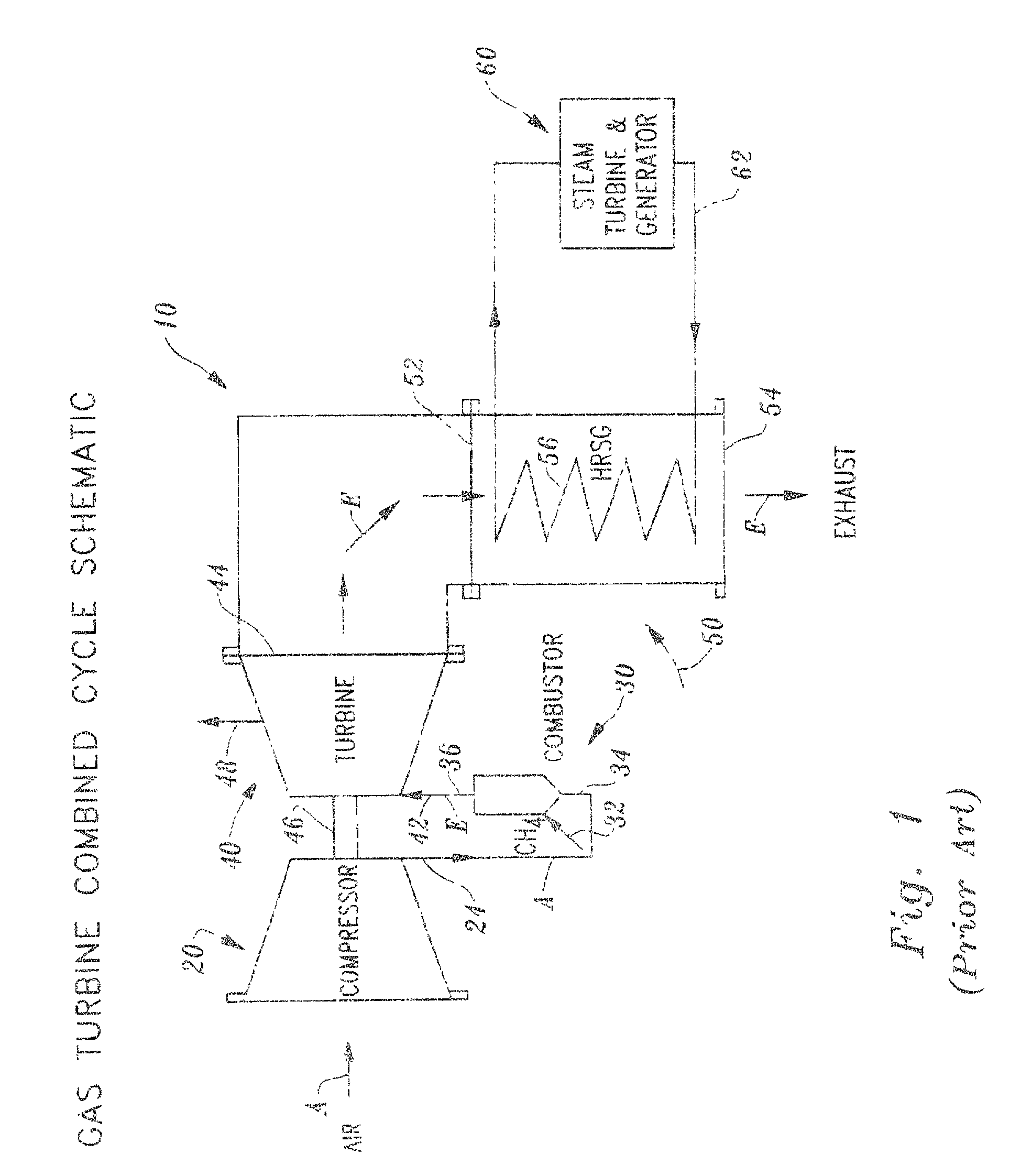

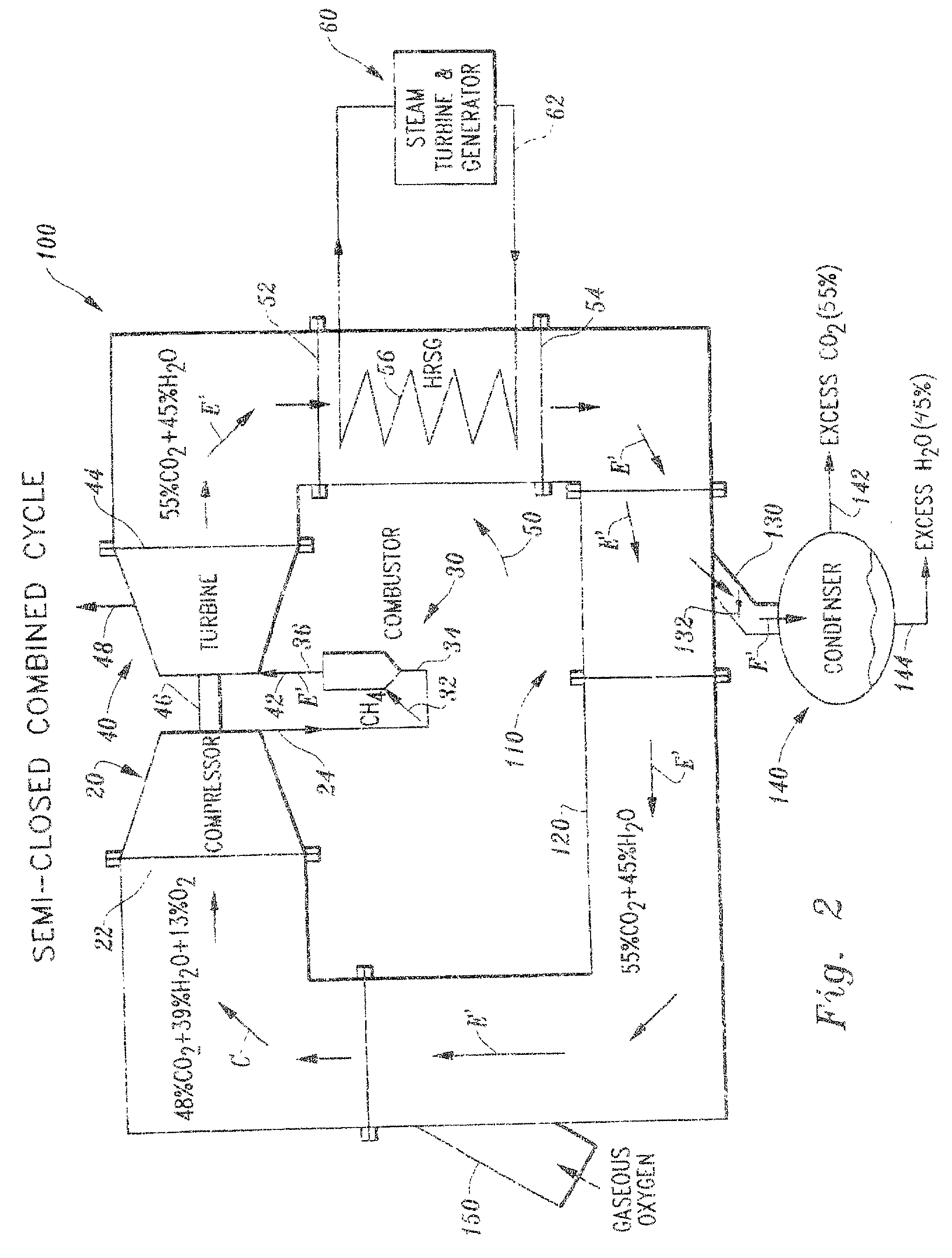

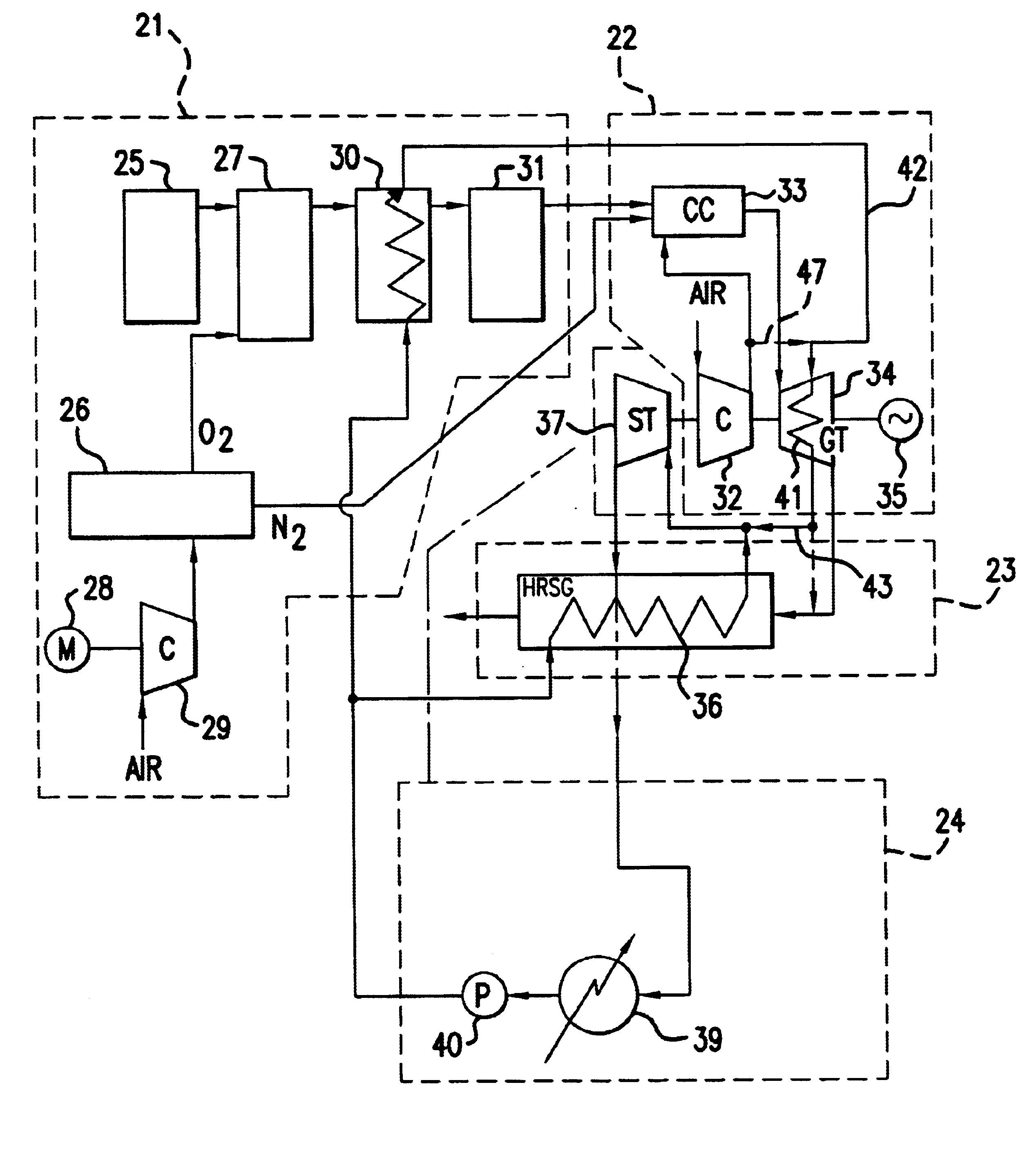

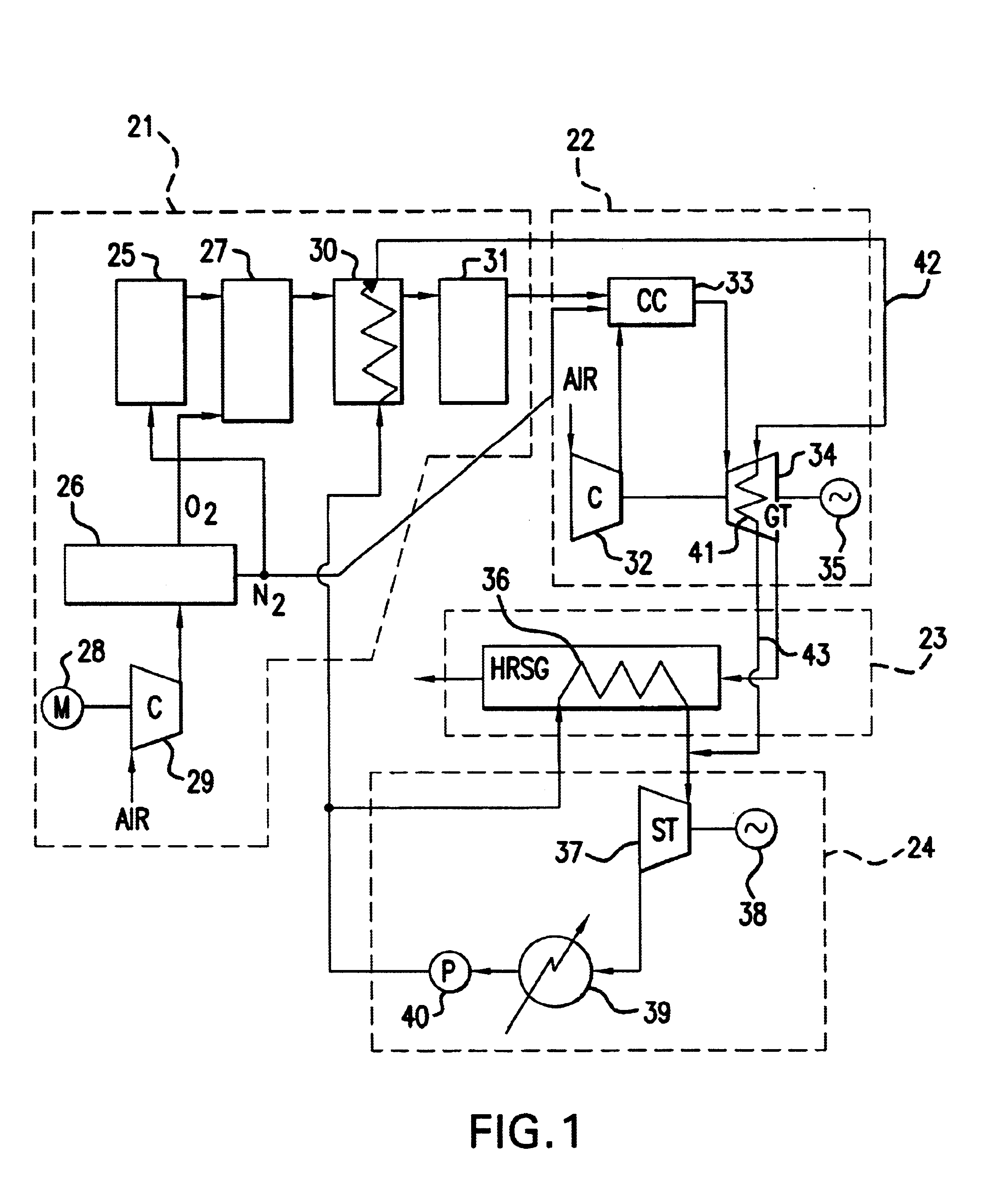

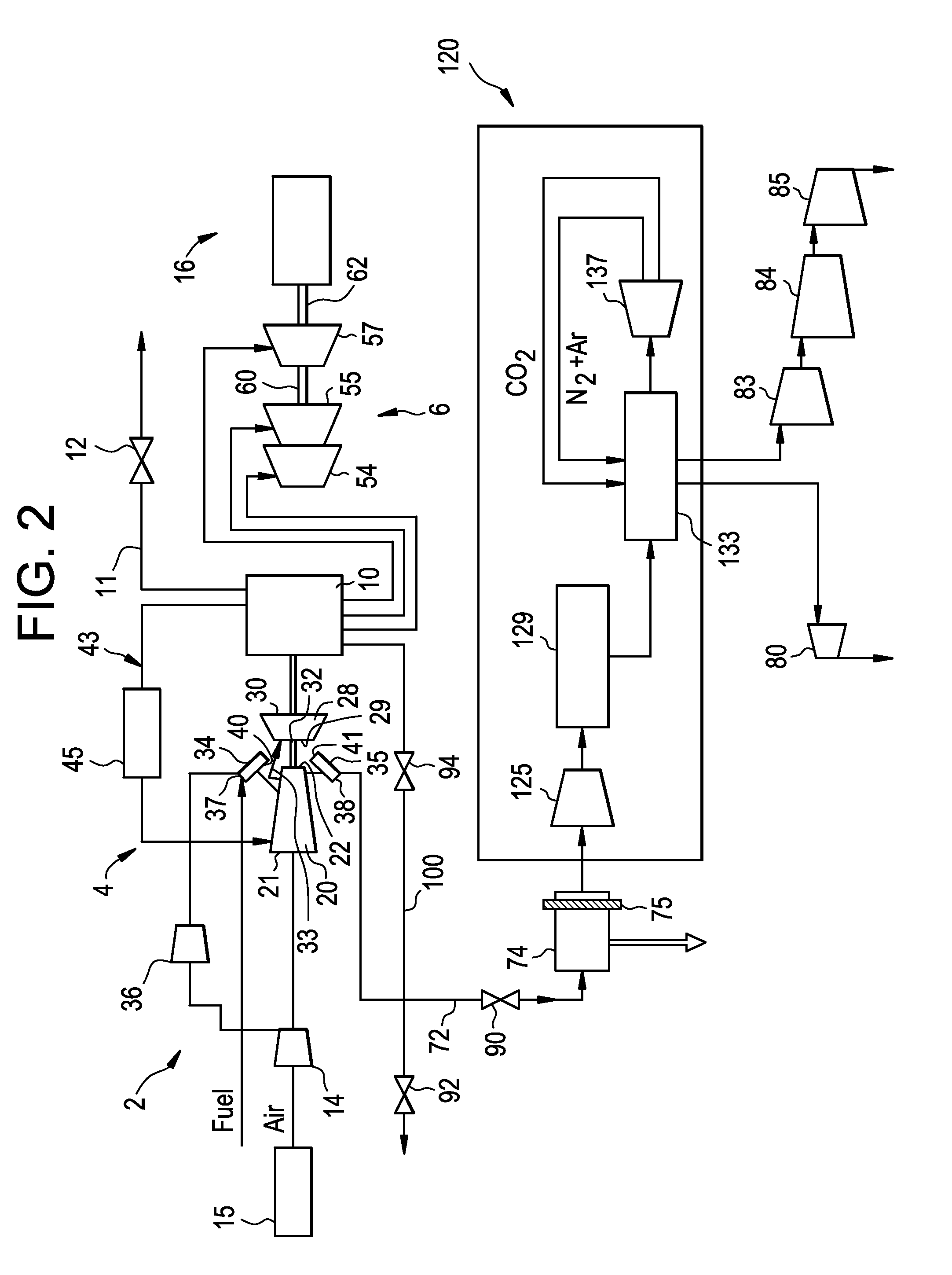

Semi-closed brayton cycle gas turbine power systems

InactiveUS20020023423A1Efficient collectionEliminate emissionsEnergy industryEfficient propulsion technologiesAtmospheric airElectric power system

A semi-closed combined cycle power system 100 is provided which can also convert an open combined cycle gas turbine 10 into a non-polluting zero emissions power system. The prior art open combined cycle gas turbine 10 includes a compressor 20 which compresses air A' and combusts the air A' with a fuel, such as natural gas. The products of combustion and the remaining portions of the air form the exhaust E' which is expanded through the turbine 40. The turbine 40 drives the compressor 20 and outputs power. The exhaust E' exits the turbine 40 and then can optionally be routed through a heat recovery steam generator 50 to function as a combined cycle. According to this invention, the exhaust E' is not emitted into the atmosphere, but rather is routed to a divider 110. The divider 110 includes two outlets for the exhaust E' including a return duct 120 and a separation duct 130 which both receive a portion of the exhaust E'. The return duct 120 routes a portion of the exhaust E' back to the compressor 20. Before reaching the compressor 20, an oxygen duct 150 adds additional oxygen to the exhaust E' to form a gas mixture C which includes CO2 and steam from the exhaust E' and oxygen from the oxygen duct 150. This gas mixture C has characteristics which mimic those of air, so that the compressor 20 need not be modified to effectively compress the gas mixture C. The gas mixture C is compressed within the compressor 20 and routed to the combustor 30 where the fuel combusts with the oxygen of the gas mixture C' and produces exhaust E' which is substantially entirely CO2 and steam. This exhaust E' is routed through the turbine 40 and expanded to drive the compressor 20 and output power. The exhaust E' exits the turbine 40 and is routed back to the divider 110, preferably by way of a heat recovery steam generator 50 or other heat removal device, so that the semi-closed cycle operates as a combined cycle power system 100. The divider 110 directs a portion of the exhaust E' to a separation duct 130 which leads to a condenser 140. In the condenser 140 the exhaust E' is separated by condensation of the steam / water portion of the exhaust and removal of the remaining CO2 as gas from the condenser 140. The only exhaust from the semi-closed power system 100 is water and CO2 from the condenser. The CO2 exhaust is substantially pure and ready for appropriate further handling and disposal. Hence, no pollutants are emitted from the semi-closed power system 100. The return duct 120 can

