Patents

Literature

871 results about "Curtain coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Curtain coating is a process that creates an uninterrupted curtain of fluid that falls onto a substrate . The substrate is transported on a conveyor belt or calender rolls at a regulated speed through the curtain to ensure an even coat of the die. The curtain is created by using a slit or die at the base of the holding tank, allowing the liquid to fall upon the substrate. Some polymers are melted and extruded for coating. Many manufactures will also include a catch pan to retrieve and reuse the excess fluid.

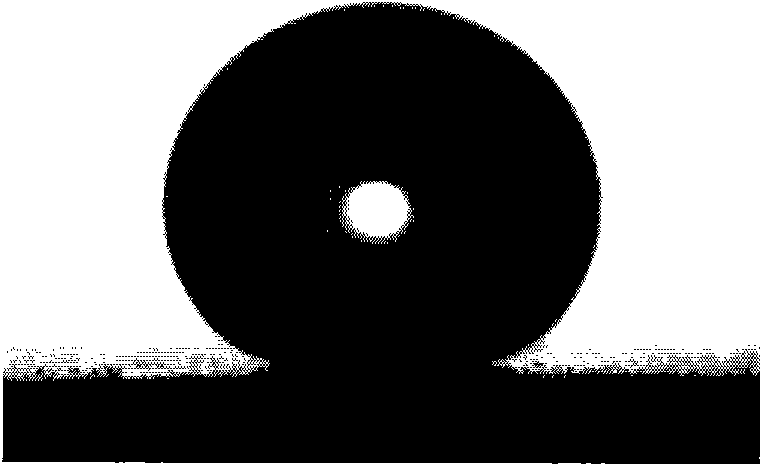

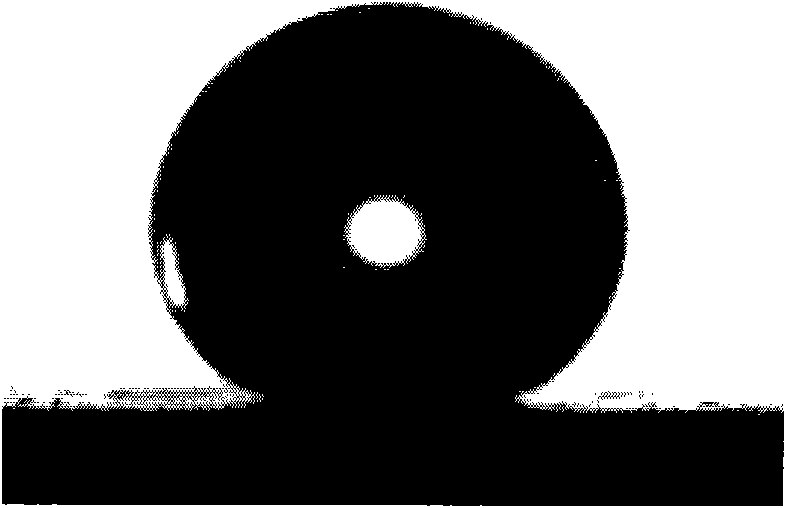

Method for preparing epoxy resin super-hydrophobic coat

InactiveCN101575478ASimple processGood repeatabilityLiquid spraying plantsMovable spraying apparatusEpoxySilica particle

The invention discloses a method for preparing an epoxy resin super-hydrophobic coat, comprising the following steps: (1), preparing collosol of the coat: dissolving silicon dioxide particles in a solvent, adding a silane coupling agent, heating and stirring for reaction, adding an epoxy resin paint and a hydrophobing agent, stirring for reaction, and obtaining the collosol of the coating layer; (2) coating film on the surface of a substrate material: coating the collosol obtained in the step (1) on the surface of the substrate through the way of lifting-pulling coating film, rotationally coating, curtain coating or spraying, after lifting, placing statically at the room temperature for using; and (3) heating and curing: putting the substrate material coated by the film in the step (2) in an oven, raising temperature to heat to make the epoxy resin cure and cross, taking out to obtain the epoxy resin super-hydrophobic coat. The invention has the advantages of easy technique, easily obtained raw materials, low cost and good repeatability; and the obtained coat has good super-hydrophobicity and self-cleaning performance for the industrial production of the super-hydrophobic paint properly.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

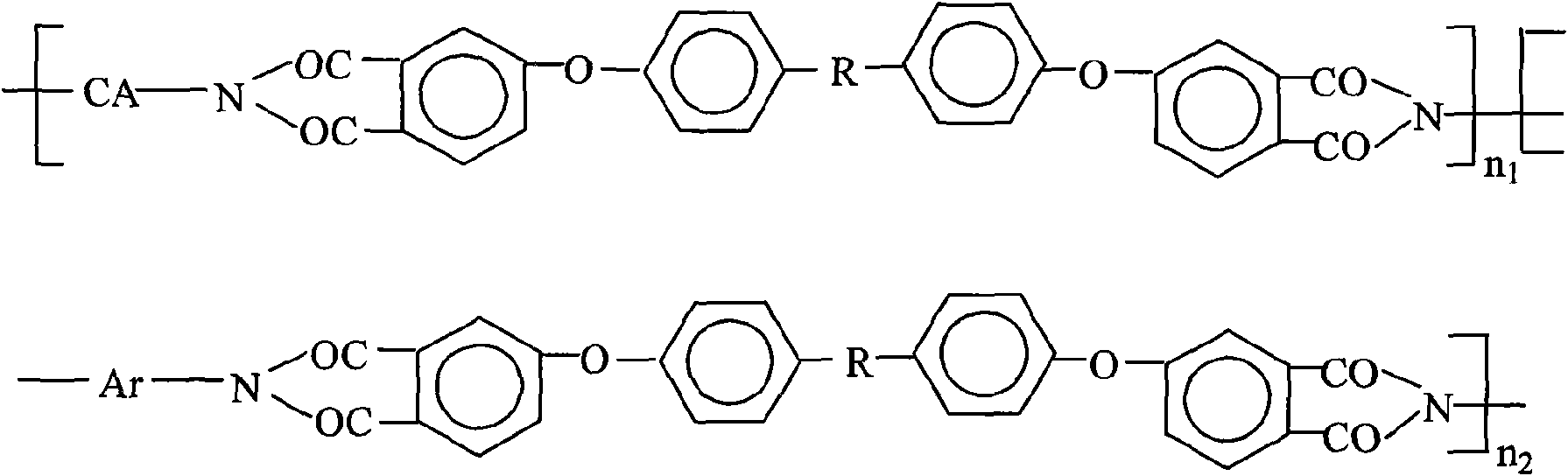

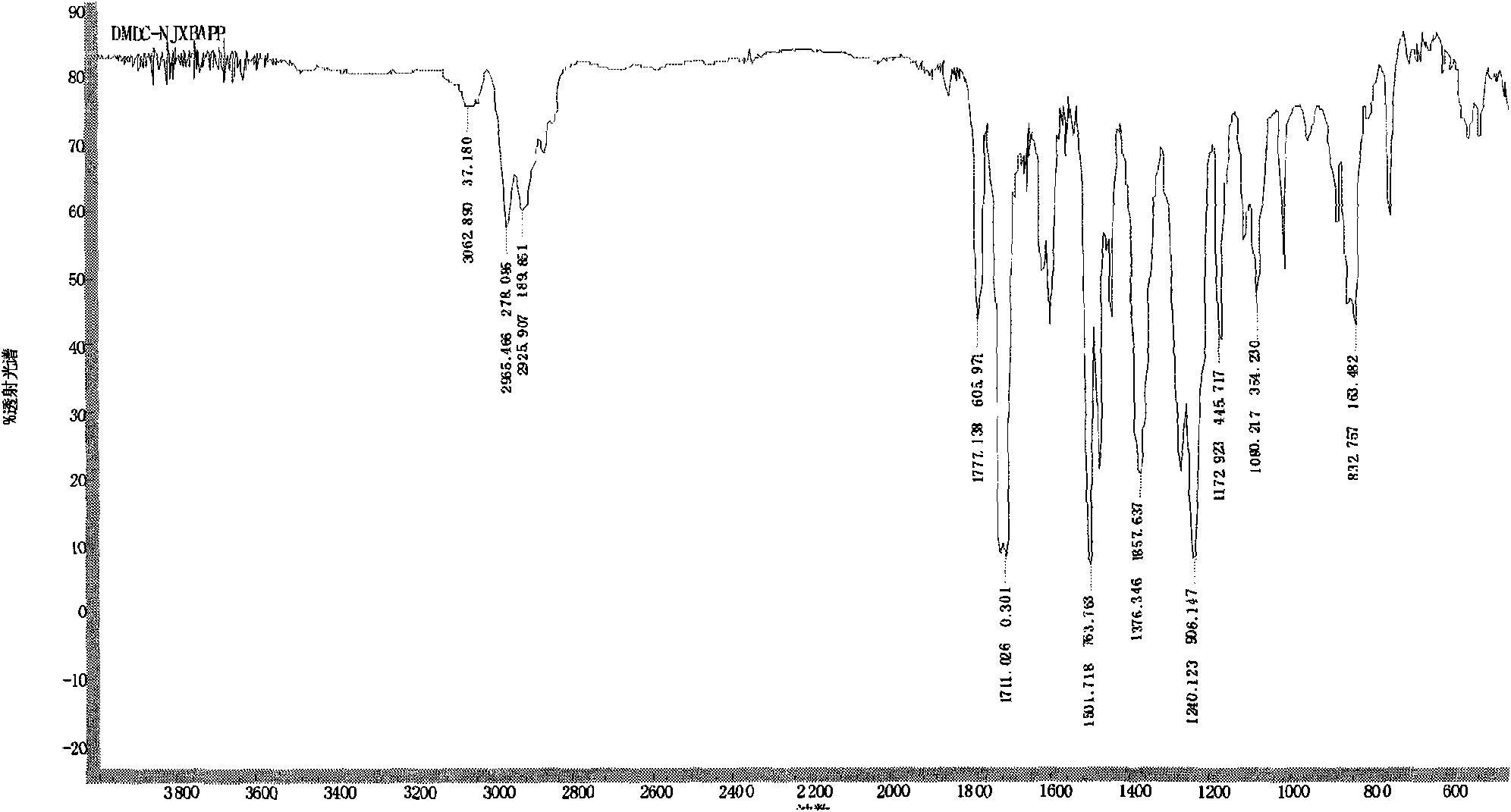

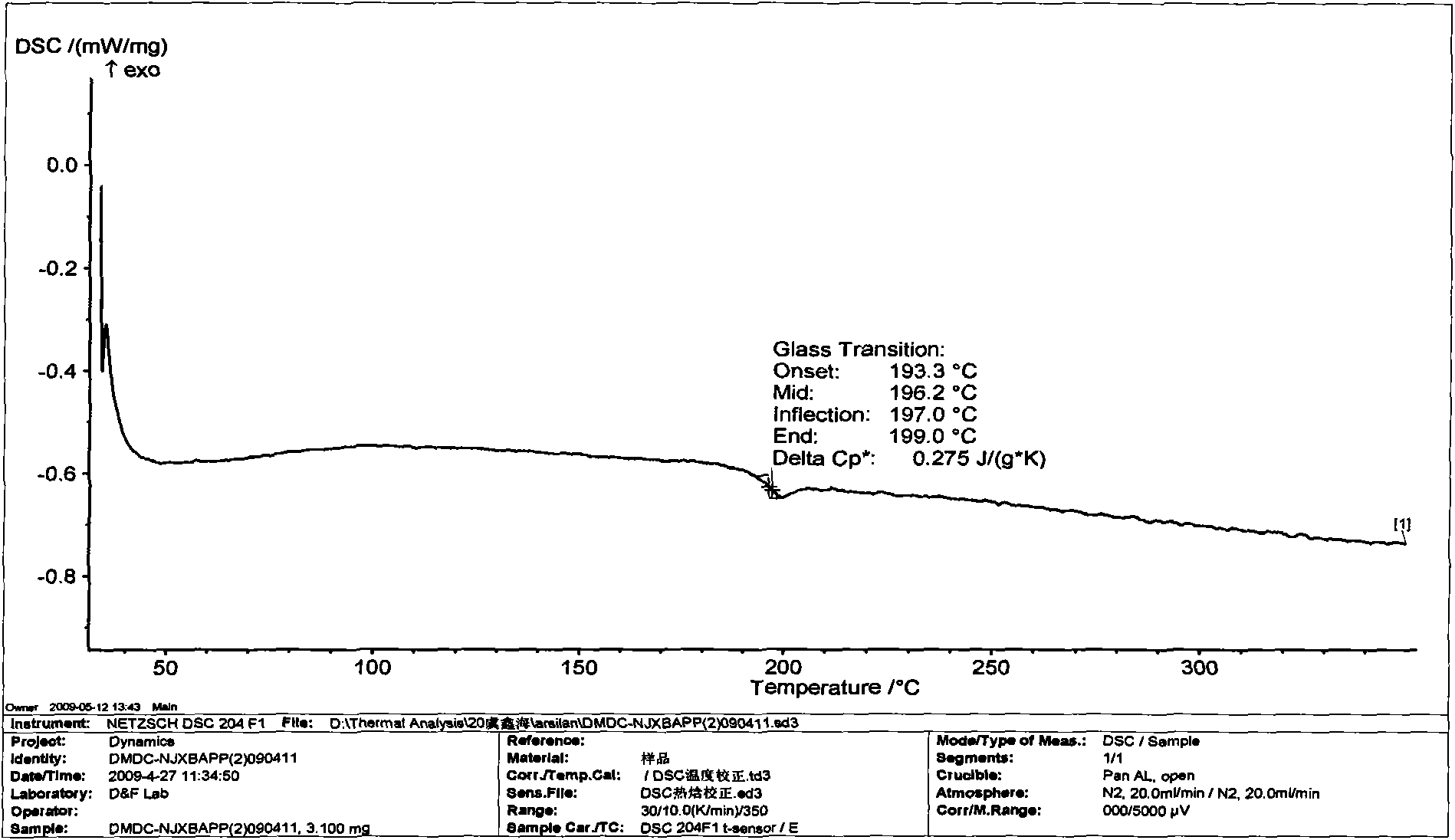

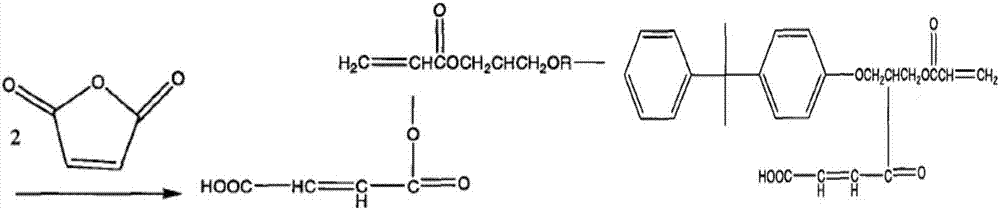

Alicyclic-containing polyimide film and preparation method thereof

InactiveCN101580637AConvenient sourceLow costTelescopesNon-linear opticsOptical communicationPhotochemistry

The invention relates to an alicyclic-containing polyimide film. The molecular structure general formula of the film is the right formula, wherein, -CA- is a bivalence connection group of an alicyclic dibasic primary amine, -Ar- is a bivalence connection group of an aromatic dibasic primary amine, and -R- is a bivalence connection group of an aromatic dibasic estolide. The preparation thereof includes: the alicyclic dibasic primary amine and the aromatic dibasic primary amine are dissolved in non-proton organic solvent with strong polarity, the aromatic dibasic estolide is added, the non-proton organic solvent with strong polarity is used for regulating the viscosity of the alicyclic-containing polyamic acid resin solution after reaction for 1-3 hours, forming is carried out in a curtain coating machine, and dehydration fever imidization, cooling and demoulding are carried out so as to obtain the film. The preparation method has mild reaction condition and low cost and is environmentally friendly; and meanwhile, the alicyclic-containing polyimide film has excellent mechanic property and heat resistant property and low water absorption, and the visible light transmission thereof is as high as more than 97%. The film has good application prospect in the fields of optical waveguide material, photorefractive material and photoelectric material in optical communication field and direct action membrane material in the liquid crystal display field and the like.

Owner:DONGHUA UNIV

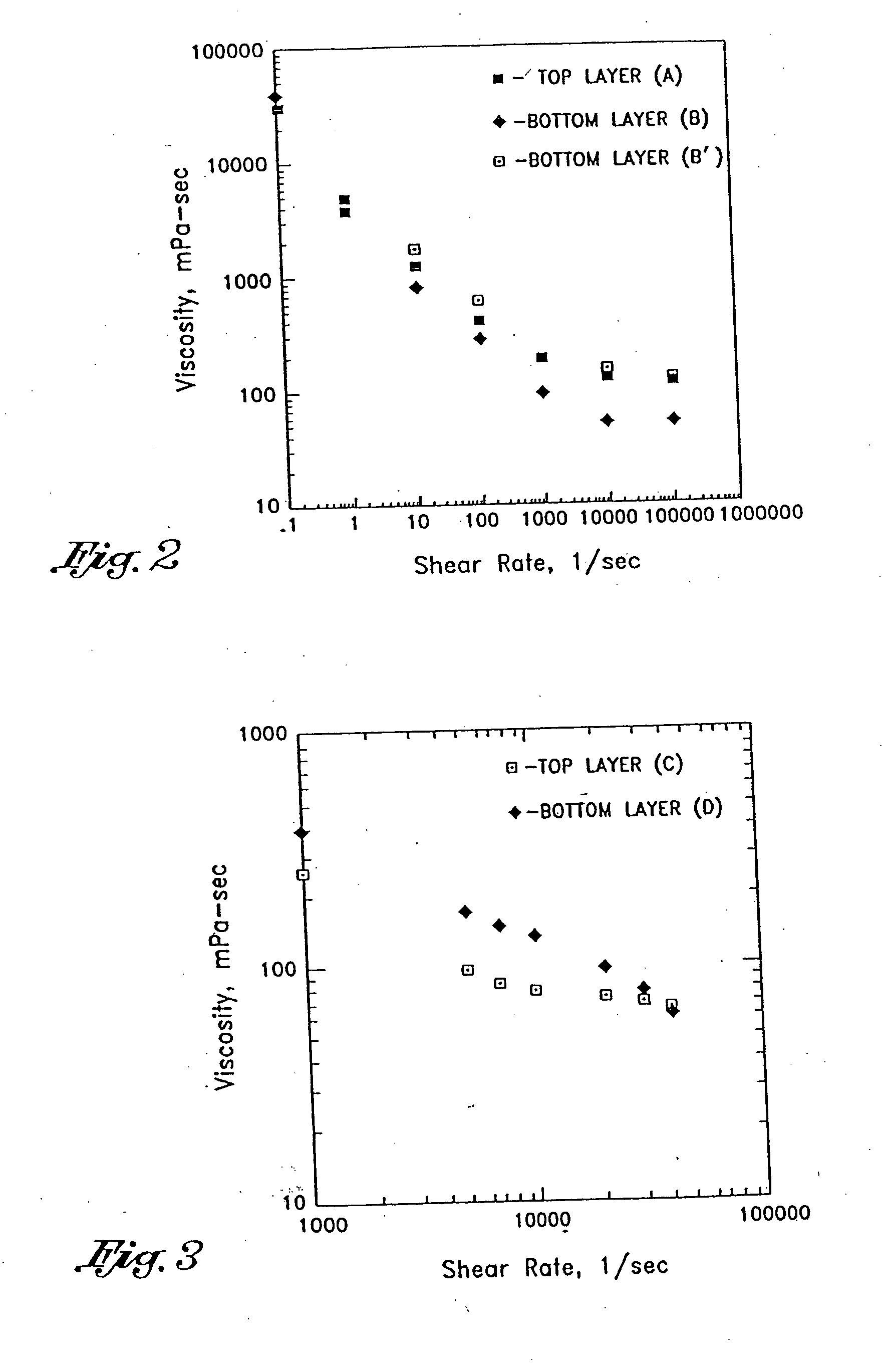

Method for forming multilayer release liners and liners formed thereby

InactiveUS20050074549A1Easy to optimizeLow costFilm/foil adhesivesLayered productsBiomedical engineeringRelease liner

Disclosed herein is a multilayer silicone release surface comprising a backing, a support layer on the backing, and a silicone layer of the support layer. The various layers of the multilayer release surface are deposited substantially simultaneously, as for example by a dual die or using curtain coating techniques.

