Patents

Literature

74 results about "High-refractive-index polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A high-refractive-index polymer (HRIP) is a polymer that has a refractive index greater than 1.50. Such materials are required for anti-reflective coating and photonic devices such as light emitting diodes (LEDs) and image sensors. The refractive index of a polymer is based on several factors which include polarizability, chain flexibility, molecular geometry and the polymer backbone orientation.

Low Tg multilayer optical films

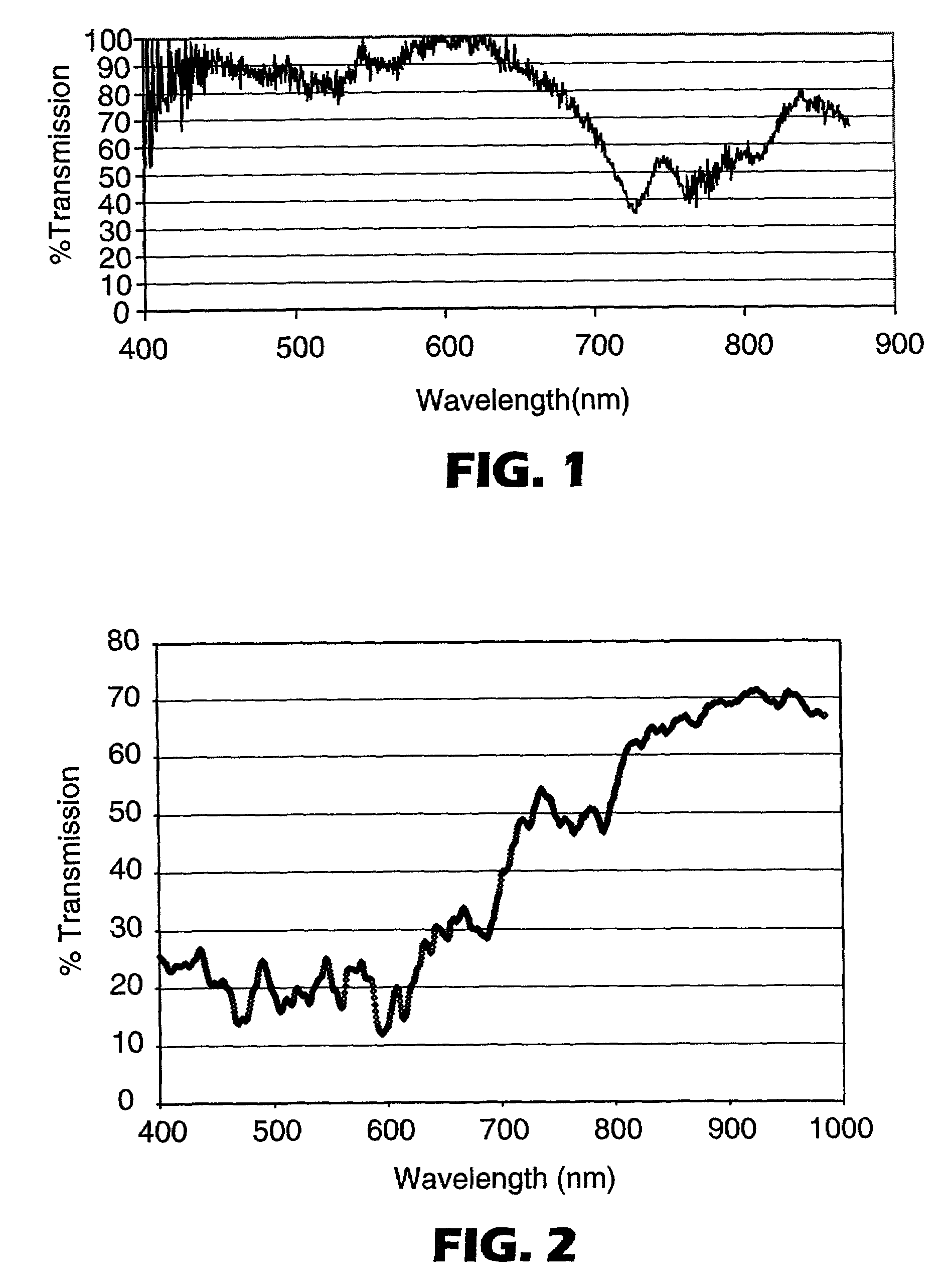

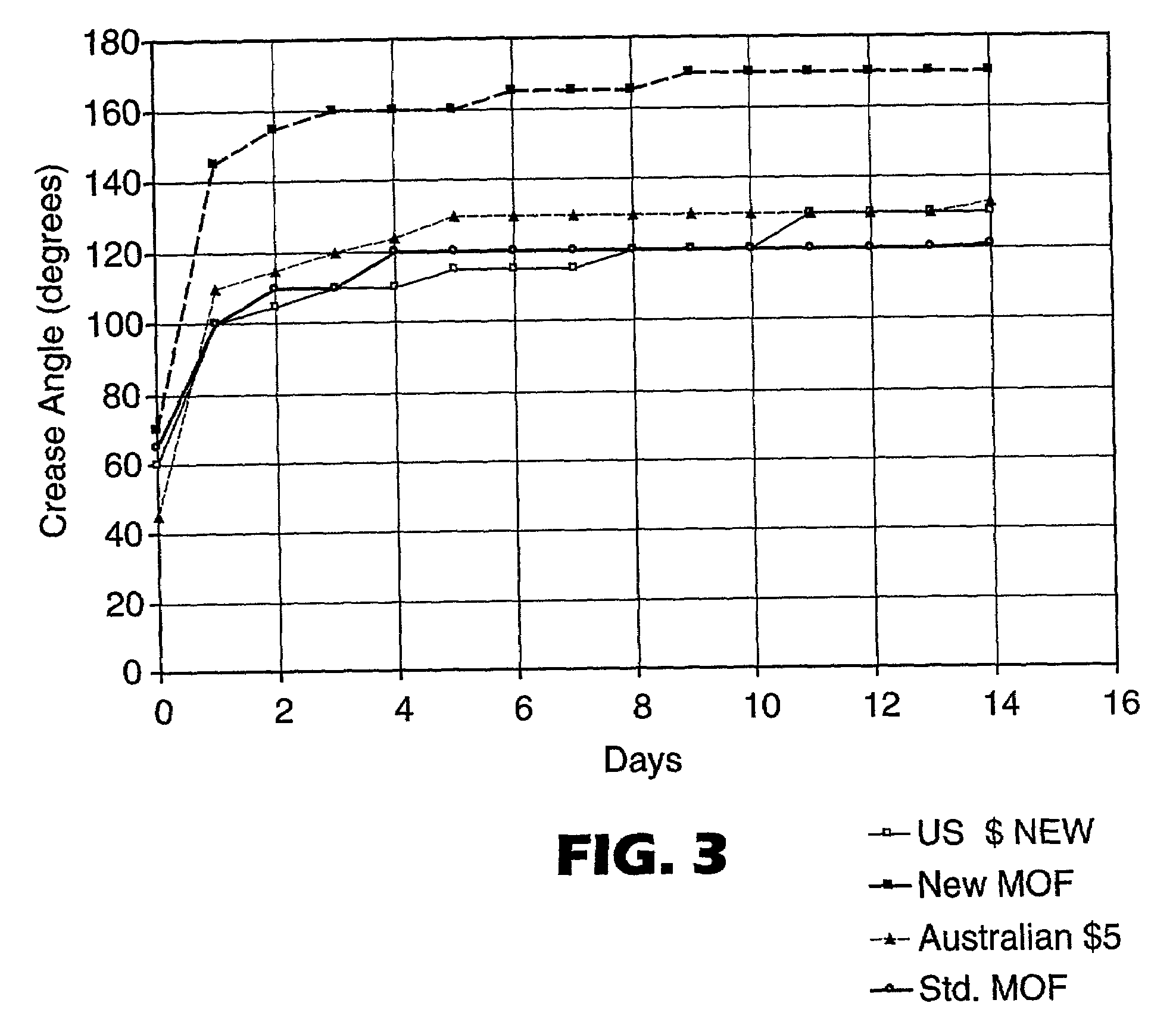

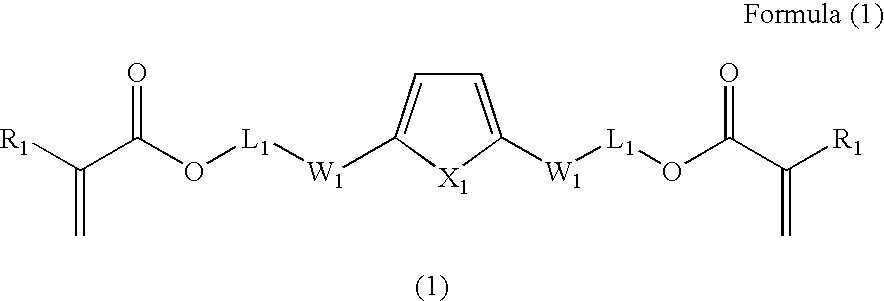

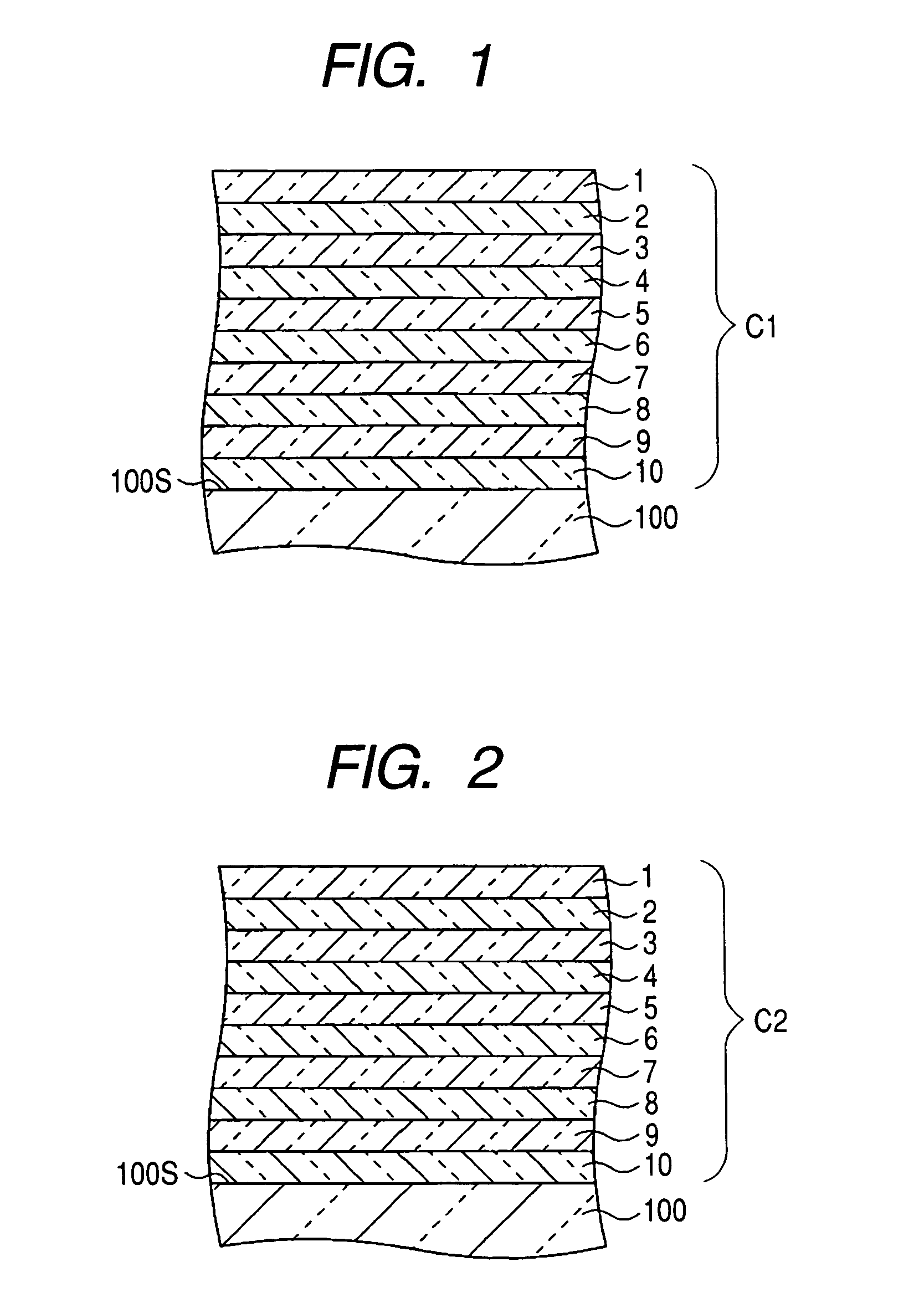

InactiveUS20030072931A1Fine creaseExcellent crumple recoveryLayered productsPolarising elementsThermoplasticPliability

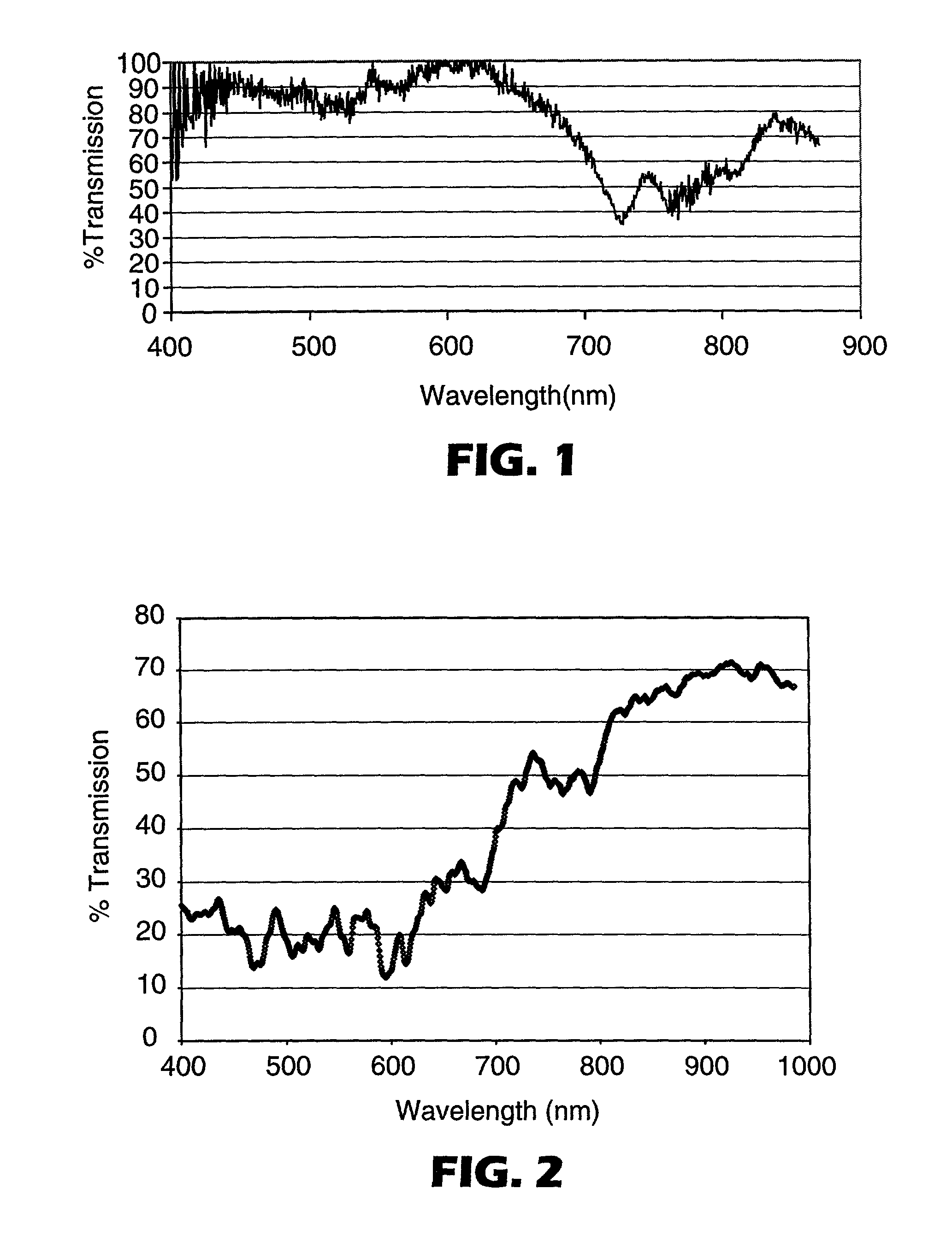

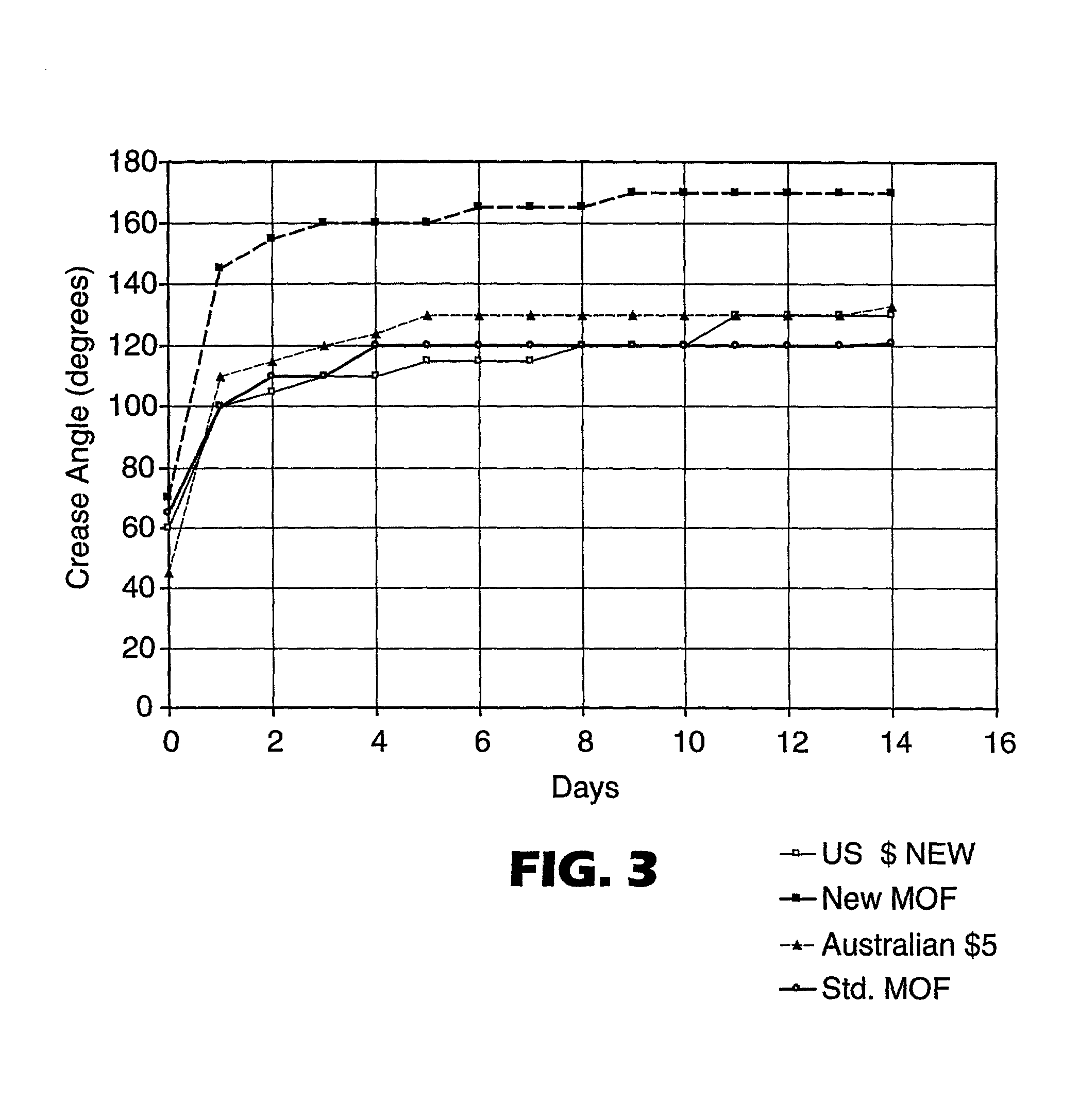

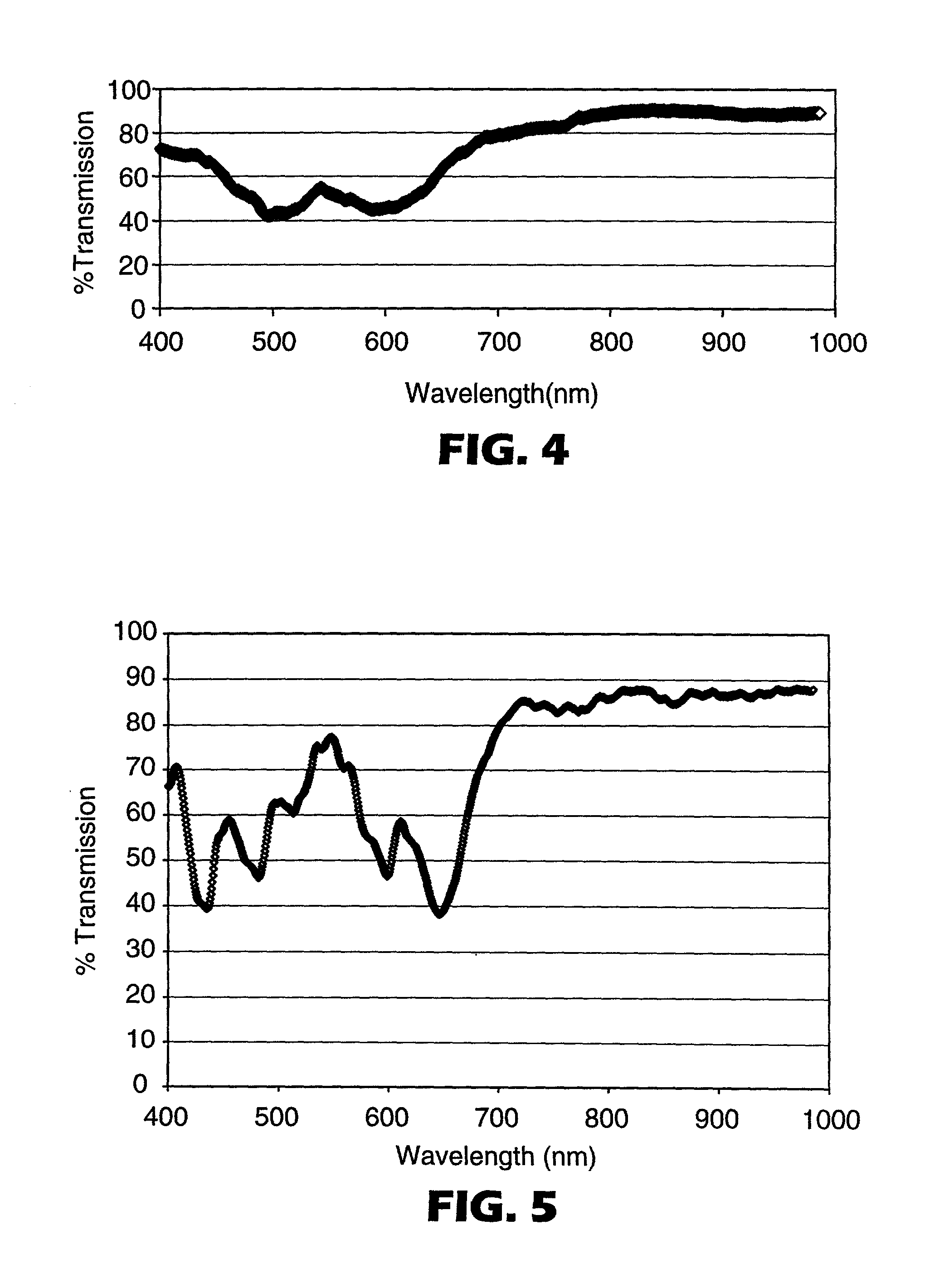

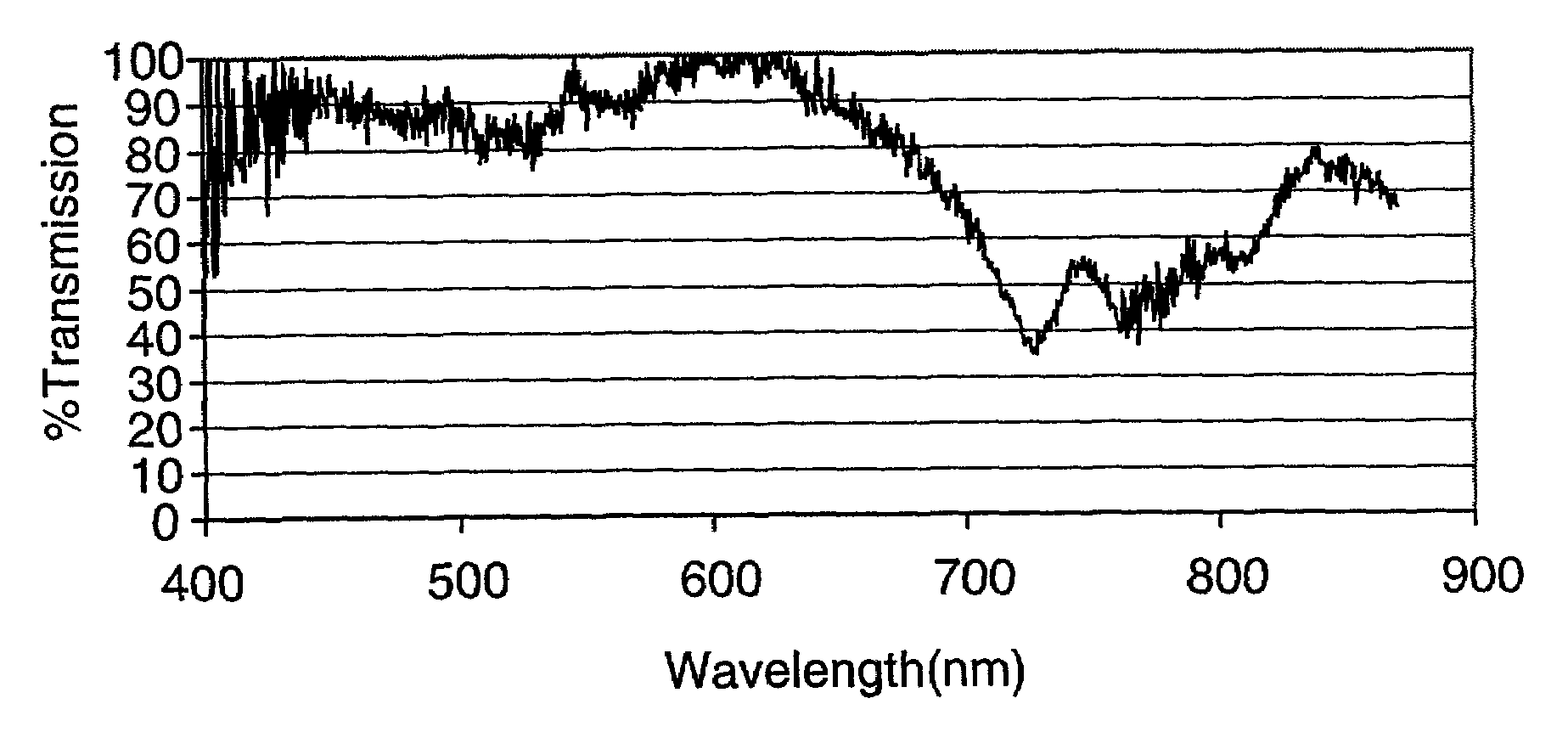

Multilayer optical films are comprised of materials with glass transition temperatures below room temperature (<30° C.). The high refractive index polymers are unique in that they exhibit mechanical properties similar to other low Tg semi-crystalline polymers, yet have significant birefringence (>0.05) when strain induced oriented. Novel combinations of comonomers for thermoplastics control the rate of crystallinity for improved processability and flexibility, giving the films crease and crumple recovery advantages.

