Neodymium iron boron (NdFeB) die for forming uniform oriented magnetic field

An orientation magnetic field and NdFeB technology, which is applied in the field of NdFeB production process molding molds, can solve the problems of product consistency deviation, achieve the effect of improving hardness and wear resistance, and solve the effect of magnetization orientation consistency deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

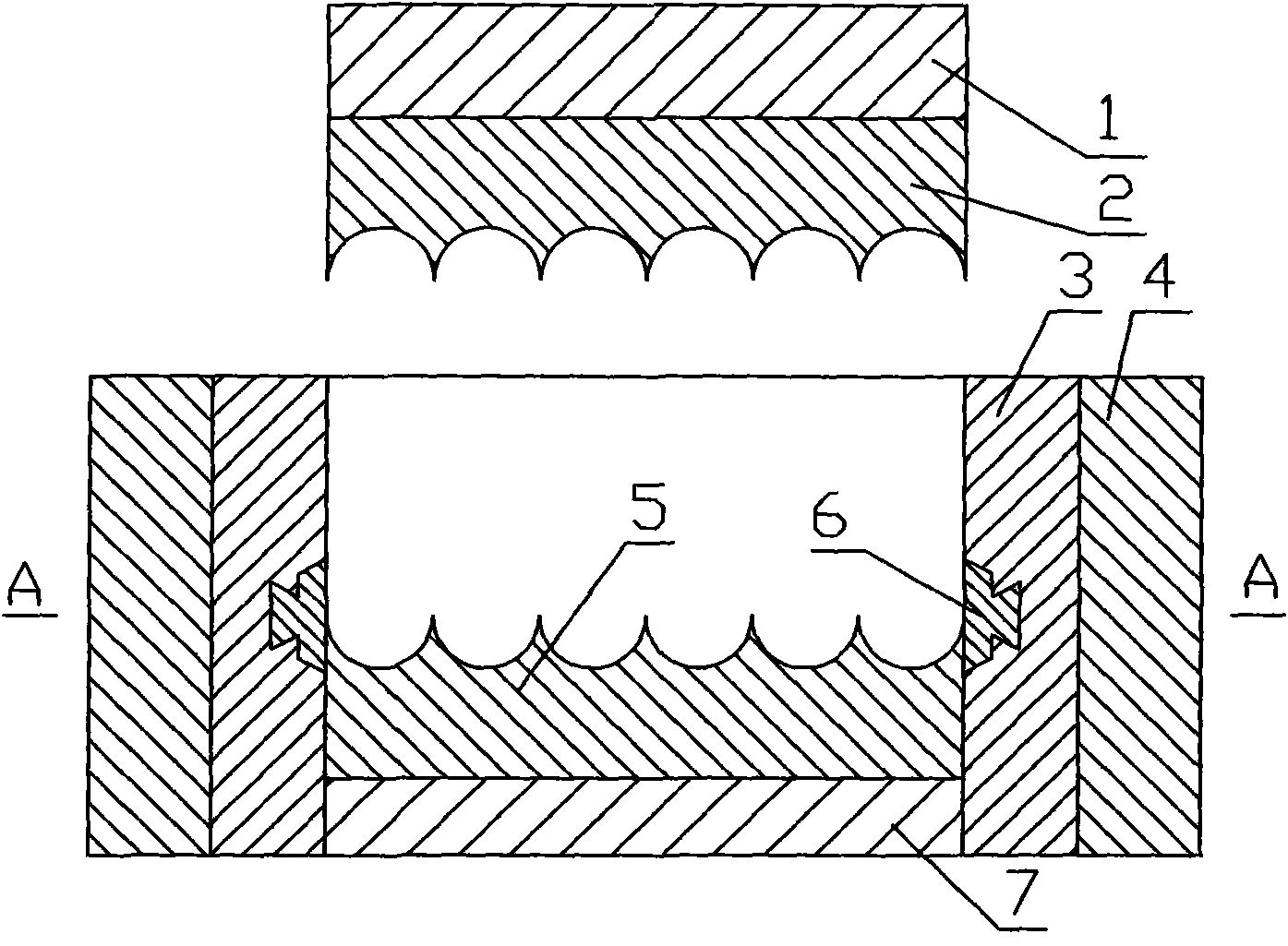

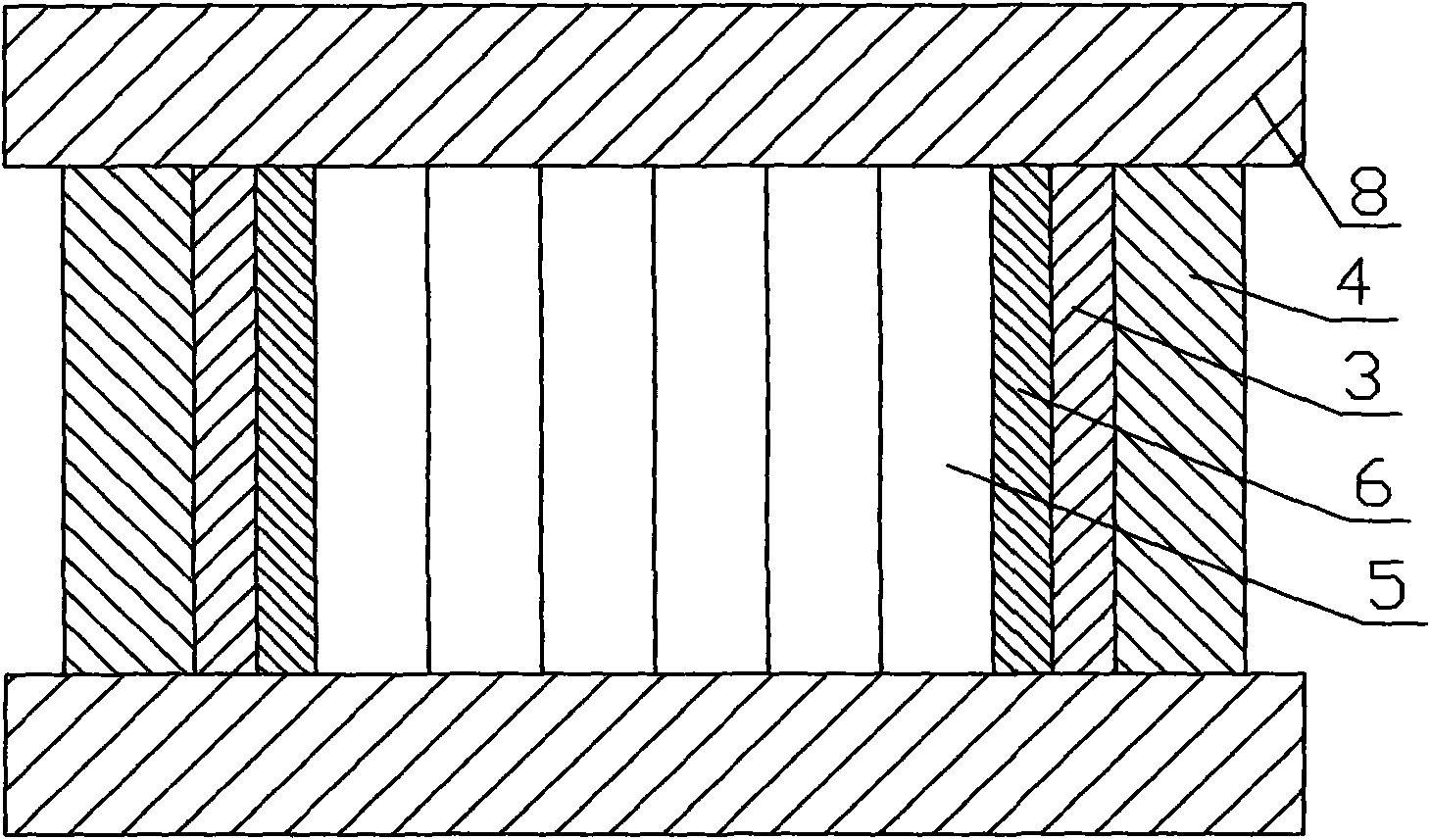

