Patents

Literature

151 results about "Proximal tibia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The proximal tibia is the upper part of the shinbone that connects to the knee joint. Proximal tibia fractures are fairly common lower-leg injuries.

Method and apparatus for minimally invasive knee arthroplasty

InactiveUS7048741B2Minimized overall profileLength minimizationDiagnosticsSurgical navigation systemsKnee replacementImage guidance

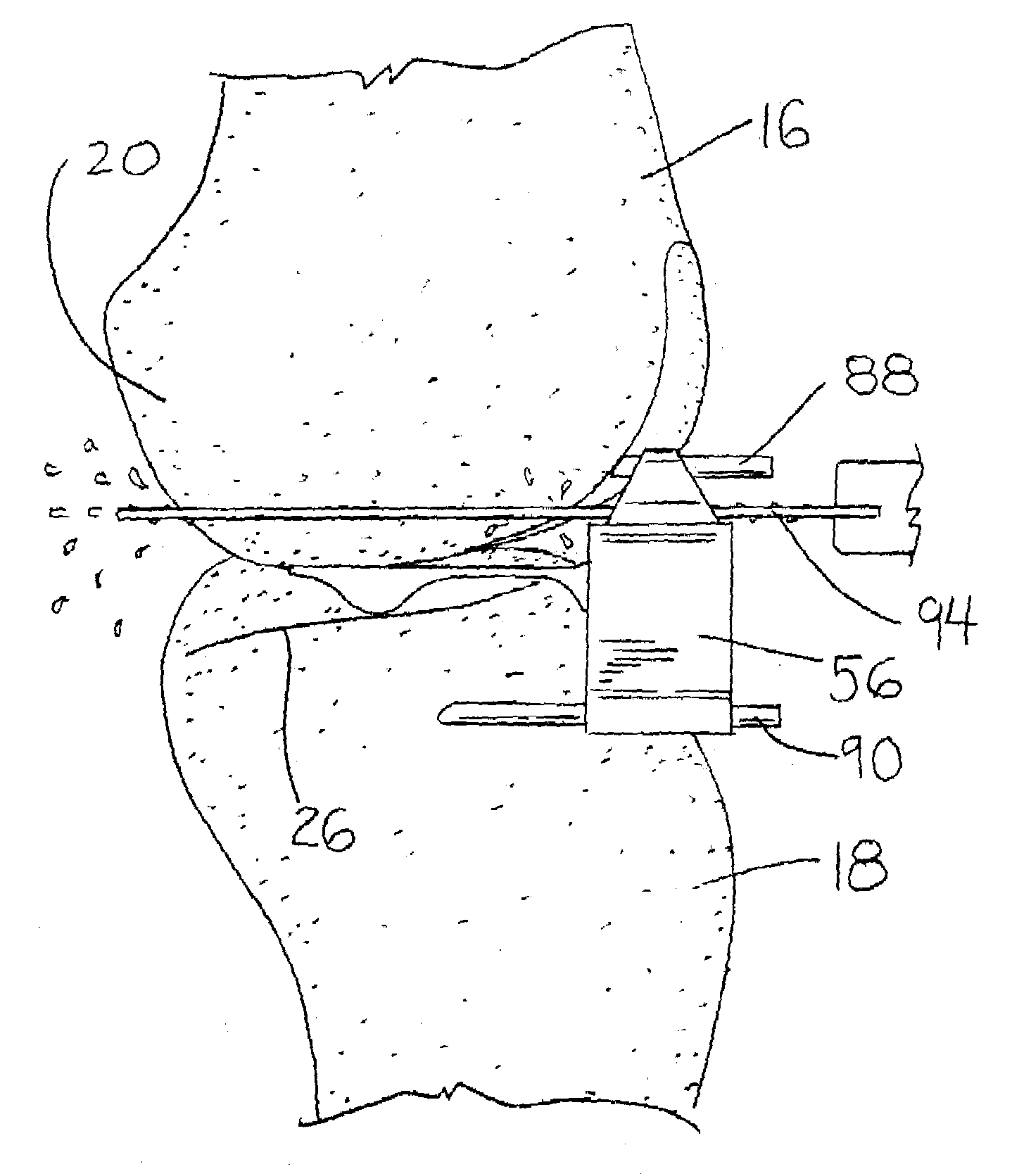

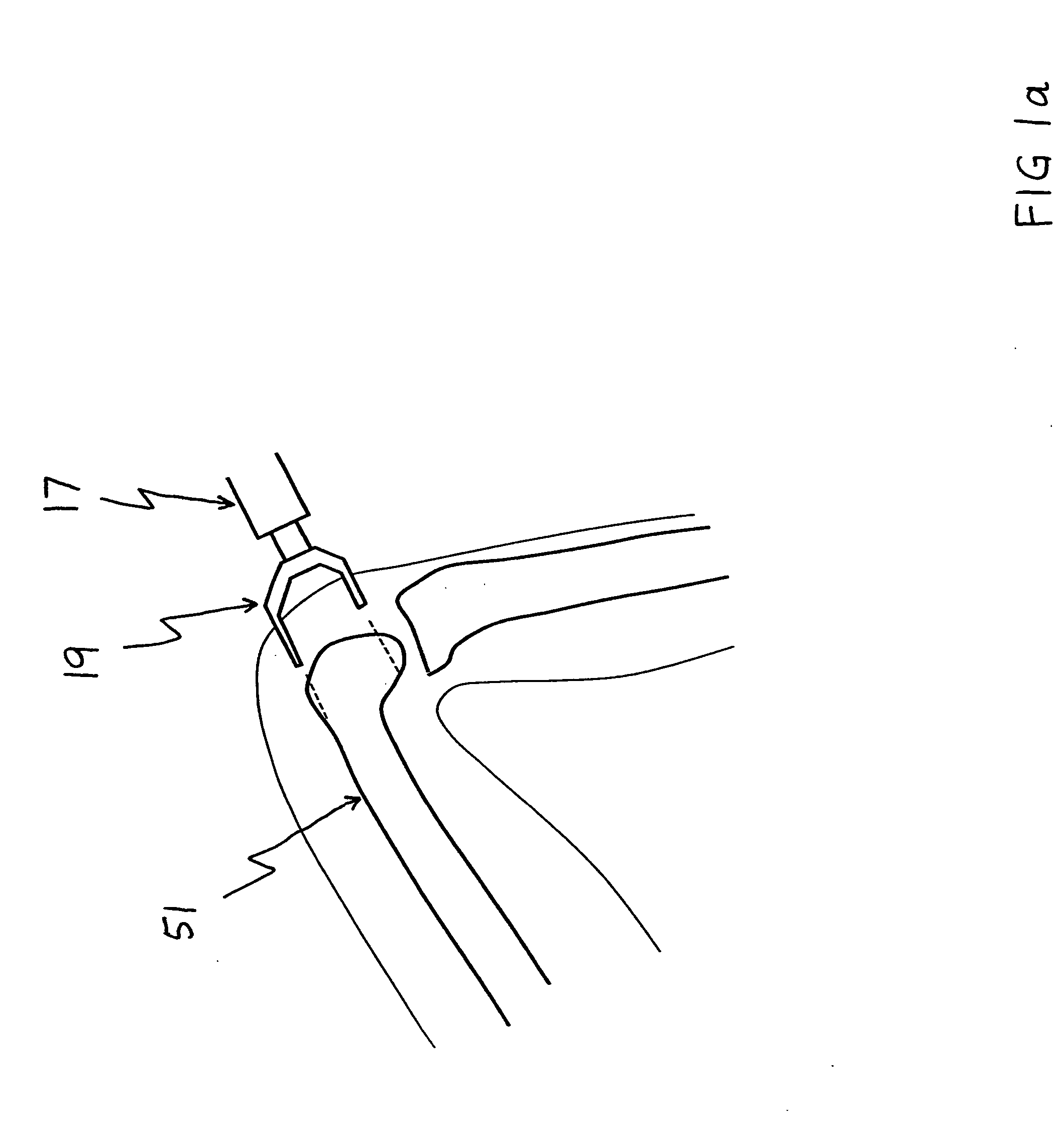

The invention is a method for performing a minimally invasive knee arthroplasty and components for this procedure. The method involves creating an incision along the medial or lateral aspect of a patient's knee, exposing the knee joint, resecting the distal end of the femur, the proximal end of the tibia and the posterior patella through the medial or lateral incision, and connecting a femoral, tibial and patellar knee replacement component through the incision. Components include specialized femoral, tibial and patellar cutting guides for use in resecting the femur, tibia and patella through the medial or lateral incision. In one embodiment, the method is performed with the aid of an image guidance system. In another embodiment, the method is performed with instruments which align the components, such as the cutting guides, without the use of an image guidance system.

Owner:SMITH & NEPHEW INC

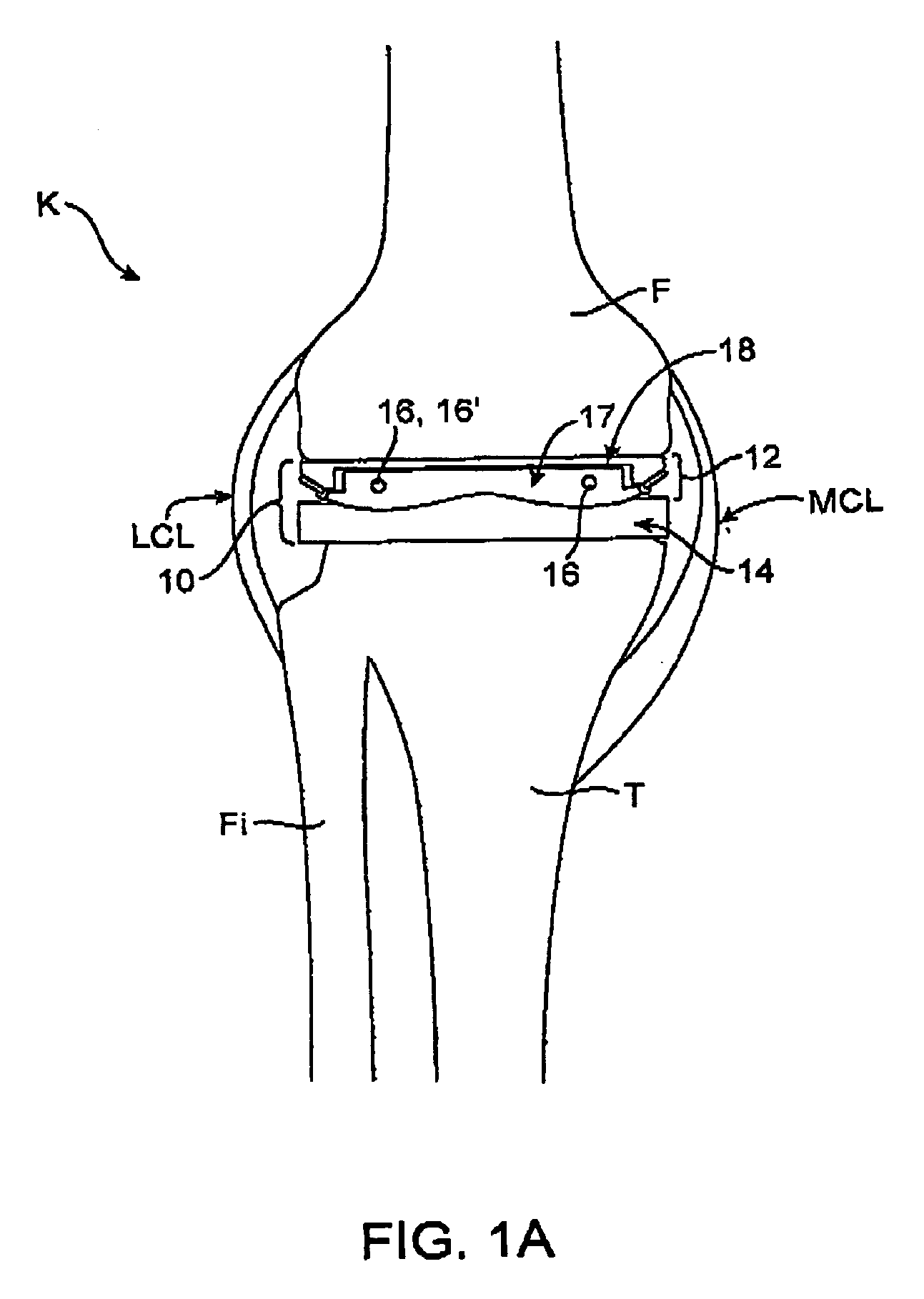

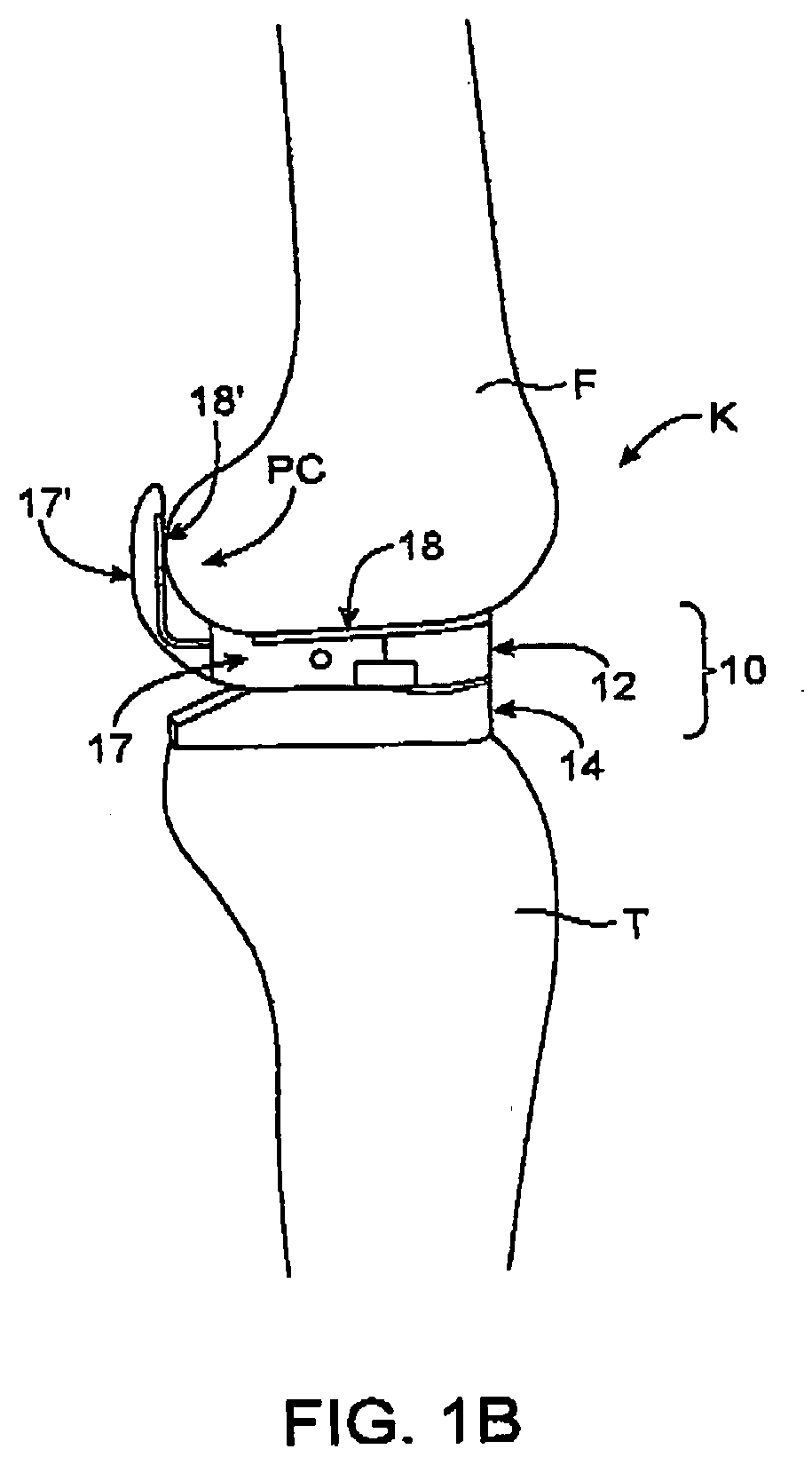

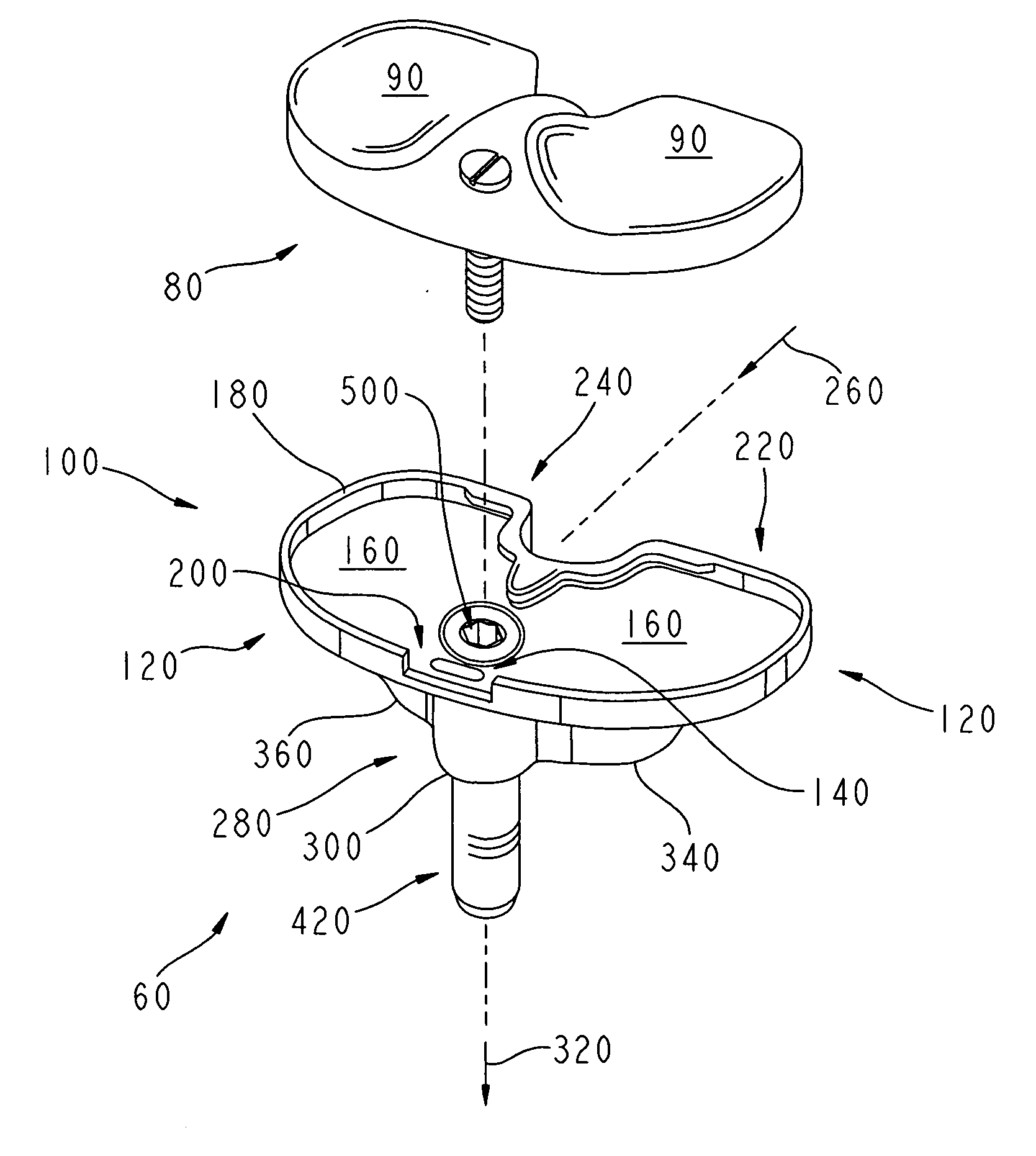

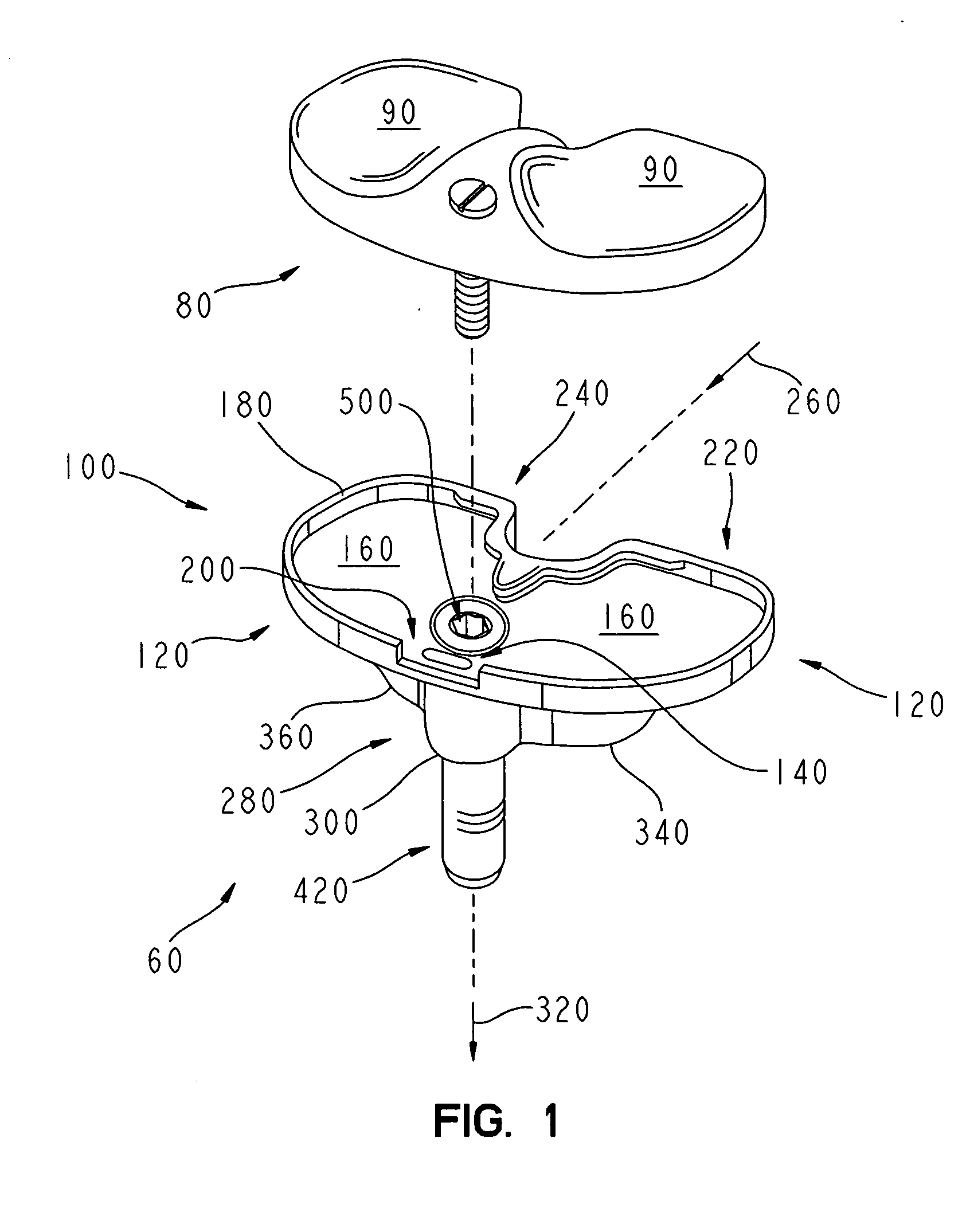

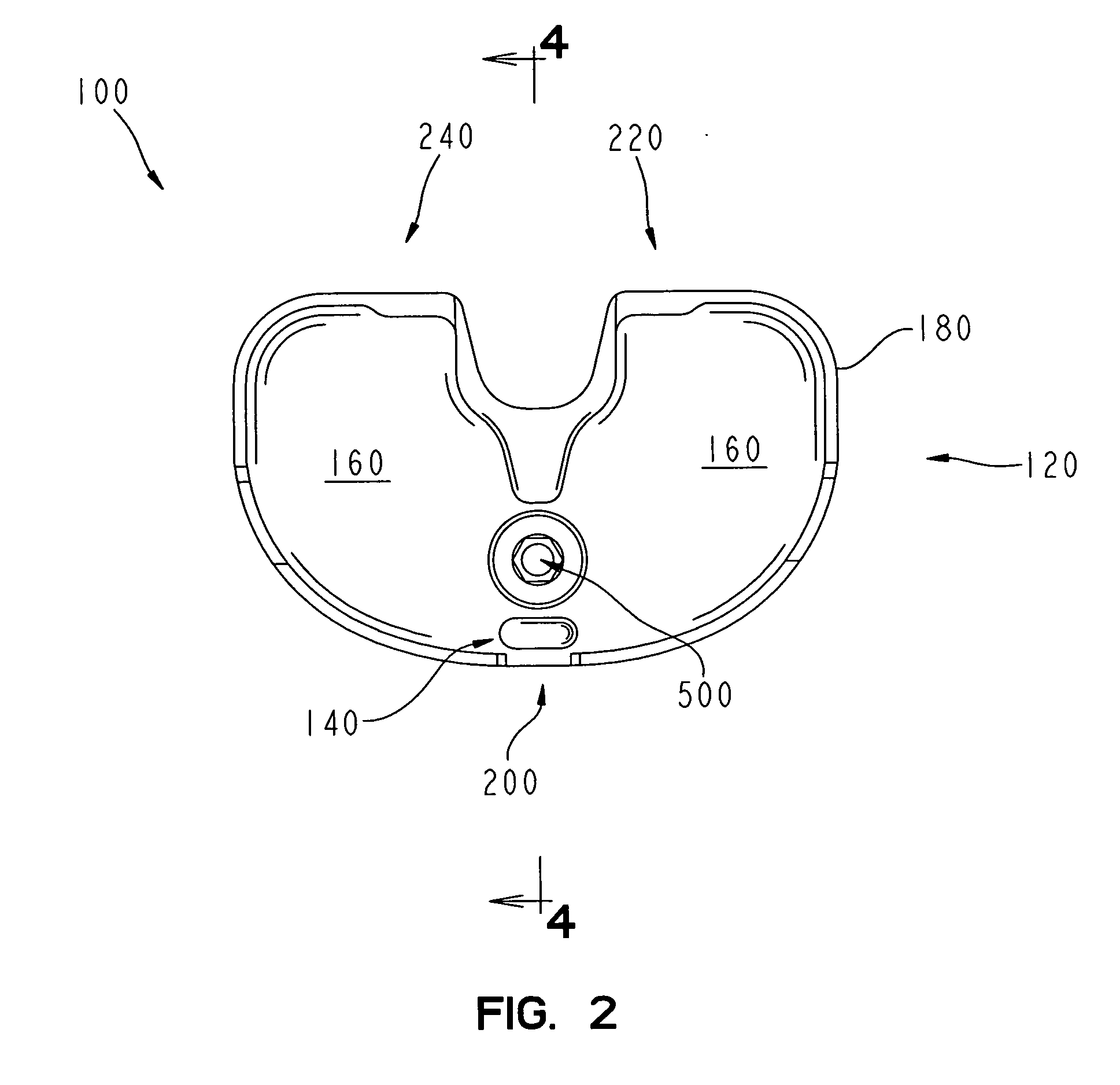

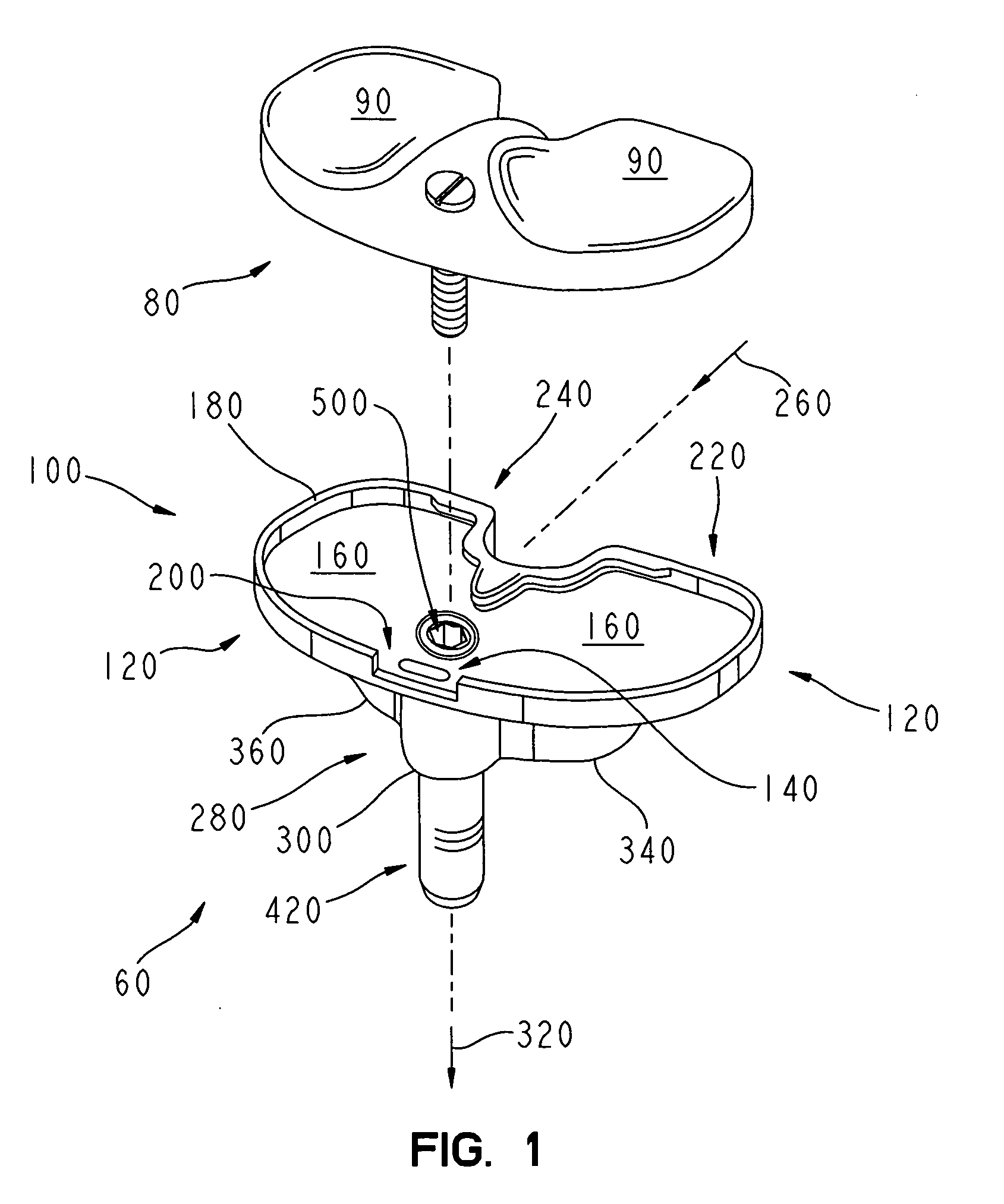

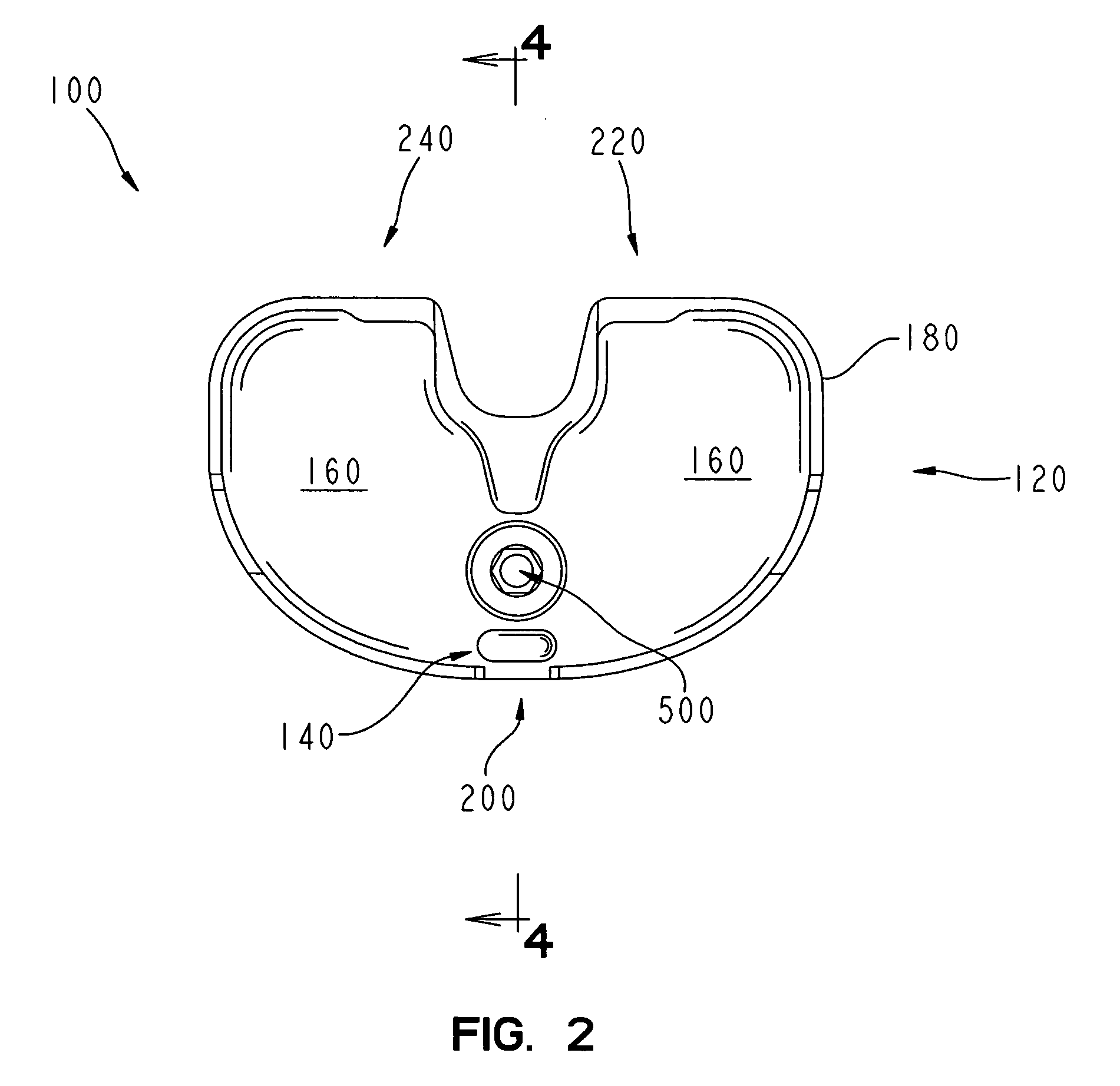

Dynamic knee balancer with opposing adjustment mechanism

ActiveUS20050267485A1Accelerated programImproved surgical outcomeDiagnosticsJoint implantsPhysical medicine and rehabilitationRange of motion

A device for performing a surgical procedure on a knee comprises a femoral assembly comprising a stationary femoral member attachable to the distal femur, an adjustable femoral member movably coupled with the stationary member to adjust tension in at least one ligament of or adjacent the knee and an adjustment mechanism coupled to the assembly. The adjustable member includes at least one positioning feature that moves relative to the distal femur as the adjustable member is adjusted and identifies at least one position on the distal femur. The adjustable member is movably couplable with a tibial member engaged with a proximal tibia to allow the knee to be moved through a range of motion without removing the femoral and tibial members. The mechanism includes an actuator positioned proximate a medial or lateral portion of the adjustable member. The actuator is configured to adjust an opposite portion of the adjustable member.

Owner:SYNVASIVE TECH

Method of implanting a uni-condylar knee prosthesis

The invention relates generally to a method for implanting a uni-condylar knee prosthesis. The method includes steps for preparing the bone surfaces of both the femoral and tibial effected compartments. The femoral compartment is prepared by making a distal cut, a posterior cuts and a posterior chamfer cut. Holes that correspond to posts on the femoral component are also prepared. The tibial compartment is prepared using a cutting guide and following the sclerotic bone formation on the proximal tibia. At least one hole is prepared in the sloped cut tibial surface to use for alignment when cementing the tibial component that has an alignment peg.

Owner:BIOMET MFG CORP

Unicondylar knee implants and insertion methods therefor

A method of preparing a knee joint for receiving a unicondylar knee implant includes preparing a first seating surface at a proximal end of a tibia, and providing a combination bur template and spacer block, the bur template having an upper end, a lower end and a curved surface extending between the upper and lower ends thereof that is adapted to conform to a femoral condyle of a femur and the spacer block extending from the lower end of the bur template and having top and bottom surfaces. The method includes flexing the knee joint so that the prepared first seating surface at the proximal end of the tibia opposes a posterior region of the femoral condyle and inserting the combination bur template and spacer block into the knee joint so that the top surface of the spacer block engages the posterior region of the femoral condyle and the bottom surface of the spacer block engages the first seating surface at the proximal end of the tibia. While the spacer block is maintained between the femur and the tibia, the knee joint is extended until the curved surface of the bur template engages the femoral condyle of the femur. The bur template is anchored to the femur and used to guide burring of the femoral condyle for preparing a second seating surface on the femur. After burring the distal end of the femoral condyle, the posterior region of the femoral condyle is resected.

Owner:HOWMEDICA OSTEONICS CORP

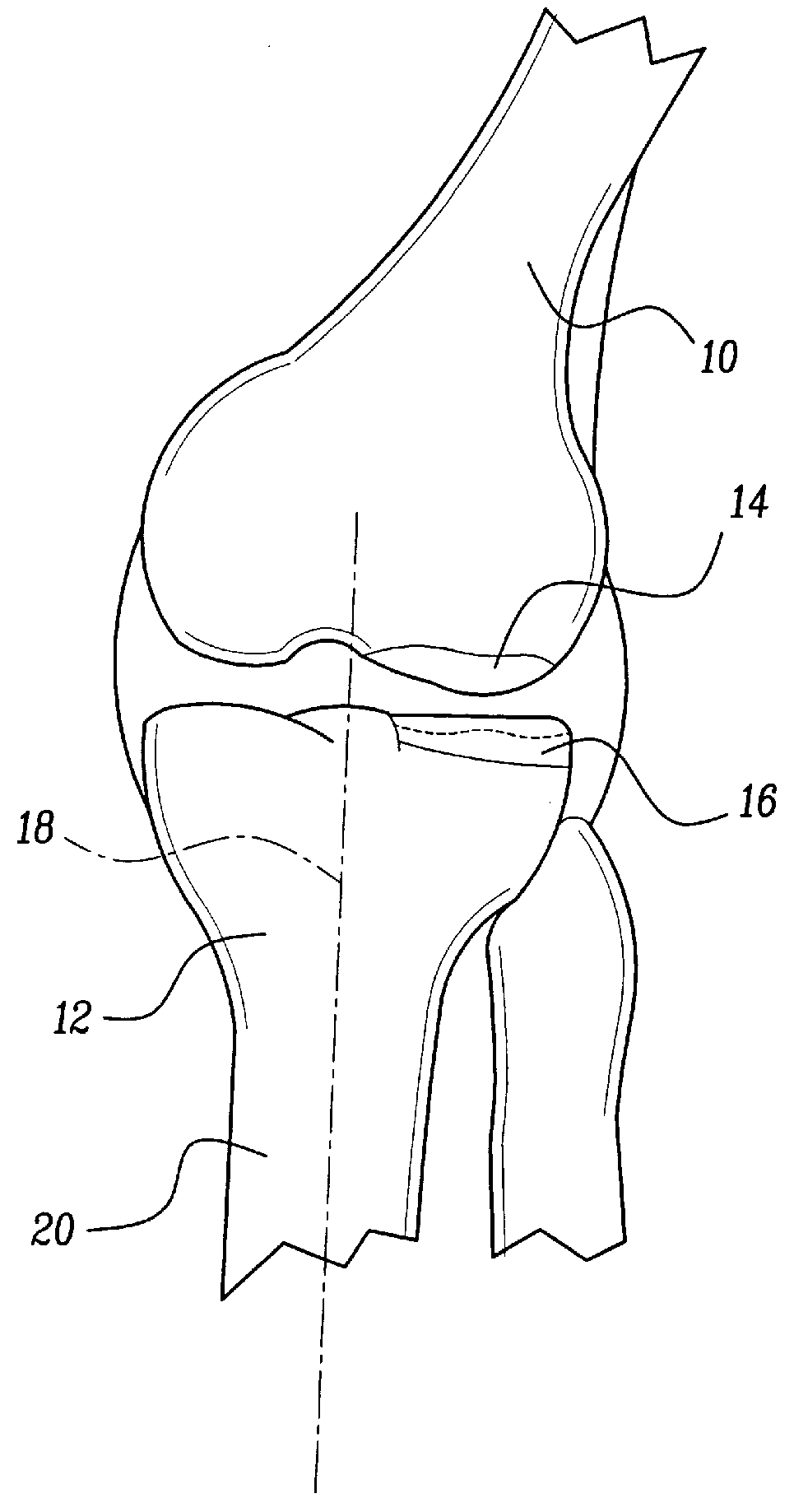

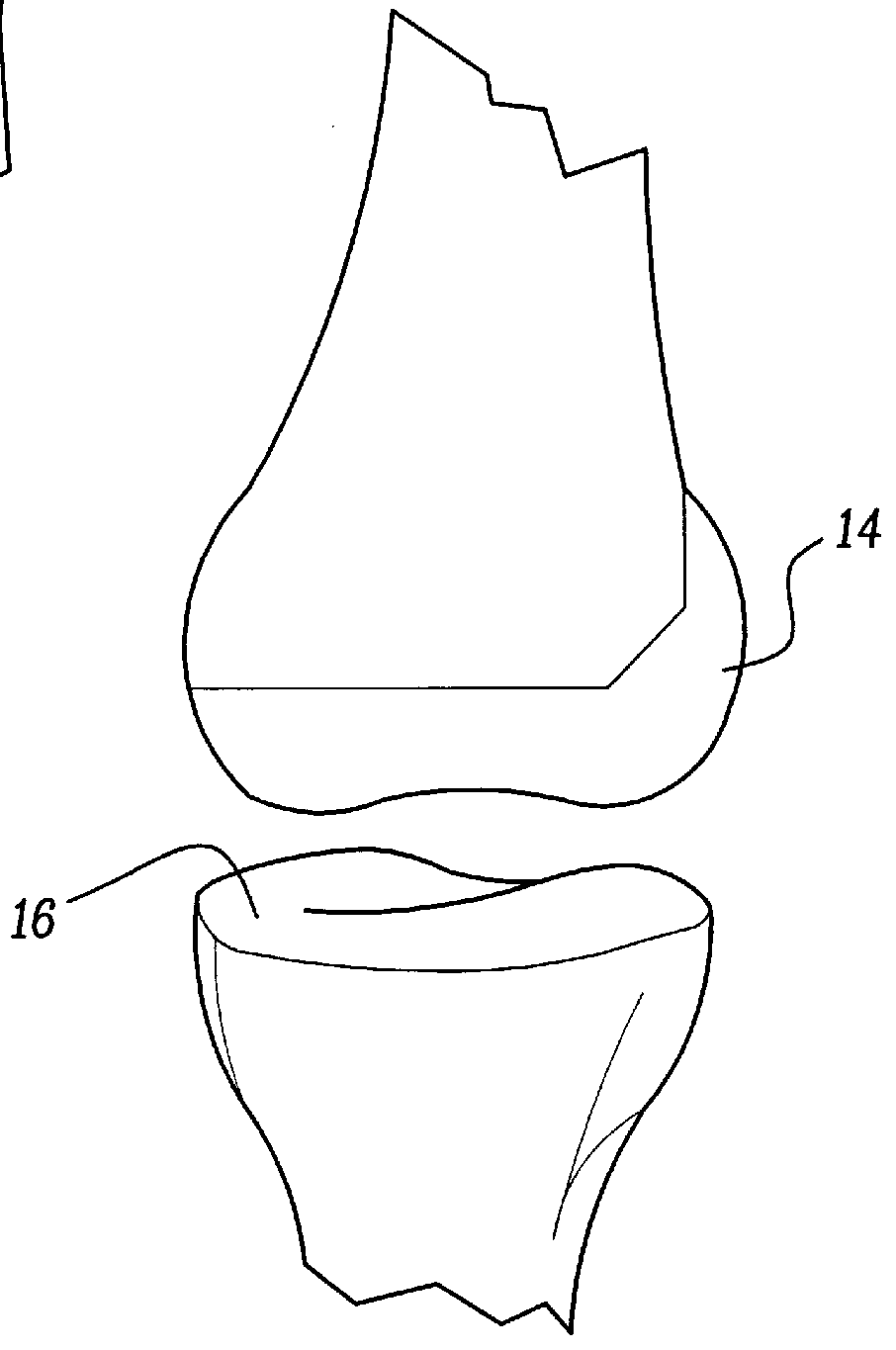

Dynamic knee balancer

ActiveUS20050177169A1Enhancing knee surgery procedureAccelerated programBone implantDiagnosticsPhysical medicine and rehabilitationRange of motion

Dynamic knee balancing devices, systems and methods provide for enhanced total knee arthroplasty (“TKA”) procedures. Devices generally include a stationary femoral member for removably attaching to a distal femur and an adjustable femoral member coupled with the stationary member for adjusting ligament tension of the knee. The adjustable femoral member includes at least one positioning feature for providing positional and / or orientation information for facilitating the TKA procedure. Additionally, the adjustable femoral member is movably couplable with a tibial member engaged with the proximal tibia to allow movement of the knee through a range of motion without removing the device from the joint space. When the adjustable femoral member is adjusted, the positional feature(s) move relative to the distal femur to provide positional information.

