Patents

Literature

107 results about "Tibial tray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

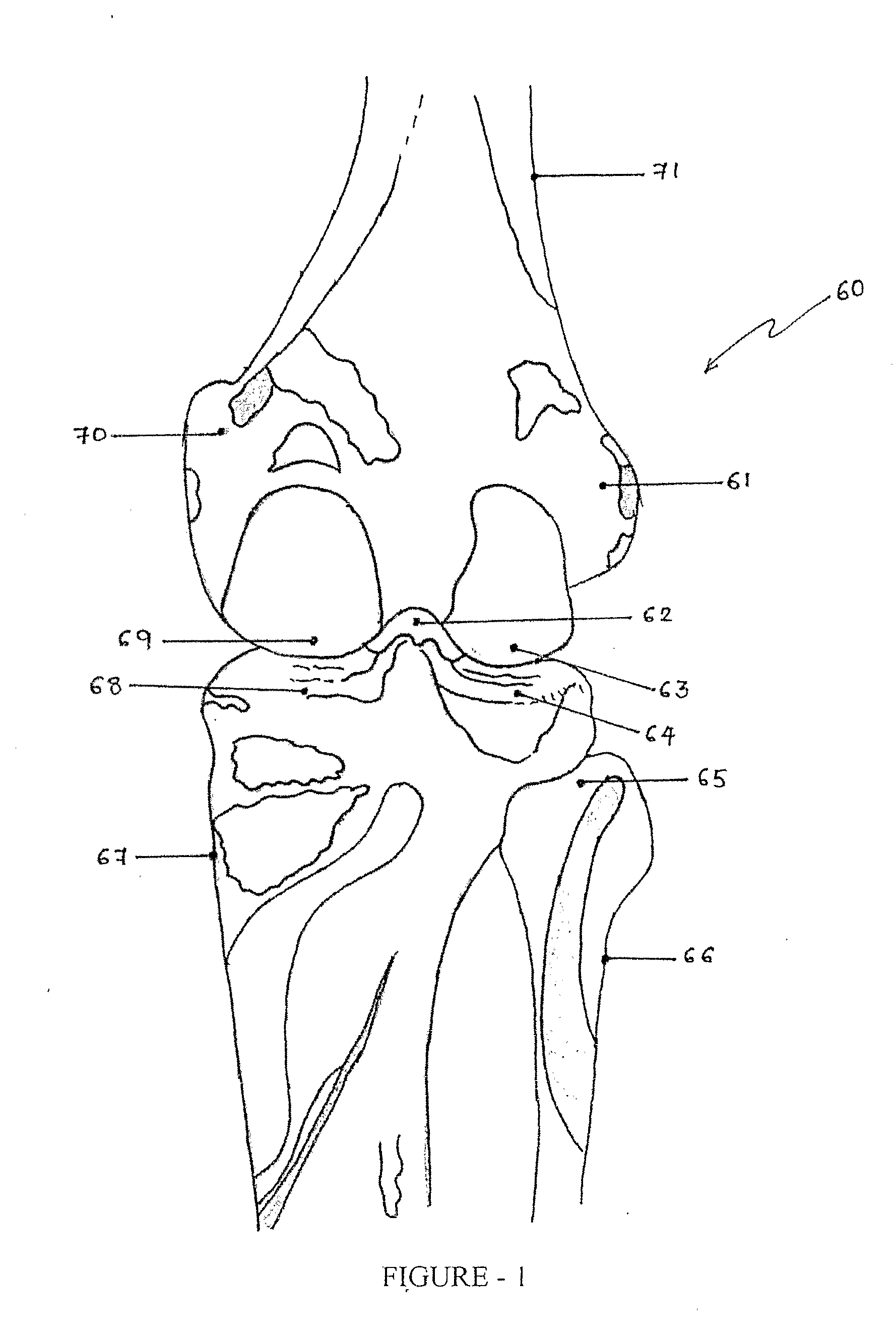

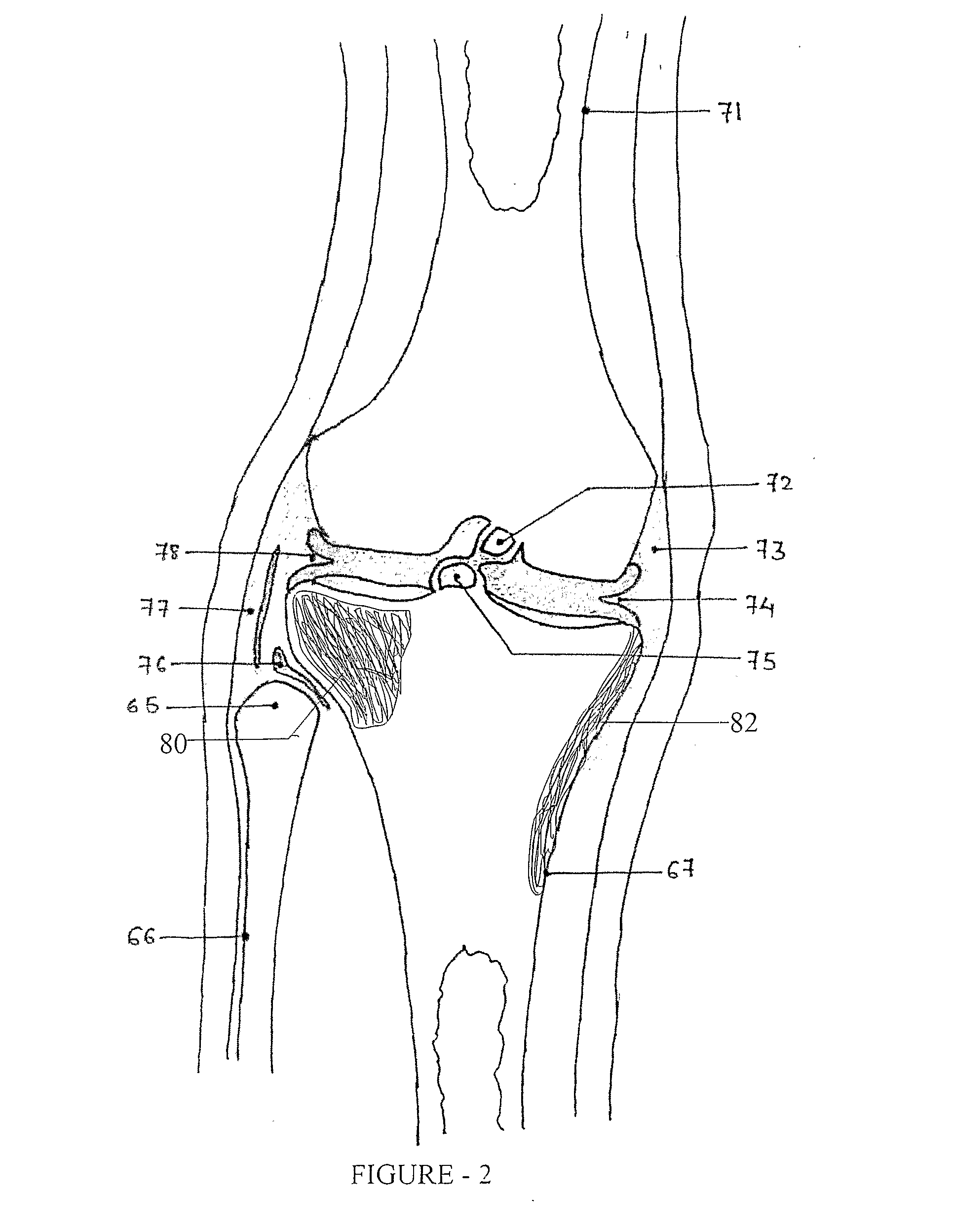

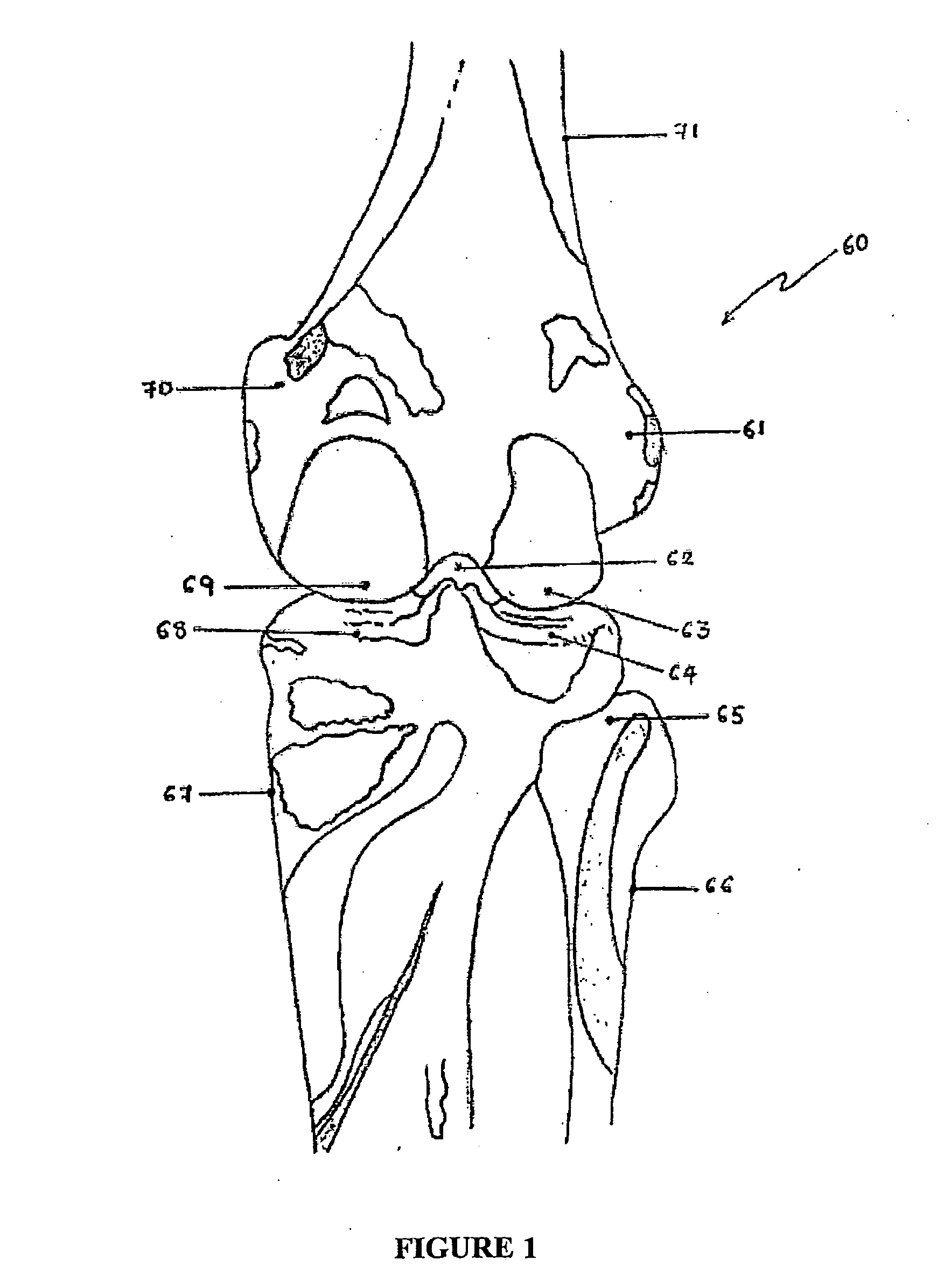

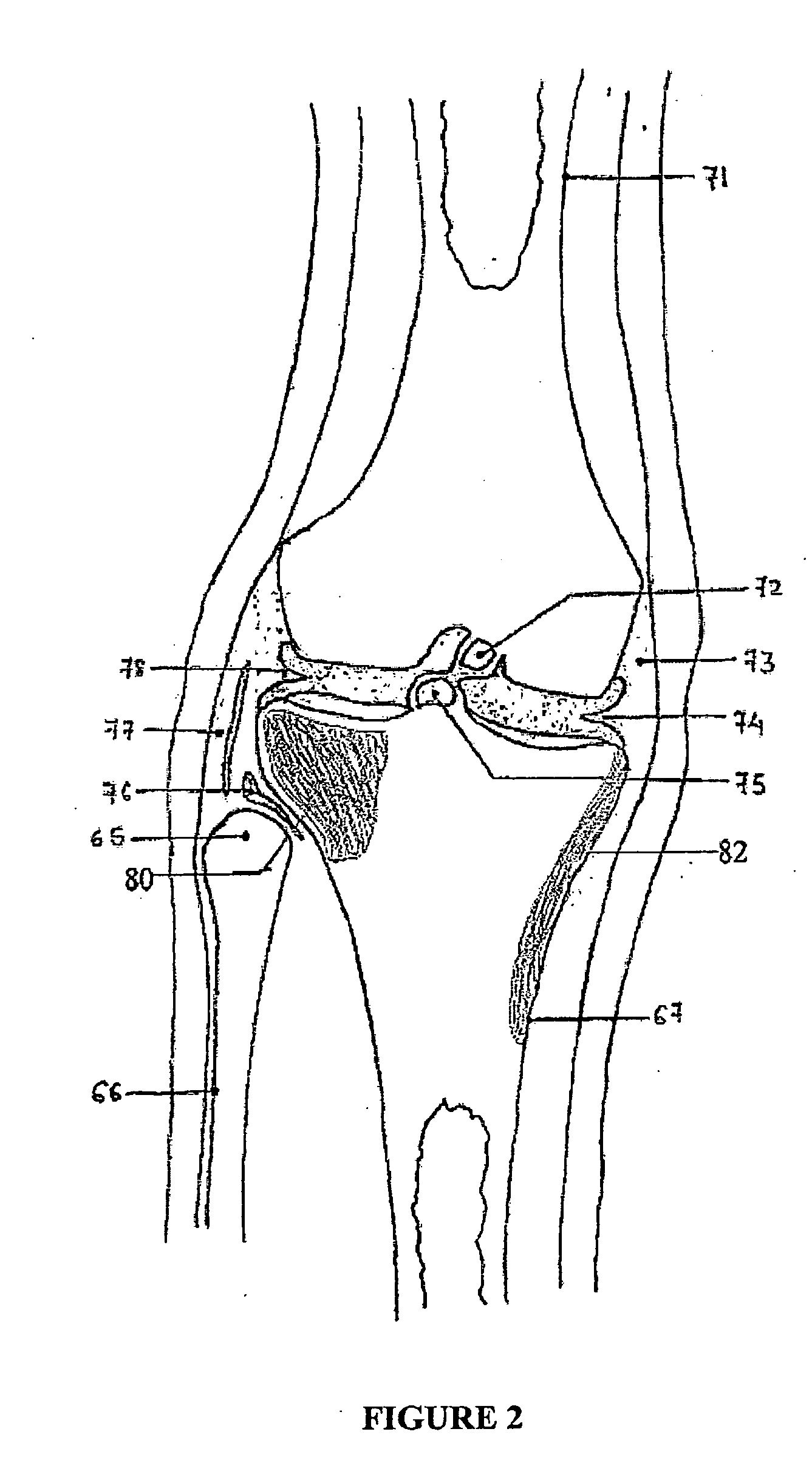

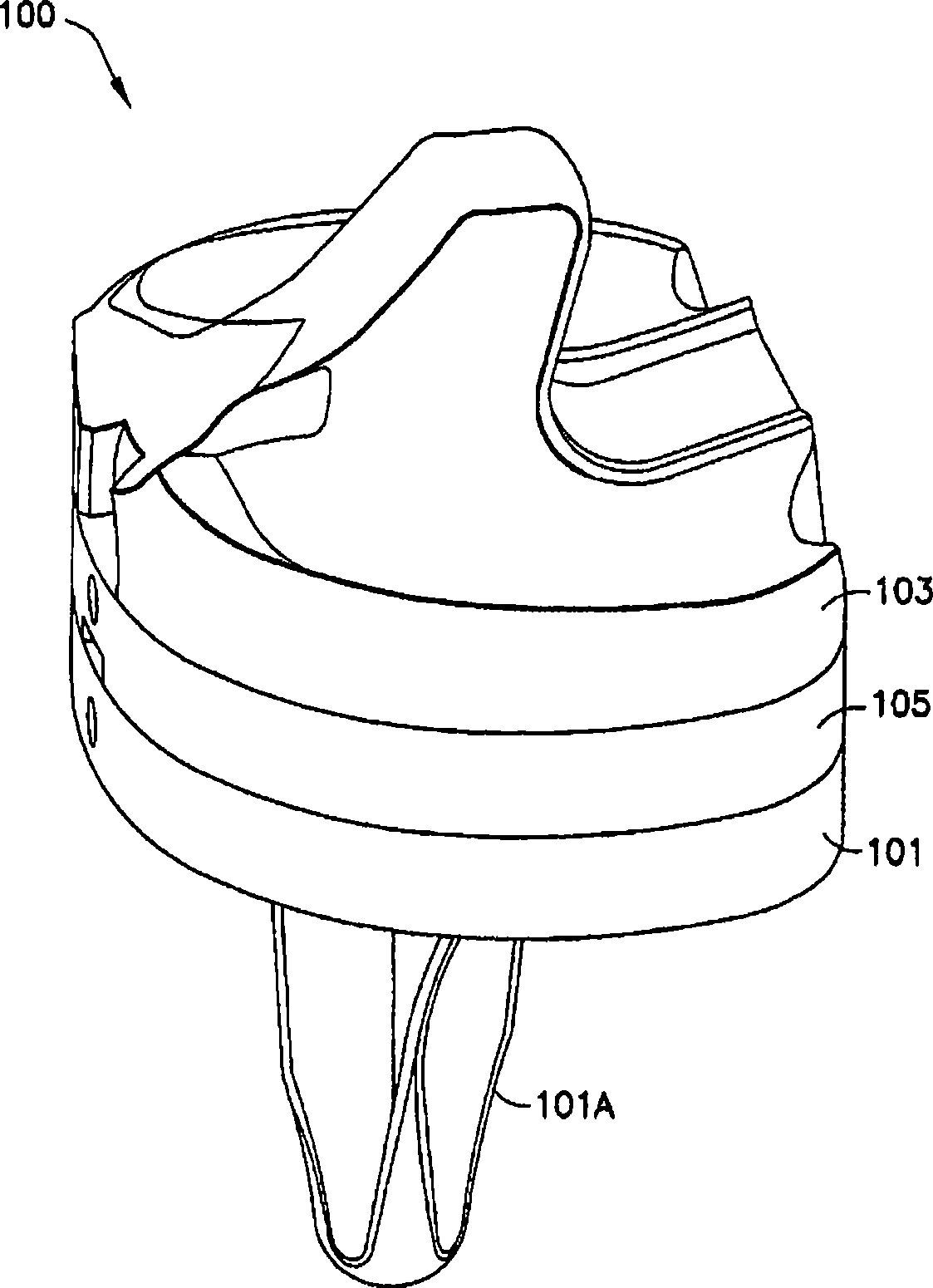

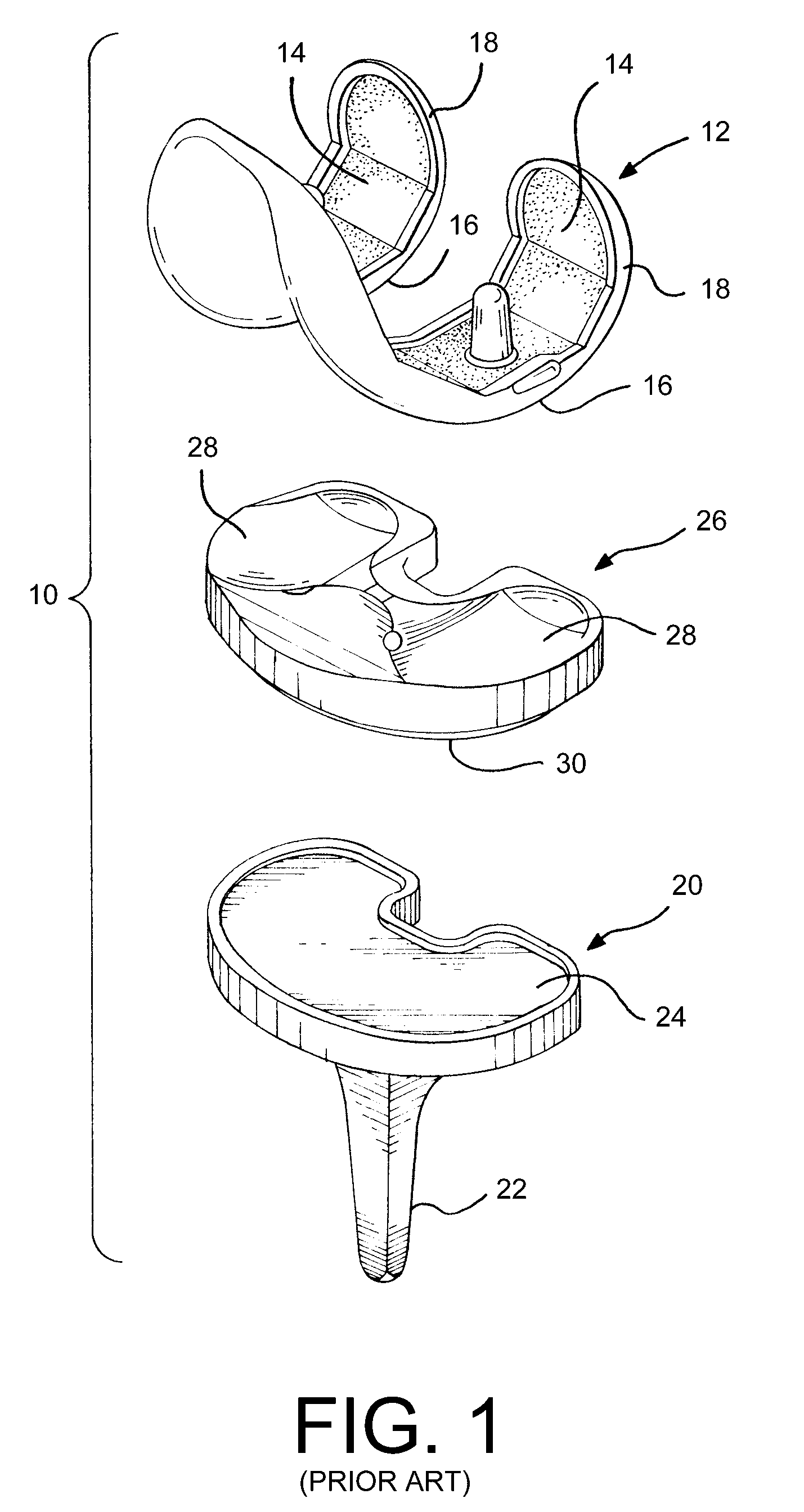

A tibial tray is part of an implant used for Total Knee Arthroplasty. The part above is attached to the shinbone and supports the upper part of the implant. Typically, tibial trays are made from solid titanium, which exhibits higher tensile strength than the surrounding tibia bone.