Owner:AVERY DENNISON CORP

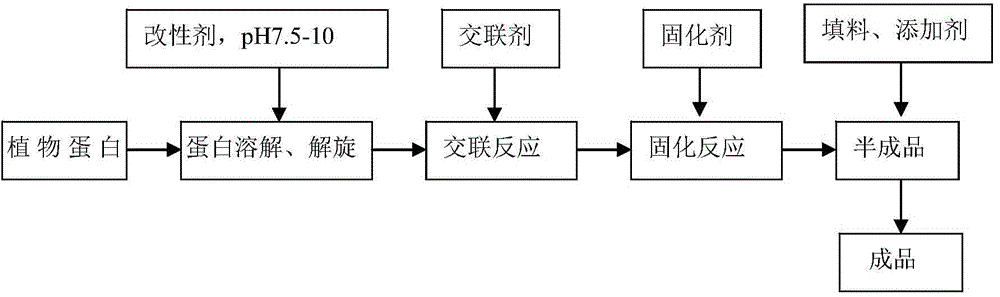

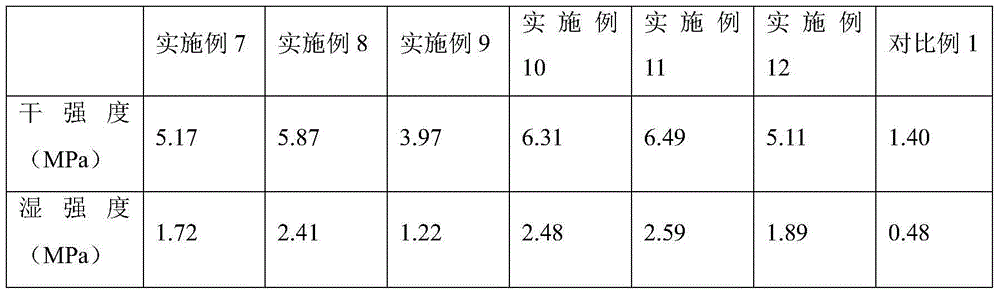

Aldehyde-free vegetable protein-based wood adhesive as well as preparation and application methods thereof

InactiveCN104610909AOvercome water resistanceOvercome strengthNon-macromolecular adhesive additivesProtein adhesivesCross-linkAdhesive

The invention belongs to the technical field of design, research and development of environment-friendly chemical materials and specifically relates to an aldehyde-free vegetable protein-based wood adhesive as well as preparation and application methods thereof. The aldehyde-free vegetable protein-based wood adhesive is prepared from the following components in parts by mass: 100 parts of water, 20-40 parts of vegetable protein, 0.1-5 parts of modifier, 20-40 parts of cross-linking agent, 2-20 parts of curing agent, 1-5 parts of packing and 0-3 parts of additive. The finished product is formed by virtue of vegetation protein dissolution, a cross-linking reaction and a curing reaction. The adhesive is mainly applied to a wood material in such a manner of roll coating, scraper coating, curtain coating or spraying, and then a composite wood artificial board can be obtained by virtue of aging, cold pressing and hot pressing.

Owner:乌鲁木齐奥森碳环生物能源有限公司

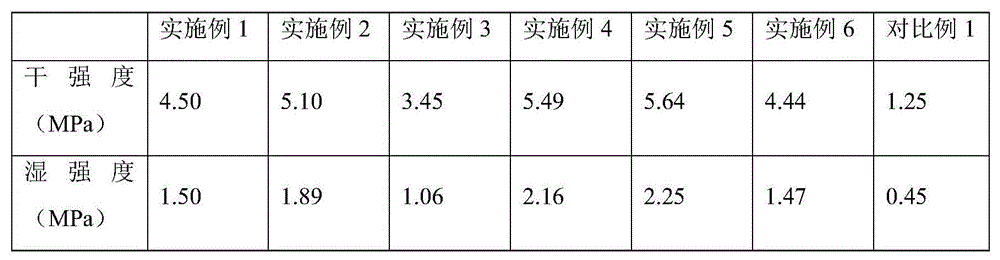

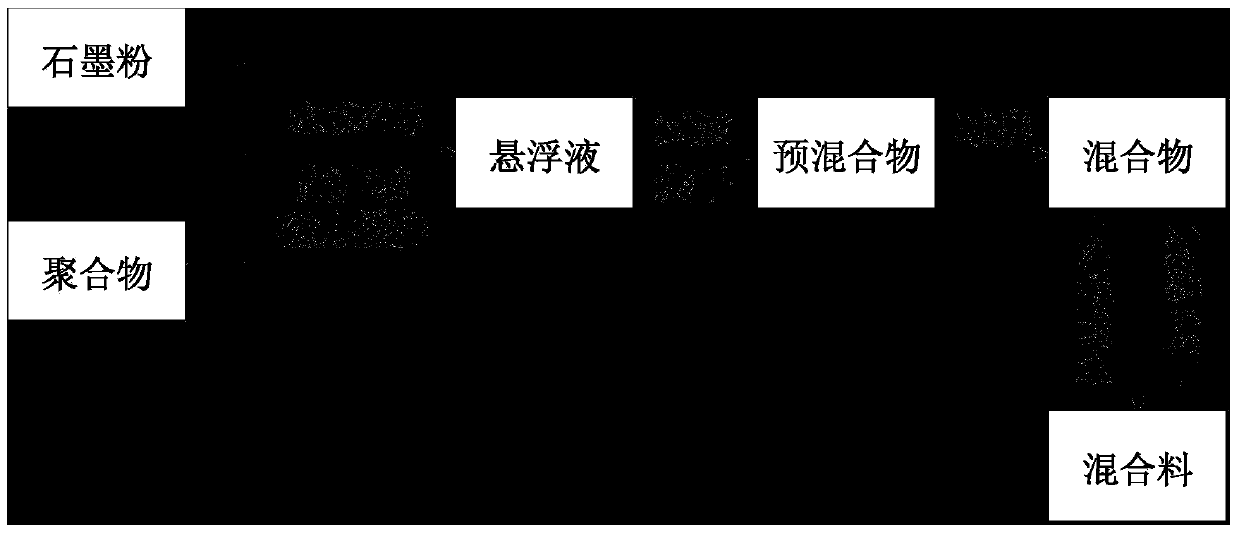

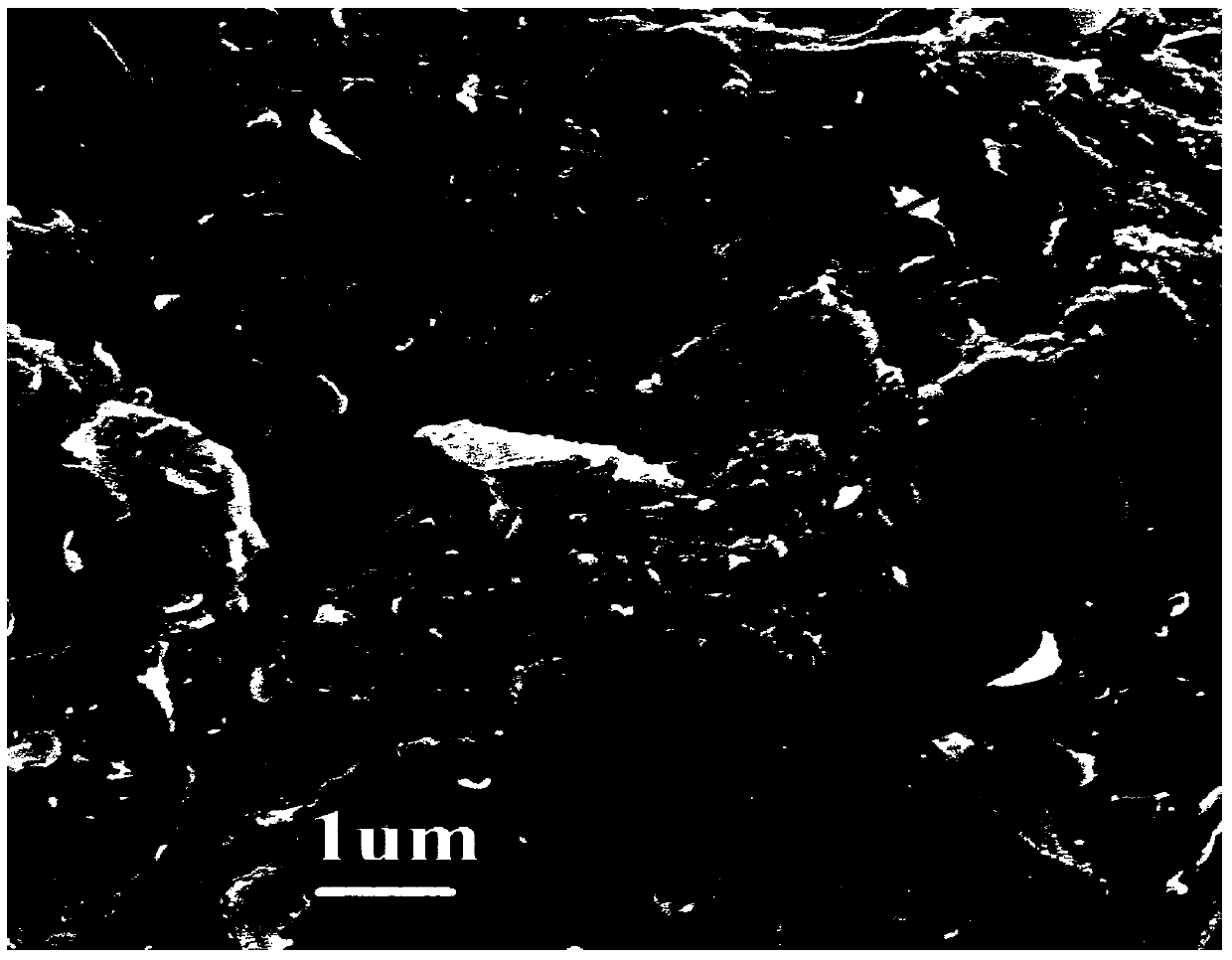

Preparation method for mixture of polymer and graphene

The invention discloses a preparation method for a mixture of a polymer and graphene. The advantage that graphite powder and the polymer are both granular powder is utilized, a graphite layer is stripped in situ according to a dry ball milling method, and the mixture of polymer and grapheme is prepared. The preparation method particularly comprises the following steps: (1) premixing the graphite powder and the polymer; (2) conducting ball milling and stripping on the pre-mixture fully in a ball mill to prepare the mixture of the graphite powder and the polymer. The preparation method adopts the dry ball milling method, so problems in solvent recovery and pollution caused by methods of solution mixing, in situ polymerization, wet ball milling, and the like are avoided; meanwhile, the defect of uneven dispersion of the graphene during fusing and dispersing process is overcome, the technological operation is simplified, and promotion and use are facilitated; the mixture of the polymer and the graphene is suitable for polymer processing methods of extrusion, injection molding, mould pressing, blow molding, curtain coating, and the like.

Owner:HUAQIAO UNIVERSITY +1

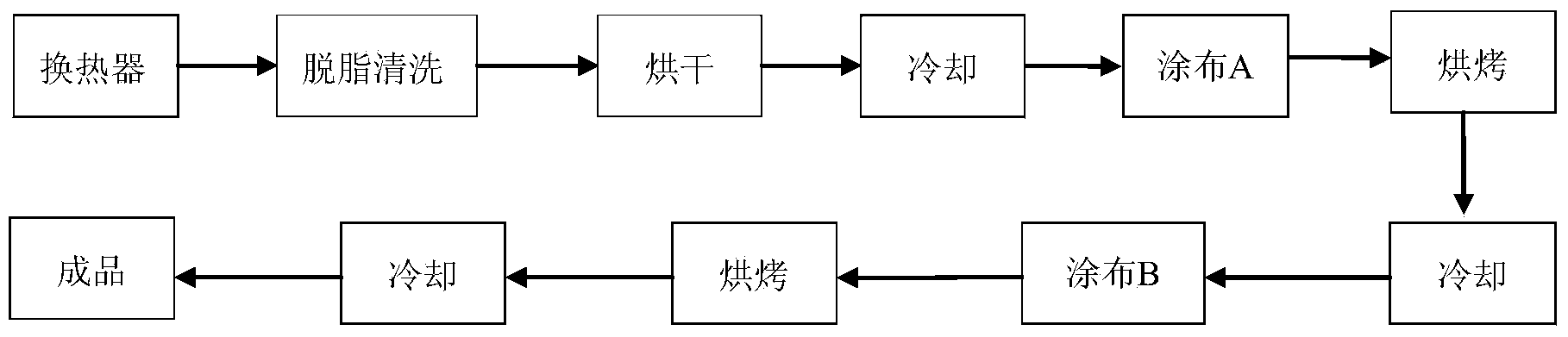

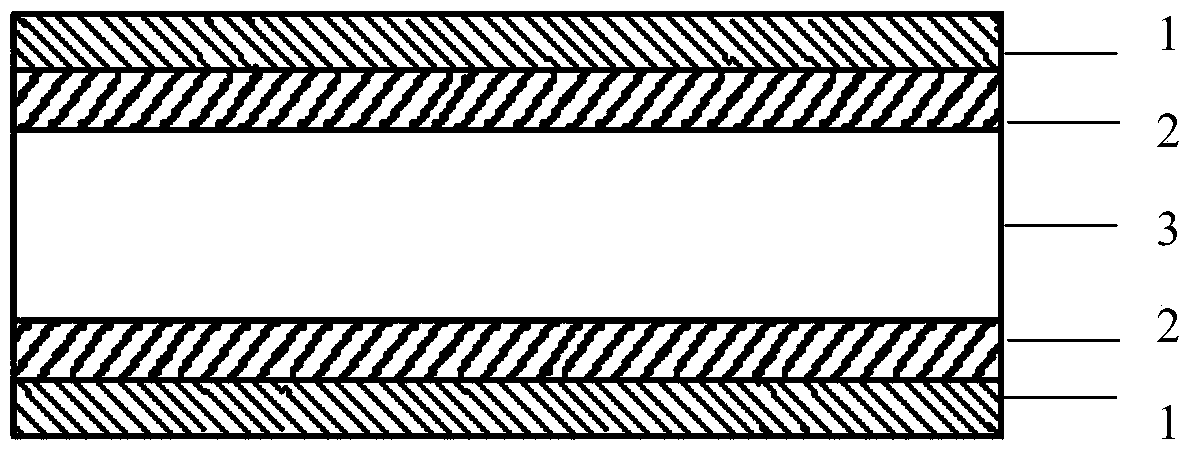

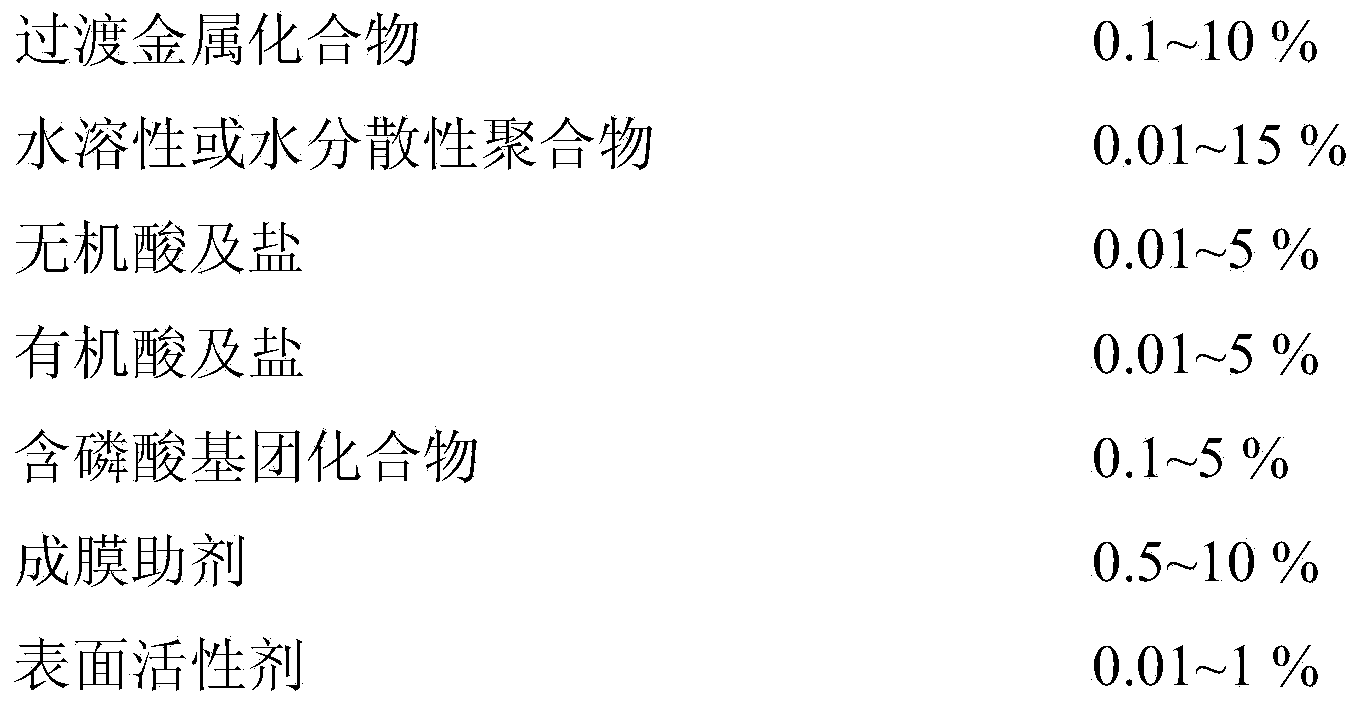

Coating composition for hydrophilic treatment of air-conditioning parallel flow heat exchanger

ActiveCN103555114AImprove hydrophilicityImprove adhesionChemical industrySynthetic resin layered productsHydrophilic coatingBusiness efficiency

The invention belongs to the technical field of hydrophilic coatings and discloses a coating composition for hydrophilic treatment of an air-conditioning parallel flow heat exchanger. The coating composition comprises a coating A and a coating B, wherein the coating A is an inorganic system A-1 which takes inorganic substances as main components or an organic system A-2 which takes organic substances as main components; the coating B is an inorganic system B-1 which takes inorganic substances as main components or an organic system B-2 which takes organic substances as main components. The coating A and the coating B are sequentially coated on the surface of a heat exchanger workpiece in a dip-coating, curtain coating or spraying mode and are sequentially roasted and cured, the heat exchanger can be endowed with lasting hydrophilcity, the formed coating is excellent in hydrophilic performance, high in adhesive force, permanent and effective; the coating is high in corrosion resistance, and the service life of the heat exchanger can be greatly prolonged; the coating is excellent and lasting in hydrophilic performance and high in adhesive force, and the energy efficiency ratio of the heat exchanger can be improved.