Owner:SYNVASIVE TECH

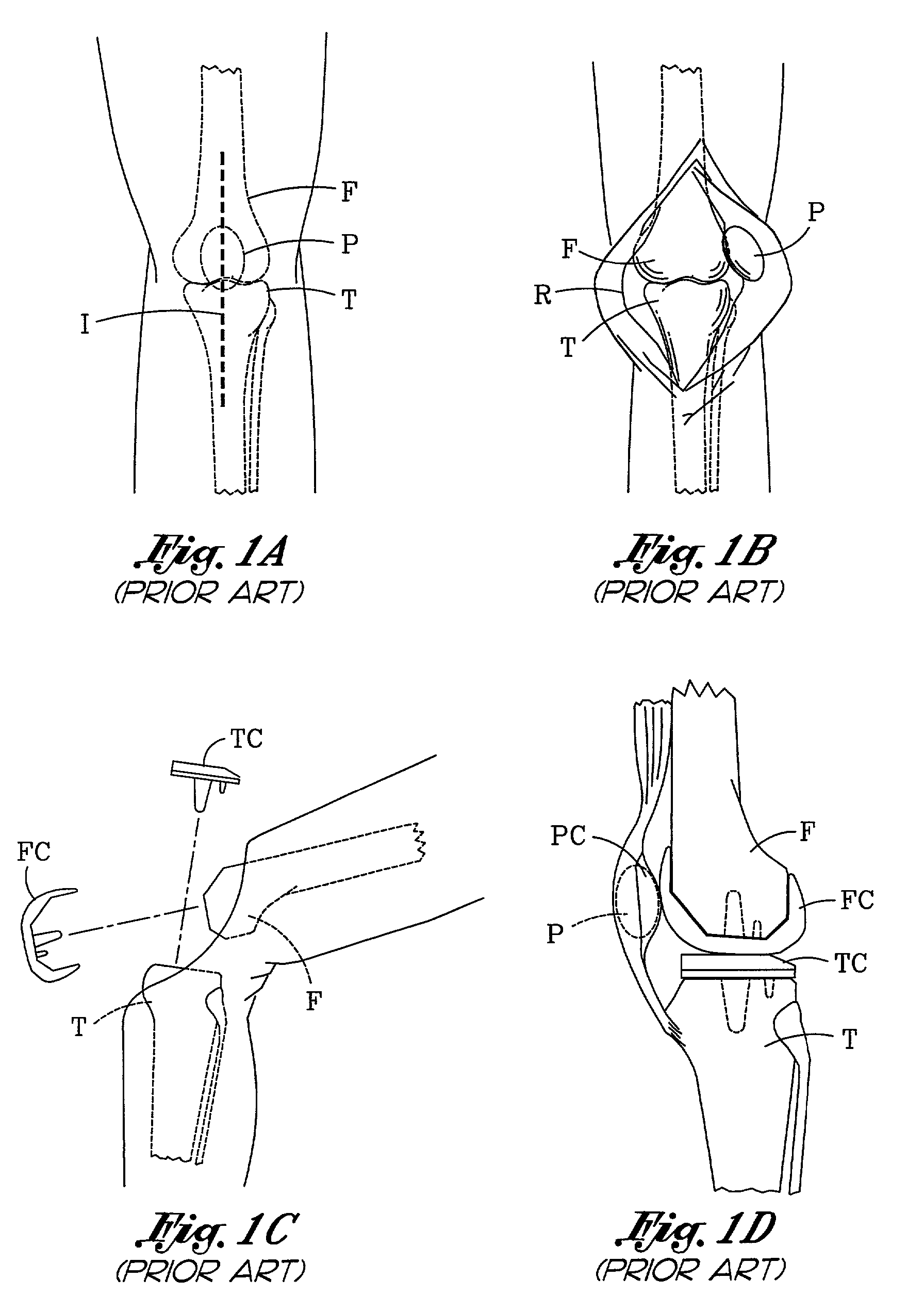

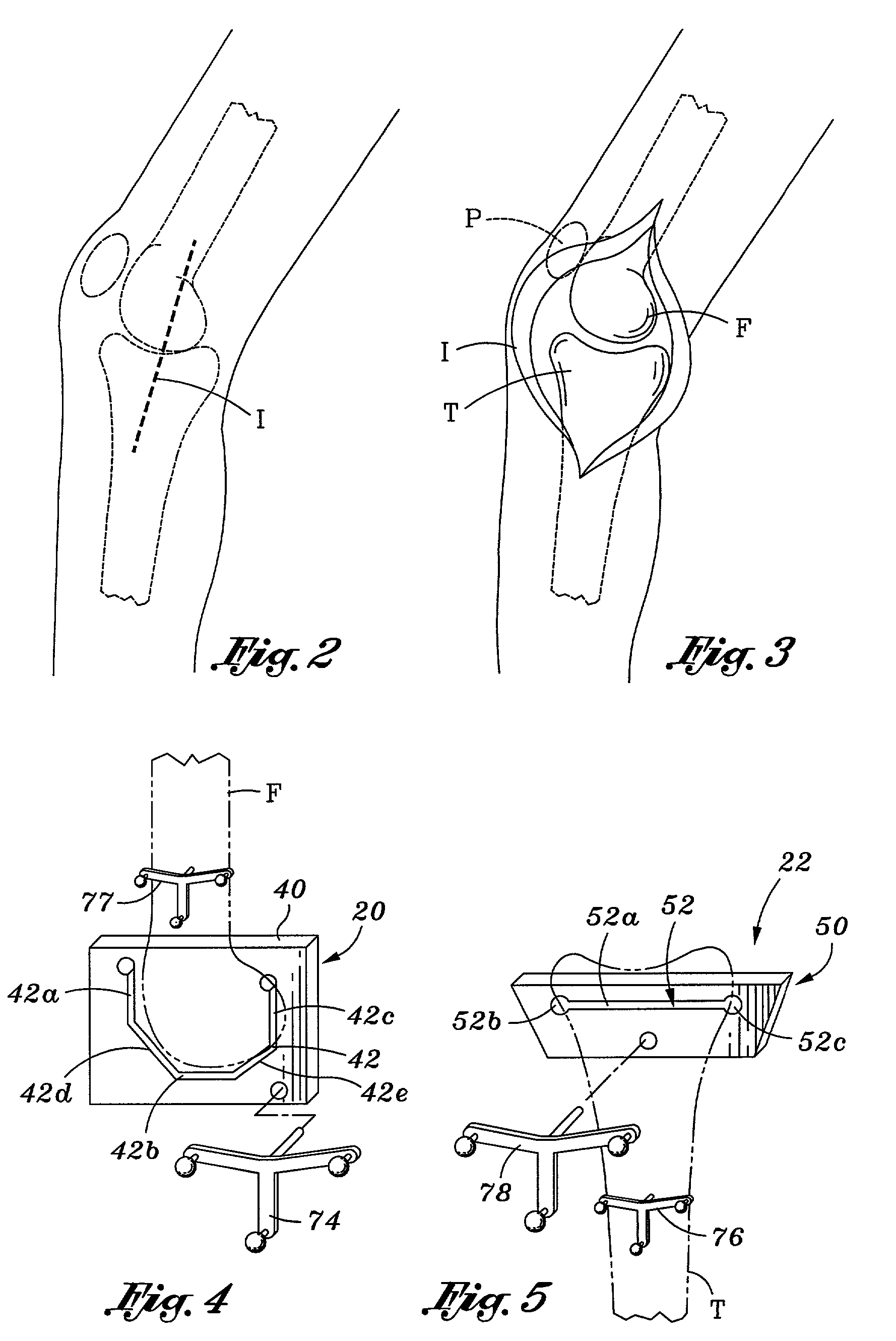

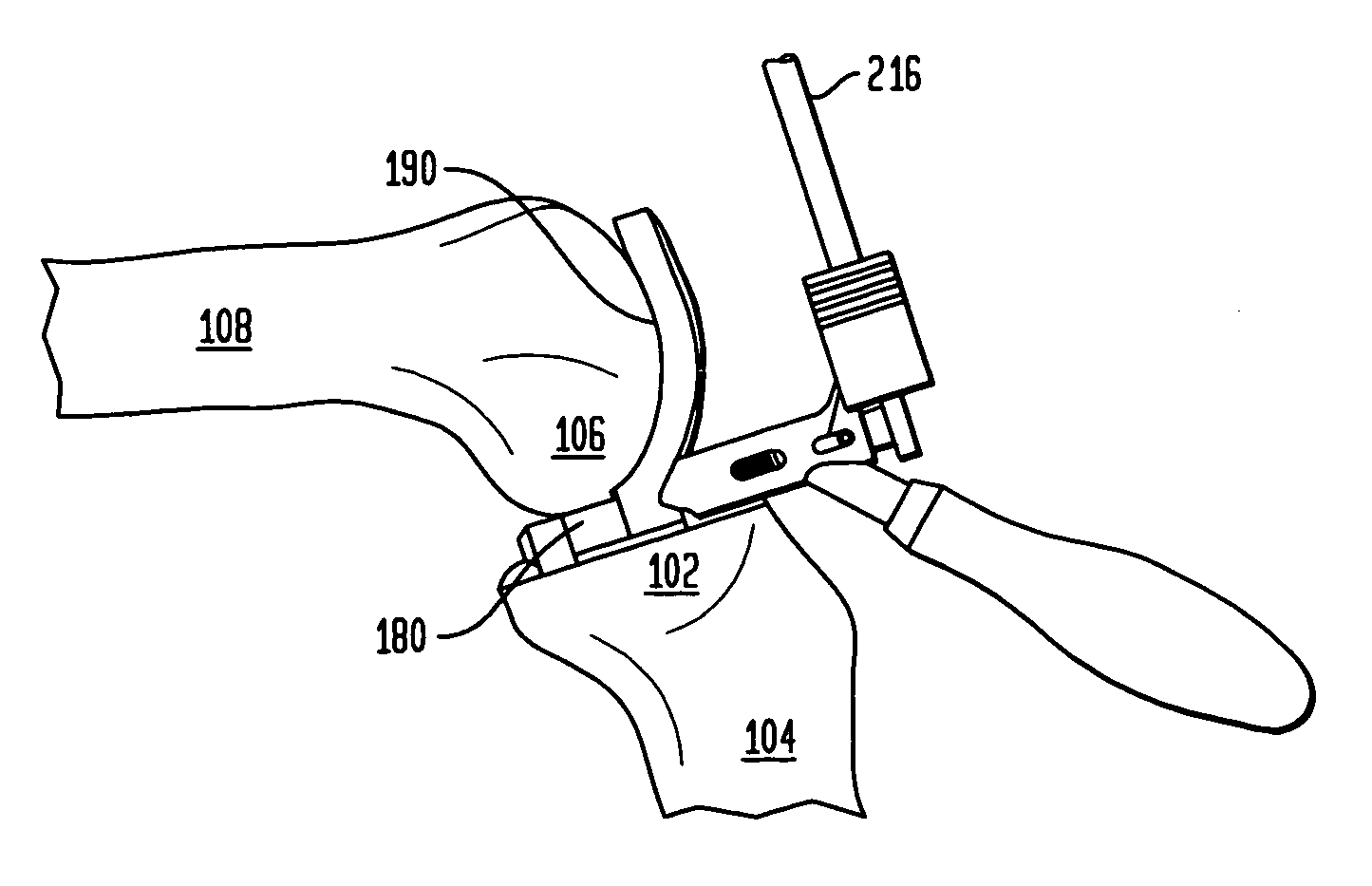

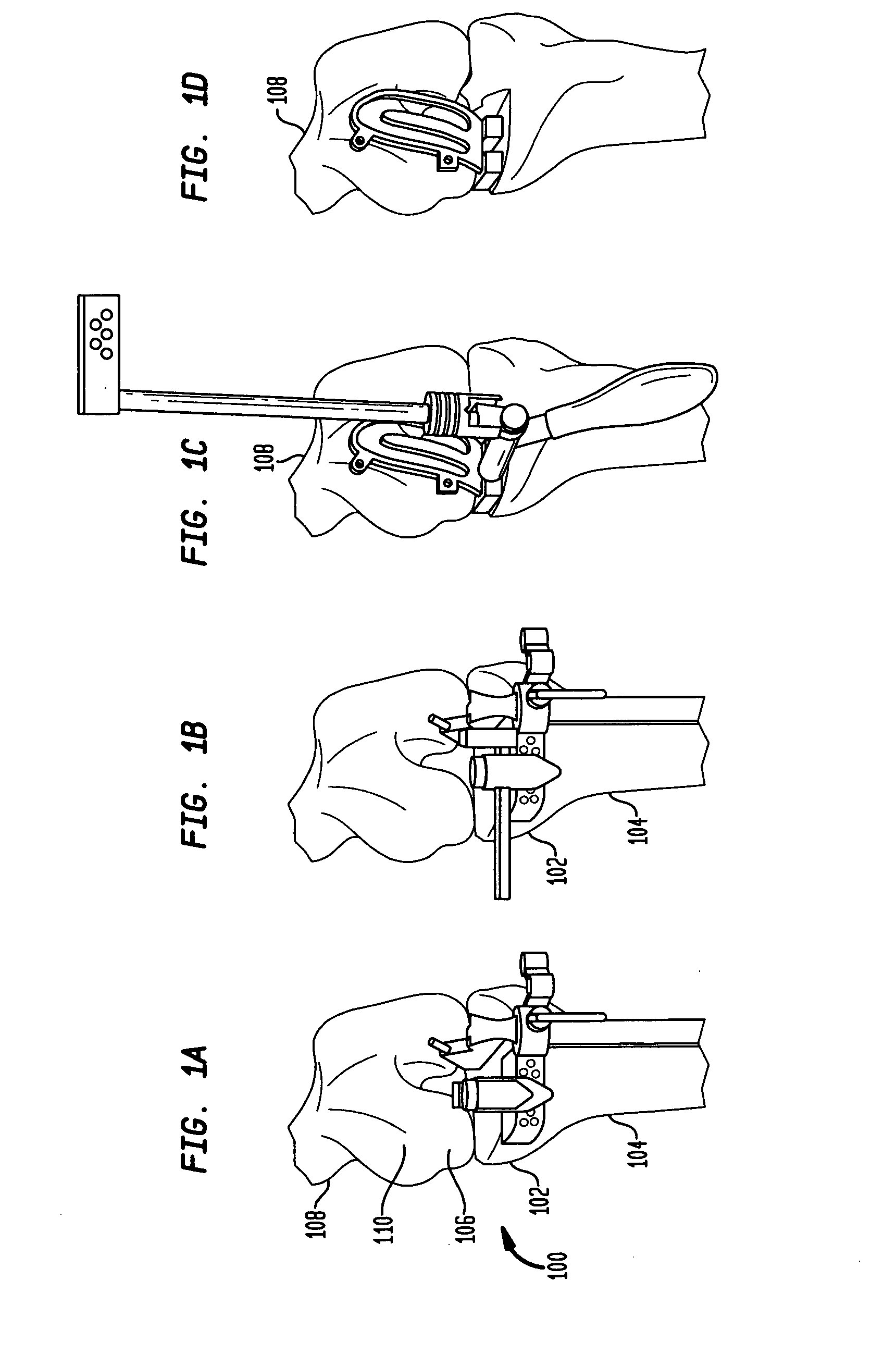

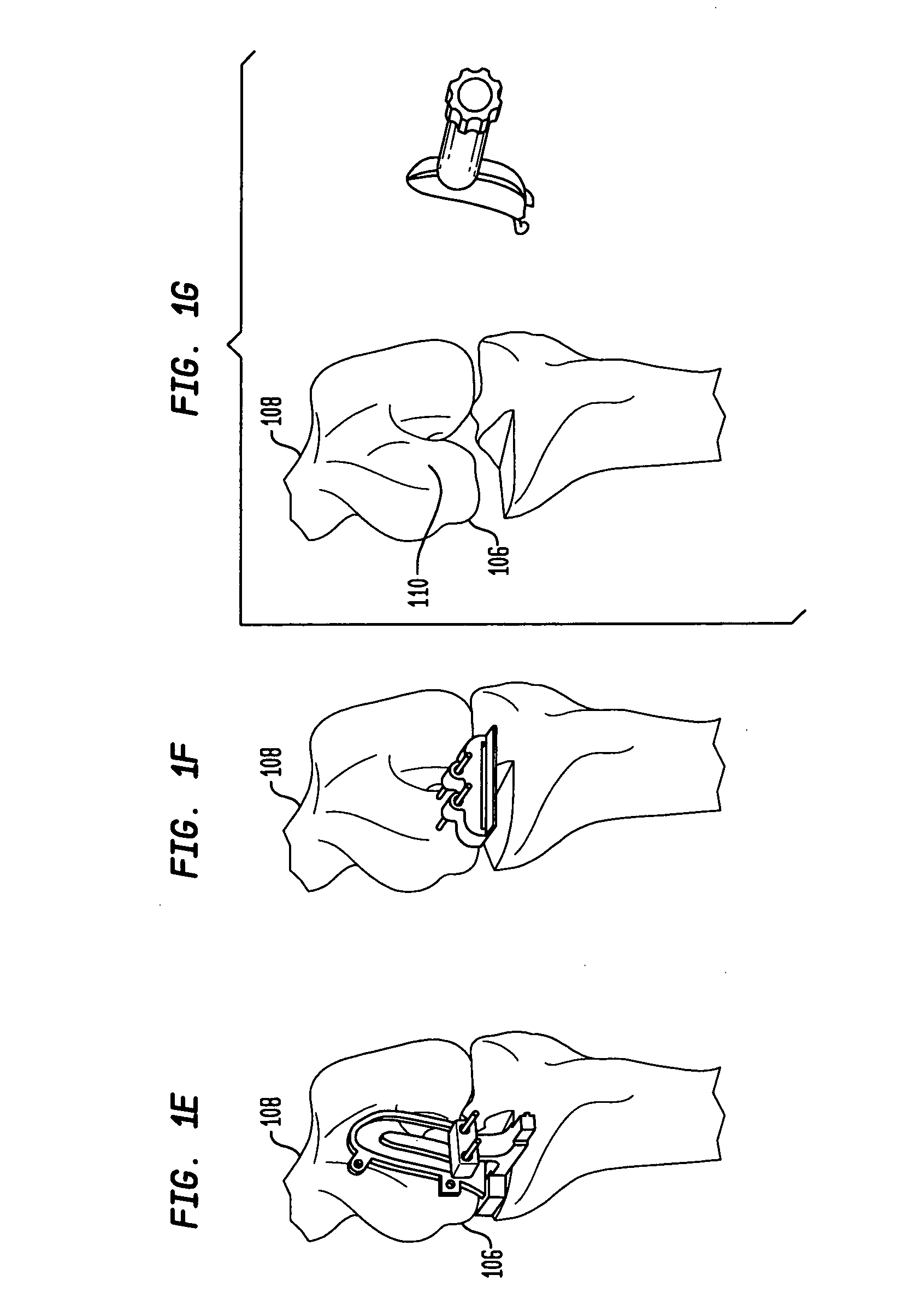

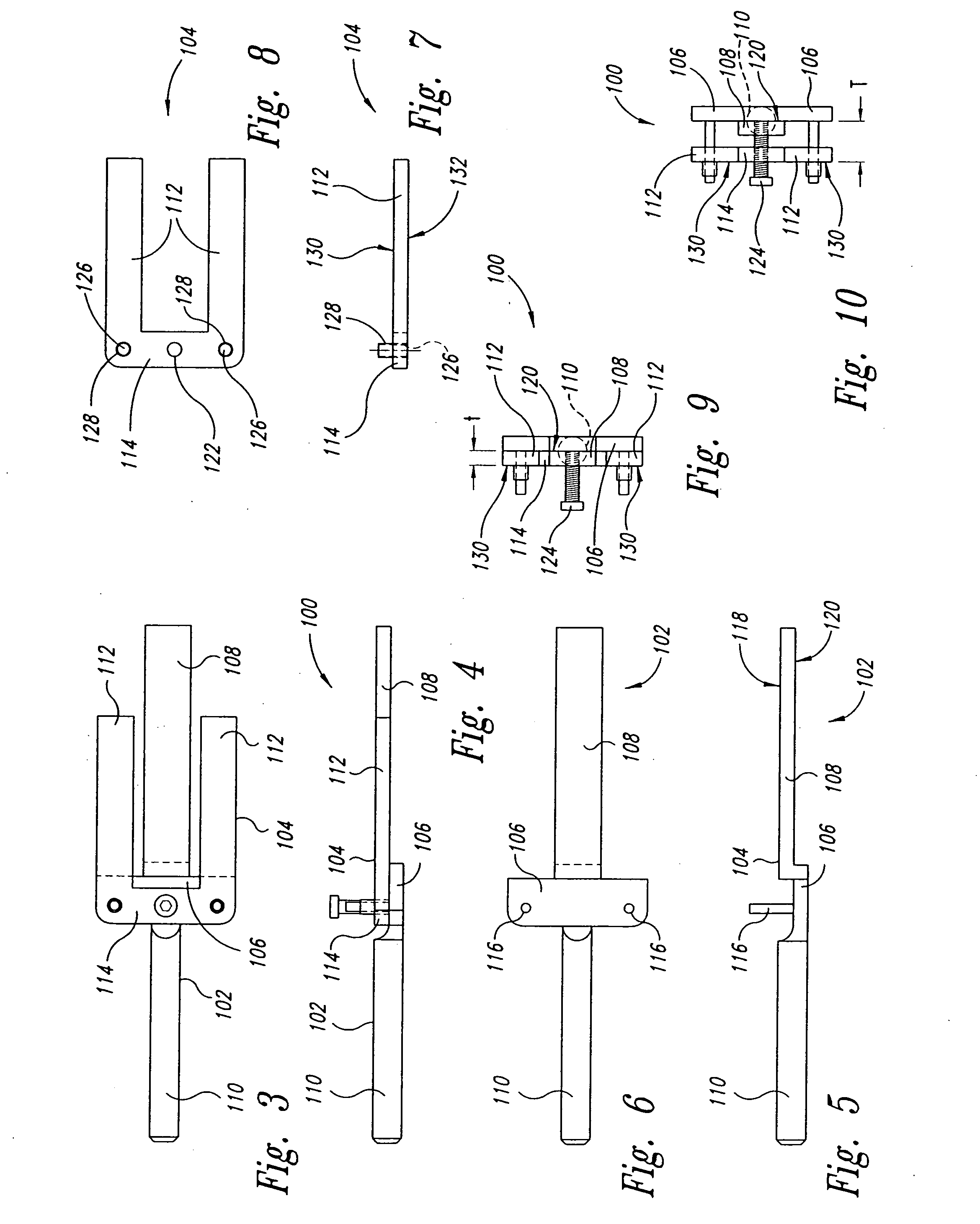

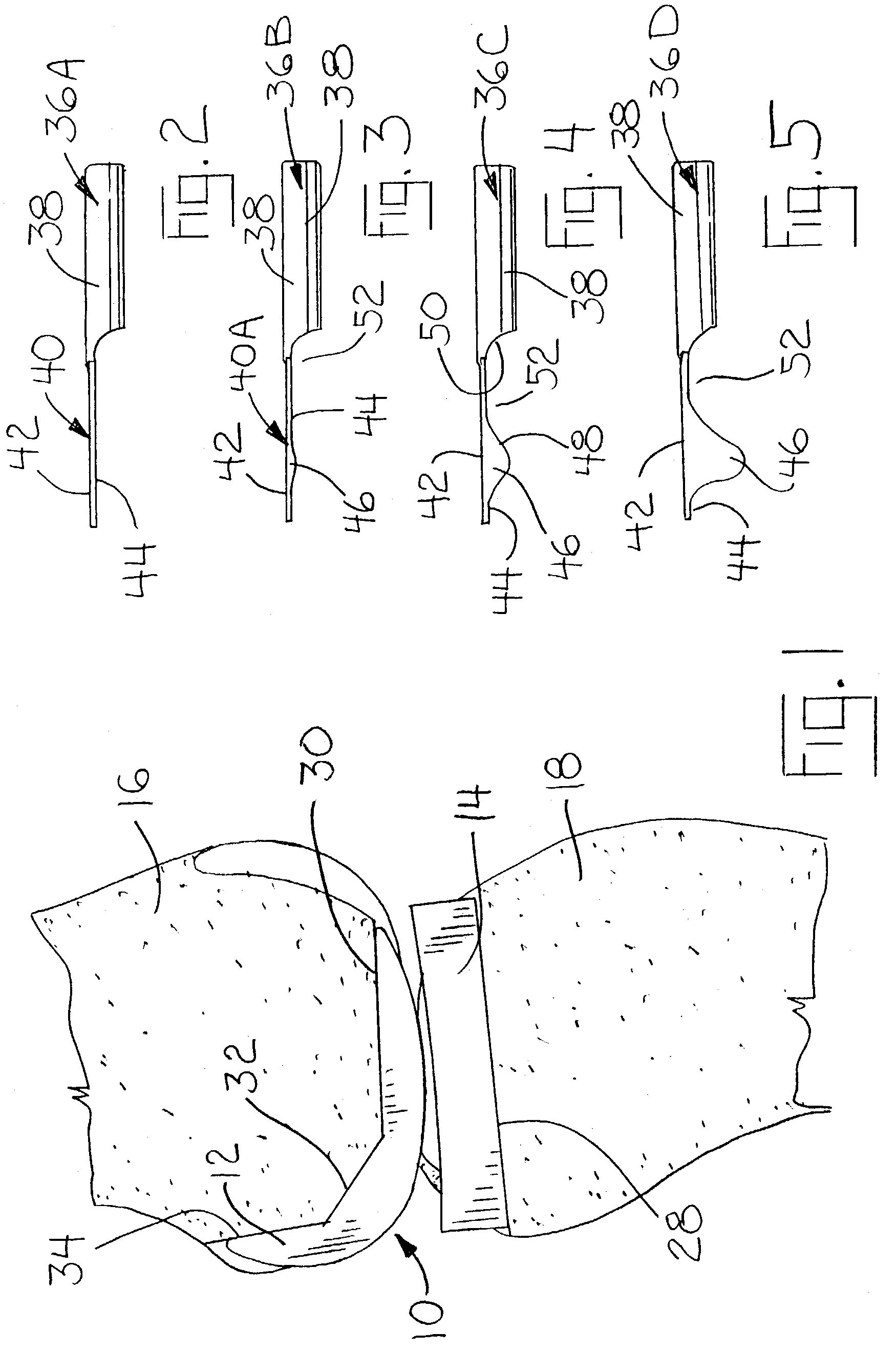

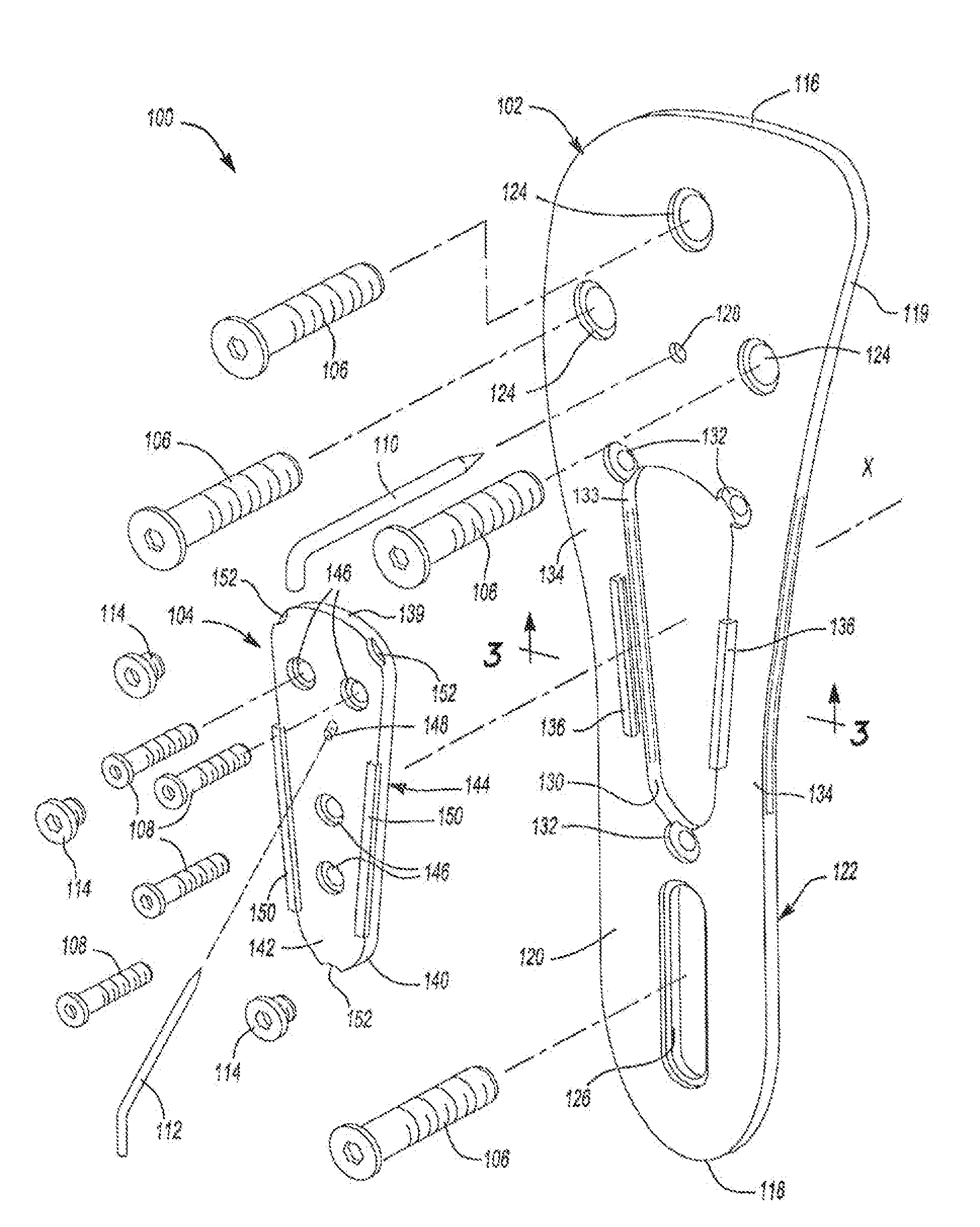

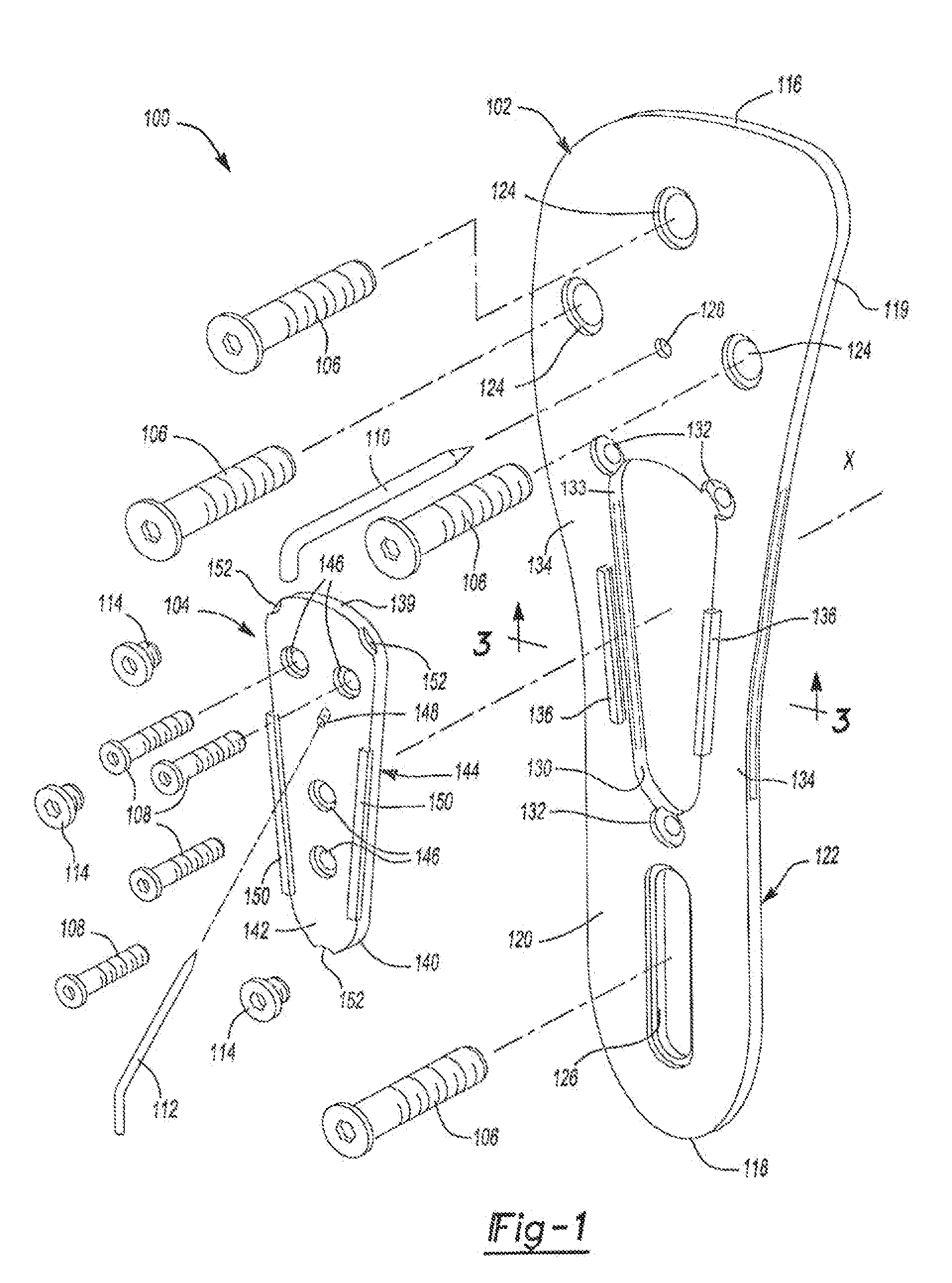

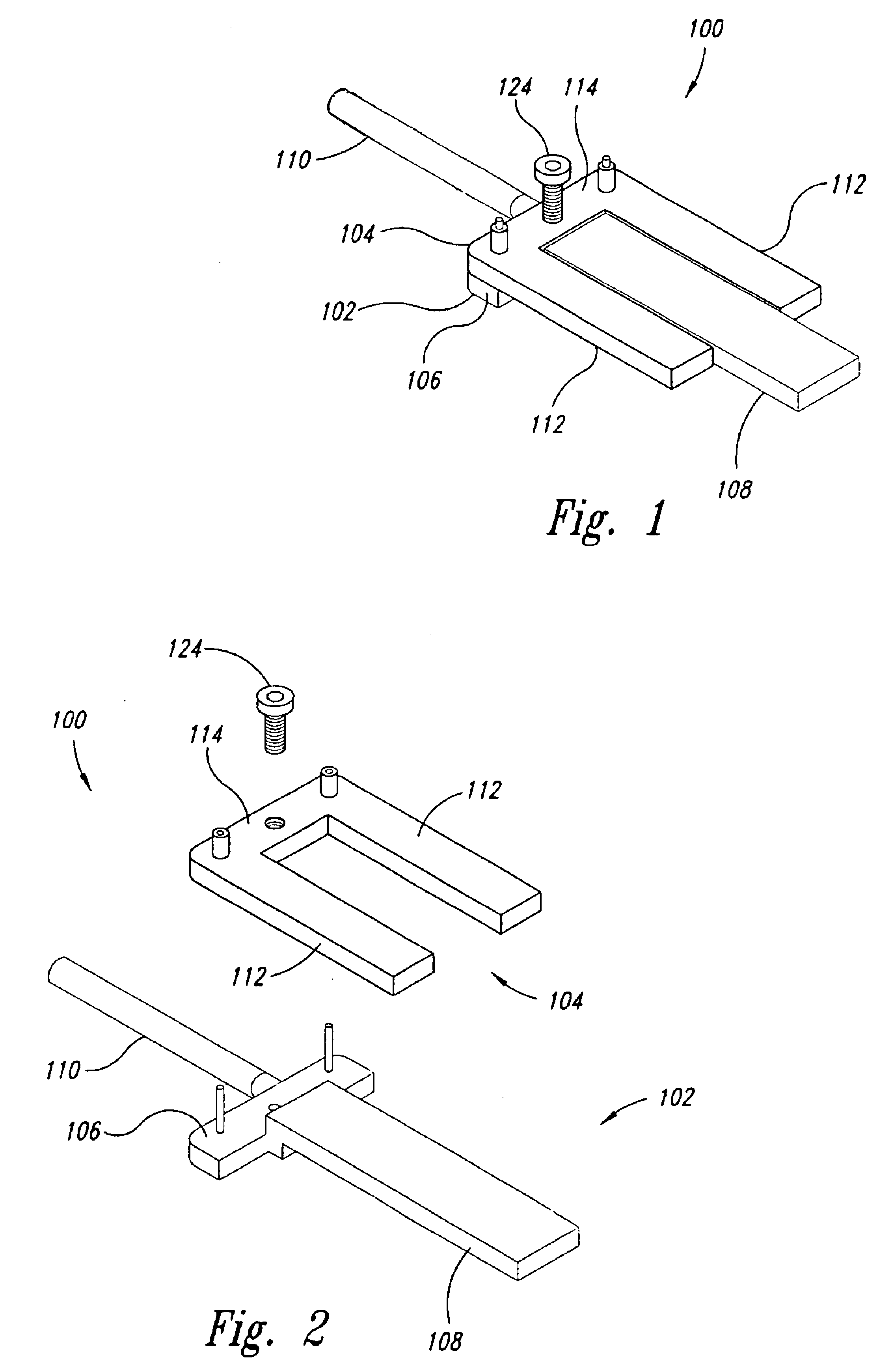

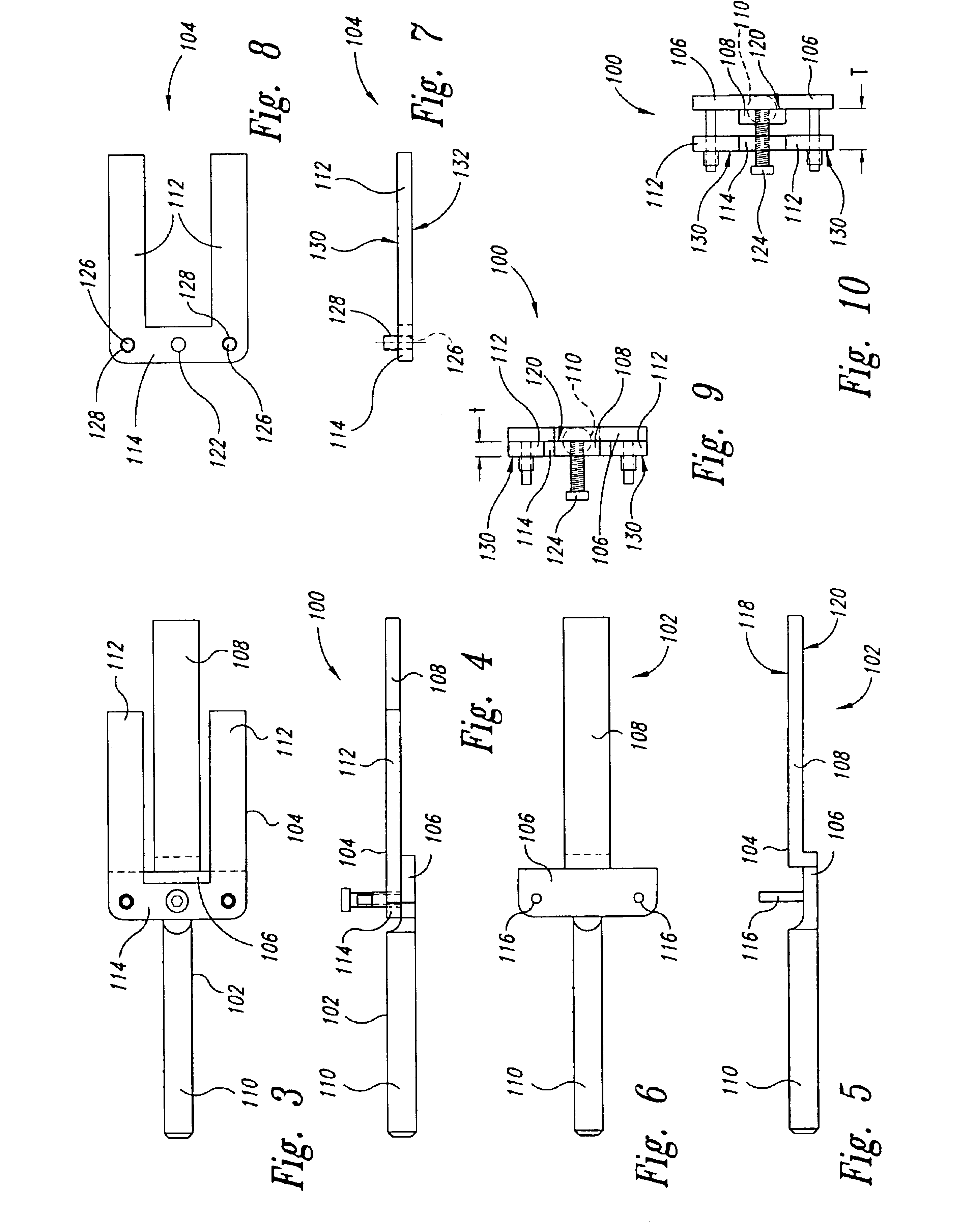

Instruments and methods for use in performing knee surgery

InactiveUS20050085920A1Avoid excessive bone removalJoint implantsKnee jointsKnee surgeryPatellar luxation

A system and method for aligning a patient's leg, for establishing the ultimate alignment of the leg prior to making a horizontal femoral cut or a horizontal tibial cut, for preparing the distal femur for receiving a femoral implant, and for making the horizontal, femoral and tibial cuts. The system and method incorporate a spacer, a cutting guide, and a template. The spacer is insertable between a distal femur and a proximal tibia to rotate the tibia with respect to the femur into the desired alignment. The cutting guide is engageable with the spacer, and can be fixed to the proximal tibia and the distal femur. The cutting guide has openings sized and shaped to guide a surgical saw to make the horizontal femoral cut and the horizontal tibial cut. The template is shaped to closely conform with the distal femur to allow the leg to be extended and to allow the procedure to be performed without dislocating a patella. Through one method of the present invention, the practitioner can select the desired ultimate alignment of the leg prior to making the horizontal, tibial and femoral cuts. As a result, when a replacement knee is implanted, the leg will be in the desired alignment.

