Biological electrospinning 3D printing device adopting low-temperature molding and preparation method for biological electrospinning 3D printing device

A 3D printing and biological technology, applied in processing and manufacturing, additive processing, etc., can solve problems such as low viscosity and poor structural formability, achieve convenient operation, improve printing formability, and solve the effects of poor formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

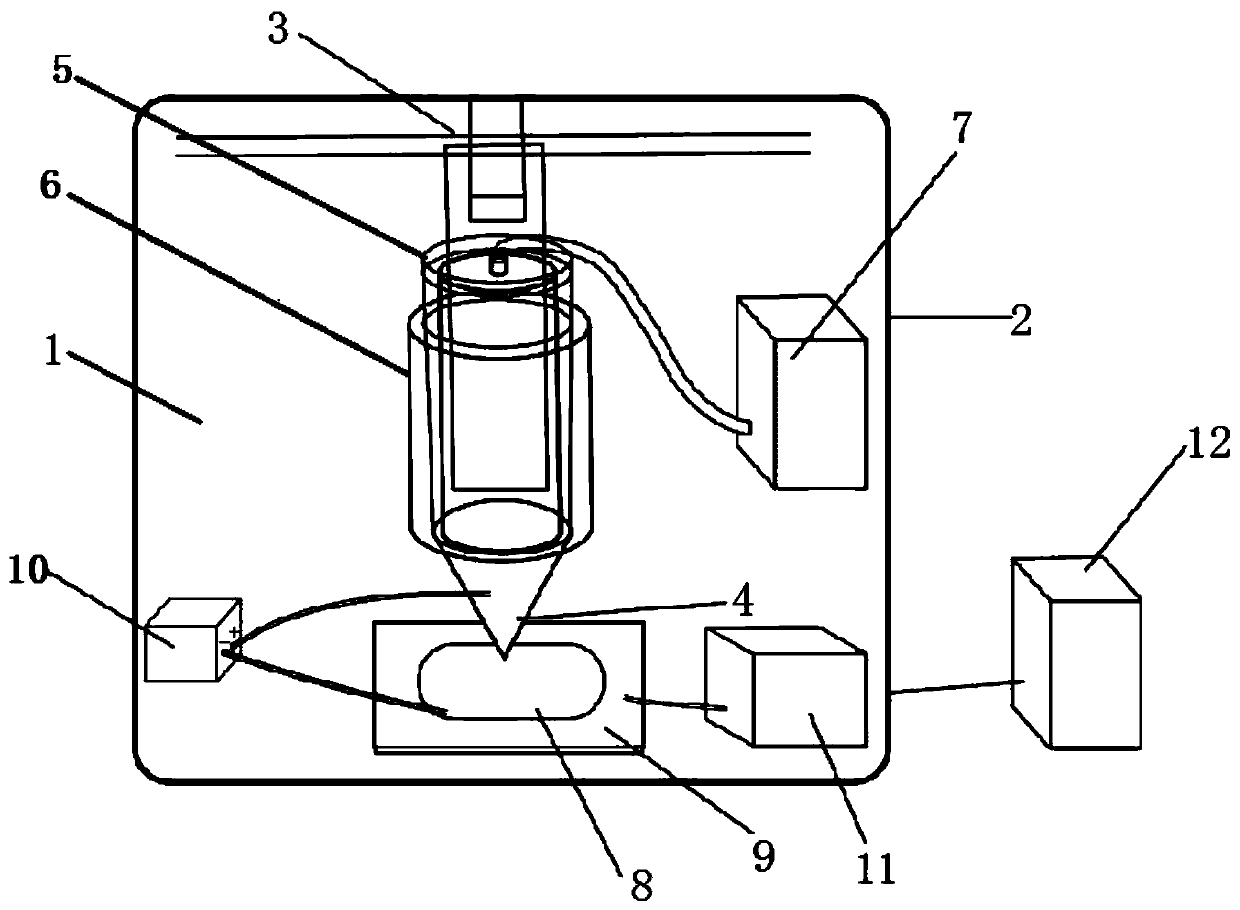

[0030] Such as Figure 1-2 As shown, the novel bio-electrospinning 3D printing device adopting low-temperature molding according to the embodiment of the present invention and its preparation method include a casing 1 and a protective cover 2 located on the outer wall of the casing 1, and the top of the casing 1 is provided with a There is a printing nozzle moving platform 3 arranged horizontally and horizontally, the bottom end of the printing nozzle moving platform 3 is provided with a matching printing nozzle 4, and the printing nozzle moving platform 3 is sleeved on the top of the printing nozzle 4 There is a barrel 5 matching it, and a heating jacket 6 matching it is set on the barrel 5, and one side of the housing 1 is provided with an air pressure squeezer with the electrical connection point of the barrel 5. out of the system 7, and the bottom end of the casing 1 and below the print nozzle 4 is provided with a printing platform 8, and the upper cover of the printing pl...

