Method for preparing grapheme/silver nanoparticles composite material by using liquid phase method

A technology of silver nanoparticles and composite materials, which is applied in the field of preparation of graphene-silver nanoparticle composite materials, can solve the problems affecting the performance of composite materials, functional groups cannot be eliminated, etc., and achieve the advantages of preventing agglomeration, uniform distribution and high bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

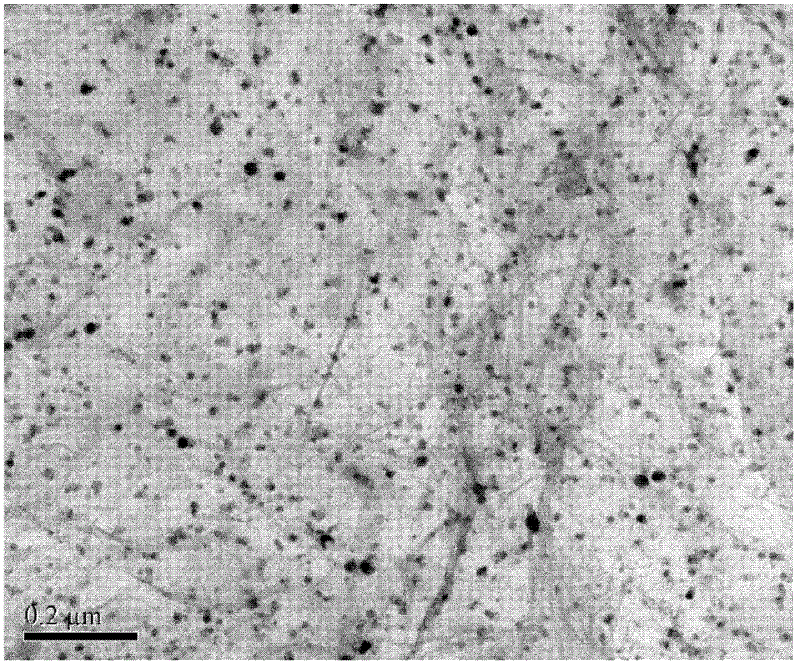

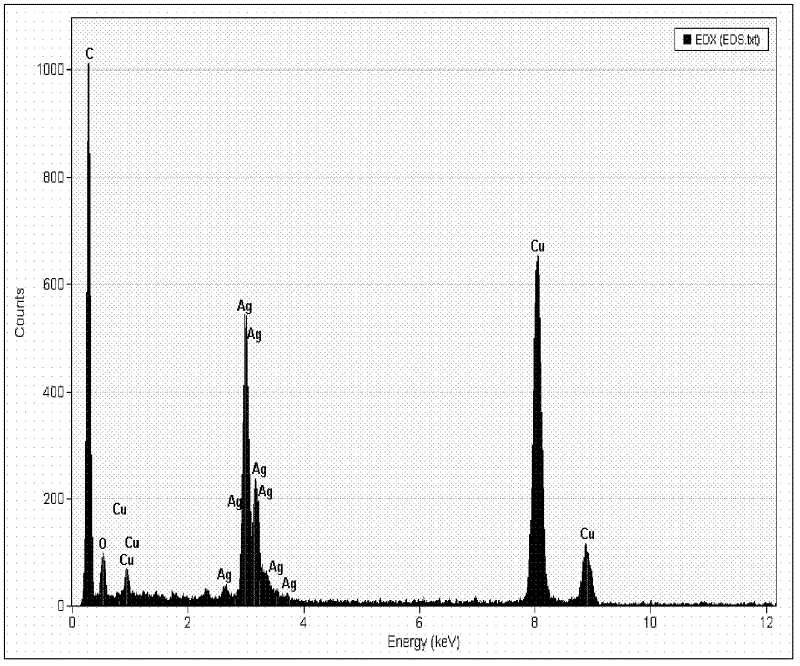

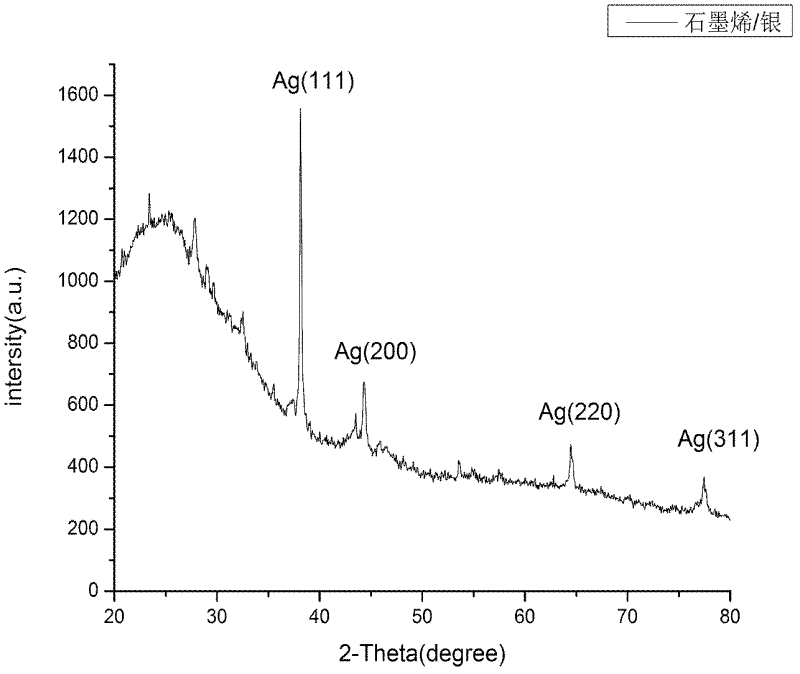

Embodiment 1

[0029] Take 10mg of graphene and disperse it in 30mL of DMF, then add 3mg of sodium lauryl sulfate, and ultrasonically treat it at 40KHz, 100W power for 100min, so as to break the agglomeration of graphene, so that the graphene sheets are evenly dispersed in the DMF solution , making the N of graphene thus, N-dimethylformamide (DMF) solution; The silver nitrate that takes 40mg is dissolved in the deionized water of 15mL, magnetic force stirs 5 minutes, makes it fully dissolve and obtains silver nitrate aqueous solution; Mix the above graphene N,N-dimethylformamide (DMF) solution and silver nitrate aqueous solution, ultrasonically vibrate for 30 minutes, then transfer to a three-necked beaker, adjust the pH value to 7, and place in a water bath at 60°C Vigorously stir the reaction for 30 minutes, after the completion of the reaction, static precipitation for 24 hours, filter the precipitated product and wash it with ethanol, acetone, and deionized water in turn, and dry it at ro...

Embodiment 2