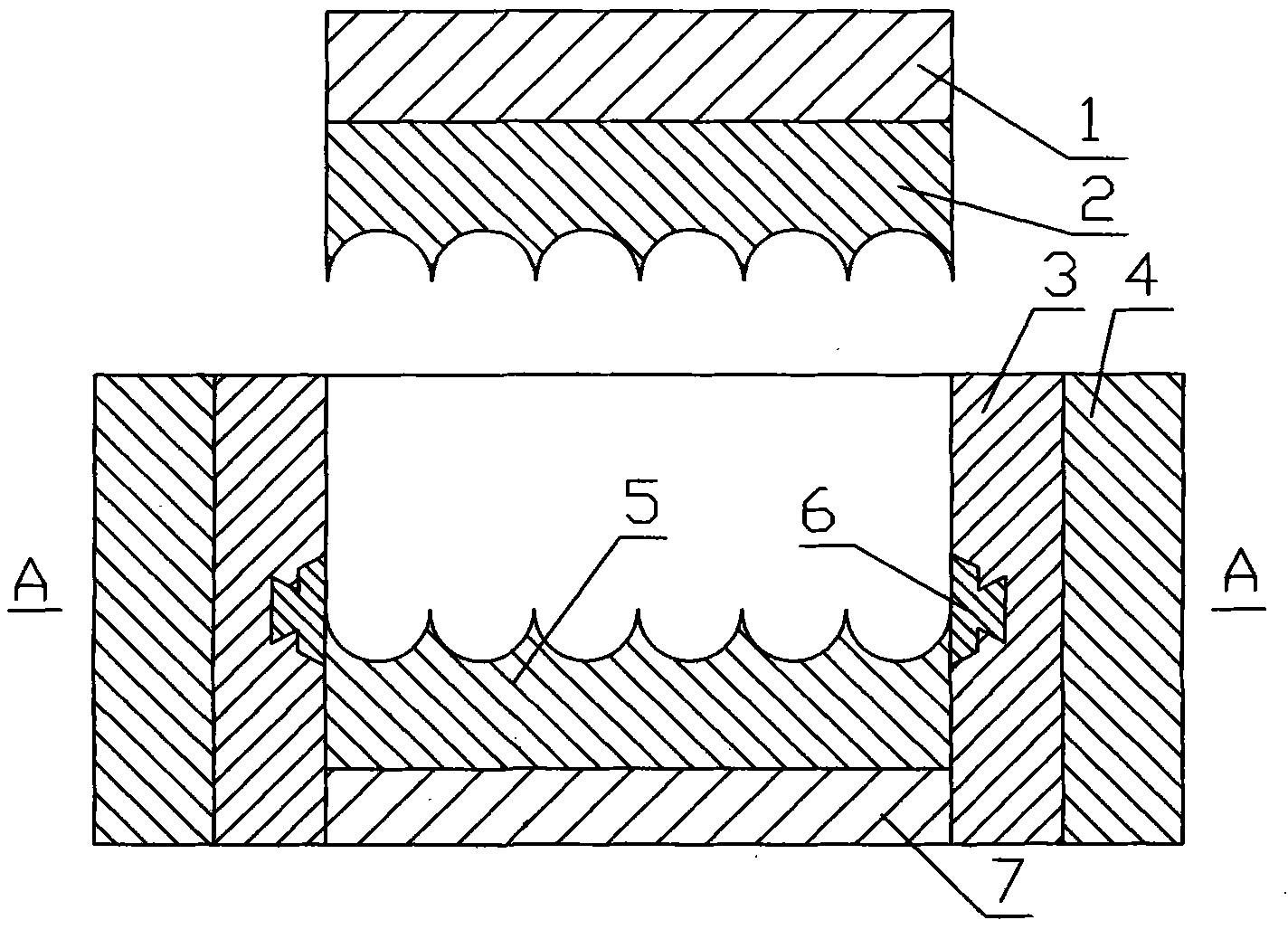

[0009] The structure of the present invention consists of a pair of end templates 8 around, a pair of side templates 4, a liftable bracket 7 at the bottom to form a box-shaped lower mold frame with an upward opening, and a pair of linings that are bonded and fixed on the inner walls of a pair of side templates 4. Plate 3, a pair of lining boards 3 inner sides of the lower mold 5 and the bracket 7, fixed on the lower surface of the upper mold rod 1 are composed of the upper mold 2; the upper end of the lower mold 5 is an opening parallel to the axis line. The lower end of the upper mold 2 is a number of semi-cylindrical cavity grooves that are parallel to the corresponding axis line and open downward. It is characterized in that: the inner side of the middle part of the lining plate 3 is centered on the parting line The wire is embedded in a magnetic strip 6. The cross-sectional shape of the magnetic strip 6 is a special-shaped conjoined body with a longitudinal trapezoid with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com