Patents

Literature

797results about How to "Improve road performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified rubber powder and its prepn and use

InactiveCN1974621ALow costReduce noiseNon-macromolecular adhesive additivesOther chemical processesRubber materialChemical reaction

The present invention relates to modified rubber powder and its preparation process and use. Structurally, the modified rubber powder has alkyl group, alkenyl group, hydroxyl group, carboxyl group, nitrile group or amino group in the side chain or has side chain connected via double bond reaction to butadiene, polystyrene, vinyl acetate, acrylate, acrylonitrile or other compound. The modified rubber powder has the structural features of rubber retained and thus excellent mechanical performance, physical and chemical performance and machining performance. The introduction of functional group to the side chain results in obviously raised compatibility with other rubber material, plastic and other polymer material, easy grafting reaction and functional group chemical reaction for further modification. In addition, the performances may be regulated via altering the sort and amount of the introduced functional groups.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

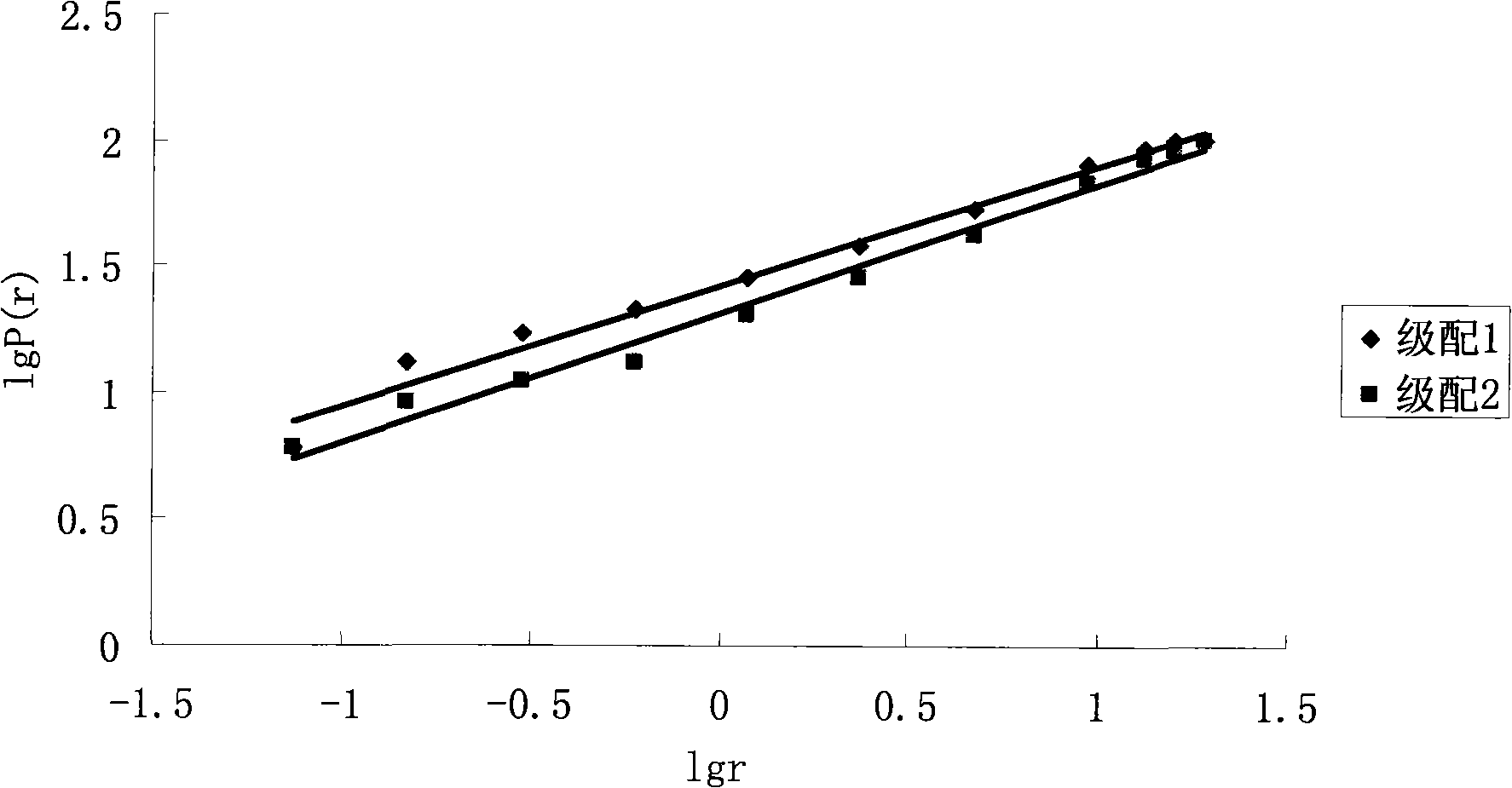

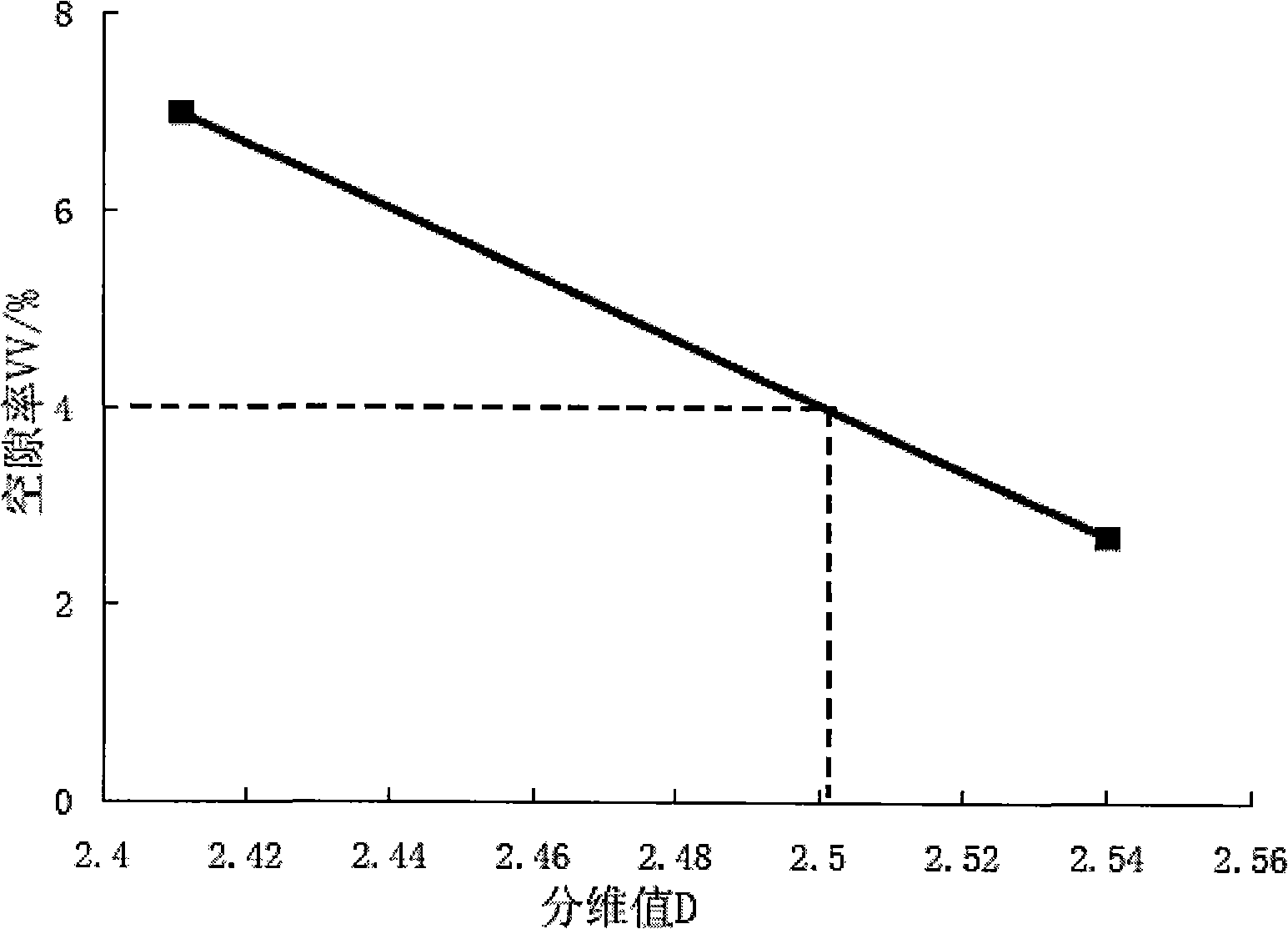

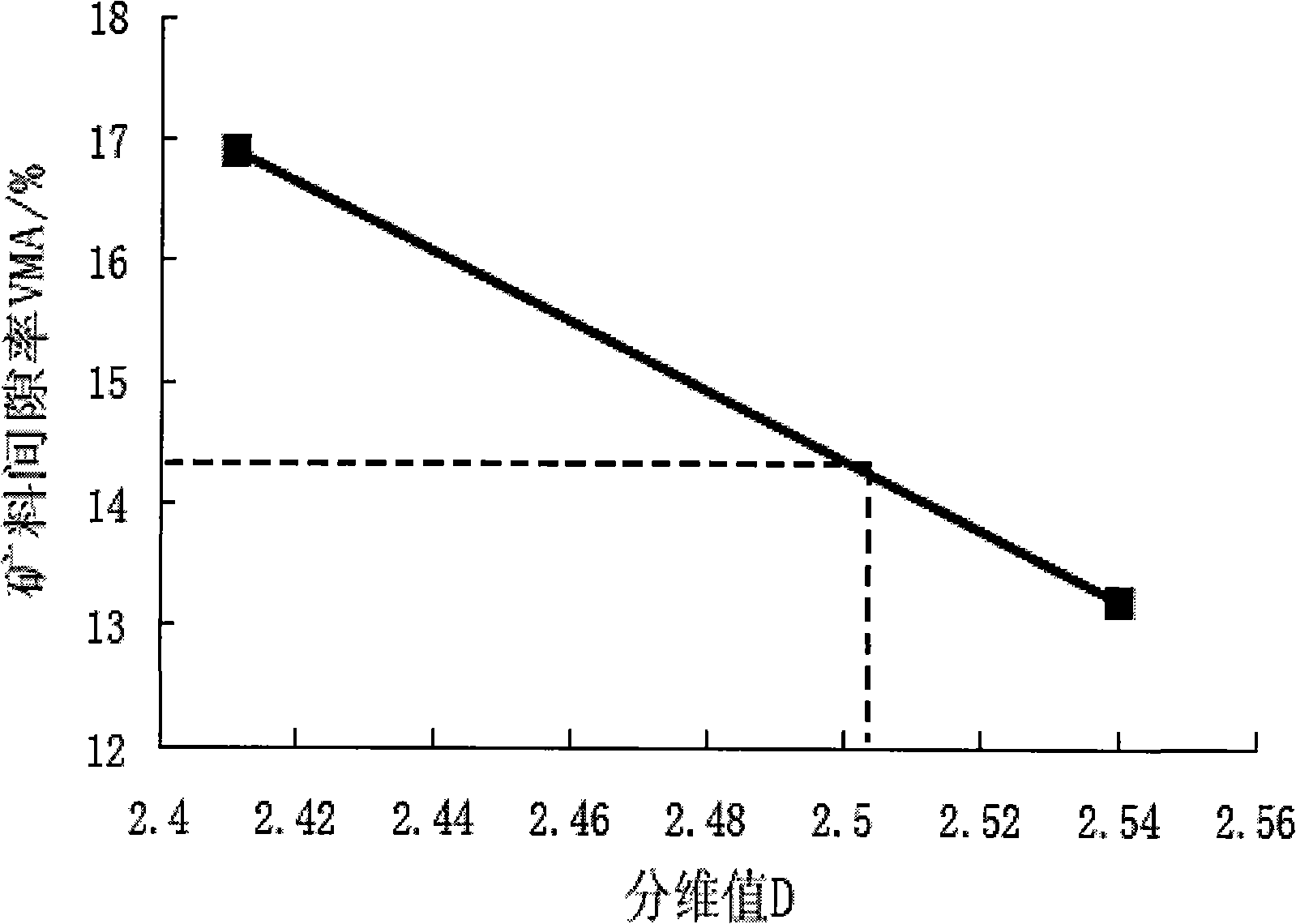

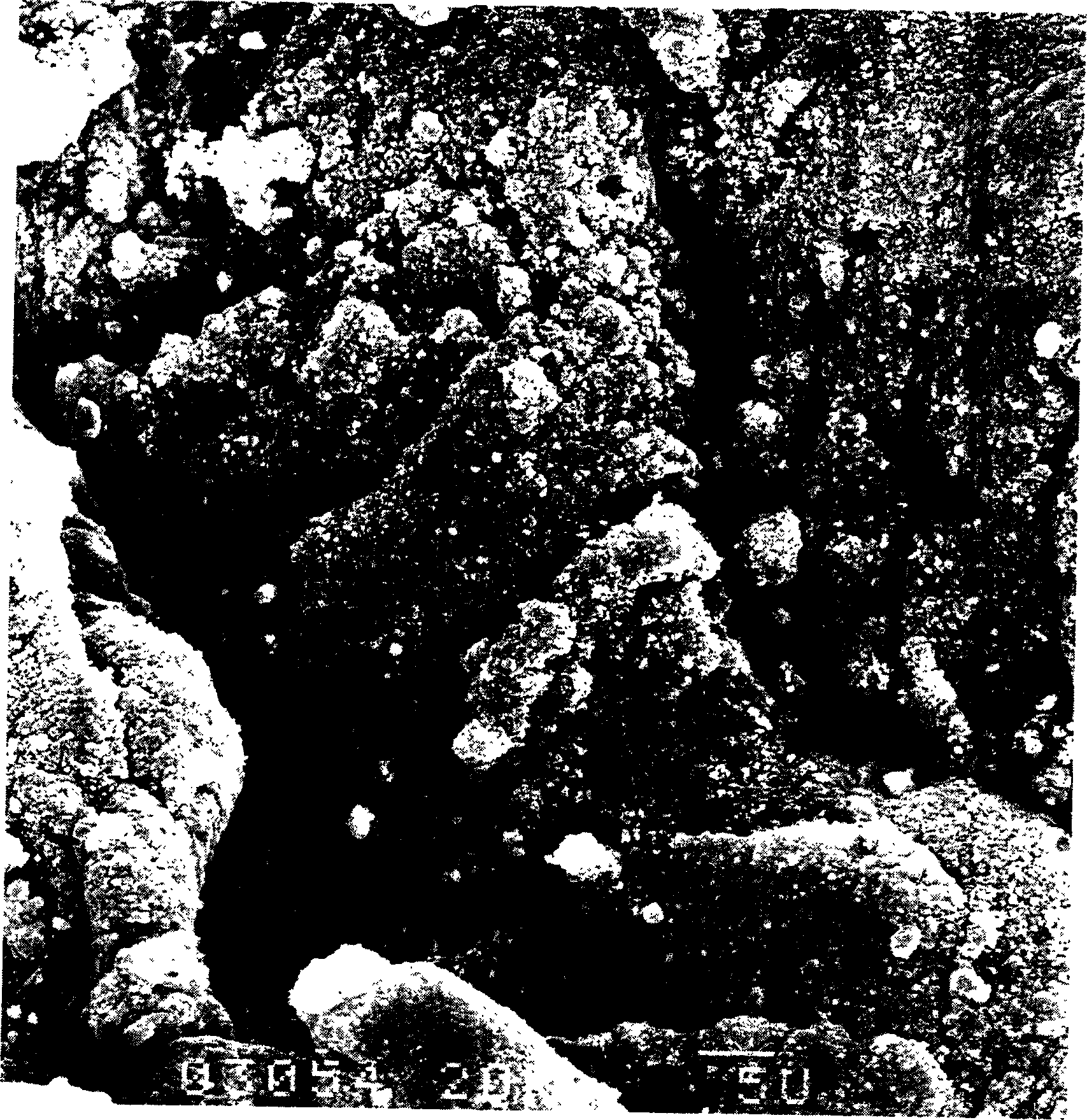

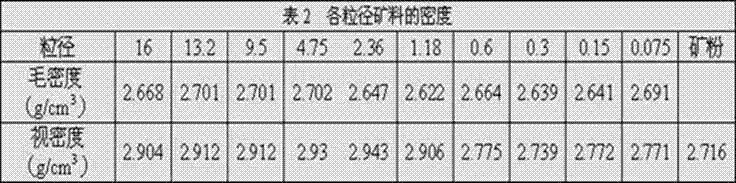

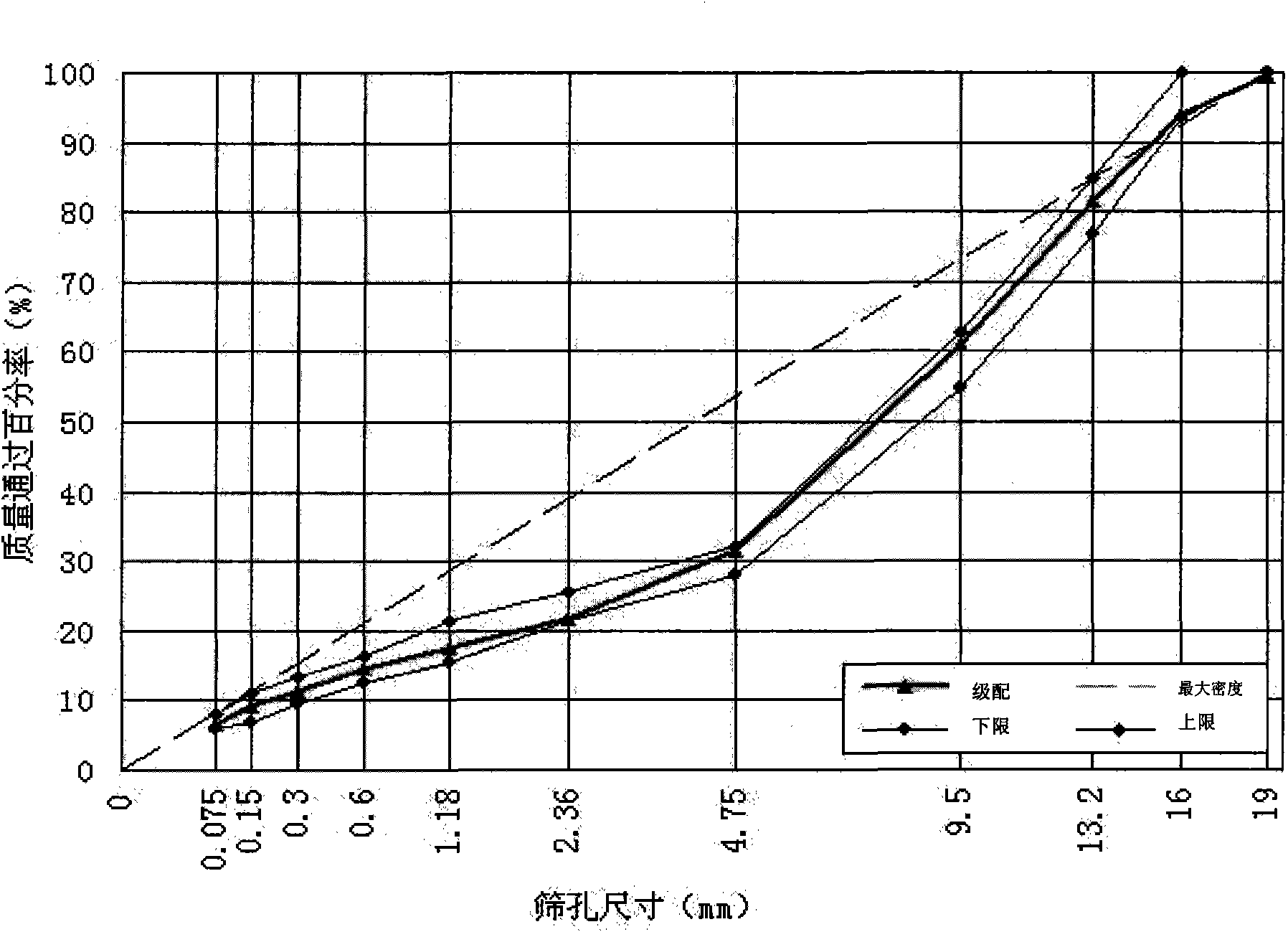

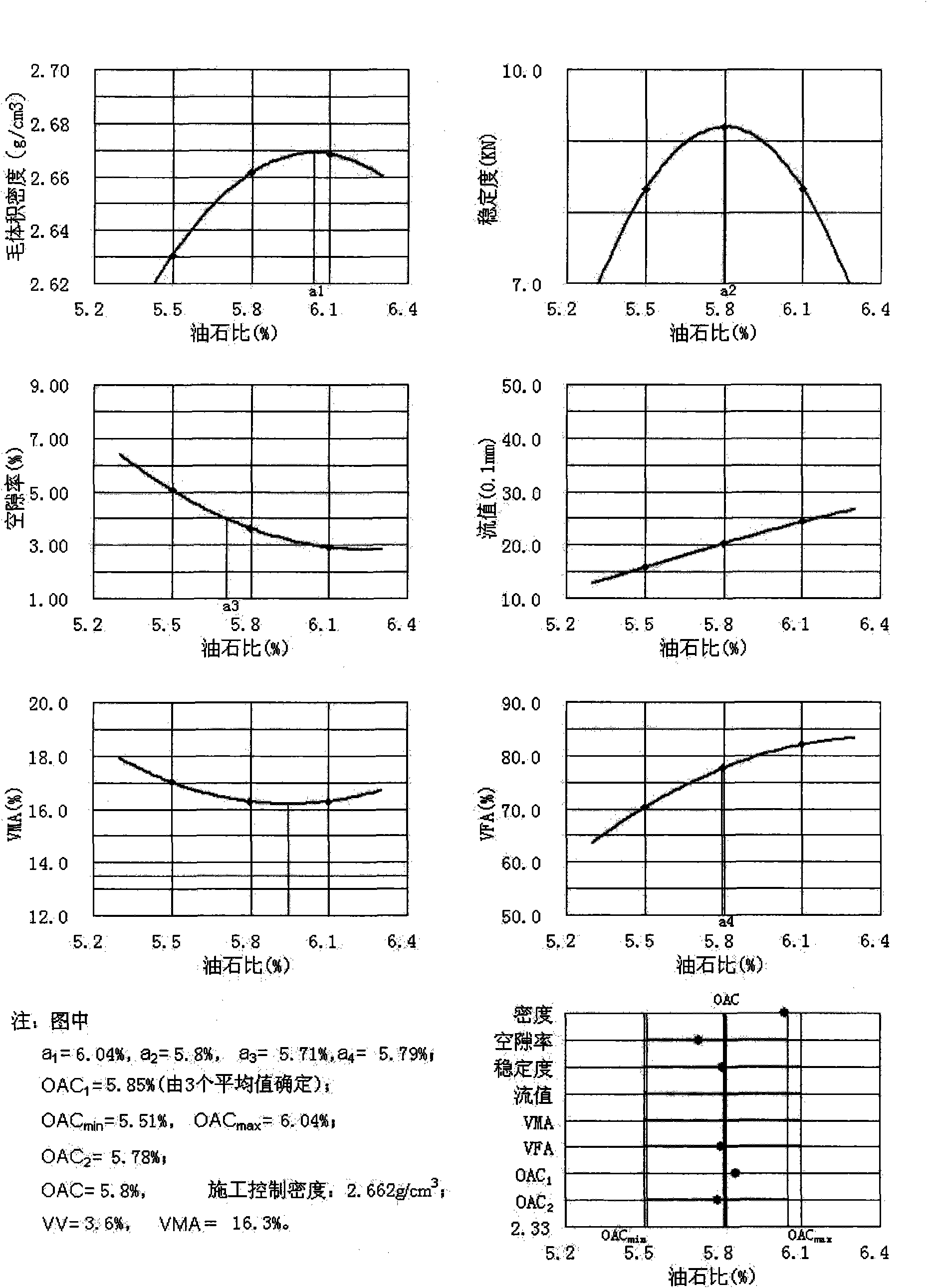

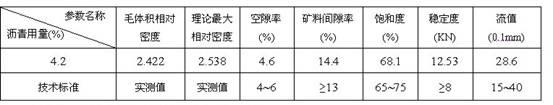

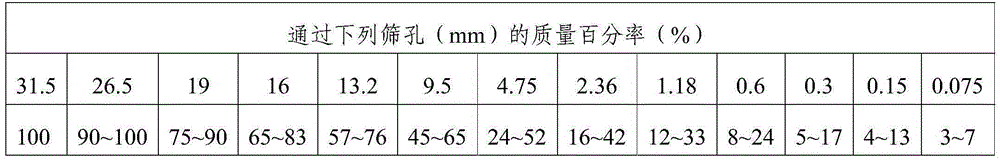

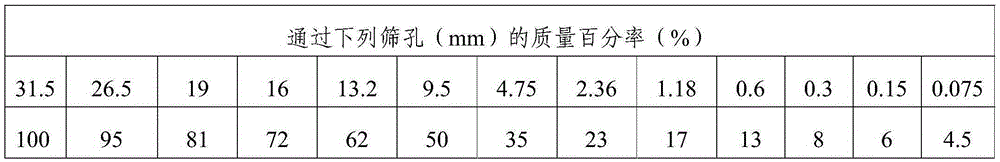

