Patents

Literature

10630results about How to "Relieve stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

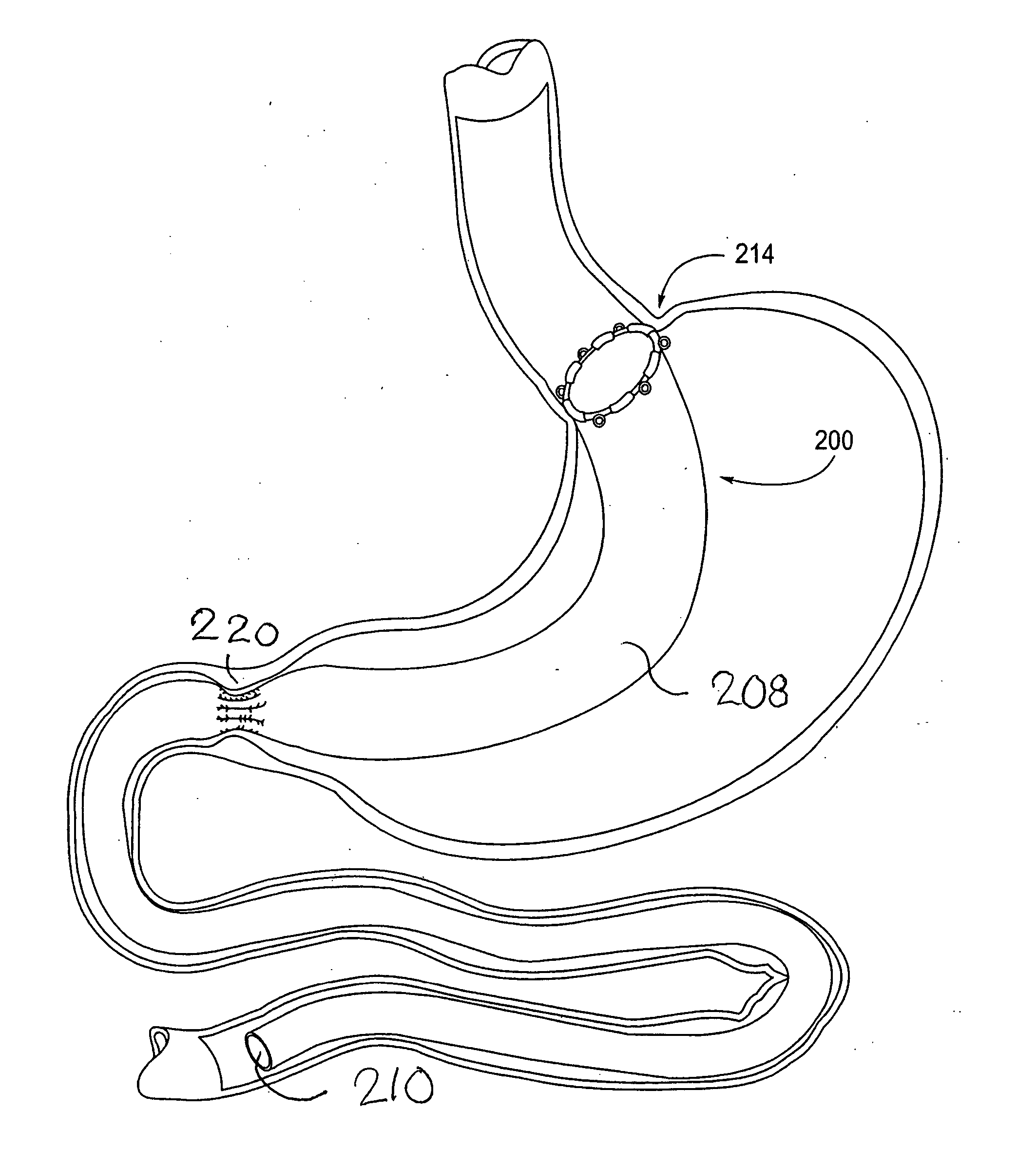

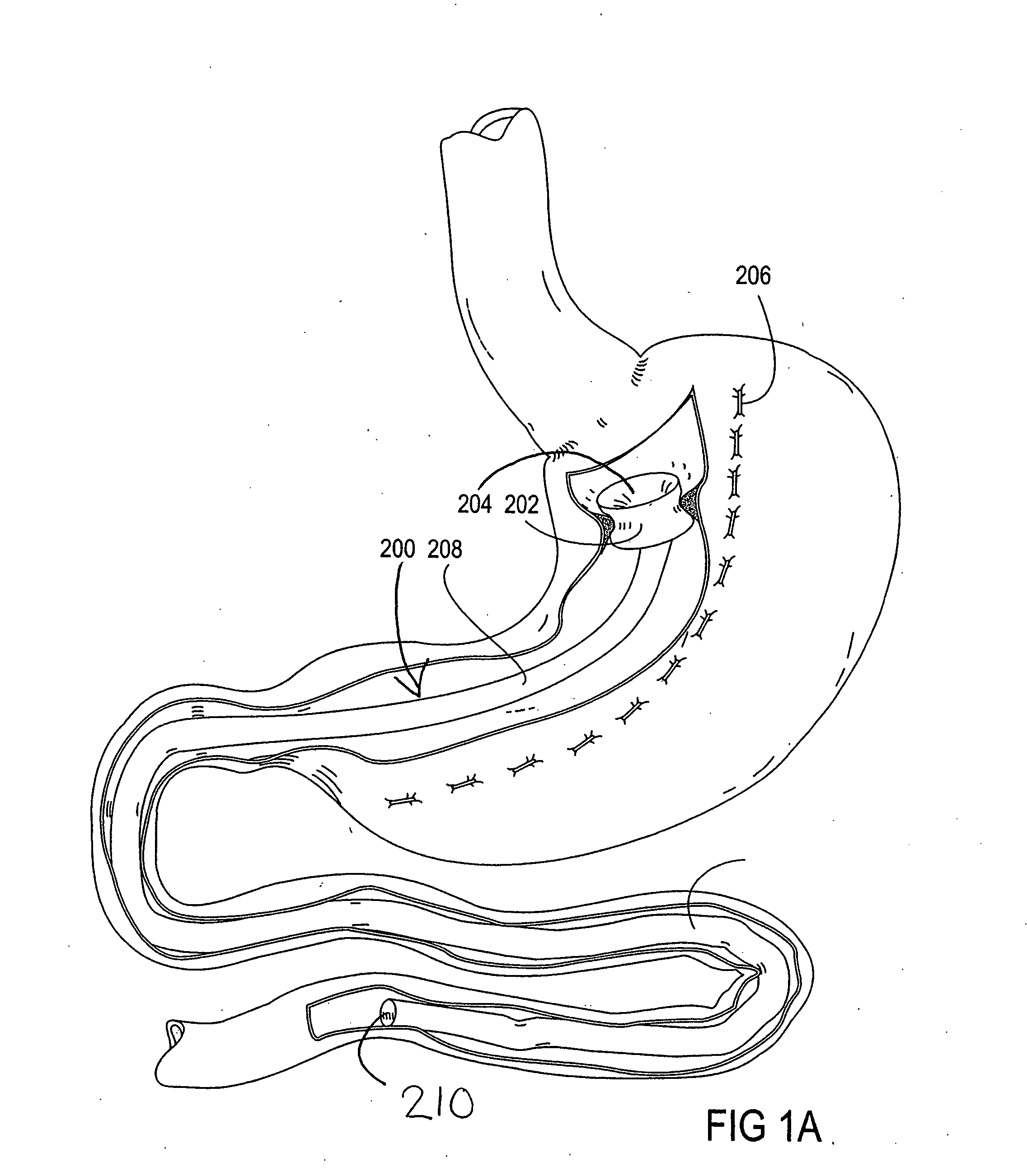

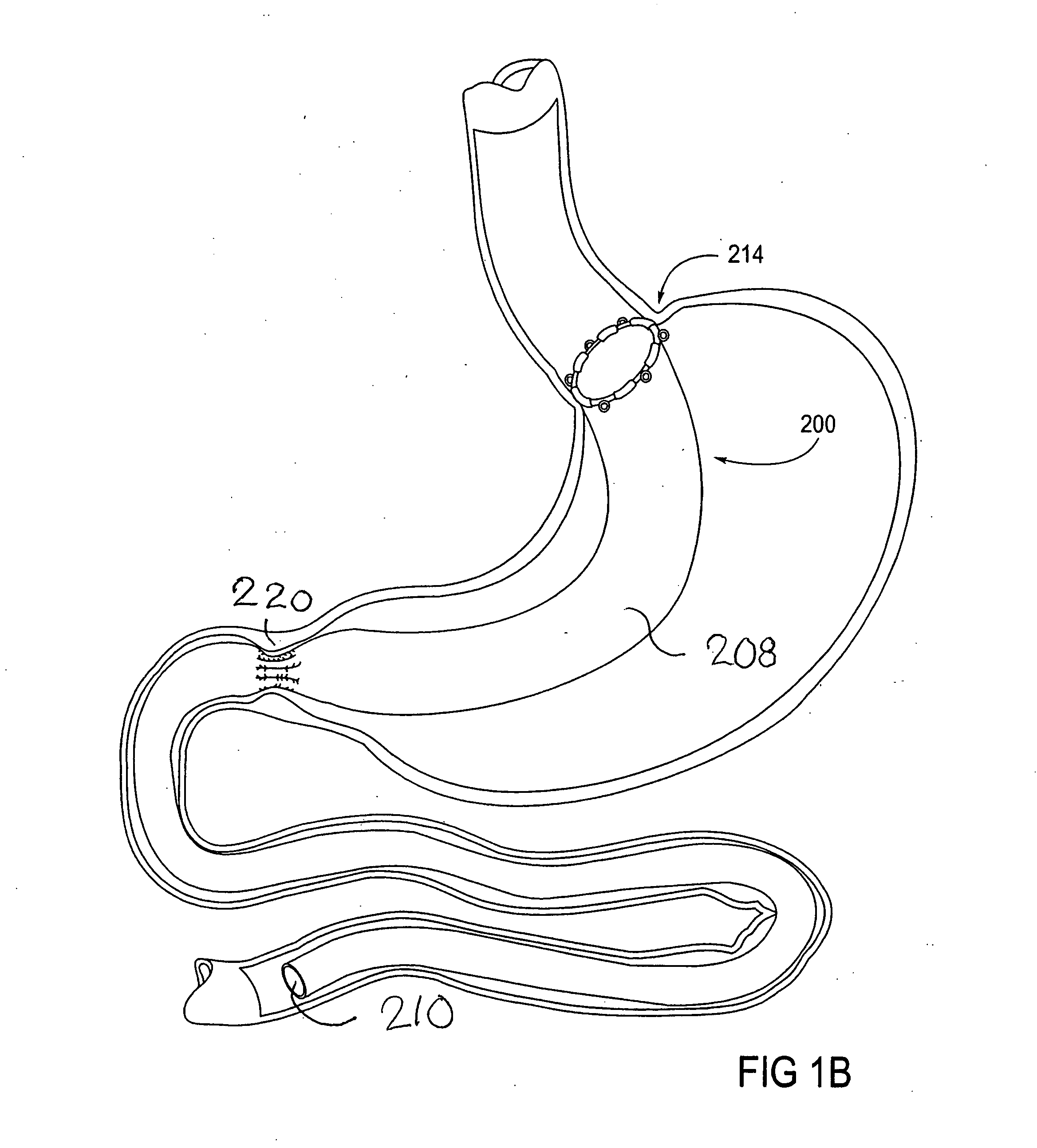

Devices and methods for treating morbid obesity

The present invention provides devices and methods for attachment of an implanted device, such as an artificial stoma device, a gastrointestinal sleeve device or an attachment cuff, within a patient's digestive tract for treatment of obesity. Special surgical fasteners provide a lasting and durable attachment to the gastrointestinal tissue without causing excessive pressure that could result in tissue erosion and detachment of the implanted device. Fastener delivery devices that facilitate peroral placement and deployment of fasteners and secondary devices are also provided. Also described are implantable devices and attachment means that avoid causing excessive pressure within the tissue by having compliance that is compatible with the gastrointestinal tissues where it is attached.

Owner:VALENTX

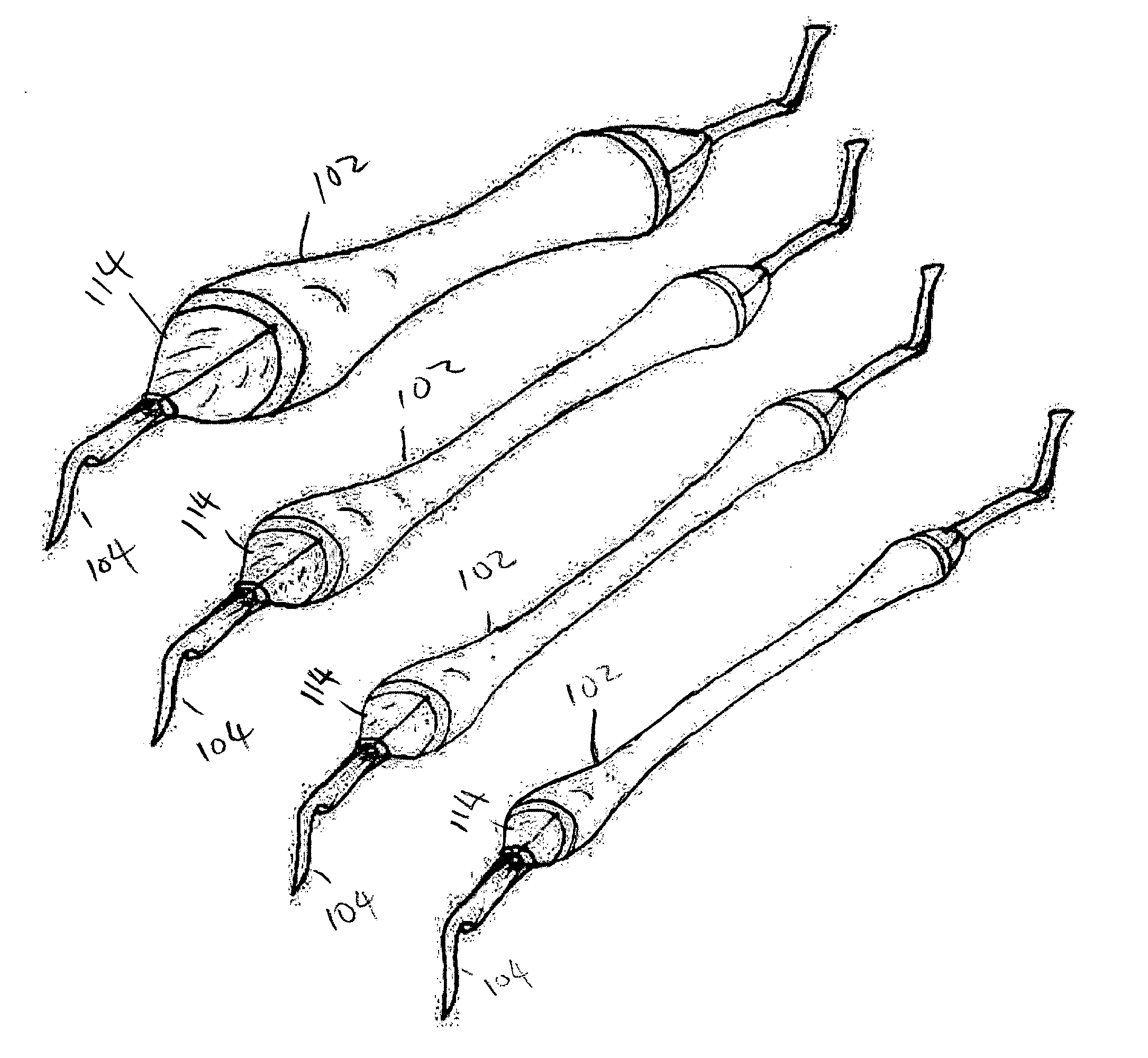

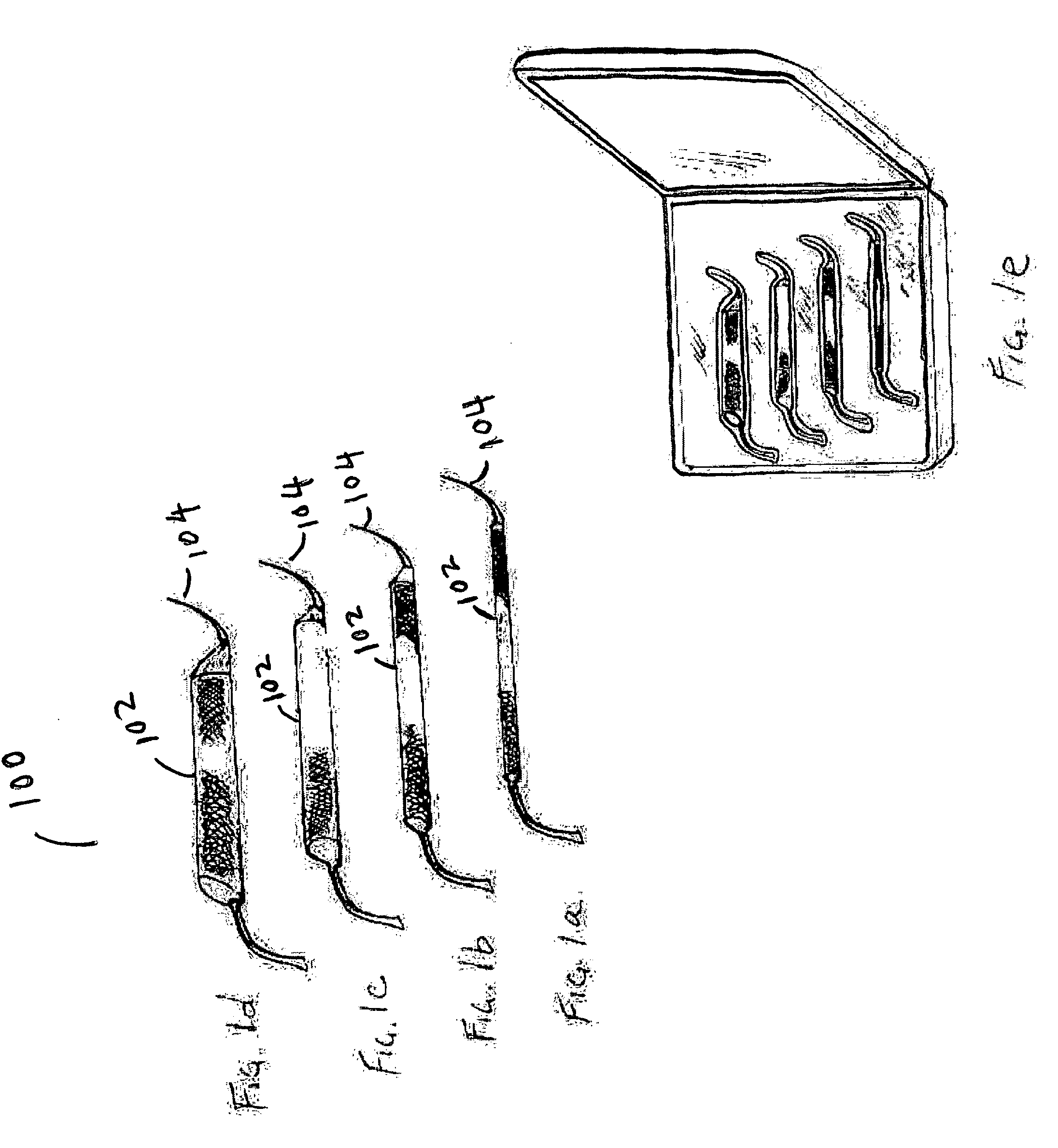

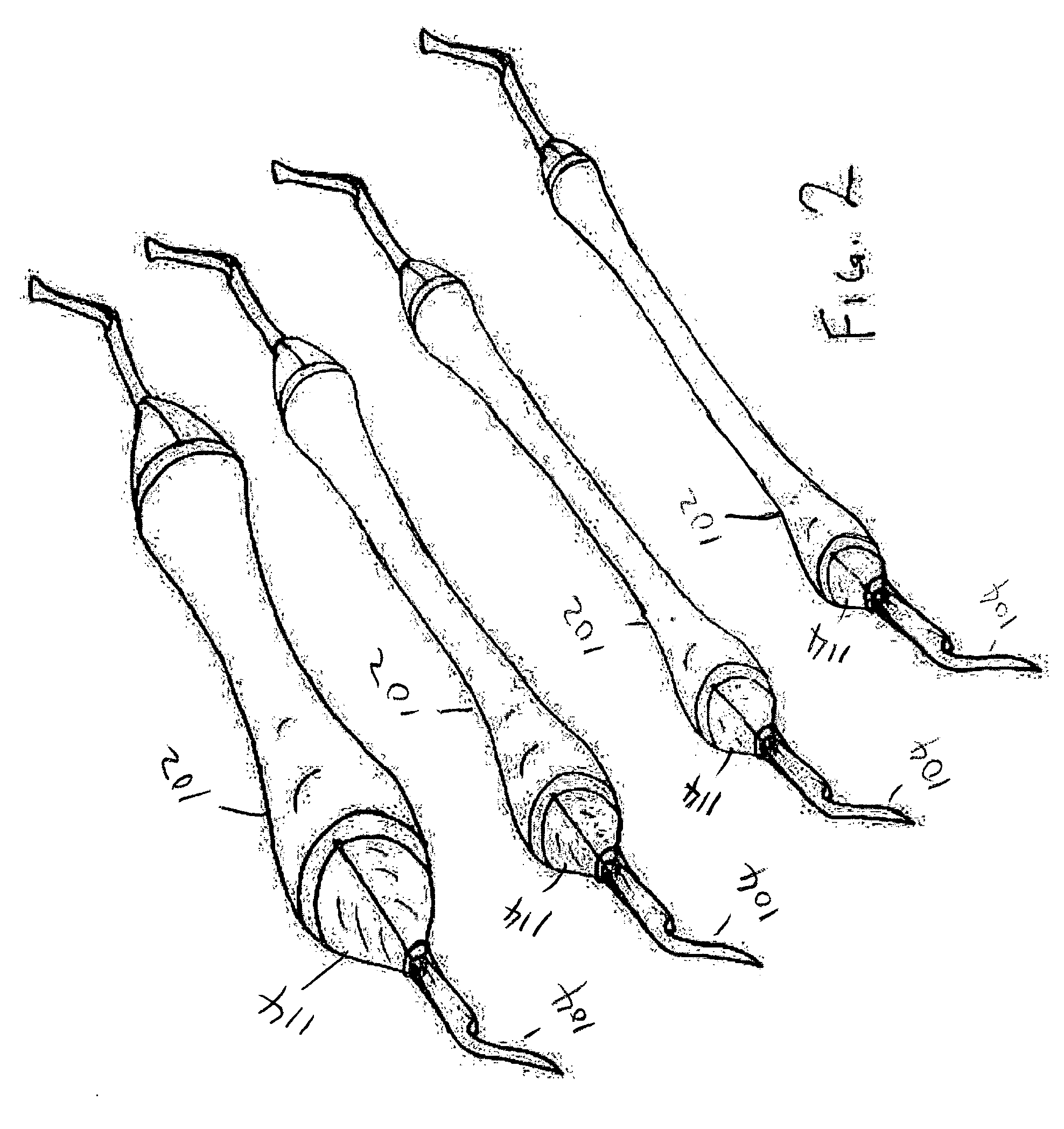

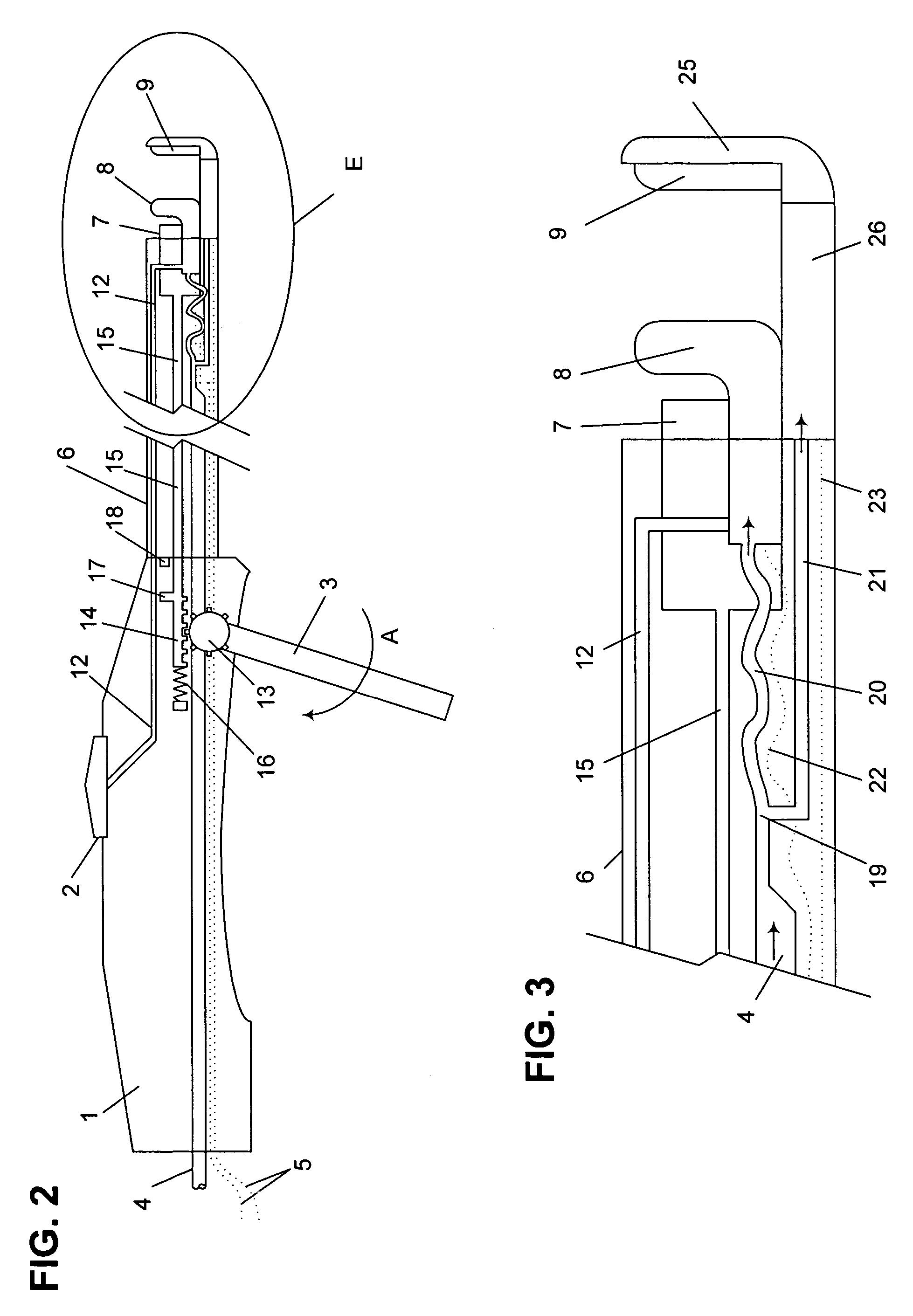

Dental instruments with stress relief

InactiveUS20060063130A1Prevent rotationRelieve pressureDental toolsTeeth cappingDental instrumentsStress relief

The present invention relates to a unique solution for relieving repetitive stress to dental professionals during the course of a day and is directed to sets of identical instruments, having handles made with varying diameters for grasping, designed to be used interchangeably throughout the day, thus cutting down on the repetitive grasping action through the change of grasp. Therefore, even if a dental professional uses the same type of instrument throughout the day, the hands, wrists and elbows can experience varying rather than repetitive action because the positioning of the hands, wrists and elbows are interchanging throughout the day. The dental instrument may also be ergonomically designed. Additionally, the instrument may also have a vibratory module. Further, a rotator may also be implemented.

