Patents

Literature

1501 results about "Electrostatic generator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electrostatic generator, or electrostatic machine, is an electromechanical generator that produces static electricity, or electricity at high voltage and low continuous current. The knowledge of static electricity dates back to the earliest civilizations, but for millennia it remained merely an interesting and mystifying phenomenon, without a theory to explain its behavior and often confused with magnetism. By the end of the 17th century, researchers had developed practical means of generating electricity by friction, but the development of electrostatic machines did not begin in earnest until the 18th century, when they became fundamental instruments in the studies about the new science of electricity. Electrostatic generators operate by using manual (or other) power to transform mechanical work into electric energy. Electrostatic generators develop electrostatic charges of opposite signs rendered to two conductors, using only electric forces, and work by using moving plates, drums, or belts to carry electric charge to a high potential electrode. The charge is generated by one of two methods: either the triboelectric effect (friction) or electrostatic induction.

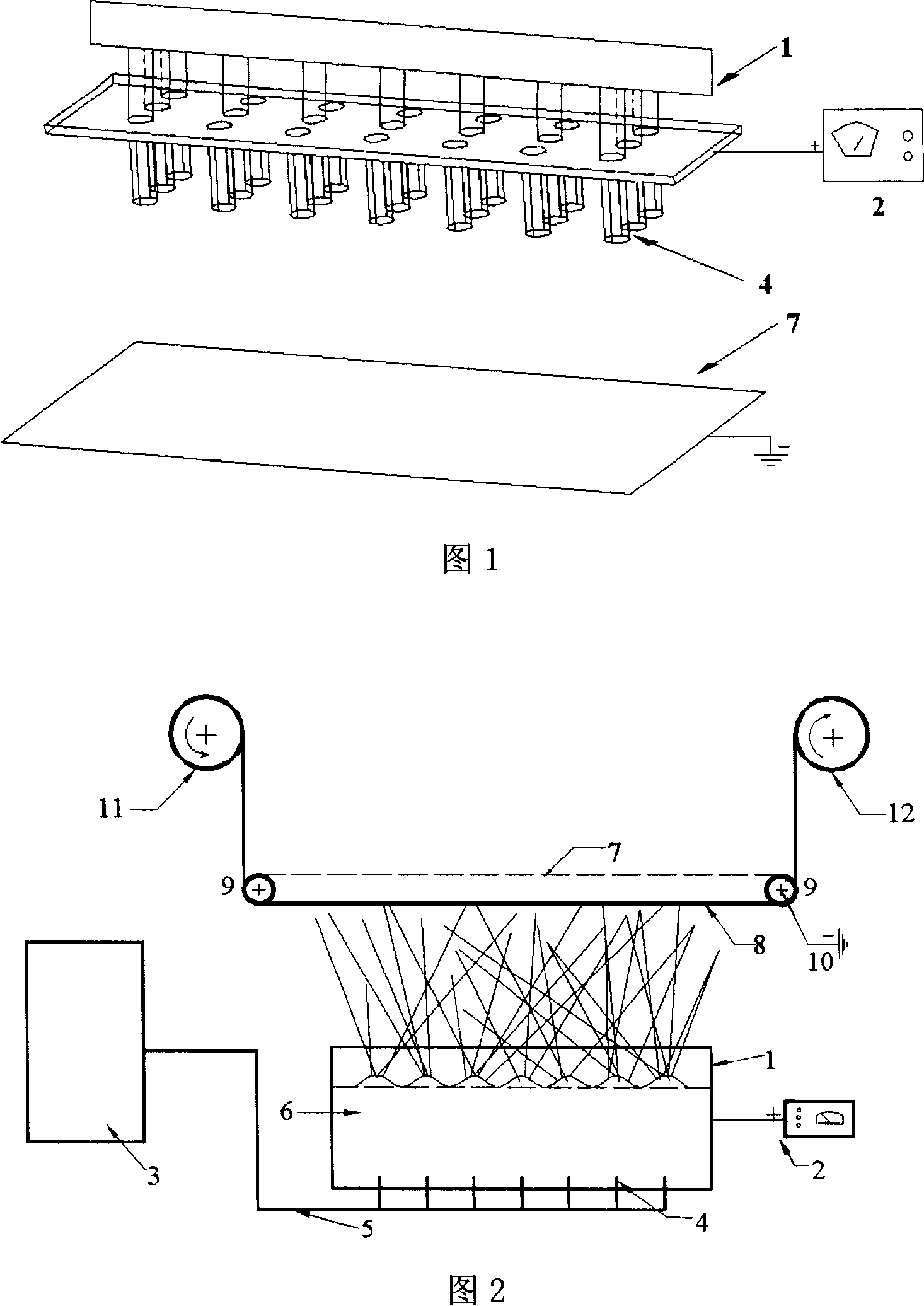

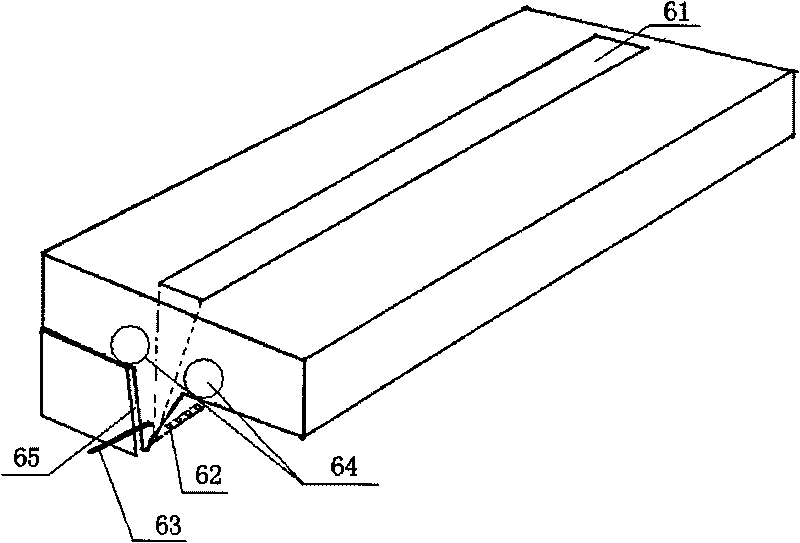

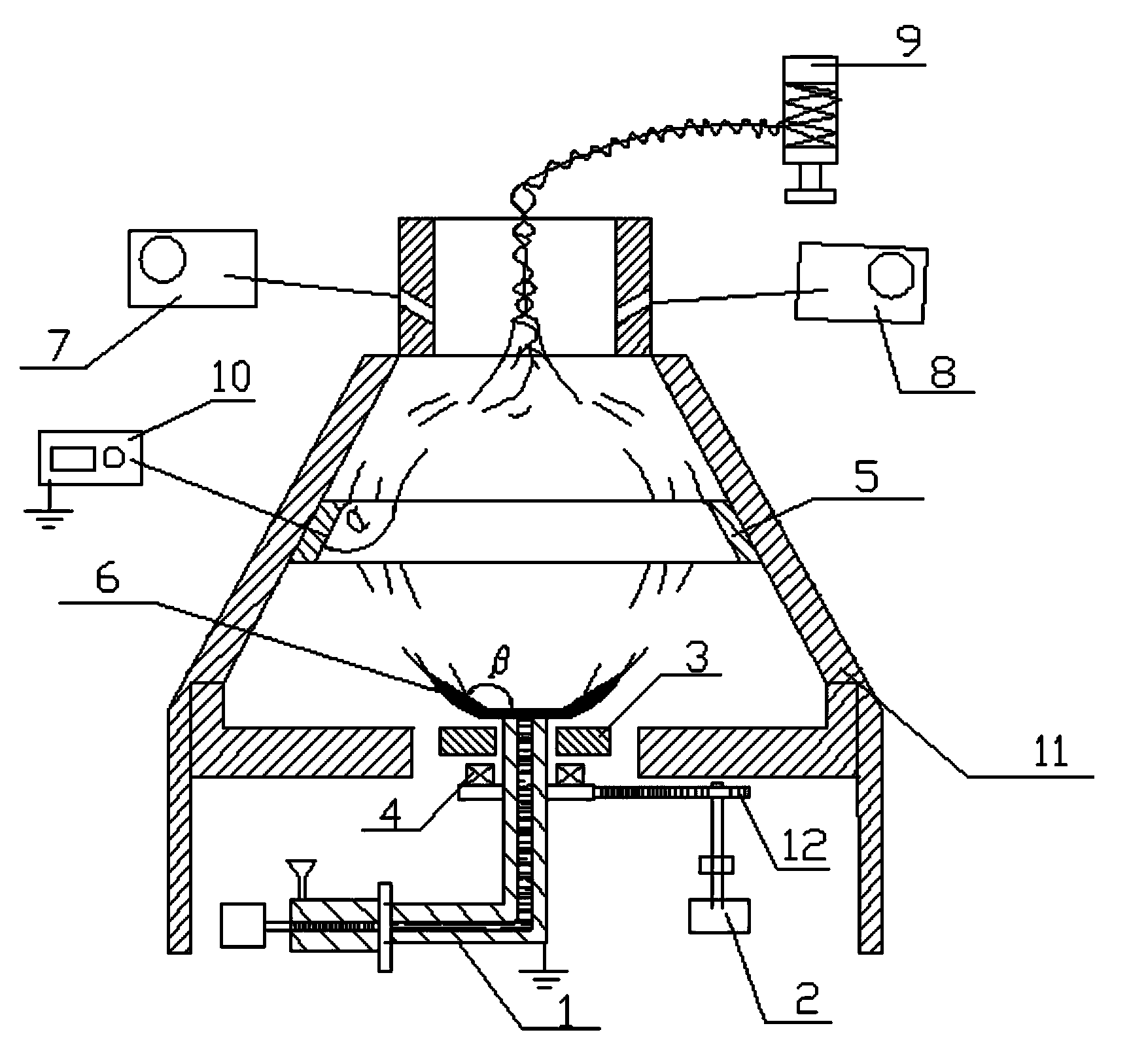

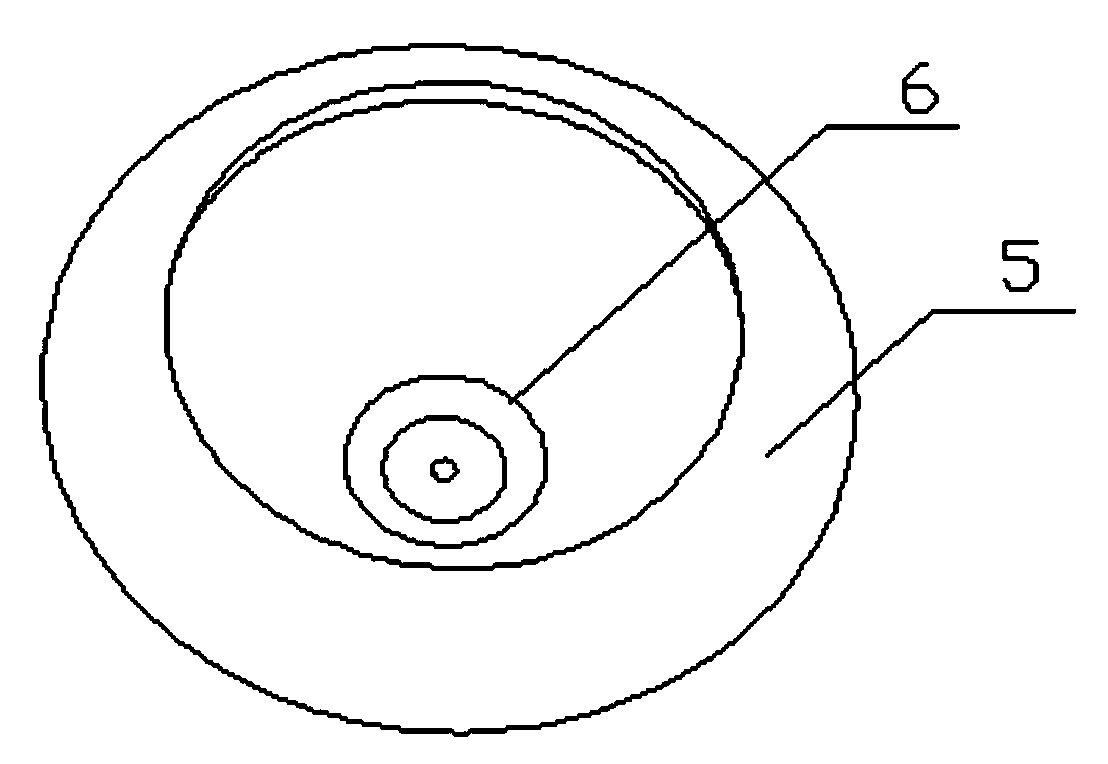

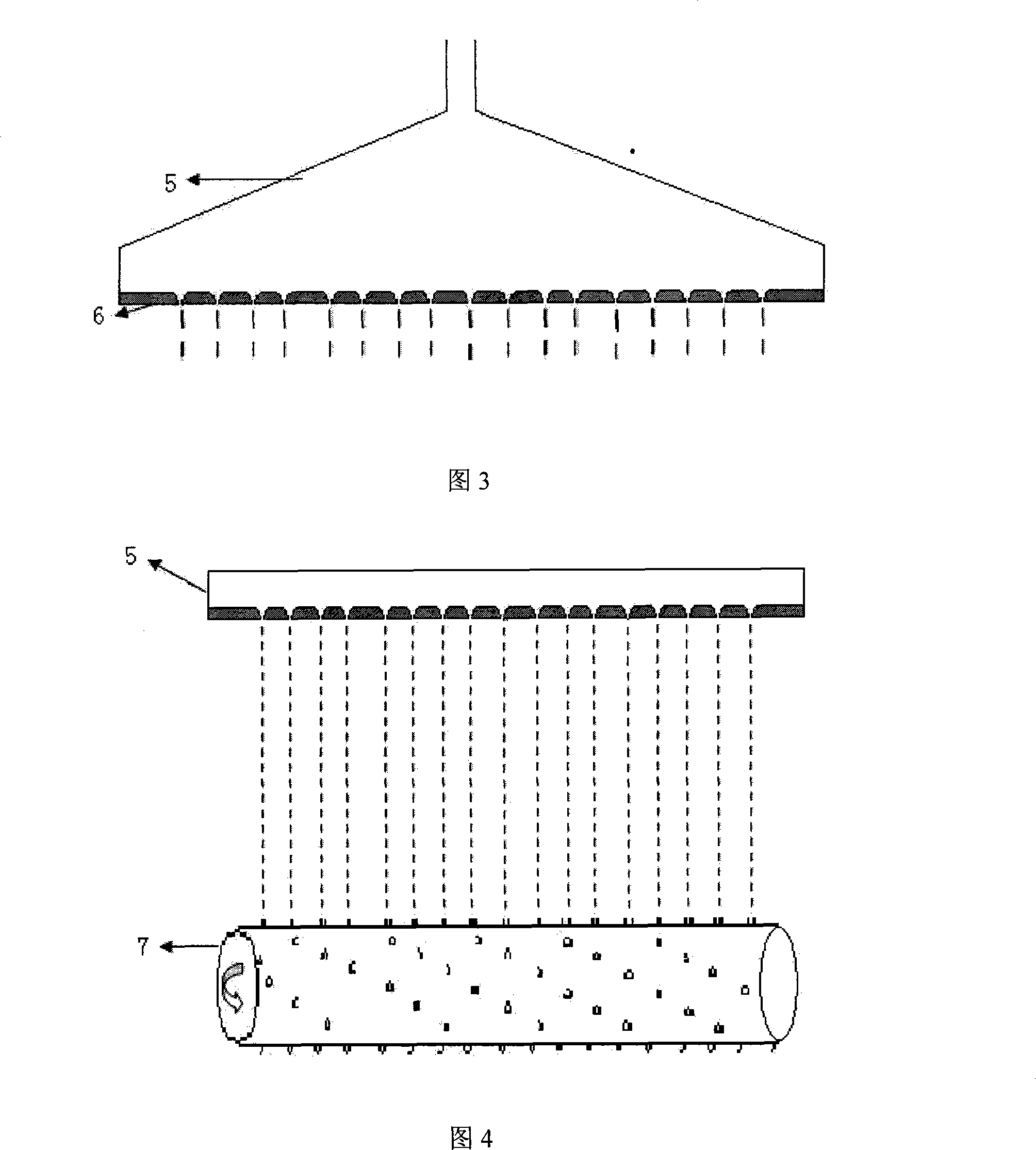

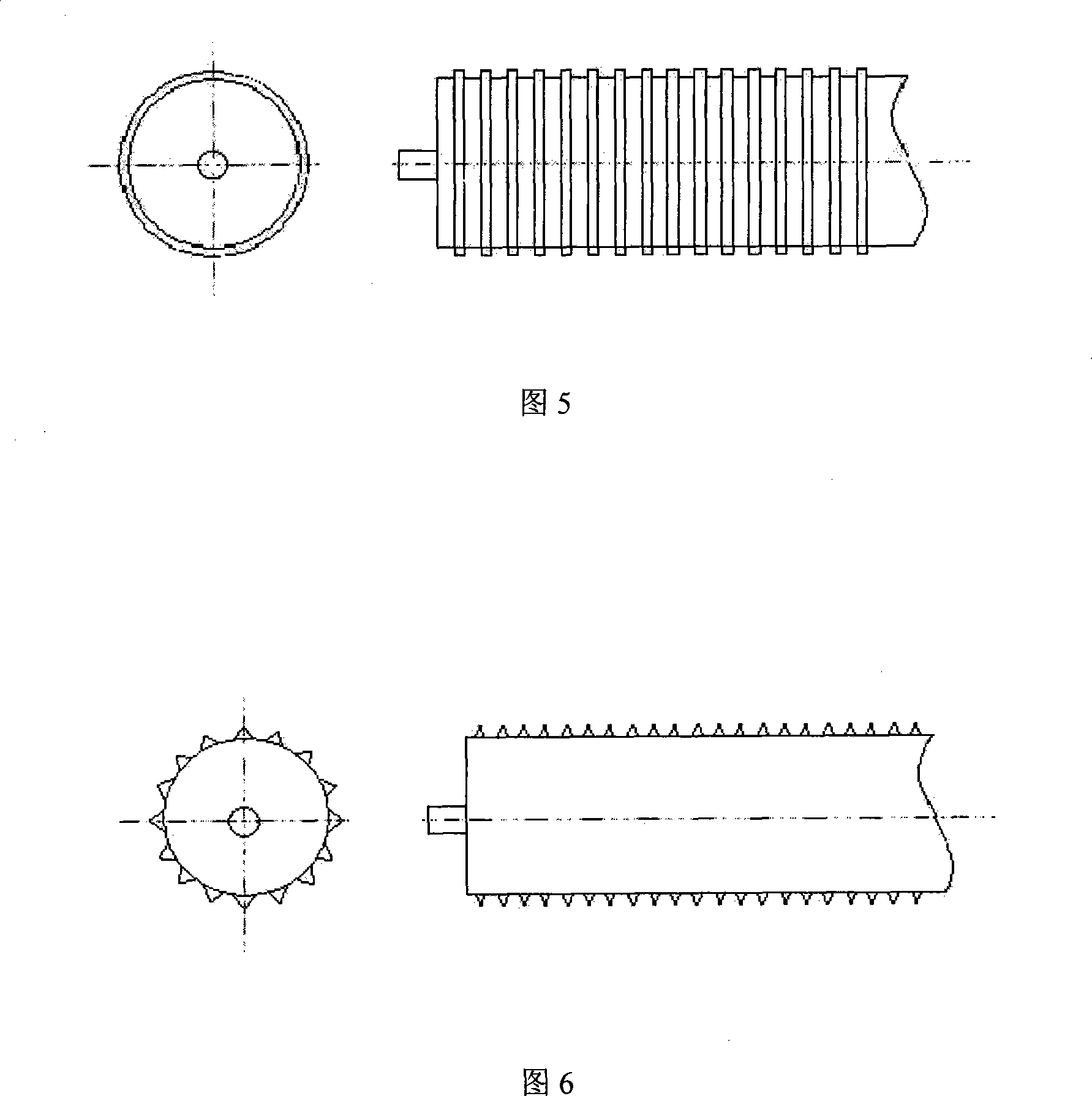

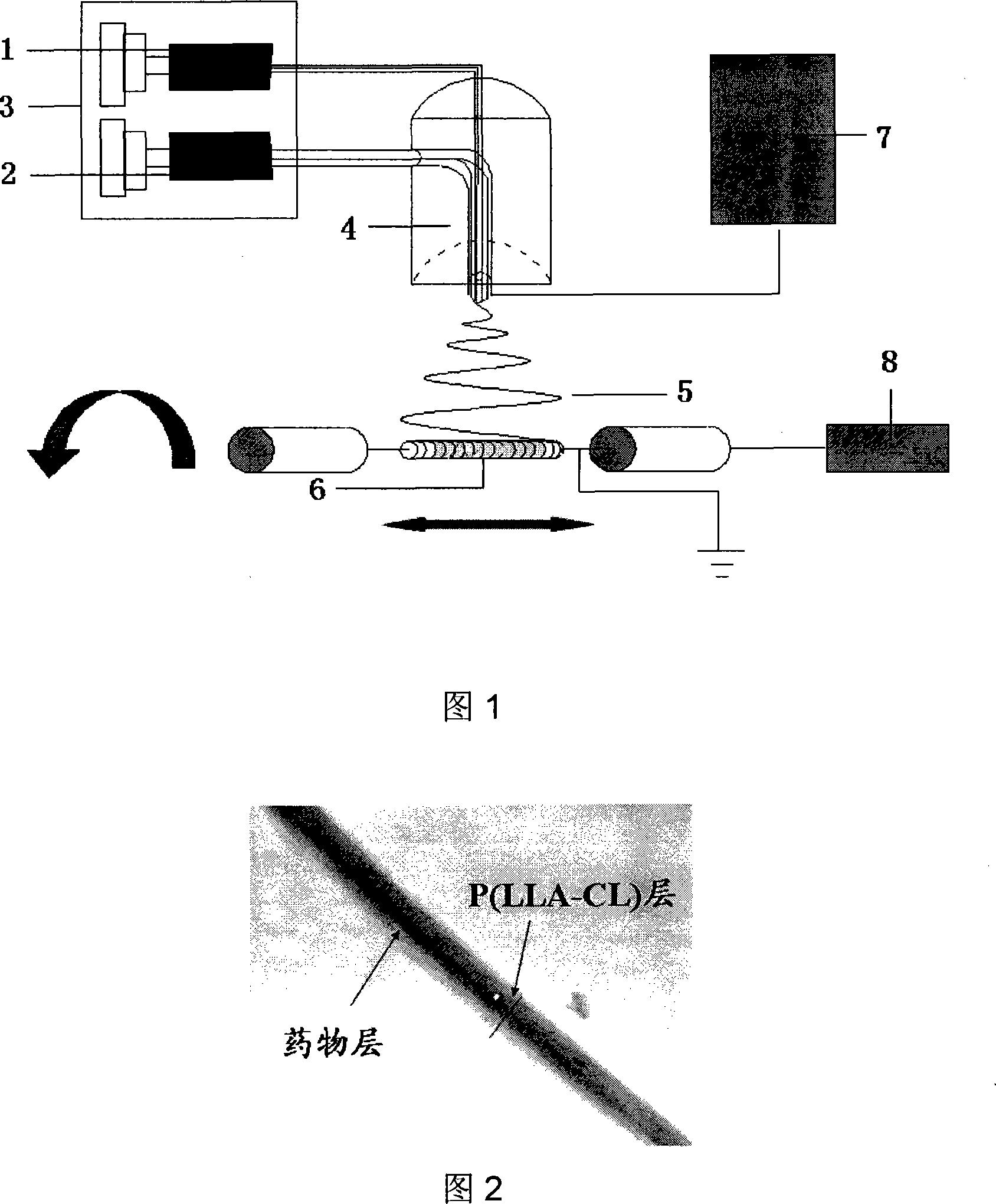

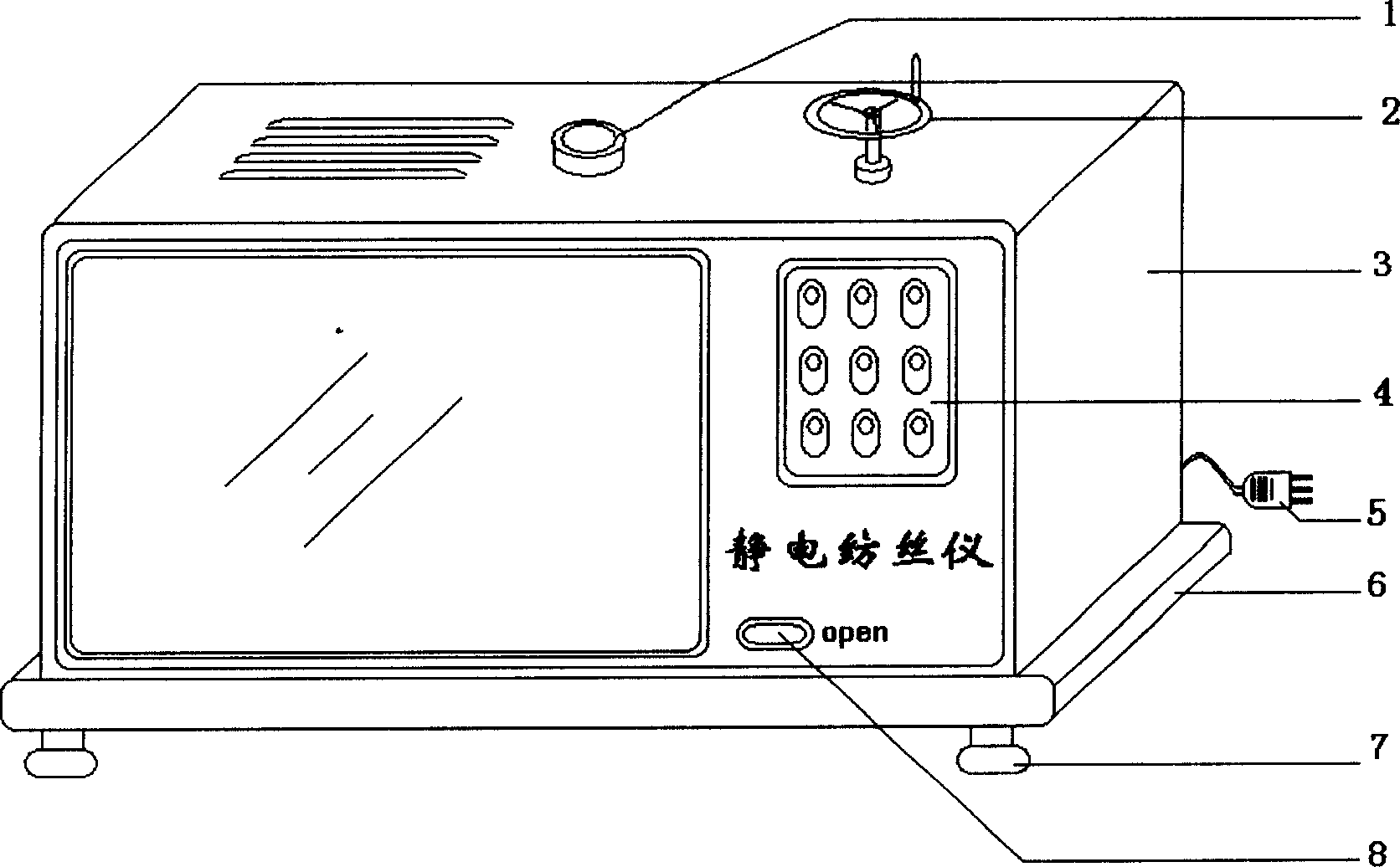

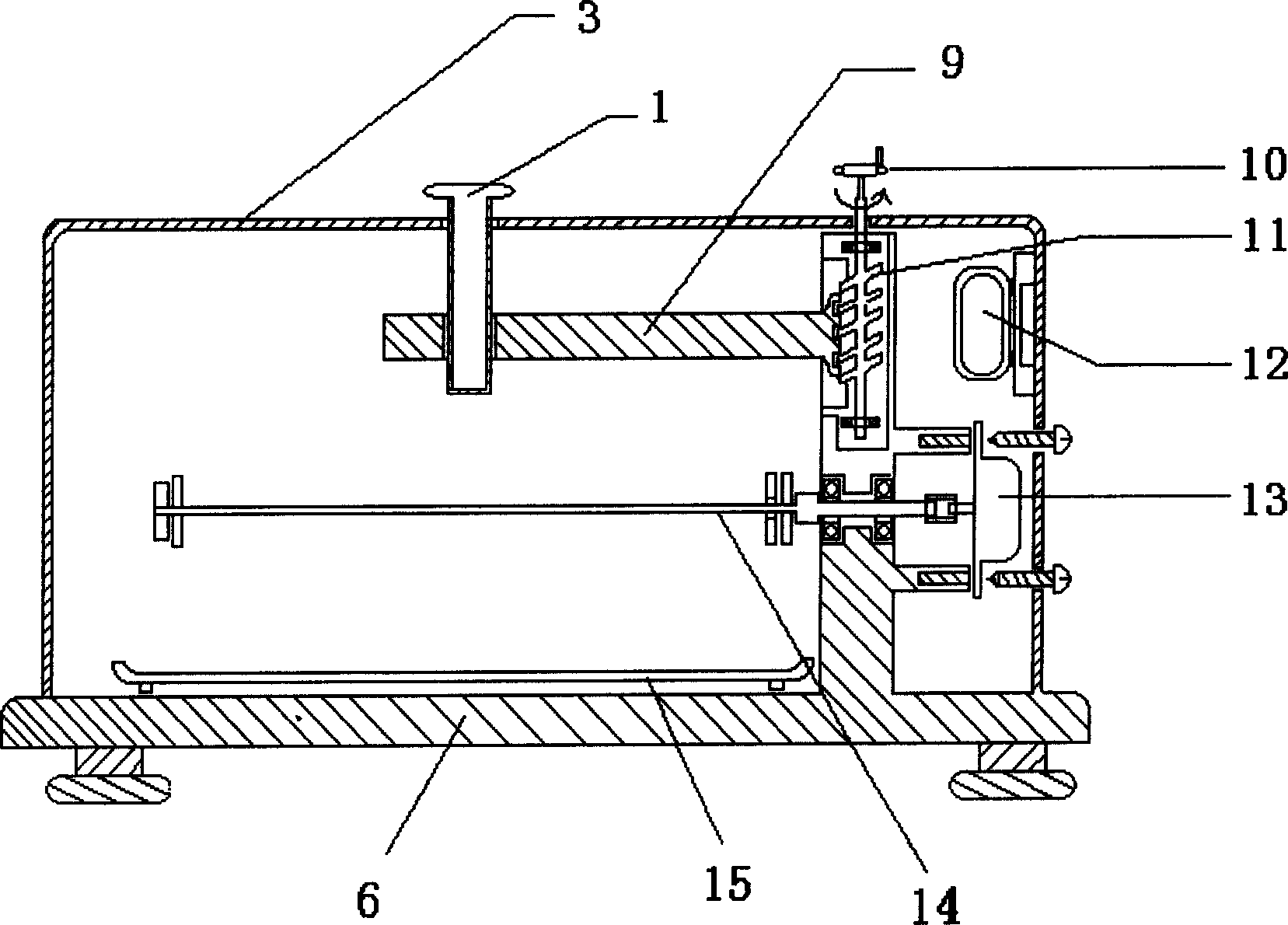

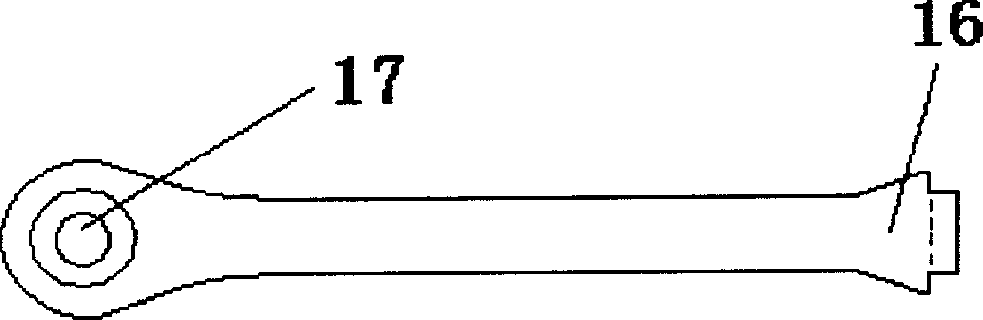

Jet type electrostatic spinning equipment capable of producing Nano fiber in bulk

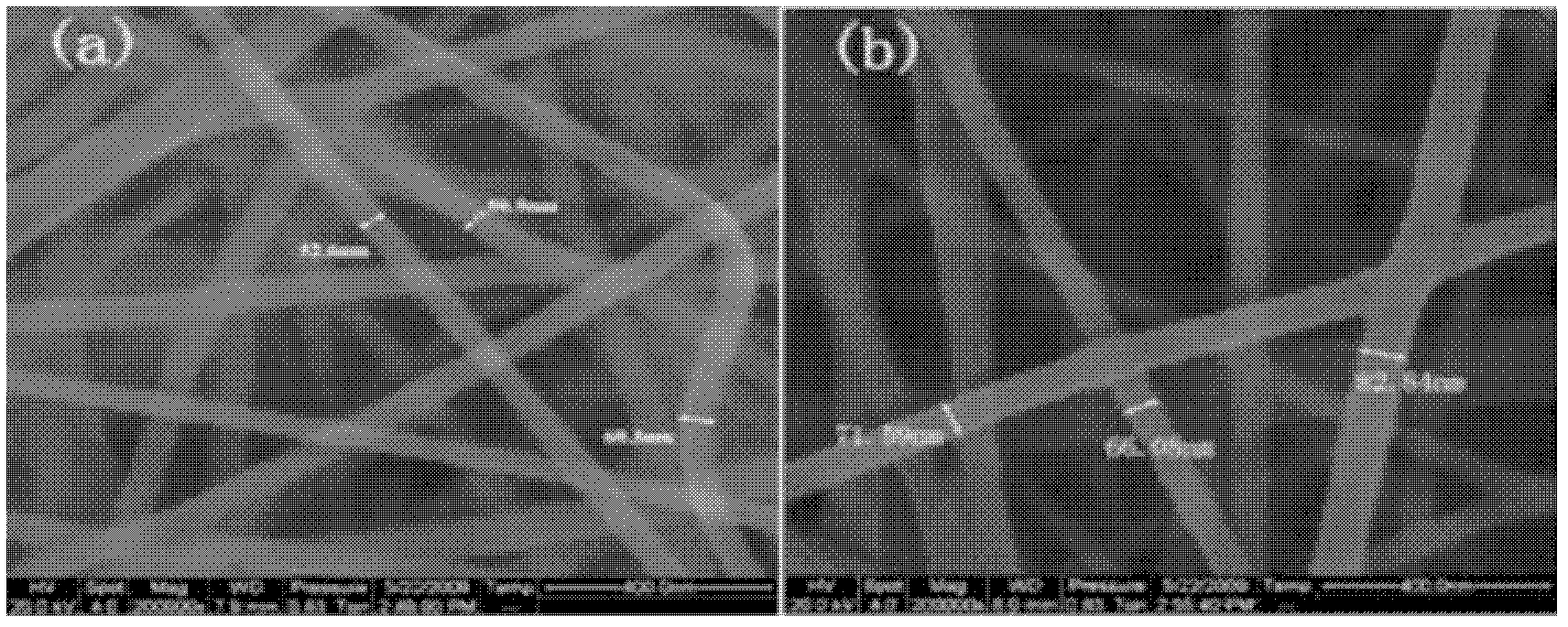

InactiveCN101003916AThe need for large-scale productionNo frequent replacementSpinnerette packsFilament/thread formingFiberHigh volume manufacturing