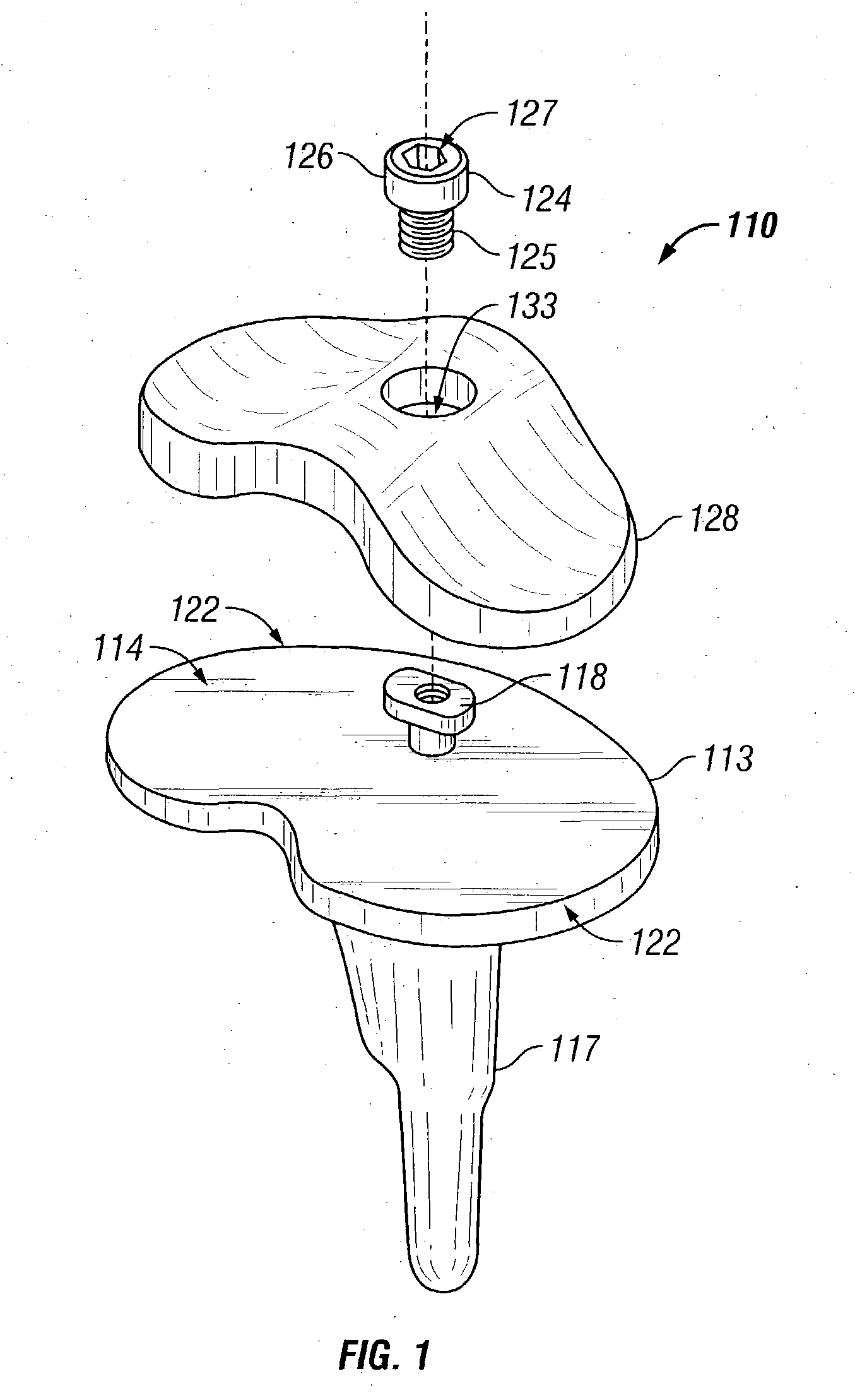

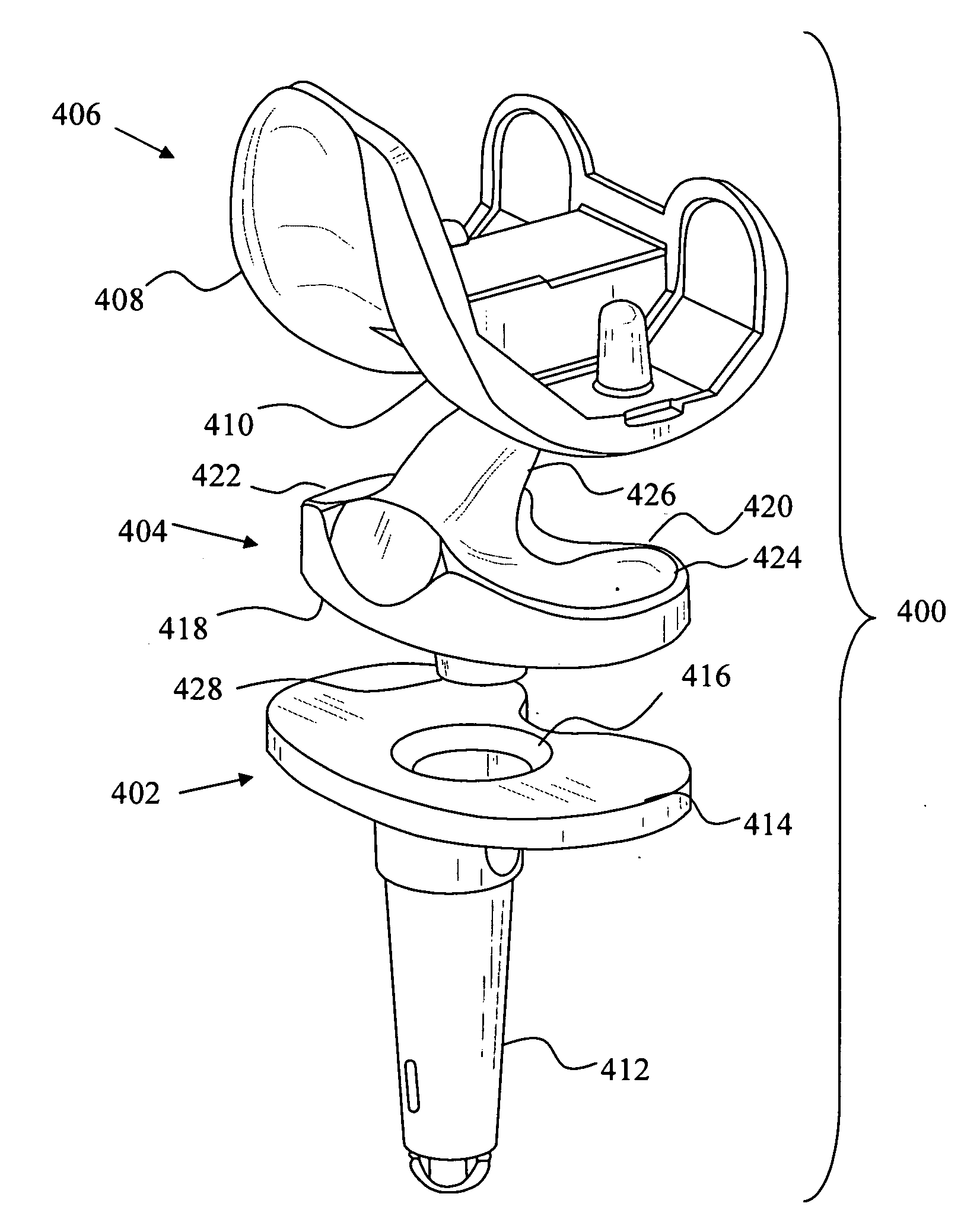

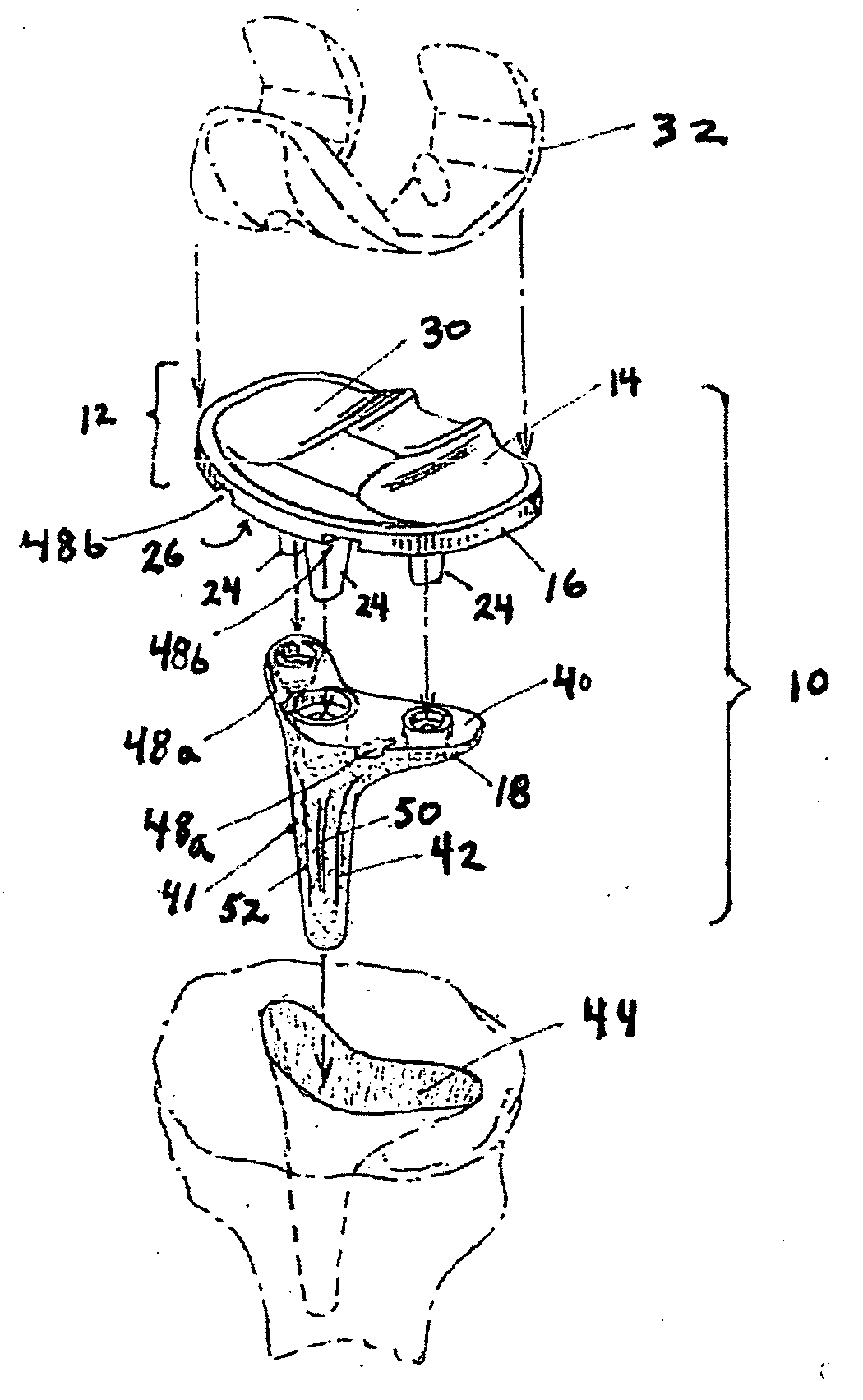

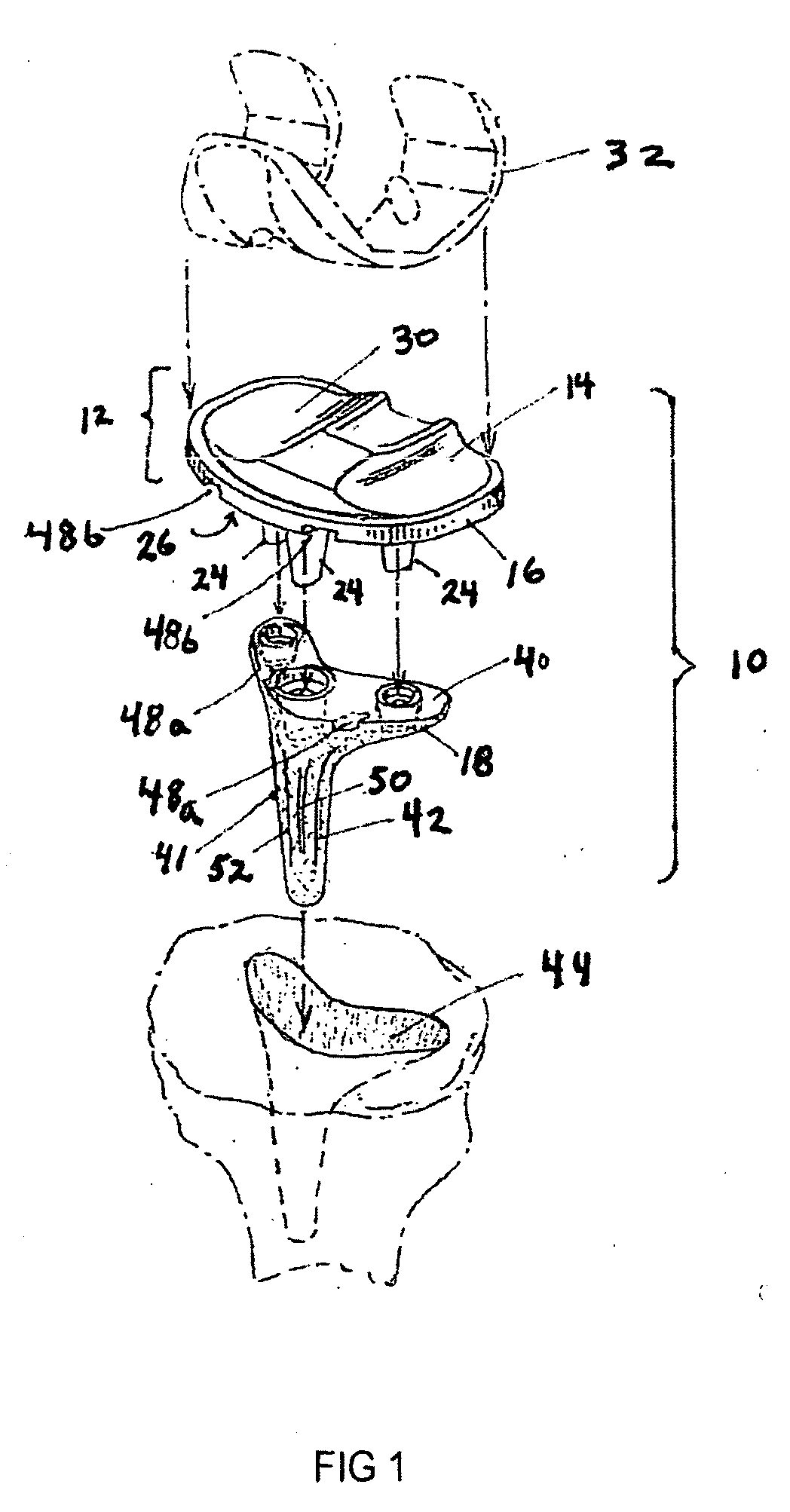

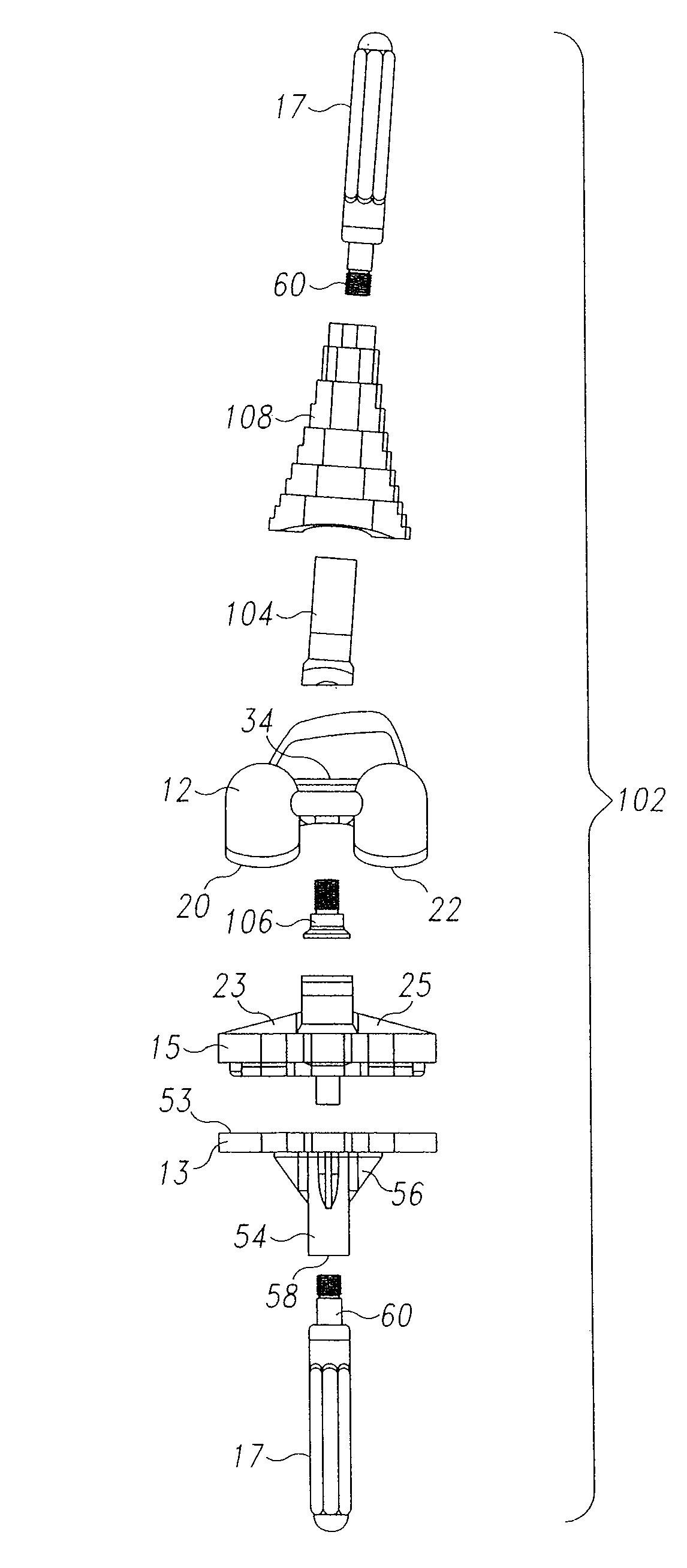

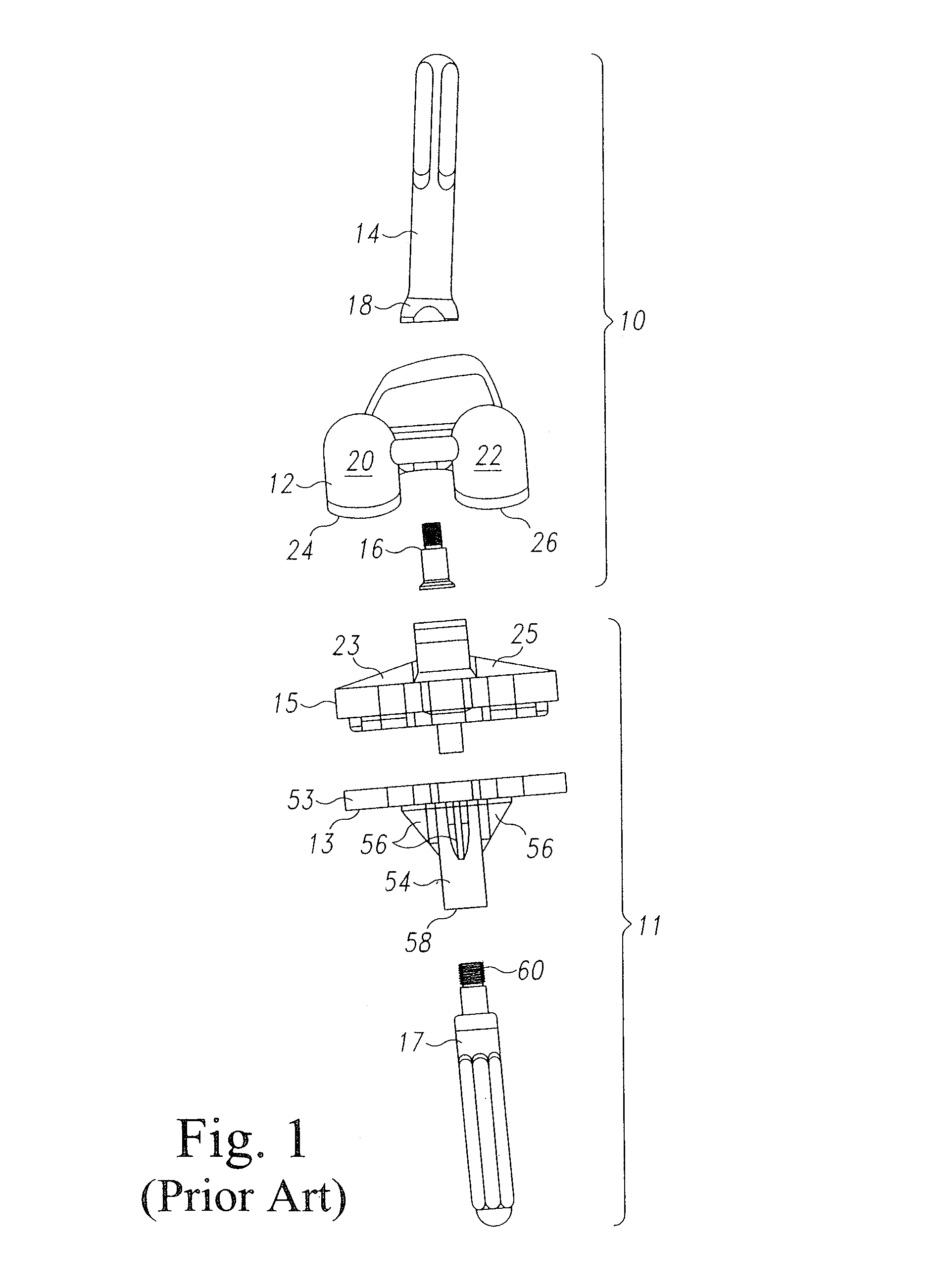

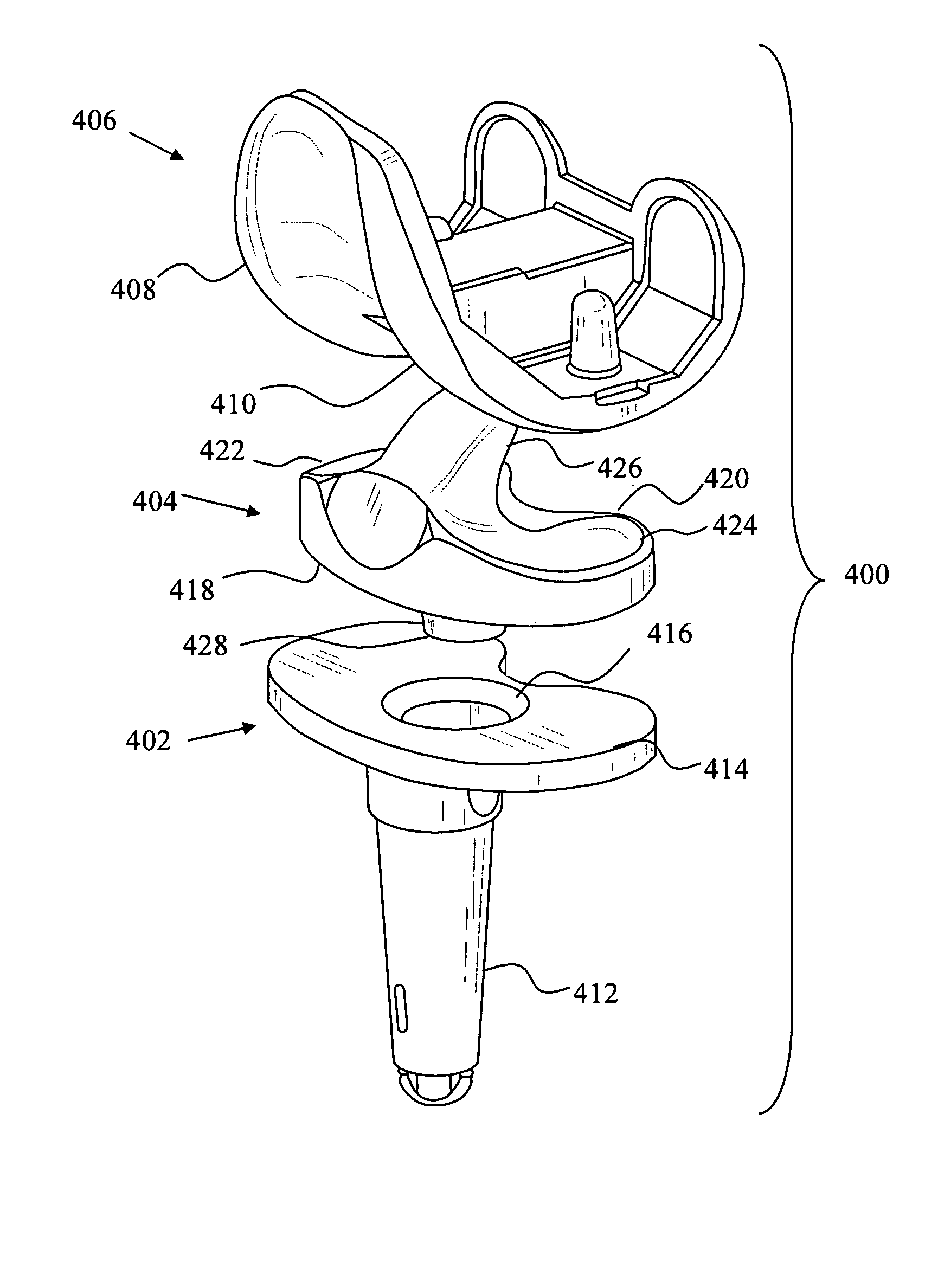

Modular orthopaedic implant system with multi-use stems

A knee implant system includes a femoral adapter. The femoral adapter has a threaded bore so that a stem extension can be threaded onto the proximal end of the adapter. The same stem extension can be threaded onto the distal end of the tibial tray so that the number of stem extensions required in the system is reduced. The femoral adapter has a tapered exterior surface so that a metaphyseal sleeve can be frictionally connected to the femoral adapter. The metaphyseal sleeve has a threaded bore so that the same type of stem extension can be threaded onto the metaphyseal sleeve. The system can include a group of adapters to give the surgeon the option of selecting the appropriate valgus angle and anterior-posterior position of the stem extension.

Owner:DEPUY SYNTHES PROD INC

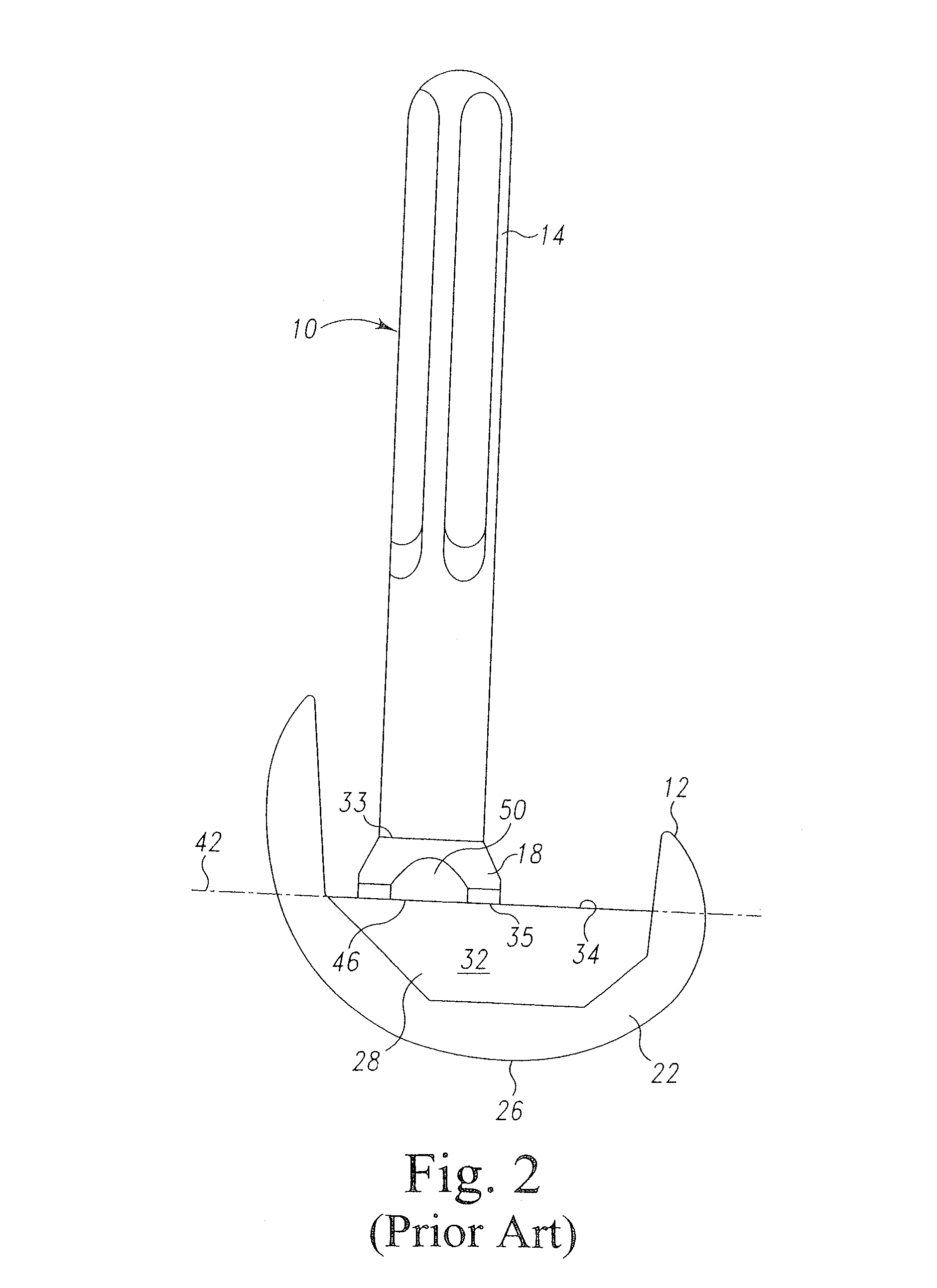

Mobile bearing tibial base prosthetic devices employing oxidized zirconium surfaces

An orthopedic implant with a diffusion-hardened surface on non-load bearing areas of the implant for interaction with non-load bearing surfaces of a polymeric bio-compatible material, such as UHMWPE (ultra-high molecular weight polyethylene). The orthopedic implant is a mobile-bearing knee prosthetic and system where a coating of oxidized zirconium is formed on the post of the tibial tray of the prosthetic for interaction with an opening of a polymeric tibial insert. The diffusion-hardened surface of the orthopedic implant provides a strengthened post and reduction in wear in the opening of the polymeric insert.