Owner:DISCUS DENTAL LLC

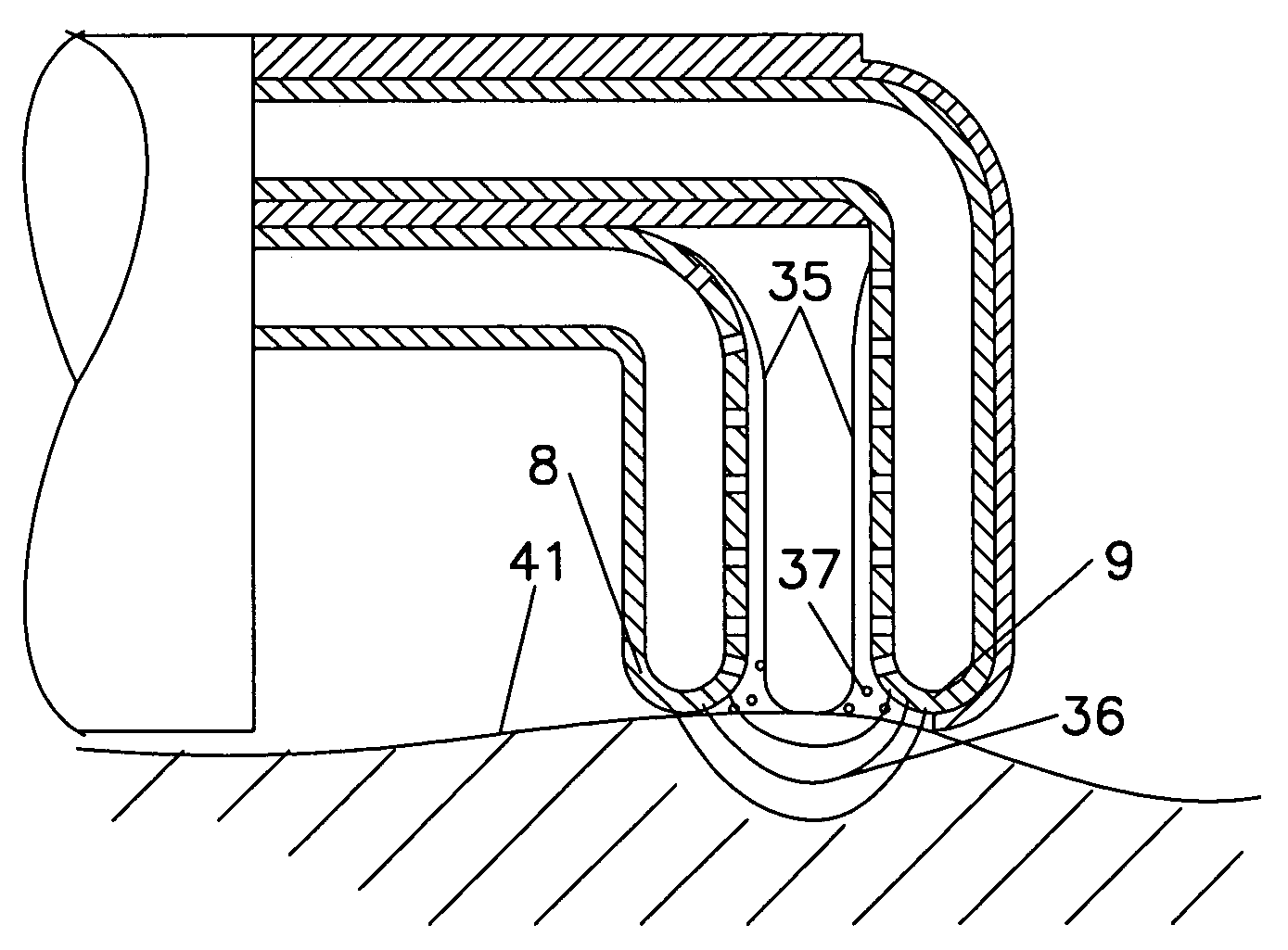

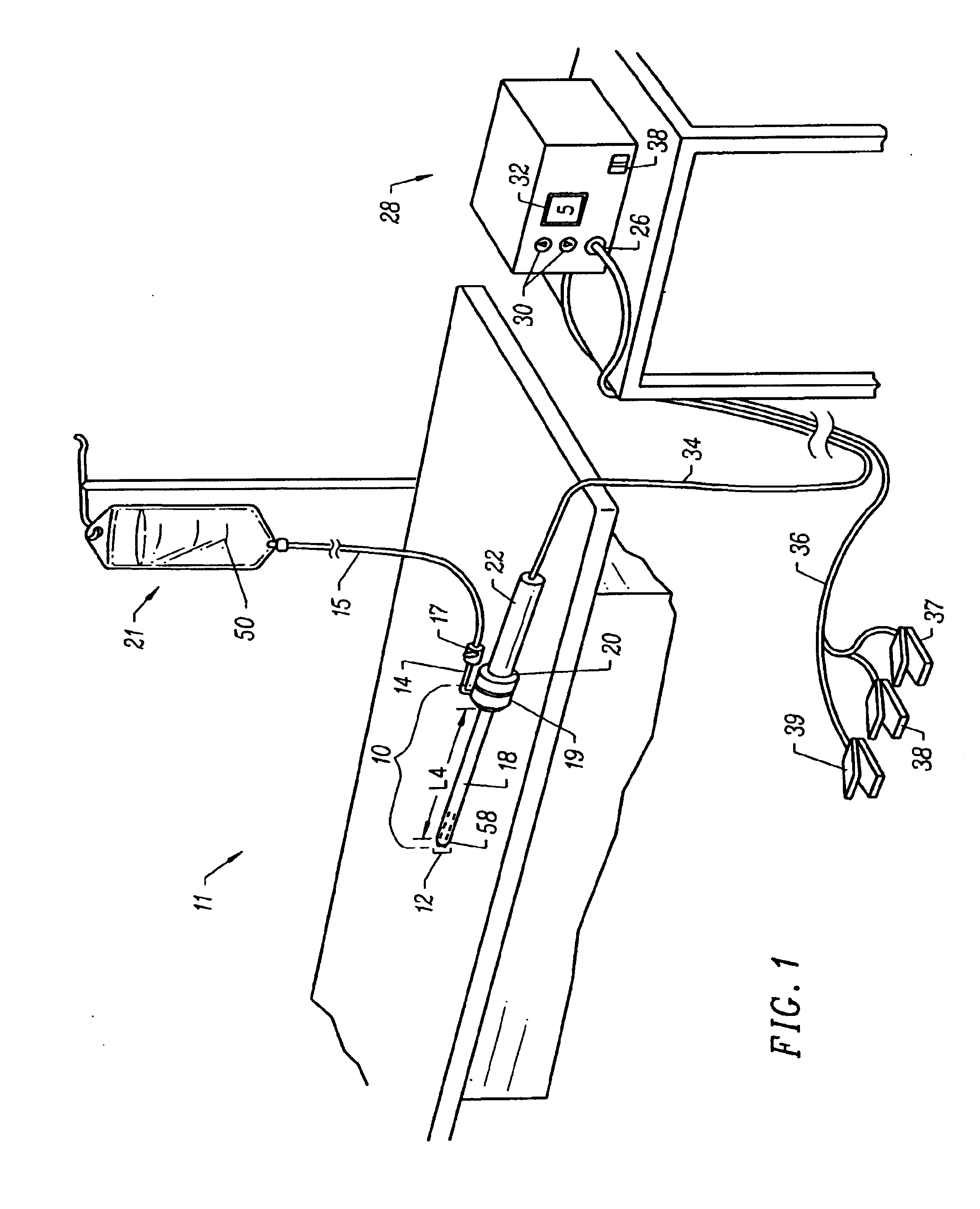

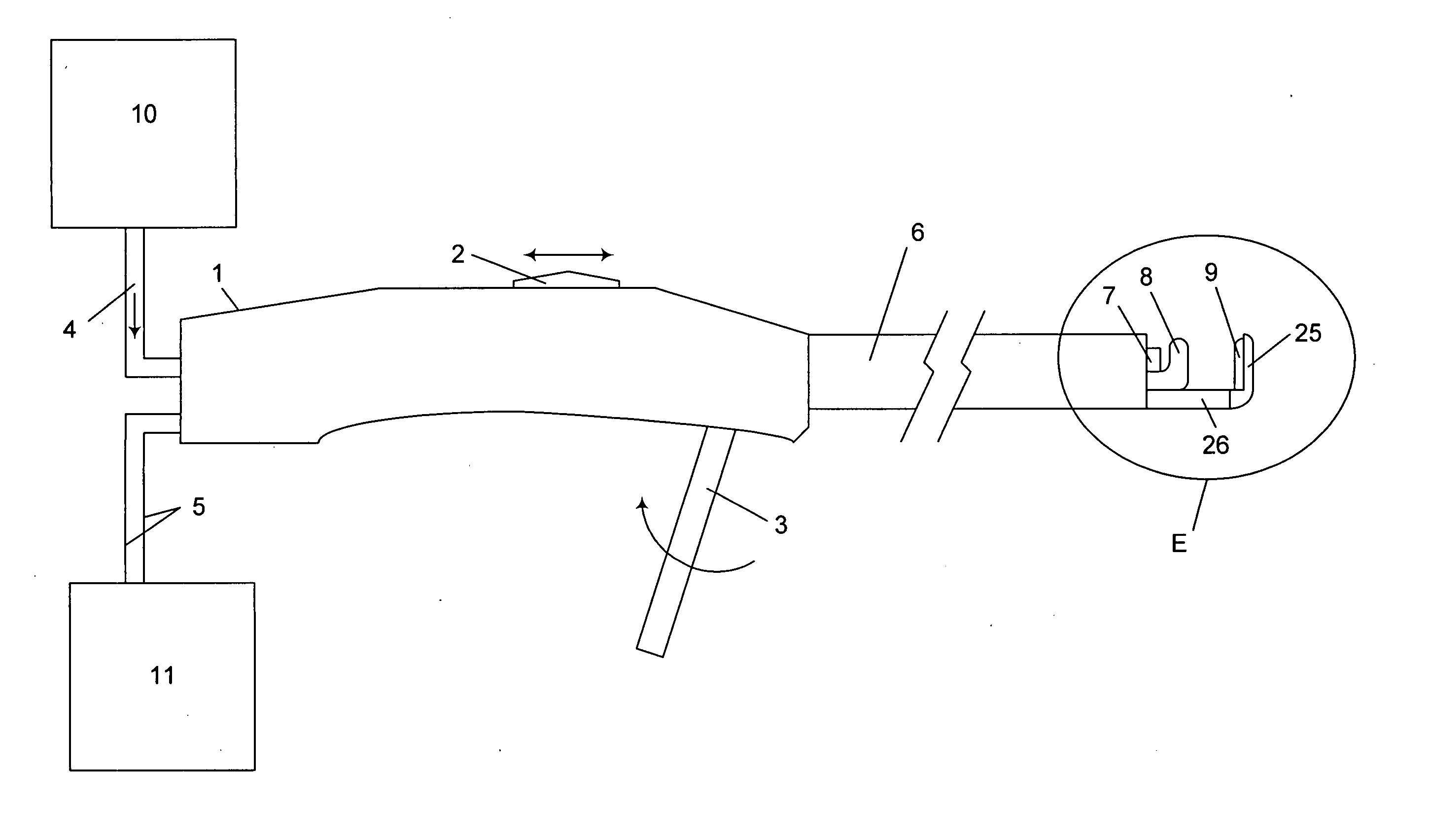

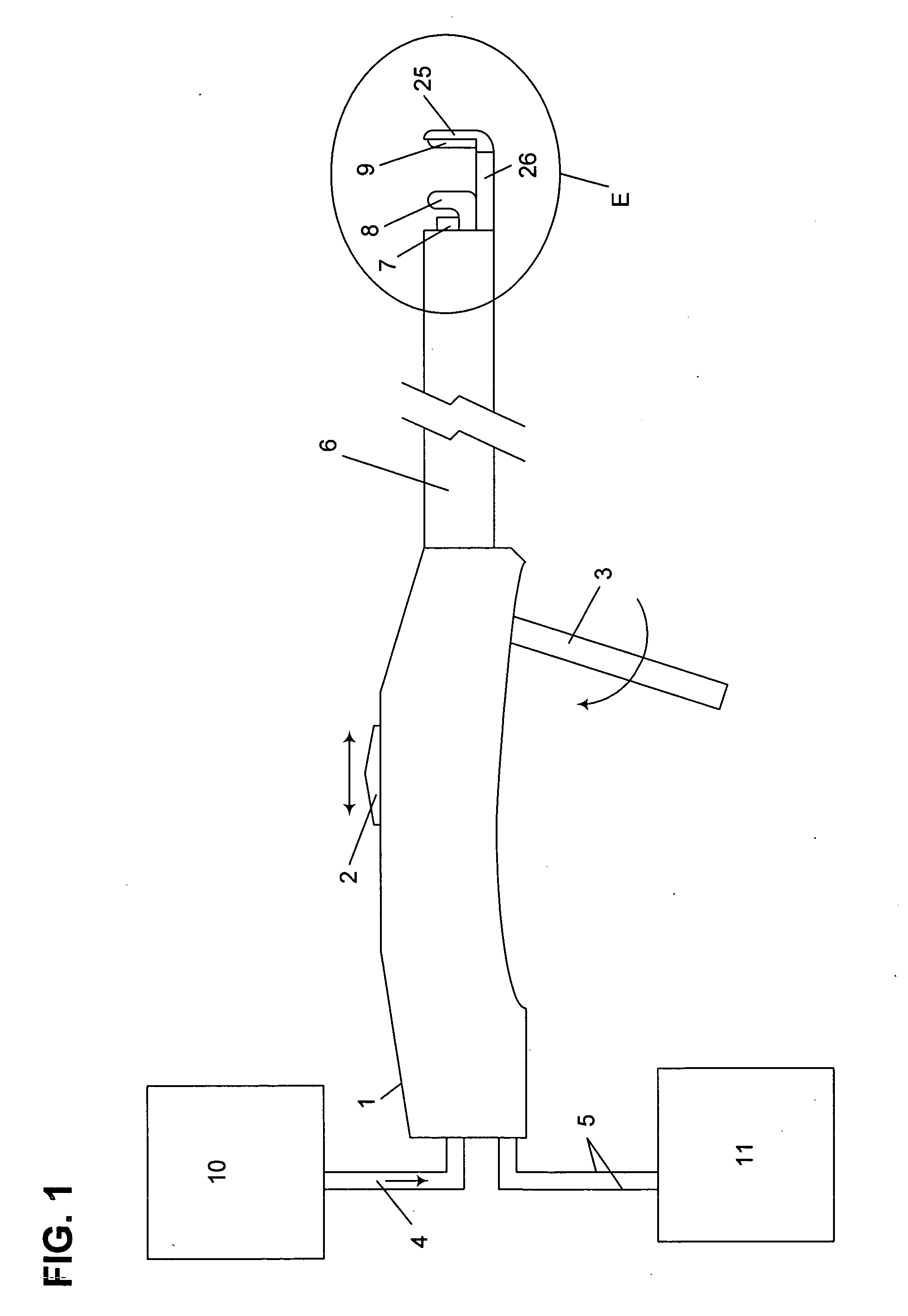

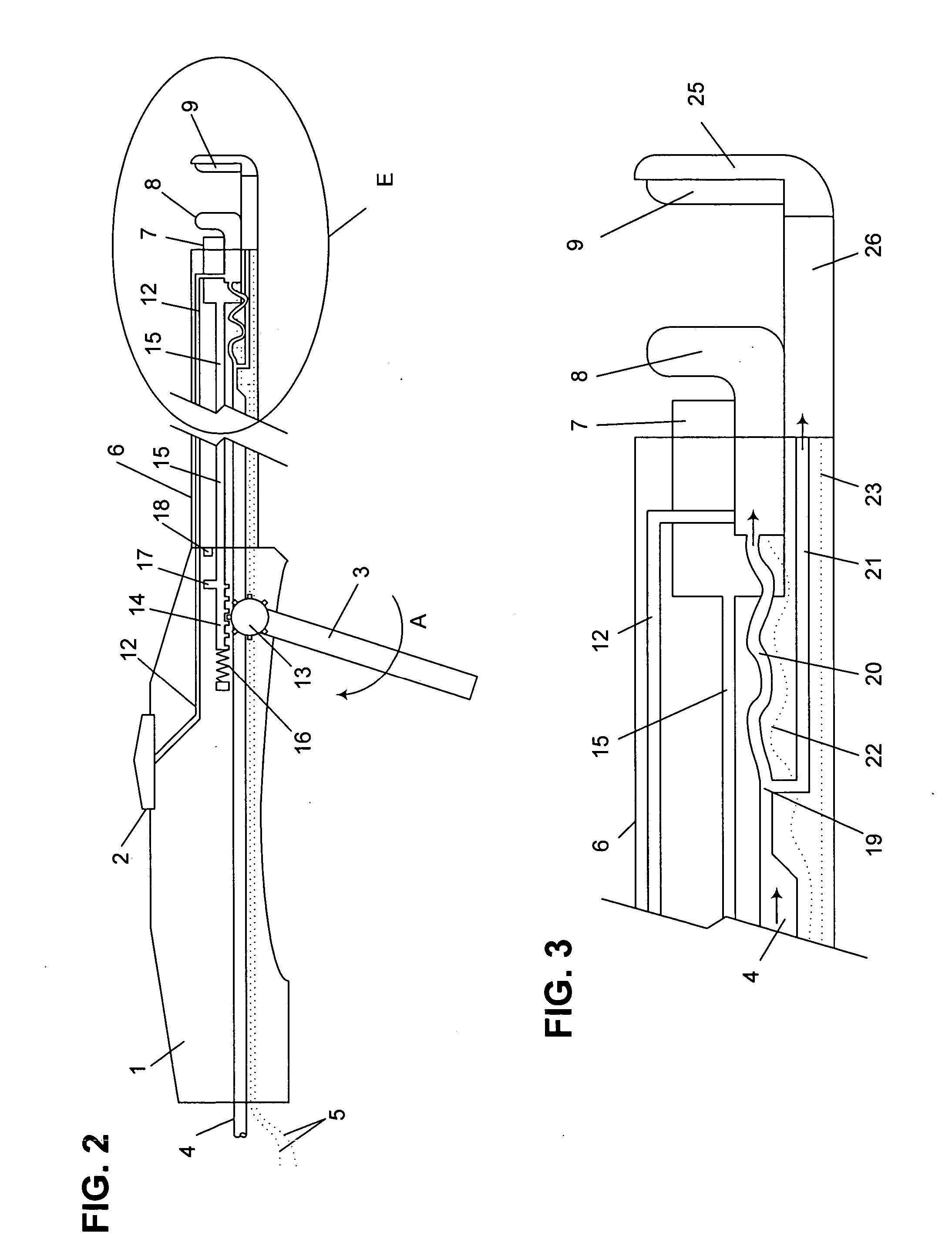

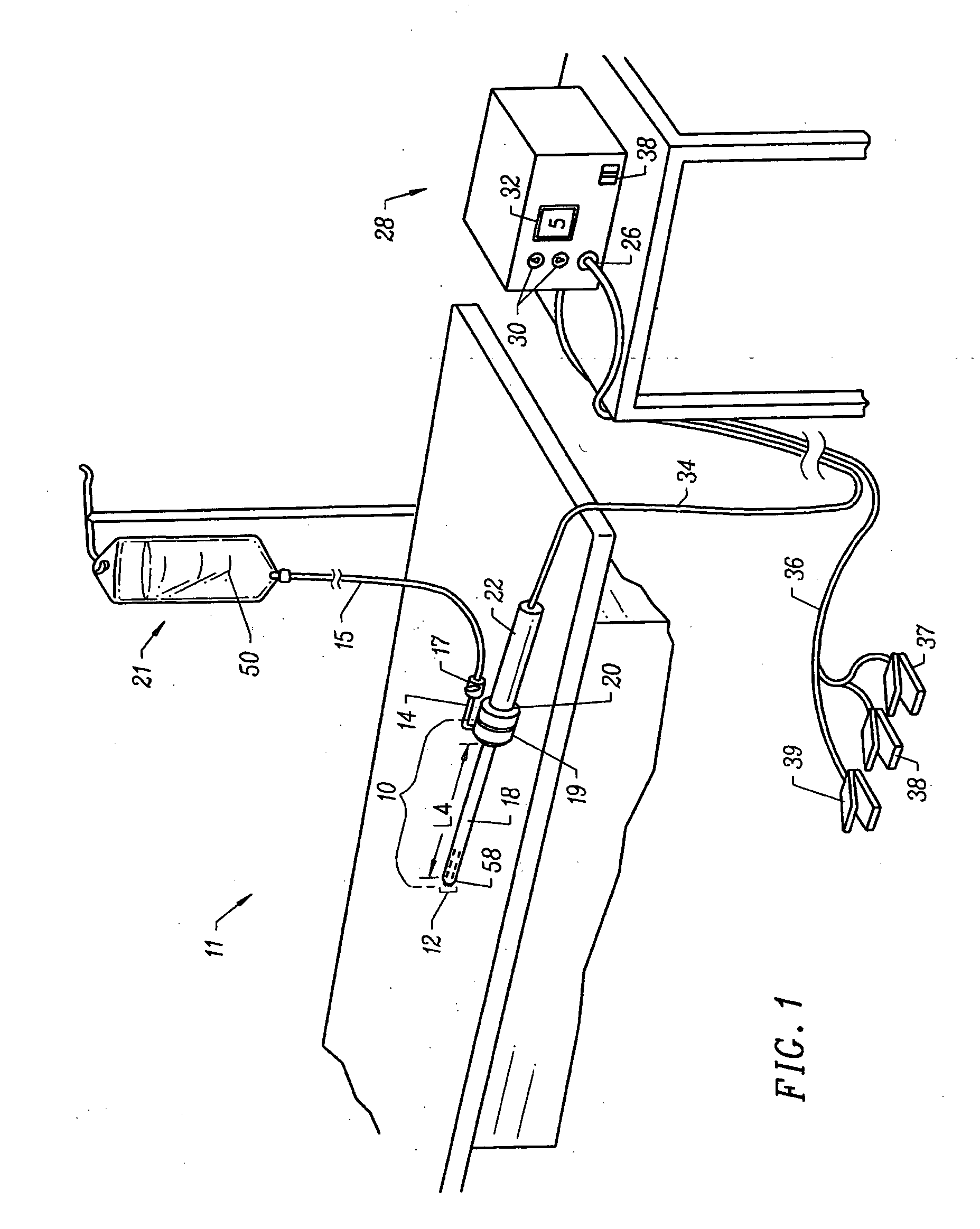

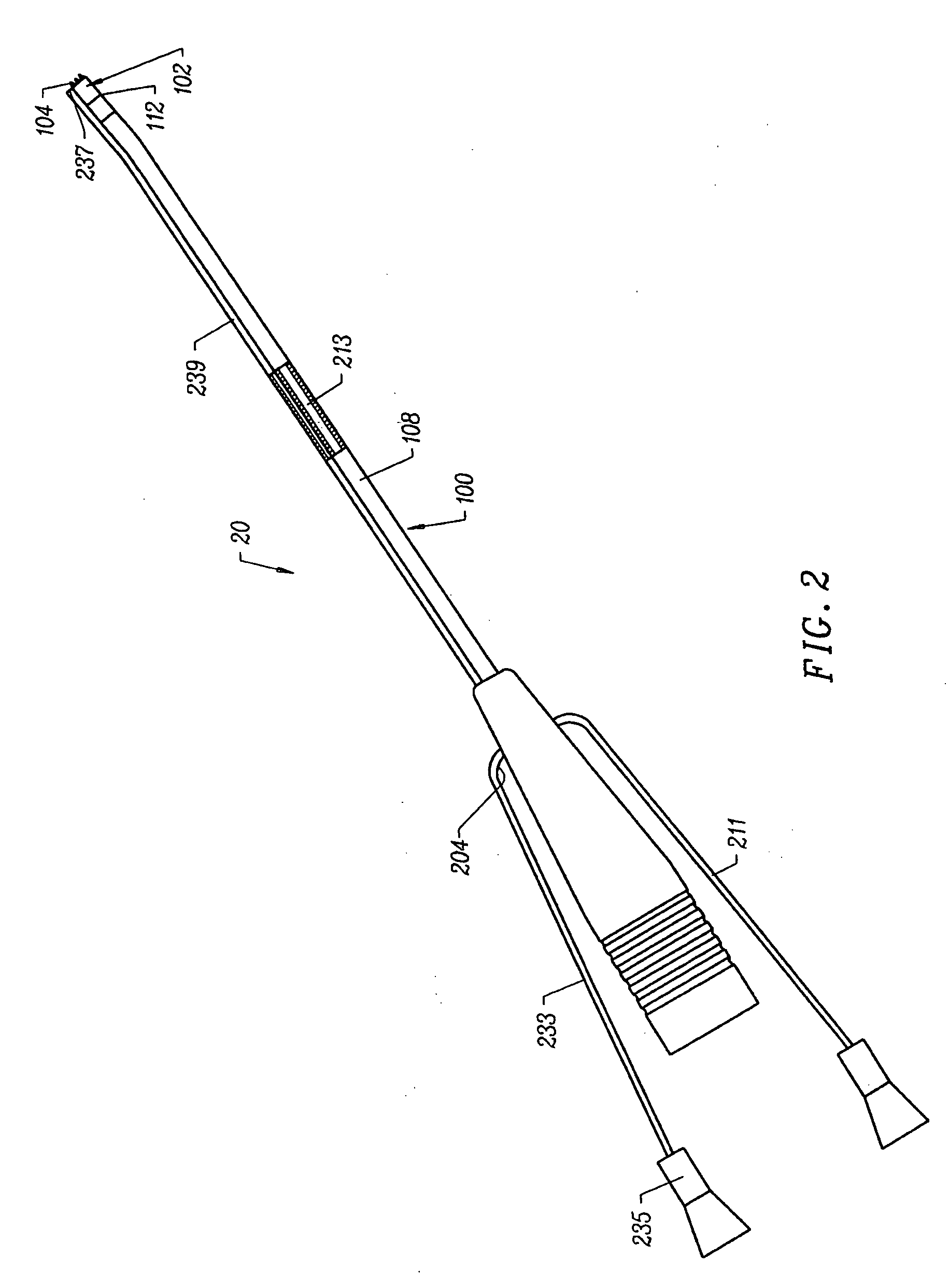

Fluid-assisted medical device

InactiveUS7645277B2Fixed spacingRelieve stressSurgical instruments for heatingSurgical forcepsMedical deviceBlood vessel

The invention provides a medical device that includes a housing, a tubular member extending from the distal end of the housing, a first arm extending from the distal end of the tubular member, the first arm including a first electrode, a second arm extending from the distal end of the tubular member, the second arm including a second electrode and being disposed coaxially with the first arm, at least one solution infusion opening on each electrode, and a solution delivery channel for delivery of a conductive solution to the solution infusion openings. According to the invention, at least one of the first arm or the second arm is translationally moveable, and at least one of the first arm or the second arm is adapted to be coupled to a source of radiofrequency energy. The invention also provides a corresponding method for treating blood vessels or other tissues of the body.

Owner:MEDTRONIC ADVANCED ENERGY

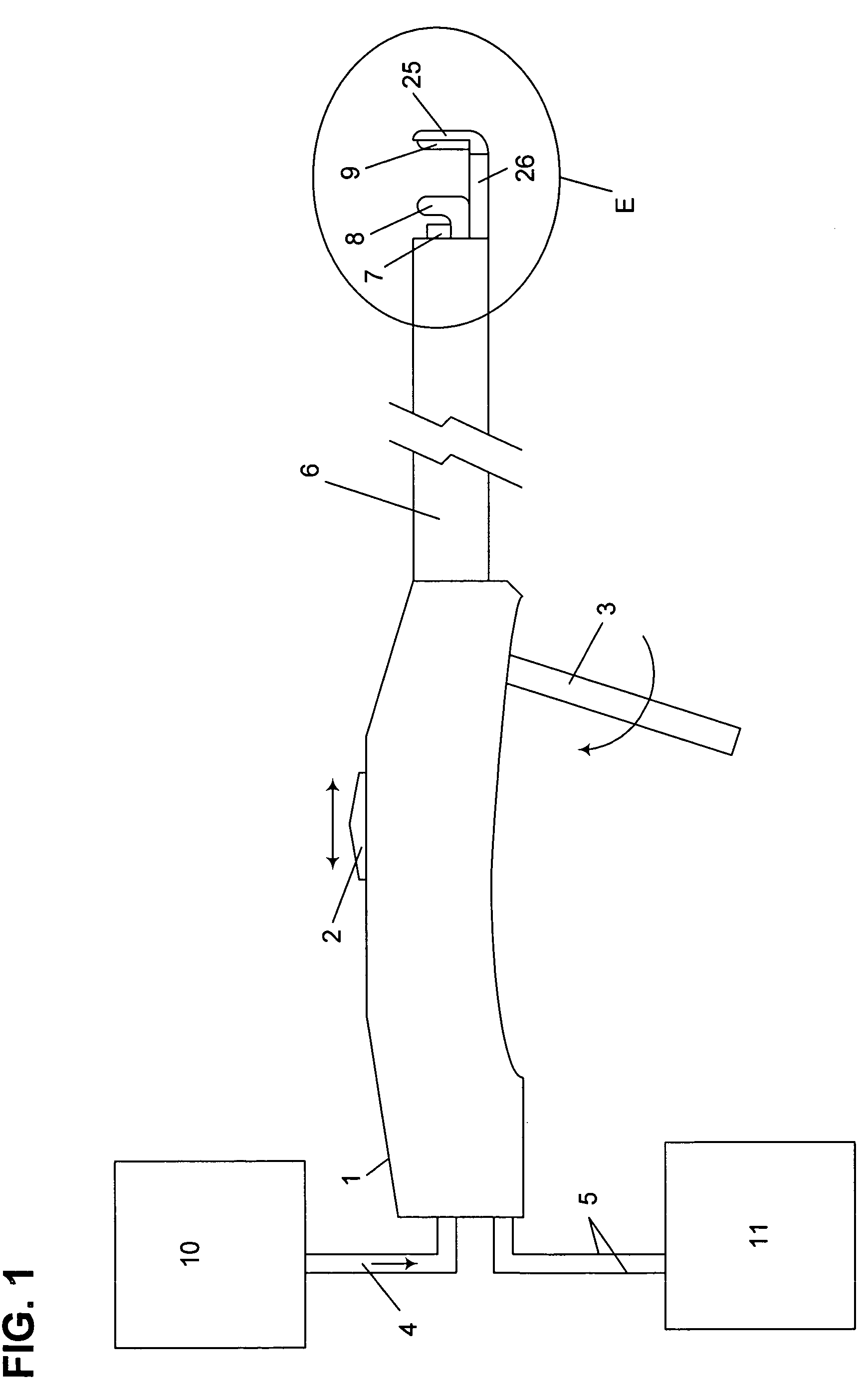

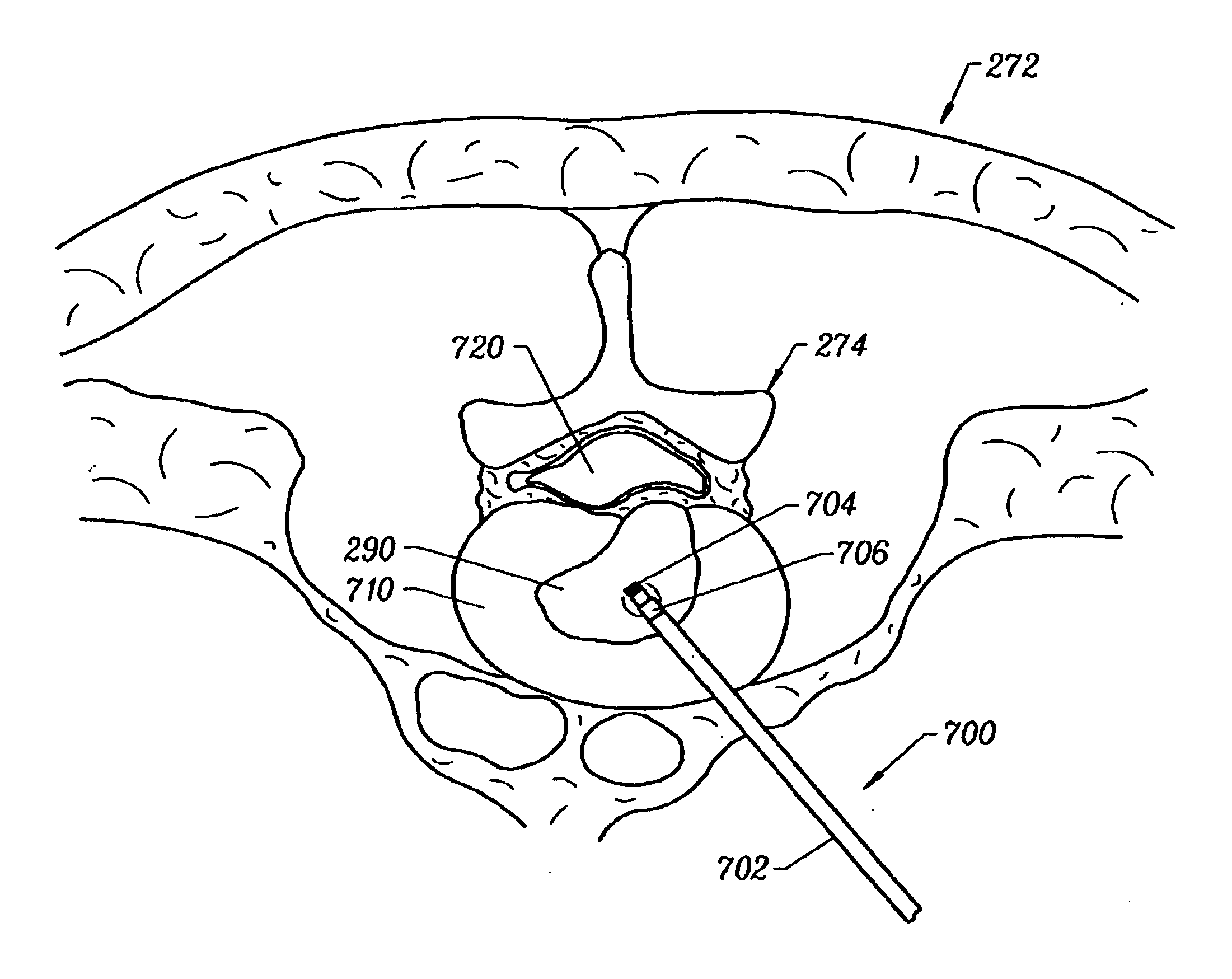

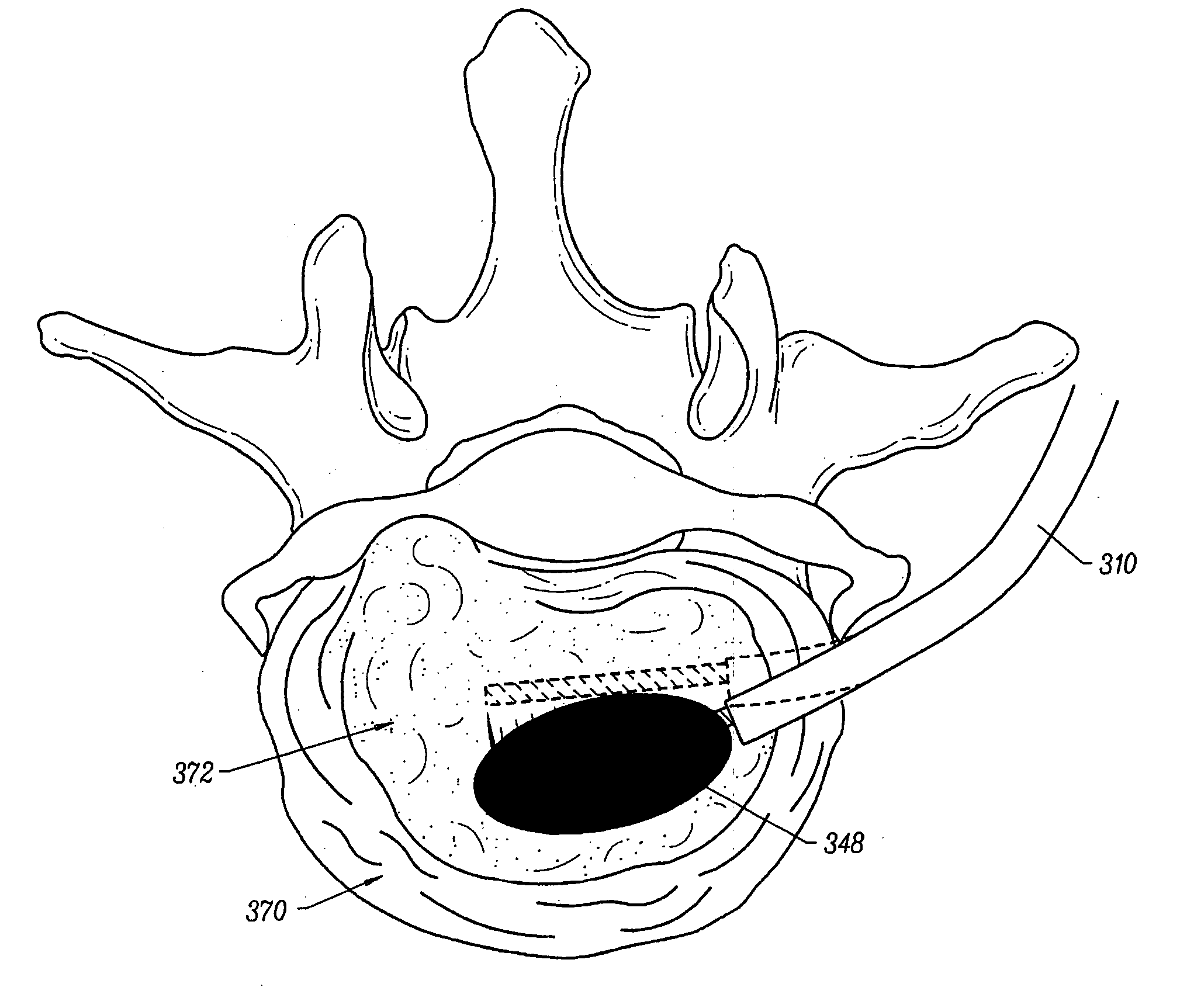

Methods for electrosurgical tissue contraction within the spine

The present invention provides systems and methods for selectively applying electrical energy to a target location within a patient's body, particularly including tissue in the spine. The present invention applies high frequency (RF) electrical energy to one or more electrode terminals in the presence of electrically conductive fluid to contract collagen fibers within the tissue structures. In one aspect of the invention, a system and method is provided for treating herniated or swollen discs within a patient's spine by applying sufficient electrical energy to the disc tissue to contract or shrink the collagen fibers within the nucleus pulposis. This causes the pulposis to shrink and withdraw from its impingement on the spinal nerve.

Owner:ARTHROCARE

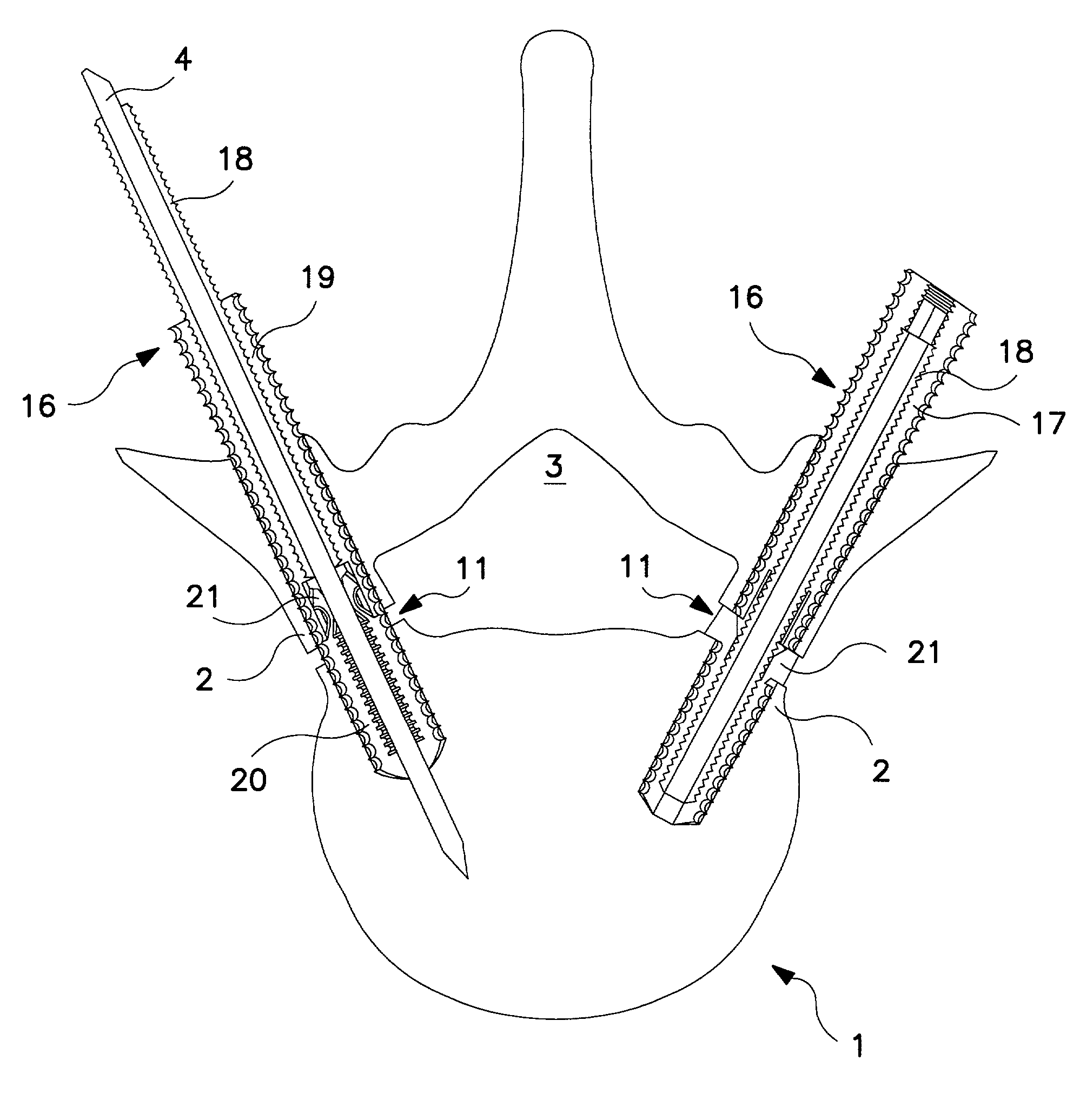

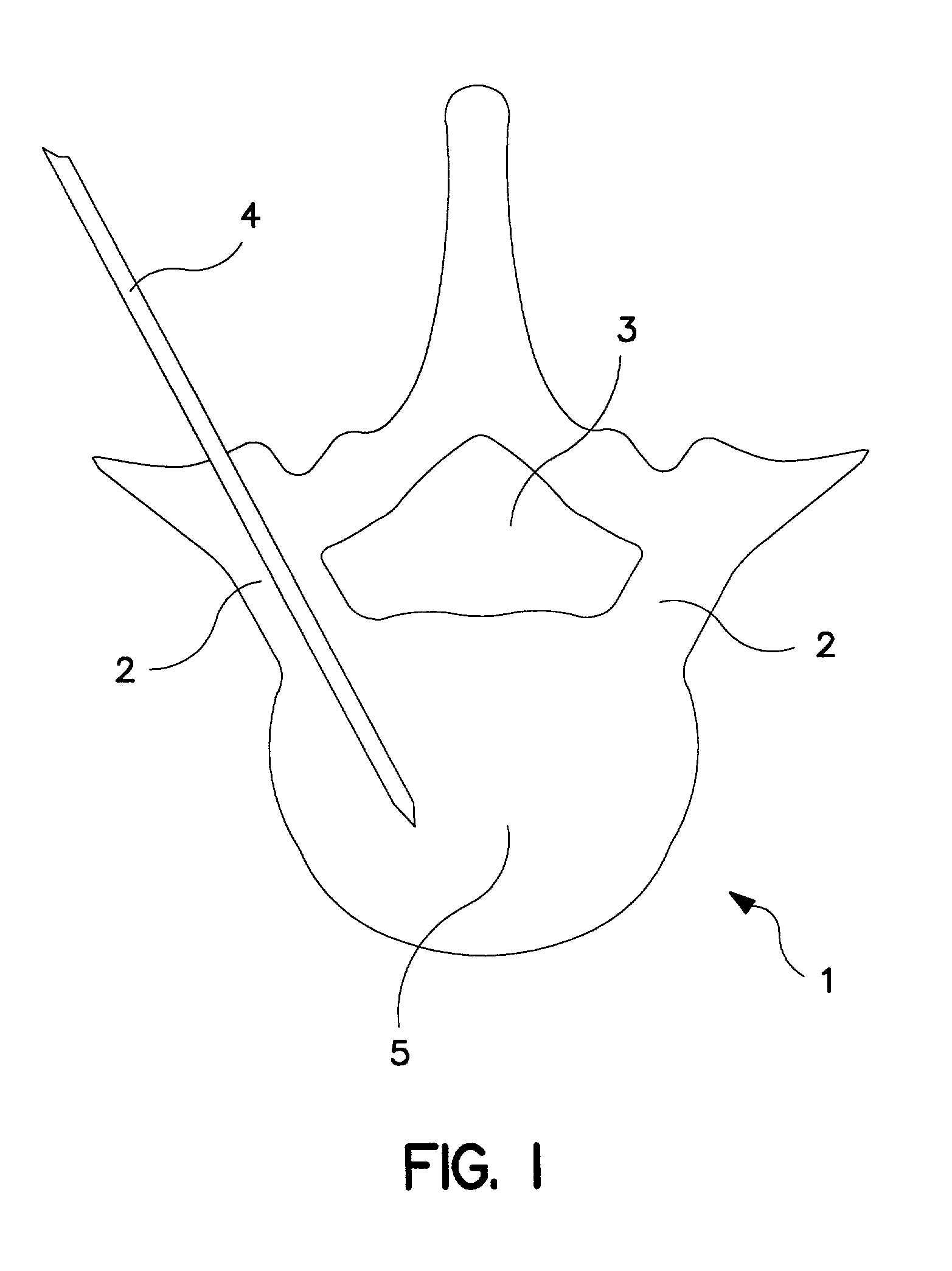

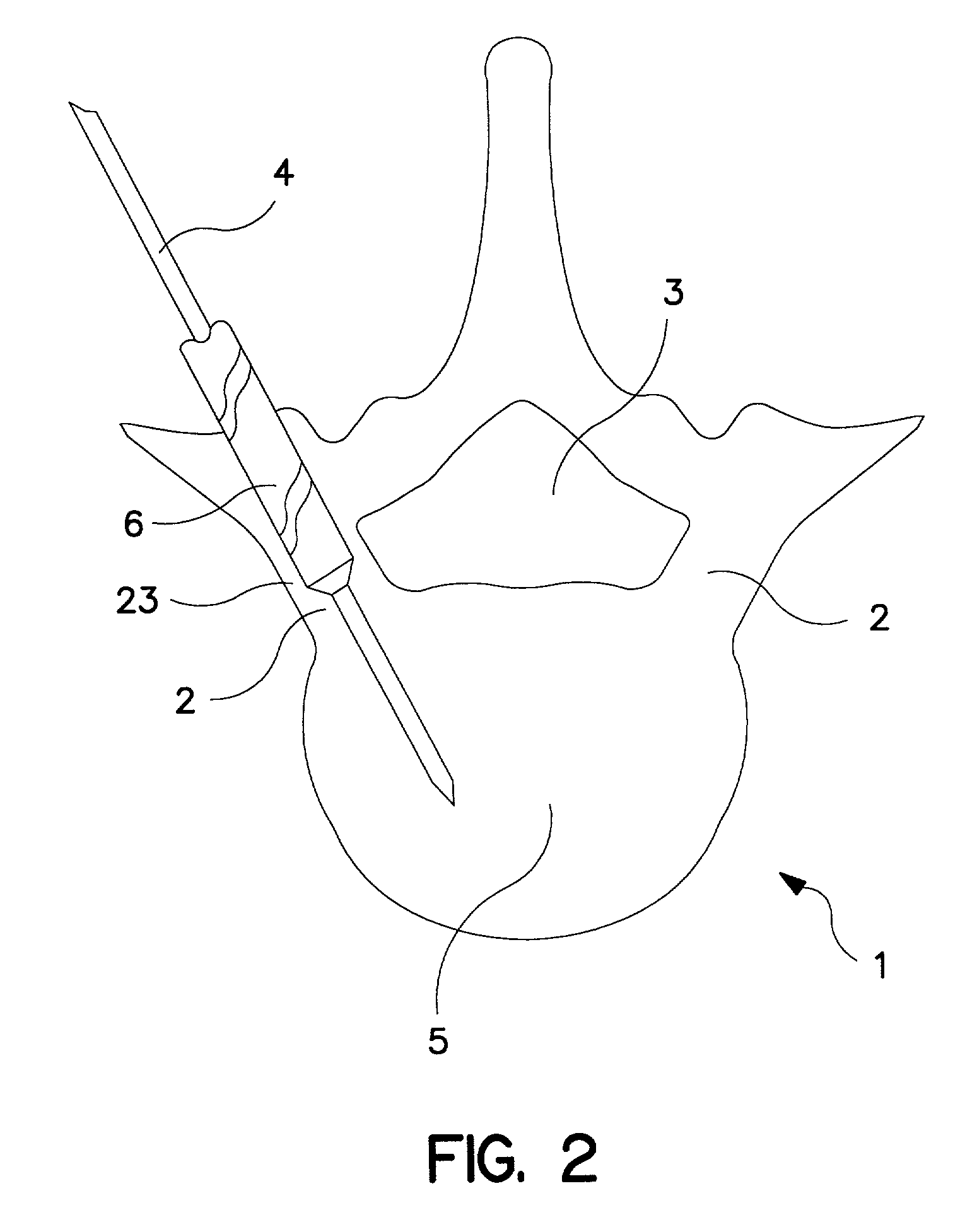

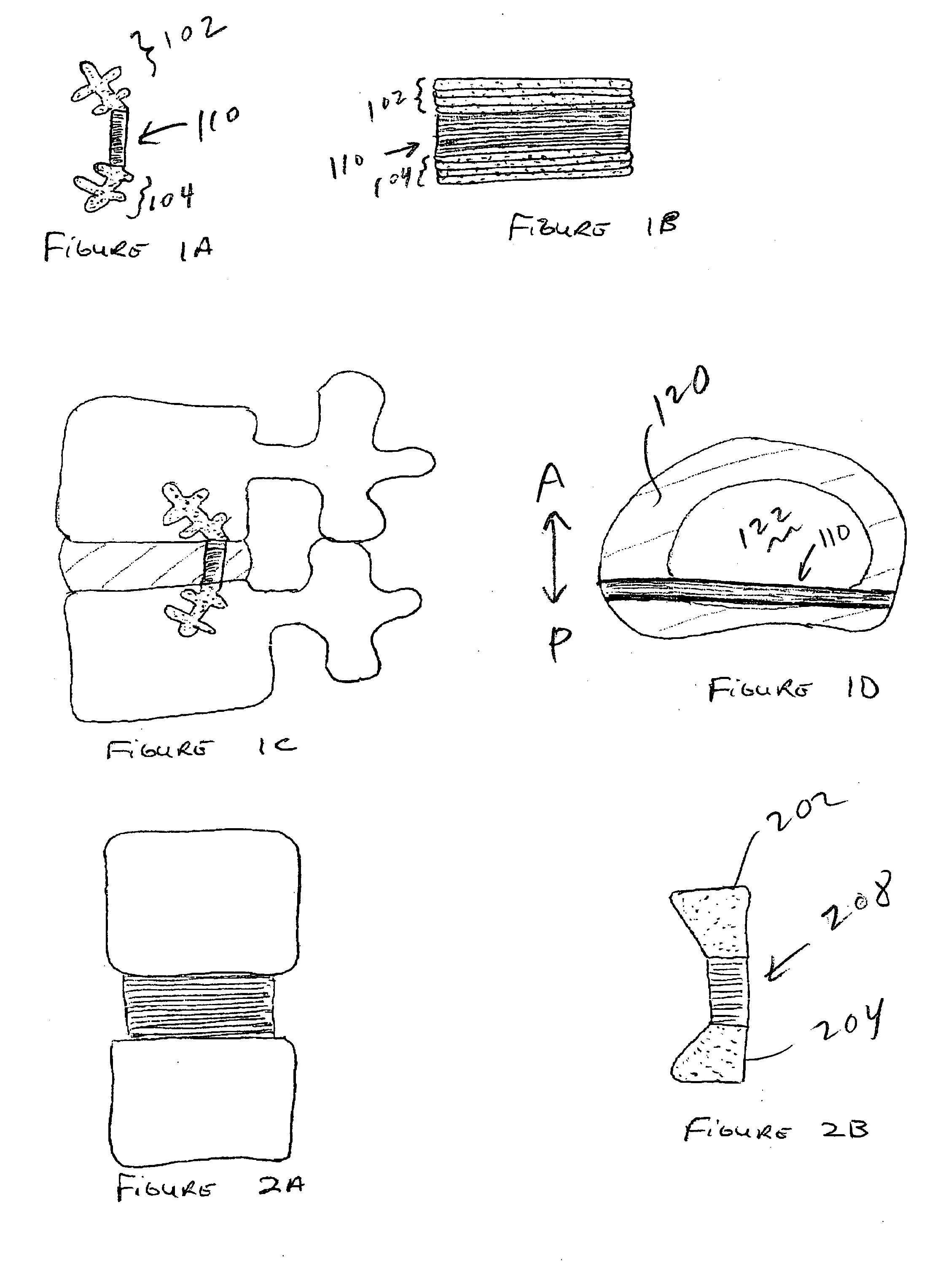

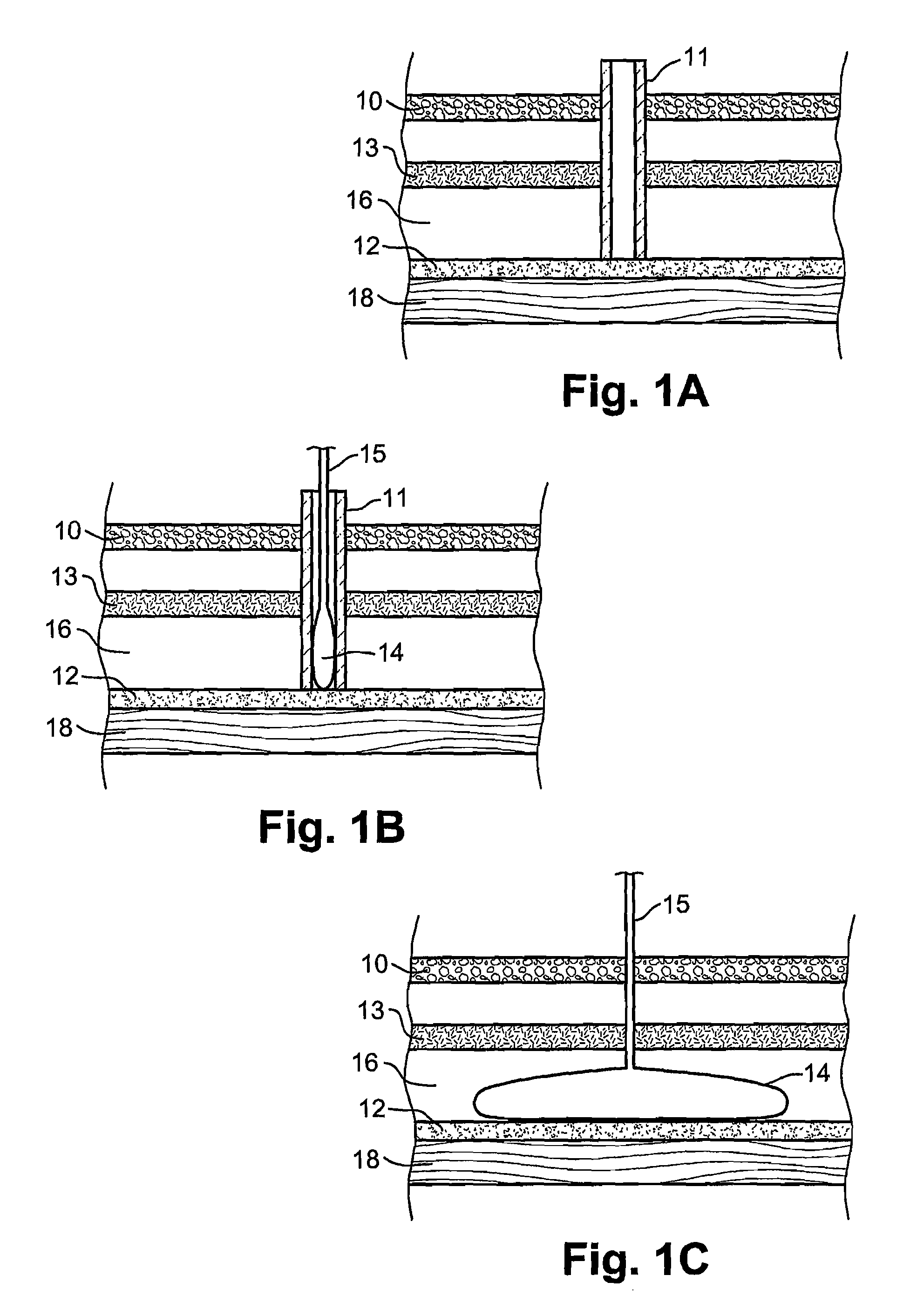

Percutaneous technique and implant for expanding the spinal canal

InactiveUS7166107B2Simple and safe and permanent and minimally invasiveRelieve stressInternal osteosythesisDiagnosticsOsteotomyBiomedical engineering

The present invention expands a spinal canal by drilling a cylindrical passage in each pedicle of a vertebra, making a circumferential pedicle cut (osteotomy) through each pedicle from within the passage, separating each pedicle cut by inserting an implant into the passage which distracts the pedicle cut to expand the spinal canal, and securing each pedicle cut, allowing the vertebra to heal with the spinal canal expanded. The implant includes an outer sleeve, an inner bolt, and expandable flanges. The outer sleeve includes an upper portion and a lower portion, with the expandable flanges connected to the lower portion and housed within the upper portion. Rotation of the inner bolt causes the upper and lower portions of the outer sleeve to separate, causing the pedicle cut to widen and the expandable flanges to radially extend into and stabilize the widened pedicle cut to effectuate expansion of the spinal canal.

