Patents

Literature

580results about How to "Good electrical and thermal conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

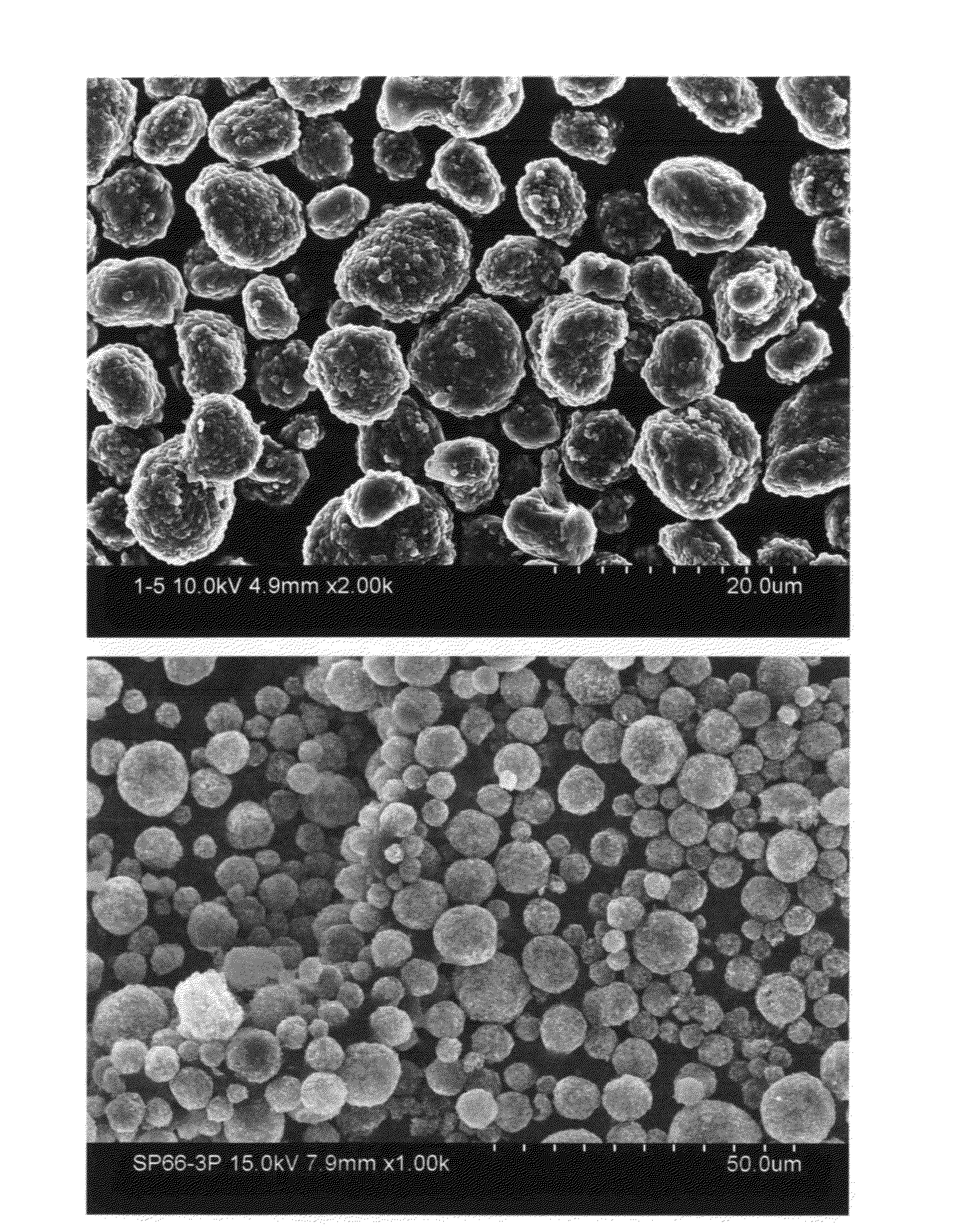

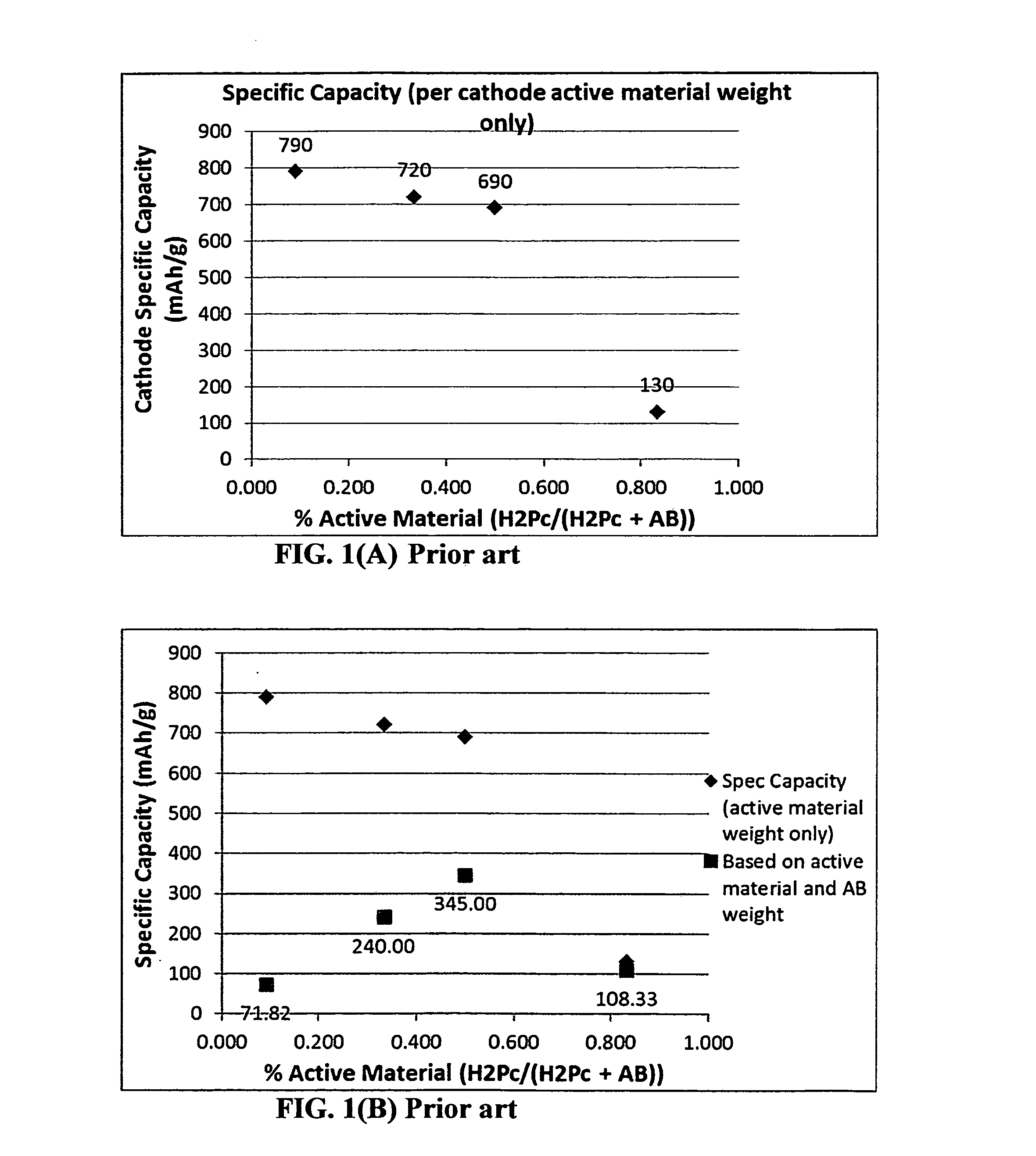

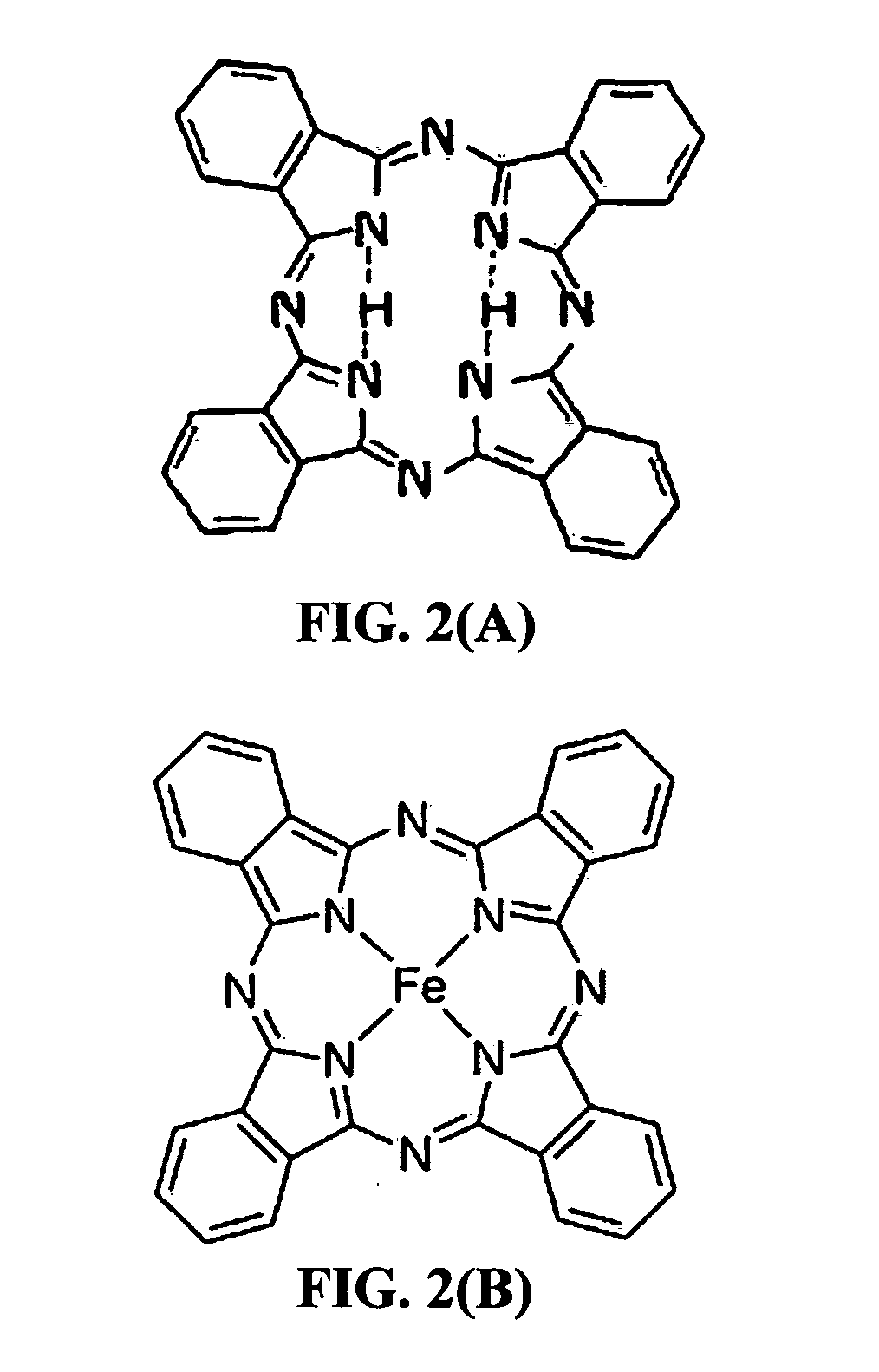

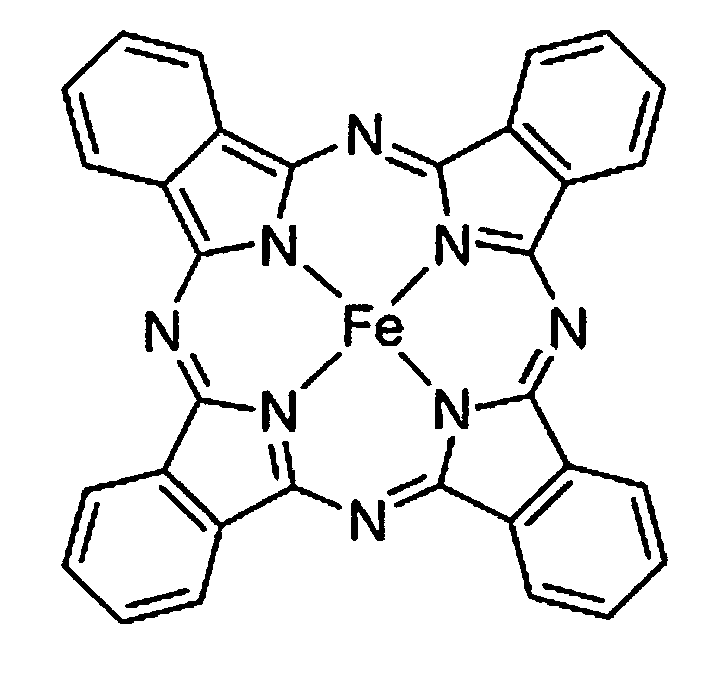

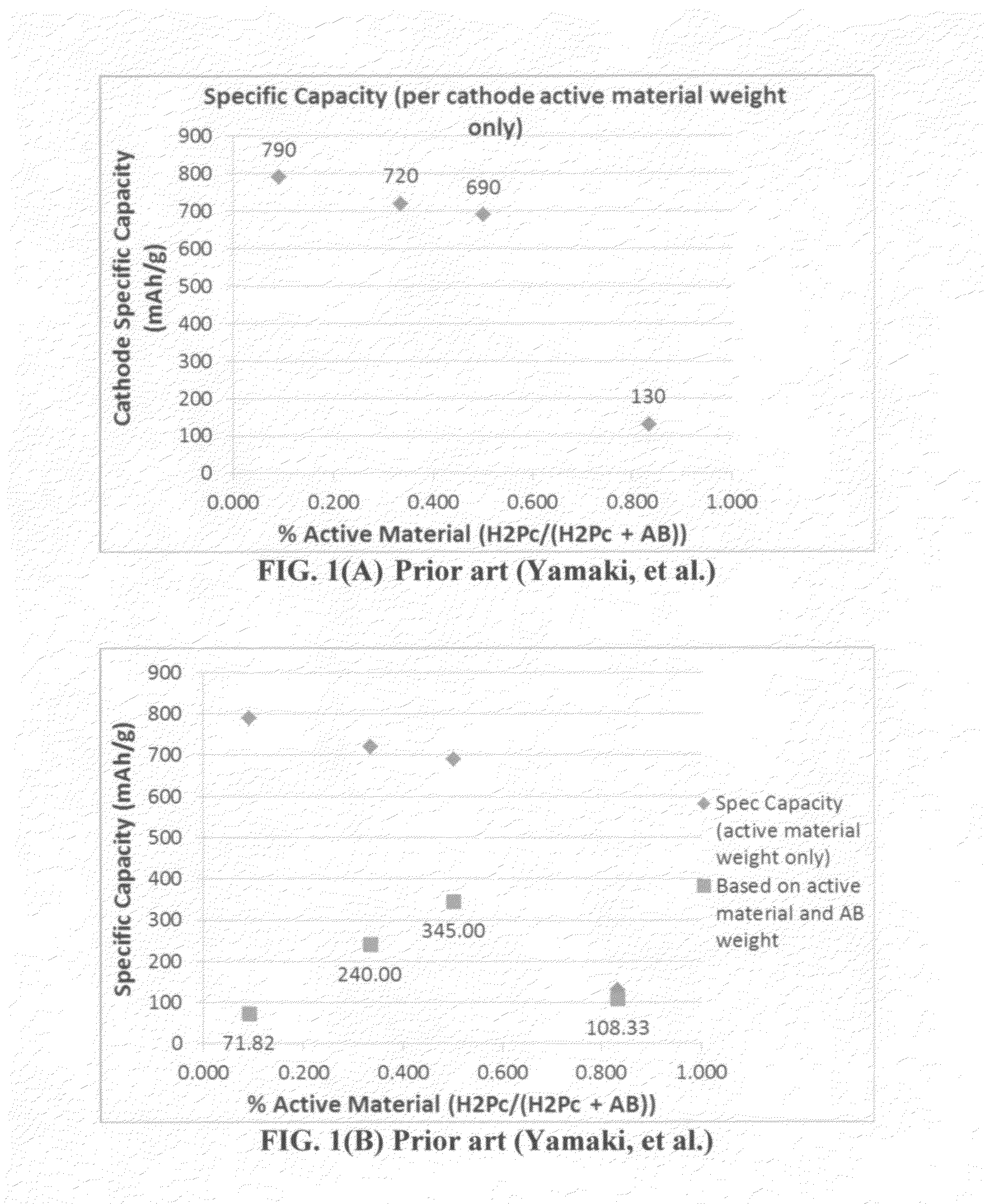

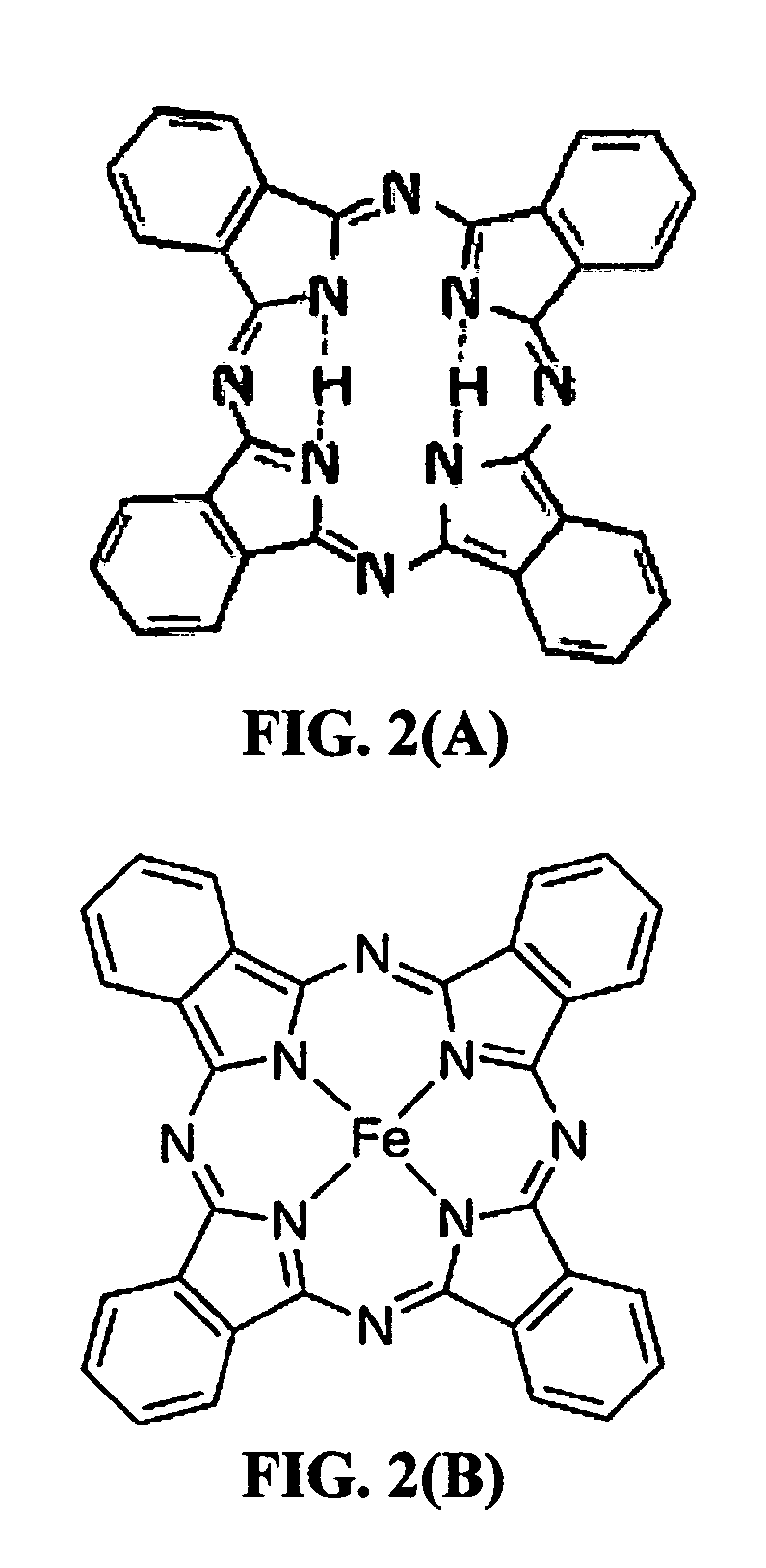

Encapsulated phthalocyanine particles, high-capacity cathode containing these particles, and rechargeable lithium cell containing such a cathode

ActiveUS20140072879A1High theoretical lithium storage capacityLow electricalMaterial nanotechnologySolid electrolyte cellsElectrical batteryPhthalocyanine

Disclosed is an electrode material comprising a phthalocyanine compound encapsulated by a protective material, preferably in a core-shell structure with a phthalocyanine compound core and a protective material shell. Also disclosed is a rechargeable lithium cell comprising: (a) an anode; (b) a cathode comprising an encapsulated or protected phthalocyanine compound as a cathode active material; and (c) a porous separator disposed between the anode and the cathode and / or an electrolyte in ionic contact with the anode and the cathode. This secondary cell exhibits a long cycle life, the best cathode specific capacity, and best cell-level specific energy of all rechargeable lithium-ion cells ever reported.

