Patents

Literature

128results about How to "Improve low temperature ductility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite of modified road asphalt by microwave radiating old rubber powder and its preparation process

InactiveCN1597782AGood dispersionGood physical and mechanical propertiesBuilding insulationsWaxMicrowave

The invention relates to a microwave-irradiated waste-rubber powder modified pitch combination and its preparing method, using higher-wax content pitch as a substrate, adding in powdery butadiene-styrene rubber and microwave-irradiated waste rubber powder, and making high-speed cutting and uniform commixing to make the modified pitch. The modified pitch has the characters of high-temperature stability, obviously increased low-temperature extensibility, good antiaging property, etc, has road performance synthetically improved and can act as high-grade road pitch for use.

Owner:NORTHWEST NORMAL UNIVERSITY

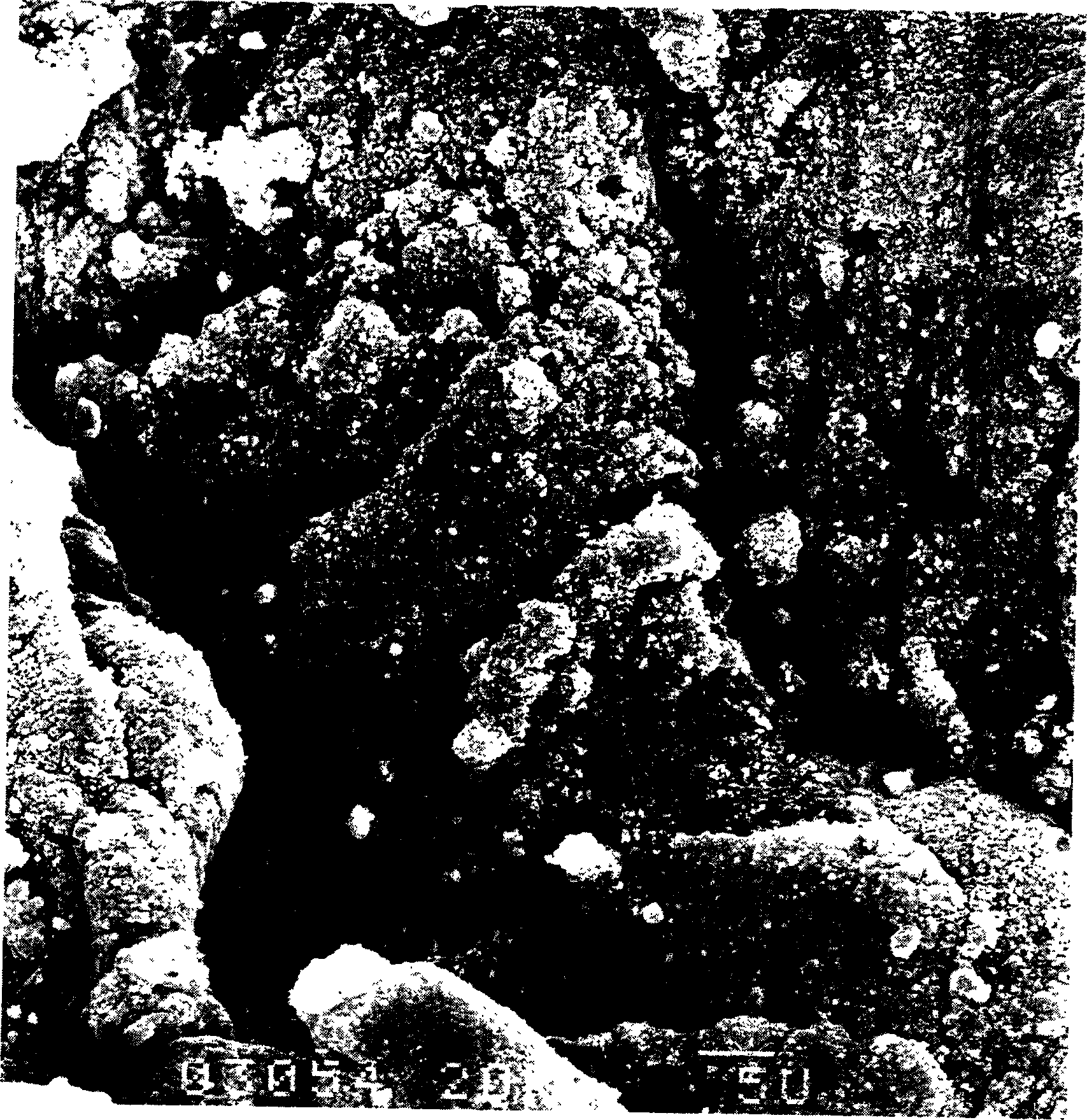

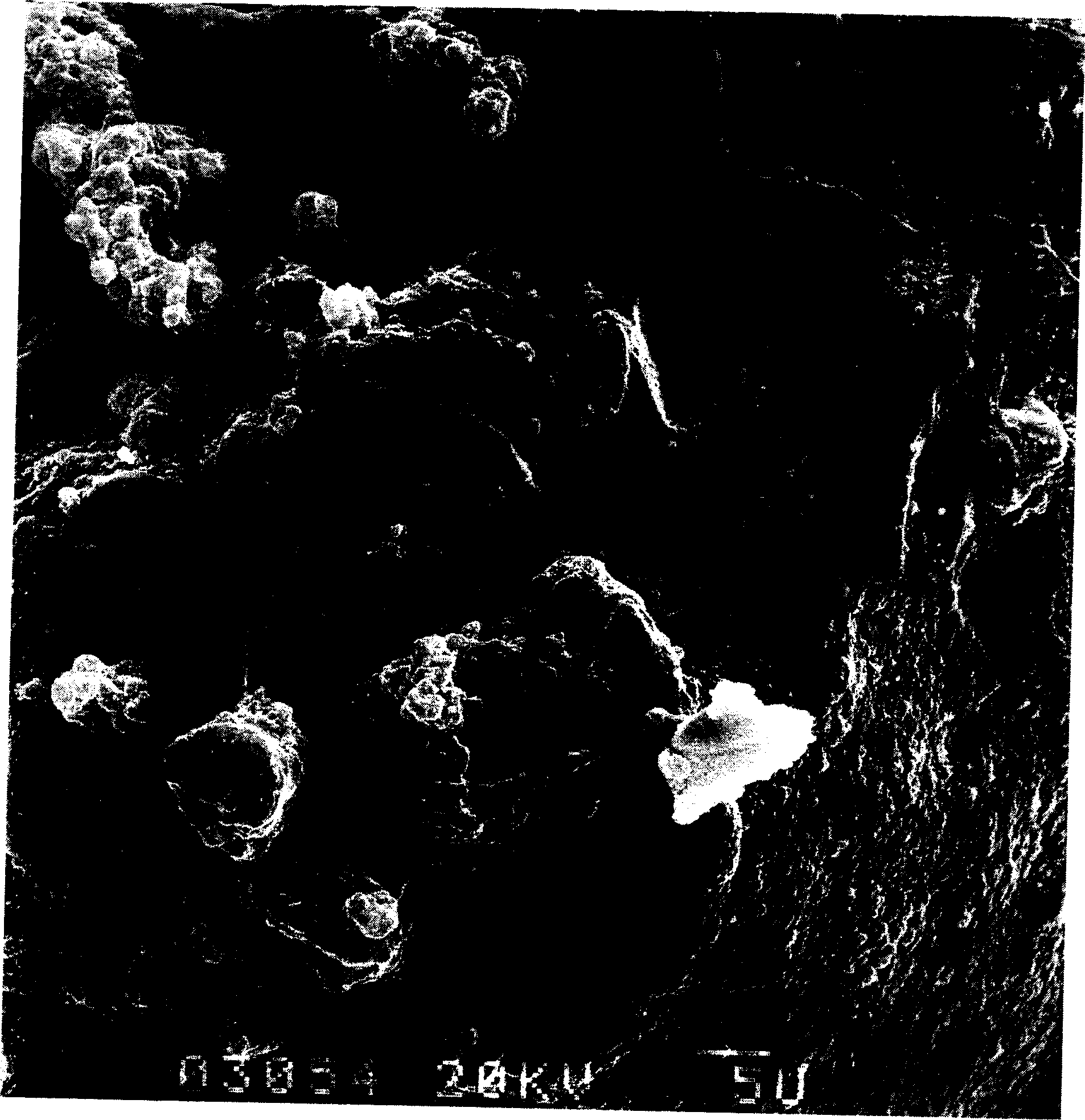

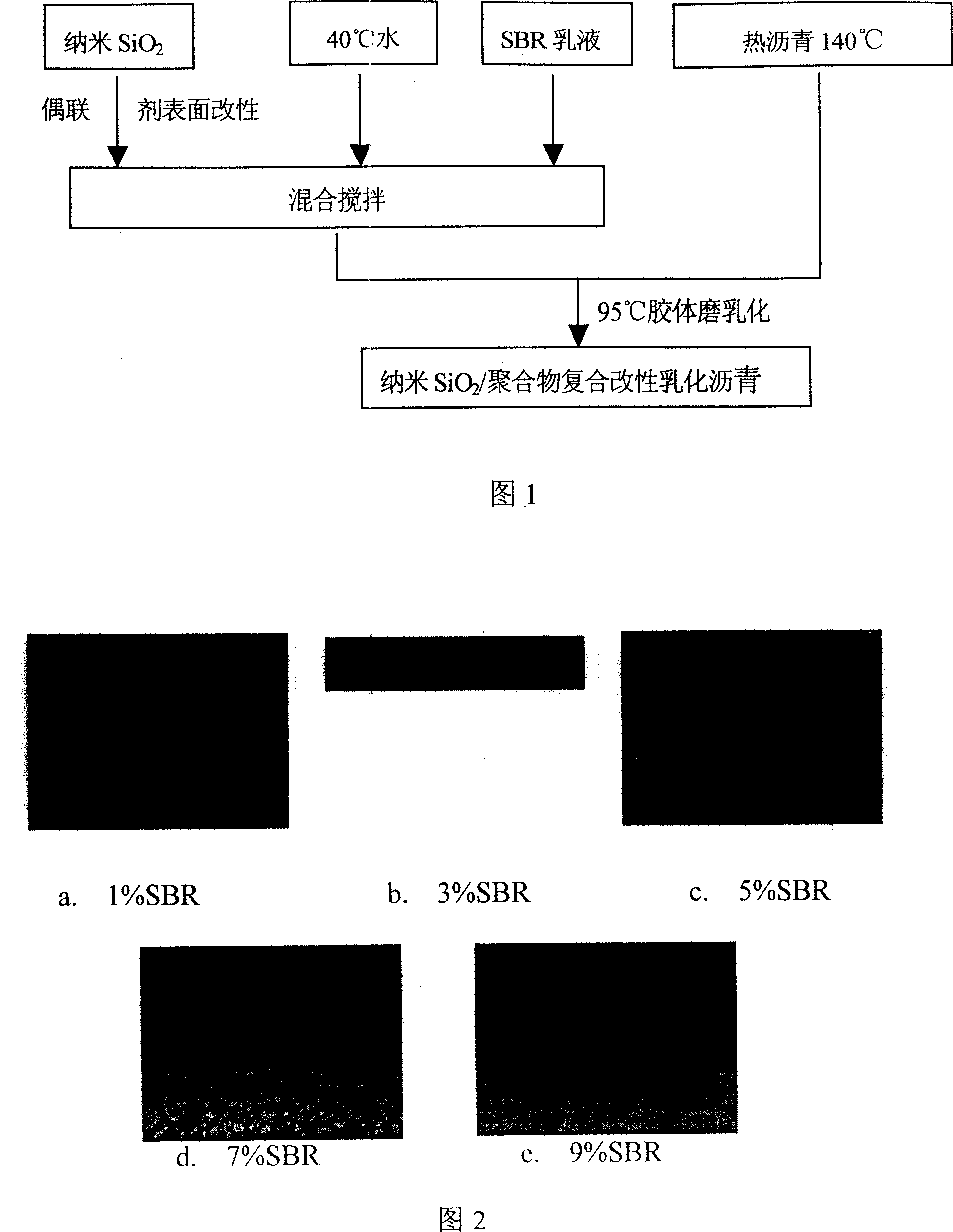

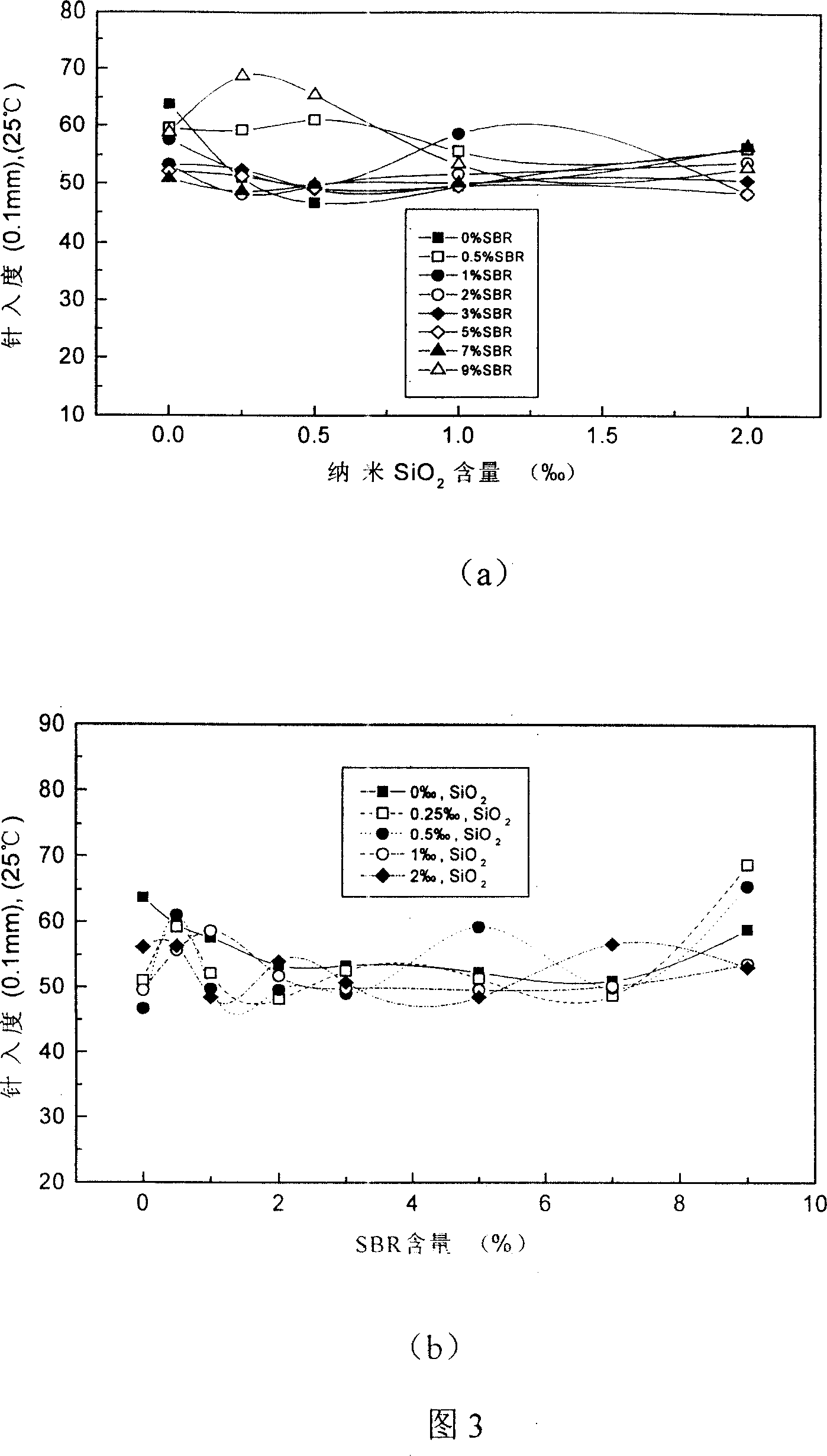

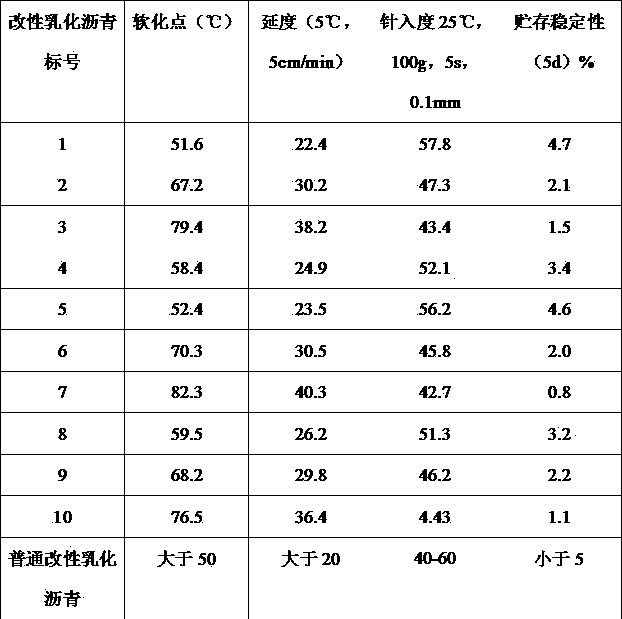

Inorganic nano particle and polymer composite modified emulsified asphalt

InactiveCN101143967AGood resistance to UV agingImprove heat aging performanceBuilding insulationsPolymer scienceButadiene-styrene rubber

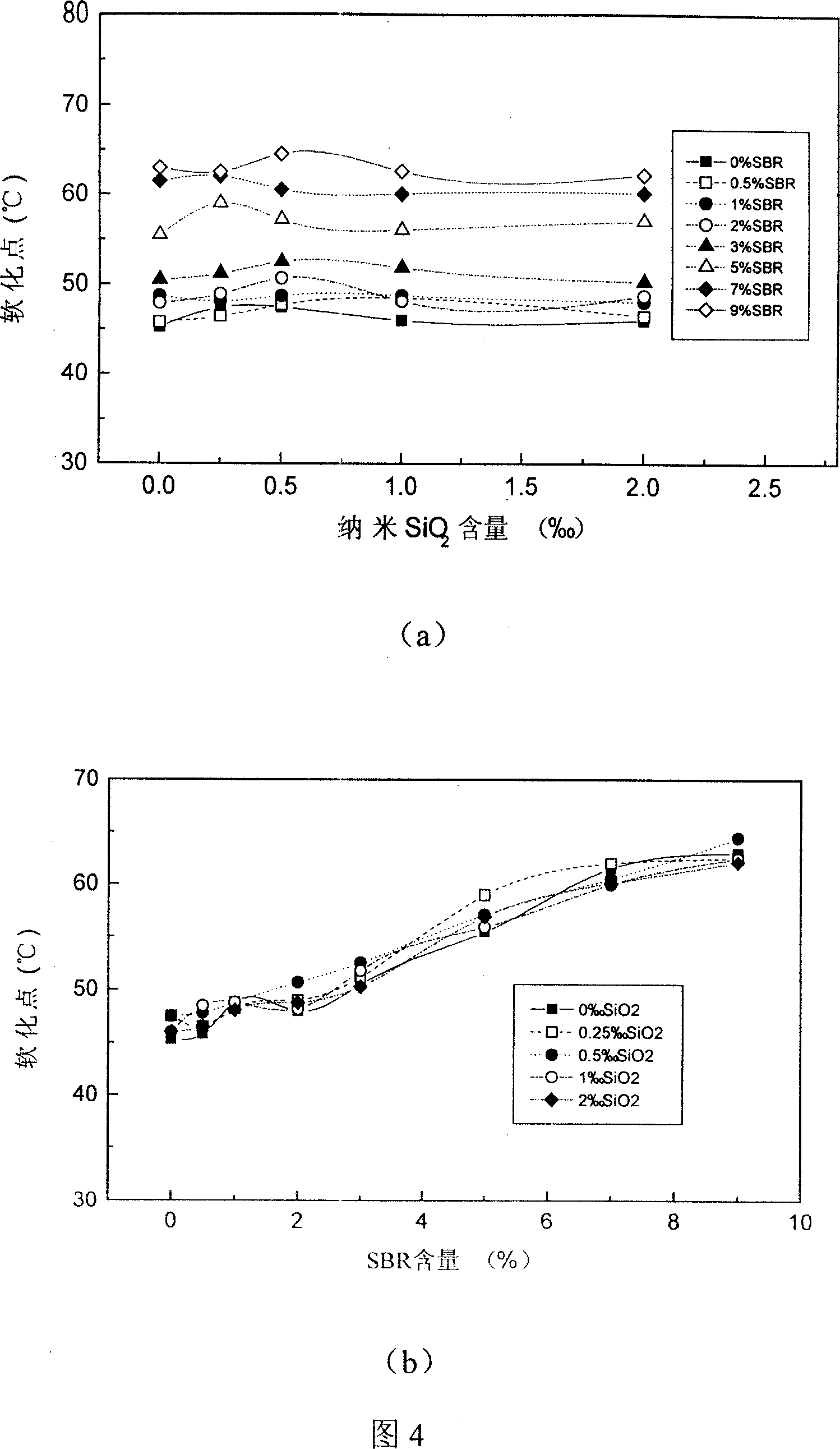

A modified emulsion asphalt compounded by inorganic nano-particles and polymer contains 200-700 parts by weight of asphalt, 2-80 parts by weight of modified inorganic nano-particles, 5-50 parts by weight of styrene-butadiene rubber latex, and 170-793 parts by weight of water, wherein the modified inorganic nano-particles is prepared by mixing 95-98 parts by weight of inorganic nano-particles with 2-5 parts by weight of coupling agent, and each components are mixed, followed by normal emulsion treatment to get the emulsion asphalt. The invention utilizes unique surface effect, small size effect and macroscopic quantum tunneling effect etc. of the inorganic nano-particles to give the product comprehensive properties, such as good wear resistance, intensity sum, anti-aging property and fine waterproof effect etc. Using the invention can increase the road maintenance cycle and decrease the cost. Furthermore, the water-proof cost of construction industry is greatly decreased.

Owner:HUNAN UNIV

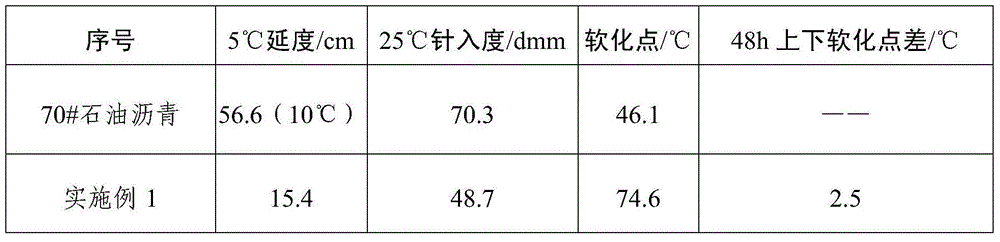

Anti-rut high-viscosity asphalt modifier, and preparation method and application thereof

InactiveCN102796388AHigh softening pointImprove ductilityBuilding insulationsElastomerPolymer science