Owner:DEPUY ACROMED INC +2

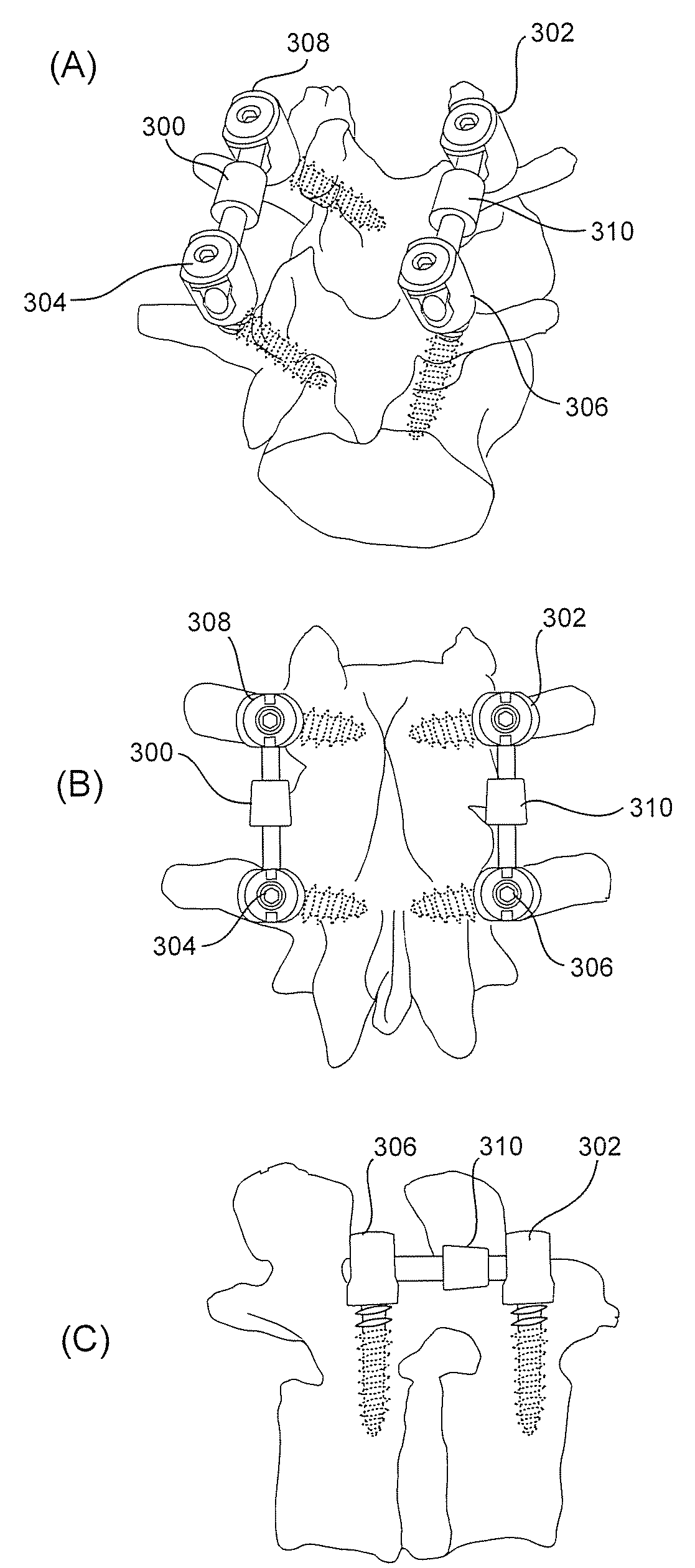

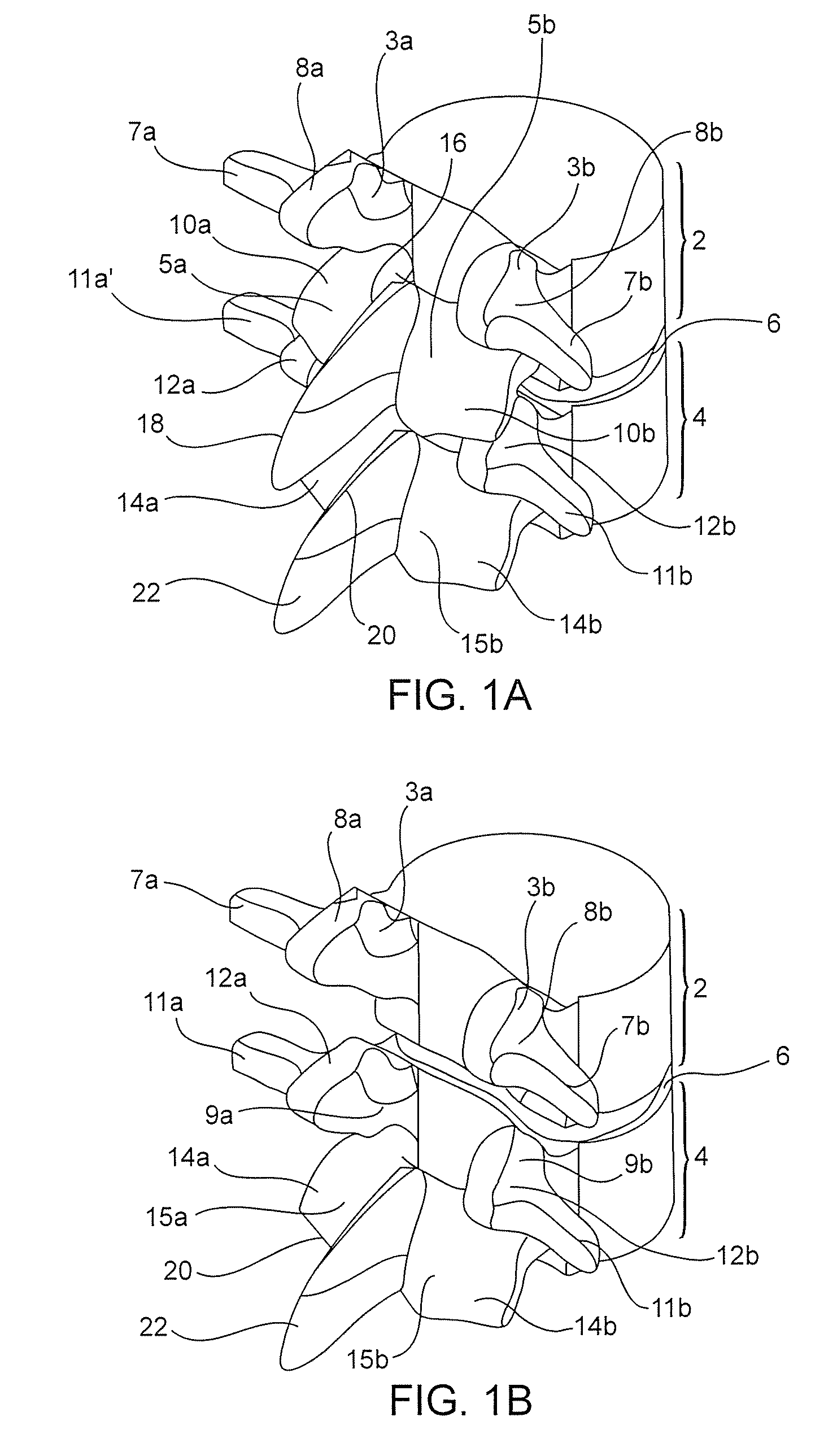

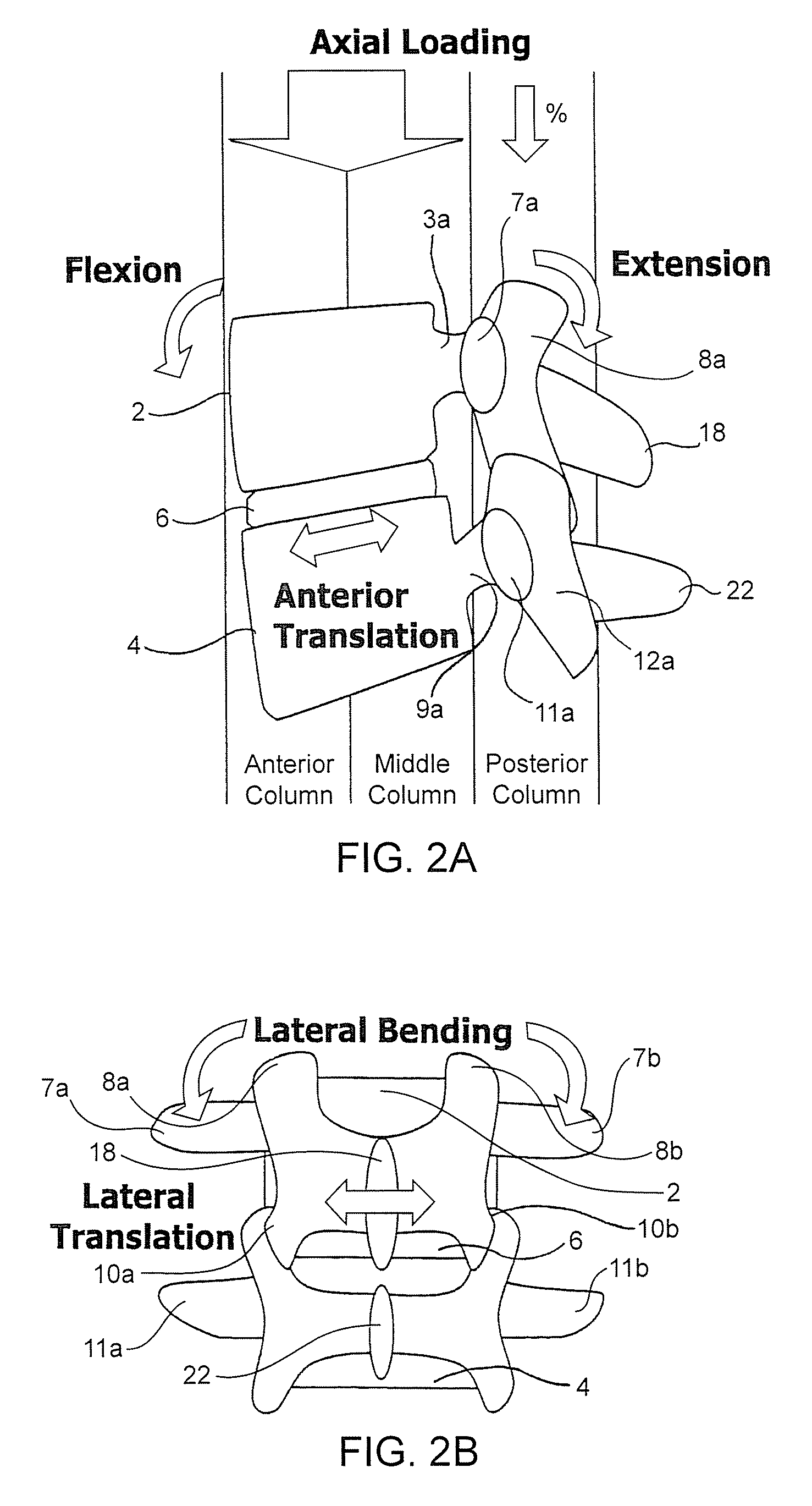

Systems and methods for stabilization of bone structures

InactiveUS20070100341A1Reduce painLong-term complicationInternal osteosythesisJoint implantsSmall incisionSpinal locomotion

A dynamic bone stabilization system is provided. The system may be placed through small incisions and tubes. The system provides systems and methods of treating the spine, which eliminate pain and enable spinal motion, which effectively mimics that of a normally functioning spine. Methods are also provided for stabilizing the spine and for implanting the subject systems.

Owner:EXACTECH INC

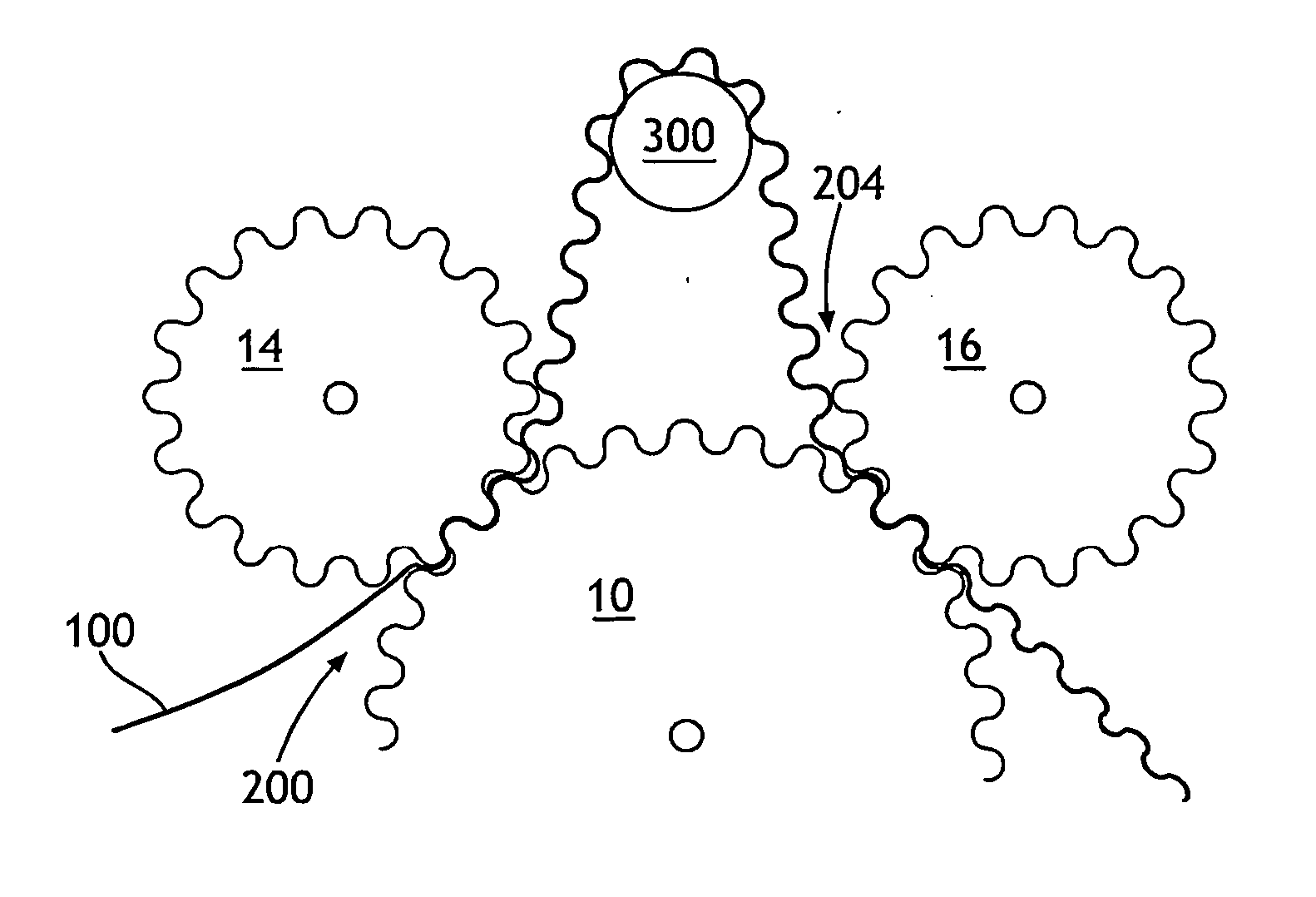

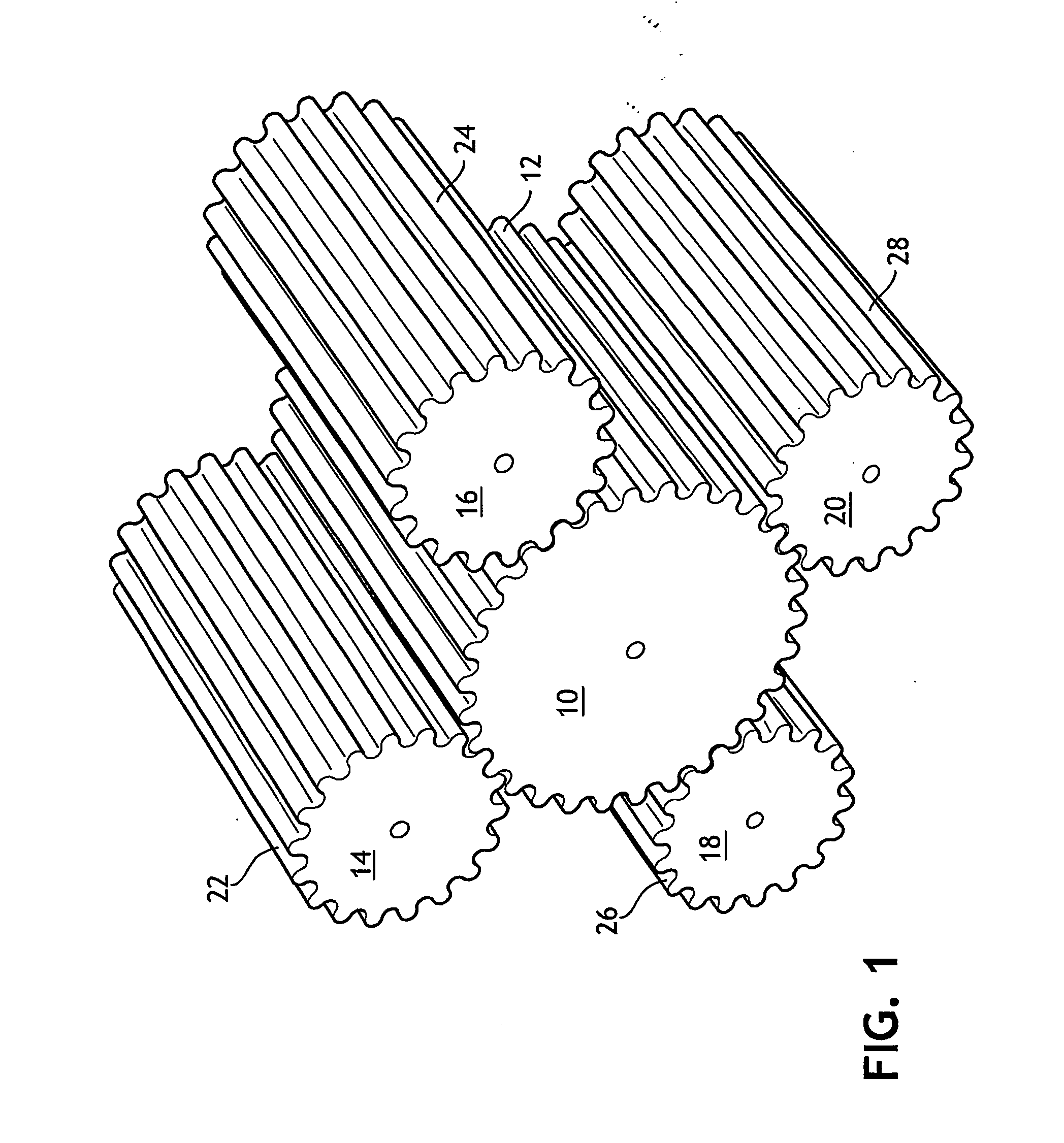

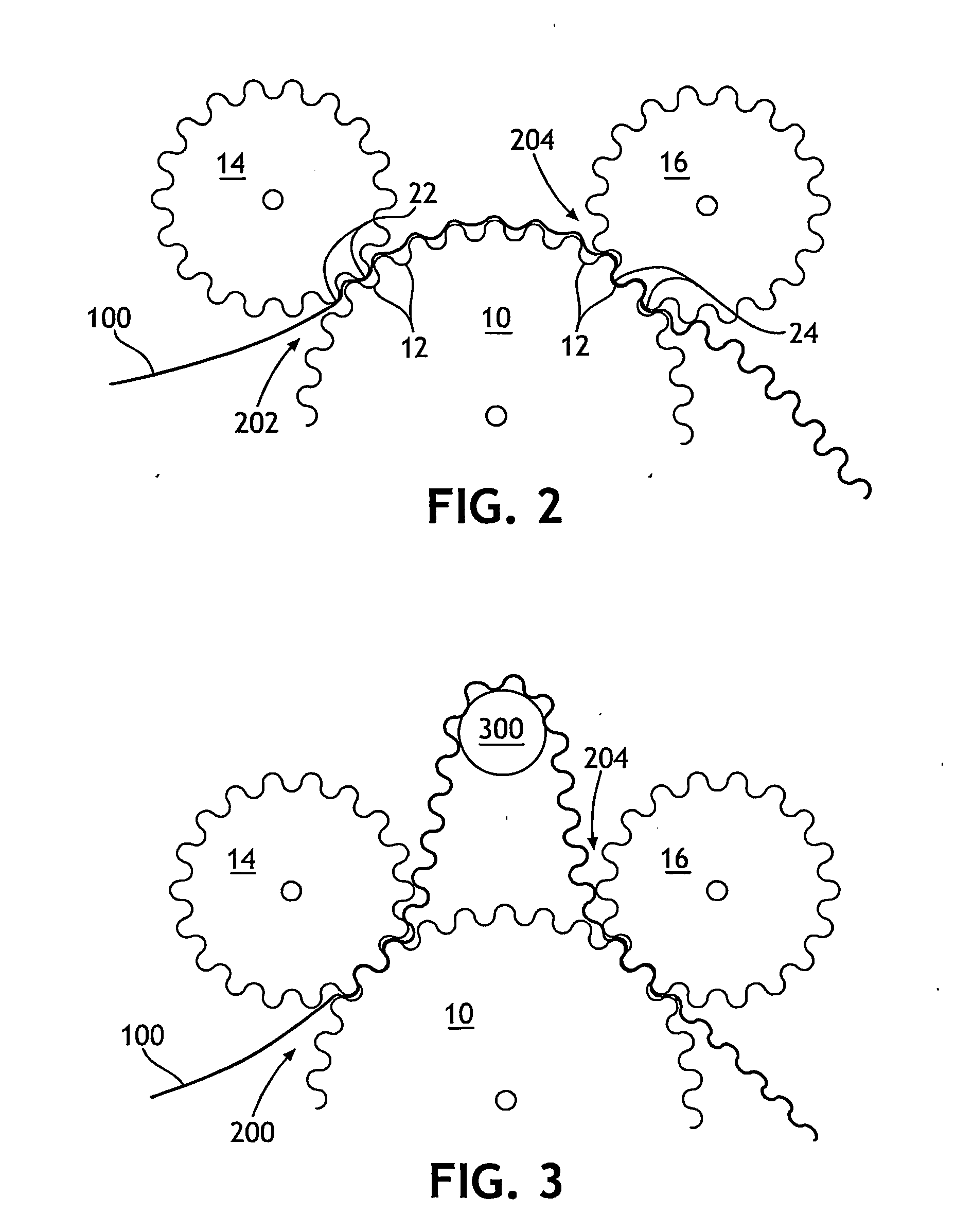

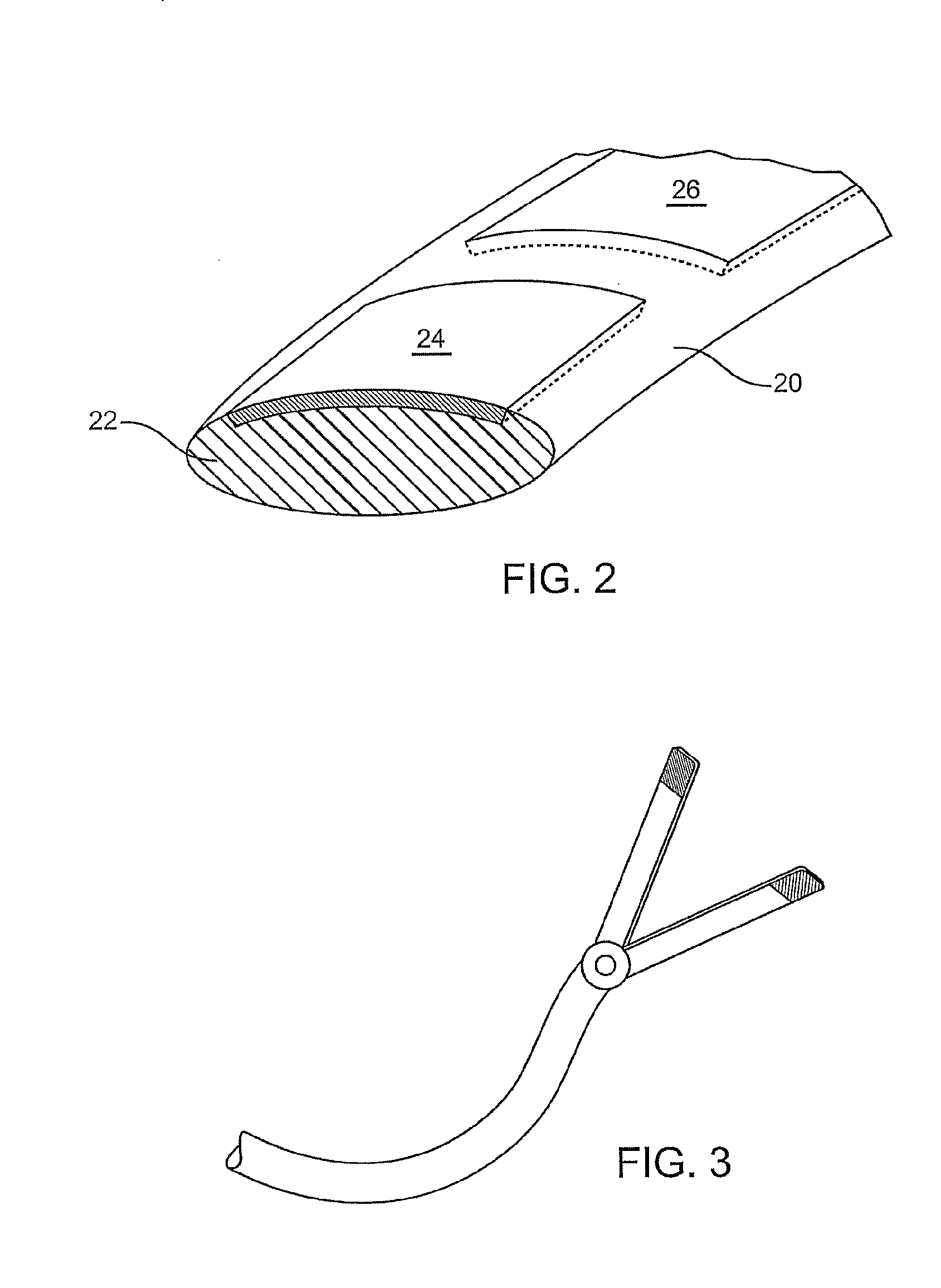

Device and process for treating flexible web by stretching between intermeshing forming surfaces

InactiveUS20060151914A1Increase flexibilityWidely vary degree of stretchDough-sheeters/rolling-machines/rolling-pinsConfectioneryPersonal Care ProductBiomedical engineering

A series of nips (200, 202, 204, 412, 414) formed by intermeshing grooves (22, 24, 26, 28) provides for a higher degree of stretch, particularly for lightweight webs (100) by stretching in stages in multiple grooved nips. The ability to adjust the degree of stretch at each nip can provide a high degree and variability of stretch with reduced web damage compared to a single step application of the same stretch. Improvements to the manufacture of lightweight components of personal care products such as diaper backing components are obtained.

