Patents

Literature

18530 results about "Organic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

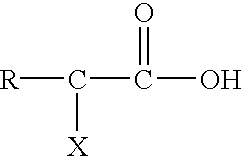

An organic acid is an organic compound with acidic properties. The most common organic acids are the carboxylic acids, whose acidity is associated with their carboxyl group –COOH. Sulfonic acids, containing the group –SO₂OH, are relatively stronger acids. Alcohols, with –OH, can act as acids but they are usually very weak. The relative stability of the conjugate base of the acid determines its acidity. Other groups can also confer acidity, usually weakly: the thiol group –SH, the enol group, and the phenol group. In biological systems, organic compounds containing these groups are generally referred to as organic acids.

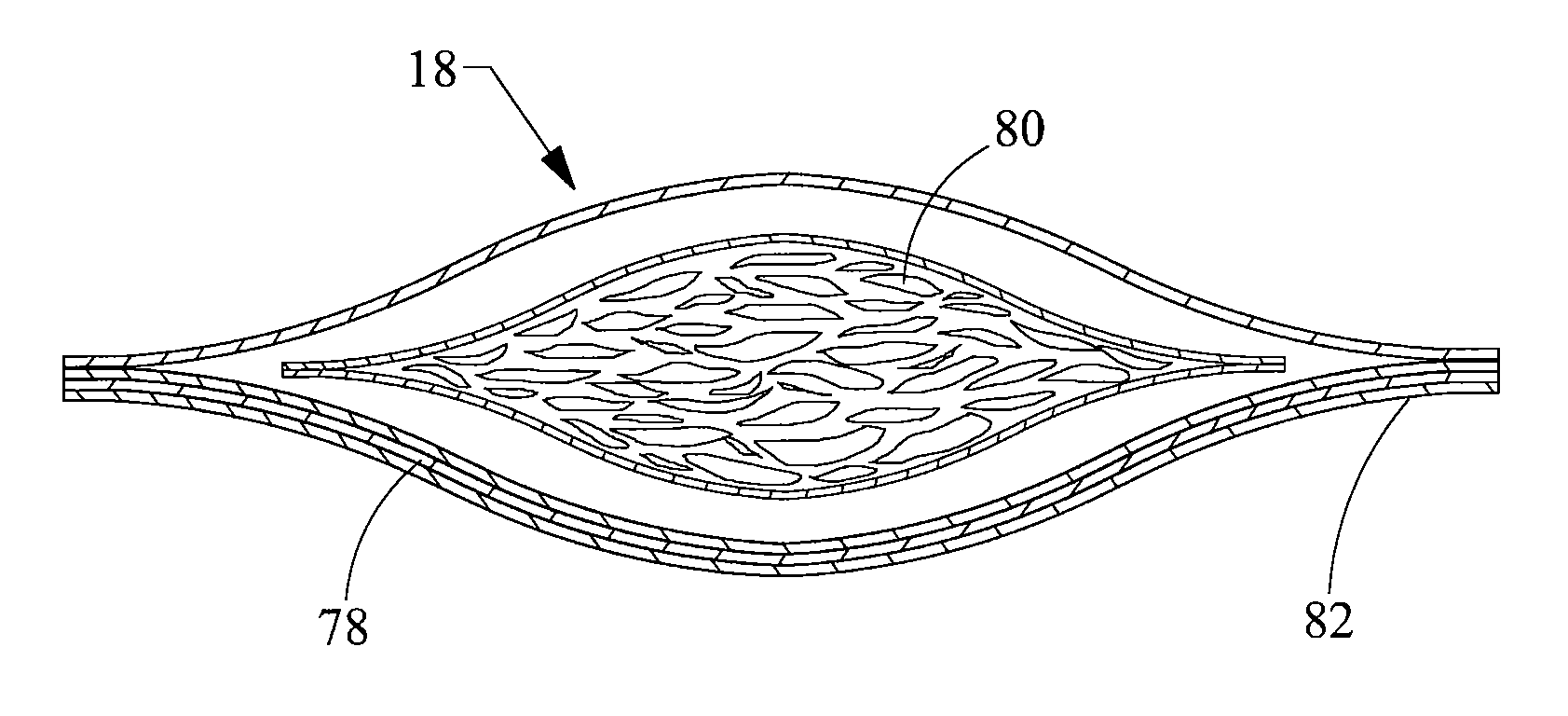

Potentiation of immune responses with liposomal adjuvants

InactiveUS6090406AGood water solubilityPractical and convenientBacterial antigen ingredientsViral antigen ingredientsLipid formationOrganic acid

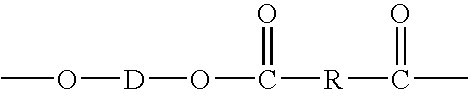

A high integrity liposome comprising at least one stabile lipid and at least one peptide-like therapeutic agent associated with said liposome, adapted for parenteral administration to an animal, including a human, and method according to manufacture and use. Immunizing dosage forms comprising a liposome and an immunogen, wherein said liposome and immunogen are present in an immunization dose. Additionally, a dosage form, including such form particularly adapted to producing an immune response, comprising a salt according to an organic acid derivative of a sterol and an immunogen wherein said organic acid derivative of a sterol and immunogen are present in an immunization dose, and method according to use is disclosed. Further, a dosage form, including such form particularly adapted to producing an immune response, comprising dimyristoylphosphatidylcholine (DMPC) / cholesterol liposomes, optionally in an aluminum hydroxide gel, and an immunogen wherein said DMPC / cholesterol and immunogen are present in an immunization dose, and method according to use.

Owner:TRANSAVE

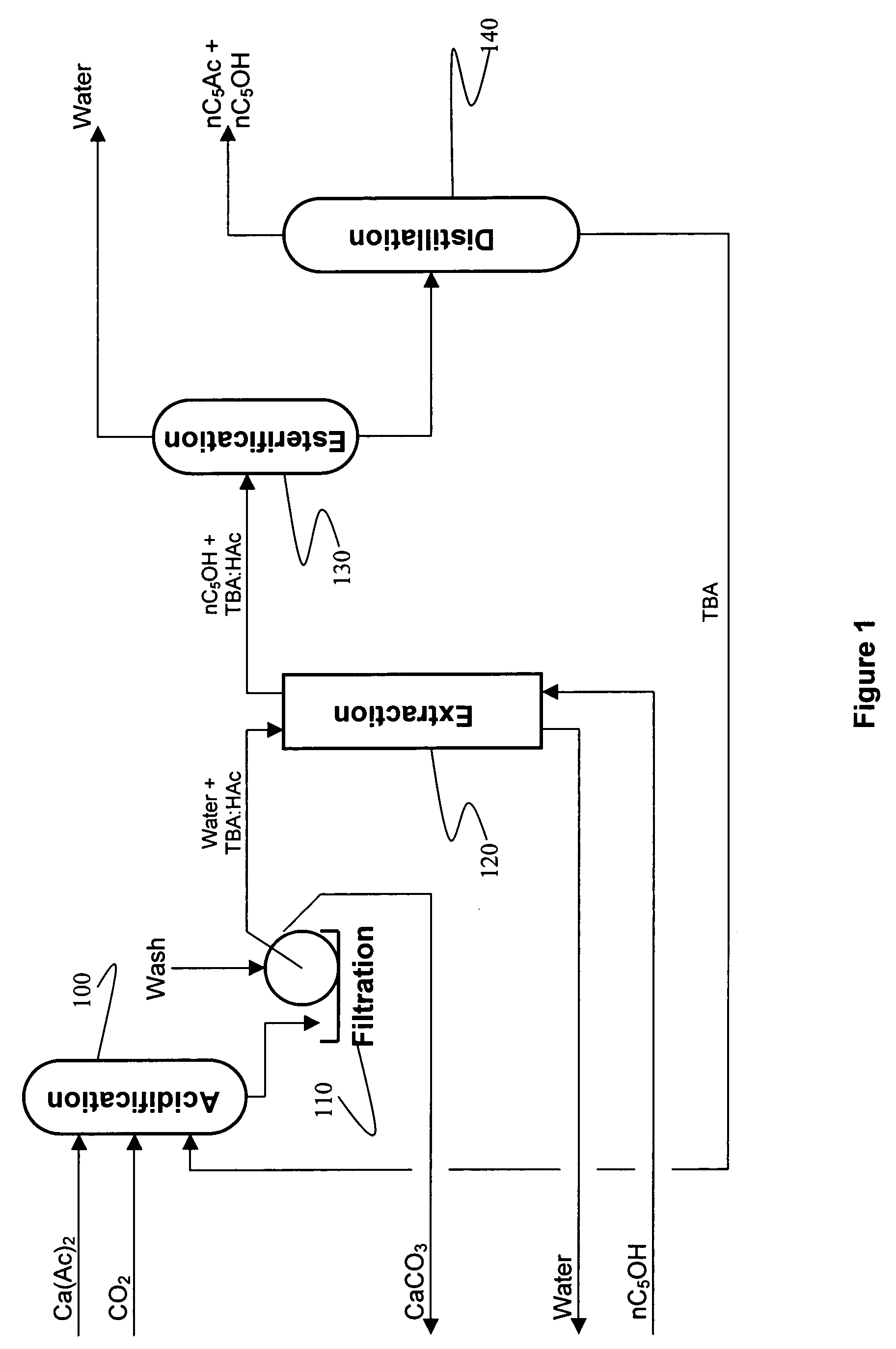

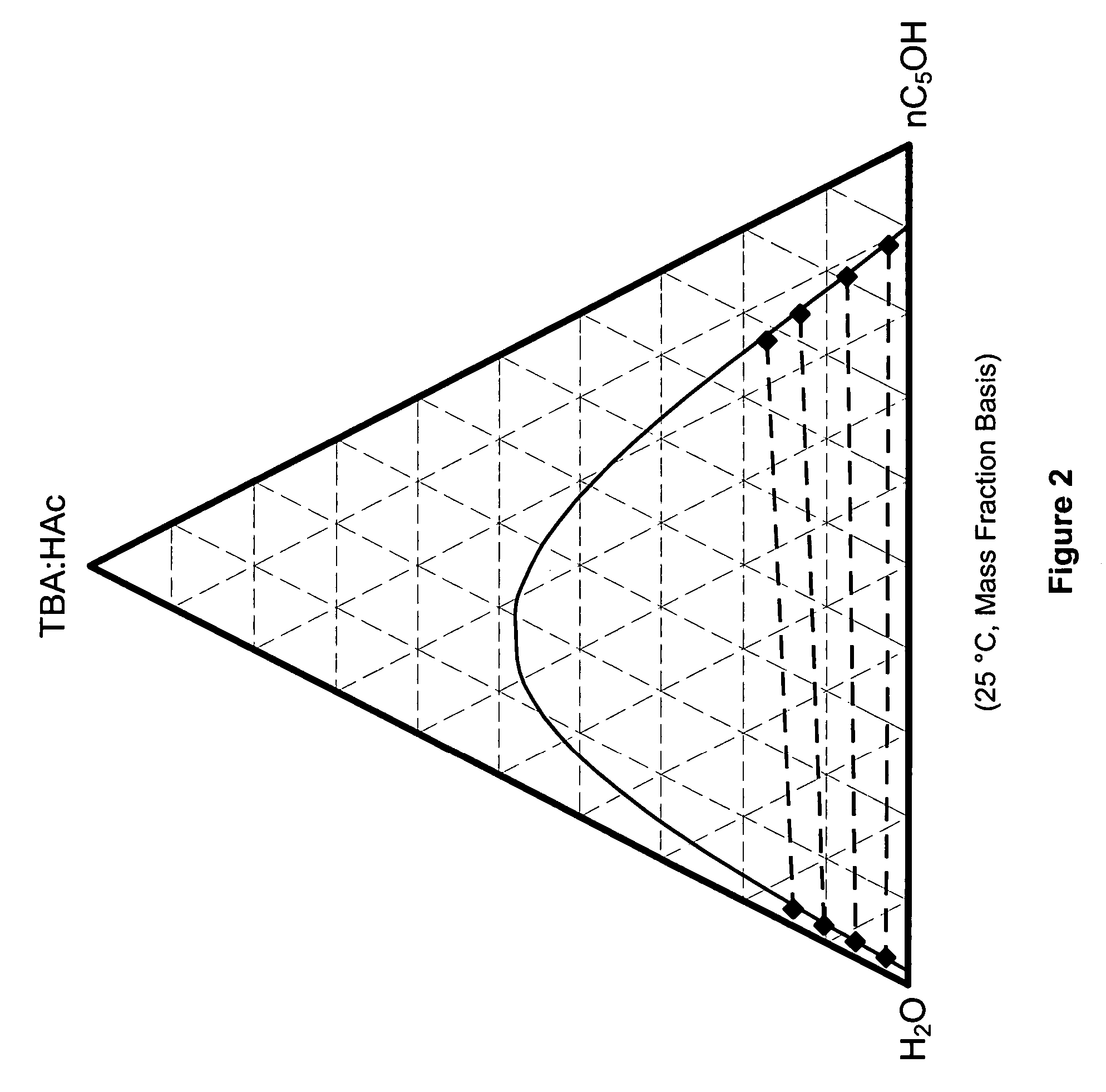

Recovery of organic acids

InactiveUS20090281354A1Promote recoveryOvercome consumptionPreparation from carboxylic acid saltsOrganic compound preparationOrganic acidReactive distillation

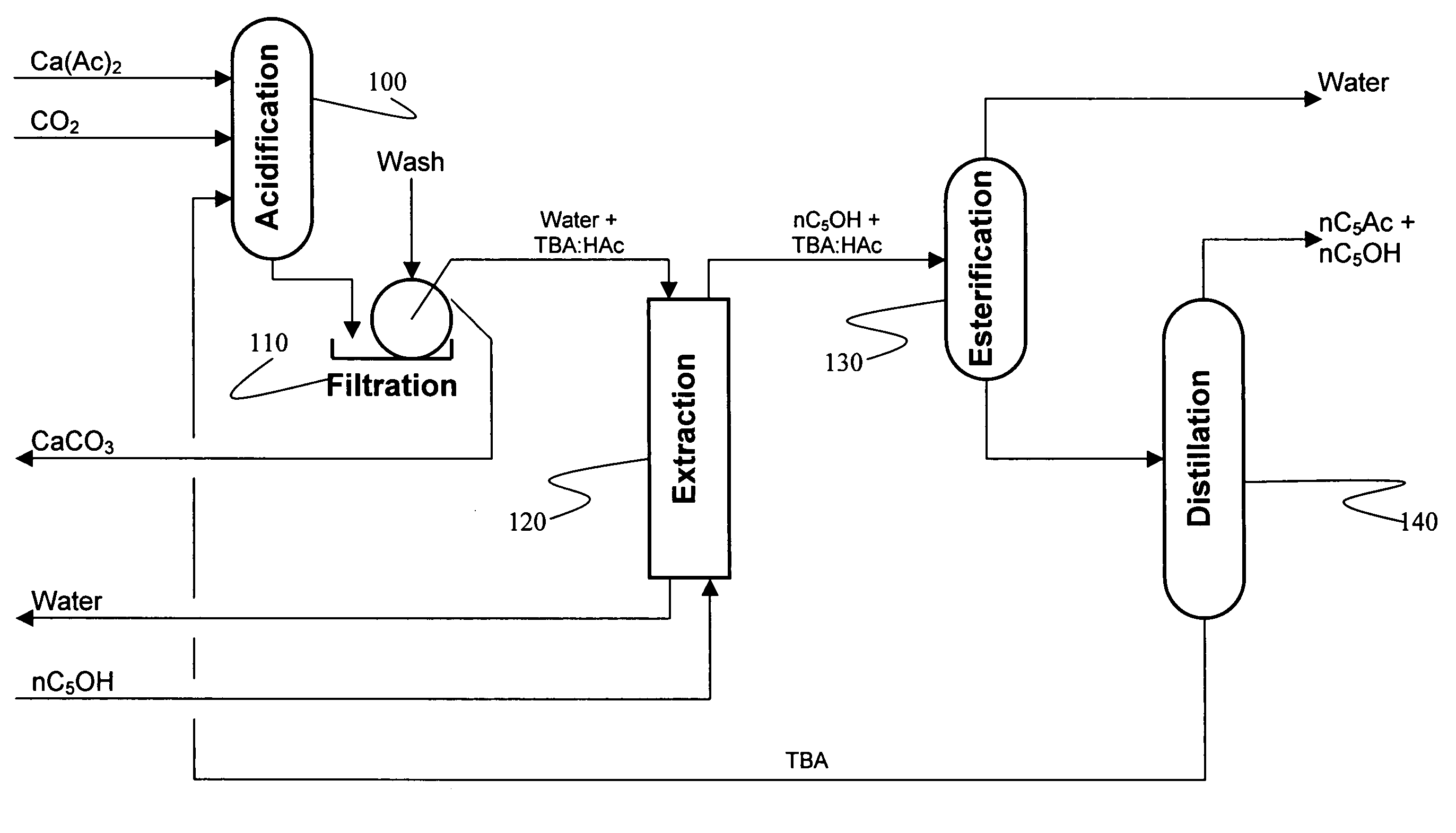

A method is disclosed for the recovery of an organic acid from a dilute salt solution in which the cation of the salt forms an insoluble carbonate salt. An amine and CO2 are introduced to the solution to form the insoluble carbonate salt and a complex between the acid and the amine. The acid / amine complex is thermally dissociated, or “cracked”, in the presence of a water immiscible solvent in which the amine is selectively soluble and in which the acid is not appreciably soluble. The organic acid may then be recovered from the water by any suitable means such as distillation, reactive distillation, extraction, or reactive extraction.

Owner:ZEACHEM

Recovery of organic acids

InactiveUS7601865B2Promote recoveryOvercome consumptionPreparation from carboxylic acid saltsOrganic compound preparationOrganic acidAlcohol

Owner:ZEACHEM

Process for the preparation of polyalkenyl succinic anhydrides

A polyalkenyl succinic anhydride is prepared with low amounts of resinous or chlorinated byproducts in a two-step process whereby a polyalkene is first reacted with an unsaturated organic acid in a thermal ene reaction, followed with exposure to a gaseous halogen in presence of an additional amount of the unsaturated organic acidic reagent. The foregoing process produces a polyisobutenyl succinic anhydride having a high ratio of succinic anhydride functional groups to polyisobutenyl backbone groups. Such a polyisobutenyl succinic anhydride is particular suitable for the production of oil-soluble hydrocarbyl succinimides that have good dispersant properties when added to lubricating oil compositions.