The invention discloses an anti-rut high-viscosity asphalt modifier, and a preparation method and application thereof. The anti-rut high-viscosity asphalt modifier is prepared from the following components in parts by mass: 10-30 parts of polyolefin, 10-30 parts of elastomer, 15-40 parts of tackifying resin and 1-20 rubber powder. The preparation method comprises the following steps: evenly mixing polyolefin, elastomer, tackifying resin and rubber powder in a mixer, carrying out melt extrusion, granulating and drying. The doping amount of the anti-rut high-viscosity asphalt modifier is 5-14% of the asphalt by mass. The anti-rut high-viscosity asphalt modifier disclosed by the invention can obviously enhance the 60 DEG C viscosity, softening point, low-temperature ductility and other technical indexes of the asphalt. The production technique of the anti-rut high-viscosity asphalt modifier is simple and convenient, and has the advantage of low cost.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Construction method of stress absorbing layer for road repairing

InactiveCN102535299AImprove low temperature ductilityImprove deformation abilityIn situ pavingsReflective crackCost (economic)

The invention relates to the technical field of road engineering, and discloses a construction method of a stress absorbing layer for road repairing. The construction method comprises the following steps of: carrying out high-speed shearing on substrate asphalt, a modifying agent and a stabilizing agent after being mixed uniformly to prepare modified asphalt; mixing coarse aggregate, fine aggregate, stuffing and the modified asphalt to prepare a stress absorbing mixture; paving the stress absorbing mixture on a road surface to be repaired, wherein the road surface to be repaired is subjected to purification treatment; and rolling to form the stress absorbing layer. The construction method disclosed by the invention has the advantages of mechanized operation, simplicity and convenience in construction process and low economic cost; the formed stress absorbing layer has the characteristics of high flexibility and high deformation restoring capacity, and can be used for effectively absorbing interlaminar stress produced during the paving of an asphalt surface layer on an old cement concrete road surface as well as weakening and delaying the transfer of contraction cracks and reflection cracks on the cement concrete road surface to the asphalt surface layer; and therefore road performance of the asphalt surface layer is improved, and service life of the asphalt surface layer is prolonged.