Owner:GLOBAL GRAPHENE GRP INC

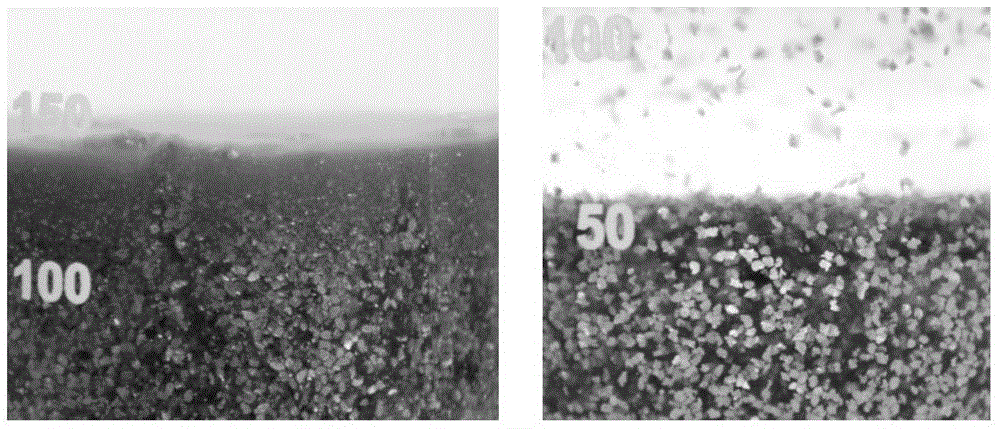

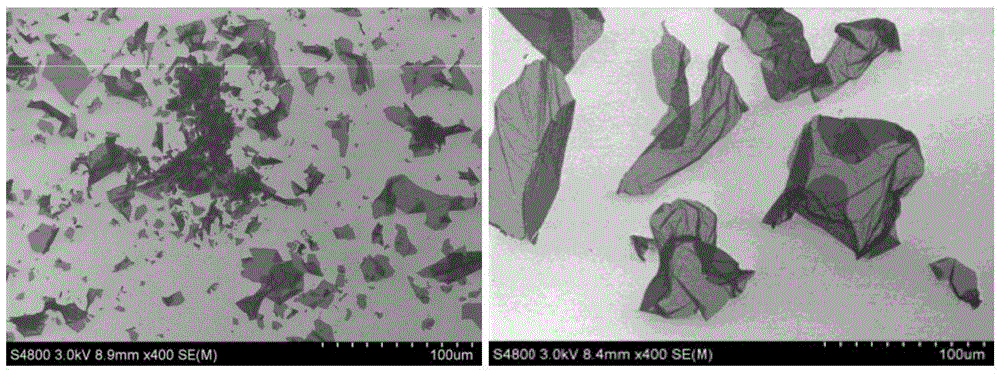

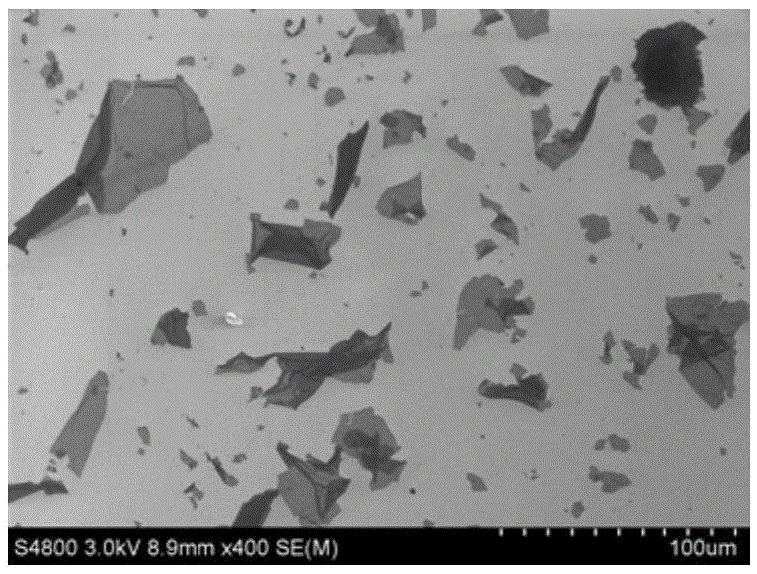

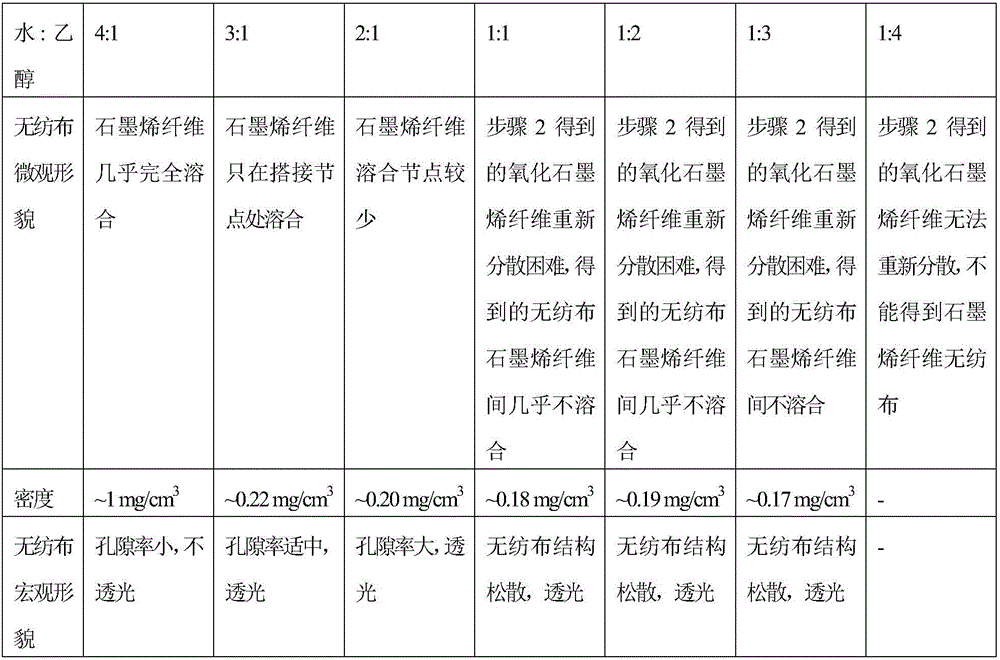

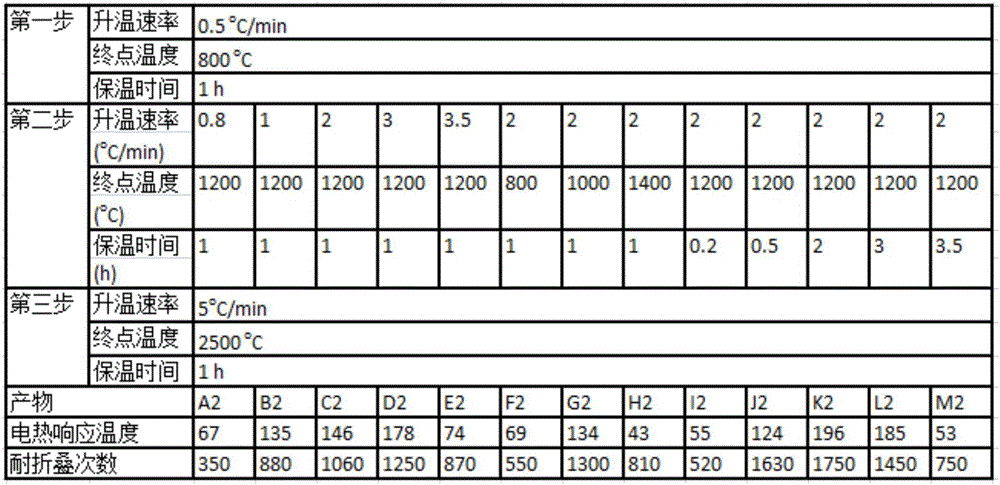

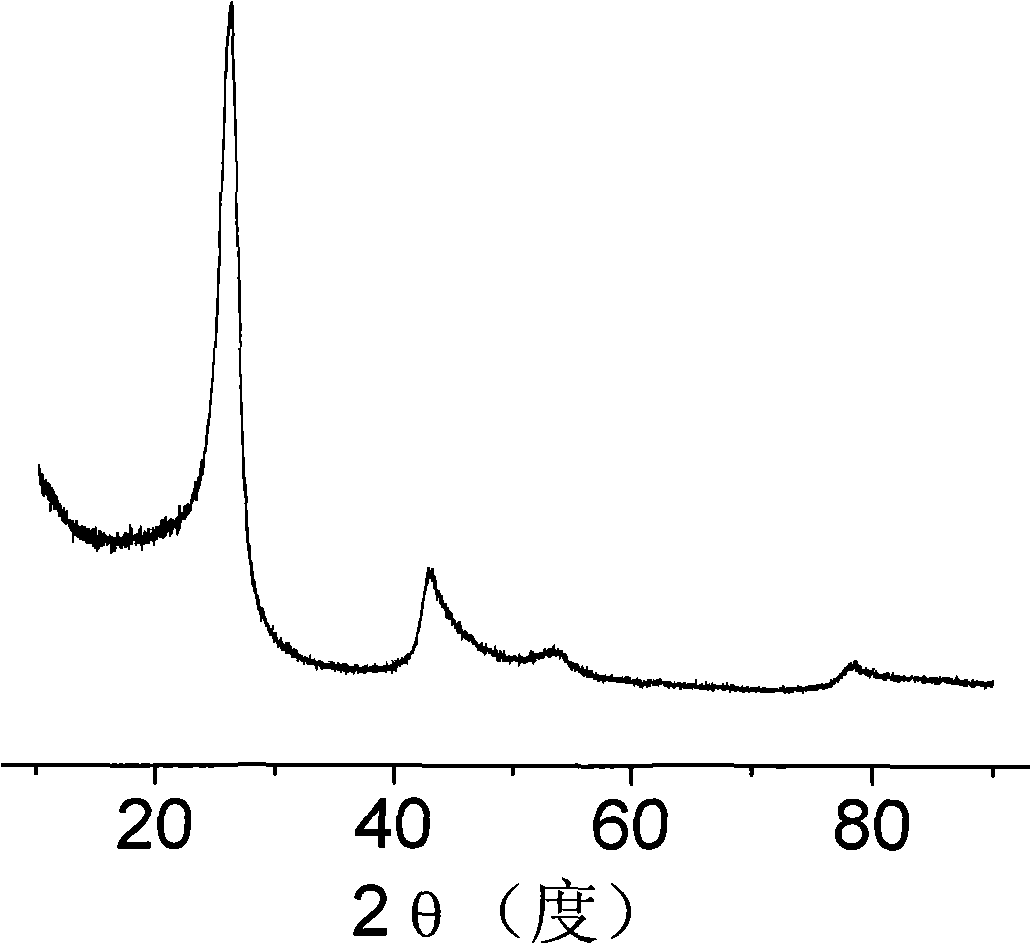

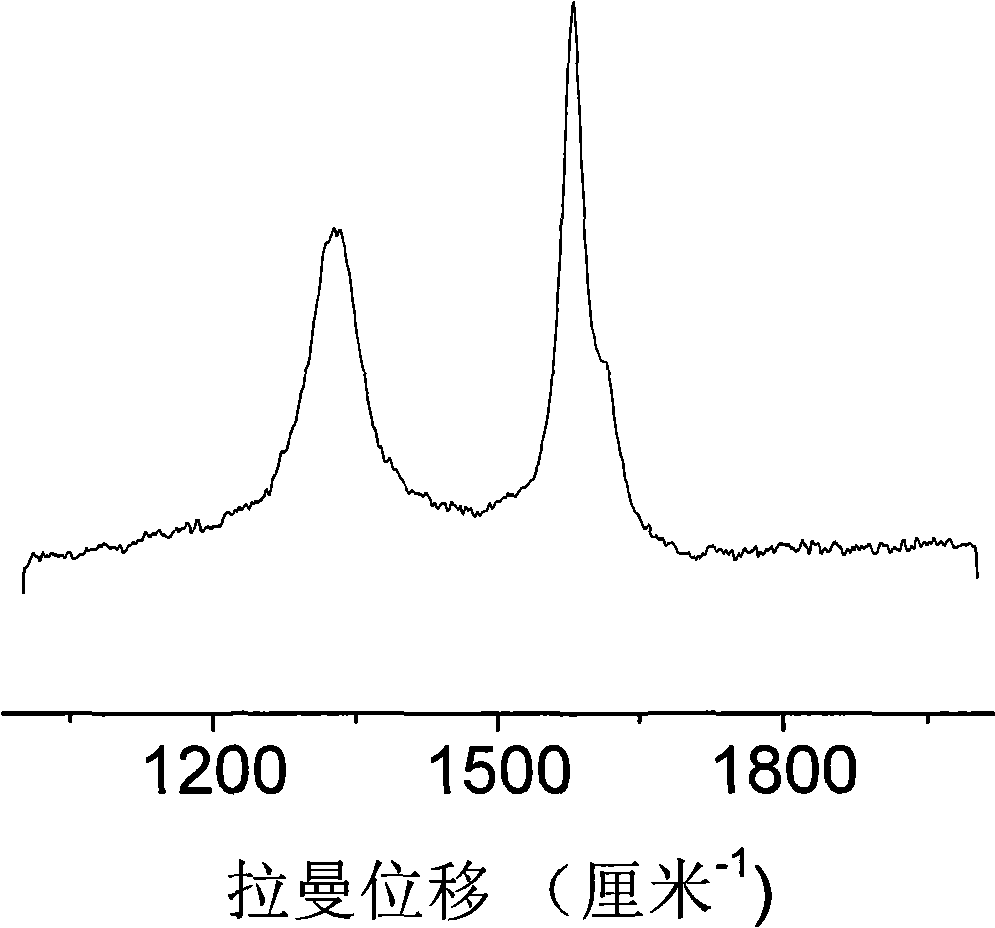

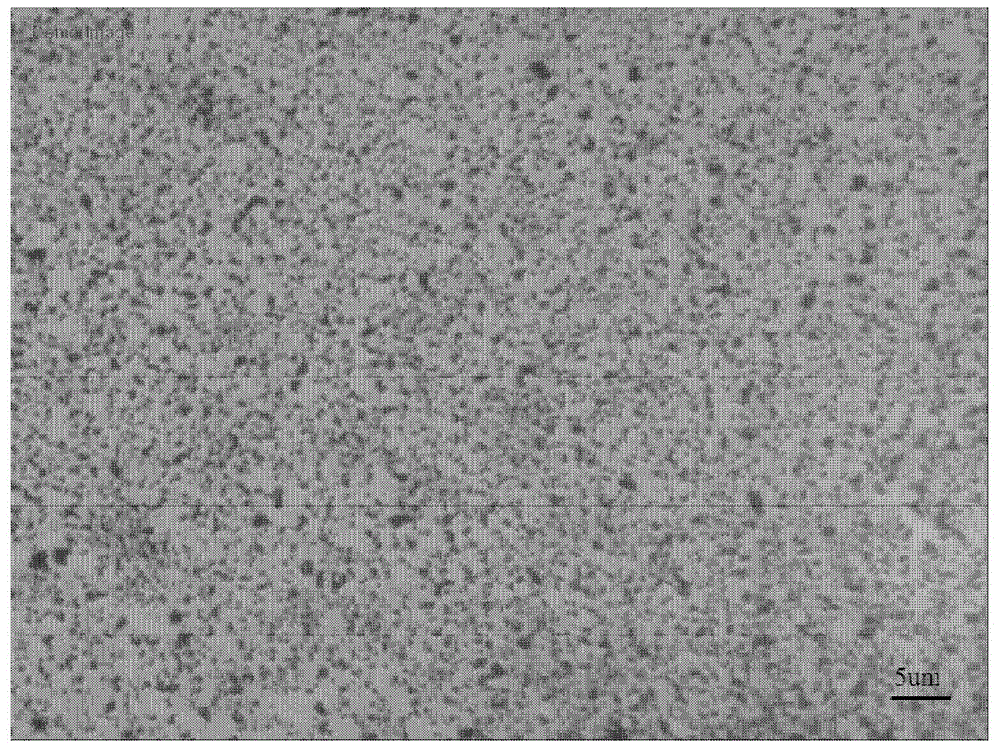

Graphene film with ultrahigh flexibility and high thermal conductivity and preparation method of graphene film

ActiveCN105523547AGuarantee unimpededGood electrical and thermal conductivityGrapheneHigh pressureCvd graphene