Owner:CLEAN ENERGY SYST

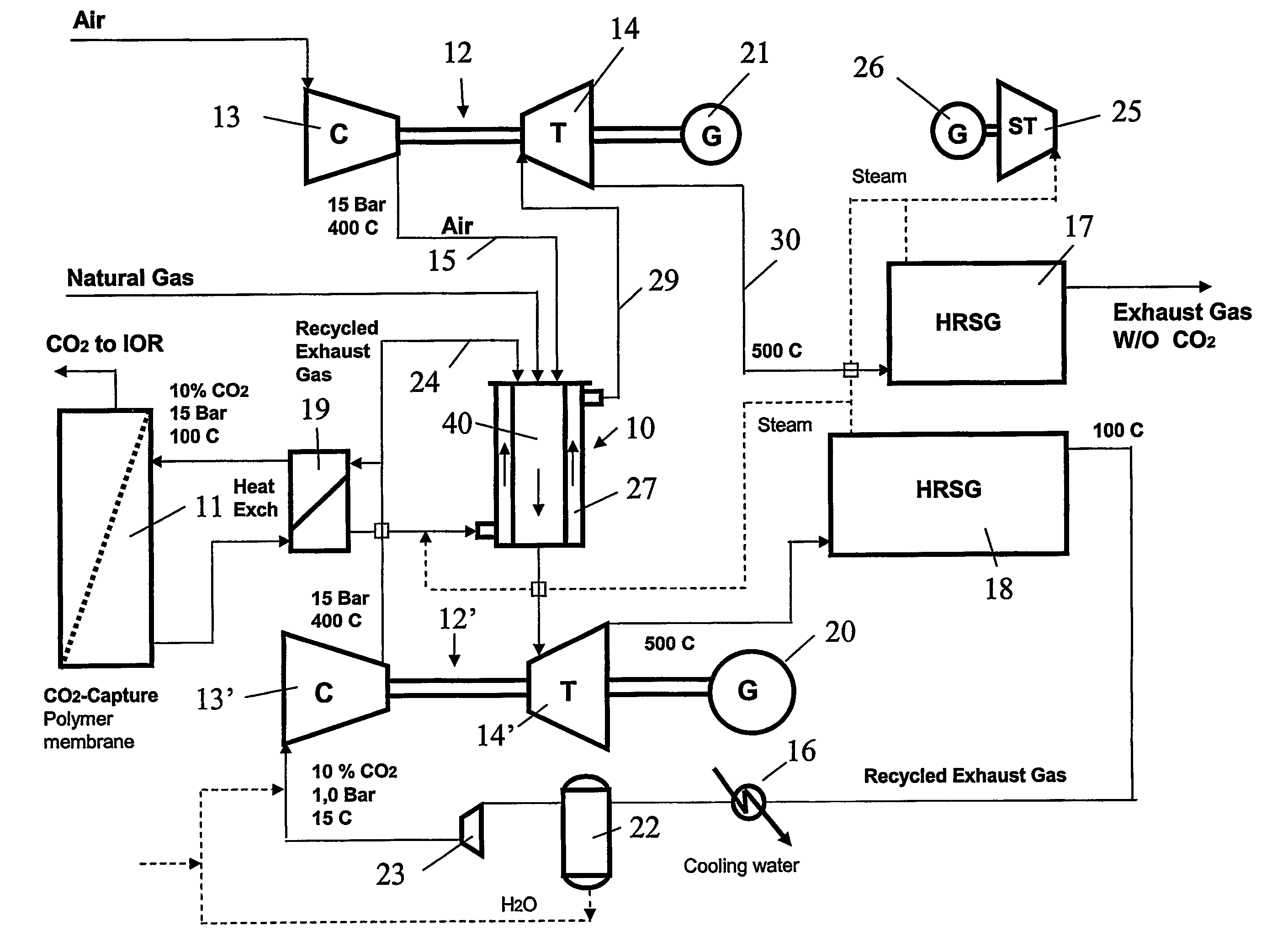

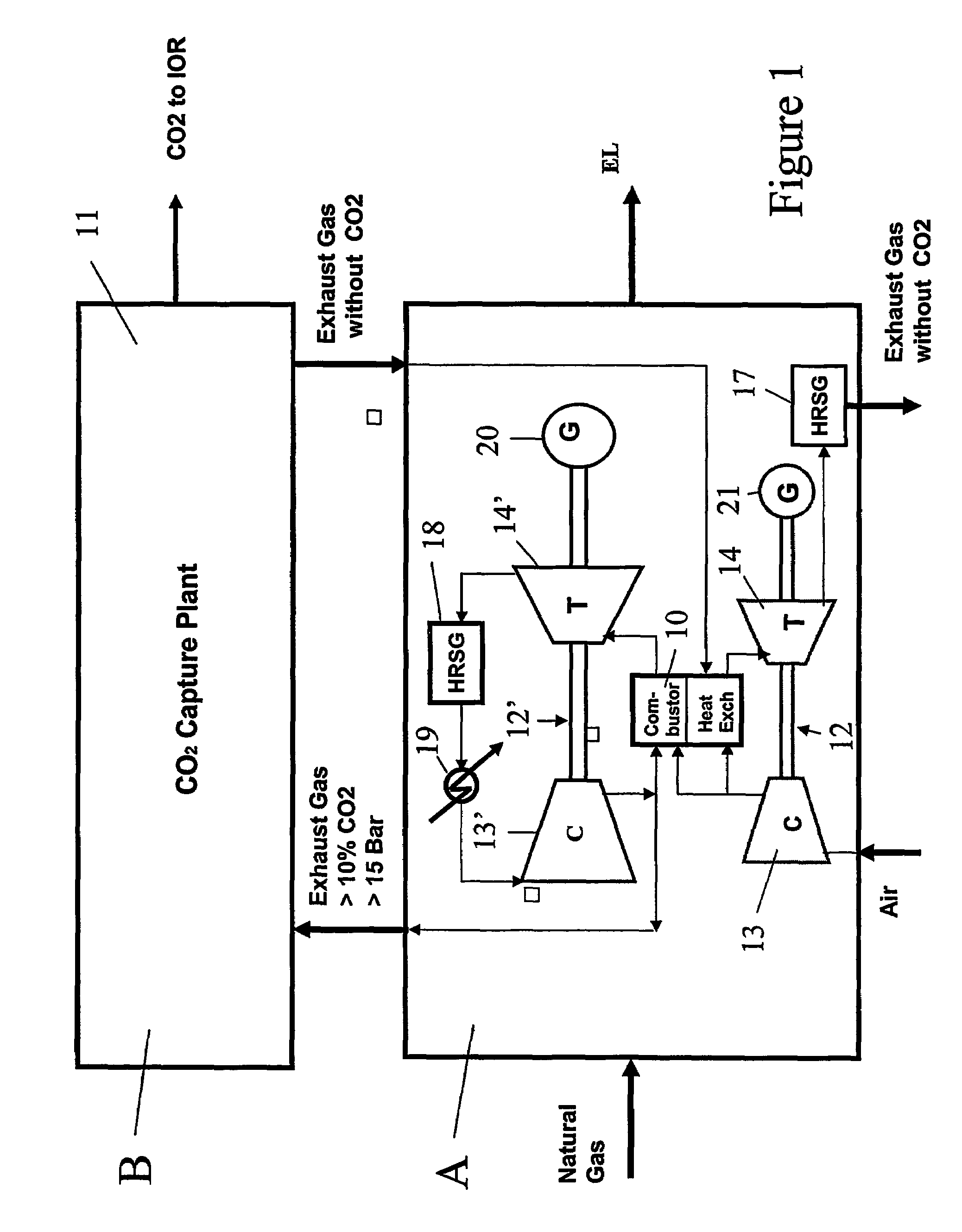

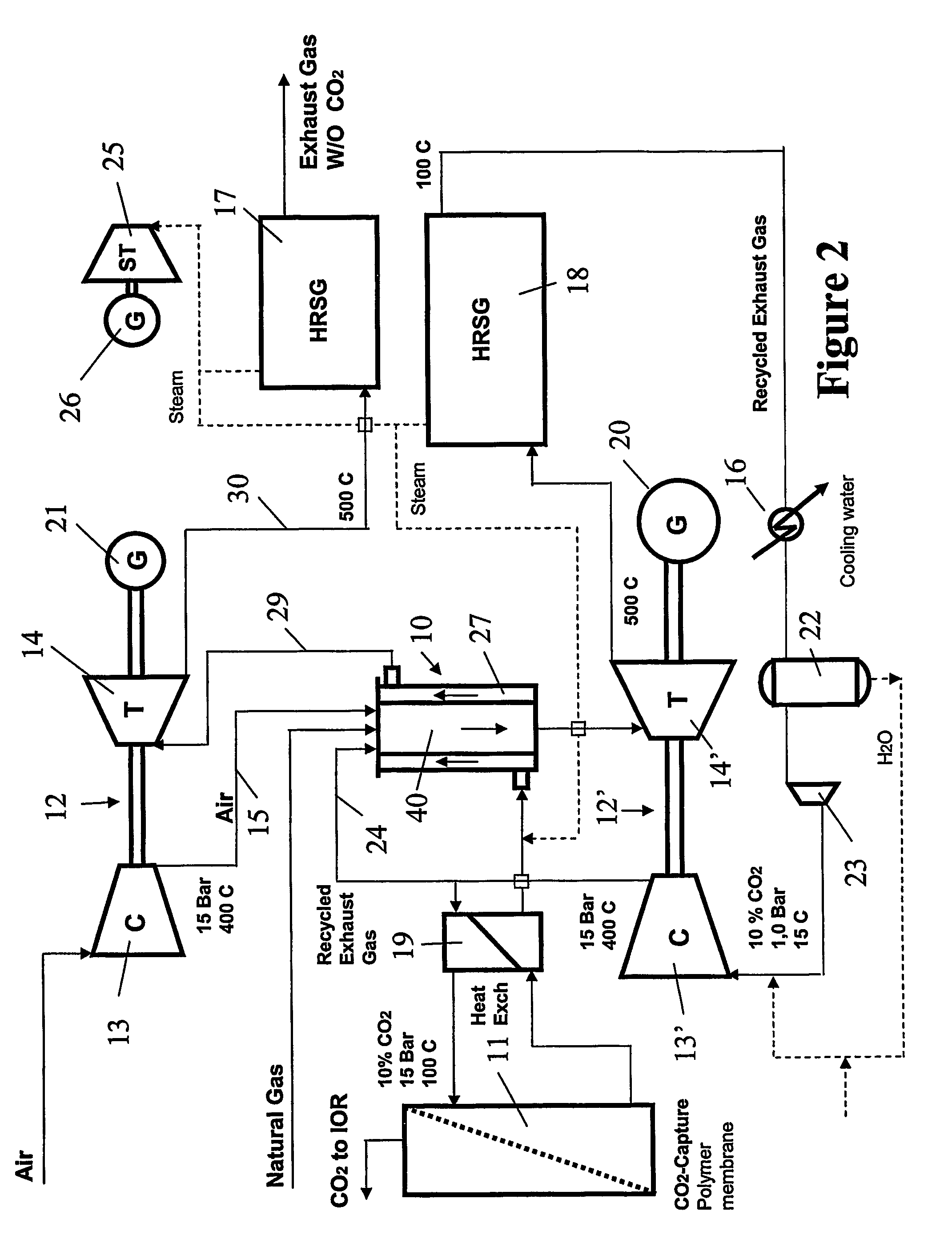

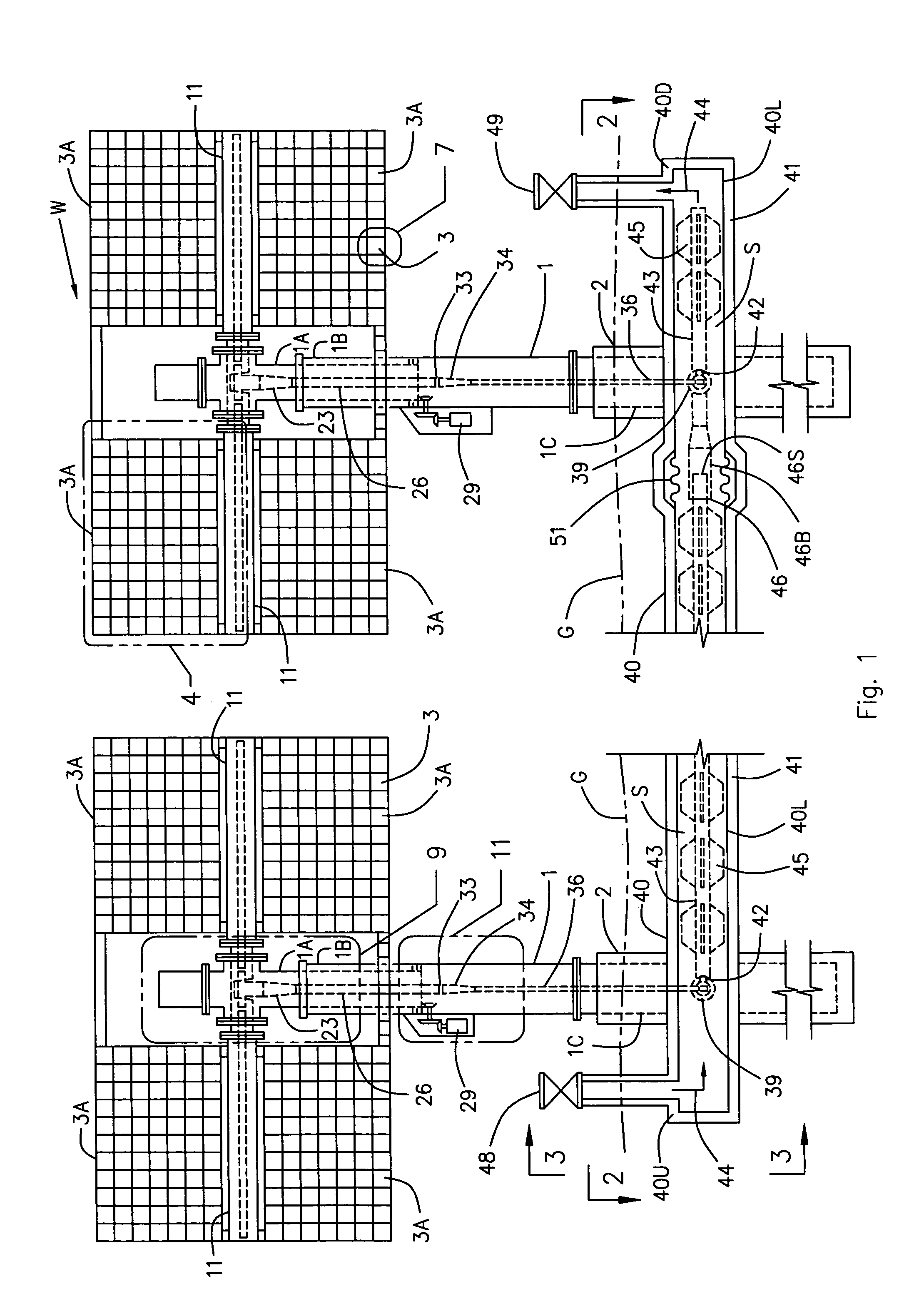

Efficient combined cycle power plant with CO2 capture and a combustor arrangement with separate flows

ActiveUS7490472B2Favourable and improved heat transferMore energyTurbine/propulsion engine coolingDispersed particle separationPower stationCombustor

The invention relates to a method for inter alia to increase the energy and cost efficiency of a gas power plant or a thermal heat plant with CO2 capturing. The power plant comprises gas turbine plants (12,12′) comprising compressor units (13,13′) and turbine units (14,14′) and further comprises a combustor (10). The combustor (10) is working in principle with to separate gas part streams where one gas part stream flows internally through the flame tube (40) of the combustor (10), while the other gas part stream is flowing along the exterior of the flame tube (40). The first gas part stream comprises additional air and re-circulated, un-cleaned flue gas from the combustor (10), said gases being combusted together with fuel inside the flame tube (40). The second gas part stream comprises cleaned flue gas which is heated up at the exterior of the flame tube (40) while the flame tube (40) is cooled down. The invention comprises also a power plant, a combustor and a CO2 capture plant.

Owner:STATOIL ASA PETRO SA (NO)

Integrated coal gasification combined cycle power generator

Embodiments of the invention provide an IGCC which achieves improved plant thermal efficiency by using a cooling steam supply system that cools the high-temperature sections of the gas turbine 34. Embodiments of the invention further provide and IGCC in which the cooling steam recovery system recovers steam after cooling the gas-turbine high-temperature section and makes practical re-use of the energy and substances within the system. Therefore, embodiments of the invention can reduce or eliminate the degradation of certain equipment by cooling the high-temperature sections. Methods are provided for increasing the thermal efficiency o an IGCC.

Owner:KK TOSHIBA

Power generation process with partial recycle of carbon dioxide

ActiveUS8220247B2Inexpensively separatedQuantity minimizationGas treatmentDispersed particle separationGeneration processElectricity

Disclosed herein is a power generation process in which a portion of the carbon dioxide generated by gaseous fuel combustion is recycled back to the power generation process, either pre-combustion, post-combustion, or both. The power generation process of the invention may be a combined cycle process or a traditional power generation process. The process utilizes sweep-based membrane separation.

Owner:MEMBRANE TECH & RES

Method and system to facilitate combined cycle working fluid modification and combustion thereof

InactiveUS20090193809A1Emission reductionEasy dischargeGas turbine plantsCombined combustion mitigationCombustion systemCombustion chamber

A method of assembling a combustion system includes providing a gas turbine engine that includes a gas turbine section coupled downstream from a combustion chamber and coupling a source of oxygen to the gas turbine engine such that a stream of oxygen discharged from the source facilitates displacing nitrogen in the working fluid of the gas turbine engine and facilitates decreasing emissions generated within the gas turbine engine.