Owner:KIMBERLY-CLARK WORLDWIDE INC

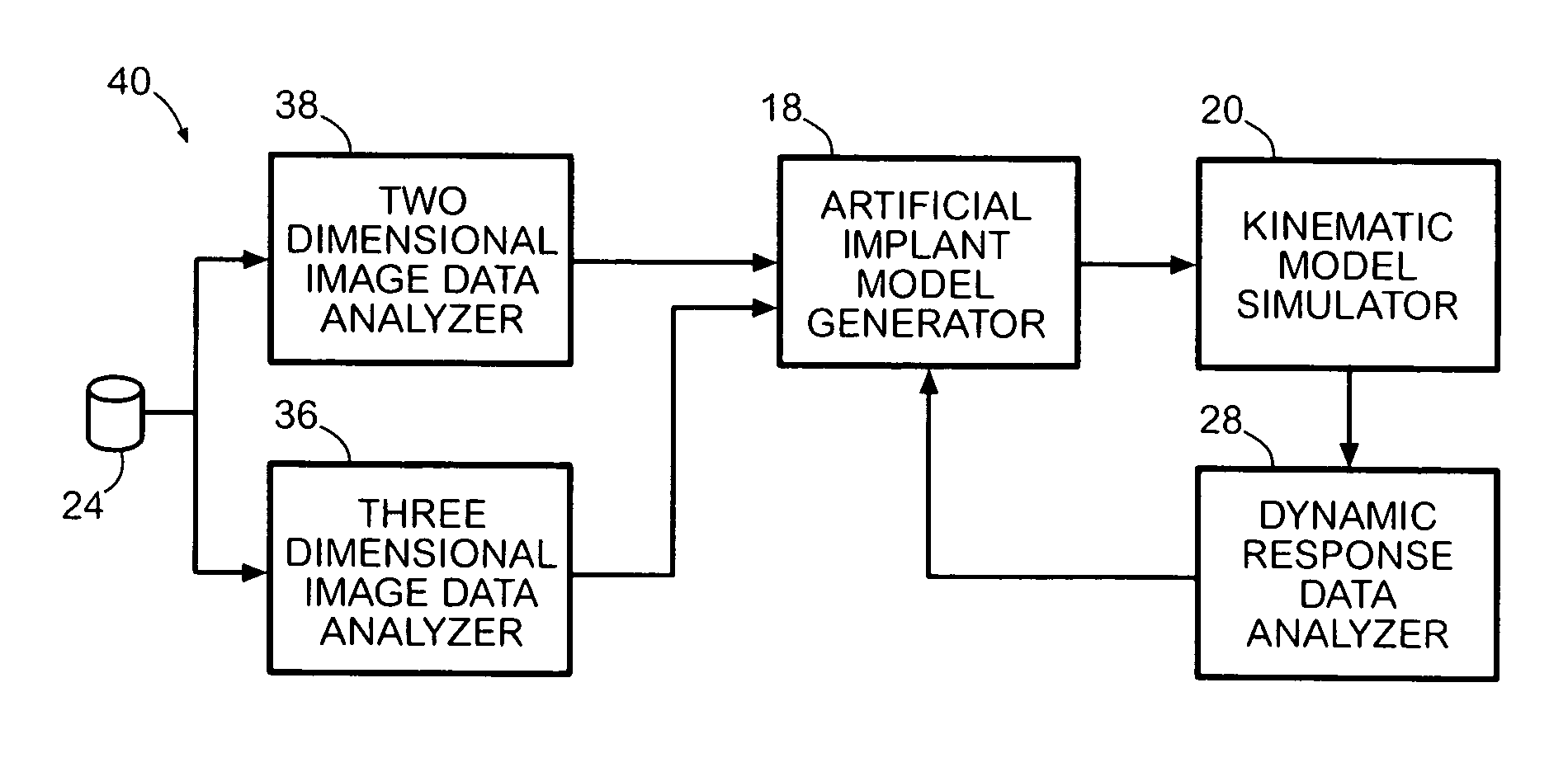

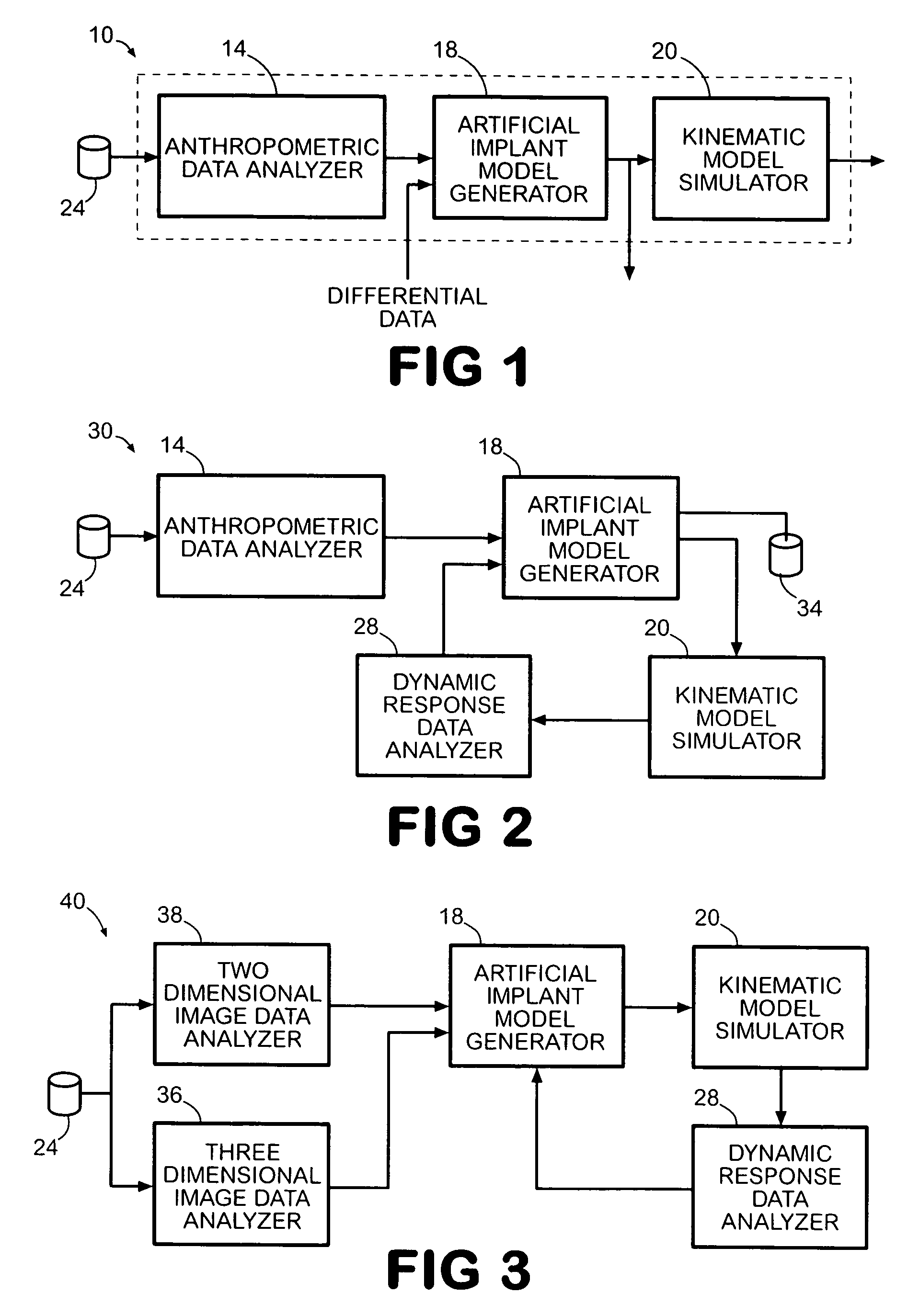

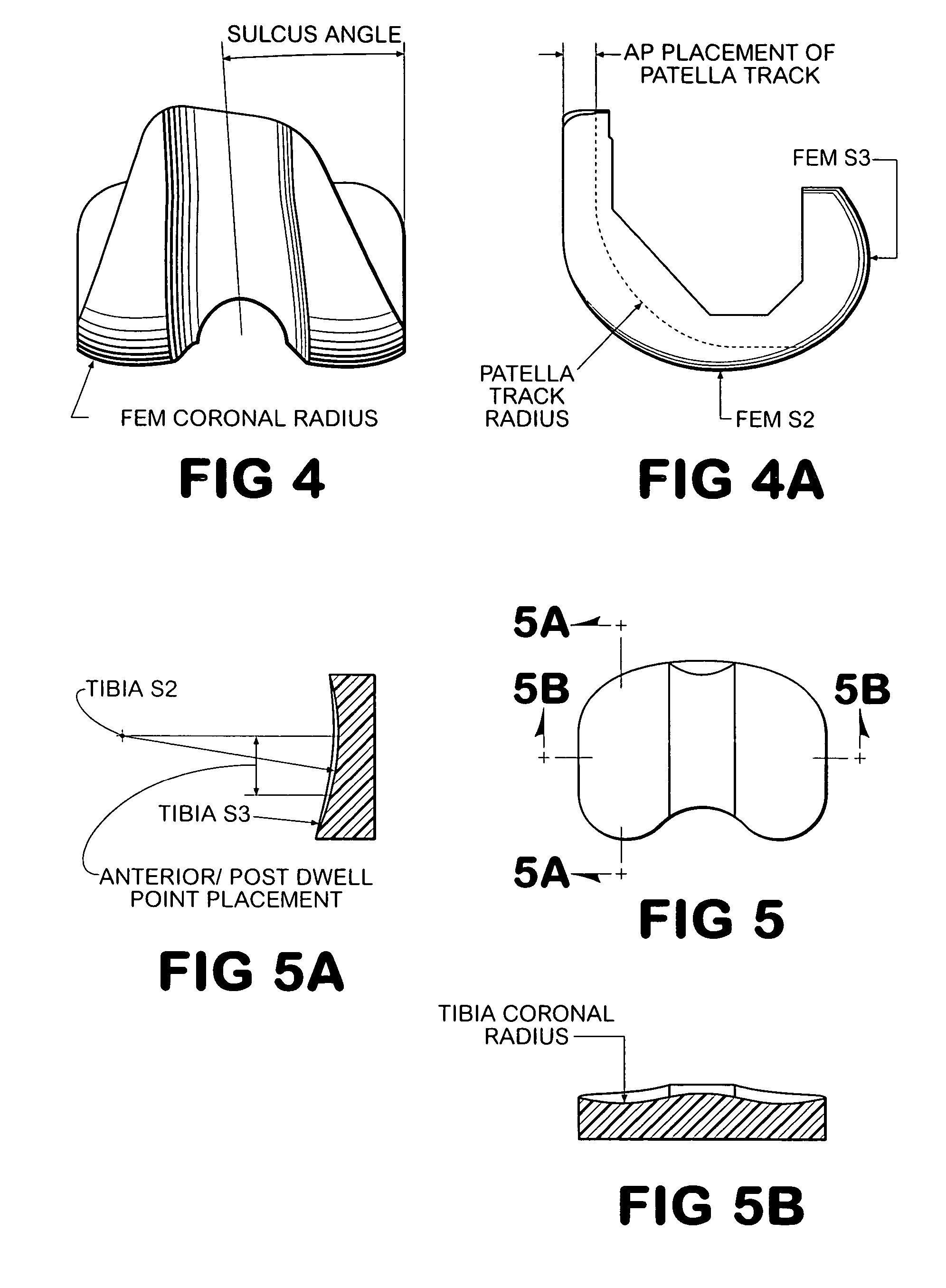

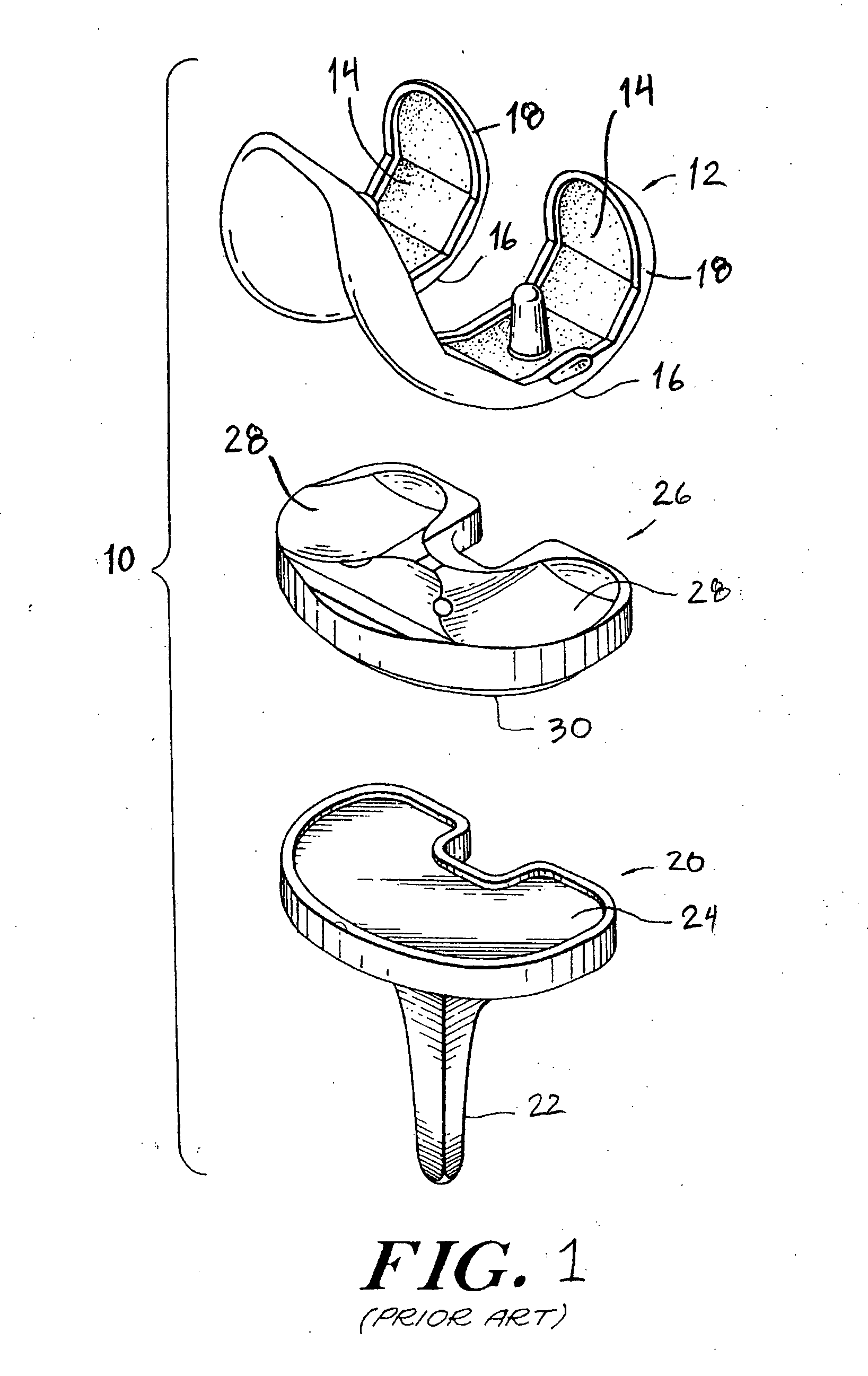

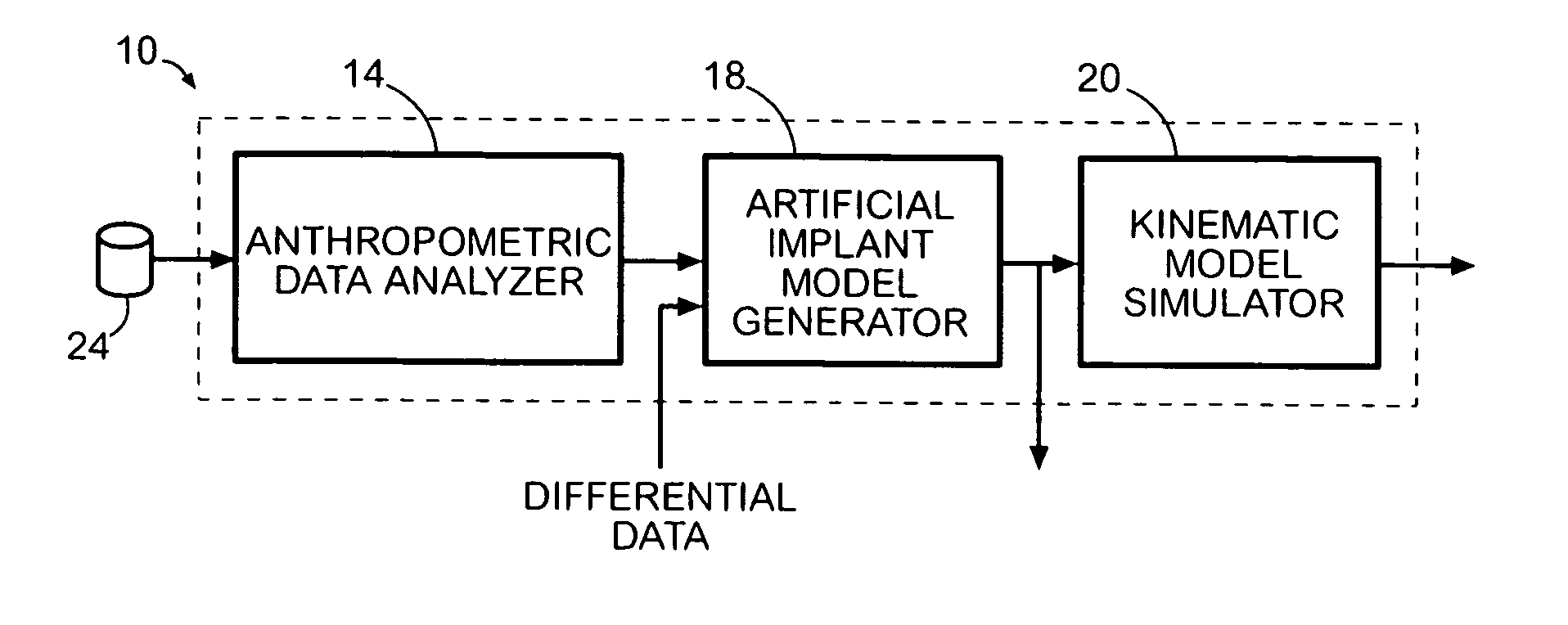

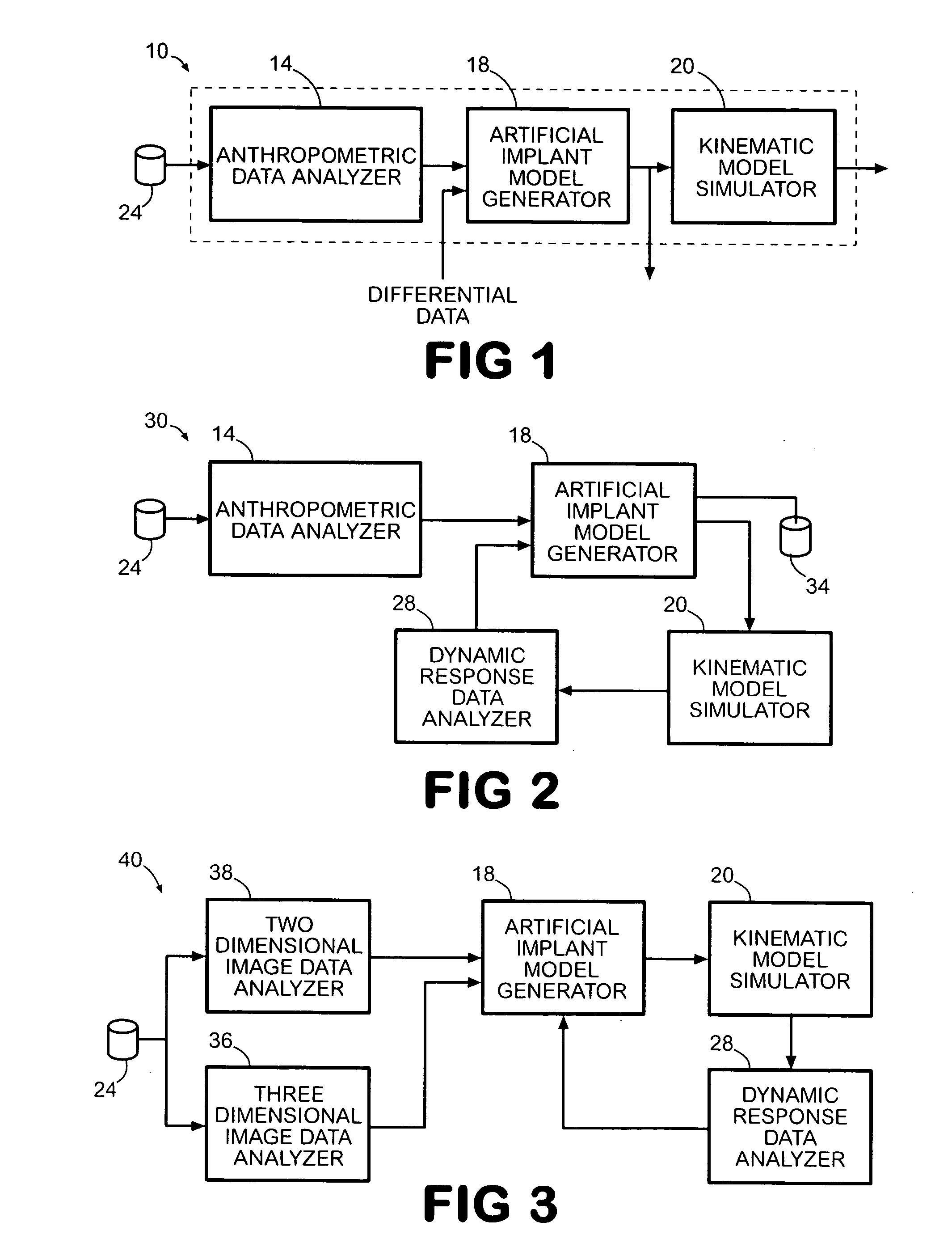

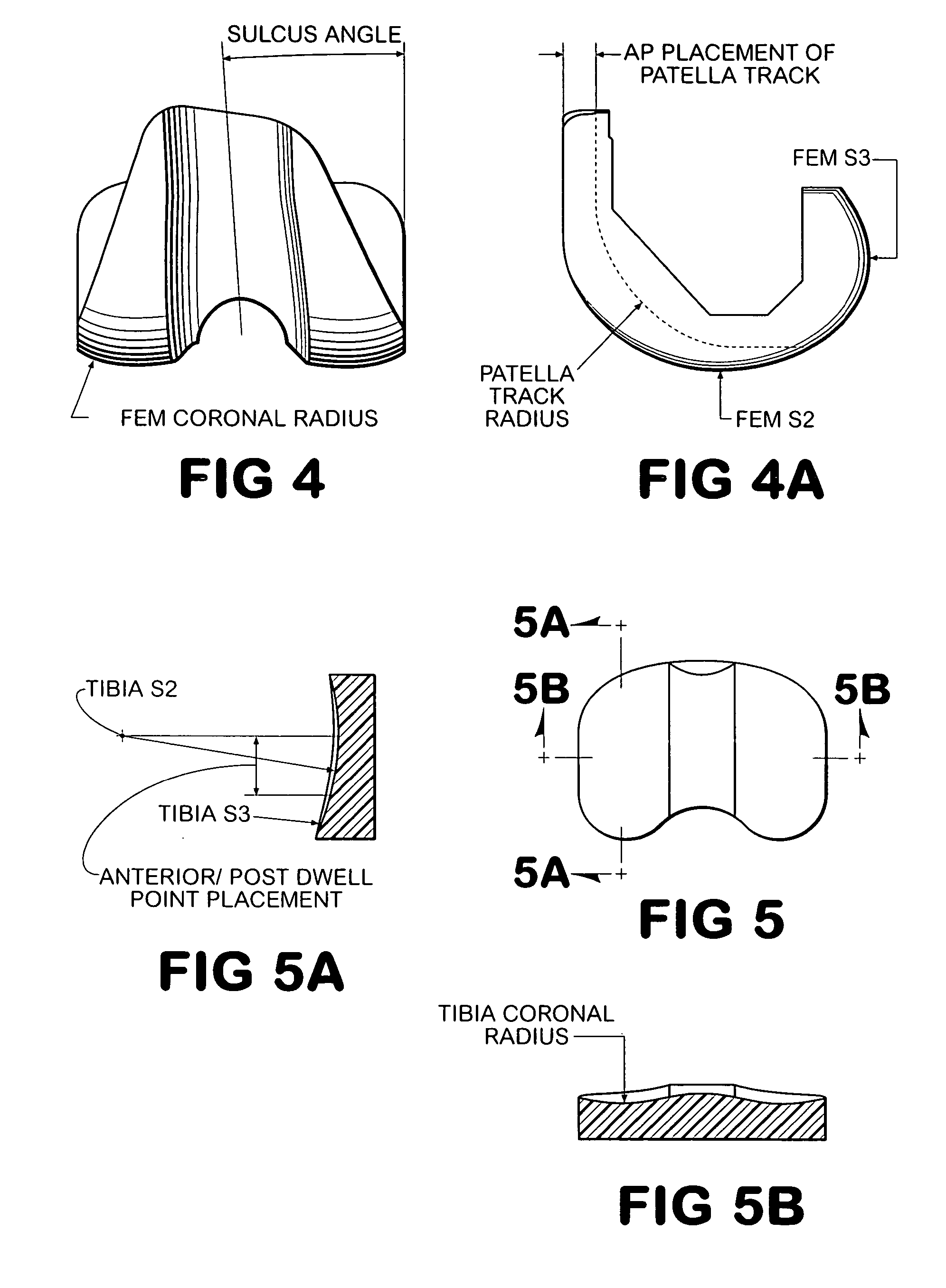

System and method for designing a physiometric implant system

ActiveUS7383164B2Economy of motionReduction of jerkPerson identificationAnalogue computers for chemical processesDynamic modelsJoints surgery

A system improves the design of artificial implant components for use in joint replacement surgeries. The system includes an anthropometric static image data analyzer, an implant model data generator, a kinematic model simulator, and a dynamic response data analyzer. The implant model data generator may also use image data of a joint in motion for modification of the implant model data used in the kinematic simulation. Dynamic response data generated by the kinematic model simulation is analyzed by the dynamic response data analyzer to generate differential data that may be used to further refine the implant model data.

Owner:DEPUY PROD INC

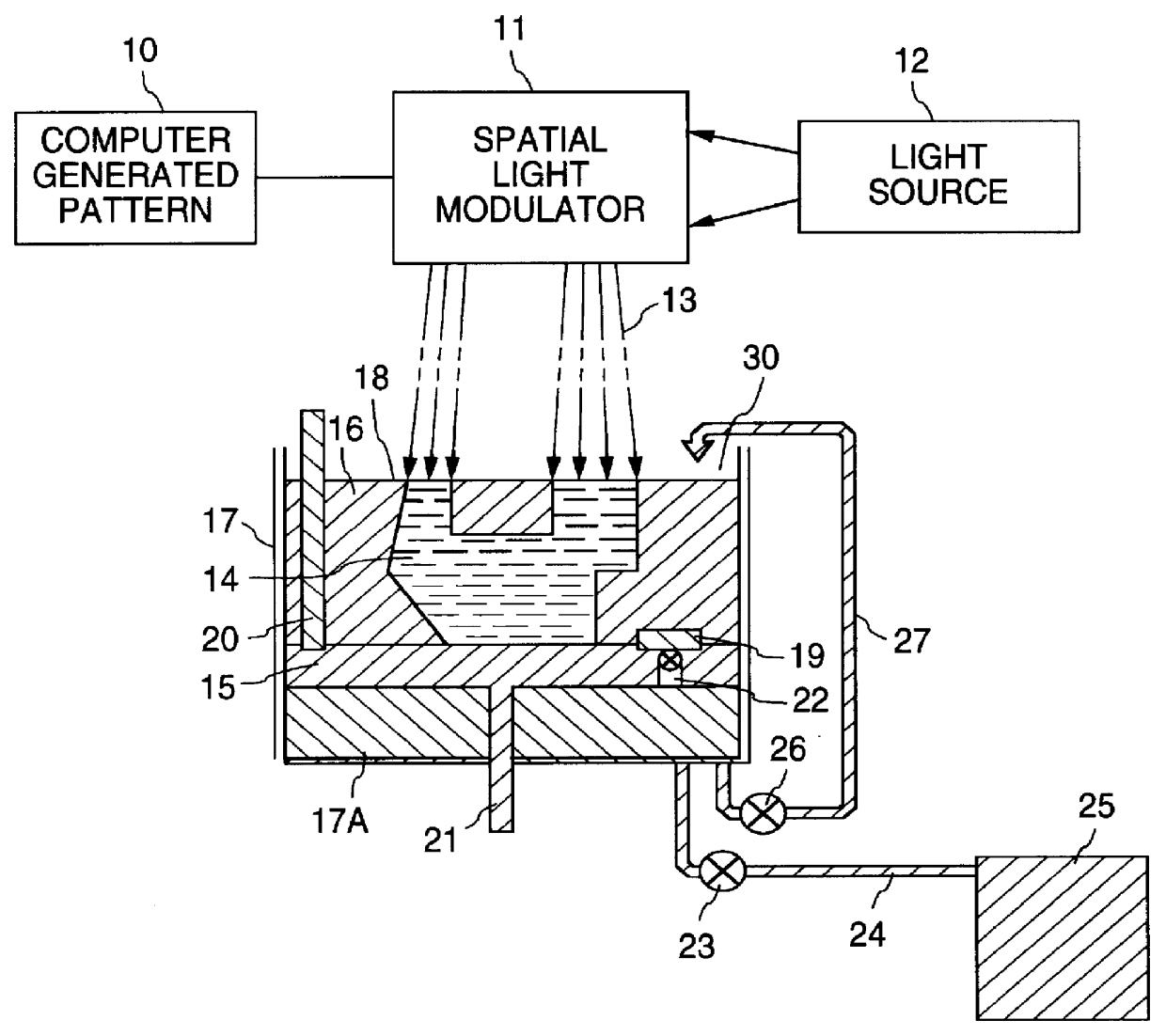

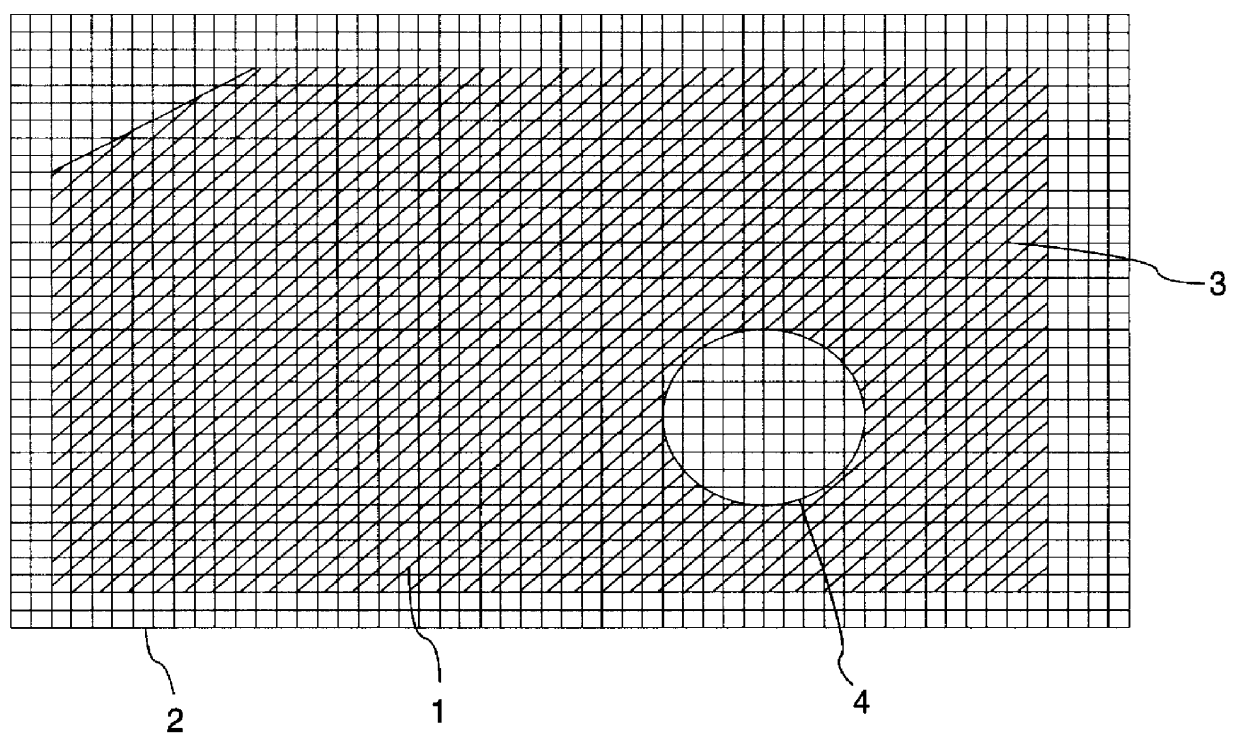

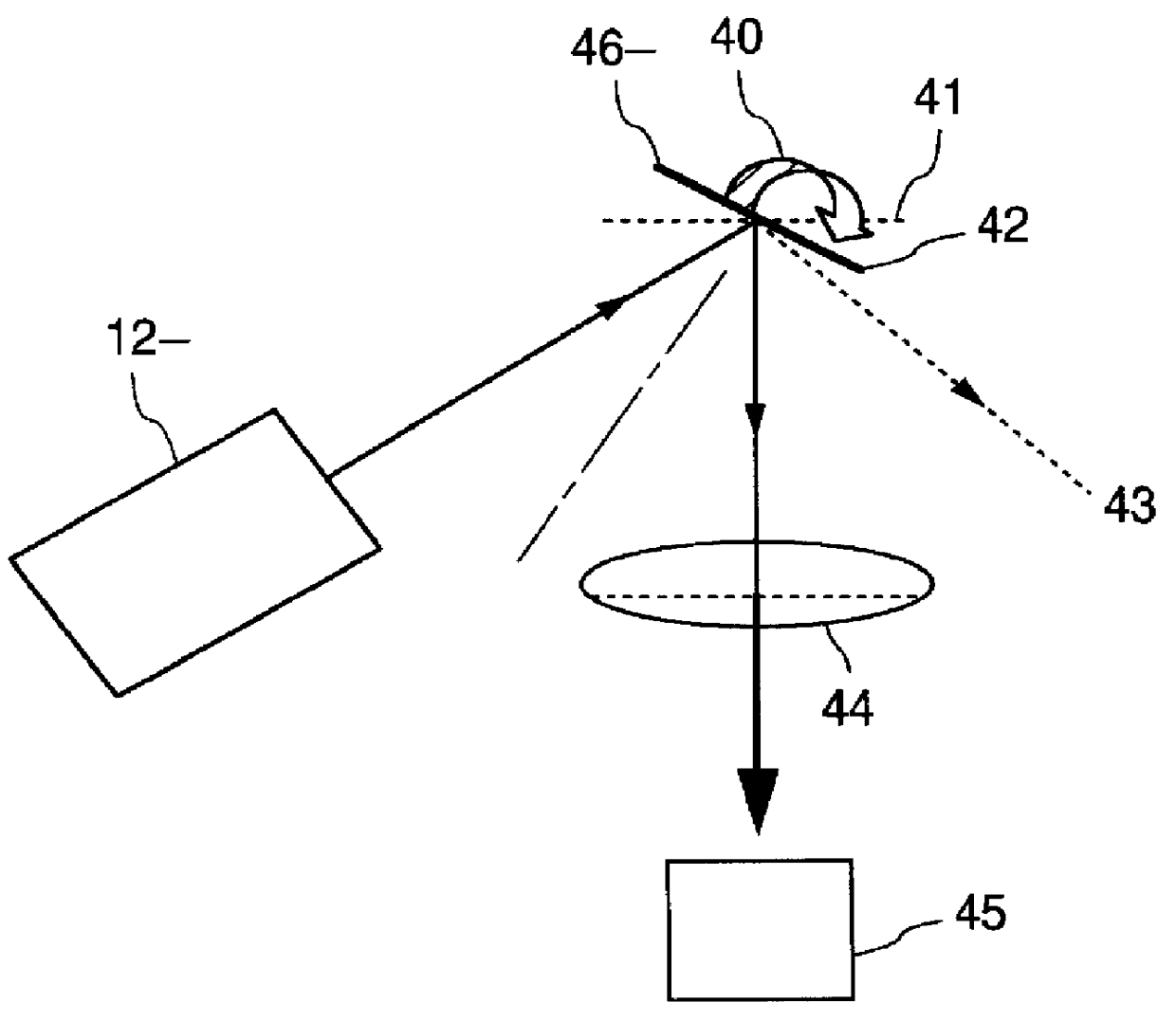

Apparatus and method for production of three-dimensional models by spatial light modulator

InactiveUS6051179AFacilitate cross-linkingHigh mechanical strengthAdditive manufacturing apparatusAnalogue computers for control systemsSpatial light modulatorWide beam

An apparatus and the method of its operation for rapid prototyping of a three-dimensional object which includes a radiant energy source of a wide beam of radiant energy of suitable intensity and wavelength for curing a layer of photo-curable resin contained in an open vat, a spatial light modulator (SLM) having an array of pixel elements which are individually digitally controllable by a computer, for modulating the radiant energy beam projected from the radiant energy source on a pixel by pixel basis, to form a series of time sequential images of the cross-sectional laminae of the object, an optical system for focusing each image formed by the SLM, one at a time, onto successive layers of photo-curable resin for predetermined exposure times to thereby form stacked laminae of cured resin, each lamina of cured resin being in the shape of a different one of the cross-sectional laminae, and a piston support for lowering each lamina of cured resin after it is formed by the SLM and for depositing a layer of resin corresponding to the thickness of one cross sectional lamina of the three-dimensional object before the step of projecting a new image by the SLM. The SLM, the piston support for lowering, and the optical system operate repeatedly and sequentially until a complete copy of the object is thereby produced.

Owner:GLOBAL FILTRATION SYST

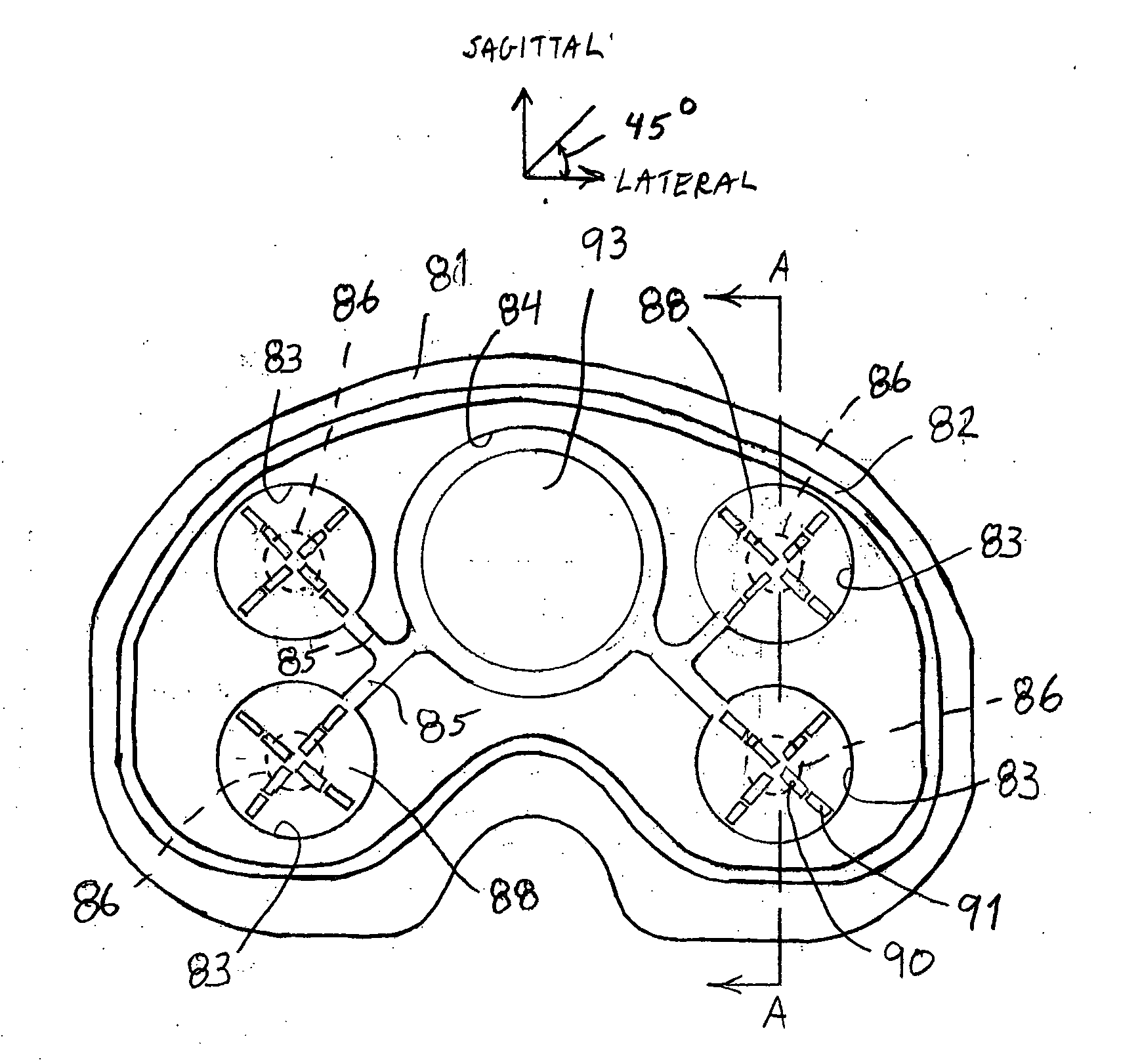

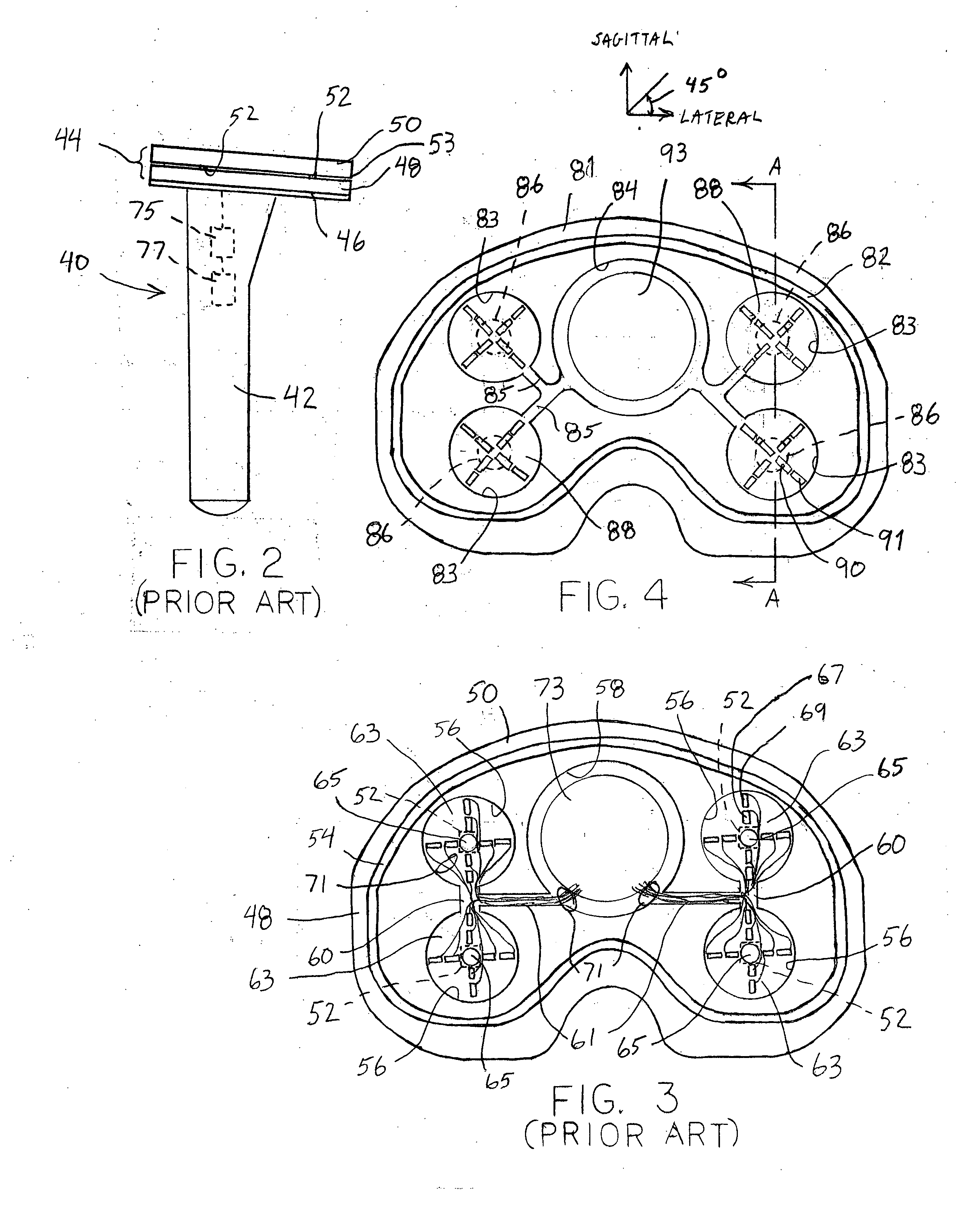

Telemetric tibial tray

ActiveUS20050010302A1Reduce riskEliminates stress riserSurgeryPerson identificationStrain rateKnee Joint

A telemetric tibial tray includes a lower plate that defines a plurality of cylindrical transducer cavities having circular load diaphragms. An upper plate is attached to the lower plate through support posts projecting from the load diaphragms. The support posts have a circular cross-section and a diameter of about 5.0 mm. The lower plate further defines wiring channels communicating between the transducer cavities and a central cavity housing the circuit board for the telemetric tray. The wiring channels are arranged at a 45 degree angle relative to the sagittal plane of the knee joint in order to reduce the effects of the wiring channel intersection on the strain sensitivity of the tray. Each transducer cavity includes a radial strain gage array with four pairs of radially aligned strain gages, each pair aligned at a 45 degree angle relative to the sagittal plane of the knee joint. Each pair of strain gages includes an inner gage positioned at the point of maximum positive micro-strain across the diaphragm when loaded, and an outer gage positioned at the point of maximum negative micro-strain, to thereby increase the differential strain measured by the gages and increase the strain sensitivity of the tibial tray.

Owner:DEPUY PROD INC

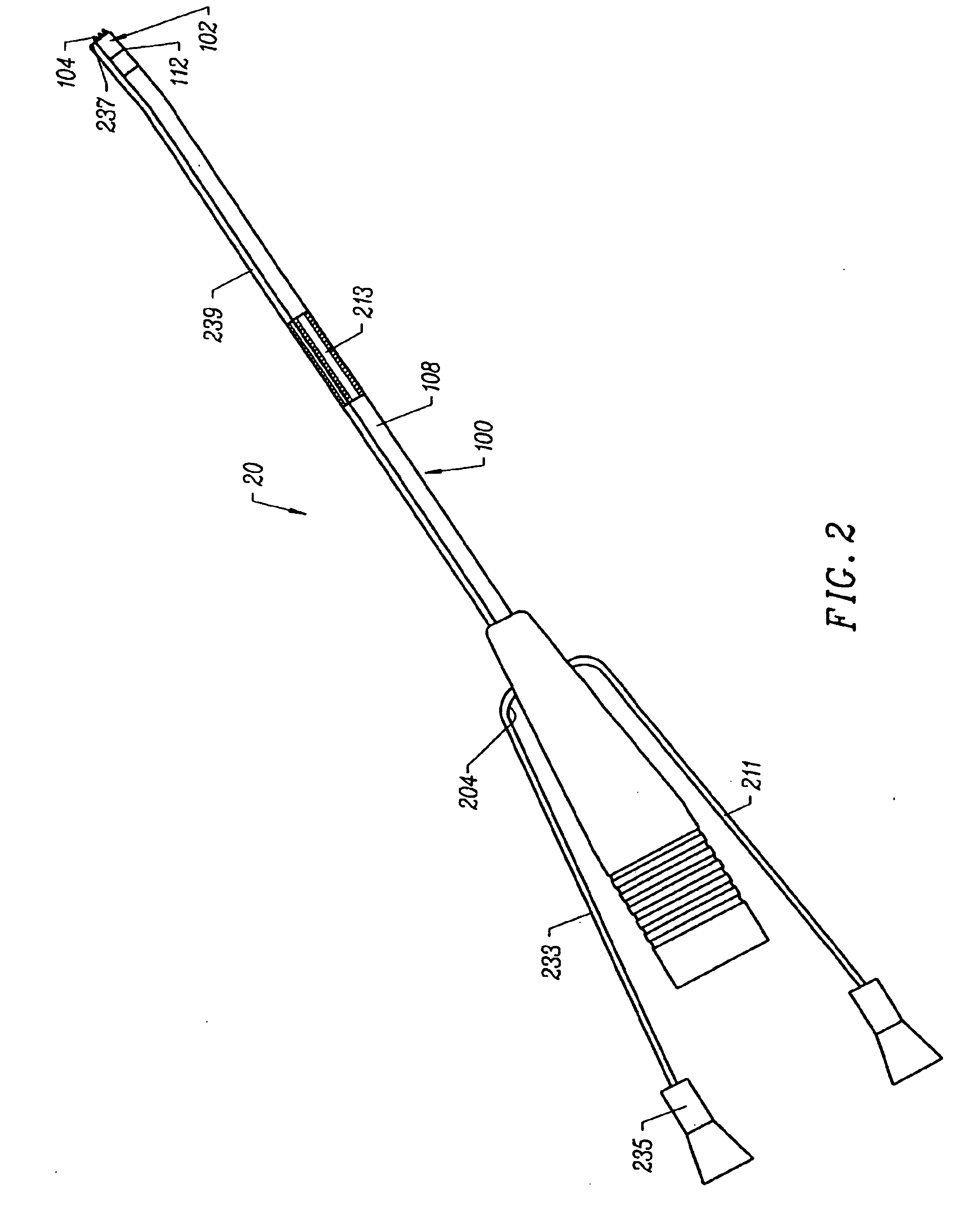

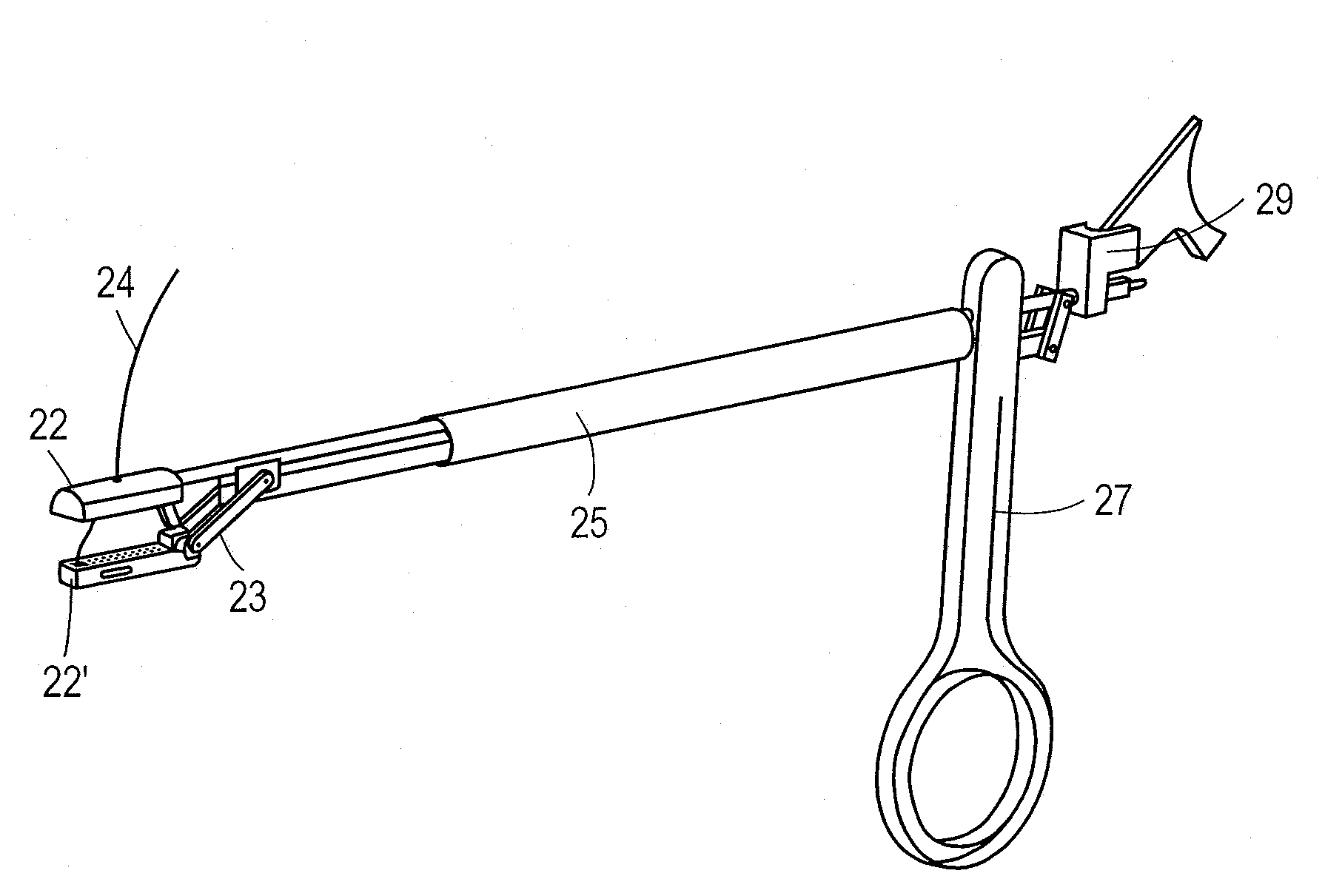

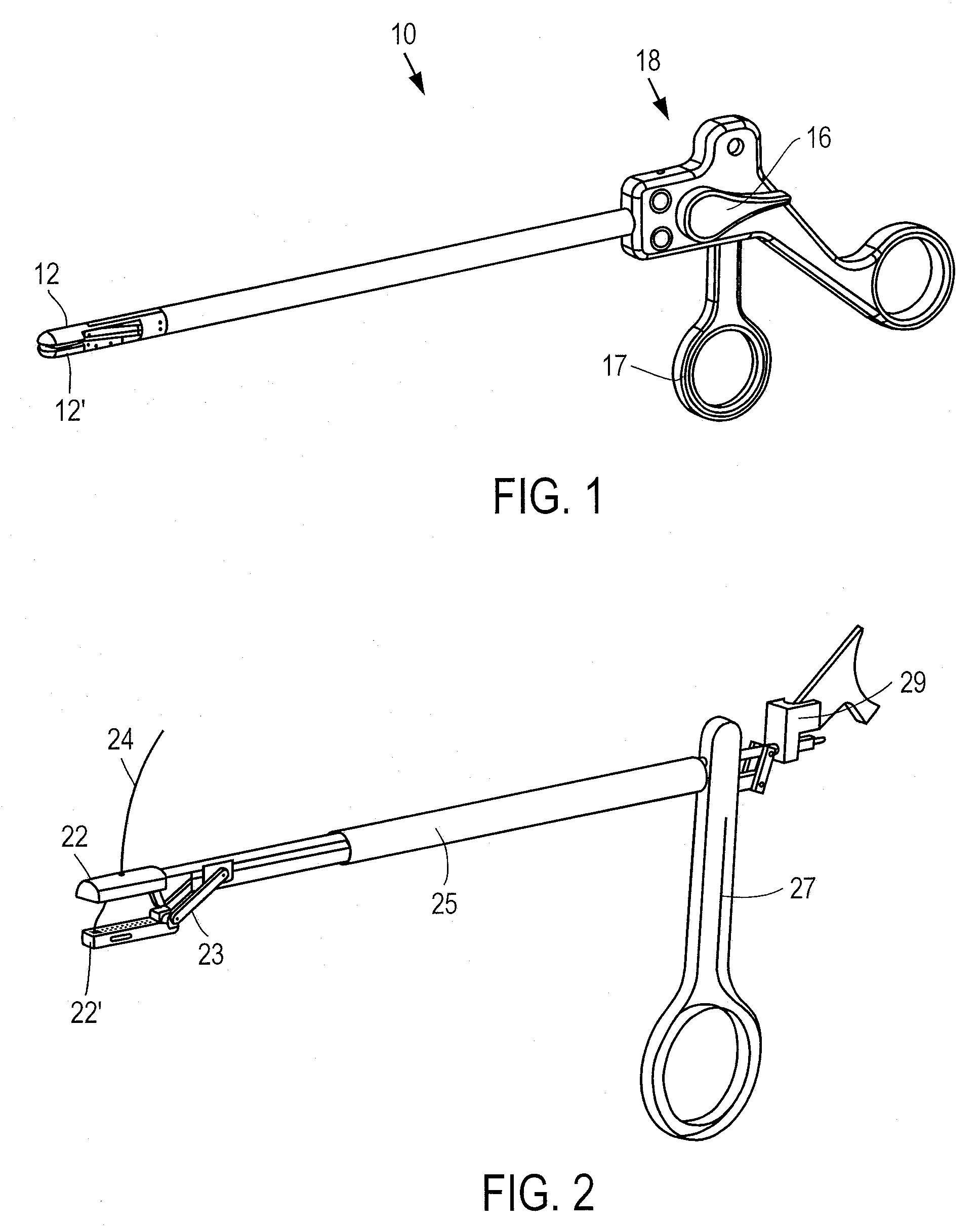

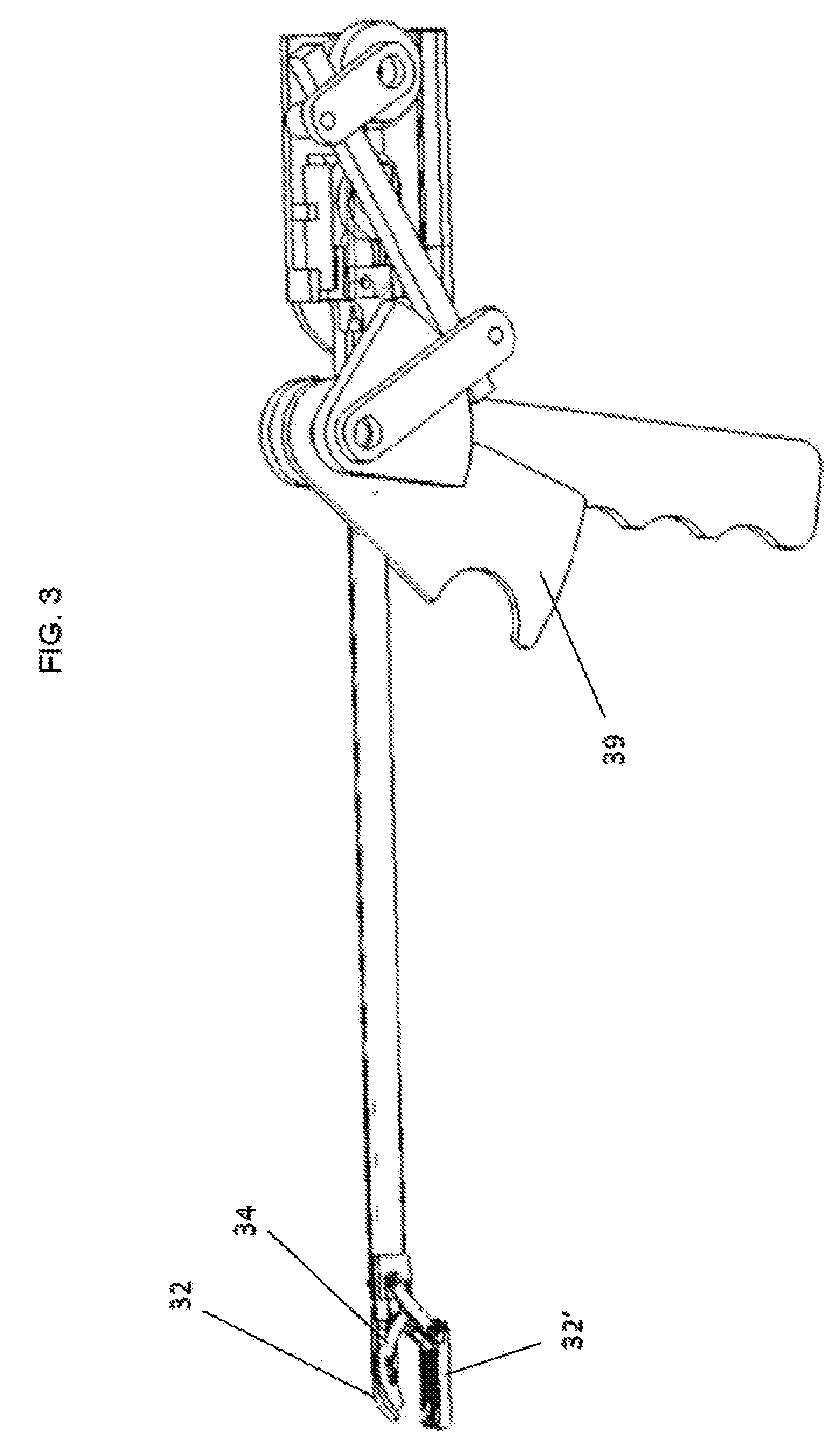

Methods and devices for continuous suture passing

InactiveUS20090012538A1Prevent “ pinching ” and damageIncrease the areaSuture equipmentsSurgical needlesContinuous sutureGeneral surgery

Described herein are suture passers for suturing tissue in a continuous manner by passing a suture attached to a suture shuttle through. A suture passer may include a first jaw, a second jaw, and a tissue perpetrator that is retractable and extendable from the first jaw. The tissue penetrator may have a suture shuttle engagement region, and the second jaw may include a shuttle dock. The suture shuttle may be transferred between the first and second jaws as the tissue penetrator is extended from the first jaw and engages the second jaw. In some variations of the tissue passer, one or both jaws are tissue penetrating. In some variations, the jaws open in parallel, allowing large tissue regions to be positioned between the jaws. Methods of using these devices are also described, as are systems and kits including these devices.

