Patents

Literature

1449results about How to "Promote sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar Cell Contacts Containing Aluminum And At Least One Of Boron, Titanium, Nickel, Tin, Silver, Gallium, Zinc, Indium And Copper

InactiveUS20090101190A1Minimises any bowingImprove electrical performanceFinal product manufacturePV power plantsIndiumTitanium

Formulations and methods of making solar cell contacts and cells therewith are disclosed. In general, the invention provides a solar cell comprising a contact made from a mixture wherein, prior to firing, the mixture comprises at least one aluminum source, at least one source of a metal including one or more of boron, titanium, nickel, tin, gallium zinc, indium, and copper, and about 0.1 to about 10 wt % of a glass component. Within the mixture, the overall content of aluminum is about 50 wt % to about 85 wt % of the mixture, and the overall combined content of boron, nickel, tin, silver, gallium, zinc, indium, copper, is about 0.05 to about 40 wt % of the mixture.

Owner:HERAEUS PRECIOUS METALS NORTH AMERICA CONSHOHOCKEN

Boron carbide based bulletproof composite ceramic and preparation method thereof

The preparation method for boron carbide composite bulletproof ceramics comprises: selecting the material by weight ratio as 85~95 boron carbide, 1~15 carborundum whisker, 2~15 silicon powder, and 1~5 boride; with anhydrous alcohol as medium, grinding and mixing the material; then drying in vacuum to prepare the mixed powder and add into the graphite mould with layers separated by graphite spacer and graphite paper; hot pressing and sintering with pressure as 30~40MPa at 1700~2000Deg. This product has low density, high strength and elastic modulus.

Owner:SHANDONG UNIV

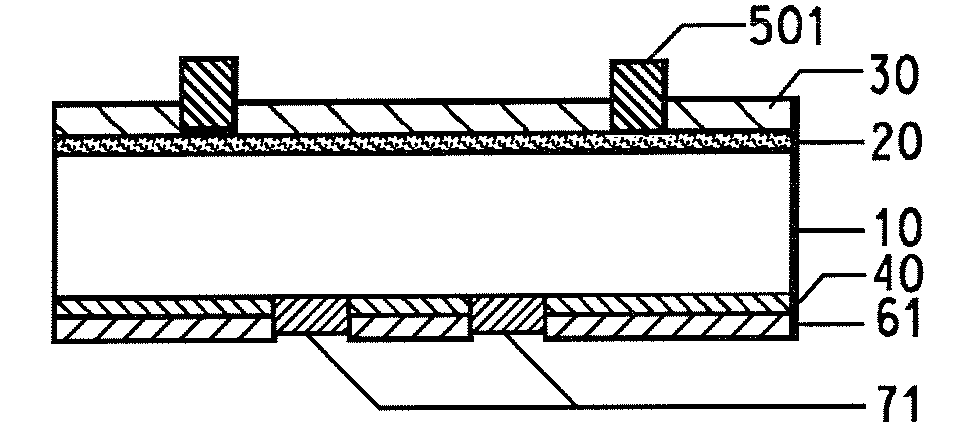

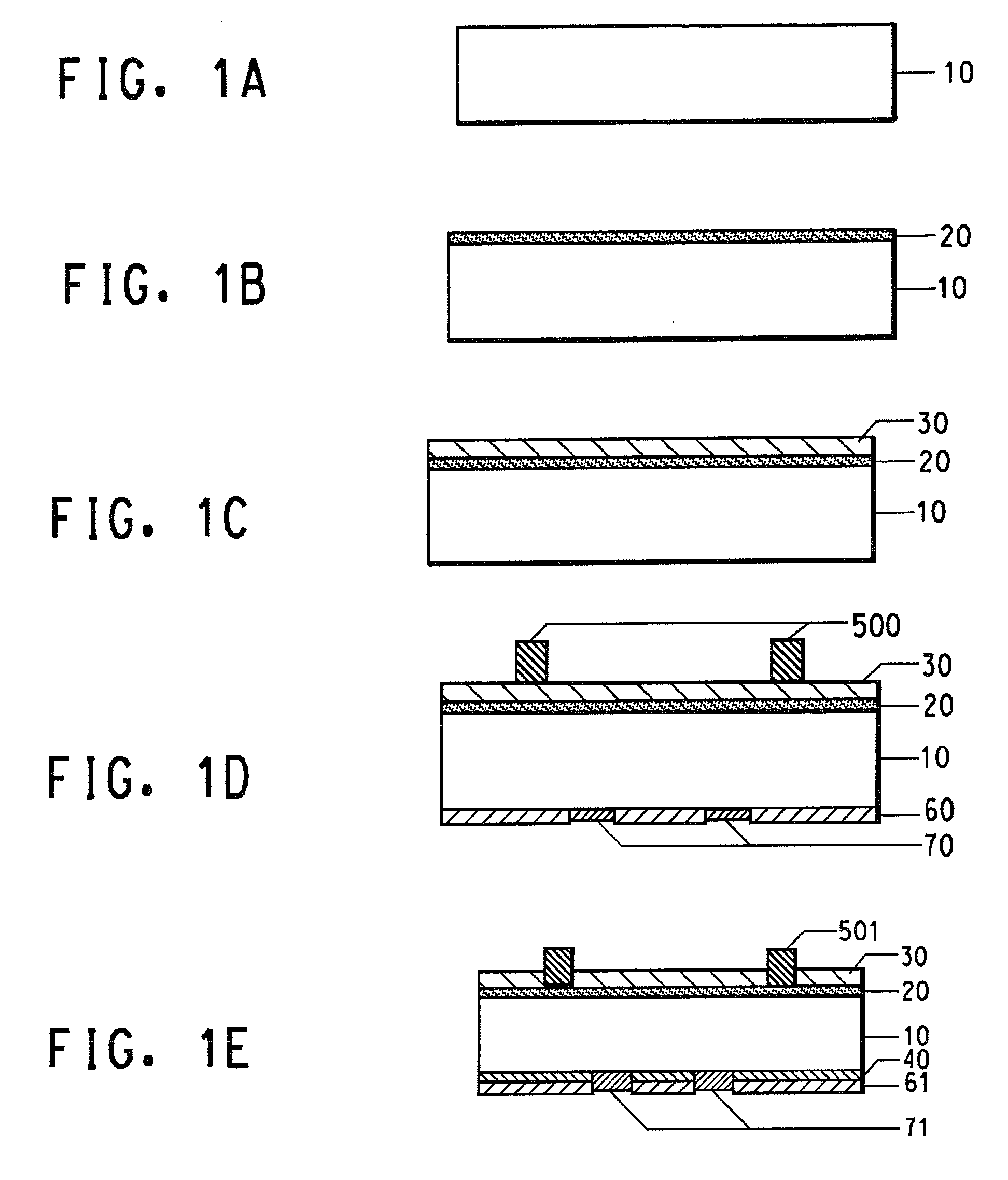

Garnet-Type Oxide Sintered Body and Method for Producing Same

ActiveUS20180175446A1High densityImprove ionic conductivityZirconium compoundsSecondary cellsLithiumHigh density

A garnet-type oxide sintered body according to the present invention includes crystal grains composed of a garnet-type oxide containing Li, La and Zr and a grain boundary composition containing boron and silicon and filling gaps between the crystal grains. The oxide sintered body has the characteristics of high density and high ion conductivity. A production method of the sintered body includes a step of providing a precursor material by mixing a garnet-type oxide powder containing Li, La and Zr with a sintering aid; a step of forming the precursor material into a formed body; and a sintering step of sintering the formed body. The sintering aid contains oxygen, boron, silicon and lithium. The oxygen and boron, or the oxygen and silicon, contained in the sintered aid form a compound.

Owner:CENT GLASS CO LTD

Preparation method for zirconium-based amorphous alloy as well as powder and large-sized block of zirconium-based amorphous alloy

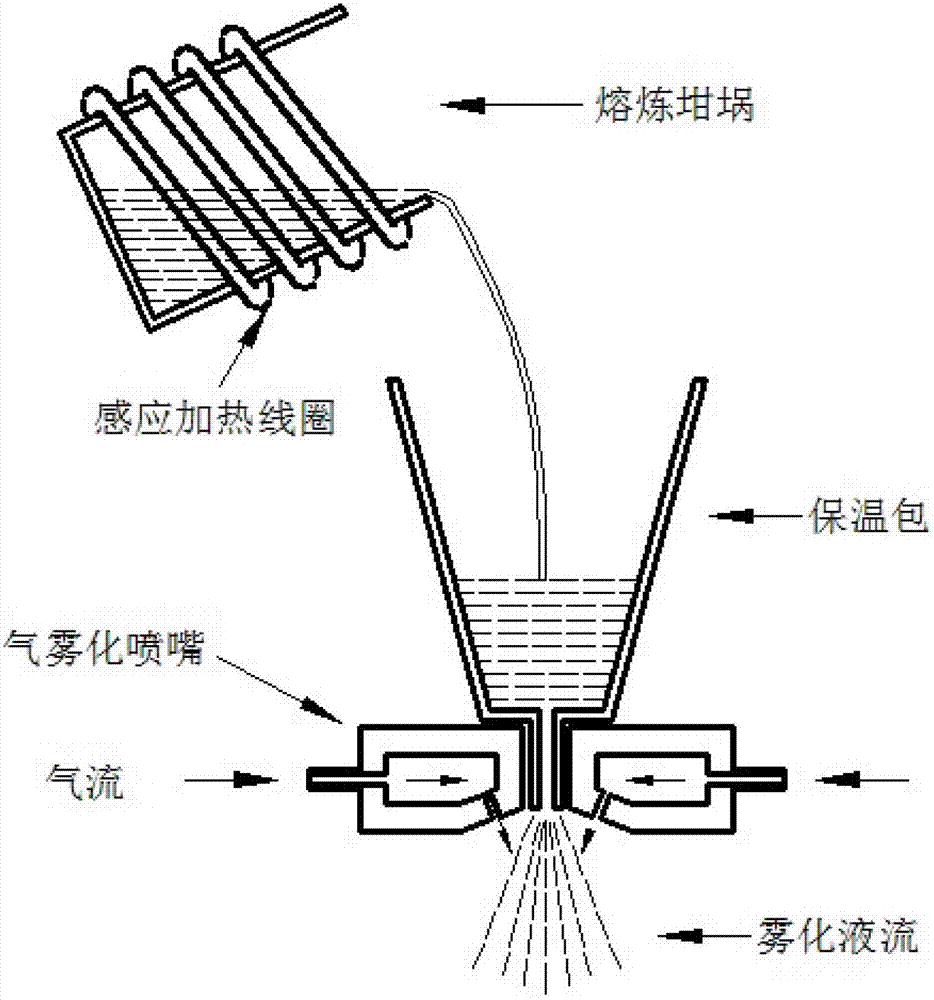

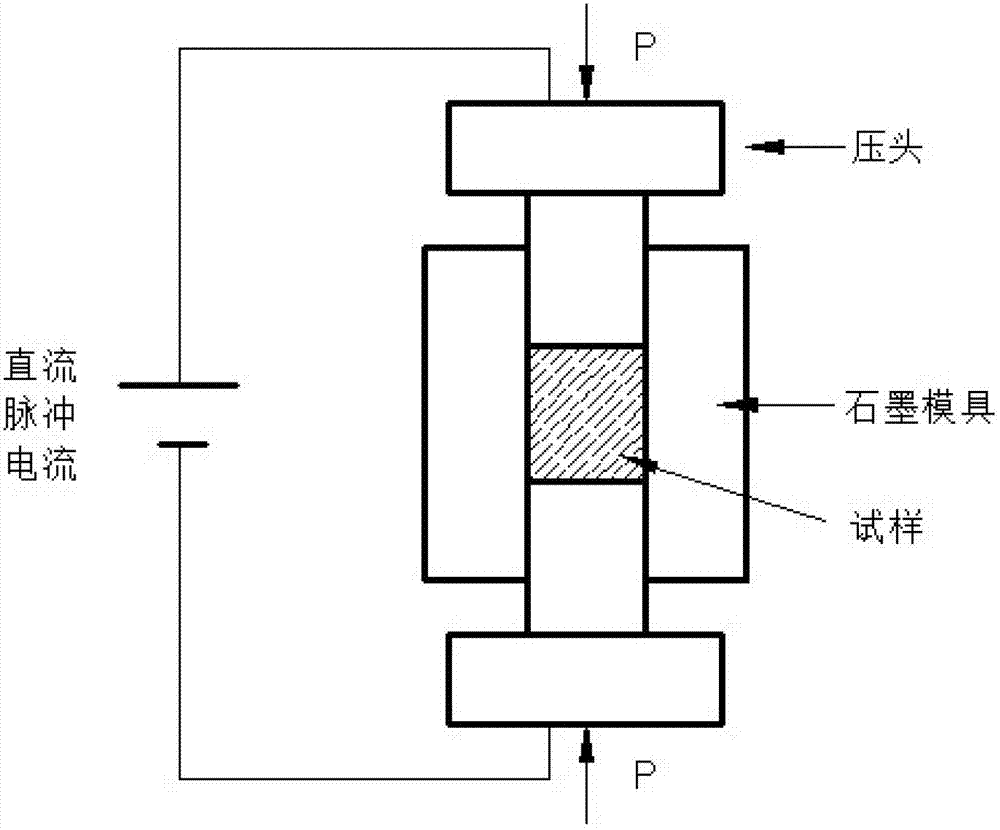

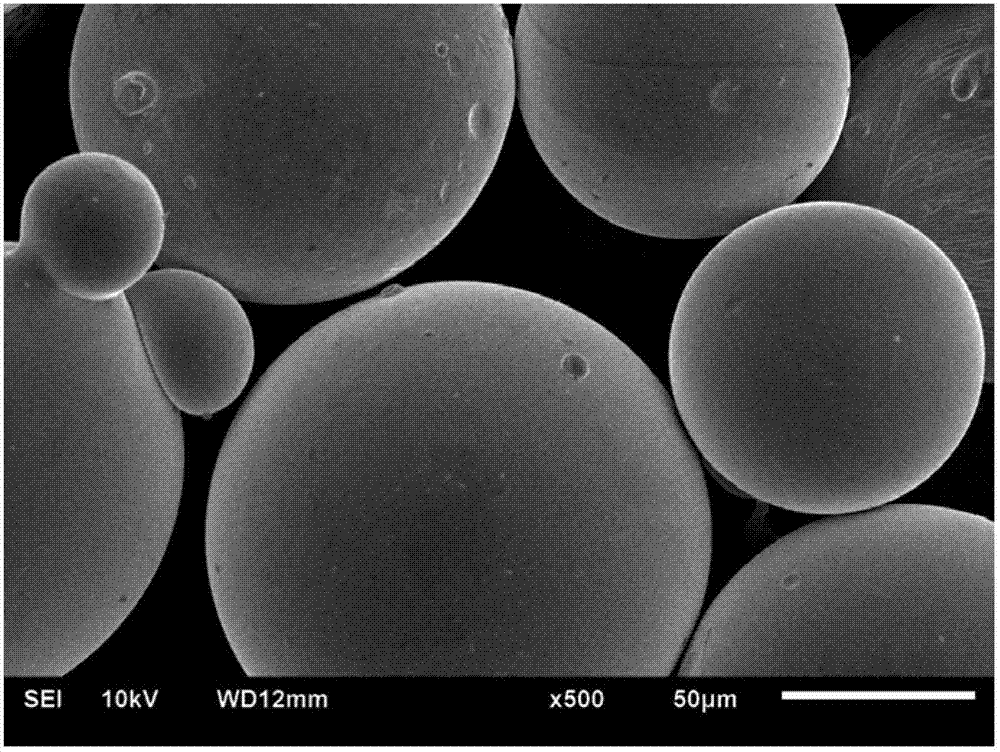

The invention relates to a preparation method for a zirconium-based amorphous alloy as well as powder and a large-sized block of the zirconium-based amorphous alloy, which belongs to the field of amorphous alloys, and is characterized by comprising the component of Zr61(Cu, Ni)27.5Al10Re1.5(at%), wherein Re is Y, La, Ce, Nd, Gd and Er, and adopting a manner of combination of the gas atomization powder milling technology and the spark plasma sintering technology. The preparation method comprises the following steps: preparing raw materials according to components of the amorphous alloy, and placing the raw materials into an induction crucible of gas atomization powder milling equipment; vacuumizing and filling inert gas for shielding; smelting to obtain an alloy solution with uniform components under the action of induction heating; pouring the alloy solution after smelting into an insulation bag at a constant speed slowly, and filling high-pressure inert gas as an atomizing medium at the same time; atomizing the alloy solution flow into small droplets under the impact of high-pressure airflow, and finally cooling to form amorphous alloy powder; collecting and screening the amorphous alloy powder; and under the protection of the inert gas, utilizing the spark plasma sintering technology to perform sintering on the amorphous alloy powder at different temperatures and pressure to obtain an amorphous alloy block.

