Patents

Literature

21264results about How to "Low density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

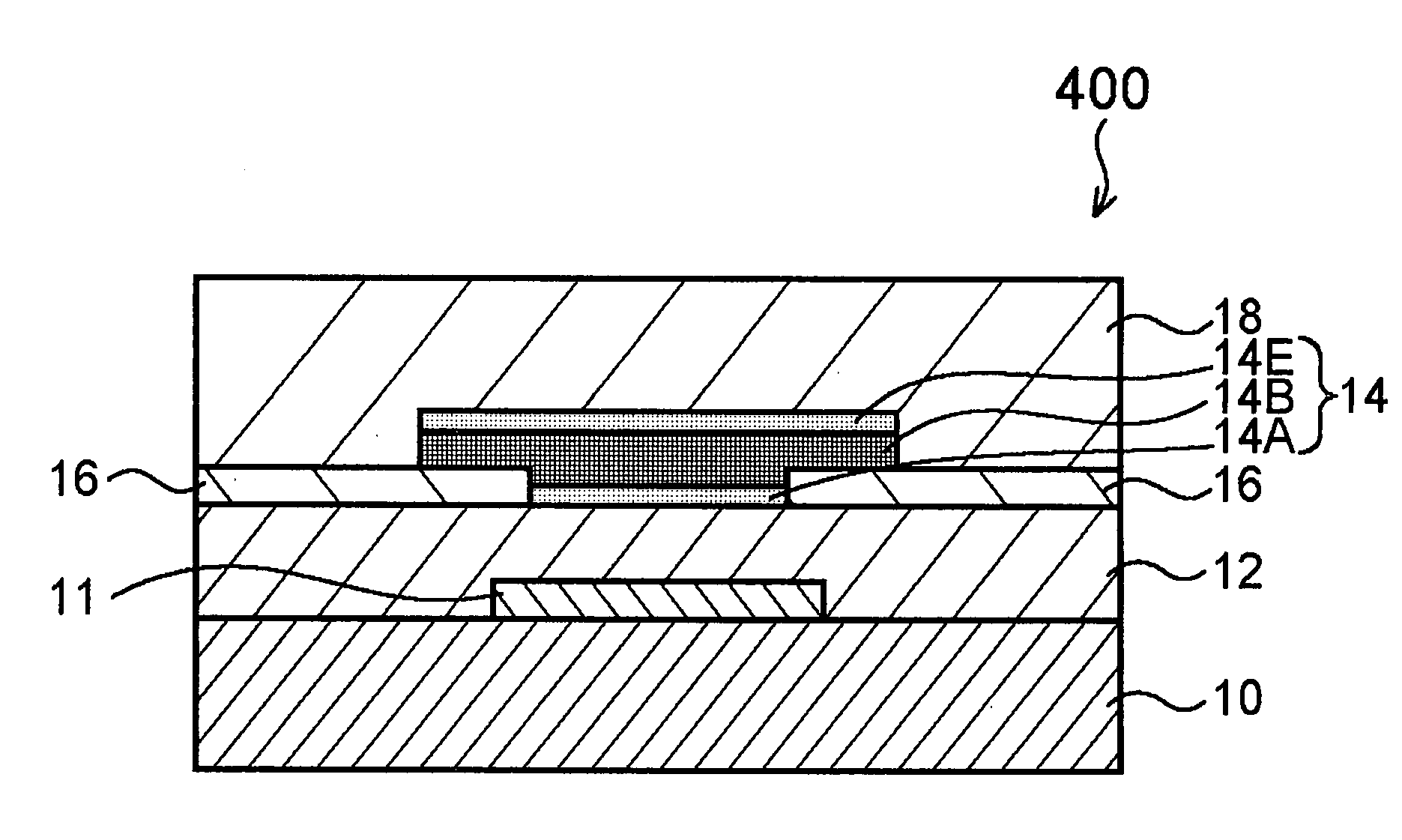

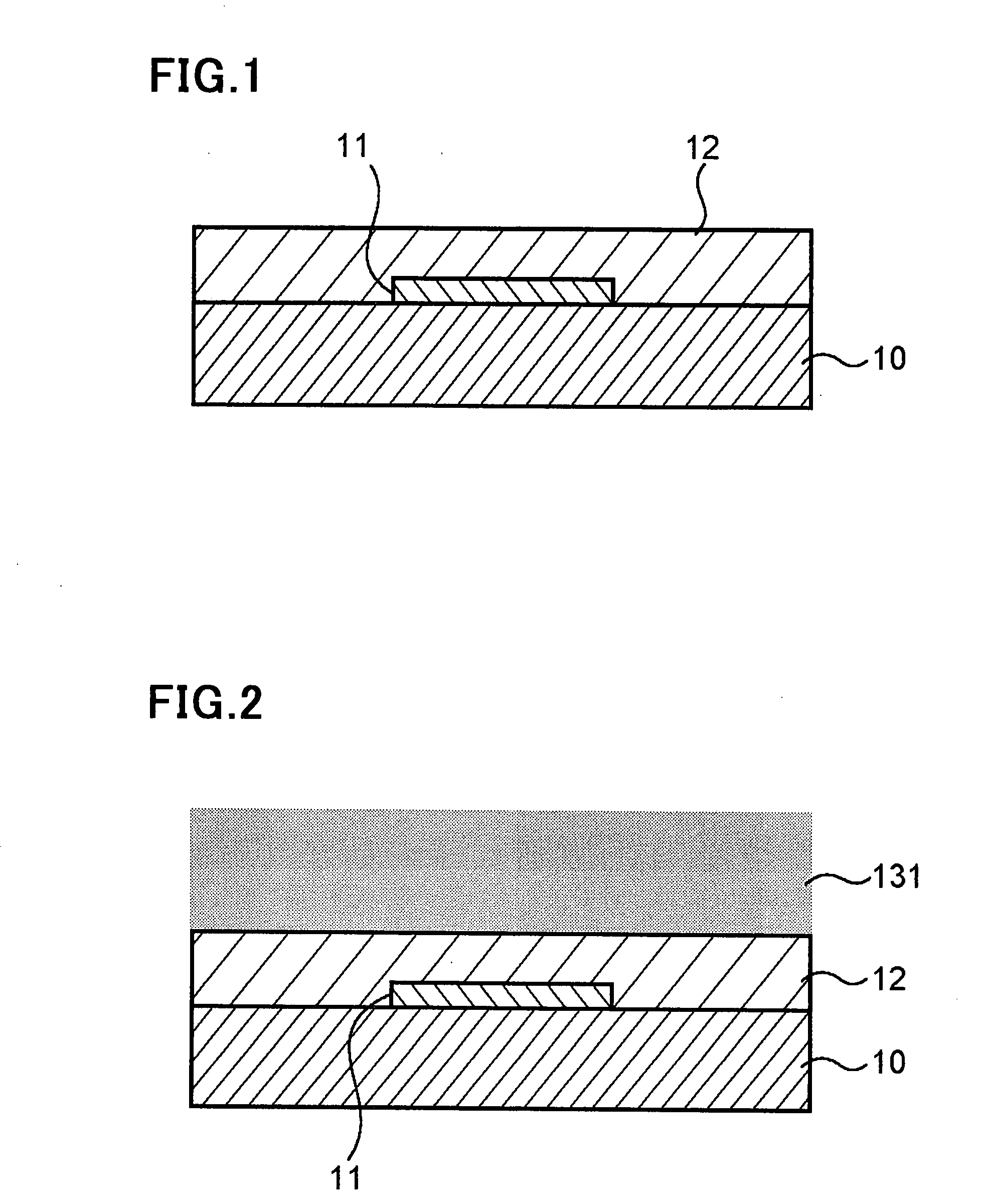

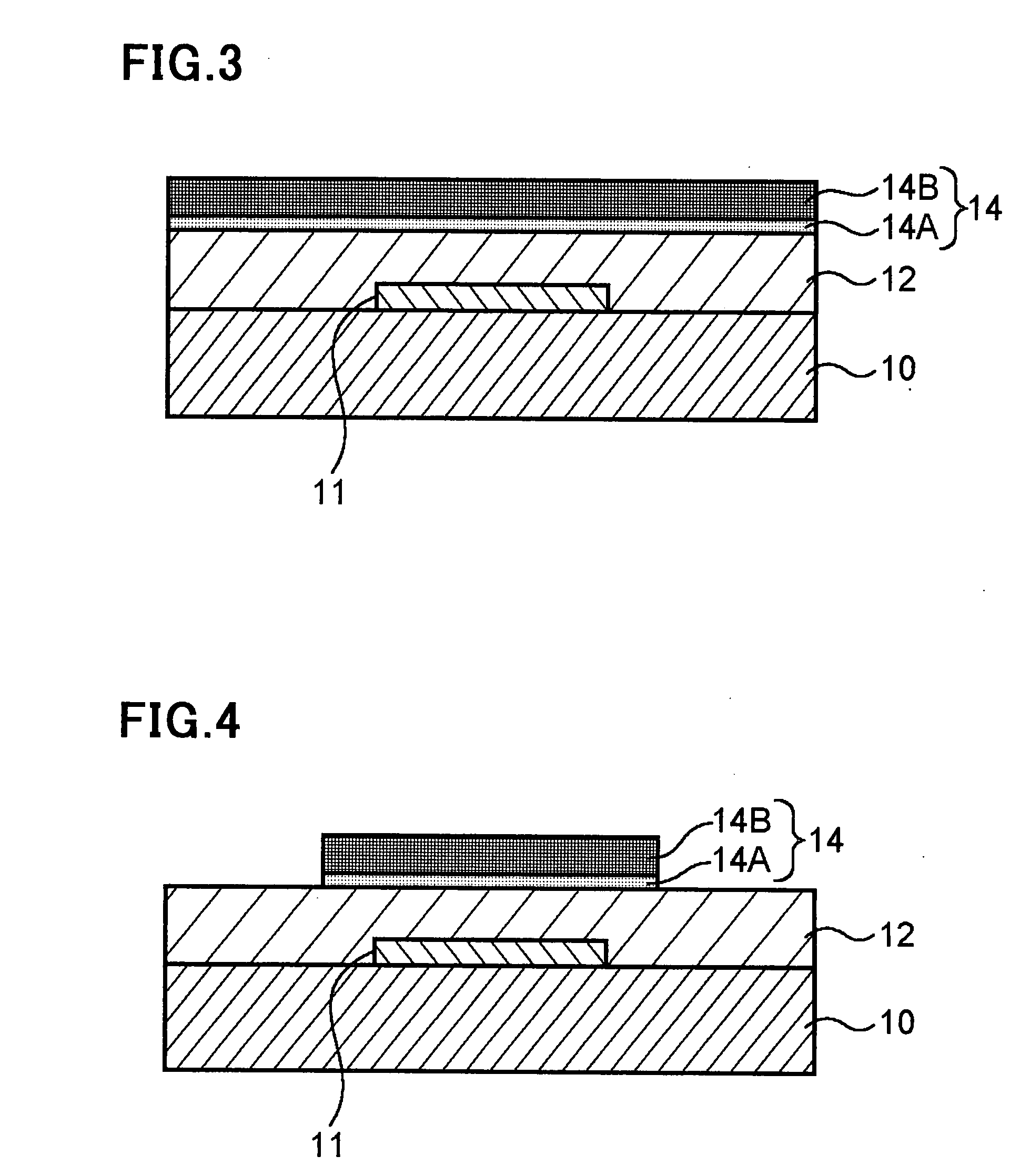

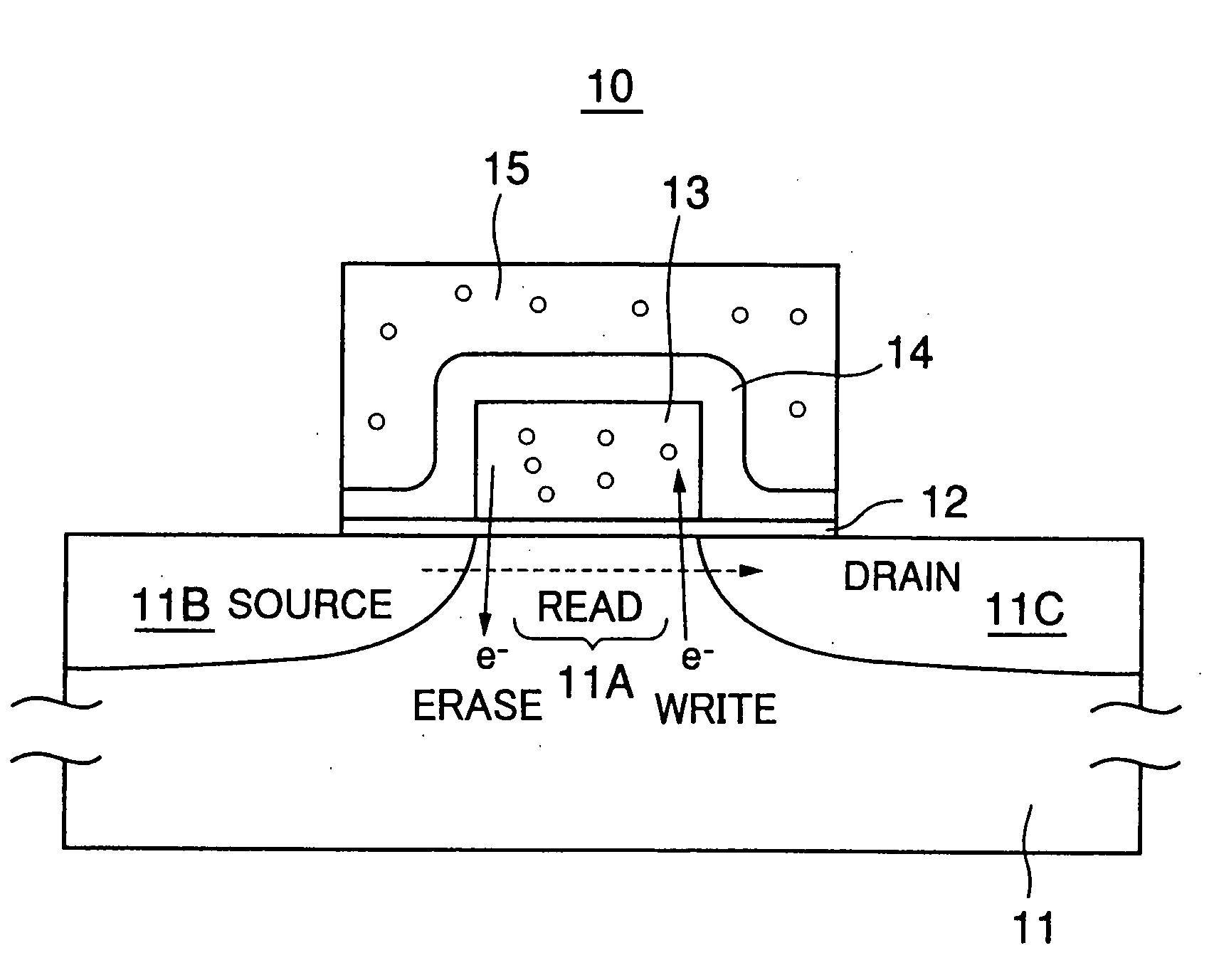

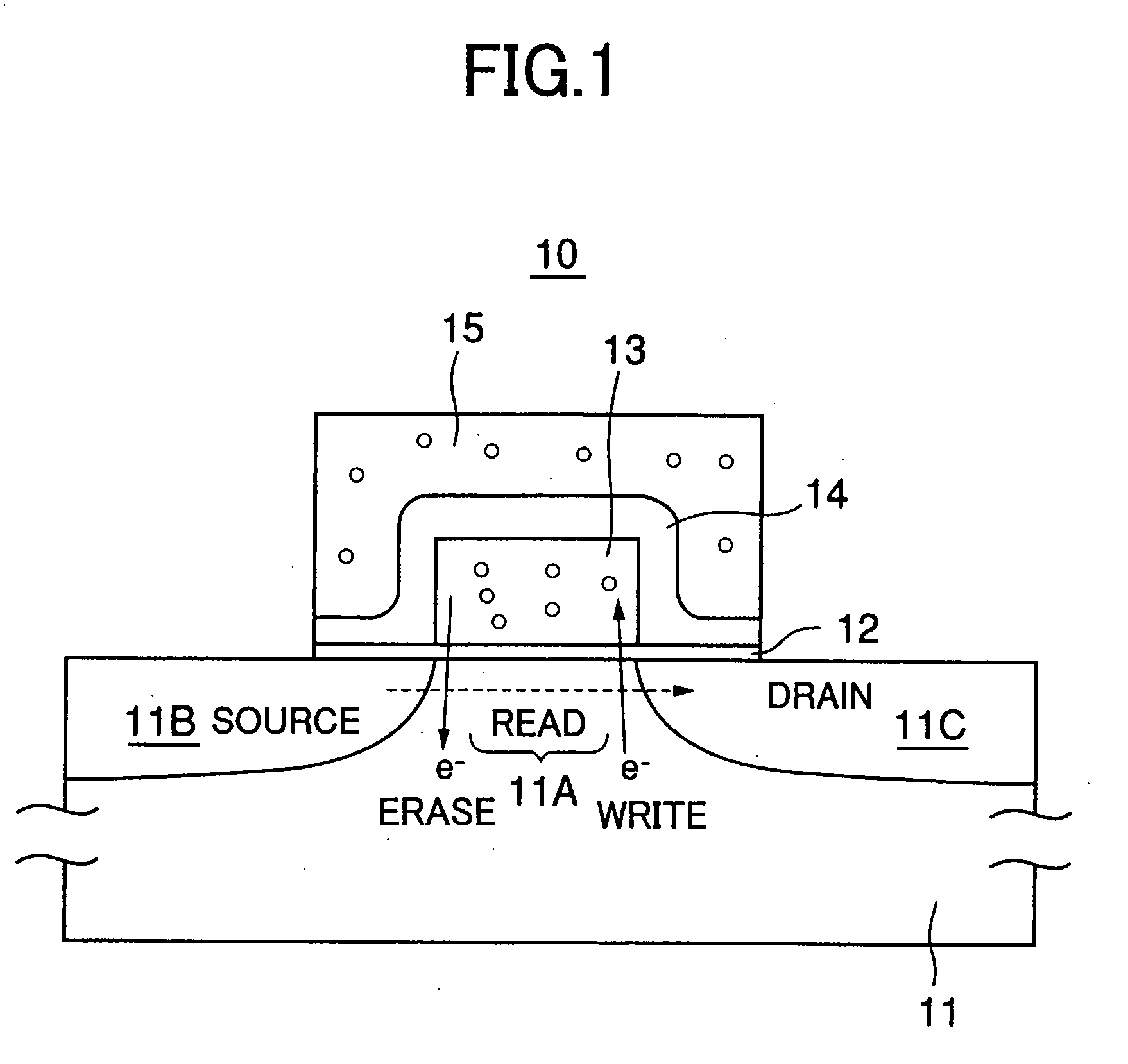

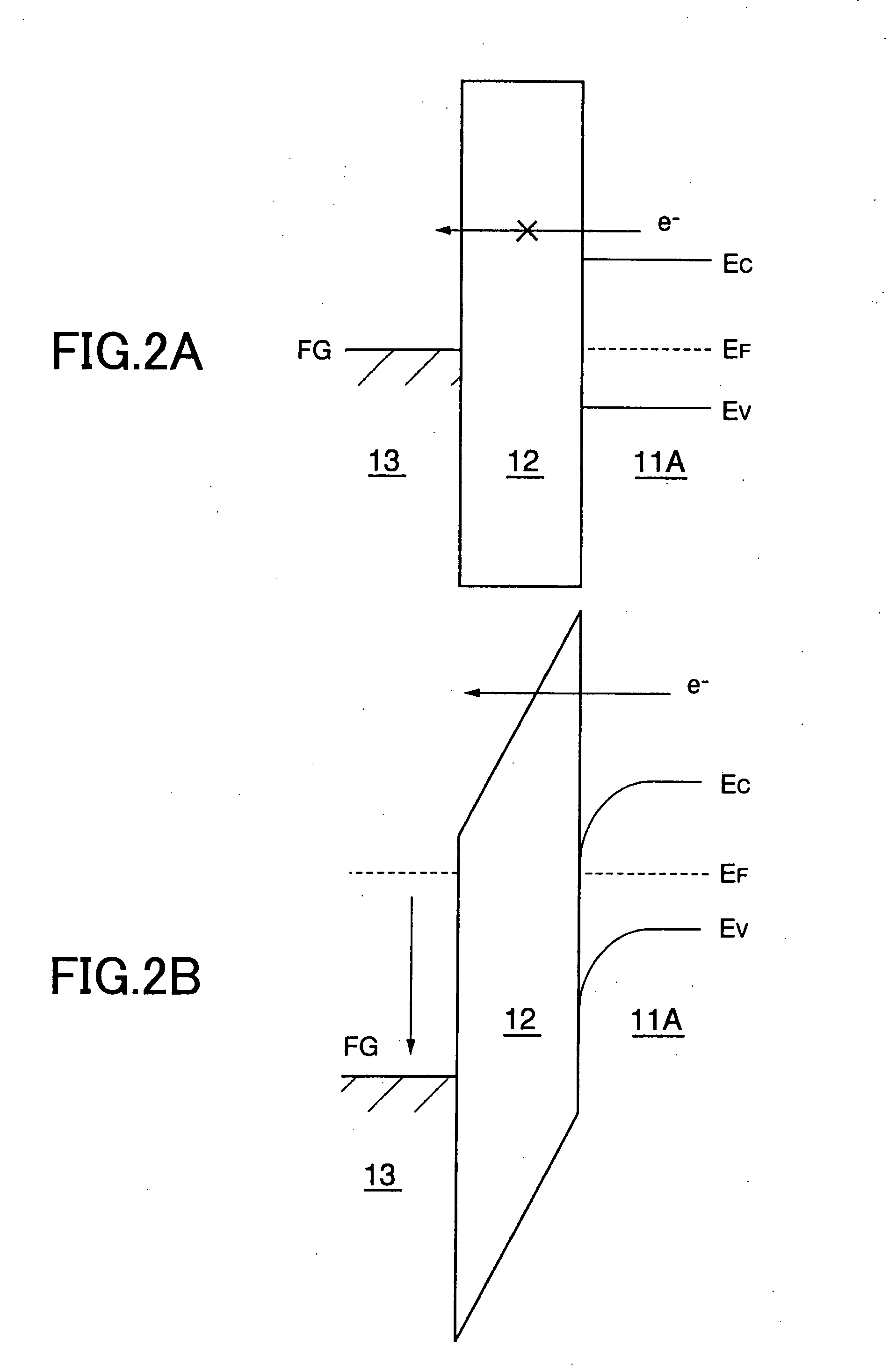

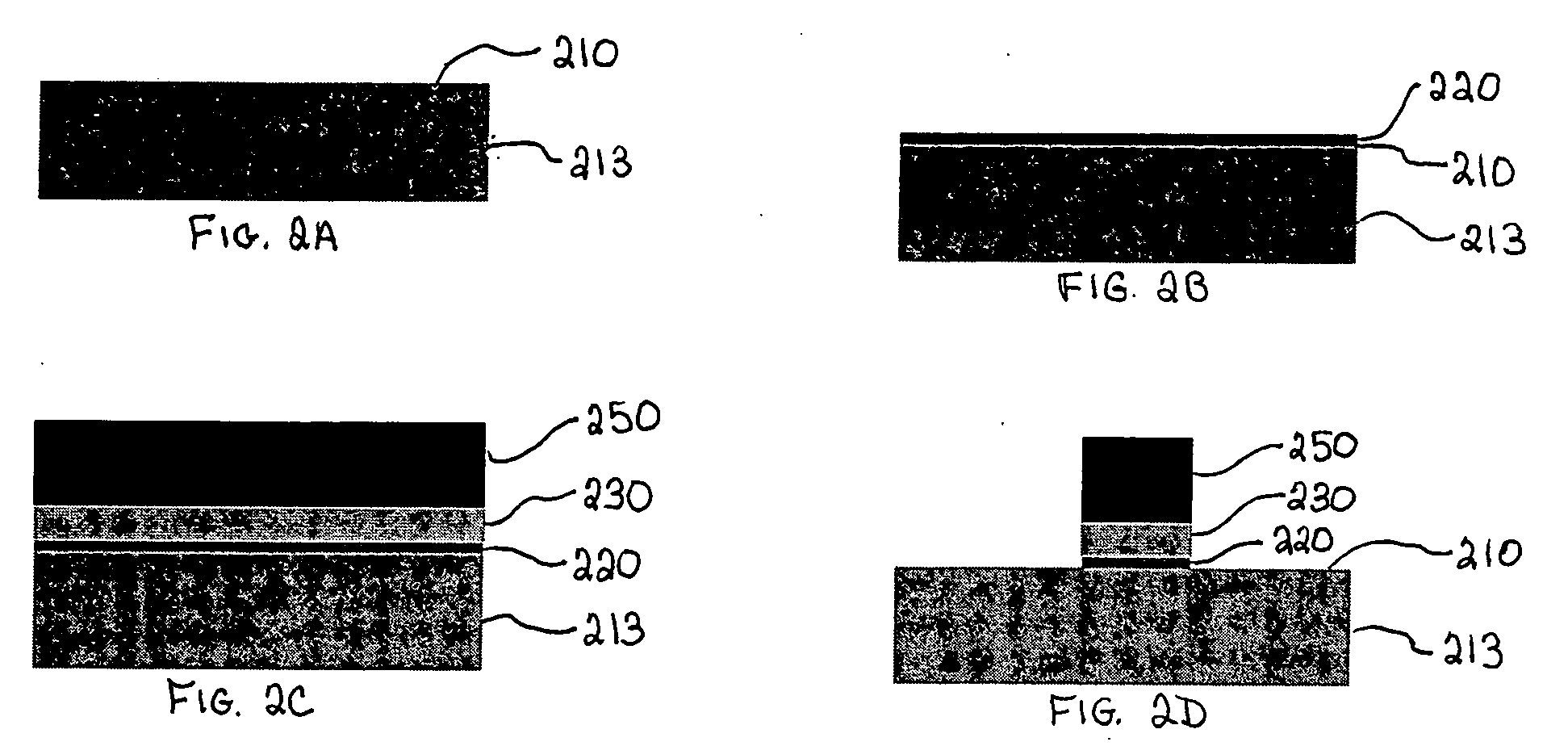

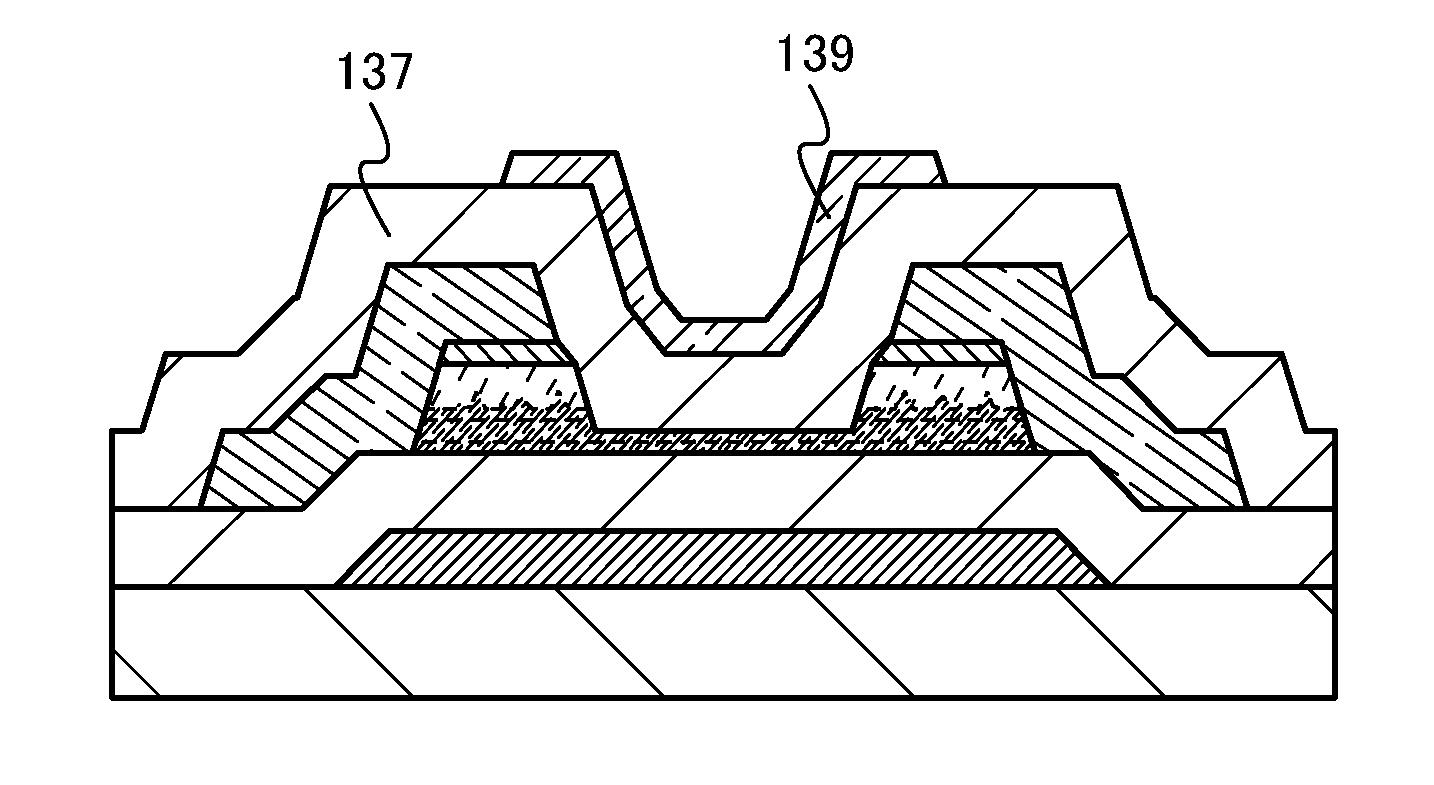

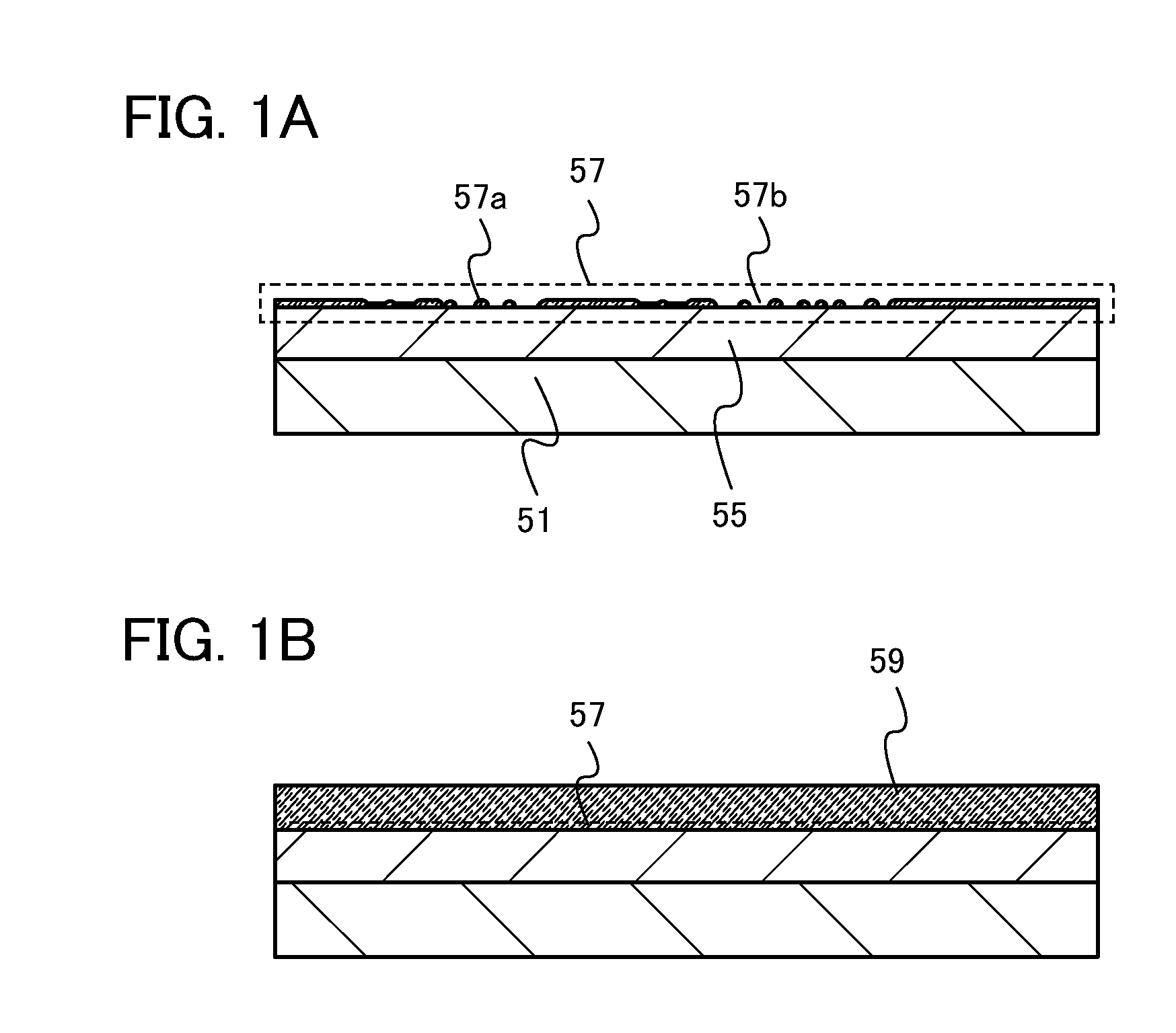

Thin-film device and method of fabricating the same

ActiveUS20080038882A1Low densityGood reproducibilitySemiconductor/solid-state device manufacturingSemiconductor devicesOxide semiconductorOxide

A thin-film device includes a first electrical insulator, an oxide-semiconductor film formed on the first electrical insulator, and a second electrical insulator formed on the oxide-semiconductor film, the oxide-semiconductor film defining an active layer. The oxide-semiconductor film is comprised of a first interface layer located at an interface with the first electrical insulating insulator, a second interface layer located at an interface with the second electrical insulator, and a bulk layer other than the first and second interface layers. A density of oxygen holes in at least one of the first and second interlayer layers is smaller than a density of oxygen holes in the bulk layer.