Owner:WILLIAMSON RICHARD V

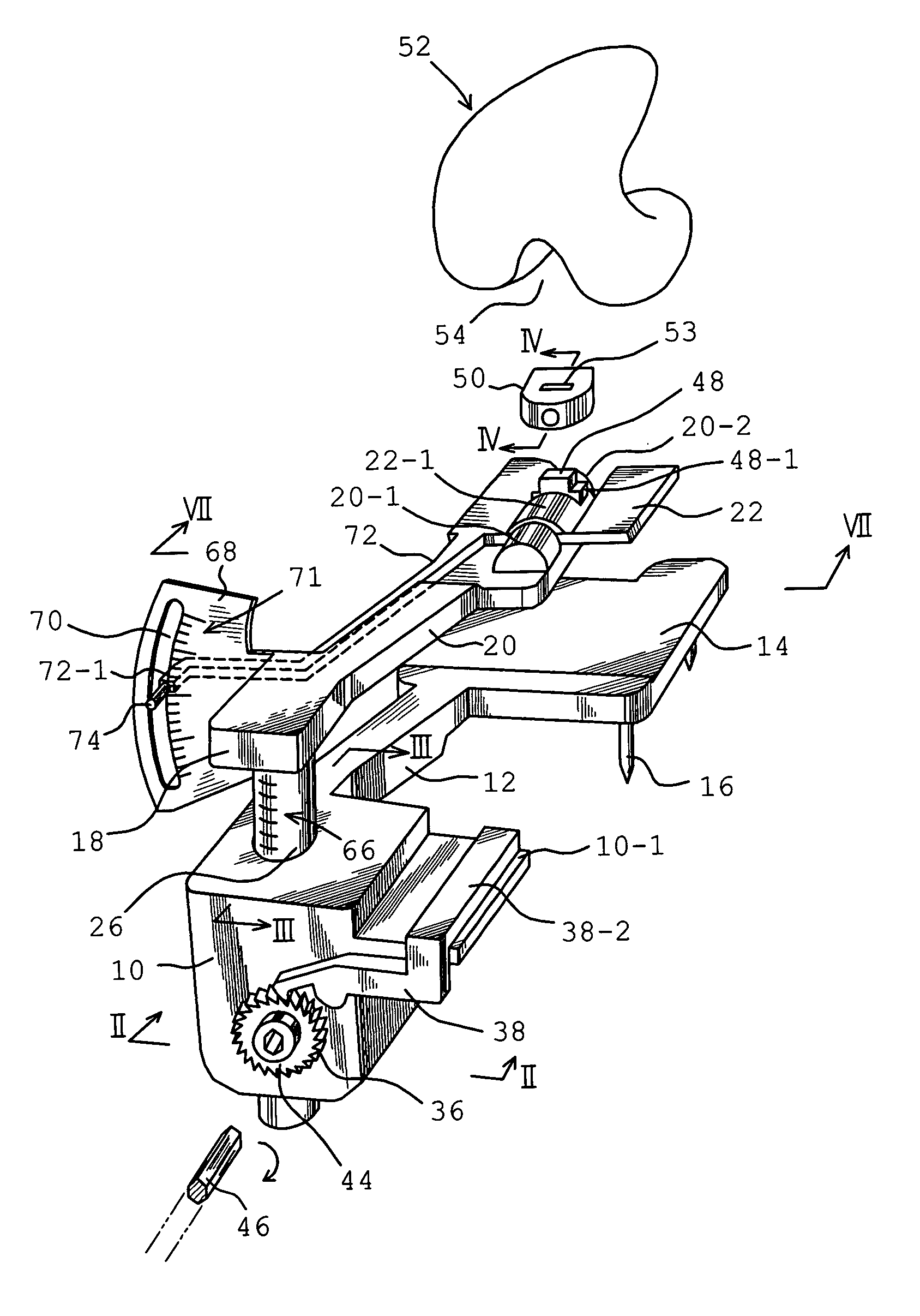

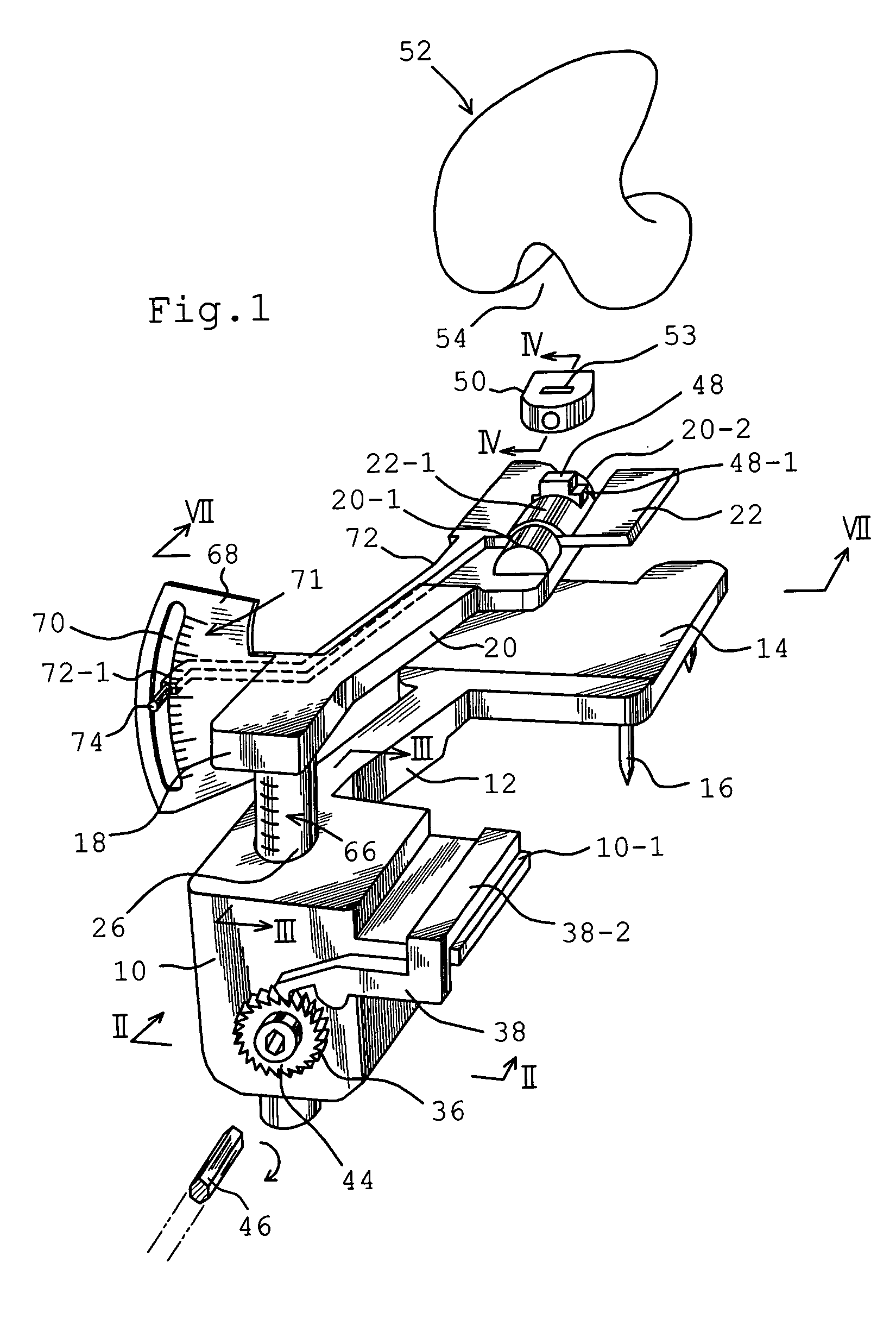

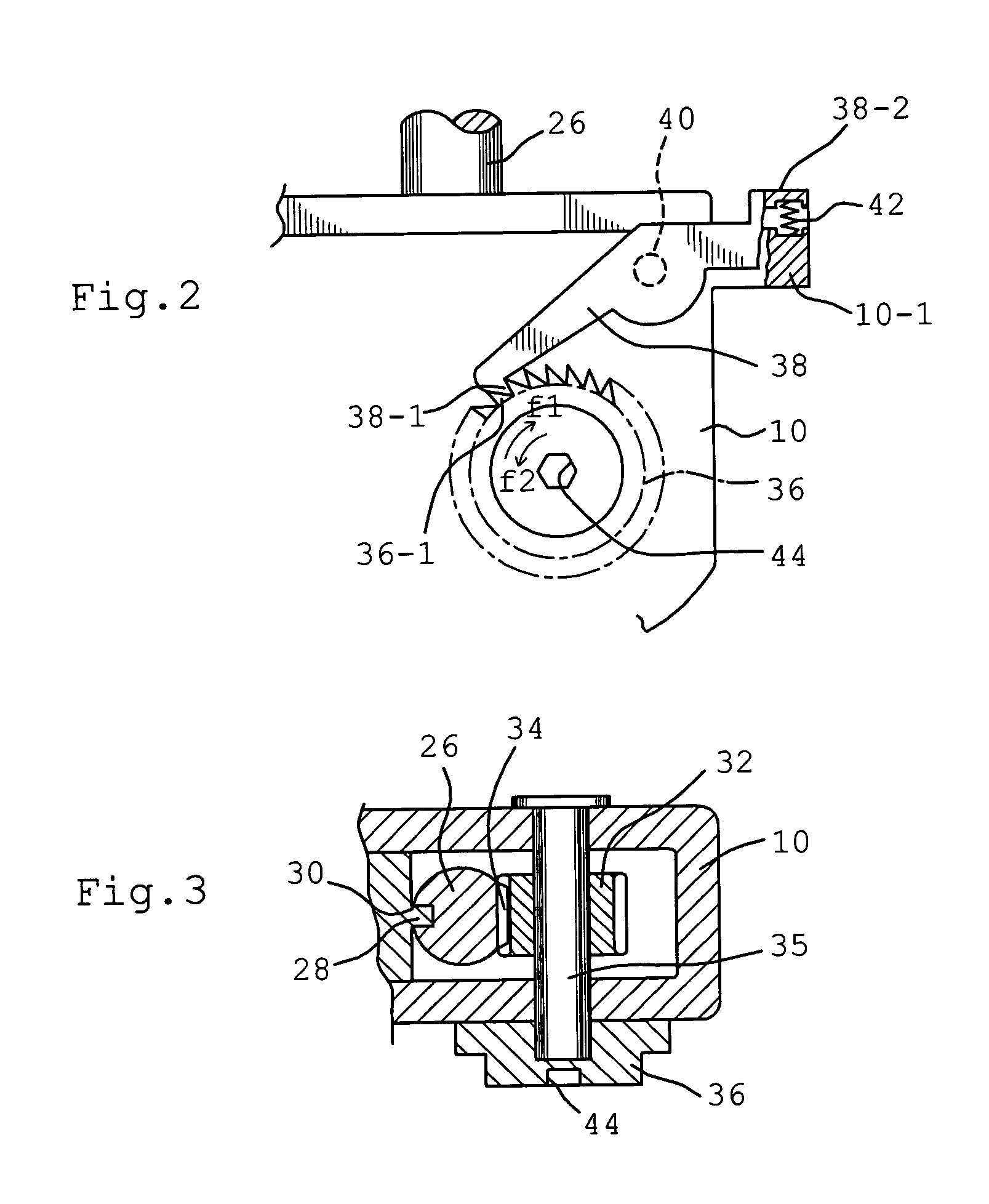

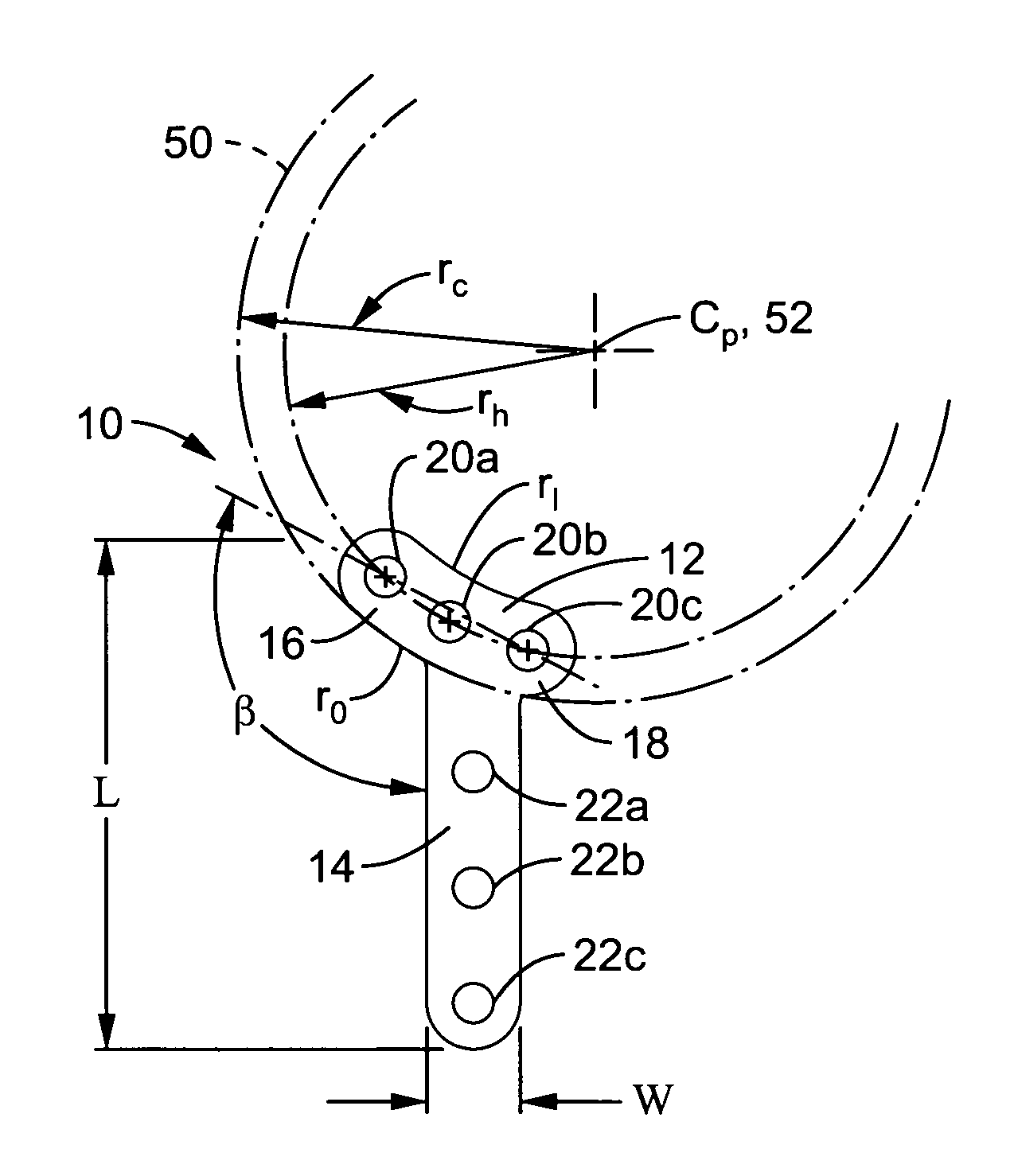

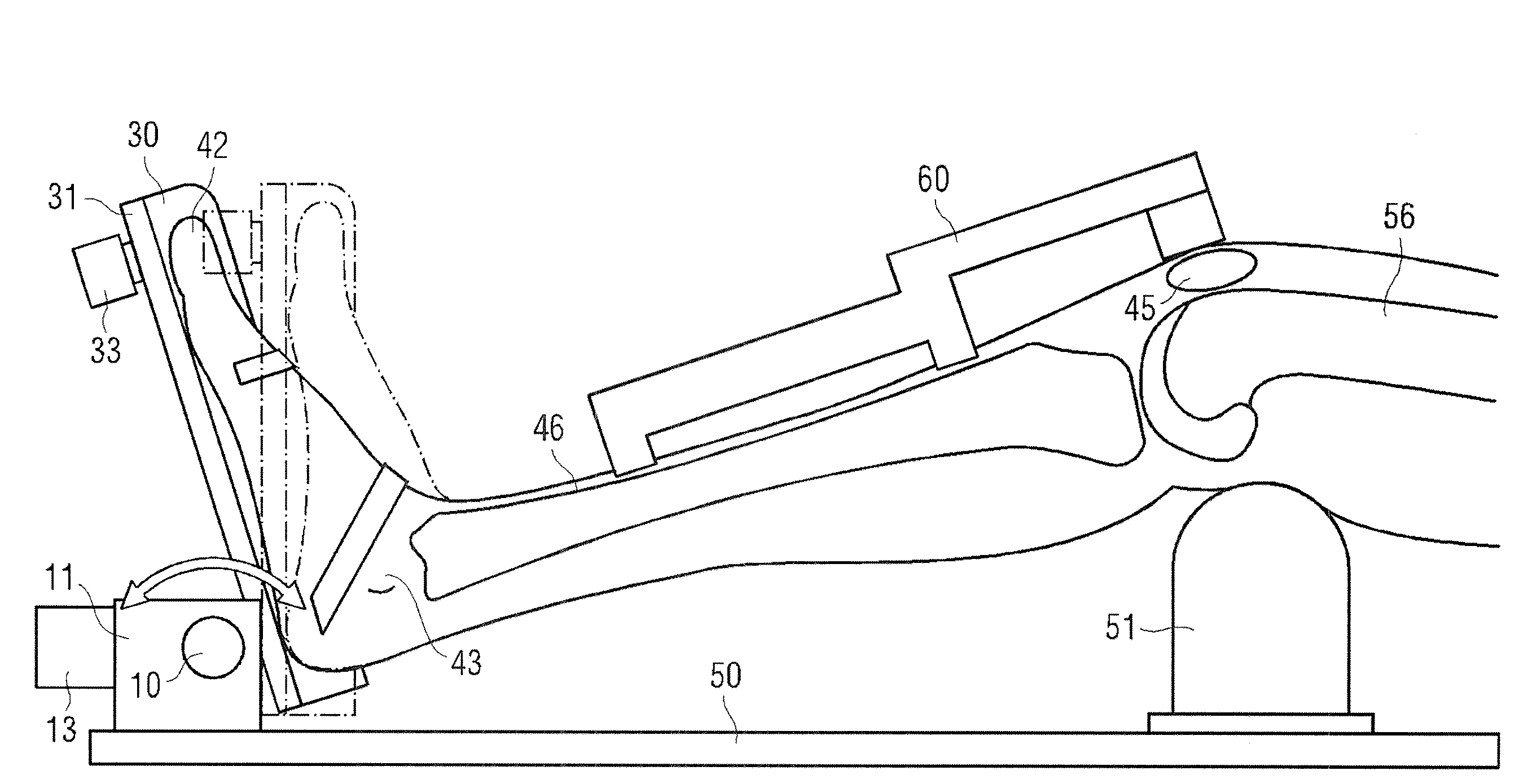

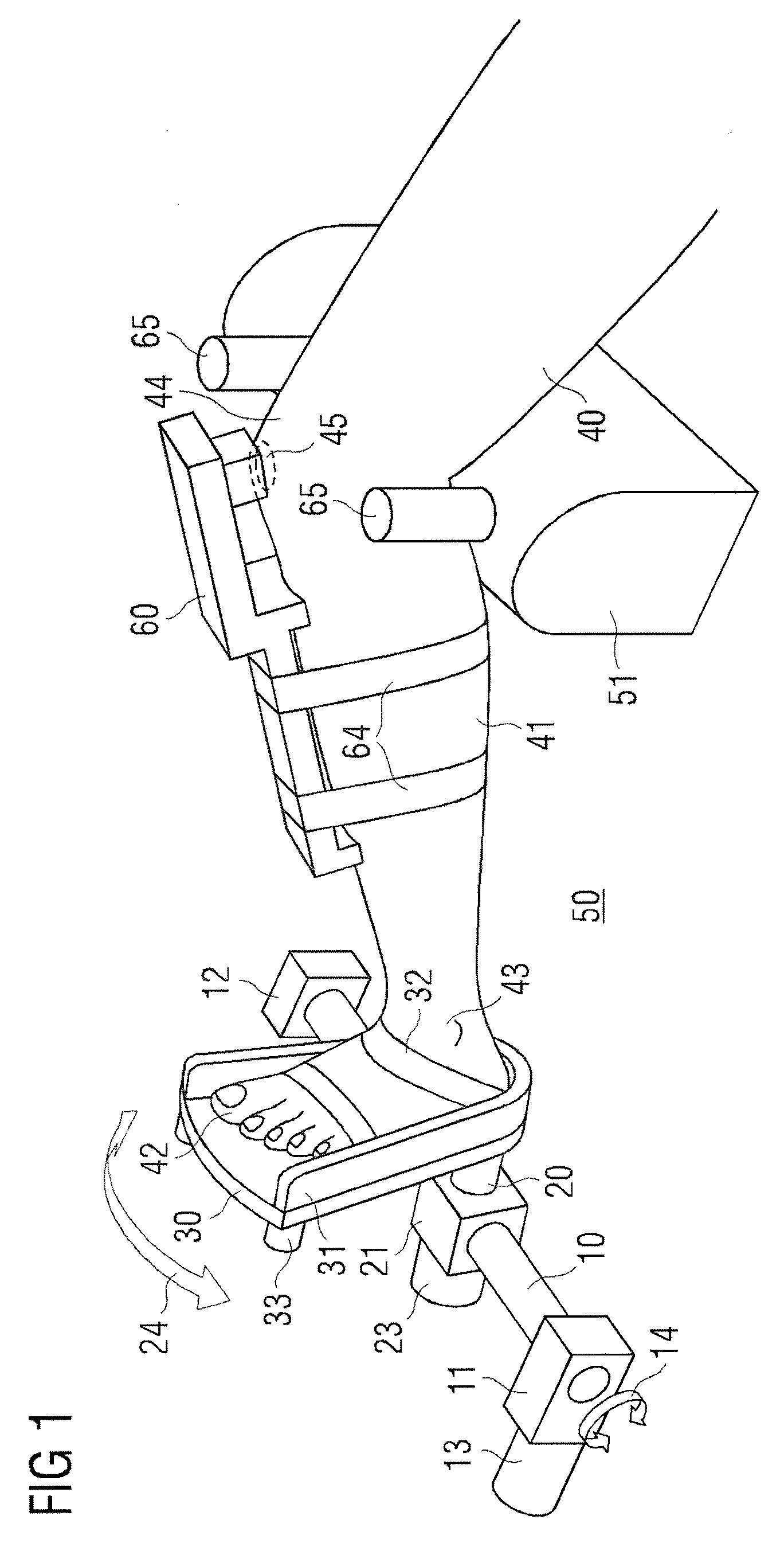

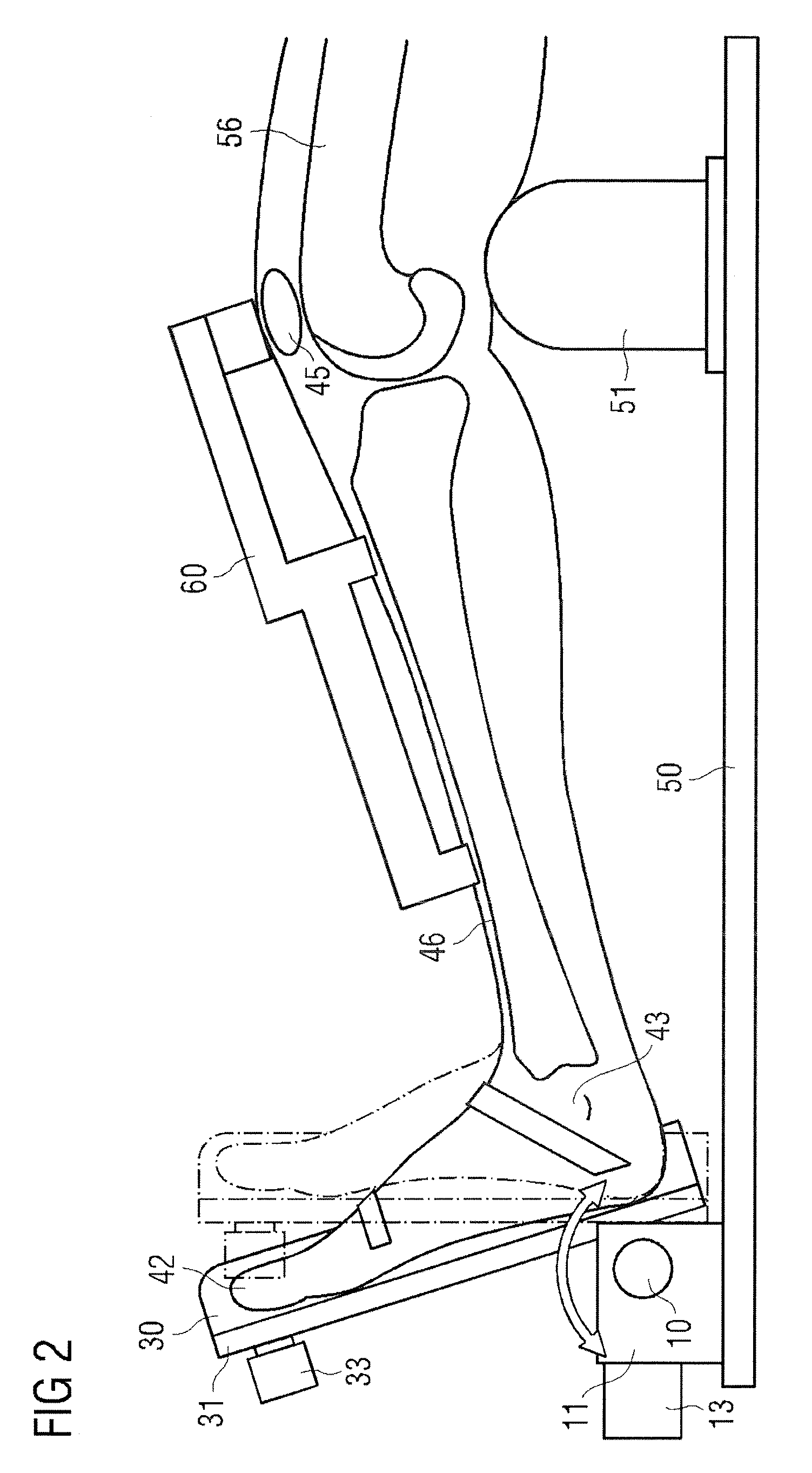

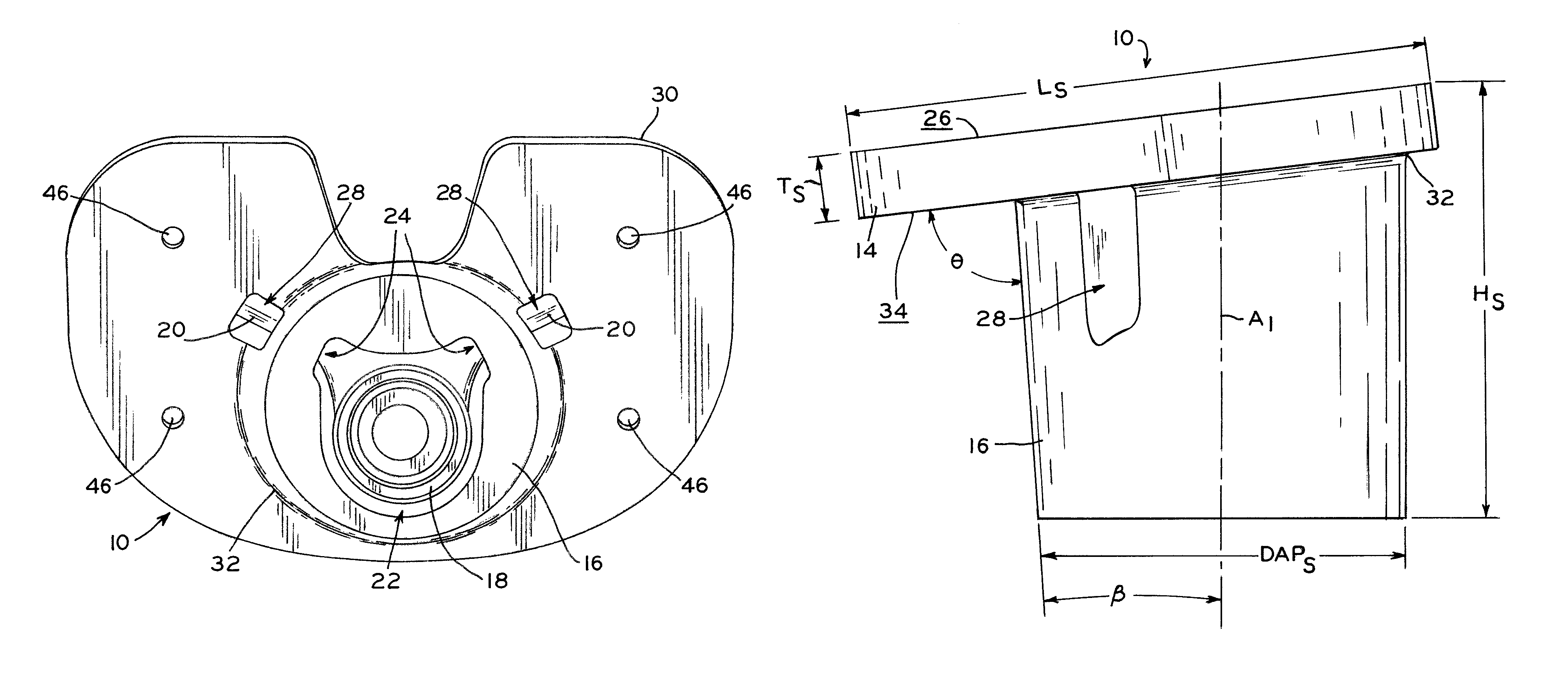

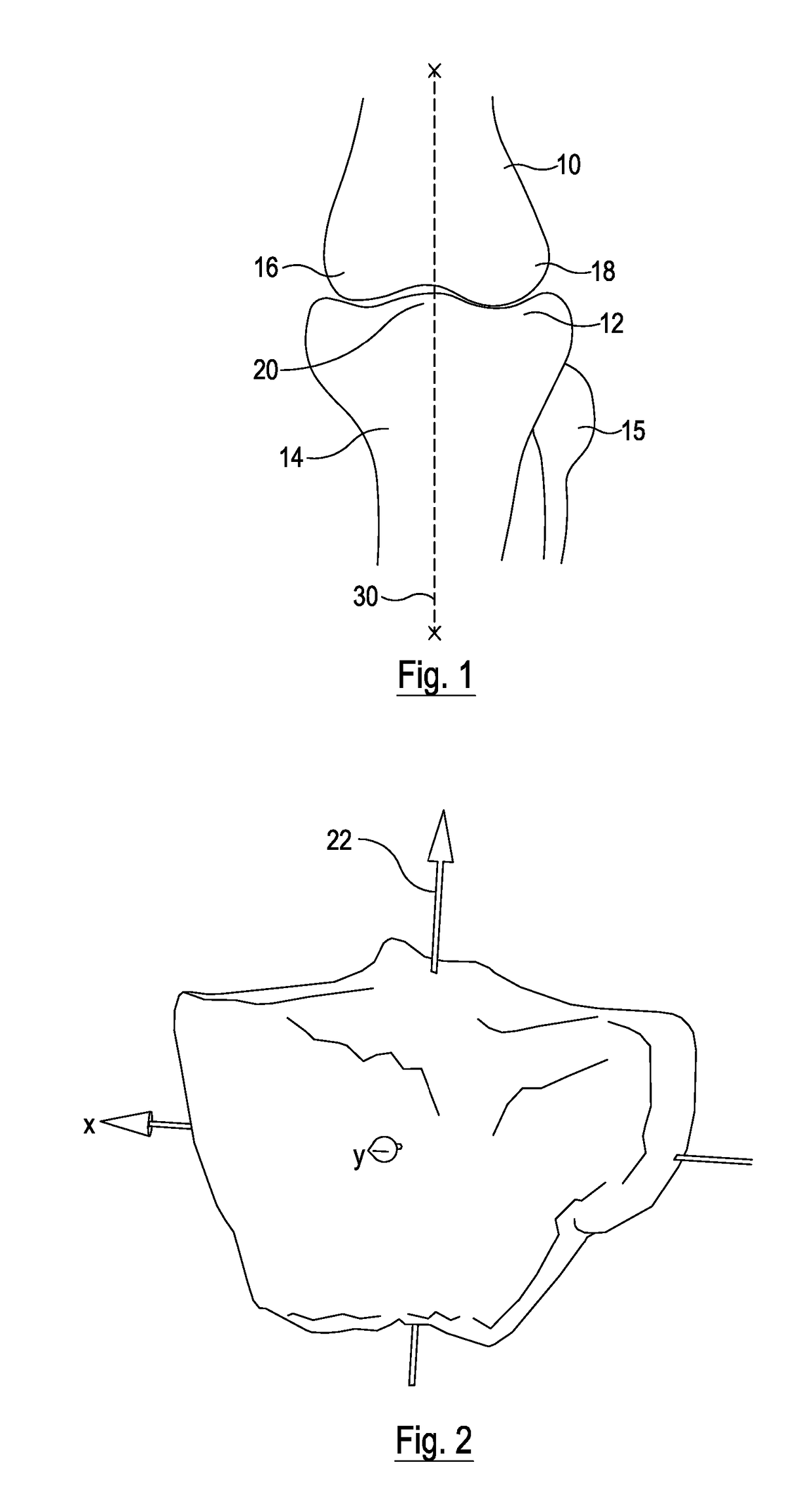

Measuring apparatus for total knee replacement operation

ActiveUS20040122441A1Smooth movementEasy to disassembleJoint implantsDiagnostic recording/measuringMeasurement devicePhysical medicine and rehabilitation

An apparatus in a total knee replacement and arthroplasty operation for measuring a joint gap and ligament balance between a osteotomized surface at a femoral distal end and a osteotomized surface at a tibial proximal end. The apparatus is provided with a base 10, from which an engaging plate 14 extends by way of an arm, so that the engaging plate 14 contacts with the osteotomized surface at the tibial proximal end. A moving body 18 is vertically movably connected to the base 10, from which moving body 18 an arm 20 extends, to which arm a supporting plate 22 is rotatably mounted about a central axis. The supporting plate 22 has, at its top surface, a projected portion 48. to which an auxiliary guiding piece 50 is connected under a snap like fitted manner. A femoral component 52 is mounted, at its groove portion 54, to the osteotomized surface at the femoral distal end. The engaging plate 14 as well as the supporting plate 22 are under an offset arrangement with respect to the base and moving body, respectively.

Owner:ZIMMER KK

Tibial tray with adjustable keel

A tibial prosthesis includes a tibial platform having a medial-lateral center and an inferior surface matable with a resected proximal tibia, and a modular keel that is fixable to the inferior surface and adjustable in a medial-lateral direction with respect to the medial-lateral center of the tibial platform.