Owner:3M INNOVATIVE PROPERTIES CO

Low Tg multilayer optical films

InactiveUS7052762B2Excellent crease and crumple recoveryHigh refractive indexOther printing matterLayered productsThermoplasticPliability

Multilayer optical films are comprised of materials with glass transition temperatures below room temperature (<30° C.). The high refractive index polymers are unique in that they exhibit mechanical properties similar to other low Tg semi-crystalline polymers, yet have significant birefringence (>0.05) when strain induced oriented. Novel combinations of comonomers for thermoplastics control the rate of crystallinity for improved processability and flexibility, giving the films crease and crumple recovery advantages.

Owner:3M INNOVATIVE PROPERTIES CO

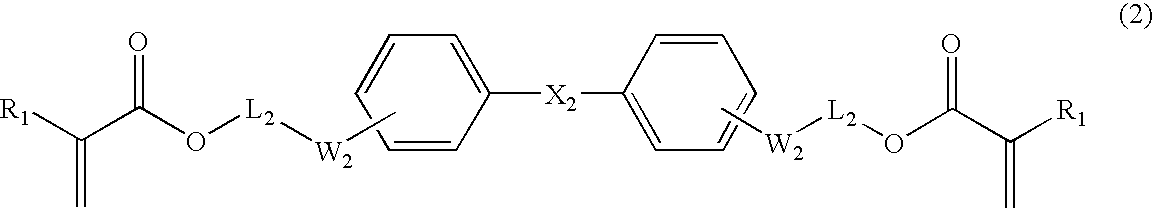

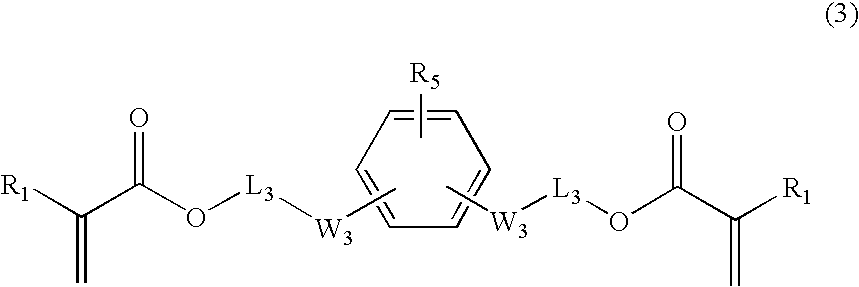

High refractive index monomers, compositions and uses thereof

The invention relates to novel sulfur-containing (meth)acrylic monomers and compositions thereof characterized by a high refractive index, for optical and industrial applications. The invention also relates to a method for preparing high refractive index polymeric materials and more specifically to a method for formation of ultraviolet cast optical lenses and compositions thereof comprising the sulfur-containing (meth)acrylic monomers.

Owner:CIBA CORP

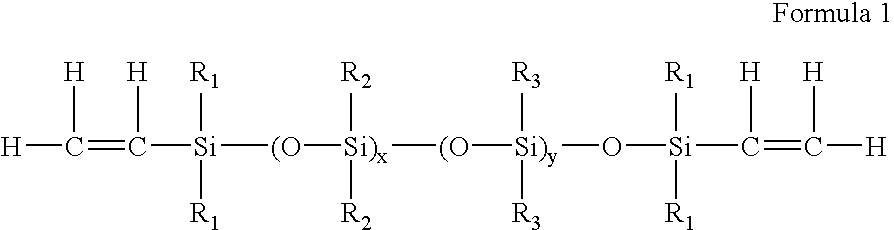

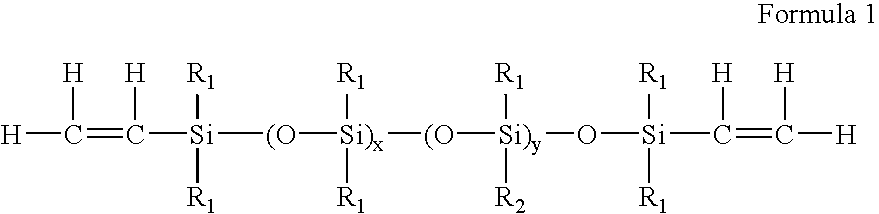

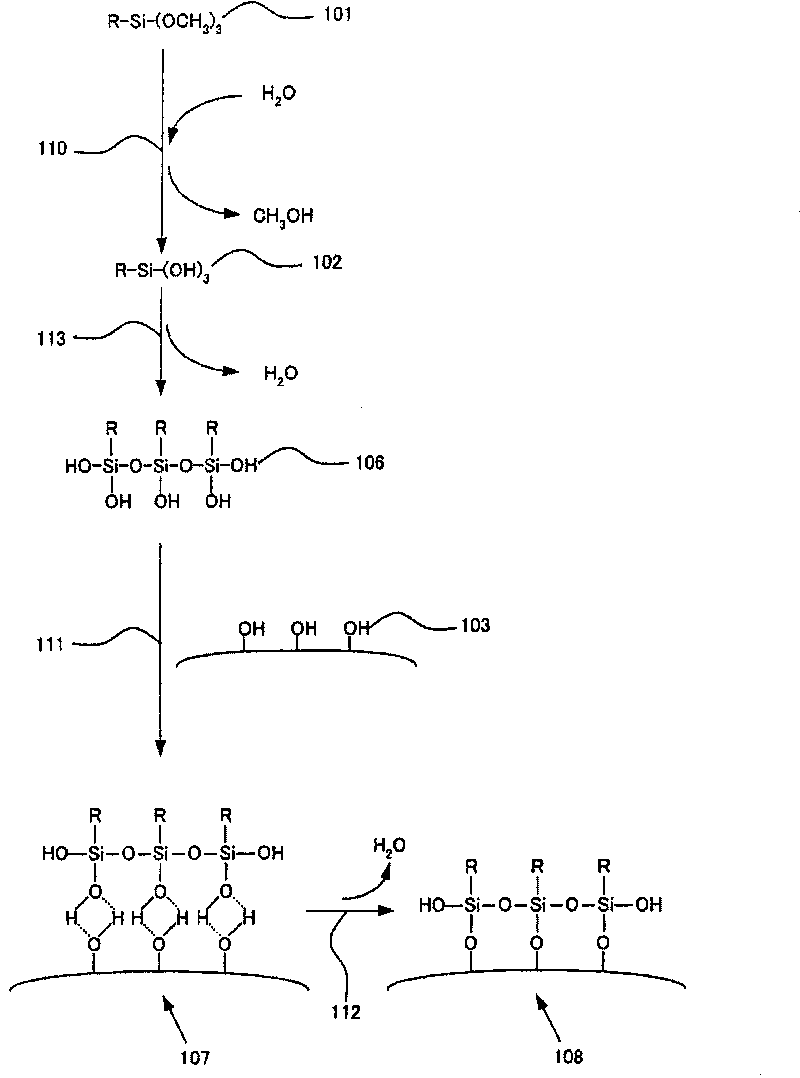

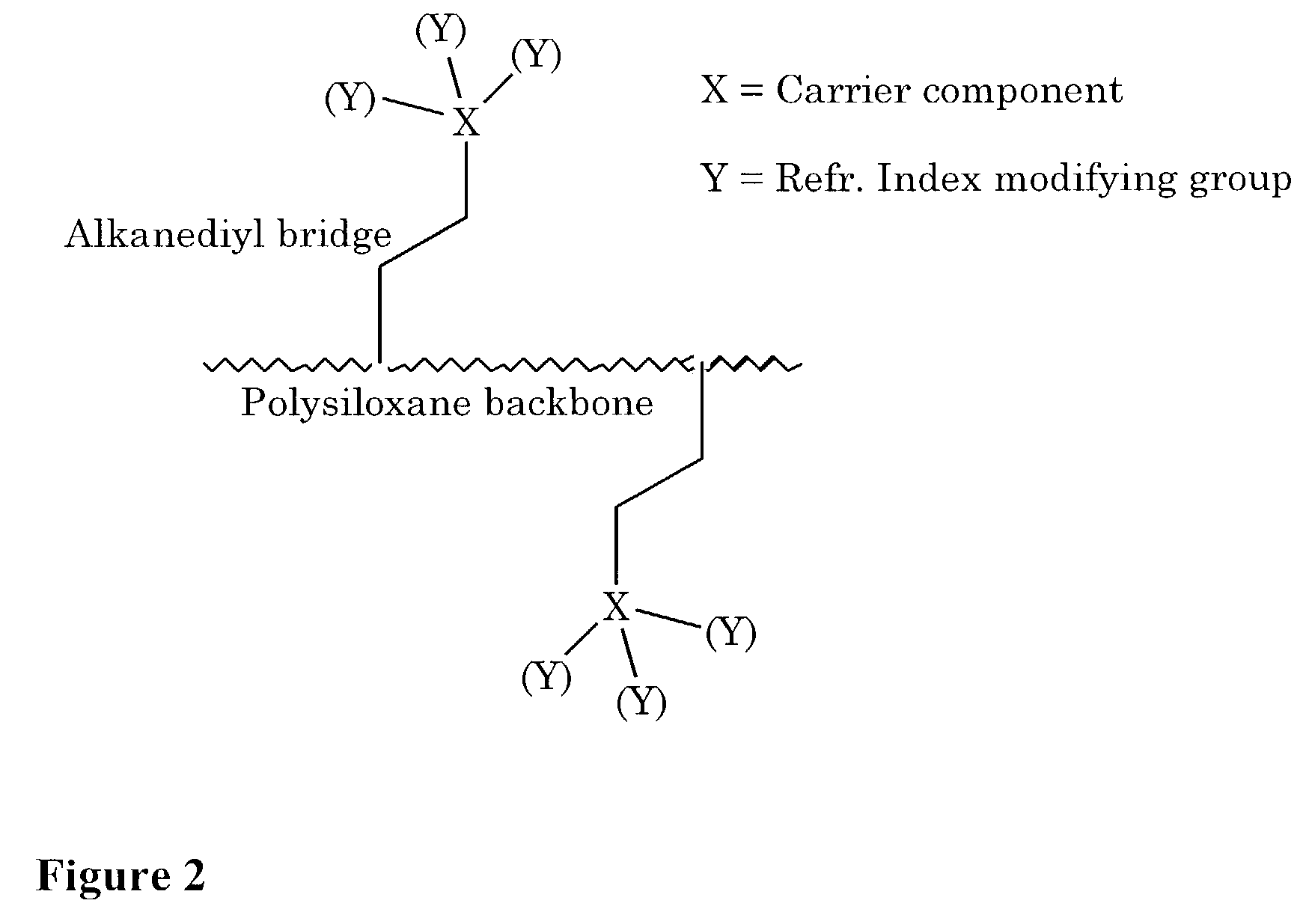

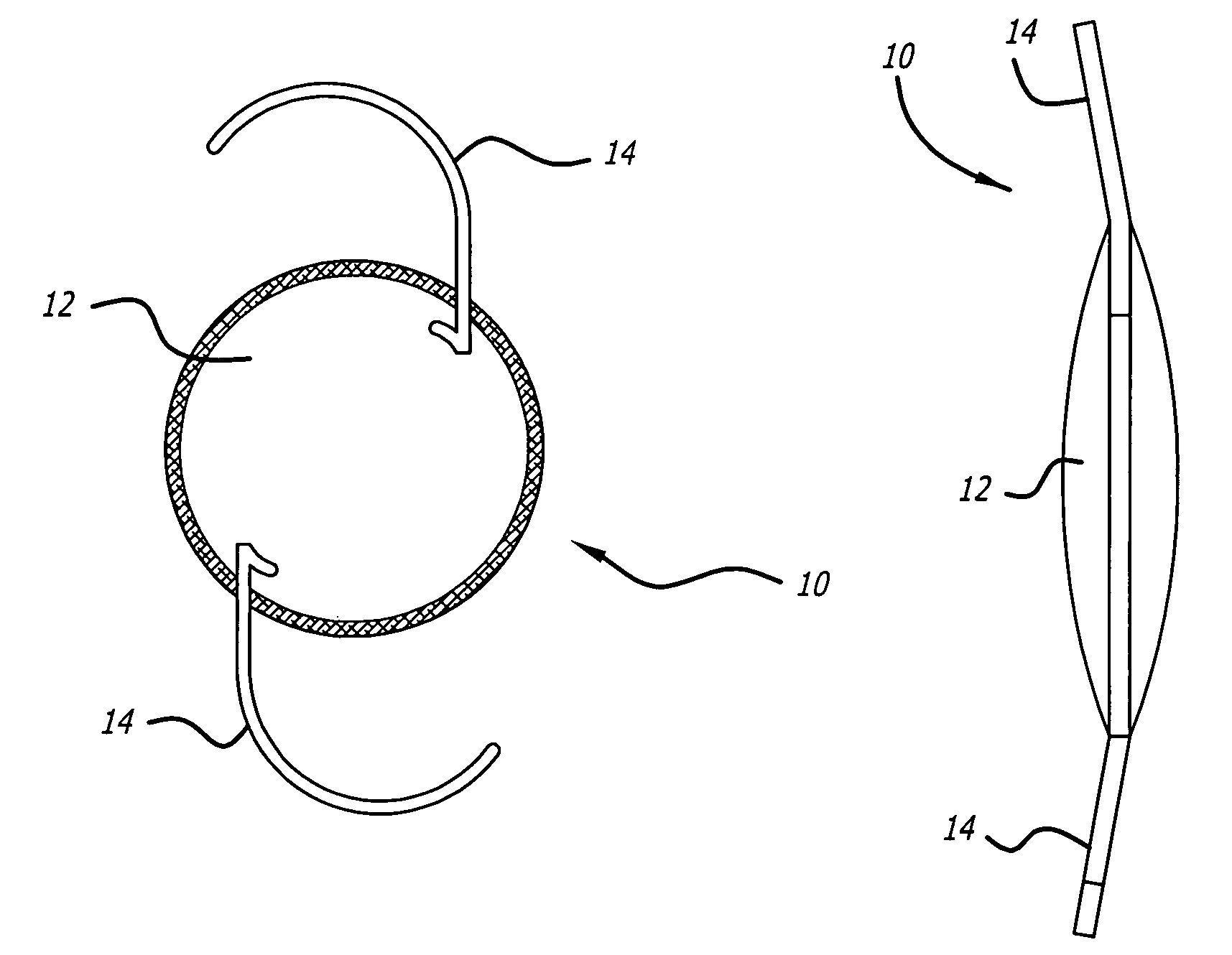

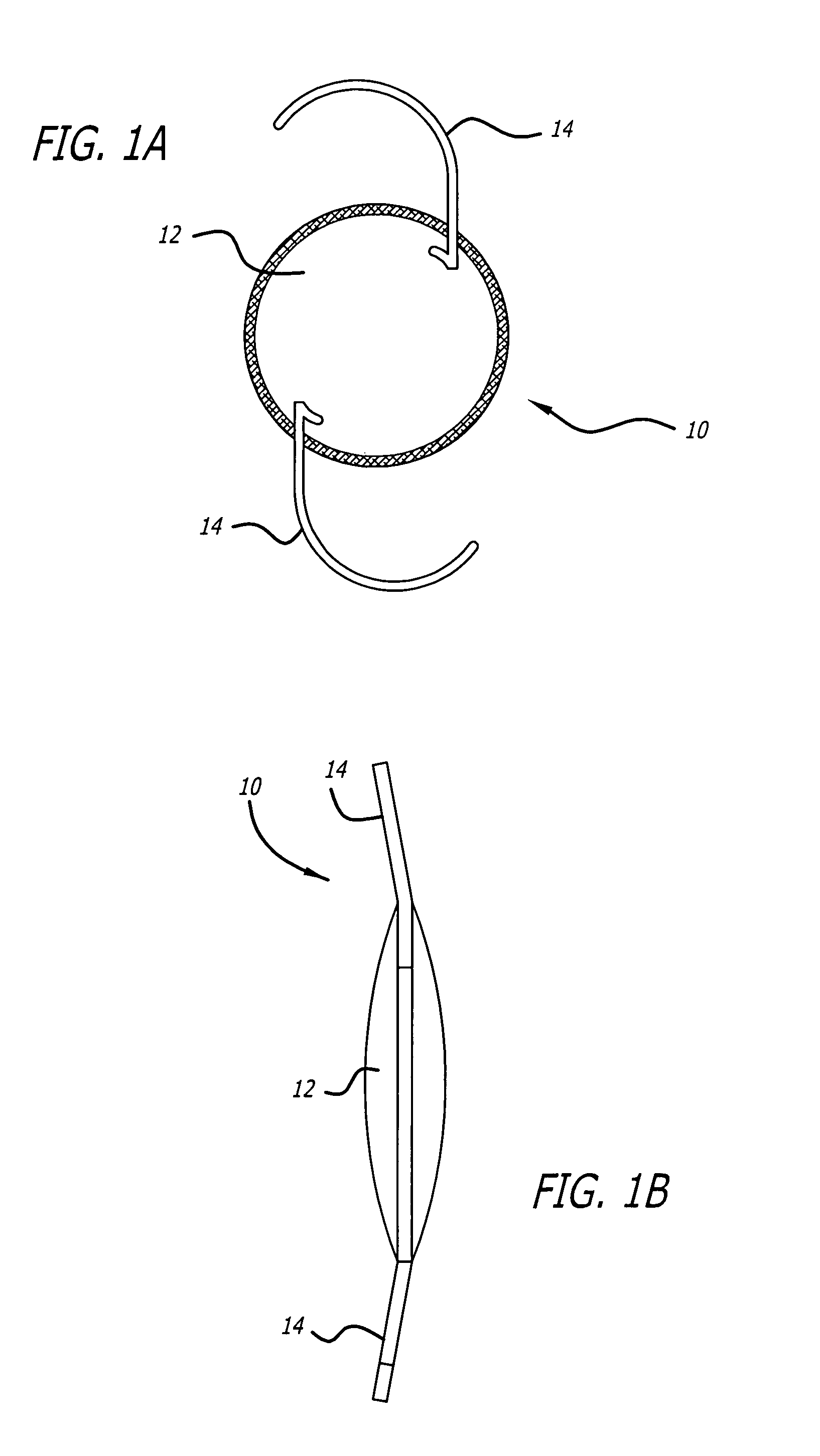

Process for the production of high refractive index polysiloxane-based polymeric compositions for use in medical devices

InactiveUS20050038219A1High refractive indexImprove homogeneityProsthesisOptical elementsPolymer scienceCorneal inlay

A process for producing polysiloxane prepolymers of improved homogeneity for use in the production of relatively high refractive index polymeric compositions is described herein. Polymeric compositions so produced are useful in the production of ophthalmic devices such as for example intraocular lenses and corneal inlays. The preferred polymeric compositions are produced through the copolymerization of one or more polysiloxane prepolymers with hydrosilane-containing polysiloxanes.

Owner:BAUSCH & LOMB INC

High refractive index polysiloxane prepolymers

InactiveUS6956087B2Quality improvementImprove reliabilityOptical articlesSkin careCorneal inlayHigh-refractive-index polymer

A process for producing polysiloxane prepolymers of improved homogeneity for use in the production of relatively high refractive index polymeric compositions is described herein. Polymeric compositions so produced are useful in the production of ophthalmic devices such as for example intraocular lenses and corneal inlays.

Owner:BAUSCH & LOMB INC

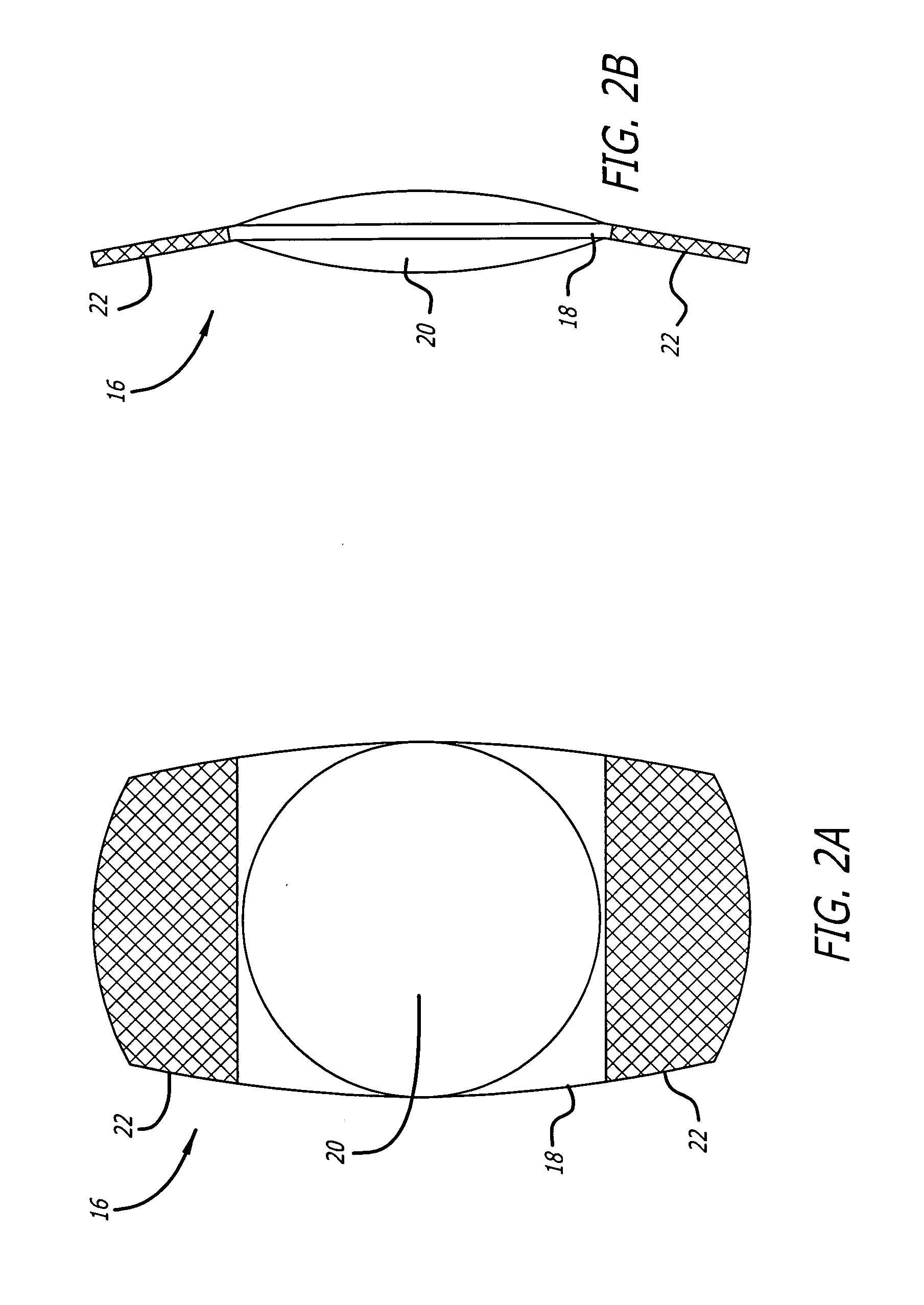

Antireflection laminate

ActiveCN101765791AHigh strengthImprove scratch resistanceCoatingsThin material handlingPolymer scienceDisplay device

This invention provides an antireflection laminate for use mainly in displays such as LCDs and PDPs. The antireflection laminate comprises a refractive index layer that has excellent scratch resistance, while containing empty particles and solid particles, and, at the same time, has a refractive index of not more than 1.45 and can ensure low reflective properties. The antireflection laminate comprises a refractive index layer having a refractive index of not more than 1.45 and is characterized in that the refractive index layer has been formed by exposing a composition for refractive index layer formation to an ionizing radiation, the composition comprises an ionizing radiation curing resin, crosslinkable empty particles comprising an outer shell layer and a porous or hollow interior surrounded by the outer shell layer, the surface of the empty particles being modified with crosslink forming groups, and crosslinkable solid particles of which the interior is neither porous nor hollow, the surface of the solid particles being modified with crosslink forming groups, and the crosslinkable groups contain an ionizing radiation curing group and have an identical or very similar structure.