Owner:NEC LCD TECH CORP

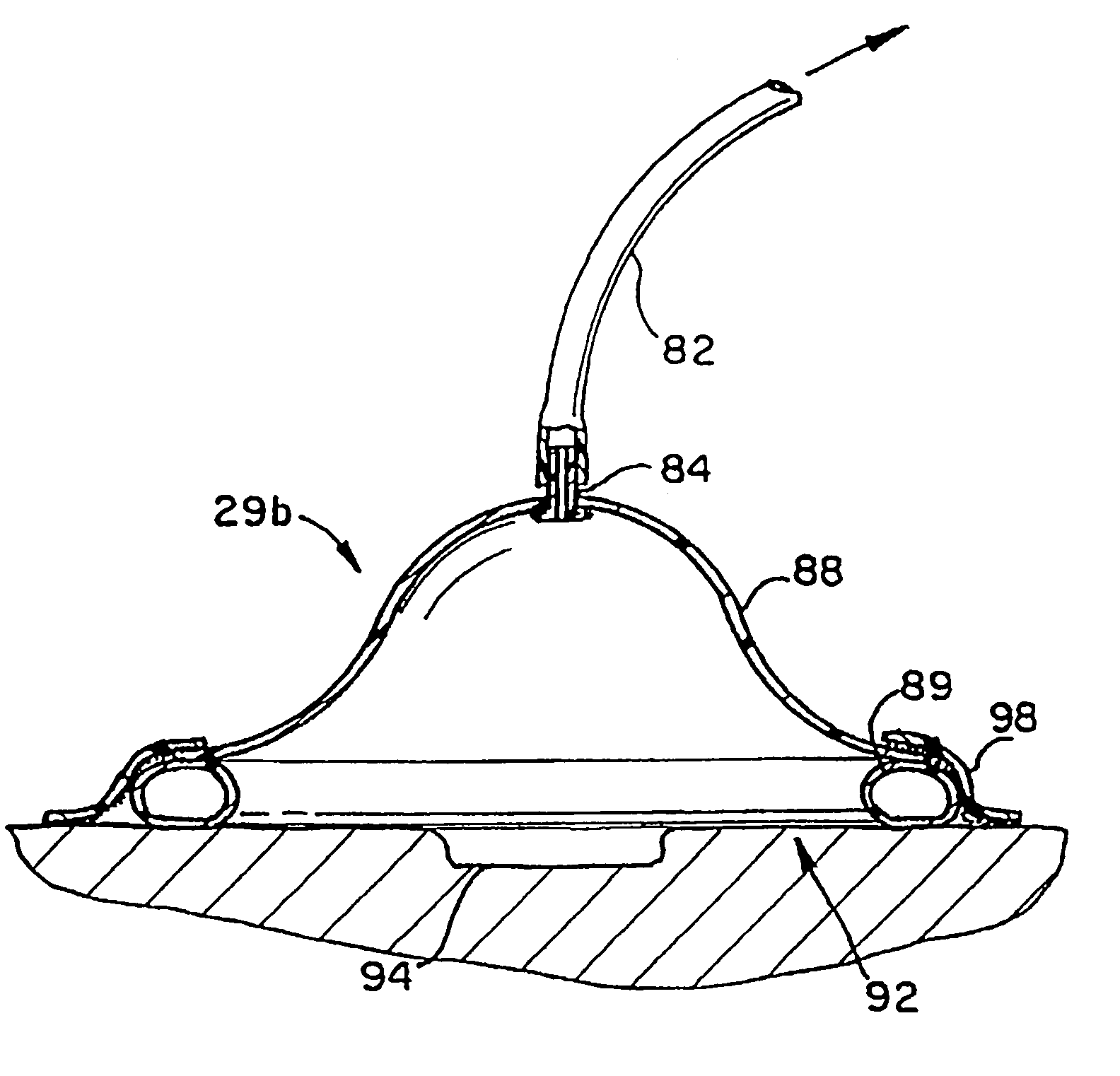

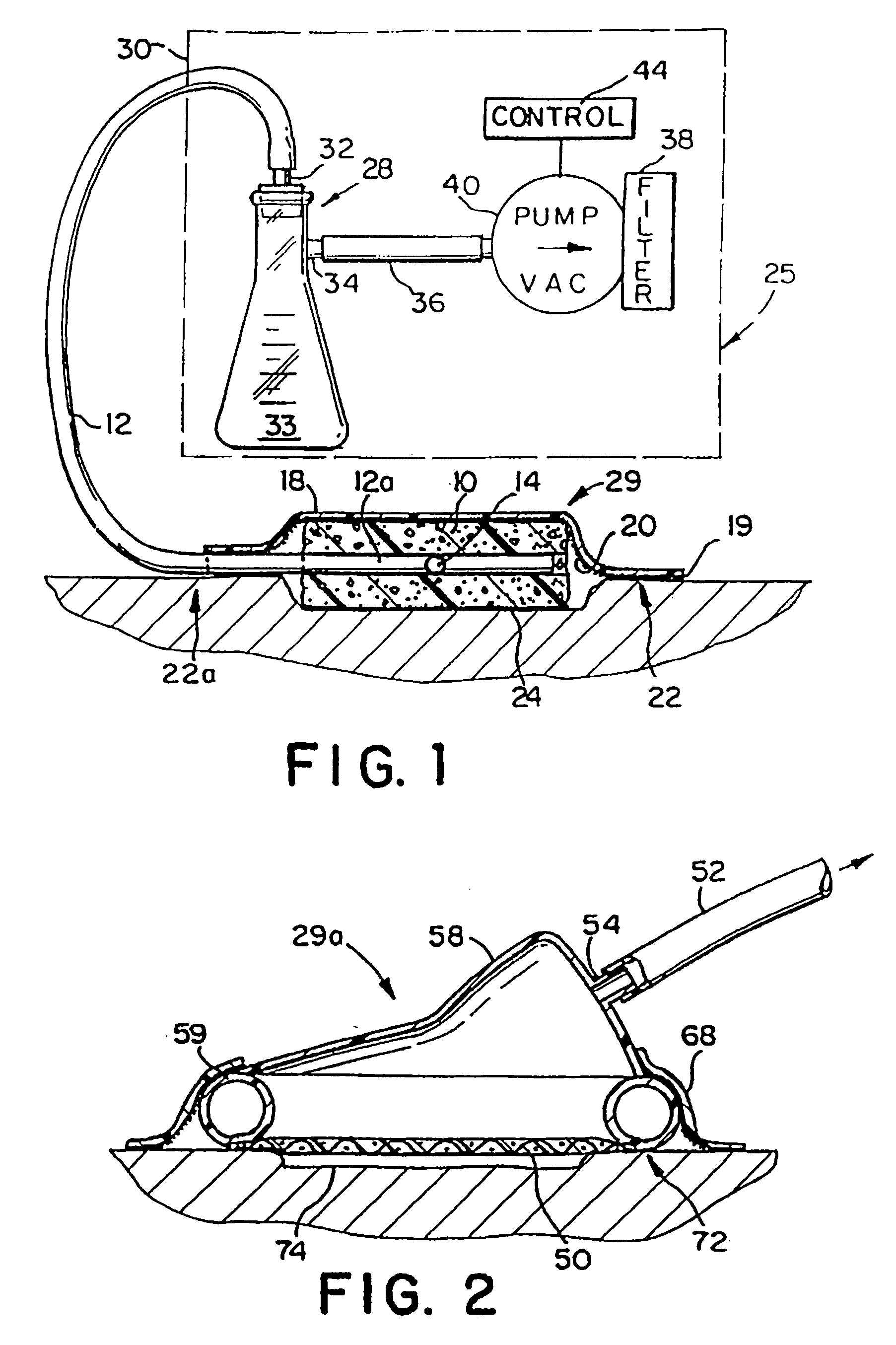

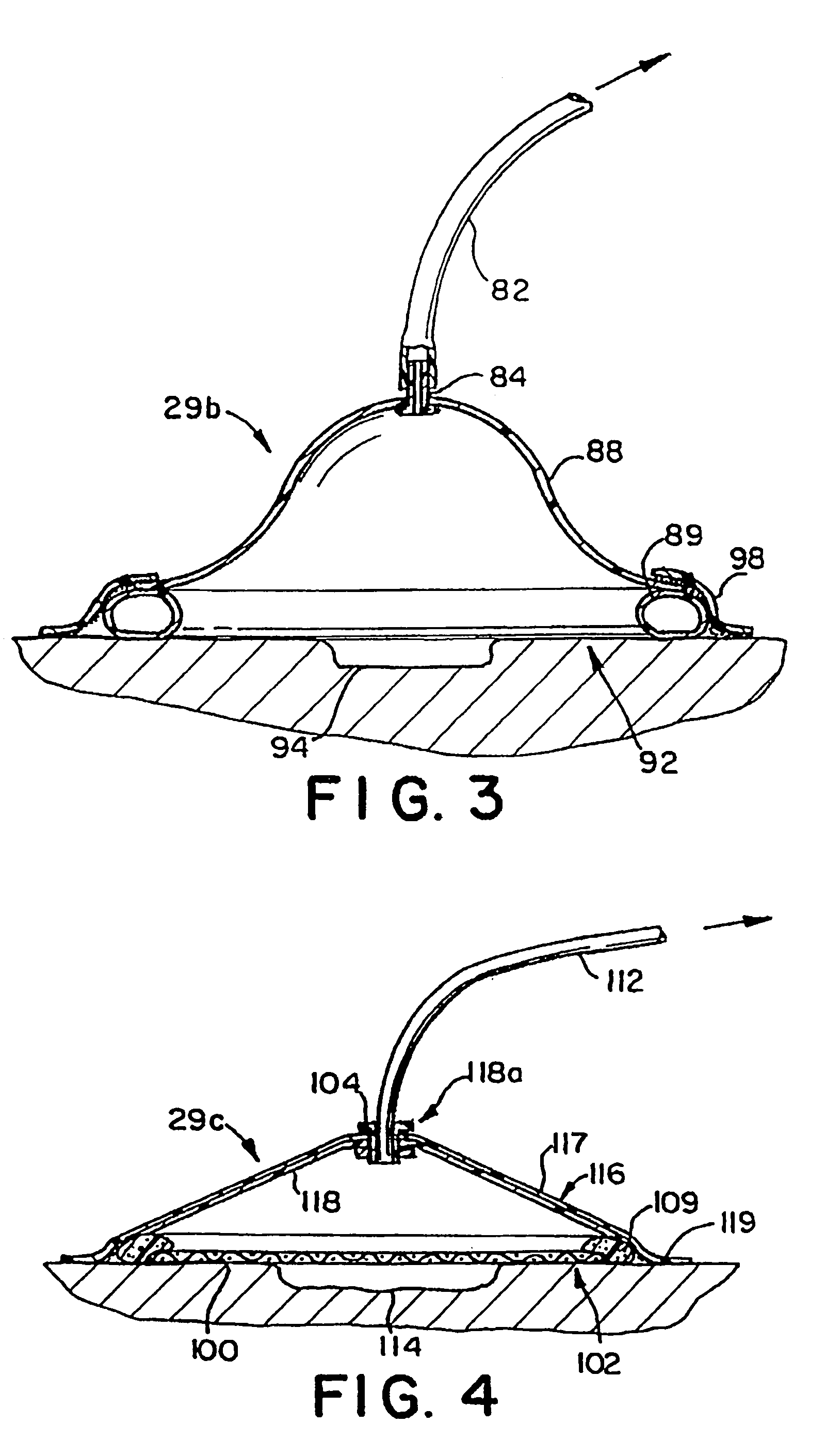

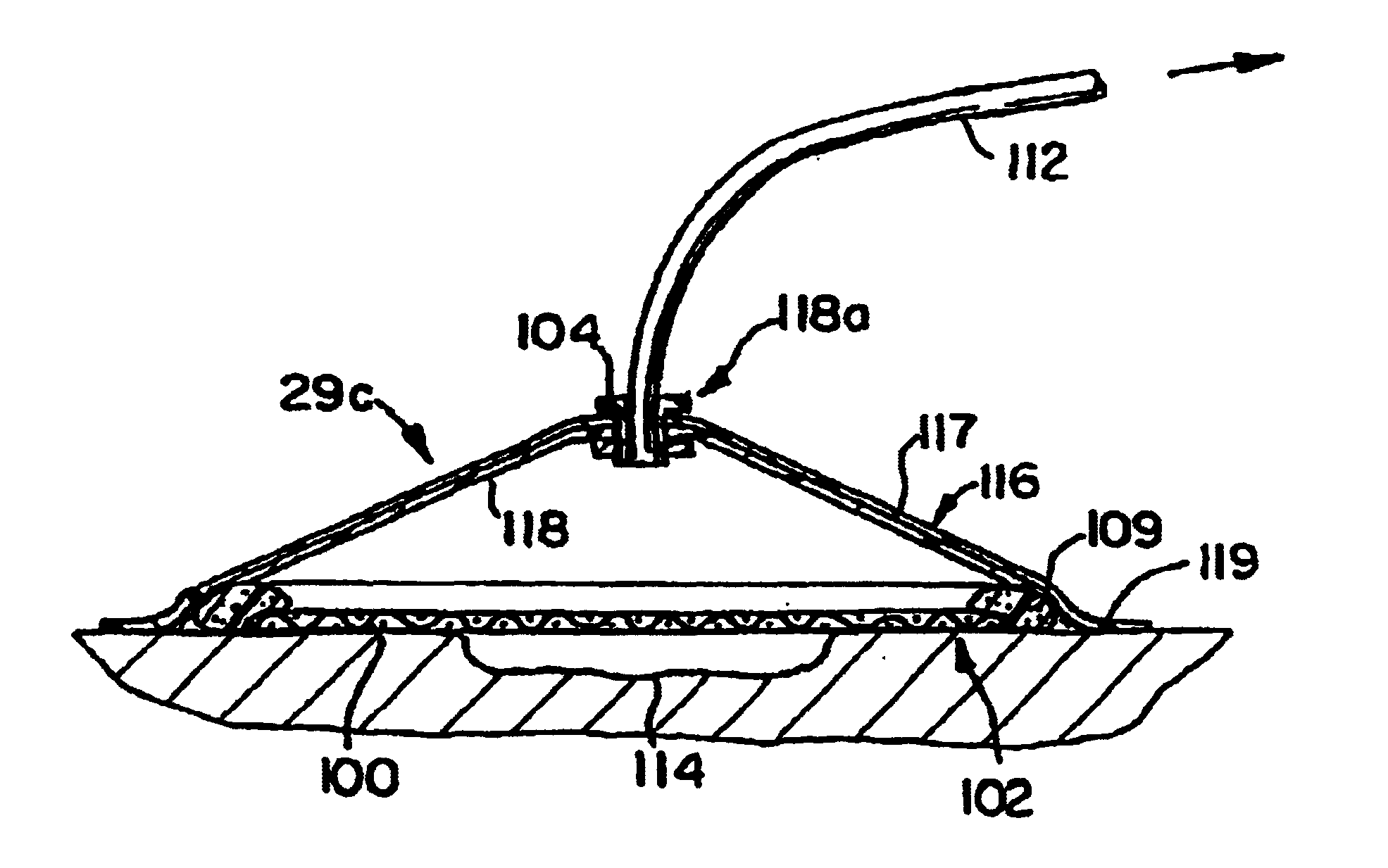

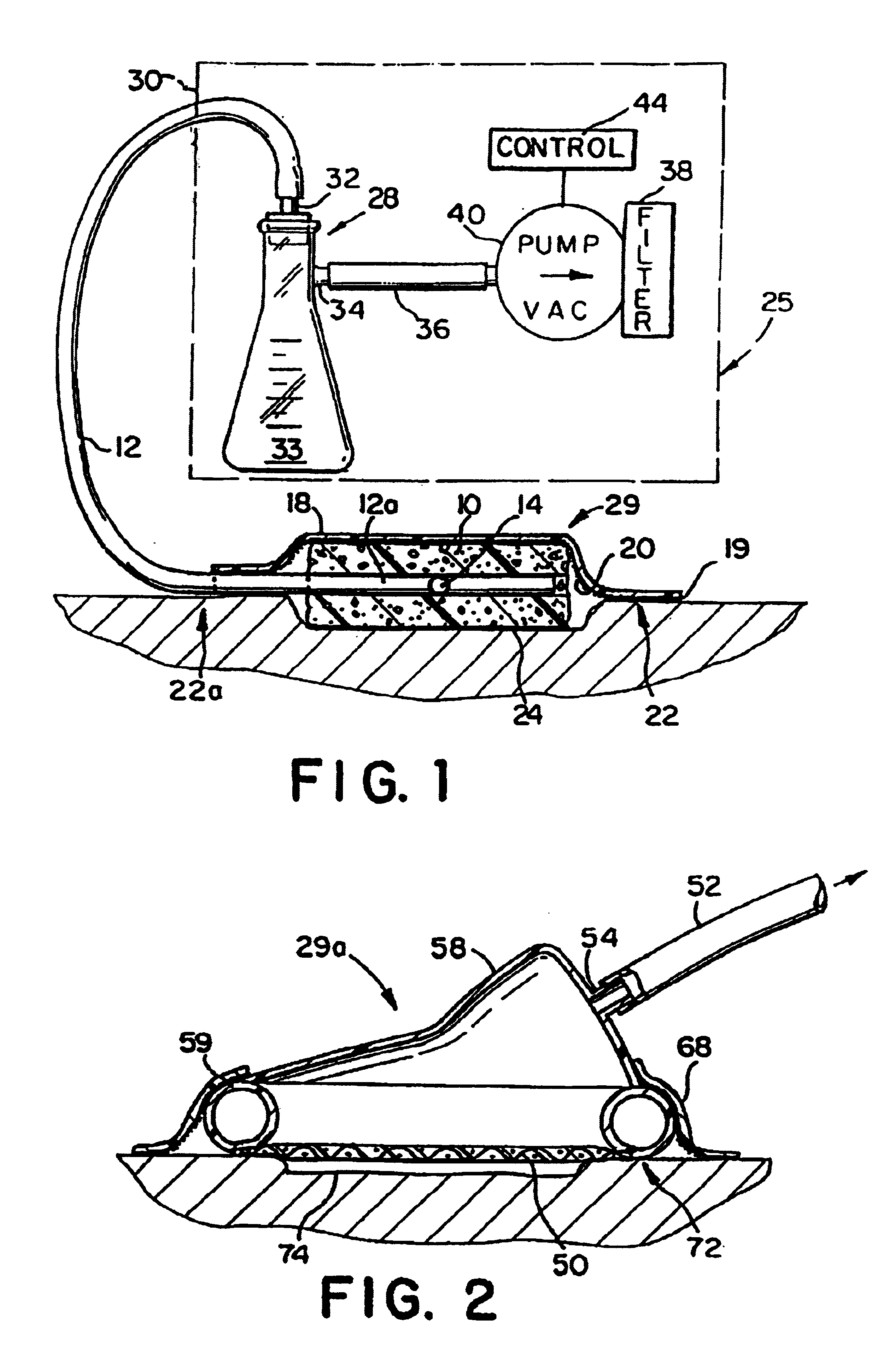

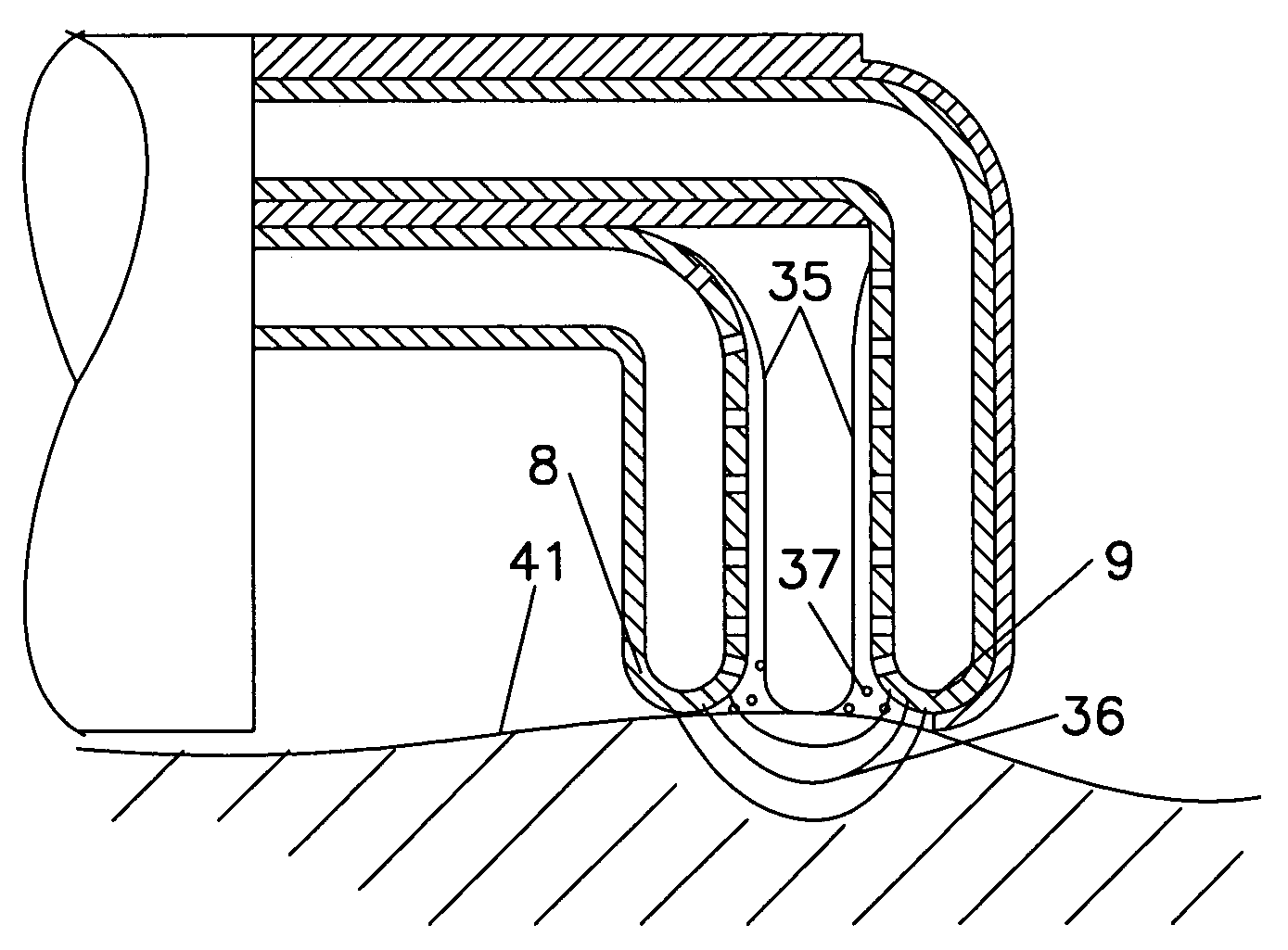

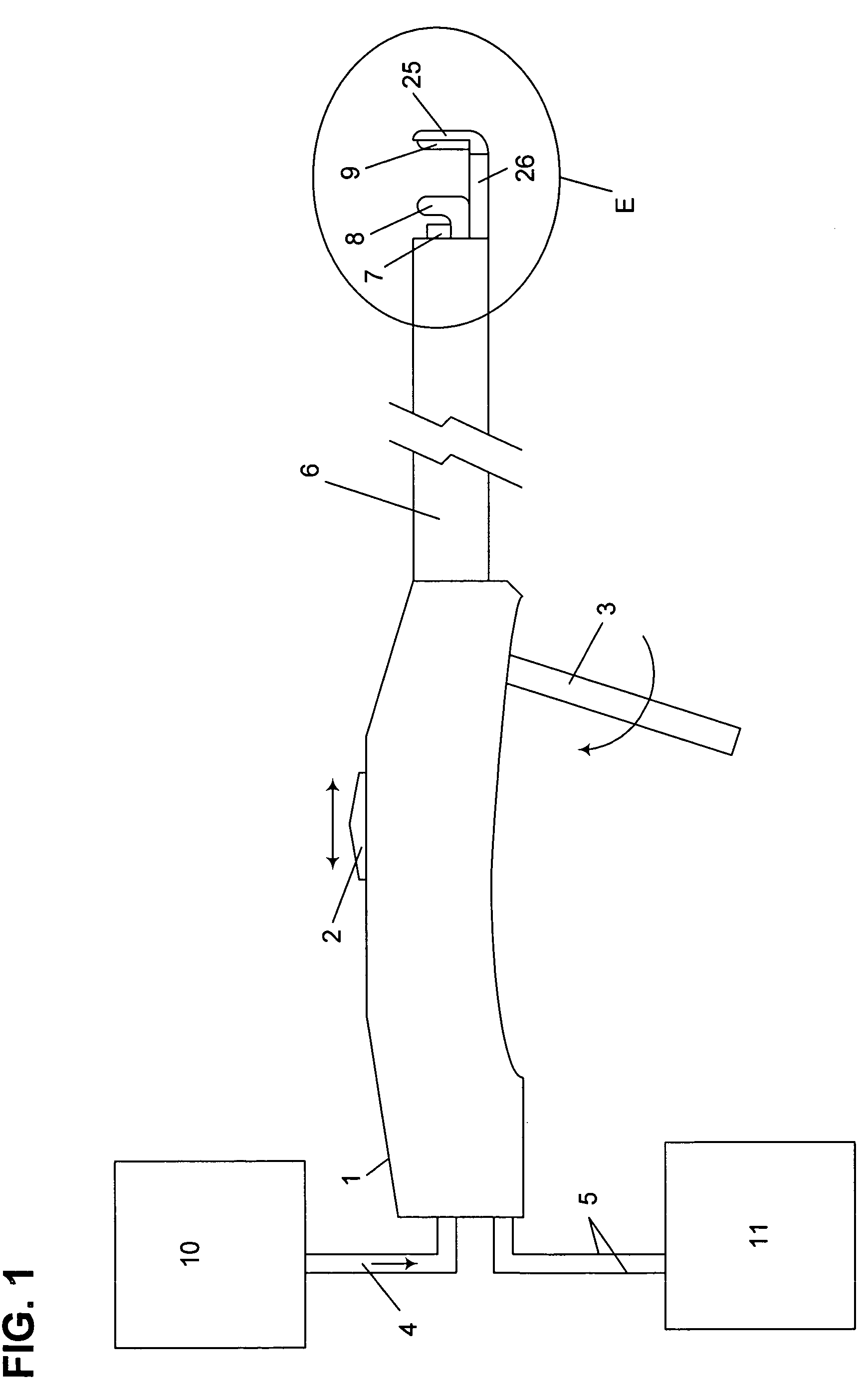

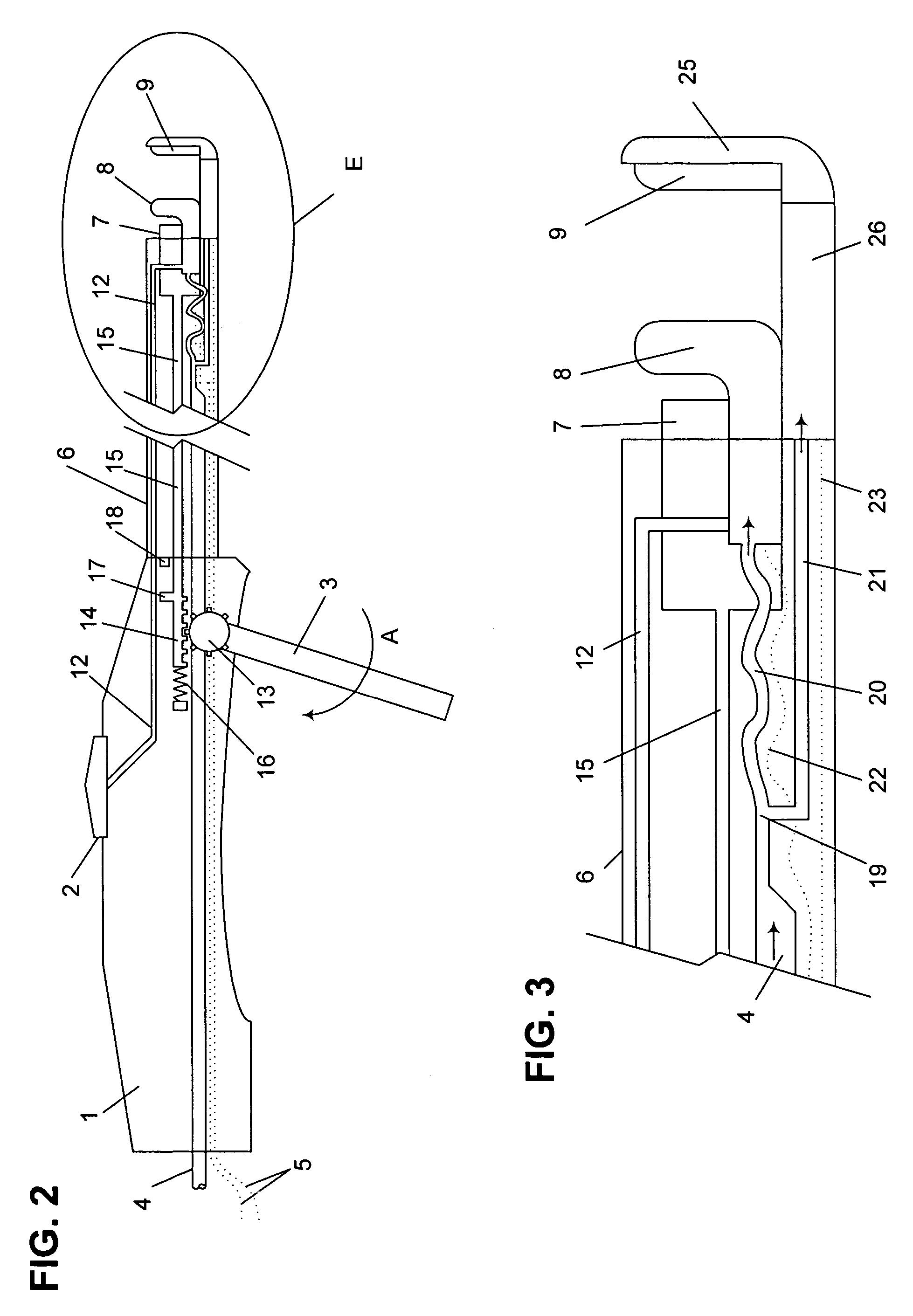

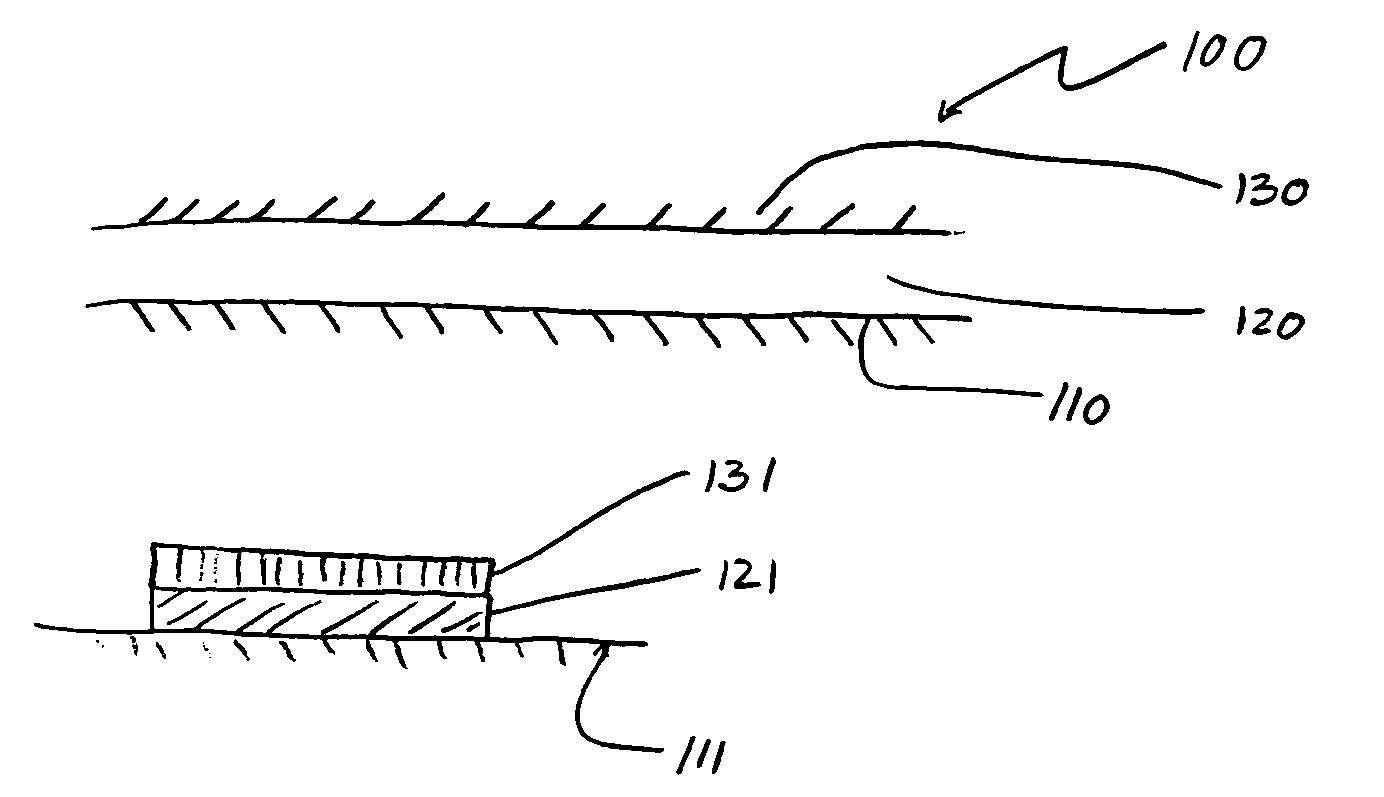

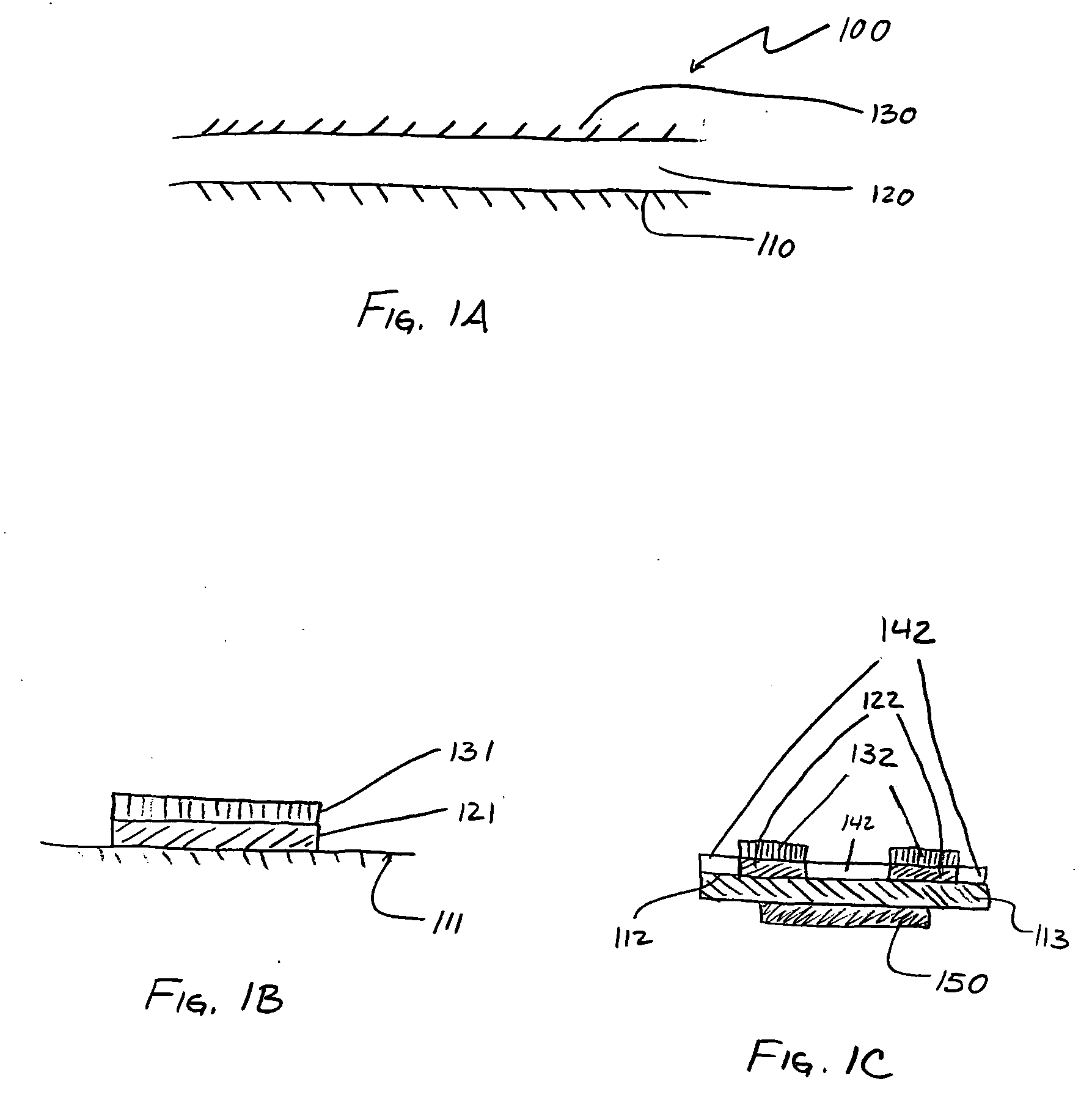

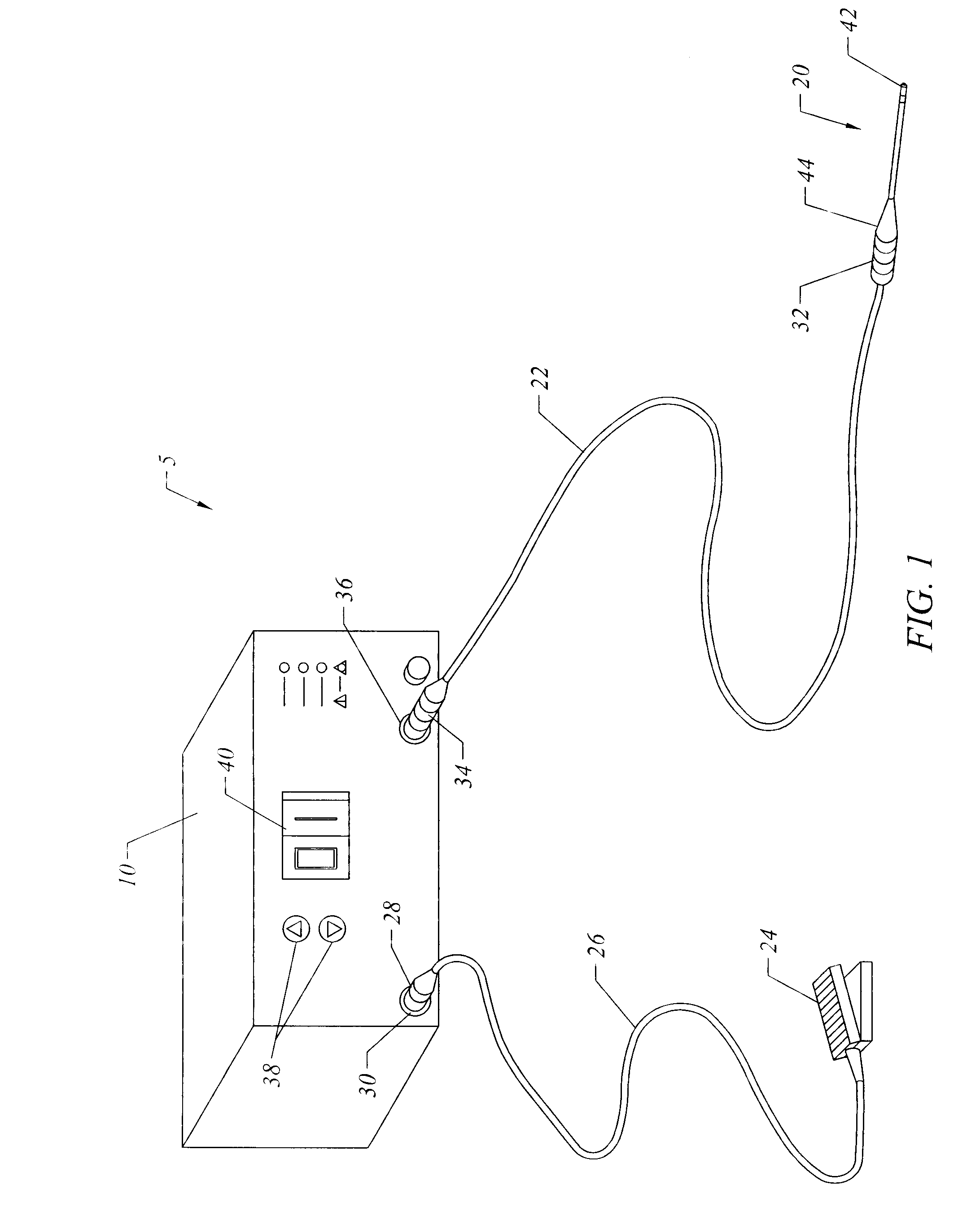

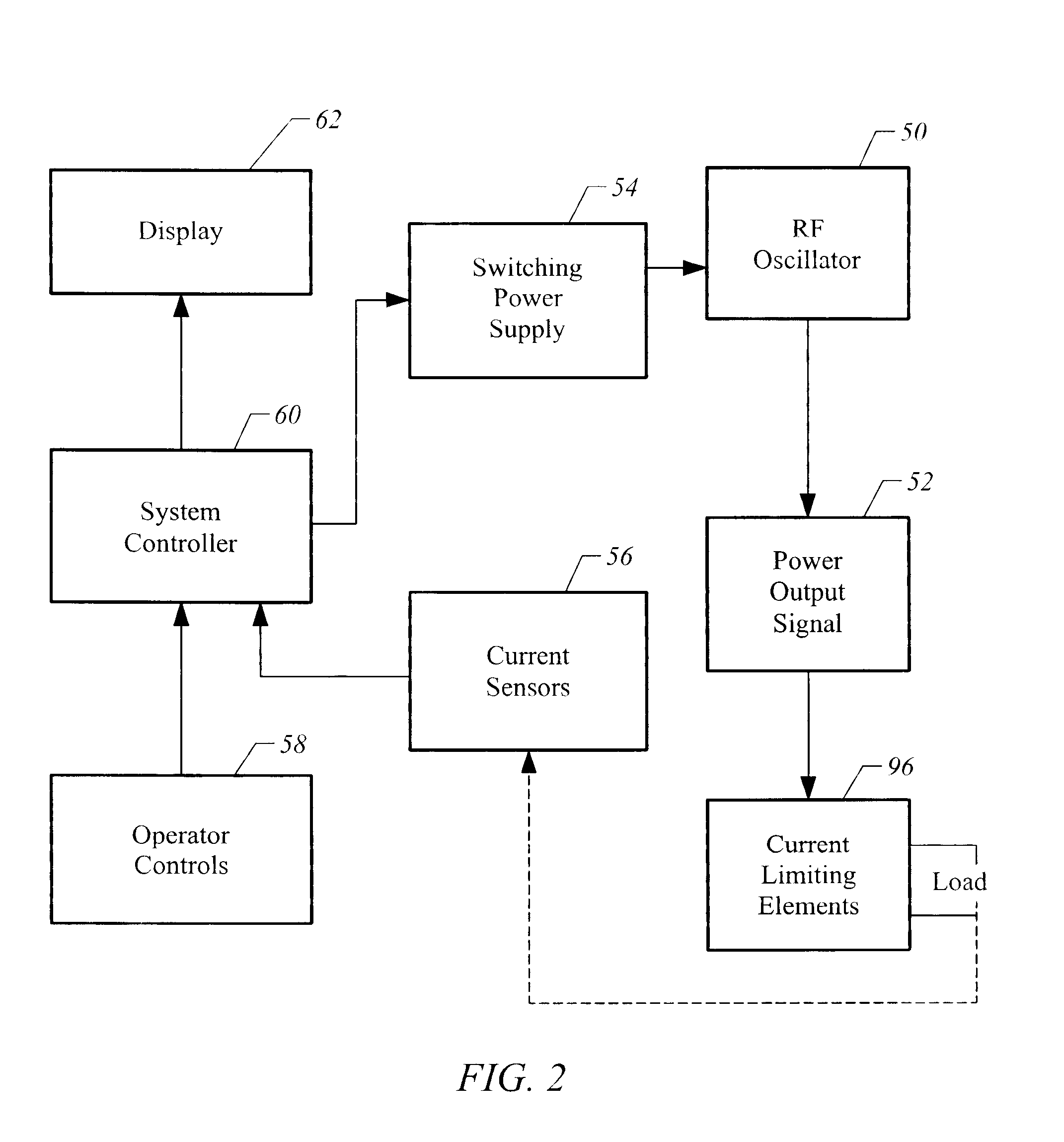

Wound treatment employing reduced pressure

InactiveUS7216651B2Reduce pressureIncreased formationDiagnosticsRespiratory masksWound siteVacuum pump

A method of treating tissue damage comprises applying a negative pressure to a wound sufficient in time and magnitude to promote tissue migration and thus facilitate closure of the wound. The method is applicable to wounds, burns, infected wounds, and live tissue attachments. A wound treatment apparatus is provided in which a fluid impermeable wound cover is sealed over a wound site. A screen in the form of an open-cell foam screen or a rigid porous screen is placed beneath the wound cover over the wound. A vacuum pump supplies suction within the wound cover over the treatment site.