Owner:DEPUY PROD INC

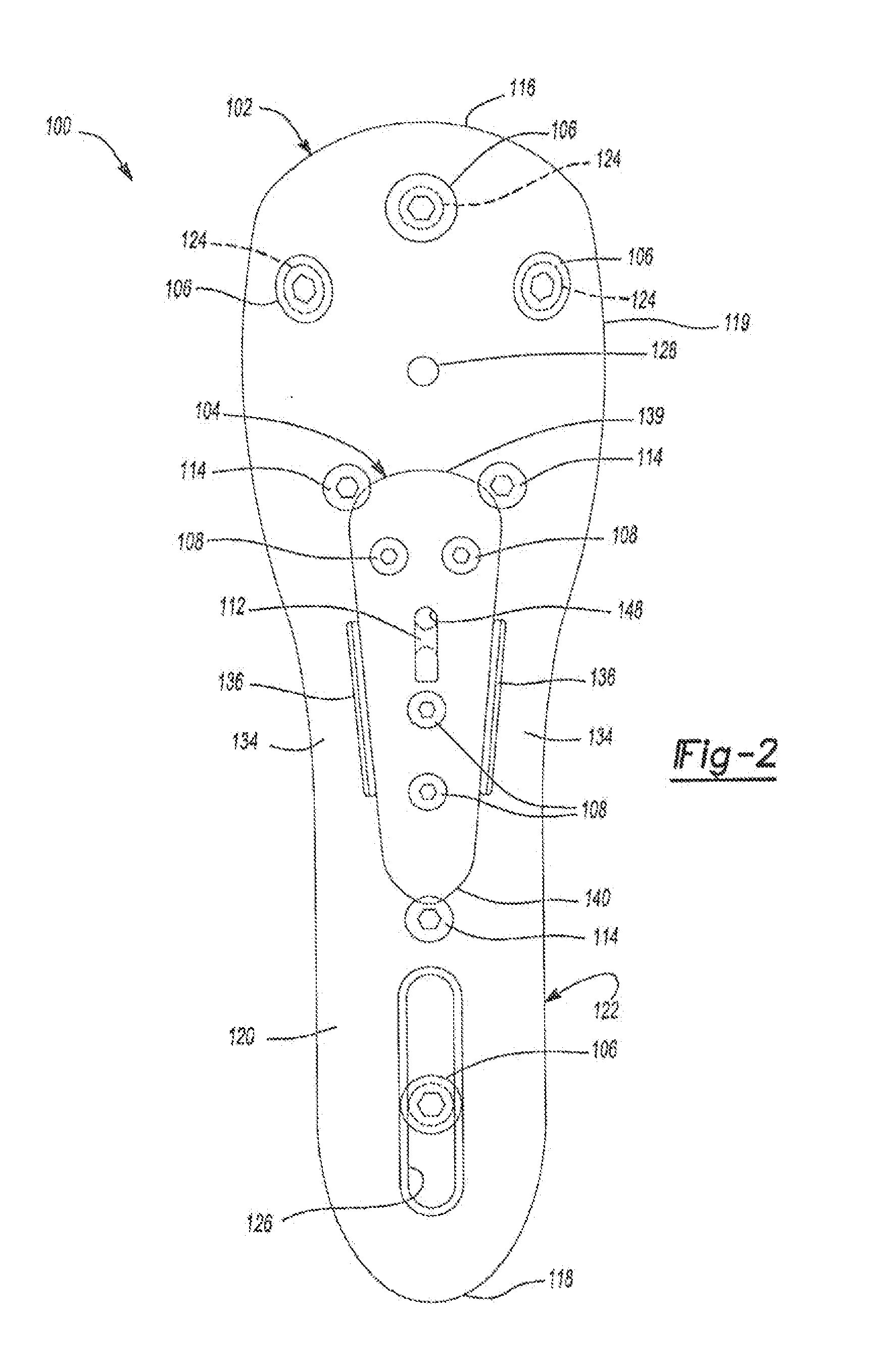

Apparatus and methods for tibial plateau leveling osteotomy

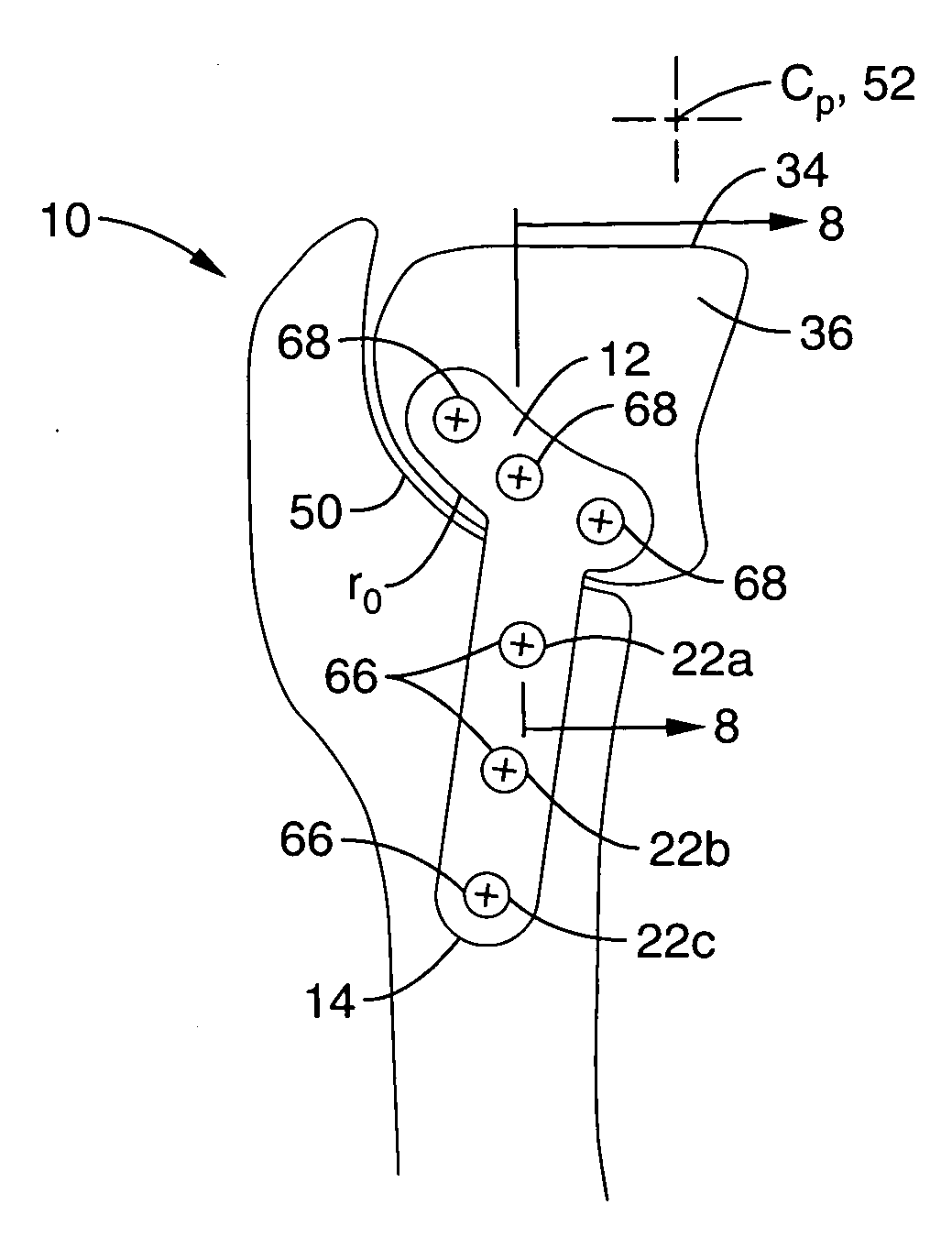

InactiveUS20060229621A1Improve fastnessAchieve correctionJoint implantsNon-surgical orthopedic devicesLong axisTibial metaphysis

A bone fixation plate and methods are disclosed for performing an optimally centered tibial plateau leveling osteotomy. The optimally centered osteotomy produces a curvilinear cut separating a section of the tibia comprising the tibial metaphysis from a proximal section of the tibia, such that the curvilinear cut has a radial center point above the tibial plateau along the long axis of the tibia, and preferably in relation to the intersection of the cruciate ligaments. An osteotomy template is also disclosed for aiding osteotomy procedures.

Owner:CADMUS CALVIN M

Tibial implant with a broad keel and a through post

A tibial implant apparatus includes a tibial plate having a medial-lateral width, and includes a generally keel-like base extending from the tibial plate. The base has a medial-lateral span within a range of about 0.6-0.9 times the width of the tibial plate. A tibial implant apparatus includes a tibial plate, a base extending from the tibial plate, and an elongated member. The elongated member includes a first portion and a second portion, and is removably attached to the base. The tibial plate and the base cooperatively define a through-channel. The elongated member is inserted superiorly into the through-channel such that the first portion of the elongated member is retained within the through-channel and the second portion of the elongated member protrudes out of the through-channel and extends inferiorly away from the base. A method for anchoring an implant in a proximal tibia is also provided.

Owner:ZIMMER TECH INC

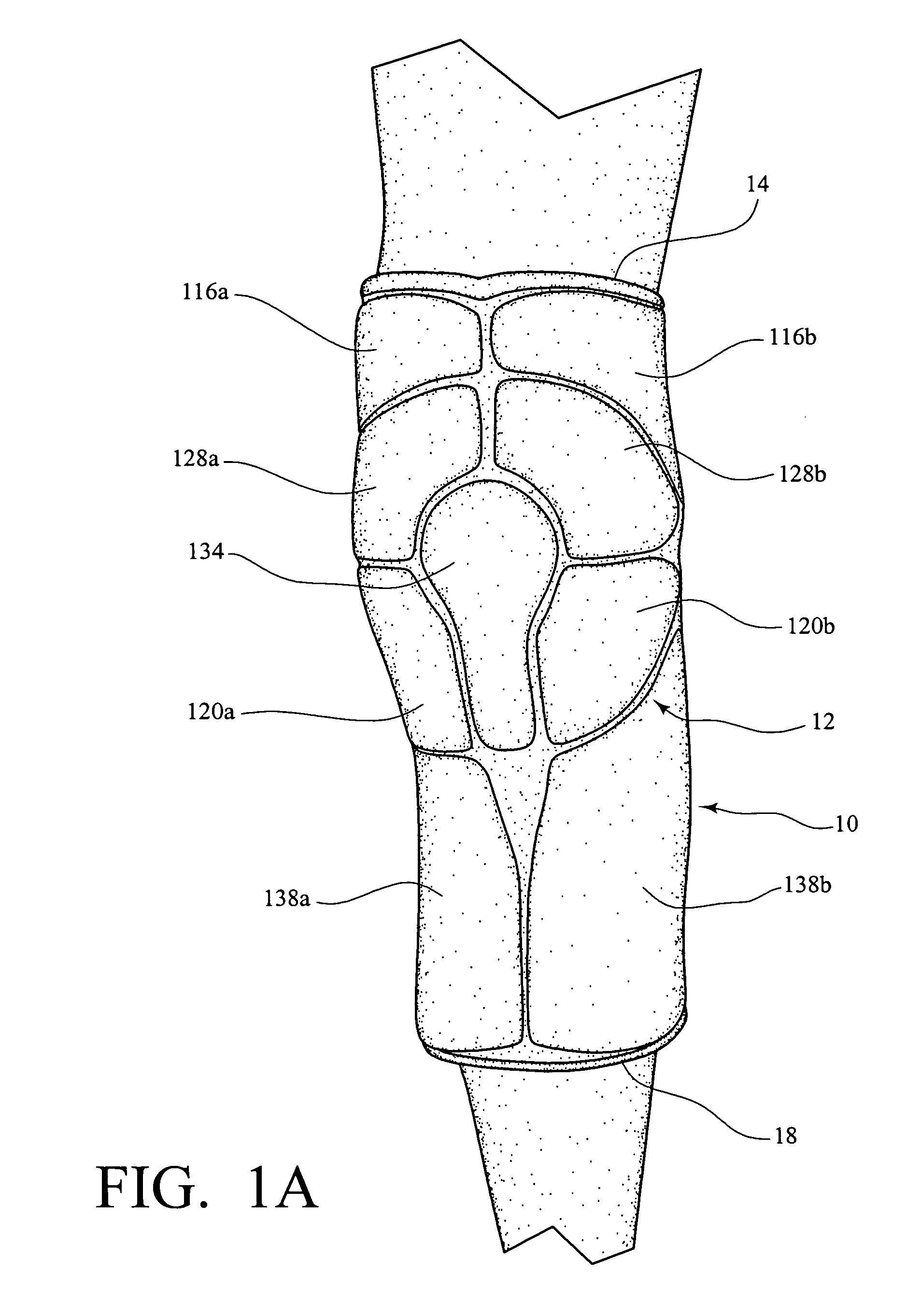

Knee protector

ActiveUS7114189B1Improve protectionProtective garmentPhysical medicine and rehabilitationKnee protector

A knee protector includes a plurality of pads positioned to cover a patella, a lower portion of the distal femur, the femoral condyles, the upper end of the fibula and an upper end of the proximal tibia with spacings between said pads to accommodate the flexion and extension of the knee when in use from a standing to a squatting position by a wearer.

Owner:HILLERICH & BRADSBY

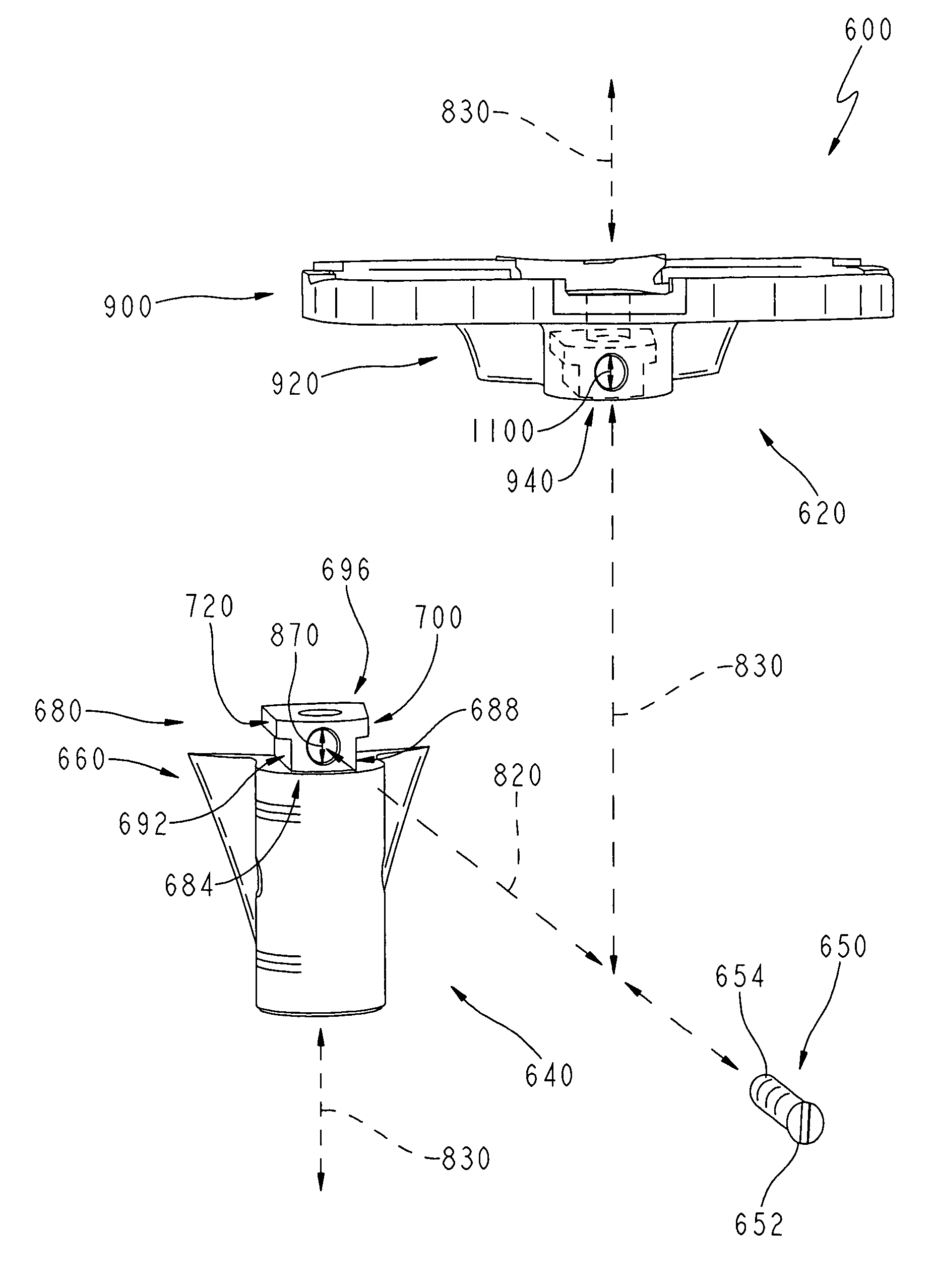

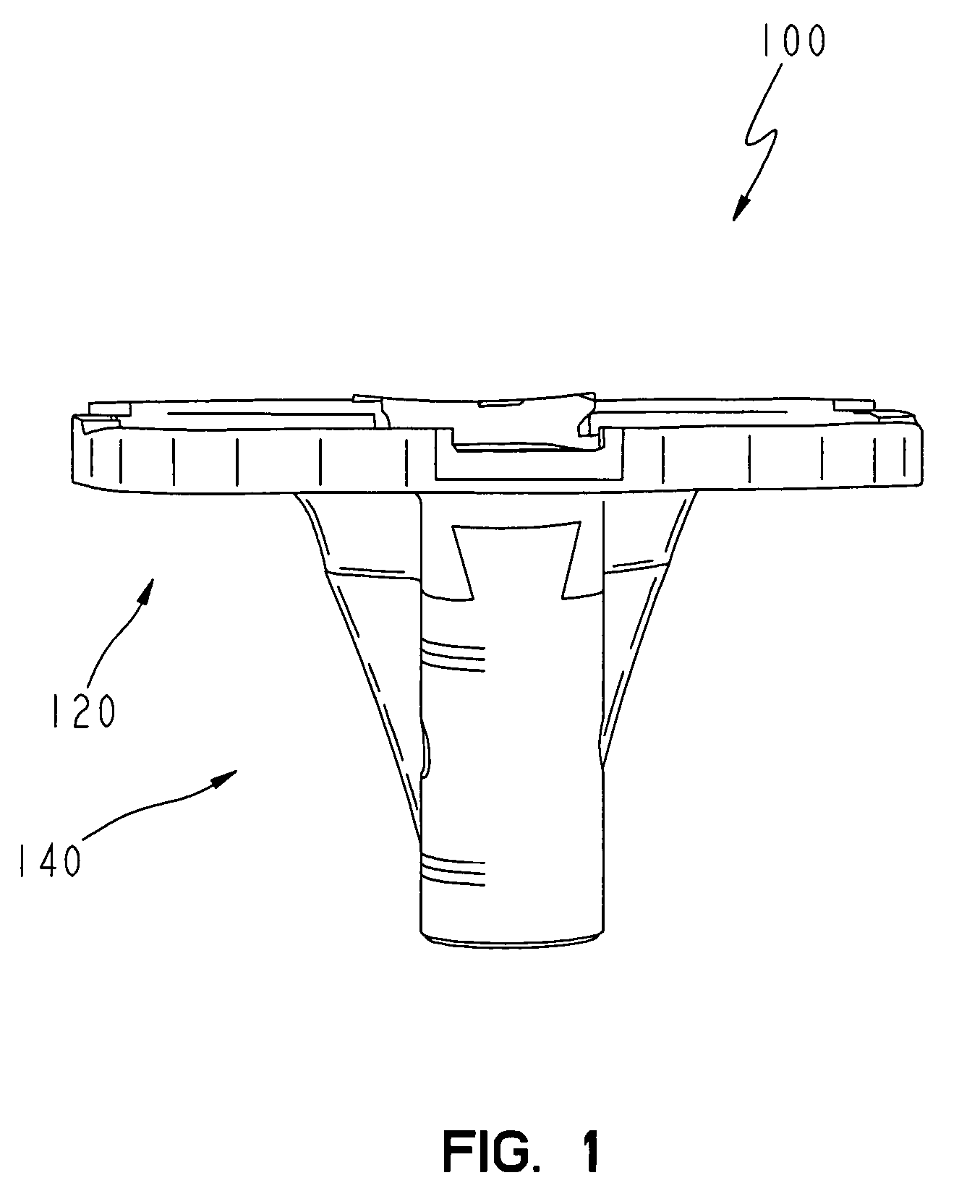

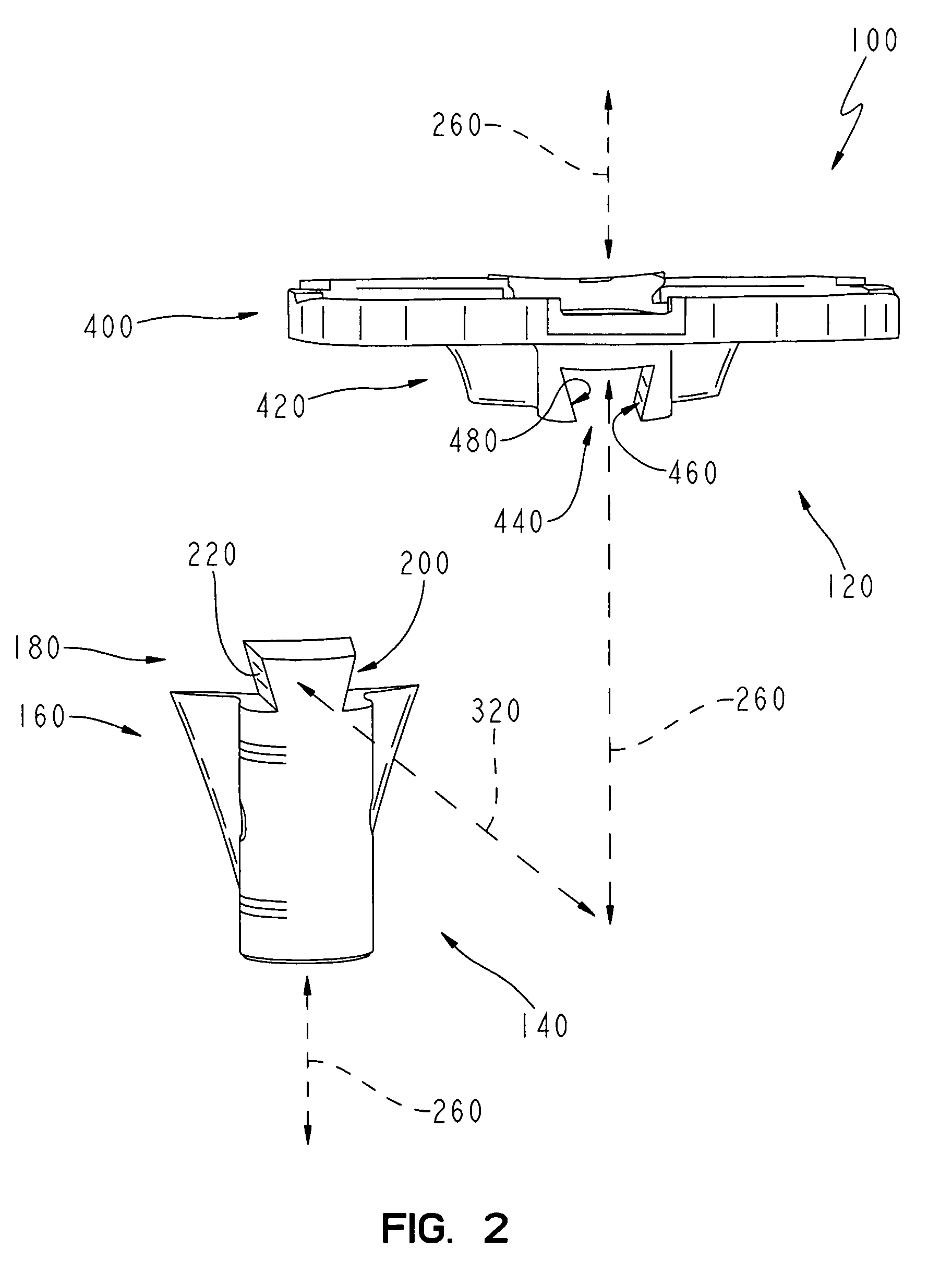

Modular tibial implant with a mortise coupling

A modular tibial implant apparatus includes a tibial plate and a tibial stem mortised to the tibial plate. A method for anchoring a tibial plate and a tibial stem relative to a proximal tibia includes anchoring the tibial stem in the proximal tibia and mortising the tibial plate to the tibial stem.

Owner:ZIMMER TECH INC

Apparatus and methods for tibial plateau leveling osteotomy

InactiveUS20060149275A1Improve fastnessAchieve correctionSurgical sawsProsthesisTibial metaphysisLong axis

A bone fixation plate and methods are disclosed for performing an optimally centered tibial plateau leveling osteotomy. The optimally centered osteotomy produces a curvilinear cut separating a section of the tibia comprising the tibial metaphysis from a proximal section of the tibia, such that the curvilinear cut has a radial center point above the tibial plateau along the long axis of the tibia, and preferably in relation to the intersection of the cruciate ligaments. The bone fixation plate has a distal expanse configured to overlay the proximal section of the tibia along the length of the tibia. The distal expanse has a plurality of mounting holes to fix the distal expanse to the proximal section of the tibia. The bone fixation plate also has a proximal expanse configured to overlay the tibial metaphysis, the proximal expanse having a plurality of mounting holes; radially spaced apart substantially equidistant from a center point.

Owner:CADMUS CALVIN M

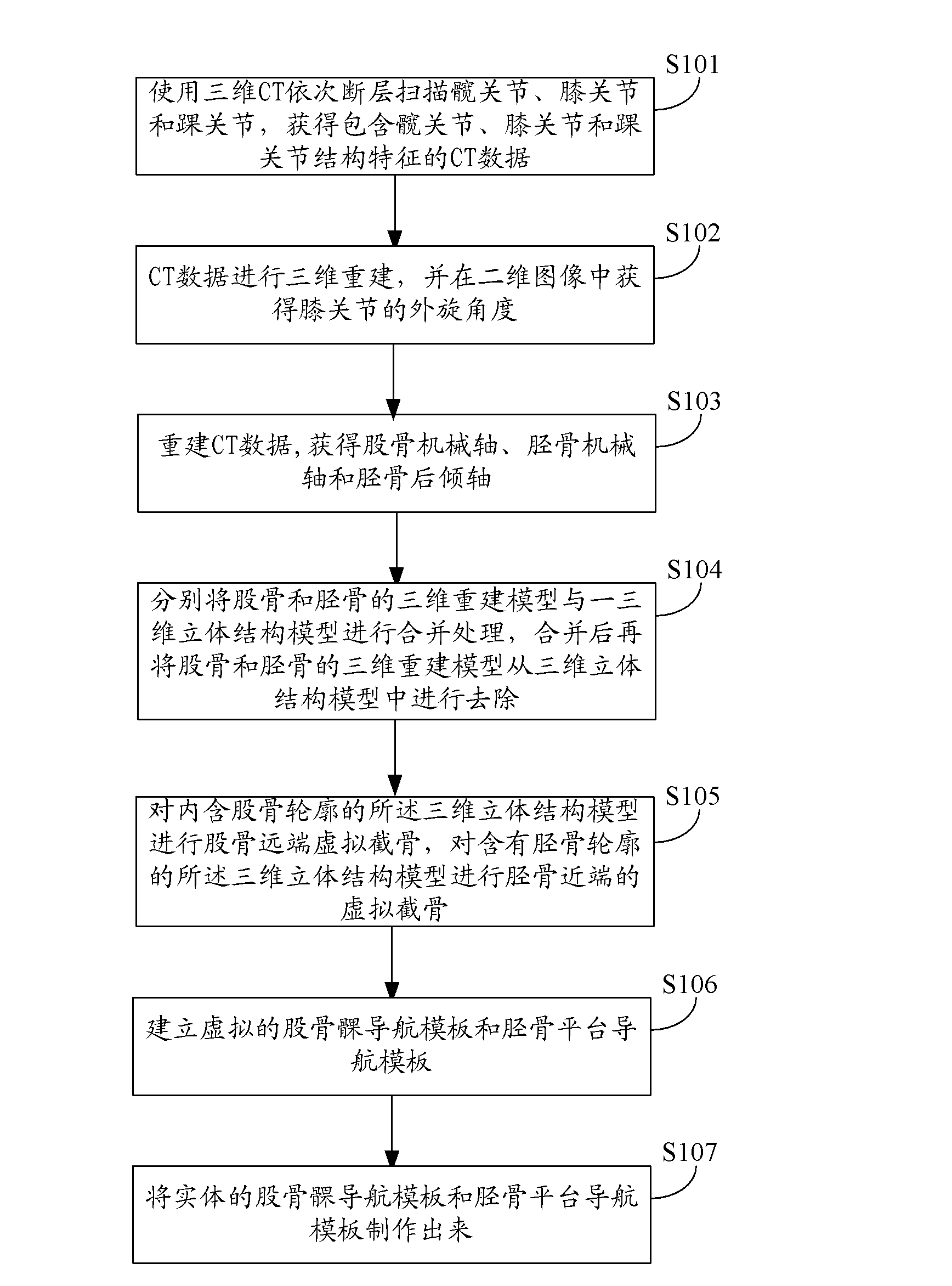

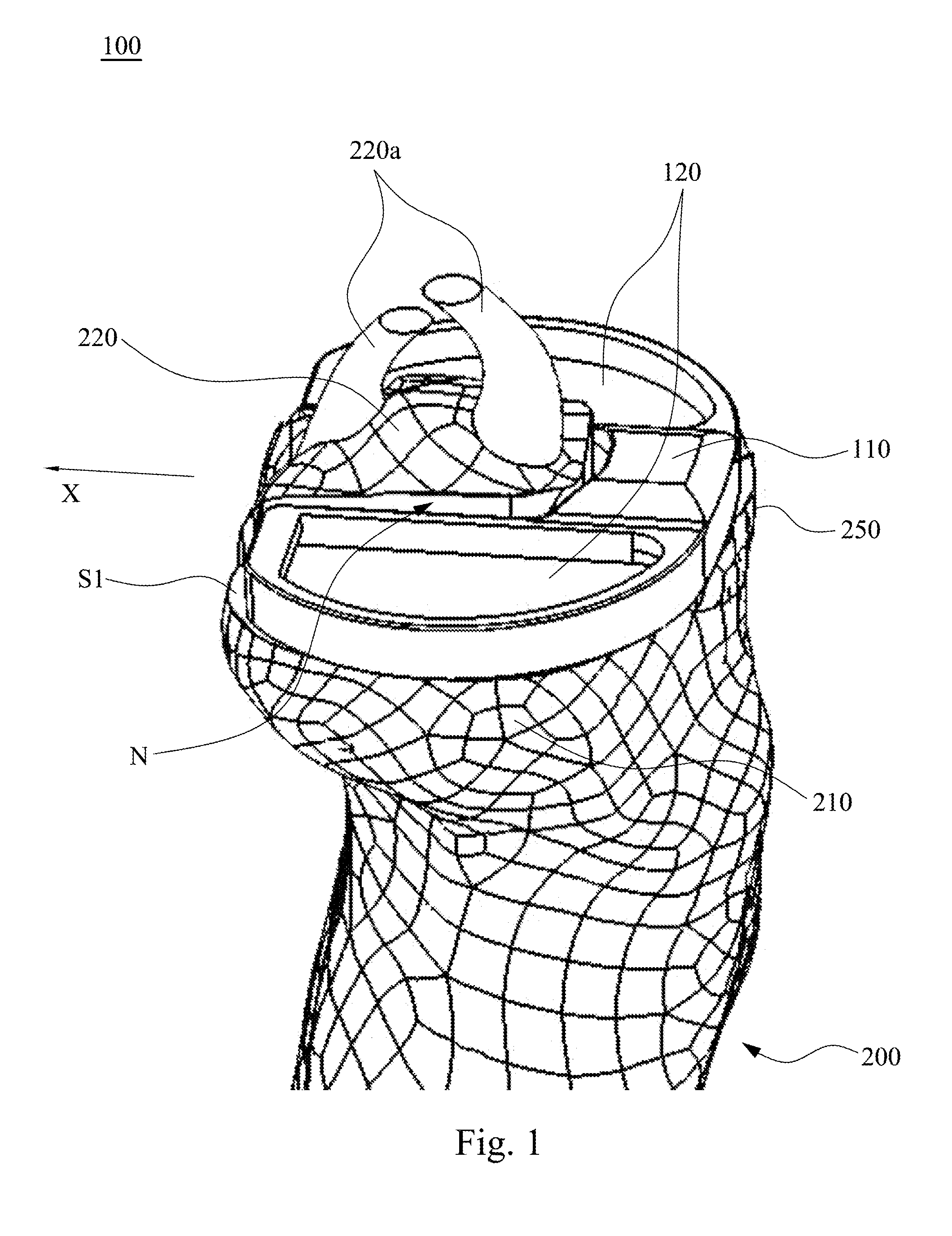

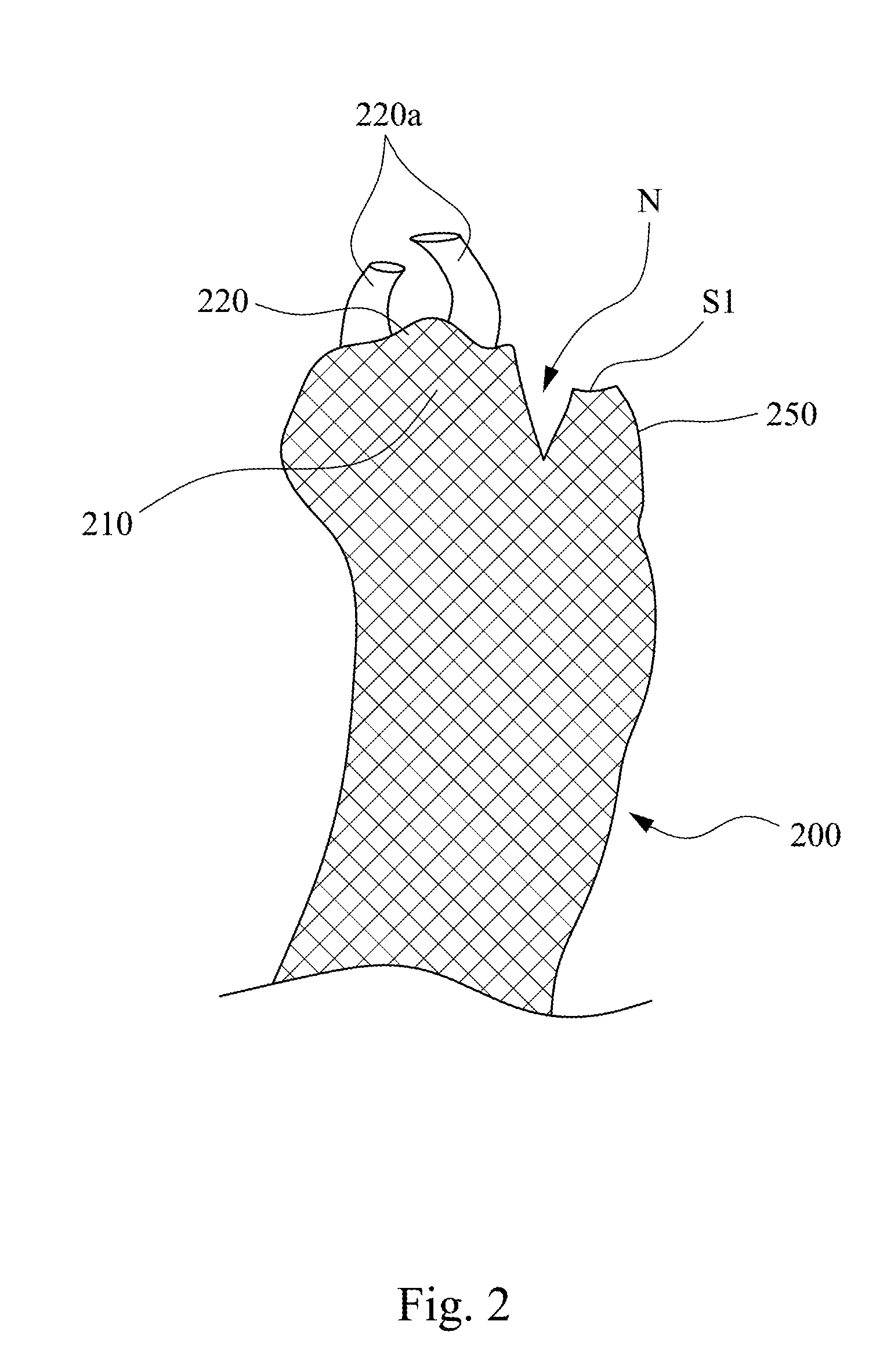

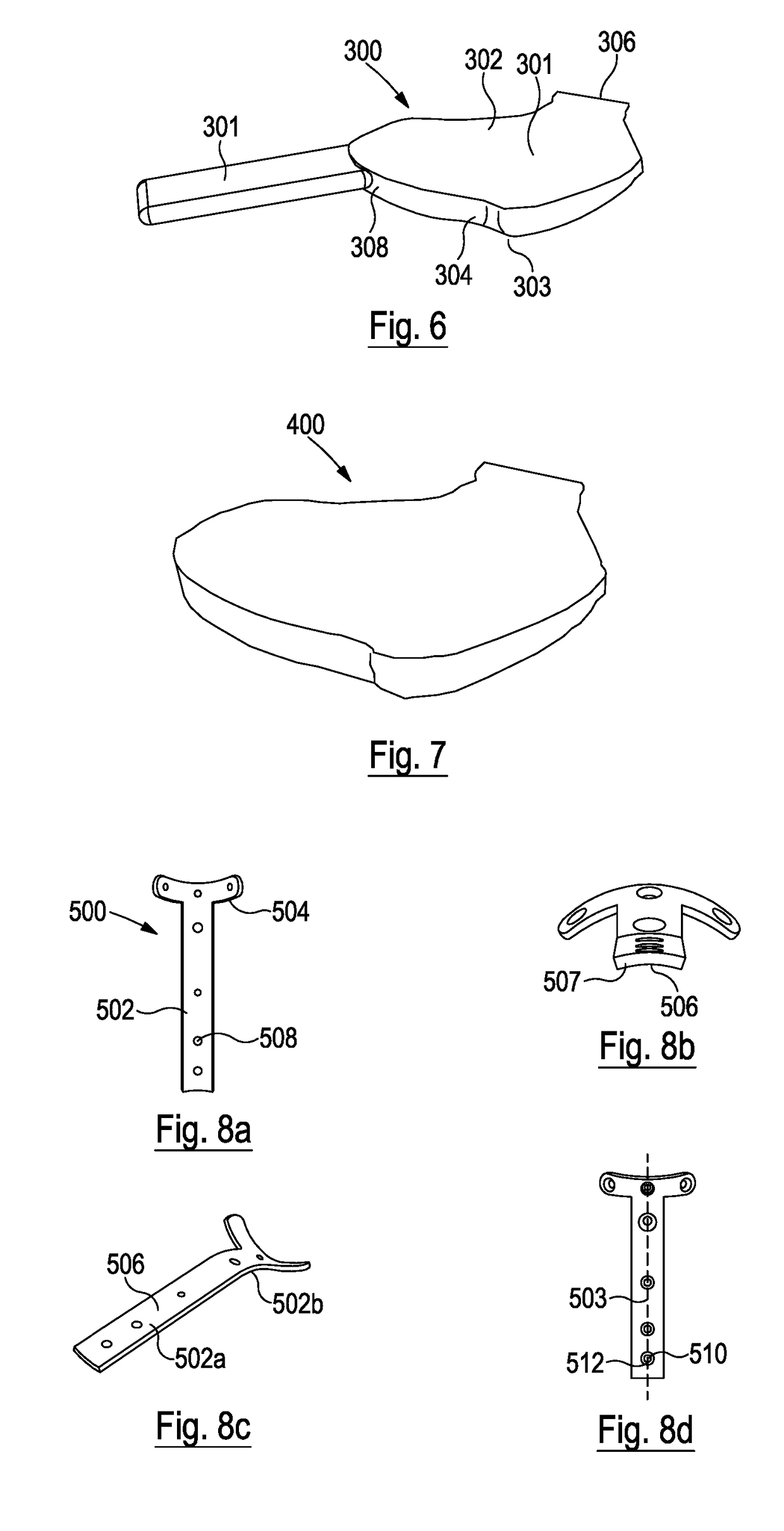

Method for manufacturing navigation template for knee replacement, and navigation template

ActiveCN102760199AAvoid offsetImprove the effect of long-term follow-upDiagnosticsSurgeryThighComputing tomography

The invention relates to a method for manufacturing a navigation template for knee replacement. The method comprises the following steps of: scanning a hip joint, a knee joint and an ankle joint through computed tomography (CT) to obtain CT data, and establishing three-dimensional reconstruction models of femur and tibia according to the CT data; respectively carrying out combination on the three-dimensional reconstruction models of thigh bone and shin bone with a three-dimensional structure, and respectively removing the three-dimensional structure models of femur and tibia from the three-dimensional structure; according to the knee replacement process, carrying out distal femoral virtual osteotomy on the three-dimensional structure model containing the femur contour, and carrying out proximal tibia virtual osteotomy on the three-dimensional structure model containing the tibia contour; and establishing virtual femur condyle navigation template and a virtual tibia platform navigation template, and manufacturing an entity condyle navigation template and an entity tibia platform navigation template. The individual navigation template manufactured by the invention be used for carrying out positioning of osteotomy and a rotating axis on the affected knee femur condyle and tibia platform, thus realizing individual precise osteotomy.