Owner:DONGHUA UNIV

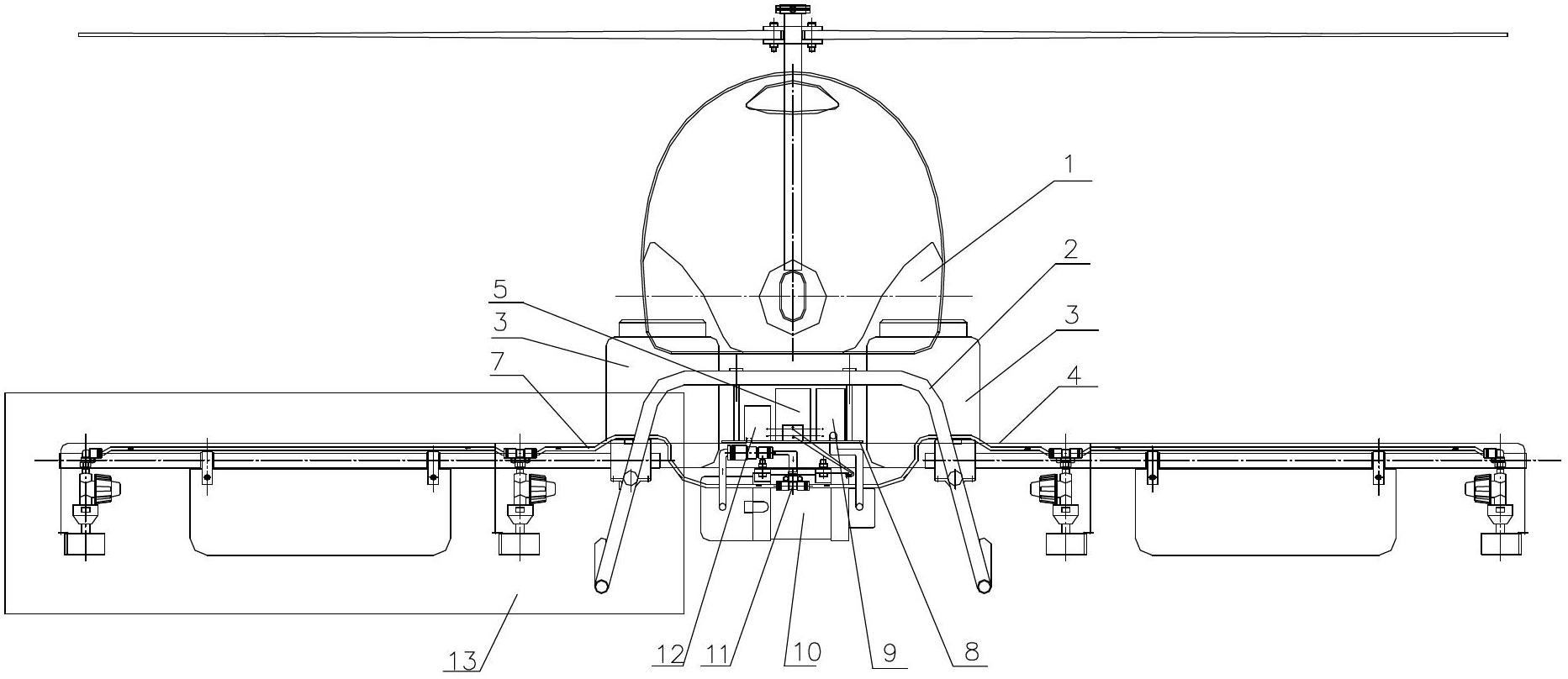

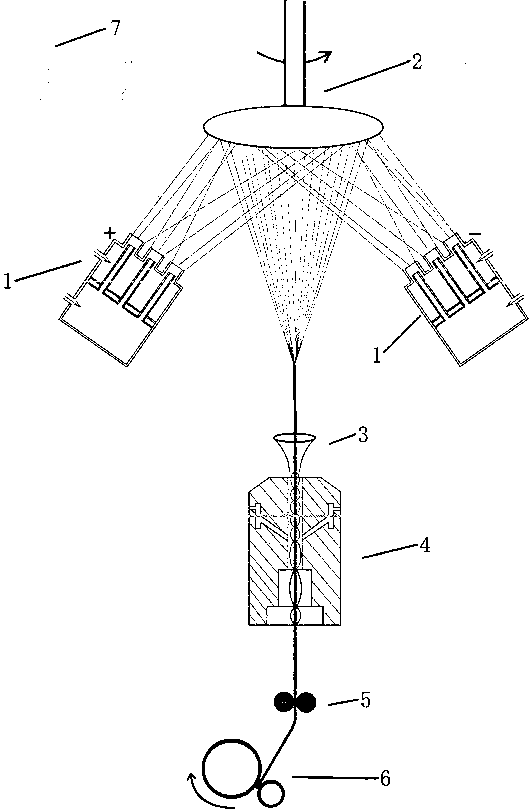

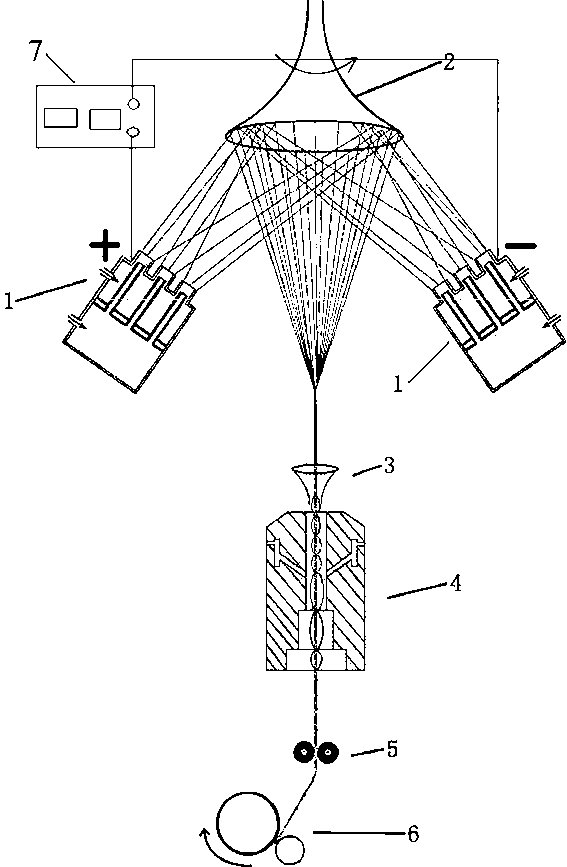

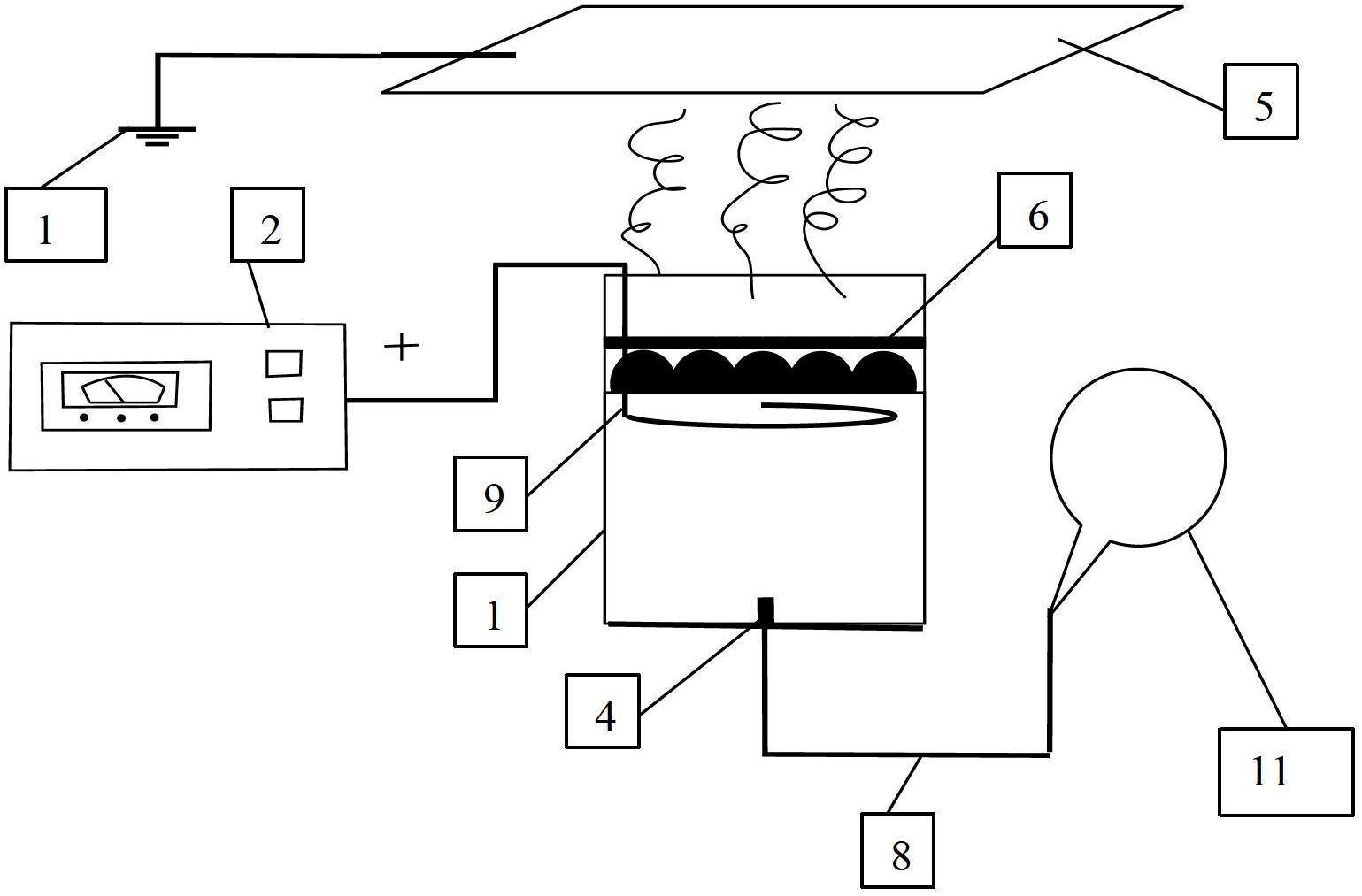

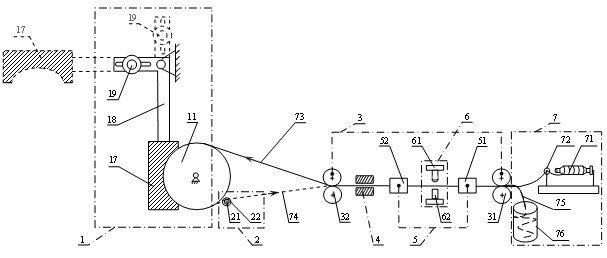

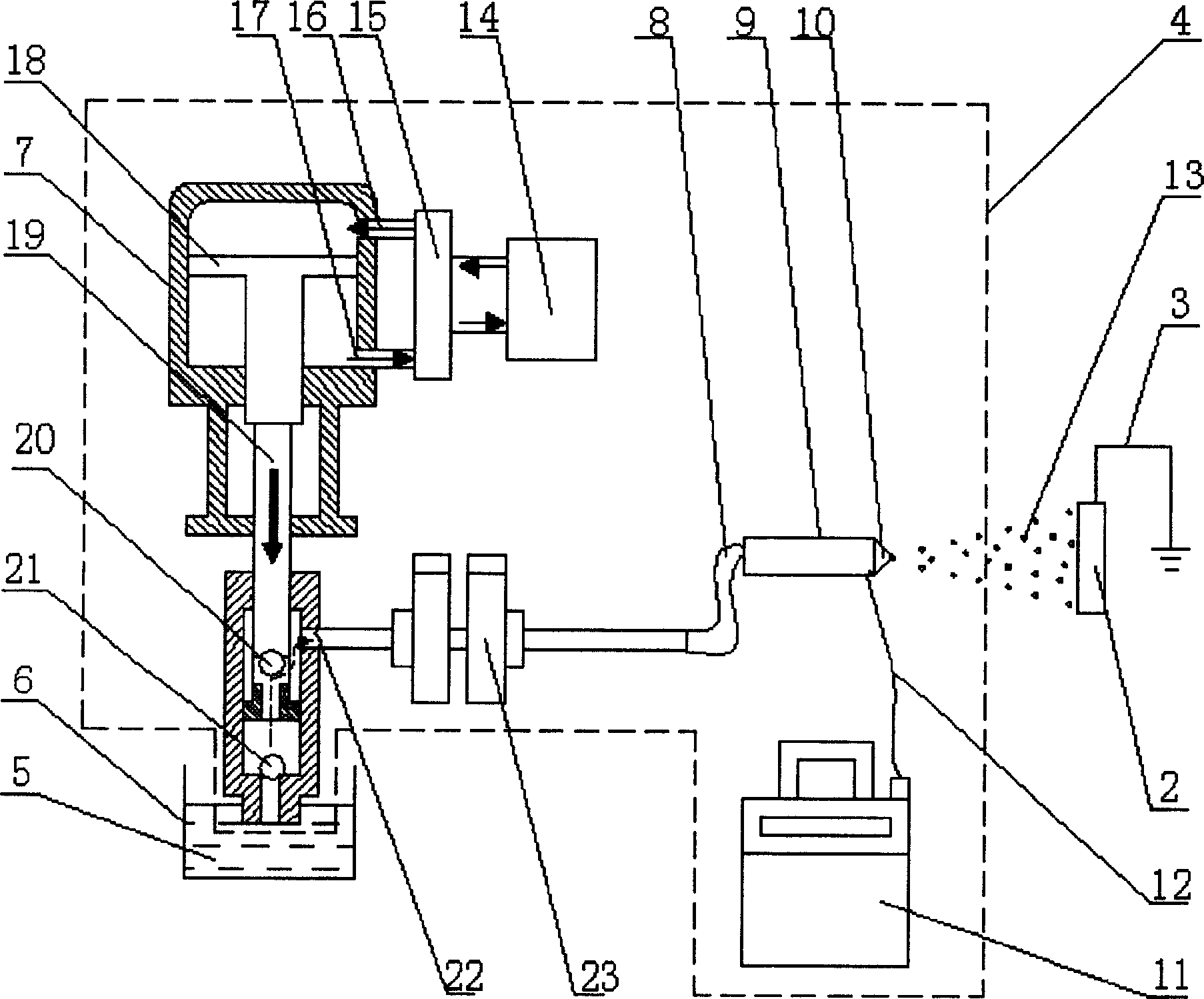

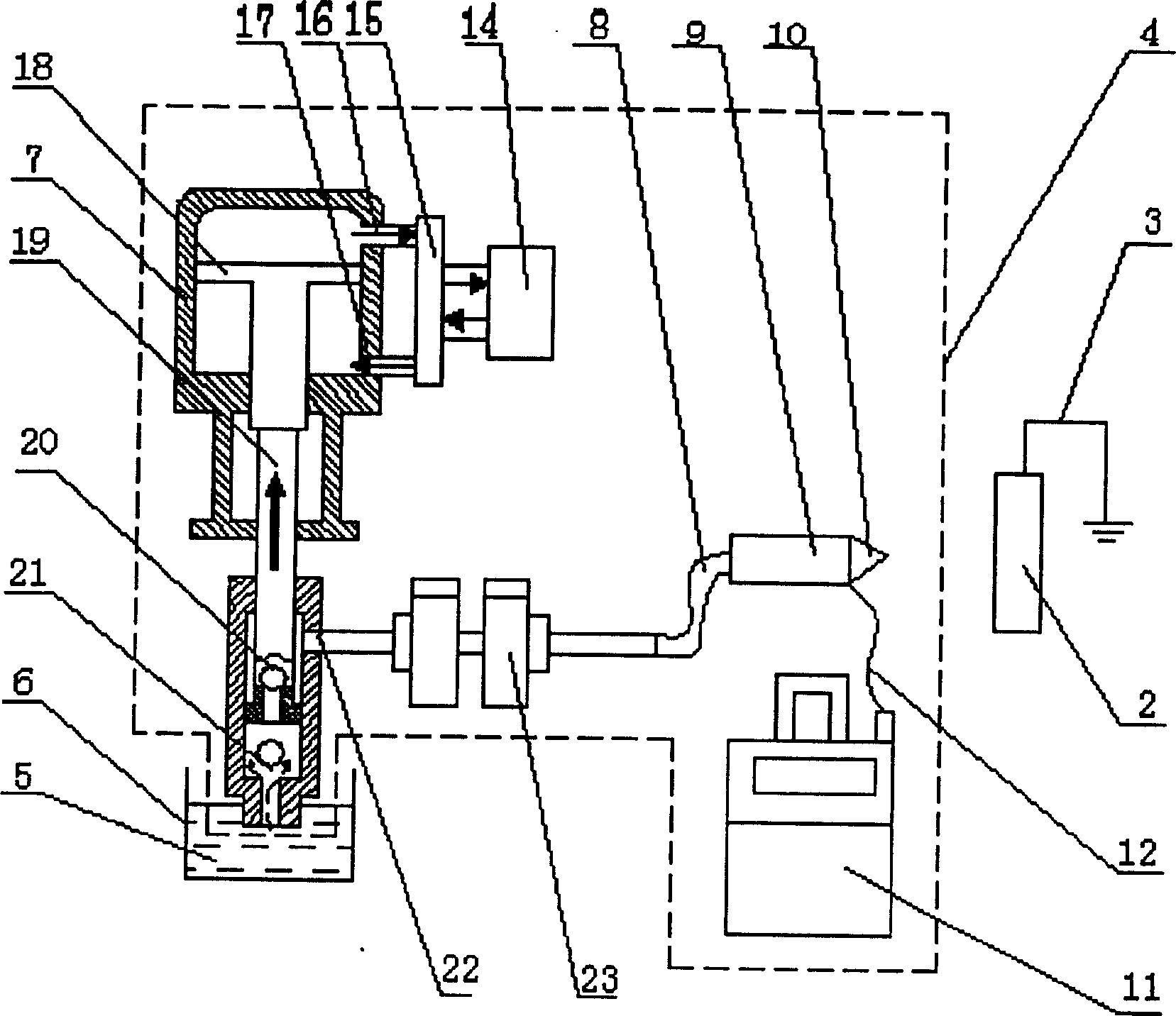

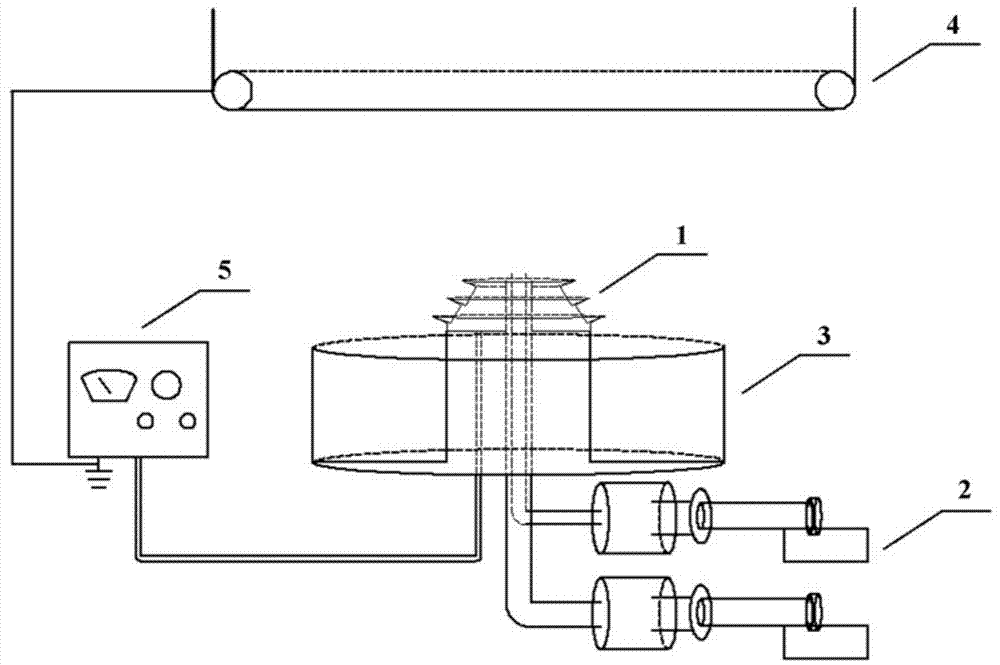

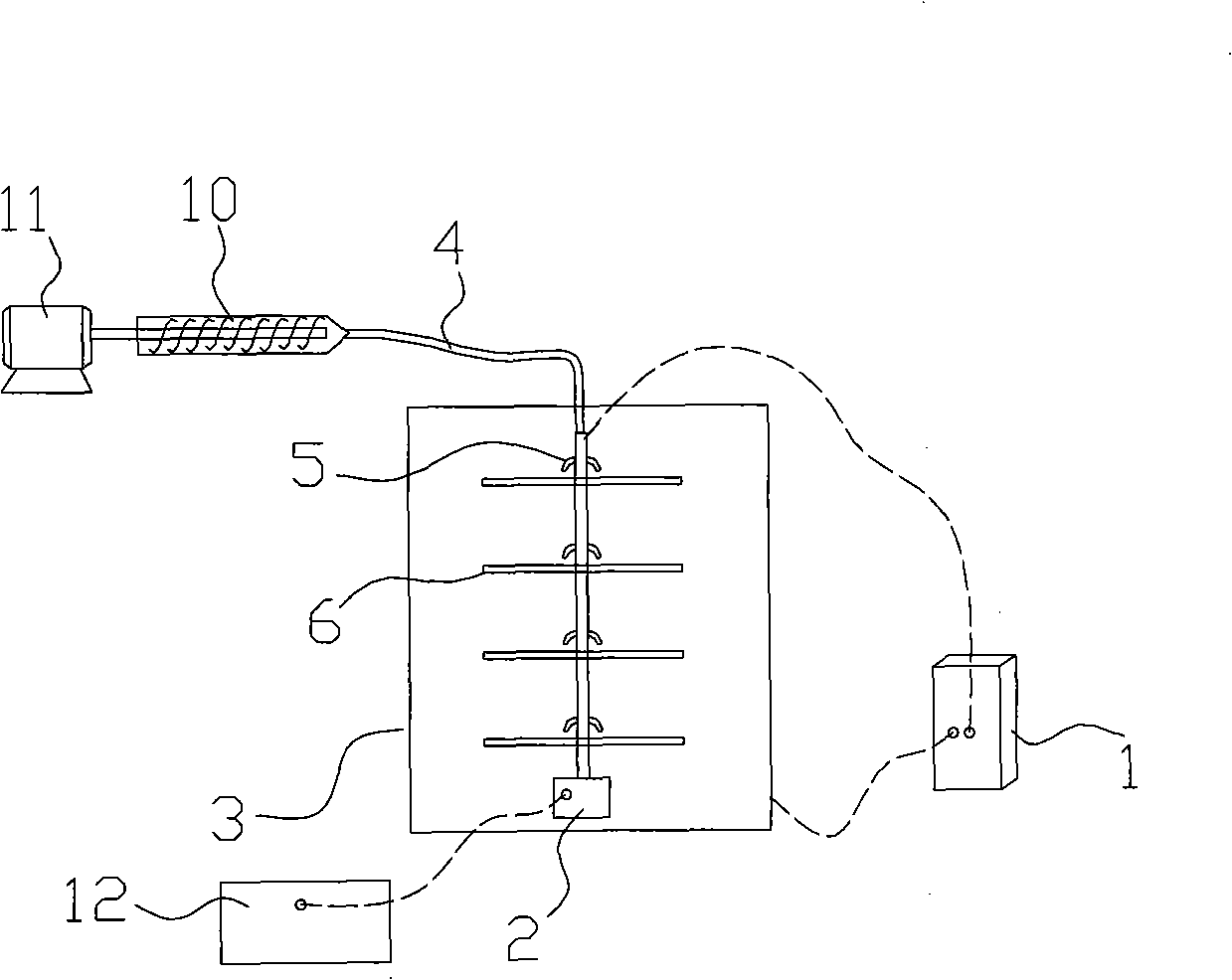

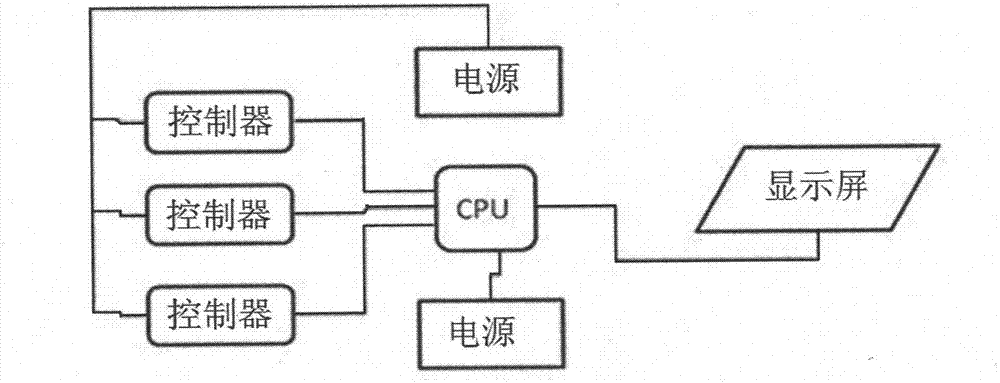

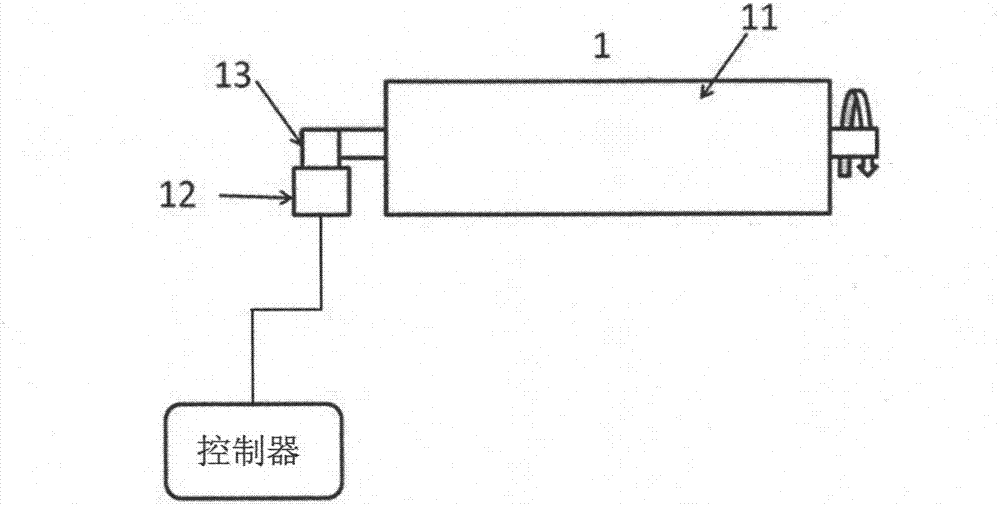

Electrostatic spraying type unmanned helicopter pesticide applying system

ActiveCN102687711ASmall particle sizeEvenly distributedAircraft componentsInsect catchers and killersDiaphragm pumpEngineering

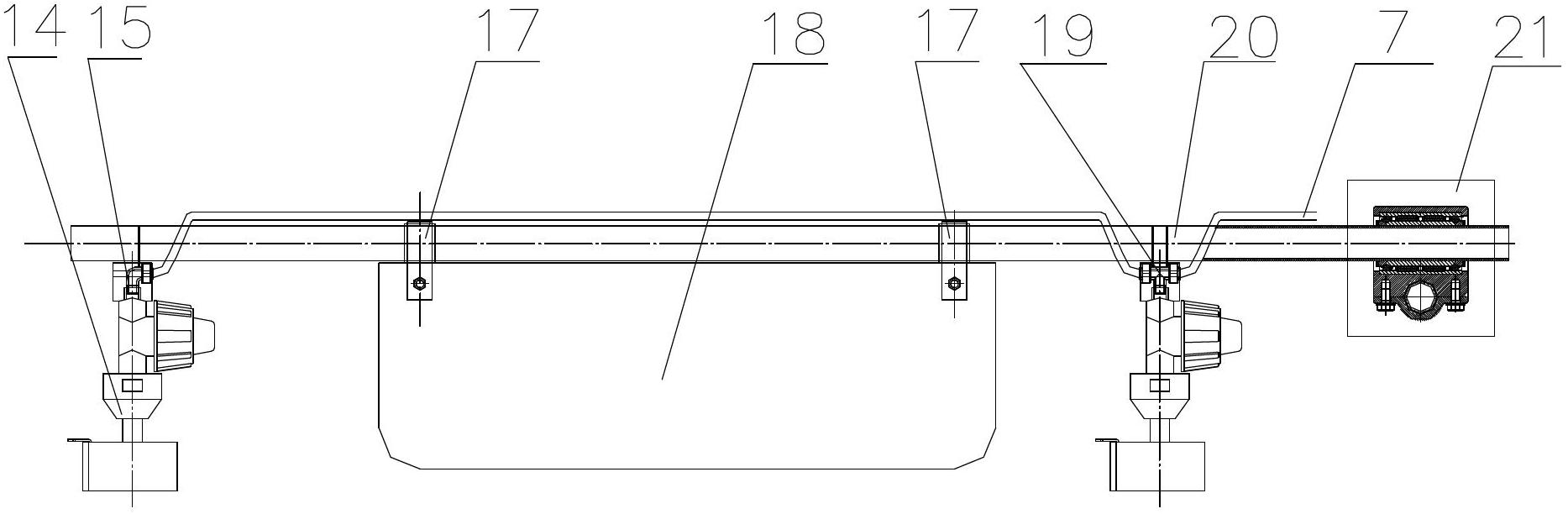

The invention discloses an electrostatic spraying type unmanned helicopter pesticide applying system. The system comprises an unmanned helicopter having a landing gear, a supporting frame, a storage battery, a high voltage electrostatic generator, an electric diaphragm pump, a pesticide box and two sets of electrostatic spraying devices, wherein the supporting frame and the landing gear are fixed; the storage battery, the high voltage electrostatic generator, the electric diaphragm pump and the pesticide box are fixed on the supporting frame; the electrostatic spraying devices are symmetrically arranged on both sides of the unmanned helicopter; and a liquid outlet of the pesticide box is communicated with a liquid inlet of the electric diaphragm pump, and a liquid outlet of the electric diaphragm pump is communicated with the liquid inlets of the electrostatic spraying devices by a tee joint respectively. The system has the advantages that the size of the sprayed charged droplets is quite small, so the droplets are high