Owner:DAI NIPPON PRINTING CO LTD

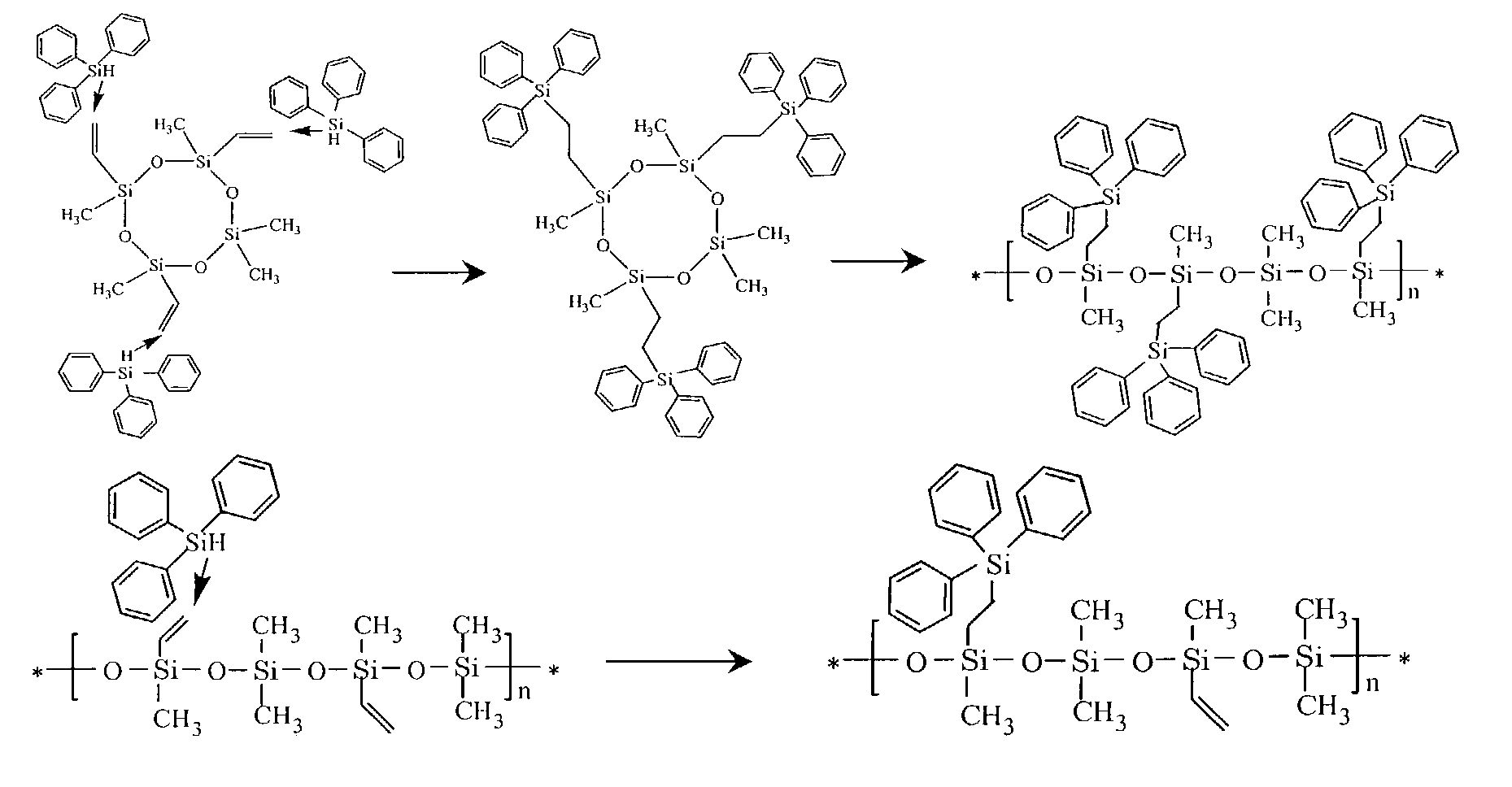

High refractive index flexible silicone

InactiveUS7217778B2High refractive indexIndex of refractionTissue regenerationIntraocular lensChemical LinkagePolymer science

The present invention discloses to a high refractive index polysiloxane (co)polymer comprising refractive index modifying groups chemically bonded in clustered configuration to the polysiloxane backbone. The invention also discloses methods for the preparation of such high refractive index polysiloxane (co)polymers. A polysiloxane according to the invention is very suitable for use as a material for the production of intra-ocular lenses.

Owner:OPHTEC

Antireflective Laminate

InactiveUS20080138606A1Improve water resistanceGood alkali resistanceLayered productsCoatingsHigh-refractive-index polymerMaterials science

Disclosed is an antireflective laminate that has significantly improved water resistance, alkaline resistance, and wetting resistance, and has improved visibility and scratch resistance. The antireflective laminate comprises a light-transparent base material and a low-refractive index layer provided on the light-transparent base material, wherein the low-refractive index layer is provided directly on a surface of the light-transparent base material or is provided on the outermost surface of one or two or more optional layers provided on the surface of the light-transparent base material, and the low-refractive index layer comprises hydrophobitized fine particles having an average particle diameter of not less than 5 nm and not more than 300 nm, and a binder.

Owner:DAI NIPPON PRINTING CO LTD

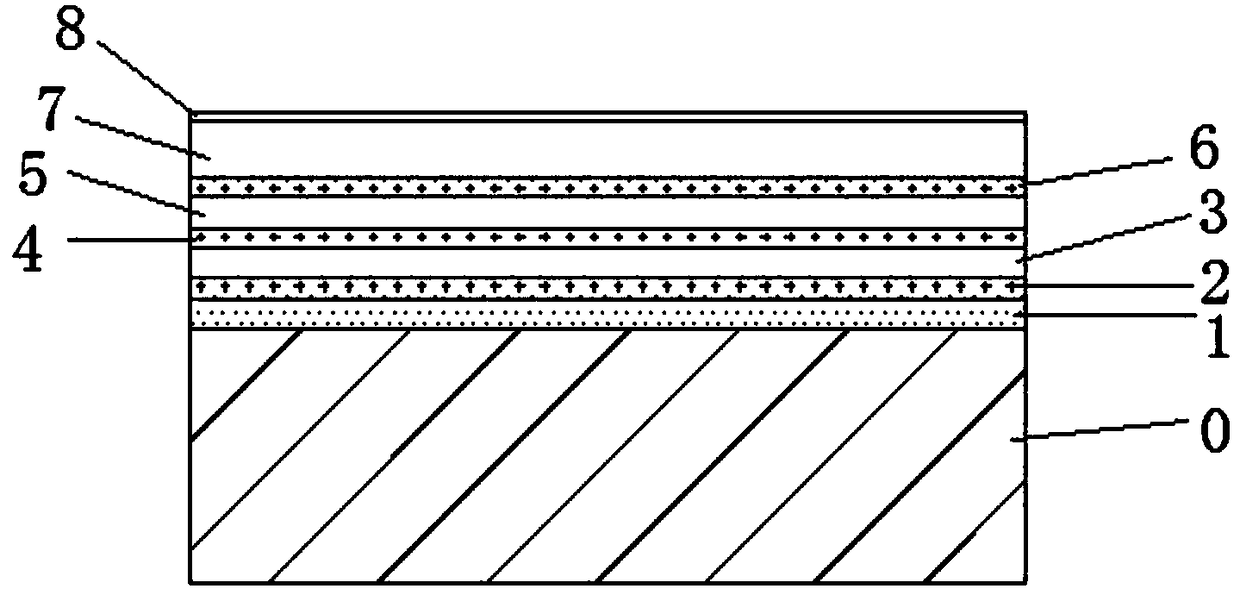

Antireflection film

InactiveUS20080032058A1Shorten speedUnsatisfactory corrosion resistanceCathode-ray/electron-beam tube vessels/containersDiffusing elementsHardnessLength wave

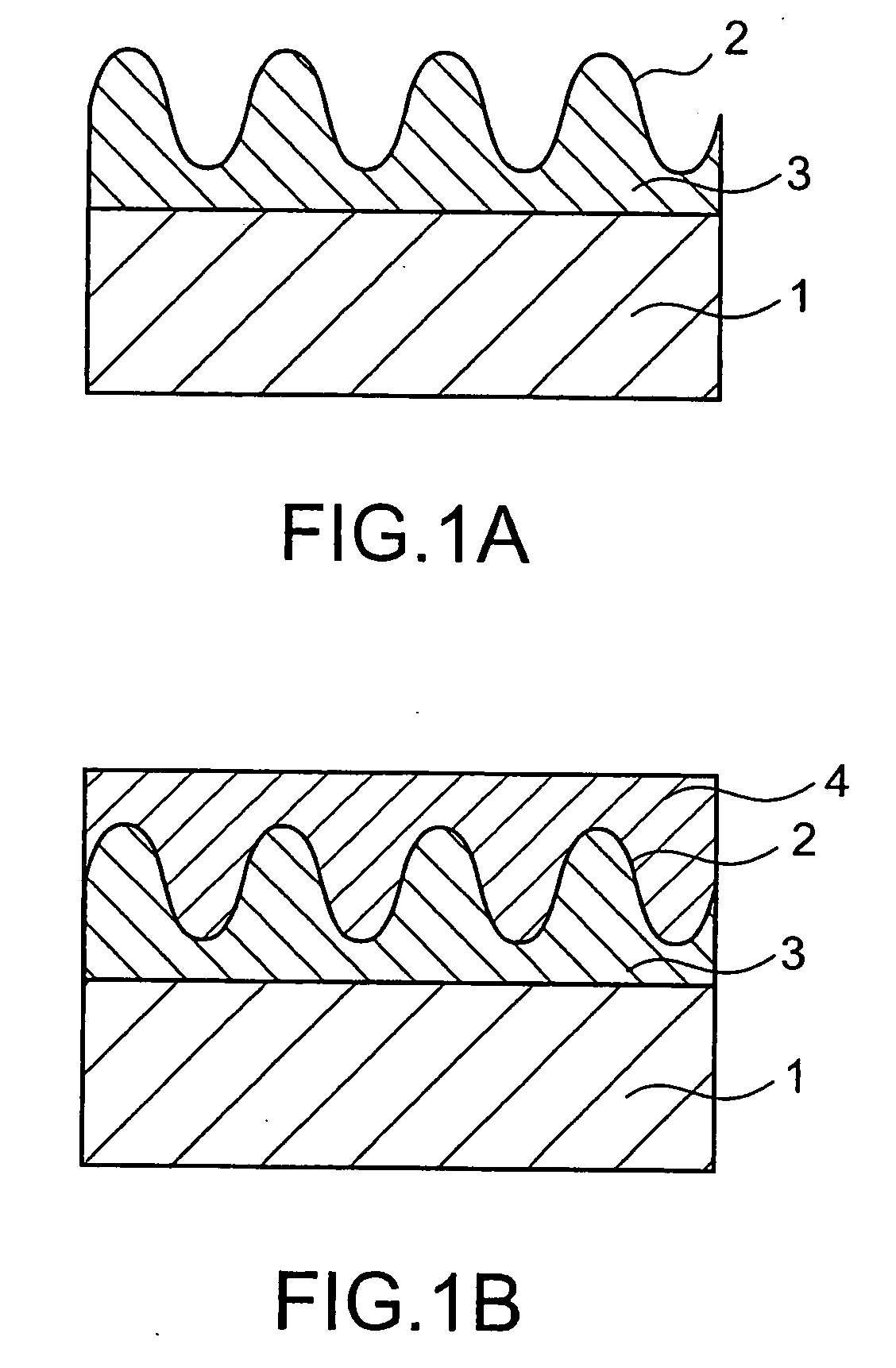

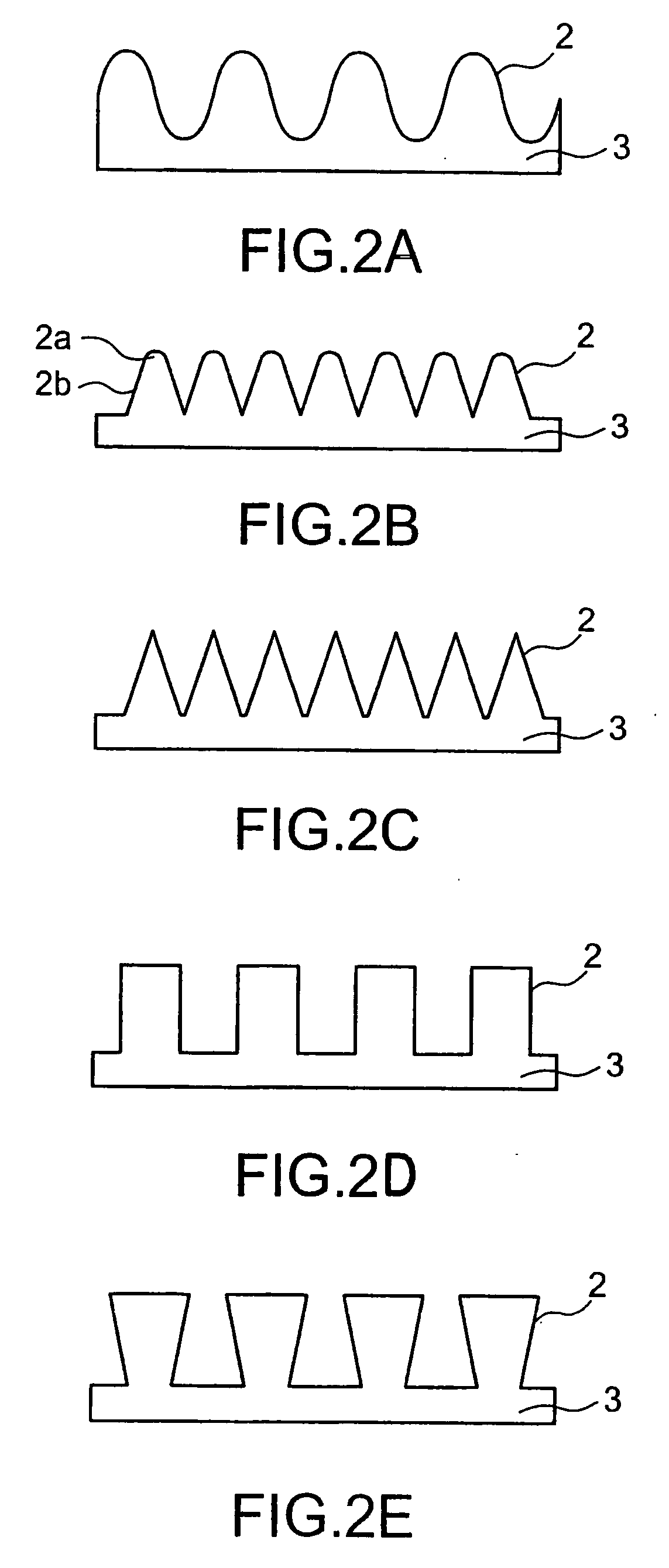

An object of the present invention is to eliminate drawbacks of conventional multi-layered antireflection films, that is, that a lot of time is required in the formation of a transparent conductive thin film and a low-refractive index layer leading to low processing speed, the corrosion resistance of the transparent conductive thin film is unsatisfactory, and the reflectance over the whole visible light region is not constant. This object can be attained by adopting a structure comprising: a transparent layer 3, with a pencil hardness of H or more, formed of a cured product of an ionizing radiation-curable resin composition; provided on one side of the transparent layer 3, a concave-convex portion 2 comprising innumerable fine concaves and convexes provided at a pitch of not more than the wavelength of light; a transparent substrate film 1 optionally provided on the transparent layer 3 on its side remote from the concave-convex portion 2; and a cover layer, having a lower refractive index than the transparent layer, preferably provided on the fine concaves and convexes.

Owner:DAI NIPPON PRINTING CO LTD

Water plasticized high refractive index polymer for ophthalmic applications

InactiveUS20010056165A1Minimal water uptakeLow water absorptionTissue regenerationIntraocular lensMethacrylateAryl

A high refractive index, foldable polymer suitable for use in ophthalmic devices, such as intraocular lenses, is provided. The polymer may be produced from a polymerization reaction of first, second and third monomeric components and a crosslinking agent. The first monomeric component includes an aryl acrylate or an aryl methacrylate. The second monomeric component, which is not an acrylate, includes a monomer having an aromatic ring with a substituent having at least one site of ethylenic unsaturation. The third monomeric component includes a high water content hydrogel-forming monomer. The resulting high refractive index copolymer is durable enough to be cut and polished when dry, and becomes soft and foldable when hydrated.

Owner:ADVANCED VISION SCI

Antireflection film

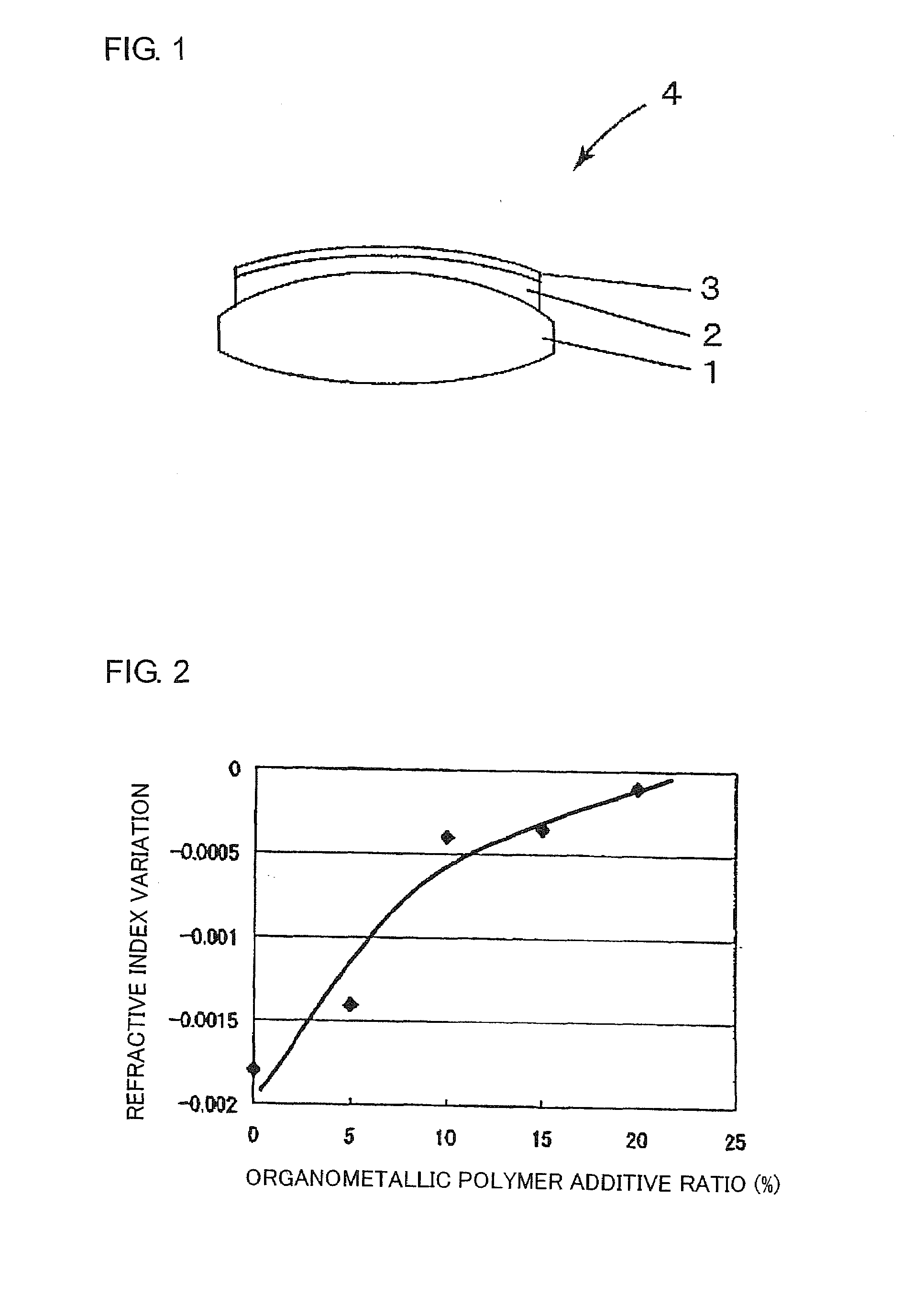

InactiveUS20020127408A1High refractive indexLayer is highLiquid crystal compositionsSynthetic resin layered productsOrganic filmHigh-refractive-index polymer

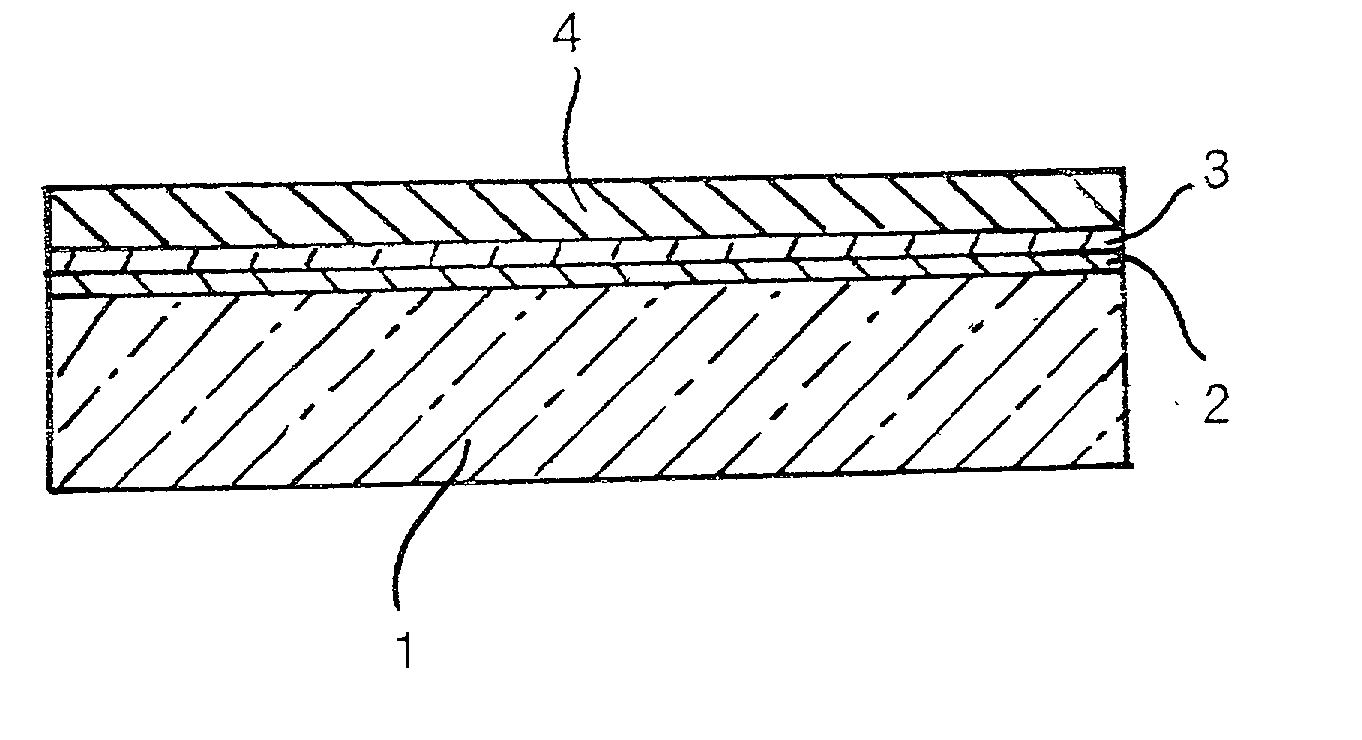

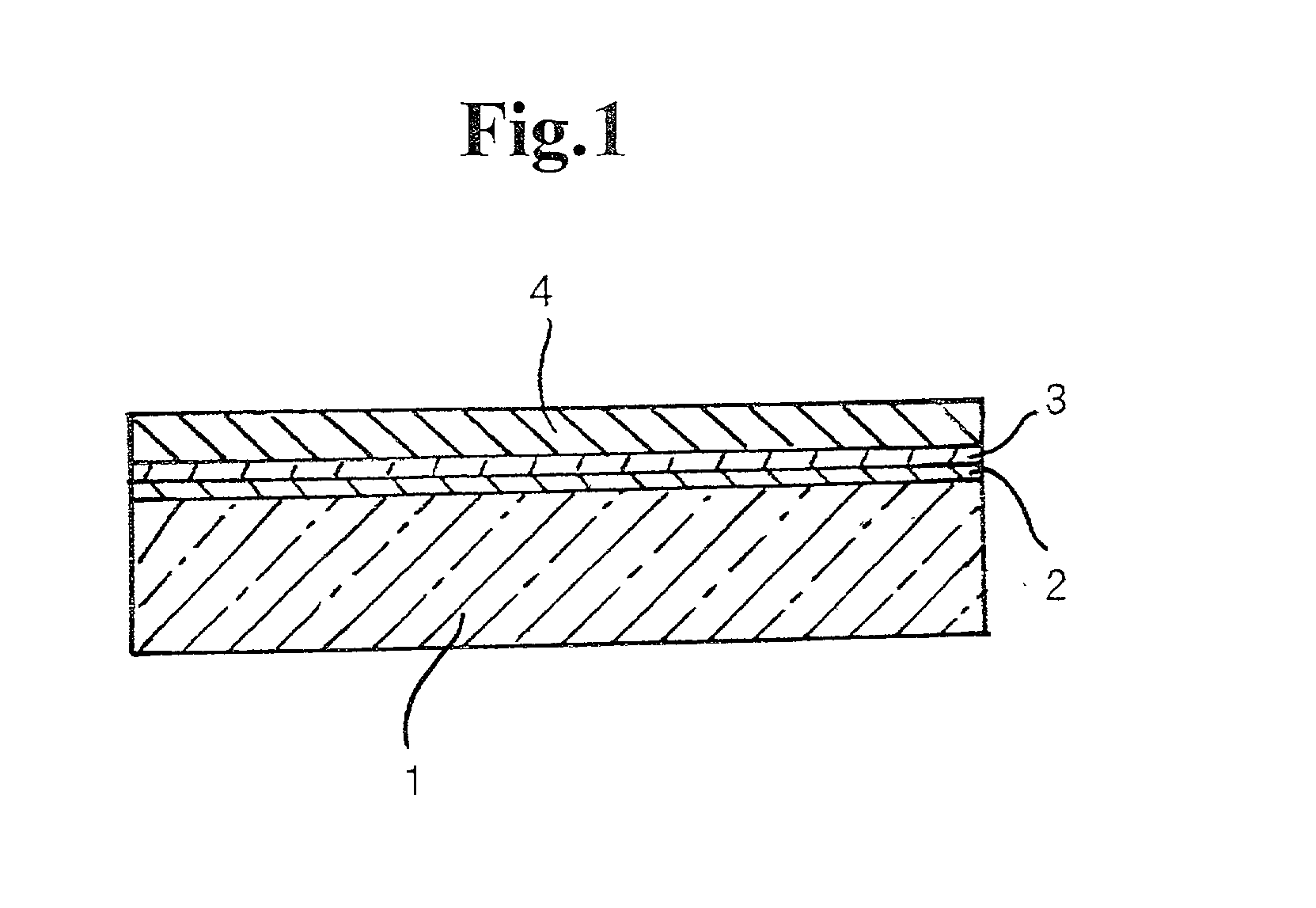

An antireflection film has an organic film 1, a hard-coating layer 2, an electrically conductive high refractive index layer 3 and a low refractive index layer 4, in which the layers 2, 3 and 4 are laminated on the organic film 1, in this order. The high refractive index layer 3 includes particles composed of two or more types of metal oxide, in which at least one of two or more types of the metal oxide is electrically conductive metal oxide. The high refractive index layer 3 has an exceedingly high refractive index. The low refractive index layer 4 may have a relatively high refractive index.