Owner:中国人民解放军联勤保障部队第九二〇医院

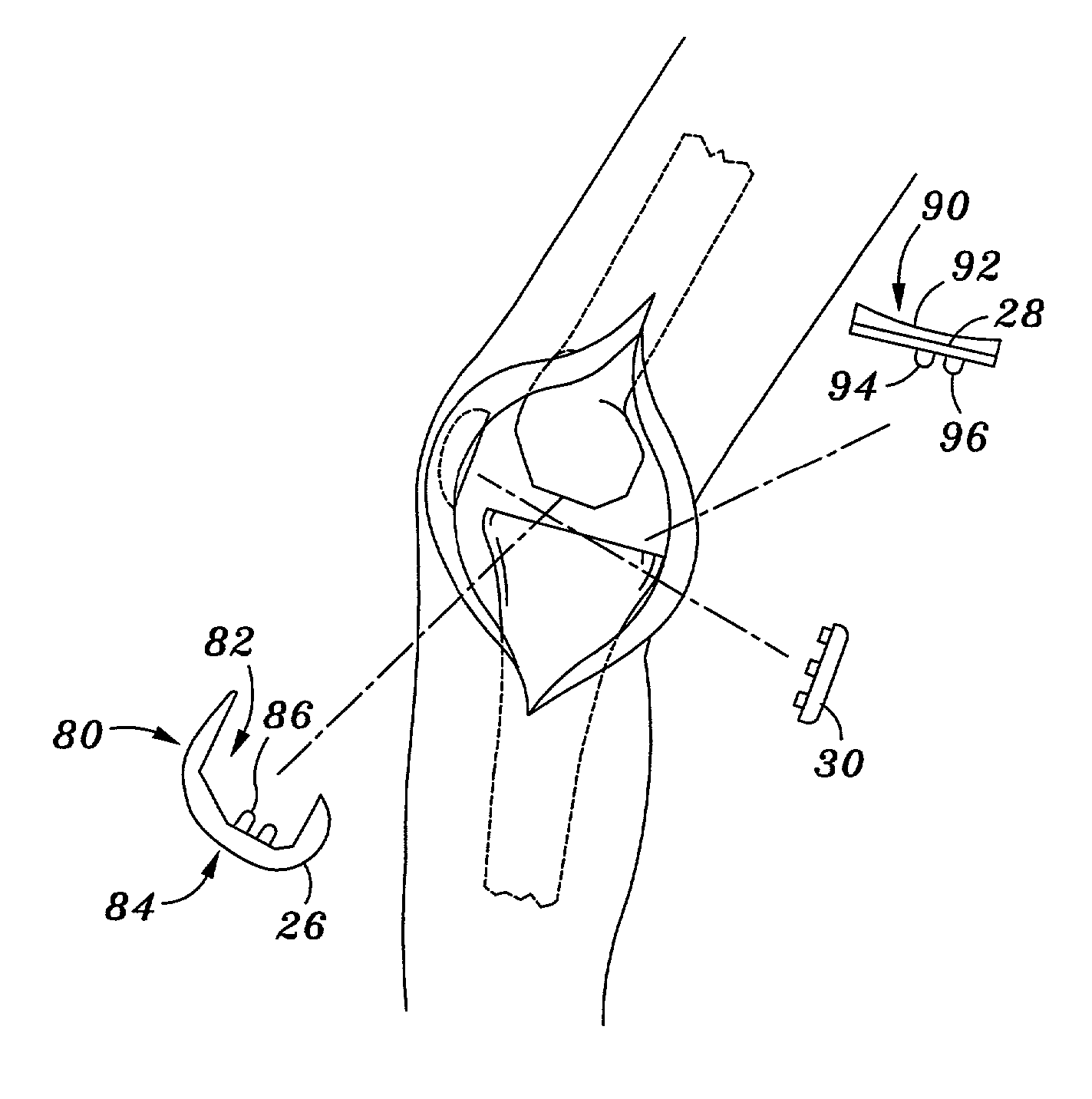

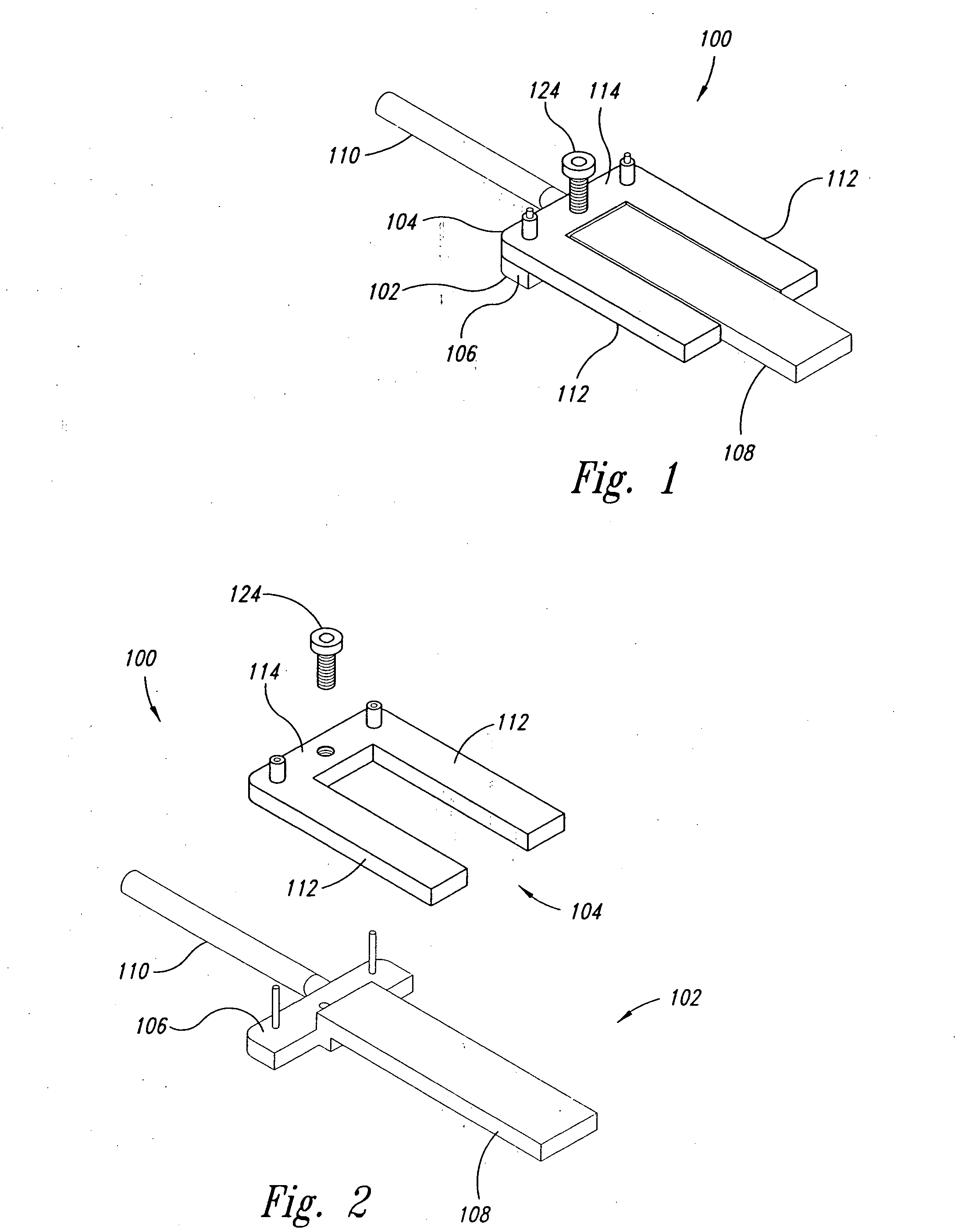

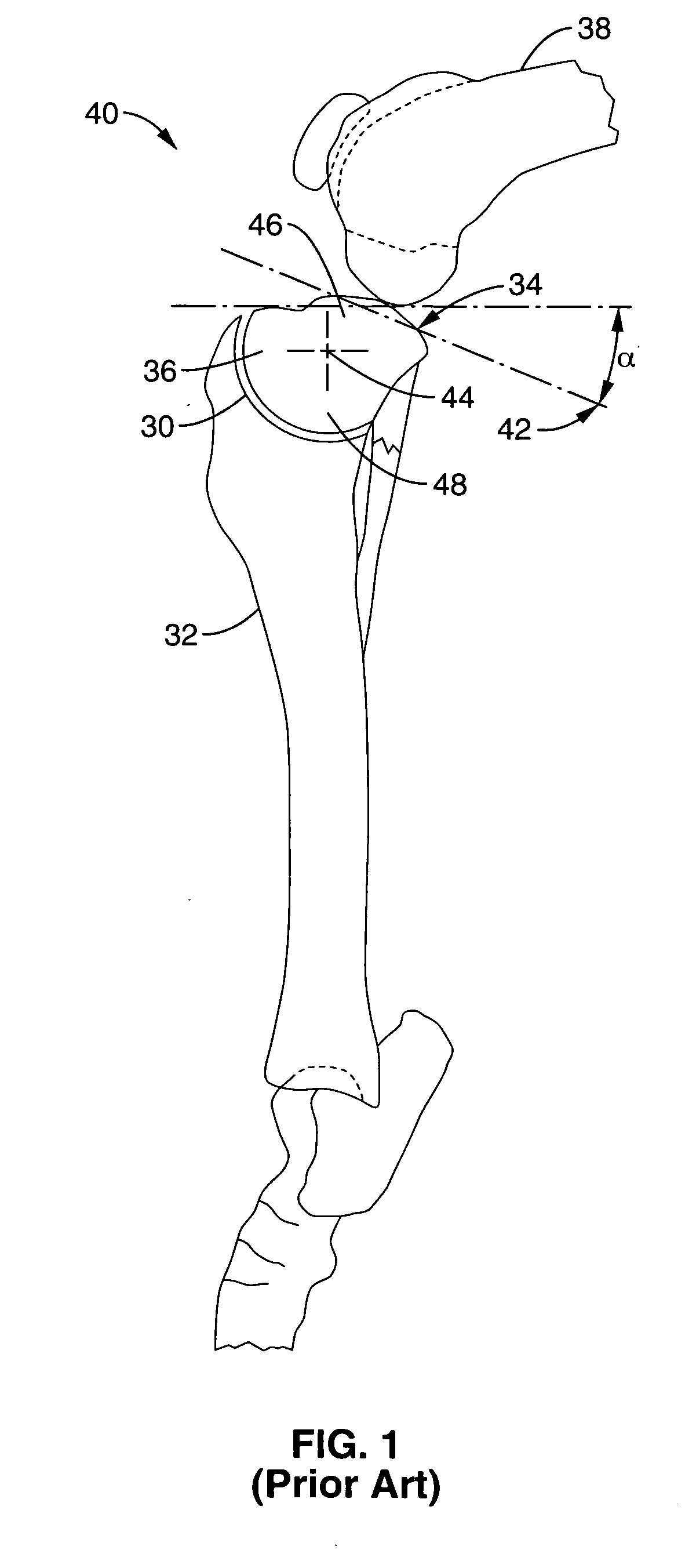

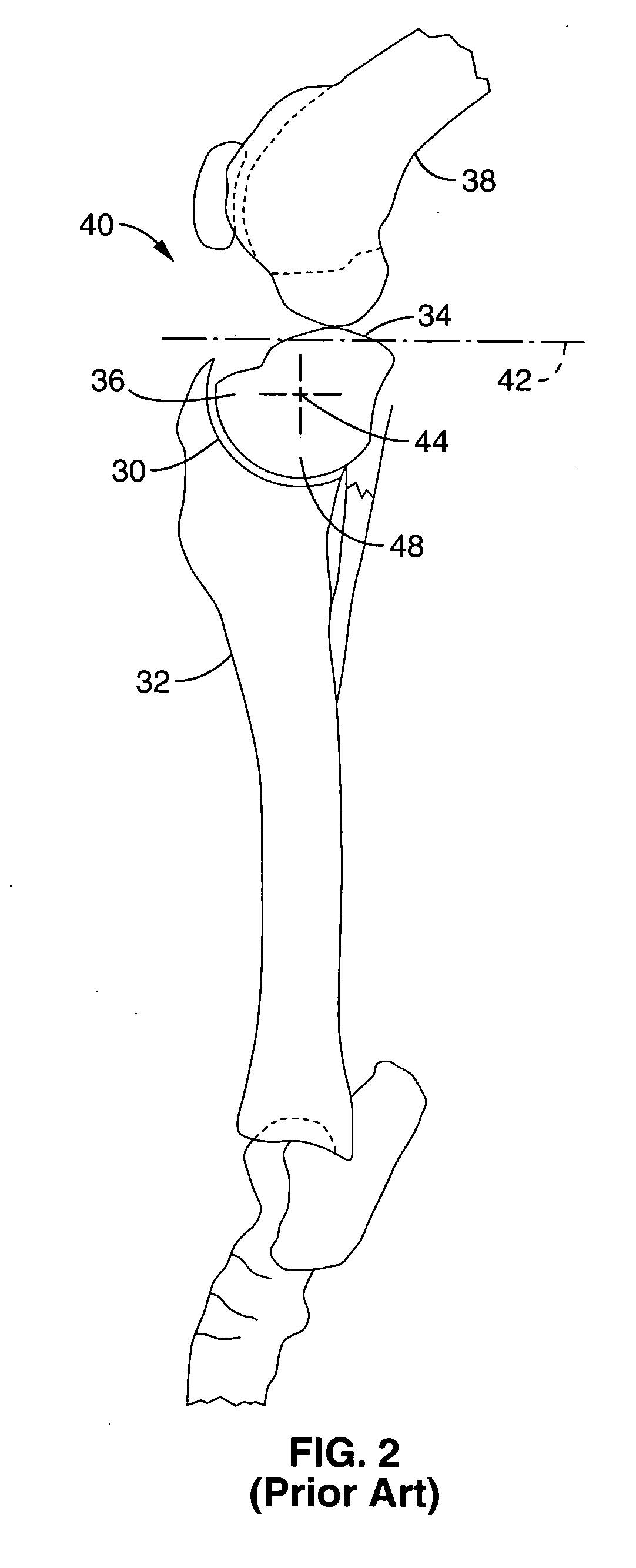

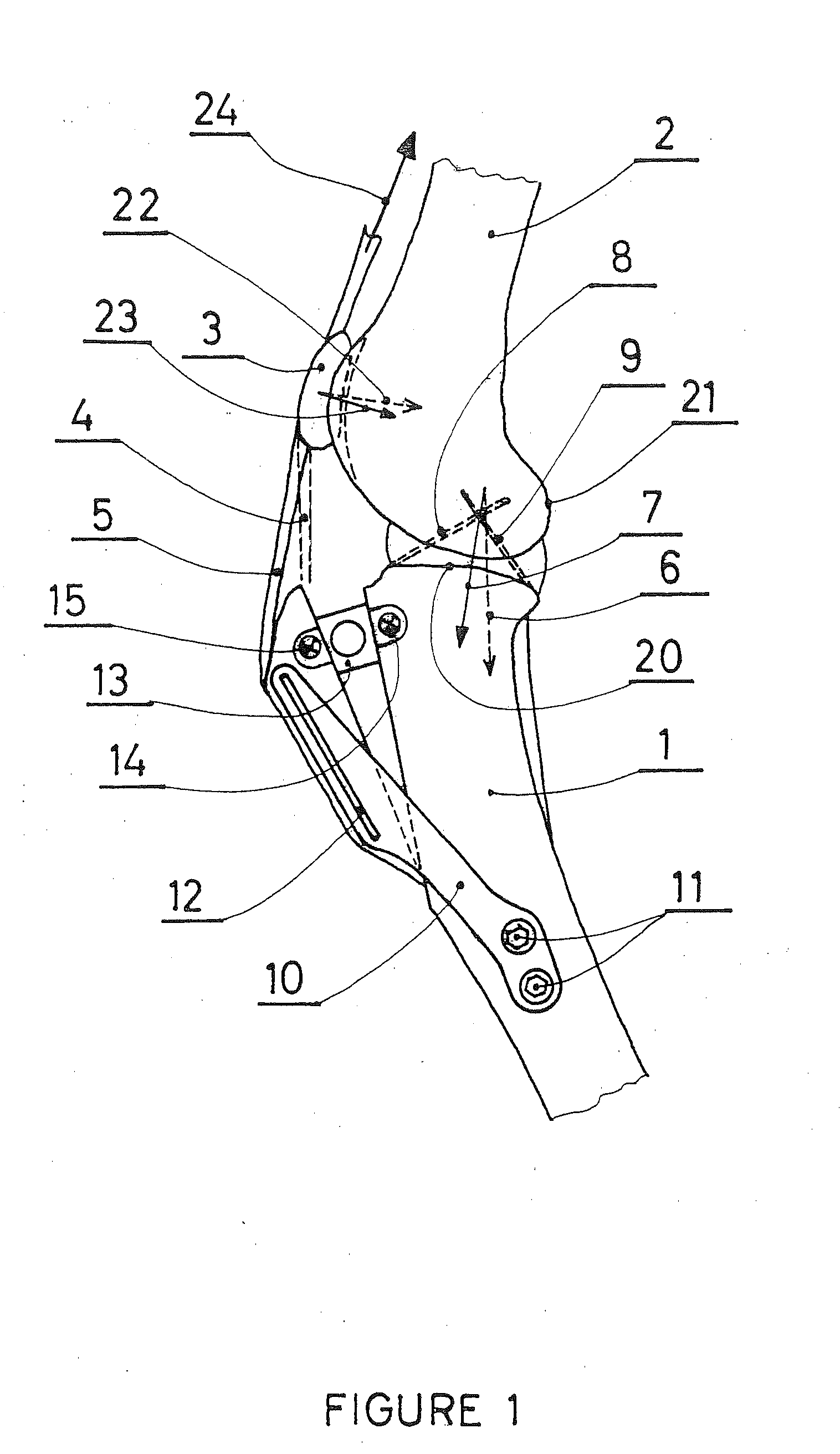

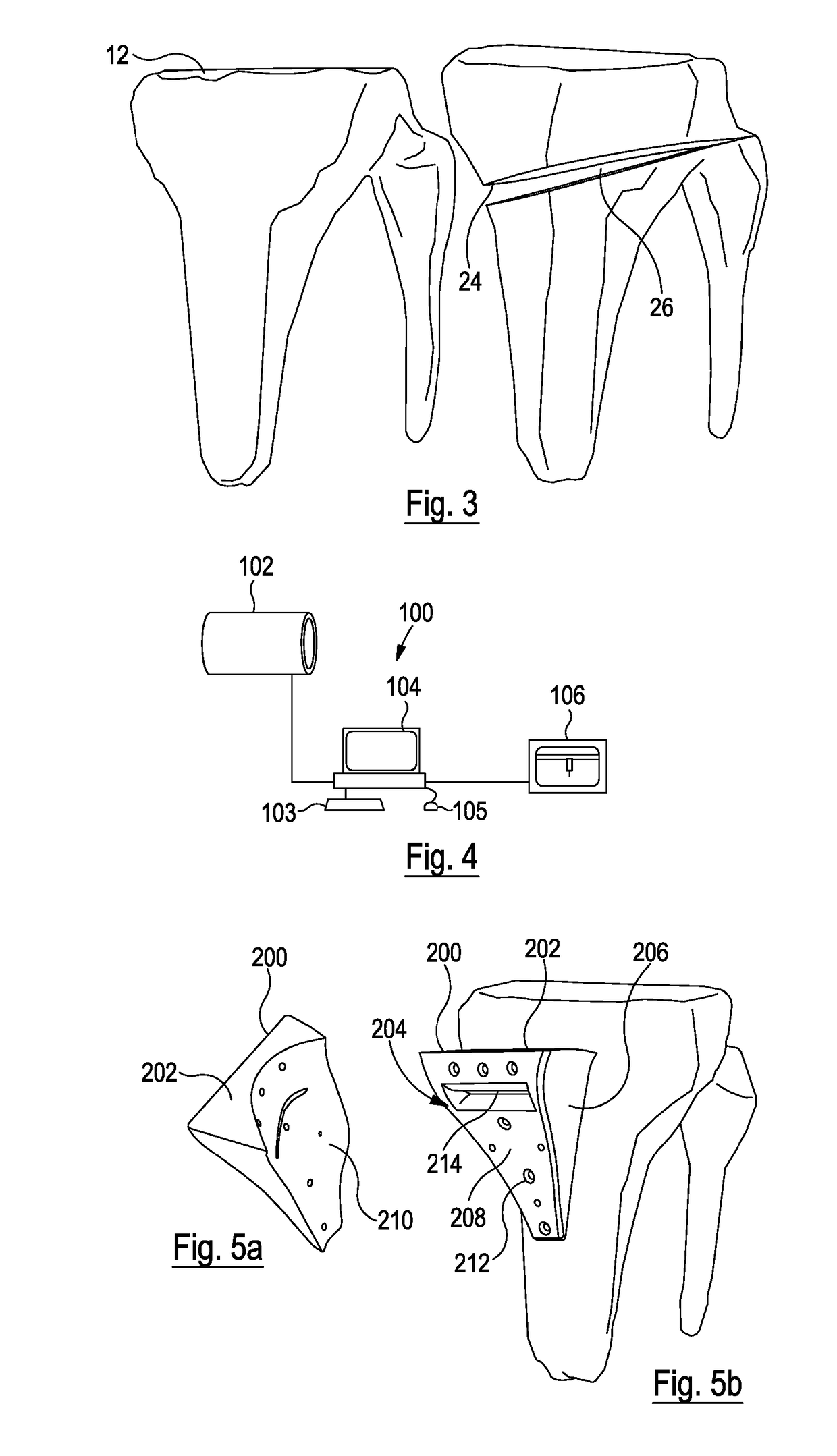

Method and apparatus for resecting a distal femur and a proximal tibia in preparation for implementing a partial knee prosthesis

A method of resecting a proximal tibia and distal femur for implanting a partial knee prosthesis uses a resecting kit which includes multiple spacers, each of which has a different spacing dimension. A surgeon selects the appropriate spacer with the amount of correction desired to align the patient's leg and installs the spacer with the spacing dimension between the distal femur and proximal tibia which is to receive the partial knee prosthesis. The spacers have projecting stems, upon which a resector is installed. The resector is then aligned with the axis selected by the surgeon according to known methods, and is pinned to the femur and proximal tibia. A distal femoral cut is then made in the femur after which the resector is removed while leaving at least two of the pins in place, the pins being headless pins. A second resector is then installed on the pins to effect the required cut of the tibia. Additional cuts are made in the femur according to known procedures, and the femoral and tibial prostheses are then installed, according to known procedures.

Owner:ZIMMER TECH INC

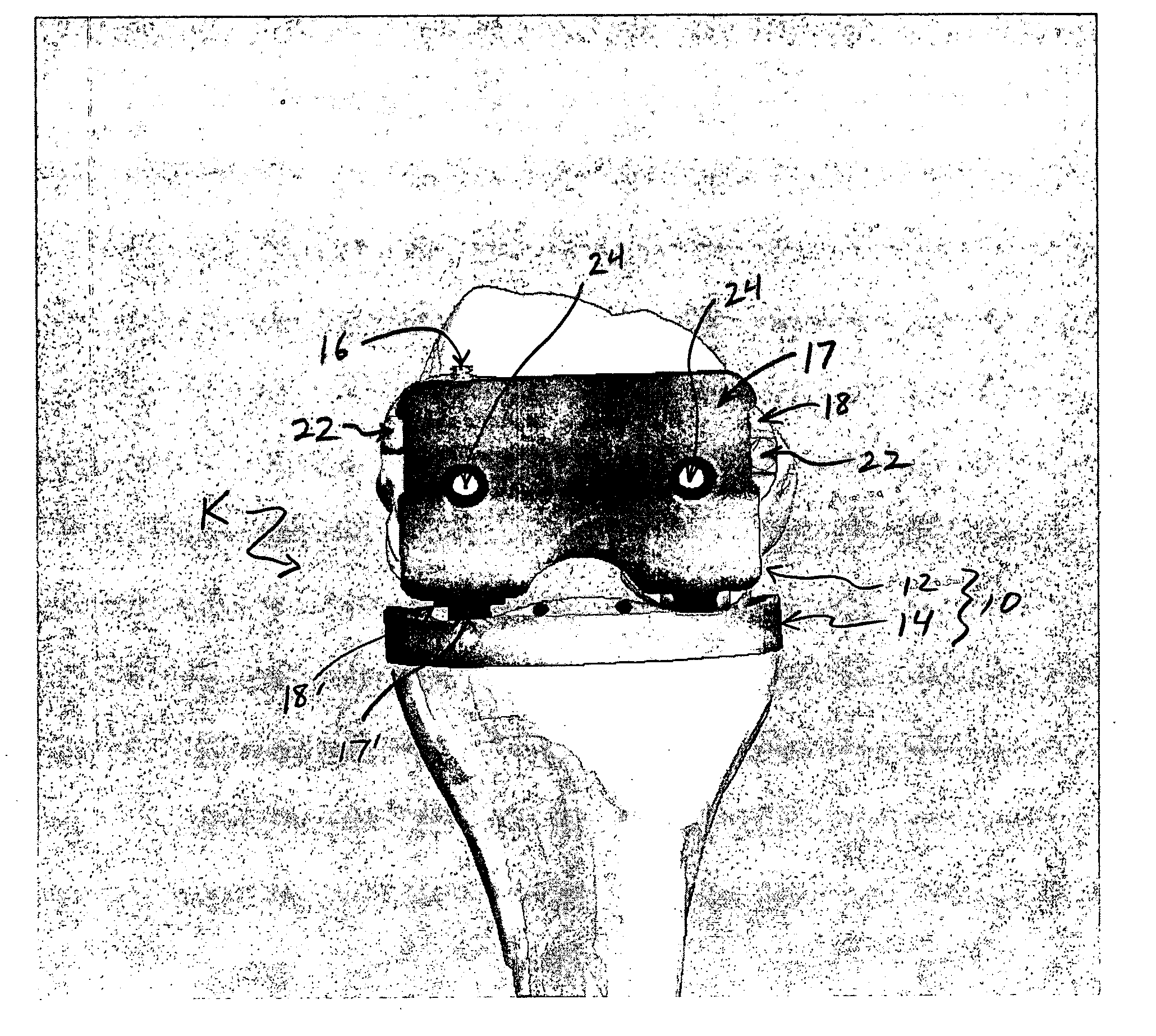

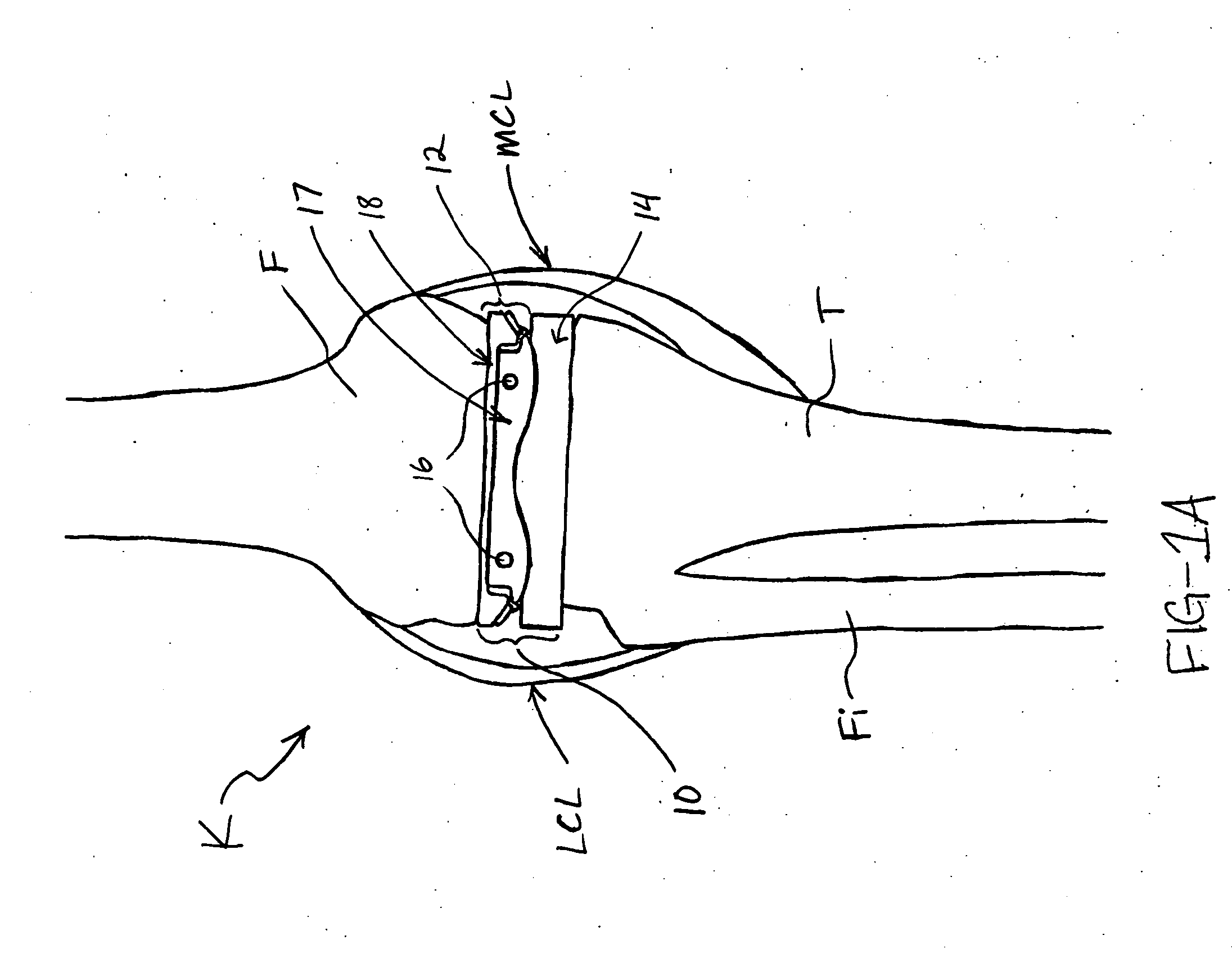

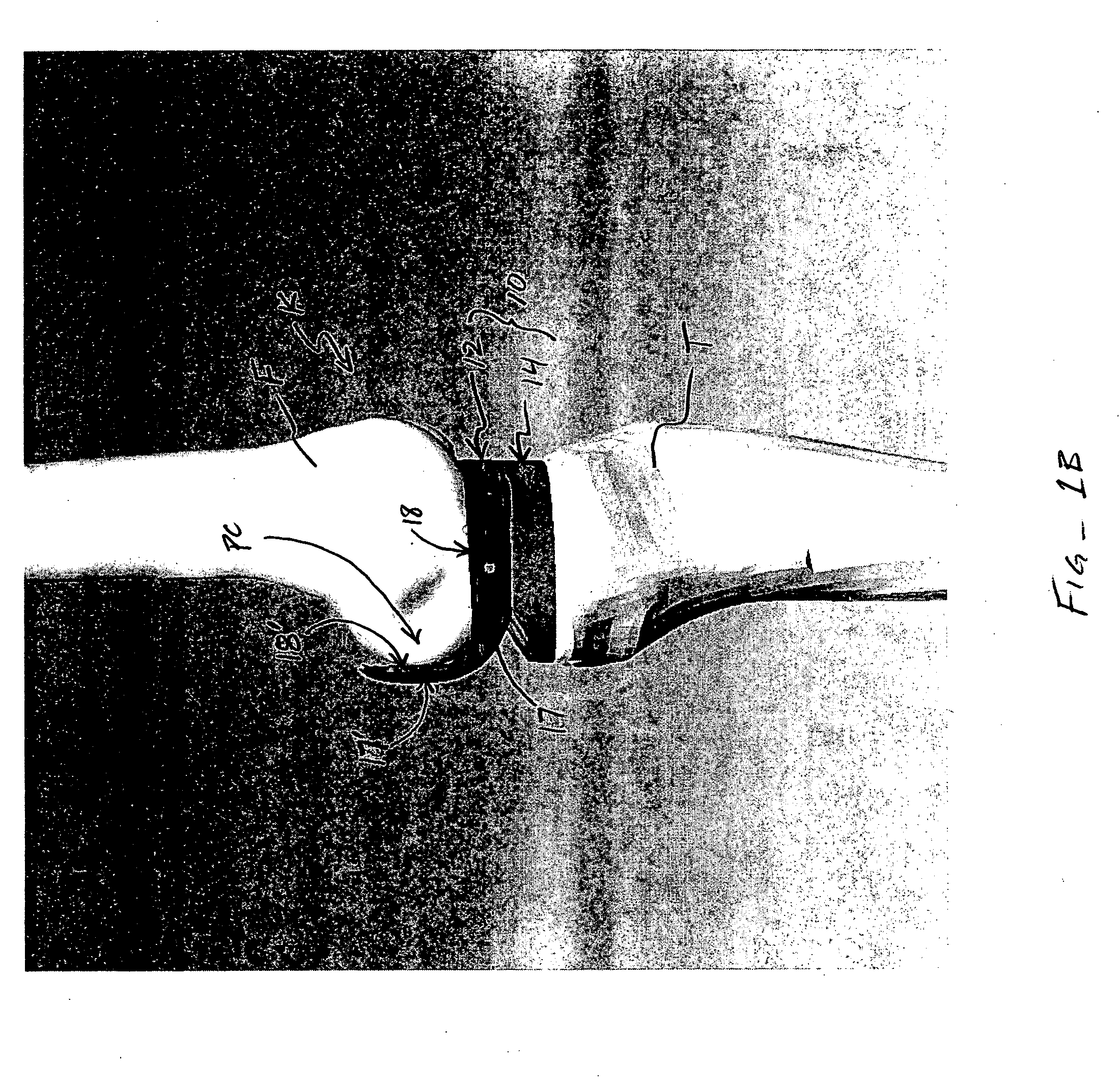

Device and method for knee ligament strain measurement

InactiveUS20090264797A1Good repeatabilityHigh precisionPerson identificationChiropractic devicesCoronal planePhysical medicine and rehabilitation

A device for measuring displacement of the tibia in relation to the femur in response to an applied force or torque on the tibia. A first shaft is tiltable about a first axis close to the ankle and approximately parallel to the coronal plane of the patient's body. A second shaft is connected to the first shaft and is rotatable about a second axis perpendicular to the first axis, and is close to the ankle and approximately parallel to the tibia. A foot support platform is mounted on the second shaft, the foot support platform being configured for attachment of the foot at a fixed position. A displacement test device is provided for applying forces to the tibia and measuring the shift or displacement of the proximal tibia relative to the distal femur.

Owner:MAYR HERMANN

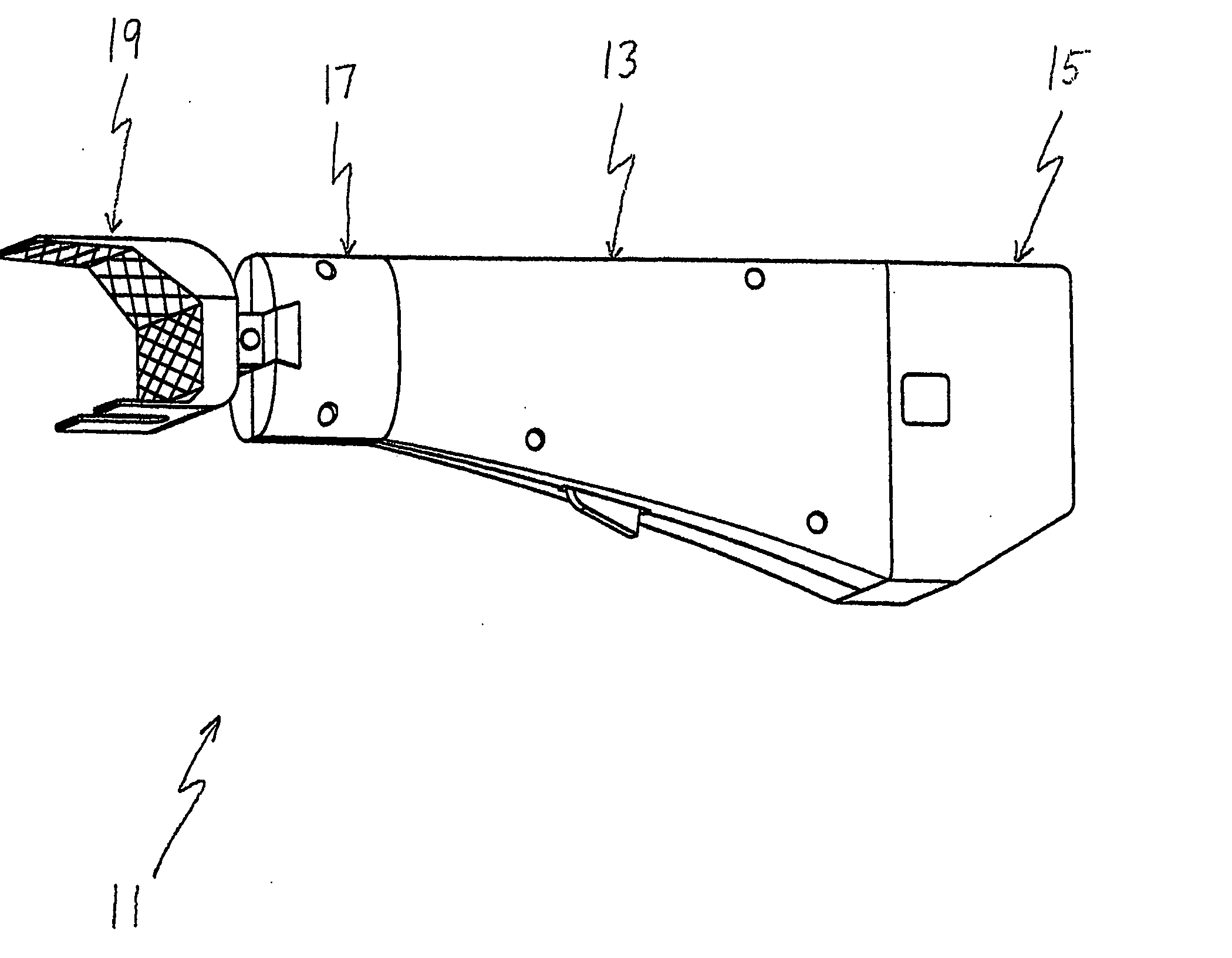

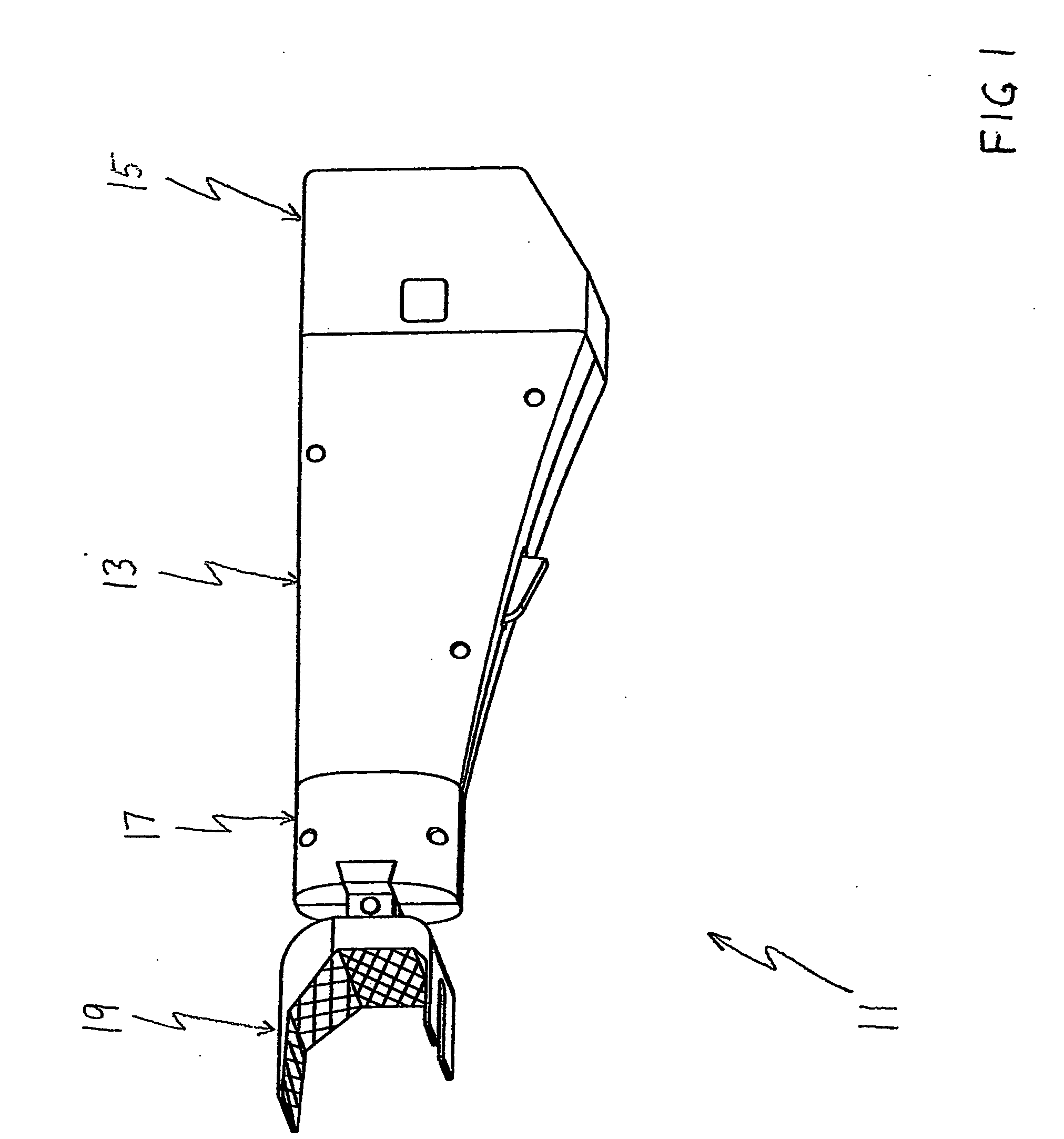

Bone shaping device for knee replacement

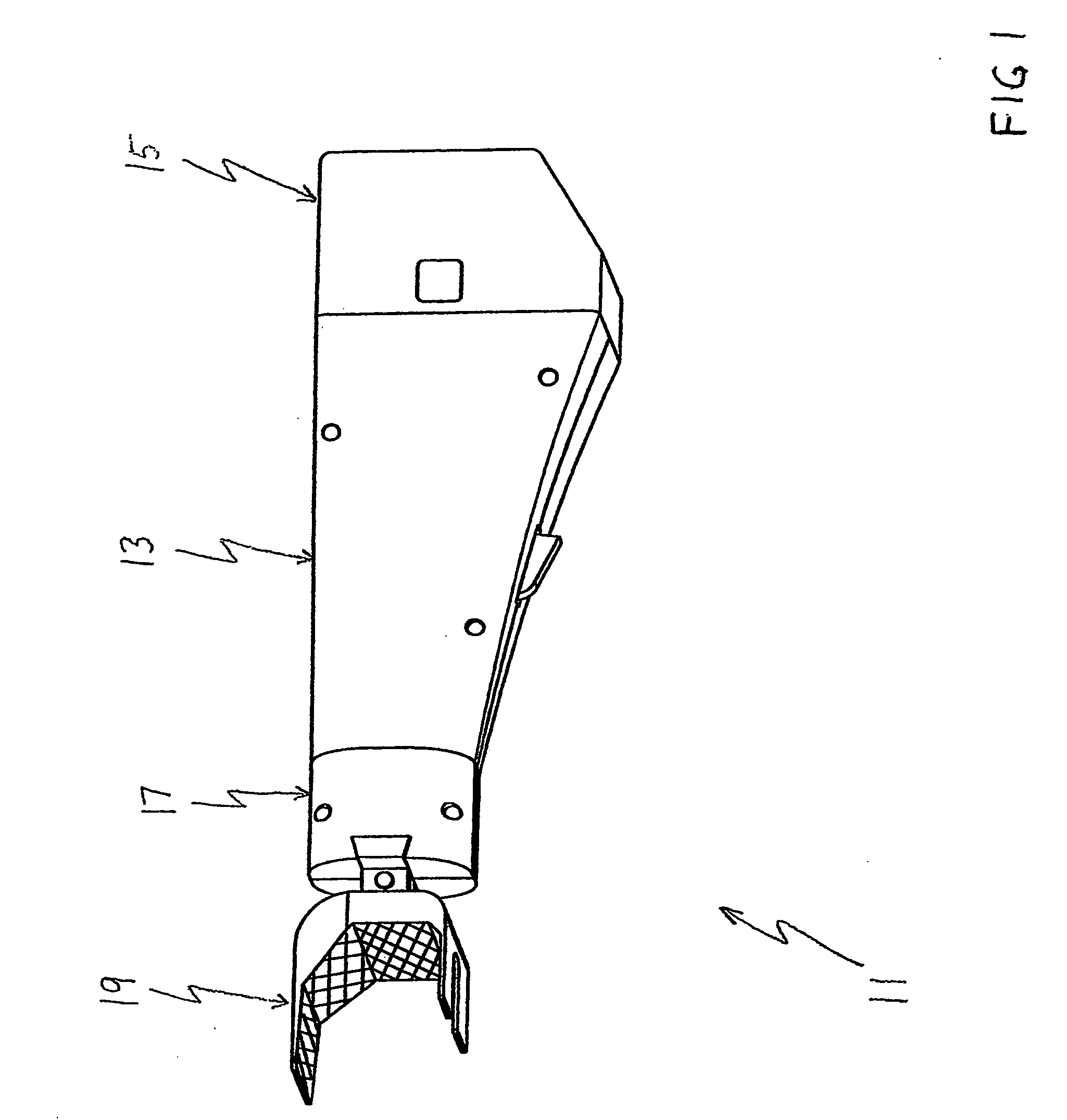

InactiveUS20050192583A1Improve accuracyImprove consistencyDiagnosticsSurgical navigation systemsTotal knee replacement surgeryArthroplasty knee

A bone surgery device with a reciprocating cutting head. The device comprises several sets of shaping surfaces sometimes including cutting blades, which are located and oriented so as to shape the distal end of the femur and the proximal end of the tibia for total knee replacements and unicompartmental knee replacements. The device, which may be hand directed or aided by spatial and directional guiding mechanisms or an optical navigation system, may also include both coolant supply for controlling heat during bone, cutting and shaping, and a suction method for carrying away fluid and debris. The device is substantially configured to the artificial joint component to be attached thereto.