Owner:中国人民武装警察部队交通指挥部

Method for preparing polymer modified asphalt by one-step method

ActiveCN101457023ASimple processEasy to operateBuilding insulationsPolymer modifiedStabilizing Agents

The invention relates to a method of preparing polymer asphalt with one step to modify the asphalt by adopting the polymer as a modifying agent. In a peptizator of 80 to 160 DEG C which account for 5 to 27 percent of the total weight of the raw materials, the polymer modifying agent and 0.1 to 2 percent of stabilizer which account for 2 to 9 percent of the total weight of the raw materials are added, and then is poured into a plastic extruder where the rotating speed is 300 to 800 rotations per second to be extruded; the extruding temperature is controlled to be 130 to 210 DEG C; the extruded polymer is directly and mixingly stirred for 0.5 to 6 hours together with the asphalt which accounts for 62 to 89.9 percent of the total weight of the raw materials, then the polymer modified asphalt is gained, which is provided with good heat preservation function, good low temperature expanding performance, anti-fatigue and anti-tearing function and relatively good weatherproof function. After being mixed with the stones, the mixed materials perform good water stability and high and low temperature stability, which can effectively improve the using performance of the asphalt pavement and prolong the service life.

Owner:PETROCHINA CO LTD +1

Vegetable oil modified asphalt composite and preparation method thereof

ActiveCN103497521APromote swellingEasy to processBuilding insulationsVegetable oilMolecular materials

The invention provides a vegetable oil modified asphalt composite and a preparation method thereof. The vegetable oil modified asphalt composite comprises the following materials with content based on the total weight of vegetable oil modified asphalt in percentage by weight: 5%-30% of vegetable oil, 65%-80% of petroleum asphalt and 5%-15% at least one of natural asphalt and a high-molecular material or a mixture of the natural asphalt and the high-molecular material, wherein the mass ratio of the natural asphalt and the high-molecular material in the mixture of the natural asphalt and the high-molecular material is (0.5:1)-(4.5:1).

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

Wide temperature range modified asphalt for roads and preparation method thereof

The invention relates to wide temperature range modified asphalt for roads. The asphalt is composed of, by weight, 80-90 parts of matrix asphalt, 1-6 parts of SBS (styrene-butadiene-styrene) modifier, 10-30 parts of activated waste tire rubber powder, 2-6 parts of light oil, 0.1-0.5 part of terpene resin and 0.1-0.5 part of elemental sulfur. The wide temperature range modified asphalt for the roads has good performances of being free of flowing at high temperature and being free of cracking at low temperature, usage temperature range can reach higher than 100 DEG C, the preparation method is simple, and production can be directly performed on original SBS modifier production devices, so that cost investment of production equipment is reduced.

Owner:甘肃交通规划勘察设计院有限责任公司

Waste polymer modified asphalt composition and preparation method thereof

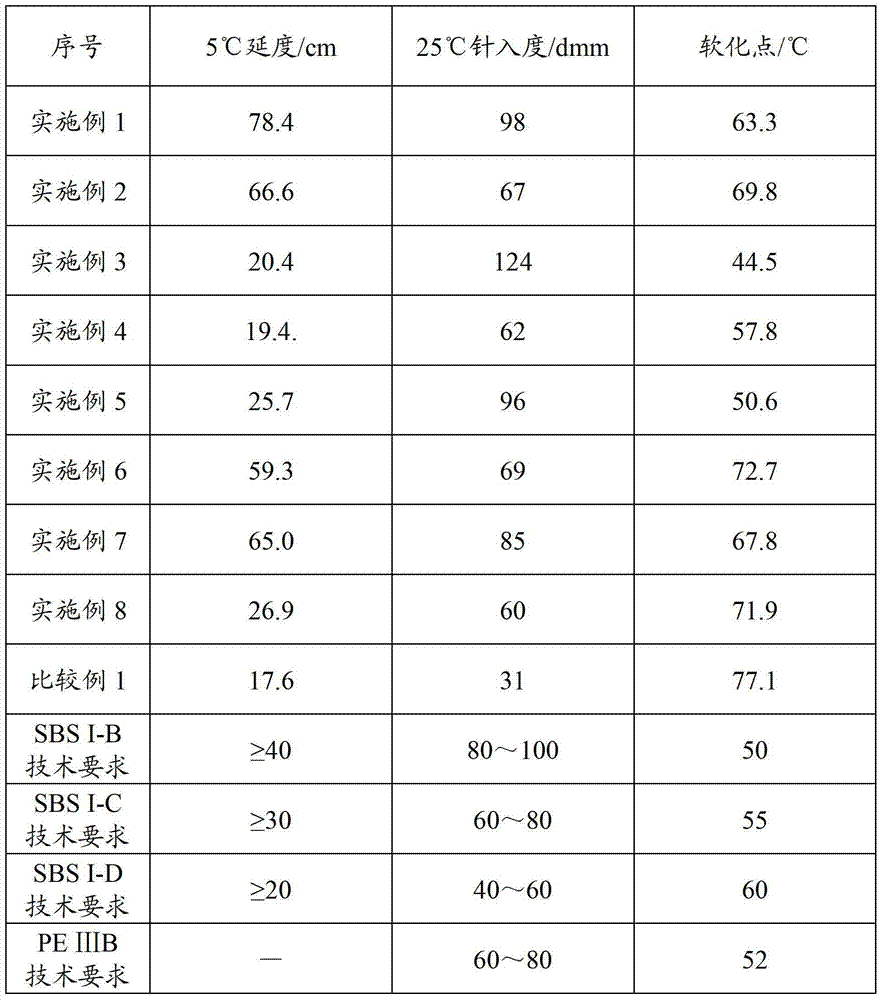

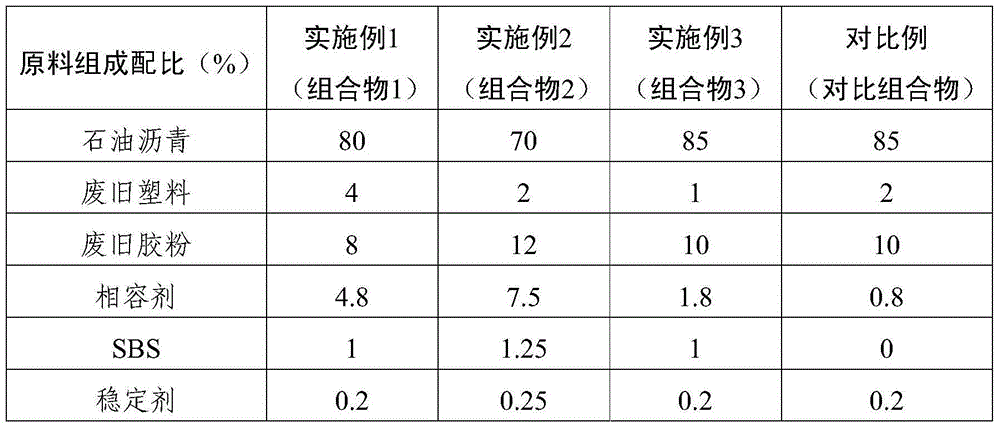

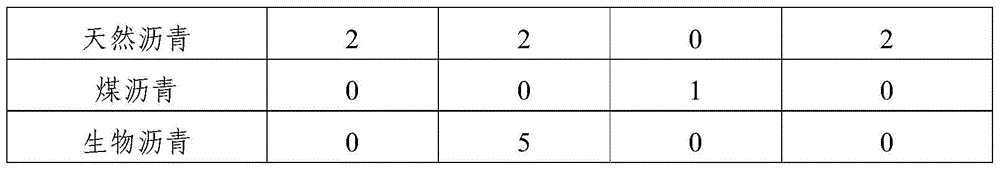

The invention relates to a waste polymer modified asphalt composition. The waste polymer modified asphalt composition comprises following components in parts by weight; 60-85 parts of petroleum asphalt, 6-20 parts of a waste polymer material, 1-8 parts of a compatilizer, 1-1.5 parts of SBS, 0.01-0.5 parts of a stabilizing agent, and 1-10 parts of one or more of native asphalt, coal pitch or biological asphalt. The waste polymer modified asphalt composition can well increase high-temperature storage stability of waste polymer material modified asphalt; pre-swelling performance of the polymer material and similar compatibility with asphalt are improved as the compatilizer is added; storage stability of the waste polymer material in asphalt can be improved extremely as a small quantity of SBS and a small quantity of the stabilizing agent are added; producing cost of the composition can be decreased as the native asphalt, coal pitch or biological asphalt replaces a portion of the petroleum asphalt; the prepared modified asphalt is excellent in high-temperature performance and low-temperature ductility; and the preparation method is simple, safe, and convenient for industrial application.

Owner:河北省高速公路邢汾管理处 +1

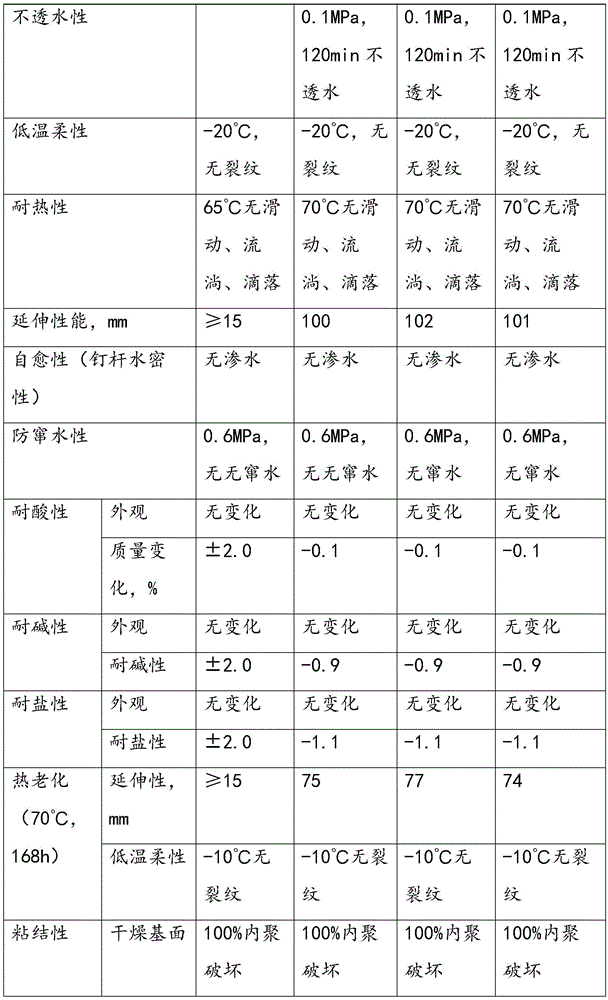

Modified asphalt waterproof coiled material

ActiveCN104960267AImprove high temperature performanceImprove low temperature ductilitySynthetic resin layered productsConstructions elementsBituminous waterproofingAntioxidant

The invention relates to the field of waterproof building materials, in particular to a modified asphalt waterproof coiled material, and aims to solve the problems such that the common polymer waterproof coiled material is low in tensile performance and poor in environment friendliness and the common modified asphalt waterproof coiled material is short in life. The modified asphalt waterproof coiled material comprises modified asphalt, polypropylene fiber cloth and PE (polyethylene) film; the modified asphalt is synthetically made from, by weight, 40 to 50 parts of asphalt, 20 to 30 parts of high-density polyethylene, 15 to 30 parts of SBS (styrene butadiene styrene) rubber, 0.2 to 2 parts of stabilizer, 0.5 to 1 part of antioxidant, 0.1 to 2 parts of photo-stabilizer, and 10 to 20 parts of filler.

