Patents

Literature

82results about How to "Good printing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ink-jet printing ink compositions having superior smear-fastness

InactiveUS6417249B1Improve printing effectGood printing performanceInksCoatingsPolyesterPolymer science

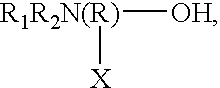

Specific core-shell binders and additives for use in ink-jet printing ink compositions are provided. One class of specific core / shell binders has the general formula [AmBnC'p]x, where A and B are hydrophobic components in which A exhibits a glass transition temperature Tg between about -150° and +25° C. and B exhibits a glass transition temperature greater than 25° C., C' is a component that forms a hydrophilic or water-soluble component in the polymer chain, and has an ionic or non-ionic structure, m<30 wt %, n>40 wt %, and p<30 wt %, with the total of m+n+p=100 wt %, and x=1 to 100,000. The molecular weight (weight average) of the polymer is between about 1,000 and 2,000,000. The polymers useful in the practice of the invention are prepared by emulsifying the monomers and then conducting a free-radical polymerization in water. The foregoing binder polymer is used in conjunction with additives comprising either (a) amine alcohols having the general formulawhere R1 and R2 are independently selected from the group consisting of hydrogen, alkyl, alkoxy, aryl, and phenoxy, R is alkyl, X is selected from the group consisting of hydrogen, alkyl, aryl, -OH, -COOH, -CHO, and substituted groups or (b) organic acids (water-soluble or water-dispersive), including polymeric acids. Other additives include amines, polyalcohols, polyamines, and polyesters. In the ink compositions of the present invention, the ratio of binder (1) to colorant (pigment) is greater than 1 to 10. The concentration of the additive is within the range of 0.005 to 50 wt %. The general ink formulation comprises: 5 to 50 wt % water-miscible solvent; 0.5 to 10 wt % colorant; 0.005 to 50 wt % additive; and water.

Owner:HEWLETT PACKARD DEV CO LP

Ultraviolet light curing printing ink for digital printing and dyeing preparation thereof

UV solidified printing ink for digital code printing and dyeing is composed of polyurethane acrylate, prepolymer, activity monomer, dyestuff, light initiator, dispersant agent and other addition agents. The prepolymer has the character of low viscosity and good flexibility. The ink doesn't contain organic solvent and has wide material adaptation, storage stability and softness.

Owner:DONGHUA UNIV

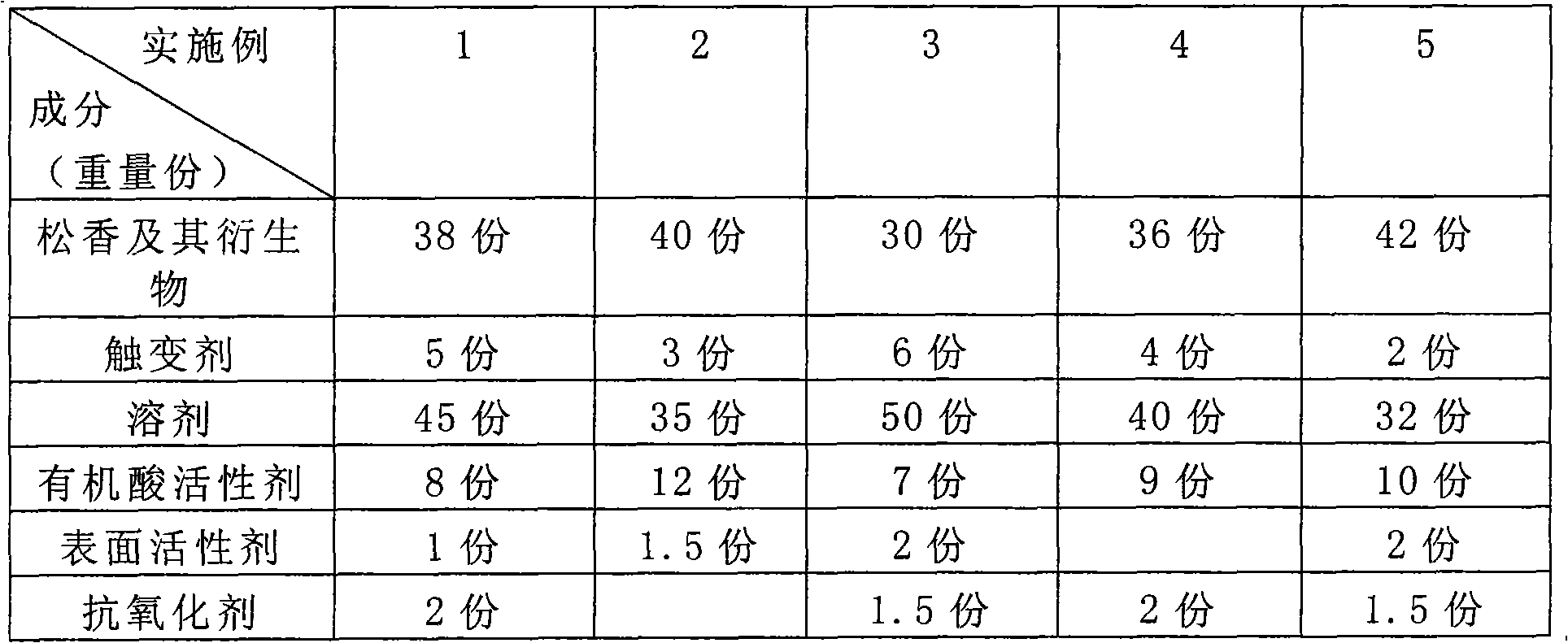

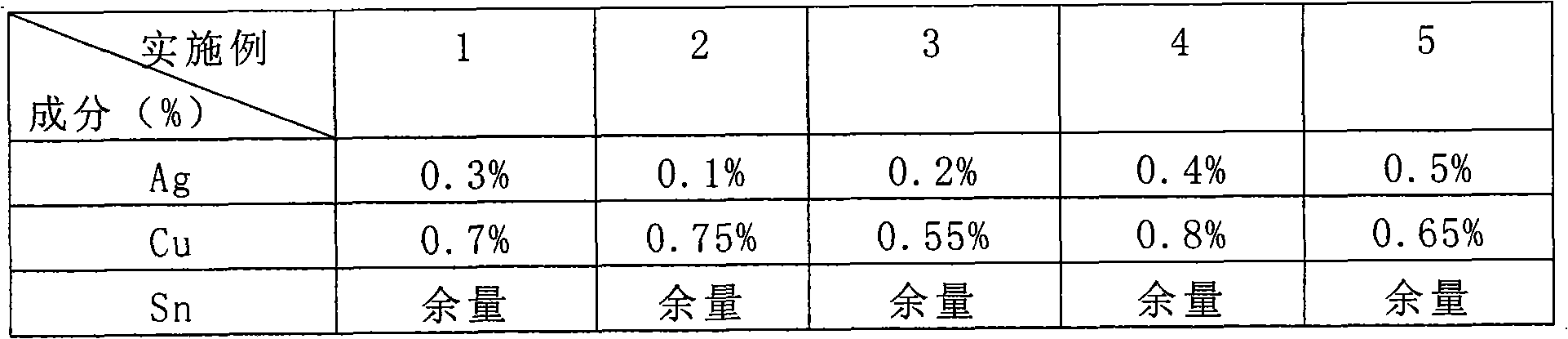

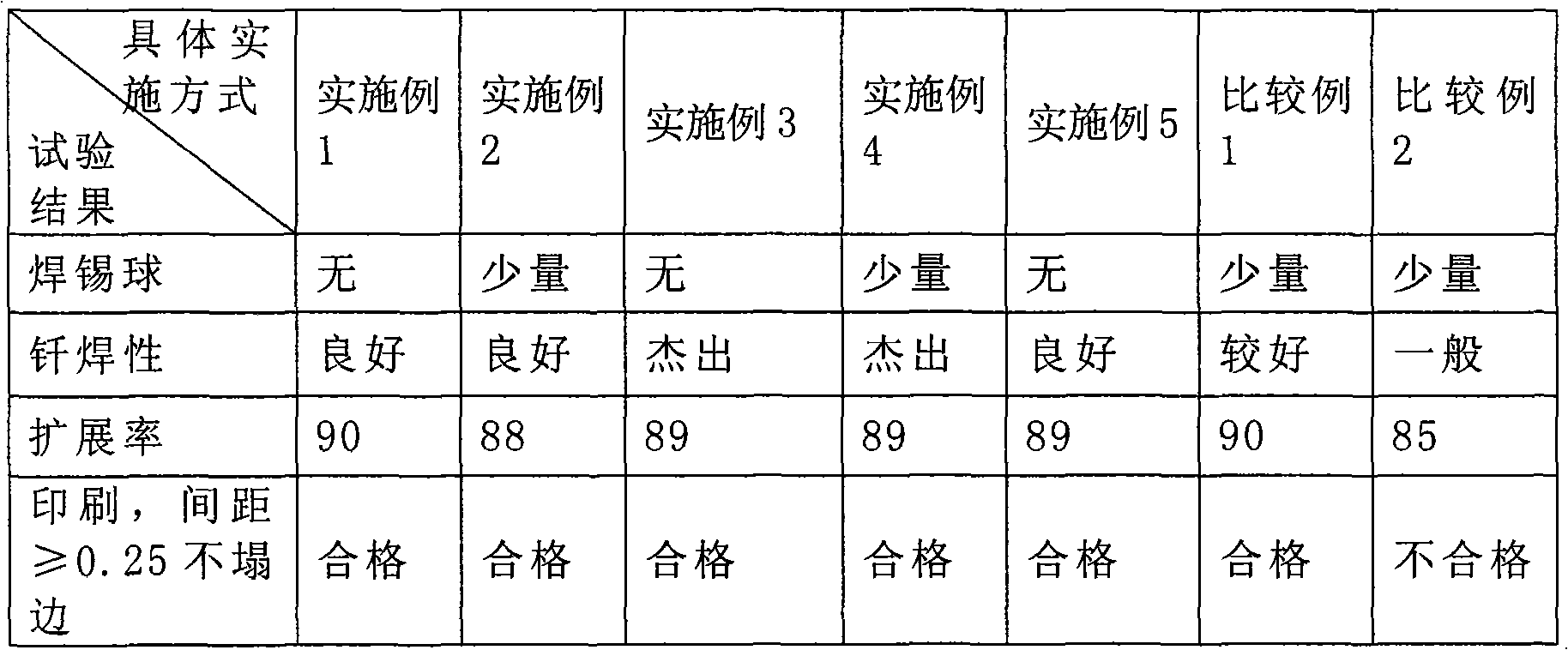

Low-silver halogen free soldering paste

InactiveCN101653876AGood printing performanceCompatibility is reasonableWelding/cutting media/materialsSoldering mediaSolderingHalogen free

The invention provides a low-silver halogen free soldering paste, which solves the problems that the existing soldering paste has high production cost and poorer soldering performance, and is not applicable to welding of components with precision spacing and the like. The low-silver halogen free soldering paste comprises the following components by weight percentage of 88 percent to 91 percent ofalloy welding powder and 9 percent to 12 percent of paste flux, wherein, the alloy welding powder comprises the following components by weight percentage of 0.1 percent to 0.9 percent of Ag, 0.1 percent to 0.8 percent of Cu and the balance Sn. The low-silver halogen free soldering paste has the advantages of low cost, good welding performance, no easy edge-collapse after printing and the like.

Owner:上海一远电子科技有限公司

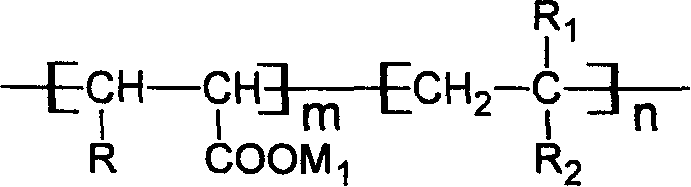

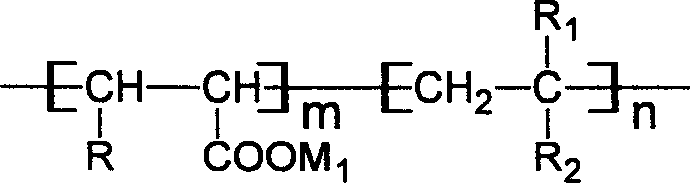

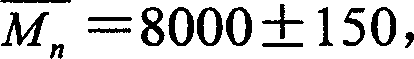

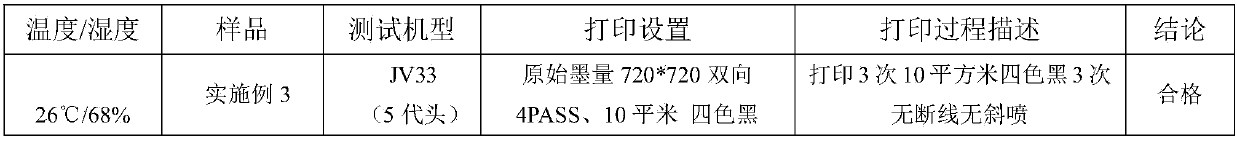

Solvent type disperse dye ink-jet printing ink and preparation method thereof

The invention provides a solvent type disperse dye ink-jet printing ink and a preparation method thereof. The ink comprises the following components in percentage by mass: 1 to 10 percent of disperse dye, 1 to 15 percent of dispersant, 0.5 to 15 percent of resin and 60 to 95 percent of organic solvent. The preparation method comprises the following steps of: adding 1 to 15 percent of dispersant and 0 to 10 percent of resin into the organic solvent, and emulsifying the mixture for 20 to 60min, adding 1 to 8 percent of dye into the mixture, grinding the mixture for 8 to 40h, and obtaining a disperse dye color paste; and adding 10 to 80 percent of disperse dye color paste and 0 to 10 percent of resin into the organic solvent, and filtering the mixture with a millipore filter between 0.2 and 2 mu m to obtain the solvent type disperse dye ink-jet printing ink. The ink has the advantages of good printing smoothness, bright lustre of patterns, and excellent sunlight fastness, washing fastness and rub resistance, and can be widely applied to multiple kinds of wide, high-speed and solvent type digital printing equipment; and the preparation method is simple and practical.

Owner:DONGHUA UNIV +1

Nano dye ink for ink jet printing and preparation method thereof

InactiveCN1687258AGuaranteed long-term stabilityAdjust surface tensionInksPrintingInk printerPrinting ink

The present invention relates to a nano pigment spray-printing ink for computer ink jet printer and colour spray plotter. Said invention adopts a high-molecular dispersing agent to modify pigment surface so as to make the pigment be stably dispersed in water medium, and adds several water-soluble cosolvents to prepare a set of colour inks, including red, yellow, blue and black four inks.

Owner:JIANGNAN UNIV

Ink and preparing method thereof

ActiveCN105369652AImprove liquidityImprove spraying effectInksDyeing processSolubilitySurface-active agents

The invention discloses ink and a preparing method thereof. The ink is prepared from, by mass, 3-20 parts of reactive dye, 5-30 parts of organic solvent, 1-5 parts of humectant, 0.1-0.5 part of preservative, 0.2-3 parts of surface active agents, 0.1-1 part of a pH conditioning agent, 1-5 parts of solubilizer and 40-120 parts of deionized water; the solubilizer is at least one of polyether polyol, ethylene oxide and a propylene epoxide block copolymer, the surface active agents are at least two of EH-6, EH-9, EH-14, 420, 440, 465, 485, 104 E and EXP.4300, and the humectant is an amino acid humectant. As the amino acid humectant is added into the ink, the moisture state of a nozzle can be well kept; at least one of polyether polyol, ethylene oxide and the propylene epoxide block copolymer serves as the solubilizer, solubility of the reactive dye in an ink system can be effectively improved, mobility and an ejection property of the ink in an ink path and a spray head are improved, and the ink can have good universality and smooth performance.

Owner:深圳市墨库图文技术有限公司

Biaxially oriented polyester film for thermal transfer ribbon, laminated film composed thereof and its production

InactiveUS6303210B1Improve productivityImprove yieldMagnetic materials for record carriersSynthetic resin layered productsMolten statePolymer science

A biaxially oriented polyester film for thermal transfer use produced by using a polyester composed of a dicarboxylic acid component and a diol component as a constituent component characterized in that said film contains a sulfonic acid quaternary phosphonium salt having an ester-forming functional group in an amount of 0.1 to 40 mmol % based on said dicarboxylic acid component, the alternate current volume resistivity of the film is 6x108 OMEGA.cm or below in molten state and the endothermic subpeak temperature of the film other than the melting point and determined by DSC is between 225° C. and the melting point, a laminated film produced by forming an adhesiveness improving layer on at least one surface of the biaxially oriented polyester film, and its production process.