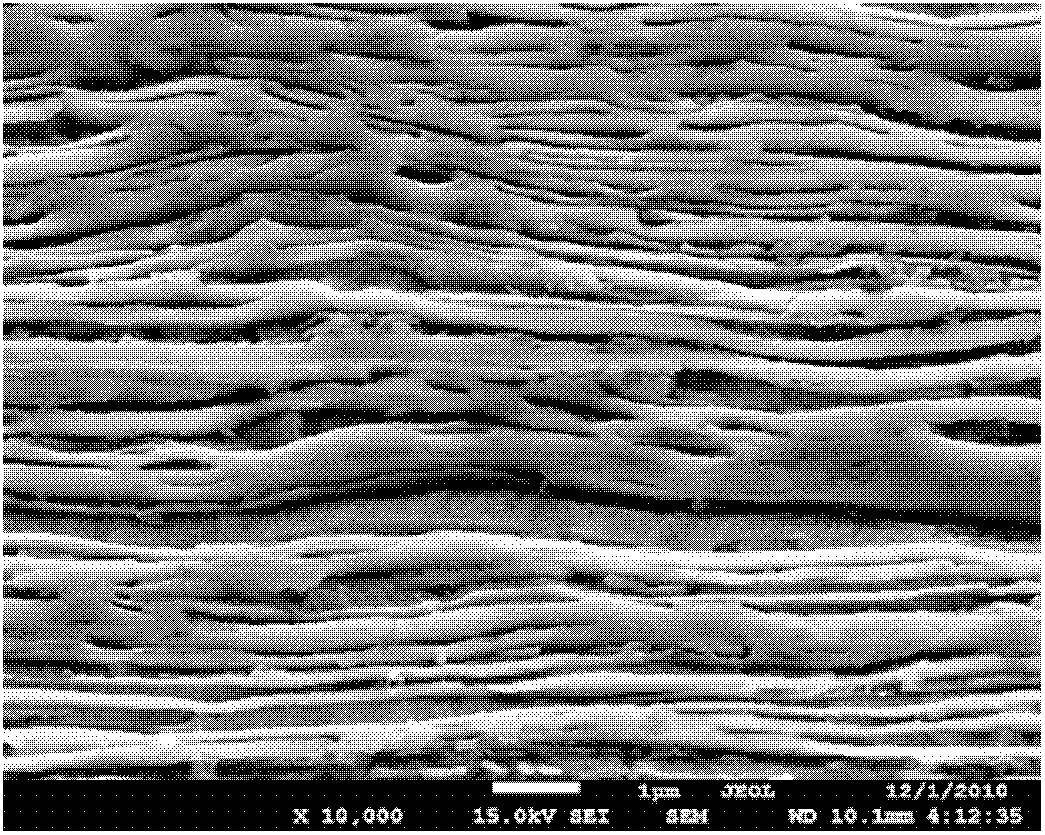

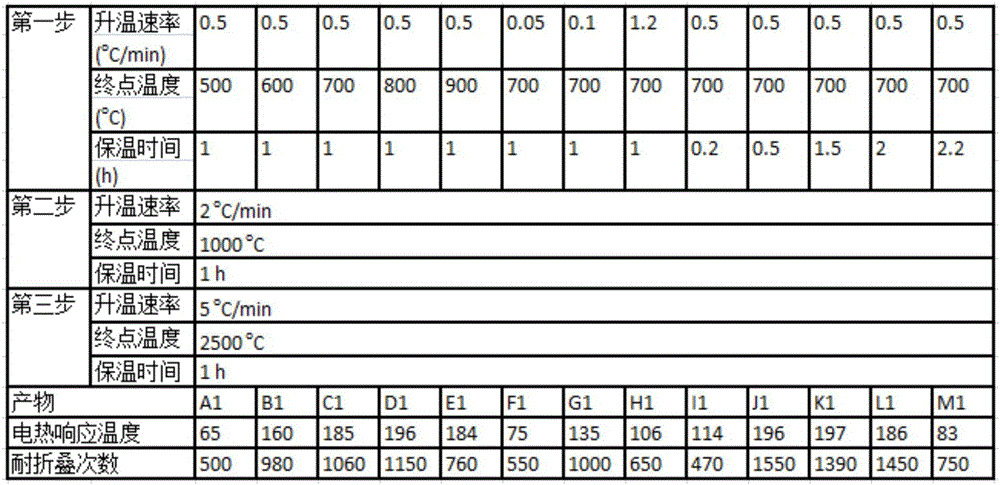

The invention discloses a graphene film with ultrahigh flexibility and high thermal conductivity and a preparation method of the graphene film. The graphene film is prepared from an ultralarge uniform graphene oxide sheet through steps of solution film-formation, chemical reduction, high-temperature reduction, high-pressure compression and the like. The graphene film is formed through physical crosslinking of macroscopic multi-layer folded graphene with microscale folds, and inter-lamella slippage can be realized, so that the graphene film has ultrahigh flexibility. The graphene lamellar structure of the graphene film is perfect, the lamellas have ultralarge crystalline areas which are about 100 mu m and contain few defects, the structure is compact after high-pressure compression, and the graphene film has ultrahigh electrical conductivity and thermal conductivity. The graphene film with ultrahigh flexibility and high thermal conductivity can be bent repeatedly more than 1,200 times, the elongation at break is 12%-18%, the electrical conductivity is 8,000-10,600 S / cm, the thermal conductivity is 1,800-2,600 W / mK, and the graphene film can be used as a high-flexibility, thermal-conducting and electric-conducting device.