Asphalt mixture mixing proportion design method based on inert solid fractal distribution characteristic

InactiveCN101318794AImprove road performanceSimple internal structureSolid waste managementCeramic shaping apparatusMathematical modelTest sample

The invention relates to a method of designing a mixed ratio for a bitumen mixture based on fractal and distributional features of ore materials. The method comprises the following steps: (1) mathematical models for particle diameter distribution and mass distribution of the ore materials are set up respectively; (2) the type and the grading limit of the bitumen mixture are determined; (3) raw materials are selected and checked; (4) graduations of two arbitrary groups of the ore materials are determined and corresponding fractal dimension values(D) are worked out; (5) the use level of the bitumen is worked out; (6) the bitumen mixture is prepared by stirring; (7) a Marshall test sample is made, the relative density of the bulk volume of the test sample is determined, the theoretical maximum relative density is determined, and the volume index is worked out; (8) relationship curves between the fractal dimension values(D) and the volume indexes are drawn; (9) the graduation of the ore materials and the optimum use level of the bitumen are determined; (10) the road performance of the bitumen mixture is tested; and (11) the construction mixed ratio of the bitumen mixture is determined. The invention utilizes the fractal theory to set up the mathematical models, and in the process of designing the mixed ratio of the bitumen mixture, the optimum bitumen use level and the optimum graduation of the ore materials meeting and regulating all design rules of the bitumen mixture can be quickly determined.