Owner:WAKE FOREST UNIV HEALTH SCI INC

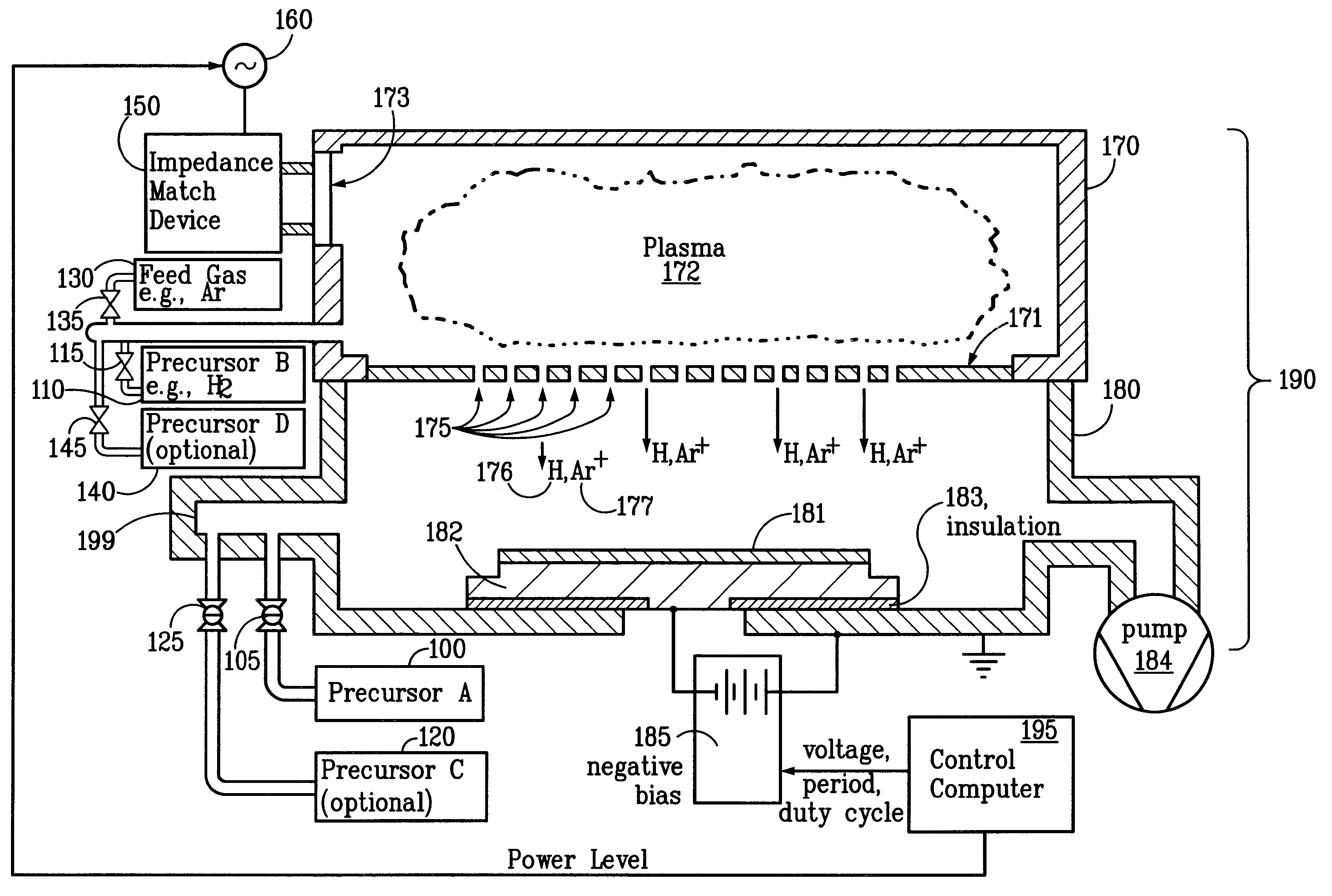

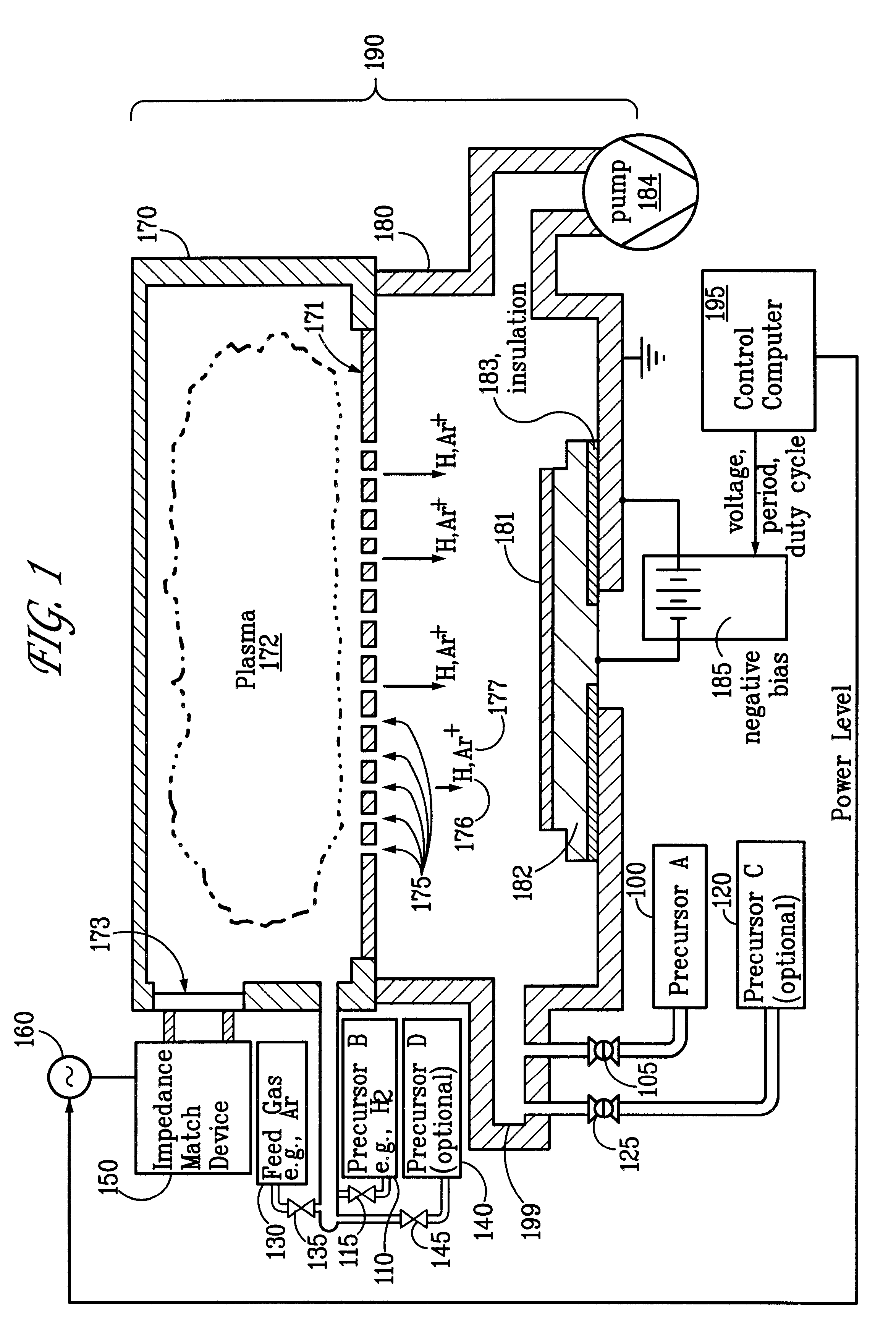

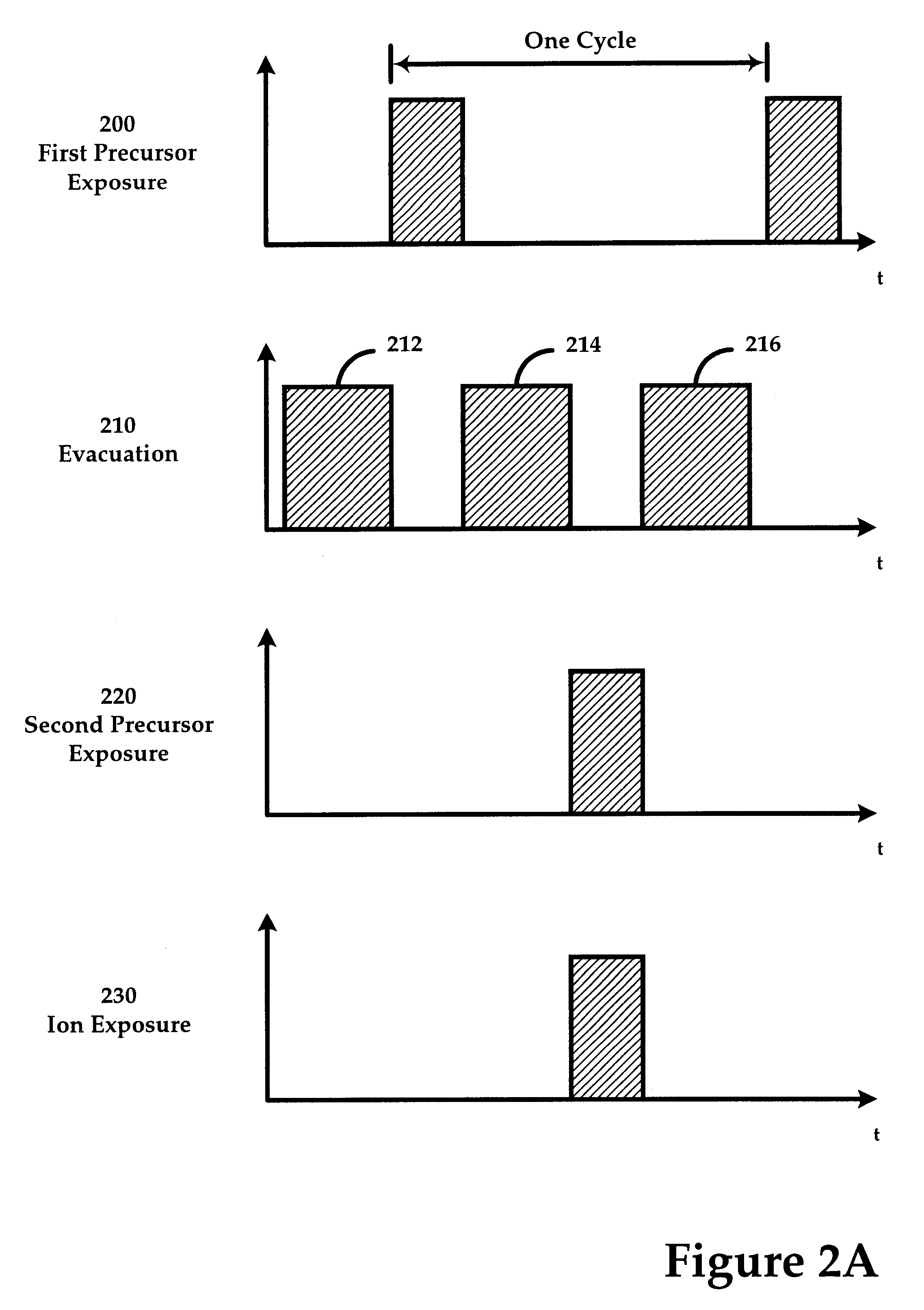

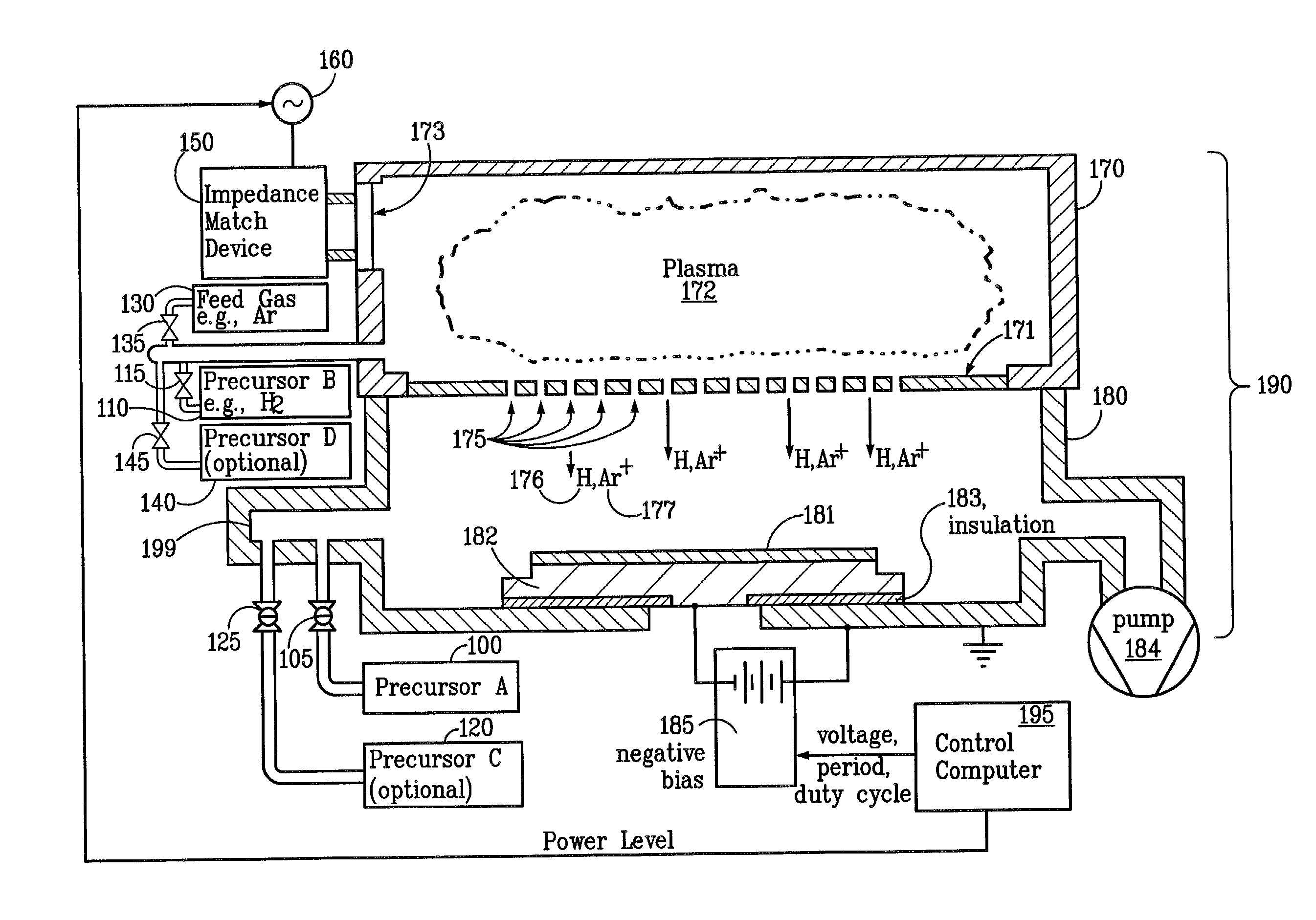

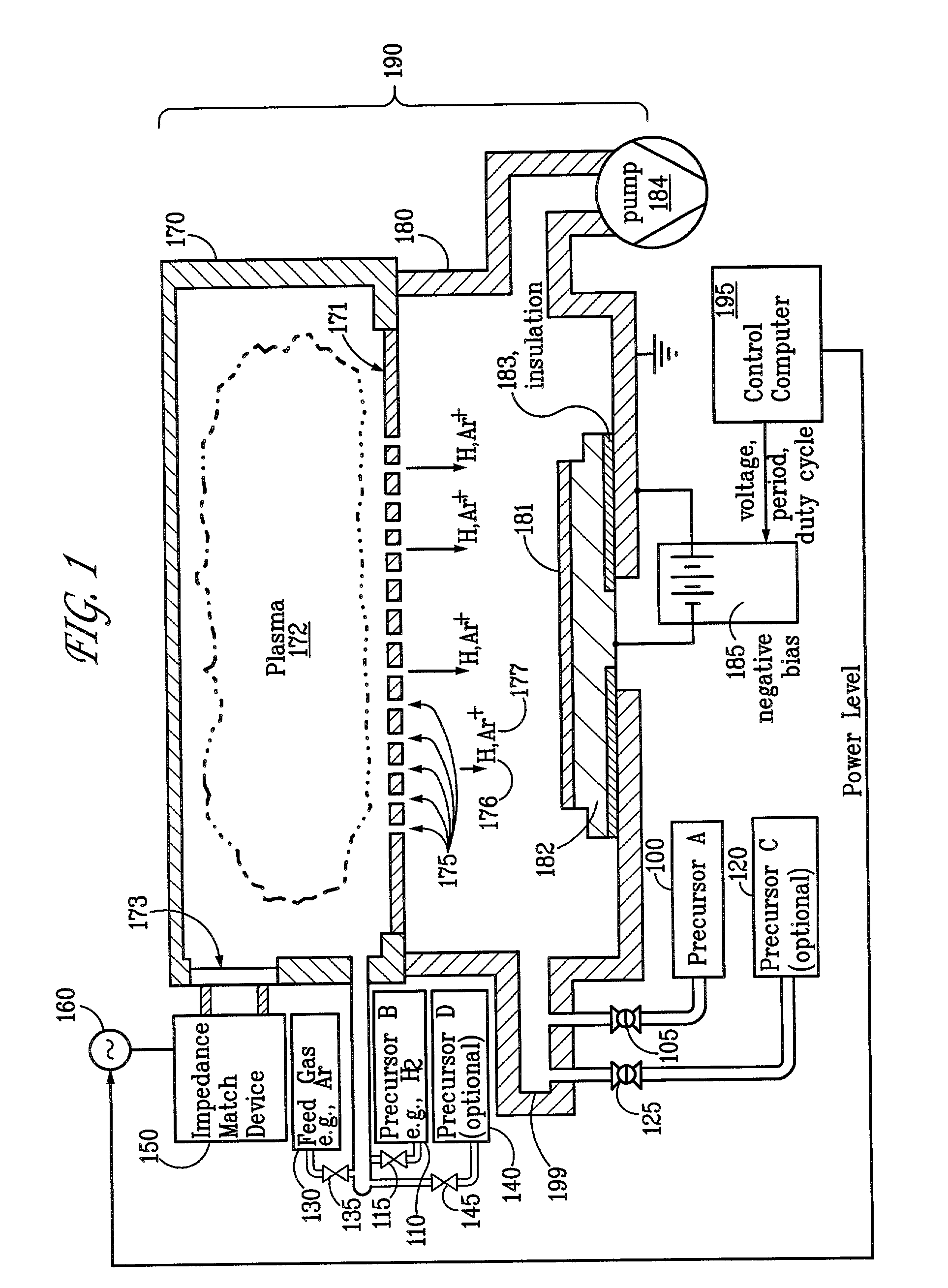

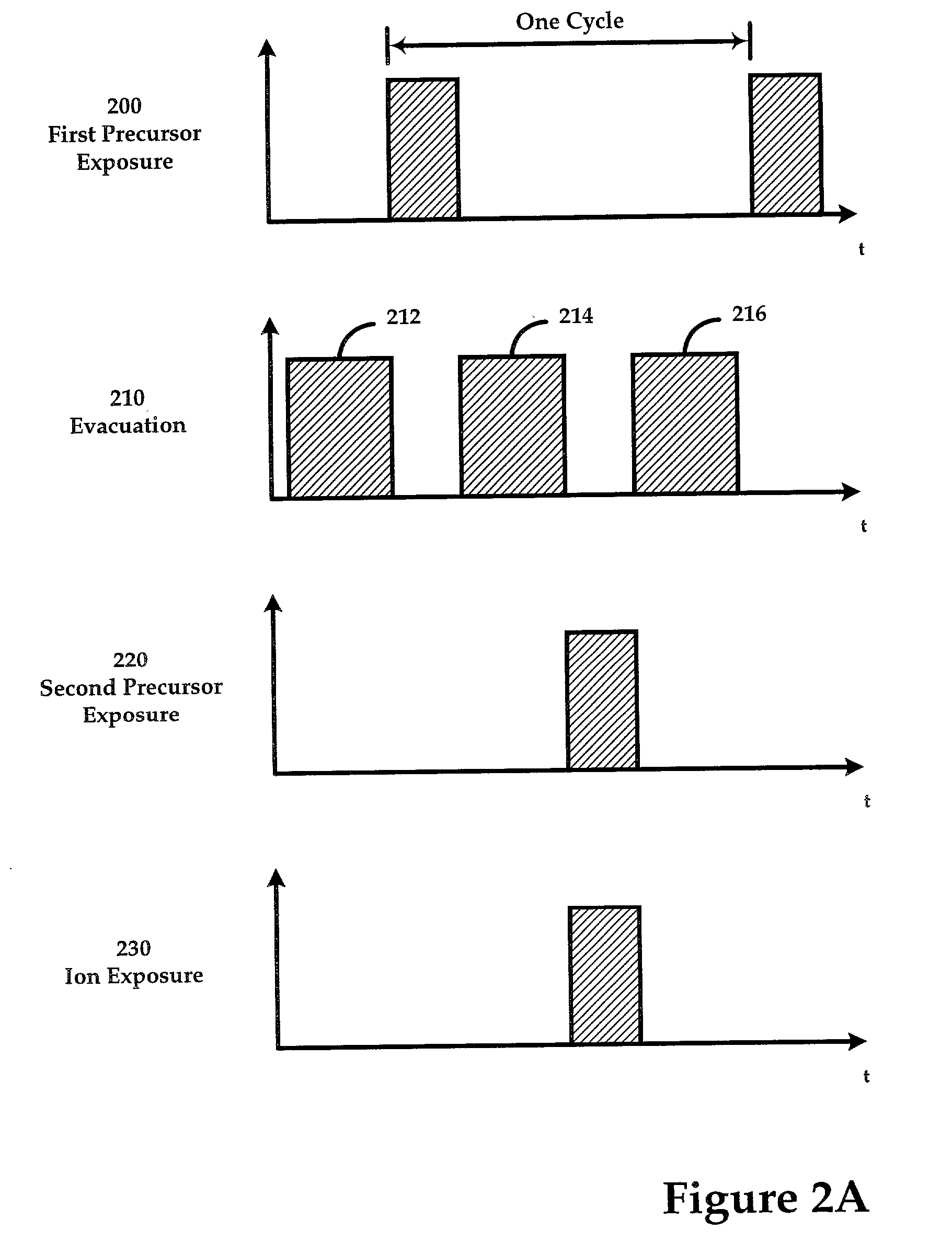

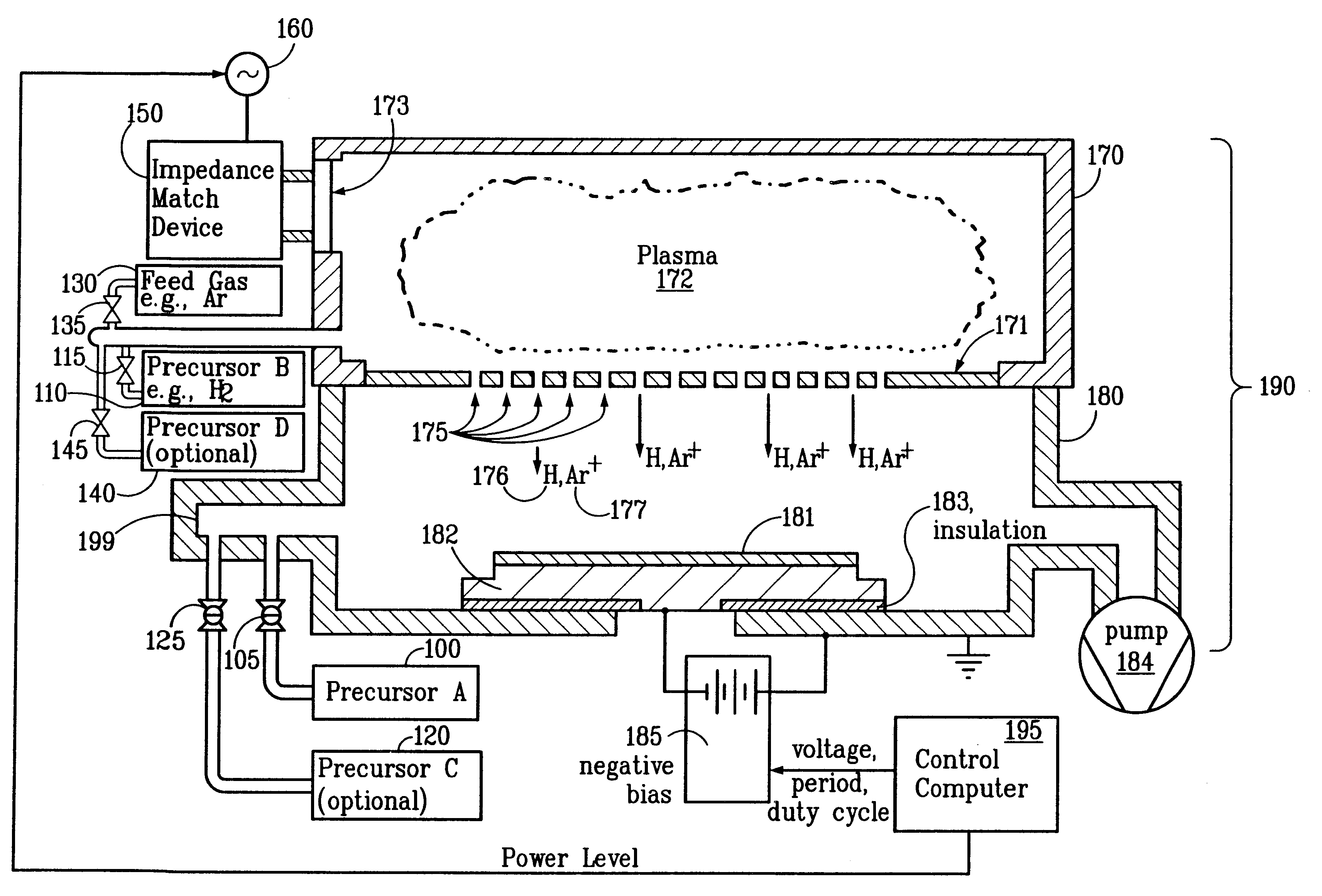

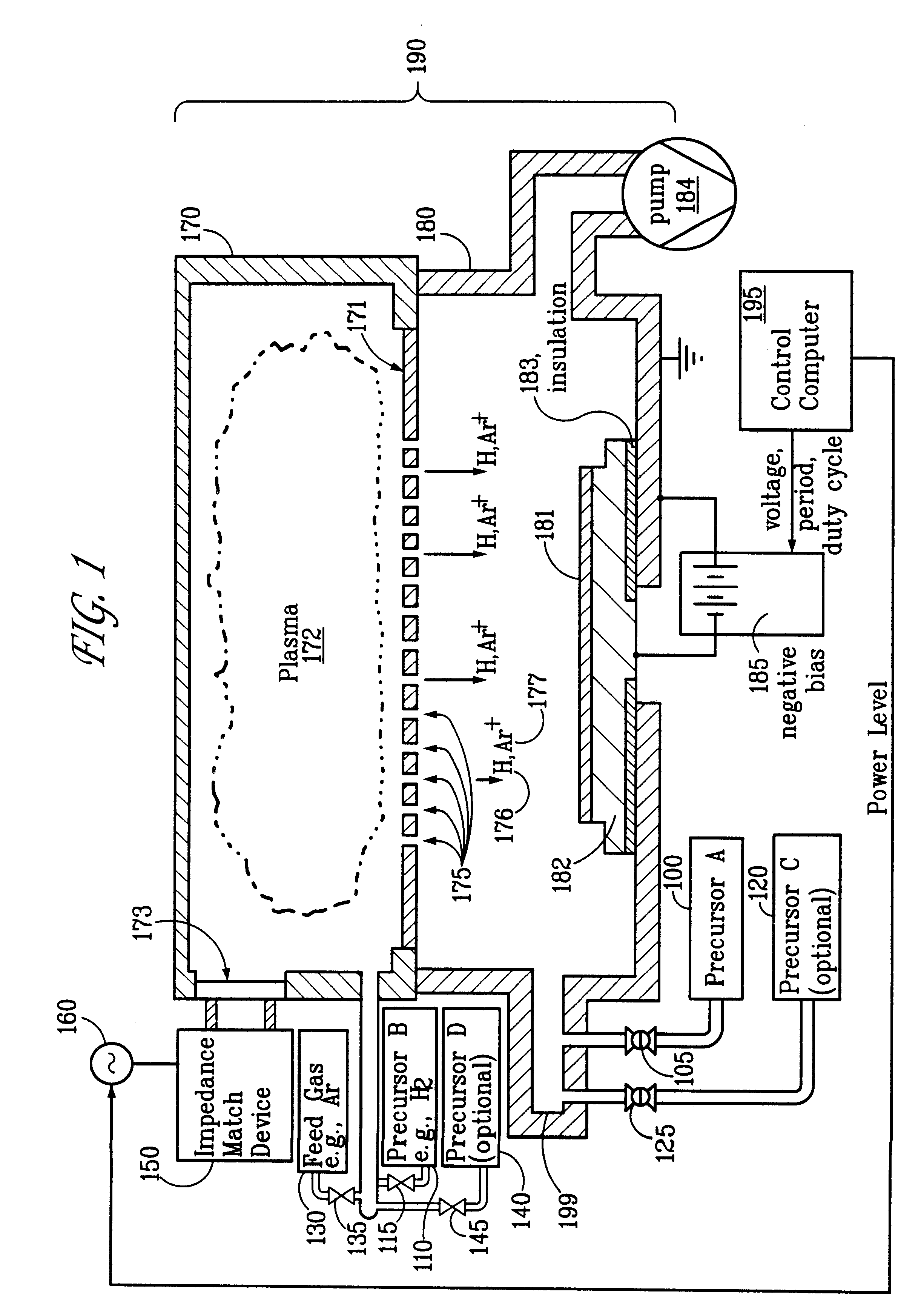

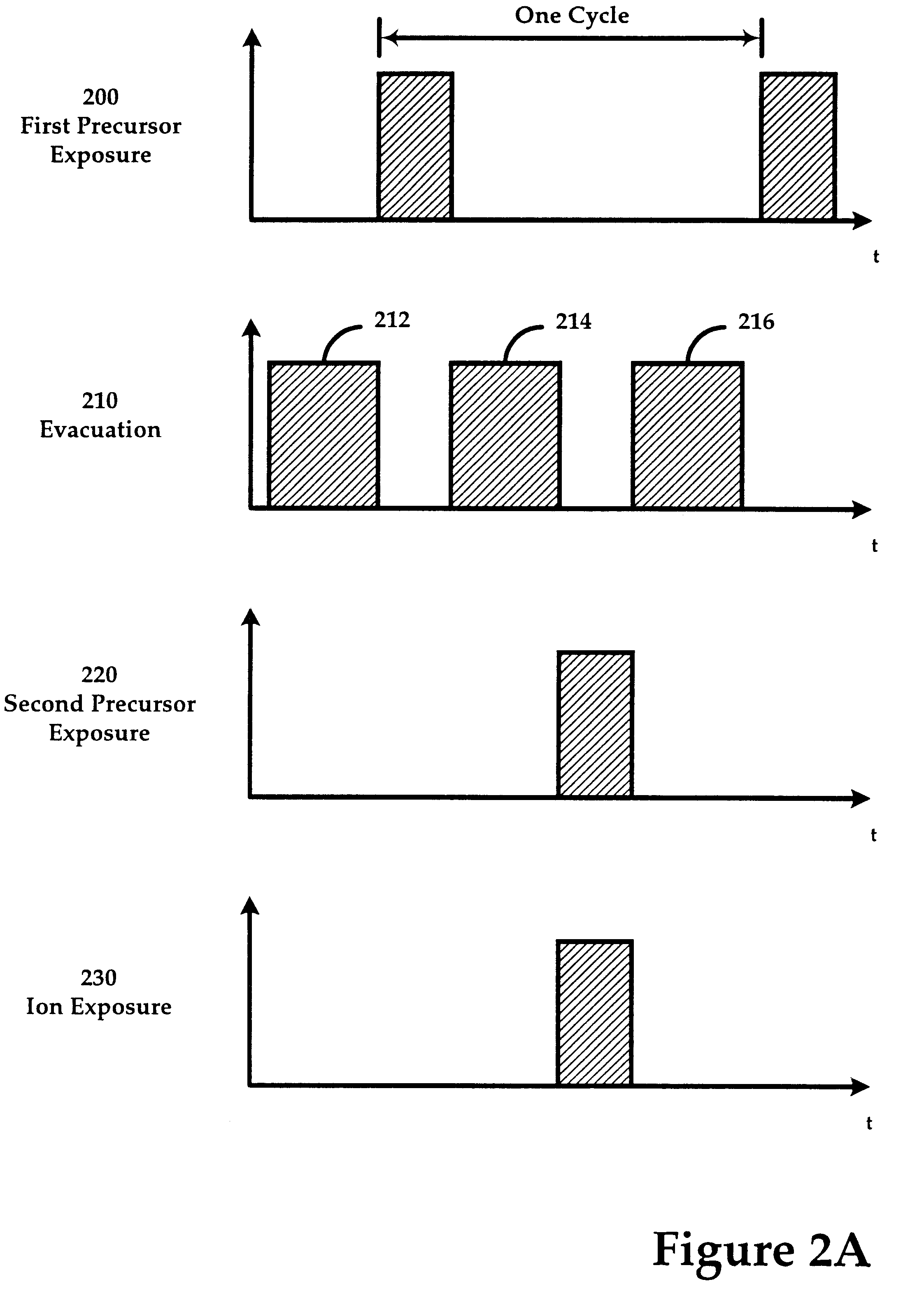

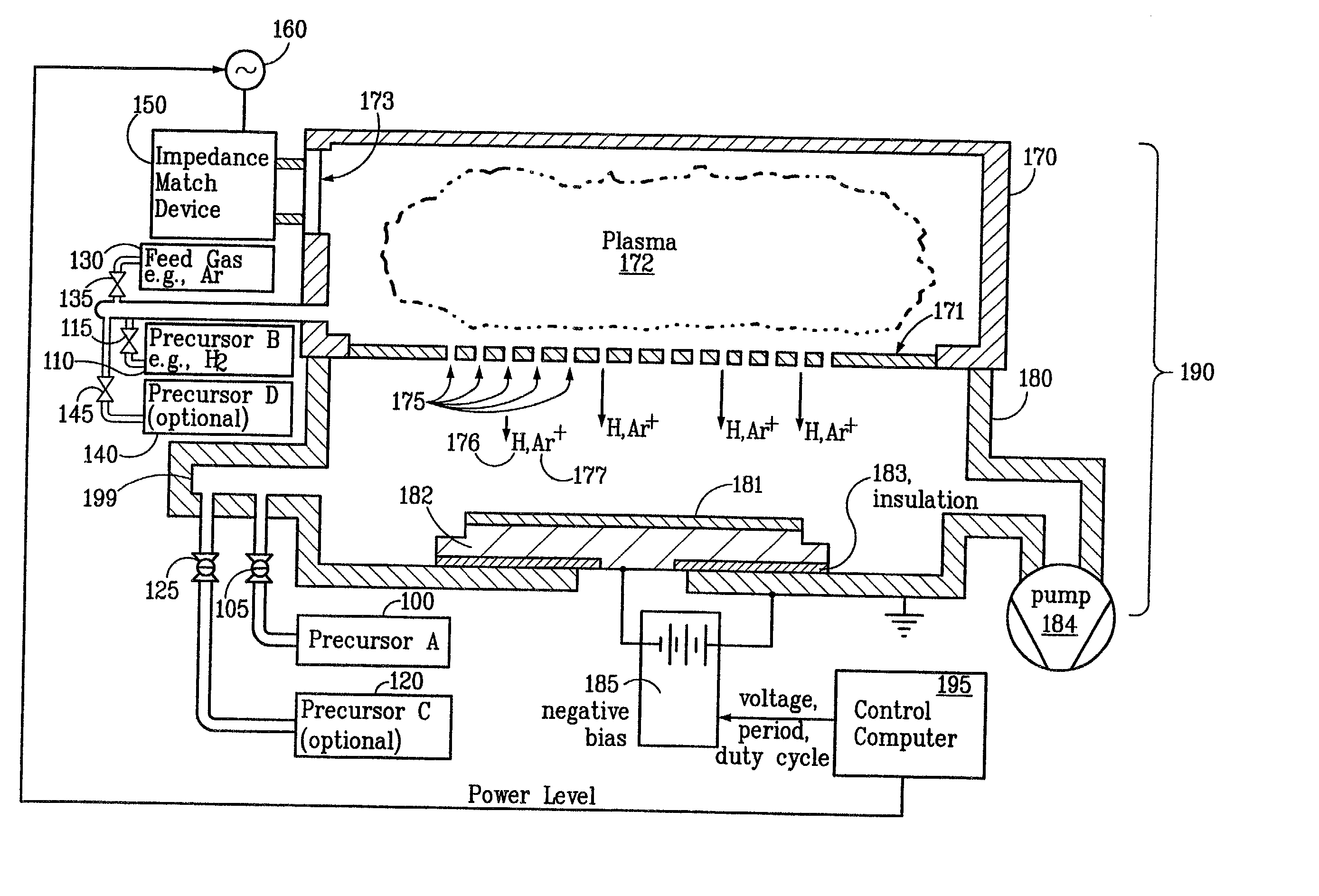

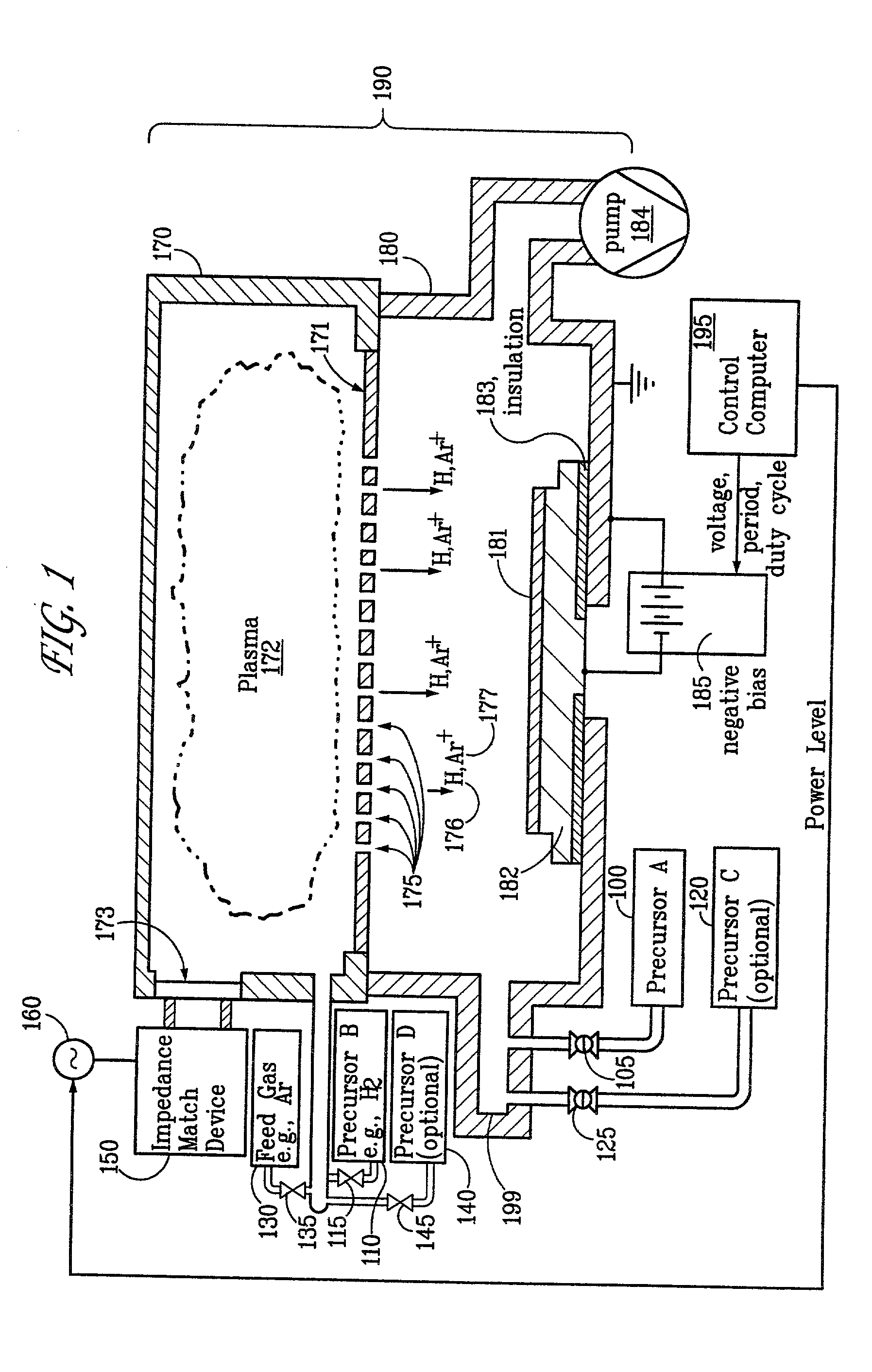

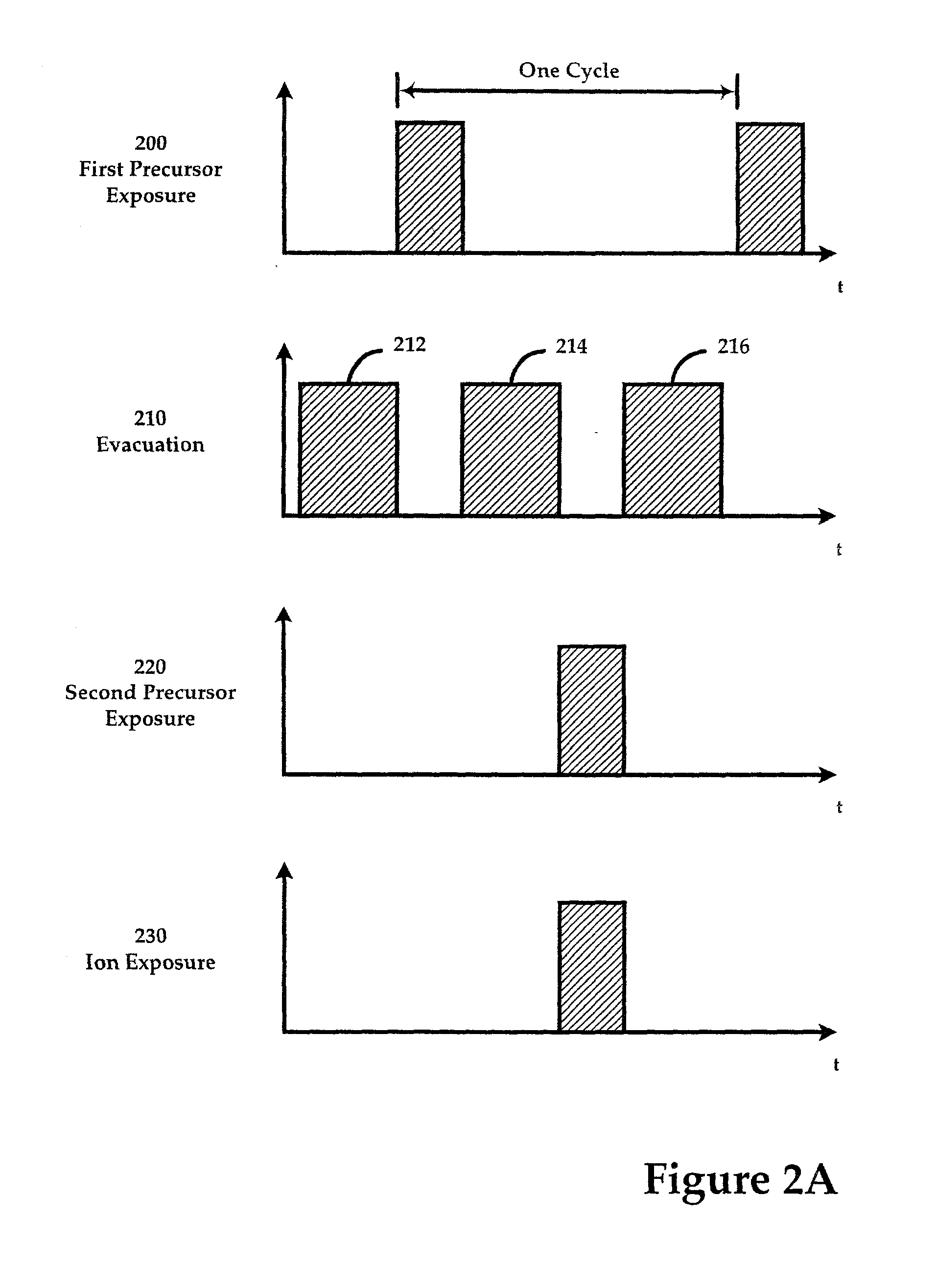

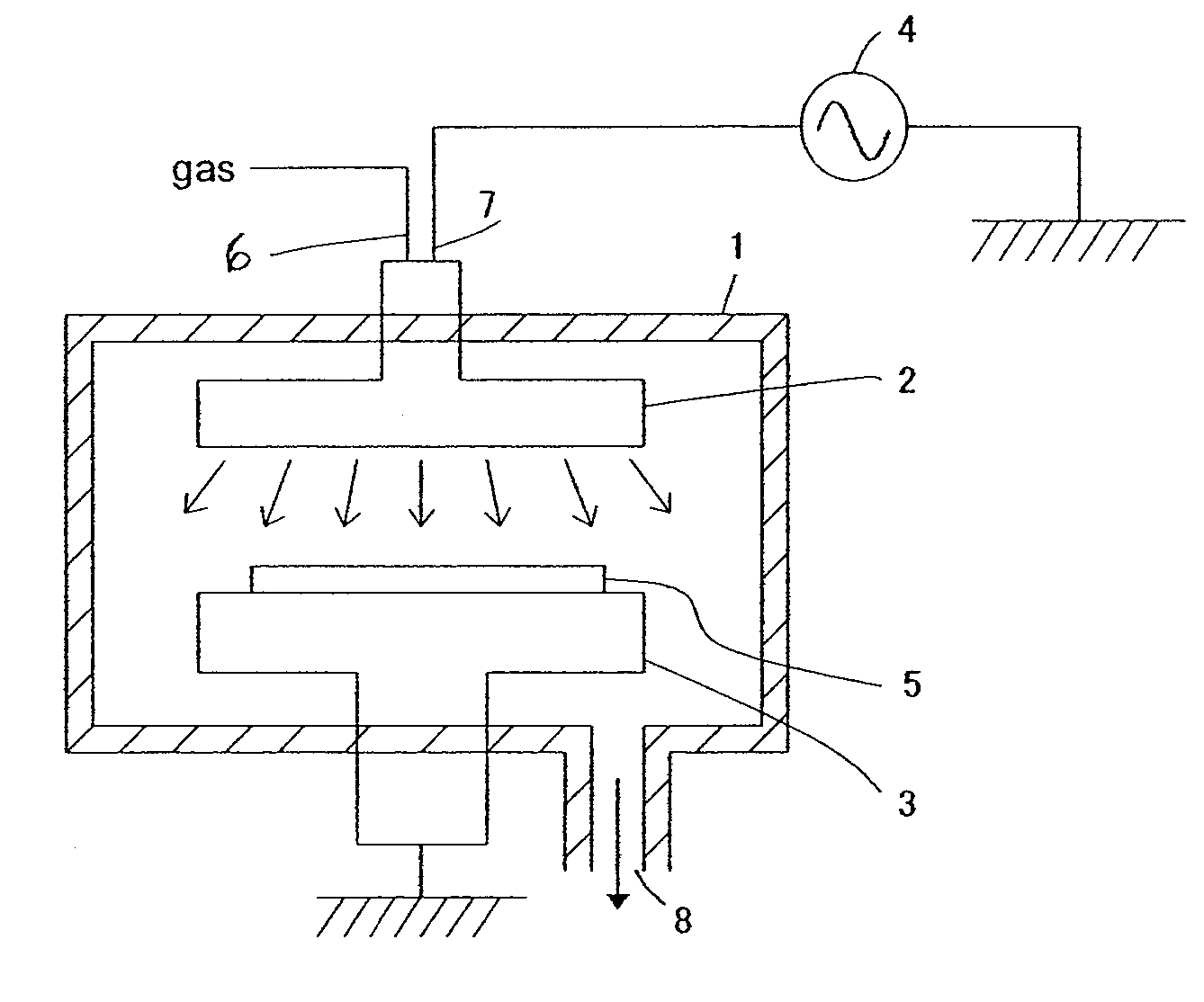

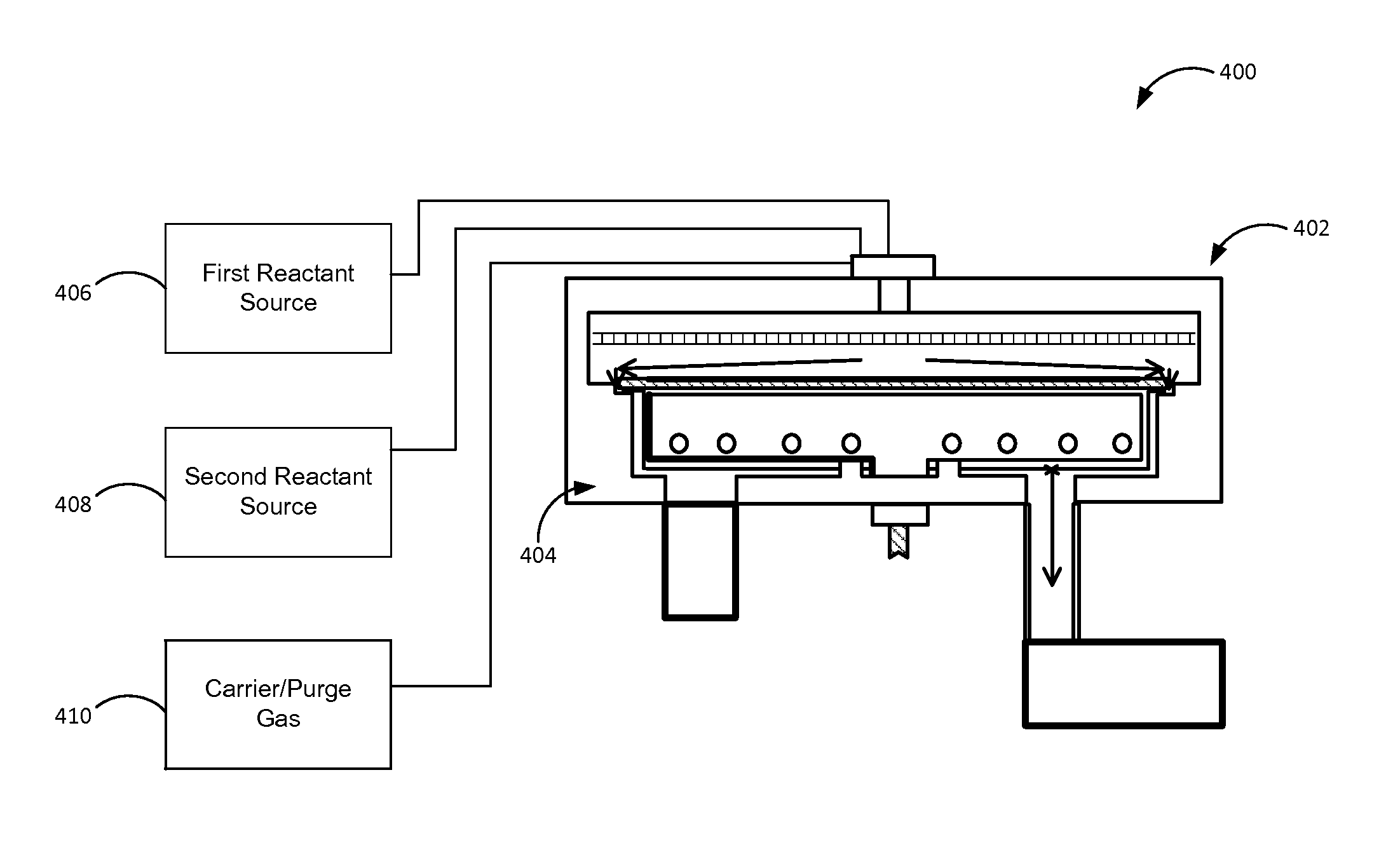

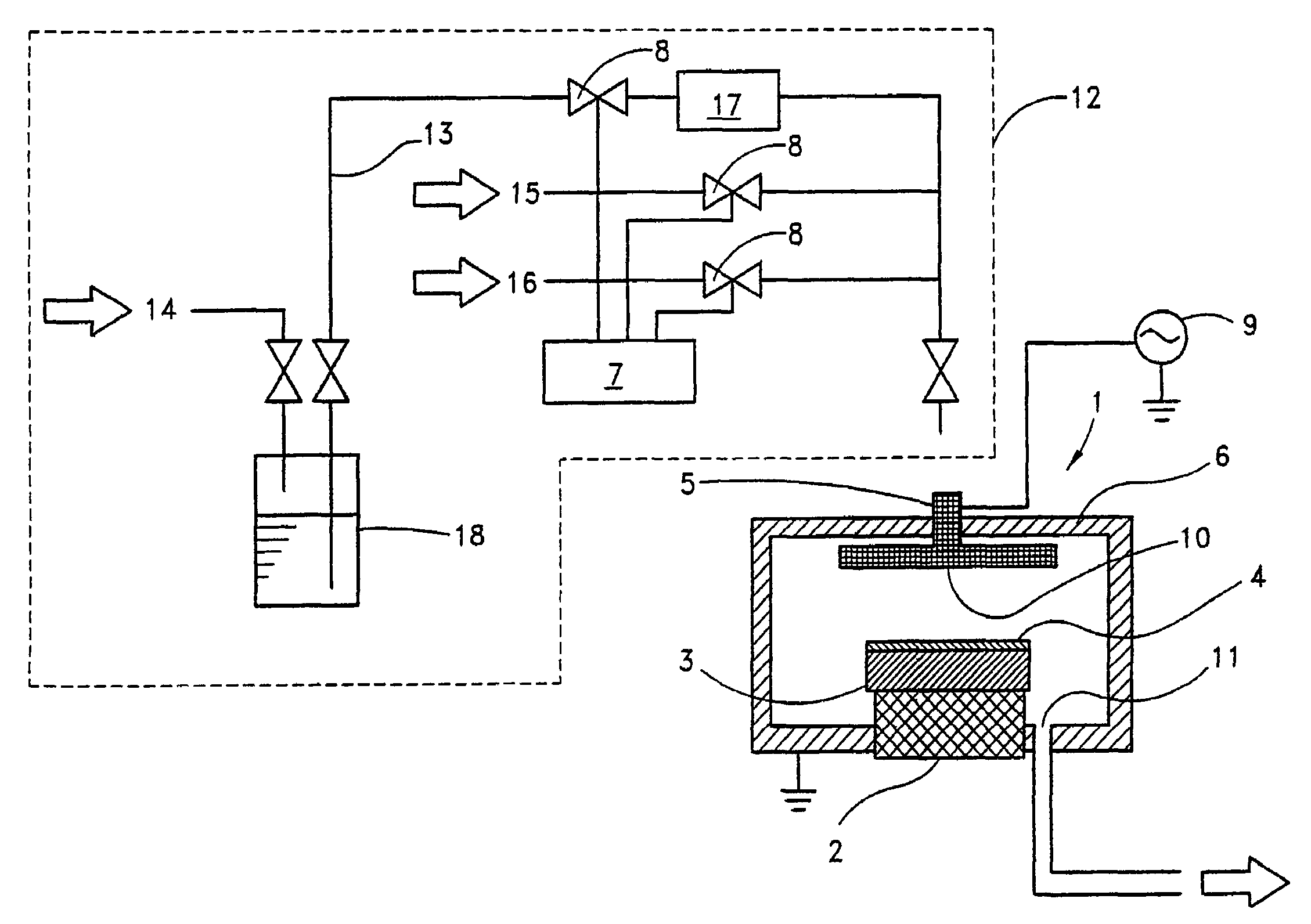

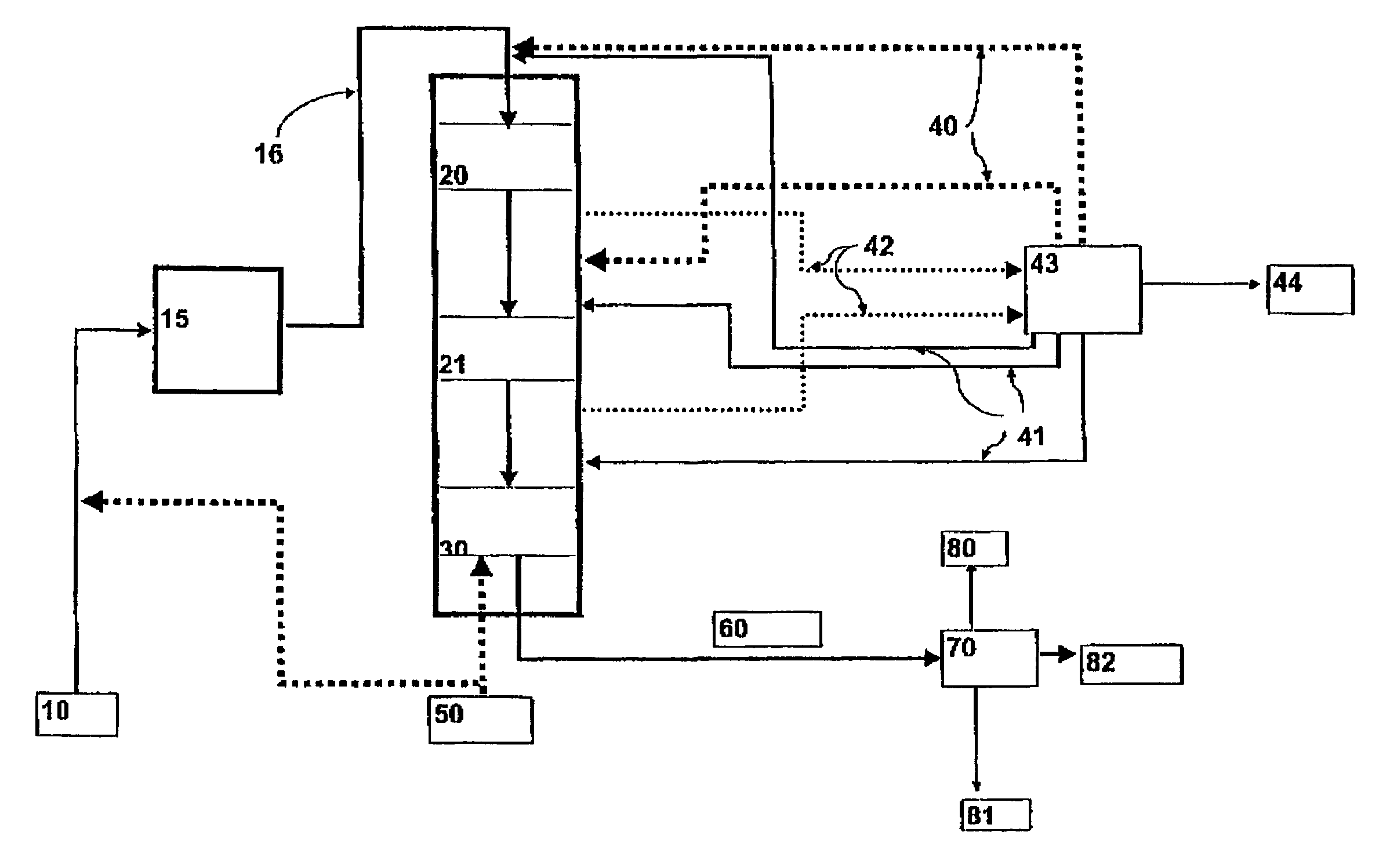

Sequential method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS6428859B1Faster efficient meanSimple methodVacuum evaporation coatingSputtering coatingSequential methodHigh density