Owner:CETERIX ORTHOPAEDICS

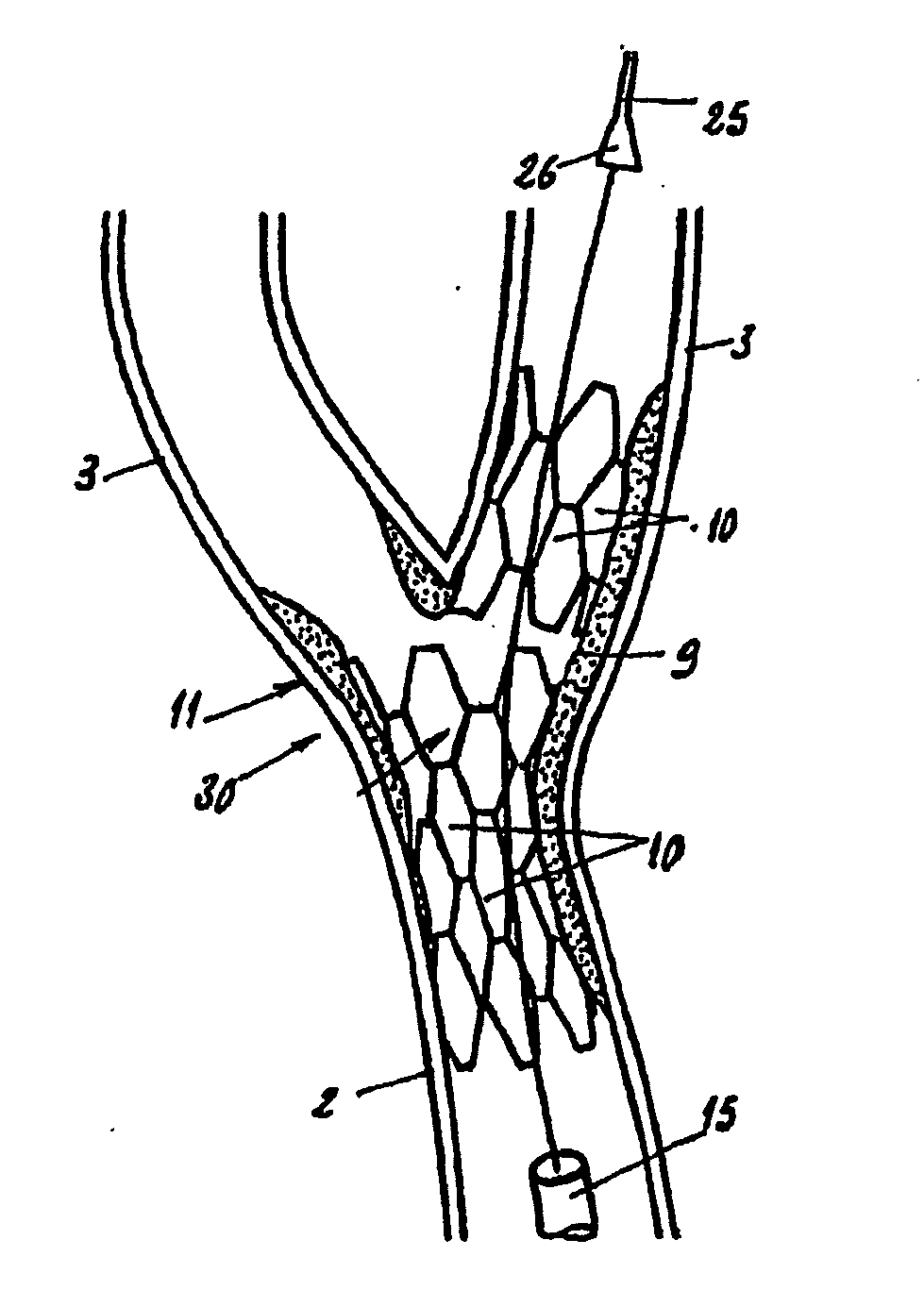

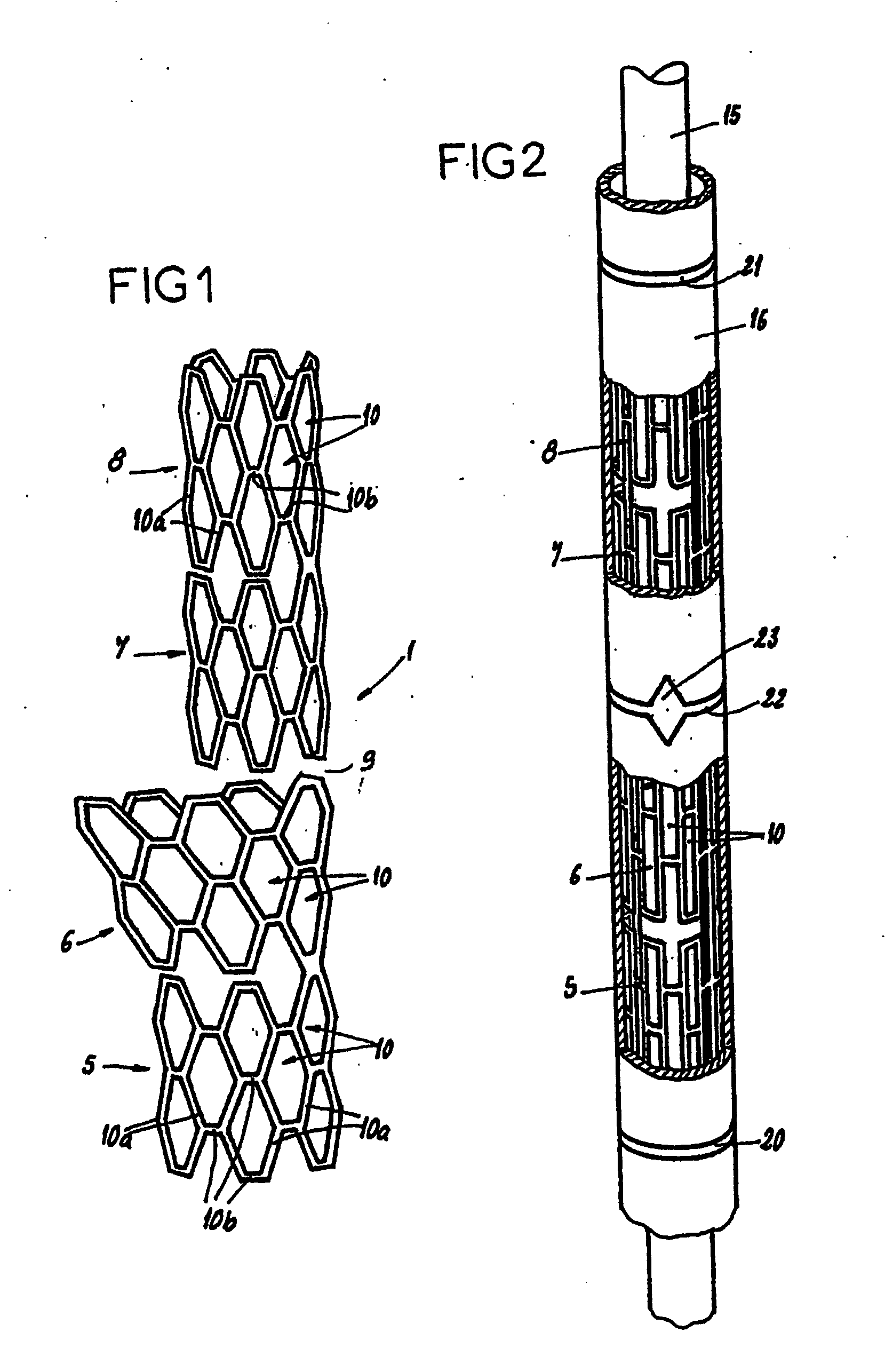

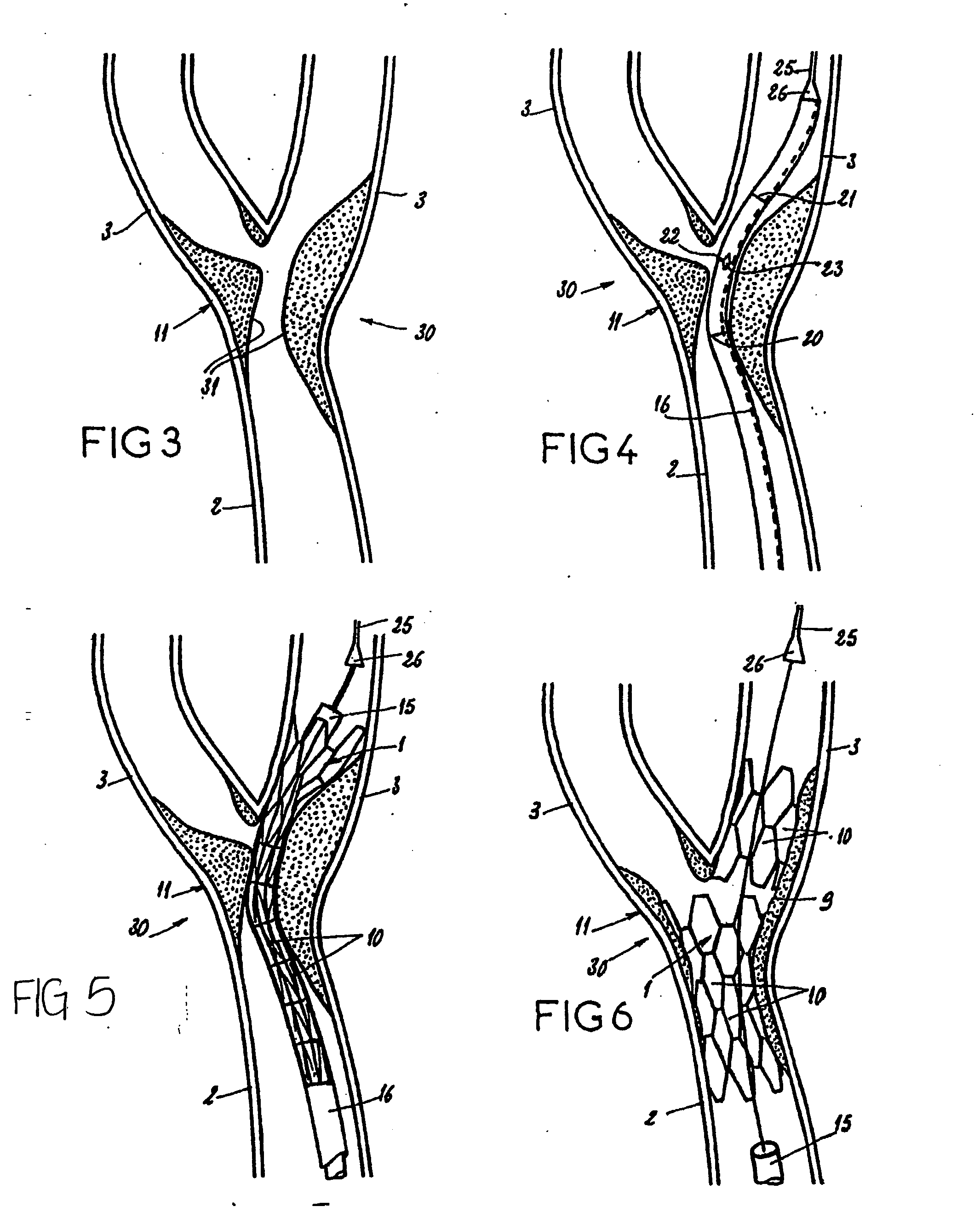

Endoprosthesis for vascular bifurcation

An apparatus for treating an area of bifurcation where a principal body conduit separates into at least two secondary conduits comprises a radially expandable first stent body. The first stent body has a substantially conical shape and a first end having a greater diameter than a second end when fully expanded. The first stent body is preferably shaped to be independent of any other stent bodies, and is free of any means for connecting to any other stent bodies when fully expanded.

Owner:SEGUIN JACQUES +1

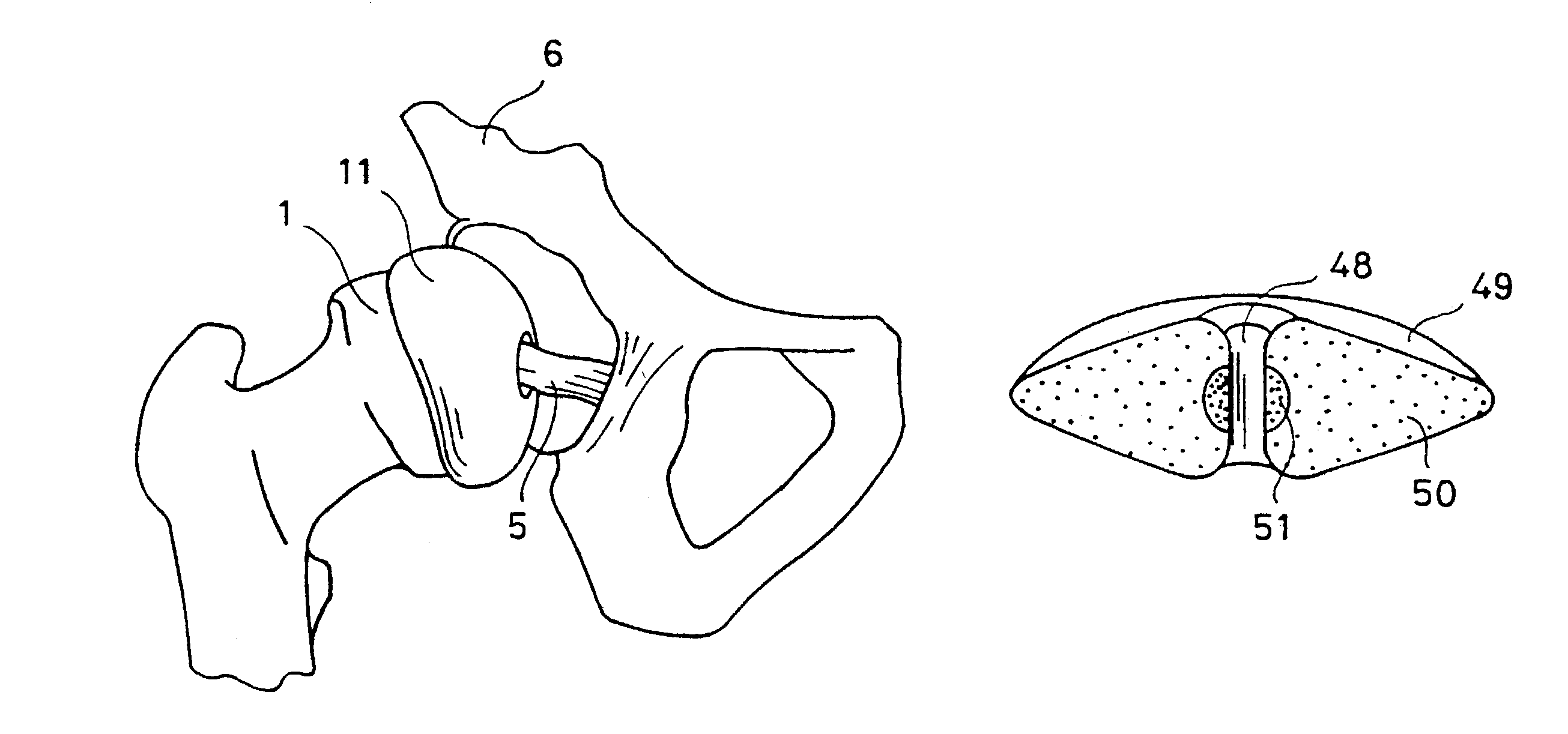

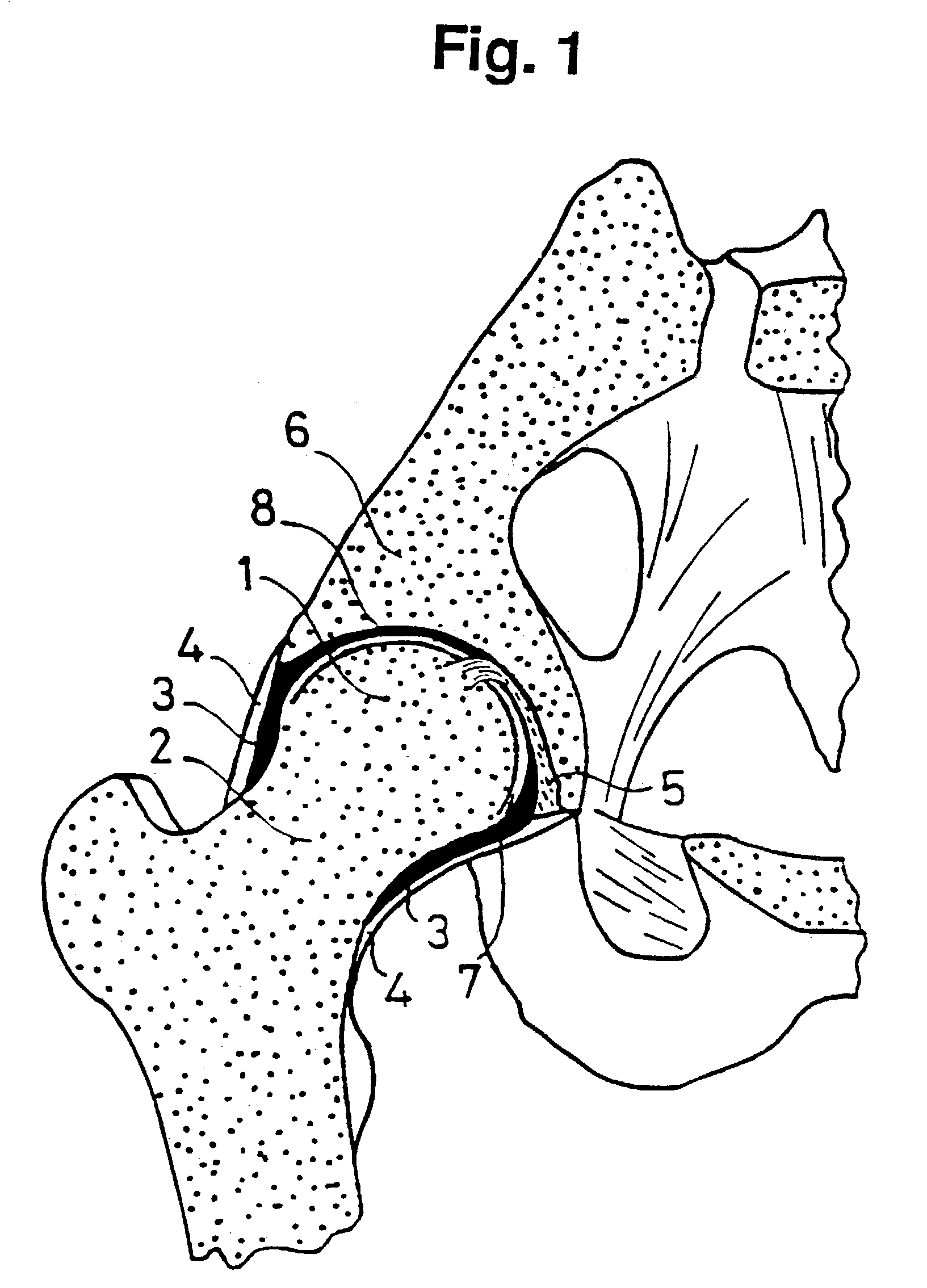

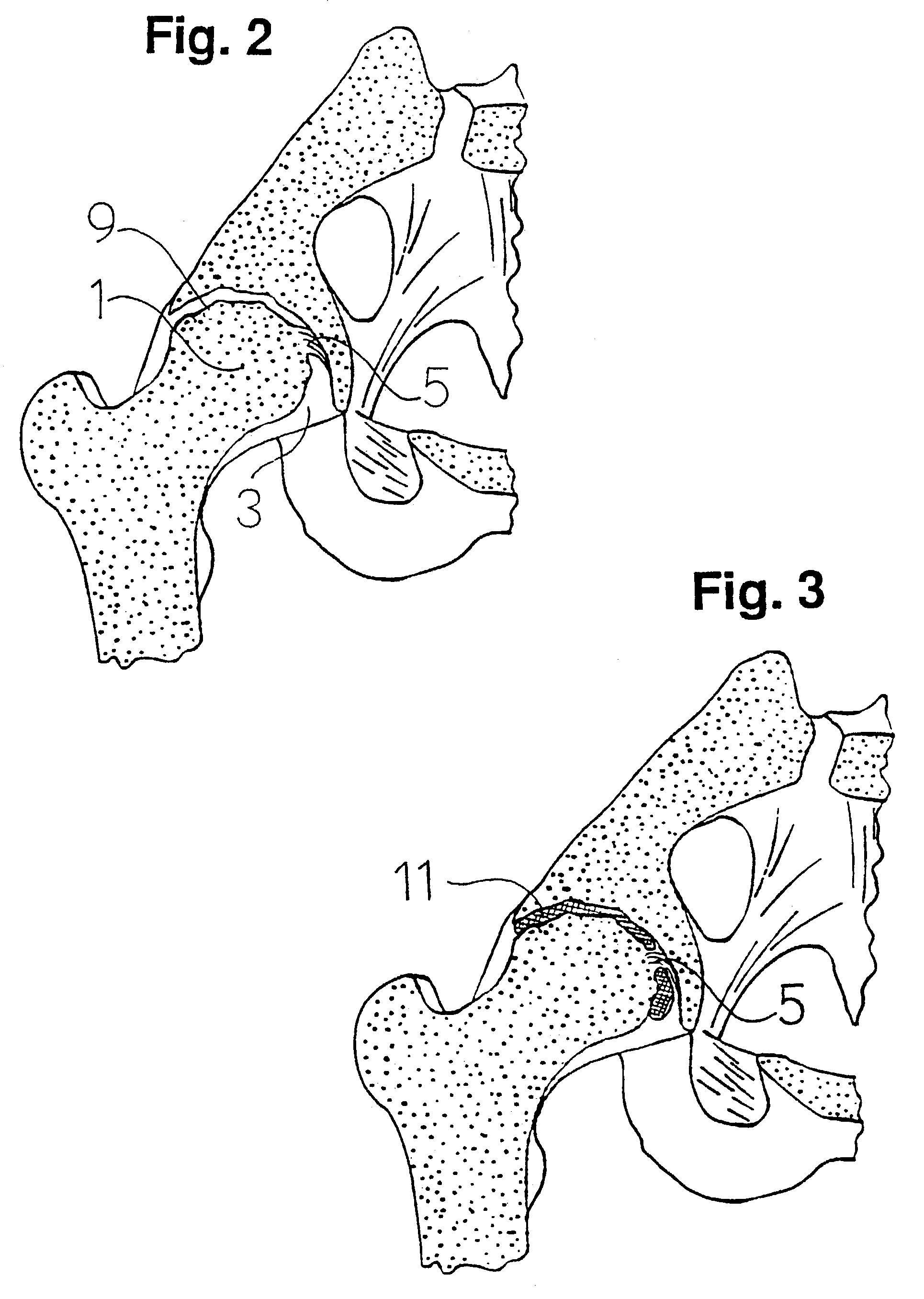

Prosthetic device

The present invention relates to a method and a device for alleviating and / or preventing conditions relating to damaged joints involving articulating surfaces. In a first aspect the present invention relates to a prosthetic device for insertion into a joint cavity of a joint of a vertebrate, such as a human, said device consisting of a biocompatible material comprising at least a first polymeric component and a second polymeric component, wherein the chain length of the first polymeric component is longer than the chain length of the second polymeric component, the polymeric components in particular being polyethylene, polypropylene and / or polyvinylpyrrolidone. A further aspect of invention relates to a method for introducing the prosthetic device into a joint, such as a method comprising locking the device to an intro-articular component, thereby fixing or retaining the device in the joint cavity in a manner which is substantially non-invasive with respect to cartilage and bone natively present in the joint cavity. Also the invention relates to an instrument for inserting a prosthetic device according to the invention, comprising means for deforming the prosthetic device into a reduced volume or a slender shape and means for grasping the intra-articular component to which the device is capable of interlocking.

Owner:DSM IP ASSETS BV

System and method for designing a physiometric implant system

ActiveUS20050197814A1Economy of motionReduction of jerkPerson identificationAnalogue computers for chemical processesJoints surgeryImaging data

A system improves the design of artificial implant components for use in joint replacement surgeries. The system includes an anthropometric static image data analyzer, an implant model data generator, a kinematic model simulator, and a dynamic response data analyzer. The implant model data generator may also use image data of a joint in motion for modification of the implant model data used in the kinematic simulation. Dynamic response data generated by the kinematic model simulation is analyzed by the dynamic response data analyzer to generate differential data that may be used to further refine the implant model data.

Owner:DEPUY PROD INC

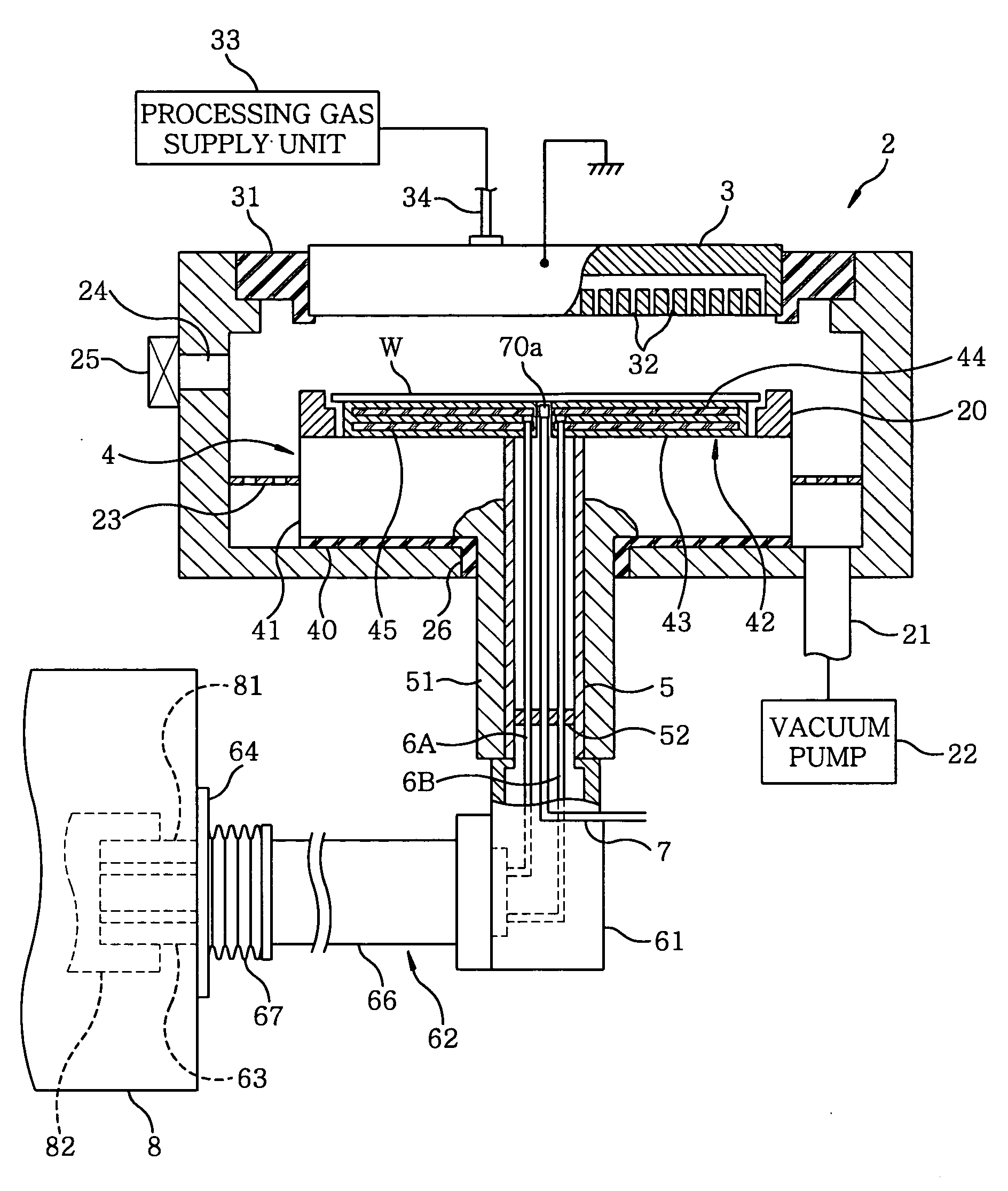

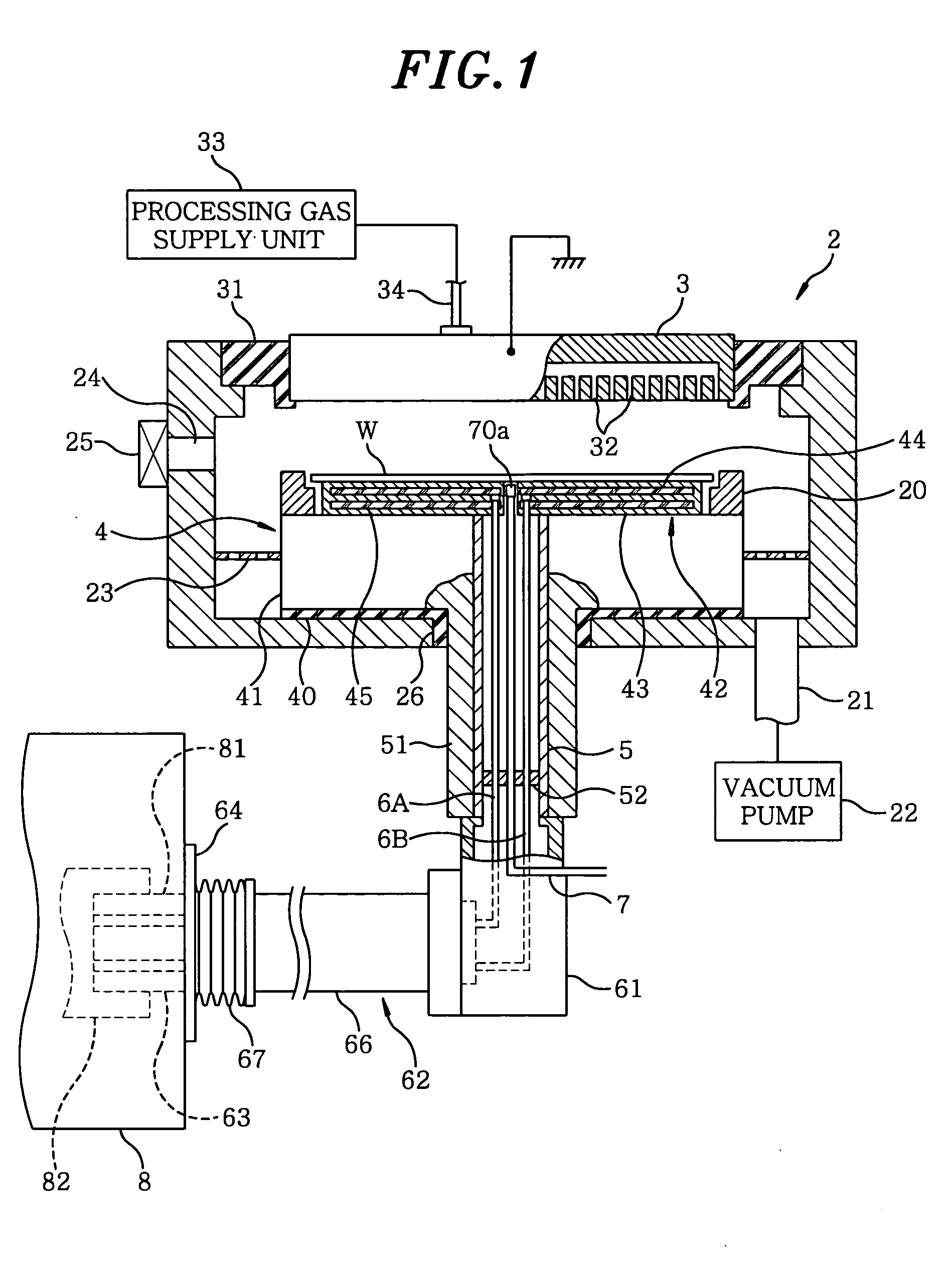

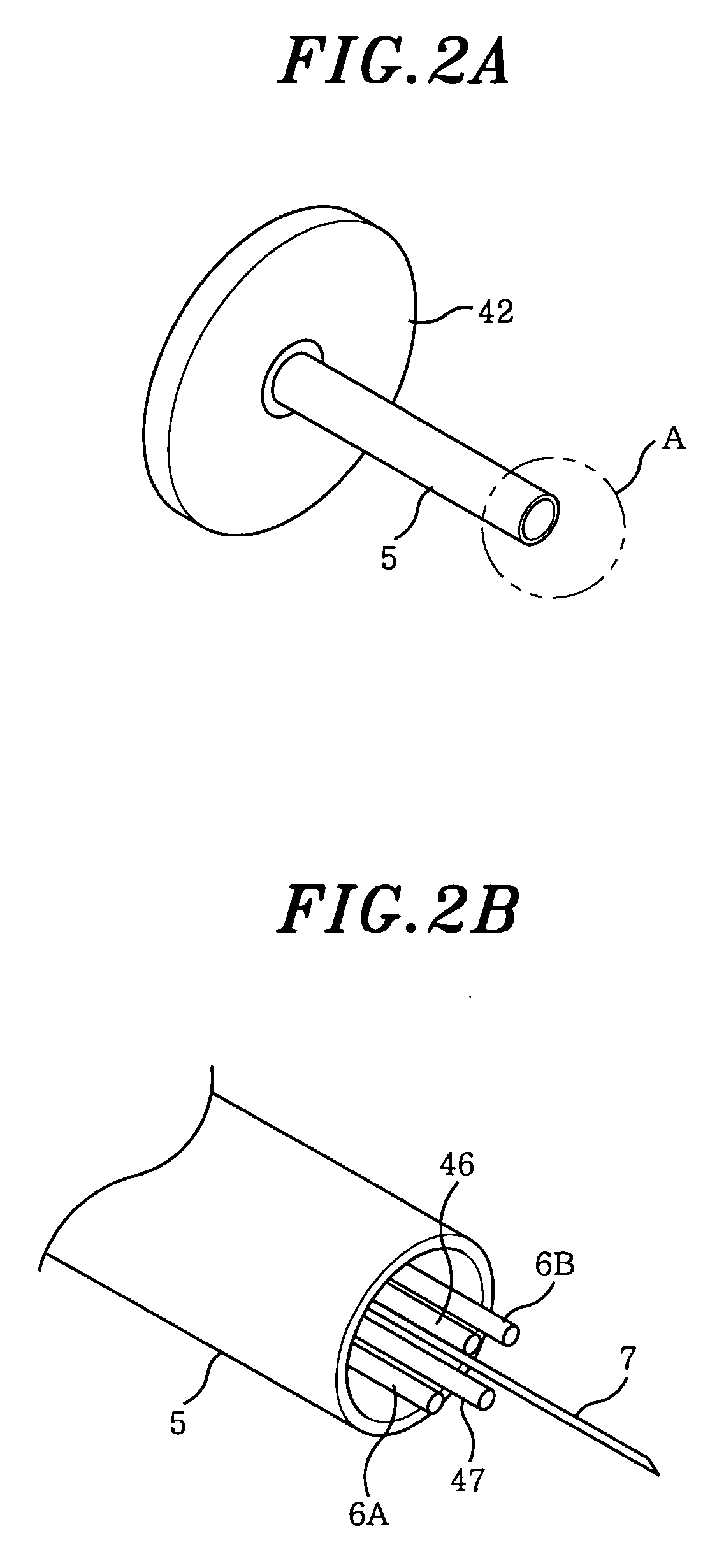

Plasma processing apparatus and mounting unit thereof

InactiveUS20050274324A1Reduce componentsSuitable for processingElectric discharge tubesSemiconductor/solid-state device manufacturingRadio frequencyPlasma treatment

A parallel plate type plasma processing apparatus including a RF feed rod for applying a high frequency power to a susceptor and a temperature detection unit for detecting the temperature of a substrate on the susceptor is configured to reduce an effect that high frequency current flowing in the RF feed rod has on temperature detection of the temperature detection unit. A surface portion of the susceptor serves as a mounting unit including an electrostatic chuck and a heater. A shaft, which is a protection pipe extracted downward from the processing chamber, is provided under the mounting unit. A chuck electrode of the electrostatic chuck serves as an electrode for applying a high frequency voltage. Provided in the shaft are two RF feed rod for supplying a power to the electrode and an optical fiber, i.e., a temperature detection unit, having a dielectric fluorescent material is disposed in a leading end thereof. Then, the two RF feed rods and bar type conductive leads for the heater are alternately arranged at equal intervals in a circumferential direction on a circle having the optical fiber at the center thereof such that the region having therein the optical fiber is an electromagnetic wave-free region since the electric force lines respectively traveling from the RF feed rods to bar type conductive leads are offset with each other.