Owner:BRIDGESTONE CORP

Water plasticized high refractive index polymer for ophthalmic applications

Owner:ADVANCED VISION SCI

Water plasticized high refractive index polymer for ophthalmic applications

InactiveUS20070010883A1High refractive indexTissue regenerationIntraocular lensMethacrylateCross-link

The current invention provides a method of forming a foldable intraocular having a high refractive index from a copolymer comprising a first monomer comprising an aryl acrylate or an aryl methacrylate; a second monomer comprising an aromatic ring comprising a substituent having one ethylenic unsaturation, provided that the second monomer is not an aryl acryate or aryl methacrylate, and a third monomer comprising one ethylenic unsaturation that, if polymerized into a homopolymer, forms a high water content hydrogel; and, optionally, a cross-linking agent.

Owner:ADVANCED VISION SCI

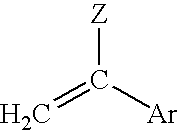

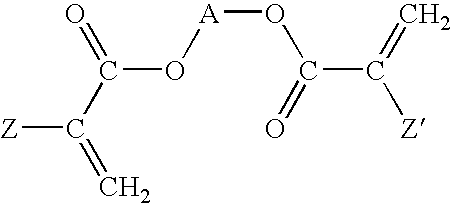

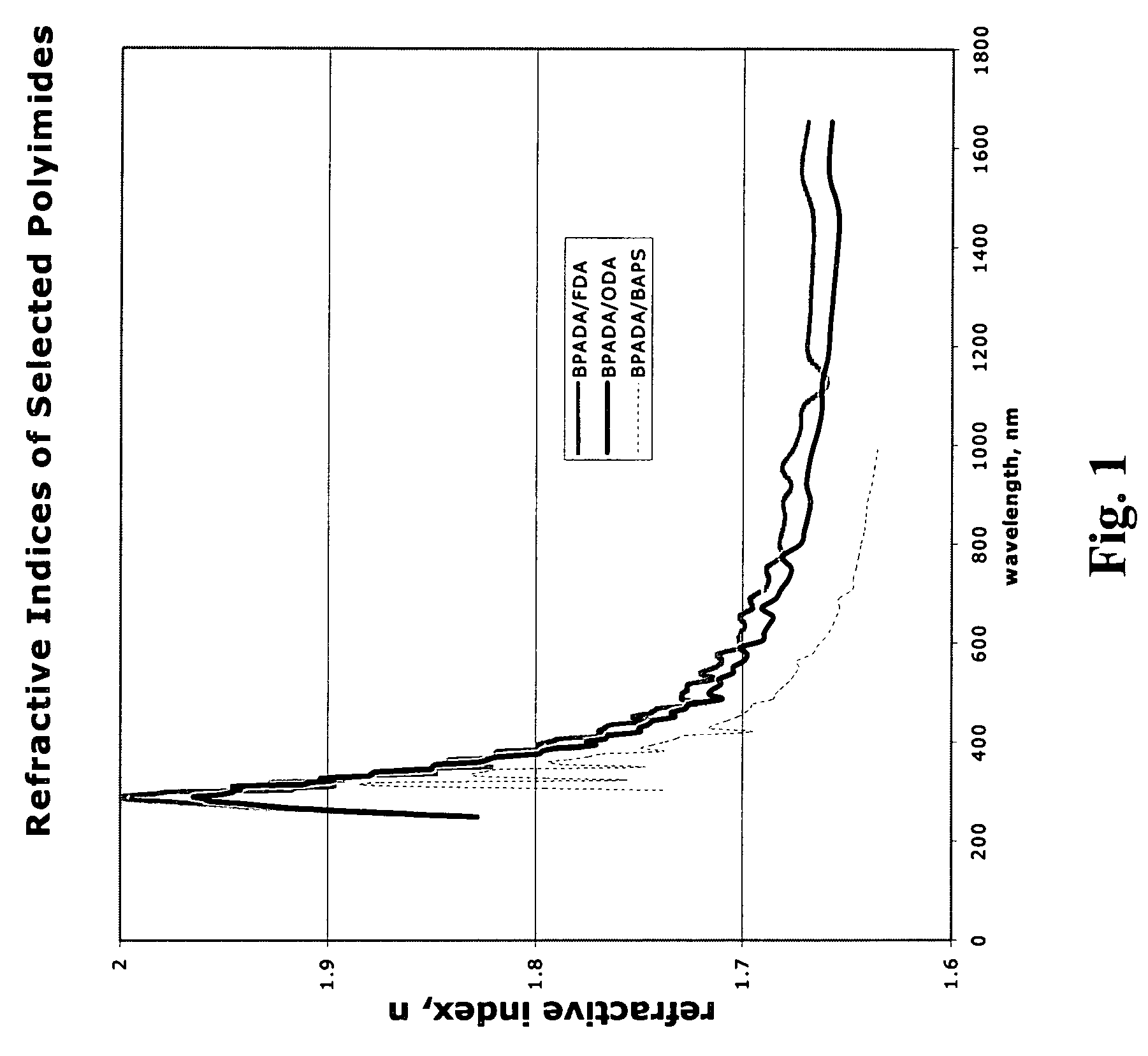

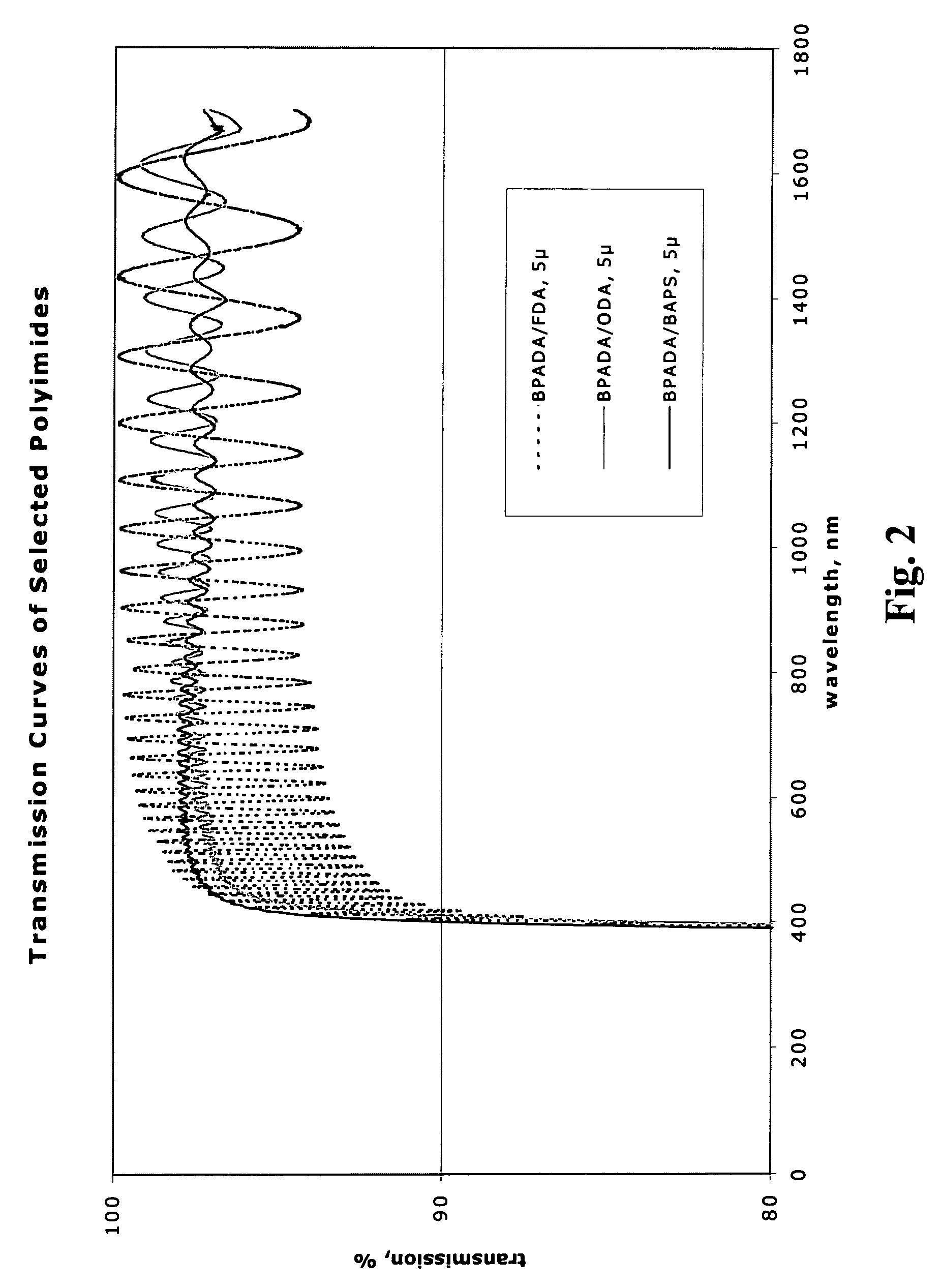

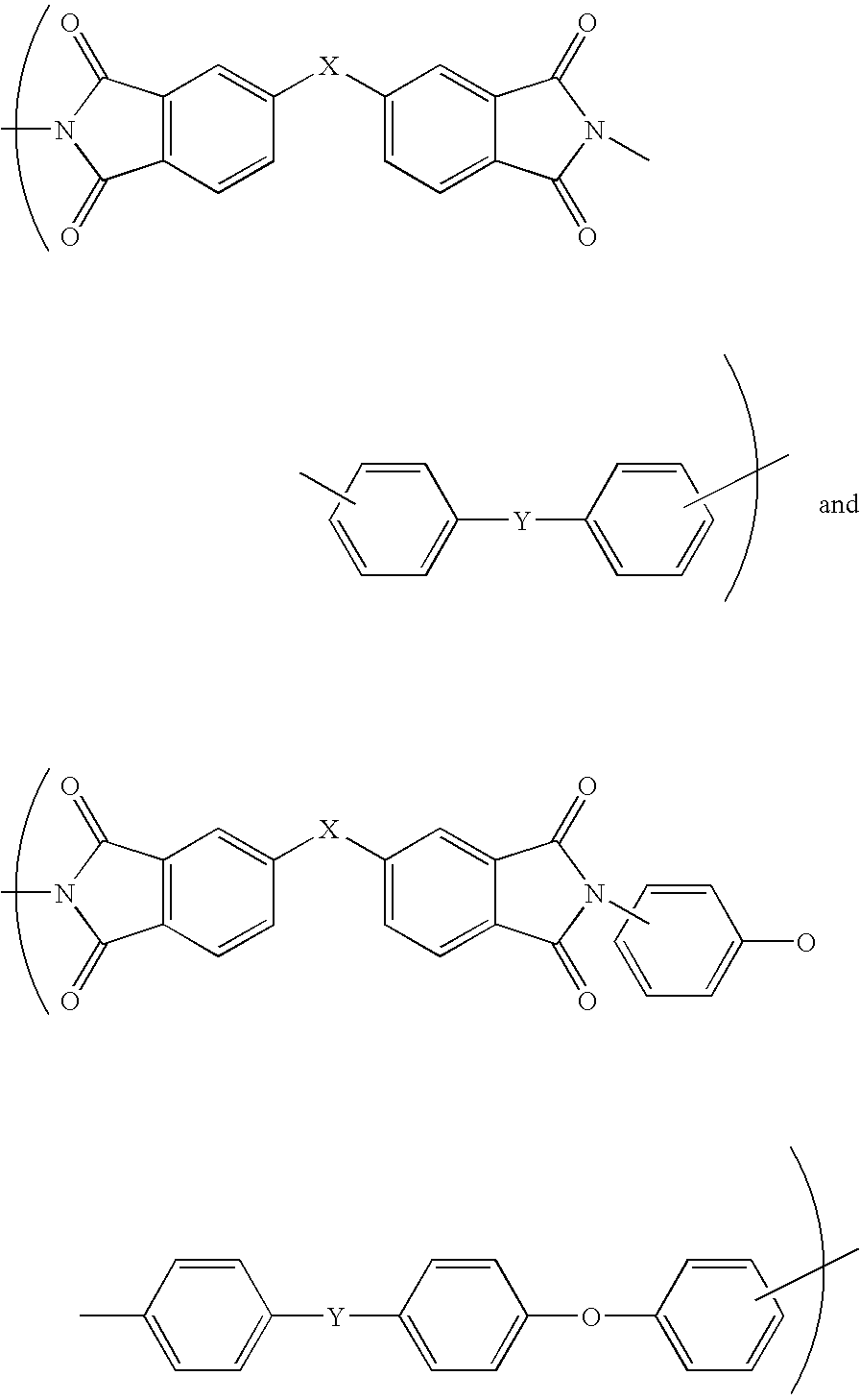

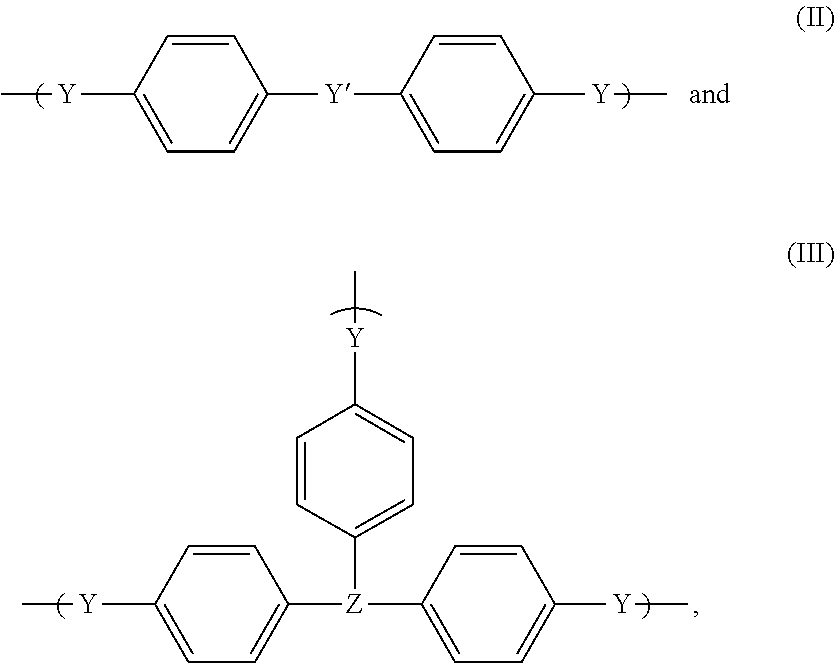

Polyimides for use as high refractive index, thin film materials

New compositions for use as high refractive index layers are provided. The compositions comprise a polyimide dispersed or dissolved in a solvent system. The polyimide can be prepared from commercially available dianhydrides and diamines. Preferred polymer include recurring monomers selected from the group consisting ofThe inventive compositions can form strong, thin films and have high refractive indices making them useful in a wide range of optical applications.

Owner:BREWER SCI +1

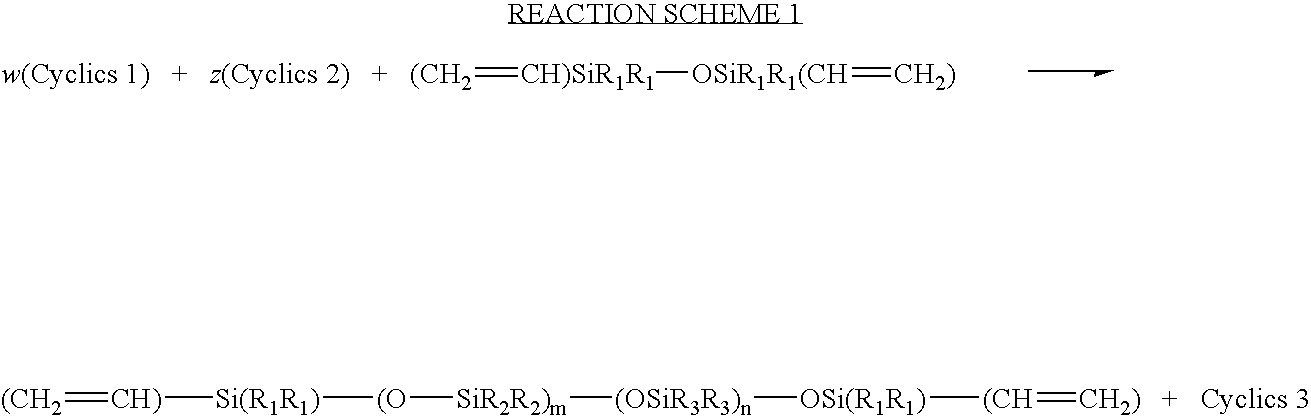

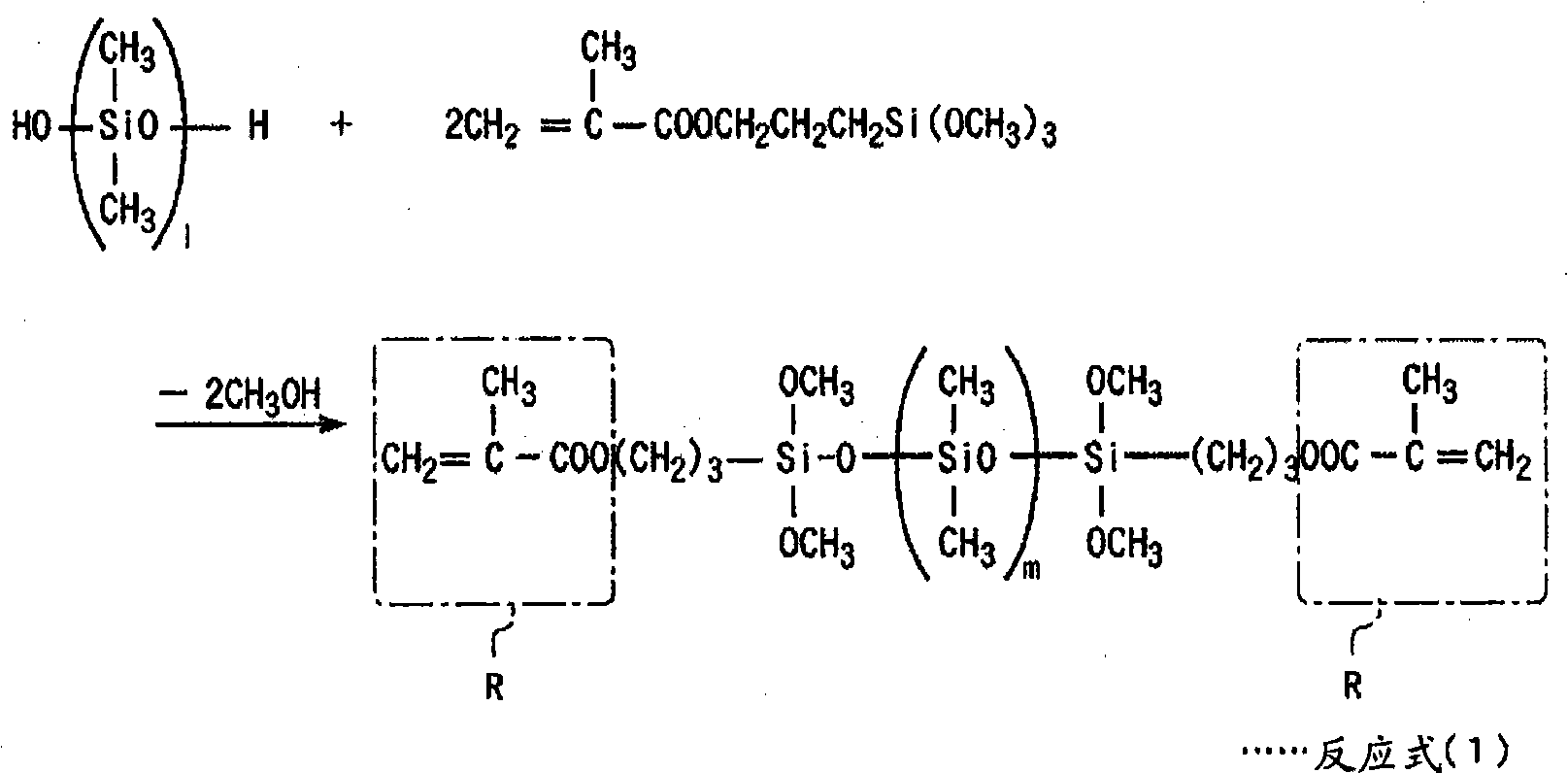

LED (Light-Emitting Diode) packaging silica gel with high refractive index, light transmittance and power, and method for preparing same

InactiveCN102775954AGood adhesionHigh strengthAdhesivesSemiconductor devicesAntioxidantTemperature resistance

An LED (Light-Emitting Diode) packaging silica gel with high refractive index, light transmittance and power is composed of two adhesives A and B according to parts by weight, wherein the adhesive A comprises the following components: phenyl vinyl polysiloxane, phenyl silicone, a quick-drying agent, a light stabilizer and an antioxidant; and the adhesive B comprises the following components: phenyl vinyl polysiloxane, phenyl hydrogen polysiloxane, a retarder, a defoamer and an ultraviolet absorber. The LED packaging silica gel employs a two-component packaging manner; the production process of the LED packaging silica gel is simple and easy to implement; the storage of the LED packaging silica gel is convenient without special requirement for the environment; and the period of storage is long, and production is facilitated. In use, the silica gel formed through simple blending is good in bonding strength, high in strength, high in light transmittance and refractive index, and has the advantages of being excellent in high-temperature resistance, good in aging and weather resistance and the like.