Owner:GENERAL ELECTRIC CO

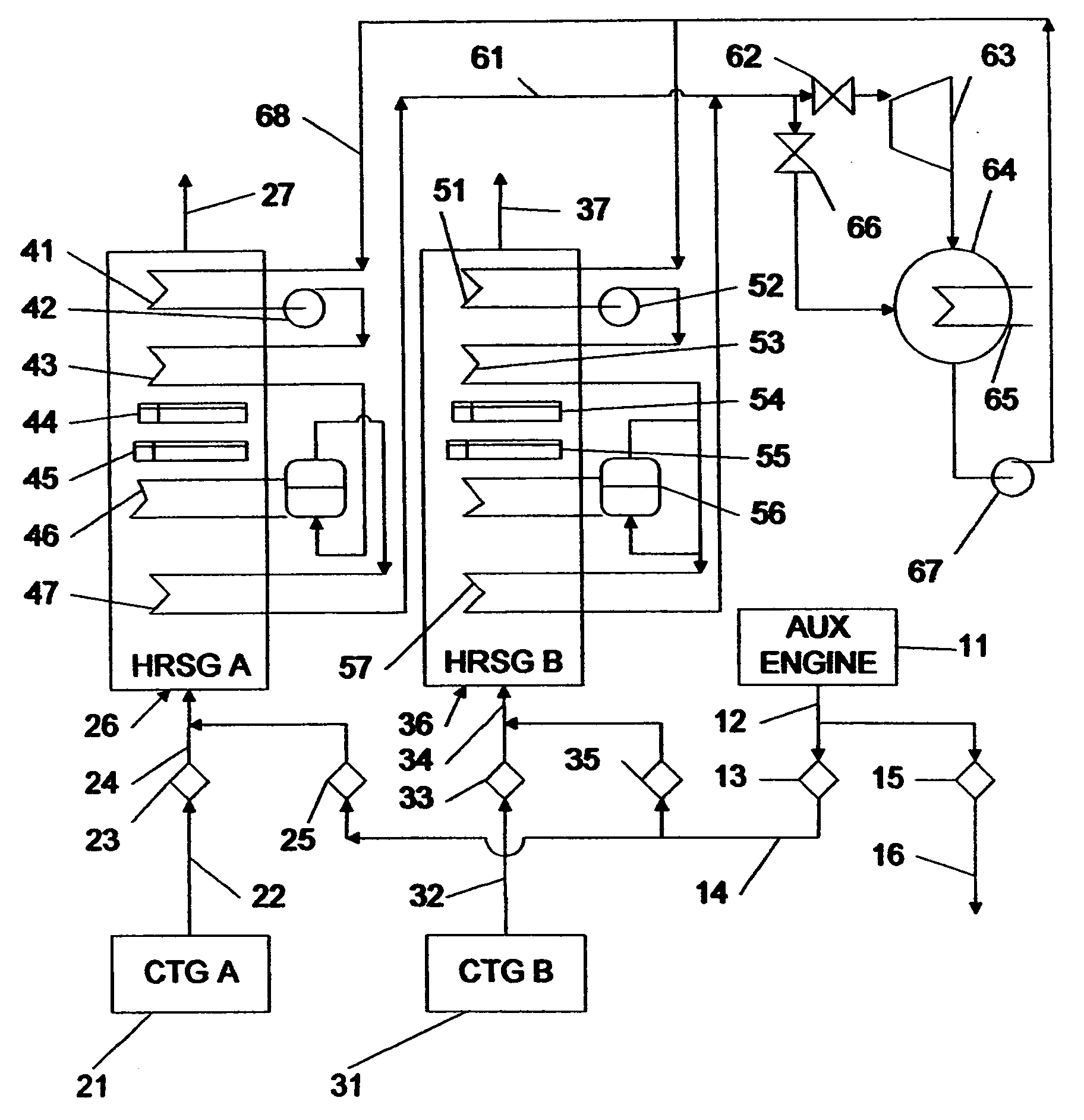

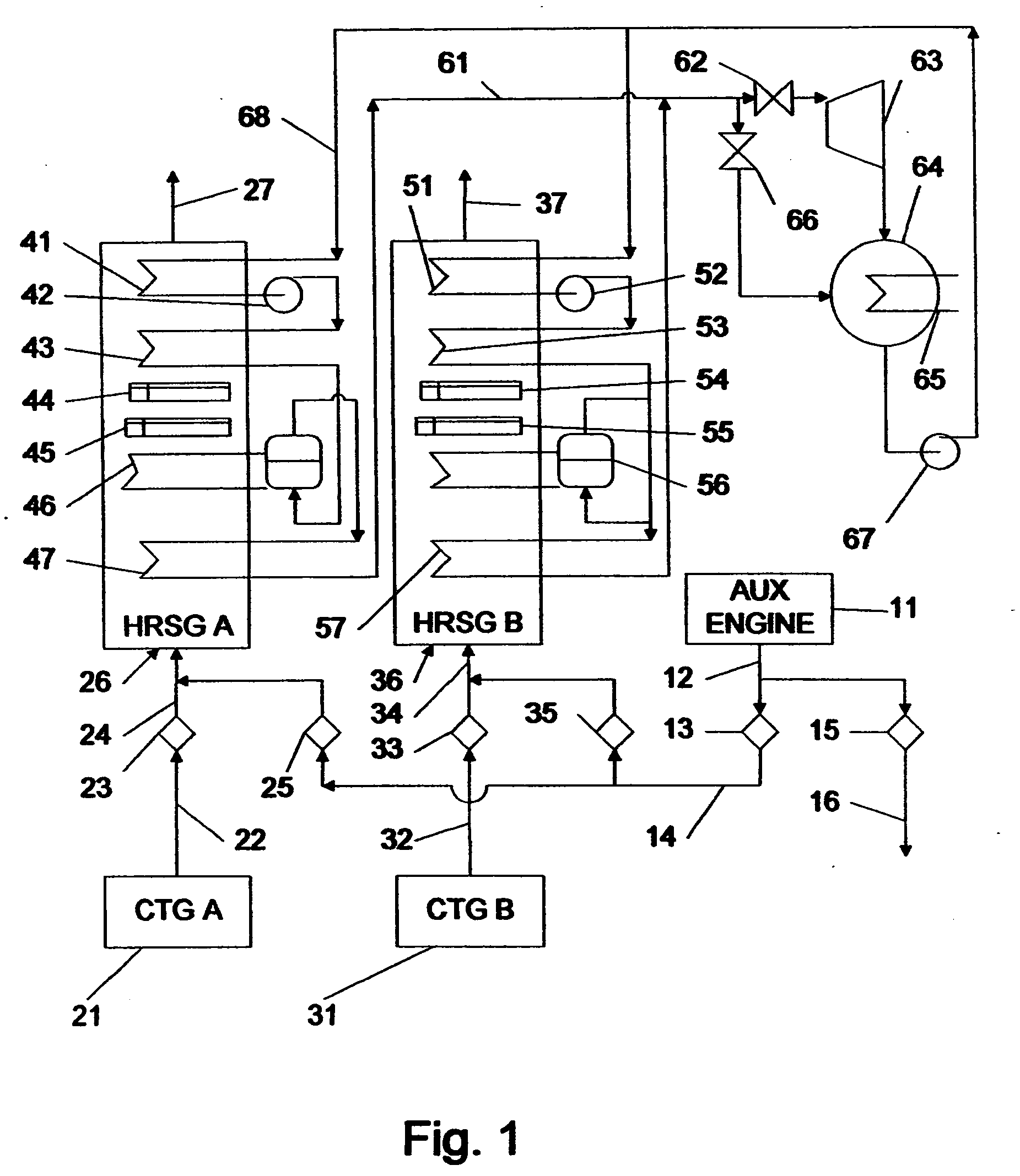

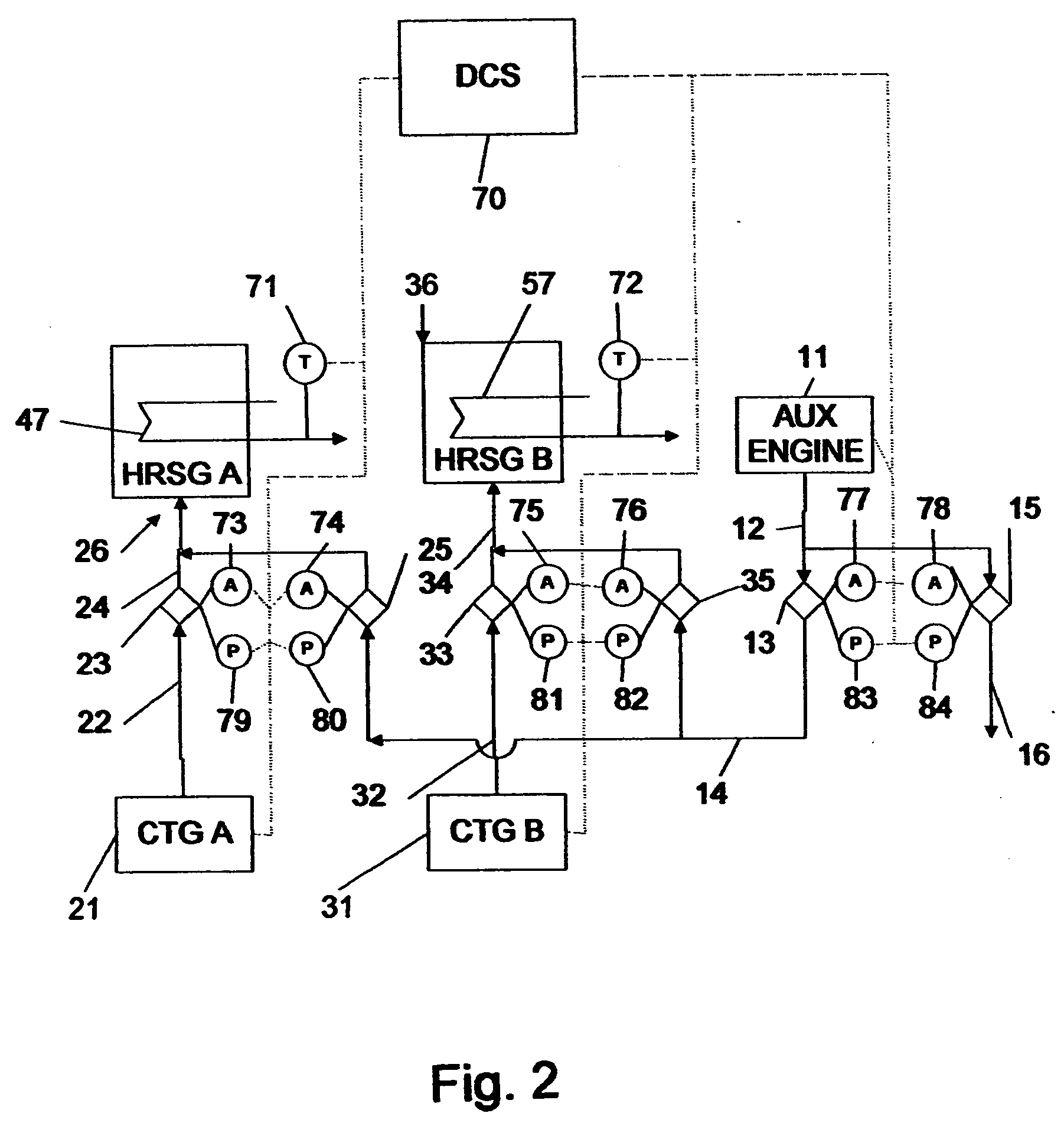

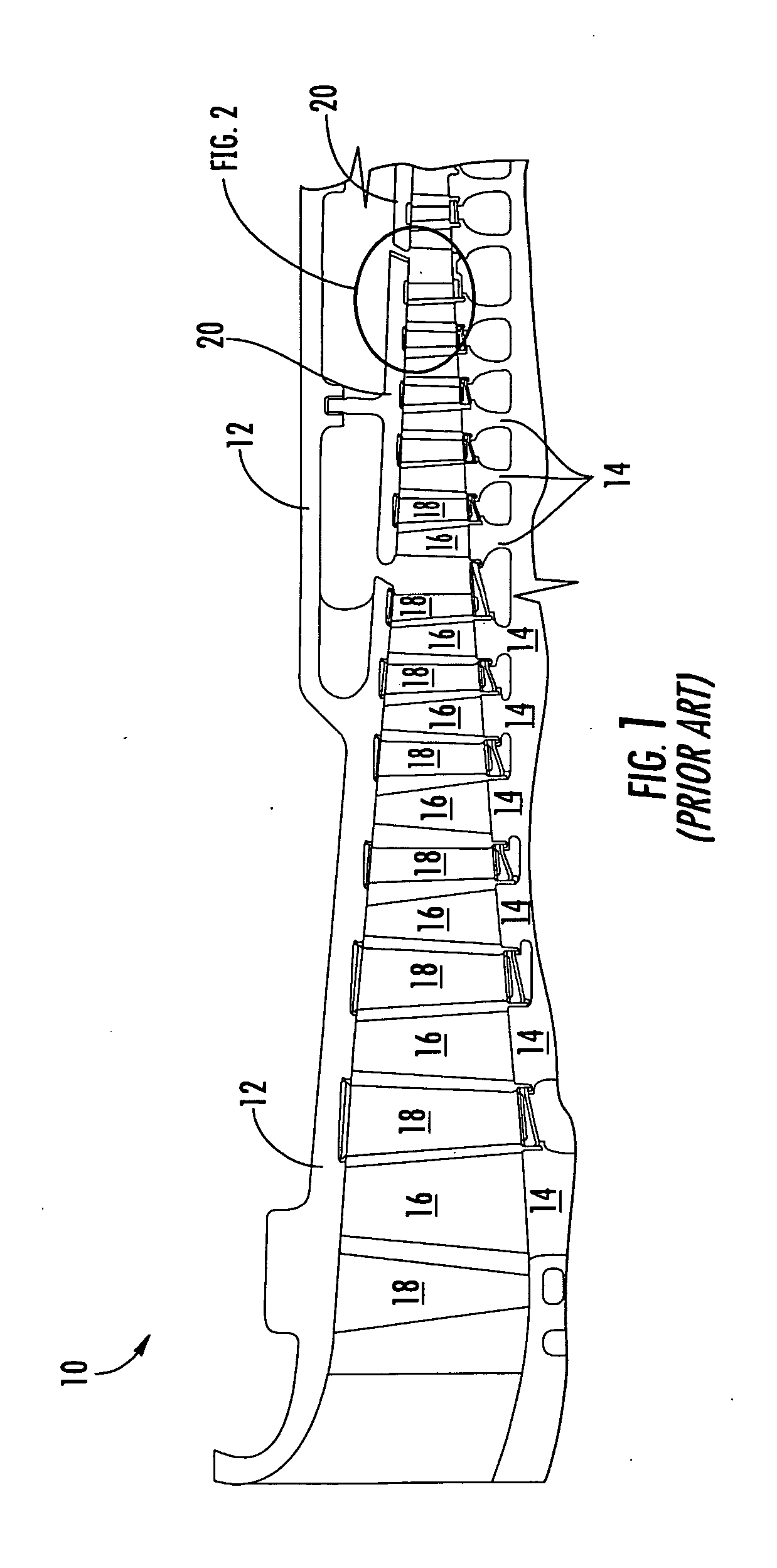

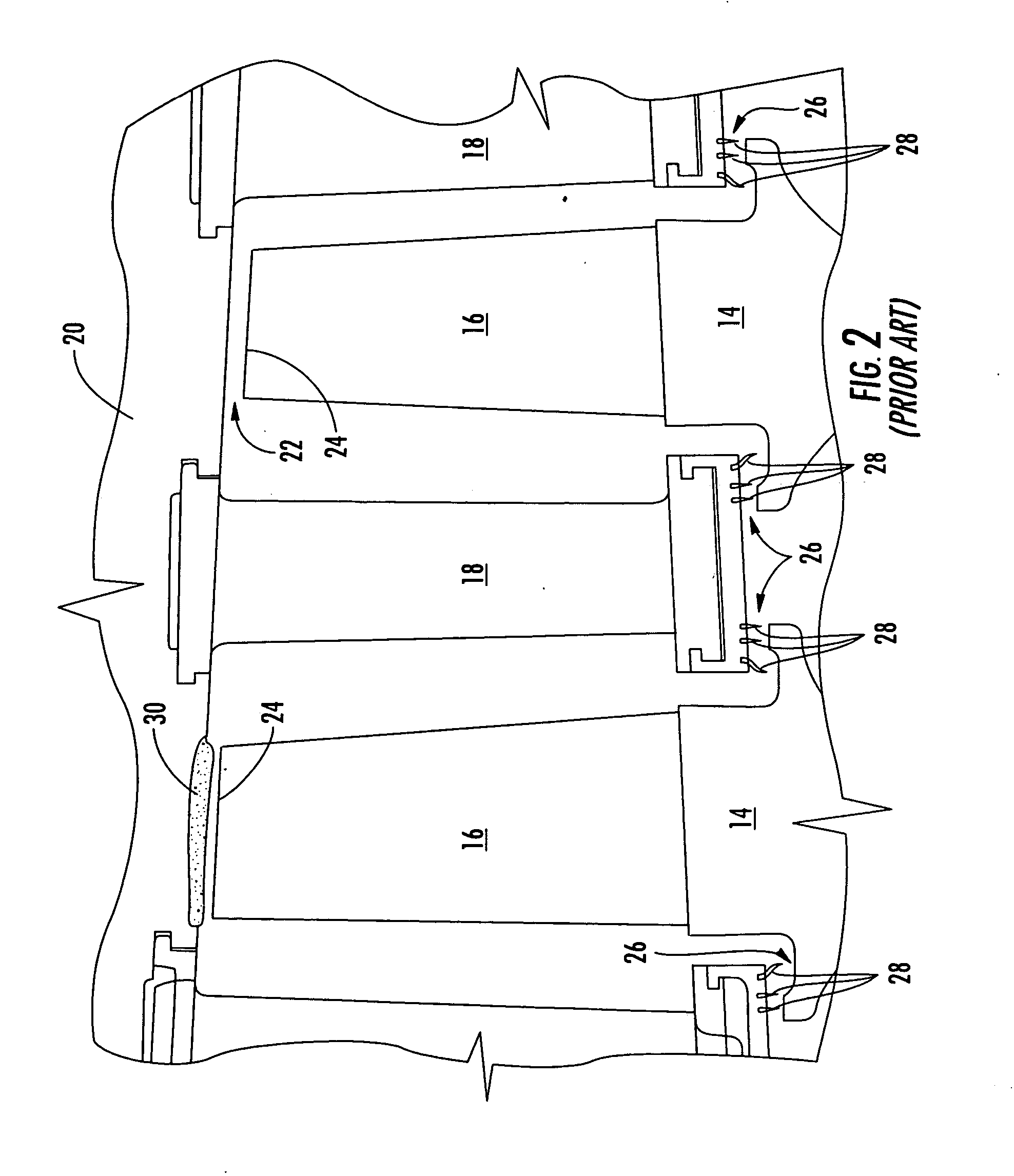

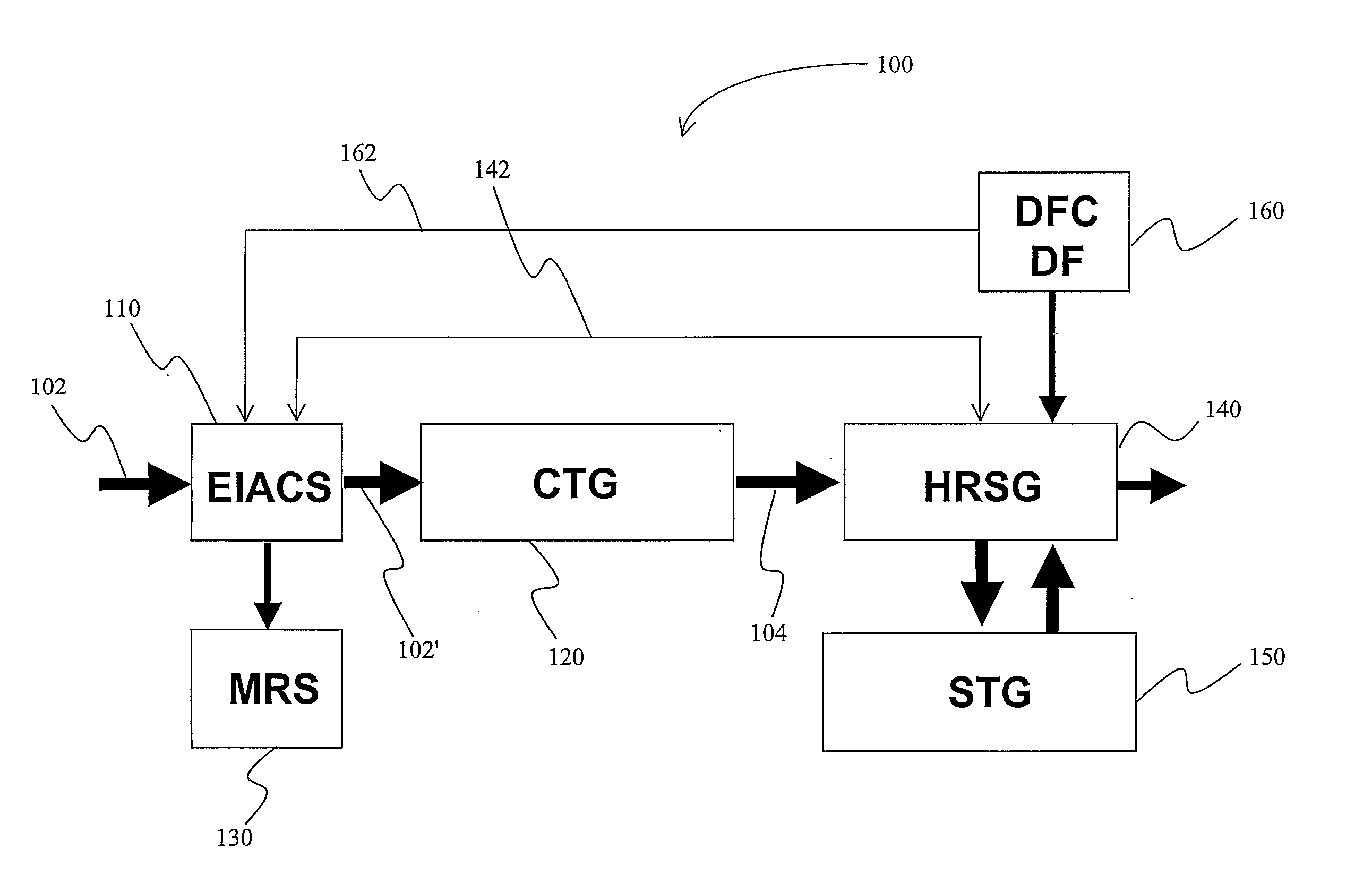

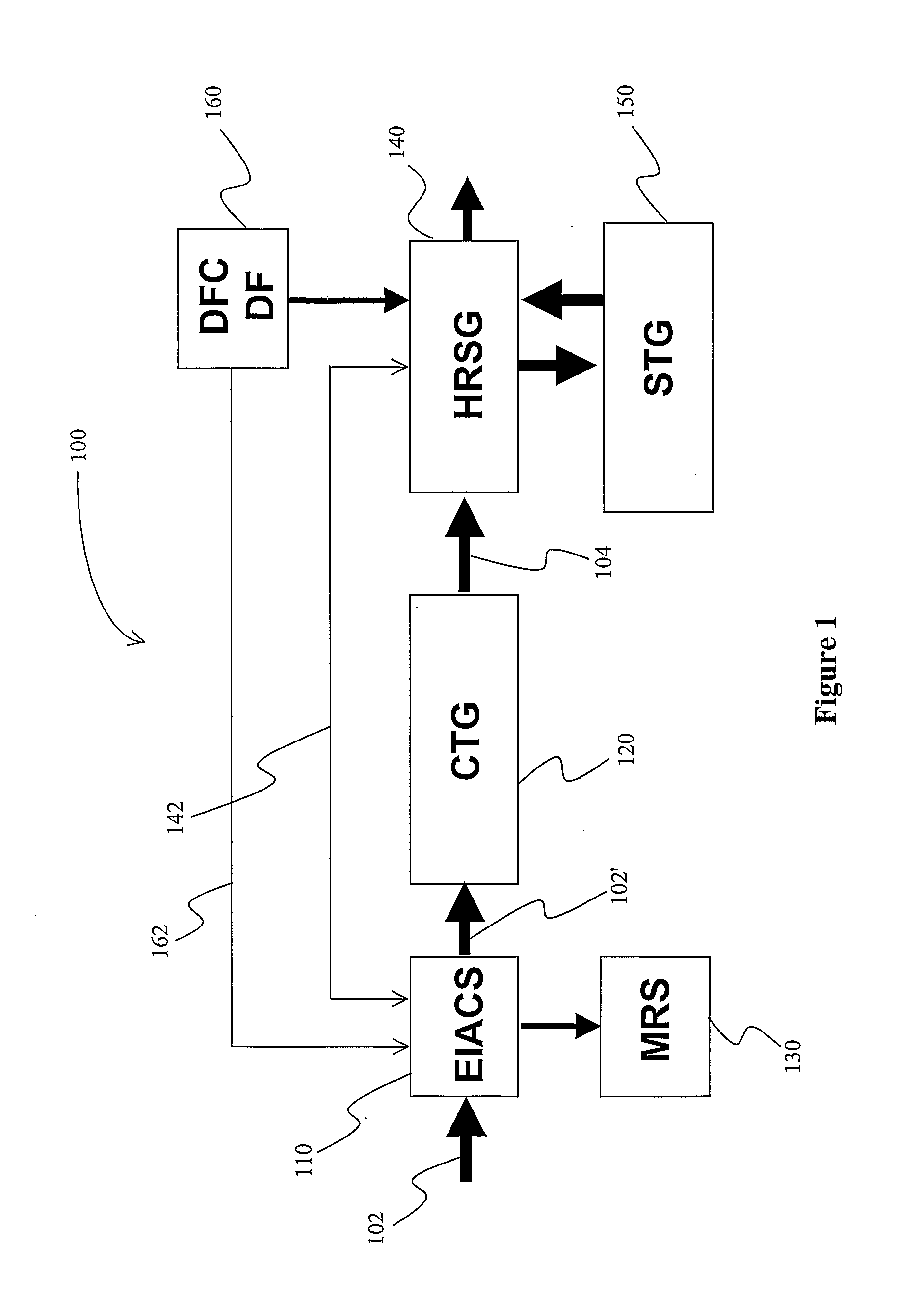

Method and apparatus for combined cycle power plant operation

InactiveUS20050034445A1Stress minimizationEmission reductionTurbine/propulsion fuel supply systemsEngine fuctionsPower stationCombustion

Methods and apparatus are disclosed for starting up a combined cycle plant using a startup duct to connect an auxiliary engine to the inlet of a plurality of HRSGs or other heat recovery systems. Each HRSG is fed by a combustion turbine. Dampers are supplied to isolate each HRSG from the startup duct and its CTG. The auxiliary engine is also ported to a stack allowing simple cycle operation. Dampers are also supplied to isolate the auxiliary engine from the startup duct and from its stack. During startups, the large CTGs will be isolated and the auxiliary engine will be connected to the HRSGs and started, allowing the HRSG to pressurize. As each HRSG pressurizes, it is isolated from the startup duct and connected to its respective CTG. The CTG is then started and loaded. The auxiliary engine is turned off and isolated when the last HRSG pressurizes.

