Composite of modified road asphalt by microwave radiating old rubber powder and its preparation process

A technology of waste rubber powder and microwave irradiation, which is applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of high content of asphalt wax, poor road performance, strong sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

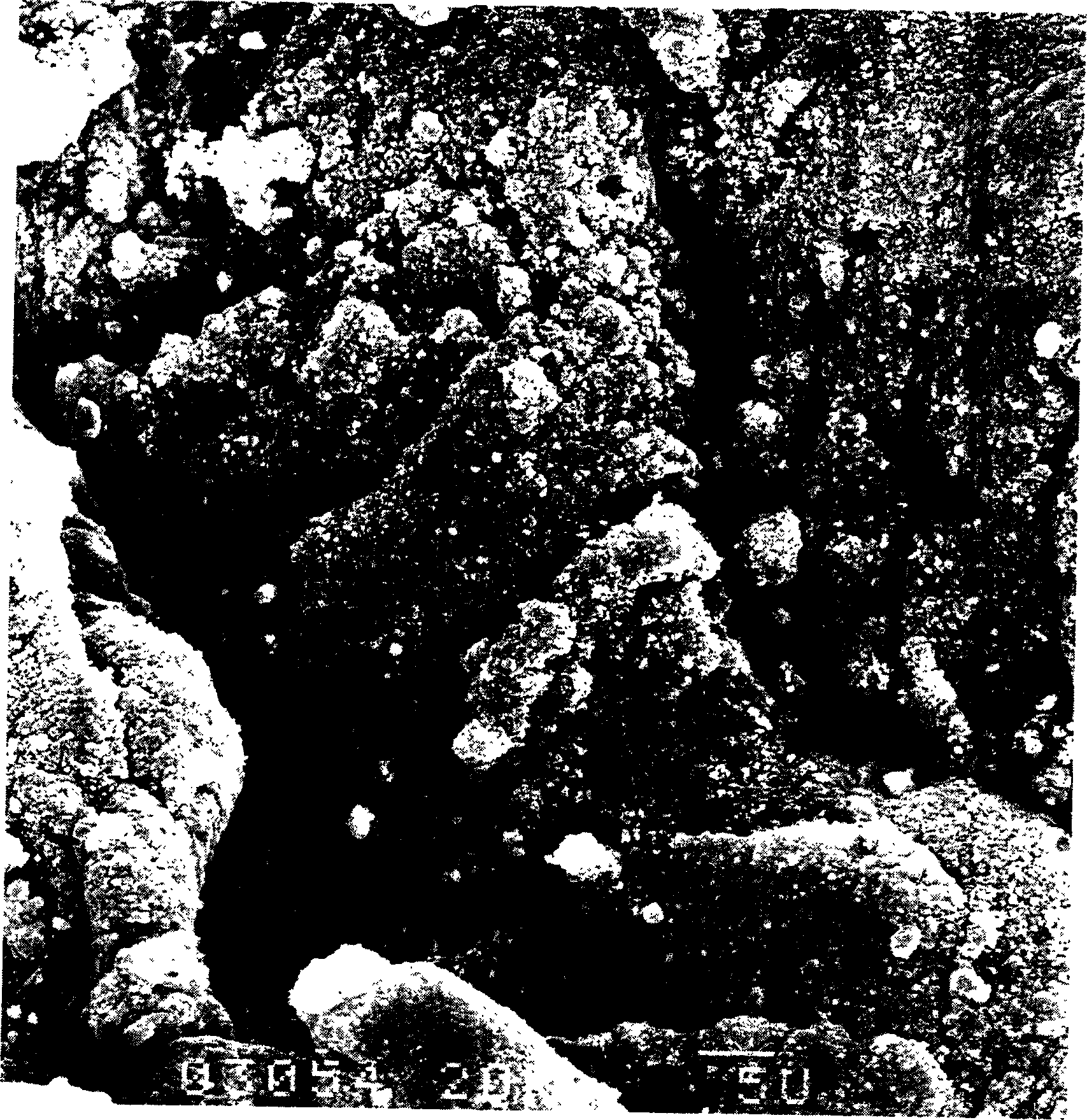

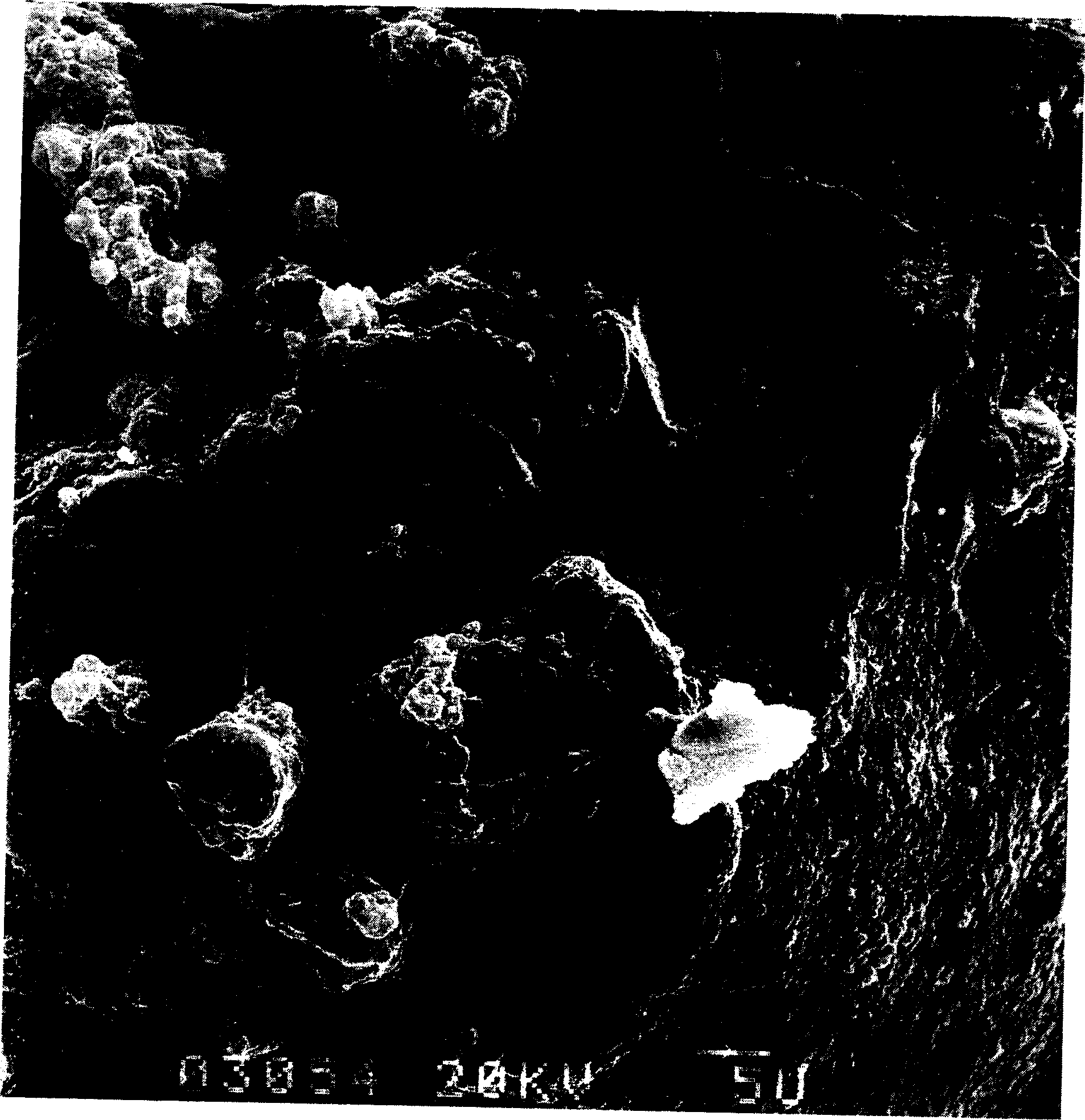

Image

Examples

Embodiment 1

[0026] Example 1, first use 2% trioctyl phosphate to pre-swell 5% waste rubber powder (80 mesh) for 40 hours, then put the rubber powder into a 360W microwave oven for 4 minutes, and then irradiate a certain amount of Add the over-processed waste rubber powder into 90% molten base asphalt, and keep stirring to avoid local overheating. While stirring, add 3% powdered styrene-butadiene rubber (SBR), make the melting temperature reach 160°C in a high-shear asphalt emulsifier, and stir for 40 minutes at a shear rate of 4500rpm / min to make it evenly blended, that is Modified bitumen is available. The measured 5-degree elongation (5cm / min, 5°C, cm) is 45, the 25-degree penetration (25°C, 100g, 5s, o.1mm) is 90, and the softening point (°C) is 50; Rotary film oven After the experiment (RTFOT), the 5-degree ductility (5cm / min, 5°C, cm) was 38, and the penetration ratio (%) was 78.

Embodiment 2