Owner:SICHUAN SHUYANG WATERPROOF MATERIAL

High efficiency resin fissures cementation glue and preparation thereof

InactiveCN101838510AImprove adhesionImprove road performanceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesRoad surfaceAromatic hydrocarbon

The invention relates to a high efficiency resin fissures cementation glue for pitch and cement road surface fissures cementation. The fissures cementation glue comprises the following components by weight percent: 10 to 15 percent of aromatic hydrocarbon, 3 to 10 percent of modifier, 1 to 3 percent of intensifier, 3 to 10 percent of cosolvent, 30 to 60 percent of resin mixture and 10 to 20 percent of heavy traffic pitch. The aromatic hydrocarbon is heated to 60 to 70 degrees centigrade, the modifier is added to be stirred for 30 minutes, the intensifier and the cosolvent are added slowly step by step, the resin and the pitch are added at last, the temperature is kept at 120 degrees centigrade for 30 minutes under stir circumstance, and then the resin fissures cementation glue with excellent performance can be obtained. In the invention, the aromatic hydrocarbon is used to form even mixture among the modifier, the resin and the pitch so that resin group and pitch group are bridged under the action of the modifier. When used on the road surface, the resin exerts the high bondability characteristic and the like. The modifier is used to improve the road performance, as improving softening point, low temperature ductility and the like. At the same time, the invention is good glue material.

Owner:安徽三缔沥青材料有限公司

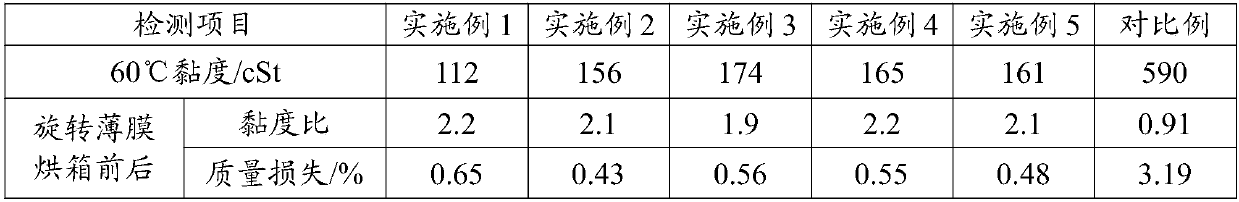

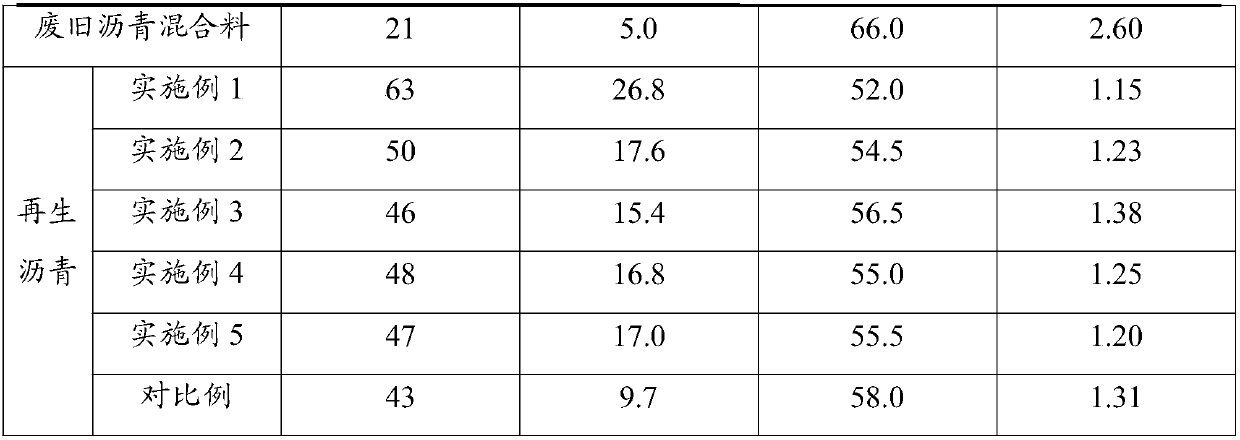

Asphalt reclaiming agent as well as preparation method and application thereof

InactiveCN107828222AImprove heat resistanceImprove stabilityBuilding insulationsPlasticizerRoad engineering

The invention provides an asphalt reclaiming agent, and belongs to the technical field of road engineering. The asphalt reclaiming agent, provided by the invention, is prepared from the following components in parts by weight: 30 to 50 parts of light base oil, 20 to 30 parts of a plasticizer, 20 to 30 parts of a stable balance agent and 5 to 10 parts of a penetrant. In the asphalt reclaiming agentprovided by the invention, the light base oil is rich in aromatic hydrocarbon, and is strong in asphaltene dissolution ability; the plasticizer can be inserted between polymer molecular chains, an interaction force between the asphalt molecular chains is weakened, and the movement ability of the asphalt molecular chains is increased, so that the low-temperature ductility of aged asphalt is increased; the balance of a reclaimed asphalt colloid system is ensured by the stable balance agent; an osmotic effect of the reclaiming agent is increased by the penetrant, the reclaiming agent is enabledto be fused with the aged asphalt on the surface of aggregated rock in a blending process, and the reclaiming performance of the asphalt reclaiming agent can be increased.

Owner:GANSU CHANGLONG HIGHWAY MAINTENANCE TECH RES INST CO LTD +1

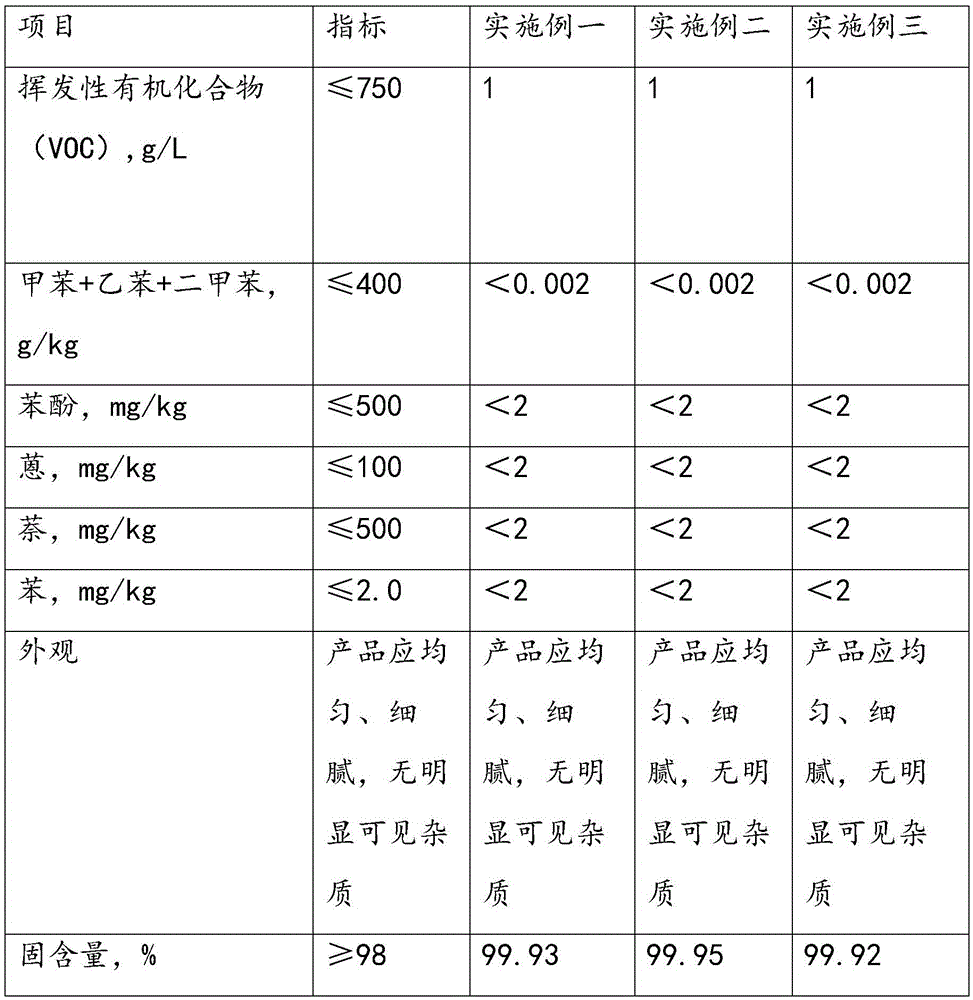

Non-curable root puncture-resistant waterproof coating and preparation method thereof

InactiveCN105542662AImprove high temperature stabilityImprove low temperature ductilityBituminous coatingsSelf-healingPlasticizer

The invention discloses a non-curable root puncture-resistant waterproof coating. The key points of the technical scheme are as follows: the non-curable root puncture-resistant waterproof coating is prepared from the following components in percentage by weight: 9-11 percent of a softening agent, 55-68 percent of 90# asphalt, 1-2 percent of SBS (Styrene- Butadiene-Styrene), 4-6 percent of SBR (Styrene Butadiene Rubber), 15-25 percent of a filling material, 0.2-0.3 percent of a stabilizing agent, 1-1.5 percent of a plasticizer and 0.6-1 percent of a root retarder and is excellent in root puncture resistance effect and good in self-healing property, heat aging resistance, heat stability and cohesive property.

Owner:BEIJING YUANDAHONGYU WATERPROOF MATERIAL CO LTD

High-grade road asphalt prepared from coal tar pitch

ActiveCN102504556AIncrease elasticityImprove ductilityBuilding insulationsCrack resistanceCross linker

The invention relates to asphalt, in particular to high-grade road asphalt prepared from coal tar pitch. The high-grade road asphalt comprises the following raw materials by part by weight: 30 to 70 parts of coal tar pitch, 15 to 30 parts of petroleum asphalt, 30 to 50 parts of solvent naphtha, 3 to 5 parts of composite polymer additive, 2 to 10 parts of antiager, and 0.3 to 0.5 part of cross linker. The high-grade road asphalt prepared from the coal tar pitch has the advantages as follows: the addition of the petroleum asphalt is reduced, and the usage amount of the coal tar pitch is increased; and the cost is reduced, and the performances of the road asphalt prepared from the coal tar pitch are improved, that is, the Engler viscosity of the asphalt is increased, the asphalt softening point is raised, the penetration degree is lowered, the high temperature stability is improved, the low-temperature ductility is greatly increased, and the low-temperature cracking resistance is remarkably improved.

Owner:车春玲

Stress absorption structured llayer of discontinuous ajar particle distribution limit mixture for asphaltum with high viscosity

InactiveCN101092808AImprove shear resistanceImprove fatigue resistanceIn situ pavingsBuilding insulationsFiberViscosity grade

This invention relates to a stress absorption structure layer of asphalt intermittent high viscosity grade semi mixture laid between a cement concrete road surface and asphalt mixture worn layer taking Embedded crowded Mineral coarse aggregate as the frame to fill mastic fat composed of high viscosity asphalt combined material, mineral powder filling material, lignin fiber stabilizer and mineral fine material among the framework, the mass percentage includes: high viscosity asphalt combined material 5-6.50, mineral powder filling material 4-6.00, lignin fiber stabilizer .020-0.40 and the rest is the intermittent semi mixture.