Owner:LANZHOU JIAOTONG UNIV

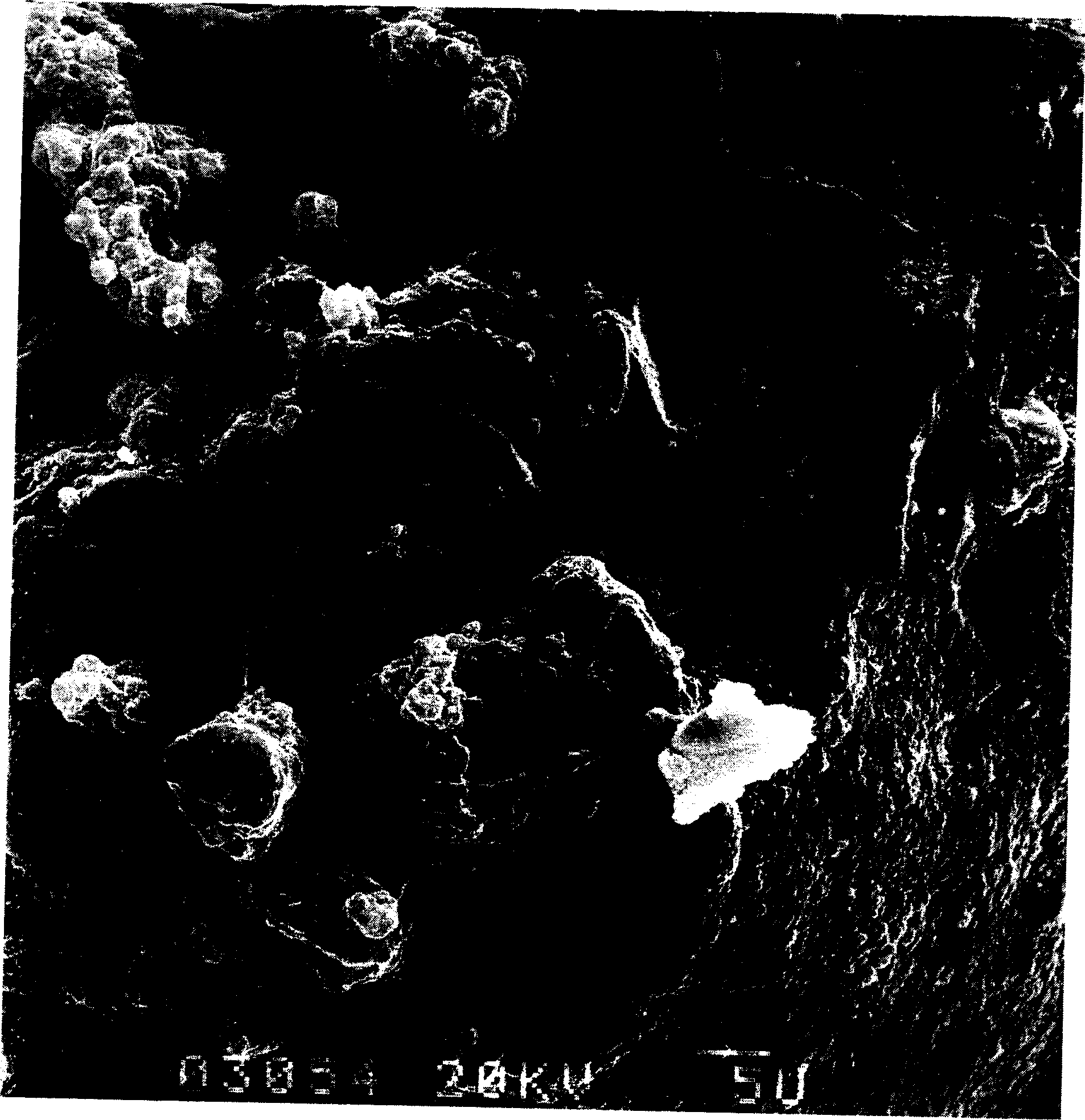

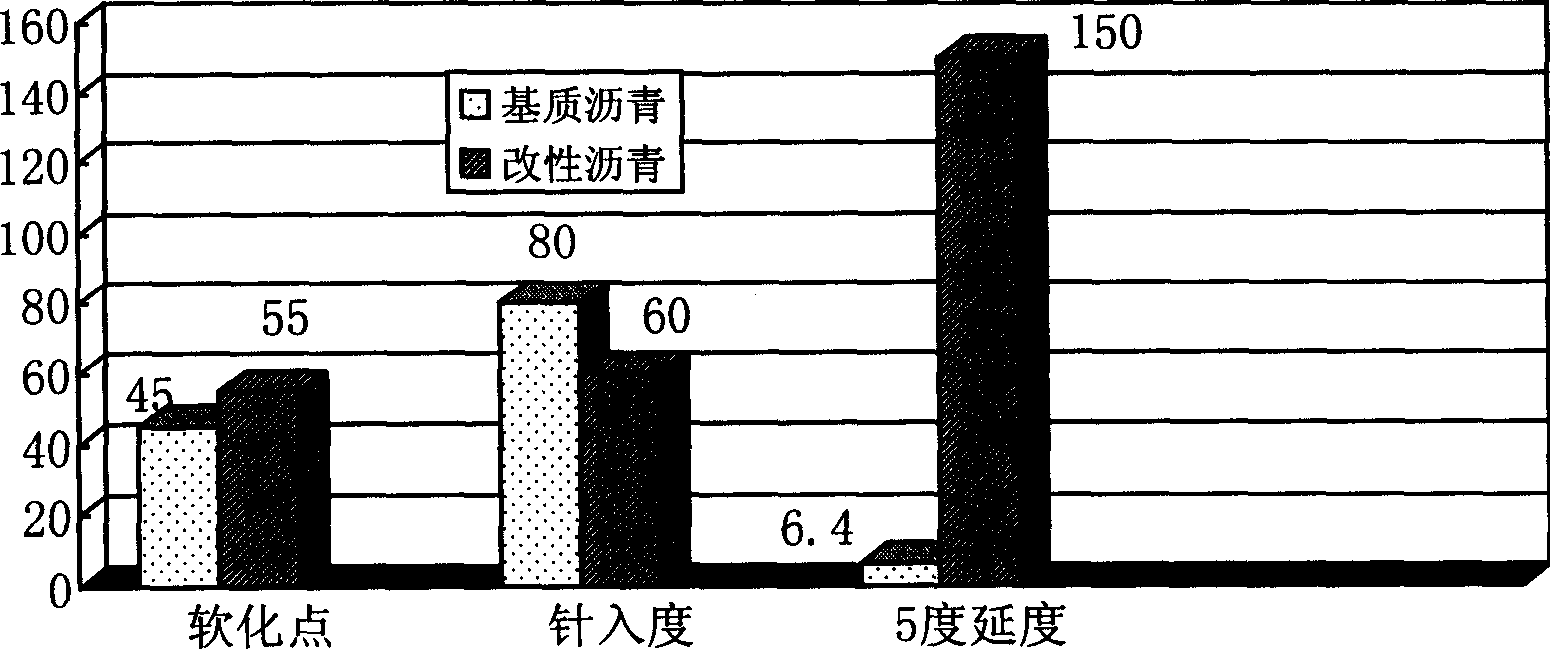

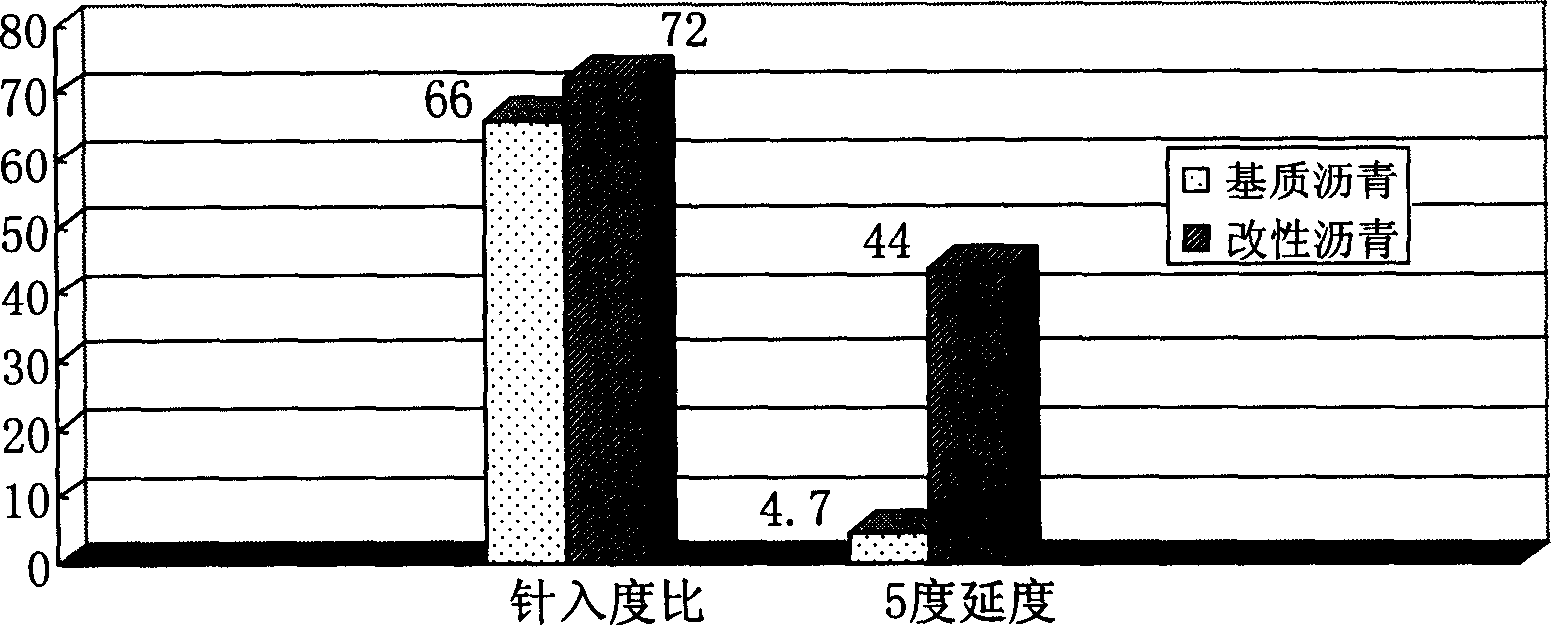

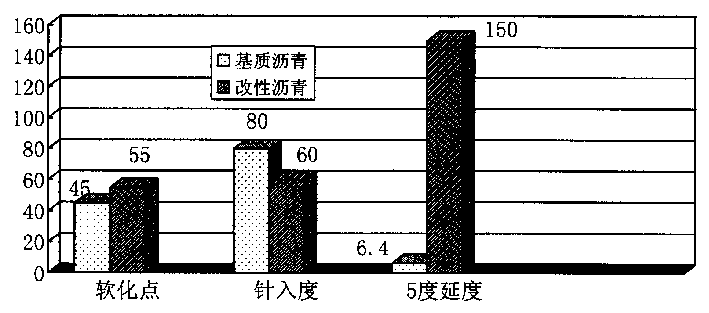

Composite of modified road asphalt by microwave radiating old rubber powder and its preparation process

InactiveCN1597782AGood dispersionGood physical and mechanical propertiesBuilding insulationsWaxMicrowave

The invention relates to a microwave-irradiated waste-rubber powder modified pitch combination and its preparing method, using higher-wax content pitch as a substrate, adding in powdery butadiene-styrene rubber and microwave-irradiated waste rubber powder, and making high-speed cutting and uniform commixing to make the modified pitch. The modified pitch has the characters of high-temperature stability, obviously increased low-temperature extensibility, good antiaging property, etc, has road performance synthetically improved and can act as high-grade road pitch for use.

Owner:NORTHWEST NORMAL UNIVERSITY

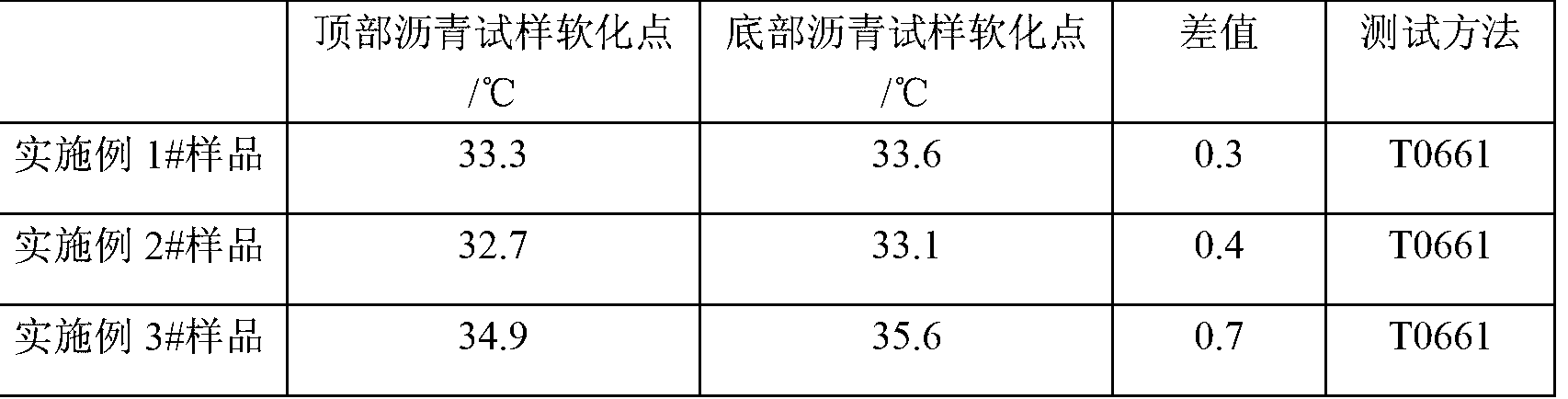

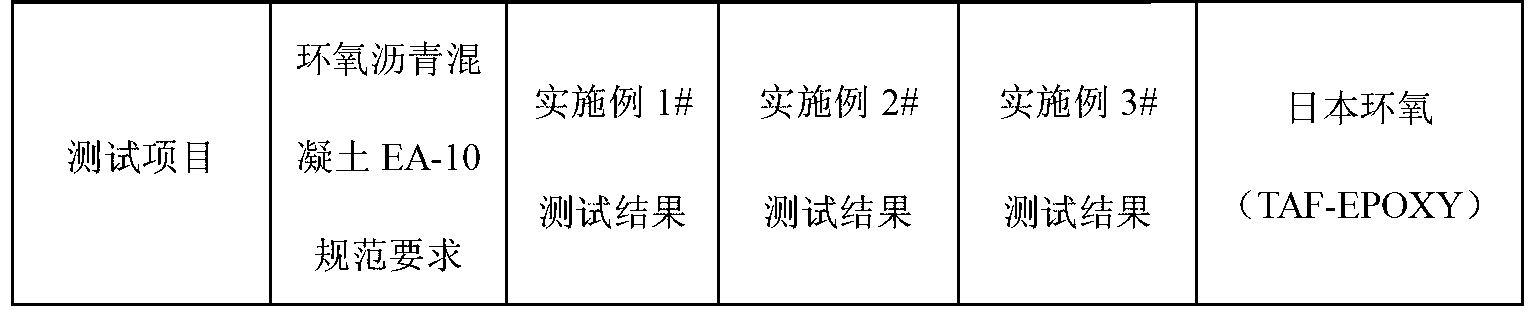

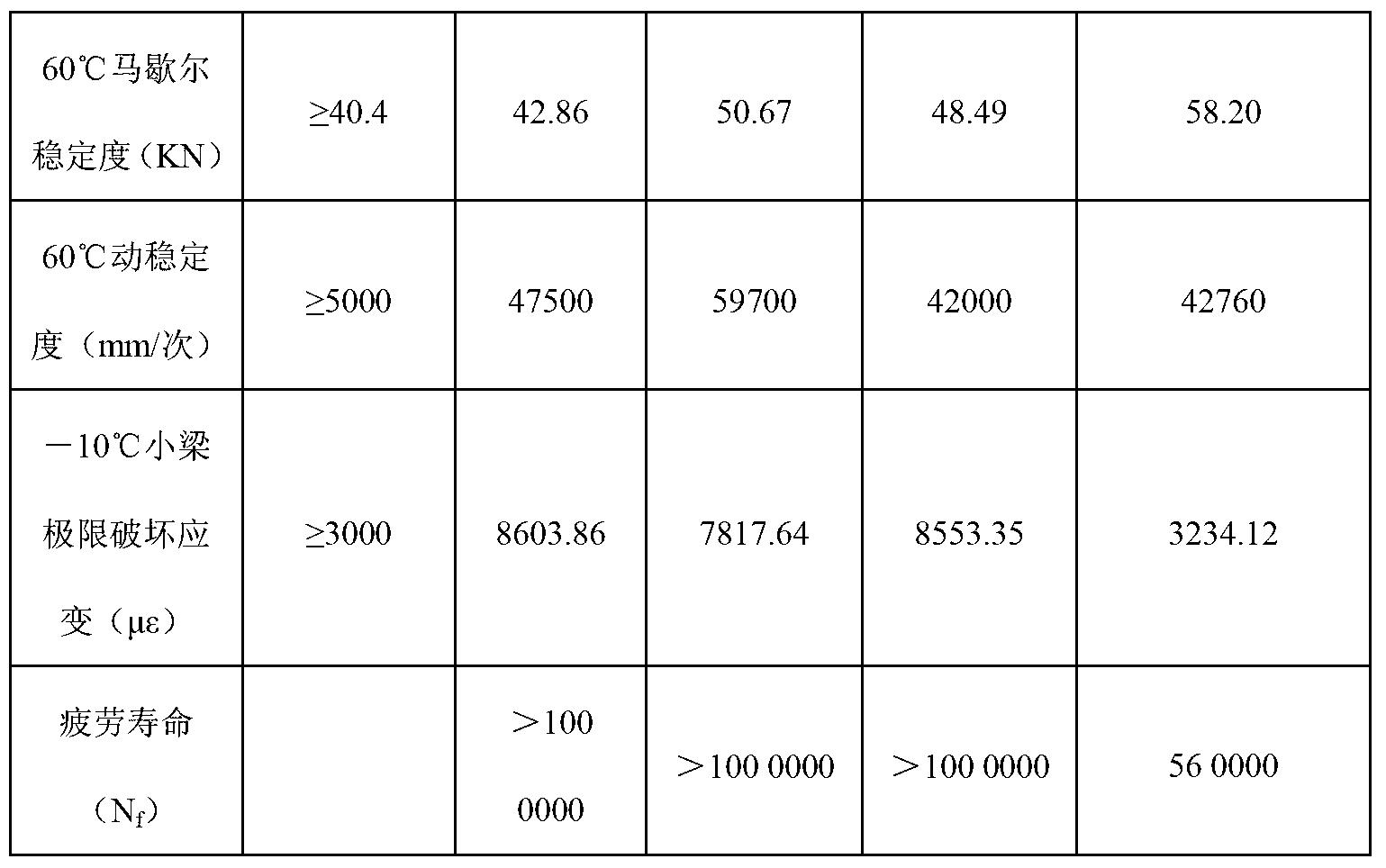

Composite modified asphalt and preparation method thereof

ActiveCN103232717AGood compatibilityHigh temperature and low temperature performanceBuilding insulationsEpoxyBridge deck

