Patents

Literature

167 results about "Joint line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Joint line [knee] definition, joint line [knee] meaning | English dictionary. joint. n a joint between two plates, planks, bars, sections, etc., when the components are butted together and do not overlap or interlock.

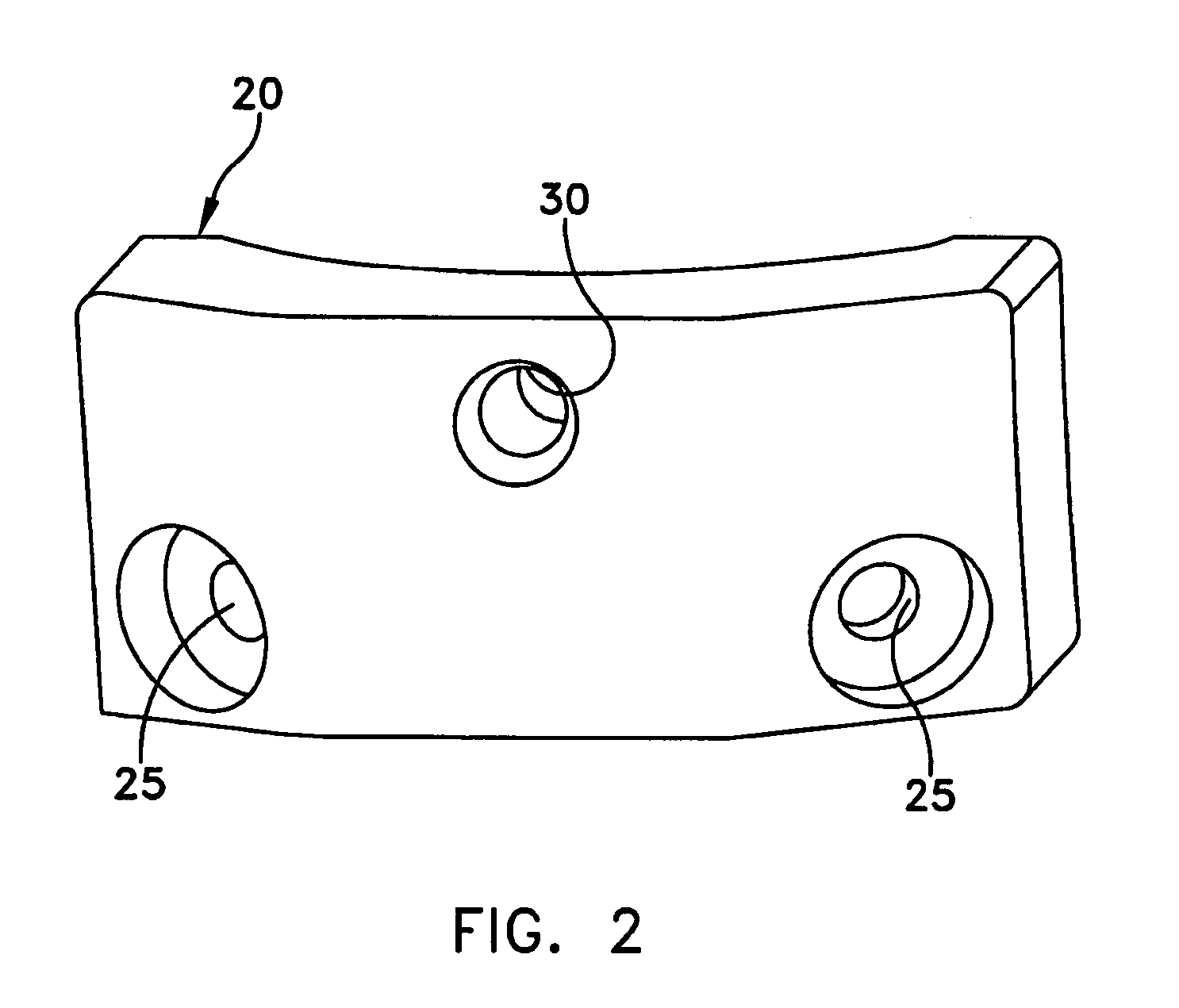

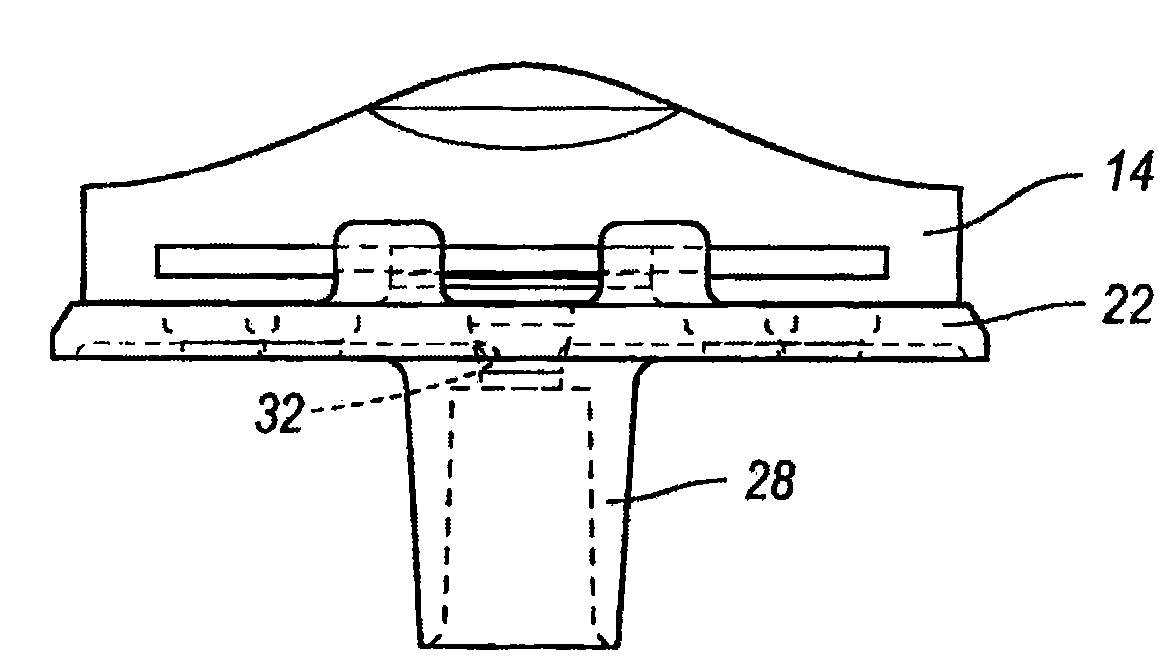

Open wedge osteotomy system and surgical method

ActiveUS20050273114A1Reduce overall surgeon learning curveInternal osteosythesisDiagnosticsImplantSurgical methods

Owner:ARTHREX

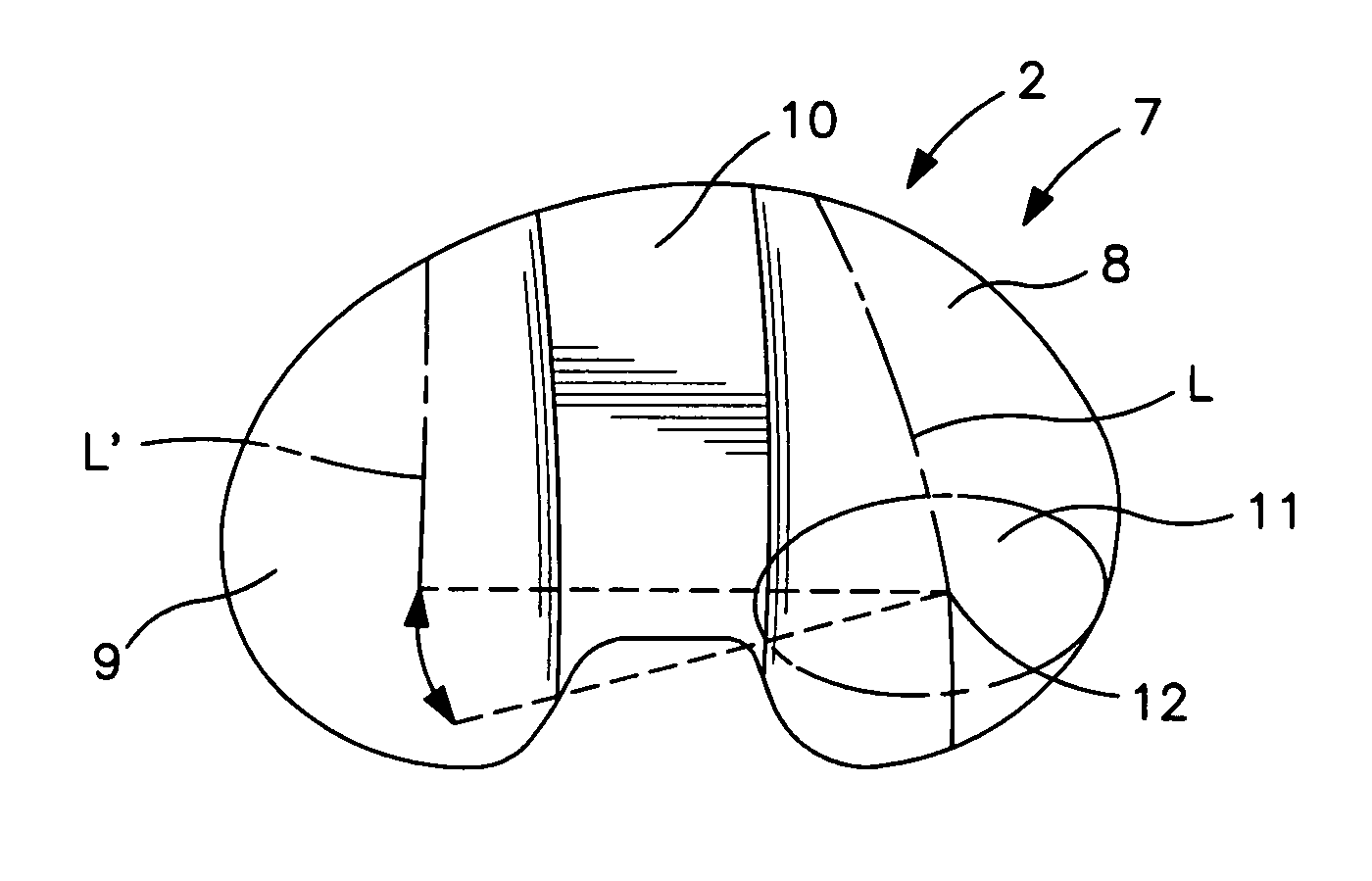

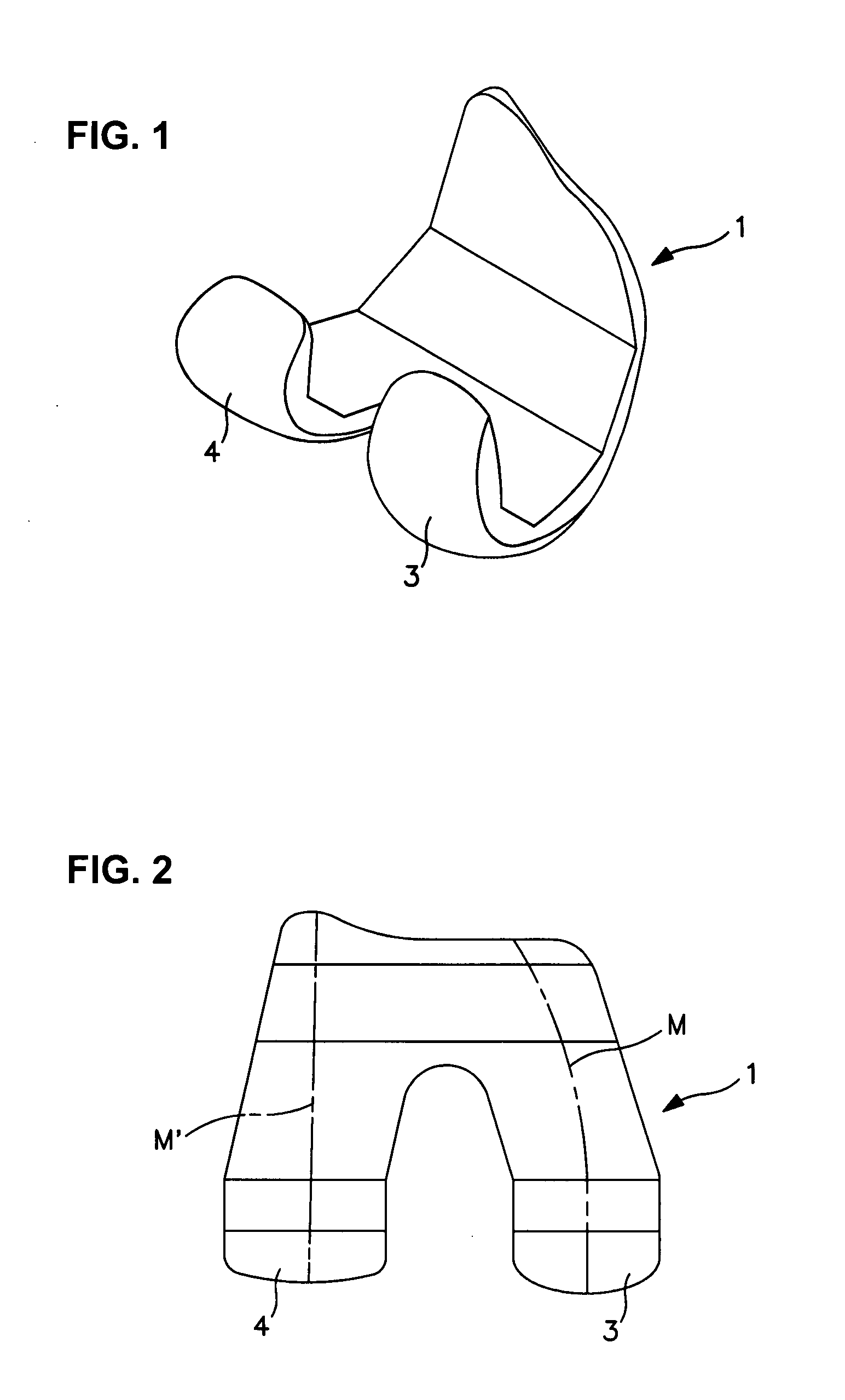

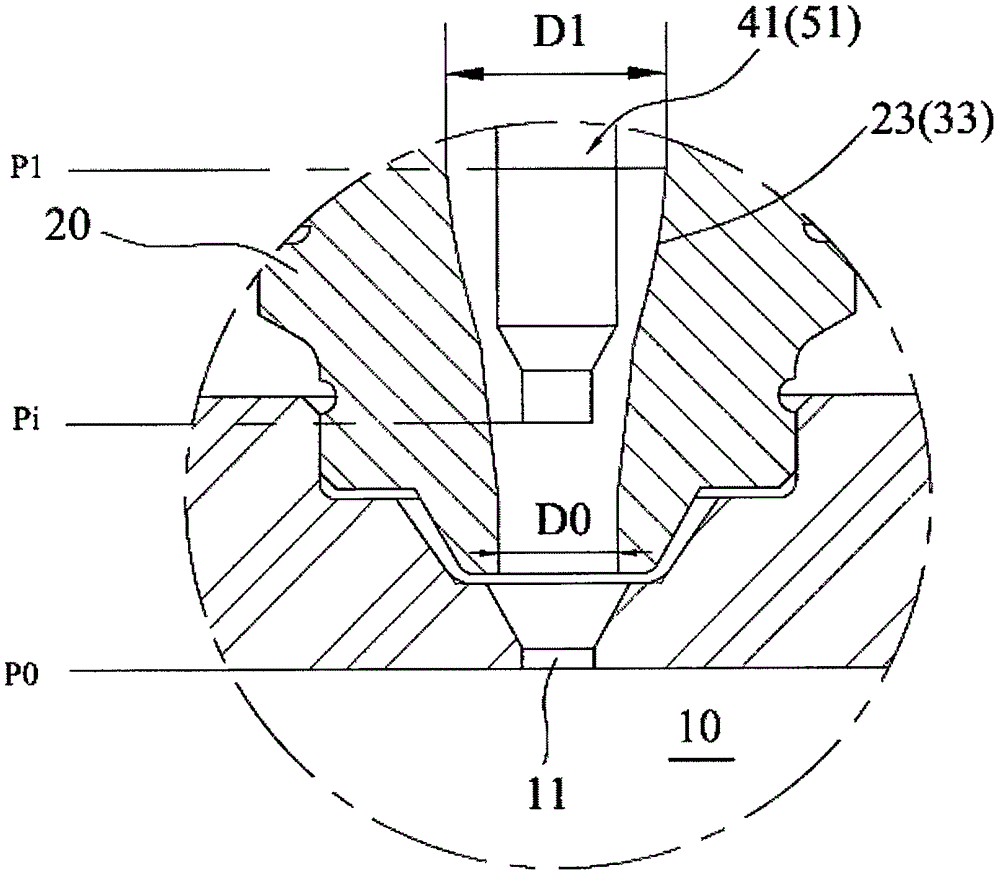

Artificial knee joint

InactiveUS7264635B2Easy to getSmooth flexion-extensionJoint implantsKnee jointsArticular surfacesTibia

An artificial knee joint including a femoral component to be attached to a femur and a tibial component to be attached to a tibia, wherein in the femur component a medial condyle thereof is thicker than a lateral condyle thereof; in the tibial component, a medial articular surface thereof, which supports the medial condyle of the femur component, is thinner or deeper than a lateral articular surface thereof, which supports the lateral condyle of the femur component; and a joint line joining the lowest points of contact surfaces between the medial and lateral condyles of the femur component and the medial and lateral articular surfaces of the tibial component in a longitudinal cross section in a medial-lateral direction is inclined inward at virtually the same angle over the entire region of an angle of flexion-extension.

Owner:NAKASHIMA PROPELLER +1

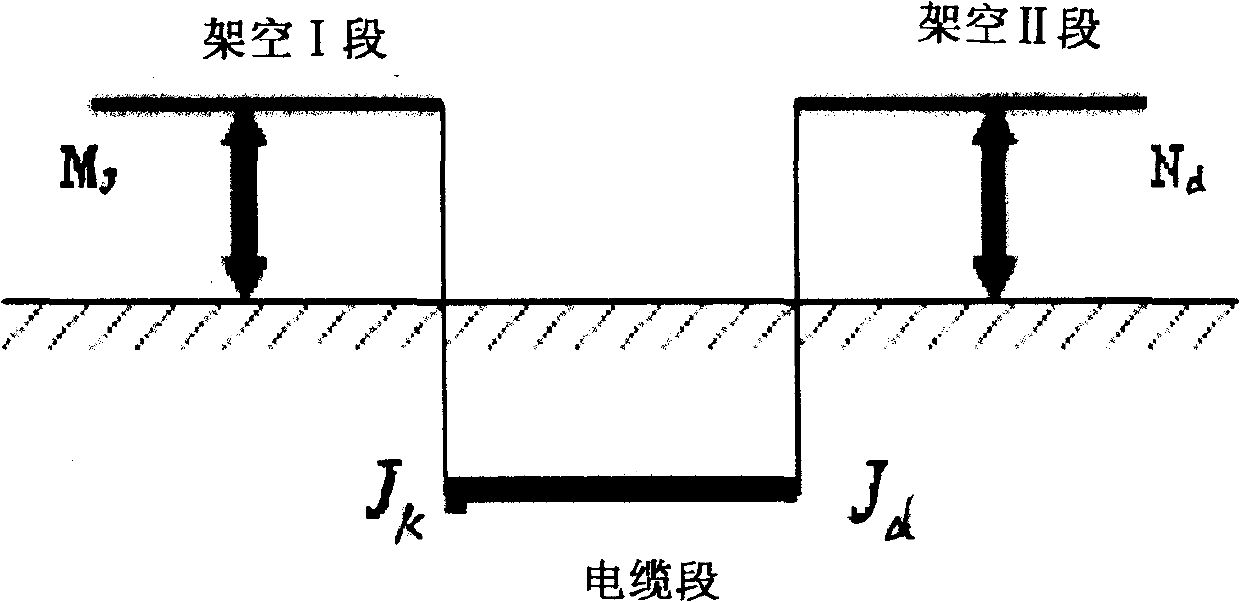

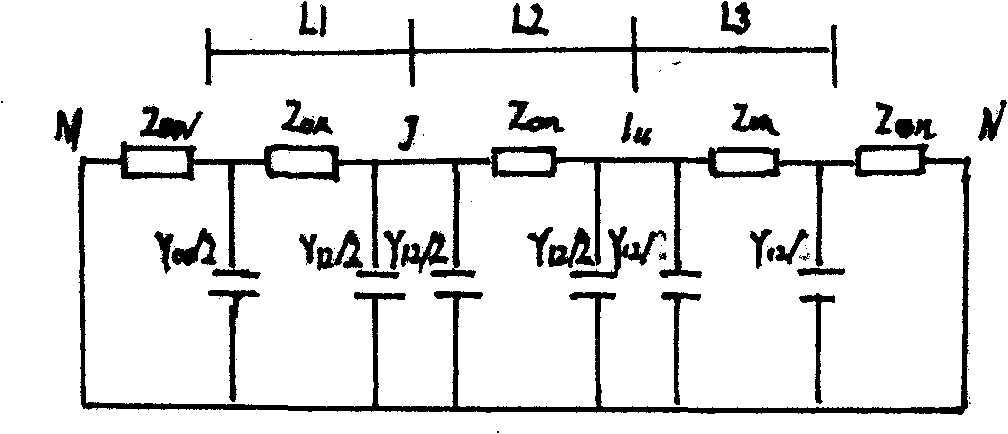

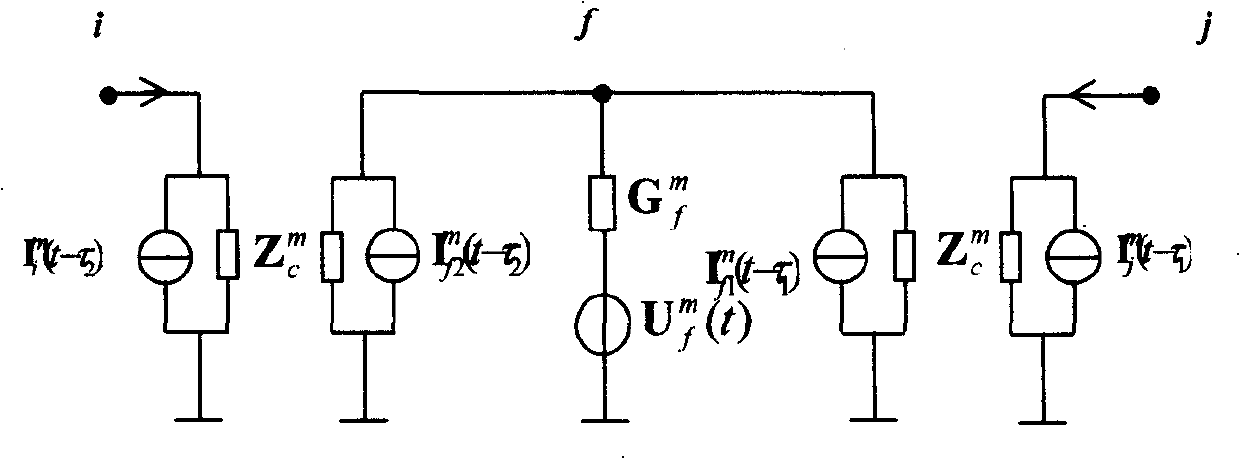

Cable-aerial mixed line fault travelling wave ranging method

InactiveCN101299538AMake up for the influence of frequency-dependent characteristicsAccurately determine the polarity of reflected wavesEmergency protective circuit arrangementsFault locationElectric power systemReflected waves

The invention relates to a cable-overhead joint line failure travelling wave range count method, particularly performing the effective fusion based on the failure range count method of the fundamental frequency and the travelling wave aiming at the particularity and the complexity of the cable joint line, belonging to the technical field of the power system relay protection. The invention judges the failure generating places firstly based on the cable-overhead junction derivated through the electric quantity at the two ends of the system attached with the negative sequence net after the failure, then performs the correct range count by the range count method of the single end; on the basis of considering the line zero modulus component couple, through comparing the performance of the current travelling wave line zero modulus component, the performance of each reflected wave is judged, to find out the fault point reflected wave, and then perform the correct range count.

Owner:KUNMING UNIV OF SCI & TECH

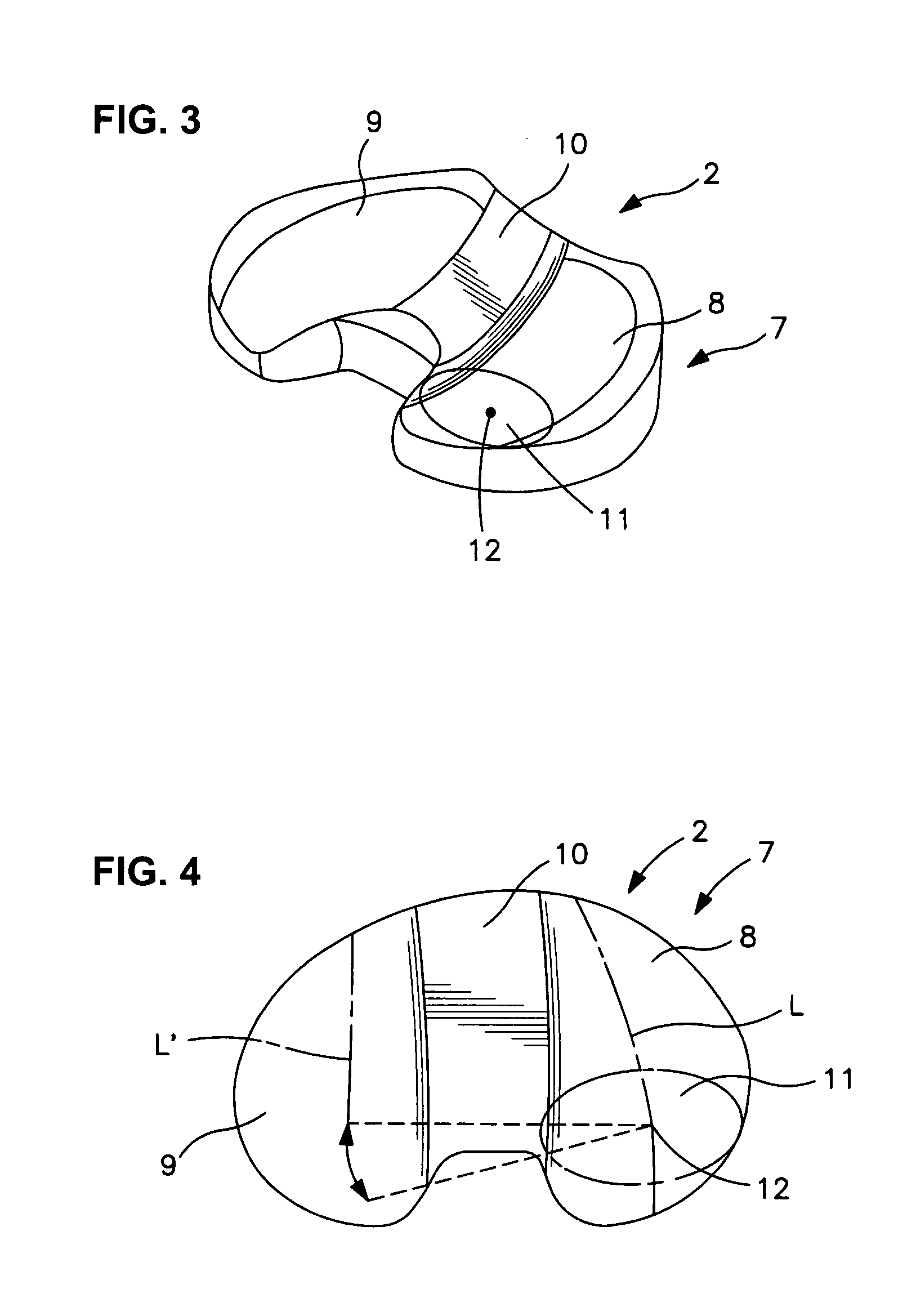

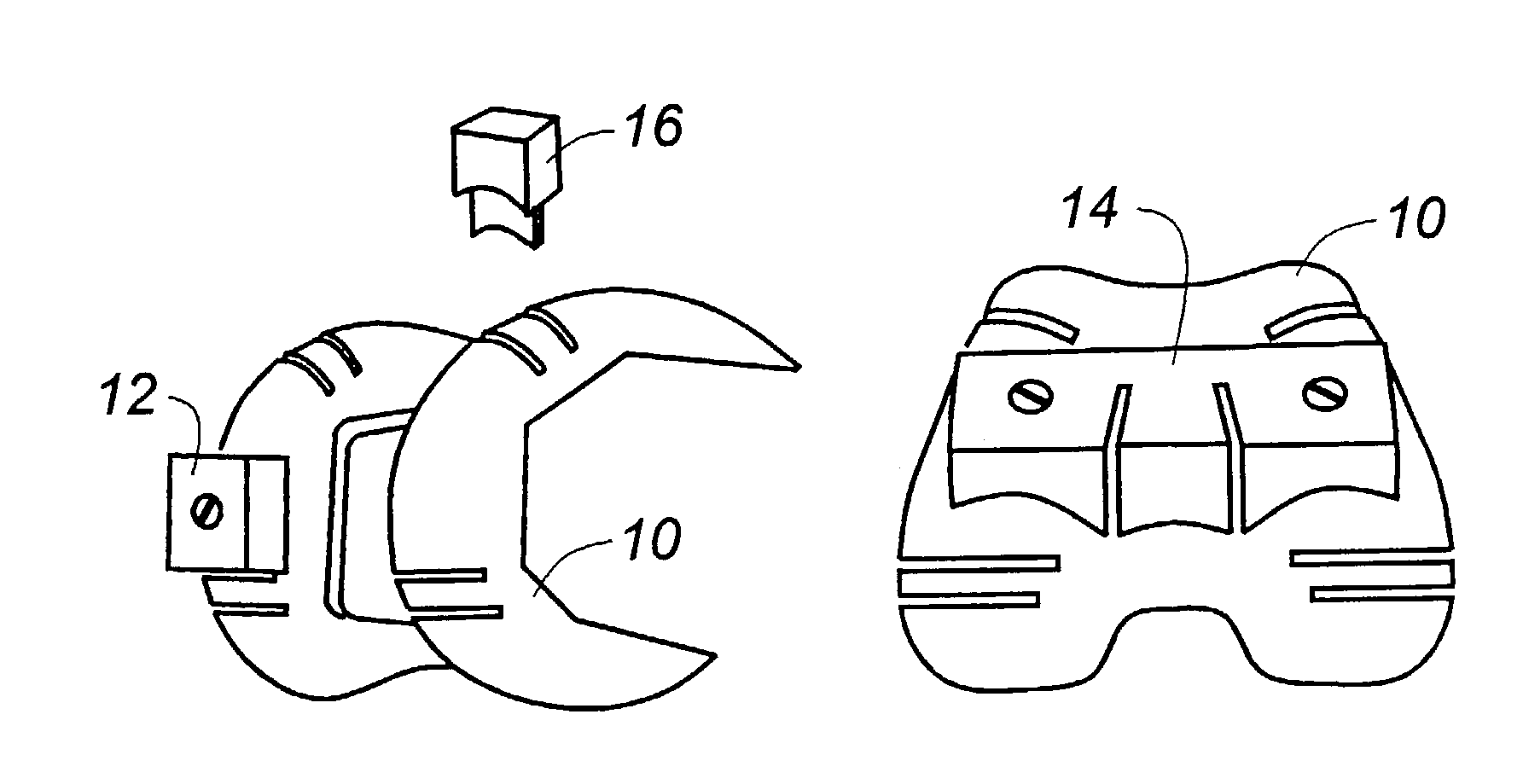

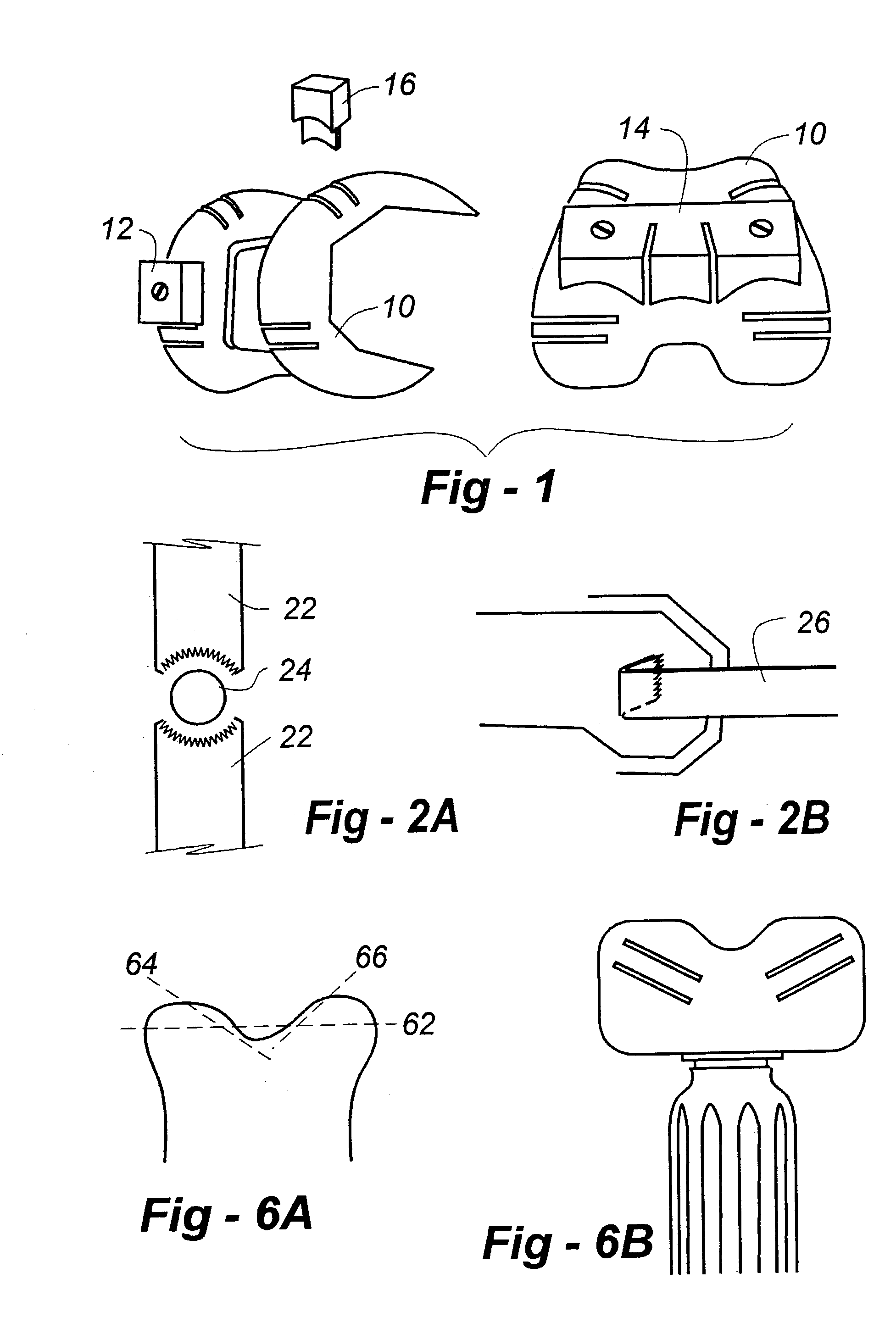

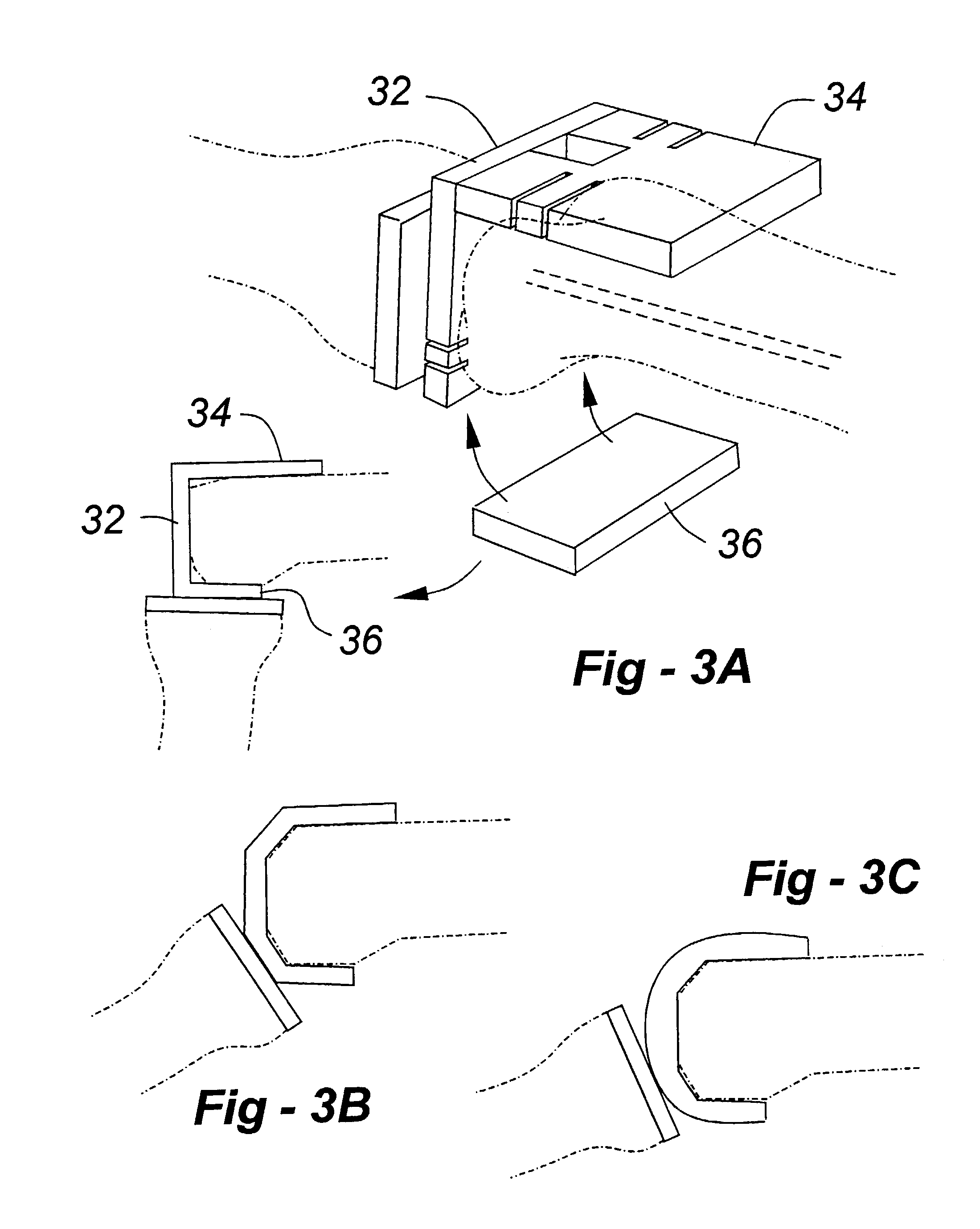

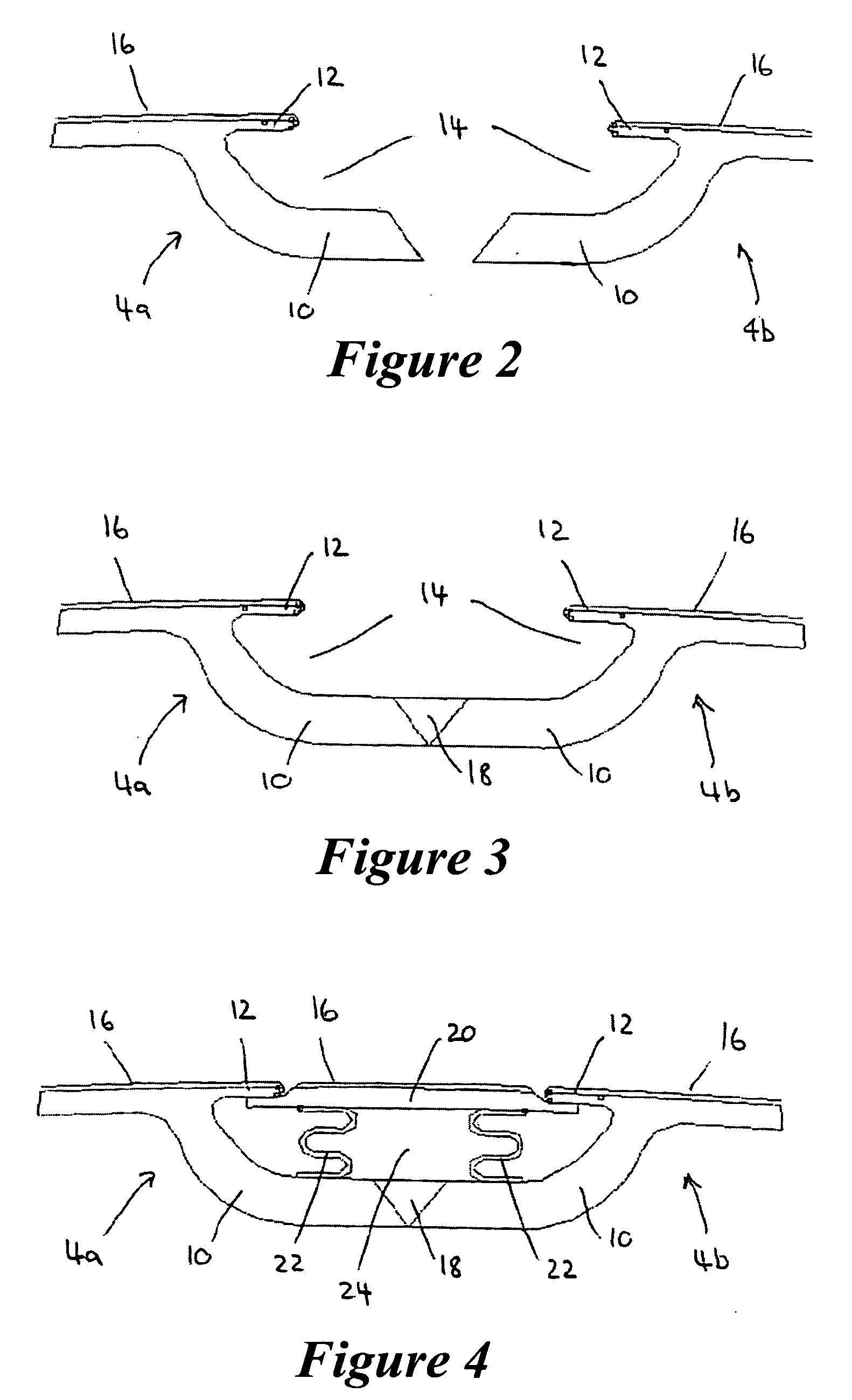

Joint replacement methods and apparatus

Apparatus and surgical techniques provide alternative cutting fixtures and other features to improve bone resection accuracy and joint stability. According to one embodiment, stabilizers are removably attached to a cutting guide to temporarily lengthen the surface against which a saw or other cutting device rests. Another embodiment provides differently shaped saw blades, having curved distal ends and right-angle bends applicable to box cuts of the type associated with cruciate sacrifice knee-replacement surgery. Methods are also disclosed whereby the box cuts, distal and posterior augment cuts may be approached from a distal perspective, both laterally and medially. A different embodiment provides a trial / cutting guide having flat surfaces as opposed to curved surfaces adapted for articulation within a joint. Yet a further alternative embodiment teaches a device for determining the joint line relative to a tibia using the fibula as reference.