Owner:杭州德烯科技集团有限公司

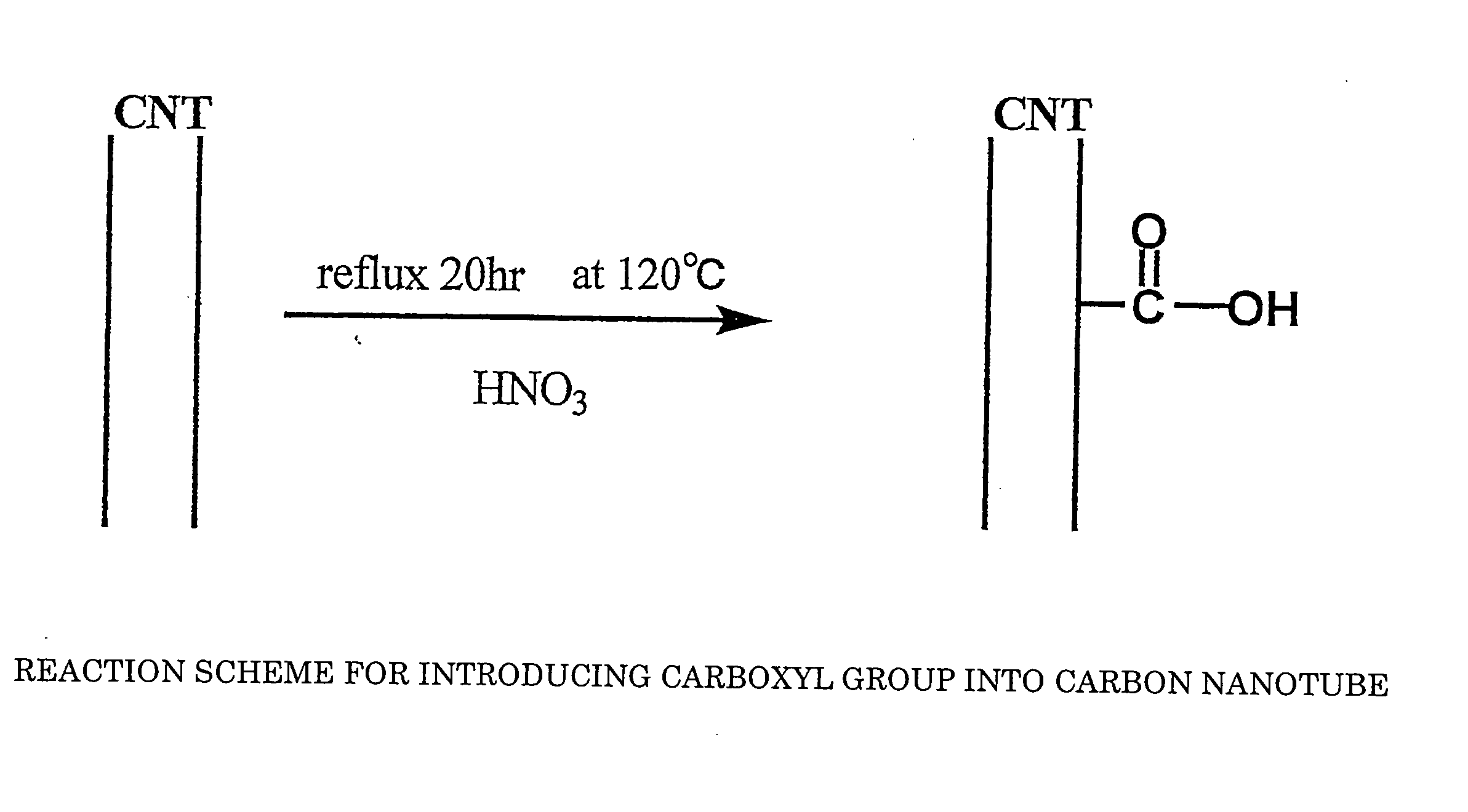

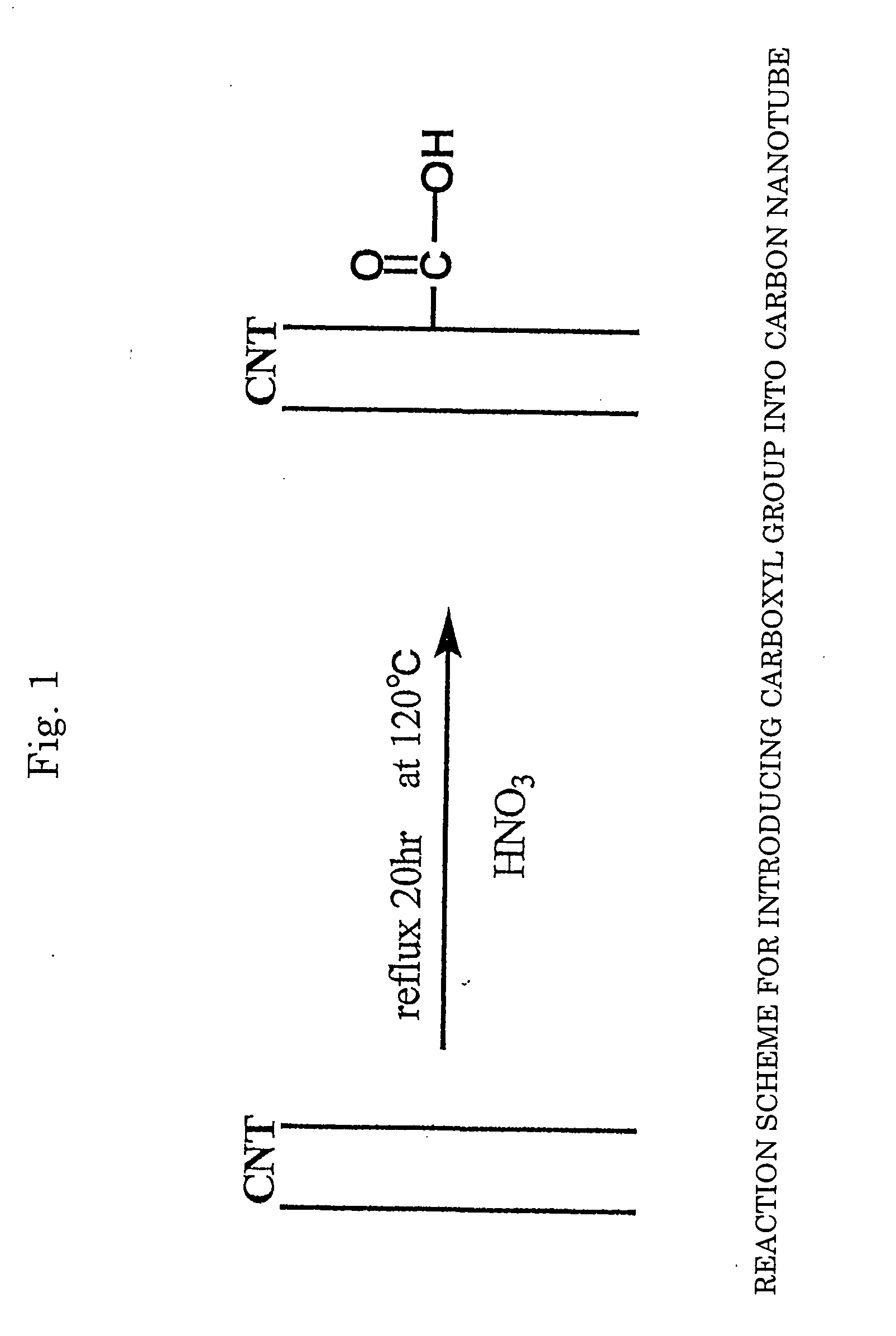

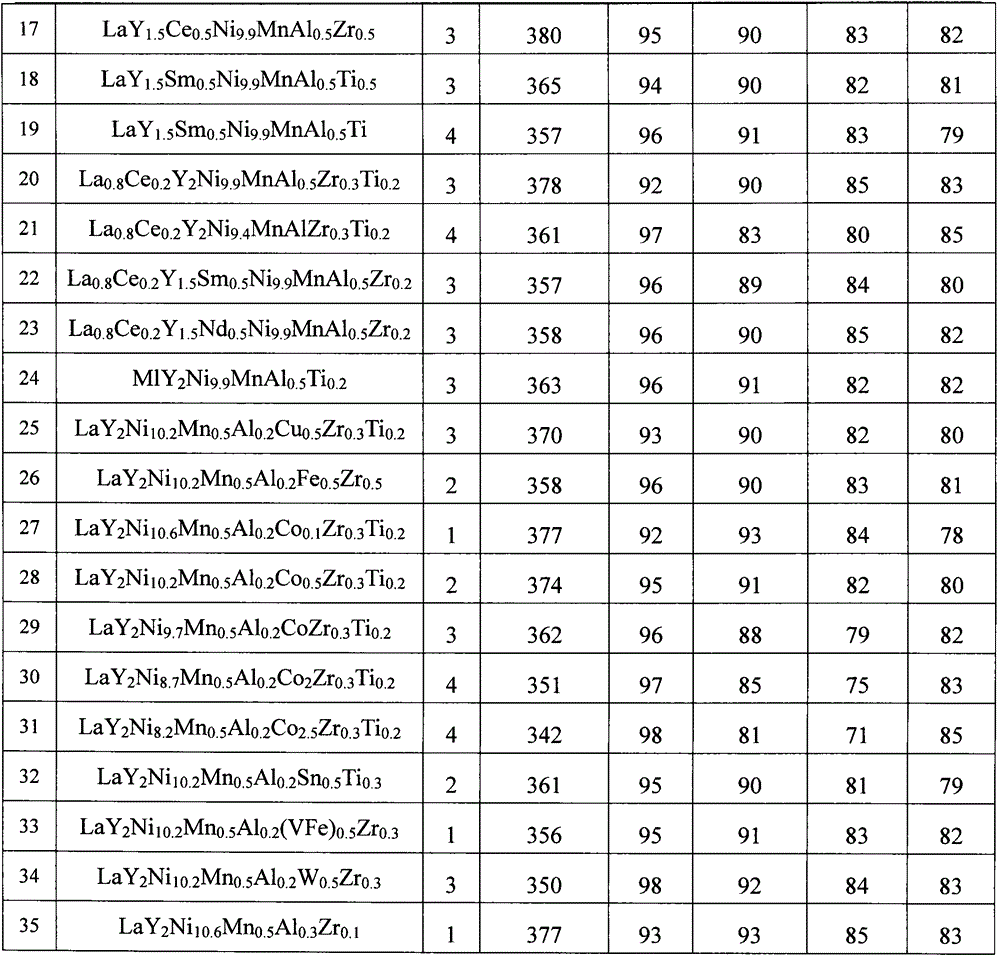

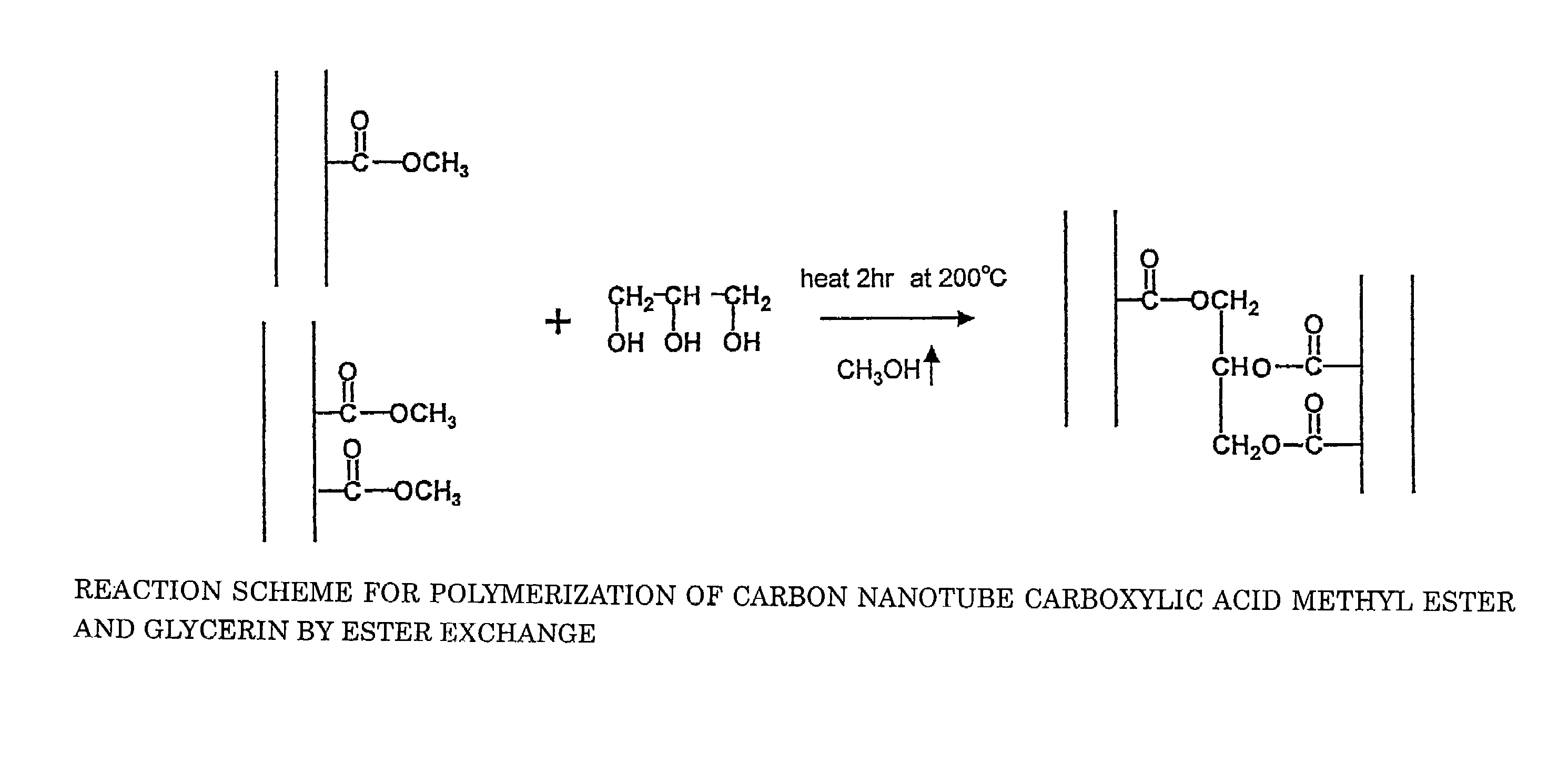

Composite and method of manufacturing the same

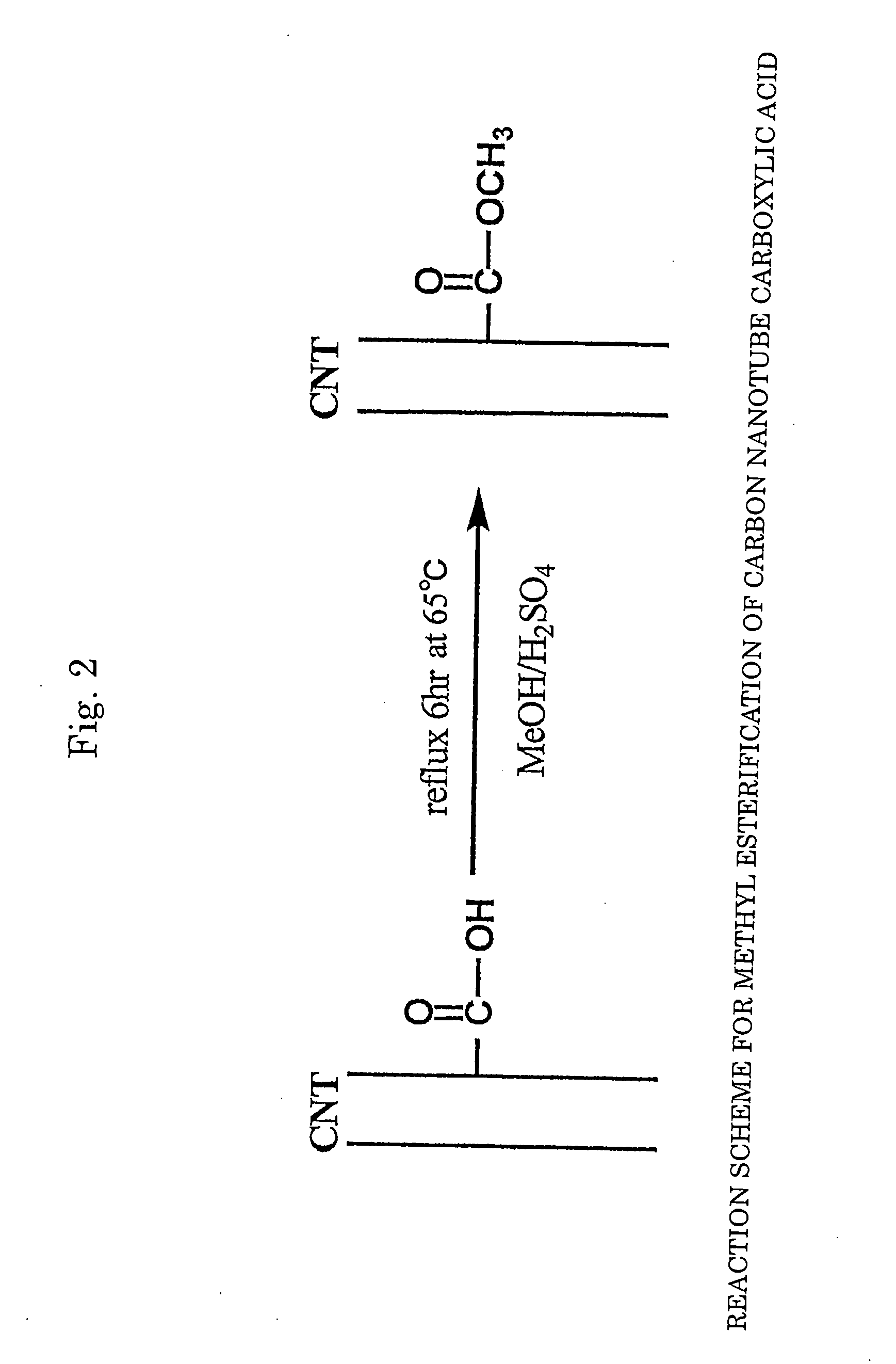

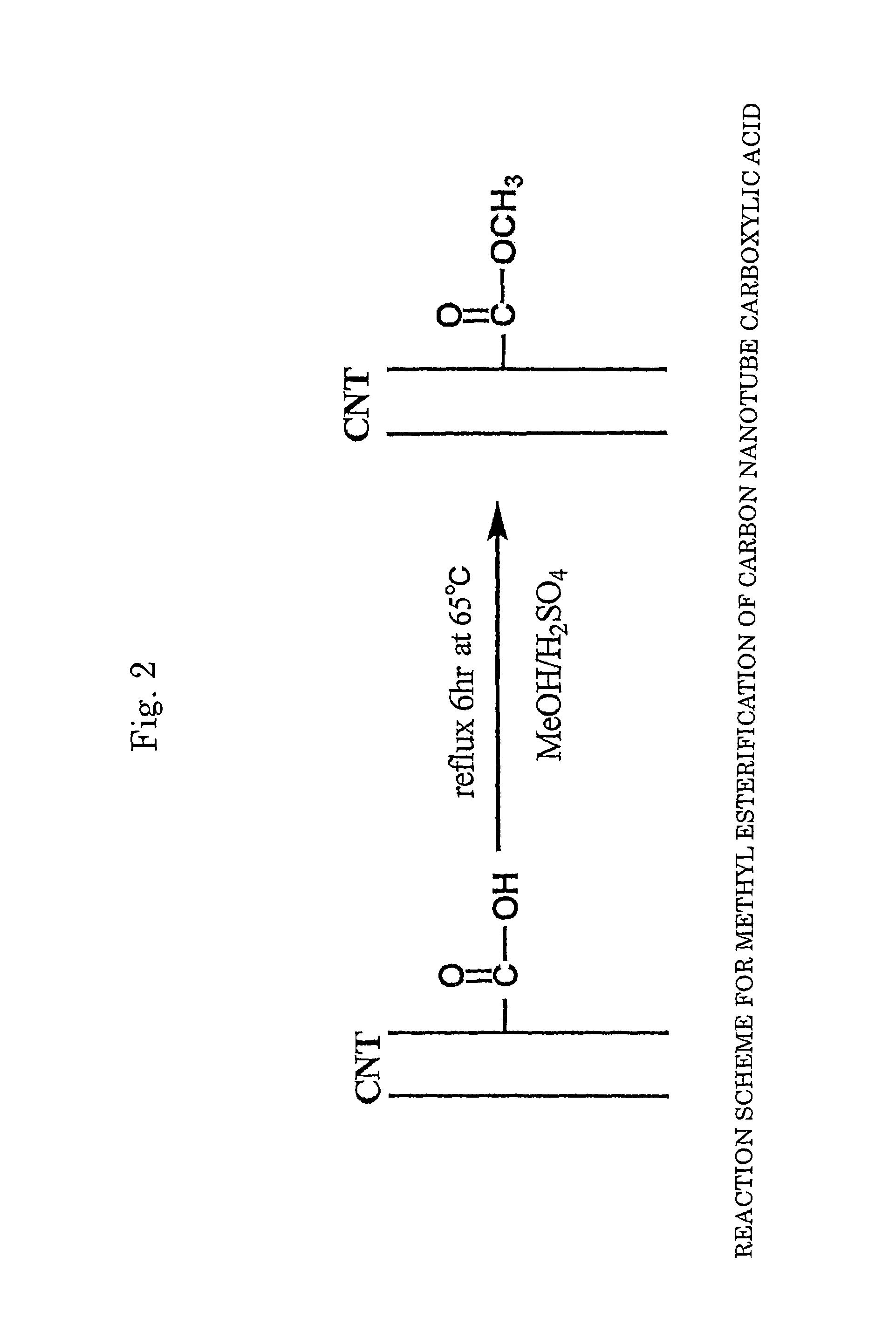

InactiveUS20070145335A1High mechanical strengthGood electrical and thermal conductivityMaterial nanotechnologyIndividual molecule manipulationCross-linkNetwork structure

To provide a composite excellent in mechanical strength or in electric conductivity and obtained by combining a carbon nanotube structure and ceramics, and a method of manufacturing the same. The composite is composed of the carbon nanotube structure and the ceramics, and, in the carbon nanotube carbon nanotube structure, functional groups bonded to multiple carbon nanotubes are chemically bonded to mutually cross-link to construct a network structure.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Preparation method of graphene-containing water-based electrothermal film

ActiveCN105906832AHigh viscosityImprove conductivityPolyurea/polyurethane coatingsHeating element materialsWater basedHydrophilization

The invention discloses a preparation method of graphene-containing water-based electrothermal film. The method comprises the following steps of: (1) carrying out hydrophilization treatment on graphene, then adding solutions of cellulose derivatives as a dispersing agent and a thickening agent, and carrying out pre-dispersion; (2) adding an auxiliary agent into the pre-dispersed graphene, and dispersing to obtain homogeneous dispersion liquid; (3) adding an adhesive into the homogeneous dispersion liquid, and mixing to obtain graphene-containing electrothermal film slurry; and (4) coating a film formation carrier with the graphene-containing electrothermal film slurry to form a graphene conducting layer, and drying to obtain the graphene-containing electrothermal film formed by the graphene conducting layer and the film formation carrier. After the preparation method is adopted, a heating body having excellent heat conduction and electric conduction properties can be prepared.

Owner:四川烯材科技有限公司

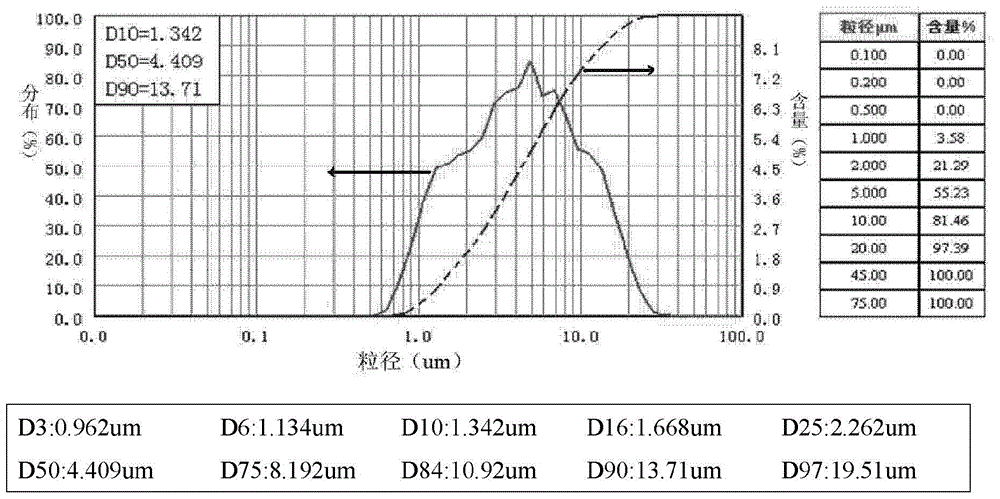

Novel nanometer phase dispersion strengthening cuprum as well as preparation method and product producing technique thereof

The invention relates to a dispersion-strengthened copper, the process for preparation thereof and the productive technology of products. The content of dispersion strengthening phase in dispersion-strengthened copper is 0.5-1.25wt%, the size of dispersion strengthening phase particle is 0.01-0.05um, and the distance is 0.1-0.5um. The process for preparing the nano-phase dispersion-strengthened copper comprises the following steps: firstly, mixing aluminium, ytterbium, lanthanum, cerium or zirconium powder with cuprous oxide powder in indoor temperature or inactive gas, and forming copper alloy powder with nanometer reinforcing phase in a copper base body through an in situ reaction synthesis method and through mechanical alloy, secondly, annealing under inactive gas, thirdly, milling compound powder and electrolytic copper powder in a second step with high energy to get nano-phase dispersion-strengthened copper alloy. Section bars which are needed are prepared through utilizing dispersion-strengthened copper which is got to anneal and do isostatic cool pressing, sintering densification and cold working. The process for preparing dispersion-strengthened copper has the advantages of low production cost, high yield and simple technique, and relative products which are prepared have excellent combination properties such as heat conductivity and electric conductivity.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

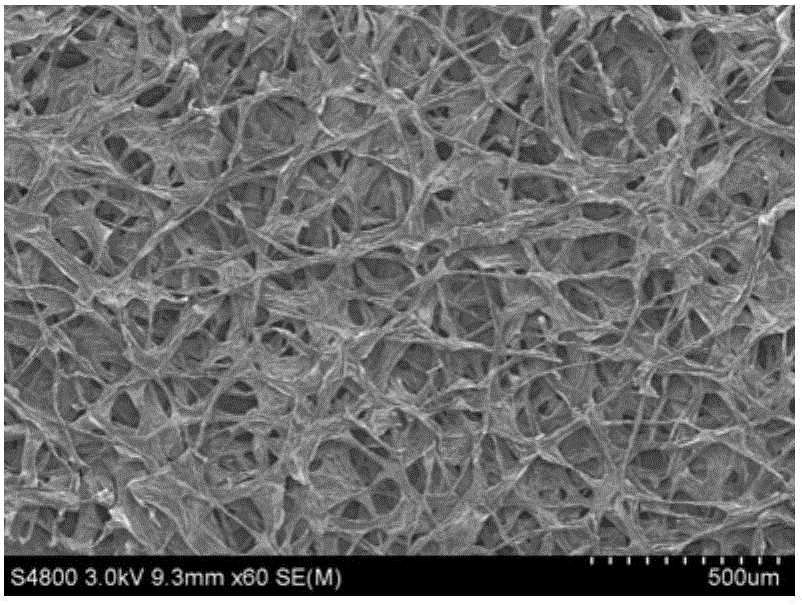

Graphene fiber non-woven fabric and preparation method thereof

ActiveCN106192201AGood electrical and thermal conductivitySimple methodNew-spun product collectionGrapheneElectricityPolymer science

The invention discloses a graphene fiber non-woven fabric and a preparation method thereof. The non-woven fabric is obtained by filtering and depositing a graphene short-fiber dispersion solution through a filter net and performing drying and reduction, so that the structural unit of the non-woven fabric is disorderly-stacked and bonded graphene short fiber, and fiber is overlapped to form a large number of holes through which liquid of gas can pass. The graphene fiber non-woven fabric has the good mechanical strength and tenacity, is completely composed of graphene fiber, does not contain high polymer materials as a skeleton or adhesives, the electricity and heat conducting performance of the reduced network structure overlapped by the graphene fiber is excellent, and the non-woven fabric can be used as a multifunctional high-performance fabric.

Owner:杭州德烯科技集团有限公司

Graphitized wetable cathode carbon block for aluminium electrolysis bath and production method thereof

InactiveCN101158048AGood electrical and thermal conductivityHigh degree of graphitizationShaping pressAluminium electrolysisGraphite

The invention relates to a graphitized wettable cathode carbon block used in an aluminum electrolytic tank and a production method thereof, and is characterized in that the graphitized wettable cathode carbon block consists of a graphitized carbon block matrix and a TiB2 compound layer integrated on the matrix. The production method of the graphitized wettable cathode carbon block is characterized in that when the cathode carbon block is produced through vibration molding, the working surface of the cathode carbon block is integrated with and molded by a TiB2 compound layer; a pressing molded greed block is roasted, leached, graphitized and processed by machine and a graphitized wettable cathode carbon block is prepared. The carbon block matrix of the graphitized wettable cathode carbon block used in the aluminum electrolytic tank of the invention has good electric and heat conductivity, and the TiB2 compound layer integrated and molded on the matrix is roasted and treated by high temperature heat process, thus the compound intensity can be effectively improved, so the graphitized wettable cathode carbon block used in aluminum electrolytic tank has excellent electrolyte corrosion resistance and aluminum liquid scouring resistance as well as good electric and heat conductivity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Novel 6063 aluminum alloy material and its production technology

The invention discloses a novel 6063 aluminum alloy material. Rare earth elements are added into the original 6063 aluminum alloy. The novel 6063 aluminum alloy material comprises, based on the weight percentage,0.36%- 0.4% of Si, 0.48% - 0.52% of Mg, 0 -0.35% of Fe, 0 -0.1% of Cu, 0 - 0.05% of Mn, 0 - 0.05% of Cr, 0 - 0.05% of Zn, 0 - 0.05% of Ti, 0.18%-0.22% rare earth elements, 0-0.1% of the remaining impurities and the balance of Al. According to the invention, the content of Mg and Si is controlled within a narrow range. At the same time, cerium-based mixed rare earth elements and alloying element boron are added, which keeps alloy material high strength and high electrical and thermal conductivity; improves machining property and plastic extrusion; and improves production efficiency.