Owner:GUANGZHOU HUMAN CHEM

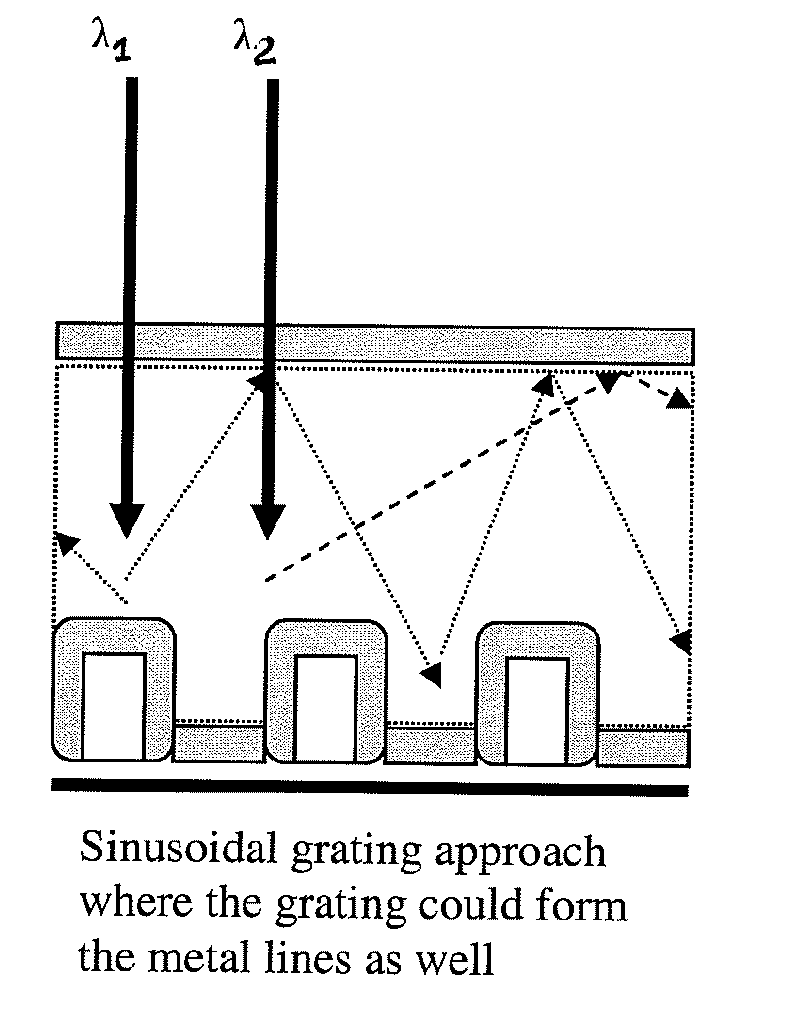

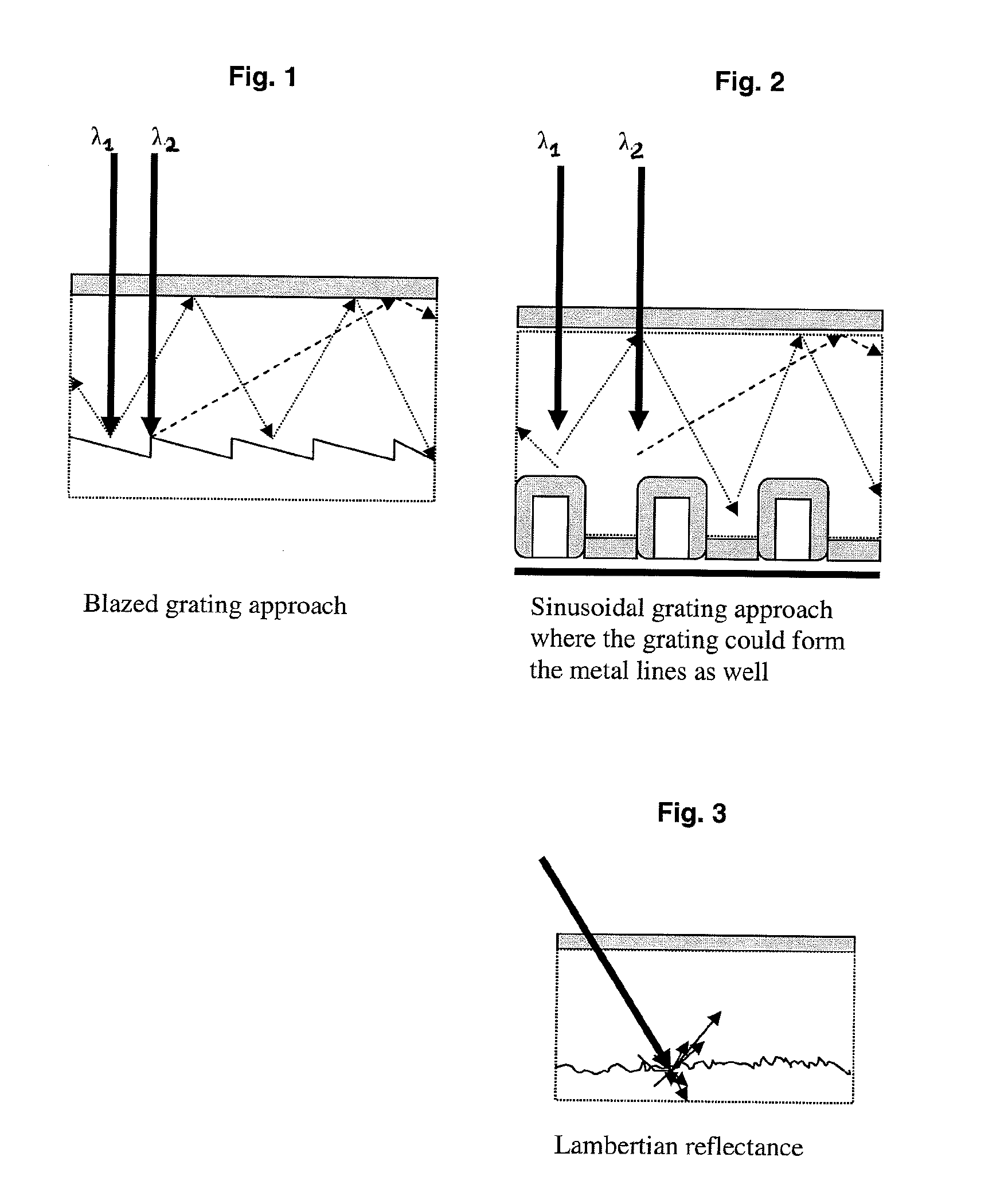

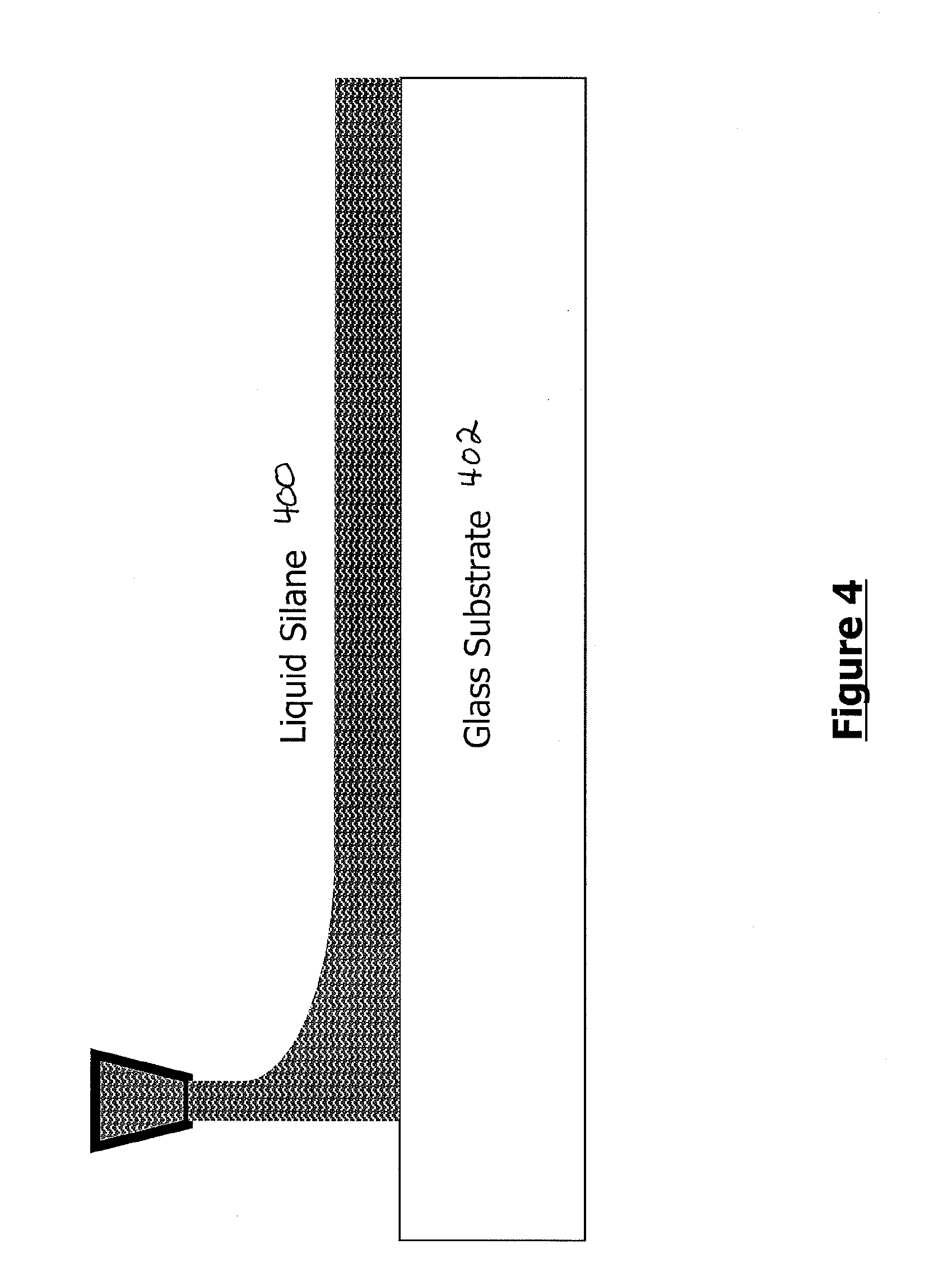

Method to create high efficiency, low cost polysilicon or microcrystalline solar cell on flexible substrates using multilayer high speed inkjet printing and, rapid annealing and light trapping

InactiveUS20090242019A1Improve efficiencyReduce $ /Watt-peakFinal product manufacturePretreated surfacesChemical reactionTrapping

Embodiments of the present invention relate to fabricating low cost polysilicon solar cell on flexible substrates using inkjet printing. Particular embodiments form polycrystalline or microcrystalline silicon solar cells on substrates utilizing liquid silane, by employing inkjet printing or other low cost commercial printing techniques including but not limited to screen printing, roller coating, gravure coating, curtain coating, spray coating and others. Specific embodiments employ silanes such as cyclopentasilane (C5H10) or cyclohexasilane (C6H12), which are liquids at room temperature but undergo a ring opening chemical reaction upon exposure to radiation of a wavelength of ultraviolet (UV) or shorter. . Opening of the rings of the liquid silane converts it into a polymerized material comprising saturated and unsaturated silicon chains of varied length. Heating to approximately 250-400° C. converts these materials into a hydrogenated amorphous silicon film. Controlled annealing at higher effective temperatures causes the amorphous film to change phase to polycrystalline or microcrystalline silicon, depending upon specific processing conditions.