Owner:MEDIDEA

Joint replacement methods and apparatus

Apparatus and surgical techniques provide alternative cutting fixtures and other features to improve bone resection accuracy and joint stability. According to one embodiment, stabilizers are removably attached to a cutting guide to temporarily lengthen the surface against which a saw or other cutting device rests. Another embodiment provides differently shaped saw blades, having curved distal ends and right-angle bends applicable to box cuts of the type associated with cruciate sacrifice knee-replacement surgery. Methods are also disclosed whereby the box cuts, distal and posterior augment cuts may be approached from a distal perspective, both laterally and medially. A different embodiment provides a trial / cutting guide having flat surfaces as opposed to curved surfaces adapted for articulation within a joint. Yet a further alternative embodiment teaches a device for determining the joint line relative to a tibia using the fibula as reference.

Owner:MASINI MICHAEL A

Knee joint prosthesis system and method for implantation

A system for cooperating with an elongated IM member during preparation of a bone for receiving a prosthesis can include a scaffold, skeleton or frame (1362). An alignment assembly (1364) can be selectively coupled to the frame. The alignment assembly can cooperate with the IM member to position the frame relative to the bone. A cutting block (1366) can be selectively coupled to the frame. According to other features, a posterior stabilized (PS) box guide assembly (1470) can have a PS box guide attachment portion that selectively couples with the first attachment portion of the frame. A posterior foot (1470) can selectively couple with a second attachment portion on the frame. The posterior foot can be positioned to occupy space of a joint line in an installed position.

Owner:BIOMET MFG CORP

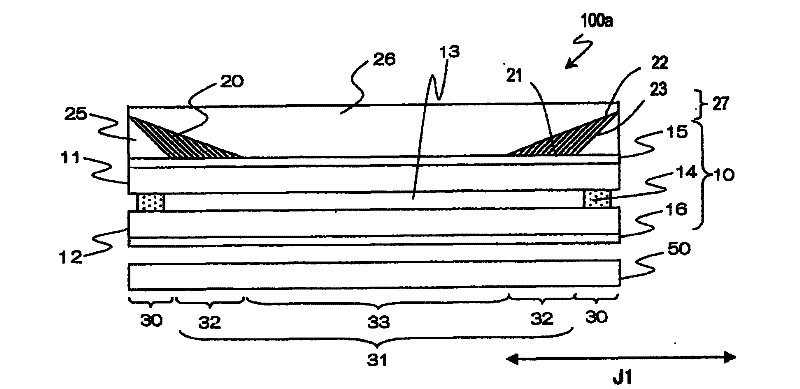

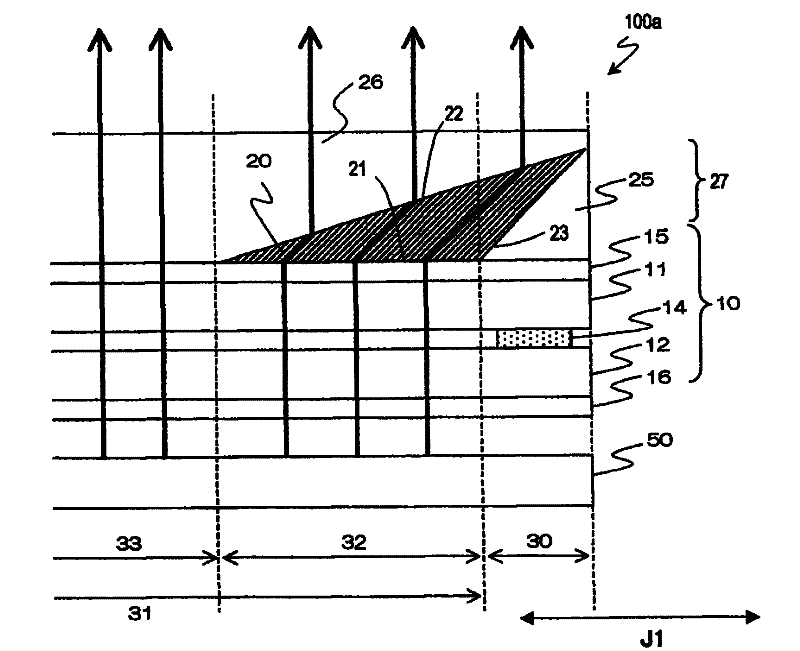

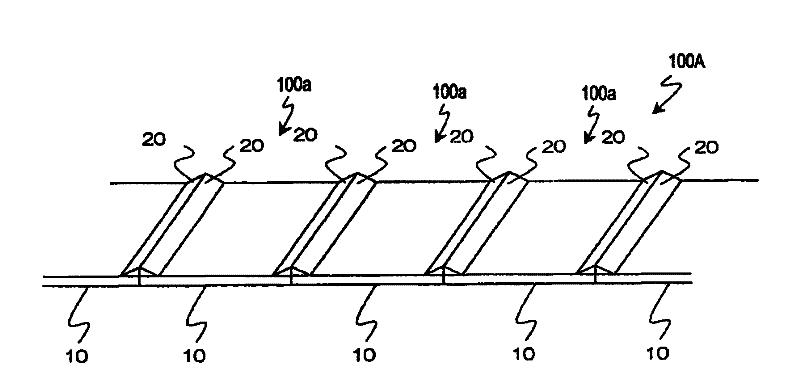

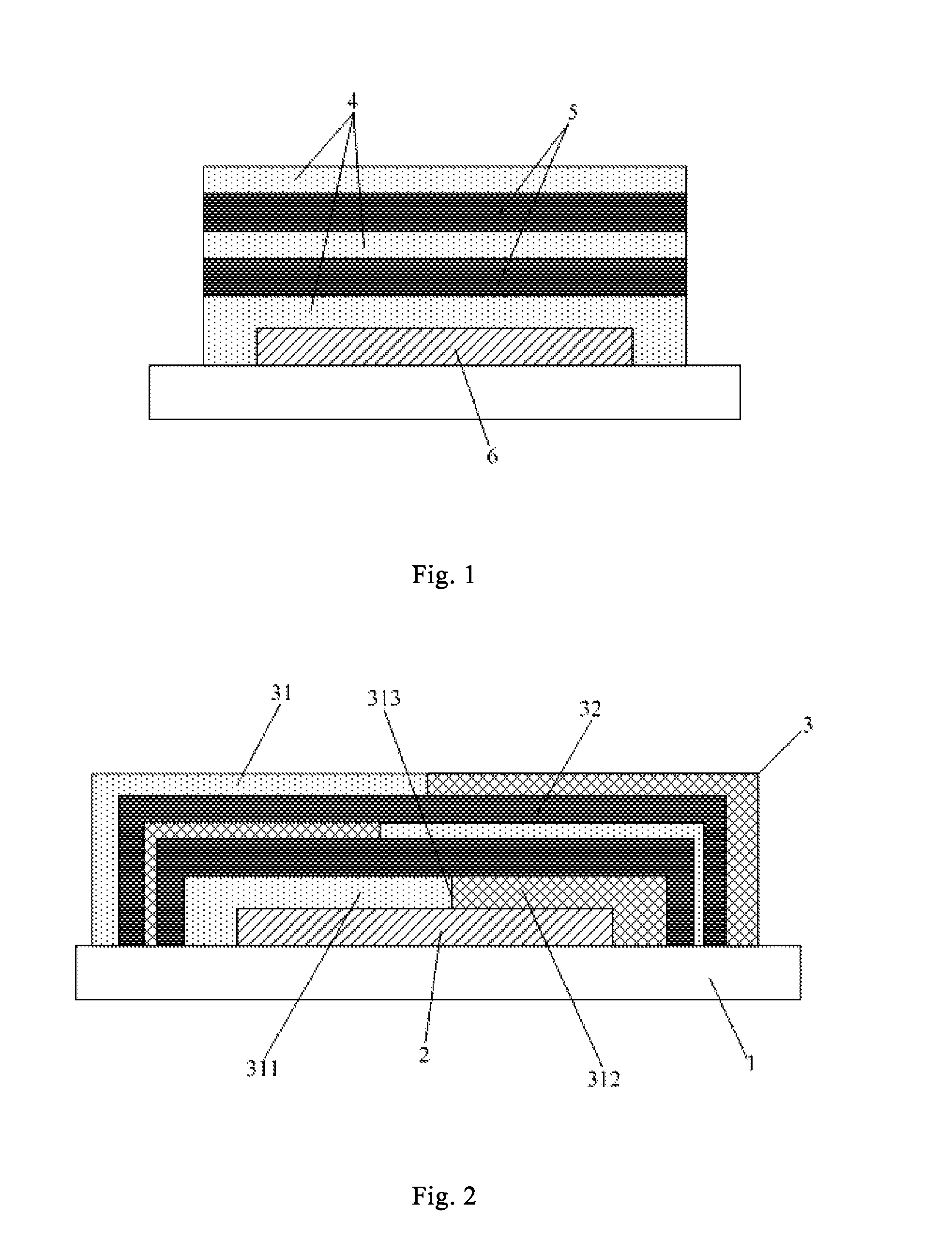

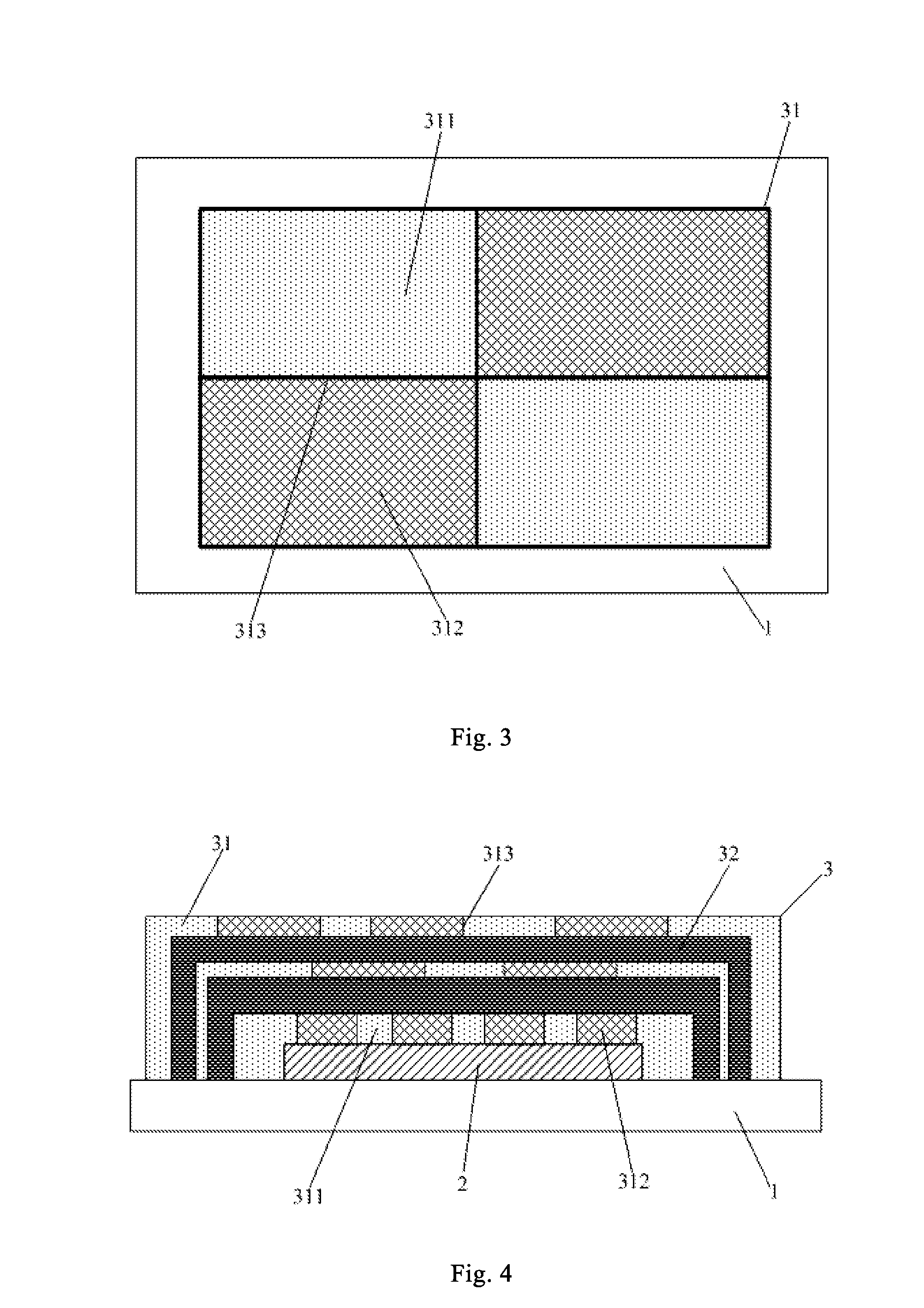

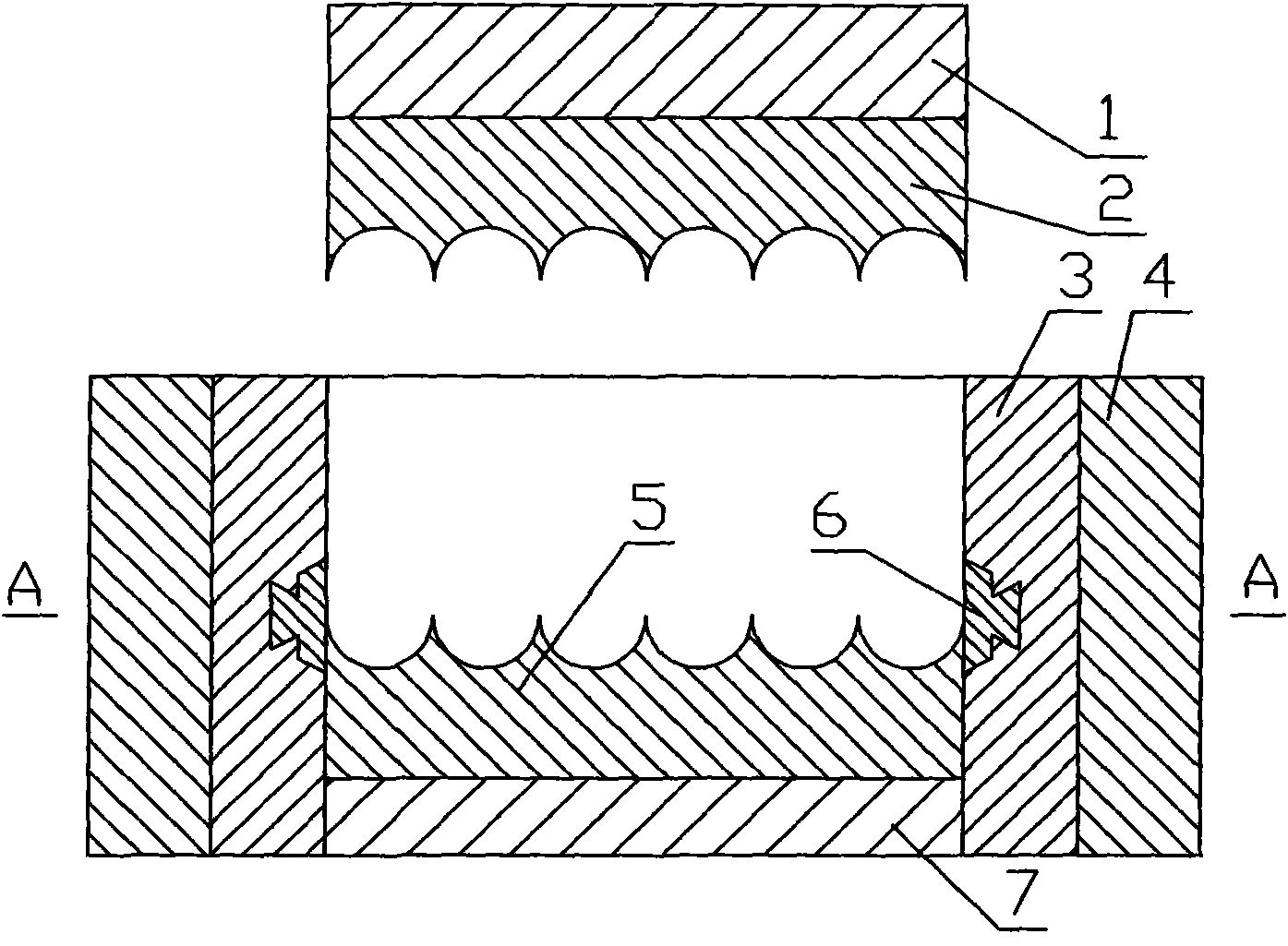

Display device

InactiveCN102216972AEasy to seeNot easy to seeTelevision system detailsColor television detailsLight guideDisplay device

A direct-view-type display device (100a) is provided with: a display panel (10), which has a display region (31) and a frame region (30) formed outside the display region; and a light guide element (20), which has a light incoming surface (21), a light outgoing surface (22), and a plurality of light guide sections formed between the light incoming surface (21) and the light outgoing surface (22). The light guide sections include a transparent section, and at least a part of the side surface of the transparent section is provided with a metal section. The light incoming surface (21) of the light guide element (20) overlaps a part (32) of the peripheral display region adjacent to the frame region (30) of the display panel (10) along a first axis (J1), and the light incoming surface is arranged in parallel to the surface of the display panel (10). In the light outgoing surface (22) of the light guide element (20), the distance from the light incoming surface (21) increases along the first axis (J1) toward the frame region (30) from the part (32) of the peripheral display region. Thus, the direct-view-type display device wherein the frame region of the display panel or a joint line formed when tiling is performed is not easily seen is provided with the structure which is simpler and lighter in weight compared with conventional structures.

Owner:SHARP KK

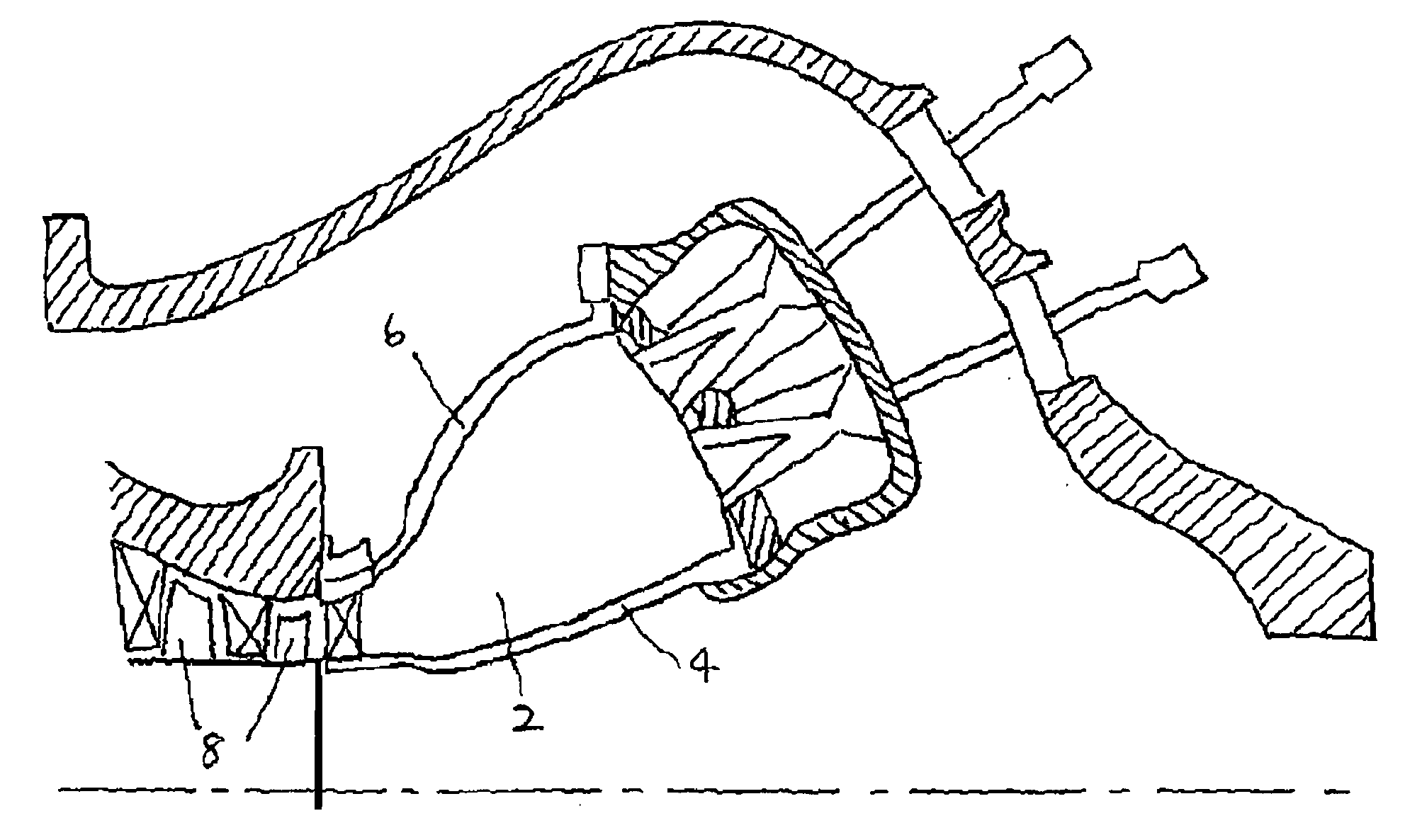

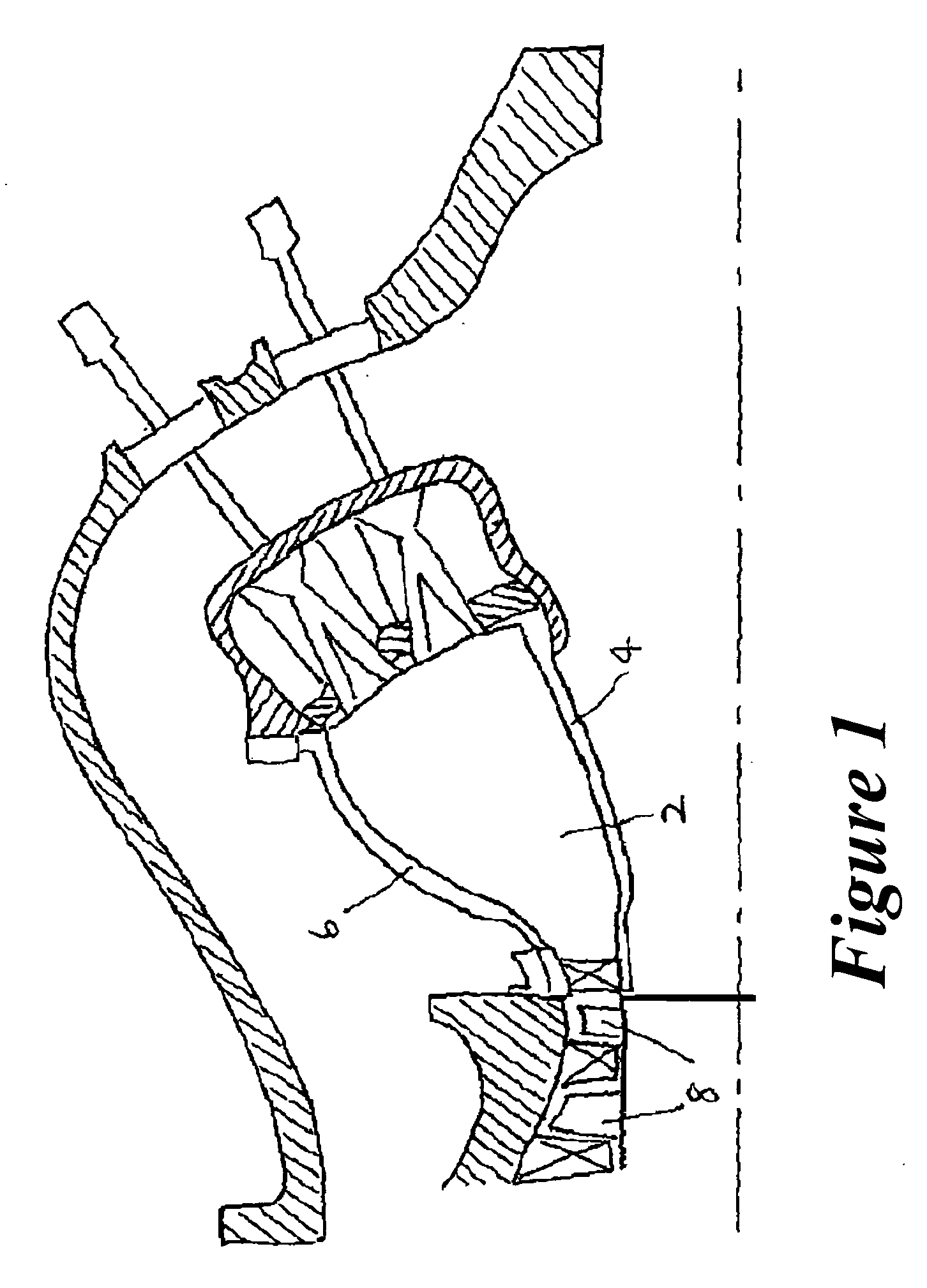

Combustor liners

ActiveUS20070180828A1Avoid enteringContinuous combustion chamberGas turbine plantsCombustorCombustion chamber

A combustor liner for use in a gas turbine engine includes a first liner section and a second liner section. They are joined together by welding or a mechanical fixing along a common join line or weld. A heat shield extends along the join line to protect it from the high temperatures and thermal stresses that are experienced by the combustor liner during the operation of the gas turbine engine. The heat shield is spaced apart from the joint line to define a passage between the heat shield and the first and second liner sections for the introduction of a cooling fluid such as air. The heat shield and the exposed surfaces of the liner sections are coated with a thermal barrier coating.

