Patents

Literature

8380results about How to "Avoid reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene/metal oxide composite cathode material for lithium ion battery and preparation

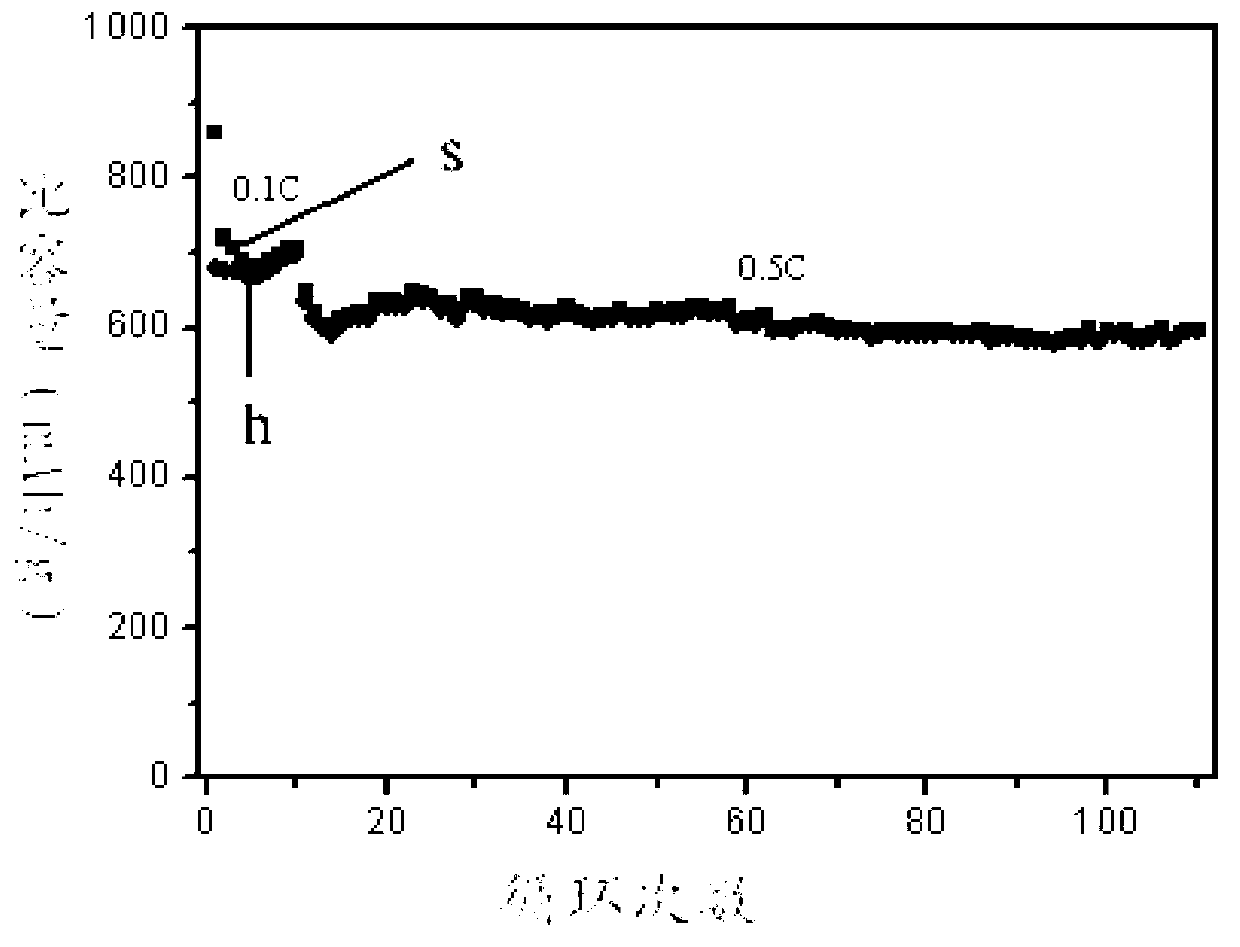

InactiveCN102646817APromote circulationExcellent rate performanceCell electrodesHigh energyIn situ polymerization

The invention belongs to the fields of material synthesis and energy technology, and especially relates to a graphene / metal oxide composite cathode material for lithium ion batteries and a preparation method thereof. Grapheme is dispersed into various metal oxide precursor salt solutions; a graphene / metal oxide compound is obtained directly by a hydrothermal method, or an graphene / metal oxide compound is obtained by a liquid in-situ polymerization method or a coprecipitation process; and the graphene / metal oxide compound is obtained by heat treatment or hydrothermal treatment. In the invention, the novel three-dimensional composite cathode material of graphene-coated metal oxide or graphene-anchored metal oxide is prepared by carrying metal oxide particles with graphene as a carrier. The obtained composite material can be used as a lithium ion battery cathode, which has a high specific capacity, excellent cycle stability and rate capability, and is expected to be used as a lithium ion battery cathode material with a high energy density and a high power density.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Wet chemistry method for preparing lithium iron phosphate

InactiveCN1431147AEasy to controlEvenly distributedElectrode thermal treatmentLi-accumulatorsChemical compositionLithium iron phosphate

A wet chemical process for preparing iron lithium phosphate includes mixing the solution or suspensions of Li source compound, Fe source compound, P source compound, doping element compound or electric conducting agent, and precipitant, reaction at 5-120 deg.C for 0.5-24 hr while stirring, filtering, washing, baking to obtain nano precursor, quickly heating to 500-800 deg.C in non-air or non-oxidizing atmosphere, calcining for 5-48 hr, and cooling. Its advantages are easy control, high uniformity and electric conductivity.

Owner:郑绵平

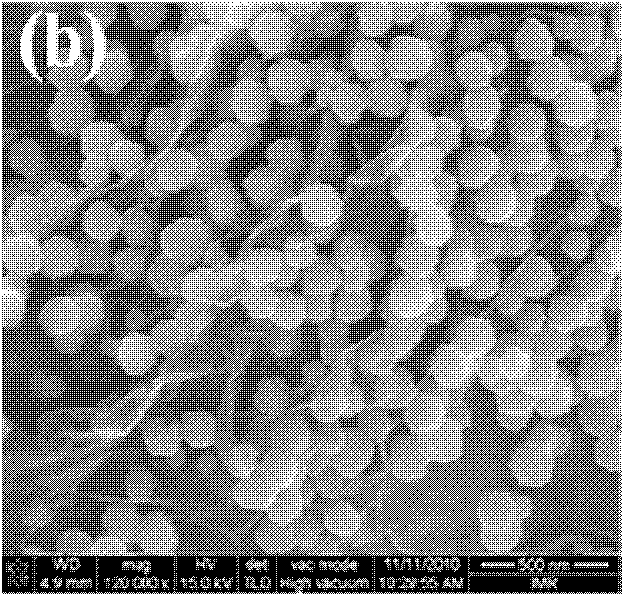

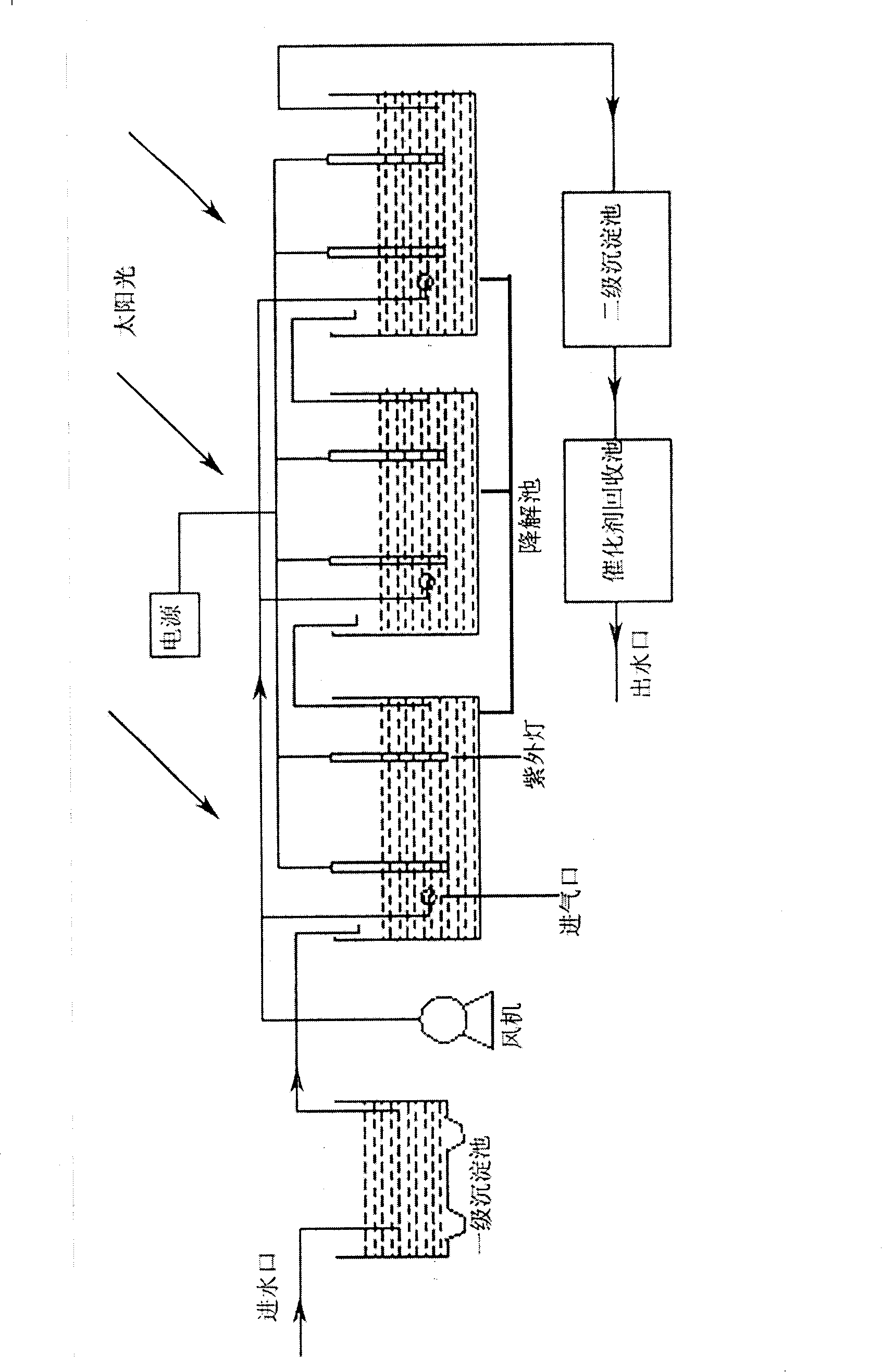

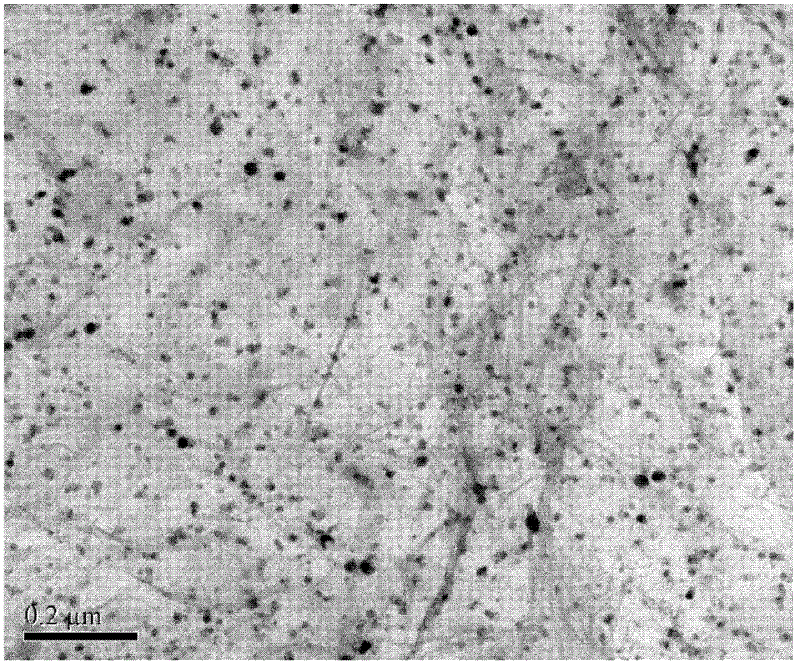

Photocatalysis oxidation treated high concentration organic trade waste

InactiveCN101219371AHigh activityImprove stabilityCatalyst carriersEnergy based wastewater treatmentHigh concentrationEmission standard

The invention relates to a modified loading nano composite photocatalyst which takes titanium dioxide as main part and adopts new reaction technique to degraded the organic industrial wastewater in a water processing system (see attached drawing 1 in Instruction). The main point on preparing the catalyst lies in that titanium dioxide active compounds loaded on different carriers are employed to prepare a loading photocatalyst with grain diameter of 5-40nm; meanwhile, different elements are mixed into the loading photocatalyst to reduce the composition between photoproduciton electron and cavity, which enables the catalyst to move the light absorbing wavelength thereof towards the visible regions, thus effectively improving the degradation rate of organic pollutants as a new environmental-friendly catalyst. As to the new technique of processing the organic industrial wastewater, the invention overcomes the defects that the present photocatalysts are only used for degrading the organic industrial wastewater with low concentration. The catalyst being irradiated respectively or simultaneously under sunbeam and ultraviolet light can decrease COD values of high-concentration organic industrial wastewater from 10000-40000mg / L to less than 100mg / L in short time, thus meeting the national emission standard.

Owner:BEIJING UNIV OF CHEM TECH

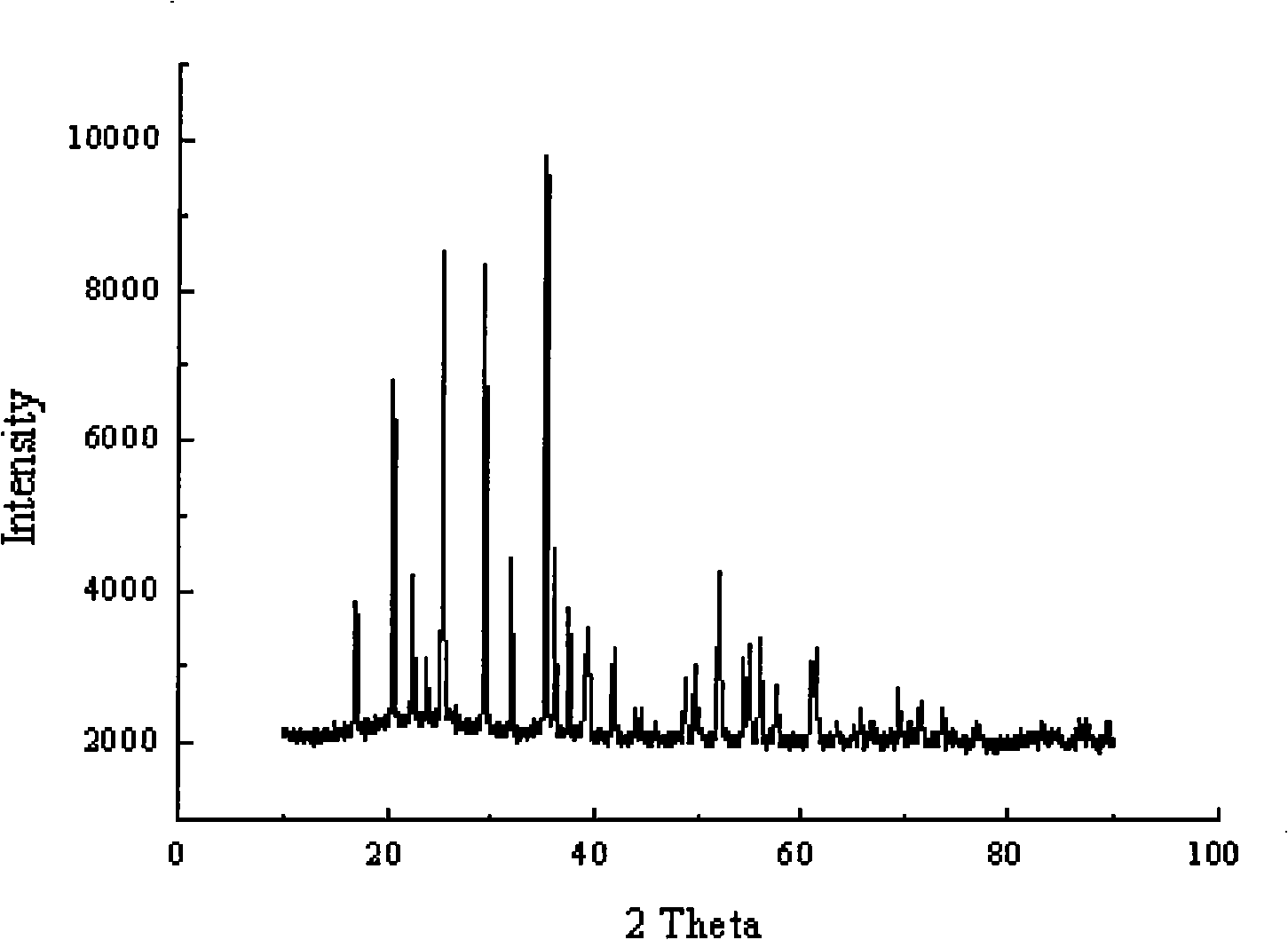

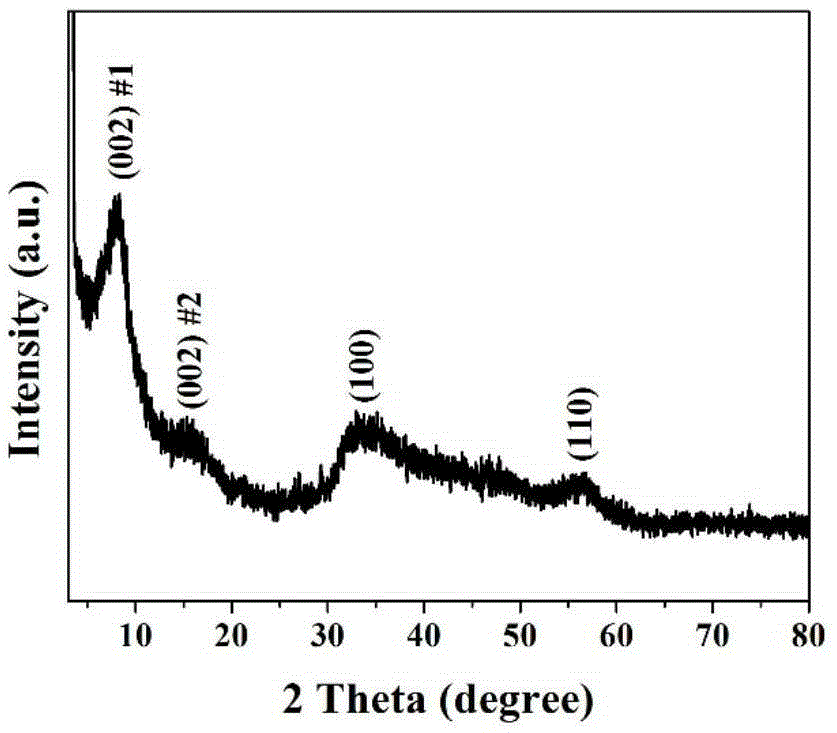

Method for preparing graphene powder

The invention relates to a method for preparing graphene powder in large scale, which is characterized by comprising the following steps of: firstly, uniformly peeling graphene oxide into a graphene oxide suspension solution; then, atomizing the graphene oxide solution by using the spray drying technology comprising spray pyrolysis drying and spray freeze drying, and removing a solvent to obtain graphene oxide powder; and finally, oxidizing grapheme by using the non-expansion heat treatment process to obtain non-agglomerative graphene powder. The continuous preparation process of the spray technology and the non-expansion heat treatment process ensure the large-scale preparation of the graphene powder. The prepared graphene powder comprising intermediate product graphene oxide powder does not have agglomeration and has good dispersivity in the solvent. The graphene powder is used as a filling material to prepare high strength composite materials, conductive composite materials, novel air-tight flame-retardant composite materials, novel nanodevices and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Copper bismuth catalyst and preparation method thereof

ActiveCN102658158AImprove wear performanceExtended service lifeOrganic compound preparationHydroxy compound preparationCooking & bakingAlcohol

The invention relates to a copper bismuth catalyst for combining chemically into 1, 4-butynediol with formaldehyde and ethyne and a preparation method thereof. The preparation method comprises the following steps of: preparing mixed solution which contains copper salt, bismuth salt, magnesium salt and dispersant; dropping alcoholic solution with an organic silicon source into the mixed solution; adjusting a pH value of the mixed solution with alkaline solution to obtain mixed precipitate; and further aging, washing, drying and baking in inert atmosphere to obtain the copper bismuth catalyst with C-MgO-SiO2 a carrier, in the catalyst, the content of CuO accounts for 25-50 weight percent, and the content of Bi2O3 accounts for 2-6 weight percent. The catalyst is applied in a reaction of combining chemically into 1, 4-butynediol with formaldehyde and ethyne, and has high catalytic activity and high selectivity.