Owner:AFTON CHEMICAL

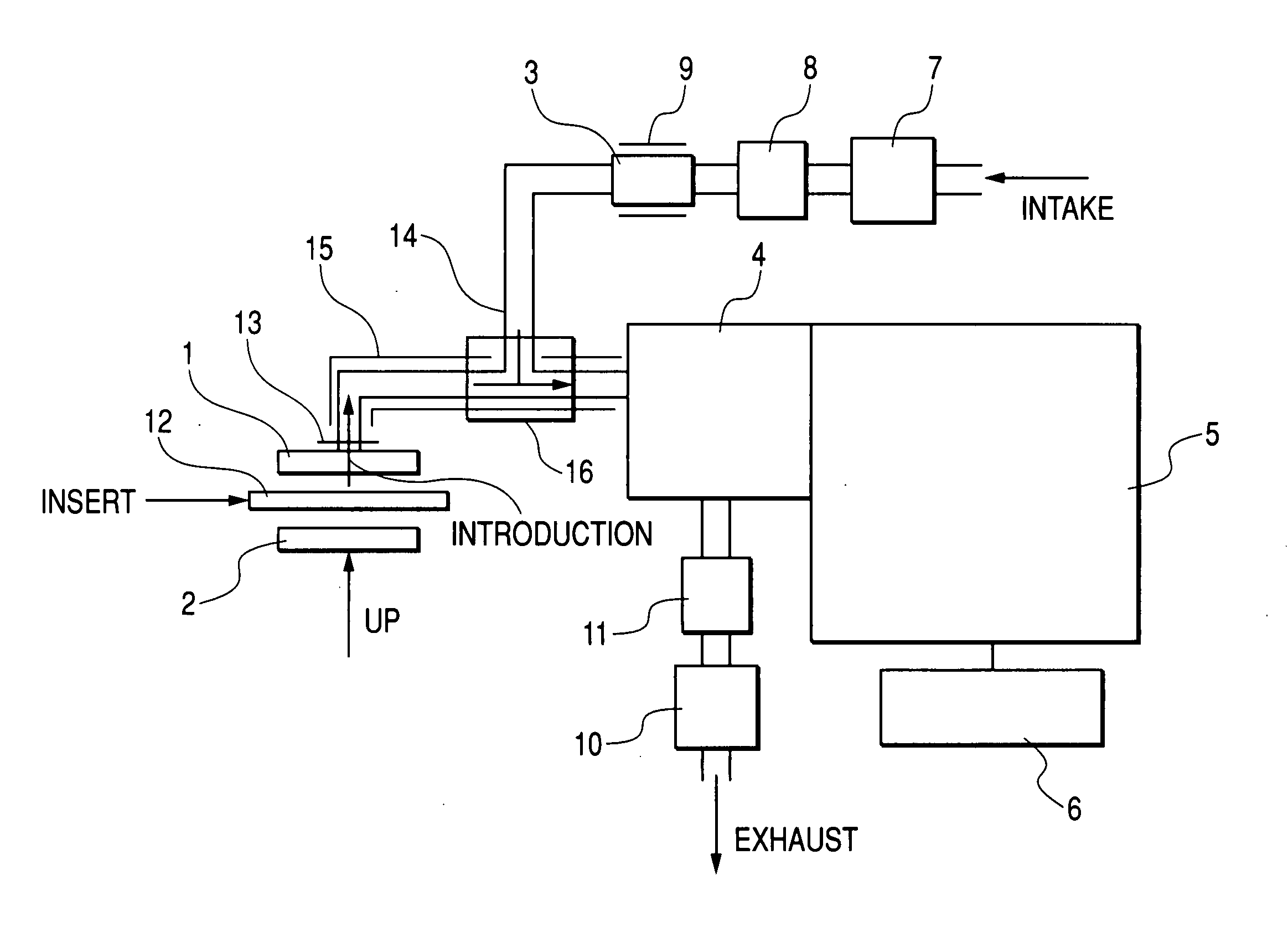

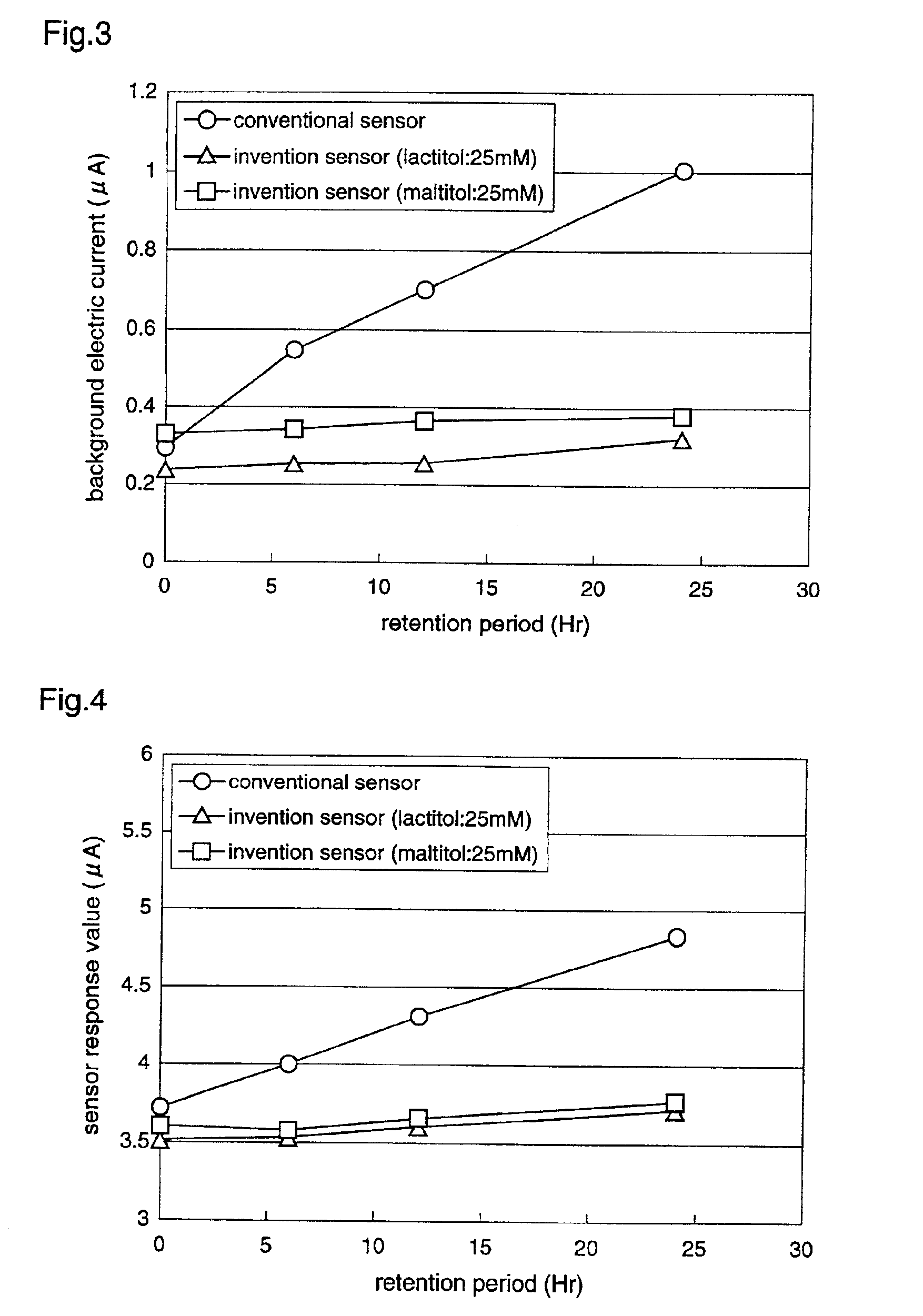

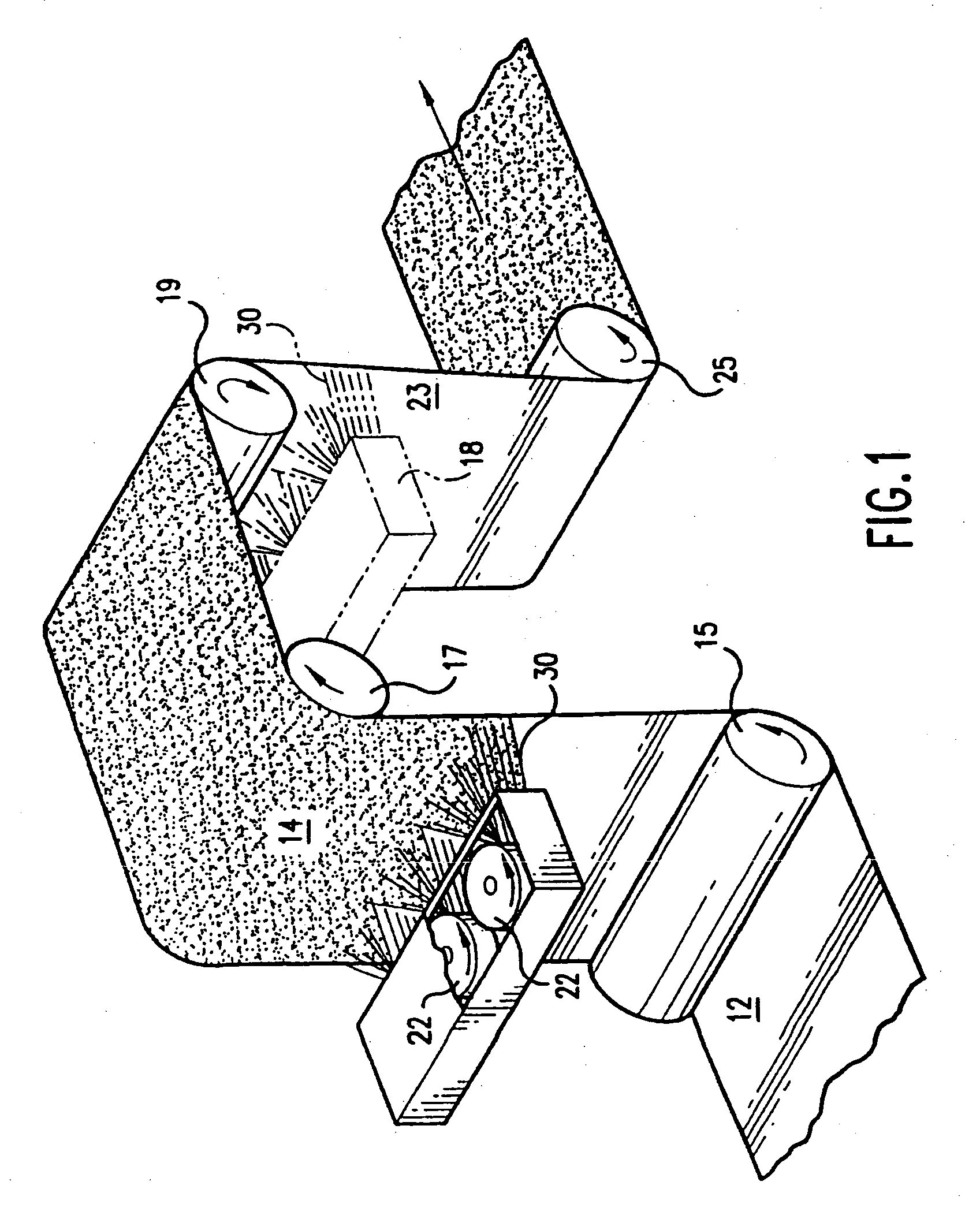

Apparatus for detecting chemical substances and method therefor

ActiveUS20050061964A1High detection sensitivityPrevent false detectionStability-of-path spectrometersAnalysis using chemical indicatorsNon detectionData treatment

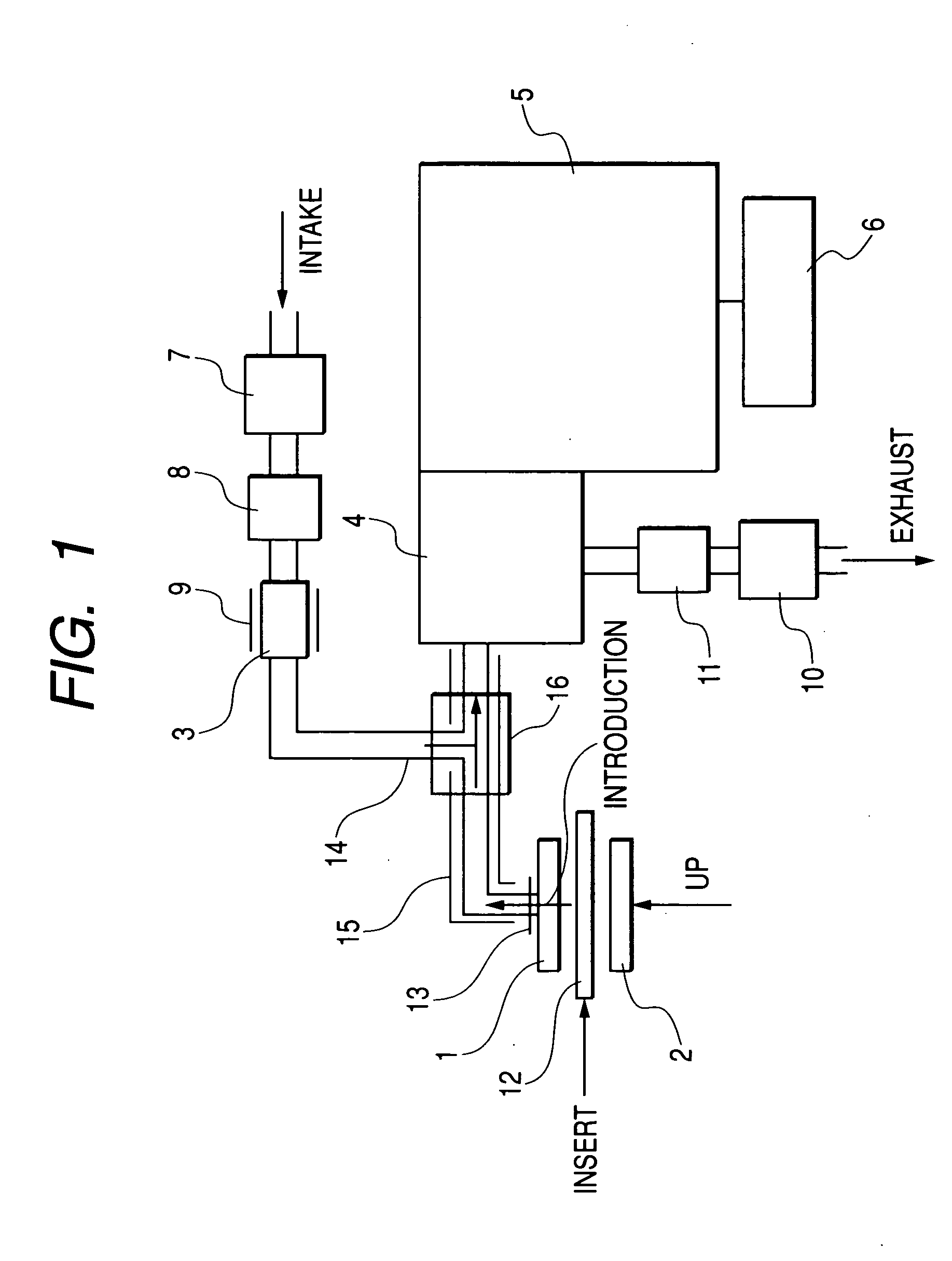

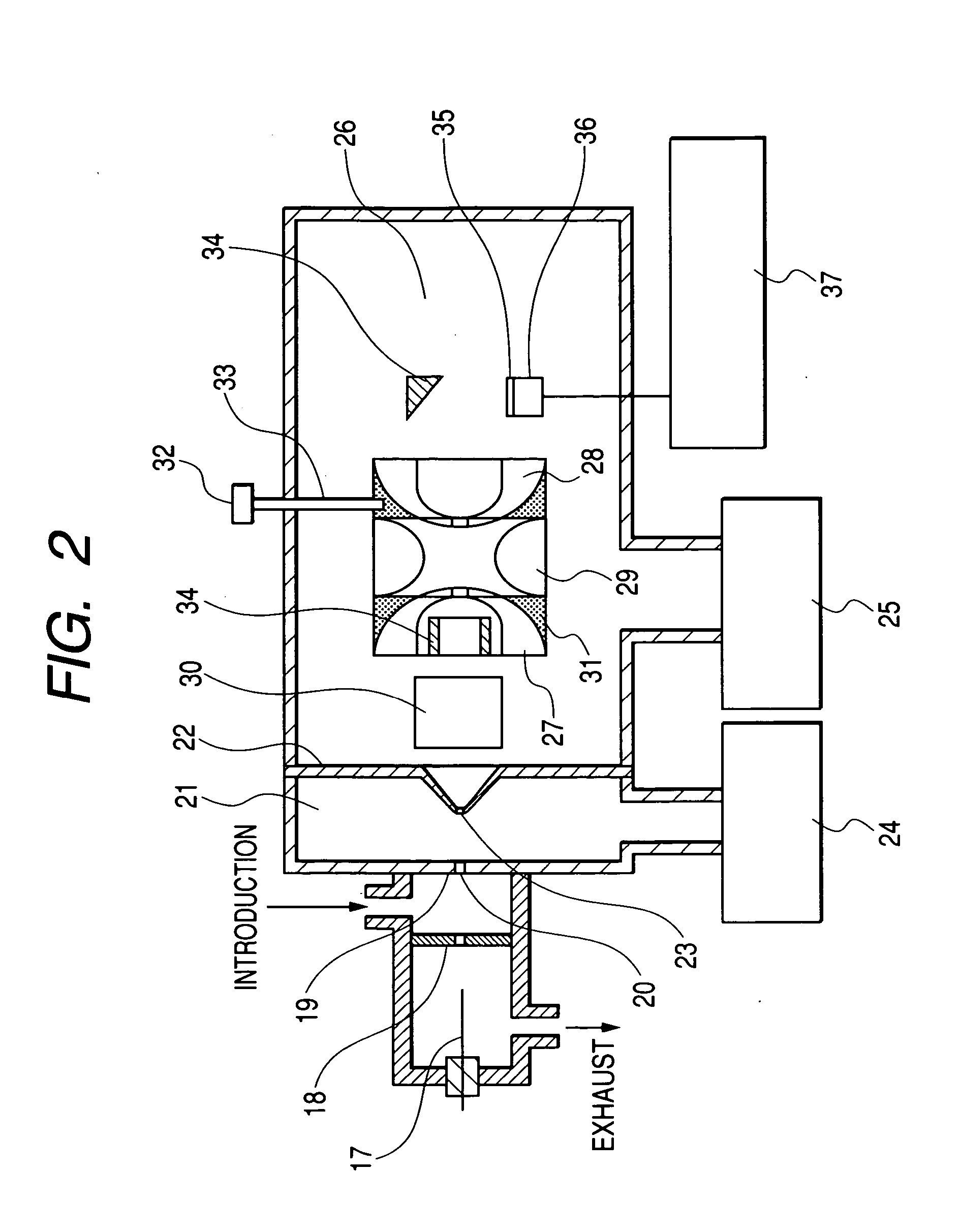

An apparatus for detecting chemical substances which is high in sensitivity and selectivity is provided. An organic acid or an organic acid salt is used to generate an organic acid gas from an organic acid gas generator 3 to be mixed with a sample gas for introduction into an ion source 4 for ionization, thereby obtaining a mass spectrum by a mass analysis region 5. A data processor 6 determines the detection or non-detection of a specific m / z of an organic acid adduct ion obtained by adding a molecule generated from the organic acid to a molecule with specific m / z generated from a target chemical substance to be detected based on the obtained mass spectrum. When there is an ion peak with the m / z of the organic acid adduct ion, the presence of the target chemical substance to be detected is determined, and an alarm is sounded. False detection can be prevented.