[0031] Take 10mg of graphene and disperse it in 30mL of DMF, then add 3mg of sodium lauryl sulfate, and ultrasonically treat it at 40KHz, 100W power for 60min, so as to break the agglomeration of graphene, so that the graphene sheets are evenly dispersed in the DMF solution ; Weigh 80 mg of silver nitrate and dissolve it in 15 mL of deionized water, stir it magnetically for 7 minutes to make it fully dissolved; mix the above two solutions, ultrasonically vibrate for 60 min, then transfer to a three-necked beaker, and use a mass fraction of 5% Adjust the pH value to 8 with ammonia water, stir vigorously in a water bath at 65°C for 60 minutes, and settle for 20 hours after the reaction is completed. Filter the precipitated product and wash it with ethanol, acetone, and deionized water in sequence, and dry it in a blast drying oven at room temperature. The graphene / silver powder obtained in 24 hours is the product of the present invention: graphene-silver nanoparticle composite ma...

Embodiment 3

[0034] Take 10mg of graphene and disperse it in 30mL of DMF, then add 3mg of sodium lauryl sulfate, and ultrasonically treat it at 40KHz, 100W power for 120min, so as to break the agglomeration of graphene, so that the graphene sheets are evenly dispersed in the DMF solution , Weigh 120 mg of silver nitrate and dissolve it in 15 mL of deionized water, stir it magnetically for 10 min to make it fully dissolved, mix the above two solutions, oscillate ultrasonically for 50 min, then transfer to a three-necked beaker with a mass fraction of 5% Adjust the pH value to 8 with enammonia water, and stir vigorously in a water bath at 65°C for 80 minutes. After the reaction is completed, the precipitation is static for 18 hours. The precipitated product is filtered and washed with ethanol, acetone, and deionized water in sequence, and placed in a blast drying oven at room temperature After drying for 24 hours, the obtained graphene / silver powder is the product of the present invention: gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com