Owner:SHANXI UNIV

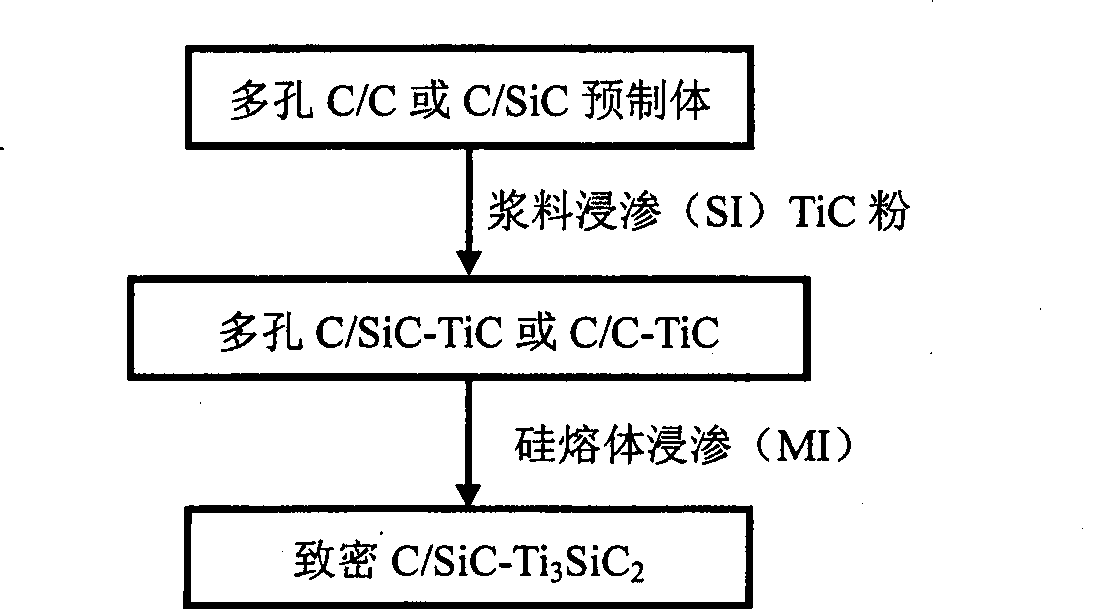

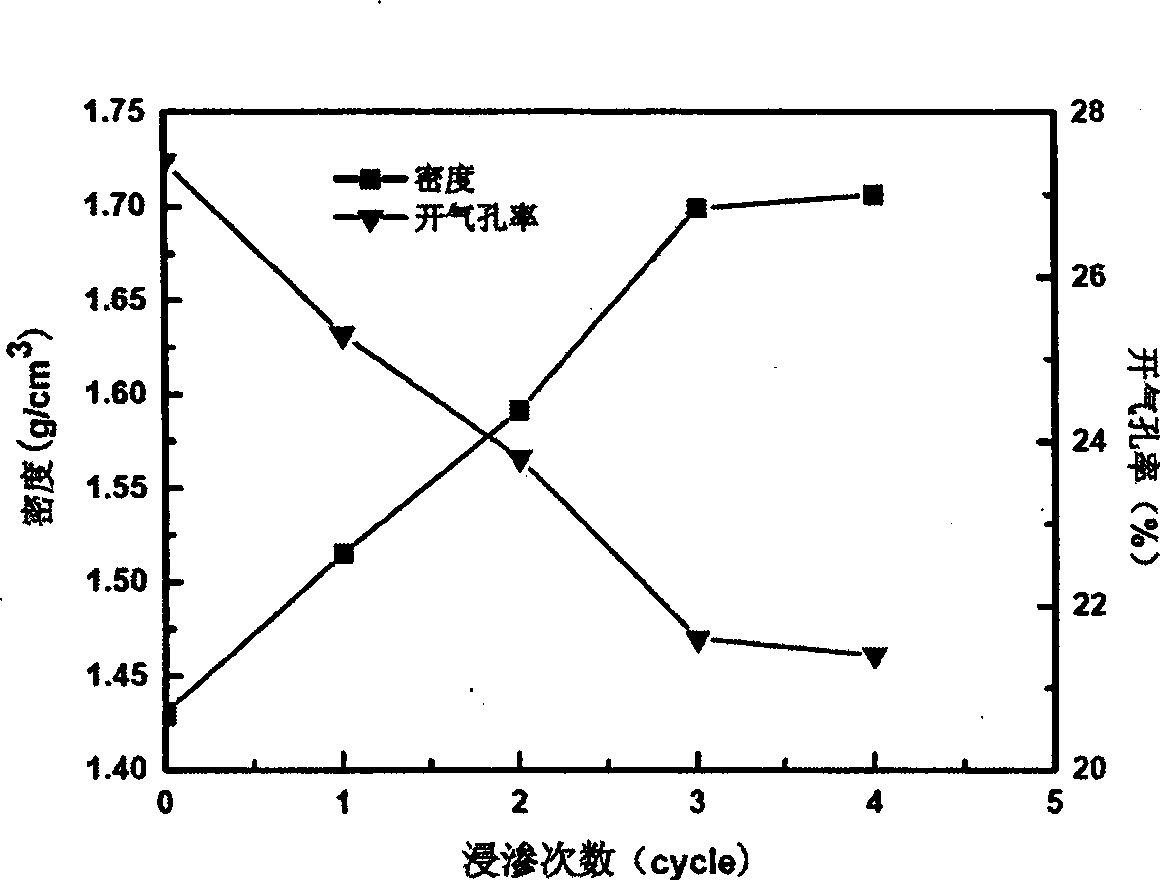

Process for producing composite material of Ti3SiC2 modified C/SiC

The invention discloses a method for preparing Ti3SiC2 modified C / SiC composite material, comprising the following steps: firstly, carrying out ultrasonic cleaning and drying on the pre-prepared body to be modified; compounding the size with distilled water, cellulose sodium carboxy methyl and TiC powder; then carrying out vacuum infiltration combined with pressure infiltration on the pre-prepared body and refrigeration and drying in vacuum; coating industrial silicon powder on the surface of the pre-prepared body; calcining the pre-prepared body in a vacuum furnace to lead the silicon to fuse to penetrate into the pre-prepared body; and cooling the pre-prepared body gradually to room temperature after full reaction in the vacuum furnace. As SI method is adopted to lead C / C or C / SiC composite material to be firstly internally filled with TiC granules, then MI method is adopted to penetrate silicon fusant, and TiC reacts with Si to generate Ti3SiC2 and SiC, the content of residue Si in the composite material is reduced, and the Ti3SiC2 phase in-situ generated in the C / SiC composite material causes the use temperature of the modified C / SiC composite material to rise from 1420 DEG C in the prior art to 1500-2300 DEG C and the fracture toughness property to rise from 8MPa.m in the prior art to 9-16 MPa.m.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

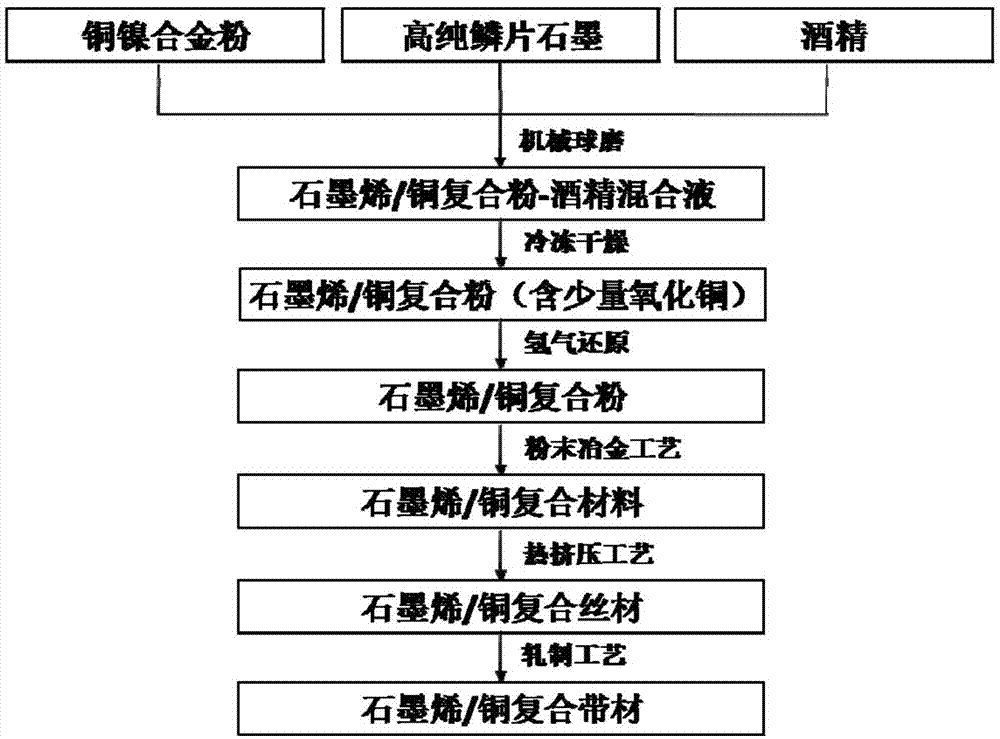

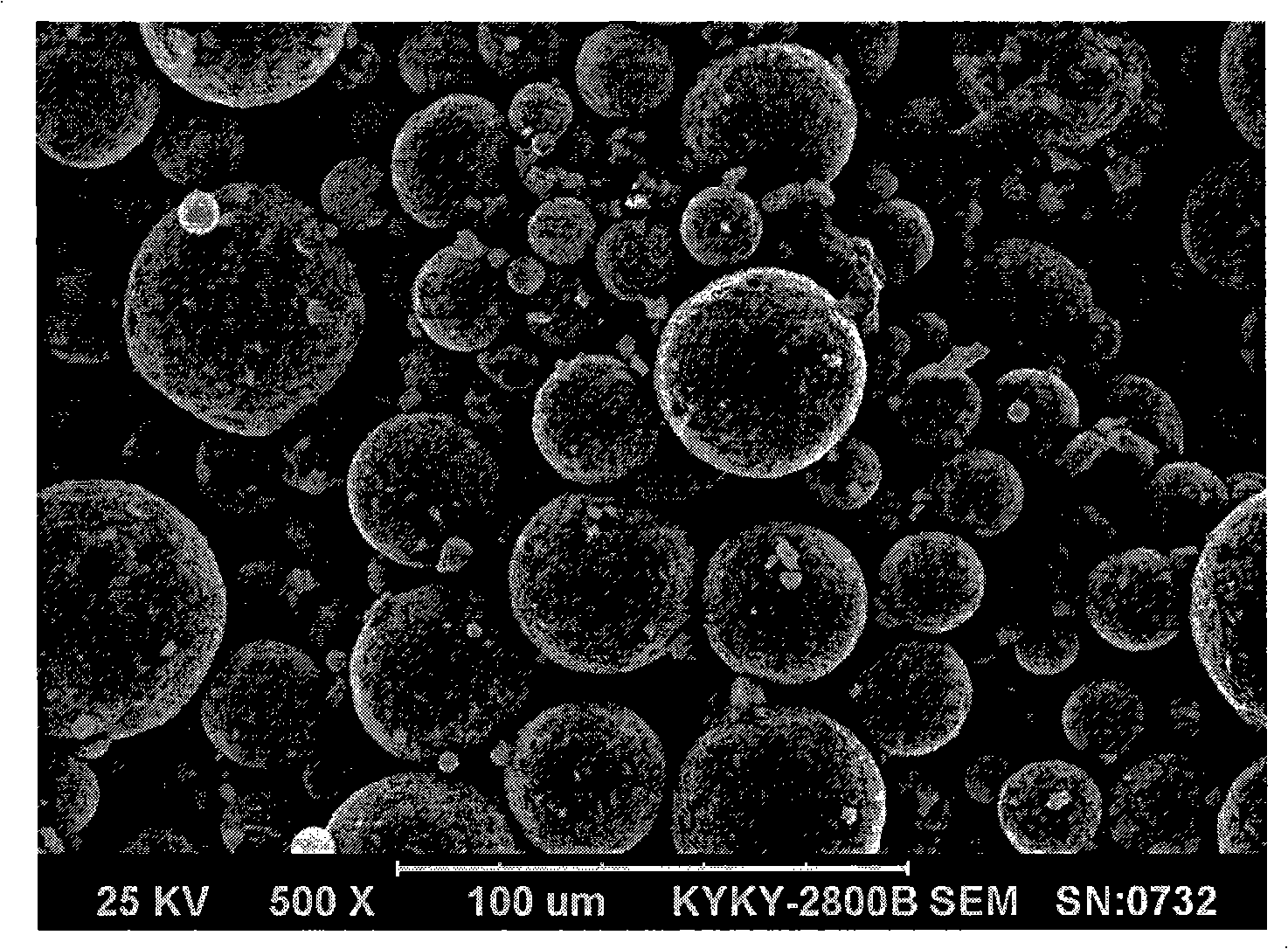

Graphene/copper composite and preparation method thereof

The invention provides a graphene / copper composite and a preparation method of the graphene / copper composite. Copper-nickel alloy powder and crystalline flake graphite are ball-milled mechanically jointly, alcohol is added as a wet milling medium during mechanical ball milling, and copper powder oxidation can be avoided. Graphene is stripped from the graphite by virtue of a mechanical force; at the same time, due to the presence of copper-nickel micro powder, a stripping process of the graphite is promoted; the spherical copper-nickel alloy powder is changed into sheeted powder by the action of the ball milling to obtain graphene / copper composite powder preliminarily; and a graphene / copper composite block, a composite wire and a composite tape are obtained by powder metallurgy, hot extrusion and rolling technologies. According to the composite, the graphene is dispersed uniformly; interface bonding between a matrix and a reinforcement; and the graphene / copper composite has excellent physical properties. According to the composite and the method, a technology is simple, a process is easy to control, and a scale production application is easy to achieve.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

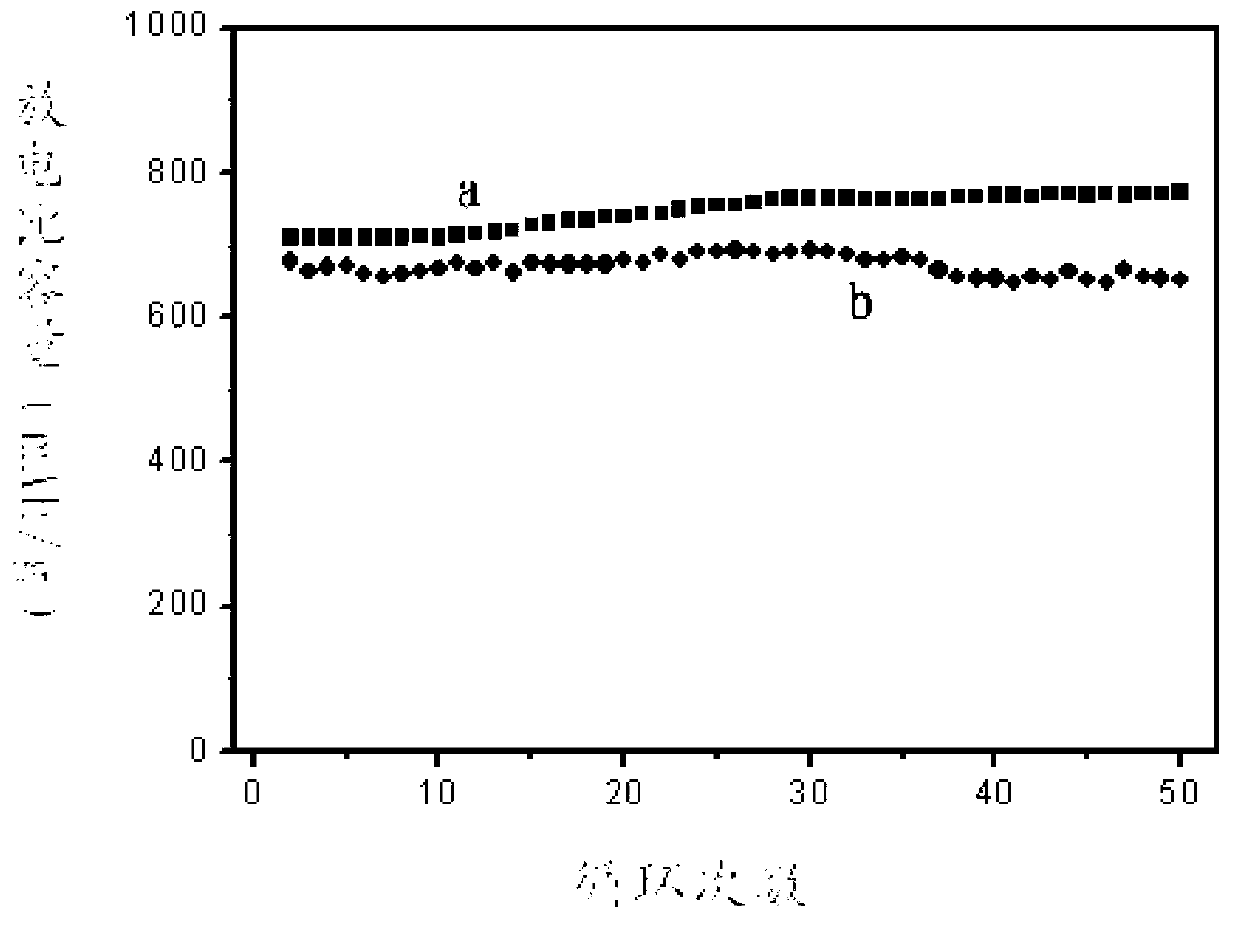

Lithium ion battery anode material manganese lithium phosphate and preparation method thereof