Owner:UNIV OF SCI & TECH BEIJING

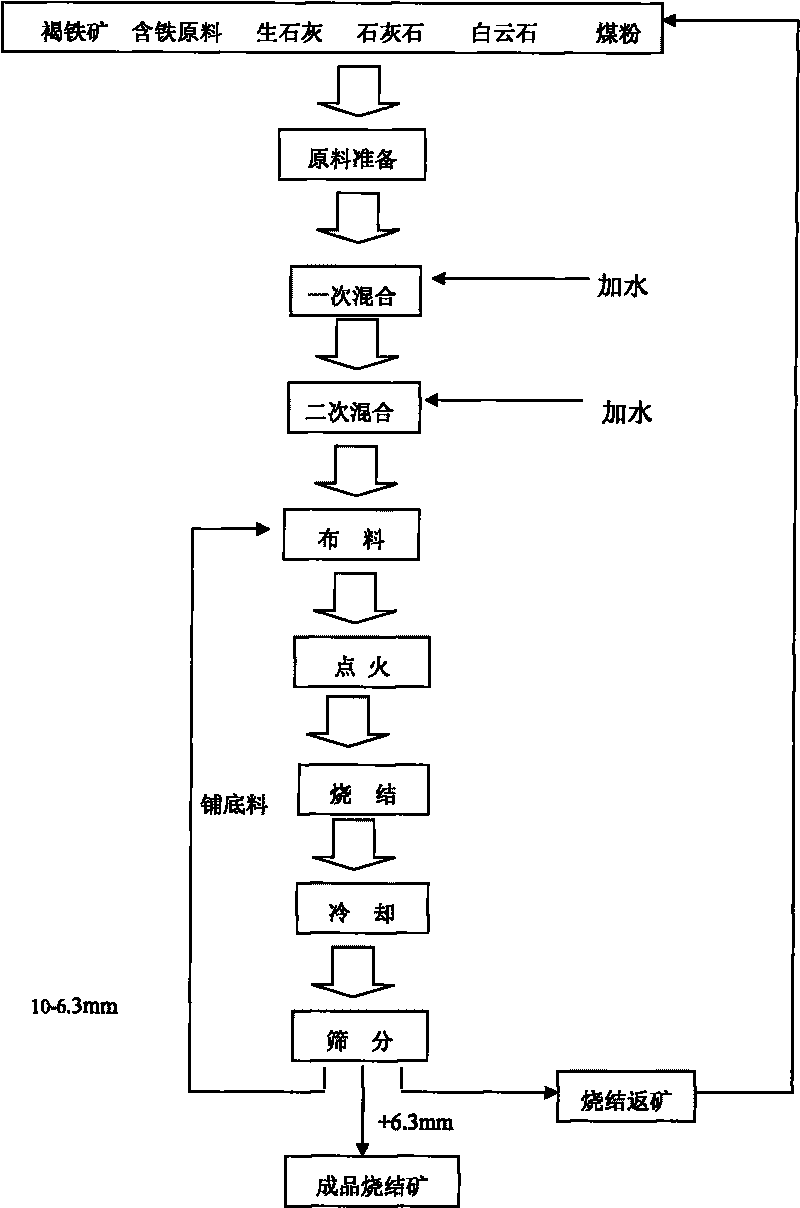

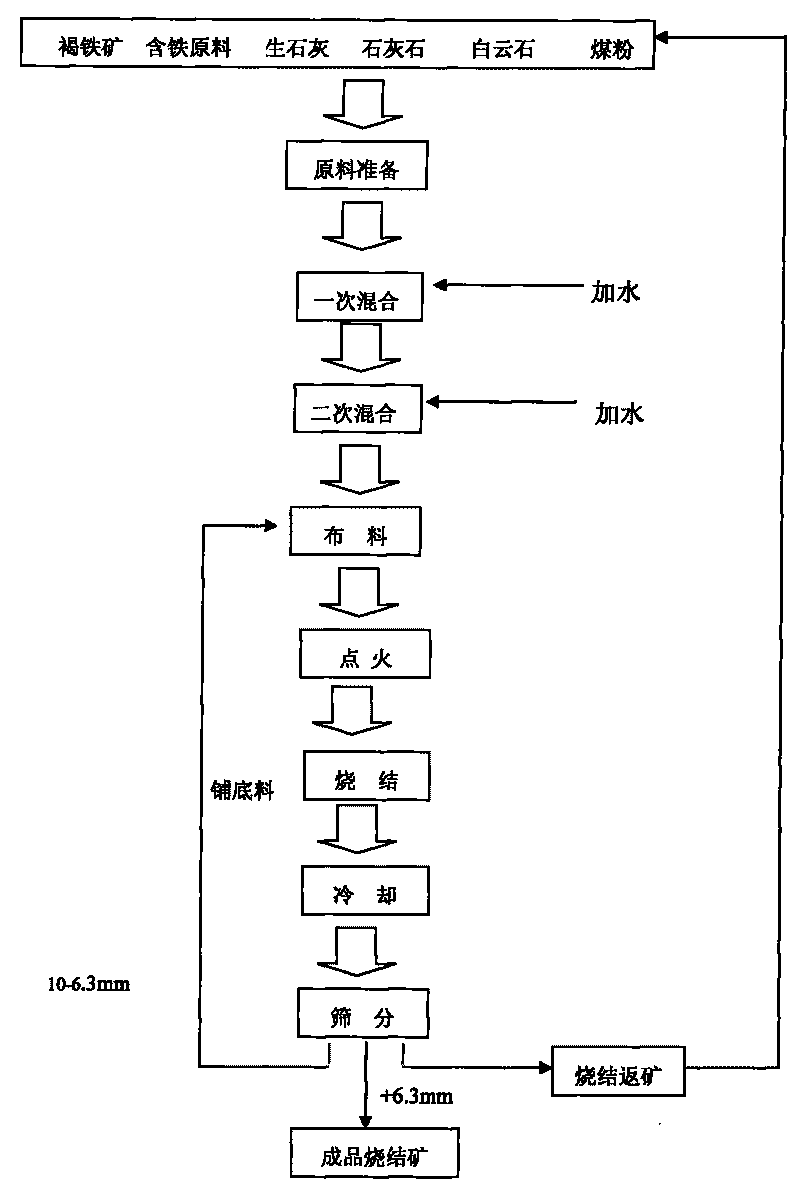

Method for intensifying limonite sintering

InactiveCN101701289APromote sinteringImprove granulation effectBlast furnace detailsSucrose solutionMoisture

A method for intensifying limonite sintering has the advantage of changing the property of the moisture of the mixture by adding sucrose solution with weight concentration being 4-10%. The solution has certain viscosity which is reduced with the increase of the temperature. In the processes of mixing and granulating, the mineral powder with fine grains is well adhered to the surfaces of pellets, thus intensifying limonite granulating, improving the intensity of the pellets of the mixture and achieving the aims of intensifying limonite sintering, improving the quality of sintered minerals and reducing solid fuel consumption. The method has better effects especially on the limonite with finer grain sizes. The sucrose has the greatest characteristic of totally reacting in the process of sintering and leaving no residues in the sinter, thus having no impact on the quality of the sinter.

Owner:WUHAN IRON & STEEL (GROUP) CORP

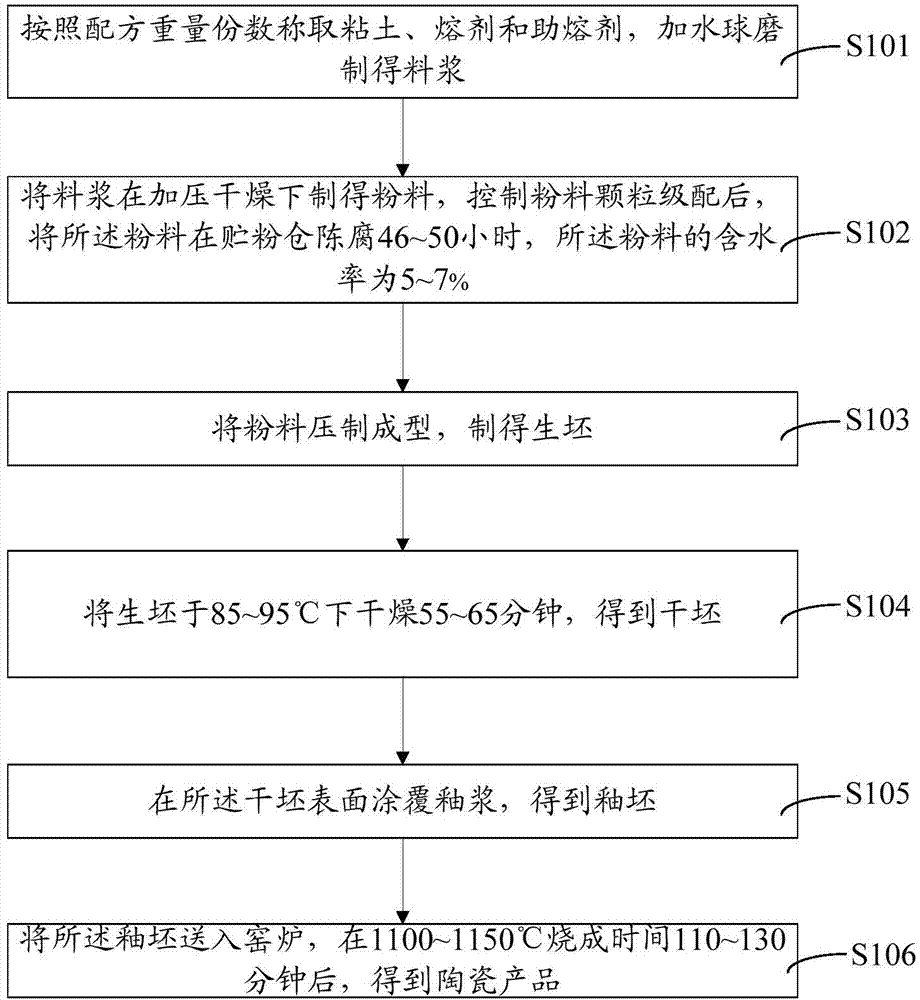

Ceramic formula and preparation method for ceramic product

The invention provides a ceramic formula, comprising, by weight, 55 to 65 parts of clay, 20 to 30 parts of a flux and 15 to 23 parts of a fluxing agent, wherein the clay is a mixture of purple sandshale and china clay mixed according to a weight ratio of 0.67 to 2.0, the flux is shale, and the fluxing agent is one or more selected from the group consisting of limestone, calcite, diopside, wollastonite, dolomite, talcum and industrial waste residue. A preparation method for a ceramic product comprises the following steps: weighing the clay, the flux and the fluxing agent according to the formula, carrying out crushing and screening with a 250-mesh sieve, wherein the weight of screen residue is 1 to 1.5%, adding water, carrying out blending to obtain slurry and then carrying out drying and granulation so as to obtain powder; grading particles and then carrying out molding so as to prepare a green body; carrying out drying so as to prepare a dry body; and carrying out firing so as to prepare a seasonal ceramic body. According to the ceramic formula and the preparation method for the ceramic product in the invention, raw materials are cheap, process is simple, firing temperature is reduced, production cost is decreased, investment for production equipment is lowered down, production efficiency is improved, and energy consumption is reduced.

Owner:怀化市亿智陶瓷有限公司

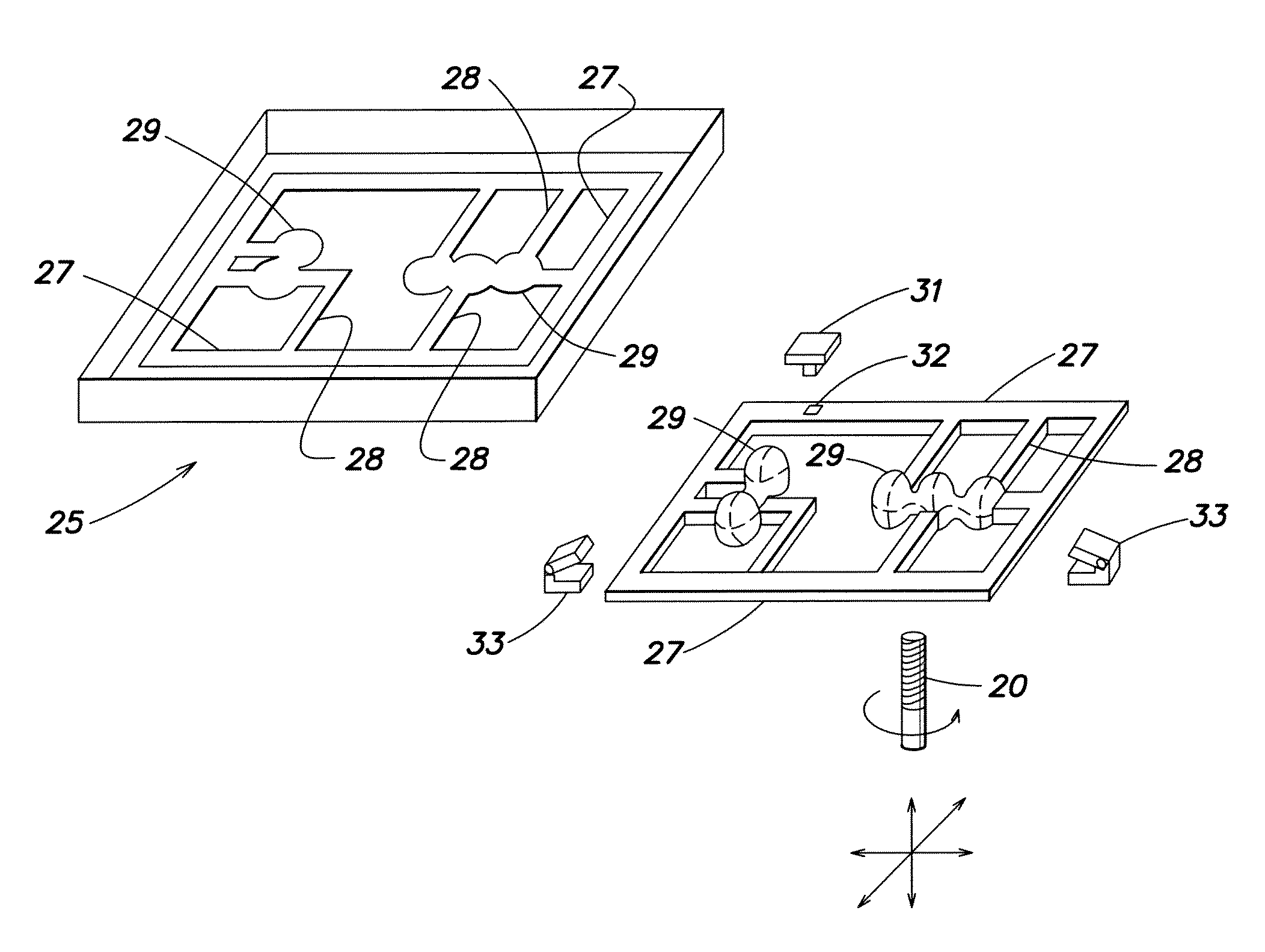

Method for manufacturing dental prostheses, method for creating a data record and computer-readable medium