Owner:邵成芬

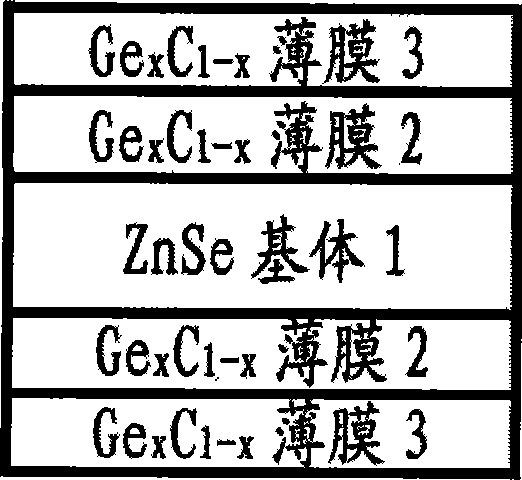

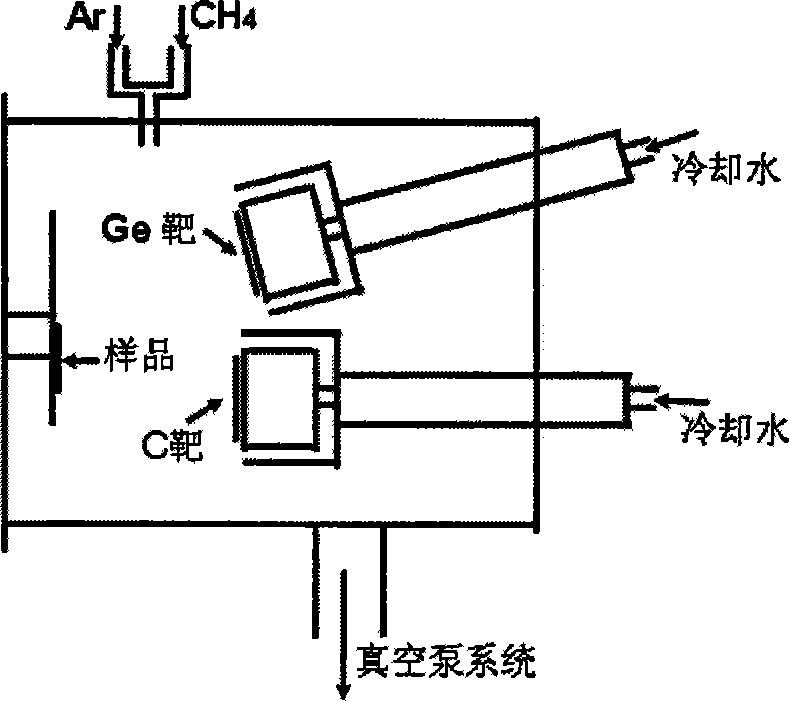

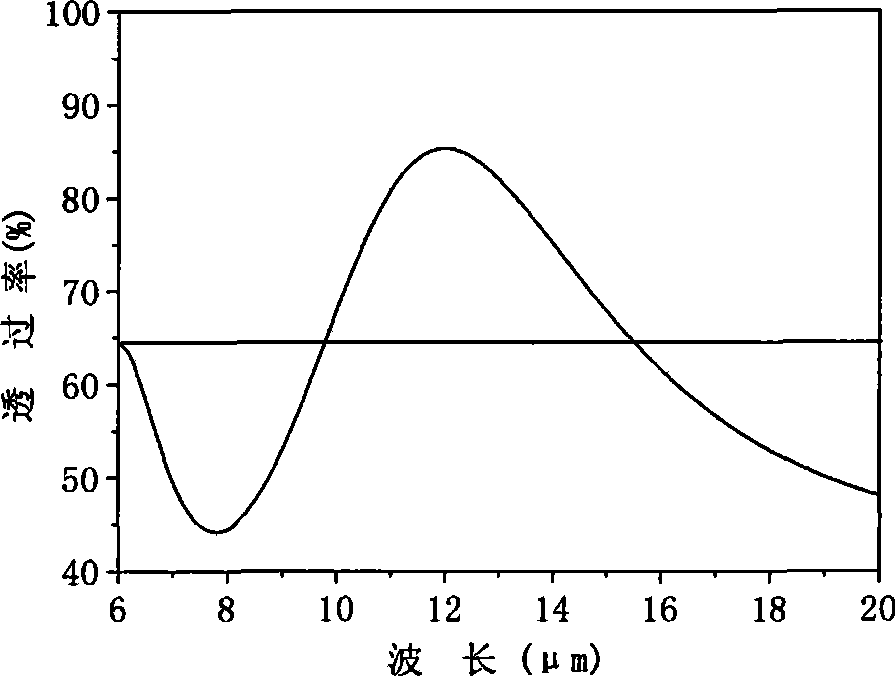

ZnSe infrared anti-reflection film and method for producing the same

InactiveCN101464530ALittle mutual restraintAchieve anti-reflection effectVacuum evaporation coatingSputtering coatingSputteringIntermediate frequency

The invention relates to an infrared anti-reflecting film and a preparation method thereof, and belongs to the technical field of films. Lambada 0 / 4 to Lambada 0 / 4 double-layer anti-reflecting films with high refractive index (2) and low refractive index (3) are prepared on a ZnSe basal body (1) in sequence through taking 3 to 12 Mu m as central wave length Lambada 0. The refractive index of the high refractive index film (2) is 3.0 to 4.0, and the optical thickness thereof is 1 to 3 Mu m; the refractive index of the low refractive index film (3) is 2.1 to 2.6, and the optical thickness thereof is 0.75 to 3 Mu m. The preparation method comprises the step of depositing the GexC1-x anti-reflecting films on single side or double sides of the ZnSe basal body by adopting the intermediate frequency and the direct current double-target magnetic control sputtering method and taking Ge and C as target sources, and CH4 and Ar mixed gas as auxiliary discharge gas. Two layers of GexC1 minus x films with different refractive indexes are prepared through controlling the sputtering current proportion of Ge and C targets and controlling the partial pressure ratio of CH4 / Ar; and the thickness of each film achieves Lambada 0 / 4 through controlling the time and other parameters. The method has the advantages of less parameter diversionary, simple control, and good anti-reflecting effect.

Owner:SICHUAN UNIV

High refractive index and optically clear copoly (carbosilane and siloxane) elastomers

InactiveUS7071279B2High refractive indexImprove recoverabilitySurgical adhesivesTissue regenerationElastomerEye lens

High refractive index and optically clear copoly(carbosilane and siloxane) elastomers and ophthalmic lenses made therefrom are provided. The elastomers are comprised of copolymers having carbosilane repeat units and siloxane repeat units. The copolymers and ophthalmic lenses of the present invention have a high refractive index and excellent folding recoverability.

Owner:STAAR SURGICAL COMPANY INC

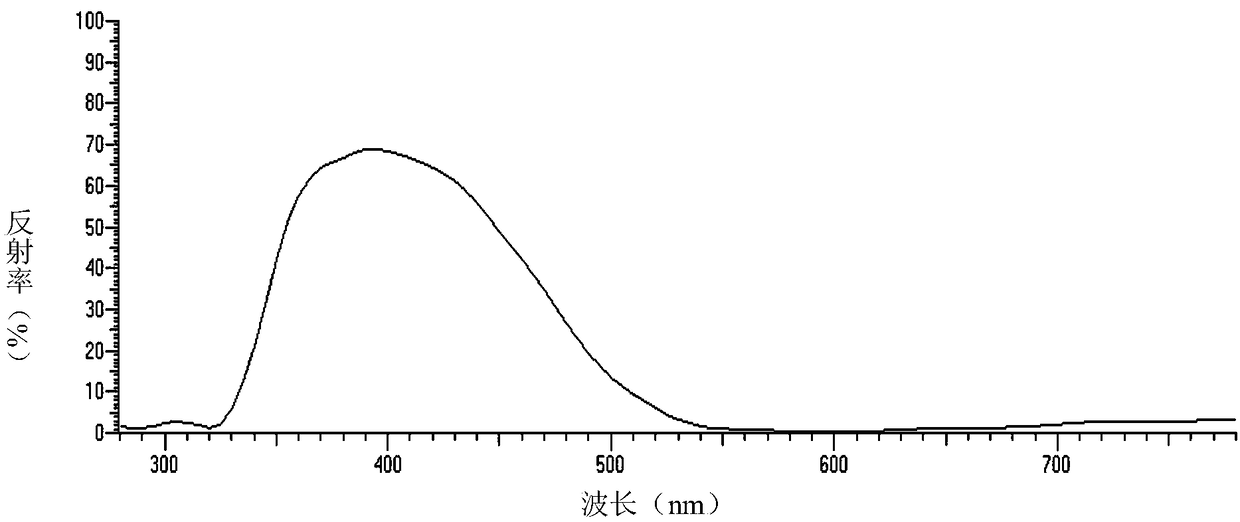

Angstrom anti-blue lens and preparation method thereof

PendingCN108303760AGood film adhesionHigh hardnessOptical filtersVacuum evaporation coatingComposite filmSalt water

The invention relates to an angstrom anti-blue lens and a preparation method thereof. The lens includes a substrate, a priming layer, a composite film layer and a protective layer. The priming layer is made of silicon dioxide or a silicon-aluminum mixture, and has a thickness of 800+ / -100 angstroms. The composite film layer includes a film formed by alternately stacking 4 layers, 6 layers or 8 layers of high refractive index layers and low refractive index layers, the high refractive index layer is made of any one of Ta2O5, Ti3O5 or Nb2O5 and has a thickness of 500+ / -100 angstroms, and the lowrefractive index layer is made of silica or a silicon-aluminum mixture. The prepared angstrom anti-blue lens has a good effect of reflecting light with a wavelength of 340-500 nm and has an anti-bluelight effect; after the lens is subjected to salt water boiling and pure water soaking cycle 11 times, no film layer falls off in a 100-square test, and the angstrom anti-blue lens has good film layer adhesive force. The angstrom anti-blue lens has a good seawater corrosion resistance, and is especially suitable for the seaside environment.

Owner:厦门美澜光电科技有限公司

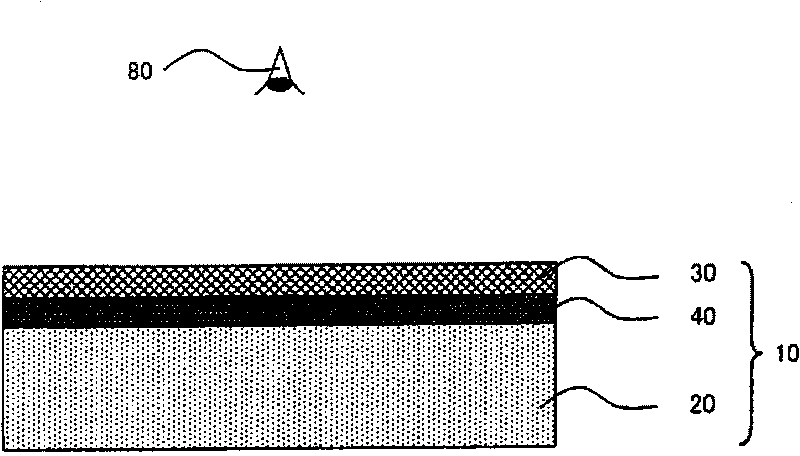

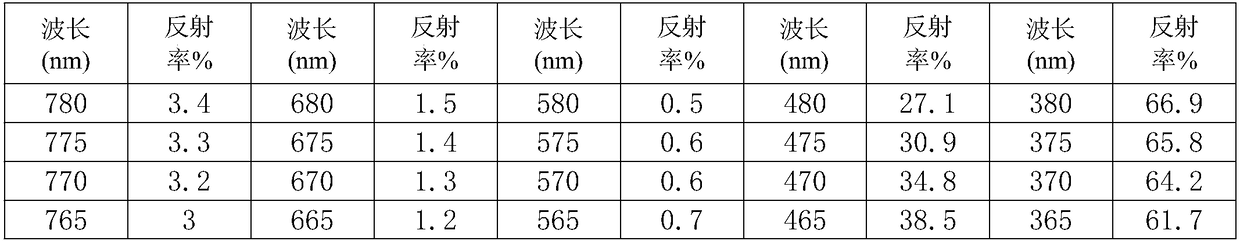

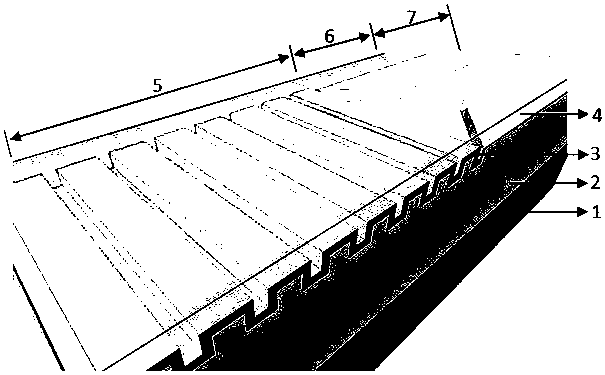

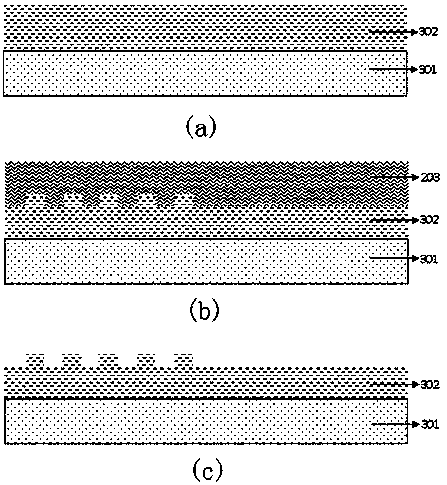

Optical communication waveband polymer waveguide grating coupler and manufacturing method thereof

PendingCN108107506AEfficient couplingReduced Lithography Resolution RequirementsOptical waveguide light guidePhotonicsOptical communication

The invention relates to an optical communication waveband polymer waveguide grating coupler and a manufacturing method thereof. The waveguide grating coupler comprises a grating structure and a waveguide structure, wherein the grating structure is composed of a substrate, a low-refractive-index waveguide lower coverage layer, a high-refractive-index medium layer, a high-refractive-index waveguidecore layer and an air layer; the waveguide structure is composed of a substrate, a low-refractive-index waveguide lower coverage layer, a high-refractive-index waveguide core layer and an air layer.A key preparation technology of the waveguide grating coupler comprises the following steps: manufacturing a main mold and a soft secondary mold; manufacturing the substrates and the low-refractive-index waveguide lower coverage layers of the grating structure and the waveguide structure; manufacturing the high-refractive-index medium layer of the grating structure; spinning and covering a high-refractive-index polymer waveguide core layer material. The optical communication waveband polymer waveguide grating coupler and the manufacturing method thereof have the advantages of simple realization technology and low cost; the difficulty of aligning a polymer waveguide and a common single-mode optical fiber through an end face coupling manner can be effectively reduced, and application researches of a polymer integrated photonic device in the aspects of optical sensing and optical interconnection are easily propelled.

Owner:FUZHOU UNIV

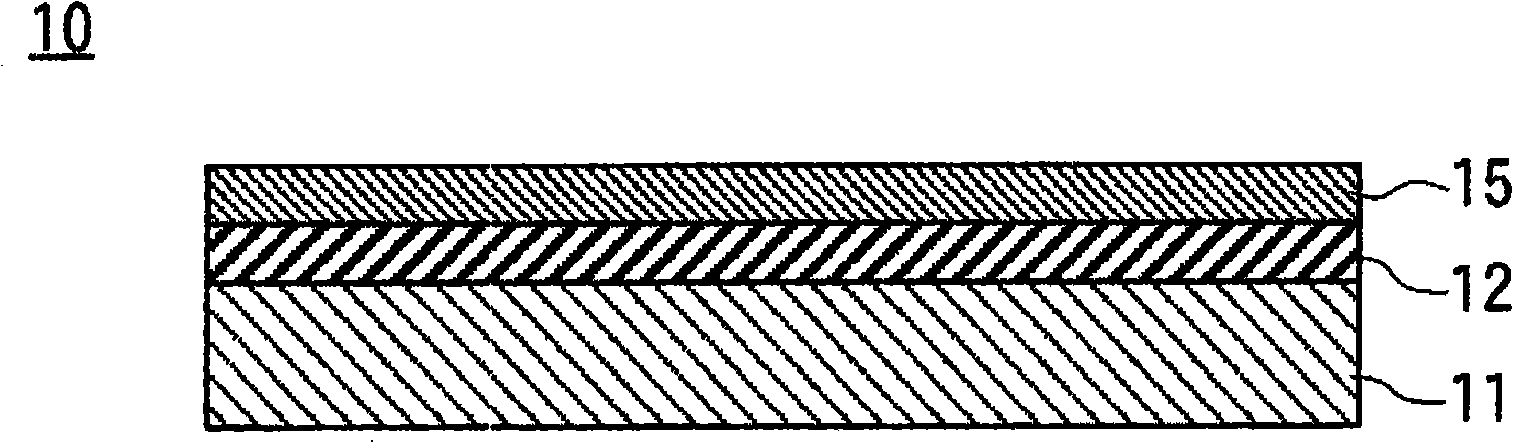

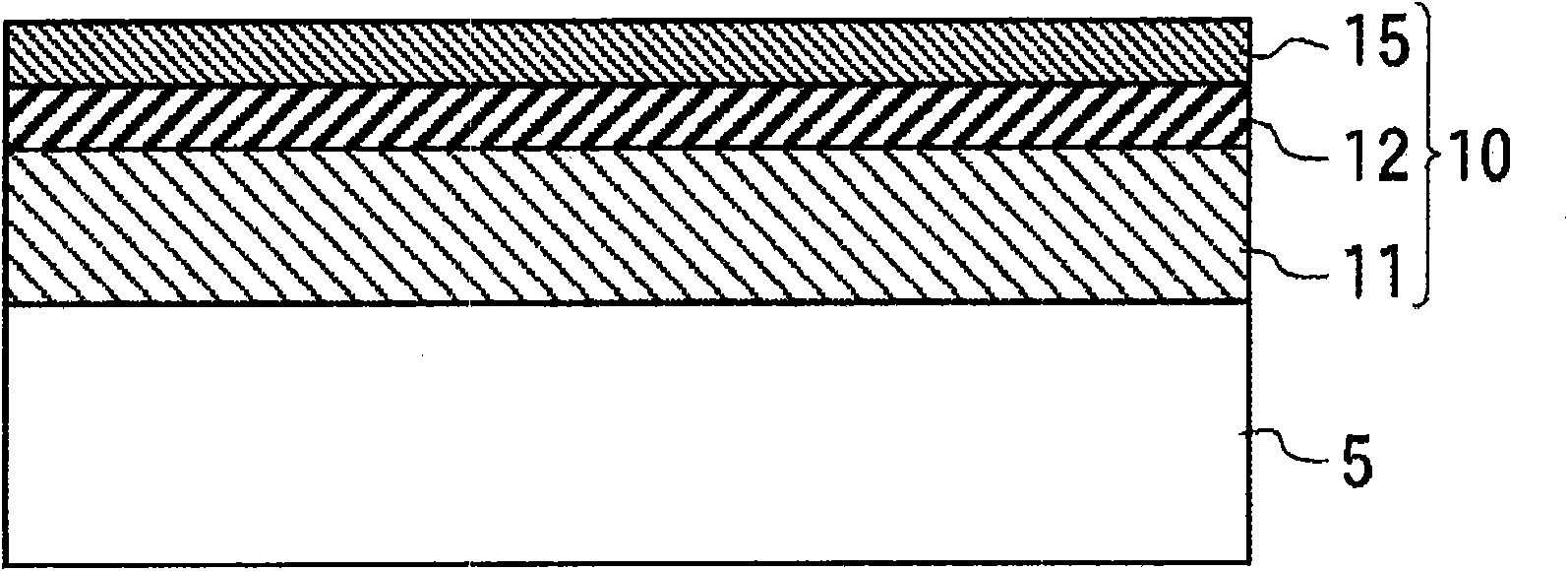

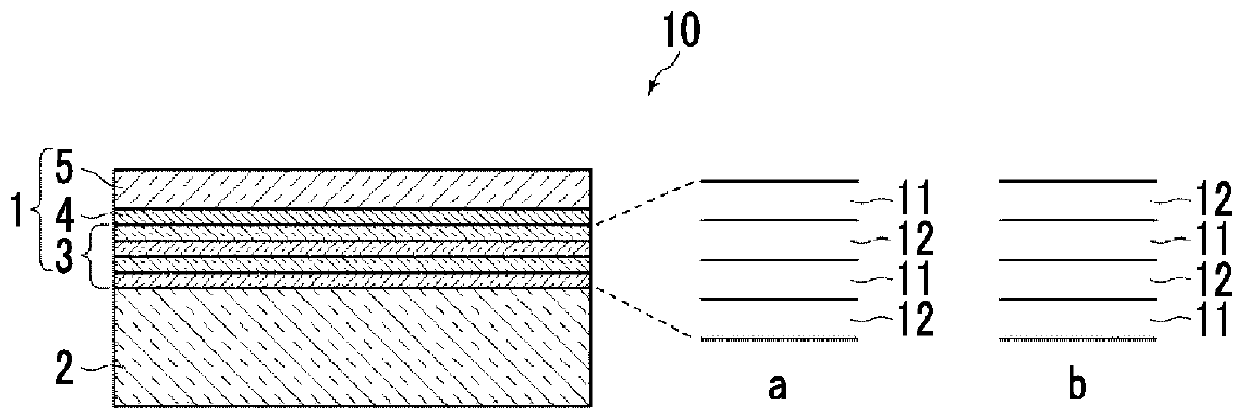

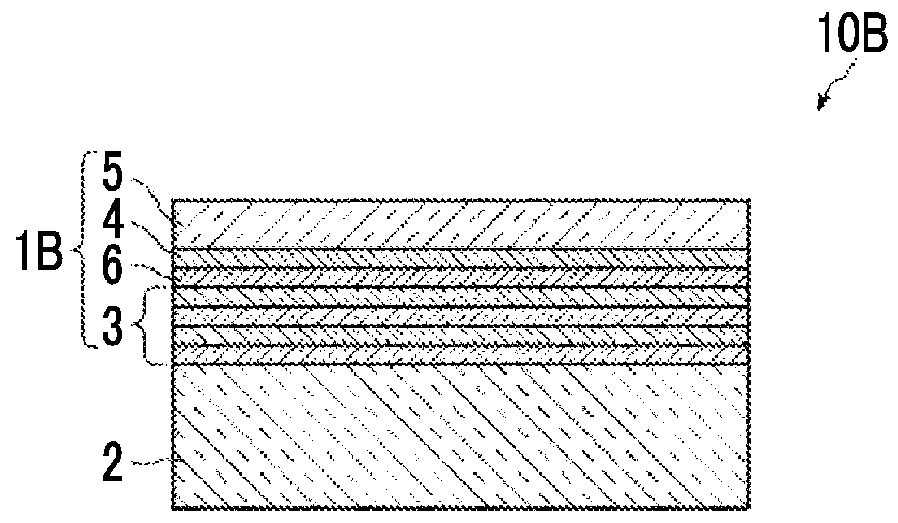

Antireflection film

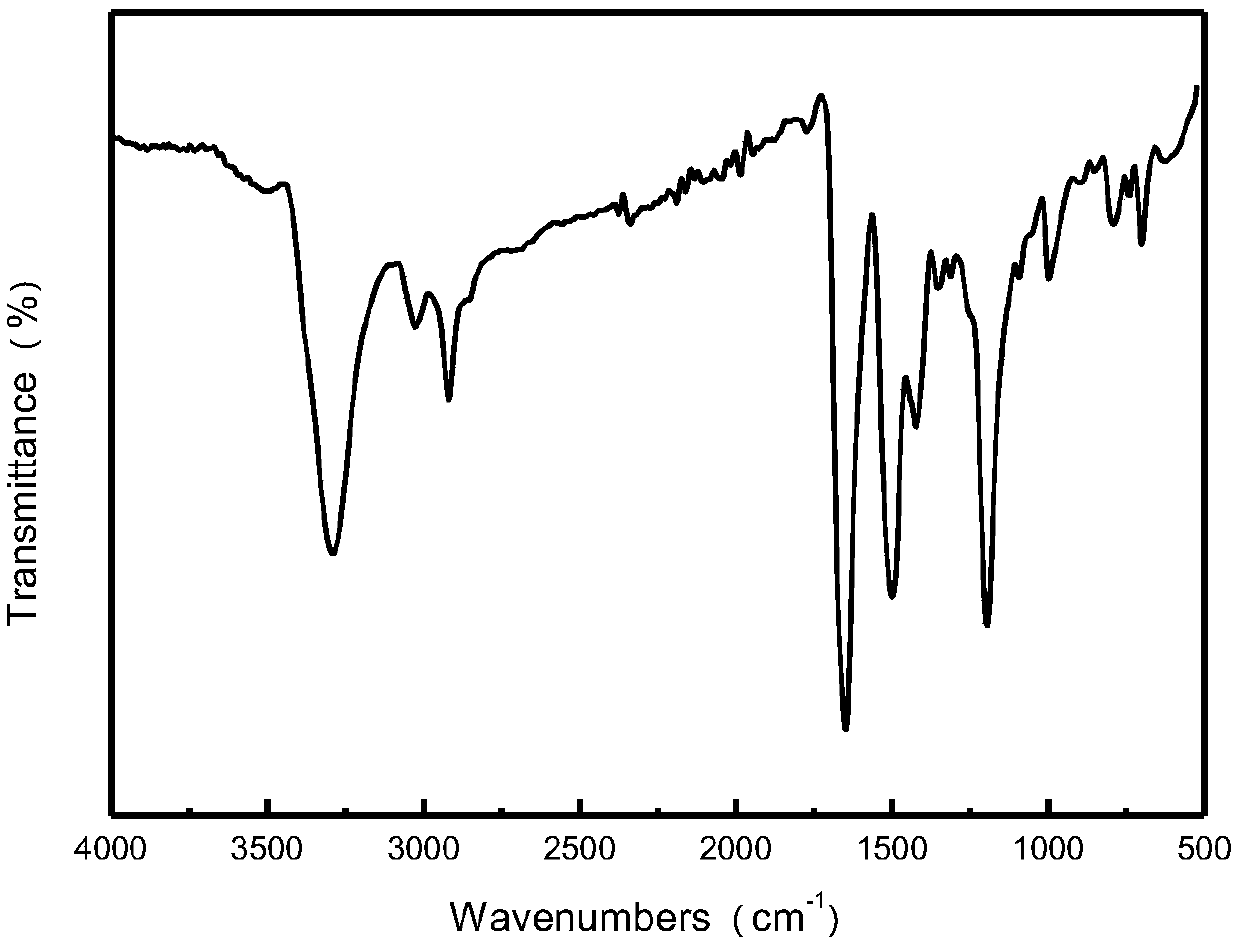

ActiveCN101784916ALow refractive indexWon't corrodeSynthetic resin layered productsAnti-reflective coatingsSilica particleMeth-

Disclosed is an antireflection film having high antifouling property. Specifically disclosed is an antireflection film (10) comprising a transparent base (11), a high refractive index layer (12) and a low refractive index layer (15). The low refractive index layer (15) is made of a cured product of a polymerizable composition which contains hollow fine particles such as hollow silica particles, a modified silicone compound, and a second resin component such as a polyfunctional (meth)acrylate.