in deposition effect and uniformly distributed, in particularly, the droplets can be attached to the back surfaces of leaves of plants, the effective utilization rate of pesticide is guaranteed and the drift loss of pesticide is lowered; and the spraying amount can be remotely controlled, so the spraying amount of the system can be changed along with the change of the flying speed.

Owner:NANJING FORESTRY UNIV

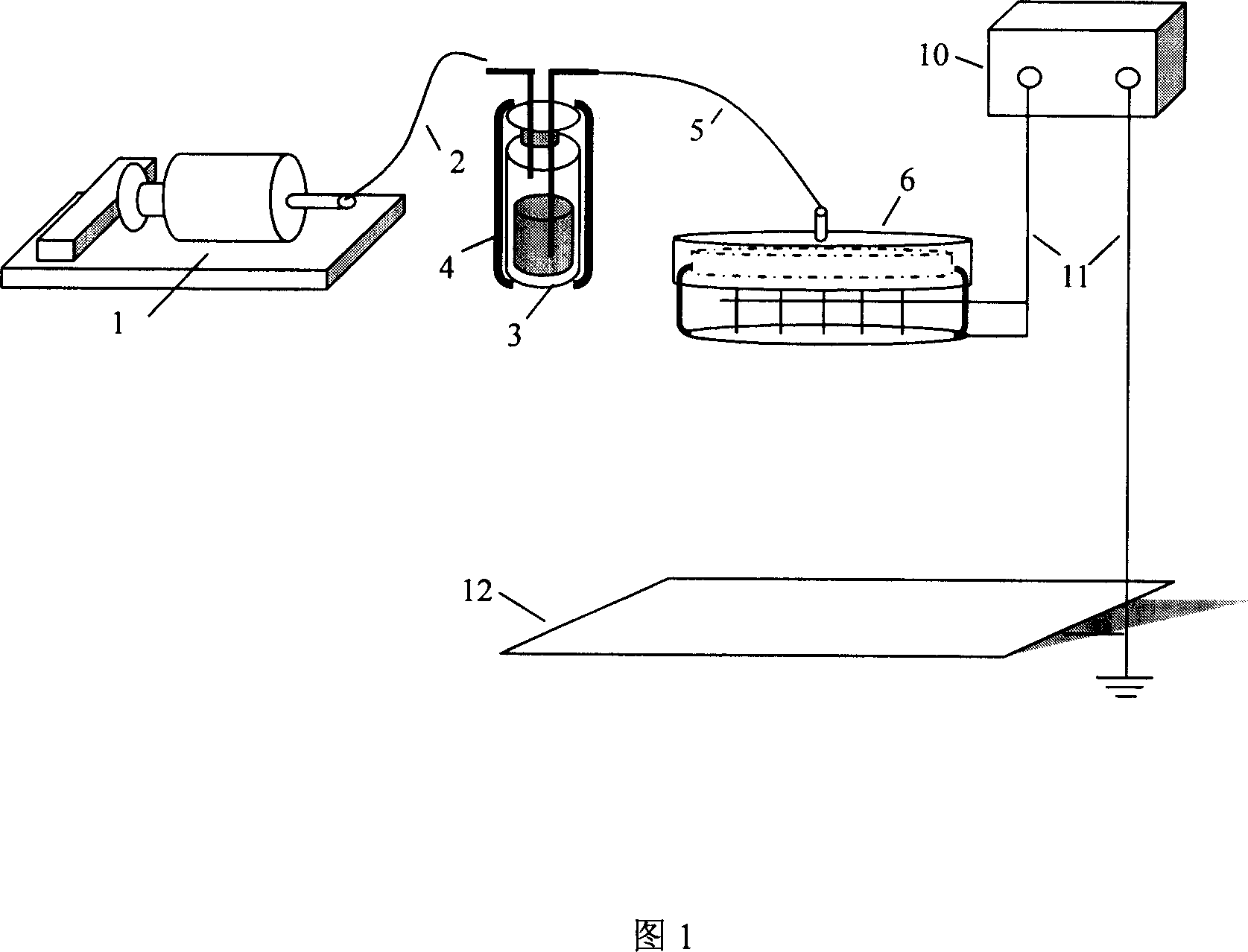

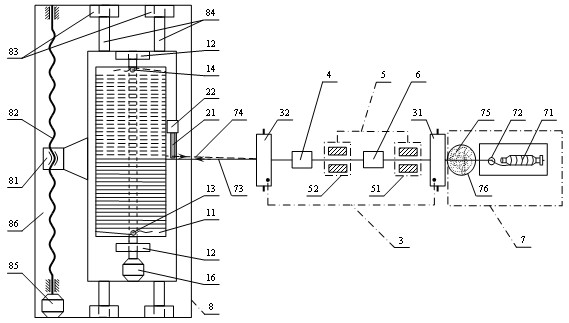

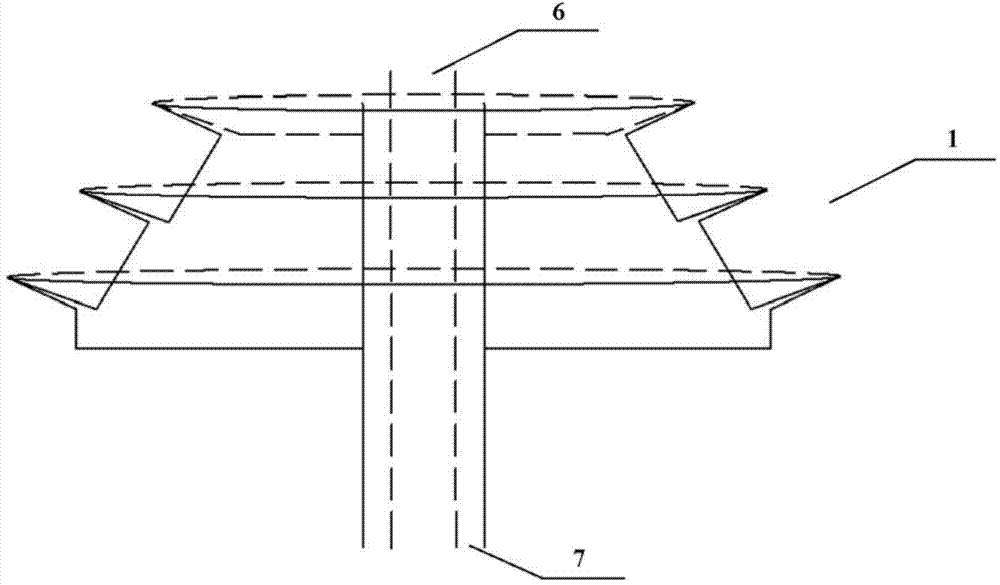

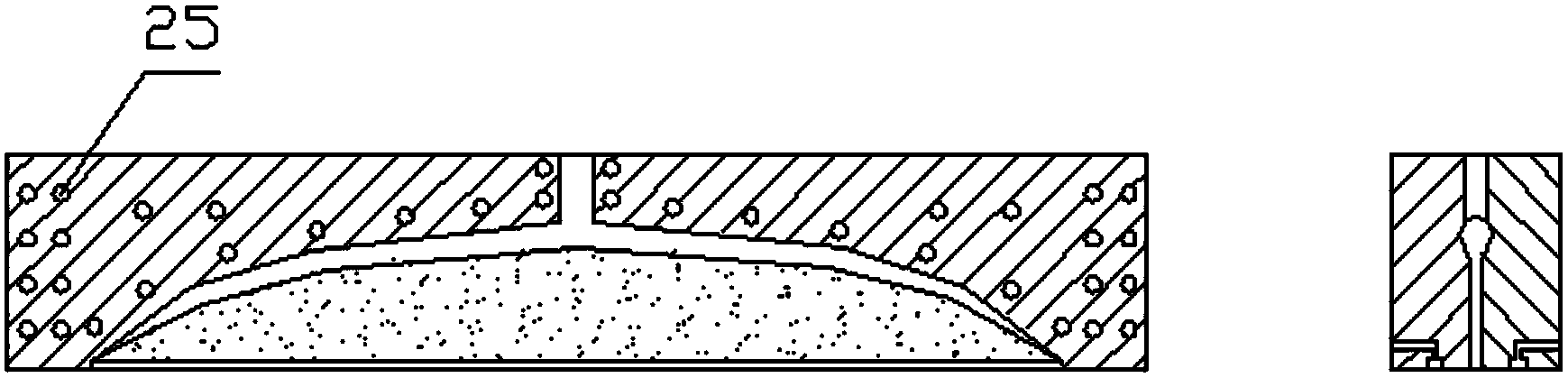

Vibrating electrostatic spinning device for nano fiber

InactiveCN1986913ANo frequent replacementNo need for frequent cleaningFilament/thread formingFiberElectrospinning

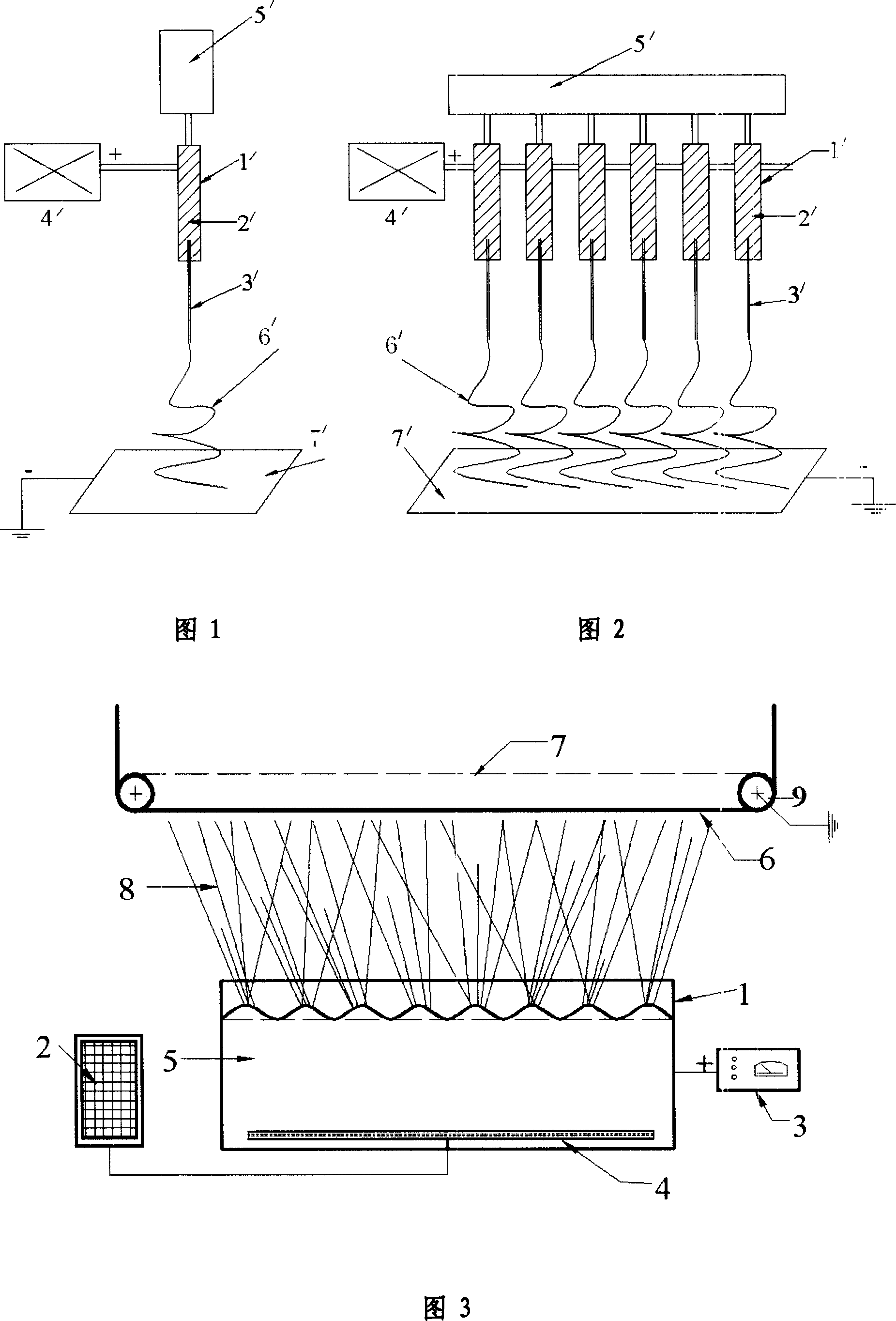

The vibrating electrostatic spinning set for nanometer fiber includes one container for holding spinning solution or melt, one high voltage electrostatic generator, one ultrasonic generator, and one piezoelectric sensor. The container is one cubic liquid storage tank with upper opening; and the piezoelectric sensor is set in the bottom of the tank and connected with the ultrasonic generator outside the tank. Over the liquid storage tank, there are one nanometer fiber conveyer and one nanometer fiber receiver, the conveyer includes guide roll, earthed electrode and conducting plate connected to the earthed electrode to form the negative pole; one electrostatic field is formed between the negative pole and the solution or melt inside the tank connected through electric plate to the high voltage electrostatic generator; and the receiver is one receiving screen. The present invention is used for producing nanometer fiber and has high production efficiency.