Owner:TOKYO ELECTRON LTD

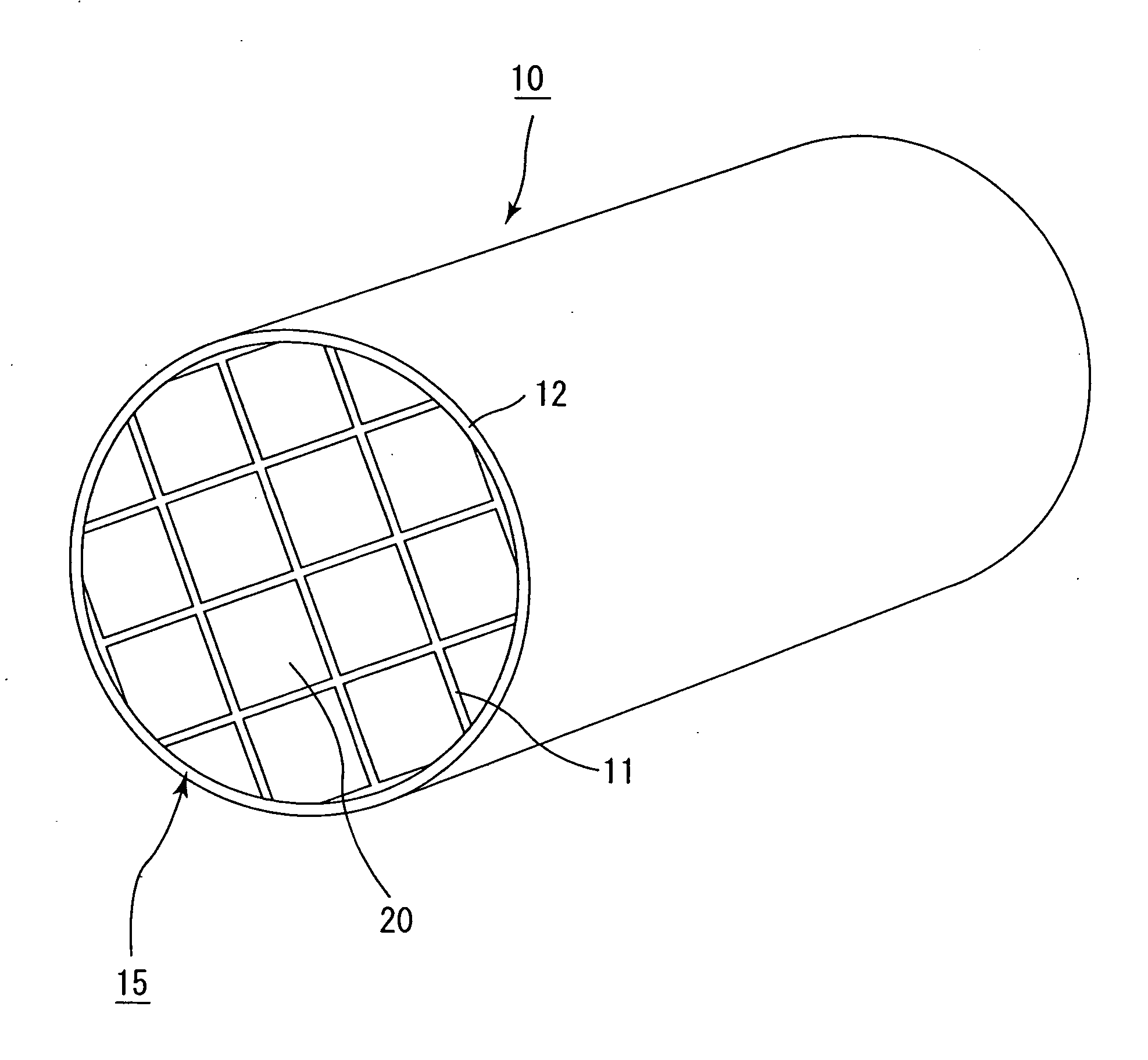

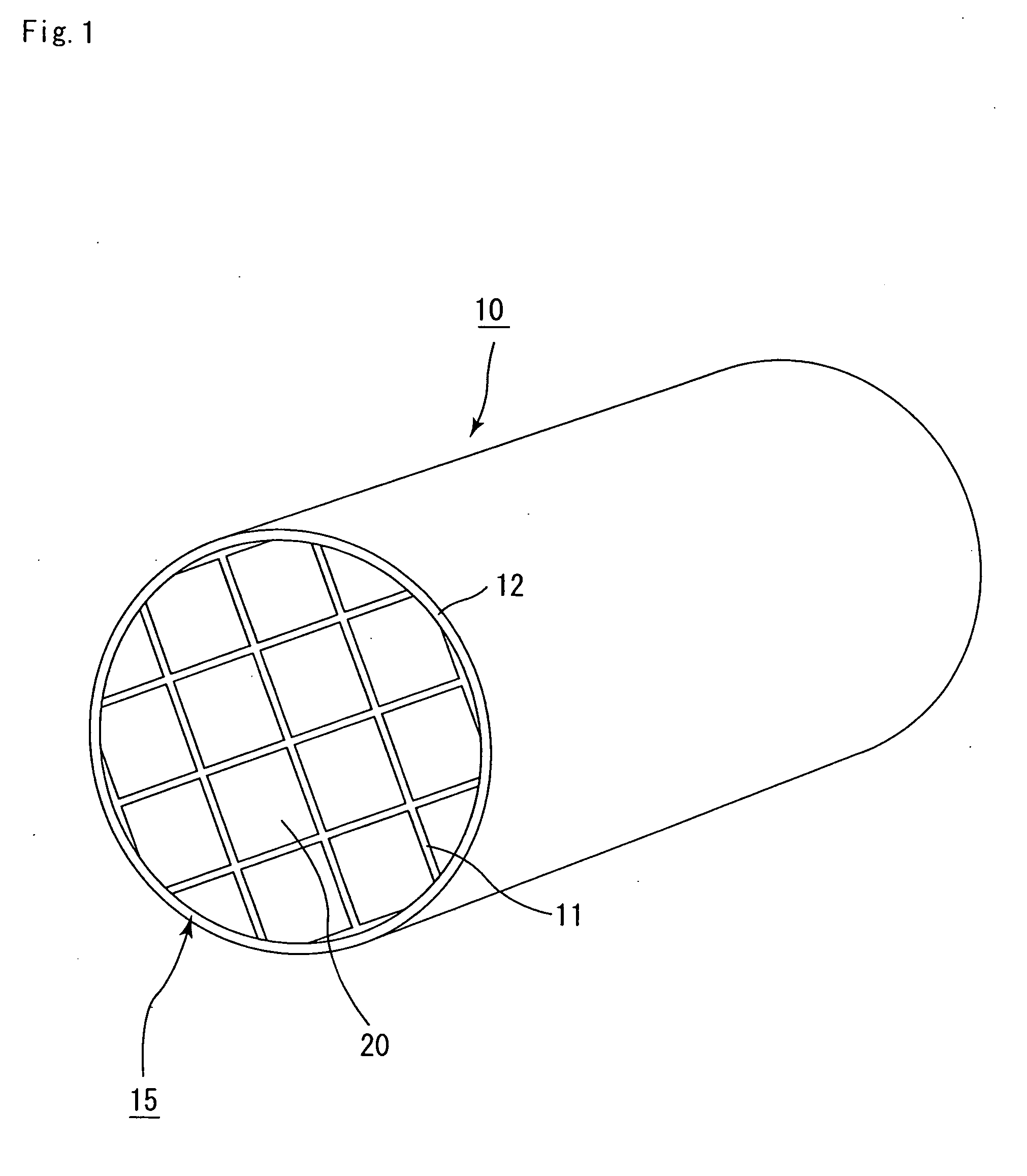

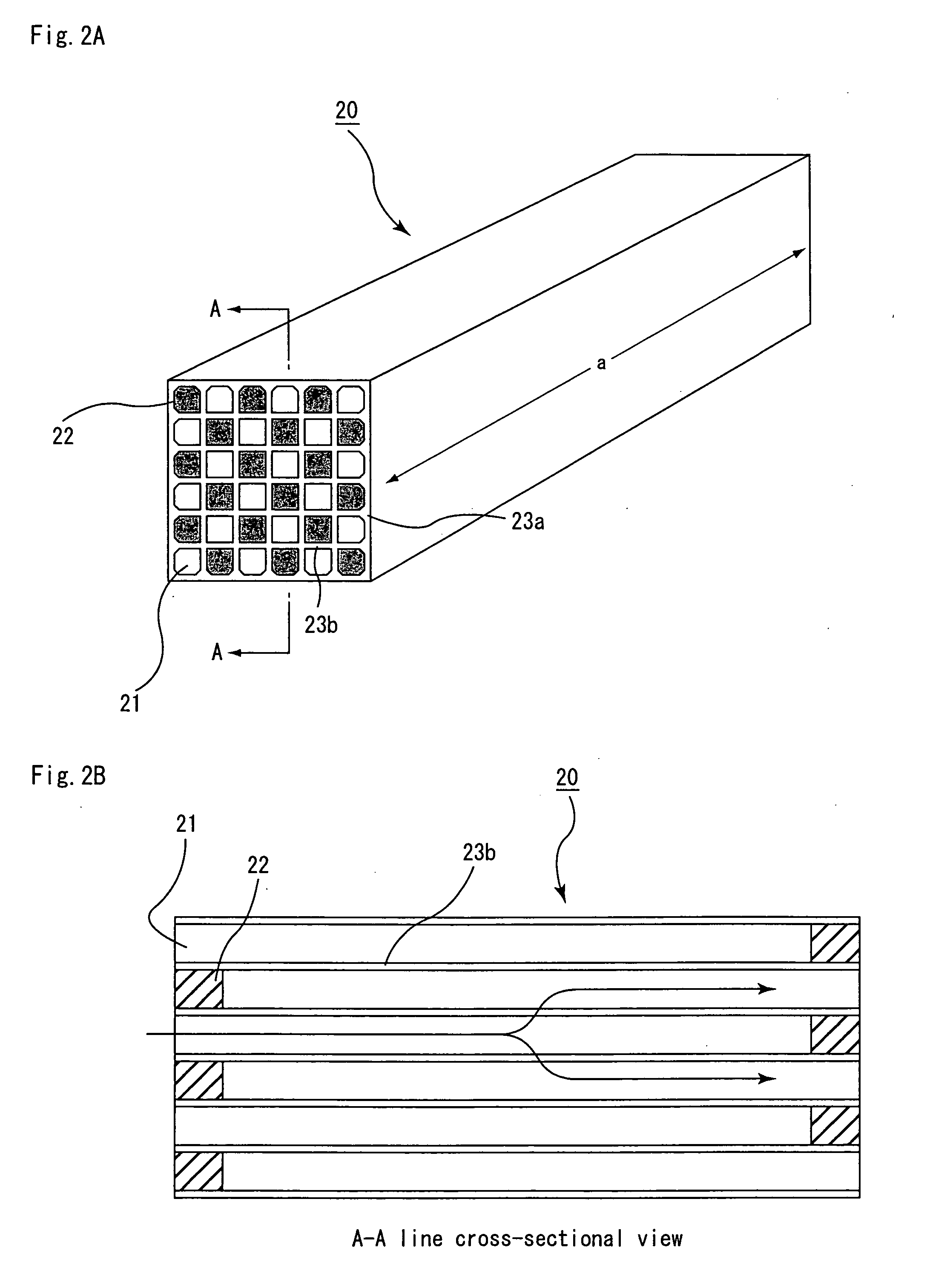

Honeycomb structured body, method for manufacturing honeycomb structured body, and exhaust gas purifying device

InactiveUS20070130897A1Avoid deformationReduce generationPhysical/chemical process catalystsInternal combustion piston enginesEdge surfaceCell wall

A honeycomb structured body in which a plurality of porous ceramic members are combined with one another by interposing an adhesive layer, each of the porous ceramic members having a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween and an outer edgewall on the outer edge surface thereof, wherein the thickness of the outer edge wall of the porous ceramic member is greater than the thickness of the cell wall, and each of the porous ceramic members has a filling body which is provided so as to fill in at least one corner portion of at least one outermost cell of the porous ceramic members.

Owner:IBIDEN CO LTD

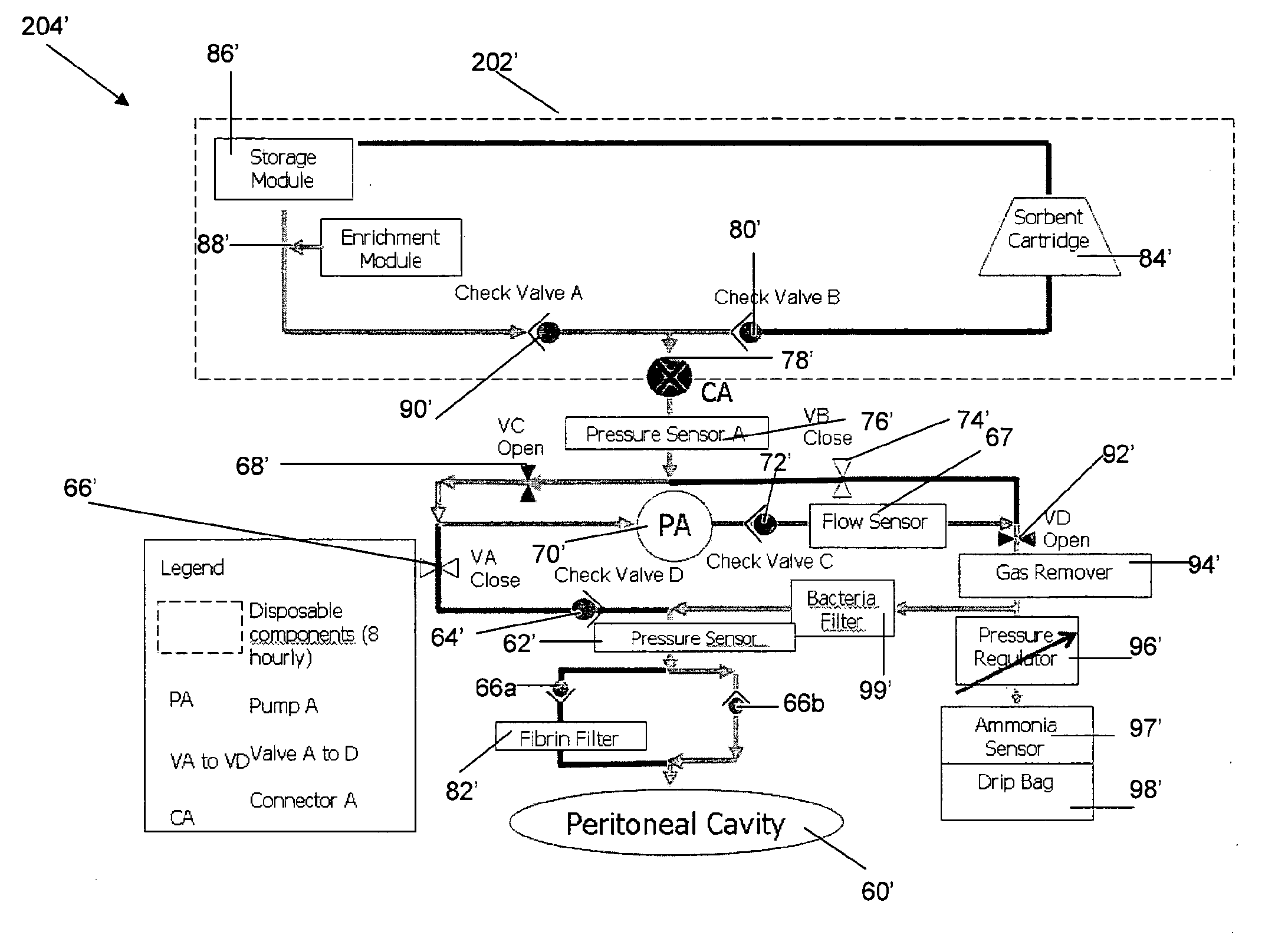

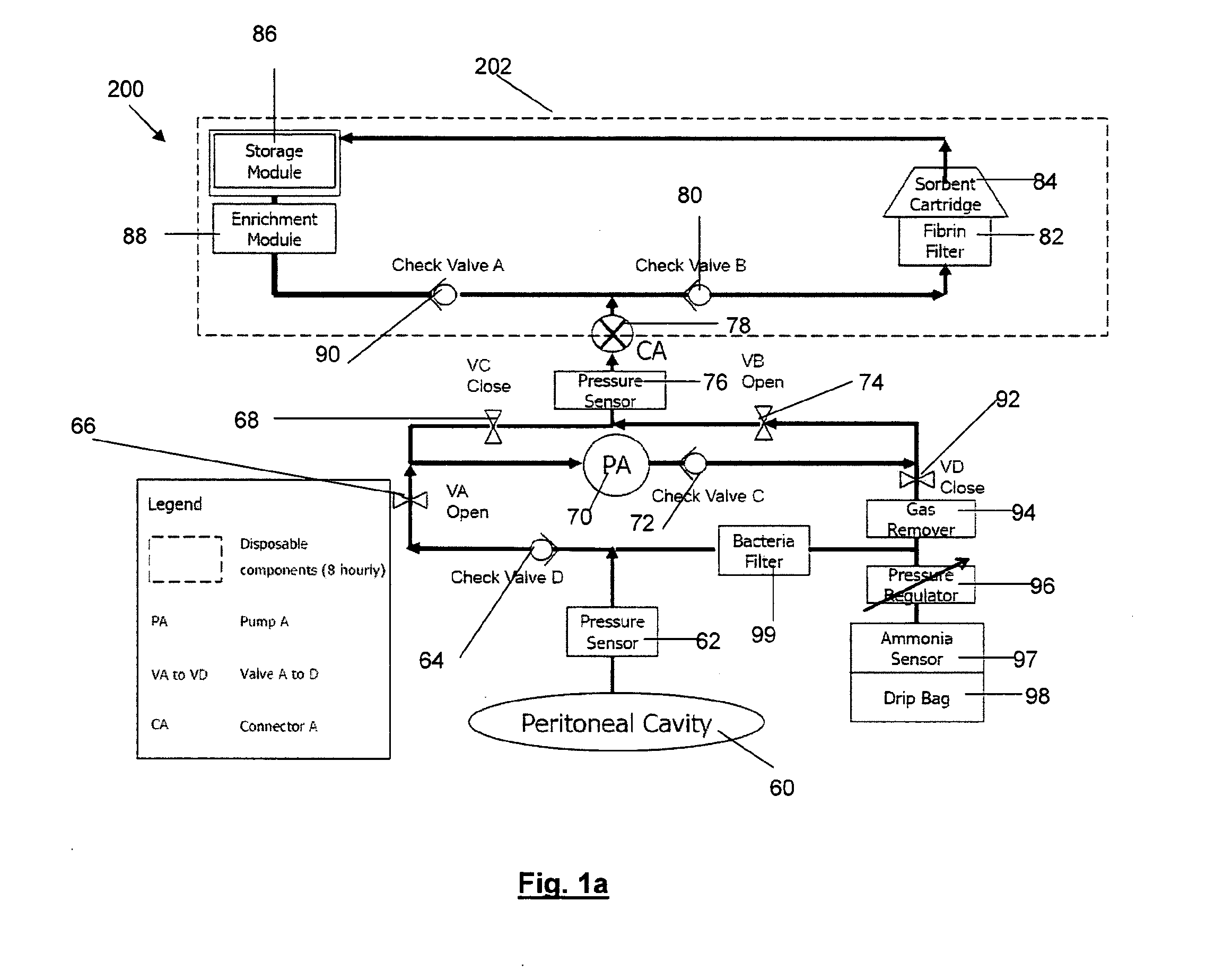

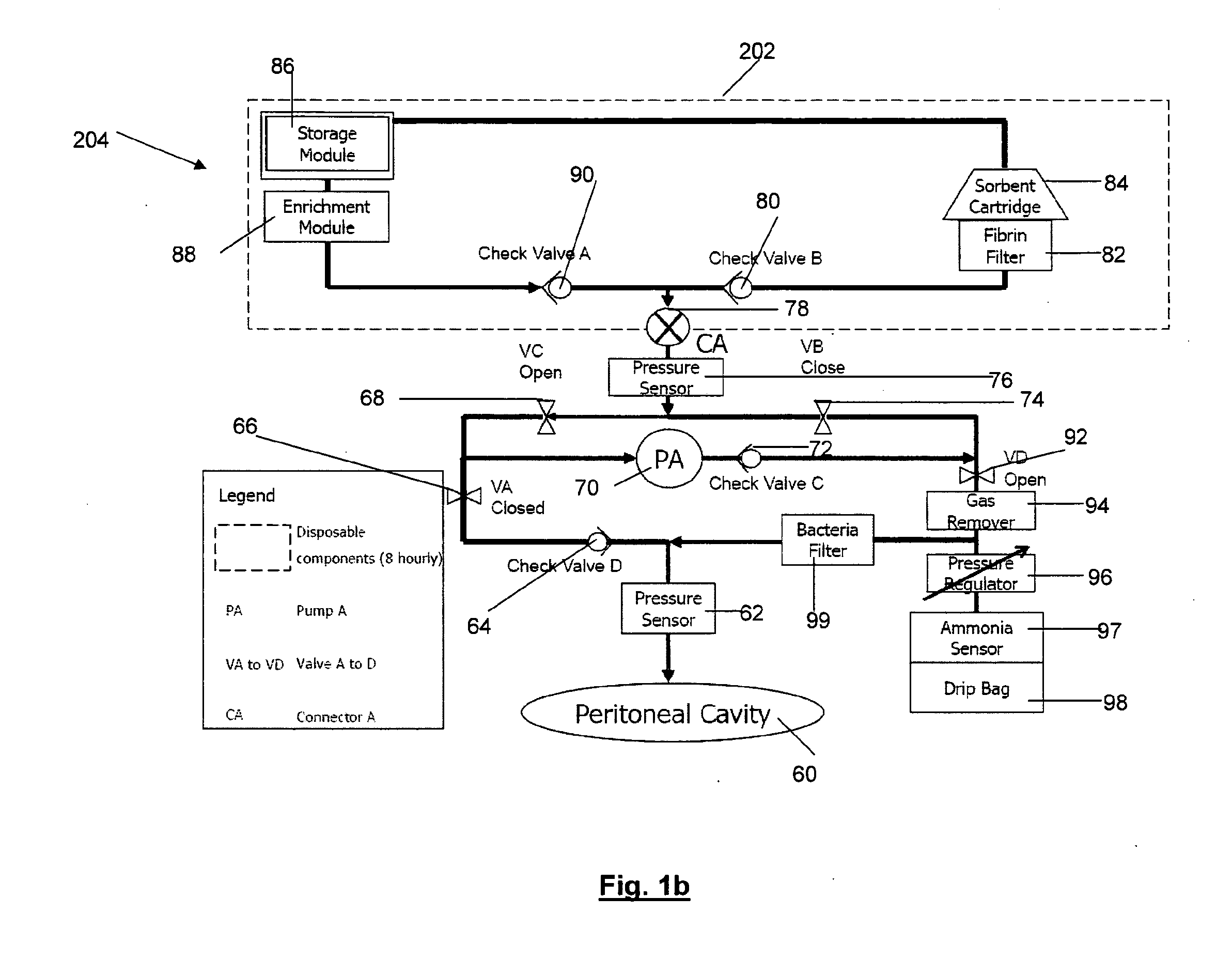

Flow system of a dialysis device and a portable dialysis device

ActiveUS20110184340A1Prevent leakagePrevent spillageSolid sorbent liquid separationAnion exchangersCatheterPeritoneal cavity

There is provided a flow system of a dialysis device including a dialysate conduit which is capable of being in fluid communication with the peritoneal cavity of a patient's body and of being in fluid communication with a flow path, the flow path allowing dialysate to flow from a patient's body to a sorbent capable of removing contaminants within the dialysate in an outflow mode and in an inflow mode returning the dialysate substantially free of contaminants to the patient's body. The device also includes a pump for moving the dialysate along the flow path in both the outflow mode and inflow mode and a plurality of valves disposed along the flow path. There is also provided a portable dialysis device.

Owner:TEMASEK POLYTECHNIC

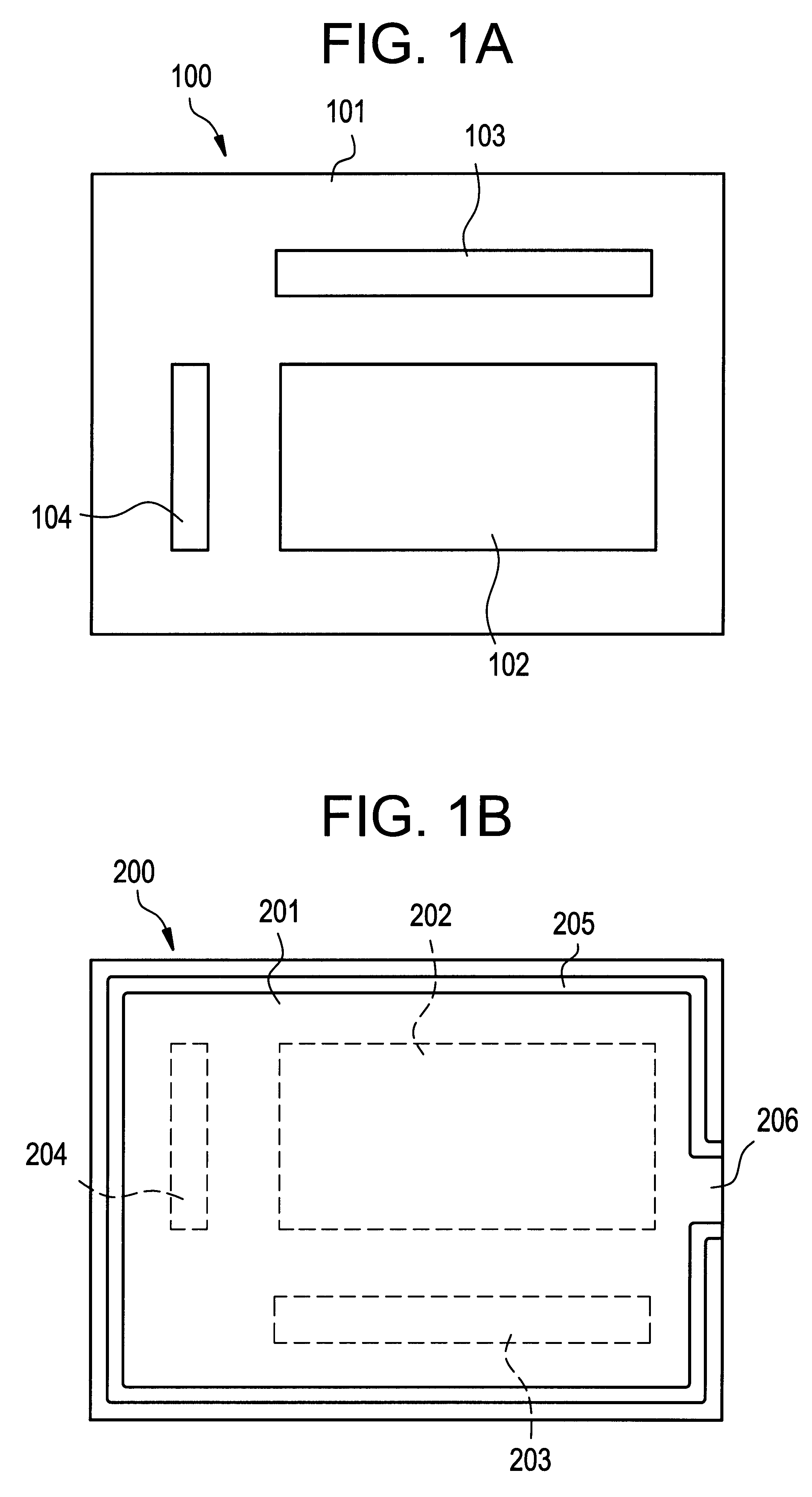

Method of manufacturing an electro-optical device

InactiveUS6465268B2Prevent be damageHigh integration densityStatic indicating devicesSolid-state devicesEngineeringElectro-optics

In an active matrix semiconductor display device in which pixel TFTs and driver circuit TFT are formed on the same substrate in an integral manner, the cell gap is controlled by gap retaining members that are disposed between a pixel area and driver circuit areas. This makes it possible to provide a uniform cell thickness profile over the entire semiconductor display device. Further, since conventional grainy spacers are not used, stress is not imposed on the driver circuit TFTs when a TFT substrate and an opposed substrate are bonded together. This prevents the driver circuit TFTs from being damaged.

Owner:SEMICON ENERGY LAB CO LTD

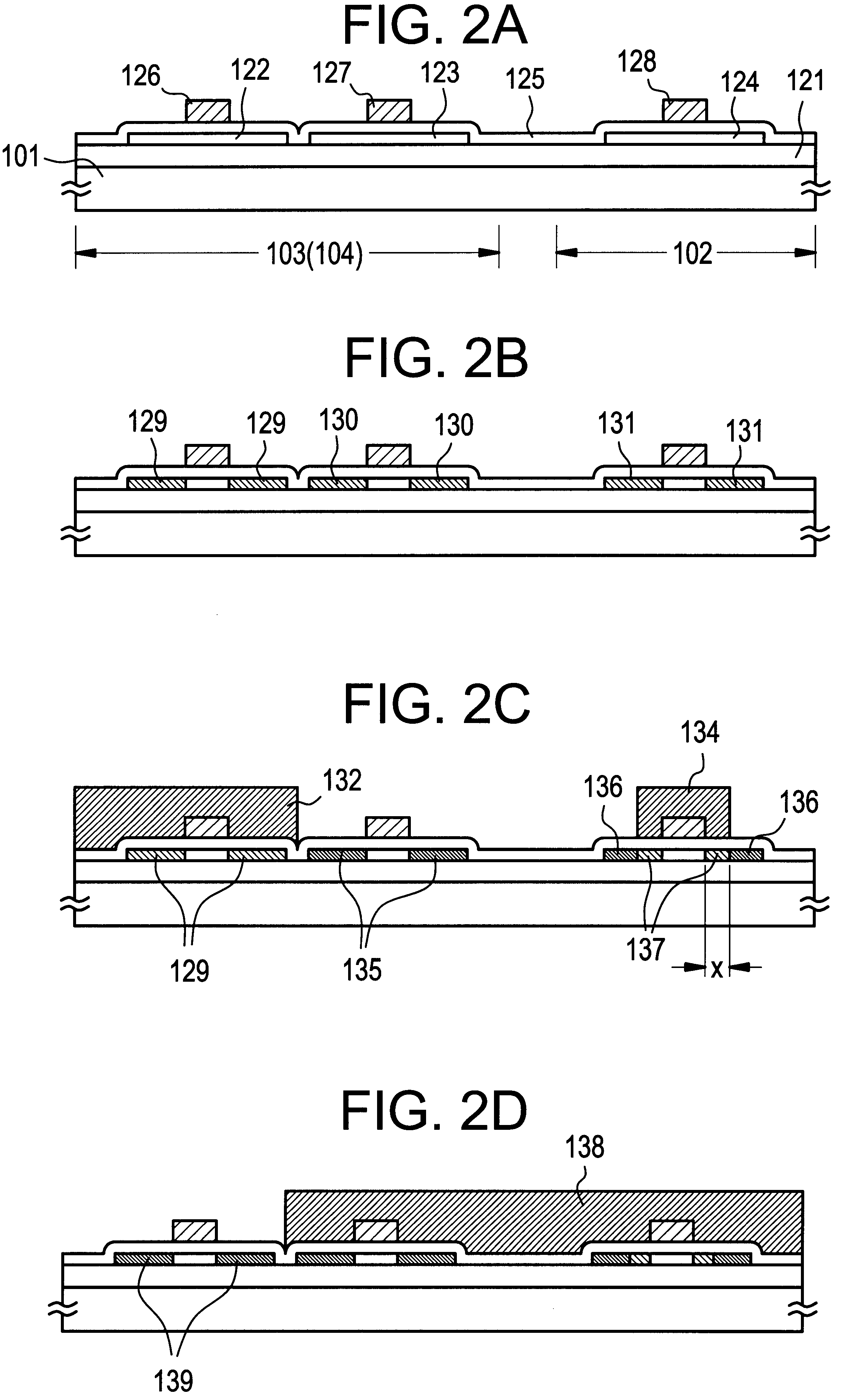

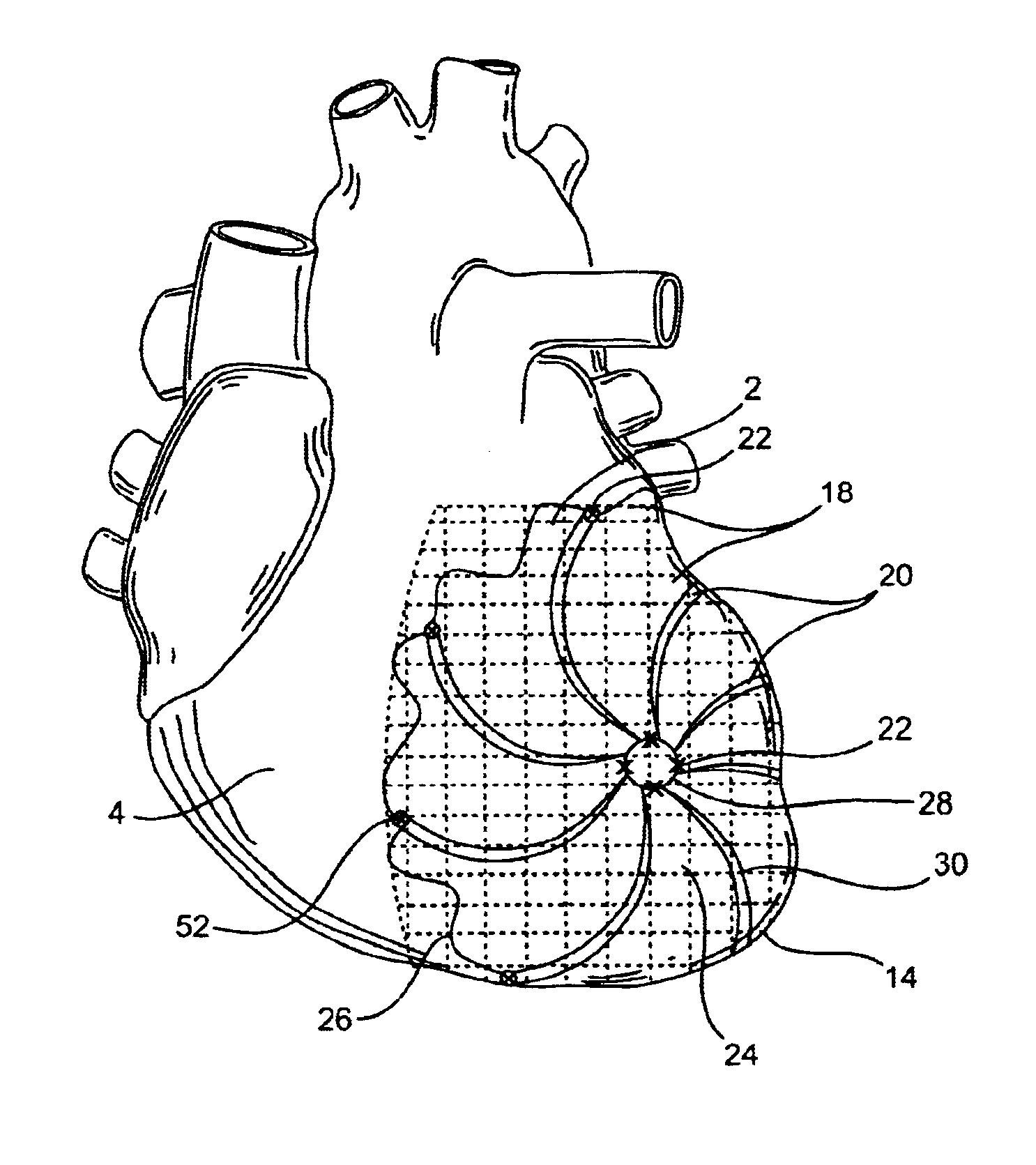

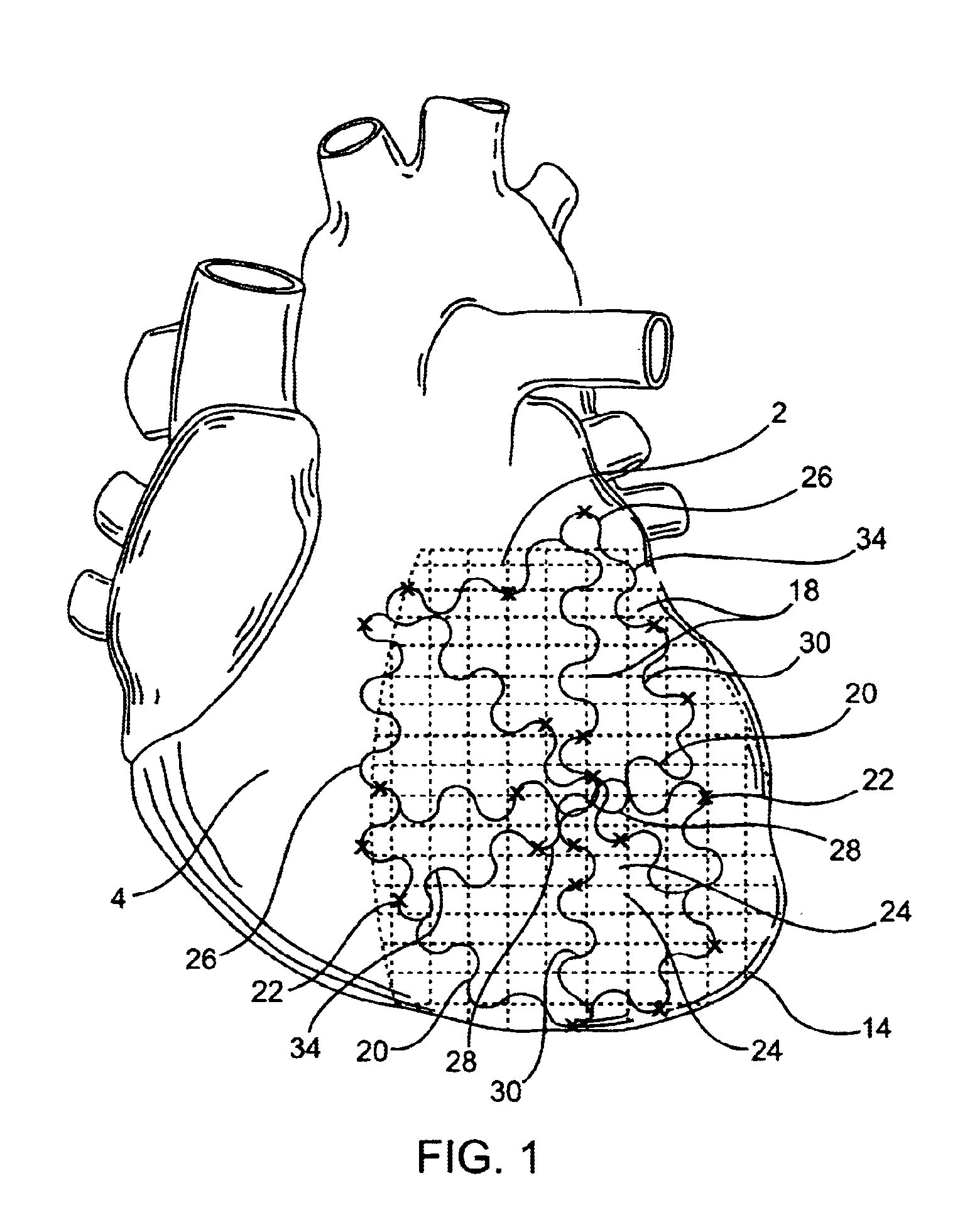

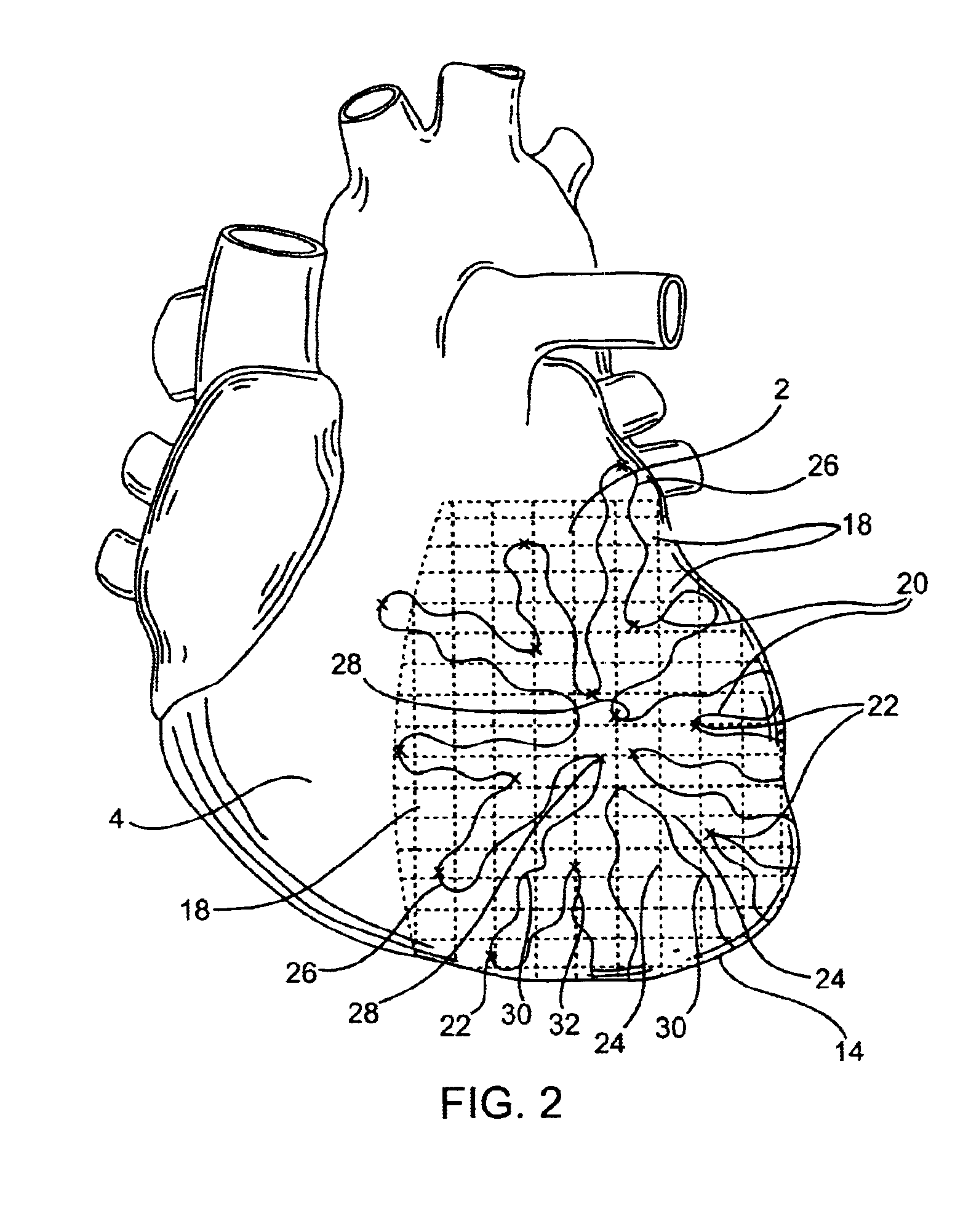

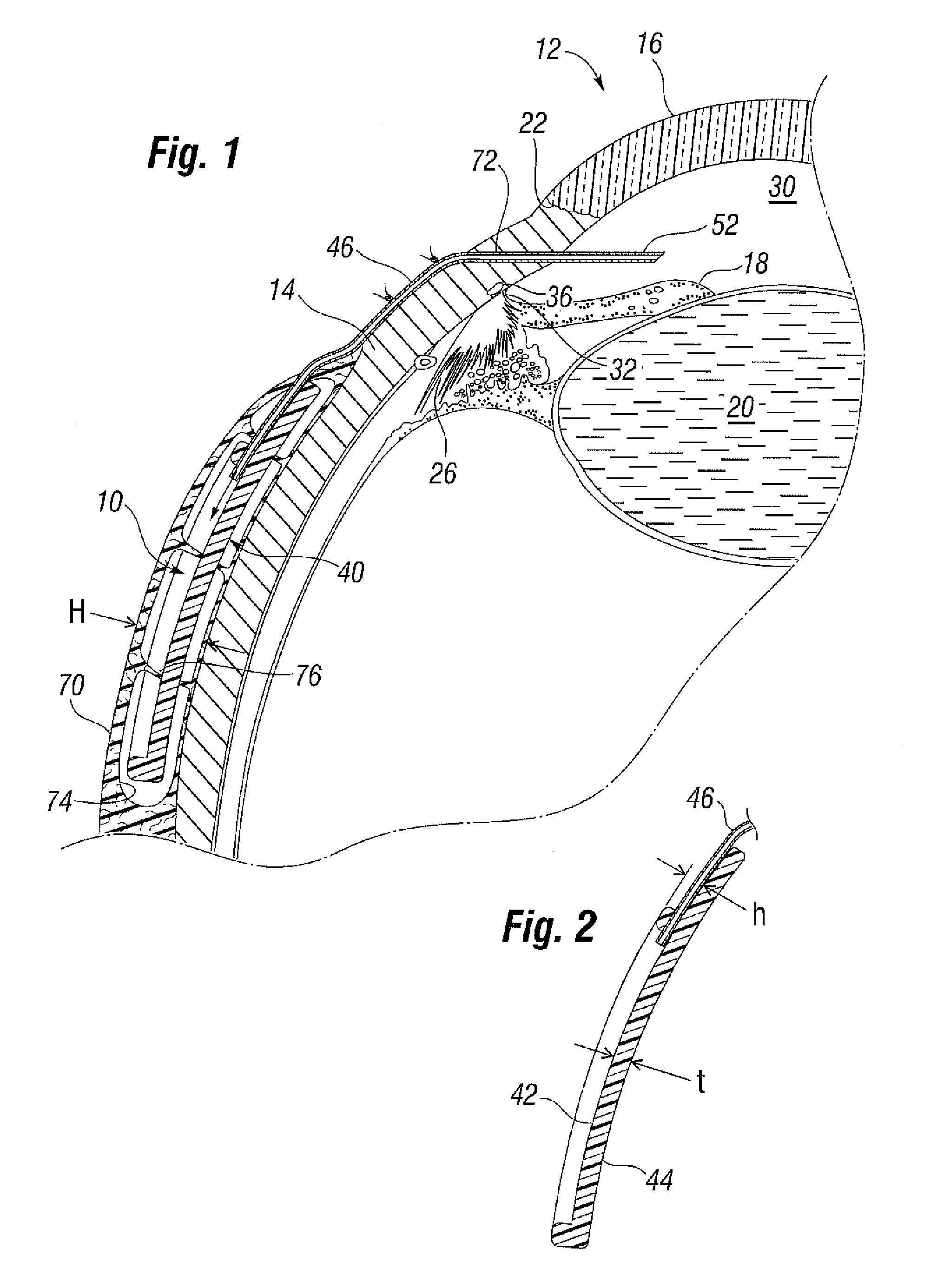

Deployable epicardial electrode and sensor array

InactiveUS20090299447A1Minimally invasiveRelieve stressEpicardial electrodesExternal electrodesElectrical controlSubxiphoid approach

Minimally invasive deployable epicardial array devices are provided. The devices include deployable platform comprising two or more effectors, such as sensors and actuators, where the devices are configured to be deployed at an epicardial location via a minimally invasive, e.g., sub-xiphoid approach. In embodiments of the present invention, at least one area of the electrode patch is an electrical control area that comprises a series of effectors, e.g., sensors and / or electrodes. Other embodiments provide localized physical constraint and dynamic mechanical stimulation of the heart to effectuate physical and biological responses. Still other embodiments provide both of these functions. Also provided are methods of using the devices, as well as systems and kits that include the devices.