The invention relates to composite modified asphalt. The composite modified asphalt is prepared from the following raw materials in percentage by weight: 23.1-45.5% of polyurethane modified epoxy resin, 5-10% of compatibilizer, 5-10% of plasticizer, 5-10% of curing agent and 40-60% of road petroleum asphalt, wherein the polyurethane modified epoxy resin is terminal-amino polyurethane modified epoxy resin, terminal-isocyanato polyurethane modified epoxy resin or imidazolyl-terminal-capped polyurethane modified epoxy resin, the compatibilizer is naphthalene oil, asphalt tar or a mixture of naphthalene oil and asphalt tar, the plasticizer is dioctyl phthalate, dibutyl phthalate or a mixture of dioctyl phthalate and dibutyl phthalate, the curing agent is a modified aromatic amine curing agent, and the road petroleum asphalt is 70# petroleum asphalt, 90# petroleum asphalt or 110# petroleum asphalt. The road performance of concrete adopting the polyurethane epoxy resin composite modified asphalt further meets the requirements of technical specifications and surpasses that of the similar imported product Japan Epoxy, so that the composite modified asphalt can be widely applied to the construction of steel bridge deck pavement, and has great significance in opening a market for domestic epoxy asphalt materials.

Owner:重庆市智翔铺道技术工程有限公司

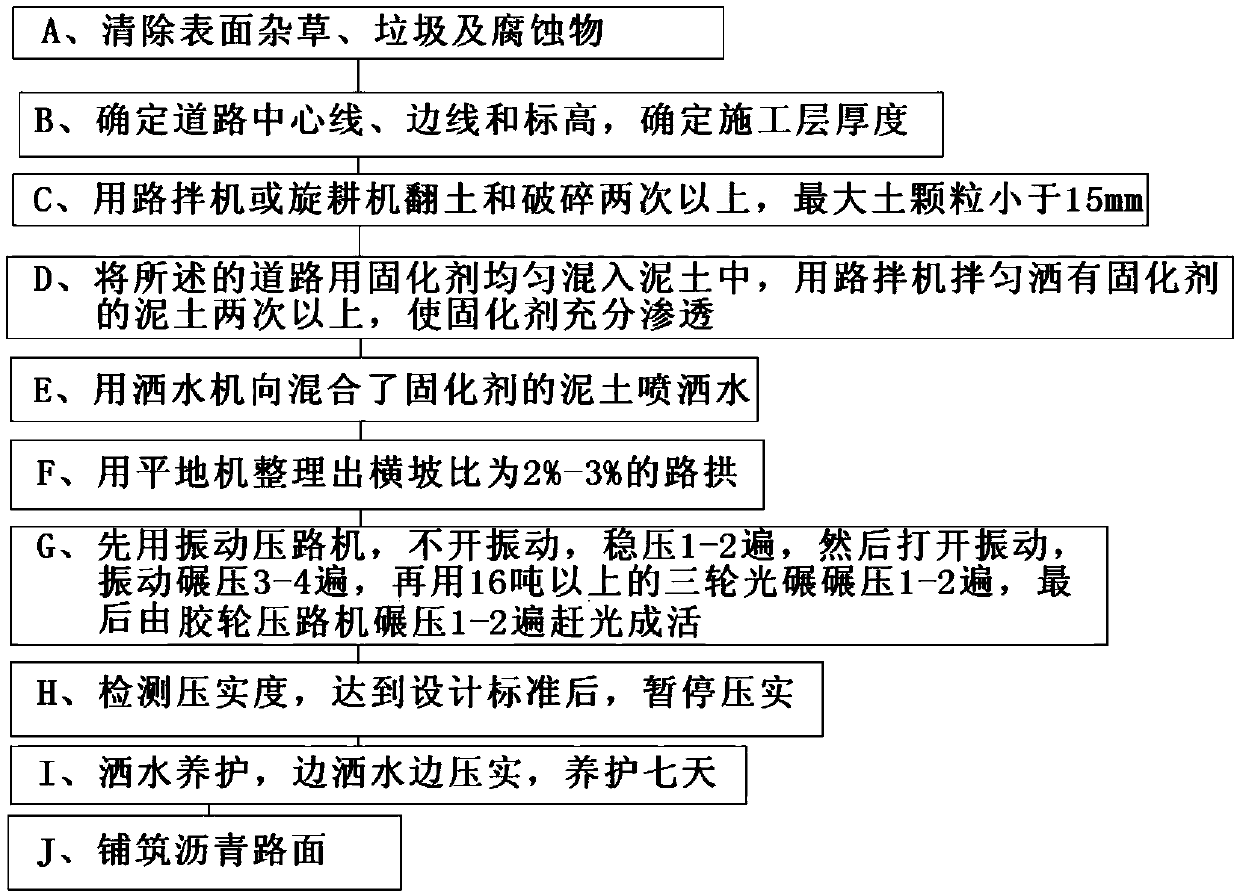

Hardening agent for road and roadbed hardening method

ActiveCN105367010AImprove physical and mechanical propertiesImprove engineering propertiesSolid waste managementEpoxyPhosphate

The invention discloses a hardening agent for a road. The hardening agent is prepared from, by weight, 10-15% of cement, 1-5% of lime, 2-3% of fly ash, 2-3% of gypsum, 1-2% of coal gangue, 1-2% of zeolite, 3-15% of sulfonated oil, 1-2% of phosphate, 1-2% of caustic alkali, 1-2% of potassium permanganate, 2-4% of sodium chloride, 2-4% of sodium carbonate, 2-3% of calcium carbonate, 2-3% of silicon powder, 1-2% of asphalt, 5-10% of sodium silicate, 1-2% of polyacrylamide, 1-2% of polyacrylic acid, 1-2% of magnesium sulfate, 1-2% of calcium carbonate, 7-10% of tar, 0.1-1% of epoxy resin, 0.6-1% of aniline furfural, 0.3-1% of calcium acrylate and 0.5-2% of carboxymethyl cellulose. The invention discloses a roadbed hardening method. The hardening agent for the road is adopted for hardening.

Owner:郑卫忠

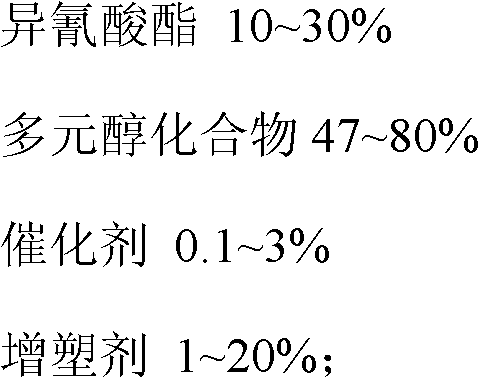

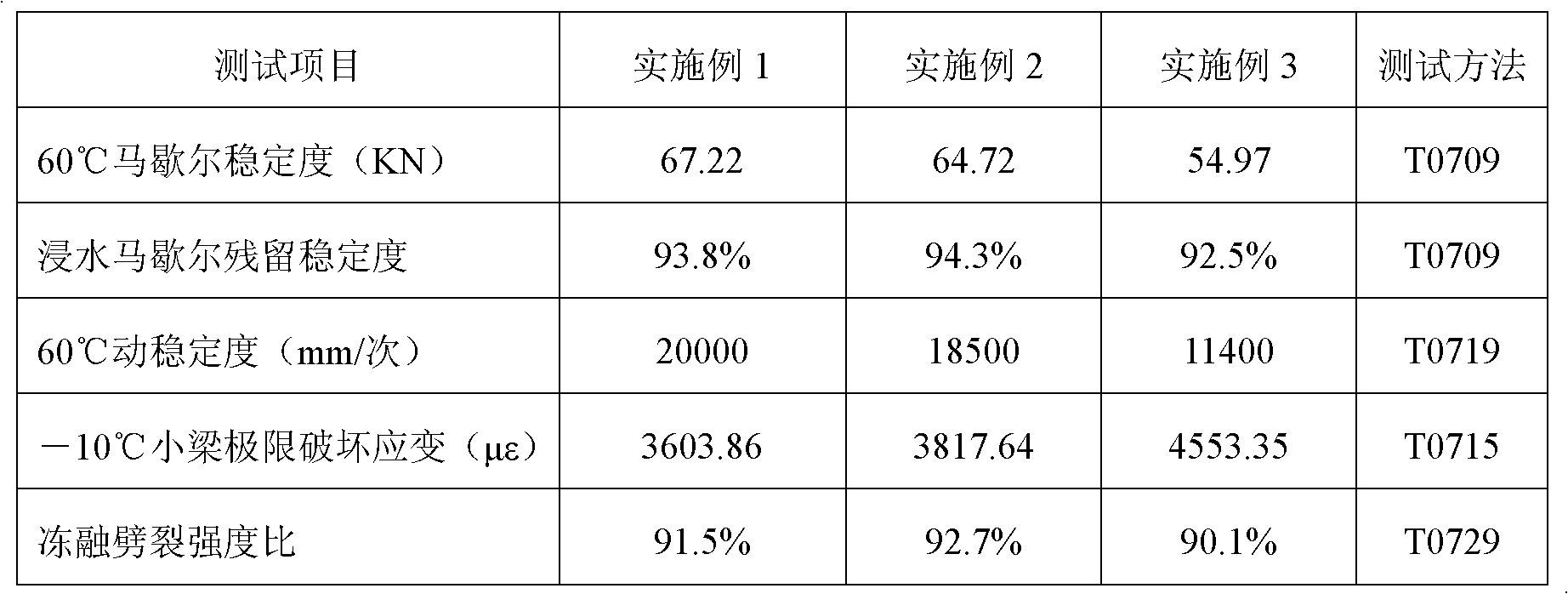

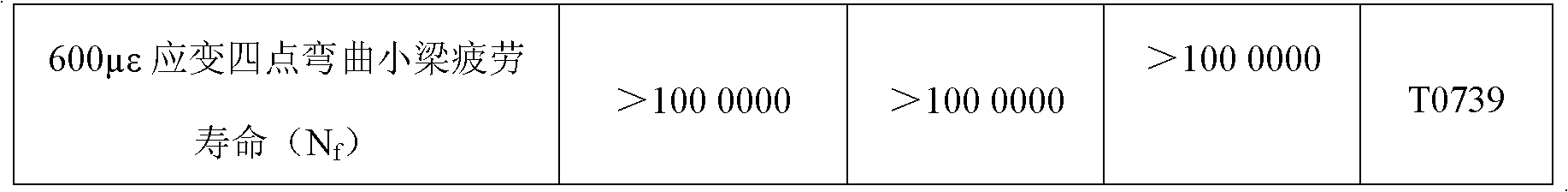

Polyurethane asphalt concrete as well as preparation method and application thereof

The invention discloses polyurethane asphalt concrete prepared from aggregate, diluted asphalt and polyurethane prepolymer which serve as raw materials, wherein the aggregate is basalt, diabase or limestone; the diluted asphalt is a mixture formed by diluting road petroleum asphalt and gasoline or diesel at a weight ratio of 100:(18-100); and the polyurethane prepolymer is prepared by reacting isocyanate with a polyalcohol compound, a catalyst and a plasticizer. The polyurethane asphalt concrete serving as cool-mixed and cool-spread type asphalt concrete is applied to pavement or repair of an asphalt road surface; compared with the conventional hot state technology for a hot-mixed and hot-repaired asphalt mixture, the polyurethane asphalt concrete has the advantages that the energy is saved, emission of a large amount of greenhouse gas and emission of toxic and harmful gas during asphalt heating are reduced, the surrounding environment is protected, and the environment pollution is reduced; and furthermore, the polyurethane asphalt concrete is operated easily and high in efficiency and cannot be limited by a transparent condition, a repair dispersion condition and the like during production and construction.

Owner:重庆市智翔铺道技术工程有限公司

Crack self-healing bituminous concrete and preparation method thereof

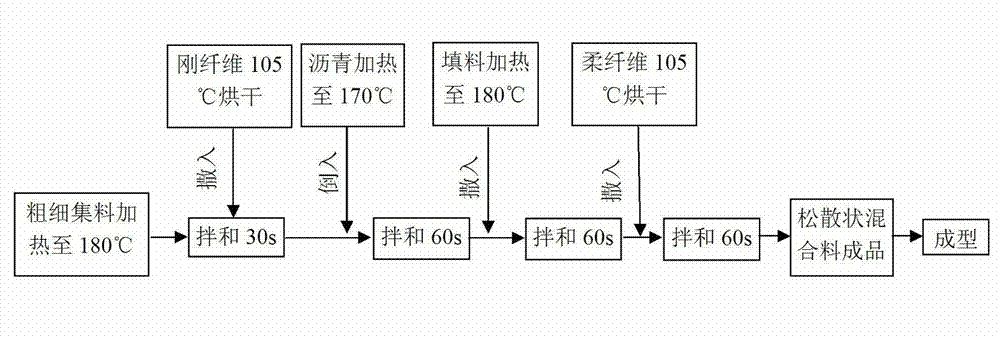

The invention relates to a crack self-healing bituminous concrete and a preparation method thereof. The bituminous concrete comprises coarse aggregate, fine aggregate, fillers, pitch, rigid fiber and flexible fiber, wherein the mixing amount of the rigid fiber is 0.50-2.5wt.% of the total amount of the coarse aggregate, the fine aggregate, the fillers and the pitch, and the mixing amount of the flexible fiber is 0.10-0.35wt.% of the total amount of the coarse aggregate, the fine aggregate, the fillers and the pitch. The preparation method of the concrete comprises the steps of weighing dried aggregates, placing the aggregates in a material containing disk, mixing the aggregates uniformly, preheating in a drying oven to the temperature of 180 DEG C, and heating the fillers separately to the temperature of 180 DEG C; preheating the pitch to the temperature ranging between 160 DEG C and 175 DEG C; drying the rigid fiber and the flexible fiber respectively for backup use according to the requirement; and firstly mixing the rigid fiber into the mixed aggregate with blending, then blending the aggregate and the liquid pitch, then blending with the fillers, then blending with the flexible fiber, and finally forming the bituminous concrete. According to the bituminous concrete and the preparation method, the low-temperature cracks of bituminous pavements are reduced to the minimum and can be healed spontaneously, early-stage cracking is avoided effectively, the service life of the bituminous pavements is prolonged, and the project implementation is convenient.