Owner:SMITH & NEPHEW INC

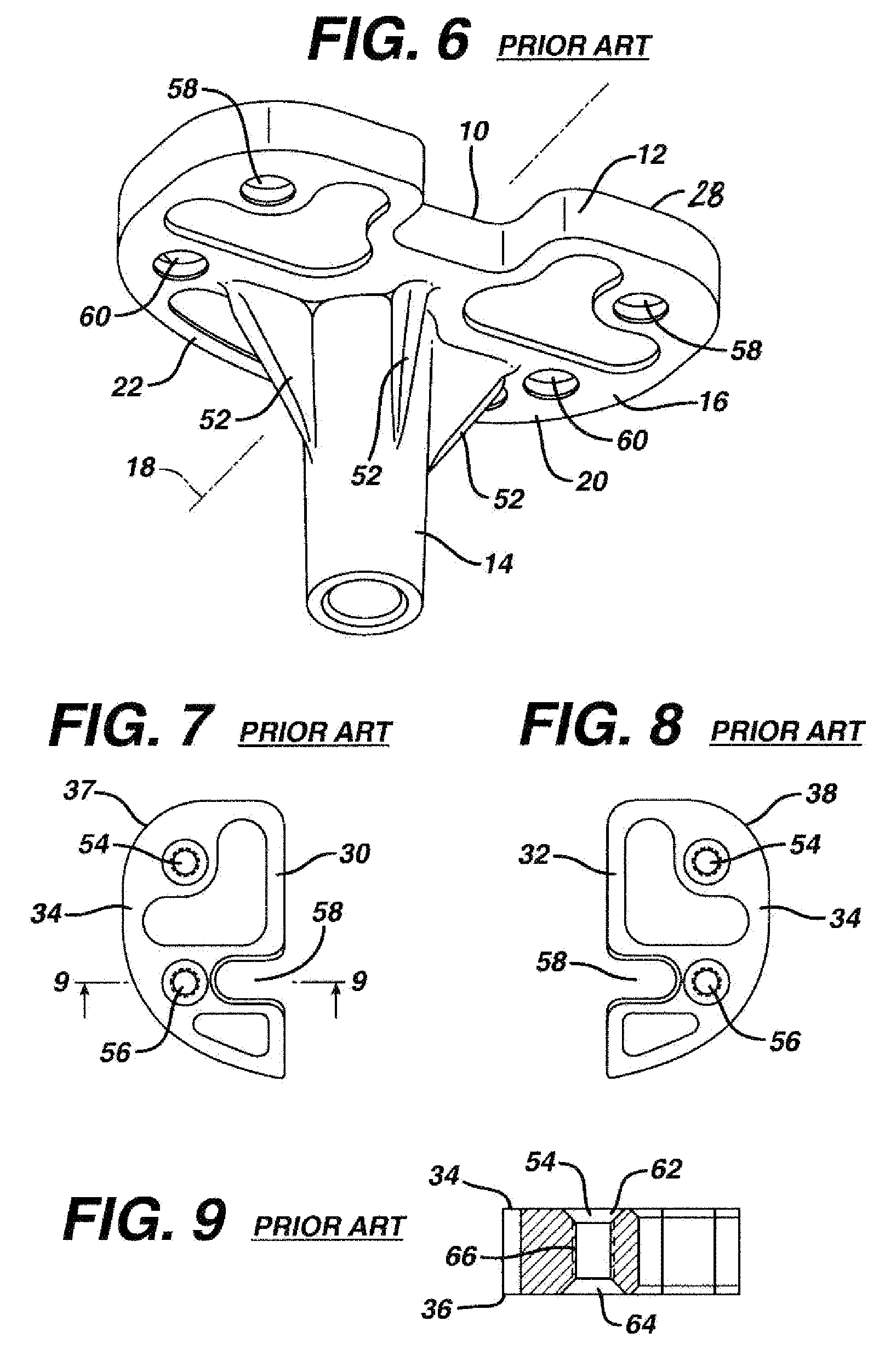

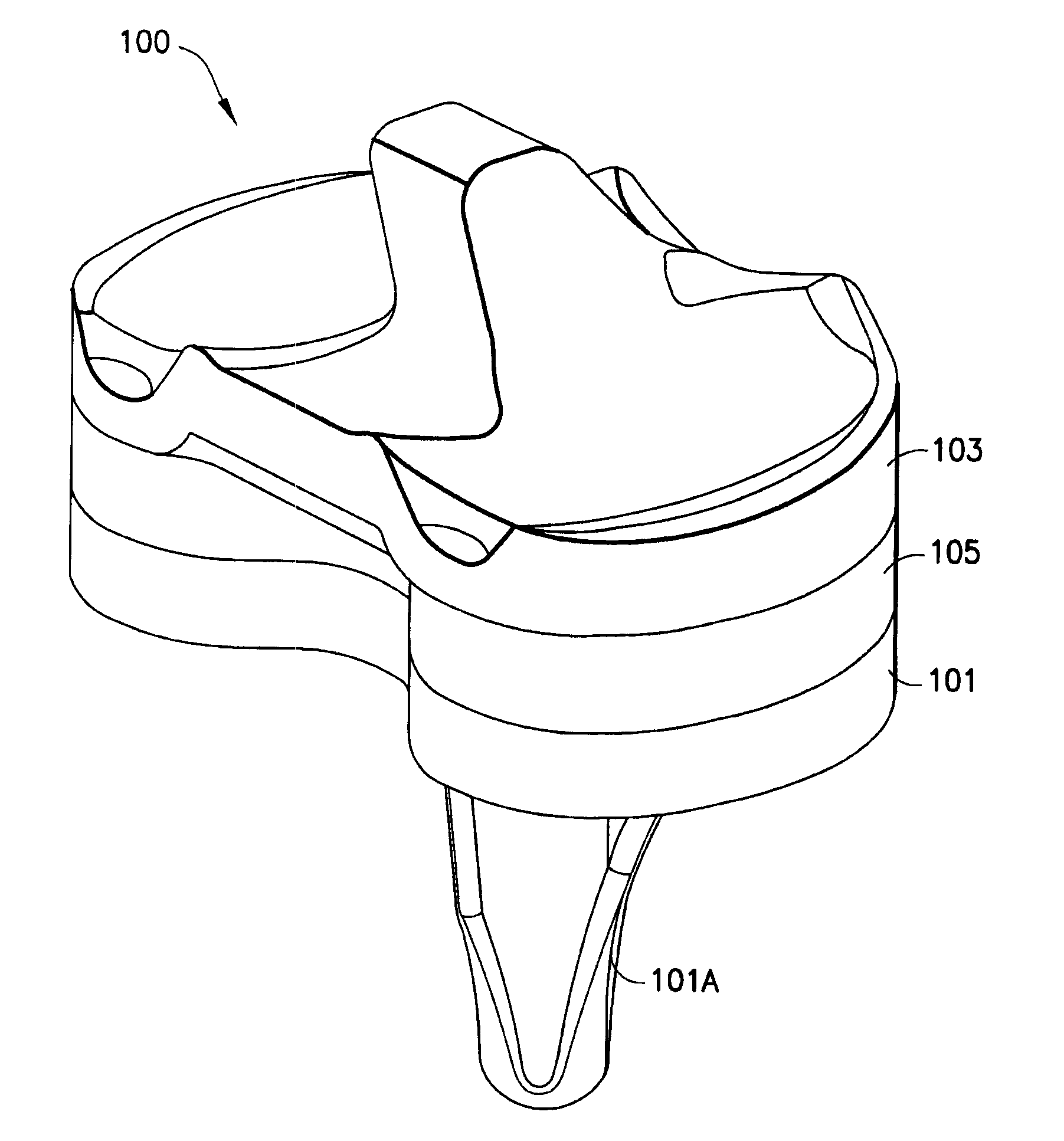

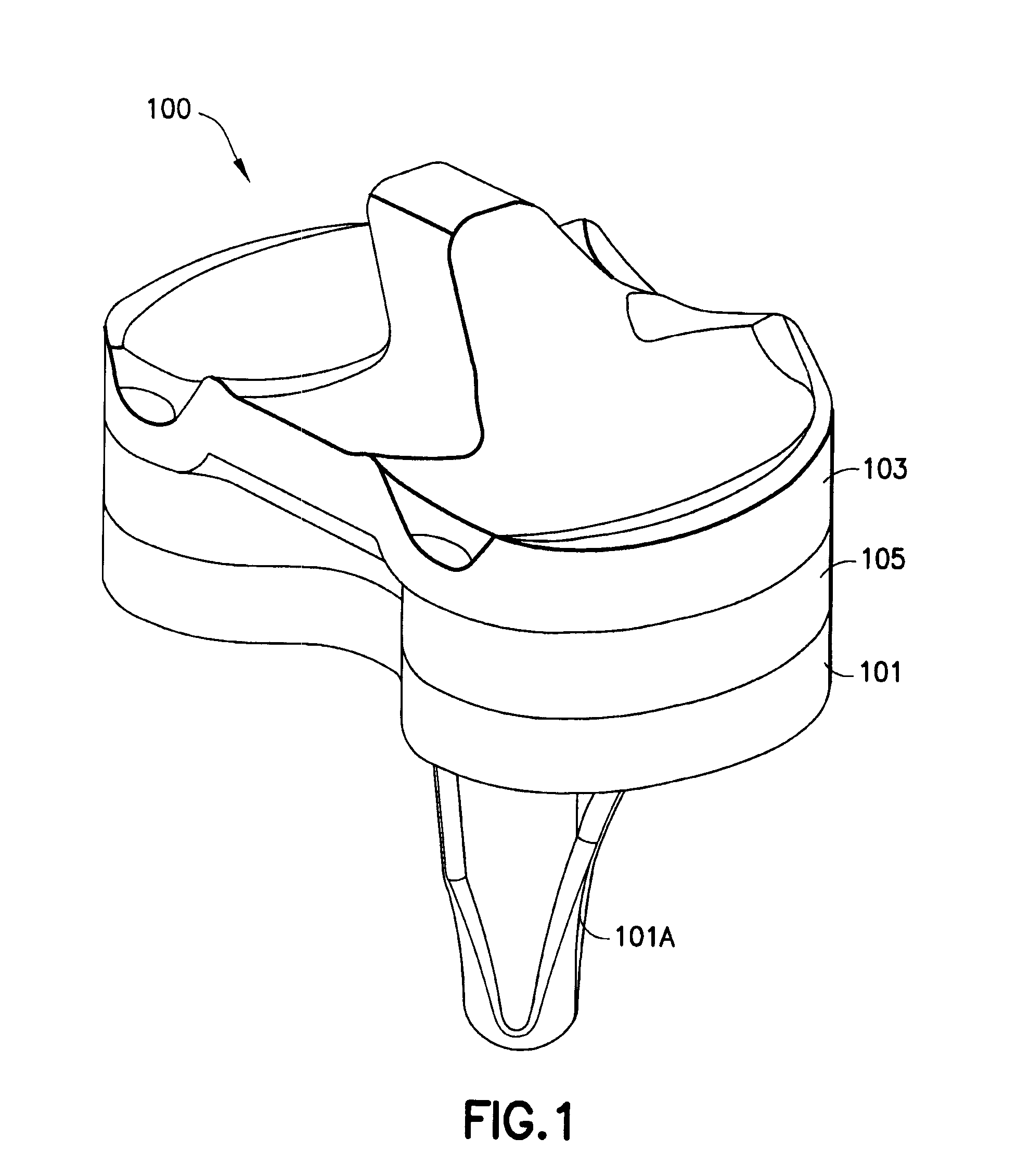

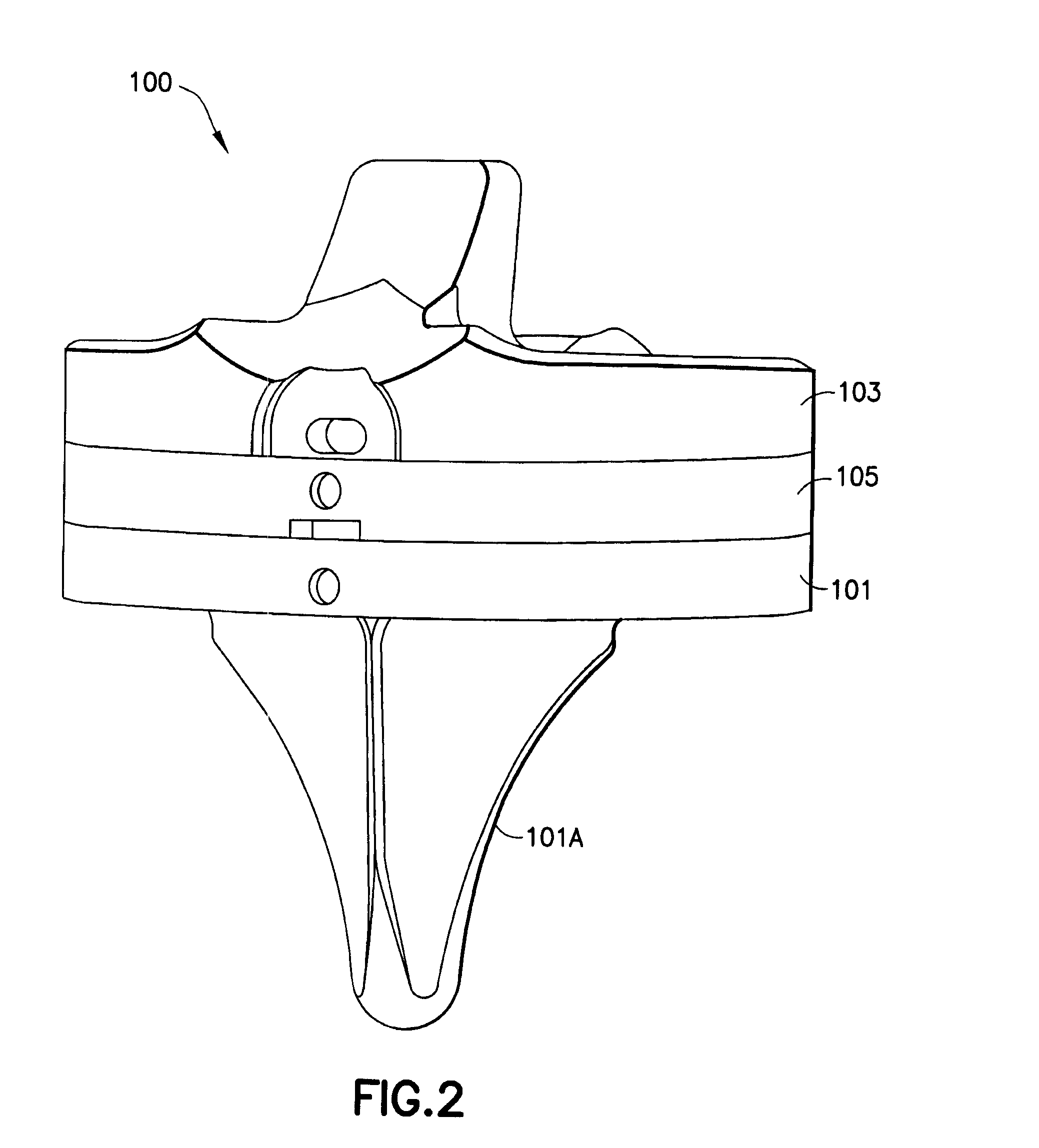

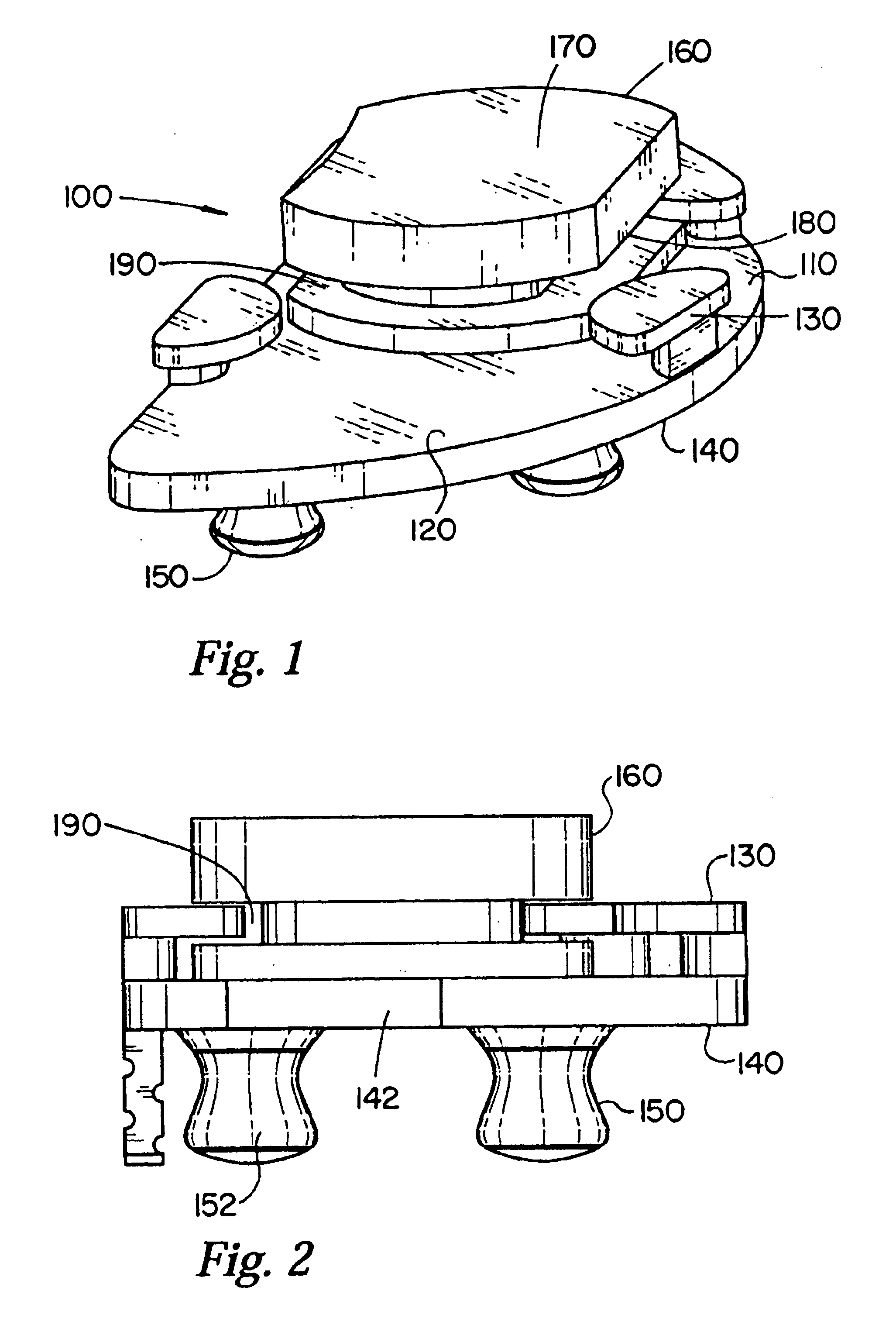

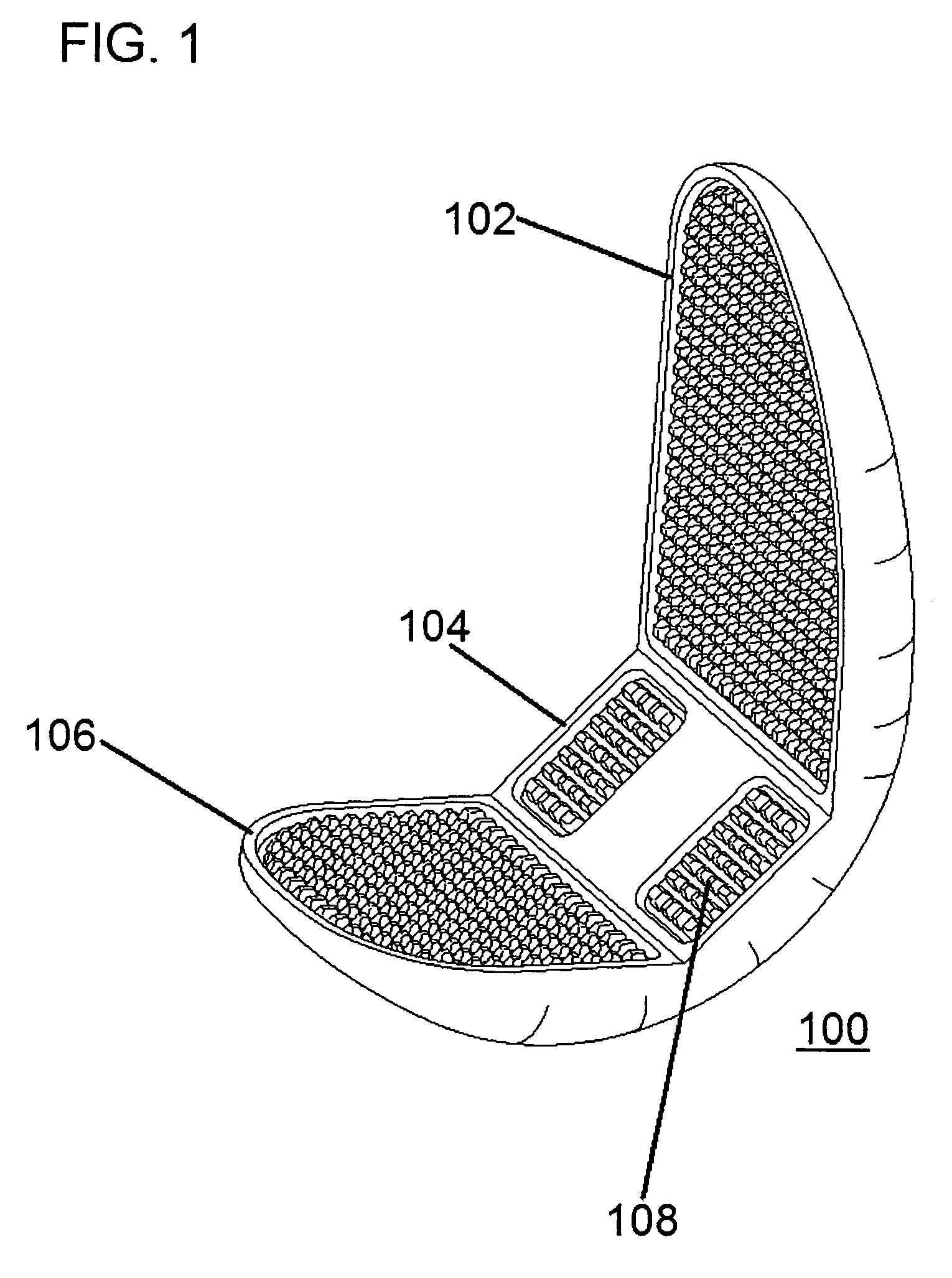

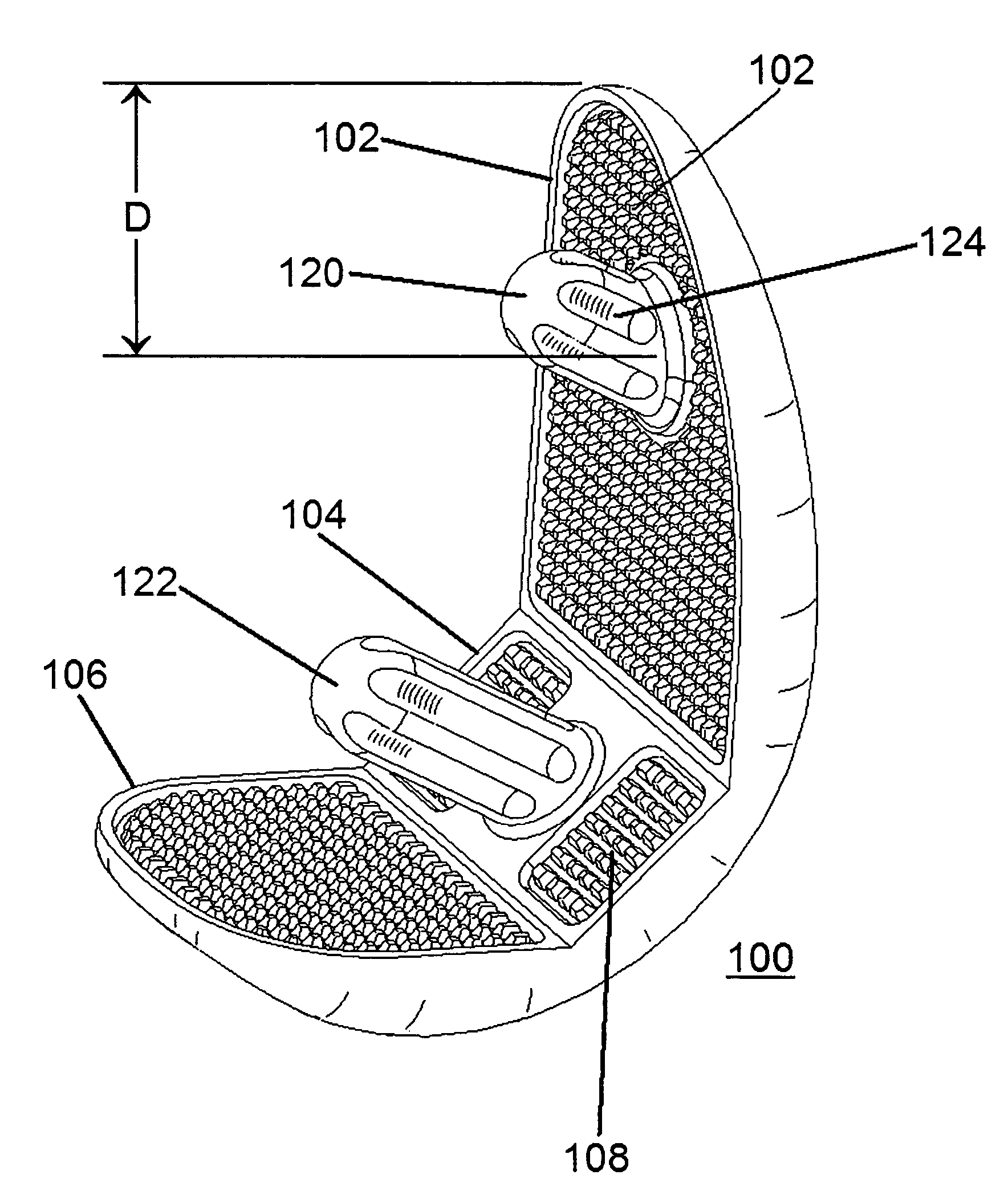

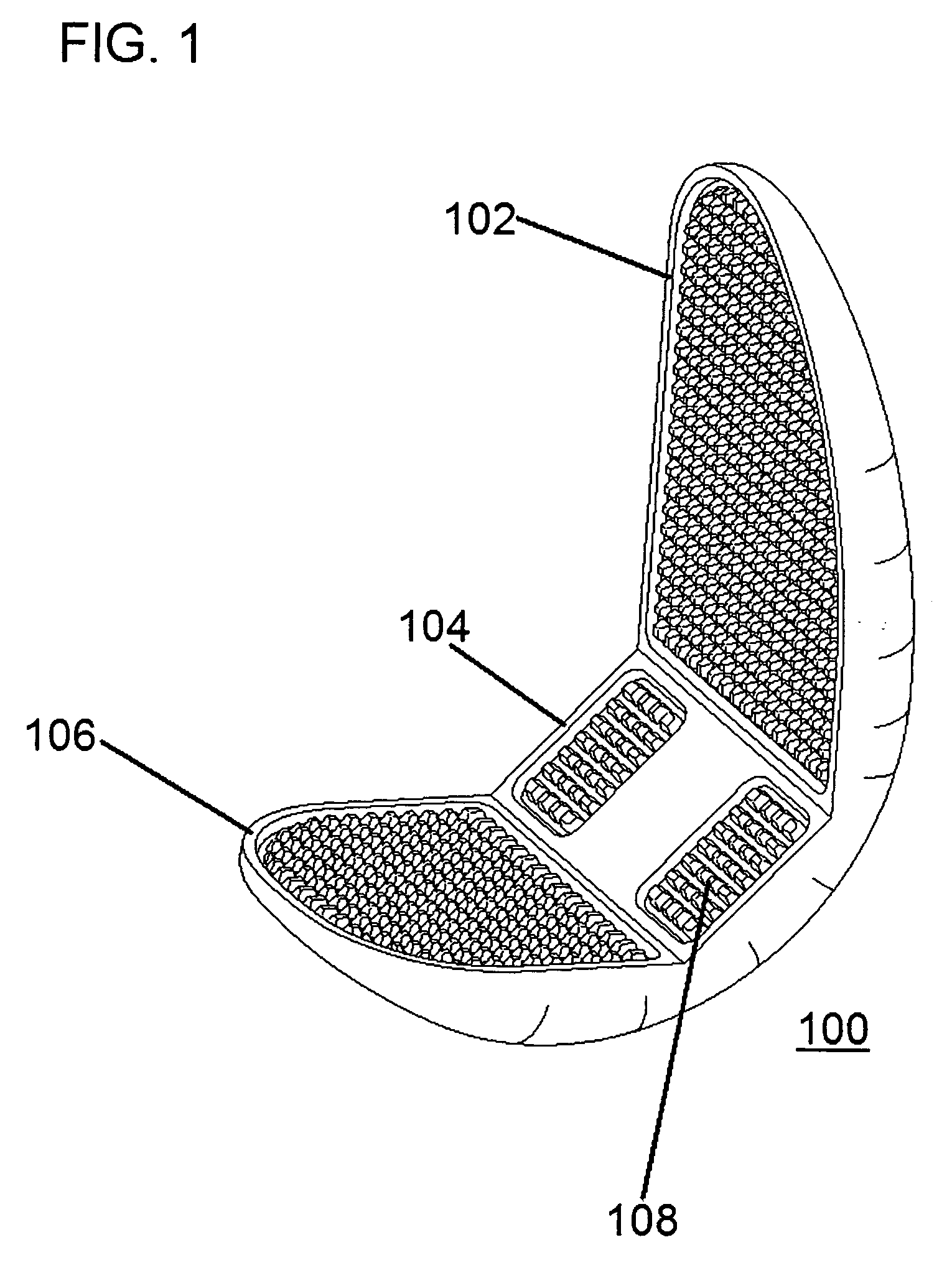

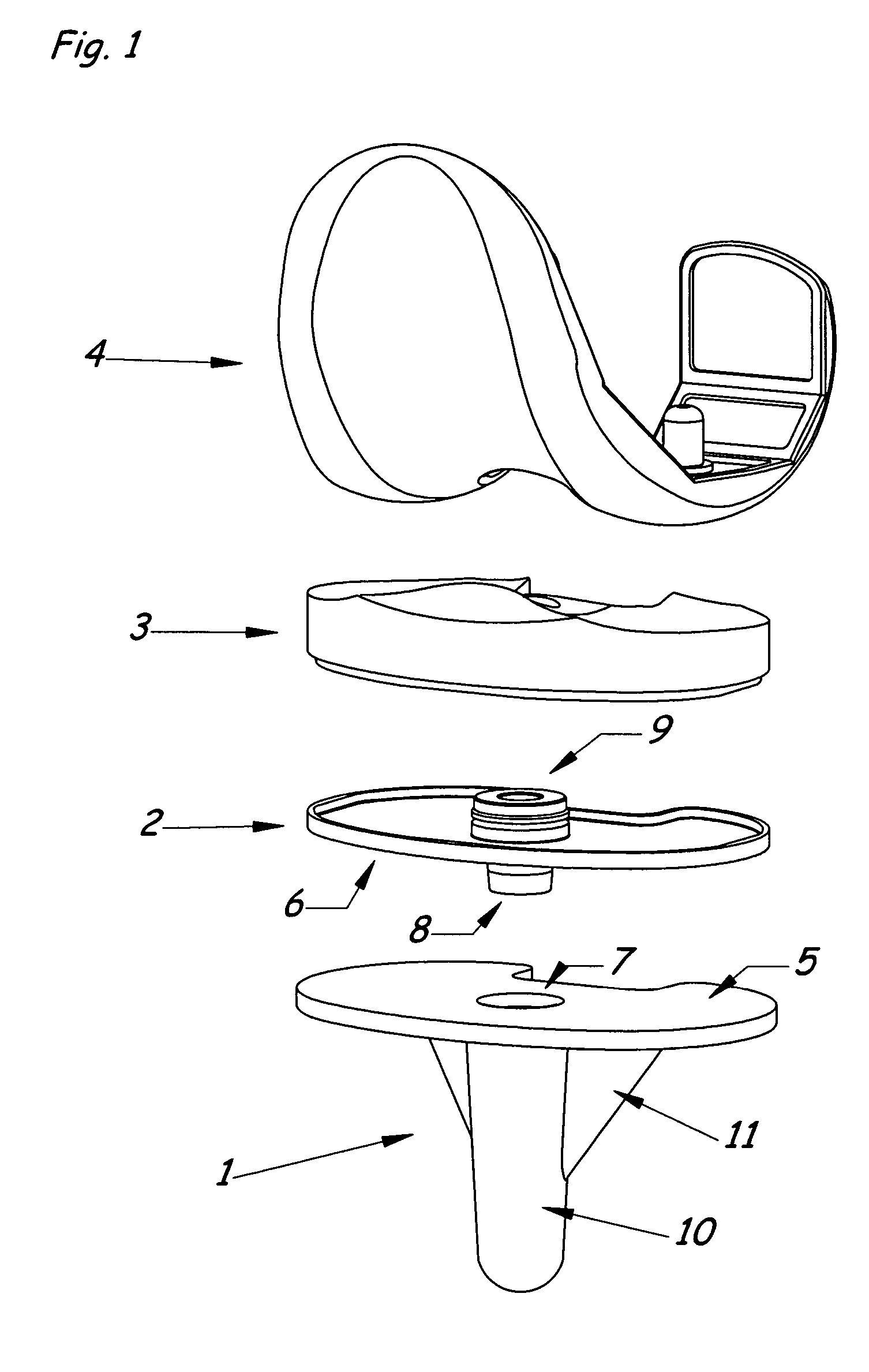

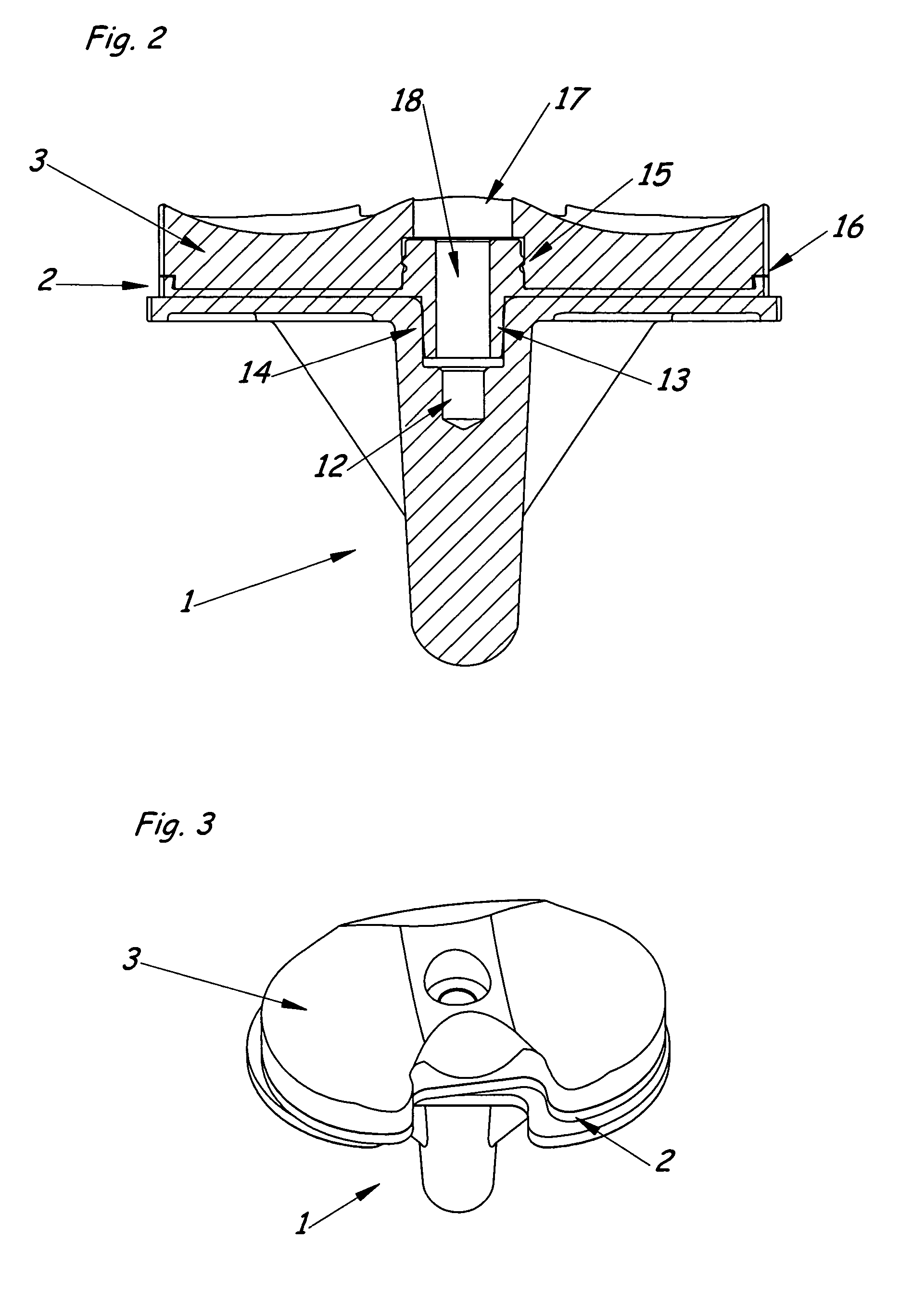

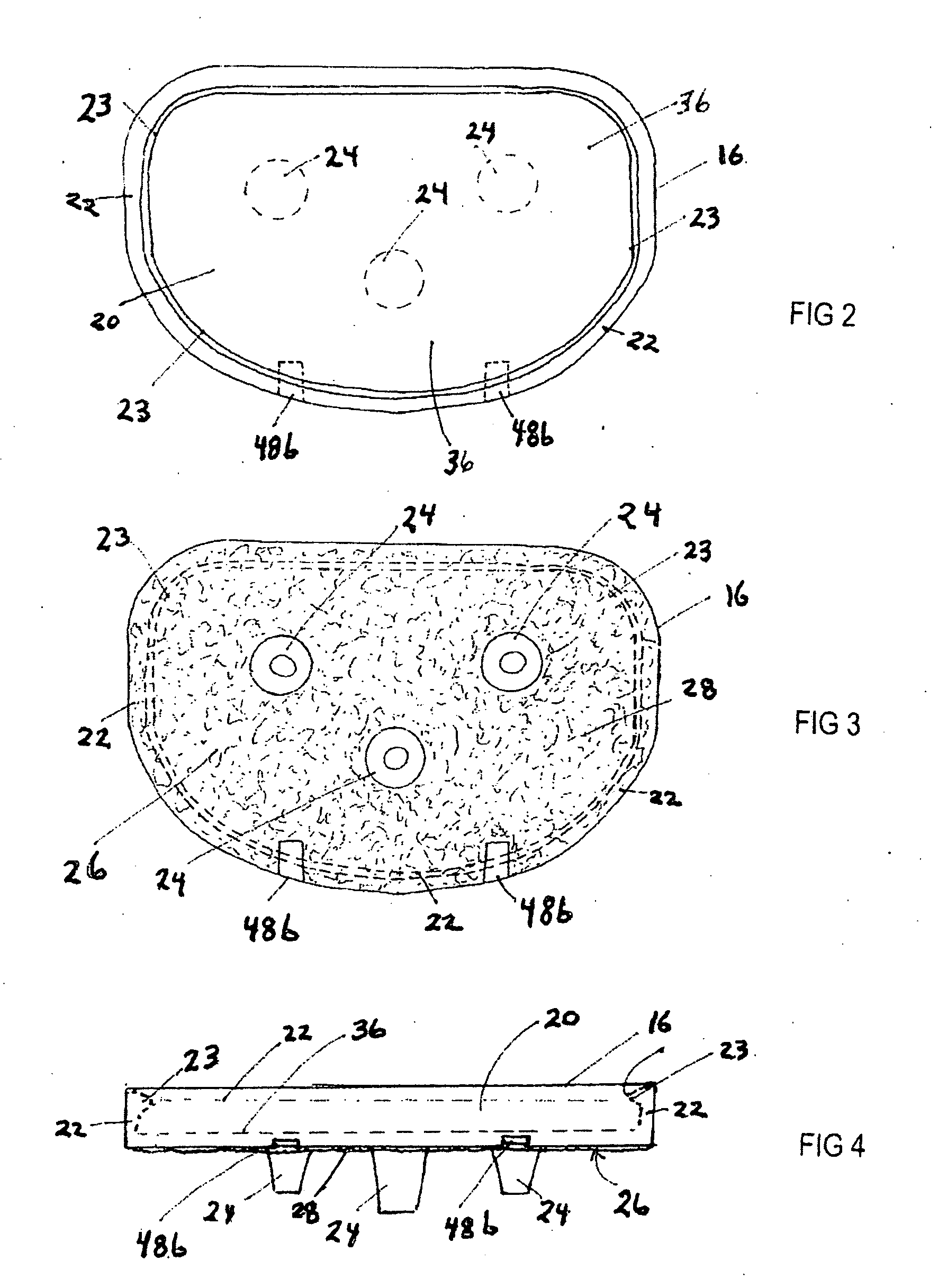

Tibial Tray Having a Reinforcing Member

A knee joint prosthesis can include a tibial component that can have a tibial tray. The tibial tray can include a platform-like tray that defines a superior surface and an inferior surface. The platform-like tray can have a tray perimeter and a raised wall formed on the inferior surface. The raised wall can be offset inboard relative to the tray perimeter. Porous material can be disposed on the inferior surface of the platform-like tray at a location generally between the raised wall and the tray perimeter.