Owner:CHENGDU SUNSHINE ALUMINUM

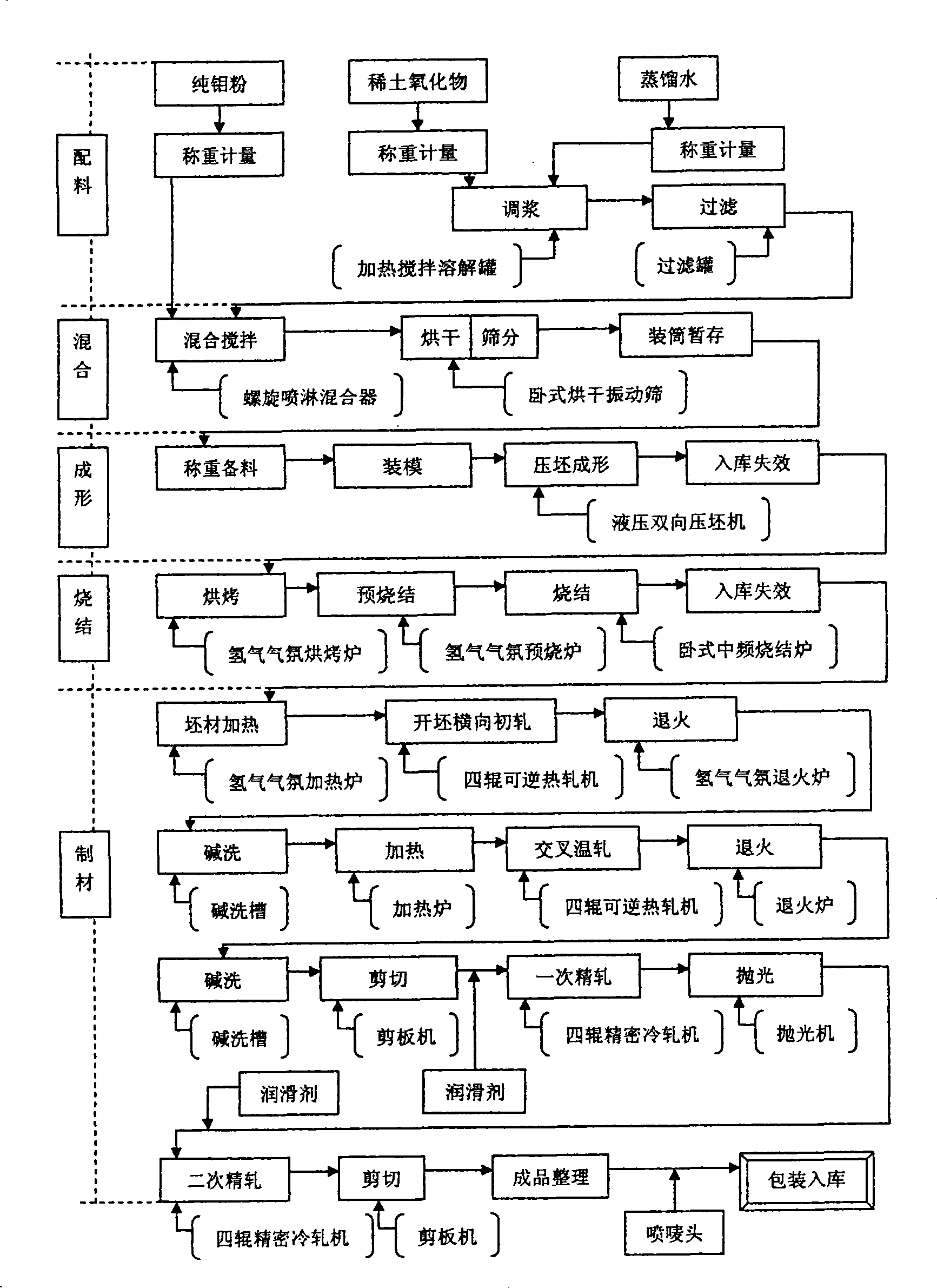

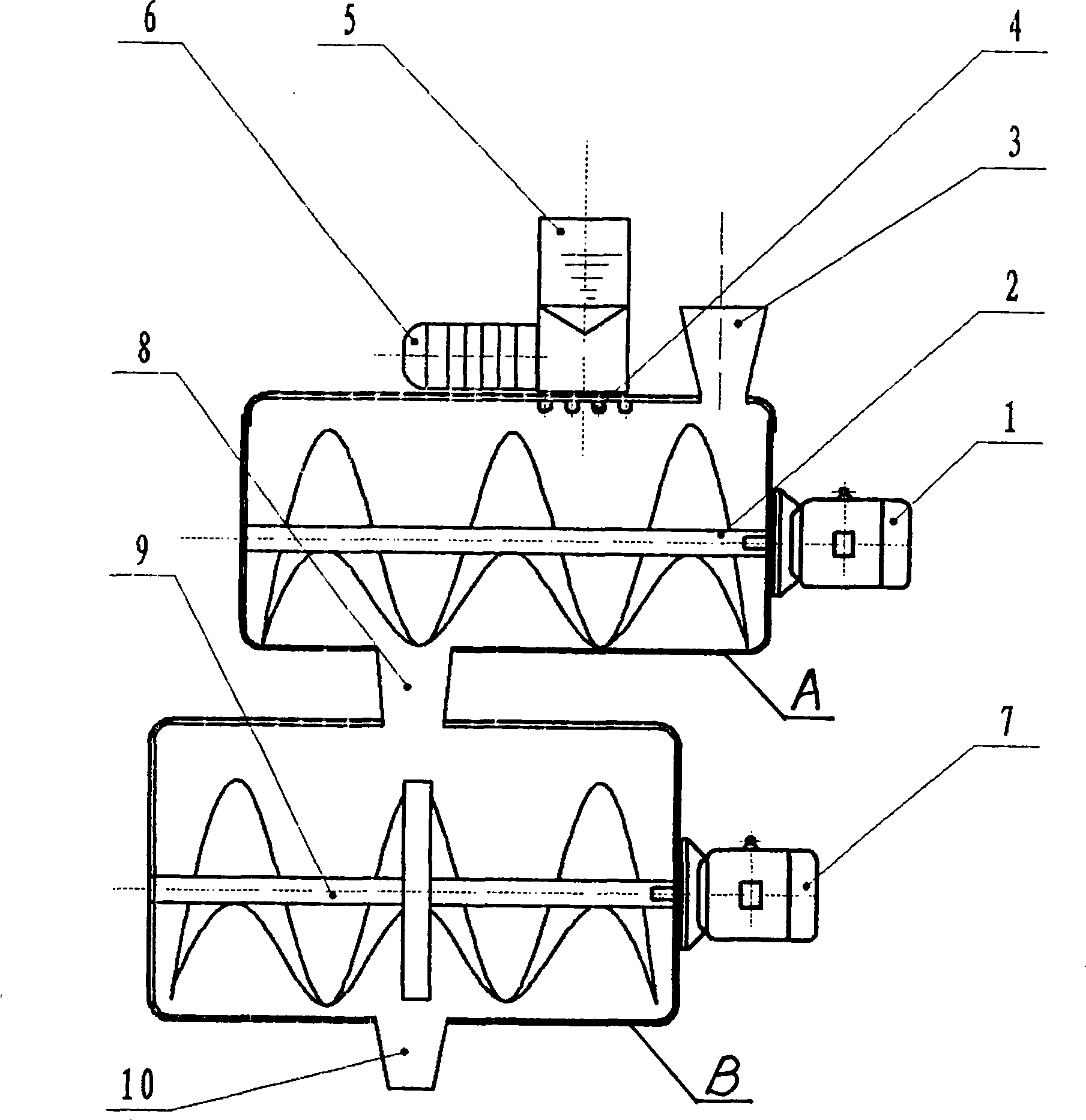

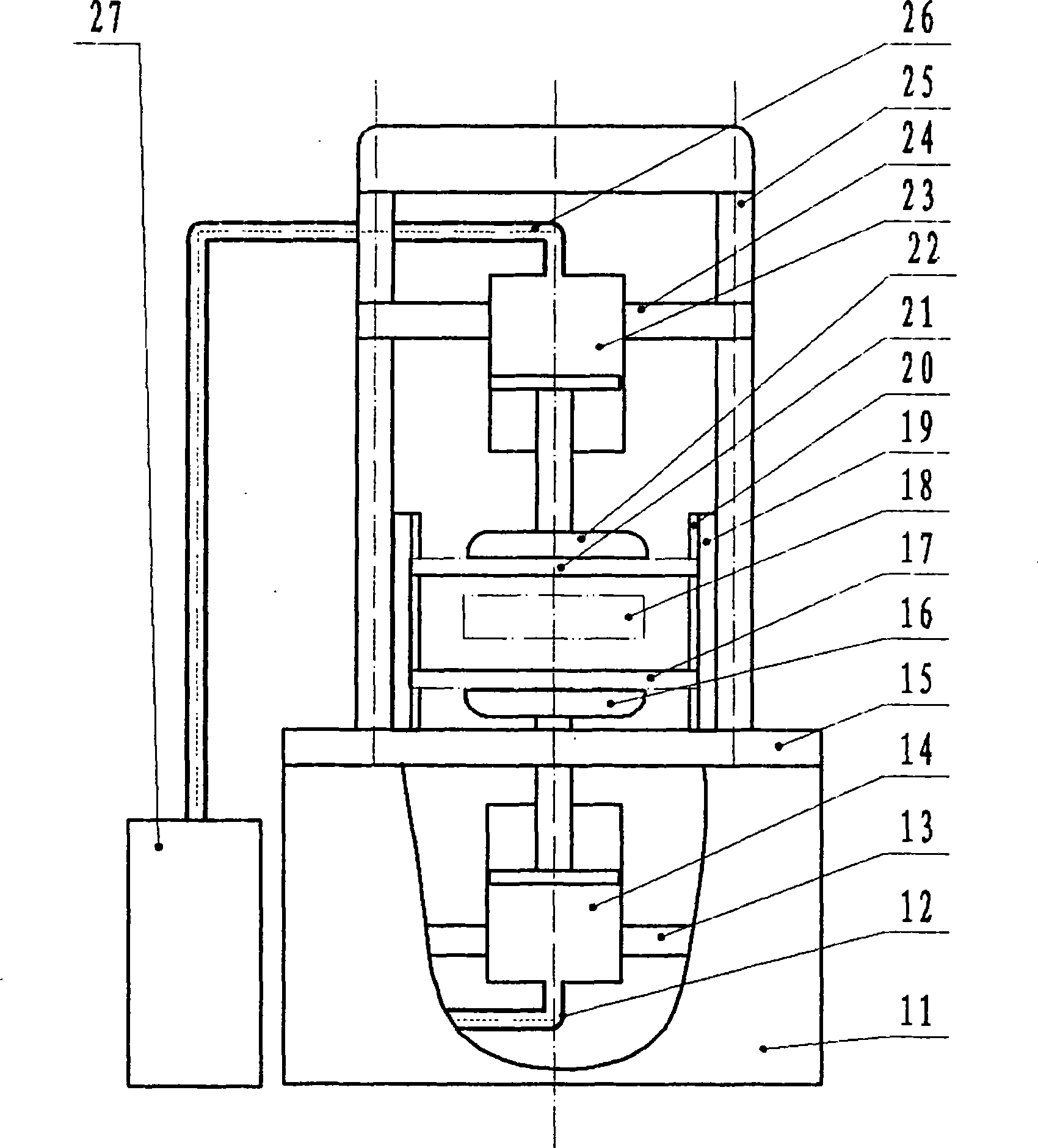

Manufacturing technology of molybdenum-based rare-earth alloy slab and equipment thereof

ActiveCN101423911AFull atomic diffusionFull liquidityRoll mill control devicesMetal rolling arrangementsExtensibilityManufacturing technology

The invention relates to a process for manufacturing the molybdenum based rare earth alloy plate and equipment for manufacturing the same, wherein pure molybdenum powder is simultaneously added with four rare earth oxides of ZrO2, Y2O3, La2O3 and Nd2O3 according to certain ratio, by utilizing the chrematistics of long and large crystal grain and strong sag resistance and anti-creep property of rare earth alloy elements and the dispersion strengthening function, the re-crystallization temperature of the metal molybdenum is increased, the mechanical performances of the molybdenum based material such as tensile property, yielding behavior and extensibility are improved, and the application range of the molybdenum based material is widened; and the manufacturing process comprises production procedures of material preparation treatment, mixing treatment, forming treatment, sintering treatment, material making treatment and the like and the setting of various technical parameters of special technical equipment and process. With the preparation process, the molybdenum based rare earth alloy plate which has the advantages of good electric conductivity and heat conductivity, excellent high-temperature resistance and corrosion resistance and better mechanical performances such as tensile property, yielding behavior and extensibility, and fills in domestic blank and can replace the imported material can be manufactured.

Owner:四平市北威钼业有限公司

Rechargeable lithium cell having a phthalocyanine-based high-capacity cathode

ActiveUS20130309561A1High coefficientLow volatilityMaterial nanotechnologyElectrode carriers/collectorsSpecific energyLarge capacity

A rechargeable lithium cell comprising: (a) an anode; (b) a cathode comprising a hybrid cathode active material composed of a graphene material and a phthalocyanine compound, wherein the graphene material is in an amount of from 0.1% to 99% by weight based on the total weight of the graphene material and the phthalocyanine compound combined; and (c) a porous separator disposed between the anode and the cathode and electrolyte in ionic contact with the anode and the cathode. This secondary cell exhibits a long cycle life and the best cathode specific capacity and best cell-level specific energy of all rechargeable lithium-ion cells ever reported.

Owner:GLOBAL GRAPHENE GRP INC

Silver/titanium dioxide composite heterostructure and preparation method thereof

InactiveCN103721708AConducive to separationEnhancing the performance of photocatalytic degradation of organic matterMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic degradationPhoto catalysis

The invention discloses a silver / titanium dioxide composite heterostructure. The silver / titanium dioxide composite heterostructure comprises a silver nanowire component and a titanium dioxide component, wherein a titanium dioxide shell covered with the silver nanowire can form a nuclear shell heterostructure, and a titanium dioxide ball is bunched on the silver nanowire so as to form a bradde chain heterostructure. The heterostructure provided by the invention has the good electricity-conduction and heat-conduction property of the silver, the heterostructure of a noble metal and a semiconductor photocatalyst is formed, the effective separation of electrons and holes is benefited, the photocatalytic degradation organic matter property is enhanced, the disadvantages that the chemical stability of the silver is poor, the surface of the silver is easy to oxidize, and the silver / titanium dioxide composite heterostructure has the wide application prospect on the photocatalysis and new energy field. The invention also discloses a preparation method, the operation of the method is simple, the controllability is strong, the repeatability is good, the heterostructures of different shapes are obtained through adjusting the collocation of a reagent, the size of the diameter of a TiO2 ball and the thickness of a titanium dioxide shell layer are adjusted by virtue of adjusting the quantity of a titanium source, and the preparation method has strong practicability.

Owner:UNIV OF JINAN

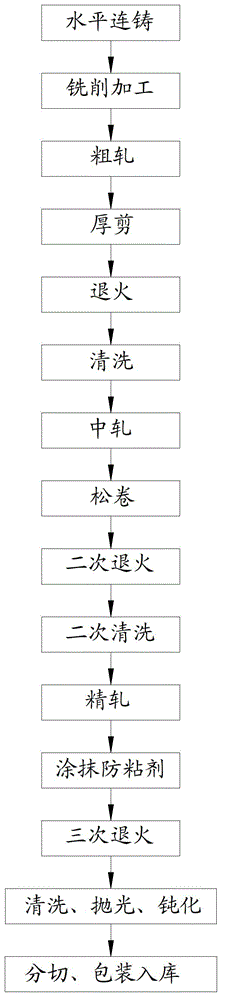

Manufacturing technology of copper strip for photovoltaic solar device

ActiveCN103331584AImprove mechanical propertiesHigh tolerance precisionPhotovoltaic solar energyManufacturing technology

The invention discloses a manufacturing technology of a copper strip for a photovoltaic solar device. According to a soft state finished copper strip obtained through the manufacturing technology, the content of Cu + Ag in the copper strip is larger than or equal to 99.98%, the oxygen content is smaller than or equal to 10ppm, the electric conductivity is larger than or equal to 100%IACS, and excellent electric conductivity and excellent thermal conductivity are achieved. The soft state finished copper strip also has a good comprehensive mechanical property, high tolerance precision and excellent surface quality, meets the performance requirement and the precision requirement for the copper strip in photovoltaic solar energy industries, and can be widely applied to manufacturing of interconnecting strips and confluence belts of the photovoltaic solar device.

Owner:江苏富威科技股份有限公司

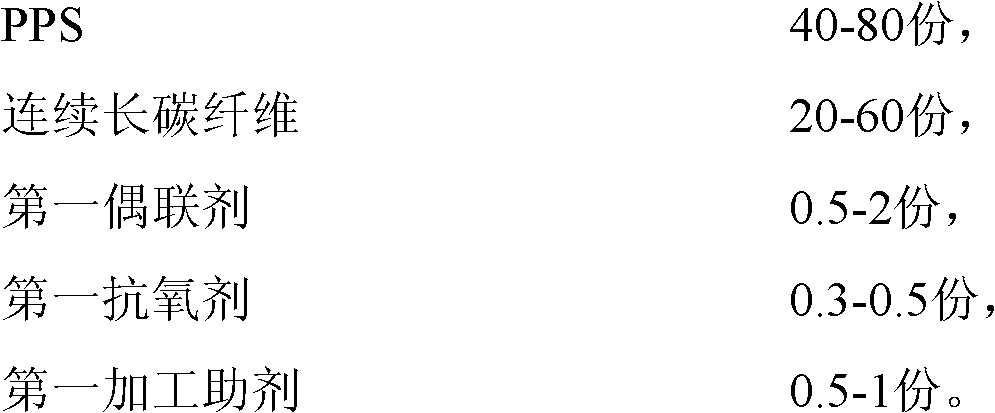

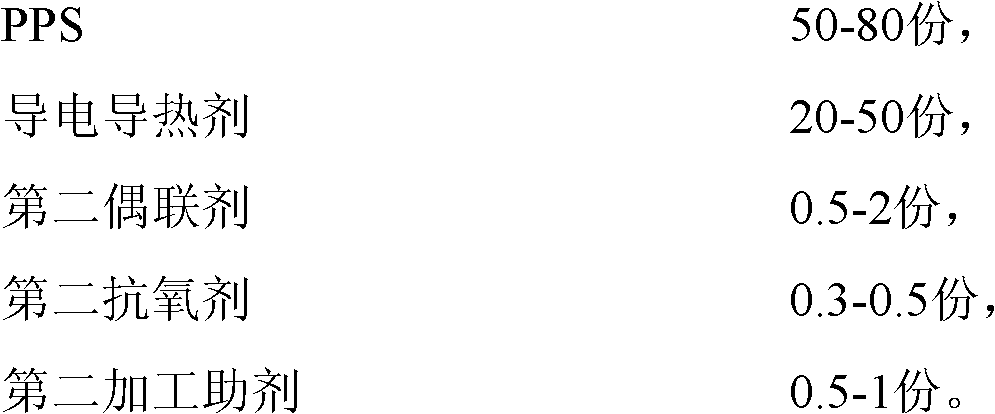

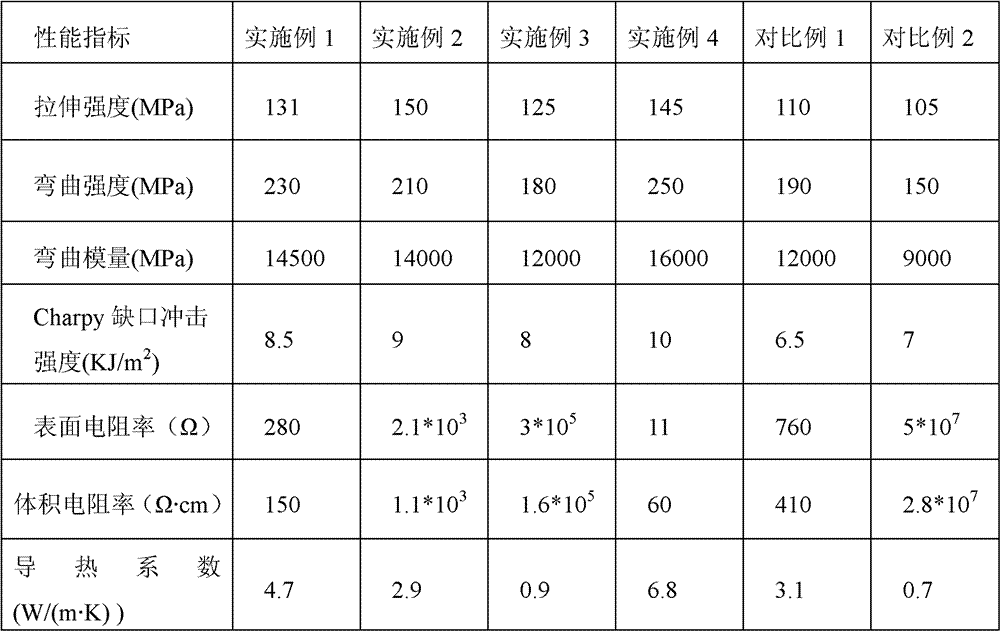

Long glass fiber reinforced electrically and thermally conductive polyphenylene sulfide composite material and preparation method thereof

The invention, belonging to the technical field of polyphenylene sulfide (PPS) composite material, discloses a long glass fiber reinforced electrically and thermally conductive polyphenylene sulfide composite material and a preparation method thereof. The composite material disclosed herein comprises the following ingredients: 30-80 weight parts of long glass fiber reinforced PPS masterbatch, and 20-70 weight parts of electrically and thermally conductive masterbatch, wherein the long glass fiber reinforced PPS masterbatch comprises 40-80 weight parts of PPS, 20-60 weight parts of continuous long glass fiber, 0.5-2 weight parts of first coupling agent, 0.3-0.5weight parts of first antioxidant, and 0.5-1 weight parts of first processing aid; and the electrically and thermally conductive masterbatch comprises 50-80 weight parts of PPS, 20-50 weight parts of electrically and thermally conductive agent, 0.5-2 weight parts of second coupling agent, 0.3-0.5 weight parts of second antioxidant, and 0.5-1 weight parts of processing aid. The preparation method disclosed herein comprises the following steps: mixing 30-80 weight parts of long glass fiber reinforced PPS masterbatch and 20-70 weight parts of electrically and thermally conductive masterbatch to prepare the long glass fiber reinforced thermal insulation polyphenylene sulfide composite material. The composite material disclosed herein has excellent thermal conducting property and mechanical property.