The present invention relates to an enhanced sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:NOVELLUS SYSTEMS

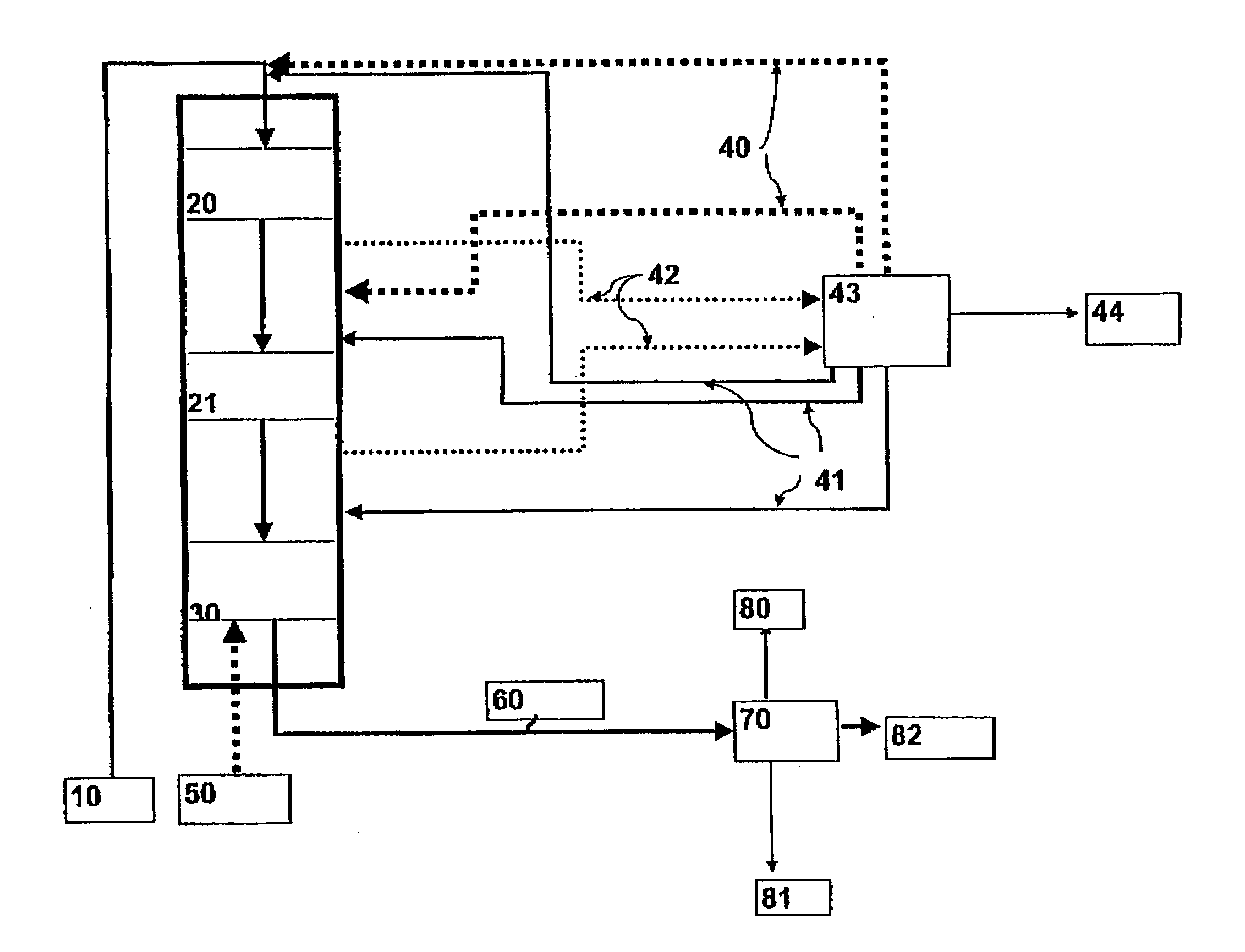

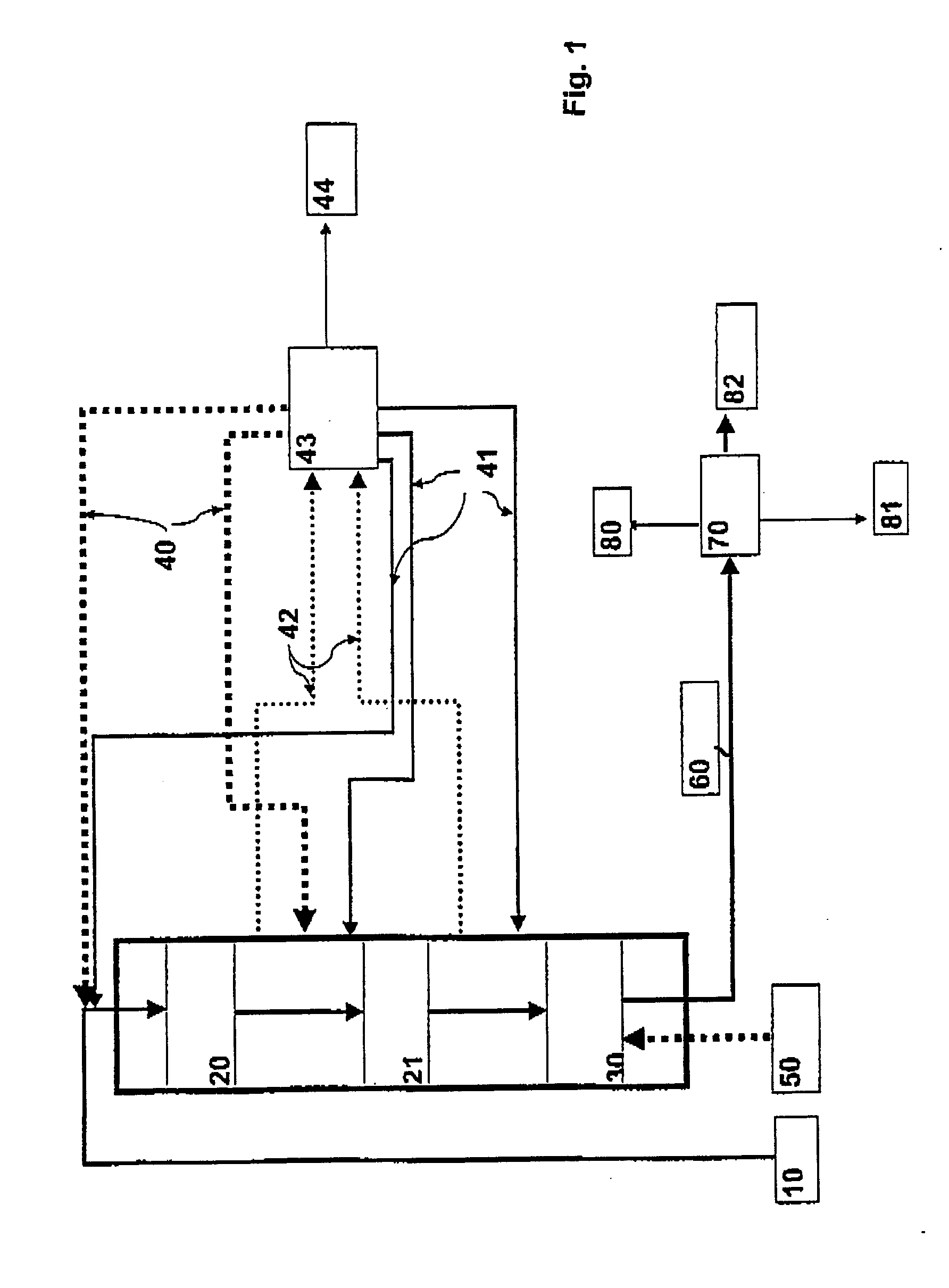

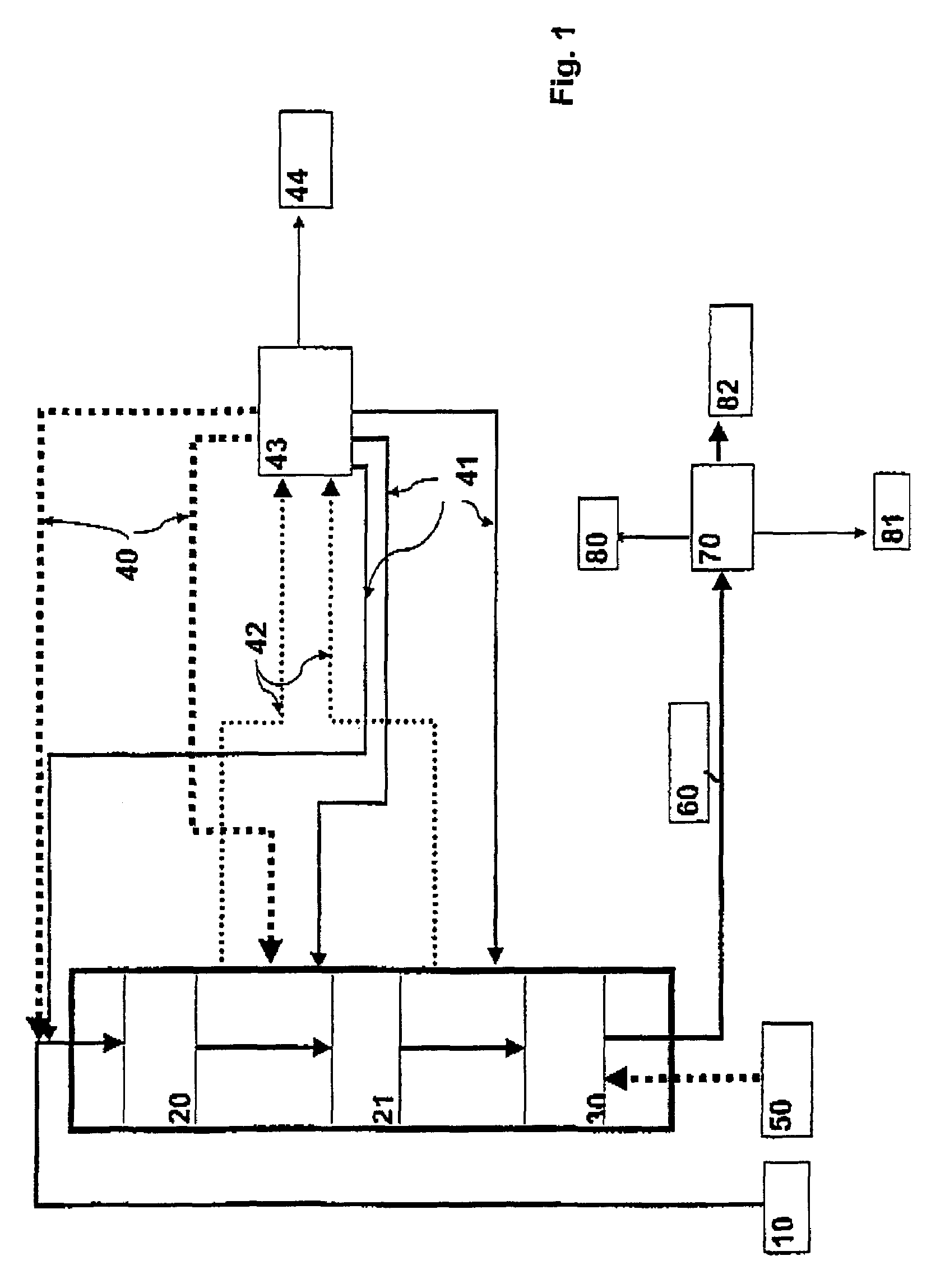

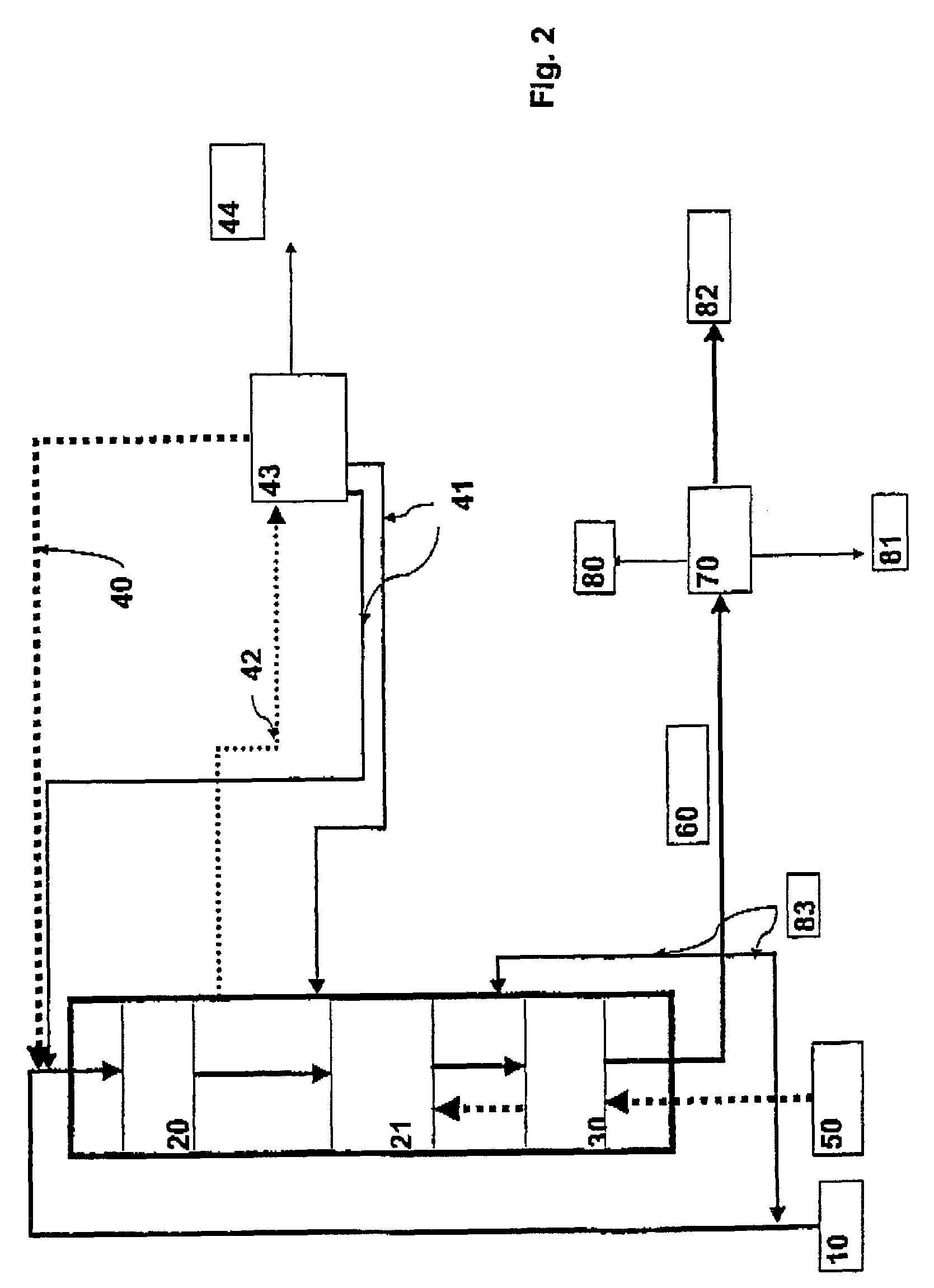

Process for producing a hydrocarbon component of biological origin

ActiveUS20040230085A1Improve performanceLow densityLiquid hydrocarbon mixture productionHydrocarbonsIsomerizationHydrocarbon

The invention relates to a process for producing a hydrocarbon component of biological origin. The process comprises at least two steps, the first one of which is a HDO step and the second one is an isomerization step operated using the counter-current flow principle. A biological raw material containing fatty acids and / or fatty acid esters serves as the feed stock.