Owner:CHEMTRON RES

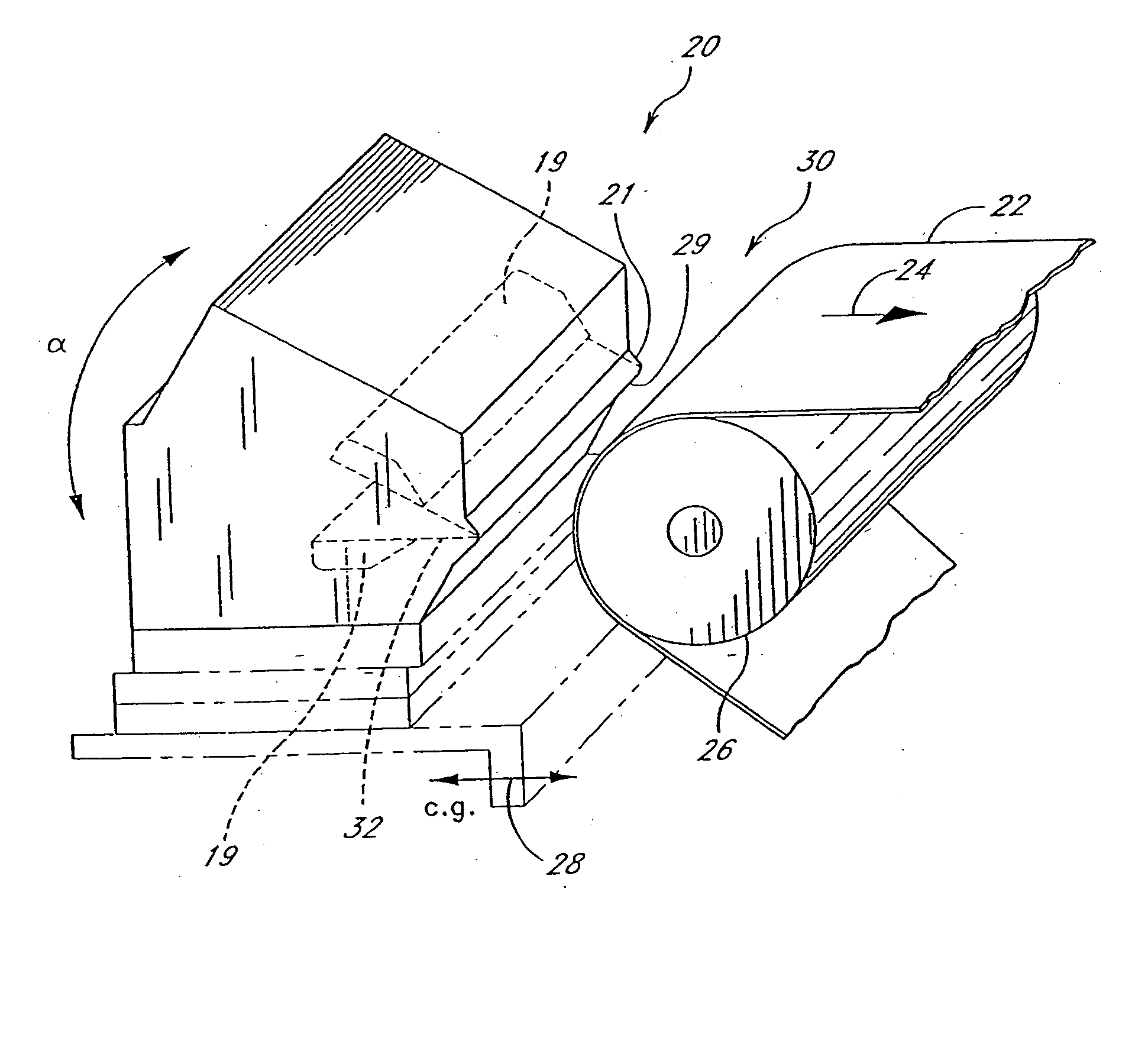

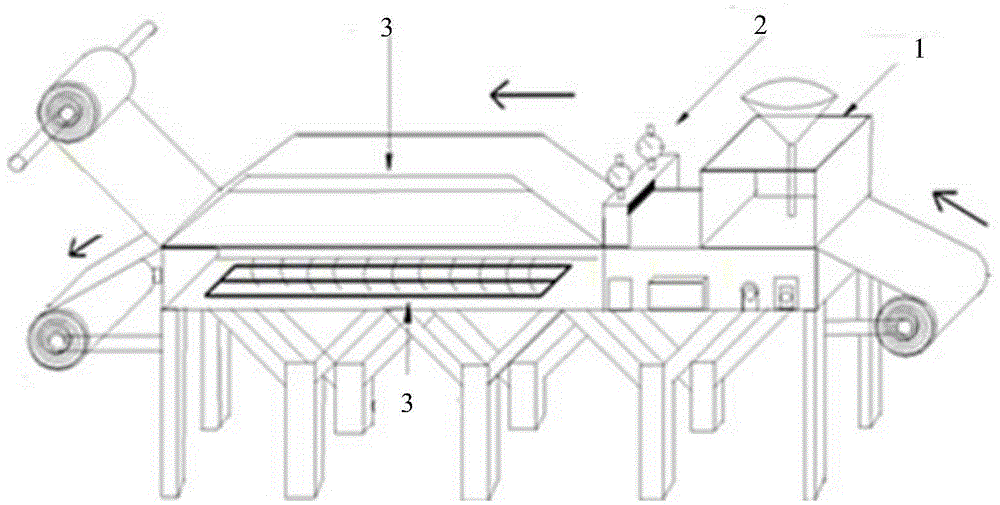

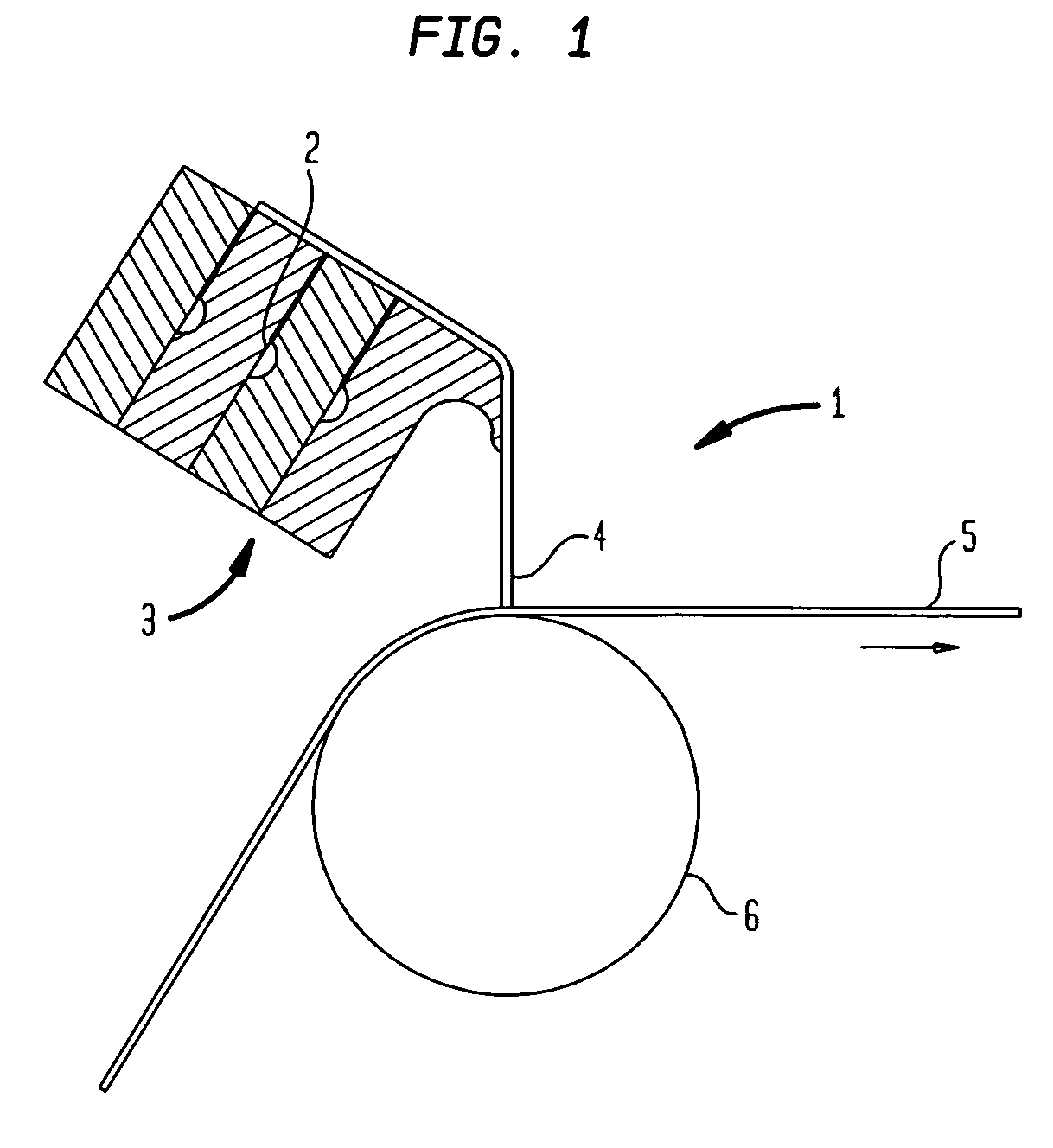

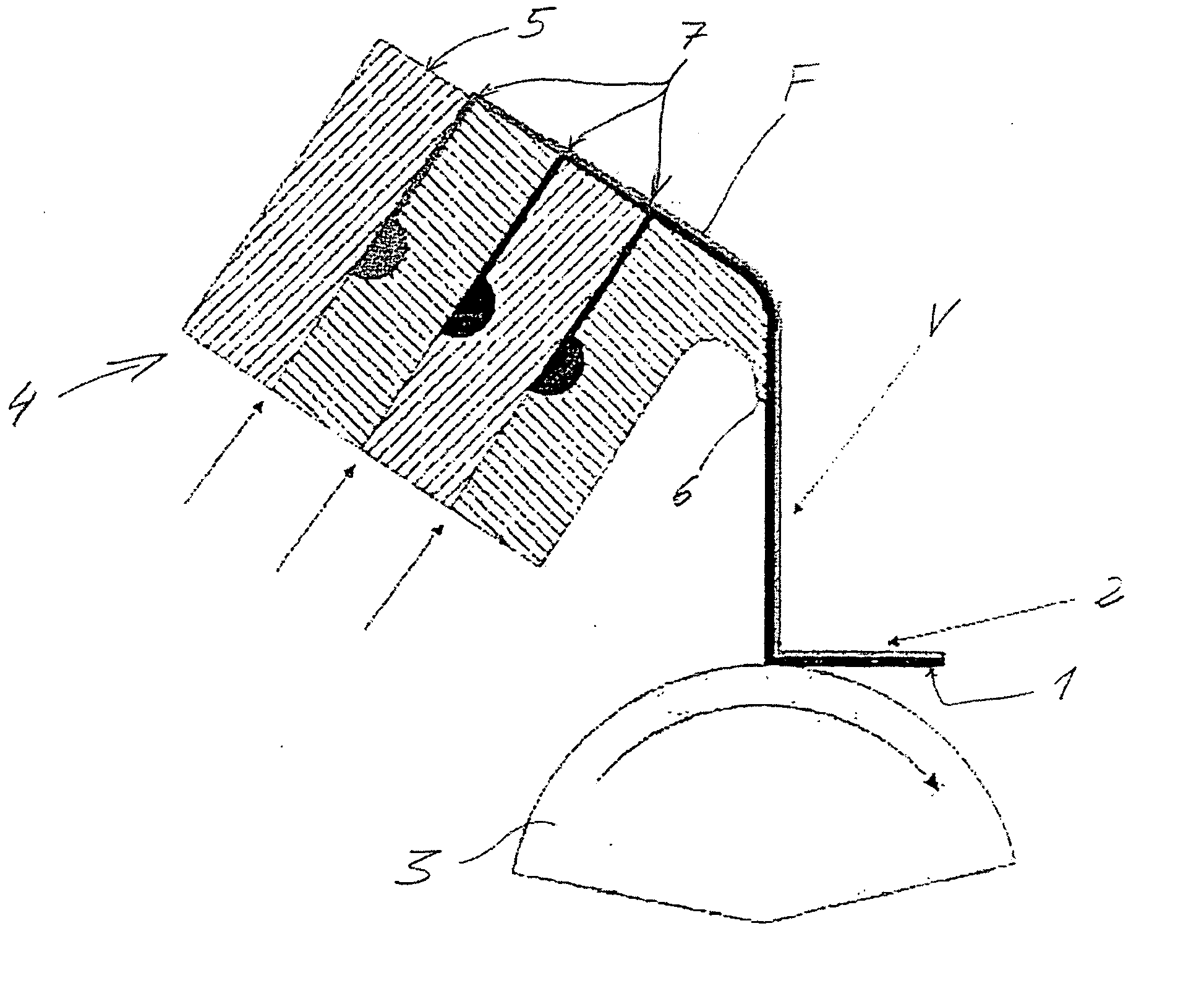

Method and apparatus for curtain coating

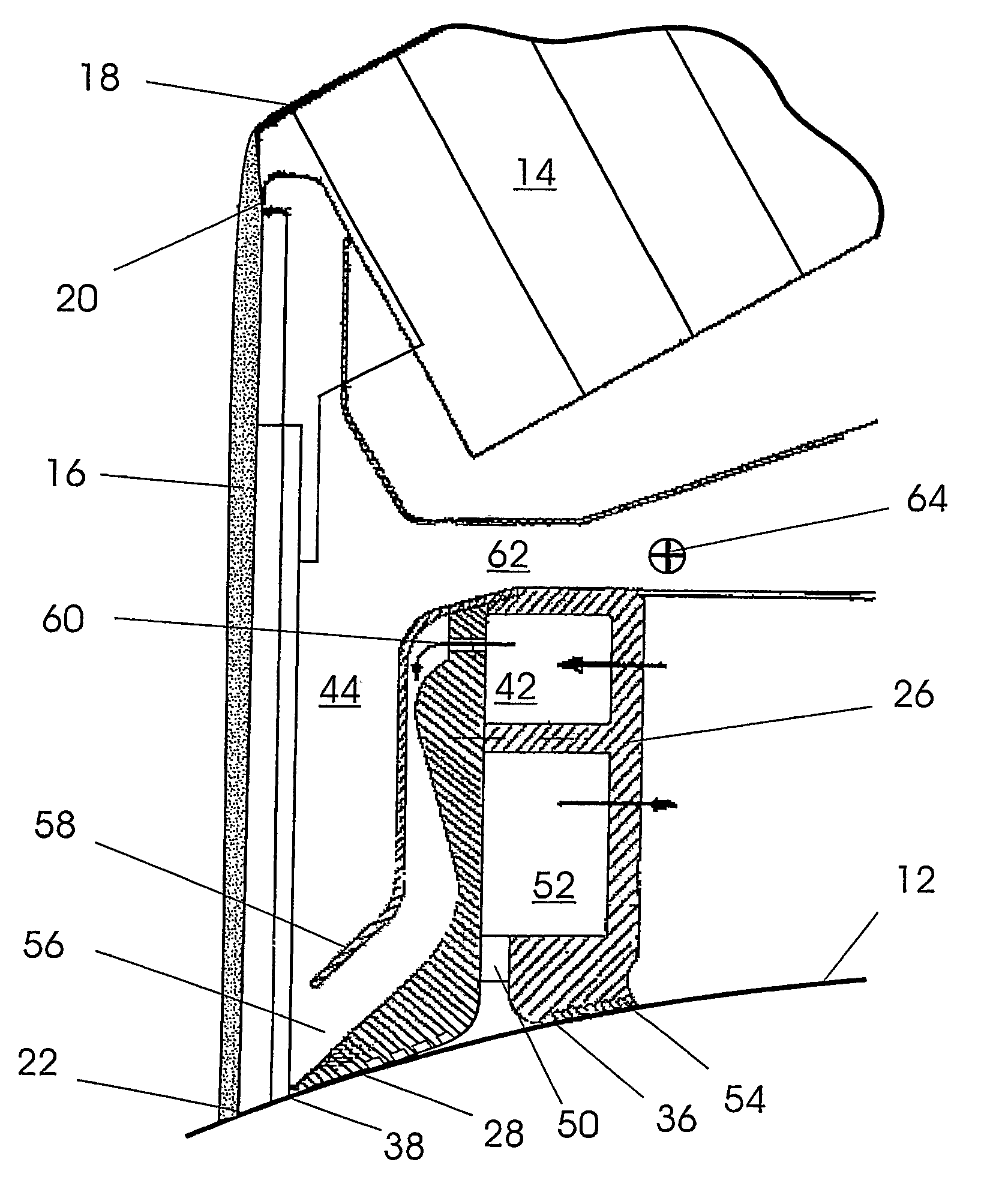

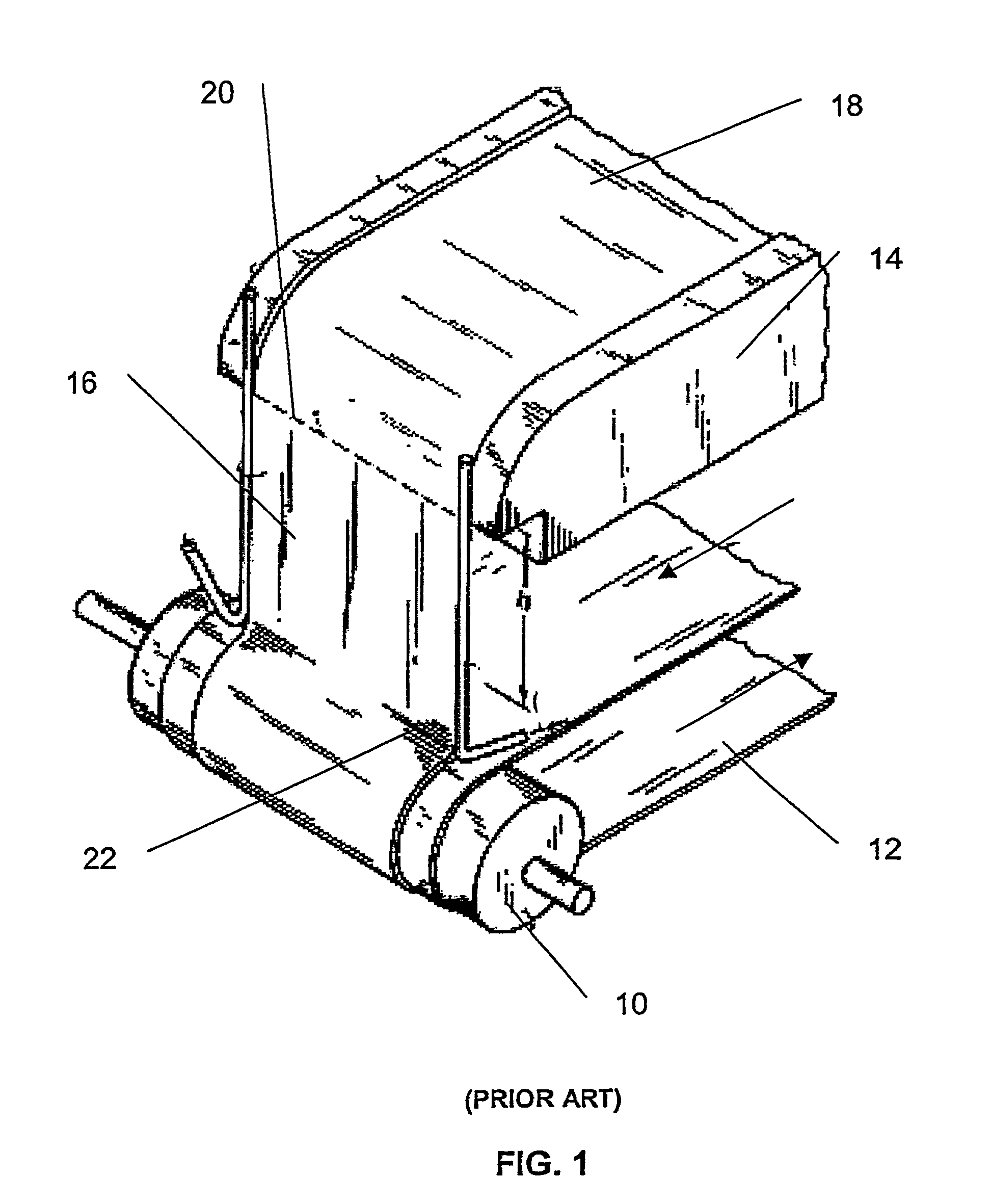

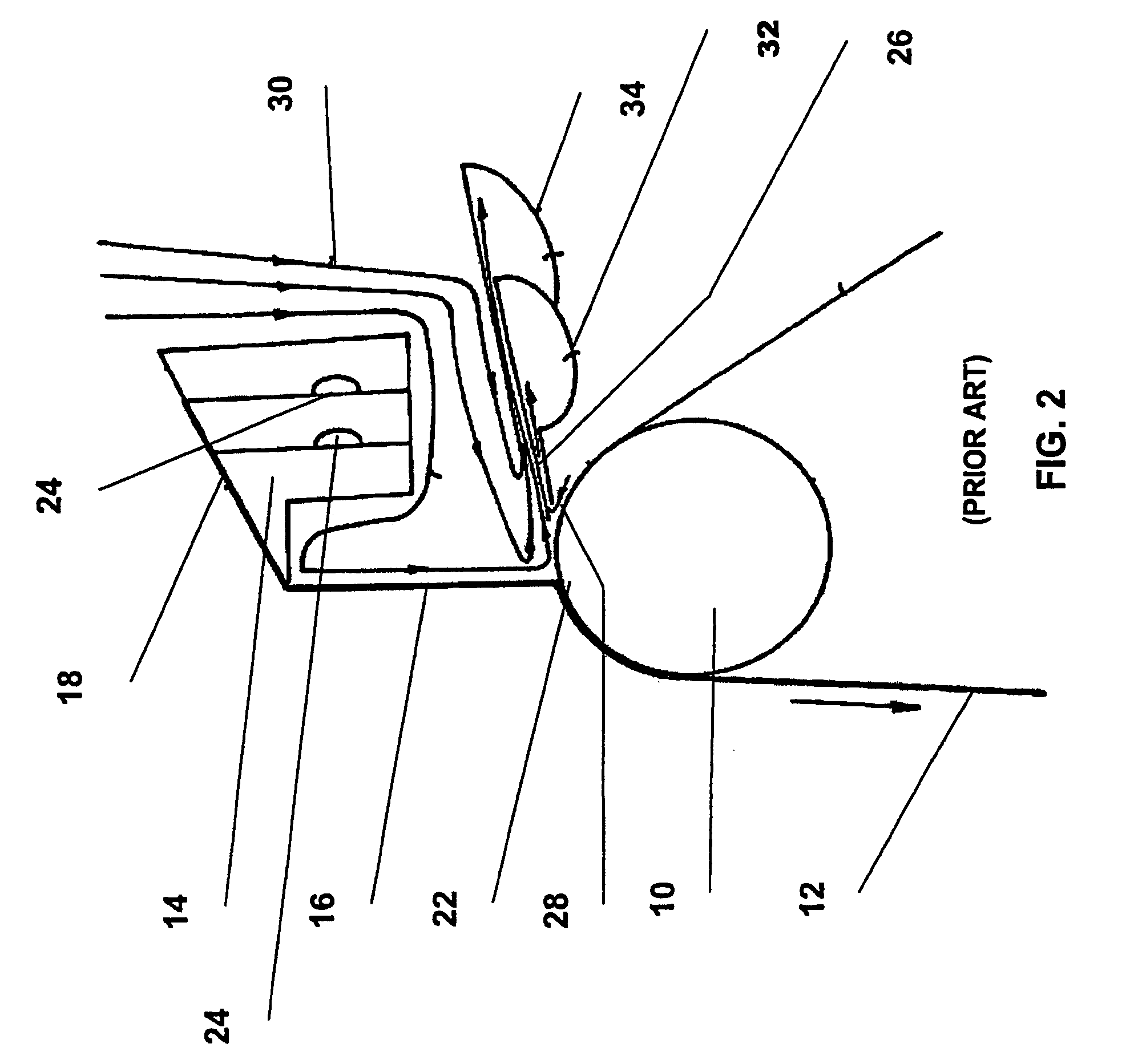

In a method and an apparatus for curtain coating of a moved substrate like a paper web substrate is moved below a liquid supply means providing a single or multilayer liquid coating in the form of a free-falling curtain impinging the substrate at a dynamic wetting line and a blade or air shield located upstream of the dynamic wetting line with respect to the moving direction of the substrate. The dynamic wetting line of the coating curtain on the substrate or web is oriented generally perpendicular to the moving direction of the substrate or web, providing substantially the same air pressure over an essential part of the coating curtain on its front and back side with respect to the moving direction of the substrate and providing a first supply air flow upstream to the wetting line. The supply air flows over a substantial length along the free-falling curtain and evacuates air from a location upstream of the supply air flow so that the air near the dynamic wetting line is moved against the moving direction of the substrate web and the boundary air layer entrained to the substrate. A second supply air is provided in proximity to the wetting line.

Owner:TRINSEO EURO GMBH

Method of preparing zirconium oxide ceramic by curtain coating method and product obtained from said method

A process for preparing the zirconium oxide ceramics by doctor blading method includes calcining the square-crystal zirconium oxide powder at 600-800 deg.C for 1-3 hr, proportionally mixing it with disperser, solvent and homogenizing agent, ball grinding for 10 hr, adding plasticizer and defoaming agent, ball grinding for 10 hr, vacuum stirring for defoaming, doctor blading, drying at 60-100 deg.C for 2-3 hr, degumming by heating to 600 deg.C and holding the temp for 4 hr, and sintering at temp lower than 1540 deg.C for 2-4 hr.

Owner:珠海粤科京华电子陶瓷有限公司

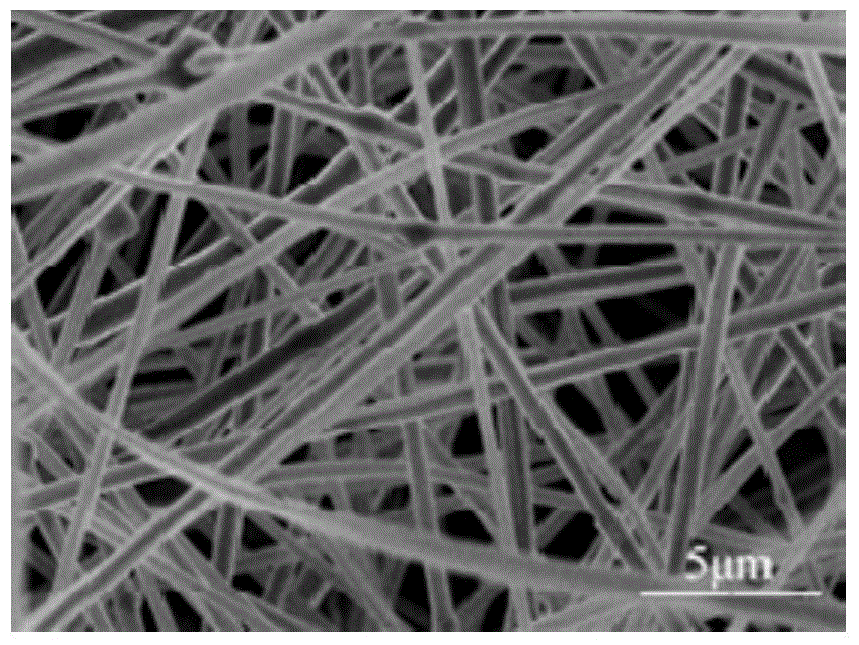

Method for preparing solid polymer electrolyte lithium ion battery

InactiveCN104638296AHigh mechanical strengthImprove securityFinal product manufactureElectrolyte accumulators manufactureFiberPolymer science

The invention provides a method for preparing a solid polymer electrolyte lithium ion battery. The method comprises the following steps: A, dissolving a high polymer into an organic solvent, and then performing electrostatic spinning to obtain a thin-layer electrostatic spinning fiber membrane on a receiver covered by an anode diaphragm; B, adding a crosslinking monomer, a lithium salt and an initiating agent into an electrolyte solvent, and mixing uniformly to prepare a precursor; C, pouring the precursor prepared in the step B into the electrostatic spinning fiber membrane, and performing curtain coating uniformly in the electrostatic spinning fiber membrane; and D, assembling a solid polymer electrolyte / electrode diaphragm and a counter electrode diaphragm into a cell, putting the cell into a shell or a bag, sealing, heating to realize in situ synthesis of the solid polymer electrolyte, and sequentially performing formation, shaping and degassing processes to prepare a formed battery. The method provided by the invention can be simultaneously used for preparing a gel / all-solid polymer electrolyte lithium ion battery, and the obtained battery is small in interface impedance, high in mechanical strength and high in safety performance.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Method for preparing nano-material-doped polymer film

The invention provides a method for preparing a nano-material-doped polymer film, and relates to the method for preparing polymer film, mainly solving the technical matters that nanometer materials in the nano-material-doped polymer film prepared by an existing method are uneven and easy to fall off, and an additional pore-forming agent is required for the nano-material-doped polymer film. The method comprises the steps of: performing hydrophilic process and organic process on the nanometer materials; dispersing the processed nanometer materials into an organic solvent to obtain a suspending liquid; adding a polymer into the suspending liquid; sealing; and heating and agitating to obtain a filming liquid; processing the filming liquid on a flat plate by curtain coating way to form liquid film; dipping the liquid film into a coagulating bath to undergo exchange between solvent and non-solvent so as to achieve phase transformation; and dipping the solidified film fallen from the flat plate into deionized water to obtain the nano-material-doped polymer film. The nano-material-doped polymer film provided by the invention can be prepared into micro-filtration film, ultra-filtration film, nano-filtration film, reverse osmosis film, and forward osmosis film, as well as flat film, tubular film or hollow fiber film and related film subassemblies. The nano-material-doped polymer film can be applied to the field of water treatment and chemical engineering separation.

Owner:黑龙江羲和高级氧化技术与装备工程有限公司

Packaging adhesive film for cross-linked POE (polyolefin elastomer) solar photovoltaic module

ActiveCN103289582AExtended service lifeImprove aging resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolymer science

The invention relates to a formula and a preparation method of a packaging adhesive film for a cross-linked POE (polyolefin elastomer) solar photovoltaic module. The main ingredient of the packaging adhesive film is silane grafted POE resin; and simultaneously, the packaging adhesive film further contains auxiliaries such as a cross-linking agent, a cross-linking assistant and an anti-aging agent. The preparation method comprises the following steps of: firstly preparing the silane grafted POE resin, then evenly mixing the grafted POE with the auxiliaries and then performing curtain coating through an extruder to obtain the adhesive film provided by the invention. After being vacuumized and hot-laminated, the cross-linking degree of the adhesive film reaches 70% or higher.

Owner:SHANGHAI HIUV NEW MATERIALS

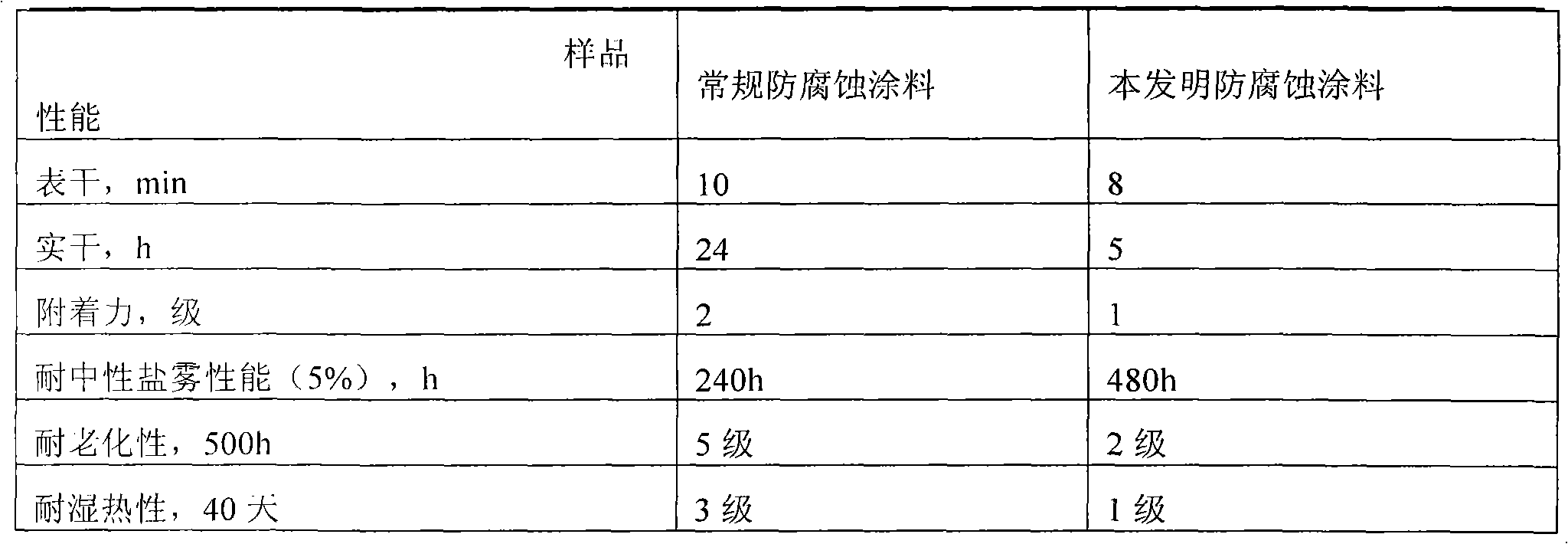

Anticorrosive paint for weather-resistant corrosion-resistant steel pipe outer wall

ActiveCN102120909AFast dryingDry fastGeneral water supply conservationAnti-corrosive paintsEpoxyWeather resistance

The invention relates to an anticorrosive paint for a weather-resistant corrosion-resistant steel pipe outer wall, which is prepared from 30-50 parts of alkyd resin, 2-5 parts of epoxy resin, 10-15 parts of terpene resin, 30-50 parts of hydrocarbon solvent, 3-8 parts of anticorrosive agent and 1-3 parts of drying agent. The paint provided by the invention can be applied by brushing, spraying, dipcoating, curtain coating or the like, and is naturally dried at normal temperature. The terpene resin adopted in the invention has high stability for oxygen, heat and light, and has excellent ageing resistance, so that the paint has excellent weather resistance. The rust inhibitor adopted in the invention can form a compact protective layer with high adhesive force on the surface of a steel pipe,and thus, prevents or slows the permeation of oxygen and water in the environment under the isolation action, thereby inhibiting the generation of corrosion microcells and performing a favorable anticorrosive protection function.