Owner:PROTEUS DIGITAL HEALTH INC

Fluid-assisted medical device

InactiveUS20060100619A1Fixed spacingRelieve stressSurgical instruments for heatingSurgical forcepsMedical deviceBiomedical engineering

The invention provides a medical device that includes a housing, a tubular member extending from the distal end of the housing, a first arm extending from the distal end of the tubular member, the first arm including a first electrode, a second arm extending from the distal end of the tubular member, the second arm including a second electrode and being disposed coaxially with the first arm, at least one solution infusion opening on each electrode, and a solution delivery channel for delivery of a conductive solution to the solution infusion openings. According to the invention, at least one of the first arm or the second arm is translationally moveable, and at least one of the first arm or the second arm is adapted to be coupled to a source of radiofrequency energy. The invention also provides a corresponding method for treating blood vessels or other tissues of the body.

Owner:MEDTRONIC ADVANCED ENERGY

Systems and methods for electrosurgical tissue contraction within the spine

The present invention provides systems and methods for selectively applying electrical energy to a target location within a patient's body, particularly including tissue in the spine. The present invention applies high frequency (RF) electrical energy to one or more electrode terminals in the presence of electrically conductive fluid to contract collagen fibers within the tissue structures. In one aspect of the invention, a system and method is provided for treating herniated or swollen discs within a patient's spine by applying sufficient electrical energy to the disc tissue to contract or shrink the collagen fibers within the nucleus pulposis. This causes the pulposis to shrink and withdraw from its impingement on the spinal nerve.

Owner:ARTHROCARE

Heart support to prevent ventricular remodeling

InactiveUS6887192B1Reducing end-diastolic diameterRelieve stressHeart valvesControl devicesSystoleCardiac functioning

This is a support device that prevents, reduces, and delays remodeling of diseased cardiac tissue, and also decreases the impact of such remodeling on collateral tissue is disclosed. The invention further reinforces abnormal tissue regions to prevent over-expansion of the tissue due to increased afterload and excessive wall tension. As a result, the support device prevents phenomenon such as systolic stretch from occurring and propagating. The support structure maintains and restores diastolic compliance, wall motion, and ejection fraction to preserve heart functionality. As such, the support device prevents and treats cardiomyopathy and congestive heart failure.

Owner:CONVERGE MEDICAL

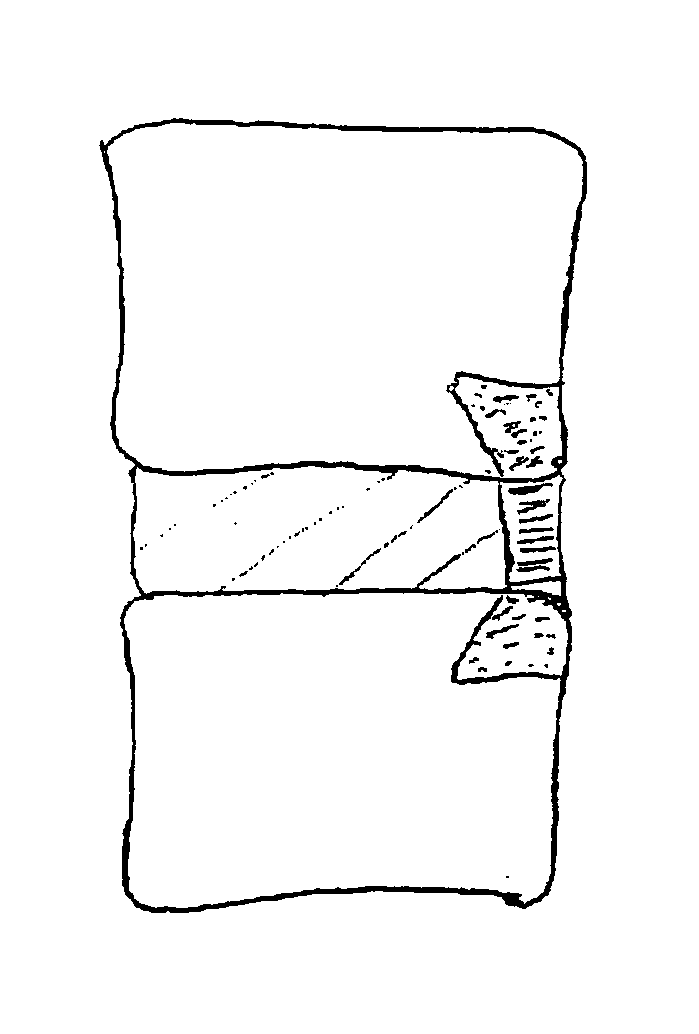

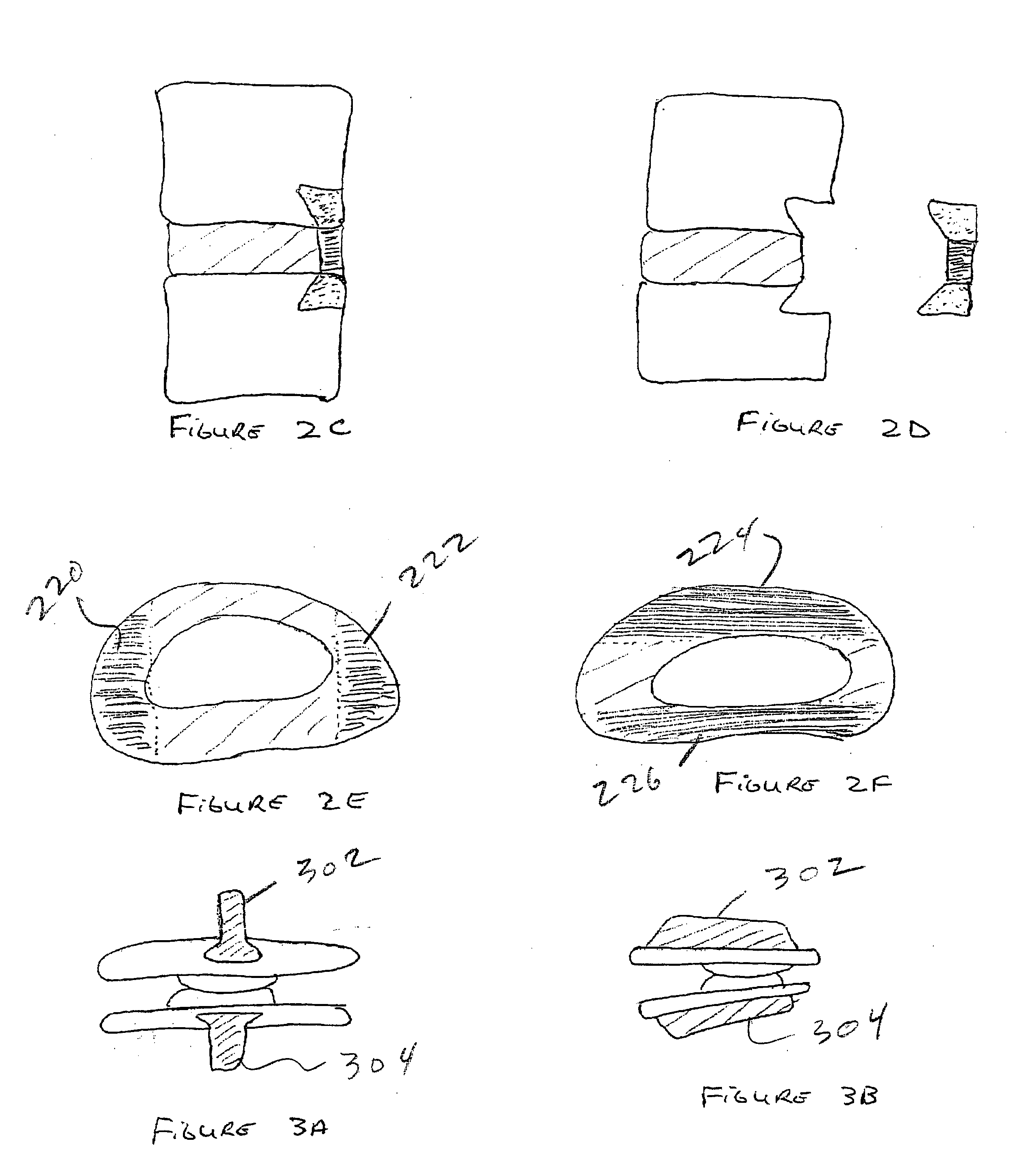

Spinal implants, including devices that reduce pressure on the annulus fibrosis

InactiveUS20050256582A1Promote reconstructionPrevents herniationInternal osteosythesisBone implantFibrosisDiscectomy

The invention broadly facilitates reconstruction of the Annulus Fibrosus (AF) or the AF and the Nucleus Pulposus (NP). Such Reconstruction prevents recurrent herniation following Microlumbar Discectomy (MLD) other procedures. The invention may also be used in the treatment of herniated discs, annular tears of the disc, or disc degeneration, while enabling surgeons to preserve the contained NP. The methods and apparatus may be used to treat discs throughout the spine including the cervical, thoracic, and lumbar spines of humans and animals. In the preferred embodiment, a spinal repair system according to the invention comprises a first end portion adapted for placement within an intervertebral body, a second end portion adapted for placement within an adjacent intervertebral body, and a bridge portion connecting the first and second end portions, the bridge portion being adapted to span a portion of an intervertebral disc space and prevent excessive outward bulging.

Owner:ANOVA

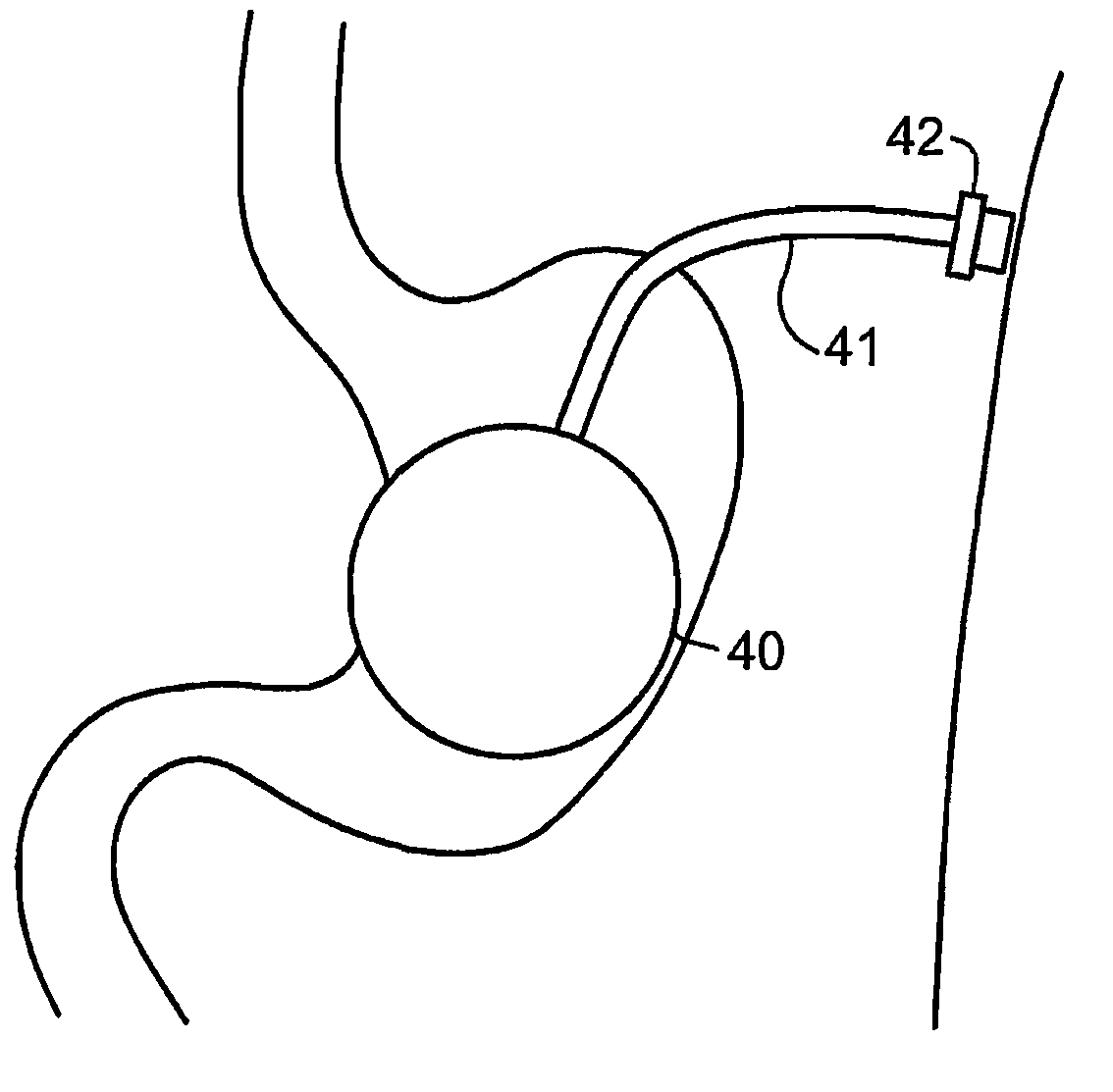

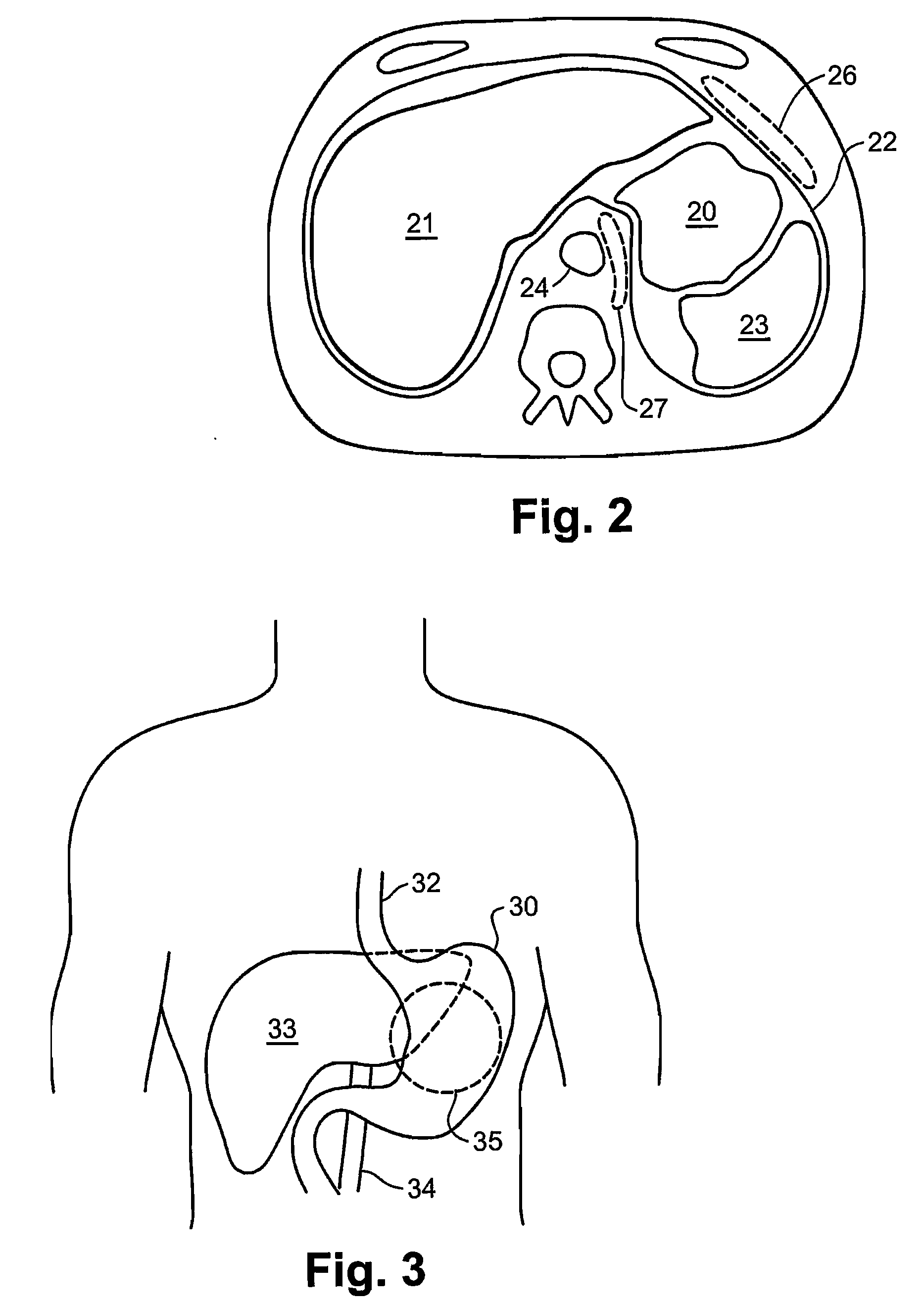

Implantable Device For Obesity Prevention

InactiveUS20080208240A1Avoid displacementExpansion is limitedSurgeryDilatorsMinimally invasive proceduresObesity prevention

A device for controlling the expansion of a hollow internal organ, comprising an inflatable balloon, which is inserted in an uninflated state into the desired position close to the organ using minimally invasive procedures. After insertion, the balloon is inflated to its required size and shape. The invention is useful for restricting the expansion of the stomach during meals, thus inducing a feeling of satiety and preventing over-eating. Inflation may be performed through a catheter connected to a readily accessible inflation port. In the case of the gastric embodiment, the balloon may be positioned pro-peritoneally, such that the procedure is surgically simple. One or more sensors located close to the organ to be controlled, may monitor a physiological effect relating to the organ, and the output of the sensor used to control the level of inflation of the balloon in order to correct the condition being monitored.

Owner:STIMPLANT

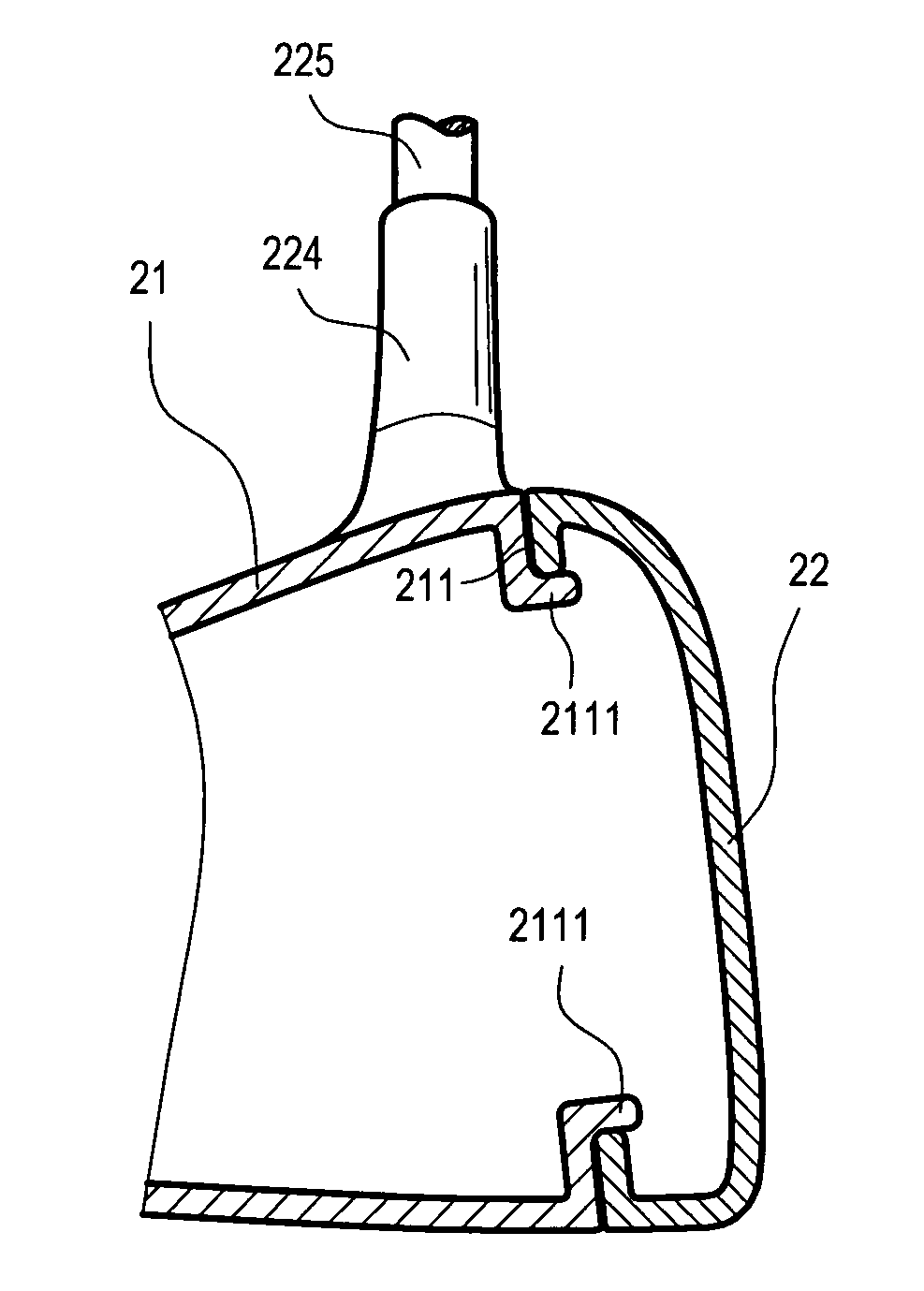

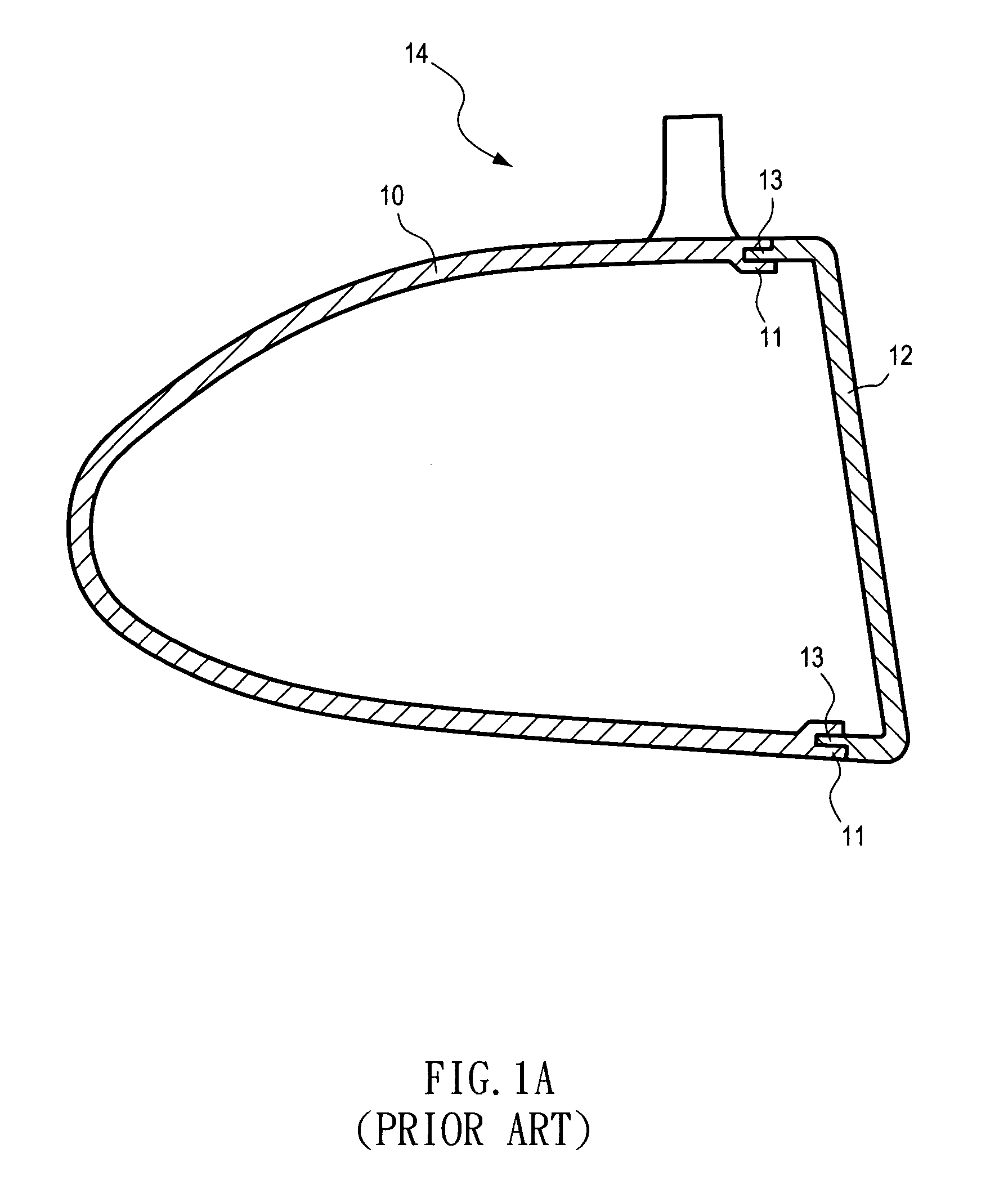

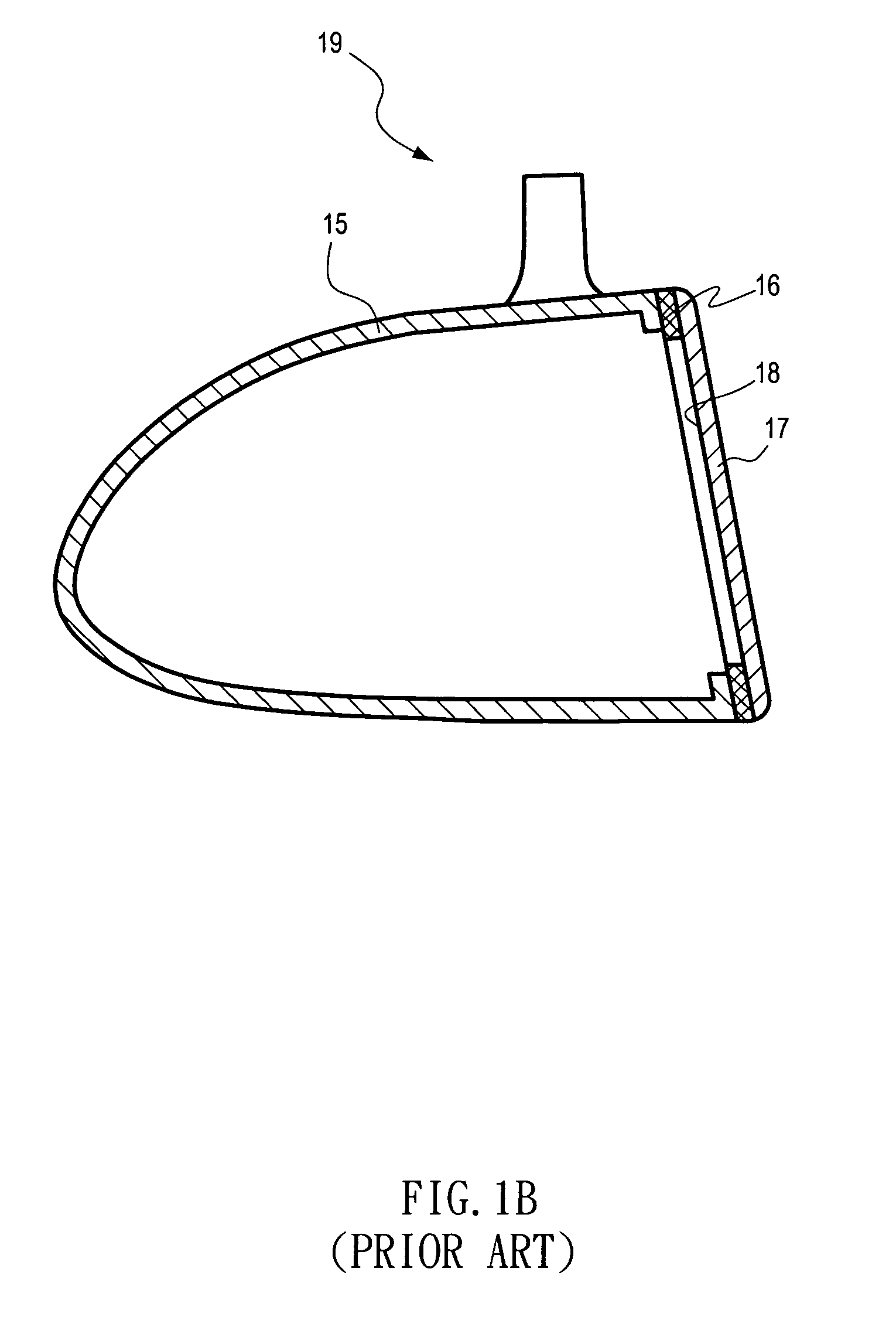

Golf club head structure

A golf club head structure includes a body portion, a hitting plate portion, and a club body combining portion. The body portion has a first junction surface forming a first hook angle therewith. The hitting plate portion has a hitting surface and a second junction surface with a buffer region spaced there-between. The second junction surface forms a second hook angle with the hitting plate portion, and butts against and attaches to the first junction surface on the same plane. The club body combining portion is provided for combining a club body. Therefore, a joint structure with a junction portion as a plane, capable of not being located on the surface of the club head and spaced by a buffer region with the hitting surface, is formed, which is applicable for solving the combination problem of the junction surface on the same plane that the casting is deformed.

Owner:ADVANCED INT MULTITECH CO LTD

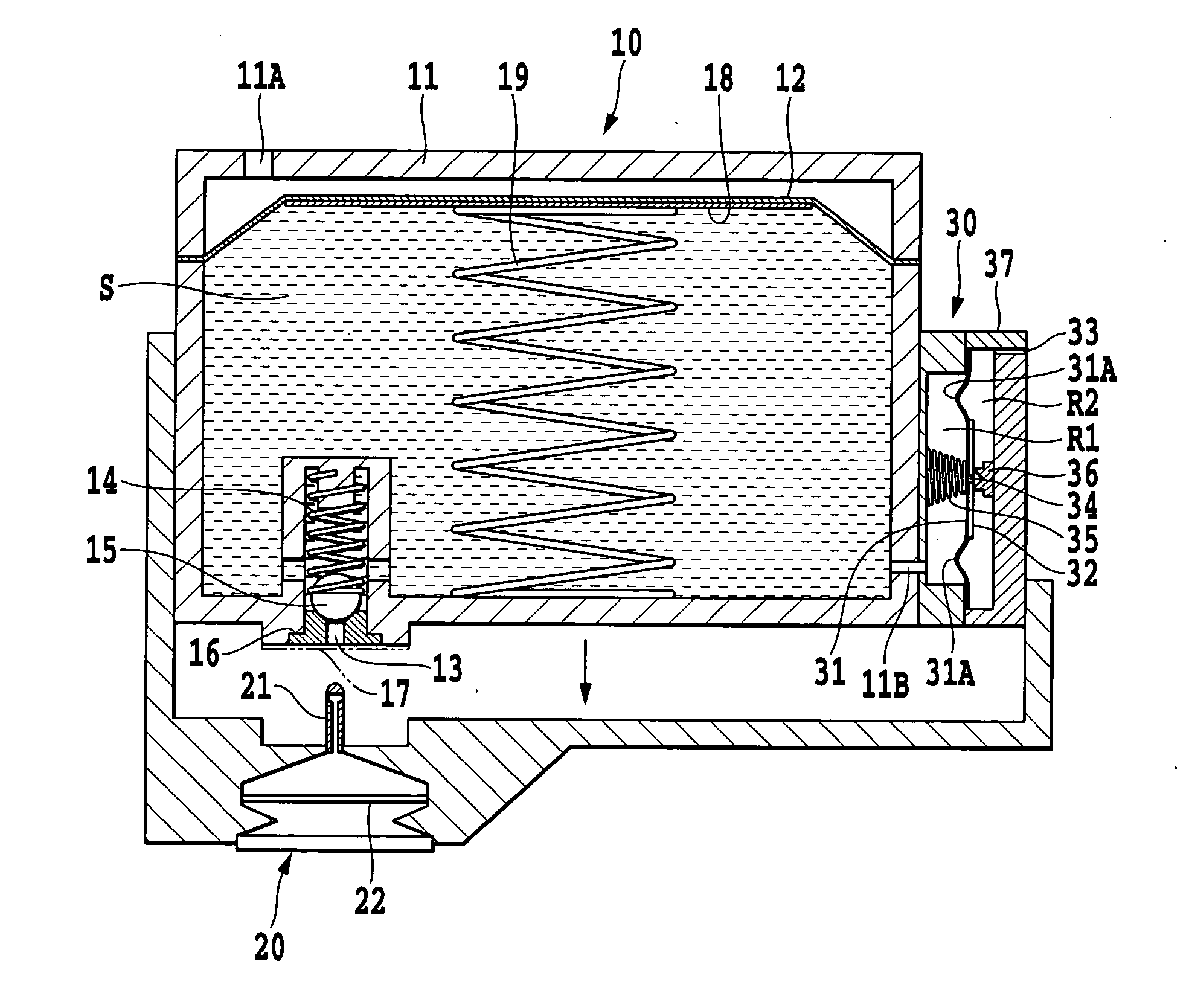

Glaucoma shunts with flow management and improved surgical performance

ActiveUS20100249691A1Improving glaucoma shuntReduce postoperative complicationsEye surgeryIntravenous devicesGlaucoma tube shuntGlaucoma

A method of treating glaucoma in an eye by managing fluid flow past an implanted shunt having an elastomeric plate and a non-valved elastomeric drainage tube. The plate is positioned over a sclera of the eye with an outflow end of the elastomeric drainage tube open to an outer face of the plate. An inflow end of the drainage tube tunnels through the sclera to the anterior chamber of the eye. The plate may have regions of greater propensity for cell adhesion alternating with regions of lesser cell adhesion. For example, regions of texturing around the plate or drainage tube may be provided to control the size of a bleb that forms over the implant. The effective surface area of the plate may be balanced against a number of fenestrations. The drainage tube has a reduced profile and may be shaped with a non-circular external cross-section to reduce its height. A scleral groove may be used to further reduce the height of the drainage tube on the sclera. A flow restrictor for the early post operative period will immediately lower the intraocular pressure (IOP) and simultanously prevent hypotony.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

