UV curing color decorative coating

A decorative coating and ultraviolet light technology, applied in the field of coatings, can solve the problems of unresolved deep-layer curing, low adhesion, and inability to reach the deep layer of the coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

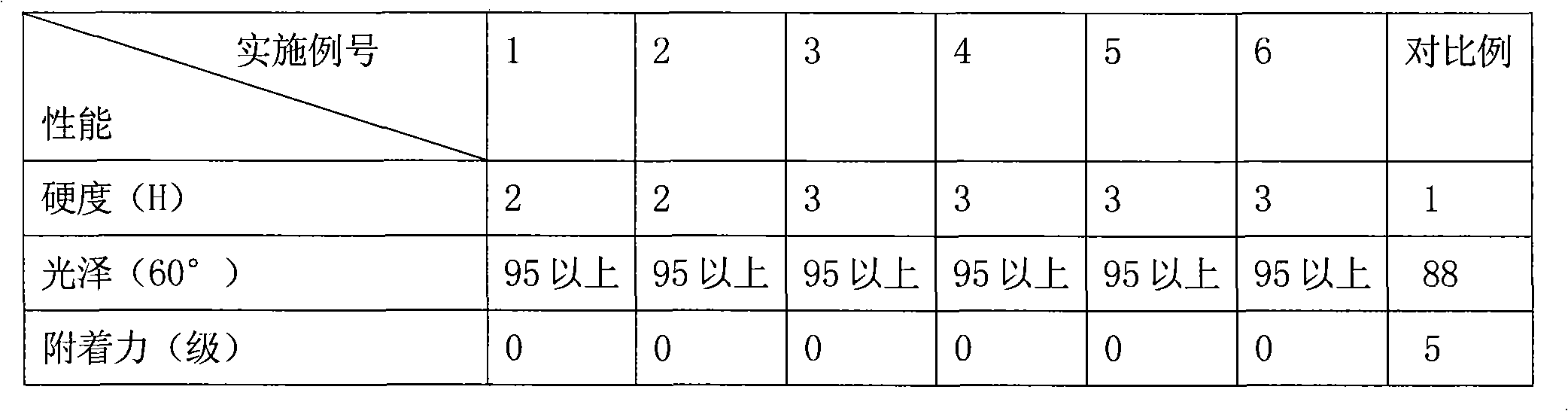

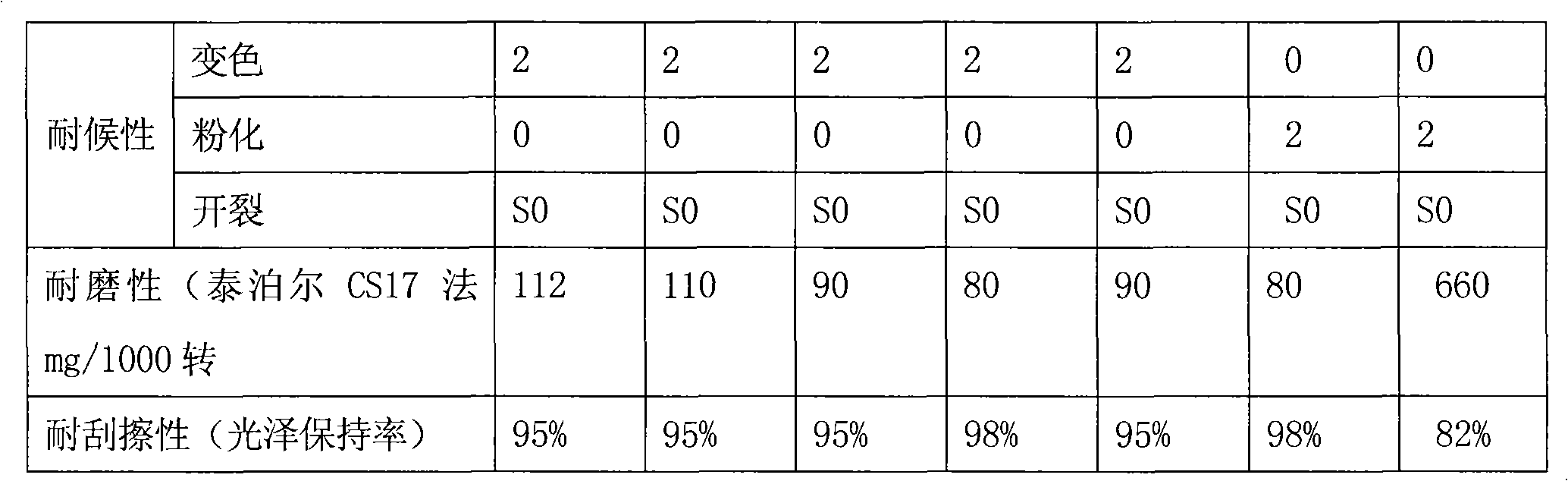

Examples

Embodiment 1

[0045] Embodiment 1. UV curing decorative paint-red

[0046] Bisphenol A epoxy acrylate (WSR-U125) 6,

[0047] Aliphatic polyurethane hexaacrylate (6145-100) 5,

[0048] Diluted aliphatic polyurethane diacrylate (611B-85) 25,

[0049] Polyester acrylate prepolymer (CN2203) 10,

[0050] Dipentaerythritol hexaacrylate (DPHA) 5,

[0051] Trimethylolpropane Triacrylate (TMPTA) 25,

[0052] Dipropylene glycol diacrylate (DPGDA) 10,

[0053] Bis(2,6-dimethoxybenzoyl)-(4′,4′-dimethyloctyl-2)phosphine oxide 1,

[0054] Pigment Red 5 2,

[0056] Silica (H18) 0.5,

[0057] Polymer wetting and dispersing agent (Disperbyk183) 0.5,

[0058] Polyether modified polydimethylsiloxane (BYK333) 0.1,

[0059] preparation:

[0060] (1) Preparation: Mix 2 / 3 of the prepolymer with all the coloring pigments, system pigments, and dispersants, then grind and disperse with a three-roller or other grinding equipment, and the fineness is required to be less than 15...

Embodiment 2

[0063] Embodiment 2. UV curing decorative coating-blue

[0064] Bisphenol A epoxy acrylate (WSR-U125) 15,

[0065] Modified bisphenol A epoxy acrylate (623-100) 10,

[0066] Aliphatic polyurethane acrylate (CN962) 5,

[0067] Polyester acrylate (QA-98) 2,

[0068] Pentaerythritol triacrylate (PETA) 7,