Owner:TIANJIN COLOROAD COATING & CHEM

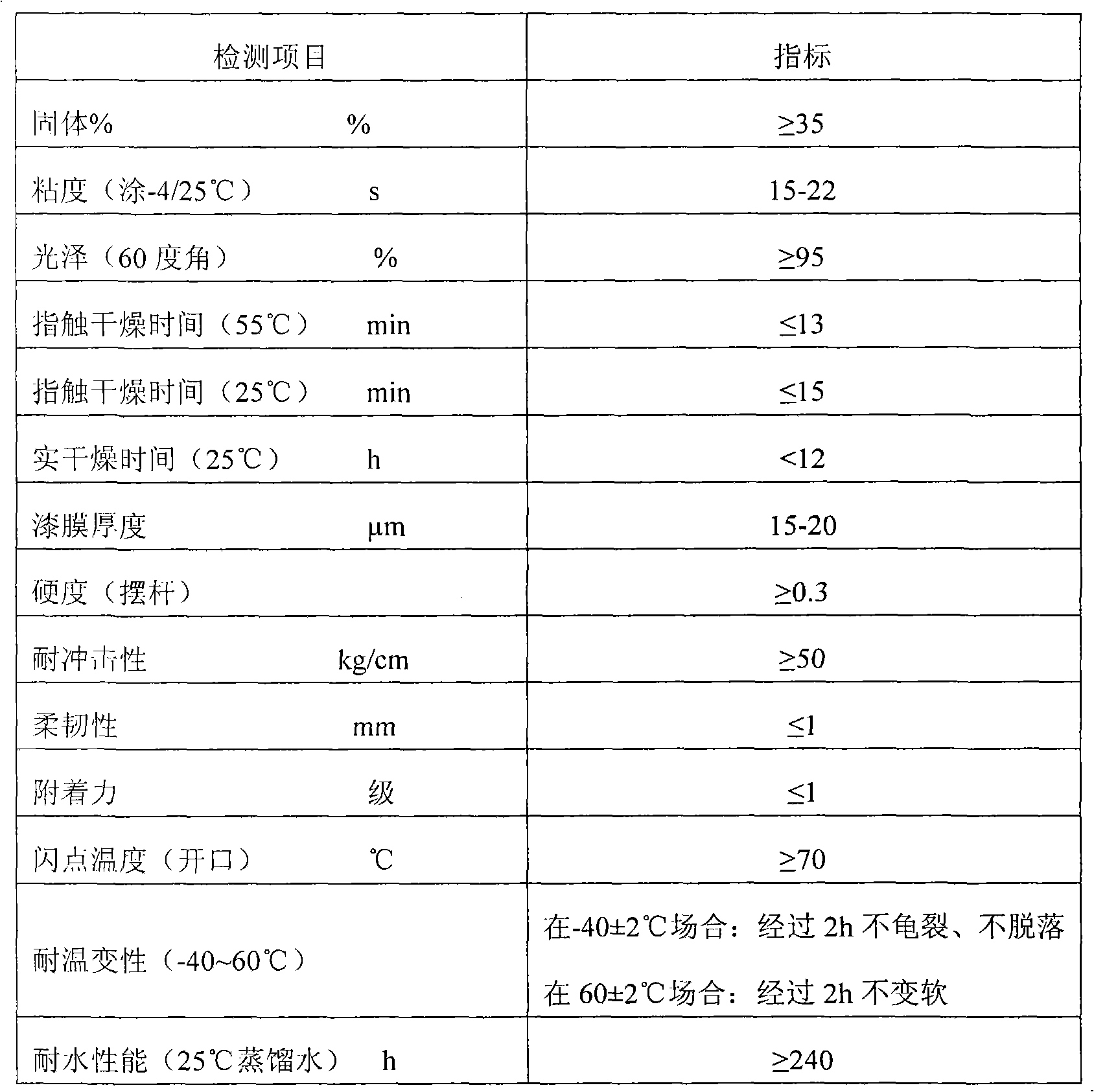

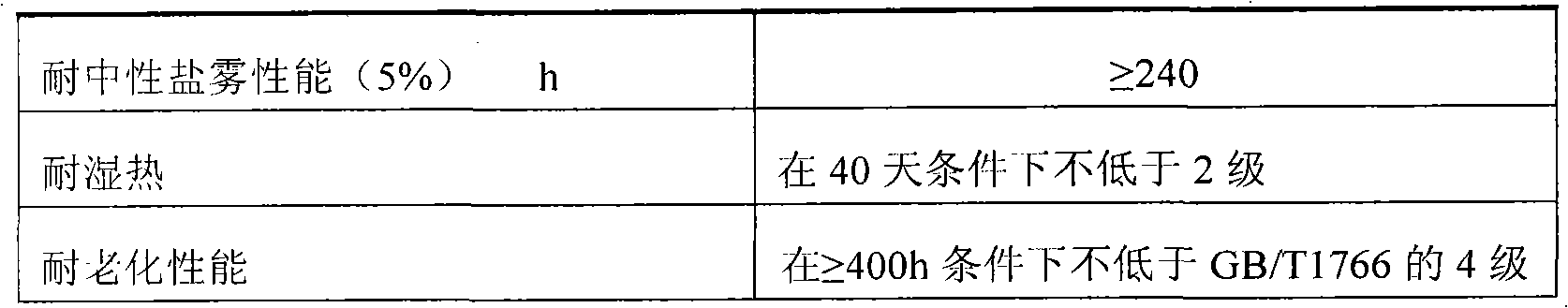

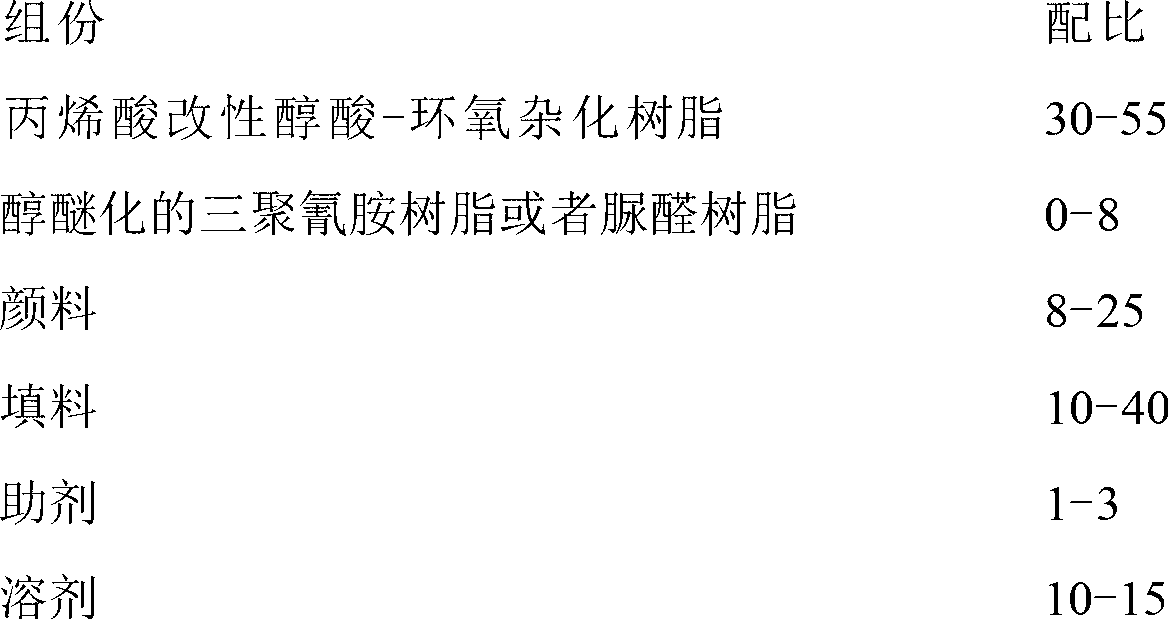

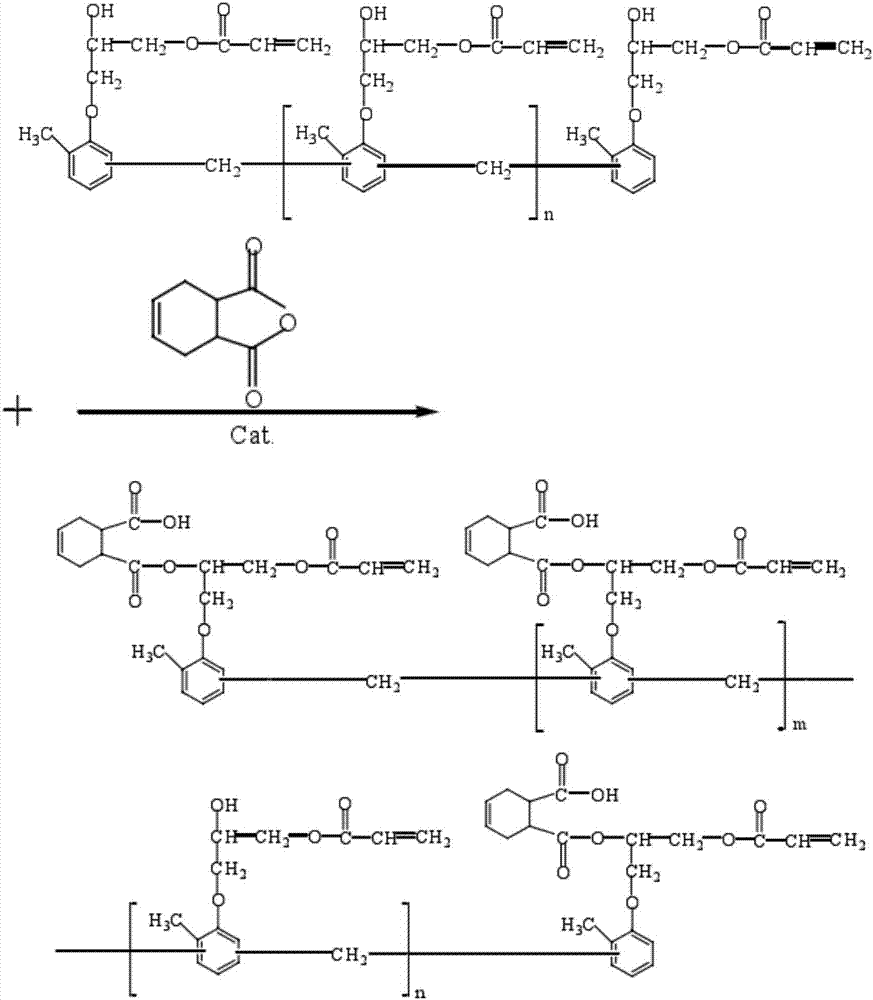

Modified dry oil alkyd resin for protective paint for metal coating on the back of the mirror and the curtain coating paint

InactiveCN1621430AImprove drynessImprove water resistancePolyester coatingsOptical elementsEpoxySolvent

The modified drying alkyd resin for curtain coated paint protecting metal coating in the back of mirror includes medium oil content drying alkyd resin in 55-70 wt%, acrylate monomer in 20-30 wt% and epoxy resin as modifier in 10-15 wt%. The medium oil content drying alkyd resin and the acrylate monomer form copolymer resin, and the copolymer resin is reacted with epoxy resin to form the modified drying alkyd resin with final viscosity of 150-300 s, acid value lower than 5 mg KOH / g and solid powder content over 50 wt%. The modified drying alkyd resin, selected cross-linking resin, pigment and solvent constitute curtain coated paint capable of well attaching to the surface of smooth metal coating.

Owner:徐金龙

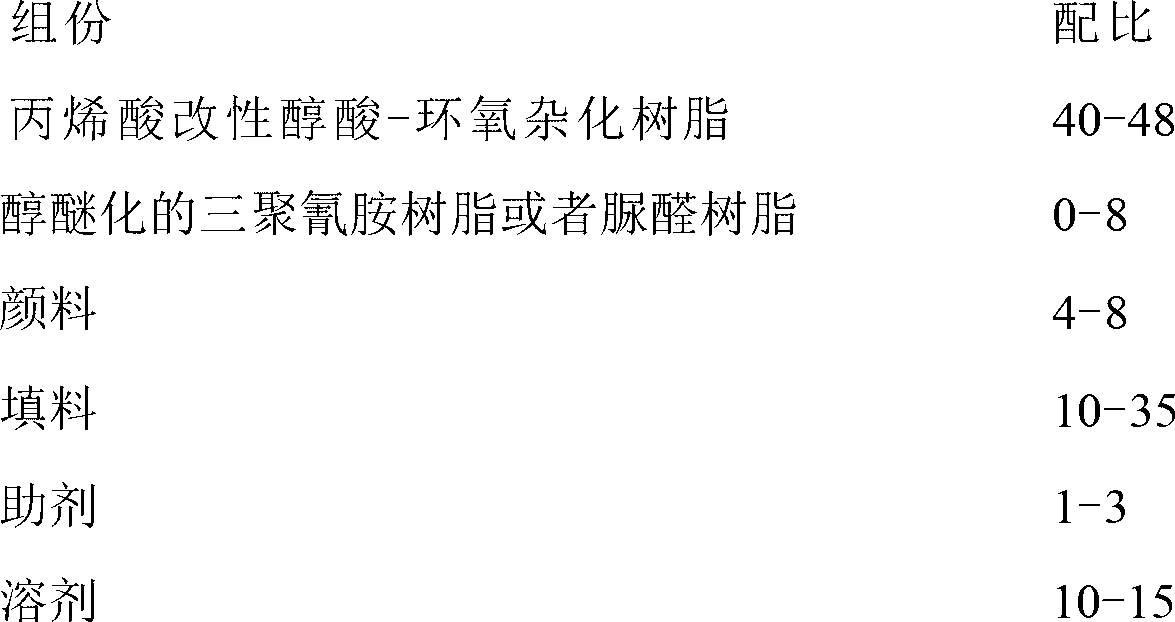

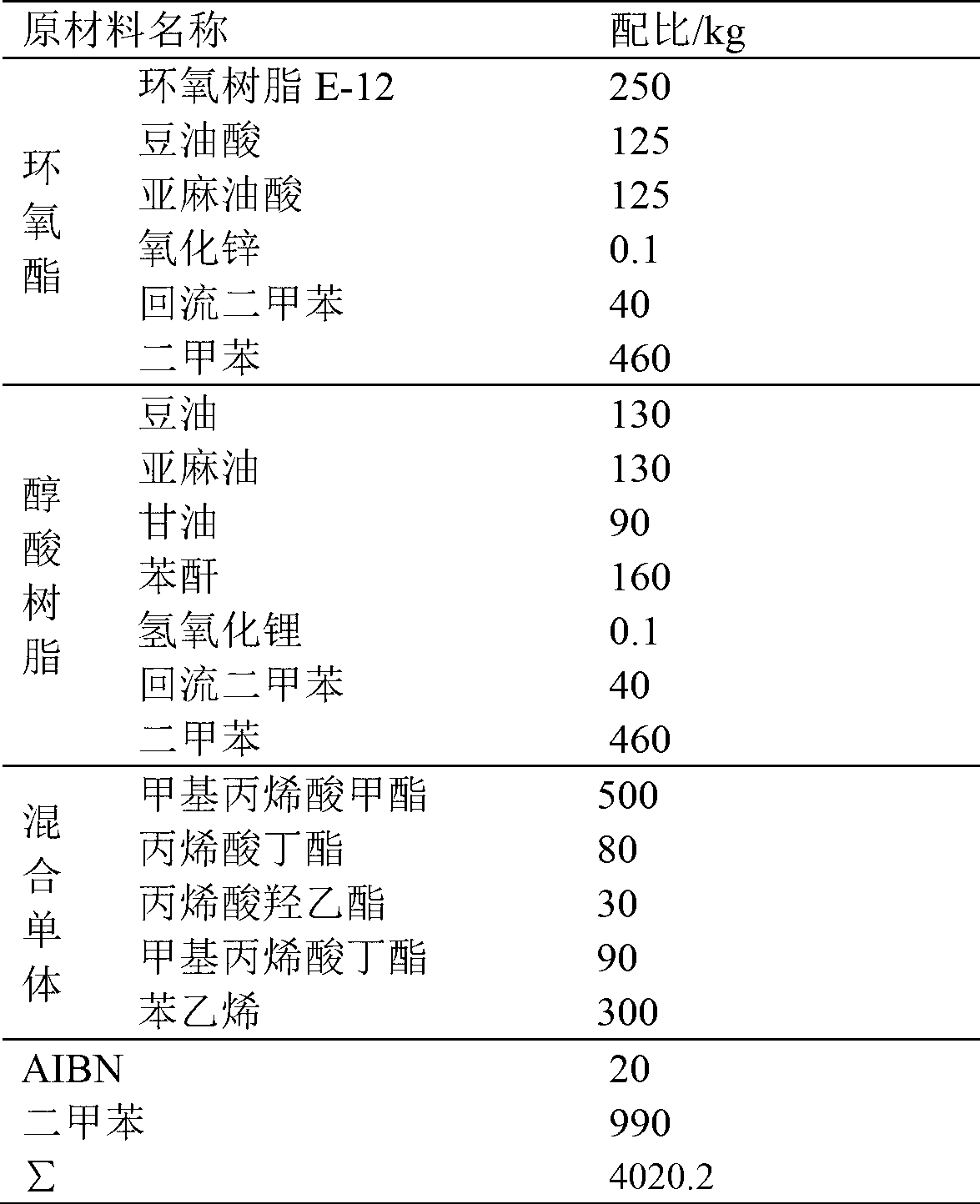

Acrylic-modified alcohol acid-epoxy ester hybrid resin and paint thereof

The invention relates to an acrylic-modified alcohol acid-epoxy ester hybrid resin which is prepared by the following steps: carrying out high-temperature esterification reaction on an epoxy resin and fatty acid under the action of an esterification catalyst to obtain epoxy ester; carrying out alcoholysis on vegetable oil and polyalcohol at high temperature, cooling, and adding polybasic acid for esterification, thereby obtaining an alkyd resin; and adding acrylic monomers into the epoxy ester-alkyd resin mixed solution, and carrying out graft polymerization under the action of an initiator to obtain the hybrid resin. The hybrid resin can be used as a main film forming material to prepare a high-temperature baking varnish together with a crosslinking agent. The high-temperature baking varnish can be used as various curtain-coating mirror back paints, including silver mirror back paints, aluminum mirror back paints, glass paints and the like, can satisfy the technological requirements for application of curtain coating production lines of which the width exceeds 3m, has a stable curtain coating, and can become completely dry after being baked at 150-130 DEG C for 3-5 minutes. The product has the advantages of low-temperature quick drying, high hardness, excellent adhesive force, dampness-heat resistance, chemical resistance, salt-fog resistance and the like.