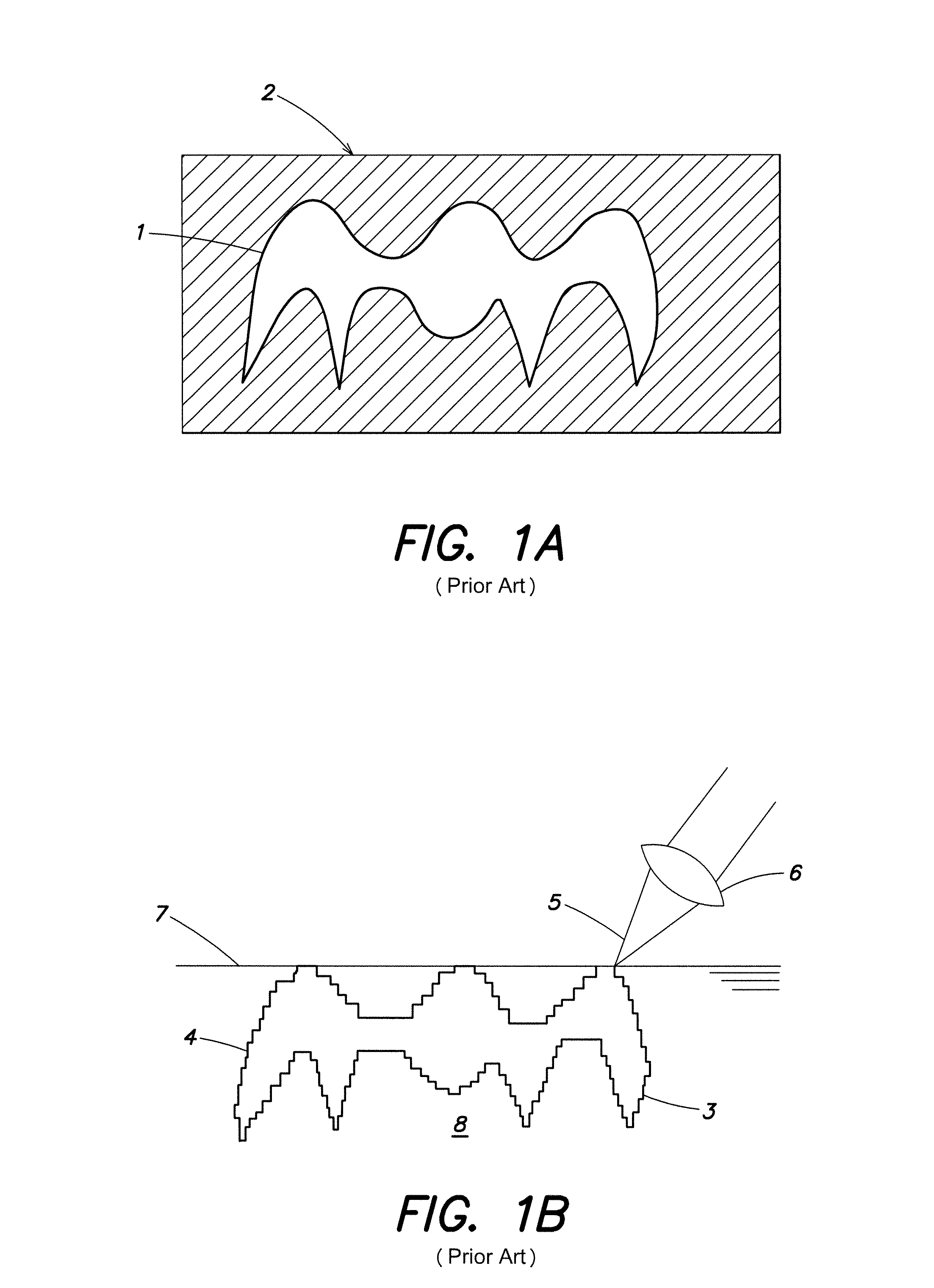

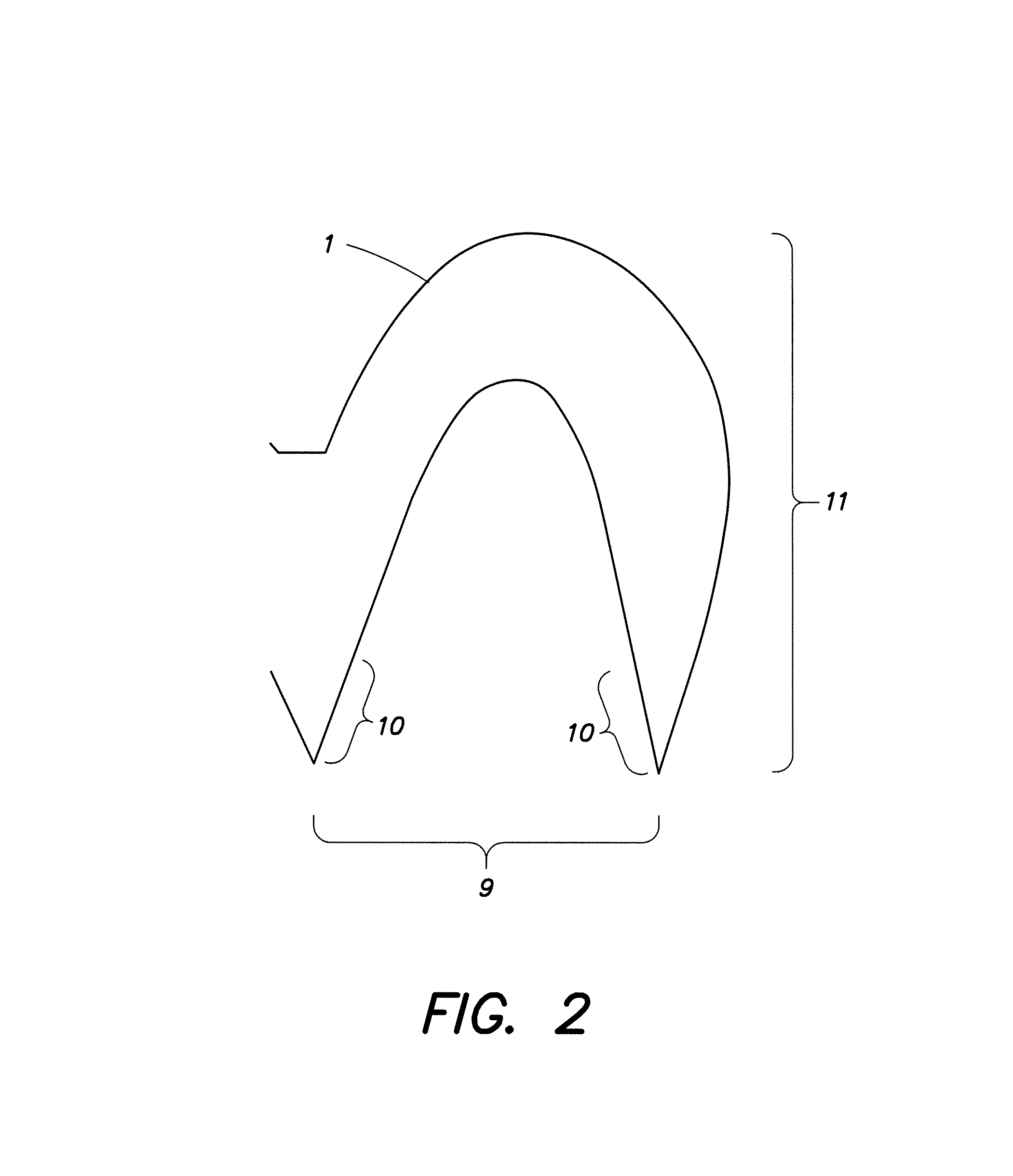

ActiveUS8021154B2Addressing slow performanceReduce processing stepsAdditive manufacturing apparatusTooth crownsDenturesProsthesis

A method for manufacturing one or several dental prostheses, comprising the steps of: performing a rapid prototyping method for manufacturing one or several dental prostheses and subsequent working, such as reworking, of the one or several dental prostheses with a machining method, such as a milling method. In addition, a method for creating a data record which can be used for a rapid prototyping method for manufacturing a dental prosthesis wherein an end data record is obtained from a starting data record, so that in at least one area of a dental prosthesis manufactured with the end data record excess material is provided, compared to a dental prosthesis manufactured with the starting data record.

Owner:INSTITUT STRAUMANN AG +1

Sintering method for high-chromic vanadium-titanium ferroferrite

The invention discloses a sintering method of high-chromine typed V-Ti-bearing iron ore, which comprises the following steps: 1) allocating limestone and fined ferric ore to make grain; 2) adding water to wet; 3) putting wet and grained materials into sintering material in the mixer to ball; adding B2O3 in the composite material; 4) adding MgO in the composite material; 5) loading the composite material into sintering cup or sintering machine to sinter over 50 deg.c; increasing the content of calcium ferrite in the sintering ore by 5% and production by 4.2-5.0%.

Owner:PANZHIHUA IRON AND STEEL

Aluminum chrome refractory material

The invention belongs to the technical field of refractory materials, in particular to an aluminum chrome refractory material, which takes white fused corundum as a body and is formed by adding scraps (the scraps are collected and crushed into the synthetic size) generated in the cold processing process of a dense chromic oxide product, Alpha-Al2O3 powder or chrome oxide green or white fused corundum powder and sintering at a high temperature in combination with an inorganic binding agent or an organic binding agent. A product obtained in the invention can be widely applied to a coal water slurry gasification furnace back lining, a hard carbon black reaction furnace inner lining, a residual oil gasification furnace inner lining in the petrochemical industry, a glass wool molten pool inner lining and the like, fully and effectively makes use of the scraps generated in the cold processing process of the dense chromic oxide product and has the characteristics of low impurity content, high refractoriness, excellent physical performance, good thermal shock resistance and strong erosion resistance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Rare earth thick film circuit electrical heating element based on aluminum nitride minicrystal ceramic substrates and its preparation technique

ActiveCN101321415AHigh thermal conductivityImprove electrical performanceHeating element materialsRare earthHigh power density

The invention provides a controllable electrical heating element of rare-earth thick-film circuit based on aluminum nitride microcrystal ceramic base plate and manufacturing method thereof, comprising base pieces and serial electronic sizing agents which are manufactured on the base pieces. The serial electronic sizing agents comprise package sizing agent and electronic sizing agent, and are all composed of three parts including a functional phase, an inorganic bonding phase and an organic carrier. The serial electronic sizing agents further comprise rare-earth resistance sizing agent. The base piece is ALN aluminum nitride microcrystal ceramic base piece. The serial electronic sizing agents are manufactured on the base piece by means of thick film circuit. The invention synchronously further provides formulations of ALN aluminum nitride microcrystal ceramic base piece, rare-earth envelopment sizing agent, rare-earth resistance sizing agent and rare-earth electrode sizing agent. The invention is environment-friendly, safe and reliable by providing with equal and controllable heating temperature field, large power, high power density, high efficiency of heat conduction, high speed of response, high efficiency for saving energy, strong capability of thermal-shock resistance, small volume and wide application range.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

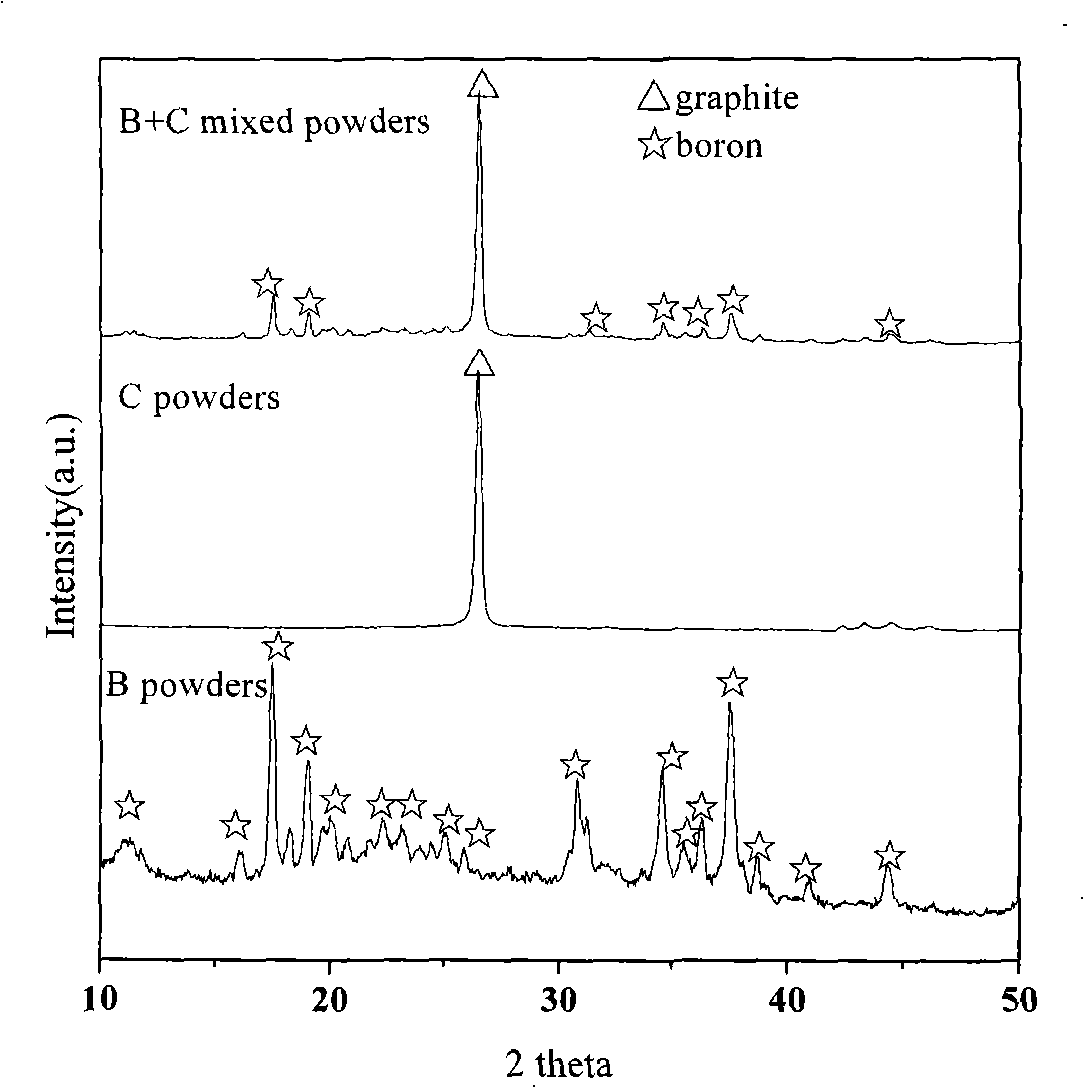

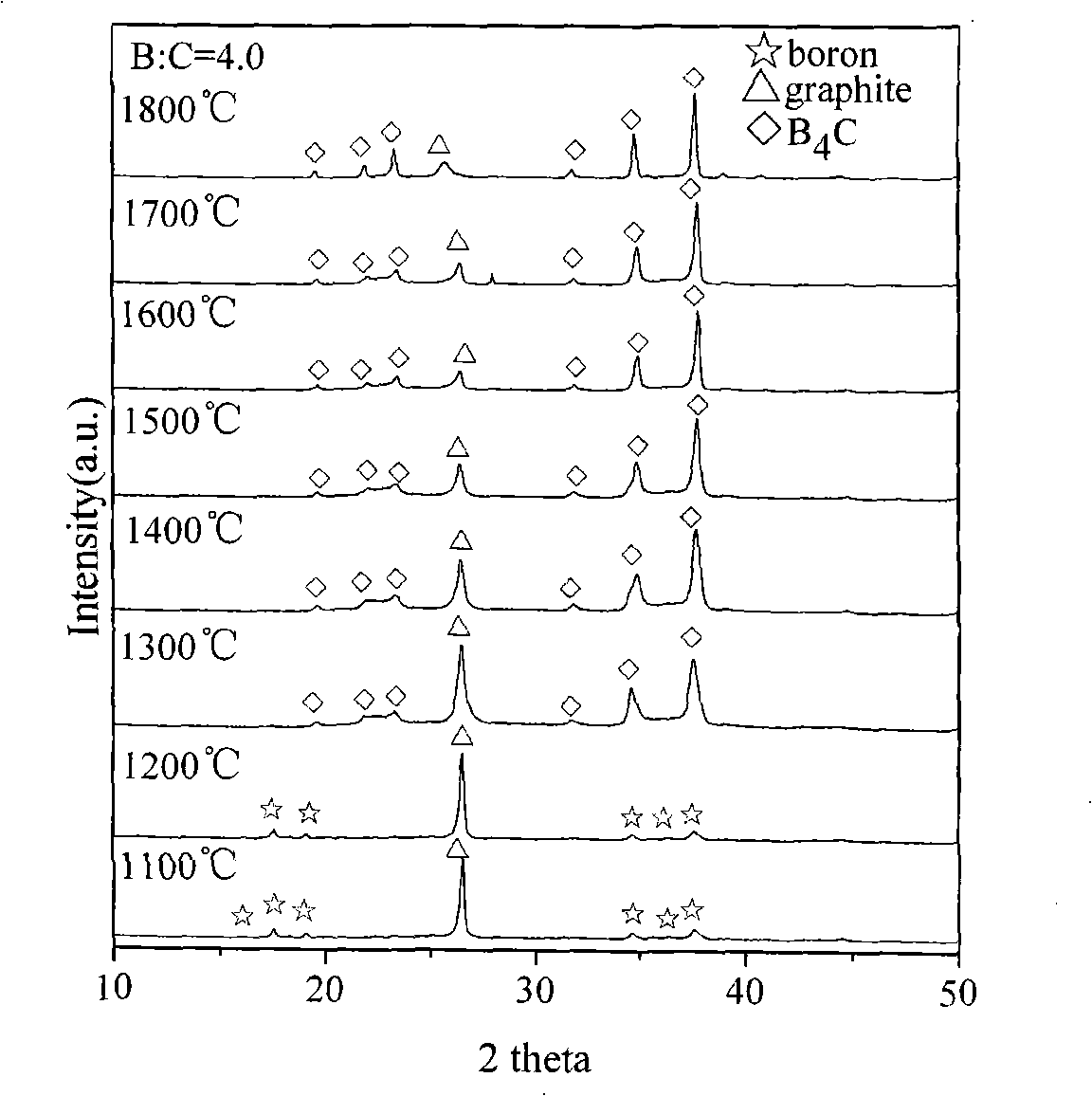

Method for preparing boron carbide ceramic

The present invention relates to a preparation method of boron carbide ceramics. In particular, the preparation method comprises the following steps: first, boron powder and carbon powder are weighed and mixed with the molar ratio of boron and carbon equal to 0.5 to 22.5; secondly, the powder prepared in the first step is arranged in a die and transmitted to discharging plasma sintering equipment for sintering, and the temperature is raised to be between 1300 and 2200 DEG C under the vacuum conditions; thirdly, the die is taken out from the discharging plasma sintering equipment and cooled to be at the room temperature; then the die is drawn away and thus the final product is prepared. In the preparation method, the direct synthesis and densification of boron carbide are completed in one step; the powder is sintered under the vacuum conditions; and the prepared boron carbide ceramics has the advantages of high purity, variety in the ratio of boron and carbon, and high hardness.

Owner:WUHAN UNIV OF TECH

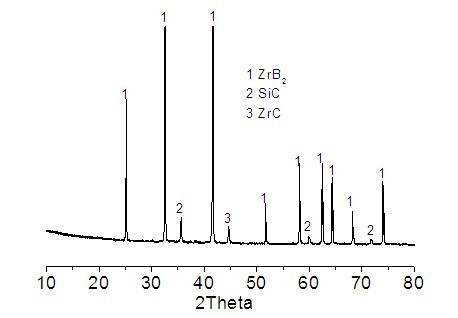

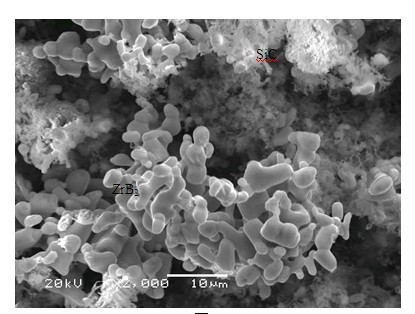

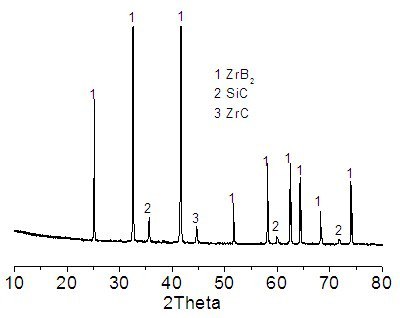

ZrB2-SiC composite powder and preparation method thereof

InactiveCN102320850AFix issues with restricted usageSynthesis temperature is lowUltra-high-temperature ceramicsRefractory

The invention discloses ZrB2-SiC composite powder and a preparation method thereof. According to the invention, zircon sand, a boron raw material and a carbon raw material are adopted as main materials. The main materials are mixed, grinded, and are heated under a temperature of 1350 to 1480 DEG C, such that the powder is obtained. The powder comprises components of, by weight: 37 to 63% of ZrSiO4, 16 to 32% of B2O3, and 20 to 28% of C, wherein the boron raw material is calculated according to the amount of B2O3, and the carbon raw material is calculated according to the amount of C element. According to the invention, natural zircon sand with a relatively low price is used as a raw material for producing high-grade ZrB2-SiC. The advantages of ZrB2 and SiC are combined. Mutual complement of advantages can be realized when ZrB2 and SiC are used in the field of high-temperature materials. ZrB2-SiC provides relatively high thermal conductivity, excellent thermal shock resistance and corrosion resistance. When ZrB2-SiC is introduced into the composite powder, high-temperature mechanical properties, oxidative stabilities and corrosion resistances of ultra-high temperature ceramics and refractory materials can be improved.