Owner:DONGHUA UNIV

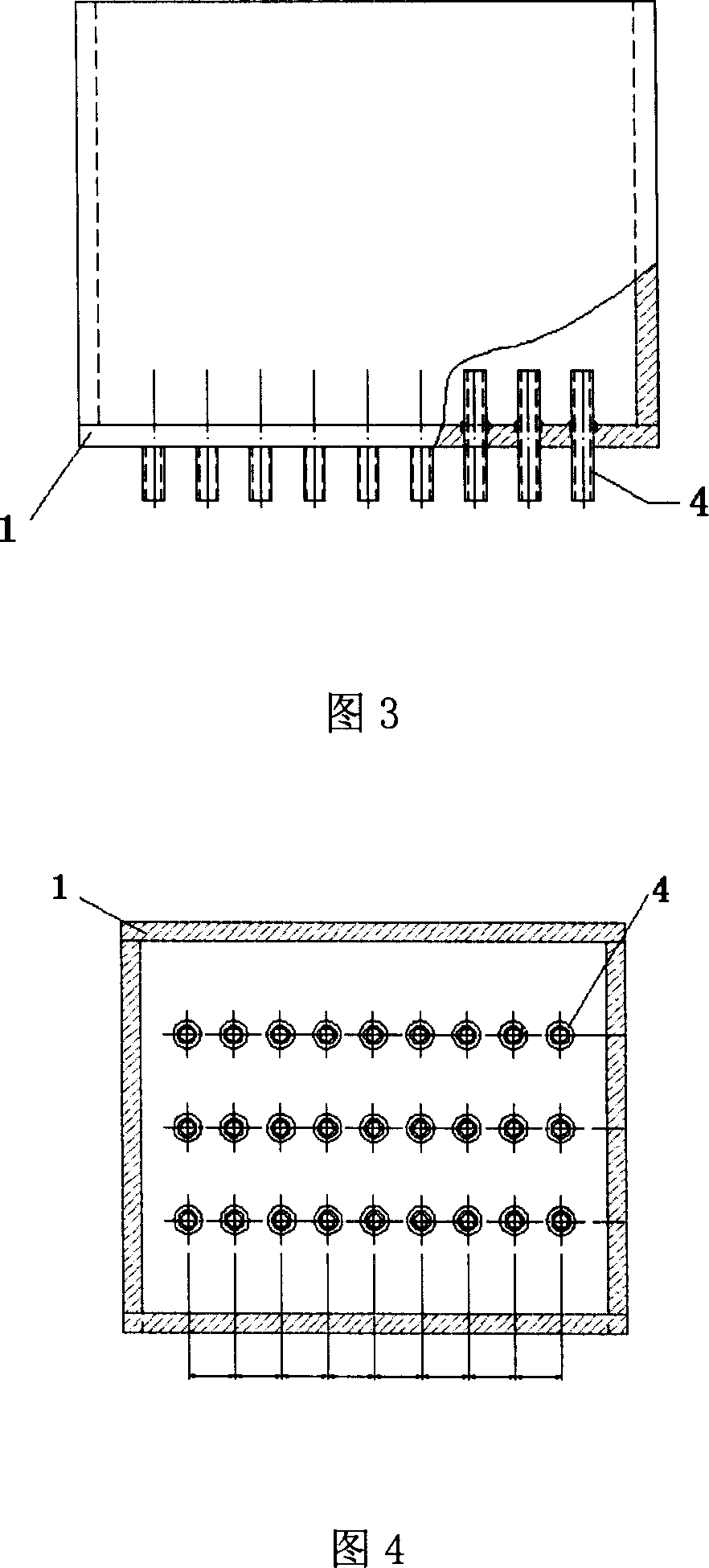

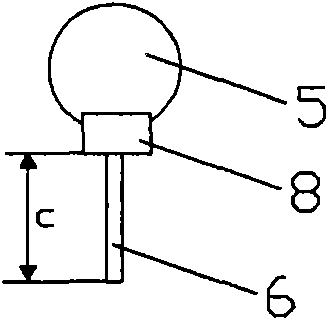

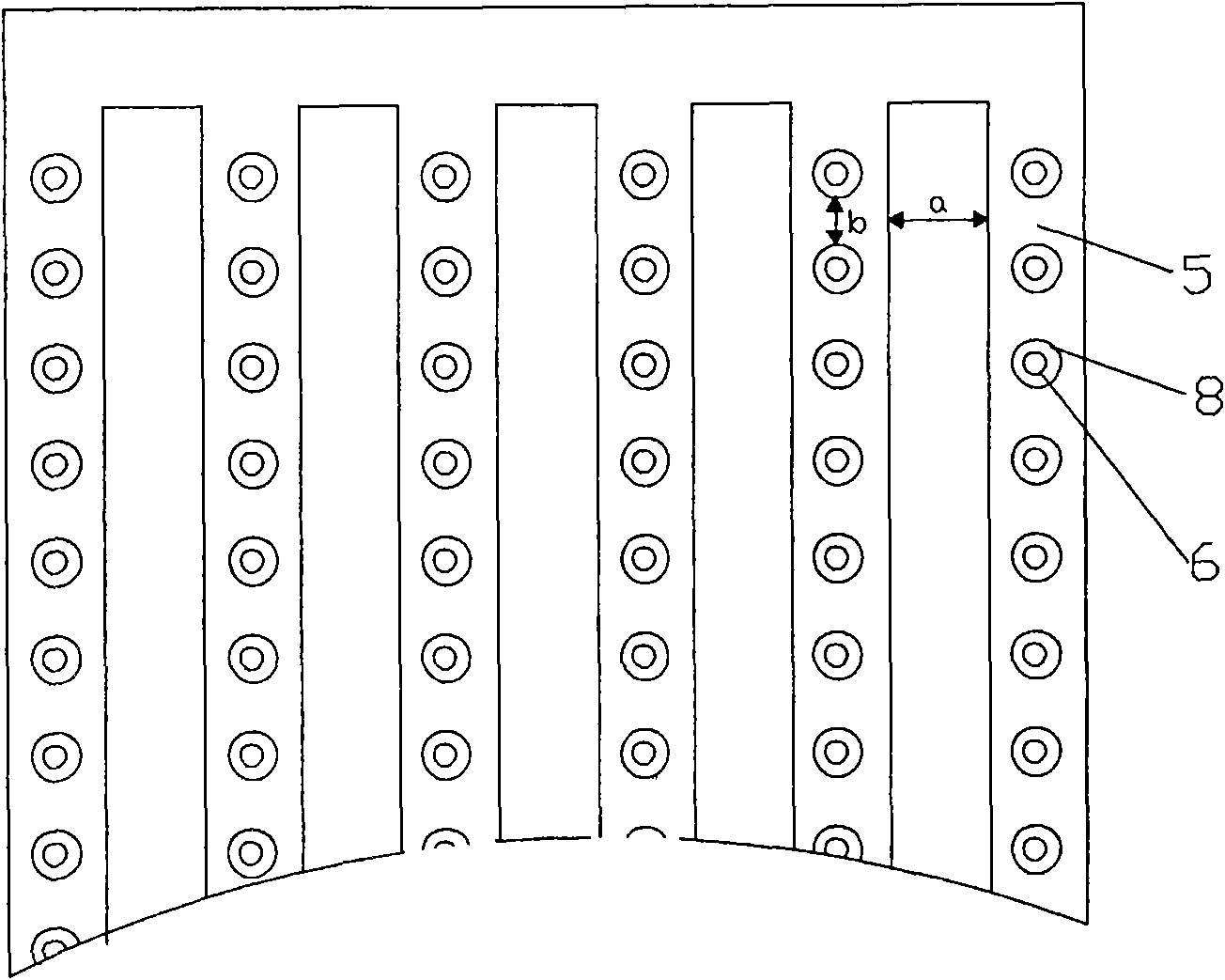

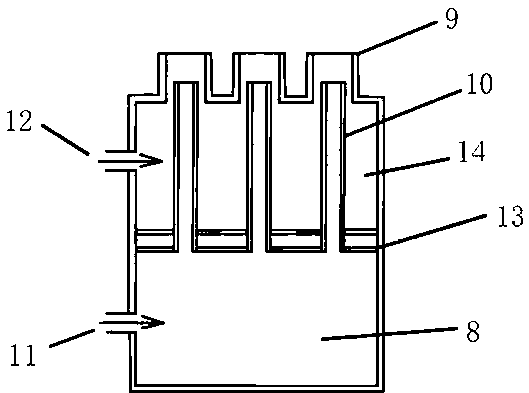

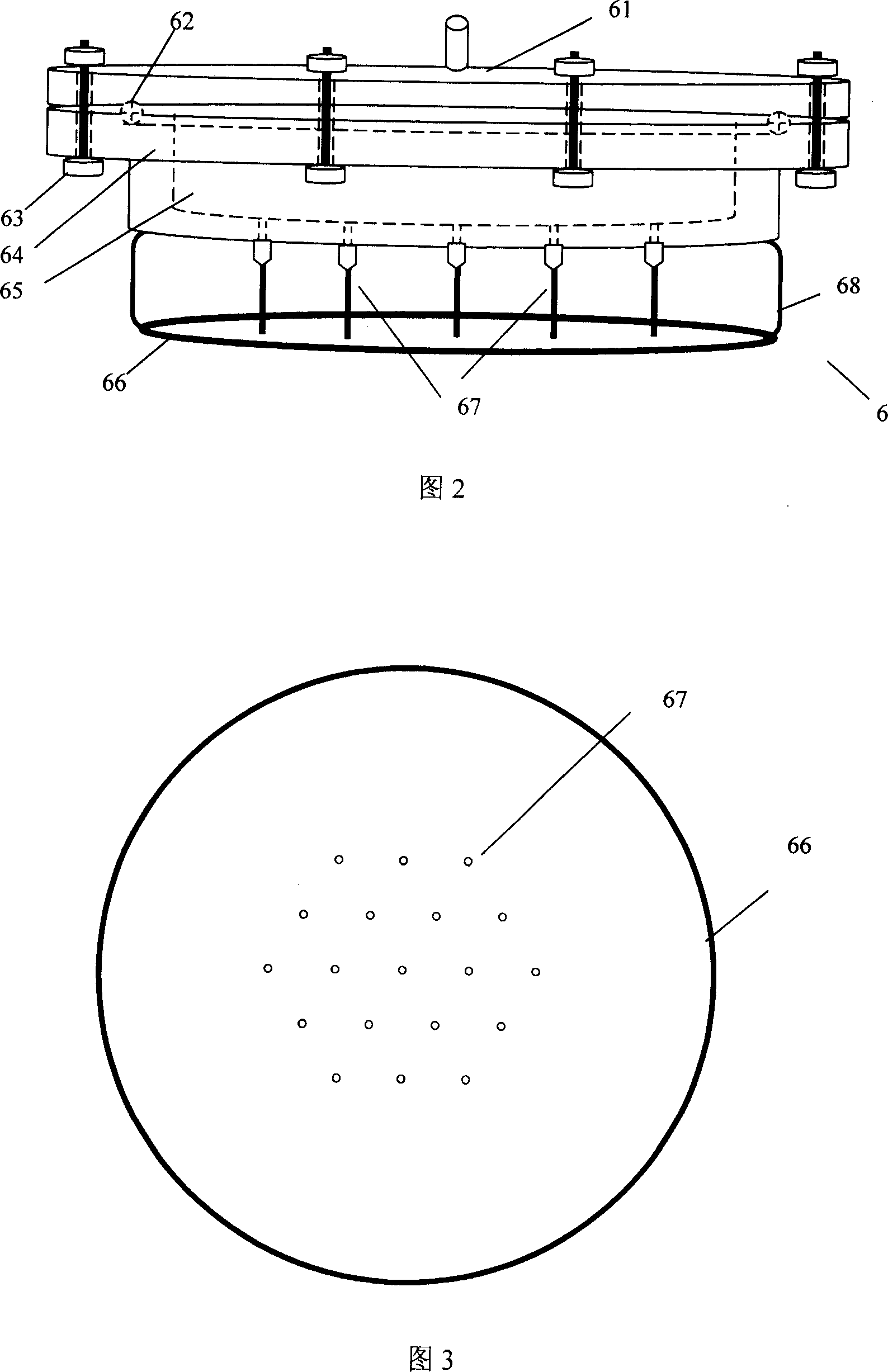

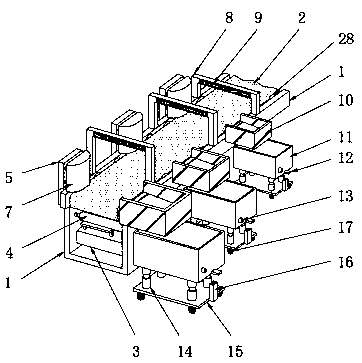

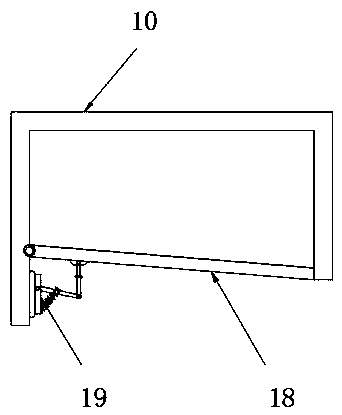

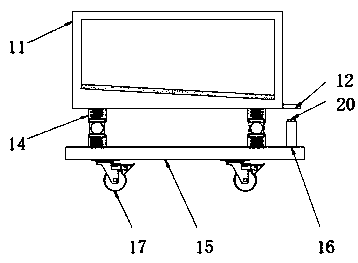

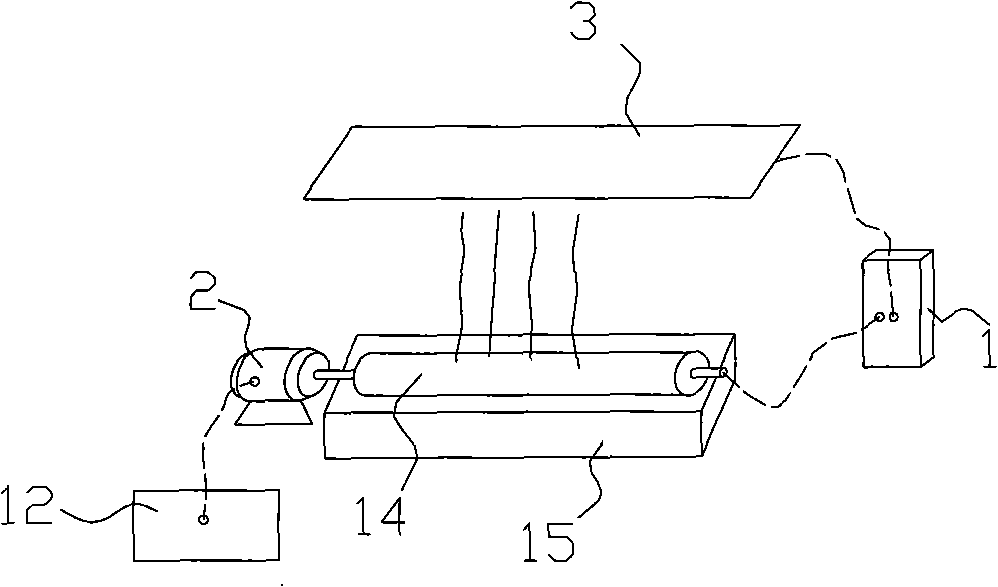

Array multi-nozzle electrospinning device

InactiveCN101586288ARealize mass productionEasy to disassembleArtificial thread manufacturing machinesFilament/thread formingFiberEngineering