Owner:TEIJIN LTD

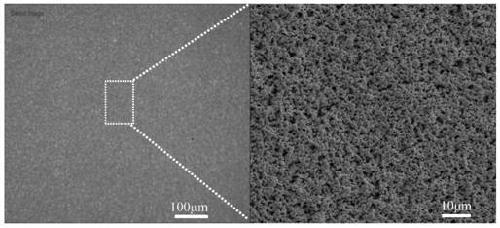

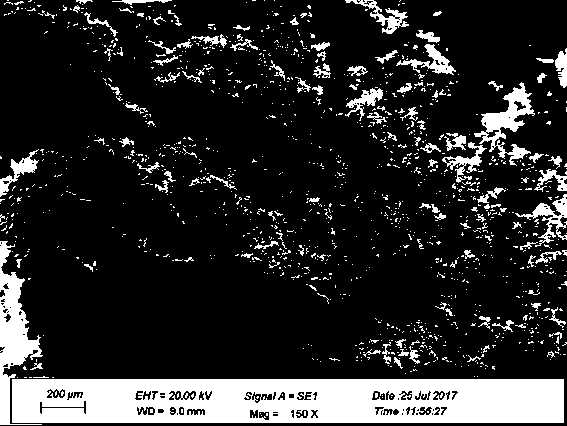

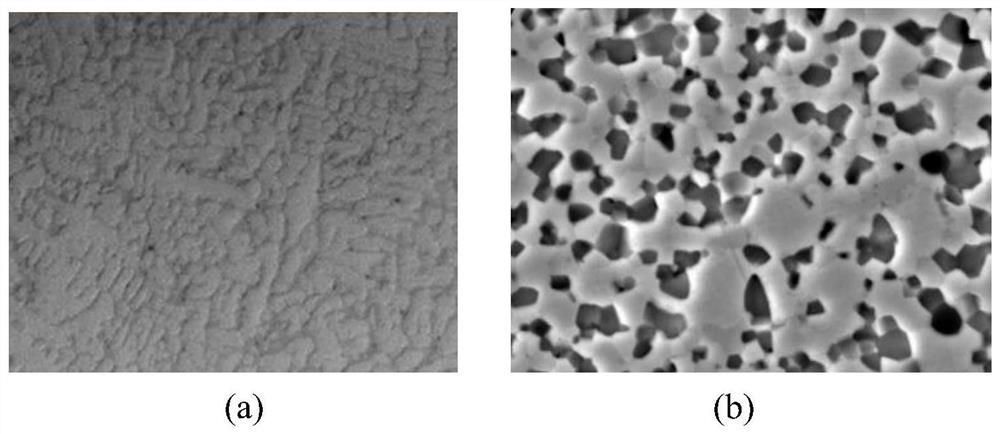

Porous material with micro-nano structure and preparation method of porous material

InactiveCN107737584AHigh porosityWide range of adsorbed substancesOther chemical processesWater contaminantsMicro nanoPorosity

The invention discloses a porous material with a micro-nano structure and a preparation method of the porous material. The problems of the existing porous material of complex preparation process, highenergy consumption, high cost and the like are solved, and the porous material with the micro-nano structure is prepared finely by adopting a rapid prototyping manufacturing frequency-division multiplexing technology. The technical scheme is described as follows: 1, the formula comprises the following ingredients by weight percent: 55-85% of polylactic acid, 10-30% of a pore-forming agent, 2-12%of a toughening agent, 1-10% of a plasticizer and 1-5% of a stabilizer; 2, the preparation method comprises the following steps: mixing, melting and extruding the polylactic acid and all the additives, so as to prepare a 3D printing wire, printing the 3D printing wire into a specific structure by adopting the FDM technology, and performing water treatment finally, so as to obtain the porous material with the micro-nano structure. The prepared porous material is high in porosity, controllable in structure and simple and efficient in preparation method and has no secondary pollution, so that theporous material can be applied for sewage treatment.

Owner:FUJIAN NORMAL UNIV

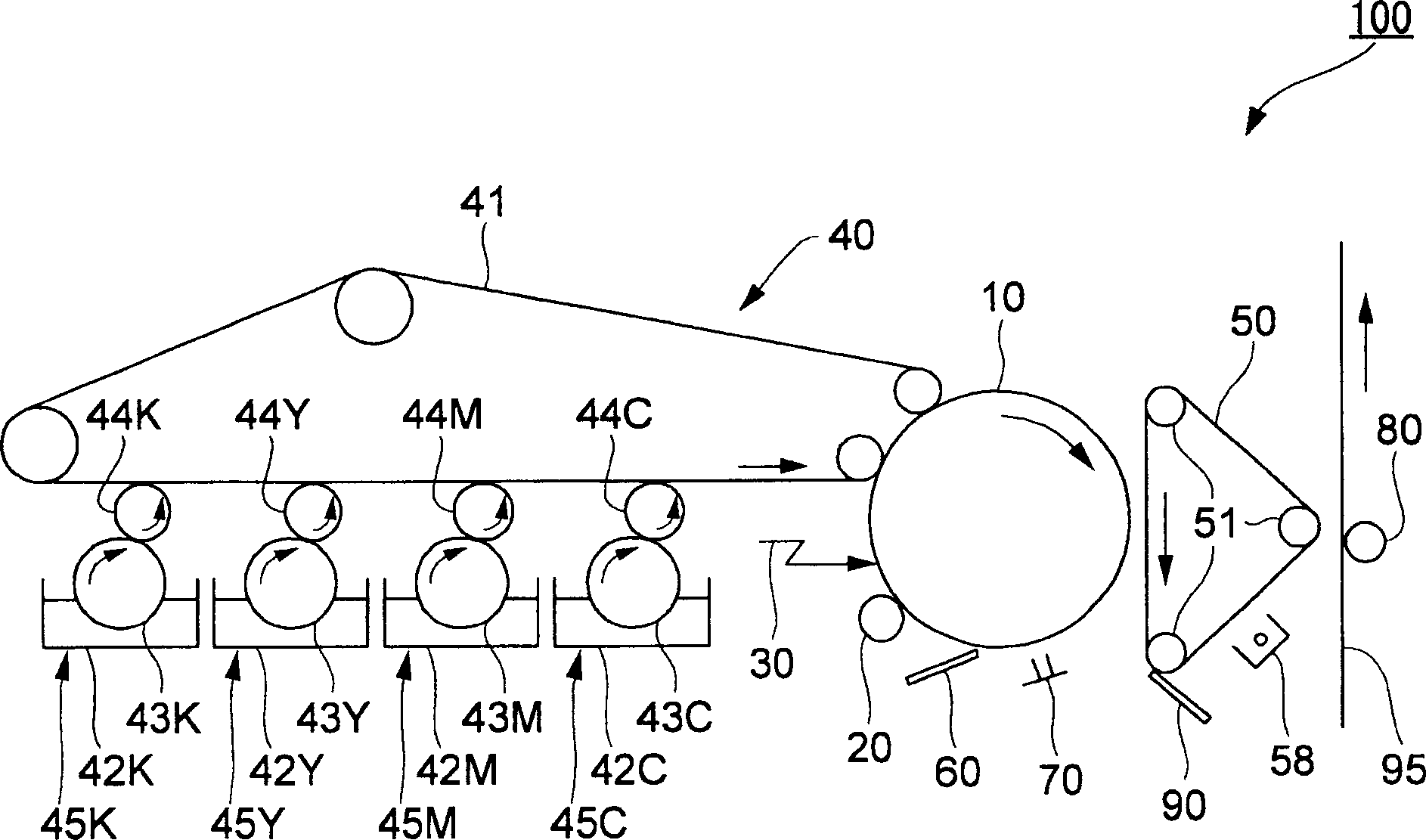

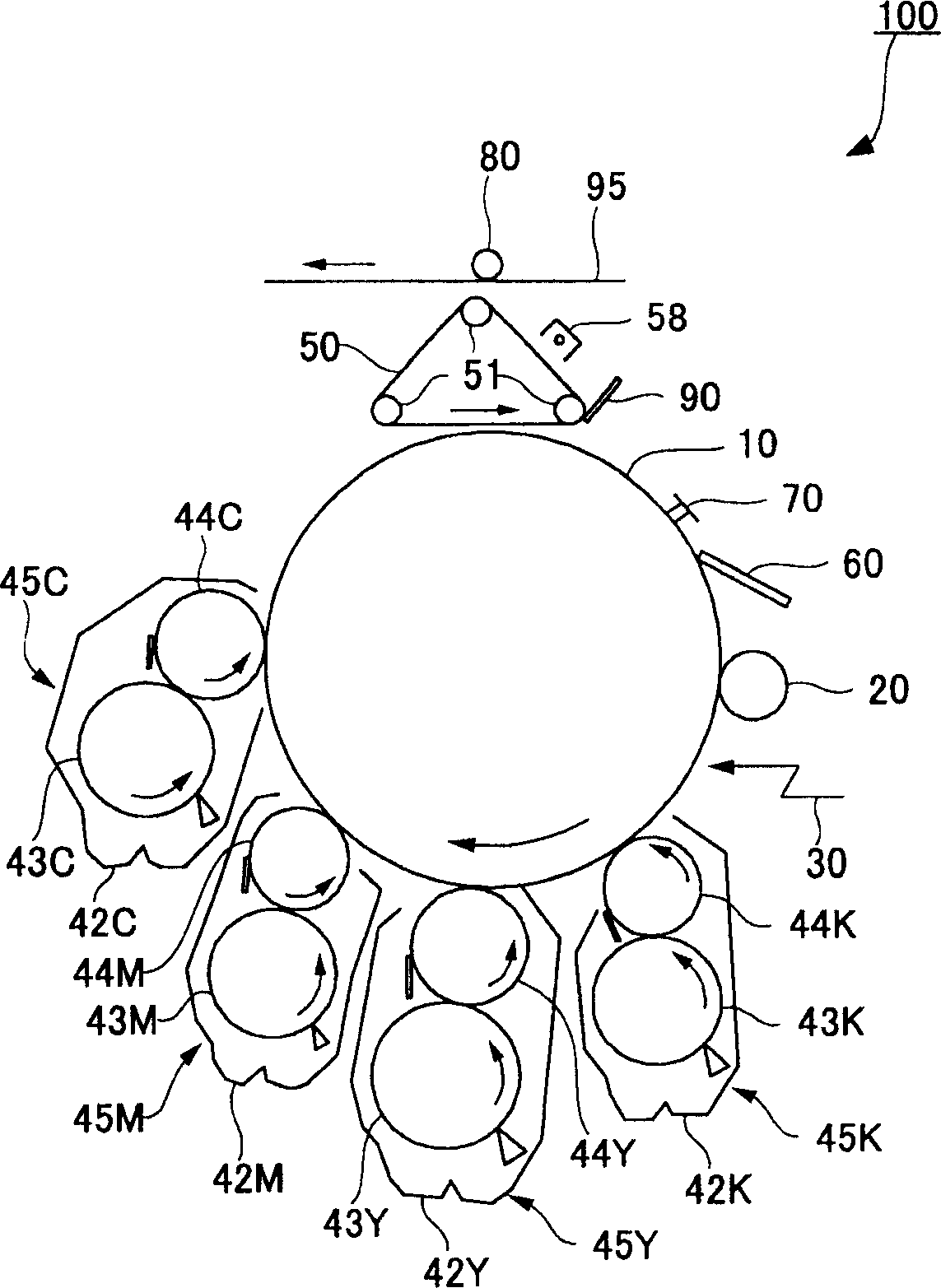

Toner, developer, toner container, process cartridge, image forming apparatus and image forming method

InactiveCN1834795AGood printing performanceGood electrificationDevelopersElectrographic process apparatusAcid valuePolyester resin

The present invention provides a toner and a developer which includes the toner. The toner is produced in an aqueous medium and includes at least a binding resin, a colorant and a dispersant which disperses the colorant. The binding resin contains 50% by mass to 100% by mass of a polyester resin, and the colorant is a pigment whose surface is given an acid treatment. The acid value of the dispersant is 1 mg KOH / g to 30 mg KOH / g, and the amine value of the dispersant is 1 mg KOH / g to 100 mg KOH / g.

Owner:RICOH KK

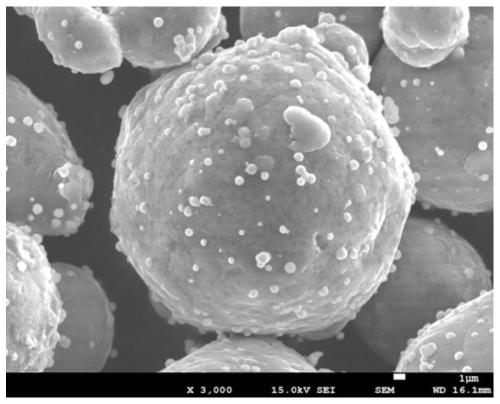

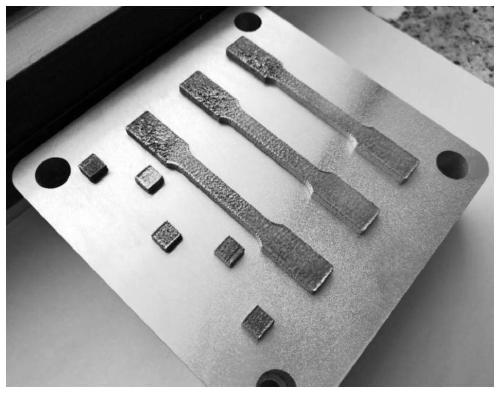

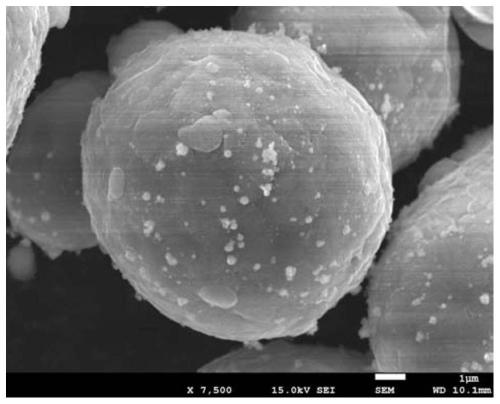

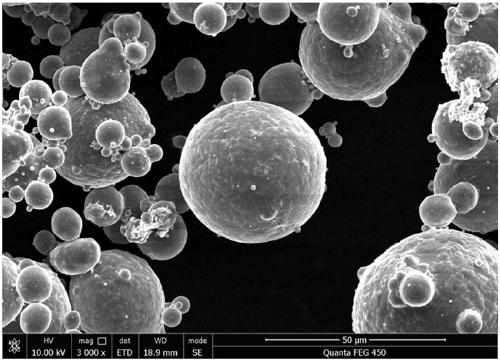

Surface modified metal powder with high laser reflectivity and 3D printing method

InactiveCN109746435AGood printing performanceSimple processAdditive manufacturing apparatusTransportation and packagingCobaltMechanical property

The invention belongs to the field of metal material preparation, and relates to surface modified metal powder with high laser reflectivity and the application of the surface modified metal powder in3D printing. According to the surface modified metal powder with high laser reflectivity and the application of the surface modified metal powder in 3D printing, nickel, cobalt or iron metal particleswith high laser absorptivity wrap the surface of aluminum, copper and aluminum alloy or copper alloy powder with high laser reflectivity by means of electroless plating, namely, the powder with highlaser reflectivity is modified into the powder with high laser absorptivity, so that the printing performance of the metal powder with high laser reflectivity in the 3D printing process is enhanced, and the 3D printing of the metal powder with high laser reflectivity can be realized. Compared with that of conventional commercial aluminum, copper and aluminum alloy or copper alloy powder used for 3D printing, the laser absorptivity and printing performance are improved after surface modification wrapping, the sphericity of the powder does not change a lot, the powder spreading process is not affected, and printed metal parts are compact and have good mechanical properties.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Water-based paint coated on metal surface

InactiveCN105670457AGood flexibilityImprove protectionAnti-corrosive paintsEpoxy resin coatingsEpoxyWater based

The invention relates to water-based paint coated on a metal surface. The water-based paint is prepared from, by weight, 15-60 parts of water-based resin, 0.1-5 parts of neutralizing agent, 0.1-10 parts of dispersing agent, 0.01-5 parts of anti-foaming agent, 10-30 parts of extender pigment, 1-10 parts of coloring pigment, 1-10 parts of anti-rust pigment, 0.1-5 parts of thickening agent, 0.1-5 parts of base material wetting agent, 25-40 parts of deionized water solvent, 5-8 parts of ethylene bis-stearamide, 10-12 parts of bauxite, 5-8 parts of silicone acrylic emulsion, 2-4 parts of surface control agent, 0-2 parts of ph controlling agent and 0.1-5 parts of other auxiliaries, wherein the water-based resin adopts water-based alkyd resin or water-based epoxy ester resin or water-based acrylic resin or water-based phosphate ester resin. The water-based paint does not contain organic solvent and is resistant to corrosion, excellent in impact resistance and friendly to environment.