Owner:ZHENGZHOU UNIV

Improved type slag splashing furnace protecting material and preparation method thereof

InactiveCN101200772ASave resourcesReduce manufacturing costSolid waste managementManufacturing convertersSteelmakingBrick

The invention provides modified slag splashing maintenance material which can be used in multiple furnaces and a preparation method thereof. The invention is characterized in that the maintenance material comprises waste magnesium carbon bricks, complex deoxidizer (metal magnesium powder, metal aluminum powder and ferrosilicon alloy), raw materials containing TiO2, etc. The mass percentage is: 30 percent to 75 percent of MgO, 3 percent to 20 percent of total C, 2 percent to 10 percent of Al2O3, 1 percent to 10 percent of TiO2, 0.3 percent to 5 percent of Mg, 1 percent to 12 percent of Al, and the residue is SiO2. The complex deoxidizer amount obviously improves the reduction of the furnace temperature on FeO and improves the yield rate of the converter steelmaking. Specifically, nitrogen that is blown in when TiO2 and splashing slag are introduced helps to form the nitrogen titanium compound with high melting point, which improves the viscosity of the slag, enhances the adhesion force of the splashing slag material to MgO-C bricks of lining bricks of the converter and improves the maintenance effect. And the bonding strength of the splashing slag layer with the converter lining bricks is improved because of the join of TiO2. The obvious effect of the splashing slag maintenance technology is obtained that one time of the slag splashing can support 3 to 5 converters rather than just one before.

Owner:PANZHIHUA SHUNTENG GRP METALLURGY MATERIAL

Method for preparing tungsten-containing alumina ceramic heating substrate

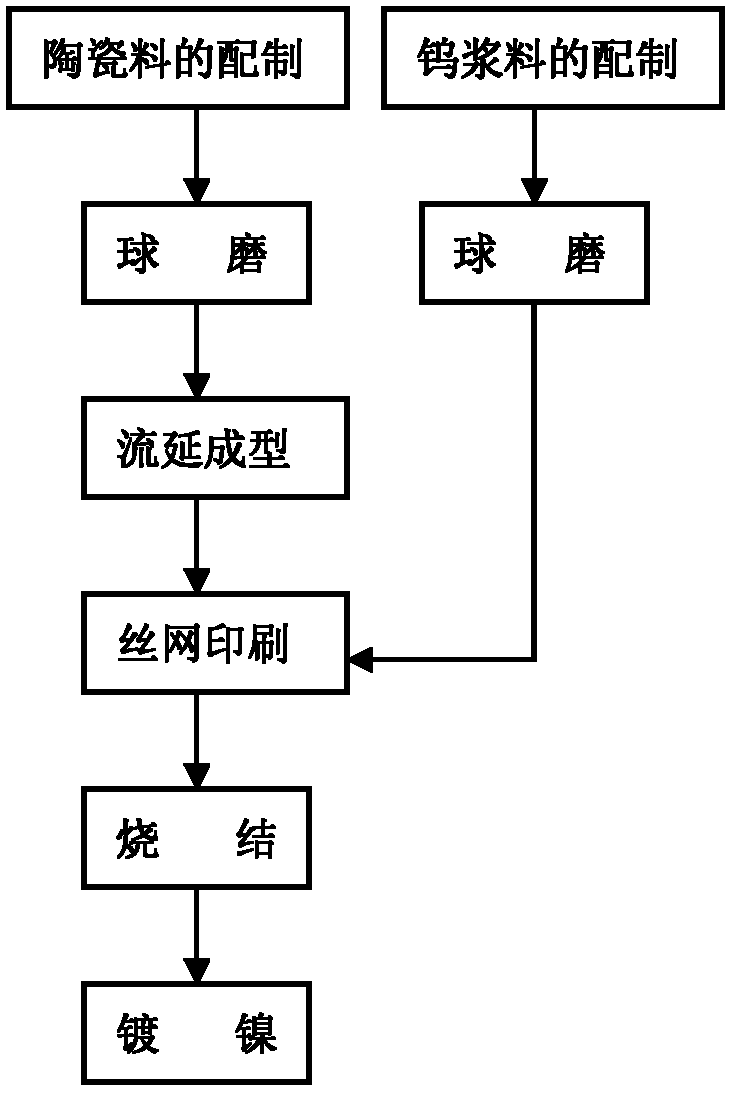

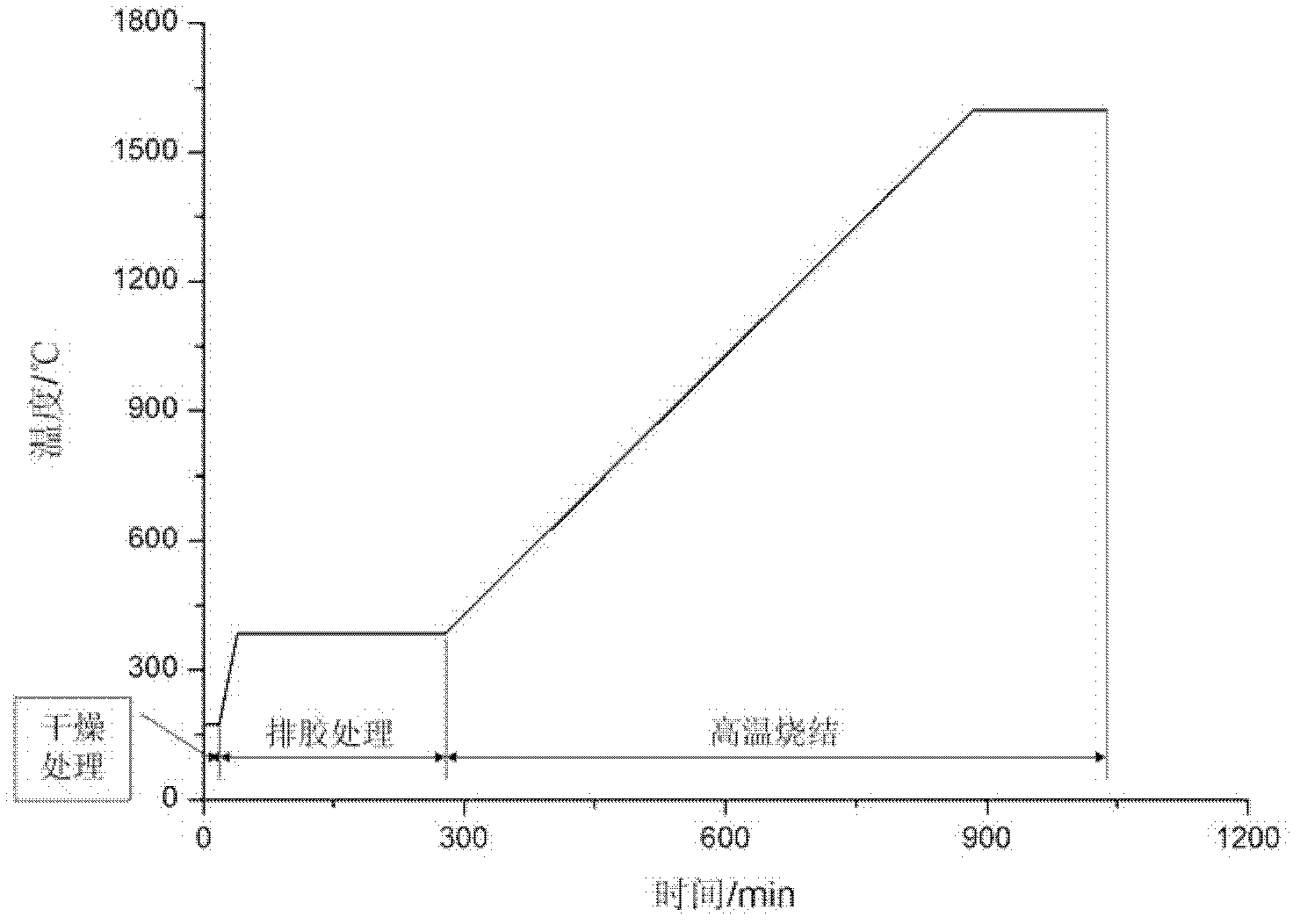

The invention provides a method for preparing a tungsten-containing alumina ceramic heating substrate, and relates to a method for preparing a ceramic heating element. The invention is capable of solving the problems of poor wettability on powder by a solvent (water), difficult defoaming on slurry, slow volatilization, long drying time, poor bonding force of ceramic and metal level after sintering during an aqueous tape-casting process. The method for preparing the tungsten-containing alumina ceramic heating substrate can substantially enhance the sintering qualification rate and production efficiency. The method comprises the following steps: preparing a premix compound and tungsten slurry, ball milling, tape-casting, screen printing, sintering and nickel plating.