[0027] Example 2, 8% waste rubber powder (80 mesh) was pre-swelled with 2% dioctyl sebacate for 40 hours, then 3 minutes with 900W microwave irradiation, and then the rubber powder irradiated by microwave Put it into 86% molten matrix asphalt, add 4% powdered styrene-butadiene rubber (SBR) in the process of continuous stirring, continue to maintain the temperature to 180 ° C, and stir for 60 minutes at a shear rate of 4500r / min to make it total Mix evenly to get modified asphalt. The measured 5-degree ductility (5cm / min, 5°C, cm) is 40, the 25-degree penetration (25°C, 100g, 5s, 0.1mm) is 85, and the softening point (°C) is 50; rotating film oven test After (RTFOT), the 5-degree ductility (5cm / min, 5°C, cm) is 40, and the penetration ratio (%) is 80.

Embodiment 3

[0028] Example 3, use 3% heavy oil to pre-swell 5% waste rubber powder (80 mesh) for 40 hours, then put the rubber powder into a 540W microwave oven for 2 minutes, and then add the rubber powder irradiated by microwaves Add 2% powdered styrene-butadiene rubber (SBR) to 88% molten base asphalt while stirring, keep the temperature up to 170°C, and stir for 40 minutes at a shear rate of 4500r / min to make it evenly blended, and the improved Sexual asphalt. The measured 5-degree ductility (5cm / min, 5°C, cm) is 49, the 25-degree penetration (25°C, 100g, 5s, o.1mm) is 92, and the softening point (°C) is 50; Rotary film oven After the experiment (RTFOT), the 5-degree ductility (5cm / min, 5°C, cm) was 39, and the penetration ratio (%) was 77.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Penetration ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com