[0069] Tripropylene glycol diacrylate (TPGDA) 20,

[0070] Neopentyl glycol diacrylate (NPGDA) 10,

[0071] Propoxylated Neopentyl Glycol Diacrylate (PO-NPGDA) 10,

[0072] 1,6-Hexanediol diacrylate (HDDA) 16,

[0073] 2-methyl-1-(4-methylmercapto)-2-morpholineacetone-1 (Irgacure907) 2,

[0074] α,α-Dimethyl-α-hydroxyacetophenone (Darocur1173) 2,

[0075] Pigment Blue 15:3 15,

[0077] Silica (H15) 0.5,

[0078] Polymer wetting and dispersing agent (Disperbyk170) 5,

[0079] Polyether modified polydimethylsiloxane (BYK333) 0.1,

[0080] Polyether modified polydimethylsiloxane (TGO432) 0.5,

[0081] preparation:

[0082] (1) Mix prepo...

Embodiment 3

[0085] Example 3. UV Curing Decorative Coating-Yellow

[0086] Diluted Modified Bisphenol A Epoxy Acrylate (6231A-80) 10,

[0087] Aliphatic urethane acrylate (CN9013) 5,

[0088] Aliphatic polyurethane acrylate (CN966B85) 10,

[0089] Polyester acrylate (CN2203) 6,

[0090] Pentaerythritol tetraacrylate (PETTA) 5,

[0091] Dipentaerythritol Pentaacrylate (DPEPA) 5,

[0092] Tripropylene glycol diacrylate (TPGDA) 15,

[0093] Dipropylene glycol diacrylate (DPGDA) 5,

[0094] 2-methyl-1-(4-methylmercapto)-2-morpholineacetone-1 (Irgacure907) 3,

[0095] 1-Hydroxycyclohexylacetophenone (Irgacure184) 2,

[0096] 2,4,6-Trimethylbenzoyldiphenylphosphine oxide (LucirinTPO) 3,

[0097] Pigment Yellow 15:3 13,

[0098] Silica (H2000) 0.3,

[0099] Polymer wetting and dispersing agent (Disperbyk171) 5,

[0100] Polyether modified polydimethylsiloxane (BYK307) 0.5,

[0101] Polyether modified polydimethylsiloxane (TEGO432) 0.5,

[0102] Fluorocarbon modified polyacrylate (E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com