Owner:ANSALDO ENERGIA SWITZERLAND AG

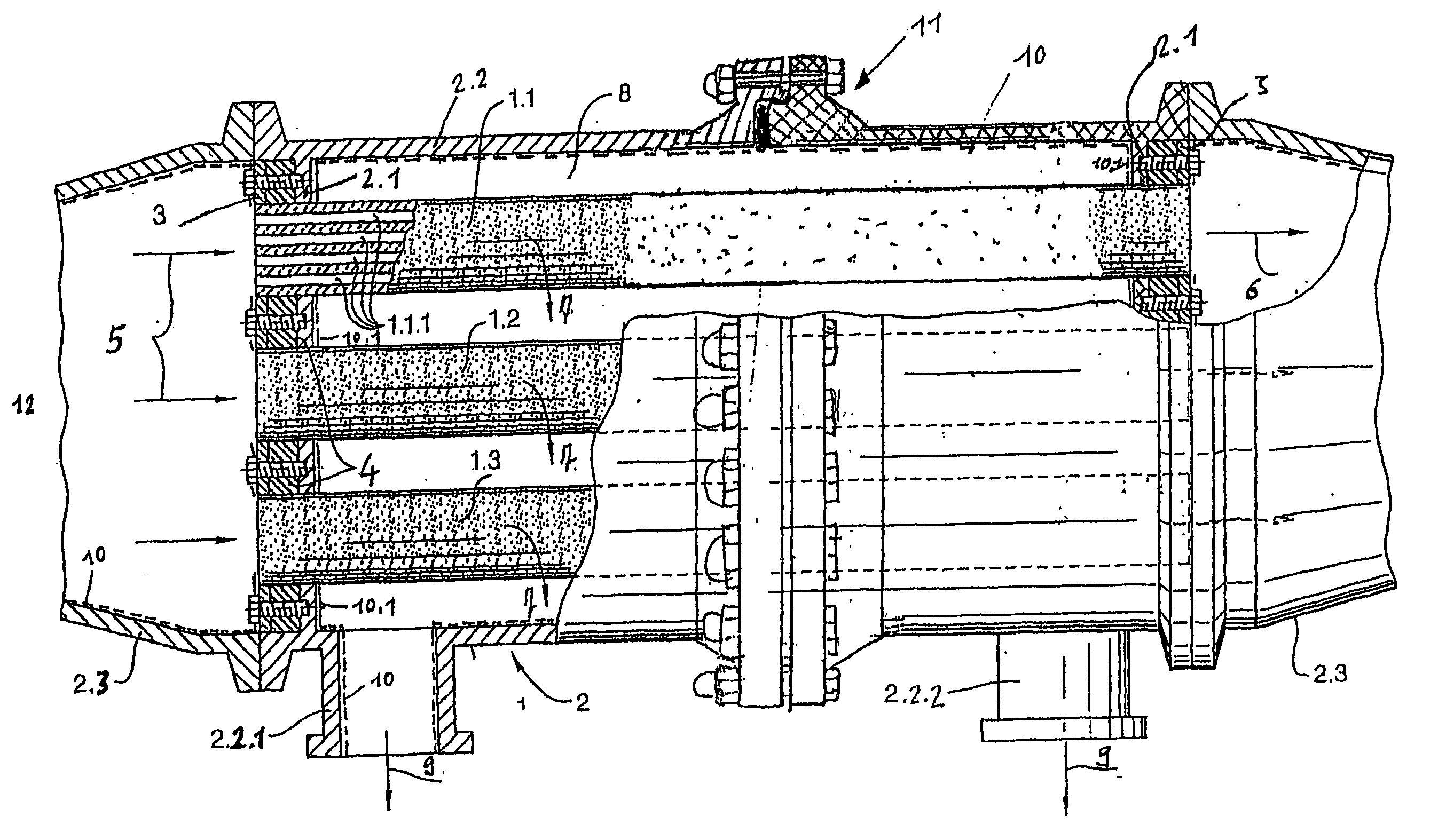

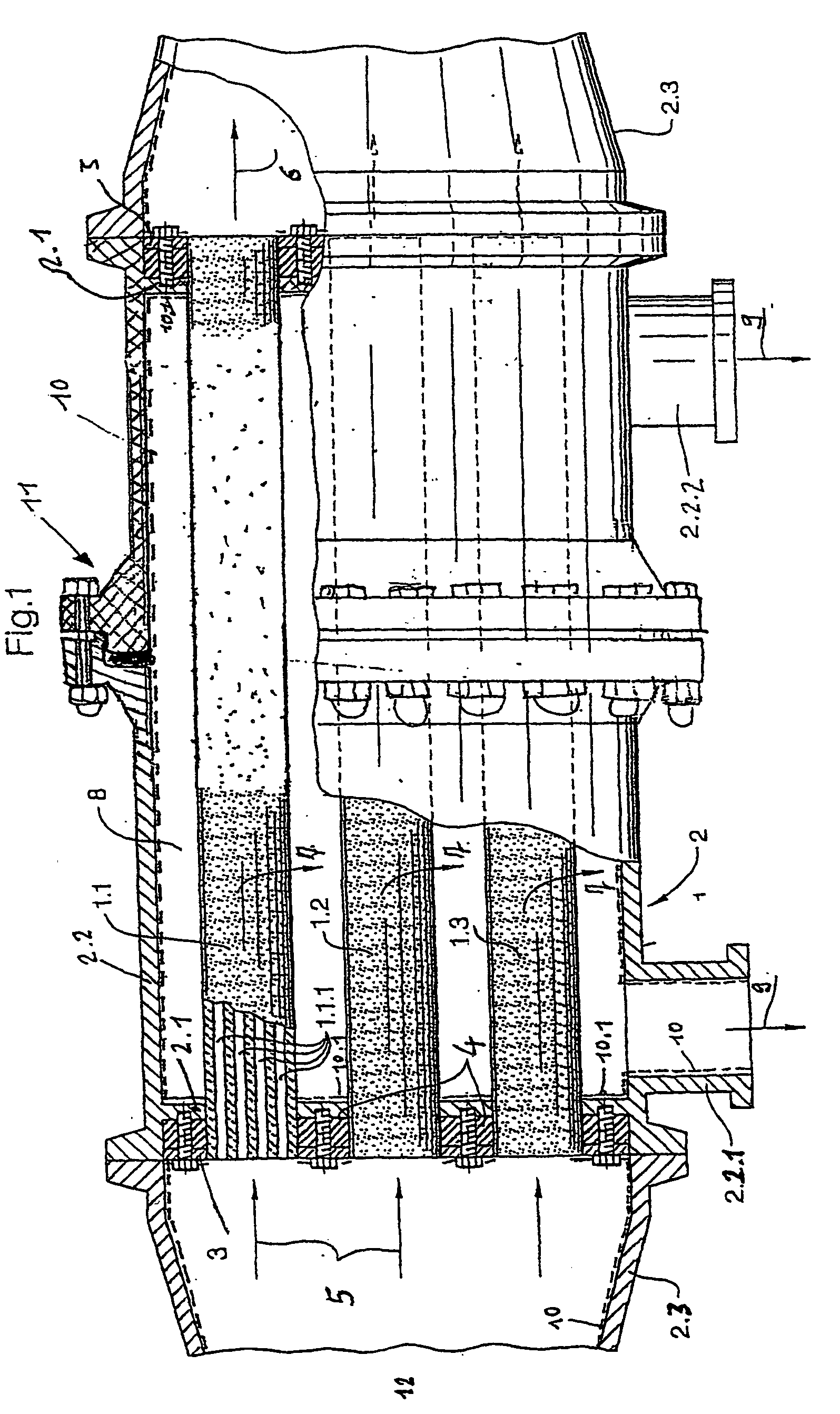

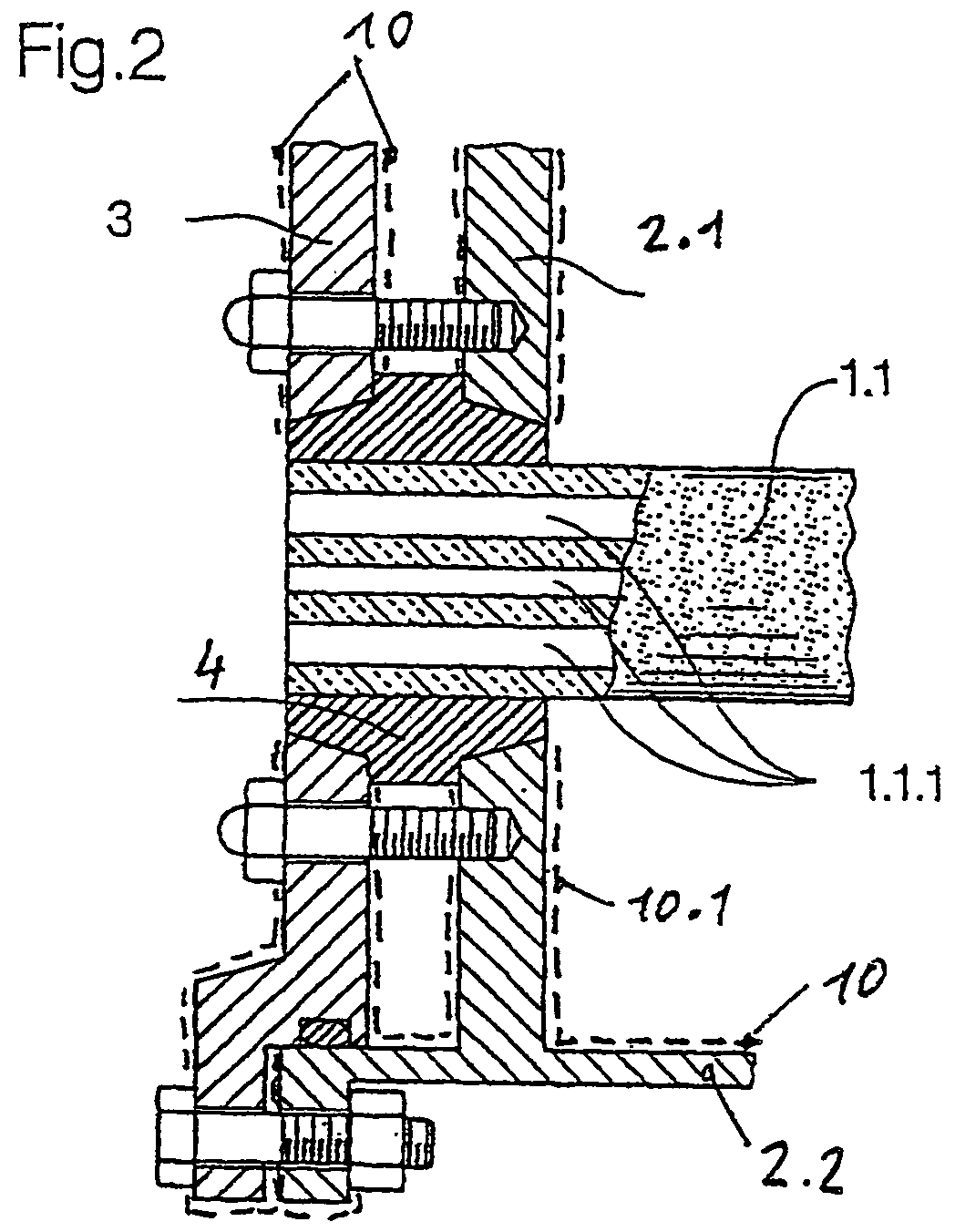

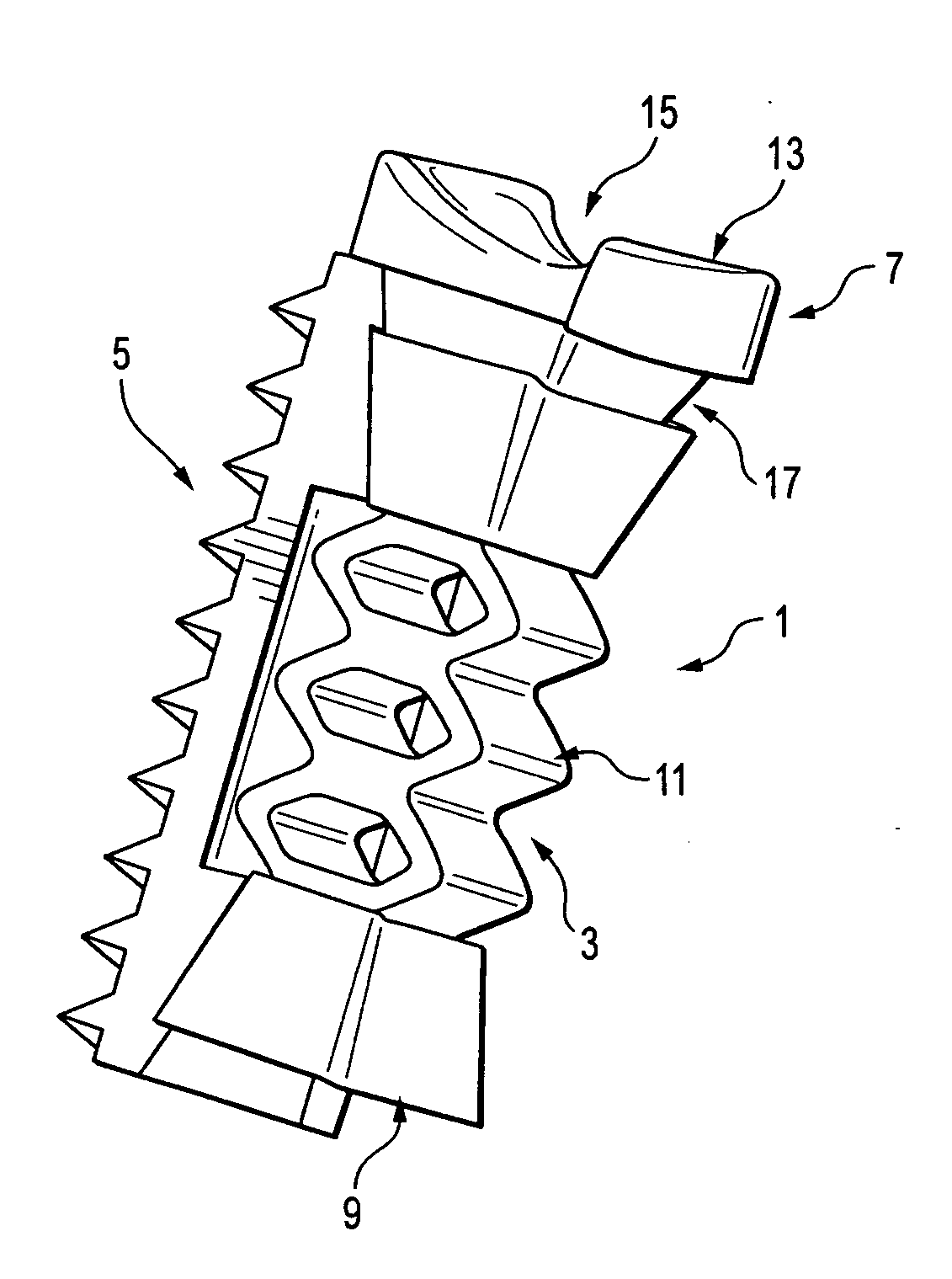

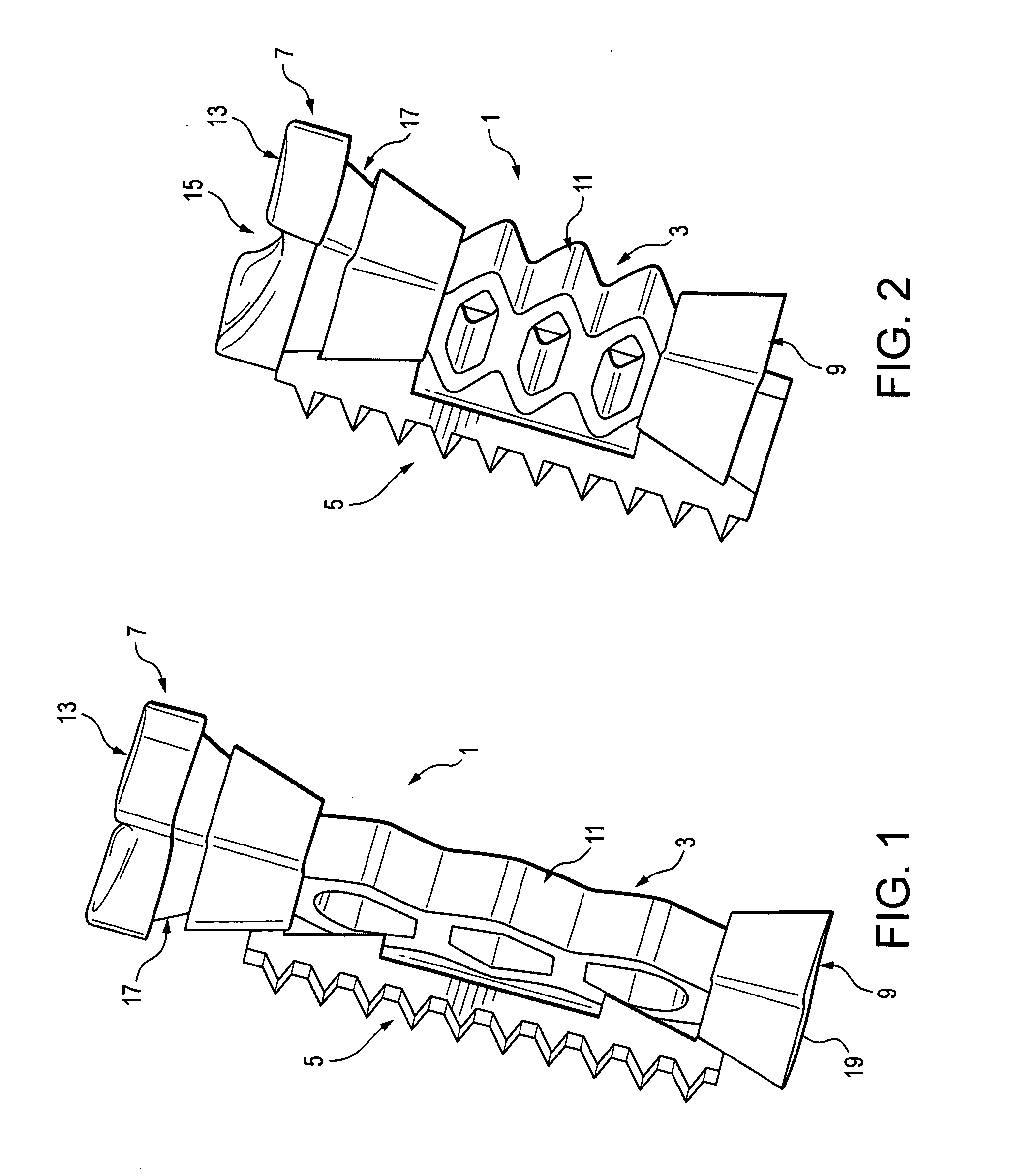

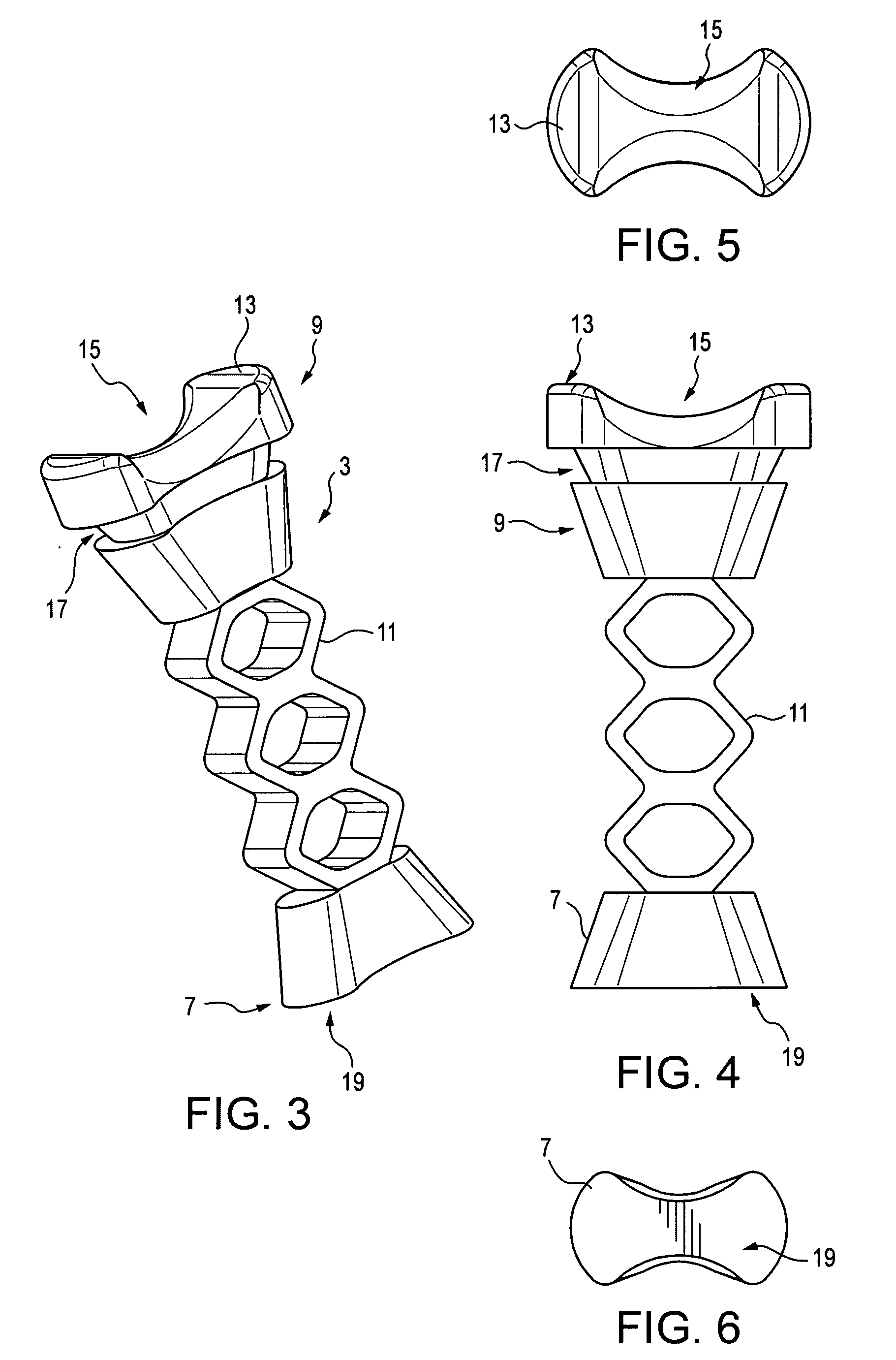

Filter module

InactiveUS20050217485A1Simple wayHigh-quality fashionCombination devicesMembranesEngineeringFilter element

The invention relates to a filter module having a module housing and at least one filter element. The filter module has at least one inlet opening, at least one filtrate outlet and a module housing having at least one joint line.

Owner:WESTFALIA SEPARATOR AG

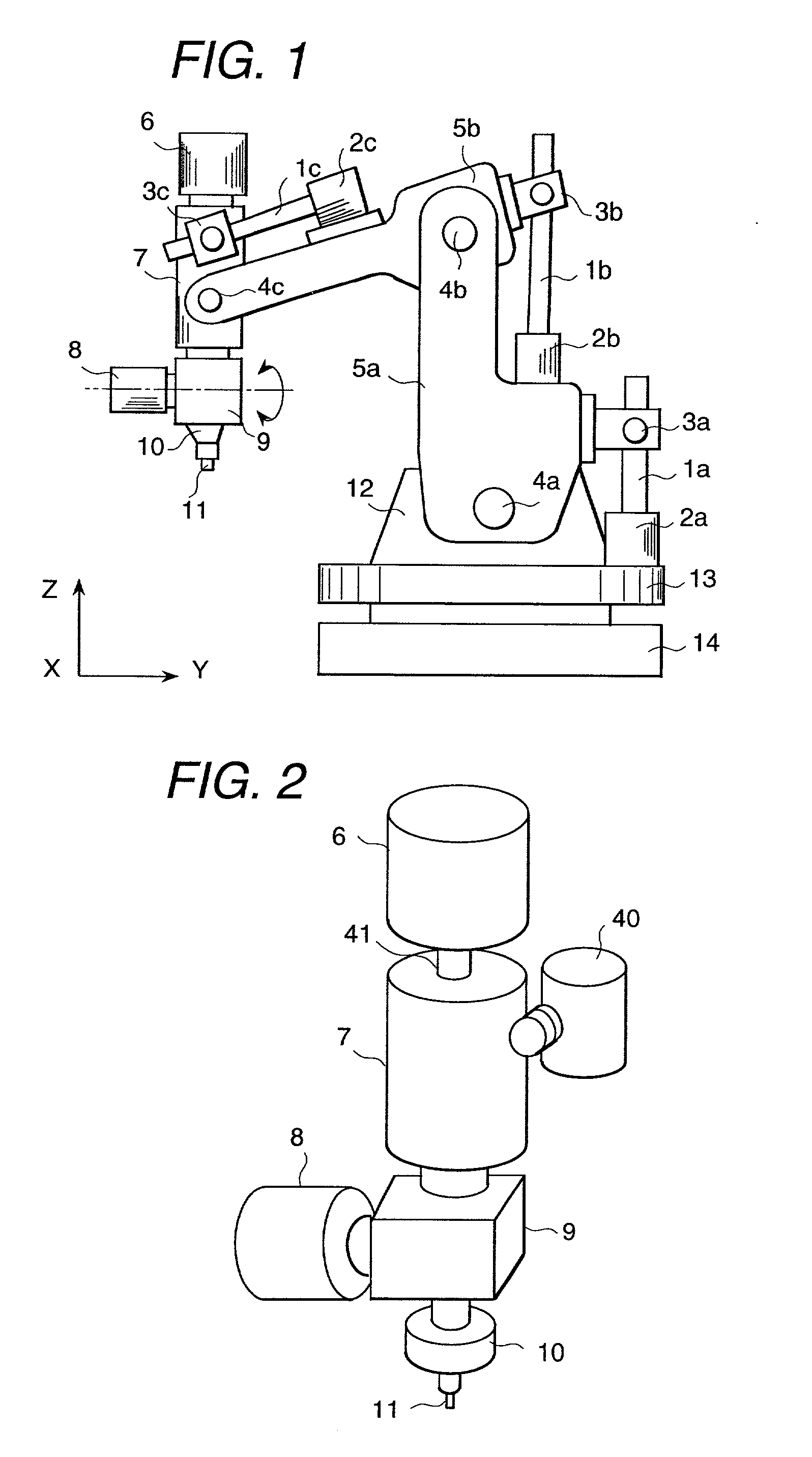

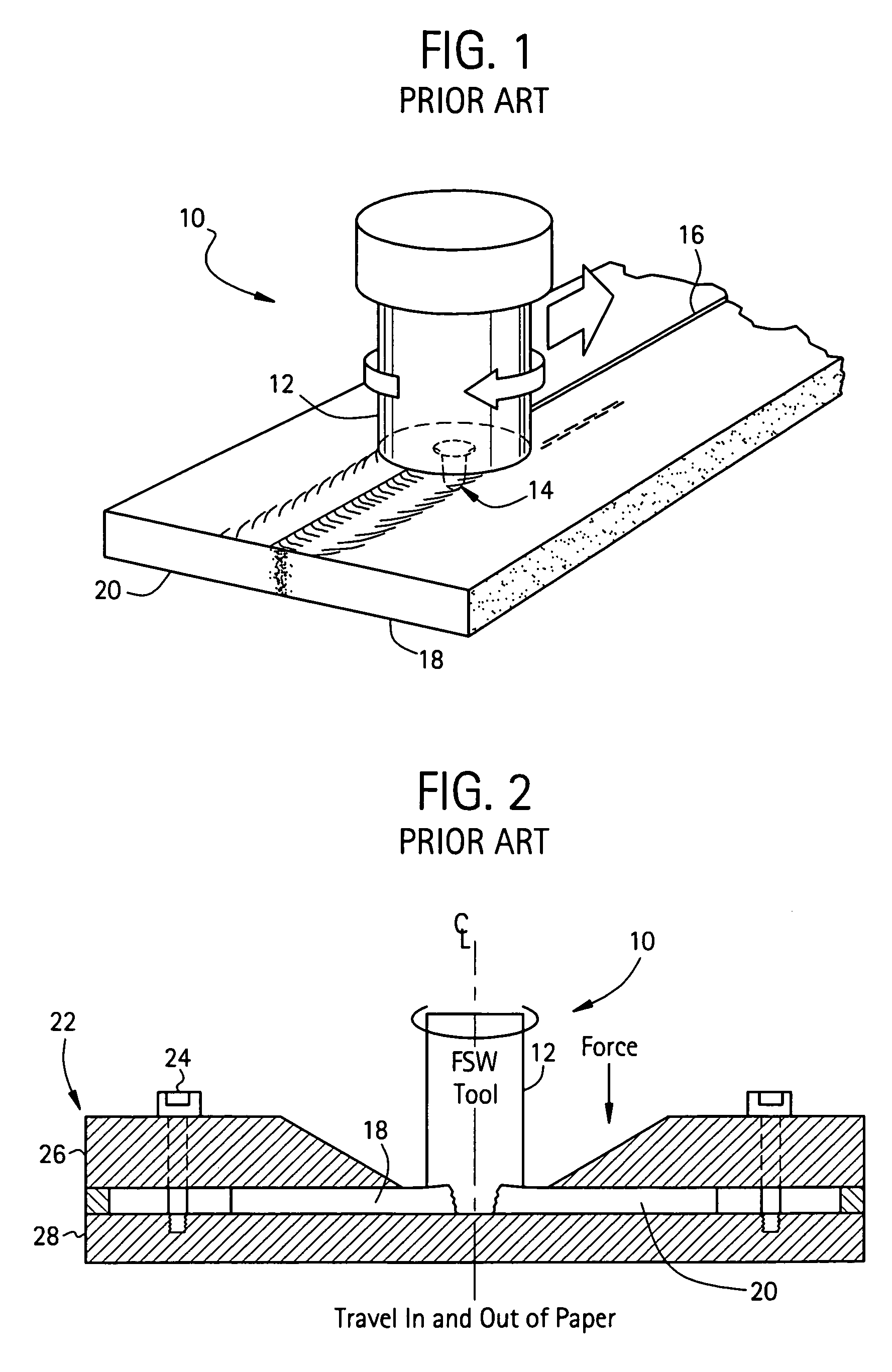

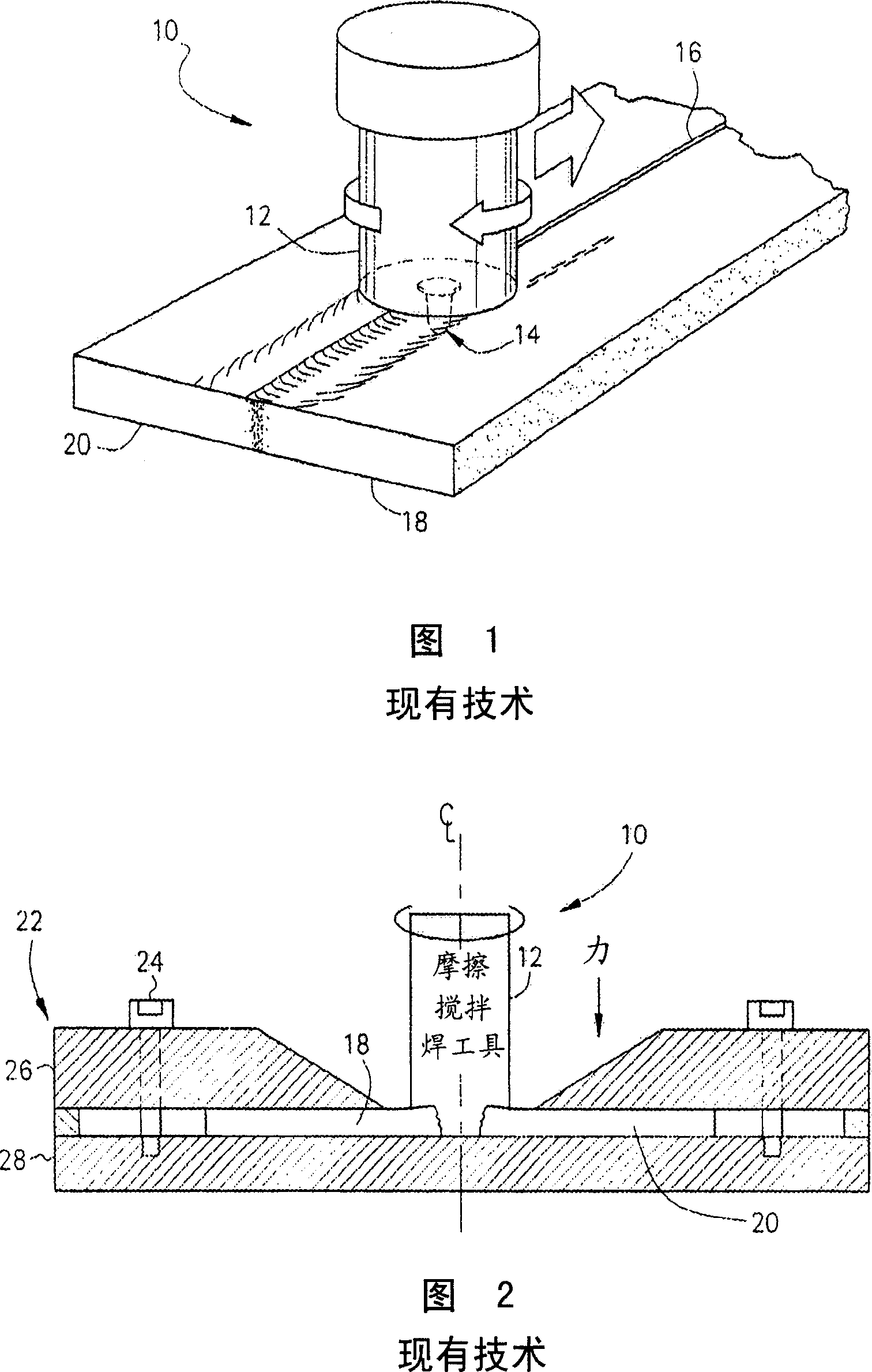

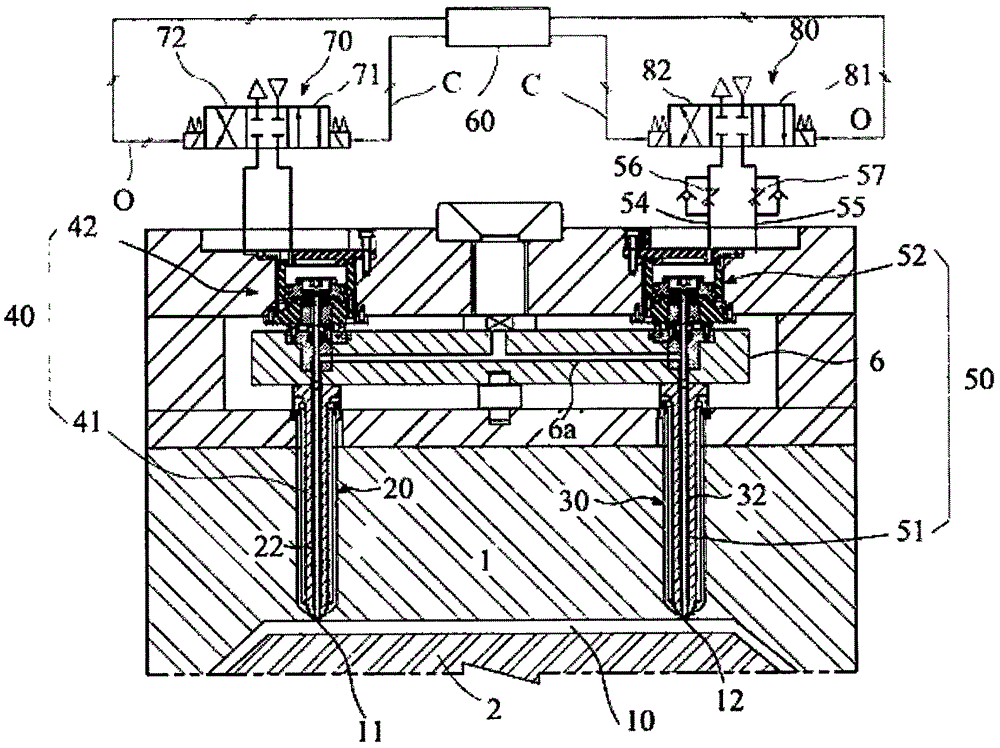

Friction stir welding method and apparatus, and welded structure

InactiveUS20020145031A1Welding/cutting auxillary devicesAuxillary welding devicesRotational axisGeometric relations

It is an object of the present invention to provide a friction stir welding method and apparatus capable of maintaining a rotating tool and workpieces at a substantially constant geometrical relation for arbitrary curved surfaces having a three-dimensional shape, as well as a welded structure obtained thereby. The present invention resides in a friction stir welding method comprising joining workpieces while setting rotational angles of two rotational axes of a rotating tool which the two rotational axes are rotatable in intersecting directions or perpendicularly intersecting directions independently of rotation of the rotating tool, detecting a normal line direction with respect to joint surfaces of the workpieces and a tangential direction of a joint line, and joining the workpieces in three-dimensional directions while setting, on the basis of the detected normal line direction and tangential direction, an angle relative to a normal line direction, as well as a tangential direction, at a tip end of the rotating tool, and also resides in a friction stir welding apparatus using the said method.

Owner:HITACHI LTD

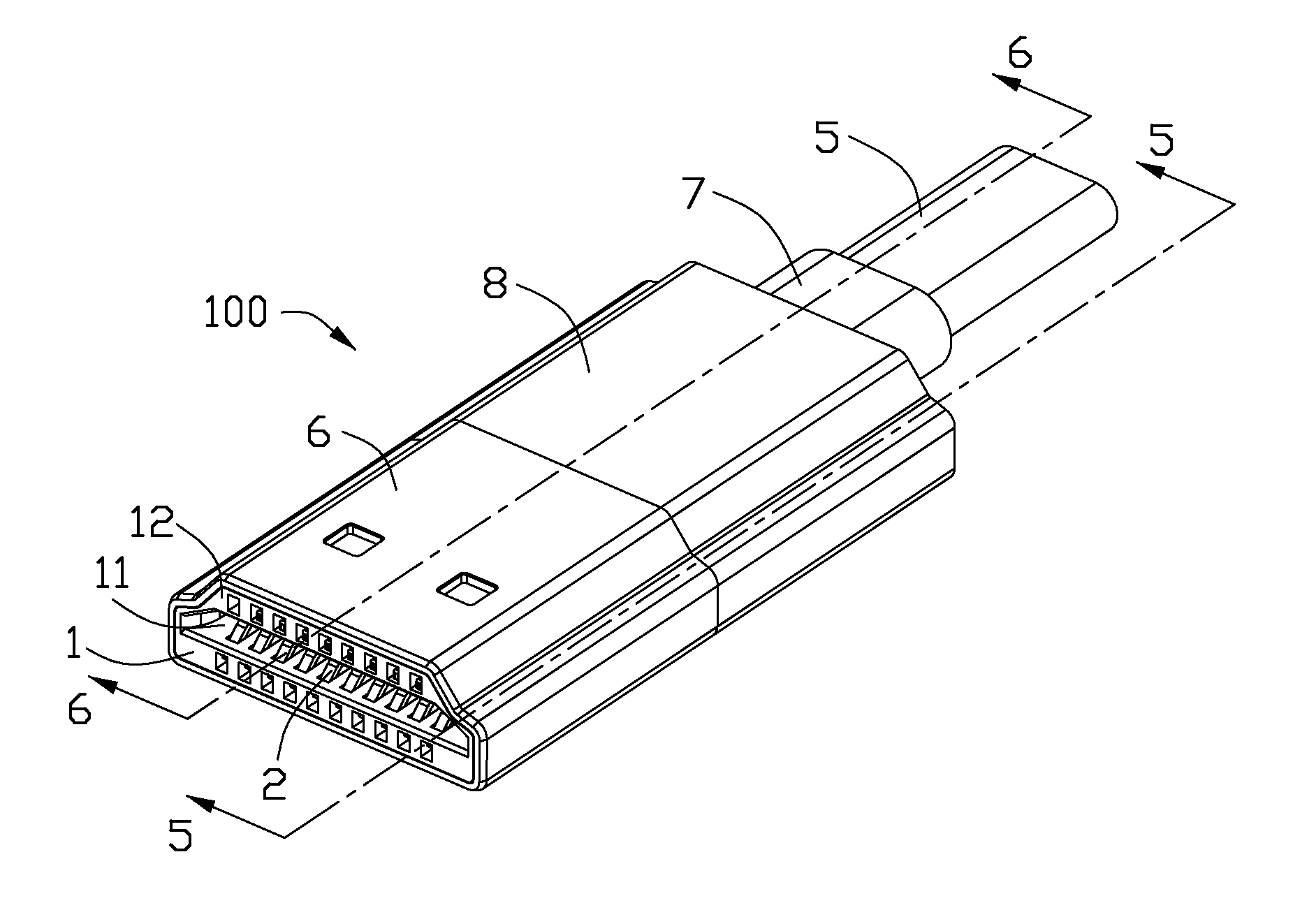

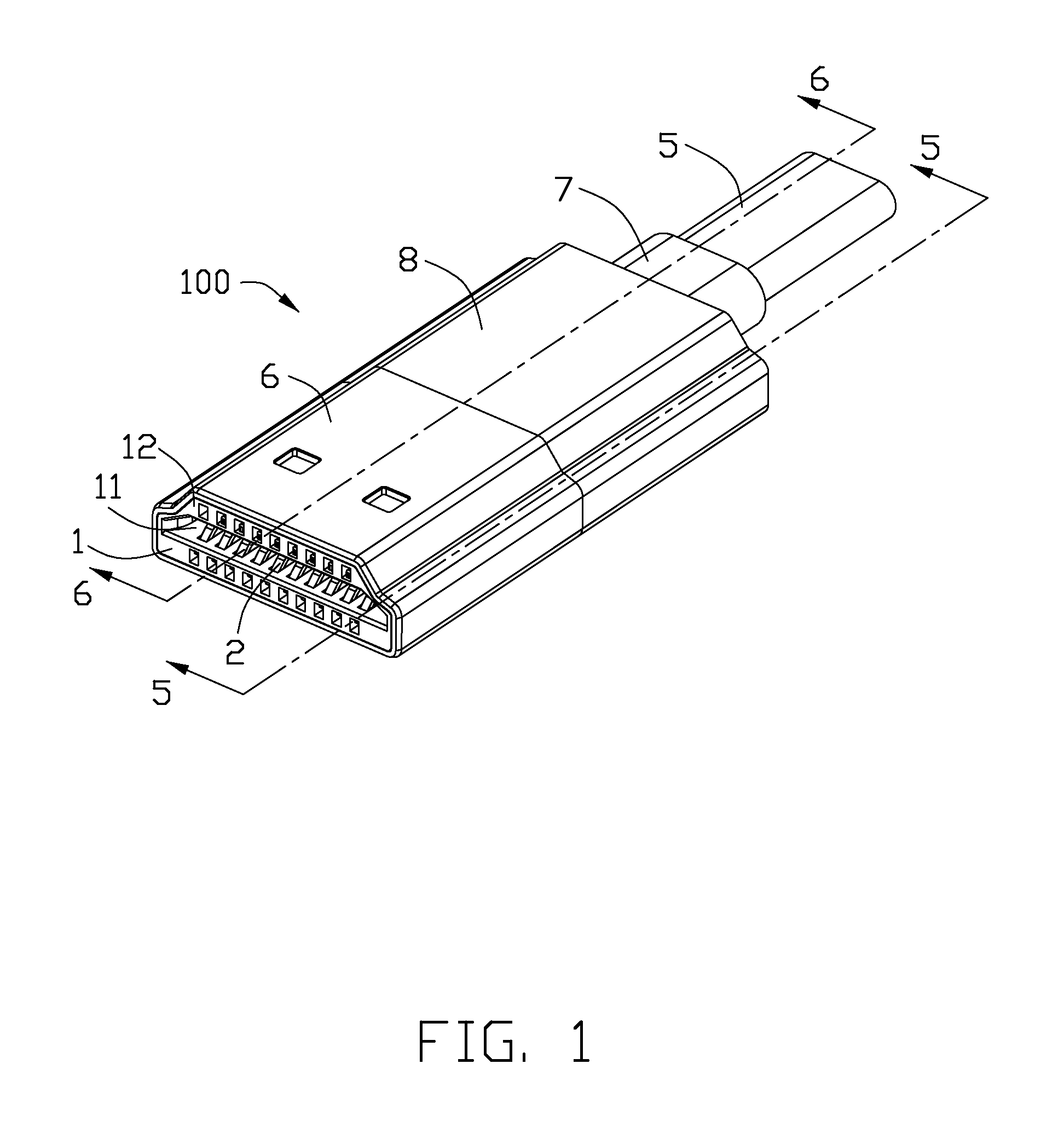

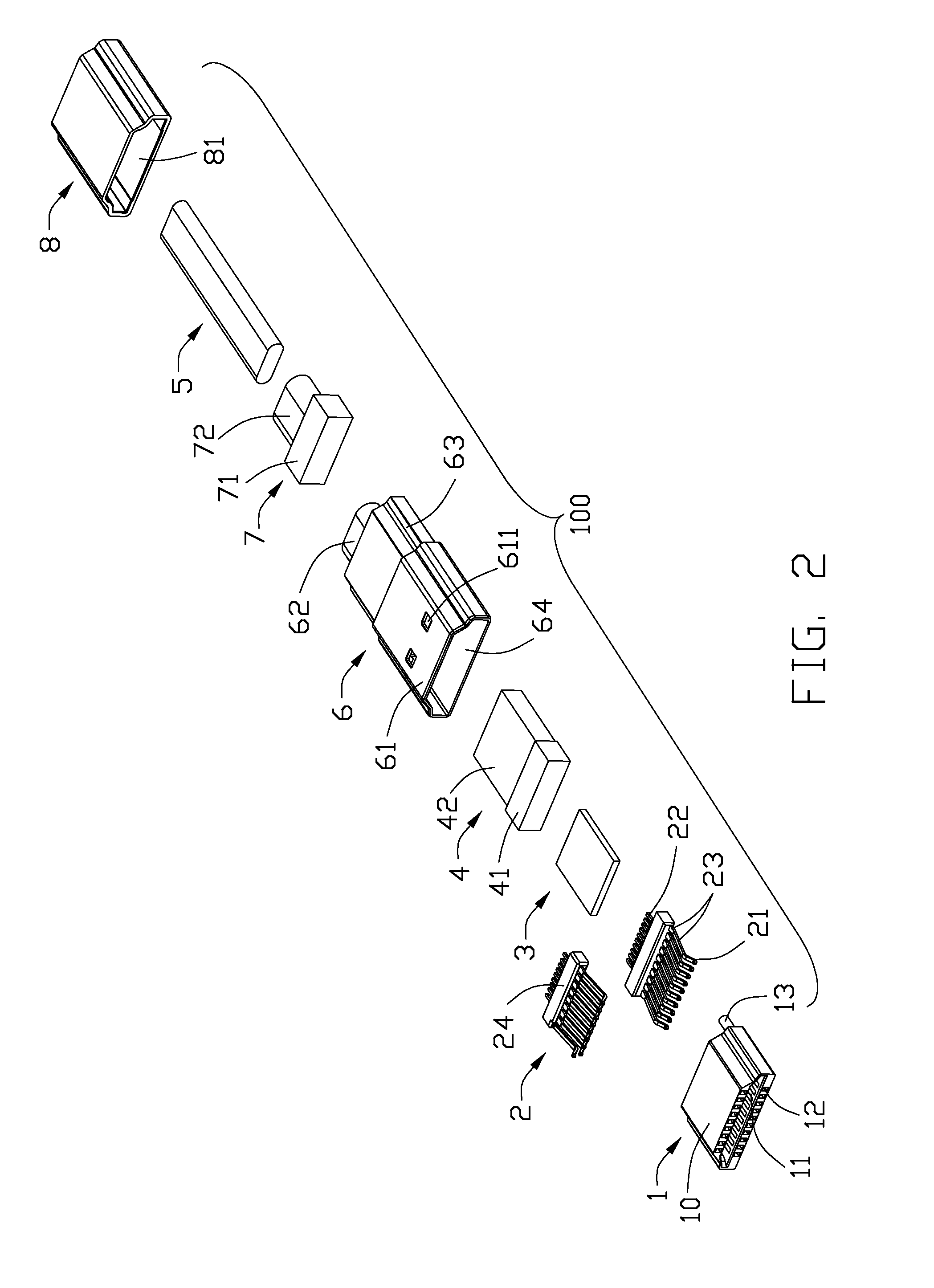

Cable assembly

ActiveUS20120028495A1Avoid formingElectrically conductive connectionsRelieving strain on wire connectionElectrical wiringJoint line

A cable assembly, comprising a housing having a main portion, a plurality of conductive terminals received in the main portion of the housing, a cable having a plurality of wires and a metal shell with a no-joint-line surface enclosing the housing and comprising a front portion enclosing the housing and a rear portion enclosing the cable and a receiving space passing through the front portion and the rear portion.