Owner:WASHINGTON GROUP INTERNATIONAL

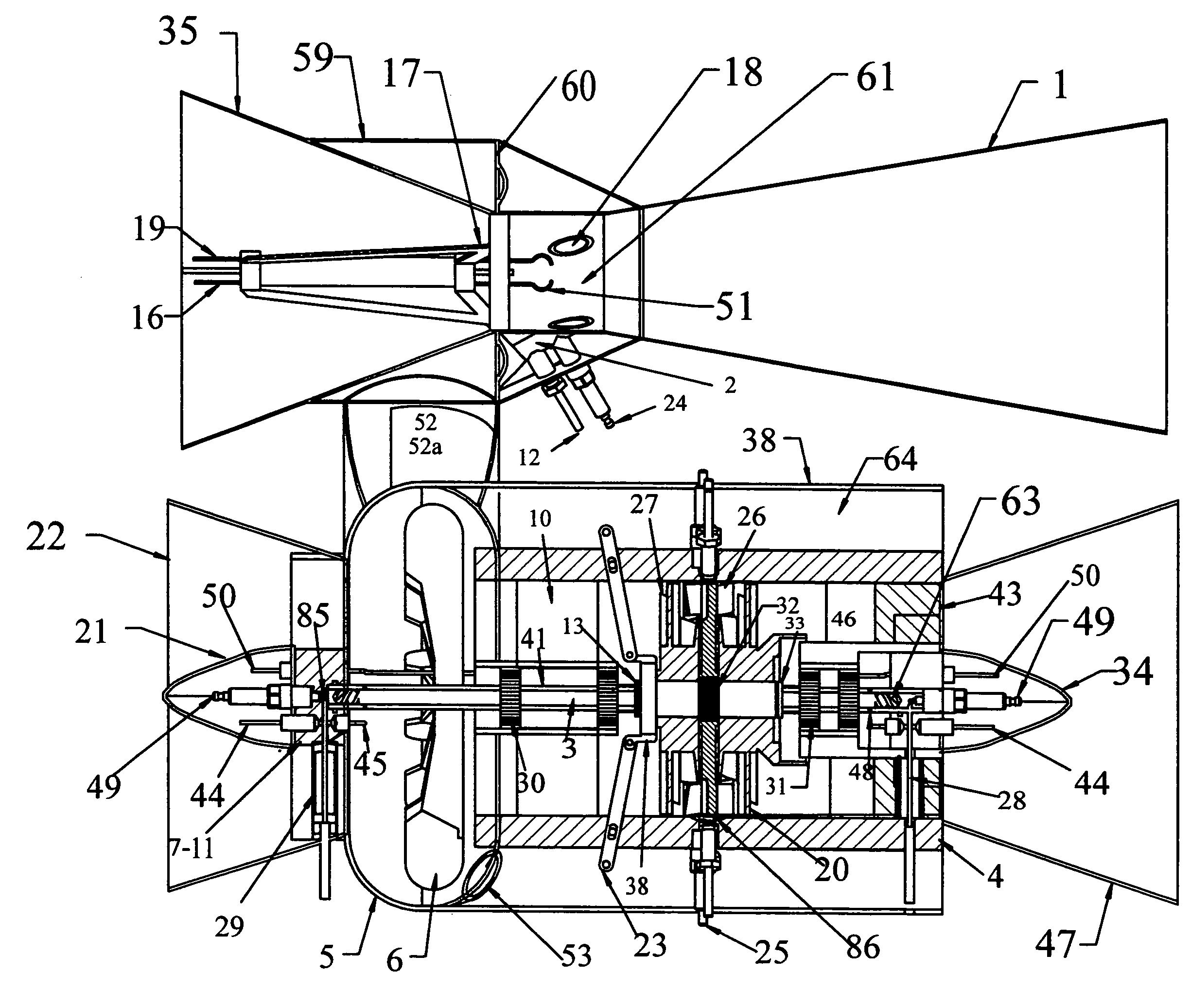

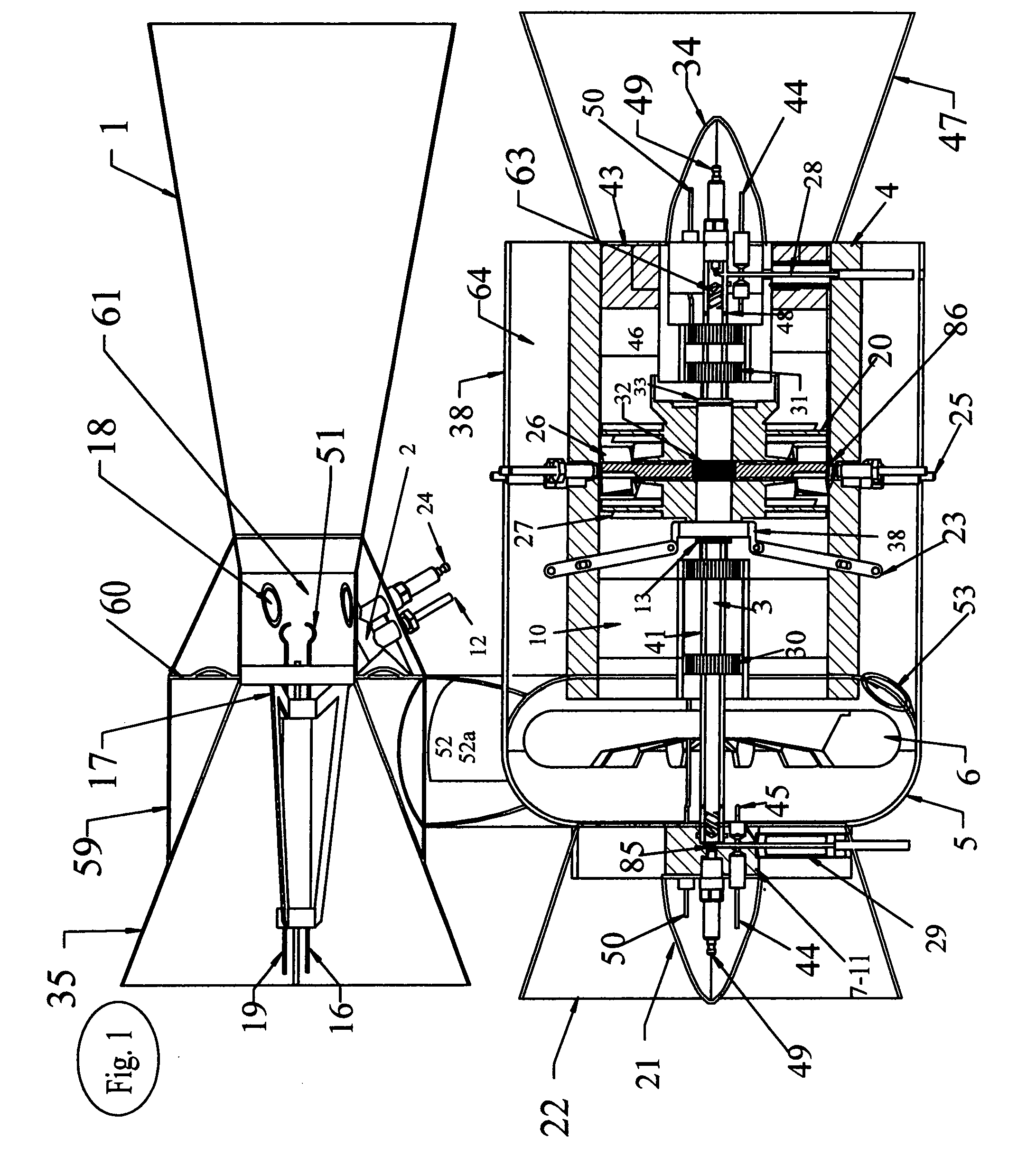

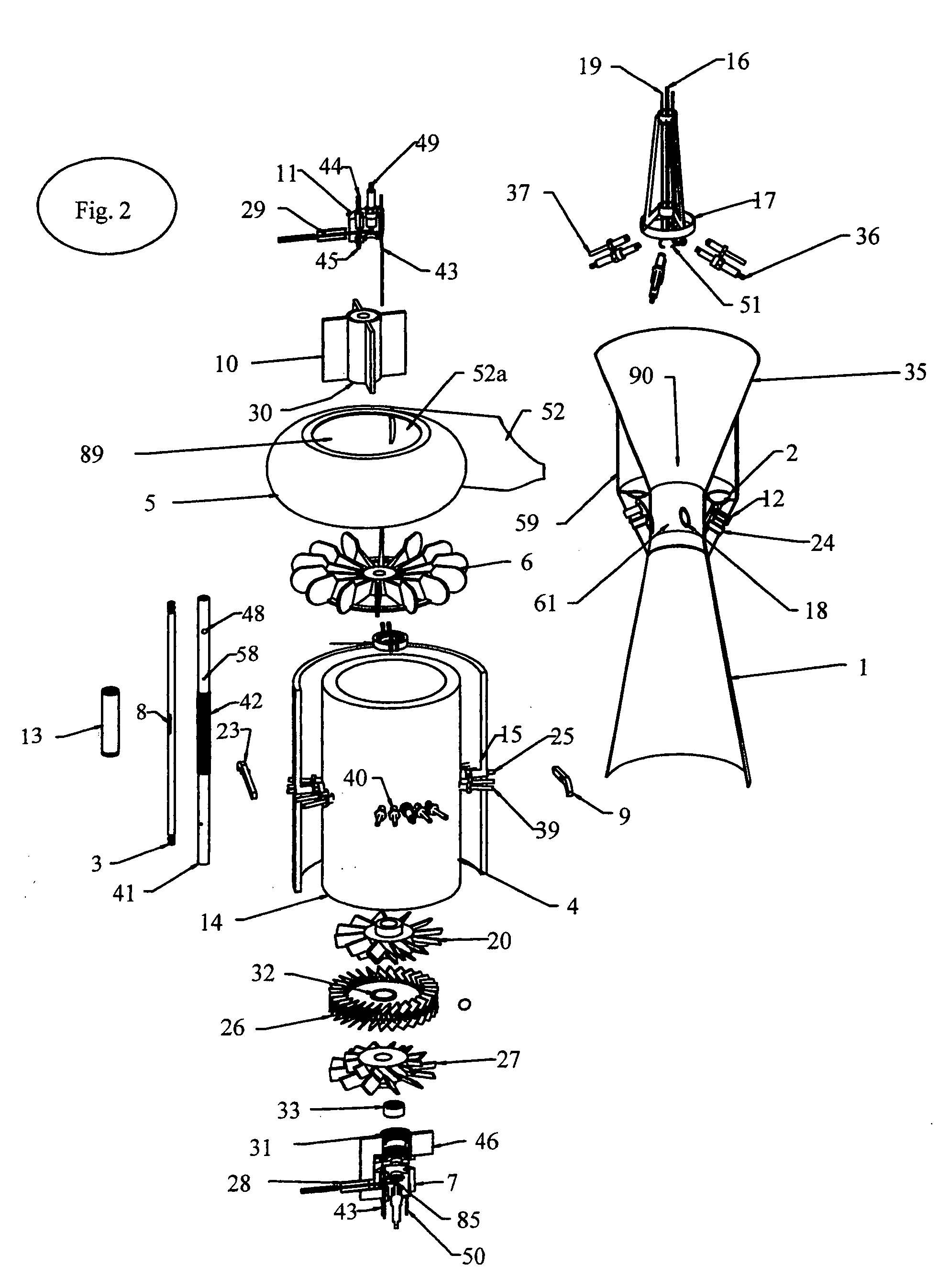

Methods of combining a series of more efficient aircraft engines into a unit, or modular units

InactiveUS20100251692A1More thermal capacityReduce environmental pollutionContinuous jet plantsRocket engine plantsRamjetFree-piston engine

The present invention generally relates to units of engines and more particularly to units containing a unique combined-cycle (combustion-detonation) “counter-rotation, anti-gyration, gyroscopic,” turbine fan-jet / free-piston engine configuration for induced air supercharging and boosting the performance of novel Ramjet engines or Ramjet engine configurations by improving internal air-stream dynamics. These dynamics are the result of co-operative air stream intermixing through convergent, supercharge-attenuated, inducted, compressed, tuned, pre-heated ambient air. Achieved through the varying of the geometric structural form and the utilization of unique engines and air induction and propulsion conformations, aided with supplemental air, fuel, oxygen and optiomal water and electrolyte charging.