Owner:HITACHI LTD

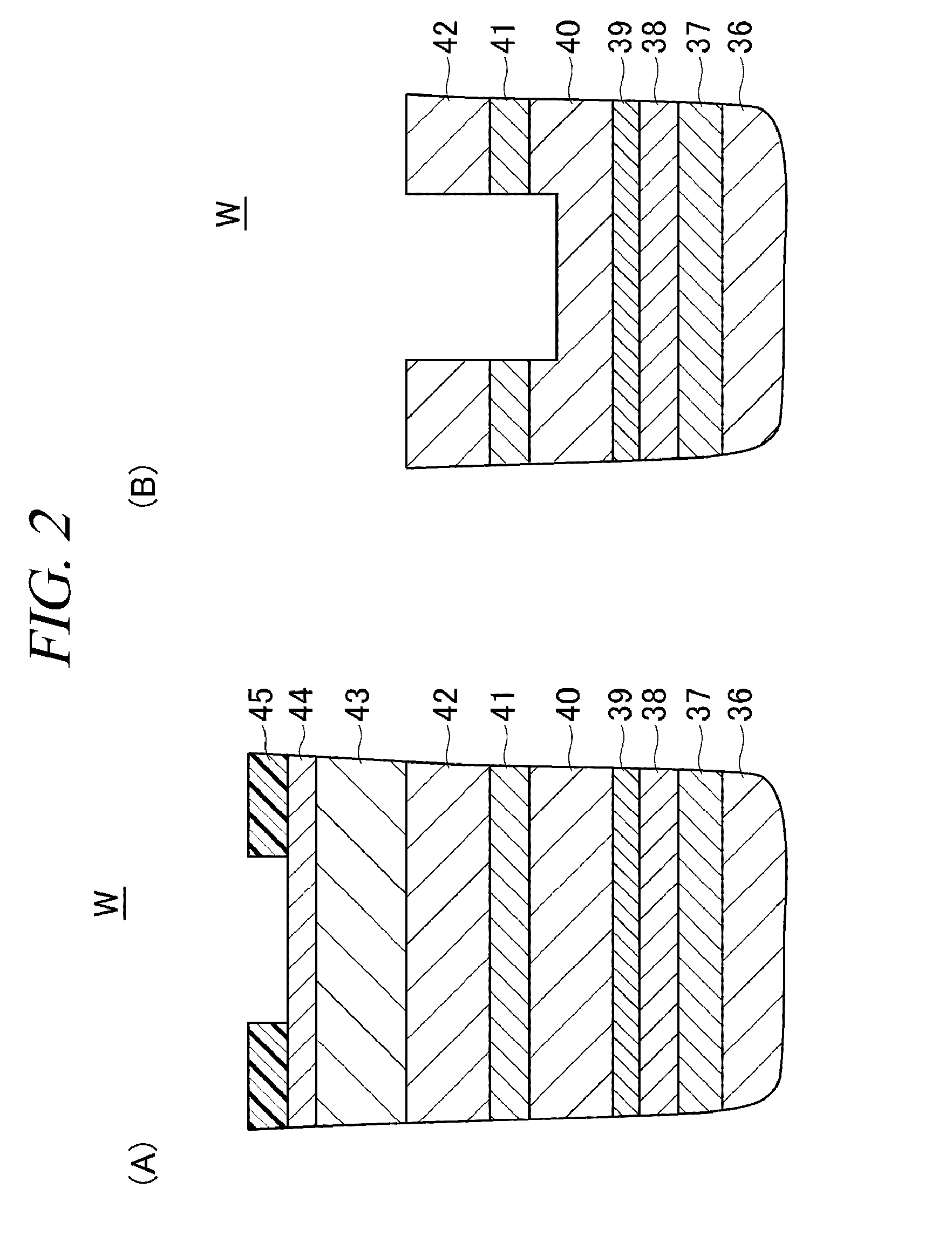

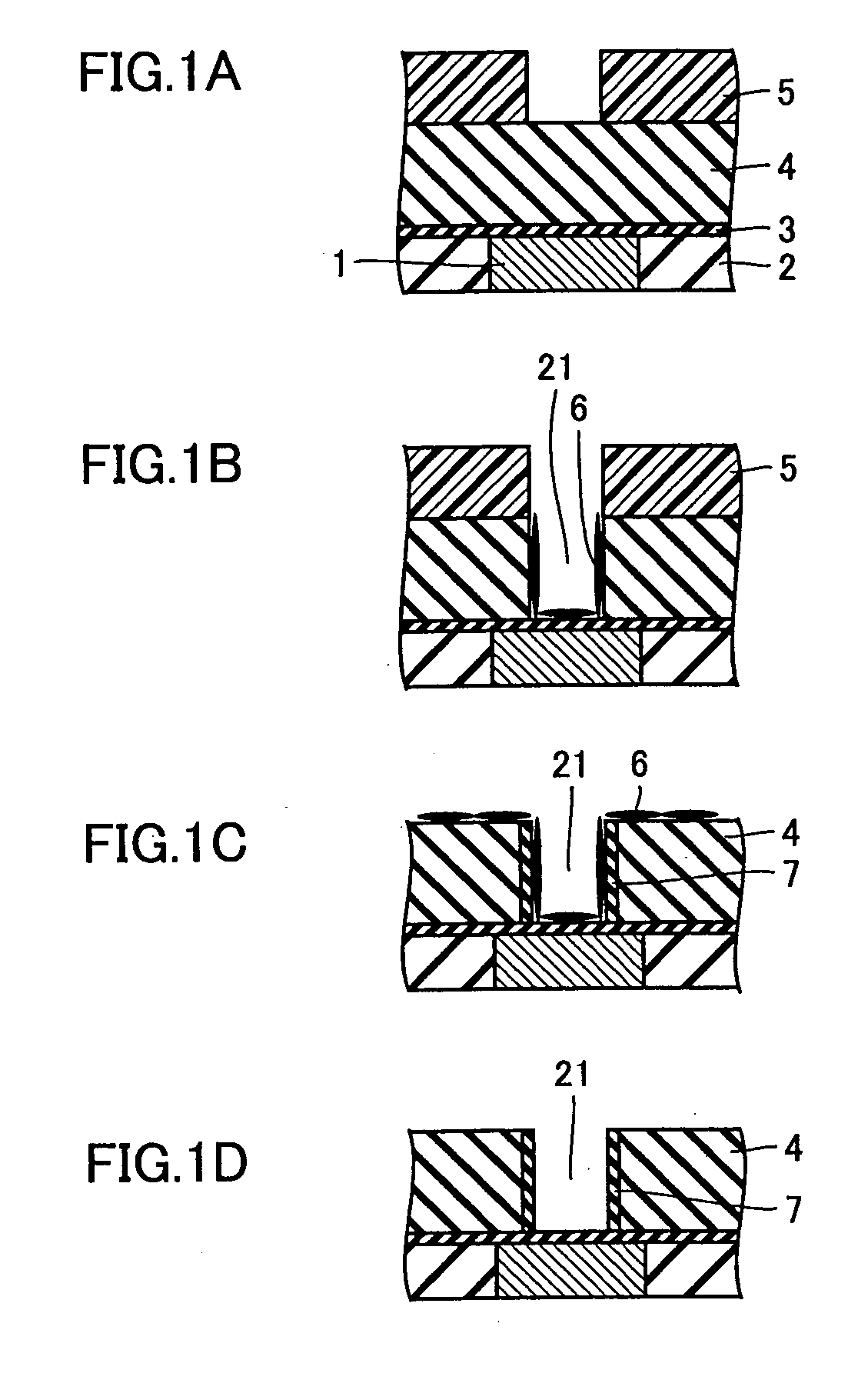

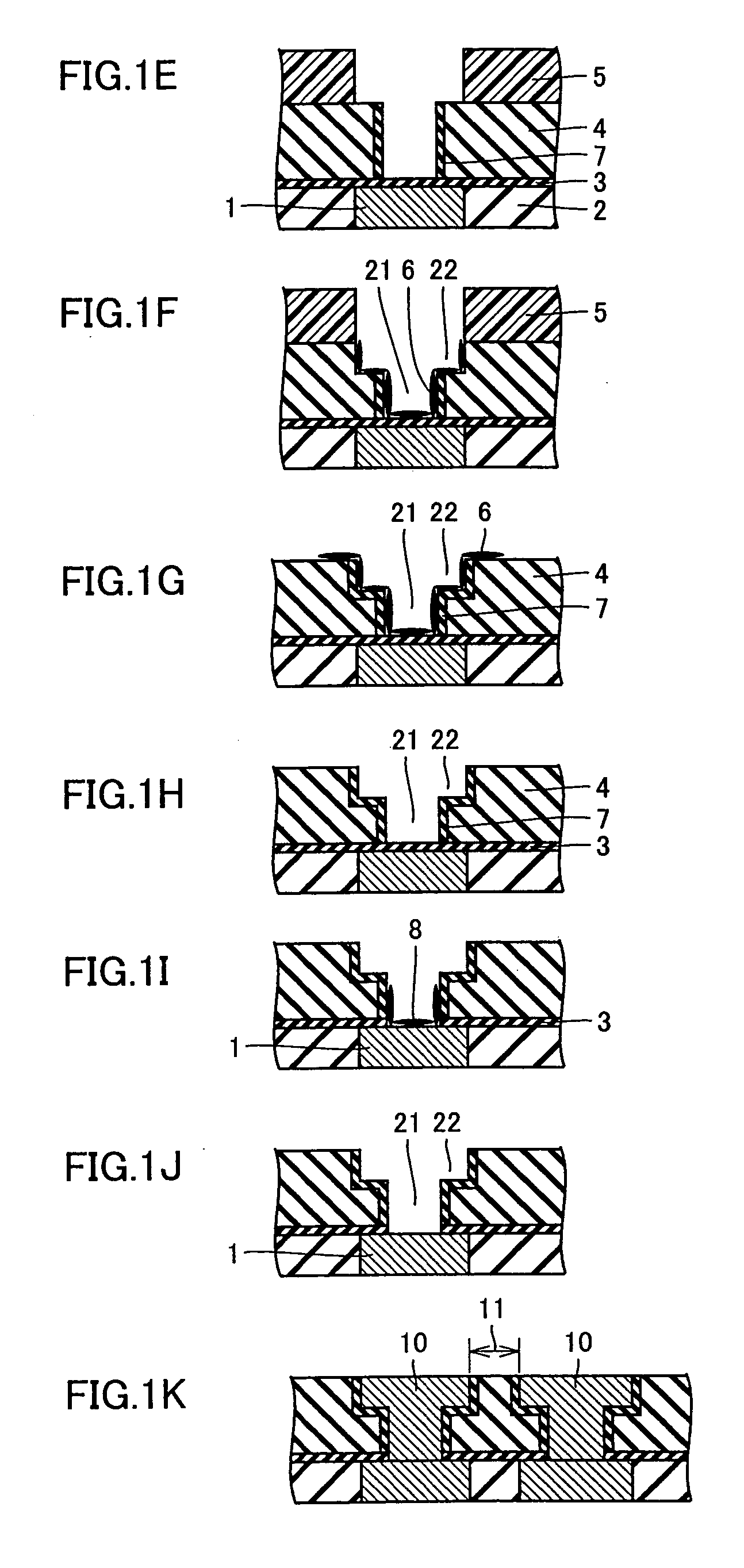

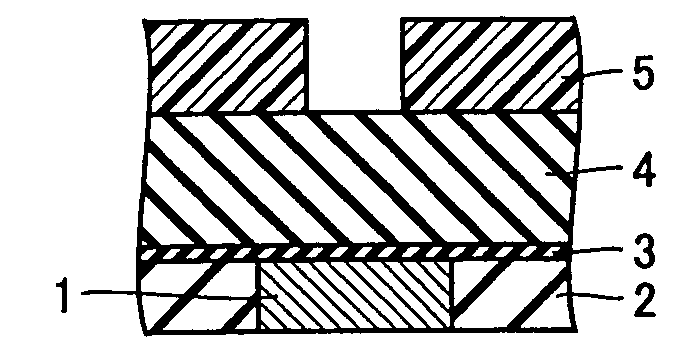

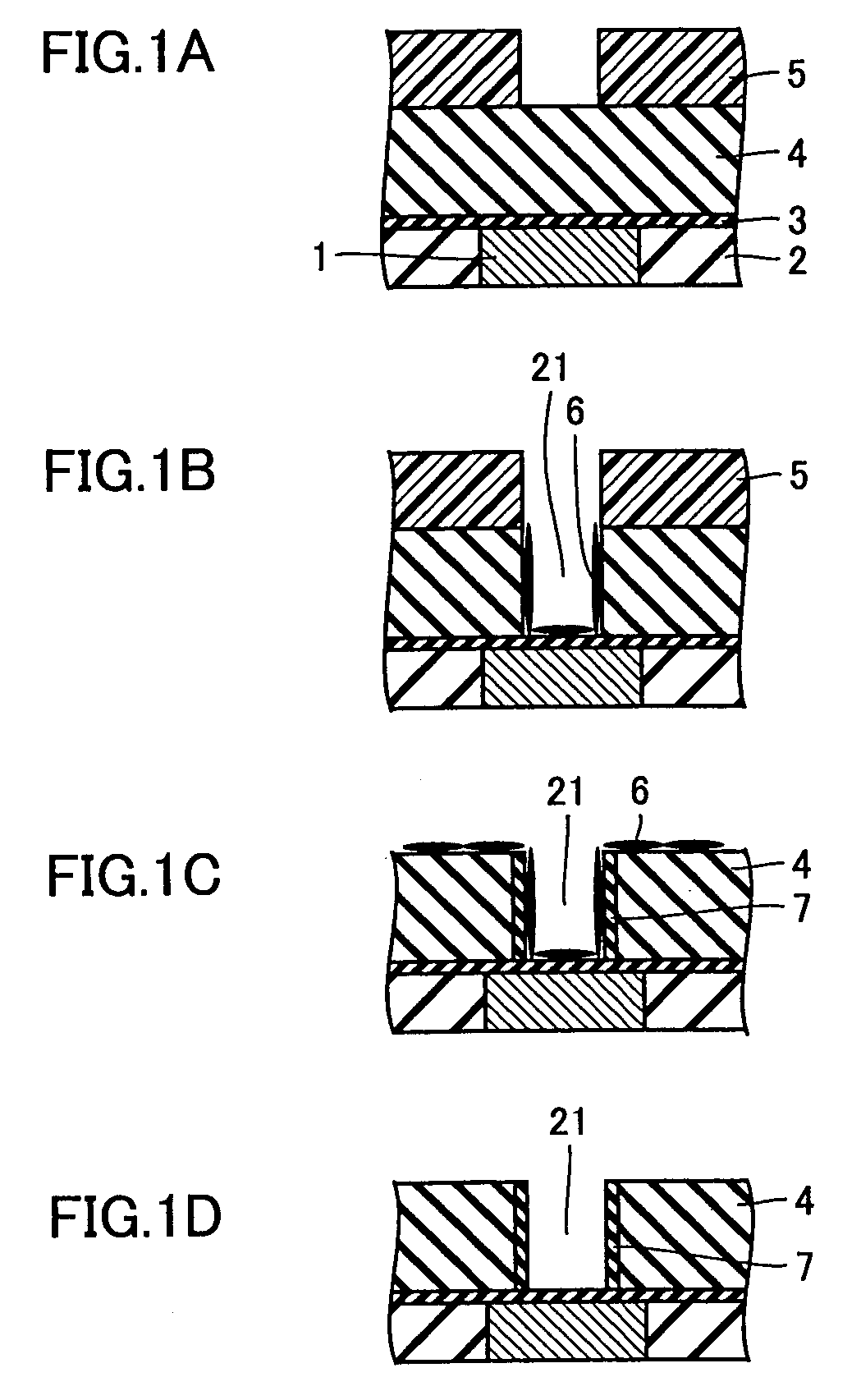

Substrate processing method

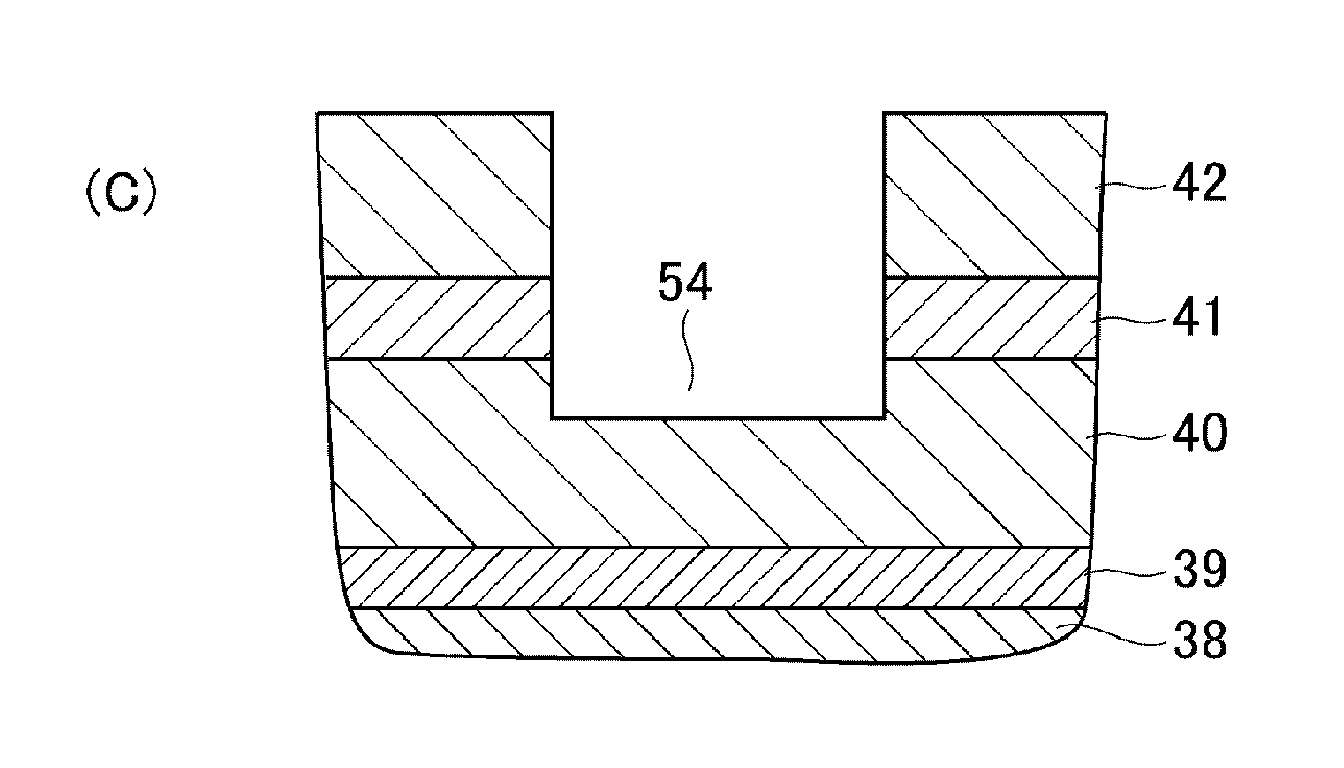

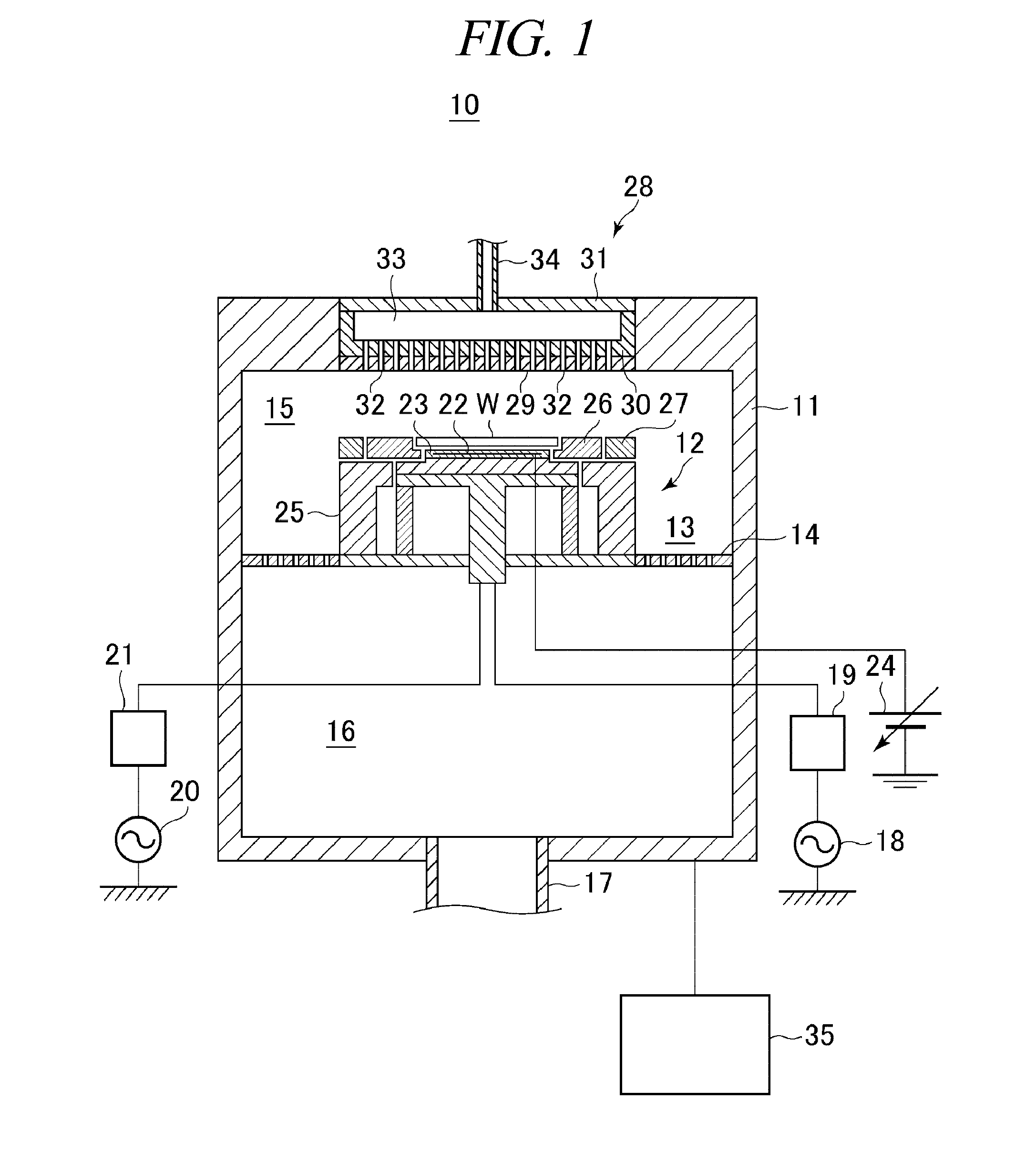

ActiveUS20120164839A1Easy to evaporateIncrease etch rateElectric discharge tubesDecorative surface effectsOrganic acidCopper atom

There is provided a substrate processing method capable of increasing an etching rate of a copper member without using a halogen gas. A Cu layer 40 having a smoothened surface 50 is obtained, and then, a processing gas produced by adding a methane gas to a hydrogen gas is introduced into an inner space of a processing chamber 15. Plasma is generated from this processing gas. In the inner space of the processing chamber 15, there exist oxygen radicals 52 generated when an oxide layer 42 is etched, and carbon radicals 53 generated from methane. The oxygen radicals 52 and the carbon radicals 53 are compounded to generate an organic acid, and the organic acid makes a reaction with copper atoms of the Cu layer 40. As a result, a complex of the organic acid having the copper atoms is generated, and the generated organic acid complex is vaporized.

Owner:TOKYO ELECTRON LTD

Highly-resilient thermoplastic elastomer compositions

A thermoplastic composition of (a) an acid copolymer, (b) a salt of a high molecular weight, monomeric organic acid; (c) a thermoplastic polymer selected from copolyetheresters, elastomeric polyolefins, styrene diene block copolymers, elastomeric polyolefins thermoplastic polyurethanes and copolyetheramides; (d) cation source; and (d) optionally a filler. Also included is use of such compositions in components of one-, two- and three-piece golf balls or multi-layered golf balls made therefrom.

