Foamed ceramic wall material with steel slag as raw material and preparation method of foamed ceramic wall material

A technology of foam ceramics and wall materials, which is applied in the production of ceramic products, ceramic materials, clay products, etc., can solve the problems of low added value of products, and achieve the effects of low production costs, reduced production costs, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The ratio of raw materials designed in this embodiment is shown in Table 1.

[0029] Table 1 Embodiment 1 raw material proportioning

[0030] Example 1

Additional straw: ferric oxide: carbon powder

mass ratio

66:24:10

6:7:3

[0031] The specific implementation steps are as follows:

[0032] Ball mill mixing: Weigh steel slag, coal gangue and talc according to the mass ratio of 66:24:10, add 6 parts of straw, 7 parts of carbon dioxide and 3 parts of carbon powder, ball mill for 2 hours, add water and mix;

[0033] Molding: Extrusion molding to get green body;

[0034] Firing: 20°C to 500°C, heat up for 96 minutes, hold at 500°C for 1 hour, 500°C to 1250°C, heat up for 120 minutes, hold at 1250°C for 2 hours, and cool down to room temperature naturally.

[0035] Performance test: According to Archimedes' law, the closed porosity of the foamed ceramics is 90%, the water absorption is 1.1%, and the density ...

Embodiment 2

[0037] The ratio of raw materials designed in this embodiment is shown in Table 2.

[0038] Table 2 Embodiment 2 raw material proportioning

[0039] Example 2

Steel slag: fluidized bed coal ash: silicomanganese slag

Additional straw: ferric oxide

mass ratio

22:50:28

18:3

[0040] The specific implementation steps are as follows:

[0041] Ball mill mixing: Weigh steel slag, fluidized bed coal ash, and silicomanganese slag at a mass ratio of 22:50:28, add 18 parts of straw, 3 parts of ferric oxide, and ball mill for 2 hours;

[0042] Molding: adding pulp waste liquid as a binder, extruding to obtain a green body;

[0043] Firing: 20°C to 500°C, heat up for 96 minutes, hold at 500°C for 1 hour, 500°C to 1020°C, heat up for 120 minutes, hold at 1020°C for 120 minutes, and cool to room temperature naturally.

[0044] Performance test: According to Archimedes' law, the closed porosity of foam ceramics is 86%, the water absorption rate is 2.1%, a...

Embodiment 3

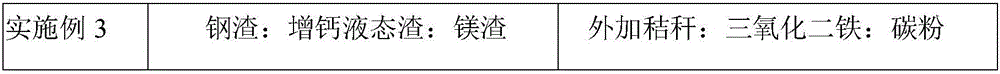

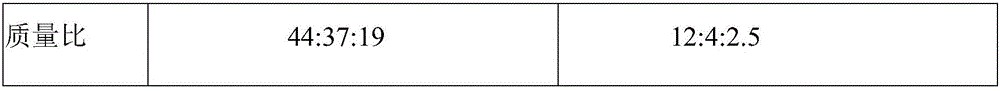

[0046] The ratio of raw materials designed in this embodiment is shown in Table 3.

[0047] Table 3 Embodiment 3 raw material proportioning

[0048]

[0049]

[0050] The specific implementation steps are as follows:

[0051]Ball mill mixing: Weigh steel slag, calcium-increasing liquid slag, and magnesium slag at a mass ratio of 44:37:19, add 12 parts of straw, 4 parts of ferric oxide and 2.5 parts of carbon powder, and ball mill for 2 hours;

[0052] Forming: adding sugar waste liquid as a binder, molding at 5MPa to obtain a green body;

[0053] Firing: 20°C to 500°C, heating up for 96 minutes, holding at 500°C for 1 hour, heating at 500°C to 1165°C, heating up for 100 minutes, holding at 1165°C for 120 minutes, and cooling to room temperature naturally.

[0054] Performance test: According to Archimedes' law, the closed porosity of foam ceramics is 49%, the water absorption rate is 2.48%, and the density is 200kg / m 3 , the compressive strength measured by universal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com