Owner:KINDE SR RONALD AUGUST

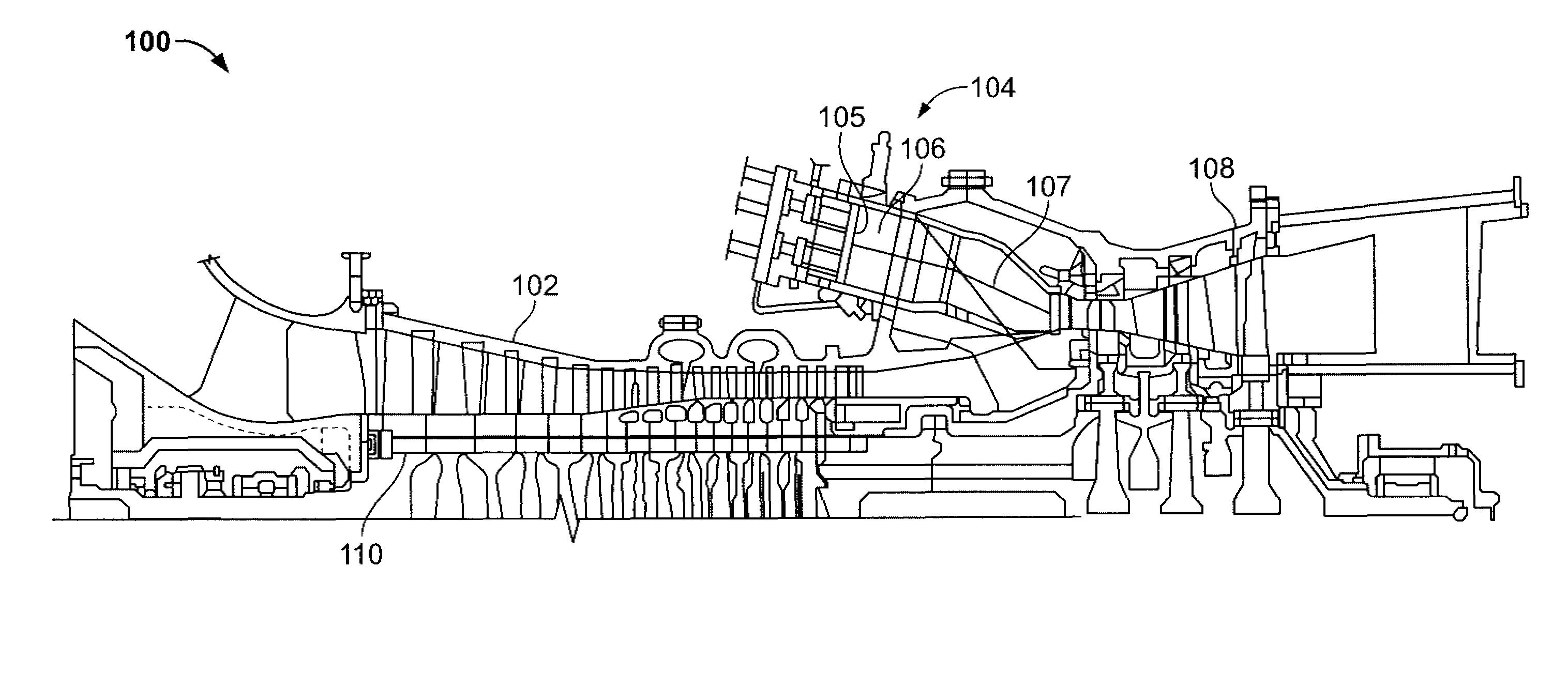

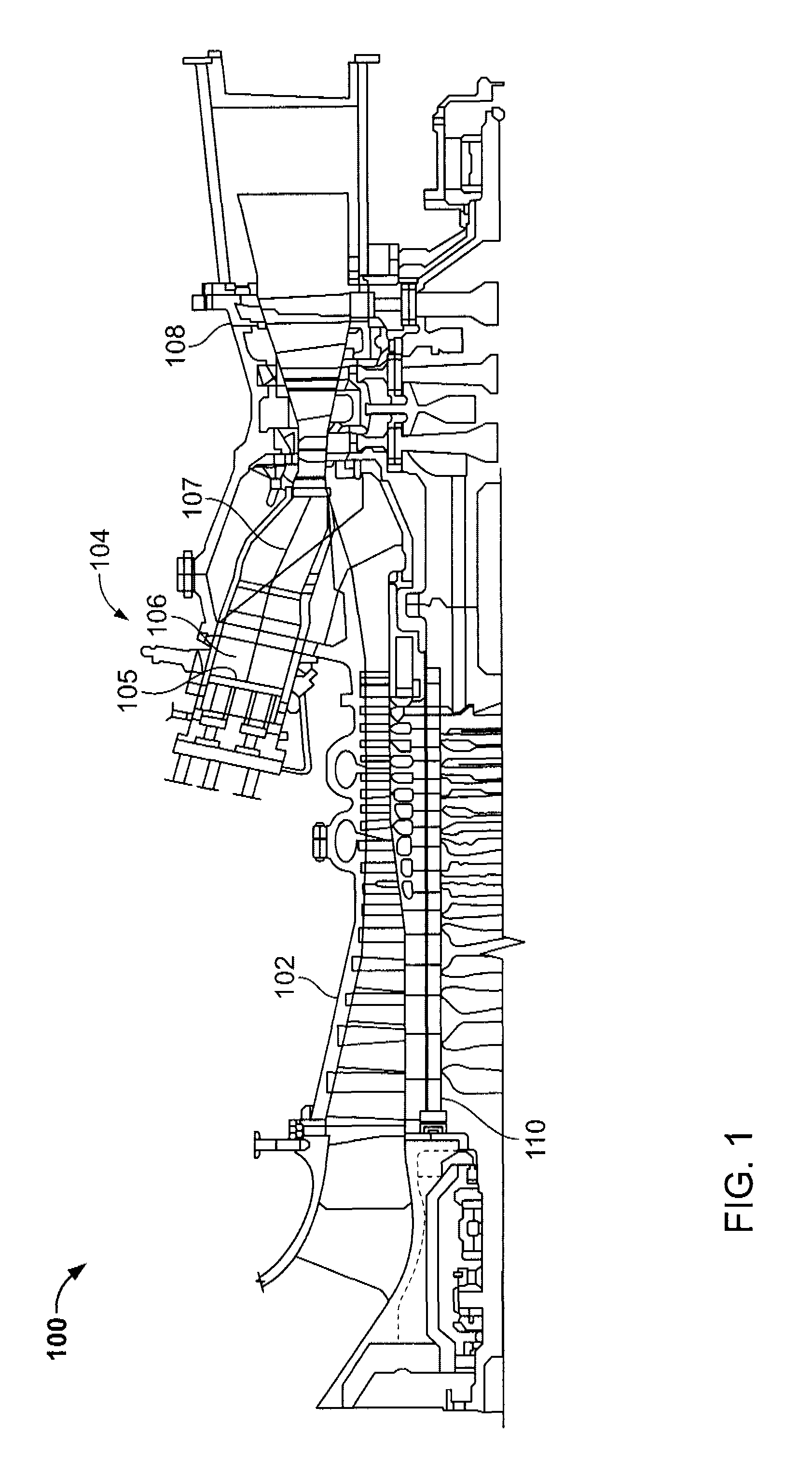

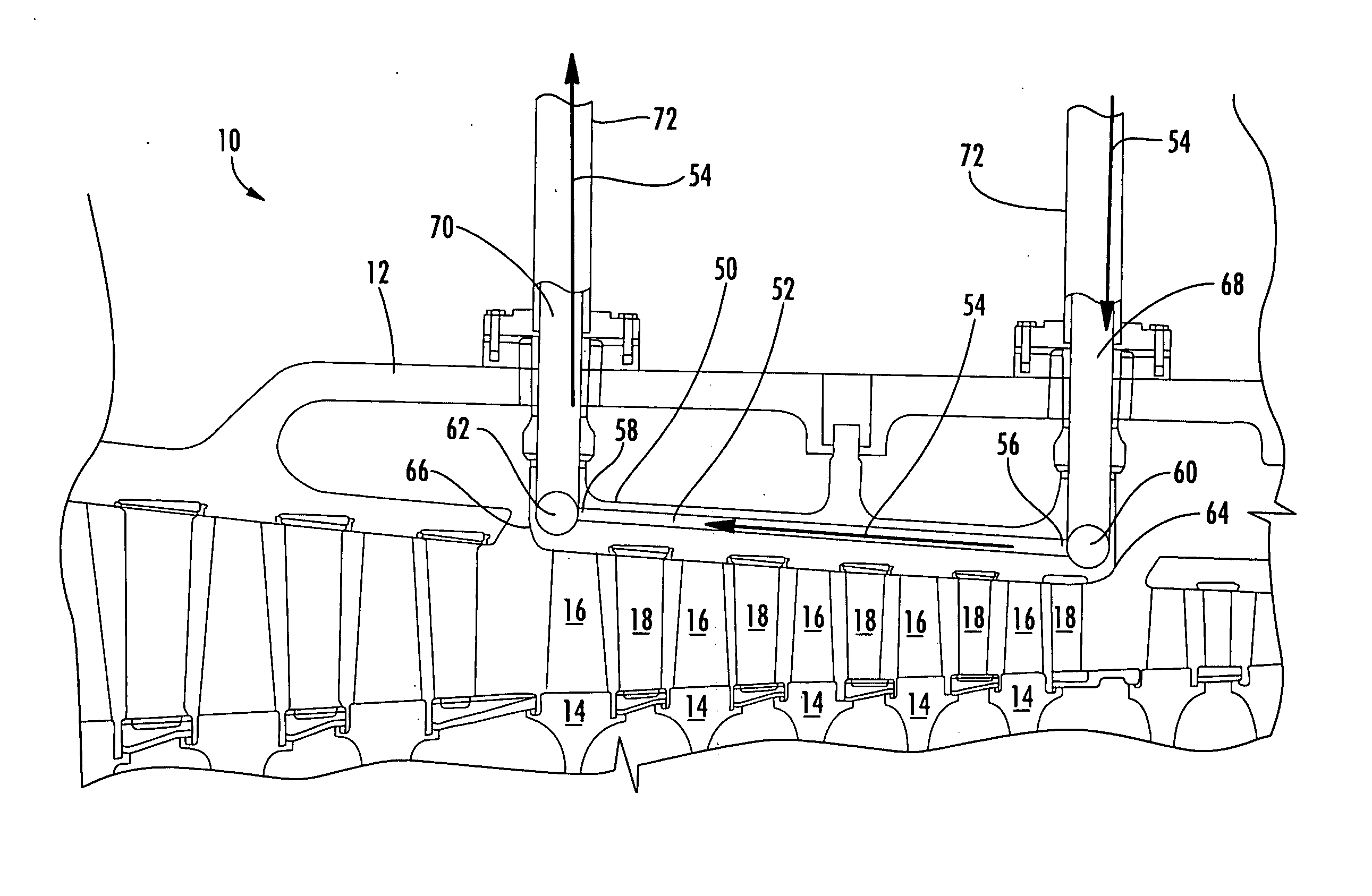

System for actively controlling compressor clearances

InactiveUS20060225430A1Reduce the temperatureMinimize radial expansionPump componentsEngine fuctionsEngineeringBleed air

Aspects of the invention relate to a system and method for actively controlling compressor clearances in a turbine engine by passing a thermal fluid in heat exchanging relation through a compressor vane carrier. During some operational conditions, such as hot restart or spin cool, it may be desirable to heat the vane carrier to enlarge or at least prevent a decrease in compressor clearances. In such cases, a heated thermal fluid can be provided by reclaiming residual exhaust energy from a heat recovery steam generator. At any condition where improved performance is desired, such as at base load operation, the vane carrier can be cooled to minimize compressor clearances. A cooled thermal fluid can be bleed air from an upstream portion of the compressor, water-cooled high pressure bleed air from a downstream portion of the compressor, or feed water from the bottoming cycle in a combined cycle engine.