Owner:HON HAI PRECISION IND CO LTD

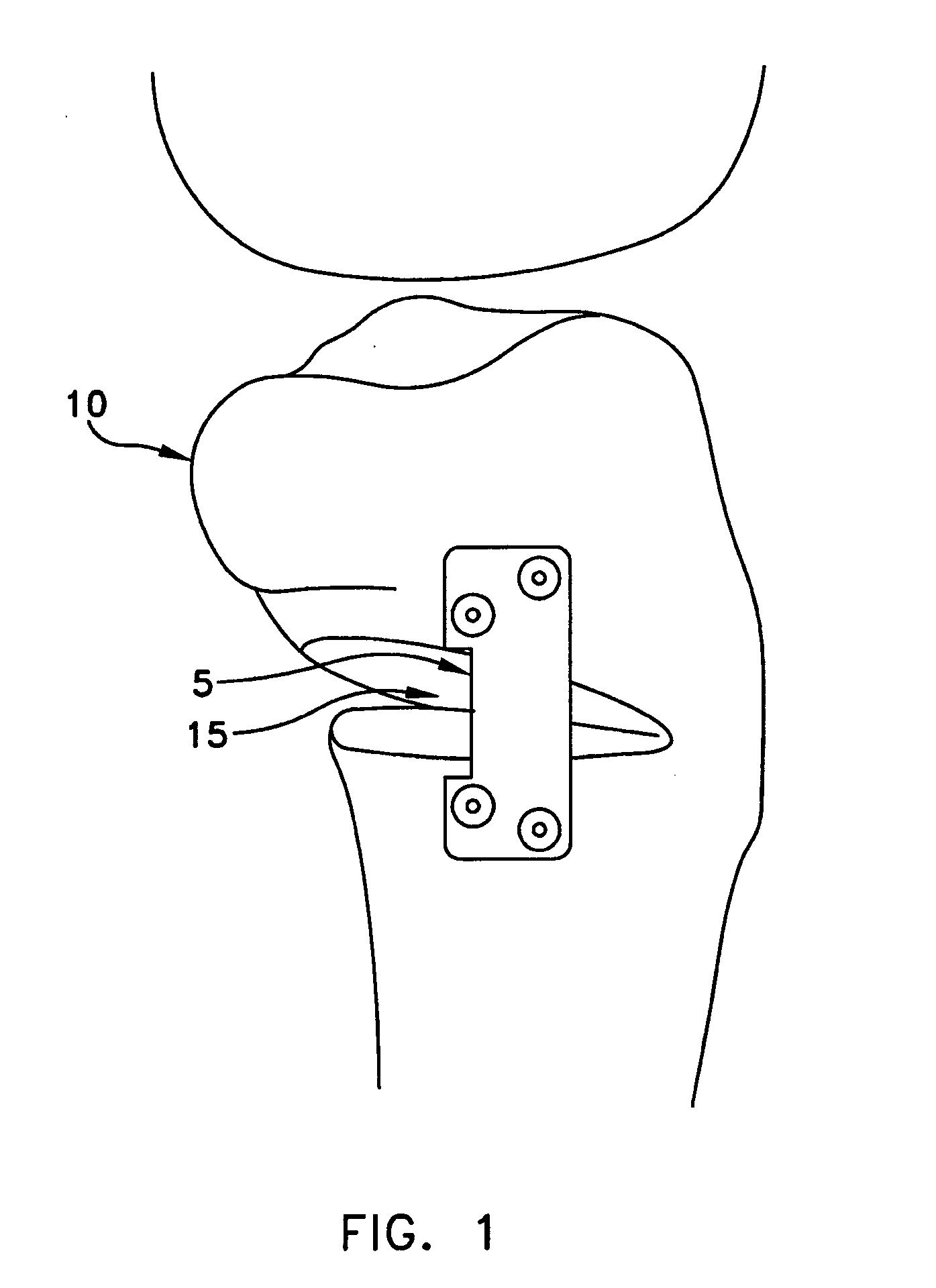

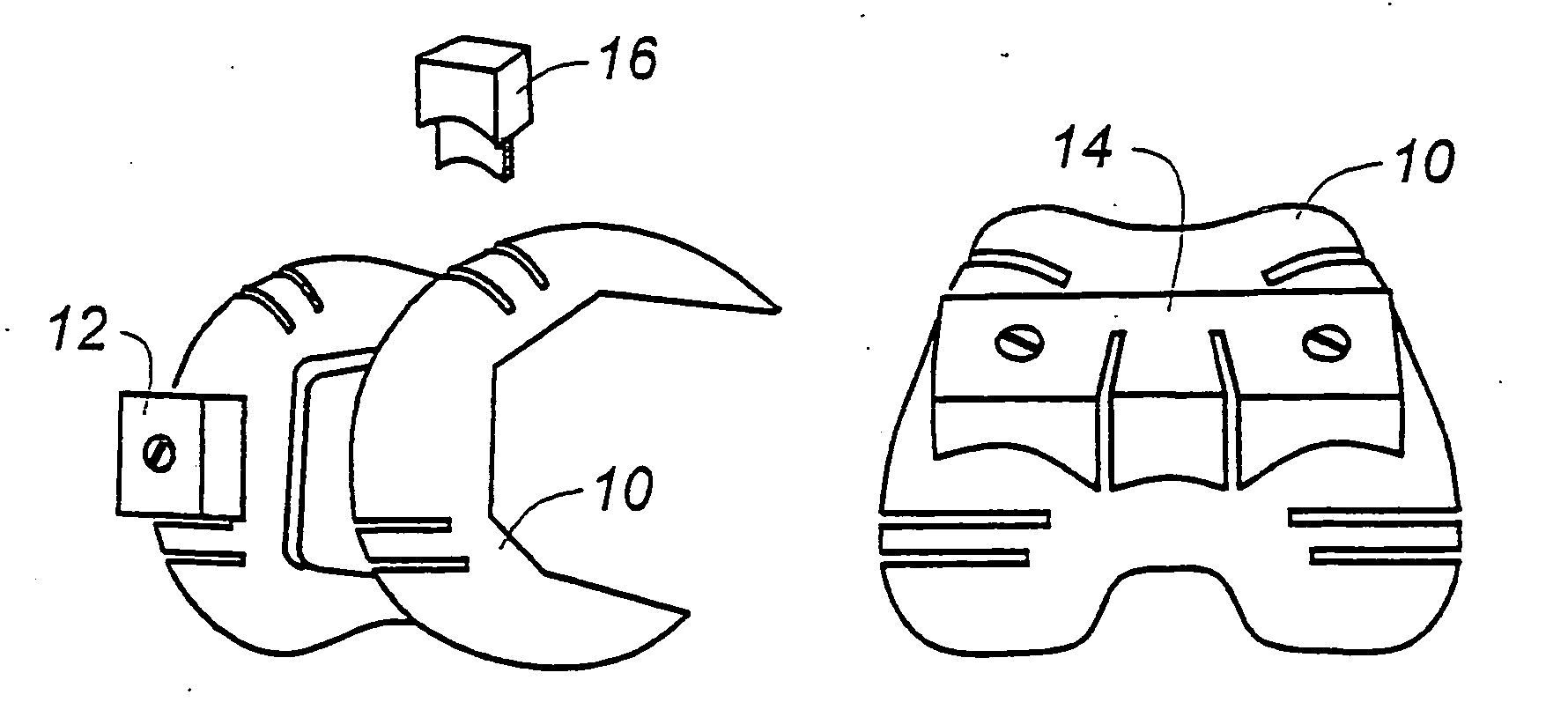

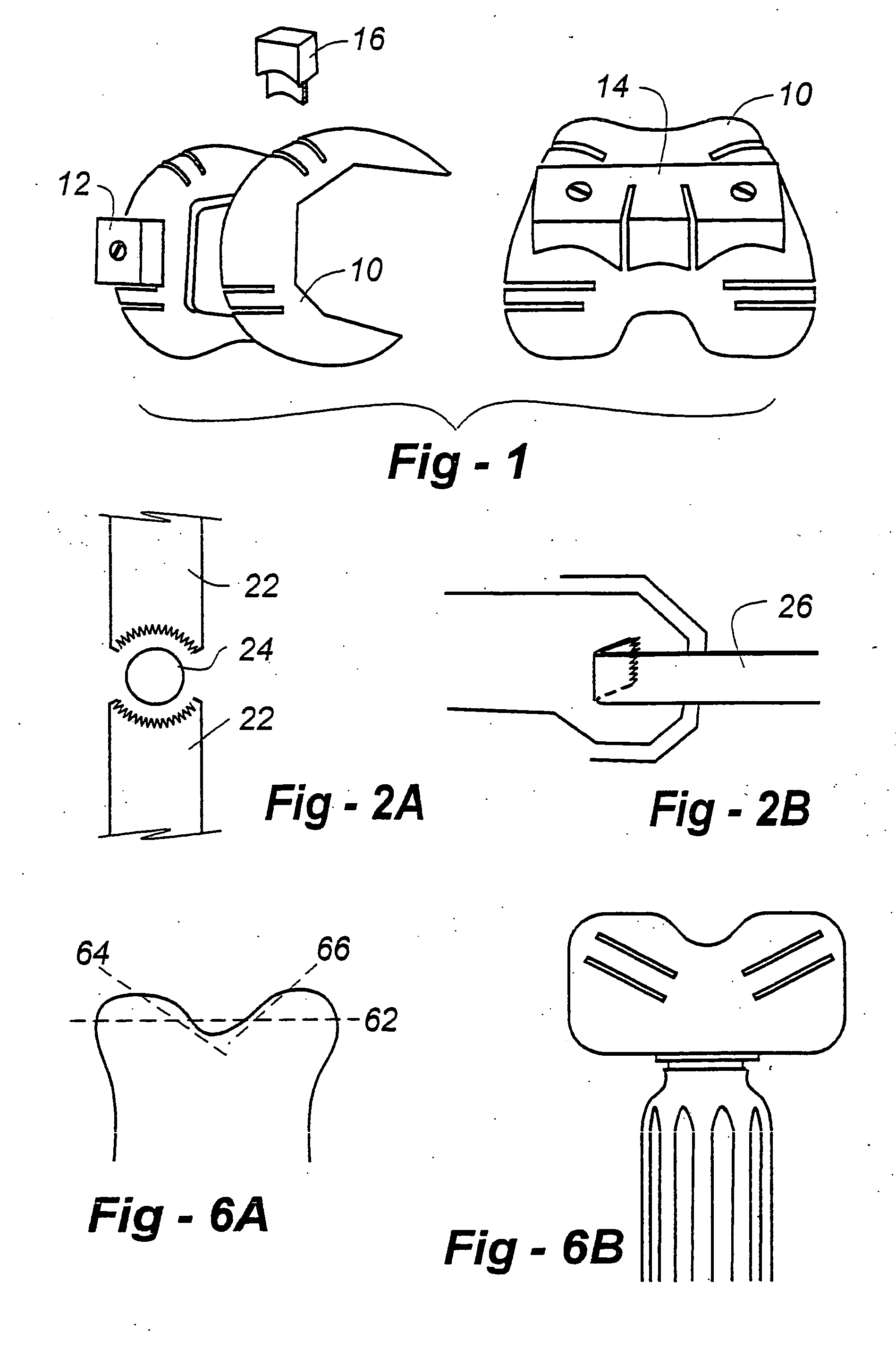

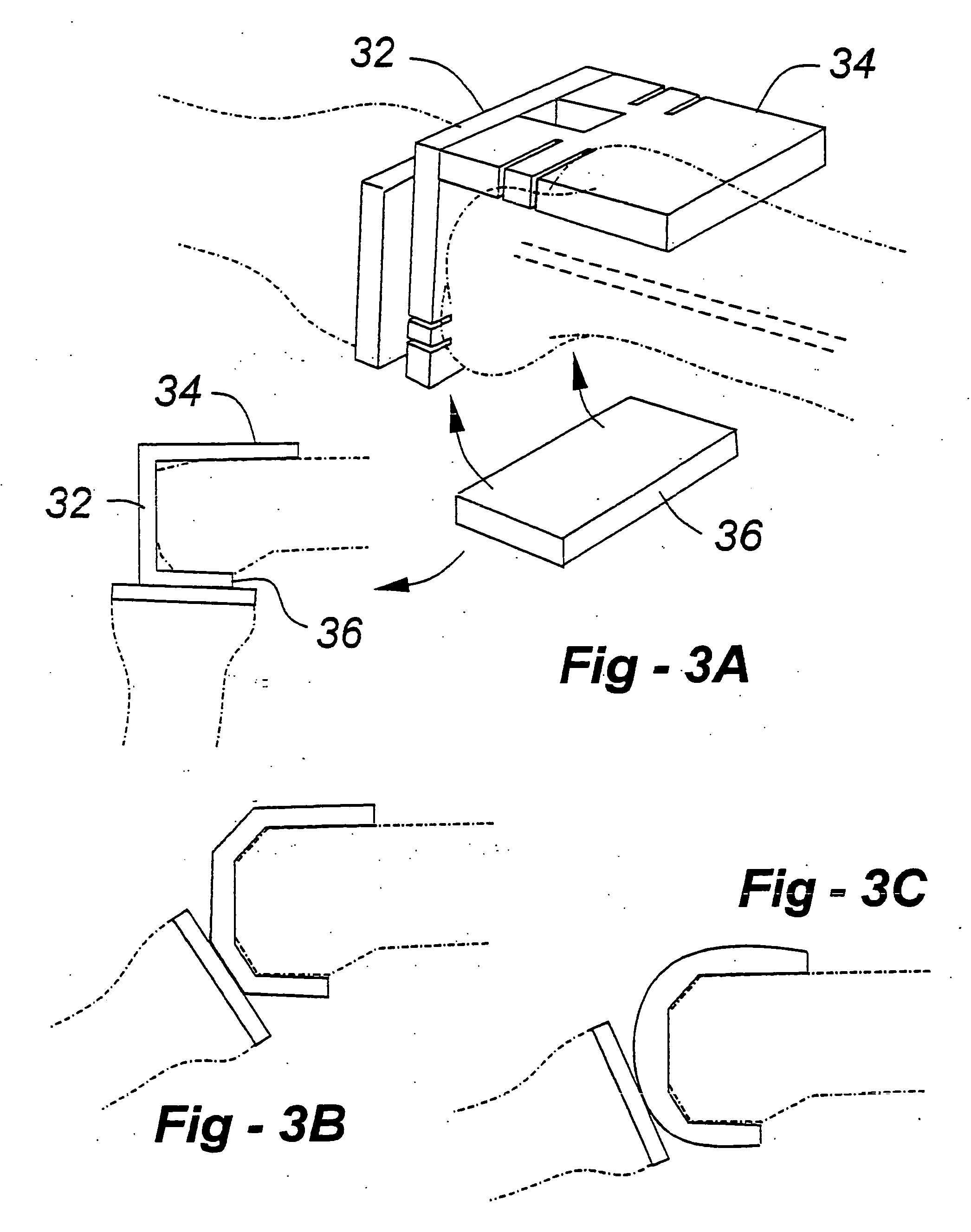

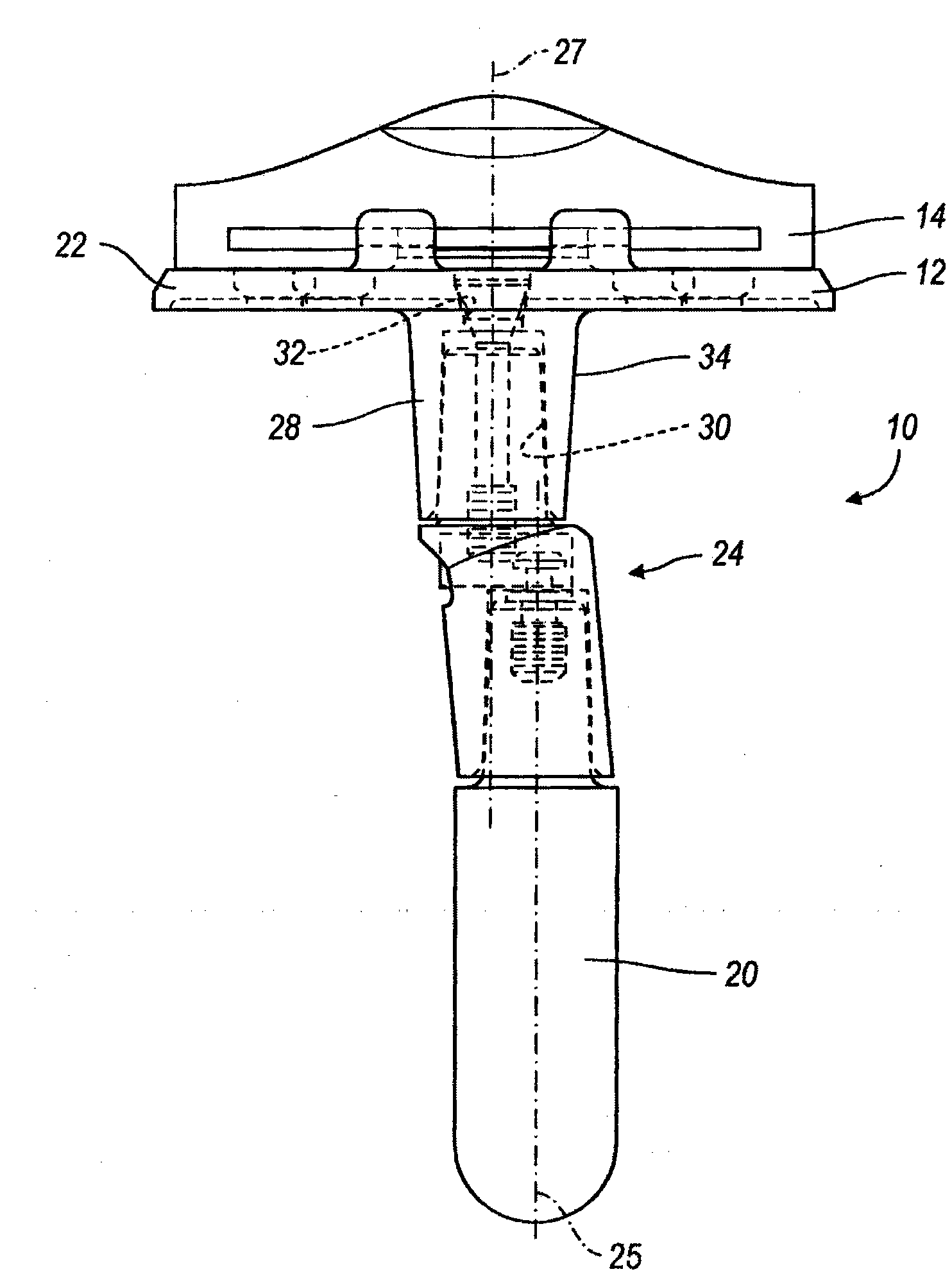

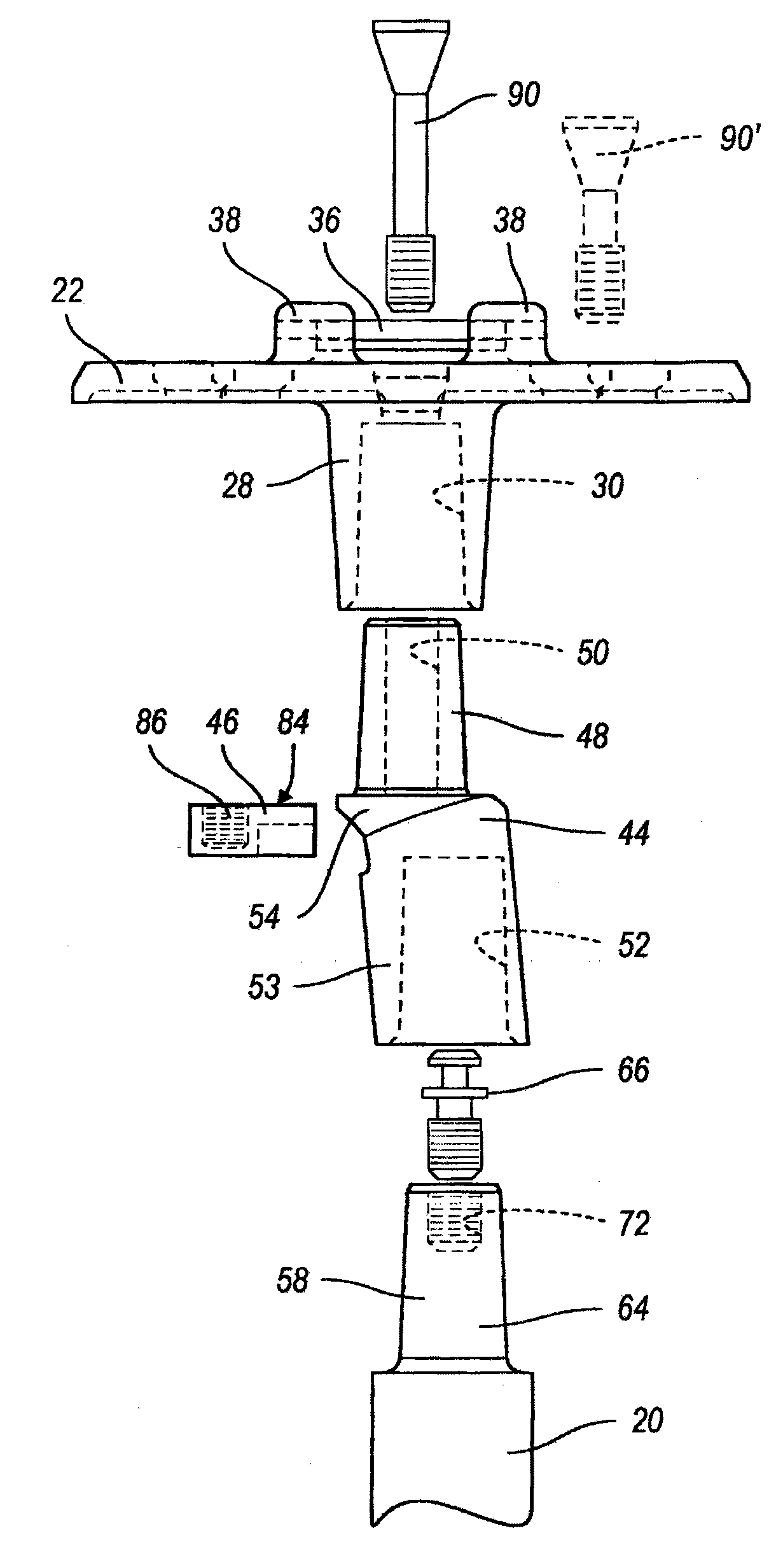

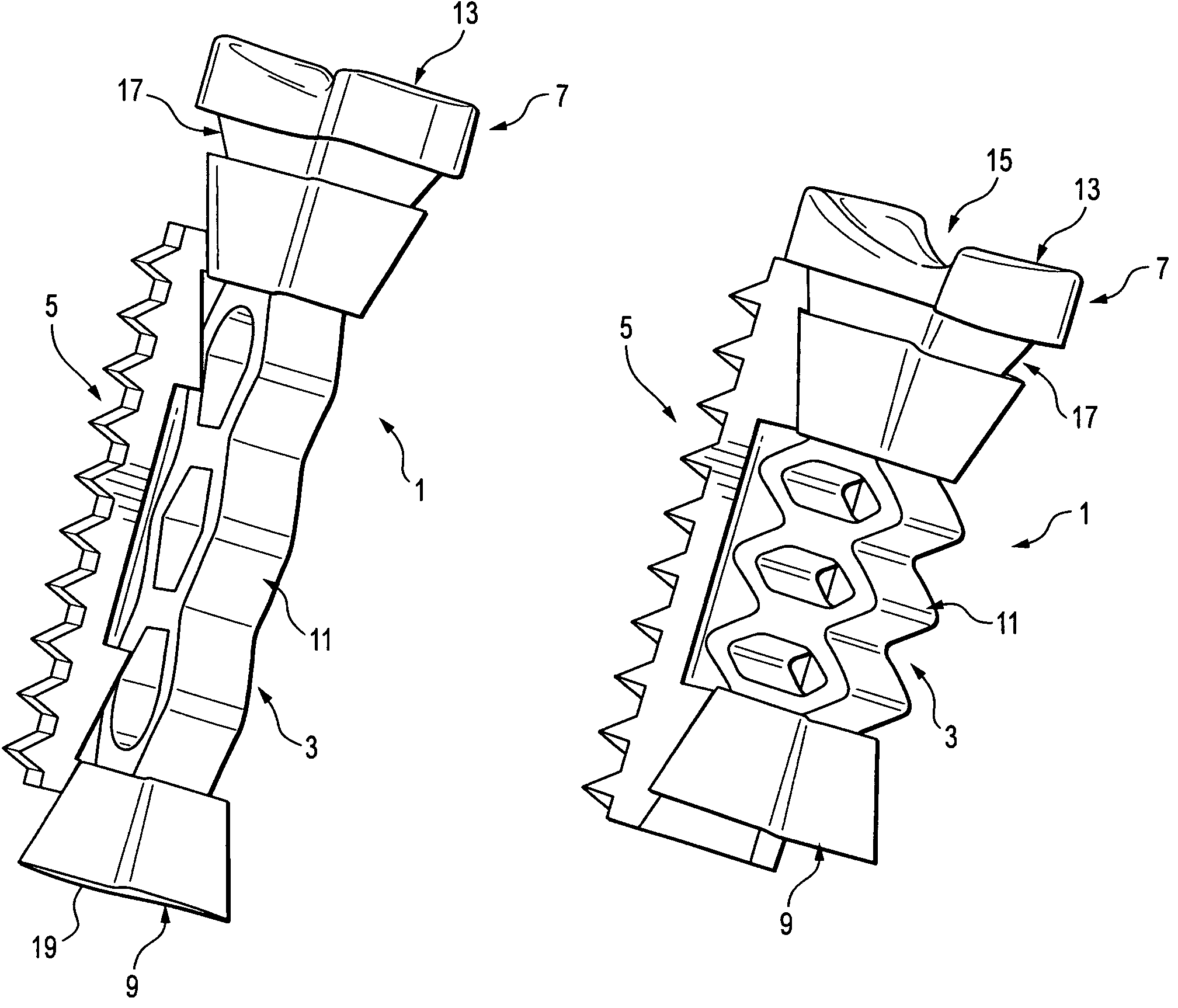

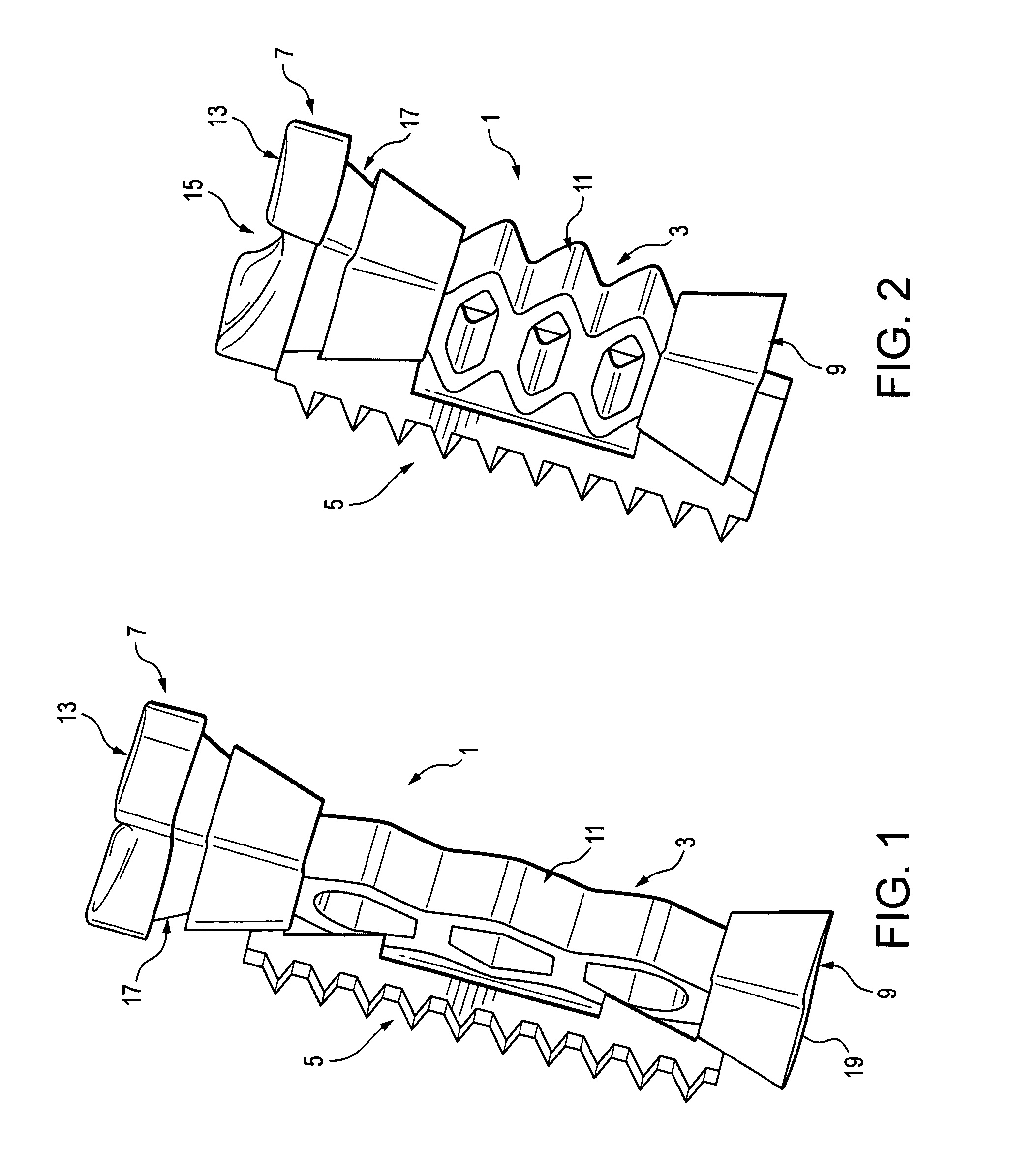

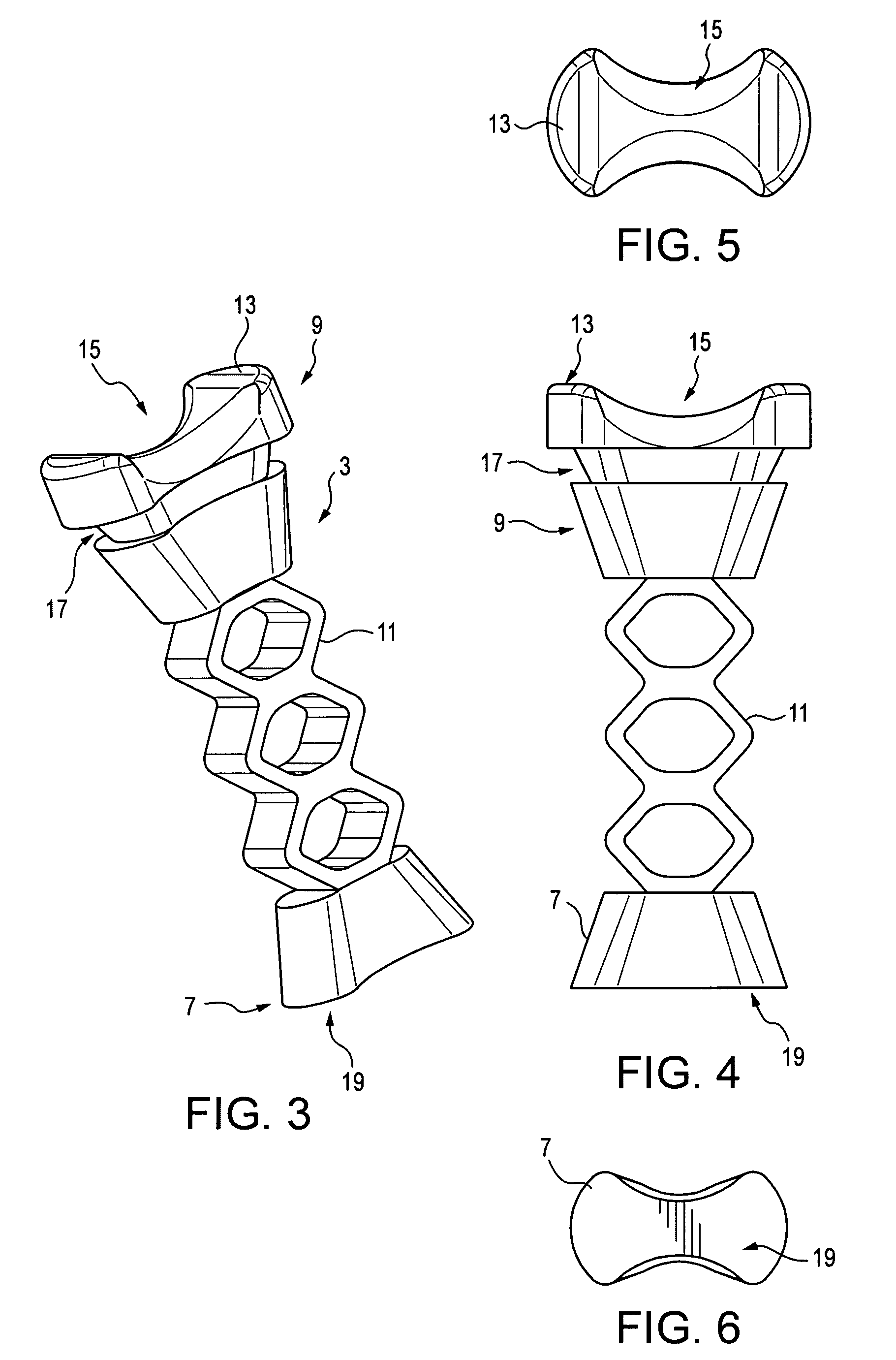

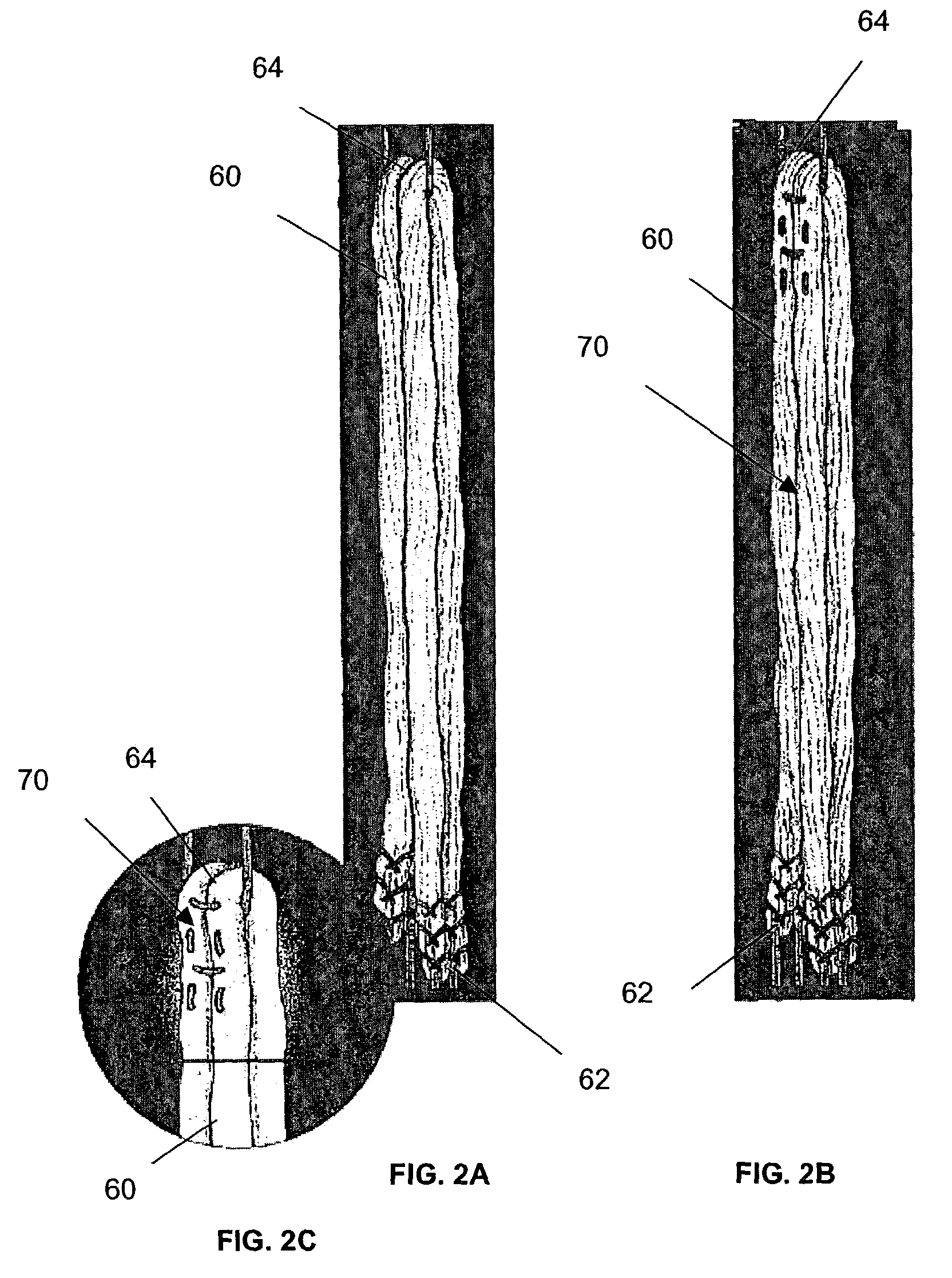

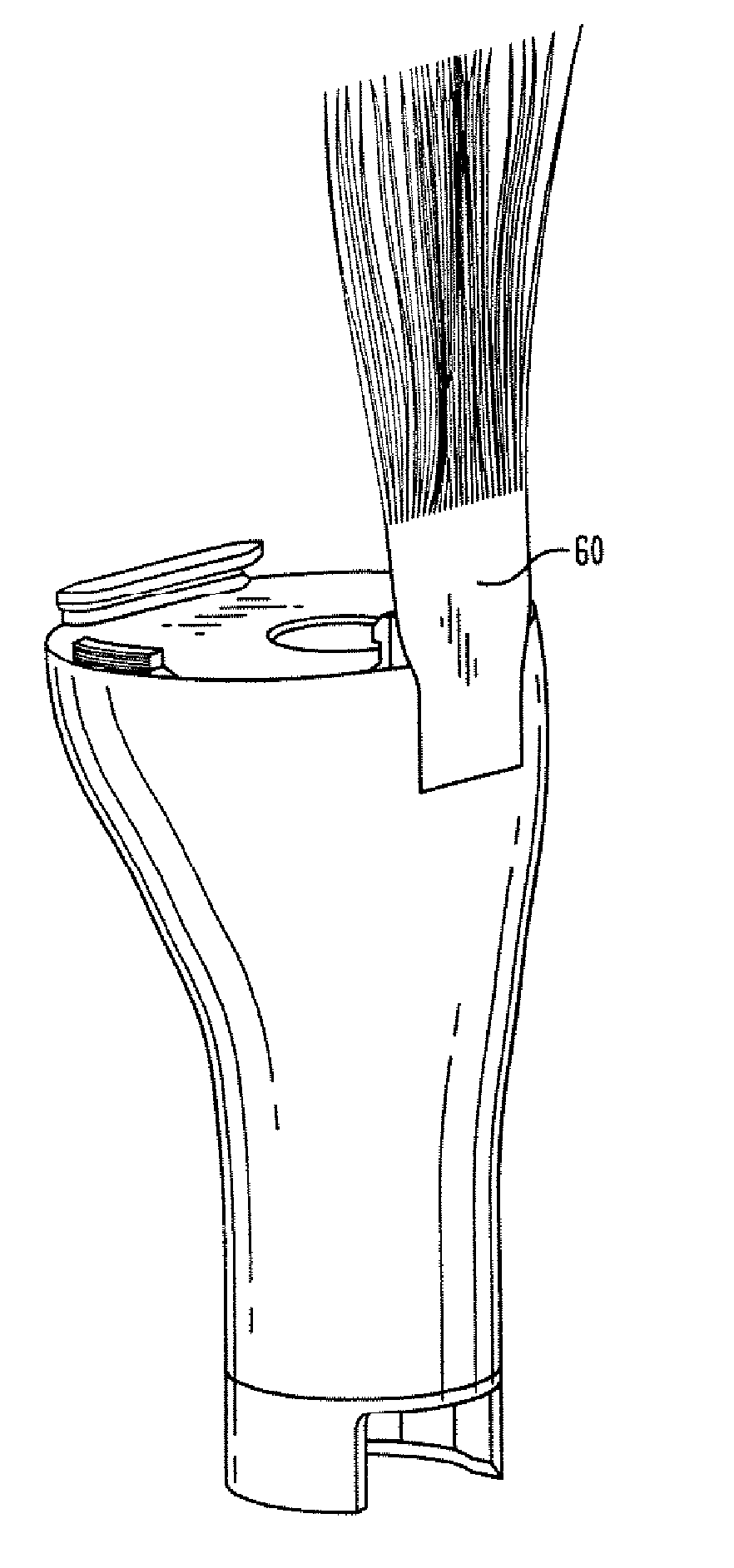

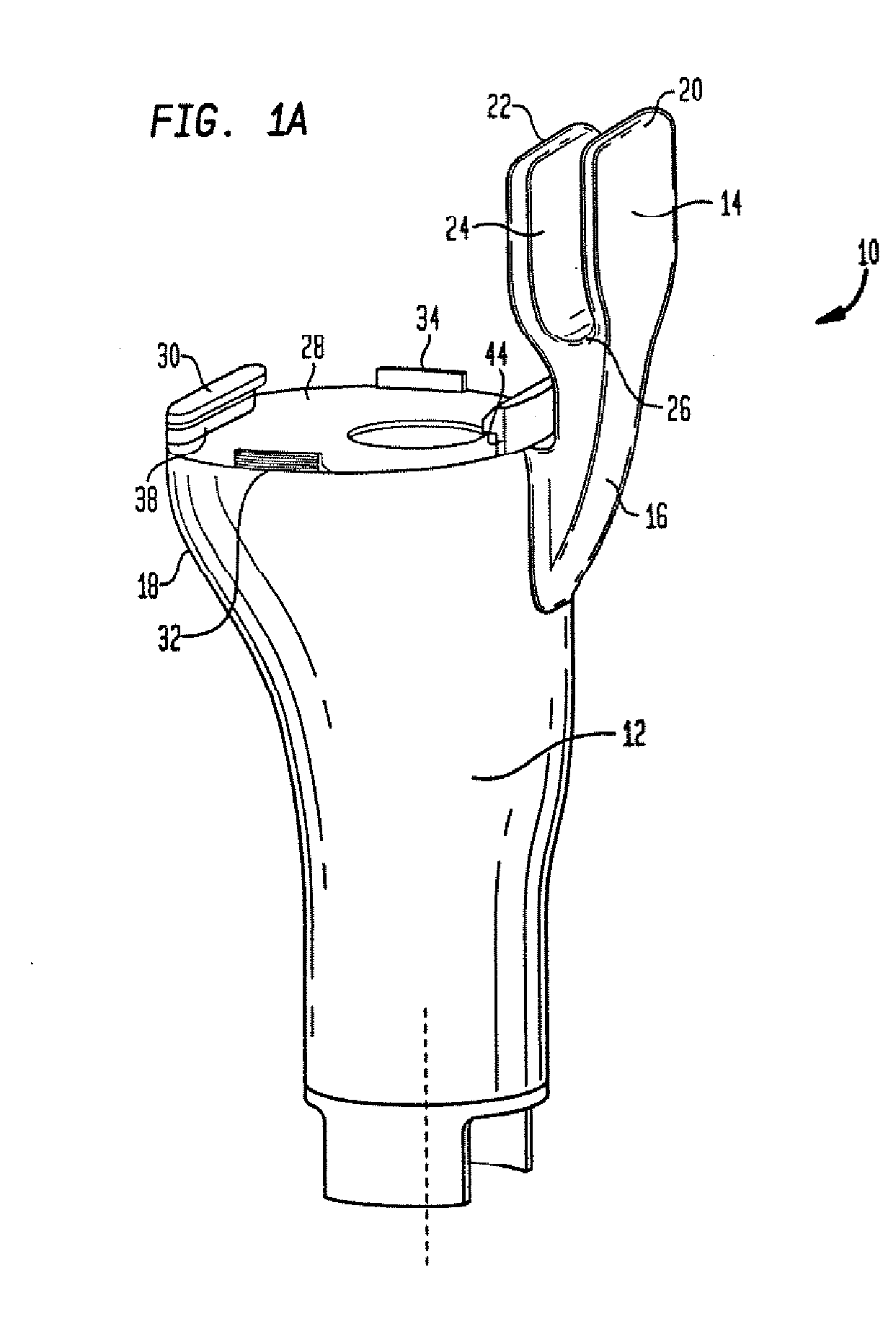

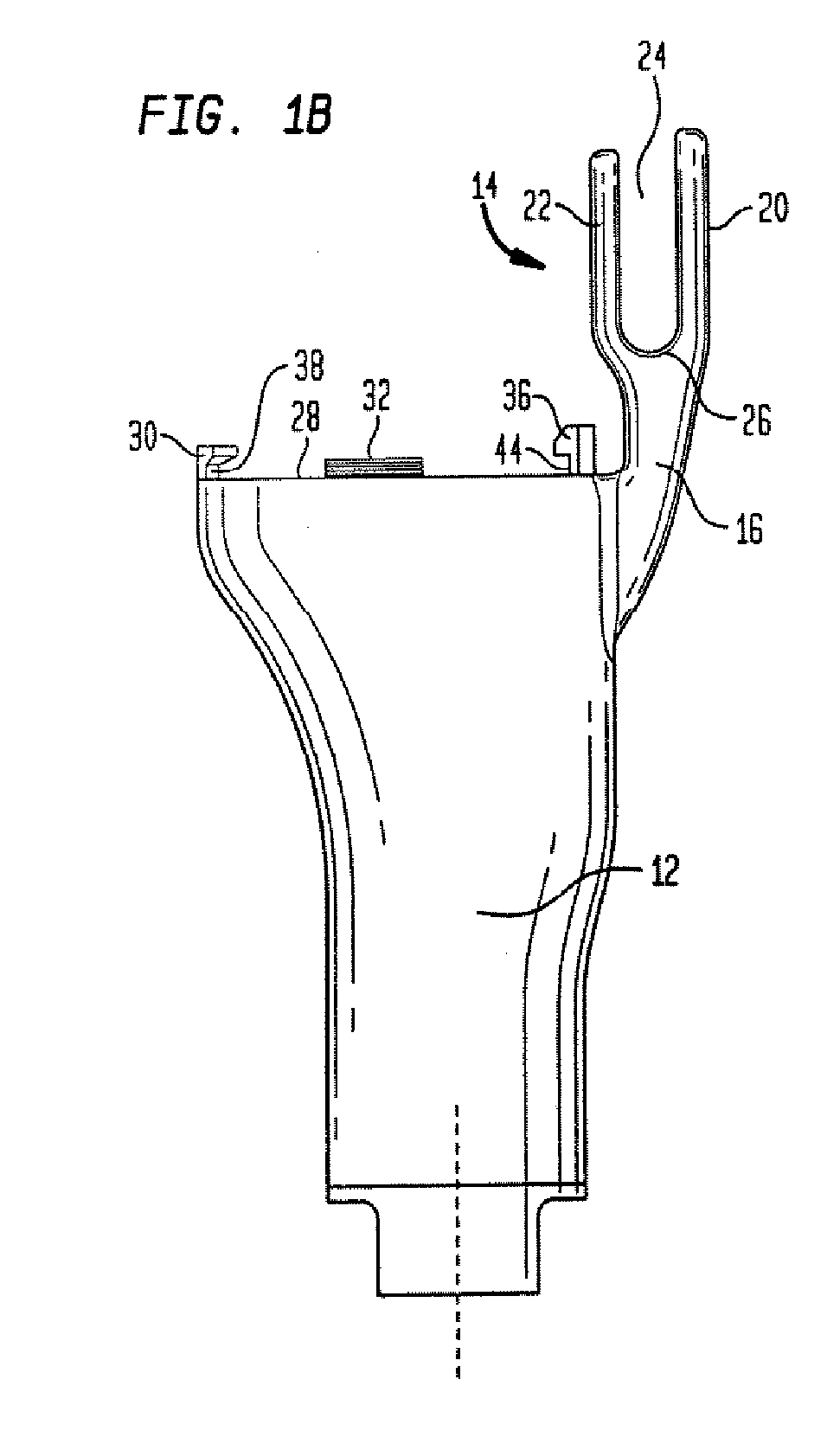

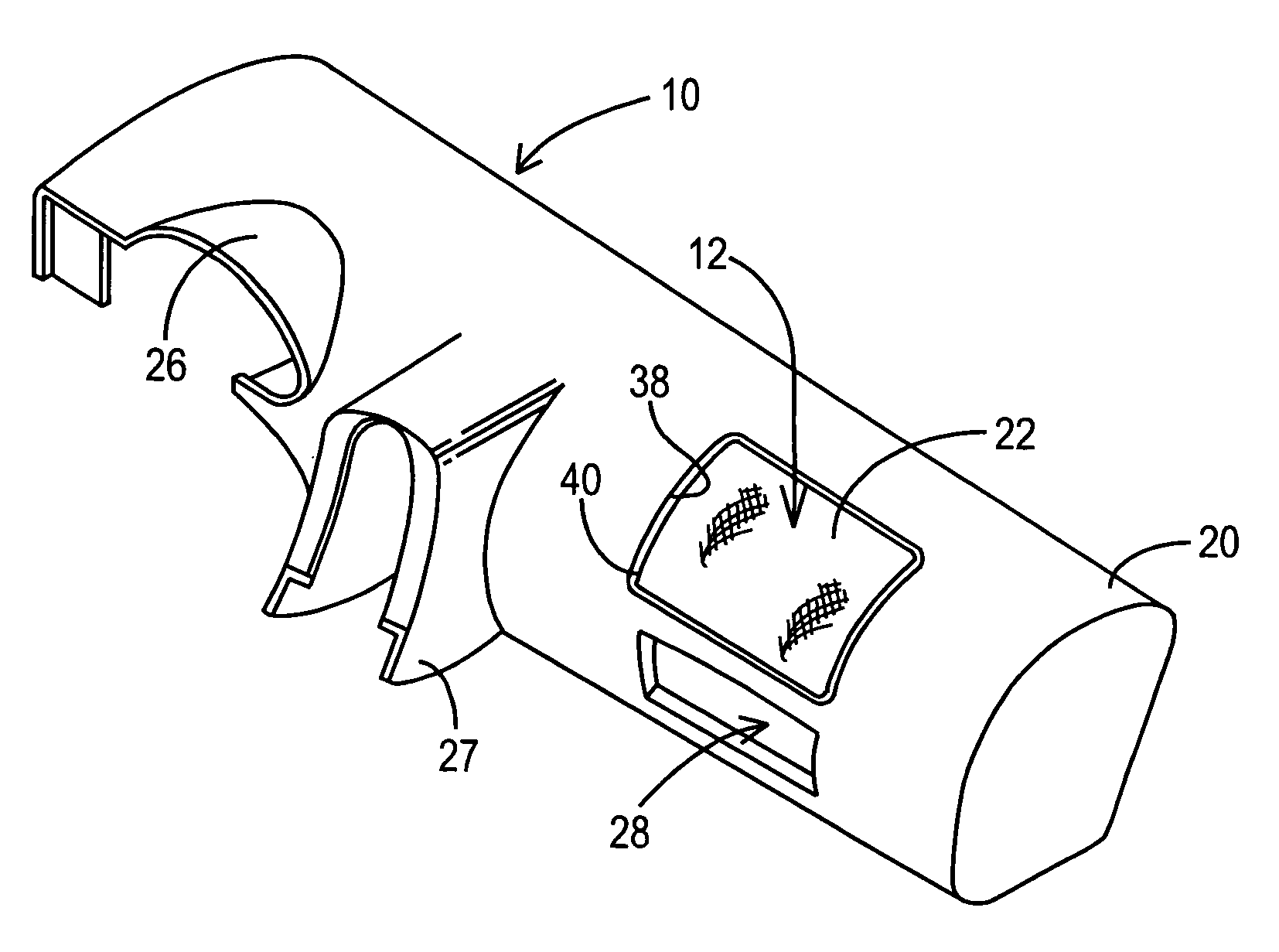

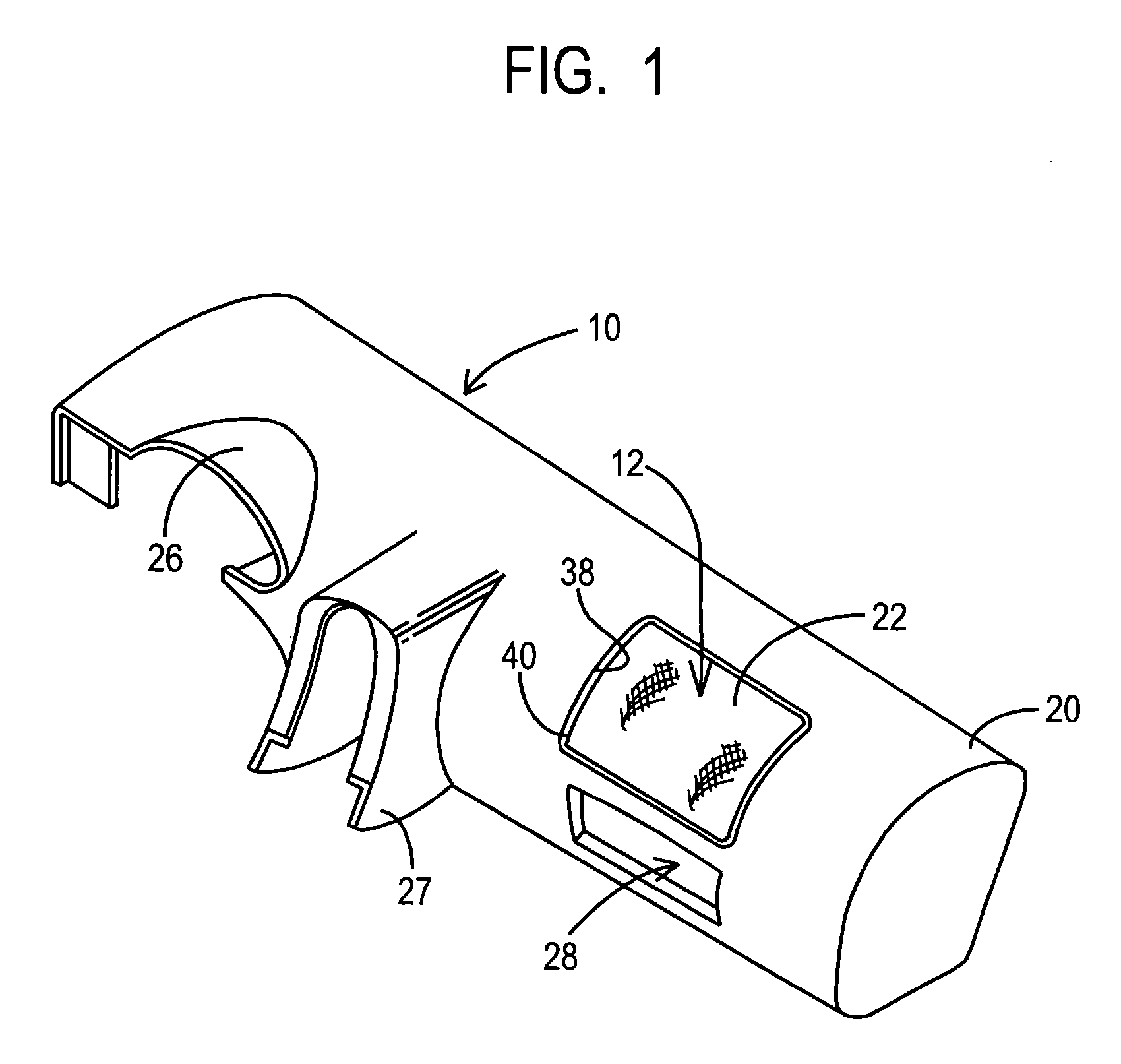

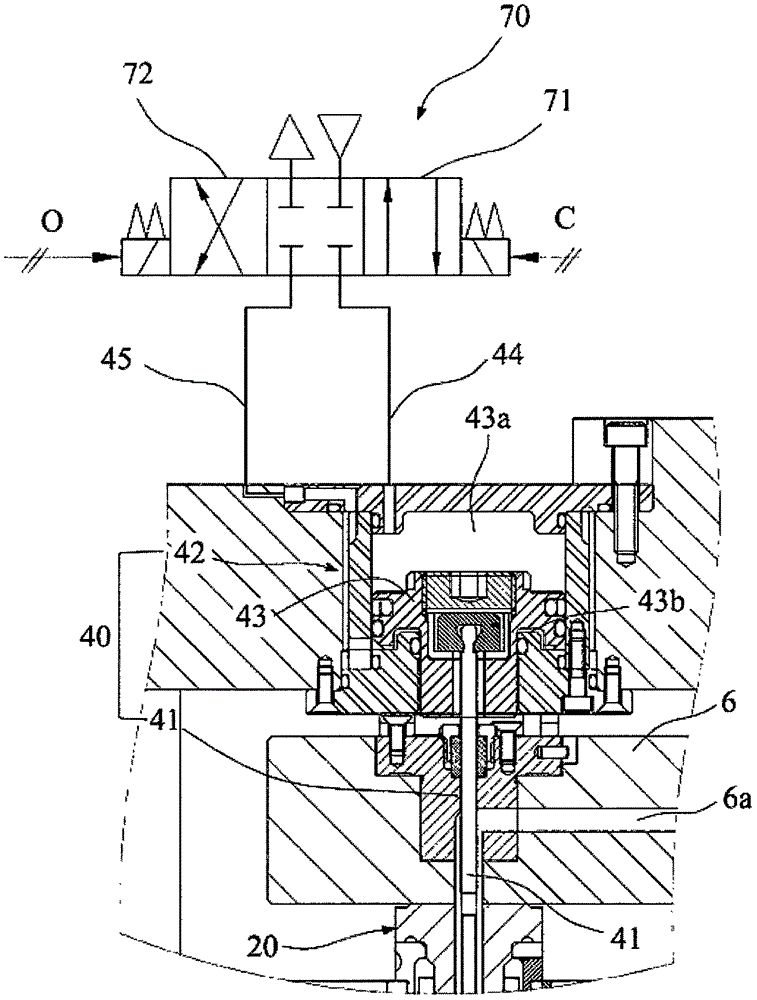

Expanding plug for tendon fixation

An expanding plug for tendon fixation features a two-part system in which an expansion pin fits inside a fixation sleeve. The fixation sleeve is configured to expand diametrically to achieve interference fixation of a graft tendon inside of a bone tunnel. Fixation sleeve expansion is urged by a two-step engagement of the expansion pin. The tendon graft is assembled to the expanding bolt and situated within a bone tunnel. Passing suture is used to pull a joint-line end of the expansion pin into the tunnel to partially expand the fixation sleeve at the joint-line end. Pulling a graft end of the expansion pin toward the joint line expands the fixation sleeve to place the expanding plug in the fully deployed configuration.

Owner:ARTHREX

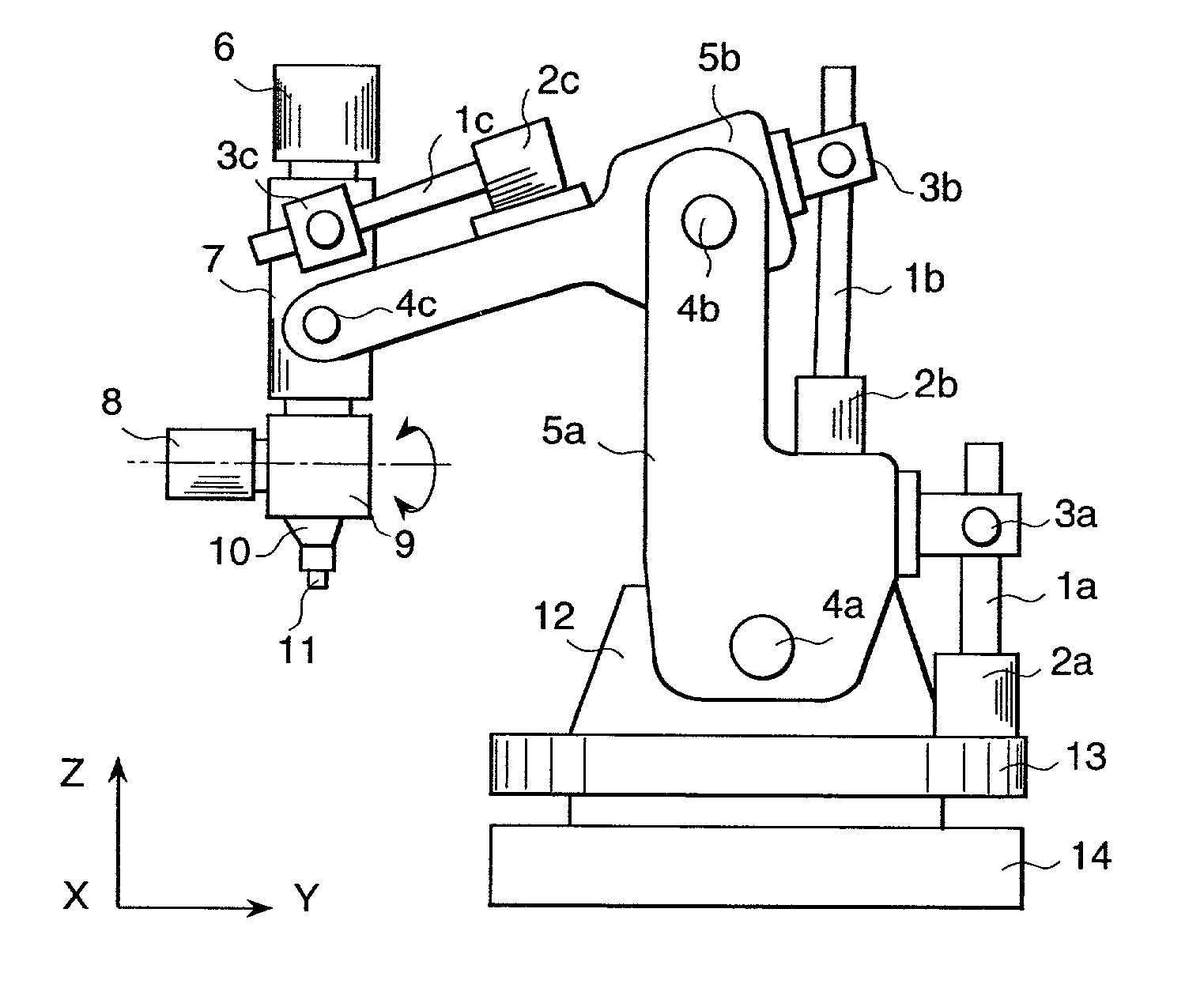

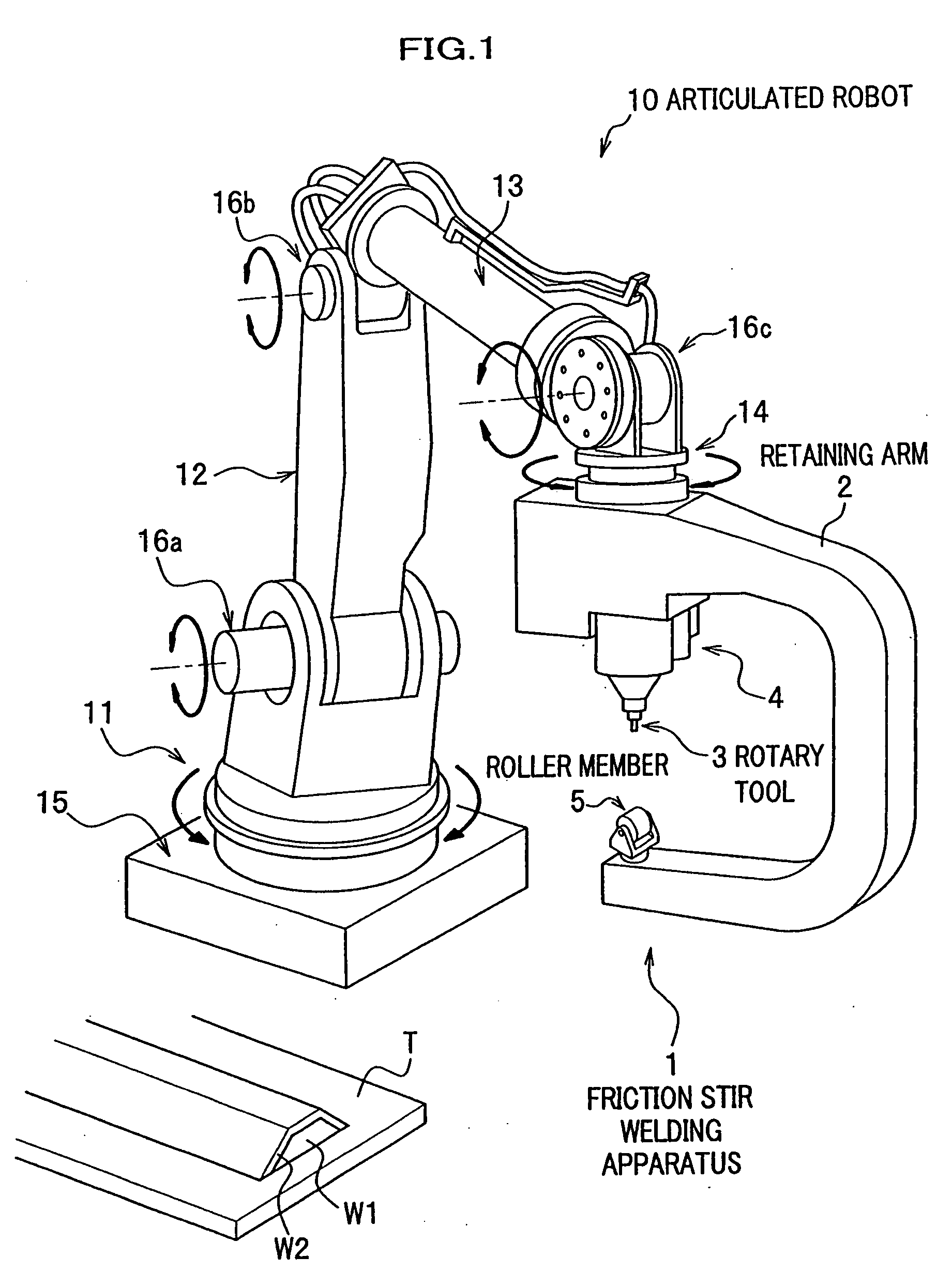

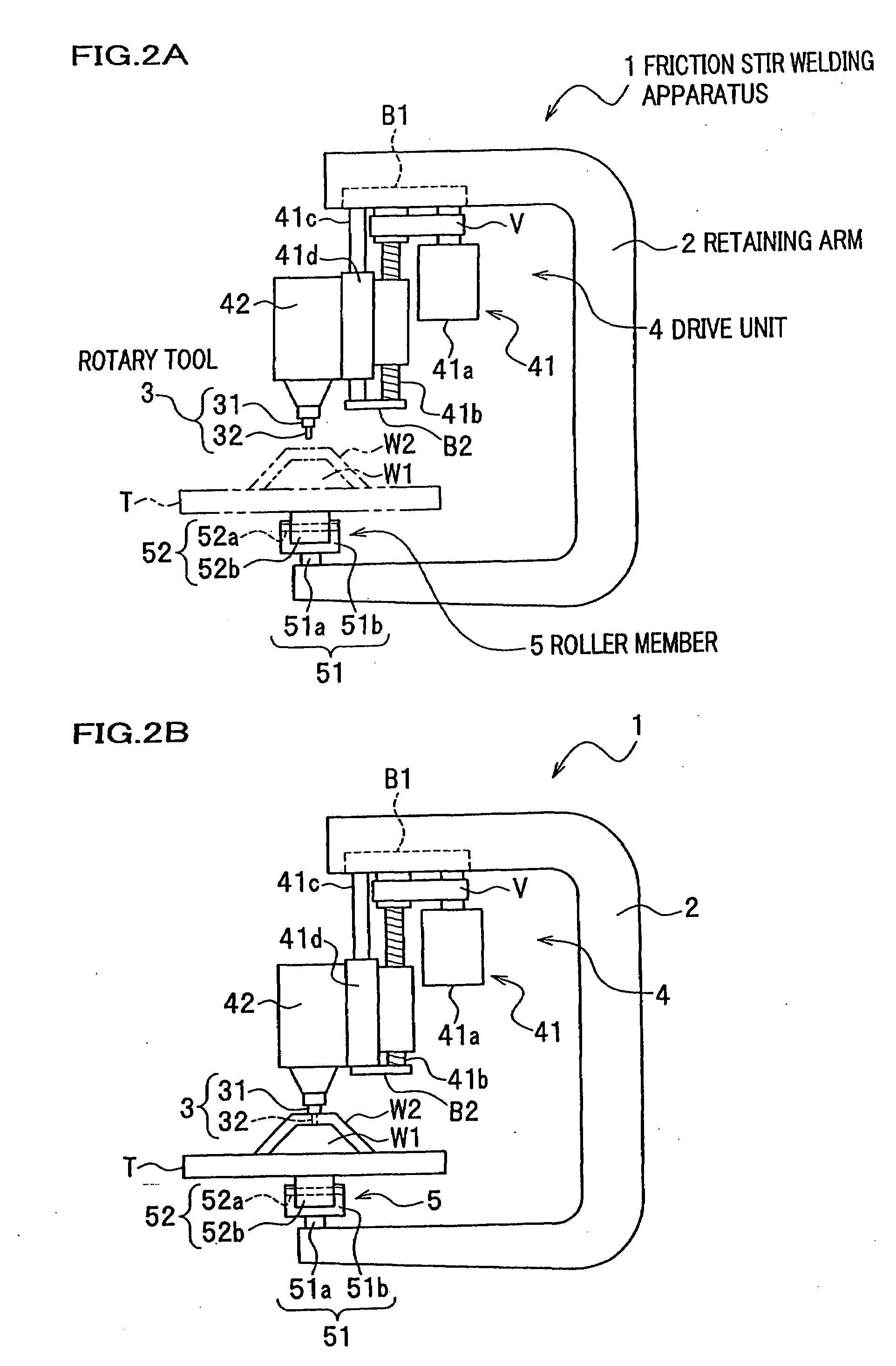

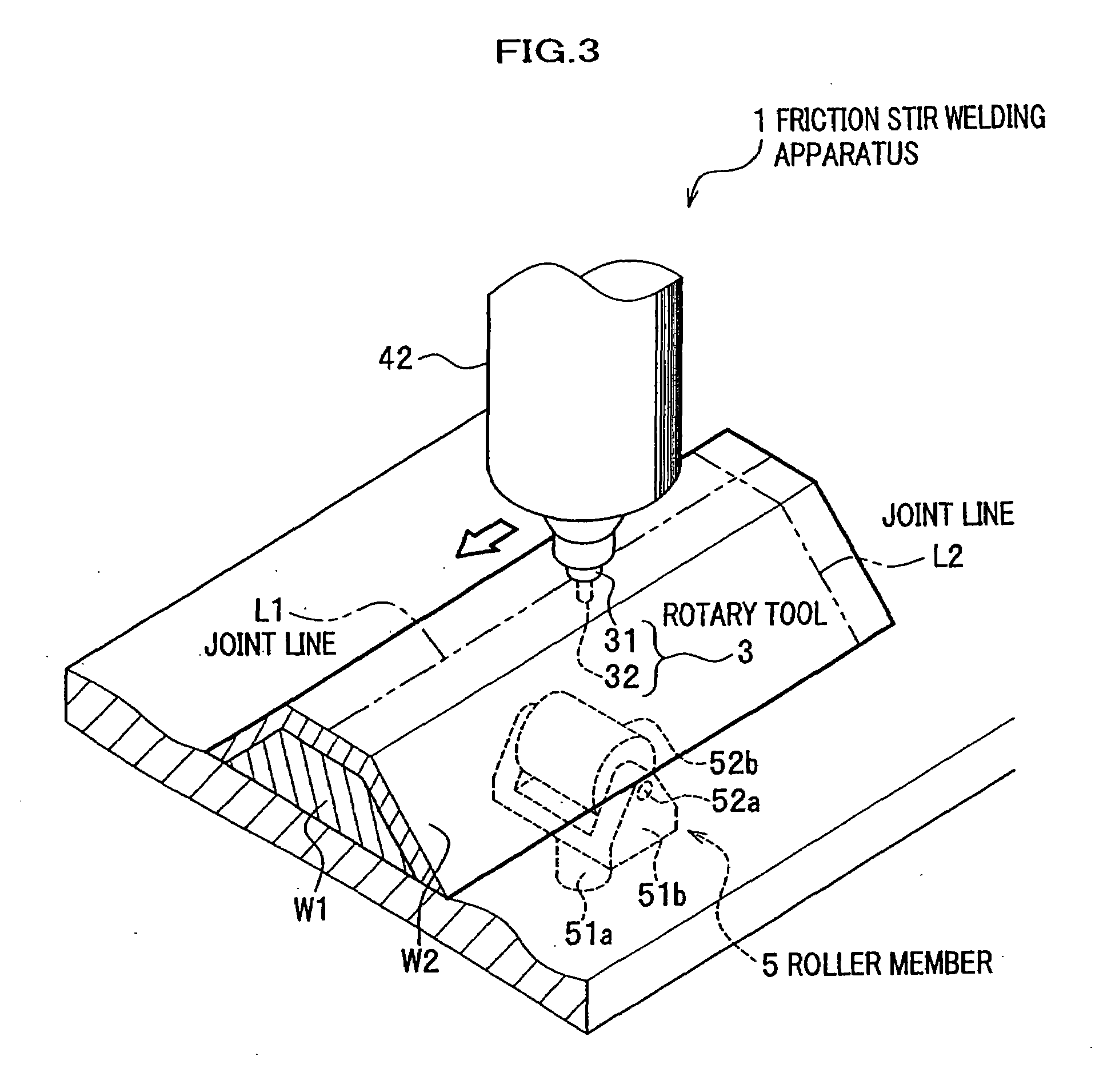

Friction stir welding apparatus and method of operating same

ActiveUS20070187466A1Efficient arrangementSoften materialCooking-vessel materialsWelding/cutting auxillary devicesEngineeringMechanical engineering