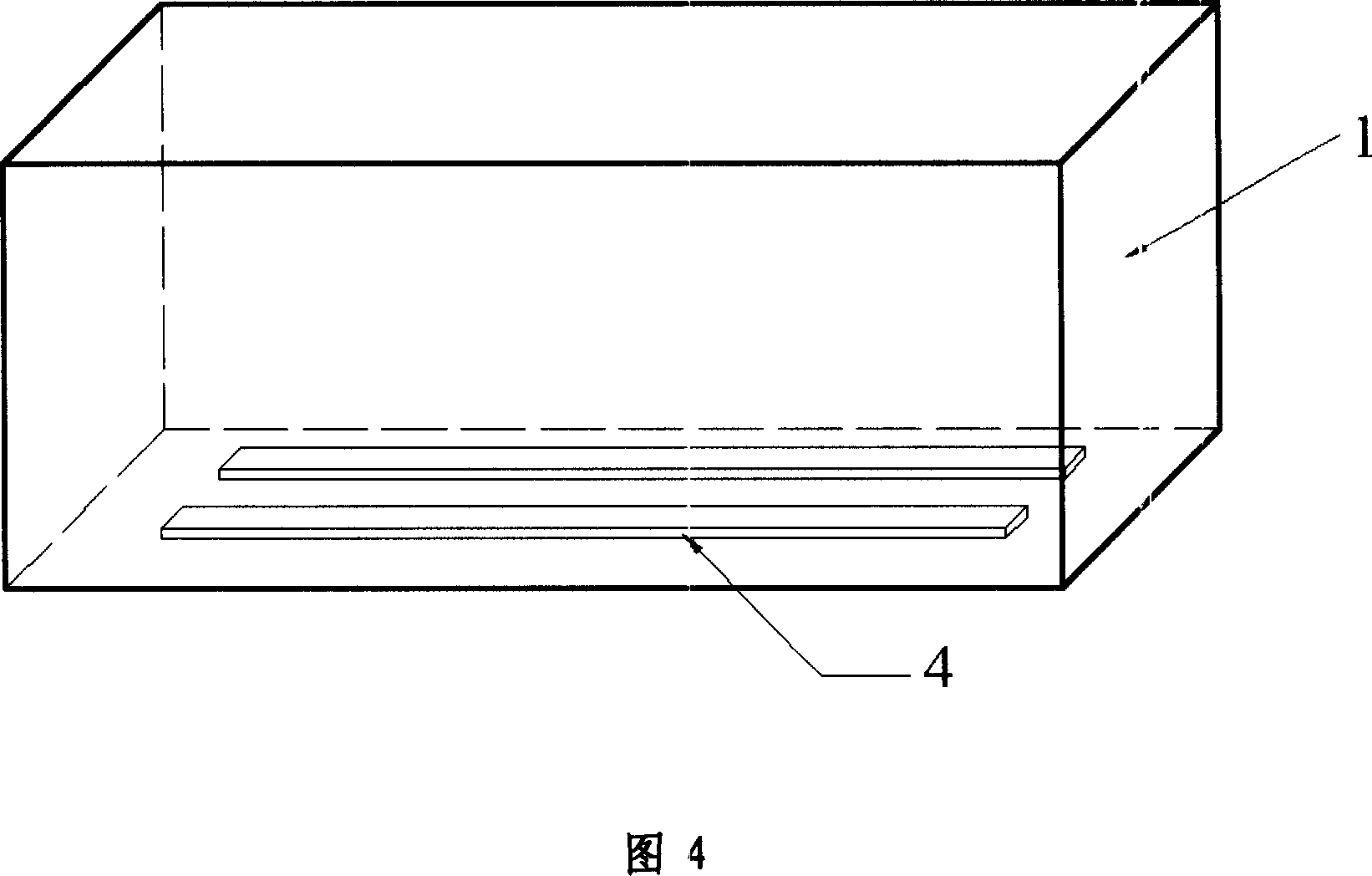

The present invention discloses an array multi-nozzle electrospinning device, including an electrospinning liquid supply apparatus, an electrospinning liquid spinning apparatus, a receiving electrode plate, an electrospun fiber transport apparatus and a high voltage electrostatic generator, the electrospinning liquid spinning apparatus includes effusers and nozzles, the nozzles are array-arranged; the electrospun fiber transport apparatus includes a feed roller apparatus and a discharge roller apparatus disposed on two ends of the receiving electrode plate respectively; the electrospun fiber receiving material is transported to the space between the electrospinning liquid spinning apparatus and the receiving electrode plate by the feed roller apparatus, and the discharge roller apparatus transports the received electrospun fiber out; the invention provided device can produce electrospun fiber membrane in large scale, and can produce both single polymer electrospun fiber membrane and multiple polymers blended layered electrospun fiber membrane for one time, and can obtain a electrospun fiber membrane with specific topological pattern by changing electrospun fiber receiving material conveniently, which satisfies various application requirements of electrospun fiber materials.

Owner:JIANGSU CHANGJIYONG BIOTECH CO LTD

Preparation method of fibrous membrane with super hydrophobic multi-stage nanometer structure

InactiveCN101928996AImprove hydrophobicitySimple processFilament/thread formingSpinning solutions preparationFiberHydrophobic polymer

The invention provides a preparation method of fibrous membrane with a super hydrophobic multi-stage nanometer structure, which is characterized by comprising the following specific steps: 1, at room temperature, adding hydrophobic polymer and hydrophobic inorganic nanoparticles into a sealed container filled with solvent, putting the sealed container on a magnetic stirrer to stir at the revolving speed of 10-200 rpm, and obtaining solution with even property; 2, at room temperature, inputting solution obtained in step 1 onto a spinning nozzle at constant flow velocity; connecting the spinning nozzle to a high voltage static generator to carry out electrostatic spinning; and receiving spun fiber by a receiver to obtain the fibrous membrane with super hydrophobic multi-stage nanometer structure. The invention can drastically improve the hydrophobic performance of the fibrous membrane.

Owner:DONGHUA UNIV

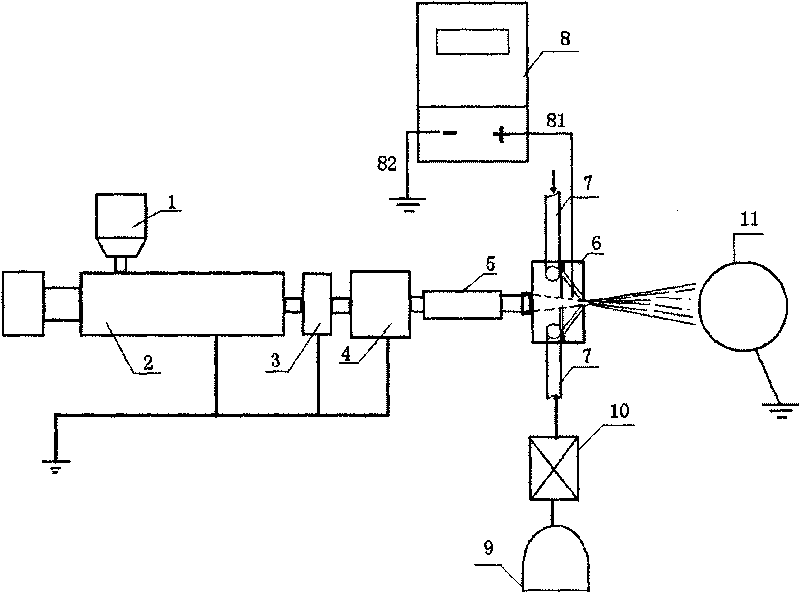

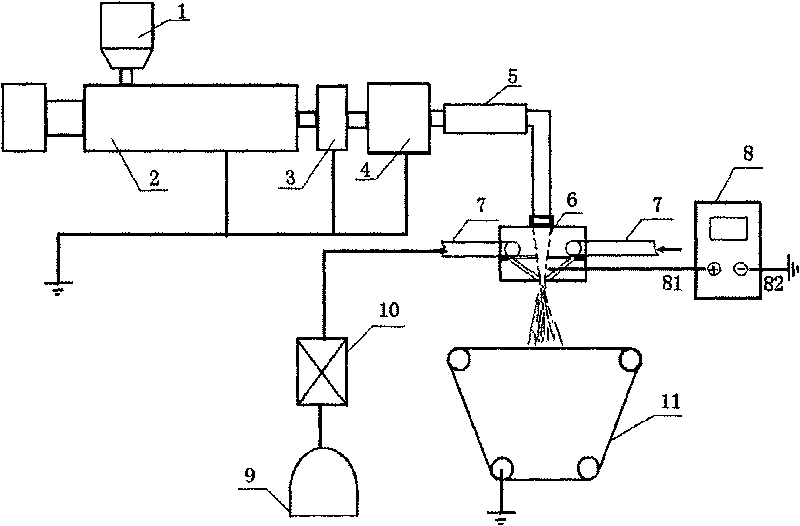

Device and method for manufacturing airflow melting electrostatic spinning nano-fiber non-woven fabric

InactiveCN101709534AThin diameterNarrow distributionSpinnerette packsSpinning head liquid feederFiberManufacturing technology

The invention relates to a device and a method for manufacturing an airflow melting electrostatic spinning nano-fiber non-woven fabric. The device for manufacturing the airflow melting electrostatic spinning nano-fiber non-woven fabric comprises a stock hoper, a screw extruder, a filter, a metering pump, a material path, a melt-blown die head, a hot-air pipeline, an air compressor, a heating device, a high voltage electrostatic generator and a receiving device. The material path is made of high thermal conductivity insulating ceramics. The method for manufacturing the nano-fiber non-woven fabric adopts the device disclosed by the invention and comprises the following processing steps: (1) preparing a polymer melt; (2) jetting nano-fibers by using airflow static electricity; and (3) moulding the non-woven fabric. The method for manufacturing the nano-fiber non-woven fabric of the invention adopts airflow-melting electrostatic spinning technology, avoids a problem of pollution of electrostatic spinning solvent, and is novel environment-friendly non-woven fabric manufacturing technology. In the manufacturing method, high voltage electrostatic is directly acted on the melt-blown die head; the melt has high and uniform charge; and simultaneously by utilizing drafting of the airflow, the prepared nano-fiber has the advantages of thin diameter and narrow distribution. The device can meet production requirements by improving the conventional melt-blown manufacturing device, and has low implementation cost and easy industrialization promotion.

Owner:TIANJIN POLYTECHNIC UNIV

Jet yarn spinning device for electrostatic spun nano fiber and preparing method

InactiveCN102703998AIncrease productionReduce volatilitySpinnerette packsFilament/thread formingYarnNanofiber

The invention discloses a jet yarn spinning device for an electrostatic spun nano fiber, which includes a collecting device, wherein two thread jetting devices are arranged on the two sides of the collecting device and connected with a high-voltage electrostatic generator; a buncher is arranged below the collecting device; the two thread jetting devices are arranged between the collecting device and the buncher and symmetrically and oppositely arranged along the axis; a jet nozzle twister is arranged below the buncher; a delivery roller is arranged below the jet nozzle twister; a winding mechanism is arranged below the delivery roller; and the collecting device, the buncher, the jet nozzle twister and the delivery roller are arranged along the same axis from top to bottom. The electrostatic spun nano fiber spinning device integrates thread jetting, collecting, drawing, twisting and winding, and can continuously prepare the electrostatic spun nano fiber yarns. The nano fiber spinning method has simple process, high yarn yield, is suitable for multiple polymer yarn solutions, and realizes the continuous and scaled preparation of the nano fiber yarns.

Owner:ZHONGYUAN ENGINEERING COLLEGE

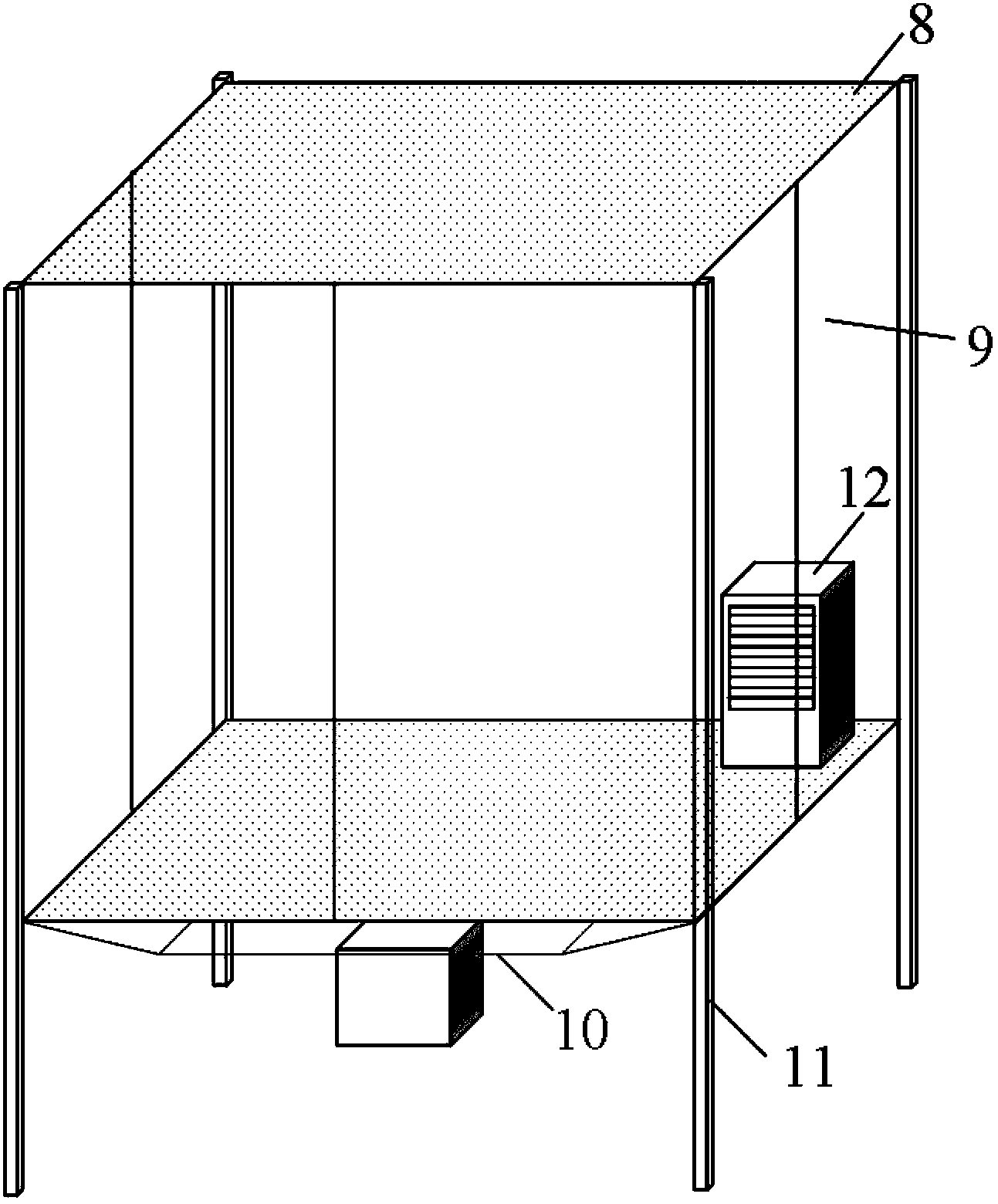

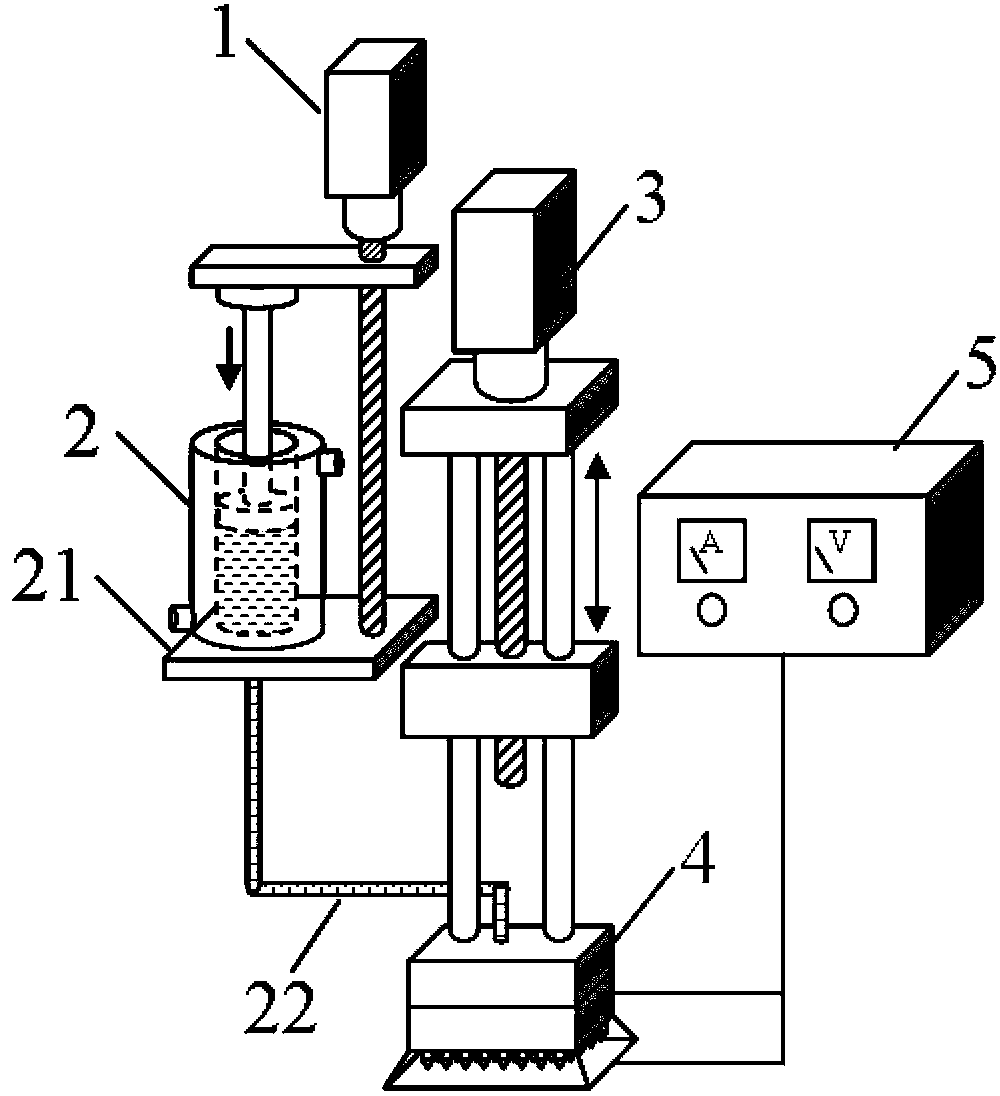

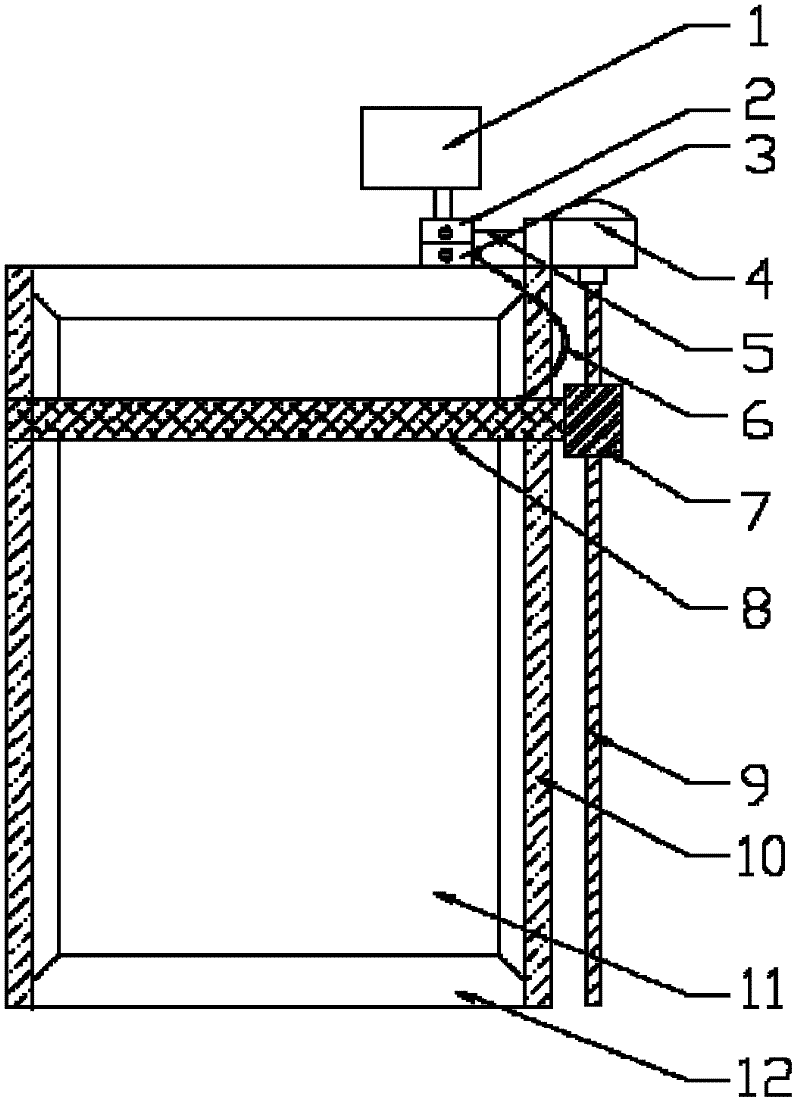

Multi-spraying-nozzle electrostatic spinning device with controllable spinning environment

InactiveCN103409818AControl impactImprove spinning efficiencySpinnerette packsFilament/thread formingFiberElectrospinning

The invention relates to a multi-spraying-nozzle electrostatic spinning device with the controllable spinning environment. The multi-spraying-nozzle electrostatic spinning device comprises a spinning environment control unit, an electrostatic spinning unit and a spinning connecting unit. An air current stabilization cover is arranged on the top of a spinning box body; an air suction and solvent recovery device is arranged at the bottom of the spinning box body; a constant-temperature and constant-humidity system is arranged in the spinning box body; a spinning liquid material barrel, a micro spinning solvent propelling device, a material barrel fixing support and an electrostatic generator are installed on the top of the spinning box body; the spinning solvent in the material barrel enters a three-dimensional multi-spraying-nozzle spinneret plate through a tube; a spinneret plate lifting device penetrates through the air current stabilization cover and is connected with the three-dimensional multi-spraying-nozzle spinneret plate; a continuous fiber mat receiving device and a horizontal receiving surface moving device are arranged below the spinneret plate. Due to the multi-spraying-nozzle electrostatic spinning device with the controllable spinning environment, an existing electrostatic spinning method is improved, the sealed spinning box body is additionally arranged to improve the electrostatic spinning environment, and accordingly requirements for temperature and humidity in the spinning process are satisfied; meanwhile, due to the adoption of the three-dimensional multi-spraying-nozzle spinneret plate, spinning efficiency is greatly improved and the multi-spraying-nozzle electrostatic spinning device with the controllable spinning environment can be applied to industrial production.

