Medium-high refractive index optical resin lens and preparation method thereof

An optical resin lens, high refractive index technology, used in optics, optical components, instruments, etc., can solve the problems of serious environmental pollution, average impact strength, poor impact strength of high refractive index optical resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Mix 20.0g 2,3-dithio(2-mercapto)-1-propanethiol, 0.008g dibutyltin dichloride, and 0.028 g release agent evenly, then mix 20.7g xylylene diisocyanate, Mix 0.004g of antioxidant, stir evenly in vacuum, then vacuum degassing, mix the components mixed for the first time with the mixture for the second time, stir and degas in vacuum for 60min, mix the mixture after vacuum degassing The liquid is injected into the glass mold, and the first curing is carried out according to the heating program. After molding, the mold is demoulded to obtain a colorless and transparent lens substrate, and then the second curing is carried out. Its refractive index is 1.656, its thermal decomposition temperature is 300.8°C, and its impact strength is 15.4kJ / m 2 .

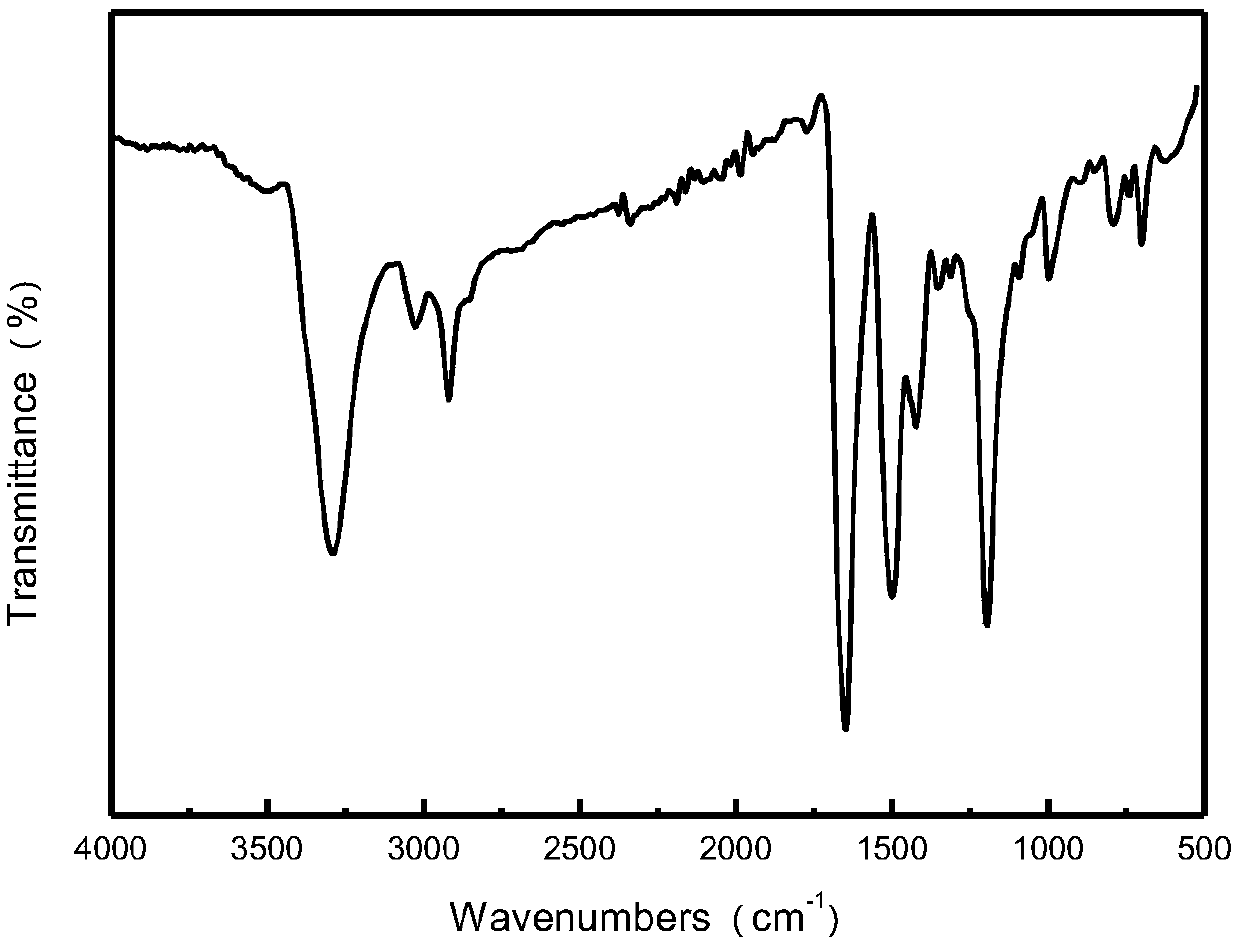

[0031] Infrared spectrum analysis: after polymerization, 2259cm- 1 The N=C=O stretching vibration peak at 3290cm- 1 The absorption peak of the N-H bond appeared at , due to hydrogen bonding, the position of the N-H bond peak shif...

Embodiment 2

[0033] Mix 30.0g of 2,3-dithio(2-mercapto)-1-propanethiol, 0.013g of dibutyltin dichloride, and 0.052 g of release agent, and then mix 34.9g of cyclohexanedimethylene di Mix isocyanate and 0.004g antioxidant, stir in vacuum evenly, then vacuum degassing, mix the first mixed component with the second mixed liquid, vacuum stir and degas for 60min, vacuum degassing The mixed liquid is injected into the glass mold, and the first curing is carried out according to the heating program. After molding, the mold is demoulded to obtain a colorless and transparent lens substrate, and then the secondary curing is carried out. Its refractive index is 1.618 and its impact strength is 21.7kJ / m 2 .

Embodiment 3

[0035] Mix 30.0g 2,3-dithio(2-mercapto)-1-propanethiol, 0.012g dibutyltin dichloride, and 0.048 g release agent, and then mix 30.3g hexamethylene diisocyanate, 0.004 g antioxidants were mixed, vacuum stirred evenly, and then vacuum defoaming was carried out, the first mixed component was mixed with the second mixed liquid, vacuum stirred and degassed for 60 minutes, and the mixed liquid after vacuum defoaming was injected into the Put it into the glass mold, carry out the first curing according to the heating program, and demould after molding to obtain a colorless and transparent lens substrate, and then carry out the second curing. Its refractive index is 1.609 and its impact strength is 47.4kJ / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com