A friction stir welding apparatus and a method of operating the friction stir welding apparatus are disclosed. The friction stir welding apparatus includes a rotary tool whose extremity constitutes a probe, a retaining arm which supports the rotary tool, and a roller provided at a position of the retaining arm opposite the rotary tool. The method includes adjusting the retaining arm so as to position workpieces between the rotary tool and the roller while adjusting the roller to turn in a direction where a joint line of the workpieces extends, rotating the rotary tool and lowering the probe until the probe presses the workpieces, gradually inserting the probe into the joint line, and moving the probe along the joint line.

Owner:HONDA MOTOR CO LTD

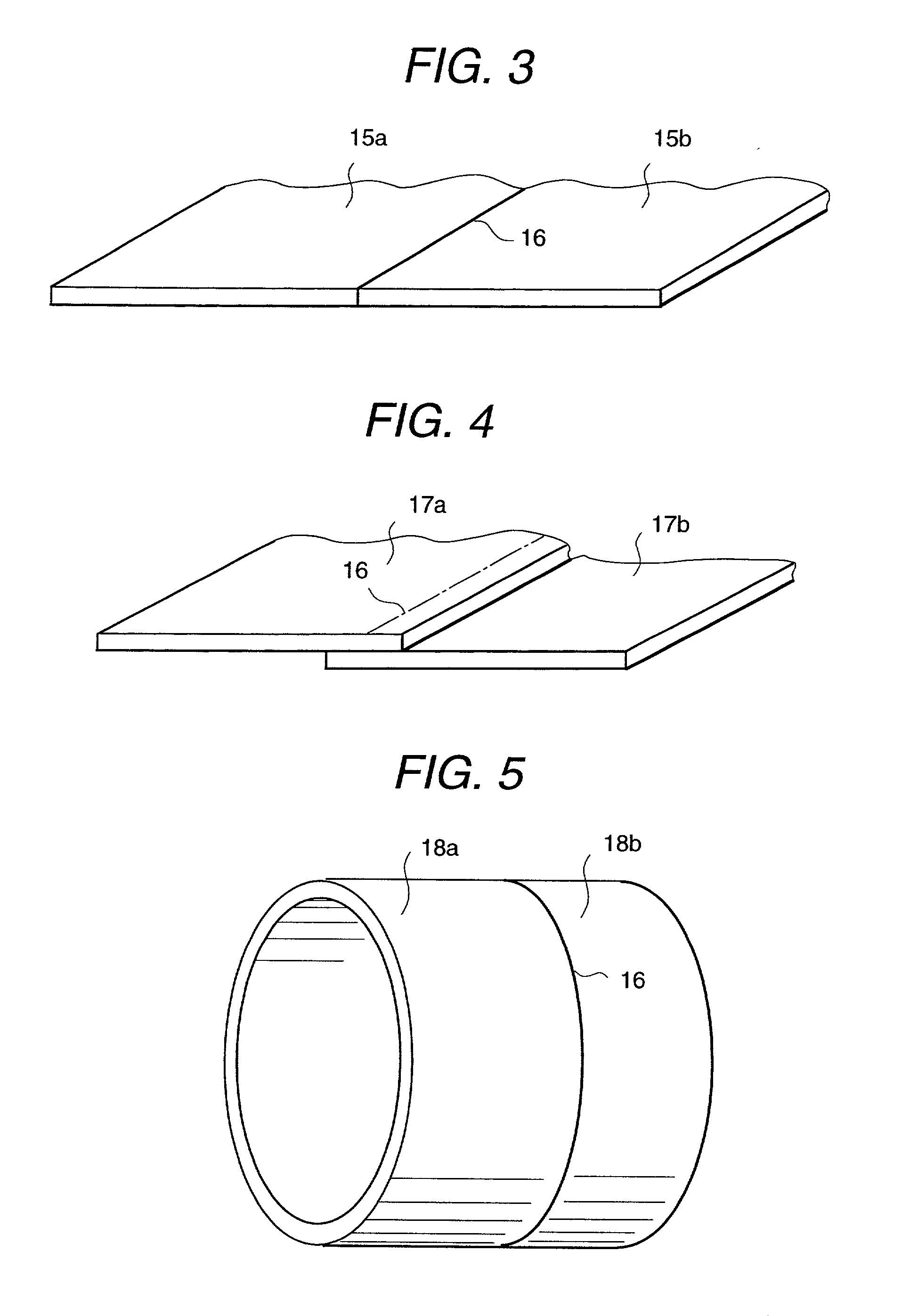

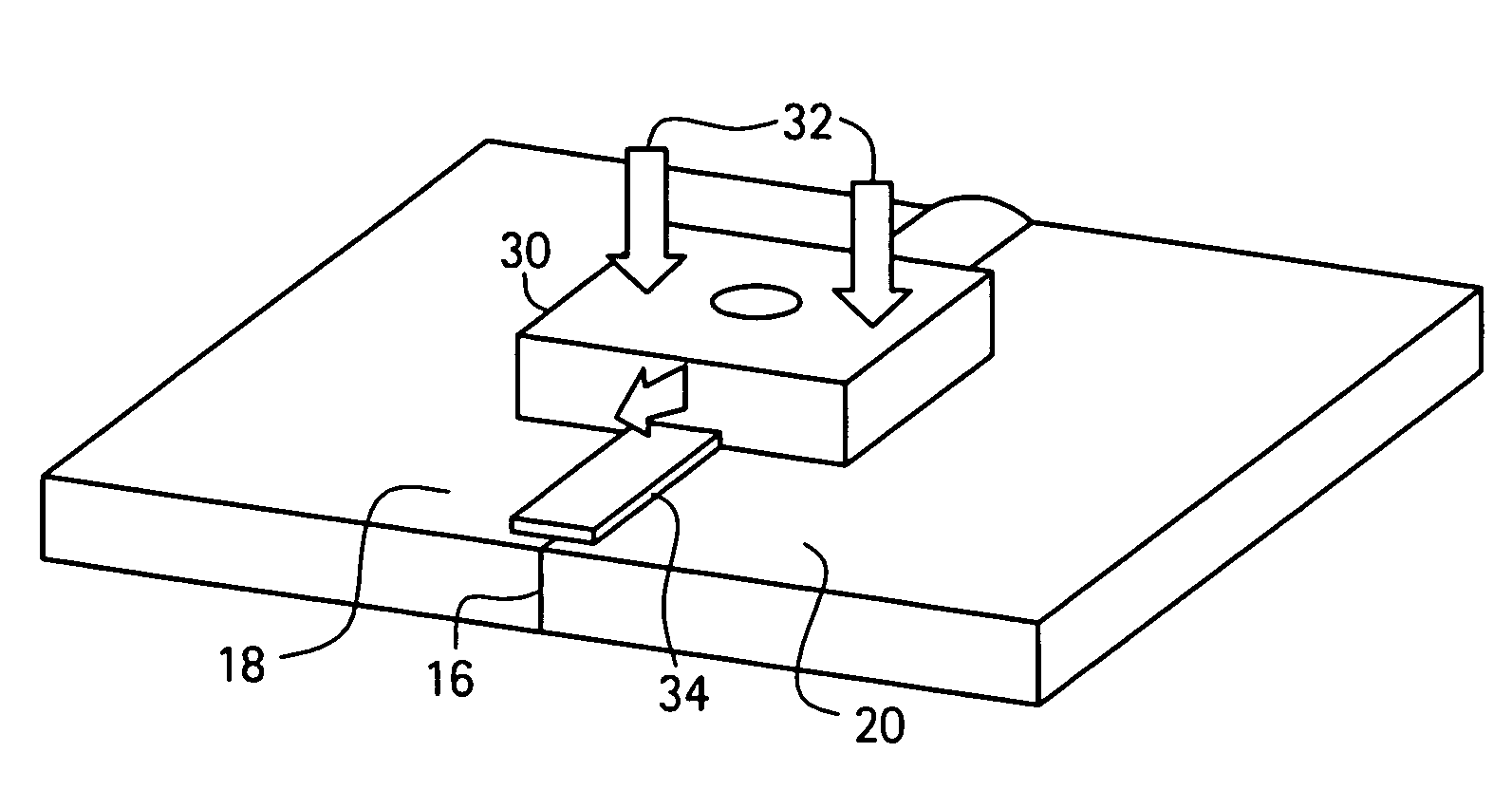

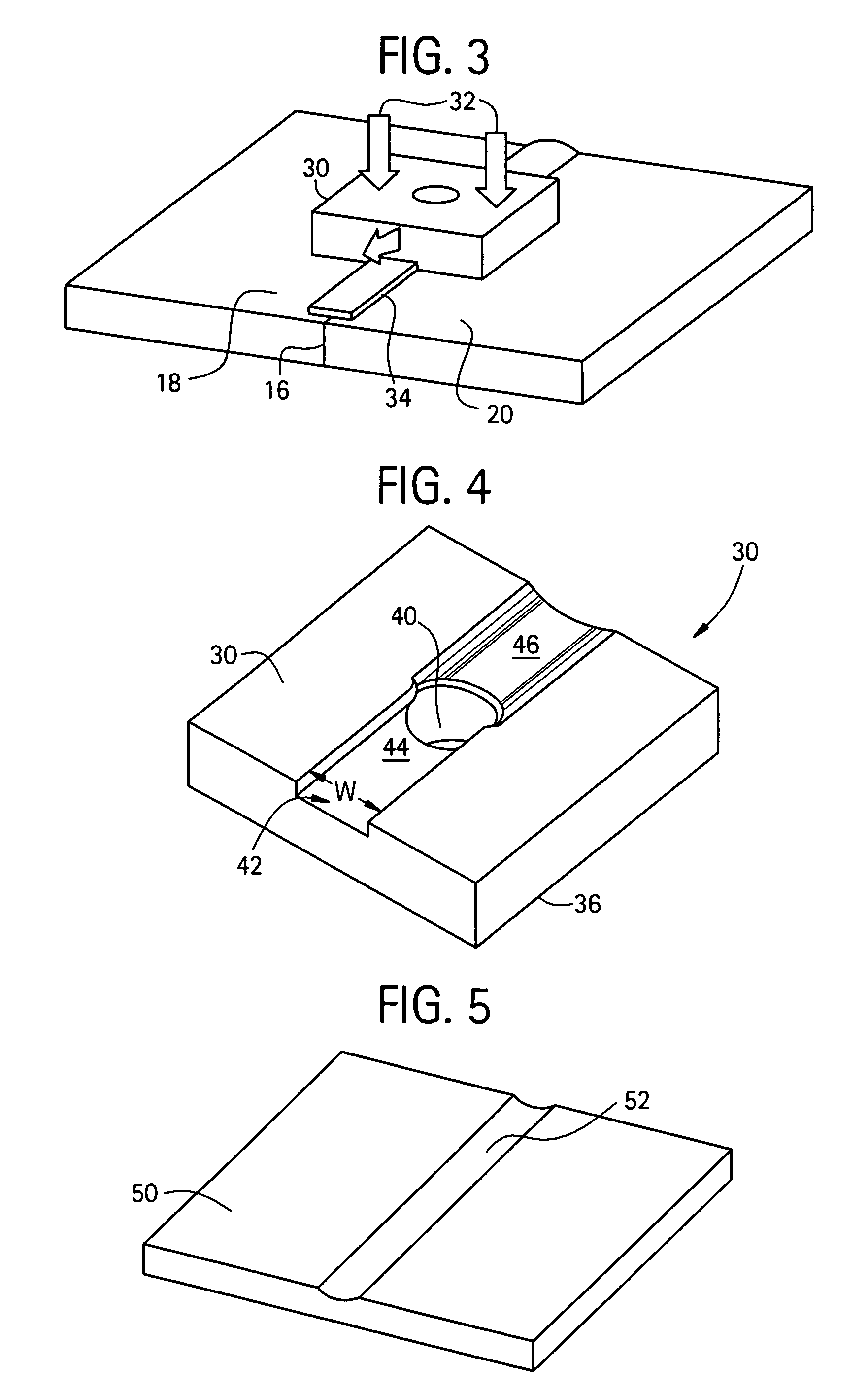

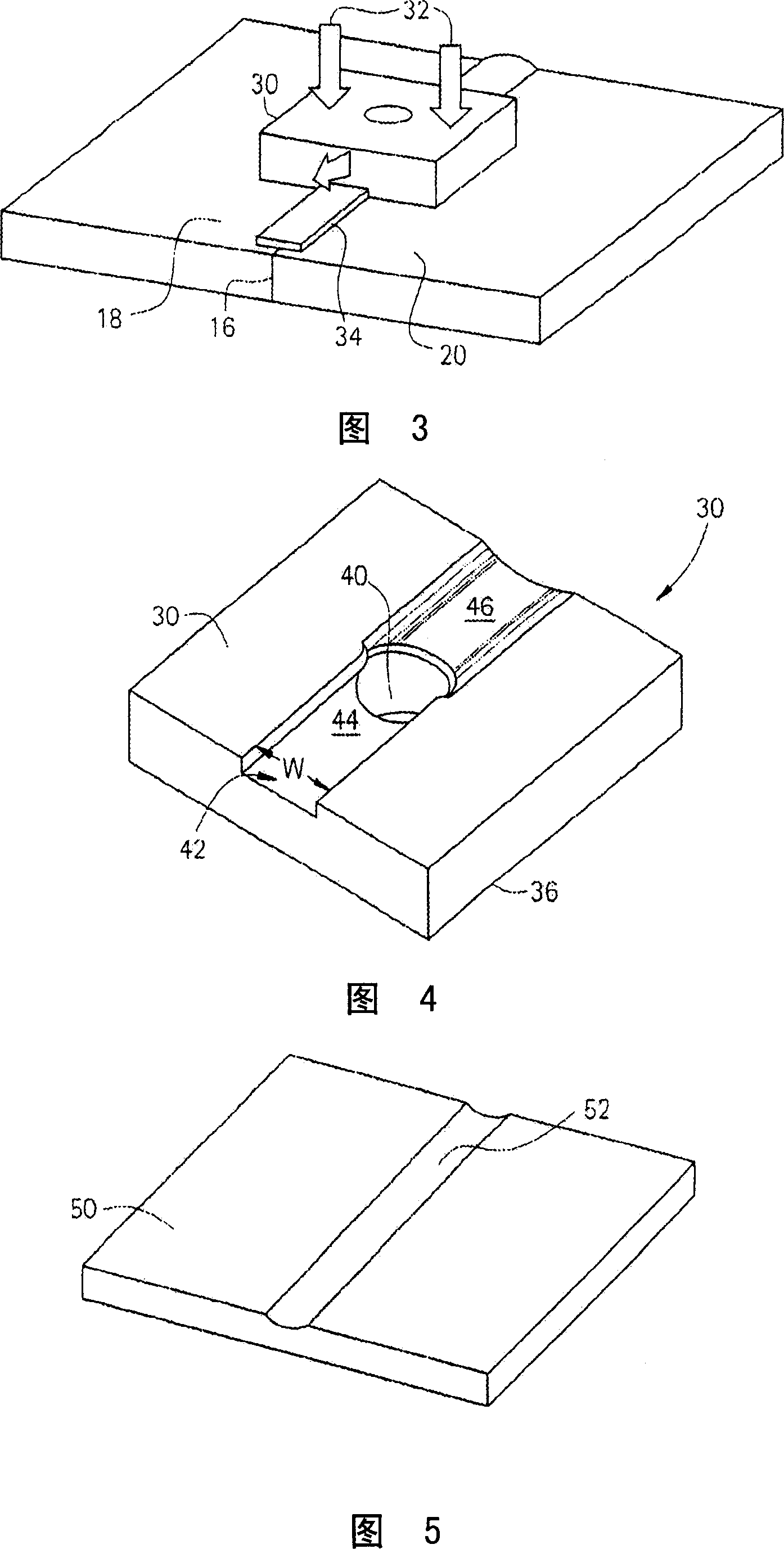

Deposition friction stir welding process and assembly

InactiveUS7455212B2Avoid dischargeWelding/cutting auxillary devicesAuxillary welding devicesFilling materialsEngineering

A deposition friction stir weld process of joining work pieces includes placing a filler material on and about a joint line formed by butting a first work piece surface against a second work piece surface; and frictionally heating the filler material to soften the filler material and portions of the first and second work piece surfaces in thermal contact with the filler material and form a weld between the first and second work pieces, wherein frictionally heating is at a temperature below a melting point of the filler material and the first and second workpiece surfaces. Also disclosed herein are friction stir welding assemblies for providing the deposition friction stir weld as well as processes for depositing filler material and contouring a workpiece surface.