Owner:DEXERIALS CORP

Medium-high refractive index optical resin lens and preparation method thereof

The invention provides a medium-high refractive index optical resin lens and a preparation method thereof. The invention aims to provide the preparation method of the medium-high refractive index resin lens adjusted in a range of 1.59 to 1.67, to meet requirements on different high-refraction polymers. Compared with the prior art, a medium-high refractive index polymer provided by the invention isexcellent in comprehensive performance, the optical resin lens with the refractive index as high as 1.67 and higher impact strength and heat resistance is prepared by adjusting the variety and proportion of raw materials, and particularly, the preparation method is simple and convenient, lower in cost and easy for industrial production. The resin is prepared from the following raw materials: oneor more polyisocyanates and one or more polythiol compounds which are added according to a ratio of 0.7:1 to 1.5:1, a phosphate release agent accounting for 0.02%-2% of the total mass, an organic tincatalyst accounting for 0.02%-2% of the total mass, and an antioxidant accounting for 0.02%-2% of the total mass.

Owner:郯城博化化工科技有限公司 +1

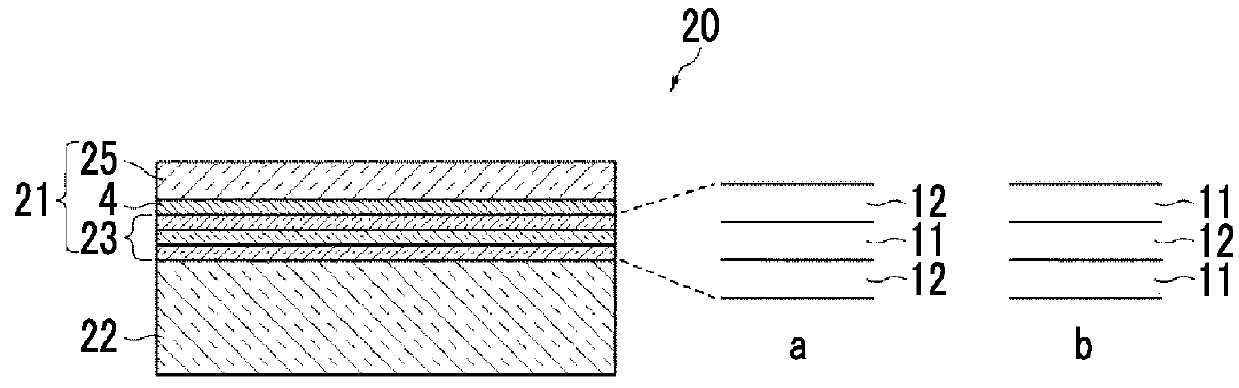

Antireflection film, optical element, and optical system

InactiveUS20180095192A1High mechanical strengthDegraded contrast in imageLayered product treatmentDiffraction gratingsHigh-refractive-index polymerDielectric layer

This antireflection film includes a dielectric layer having a surface exposed to air and having a refractive index of 1.35 or more and 1.51 or less, a metal layer having an interface with the dielectric layer, containing silver, and having a thickness of 5 nm or less, and an interlayer having an interface with the metal layer and constituted by a laminate formed by alternately laminating total four layers or more of a layer of high refractive index having a relatively high refractive index and a layer of low refractive index having a relatively low refractive index and is laminated on a substrate having a refractive index of 1.61 or more in the order of the interlayer, the metal layer, and the dielectric layer.

Owner:FUJIFILM CORP

Optical polymer material and optical component

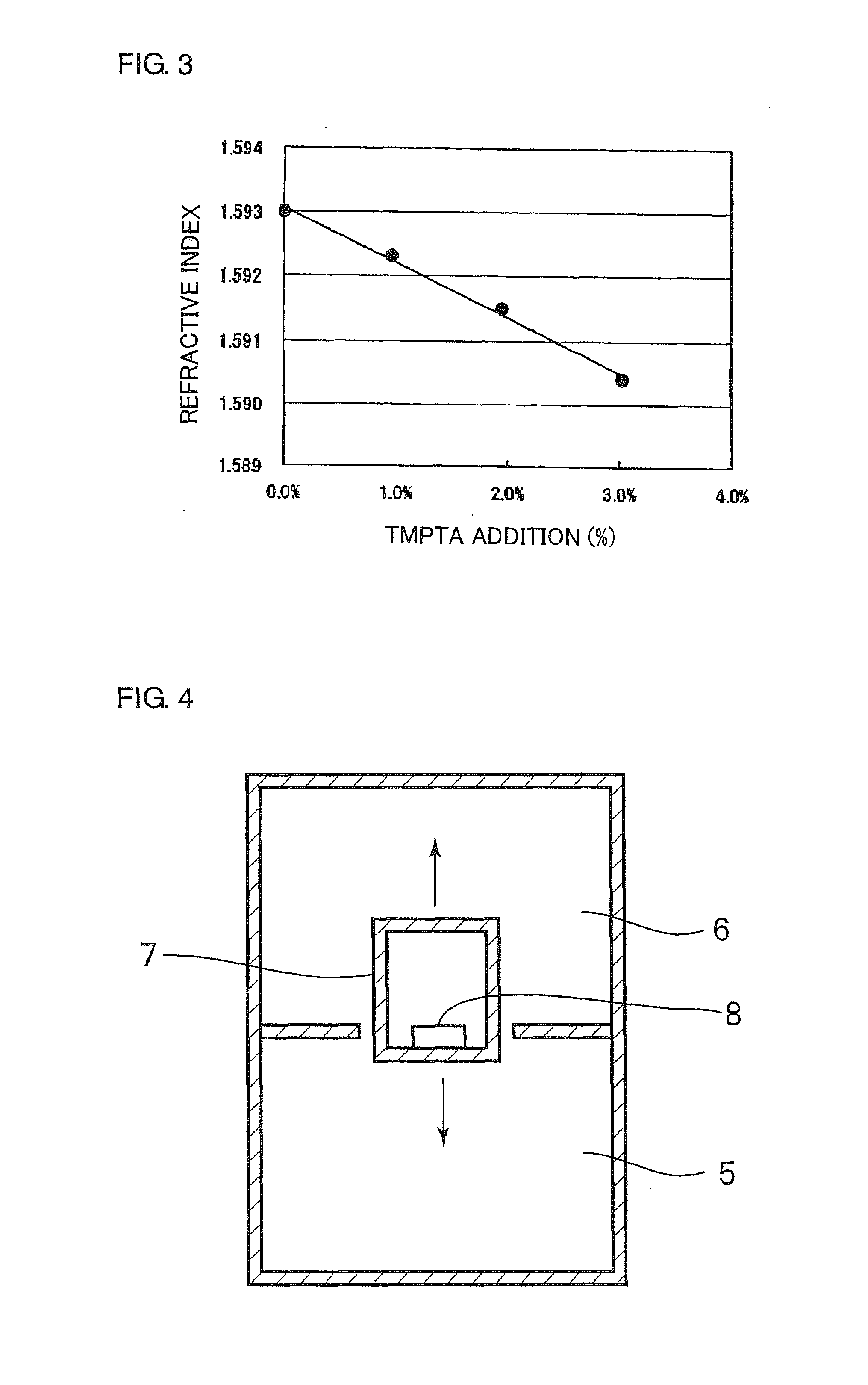

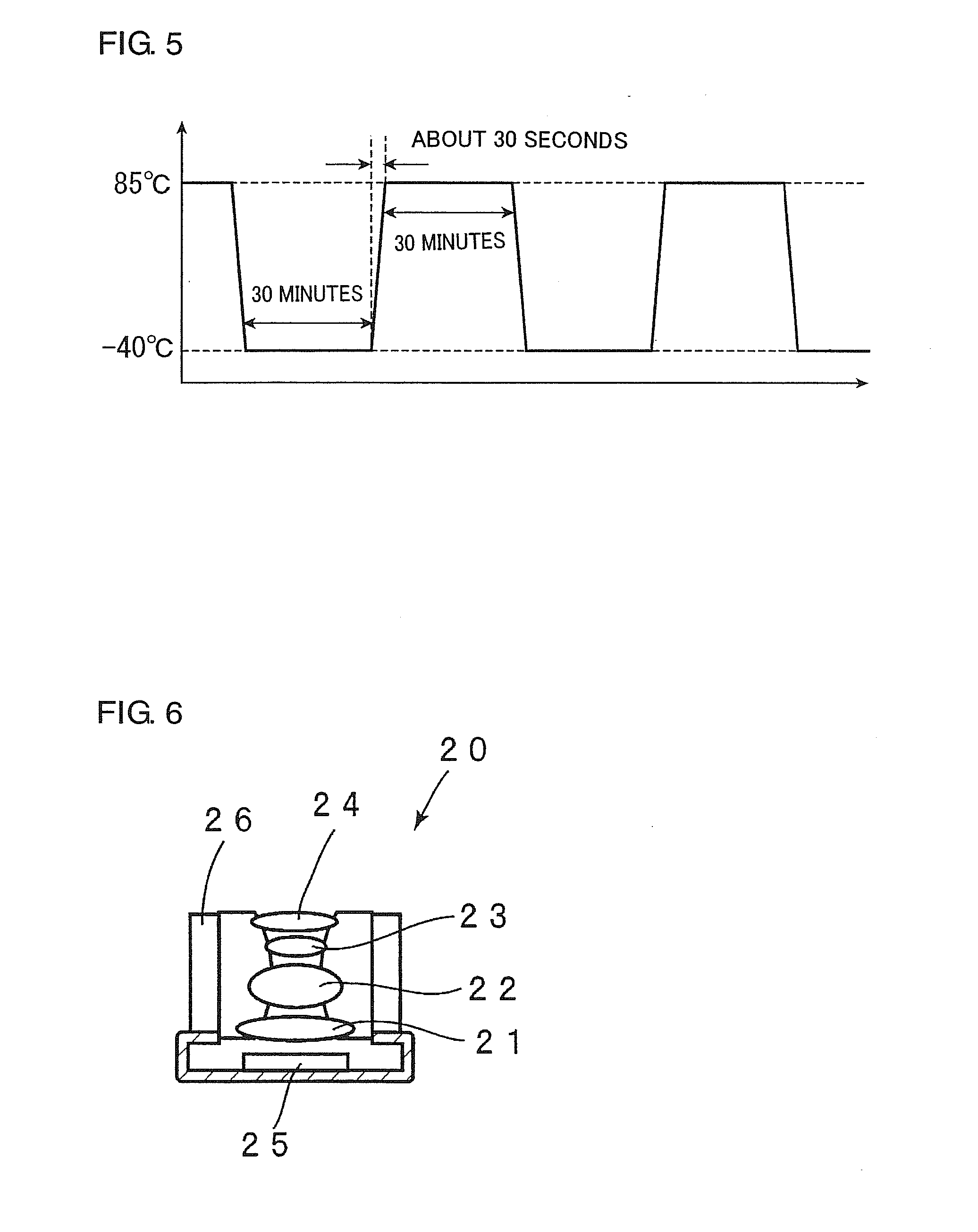

InactiveUS20080233417A1Low viscosityHigh refractive indexSynthetic resin layered productsThin material handlingArylMeth-

The invention provides an optical polymer material having a low viscosity before curing, a high refractive index of a cured product, little alteration of refractive index under high temperature and high humidity, and an excellent heat resistant shock property and an optical component using the optical polymer material.The optical polymer material is characterized in that the material contains a fluorene compound having four (meth) acryloyl groups and a (meth) acrylate having an aryl group and may further contain -M-O-M- bond (M is a metal atom), an organometallic polymer having an aryl group, a monofunctional (meth)acrylate and / or a polyfunctional (meth)acrylate.

Owner:SANYO ELECTRIC CO LTD

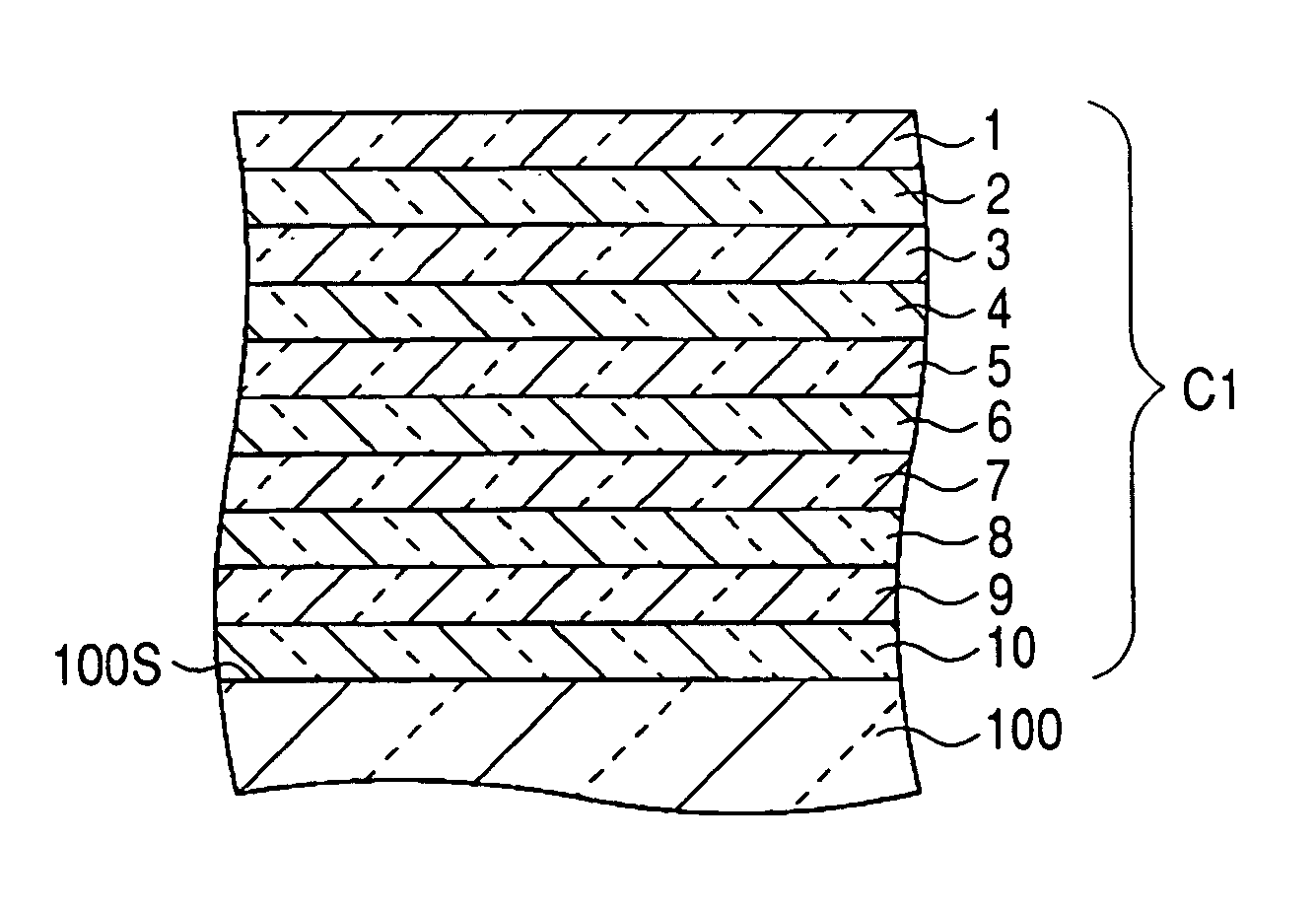

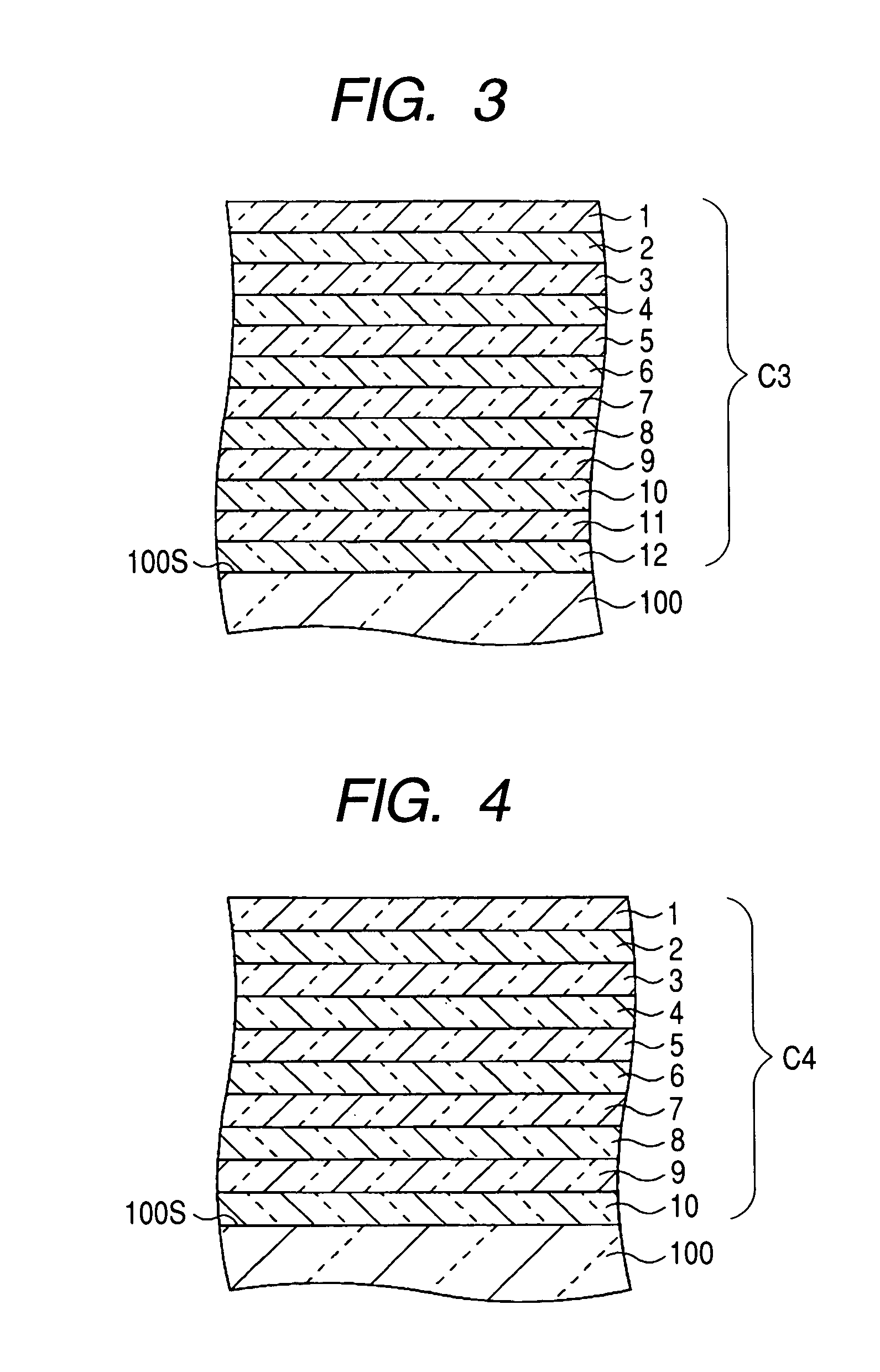

Antireflection film

InactiveUS7773301B2Reduce reflectivitySuppress generationLayered productsCoatingsRefractive index contrastOptoelectronics

An antireflection film is disposed on a surface of an optical substrate, and consists of first to tenth layers to stacked sequentially from the opposite side to the optical substrate. The first layer, the fourth layer and the ninth layer are low-refractive index layers made of a low-refractive index material exhibiting a refractive index of 1.35 to 1.50 with respect to the d-line. The third layer, the fifth layer, the seventh layer and the tenth layer are intermediate-refractive index layers made of an intermediate-refractive index material exhibiting a refractive index of 1.55 to 1.85 with respect to the d-line.The second layer, the sixth layer and the eighth layer are high-refractive index layers made of a high-refractive index material exhibiting a refractive index that is in a range from 1.70 to 2.50 with respect to the d-line, and that is higher than the refractive index of the intermediate-refractive index material.

Owner:FUJI PHOTO OPTICAL CO LTD

All-organic high refractive index materials

ActiveUS20160177128A1Layer is highSynthetic resin layered productsPretreated surfacesMicrometerHigh-refractive-index polymer

Owner:BREWER SCI

Near-infrared reflective film and near-infrared reflector provided with the same

The near-infrared reflective film has, on a base material, a high refractive layer containing a water-soluble polymer and a metal oxide particle having a refractive index higher than the refractive index of the water-soluble polymer, and a low refractive layer containing a water-soluble polymer and a metal oxide particle having a refractive index lower than the refractive index of the water-soluble polymer are alternately laminated individually in two or more layers. The total number of the layers of the high refractive layer and the low refractive layer is n. The total film thickness of the component layers from the region of n / 2 to the base material is Σd1, and the total film thickness of the component layers from the region of n / 2 to the outermost layer is Σd2. The film thickness ratio Σd1 / Σd2 is from 1.05 to 1.80.