Owner:ZHENGZHOU UNIV

Bentonite composition modified asphalt and its preparing method

InactiveCN1587320AImprove high and low temperature performanceImprove road performanceBuilding insulationsWaxButadiene-styrene rubber

The bentonite composition modified asphalt consists of asphalt in 94-98 portions, bentonite in 1-3 portions and powdered styrene-butadiene rubber in 1-3 portions. The bentonite is at least one of calcium base bentonite, sodium bentonite and organic bentonite. The preparation process of the bentonite composition modified asphalt includes the following steps: eliminating sand in bentonite, drying, grinding and 325-mesh sieving bentonite; adding bentonite into the asphalt matrix; and adding powdered styrene-butadiene rubber while slowly stirring to mix homogeneously. The modified asphalt has the features of high temperature stability, low temperature cracking resistance, excellent anti-ageing performance, low cost, etc.

Owner:NORTHWEST NORMAL UNIVERSITY

Warm-mix bitumen mixture and preparation therof

ActiveCN101302348AEasy to produceSimple processIn situ pavingsClimate change adaptationSocial benefitsEconomic benefits

The invention discloses a warm-mix asphalt mixture and a method for preparing the same. The warm-mix asphalt mixture comprises the following compositions by weight percent: 90 to 96 percent of mineral aggregate, 2 to 5 percent of asphalt and 2 to 5 percent of warm-mix asphalt modifying agent. The method comprises the following steps of: adding the mineral aggregate which is heated up to a temperature of between 140 and 155 DEG C into a mixing cylinder; adding heat asphalt with a temperature between 130 and 140 DEG C according to a proportion to stir for 20 to 30 seconds; and adding the warm-mix asphalt modifying agent to stir for 20 to 30 seconds to acquire the warm-mix asphalt mixture. The warm-mix asphalt mixture can be used for paving a high-grade pavement, has the characteristics of excellent pavement performance, simple technology, low requirement of manufacturing equipment, convenient use, popularization facilitation, greatly saved construction cost, great economic benefit and social benefit, green ecology and sustainable development accordance.

Owner:何子豪 +1

Steel slag and rubber asphalt concrete and preparation method thereof

The invention provides a steel slag and rubber asphalt concrete and a preparation method thereof. In the concrete, the steel slag is selected as a coarse aggregate and rubber asphalt is selected as a binder, and the concrete further comprises a fine aggregate and a filler; the mineral aggregate of the asphalt mixture is graded to form a coarse aggregate gap gradation framework solid type; the ratio of the rubber asphalt to the mineral aggregate is comprehensively determined through a Marshall compacting experiment to determine the range via the volume parameter of a Marshall test piece and verification on the road properties such as high-temperature rutting resistance and water damage resistance; when the rubber asphalt and the mineral aggregate are mixed and stirred, the heating temperature of the rubber asphalt is 175-180 DEG C and the heating temperature of the mineral aggregate is 10-30 DEG C higher than that of the rubber asphalt; moreover, the dry mixing time of the mineral aggregate is 15-20 s and the wet mixing time of the mineral aggregate is 35-40 s; and the ex-factory temperature of the steel slag and rubber asphalt concrete formed after the mixing and the stirring is 175-185 DEG C. The invention replaces the mineral aggregate by the steel slag, and can recycle the waste materials, save the stone resources, and reduce the destruction from the stone mining to the environment.

Owner:RES INST OF HIGHWAY MIN OF COMM

Two-stage Design Method of Buton Rock Asphalt Modified Asphalt Mixture

The invention relates to a two stage design method of buton rock asphalt modified asphalt mixtures, comprising two concrete stages of: in a first stage, BRA is not added, an optimal bitumen aggregate ratio of matrix asphalt mixtures is obtained under a condition of a mixing temperature being 155-165 DEG C; in a second stage, BRA is added on the basis of the optimal bitumen aggregate ratio of matrix asphalt mixtures obtained in the first stage, an optimal bitumen aggregate ratio of BRA modified asphalt mixtures is obtained under a condition of a mixing temperature being 165-175 DEG C. In comparison with common non-modified hot mix asphalt mixtures, the road performance of the hot mix asphalt mixtures is improved. In comparison with SBS modified asphalt mixtures, the road performance of thehot mix asphalt mixtures is basically equal, but the cost can be reduced by over 20%. The design method provided by the invention can make the design of buton rock asphalt modified asphalt mixtures to be more convenient and accurate. Buton rock asphalt modified asphalt mixtures under the design method have better road performance than that of the common matrix asphalt and the partly modified asphalt mixtures. The design method is a high cost performance design method of asphalt mixtures, and can be applied to paving in surfacing projects of urban streets and roads of all grades.

Owner:TONGJI UNIV

Preparation method for asphalt concrete with conduction function

InactiveCN101215124ALow costAlleviate problems such as insufficient aggregateSolid waste managementForeign matterMaterials preparation

The invention relates to a process for preparing asphaltic concrete with conducting function, which is characterized in that the process includes the procedures of 1), preliminary treatment of aggregates, which means washing away the foreign matters of the steel slag with water. 2), raw materials preparation, which means that the percentage by weight of each component is that rough aggregates is 55%-80%, fine aggregates is 13%-30%, mineral filler is 7%-15%, the rough aggregates, fine aggregates and mineral filler are selected to reserve as aggregates, consumption of asphalt cement is 6%-8% of the weight of the aggregates, consumption of fabric stabilizer is 0.1%-0.5% of the gross weight of the aggregates and the asphalt cement, consumption of conducting material is 10-30% of the weight of the asphalt cement, and gradation design of SMA mixture is employed. 3), mixture blending, which means charging fractionally and blending multitime, the temperature is kept not lower 150 DEG C when molding. The preparing process has simple technique and low cost. The prepared asphaltic concrete has good conducting function and pavement using property.

Owner:WUHAN UNIV OF TECH

Modified asphalt material for road and its prepn

The present invention relates to one kind of modified asphalt material for road and its preparation. The modified asphalt material is prepared with asphalt with high wax content as base material and through adding powdered styrene-butadiene rubber, natural asphalite and organic metallic soap. The modified asphalt has the features of high temperature stability, low temperature crack resistance, fatigue resistance, peeling resistance, antiageing, etc. as well as improved comprehensive road use performance.

Owner:INST OF POLYMER NORTHWEST NORMAL UNIV

Reinforced emulsified asphalt concrete for roads and preparation method of concrete

The invention discloses reinforced emulsified asphalt concrete for roads and a preparation method of the concrete. The reinforced emulsified asphalt concrete for the roads comprises aggregate, waterborne epoxy resin emulsion and emulsified asphalt, wherein the weight ratio of aggregate to waterborne epoxy resin emulsion to emulsified asphalt is (90-110): (0.1-10): (7-20). The reinforced emulsified concrete disclosed by the invention can be used as cold-mixed and cold-laid asphalt concrete for being applied to spreading or repairing and the like of asphalt pavements, can solve the problems of high temperature sensitivity, insufficient binding capacity, poor durability and the like of traditional asphalt type material, and retains the advantages of low pollution and easiness in construction and operation of the emulsified asphalt and obtains excellent performances of high strength, high binding force, durability in use and the like through waterborne epoxy resin.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

Method for producing damping porous denoise tunnel asphalt covering material

ActiveCN101173104AExcellent structural performanceImprove skid resistanceBuilding insulationsFiberSurface layer

The invention relates to a preparation method of a tunnel asphalt surface layer material. A preparation method for damping porous noise-reducing tunnel asphalt pavement material is characterized in that it comprises the following steps: 1) preparation of high-viscosity and high-elasticity modified asphalt: base asphalt according to the mass ratio of each component: modifier SBS : Activated rubber powder: Viscosifying compatibilizer: Antioxidant: Stabilizer=100: 6.0~18.3: 20.2~45.7: 1.2~3.7: 0.2~1.4: 0.4~1.9, select; obtain high viscosity and high elasticity modification Asphalt; 2) Add flame retardant to high-viscosity and high-elasticity modified asphalt, heat and melt high-viscosity and high-elasticity modified asphalt to add flame retardant, stir for 3-9 minutes, and stand at 150-170°C for 15-30 minutes to obtain Flame-retardant high-viscosity high-elasticity modified asphalt; 3) according to the mass ratio, mineral material: flame-retardant high-viscosity high-elasticity modified asphalt: fiber stabilizer = 100: 3.6~5.2: 0.1~0.4, choose; noise tunnel asphalt surface material. The invention has the functions of noise reduction, flame retardancy and anti-skid.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Warm-mixing recycled asphalt mixture preparation method

ActiveCN105293996AEmission reductionImprove road performanceClimate change adaptationMass contentAsphalt

The invention discloses a warm-mixing recycled asphalt mixture preparation method which comprises the following steps: I, preparing a compound regenerant; II, preparing a compound warm-mixing agent; III, measuring the mass content and natural gradation of old asphalt in an RAP material and respectively determining mass ratios of novel aggregate and novel mineral powder which are required for preparing the warm-mixing recycled asphalt mixture to the RAP material; IV, preparing a warm-mixing recycled asphalt mixture sample and determining an optimum asphalt-aggregate ratio of the warm-mixing recycled asphalt mixture; V, under the condition of the optimum asphalt-aggregate ratio, preparing the warm-mixing recycled asphalt mixture. According to the invention, the recycling rate of the RAP material reaches 70% or above, meanwhile, secondary aging of the asphalt mixture is avoided, the advantages of energy saving and carbon emission and harmful gas emission reduction are realized and the warm-mixing recycled asphalt mixture prepared through the preparation method has good pavement performance.

Owner:CHANGAN UNIV

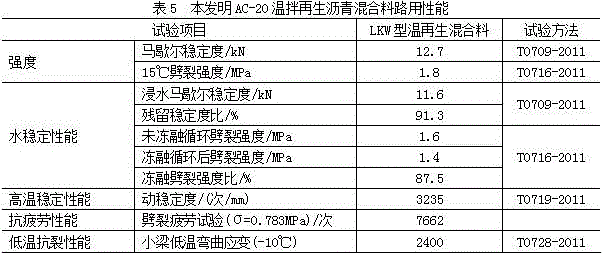

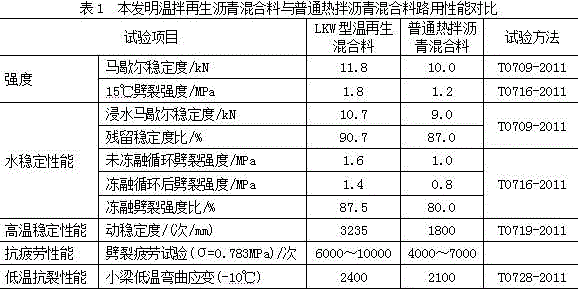

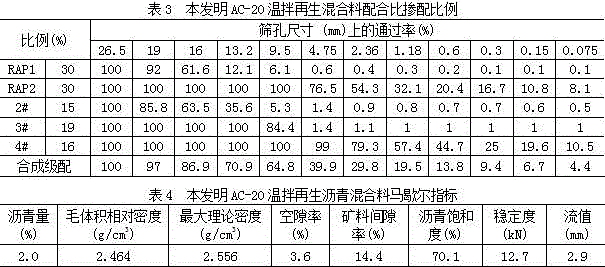

Warm mix recycled asphalt mixture with high RAP (Reclaimed Asphalt Pavement) mixing amount and high performance and preparation method of warm mix recycled asphalt mixture

InactiveCN106186837AHigh strengthImprove fatigue resistanceSolid waste managementClimate change adaptationLow emissionMaterials science

The invention provides a warm mix recycled asphalt mixture with a high RAP (Reclaimed Asphalt Pavement) mixing amount and high performance and a preparation method of the warm mix recycled asphalt mixture, and belongs to the technical field of highway construction materials. The mixture is prepared from the following components in percentage by mass: 50 to 70 percent of RAP material, 28.2 to 47.2 percent of aggregate and 1.8 to 2.8 percent of newly-doped asphalt and warm mix regenerant; the content of the warm mix regenerant is 0.3 to 0.5 percent of the mass of the newly-doped asphalt. The preparation method comprises the following steps of reclaiming and stacking of the RAP material, crushing and screening of a reclaimed material, stacking and detection of a reference material in different bins, and preparation of the warm mix recycled asphalt mixture. The RAP material, the aggregate, the asphalt and the warm mix regenerant are taken according to the requirement of raw material proportioning and are subjected to mixing treatment according to a conventional production technique of a hot-mixed asphalt mixture, wherein the mixing temperature is 120 to 140DEG C, and the mixing time is 20 to 35s, and finally the recycled asphalt mixture is obtained. The warm mix recycled asphalt mixture has the advantages of high RAP mixture ratio, low heating and constructing temperature, good constructability, easiness and pavement performance, low energy consumption, low emission and the like.