Owner:XIAMEN UNIV

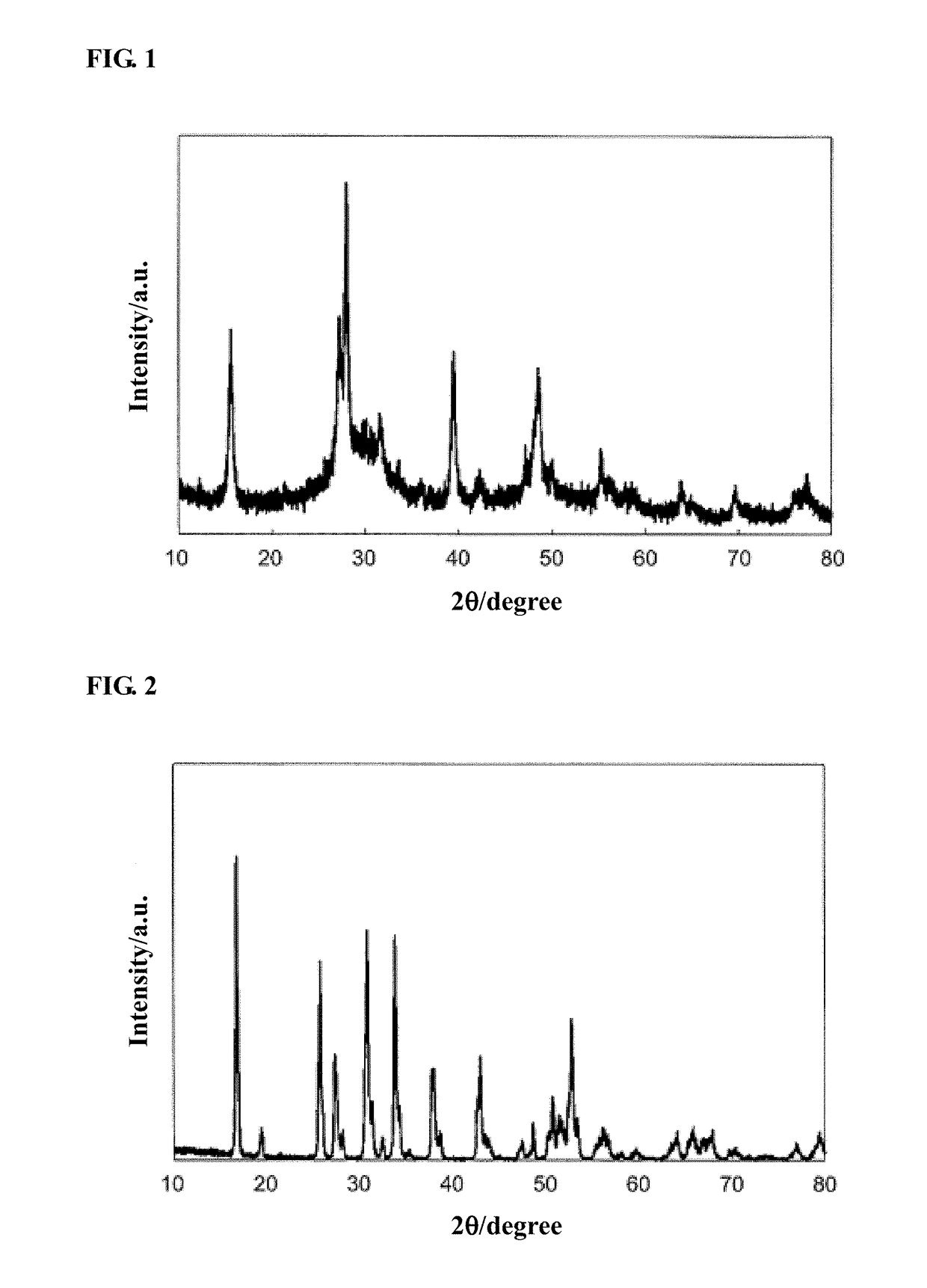

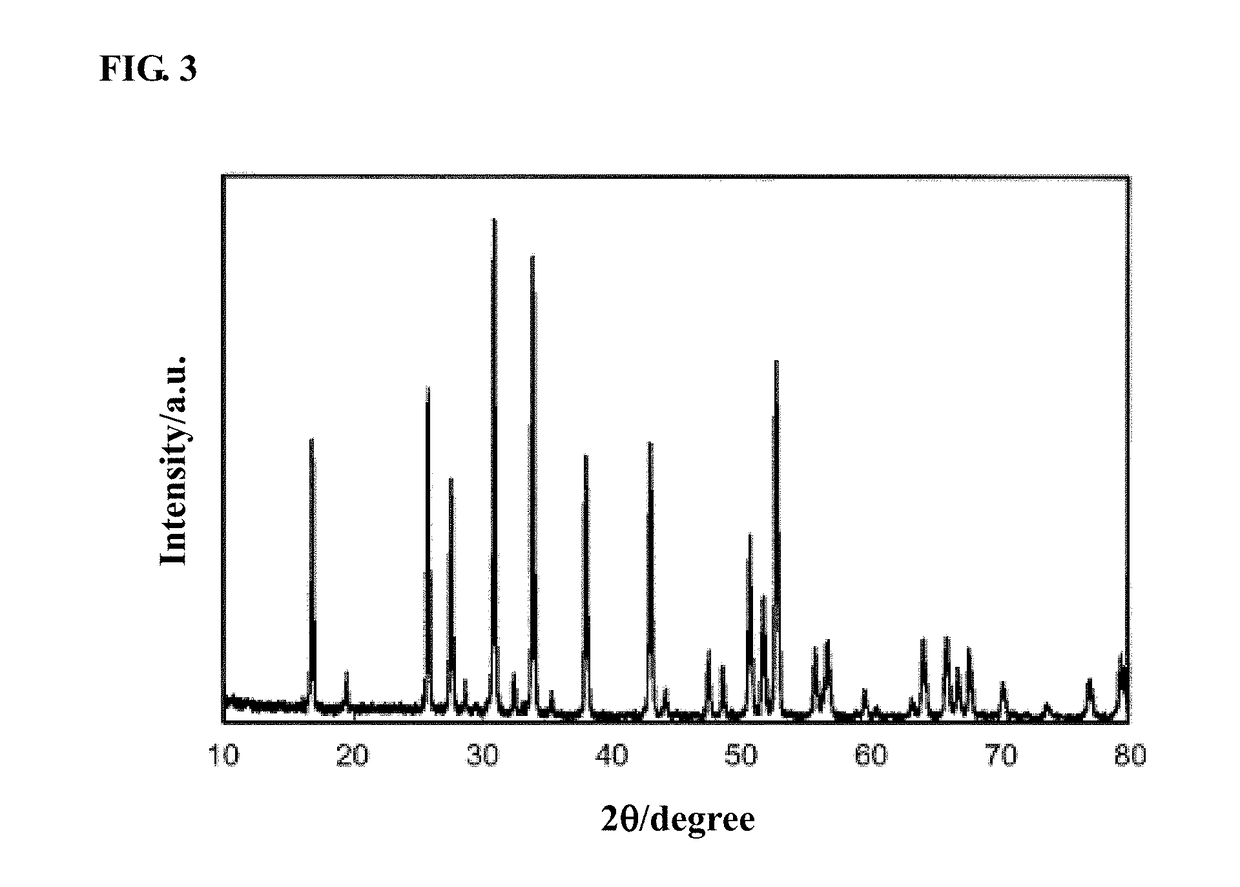

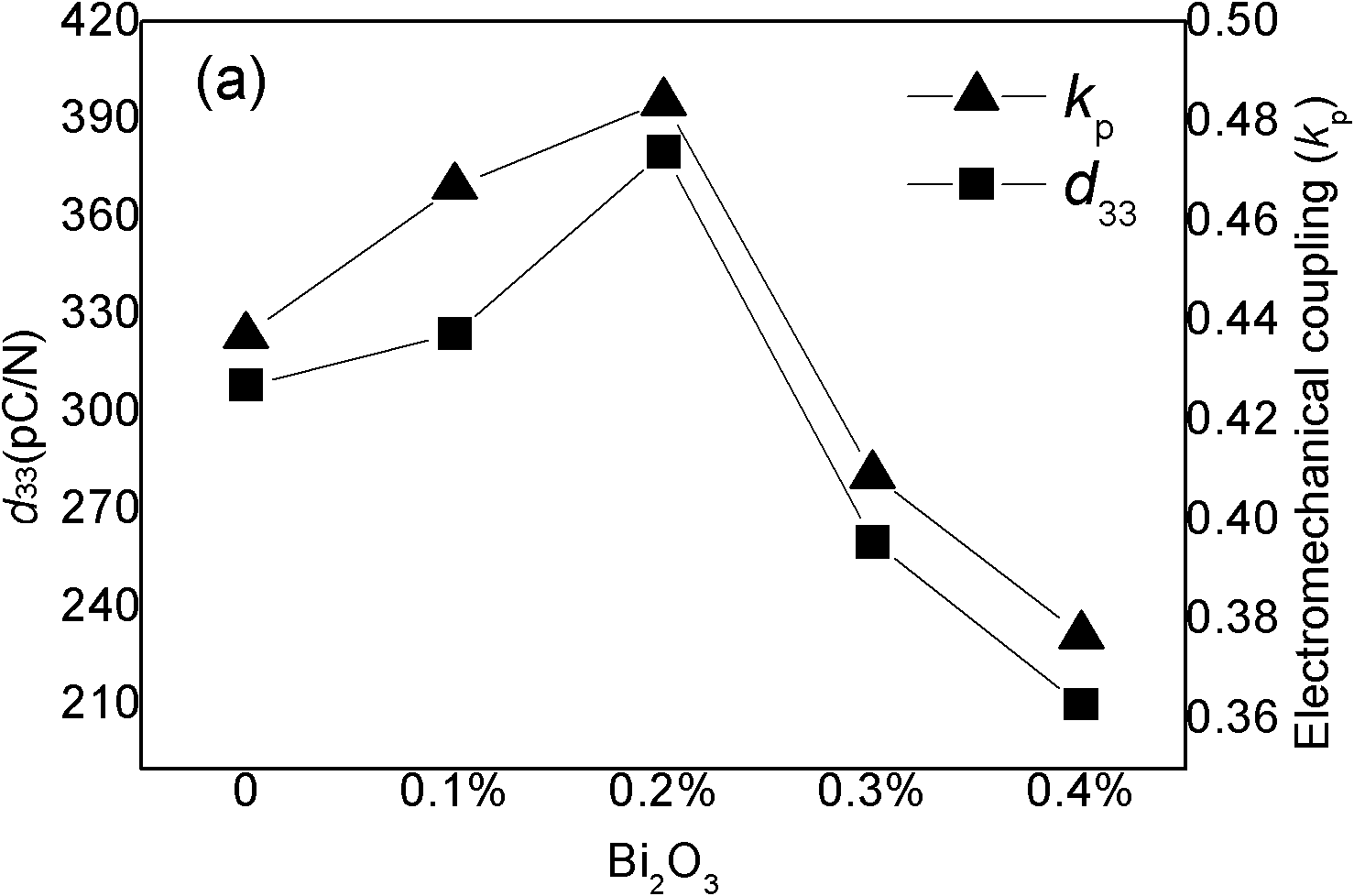

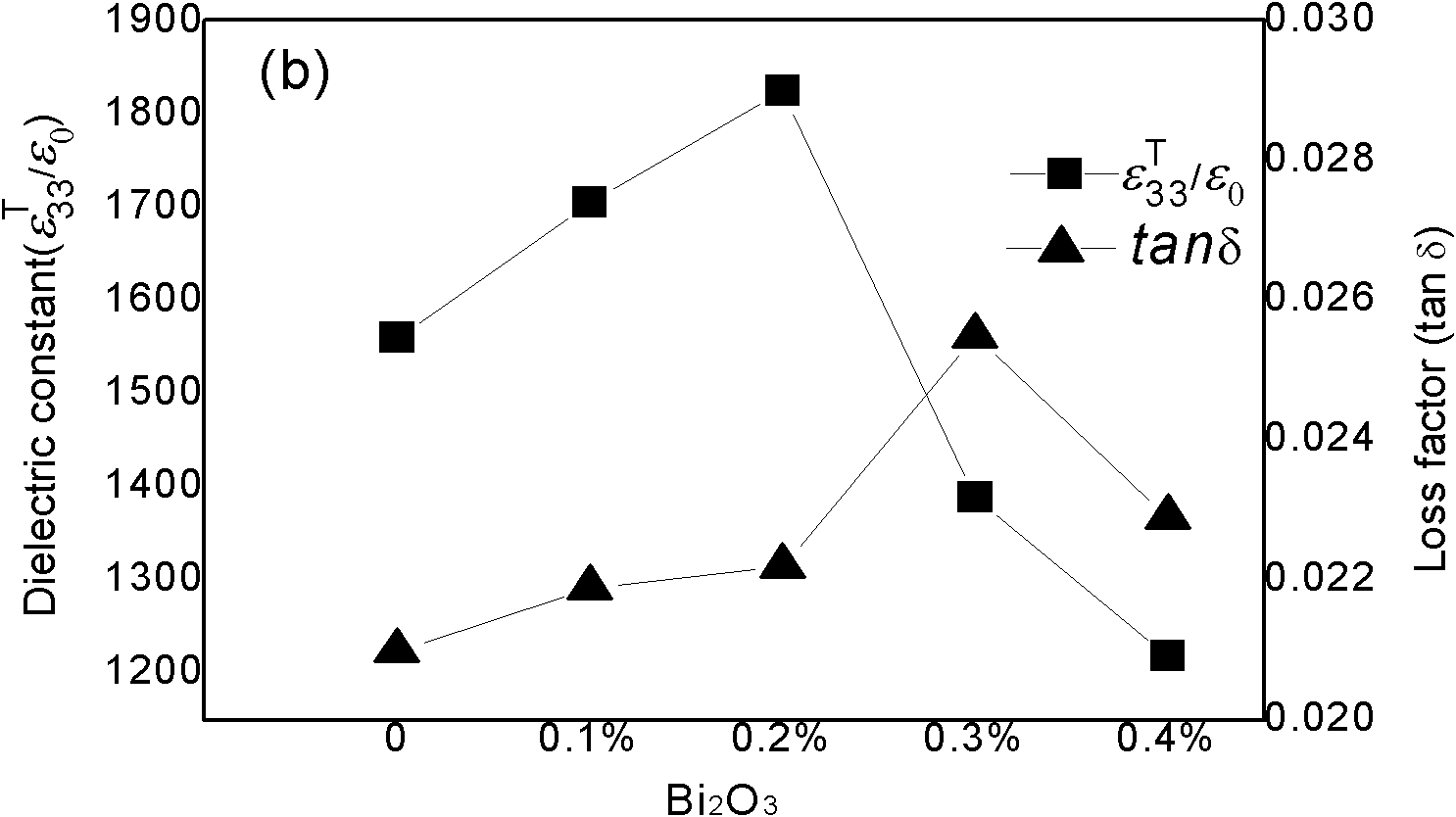

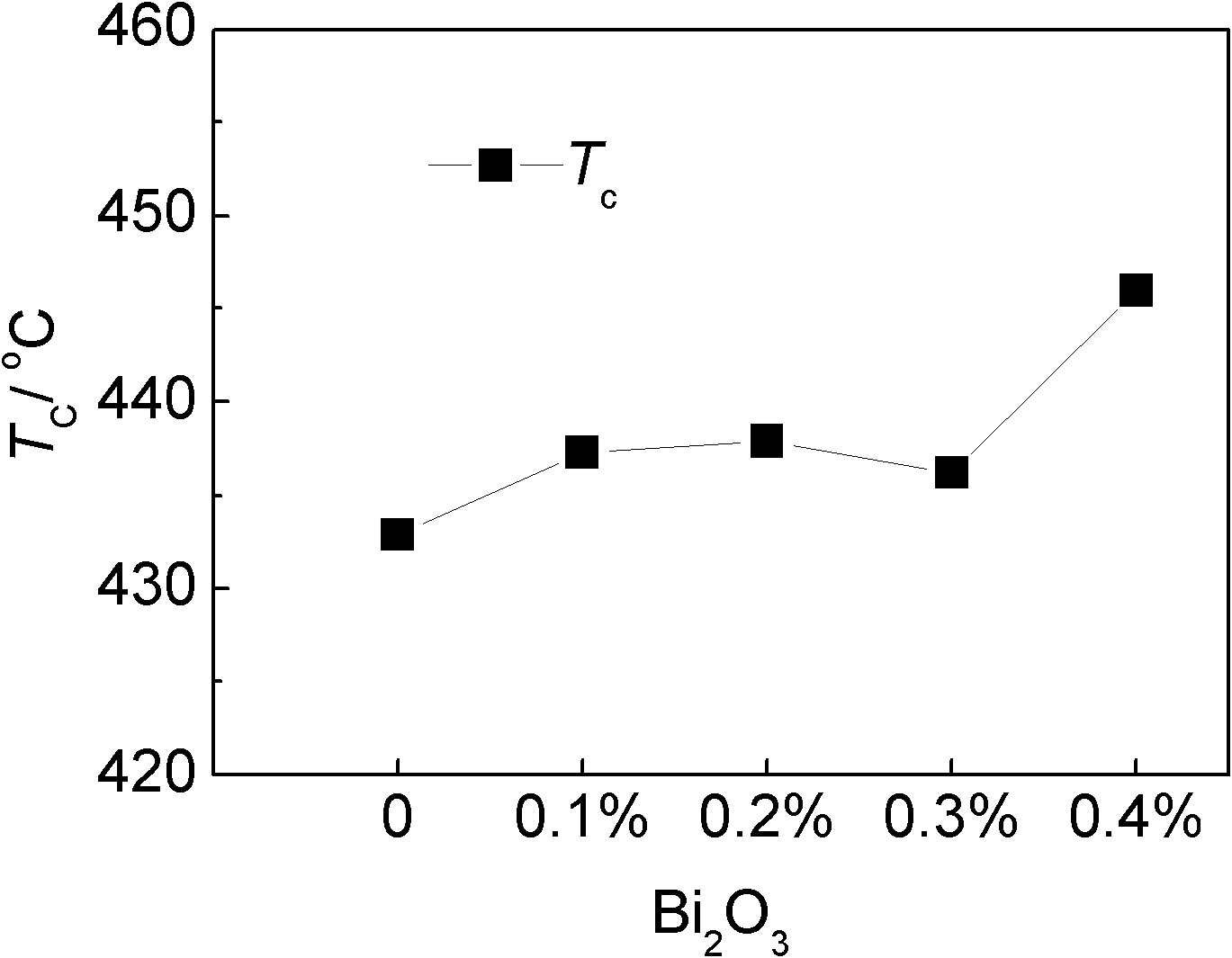

Bismuth scandate-lead titanate high-temperature piezoelectric ceramic material and preparation method thereof

InactiveCN102180665AStoichiometric ratio is accurateLower sintering temperatureCeramic sinteringCurie temperature

The invention discloses a bismuth scandate-lead titanate high-temperature piezoelectric ceramic material. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material comprises a matrix with the chemical formula of xBiScO3-(1-x)PbTiO3 and bismuth trioxide (Bi2O3) in an amount which is less than 0.4 percent of the total weight of the matrix. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material is prepared by adding excess Bi2O3 into raw materials of Sc2O3, Bi2O3, Pb3O4 and TiO2 in the metering ratio according to the chemical formula of xBiScO3-(1-x)PbTiO3, wherein x is 0.35 to 0.38; and the using amount of the excess Bi2O3 is 0.1 to 0.4 percent of the total weight of the raw materials of Sc2O3, Bi2O3, Pb3O4 and TiO2 in the metering ratio according to the chemical formula of xBiScO3-(1-x)PbTiO3. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material solves the problems that ceramic sintering temperature is increased and piezoelectric and dielectric properties are reduced due to deviation of a stoichiometric ratio caused by bismuth volatilization in the sintering process of BSPT ceramic, and has high Curie temperature, excellent piezoelectric property and an actual application value in high-temperature electronic equipment. The invention also discloses a preparation method for the bismuth scandate-lead titanate high-temperature piezoelectric ceramic material. In the preparation method, the piezoelectric ceramic material is prepared by synthesizing and sintering at lower temperature, so production cost is reduced, process steps are simplified, and the material has actual application value.

Owner:MORNSUN GUANGZHOU SCI & TECH +1

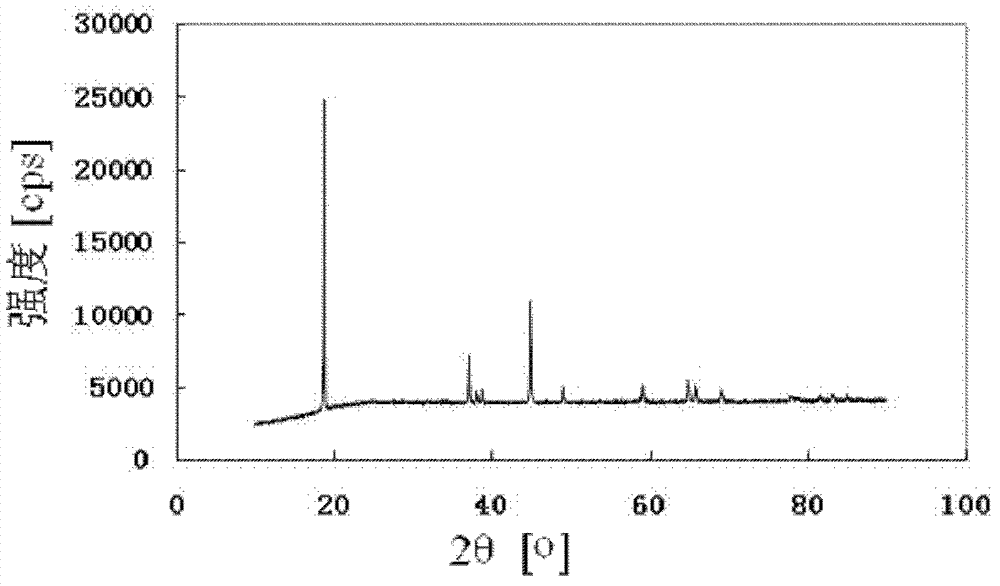

Preparation method of high corrosion resistance sintered neodymium iron boron

InactiveCN1913053AImprove corrosion resistancePromote sinteringInorganic material magnetismChemical platingMechanical crushing

This invention discloses a preparation method for anti-corrosion sintered NdFeB including: 1, preparing the NdFeB alloy by casting or rapid hardening rejection band strip technology then applying ball grinding or gas flow grinding to process powder after hydrogen explosion or mechanical crushing, 2, confecting oil eliminator, activated solution and chemical plating solution, 3, eliminating oil from the magnetic powder with oil eliminator then dunk rinsing with activated solution, 4, adding the powder into a plating solution for chemical-plating copper then drying it with vacuum drier, 5, pressing the dried powder to molded-blanks, 6, preparing the molded-blanks to sintered magnet in a high vacuum sintering oven.

Owner:ZHEJIANG UNIV

Powder comprising ceramic granules

ActiveUS20120282469A1Raise the level of performanceReduce contentSynthetic resin layered productsCellulosic plastic layered productsCeramic sinteringVitrification

The invention relates to a granulated powder intended, in particular, for the production of ceramic sintered parts, said powder having the following chemical weight composition, based on dry matter, namely: at least 1% of a first binder having a glass transition temperature less than or equal to 25° C.; 0-4% of an additional binder having a glass transition temperature greater than 25° C.; 0-4% of a temporary additive different from the first binder and the additional binder, the total content of the first binder, the additional binder and the temporary additive being less than 9%; 0-15% of an additive for sintering the ceramic material; at least 2% impurities; and the remainder comprising a ceramic material, and optionally an agent for stabilising said ceramic material, to make up 100%. According to the invention, the median diameter D50 of the powder is between 80 and 130 μm, the percentile D99.5 is less than 500 gm and the relative density of the granules is between 30% and 60%.

Owner:FIVEN NORGE AS

Low-cost sintered neodymium iron boron magnet and production method thereof

ActiveCN102592777AInhibition appearsImprove performancePermanent magnetsInductances/transformers/magnets manufactureNiobiumMaterials science

The invention discloses a low-cost sintered neodymium boron magnet, which comprises components including, by weight percentage, 5.0-6.5% of Pr (praseodymium), 20-28% of Nd (neodymium), 3-5% of Ho (holmium), 1.0-1.1% of boron, 0.4-0.8% of Al (aluminum), 0.1-0.2 % of Zr (zirconium), 0.4-0.6% of Nb (niobium), 0.12-0.17% of Cu (copper), 0.03-0.08% of Ga (gallium), 0.4-1.0% of Co (carbon monoxide) andthe balance iron. The production method includes: pretreatment of raw materials, ingot casting and smelting, hydrogen decrepitation and pulverization, magnetic field orienting and forming, isostatic processing, sintering, ageing and detecting. In the low-cost sintered neodymium boron magnet, high-cost dysprosium of rare metal is substituted by low-cost holmium of rare metal, so that production cost of products is reduced without affecting magnetic performances of the sintered neodymium boron magnet. Furthermore, the production method is simple in operation, excellent ingot casting structure can be obtained by ingot casting and smelting process, and the high-performance sintered neodymium iron boron magnet can be obtained.

Owner:宁德市星宇科技有限公司

Method for controlling grain size to produce ITO target

The invention relates to a photoelectric material technique, in particular to a method for controlling the grain size to produce ITO target. ITO powder is passivated under different temperatures in advance, so that the grain size of the ITO powder can be preliminarily increased and activity is reduced, the materials passivated under different temperatures are then mixed according to different proportions and ball-milled, and finally, after processes such as spray granulation, pressing and normal-pressure atmosphere sintering, the fine-grain ITO target with the grain size of 4Mu m to 10Mu m is prepared. The invention can prepare small-grain size and uniformly distributed ITO target by way of normal-pressure atmosphere sintering, the sintering temperature is decreased, and the sintering efficiency is increased; the technique is simple, the production cost is low, continuous and mass production can be easily carried out, and large-specification, high-quality ITO target can be sintered.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Ceramic binding agent for ceramic grinding block and preparation method thereof

ActiveCN103551971AGood gripLower sintering temperatureAbrasion apparatusGrinding devicesPowder metallurgyOxide

The invention discloses a ceramic binding agent for a ceramic grinding block and a preparation method thereof and belongs to the technical field of powder metallurgy materials. The ceramic binding agent aims at achieving the effects that the retention to diamond is good, the expansion coefficient is matched with expansion coefficients of silicon carbide, brown aluminum oxide and the diamond, and the sintering temperature of a finished product is low. The ceramic binding agent is formed by the following powder materials of, by weight, 20 to 55 kilograms of silicon dioxide, 5 to 25 kilograms of aluminum oxide, 0 to 5 kilograms of zinc oxide, 0 to 5 kilograms of titanium dioxide, 0 to 7 kilograms of zirconium oxide, 10 to 20 kilograms of sodium carbonate, 5 to 15 kilograms of lithium carbonate and 8 to 30 kilograms of boric acid. According to the ceramic binding agent for the ceramic grinding block, the ceramic grinding block has the advantages of being low in sintering temperature, good in self-sharpening, good in sharpness, long in service life, low in carbon and environmentally friendly.