Owner:EI DU PONT DE NEMOURS & CO

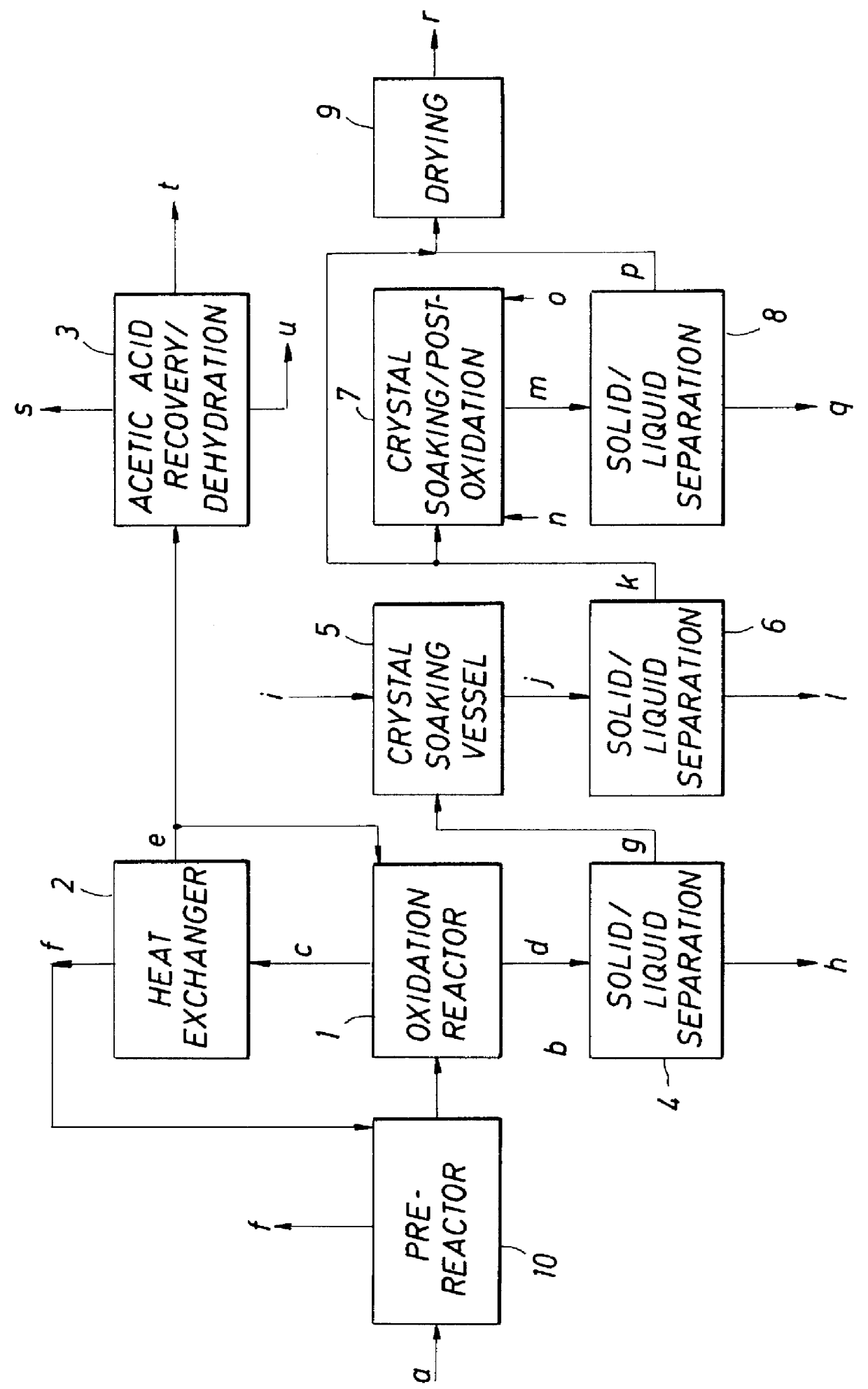

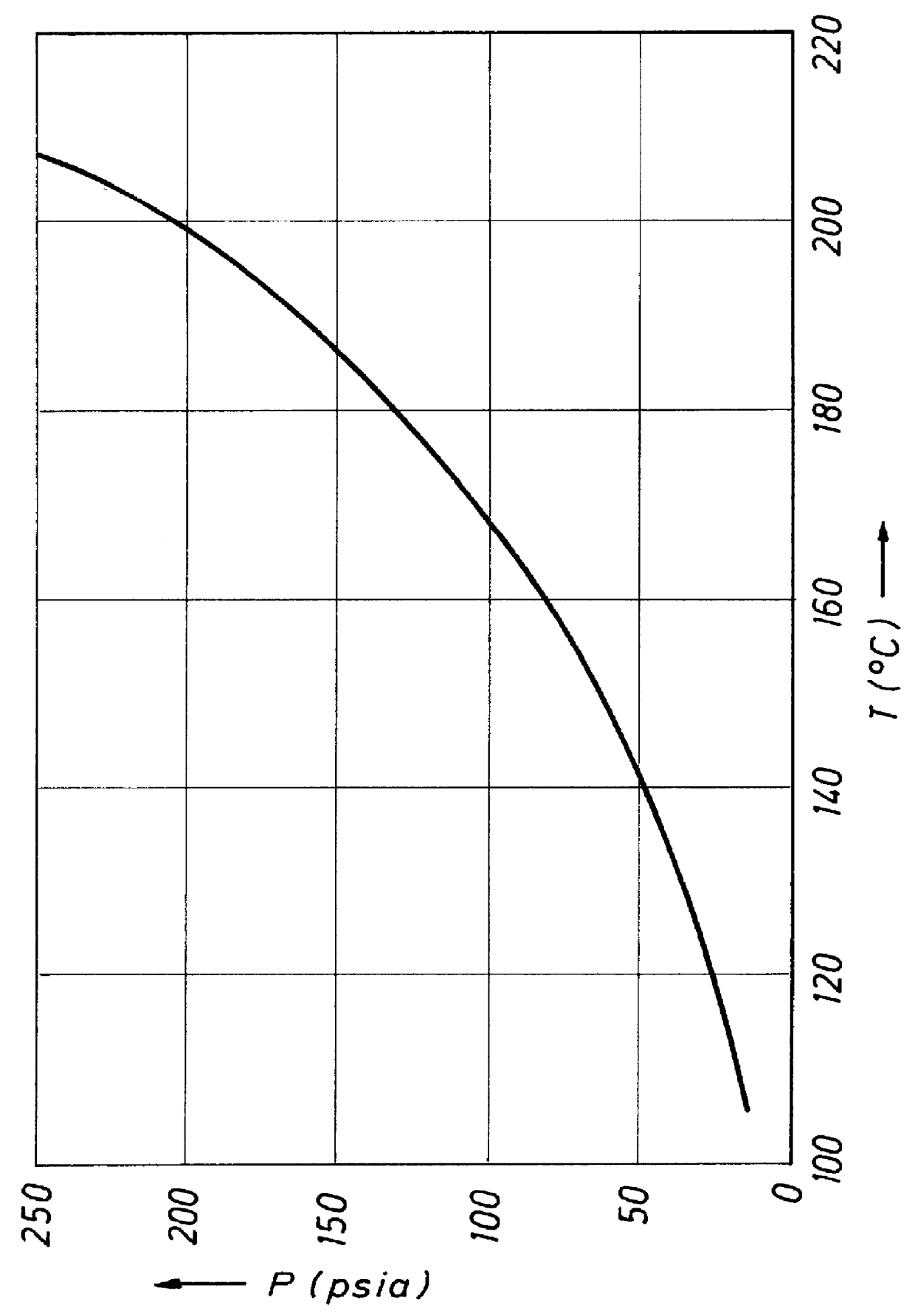

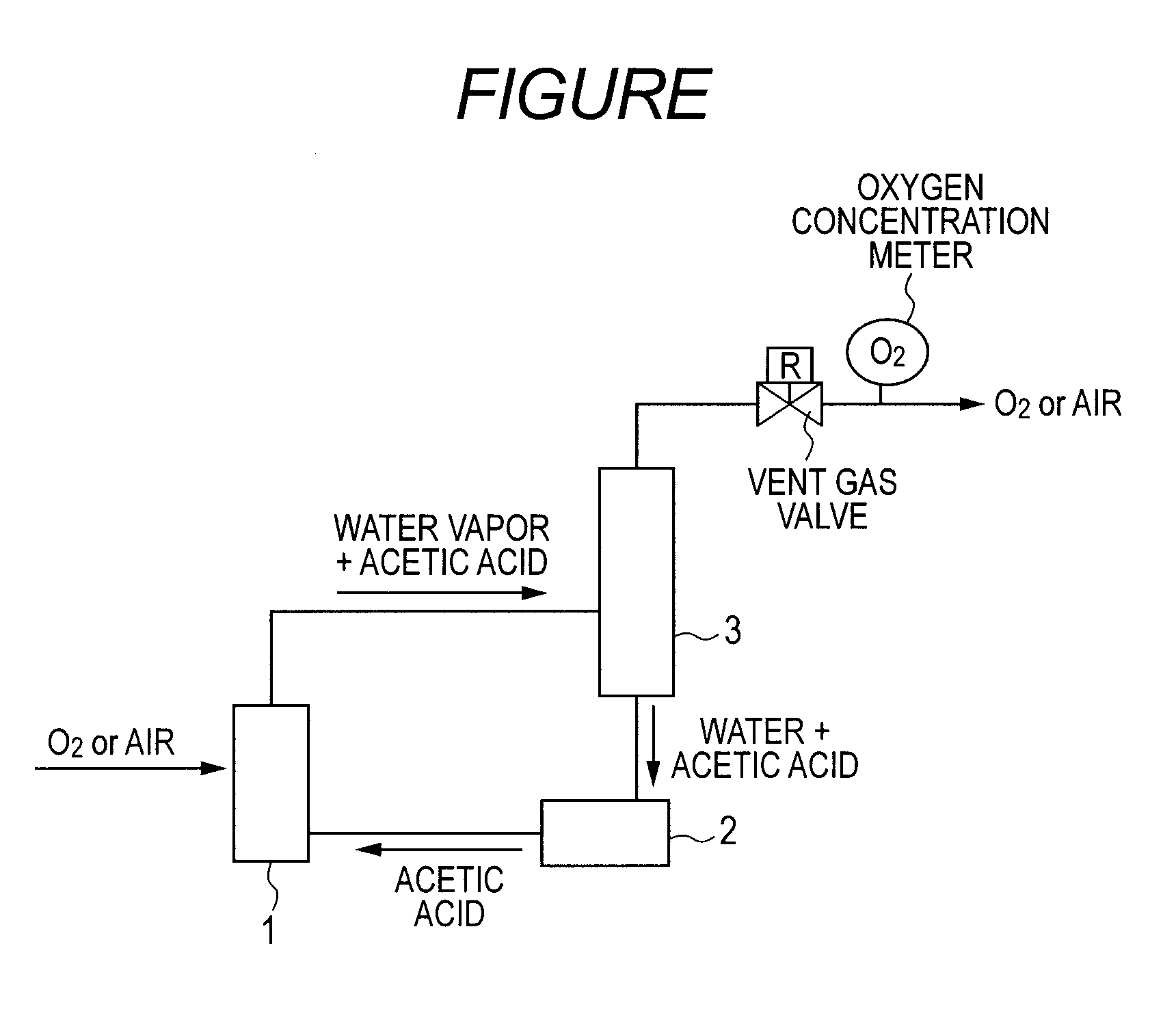

Method to produce aromatic dicarboxylic acids using cobalt and zirconium catalysts

InactiveUS6153790AAvoid problemsEfficient removalOrganic compound preparationChemical recyclingOrganic acidWater vapor

A process to produce terephthalic acid is provided, the process including the steps of: providing a feed stream comprising a dialkyl substituted aromatic and in an organic acid solvent: contacting the feed stream with an oxidant, the oxidant containing at least 50% by volume oxygen and at an oxygen partial pressure of at least 1 psia, at a temperature between about 80 DEG C. and about 130 DEG C., in the presence of a catalyst system comprising zirconium and cobalt, wherein the contacting is done in a stirred tank reactor; removing from the stirred tank reactor a vapor stream comprising the organic acid, water vapor and unreacted oxidant; condensing at least a portion of the organic acid and water from the vapor stream; separating at least a portion of the water from the organic acid back to the stirred tank reactor; returning at least a portion of the condensed organic acid back to the stirred tank reactor; continuously recovering from the stirred tank reactor a product comprising a diacid substituted aromatic; isolating solid crystals of diacid substituted aromatic from the reactor product; and recovering from the solid crystals a diacid substituted aromatic having a purity of preferably at least 97% by weight.

Owner:SHELL OIL CO

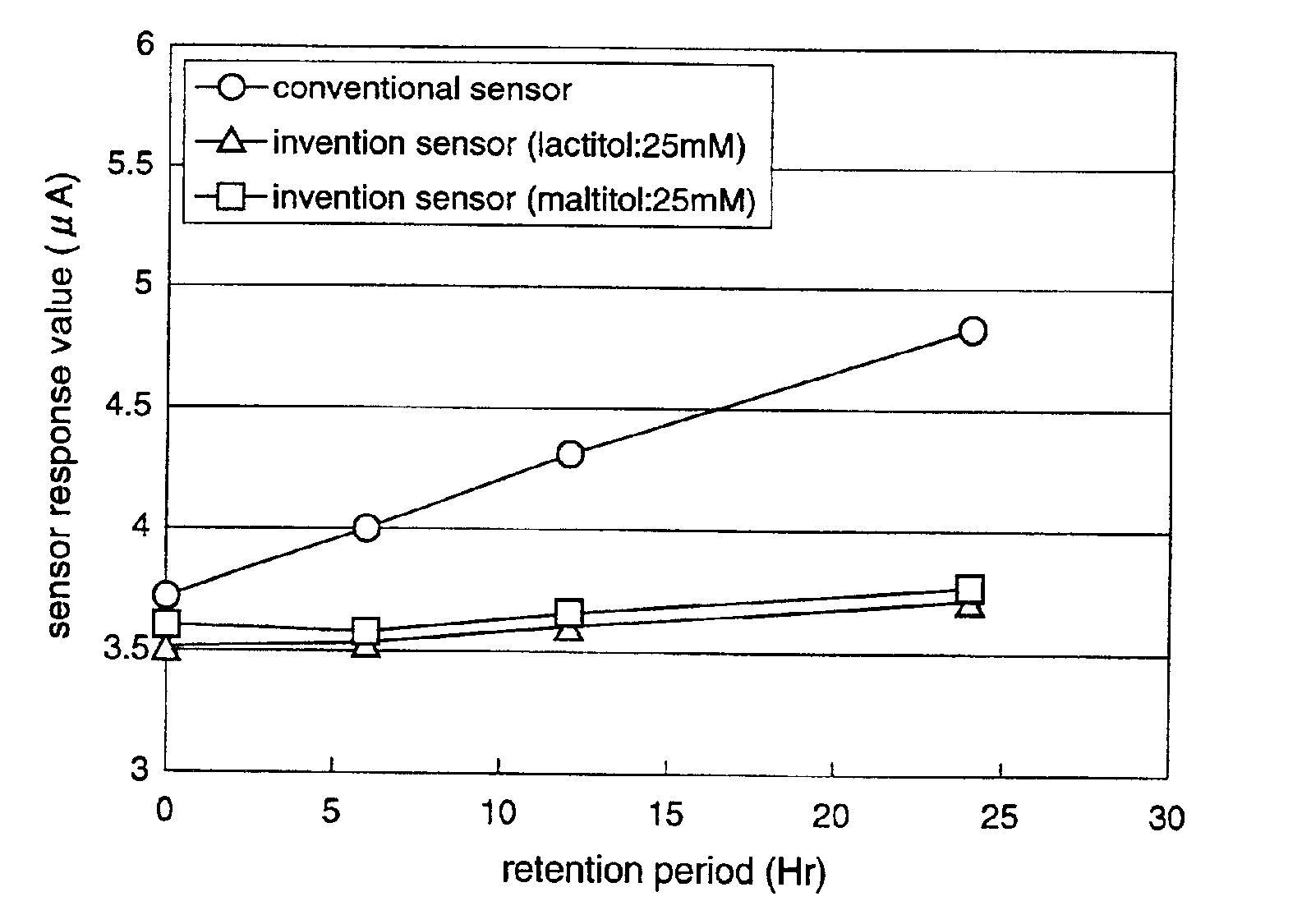

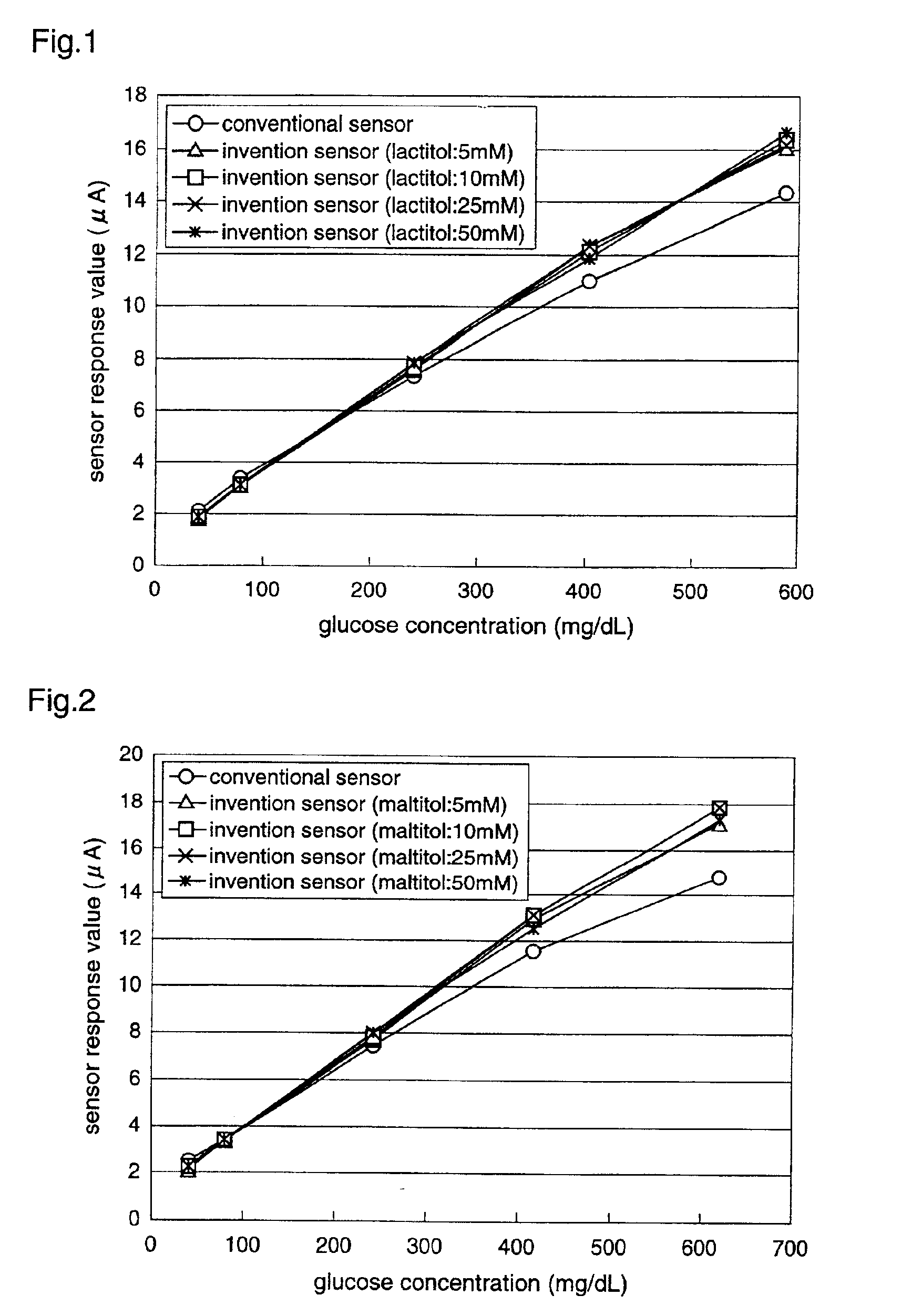

Biosensor

InactiveUS6911131B2Achieve effectImprove stabilityImmobilised enzymesBioreactor/fermenter combinationsOrganic acidAlcohol sugars

In a biosensor for measuring a specific substance in a liquid sample, one or a combination of sugar alcohol, metallic salt, organic acid or organic acid salt which has at least one carboxyl group in a molecule, and organic acid or organic acid salt which has at least one carboxyl group and one amino group in a molecule, is included in a reagent layer provided on electrodes, thereby providing a highly-accurate biosensor which is excellent in stability and has high response (sensitivity, linearity) of the sensor to the substrate concentration.

Owner:PHC HLDG CORP

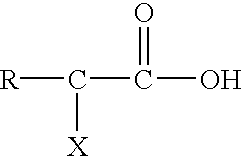

Post clean treatment

InactiveUS6546939B1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsHydroxylamineHydrazine compound

A composition for removal of chemical residues from metal or dielectric surfaces or for chemical mechanical polishing of a copper or aluminum surface is an aqueous solution with a pH between about 3.5 and about 7. The composition contains a monofunctional, difunctional or trifunctional organic acid and a buffering amount of a quaternary amine, ammonium hydroxide, hydroxylamine, hydroxylamine salt, hydrazine or hydrazine salt base. A method in accordance with the invention for removal of chemical residues from a metal or dielectric surface comprises contacting the metal or dielectric surface with the above composition for a time sufficient to remove the chemical residues. A method in accordance with the invention for chemical mechanical polishing of a copper or aluminum surface comprises applying the above composition to the copper or aluminum surface, and polishing the surface in the presence of the composition.