Owner:上海事升新材料有限公司

Nano-graphene loaded wax liquor, and preparation method and use thereof

ActiveCN103468004AGood electrical and thermal conductivityGood self-lubricating performanceFibre treatmentInksTotal solid contentCvd graphene

The invention belongs to the technical field of fine chemical engineering polymer materials, and specifically relates to nano-graphene loaded wax liquor, and a preparation method and a use thereof. The wax liquor is a wax dispersion which is formed by loading ultrafine nano-graphene particles having the particle size in the range from 20 to 40 nm on wax particles having the particle size in the range from 200 to 800 nm; and the total solid content of the wax liquor is 15-25%. The preparation method provided by the invention is used for successfully solving the dispersion and aggregation problems of graphene while being used for a paint or an ink body; and the nano-graphene loaded wax liquor prepared by the preparation method is used for paint, ink or leather finishing, and has the effects of rub resistance, static resistance and electromagnetic wave blocking.

Owner:NANJING TIANSHI NEW MATERIAL TECH

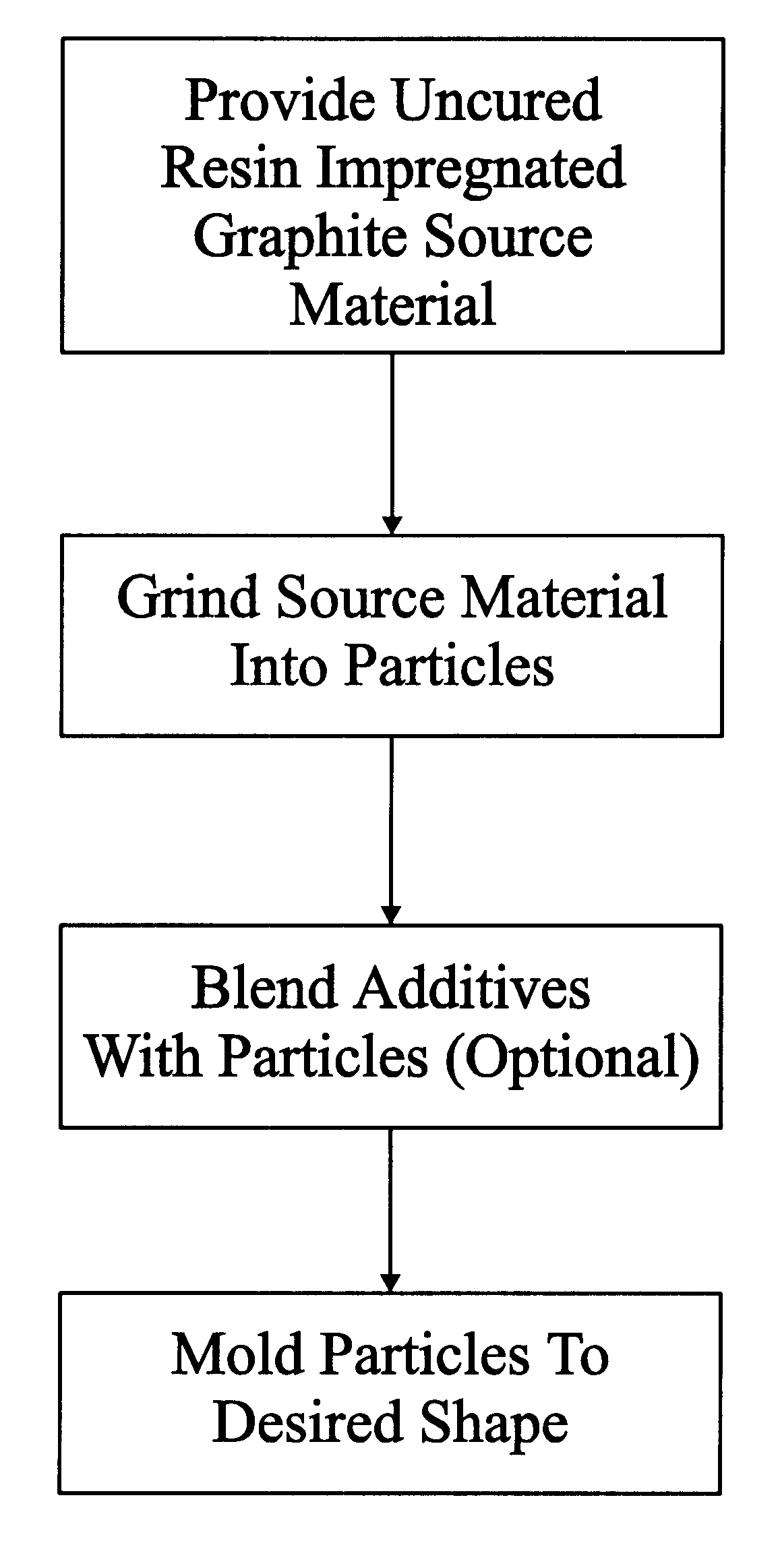

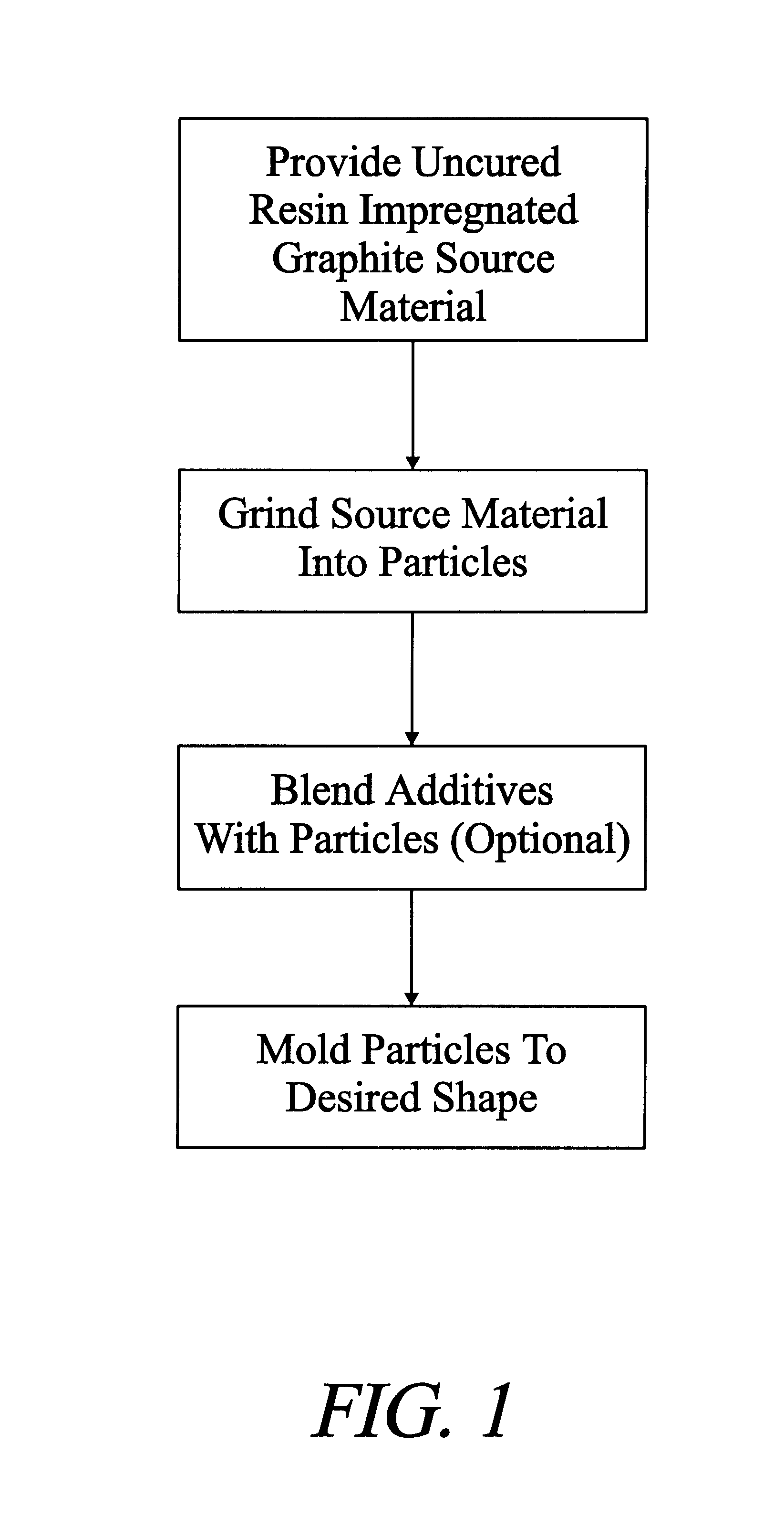

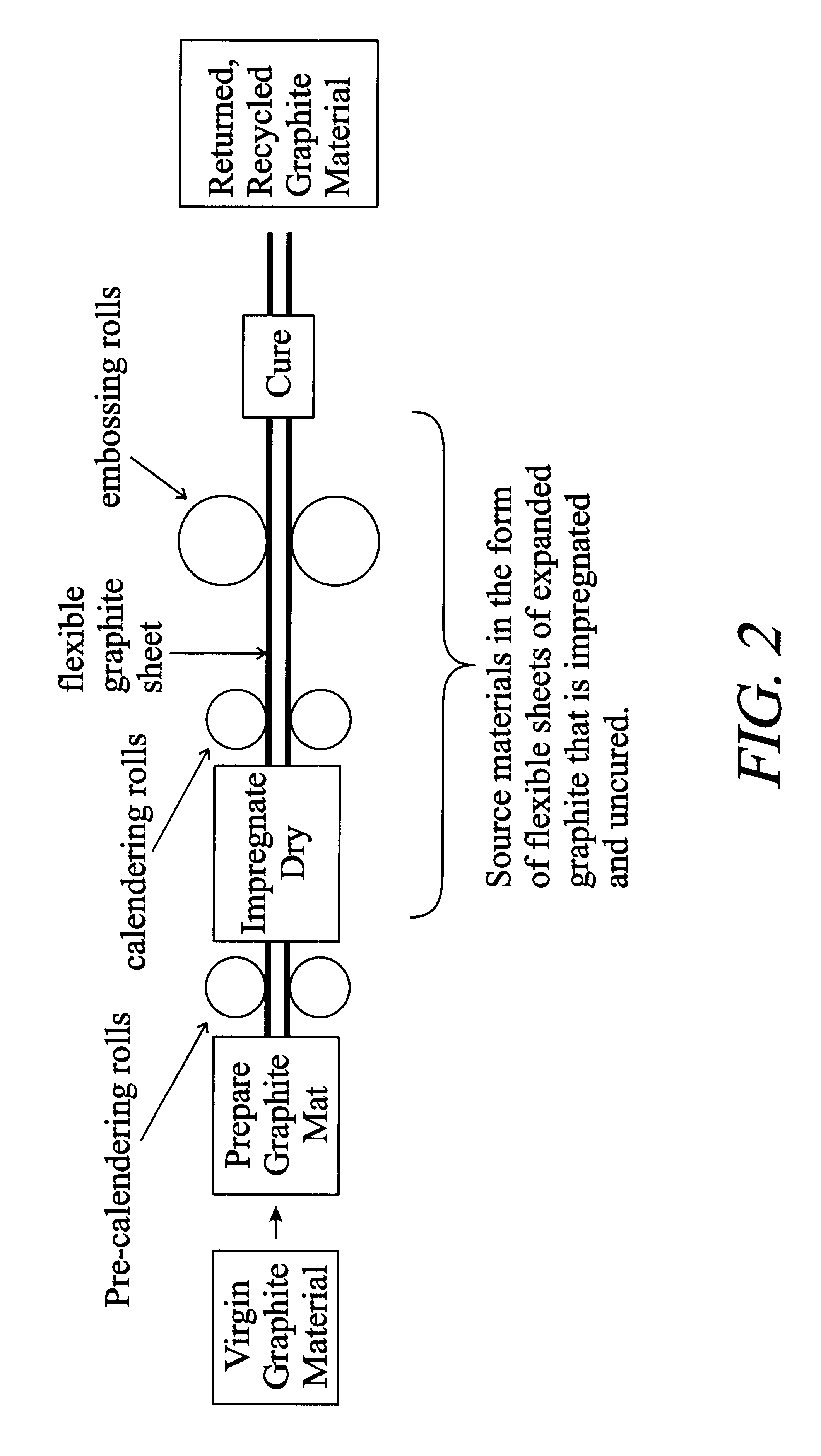

Molding of materials from graphite particles

InactiveUS6613252B2Good electrical and thermal conductivityReduce disposal costsMaterial nanotechnologyArtificial filament recoveryPolymer scienceFuel cells

A method of manufacturing material suitable for the construction of a component of a fuel cell, such as a flow field plate or electrode. Uncured resin impregnated flexible graphite sheet is ground into particles. Without re-expanding the particles, and without adding further resin to the particles, the particles are molded into the form of the desired material. The material is then cured. Additives may be mixed with the particles to improve the properties of the material.

Owner:GRAFTECH INT HLDG INC

Preparation method and application of high thermal and electrical conductivity adhesive

ActiveCN108102579AInhibition of sintering activityImprove transmission efficiencyNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesiveElectronic chip

The invention discloses a preparation method and application of a high thermal and electrical conductivity adhesive. The heat transfer between a high-frequency, high-heat and high-density electronic chip and a heat sink is satisfied, and the reliability and the stability of the service of high-power electronic components are improved. A conductive filler used in the high thermal and electrical conductivity adhesive provided by the invention is nano-silver heat-reduced from flake silver powder and an organic silver complex. The high thermal and electrical conductivity adhesive is prepared fromthe following raw materials by mass percent: 65 to 75 wt% of flake silver, 13 to 22 wt% of organic silver complex, and 12 to 18 wt% of organic carrier. The preparation method and application of the high thermal and electrical conductivity adhesive disclosed by the invention have the advantages that an organic silver complex solution is adopted to effectively regulate and control the viscosity of aslurry, the microscopic interface defects caused by the flake silver as a 'framework' are overcome, the phonon transmission efficiency is improved, and a more efficient thermal conductivity path is constructed; on the other hand, during heat curing, the organic silver complex undergoes in-situ reduction sintering while resin is cured by heating, an effective link between a substrate and a chip can be achieved, and a high-thermal-conductivity structure can be constructed.

Owner:KUNMING INST OF PRECIOUS METALS

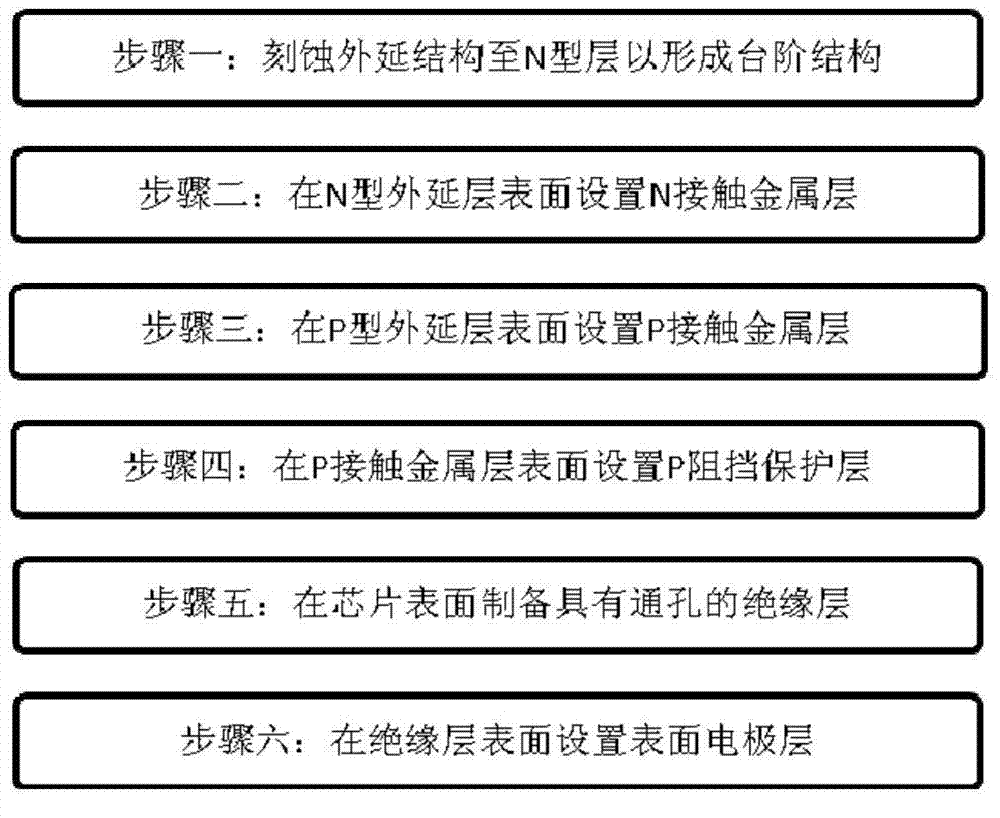

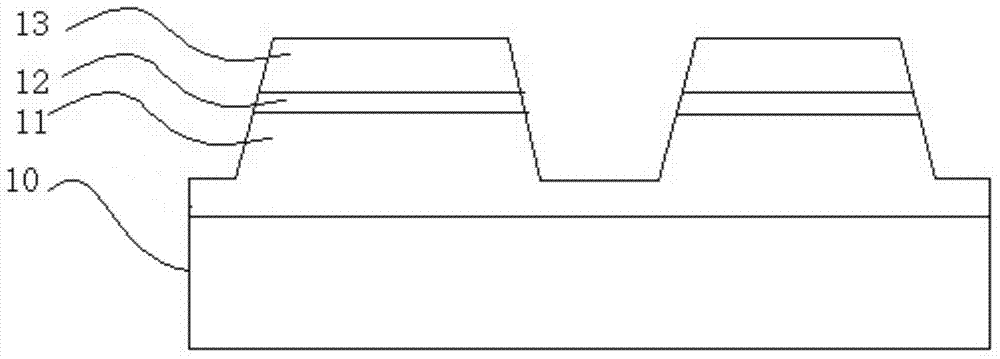

Flip LED (light-emitting diode) chip with high luminous efficiency and good heat radiating performance and preparation method thereof

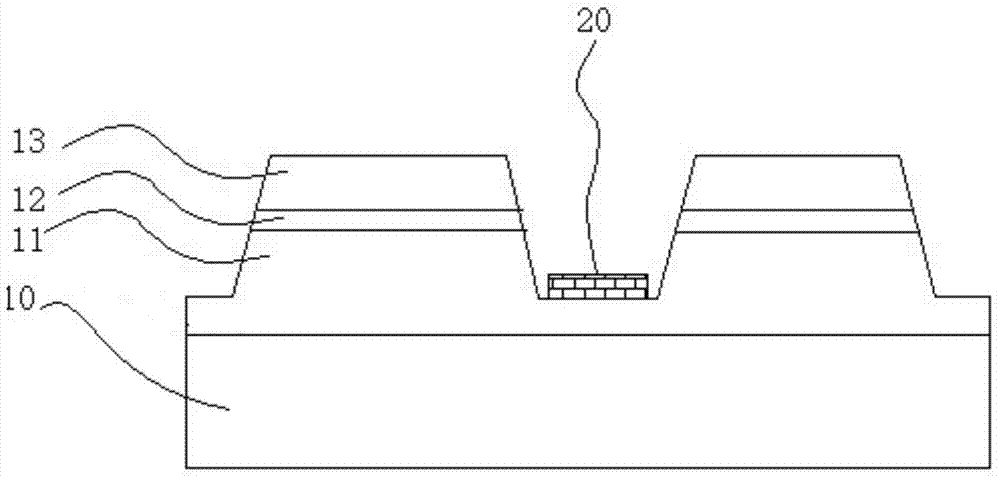

ActiveCN104505446AGood electrical and thermal conductivityIncrease reflective areaSemiconductor devicesLight-emitting diodeMetal

The invention provides a flip LED (light-emitting diode) chip with high luminous efficiency and good heat radiating performance and a preparation method thereof. The LED chip comprises an epitaxial substrate, wherein an N type epitaxial layer, a light-emitting layer and a P type epitaxial layer are sequentially laminated on the upper surface of the epitaxial substrate; a concave hole is formed in the P type epitaxial layer, downwards penetrates through the light-emitting layer and extends to the N type epitaxial layer; a P contact metal layer, a P baffle protecting layer and a P surface electrode layer are sequentially laminated on the upper surface of the P type epitaxial layer; the lower surface of the P baffle protecting layer and the upper surface of the P contact metal layer are overlapped; an N contact metal layer and an N surface electrode layer are sequentially laminated on the upper surface of the N type epitaxial layer corresponding to the bottom of the concave hole; a clearance is reserved between the N contact metal layer and the edge of the concave hole; an insulating layer is arranged on the wall surface of the clearance. The flip LED chip provided by the invention has high heat-conducting property and conductivity, and improvement of the luminous efficiency of the LED chip is facilitated by the structure.

