Special regenerant suitable for regenerating modified asphalt and prepared method thereof

A technology of modified asphalt and rejuvenating agent, which is used in building components, building insulation materials, buildings, etc., can solve problems such as the inability to meet the regeneration requirements of modified asphalt, and achieve high temperature stability and low temperature crack resistance. The effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Put 359g of vacuum residual oil and 100g of furfural extracted oil into the reactor, preheat to 130°C while stirring, add 60g of styrene-butadiene-styrene block copolymer into the reactor, and keep the above Stir at temperature for 30 minutes; then raise the temperature to 150°C, increase the stirring speed, and stir rapidly for 15 minutes; reduce the stirring speed and cool to 90°C, add 60g of 180# solvent oil, 12g of sulfur, 2g of 2,6-ditert-tert Butyl-4-methylphenol and 1g 4-methyl-6-tert-butylphenol antioxidant, 4g AS-P and 2gAD-here LOF 65-00 anti-stripping agent, keep stirring at the above temperature for 15min, and finally cool to room temperature , to produce asphalt modified regenerant SBTII-1.

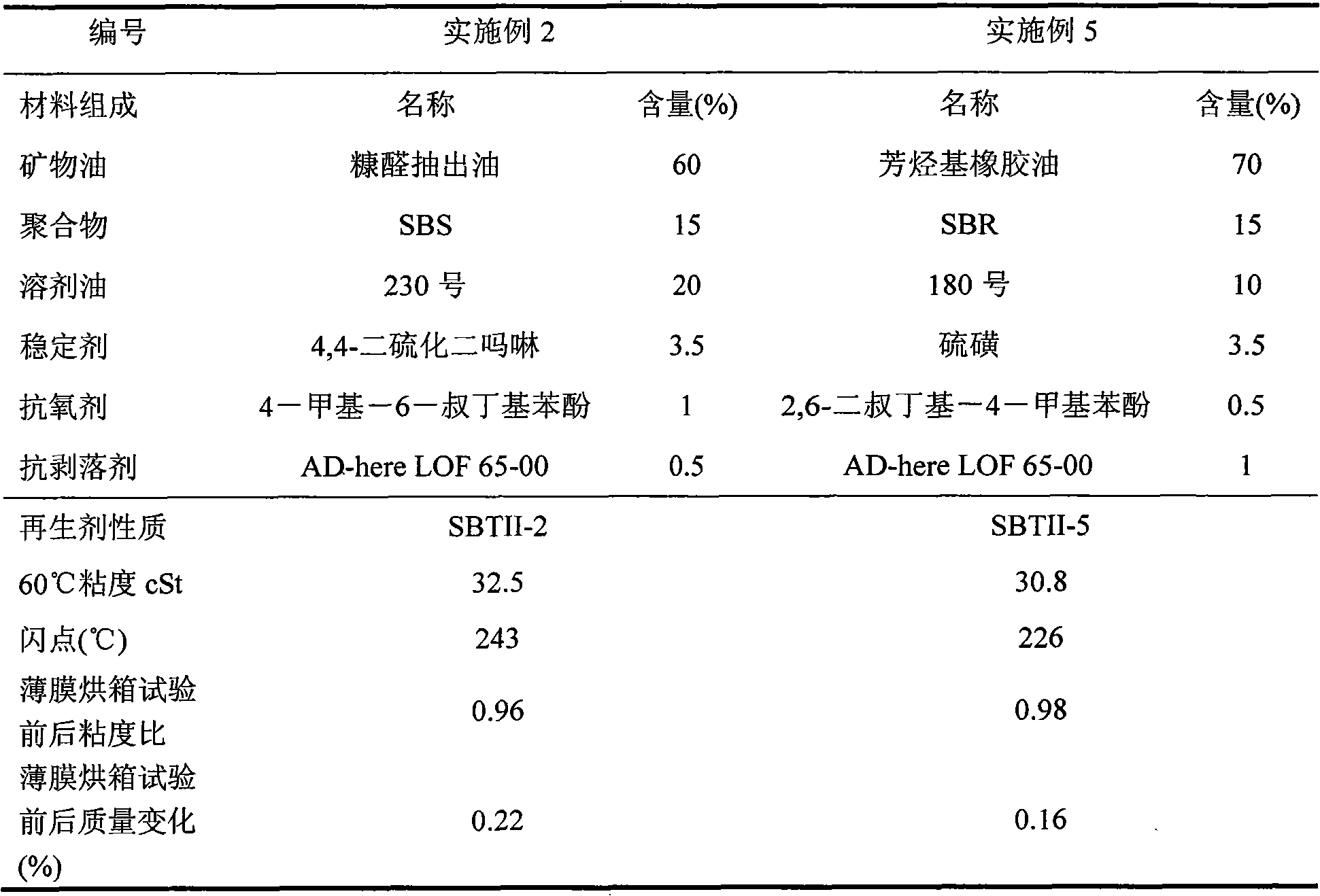

Embodiment 2

[0025] Put 360g of furfural oil into the reactor, preheat to 130°C while stirring, add 90g of styrene-butadiene-styrene block copolymer into the reactor, keep stirring at the above temperature for 30min; then raise the temperature to 150°C ℃, increase the stirring speed, and stir rapidly for 15 minutes; reduce the stirring speed and cool to 90°C, add 120g of 230# solvent oil, 21g of 4,4-dimorpholine disulfide, 6g of 4-methyl-6- tert-butylphenol and 3g AD-here LOF65-00 anti-stripping agent, keep stirring at the above temperature for 15 minutes, and finally cool to room temperature to make oily viscous asphalt modified rejuvenator SBTII-2.

Embodiment 3

[0027] Put 240g of furfural extracted oil into the reactor, preheat to 130°C while stirring, add 120g of styrene-isoprene-styrene block copolymer into the reactor, keep stirring at the above temperature for 30min; then raise the temperature to 150°C, increase the stirring speed, and stir rapidly for 15 minutes; reduce the stirring speed and cool to 90°C, add 100g of 180# and 80g of 230# solvent oil, 18g of sulfur, 6g of 2,6-di-tert-butyl-4 - methylphenol and 6g AS-P anti-stripping agent, keep the above temperature and stir for 15min, and finally cool to room temperature to make oily viscous asphalt modified regeneration agent SBTII-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com