Owner:DUPONT AIR PRODS NANOMATERIALS

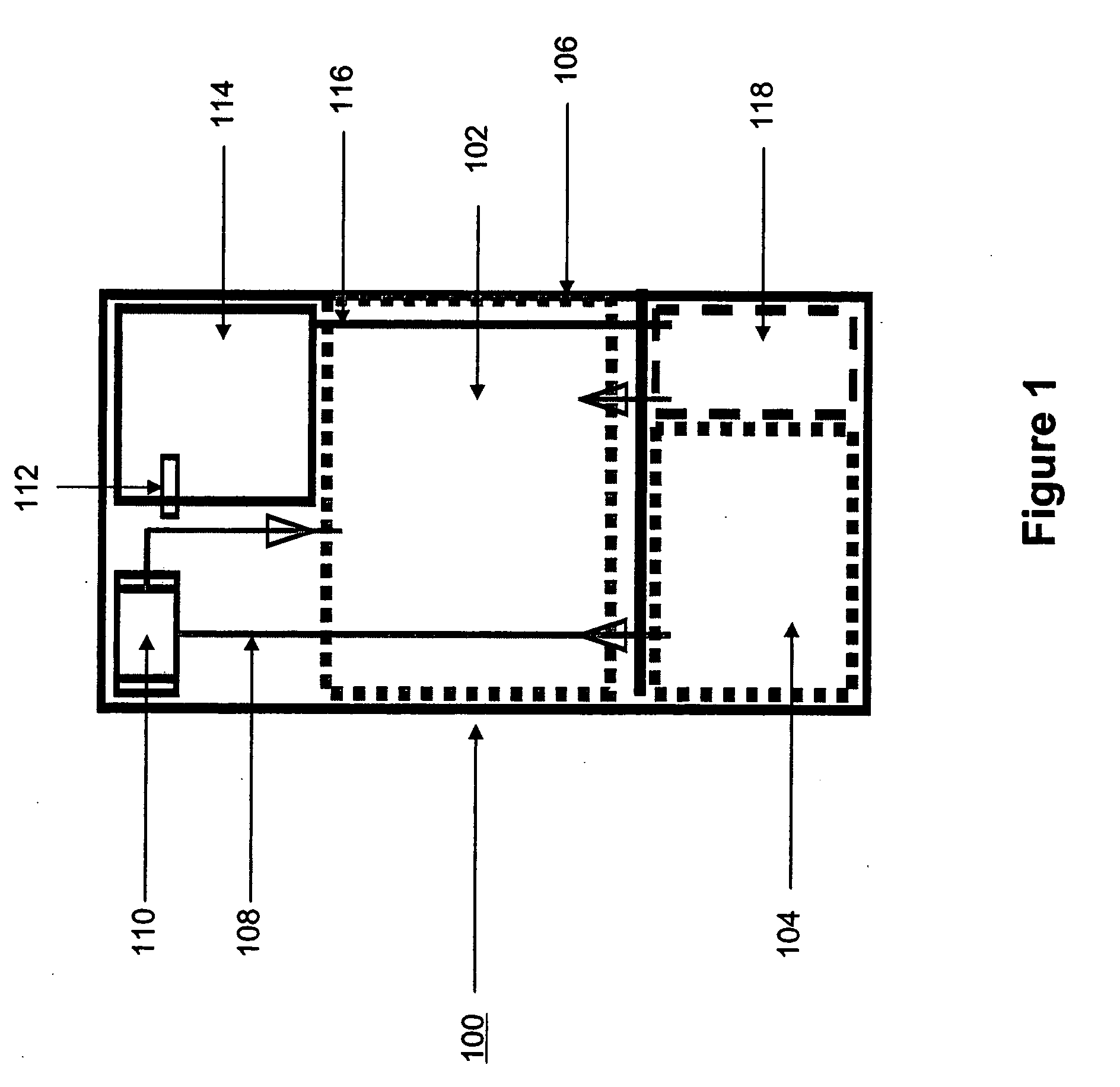

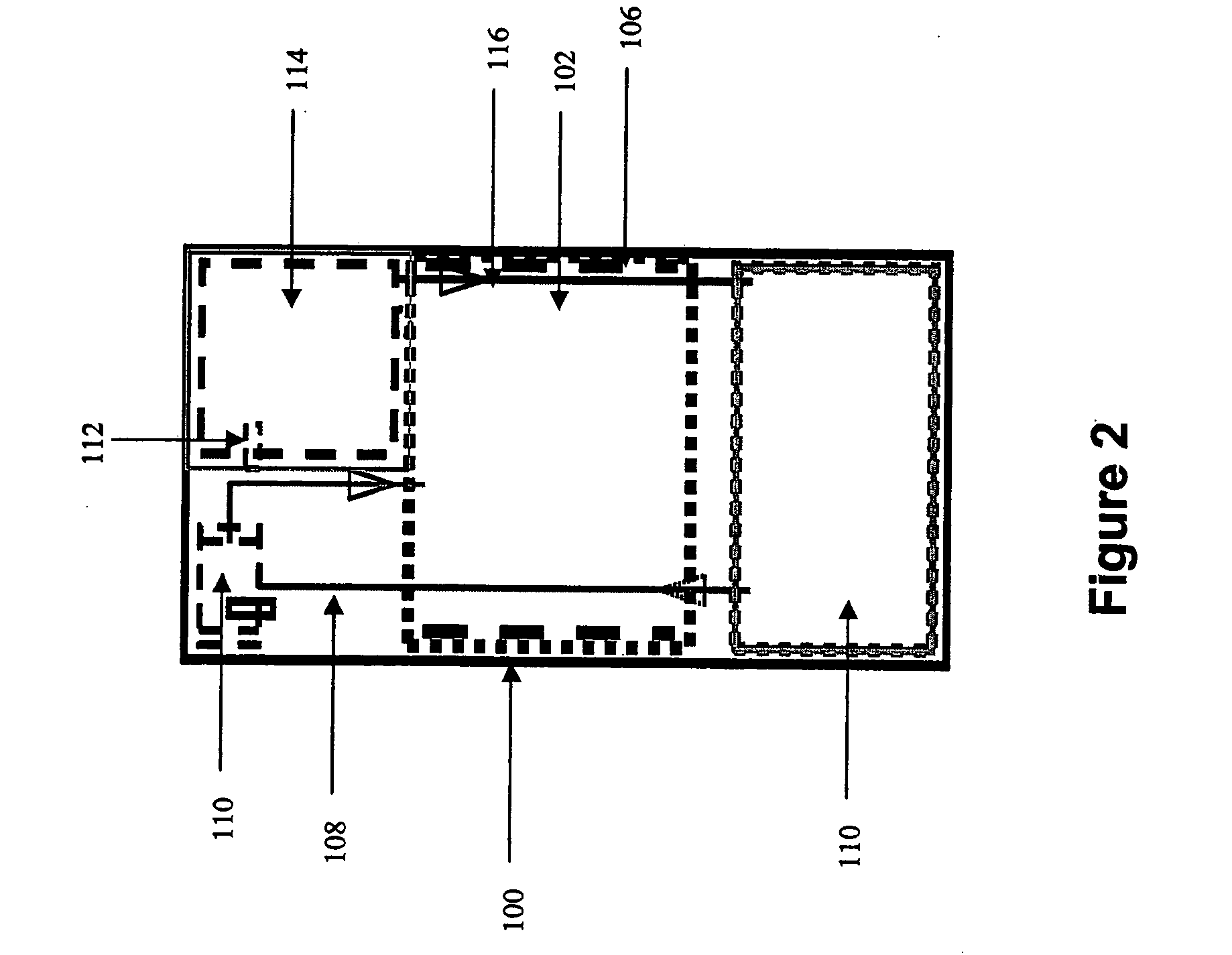

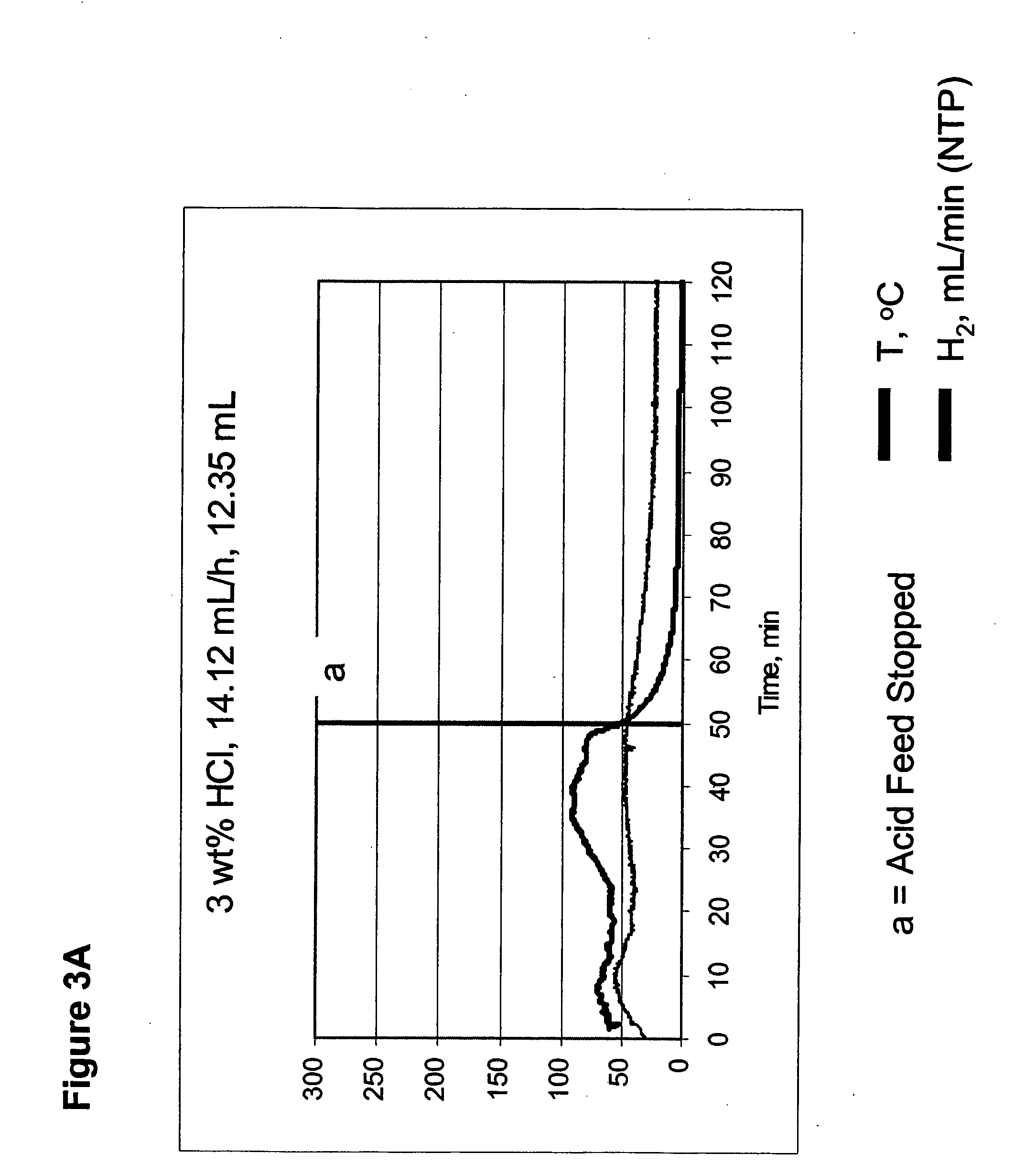

Systems and methods for hydrogen generation from solid hydrides

InactiveUS20050238573A1Regulate rateReactant parameters controlHydrogen productionO-Phosphoric AcidAlkaline earth metal

A system is disclosed for hydrogen generation based on hydrolysis of solid chemical hydrides with the capability of controlled startup and stop characteristics wherein regulation of acid concentration, acid feed rate, or a combination of both control the rate of hydrogen generation. The system comprises a first chamber for storing a solid chemical hydride and a second chamber for storing an acidic reagent. The solid chemical hydride is a solid metal borohydride having the general formula MBH4, where M is selected from the group consisting of alkali metal cations, alkaline earth metal cations, aluminum cation, zinc cation, and ammonium cation. The acidic reagent may comprise inorganic acids such as the mineral acids hydrochloric acid, sulfuric acid, and phosphoric acid, and organic acids such as acetic acid, formic acid, maleic acid, citric acid, and tartaric acid, or mixtures thereof.

Owner:MILLENNIUM CELL

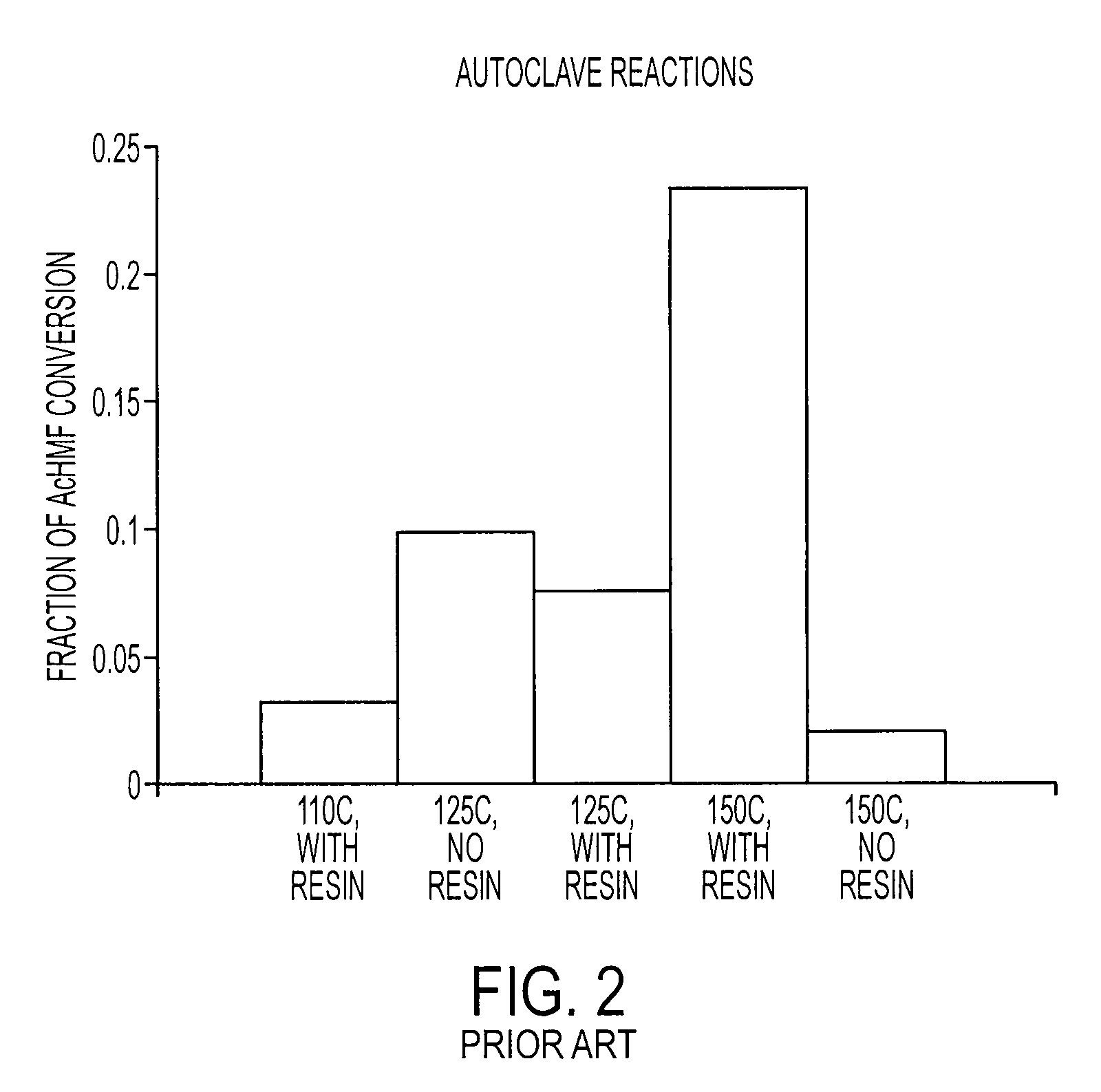

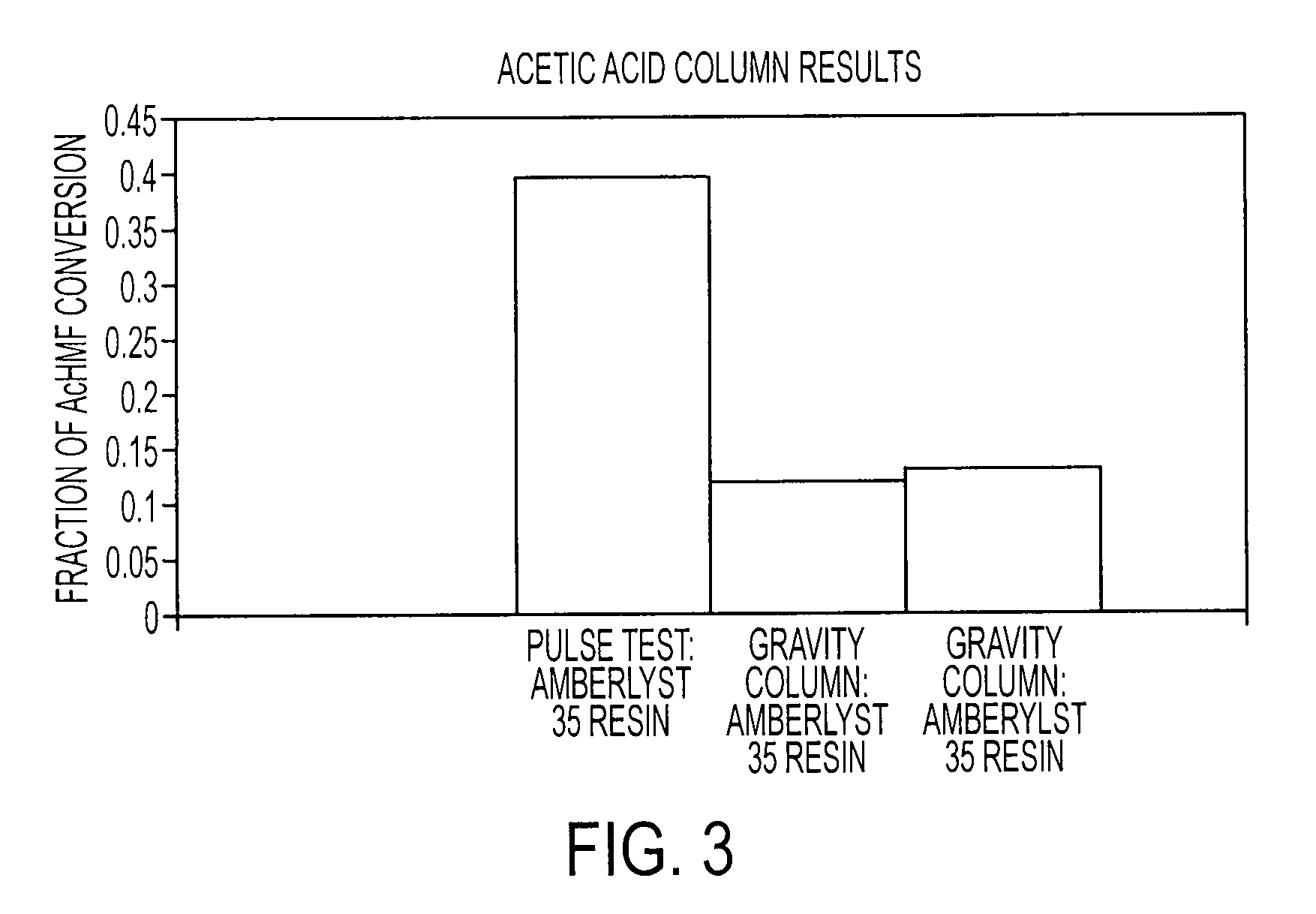

Conversion of carbohydrates to hydroxymethylfurfural (HMF) and derivatives

InactiveUS20090156841A1Increase conversion rateStable formOrganic compound preparationCarboxylic compound preparationMANGANESE ACETATEFuran

A method of producing substantially pure HMF, HMF esters and other derivatives from a carbohydrate source by contacting the carbohydrate source with a solid phase catalyst. A carbohydrate starting material is heated in a solvent in a column and continuously flowed through a solid phase catalyst in the presence of an organic acid, or heated with the organic acid and a solid catalyst in solution to form a HMF ester. Heating without organic acid forms HMF. The resulting product is purified by filtration to remove the unreacted starting materials and catalyst. The HMF ester or a mixture of HMF and HMF ester may then be oxidized to 2,5-furandicarboxylic acid (FDCA) by combining the HMF ester with an organic acid, cobalt acetate, manganese acetate and sodium bromide under pressure. Alternatively, the HMF ester may be reduced to form a furan or tetrahydrofuran diol.