Owner:SIEMENS ENERGY INC

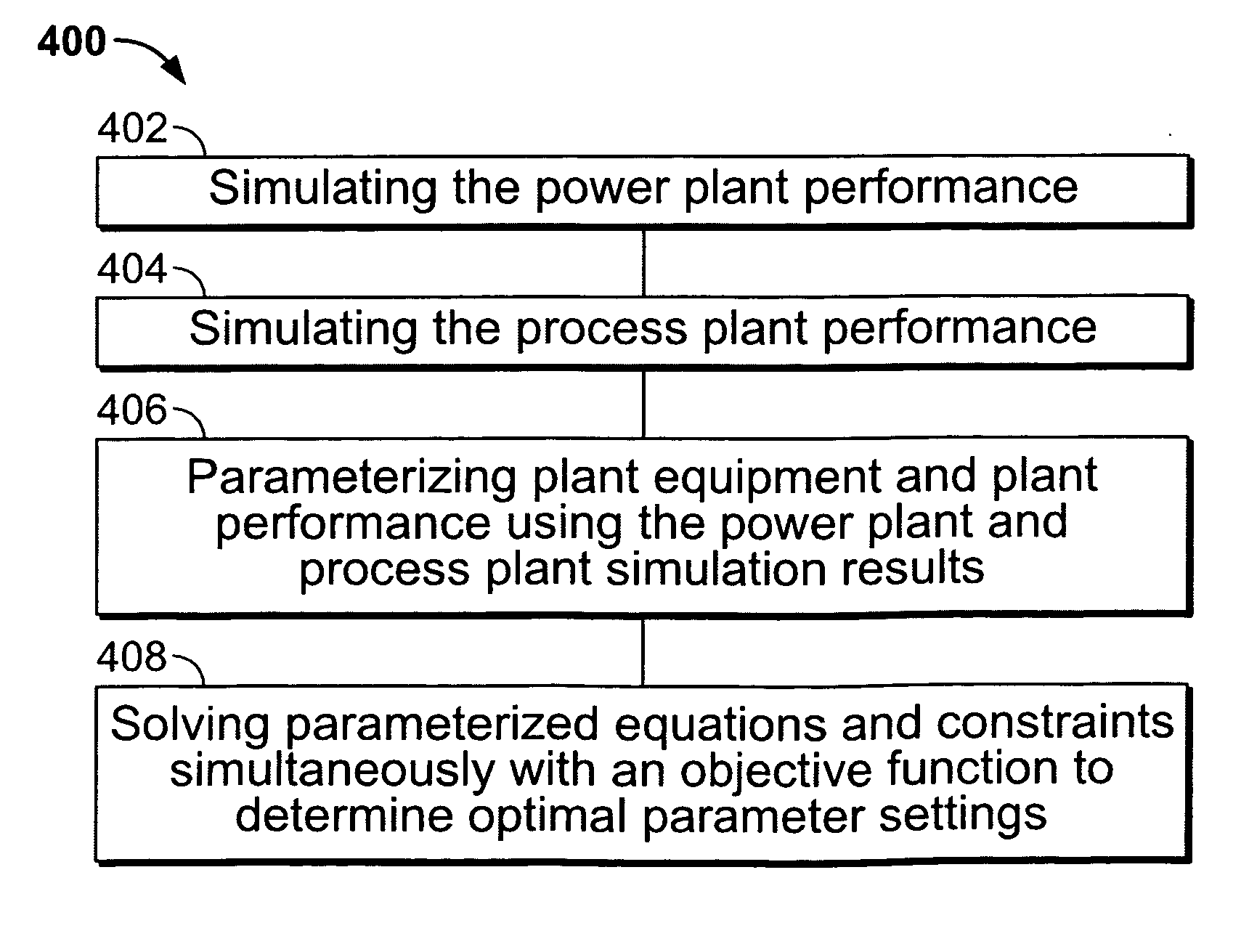

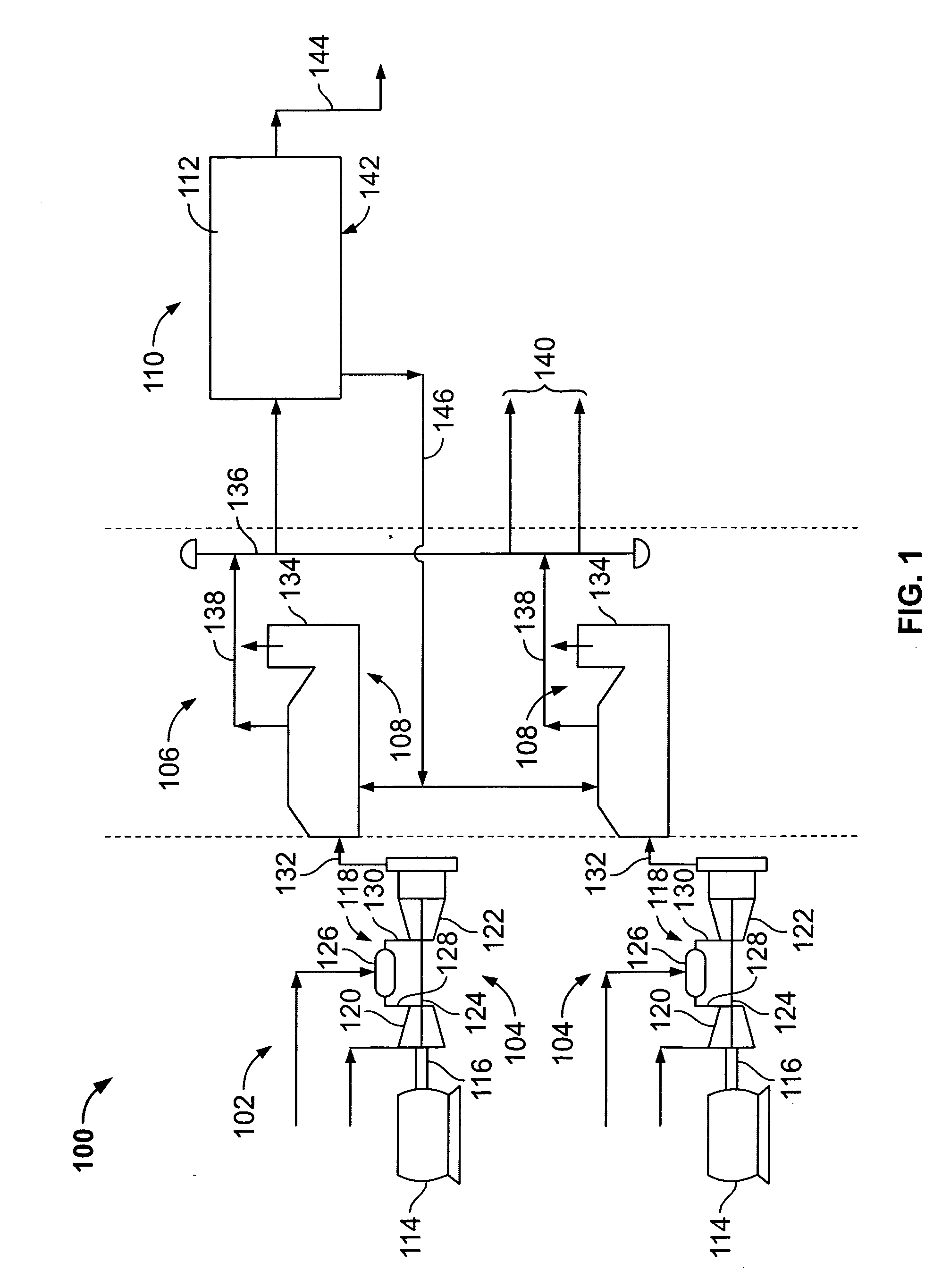

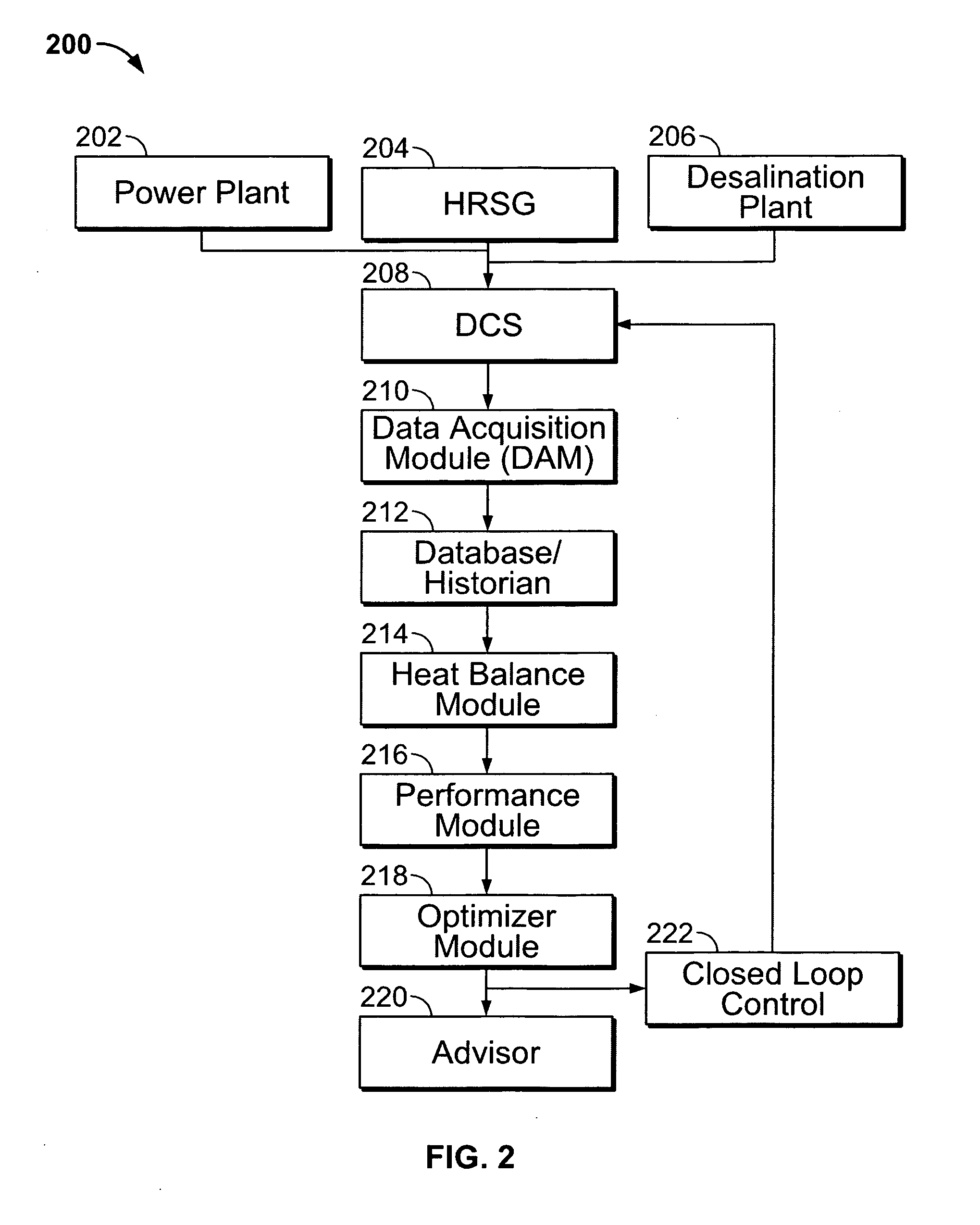

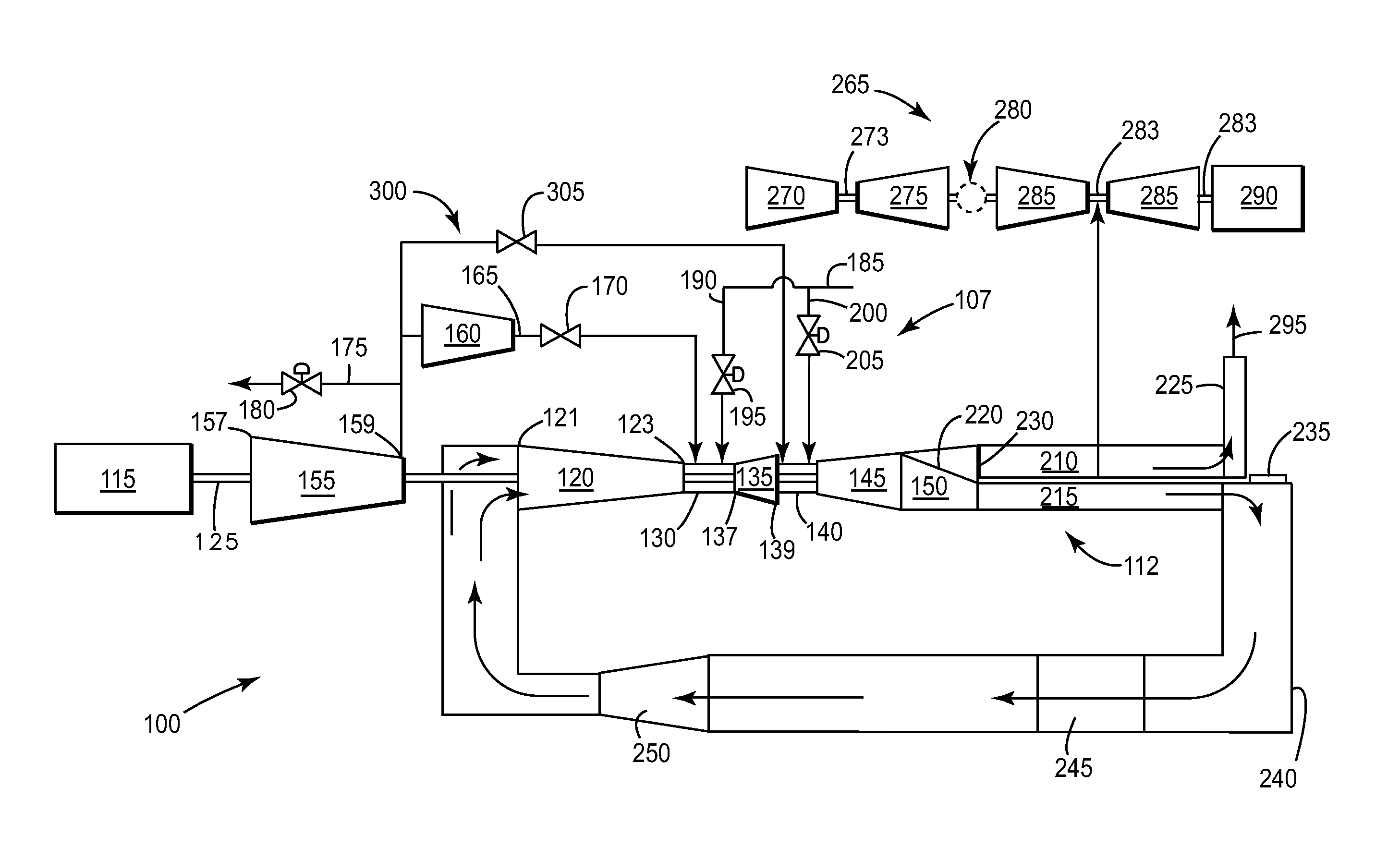

Methods and apparatus for optimizing combined cycle/combined process facilities

InactiveUS20060178782A1Improve efficiencyLevel controlAnalogue computers for nuclear physicsPower stationEngineering

Methods and systems for operating combined cycle electrical generating plants is provided. The method includes simulating the electrical power plant performance, simulating the steam utilizing process plant performance, parameterizing plant equipment and plant performance using the power plant and process plant simulation results, and solving parameterized simultaneous equations and constraints with an objective function to determine parameter settings that facilitate enhancing an efficiency of the combined cycle electrical generating / steam-utilizing process plant.

Owner:GENERAL ELECTRIC CO

Method and system for controlling a powerplant during low-load operations

The present invention provides a system and method of operating a combined-cycle powerplant at part-load without shutting down an HRSG and steam turbine. The present invention may apply to a powerplant operating in an open-cycle mode. The present invention may also apply to a powerplant operating in a closed-cycle mode.

Owner:GENERAL ELECTRIC CO

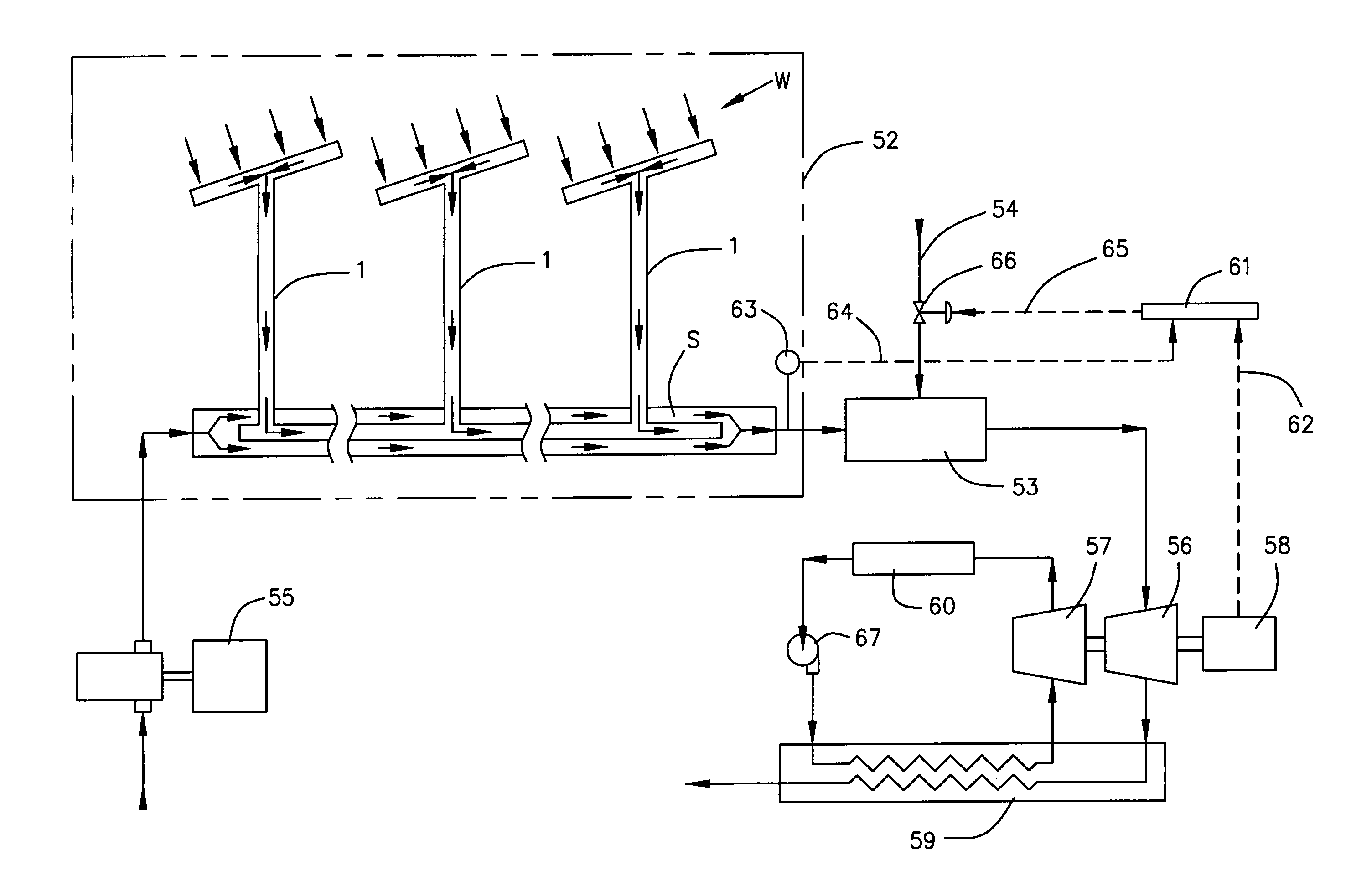

Solar blackbody waveguide for efficient and effective conversion of solar flux to heat energy

A solar blackbody waveguide that captures and uses sunlight to heat a thermal working or heat transfer fluid. Solar cell arrays capture the sunlight. The arrays are movably mounted on solar towers to track the daily movement of the sun and to maintain the proper angle with the horizon throughout the year. The arrays direct the light into a series of light pipes to deliver the light into a solar coil located within an underground insulated pipeline. Energy from the light rays is absorbed by the solar coil and transferred to the thermal working fluid or heat transfer fluid flowing between the solar coil and the insulated pipeline. The energy laden thermal working or heat transfer fluid is removed from the downstream end of the insulated pipeline so that it can be used with existing technologies, such as with a combined cycle gas turbine, boiler, or steam generator.

Owner:MECHAM TRAVIS W

Method and apparatus for using geothermal energy for the production of power

ActiveUS20060026961A1Delay water lossLow densityEngine fuctionsGas turbine plantsPower stationTemperature difference