Owner:常州市弘可利办公用品有限公司 +1

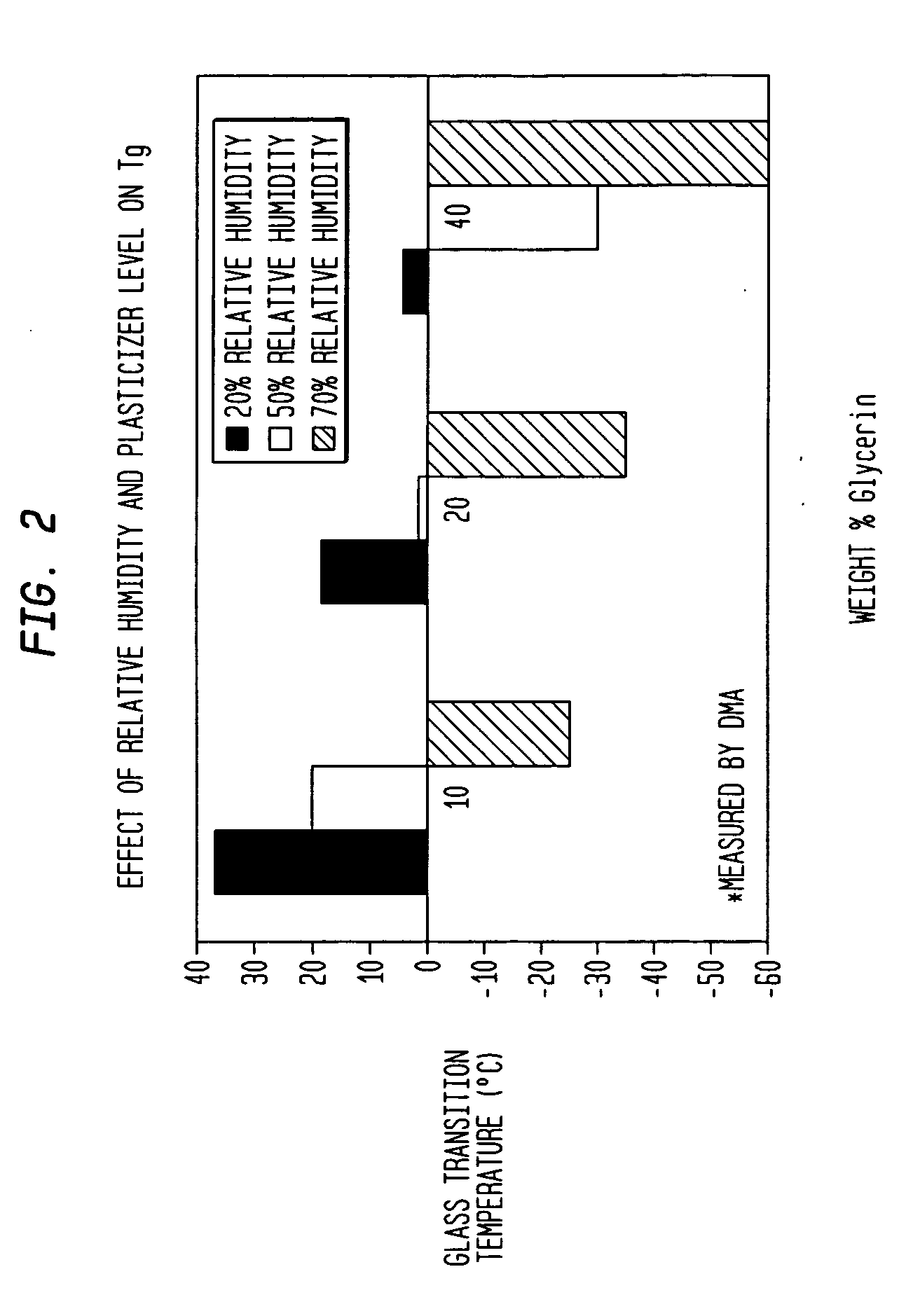

Nanocellulose enhanced full-biodegradable thin film and preparation method thereof

The invention relates to a nanocellulose enhanced full-biodegradable thin film and a preparation method thereof. The nanocellulose enhanced full-biodegradable thin film is prepared from the biodegrade nanocellulose as an enhancer and accessories such as a gel, a coagulant aid, a plasticizer, a defoamer, a dispersant and a cross-linking agent by virtue of the processes of mixing, defoaming, curtain coating, drying and the like. The obtained thin film is full-biodegradable, better in enhancement effect and environment-friendly.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Process for printing and doping solid wood and wood composite floor boards

InactiveCN101591969ASatisfy the pursuitSave resourcesPretreated surfacesWood working apparatusSolid woodPulp and paper industry

The invention relates to the field of floor boards, in particular to a process for printing and doping solid wood and wood composite floor boards. The method comprises the following steps: material preparing; the material processing; wood grain preparing; special adhesive agent printing; UV drying; oil sands doping; bouncing putty doping; UV drying; the oil sand doping; printing special adhesive agent for the substrate board surface; printing mask primer; UV drying; printing special ink varnish; wood grain transfer printing; wearable primer printing; UV drying; sanding primer printing; UV drying; roller paint doping; curtain coating of finishing coat; and four lamp drying. The process can print various natural wood grains according to client requirement, and greatly save wood resources which are reduced day by day.

Owner:史海龙

Heat isolating composite film and its prepn and use

InactiveCN1672921ASimple compositionReasonable functionSynthetic resin layered productsComposite filmHeat conducting

The present invention relates to one kind of heat isolating composite film and its preparation process and use. Structurally, the heat isolating composite film consists of compounded base polymer film of high strength and low heat conducting coefficient, metal layer with high reflecting performance, metal oxide layer with high heat isolating performance and outer polymer film with low heat conducting coefficient and high hot adhering strength. The composite film may have thickness of 12-1000 micron. The heat isolating composite film is prepared through evaporation plating one very thin compact metal layer and one very thin loose metal layer successively onto rolled polymer film and then oxidizing, or evaporation plating metal oxide layer directly; and final rolling or curtain coating one other polymer film layer. The heat isolating composite film has excellent heat insulating performance, is light, thin and soft, and may be used in various flexible heat insulating material.

Owner:DONGHUA UNIV

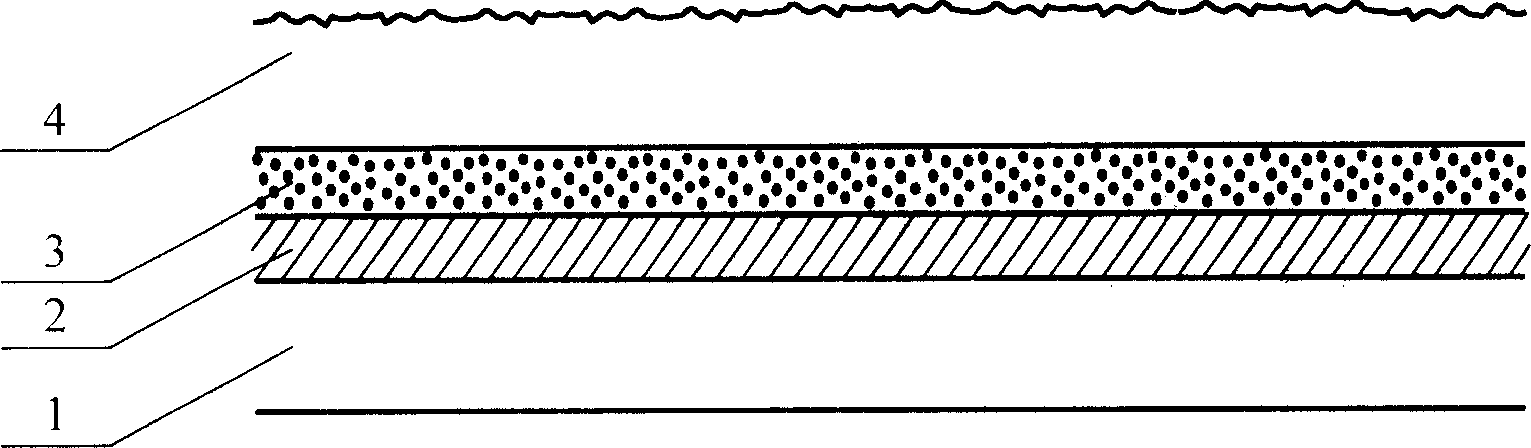

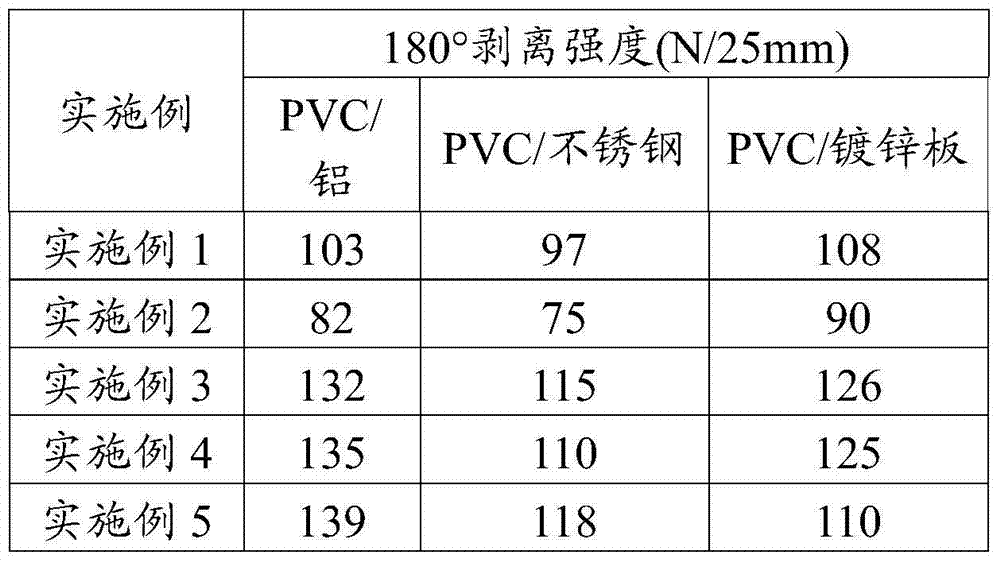

PVC (polyvinyl chloride)/metal bonding hot melt adhesive film and preparation method thereof

ActiveCN103756577AGood adhesionHigh bonding strengthNon-macromolecular adhesive additivesFilm/foil adhesivesPolyolefinPolyvinyl chloride

The invention relates to a PVC (polyvinyl chloride) / metal bonding hot melt adhesive film. The raw material formula of the film comprises the following components in parts by weight: 15-40 parts of maleic anhydride modified polyethylene-ester copolymer, 40-70 parts of polyethylene-ester copolymer, 10-30 parts of polyolefin copolymer, 0.1-1 part of an initiating agent, 0.2-2 parts of silane and 0.1-2 parts of a crosslinking agent. The invention also relates to a preparation method of the hot melt adhesive film, and the preparation method comprises the steps of fully and uniformly mixing the component raw materials according to the formula, granulating through extrusion, and further performing curtain coating to obtain the hot melt adhesive film. Compared with the prior art, the PVC / metal bonding hot melt adhesive film disclosed by the invention can be used for quickly bonding PVC with a metal material, has better adhesive properties, and is green, environmentally friendly and pollution-free.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

Thermal recording material

InactiveUS7192904B2Decrease of background foggingHigh sensitivityPattern printingAblative recordingHeat sensitiveRecording layer

The present invention provides a heat-sensitive recording material comprising a substrate and a heat-sensitive recording layer provided thereon, the layer comprising a color forming system that combines an electron-donating colorless dye and an electron-accepting compound, in which the electron-accepting compound is a compound represented by the formula R1-Ph-SO2R2 (wherein R1 represents a hydroxyl group or an alkyl group, R2 represents -Ph, —NH-Ph, -Ph-OR3 or —NH—CO—NH-Ph, R3 represents an alkyl group, and Ph represents a phenyl group), and at least the heat-sensitive recording layer is formed by curtain-coating a coating solution for the heat-sensitive recording layer.

Owner:FUJIFILM CORP +1

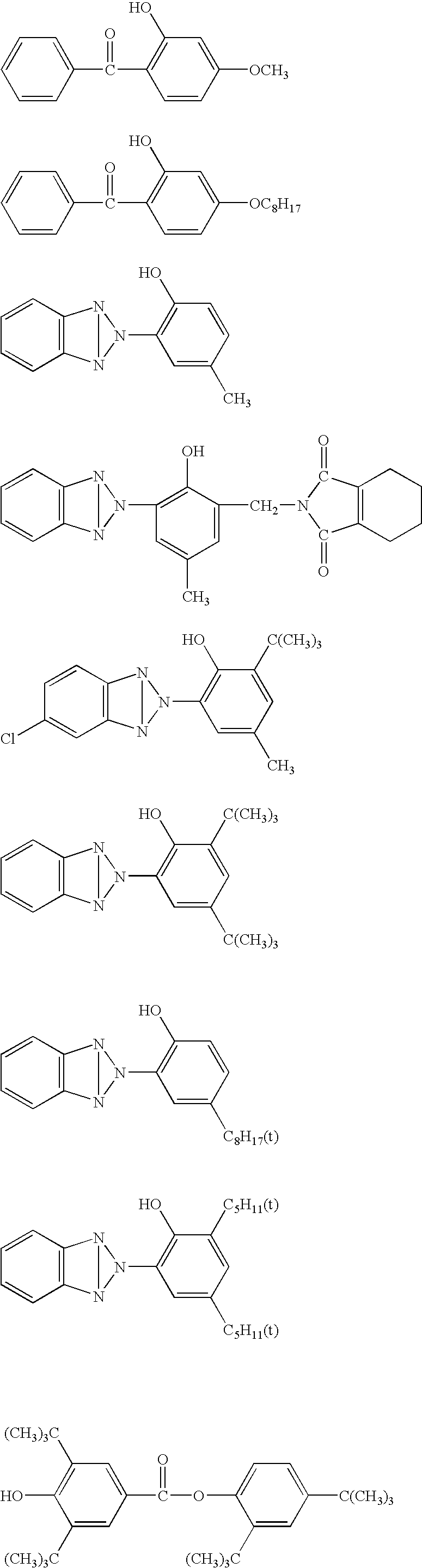

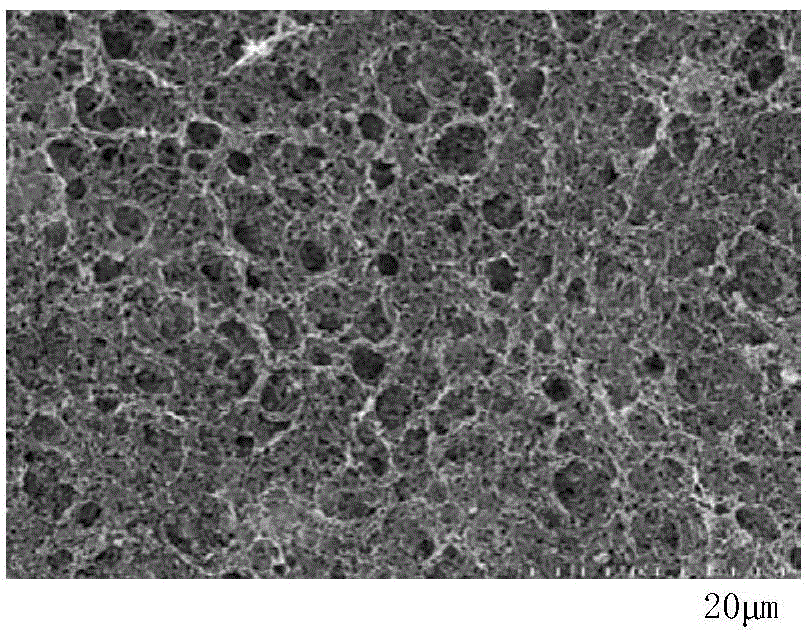

Graphene/titanium dioxide composite porous material, preparation method and application thereof

InactiveCN104157833AEasy to prepareLow costHybrid capacitor electrodesCell electrodesScale structureSolvent

A graphene / titanium dioxide composite porous material, a preparation method and an application thereof. The invention relates to porous materials. The composite material has an interpenetrated pore structure with a substrate structure size being 100 nm-5 [mu]m and a pore diameter being 100 nm-5 [mu]m. The composite material is in a three-dimension net-pore structure. A micro-scale structure of the substrate is a continuous phase composed of graphene and nano titanium dioxide is dispersed on a dispersed graphene sheet layer. The graphene / titanium dioxide composite porous material is prepared by following steps including: dissolving a styrene segmented copolymer in a selective solvent to form a polymer micelle solution; adding a graphene oxide solution; adding titanium dioxide after the graphene oxide solution and the polymer micelle solution being mixed uniformly; performing ultrasound wave treatment; performing a curtain coating process on a carrying plate which is placed in a saturated atmosphere of a precipitant to obtain a polymer / graphene oxide / titanium dioxide composite porous material after the solvent being volatilized; performing a carbonizing process in an inert atmosphere with the carrying plate to obtain a product. The composite porous material can be applied in preparation of a graphene / titanium dioxide porous composite electrode which can be used in the fields such as photocatalysis, a lithium ion battery, a super capacitor and the like.

Owner:XIAMEN UNIV

Production method of nuclear fuel clad element

ActiveCN104628395AImprove mechanical propertiesImprove thermal conductivityOptical rangefindersNuclear energy generationComposite ceramicSlurry