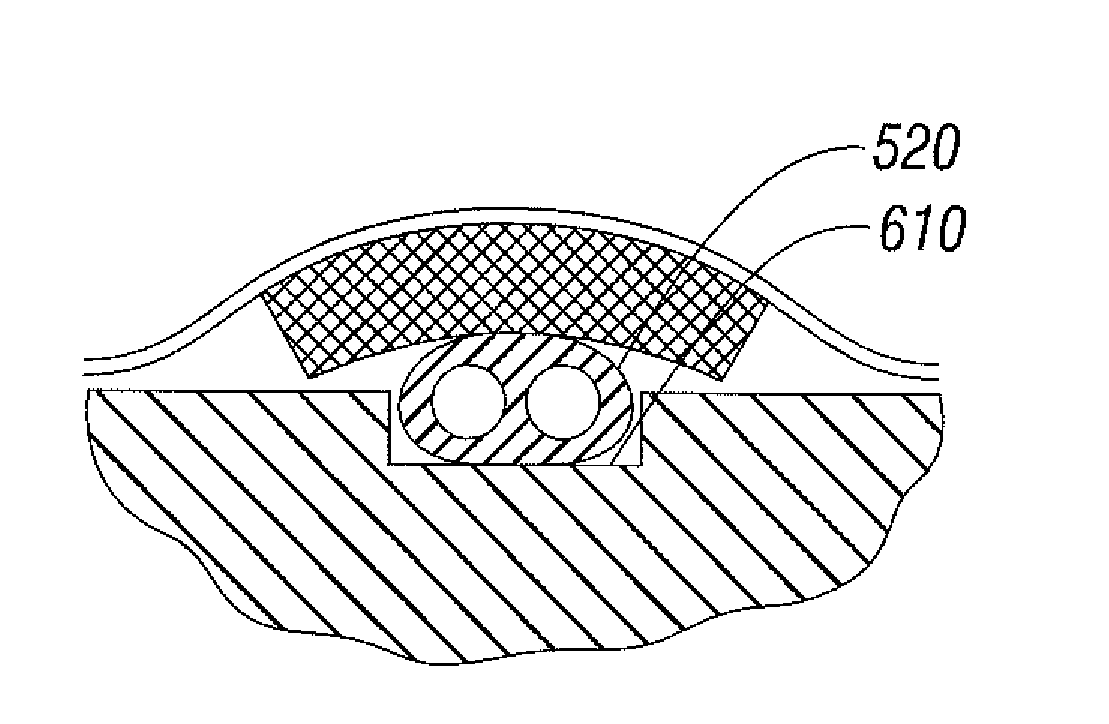

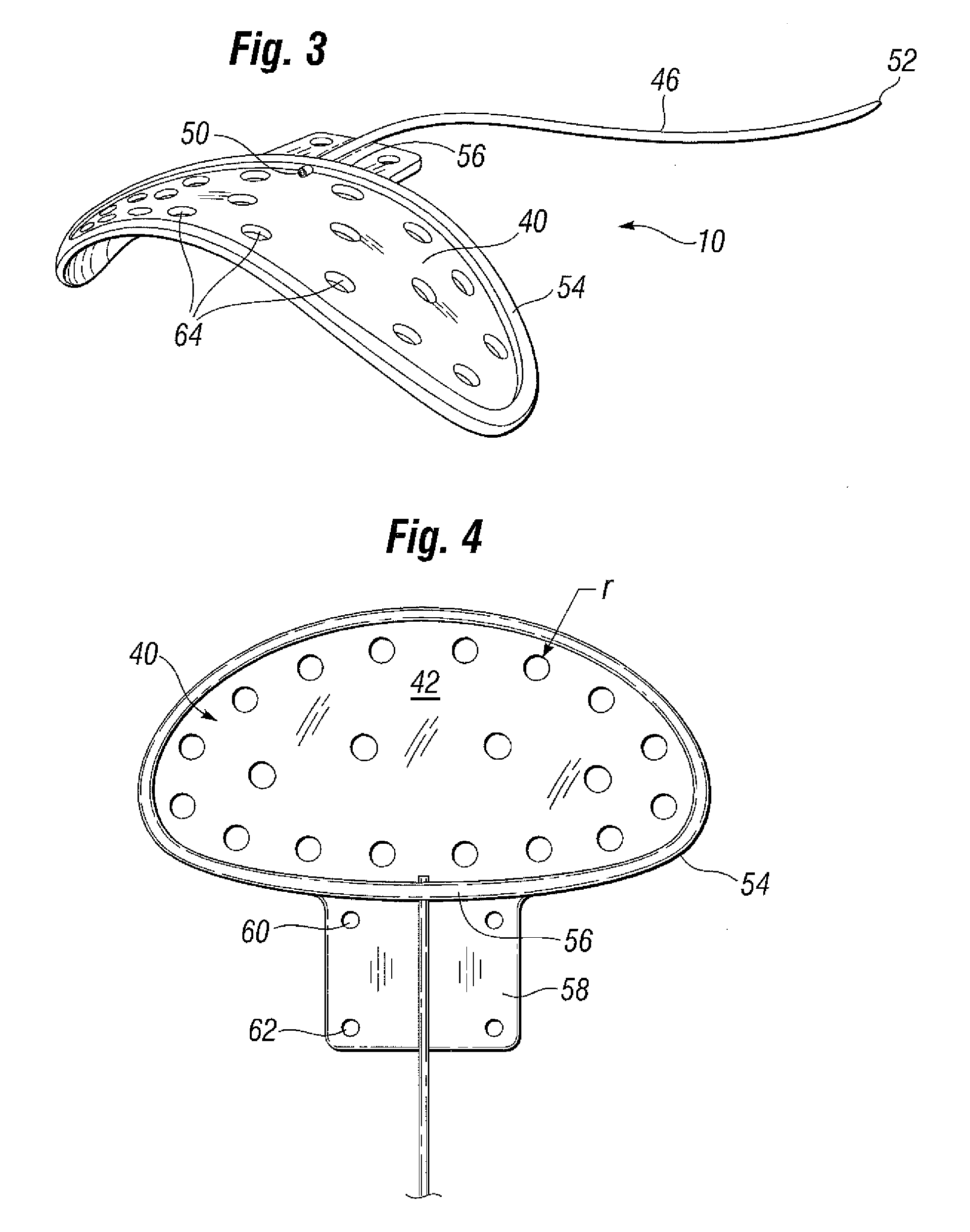

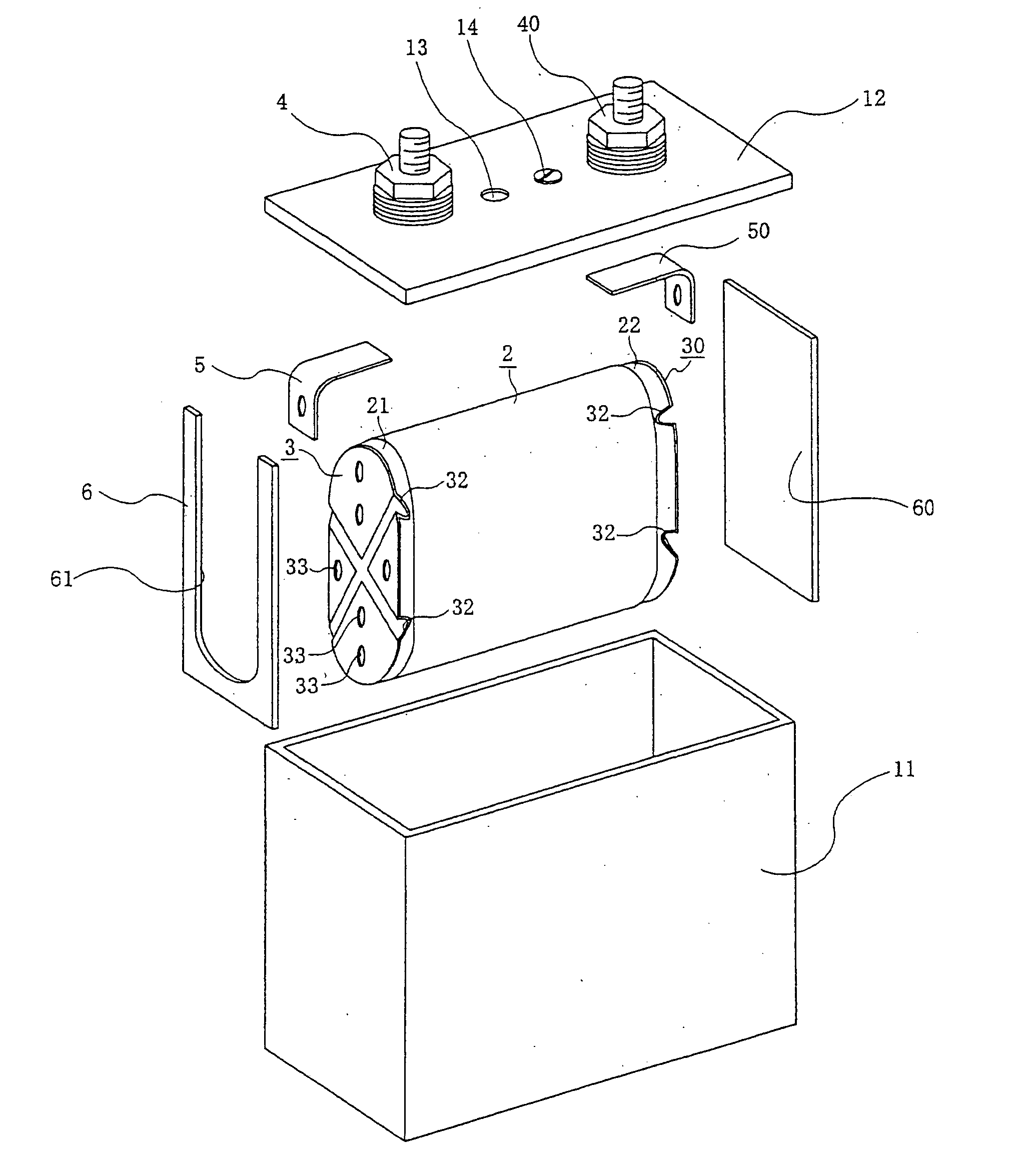

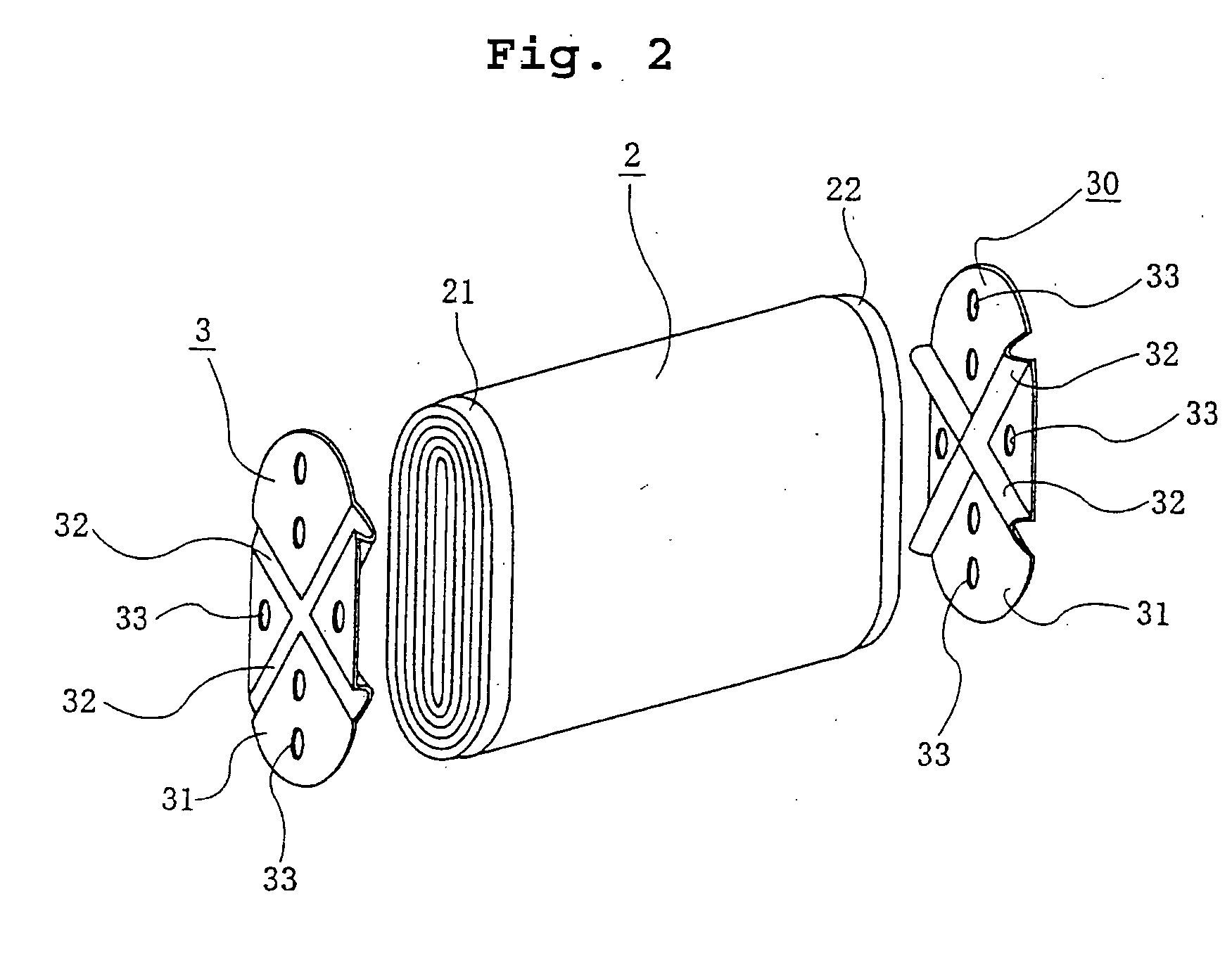

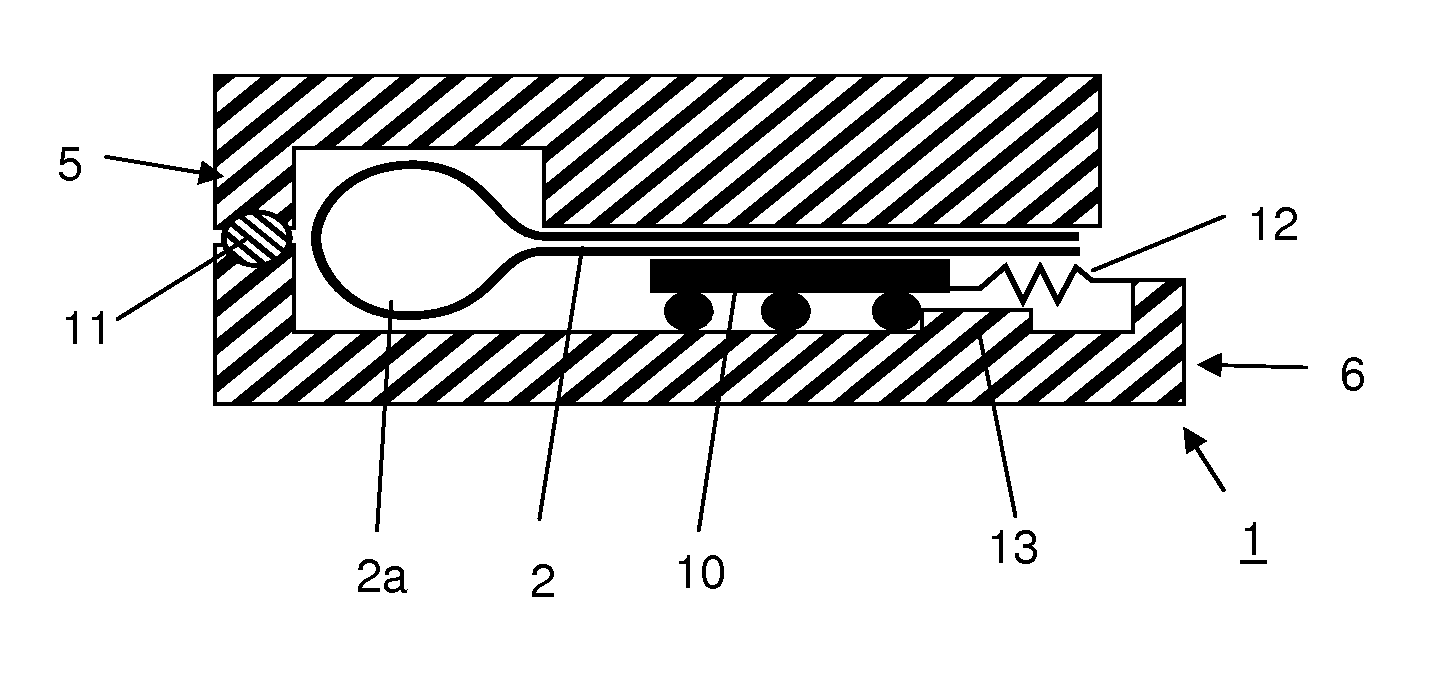

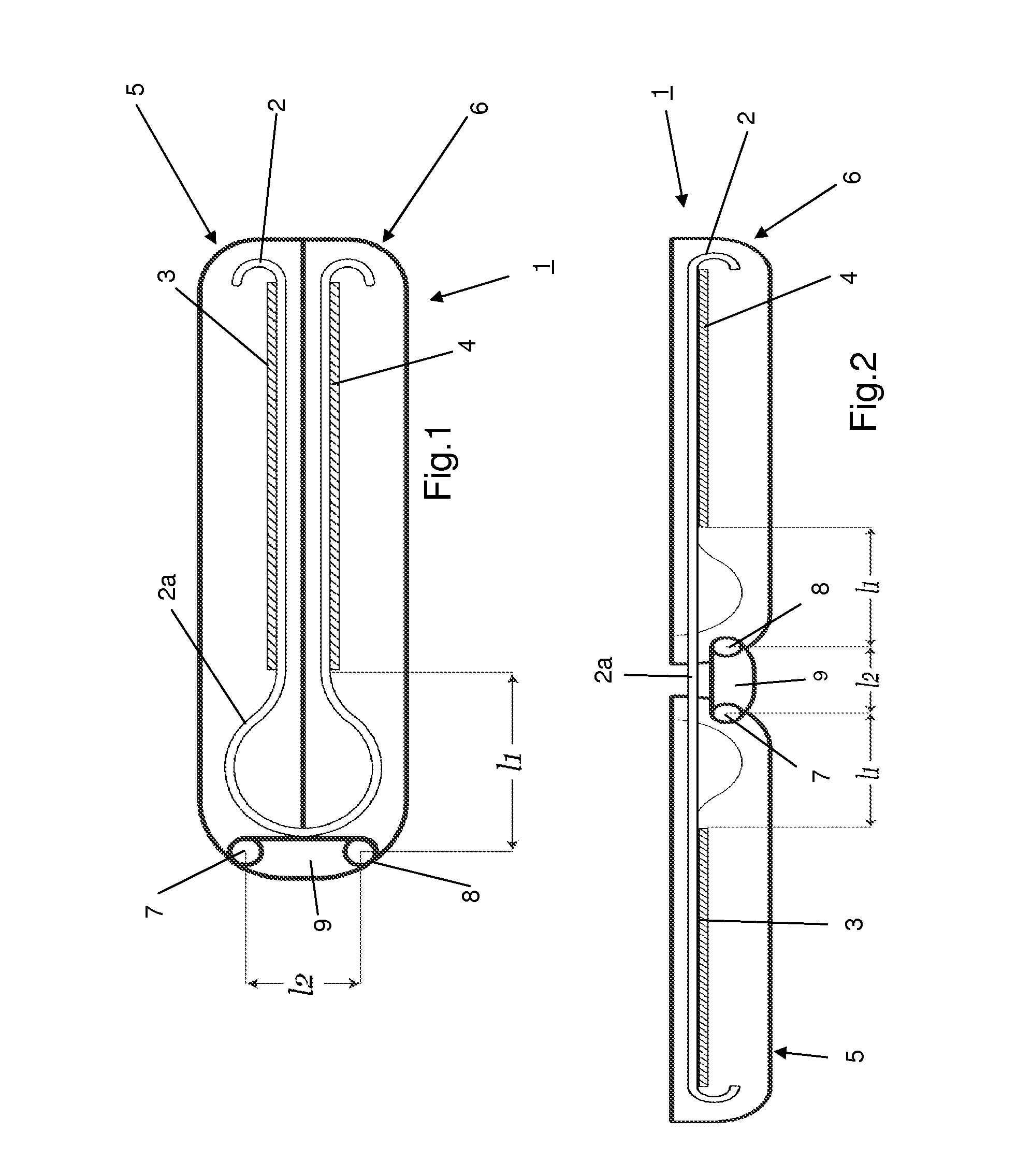

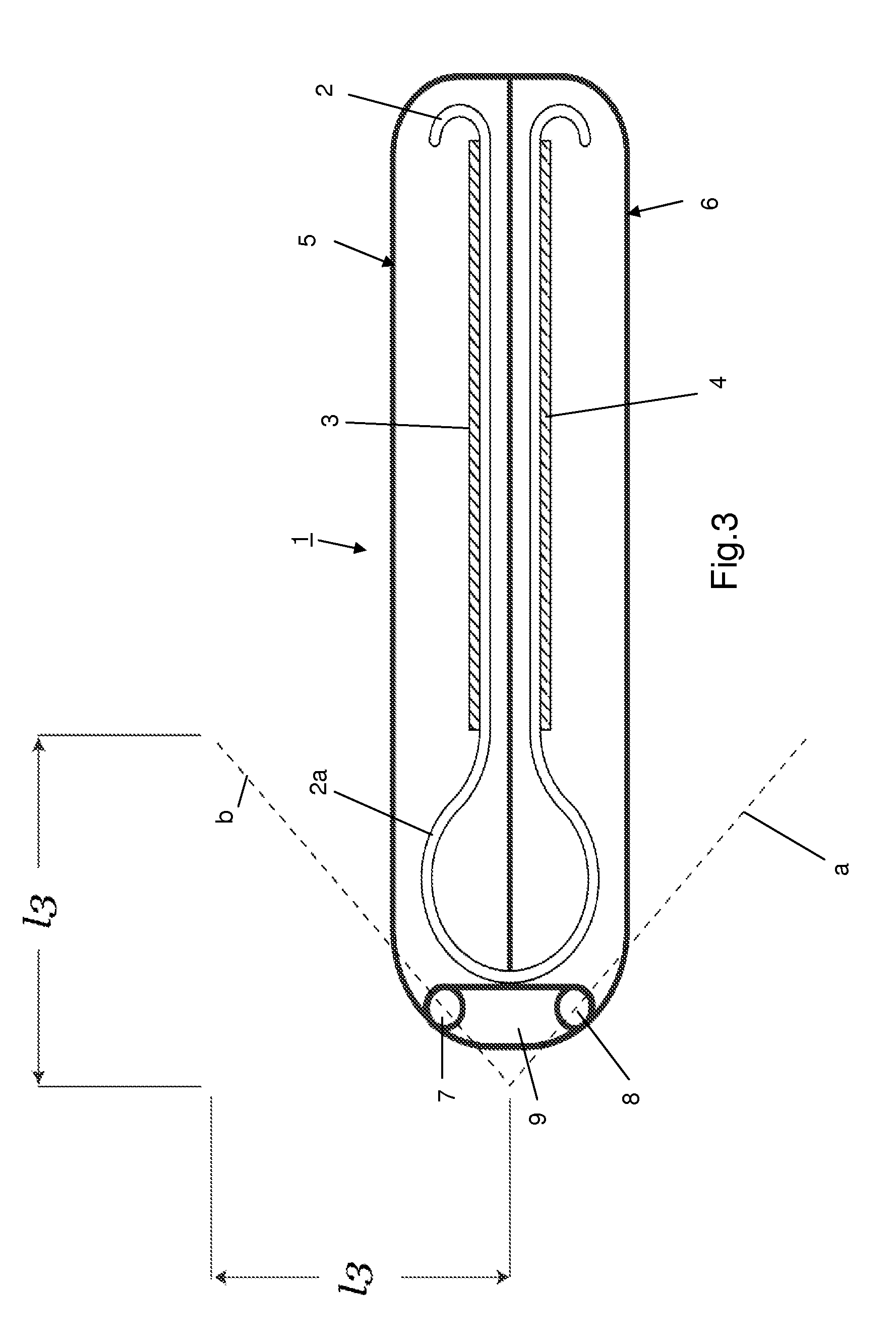

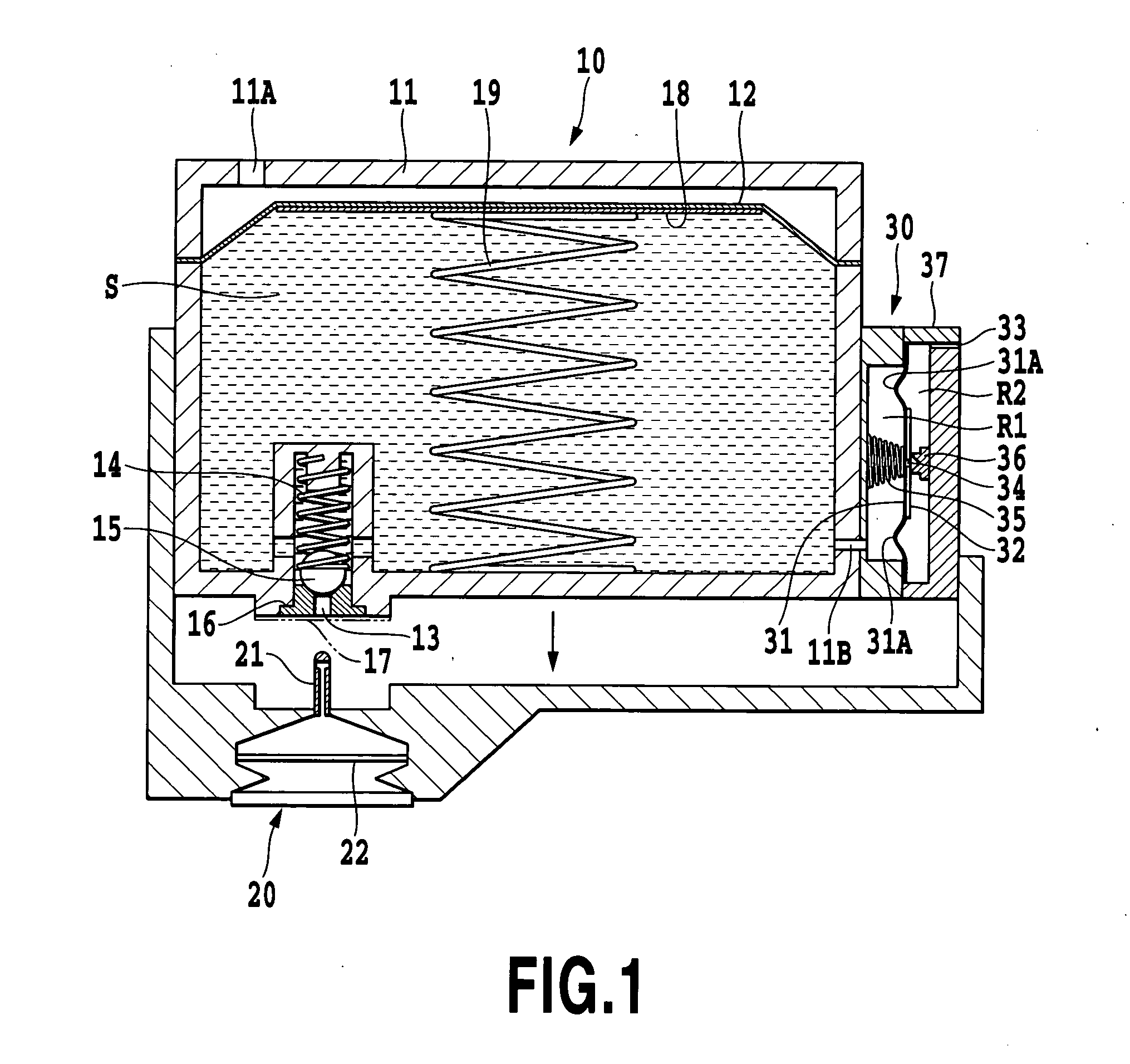

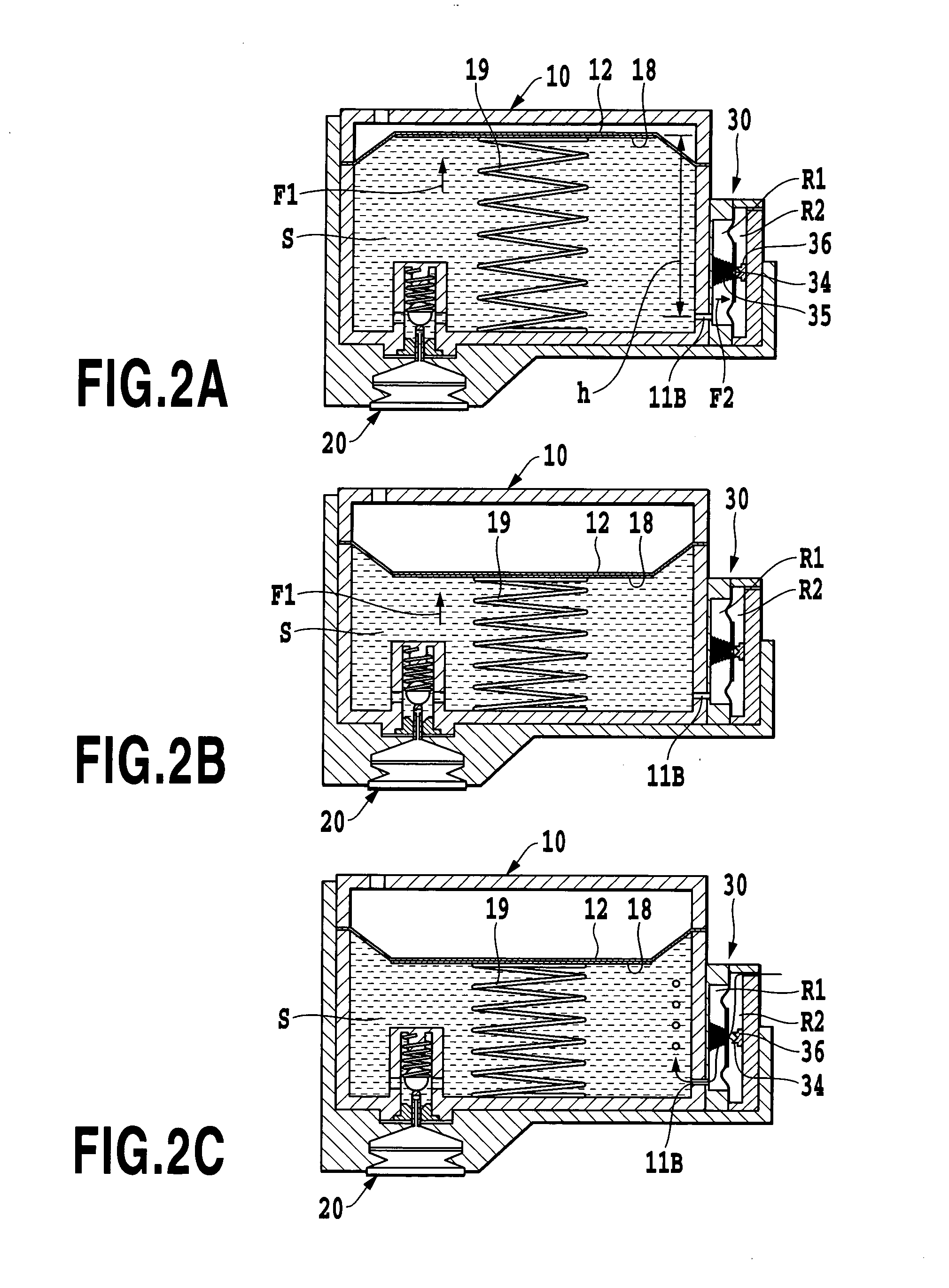

Prismatic battery

InactiveUS20040191612A1Easily assembleNo unnecessary stressFinal product manufactureElectrode carriers/collectorsCurrent collectorElectrical and Electronics engineering

A prismatic battery wherein a wound electrode (2) is housed in a battery can (1) including a sealing plate (12) fixed onto an opening of a prismatic case (11) with the outer surface of the electrode (2) aligned with the bottom of the prismatic case (11). Current collector plates (3), (30) are placed at both ends of the wound electrode (2) where edges (21), (22) of a pair of positive and negative electrodes project. The current collector plates (3), (30) are connected to a pair of positive and negative electrode terminals (4), (40). The current collector plates (3), (30) and the electrode terminals (4), (40) are connected by flexible flexible lead members (5), (50).

Owner:SANYO ELECTRIC CO LTD

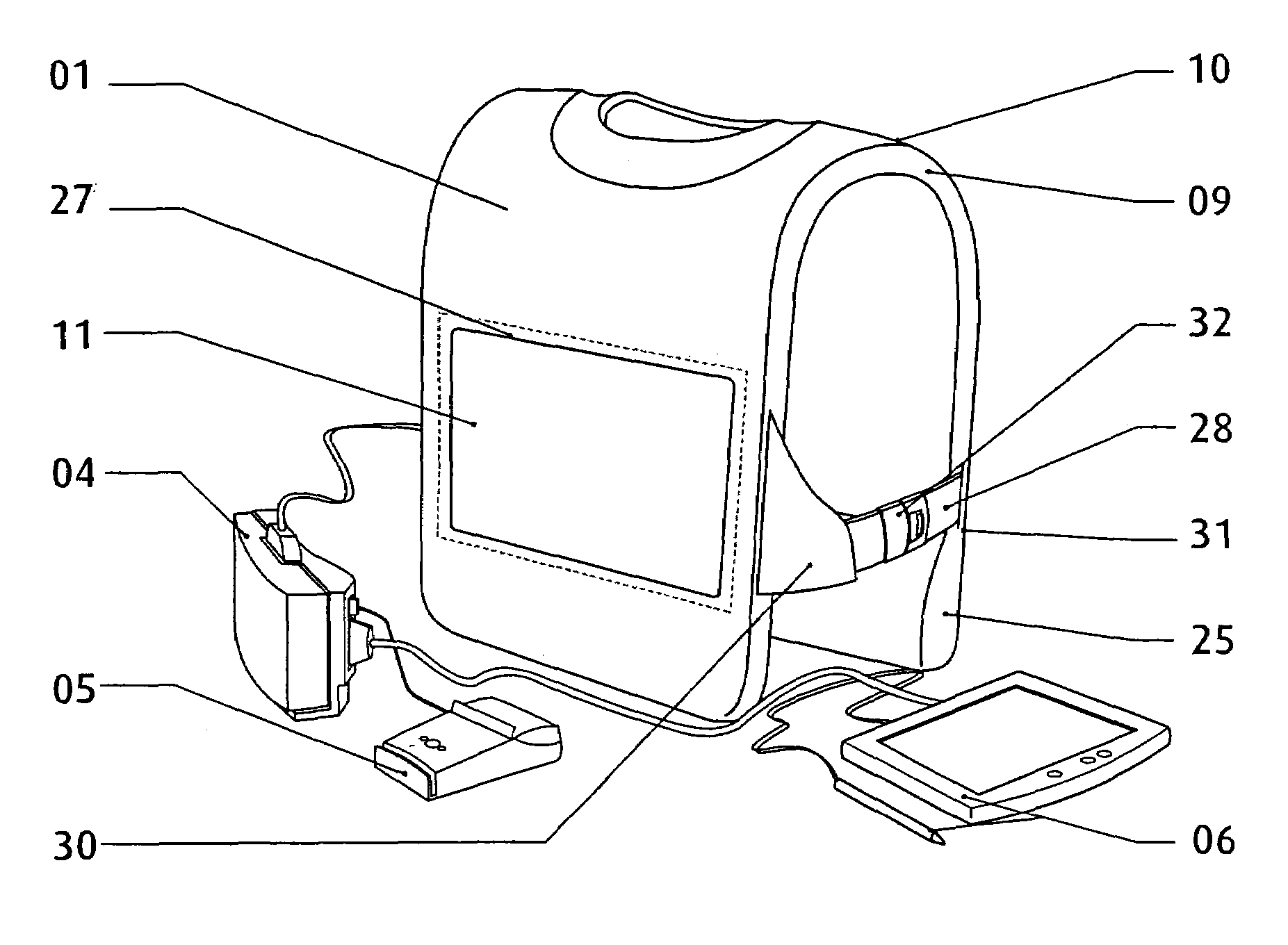

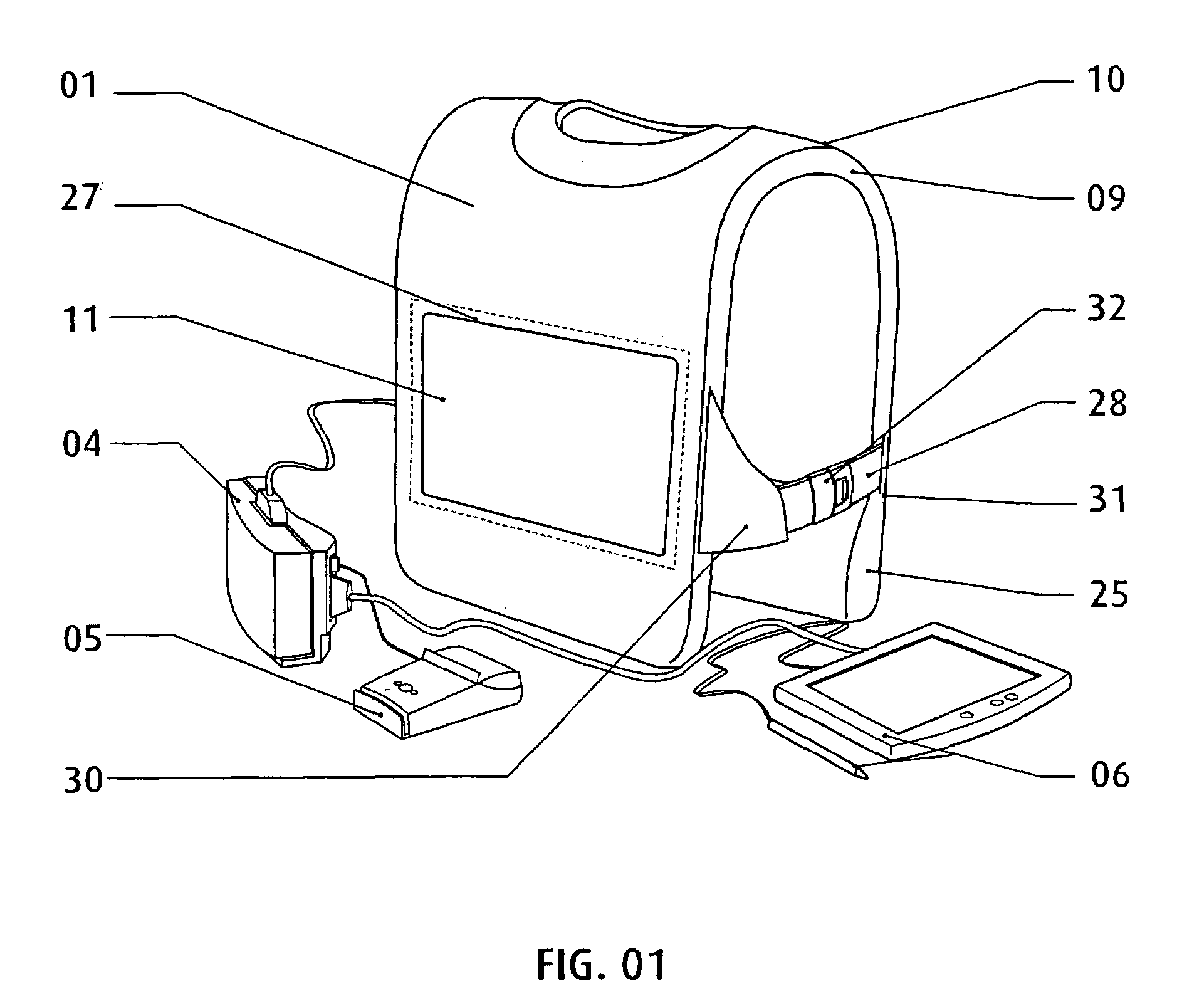

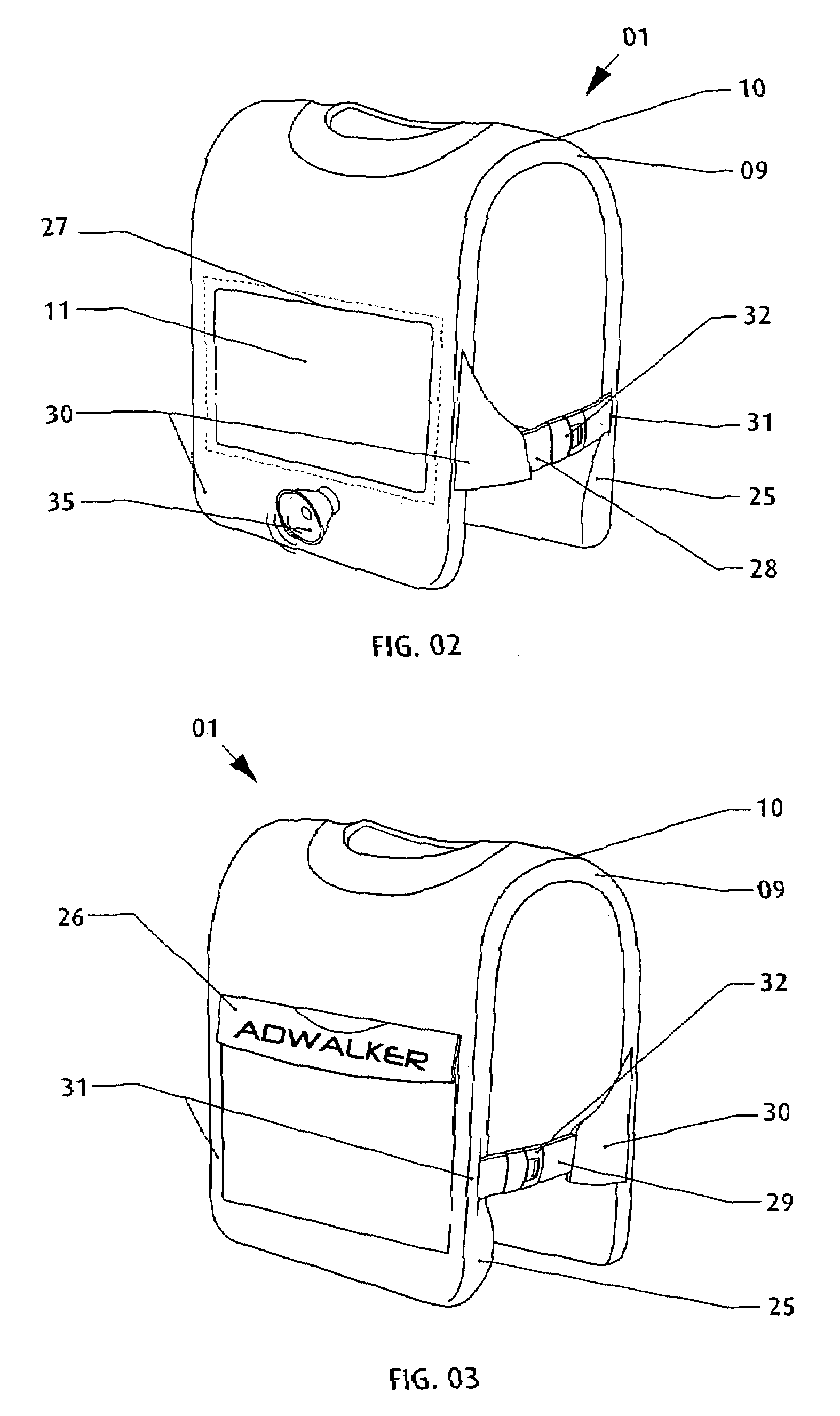

Apparatus

InactiveUS7265970B2Improve comfortImprove liquidityDigital data processing detailsGarmentsEngineeringWearable computer

An apparatus (1) for supporting a mobile electronic display system. The mobile electronic display system includes a display element (11) and a power source (12). In use a wearable computer (4) controls operation of the display element (11). The apparatus (1) comprises a relatively rigid support frame (8), a relatively soft cushion member (9), and a cover (10) for the support frame (8). The support frame (8) is suitable for being worn by a person to support the mobile electronic display system. The support frame (8) comprises a front support frame part (13) located at the front of the wearer, a rear support frame part (14) located at the rear of the wearer, a first bearing member (15) extending over a first shoulder of the wearer, and a second bearing member (16) extending over a second shoulder of the wearer.

Owner:ADWALKER PUBLIC LIMITED COMPANY

Display system having a continuous flexible display with display supports

InactiveUS20130342094A1Relieve stressKeep displayStatic indicating devicesAdvertisingDisplay deviceSpring force

A display system comprises a continuous flexible display and two main display supports being hingeably connected with respect to each other between a closed storage position and a planar open position for fixing the flexible display in an open position. Each of the supports is structurally configured to support respectively a first and a second portion of the flexible display, a segment of the flexible display is located between the said respective portions of the flexible display in the open position. The display system comprises a spring force biased mechanism operative in either the open or closed position or both the open and closed positions of the flexible display, biasing said segment of the flexible display in the respective position.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com