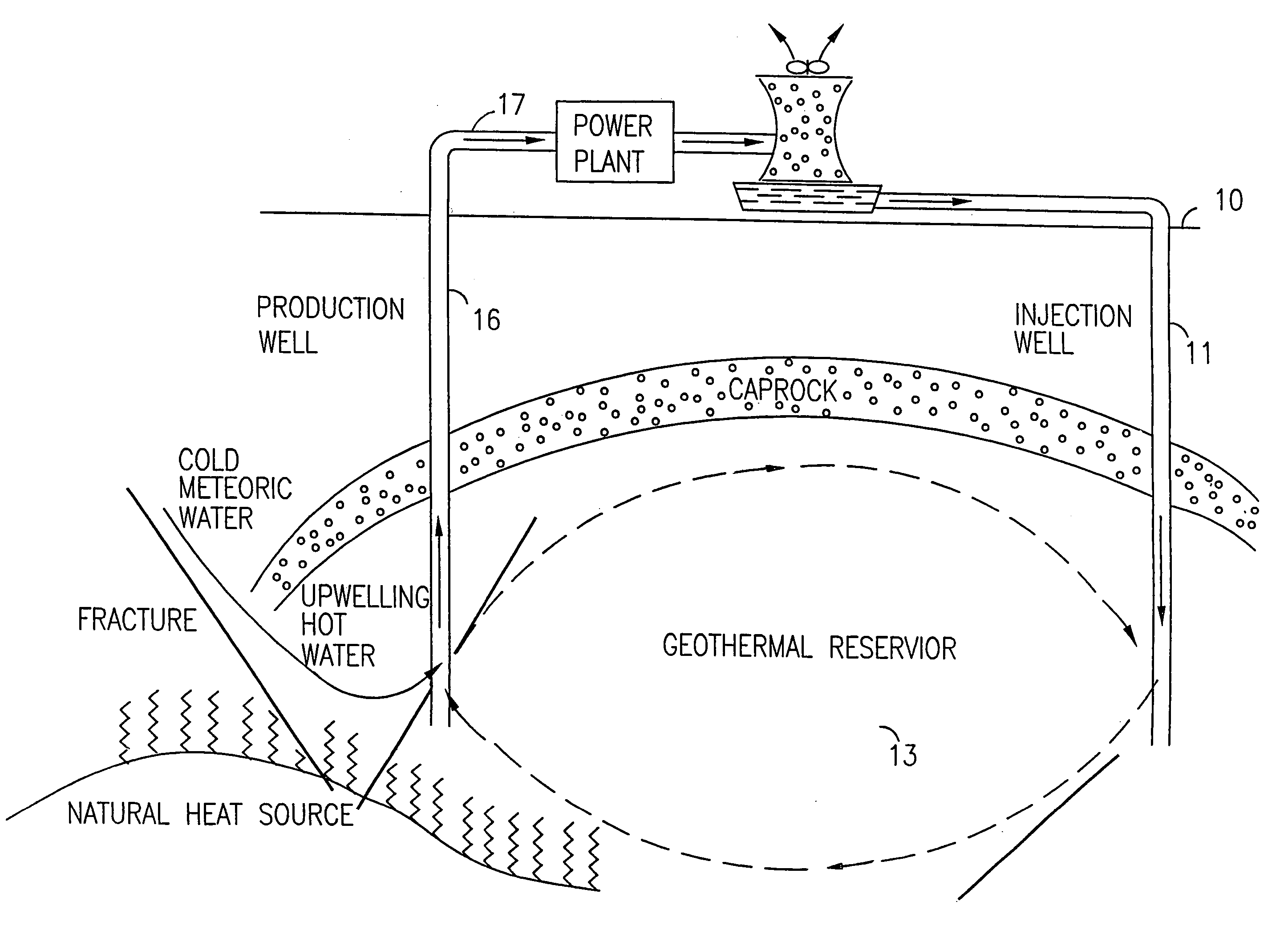

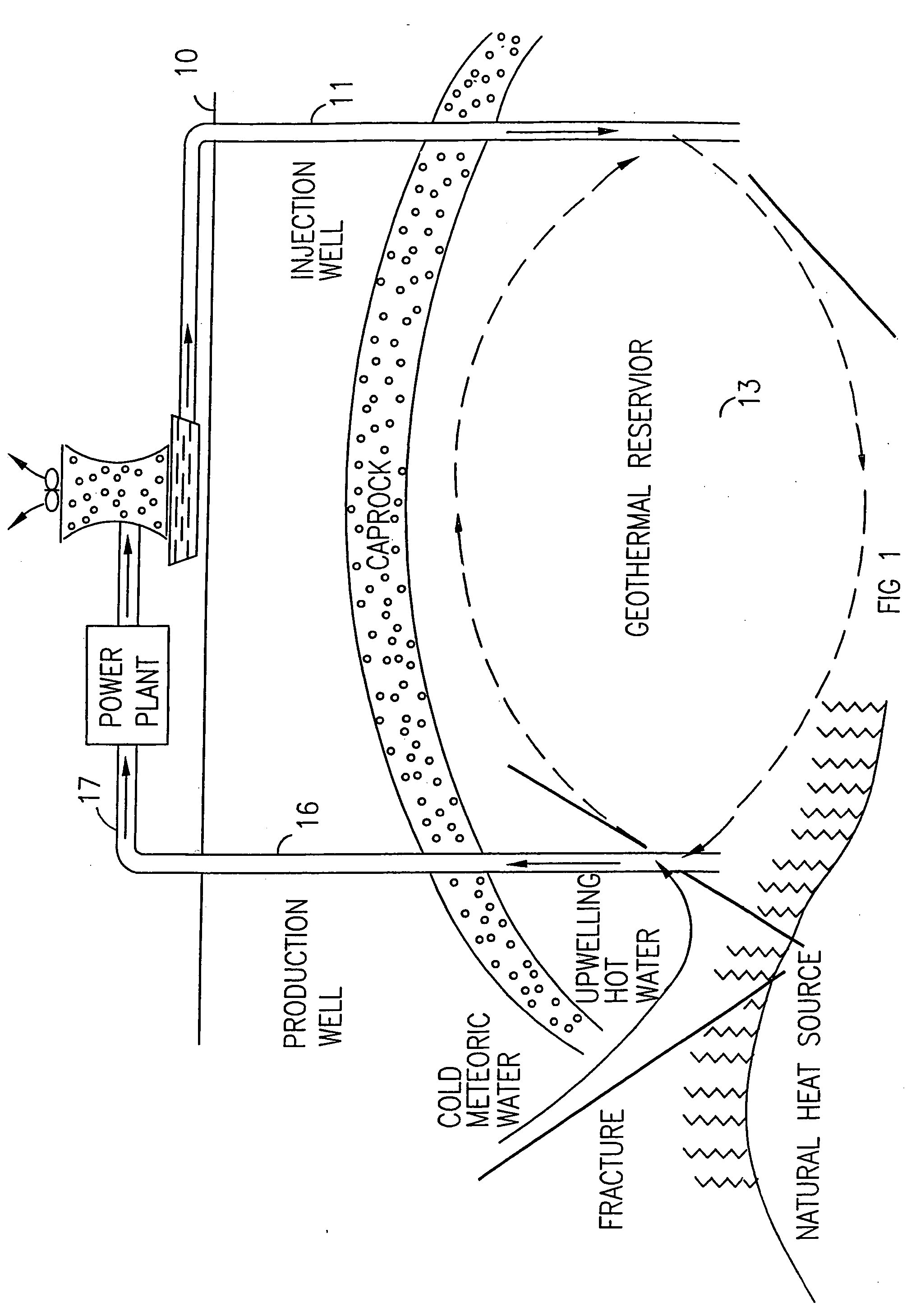

The method of the invention comprises enhancing the flow of geothermal fluid (water and / or steam and / or mixtures thereof) from at least one injection well to at least one production well, by the following steps: providing a first, horizontal, geothermal well, which is used as said injection well; injecting water into said injection well; providing a second, horizontal, geothermal well, which issued as said production well such that said second, horizontal, production, geothermal well is substantially horizontally and vertically spaced from said first, horizontal, injection, geothermal well and located at a shallower depth than said first, horizontal, injection, geothermal well; recovering geothermal fluid from said production well; and generating a water density difference and a pressure difference between said first horizontal, injection well and said second horizontal, production well. Furthermore, the invention comprises an apparatus for enhancing the flow of geothermal fluid from at least one injection well to at least one production well, which comprises a first horizontal geothermal well, which is used as said injection well and into which water is injected; a second horizontal, geothermal well, which is used as said production well and from which geothermal fluid issues, wherein said second, horizontal, production, geothermal well is substantially horizontally and vertically spaced from said first, horizontal, injection, geothermal well and located at a shallower depth than said first, horizontal, injection, geothermal well; and means for producing a pressure difference between said first horizontal, injection well and said second horizontal, production well and utilizing the water density difference induced by the temperature difference. Preferably, binary geothermal power plants or combined cycle geothermal power plants can be used to produce power from geothermal fluid recovered from the production well.

Owner:ORMAT TECH INC

Combined cycle power plant including a carbon dioxide collection system

A combined cycle power plant includes a compressor section including a compressor inlet and a compressor outlet, and a turbine section operatively connected to the compressor section. The turbine section includes a turbine inlet and a turbine outlet. A heat recovery steam generator (HRSG) is fluidly connected to the turbine outlet. A combustor includes a head end and a combustor discharge. The head end is fluidly connected to the compressor outlet and the combustor discharge is fluidly connected to the turbine inlet. A carbon dioxide collection system is fluidly connected to one of the compressor outlet and the head end of the combustor. The carbon dioxide collection system is configured and disposed to extract a first fluid comprising carbon dioxide and a second fluid from a substantially oxygen free fluid flow passed from the one of the compressor outlet and the head end of the combustor.

Owner:GENERAL ELECTRIC CO

Triple Cycle Power Plant

InactiveUS20080034727A1High power outputQuality improvementGas turbine plantsSteam engine plantsPower stationNuclear engineering

Abstract: A refrigeration cycle is integrated into a combined cycle power plant to form a triple cycle power plant in which gas turbine generator inlet air is chilled and dehydrated to increase the mass flow of the inlet air, and in which duct firing in HRSG is increased in dependence of the increased mass flow. In further preferred integration aspects, the heat from the inlet chiller refrigerant is provided to the HRSG.

Owner:FLUOR TECH CORP

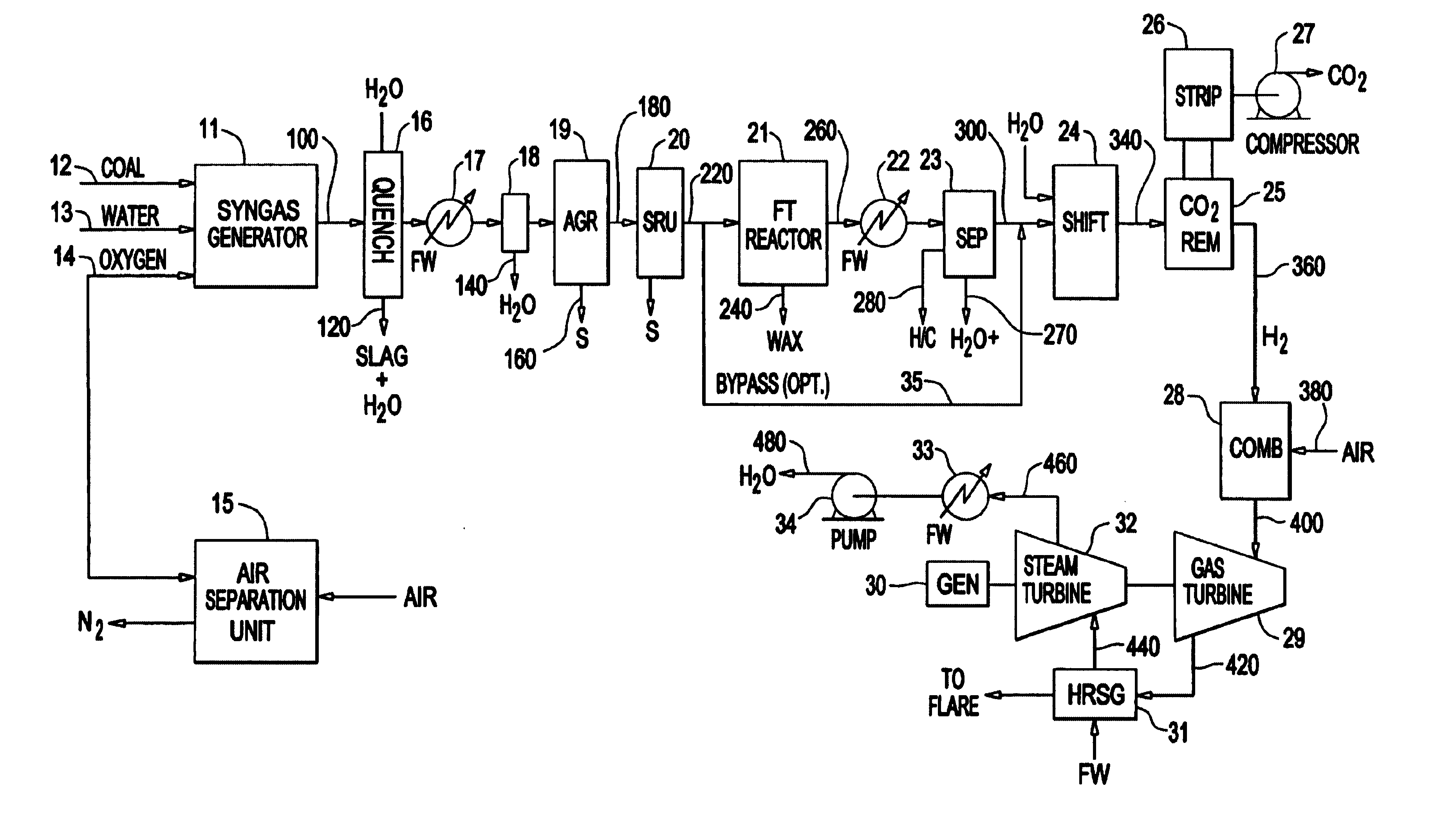

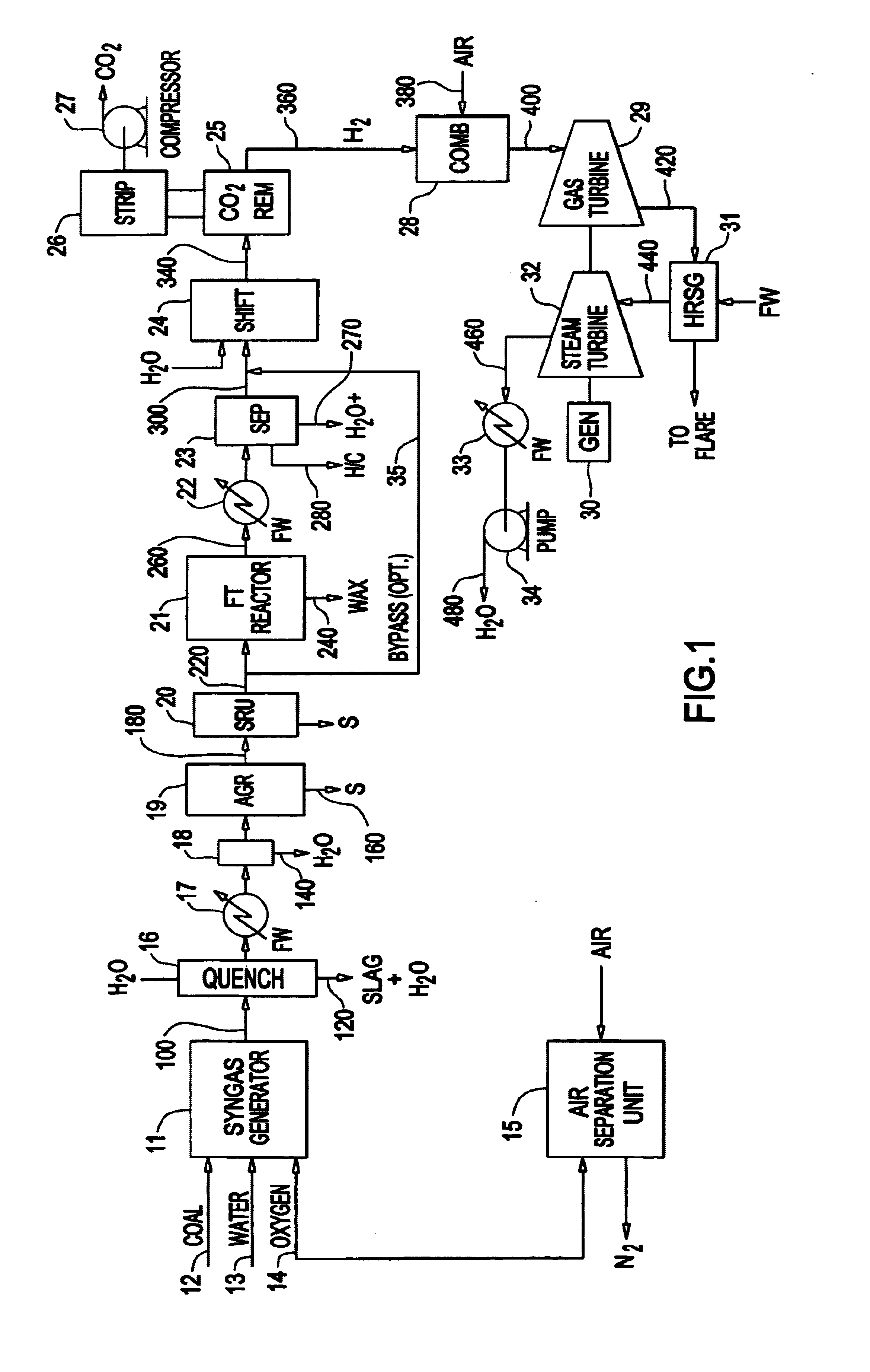

Integrated Fischer-Tropsch and power production plant with low CO2 emissions

A plant for producing Fischer-Tropsch liquids and electrical power with greatly reduced emissions of carbon dioxide to the atmosphere is made up of a syngas generator unit, an air separation unit, a Fischer-Tropsch unit, a CO2 removal unit, and a combined cycle electricity generation unit. Each of Fischer-Tropsch liquids, carbon dioxide, and electrical power can be recoverable under proper economic conditions. Electrical power is recoverable by the use of a gas turbine fueled by predominantly hydrogen and a steam turbine powered by steam generated by cooling exhaust gases from the gas turbine. Sequestration of CO2 and fueling the gas turbine with hydrogen reduces the amount of greenhouse gases emitted to the atmosphere.

Owner:RES USA LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com