Owner:云南省公路科学技术研究院

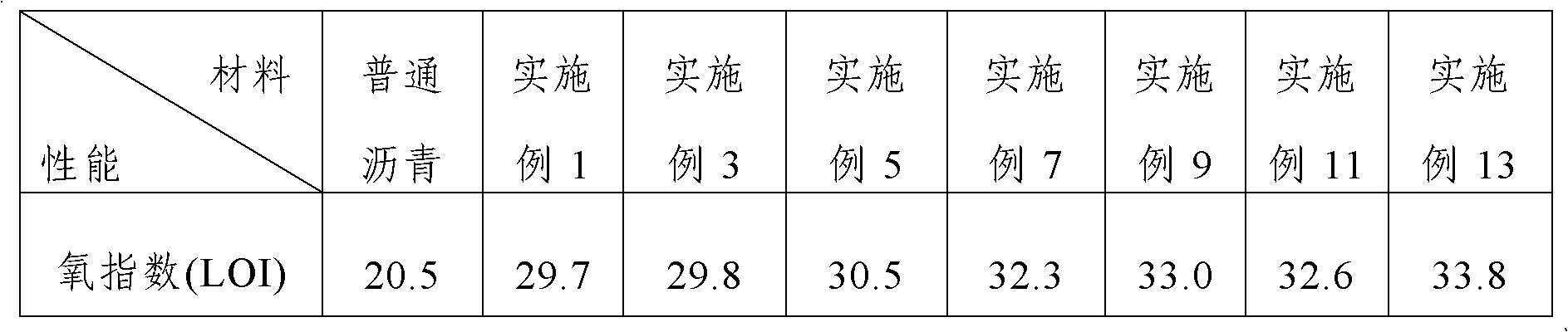

Synergic flame retardance asphalt material and preparation method thereof

InactiveCN102604396AImprove flame retardant performanceImprove application performanceBuilding insulationsMagnesiumBituminous materials

The invention discloses a synergic flame retardance asphalt material, which is characterized in that the asphalt material is prepared by mixing the following raw materials in parts by weight: 100 of asphalt, 0.2-40 of metal hydroxide, 0.1-30 of layered silicate; the asphalt is one or more of petroleum asphalt, rock asphalt and coal pitch; and the metal hydroxide is aluminum hydroxide and / or magnesium hydroxide. The invention also provided a preparation method of the synergic flame retardance asphalt material. According to the invention, the synergic flame retardance function of the metal hydroxide and the layered silicate is utilized to perform nano composite modification on asphalt; compared with the common organic flame retardant (such as a halogen flame retardant), the flame retardance technique adopted by the synergic flame retardance asphalt material is a green, non-toxic and environmentally friendly flame retardance technique; and the various road performances of the flame retardance asphalt material are good, the use requirements are met, the period of the storage stability can reach above one year, and the temperature sensitivity and the ageing resistance are obviously better than those of common asphalt.

Owner:CHANGAN UNIV

Strong-viscosity emulsified modified asphalt and preparation method thereof

ActiveCN102061099AImprove road performanceImprove adhesionBuilding insulationsPolymer scienceChipseal

The invention discloses strong-viscosity emulsified modified asphalt and a preparation method thereof. The emulsified modified asphalt comprises the following components in percent by mass: 62-70 percent of SBS (Styrene Butadiene Styrene block copolymer) modified asphalt, 0.5-1.5 percent of blender, 0.8-1.5 percent of emulsifying agent, 1-2 percent of stabilizing agent, 0.3-0.5 percent of thickening agent and the balance of water. The preparation method comprises the steps of: preparing the SBS modified asphalt, adding the blender; adding the emulsifying agent, the stabilizing agent and the thickening agent into water to prepare liquid soap; and uniformly dispersing the modified asphalt and the liquid soap by using a colloid mill to obtain the emulsified modified asphalt. The method disclosed by the invention has the advantages of easy obtaining of the raw materials and simple preparation process; and the strong-viscosity emulsified modified asphalt has excellent road service performance, solves the technical problems of poor caking effect of tack coat oil for the common ultrathin wear layer, easiness of bleeding and low strength of a stone-chip seal coat, can remarkably improve the interlayer caking capacity when used as the tack coat oil, and can remarkably improve the strength and the deformation-resisting capacity of the seal coat when used as the stone-chip seal coat.

Owner:辽宁省交通科学研究院有限责任公司

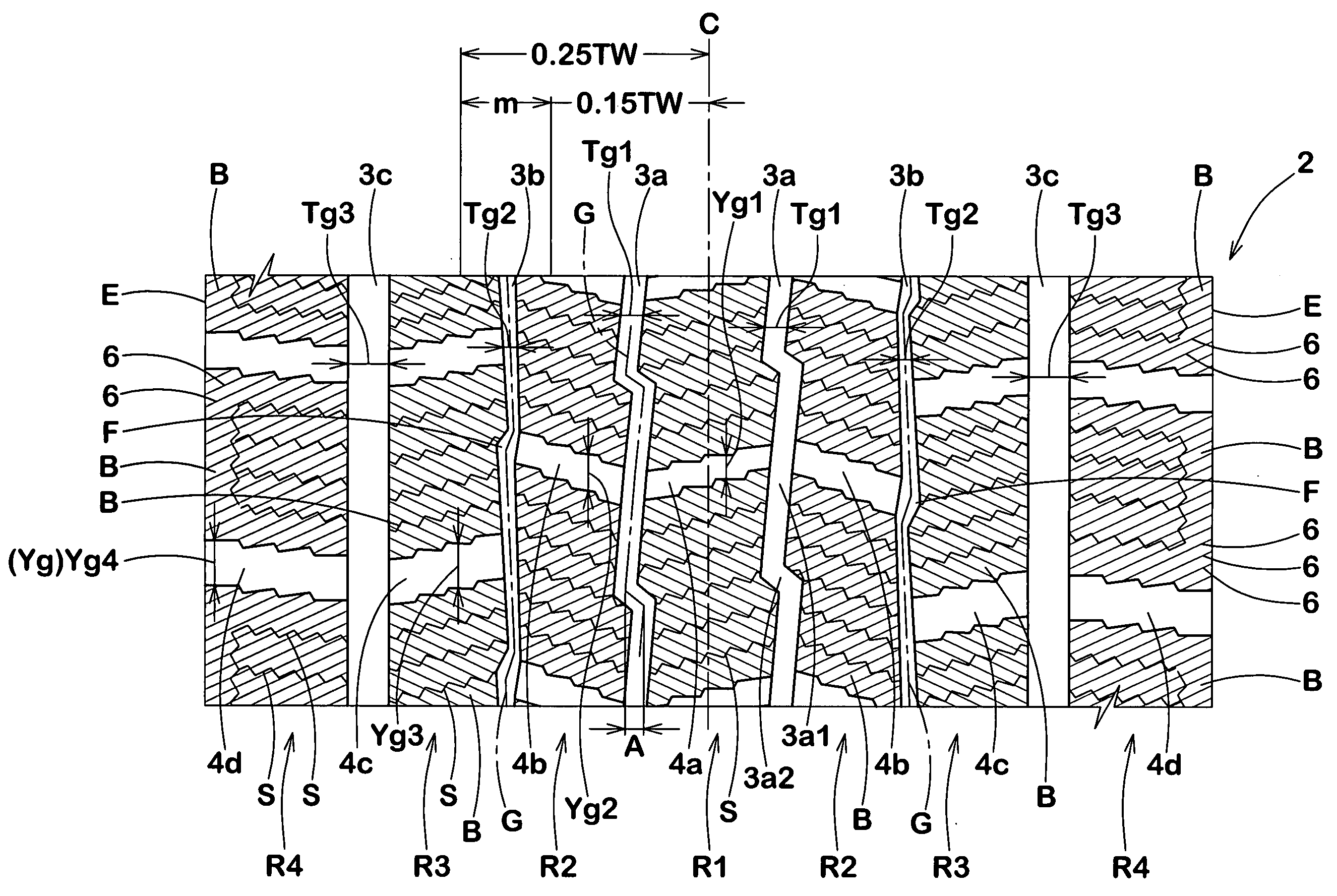

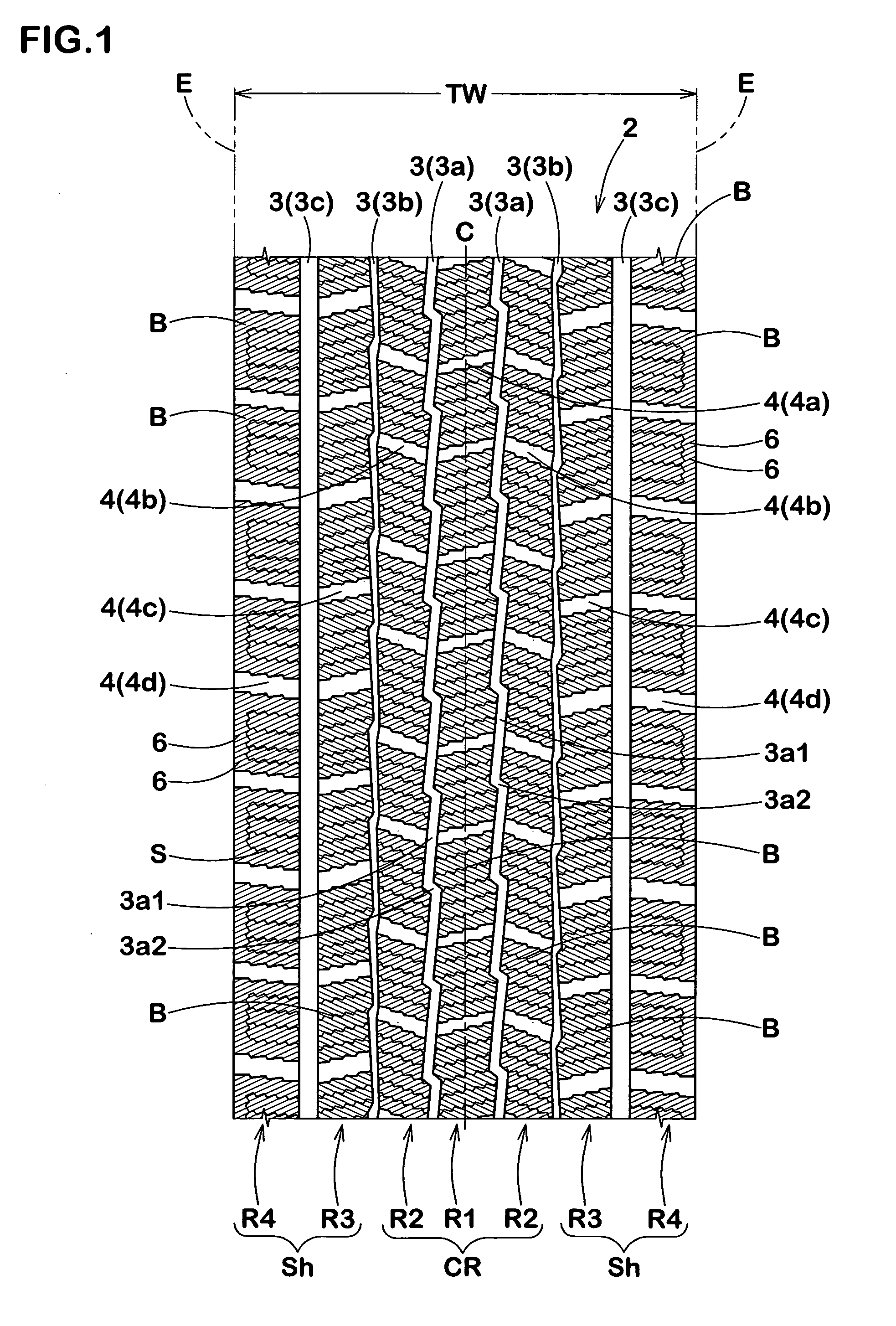

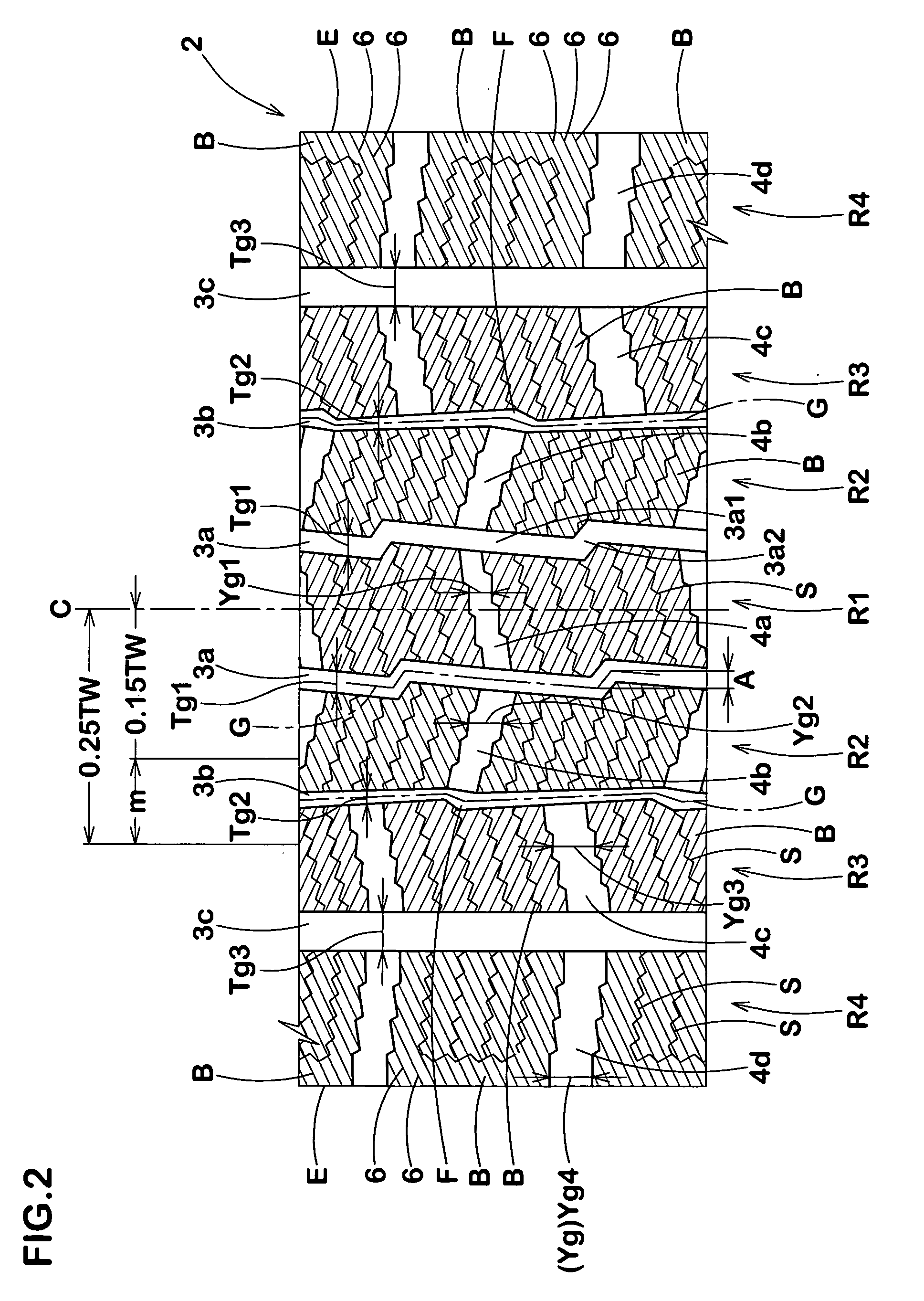

Studless tire

InactiveUS20080202658A1Reduce coefficient of frictionIncrease friction forceTyre tread bands/patternsNon-skid devicesGround contactShoulder region

A studless tire capable of exhibiting excellent performances on both icy road and snow-covered road, including tread portion 2 having a pair of middle circumferential grooves 3b each extending in a region between 15% and 25% of tread width TW from tire equator C to provide crown region CR between the middle grooves 3b and a pair of shoulder regions Sh between the middle groove 3b and ground contact edge E, wherein the crown region CR includes rows R1, R2 of blocks B having sipes S and defined by zigzag inner circumferential grooves 3a and crown lateral grooves 4a, 4b, each shoulder region Sh includes rows R3, R4 of blocks B having sipes S and defined by linear outer circumferential grooves 3c and shoulder lateral grooves 4c, 4d, and groove area rate Gs (%) of shoulder regions Sh is larger than groove area rate Gc (%) of crown region CR so that the difference (Gs−Gc) is from 3 to 7%.