Owner:BIOMET MFG CORP

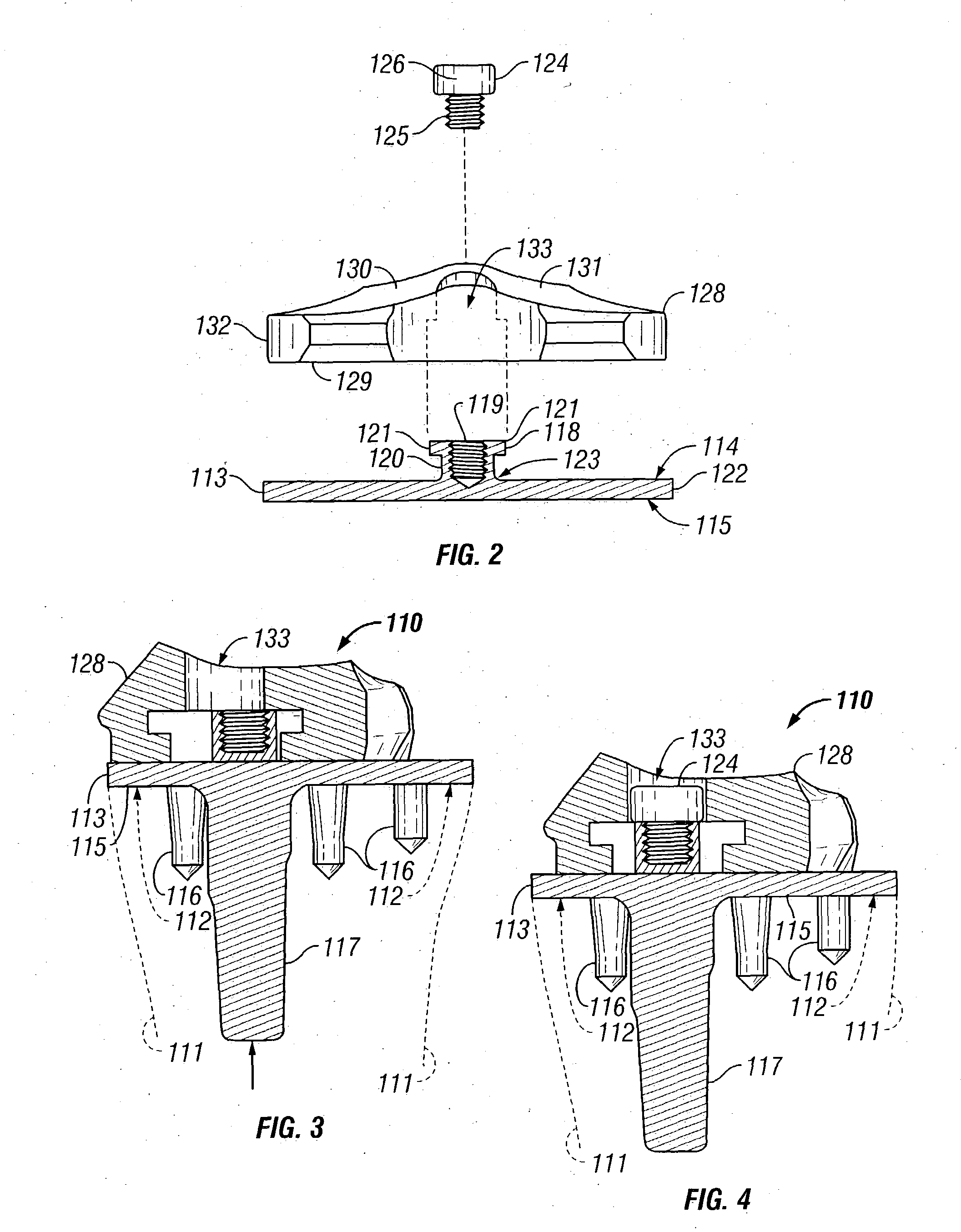

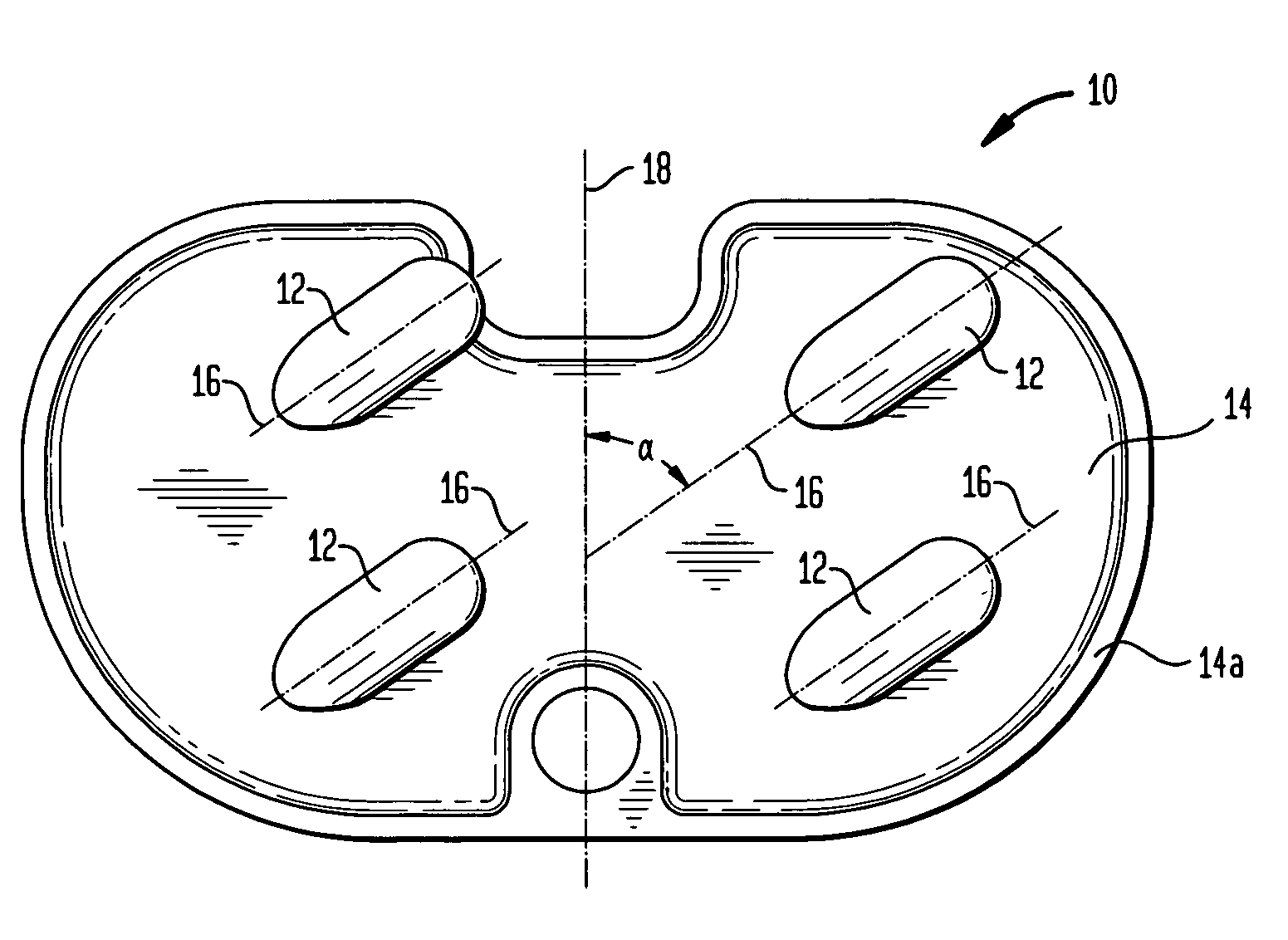

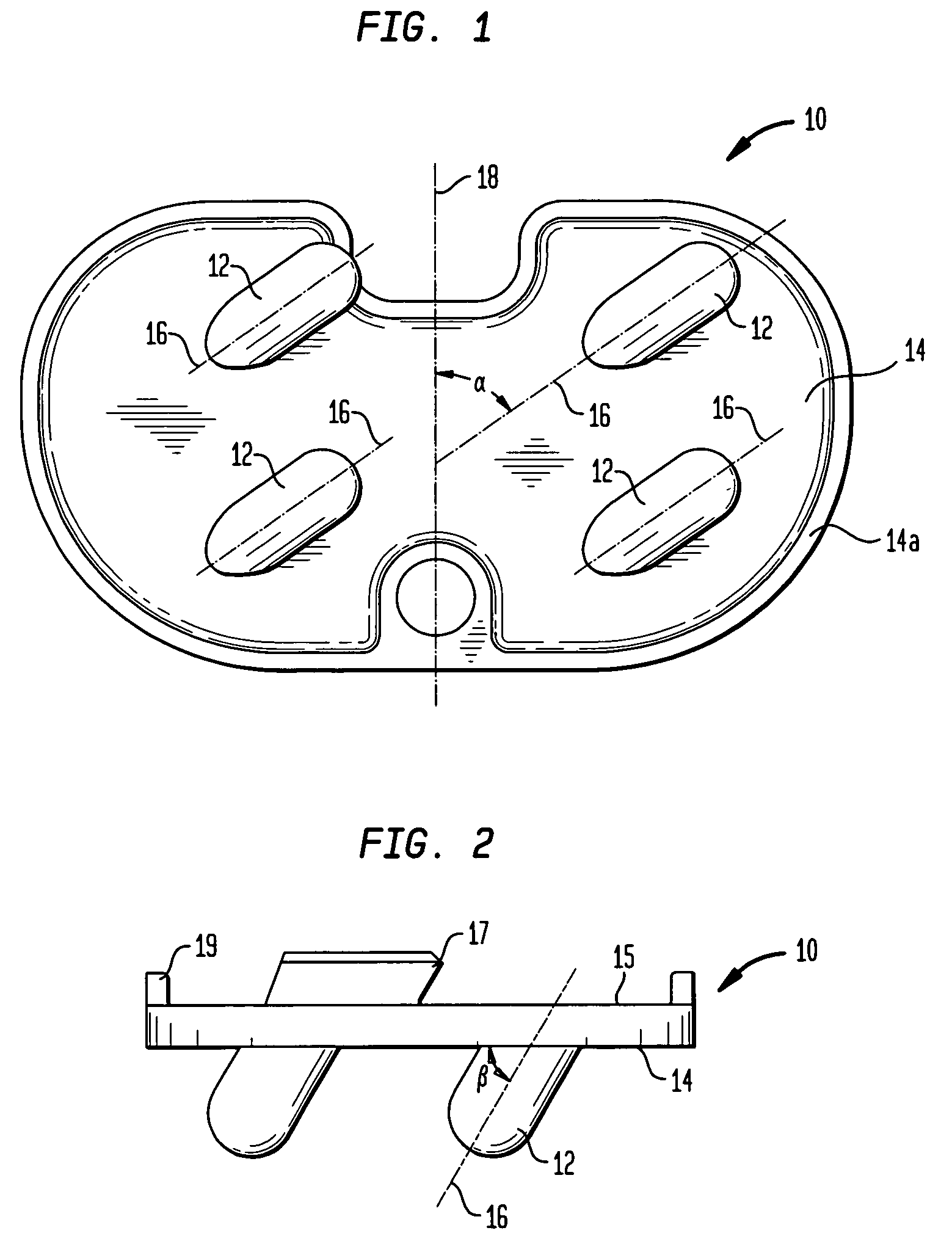

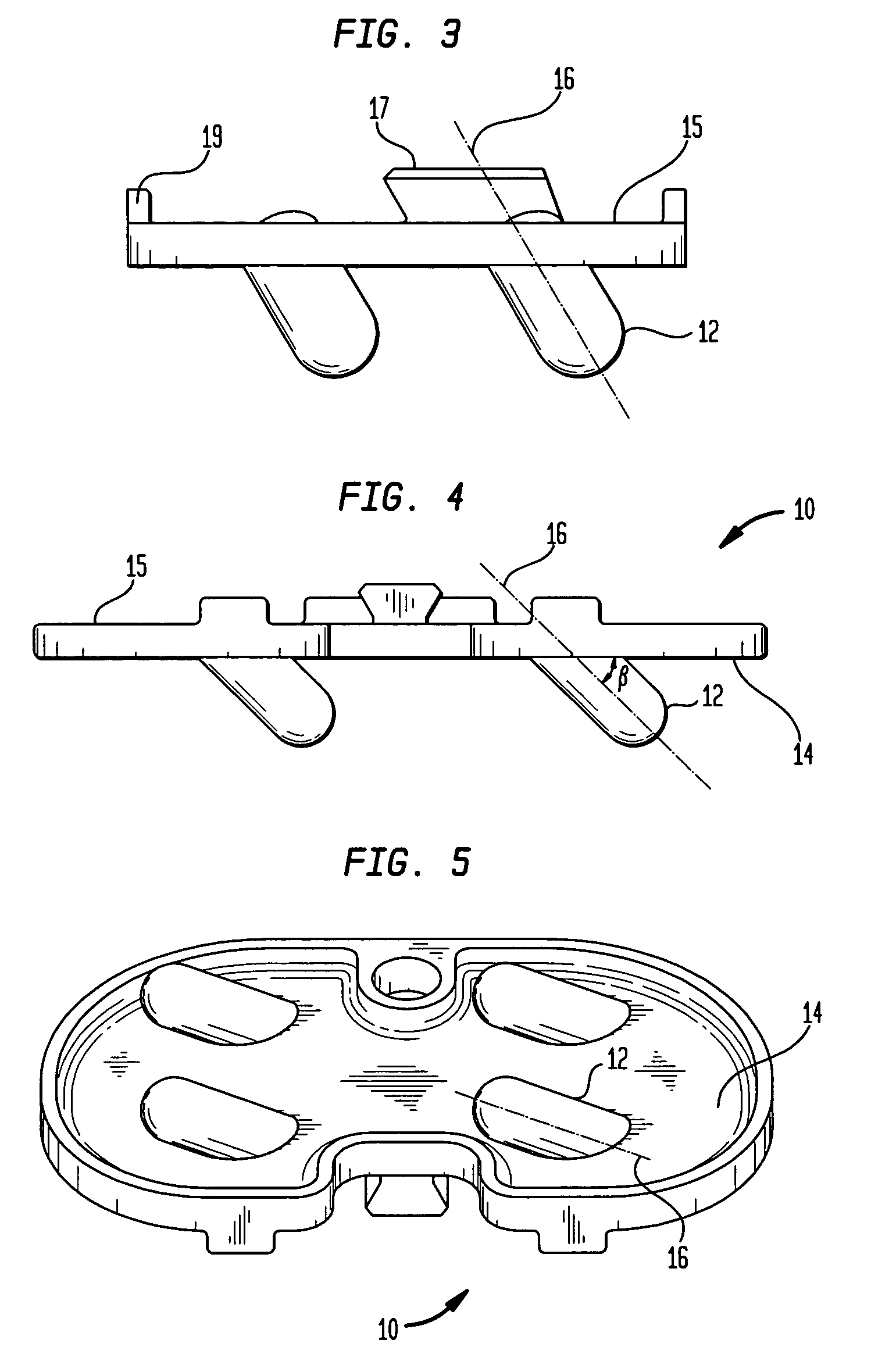

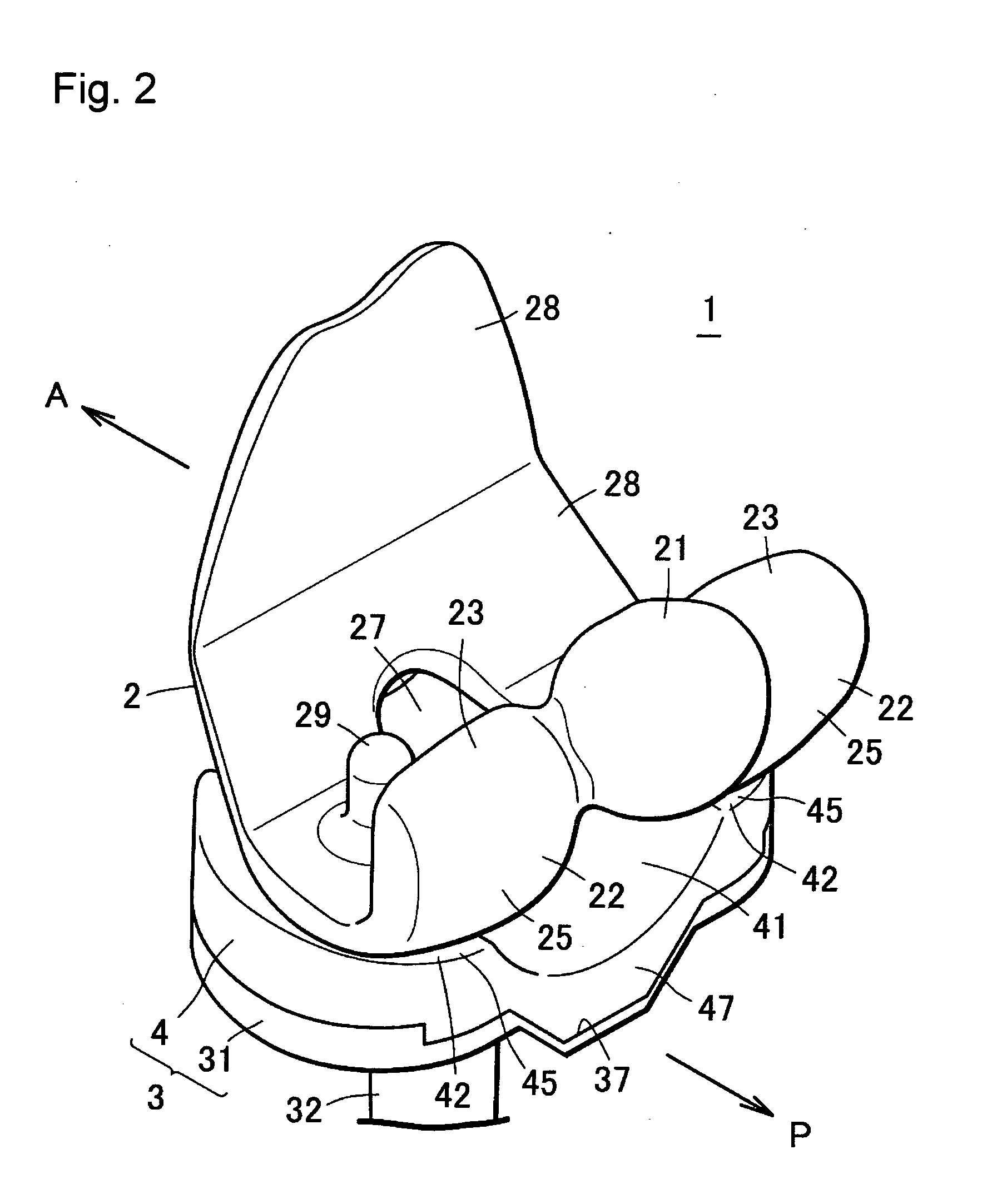

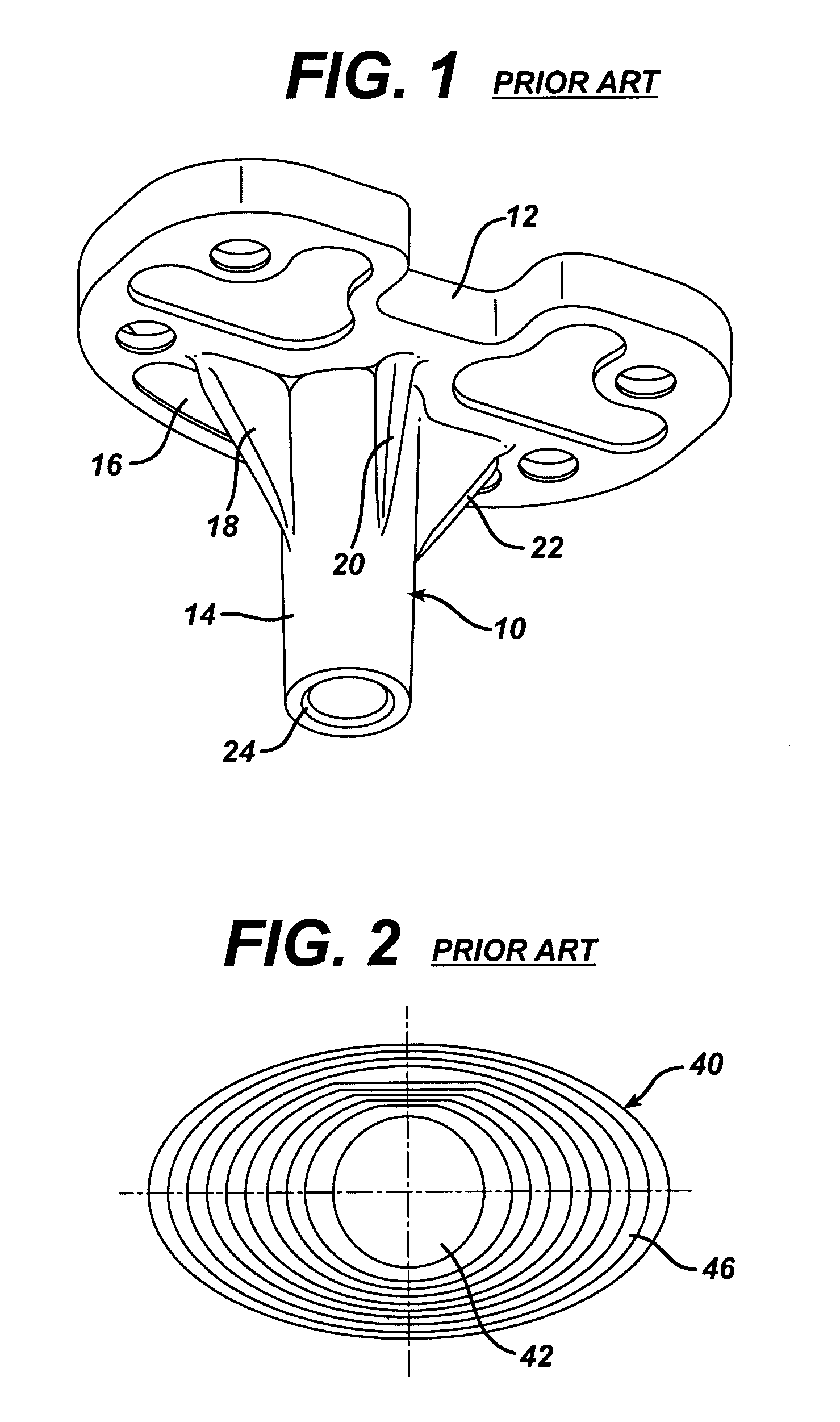

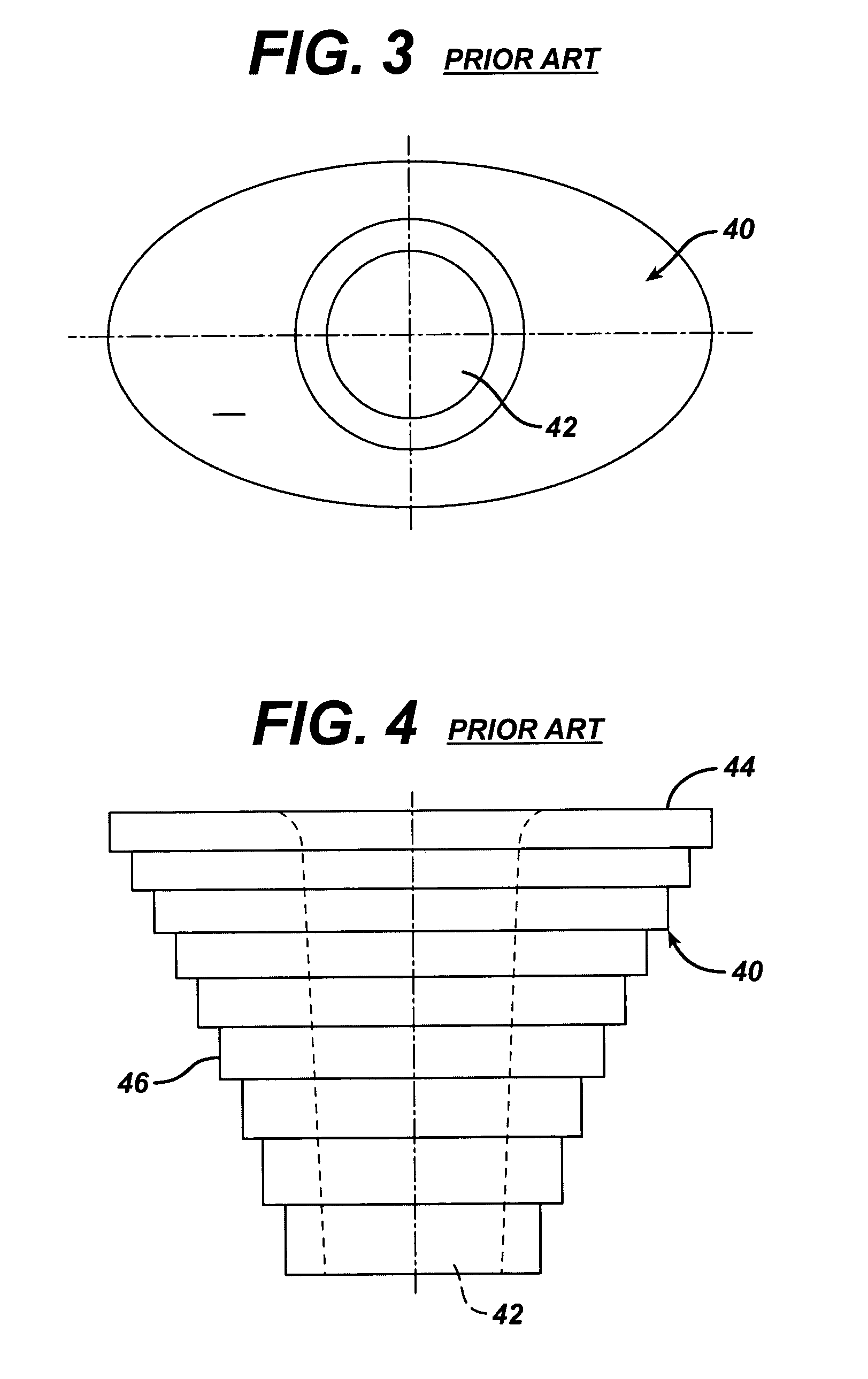

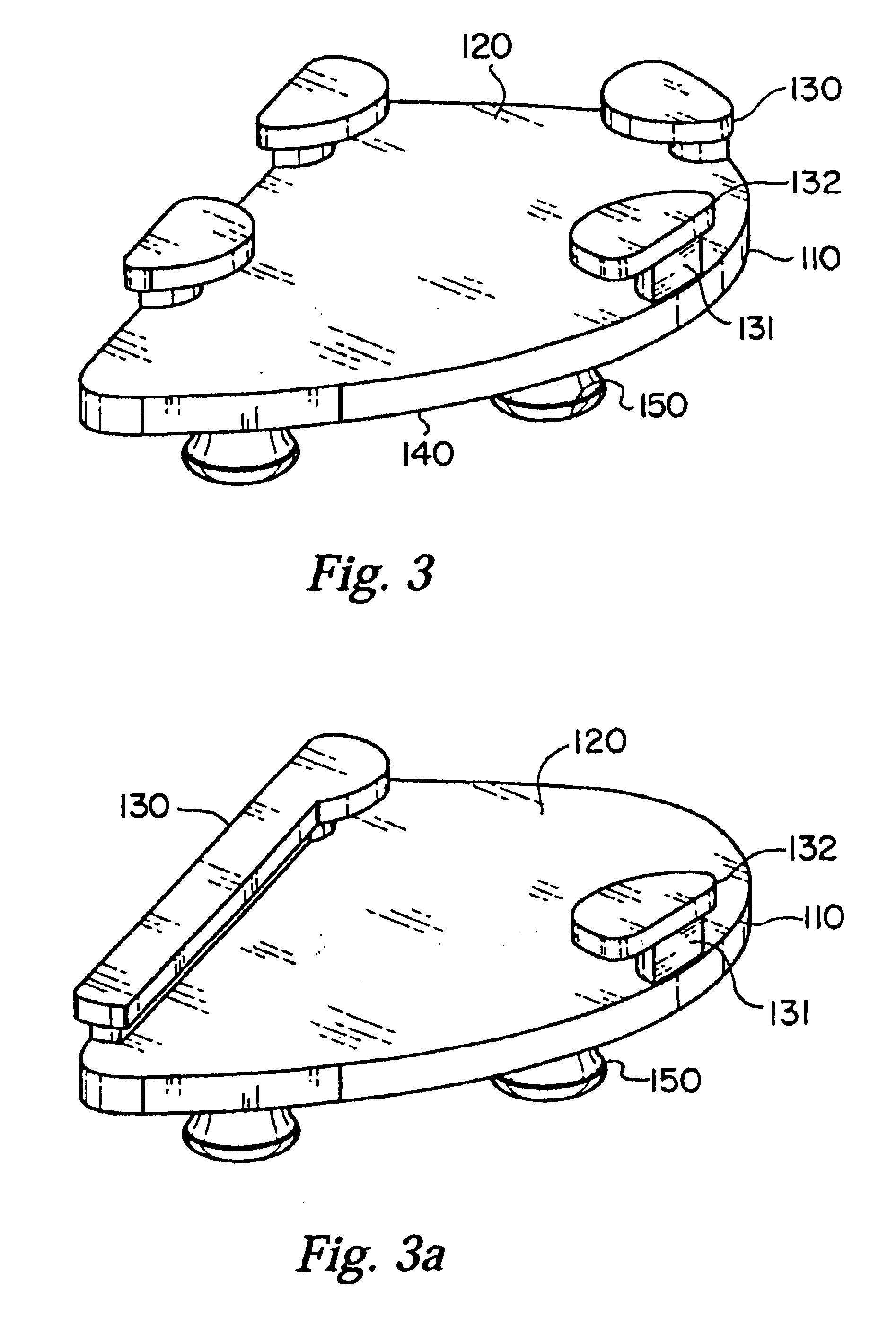

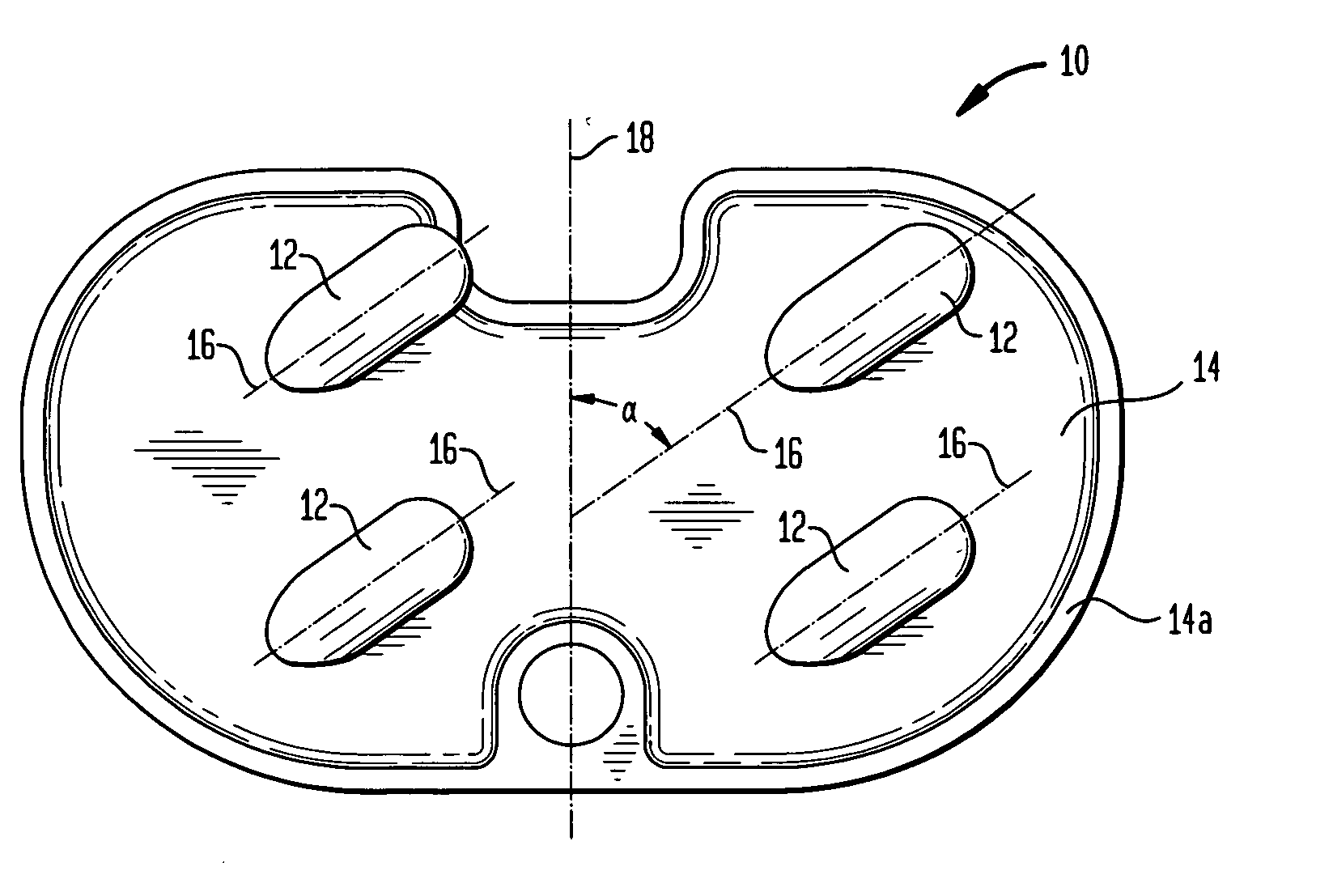

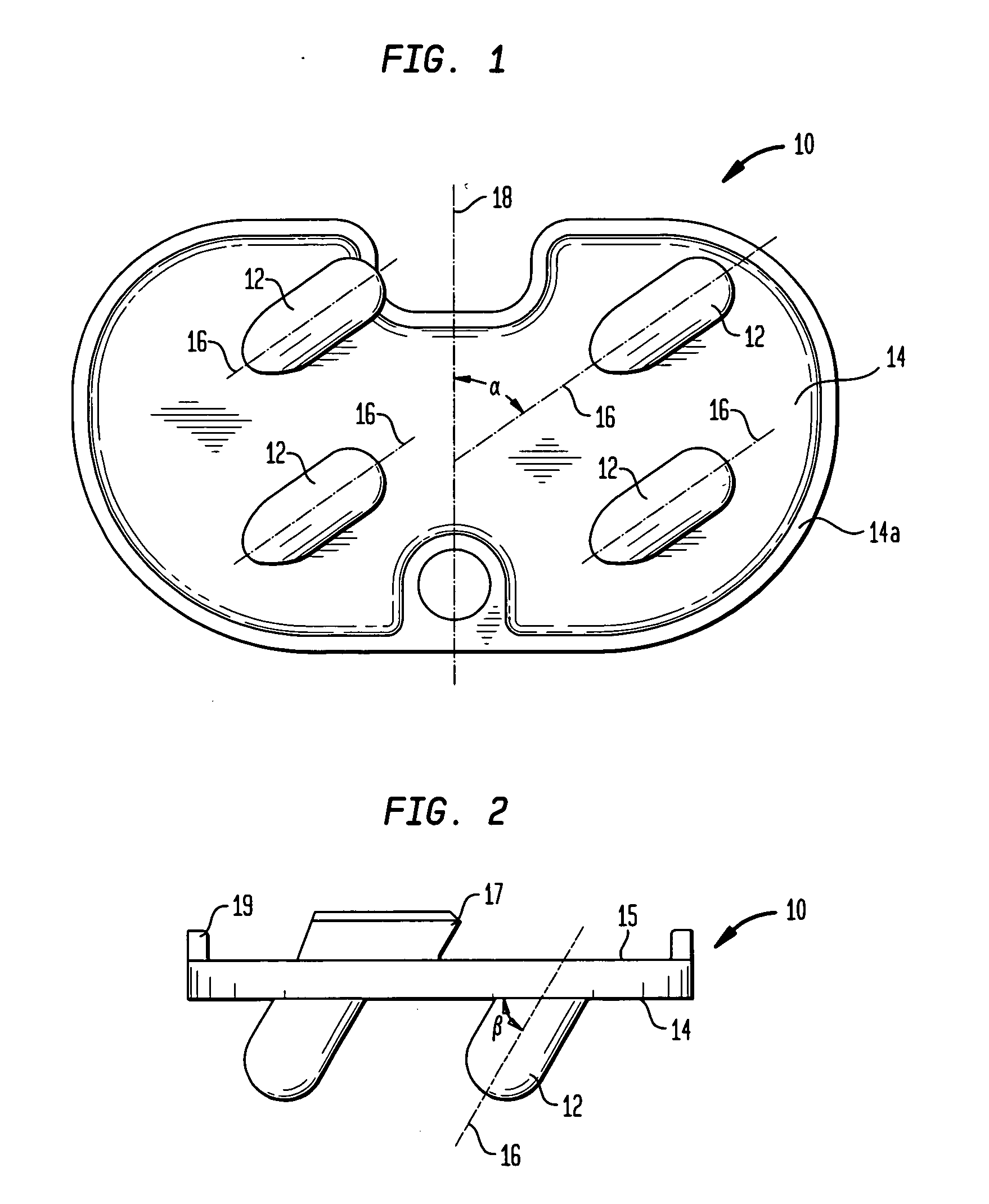

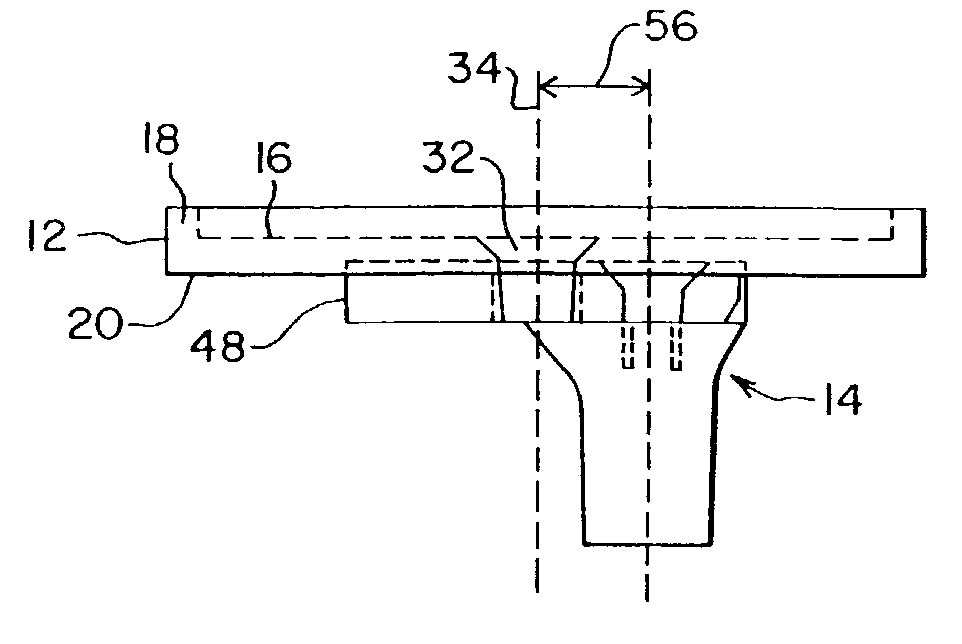

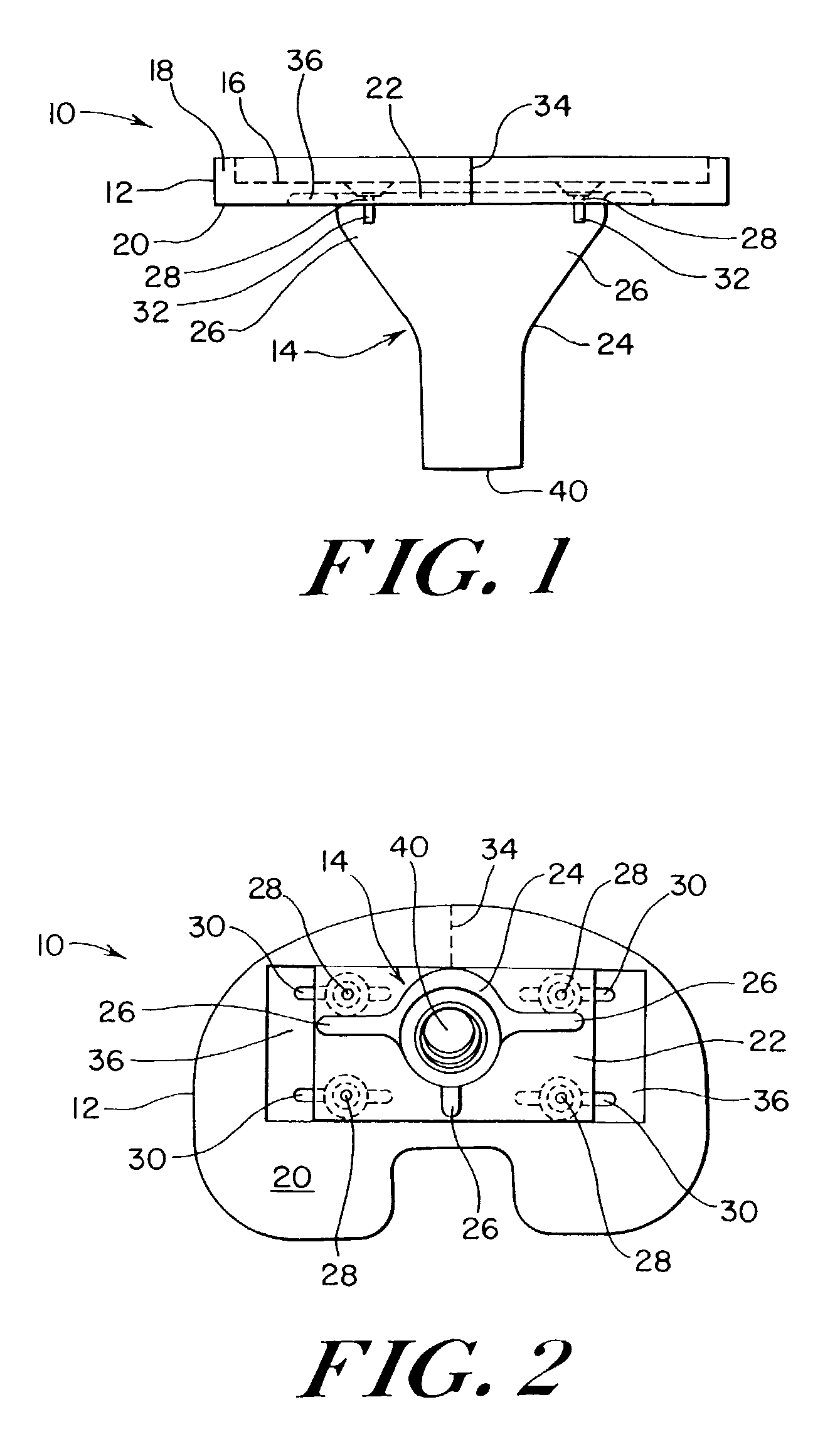

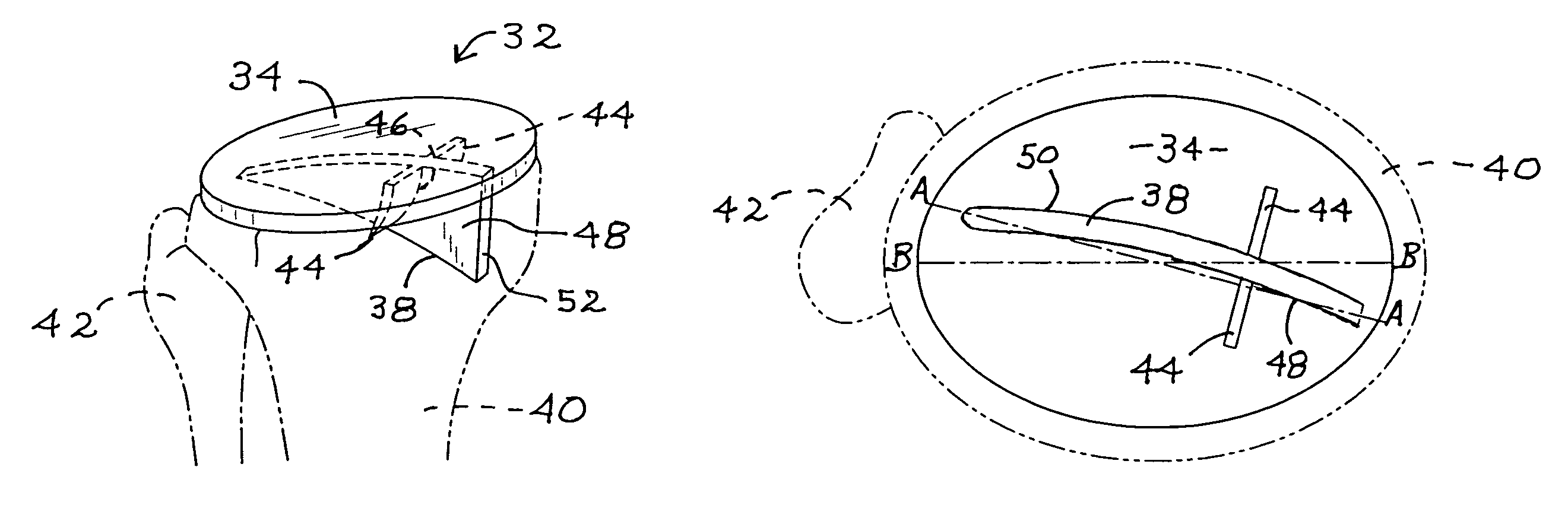

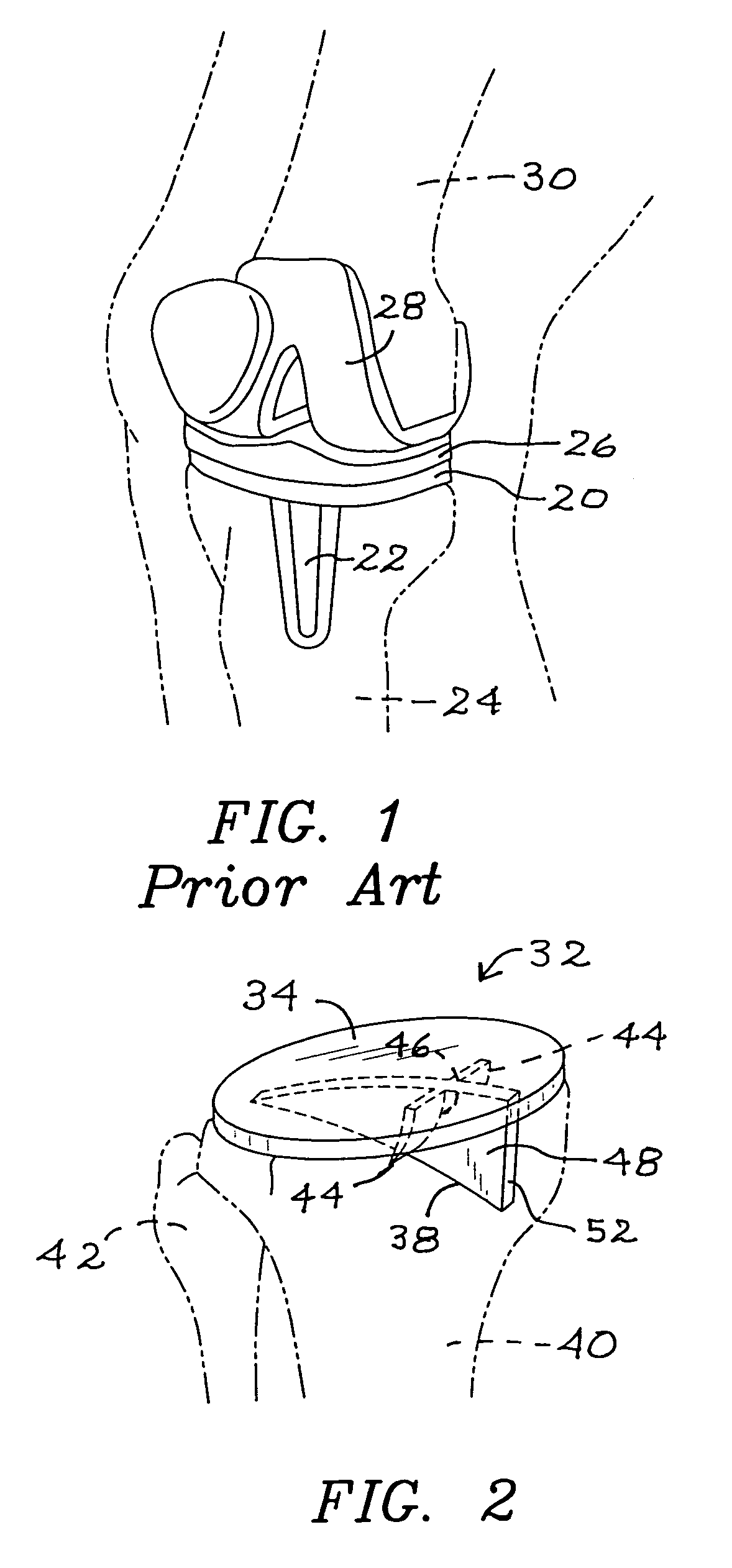

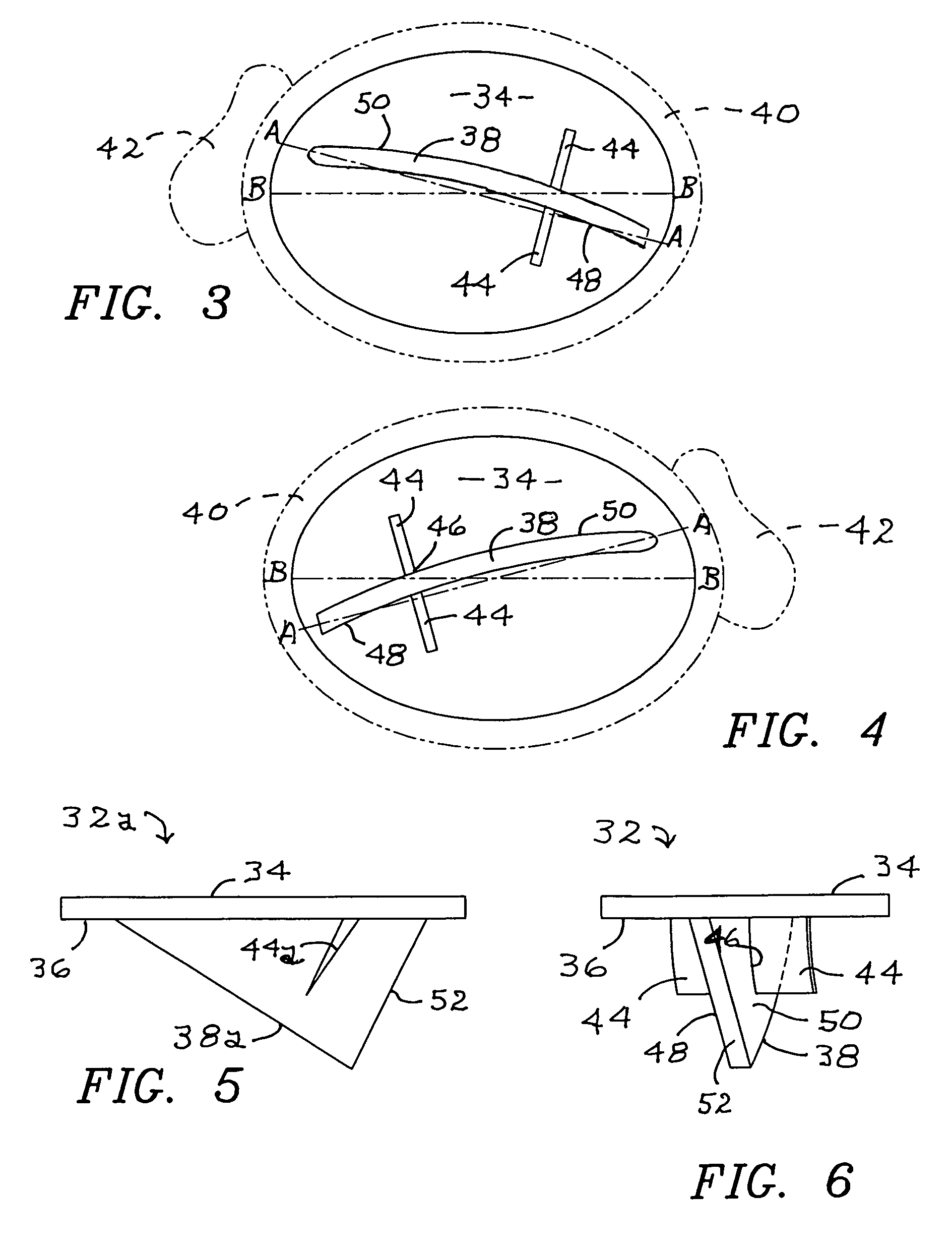

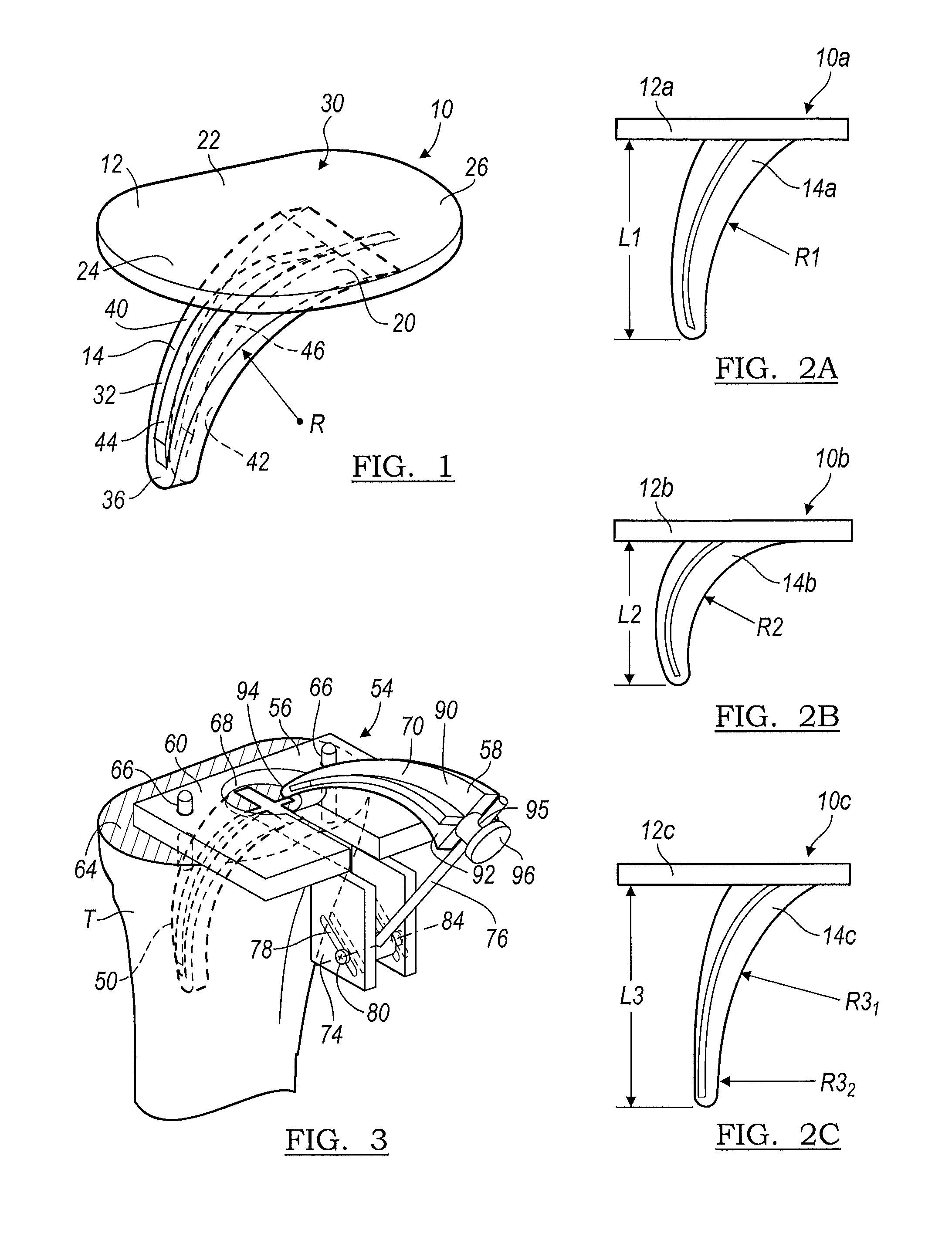

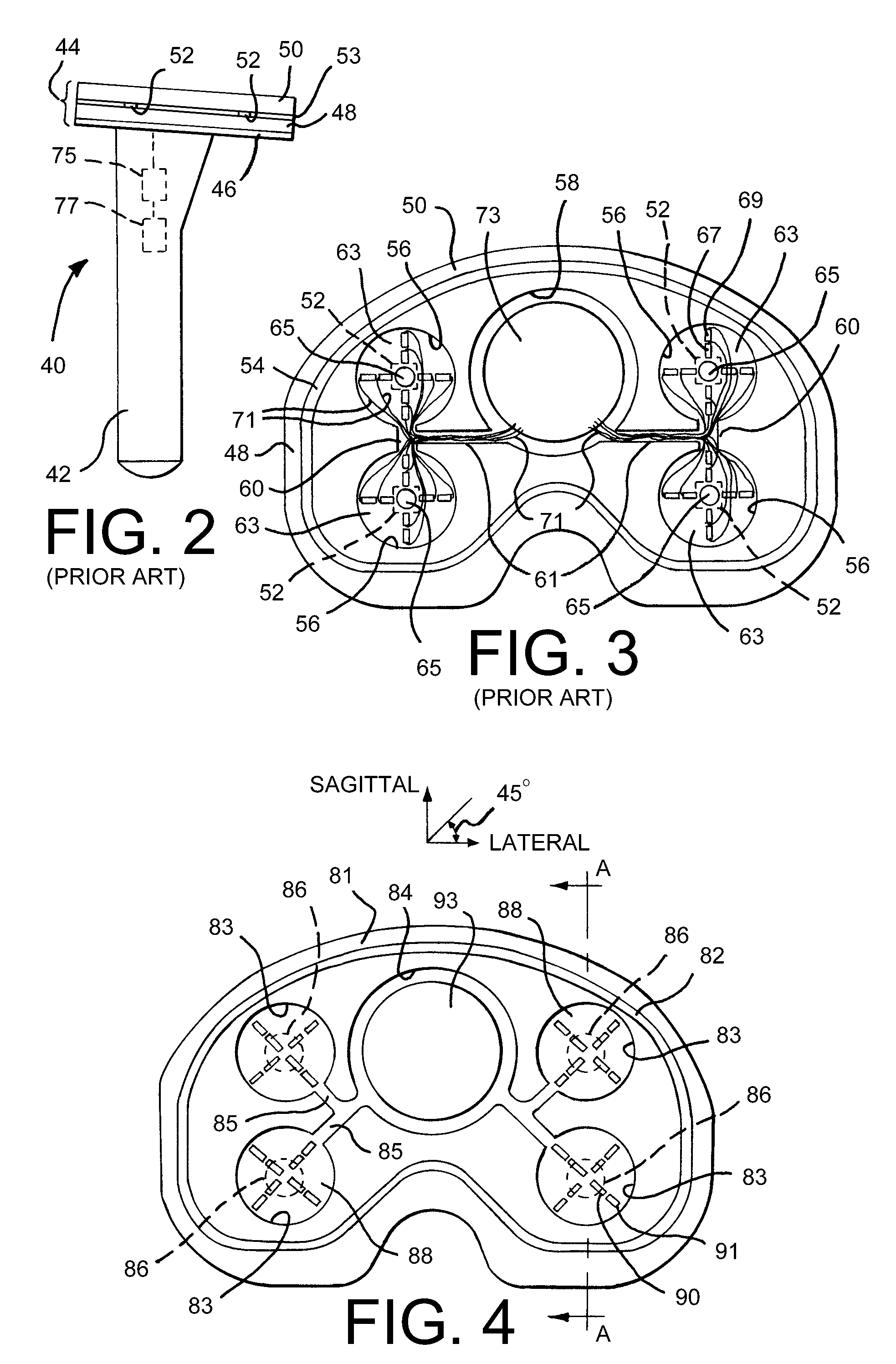

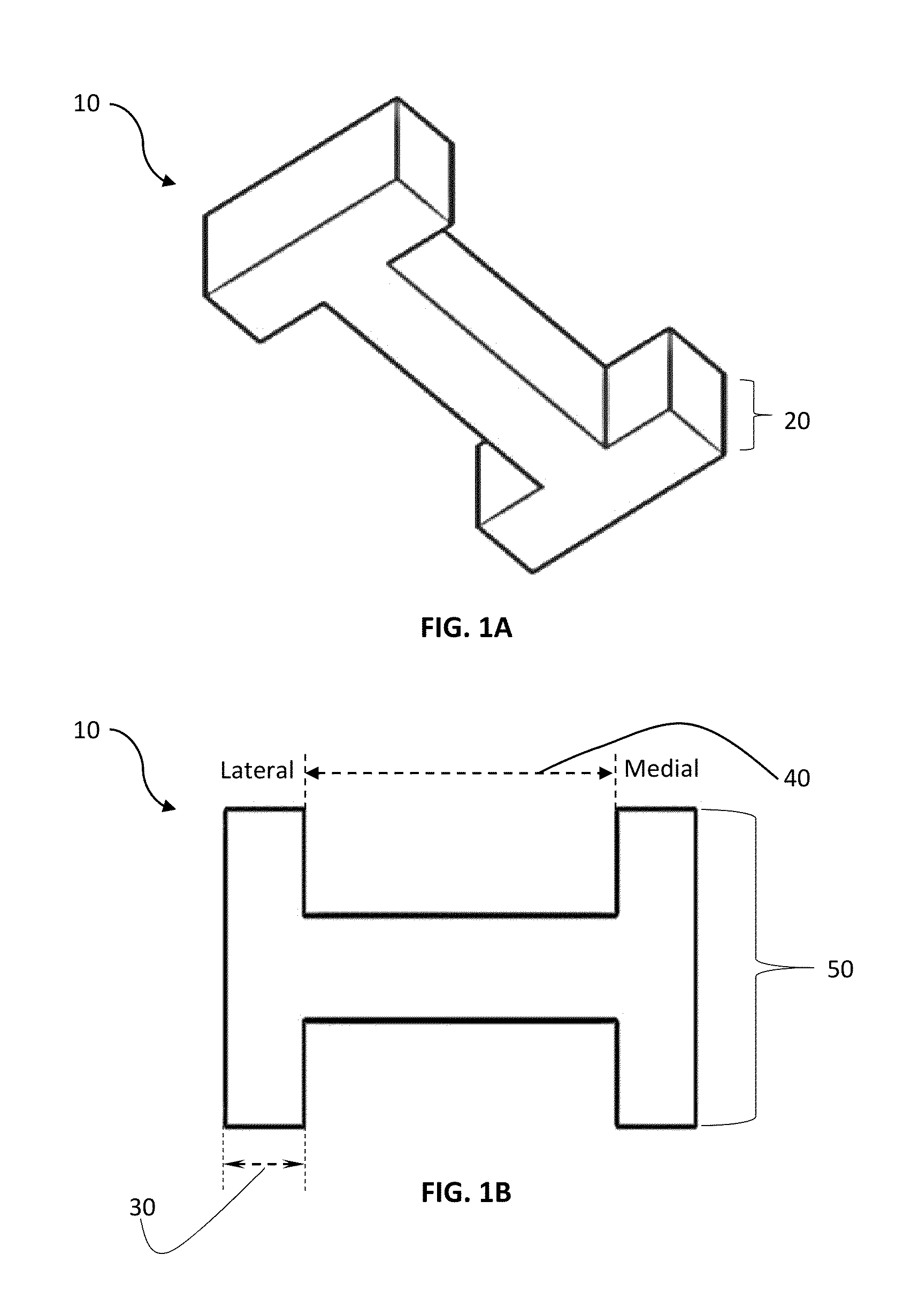

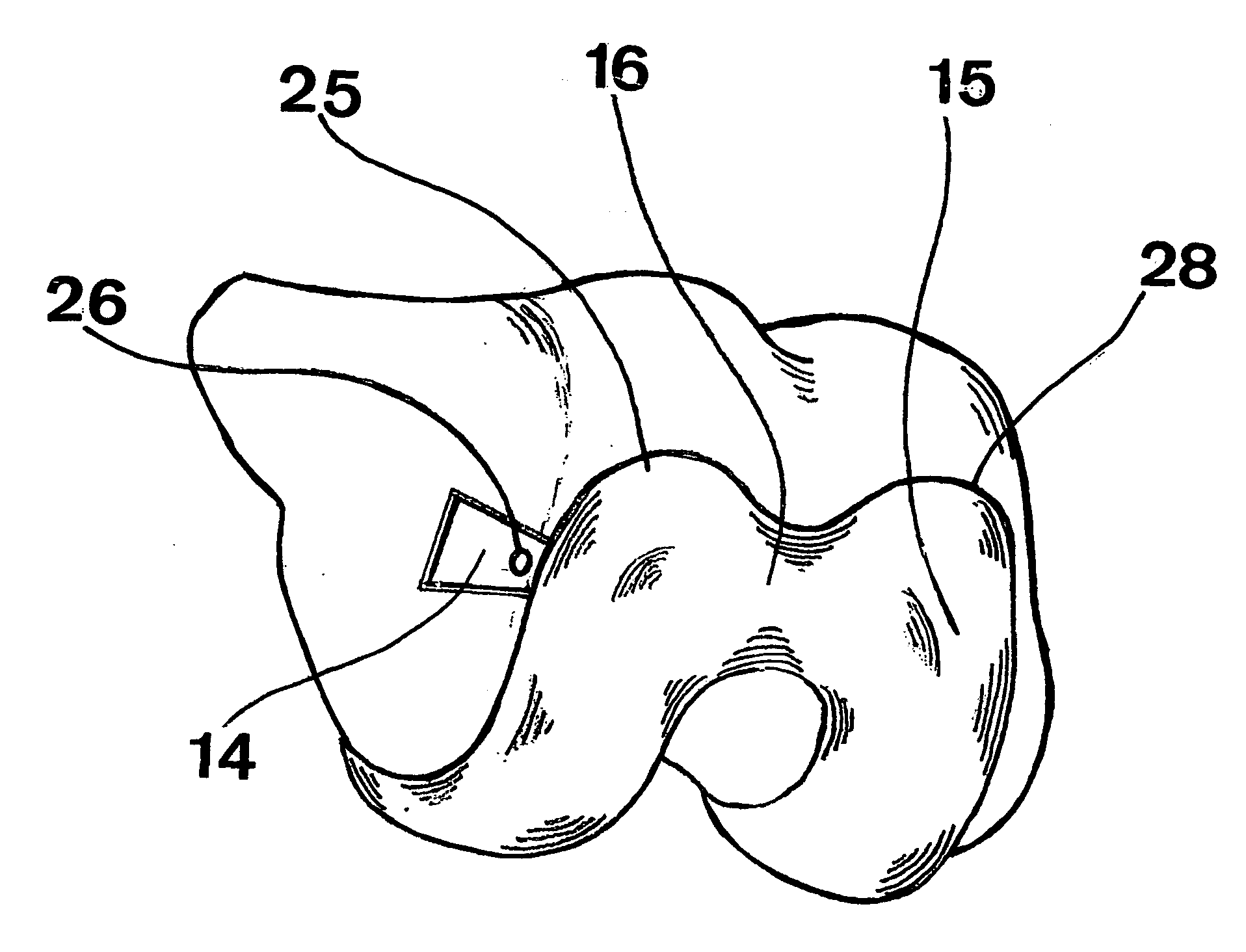

Orthopedic implant with angled pegs

An orthopedic implant, such as a tibial tray, includes a body having a bone contacting surface with at least one and preferably two pegs extending from the bone contacting surface. Each of the pegs has a longitudinal axis angled with respect to the bone contacting surface and also angled in at least one direction consisting of a medial-lateral direction, an anterior-posterior direction and an inferior-superior direction. In the case of the tibial tray, the pegs form a non-perpendicular angle with the bone contacting surface of the baseplate and are angled in both a posterior direction and a medial or lateral direction.

Owner:HOWMEDICA OSTEONICS CORP

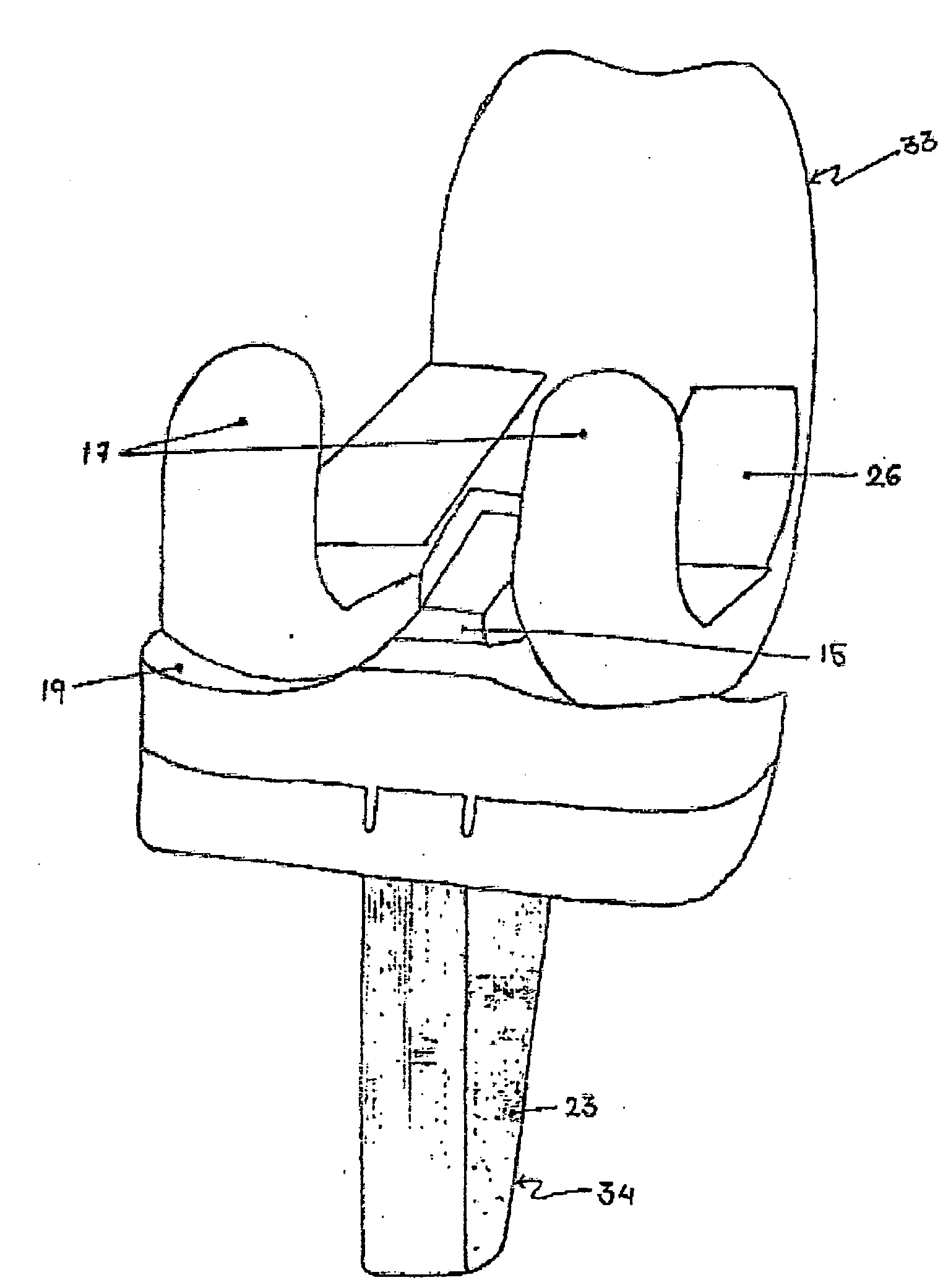

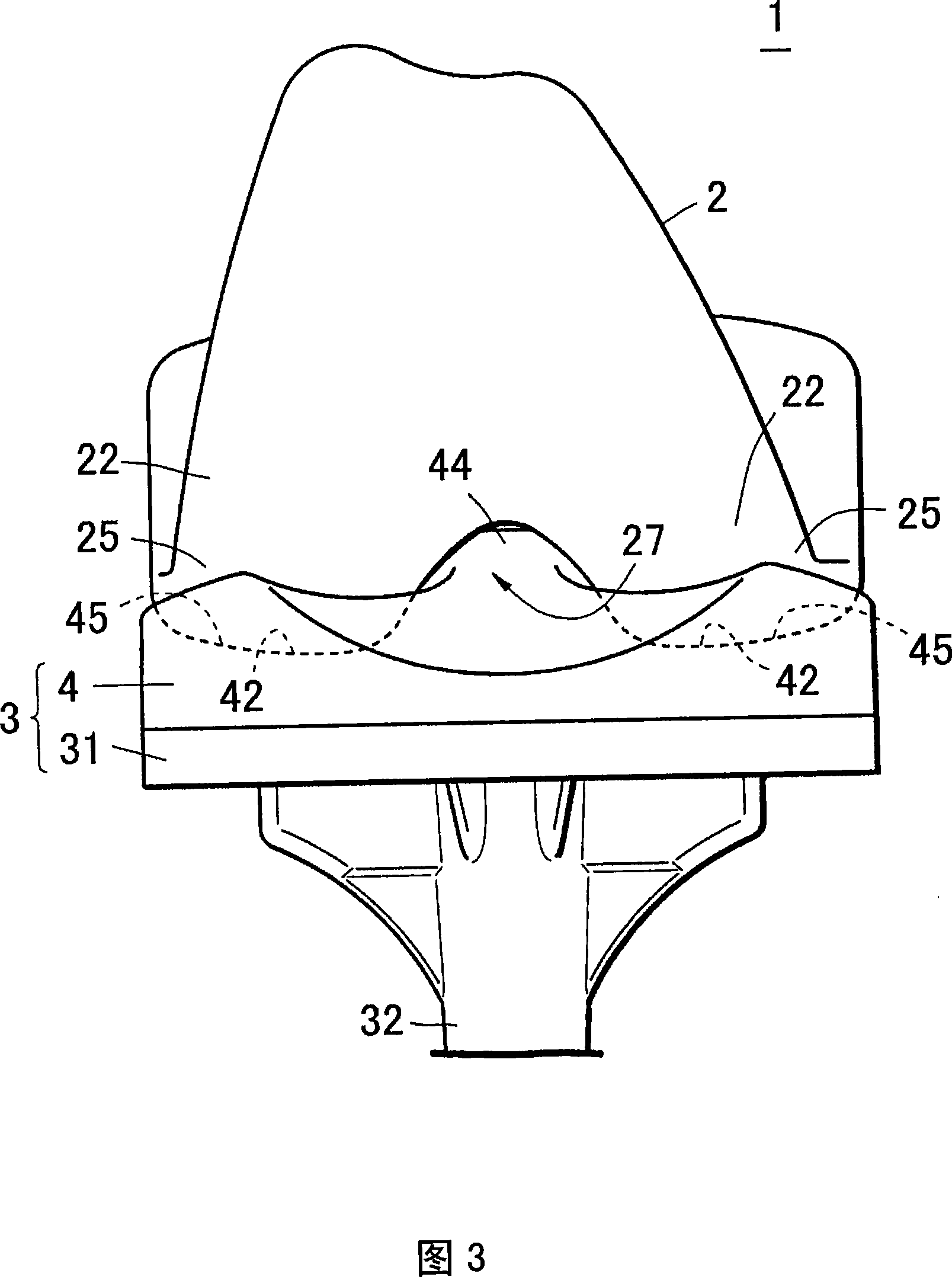

Knee Joint Prosthesis

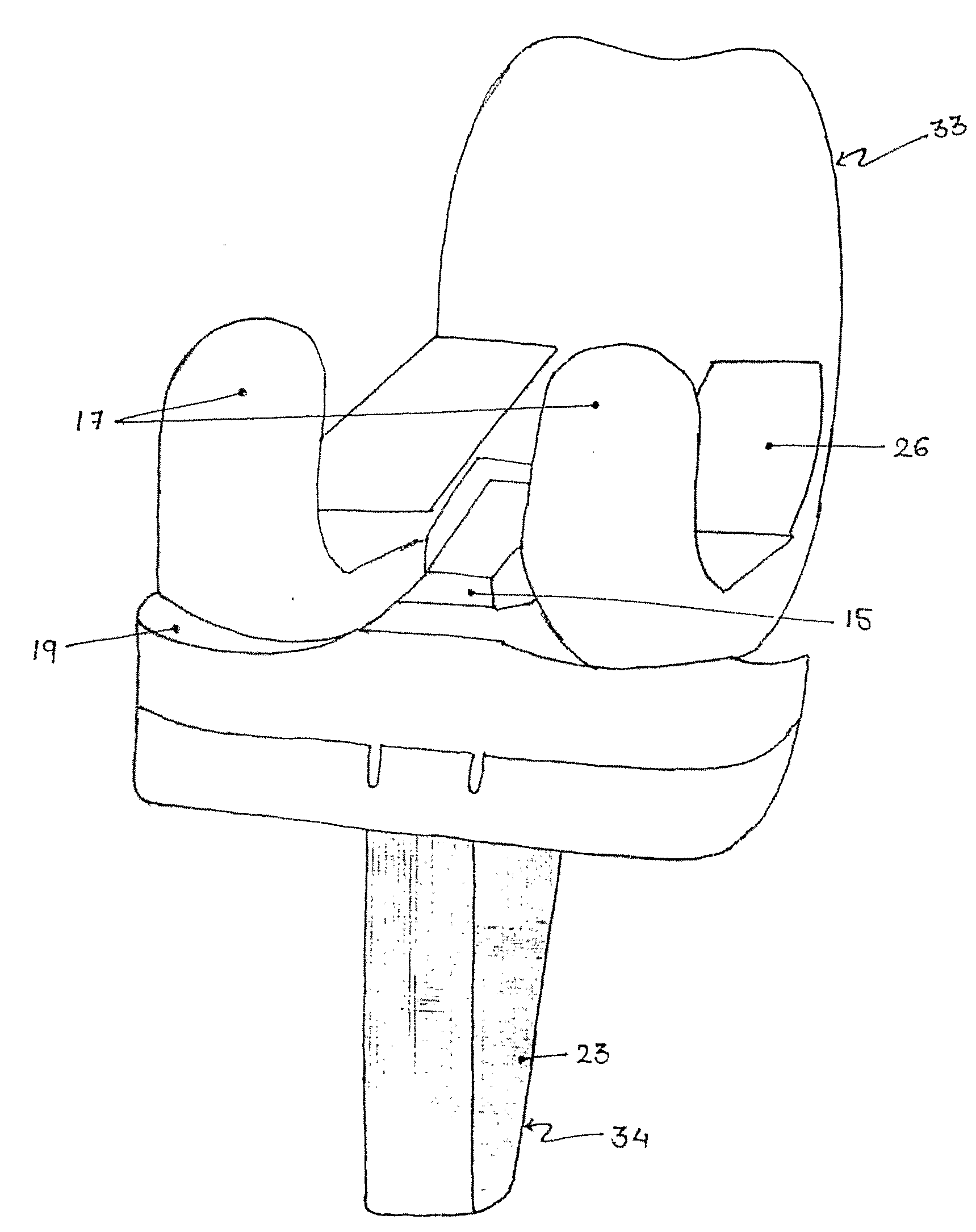

A knee joint prosthesis is disclosed. The prosthesis has a femoral component and a tibial component. The tibial component has a tibial plateau element fitted in a tibial tray element. A hemi capstan shaped bridge member is provided between replicated condyles on the femoral component. A specially shaped post is provided between kidney shaped meniscal depression on the tibial plateau element. The bridge member and the post act together to form an additional joint for load transfer during deep flexion of the prosthesis in its operative configuration.