Owner:BEIHUA UNIV

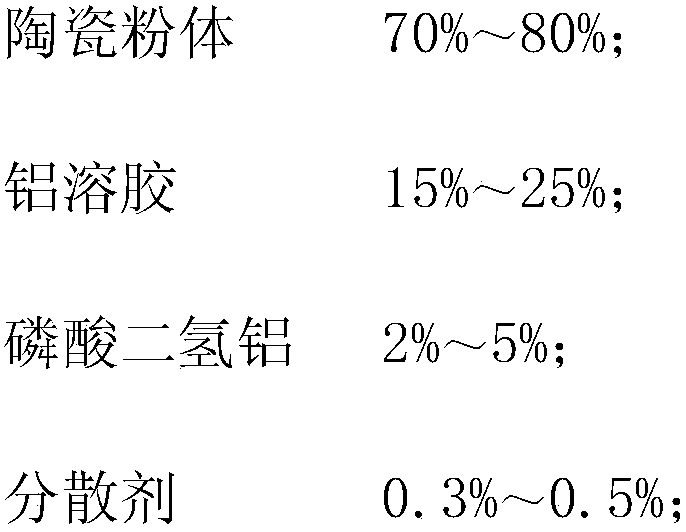

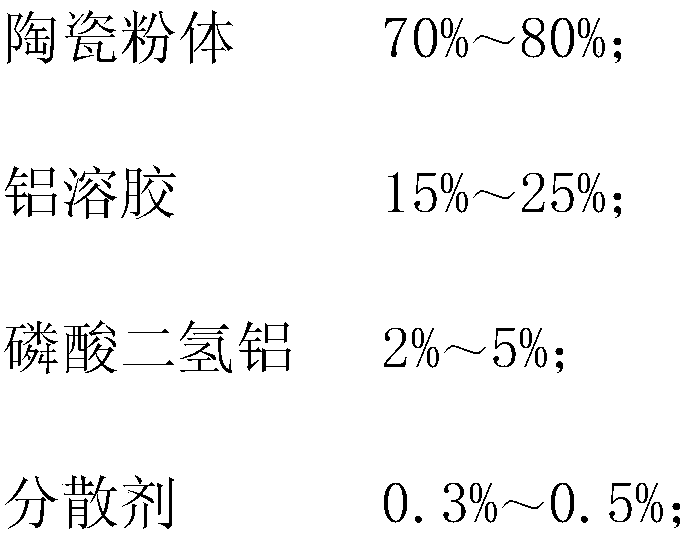

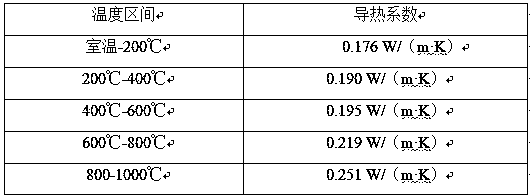

Alumina ceramic slip suitable for 3D printing, preparation method and application thereof

The invention provides an alumina ceramic slip suitable for 3D printing, a preparation method and an application thereof. The alumina ceramic slip comprises the following raw materials by mass percentage: 70-80% of ceramic powder, 15-25% of aluminium sol, 2-5% of aluminium dihydrogen phosphate, and 0.3-0.5% of a dispersant, wherein the ceramic powder contains alumina. By using the technical scheme, the technical problems of large amount of required plasticizer used for the ceramic slip, environment pollution, low intensity of prepared ceramic part, and high required sintering temperature in the prior art can be solved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