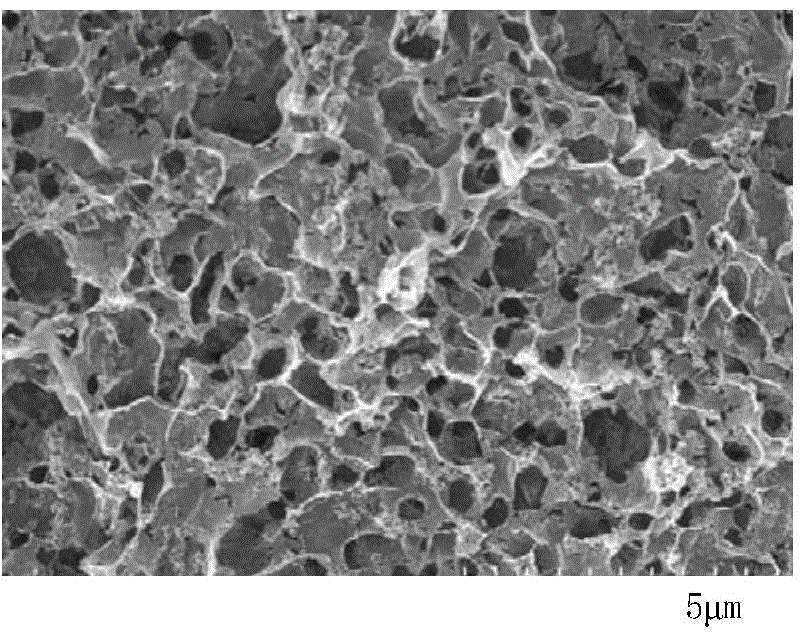

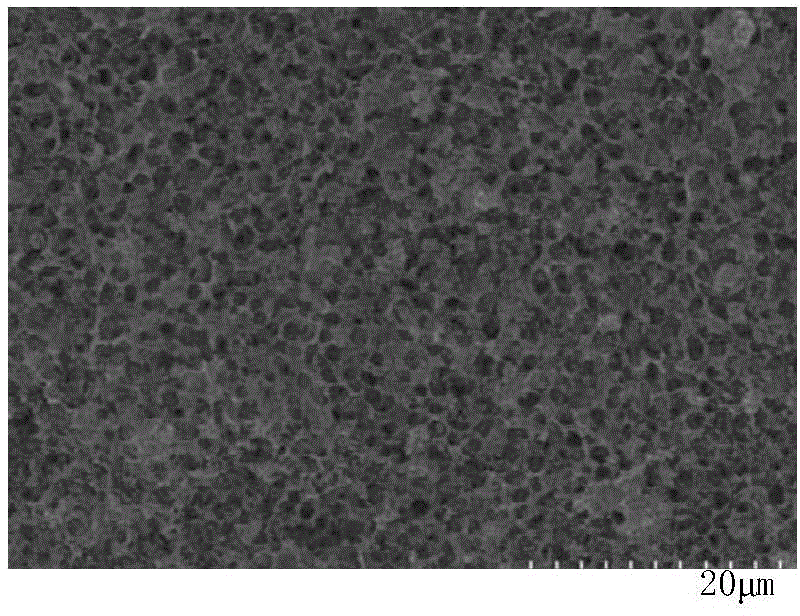

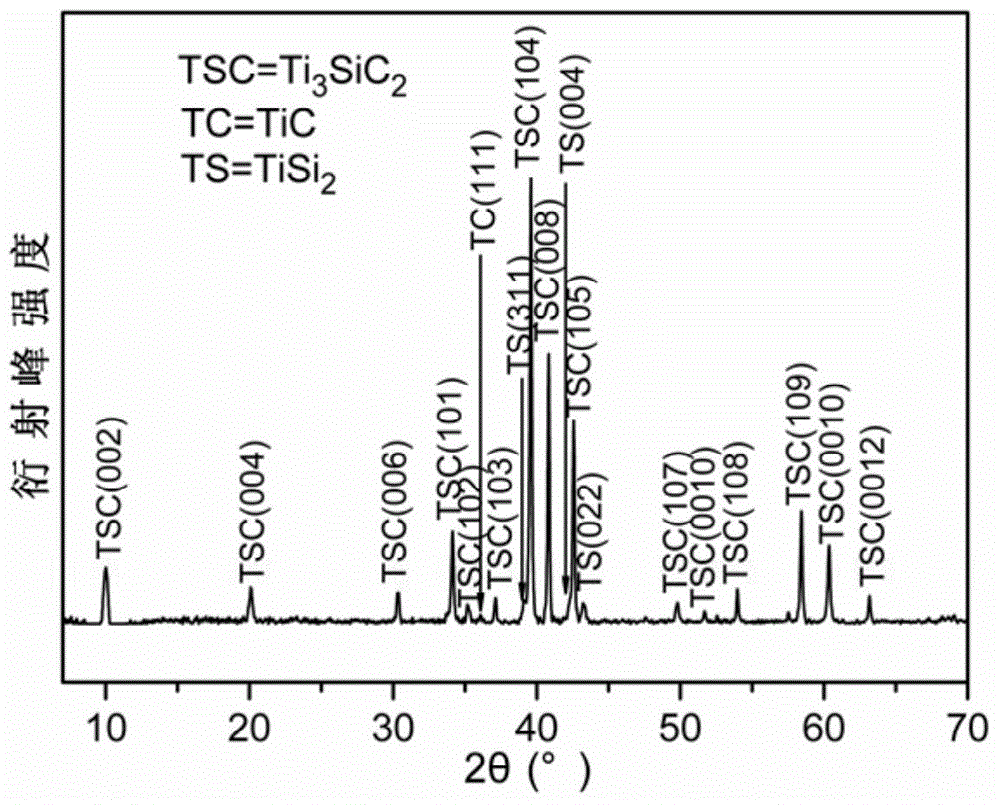

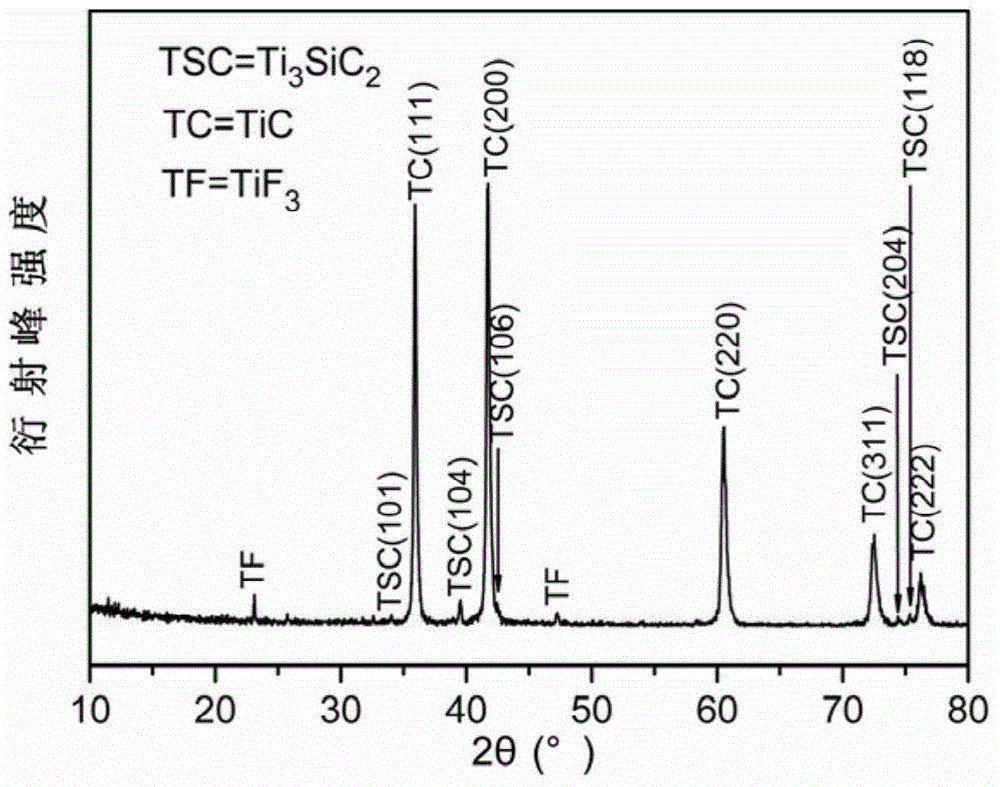

The invention provides a production method of a nuclear fuel clad element. The method comprises the following steps: selecting an MAX phase ceramic material, silicon carbide, an MAX phase-based composite ceramic material or a silicon carbide-based composite ceramic material, processing the above ceramic material to prepare a slurry, carrying out vacuum defoaming, making a ceramic film with the thickness of 10[mu]m-10mm on a base band through a curtain coating or draw-off process, winding to make a clad element blank, drying, carrying out rubber discharging, sintering, and carrying out surface treatment to obtain the nuclear fuel clad element. The production method has the advantages of simplicity, easy implementation, low cost, overcoming of the disadvantage of difficult processing of ceramic materials, high production efficiency, short cycle and easy industrialization. When the ceramic material is a Ti3SiC2-baed ceramic material, the ceramic material can resist molten fluorine salt corrosion, and can be used as a fluorine salt fuel clad element material in a nuclear reactor, so practical demands of a thorium-based fourth generation fission reactor nuclear energy system on the structure material are met.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

PVOH barrier performance on substrates

Disclosed are coated substrates and methods for producing coated substrates. At least one surface of the substrates is coated with a polyvinyl alcohol polymer to render the substrates resistant to oil and grease. The polyvinyl alcohol polymer is coated at levels of a least 7 g / m2, based upon area of the coated surface of the substrate. Alternatively, the coating concentration is at least 5 wt. % of the weight of the substrate. The coatings may be applied by curtain coating or means and comprise at least one layer of a polyvinyl alcohol solution.

Owner:CELANESE INT CORP

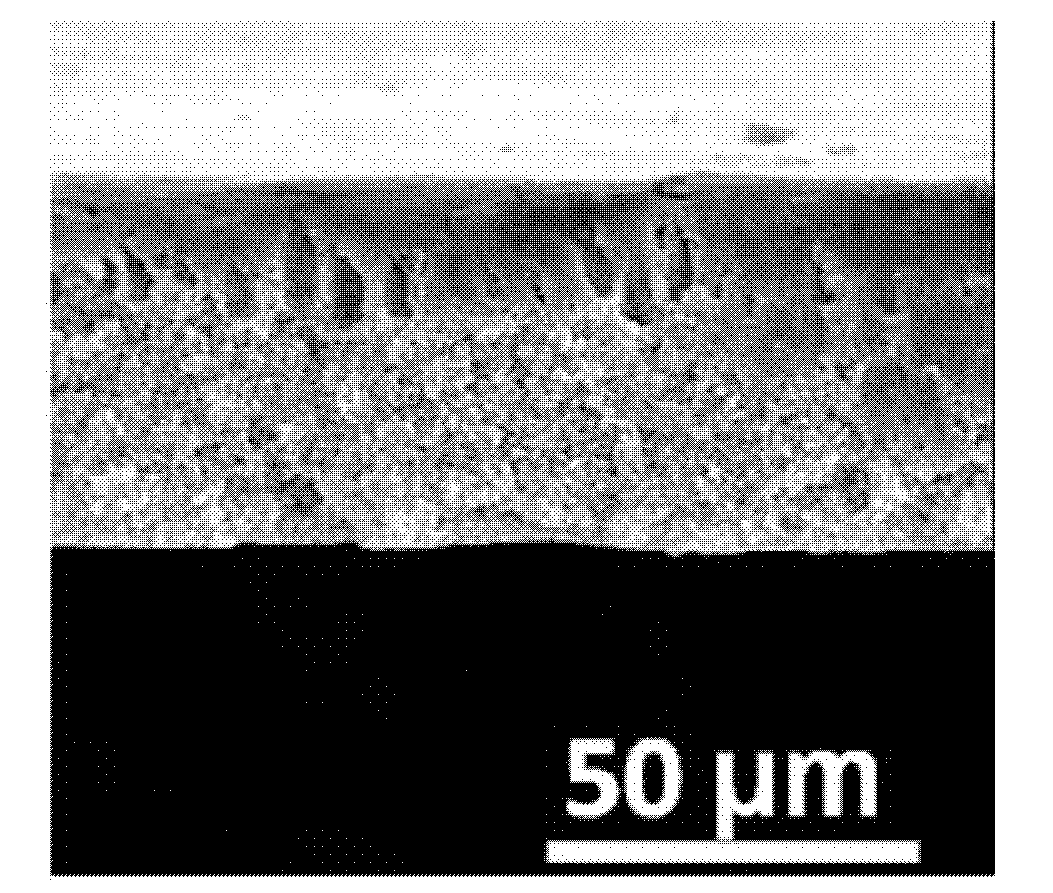

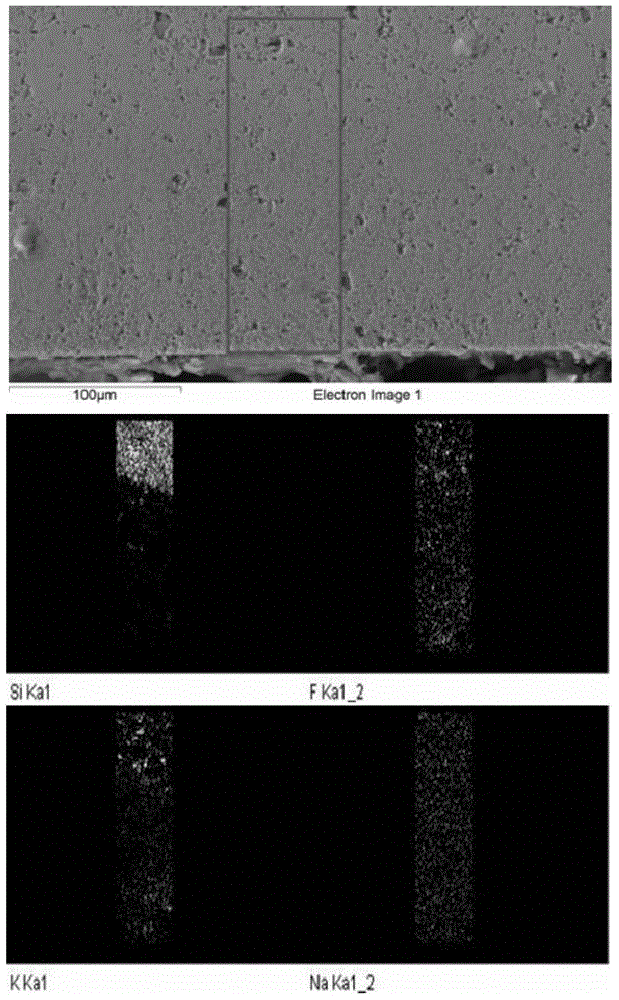

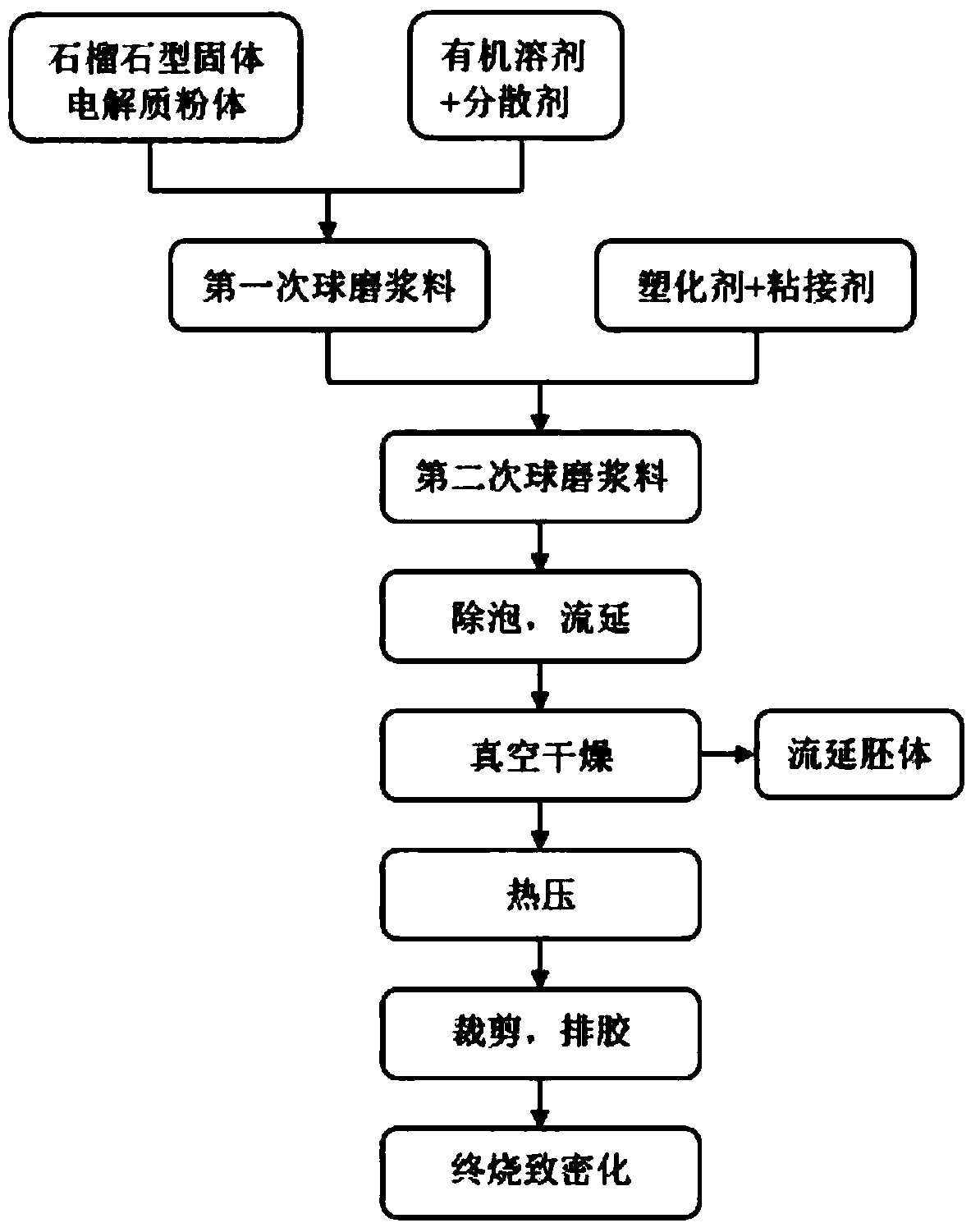

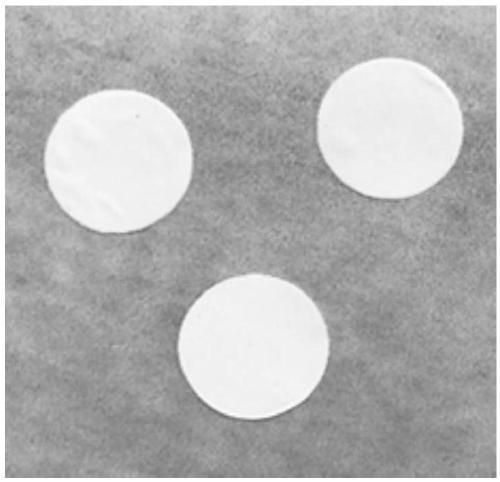

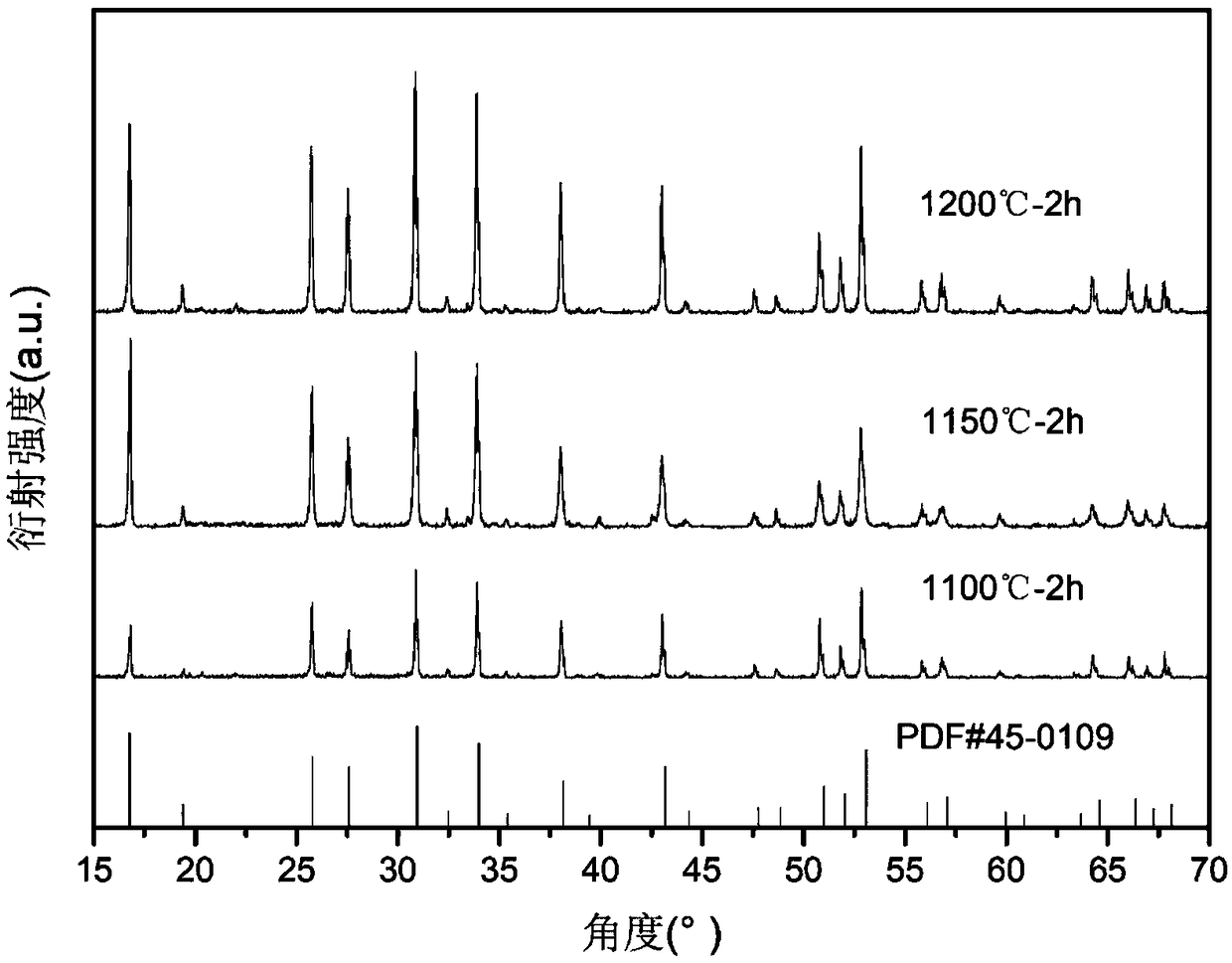

Preparation method of micron-sized garnet type inorganic solid electrolyte membrane

InactiveCN109378525AHigh ionic conductivity at room temperatureIncrease energy densityFinal product manufactureElectrolytesOrganic solventPlasticizer

The invention relates to a preparation method of a micron-sized garnet type inorganic solid electrolyte membrane. The preparation method comprises the following steps: firstly, mixing garnet type inorganic solid electrolyte with certain particle size with an organic solvent and a dispersant for ball milling, then adding a plasticizer and a binder for secondary ball milling, defoaming obtained slurry, carrying out curtain coating to form a film, drying, carrying out hot-pressing, removing the binder and sintering to form the garnet-type solid electrolyte membrane with the thickness of 20 to 200micrometers. Compared with the existing method, the preparation method has the advantages of low cost, simple equipment, stable process, easy industrialization and the like; and the obtained membraneproduct has high ionic conductivity and controllable thickness.

Owner:WUHAN UNIV OF TECH

Method for preparing nano functionalized high-molecular ultrafiltration membrane

InactiveCN102166482AImprove mechanical propertiesImprove hydrophilicitySemi-permeable membranesSpinningUltrafiltration

The invention provides a method for preparing a nano functionalized high-molecular ultrafiltration membrane in order to fully use the nano effect of an inorganic nano material in the ultrafiltration membrane to improve the mechanical property, the hydrophillic nature and the anti-pollution performance of the membrane. The method comprises the following steps of: after completely dissolving film forming high molecules and a pore-forming additive, adding a pre-prepared inorganic nano sol; uniformly stirring and blending the mixture; directly spinning the mixture or performing curtain coating on the mixture to form a membrane; and soaking the spun mixture or the membrane in a coagulation bath to form the membrane. In the film forming process, a high-molecular gel split phase and a nano sol are hydrolyzed to form nano particles; and finally, the inorganic inorganic high-molecular ultrafiltration membrane with uniformly distributed nano particles is obtained.