Owner:DONGHUA UNIV

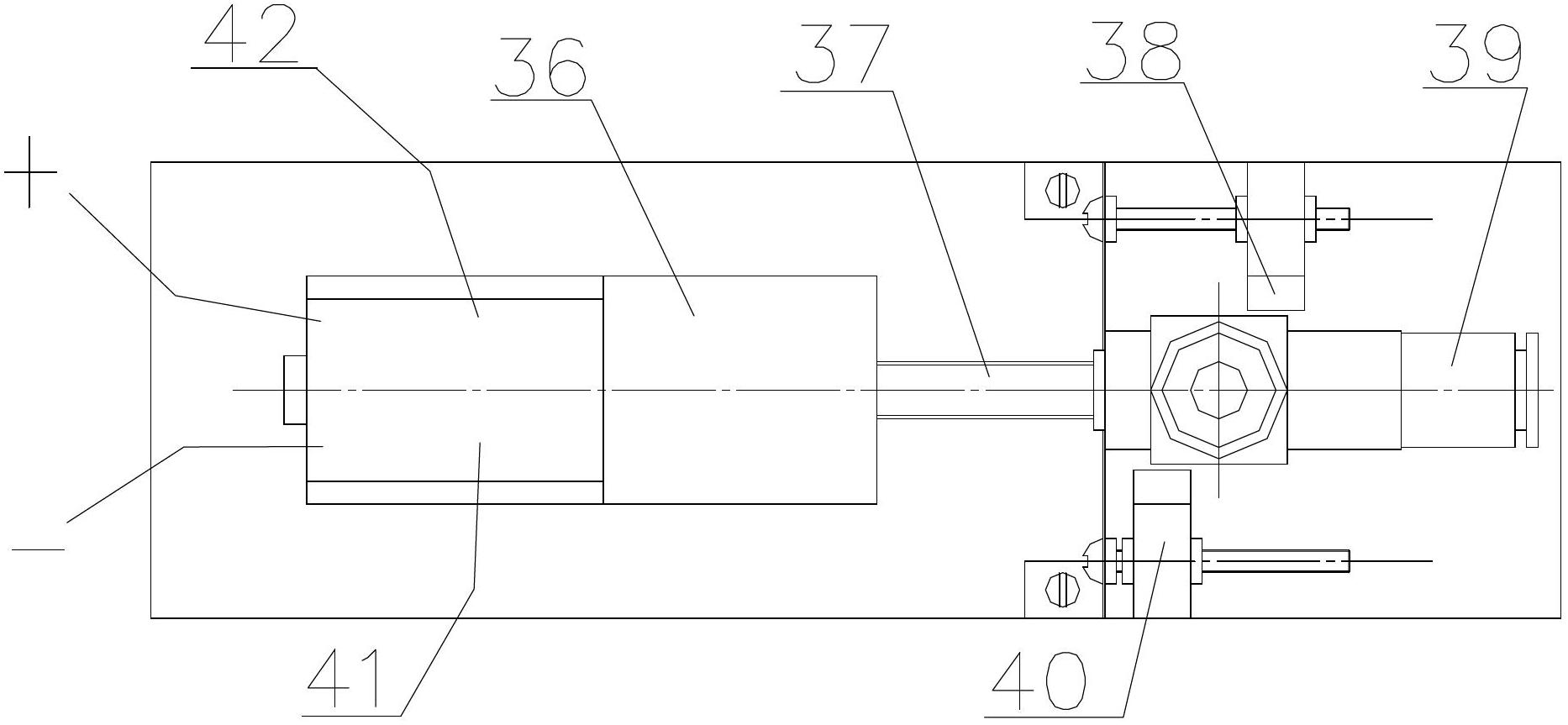

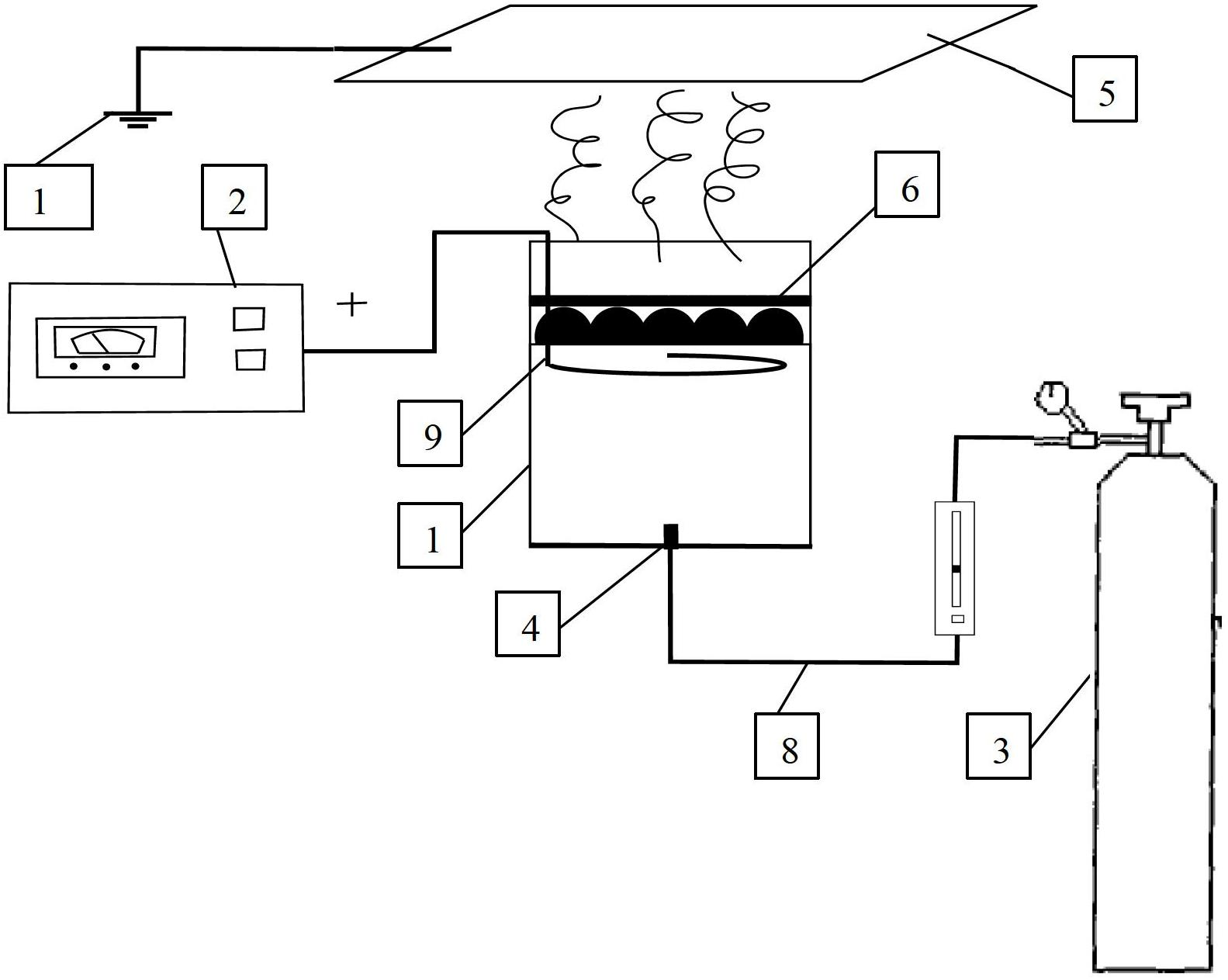

Device and method for preparing polysulfonamide nanometer fiber nets by means of airflow-electrostatic combination

ActiveCN102534822AOvercome surface tensionLarge specific surface areaStretch-spinning methodsFiberElectrospinning

The invention discloses a device and a method for preparing polysulfonamide nanometer fiber nets by means of airflow-electrostatic combination. The device comprises a liquid storage tank, an air chamber, an electrostatic generator and a receiving device, a plurality of spinnerets are arranged at the bottom of the liquid storage tank, the air chamber is arranged outside the liquid storage tank, air outlets in the number equal to that of the spinnerets at the bottom of the liquid storage tank are arranged at the bottom of the air chamber, the spinnerets are arranged inside the air outlets, an electrode with multiple pins are led from the positive electrode of the electrostatic generator to be connected with the spinnerets, and a lead is led from the negative electrode of the electrostatic generator to be connected with the receiving device. The method includes steps of combining the airflow method and the electrostatic spinning method effectively to prepare the polysulfonamide nanometer fiber nets. By the device and the method for preparing the polysulfonamide nanometer fiber nets, the specific surface area of the polysulfonamide nanometer fibers is enlarged greatly, the problem of blockage of existing electrostatic spinning needles due to inflow of the airflow is alleviated greatly, and spinning efficiency is improved. Besides, nanometer fibers can be prepared at the normal temperature directly, so that production procedures are simplified and production cost is saved.