Owner:SANCHETI KANTILAL HASTIMAL

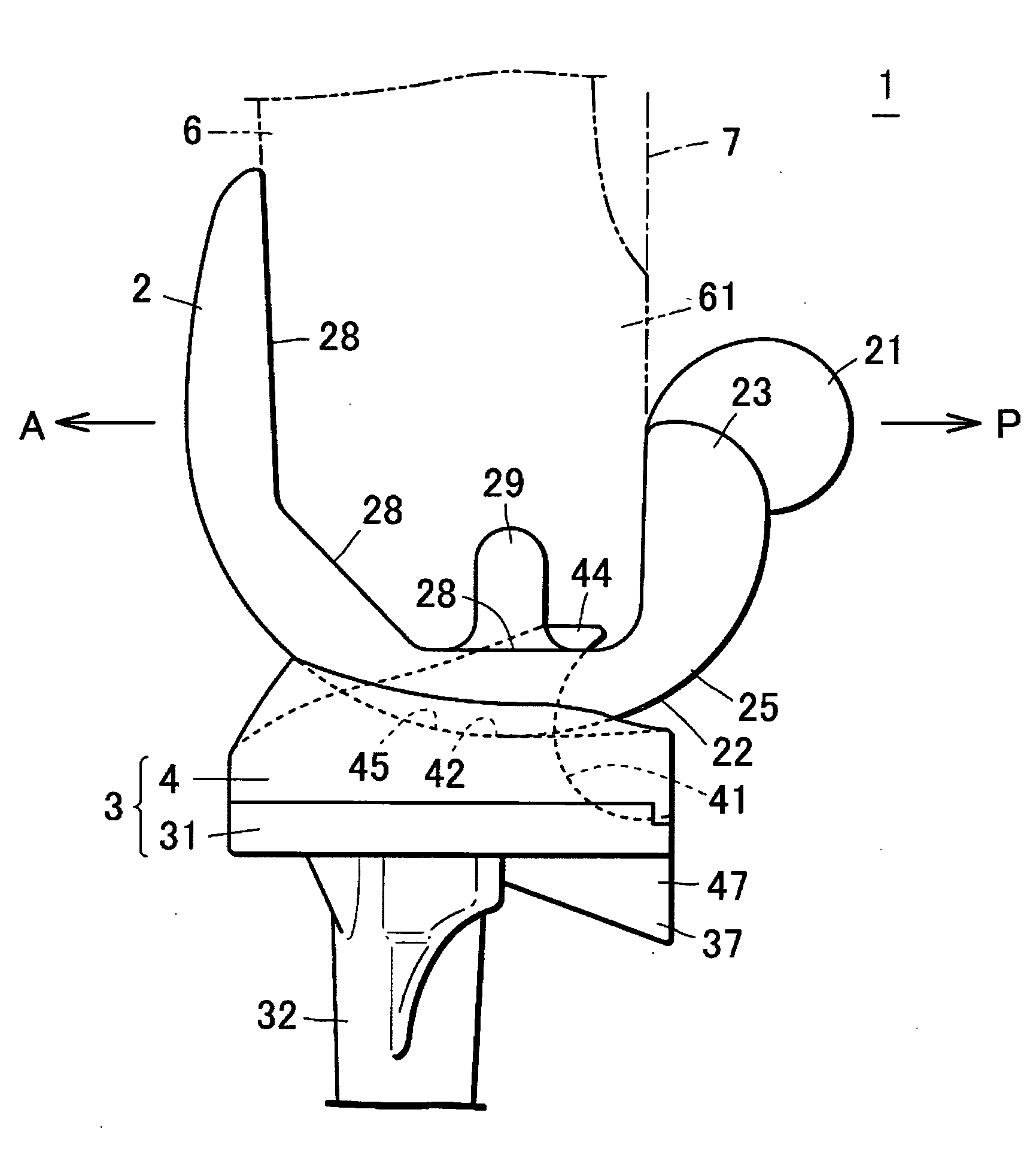

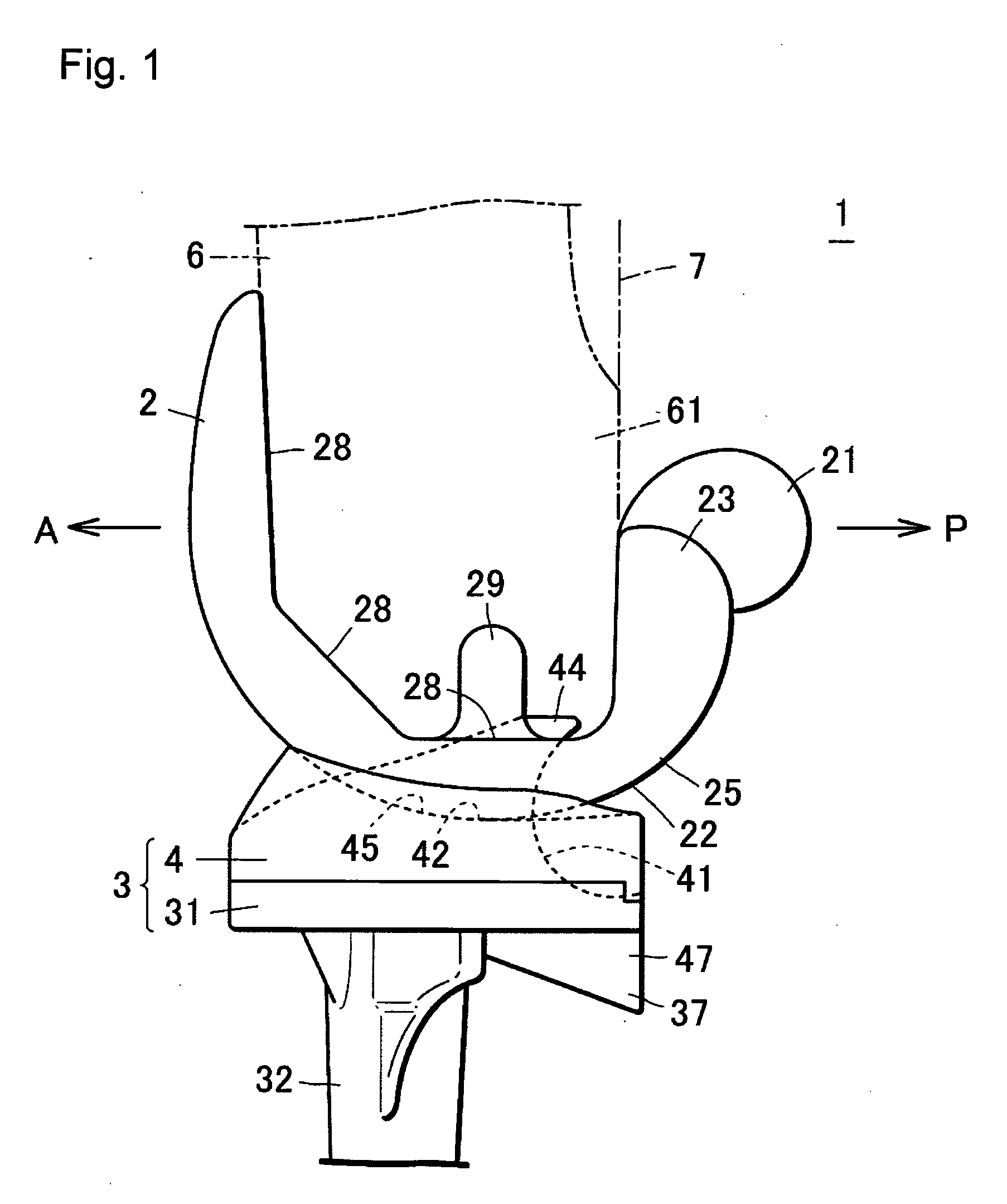

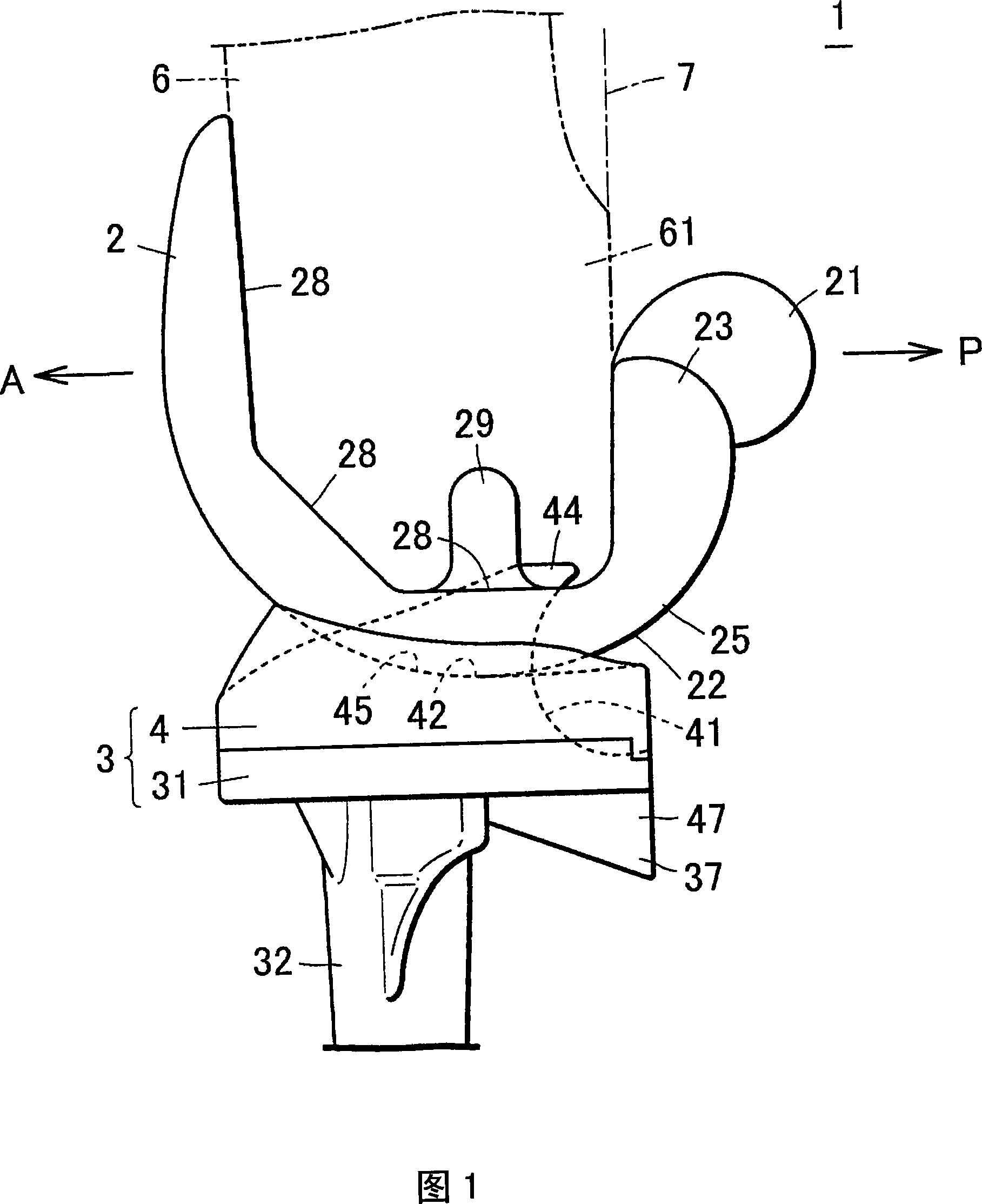

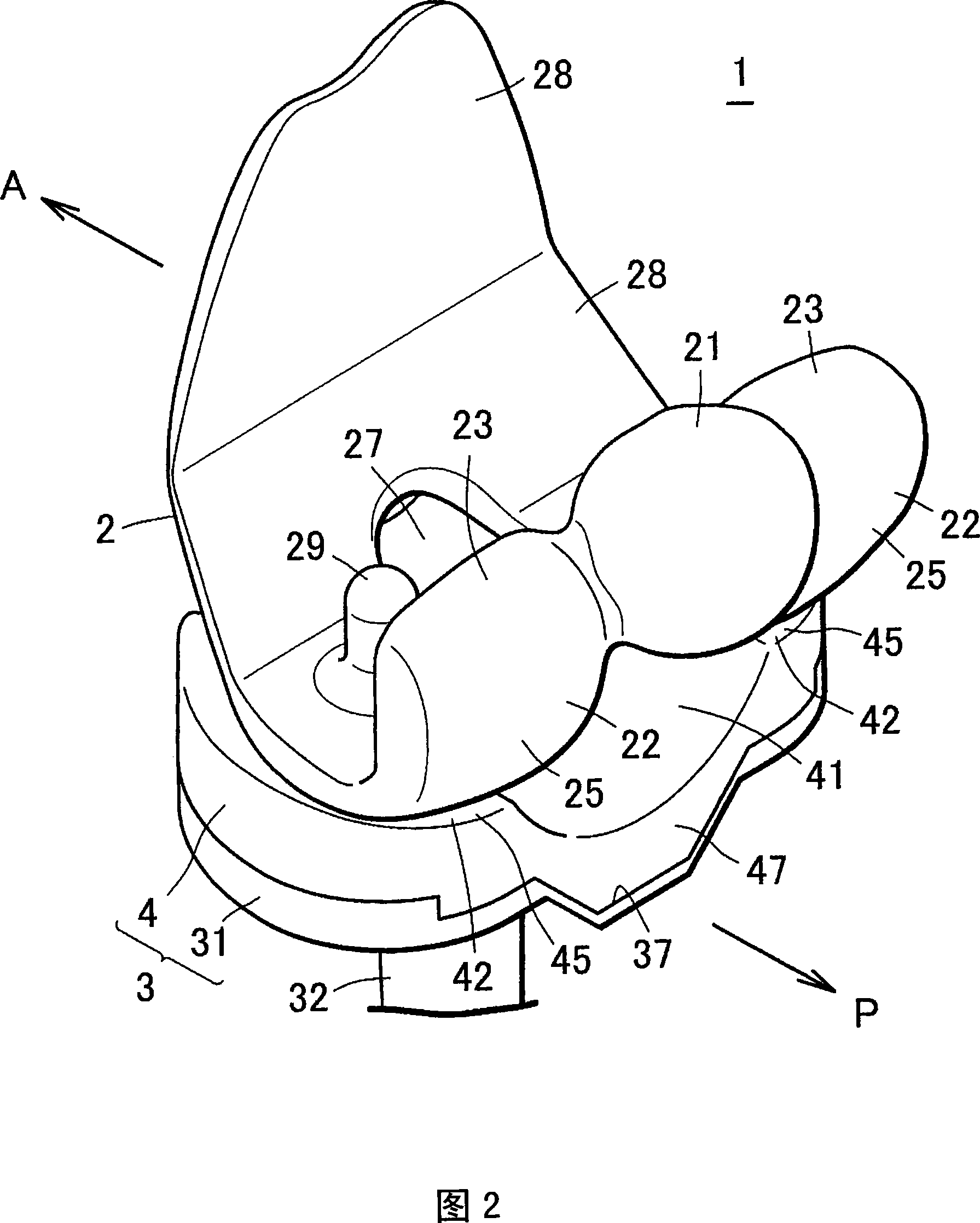

Artificial knee joint

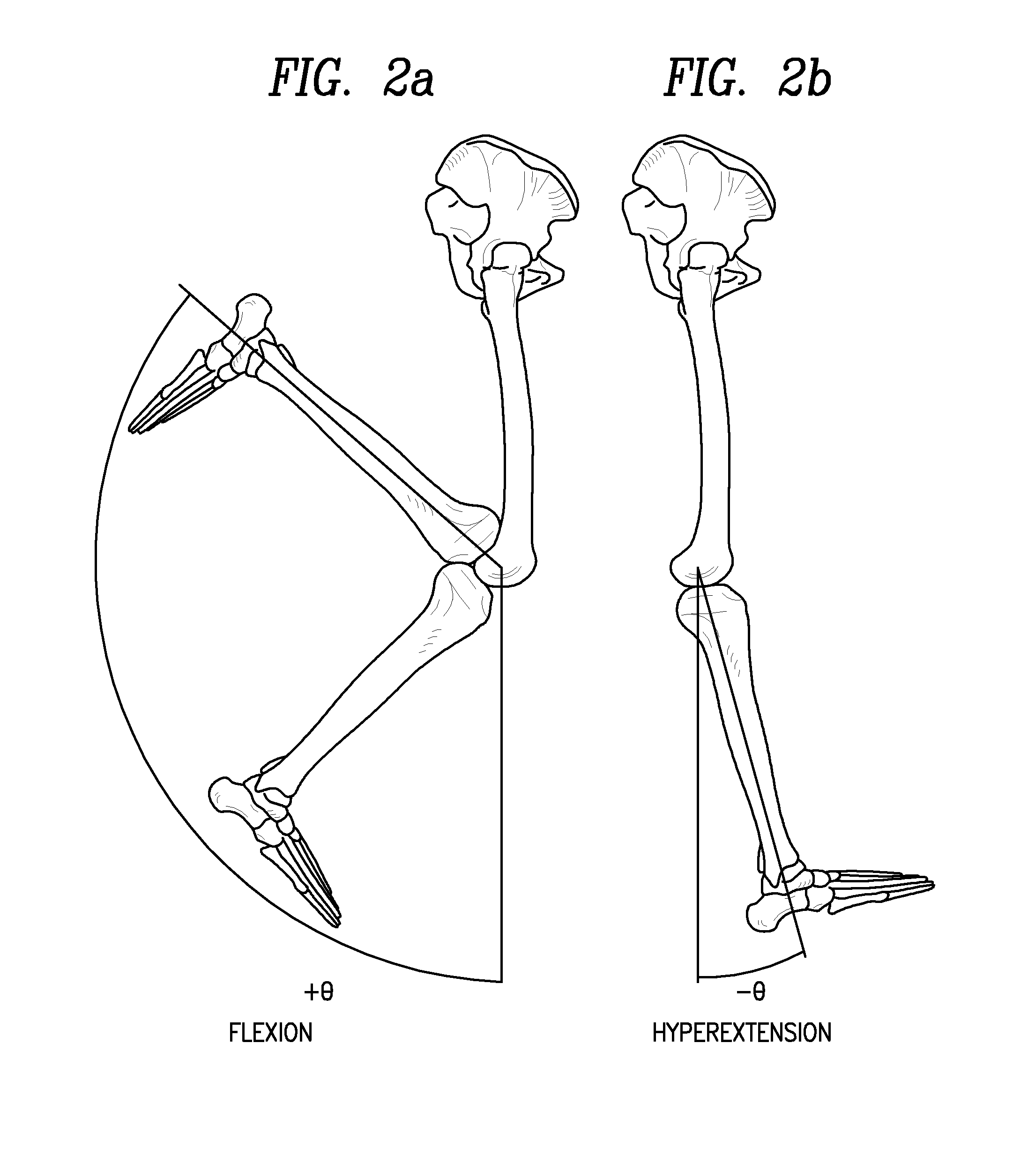

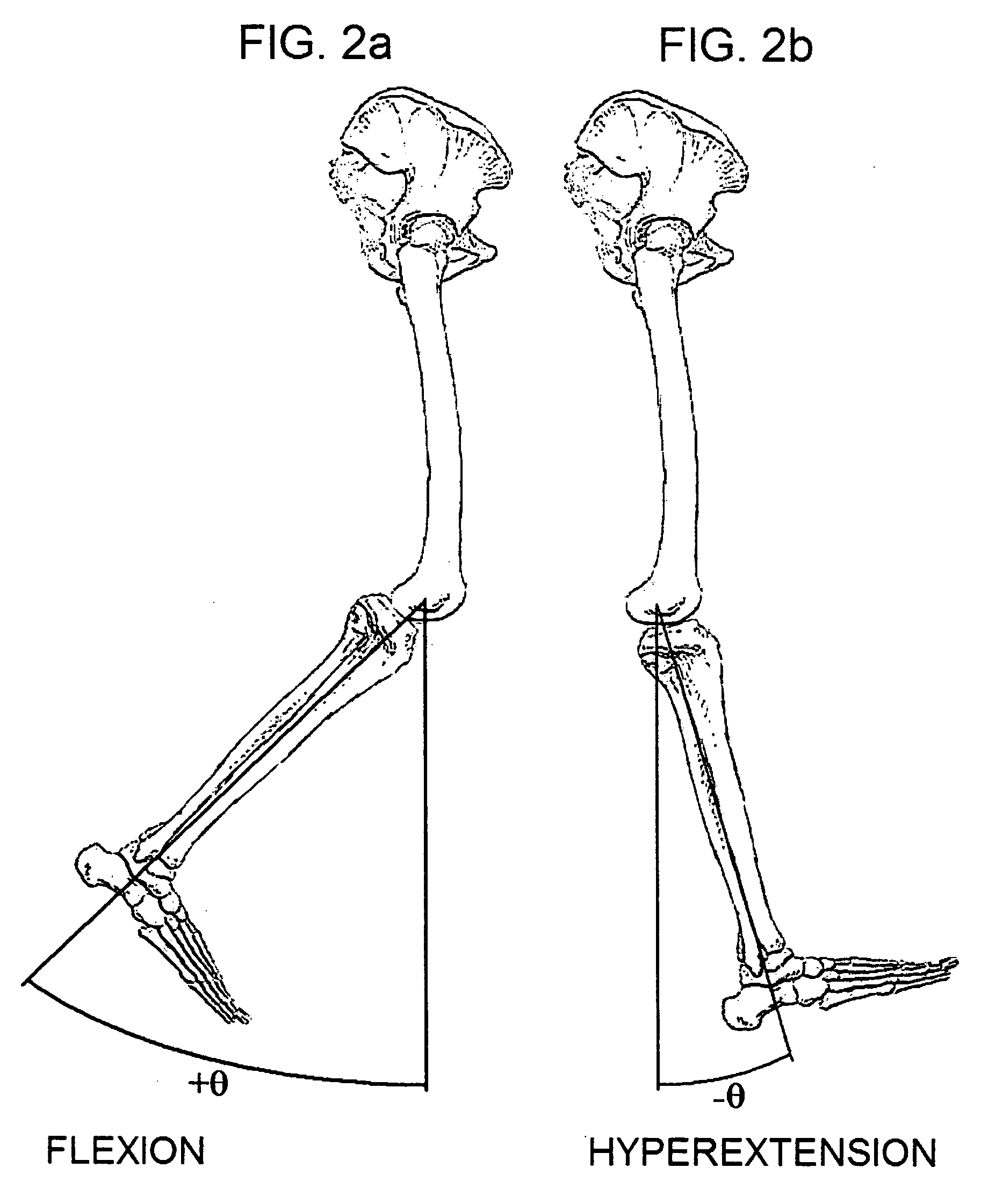

An artificial knee joint that compresses both osseous impingement and soft tissue impingement from occurring and can endure usage over a long period of time is provided.The artificial knee joint of the present invention comprises a femoral component, a tibial tray and an insert plate fixed onto the top surface of the tibial tray. The femoral component comprises a femoral articular surface and a cam that is provided on the rear end of the femoral articular surface and protrudes from the femoral articular surface, the insert plate comprises a tibial articular surface that makes contact with the femoral articular surface and a cam-receiving slide surface that makes contact with the cam. When the knee is extended, the joint takes a first sliding state in which the femoral articular surface slides against the tibial articular surface. When the knee is bent at an angle in a range from 90 to 160 degrees, the joint shifts from the first sliding state to a second sliding state in which the cam slides on the cam-receiving slide surface. When the knee is bent deeply with a bending angle of 180 degrees, the second sliding state is assumed in which a resection surface of the femoral component and the rear end of the insert plate are offset.

Owner:KYOCERA CORP +1

Universal tibial augment

A prosthetic knee system has a tibial component and a universal augment. A single augment can be used to support the tibial tray on either the medial or lateral side. The augment has reverse image sides and a through-bore with no threads. The tibial tray has a complementary threaded bore. The through-bore of the augment has a plane of symmetry perpendicular to its central longitudinal axis.

Owner:DEPUY PROD INC

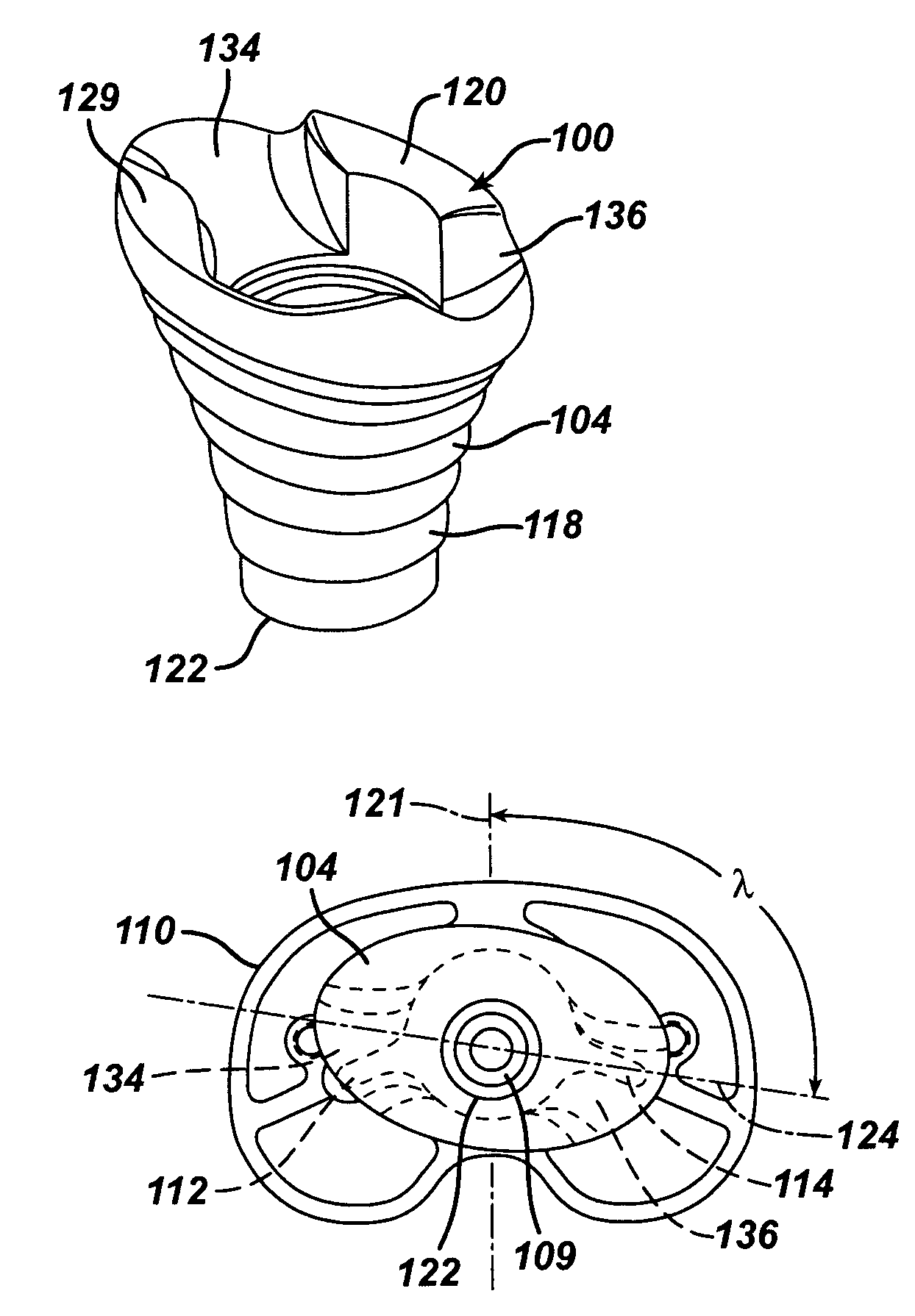

Prosthetic tibial component with modular sleeve

A prosthetic knee system has a tibial component and a modular sleeve. The tibial component has a tibial tray, a stem and keels extending between the distal surface of the tray and the stem. The modular sleeve has an oval proximal surface with spaced reliefs. The reliefs and keels are sized, shaped and positioned to allow the modular sleeve to be mounted on the tibial component with the stem of the tibial component received in the interior channel of the sleeve and the keels of the tibial component received in the spaced reliefs of the modular sleeve, and to allow for some relative rotation between the tibial component and the sleeve. The system gives the surgeon the freedom to implant the tibial component alone, with the keels providing stability, or, in the case of bone deficiency, to implant the tibial component and sleeve as an assembly.