ActiveCN101320809AImprove electronic conductivityEvenly dispersedElectrode manufacturing processesPhosphorus compoundsCapacitanceLithium iron phosphate

The invention discloses a manganese / lithium phosphate of lithium iron battery positive pole material and a production method thereof, the technical issue to be solved is to improve electrochemical performances of the positive pole material. The material of the invention includes substrates of manganese / lithium phosphate which are covered by a carbon material covering layer, the lithium covering the manganese / lithium phosphate behind the carbon material covering layer is spherical and has microscopic characteristics of being near spherical, rhombic, tapered, tabular, layered or / and block-shaped as well as of having 0.5-30 mum long and short axles. The production method comprises the following steps of: production of nanometer particles, liquid phase mixed reaction, production of precursor, sintering treatment, covering organic substances. Compared with the prior art, the invention improves the electron conductivity of the manganese / lithium phosphate by covering with carbon liquid phase, the carbon sufficiently covers active materials to efficiently prevent particle aggregation, the invention has the characteristics of about 4V of discharge voltage, high discharge and charge capacitance, excellent circulation stability, high safety, simple process, low cost and little influence on the environment.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

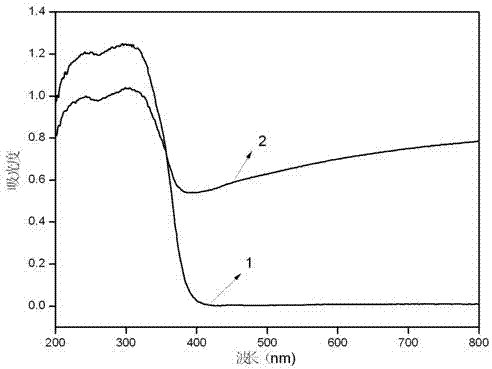

Nano titanium dioxide/ acrylate composite emulsion and preparation method thereof

InactiveCN102516477AAvoid reunionStable structureCoatingsGraft polymer adhesivesPtru catalystPolymer chemistry

The invention discloses nano titanium dioxide / acrylate composite emulsion and a preparation method thereof. The method comprises the following steps of: hydrolyzing butyl titanate to generate nano titanium dioxide sol in absolute ethanol by using hydrochloric acid as a catalyst, adding a vinyl-containing silane coupling agent for modifying the sol, performing centrifugal washing, drying and grinding on the obtained product to obtain nano titanium dioxide, and thus obtaining the nano titanium dioxide / acrylate composite emulsion by using acrylate monomers of methyl methacrylate, butyl acrylate and the like as reaction monomers and adopting a method combining in-situ emulsion polymerization and seed emulsion polymerization. The nano titanium dioxide / acrylate composite emulsion prepared by the method has good storage stability and is stable in a polymerization reaction process; and a film formed by the composite emulsion has good hardness, impact strength and heat resistance.

Owner:SOUTH CHINA UNIV OF TECH

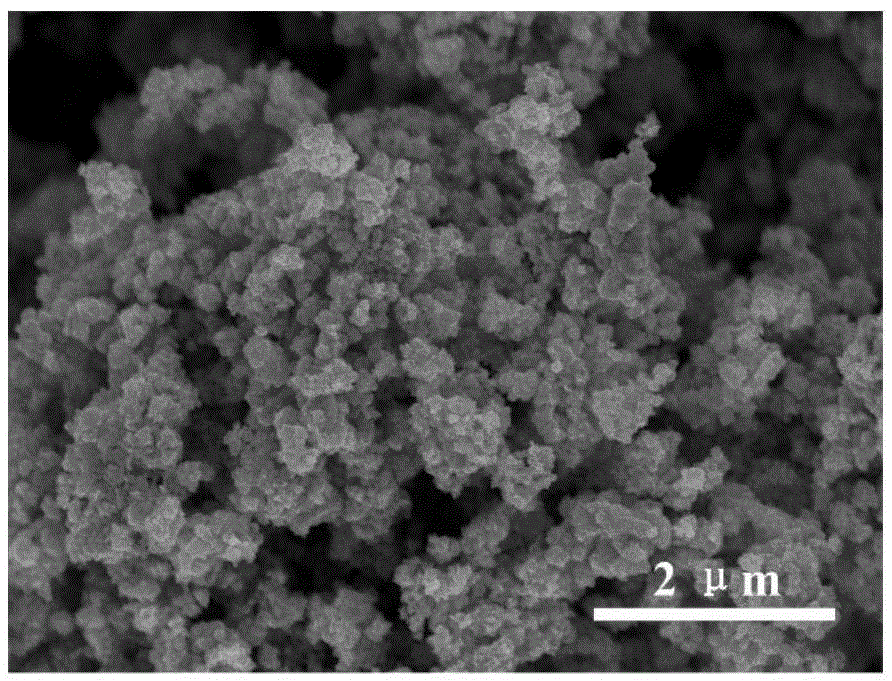

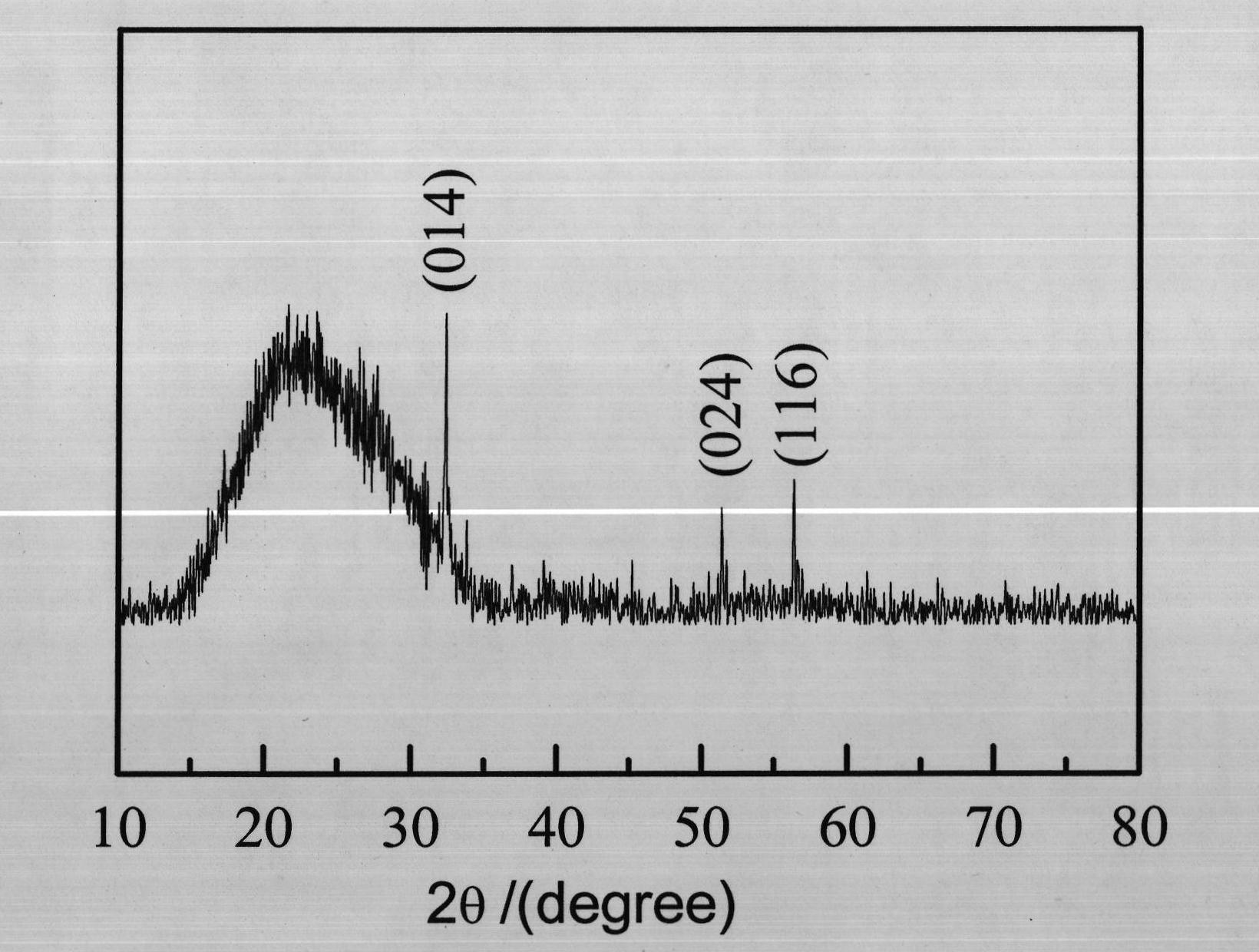

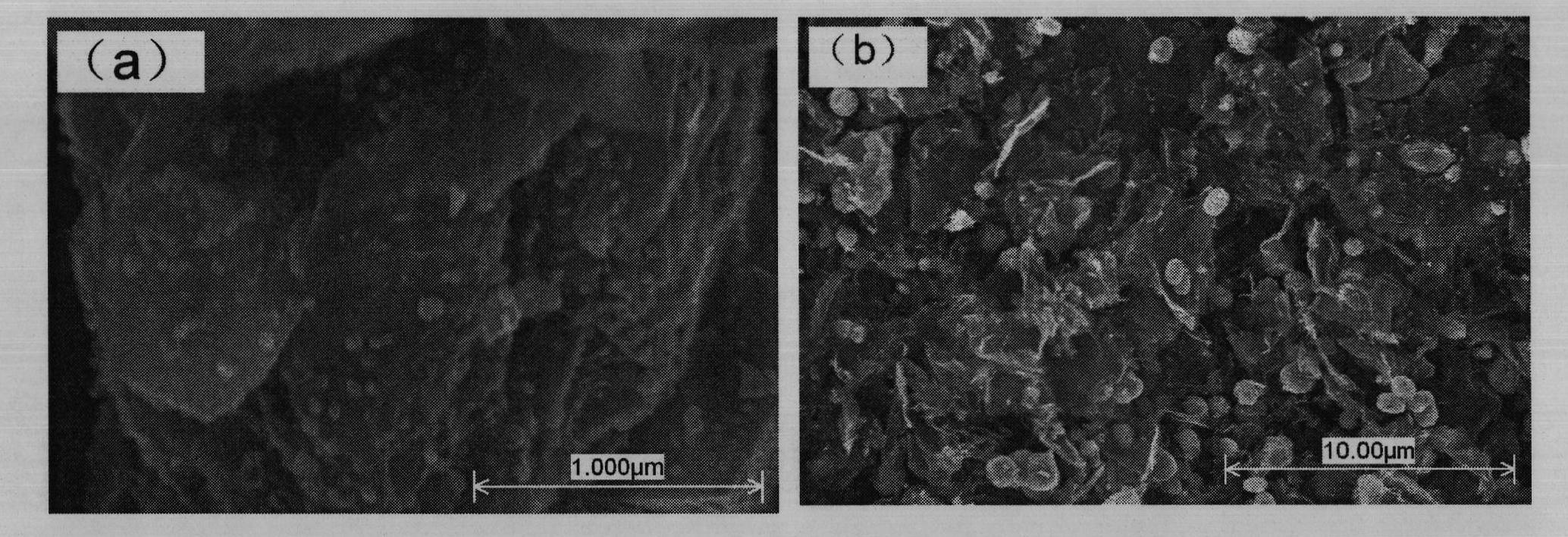

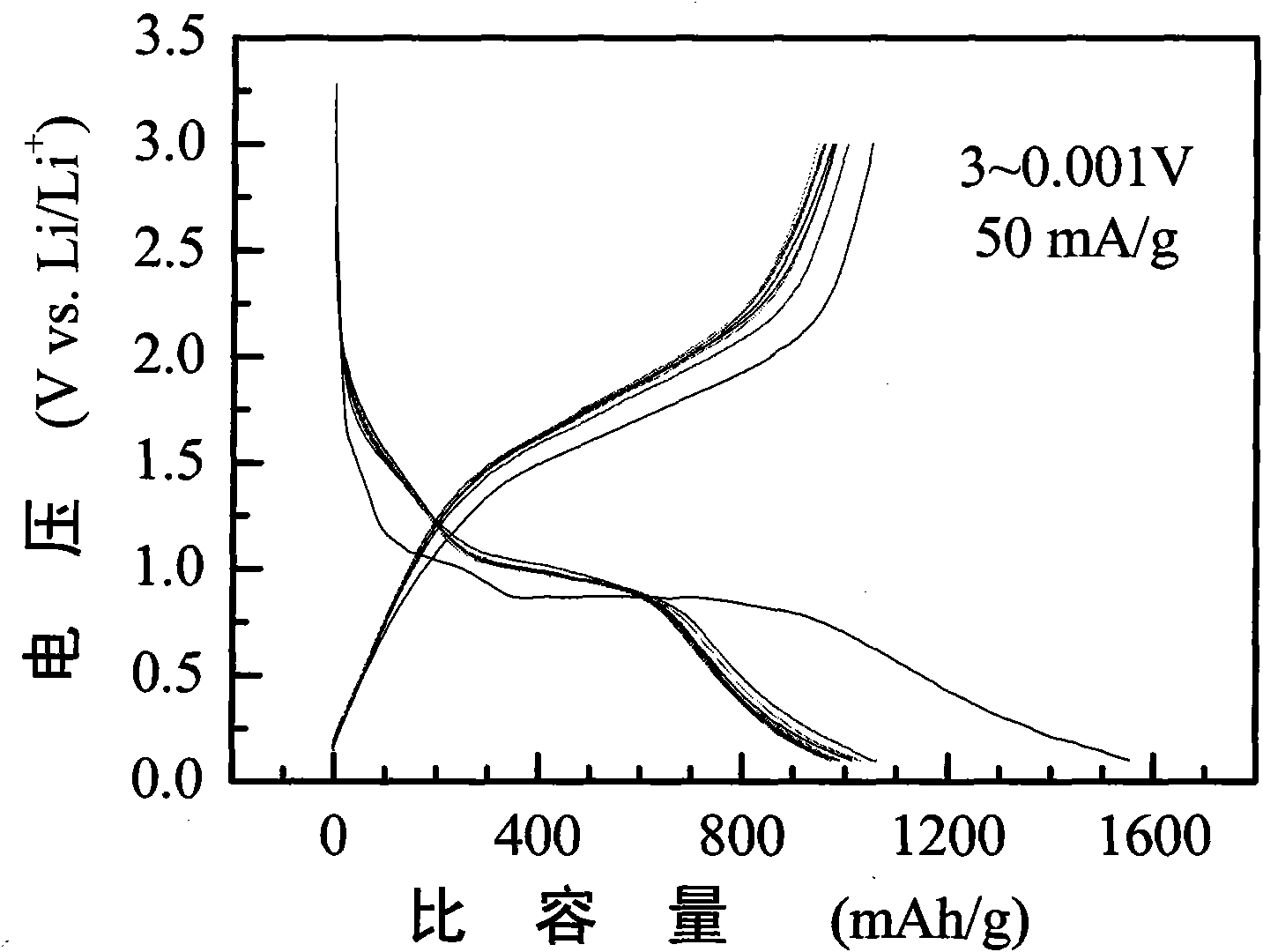

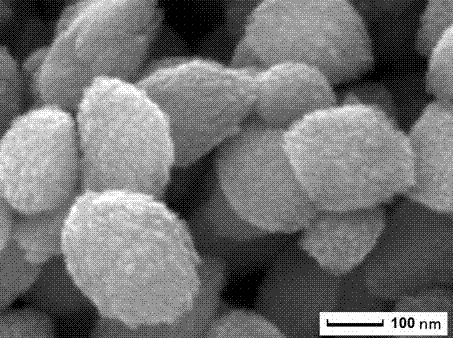

Cobalt-intercalated molybdenum sulfide secondary battery material and preparation method and application thereof

InactiveCN106611837AAvoid reunionAvoid stackingMaterial nanotechnologyHybrid capacitor electrodesLevel structureChemical solution

The invention relates to a cobalt-intercalated molybdenum sulfide secondary battery material and a preparation method and an application thereof. A three-dimensional cobalt-intercalated molybdenum sulfide multi-level structure is prepared by adopting a chemical solution method; firstly, a cobalt salt, a molybdenum salt and a sulfur source are dispersed into a solvent to prepare a reaction liquid; and then the prepared reaction liquid is subjected to solvent thermal treatment to obtain the three-dimensional cobalt-uniformly-intercalated molybdenum sulfide multi-level structure which is self-assembled by graphene-like ultra-thin nanosheets, wherein the size of the multi-level structure is about 100nm. The invention also discloses a preparation method for the multi-level structure. The secondary battery material prepared by the method is stable in nanomaterial performance, and long in cycle life when the secondary battery material is used as a negative electrode material of a lithium ion battery and an electrode material of a supercapacitor.