Owner:GENERAL ELECTRIC CO

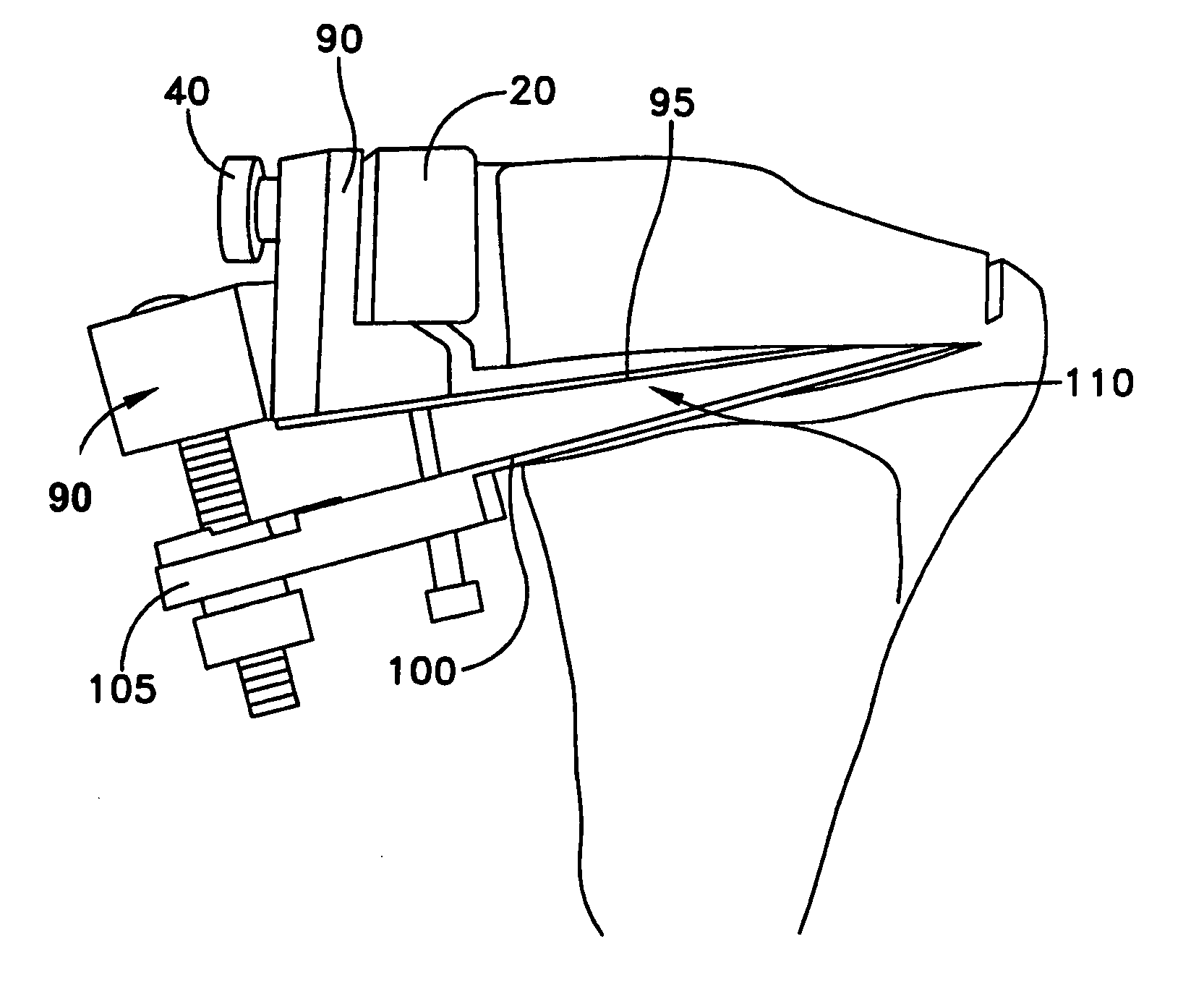

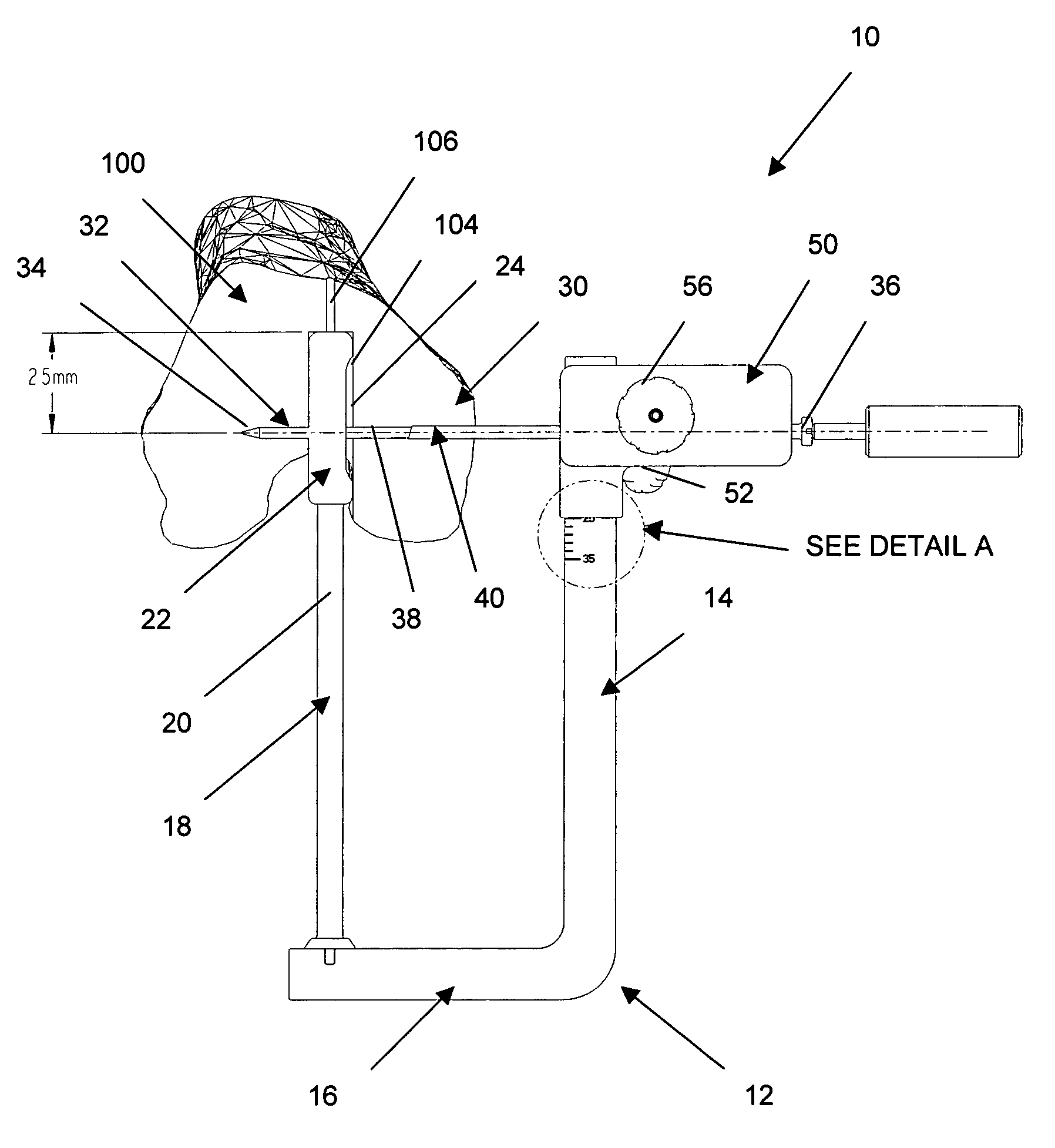

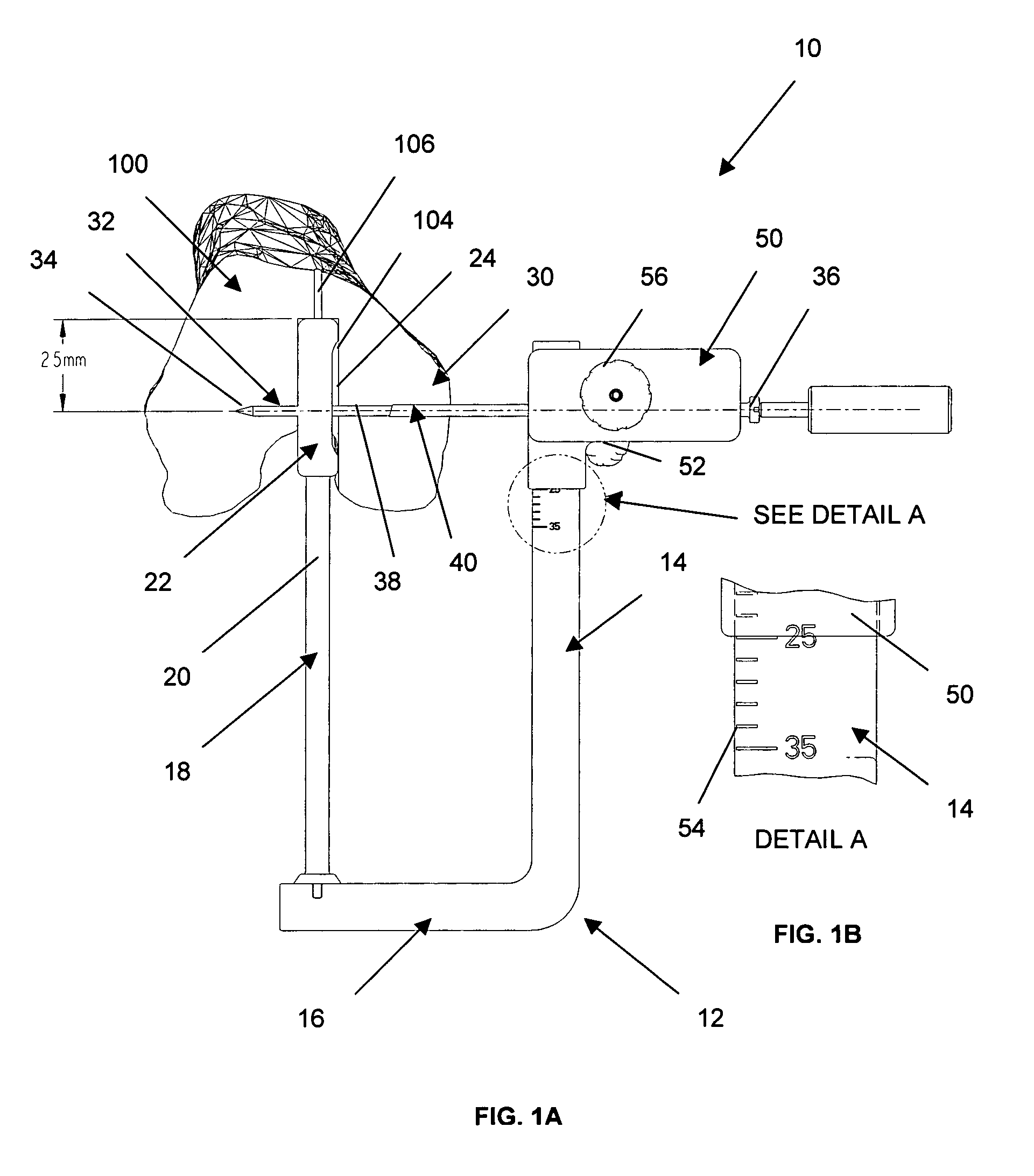

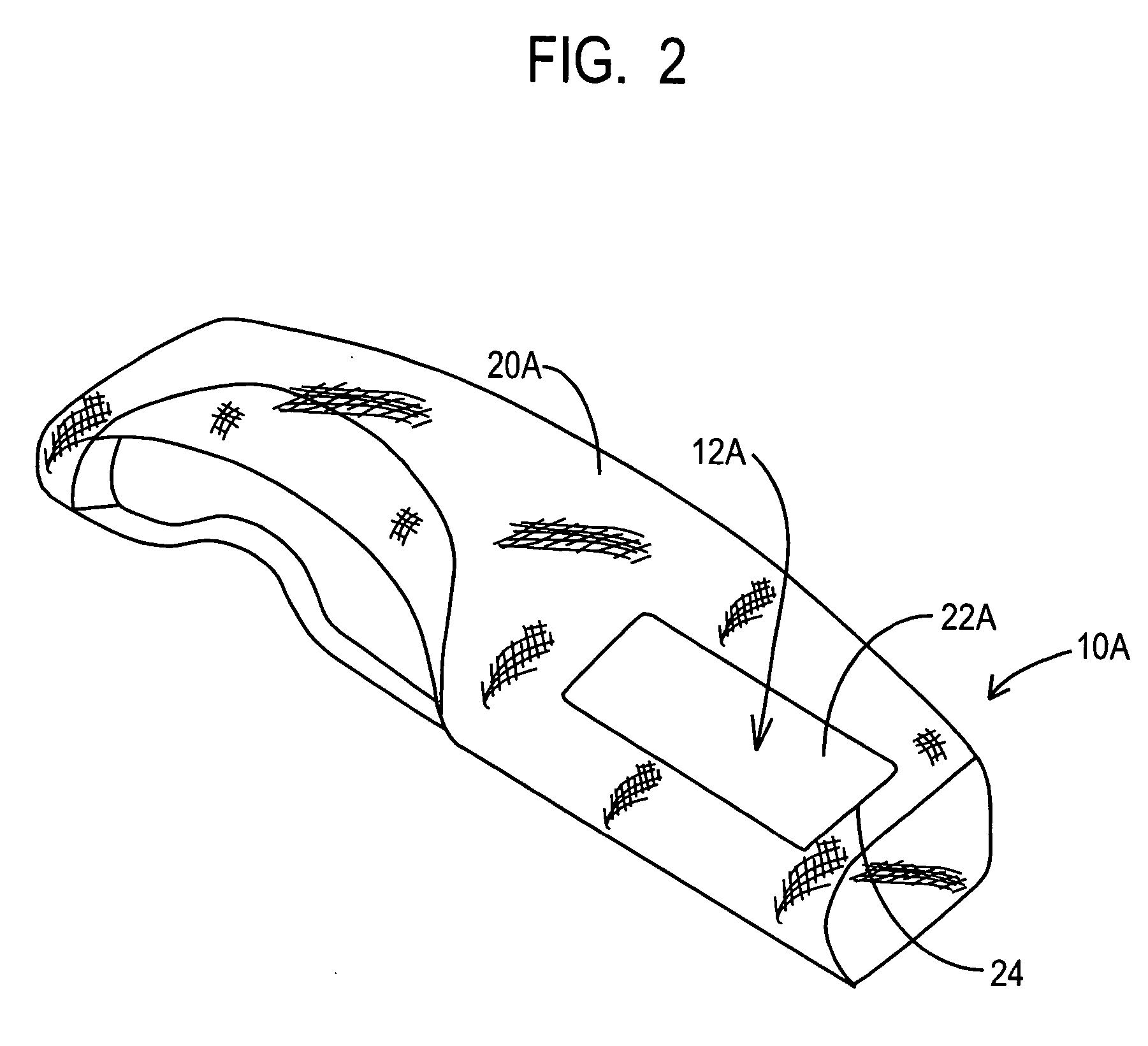

Adjustable drill guide assembly and method of use

An adjustable drill guide is provided that can be used to deliver a cross pin at a distance near the entrance to the femoral bone tunnel during ligament surgery. The cross pin positioned at the joint line, or tunnel opening, compresses and secures the graft within the bone tunnel, thereby preventing the graft from swaying back and forth post surgery when the joint is in motion. The adjustable drill guide assembly comprises a guide frame that includes an arm portion and a base portion that extends transversely to the arm portion. A rod member connects to the base portion for extending into the hone tunnel of the bone. Also included is a guide member configured for connection to the arm portion. The guide member is configured to be in moveable and lockable disposition along a length of the arm portion.

Owner:DEPUY SYNTHES PROD INC

Expanding plug for tendon fixation

An expanding plug for tendon fixation features a two-part system in which an expansion pin fits inside a fixation sleeve. The fixation sleeve is configured to expand diametrically to achieve interference fixation of a graft tendon inside of a bone tunnel. Fixation sleeve expansion is urged by a two-step engagement of the expansion pin. The tendon graft is assembled to the expanding bolt and situated within a bone tunnel. Passing suture is used to pull a joint-line end of the expansion pin into the tunnel to partially expand the fixation sleeve at the joint-line end. Pulling a graft end of the expansion pin toward the joint line expands the fixation sleeve to place the expanding plug in the fully deployed configuration.

Owner:ARTHREX

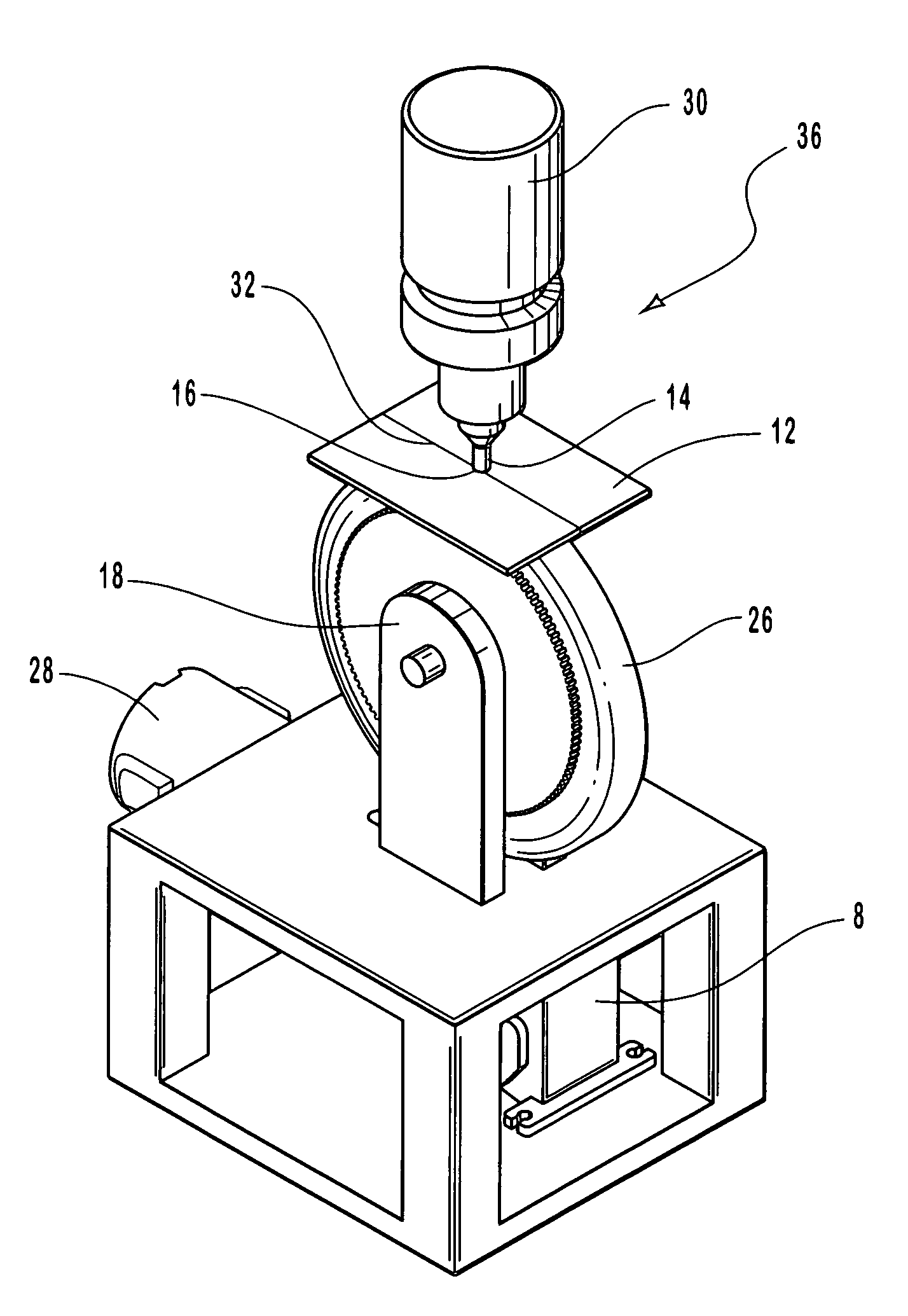

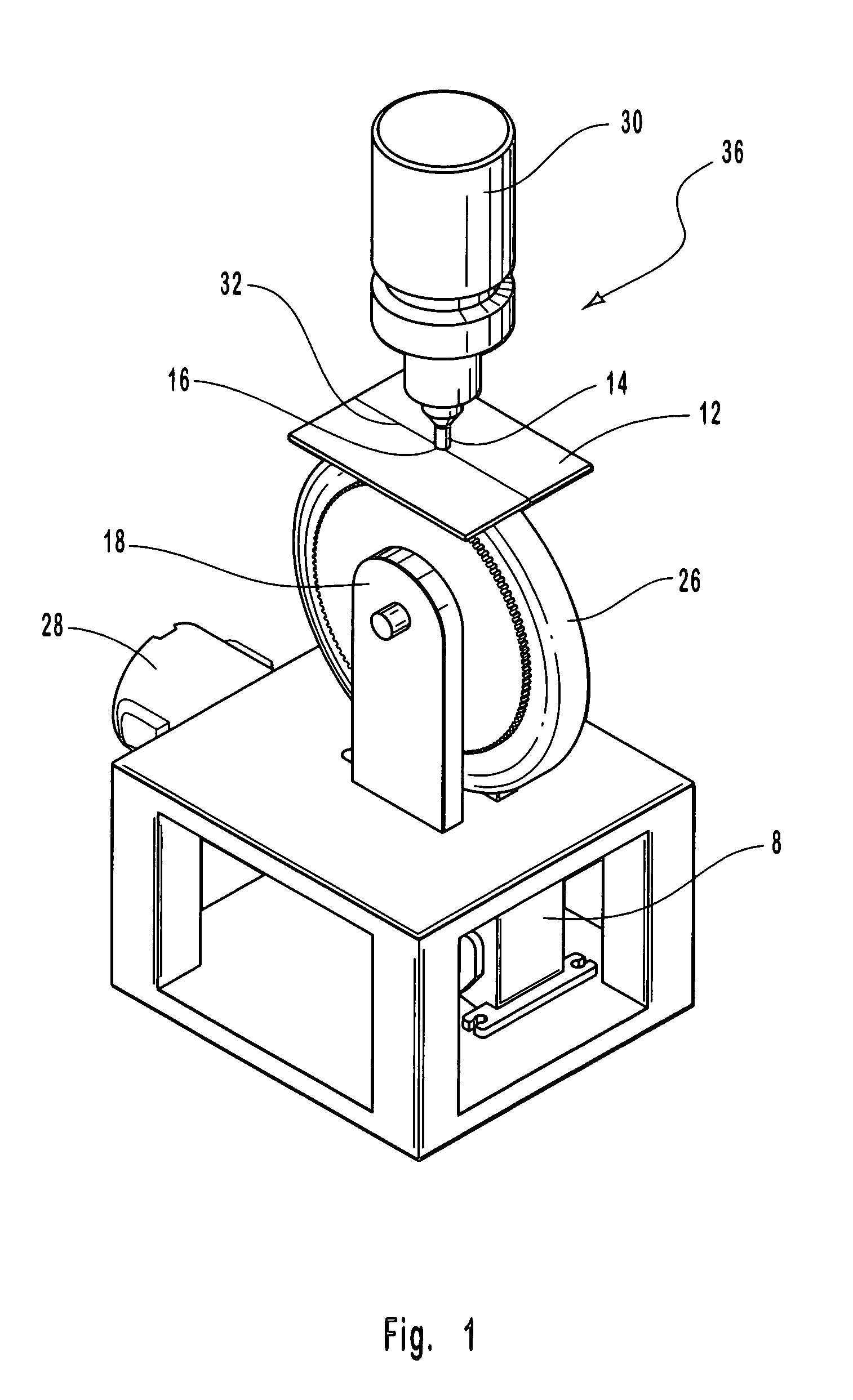

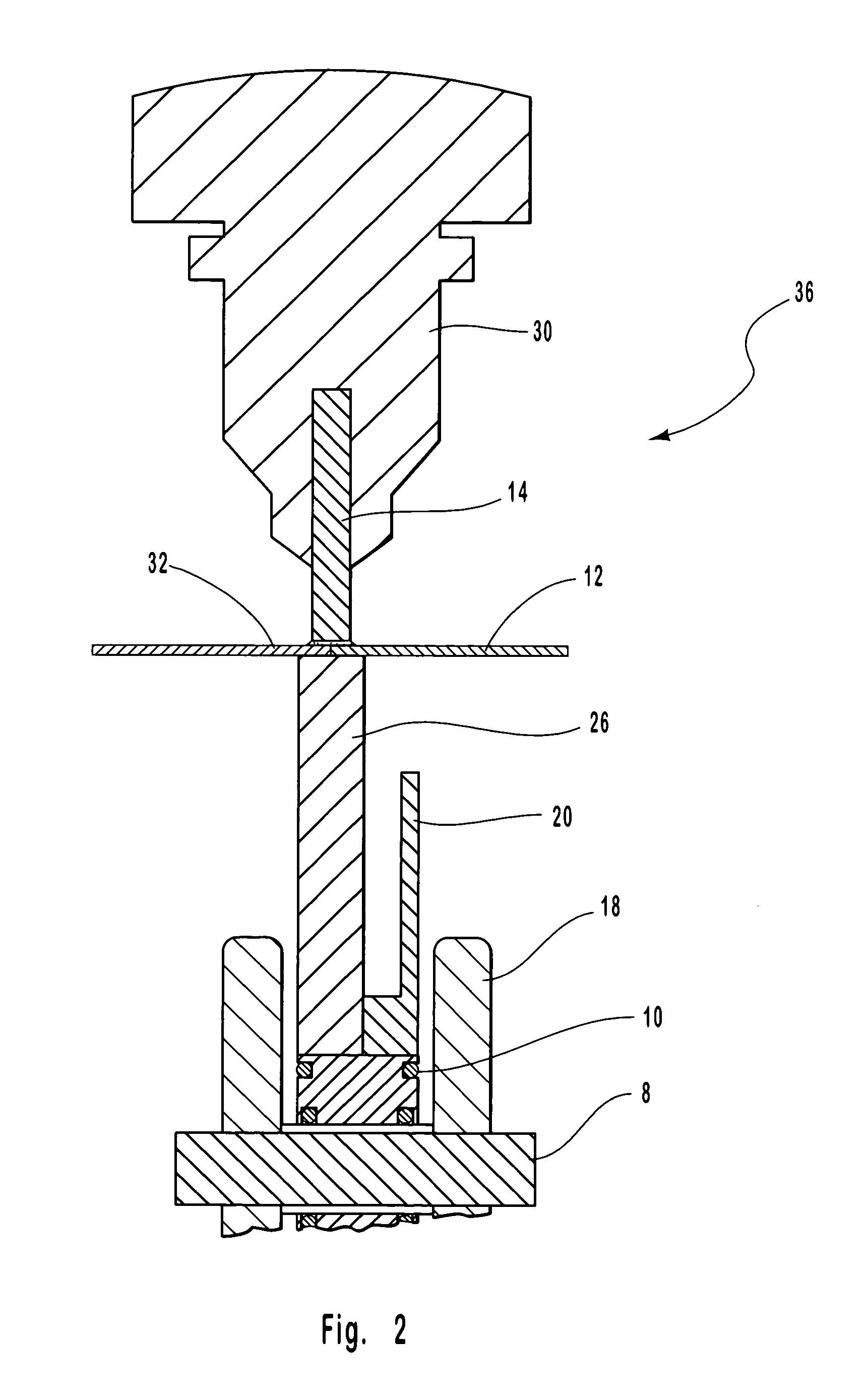

Apparatus and method for performing non-linear friction stir welds on either planar or non-planar surfaces

InactiveUS7210610B2Eliminate needEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesHigh integrityEngineering

A method and device enabling friction stir welding along non-linear joint lines or seams on either planar or non-planar surfaces are provided. The device features four roller clamps located on upper and lower pieces. It also contains a non-consumable tool with a profiled probed end that engages work pieces and follows along a non-linear or linear joint lines in order to achieve high-integrity friction stir welds. No special anvil is required and the device can be manually or automatically operated and controlled. Operating similarly to a conventional sewing machine, this device and process enable an operator or user to manually guide work pieces to be welded through a friction stir welding tool and allows for flexibility in the path of the weld and the types of material being welded.

Owner:BRIGHAM YOUNG UNIV

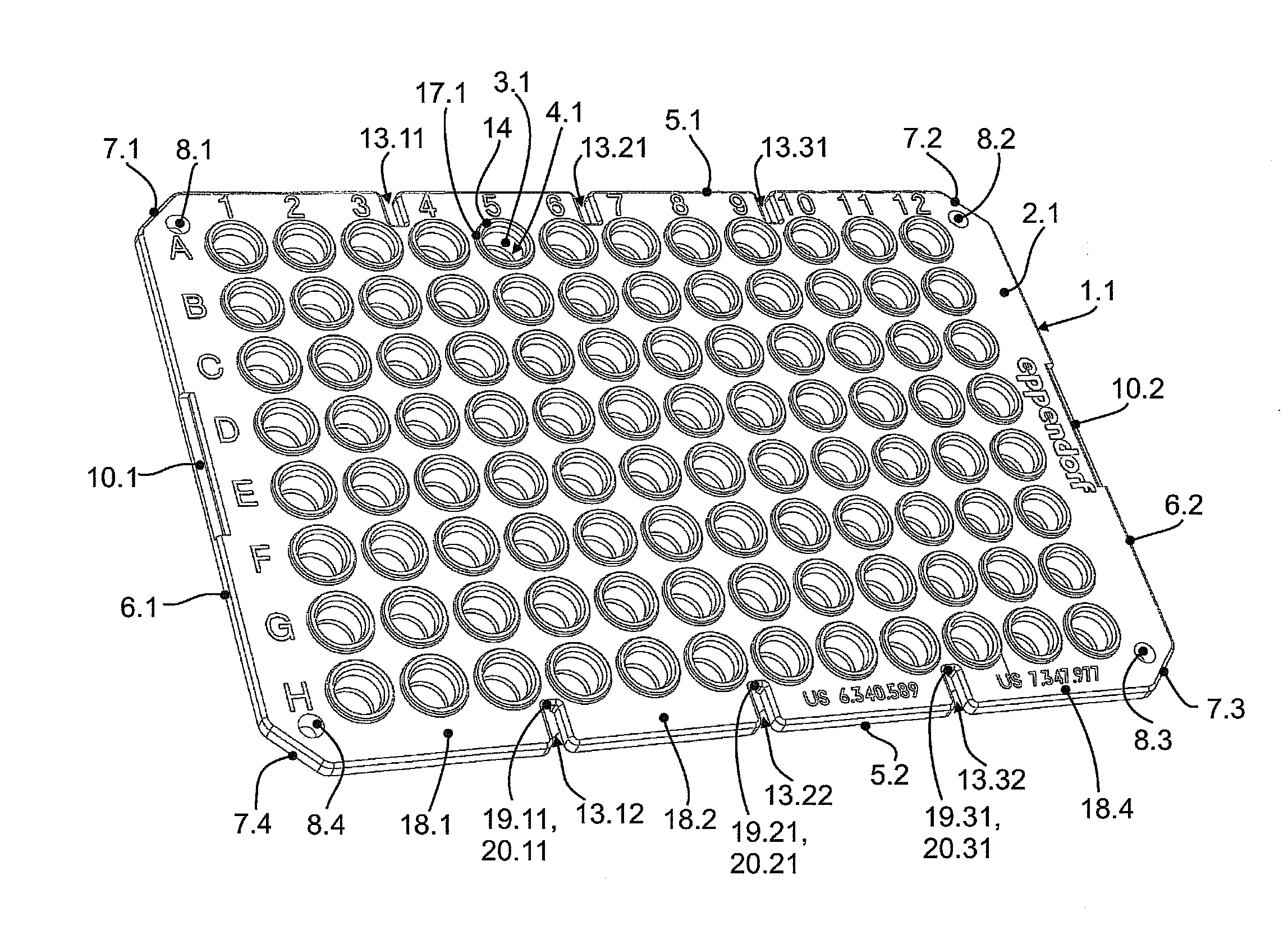

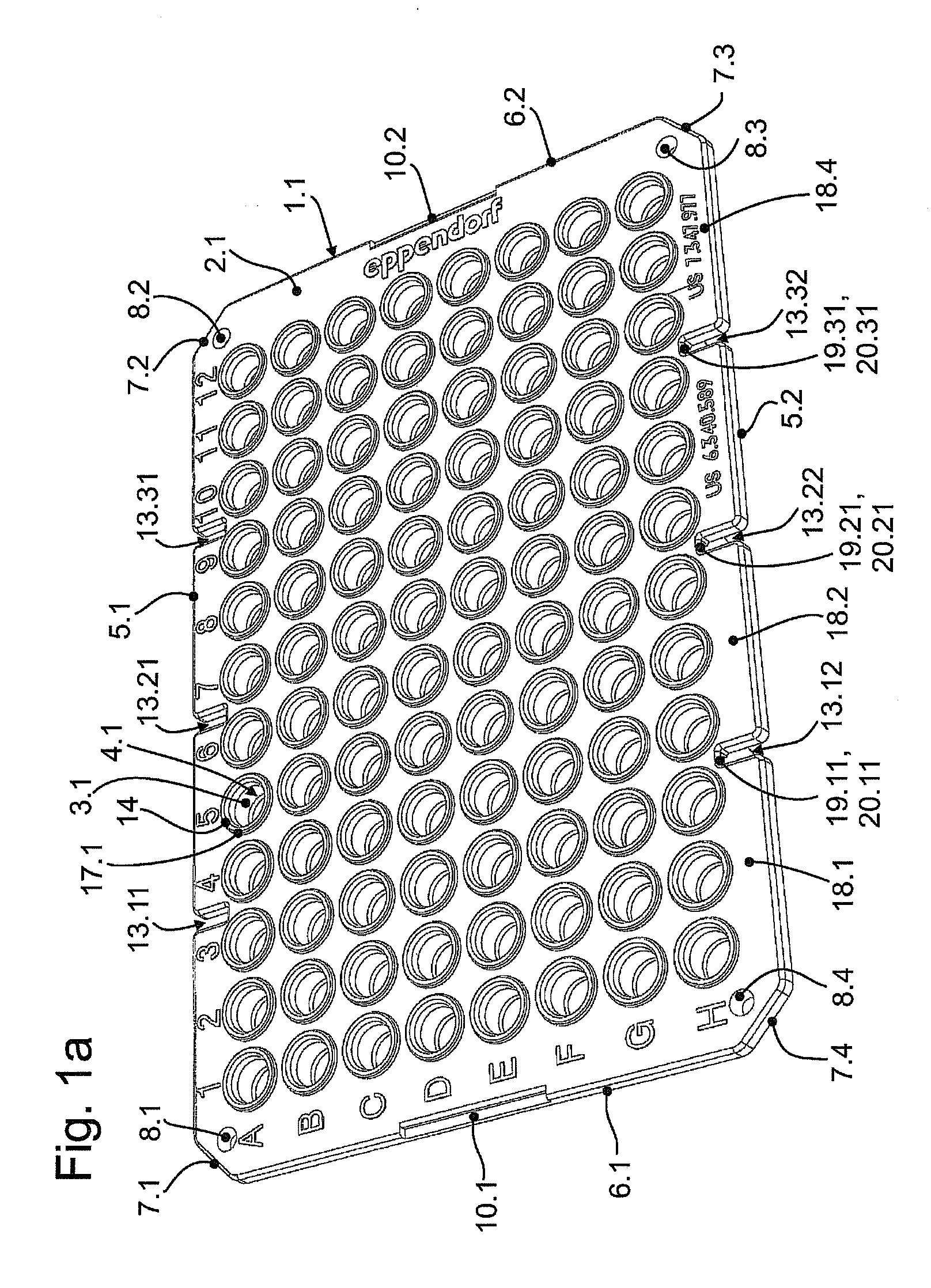

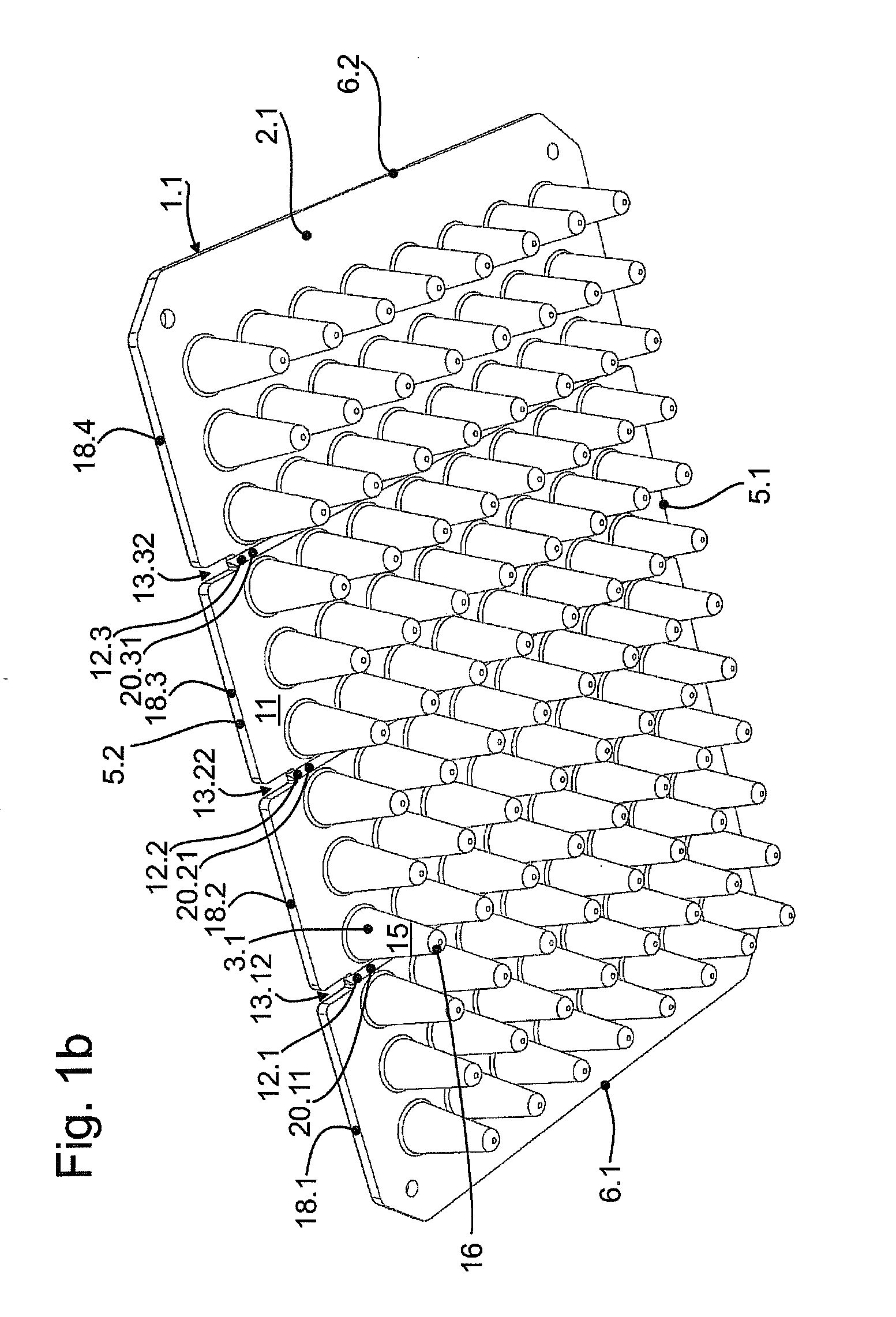

Microtiter plate

InactiveUS20110286897A1Simplifies targeted separationEasy to separateChemical analysis using titrationWood working apparatusEngineeringMechanical engineering

Microtiter plate made of plastic, having a plurality of wells in a plate which has at least one break line that divides the plate into various segments. The break line includes a joint line which is formed by molding together various segments of the plate.