Owner:WALKER PETER STANLEY +1

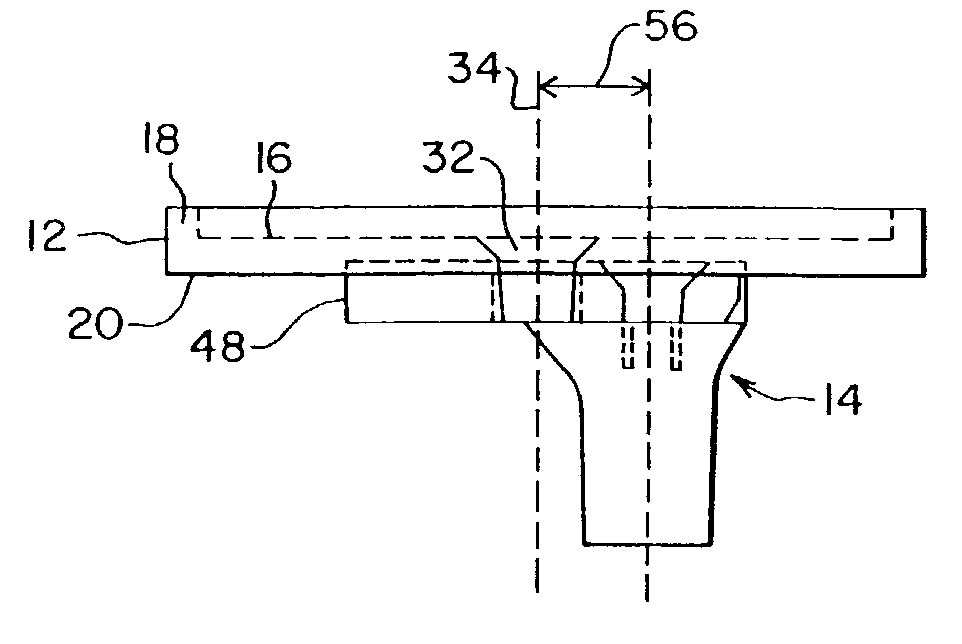

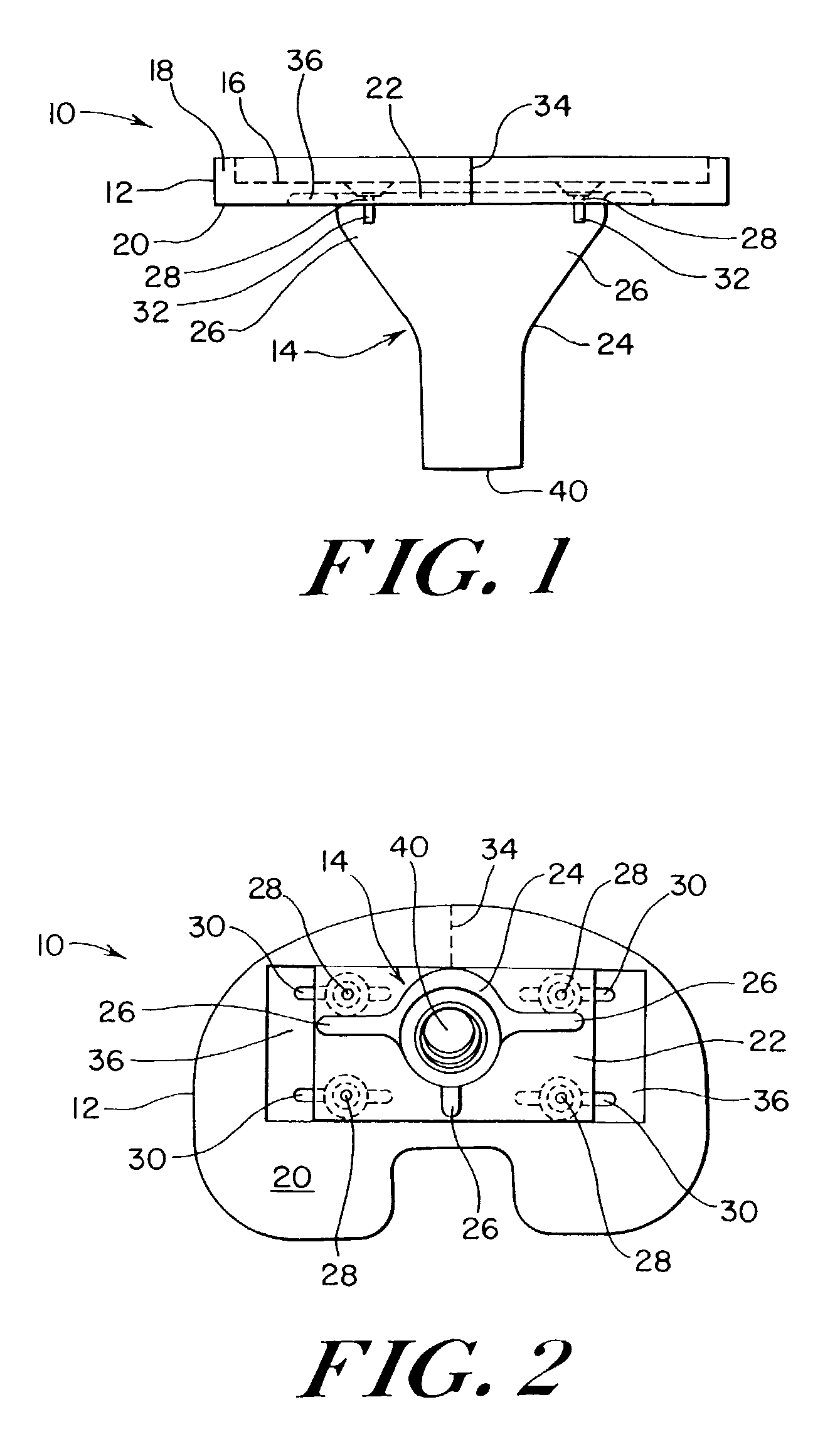

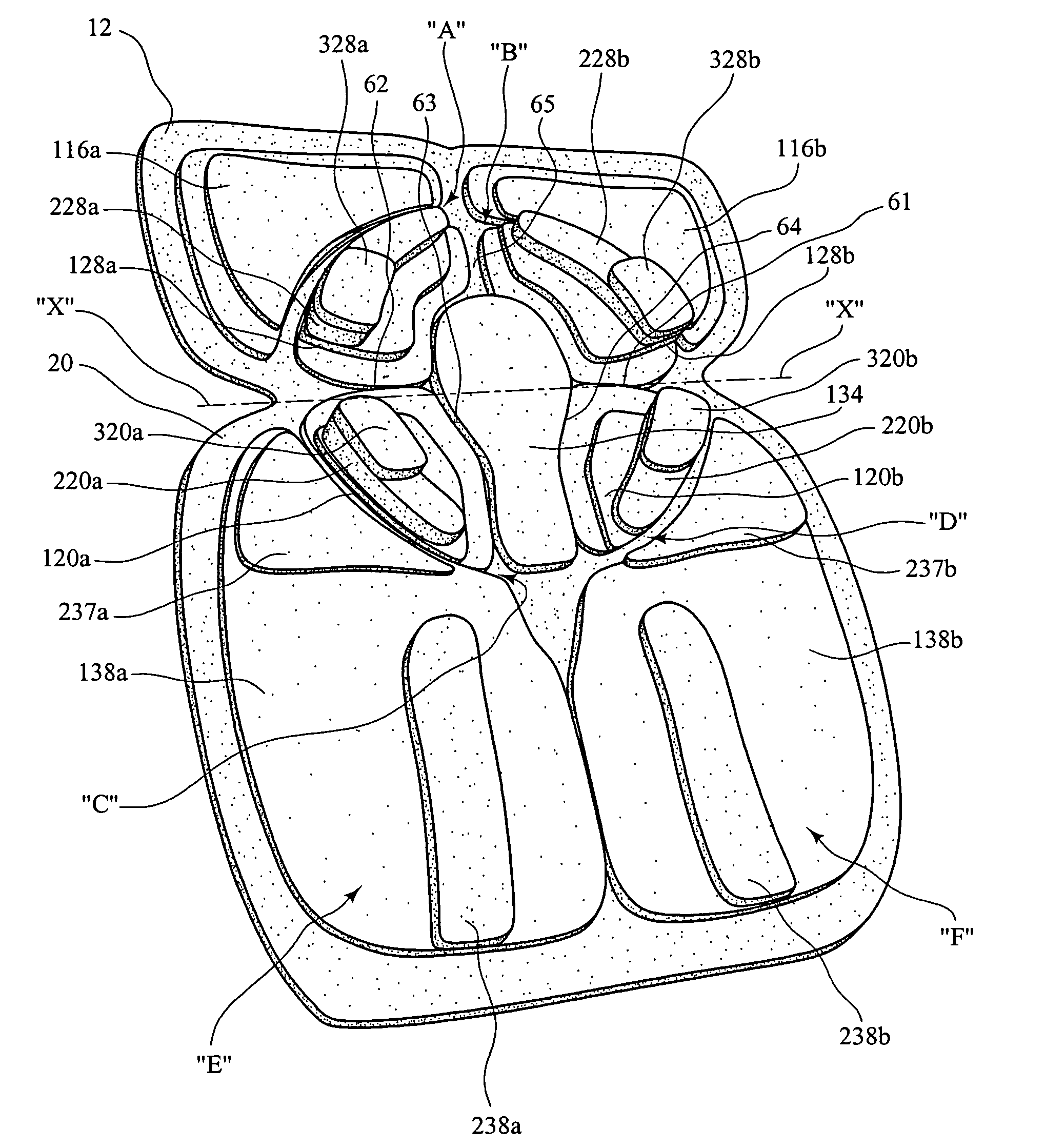

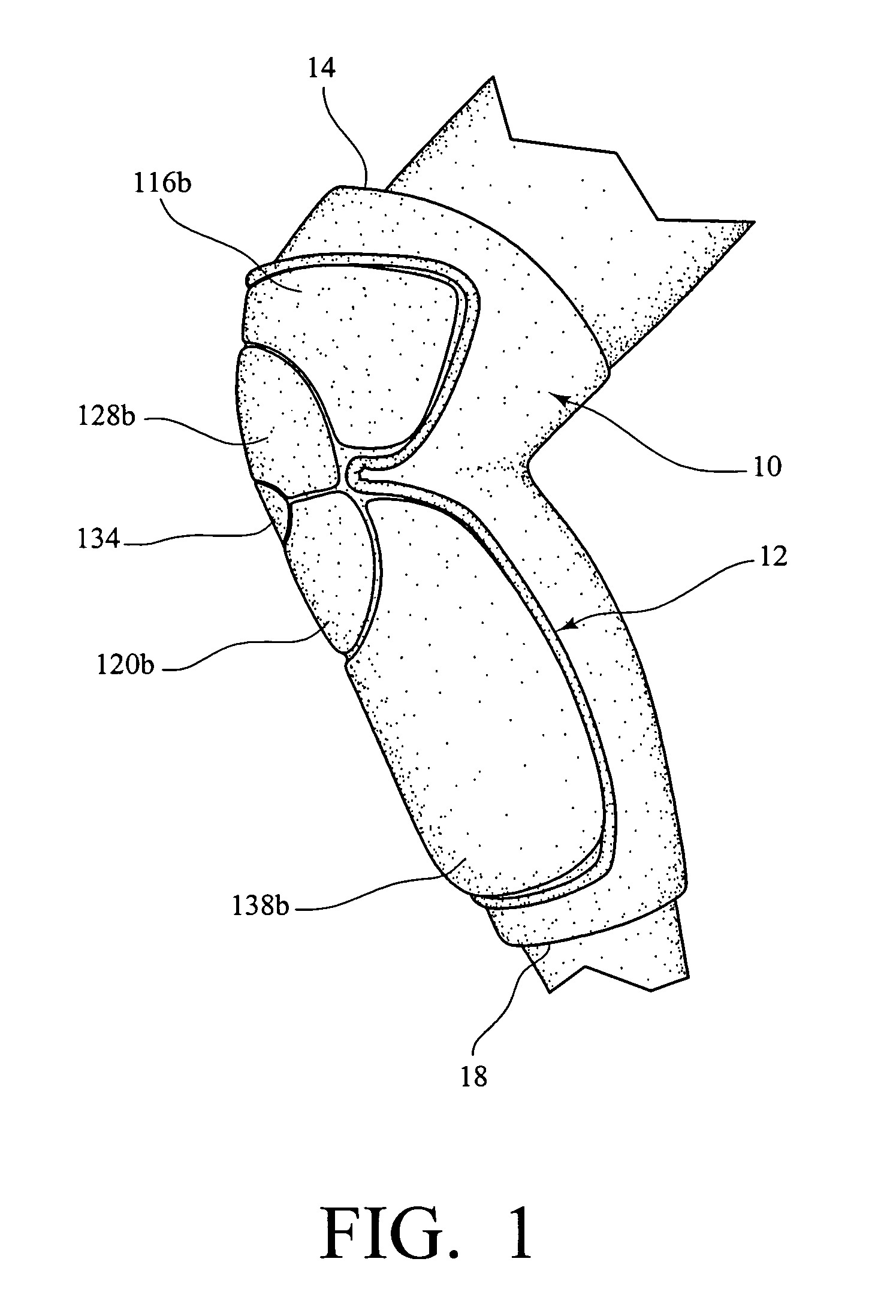

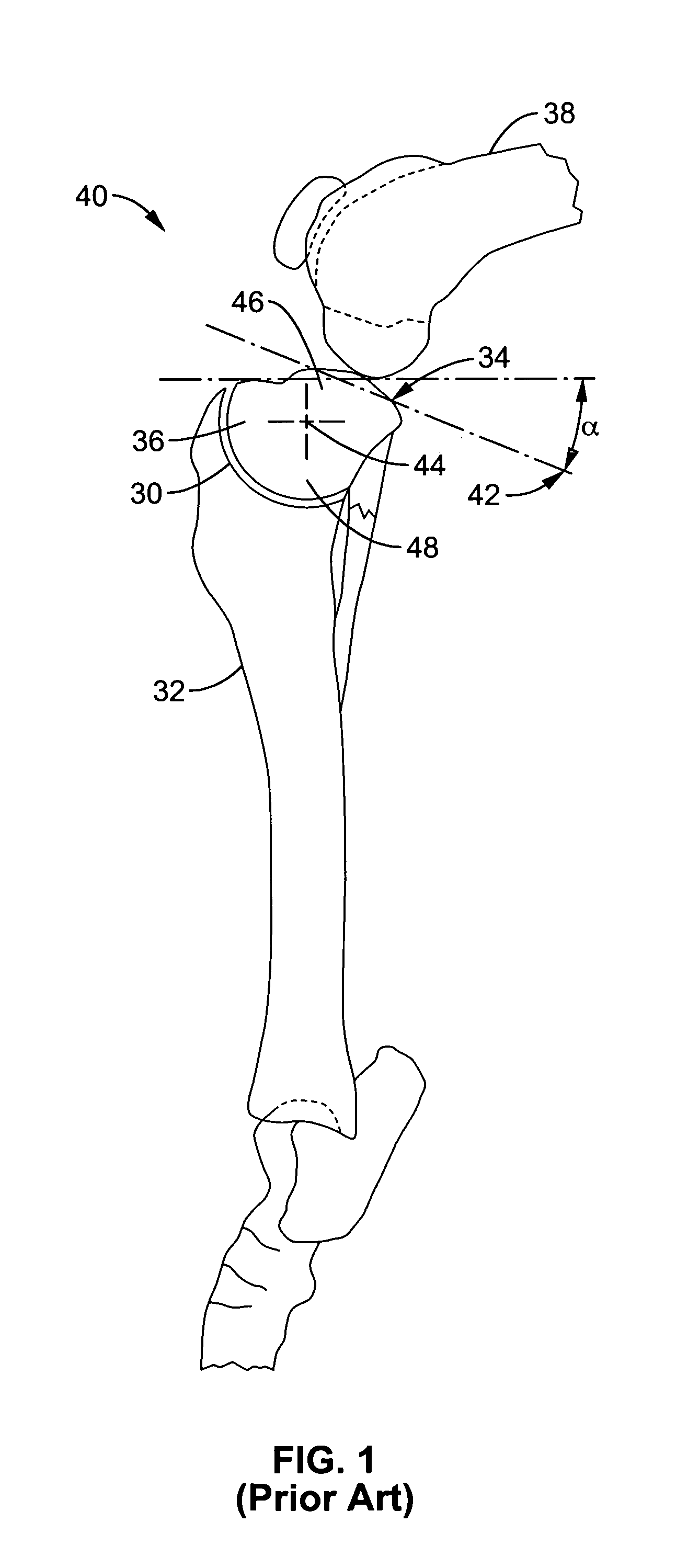

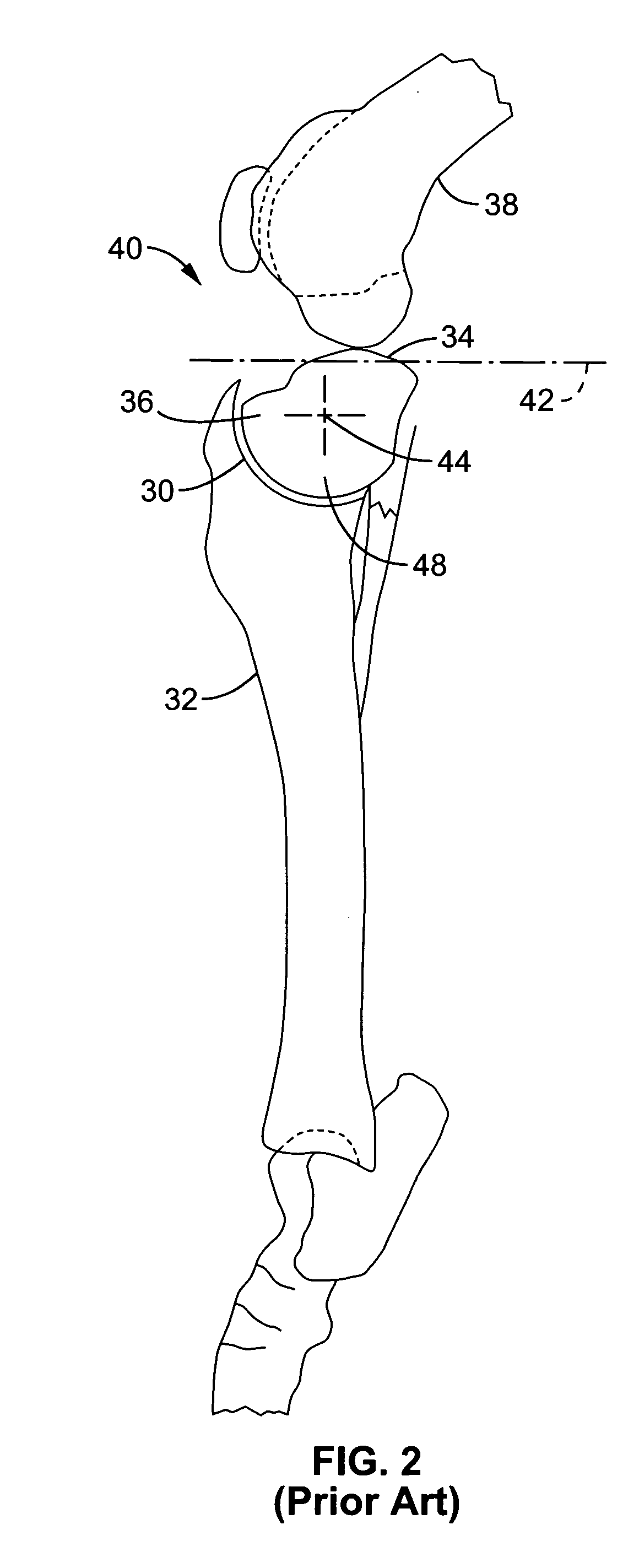

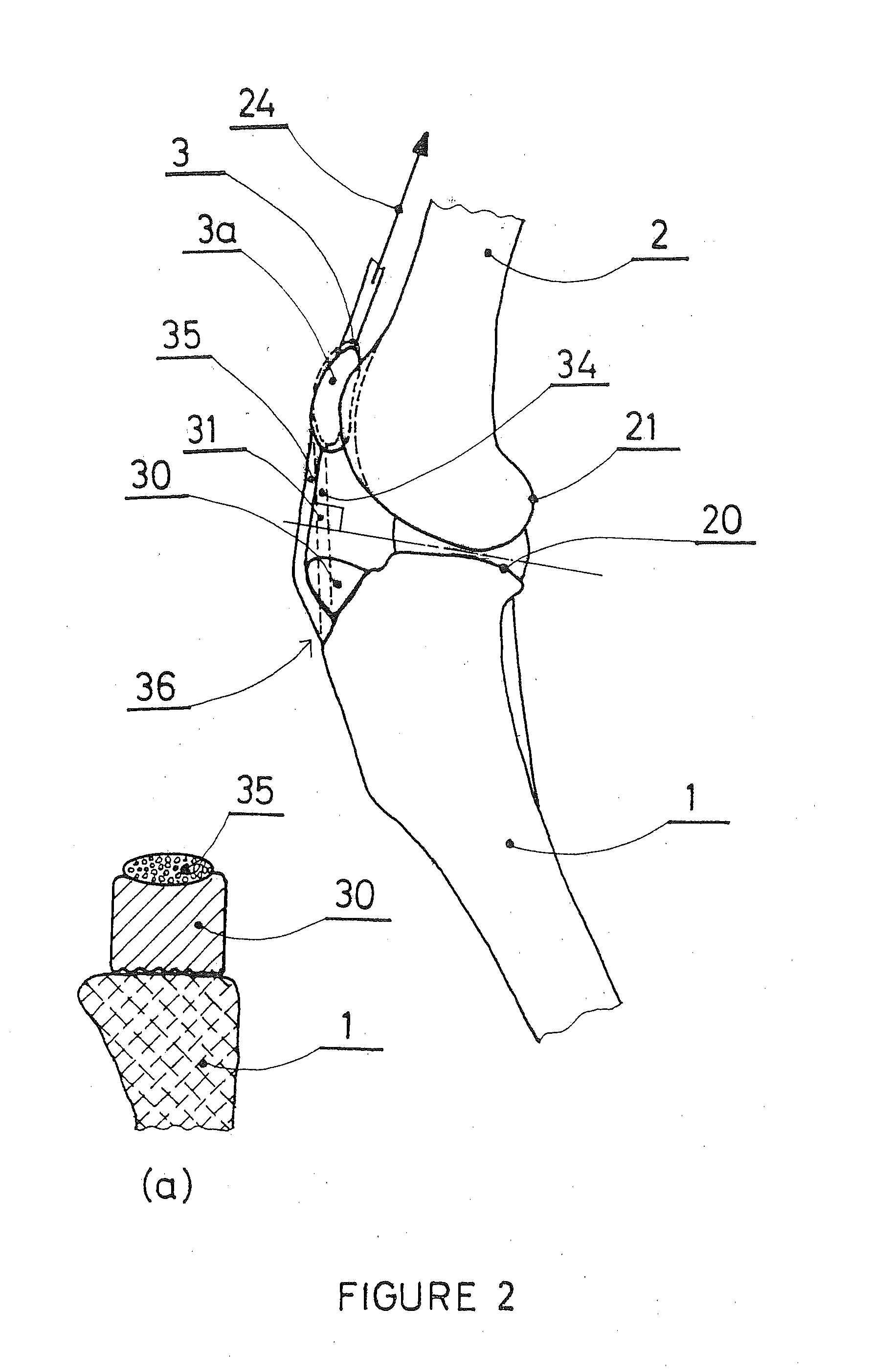

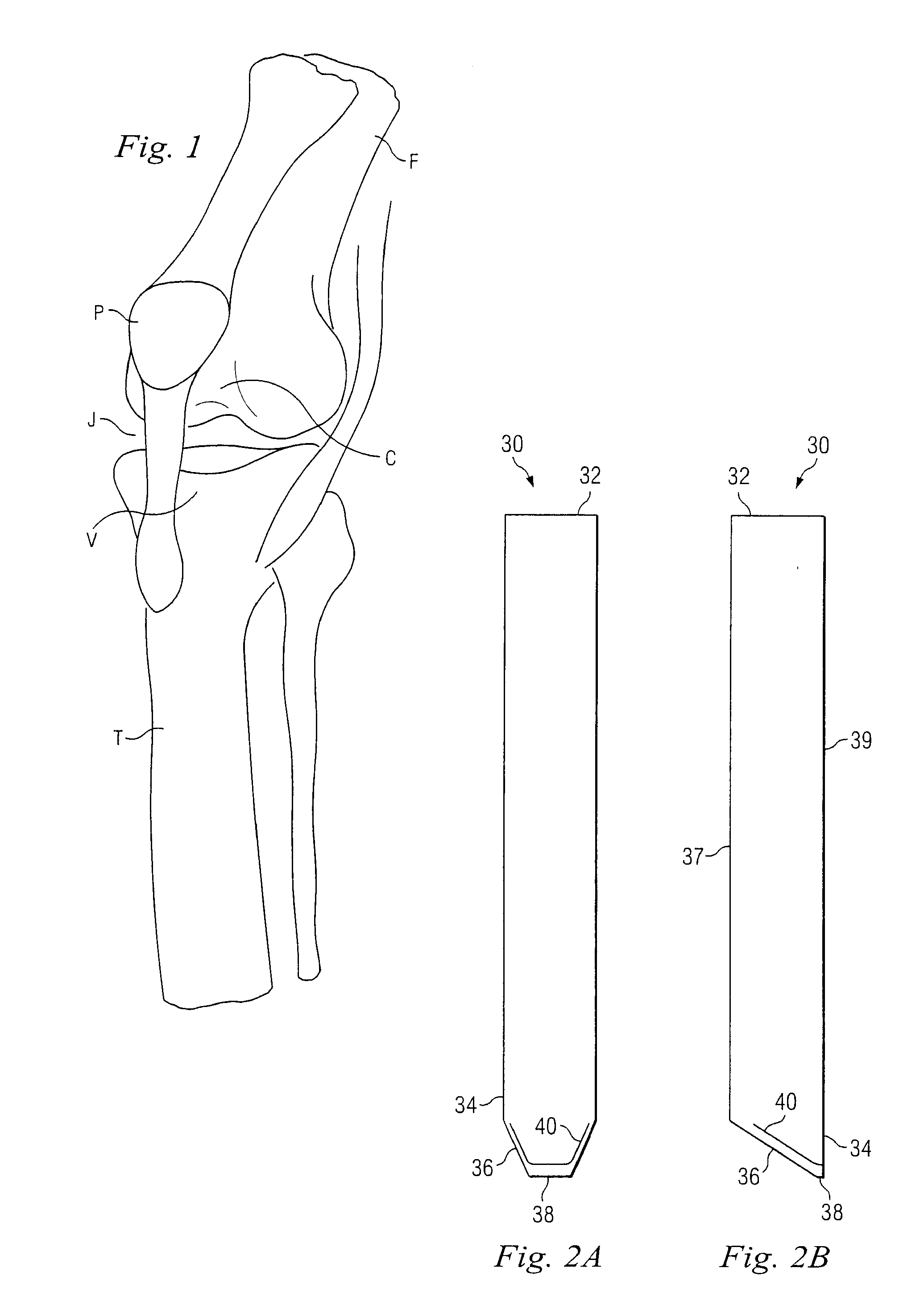

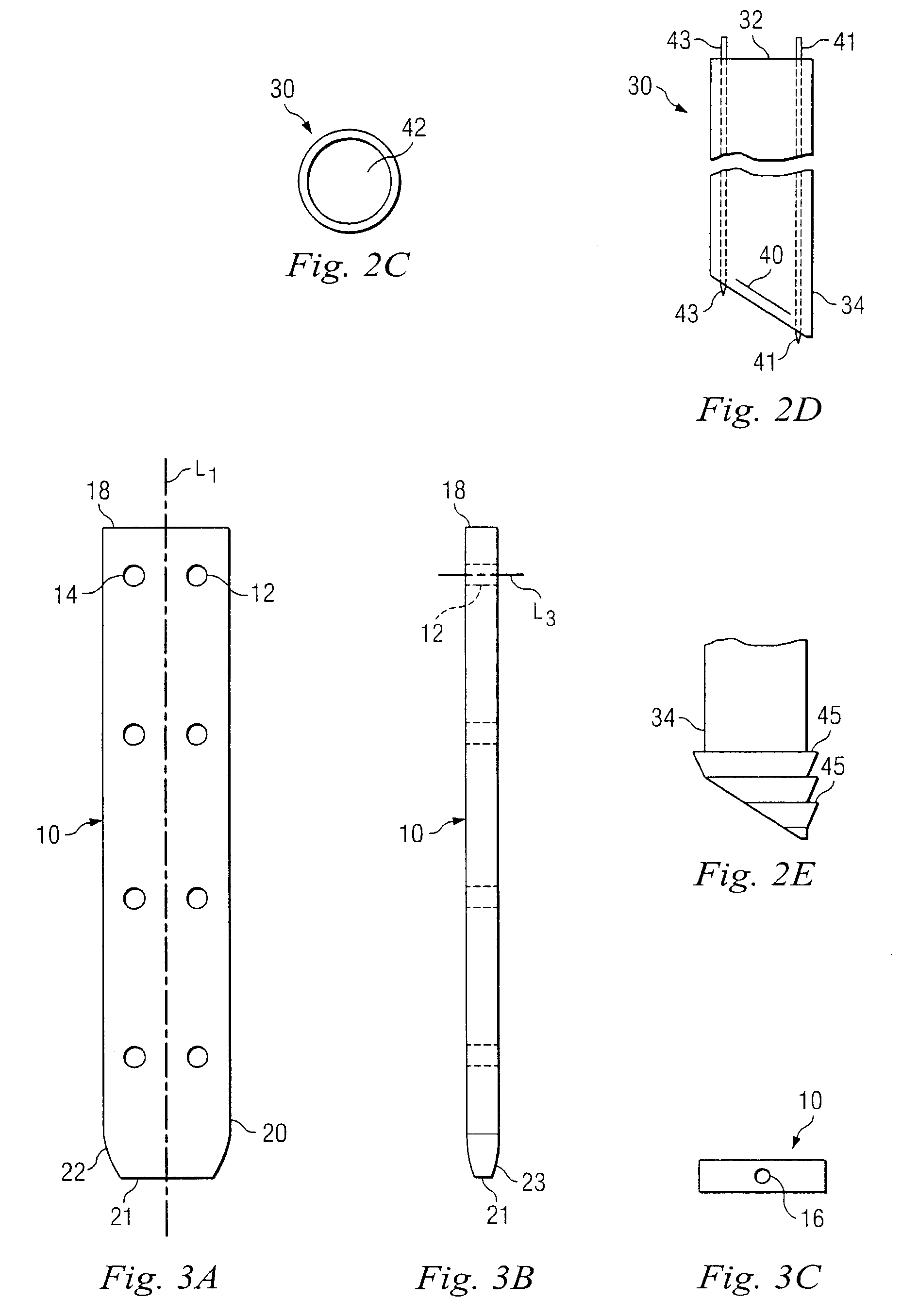

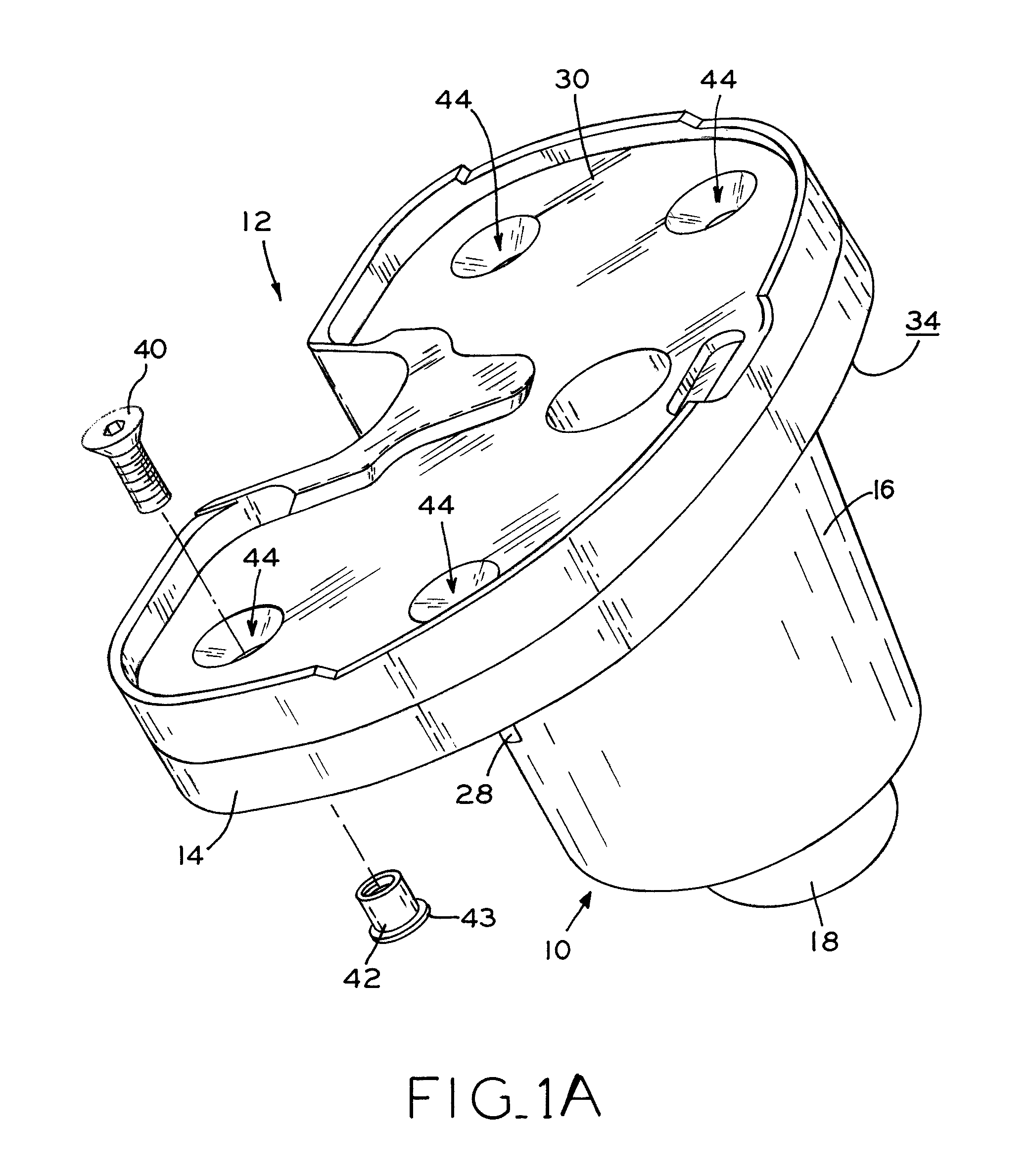

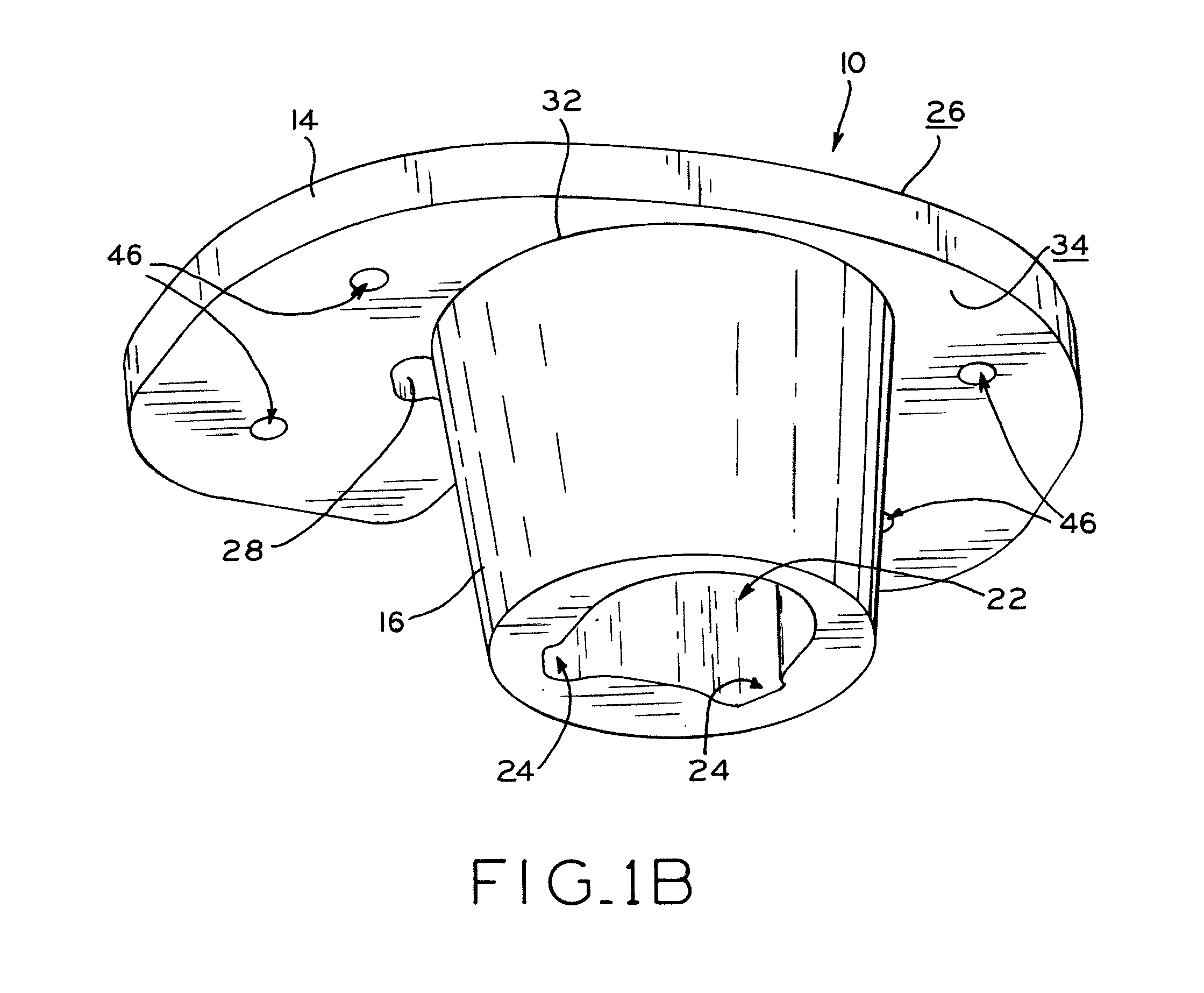

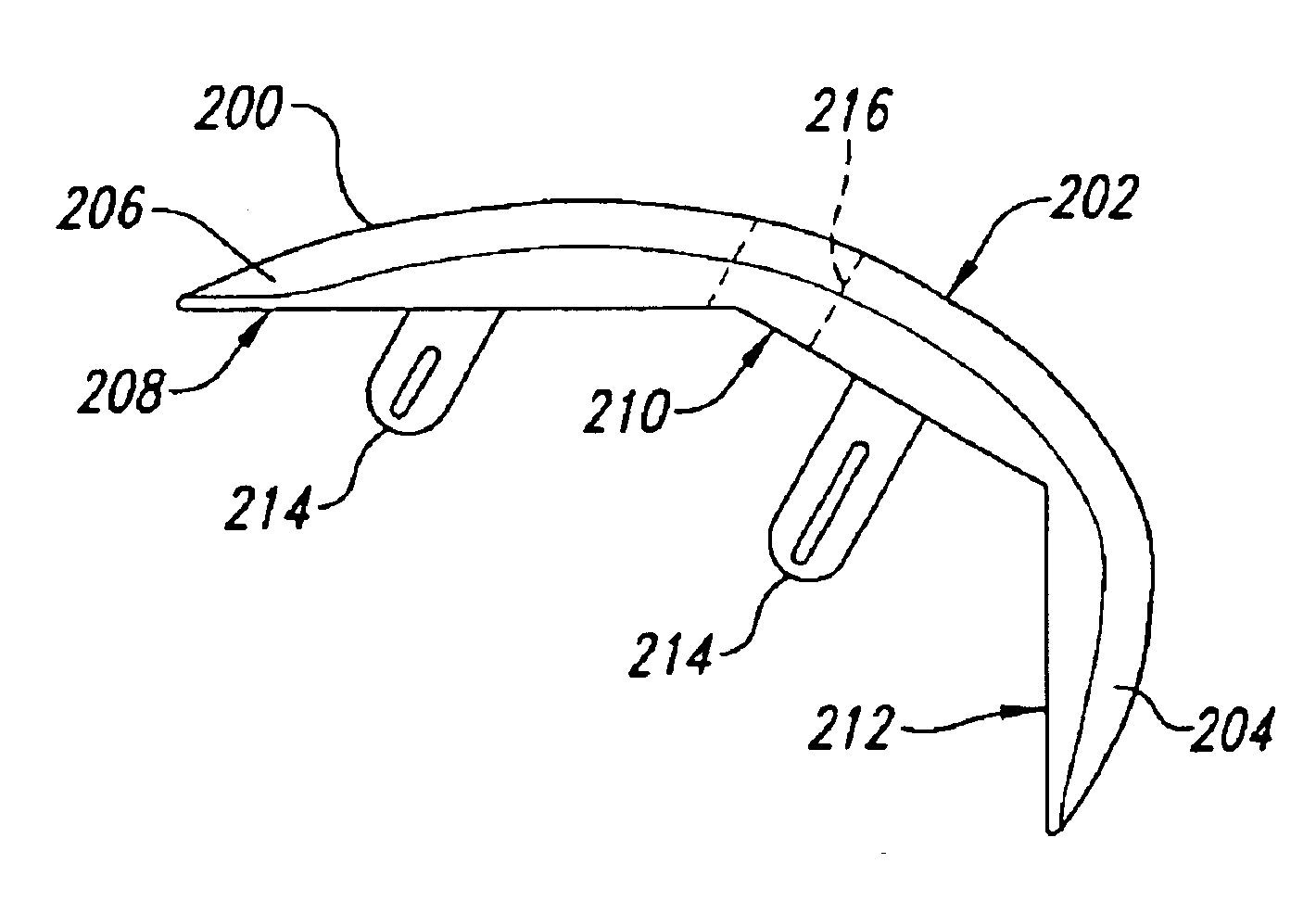

Patellar ligament spacer for acl injuries

ActiveUS20130190886A1Invasive stabilizationReduce frictionSurgeryJoint implantsPosterior cruciate ligamentAnterior Cruciate Ligament Injuries