Owner:OYJ NESTE OIL +1

System and method for modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS20020104481A1Faster efficient meanSimple methodSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh densitySubject matter

The present invention relates to an enhanced sequential or non-sequential atomic layer deposition (ALD) apparatus and technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method; and, 4) providing a means of improved radical generation and delivery. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. [37 C.F.R. § 1.72(b)].

Owner:ANGSTRON SYST

Wound treatment employing reduced pressure

A method of treating tissue damage comprises applying a negative pressure to a wound sufficient in time and magnitude to promote tissue migration and thus facilitate closure of the wound. The method is applicable to wounds, burns, infected wounds, and live tissue attachments. A wound treatment apparatus is provided in which a fluid impermeable wound cover is sealed over a wound site. A screen in the form of an open-cell foam screen or a rigid porous screen is placed beneath the wound cover over the wound. A vacuum pump supplies suction within the wound cover over the treatment site.

Owner:WAKE FOREST UNIV HEALTH SCI INC

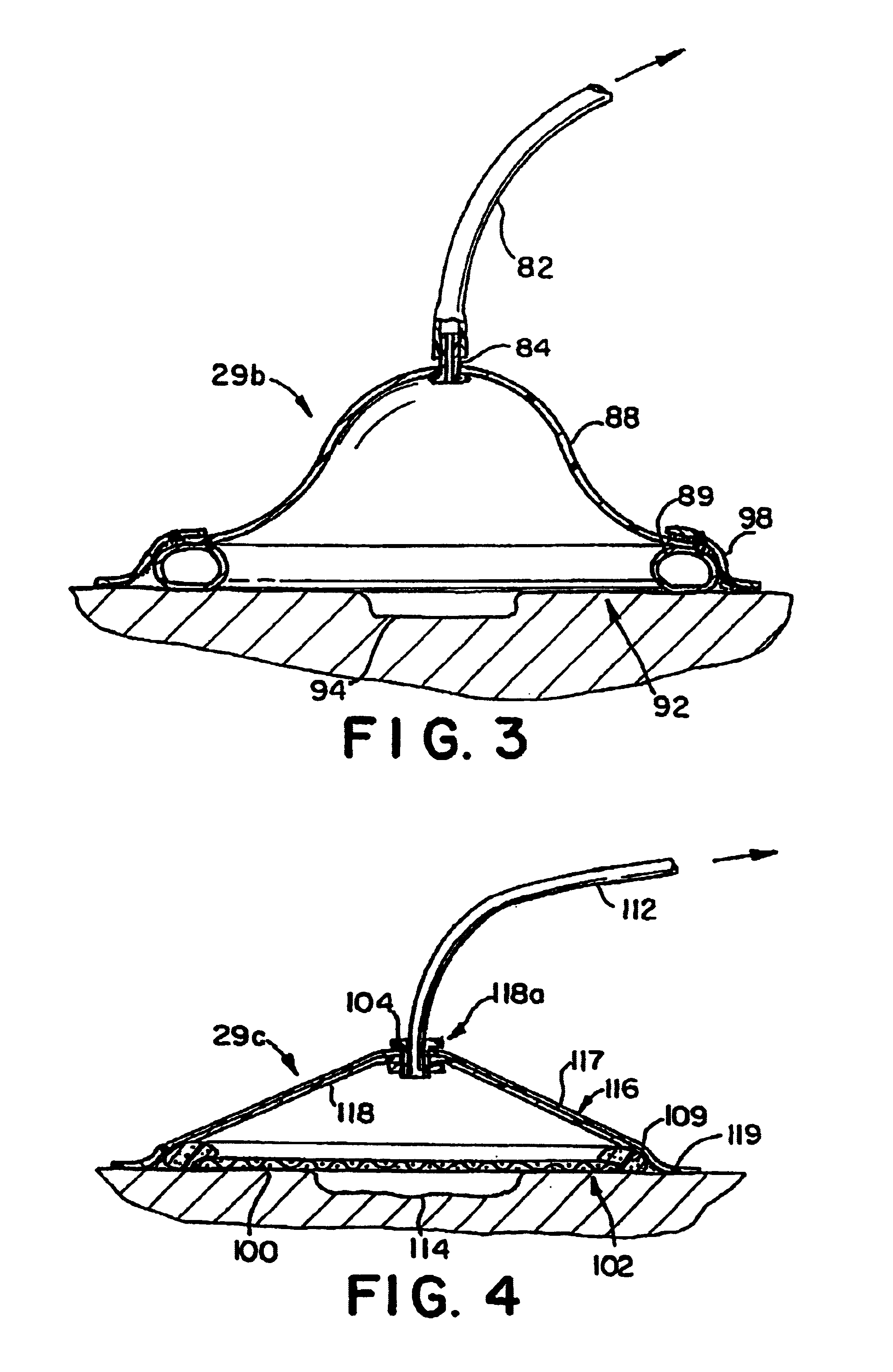

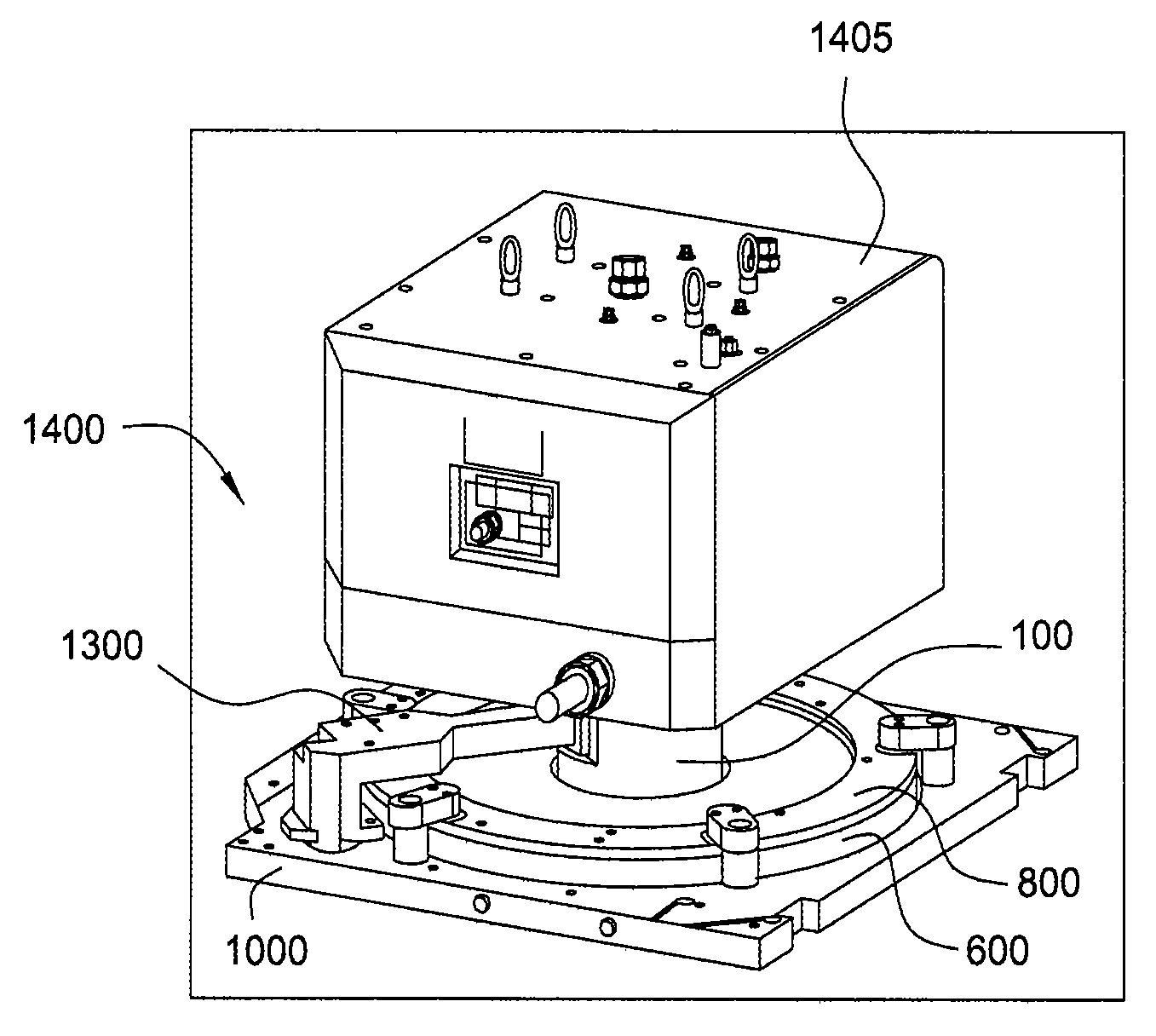

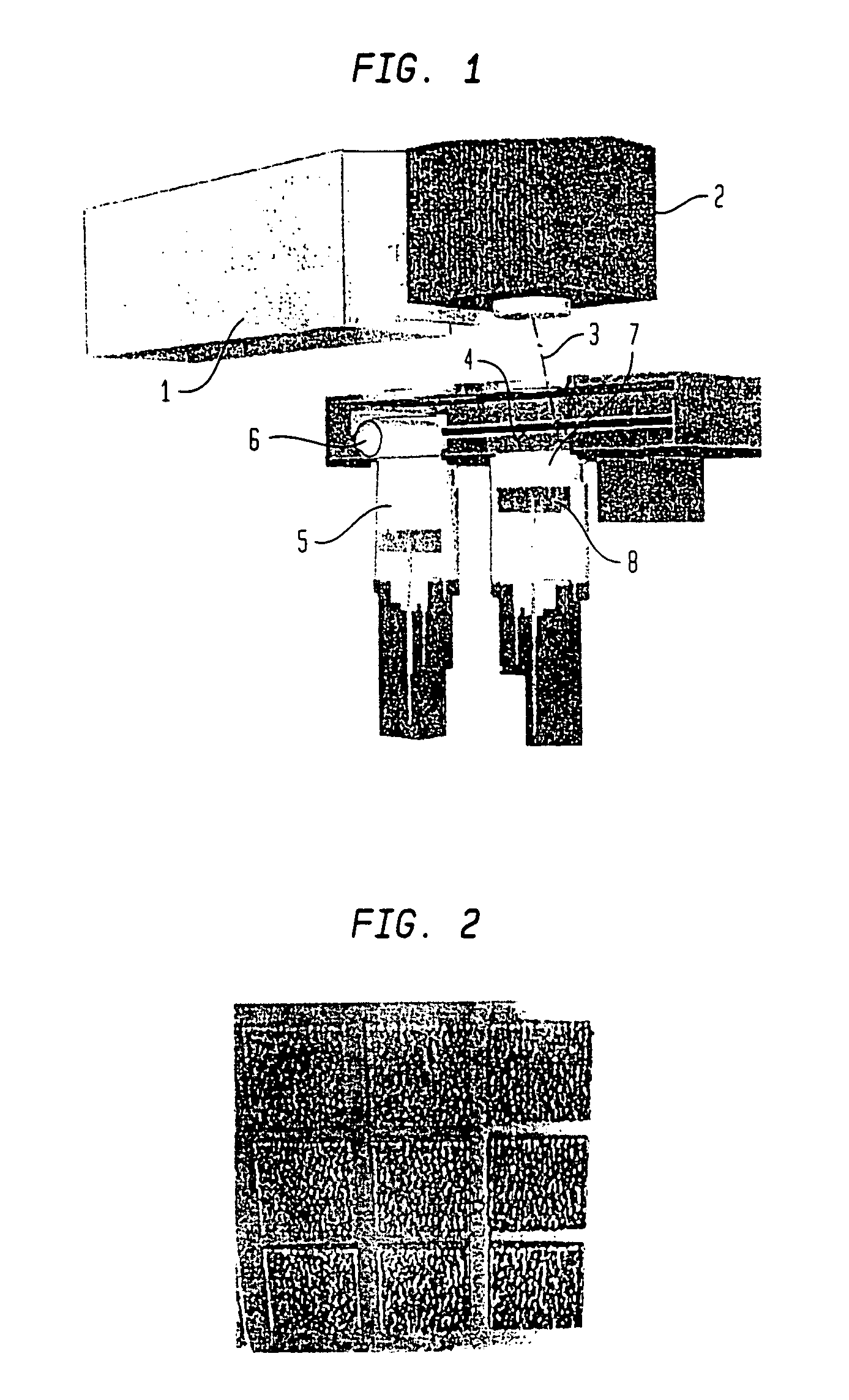

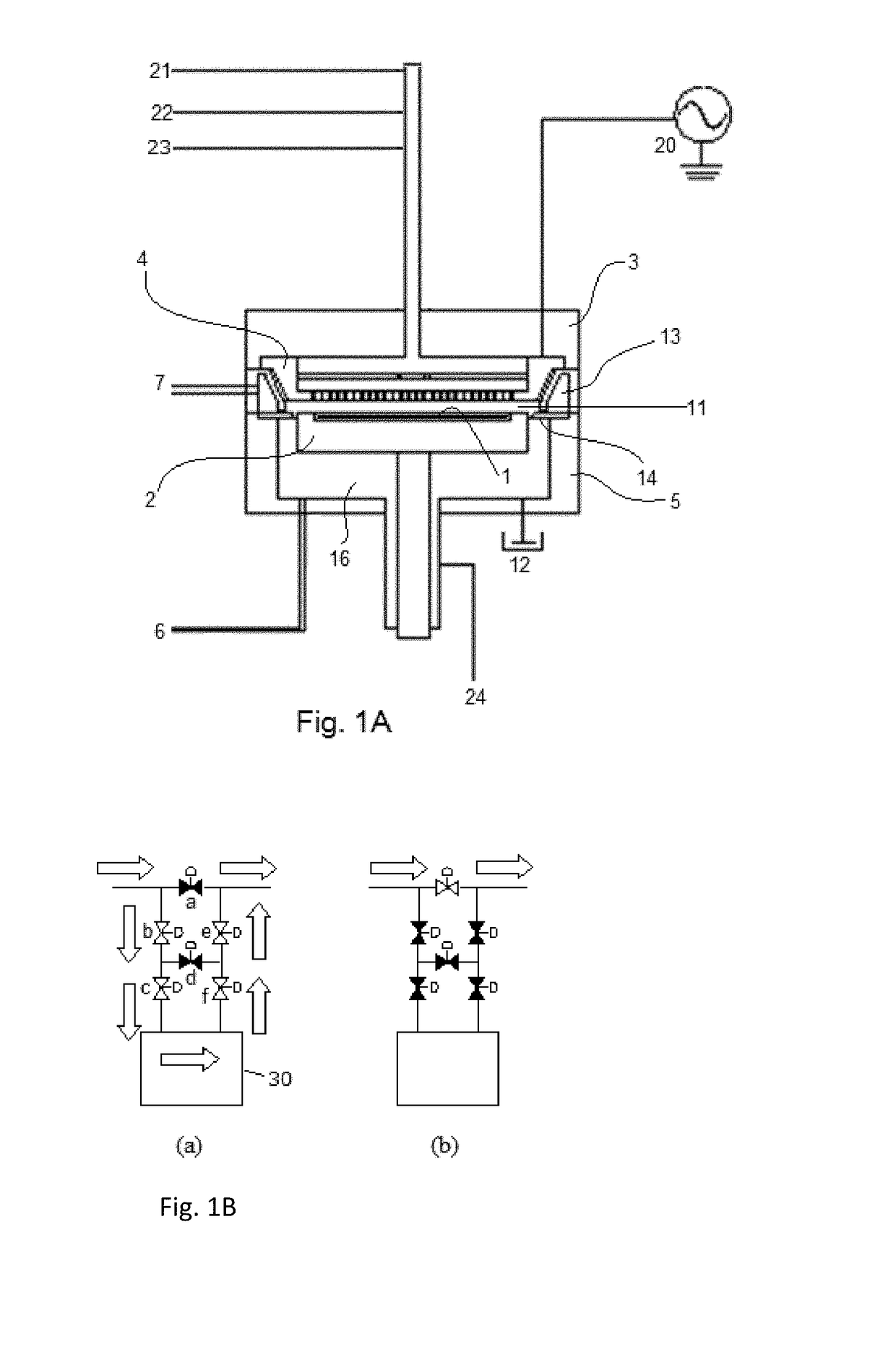

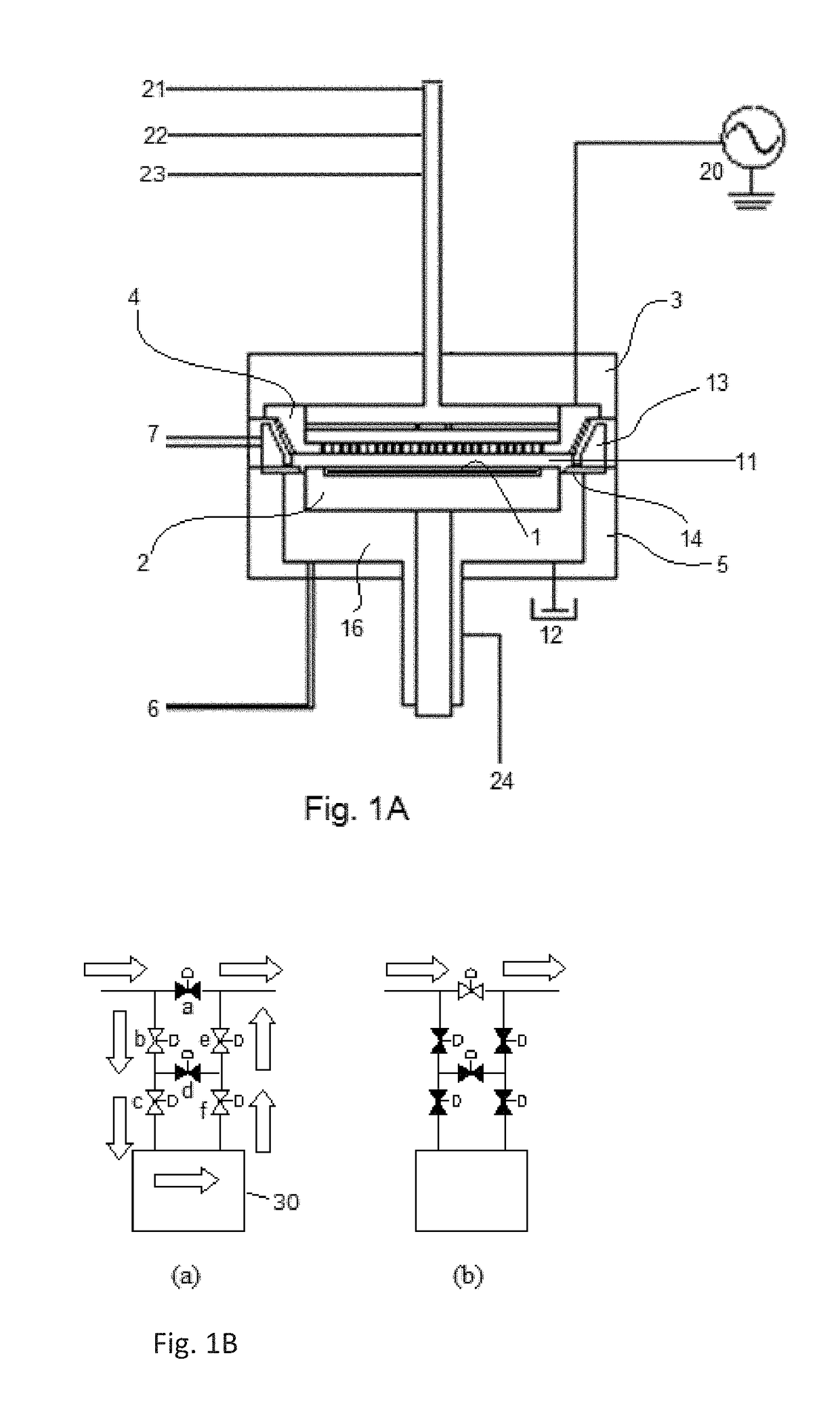

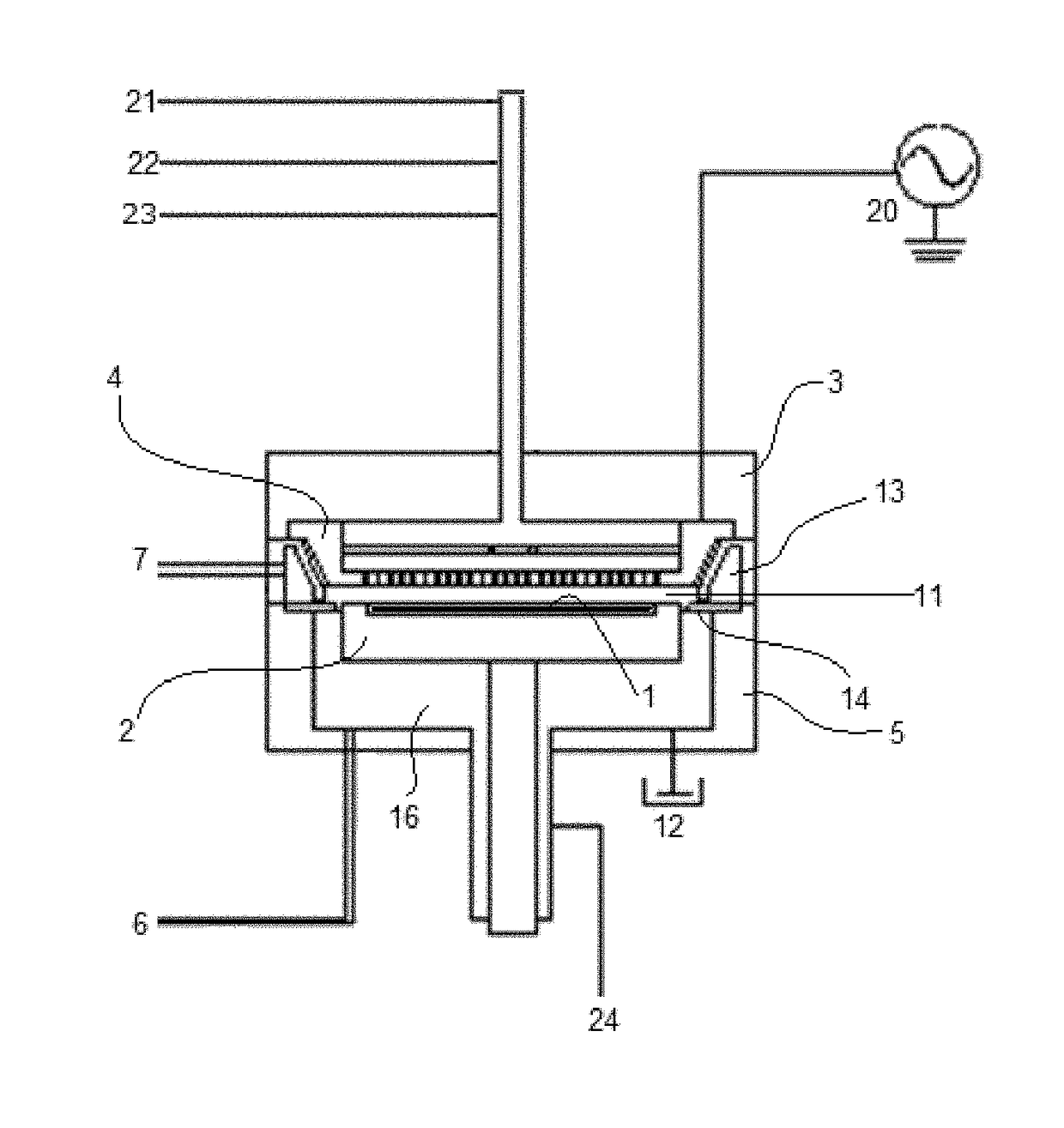

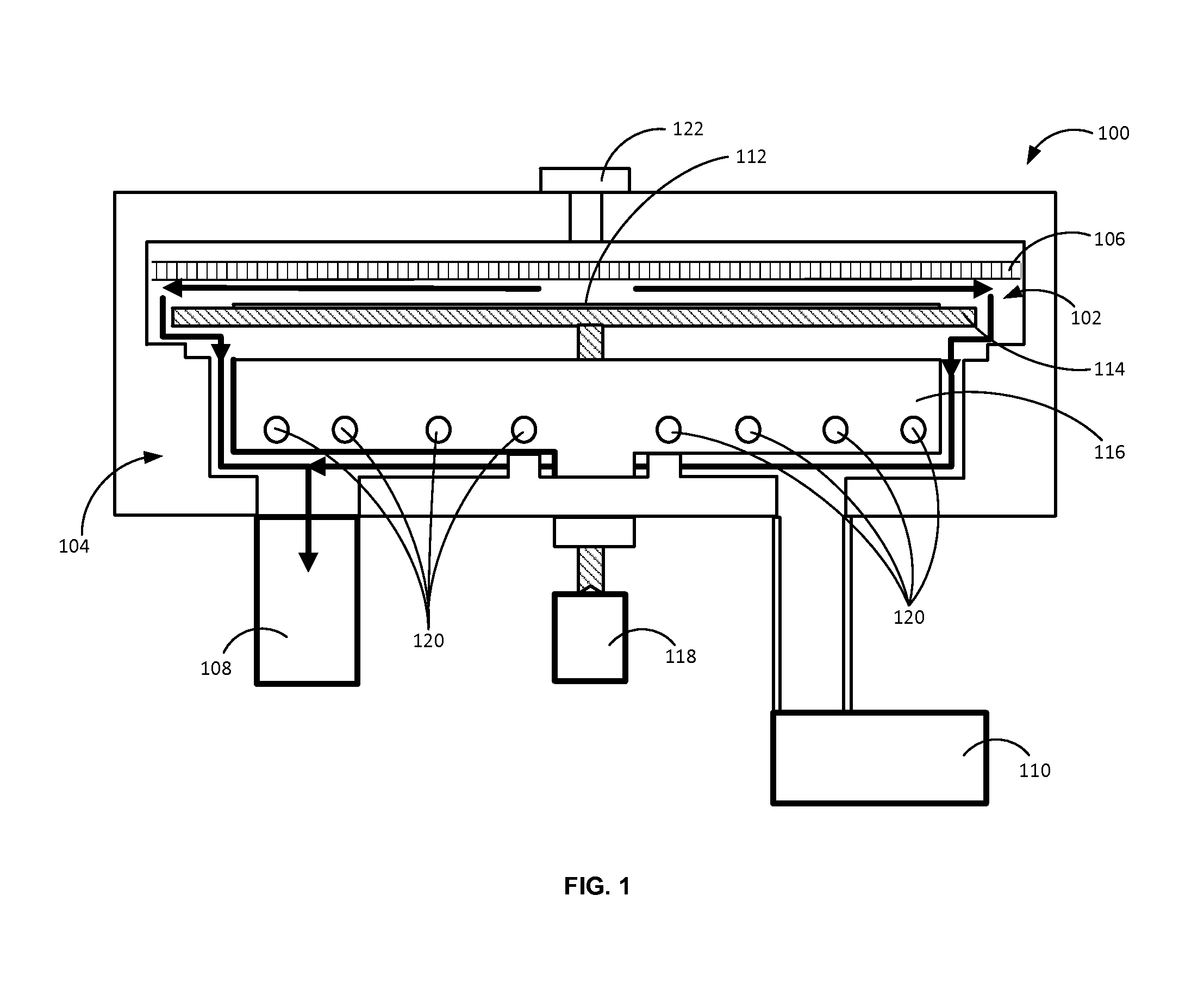

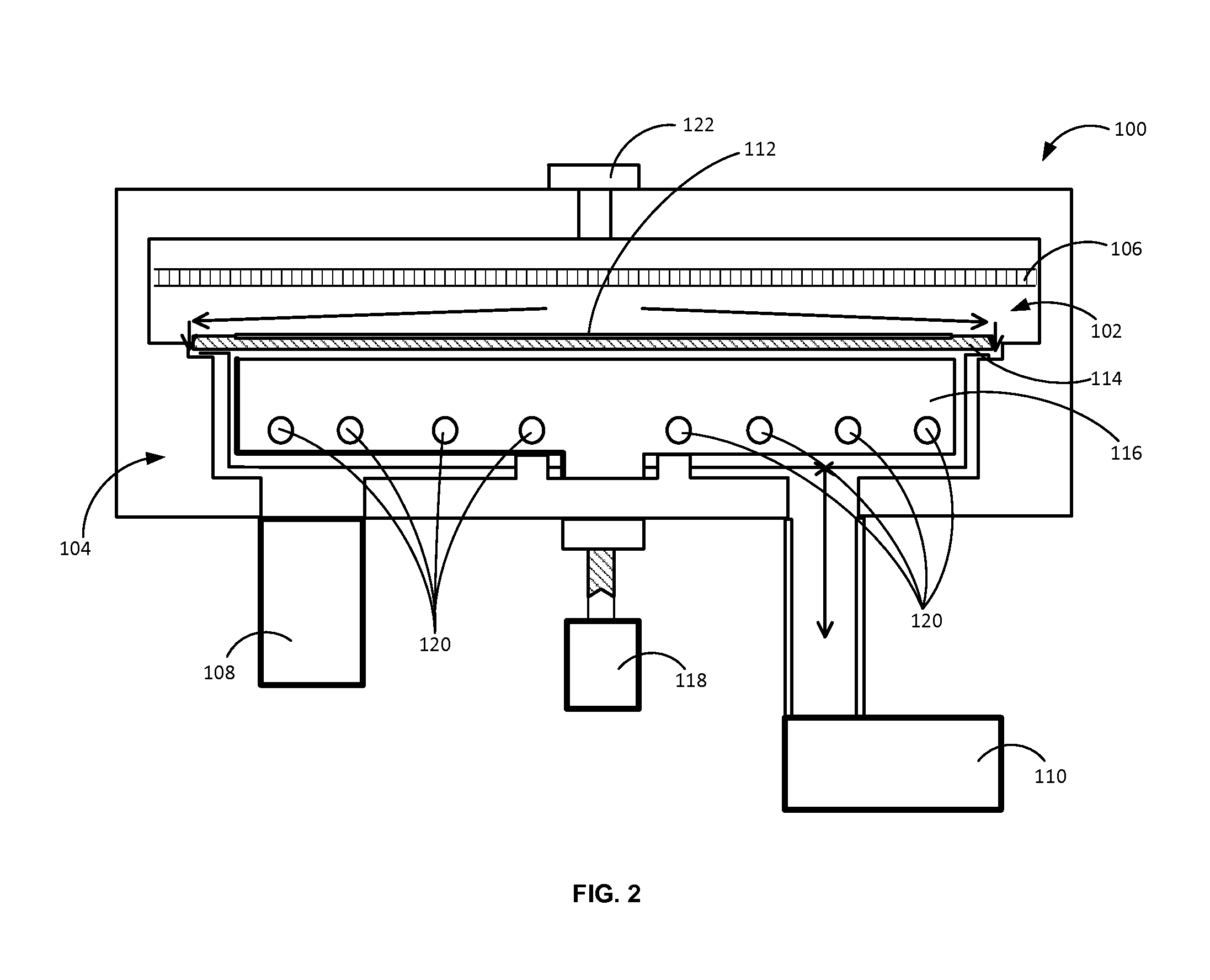

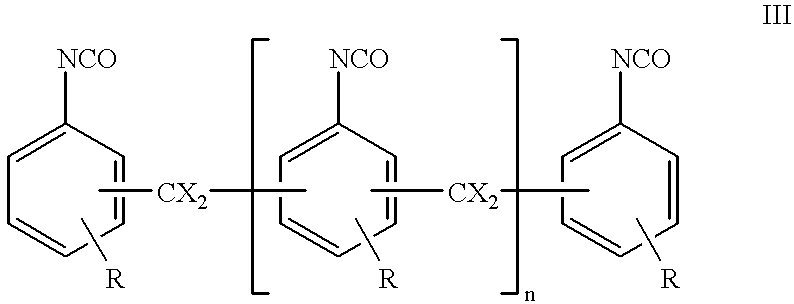

Apparatuses and methods for atomic layer deposition

ActiveUS20100003406A1Hole densityHigh hole densityElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaAtomic layer deposition

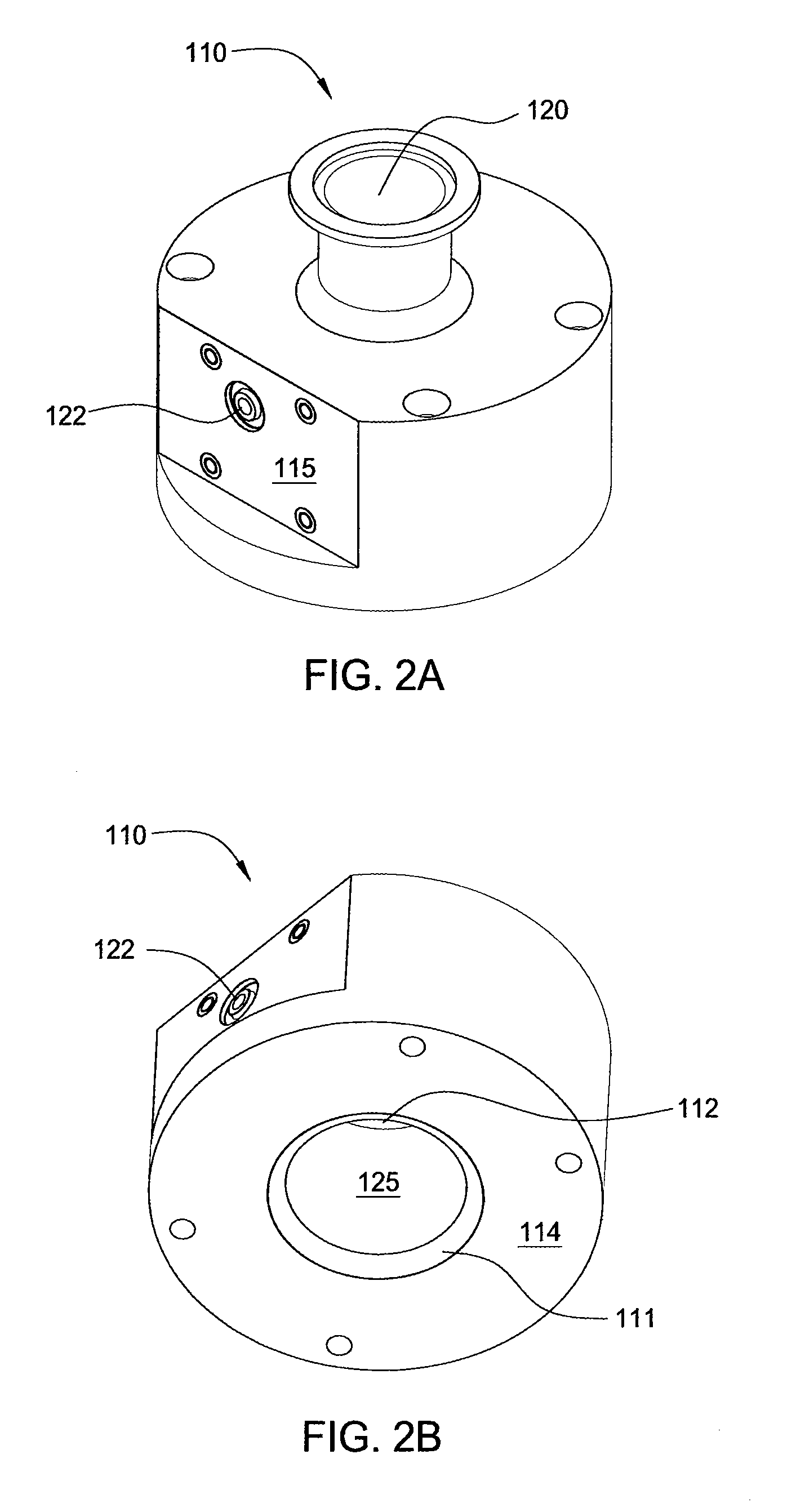

Embodiments of the invention provide apparatuses and methods for atomic layer deposition (ALD), such as plasma-enhanced ALD (PE-ALD). In some embodiments, a PE-ALD chamber is provided which includes a chamber lid assembly coupled with a chamber body having a substrate support therein. In one embodiment, the chamber lid assembly has an inlet manifold assembly containing an annular channel encompassing a centralized channel, wherein the centralized channel extends through the inlet manifold assembly, and the inlet manifold assembly further contains injection holes extending from the annular channel, through a sidewall of the centralized channel, and to the centralized channel. The chamber lid assembly further contains a showerhead assembly disposed below the inlet manifold assembly, a water box disposed between the inlet manifold assembly and the showerhead assembly, and a remote plasma system (RPS) disposed above and coupled with the inlet manifold assembly, and in fluid communication with the centralized channel.