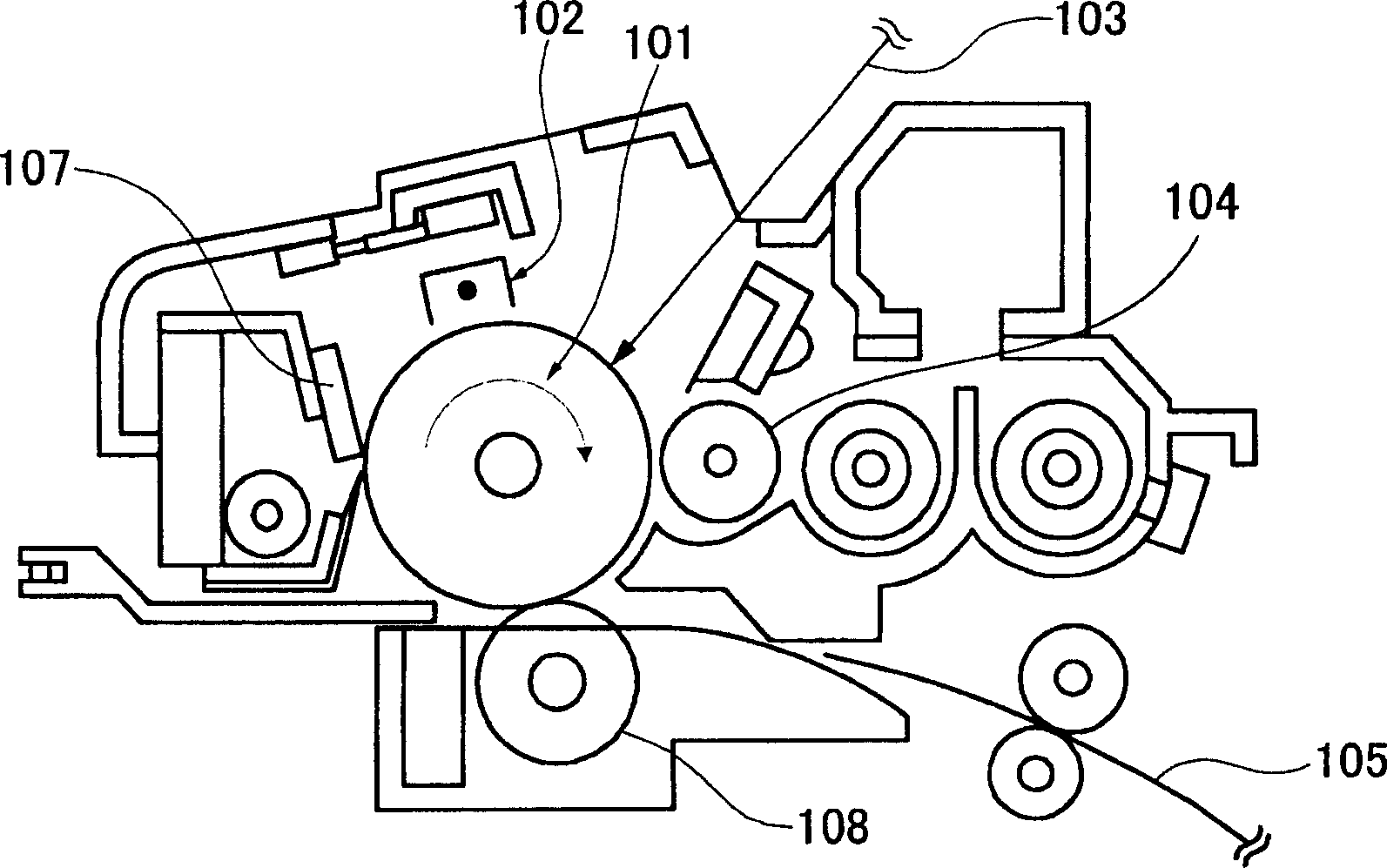

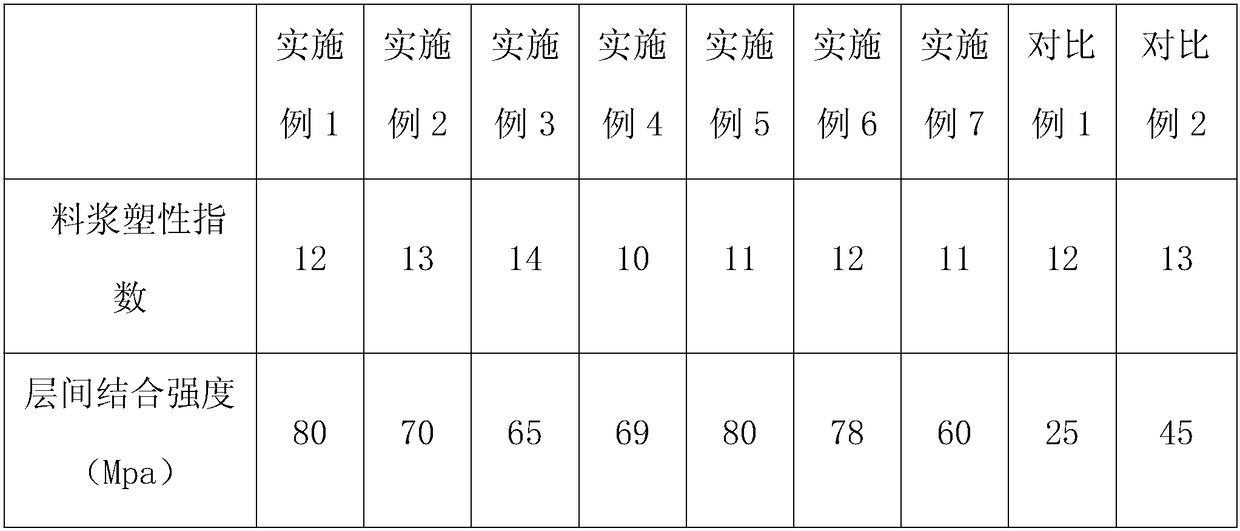

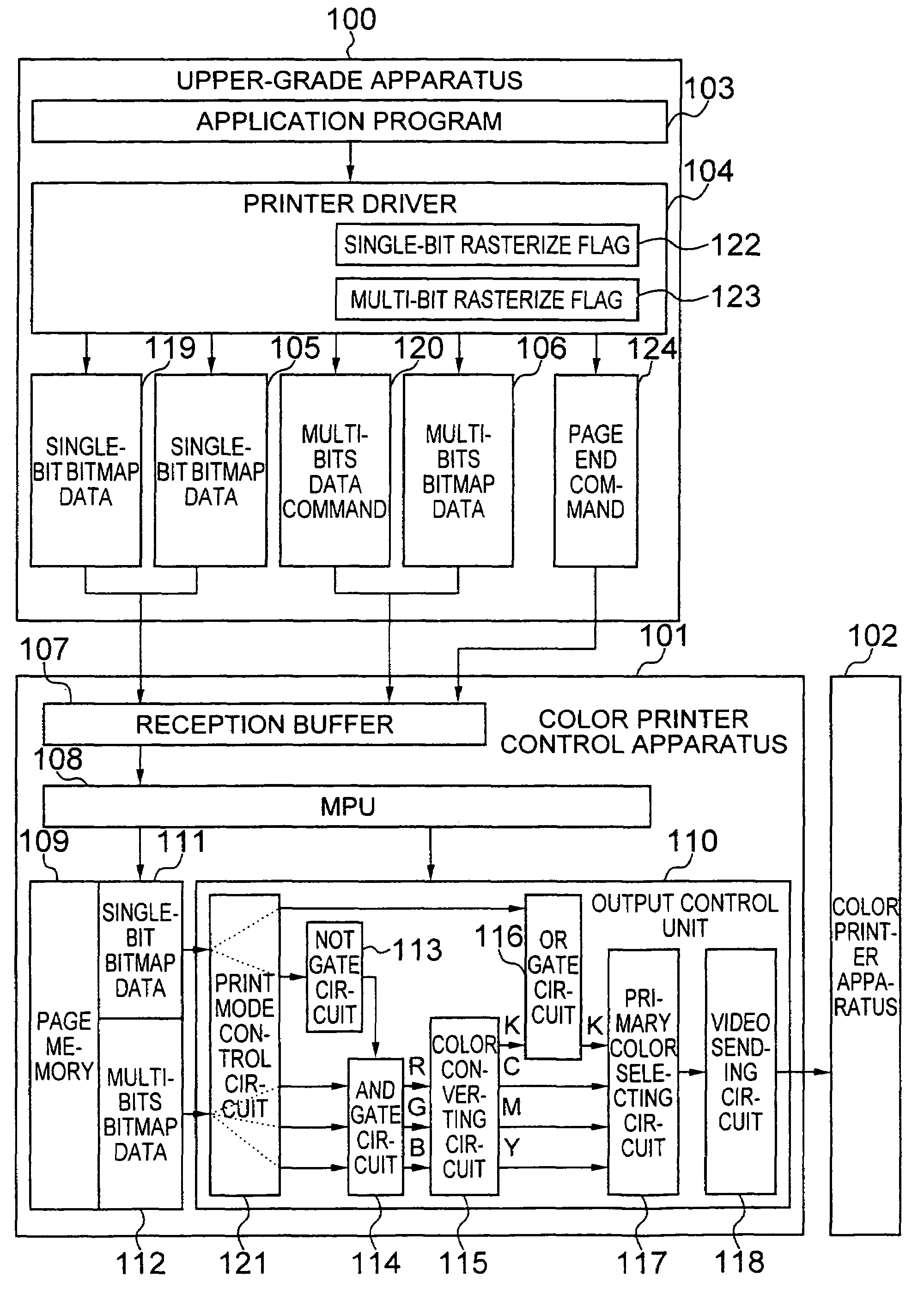

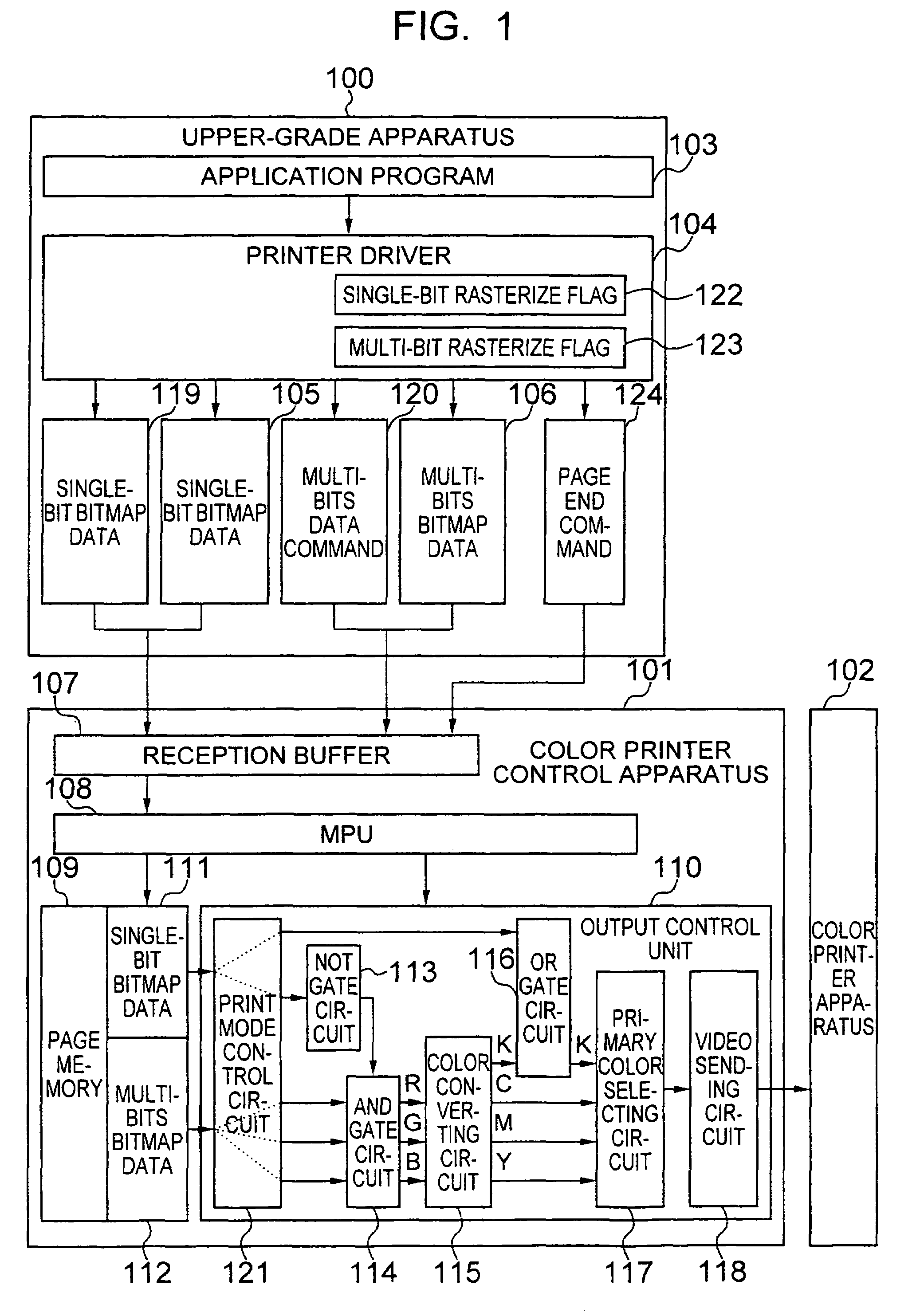

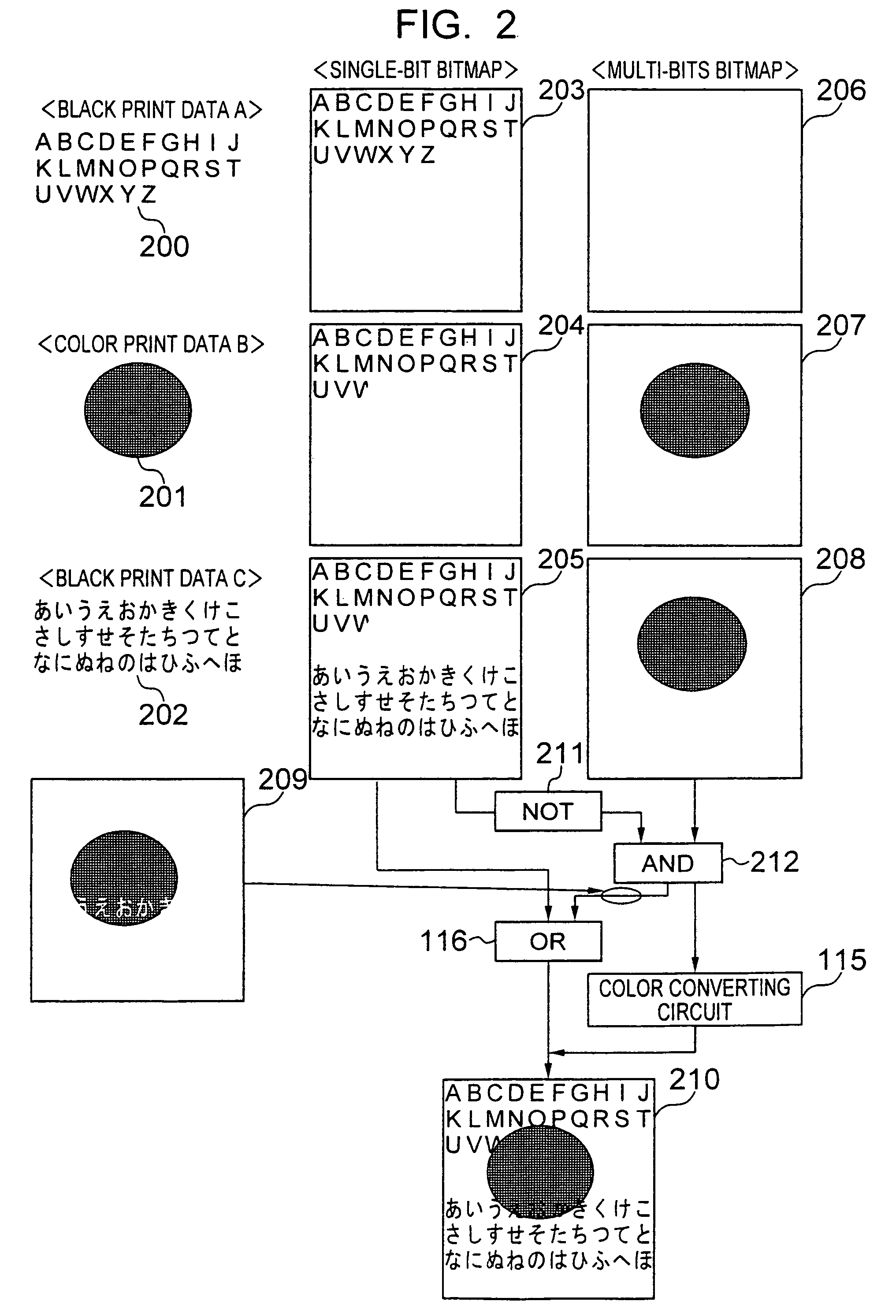

Color printing apparatus

InactiveUS7301669B1Reduce the amount of informationOperation is uselessArchitecture for particular functionDigitally marking record carriersColor printingCons

A color printing apparatus includes a printer driver for receiving a print instruction of print data issued from an application program, and for rasterizing the print data to produce con-tone / multi-bits bitmap data and bi-tone / single-bit bitmap data; a page memory for independently storing thereinto both the con-tone / multi-bits bitmap data and the bi-tone / single-bit bitmap data; a control unit for executing a control operation in such a manner that the con-tone / multi-bits bitmap data is converted into con-tone / multi-bits print data, the bi-tone / single-bit bitmap data is converted into bi-tone / single-bit print data, and at least one of the con-tone / multi-bits print data-and the bi-tone / single-bit print data is stored into the page memory in a bitmap format; and an output control unit for reading at least any one of the con-tone / multi-bits print data and the bi-tone / single-bit print data from the page memory, and for logically synthesizing the print data with each other to output the synthesized print data to a color printing unit, reducing the data amount of the bitmap data.

Owner:RICOH PRINTING SYST +1

Aluminum alloy composite material for 3D printing, 3D printing product and preparation method thereof

InactiveCN109266916AGood printing performanceGrain refinementAdditive manufacturing apparatusIncreasing energy efficiencyVolumetric Mass DensityAlloy composite

The invention discloses an aluminum alloy composite material for 3D printing, a 3D printing product and a preparation method thereof. The aluminum alloy composite material for the 3D printing is capable of introducing TiB2 and Si into an aluminum alloy, apparently improving laser absorptivity, and reducing a melting point. The obtained composite material has certain mobility, and a good printing property, can be applied for the laser 3D printing, is better in melting formability of a laser selective area, and high in density of a formed part, and has good performance.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Preparation method of medical polylactic acid modified calcium phosphate bone cement composite 3D printing material

ActiveCN108295302AHigh mechanical strengthBoth mechanical strengthTissue regenerationProsthesisCalcium biphosphateRare earth

The invention relates to the technical field of 3D printing materials, in particular to a preparation method of a medical polylactic acid modified calcium phosphate bone cement composite 3D printing material. The preparation method of the medical polylactic acid modified calcium phosphate bone cement composite 3D printing material comprises steps as follows: S1, preparation of modified hectorite;S2, preparation of rare earth modified calcium phosphate powder; S3, preparation of the medical polylactic acid modified calcium phosphate bone cement composite 3D printing material. The composite obtained with the preparation method of the medical polylactic acid modified calcium phosphate bone cement composite 3D printing material has excellent printing performance and outstanding application performance, has the advantages of excellent mechanical strength, mechanical performance and compressive strength and has the mechanical strength of inorganic calcium phosphate materials and flexibilityof polymer polylactic acid materials, and besides, the preparation process is simpler and lower in production cost.

Owner:ZHONGSHAN POLYTECHNIC

Conductive paste for PERC solar cell, preparation method and application thereof

InactiveCN106448806ALow toxicityReduce corrosionNon-conductive material with dispersed conductive materialPhotovoltaic energy generationConductive pasteOrganic solvent

The invention provides a preparation method of a conductive paste for a PERC solar cell and application thereof. An aluminum-silicon mixed conductive paste containing doping elements according to the present invention comprises 60 to 85 percent of aluminum powder, 5 to 25 percent of doped silicon nanoparticles, 0.1 to 5 percent of inorganic binder and 15 to 35% of organic carriers, wherein the organic carriers are mainly composed of an organic solvent, a thickening agent and a plasticizer. Compared with existing aluminum conductive paste products, the conductive paste for the PERC solar cell of the invention is printed on the back of the a battery sheet, and in a cell sintering process, on one hand, back holes can be reduced to promote the formation of a silicon aluminum alloy layer and reduce contact resistance; on the other hand, the back field doping concentration and the junction depth can be increased, and the composite rate on the back surface can be reduced in order to improve the PERC cell photoelectric conversion efficiency.

Owner:YANCHENG INST OF TECH

Manufacturing method of heavy ion micropore antifault membrane

InactiveCN1410950AEase of mass productionHigh transparencyStampsIdentification meansEtchingComposite film

The invention belongs to the anti false technical area including following procedures. The precoat film is made by pre coating the anticorrosive hot-melt adhesive on the anticorrosion plastic film. The plastic film exposed by the heavy ion becomes the irradiation film. The composite film is prepared by heating the precoat film and the irradiation film together. Then, the chemical etching makes the aperture of the heavy ion micropore in 3-5 mu m. After etching, with the precoat film being removed from the irradiation film covered, through the rinsing and baking processes, the anti-false film of the heavy oil is obtained. It is milk-white in the pattern area of the anti-false film and it keeps the original transparency in non-pattern area. The invention possesses the features of double-faced protection, the clear pattern, low cost and easy of preparing the precoat film in large scale.

Owner:北京清华试金石新技术有限公司

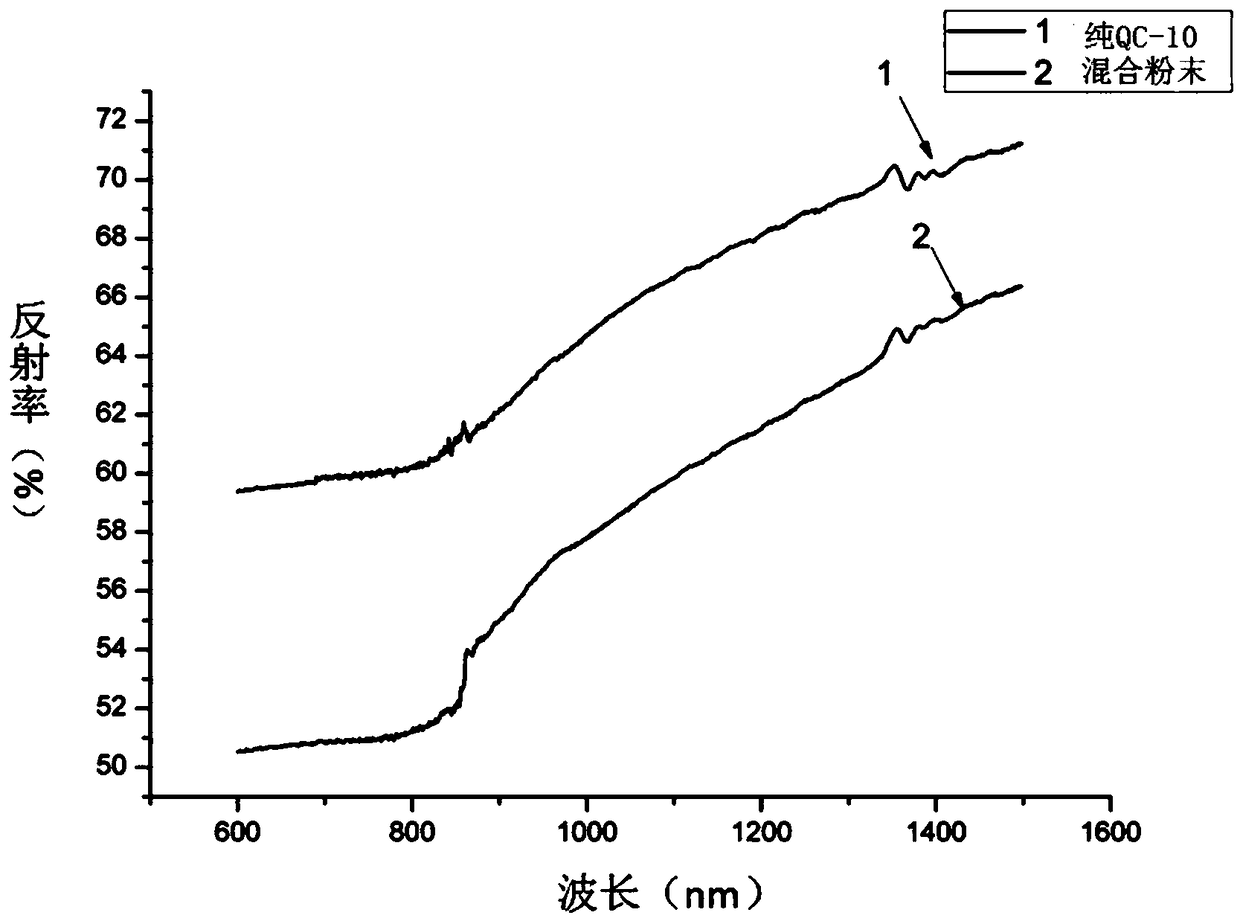

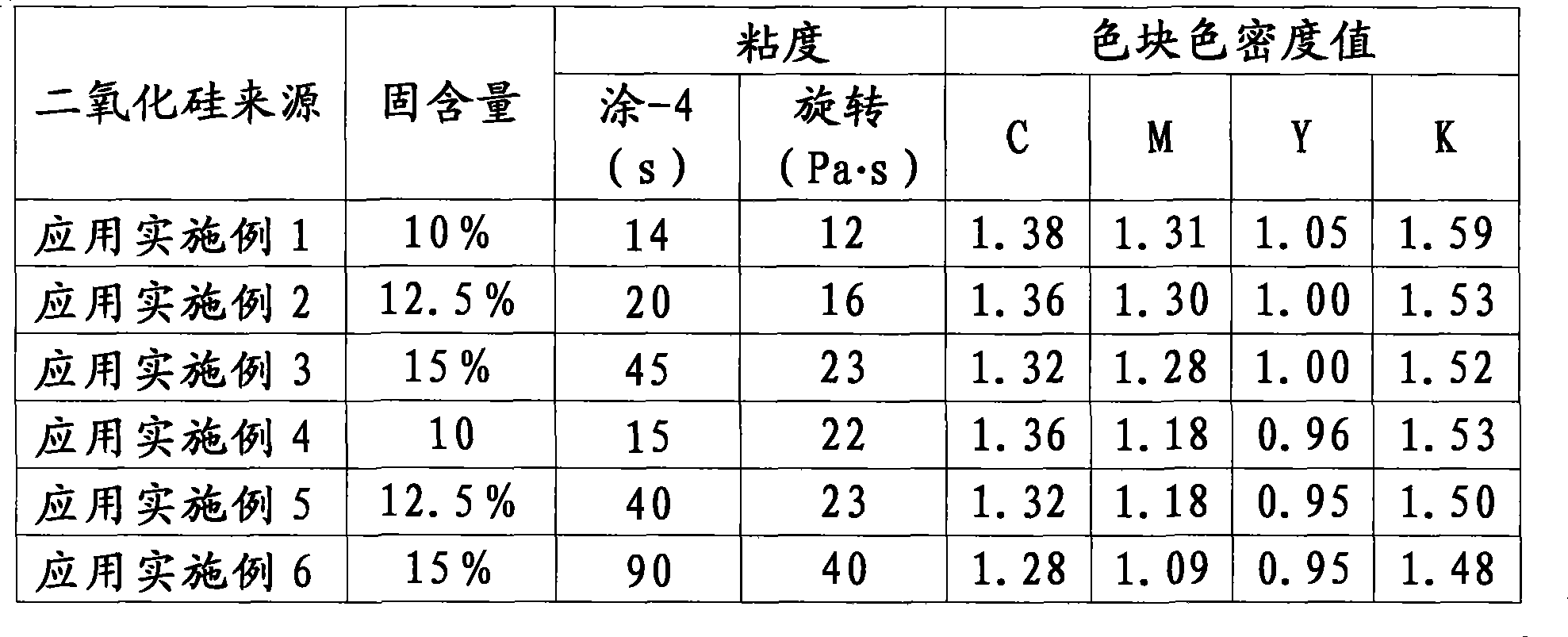

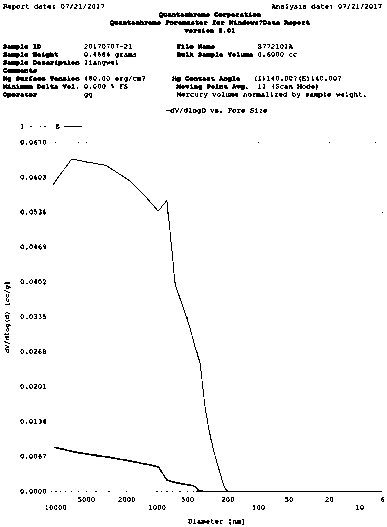

Silicon dioxide, and preparation and use thereof

InactiveCN101475178AStrong color reproductionImprove performanceSilicaDuplicating/marking methodsSilicon dioxideChemistry

The invention relates to silicon dioxide, a method for preparing the same and application of the silicon dioxide in an ink absorption coating layer. The silicon dioxide is used as the ink absorption coating layer of paint, has no special requirement on other compositions forming the coating layer, and has the advantages of high fastness, low viscidity, and the like; and colorful ink-jet printing paper containing the silicon dioxide has strong color reducing performance and other excellent printing performances. The silicon dioxide is characterized in that pore volume is between 0.5 and 1.2 cm / g; specific surface area is between 100 and 280 m / g; DBP absorption value is between 200 and 350g / 100g; d50 is between 2 and 15 mu m; (pore volume+9.569*10*DBP absorption value) / d50 is more than or equal to 0.16 and less than or equal to 0.58, wherein the meaning of each symbol is stated as an instruction book.