Owner:SUMITOMO RUBBER IND LTD

Waterborne polyurethane emulsified asphalt concrete as well as preparation method and application thereof

The invention discloses a waterborne polyurethane emulsified asphalt concrete which is prepared from the following raw materials: mineral aggregates, emulsified asphalt and waterborne polyurethane emulsion, wherein the weight ratio of the mineral aggregates, the emulsified asphalt and the waterborne polyurethane emulsion is 100:(1-20):(7-20). The invention also discloses a preparation method of the waterborne polyurethane emulsified asphalt concrete, and the preparation method comprises the following steps: mixing the waterborne polyurethane emulsion with the emulsified asphalt, and uniformly stirring, so that waterborne polyurethane modified emulsified asphalt is obtained; adding the waterborne polyurethane modified emulsified asphalt into the mineral aggregates, uniformly stirring, and carrying out maintenance on the obtained product; or uniformly stirring the mineral aggregates, the emulsified asphalt, and the waterborne polyurethane emulsion, and carrying out maintenance on the obtained product. The prepared waterborne polyurethane emulsified asphalt concrete not only has the advantages of cold-mixed asphaltic concrete, but also has excellent mechanical properties and stability; the waterborne polyurethane emulsified asphalt concrete is excellent in pavement performance, and can be used for greatly prolonging the service life of pavements; and the maintenance time is short, and the traffic can be implemented in 1-3 days, therefore, the waterborne polyurethane emulsified asphalt concrete can be applied to the preparation of asphalt concrete paving materials, asphalt pavement repair materials, slurry seals for maintenance and asphalt mortar for micro-surfacing and high-speed railways.

Owner:山东大山绿道工程科技有限公司

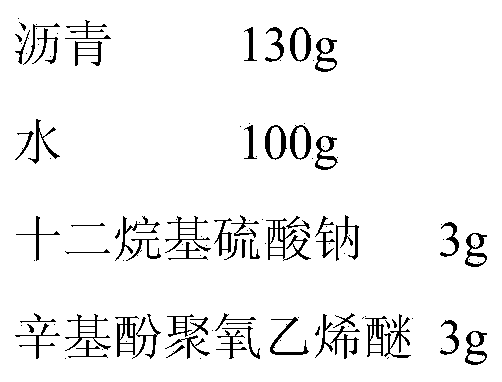

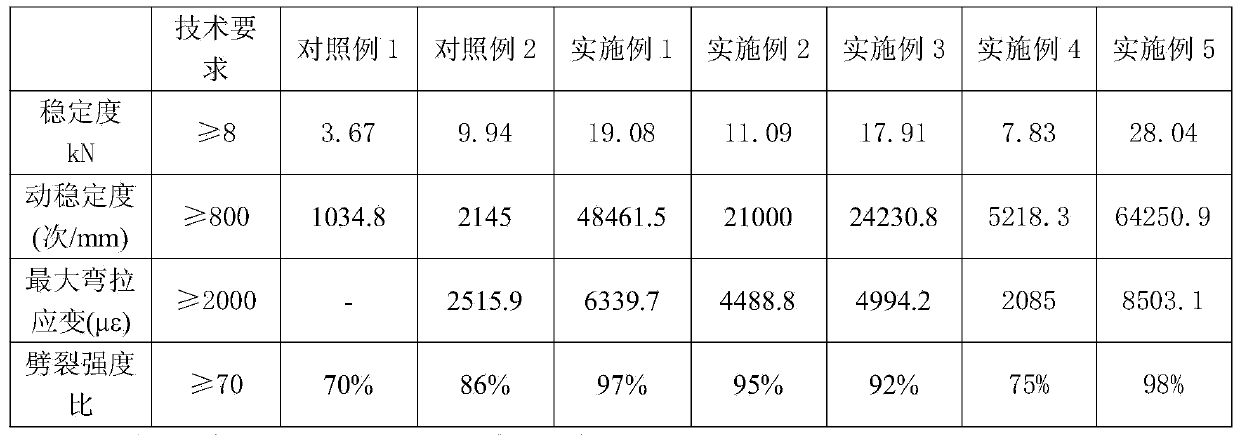

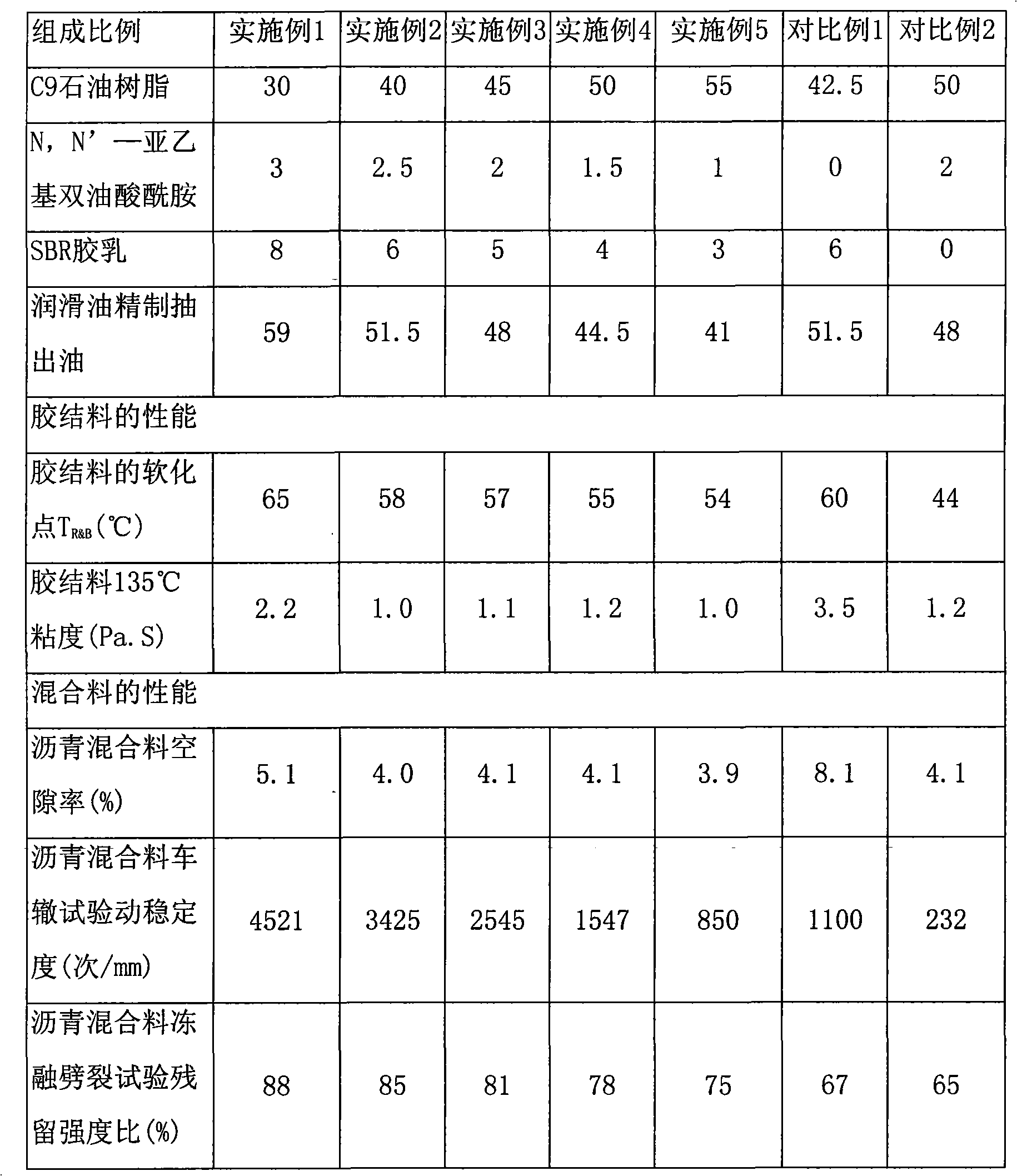

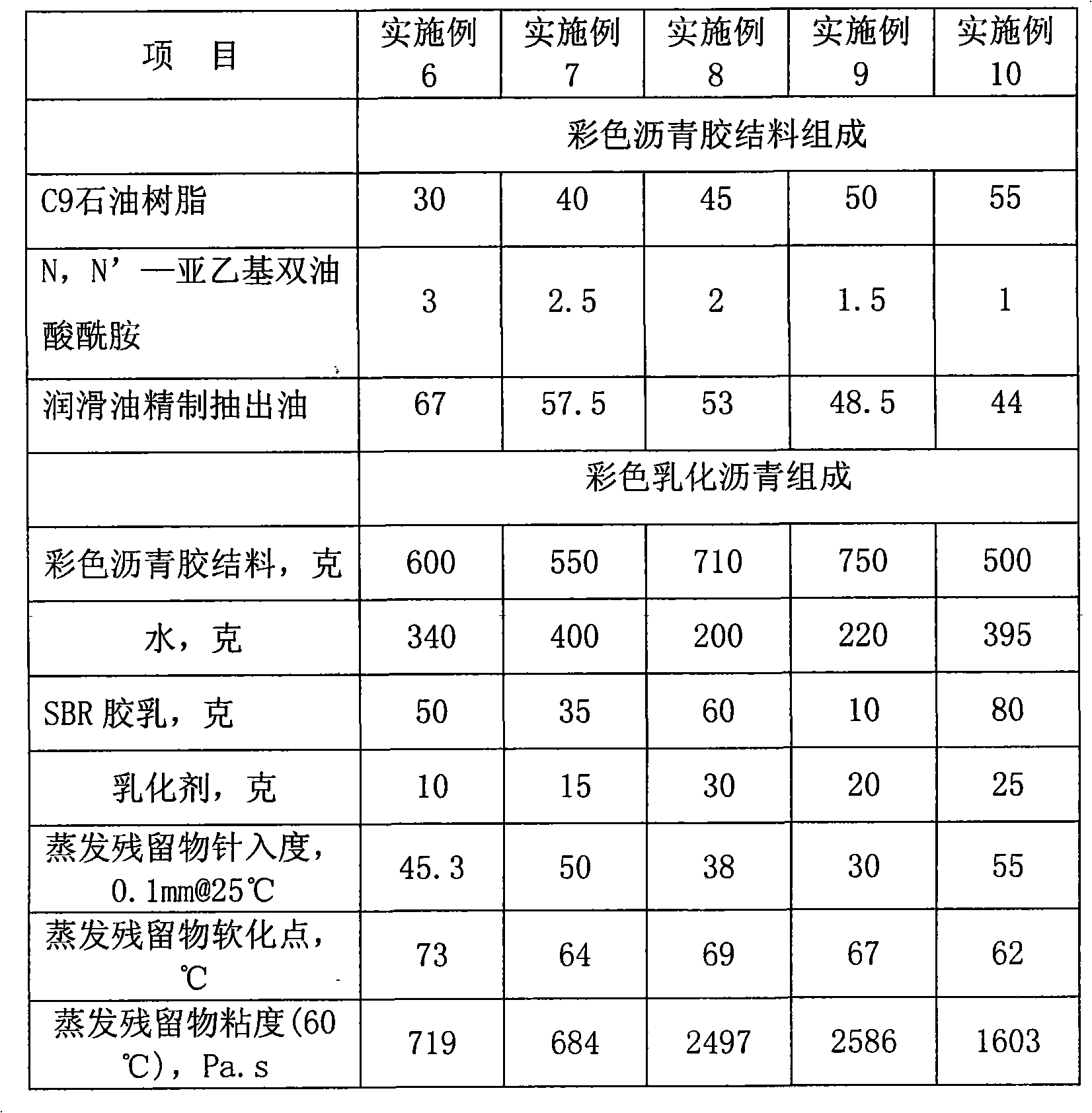

Color emulsified asphalt and preparation method thereof

InactiveCN101585952AImprove adhesionImproved high temperature stability and low temperature crack resistanceWater damageLubricant

The invention discloses a color emulsified asphalt and preparation method thereof, characterized in that color bituminous cements, emulsifier, water and modifying SBR rubber latex are included. According to proportioning by weight, parts of components are: 50.0 to 75.0 of color bituminous cements, 0.5 to 3.0 of emulsifier, 1.0 to 10.0 of modifying SBR rubber latex; 20 to 40 of water. The component and weight percent of the color bituminous cements comprise 30% to 65% of petropols, 1% to 3% of N,N'ethylidene bioleoylamido; lubricant or extract oil residual of lubricant. By selection of bituminous cements, in particular small amount of N,N'ethylidene bioleoylamido and SBR rubber latex, compared with other bituminous cements formulation, the formulation has better adhesiveness, which can prevent damages such as water damage, loose and peeling off of color path surface paved as well as tracks.

Owner:上海梁韵实业有限公司

Semi-flexible composite pavement structure and preparation method thereof

The invention provides a semi-flexible composite pavement structure and a preparation method thereof. The semi-flexible composite pavement structure comprises components in percentage by weight as follows: 70%-80% of a macro-porous asphalt mixture matrix and 20%-30% of rubber powder cement mortar; the macro-porous asphalt mixture matrix is prepared firstly, then the rubber powder cement mortar is prepared, the rubber powder cement mortar is poured into a mixture gap of the macro-porous asphalt mixture matrix finally, and a product can be utilized after maintenance. According to the semi-flexible composite pavement structure, the defects of asphalt pavements and cement concrete pavements in China at present are overcome, rigidity of the cement concrete pavements and the flexibility of the asphalt pavements are integrated, the respective advantages of rigid and flexible pavement structures can be sufficiently played, the respective defects of the rigid and flexible pavement structures are overcome, and the semi-flexible composite pavement structure is a novel pavement structure with better pavement performance and higher cost performance.