Owner:APPLIED MATERIALS INC

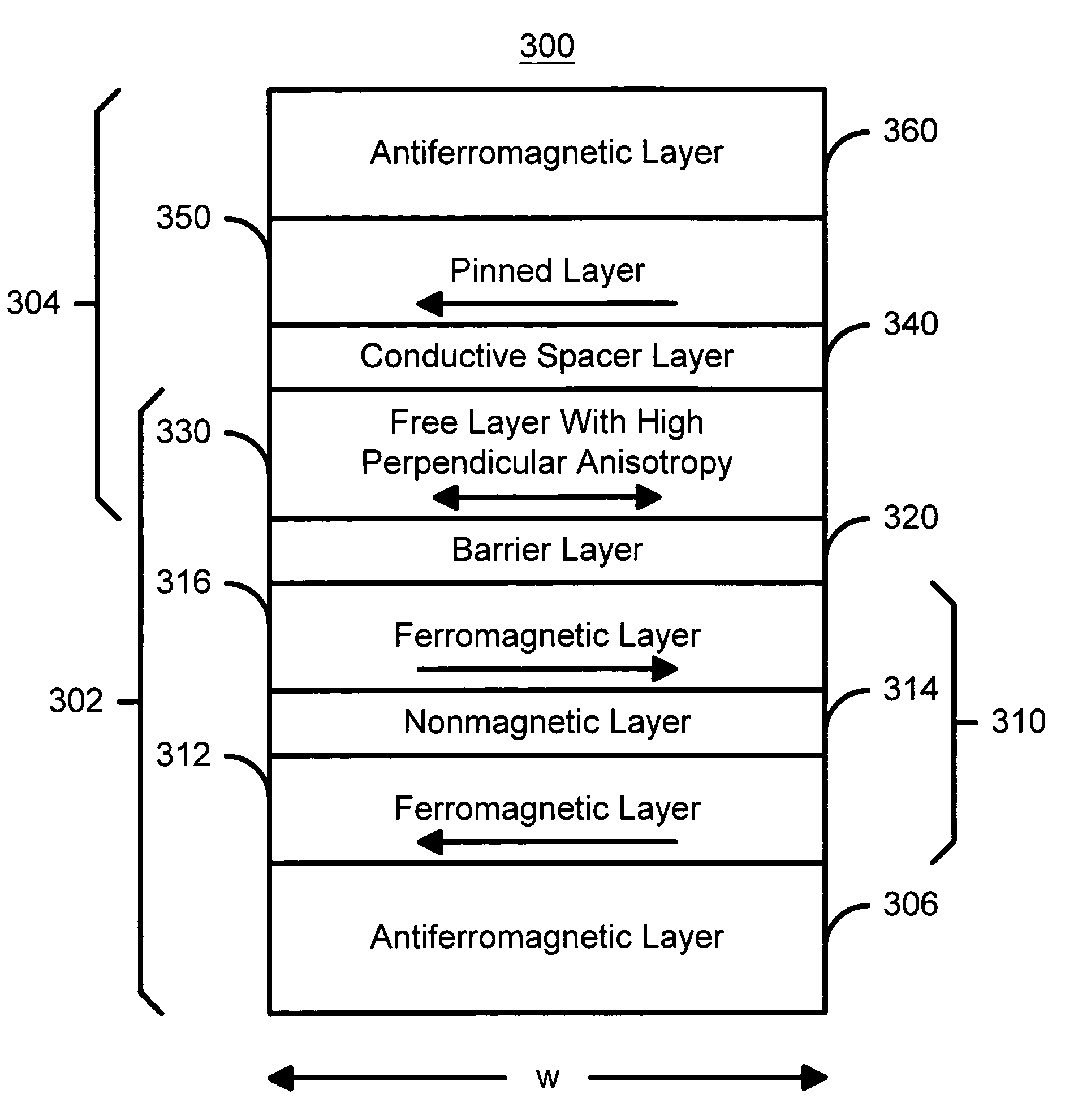

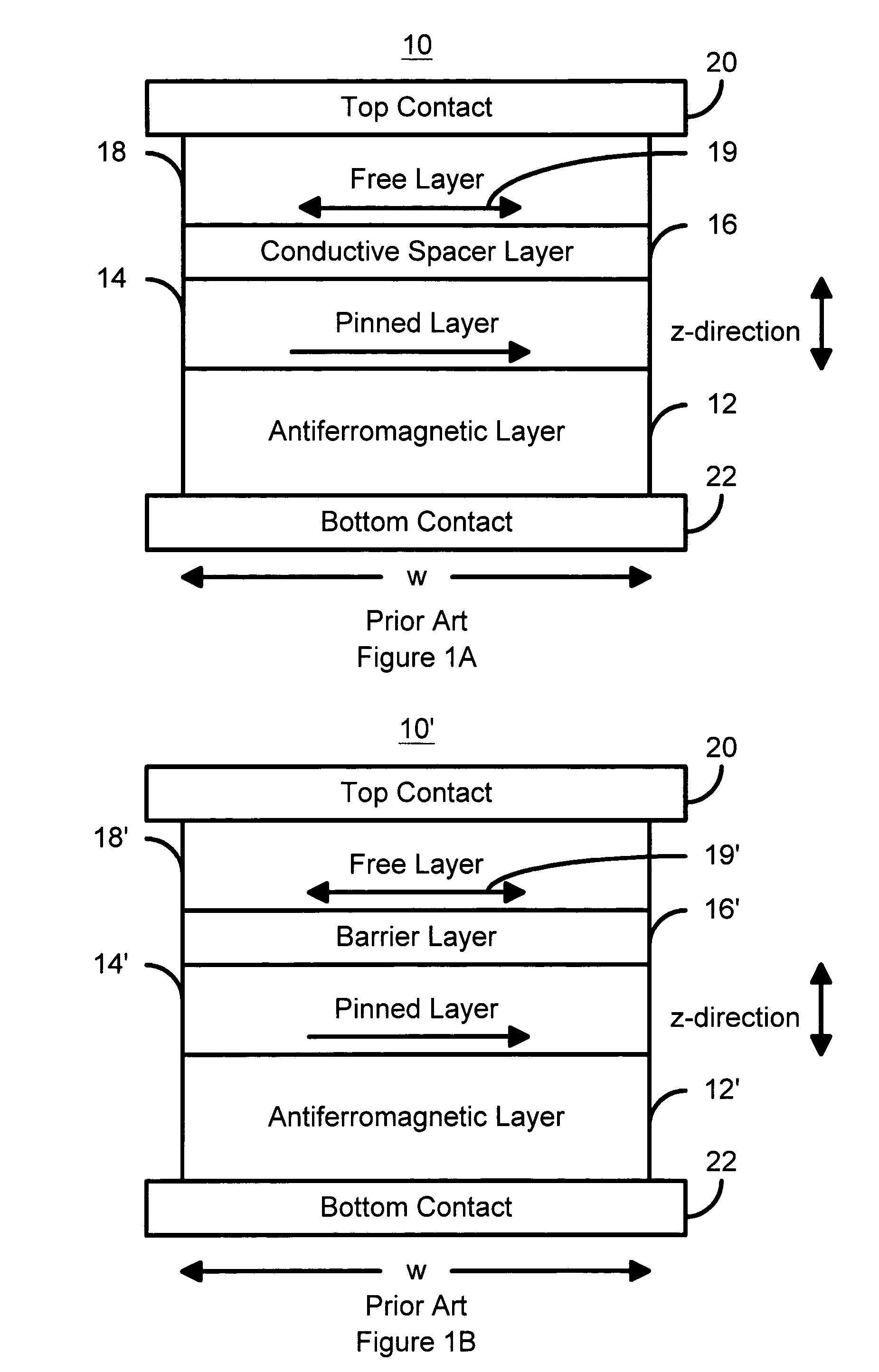

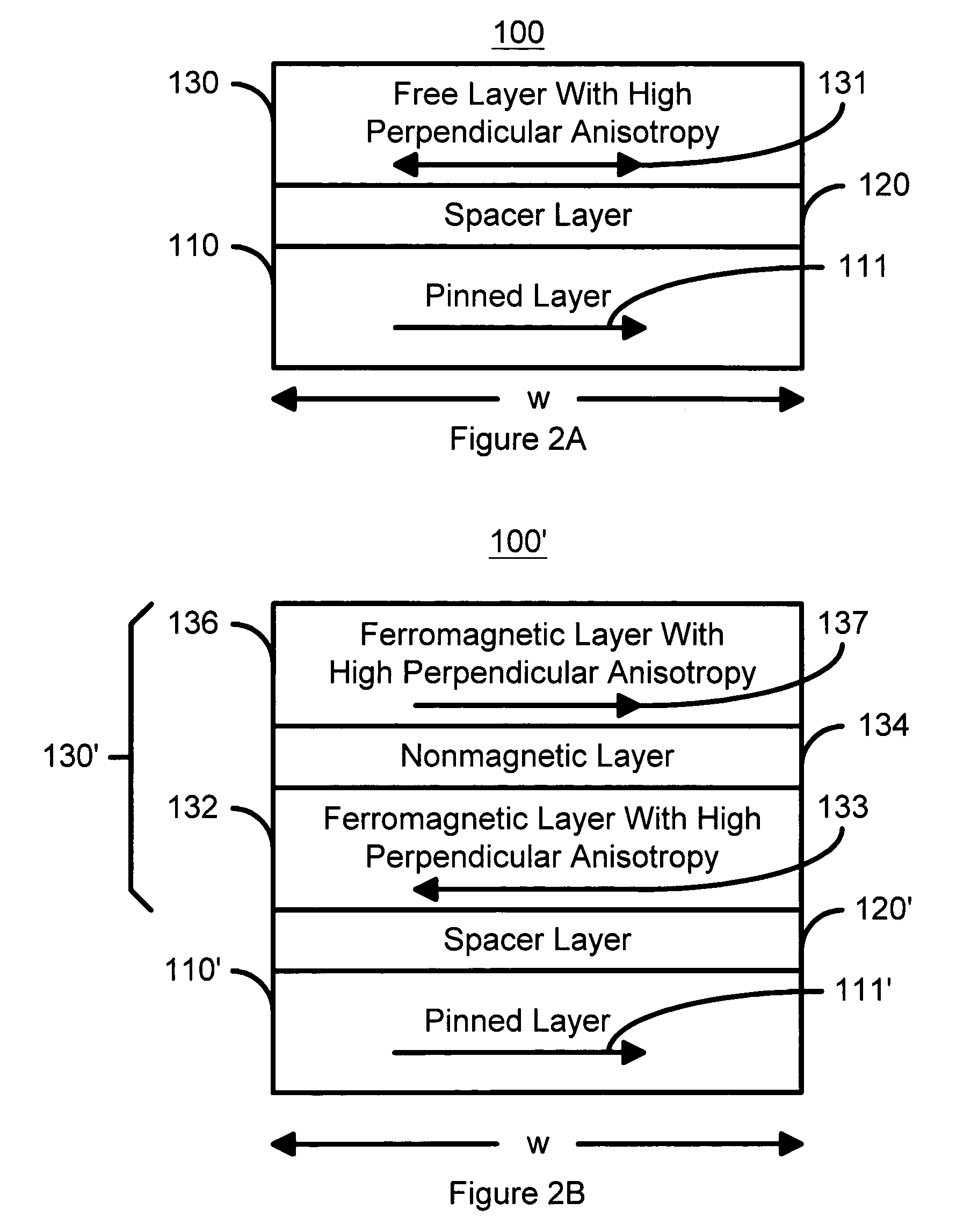

Spin transfer magnetic element with free layers having high perpendicular anisotropy and in-plane equilibrium magnetization

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes pinned, nonmagnetic spacer, and free layers. The spacer layer resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The magnetic element may also include a barrier layer, a second pinned layer. Alternatively, second pinned and second spacer layers and a second free layer magnetostatically coupled to the free layer are included. At least one free layer has a high perpendicular anisotropy. The high perpendicular anisotropy has a perpendicular anisotropy energy that is at least twenty and less than one hundred percent of the out-of-plane demagnetization energy.

Owner:SAMSUNG SEMICON

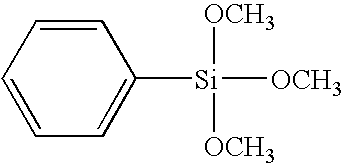

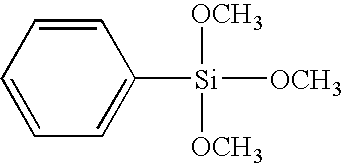

Organosilane compounds for modifying dielectrical properties of silicon oxide and silicon nitride films

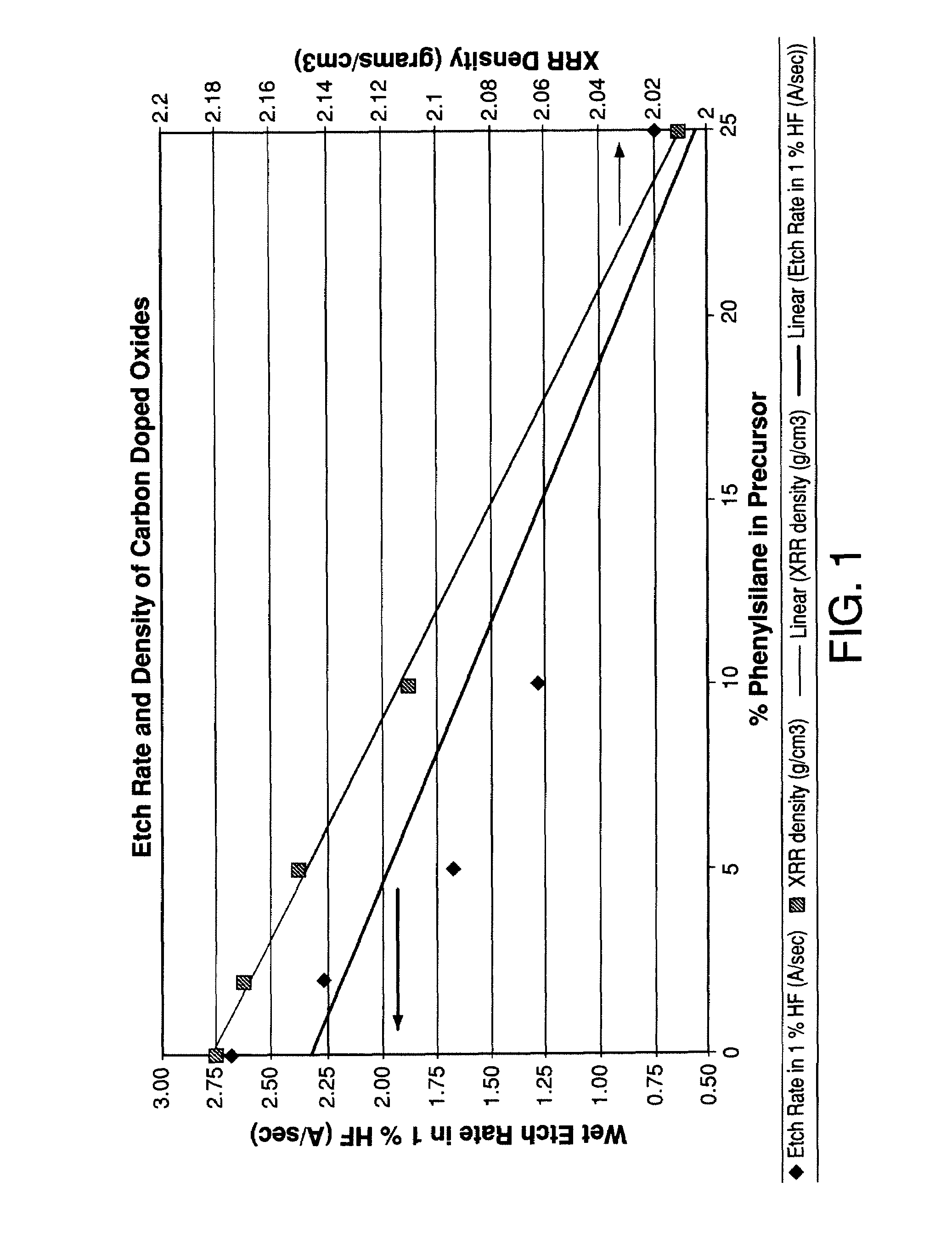

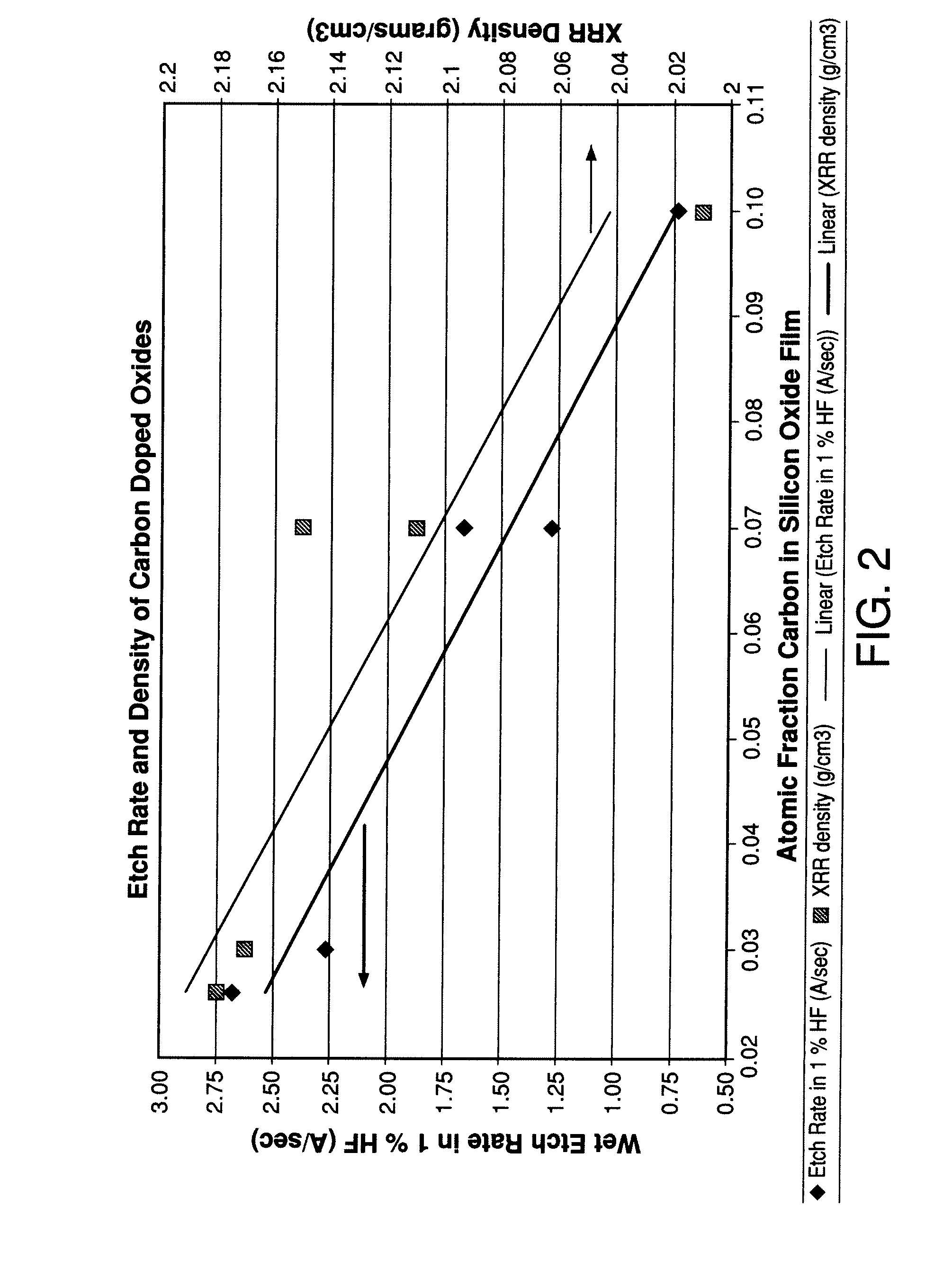

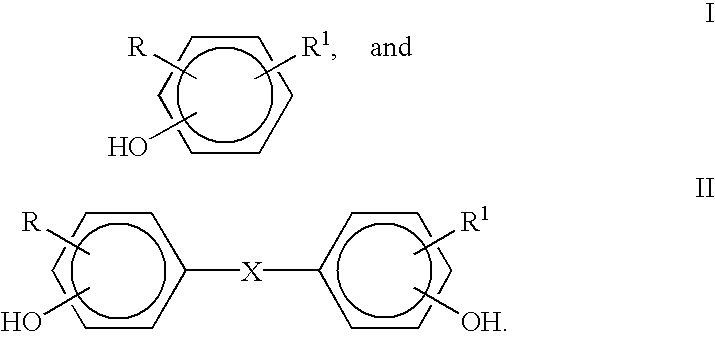

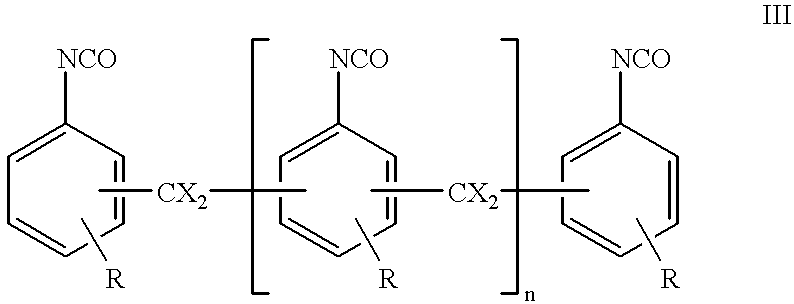

InactiveUS20080124946A1Excellent etch resistanceIncreasing flow ratioSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideChemical Modifier

The present invention discloses a process for depositing a carbon containing silicon oxide film, or a carbon containing silicon nitride film having enhanced etch resistance. The process comprises using a silicon containing precursor, a carbon containing precursor and a chemical modifier. The present invention also discloses a process for depositing a silicon oxide film, or silicon nitride film having enhanced etch resistance comprising using an organosilane precursor and a chemical modifier.

Owner:VERSUM MATERIALS US LLC

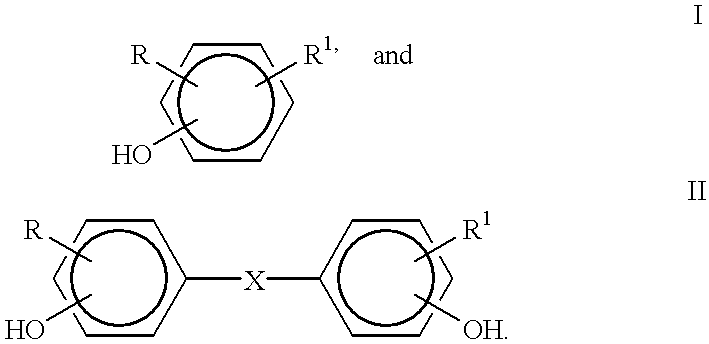

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS6582819B2Low densityEasy to transportGranule coatingPretreated surfacesFiltrationArtificial turf

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

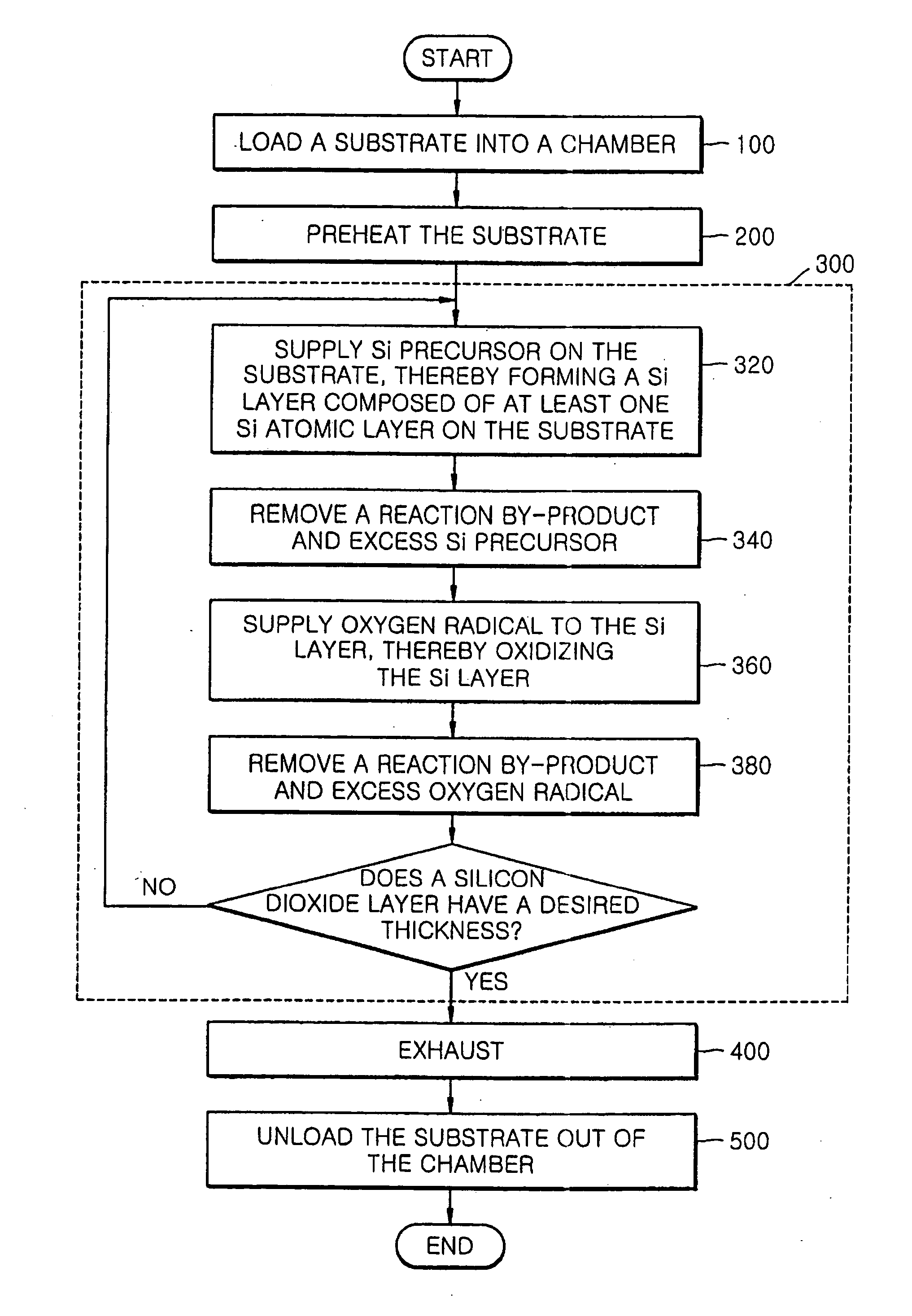

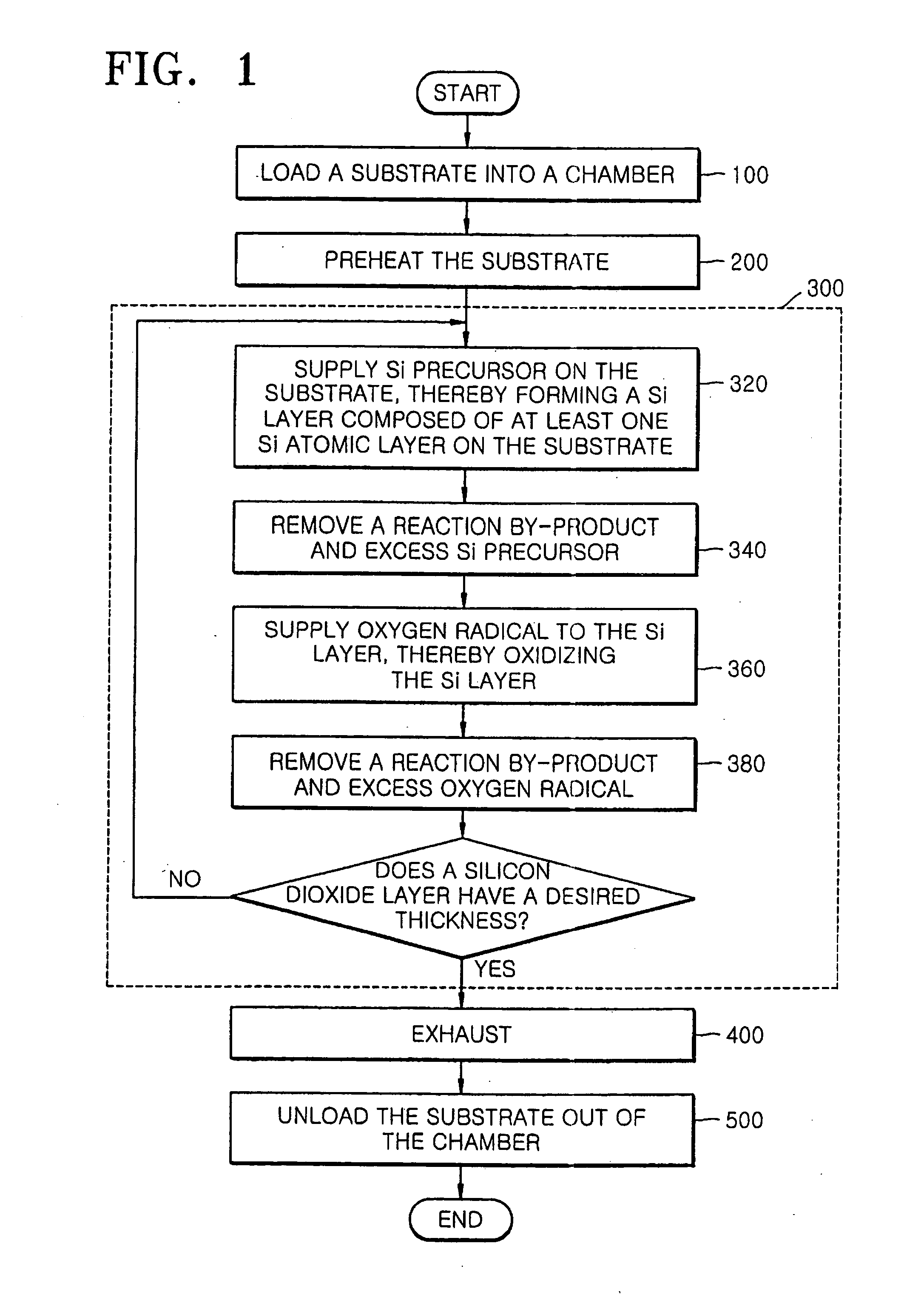

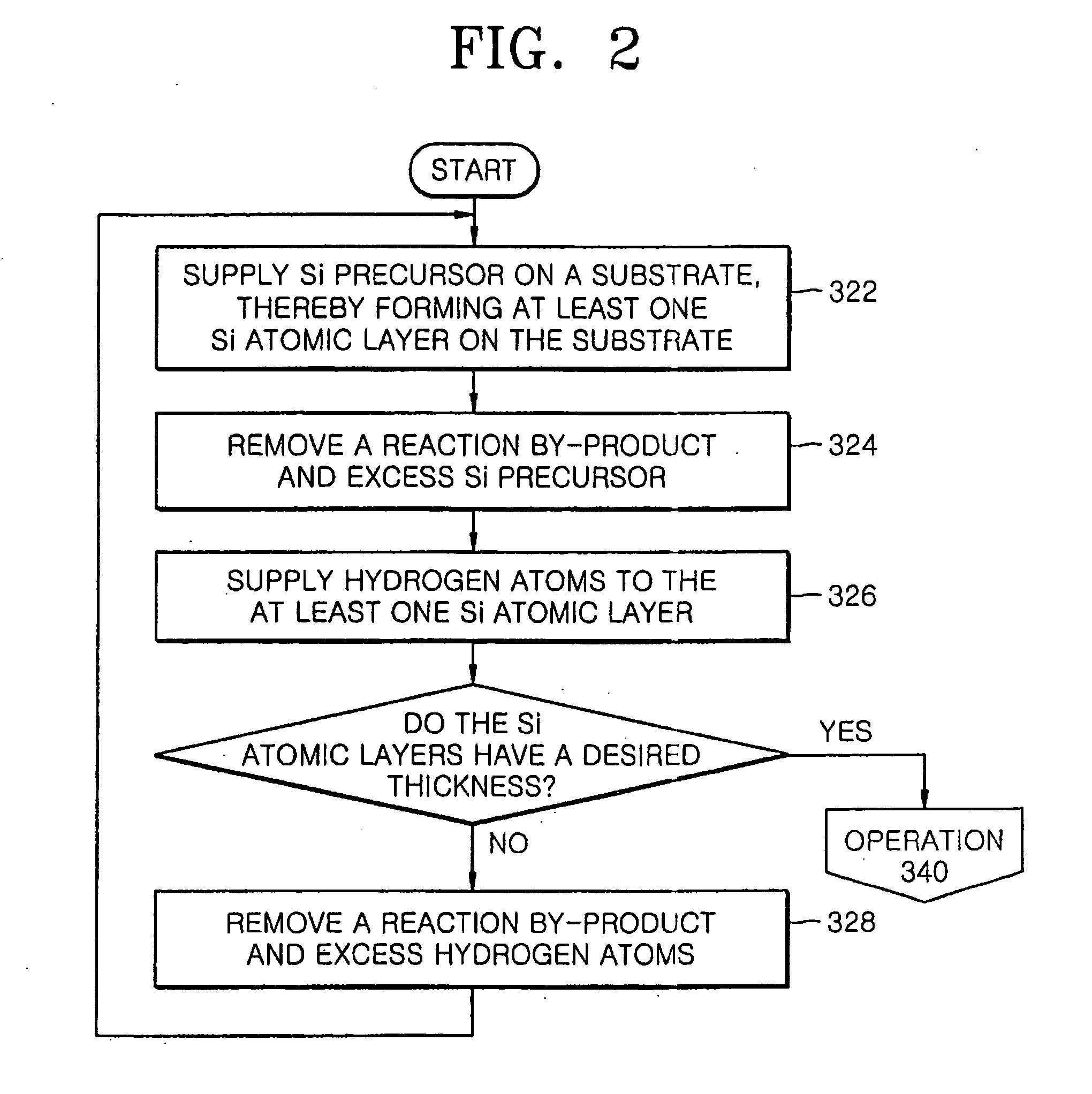

Methods of forming silicon dioxide layers using atomic layer deposition

InactiveUS20070111545A1Good step coverageReduce trap densitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingOptoelectronicsOxygen

Provided herein are methods of forming a silicon dioxide layer on a substrate using an atomic layer deposition (ALD) method that include supplying a Si precursor to the substrate and forming on the substrate a Si layer including at least one Si atomic layer; and (b) supplying an oxygen radical to the Si layer to replace at least one Si—Si bond within the Si layer with a Si—O bond, thereby oxidizing the Si layer, to form a silicon dioxide layer on the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