Owner:SHANGHAI JIAO TONG UNIV

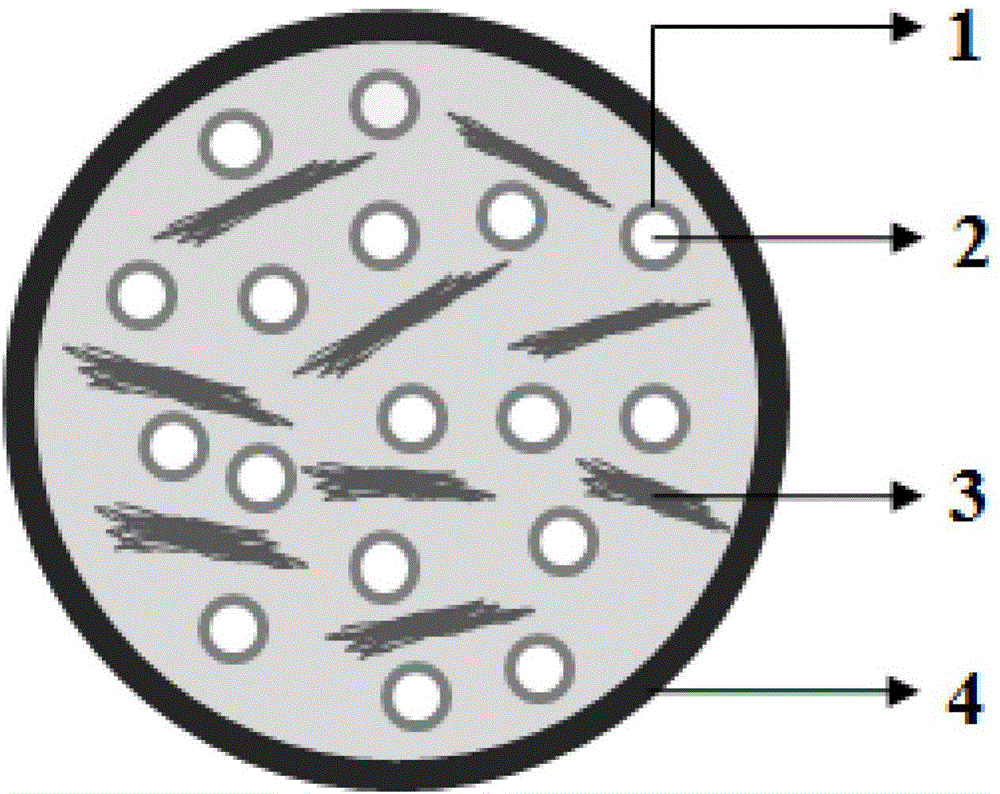

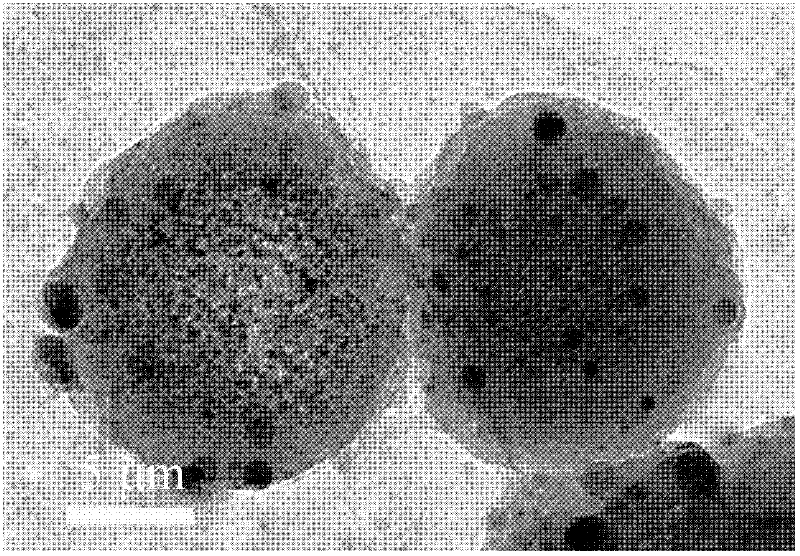

Carbon-coated nano silicon/graphene/cracked carbon layer composition material, preparation method, and lithium ion battery including the composition material

InactiveCN106067547AAchieve perfect compoundSimple processMaterial nanotechnologyCell electrodesNano siliconCarbon layer

The invention relates to a carbon-coated nano silicon / graphene / cracked carbon layer composition material, a preparation method thereof, and a lithium ion battery including the composition material. The composite material comprises spherical particles formed by uniformly dispersing carbon-coated nano silicon in graphene sheets, and a cracked carbon layer which coats the surfaces of the spherical particles. The carbon-coated nano silicon comprises nano silicon and carbon coating layer which coats the surface of the nano silicon. The method is simple, has excellent process performance and is environment-friendly. The carbon-coated nano silicon / graphene / cracked carbon layer composition material has stable structure and high compact density, has excellent performance when being used as an anode material of the lithium ion battery, has high anode capacity, excellent rate capability and cyclic performance, is more than 1500 mAh / g in first-time reversible capacity, is more than 90% in first-time coulomb efficiency and is more than 90% in 500-time cyclic capacity retention ratio and has low expansion.

Owner:BTR NEW MATERIAL GRP CO LTD

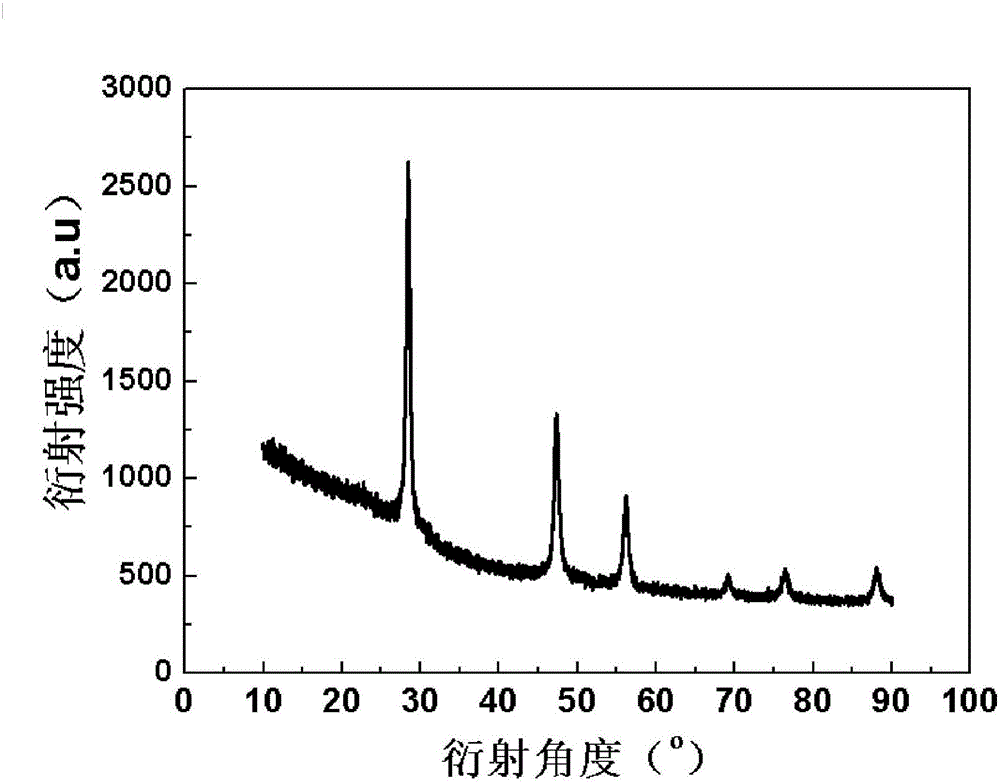

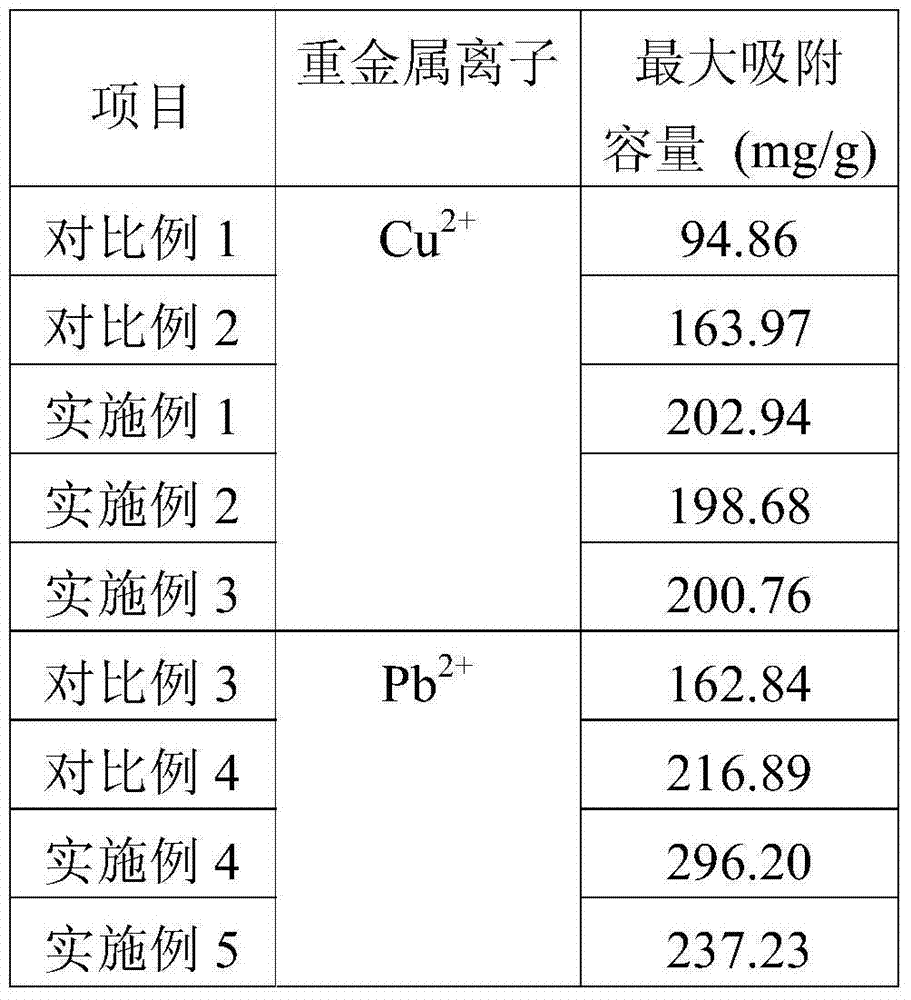

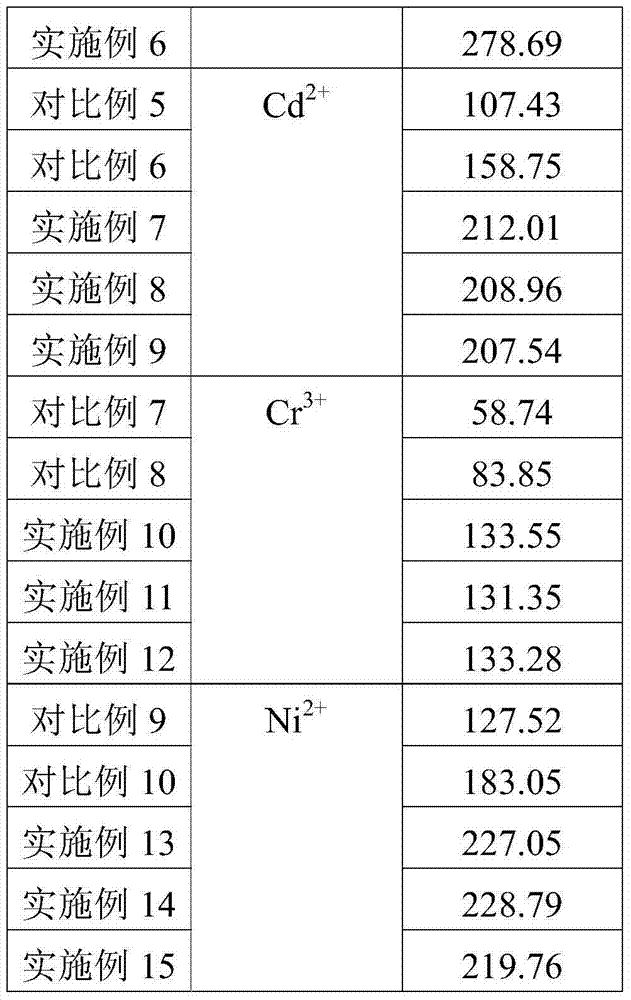

Composite hydrogel for adsorption of heavy metal ions and preparation method thereof

ActiveCN104226281ASimple preparation processGood biocompatibilityOther chemical processesAlkali metal oxides/hydroxidesIonHeavy metals

The invention discloses composite hydrogel for adsorption of metal ions and a preparation method thereof. The hydrogel comprises, by weight, 5-95 parts of polyvinyl alcohol, 5-95 parts of chitosan, 0.1-20 parts of modified graphene oxide and 2-6 parts of sodium alginate, the weight ratio between the polyvinyl alcohol and the chitosan is (5: 95)-(95: 5), modified graphite oxide includes modified graphene oxide modified by dopamine and / or modified graphene oxide modified by ferroferric oxide, all components are uniformly mixed in a certain sequence, and the composite hydrogel is obtained under special conditions. The composite hydrogel for adsorption of the heavy metal ions and the preparation method thereof have the advantages that high speed, high efficiency, high adsorption capacity and high selectivity are achieved, the adsorption effect on the heavy metal ions is remarkable, meanwhile, the preparation process is simple, and the operability is high.

Owner:JIANGNAN UNIV

Graphene/carbon black thermoplastic resin master batch with high dispersibility and preparation method thereof

The invention discloses a graphene / carbon black thermoplastic resin master batch with high dispersibility and a preparation method thereof. The graphene / carbon black compound in the master batch is formed in an electrostatic self-assembly manner, and comprises 10-50% of graphene, 5-20% of carbon black, 0.5-10% of surfactant, 10-65% of carrier resin and 2-10% of assistant. The preparation method comprises the following steps: (1) compounding and dispersing graphene by adopting the surfactant to control the positive electricity of the graphene surface; (2) forming a stable graphene / carbon black compound from the modified graphene and carbon black with positive electricity through electrostatic incorporation in a self-assembly manner; (3) preparing the graphene / carbon black thermoplastic resin master batch with high dispersibility by matching with a solution blended process, a melt-blending method and an in-situ polymerization method; (4) adding the assistant to extrude and pelletize, so as to prepare the graphene / carbon black / thermoplastic resin master batch particles after processing the master batch. By adopting the obtained master batch, the problems of difficult charging of graphene powder, uneven dispersion, dust pollution, unstable product performance and the like are solved.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

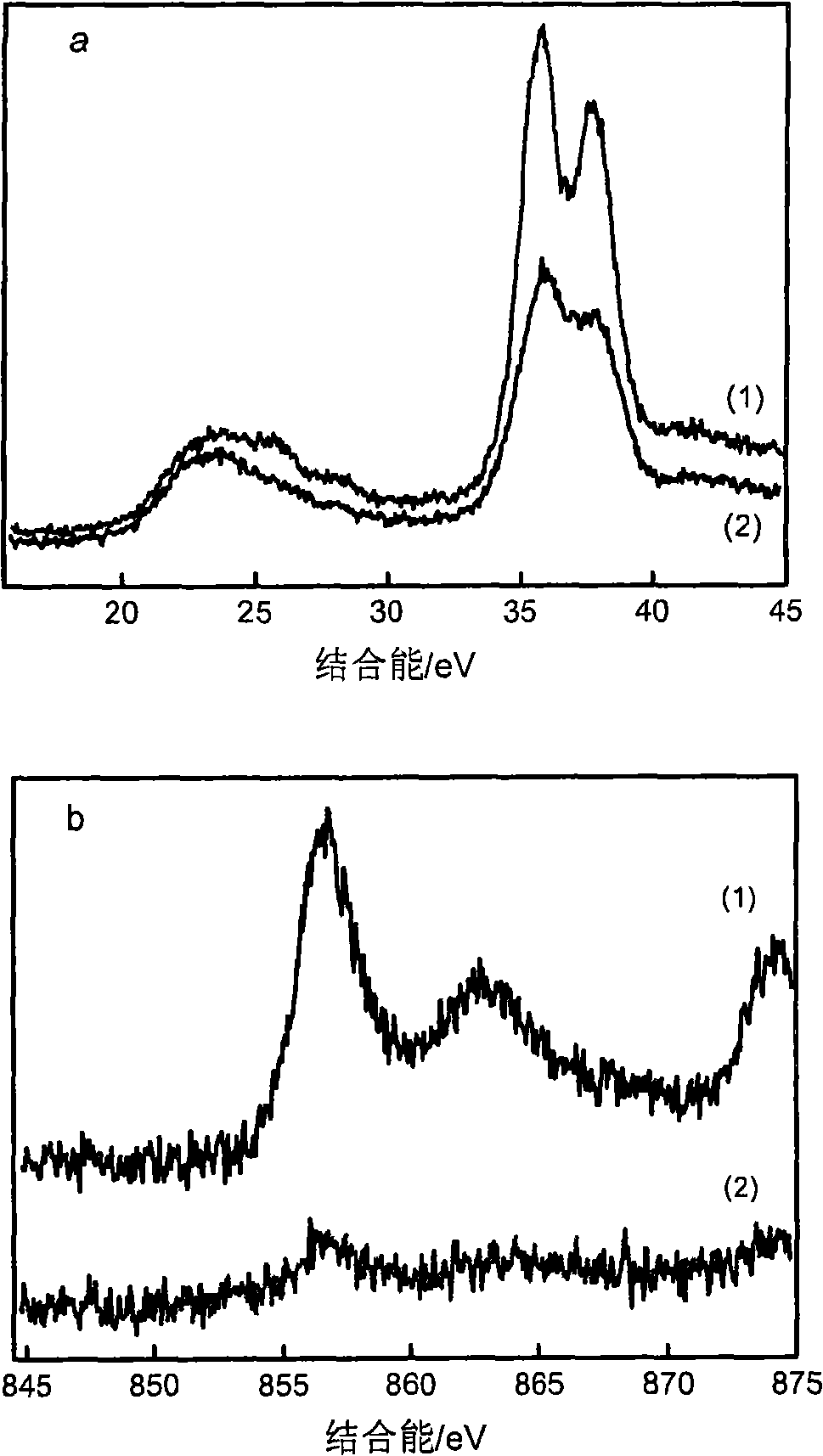

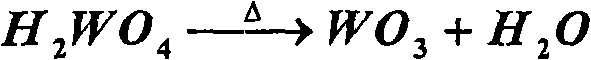

Preparation of hydrogenation catalyst

InactiveCN101298047AEvenly dispersedSmall sizeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHigh activationReaction temperature

The invention provides a method for preparing a hydrogenation catalyst with high activation. A disposition method is adopted to carry out step-by-step loading to the active components of the metals of VIB and VIII families; the VIB metal comprises tungsten or molybdenum, while the VIII metal comprises nickel or cobalt; a carrier is alumina. The loading of VIB metal takes a corresponding soluble salt as raw material, an acid solution as a precipitator and a cationic surface active agent as a dispersant. In a hydrothermal condition, the corresponding soluble salt, the acid solution and the cationic surface active agent produce metallic oxide particles by a liquid deposition reaction; the loading of VIII metal also takes a corresponding soluble salt as raw material and carbamide as a precipitator; the adding of the precipitator and the generation of precipitation are separated by controlling reaction temperature in sections and even precipitation is realized to disperse the particles of the active components on the carrier evenly. The hydrogenation catalyst prepared shows good effects in the respects of desulfurization and denitrification activation and can greatly reduce the usage of the active components.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