Owner:DEPUY PROD INC

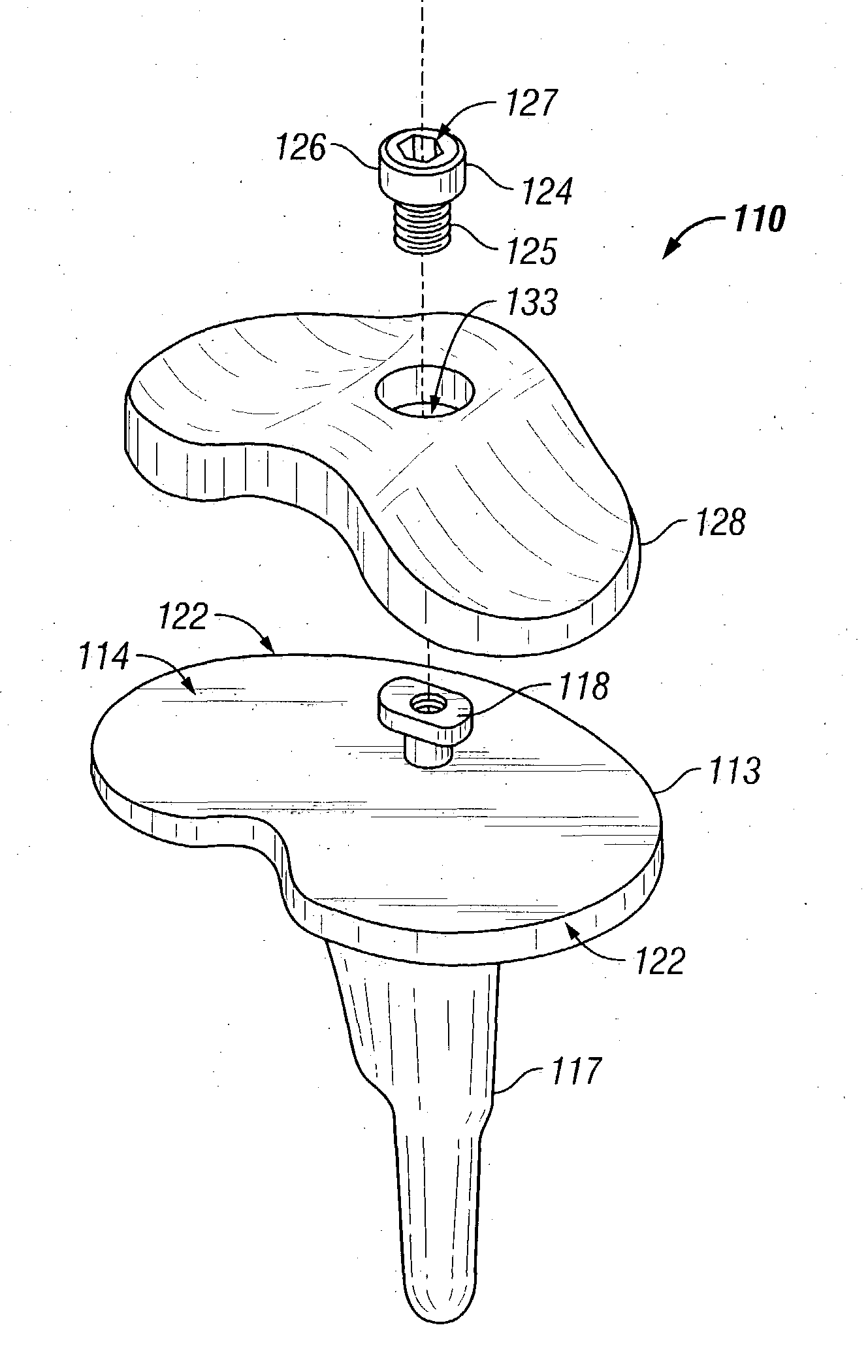

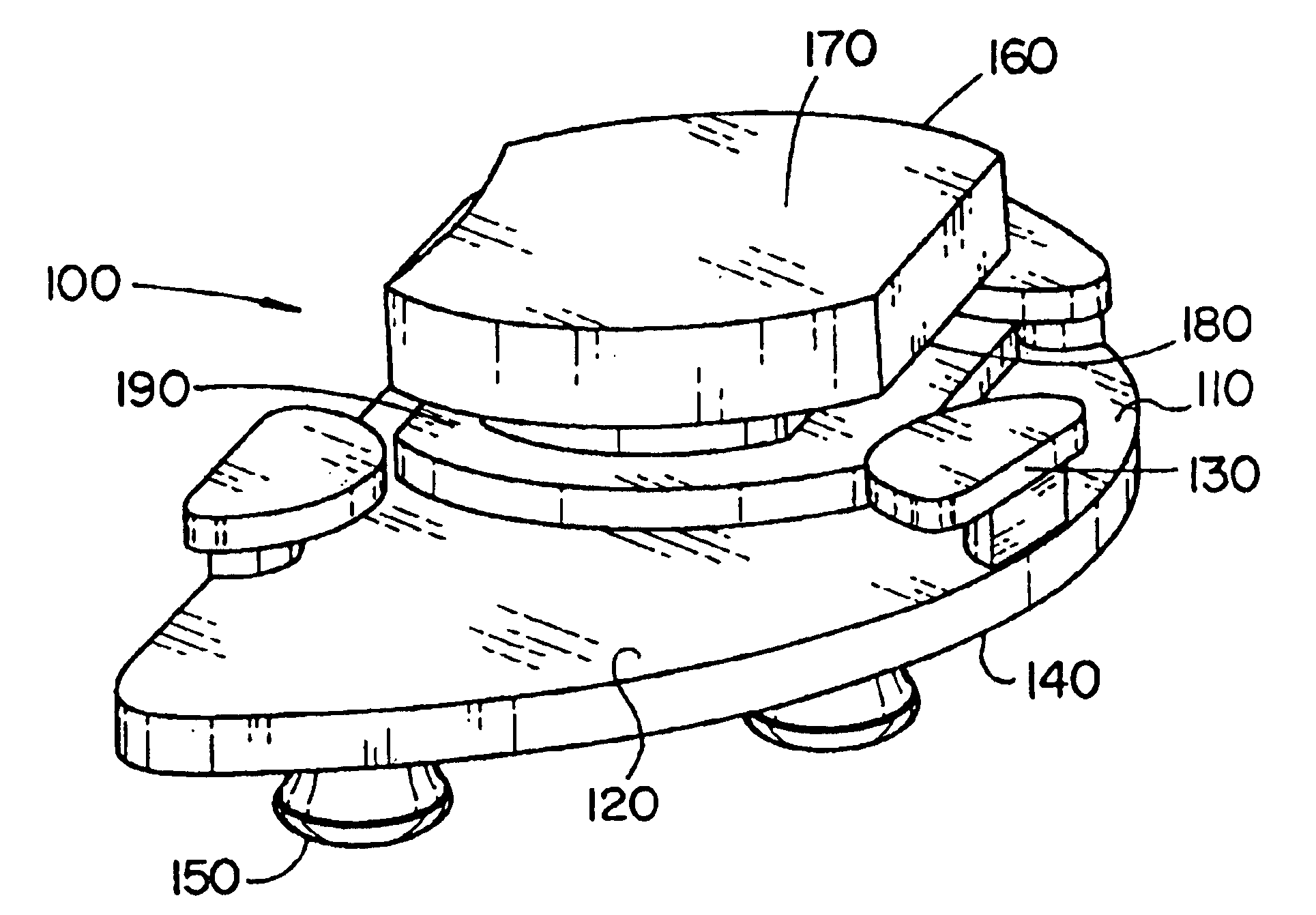

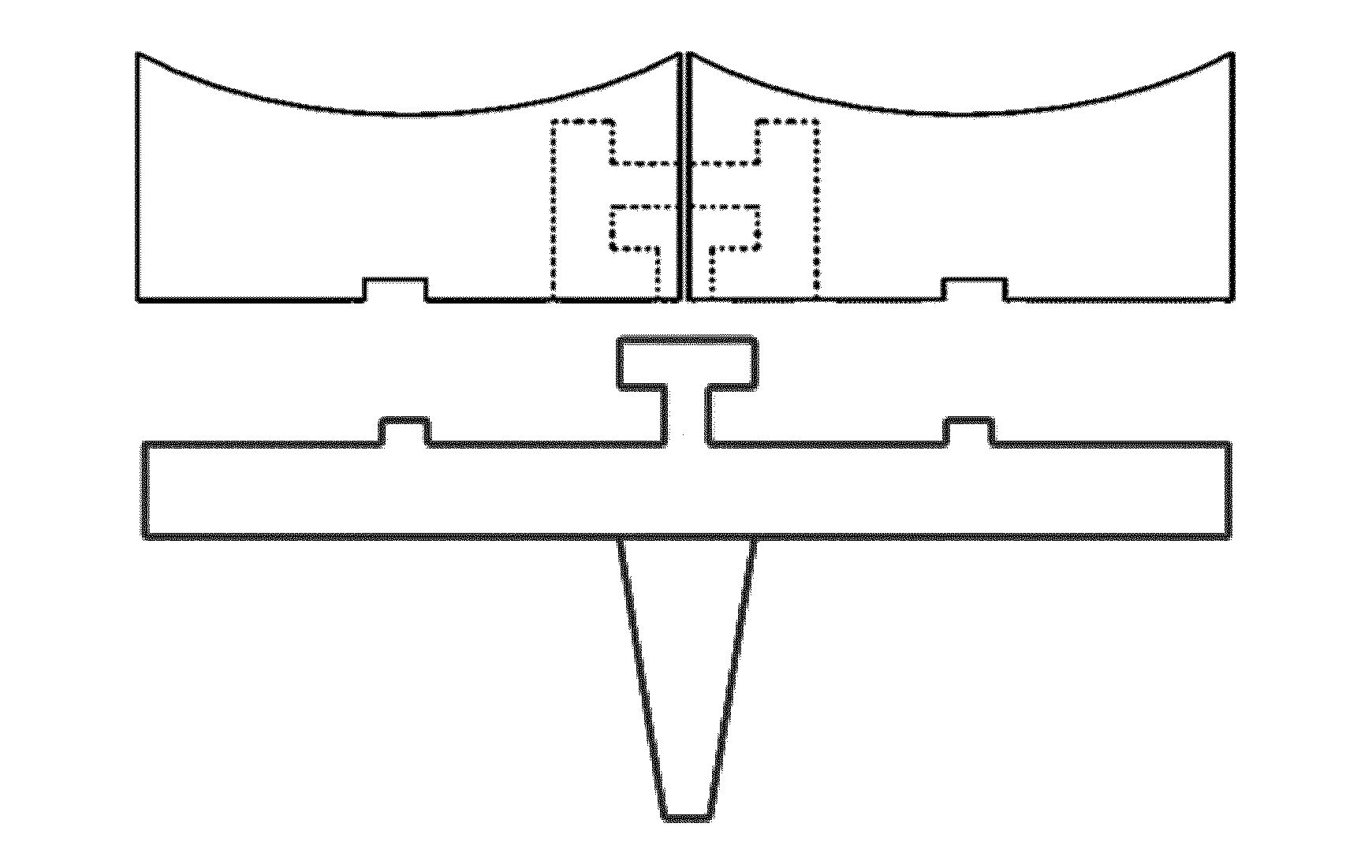

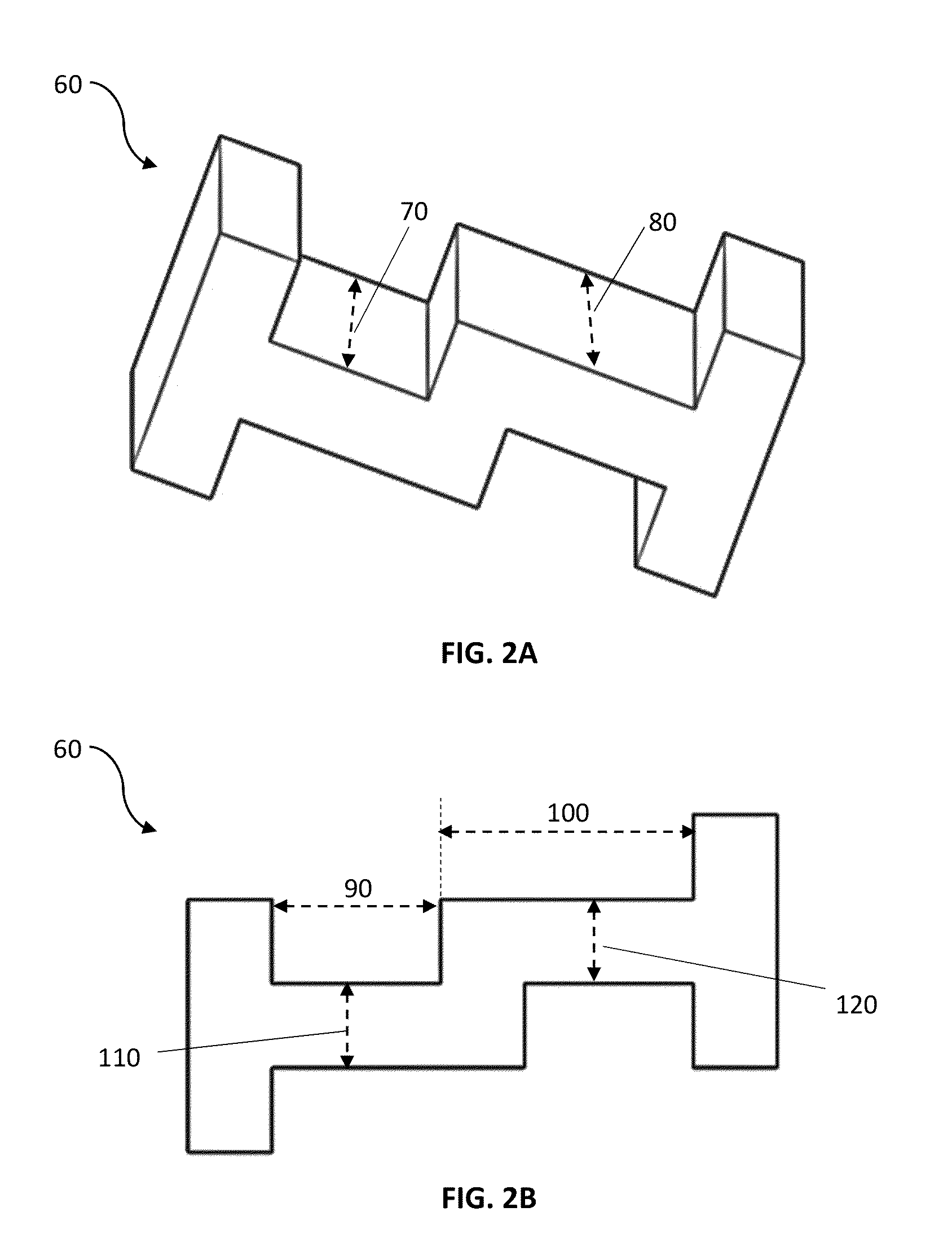

System and method for adjusting the thickness of a prosthesis

The present invention relates to a system and method for adjusting a thickness of a prosthesis (e.g., a knee implant). In one embodiment, a knee prosthesis for implantation in a patient is provided, comprising: a tibial tray, wherein the tibial tray comprises an upper surface and a lower surface, and the lower surface of the tibial tray is disposed adjacent a tibia of the patient; a tibial insert, wherein the tibial insert comprises an upper surface and a lower surface; a tibial spacer, wherein the tibial spacer comprises an upper surface and a lower surface, and wherein the tibial spacer is disposed between the tibial tray and the tibial insert such that the lower surface of the tibial spacer is adjacent the upper surface of the tibial tray and the upper surface of the tibial spacer is adjacent the lower surface of the tibial insert; and at least one locking mechanism, wherein the locking mechanism locks the tibial spacer to the tibial tray to form a locked spacer / tray assembly such that the locking mechanism substantially prohibits at least relative up-down movement between the tibial spacer and the tibial tray when the locked spacer / tray assembly is implanted in the patient. In one example, the locking mechanism may further lock the tibial spacer to the tibial insert to form a locked insert / spacer / tray assembly such that the locking mechanism substantially prohibits at least relative up-down movement between the tibial spacer and the tibial insert when the locked insert / spacer / tray assembly is implanted in the patient. In another embodiment, a method for implanting a knee prosthesis in a patient is provided, comprising: providing a tibial tray, wherein the tibial tray comprises an upper surface and a lower surface, and the lower surface of the tibial tray is disposed adjacent a tibia of the patient; providing a tibial insert which has a shelf life and which is not readily re-sterilizable after the shelf life has expired, wherein the tibial insert comprises an upper surface and a lower surface; and providing a tibial spacer which has a shelf life and which is re-sterilizable after the shelf life has expired, wherein the tibial spacer comprises an upper surface and a lower surface, and wherein the tibial spacer is disposed between the tibial tray and the tibial insert such that the lower surface of the tibial spacer is adjacent the upper surface of the tibial tray and the upper surface of the tibial spacer is adjacent the lower surface of the tibial insert.

Owner:EXACTECH INC

Mobile bearing unicompartmental knee

An orthopedic knee component for implanting within a single compartment of a human knee includes, in a first embodiment a tibial tray having a superior surface having a plurality of tabs disposed along an exterior edge thereof, a bearing component having a superior surface adapted to articularly engage a femoral knee prosthesis and a circumferential groove disposed therearound with which the tabs of the tibial tray cooperatively engage such that the bearing component is movable relative to the tibial tray. In a second embodiment, an orthopedic knee component for implanting within a single compartment of a human knee includes: a tibial tray in supporting engagement with a bearing component, wherein the bearing component includes a superior surface adapted to articularly engage a femoral knee prosthesis and a pair of slots disposed along the superior surface of the bearing component, the femoral component having a pair of rails extending from the articulating surface thereof such that the rails can slidingly engage the slots, and such that the bearing component is movable relative to the tibial tray.

Owner:ZIMMER TECH INC

Knee joint prosthesis

A knee joint prosthesis is disclosed. The prosthesis has a femoral component and a tibial component. The tibial component has a tibial plateau element fitted in a tibial tray element. A hemi capstan shaped bridge member is provided between replicated condyles on the femoral component. A specially shaped post is provided between kidney shaped meniscal depression on the tibial plateau element. The bridge member and the post act together to form an additional joint for load transfer during deep flexion of the prosthesis in its operative configuration.

Owner:SANCHETI KANTILAL HASTIMAL

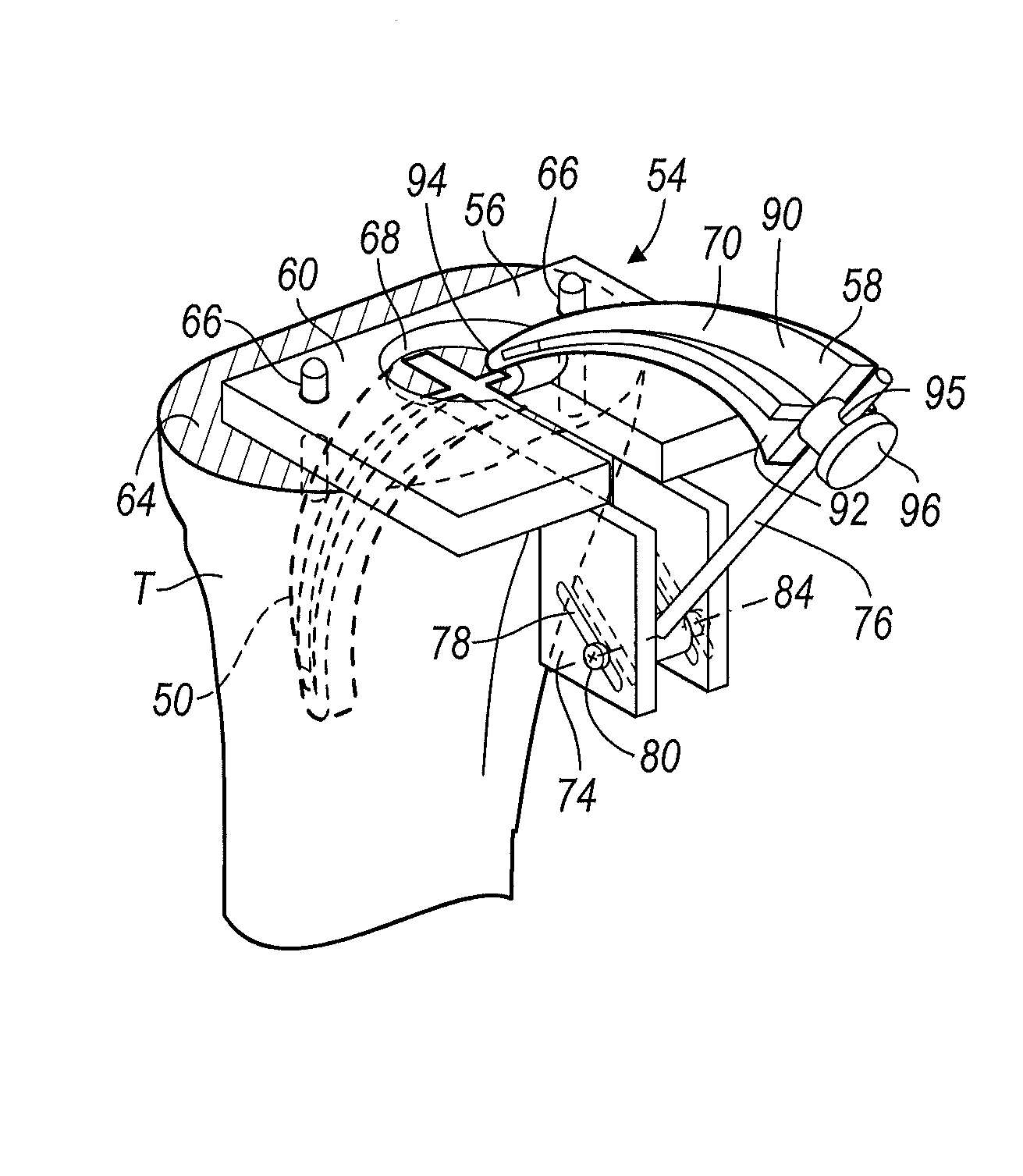

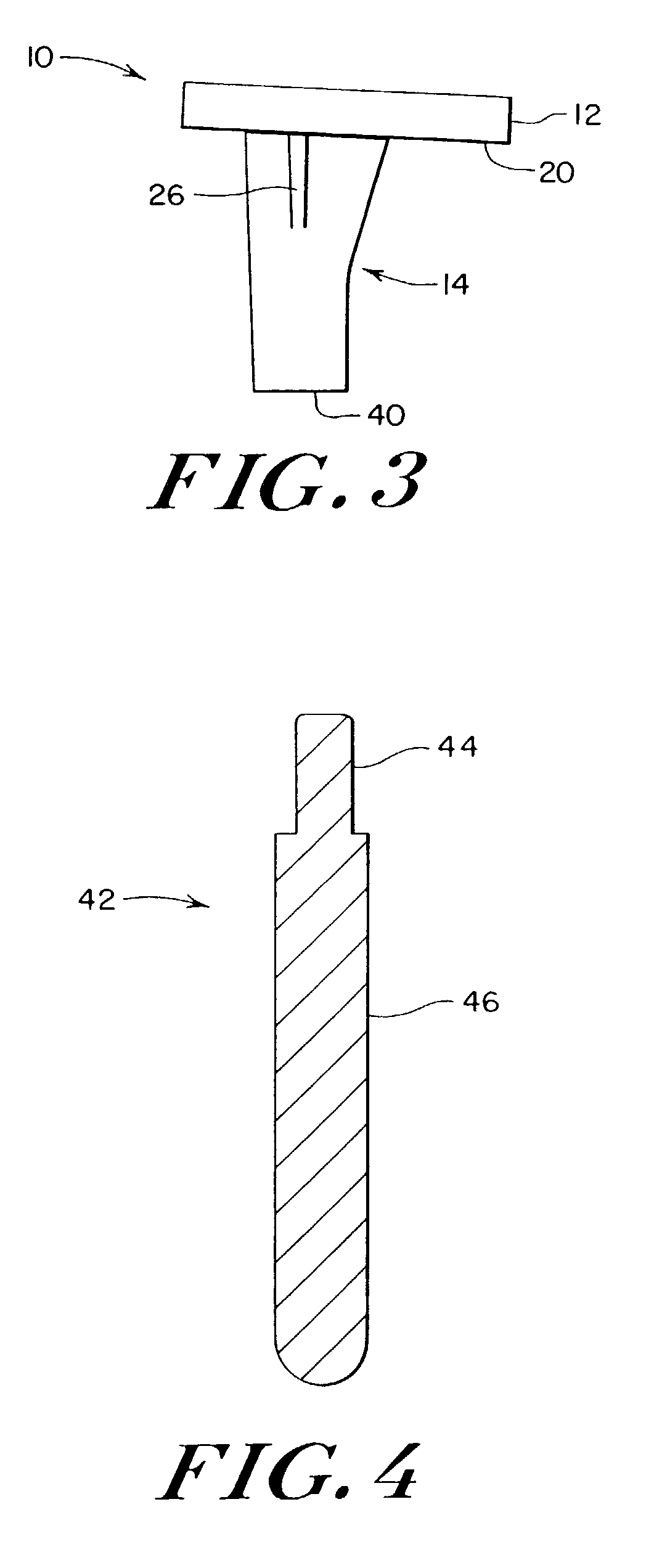

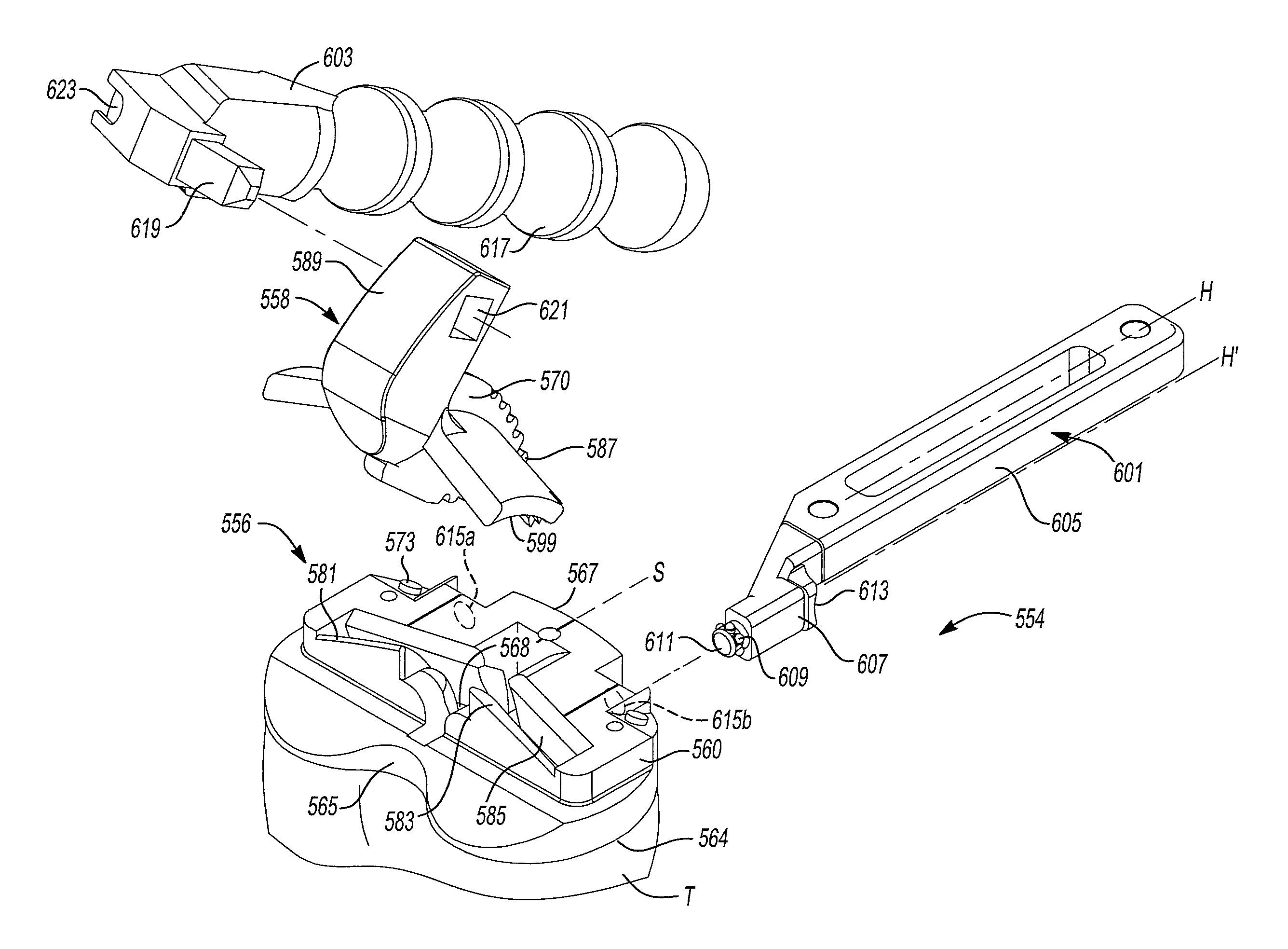

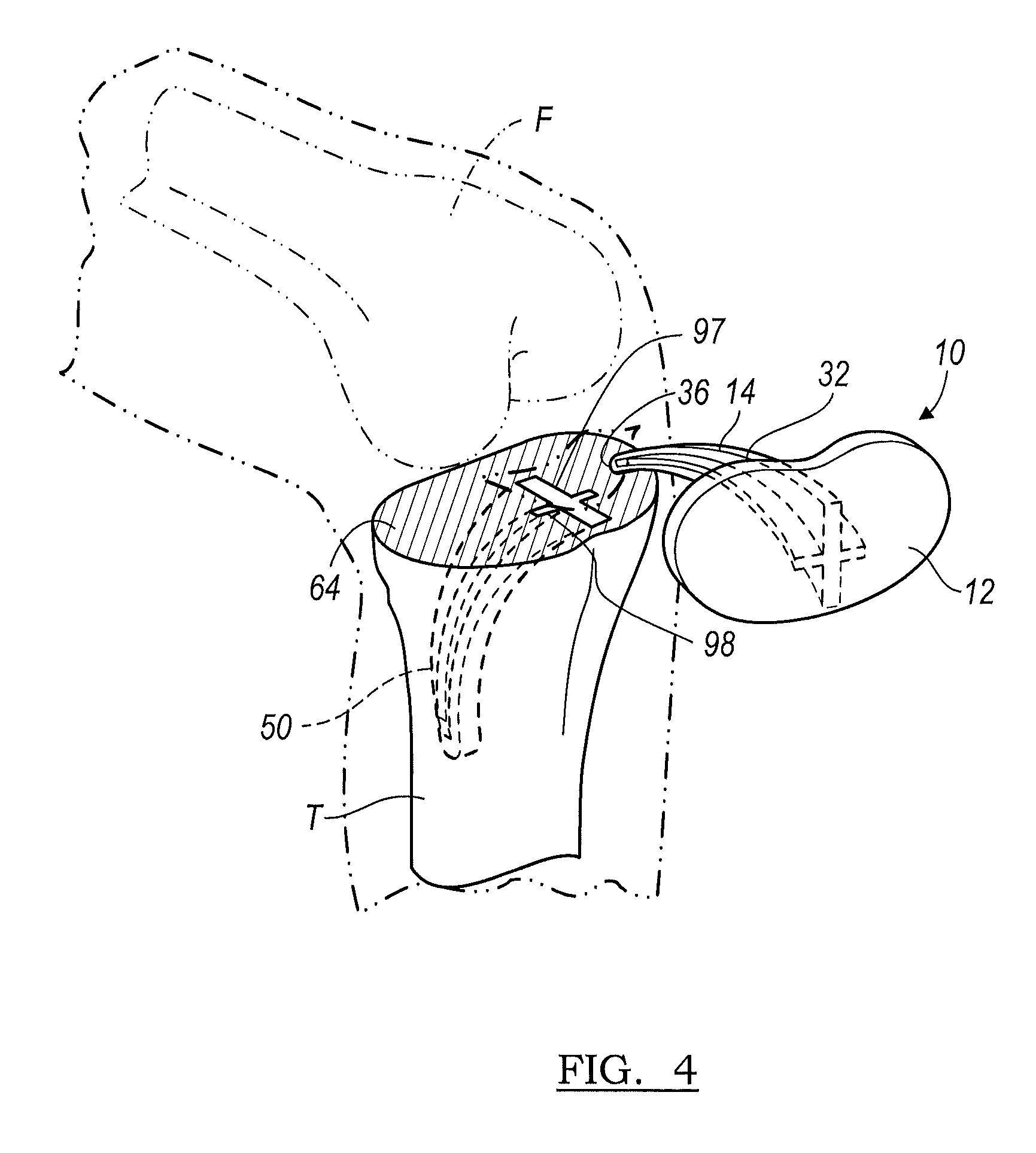

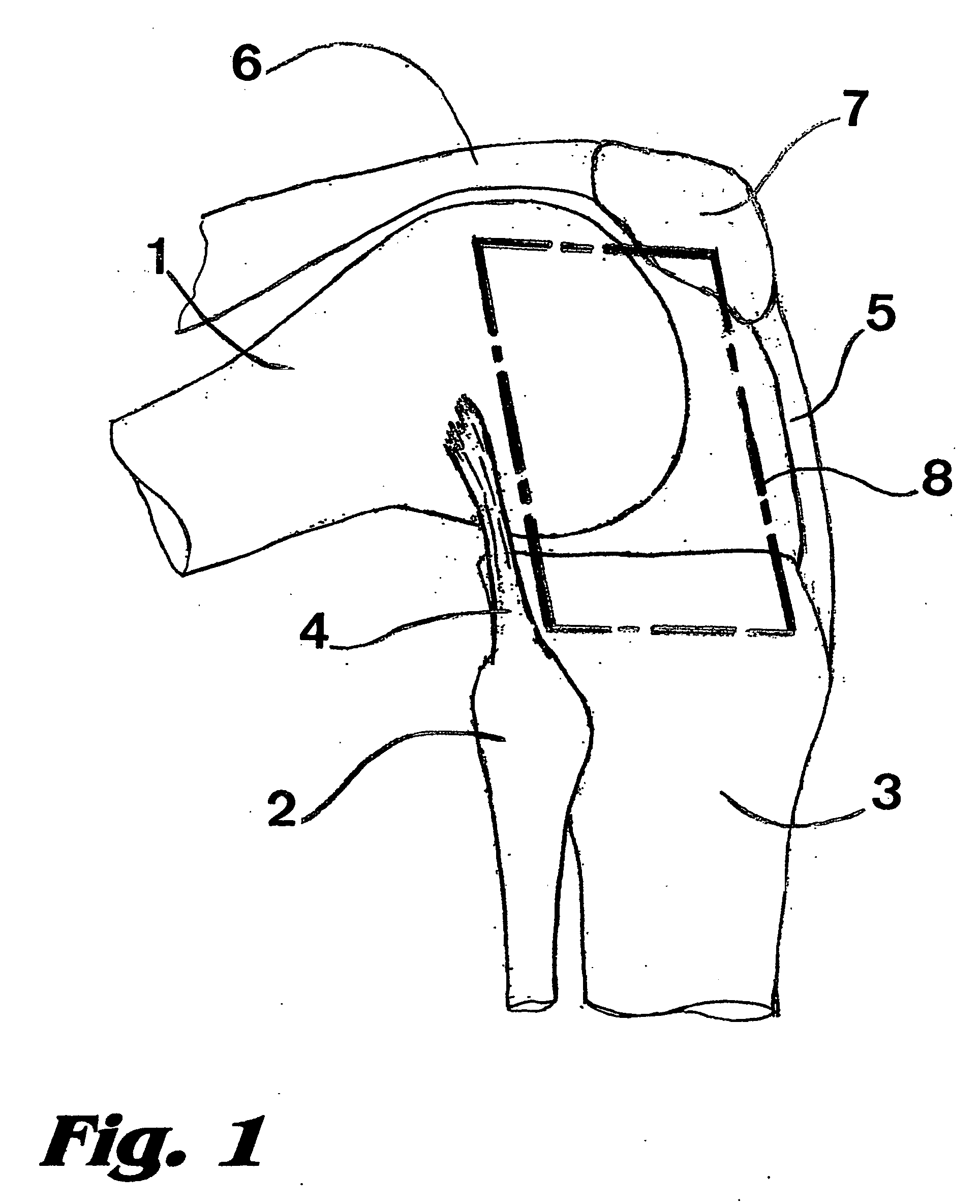

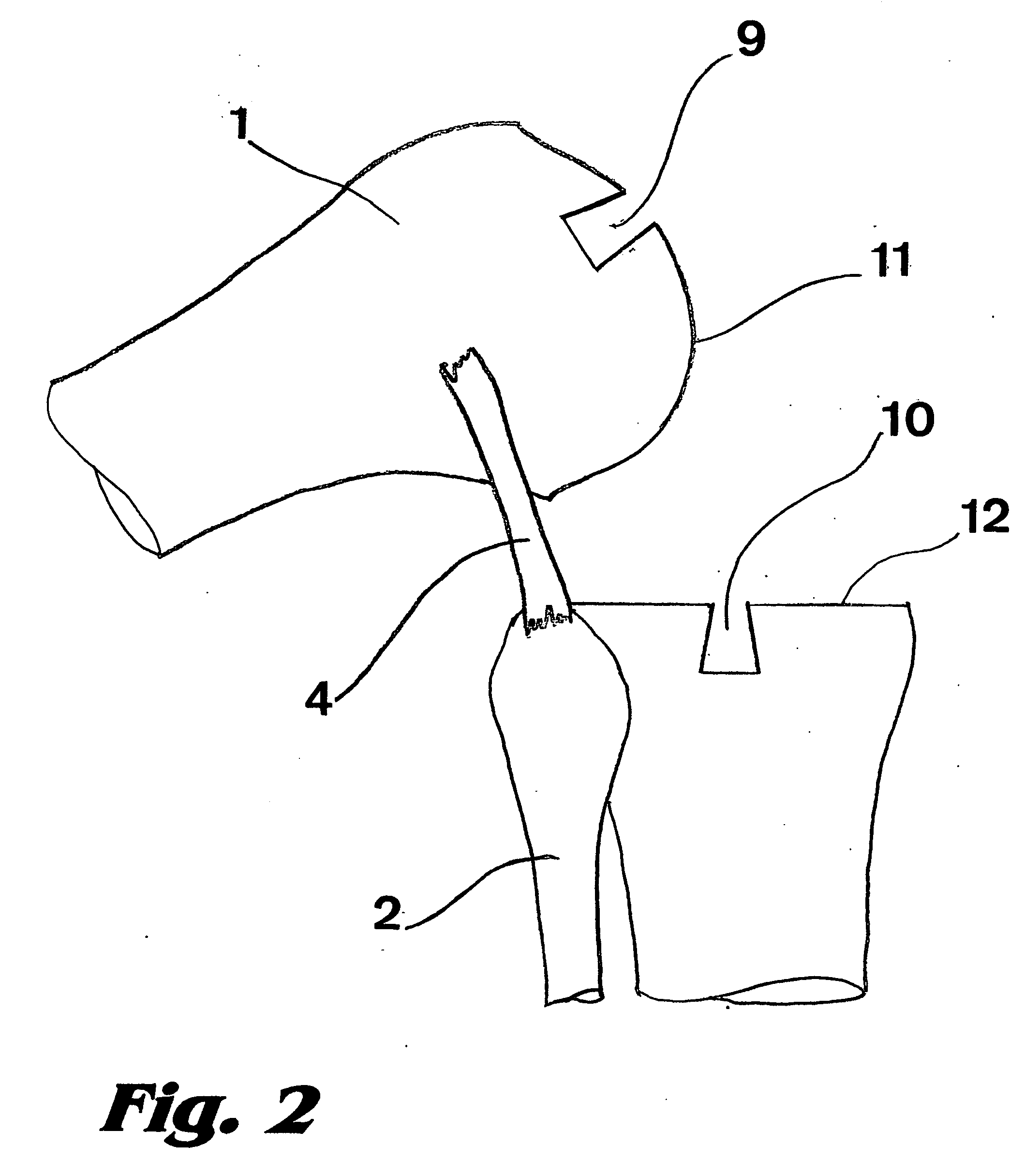

Instrumentation And Method For Implanting A Curved Stem Tibial Tray

A punch assembly for preparing a tibia bone for a prosthesis includes a static component configured to be supported by the tibia bone and a dynamic component that includes a punch having a stem. The dynamic component is supported for movement relative to the static component along a generally arcuate path to prepare an aperture having an arcuate contour in the tibia bone. A method of preparing a tibial aperture for is also disclosed.

Owner:BIOMET MFG CORP

Orthopedic implant with angled pegs

An orthopedic implant, such as a tibial tray, includes a body having a bone contacting surface with at least one and preferably two pegs extending from the bone contacting surface. Each of the pegs has a longitudinal axis angled with respect to the bone contacting surface and also angled in at least one direction consisting of a medial-lateral direction, an anterior-posterior direction and an inferior-superior direction. In the case of the tibial tray, the pegs form a non-perpendicular angle with the bone contacting surface of the baseplate and are angled in both a posterior direction and a medial or lateral direction.

Owner:HOWMEDICA OSTEONICS CORP

Unicondylar knee implant

Owner:ARTHREX

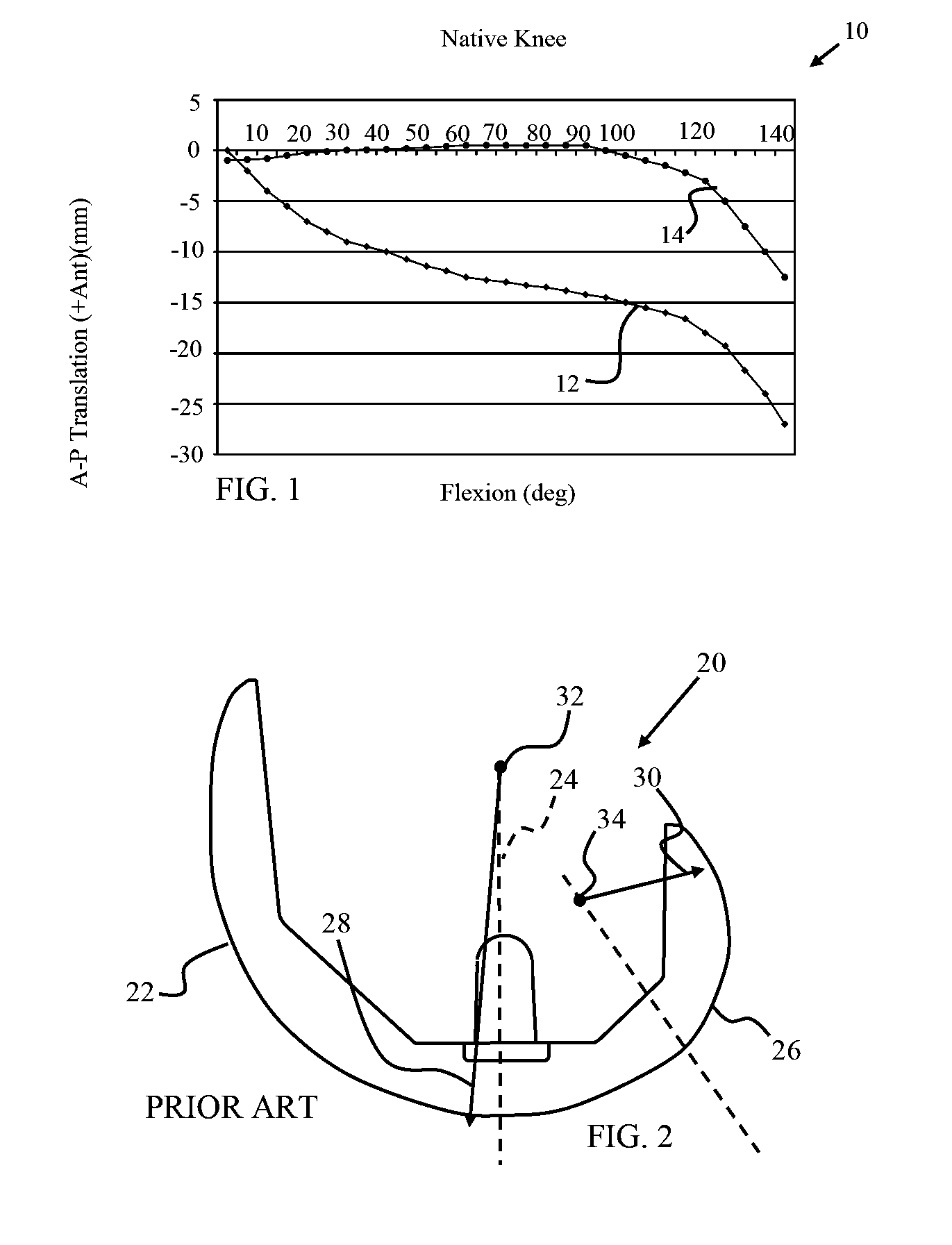

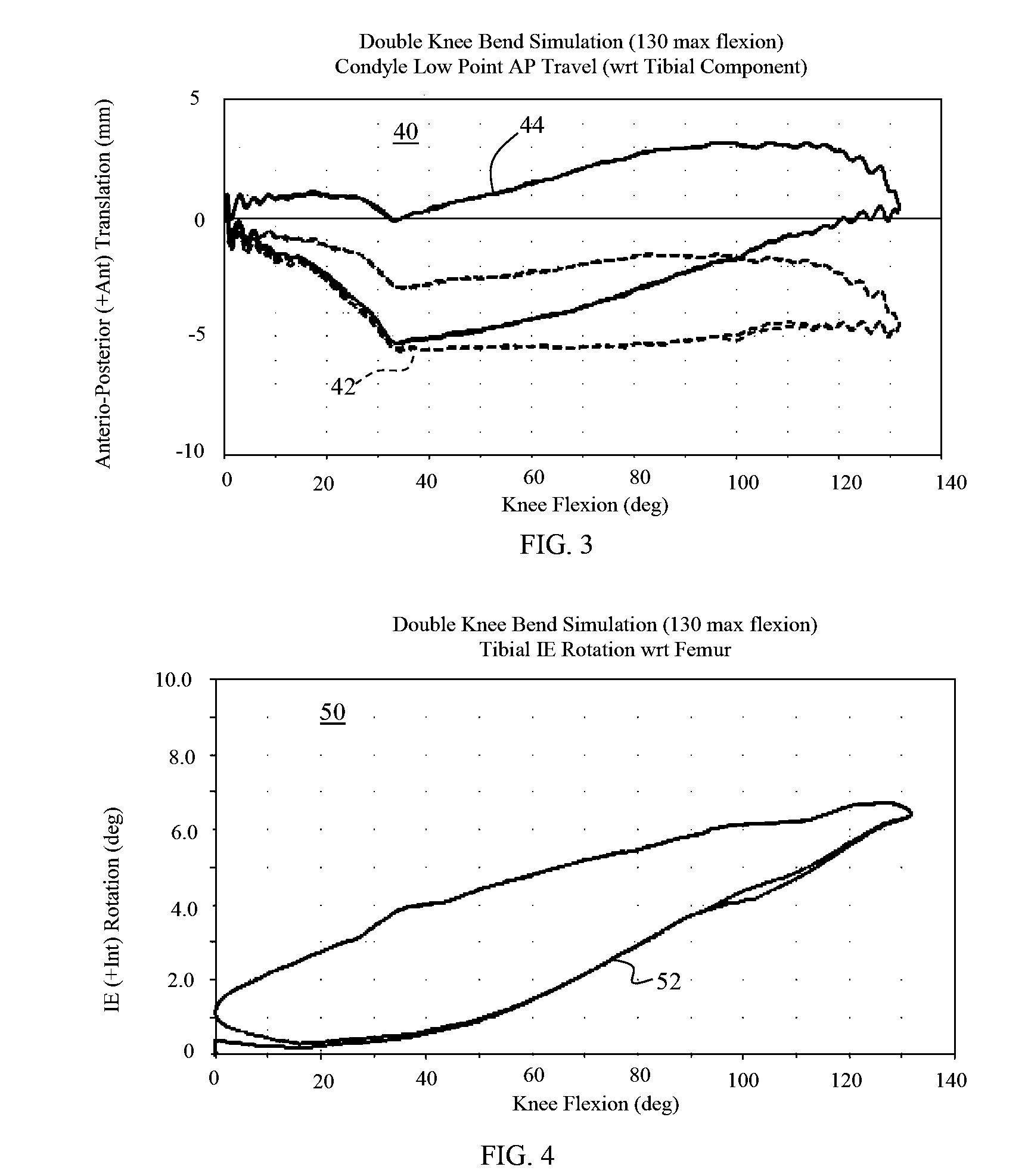

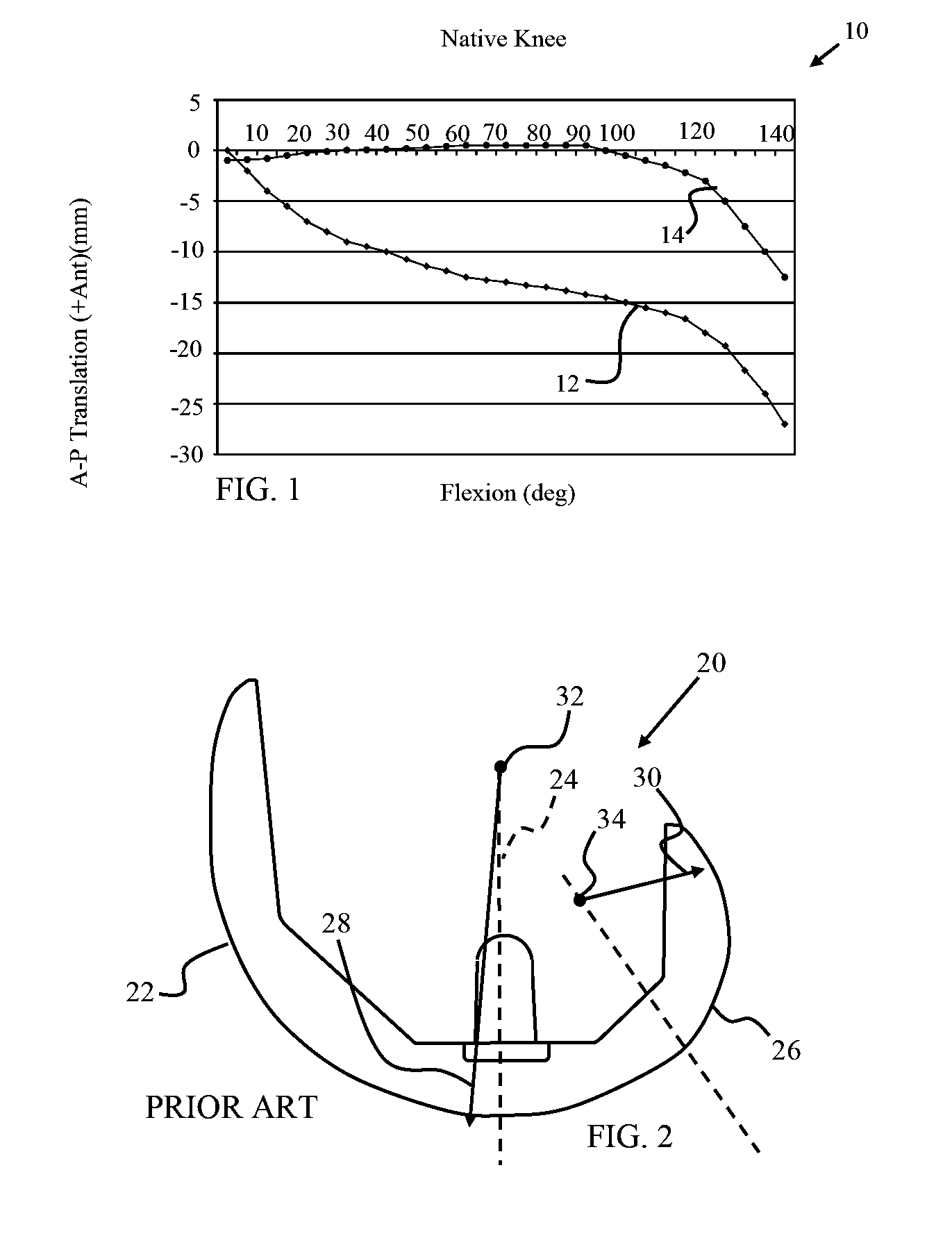

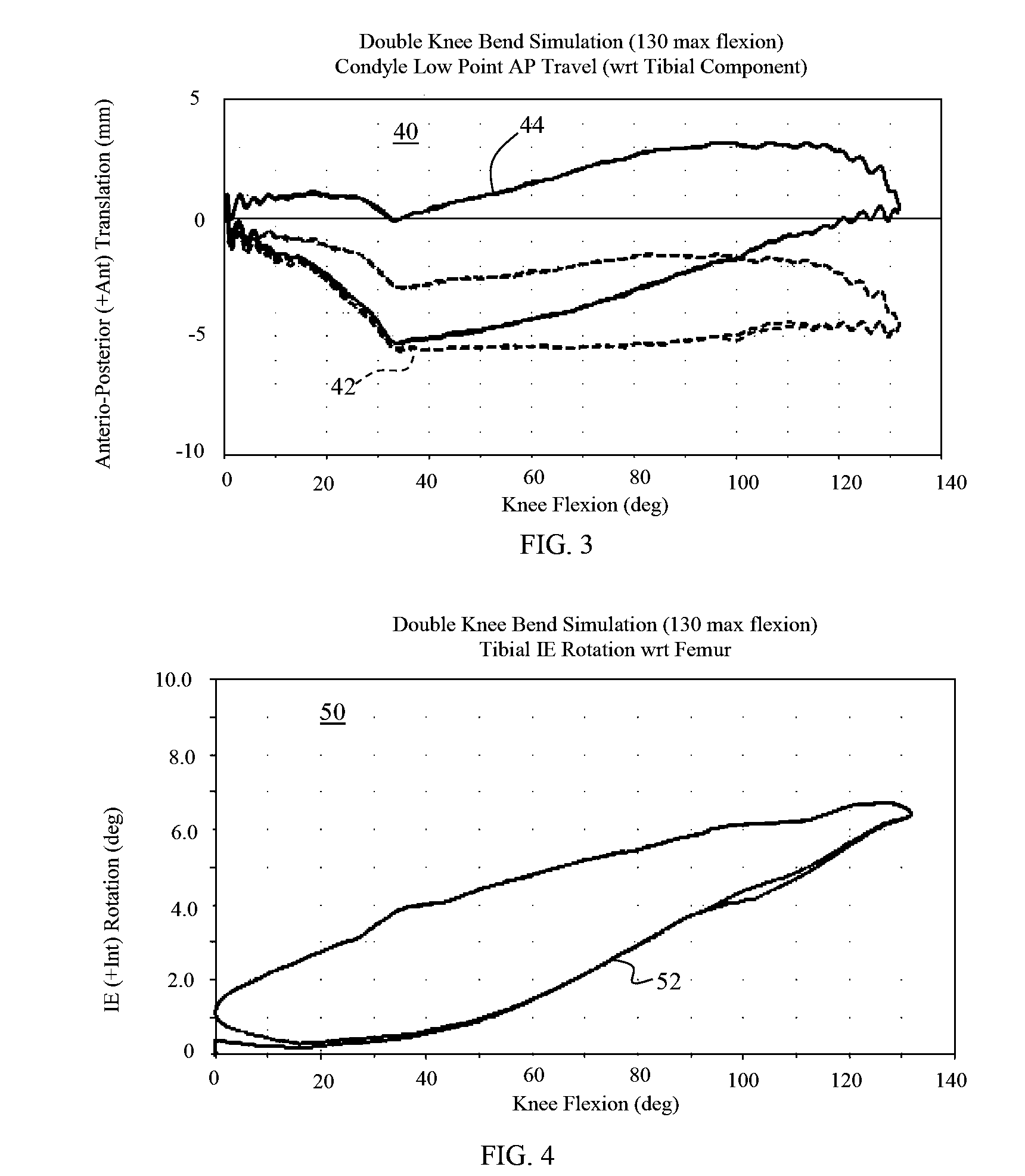

Antero-posterior placement of axis of rotation for a rotating platform

A knee replacement system includes a femoral component including a lateral condylar articulating portion and a medial condylar articulating portion, a tibial tray including an upper articulating surface, and a tibial insert including (i) a first articulating portion for articulating with the lateral condylar articulating portion with a first condylar dwell point, (ii) a second articulating portion for articulating with the medial condylar articulating portion with a second condylar dwell point, (iii) a lower articulating surface for articulating with the upper articulating surface, and (iv) a coupling member for coupling with the tibial tray and defining an axis of rotation about which the tibial insert rotates with respect to the tibial tray, the axis of rotation intersecting the upper articulating surface at a location posterior to a dwell axis including the condylar dwell points when the dwell axis is projected onto the upper articulating surface.