Owner:XIAMEN LEEBAM MEMBRANE TECH

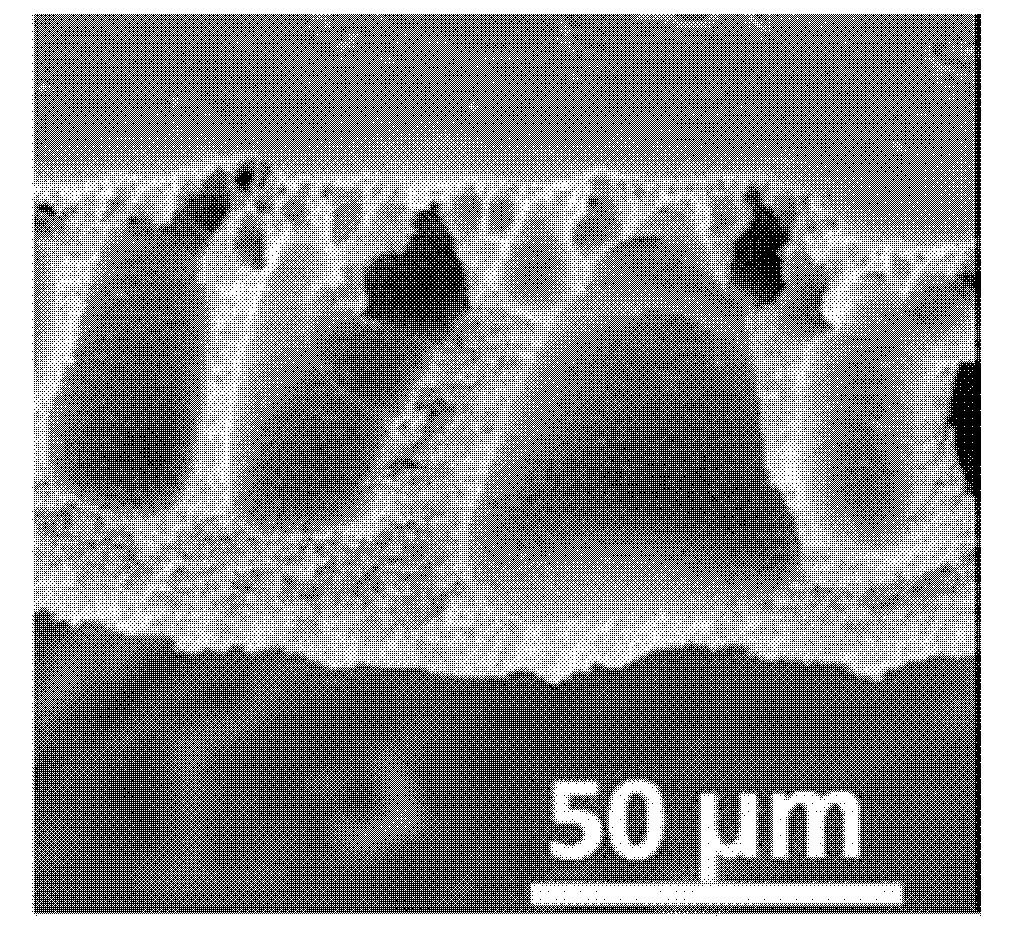

Nano-silver porous silicone rubber/polyurethane-containing double-layer artificial skin and preparation method thereof

InactiveCN103948960ACapable of absorbing effusionWaterproofAbsorbent padsProsthesisFoaming agentSolvent

The invention discloses a nano-silver porous silicone rubber / polyurethane-containing double-layer artificial skin and a preparation method thereof. The nano-silver porous silicone rubber / polyurethane-containing double-layer artificial skin is characterized in that the artificial skin contains a dermis and epidermis double-layer structure; a dermis layer is prepared from loose porous polyurethane; an epidermis layer is prepared from antibacterial agent-containing silicone rubber. A preparation method of the dermis layer comprises the following steps: dissolving the polyurethane, adding a pore-foaming agent, defoaming, carrying out curtain coating so as to form a film, volatilizing a solvent, soaking so as to leach out the pore-foaming agent, and drying so as to obtain a porous polyurethane film. A preparation method of the epidermis layer comprises the following steps: dissolving a silicone rubber precursor, carrying out ultrasonic dispersion on a nano-silver solution, adding the pore-foaming agent, defoaming, carrying out blade coating or curtain coating so as to form a film, volatilizing a solvent, curing so as to obtain an embryonic film, soaking so as to leach out the pore-foaming agent, and drying so as to obtain a silicone rubber microporous film. The preparation method of the double-layer artificial skin comprises the following steps: coating the polyurethane film with polyvinyl alcohol, acid liquor and a crosslinking agent, then covering the polyurethane film by using the silicone rubber film, volatilizing a solvent, and carrying out heat treatment so as to obtain the double-layer artificial skin. The nano-silver porous silicone rubber / polyurethane-containing double-layer artificial skin has the effects of water resistance, air permeability, bacterial inhibition, virus killing and effective absorption of hydrops.

Owner:SICHUAN UNIV +1

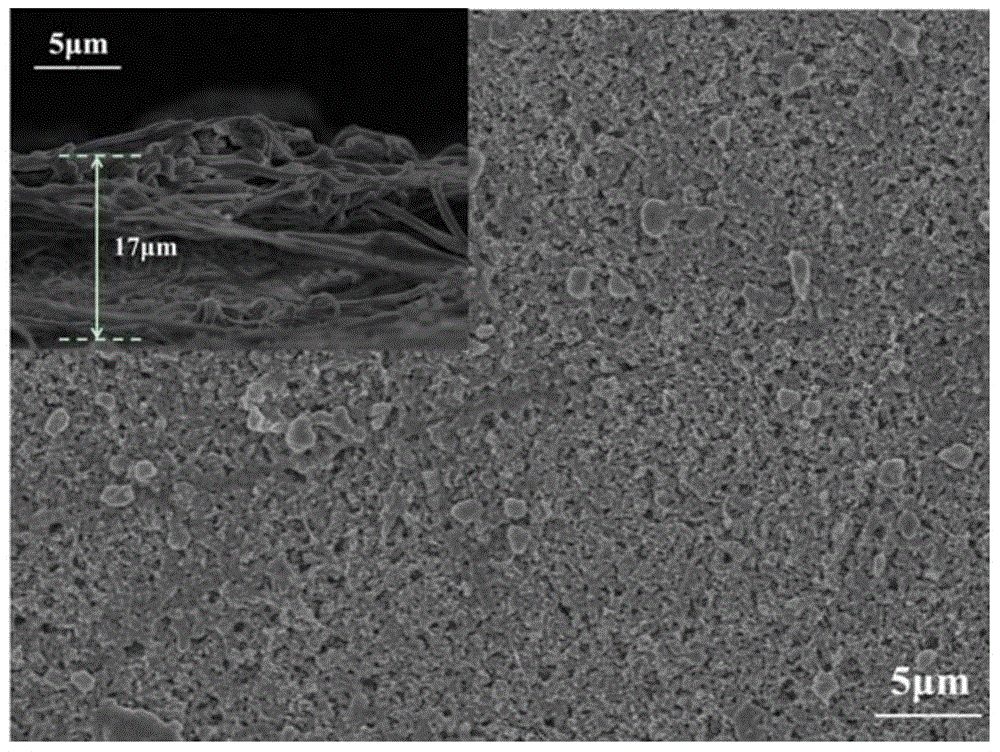

High-per formance carbon material preparing method by water-base curtain coating technology

InactiveCN1472833AGood electrical and thermal conductivityReduced electrical and thermal conductivityCell electrodesFuel cellsFiberCarbon composites

A method of water-base casting technological preparation of the carbon material with advanced property, it belongs to the field of fuel cell, adopt intermediate phase carbon powder as raw materials, take short carbon fiber or grahpite as the enhanced modified material, the solution of casting slurry adopts the mixture of the water and alcohol, through the water-base cast techniques prepare the carbon / carbon composite green compacts, press the multiplayer casting green compacts to gain the laminating green compacts which have air interval channel, then through the high temperature sintering technique and the resin impregnation sealing of hole, finally get the bipolar plate of fuel cell of proton exchange membrane. This invention adopts firstly the casting forming technique to prepare the carbon / carbon composite bipolar plate.

Owner:SHANGHAI JIAO TONG UNIV

Curtain-coated polyvinyl alcohol oil and grease barrier films

A method of providing an oil and grease resistant coating to a substrate includes the steps of (i) providing a substrate with a first and second surface to a coating station; (ii) curtain coating at least one surface of the substrate with an aqueous polyvinyl alcohol composition to form a nascent polyvinyl alcohol barrier film thereon; and (iii) drying the nascent polyvinyl alcohol barrier film to form a polyvinyl alcohol oil and grease barrier coating; wherein the polyvinyl alcohol composition as well as the substrate and coating and drying conditions are selected such that the polyvinyl alcohol oil and grease barrier coating is substantially pinhole free, characterized in that the barrier coating exhibits a TAPPI 559 kit test rating of at least 7.

Owner:MILLER GERALD D

Highly-heatproof water-soluble alkali-developable UV photosensitive anti-etching ink

ActiveCN106854394AInksPhotosensitive materials for photomechanical apparatusSolubilityUltraviolet lights

The invention discloses a highly-heatproof water-soluble alkali-developable UV photosensitive anti-etching ink. The ink comprises, by weight, 120-150 parts of an aqueous photosensitive oligomer, 8-12 parts of a photosensitive monomer, 0.8-1.2 parts of a wetting agent, 0.1-0.4 parts of a dispersant, 0.2-0.5 parts of an anti-sag agent, 2-5 parts of an antifoaming agent, 4-6 parts of a drier, 8-15 parts of an aqueous photoinitiator, 0.6-1.5 parts of a pigment, 0.6-1.2 parts of a thixotropic agent, 40-70 parts of a filler and 2-5 parts of water. All above component raw materials are mixed in proportion, and are fully stirred and uniformly mixed, the obtained mixture is ground by a three-roller grinder to make the fineness be not more than 5 [mu]m, the surface of a printed circuit board is coated with the ground mixture in a screen printing, spraying or curtain coating manner, and the mixture undergoes radiation curing by using an ultraviolet light source to form an anti-etching coating layer. The ink disclosed in the invention has photosensitivity and water solubility, and an ink film formed by the ink has good heatproof property, high hardness and good anti-electroplating performance.

Owner:JIANGSU KUANGSHUN PHOTOSENSITIVITY NEW MATERIAL

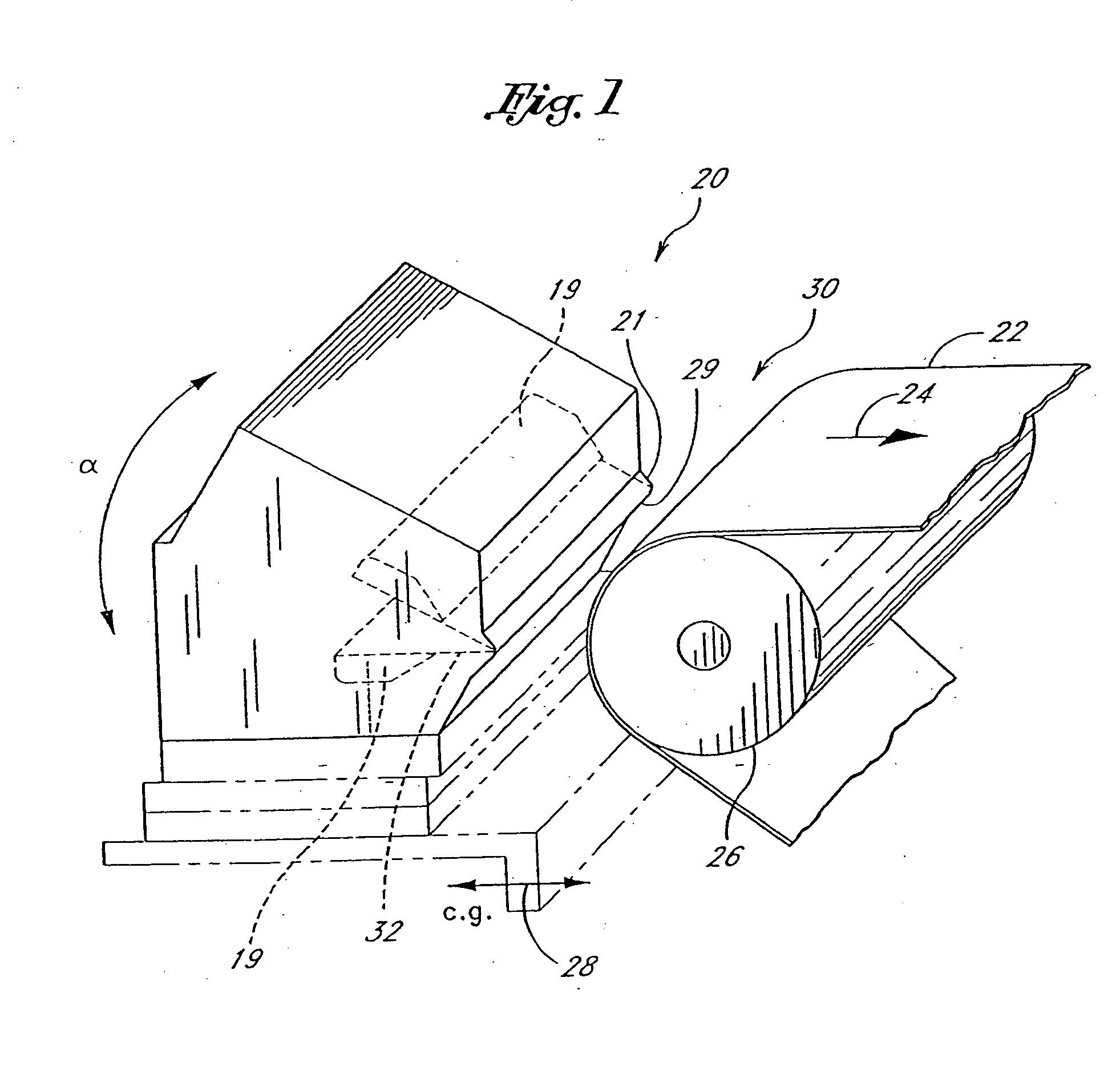

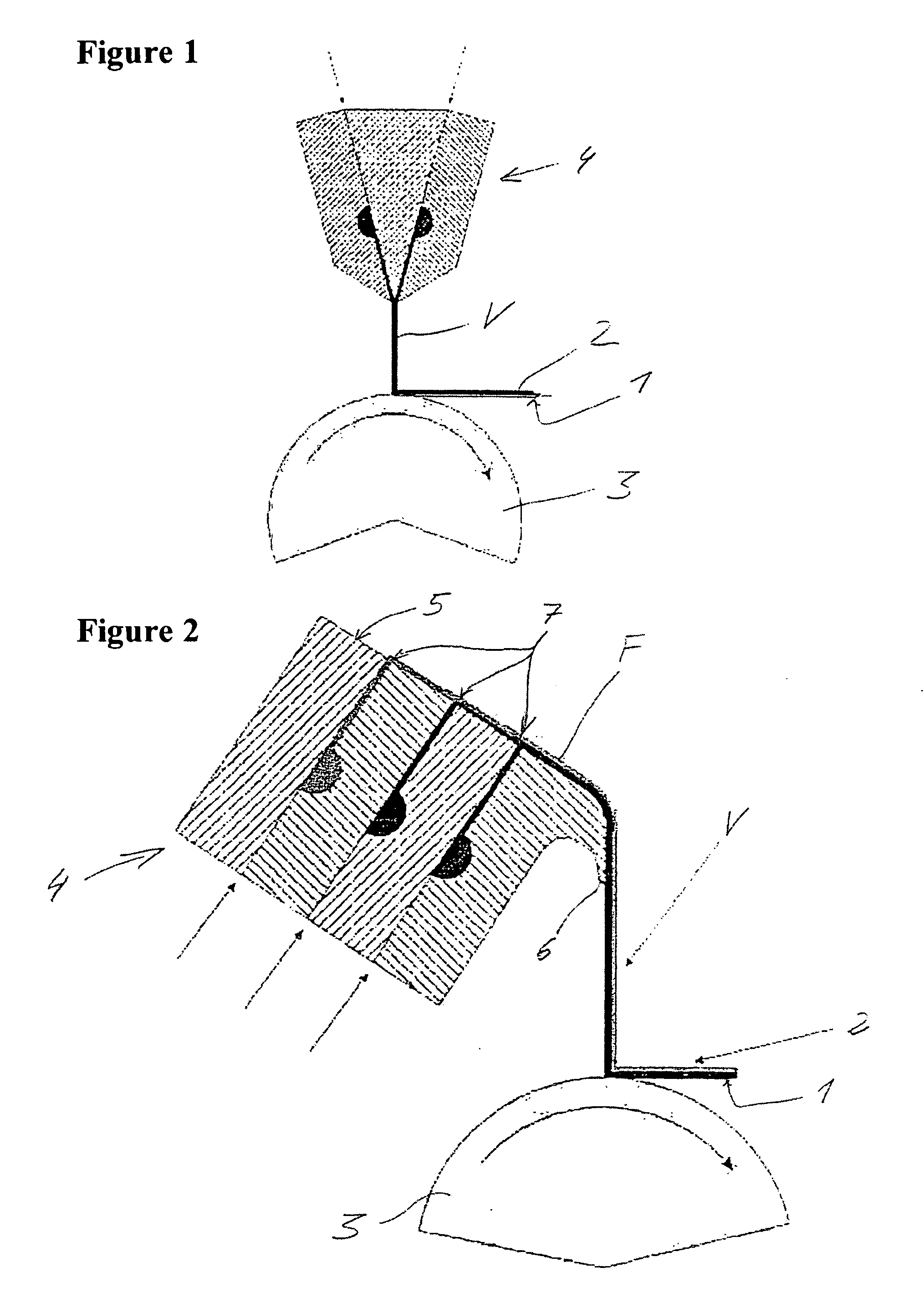

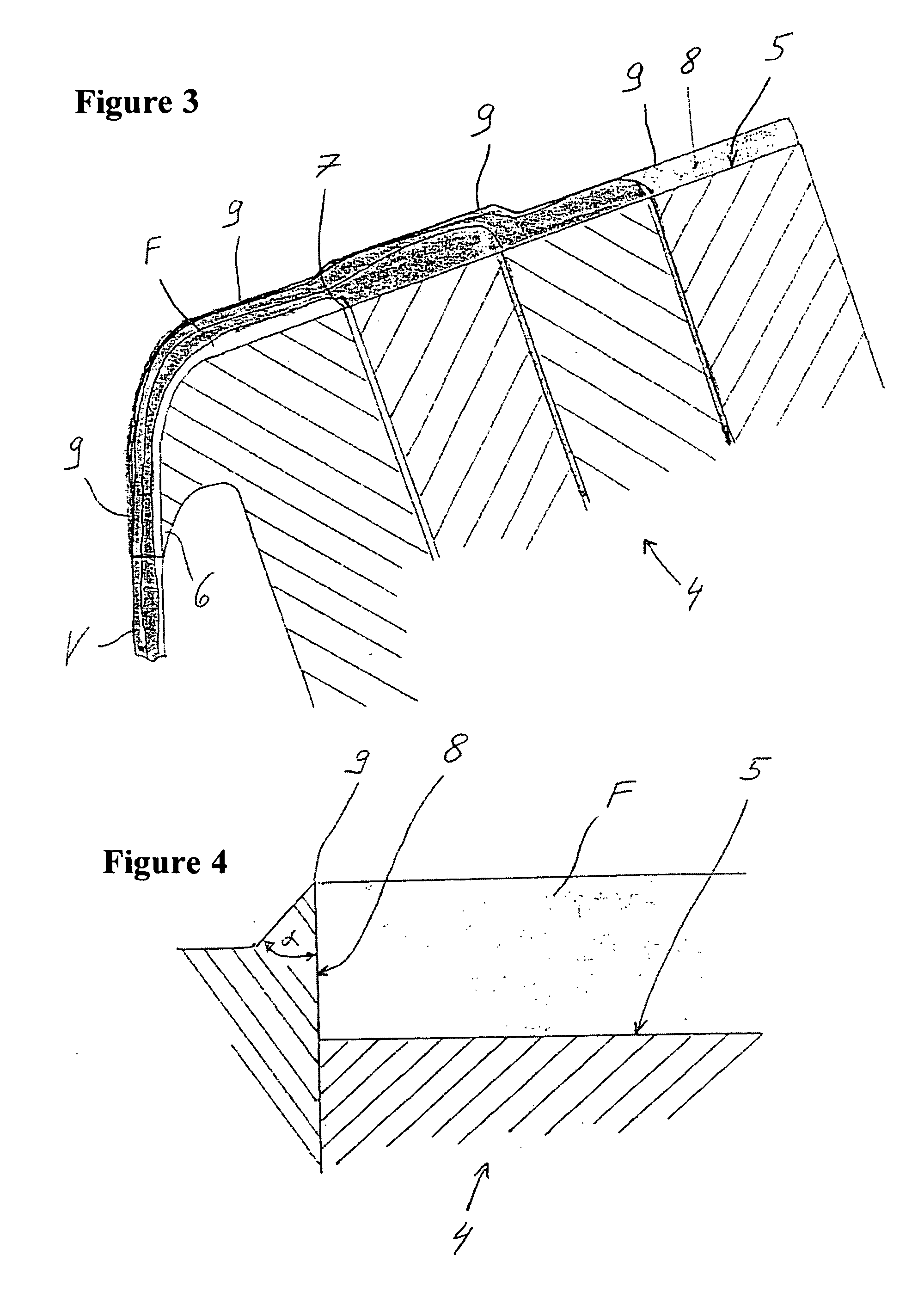

Curtain coater and curtain coating method

InactiveUS20070137563A1Reduce peripheral effectReduce impactLiquid surface applicatorsCoatingsFree fallingBiomedical engineering

A curtain coating device for the coating of a moving substrate, comprising a nozzle device, for the generation of a curtain dropping onto the substrate, made up of at least one coating fluid and a curtain guide structure with a guide surface, which laterally guides the curtain, whereby the guide surface is convex to the curtain along a width exceeding the depth of the curtain when measured transversely. Additionally, a curtain coating method, whereby a curtain made up of at least one coating fluid is deposited on a moving substrate in free fall and guided on both sides by means of a convex guide surface transverse to the curtain.

Owner:POLYTYPE CONVERTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com