Owner:ARCHER DANIELS MIDLAND CO

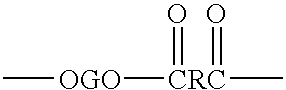

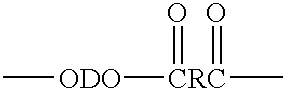

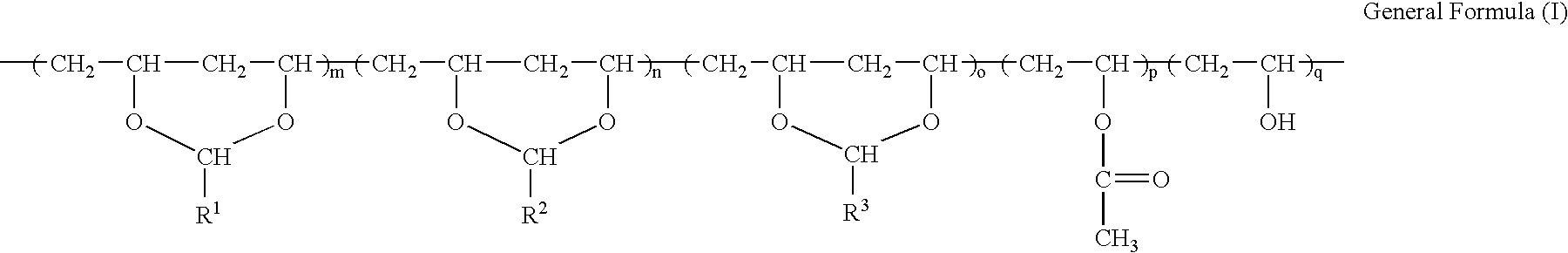

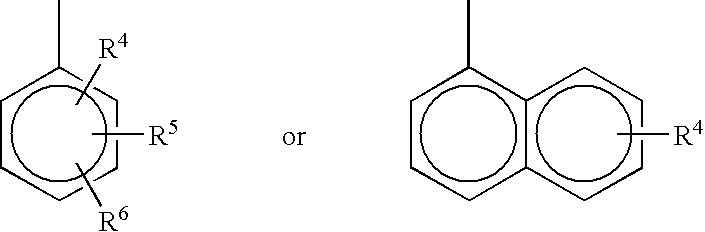

Light-sensitive lithographic printing plate

InactiveUS20050214677A1High developing latitudeExcellent printing durabilityPhotosensitive materialsLithographyOrganic acidPlanographic printing

A light-sensitive lithographic printing plate comprising a hydrophilic substrate provided thereon with a layer sensitive to infrared light rays comprising (A) a polymer represented by the following general formula (I); (B) an organic acid and / or a cyclic acid anhydride; and (C) a light-heat conversion substance. The light-sensitive lithographic printing plate is excellent in the both printing durability and the developing latitude.

Owner:FUJIFILM HLDG CORP

Removing solution

InactiveUS20060138399A1Eliminate residueImprove solubilityDetergent mixture composition preparationSolid-state devicesHydrogen fluorideOrganic acid

The present invention provides a resist-removing solution for low-k film and a cleaning solution for via holes or capacitors, the solutions comprising hydrogen fluoride (HF) and at least one member selected from the group consisting of organic acids and organic solvents. The invention also provides a method of removing resist and a method of cleaning via holes or capacitors by the use of the solutions.

Owner:DAIKIN IND LTD

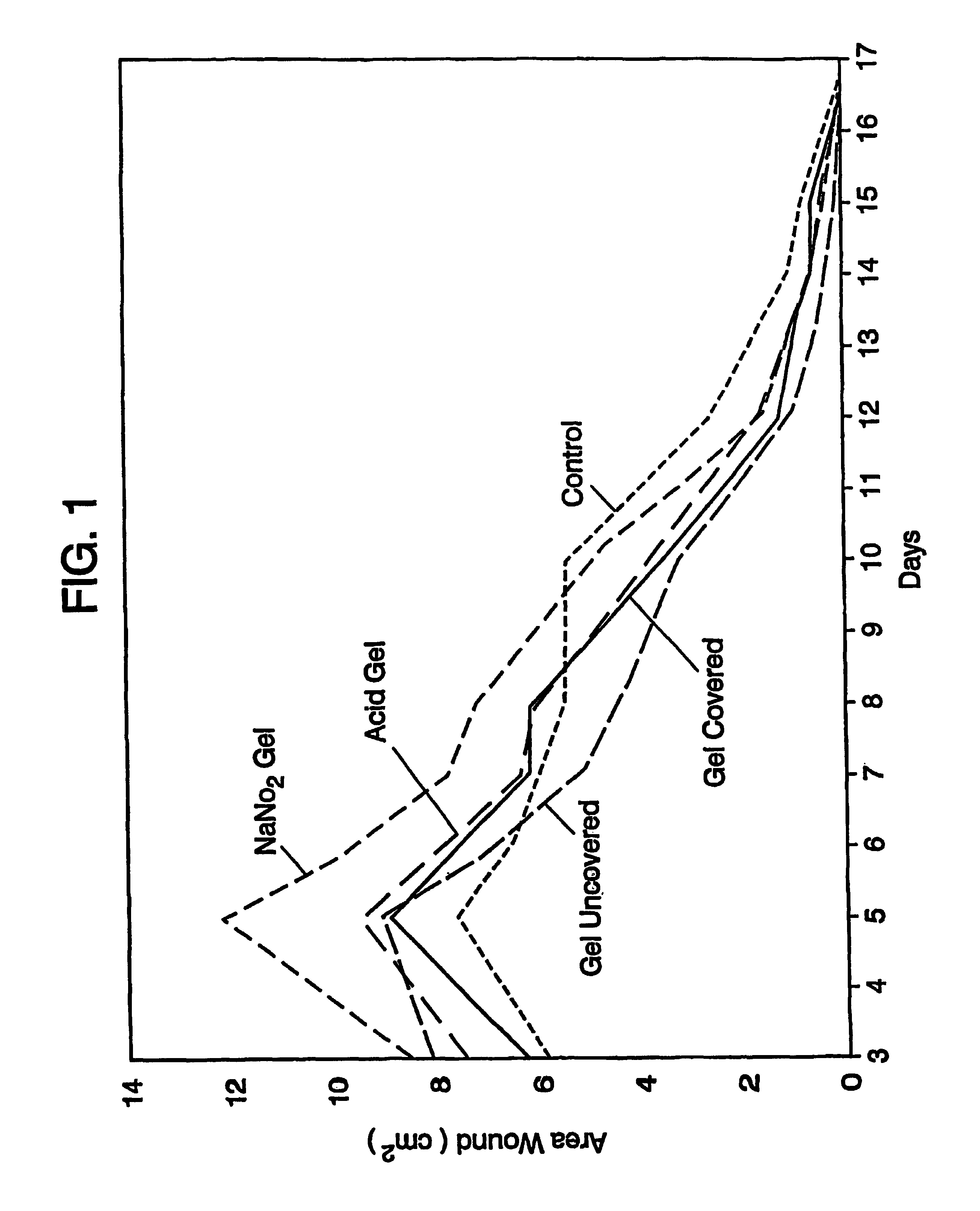

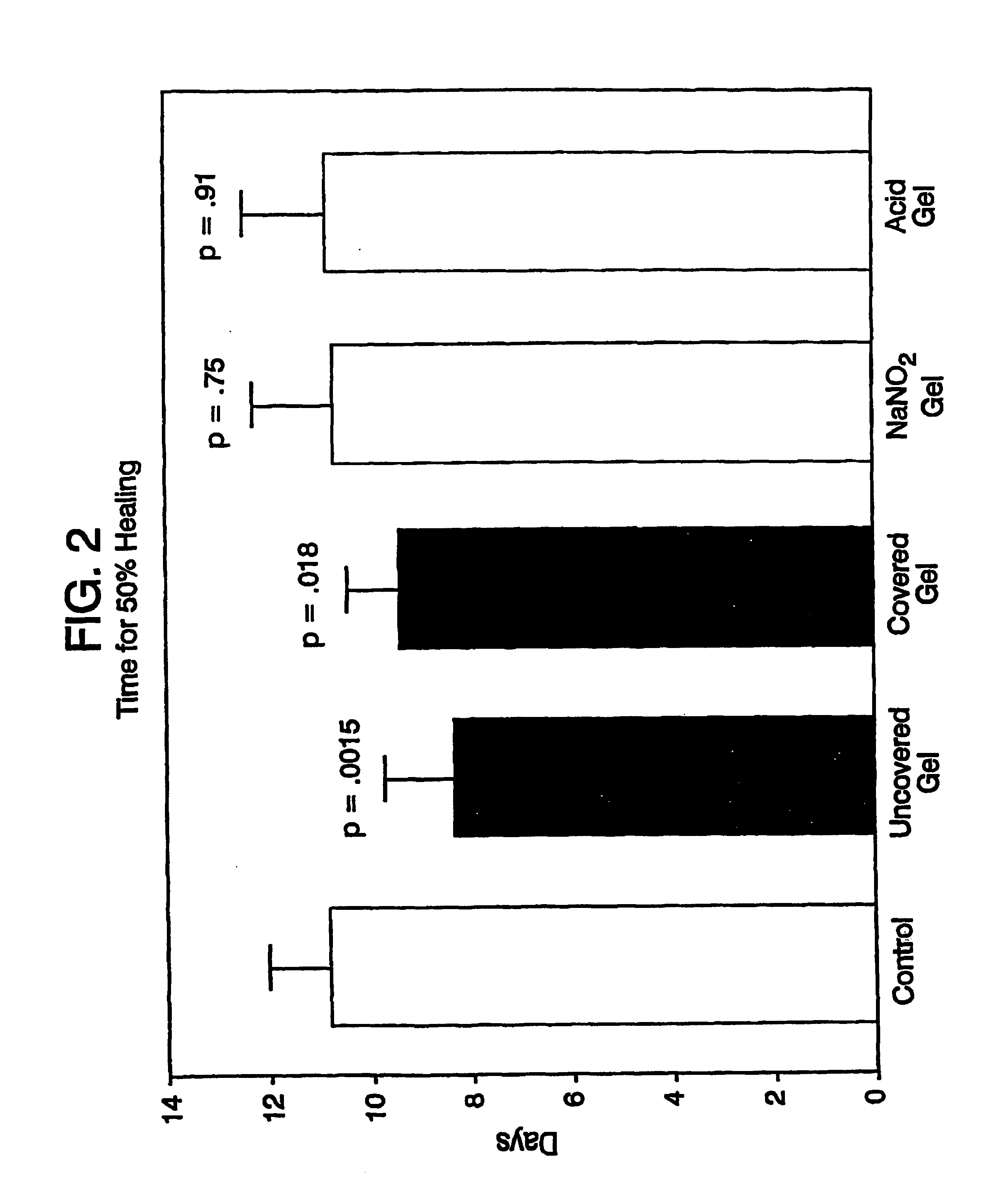

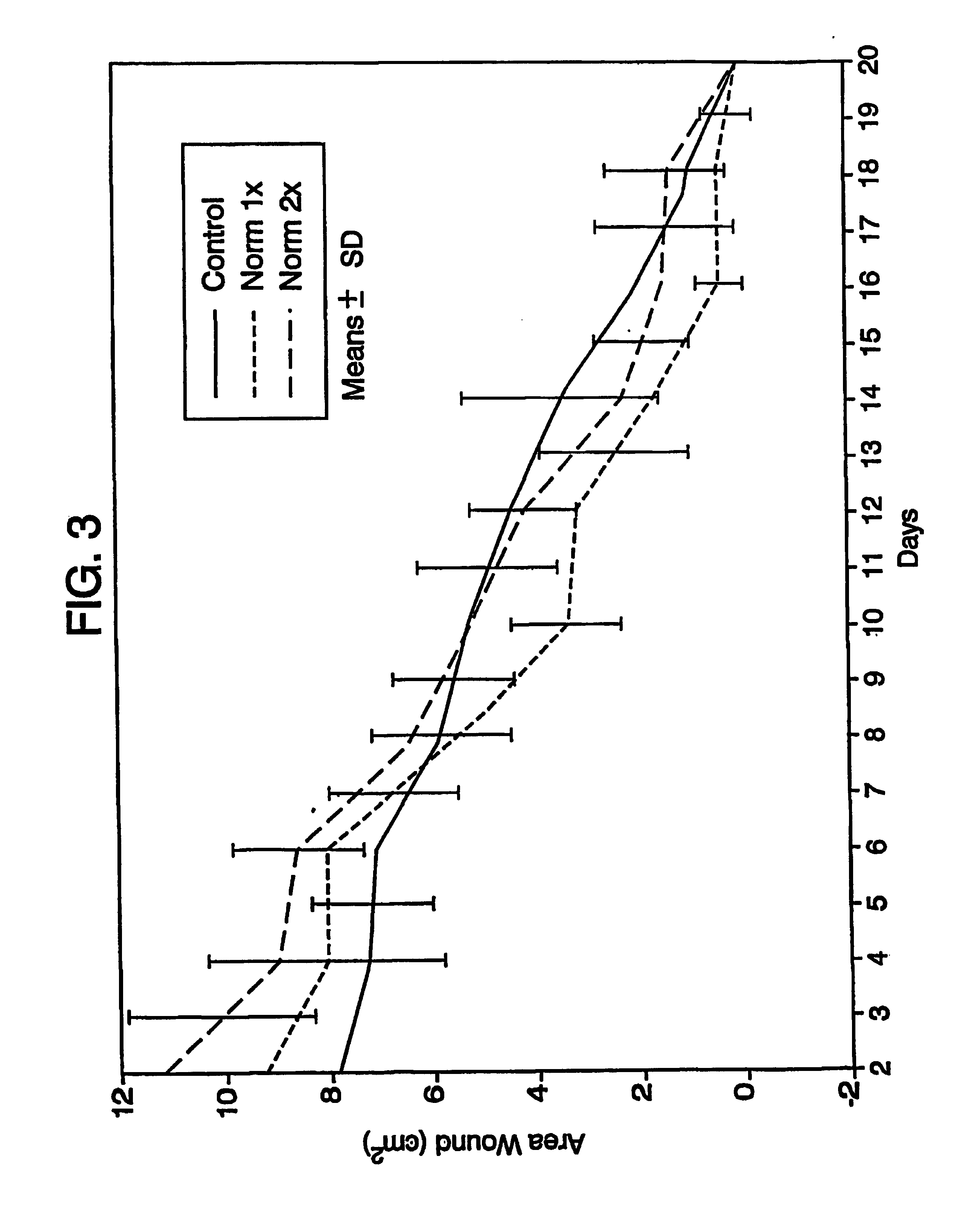

Systems and methods for topical treatment with nitric oxide

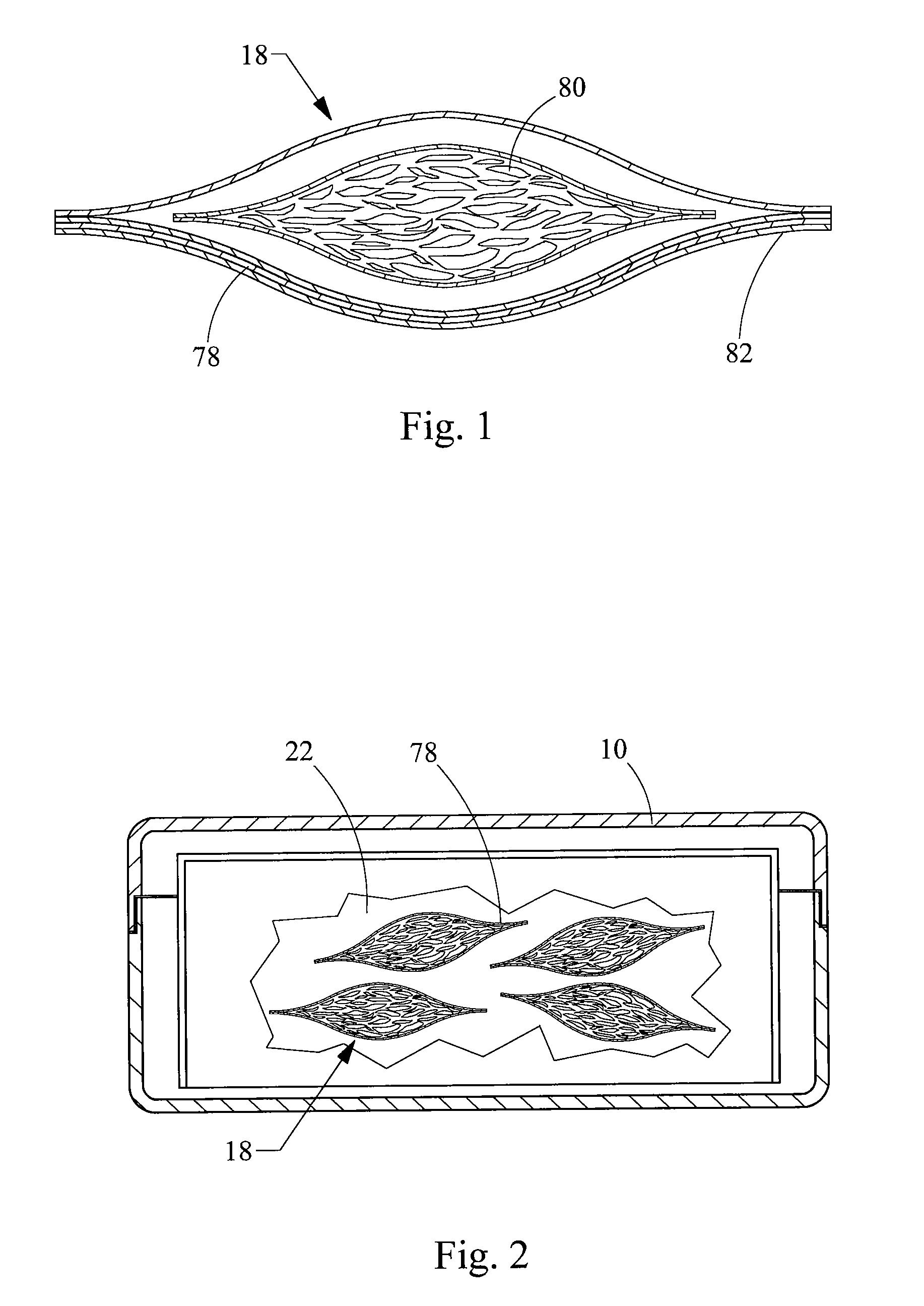

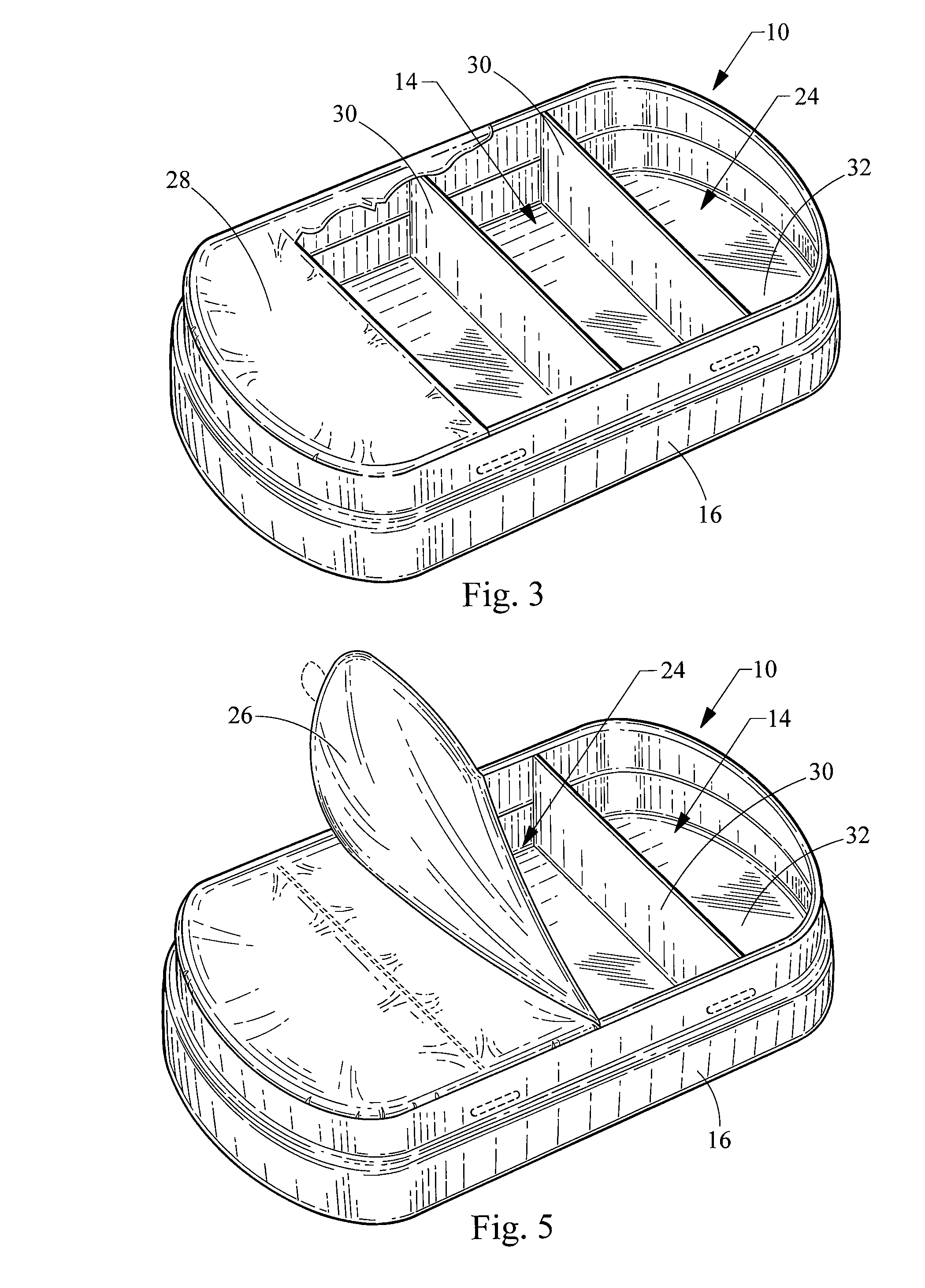

InactiveUS7048951B1Reduce skin irritationBiocideInorganic active ingredientsSandwich likeTransdermal patch

A simple, biocompatible system and procedure for generating nitric oxide (NO) is described. A mixture of powdered sodium nitrite, ascorbic acid, and maleic acid (or another organic acid of adequate strength) immediately generates nitric oxide (NO) on treatment with water. To slow down the NO generation, one may prepare an ointment from a nonaqueous medium (petrolatum, Vaseline™) and the three powdered ingredients, which on being applied topically on the skin will release NO as water permeates through this medium; alternatively, one may convert the aqueous sodium nitrite solution into a gel with hydroxyethylcellulose (or other gel-forming compound) and combine this gel with another gel obtained from aqueous ascorbic and maleic acids with hydroxyethylcellulose for topical application (on intact skin, burns intra-cavity, burns, intra-cavity, etc.). The two gels may be admixed immediately before use (possibly from a single container with separate chambers and dual nozzle, via pushing or squeezing the two gels through the nozzle), or may be applied in sandwich-like fashion (possibly as a transdermal patch) for further slowing down the delivery of NO.