Owner:北京航天赛德科技发展有限公司

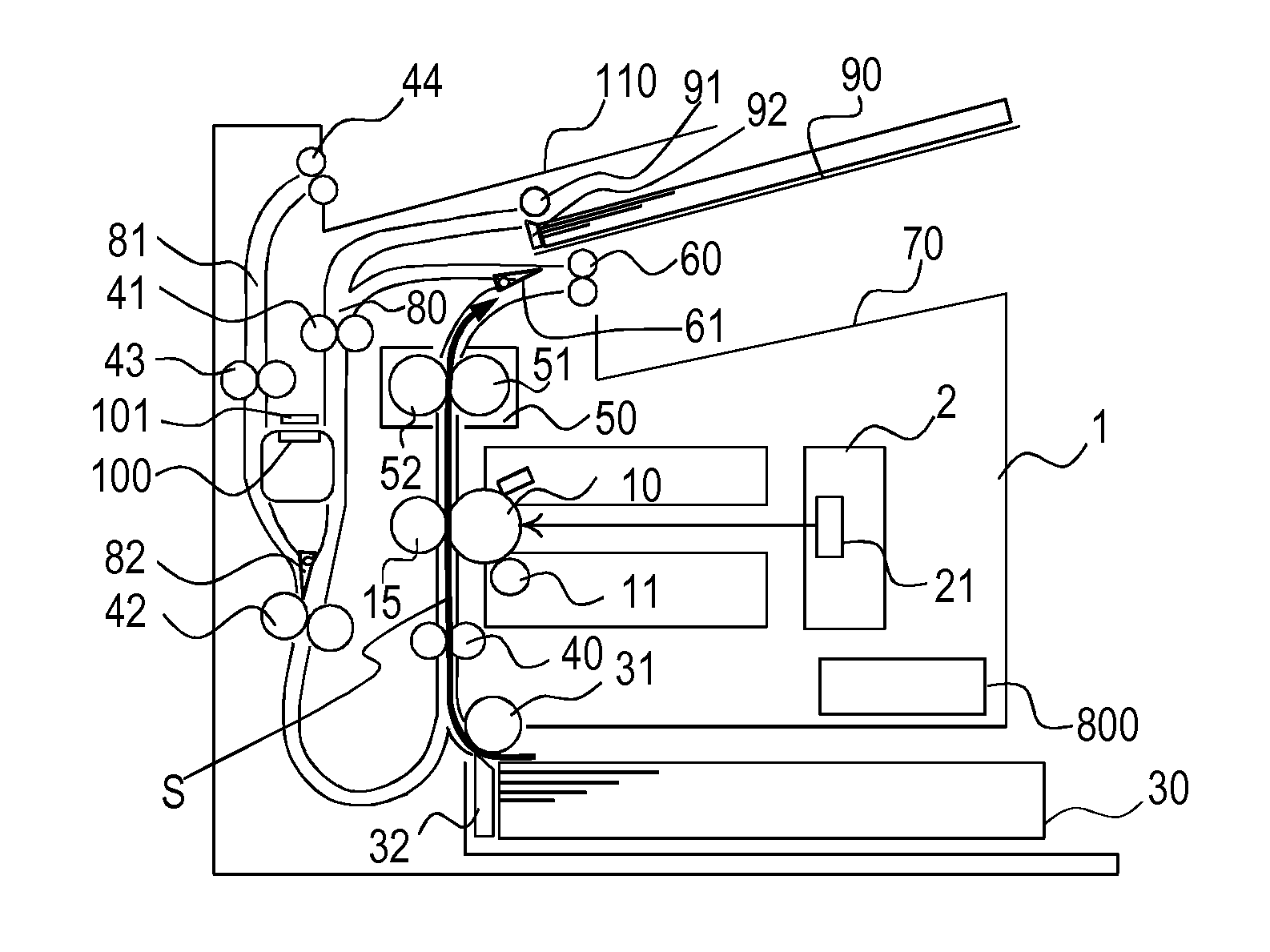

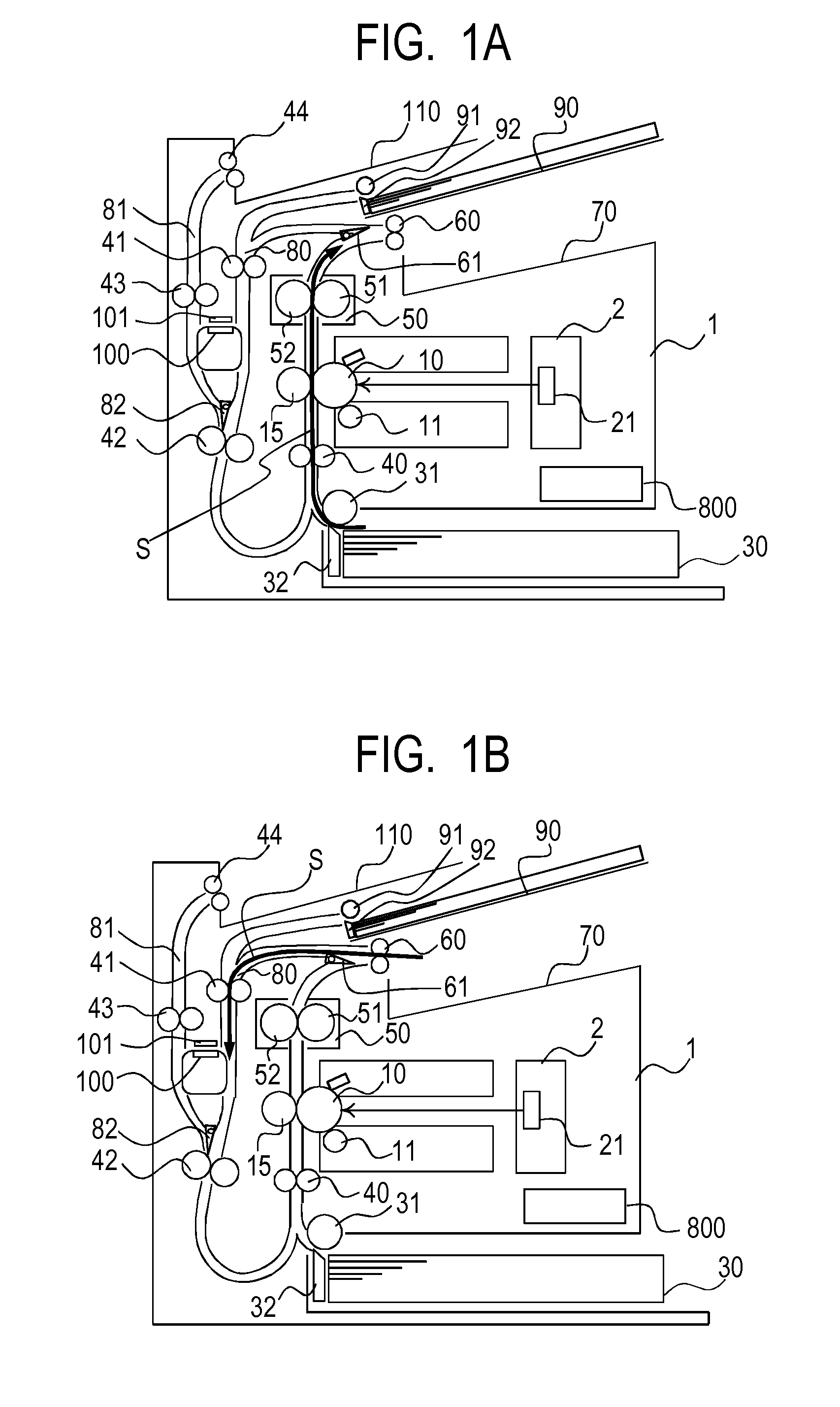

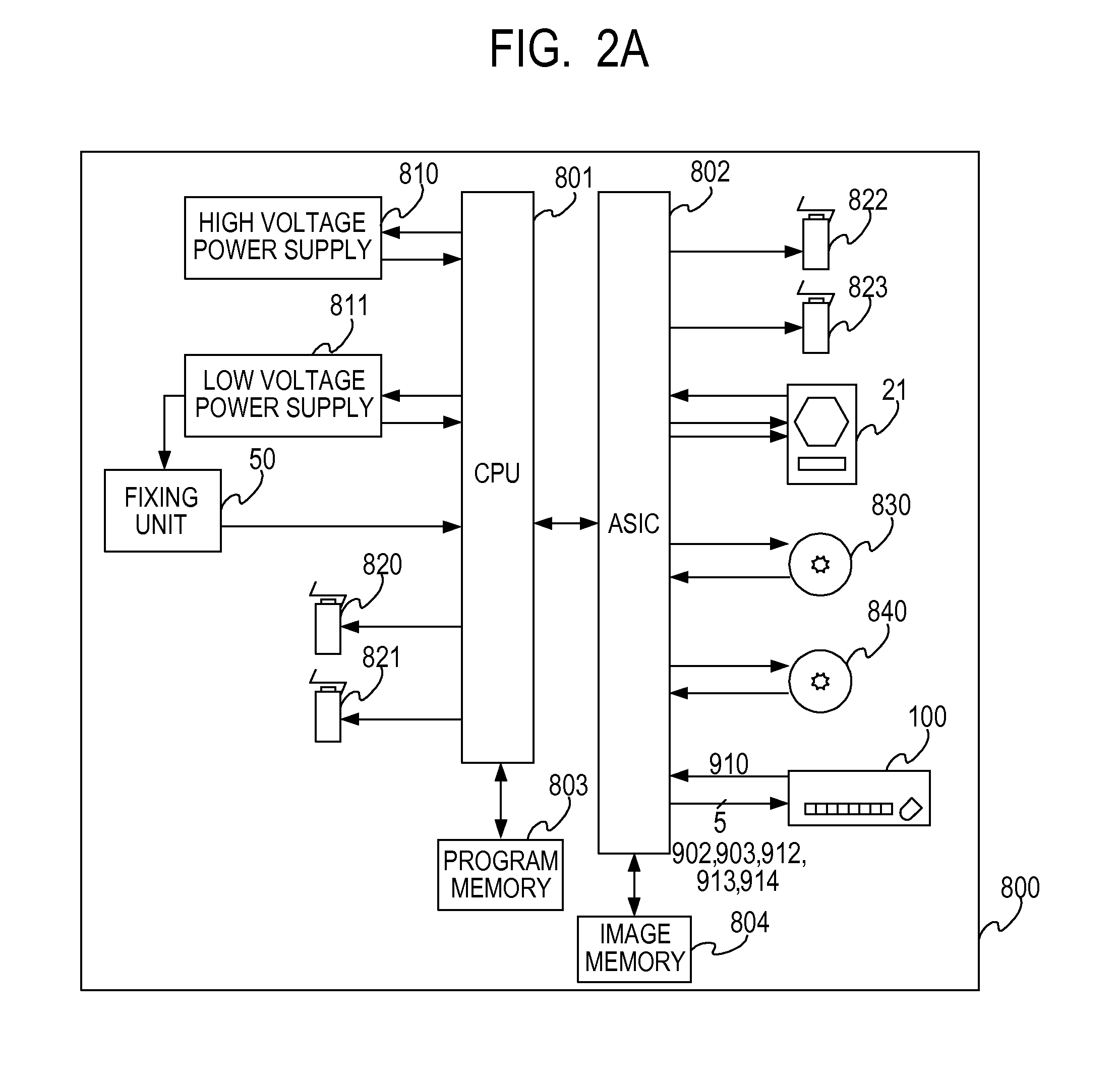

Image forming apparatus

ActiveUS20130293907A1Improve productivityGood printing performanceVisual presentation using printersElectrographic process apparatusImage formationComputer science

The image forming apparatus includes an image forming unit for forming an image on a recording material; an original read unit for reading an original at a read position facing a conveyance path in which the recording material and the original are to be conveyed selectively, and a control unit for switching a position of the original read unit to a position different from the read position during a period in which the recording material is being conveyed along the conveyance path.

Owner:CANON KK

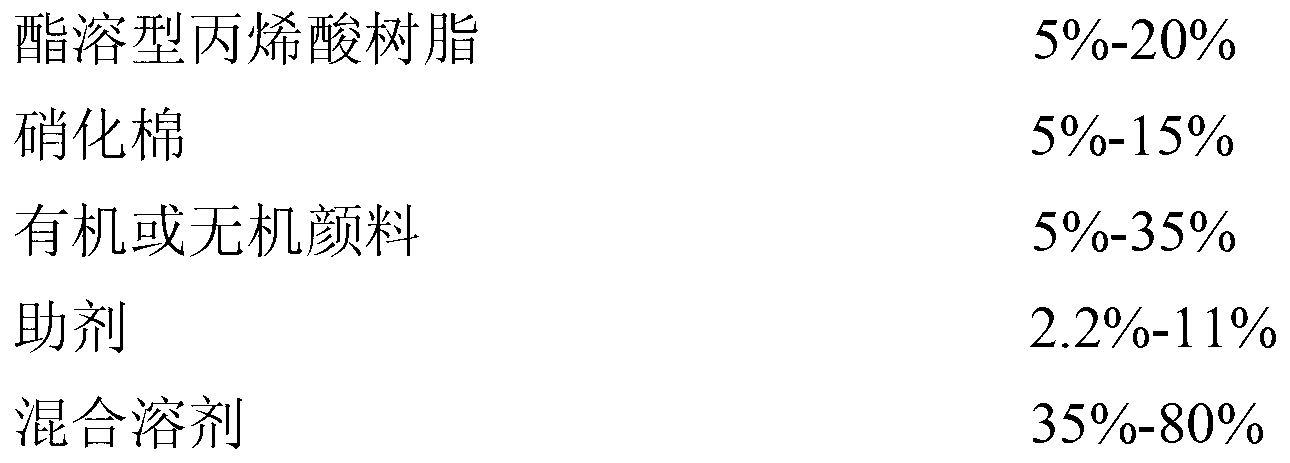

High-temperature resistant ester-soluble printing ink

The invention provides a high-temperature resistant ester-soluble printing ink, belonging to the field of ink printing. The ink comprises the following components in percentage by weight: 5-20% of ester-soluble acrylic resin, 5-15% of nitrocotton, 5-35% of organic or inorganic pigment, 2.2-11% of assistant and 35-80% of mixed solvent. The ink is mainly used for gravure food paper packages and has the following advantages of high gloss, good levelling and good printing color development performance; due to low viscosity, the ink hardly causes falling of paper fibers or stains paper when used for printing; due to high drying speed, no solvents such as benzene, ketone or the like and little solvent residue, the ink meets the requirements of human safety and environmental protection and suitable for food package printing; and due to the high-temperature resistance, the ink can resist 180 DEG C high temperature at most and is capable of sealing heat without losing color.