Owner:KONICA MINOLTA INC

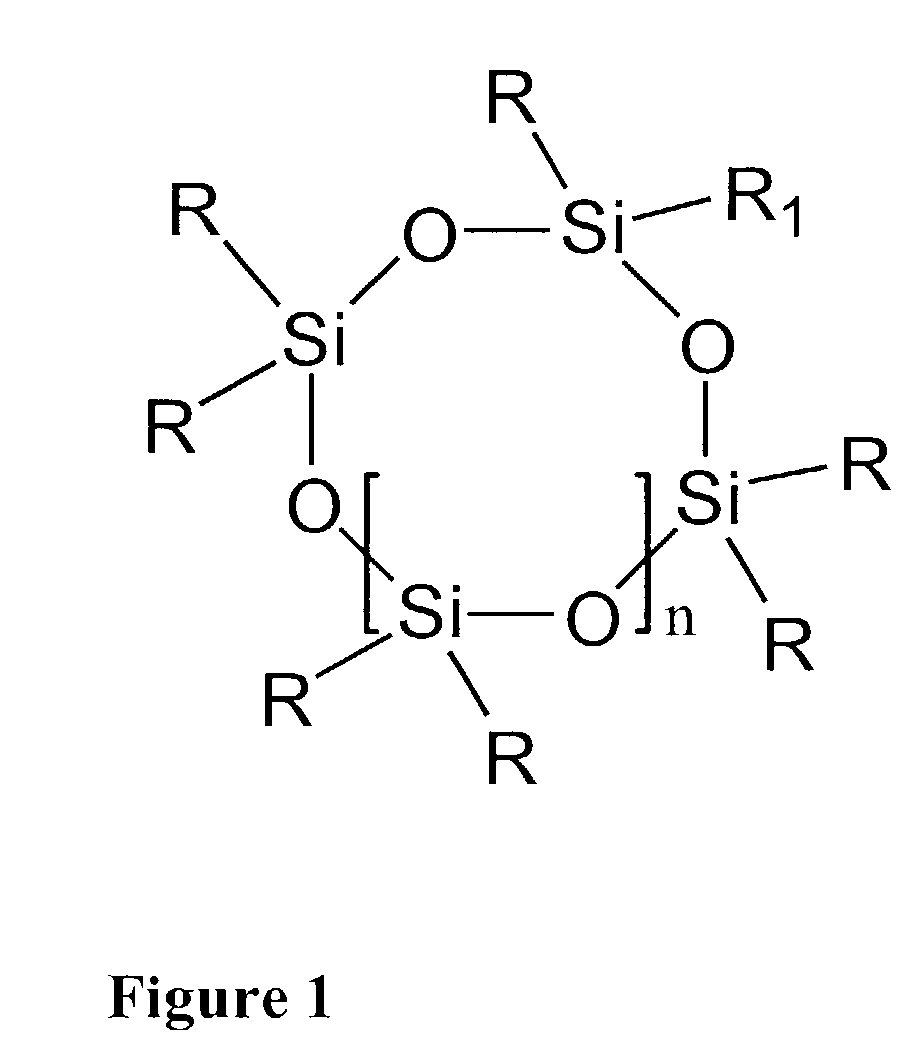

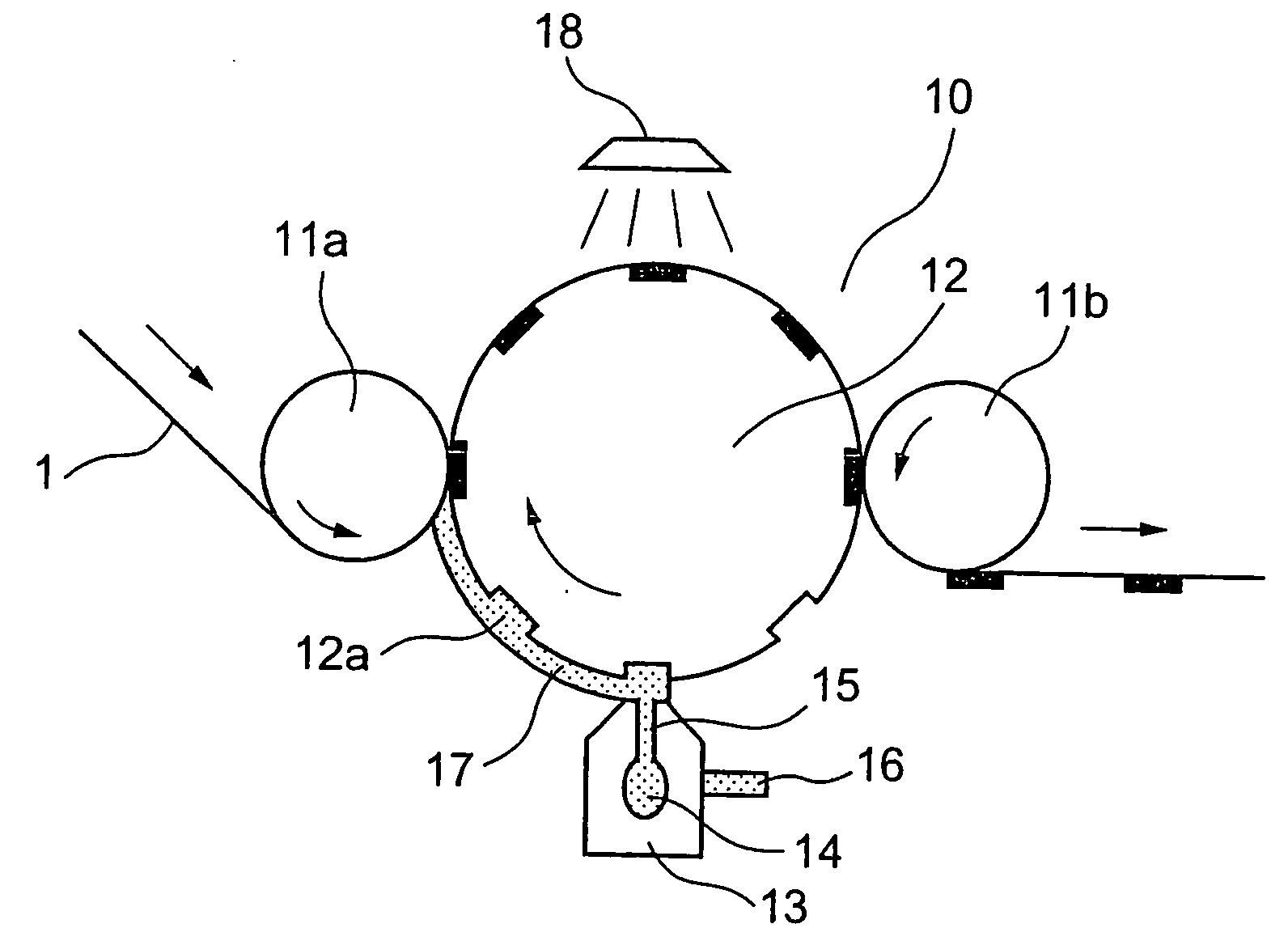

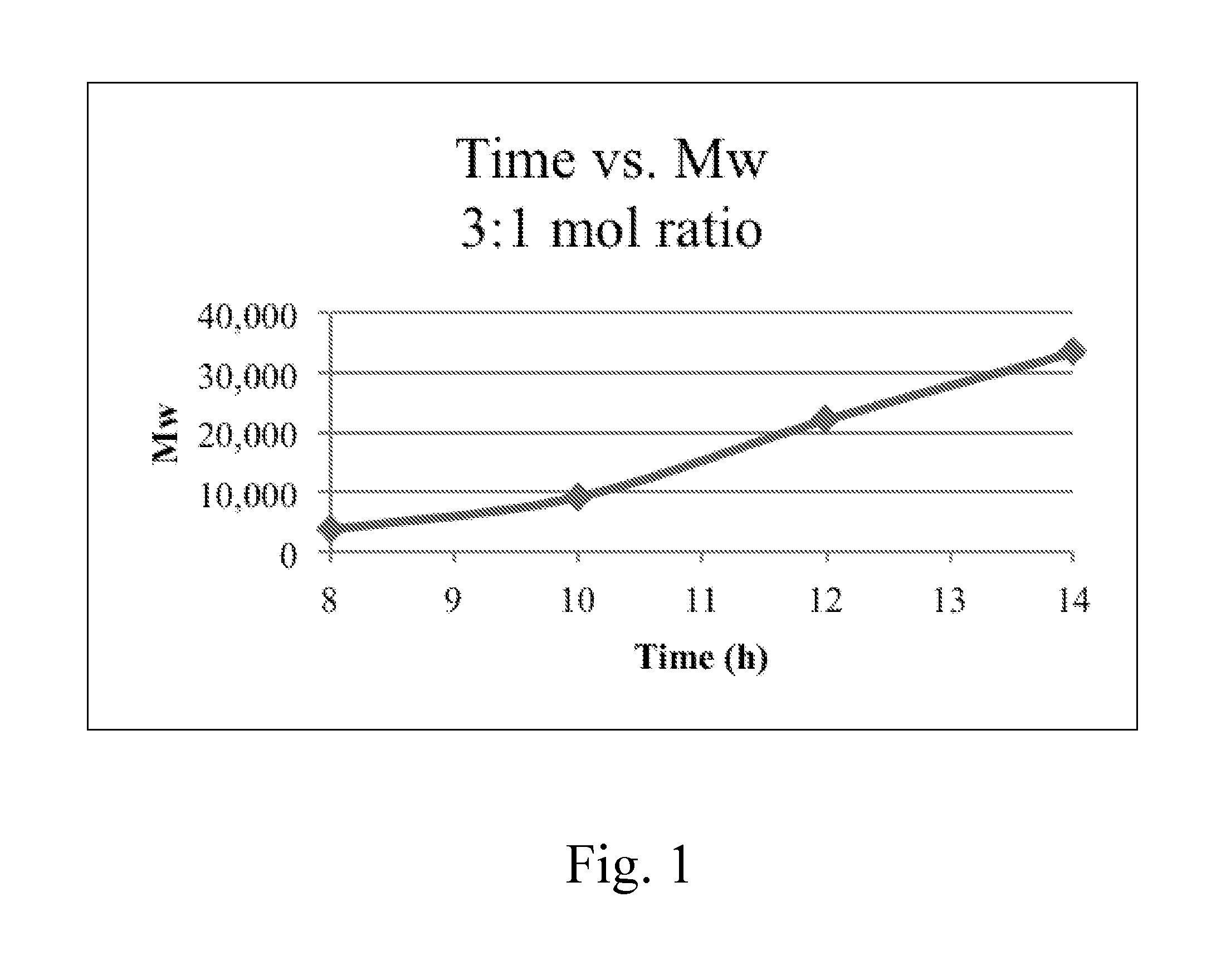

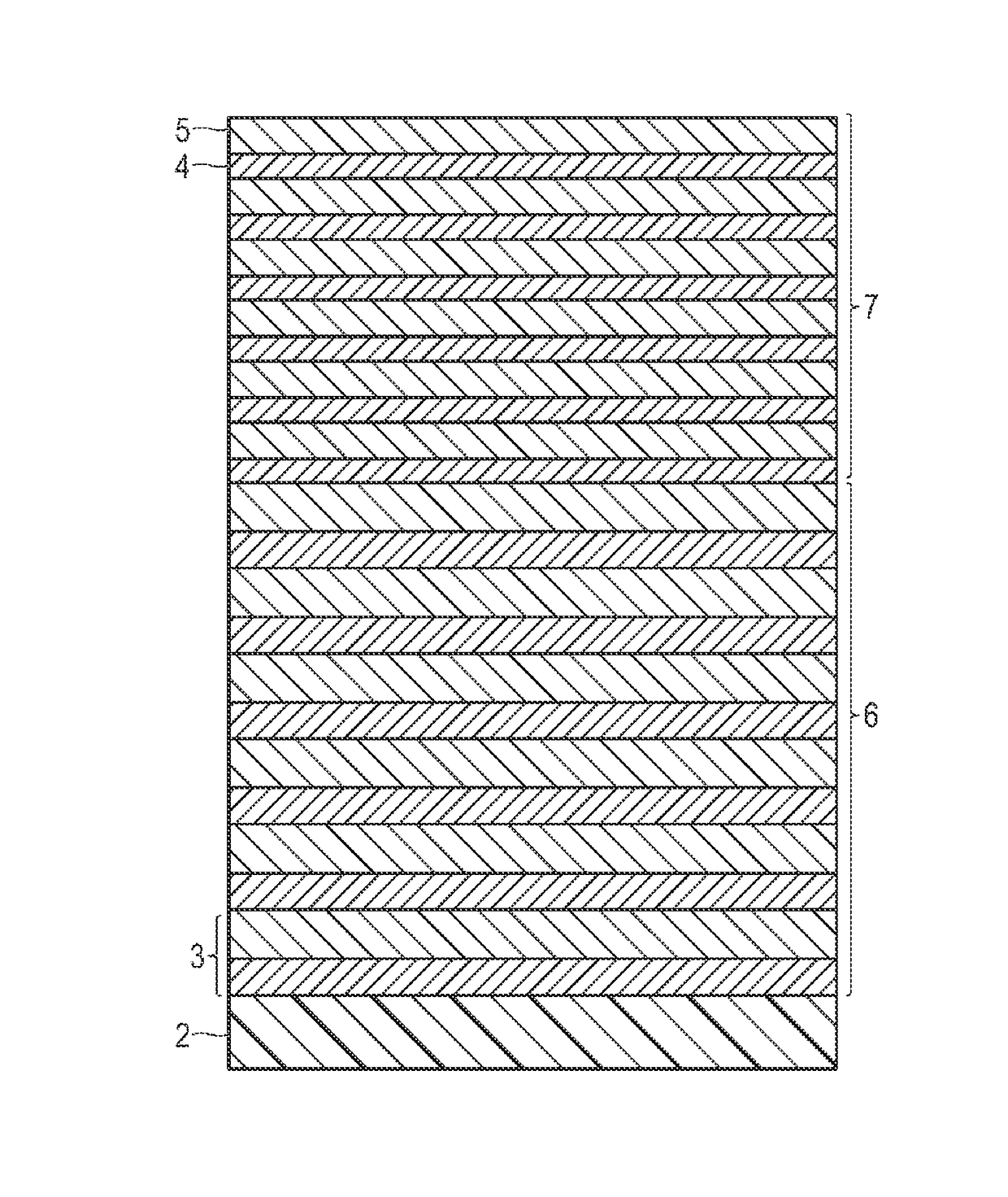

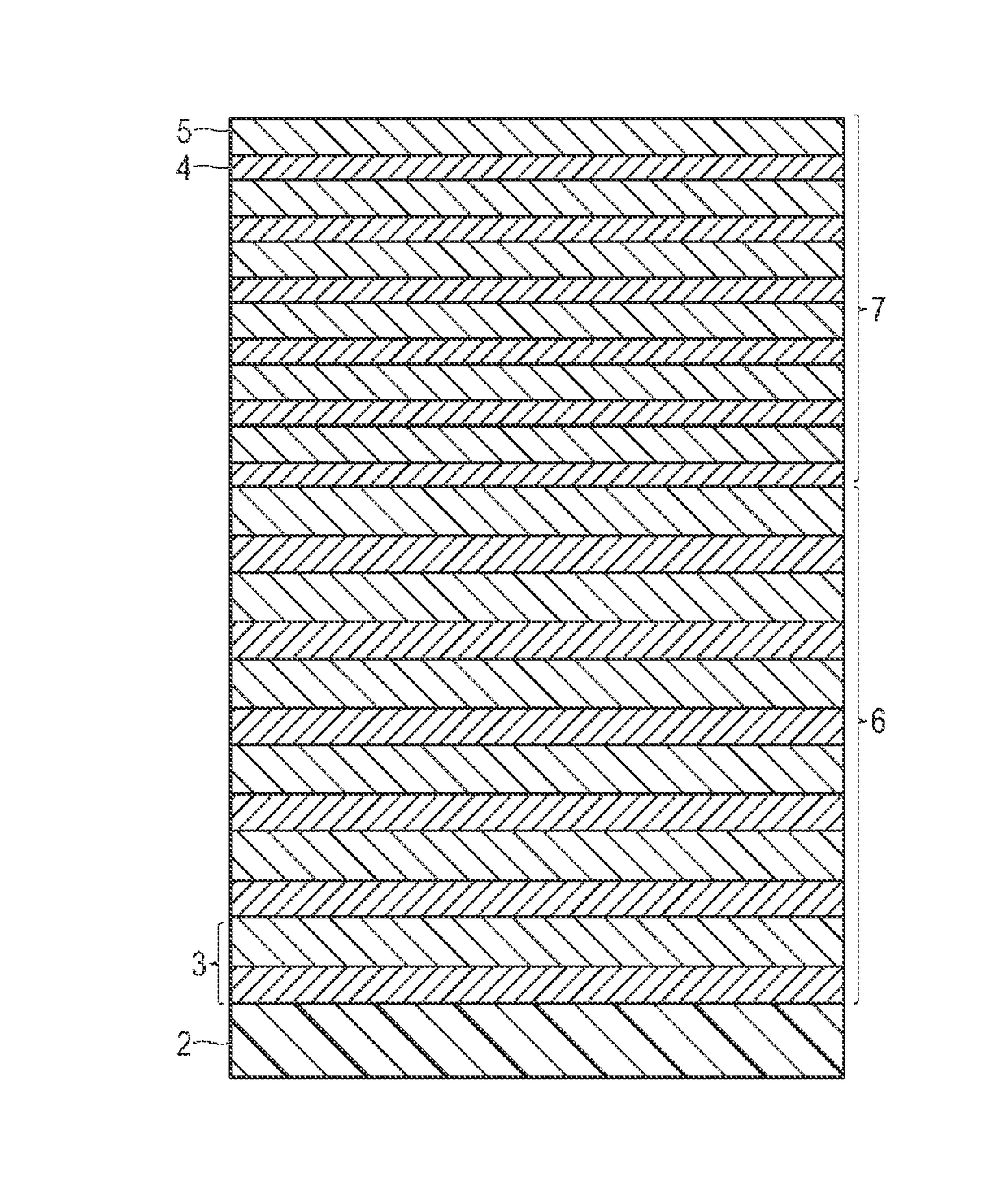

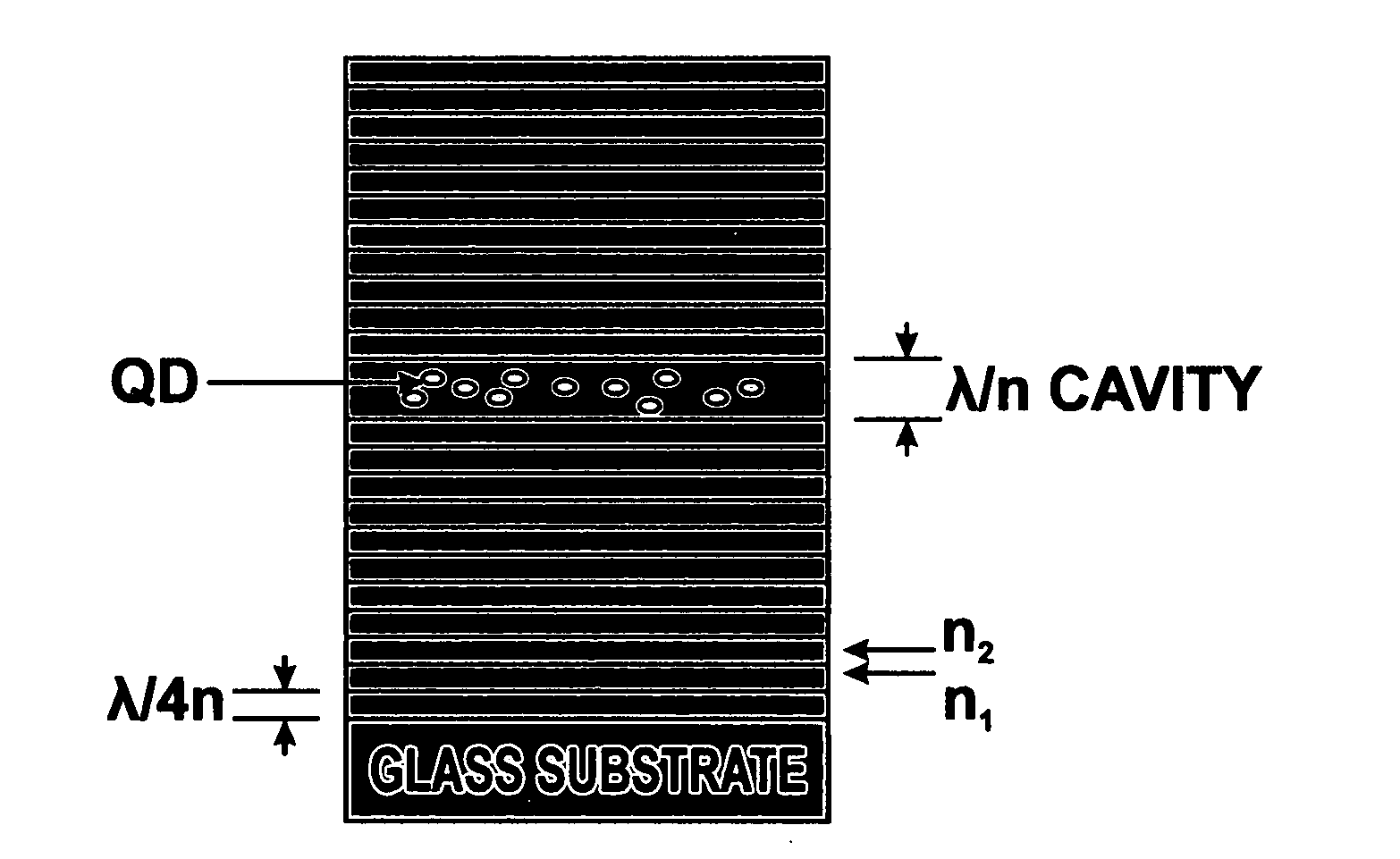

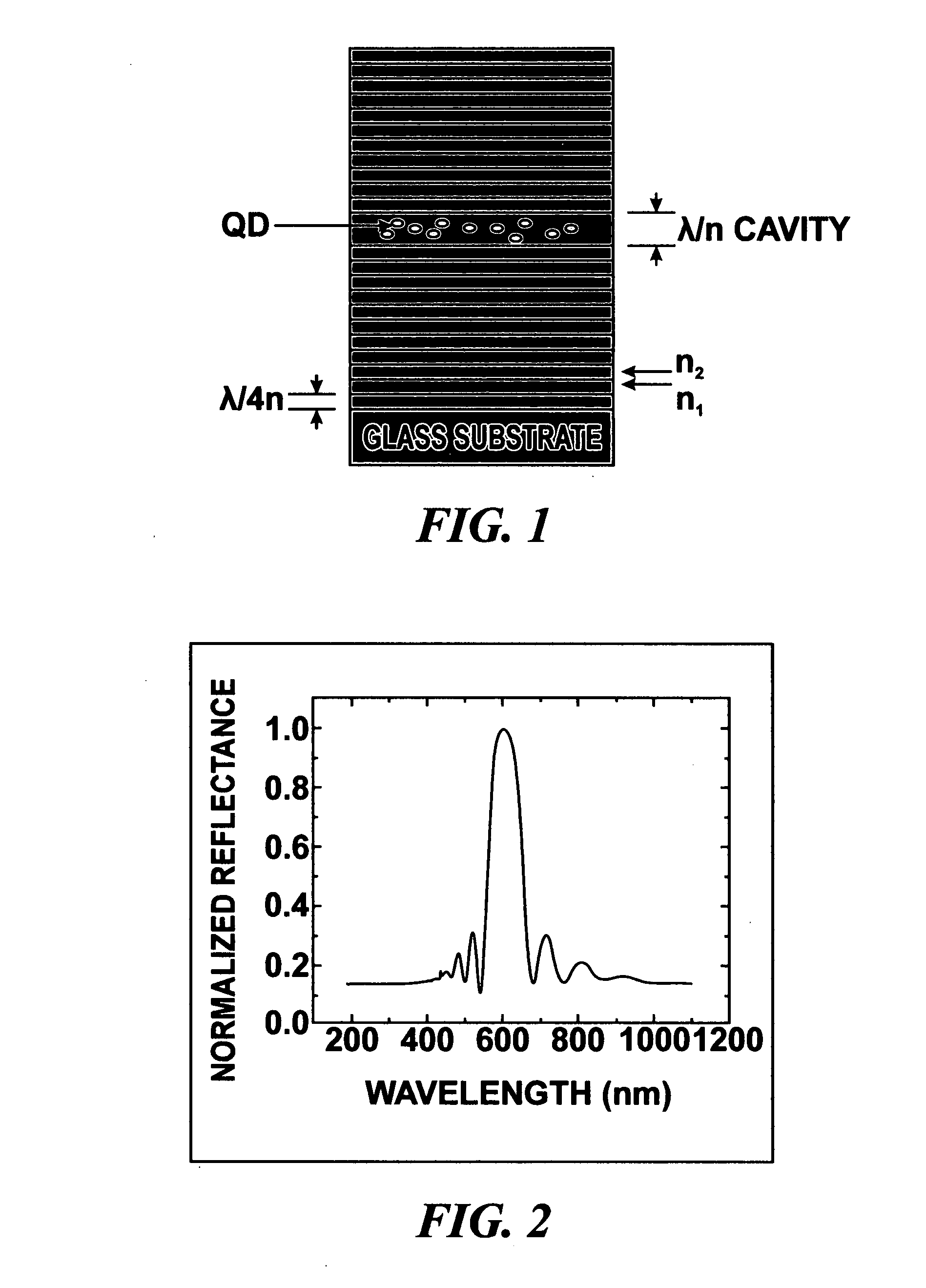

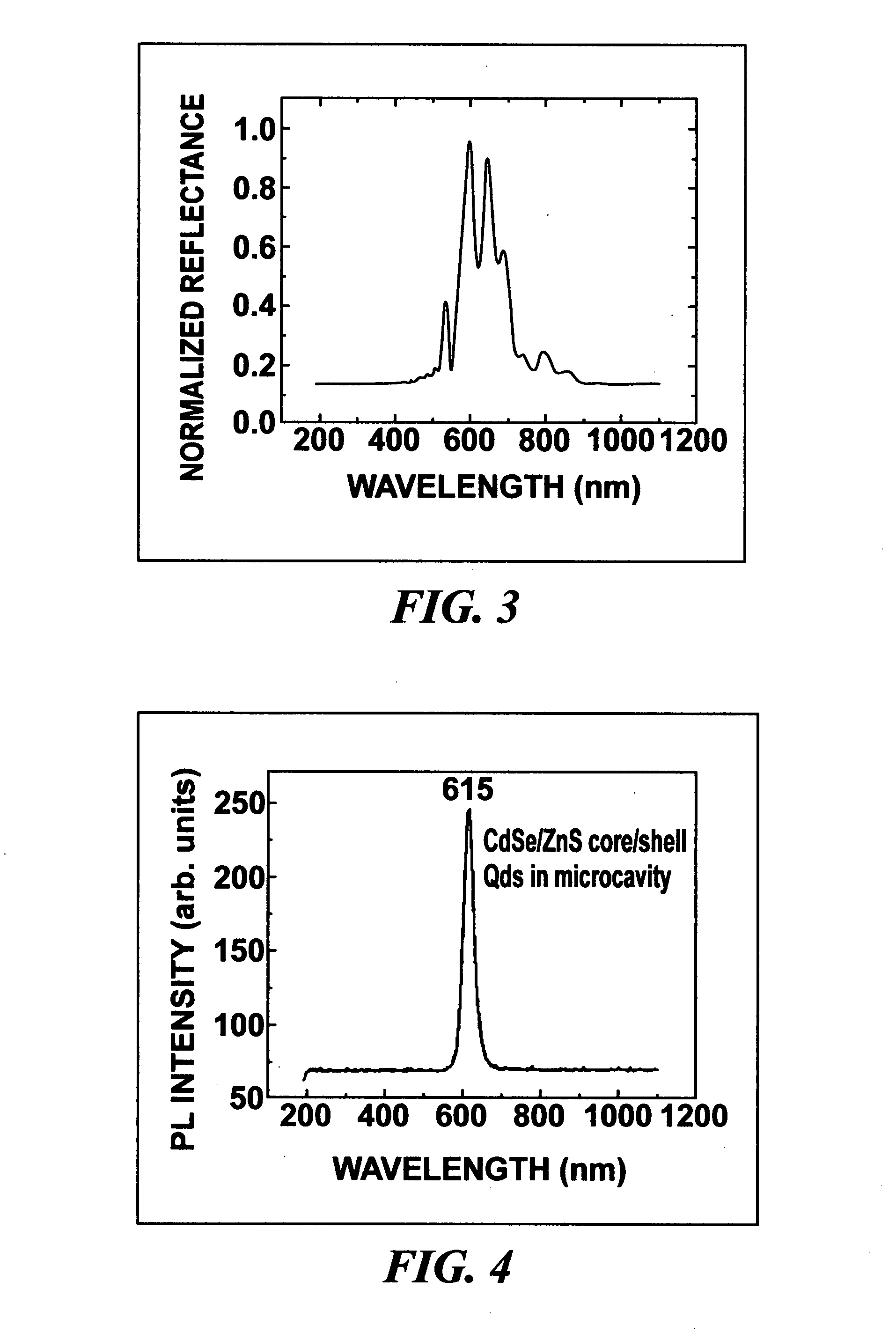

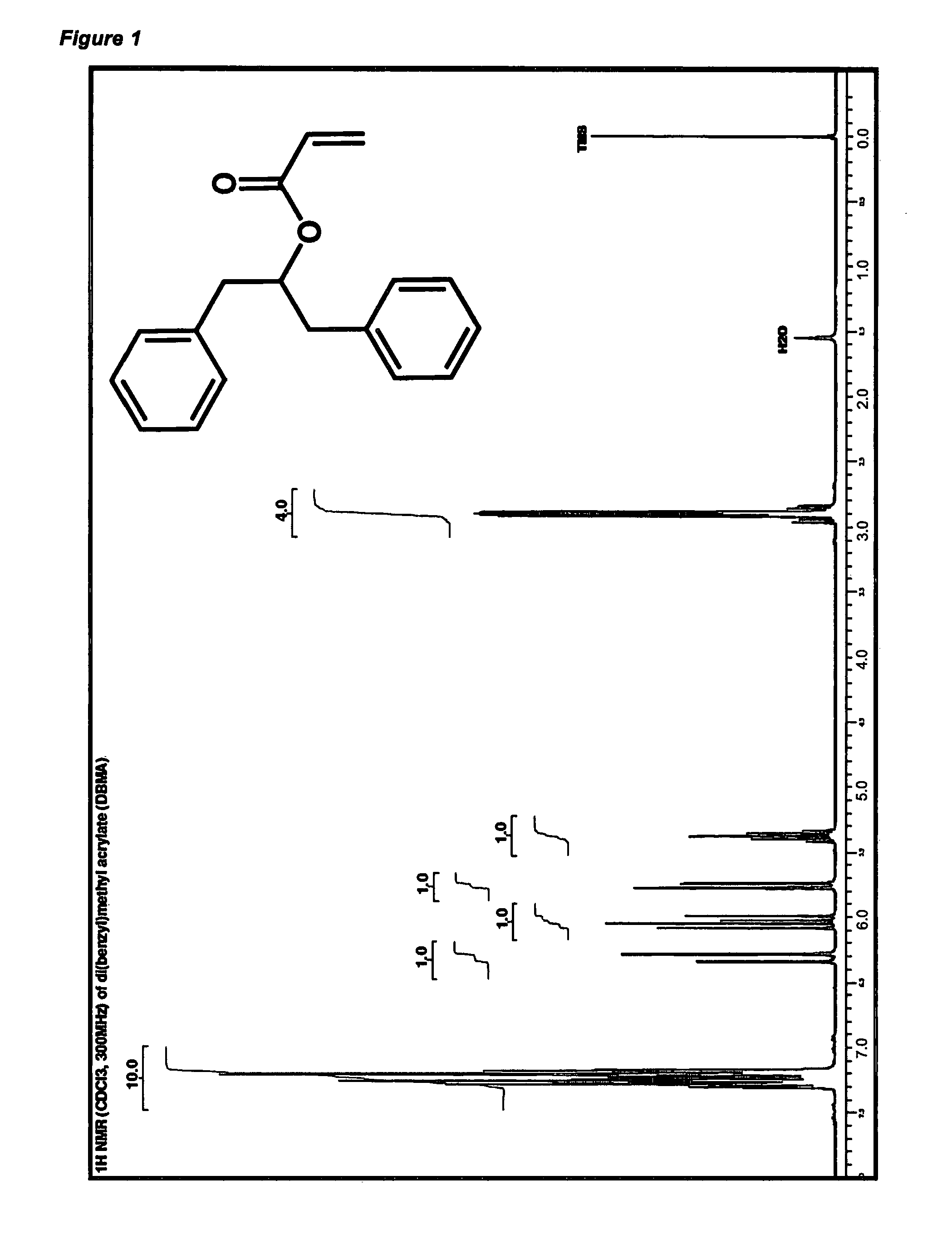

Spin-coated polymer microcavity for light emitters and lasers

InactiveUS20100097691A1Optical resonator shape and constructionLuminescent compositionsHigh reflectivityHigh-refractive-index polymer

A spin-coated polymer microcavity for light emitters and lasers producing enhancement of spontaneous emission rate from colloidal CdSe / ZnS core / shell quantum dots embedded in a one dimensional polymer microcavity structure at room temperature. The polymer microcavity structures are fabricated using spin coating. Alternating layers of polymers of two different refractive indices were stacked to form the Distributed Bragg reflectors (DBRs). To achieve high reflectivity, the polymers for the DBR structures were chosen so that they have a relatively high refractive index ratio. The high and low refractive index polymers chosen were poly-N(vinylcarbazole) (PVK) and poly acrylic acid (PAA), with refractive indices of 1.683 and 1.420 at 600 nm, respectively. Thin films of quarter wavelength thickness of the two polymers are alternately spin coated on a glass substrate to make the DBR structures. Greater than 90% reflectivity is obtained using ten periods of the structure. A PVK cavity layer of λ thickness embedded with CdSe / ZnS core / shell quantum dots is sandwiched between two of these DBRs to form the entire microcavity structure. The bottom and top DBRs comprise ten and five periods, respectively.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

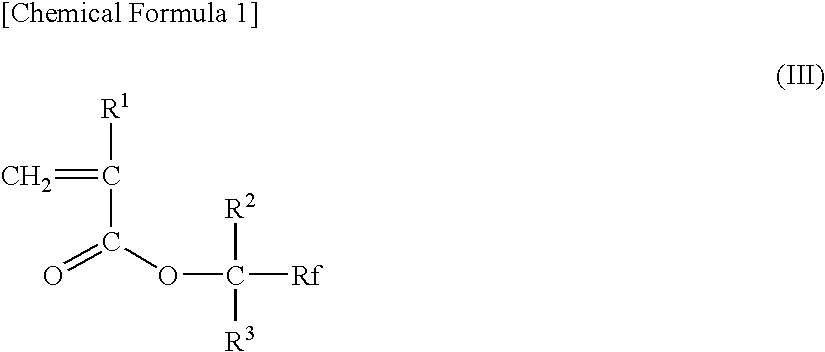

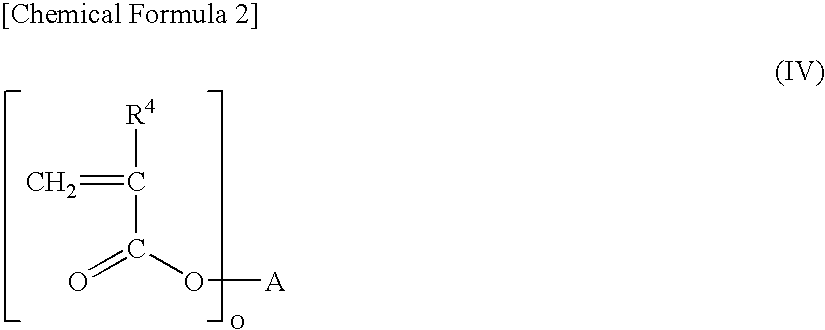

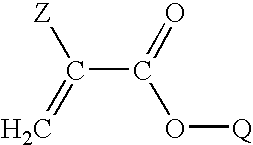

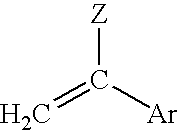

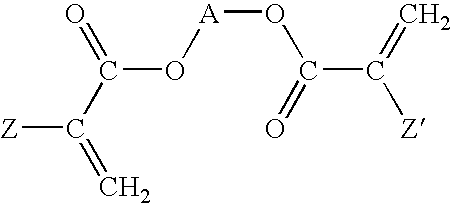

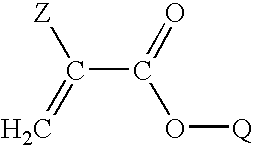

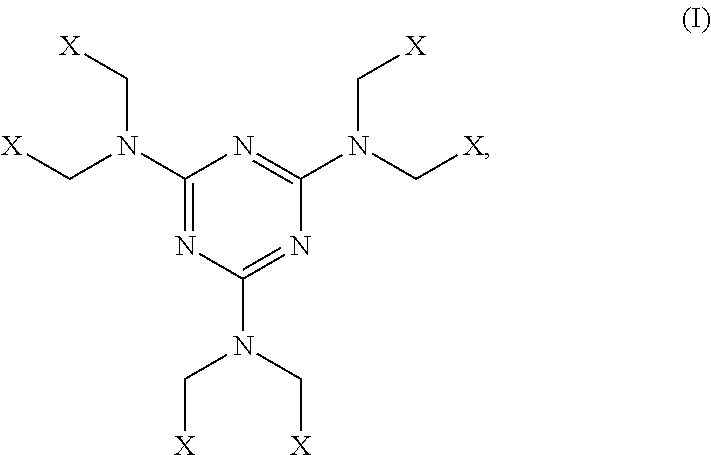

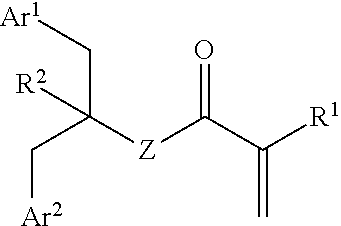

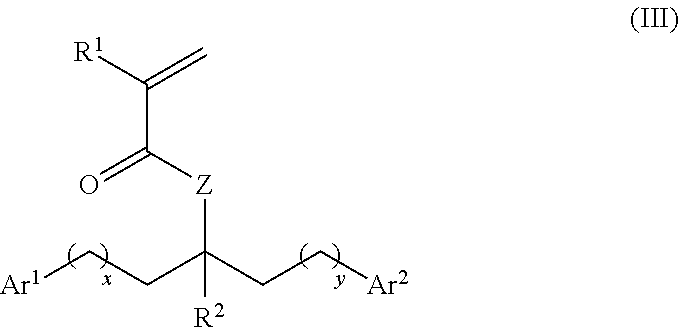

Monomers for use in a polymerizable composition and high refractive index polymer for opthalmic applications

InactiveUS20160194424A1Good optical performanceReduce incision sizeOrganic chemistryOther chemical processesArylPolymer science

Provided are monomers of formula (I), polymerizable compositions comprising the monomer of formula (I) optionally together with other co-polymerizable monomers and polymers obtained or obtainable from the polymerizable compositions, where the monomer of formula (I) is represented thus: Wherein —R1 is —H or alkyl; —Z— is -0-, —NH—, or —N(R)—, where —R is optionally substituted alkyl or aryl; -Ar1 and -Ar2 are each independently optionally substituted aryl; and —R2 is —H, or optionally substituted alkyl or aryl.