Owner:SHANGHAI PUDONG ROAD & BRIDGE CONSTR

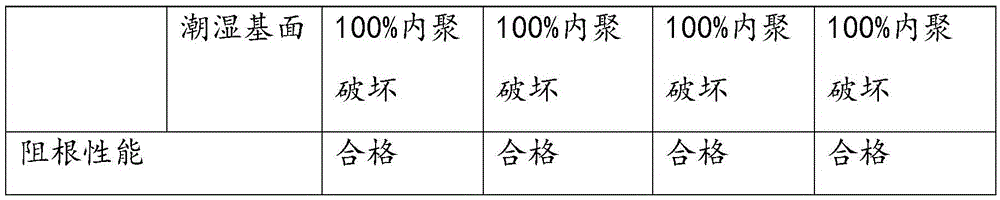

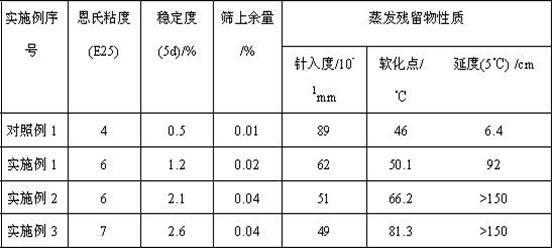

Modified asphalt as well as preparation method thereof

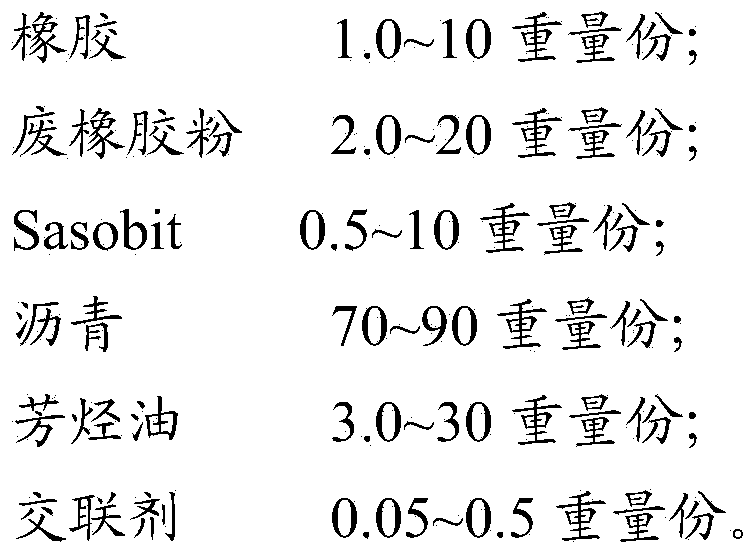

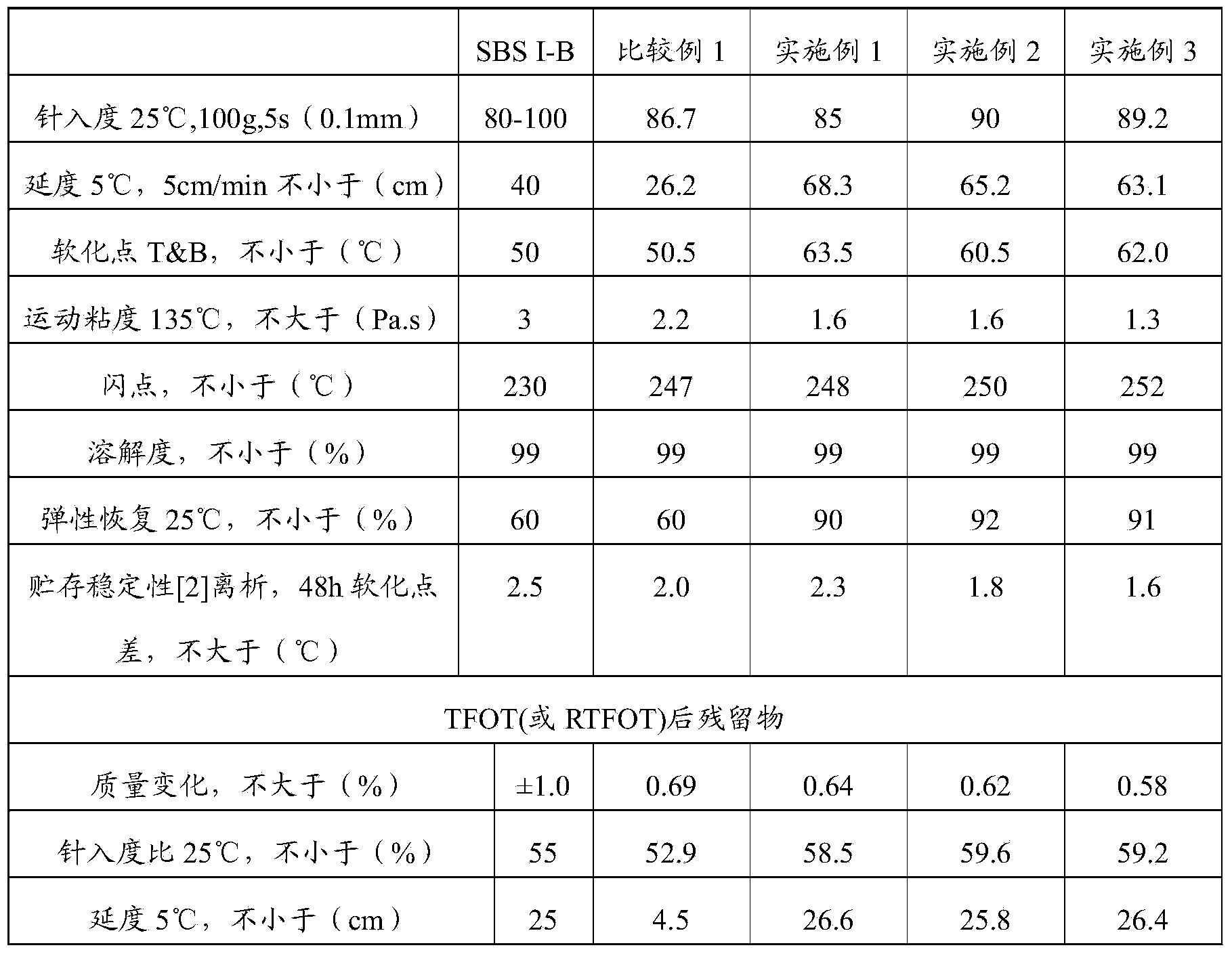

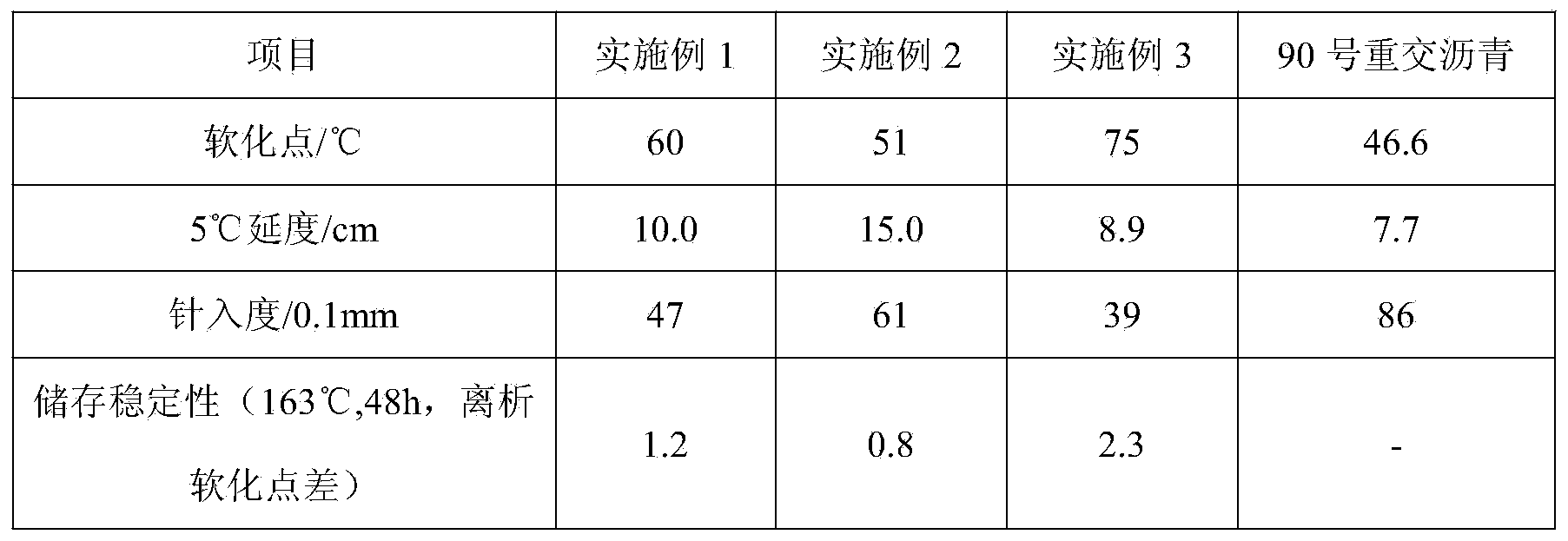

ActiveCN103468010AImprove low temperature performanceImprove low temperature ductilityBuilding insulationsHigh temperature storageSwelling capacity

The invention provides modified asphalt as well as a preparation method thereof. The preparation method comprises the following step: mixing, heating and stirring 70-90 parts of asphalt, 3.0-30 parts of aromatic hydrocarbon oil, 2.0-20 parts of waste rubber powder, 1.0-10 parts of rubber, 0.5-10 parts of Sasobit and 0.05-0.5 part of a crosslinking agent to obtain the modified asphalt. Compared with the prior art, polymer rubber, waste rubber powder, aromatic hydrocarbon oil, Sasobit and the crosslinking agent are adopted to jointly modify the asphalt. The rubber has better low temperature performance and can improve the low temperature ductility of the asphalt, and meanwhile, does not damage other pavement performances of the asphalt. The aromatic hydrocarbon oil has higher swelling capacity to the rubber and the waste rubber powder, so that the compatibility of the asphalt and modification materials is improved. The crosslinking agent can further improve the high temperature storage stability of a finished product so as to prevent separation. Sasobit can reduce the construction temperature of the asphalt.

Owner:SHANDONG JINSHI BITUMEN CO LTD

Asphalt pavement net-shaped crack treatment regeneration sealing layer material and preparation method thereof

The invention relates to an asphalt pavement net-shaped crack treatment regeneration sealing layer material and a preparation method thereof. The asphalt pavement net-shaped crack treatment regeneration sealing layer material is characterized by being composed of the raw materials in parts by weight: 70-100 parts of a composite emulsion and 200-400 parts of a fine aggregate; the composite emulsion is prepared by mixing the raw materials in pars by weight: 20-50 parts of an inorganic solution and 200-600 parts of an organic emulsion; the inorganic solution is an acidic silicon solution or a neutral silicon solution, the silica content is 10-30% (mass), the pH value is 3-7, the sodium oxide content is less than 0.5% (mass), and the average particle size is 10-20 nm; the organic emulsion comprises the raw materials by weight: 100 parts of a regeneration agent emulsion and 100-500 parts of modified emulsified asphalt. The asphalt pavement net-shaped crack treatment regeneration sealing layer material has strong permeability, plays good seam-sealing and waterproof roles in cracks, and has remarkable regeneration and reduction improvement effects on aged asphalt.