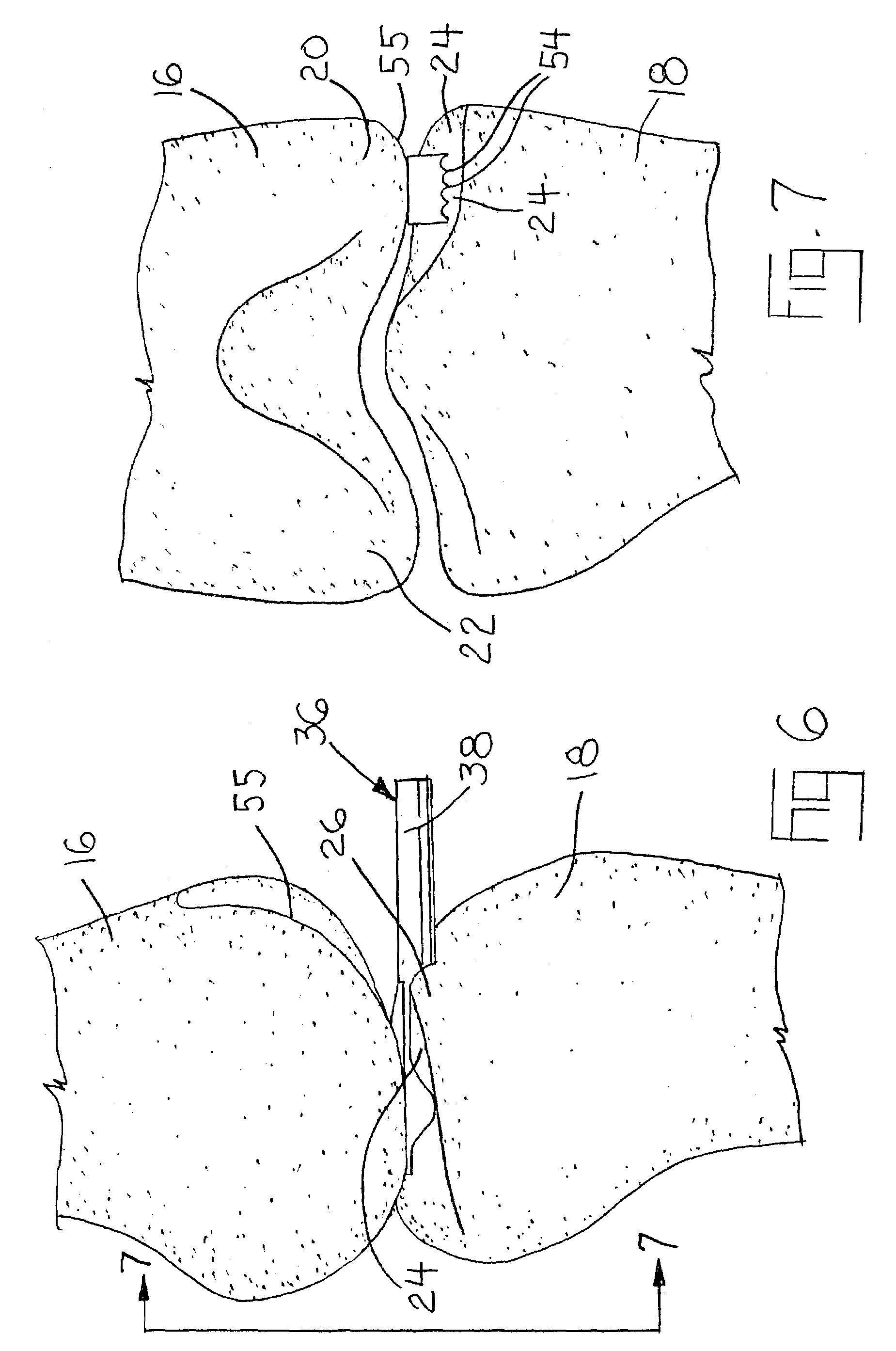

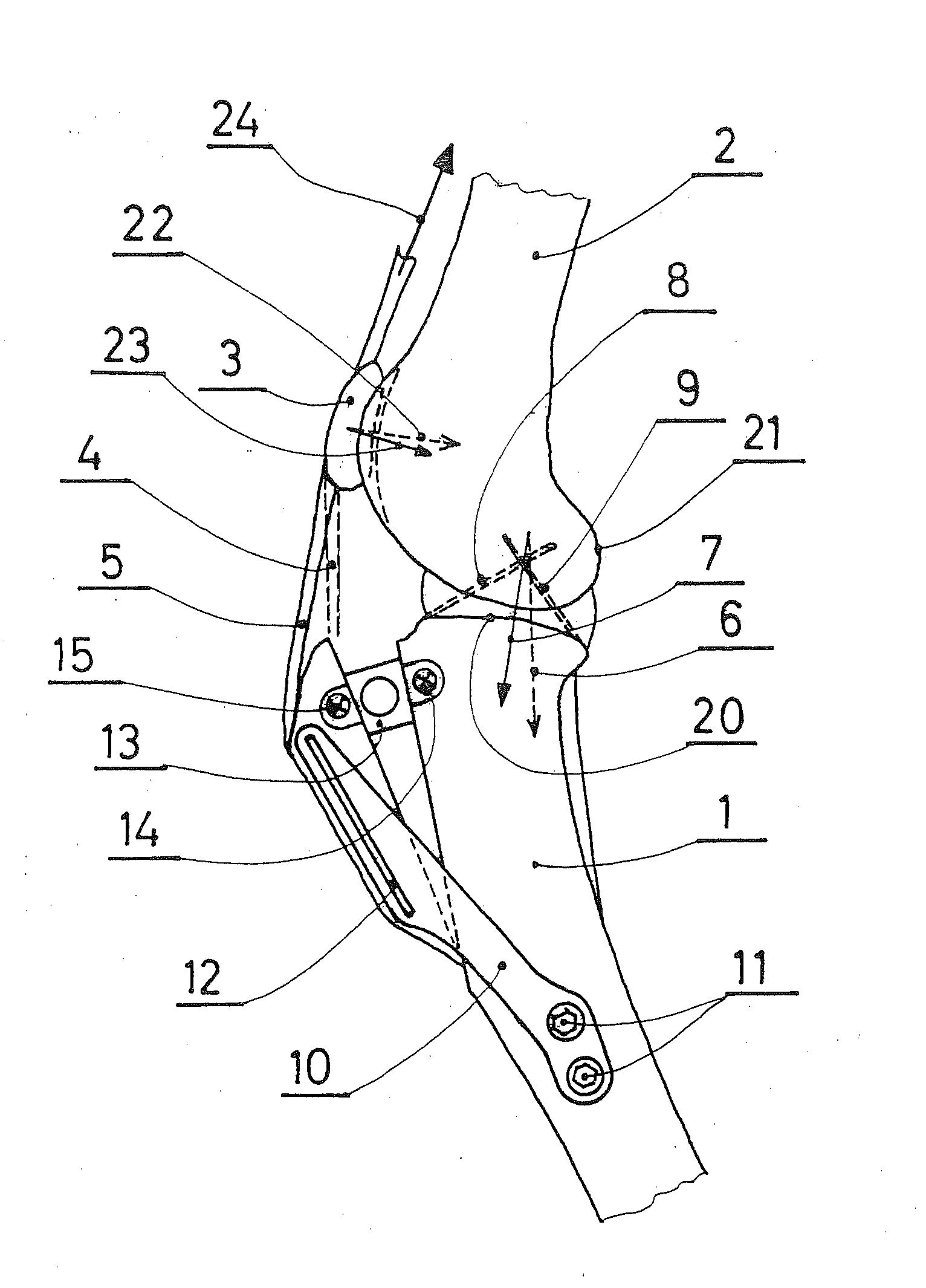

A method and implant to treat anterior cruciate ligament (ACL) injuries are disclosed. The method involves advancing the insertion of the patellar ligament to the proximal tibia. The implant includes a spacer (30) which is inserted between the patellar ligament and the tibia and fixed to the tibia. The spacer decreases the angle between the patellar ligament and the tibia plateau and consequently modifies the internal joint force, restoring stability to the joint even if the ACL is ruptured. The method and implants are applicable to both human and canine patients.

Owner:KYON

Bone shaping device for knee replacement

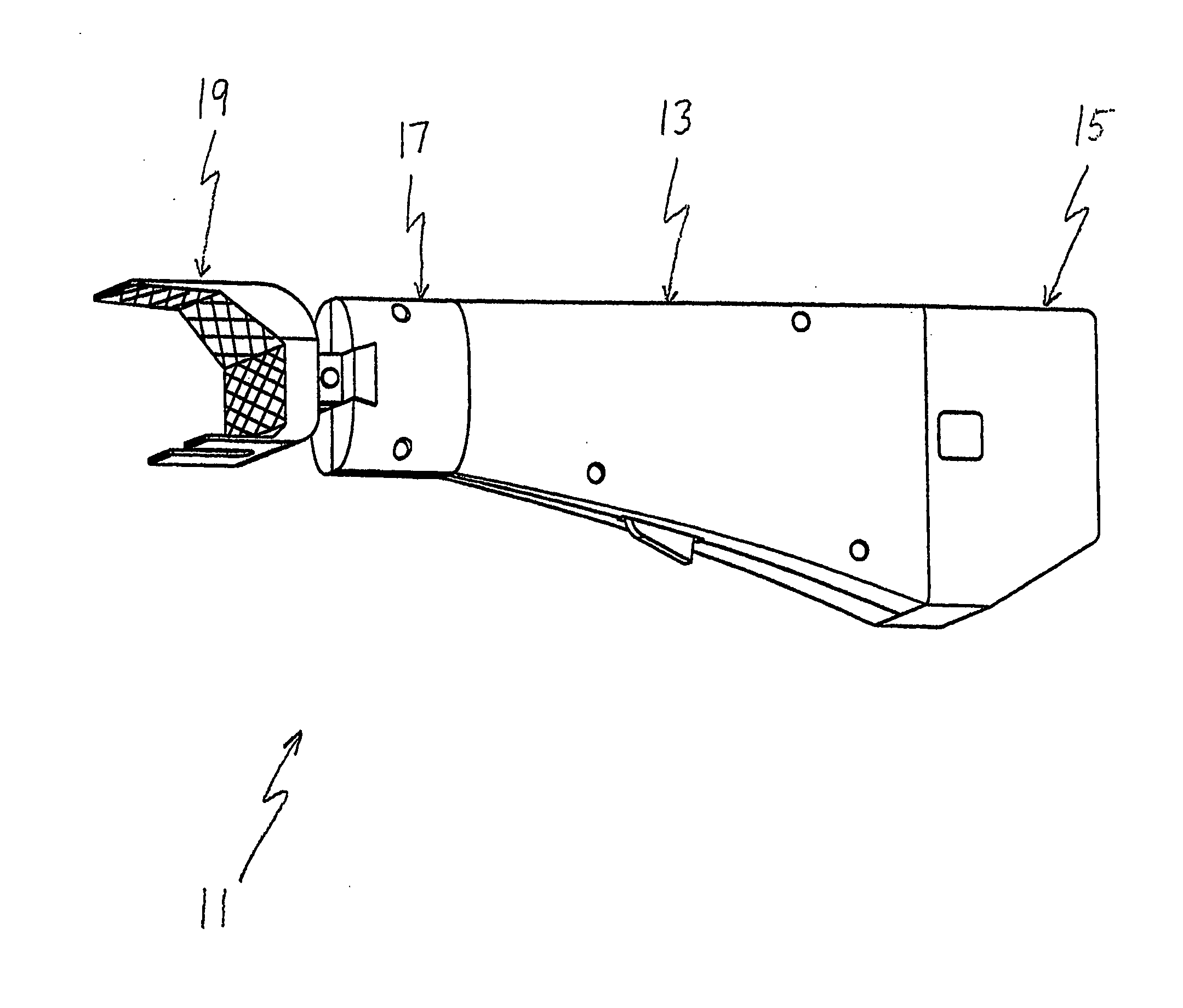

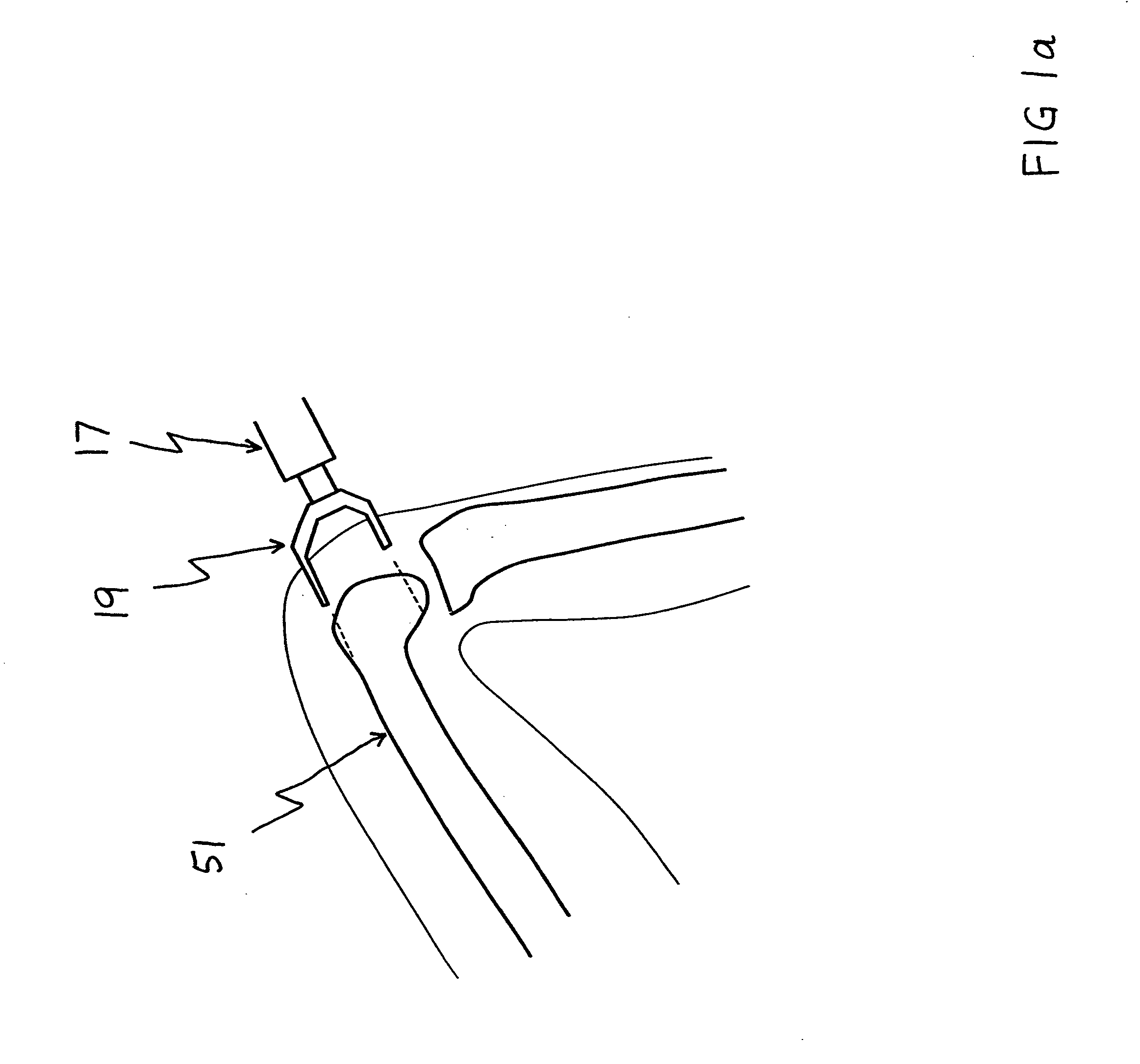

InactiveUS20050192584A1Reduction in time taken to cutReduction in to shape bone surfaceDiagnosticsSurgical navigation systemsTibiaKnee Joint

A bone surgery device with a reciprocating cutting head. The device comprises several sets of shaping surfaces sometimes including cutting blades, which are located and oriented so as to shape the distal end of the femur and the proximal end of the tibia for total knee replacements and unicompartmental knee replacements. The device, which may be hand directed or aided by spatial and directional guiding mechanisms or an optical navigation system, may also include both coolant supply for controlling heat during bone cutting and shaping, and a suction method for carrying away fluid and debris. The device is substantially configured to the artificial joint component to be attached thereto.

Owner:WALKER PETER STANLEY +1

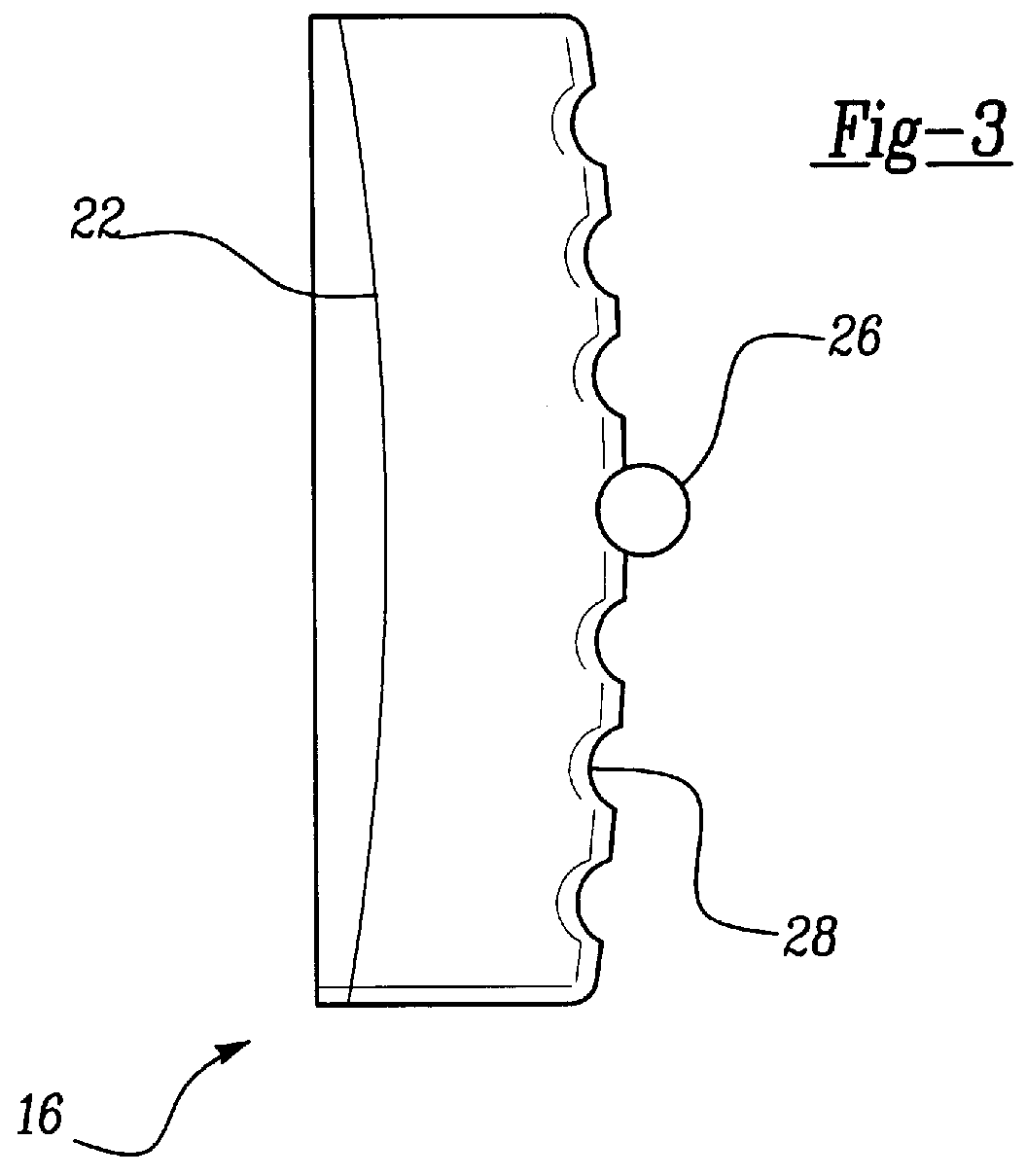

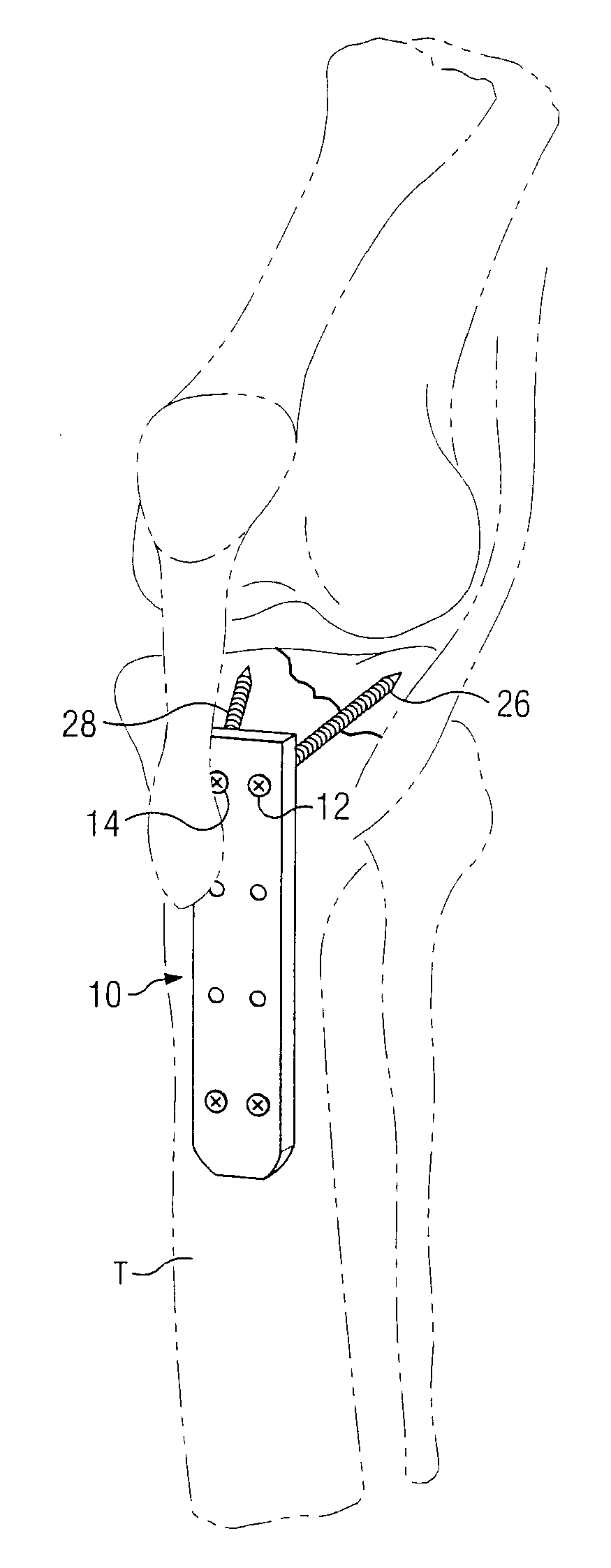

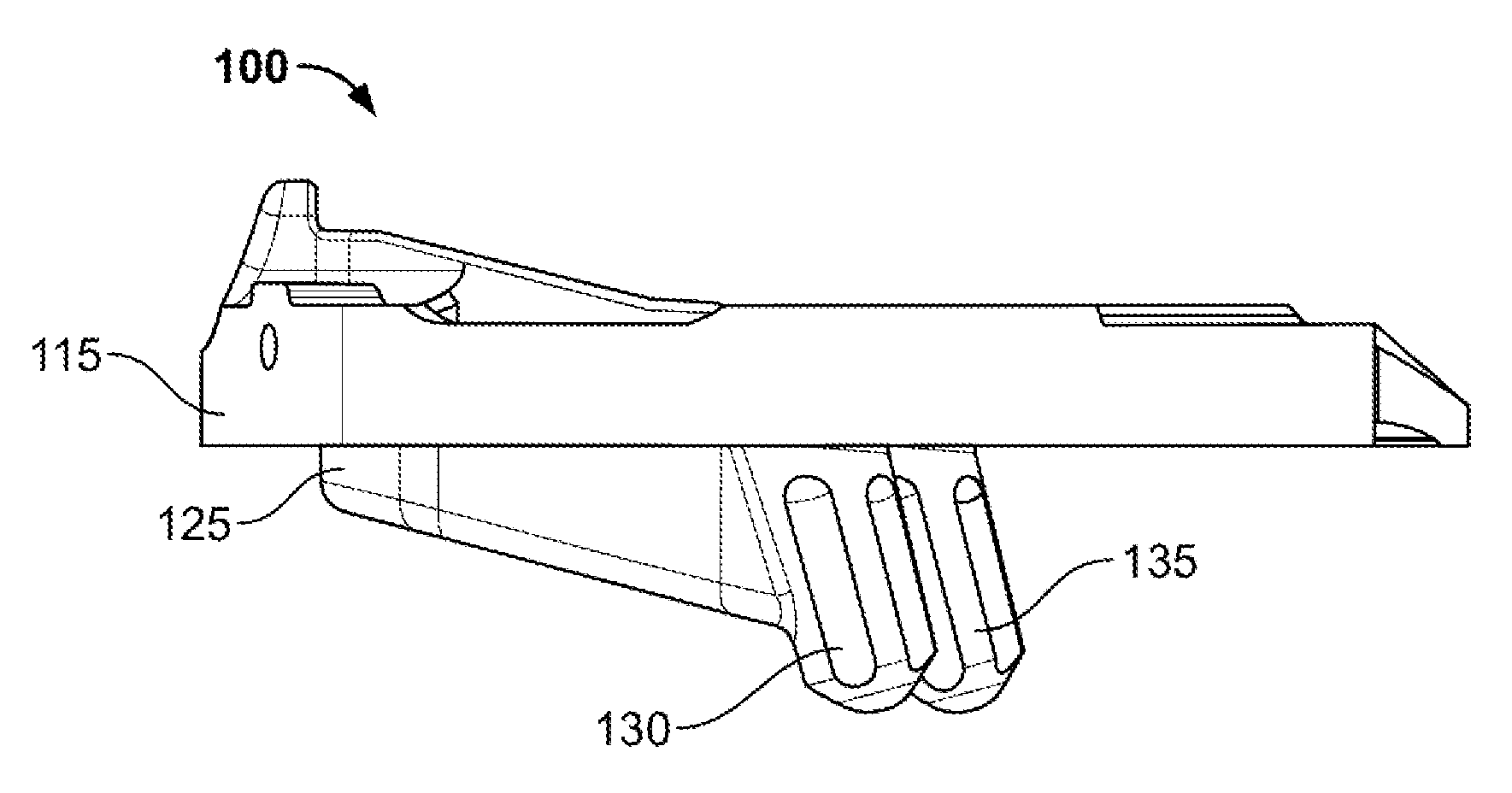

Percutaneous Fixator and Method of Insertion

The present invention provides a technique for percutaneous intramedullary fixation. A protective outer sheath is provided for internal fixation of the proximal tibia. Additionally, a unique intramedullary plate is provided that is adapted for percutaneous insertion into the intramedullary canal of a long bone. A plate holder is also provided that may be utilized through the outer sheath to drive and position a fixation plate within the intramedullary canal.

Owner:COLE J DEAN

Stabilizing prosthesis support structure

ActiveUS8900317B2Promote recoveryFacilitates preservation and rebuildingJoint implantsKnee jointsBone stockBone ingrowth

A tibial support structure includes a platform portion and a medullary portion that are monolithically formed as a single piece. The medullary and platform portions of the augment component are adapted to accommodate and mechanically attach to a tibial baseplate, and are individually shaped and sized to replace damaged bone stock both within the tibia, as well at the tibial proximal surface. The monolithic formation of the tibial support structure provides a strong and stable foundation for a tibial baseplate and facilitates restoration of the anatomic joint line, even where substantial resections of the proximal tibia have been made. The tibial support structure may be made of a bone-ingrowth material which facilitates preservation and rebuilding of the proximal tibia after implantation, while also preserving the restored joint line by allowing revision surgeries to be performed without removal of the tibial support structure.

Owner:ZIMMER INC

Tibial base plate and method for attaching a tibial base plate on a tibia

A tibial base plate for attaching to a resected surface at a proximal end of a tibia is provided. The tibial base plate includes a bridge, a pair of compartments and a stem. The bridge has a first contact surface sitting on the resected surface. The compartments are disposed at opposite sides of the bridge and extend in an anterior-posterior direction to form a notch to accommodate a tibial eminence. Each of the compartments has a second contact surface sitting on the resected surface. The stem is connected to the bridge and the compartments and inset into the proximal end of the tibia. The stem has an outer surface. The outer surface is canted towards the notch as insetting into the proximal end of the tibia. The stem is engaged with a cutting slot on the resected surface into the proximal end of the tibia.

Owner:AOD HLDG

Method and apparatus for osteosynthesis

A bone plate assembly including a first plate, a coupler, a second plate, and a guide; the first plate defining a window and having a first major surface adapted to conform to a native bone structure. The coupler such as a beveled edge and / or slide mechanism can be formed on a second major surface of the first plate opposite the first major surface. The second plate can be adapted to engage the coupler, to cover the window, and to conform to the native bone structure. The second plate can include through holes adapted to receive bone screws. The guide can be adapted to engage the coupler and to guide at least one of a cutting tool and / or a dilation tool. The native bone structure is distal radius, proximal femur, distal femur, proximal tibia, distal tibia or calcaneus.

Owner:KIRITSIS PAUL

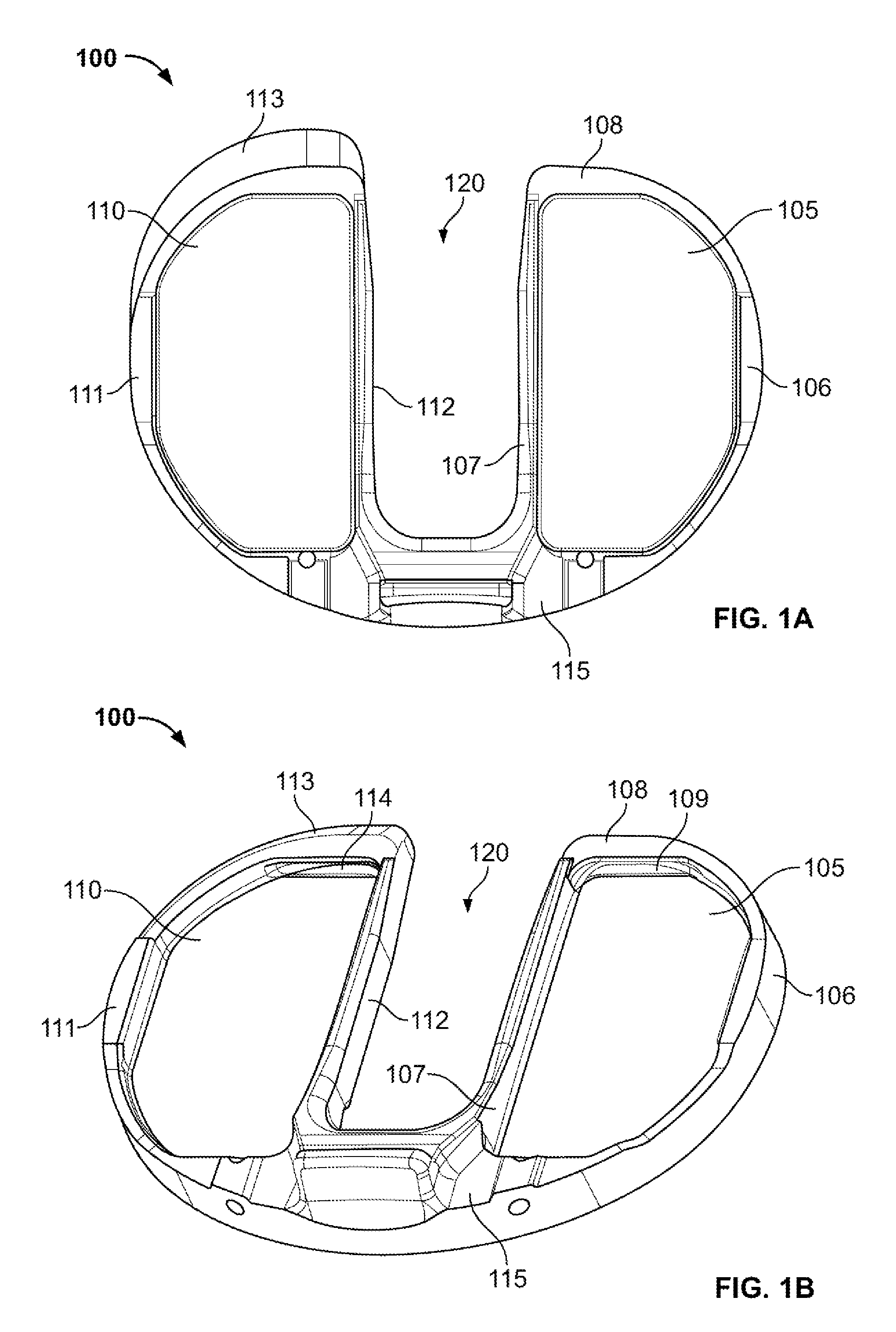

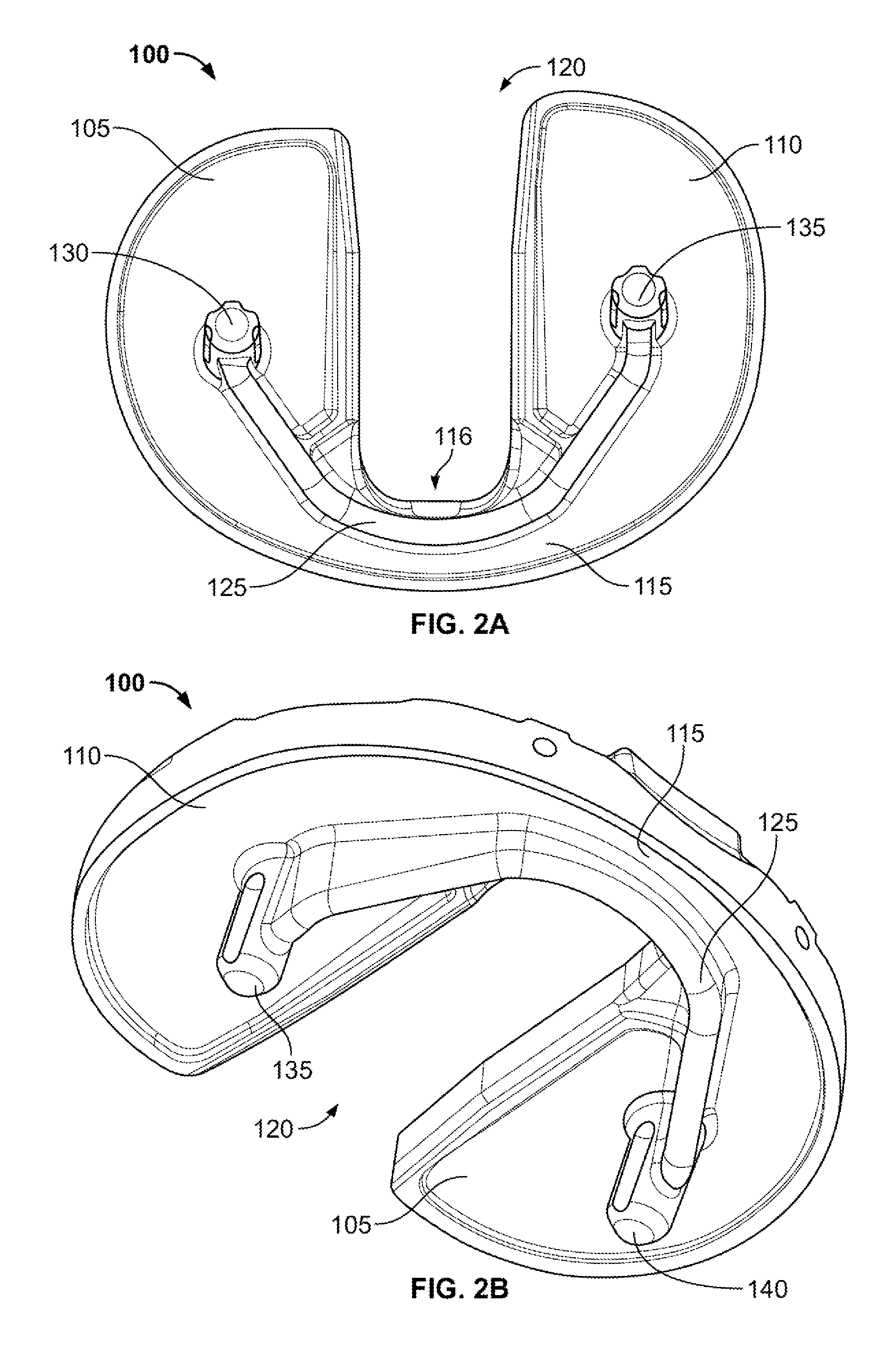

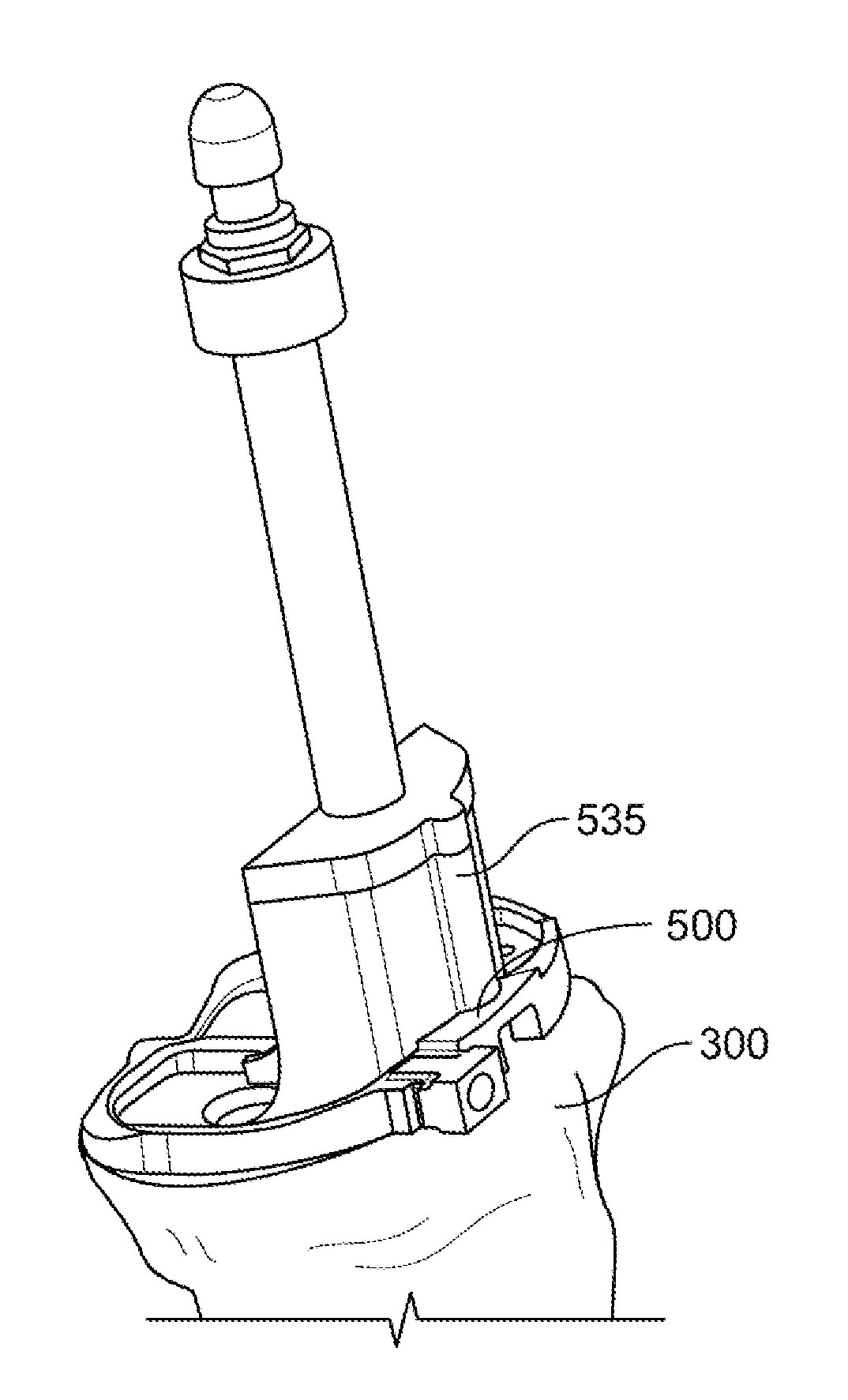

Bicruciate retaining tibial implant system

A bicruciate retaining tibial implant baseplate includes a tibial baseplate with medial and lateral condylar portions configured to receive bearing inserts. The baseplate includes an anterior bridge connecting the medial and lateral portions. A posterior wall of the anterior bridge may be angled to provide downward force on a correspondingly angled anterior portion of the tibial eminence when the baseplate is implanted. A method of preparing the tibia for implant includes a punch tower and punch guide configured to both cut the anterior tibial eminence and provide protection to the tibial eminence during resection of the proximal tibia.