Owner:NITRIC SOLUTIONS

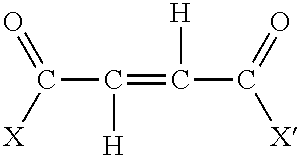

Highly-neutralized ethylene copolymers

Melt-processable, highly-neutralized ethylene, C3 to C8 alpha,beta ethylenically unsaturated carboxylic acid copolymers and process for making them. Copolymers are made by incorporating a C4 to less than a C36 aliphatic, mono-functional organic acid and neutralizing greater than 90% to 100% of the acid groups present concurrently with or subsequently to the incorporation of the organic acid.

Owner:PERFORMANCE MATERIALS NA INC

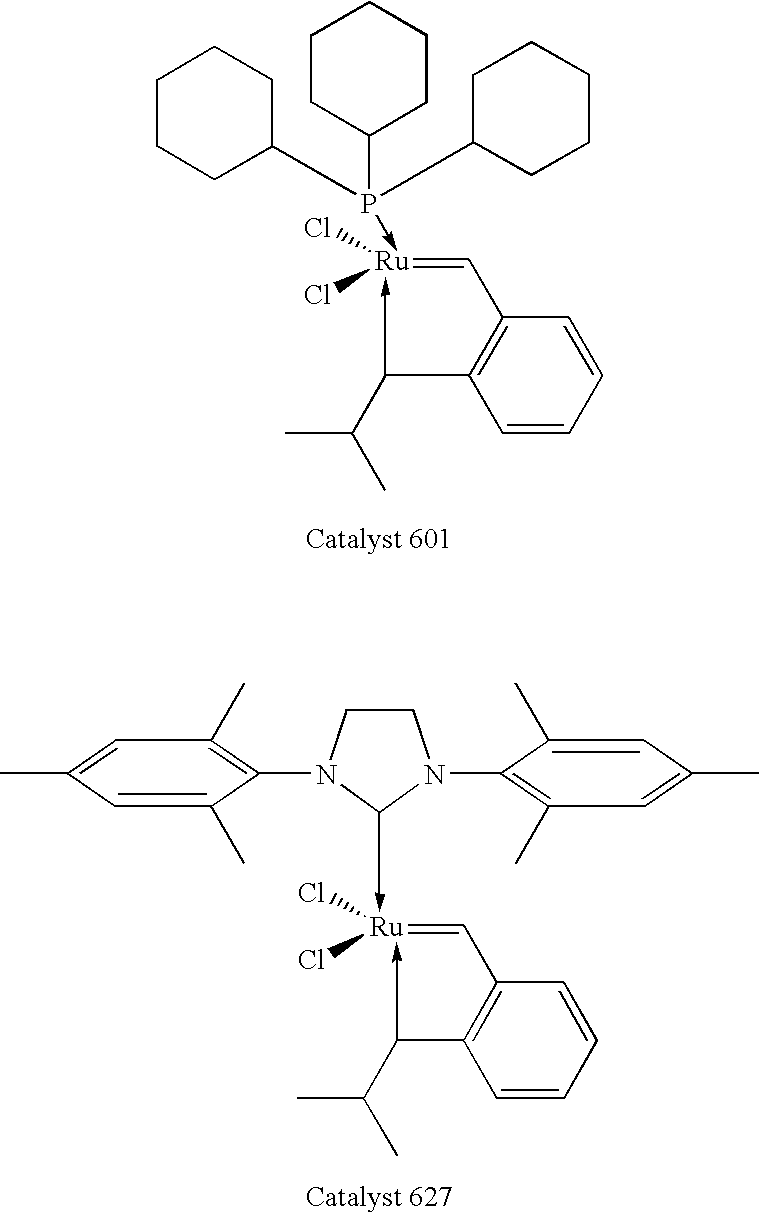

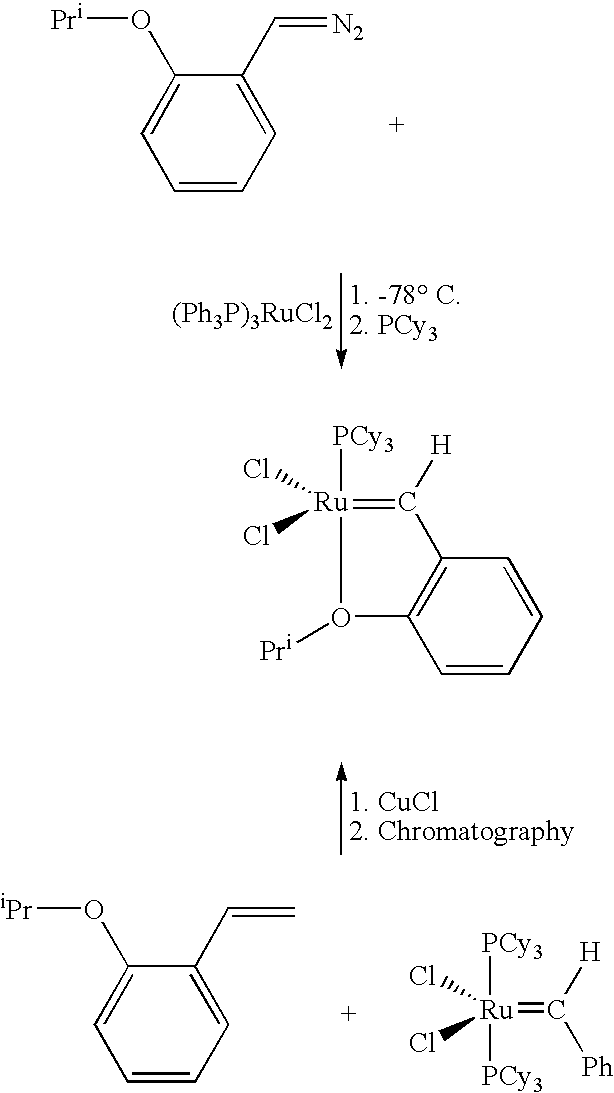

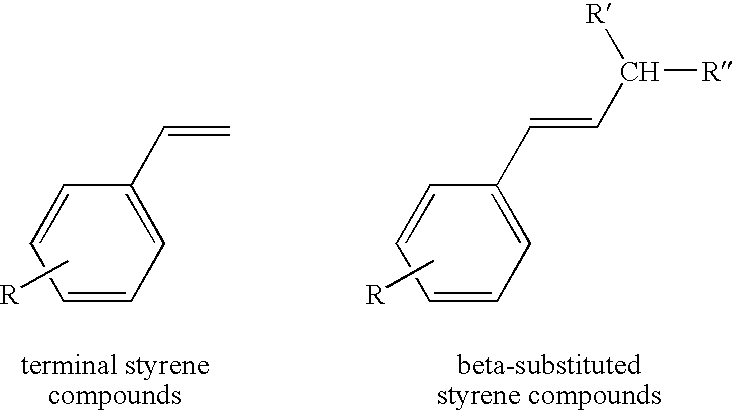

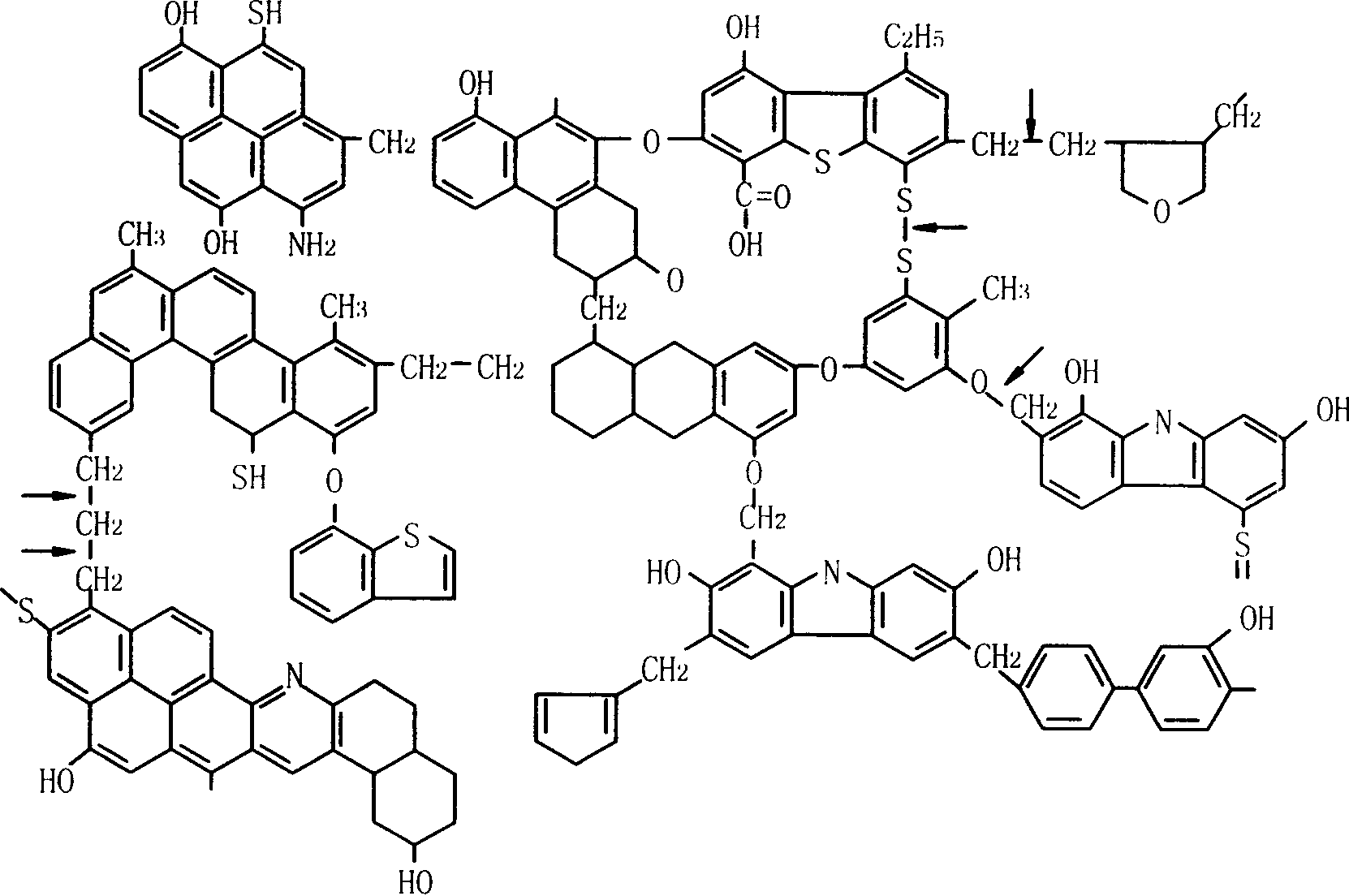

Chelating carbene ligand precursors and their use in the synthesis of metathesis catalysts

InactiveUS7026495B1High yieldImprove isolationRuthenium organic compoundsGroup 5/15 element organic compoundsHigh concentrationCarbene

Chelating ligand precursors for the preparation of olefin metathesis catalysts are disclosed. The resulting catalysts are air stable monomeric species capable of promoting various metathesis reactions efficiently, which can be recovered from the reaction mixture and reused. Internal olefin compounds, specifically beta-substituted styrenes, are used as ligand precursors. Compared to terminal olefin compounds such as unsubstituted styrenes, the beta-substituted styrenes are easier and less costly to prepare, and more stable since they are less prone to spontaneous polymerization. Methods of preparing chelating-carbene metathesis catalysts without the use of CuCl are disclosed. This eliminates the need for CuCl by replacing it with organic acids, mineral acids, mild oxidants or even water, resulting in high yields of Hoveyda-type metathesis catalysts. The invention provides an efficient method for preparing chelating-carbene metathesis catalysts by reacting a suitable ruthenium complex in high concentrations of the ligand precursors followed by crystallization from an organic solvent.

Owner:UMICORE AG & CO KG

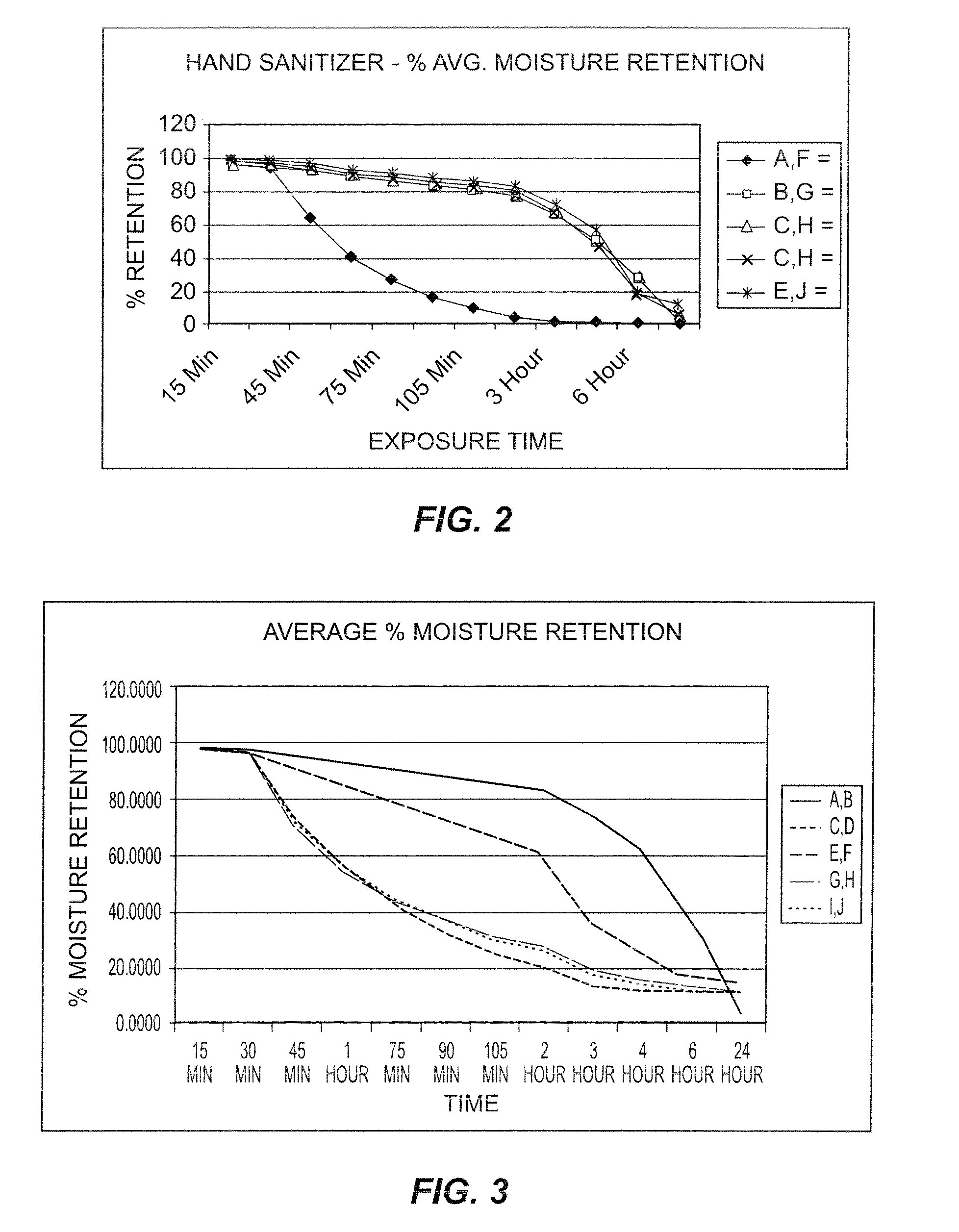

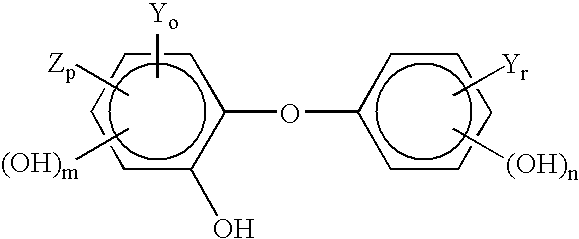

Alcohol-containing antimicrobial compositions having improved efficacy

InactiveUS20070281999A1Improve efficacyReduce skin irritationSalicyclic acid active ingredientsBiocideOrganic acidAlcohol

Antimicrobial compositions having a rapid antiviral and antibacterial effectiveness, and a persistent antiviral effectiveness, are disclosed. The antimicrobial compositions contain (a) a disinfecting alcohol, (b) a blend containing a C12 to C22 alcohol and an ethoxylated C12 to C22 alcohol, such as a cetearyl alcohol and cetereth-20 blend, a cetearyl alcohol, steareth-20, and steareth-10 blend, or a mixture thereof, (c) an optional organic acid, and (c) water.

Owner:DIAL CORPORATION

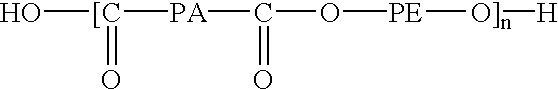

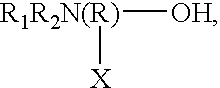

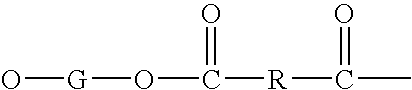

Ink-jet printing ink compositions having superior smear-fastness

InactiveUS6417249B1Improve printing effectGood printing performanceInksCoatingsPolyesterPolymer science

Specific core-shell binders and additives for use in ink-jet printing ink compositions are provided. One class of specific core / shell binders has the general formula [AmBnC'p]x, where A and B are hydrophobic components in which A exhibits a glass transition temperature Tg between about -150° and +25° C. and B exhibits a glass transition temperature greater than 25° C., C' is a component that forms a hydrophilic or water-soluble component in the polymer chain, and has an ionic or non-ionic structure, m<30 wt %, n>40 wt %, and p<30 wt %, with the total of m+n+p=100 wt %, and x=1 to 100,000. The molecular weight (weight average) of the polymer is between about 1,000 and 2,000,000. The polymers useful in the practice of the invention are prepared by emulsifying the monomers and then conducting a free-radical polymerization in water. The foregoing binder polymer is used in conjunction with additives comprising either (a) amine alcohols having the general formulawhere R1 and R2 are independently selected from the group consisting of hydrogen, alkyl, alkoxy, aryl, and phenoxy, R is alkyl, X is selected from the group consisting of hydrogen, alkyl, aryl, -OH, -COOH, -CHO, and substituted groups or (b) organic acids (water-soluble or water-dispersive), including polymeric acids. Other additives include amines, polyalcohols, polyamines, and polyesters. In the ink compositions of the present invention, the ratio of binder (1) to colorant (pigment) is greater than 1 to 10. The concentration of the additive is within the range of 0.005 to 50 wt %. The general ink formulation comprises: 5 to 50 wt % water-miscible solvent; 0.5 to 10 wt % colorant; 0.005 to 50 wt % additive; and water.

Owner:HEWLETT PACKARD DEV CO LP

Highly-neutralized thermoplastic copolymer center for improved multi-layer core golf ball

InactiveUS20060128904A1Fibre treatmentSynthetic resin layered productsOrganic acidCoefficient of restitution

A golf ball comprising a center comprising a highly-neutralized thermoplastic copolymer of ethylene and an α,β-unsaturated carboxylic acid, the acid being 100% neutralized by a salt of an organic acid, a cation source, or a suitable base of the organic acid; a cover; and an intermediate layer disposed between the center and the cover; wherein the golf ball has a first coefficient of restitution of 0.81 or greater when measured at an incoming velocity of 125 ft / s; and a sphere resulting from a combination of the center and the intermediate layer has a compression of 60 or greater.