Owner:EPPENDORF AG

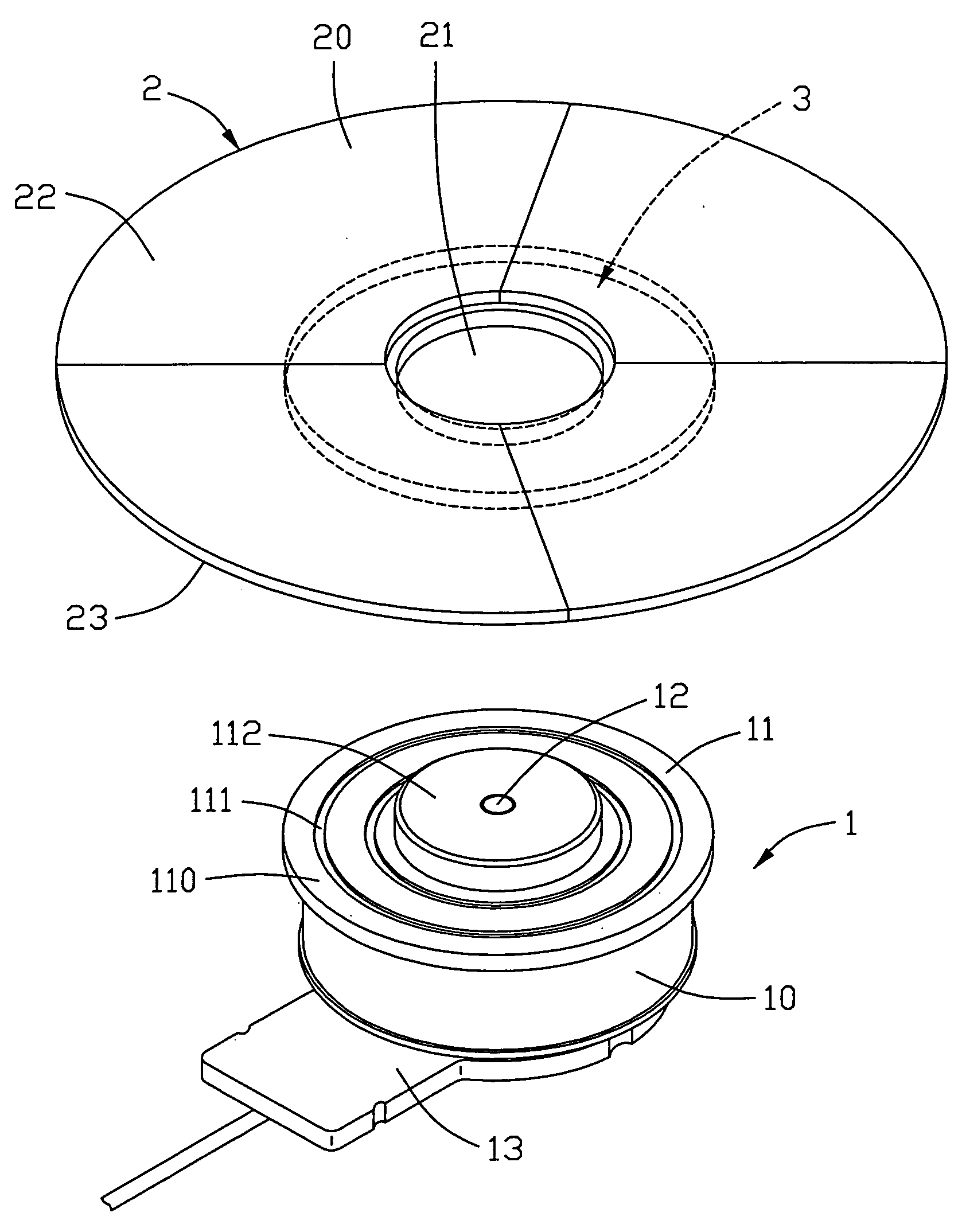

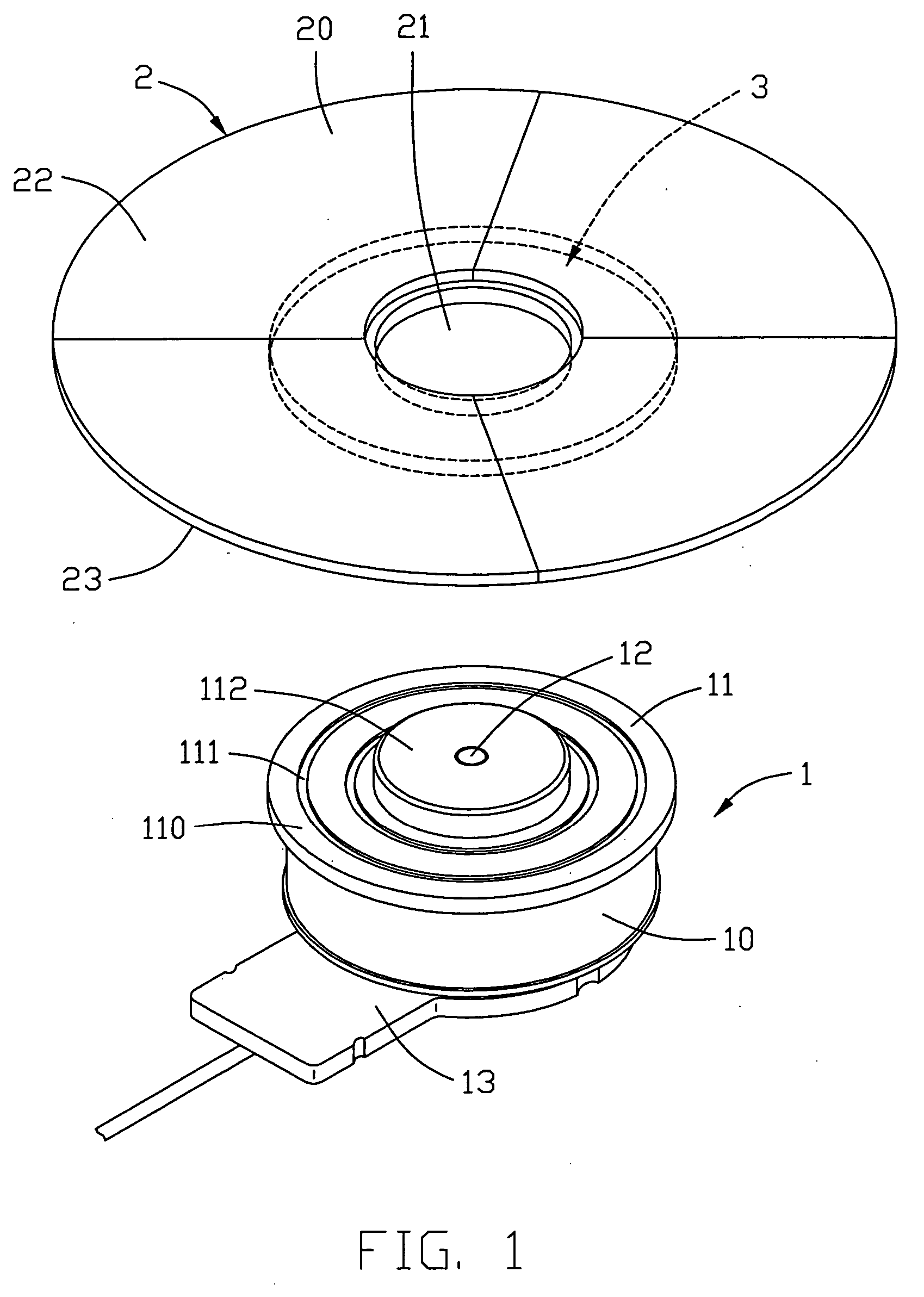

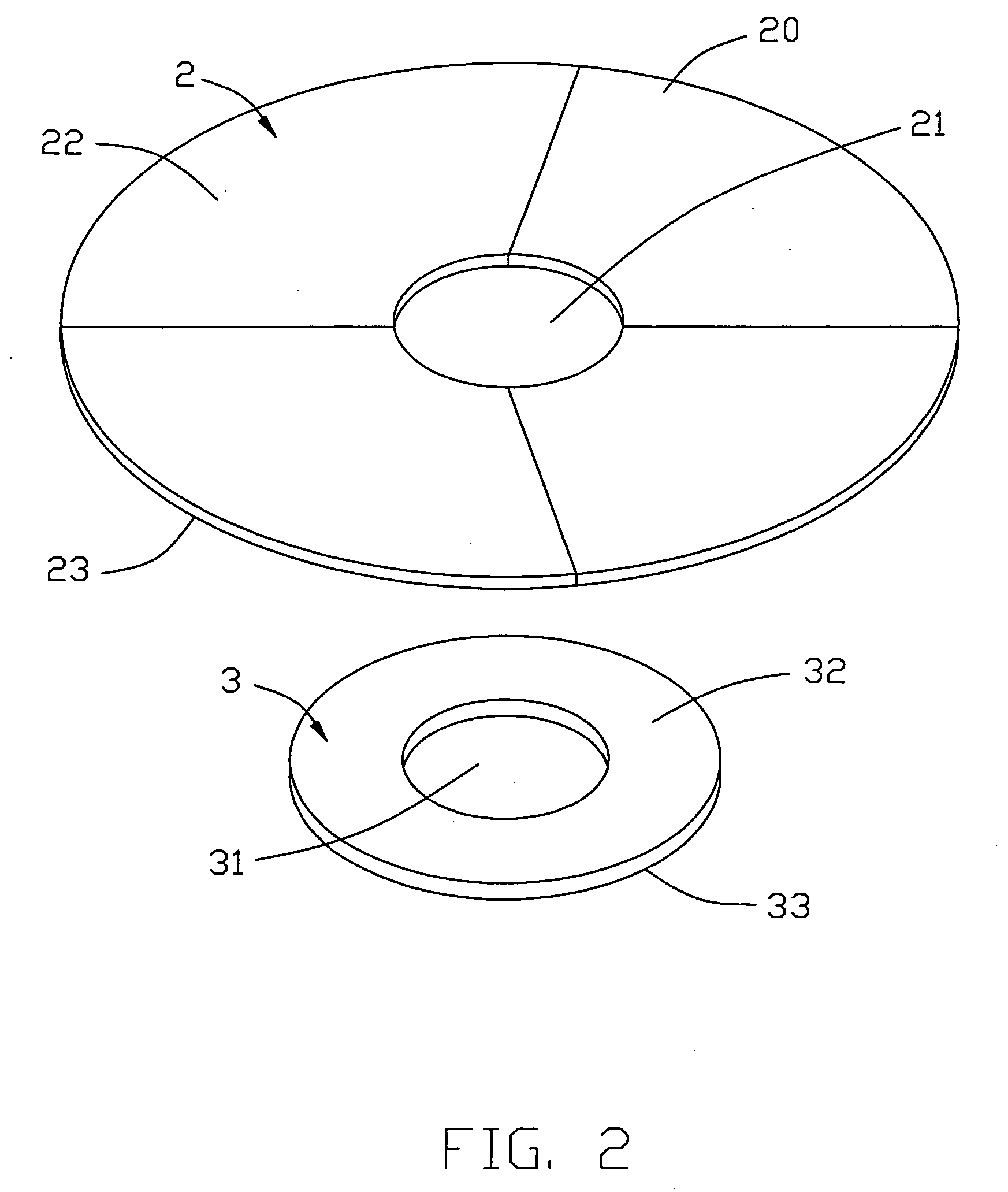

Color wheel and its manufacturing method

InactiveUS20060126199A1Reduce riskSolve the real problemProjectorsColor television detailsColor wheelRotating disc

A color wheel, for use in a Digital Light Processing (DLP), capable of preventing a color filter from escaping away is disclosed. The color wheel includes a motor having a spindle to which a rotating disc is mounted, and a filter element mounted to the rotating disc. The filter element includes a filter ring comprising a plurality of sectors having radially extending edges jointed to each other and forming a joint line between jointed edges, and a positioning ring coaxially mounted to the filter ring to hold the sectors together, the positioning ring being positioned on and fixed to the rotating disc and interposed between the filter ring and the rotating disc to fix the filter ring to the rotating disc.

Owner:ASIA OPTICAL CO INC

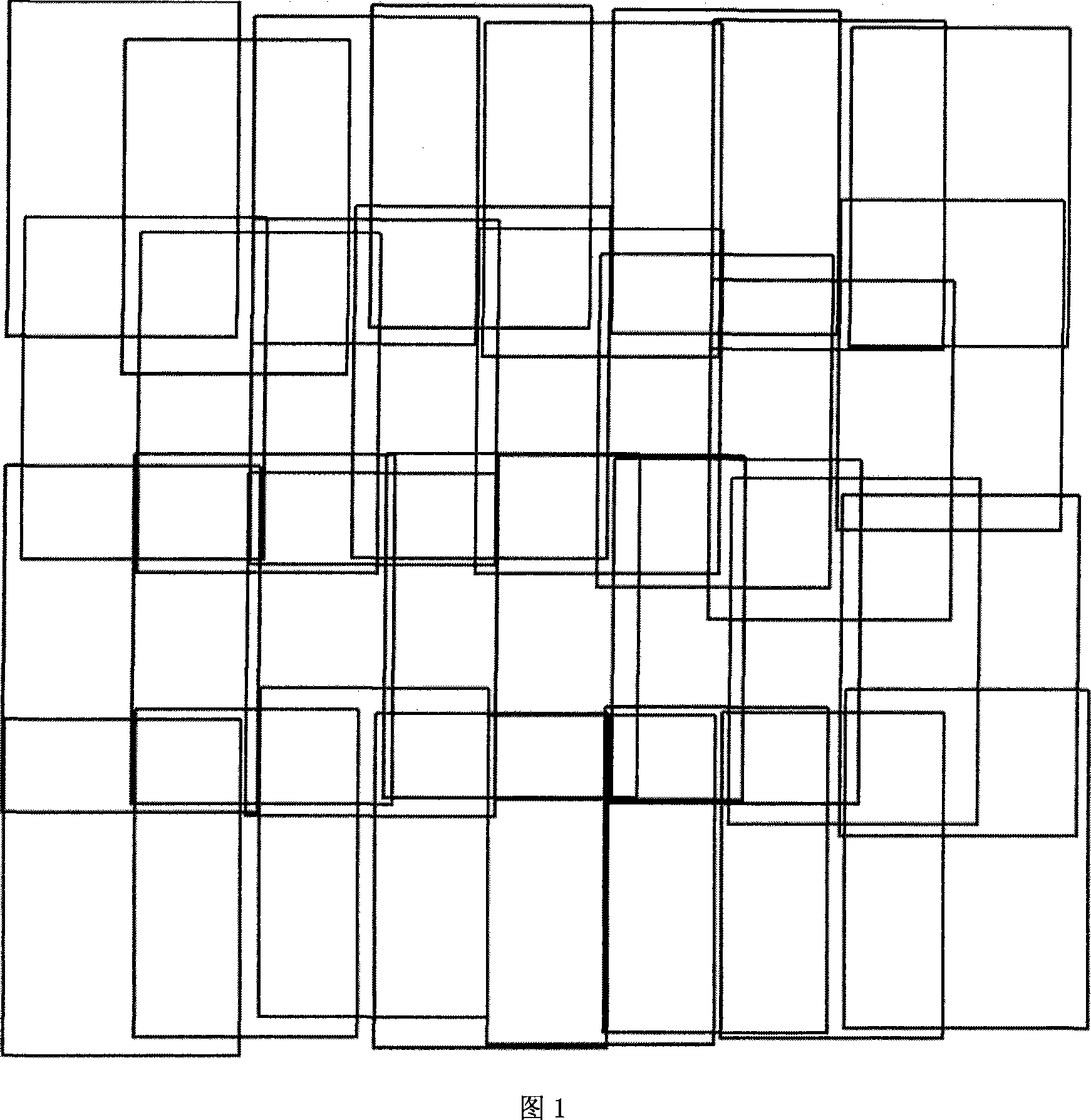

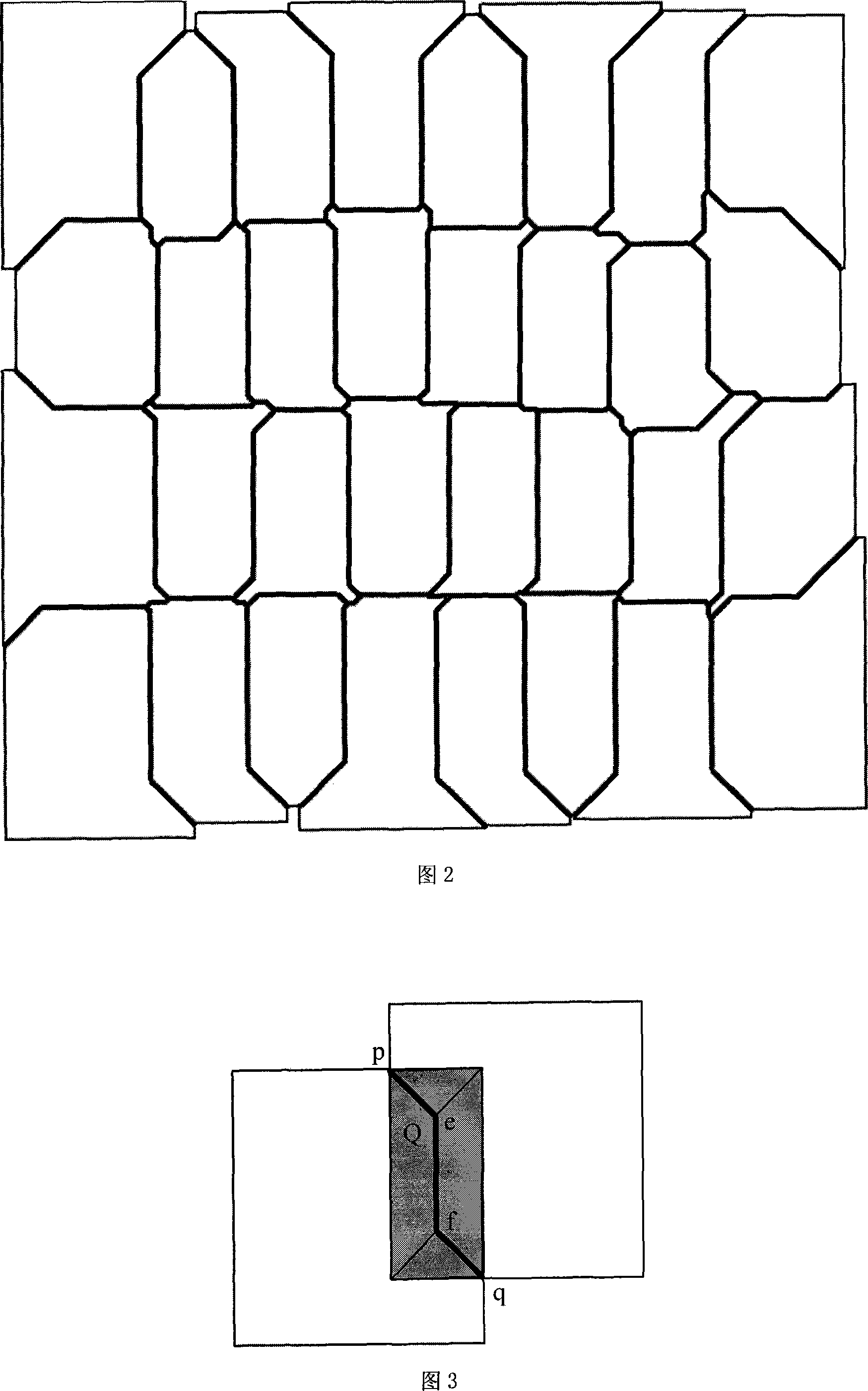

Method for automatically generating joint line network

InactiveCN101206765ASolve the problem of automatic generationAvoid accumulationImage enhancementImage analysisPattern recognitionTreatment results

The invention relates to an automatic generation method for a seaming network under the condition of a mosaic treatment to digital ortho images, comprising the following steps: effective ranges of various digital ortho images are acquired and represented in the form of quadrangles; a partition line between every two images with an overlapped area is calculated; effective mosaic polygons of various images are calculated; the seaming network is generated. After generation of the seaming network through above steps, the mosaic treatment can be performed on the basis, and pixels in each image which are useful to the mosaic treatment can be conveniently obtained; seamings related to each image and images related to each segment of seaming are convenient for direct generation of mosaic results, and mosaic flexibility and efficiency can be guaranteed and error accumulation and generation of intermediate results are avoided; moreover, treatment results have no relationship with image sequence. The invention can effectively solve the problem of automatic generation of the seaming network under the condition of the mosaic treatment of a plurality of remote sensing images within the area coverage.

Owner:WUHAN UNIV

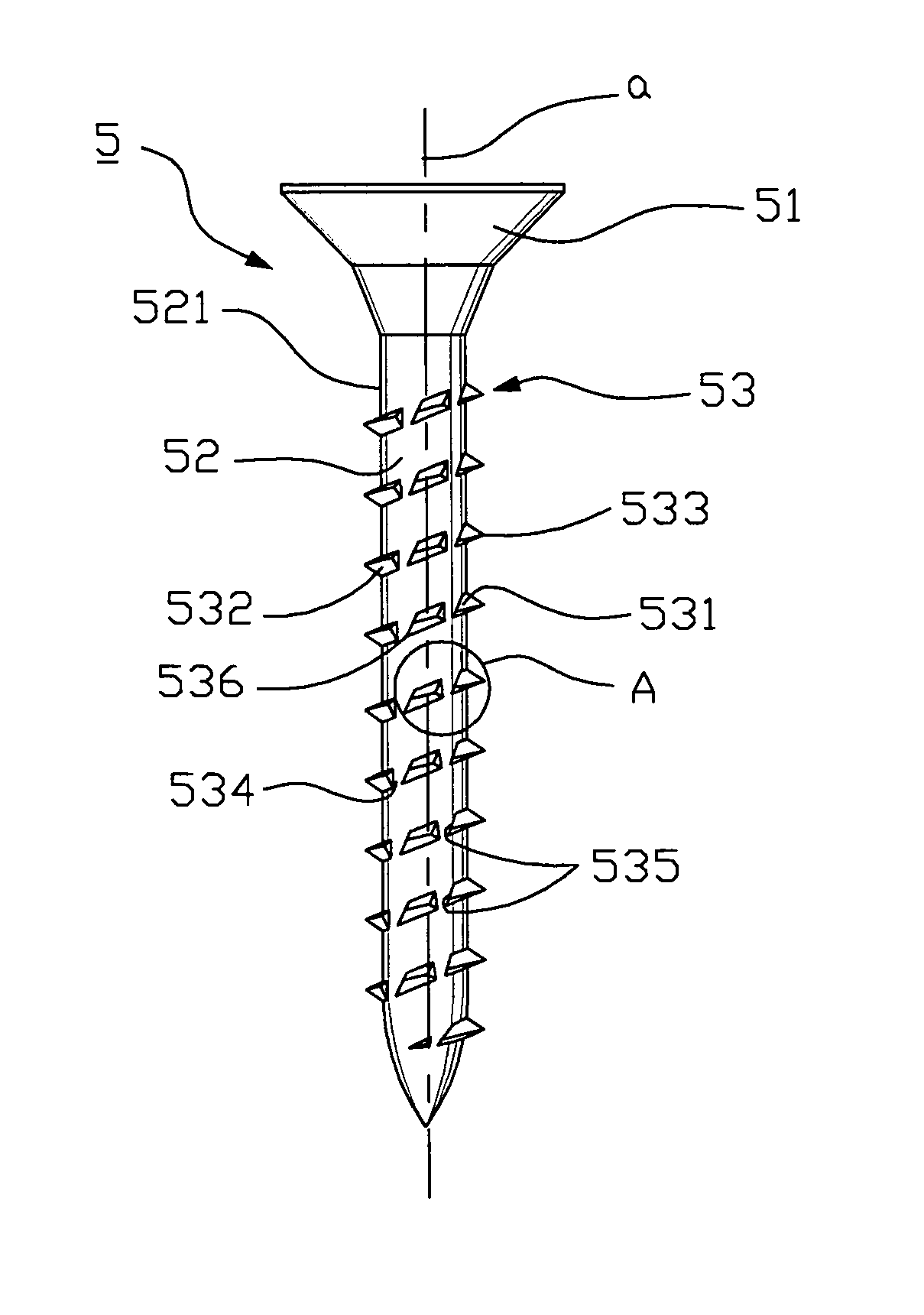

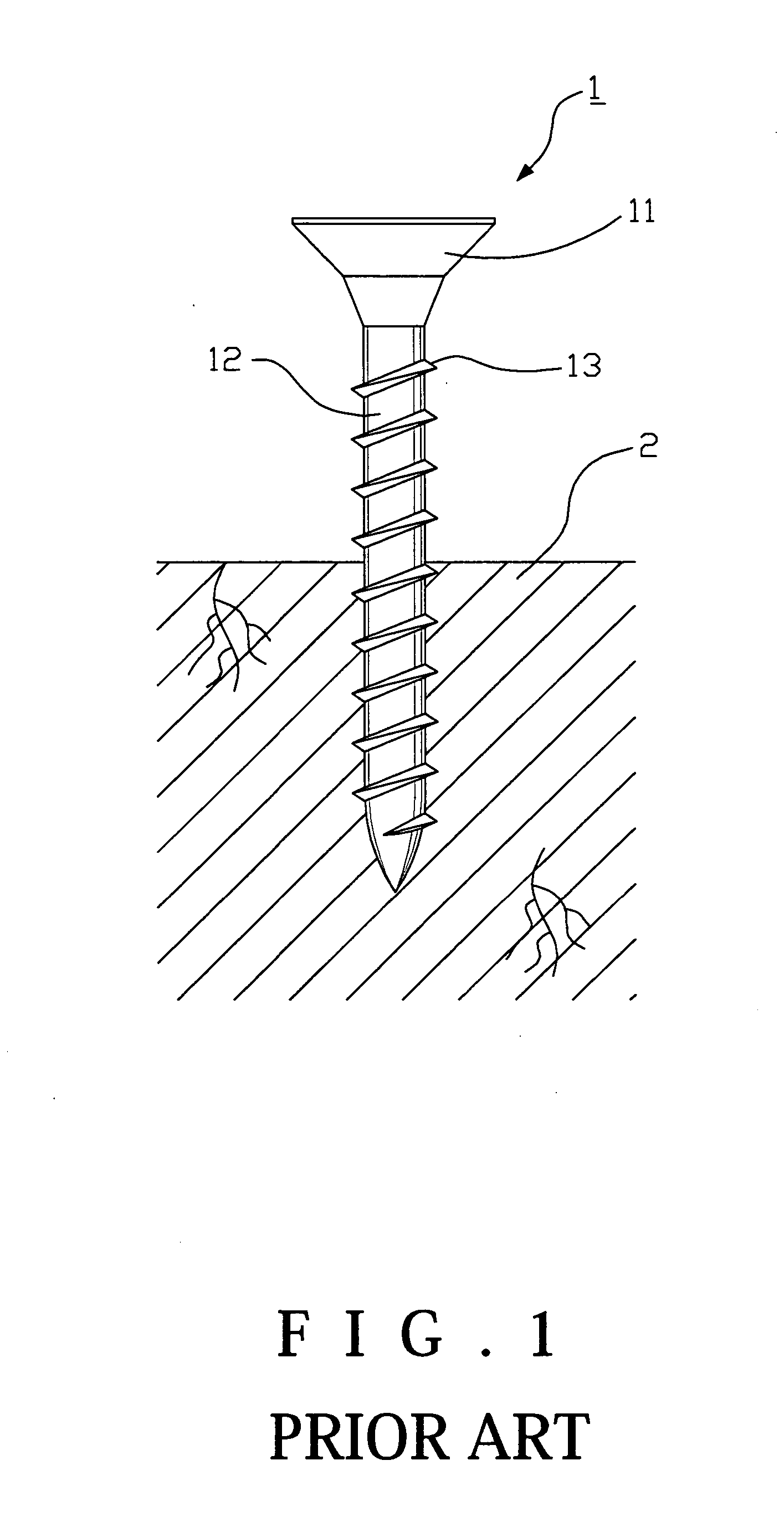

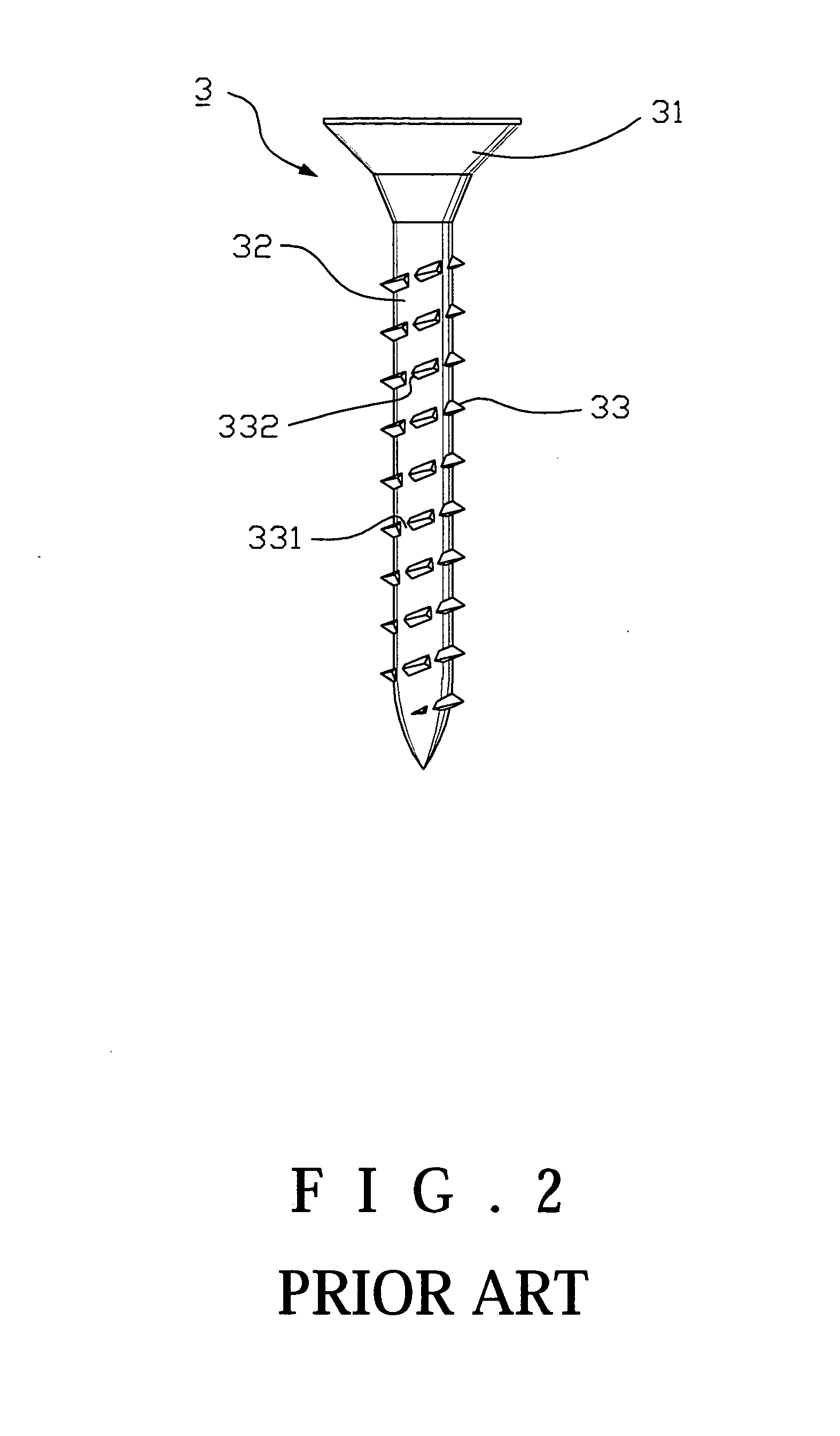

Screw

A screw including a head, a shank under the head in a whole body, and a thread helically built upon the outside trunk of the shank. The thread projects from the circular trunk of the shank and consists of an upper flank, a low flank, and an edge on the joint line of the upper and low flanks, and an even number of axial slots formed on the thread. Every axial slot is beveled with a back angle to form a tilt surface from the upper flank to the low flank to form a cutting edge for facilitating the rapid fastening with a smaller tapping torque.

Owner:SU KUO TAI

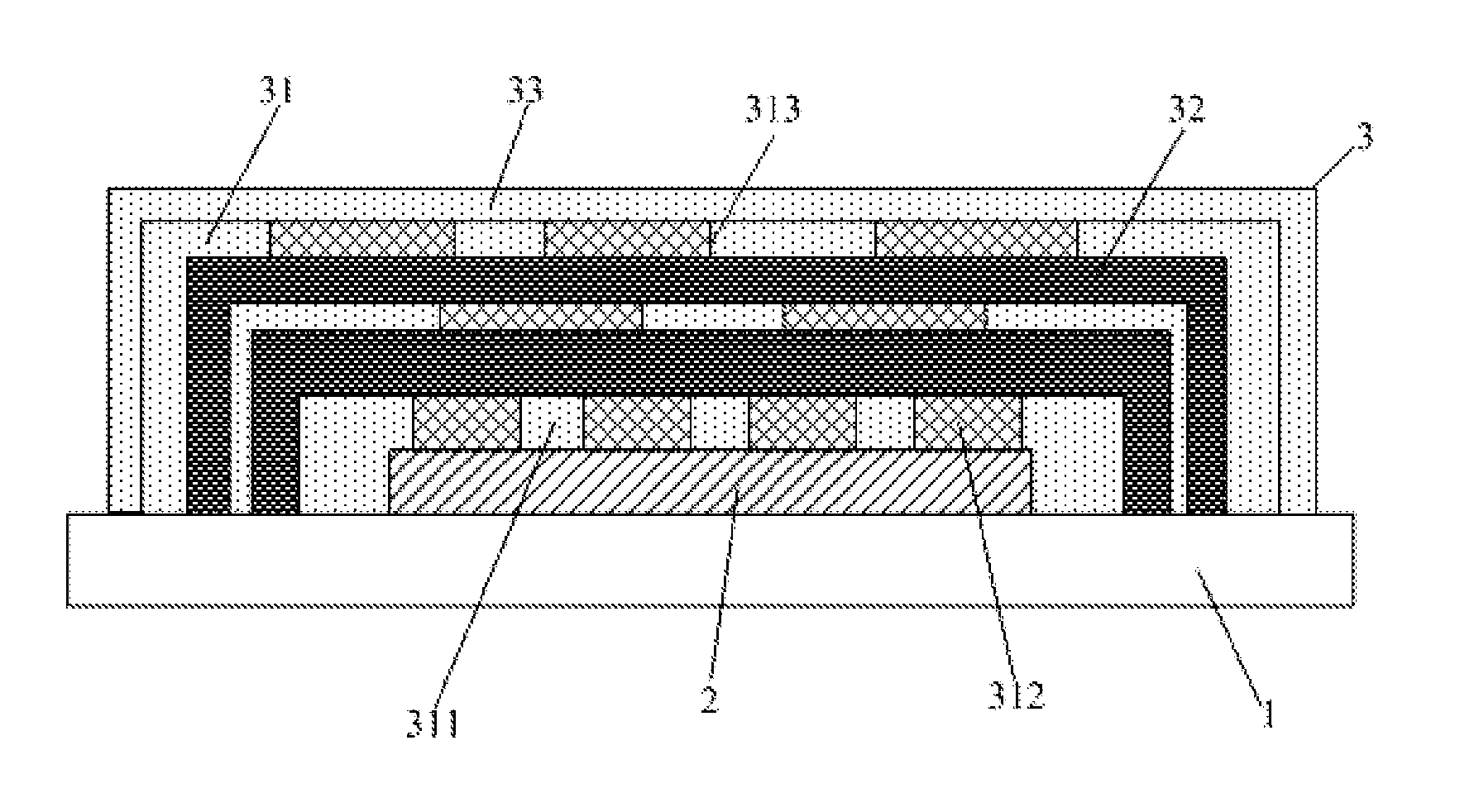

Display Panel, Manufacturing Method Thereof, and Display Device

ActiveUS20160254489A1Improve bending performanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceWater block

The present invention provides a display panel, a manufacturing method thereof and a display device. The display panel comprises a first substrate, a display component provided on the first substrate, and a packaging structure for packaging the display component on the first substrate, wherein the packaging structure includes at least two first water blocking layers and at least one planarization layer that are stacked alternately above the display component, each first water blocking layer includes a plurality of first areas and a plurality of second areas, and joint lines between the first areas and the second areas in any two first water blocking layers are staggered with each other.

Owner:BOE TECH GRP CO LTD

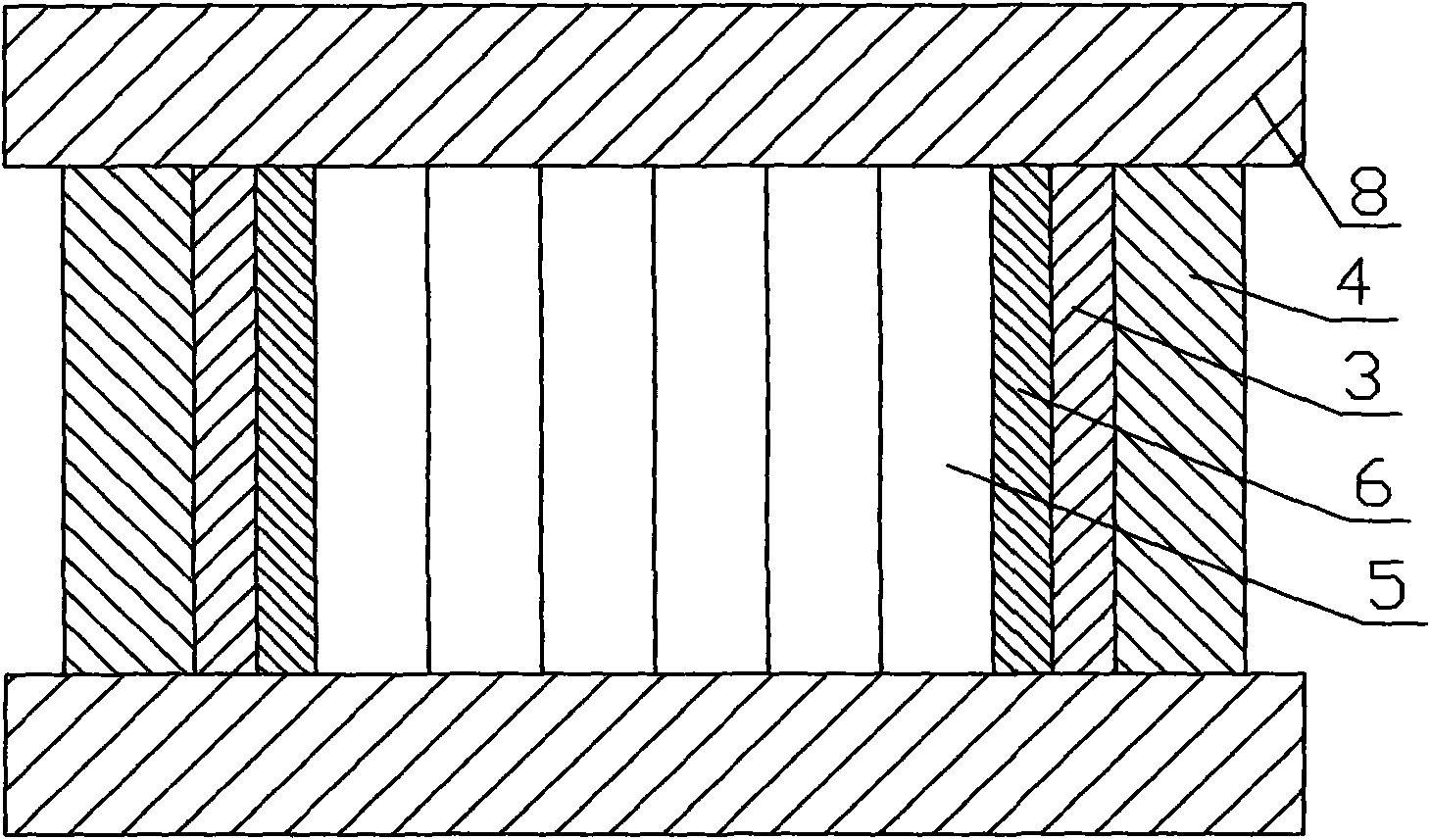

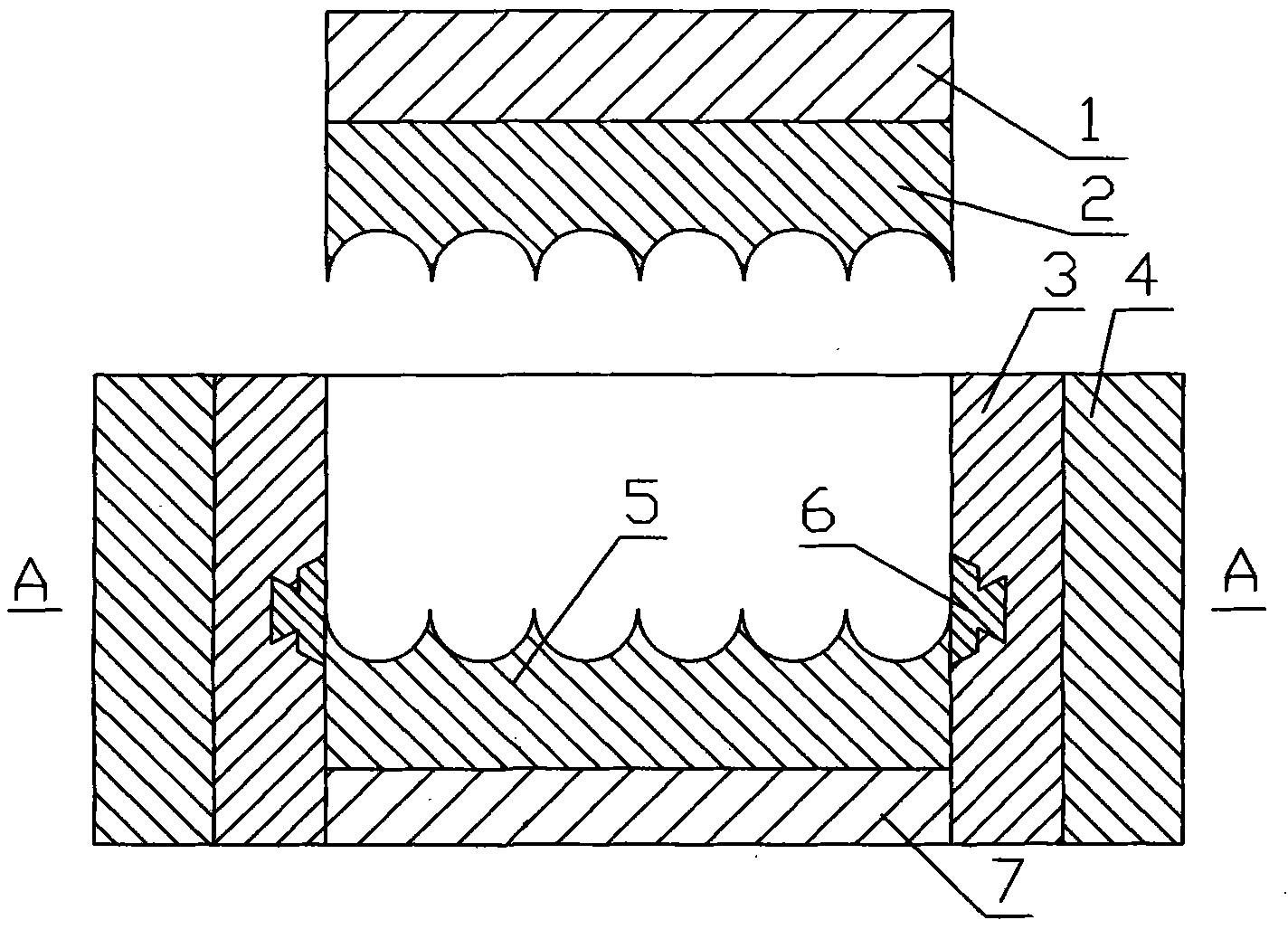

Neodymium iron boron (NdFeB) die for forming uniform oriented magnetic field

The invention provides a neodymium iron boron (NdFeB) die for forming a uniform oriented magnetic field, and relates to the forming die for an NdFeB production process. The die consists of a box-type lower mold frame with an opening upwards composed of a pair of end templates and a pair of side templates on the periphery and a liftable bracket at the bottom part, lining plates on the inner walls of the side templates, lower dies and brackets in the lining plates, and upper dies fixed under upper die extension rods, wherein, the upper end parts of the lower dies are equipped with a plurality of semi-cylindrical cavity grooves with openings upwards, and the lower end parts of the upper dies are correspondingly equipped with a plurality of semi-cylindrical cavity grooves with openings downwards; and a magnetic conductive strip is embedded into the inside of the middle part of each lining plate with a joint line as a centre line, and the section of the magnetic conductive strip is of a double-trapezoid conjoint shape. The die of the invention has the following advantages of improving uniformity deviation from 12% to 3% and strengthening rigidity and wear resistance of the working region of the die.