Owner:CONTAMAC

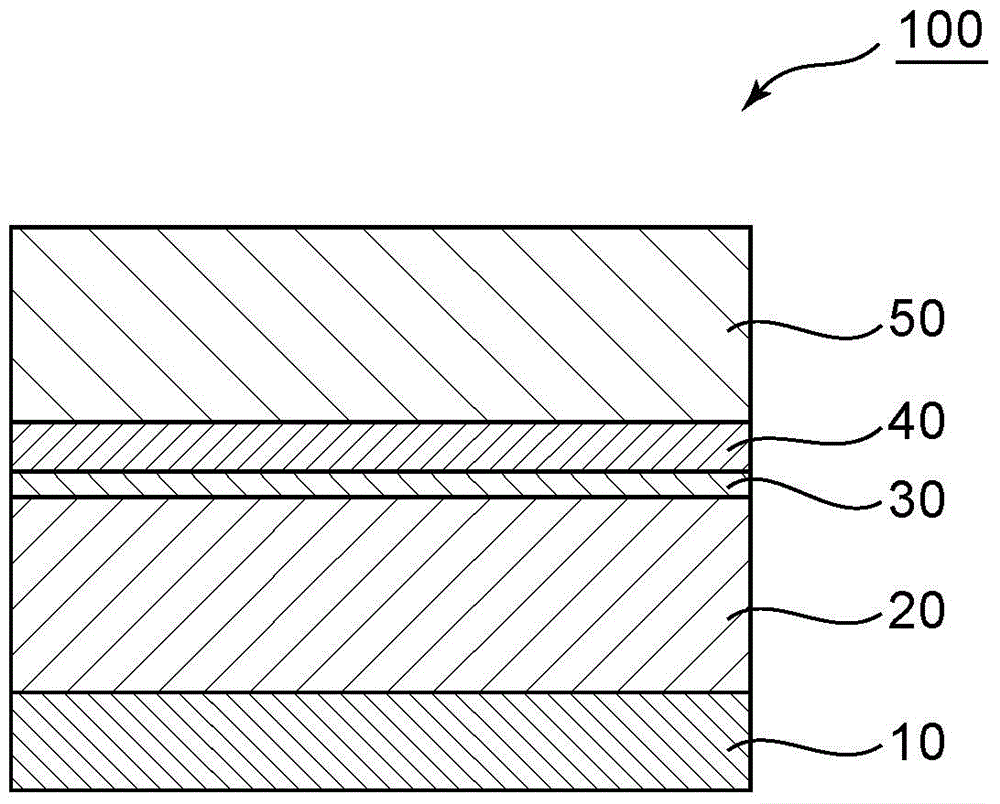

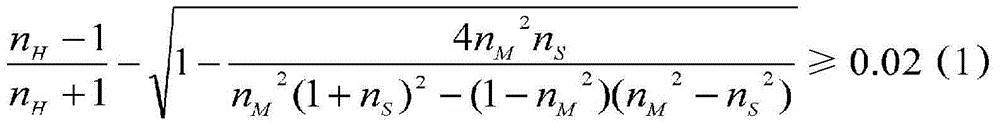

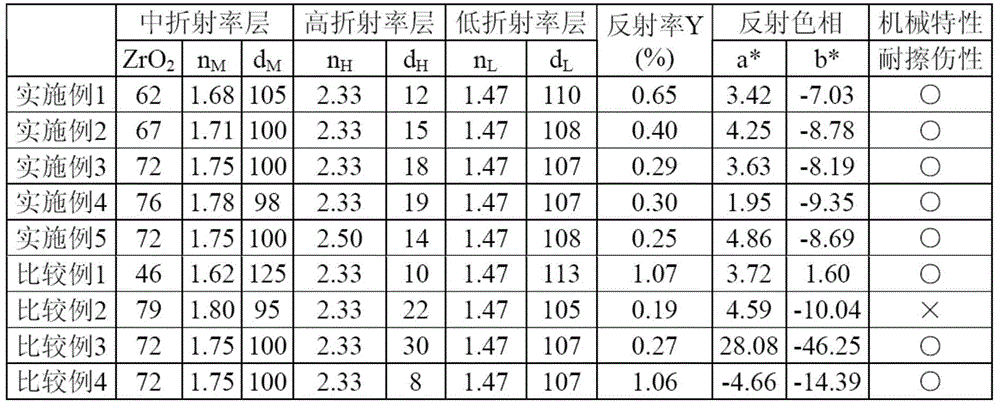

Anti-reflection film and production method therefor

ActiveCN104956241AExcellent mechanical propertiesImprove productivityLayered productsVacuum evaporation coatingProduction rateInorganic particle

Provided is an anti-reflection film that can be produced in a highly-productive manner and at low cost, that has excellent reflection properties (i.e., low reflectivity) over a wide spectrum and excellent reflection hues that are close to neutral, and that has excellent mechanical properties. This anti-reflection film comprises a substrate, and, in order from the substrate side, a medium refractive index layer, a high refractive index layer, and a low refractive index layer. The refractive index of the substrate ranges from 1.45 to 1.65. The medium refractive index layer: is formed by applying and curing a composition for forming a medium refractive index layer, which contains a binder resin and inorganic particles, on the substrate; has a refractive index ranging from 1.67 to 1.78; and has a thickness of 70 nm to 120 nm. The high refractive index layer has a refractive index that ranges from 2.00 to 2.60, and has a thickness of 10 nm to 25 nm. The low refractive index layer has a refractive index that ranges from 1.35 to 1.55, and has a thickness of 70 nm to 120 nm.

Owner:NITTO DENKO CORP

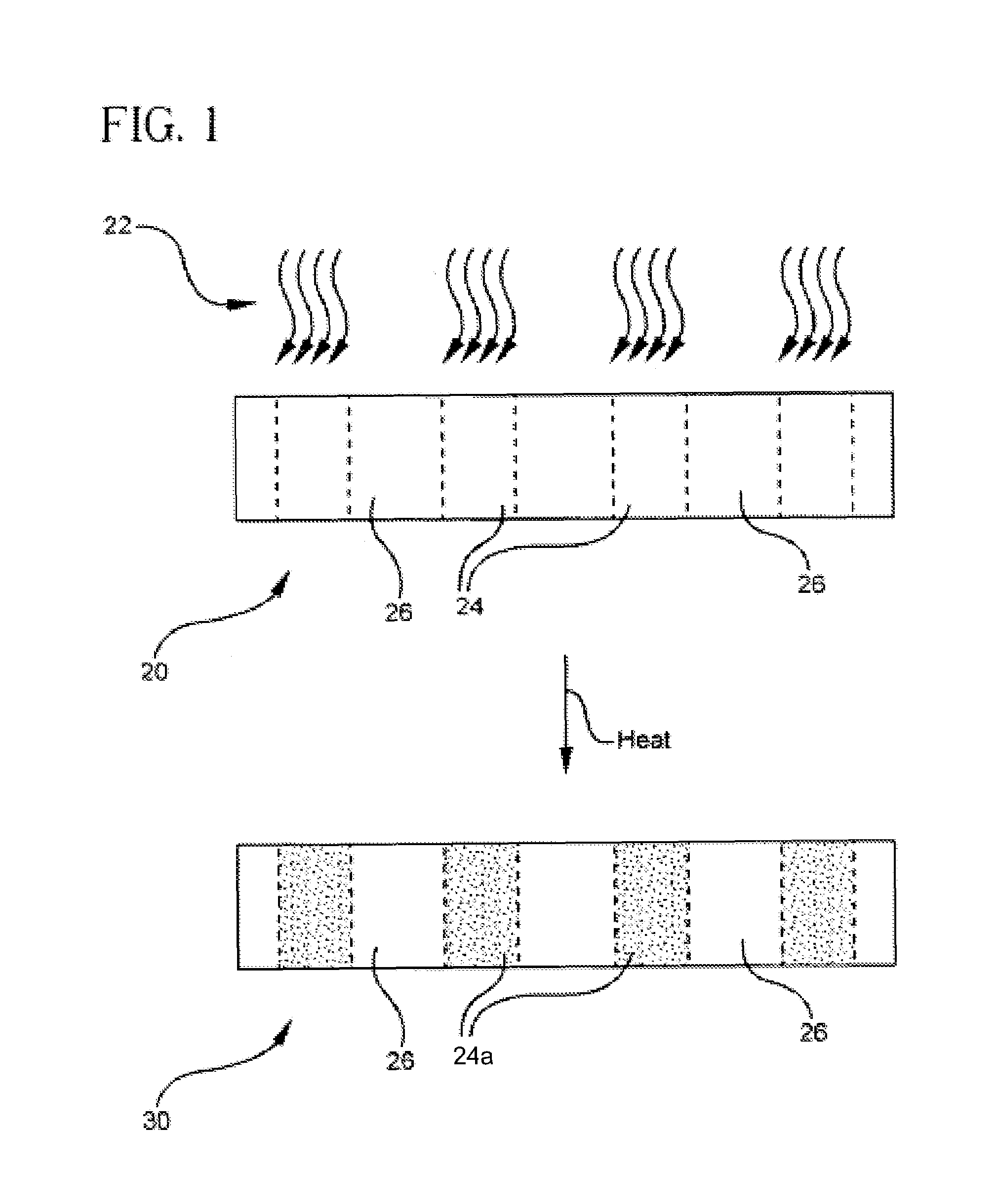

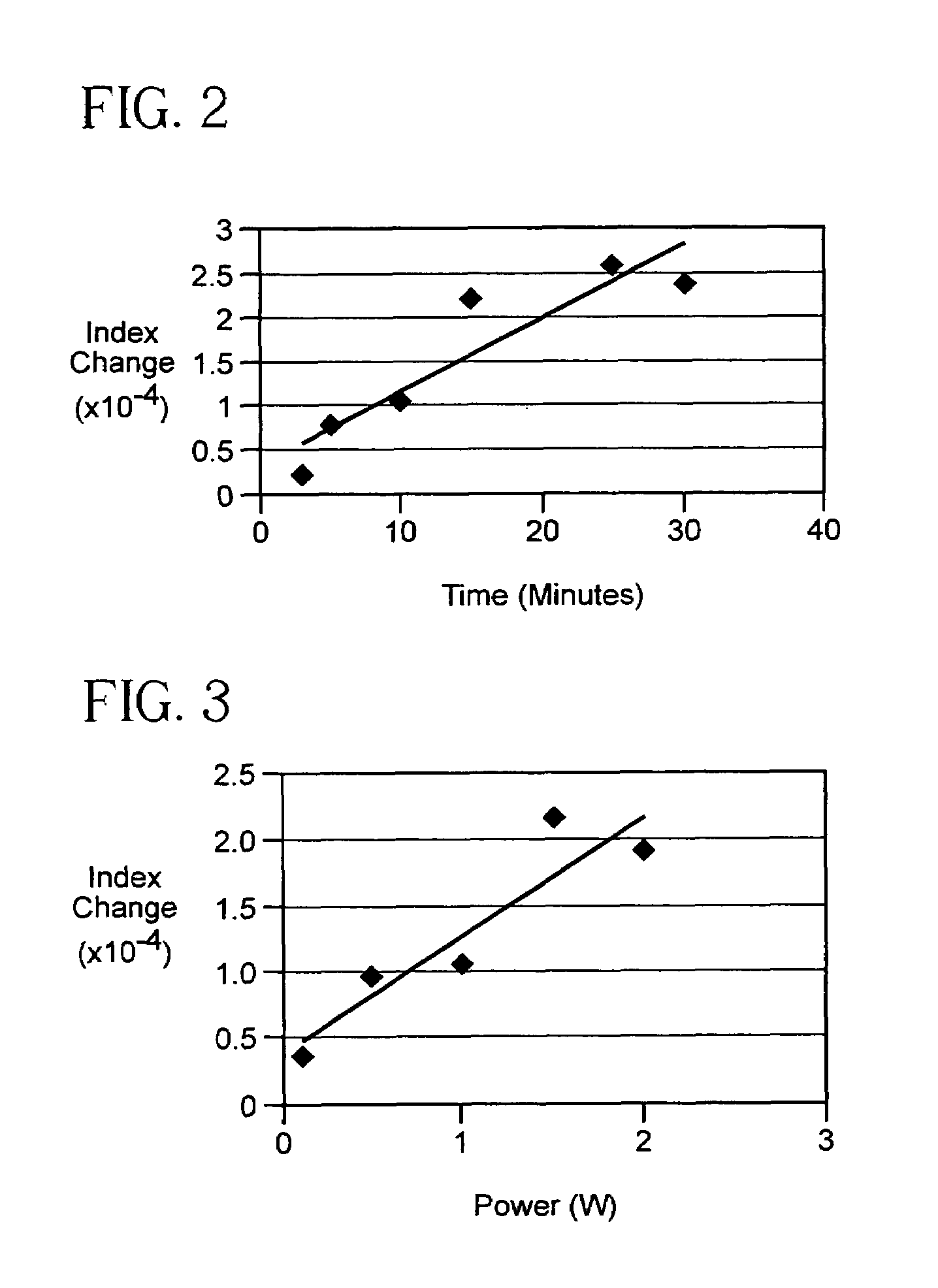

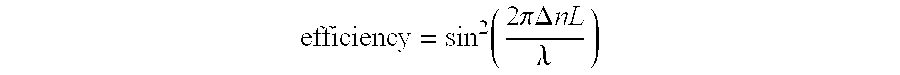

Photorefractive glass and optical elements made therefrom

ActiveUS7288495B2Easy to manufactureHigh refractive index changeOptical waveguide light guideLength waveHigh-refractive-index polymer

The present invention provides an alkali alumino-silicate Na—F-containing glass material and a method of making the alkali alumino-silicate Na—F-containing glass material, with the glass material capable of being made photosensitive and thus formed into optical elements at wavelengths ranging between about 240 to 350 nm, and more particularly at the standard 248 nm wavelength of excimer lasers. Also disclosed is optical element wherein a refractive index pattern formed in the alumino-silicate Na—F containing glass material, the refractive index pattern including regions of high refractive index and regions of low refractive index, the difference between the refractive indices of the high refractive index regions and the low refractive index regions being at least 4×10−5 at a wavelength of 633 nm.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com