Owner:DEPUY (IRELAND) LTD

Tibial tray with adjustable keel

A tibial prosthesis includes a tibial platform having a medial-lateral center and an inferior surface matable with a resected proximal tibia, and a modular keel that is fixable to the inferior surface and adjustable in a medial-lateral direction with respect to the medial-lateral center of the tibial platform.

Owner:DEPUY PROD INC

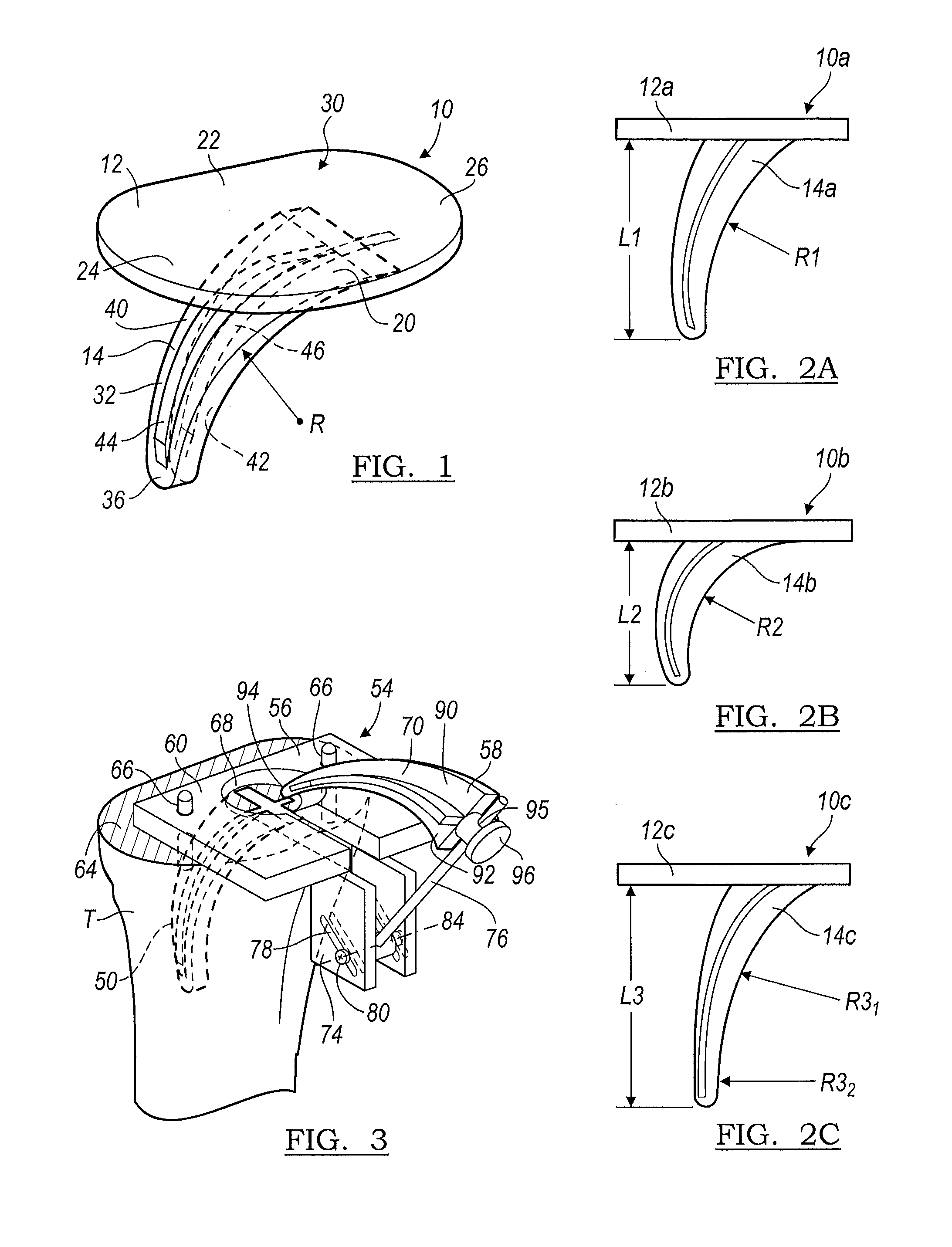

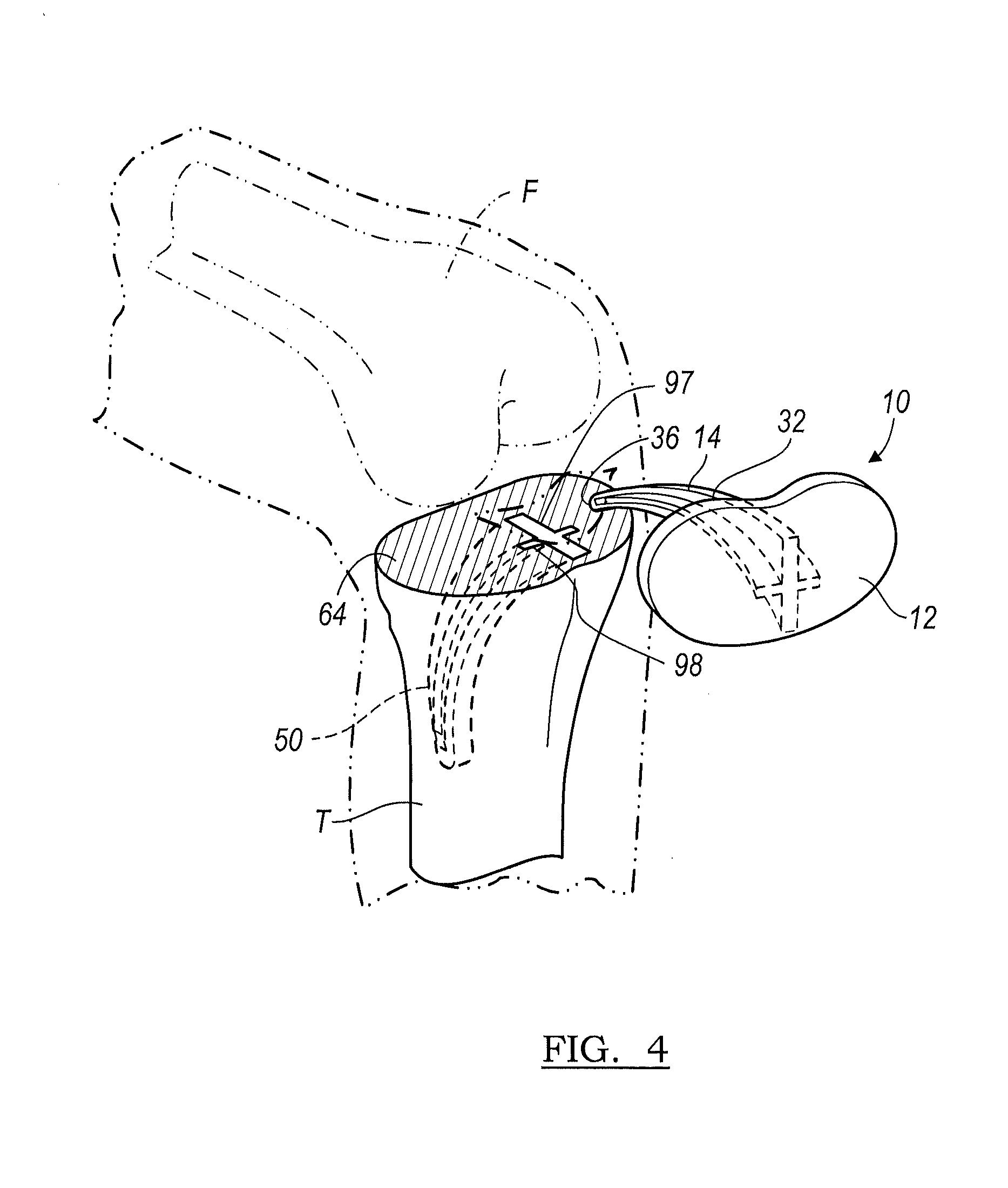

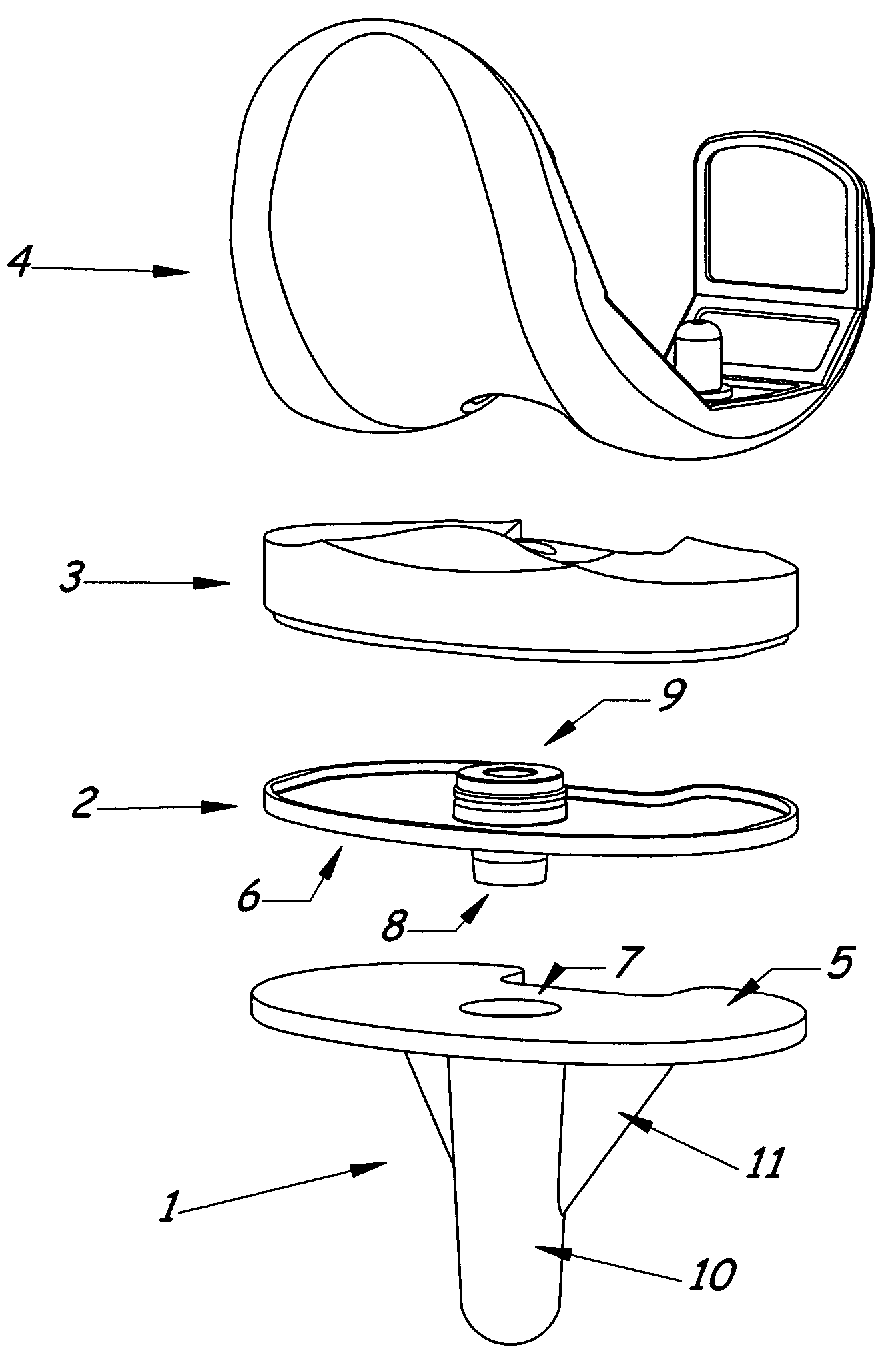

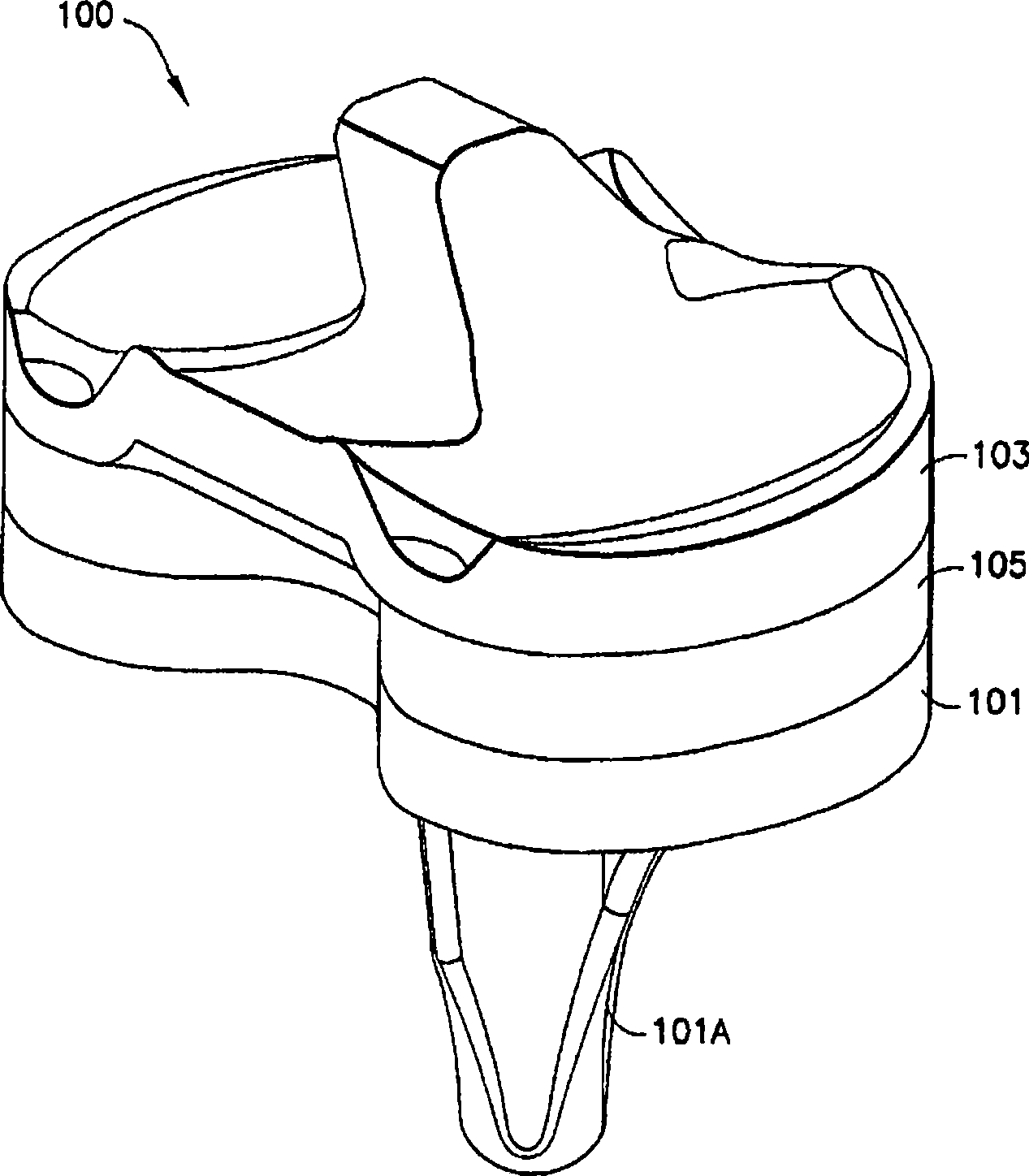

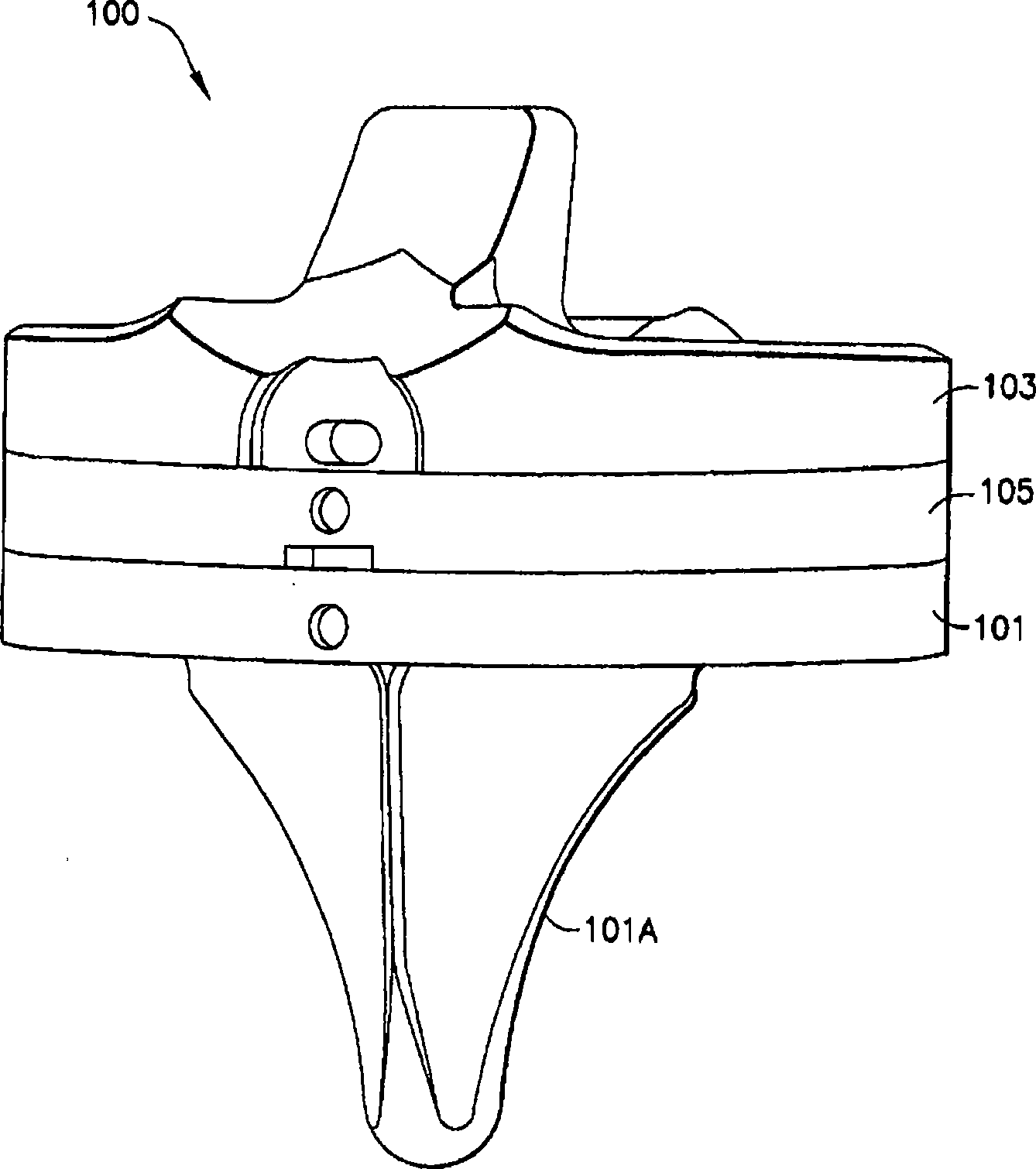

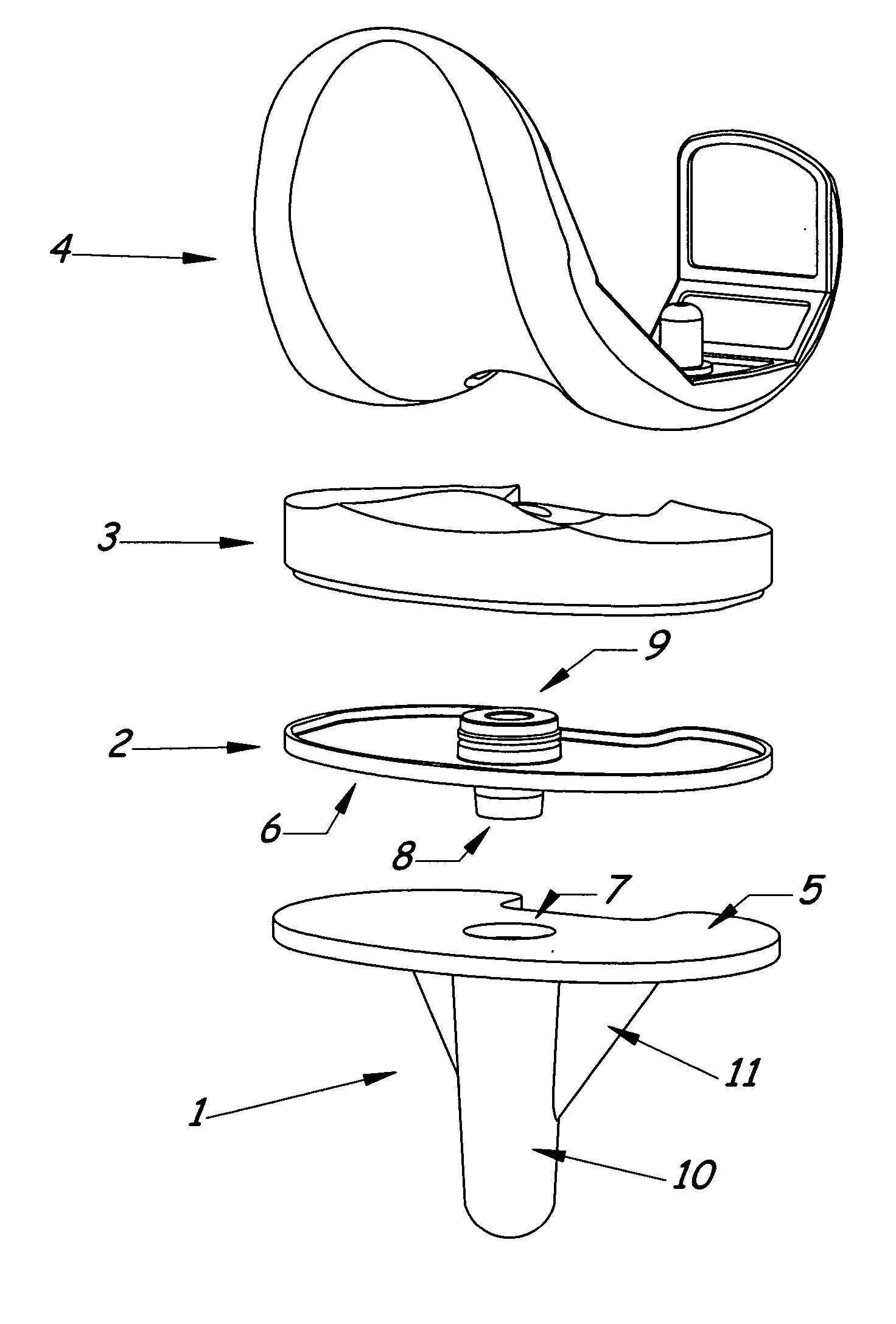

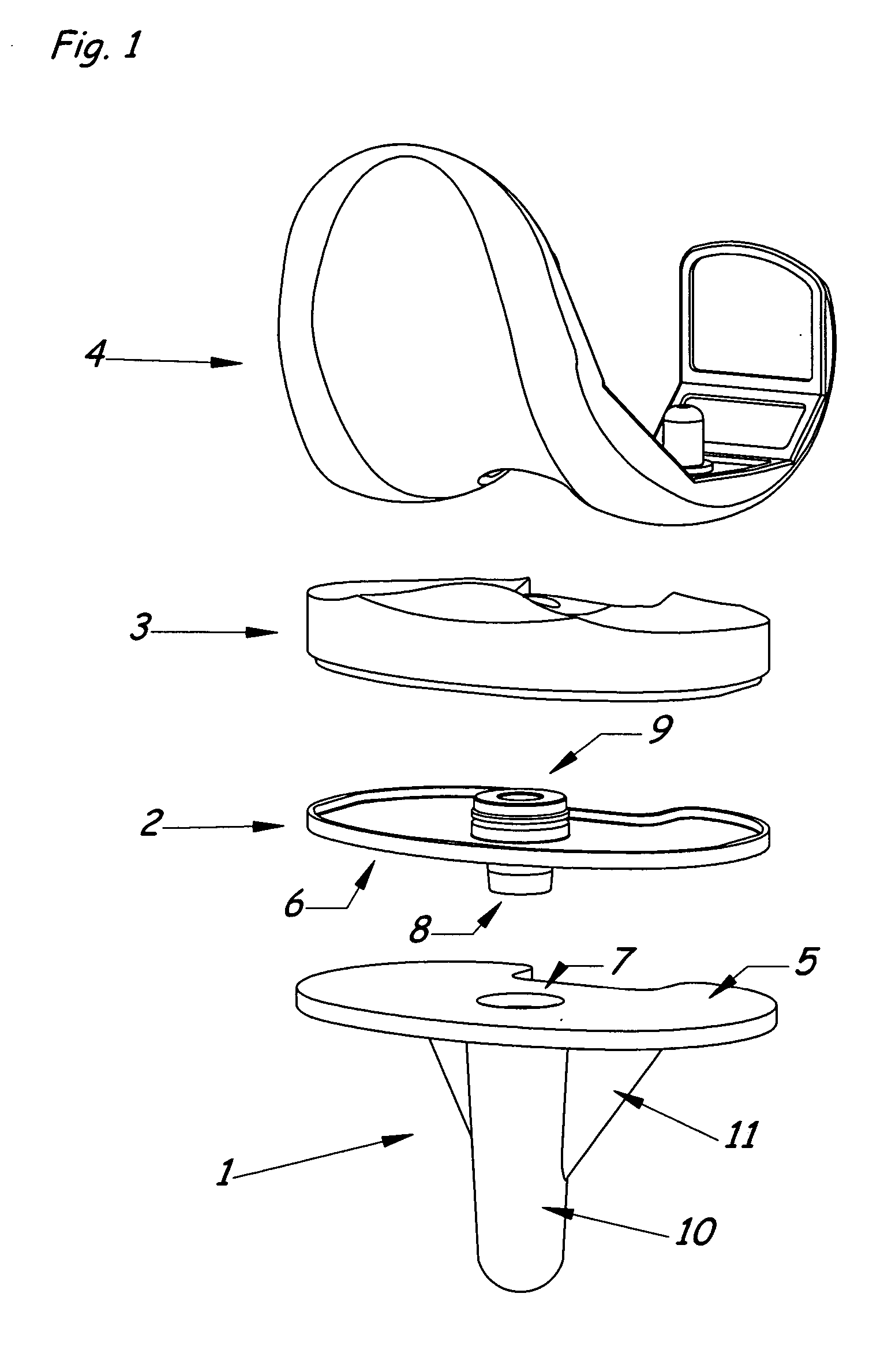

Unicondylar knee implant

A unicondylar knee implant system according to one embodiment includes a unicondylar femoral knee component having a single sagittal radius, a tibial bearing component, and a tibial tray component having a self-locking keel. The unicondylar knee implant system also provides for a locking mechanism for securing the tibial bearing component onto the tibial tray component. The unicondylar knee system allows for a simplified surgical technique, complete interchangeability between sizes, and a more MIS compatible implant system.

Owner:ARTHREX

Modular knee prosthesis

A joint prosthesis may include a tibial tray, a tibial base, a tibial articular member, and a femoral articular member. In some embodiments, a coupler engages the tray, and optionally the base, with an interference fit. In some embodiments, the base engages the tray with an interference fit.

Owner:OMNILIFE SCI INC

System and method for adjusting the thickness of a prosthesis

The present invention relates to a system and method for adjusting a thickness of a prosthesis. A knee prosthesis for implantation may be provided, comprising: a tibial tray, wherein the tibial tray comprises an upper surface and a lower surface, and the lower surface of the tibial tray is disposed adjacent a tibia of the patient; a tibial insert, with an upper surface and a lower surface; a tibial spacer, with an upper surface and a lower surface. The spacer is disposed between the tibial tray and the tibial insert such that the lower surface of the tibial spacer is adjacent the upper surface of the tibial tray and the upper surface of the tibial spacer is adjacent the lower surface of the tibial insert; and at least one locking mechanism, wherein the locking mechanism locks the tibial spacer to the tibiat tray to form a locked spacer / tray assembly.

Owner:EXACTECH INC

Precision Total Knee Arthroplasty

Owner:UNGER ANTHONY S

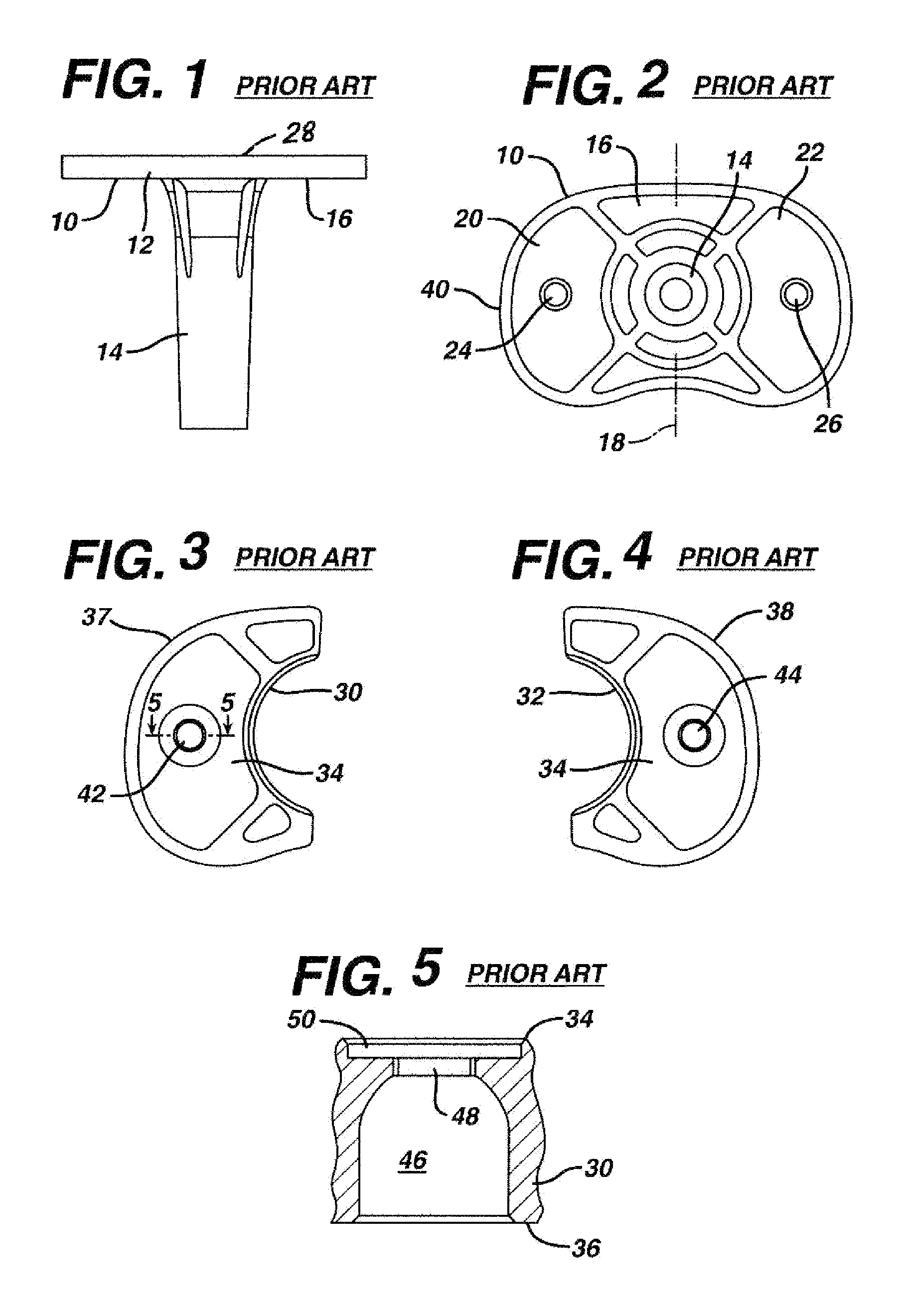

Tibial tray for total knee arthroplasty

InactiveUS7524334B2Improve usabilityProvide stabilitySurgeryJoint implantsTotal hip arthroplastyKeel

An improved one piece tibial tray uniquely characterized by its construction including an asymmetric keel extending from the bottom of the tibial tray base plate, whereby insertion of the tray during arthroplasty may be accomplished with a smaller than normal incision, enhancing the efficacy and safety of the surgical procedure. A fin on either or both sides of the asymmetric fin may be provided for enhanced stability of the tray.

Owner:HAIDUKEWYCH GEORGE J

Instrumentation and method for implanting a curved stem tibial tray

A punch assembly for preparing a tibia bone for a prosthesis includes a static component configured to be supported by the tibia bone and a dynamic component that includes a punch having a stem. The dynamic component is supported for movement relative to the static component along a generally arcuate path to prepare an aperture having an arcuate contour in the tibia bone. A method of preparing a tibial aperture for is also disclosed.

Owner:BIOMET MFG CORP

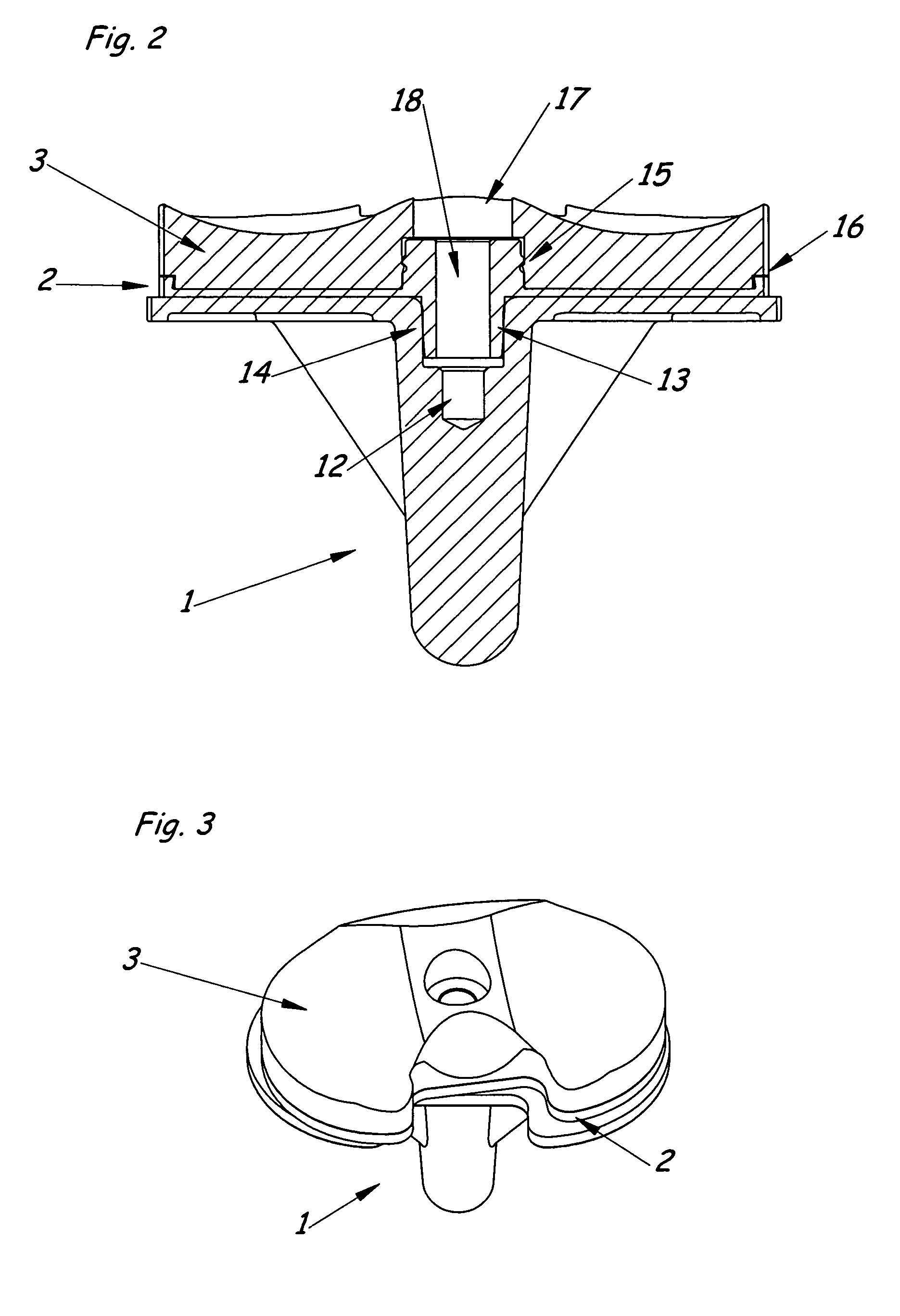

Artificial knee joint

InactiveCN101222886ANatural movementWalking smoothlyJoint implantsKnee jointsTibiaArticular surfaces

An object of the present invention is to provide an artificial knee joint that can avoid both bony contact and soft tissue contact and is durable for long-term use. The artificial knee joint of the present invention includes a femur, a tibial tray, and an insertion plate fixed to the tibial tray. The femur portion includes: a femoral articular surface, and a cam portion protruding from the femoral articular surface provided at the rear end of the femoral articular surface, and the insertion plate includes: a tibial articular surface that abuts on the femoral articular surface, and A cam sliding movement surface that abuts on the cam portion. When the knee is extended, it is the first sliding state where the articular surface of the femur slides on the articular surface of the tibia, within the bending angle of 90° to 160°, from the first sliding state to the sliding movement of the cam part on the cam sliding surface The second sliding movement state shifts. When the knee is bent at a bending angle of 180°, the osteotomy surface of the femur and the rear end of the insertion plate are offset through the second sliding movement state.