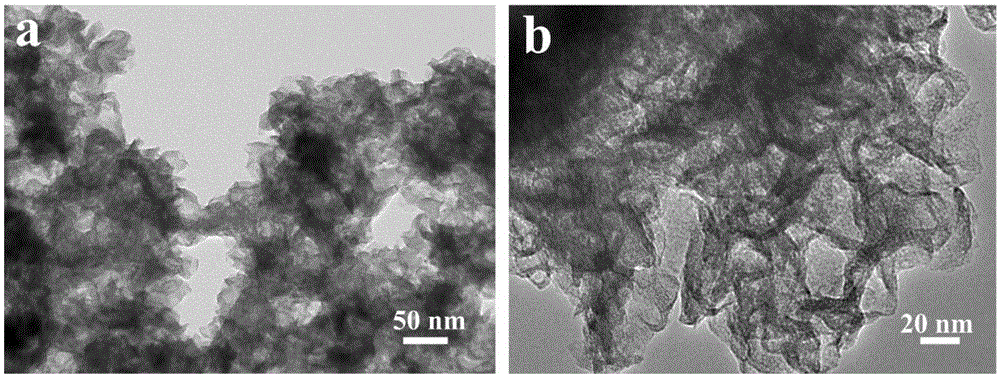

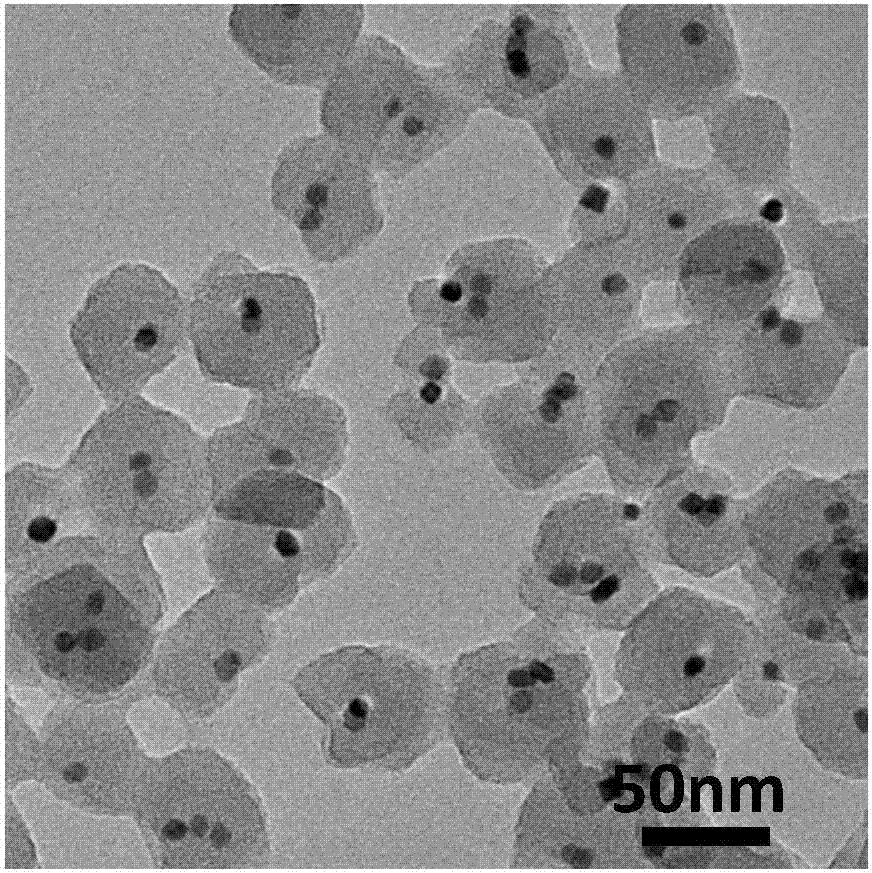

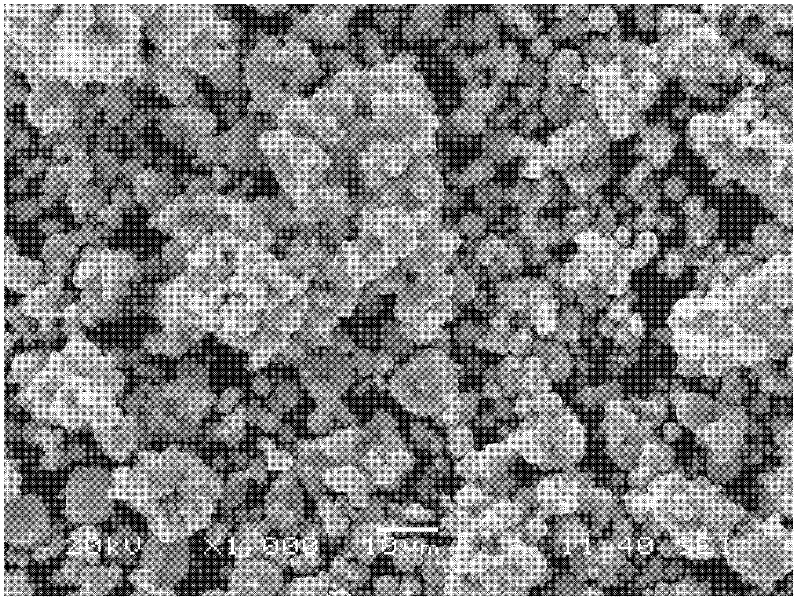

Graphene-based nano iron oxide composite material and preparation method thereof

InactiveCN102130334AAvoid reunionPrevent heavy stackingMaterial nanotechnologyCell electrodesNano compositesFreeze-drying

The invention discloses a graphene-based nano iron oxide composite material and a preparation method thereof. By the method, iron oxide nano granules with uniform diameter and controllable shape and components can be loaded on graphene. The method comprises the following steps of: uniformly dispersing graphite oxide into deionized water by adopting an ultrasonic method to obtain graphene oxide solution; adding an iron salt precursor into the obtained solution and mixing the precursor and the solution uniformly, adjusting the pH of the solution, and hydrolyzing the iron salt; putting the mixed solution into a reaction kettle and performing hydrothermal reaction; and finally, cleaning and freeze-drying the obtained product to obtain the graphene-based nano iron oxide composite material. The raw materials are common and easily obtained, the cost is low, and the preparation process is simple, safe and environmentally-friendly; the prepared graphene-based nano iron oxide composite material has good structural stability and monodispersity; when the composite material is used as a lithium iron battery electrode material, the charge / discharge capacity can reach over 1,000mAh / g; and the composite material has good multiplying power performance and cycle life.

Owner:CHINA UNIV OF MINING & TECH

Nano porous corrosion-resistant heat-insulated coating material taking thixotropic colloid as template agent and preparation method for corrosion-resistant heat-insulated coating material

ActiveCN105315743AAvoid reunion and scatter problemsSimple preparation processChemical industryAnti-corrosive paintsAqueous corrosionCorrosion prevention

The invention relates to an aqueous nano porous corrosion-resistant heat-insulated coating material and a preparation method for the corrosion-resistant heat-insulated coating material and particularly relates to an aqueous corrosion-resistant heat-insulated coating material, which has a nano porous structure, prepared through forming an aqueous-phase uniform three-dimensional-network nano porous structure by taking thixotropic colloid as a template agent and adding a film forming agent, a reinforcing powder material, a functional powder material and admixtures. The preparation method for the corrosion-resistant heat-insulated coating material, disclosed by the invention, is simple and easy in operation and low in production cost, is environment-friendly and safe and is beneficial to mass production. The nano porous corrosion-resistant heat-insulated coating material disclosed by the invention has excellent heat insulating and corrosion resisting properties and can be applied to the heat insulating and corrosion resisting of equipment such as high-temperature furnace hearths, pipelines and valves in the fields of aerospace and military industries, metallurgical forging, petroleum refining, electric power and the like, so that the safety of use and the level of energy saving and consumption lowering are improved.

Owner:浙江圣润纳米科技有限公司

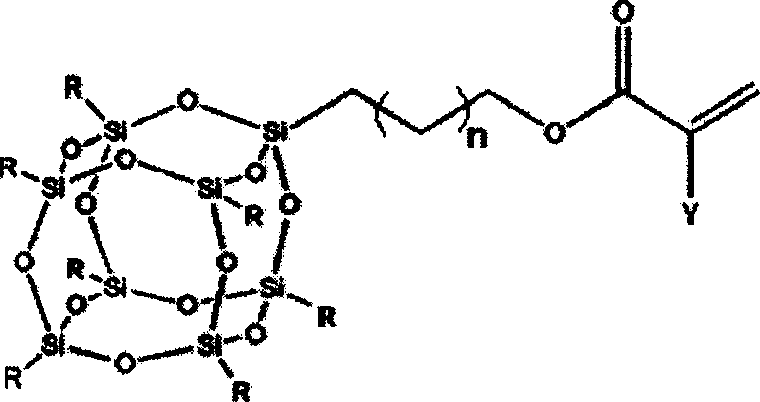

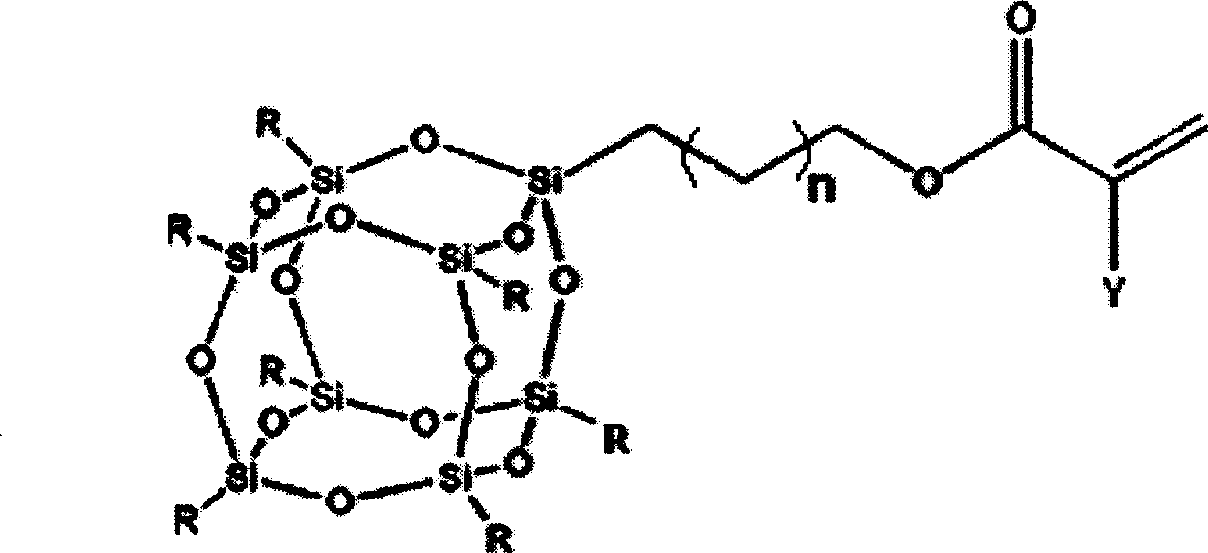

Coating material containing POSS acrylate copolymer and preparing method

The invention relates to a manufacturing method for coat material containing POSS acrylate copolymer. It takes free radical copolymerized to acr monomer and other acr monomer, and uses as modifier adding into the base compounding of UV coat, after taking UV solidification the coat material of high rigidity would be gained. The constituent includes 40-55% light-cured resin, 5-20% active modifier, 20-45% spike, 1-10% photoinitiator, 2-10% anti-foam additive. The rigidity of coat could reach to 6H, and the shrinkage ratio could reach 2%.

Owner:XIAMEN UNIV

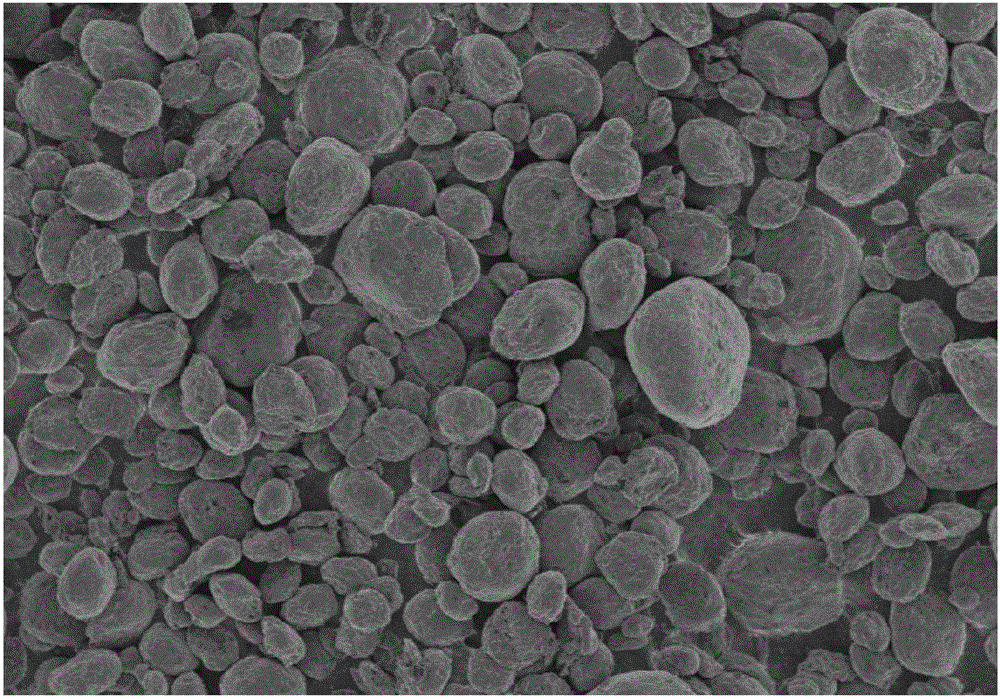

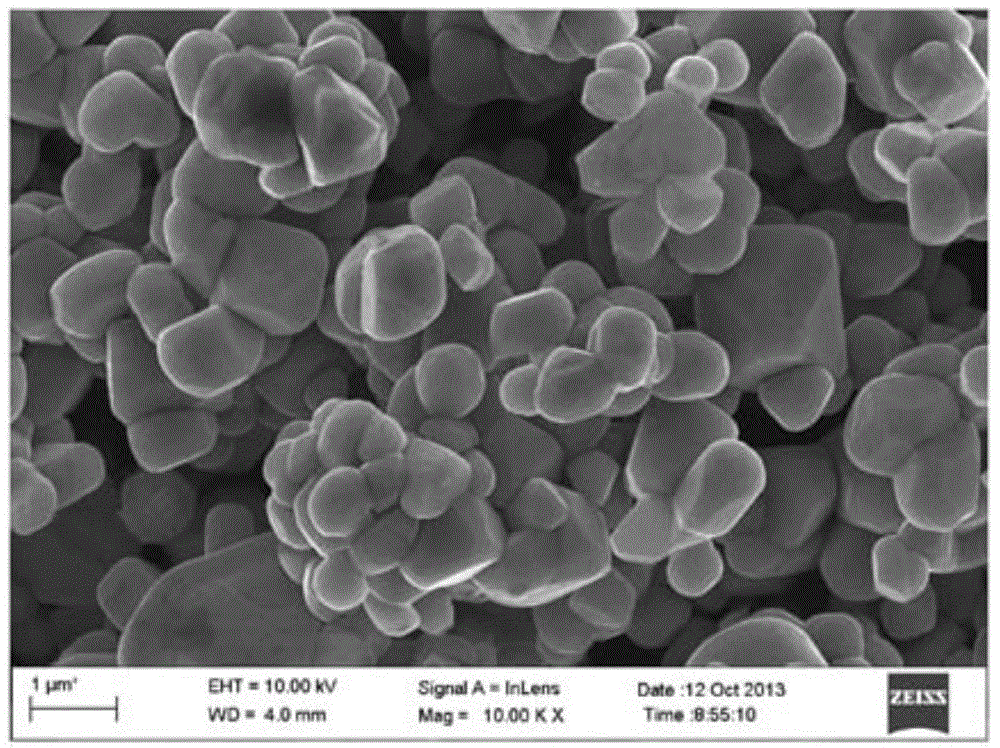

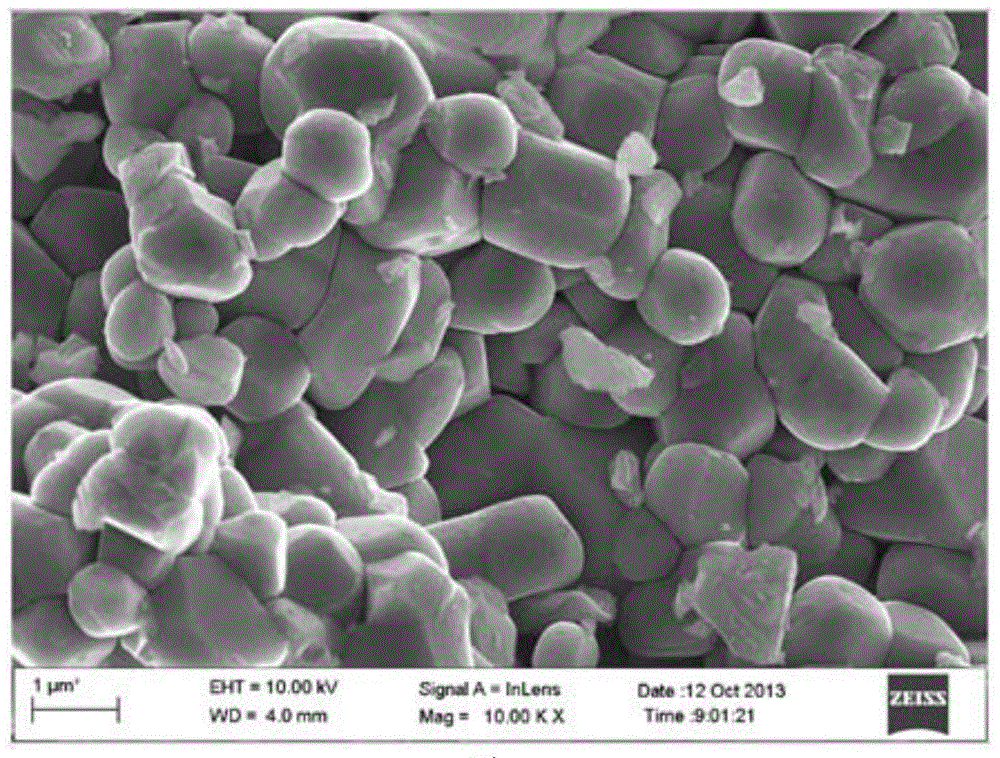

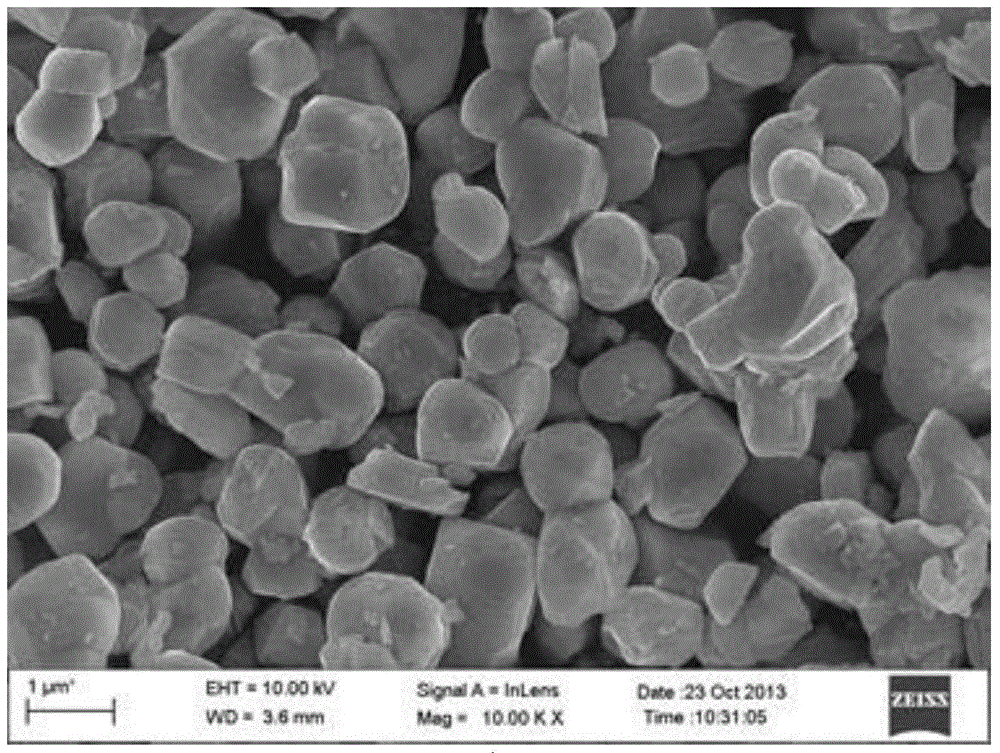

Preparation method of single-crystal-morphology lithium ion battery ternary positive material