Owner:宁德市星宇科技有限公司

Prosthesis Having A Soft Tissue Attachment Element

A prosthetic bone implant, the bone implant forming one side of a joint and including a prosthesis and a soft tissue attachment component. The soft tissue attachment component is connected to the bone implant and extends outwardly therefrom and towards a joint line. The soft tissue attachment component is moveable with respect to the prosthesis while connected thereto.

Owner:HOWMEDICA OSTEONICS CORP

Cloth covered instrument panel

InactiveUS20060177620A1Gap be minimalQuality improvementSynthetic resin layered productsLaminationEngineeringMechanical engineering

An instrument panel for a vehicle comprising a first coverstock segment having an outer surface and an inner surface and a mating edge disposed along a portion of a common perimeter of the outer surface and inner surface. A second coverstock segment is supplied having an outer surface and inner surface and a mating edge disposed along a portion of a common perimeter bounding the outer surface and the inner surface, the second coverstock segment bonded to the first coverstock segment along the respective mating edges forming a joint line. At least one of the first coverstock segment and the second coverstock segment is a cloth or fabric.

Owner:COLLINS & AIKMAN PROD CO

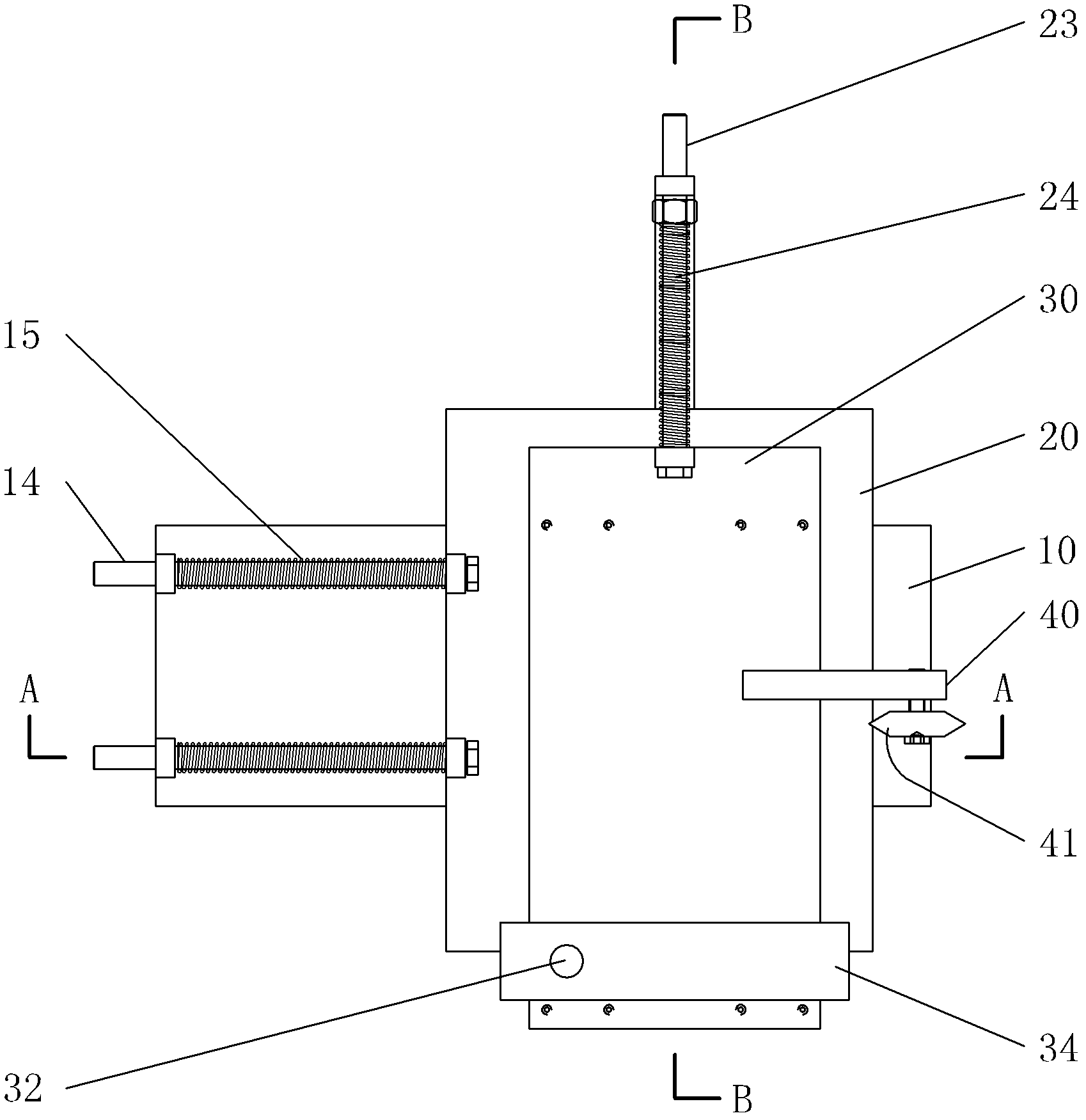

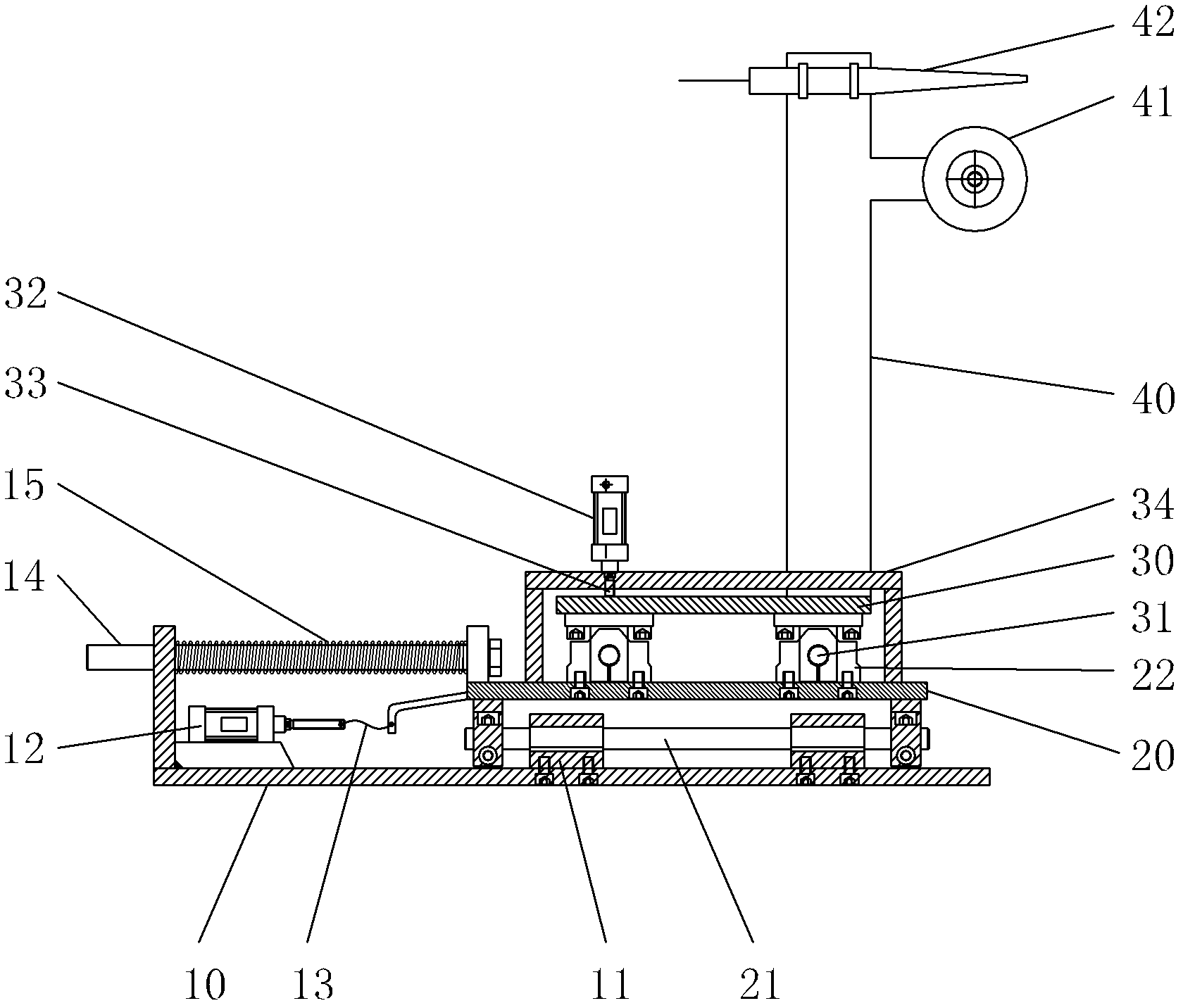

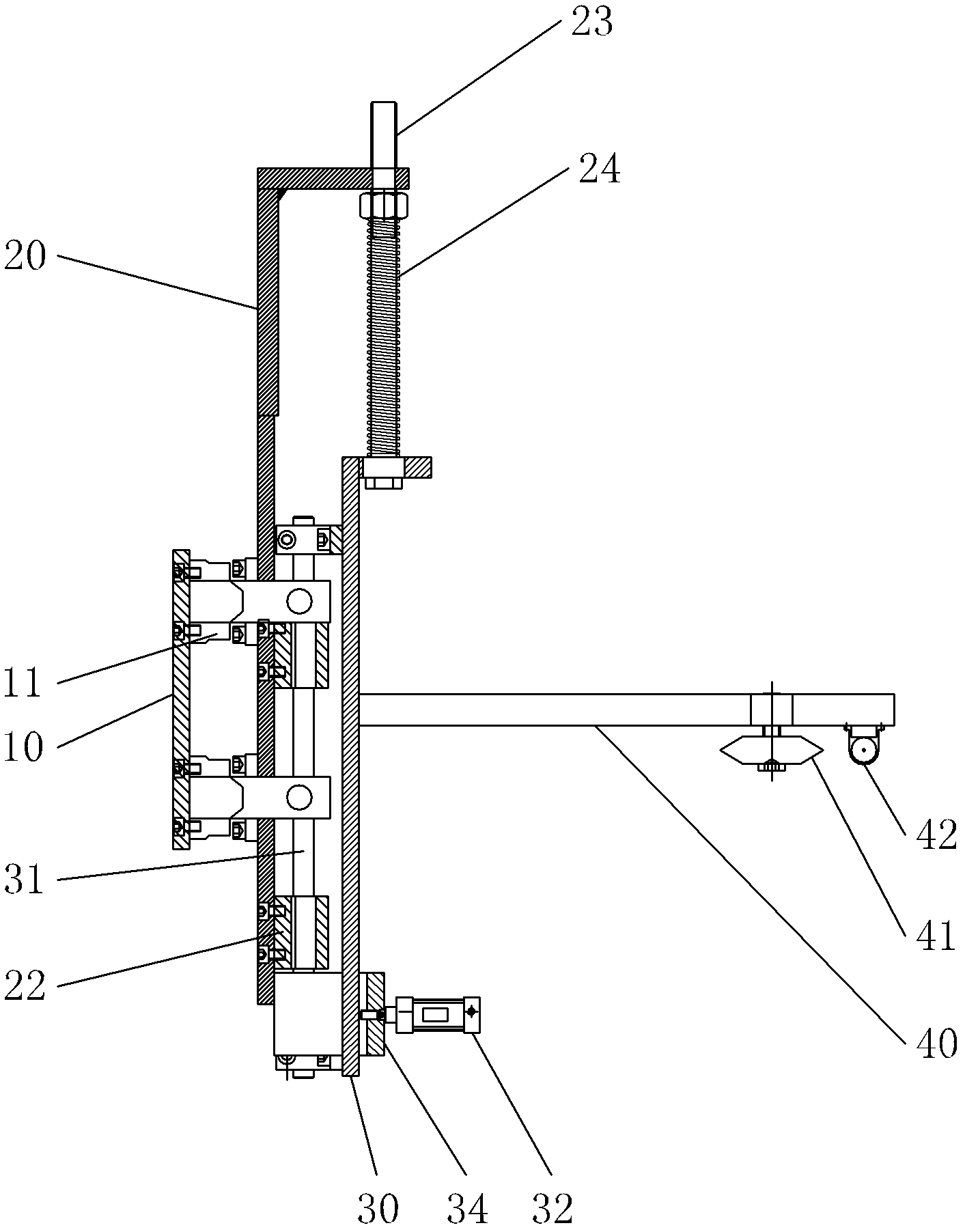

Automatic tracking seam welding/cutting manipulator

InactiveCN102513755AEasy to installEasy maintenanceWelding/cutting auxillary devicesArc welding apparatusWeld seamSlide plate

The invention belongs to the technical field of a welding machine, and particularly relates to a creeping-type automatic tracking seam welding machine, which is characterized in that: a slide plate which can move transversely along a base is arranged on the base, a compression spring is arranged between the slide plate and the base, the slide plate is provided with a slide platform which moves longitudinally along the slide plate, a compression spring is arranged between the slide plate and the slide platform, the slide platform is provided with a cantilever, one side on the outer end part of the cantilever is provided with a roller which rolls along an annular seam of a work-piece to be welded, a welding torch is arranged on the cantilever at one side of the roller, a joint line of centers of the welding torch and of the roller is parallel to a central line in the length direction of the cantilever, and one side of the line of centers of the welding torch and the roller is provided with a press block or a press wheel for pressing one side welding element or an outer layer welding element. The automatic tracking seam welding / cutting manipulator has beneficial effects that: the automatic tracking seam welding / cutting manipulator has a simple structure and low production cost, is convenient to install, repair and use, can automatically track a seam trace to realize the movable welding, has high welding quality, and is suitable for seam welding annular weld seams.

Owner:柯友义

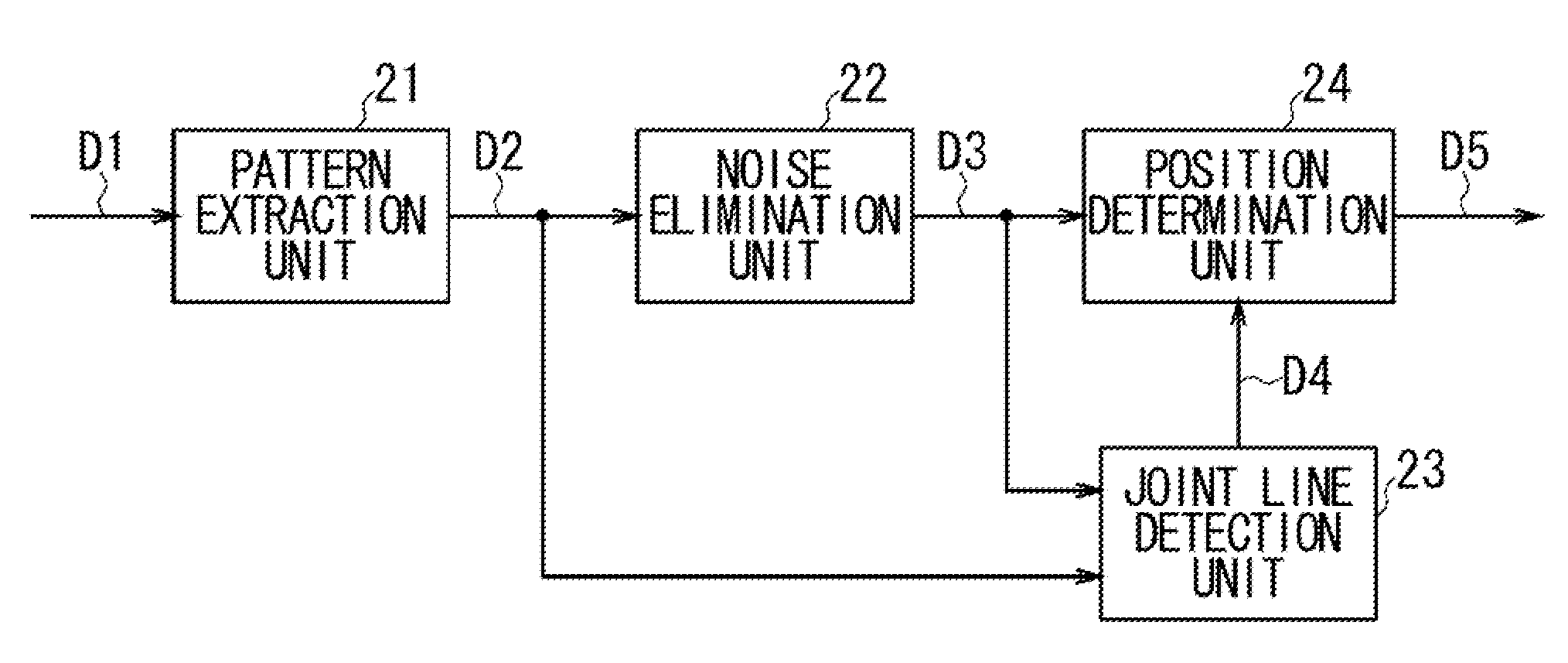

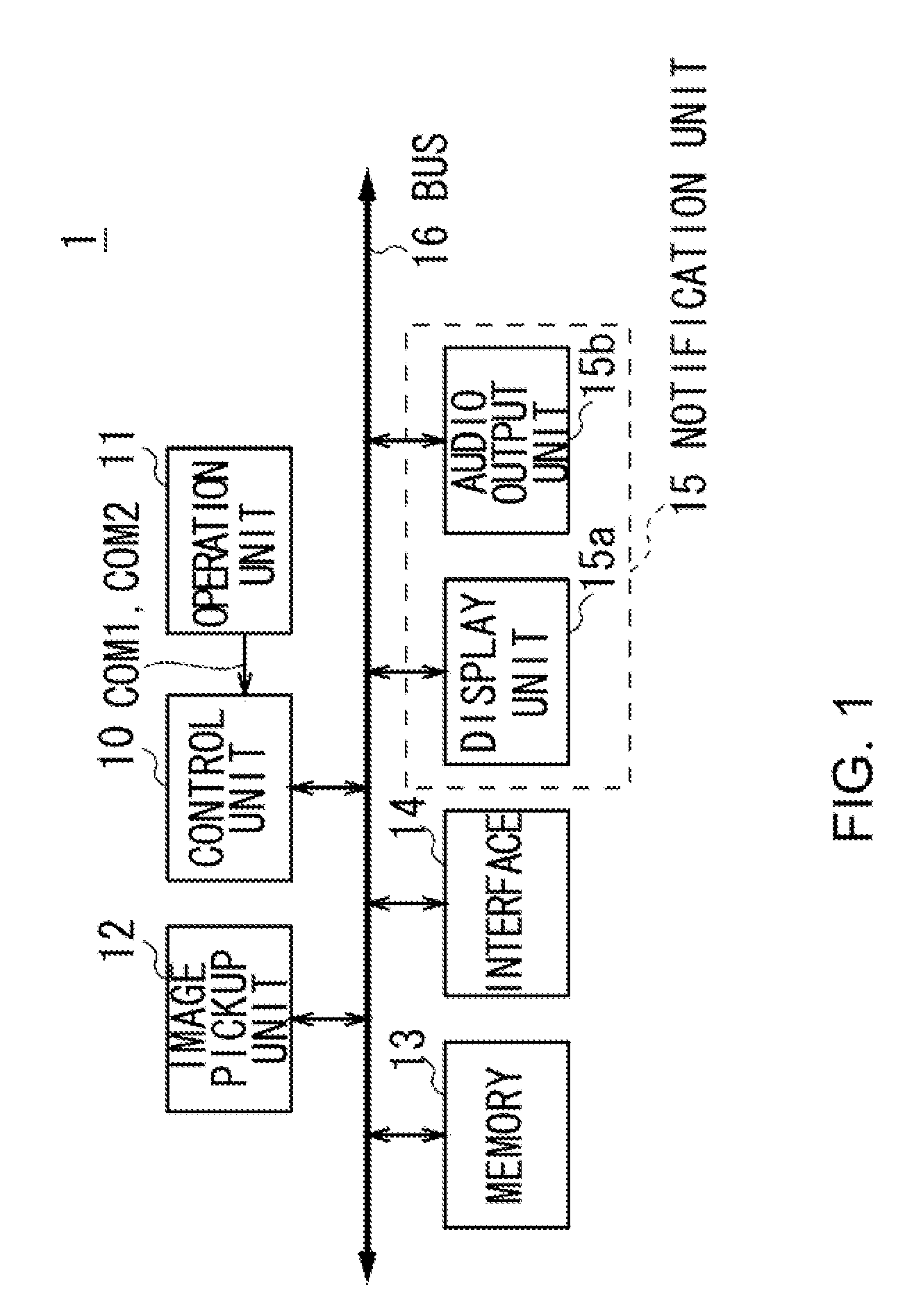

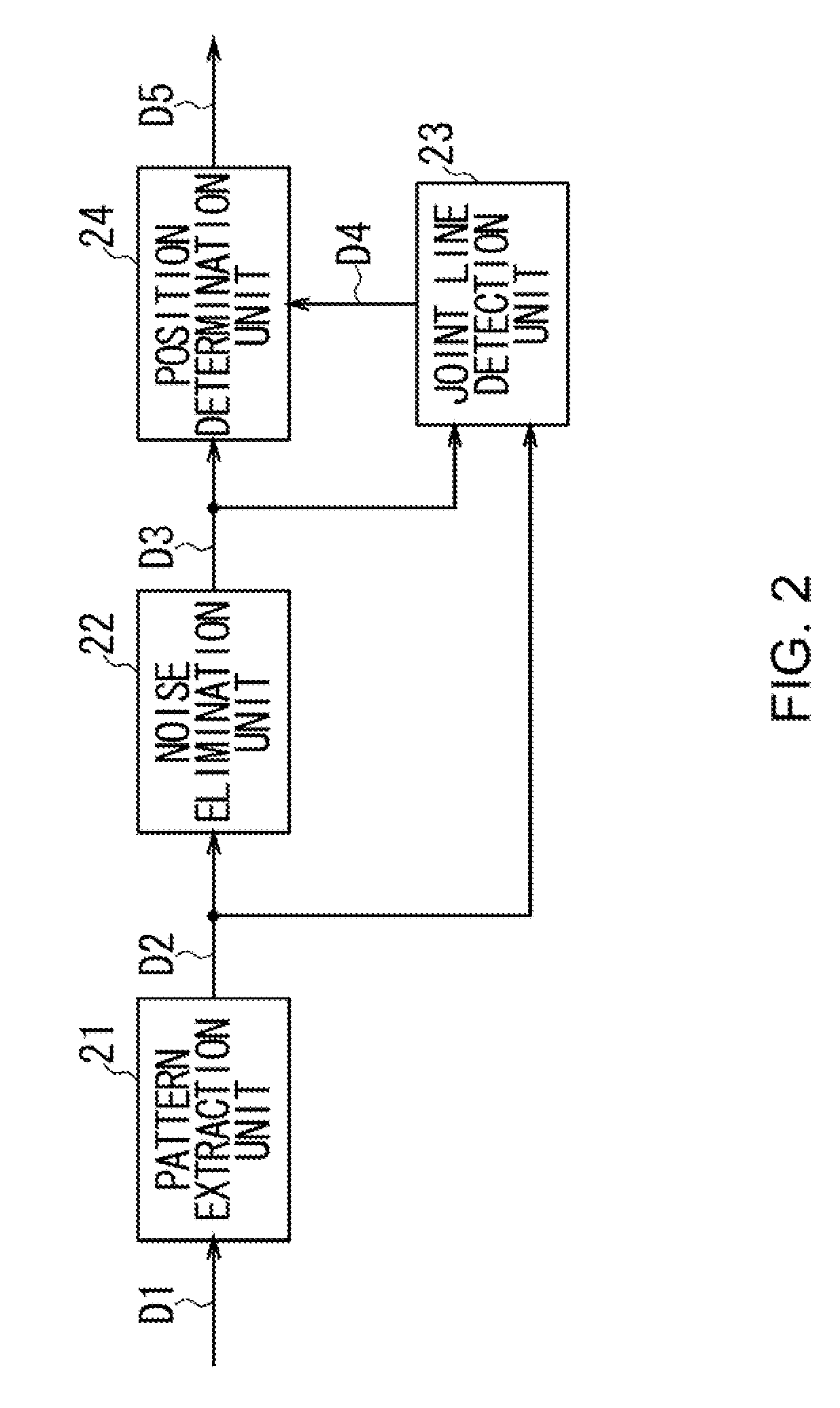

Image Determination Device, Image Determination Method, and Program

InactiveUS20080273762A1Increase freedomSubcutaneous biometric featuresBlood vessel patternsThree vesselsComputer vision

An image determination device according to the present invention includes: an extraction means for extracting a figuration pattern of an identification subject in a finger reflected on an image; a detection means for detecting a joint line in the finger; and a determination means for determining the image as an image to be registered or an image to be collated with a registration subject when a joint line exists in a first range which is set in one of respective regions obtained when separating the image with the center line that corresponds to a direction perpendicular to the longitudinal direction of the finger and that is set as the border, and a blood vessel amount which is equal to or more than a predetermined threshold value exists in a second range which is set in the other region different from the region in which the first range is set.

Owner:SONY CORP

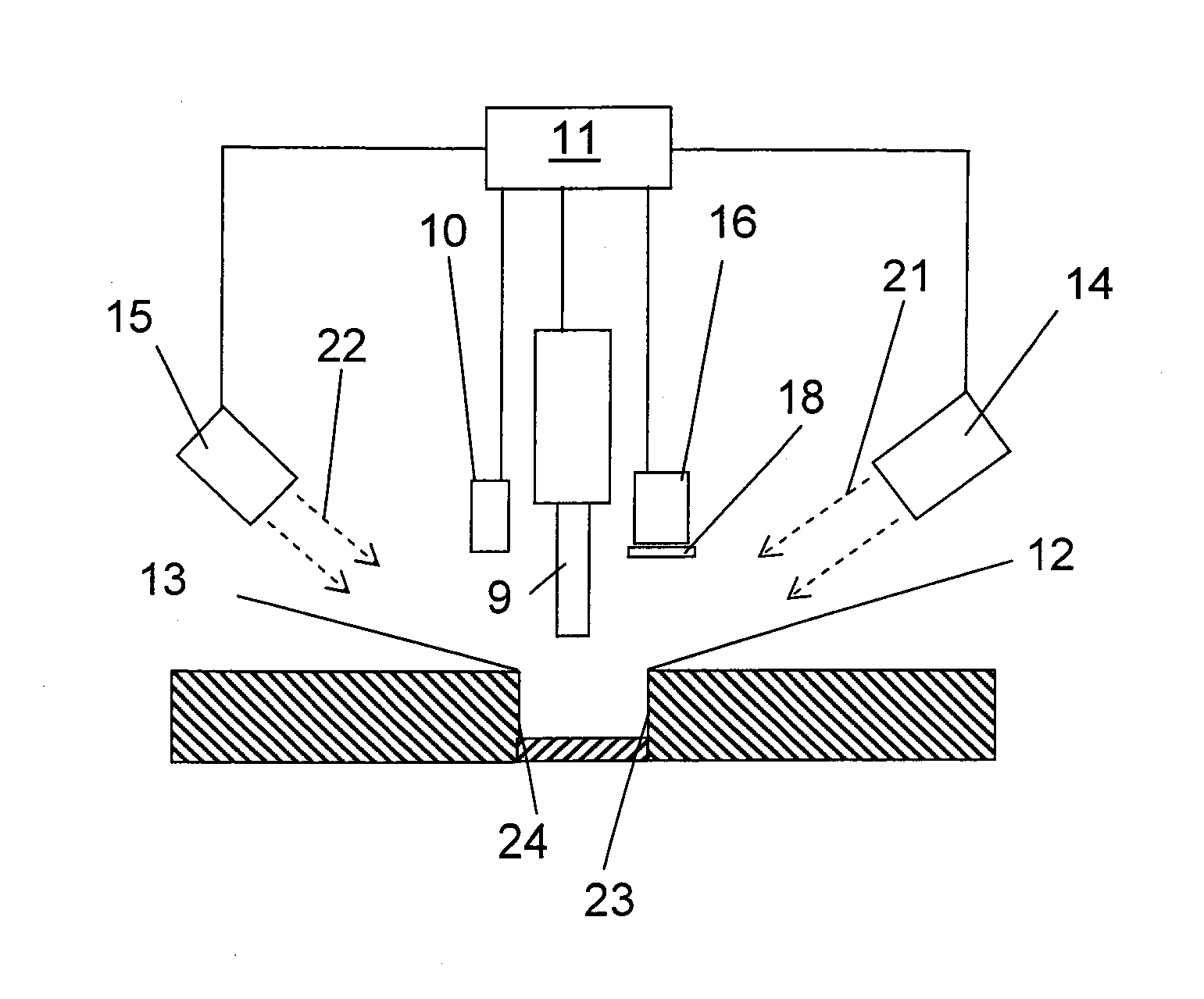

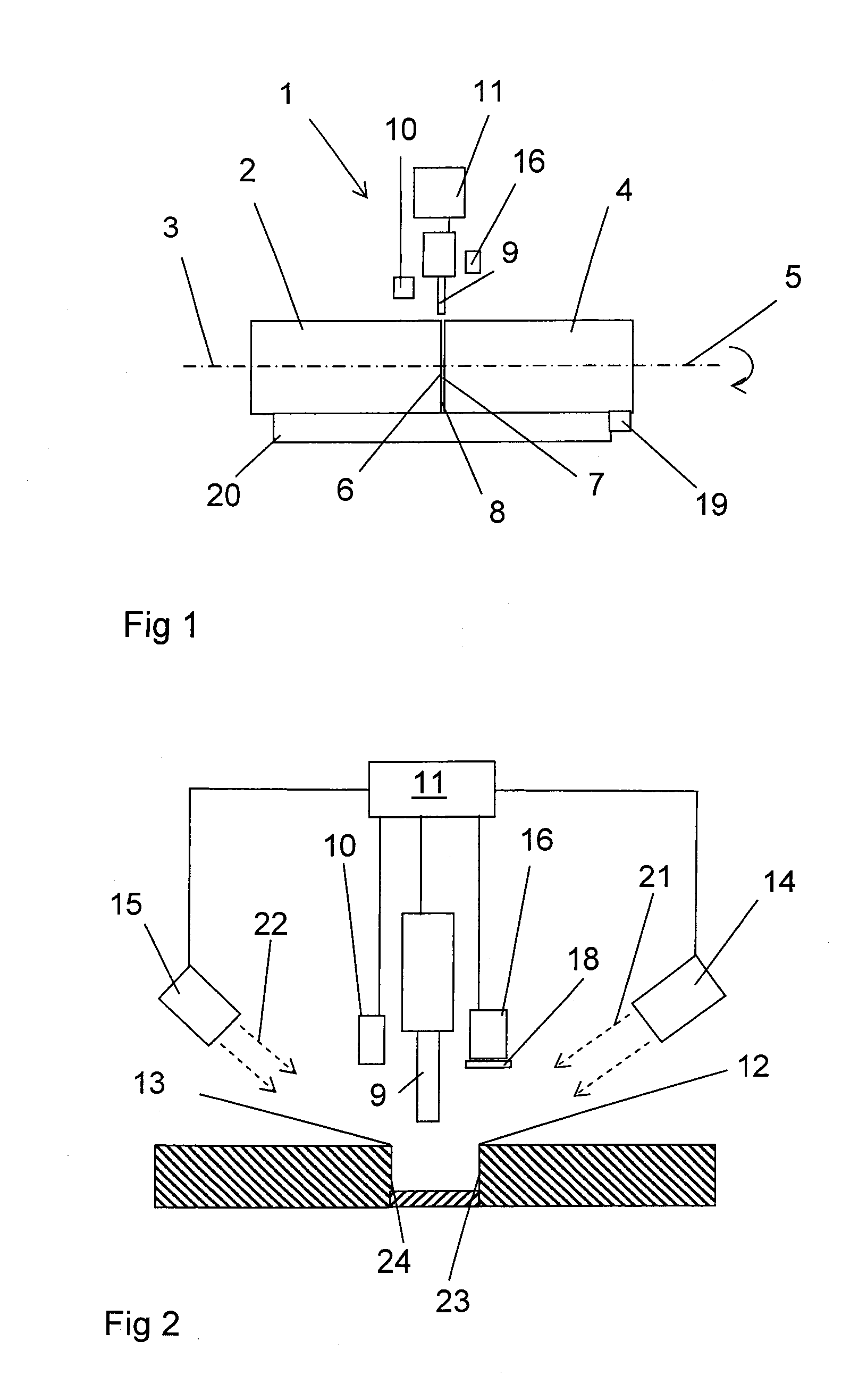

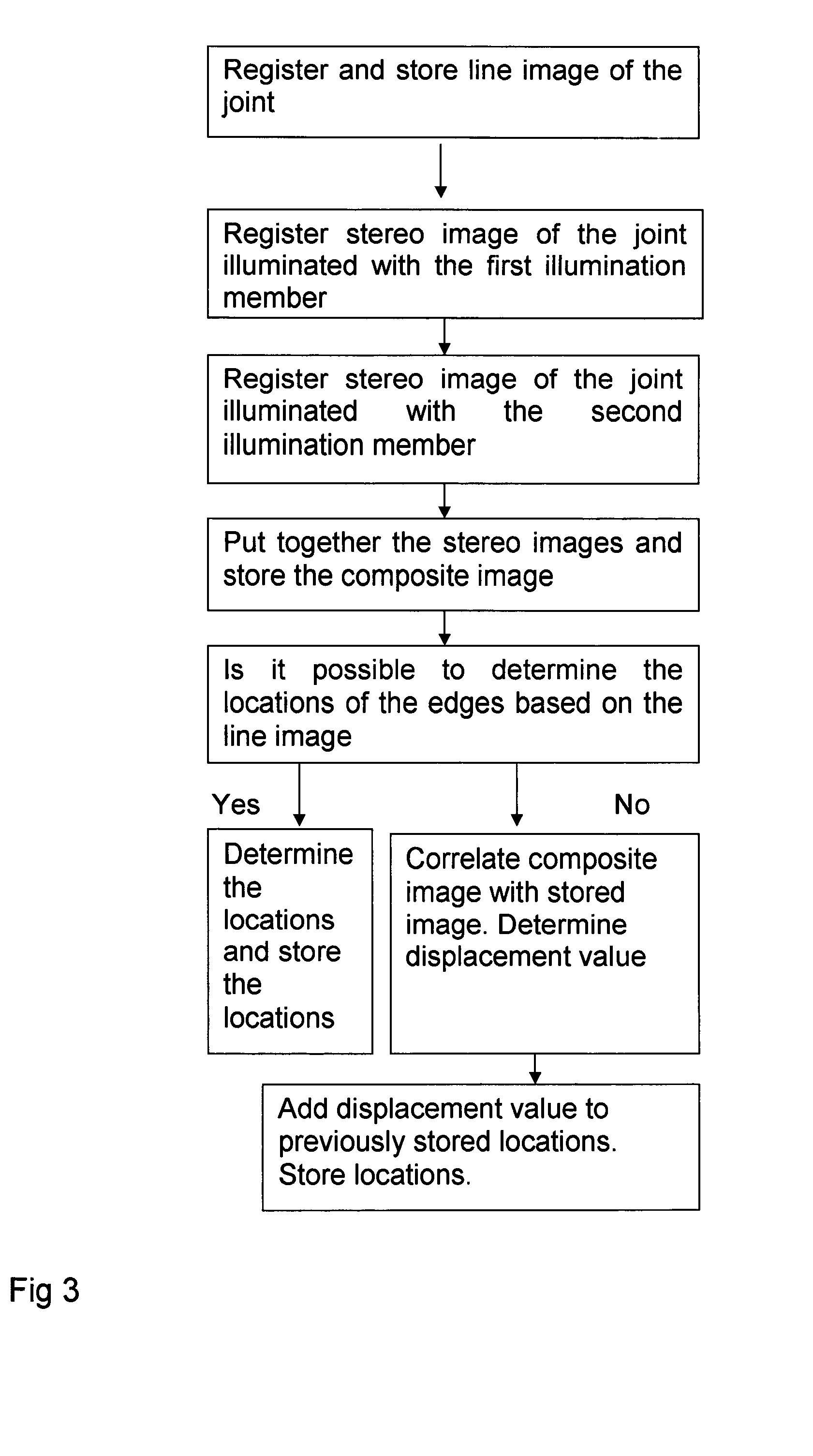

Device and method for automatic multiple-bead welding

InactiveUS20120145771A1Robust joint trackingRobust trackingAutomatic control devicesPrecision positioning equipmentTriangulationLight beam

A welding device and a method for automatic multiple-bead welding, wherein a line illumination member is arranged to illuminate the joint by scanning a light beam across the joint line. A camera is arranged for the registration of line images of the joint when it is illuminated with the scanned light beam. The locations of the edges of the joint are determined by means of triangulation based on the registered line image. The welding device can include a stereo image member arranged to register photometric stereo images of the joint substantially simultaneously with the registration of the line images. The welding device is arranged to, during welding of a weld joint with a plurality of weld beads, control the welding head in dependence on both stereo images and line images.

Owner:ESAB AB

Deposition friction stir welding process and apparatus

InactiveCN1978118AWelding/soldering/cutting articlesMetal working apparatusFilling materialsThermal contact

A deposition friction stir weld process of joining work pieces includes placing a filler material on and about a joint line formed by butting a first work piece surface against a second work piece surface; and frictionally heating the filler material to soften the filler material and portions of the first and second work piece surfaces in thermal contact with the filler material and form a weld between the first and second work pieces, wherein frictionally heating is at a temperature below a melting point of the filler material and the first and second workpiece surfaces. Also disclosed herein are friction stir welding assemblies for providing the deposition friction stir weld as well as processes for depositing filler material and contouring a workpiece surface.

Owner:GENERAL ELECTRIC CO

Sprue valve needle action device of hot runner injection mold

The invention discloses a sprue valve needle action device of a hot runner injection mold. The sprue valve needle action device comprises an upper building block, a lower building block, a nozzle sprue valve needle device and a control part. A single mold core is formed between the upper building block and the lower building block. A plurality of sprues are arranged in the mold core, and nozzles are arranged in the sprues. A time sequence device of the controller controls up and down actions of the nozzle sprue valve needle device according to control signals, and opening and closing of the sprues are controlled in order through the up and down actions of the nozzle sprue valve needle device. By means of the manner, the sprue valve needle action device of the hot runner injection mold opens and closes the multiple sprues in order according to the control signals of the time sequence device, and bad injection forming phenomena such as marks or joint lines cannot occur at the confluence places or fields where fused resin is injected into the mold core in order.

Owner:哈希斯热流道科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com