Owner:上海乐辛新材料科技有限公司

Polyethylene/rubber powder blend modified asphalt and preparation method thereof

InactiveCN103709770AReasonable priceEasy to operateBuilding insulationsCrack resistanceAging resistance

The invention provides a polyethylene / rubber powder blend modified asphalt which is composed of a matrix asphalt and a polyethylene / rubber powder blended substance, wherein the polyethylene / rubber powder blended substance is composed of the following components in percentage by weight: 40-52% of polyethylene, 45-59% of rubber powder and 1-3% of crosslinking agent; and the weight ratio of the polyethylene / rubber powder blended substance to the matrix asphalt is (5-15):100. According to the polyethylene / rubber powder blend modified asphalt, the softening point is enhanced, the penetration degree is lowered, and the anti-rut property of the asphalt mixture is enhanced; the ductility is enhanced, and the low temperature ductility is improved; the aging resistance is improved; and the storage stability of the modified asphalt is enhanced, and the storage and transportation properties of the modified asphalt are improved. The polyethylene / rubber powder blend modified asphalt provides flexibility, fatigue resistance and cracking resistance for the asphalt pavement, thereby prolonging the service life of the pavement.

Owner:中华人民共和国泰州出入境检验检疫局

Preparation method of stable SBS (Styrene Butadiene Styrene) modified asphalt

InactiveCN103525107AImprove low temperature ductilityImprove high temperature performanceBuilding insulationsDuctilityButadiene-styrene rubber

The invention discloses a preparation method of stable SBS (Styrene Butadiene Styrene) modified asphalt. The method comprises the steps of: under normal pressure, mixing polystyrene-polybutadiene-polystyrene triblock copolymer (SBS) serving as a thermoplastic elastomer and asphalt by virtue of high-speed shearing and mixing equipment at the temperature of 170-180 DEG C, then adding additives, shearing at the temperature of 160-170 DEG C, and finally obtaining the SBS modified asphalt product with high stability, wherein the SBS is in a linear structure, and the additives are inorganic clay and polysulfide. With the adoption of the preparation method, the prepared modified asphalt has good high-temperature storage stability, the high temperature performance and the water stability of the modified asphalt are greatly improved, the low-temperature ductility of the modified asphalt is better than that of the modified asphalt prepared from star-type SBS, and the whole performance of the modified asphalt is better than that of the star-type SBS modified asphalt; various performances and the pavement performance of the high-stability SBS modified asphalt are integrally improved when the problem of the storage stability is solved; and in addition, the preparation is convenient, the processing flow is short, the equipment is simple, the process condition is mild, the production is rapid, and the modification cost is low.

Owner:SHANXI PROVINCIAL RES INST OF COMM

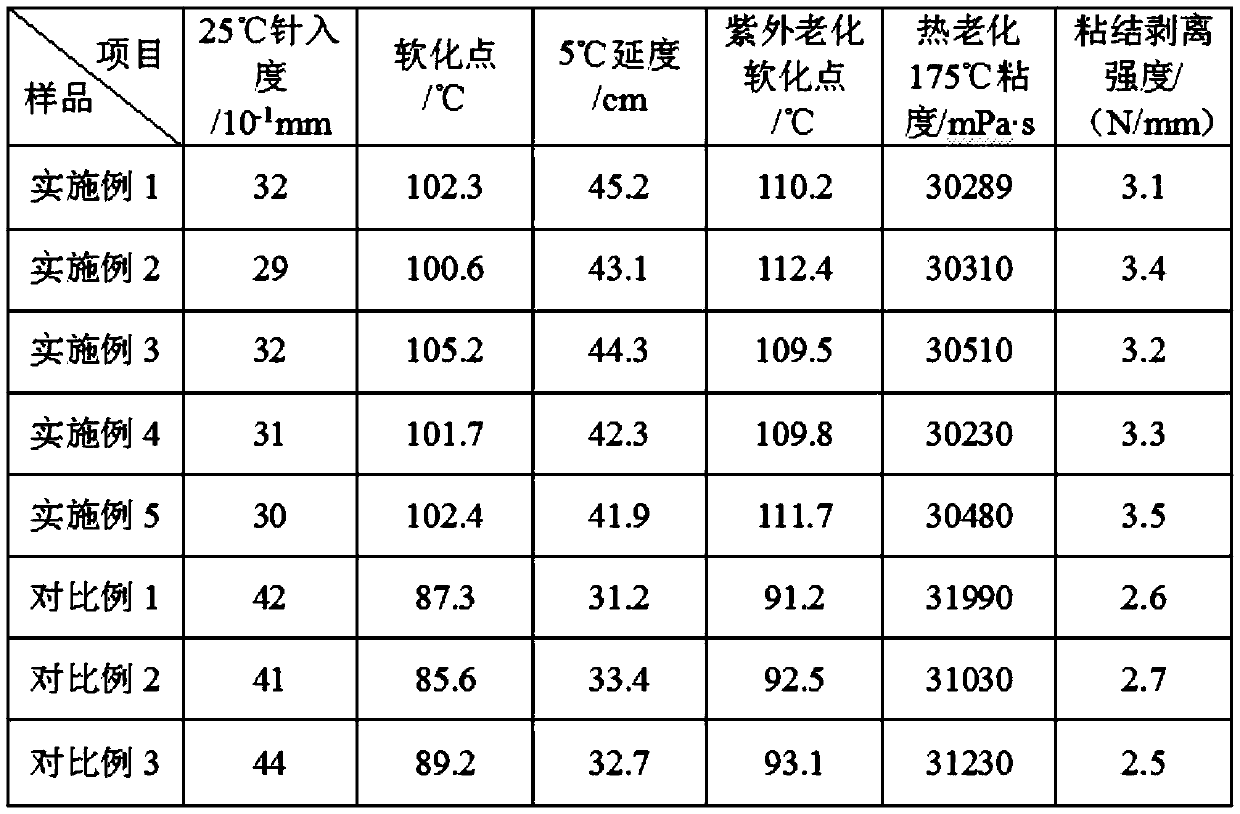

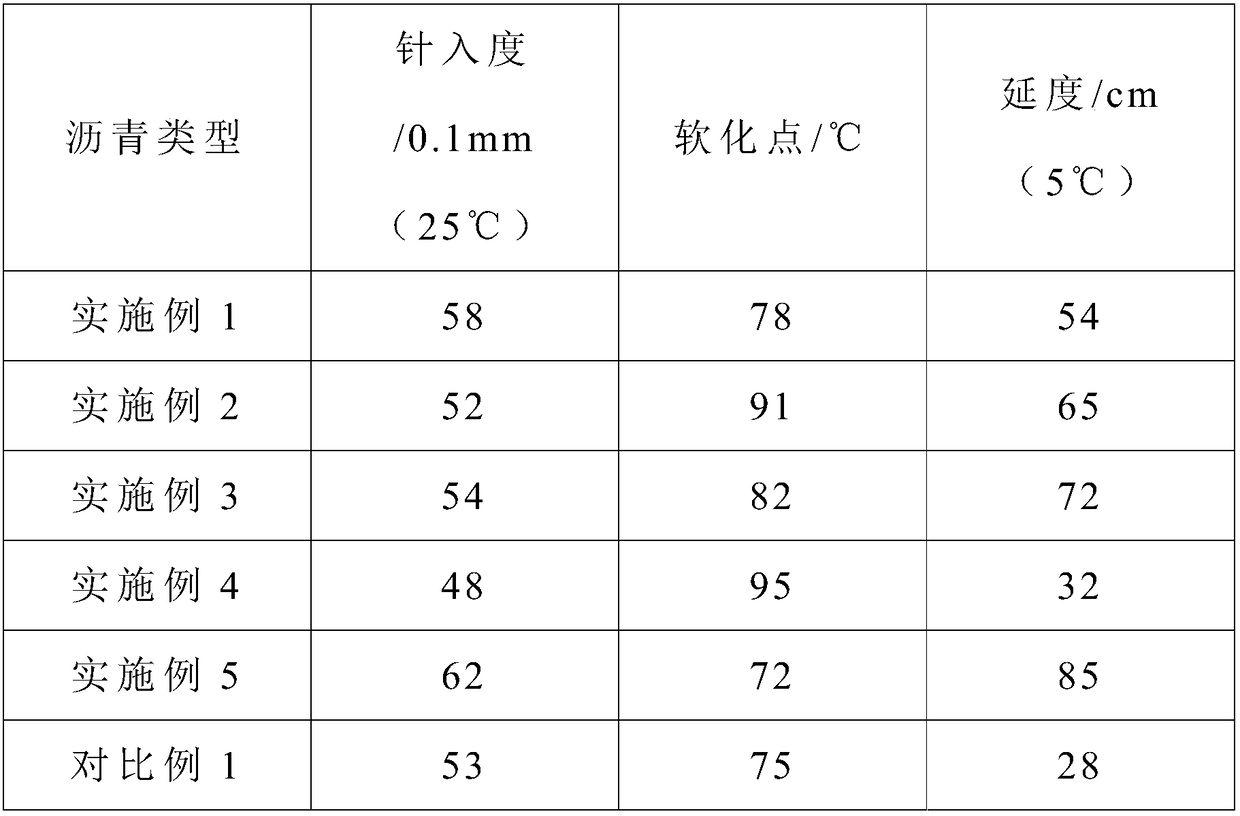

Polymer modified asphalt and preparation method thereof

PendingCN109897390AAvoid reunionGood storage stabilityBuilding insulationsPolymer modifiedPolymer science

The invention discloses a polymer modified asphalt and a preparation method thereof. The polymer modified asphalt comprises base asphalt, a polymer, a coupling agent, a promoter and a compatibilizer.The preparation method of the polymer modified asphalt comprises the following steps: weighing the base asphalt and the polymer, and ultrasonically dispersing the base asphalt and the polymer while stirring under a heating condition to achieve uniform mixing in order to obtain a polymer-base asphalt mixture; and weighing the coupling agent, the promoter and the compatibilizer, adding the weighed materials into the polymer-base asphalt mixture, performing ultrasonic dispersing while stirring, carrying out a reaction for a period of time, performing shearing treatment by a high-speed shearing machine, and naturally cooling the sheared reaction product to room temperature to obtain the polymer modified asphalt. Experimental results show that the prepared polymer modified asphalt has the advantages of good low temperature performances, good high temperature performances, good aging resistance, excellent bonding property and high storage stability.

Owner:张莉

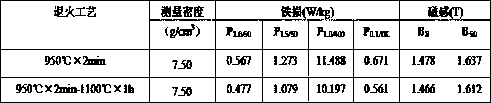

Alloying-based high-silicon thin steel strip and preparation method thereof

The invention relates to an alloying-based high-silicon thin steel strip and preparation method thereof. The technical scheme of the alloying-based high-silicon thin steel strip is as follows: the silicon content of the high-silicon thin steel strip is 5.5-7.0wt%, the copper content is 0.05-2.5wt%, and the rest is iron and other unavoidable impurity. The preparation method is as follows: using ingot iron, commercial silicon and pure copper as raw materials and burdening according to the chemical component of the high-silicon thin steel strip, smelting the raw materials in a medium-frequency vacuum induction furnace, casting at 1300-1650 DEG.C to form casting blank, forging the casting blank at 750-1250 DEG.C to form a slab with thickness of 10-20mm, hot-rolling the slab at 700-1250 DEG.C to form a thin strip with thickness of 0.6-0.8mm, and finally warm-rolling the thin strip at 150-750 DEG.C to 0.2-0.3mm. The alloying-based high-silicon thin steel strip provided by the invention is low in cost, simple in process and capable of utilizing the existing apparatus, the fragility of the prepared alloying-based high-silicon thin steel strip is obviously improved, the plasticity is obviously improved, the strip shape is good and the magnetic performance is excellent.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing low-temperature cross-linked emulsified SBS pitch modifier

InactiveCN103965492AReduce pollutionImprove low temperature brittlenessBuilding insulationsCross-linkMaterials preparation

The invention discloses a method for preparing a low-temperature cross-linked emulsified SBS pitch modifier. The method comprises the following steps: material preparation, sol preparation, liquid soap preparation, latex preparation, finished product preparation and the like. The low-temperature cross-linked emulsified SBS pitch modifier obtained according to the method has the advantages that the high-temperature flexibility and low-temperature fragility of pitch can be effectively improved; the softening point and low-temperature ductility of pitch can be improved.