Owner:东莞市锐达涂料有限公司

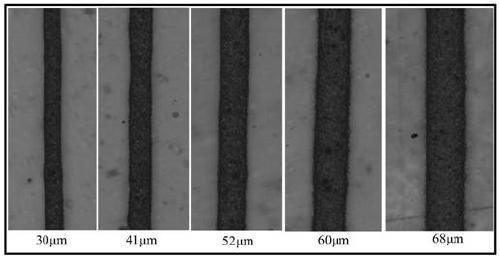

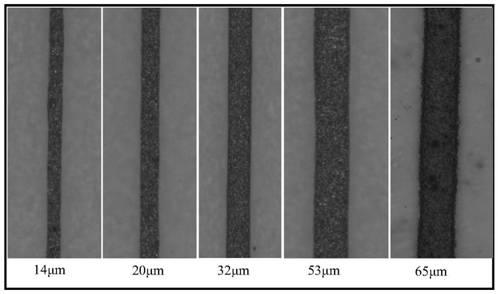

Preparation method of nano-silver paste for electric field driven jet micro-nano 3D printing

ActiveCN111180107AGuaranteed stabilityEvenly dispersedMaterial nanotechnologyNon-conductive material with dispersed conductive materialSilver pastePolymer resin

The invention provides a preparation method of nano-silver paste for electric field driven jet micro-nano 3D printing, and belongs to the technical field of conductive silver paste and micro-nano 3D printing. The nano-silver paste is composed of modified nano-silver powder, an organic carrier and polymer resin, wherein the weight ratio of the modified nano-silver powder to the organic carrier to the polymer resin is 55-75: 15-40: 1-10; and the organic carrier is composed of an organic solvent, a thickener, a plasticizer, a surfactant, a dispersing agent, a leveling agent and an additive, wherein the weight percentage ratio of the organic solvent to the thickener to the plasticizer to the surfactant to the dispersing agent to the leveling agent to the additive is 60-90: 2-10: 3-10: 1-8: 1-10: 1-10: 1-10. By modifying the nano-silver powder and adjusting all the components, the viscosity of the nano-silver powder is matched with electric field driven jet micro-nano 3D printing, ultra-fine large-depth-width-ratio high-performance conductive pattern manufacturing is achieved, and finally, excellent adhesive force and conductive performance are achieved, and particularly, the problem that due to agglomeration of nano silver materials, the use performance is unstable is solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

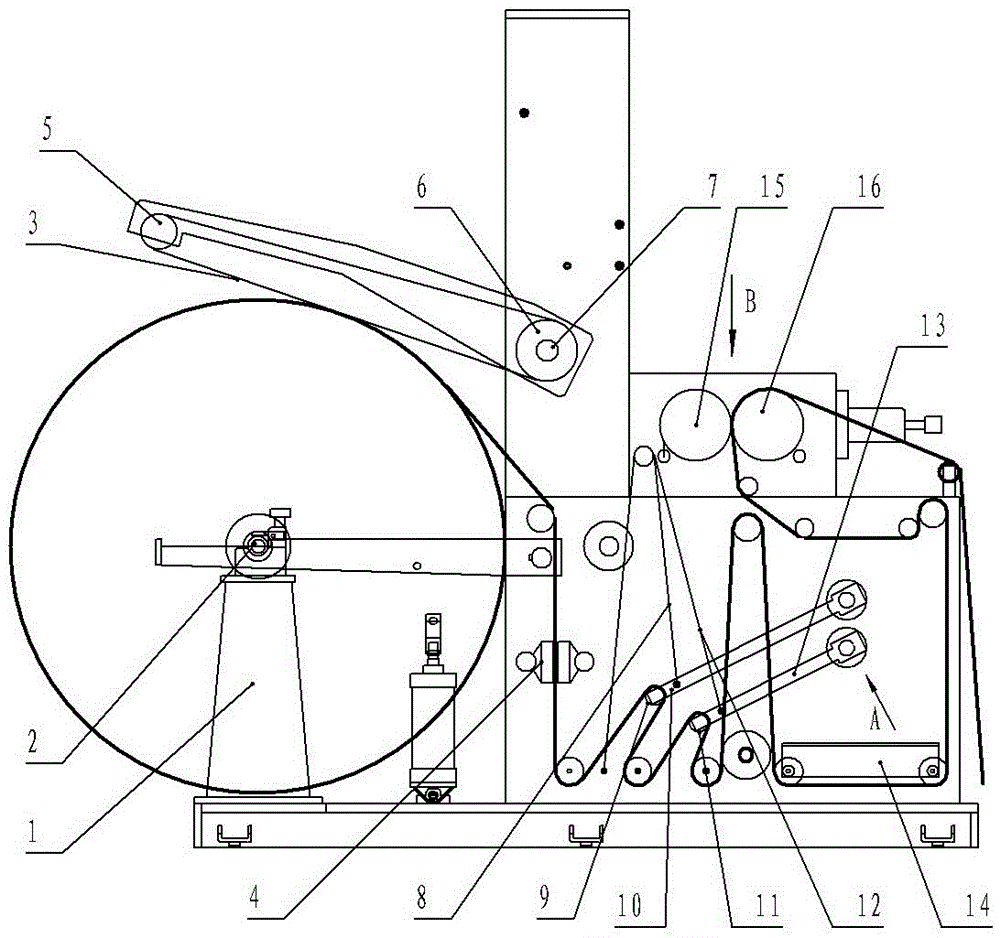

Paper unwinding machine with double floating rolls

InactiveCN106006117AImprove stabilityMake sure the tension is constantWebs handlingPulp and paper industryUnstable status

The invention discloses a paper unwinding machine with double floating rolls, and belongs to the technical field of printing machinery. The paper unwinding machine comprises an unwinding unit, wherein the unwinding unit is provided with an unwinding roll installed on an unwinding rack and an unwinding belt arranged at one side of the unwinding roll, and connected and driven through an unwinding drive device, and the unwinding drive device is provided with a motor controlled by a variable-frequency speed adjustor. The paper unwinding machine is characterized in that at least two tension disturbance absorption devices are sequentially arranged on a paper output channel of the unwinding unit; each tension disturbance absorption device is composed of one floating roll installed on a swinging rod connected with a pull spring; a sensor for detecting a rotating position of the corresponding swinging rod is arranged on the tension disturbance absorption device located at the end; and an output end of the sensor is electrically connected with an input end of the variable-frequency speed adjustor. According to the paper unwinding machine disclosed by the invention, the problems that a material is mellow and easy to stretch, and a tension is in an instable state in web-fed printing due to different outer diameters and low roundness of paper reels can be solved.

Owner:王金根 +1

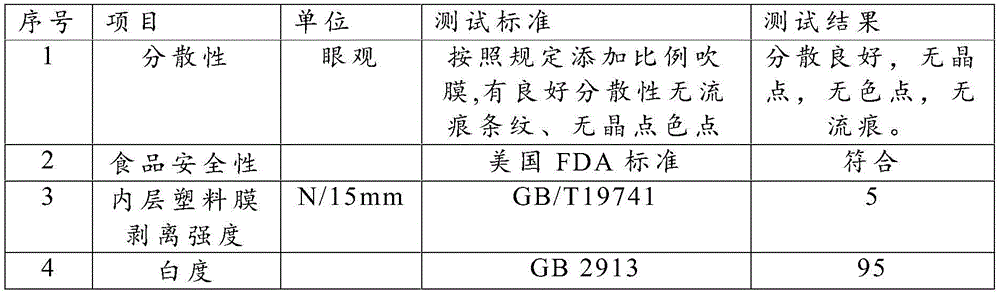

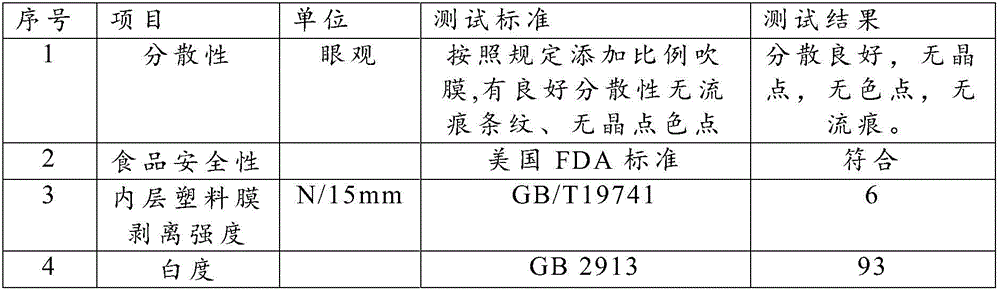

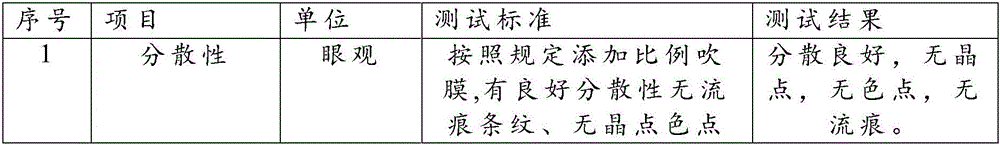

Special white master batch for liquid packaging film, preparation method and application thereof

Owner:QINGDAO RICH PLASTIC NEW MATERIAL

3D printing molding material

ActiveCN108178659AGood for maintaining size and shapeSmall coefficient of thermal expansionAdditive manufacturing apparatusCeramicwareAdhesiveSintering shrinkage

The invention provides a 3D printing molding material which consists of the following components: graded modified aluminum oxide powder, yellow dextrin powder and an adhesive, wherein the adhesive accounts for 5-50% of the mass of the molding material; the amount ratio of the graded modified aluminum oxide powder to the yellow dextrin powder is (65-97):(15-25). An aluminum oxide ceramic made of the molding material after sintering is of a micro-pore structure which is high in pore rate, uniform in aperture and controllable in distribution, in addition, the sintering shrinkage rate of the material is low, the size and the shape of the material can be maintained, and cracking can be avoided.

Owner:ZHENGZHOU UNIV

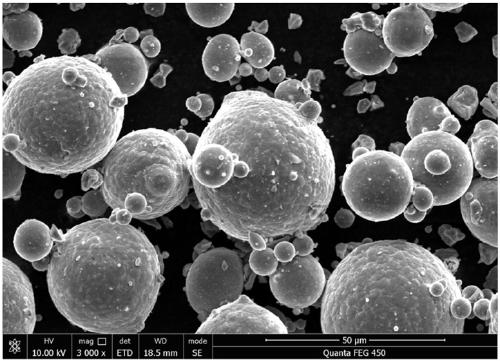

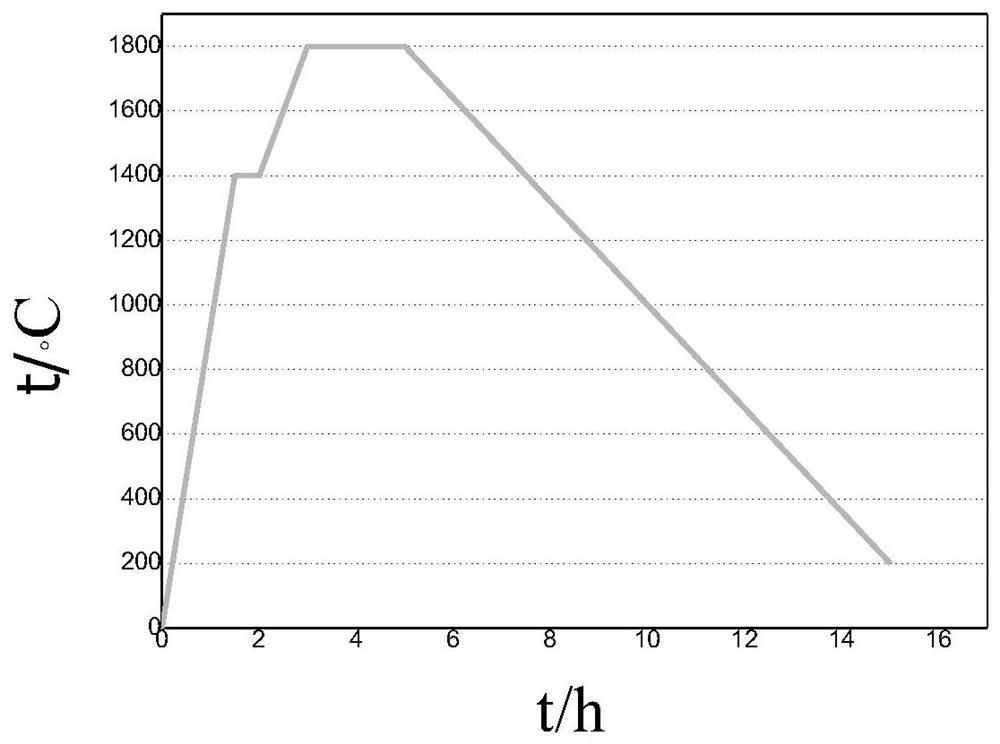

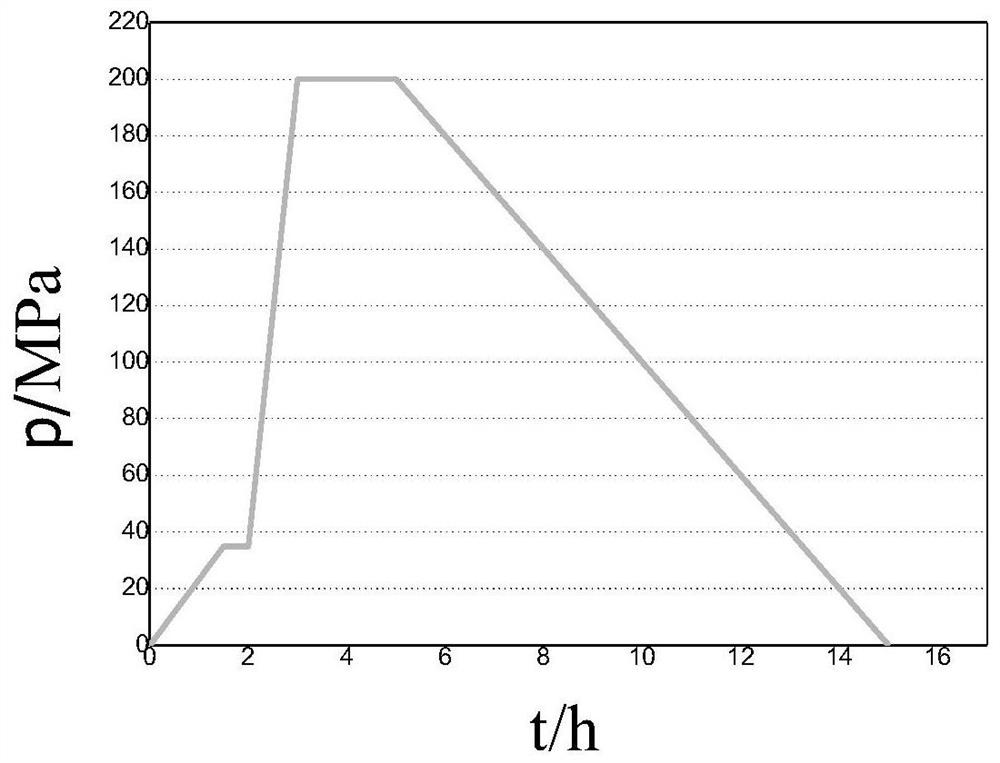

Preparation method of high-temperature spherical molybdenum alloy powder

ActiveCN112828298AGood printing performanceImprove developmentNuclear energy generationTransportation and packagingOxidation resistantHot isostatic pressing

The invention provides a preparation method of high-temperature spherical molybdenum alloy powder. The preparation method comprises the following steps: screening molybdenum, silicon, boron, zirconium and titanium powder particles without impurities on the surfaces according to the proportion of 86.9%-89.1% of Mo powder, 1.3%-1.6% of Si powder, 0.99%-1.1% of B powder, 2.8%-3.8% of Zr powder and 5.81%-6.6% of Ti powder, mixing materials in a solid-solid mixing manner, preparing pre-alloyed powder with uniform particles by utilizing mechanical ball milling or high-energy ball milling, performing hot isostatic pressing sintering on the ball-milled powder to obtain a molybdenum alloy blank, and then obtaining the spherical molybdenum alloy powder resistant to high-temperature oxidation with a plasma rotary atomization powder preparation process. The prepared molybdenum alloy powder has good toughness, crack generation can be inhibited, high-temperature oxidation resistance is achieved, and compared with a traditional powder preparation process, the molybdenum alloy powder has better fluidity and sphericity degree, thereby having wide application prospects and popularization value.