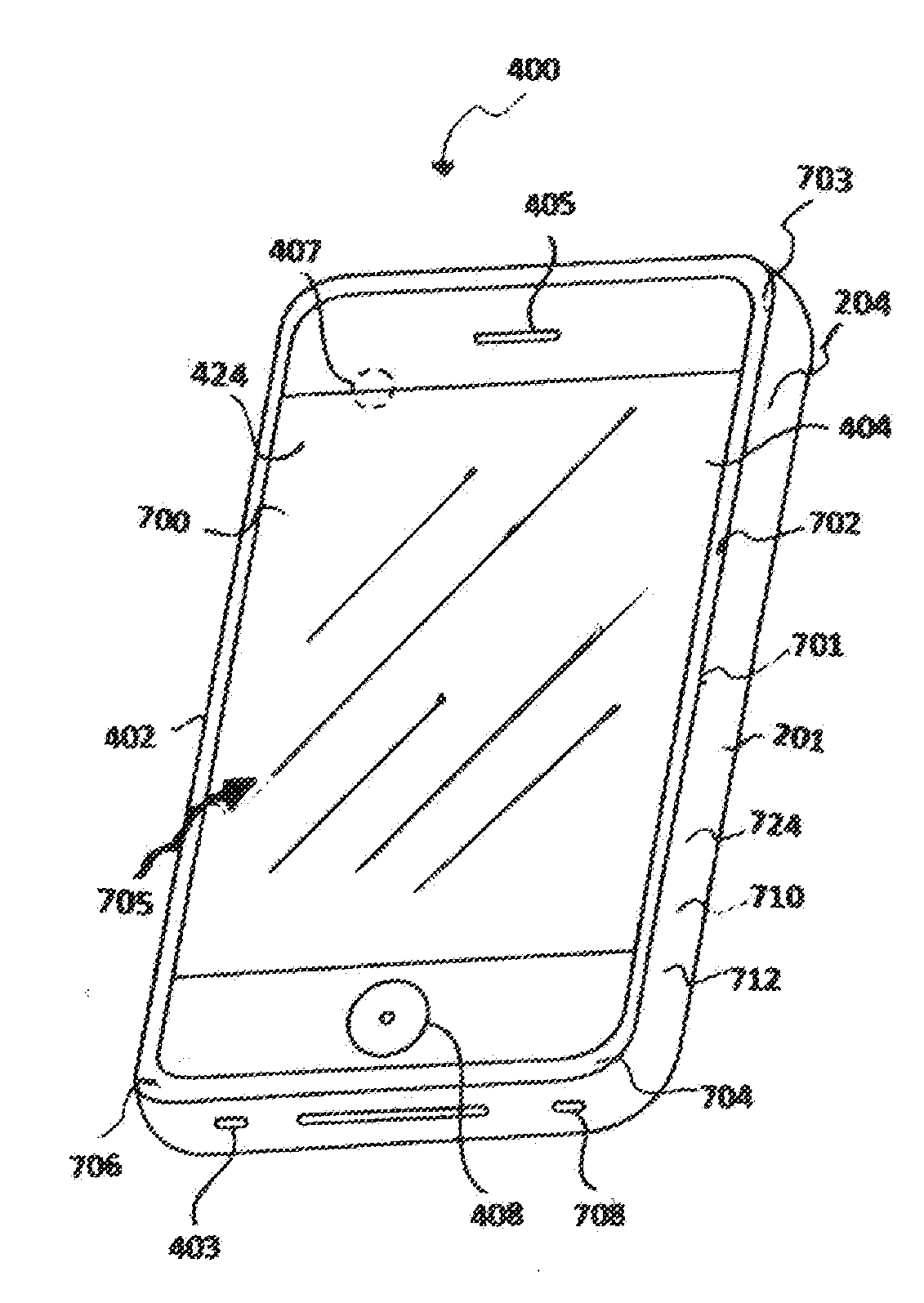

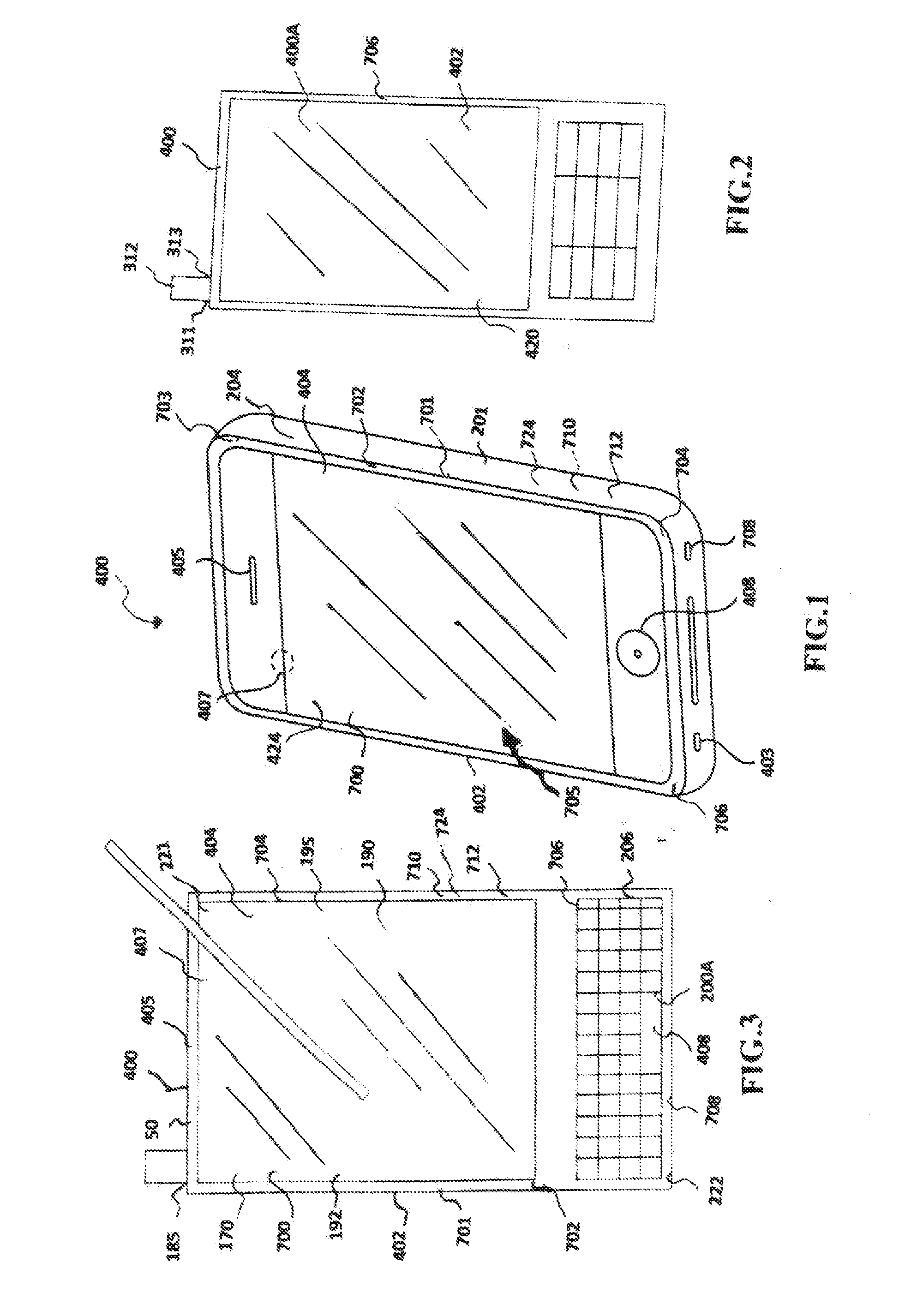

Energy harvesting computer device in association with a communication device configured with apparatus for boosting signal reception

ActiveUS20130157729A1Improve consumer electronics hybrid consumer electronics performanceLow densityMaterial nanotechnologyEnergy efficient ICTCellular telephoneCommunication device

Disclosed embodiments comprise an energy harvesting computer device in association with a communication device comprising interactive user interface operatively configured with CMOS multiple antennas on chip for boosting signal receptions and for providing faster data transmission speed. Disclosed embodiment encompasses three modes of communications—the Cell phone, wireless Internet applications, and Global communication and media information. Embodiments provide communication apparatus operable to enhance mobile communication efficiency with touch sensitive display comprising energy harvesting platform in communication with a charging circuit board configured with memories, processors, sensors, and modules. Embodiments further provide a gaming device, a wireless media device configured with touch pads comprising sensors being embedded in silicon substrate and fused in nano-fiber / microfiber material having excellent electrical characteristics. Certain embodiments provide communication apparatus configured for voice enabled applications comprising human voice auditory operable to convert text into voice auditory and / or voice auditory into text applications.

Owner:TABE JOSEPH AKWO

Continuous method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS6416822B1Faster efficient meanSimple methodPretreated surfacesSemiconductor/solid-state device manufacturingHigh densityVolumetric Mass Density

The present invention relates to an enhanced non-sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method.

Owner:NOVELLUS SYSTEMS

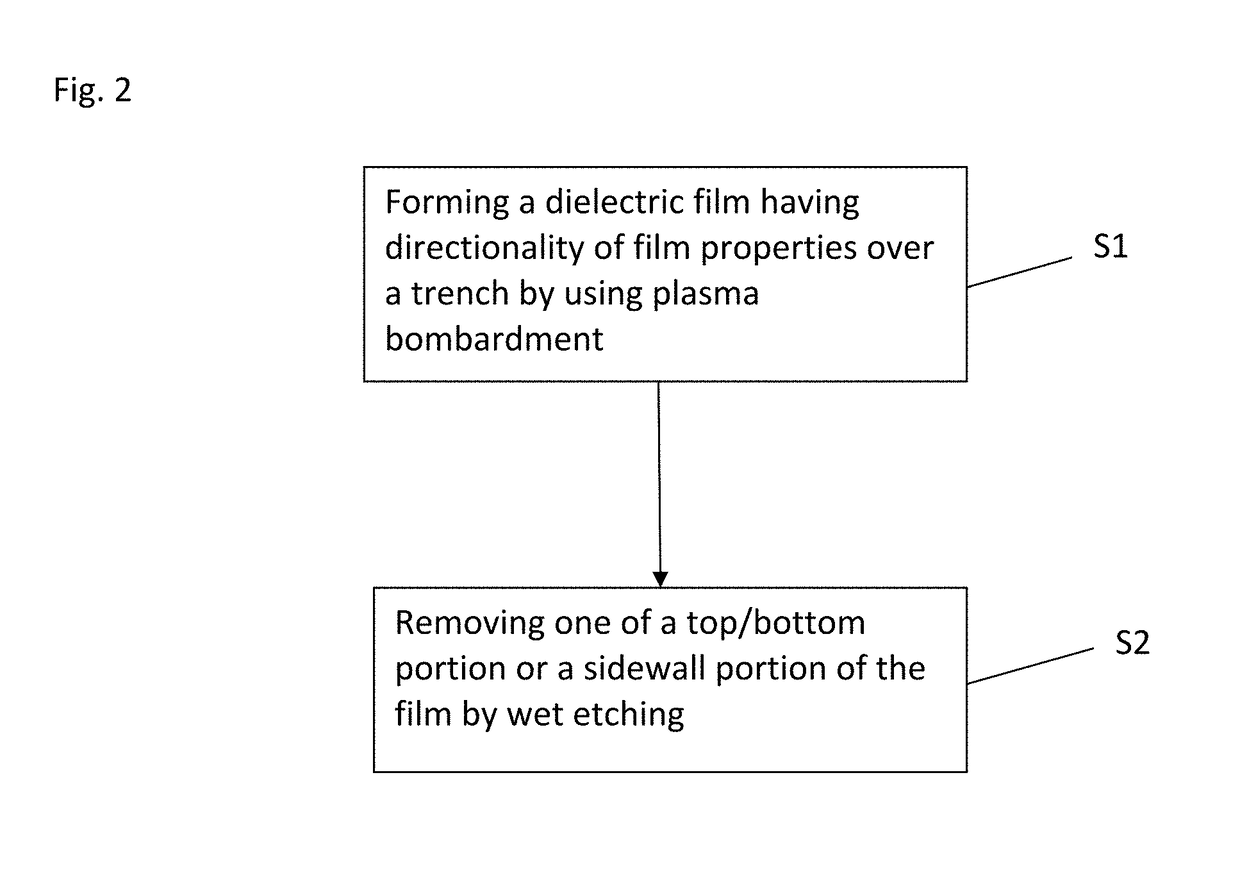

Dielectric film and formation method thereof, semiconductor device, non-volatile semiconductor memory device, and fabrication method for a semiconductor device

InactiveUS20080277715A1Improve wiring speedLow working voltageTransistorSemiconductor/solid-state device detailsDielectricHydrogen

Owner:FOUND FOR ADVANCEMENT OF INT SCI

Fluid-assisted medical device

InactiveUS7645277B2Fixed spacingRelieve stressSurgical instruments for heatingSurgical forcepsMedical deviceBlood vessel

The invention provides a medical device that includes a housing, a tubular member extending from the distal end of the housing, a first arm extending from the distal end of the tubular member, the first arm including a first electrode, a second arm extending from the distal end of the tubular member, the second arm including a second electrode and being disposed coaxially with the first arm, at least one solution infusion opening on each electrode, and a solution delivery channel for delivery of a conductive solution to the solution infusion openings. According to the invention, at least one of the first arm or the second arm is translationally moveable, and at least one of the first arm or the second arm is adapted to be coupled to a source of radiofrequency energy. The invention also provides a corresponding method for treating blood vessels or other tissues of the body.

Owner:MEDTRONIC ADVANCED ENERGY

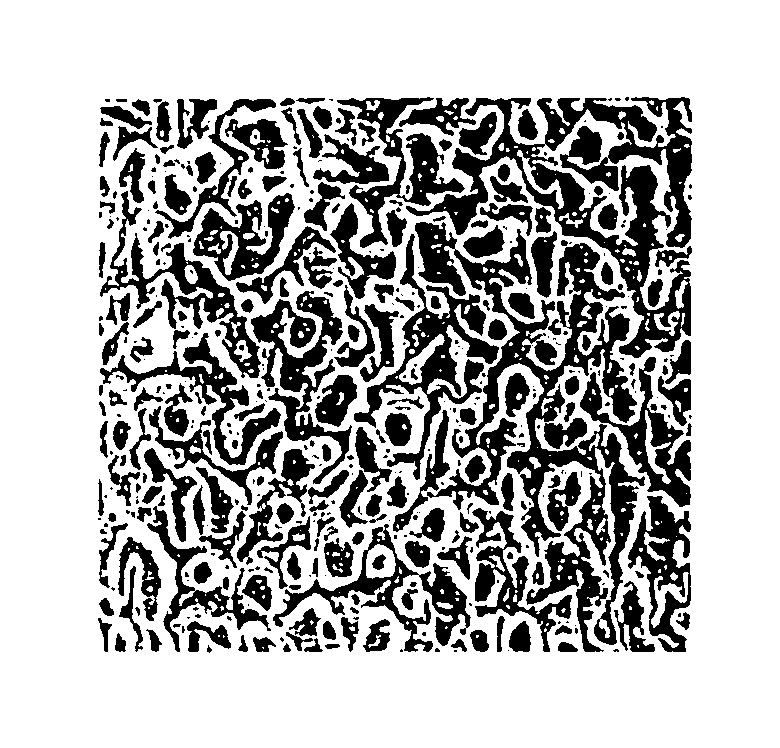

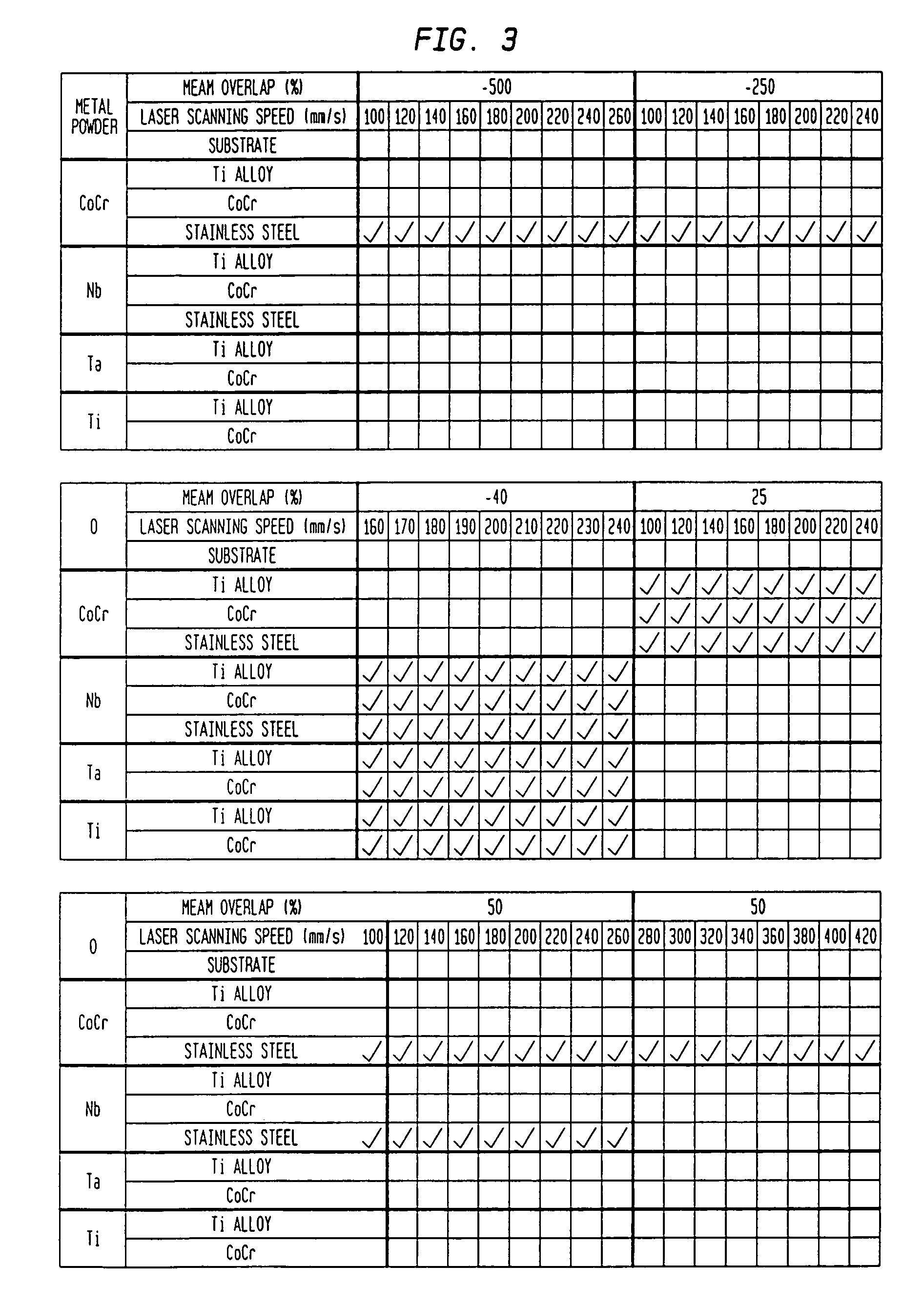

Laser-produced porous surface

ActiveUS7537664B2Decrease in densityIncrease porosityMolten spray coatingJoint implantsLayer wisePorosity

A method of fabricating a porous or partially porous three-dimensional metal article for use as a tissue ingrowth surface on a prosthesis. The porous article is formed using direct laser remelting in a cross section of a layer of metallic powder on a build platform without fusing thereto. The power, speed, spot size and beam overlap of the scanning laser is coordinated so that a predetermined porosity of the metallic powder can be achieved. Laser factors also vary depending from the thickness of the powder layer, type of metallic powder and size and size distribution of the powder particles. Successive depositing and remelting of individual layers are repeated until the article is fully formed by a layer-by-layer fashion. In an additional embodiment, a first layer of metallic powder may be deposited on a solid base or core and fused thereto.

Owner:UNIV OF LIVERPOOL +1

Continuous method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS20020164423A1Faster efficient meanSimple methodPretreated surfacesSolid state diffusion coatingHigh densityOptoelectronics

The present invention relates to an enhanced sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method.

Owner:NOVELLUS SYSTEMS

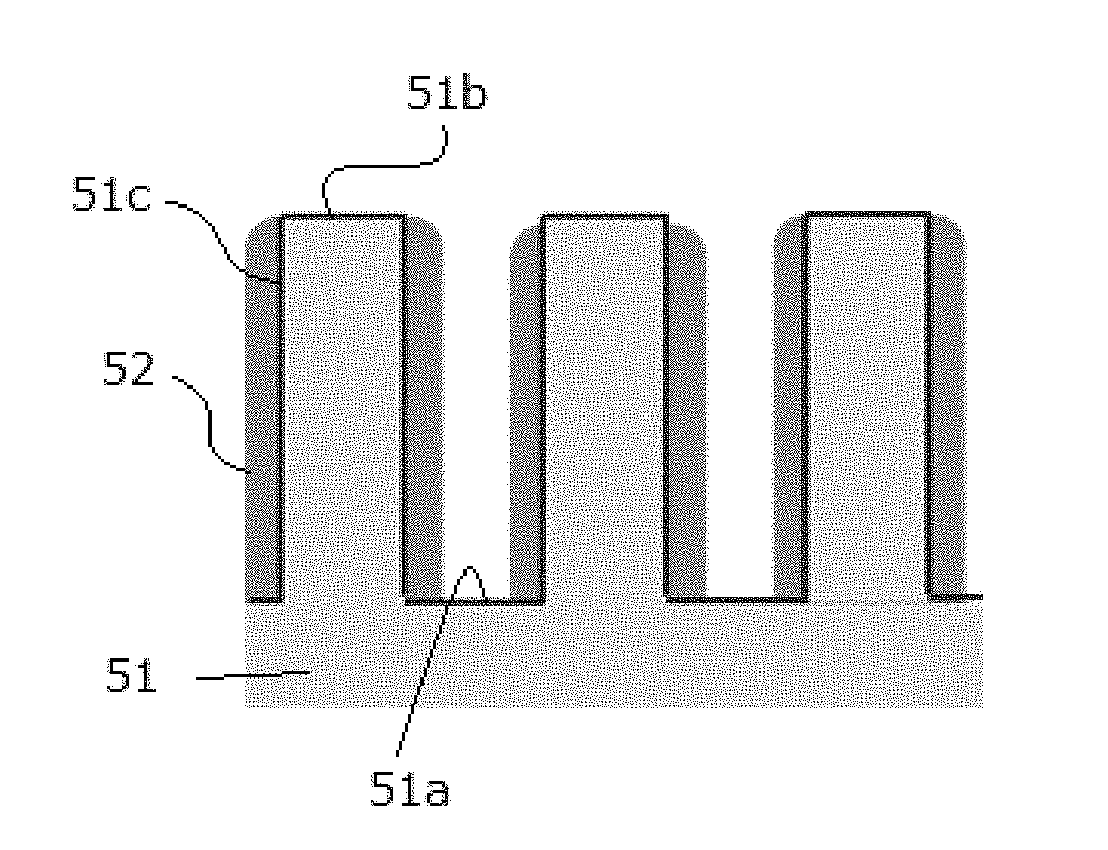

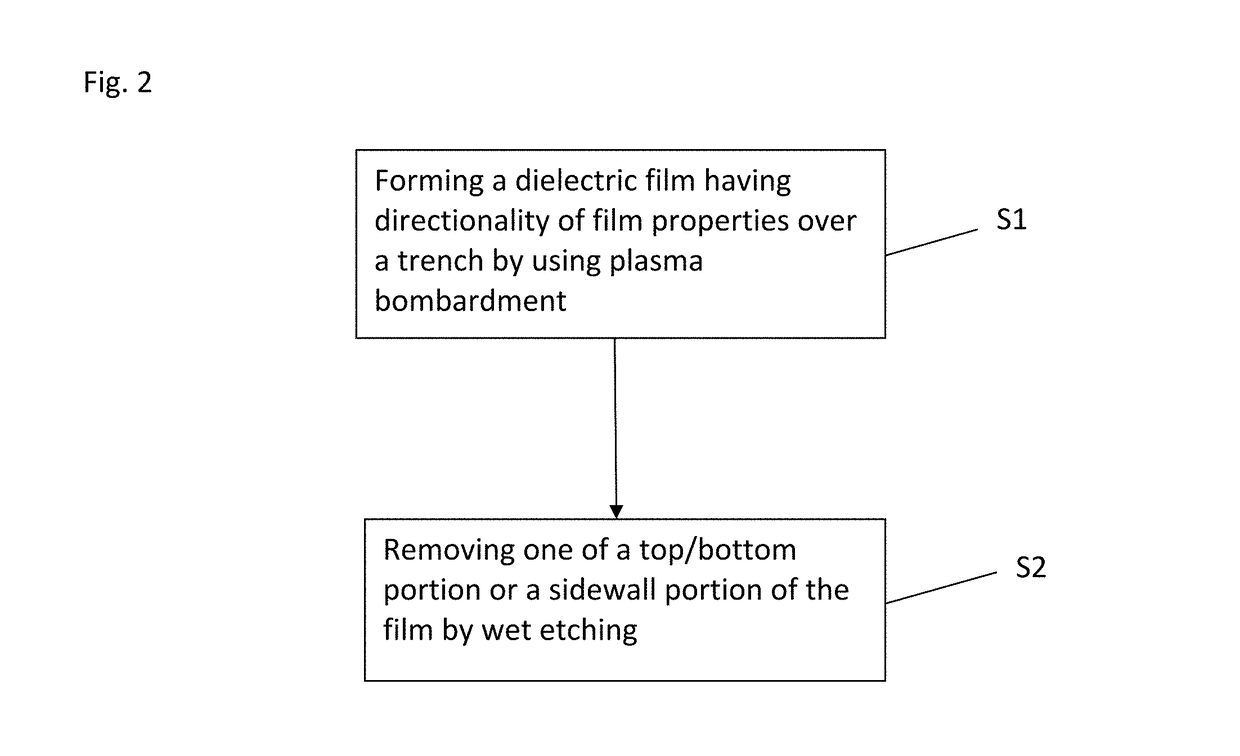

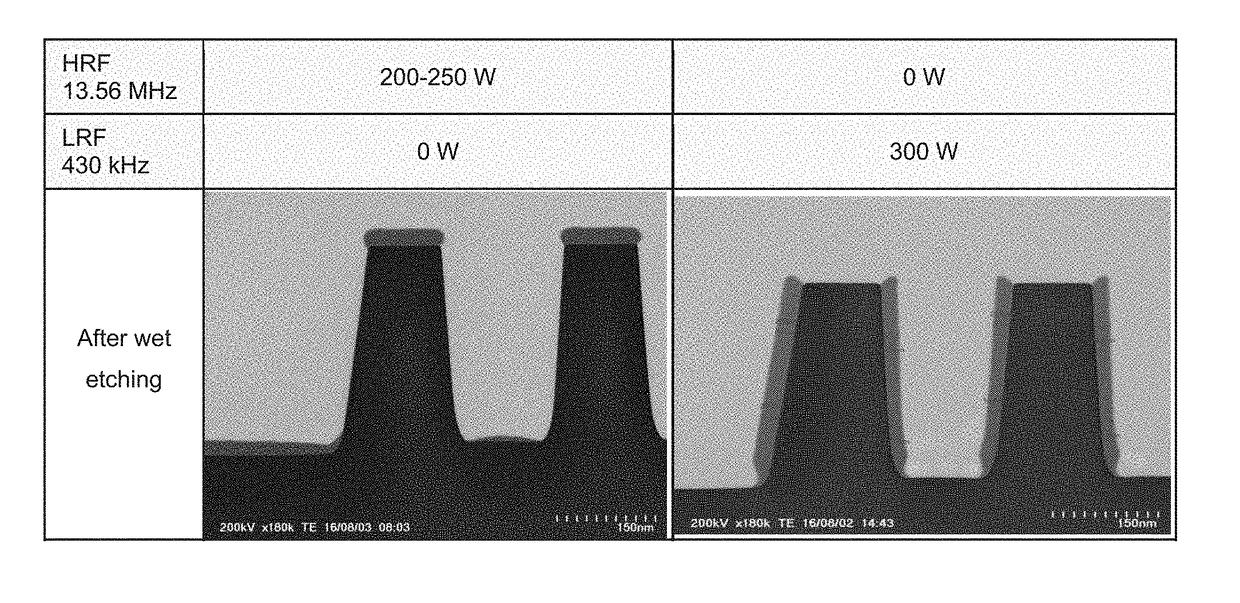

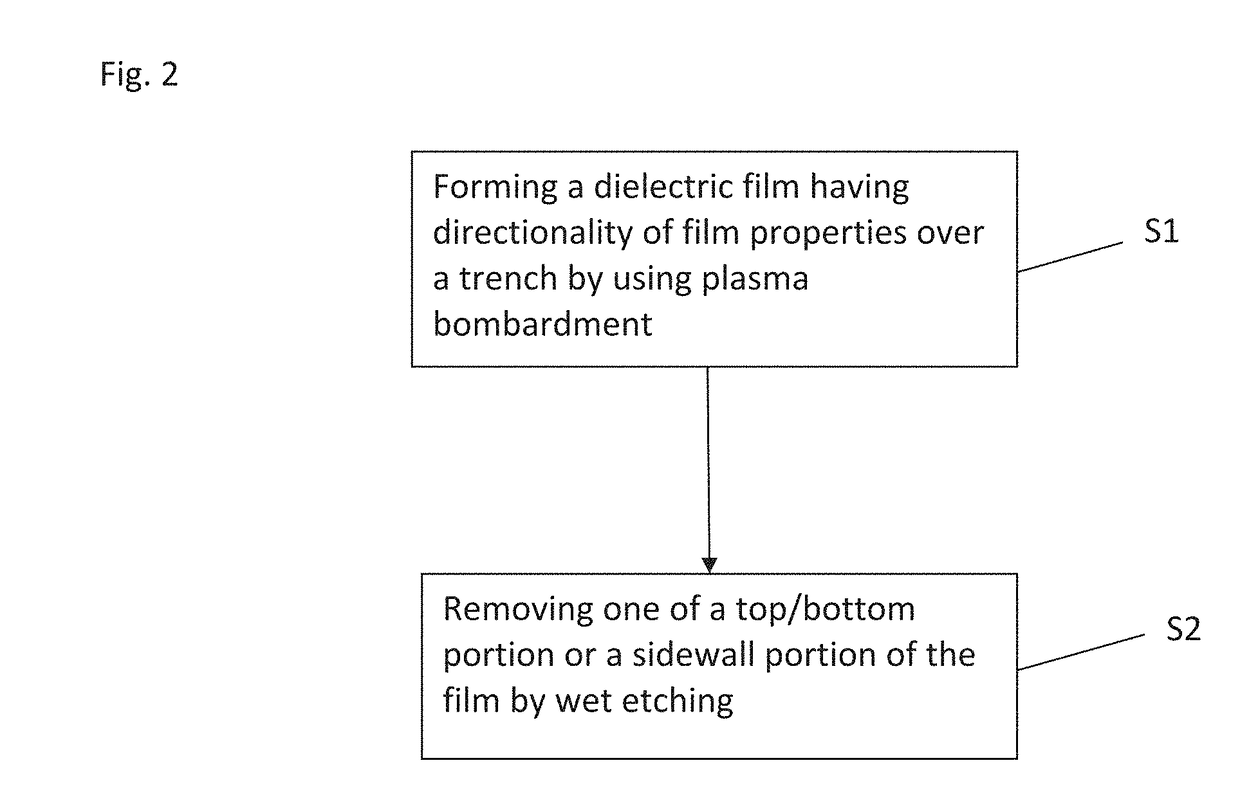

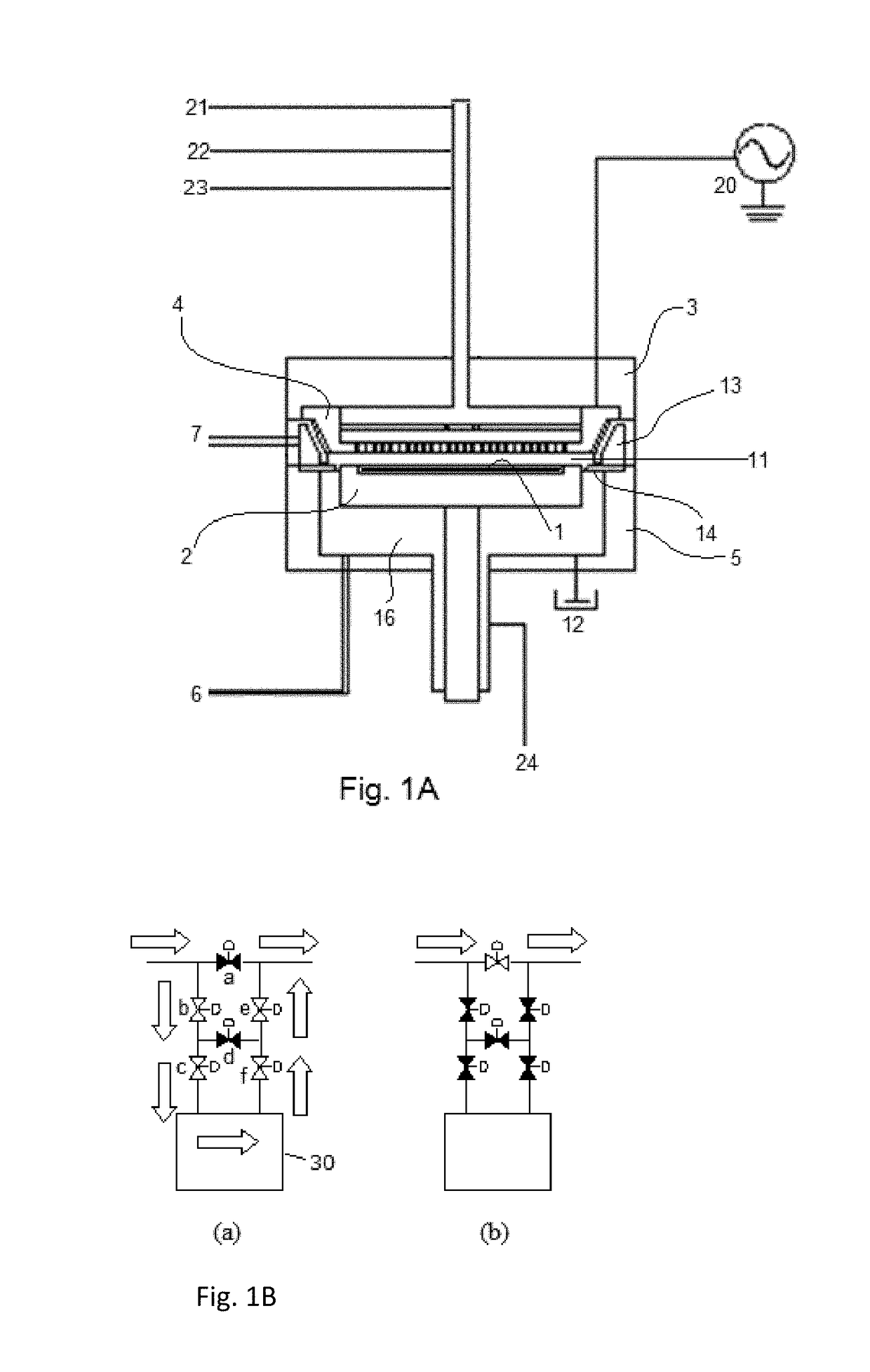

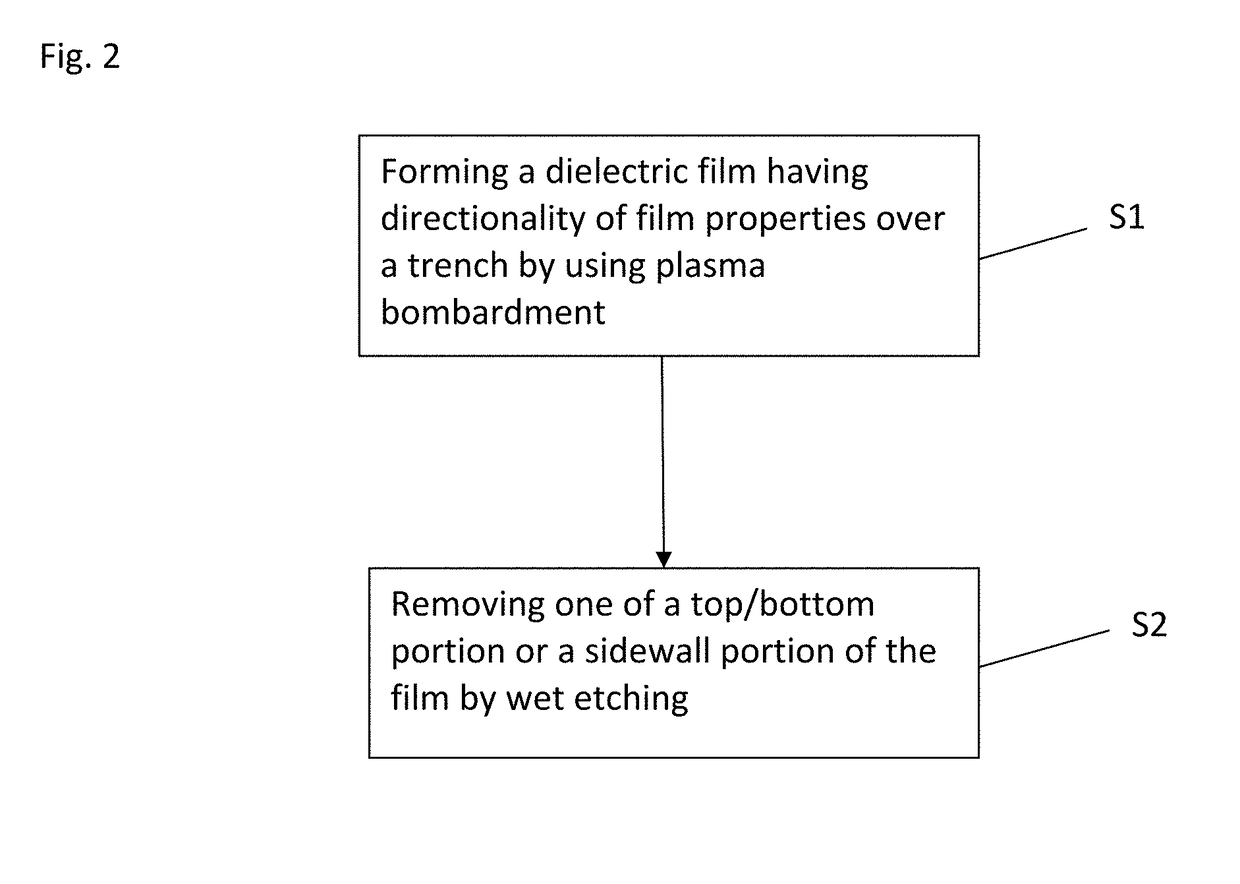

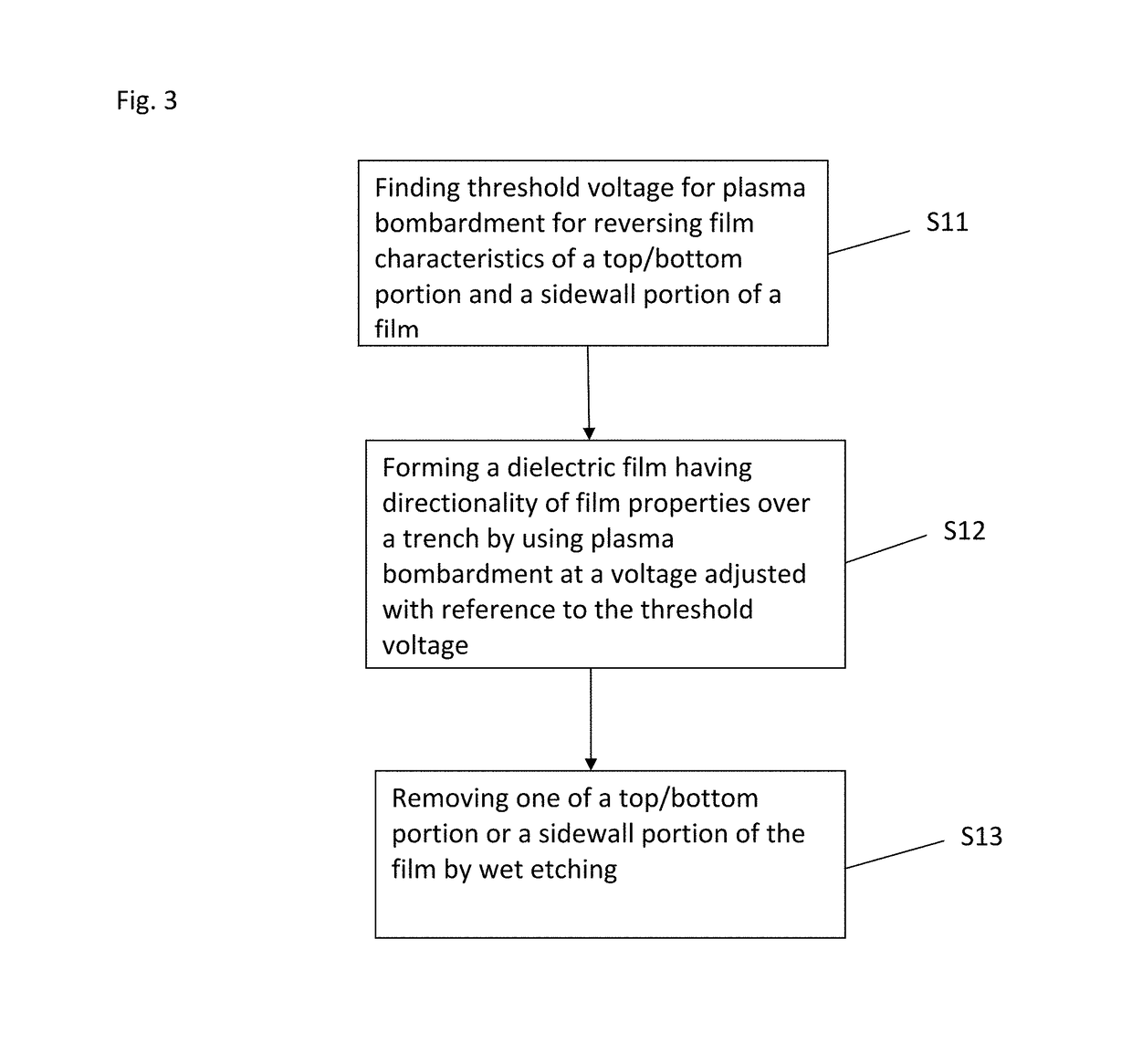

Method for forming silicon nitride film selectively on sidewalls or flat surfaces of trenches