Owner:BOSUN TOOLS CO LTD

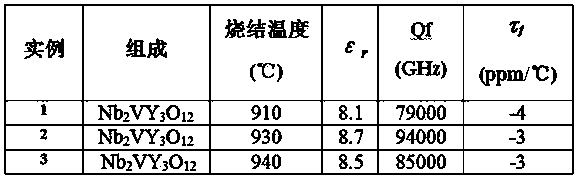

Temperature stable type microwave dielectric ceramic Nb2VY3O12 with ultralow dielectric constant

ActiveCN104211397APromote sinteringImprove temperature stabilityTemperature coefficientLow-k dielectric

The invention discloses a temperature stable type microwave dielectric ceramic Nb2VY3O12 with an ultralow dielectric constant as well as a preparation method thereof. The preparation method comprises the following steps: (1) weighing and blending original powder of Nb2O5, V2O5 and Y2O3 with the purity over 99.9% (weight percentage) according to composition of Nb2VY3O12; (2) mixing the raw material in the step (1) for 12 hours by a wet ball-mill, wherein the ball-milling medium is distilled water; and drying and pre-calcining for 6 hours in the atmosphere of 850 DEG C; and (3) adding an adhesive into the powder prepared in the step (2) and granulating, then compressing and moulding, and finally, sintering for 4 hours in the atmosphere of 910-940 DEG C; and the adhesive is a 5% polyvinyl alcohol solution, and the additive amount of polyvinyl alcohol accounts for 3% of total weight of the powder. The ceramic prepared by the invention is well sintered at 910-940 DEG C, the dielectric constant reaches 8.1-8.7, the quality factor Qf value reaches 79000-94000GHz, and the temperature coefficient of resonance frequency is small. The temperature stable type microwave dielectric ceramic Nb2VY3O12 has huge application value industrially.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

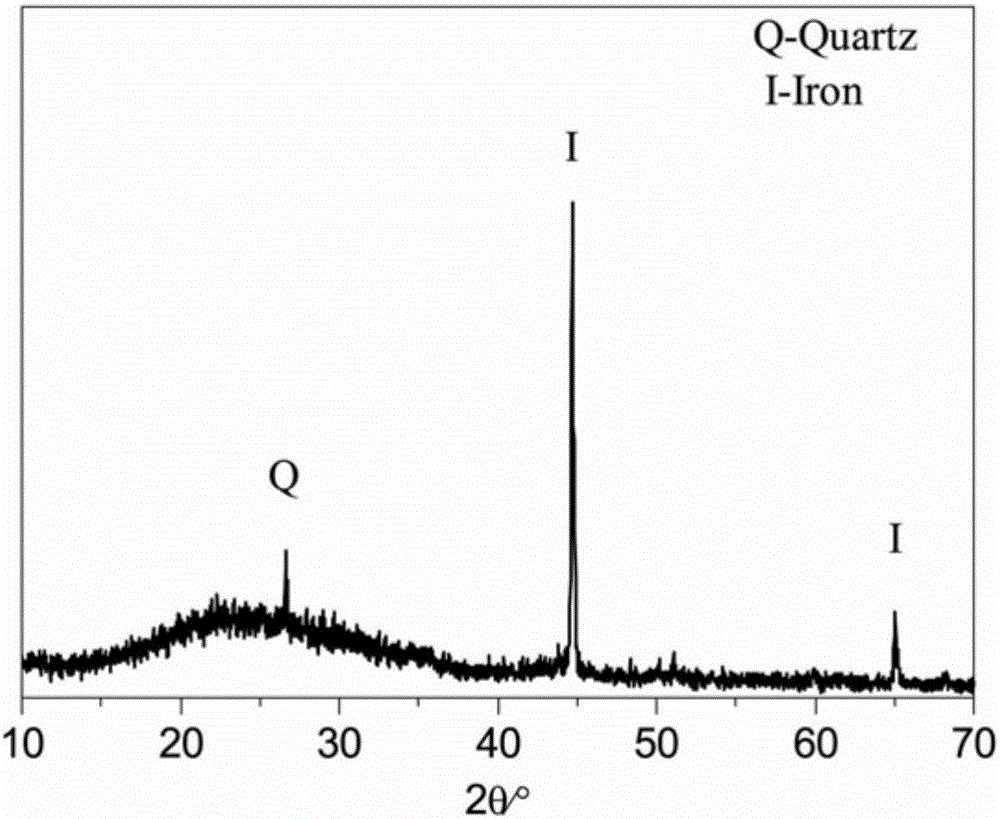

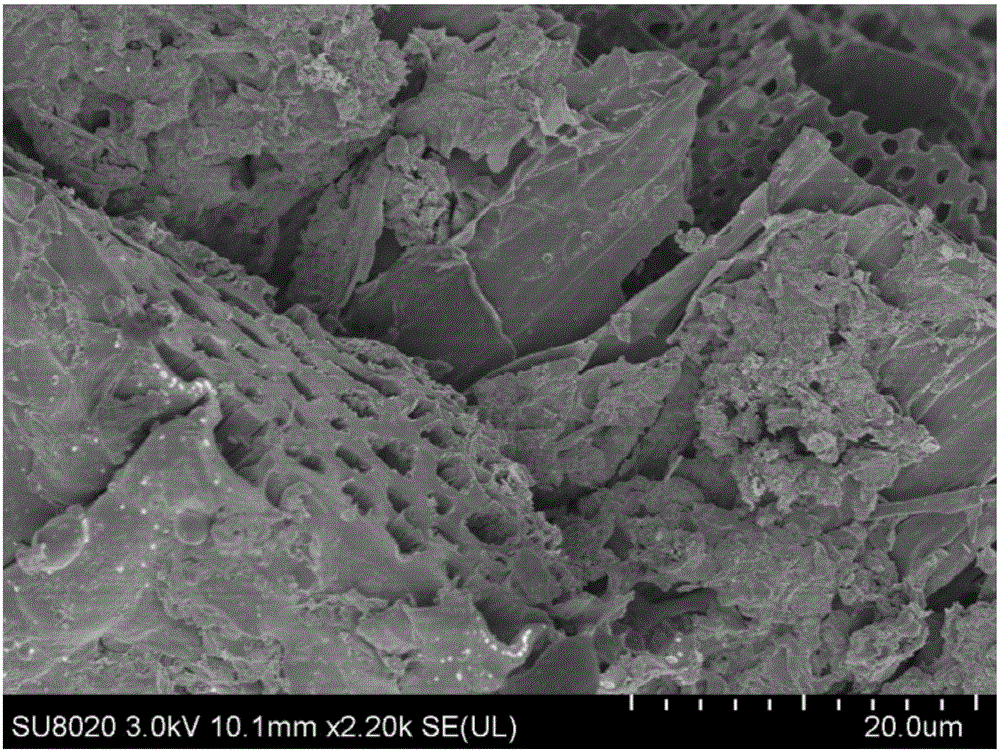

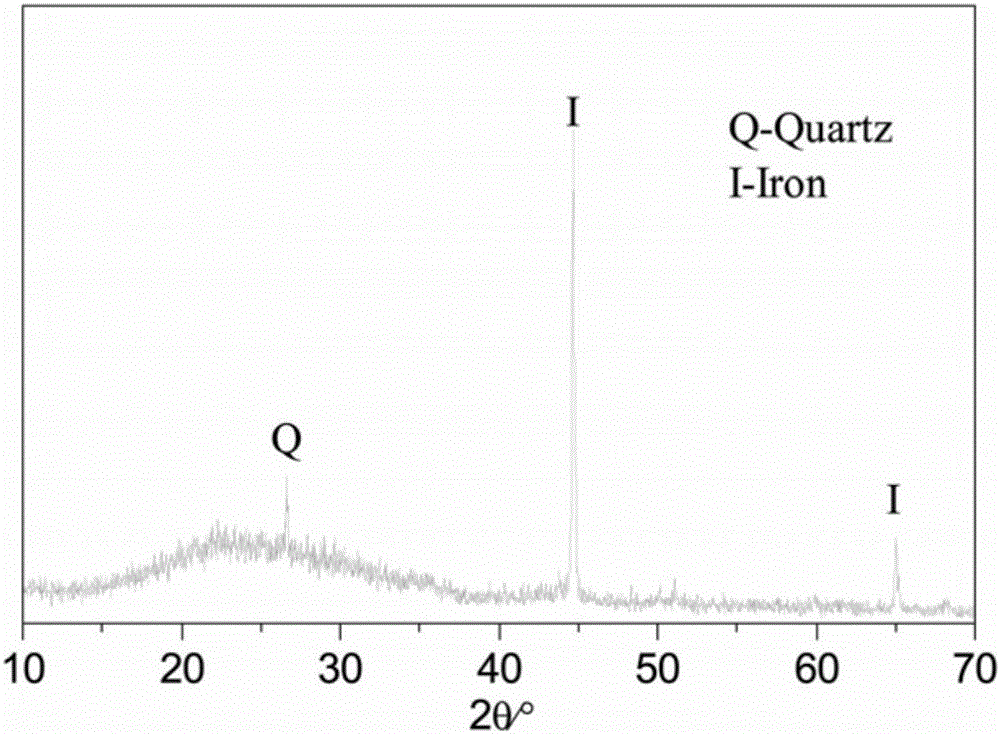

Fe/C composite porous structure material as well as preparation method and application thereof

ActiveCN105776506AHigh particle strengthHas a bonding effectTreatment using aerobic processesContaminated soil reclamationPorosityMagnetic susceptibility

The invention discloses a Fe / C composite porous structure material as well as a preparation method and application thereof. The Fe / C composite porous structure material is characterized by being prepared from low-grade sedimentary iron ore and biomass as raw materials in manners of crushing, mixing, extrusion molding and pyrolysis and reduction reaction in the presence of hydrogen atmosphere at 650-900 DEG C, wherein the main phase composition comprises biomass carbon and zero-valent iron. The Fe / C composite porous structure material disclosed by the invention is high in opening porosity, magnetic susceptibility, adsorbability and biological chemical activity, can be used for treating eutrophicated river water, living sewage and landscape water bodies, or can be used for mediation of underground water pollution and polluted soil.

Owner:HEFEI UNIV OF TECH

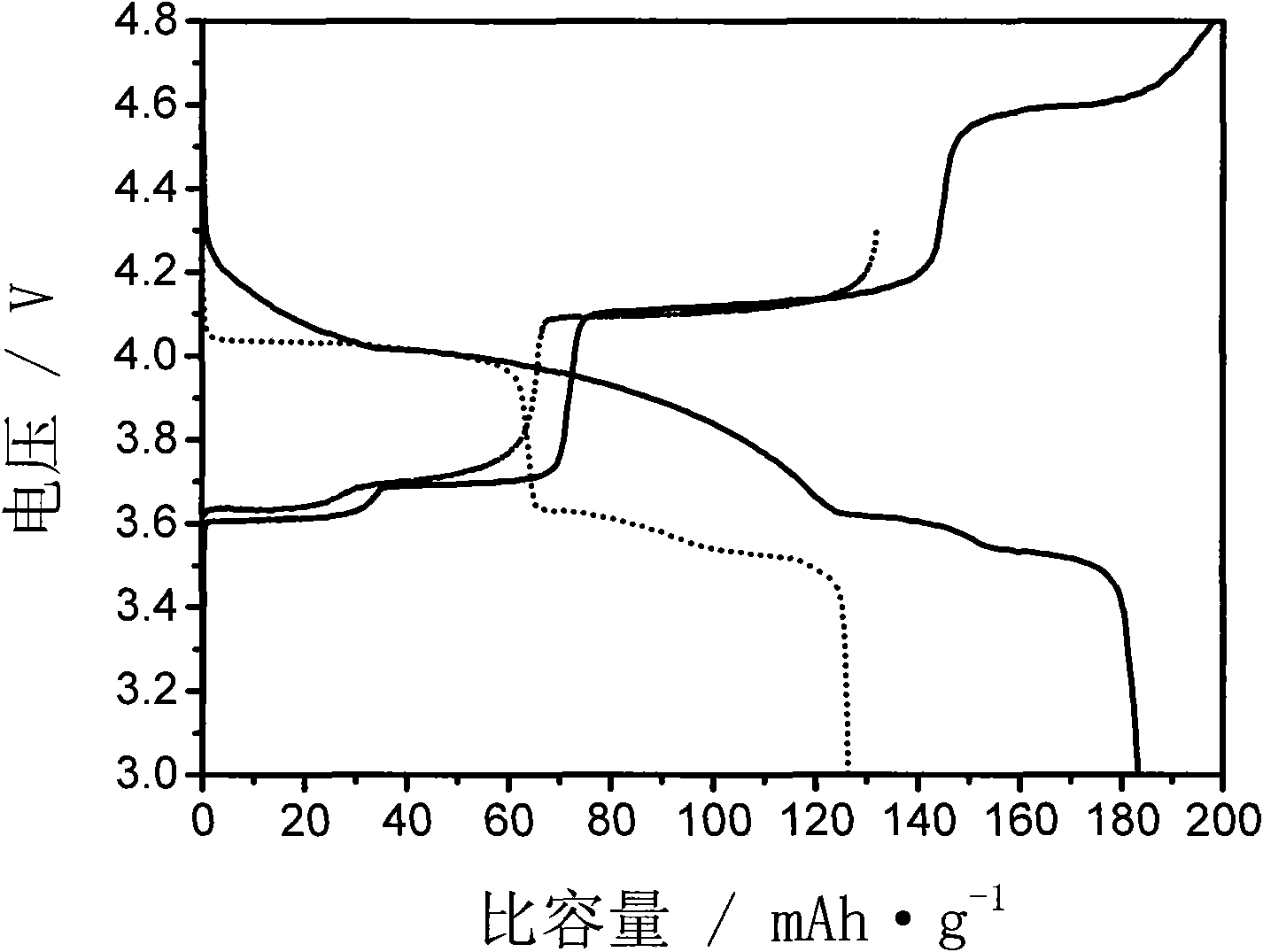

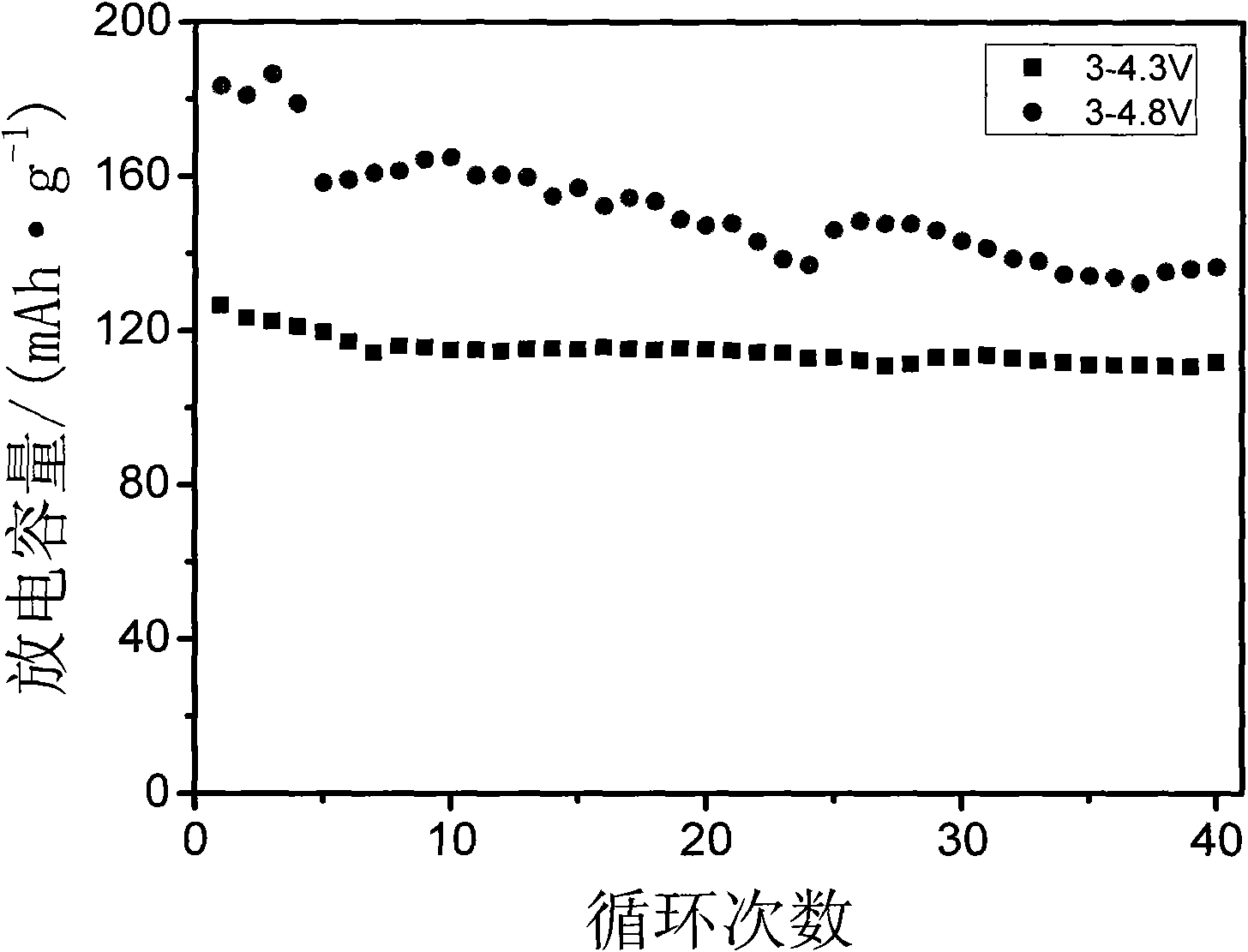

Nickel-based positive electrode material, and preparation method thereof and battery

ActiveCN103094576AIncrease capacityImprove structural stabilityCell electrodesSecondary cellsMetallurgySlurry

The invention relates to a nickel-based positive electrode material, and a preparation method thereof and a battery. The composition of the nickel-based positive electrode material is LiaNibCocMndMeM'fO2-g / 2Fg (M is at least one selected from Ti, Zr, Al, Fe, Cr, Si, and Cu; M' is at least one selected from Mg, Ca, Sr, Ba, and W; a is no smaller than 0.95 and no greater than 1.2; b is no smaller than 0.2 and no greater than 0.9; c is no smaller than 0 and no greater than 0.4; d is no smaller than 0 and no greater than 0.4; e+f is greater than 0.05and no greater than 0.2; and g is greater than 0.02 and no greater than 0. 1). Anions and cations are used in co-doping. With a synergistic effect, nickel-based positive electrode material capacity, structural stability and circulation performance are greatly improved. The preparation method at least comprises the 4 steps that: (1) corresponding raw materials are weighed according to the molar ratio consistent with LiaNibCocMndMeM'fO2-g / 2Fg; (2) the raw materials are subjected to wet grinding; (3) slurry obtained by grinding is dried; and (4) the dried material is subjected to solid-phase synthesis under a temperature of 500-1100 DEG C. With the process, the raw materials can be more uniformly dispersed, and the obtained product has the advantages of high capacity and good circulation performance. The process is simple, and has the advantages of low cost and suitability for large-scale industrialized productions. With the process, problems such as complicated process and acid and alkali pollution of a wet chemical precursor preparation method are avoided. The invention also relates to a battery with the material as an active substance.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