Owner:AIR FORCE UNIV PLA +1

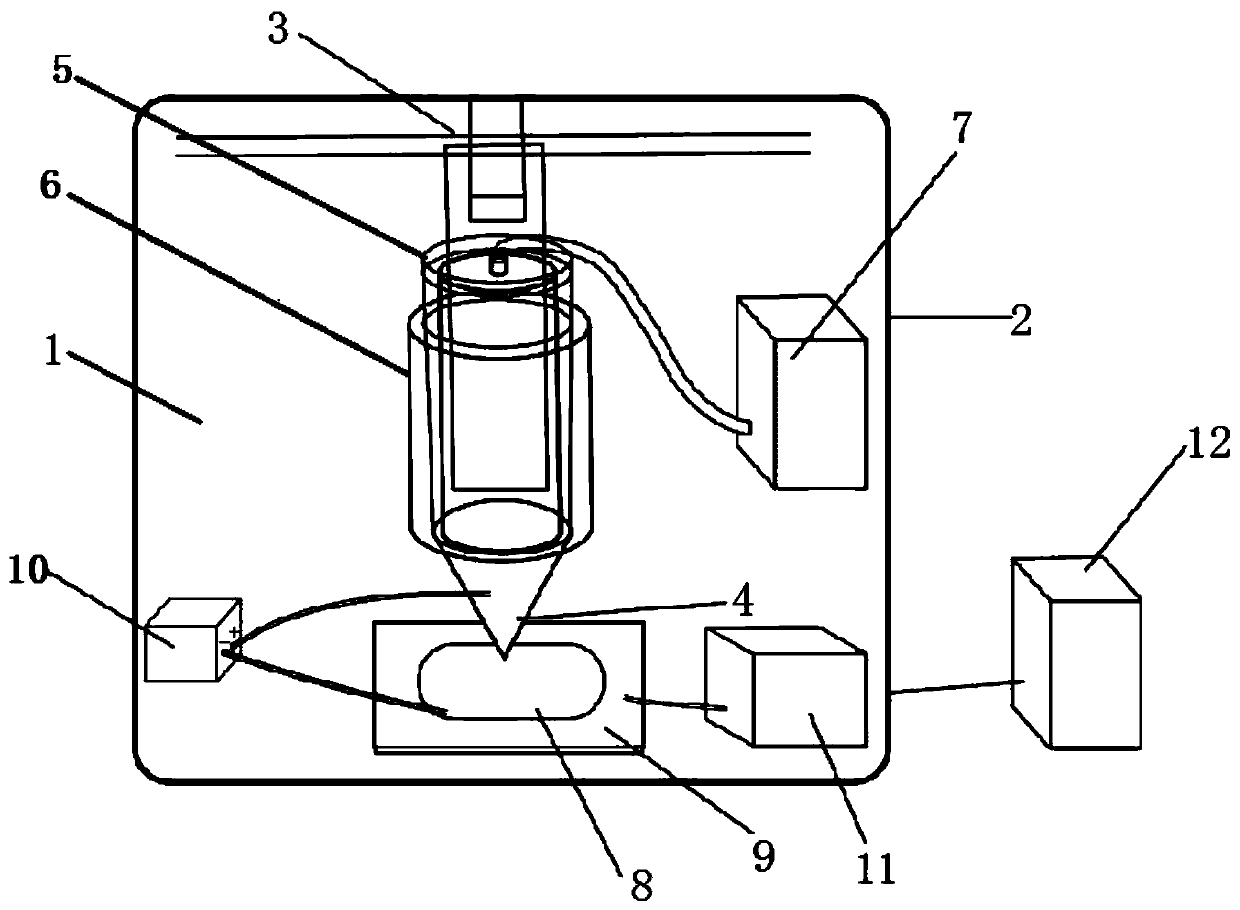

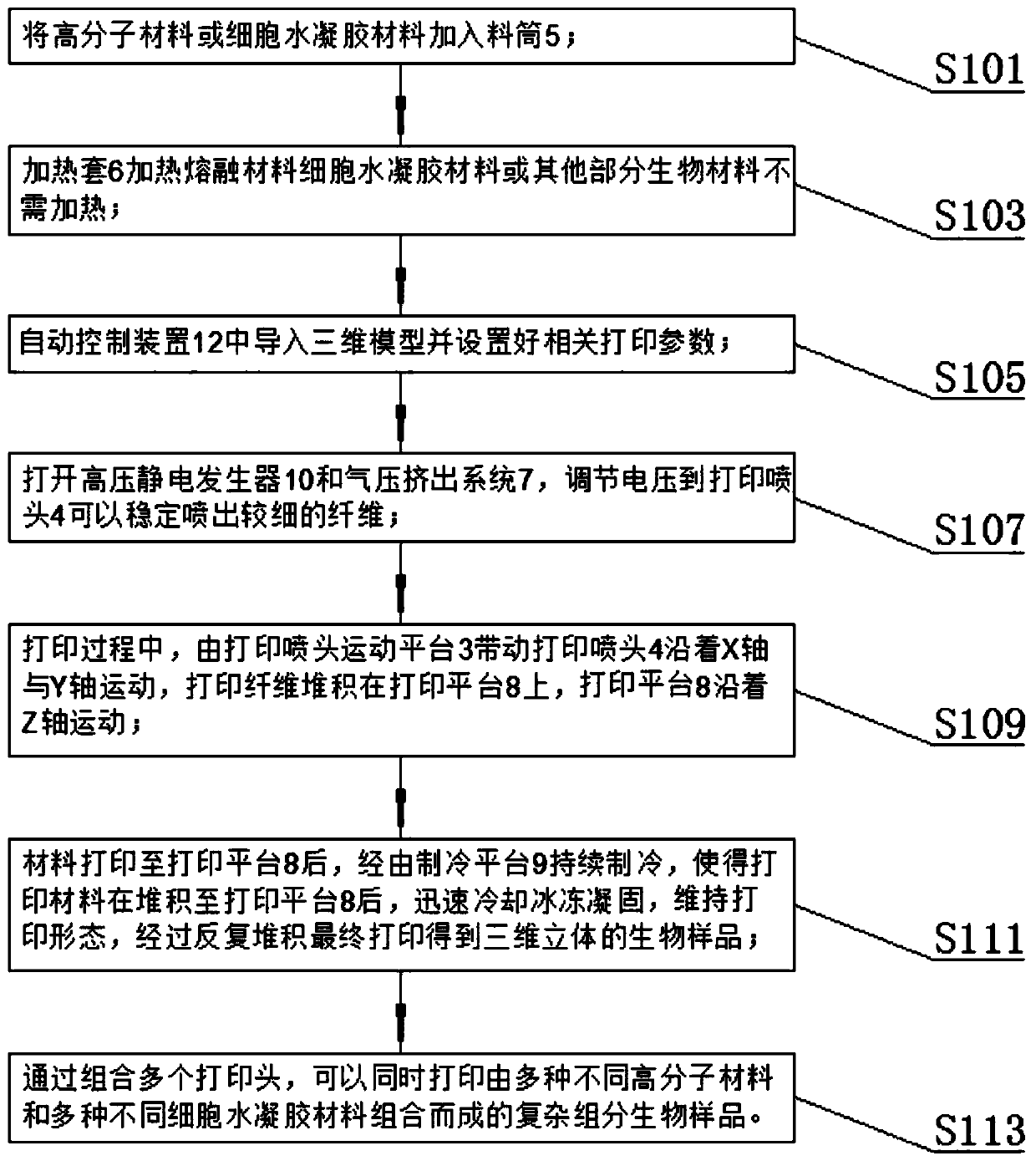

Biological electrospinning 3D printing device adopting low-temperature molding and preparation method for biological electrospinning 3D printing device

PendingCN110466153AMaintain morphological structureGood molding effectAdditive manufacturing apparatusAdditive manufacturing processesHead movementsElectrical connection

The invention discloses a biological electrospinning 3D printing device adopting low-temperature molding. The biological electrospinning 3D printing device comprises a shell and a protection hood located on the outer wall of the shell, wherein the inner top end of the shell is provided with a printing spray-head movement platform horizontally arranged in the horizontal direction, the bottom end ofthe printing spray-head movement platform is provided with a printing spray head matched with the printing spray-head movement platform, the position, on the printing spray-head movement platform, located at the top end of the printing spray head is provided with a material barrel matched with the printing spray head in a sleeved manner, the material barrel is provided with a heating sleeve matched with the material barrel in a sleeved manner, one side of the inner portion of the shell is provided with an air pressure extrusion system in electrical connection with the material barrel, and theposition, at the inner bottom end of the shell, located below the printing spray head is provided with a printing platform. The biological electrospinning 3D printing device adopting the low-temperature molding and a preparation method for the biological electrospinning 3D printing device have the beneficial effects that on the basis of electrospinning biological D printing, by means of the additional installation of a refrigeration platform, printing materials are made to be rapidly cooled and solidified in the platform, the printing object form structure is maintained, and the printing formability is greatly improved; and the biological electrospinning 3D printing device is convenient to operate, and the problem of the poor formability of biological three-dimensional printing materialsis solved.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

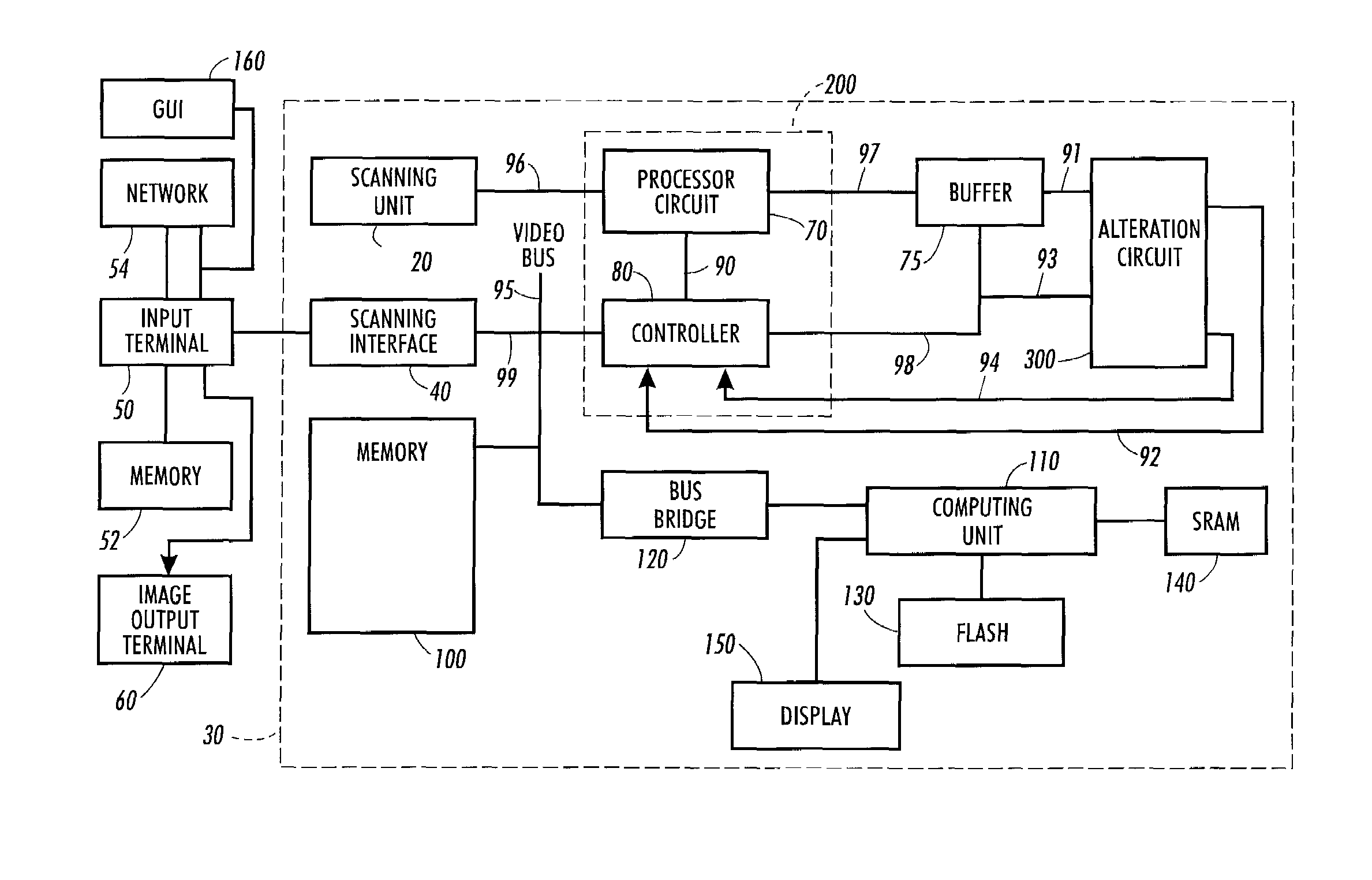

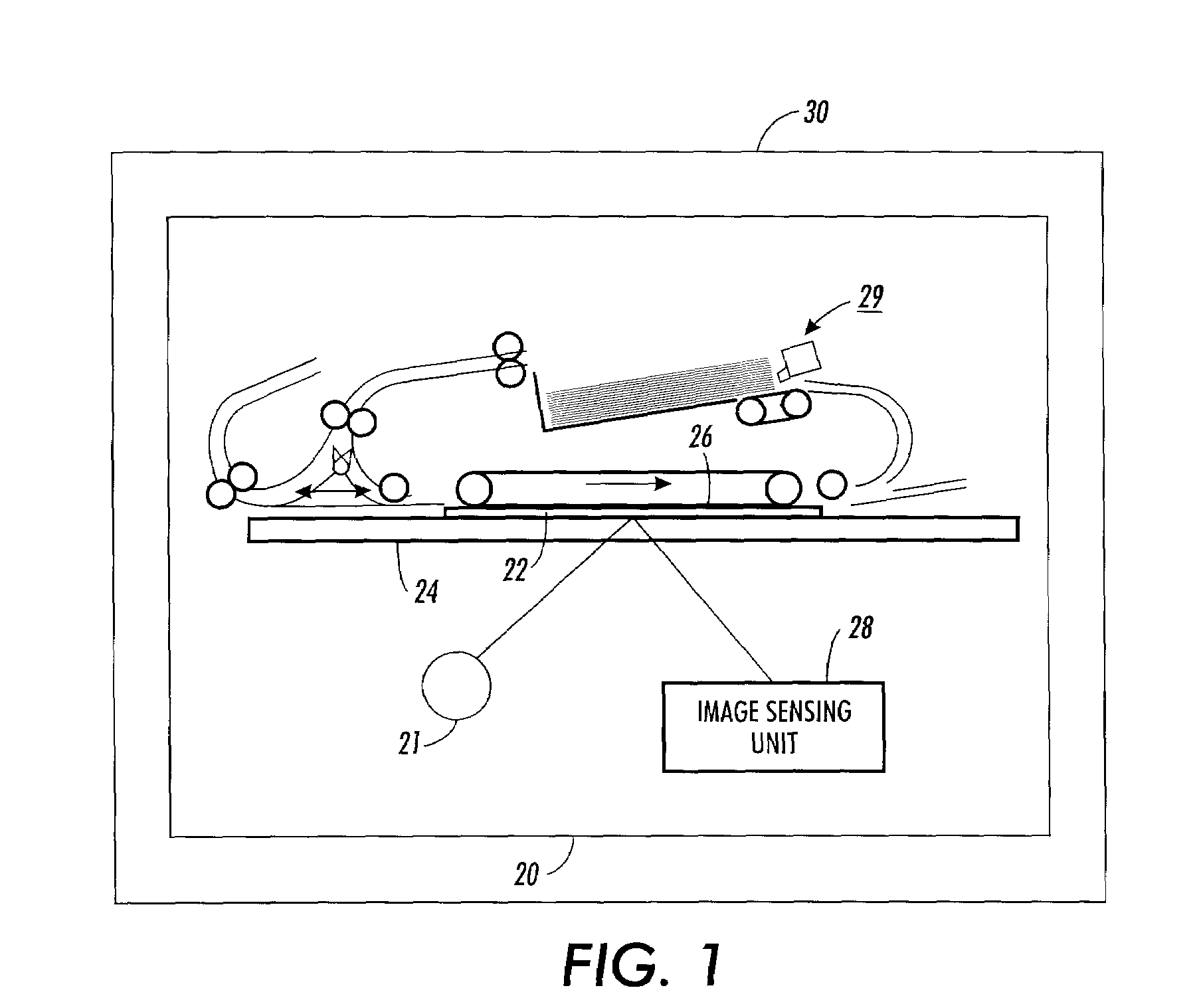

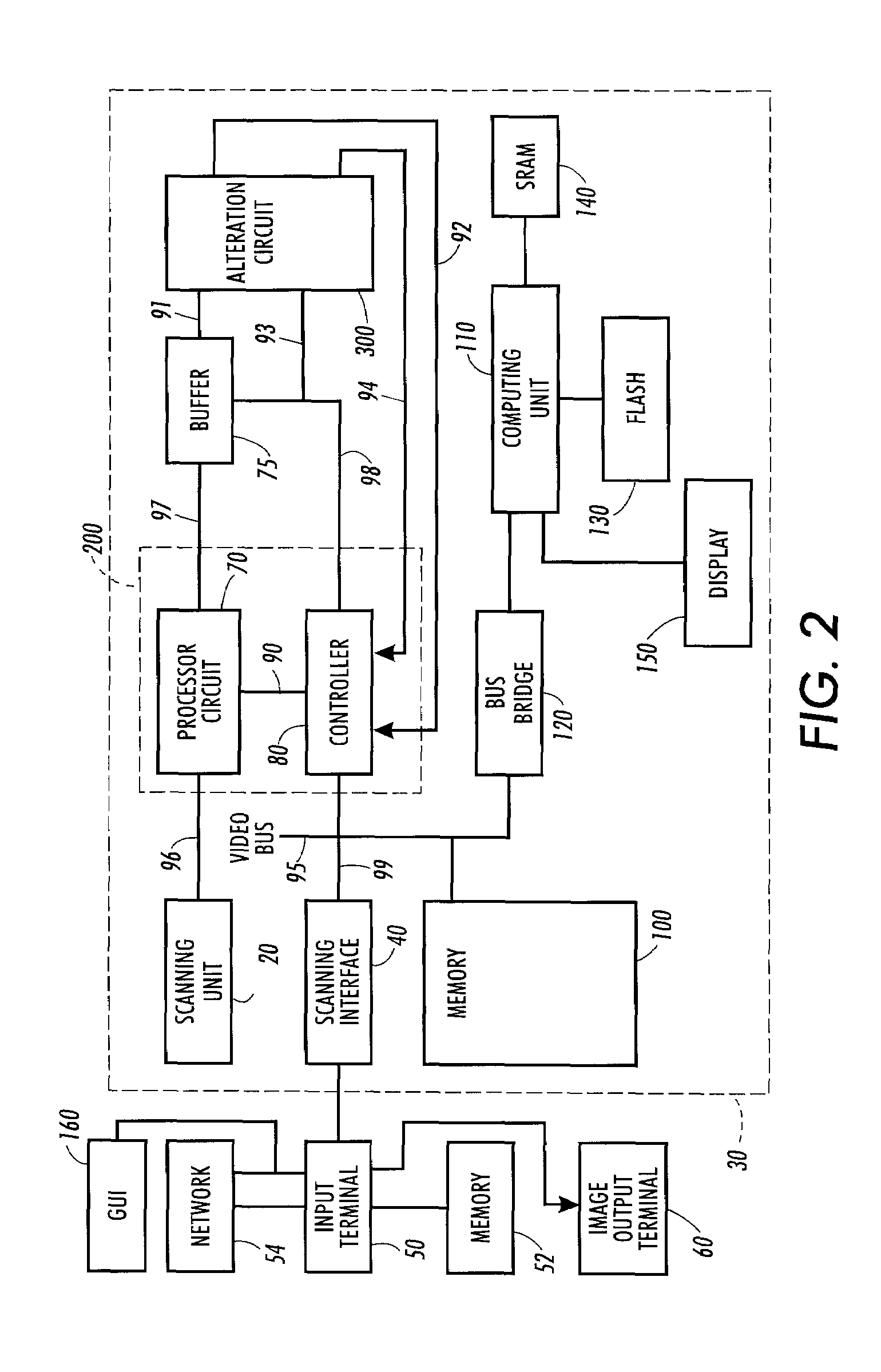

Systems and methods that alter electronic data based on availability of time

ActiveUS7420712B2Improve quality and performance and efficiencyImprove efficiencyImage enhancementMultiprogramming arrangementsComputer architectureIdle time