ActiveCN104979546AGood dispersionOvercoming the problem of easy reunificationCell electrodesLithium electrodeOxide

The invention discloses a preparation method of a single-crystal-morphology lithium ion battery ternary positive material. The method comprises the following steps: (1) preparing an inflorescence-shaped ternary positive material precursor particles by clustering lamellar primary particles in a coprecipitation method, wherein the D50 of the precursor particles is 2-5micron, the BET is more than 100m<2> / g, and the valences of nickel, cobalt and manganese are +2; (2) mixing a precursor obtained by adopting the coprecipitation method with auxiliaries to obtain a mixture 1, and performing high-temperature sintering on the mixture 1 at the temperature between 600-950 DEG C so as to obtain a round-likely roundness type oxide; (3) mixing the round-likely roundness type oxide precursor obtained by the high-temperature sintering with a lithium salt so as to obtain a mixture 2, and performing sintering on the mixture 2 at the temperature between 700-1000 DEG C so as to obtain a product; and (4) dispersing the product obtained by sintering in the step (3), and performing heating treatment on the dispersed product at the temperature between 780-1000 DEG C so as to obtain the single-crystal-morphology lithium ion battery ternary positive material. The prepared positive material is made from the uniform single-crystal primary particles with good dispersibility, and the problem that the primary particles are easy to cluster in the high-temperature sintering process in a conventional method can be effectively overcome.

Owner:CONTEMPORARY AMPEREX TECH CO

Novel nano calcium carbonate used for plastic film and preparation method thereof

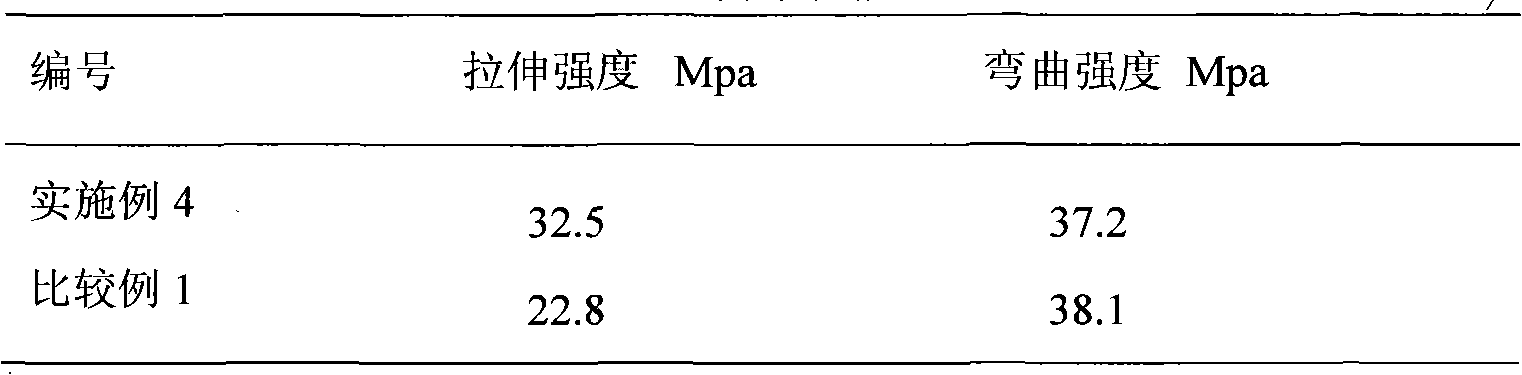

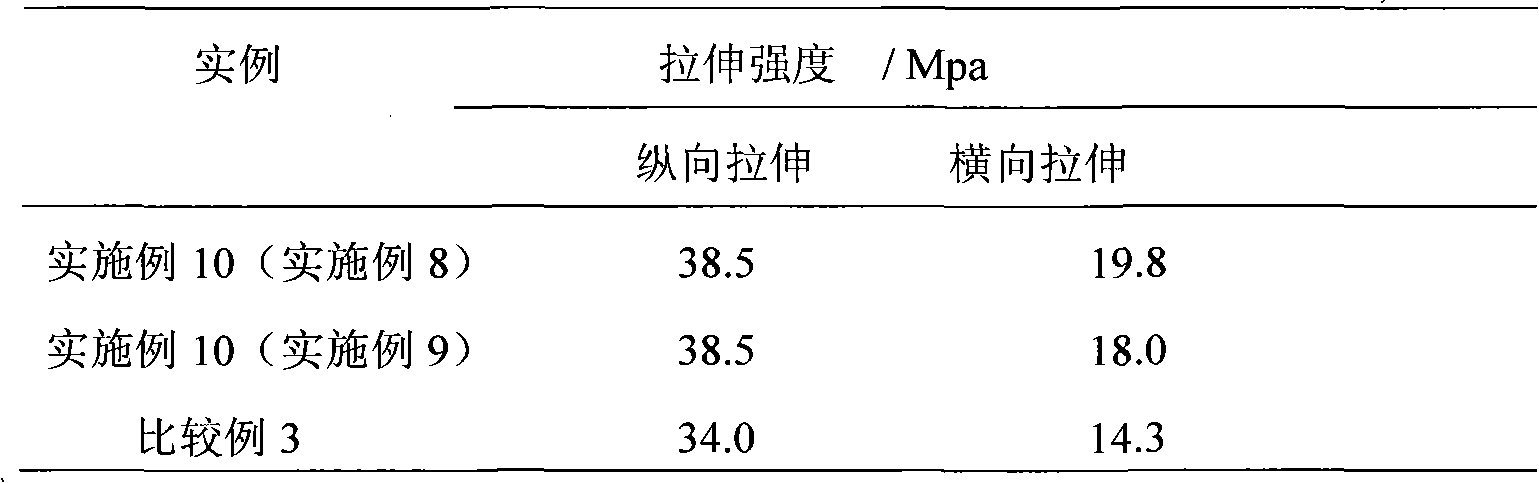

InactiveCN101967298AImprove hydrophobicityAvoid reunionPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPolyolefinMechanical property

The invention discloses novel nano calcium carbonate used for a plastic film and a preparation method thereof. A Ca(OH)2 suspension and CO2 are carbonized in a reactor to generate the nano calcium carbonate, and then the obtained nano calcium carbonate is subjected to liquid phase coating treatment or is directly subjected to mixed coating by using dried nano calcium carbonate and a surfactant to obtain nano calcium carbonate powder which is highly dispersed and surface-activated. The invention has the advantages that: the process is simple, the nano calcium carbonate is effectively dispersed in a polymer and a remarkable enhancement effect can be achieved on the premise of ensuring the transparency. The nano calcium carbonate prepared by adopting the invention can remarkably improve the mechanical property of a polyolefin material; after the nano calcium carbonate is used for polyethylene plastic, the tension strength of the material is greatly improved; and after the nano calcium carbonate is used for a polyolefin film, a fish eye is free, and the high transparency of the film is maintained.

Owner:山东海泽纳米材料有限公司

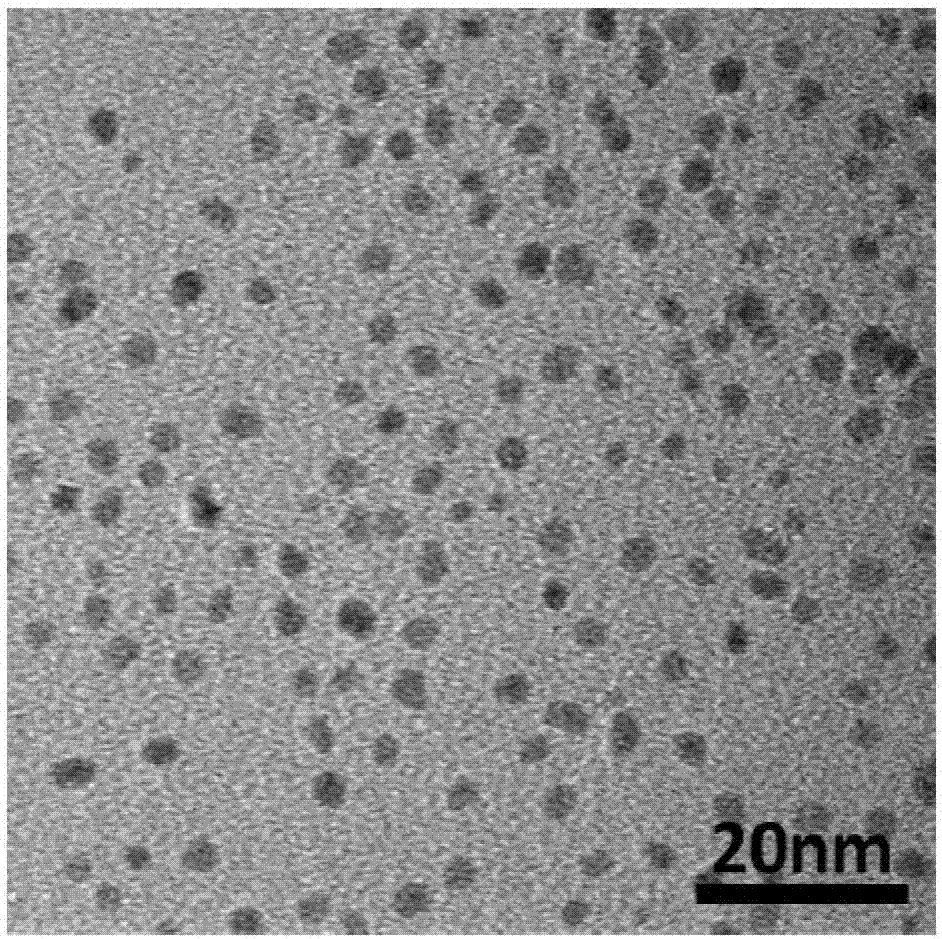

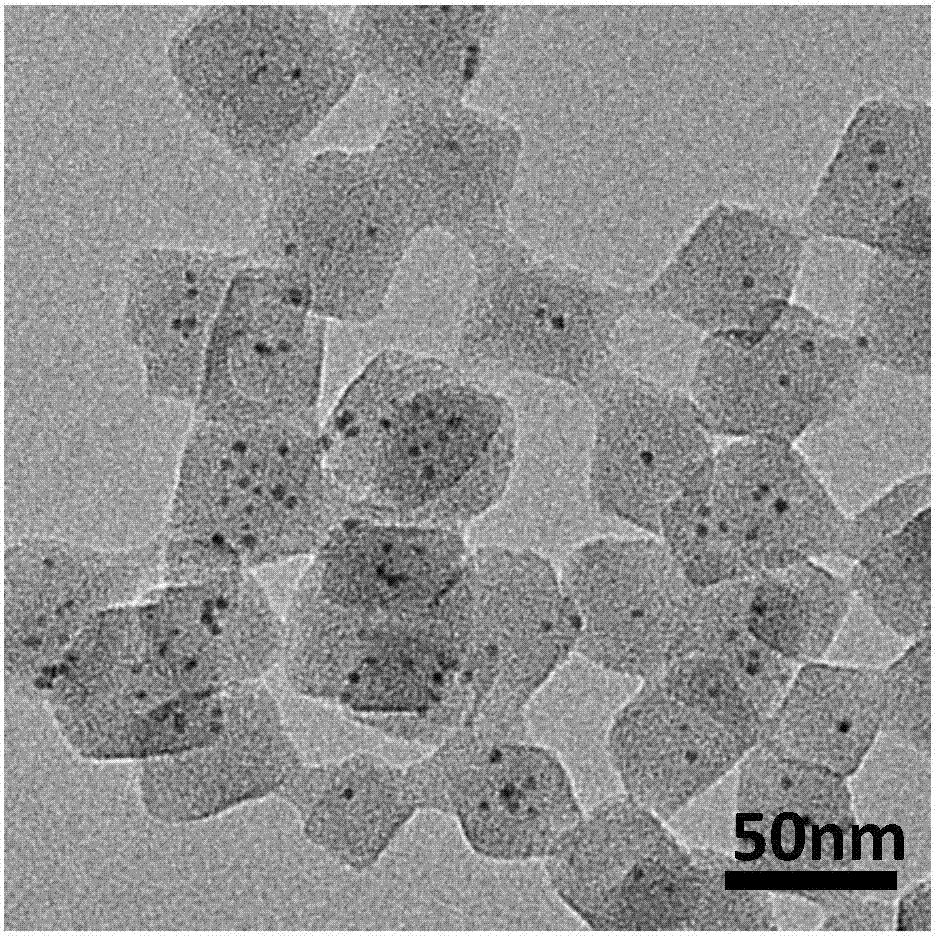

Preparation method of nano-particle@minisize metal organic frame material

InactiveCN107349964AAvoid reunionShort diffusion pathMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsMetal-organic frameworkBiological imaging

The invention relates to a preparation method of a nano-particle@minisize metal organic frame material. The preparation method comprises the following steps of 1, preparing nano-particles modified by polyvinylpyrrolidone; 2, adding the obtained nano-particles into an MOF growth reaction solution, the addition amount of an adjusting agent is controlled, and the nano-particle@minisize metal organic frame material is obtained. The method is simple and easy to implement, mild in condition and high in applicability, and the prepared nano-particle@minisize metal organic frame material can effectively prevent nano-particle aggregation, meanwhile has the advantages of being good in size selectivity, and short in diffusion range between the surface of the metal organic framework and the active center of nano-particles, and has the wide application prospect in the fields of catalysis, biological imaging and the like.

Owner:BEIJING UNIV OF CHEM TECH

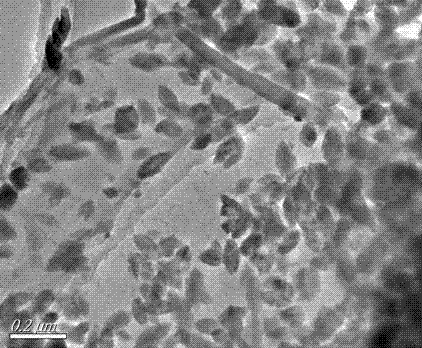

Graphene/mesoporous titanium dioxide visible light catalyst and preparation method

InactiveCN102350334AUniform particle sizeUniform sizePhysical/chemical process catalystsWater/sewage treatment by irradiationDispersityAcetic acid

The invention relates to a graphene / mesoporous titanium dioxide visible light catalyst and a preparation method, and belongs to the technical fields of nanometer composite materials and photocatalysis. The method comprises the following steps of: adding a graphene oxide into glacial acetic acid, and performing ultrasonic dispersion to obtain dispersion liquid of the graphene oxide; and adding a titanium source into the dispersion liquid of the graphene oxide, and preparing the graphene / mesoporous titanium dioxide nanometer composite visible light catalyst in a one-step in-situ form by a hydrothermal method. The graphene / mesoporous titanium dioxide visible light catalyst has the advantages of readily available raw materials and low cost, the preparation process is simple and convenient, and titanium dioxide in the obtained nanometer composite material has a nanometer poroid structure, a regular size and a special appearance; and titanium dioxide nanometer granules can be distributed onthe surface of graphene and are high in dispersity. Photocatalytic degradation experiments indicate that the graphene / mesoporous titanium dioxide nanometer composite light catalyst has a good photocatalytic degradation effect on rhodamine B under the irradiation of visible light, and is an ideal nanometer composite visible light catalyst.