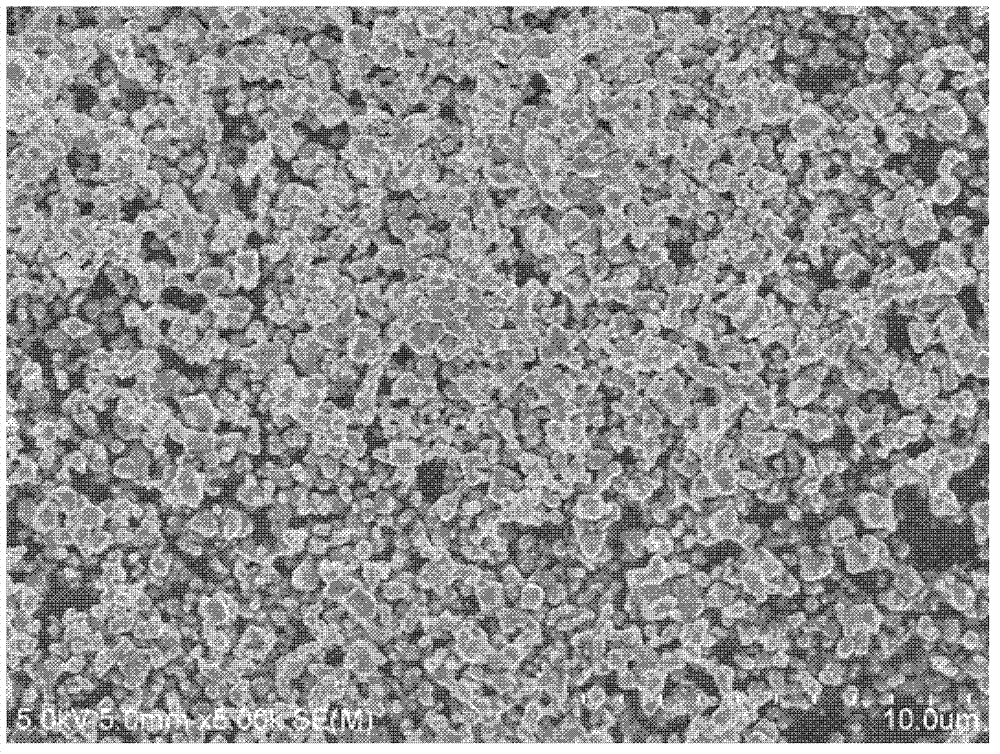

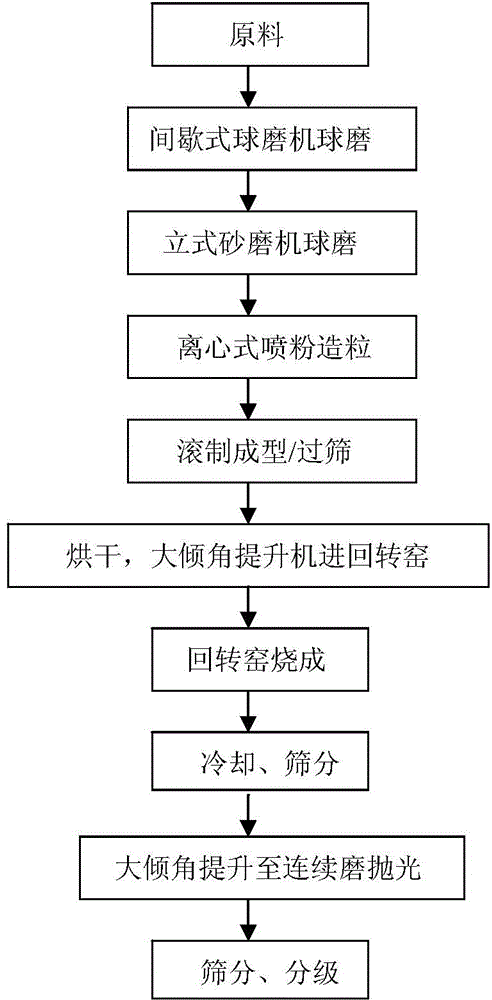

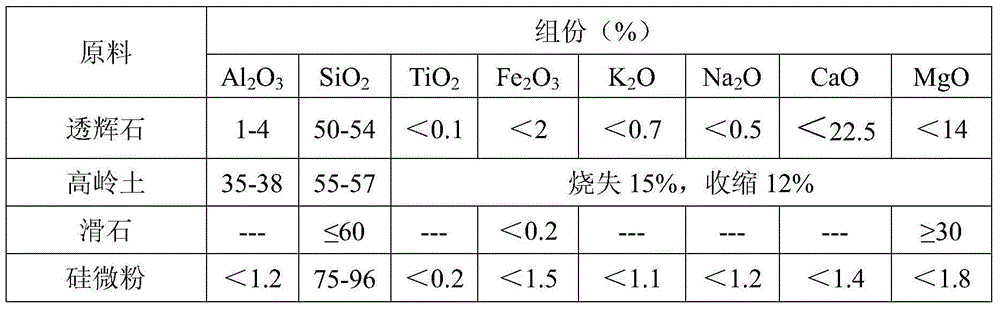

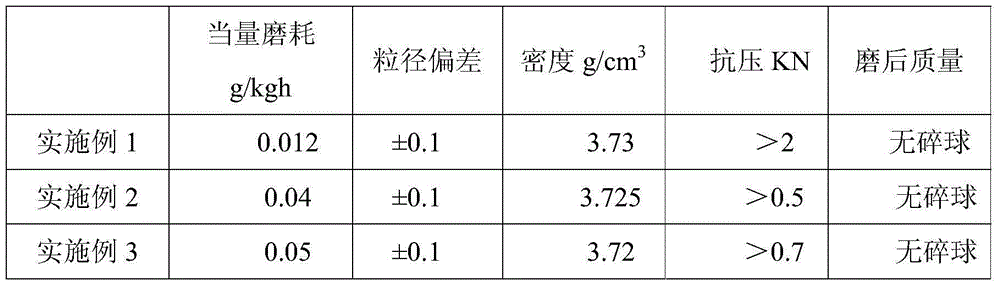

Preparation method of aluminum oxide microbeads

ActiveCN104150882ALower firing temperatureAvoid stickingOther chemical processesPhase conversionBall mill

The invention discloses a preparation method of aluminum oxide microbeads. The preparation method comprises the following steps: by adopting aluminum oxide powder with lower alpha phase conversion rate (80-90%) as a main raw material, adding a composite sintering additive, ball-milling through an intermittent ball mill and a vertical sand mill, and then performing centrifugal type spray pelletization, rolling to forming, drying, sintering in a rotary kiln, and continuous grinding and polishing, to obtain the aluminum oxide microbeads. According to the preparation method, the aluminum oxide powder with relatively low alpha phase conversion rate is adopted, activity of the remaining gamma-aluminum oxide phase in the aluminum oxide powder promotes the sintering of the aluminum oxide, the addition amount of the sintering additive is decreased, and meanwhile the problem that the aluminum oxide microbeads during the sintering of the rotary kiln are caked and collided to be deformed due to excessive glass phase can be solved. Rotary kiln sintering equipment is introduced, the microbeads are under a moving status during the sintering of the rotary kiln, and are evenly heated during sintering, thus being uniform in the structure and performances. The prepared aluminum oxide microbeads have the characteristics of being low in abrasion, high in strength and density, uniform in particle size, free from breakage of beads, and the like.

Owner:JINGANG NEW MATERIALS

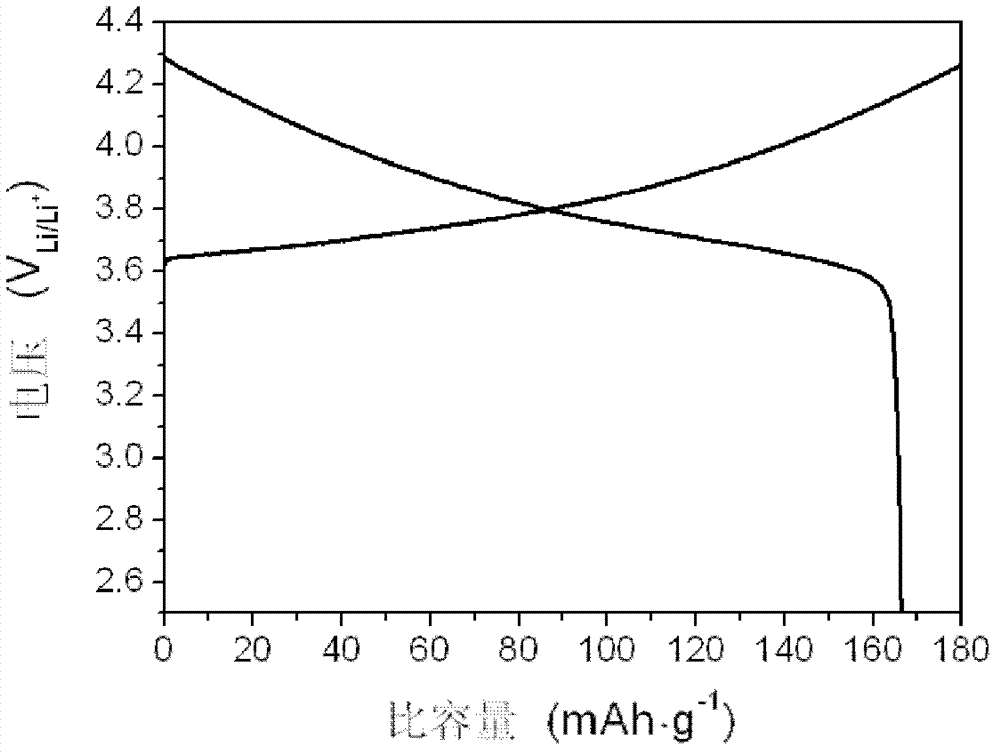

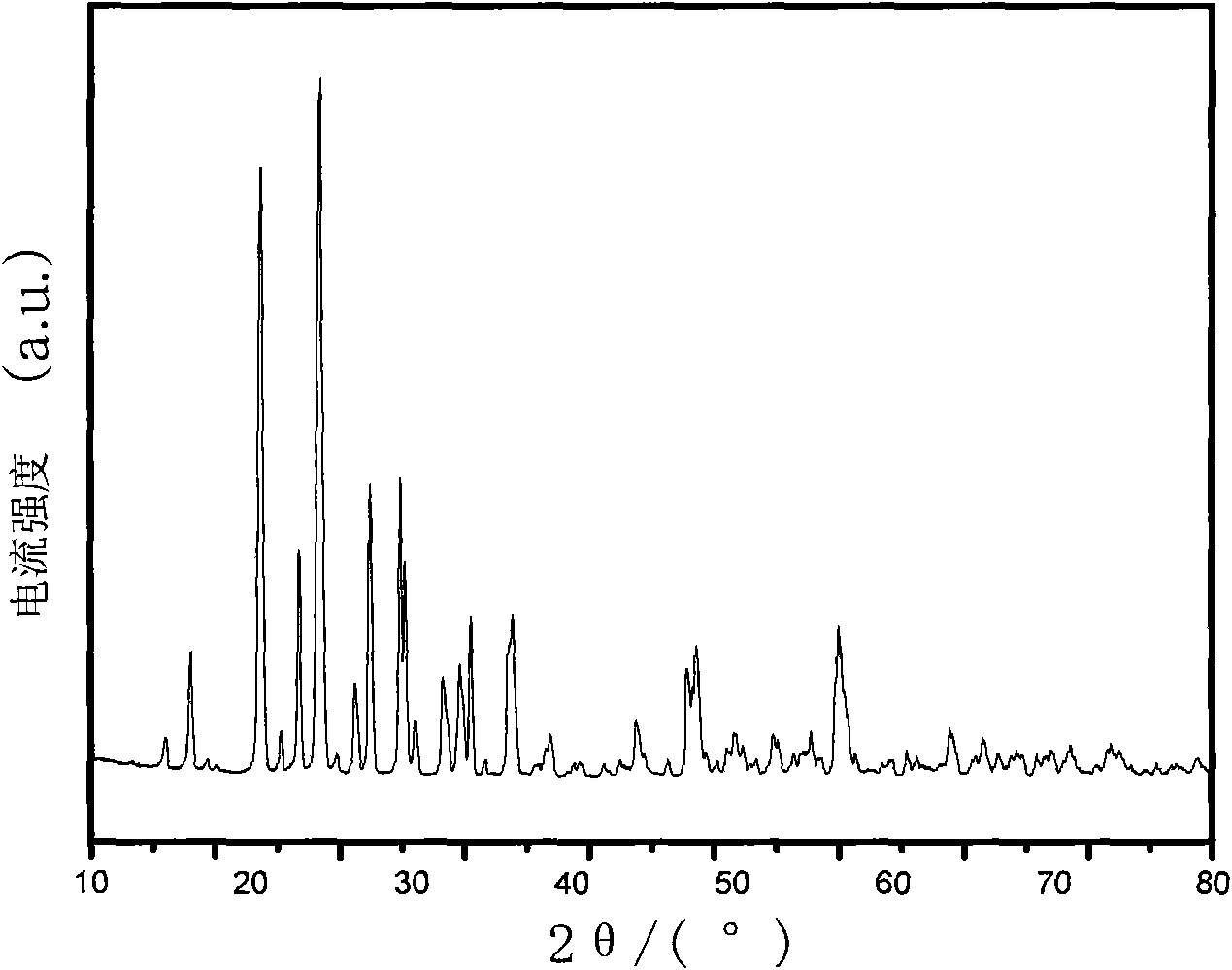

Method for preparing lithium vanadium phosphate as lithium ion battery anode material

InactiveCN101651205AUniform particle size distributionHigh specific capacityElectrode manufacturing processesMuffle furnacesLithium vanadium phosphate batteryMicrowave sintering

The invention discloses a method for preparing lithium vanadium phosphate as a lithium ion battery anode material, which comprises the following steps: (1) preparing reaction precursor gel of an anodematerial by a sol-gel method; (2) presintering the reaction precursor gel prepared in the step (1); and (3) placing a material obtained by presintering into a microwave sintering furnace to sinter. The invention combines the sol-gel method with a microwave sintering method and can prepare a product with favorable electrode plate processing ability, electrical conductivity and electrochemical performance by sintering in tens of minutes. The method has high production efficiency, low energy consumption, easy control of technical parameter, favorable batch stability and low production cost and is suitable for mass industrial production.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

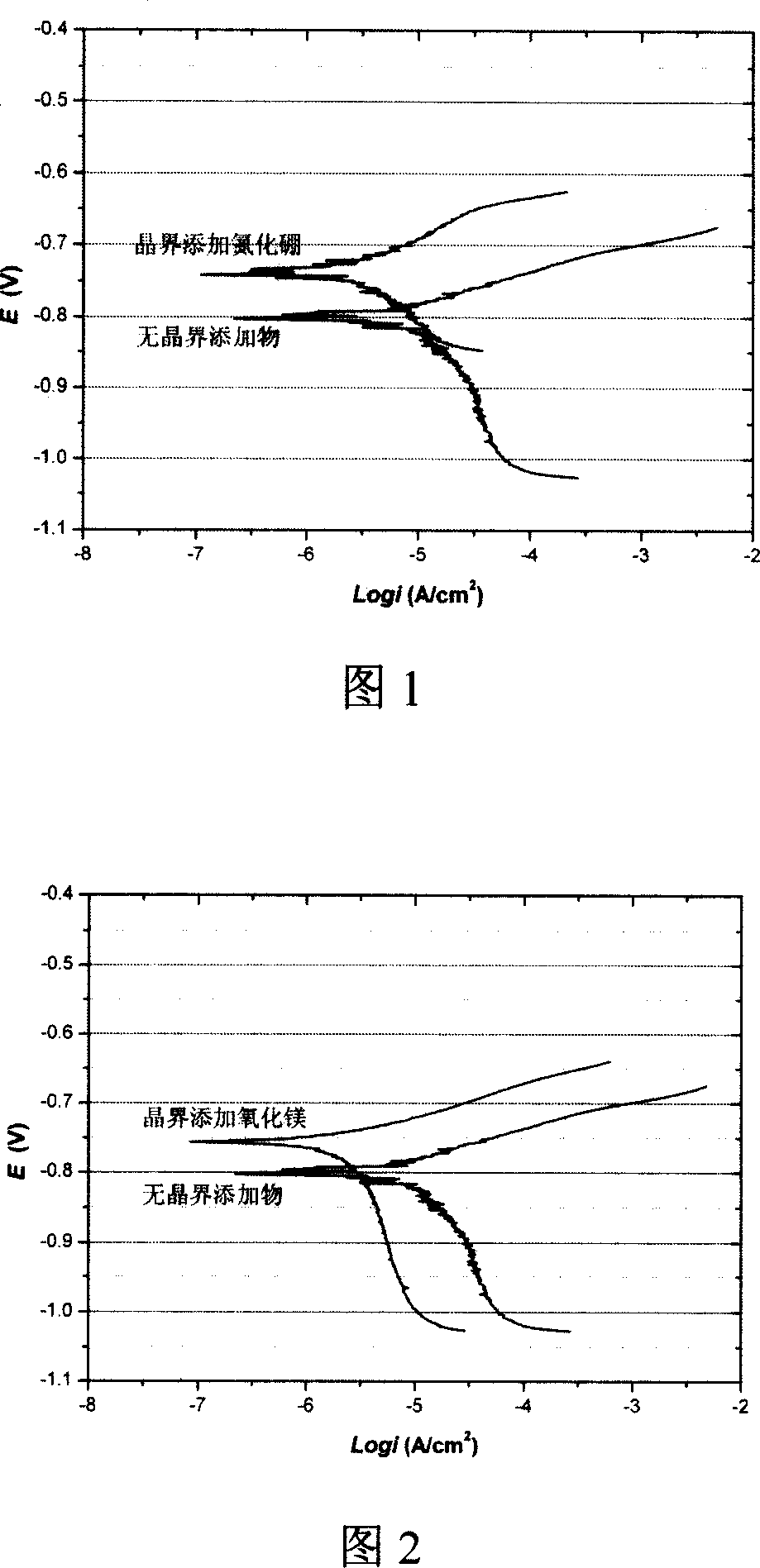

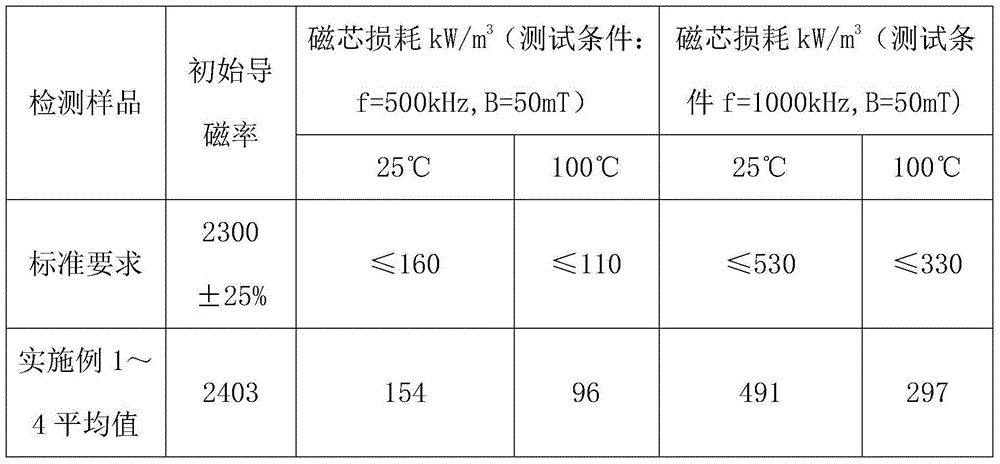

Method for increasing neodymium-iron-boron permanent magnetic performance and corrosion-resisting performance

The method includes steps: (1) using ingot-casting technique to manufacture Nd-Fe-B ingot-casting alloy, or using technique of rapid hardening sheet to produce rapid hardening sheet of Nd-Fe-B alloy; (2) first carrying out coarse crushing for alloy, then producing powder through airflow grinding; (3) adding powder of boron nitride or magnesia, and mixing them evenly; (4) pressure molding oriented mixed powders under magnetic field, and then carrying out cold isopressing process for blanks; (5) sintering and tempering blanks in high vacuum sintering furnace. Nd-Fe-B magnet produced according to the invention possesses better magnetic performance and corrosion resistance than magnetic performance and corrosion resistance of magnet without adding powder of boron nitride or magnesia.