A multifunctional device that processes electronic data includes a processor that processes the electronic data, a memory that stores the electronic data, an alteration circuit that alters the structure of the electronic data and a controller that determines whether idle time exists when the electronic data is stored in the memory, and controls the alteration circuit to alter the electronic data when the controller determines that idle time exists. Moreover, a method of processing electronic data includes processing the electronic data, storing the electronic data, controlling the electronic data by determining whether idle time exists when the electronic data is stored and altering the electronic data when sufficient idle time exists.

Owner:XEROX CORP

Fully-degradable bio-based composite material product and preparation method thereof

The invention discloses a fully-degradable bio-based composite material product and a preparation method thereof. The bio-based composite material product is prepared from the following raw materialsin parts by weight: 25-80 parts of biomass, 10-25 parts of a p-dioxanone polymer, 30-50 parts of polylactic acid, 50-100 parts of PBTA resin, 1-10 parts of a composite compatibilizer, 0.5-3 parts of alubricant and 0.8-1.5 parts of a plasticizer, wherein the composite compatibilizer is prepared from a coupling agent, mineral oil and a surfactant. The composite material product provided by the invention has the characteristics of high biodegradation rate and complete degradation, has excellent mechanical properties, and can be recycled many times. Meanwhile, the composite material product is convenient to print and excellent in printing performance.

Owner:LIAONING XINGFUREN TECH CO LTD +1

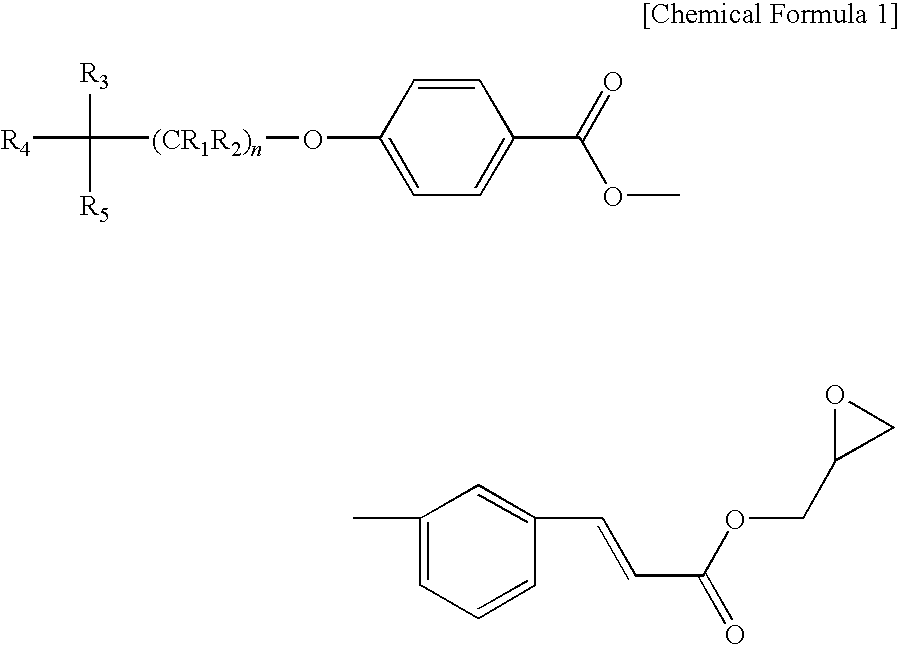

Epoxy Compound for Liquid Crystal Photo-Alignment Agent, Liquid Crystal Photo-Alignment Agent, and Liquid Crystal Photo-Alignment Film

InactiveUS20100155661A1Good printing performanceIncrease brightnessLiquid crystal compositionsOrganic chemistryLiquid crystalCrystallography

Disclosed is an epoxy compound for a liquid crystal photo-alignment agent, a liquid crystal photo-alignment agent, and a liquid crystal photo-alignment film. The epoxy compound is represented by the following Chemical Formula 1.In the above Chemical Formula 1, each substituent is the same as defined in the specification.Since the epoxy compound according to an embodiment of the present invention may be prepared through a simple manufacturing process, it is possible to provide a liquid crystal photo-alignment agent and a liquid crystal photo-alignment film that are economical and have excellent substrate printability and reliability, and superb photoelectric characteristics.

Owner:CHEIL IND INC

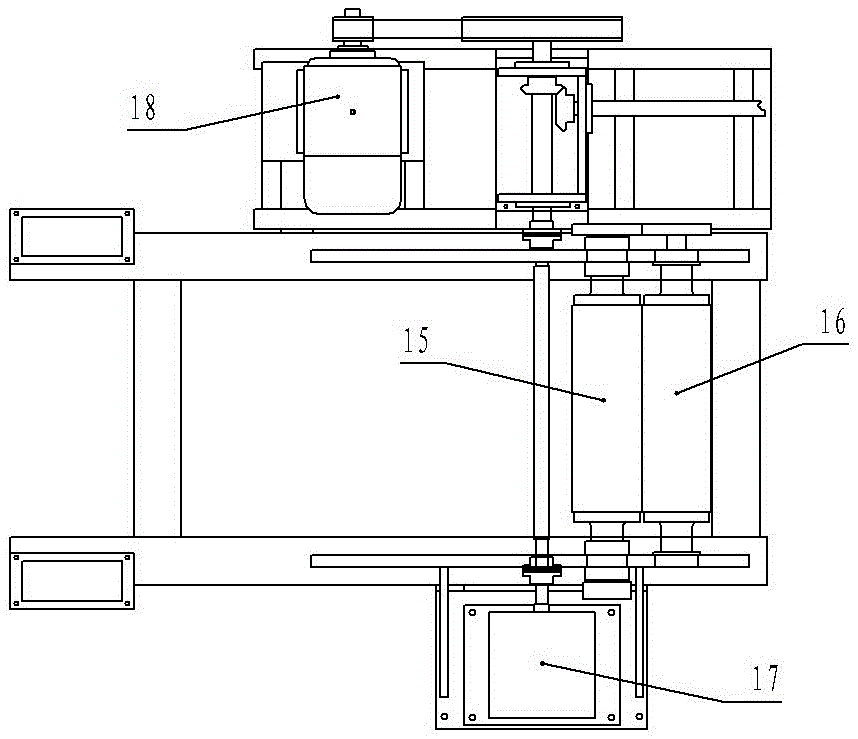

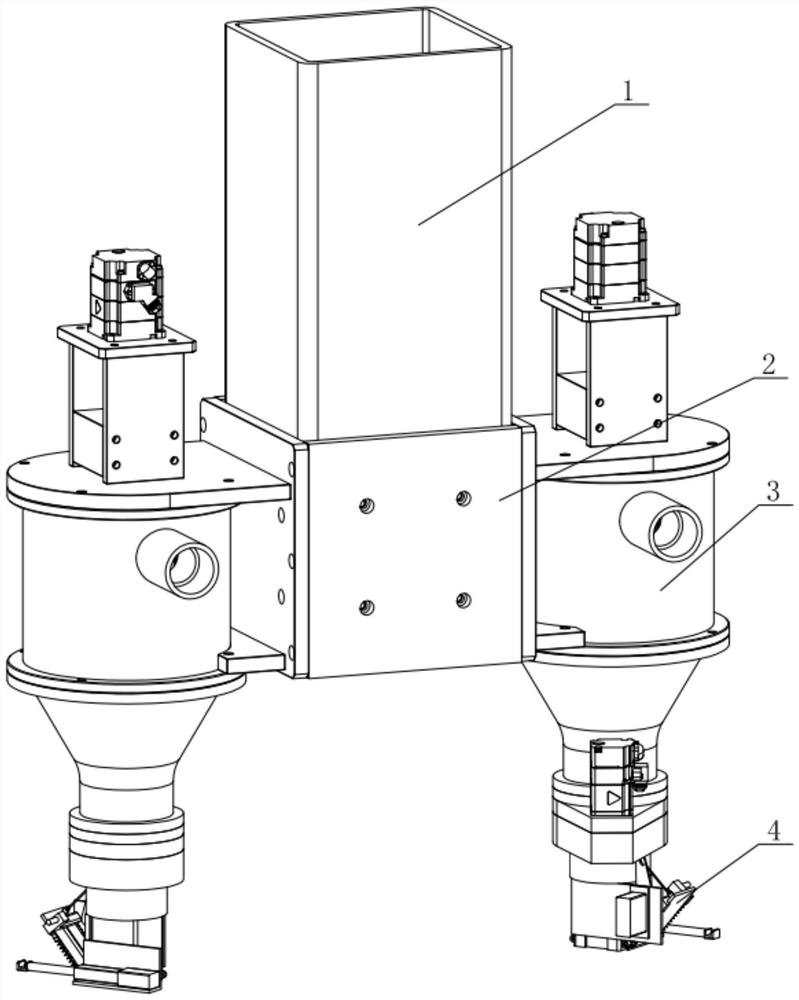

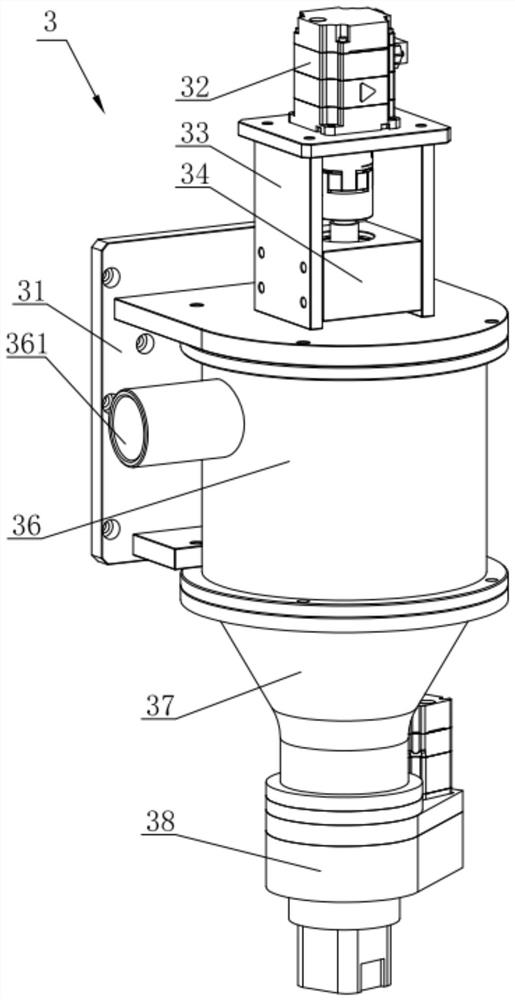

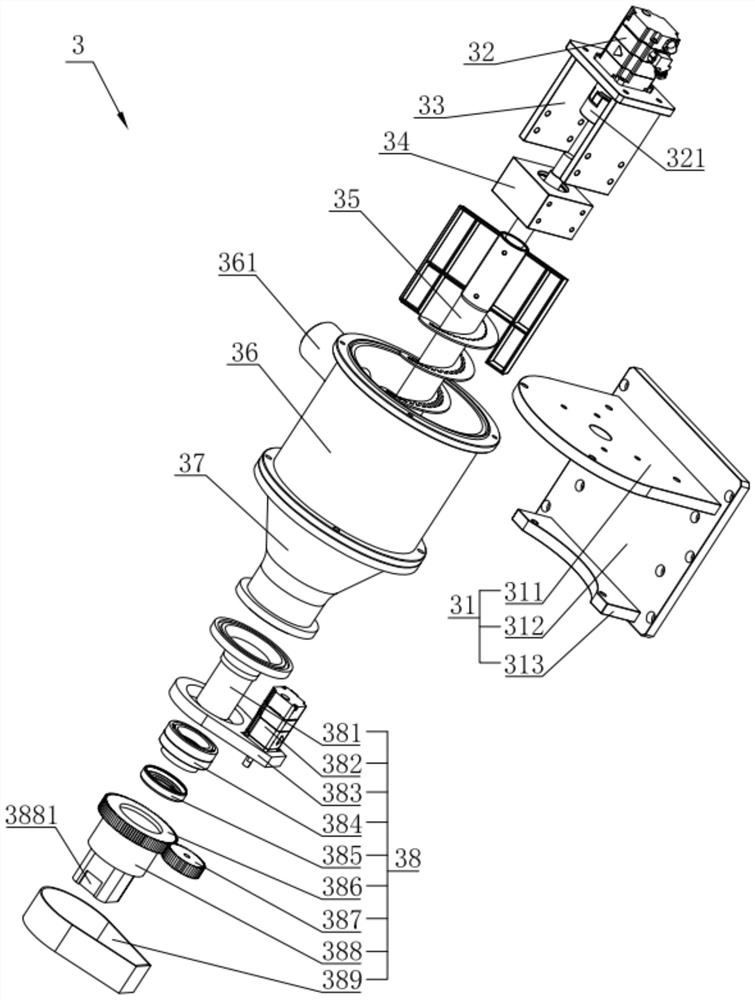

Nozzle rotating double-spray-head type cement 3D printing structure and using method thereof

ActiveCN112720778ACompact structureReasonable structureAdditive manufacturing apparatusHollow article cleaningElectric machineryStructural engineering

The invention relates to a nozzle rotating double-spray-head type cement 3D printing structure and a using method thereof. The nozzle rotating double-spray-head type cement 3D printing structure comprises a stand column, and spray head assemblies are symmetrically installed on the side face of the stand column. Each set of spray head assembly comprises a supporting base fixedly installed on the stand column, a feeding cylinder is fixedly installed on the outer side of each supporting base, a feeding motor is installed above each feeding cylinder, a spiral shaft is installed at the downward output end of each feeding motor, and each spiral shaft stretches downwards into the corresponding feeding cylinder. A communicating extrusion cylinder is mounted at the bottom of each feeding cylinder, and a nozzle piece is mounted at the bottom of each extrusion cylinder through a nozzle rotating assembly. A feeding hole is formed in the upper part of the side wall of each feeding cylinder and is connected with an external cement conveying pump through a hose. An automatic cutting and sealing mechanism is mounted on the outer side wall of each nozzle piece. Cement enters the feeding cylinders through the hoses under the action of the cement conveying pumps, the spiral shafts rotate to extrude the cement downwards, and the nozzle rotating assemblies drive the nozzle pieces to rotate relative to the extrusion cylinders. The two sets of spray head assemblies cooperate with each other or work independently, are suitable for printing components of various shapes or colors, and are good in practicability and high in use flexibility.

Owner:江苏集萃复合材料装备研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com