Owner:APT ELECTRONICS

Weak electricity copper base electric contact composite material and method for making same

InactiveCN101106024AStrong welding resistanceImprove arc extinguishing effectContactsWear resistantLow voltage

The invention relates to a copper base electrical contact compound material, in particular to a weak current copper base electrical contact compound material used for low voltage electric switch, and a method to prepare the compound material. The compound material is composed of materials by the following proportions: 0.5-4 percent bismuth, 0.5-4 percent TiAl metal compound, 0.05-0.6 percent rare earth material, and the rest copper and other unavoidable impurities. The preparation method is: mixing powder in ball mill; cold pressing; sintering; secondary molding; and secondary sintering; the compound material produced with the invention has the advantages of strong anti-fusion welding performance, and good arc extinguishing performance and oxidation resistant performance. The electricity conductivity is similar to that of silver base electrical contact compound material, and wearing-resistant performance superior to that of the original boron carbide copper base and silver base electrical contact compound material. Therefore, the compound material is a cheap replacement for silver alloy electrical contact in low voltage switches.

Owner:UNIV OF JINAN

Molybdenum copper alloy foil sheet and preparation method thereof

The invention provides a molybdenum copper alloy foil sheet and a preparation method thereof. The thickness of the molybdenum copper alloy foil sheet is 0.1-1.0mm. Molybdenum phases and copper phases are uniformly distributed in a short-fiber mode. The copper phases are in lap joint with each other. The molybdenum copper alloy foil sheet comprises 20wt%-50wt% of copper with the balance being molybdenum. The preparation method includes the steps of carrying out compression moulding, presintering and infiltration sintering on mixed powder after the mixed powder is subjected to high-energy ball-milling treatment, obtaining a molybdenum copper alloy plate, and carrying out hot rolling, heat treatment and cold rolling on the molybdenum copper alloy plate to obtain the molybdenum copper alloy foil sheet. Through adoption of the high-energy ball-milling treatment, the infiltration sintering and appropriate rolling process, the molybdenum copper alloy foil sheet and the preparation method thereof solve the problems that existing molybdenum copper alloy is poor in deformation processing performance and low in density. The molybdenum copper alloy foil sheet prepared through the method is smooth and clean in surfaces and excellent in thermal conductance performance, has more than 99% of high density, and is applicable for the field of preparation and application of electronic packaging materials and heat sink materials.

Owner:GRIMAT ENG INST CO LTD

Composite electrode material and preparing method thereof

ActiveCN106847529ASolve the problem of easy heat and difficult heat dissipationImprove cycle performance and service lifeHybrid capacitor electrodesHybrid/EDL manufacturePorous metalNanotechnology

The invention provides a composite electrode material and a preparing method thereof. The composite electrode material comprises a carbon-based film, a porous metal layer and an electrochemical activity substance layer, wherein the carbon-based film, the porous metal layer and the electrochemical activity substance layer are sequentially arranged; the electrochemical activity substance layer is formed in an in-situ-growth mode on the surface of the porous metal layer. The preparing method of the composite electrode material includes the following steps that the carbon-based film is provided, porous metal is deposited on a surface of the carbon-based film with the electroplating method, and the porous metal layer is prepared; electrochemical activity substances grow on the surface of the porous metal layer in an in-situ mode, and the electrochemical activity substance layer is prepared.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Foldable electrothermal film device based on graphene

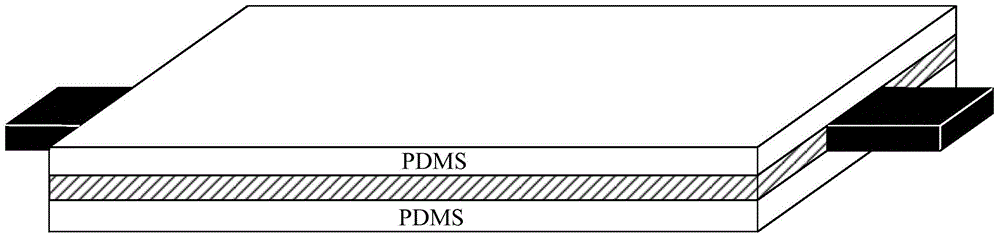

ActiveCN105752963AGuarantee unimpededGood electrical and thermal conductivityGrapheneOhmic-resistance heatingTectorial membranePolymer science

The invention discloses a foldable electrothermal film device based on graphene.The foldable electrothermal film device comprises a heating element, protecting films and current intercepting bodies, wherein the heating element is a super-flexible graphene film obtained by subjecting large-piece even graphene oxide to solution film formation, chemical reduction, high-temperature reduction, high-pressure pressing and the like.The graphene film is formed by macroscopic multilayer-fold graphene with micro-scale folds through physical crosslinking, every two lamellas of the graphene film can slide relative to each other, and high flexibility is achieved.The graphene lamellas have few defects and are perfect in structure, extremely large in lamella crystalline area (about 100 micrometers) and compact in structure after the high-pressure pressing, and the electrothermal film prepared by the graphene film is super-high in conductivity and thermal conductivity.The super-flexible graphene electrothermal film can be repeatedly bent for more than 1200 times, the elongation at break of the electrothermal film is 12-18%, the conductivity of the electrothermal film is 8000-10600S / cm, and the thermal conductivity of the electrothermal film is 1800-2600W / mK.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

Graphitized stephanoporate material with carbon element and method of producing the same

The invention relates to a method for preparing graphitized porous carbon materials, which comprises that: hydrous metal oxide nano-particles dispersed in an aqueous solution are taken as templates to form metal oxide-organic polymer composite structures through condensation polymerization of a phenolic aldehyde precursor around a template phase; and in the subsequent high-temperature carbonization process, the composition structures form graphitized structures under the catalysis action of metal, and the graphitized porous carbon materials are obtained after the metal is dissolved by acid, wherein partial materials have magnetism. The materials can be applied in the fields of battery, adsorption, catalysis, water pollution removal, and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

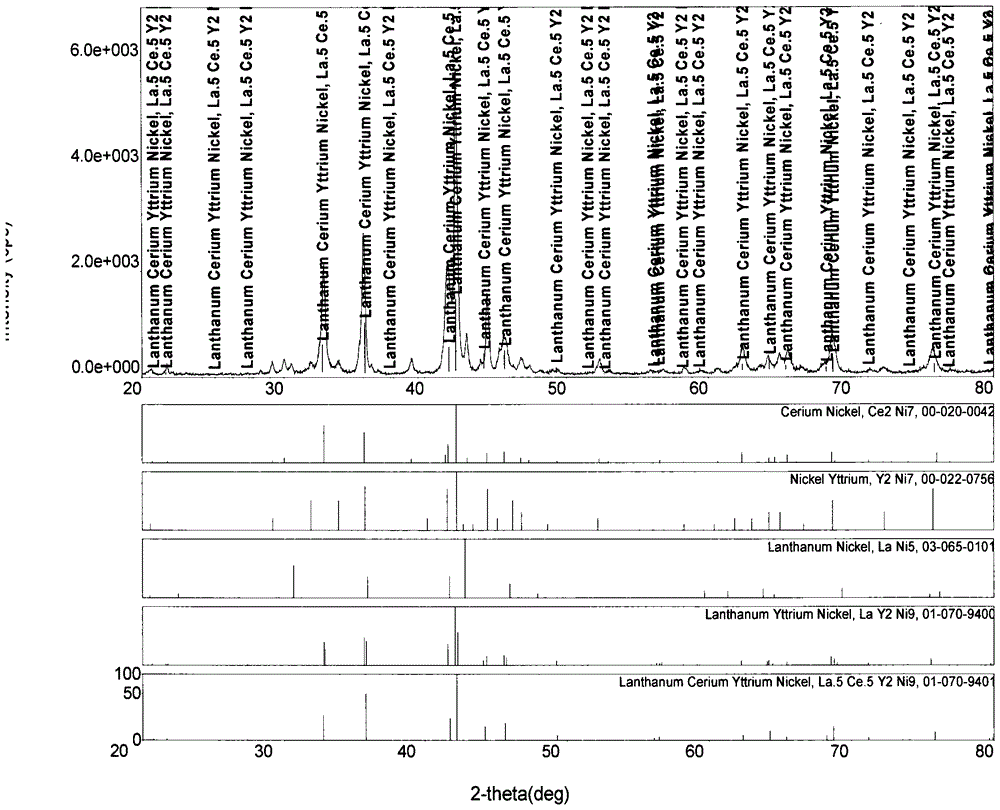

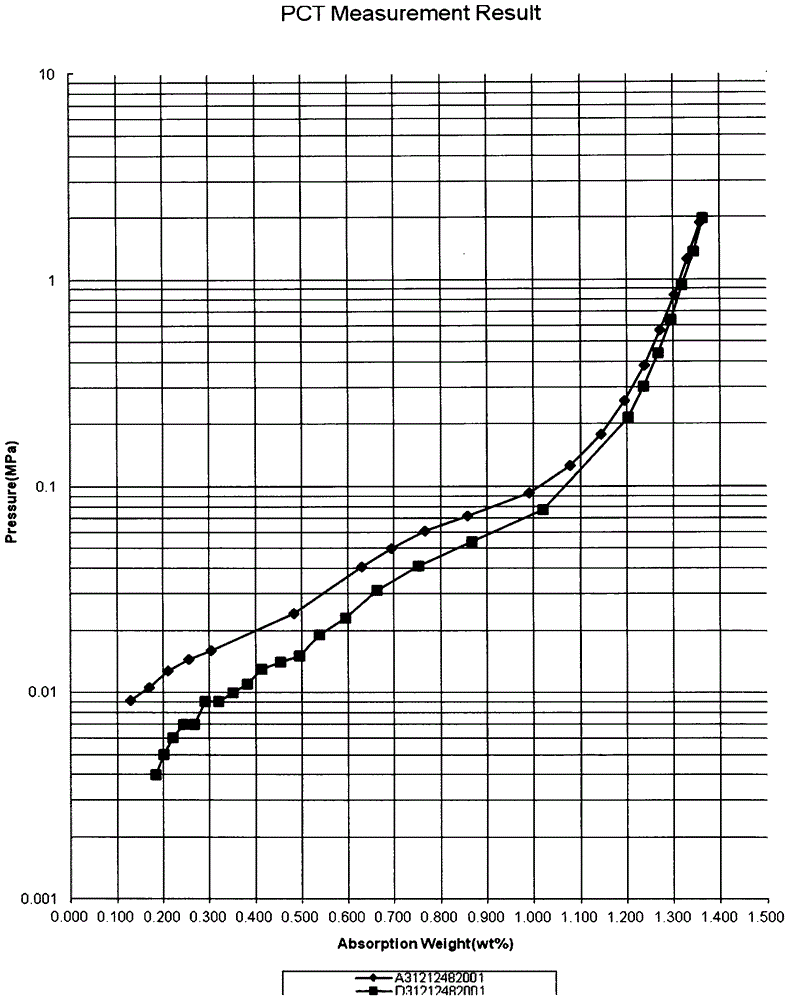

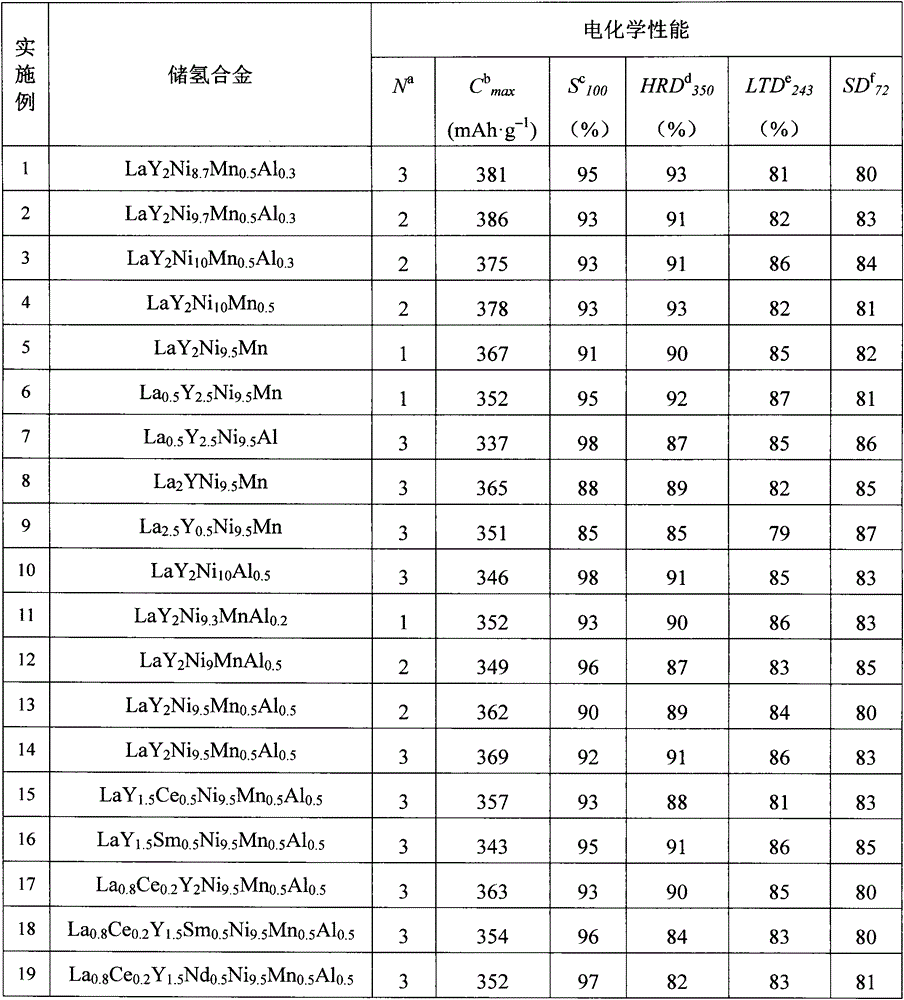

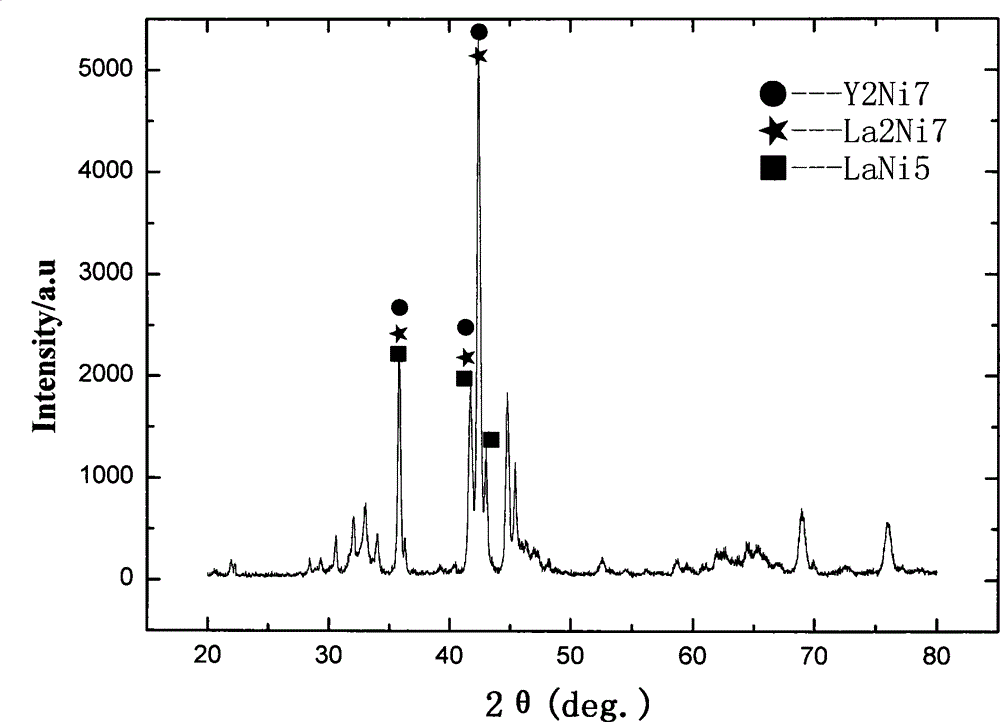

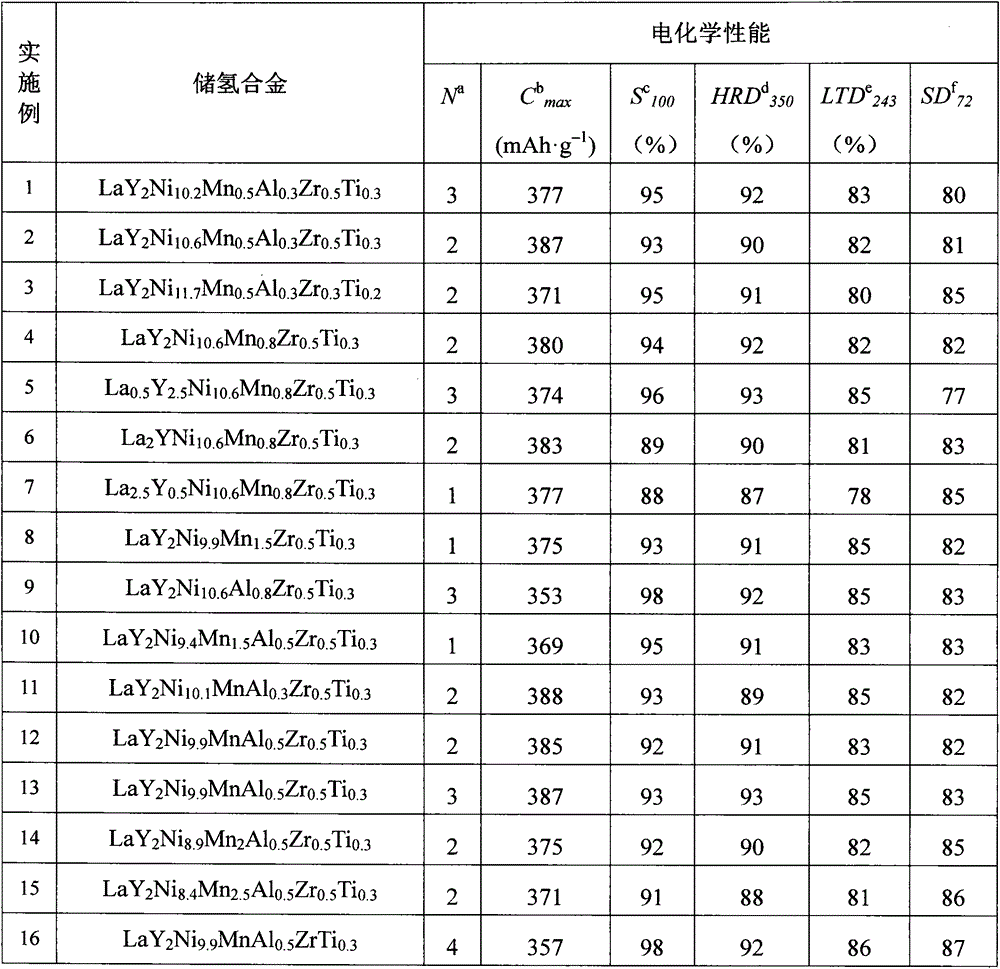

Yttrium-nickel rare earth-based hydrogen storage alloy

ActiveCN104532095AStructural stress reliefEliminate component segregationAlkaline accumulator electrodesGas phaseRare earth