Owner:安徽路达泰克沥青新材料有限公司

Modified asphalt composition with excellent low-temperature performance and preparation method of modified asphalt composition

InactiveCN108165036AImprove low temperature ductilityGood low temperatureBuilding insulationsAntioxidantRoad engineering

The invention relates to the technical field of road engineering and specifically discloses a modified asphalt composition with excellent low-temperature performance and a preparation method of the modified asphalt composition. The modified asphalt composition is prepared from the following raw material components in parts by mass: 100 parts of matrix asphalt, 2 to 5 parts of styrene-butadiene-styrene block copolymer resin, 0.5 to 2 parts of styrene-butadiene rubber, 0.5 to 2 parts of aromatic oil, 0.5 to 3 parts of plasticizer, 0.5 to 1.5 parts of C9 petroleum resin, 0.5 to 1.5 parts of polyethylene wax, 0.1 to 0.5 parts of sulfur, 0.1 to 0.5 parts of antioxidant and 0.5 to 1.5 parts of phosphate. According to the modified asphalt composition disclosed by the invention, the low-temperature ductility of the modified asphalt is improved by the combination action of the aromatic oil, the plasticizer, the styrene-butadiene rubber and the C9 petroleum resin; the prepared modified asphalt composition with the excellent low-temperature performance has the advantages of excellent low-temperature performance, high low-temperature ductility and suitability for being used in cold regions.

Owner:SUZHOU TOPOLINE TECH

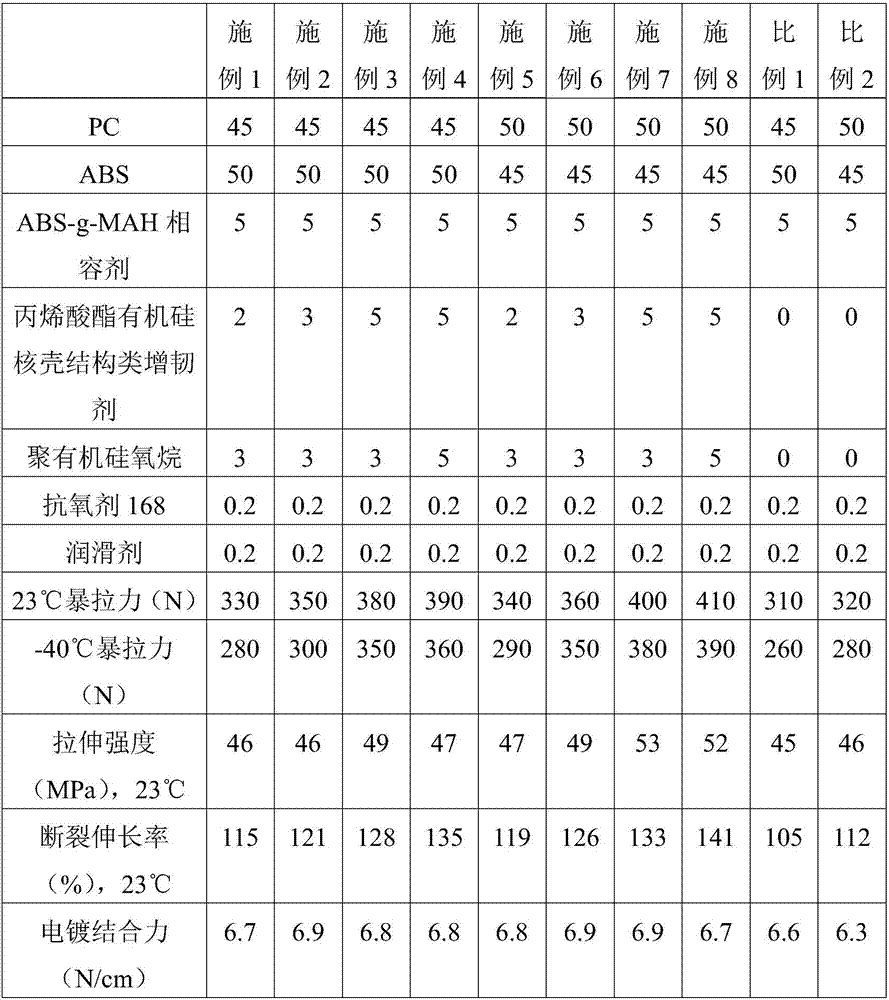

Electroplate PC/ABS alloy material resistant to low temperature violent pulling and preparation method thereof

ActiveCN107266849AExcellent low temperature and room temperature tensile strengthExcellent elongation at break at low temperature and room temperatureOrganosiliconAcrylate

The invention discloses an electroplate PC / ABS alloy material resistant to low temperature violent pulling and a preparation method thereof. The electroplate PC / ABS alloy material resistant to low temperature violent pulling comprises PC, ABS, an ABS-g-MAH compatilizer, a acrylate-organosilicon core-shell structure toughening agent, polyorganosiloxane, an antioxidant 168, and a lubricant. The electroplate PC / ABS alloy material provided by the invention is added with polyorganosiloxane and the acrylate-organosilicon core-shell structure toughening agent, the polyorganosiloxane and the acrylate-organosilicon core-shell structure toughening agent are collaborative, so that the electroplate PC / ABS alloy has high low temperature and room temperature tensile strength, low temperature and room temperature elongation at break. At the same time, the electroplate PC / ABS alloy material maintains good electroplating performance.

Owner:上海跃贝新材料科技股份有限公司

Special modified cold-mixing asphalt for cold-region normal-temperature mixing-type asphalt concrete

InactiveCN101735625ALow kinematic viscosityReduce internal friction angleBuilding insulationsEvaporationRoom temperature

The invention provides special modified cold-mixing asphalt for cold-region normal-temperature mixing-type asphalt concrete, which comprises linear liquid SBS, heavy traffic asphalt, surfactant, organic additives and water. The weight percentages of the components are: 50 to 70 percent of heavy traffic asphalt, 2.5 to 15 percent of linear liquid SBS, 1.2 to 11 percent of cationic surfactant, 3 to 6 percent of organic additives, and 20 to 30 percent of water. The water and the cationic surfactant are mixed pro rata and then are fully mixed through an emulsifier to form soap liquid; the heavy traffic asphalt is heated to between 100 and 170 DEG C; the soap liquid is heated to between 45 and 80 DEG C; the heavy traffic asphalt, the soap liquid, the linear liquid SBS and the organic additives are rapidly mixed in a mixing-melting device; and a uniform stable suspended substance is formed through a grinding machine, fully stirred, cooled to normal temperature and stored, thus the asphalt can be obtained. The problem that cold-mixing asphalt is too fast to demulsify, unstable in performance, short in storage time and poor in regional adaptability is solved. Evaporation residue of the asphalt mixture can greatly improve pavement performance. In addition, the asphalt has the advantages of simple process, stable performance and wide use.

Owner:李国涛

Composite modified coal asphalt and preparation method thereof

ActiveCN105419361AIncrease contentImprove performanceBuilding insulationsPolycyclic aromatic hydrocarbonPolyethylene glycol

The invention relates to composite modified coal asphalt and a preparation method thereof. The composite modified coal asphalt includes the following raw materials, by mass, 30-90 parts of mid-temperature coal asphalt, 10-70 parts of petroleum coal asphalt, 0.1-5 parts of phthalate, 0-10 parts of polyethylene glycol, 0.1-10 parts of a SBS modifier, and 0-5 parts of nano calcium carbonate. The composite modified coal asphalt, compared with the prior art, has following advantages: the coal asphalt is improved in both high- and low-temperature performance, and especially, ductility at 5 DEG C reaches more than 50 cm without damage on the high-temperature performance, wherein the softening point of the coal asphalt is still maintained to be about 70 DEG C. The coal asphalt is free of long-time heating and can be prepared just through a normal modifying process. The coal asphalt is not only improved in high- and low-temperature performance but also significantly reduced in content of polycyclic aromatic hydrocarbon. The modifying process and requirement are more suitable for device and construction specifications of modified asphalt in the prior art.

Owner:SHANXI PROVINCIAL RES INST OF COMM

Waterproof material

InactiveCN106189296AImprove waterproof performanceImprove aging resistanceBuilding insulationsEPDM rubberAntimony tin oxide

The invention discloses a waterproof material. The waterproof material comprises the following raw materials in parts by weight: 20-30 parts of asphalt, 10-20 parts of EPDM rubber, 5-10 parts of polymer emulsion with a core-shell structure, 5-10 parts of polyurethane, 3-8 parts of high-density polyethylene, 3-6 parts of nano-graphene, 4-8 parts of nano antimony tin oxide, 3-10 parts of tourmaline powder, 2-6 parts of polypropylene fibers, 3-10 parts of quartz sand, 1-2 parts of an antioxidant, 2-8 parts of calcined diatomite, 3-8 parts of expanded perlite, 0.5-2.5 parts of a defoamer, 1-2 parts of an anti-mildew bactericide, 1-3 parts of a dispersing agent and 1-2 parts of a stabilizer. The waterproof material has excellent waterproof effect as well as good aging resistance, corrosion resistance, stabproofness, chemical resistance and anti-static performance, and the tension strength and the heat resistance of the material are improved. The waterproof material adopts simple raw materials and has high tensile strength, good extension property, better mechanical strength, smaller linear expansion coefficient and the like, thereby being wide in application range. The high-temperature property and the low-temperature ductility of the waterproof material are improved substantially by added high-density polyethylene, and the combination property is superior.

Owner:安庆越球建筑防水材料有限公司

Composite modified asphalt material applicable to anti-crack layer with pavement structure and preparation method thereof

ActiveCN102876058AImprove fatigue lifeReduce singularityBuilding insulationsRoad surfaceReflective crack

The invention discloses a composite modified asphalt material applicable to an anti-crack layer with a pavement structure and a preparation method of the composite modified asphalt material. The composite modified asphalt comprises the following components by weight: 83.2-87.6 parts of substrate asphalt, 3.1-4.2 parts of thermoplastic styrene butadiene rubber (SBS), 1.3-1.7 parts of powder butadiene styrene rubber (PSBR), 5.3-6.7 parts of desulfuration rubber powder, 1.8-2.5 parts of acetyl tributyl citrate (ATBC), and 0.9-1.7 parts of accelerant, the sum of the parts in weight is 100, the accelerant is rubber filling oil. The composite modified asphalt is applicable to the anti-crack layer with the pavement structure; the anti-crack layer is usually used for a rigid-flexible composite pavement layer for additionally paving asphalt surface layer on a concrete rigid base layer with seams (old concrete pavement), also can be used for semi-rigid base asphalt pavement, so that delay the forming and expanding of reflection cracks can be delayed, the capability of the pavement structure is improved to resist fatigue cracks, the service quality of the pavement structure is improved, and the service life of the pavement structure is prolonged.