Owner:JIANGSU UNIV

High salinity wastewater treatment corrosion-resistant anti-fouling membrane as well as preparation method and application thereof

ActiveCN107715700AImprove performanceNot easy to fall offMembranesSemi-permeable membranesClay mineralsPollution

The invention relates to a method of the technical field of environment protection and in particular to a high salinity wastewater treatment corrosion-resistant anti-fouling membrane as well as a preparation method and application thereof. The preparation method comprises the following steps: by taking a mixture of clay minerals and oceanic nodule minerals as inorganic nano particles, modifying the inorganic nano particles with dopamine, and combining a PVDF (Polyvinylidene Fluoride) polymer with the nano particles, thereby obtaining the high salinity wastewater treatment corrosion-resistant anti-fouling membrane. The invention aims to improve the water flux, the corrosion resistance and the pollution resistance of the membrane, the mixture of the clay minerals and the oceanic nodule minerals is adopted as the inorganic nano particles, the inorganic nano particles are subjected to surface modification with dopamine, combination of the nano particles and the PVDF is promoted, the obtained membrane is capable of efficiently treating high salinity wastewater and meanwhile has properties of corrosion and fouling resistance; in addition, the dopamine has a great amount of hydrophilic groups of amino, particle aggregation is prevented, the hydrophilcity of the membrane is improved, and the difficulties that materials are not uniformly dispersed and are easily dropped off in the use process are solved.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

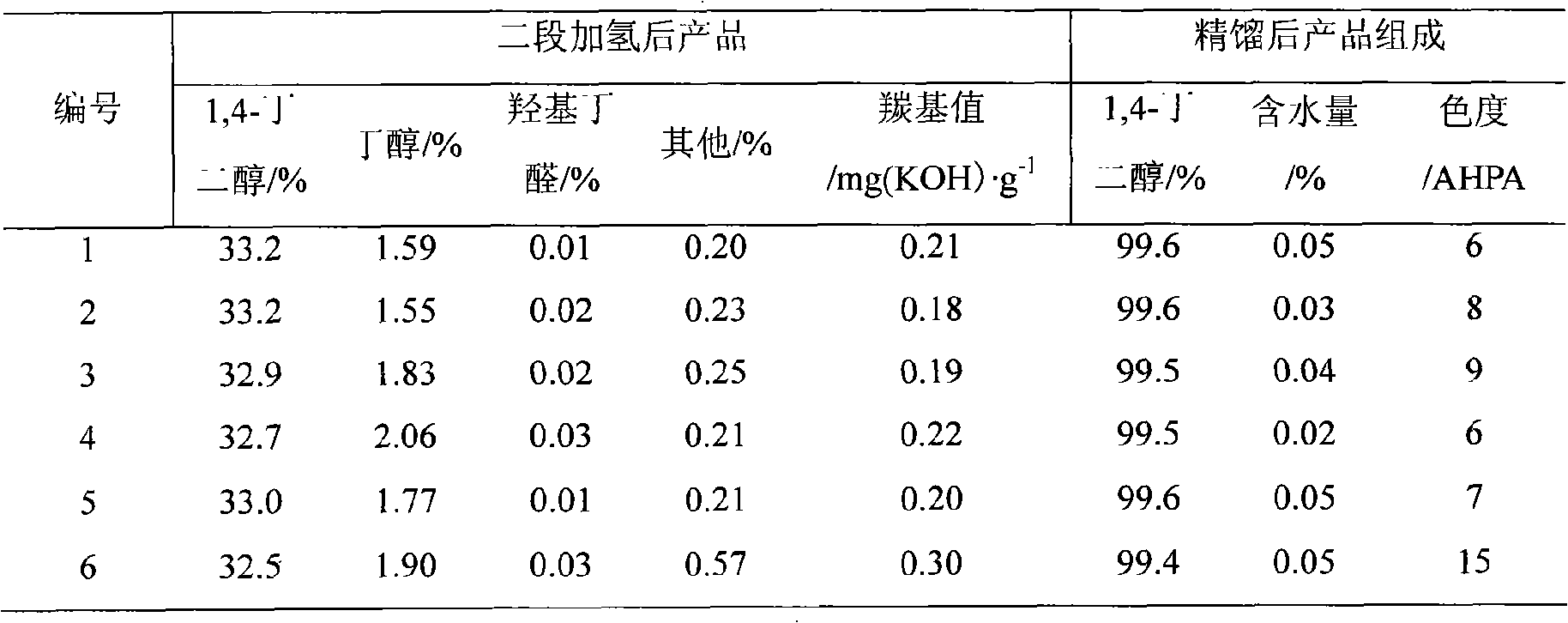

Preparation method of butanediol secondary hydrogenation catalyst by butynediol two-step hydrogenation

ActiveCN101306368AUniform depositionGood dispersionPreparation by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickel saltSURFACTANT BLEND

The invention provides a method for preparing a butanediol secondary hydrogenation catalyst through adopting the butynediol two-step hydrotreation, and the method comprises the following steps: an accelerant is introduced into an alumina carrier; the carrier is heated; mixed nickel complex solution containing organic nickel salt, inorganic nickel salt and surfactant is prepared; the mixed nickel salt solution is dipped on the heated carrier, and the catalyst product with the nickel content of 5-25 w% and the accelerant content of 0.001-6 w% can be obtained by drying, baking, deoxidizing and passivating. The catalyst can be used in the process of preparing the butanediol secondary hydrogenation by adopting the butynediol two-step hydrotreation, the carbonyl can be reduced to be lower than 0.2 mg (KOH)*g<-1>, and the contents of acetal and butylene glycol are enabled to be reduced to the lowest level. Through the subsequent rectification, the butylene glycol product with the purity more than or equal to 99.5 percent and the chromaticity lower than or equal to 10 AHPA can be produced.

Owner:SHANXI UNIV

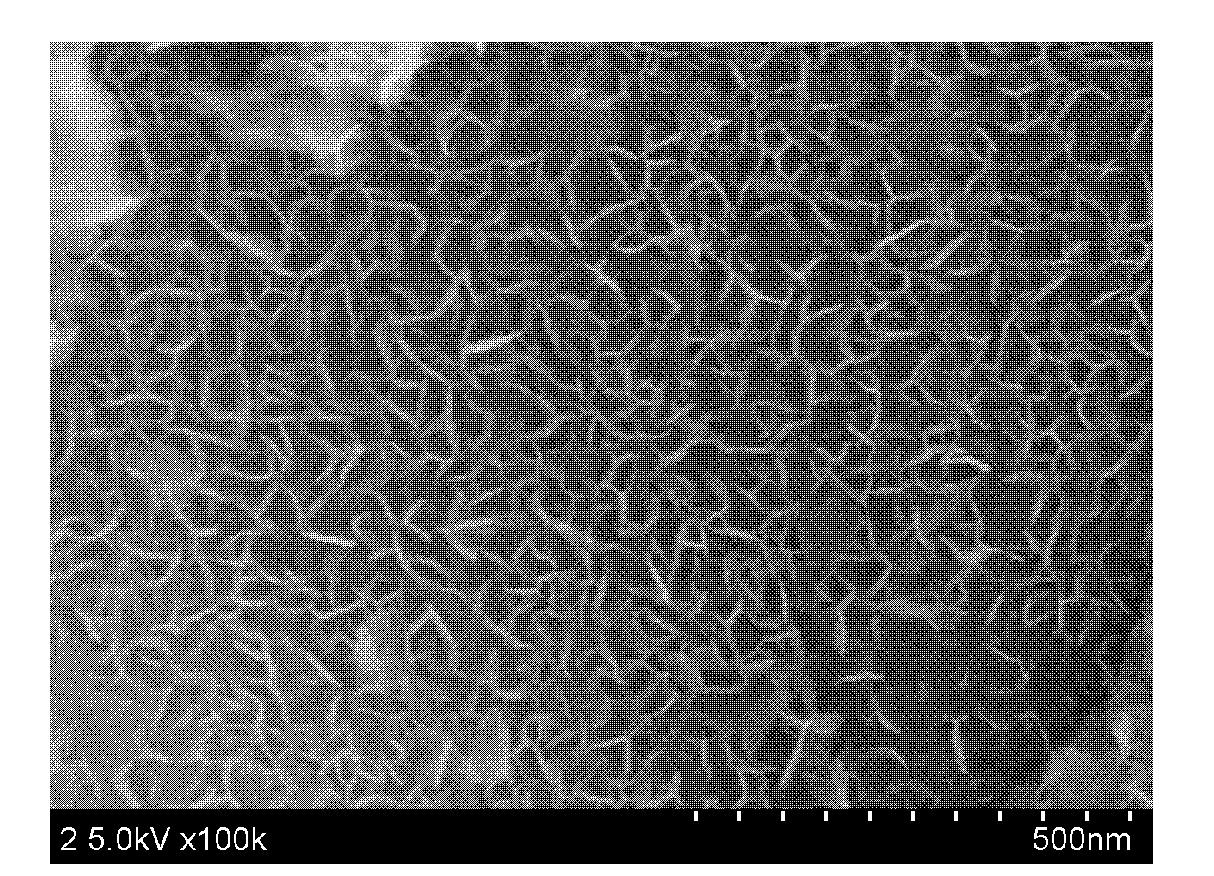

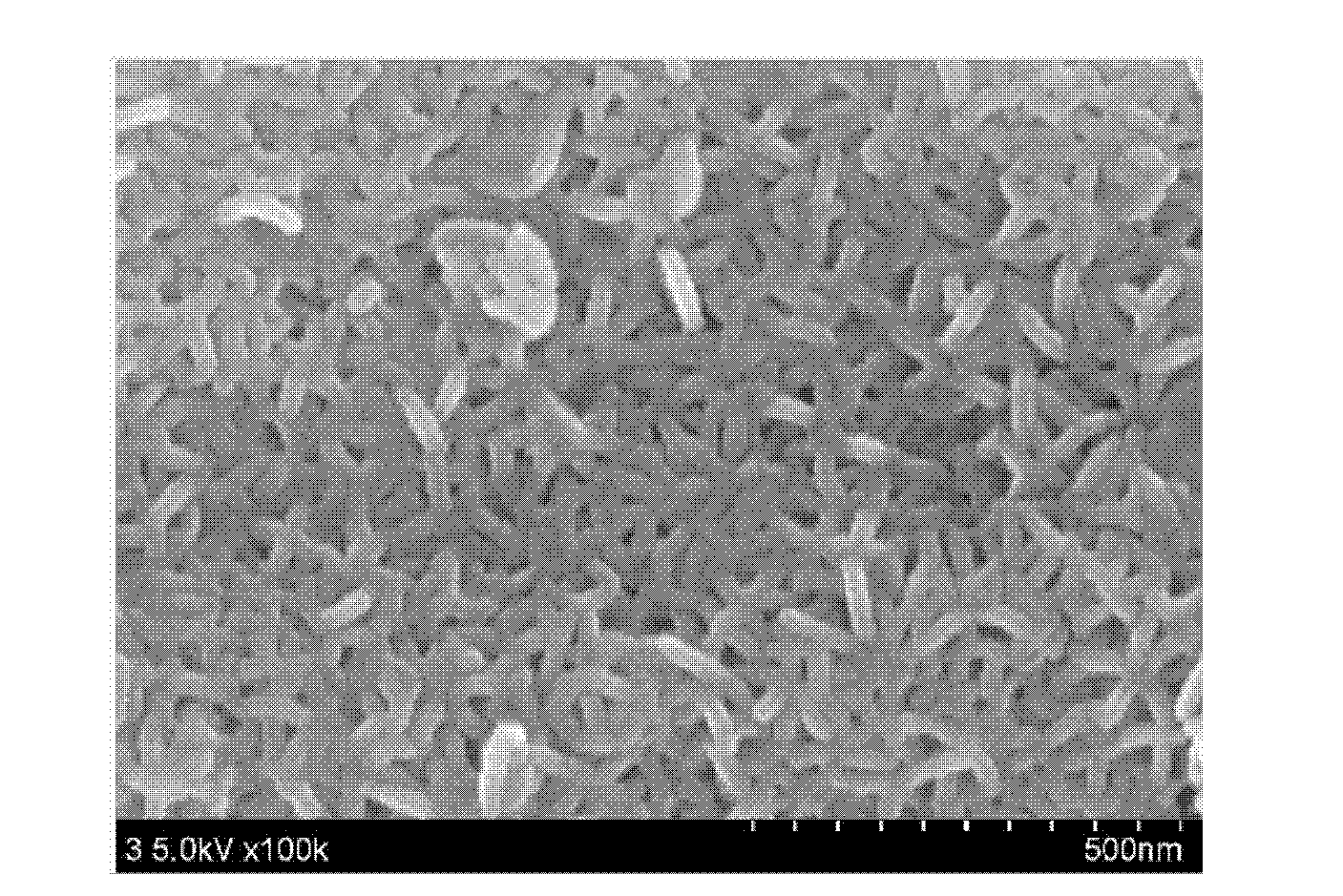

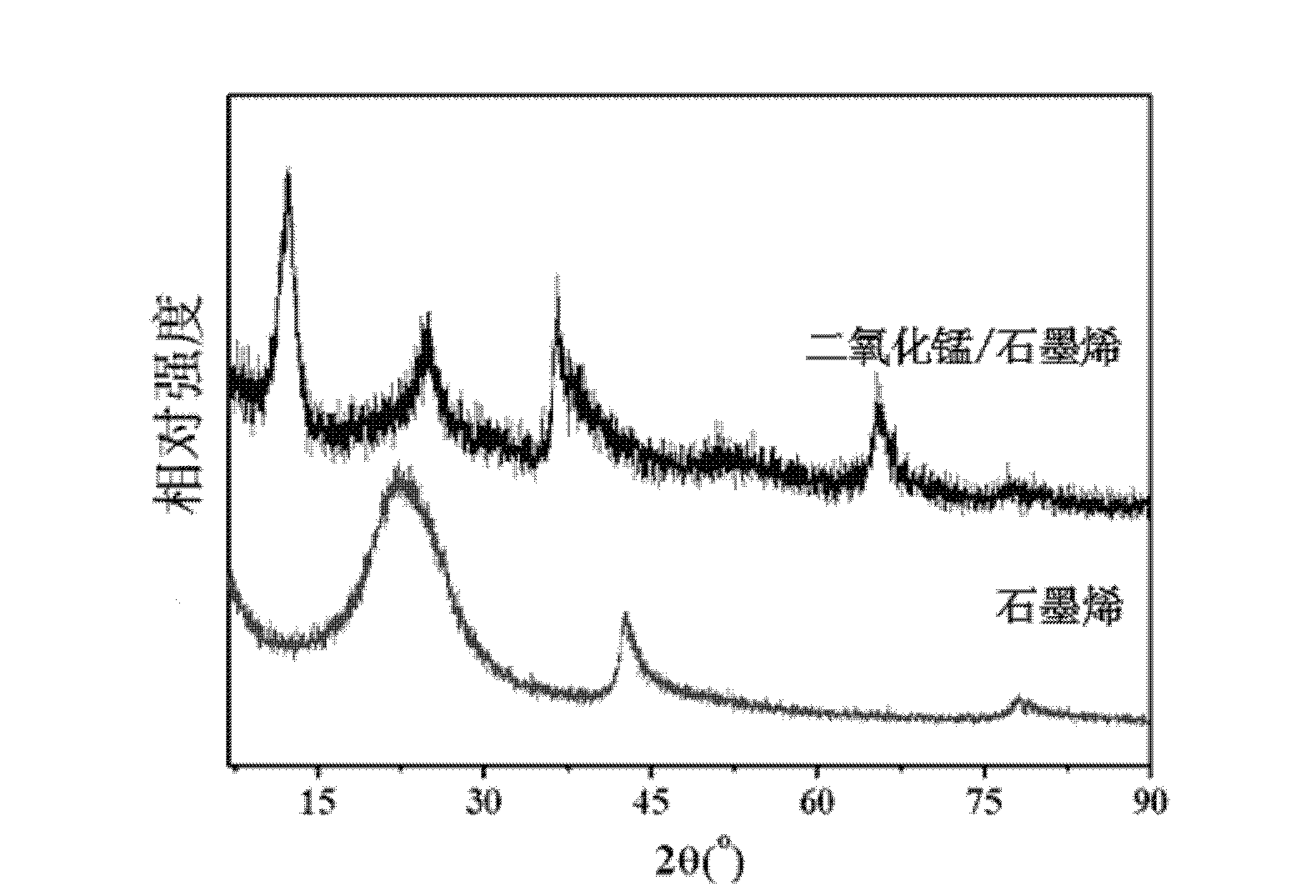

A kind of preparation method of graphene and manganese dioxide nanocomposite material

InactiveCN102275903AReduce typesLow costMaterial nanotechnologyManganese oxides/hydroxidesHydrazine compoundManganese

The invention relates to a preparation method of a graphene and manganese dioxide nanocomposite material, comprising: (1) stirring and mixing graphite, potassium nitrate and concentrated sulfur evenly, adding potassium permanganate, and reacting at 30-40° C. for 20-40 minutes , add deionized water at room temperature, add hydrogen peroxide after reacting for 15 to 30 minutes to obtain graphite oxide; (2) disperse the above graphite oxide in water, add hydrazine hydrate, and react at 95°C for 1 to 24 hours to obtain graphene (3) ultrasonically disperse the graphene in a saturated potassium permanganate solution, add acid, and react at 60-80° C. for 1-5 hours to obtain graphene and manganese dioxide nanocomposite material. The invention has the advantages of simple reaction, easy control, convenient operation and simple process; the obtained composite material has broad application prospects and can be used for catalysts, biosensing materials, electrode materials of lithium ion batteries and supercapacitor electrode materials, and the like.

Owner:DONGHUA UNIV

Lithium ion battery phosphatic composite cathode material and preparation method thereof

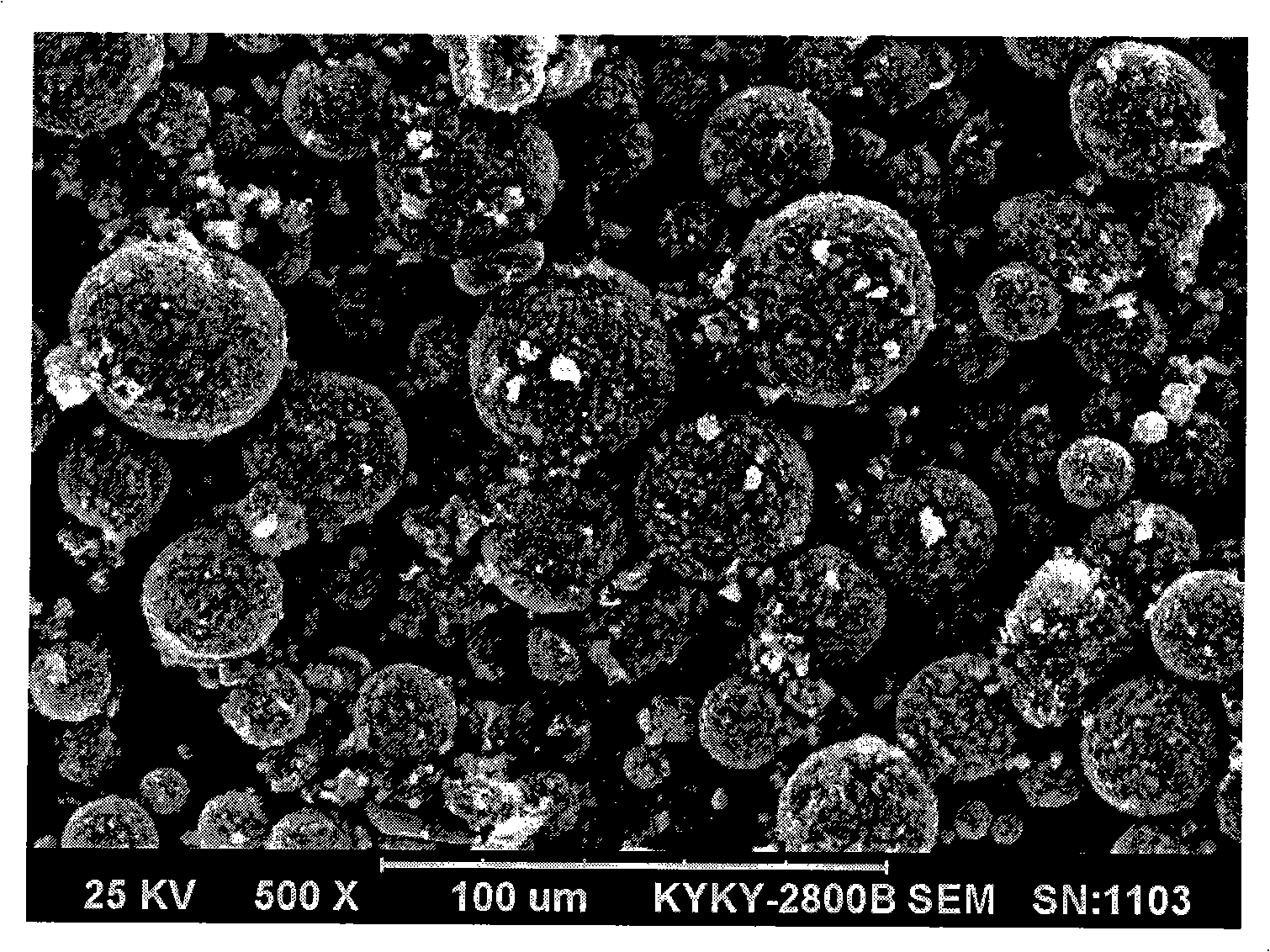

ActiveCN102244263AEasy to processImprove electrochemical performanceCell electrodesMicro structurePhosphoric acid

The invention discloses a lithium ion battery phosphatic composite cathode material and a preparation method thereof. The composite material is a multinuclear core shell structure composed of a plurality of cores and a housing layer, the cores are lithium iron phosphate particles wrapped by lithium vanadium phosphate and the housing layer is amorphous carbon. Preparation of the lithium iron phosphate particles wrapped by lithium vanadium phosphate comprises the following steps: preparing precursor sol with a sol gel method, adding lithium iron phosphate powder to disperse uniformly, carrying out spray drying on the above mixture, calcining the above resultant in inert gas, and followed by cooling and grinding to obtain the lithium iron phosphate particles wrapped by lithium vanadium phosphate. Preparation of the composite cathode material comprises the following steps: dissolving a carbon source compound into deionized water, adding core materials, dispersing the above resultant uniformly, carrying out second spray drying, calcining the above resultant in inert gas, and followed by cooling to obtain the composite cathode material. The composite material prepared in the invention has good electronic conduction performance, good ionic conduction performance and excellent electrochemistry performance. Because of existence of lithium vanadium phosphate, energetic density of a material is raised. Because of the multinuclear core shell structure like nano / micro structures, the composite material has good processing performance, and tap density of the material is greatly raised.