The invention relates to A2B7 type RExYnNiz-a-bMnaAlb hydrogen storage alloy. The alloy is good in pressure-composition-isothermality, and has a maximum hydrogen storage amount of up to more than 1.36 wt.% under usual conditions. The alloy of the invention has better electrochemical performance as a hydrogen storage electrode and better gas-phase hydrogen absorption and desorption performance as a hydrogen storage material than traditional LaNi5 type hydrogen storage alloy; the alloy contains no magnesium element in the composition, so the preparation method of the alloy is simple and safe when compared with that of traditional rare earth-magnesium-nickel-based A2B7 type hydrogen storage alloy.

Owner:BAOTOU RES INST OF RARE EARTHS +2

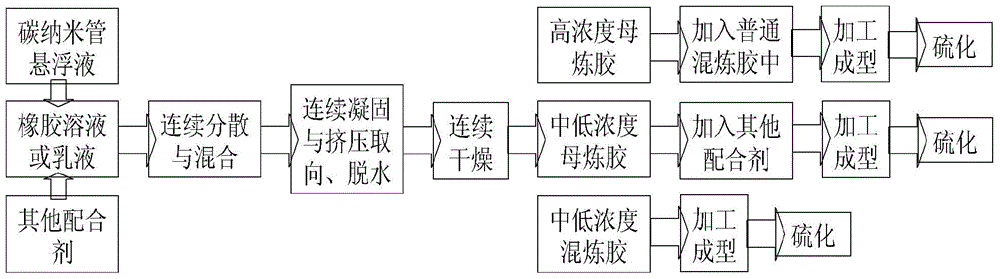

Liquid phase continuous mixing process of high dispersion carbon nanotube masterbatch and rubber product thereof

The invention discloses a liquid phase continuous preparation method of a carbon nanotube masterbatch. The method includes: preparing a carbon nanotube suspension; concinuously dispersing and mixing the carbon nanotube suspension with a rubber solution / emulsion and an optional rubber compounding ingredient solution / suspension to obtain a carbon nanotube / rubber / solvent mixture; carrying out solidification and continuous extrusion on the carbon nanotube / rubber / solvent mixture simultaneously to realize carbon nanotube orientation, and removing water or the solvent to obtain the carbon nanotube / rubber mixture; and continuously drying the carbon nanotube / rubber mixture to obtain the carbon nanotube masterbatch. The invention also includes the carbon nanotube masterbatch obtained by the liquid phase continuous preparation method and the rubber product prepared from the carbon nanotube masterbatch.

Owner:SHANDONG DAZHAN NANO MATERIALS

Preparation process of graphene coating fabric

The invention discloses a preparation process of a graphene coating fabric. The preparation process comprises the following steps of 1 plate making, 2 solution preparation, 3 coating, 4 drying and shaping and 5 curing. The invention also provides a grapheneformula and a coating process thereof. The high electric and thermal conductivity properties of the textile fabric are improved, the washing resistance is improved, the anti-static-electricity and conductive functions of the fabric are excellent and durable, the fabric is better than conductive fiber commonly used in the market in effect, patterns can be designed for a coating, for example, micro circuit board carving, graphene can replace electric wires, circuit electrification can be formed on a garment material, various micro-electronic components are added to make intelligent clothes, and the fabric requirements of the scientific era are met.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

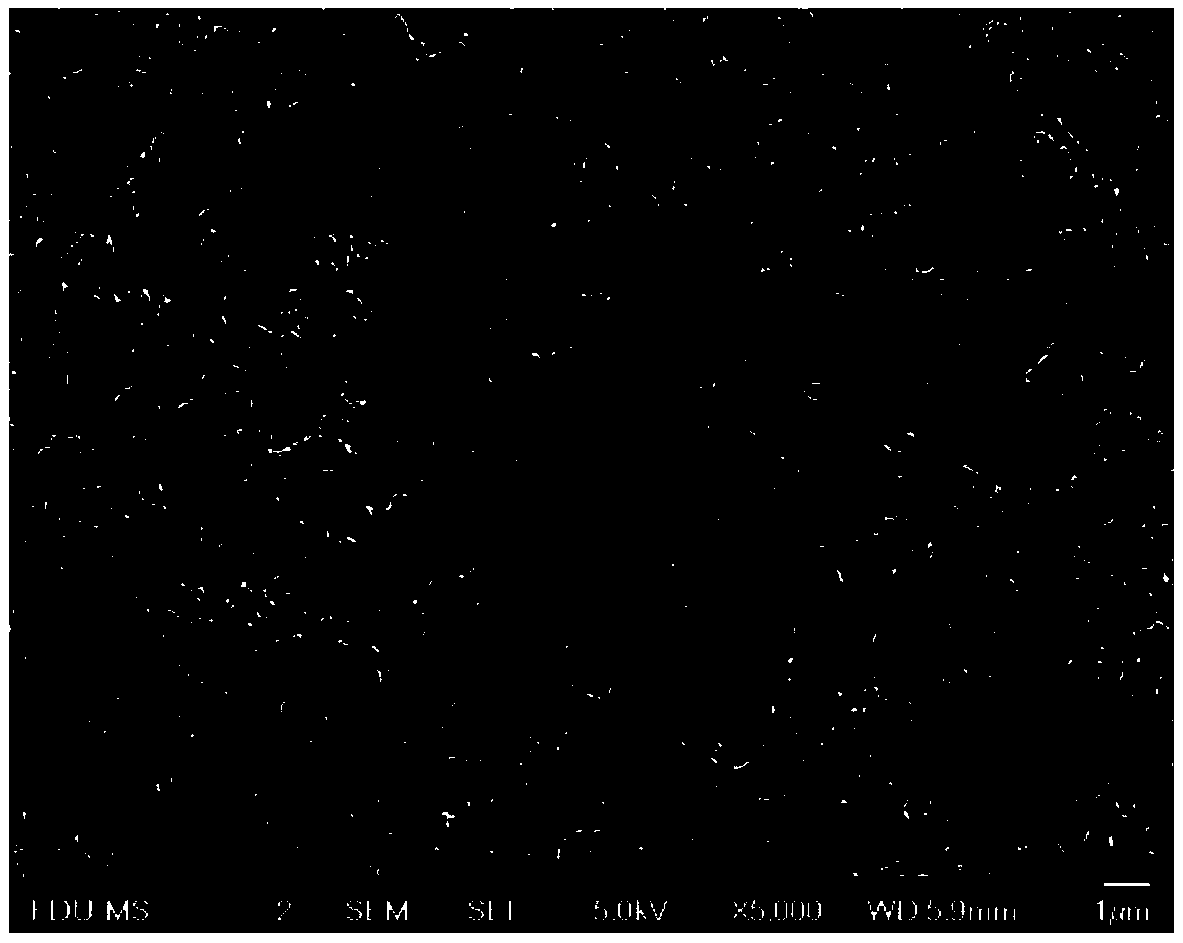

Nano-copper soldering paste, preparing method thereof and copper-copper bonding method

ActiveCN109317859AGuaranteed not to be oxidizedPromote sinteringWelding/cutting media/materialsSoldering mediaNano copperSoldering

The invention belongs to the technical field of electronic materials, and discloses nano-copper soldering paste, a preparing method thereof and a copper-copper bonding method achieved through the nano-copper soldering paste. The nano-copper soldering paste comprises, by mass percent, 50 to 90% of nano-copper particles, 5 to 25% of hydramine and 0 to 45% of a viscosity modifier. The nano-copper soldering paste is used for copper-copper bonding, the sintering temperature can be reduced, oxidation and agglomeration of the nano-copper particles can be avoided, in the 200 DEG C air, sintering can be finished, and the copper-copper inter-connection structure with the higher shear strength can be obtained.

Owner:FUDAN UNIV

A5B19 type rare earth-yttrium-nickel system hydrogen storage alloy added with zirconium and titanium elements

ActiveCN104152749AIncrease capacityThe manufacturing method is simple and safeCell electrodesRare earthTitanium

The invention relates to rare earth system hydrogen storage alloy with the general formula of RExYyNiz-a-b-cMnaAlbMcZrATiB. The peak capacity of an alloy electrode is higher than that of LaNi5 type hydrogen storage alloy, and the manufacturing method is simple and safe. The hydrogen storage alloy has the good activation property, the rate discharge capability, and charging and discharging or hydrogen absorption and desorption circular stability, can be used in the wider temperature range, and is small in self discharging. The method can be used for manufacturing a cathode of an alkaline rechargeable battery and a rechargeable battery with the hydrogen storage alloy.

Owner:BAOTOU RES INST OF RARE EARTHS +2

Composite and method of manufacturing the same

InactiveUS7244373B1High mechanical strengthGood electrical and thermal conductivityMaterial nanotechnologyIndividual molecule manipulationCross-linkNetwork structure

To provide a composite excellent in mechanical strength or in electric conductivity and obtained by combining a carbon nanotube structure and ceramics, and a method of manufacturing the same. The composite is composed of the carbon nanotube structure and the ceramics, and, in the carbon nanotube carbon nanotube structure, functional groups bonded to multiple carbon nanotubes are chemically bonded to mutually cross-link to construct a network structure.

Owner:FUJIFILM BUSINESS INNOVATION CORP

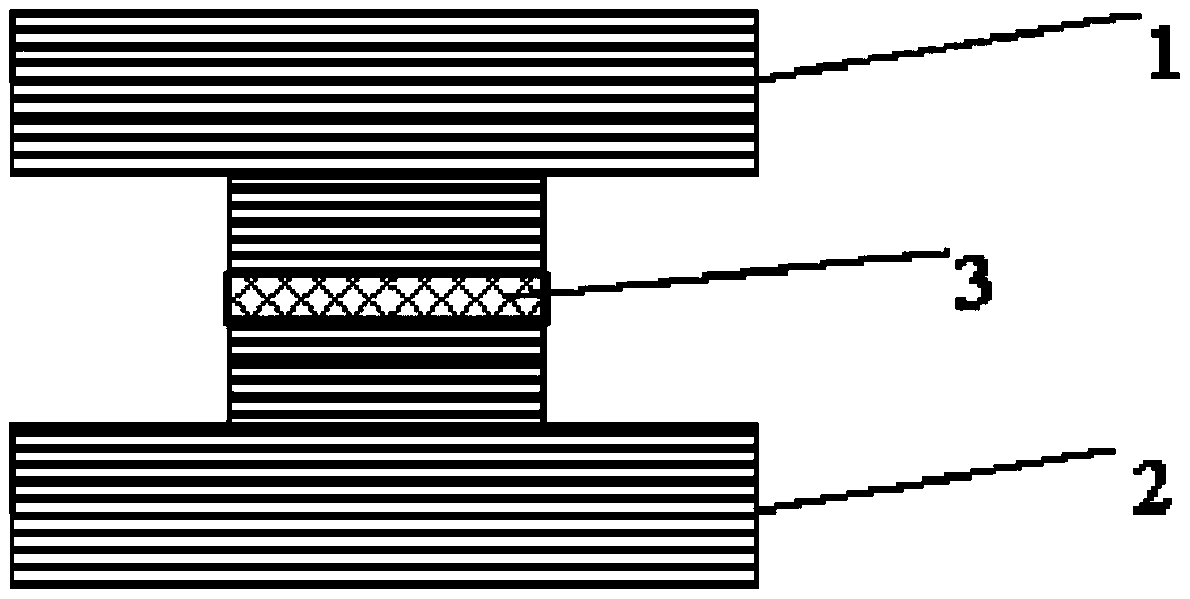

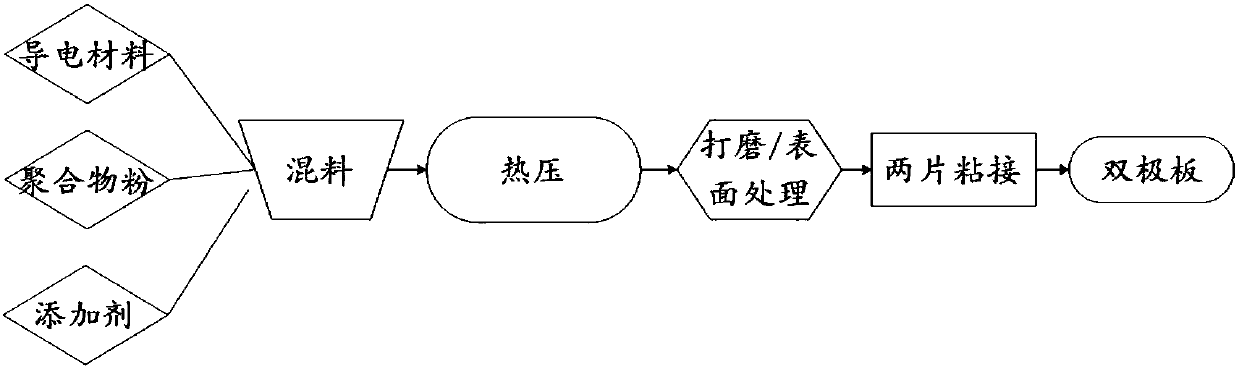

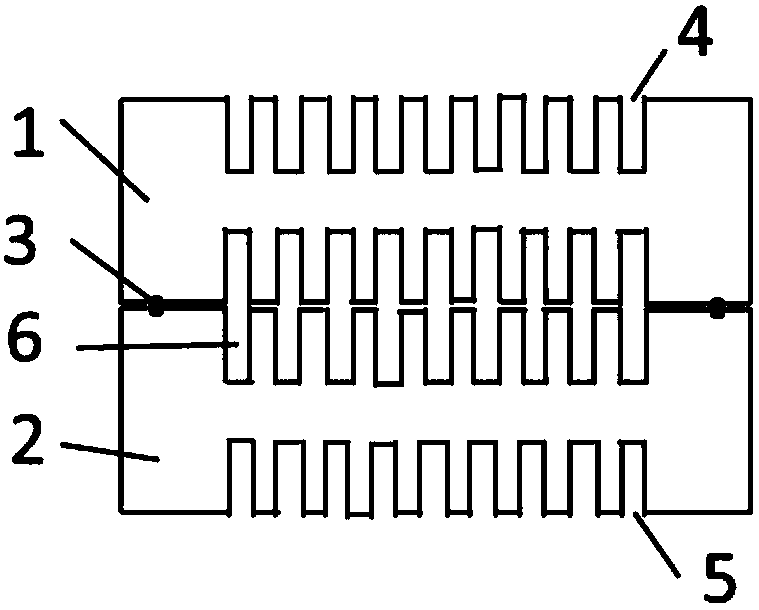

Preparation method and application of bipolar plate

InactiveCN109921053AHigh mechanical strengthGood electrical and thermal conductivityFuel cellsCooling channelPolymer

The invention provides a preparation method of a bipolar plate. The preparation method comprises the steps of preparing raw materials, preparing a monopole plate through a mold hot-pressing method andpreparing the bipolar plate through gluing. The prepared bipolar plate comprises an anode plate, a cathode plate and a cooling channel formed by bonding the anode plate and the cathode plate, by reasonably controlling the content of the polymer and reasonably optimizing the hot-pressing preparation process conditions, the high conductivity and excellent mechanical strength of the bipolar plate are ensured, and by adjusting the technological parameters of blade coating, brush coating, silk-screen printing or dispensing, the good sealing of the polar plate is realized, and a cooling flow channel is ensured. The prepared bipolar plate is applied to a proton exchange membrane fuel cell, and a good performance result is obtained.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparing method for silver plating graphene enhanced copper-based electric contact material

ActiveCN105950904AGood electrical and thermal conductivityImprove welding resistanceTransportation and packagingMetal-working apparatusSilver plateChemical plating

The invention relates to a copper-based electric contact material used in a middle-low-voltage electric appliance switch, in particular to a preparing method for a silver plating graphene enhanced copper-based electric contact composite material. The copper-based composite material comprises, 0.5 wt.%-4 wt.% of bismuth, 0.05 wt.%-0.5 wt.% of yttrium, 0.1 wt.%-0.5 wt.% of graphene (silver plating), 1wt.%-5wt. / % of silver and the balance copper and other inevitable impurities. Copper-yttrium alloy powder is prepared and subjected to chemical silver plating, the copper-yttrium alloy powder and graphene subjected to silver plating treatment are subjected to ball milling and mixed evenly, and the electric contact material is finally prepared through pressing and sintering. The surface of copper powder is subjected to silver plating so that the anti-oxidation performance of the material can be improved, the graphene is subjected to silver plating treatment so that combination between the graphene and a copper base body can be enhanced, and therefore the comprehensive performance of the material is improved, and the copper-based electric contact material good in electric conductivity, resistant to electric arc erosion and excellent in welding resistance is finally obtained.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com