ActiveUS20170243734A1Improve film qualityDecreasing density of filmElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingChemical resistance

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing either one of but not both of the top / bottom portion and the sidewall portion of the film by wet etching which removes the one of the top / bottom portion and the sidewall portion of the film more predominantly than the other according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

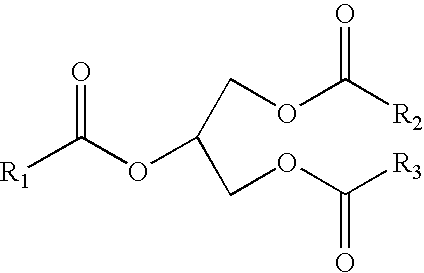

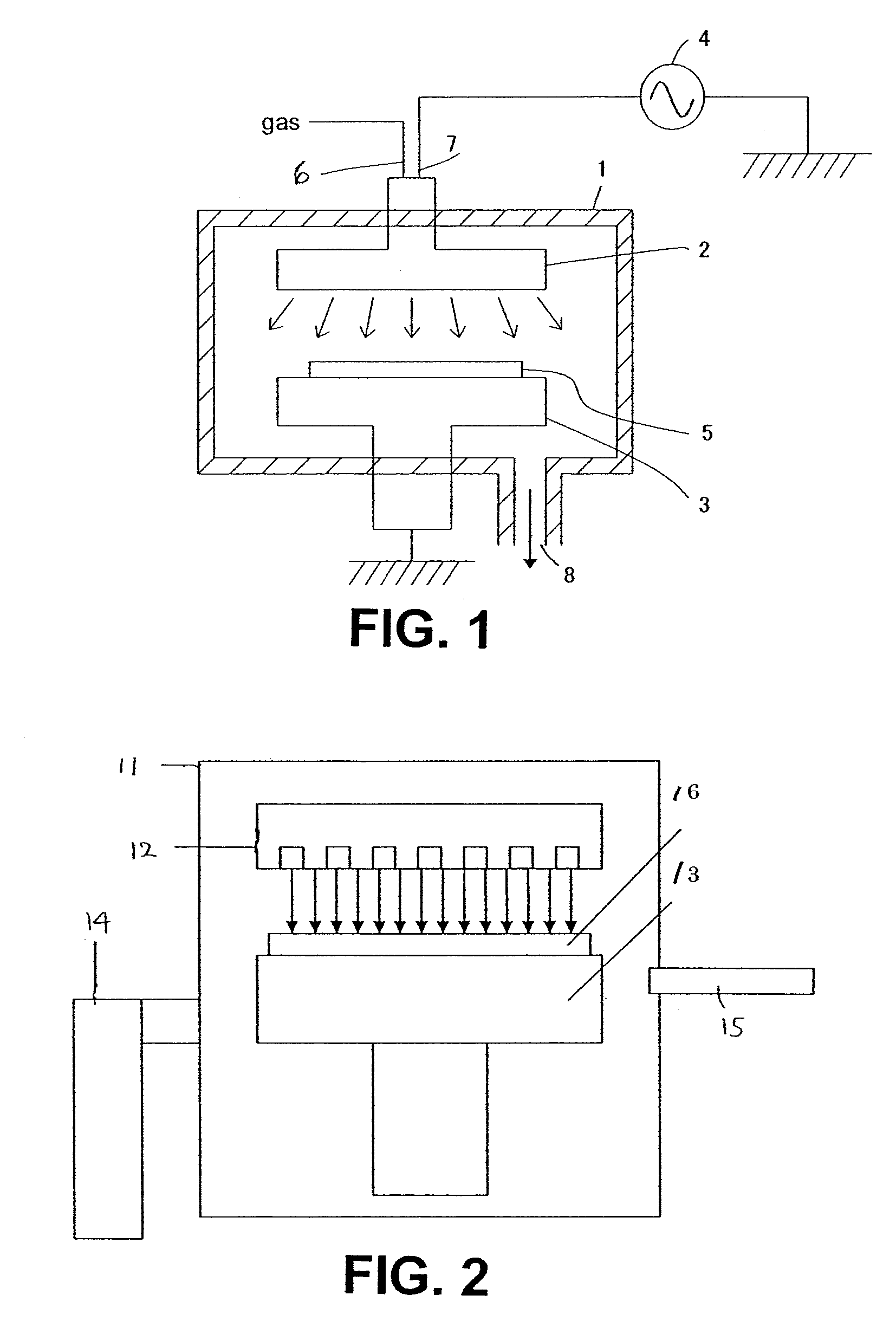

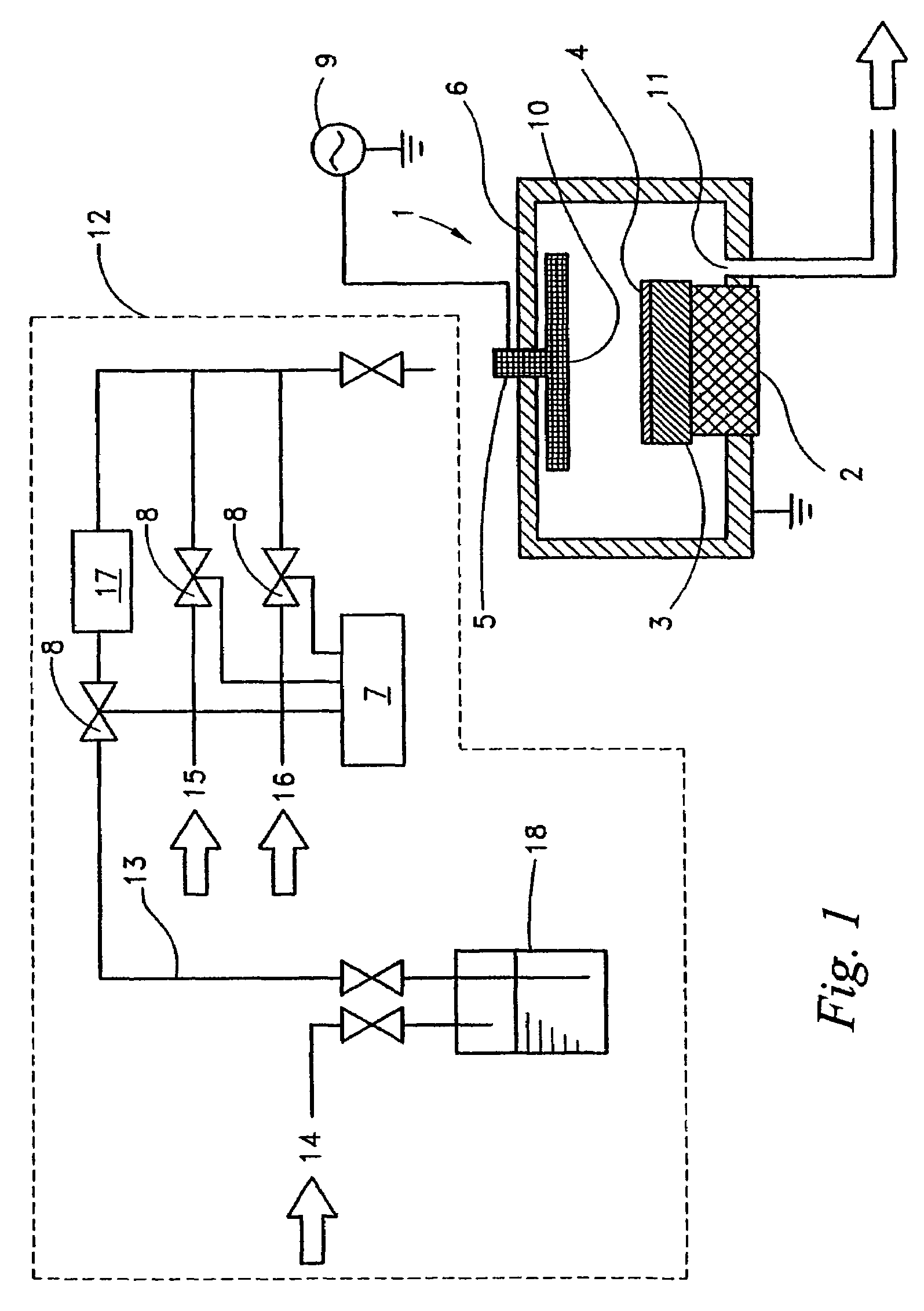

Method for forming insulation film

InactiveUS7354873B2Reduce distanceGood film densitySolid-state devicesSemiconductor/solid-state device manufacturingPlasma reactionResidence time

A method for forming an insulation film having filling property on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, O, H, and optionally C or N on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

Method for forming silicon nitride film selectively on sidewalls or flat surfaces of trenches

ActiveUS20170250068A1Improve film qualityDecreasing density of filmElectric discharge tubesSemiconductor/solid-state device manufacturingSilicon nitrideEtching

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing either one of but not both of the top / bottom portion and the sidewall portion of the film by wet etching which removes the one of the top / bottom portion and the sidewall portion of the film more predominantly than the other according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

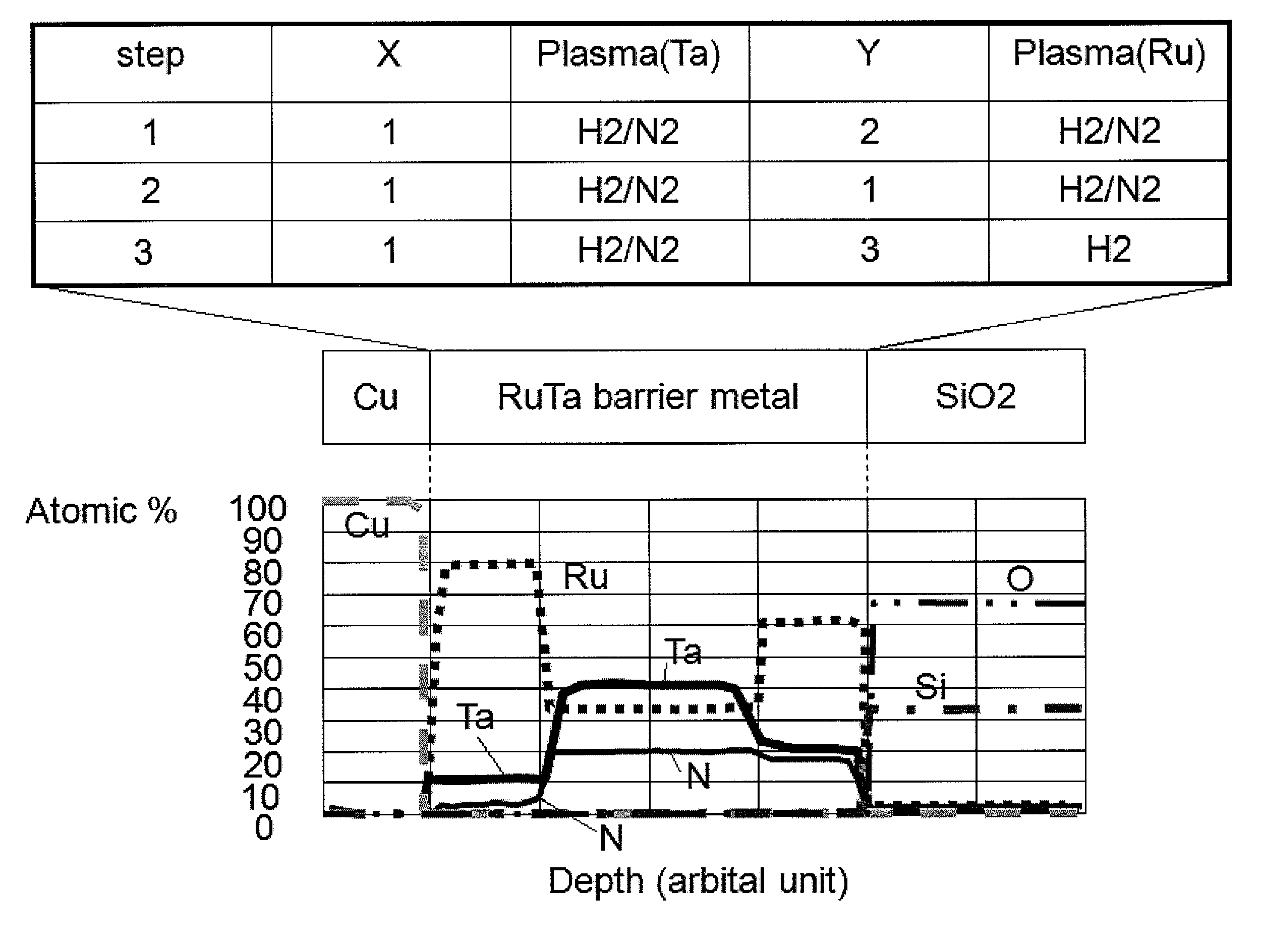

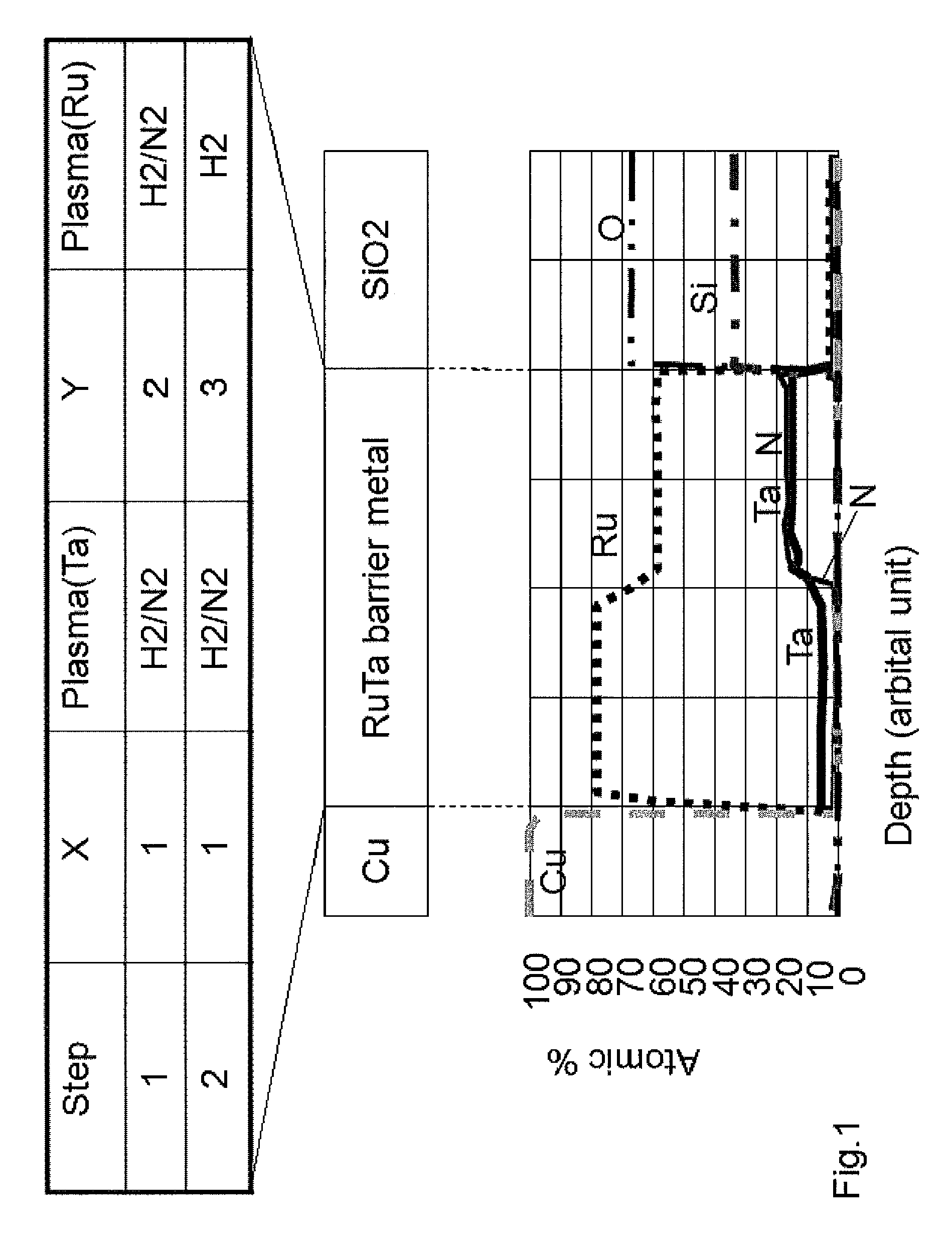

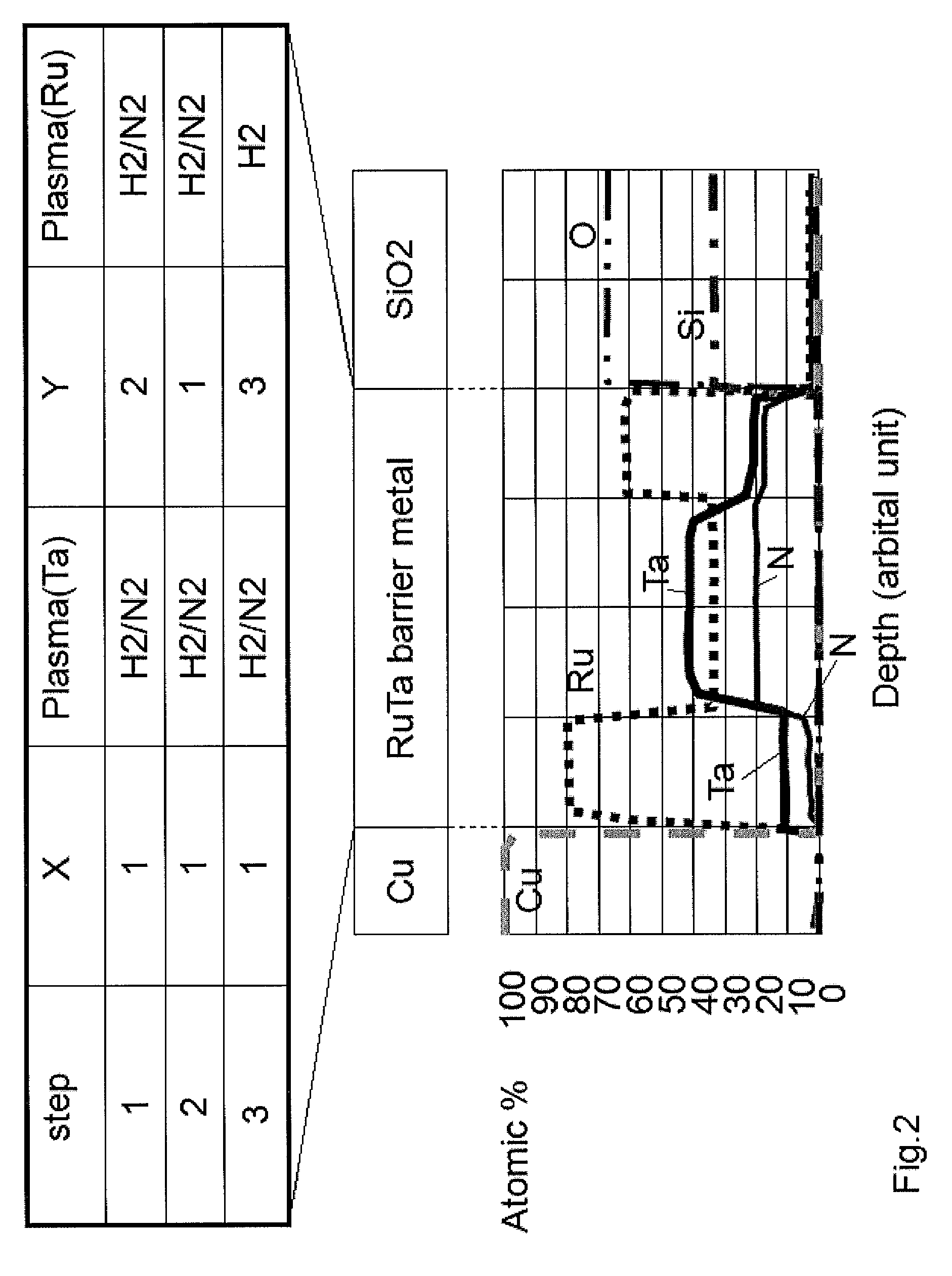

Atomic composition controlled ruthenium alloy film formed by plasma-enhanced atomic layer deposition

ActiveUS8084104B2Reduce resistanceLow densitySemiconductor/solid-state device detailsSynthetic resin layered productsRutheniumAlloy

A metal film composed of multiple atomic layers continuously formed by atomic layer deposition of Ru and Ta or Ti includes at least a top section and a bottom section, wherein an atomic composition of Ru, Ta or Ti, and N varies in a thickness direction of the metal film. The atomic composition of Ru, Ta or Ti, and N in the top section is represented as Ru(x1)Ta / Ti(y1)N(z1) wherein an atomic ratio of Ru(x1) / (Ta / Ti(y1)) is no less than 15, and z1 is 0.05 or less. The atomic composition of Ru, Ta or Ti, and N in the bottom section is represented as Ru(x2)Ta / Ti(y2)N(z2) wherein an atomic ratio of Ru(x2) / (Ta / Ti(y2)) is more than zero but less than 15, and z2 is 0.10 or greater.

Owner:ASM JAPAN

Method for forming silicon nitride film selectively on sidewalls or flat surfaces of trenches

ActiveUS9754779B1Low densityPlasma-enhanced chemical vapor depositionElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingChemical resistance

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing either one of but not both of the top / bottom portion and the sidewall portion of the film by wet etching which removes the one of the top / bottom portion and the sidewall portion of the film more predominantly than the other according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

Method for forming an interface between germanium and other materials

InactiveUS20060099782A1Improved carrier mobilityHinder germanium oxide formationSemiconductor/solid-state device manufacturingSemiconductor devicesIntegrated circuitSemiconductor structure

Interfaces that are portions of semiconductor structures used in integrated circuits and optoelectronic devices are described. In one instance, the semiconductor structure has an interface including a semiconductor surface, an interfacial layer including sulfur, and an electrically active layer (e.g., a dielectric or a metal). Such an interface can inhibit oxidation and improve the carrier mobility of the semiconductor structures in which such an interface is incorporated. The interfacial layer can be created by exposure of the semiconductor surface to sulfur donating compounds (e.g., H2S or SF6) and, optionally, heating.

Owner:MASSACHUSETTS INST OF TECH

Multiple temperature range susceptor, assembly, reactor and system including the susceptor, and methods of using the same

ActiveUS20160097123A1Facilitate rapid provisionHigh materialLiquid surface applicatorsChemical vapor deposition coatingAirflowEngineering

Susceptor assemblies, reactors and systems including the assemblies, and methods of using the assemblies, reactors, and systems are disclosed. Exemplary susceptor assemblies include two or more sections that can be moved relative to each other to allow rapid changes in a substrate temperature. The movement of the two or more sections can additionally or alternatively be used to manipulate conductance of gas flow though a reactor.

Owner:ASM IP HLDG BV

Method for forming insulation film

InactiveUS7582575B2Reduce trafficReduce volumeSolid-state devicesSemiconductor/solid-state device manufacturingPlasma reactionResidence time

A method for forming an insulation film on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, C, O, and H on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

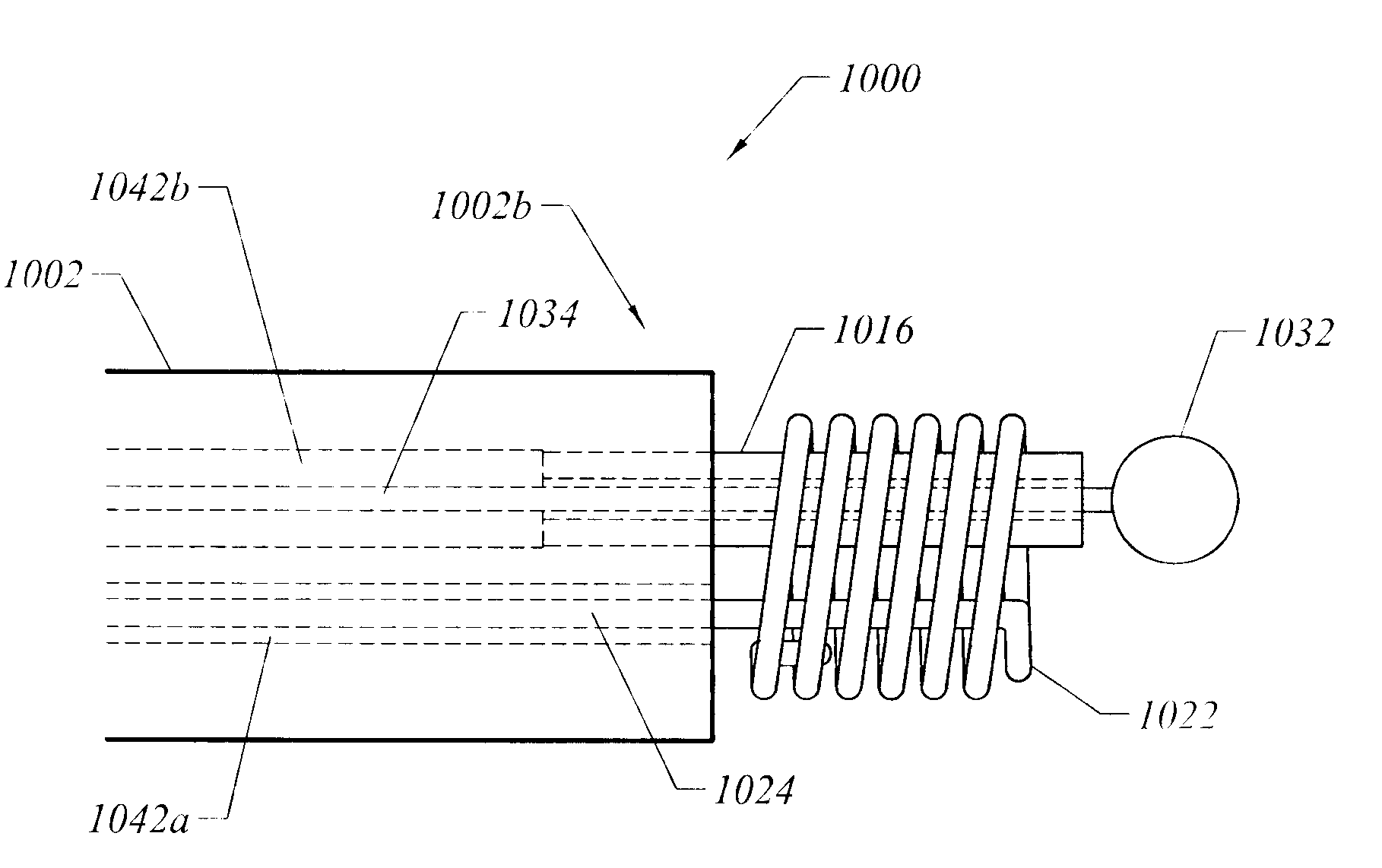

Electrosurgical apparatus and methods for treatment and removal of tissue

InactiveUS7186234B2Promote wettingReduce the possibilitySurgical instruments for heatingActive electrodeTarget tissue

Apparatus and methods for ablating, severing, cutting, shrinking, coagulating, or otherwise modifying a target tissue to be treated. In a method for treating a target tissue, an active electrode of an electrosurgical probe is positioned in at least close proximity to the target tissue in the presence of an electrically conductive fluid. A high frequency voltage is then applied between the active electrode and a return electrode, wherein, the high frequency voltage is sufficient to volumetrically remove (ablate), sever, or modify at least a portion of the target tissue. The probe comprises a multi-lumen shaft having a plurality of internal lumens, and a return electrode coil oriented substantially parallel to the shaft distal end. The active electrode may be in the form of a metal disc, a hook, or an active electrode coil. In the latter embodiment, the active electrode coil is typically arranged substantially orthogonal to the return electrode coil. Methods of making an active electrode coil, a return electrode coil, and an electrosurgical probe are also disclosed.

Owner:ARTHROCARE

Process for producing a hydrocarbon component of biological origin

ActiveUS7232935B2Improve performanceLow densityHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionIsomerizationHydrocarbon

The invention relates to a process for producing a hydrocarbon component of biological origin. The process comprises at least two steps, the first one of which is a HDO step and the second one is an isomerization step operated using the counter-current flow principle. A biological raw material containing fatty acids and / or fatty acid esters serves as the feed stock.

Owner:OYJ NESTE OIL +1

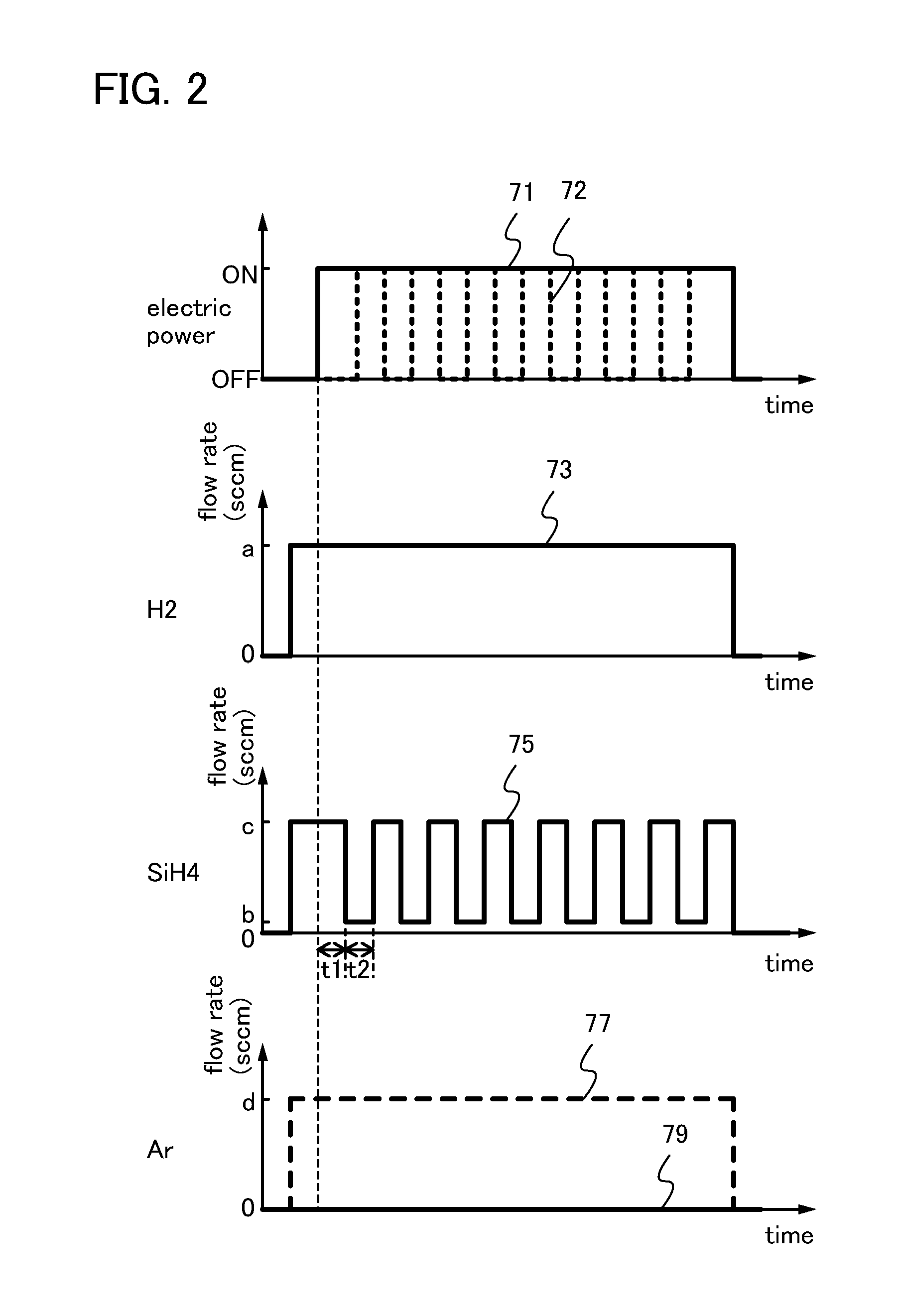

Method for manufacturing semiconductor device

InactiveUS20110318888A1High crystallinityExcellent electrical propertiesSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenEngineering

A method for manufacturing a semiconductor device comprises the steps of forming a seed over the insulating film by introducing hydrogen and a deposition gas into a first treatment chamber under a first condition and forming a microcrystalline semiconductor film over the seed by introducing hydrogen and the deposition gas into a second treatment chamber under a second condition: a second flow rate of the deposition gas is periodically changed between a first value and a second value; and a second pressure in the second treatment chamber is higher than or equal to 1.0×102 Torr and lower than or equal to 1.0×103 Torr.

Owner:SEMICON ENERGY LAB CO LTD

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS20020048676A1Point becomes highImprove interfacial organic-inorganic adhesionPigmenting treatmentDead plant preservationFiltrationArtificial turf

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

Method for forming silicon nitride film selectively on sidewalls of trenches

ActiveUS20190057857A1Low densityPlasma-enhanced chemical vapor depositionElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingChemical resistance

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing the sidewall portion of the film by wet etching which removes the sidewall portion of the film more predominantly than the top / bottom portion according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com