Owner:SHANGHAI JIAO TONG UNIV

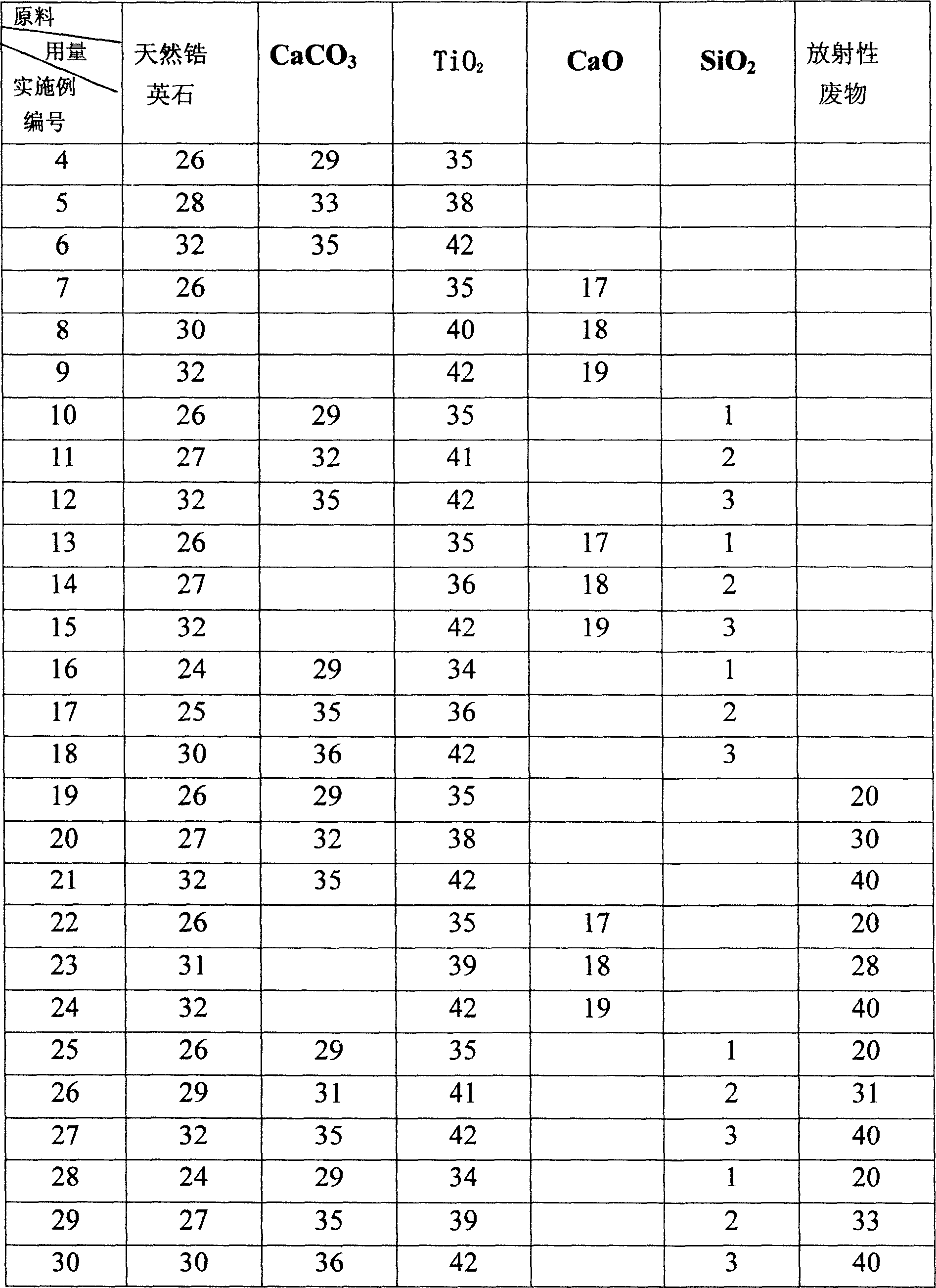

Soft magnetic ferrite material and preparation process thereof

The invention discloses a soft magnetic ferrite material. Raw materials for preparing the soft magnetic ferrite material comprise composite materials and auxiliary materials. The composite materials comprise iron oxide, manganese oxide and zinc oxide. The auxiliary materials comprise 0-6000 ppm of nickel oxide, 100-800 ppm of calcium carbonate, 0-500 ppm of lithium carbonate, 20-120 ppm of silicon dioxide, 0-230 ppm of magnesium oxide, 0-180 ppm of niobium oxide, 700-2000 ppm of cobalt oxide, 0-350 ppm of bismuth oxide, 100-600 ppm of vanadium oxide, 0-2500 ppm of titanium dioxide, 0-500 ppm of copper oxide, and 100-500 ppm of zirconium oxide. The invention also discloses a preparation process of the soft magnetic ferrite material. The soft magnetic ferrite material has high initial magnetic permeability and low magnetic core loss.

Owner:ZHONGDE ELECTRONICS

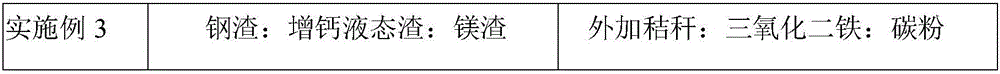

Method for preparing high radioactive waste curing treatment base material

InactiveCN1767077AInexpensive curing processPromote engineering applicationRadioactive decontaminationMetallurgyReaction temperature

The invention relates to a method for preparing high radioactivity waste solidification treating base material which comprises the following steps: preparing the material: using nature hyacinth, CaCO3 and TiO2 as raw material and extracting them by weight ration: nature hyacinth: CaCO3:TiO2 =26-32:29-35:35-42; correct grinding: loading each raw material into the correct grinding device, adding the grinding ball to do correct grinding 30-60 minutes; burning: burning at the temperature 1150 deg. to 1350 deg. 20-60 minutes to obtain the product.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Foamed ceramic wall material with steel slag as raw material and preparation method of foamed ceramic wall material

ActiveCN106146027ALow water absorptionReduce manufacturing costCeramic materials productionCeramicwareFoaming agentSlag

The invention provides a foamed ceramic wall material with steel slag as the raw material. The foamed ceramic wall material is mainly prepared from, by weight, 22-66 parts of steel slag, 24-50 parts of aluminum-rich waste, 10-28 parts of magnesium-rich material, 6-18 parts of additional biologic material and 3-10 parts of foaming agent at low temperature through mixing, ball-milling, forming and sintering at a temperature of 1020-1250 DEG C. The prepared foamed ceramic wall material is low in production cost, waste is turned into wealth, air holes are not communicated and do not absorb water, and the foamed ceramic wall material has the advantages of being high in air hole closing rate, low in water absorption rate, high in tensile strength and the like and is a heat preservation and insulation wall material good in performance.

Owner:射阳县射阳港渔工贸开发有限公司

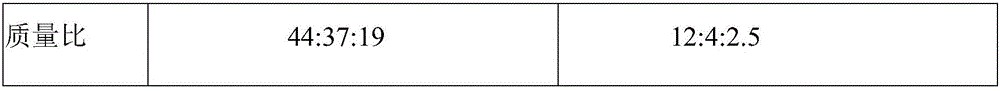

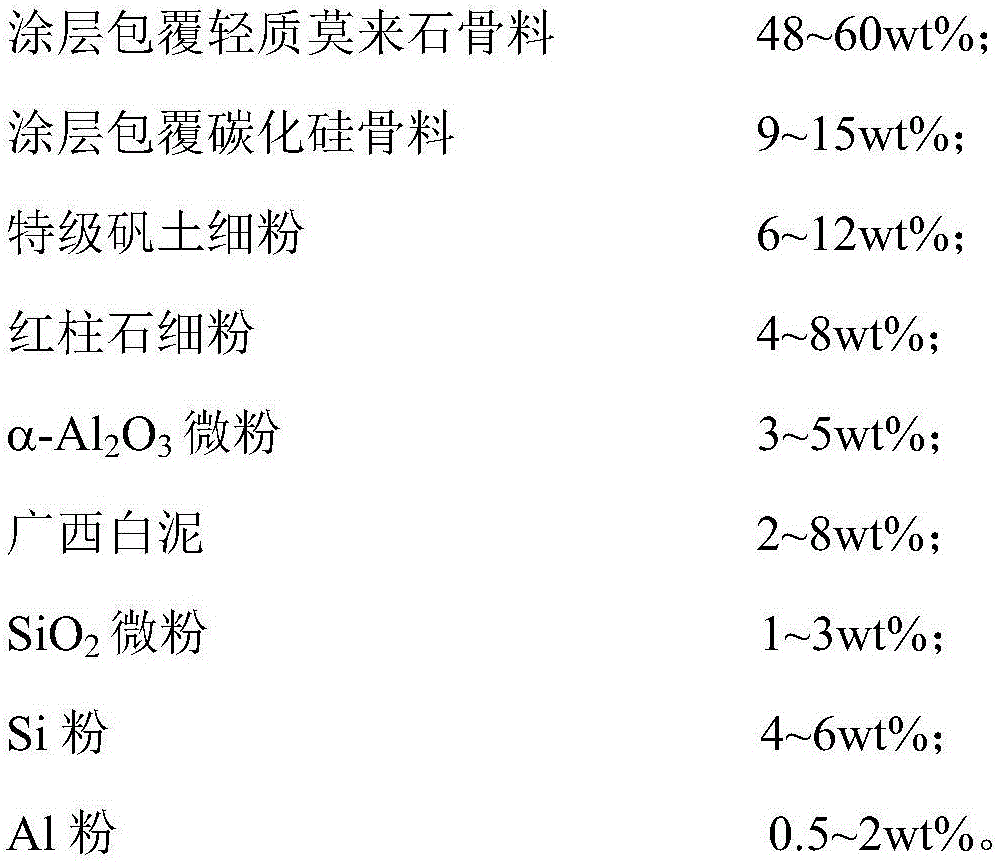

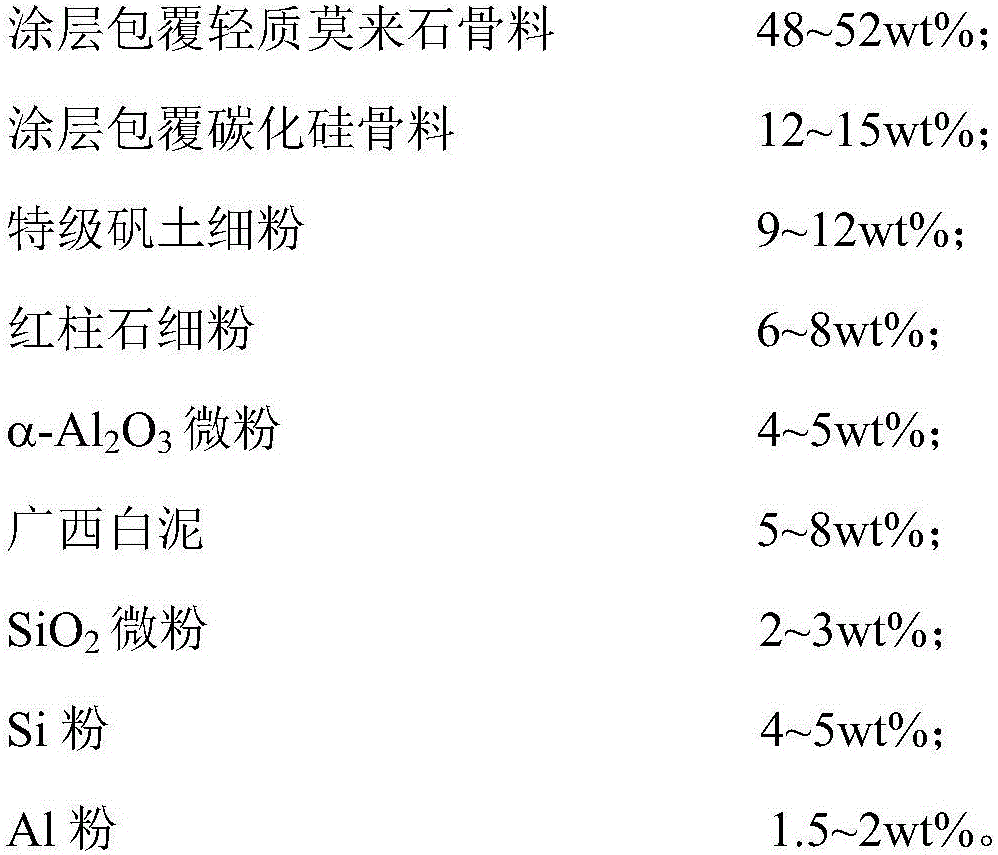

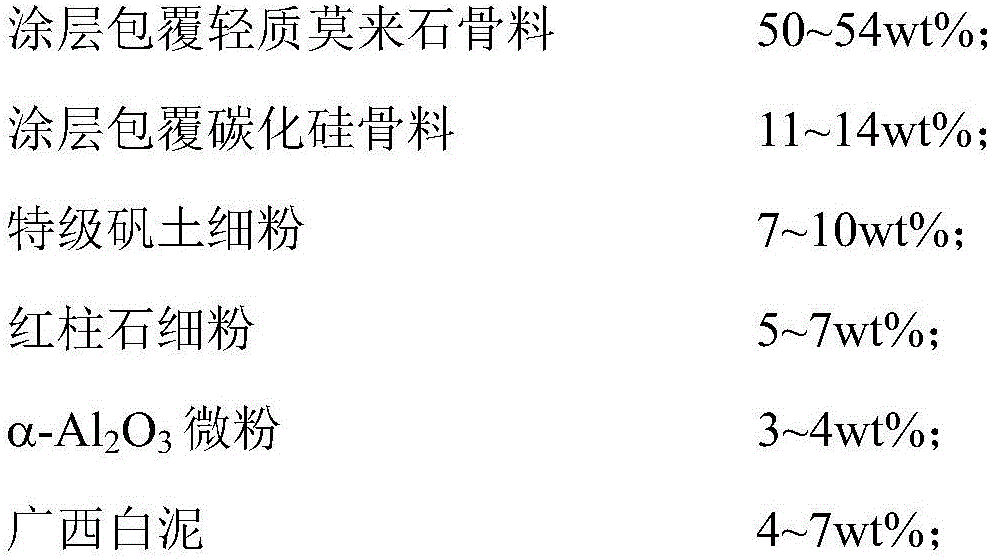

Mullite silicon carbide complex-phase fireproof material and preparation method thereof

The invention relates to a mullite silicon carbide complex-phase fireproof material and a preparation method thereof. The mullite silicon carbide complex-phase fireproof material is characterized in that 48-60wt% of coating cladding mullite light aggregate, 9-15wt% of coating cladding silicon carbide aggregate, 6-12wt% of top-grade bauxite fine powder, 4-8wt% of andalusite fine powder, 3-5wt% of alpha-Al2O3 micro powder, 4-8wt% of Guangxi white clay, 1-3wt% of SiO2 micro powder, 4-6wt% of Si powder and 0.5-2wt% of Al powder are used as raw materials. The preparation method comprises the following steps of firstly mixing two kinds of the aggregate in the raw materials, adding a bonding agent, then performing mixed refining on the mixed aggregate, the bonding agent and other raw materials, performing material trapping, performing compression moulding, performing drying, and performing baking under the condition of 1250-1400 DEG C so as to obtain the mullite silicon carbide complex-phase fireproof material. The mullite silicon carbide complex-phase fireproof material prepared by the preparation method disclosed by the invention has the excellent characteristics of being low in heat conduction coefficients, good in erosion resistance, and high in intensity.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com