Owner:STRYKER CORP

Instruments and methods for use in performing knee surgery

A system and method for aligning a patient's leg, for establishing the ultimate alignment of the leg prior to making a horizontal femoral cut or a horizontal tibial cut, for preparing the distal femur for receiving a femoral implant, and for making the horizontal, femoral and tibial cuts. The system and method incorporate a spacer, a cutting guide, and a template. The spacer is insertable between a distal femur and a proximal tibia to rotate the tibia with respect to the femur into the desired alignment. The cutting guide is engageable with the spacer, and can be fixed to the proximal tibia and the distal femur. The cutting guide has openings sized and shaped to guide a surgical saw to make the horizontal femoral cut and the horizontal tibial cut. The template is shaped to closely conform with the distal femur to allow the leg to be extended and to allow the procedure to be performed without dislocating a patella. Through one method of the present invention, the practitioner can select the desired ultimate alignment of the leg prior to making the horizontal, tibial and femoral cuts. As a result, when a replacement knee is implanted, the leg will be in the desired alignment.

Owner:WILLIAMSON RICHARD V

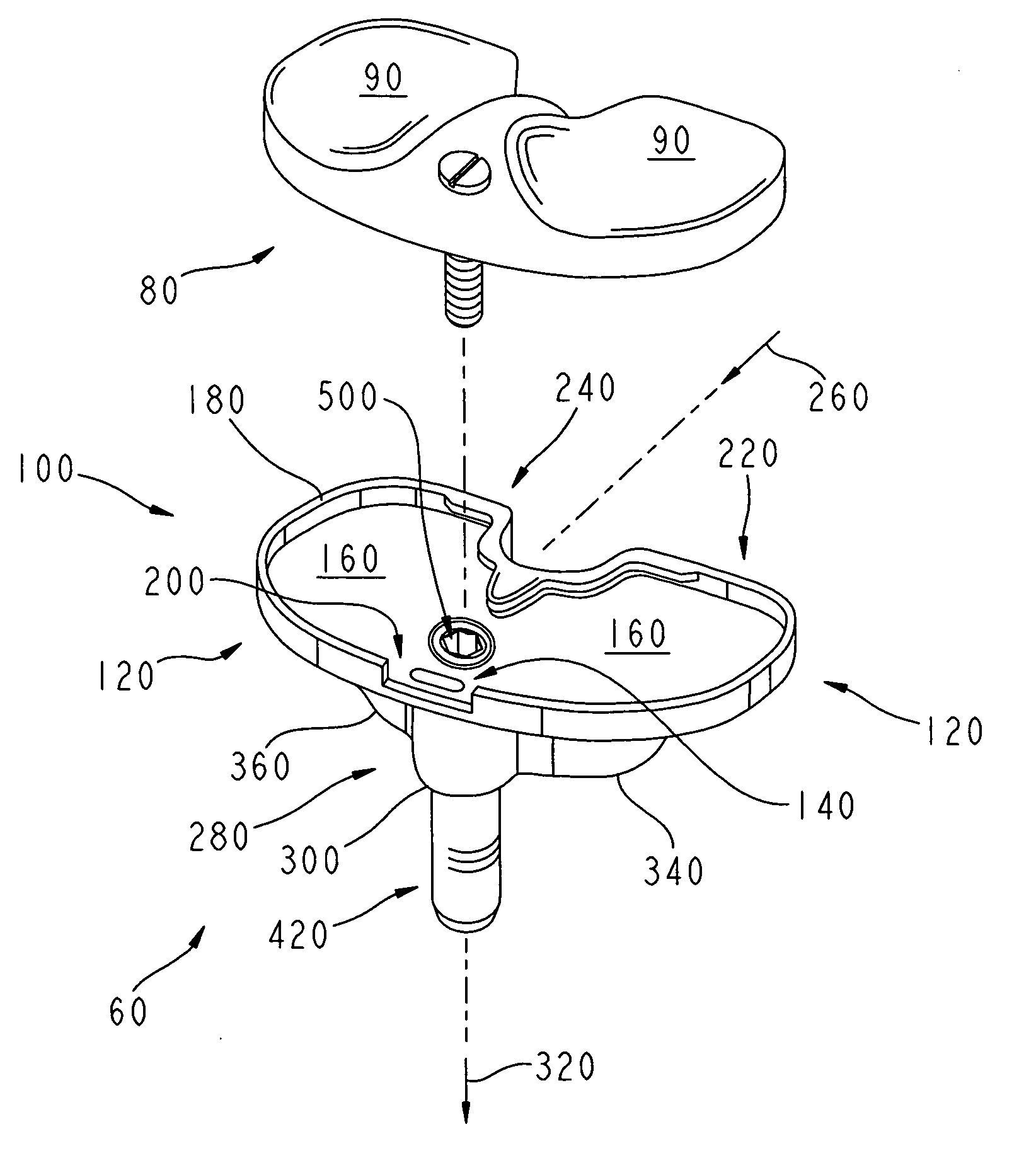

Proximal Tibial Osteotomy System

A support plate, for supporting the two parts of a tibia after a tibial osteotomy, is generally in the shape of a T with a stem having top and bottom ends and a cross piece extending across the top end of the stem. The support plate has a rear surface arranged to contact the tibia. The rear surface of the stem is convex in its central longitudinal plane over a first region of the plate, and the rear surface of the cross piece is concave in its transverse plane.

Owner:OXFORD UNIV INNOVATION LTD

Tibial implant with a through post

A tibial implant apparatus includes a tibial plate, a base extending from the tibial plate, and an elongated member. The elongated member includes a first portion and a second portion. The tibial plate and the base define a through-channel. The first portion of the elongated member is retained in the through-channel. The second portion of the elongated member extends away from the base. An implant apparatus for a proximal tibia is also provided. A method for anchoring a first member of a tibial implant and a second member of a tibial implant in a proximal tibia is also provided.

Owner:ZIMMER TECH INC

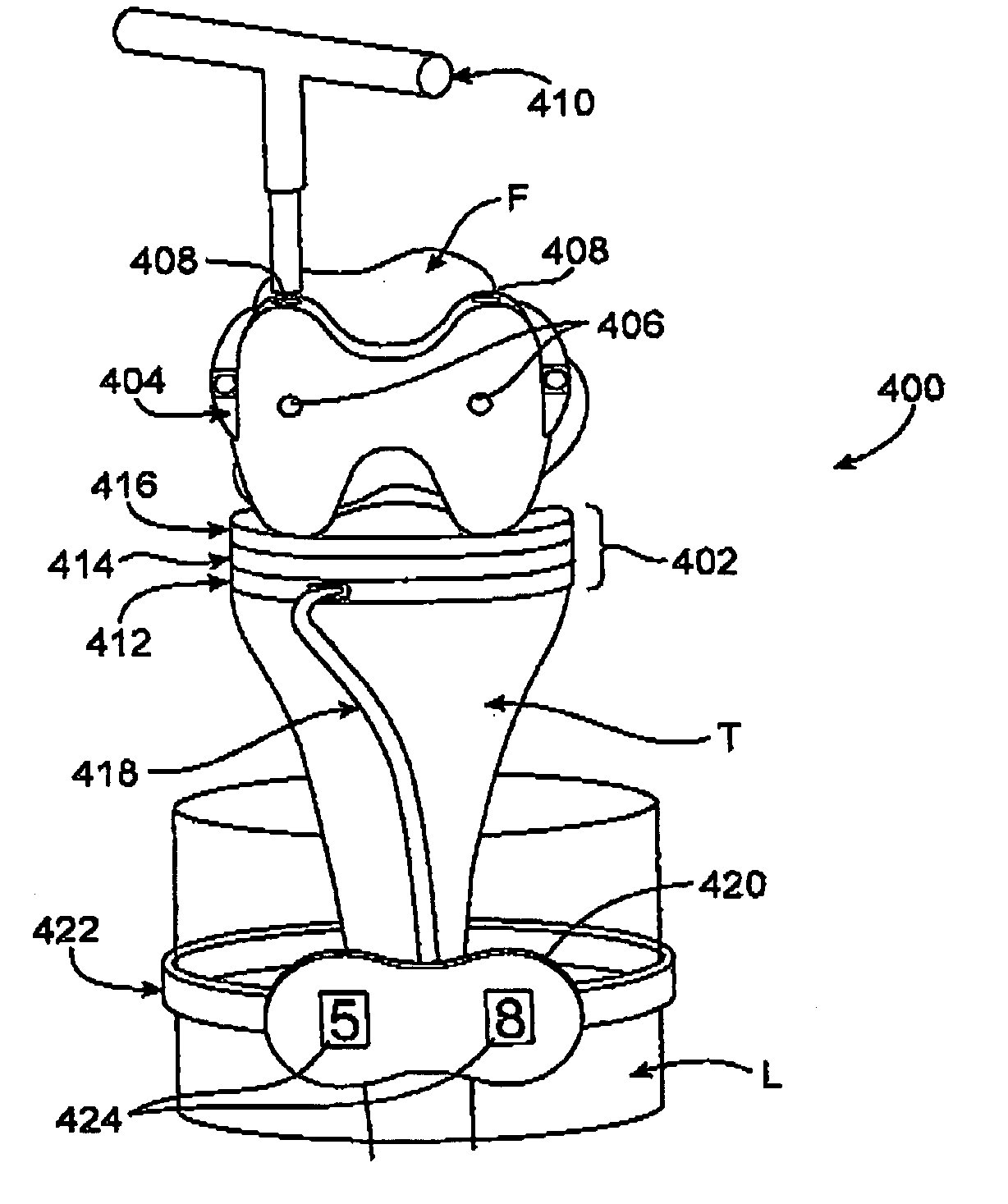

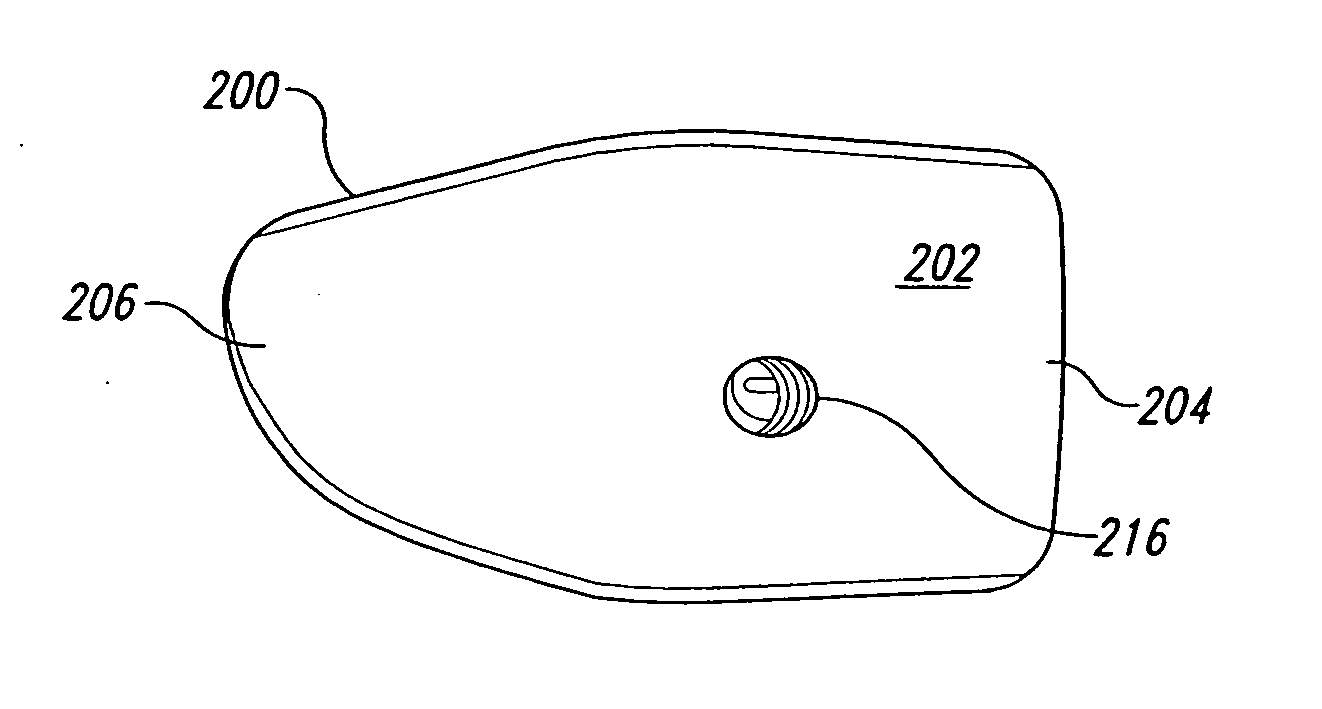

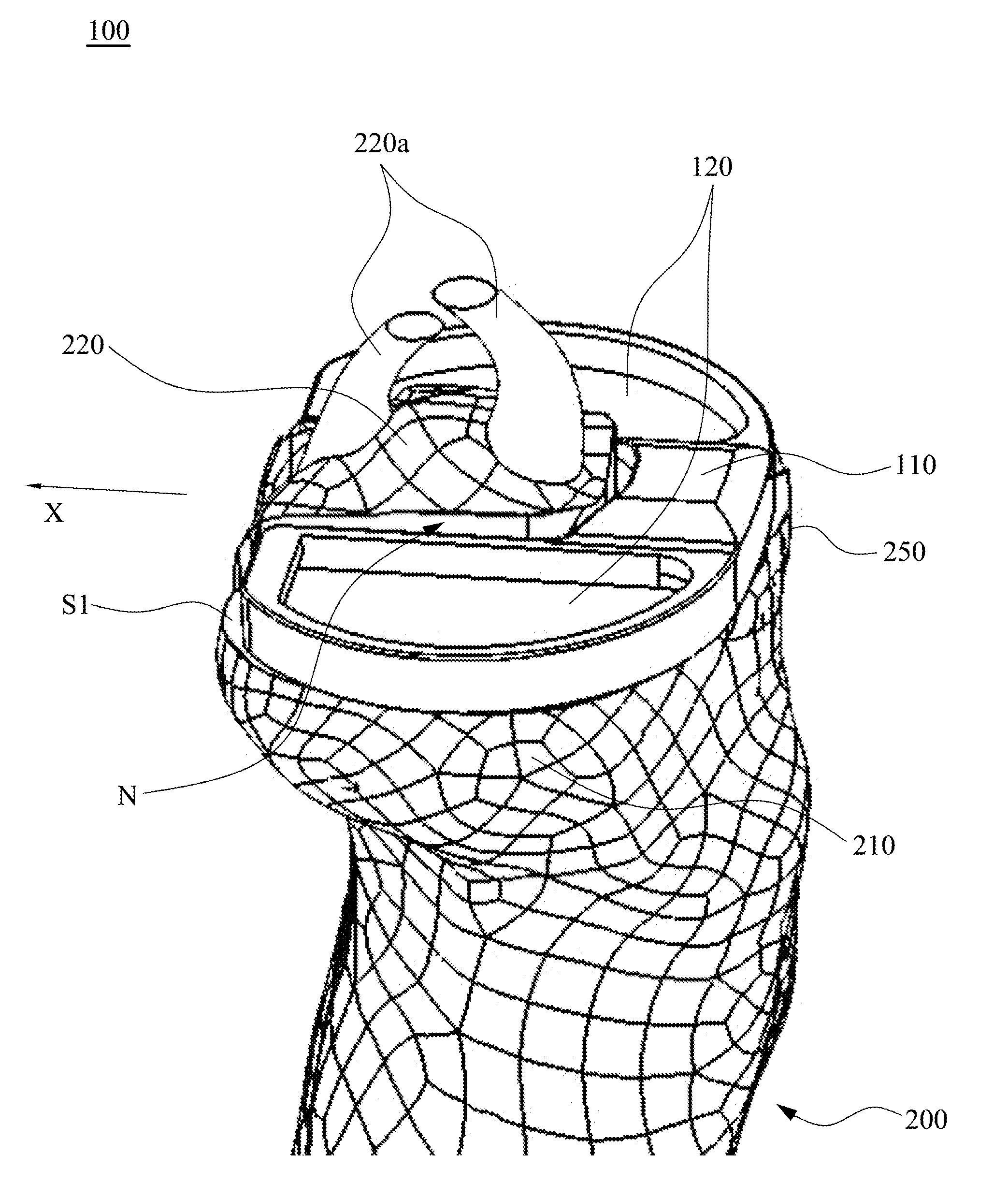

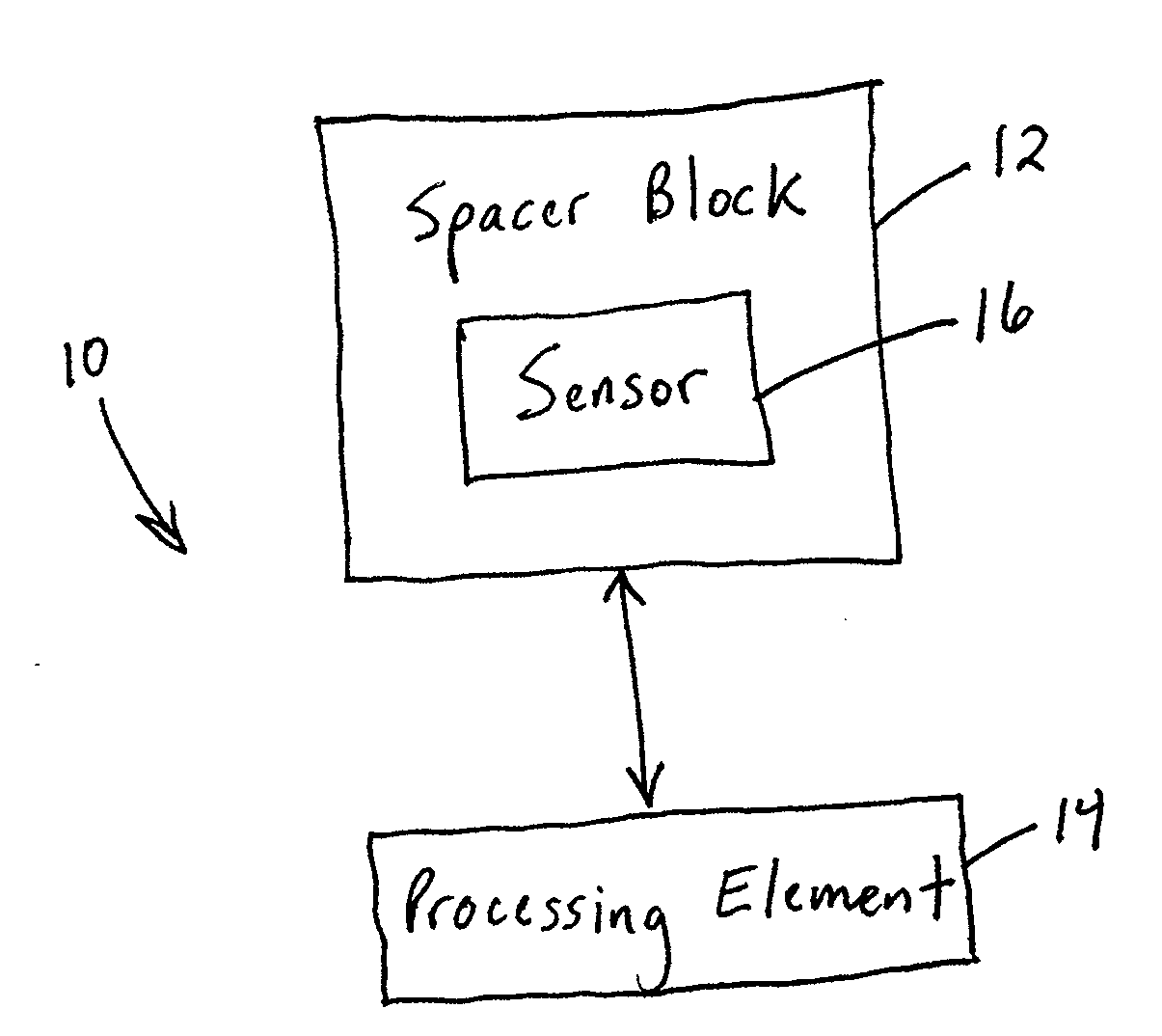

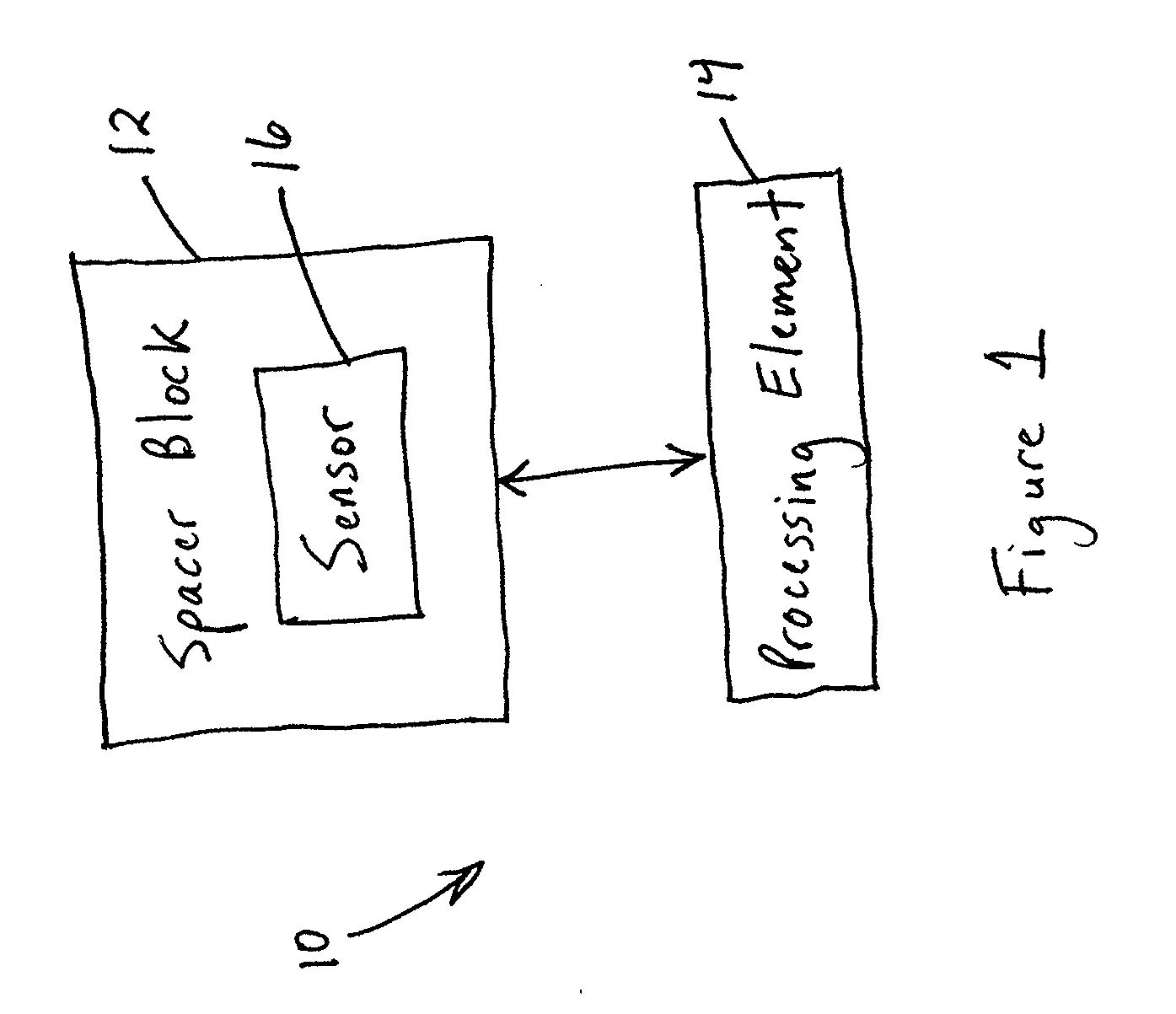

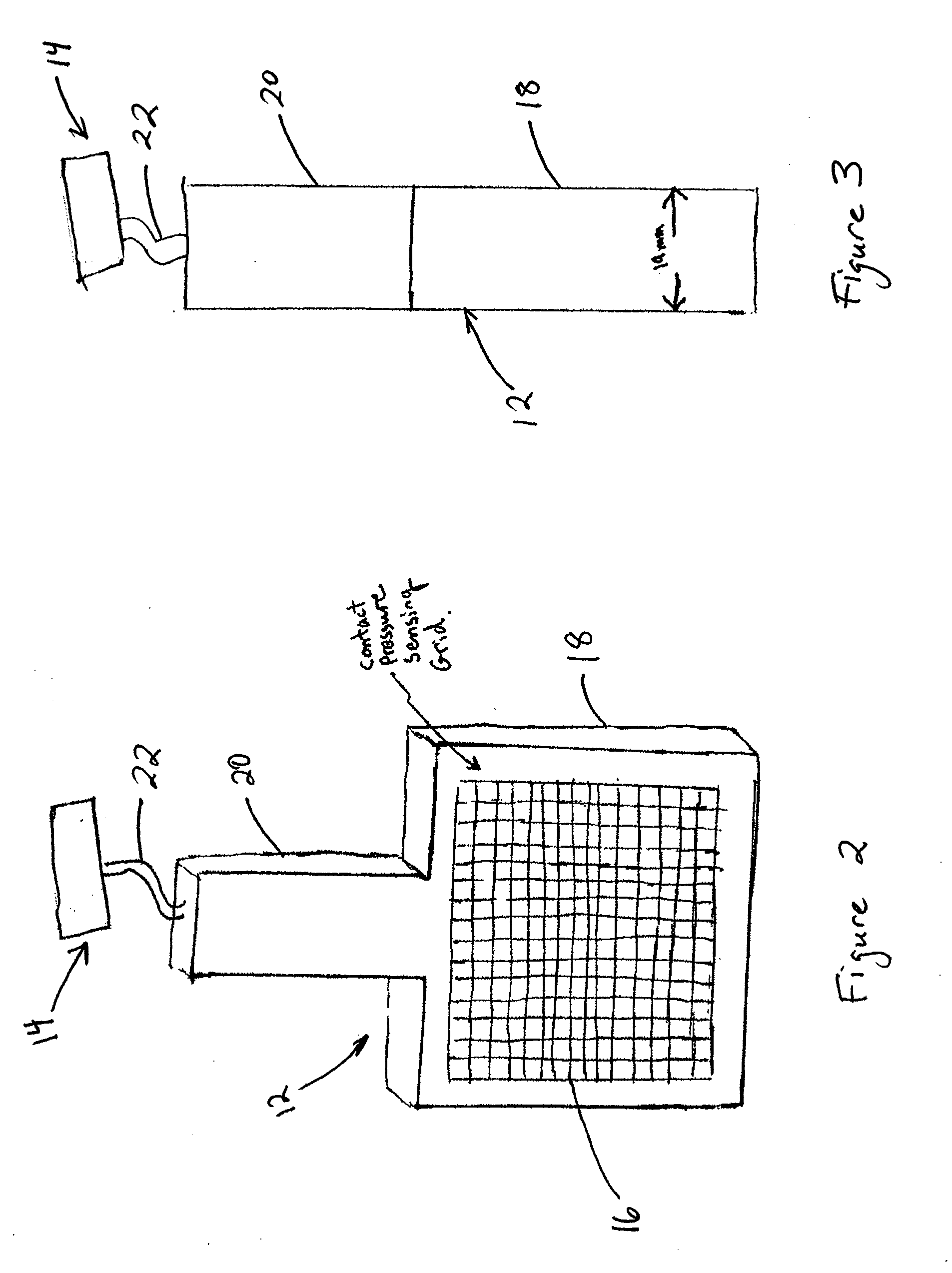

Spacer block with sensor for total knee arthroplasty

Embodiments of the present invention relate to a force sensing system and method for total knee arthroplasty. For example, a force sensing system includes a spacer block that is adapted to be positioned adjacent a resected distal femur and a resected proximal tibia. The spacer block is configured to receive a first force applied by the resected distal femur and a second force applied by the resected proximal tibia. The force sensing system also includes at least one sensor that is associated with the spacer block and that is adapted to measure one or more forces exerted on the spacer block. Moreover, the force sensing system includes a display that is adapted for displaying an indication of the one or more forces measured by the at least one sensor.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

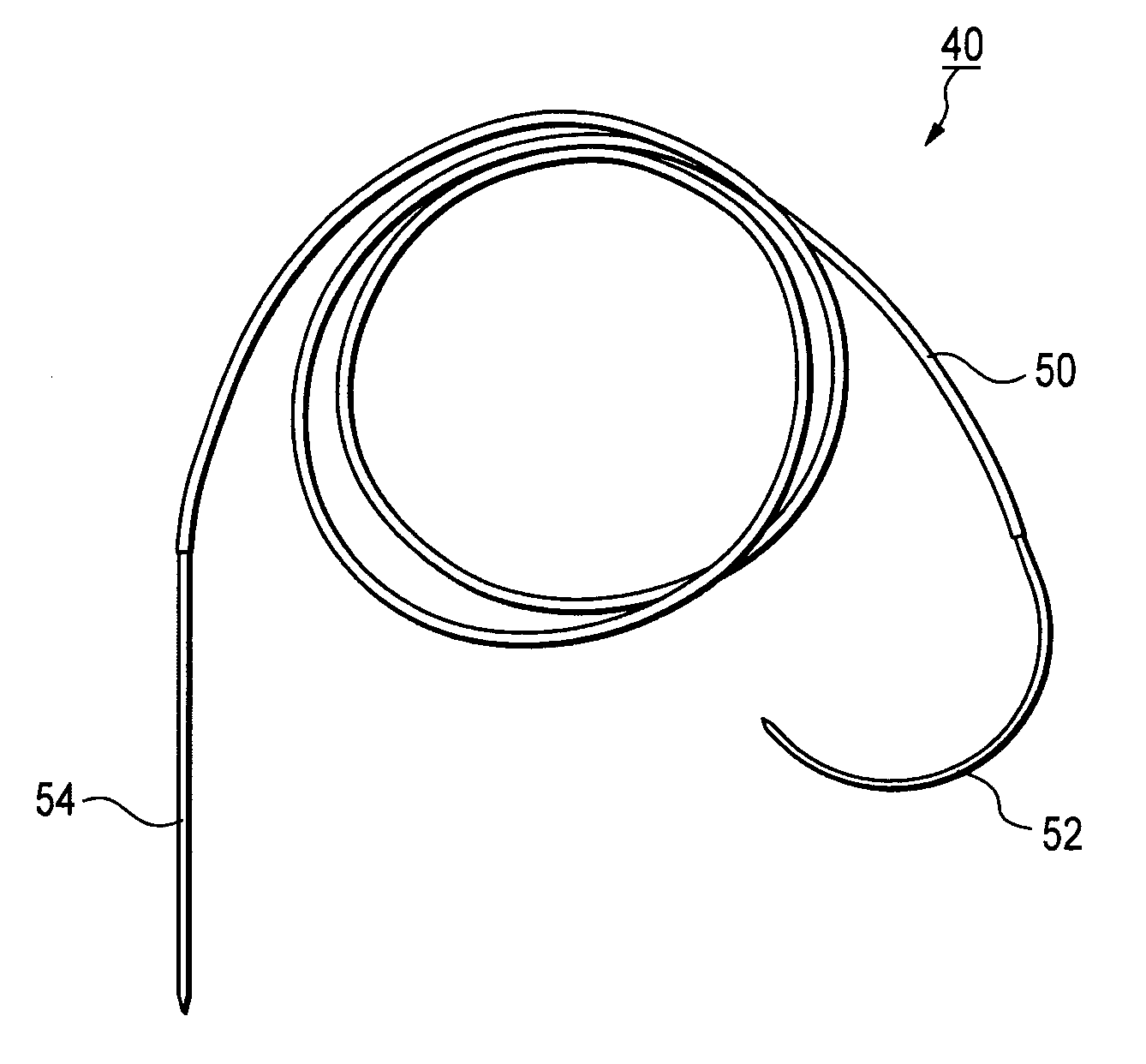

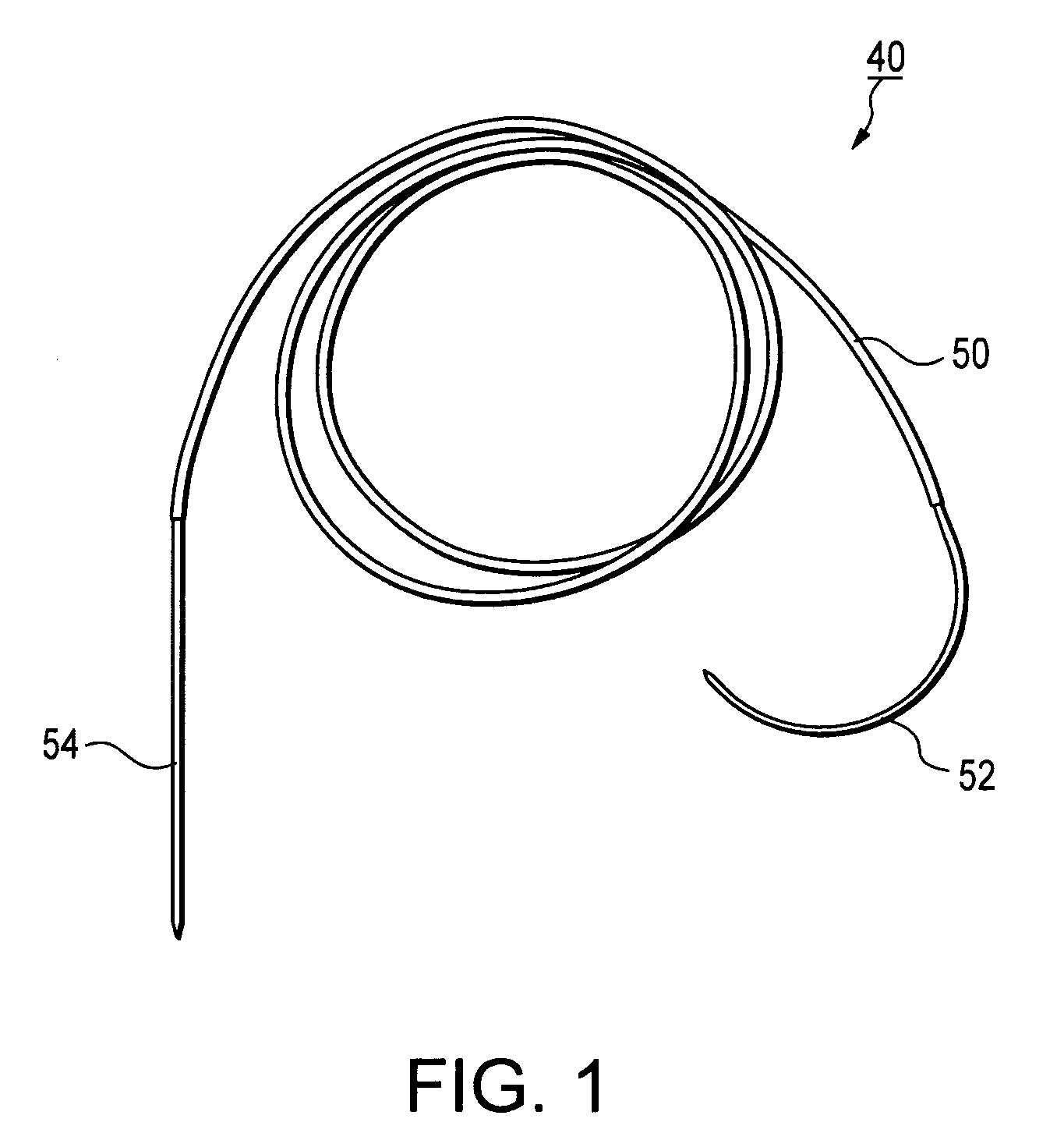

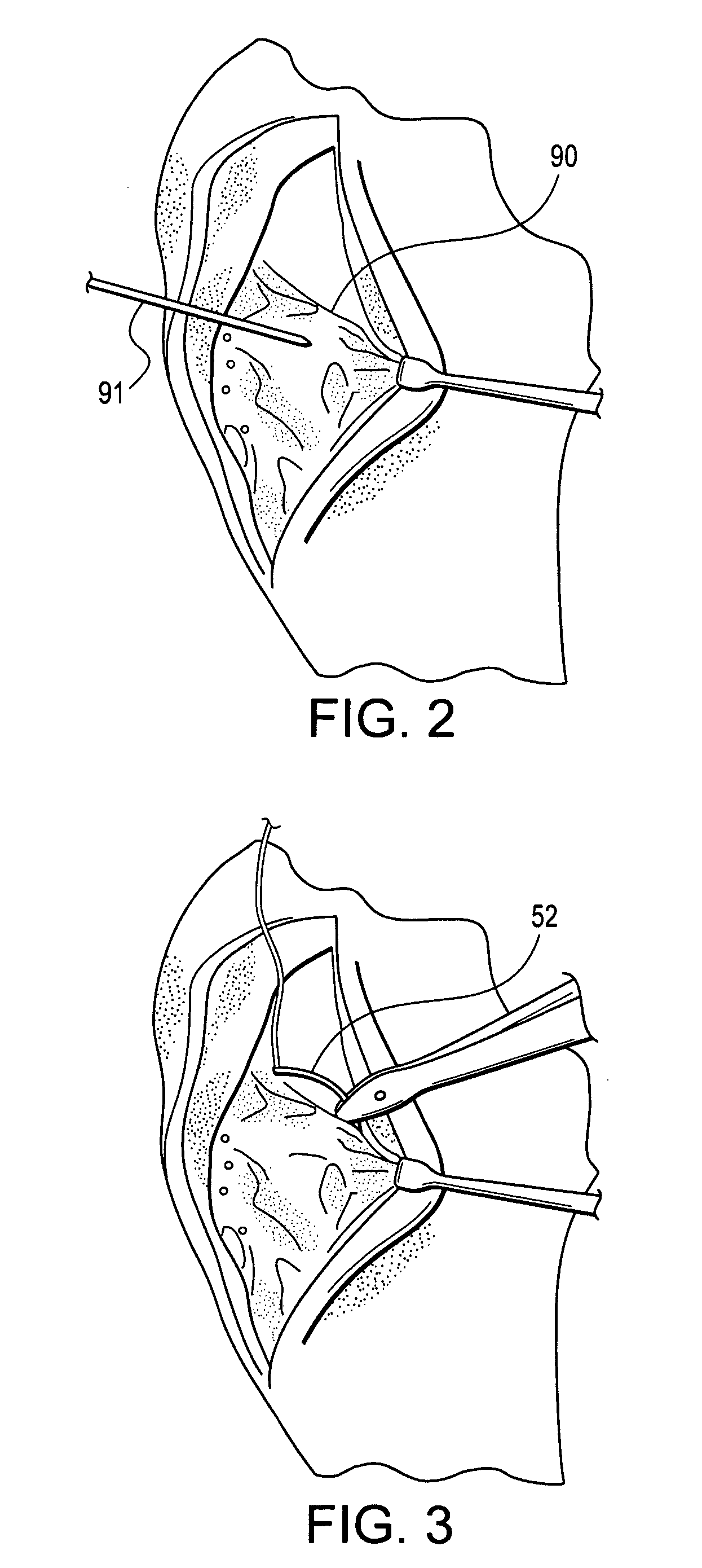

Method and suture needle construct for cruciate ligament repair

A suture needle construct and method for extracapsular ligament reconstruction in mammals. The joint is first is first explored, and the damaged ligament and meniscus are debrided. The joint capsule is closed and a tunnel is created at the appropriate location in the proximal tibia for tibial fixation. Subsequent to the formation of the tibial tunnel, a suture having a substantially curved needle at one end and a substantially straight needle at the other end is brought in the proximity of the joint. The suture is passed around the lateral fabella using the substantially curved needle, then deep to the patellar ligament using the substantially straight needle, and through the tibial tunnel using the straight needle. The needles are cut off, and the sutures are tensioned over repair site.

Owner:ARTHREX

Bicruciate retaining tibial implant system

A bicruciate retaining tibial implant baseplate includes a tibial baseplate with medial and lateral condylar portions configured to receive bearing inserts. The baseplate includes an anterior bridge connecting the medial and lateral portions. A posterior wall of the anterior bridge may be angled to provide downward force on a correspondingly angled anterior portion of the tibial eminence when the baseplate is implanted. A method of preparing the tibia for implant includes a punch tower and punch guide configured to both cut the anterior tibial eminence and provide protection to the tibial eminence during resection of the proximal tibia.

Owner:STRYKER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com