Owner:广西交通职业技术学院

Special cement-base patching material and cement concrete pavement quick repairing method

ActiveCN105294049AShort setting timeImprove early strengthRoads maintainenceMagnesium orthophosphateEmulsion

The invention discloses a special cement-base patching material and a corresponding cement concrete pavement quick repairing method built according to the special cement-base patching material. The patching material is prepared from the following ingredients in specific weight parts: magnesium phosphate cement, sulphate aluminum cement, early strength agents, water reducing agents, redispersible emulsion powder, pulverized fuel ash, silicon carbide, fine sand powder, detritus, carbon fiber and water-solubility polyurethane. The special cement-base patching material has the advantages that the mechanical performance, the anti-abrasion performance, the waterproof anti-permeability performance, the durability performance and the like meet application requirements; required construction equipment is simple; the construction process is simple and convenient; the influence of weather on construction is little; the construction can be performed at normal temperature and in rainy and snowy weather; the maintenance time is short; the traffics can be fast opened; the influence on the traffics is little; good social benefits and social benefits are realized; the engineering application prospects are wide.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

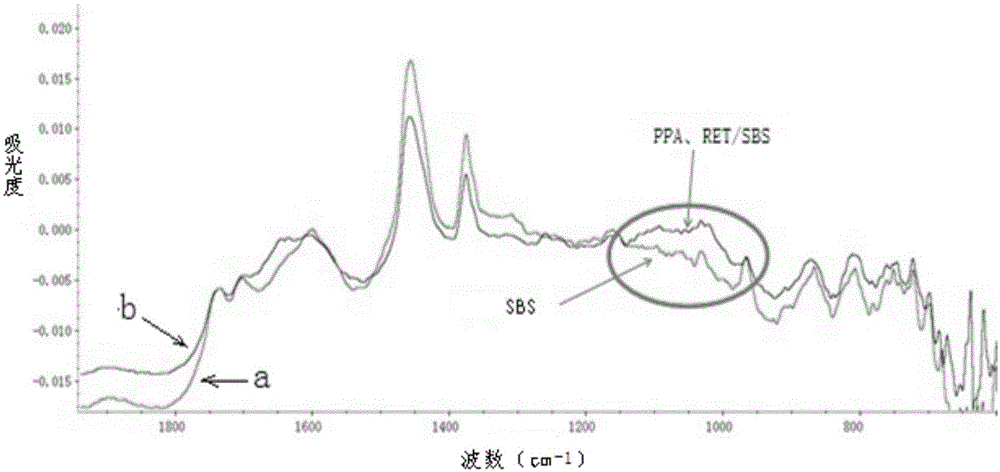

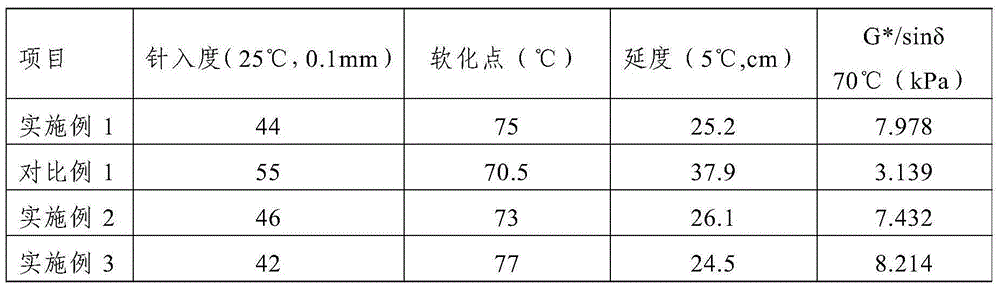

SBS modified asphalt and preparation method thereof

ActiveCN105038280AGood storage stabilityImprove stabilityBuilding insulationsPhosphoric acidHeat stability

The invention discloses SBS modified asphalt. The SBS modified asphalt is prepared with, by weight, 100 parts of matrix asphalt, 2.0-3.5 parts of SBS asphalt modifier, 1-2 parts of RET asphalt modifier, 0.2-0.5 part of polyphosphoric acid, 3-4 parts of compatilizer and 0.1-0.15 part of stabilizer. In addition, the invention further discloses a method for preparing the SBS modified asphalt. The method comprises the steps of 1, heating the matrix asphalt, adding the matrix asphalt into the compatilizer, stirring the mixture uniformly, and obtaining mixed materials; 2, adding the SBS asphalt modifier and the RET asphalt modifier into the mixed materials, stirring the mixture uniformly, conducting cutting, adding the stabilizer, continuing cutting, adding polyphosphoric acid, stirring the mixture uniformly, and obtaining the SBS modified asphalt. The SBS modified asphalt is chemical stabilization type SBS modified asphalt, great high temperature performance and anti-track performance are achieved, and the heat stability of the SBS modified asphalt is superior to that of traditional SBS modified asphalt.

Owner:CHANGAN UNIV

Colored asphalt and preparation method thereof

ActiveCN102952405AEasy constructionEasy to manufactureIn situ pavingsRoads maintainencePetroleum resinRoad surface

The invention relates to asphalt and a preparation method thereof, and specifically relates to colored asphalt and a preparation method thereof. The colored asphalt comprises the components of, by weight: 30-50% of C5 petroleum resin, 30-55% of C9 petroleum resin, 5-30% of an inorganic pigment, 1-6% of a powdery styrene-butadiene rubber SBR modifying agent, 0.5-6% of a powdery thermoplastic styrene-butadiene rubber SBS modifying agent, and 5-20% of powdery solid rosin. According to the colored asphalt and the preparation method thereof provided by the invention, the colored asphalt is prepared into powdery solid or solid particles, and is directly added into a stirring tank and is mixed with heated graded stones with a certain temperature, such that colored asphalts with various colors can be directly produced, and road pavement and rolling constructions can be carried out. With the method, colored asphalt mixture preparation process is greatly simplified, and colored pavement construction is greatly simplified.

Owner:SHENZHEN TEAMTECH ROAD MATERIALS CO LTD

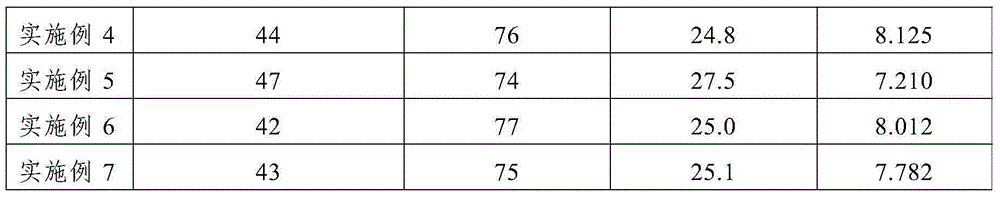

Industrial waste residue soil stabilizer and preparation method and construction method thereof

The invention discloses an industrial waste residue soil stabilizer. The industrial waste residue soil stabilizer is prepared from 5-50% of raw material steel slag powder, 20-40% of slag powder, 5-30%of fly ash, 8-25% of waste gypsum, 0-17% of coal gangue and 10-30% of carbide slag through the following method: firstly, raw materials including fly ash, coal gangue powder, waste gypsum, steel slagpowder and slag powder are sequentially added into a coulter type stirrer and are uniformly mixed at a high speed of 1500-2000 r / min for 20-30 min, finally, the carbide slag is added, stirring continues to be conducted for 10-20 min, and an obtained curing agent finished product is bagged, sealed and stored. The industrial waste residue soil stabilizer prepared by the invention can replace cementand lime to be applied to roadbed improvement and treatment, has the outstanding advantages of no calcination, energy conservation, environmental protection and the like, has obvious price advantagecompared with cement and lime, plays a positive role in promoting the resource utilization of industrial wastes such as fly ash, carbide slag, steel slag and the like, and has wide and far-reaching significance.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

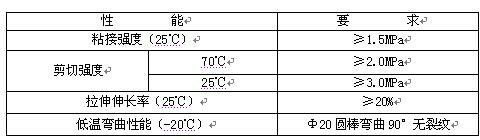

High efficiency resin fissures cementation glue and preparation thereof

InactiveCN101838510AImprove adhesionImprove road performanceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesRoad surfaceAromatic hydrocarbon

The invention relates to a high efficiency resin fissures cementation glue for pitch and cement road surface fissures cementation. The fissures cementation glue comprises the following components by weight percent: 10 to 15 percent of aromatic hydrocarbon, 3 to 10 percent of modifier, 1 to 3 percent of intensifier, 3 to 10 percent of cosolvent, 30 to 60 percent of resin mixture and 10 to 20 percent of heavy traffic pitch. The aromatic hydrocarbon is heated to 60 to 70 degrees centigrade, the modifier is added to be stirred for 30 minutes, the intensifier and the cosolvent are added slowly step by step, the resin and the pitch are added at last, the temperature is kept at 120 degrees centigrade for 30 minutes under stir circumstance, and then the resin fissures cementation glue with excellent performance can be obtained. In the invention, the aromatic hydrocarbon is used to form even mixture among the modifier, the resin and the pitch so that resin group and pitch group are bridged under the action of the modifier. When used on the road surface, the resin exerts the high bondability characteristic and the like. The modifier is used to improve the road performance, as improving softening point, low temperature ductility and the like. At the same time, the invention is good glue material.

Owner:安徽三缔沥青材料有限公司

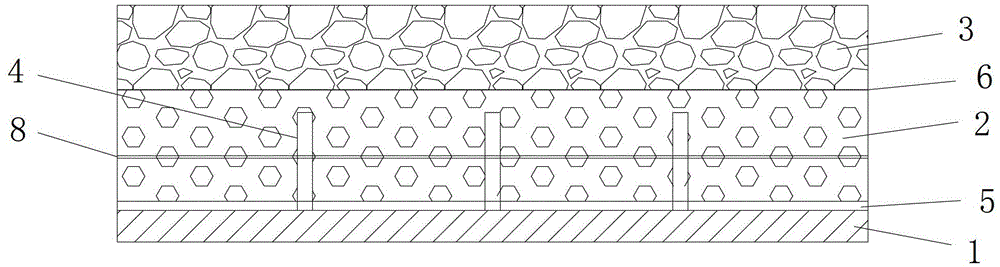

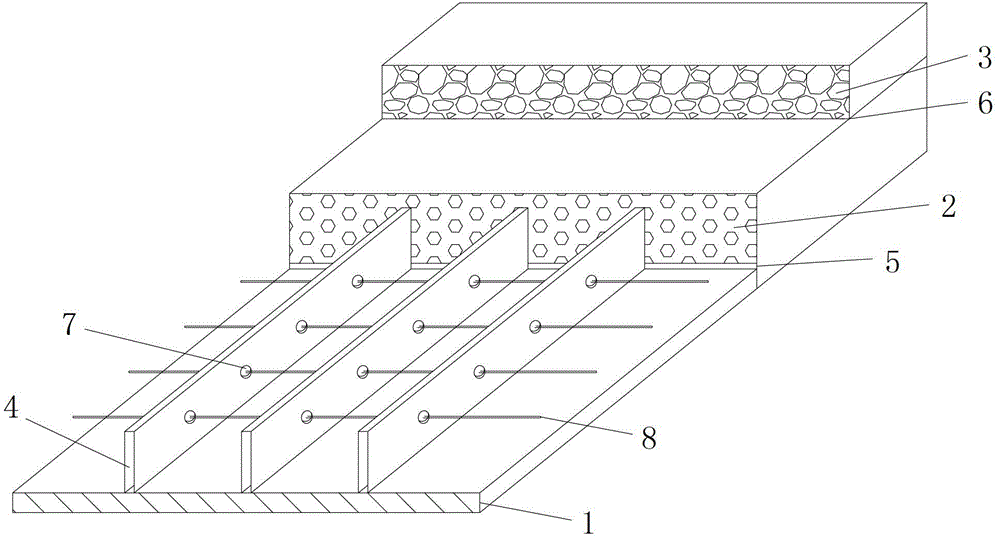

Steel deck composite pavement structure laying grid type shear connectors

InactiveCN102979037ASimple structureReasonable designPaving reinforcementsIn situ pavingsSheet steelSurface layer

The invention discloses a steel deck composite pavement structure laying grid type shear connectors. The steel deck composite pavement structure comprises a steel deck plate, a lightweight concrete lower surface layer laid on the steel deck plate and an asphalt concrete upper surface layer laid on the lightweight concrete lower surface layer, wherein a waterproof bonding layer is arranged between the lightweight concrete lower surface layer and the asphalt concrete upper surface layer; the grid type shear connectors are laid in the lightweight concrete lower surface layer, the grid type shear connectors comprise multiple longitudinal connectors which are laid in the longitudinal direction of a bridge and multiple transverse connectors which are laid in the transverse direction of the bridge, and the multiple longitudinal connectors are connected into a whole through the multiple transverse connectors; the longitudinal connectors are of long strip-shaped steel plates fixed on the steel desk plate and the transverse connectors are of steel bar bundles; and a plurality of holes are formed at the middle parts of the long strip-shaped steel plates from the front to the back. The steel deck composite pavement structure disclosed by the invention has the advantages of simple structure, reasonable design, simplicity and convenience in construction and good stress performance, and can solve the problems that an asphalt surface layer of the existing steel desk pavement structure is prone to rutting, slippage delamination, upheaval and the like.

Owner:CHANGAN UNIV

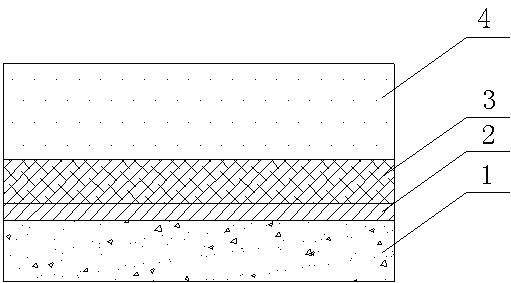

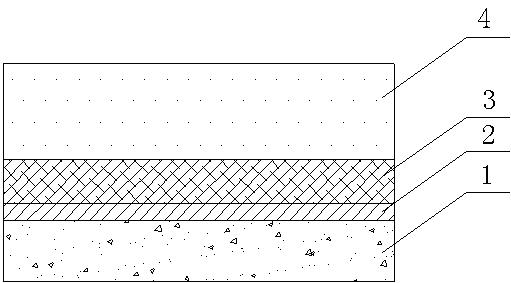

Pavement structure for cement concrete bridge deck and pavement method thereof

InactiveCN102002909AEfficient removalImprove interlayer adhesionBridge structural detailsEpoxyBridge deck

The invention relates to the technical field of traffic engineering, in particular to a pavement structure directly paved on a cement concrete bridge deck and a pavement method thereof. The pavement structure for the cement concrete bridge deck comprises a waterproof bonding layer, a stress absorption layer and a road surface layer, which are sequentially paved on the cement concrete bridge deck from bottom to top, wherein the waterproof bonding layer comprises a basalt gravel layer bonded on the cement concrete bridge deck through epoxy resin and a reactive waterproof binding agent layer coated on the basalt gravel layer. The invention also discloses a pavement method for the pavement structure. The pavement structure and the pavement method thereof enhance the bonding and shearing action between a pavement layer and a cement concrete slab, improve the using effect and service life of the pavement layer, reduce the temperature of mixing, transporting and paving, save energy and reduce environmental pollution; and the total thickness of the bridge deck pavement system is only 30 to 40 mm, so that the dead load of the bridge deck is greatly reduced, the pavement materials are saved and the construction cost is reduced.

Owner:CHONGQING JIAODA ROAD BRIDGE TECH RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com