Owner:CENT SOUTH UNIV

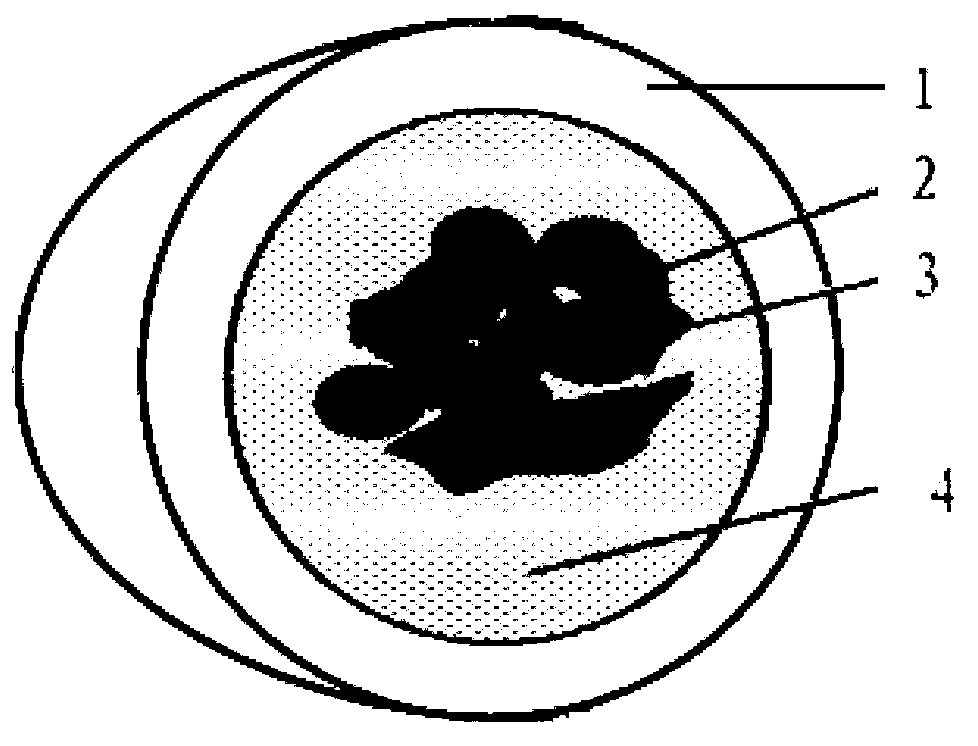

Lithium ion battery cathode material and preparation method thereof as well as lithium ion battery

ActiveCN103346293AImprove conductivityBuffers large volume changesCell electrodesSecondary cellsNanoparticleNetwork structure

The invention provides a lithium ion battery cathode material and a preparation method of the lithium ion battery cathode material as well as a lithium ion battery. The lithium ion battery cathode material comprises an inner core, a middle layer outside the inner core and an outer shell wrapping the middle layer, the inner core is Si-C particles, the middle layer is a foam layer, the outer shell is an amorphous carbon layer and the Si-C particles are formed by Si particles and C materials. Compared with the prior art, a middle carbon foam layer existing between the Si-C particle inner core and the amorphous carbon outer shell can form an conductive network structure, thus improving conductivity of a material and buffering enormous volume change of Si particles in the charge-discharge processes; and the amorphous carbon outer shell layer can maintain the core-shell structure of the cathode material, and the cladding layer of the core-shell structure can buffer the volume change, improve cycling stability of electrodes, reduce contact between active substances and an electrolyte, improve first coulombic efficiency of an electrode, prevent nanoparticle aggregation and enhance electrode conductivity.

Owner:宁波富理电池材料科技有限公司

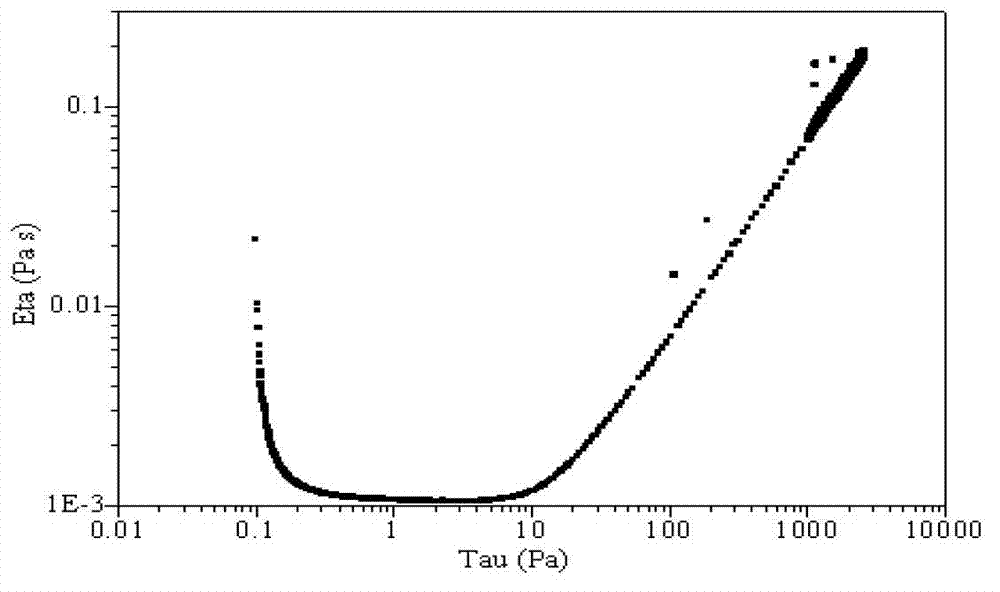

Shear thickening fluid based on molecular colloid and preparation method and application of shear thickening fluid

ActiveCN102926211AImprove the protective effectAvoid reunionGroup 4/14 element organic compoundsFibre treatmentFiberOrganic solvent

The invention relates to shear thickening fluid based on a molecular colloid, as well as a preparation method and an application of the shear thickening fluid. The shear thickening fluid consists of an organic solvent and a molecular colloid system formed by inorganic nano grains, boric acid, hydroxyl silicone oil and a plasticizing agent, and is used for dipping high-property fiber fabric and preparing a protective material to improve a puncture-proof property of the material; the preparation technology is simple; the preparation period is short; the controllability of an operation is high; the stability of the property of a product is improved; the energy consumption is reduced; and moreover, large-scale production is facilitated.

Owner:BEIJING UNIV OF CHEM TECH

High-performance graphene/cellulose composite hydrogel and aerogel and preparation methods thereof

The invention belongs to the field of the material science and in particular relates to a high-performance graphene / cellulose composite hydrogel and aerogel and preparation methods thereof. The preparation method of the high-performance graphene / cellulose composite hydrogel comprises the following steps: (1) adding graphite oxide to ionic liquid and ultrasonically dispersing to obtain an ionic liquid solution of the graphite oxide; preparing an ionic liquid solution of cellulose having the mass fraction of 4-6wt%; (2) adding a reducing agent to the ionic liquid solution of graphite oxide, and reducing at 80-100 DEG C for 2-24 hours, thereby obtaining an ionic liquid mixed solution of reduced graphite oxide; (3) mixing the ionic liquid mixed solution of reduced graphite oxide with the ionic liquid solution of cellulose; (4) defoaming the obtained final mixed solution, regenerating by use of a coagulating bath, and washing, thus obtaining the graphene / cellulose composite hydrogel. The composite gel prepared by the preparation method has excellent properties, particularly has excellent the mechanical properties, and can be widely applied.

Owner:SOUTH CHINA UNIV OF TECH

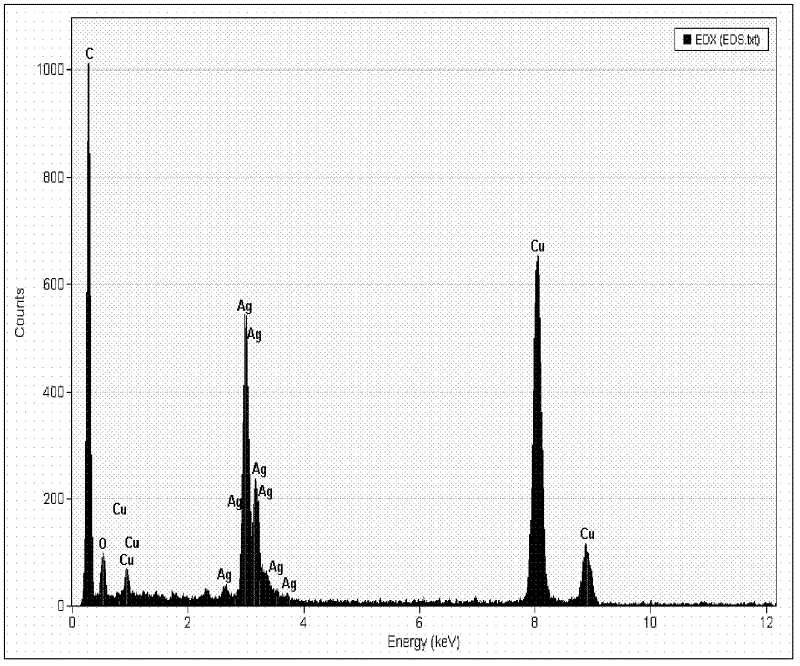

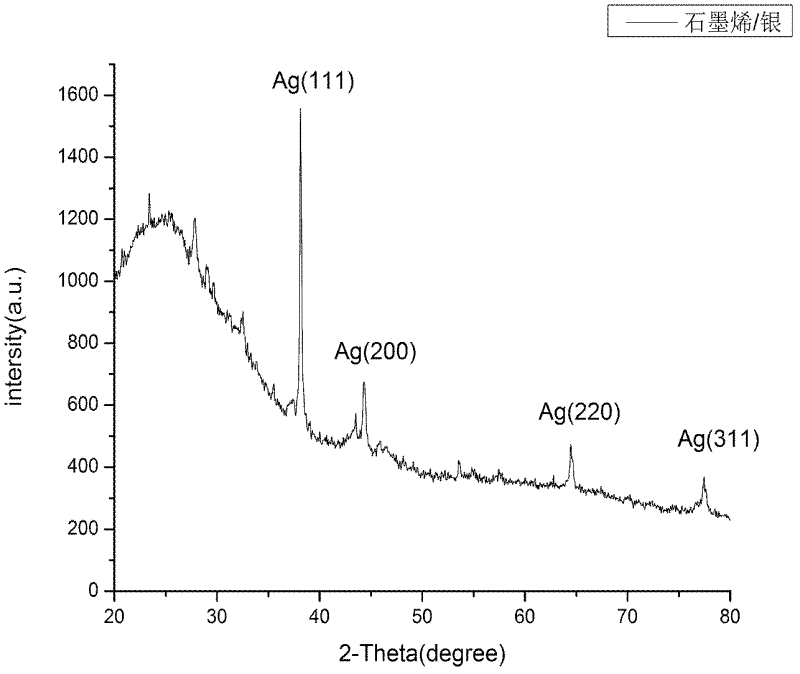

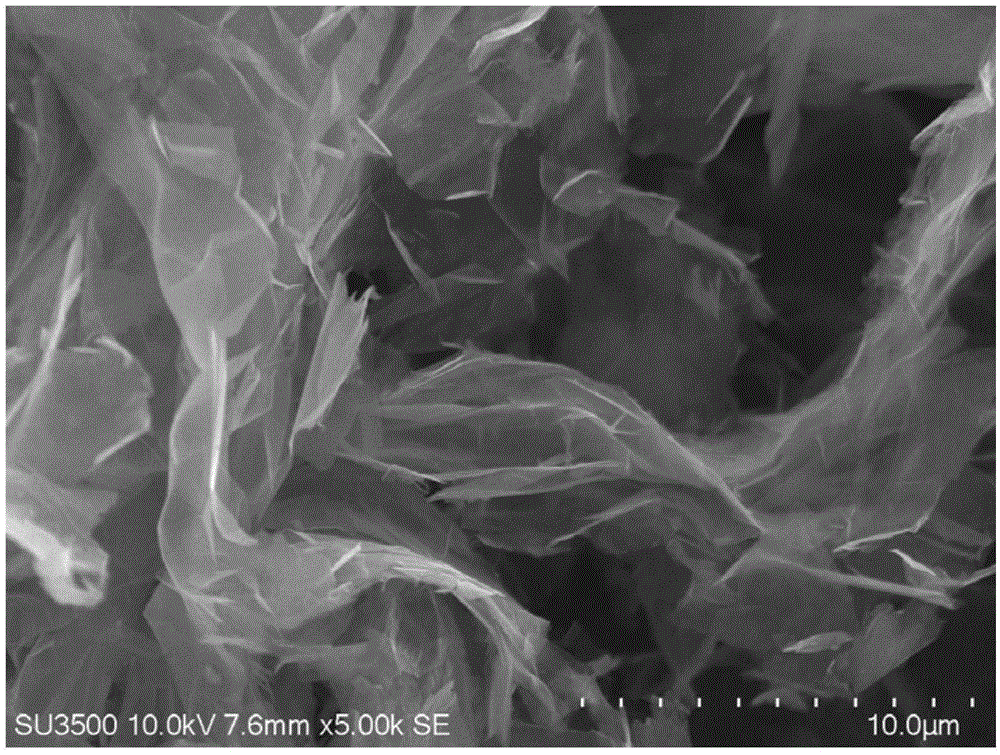

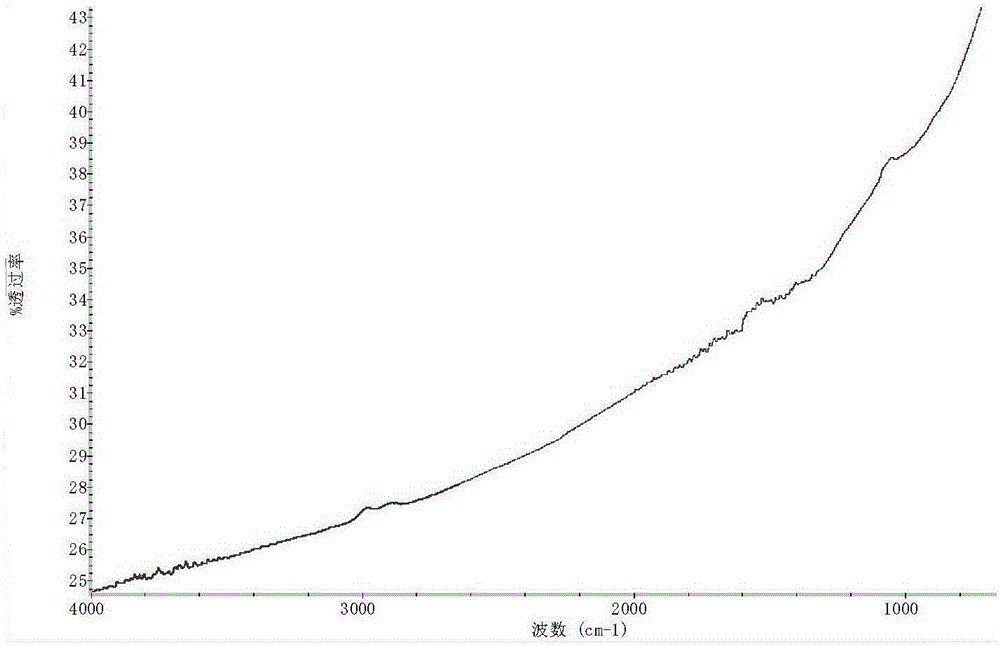

Method for preparing grapheme/silver nanoparticles composite material by using liquid phase method

ActiveCN102614871ALow impurity contentHigh bonding strengthMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsBond strengthElectron

The invention discloses a method for preparing a grapheme / silver nanoparticles composite material by using a liquid phase method. N and N-dimethyl formamide (DMF) serve as a reducing agent, grapheme powder with purity as high as 99% serves as a carrier, and silver forms a core and grows on a grapheme layer under a soft reaction condition to obtain the grapheme / silver nanoparticles composite material. The preparation method has the advantages of being simple, convenient, rapid and high-efficient in process, the grapheme / silver nanoparticles composite material prepared by using the method is high in purity and less in impurity content, and silver nanoparticles generated on the surface layer of the grapheme are small in particle size, uniform in distribution and high in bond strength with the grapheme. The silver nanoparticles are closely absorbed on the grapheme layer, aggregation of the grapheme is effectively avoided, and application of the grapheme / silver nanoparticles composite material in the fields of electron, catalysis, antibiosis and the like can be enlarged.

Owner:TIANJIN UNIV

Graphene aqueous slurry, and preparation method thereof

The invention belongs to the field of graphene material, and provides a graphene aqueous slurry, and a preparation method thereof. The graphene aqueous slurry comprises an aqueous dispersion liquid and a graphene material dispersed in the aqueous dispersion liquid, wherein the aqueous dispersion liquid contains a surfactant. The preparation method comprises following steps: graphite oxide solid or expansible graphite solid is taken as a raw material, and expansion treatment is carried out so as to prepare expanded graphite; the expanded graphite is immersed into an aqueous stripping liquid for infiltration treatment so as to obtain a mixture containing the expanded graphite; the mixture containing the expanded graphite is subjected to high-speed shearing or ultrasonic treatment so as to remove the aqueous stripping liquid so as to obtain a graphene wet material; the graphene wet material is added into the aqueous dispersion liquid, and high-speed shearing is carried out so as to obtain the graphene aqueous slurry.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com