Owner:SAGA UNIVERSITY +1

Modular knee prosthesis

A joint prosthesis having in part a tray that is supported by metaphyseal bone, such as the tibial component of a knee prosthesis. The tibial tray and tibial bearing portions can be de-coupled, resulting in two or more distinct pieces

Owner:OMNILIFE SCI INC

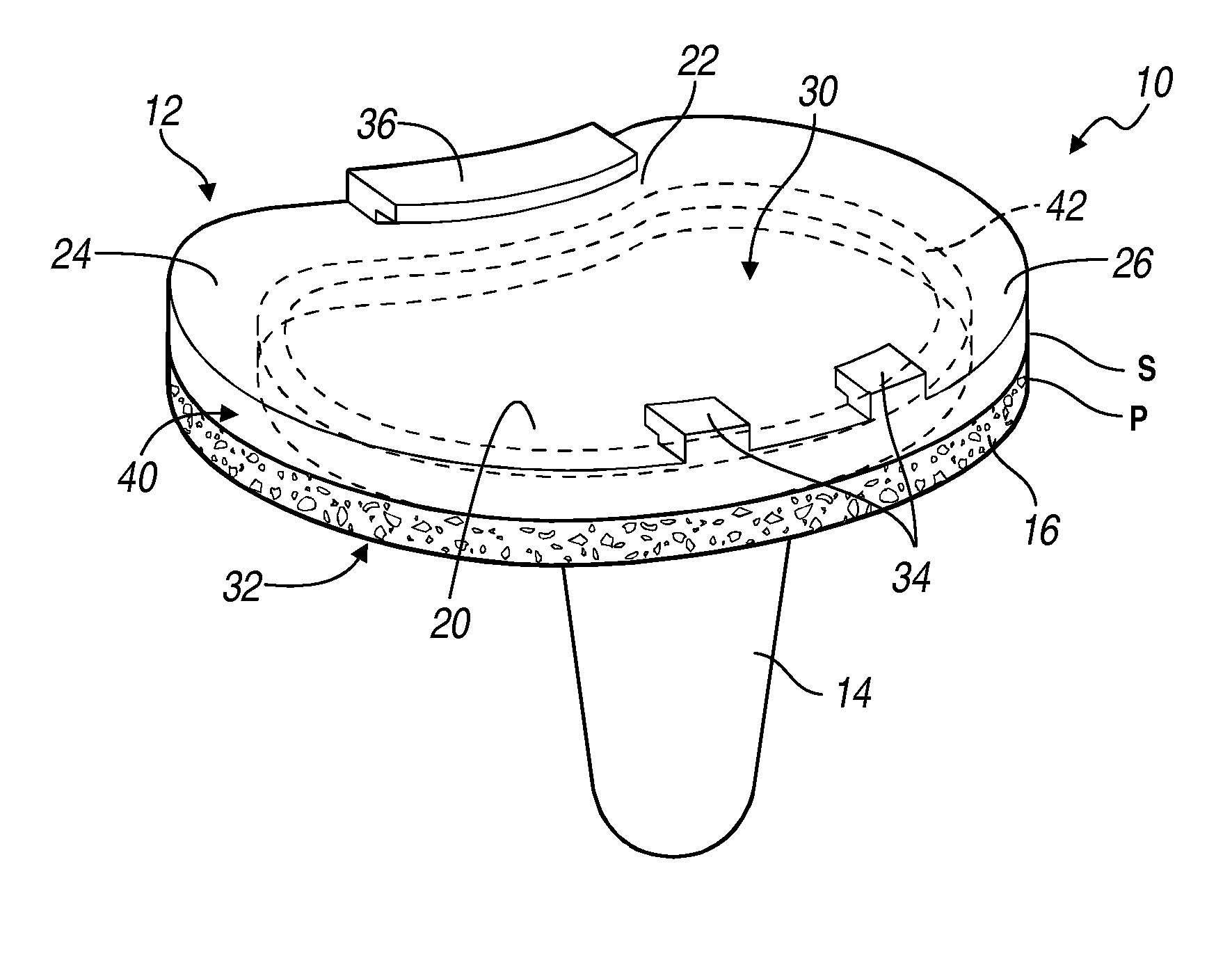

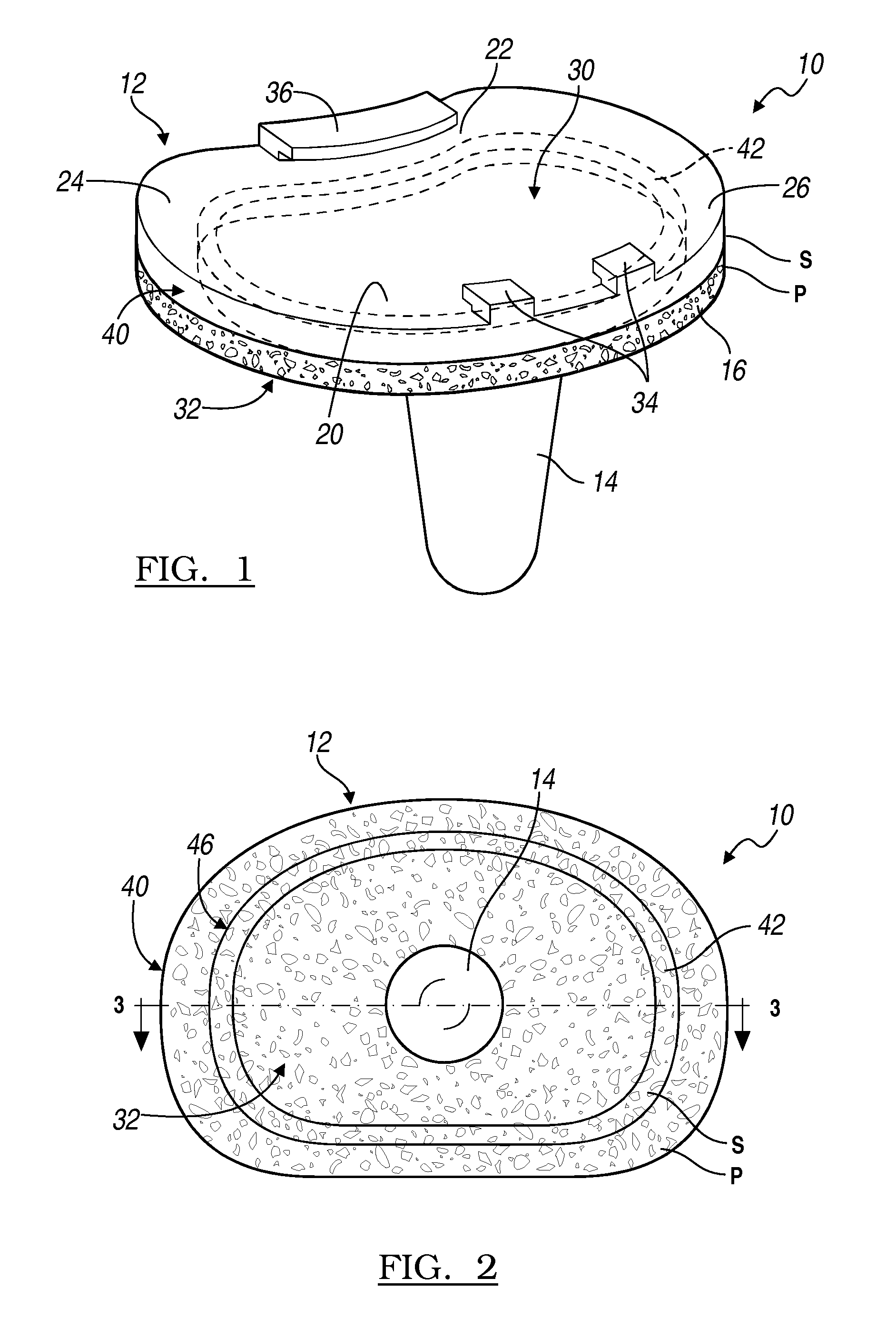

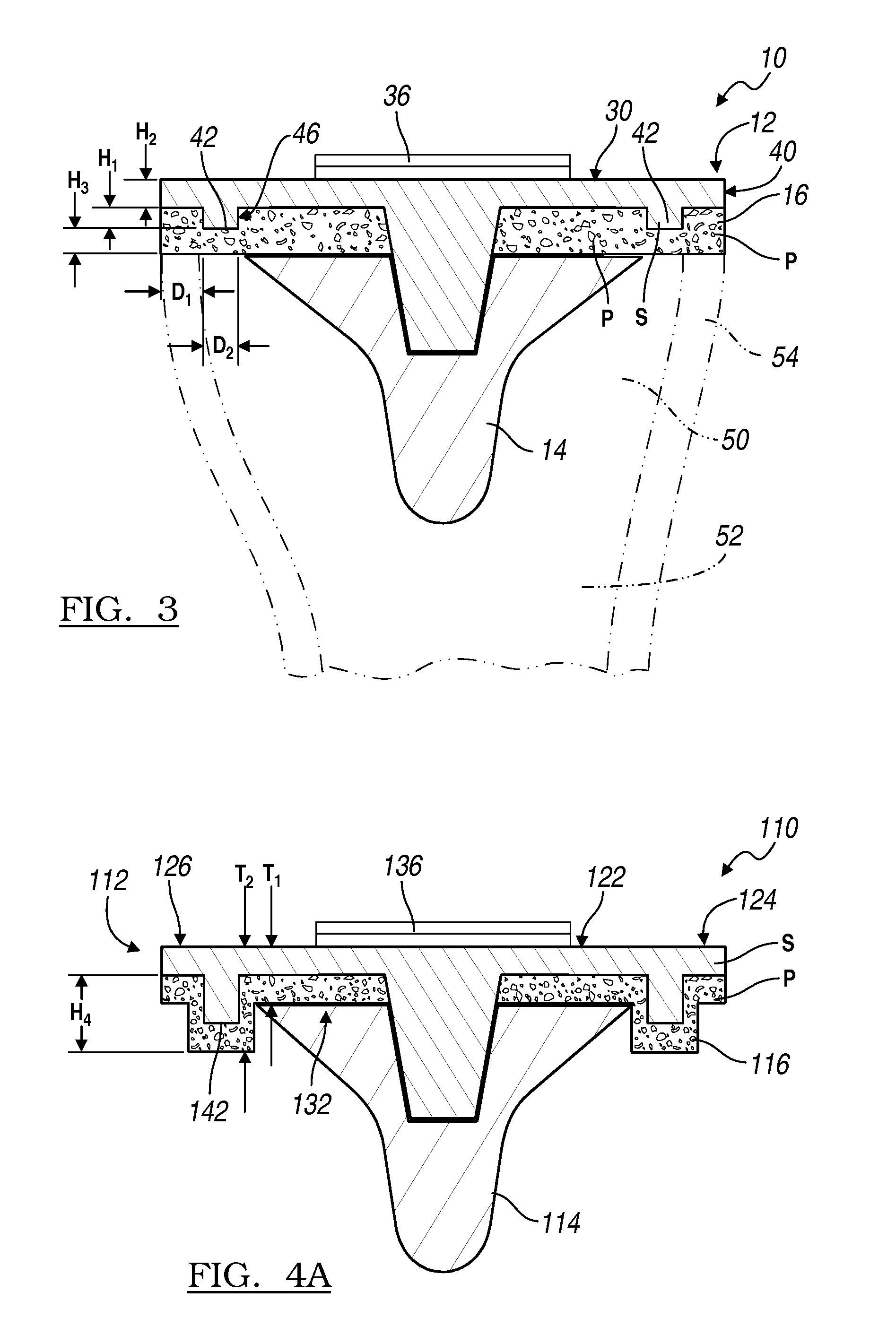

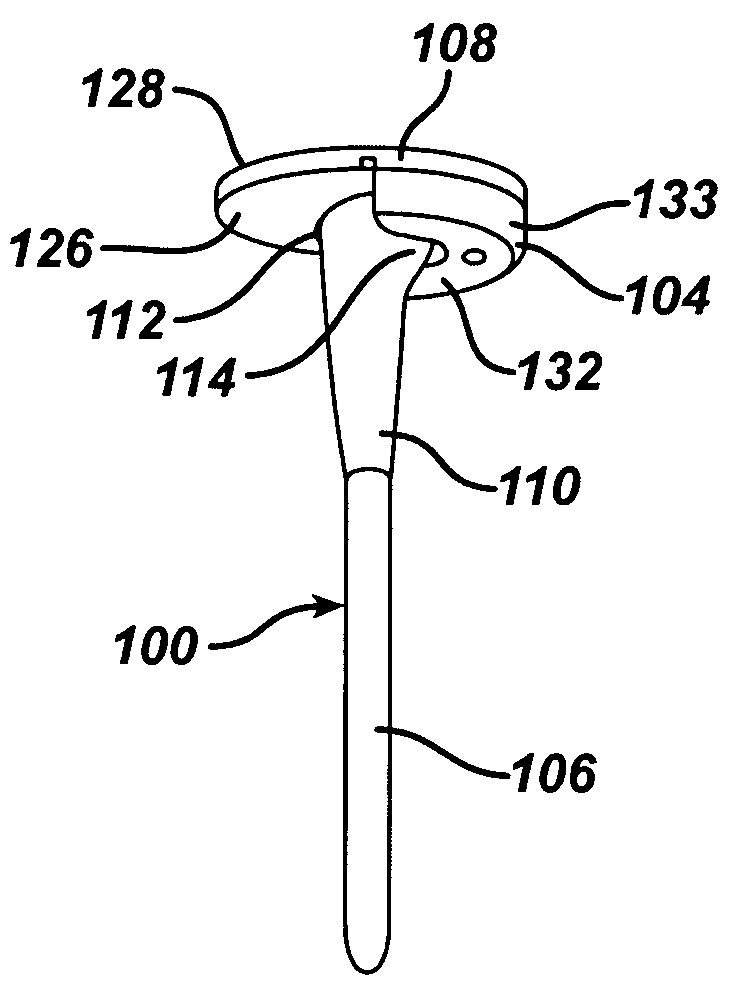

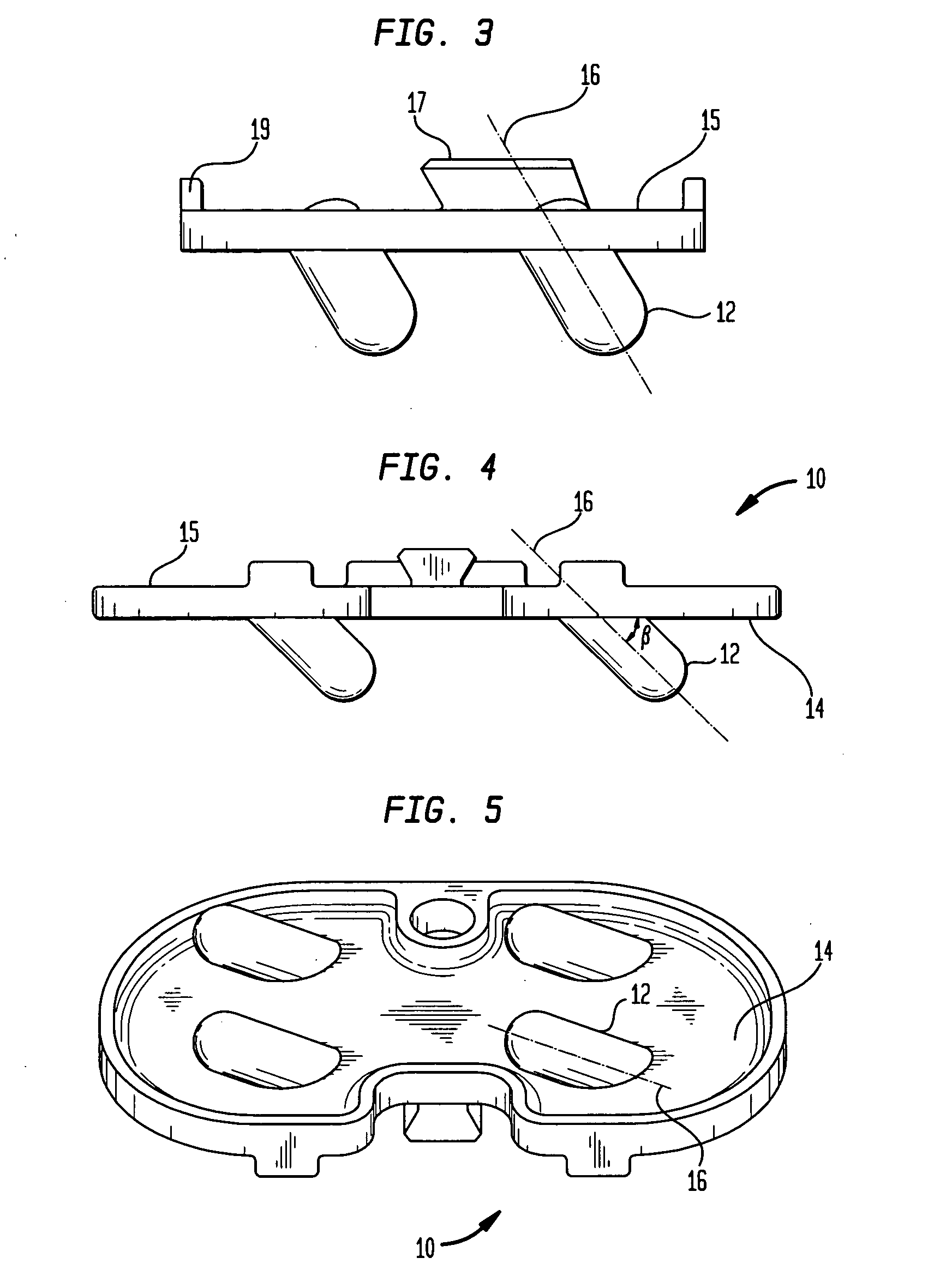

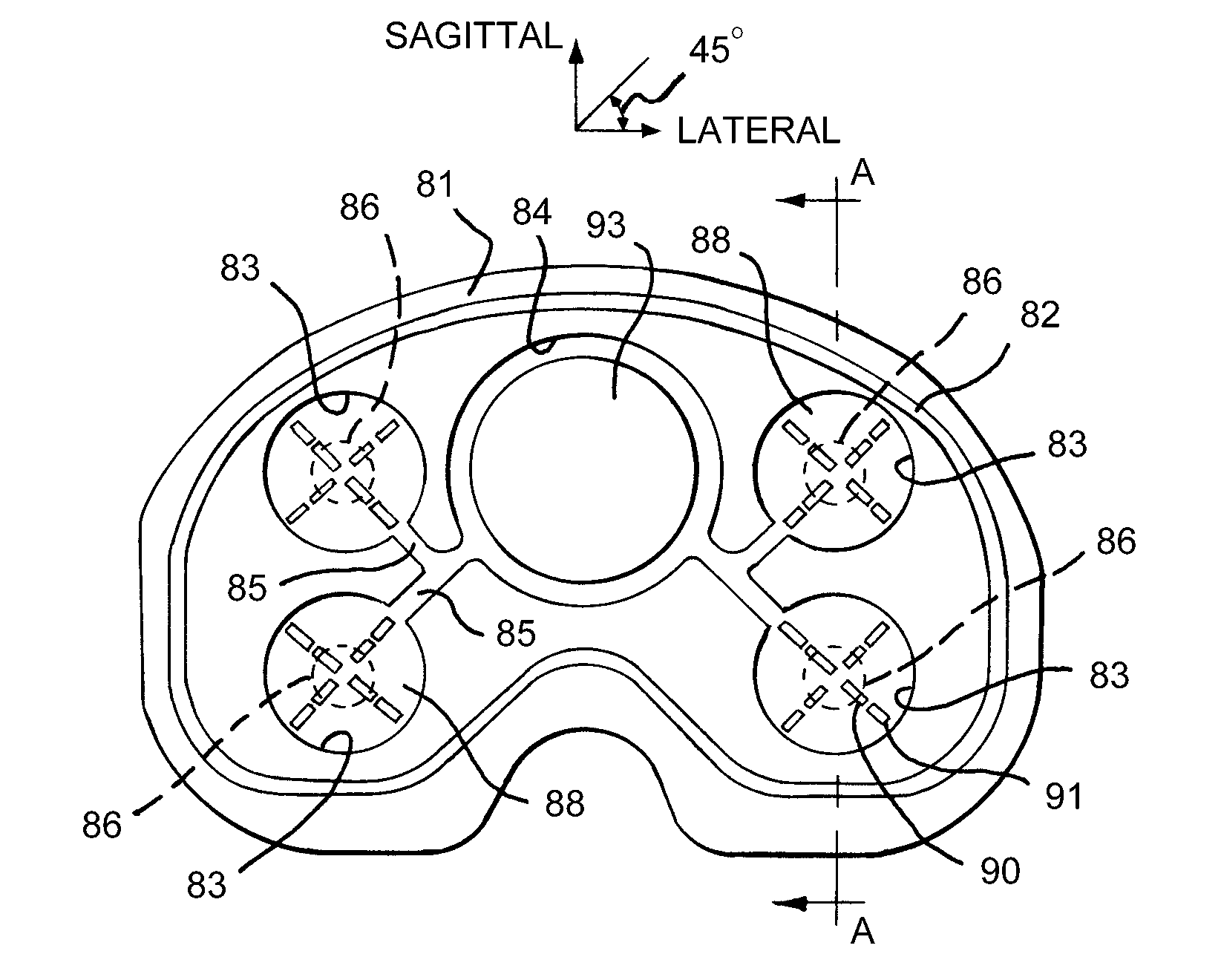

Telemetric tibial tray

ActiveUS7470288B2Maximizes load-bearing areaSacrificing flex responsivenessSurgeryPerson identificationTibiaSagittal plane

A telemetric tibial tray includes a lower plate that defines a plurality of cylindrical transducer cavities having circular load diaphragms. An upper plate is attached to the lower plate through support posts projecting from the load diaphragms. The support posts have a circular cross-section and a diameter of about 5.0 mm. The lower plate further defines wiring channels communicating between the transducer cavities and a central cavity housing the circuit board for the telemetric tray. The wiring channels are arranged at a 45 degree angle relative to the sagittal plane of the knee joint in order to reduce the effects of the wiring channel intersection on the strain sensitivity of the tray. Each transducer cavity includes a radial strain gage array with four pairs of radially aligned strain gages, each pair aligned at a 45 degree angle relative to the sagittal plane of the knee joint. Each pair of strain gages includes an inner gage positioned at the point of maximum positive micro-strain across the diaphragm when loaded, and an outer gage positioned at the point of maximum negative micro-strain, to thereby increase the differential strain measured by the gages and increase the strain sensitivity of the tibial tray.

Owner:DEPUY PROD INC

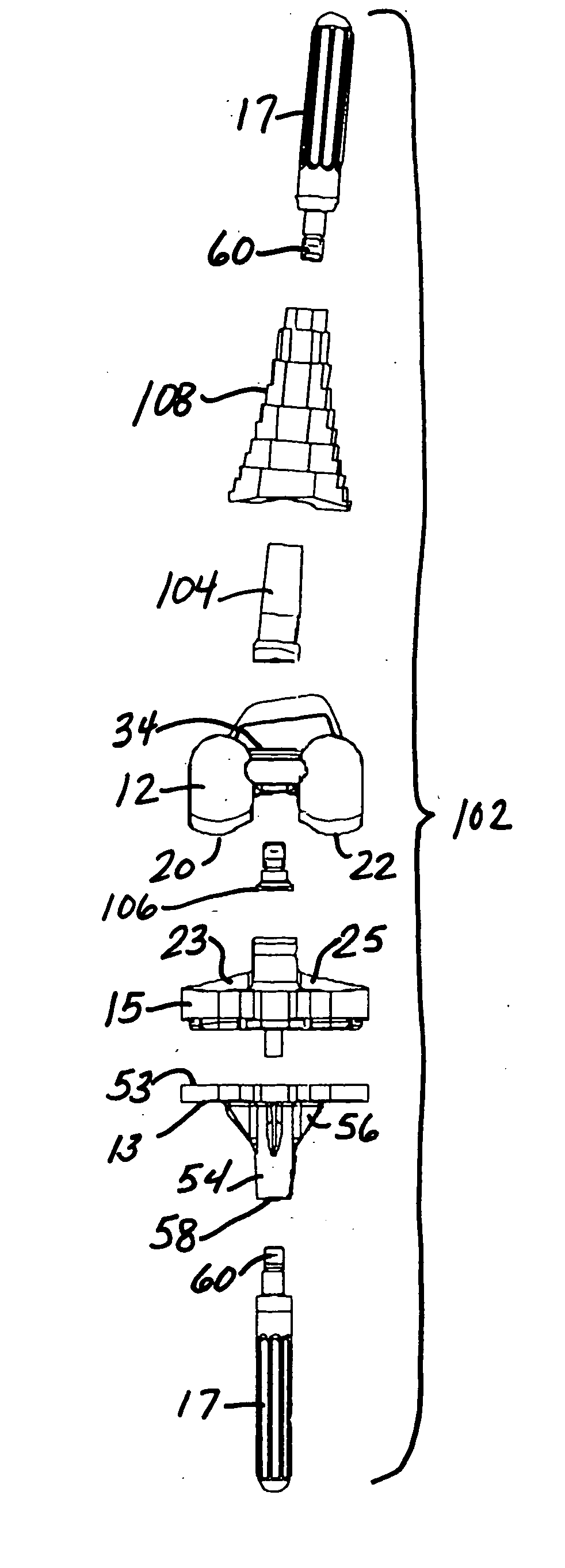

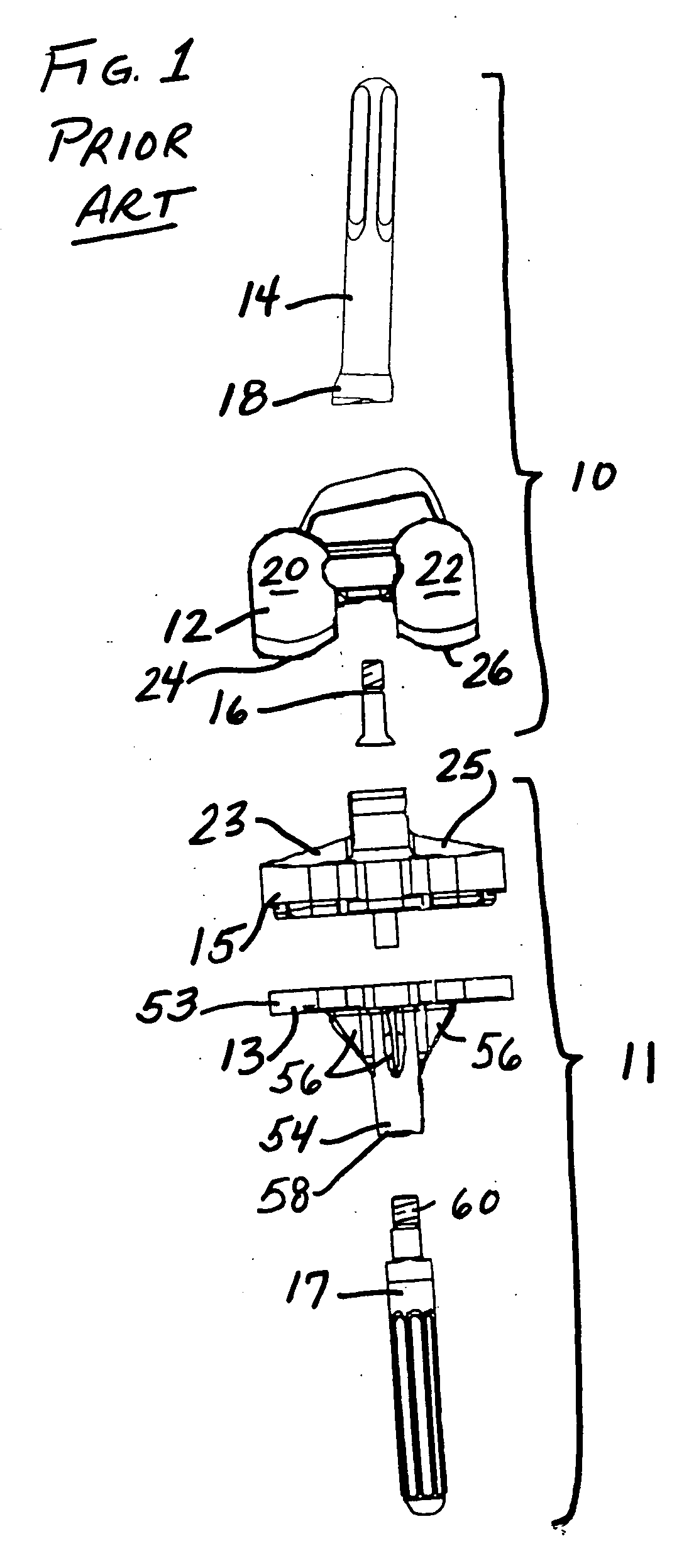

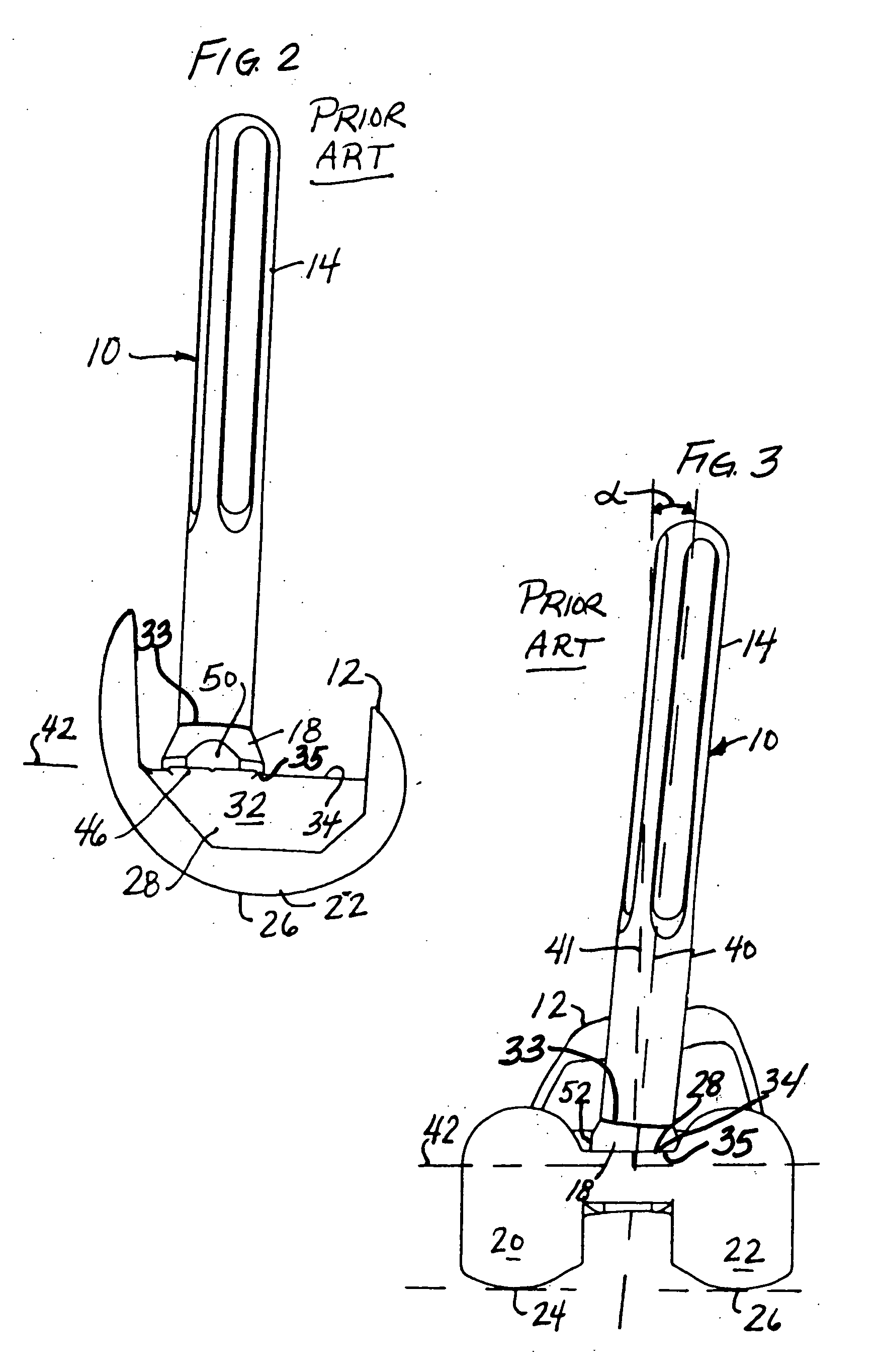

Modular orthopaedic implant system with multi-use stems

A knee implant system includes a femoral adapter. The femoral adapter has a threaded bore so that a stem extension can be threaded onto the proximal end of the adapter. The same stem extension can be threaded onto the distal end of the tibial tray so that the number of stem extensions required in the system is reduced. The femoral adapter has a tapered exterior surface so that a metaphyseal sleeve can be frictionally connected to the femoral adapter. The metaphyseal sleeve has a threaded bore so that the same type of stem extension can be threaded onto the metaphyseal sleeve. The system can include a group of adapters to give the surgeon the option of selecting the appropriate valgus angle and anterior-posterior position of the stem extension.

Owner:DEPUY SYNTHES PROD INC

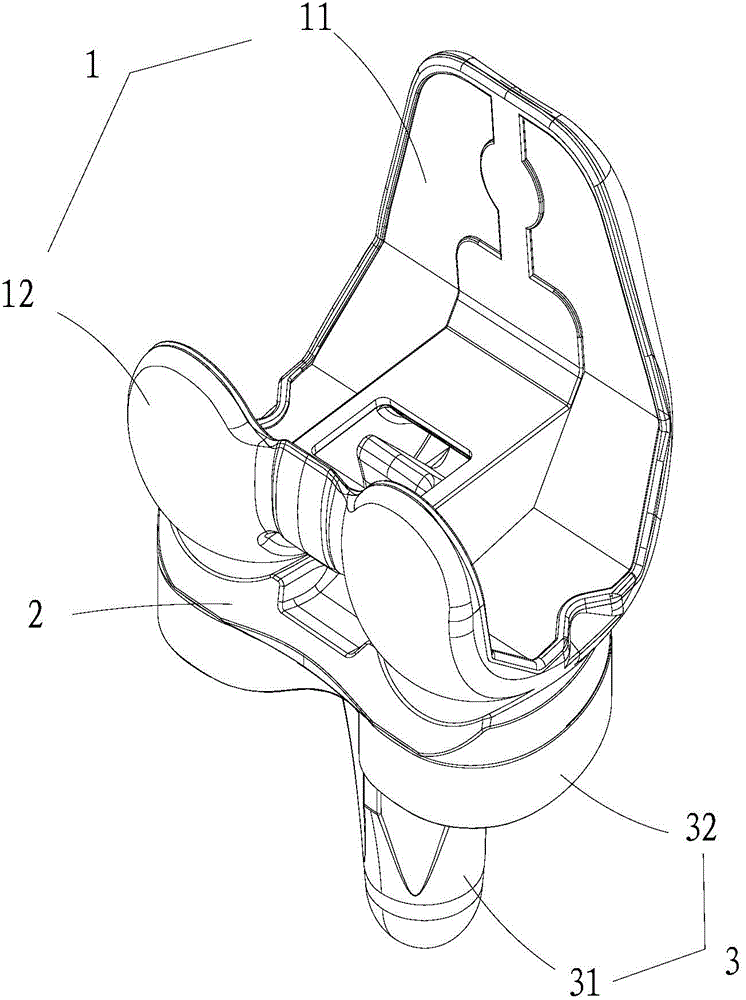

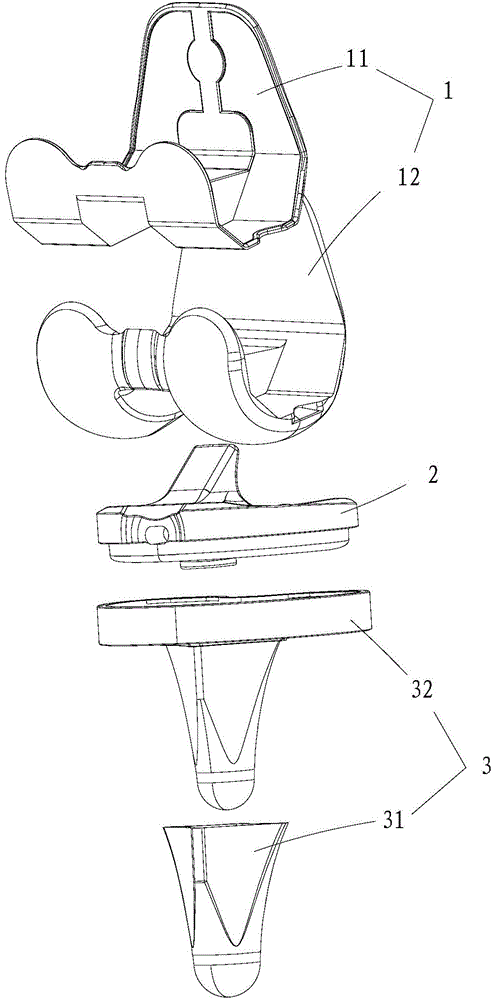

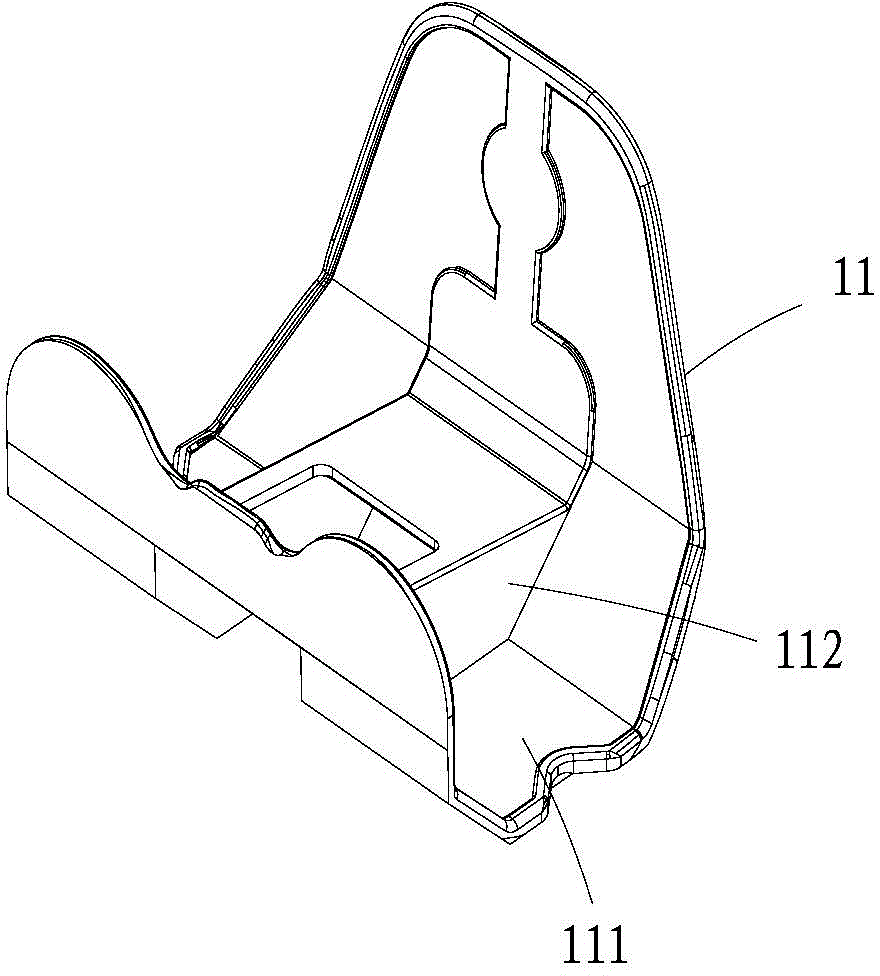

Connecting Mechanism for Medial and Lateral Polyethylene Bearing Surfaces for Knee Replacement

InactiveUS20140039636A1Quick and strong lockingAvoid mechanical failureJoint implantsKnee jointsFixed bearingMobile bearing

Disclosed herein are improved methods, apparatus and / or systems for a tibial implant assembly that can facilitate balancing, positioning, insertion, locking and maneuvering of the modular tibial inserts during knee surgery. The system may include a plurality of modular tibial inserts with locking or engagement mechanisms that allow creation of a modular insert assembly, and a corresponding tibial tray and optional tray components. The system allows the quick and convenient mating and locking of the tibial insert assembly to the tibial tray. The various components can accommodate mobile-bearing and fixed-bearing designs for the tibial tray.

Owner:KURTZ WILLIAM B

Porous total knee prosthesis

InactiveCN104644290ASuperior Biological Fixed EffectExtended service lifeJoint implantsKnee jointsArticular surfacesArticular surface

A porous total knee prosthesis comprises a femoral ankle prothesis, an artificial meniscus and a tibial tray prothesis, wherein a connection hole is formed in a solid main body part of the femoral ankle prothesis; a first porous fixing layer which can play a fixing role together with the femoral bone is arranged on the surface, combined with the femur of a patient, of the solid main body part in a covering manner; a structure wrapping the femoral end subjected to osteotomy is formed on the surface, opposite to the femur of the patient, of the first porous fixing layer, and two femoral articular surfaces are symmetrically arranged on the surface, back to the femur, of the first porous fixing layer; the artificial meniscus is provided with a protrusion matched with the connection hole and used for preventing the femoral ankle prothesis from dislocation, tibial articular surfaces matched with the femoral articular surfaces and a connection part matched with the tibial tray prothesis; and a locating part matched with the connection part is arranged at the upper end of the tibial tray prothesis, a second porous fixing layer is arranged on the outer surface of a supporting part at the lower end of the tibial tray prothesis in a covering manner, and a third porous fixing layer is arranged on the surface of a tibial bonding surface. The porous total knee prosthesis has a strong binding force with the femoral bone of the patient, facilitates growing-in of bone tissues and can achieve a relatively good biological fixation effect.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Bicondylar knee resurfacing prosthesis

A bicondylar knee resurfacing prosthesis for limited knee resurfacing procedure inserted through a direct mini lateral approach, which avoid disruption of the extensor mechanism or damage to the quadriceps tendon. The inventive device includes a reduced femoral component, a metallic tibial tray and a polyethylene tibial insert.A metallic reduced femoral component having a thin polished convex articular surface in a form of two condyles, medial and lateral, connected with an intercondylar bridge. The concave surface having a metallic dovetail transverse ridge across the entire width of the femoral component precisely positioned at the level of maximum weight bearing contact in full extension. The concave surface provides fine asperities and voids to allow bone ingrowth or can be cemented using conventional methyl methacrylate bone cement.The tibial tray provides a dovetail recess along the superior surface and transversely across its entire width, which will slidingly receive the polyethylene tibial insert. The bottom surface of the metallic tibial tray in contact with the tibial plateau has a dovetail ridge, which extends transversely along the entire width of the tibial component securing the tibial component to the resected tibial plateau.The tibial insert is made of polyethylene and has the same shape and size of the tibial metallic tray. It provides a dovetail that matches the one on the tibial tray so it can be easily driven in and locked in place. The surface of the tray provides two shallow condylar grooves that conformably match the condylar convex surfaces of the metallic femoral component.

Owner:TERMANINI ZAFER

Antero-posterior placement of axis of rotation for a rotating platform

A knee replacement system includes a femoral component including a lateral condylar articulating portion and a medial condylar articulating portion, a tibial tray including an upper articulating surface, and a tibial insert including (i) a first articulating portion for articulating with the lateral condylar articulating portion with a first condylar dwell point, (ii) a second articulating portion for articulating with the medial condylar articulating portion with a second condylar dwell point, (iii) a lower articulating surface for articulating with the upper articulating surface, and (iv) a coupling member for coupling with the tibial tray and defining an axis of rotation about which the tibial insert rotates with respect to the tibial tray, the axis of rotation intersecting the upper articulating surface at a location posterior to a dwell axis including the condylar dwell points when the dwell axis is projected onto the upper articulating surface.

Owner:DEPUY (IRELAND) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com