Owner:ACUSHNET CO

Antimicrobial composition

An antimicrobial composition that involves a synergistic mixture in terms of active agents, of a primary antimicrobial agent, such as polyhexamethylene biguanide (PHMB), a secondary antimicrobial agent, and optionally an organic acid against various kinds of microbes is described. Various additional processing aids, such as alcohols and surfactants, may also be incorporated within the mixture. The composition allows one to use a significantly less concentration of individual constituent antimicrobial agents to achieve the same or a better degree of antimicrobial efficacy. The antimicrobial composition can be applied to the surface of almost any kind of substrate material, and can achieve a killing-efficacy of about 3 Log10 reduction in microbes within 30 minutes under ambient conditions.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Antibody-containing solution pharmaceuticals

InactiveUS20050118163A1Suppress formationLong-term storage stabilityBiocidePharmaceutical delivery mechanismFreeze thawingOrganic acid

An antibody-containing solution formulation comprising an organic acid and a surfactant as stabilizers; a method for suppressing the formation of visible insoluble matter and / or insoluble particles due to the presence of metal ions in an antibody-containing solution formulation, which comprises adding an organic acid to the solution; a method for suppressing the formation of visible insoluble matter and / or insoluble particles during shaking and freezing-thawing of an antibody-containing solution, which comprises adding a surfactant to the solution; and a method for stabilizing an antibody-containing solution, which comprises adding an organic acid and a surfactant.

Owner:CHUGAI PHARMA CO LTD

Cleaning composition for removing resists and method of manufacturing semiconductor device

InactiveUS20040106531A1Surface-active detergent compositionsNon-surface-active detergent compositionsResistCopper interconnect

The cleaning composition for removing resists includes a salt of hydrofluoric acid and a base not containing a metal (A component), a water-soluble organic solvent (B1 component), at least one acid selected from a group consisting of organic acid and inorganic acid (C component), water (D component), and optionally an ammonium salt (E1 component), and its hydrogen ion concentration (pH) is 4-8. Thus, in the manufacturing process of a semiconductor device such as a copper interconnecting process, removing efficiency of resist residue and other etching residue after etching or ashing improves, and corrosion resistance of copper and insulating film also improves.

Owner:PANASONIC CORP +2

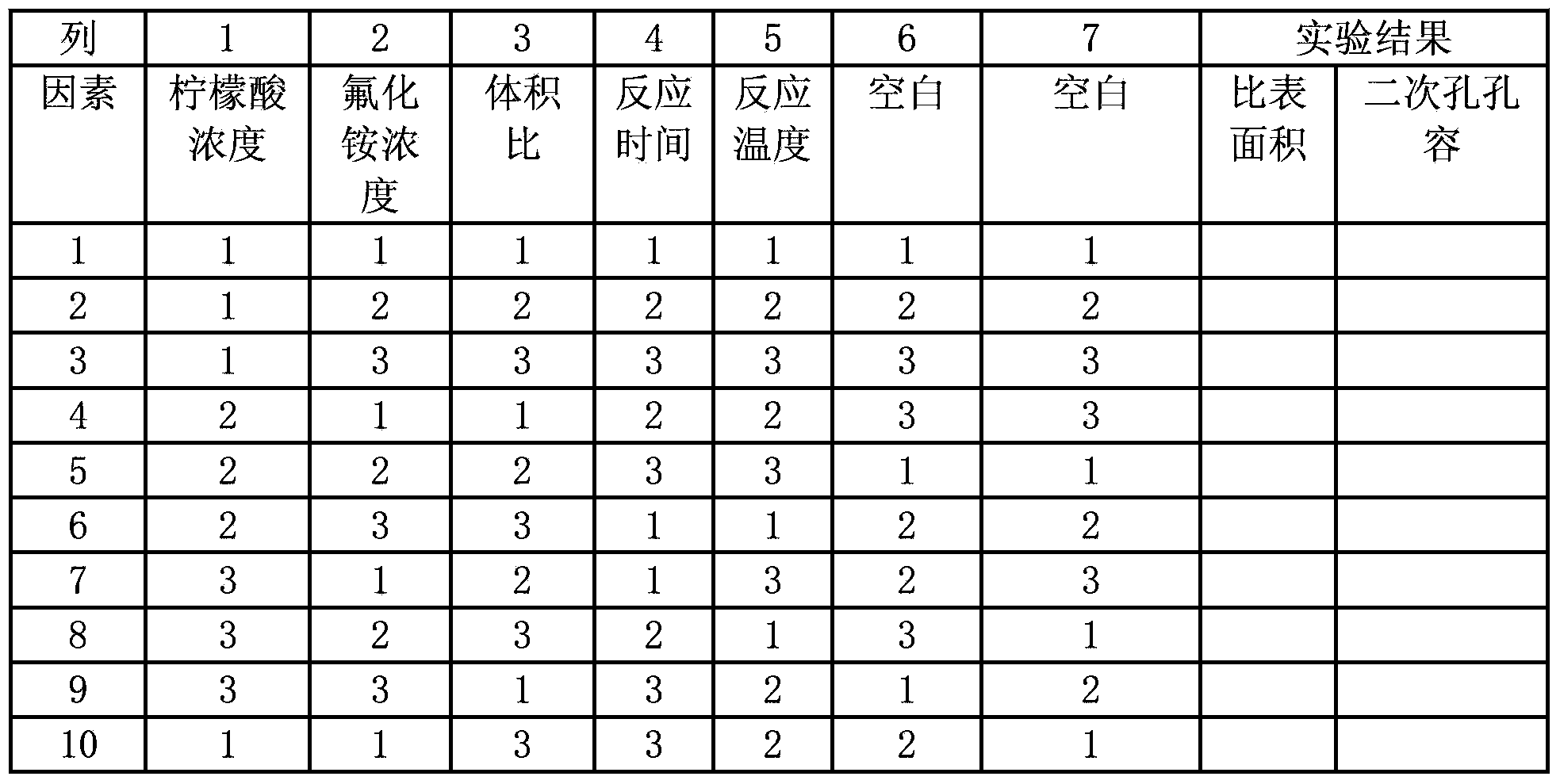

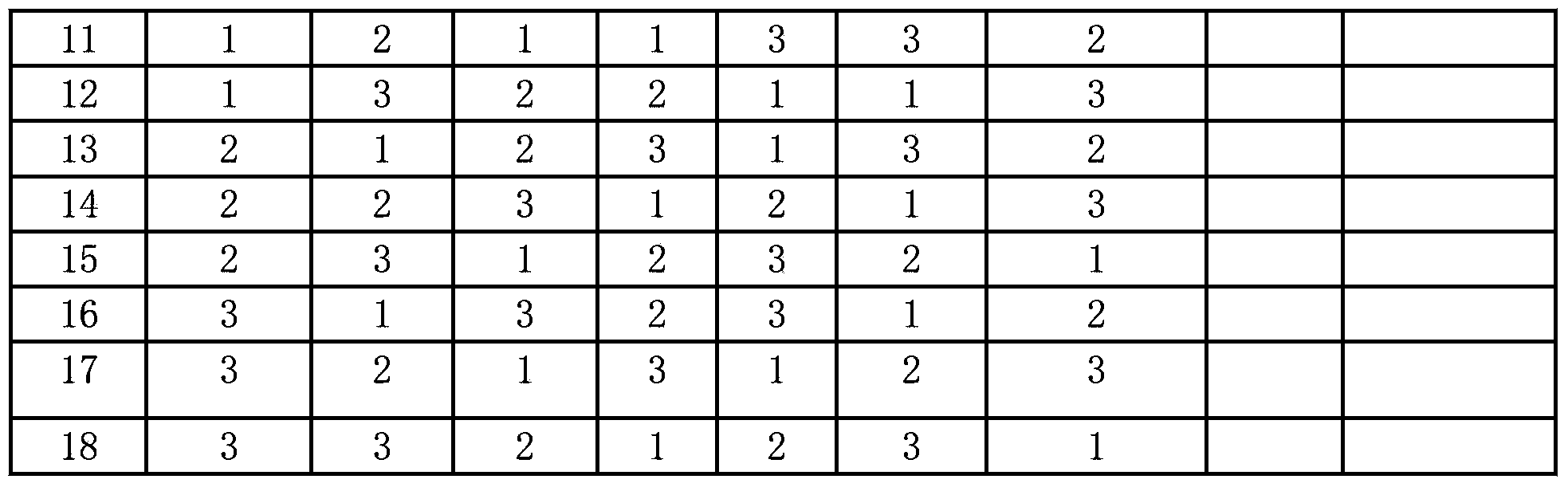

Method for modifying mesoporous-rich USY (Ultra-Stable Y) molecular sieve in combined manner

InactiveCN104229823ASmall cell constantIncreased secondary pore contentFaujasite aluminosilicate zeoliteInorganic saltsMolecular sieve

The invention relates to a method for modifying a USY (Ultra-Stable Y) molecular sieve. The method is characterized in that organic acid and an inorganic salt dealuminizing reagent are simultaneously added in a modifying process for organic acid-inorganic salt combined modification, and optimum process conditions, namely optimum concentration, volume ratio, reaction time, reaction temperature and the like, of an organic acid and an inorganic salt solution are determined by virtue of an orthogonal test. Compared with an industrial USY molecular sieve, the USY molecular sieve obtained by adopting the method disclosed by the invention is obviously increased in secondary pore content, can be kept at higher crystallinity and is enhanced in silica-alumina ratio, reduced in lattice constant and suitable for high-medium oil type hydrocracking catalyst carriers.

Owner:PETROCHINA CO LTD +1

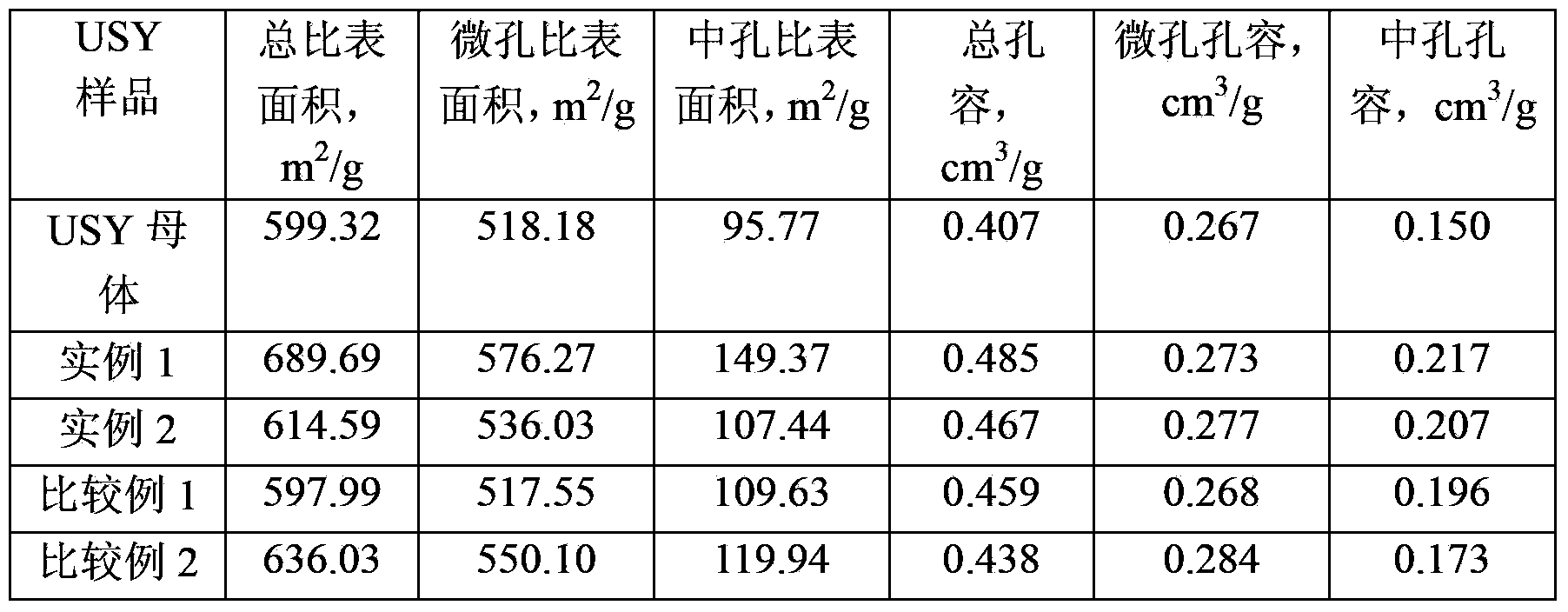

Plant nutrient solution for soilless culture of tomato

The invention provides a plant nutrient solution for soilless culture of tomato. The plant nutrient solution is prepared by the following raw materials in part by weight: 2 to 4 parts of potassium nitrate, 3 to 8 parts of calcium nitrate, 1 to 5 parts of magnesium sulfate, 1 to 3 parts of potassium phosphate, 1 to 2 parts of potassium sulphate, 1 to 2 parts of monopotassium phosphate, 0.1 to 0.15 part of Na2-EDTA, 0.05 to 0.1 part of Fe-EDTA, 0.01 to 0.05 part of molybdic acid, 0.01 to 0.03 part of manganese sulfate, 0.3 to 0.5 part of sodium tetraborate, 2 to 4 parts of superphosphate, 0.003 to 0.01 part of zinc sulfate, 0.001 to 0.002 part of copper sulfate, 0.001 to 0.003 part of ammonium nitrate, 1 to 3 parts of urea, 1 to 2 parts of organic acid, 0.5 to 1 part of beta cyclodextrin, 0.05 to 0.1 part of vitamin B, 2 to 4 parts of chitosan, 1 to 2 parts of nicotinamide, 0.5 to 2 parts of amino acid, 0.3 to 0.5 part of diethyl aminoethyl hexanoate, 0.02 to 0.5 part of gibberellin, and 5,000 to 7,000 parts of water. According to experiment, the plant nutrient solution provided by the invention can be used for carrying out soilless culture of tomato, and the tomato has high plant height, thick stem, high cluster and high output.

Owner:山西田森杜氏番茄科技有限公司

Cleaning composition for removing resists and method of manufacturing semiconductor device

InactiveUS7250391B2Good removal effectInhibitionSemiconductor/solid-state device manufacturingNon-surface-active detergent solventsResistCopper interconnect

The cleaning composition for removing resists includes a salt of hydrofluoric acid and a base not containing a metal (A component), a water-soluble organic solvent (B1 component), at least one organic acid or inorganic acid (C component), water (D component), and, optionally, an ammonium salt (E1 component), and having a pH 4-8. Thus, in manufacturing a semiconductor device, such as a copper interconnecting process, efficiency of removing resist residue and other etching residue after etching or ashing is improved, and corrosion resistance of a copper and an insulating film is also improved.

Owner:PANASONIC CORP +2

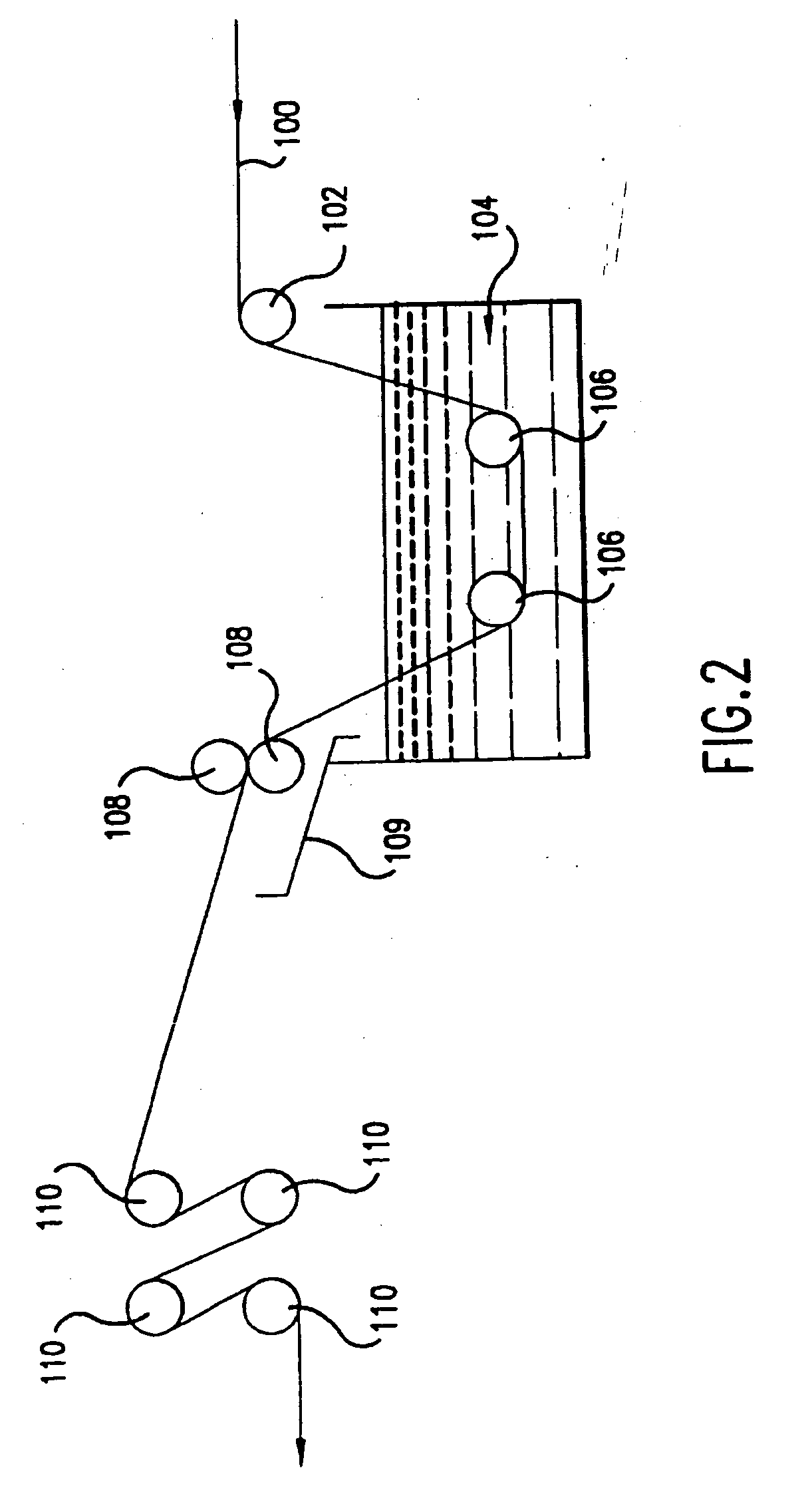

Timed pulsatile drug delivery systems

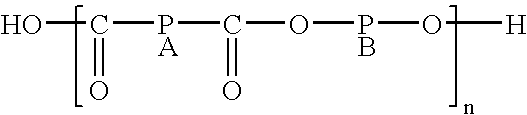

A pharmaceutical dosage form such as a capsule capable of delivering therapeutic agents into the body in a time-controlled or position-controlled pulsatile release fashion, is composed of a multitude of multicoated particulates (beads, pellets, granules, etc.) made of one or more populations of beads. Each of these beads except an immediate release bead has at least two coated membrane barriers. One of the membrane barriers is composed of an enteric polymer while the second membrane barrier is composed of a mixture of water insoluble polymer and an enteric polymer. The composition and the thickness of the polymeric membrane barriers determine the lag time and duration of drug release from each of the bead populations. Optionally, an organic acid containing intermediate membrane may be applied for further modifying the lag time and / or the duration of drug release. The pulsatile delivery may comprise one or more pulses to provide a plasma concentration-time profile for a therapeutic agent, predicted based on both its pharmaco-kinetic and pharmaco-dynamic considerations and in vitro / in vivo correlations.

Owner:ADARE PHARM INC

Smokeless tobacco products and processes

InactiveUS20100018540A1Improve barrier propertiesObstruct passageTobacco treatmentTobacco devicesOrganic acidTobacco product

A smokeless tobacco product is provided. A tobacco product configured for insertion into the mouth of a user of that product comprises a tobacco formulation including a granular tobacco composition enclosed within a water-permeable pouch that has been treated with a substance selected from the group consisting of: an analgesic, a buffer, a coloring, an effervescent, or an organic acid.

Owner:R J REYNOLDS TOBACCO COMPANY

Method of producing 2,5-furandicarboxylic acid

Provided is a method of producing FDCA by which high-purity FDCA can be produced in high yield. 2,5-furandicarboxylic acid is produced by: bringing 5-hydroxymethylfurfural into contact with an oxidant in an organic acid solvent in the presence of bromine and a metal catalyst; and allowing 5-hydroxymethylfurfural and the oxidant to react with each other while removing water produced by the reaction.

Owner:CANON KK

Catalytic combustion adjuvant for coal

A catalytic combustion improver of coal for increasing combustion efficiency and decreasing the exhaust of SO2, CO and NOx is composed of the primary raw materials chosen from 17 salts of organic acid, including acetate, oxalate, succinate, etc, the organic compound prepared by reaction between 17 organic acids and ore, metal, metallic oxide, or compound, chloride, etc, and the secondary raw materials chosen from high-caloricity agent, surface coating agent, solvent, assistant, emulsifying disperser, sulfur fixating agent and filler.

Owner:尹小林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com