Owner:清远市金运再生资源有限公司

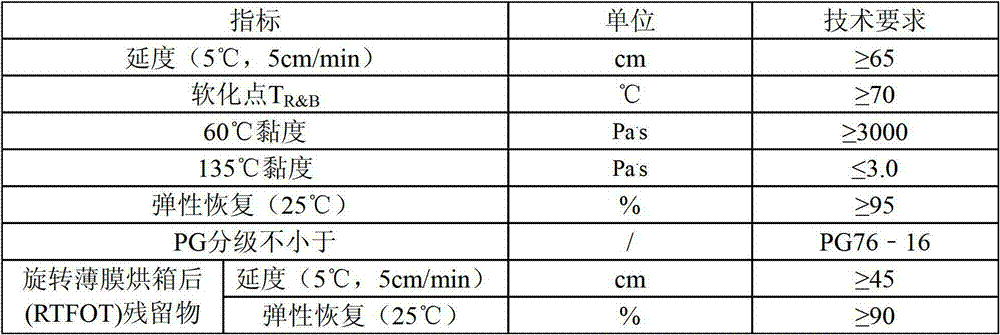

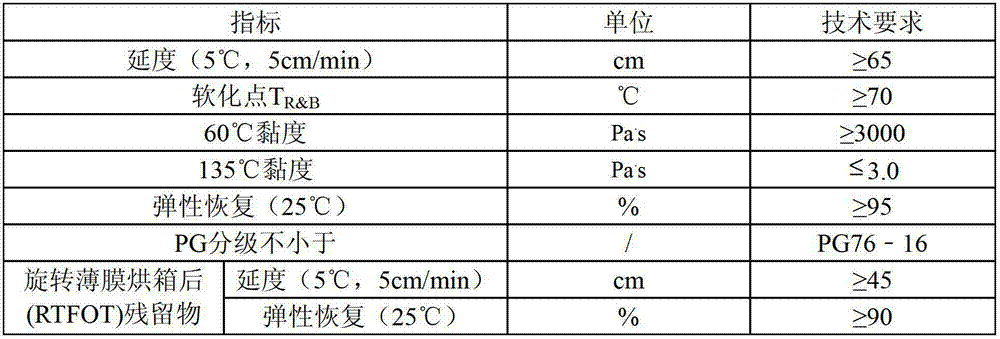

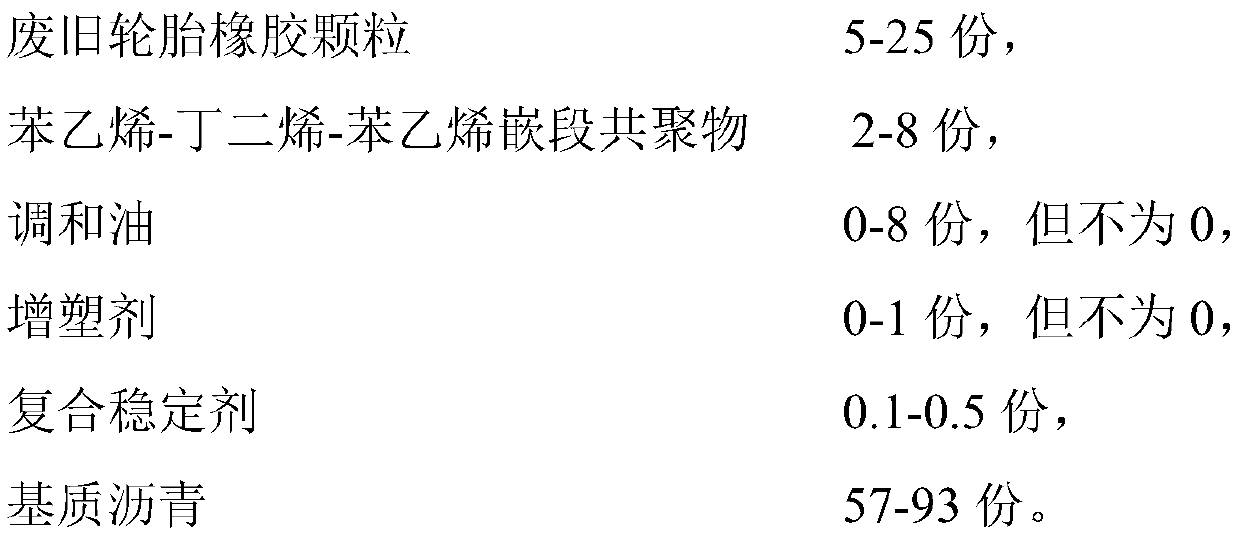

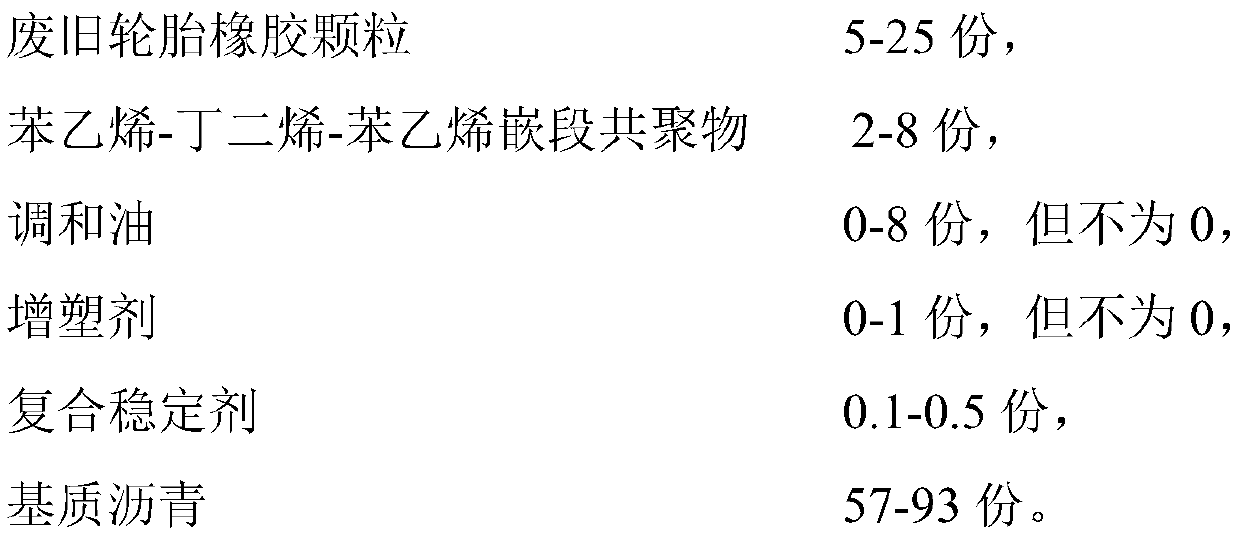

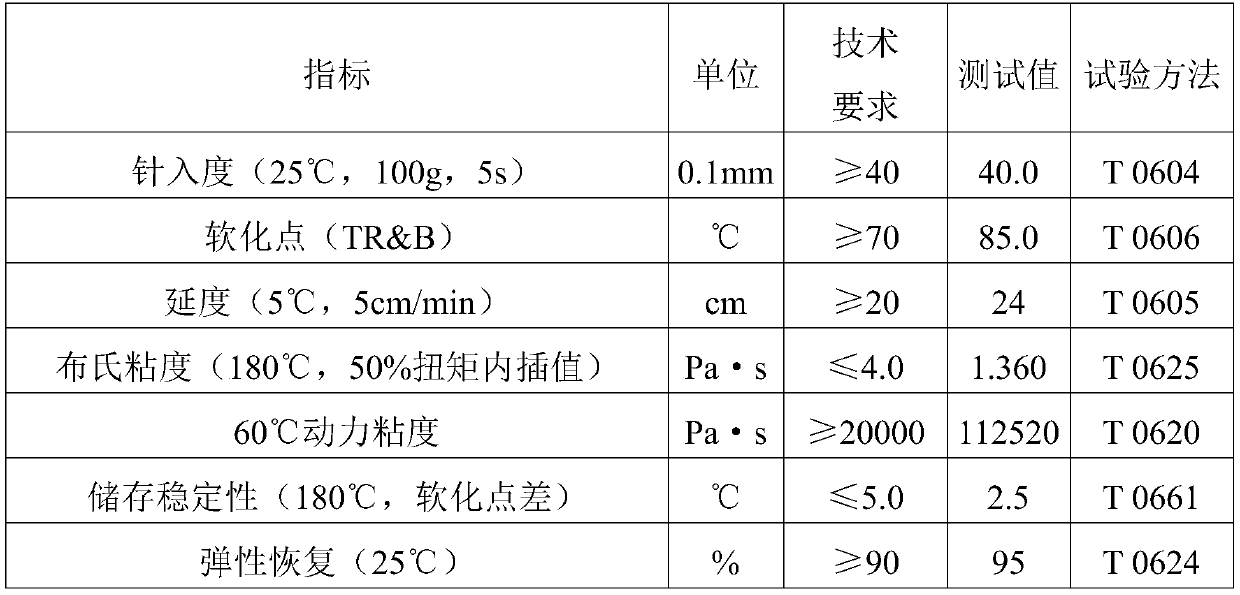

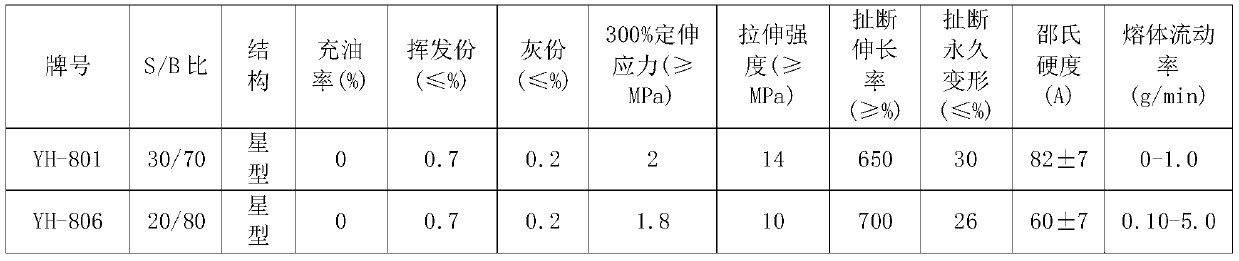

Compounded high-viscosity high-elasticity asphalt material and preparation method therefor

InactiveCN110452550AHigh viscosityIncreasing the thicknessBuilding insulationsPlasticizerBituminous materials

The invention relates to a compounded high-viscosity high-elasticity asphalt material and a preparation method therefor. The asphalt material is prepared from the following ingredients in parts by weight: 5-25 parts of waste tire rubber granules, 2-8 parts of styrene-butadiene-styrene block copolymer, 0-8 (but 0 is exclusive) parts of blend oil, 0-1 (but 0 is exclusive) part of plasticizer, 0.1-0.5 part of composite stabilizer and 57-93 parts of matrix asphalt. Compared with the prior art, the asphalt material prepared by the method has the advantages that the kinetic viscosity at the temperature of 60 DEG C is not smaller than 20,000Pa.s, the recovery of elasticity at the temperature of 25 DEG C is not smaller than 90%, the storage stability at the temperature of 180 DEG C is not greaterthan 4.0 DEG C, the asphalt material has good mechanical properties and storage stability, the high-temperature rut resistance of pervious asphalt concrete can be improved, the low-temperature frost heave resistance of the pervious asphalt concrete can also be improved, the durability of the pervious asphalt concrete is remarkably improved, and the service life of the pervious concrete is prolonged.

Owner:TONGJI UNIV +1

Special modified asphalt for cast asphalt concrete, and preparation method thereof

InactiveCN110499034AReduce penetrationHigh softening pointBuilding insulationsButadiene-styrene rubberToughening

The invention provides a special modified asphalt for cast asphalt concrete, and a preparation method thereof. The special modified asphalt comprises 100 parts of asphalt, 2-15 parts of an SBS (styrene-butadiene-styrene) block copolymer, 2-15 parts of hard asphalt and 1-10 parts of a toughening agent. The special modified asphalt for cast asphalt concrete can reach or exceed the softening point ofcommon cast asphalt, so the special modified asphalt has a good high-temperature stability; the special modified asphalt has a better low-temperature anti-cracking performance than common cast modified asphalt; and the special preparation method is adopted, so the modified asphalt of the invention has a very high storage stability, and is not prone to separate and crust at a high temperature.

Owner:上海同沥新材料科技有限公司

Repairing material for color asphalt pavement, and preparation method thereof

The invention discloses a repairing material for a color asphalt pavement, and a preparation method thereof, wherein the repairing material comprises, by mass, 10-22% of a petroleum resin, 35-50% of acompatibilizer, 2-9% of a polymer, 15-50% of a viscosity reducing agent, 0.05-1.0% of a vulcanizing agent, 0.1-1.5% of an anti-aging agent, and 0.05-1.0% of an activator. According to the present invention, the repairing material has advantages of excellent high-temperature performance, excellent low-temperature performance, good stability, high softening point, strong adhesion, high low-temperature elongation rate and high low-temperature ductility, can be stored at room temperature for more than one year, and can be well mixed with color pigments at a room temperature so as to effectively repair the color asphalt pavement with small-area damage after the mixing.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com