Embodiment 2

[0032] Such as Figure 1-2 As shown, a heat-conducting and insulating ceramic is provided between the cooling platform 9 and the printing platform 8 to avoid the influence of the electric field while cooling. The printing nozzle moving platform 3 controls the horizontal movement of the X-axis and the Y-axis of the printing nozzle 4, so The negative pole of the high voltage electrostatic generator 10 is electrically connected to the printing platform 8 .

[0033] In order to understand the above-mentioned technical solution of the present invention more clearly, the above-mentioned solution of the present invention will be described in detail below through specific examples.

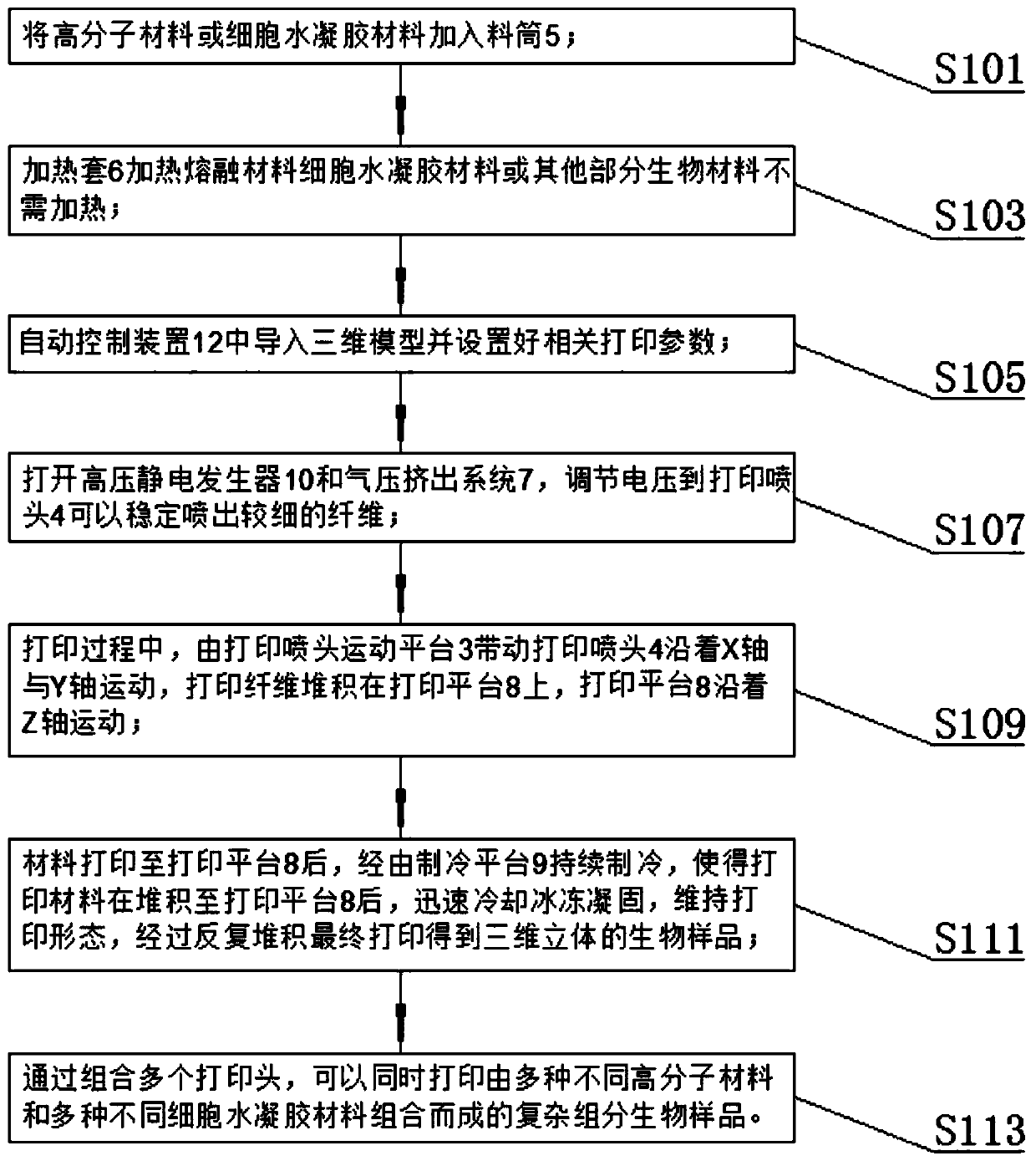

[0034] The preparation of the low-temperature forming bio-electrospinning 3D printing device includes the following steps:

[0035] Step S101, adding polymer material or cell hydrogel material into barrel 5;

[0036] Step S103, the heating jacket 6 heats the molten material, and the cell hydrogel materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com