Owner:SHANGHAI UNIV OF ENG SCI

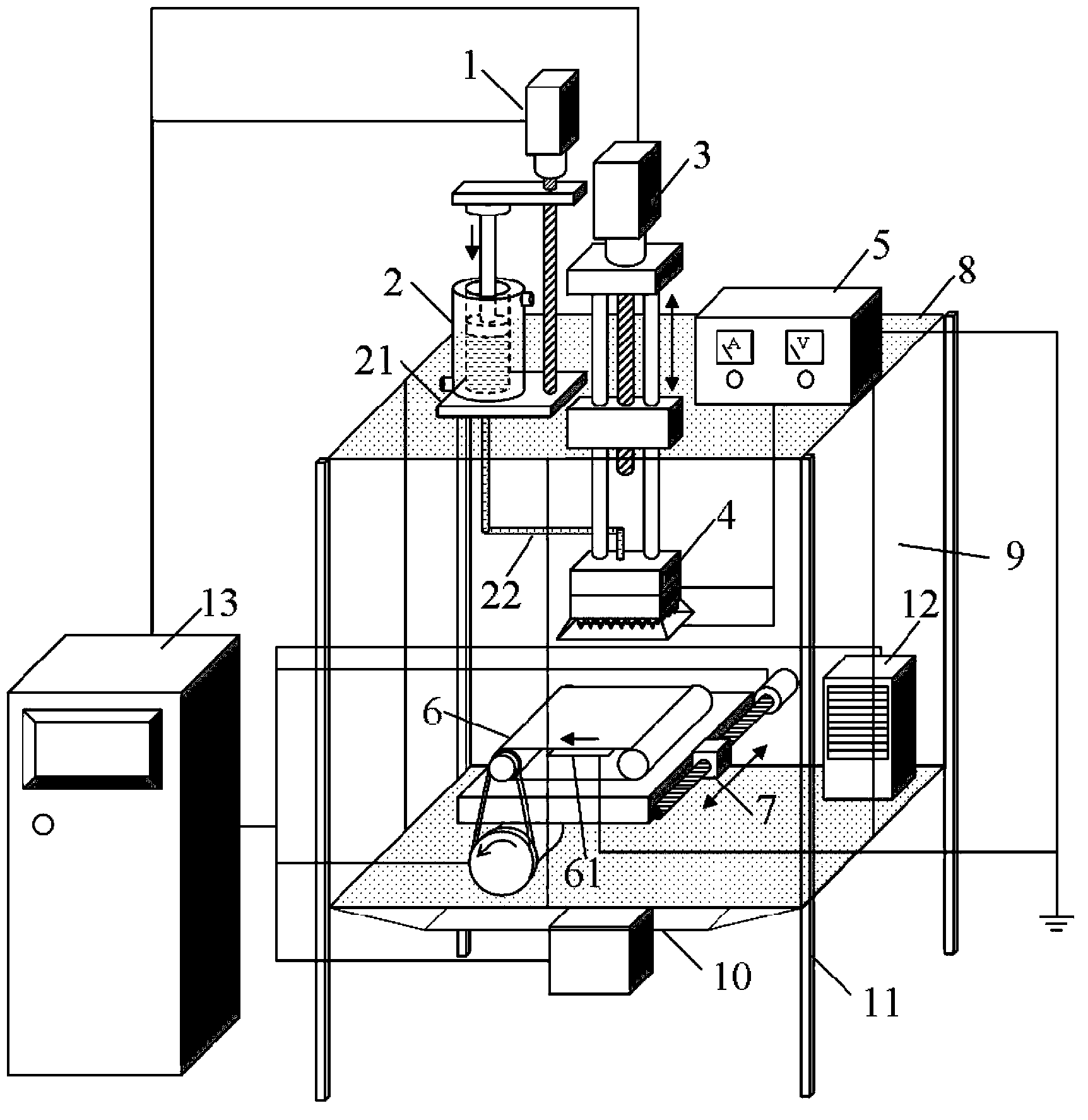

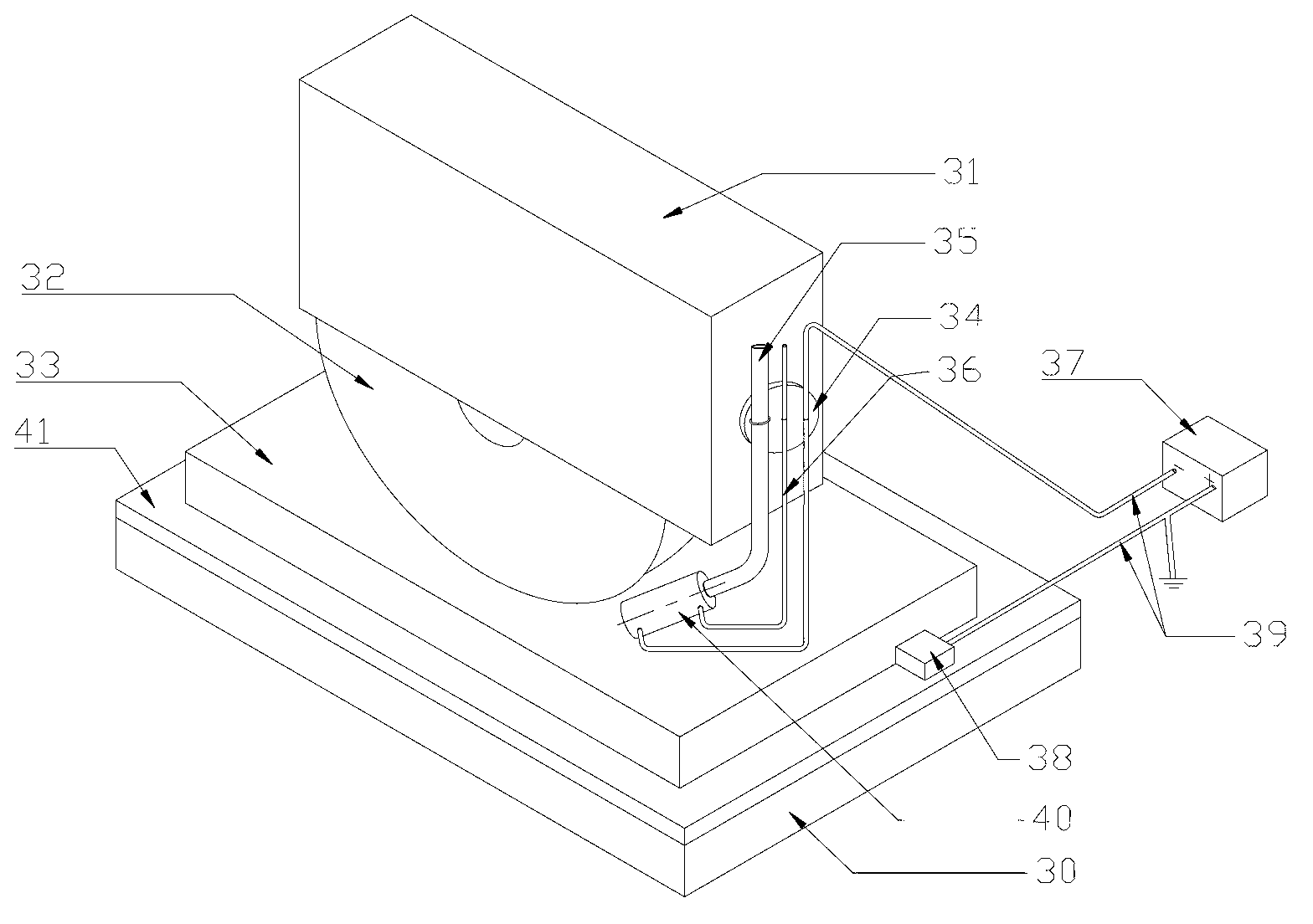

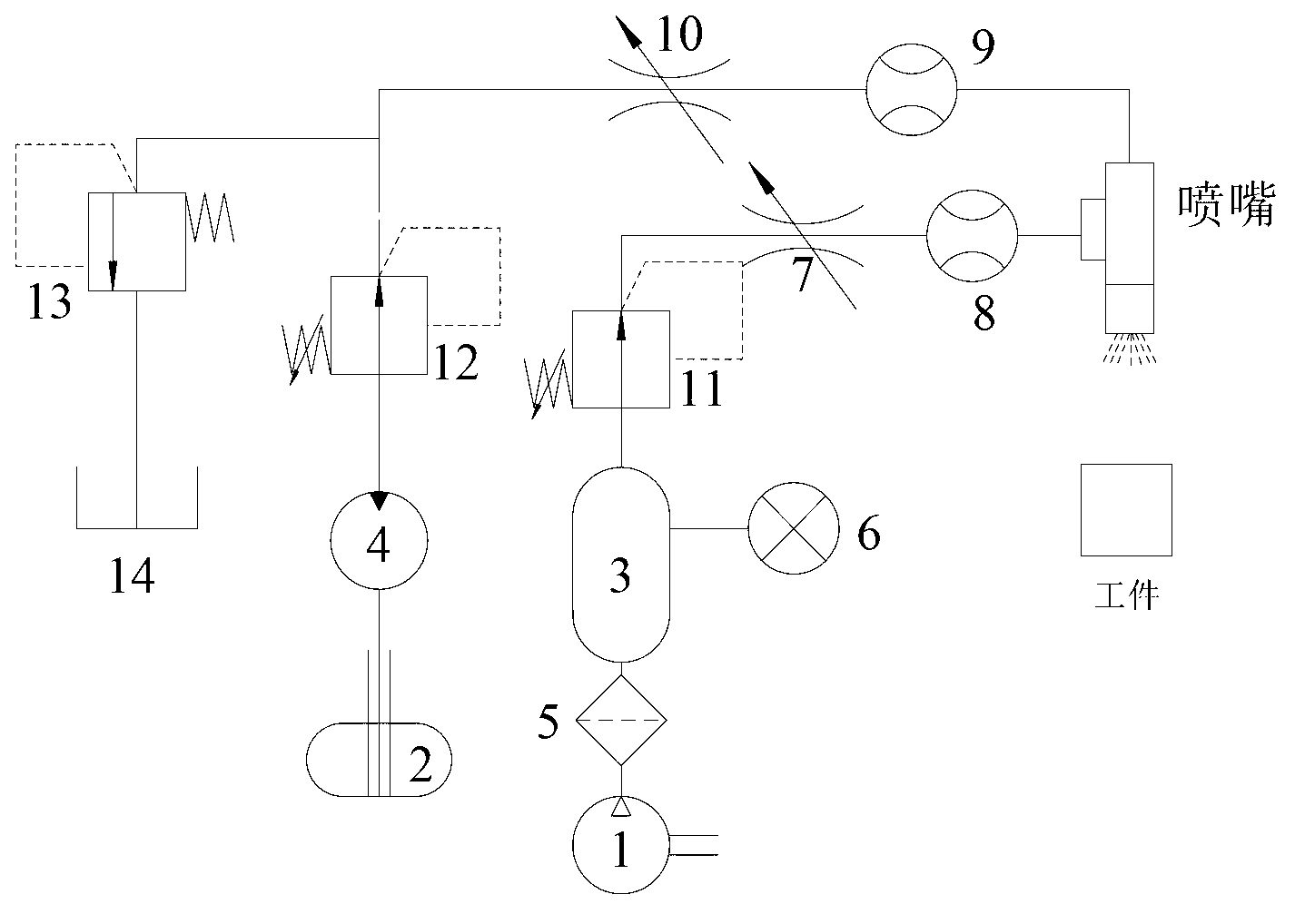

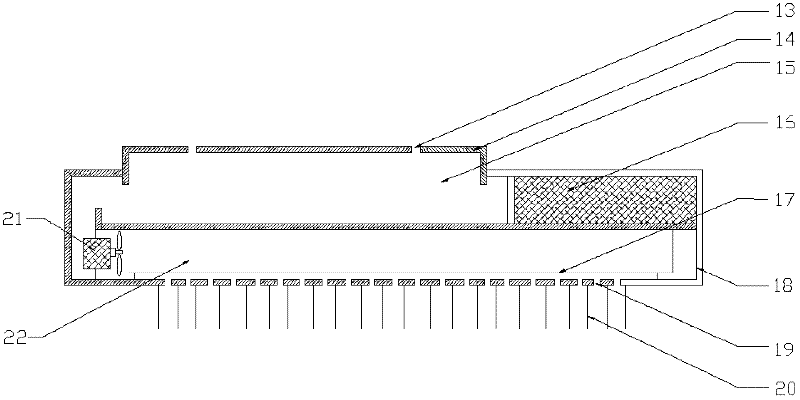

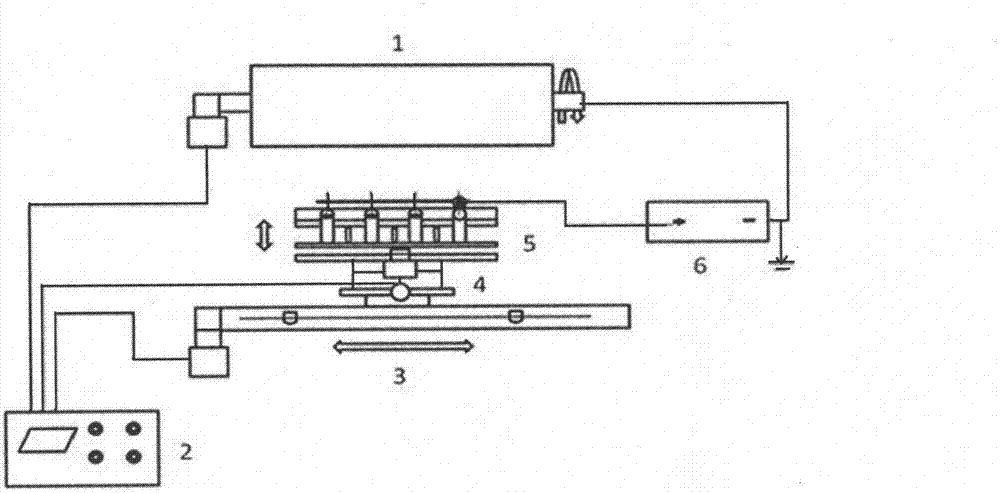

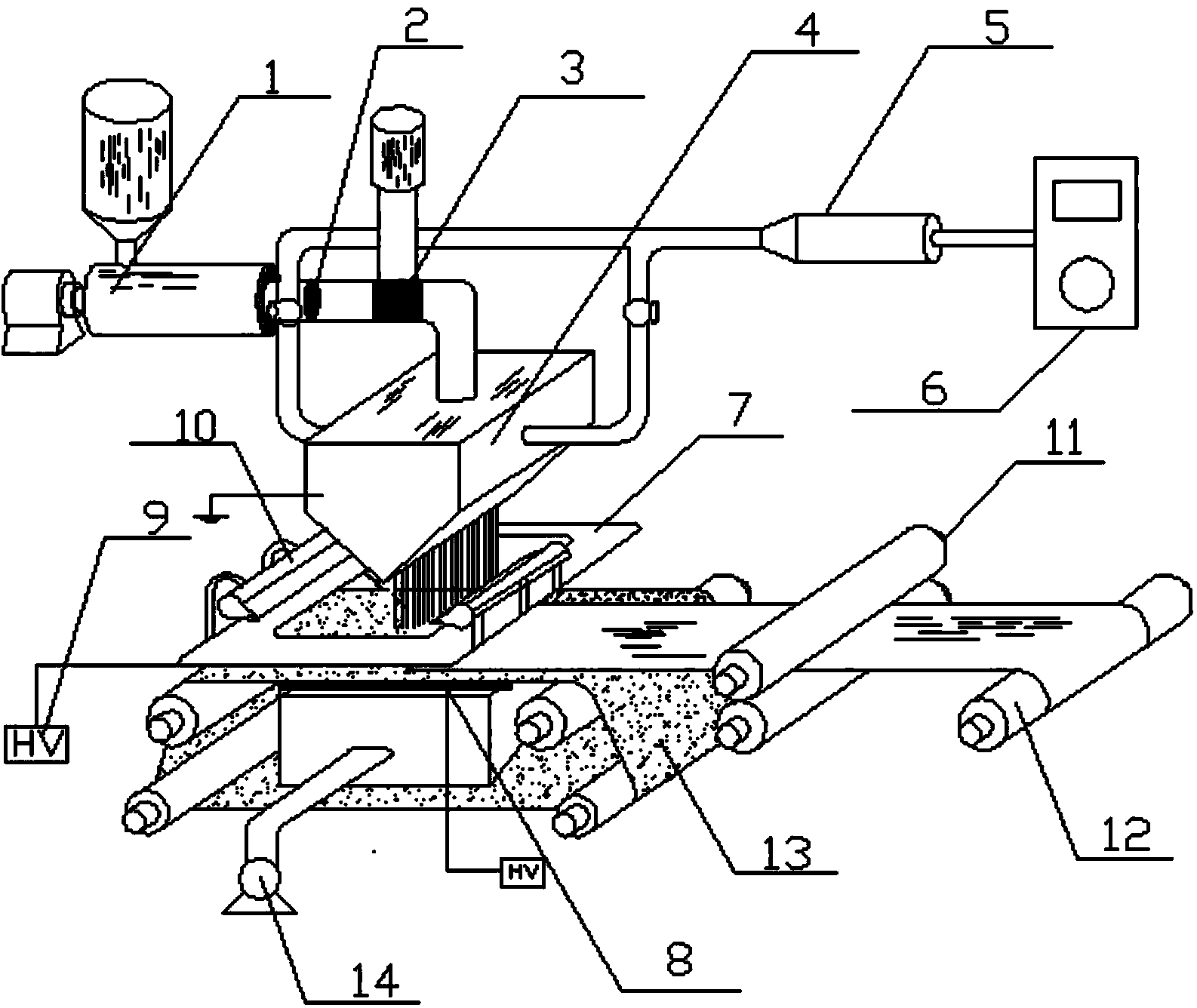

Nano fluid electrostatic atomizing controllable jet stream minimal lubricating and grinding system

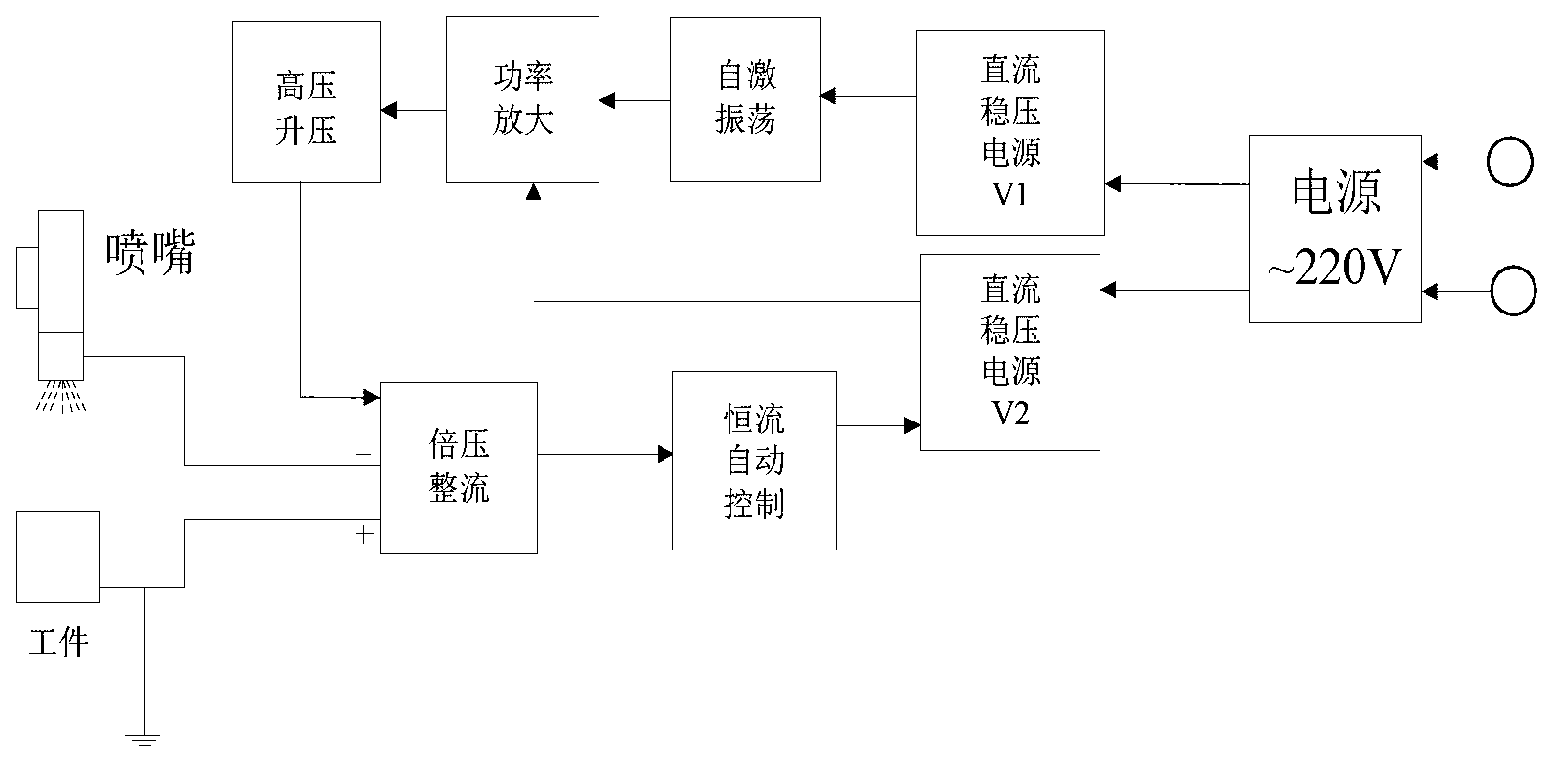

ActiveCN103072084AReduce drift lossIncrease profitGrinding/polishing safety devicesMachined surfaceHigh-voltage direct current

The invention relates to a nano fluid electrostatic atomizing controllable jet stream minimal lubricating and grinding system. Sprayed fog drops can be controllably distributed through the electrostatic principle, so that the pollution to environment is reduced, and better health security is provided to workers. A grinding system is provided with a corona charging nozzle, wherein a nozzle body of the corona charging nozzle is connected with a liquid supply system and an air supply system; a high-voltage direct-current electrostatic generator on the lower part of the nozzle body is connected with the cathode of an adjustable high-voltage direct-current power supply; the anode of the adjustable high-voltage direct-current power supply is connected with a workpiece charging device; and the workpiece charging device is attached to the non-machined surface of a workpiece. Nano fluid grinding liquid is fed into the corona charging nozzle through the liquid supply system, meanwhile the air supply system feeds compressed air into the corona charging nozzle, the nano fluid grinding liquid is charged into controllable jet stream by the high-voltage direct-current electrostatic generator while being driven by the compressed air to be sprayed out and atomized from the nozzle body, and the controllable jet stream is controllably distributed to a grinding area of the machined workpiece under the actions of electric field force and aerodynamic force.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

High-performance multineedle electrostatic spinning jet device

InactiveCN1962966AUniform thicknessReduce jet electrostatic repulsionSpinnerette packsFilament/thread formingFiberElectrospinning

The efficient multineedle electrostatic spinning sprinkling device includes constant pressure supplying system, spinnerette connected with the constant pressure supplying system, receiver electrode plate and electrostatic generator; said spinnerette is multineedle combined spinnerette, it includes spinnerette main body, cover and seal ring the two, the main body is provided with fluid cavity,the bottom of the main body is equipped with several metal nozzles, three adjacent metal nozzles are set up in regular triangle and the abduction of each circle of metal nozzles is in regular hexagon; insulated supporting parts are installed on the bottom of the main body, metal rings encompassing all metal nozzles are installed on the lower of said supporting parts, said metal rings and metal nozzles are connected with electrostatic generator directly. The invention achieves the goal of multi-needle injection simultaneously by improving the intensity of field of spinnerette, reduces the fluid jet electrostatic repulsion forces greatly caused by the small distance between the needles and makes the receiver can receive fiber in small range, so increases the efficiency in unit area and obtains carpet fiber with more uniform thickness.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

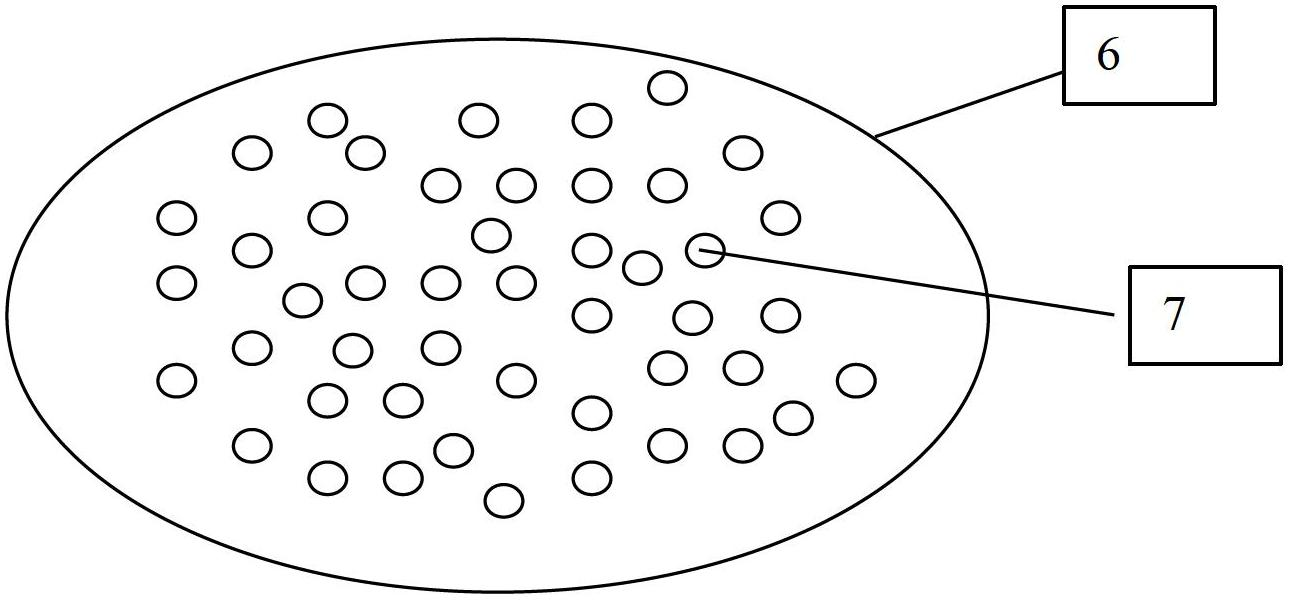

Porous bubble electrostatic spinning device

InactiveCN102660783ARealize large-scale productionIncrease productivityArtificial thread manufacturing machinesFilament/thread formingSprayerAir pump

A porous bubble electrostatic spinning device comprises a liquid storage tank, a high pressure electrostatic generator, an air pump, a sprayer, and a dash receiver, wherein the sprayer is connected with the air pump through an air duct, the dash receiver is connected with a grounded electrode, an opening is arranged at the upper end of the liquid storage tank, the liquid storage tank is connected with the high pressure electrostatic generator through a metal electrode, the liquid storage tank is internally provided with a middle flat plate, and a plurality of small holes with adjustable diameters are formed in the middle flat plate in a penetrating way. As the small holes are formed in the middle flat plate, solution in the liquid storage tank generates a large quantity of bubbles through the plurality of small holes under the action of the air pump. When filed stress is greater than surface tension of the solution, and jet flow is ejected from the top of the bubbles and is deposited on the dash receiver to form a large amount of nanofiber. The porous bubble electrostatic spinning device can produce the nanofiber in a large scale, so that according to the device, the production efficiency is high, the production cost is low, the equipment is simple, the operation is easy, the adaptability is high and the requirement of batch production can be met.

Owner:SUZHOU UNIV

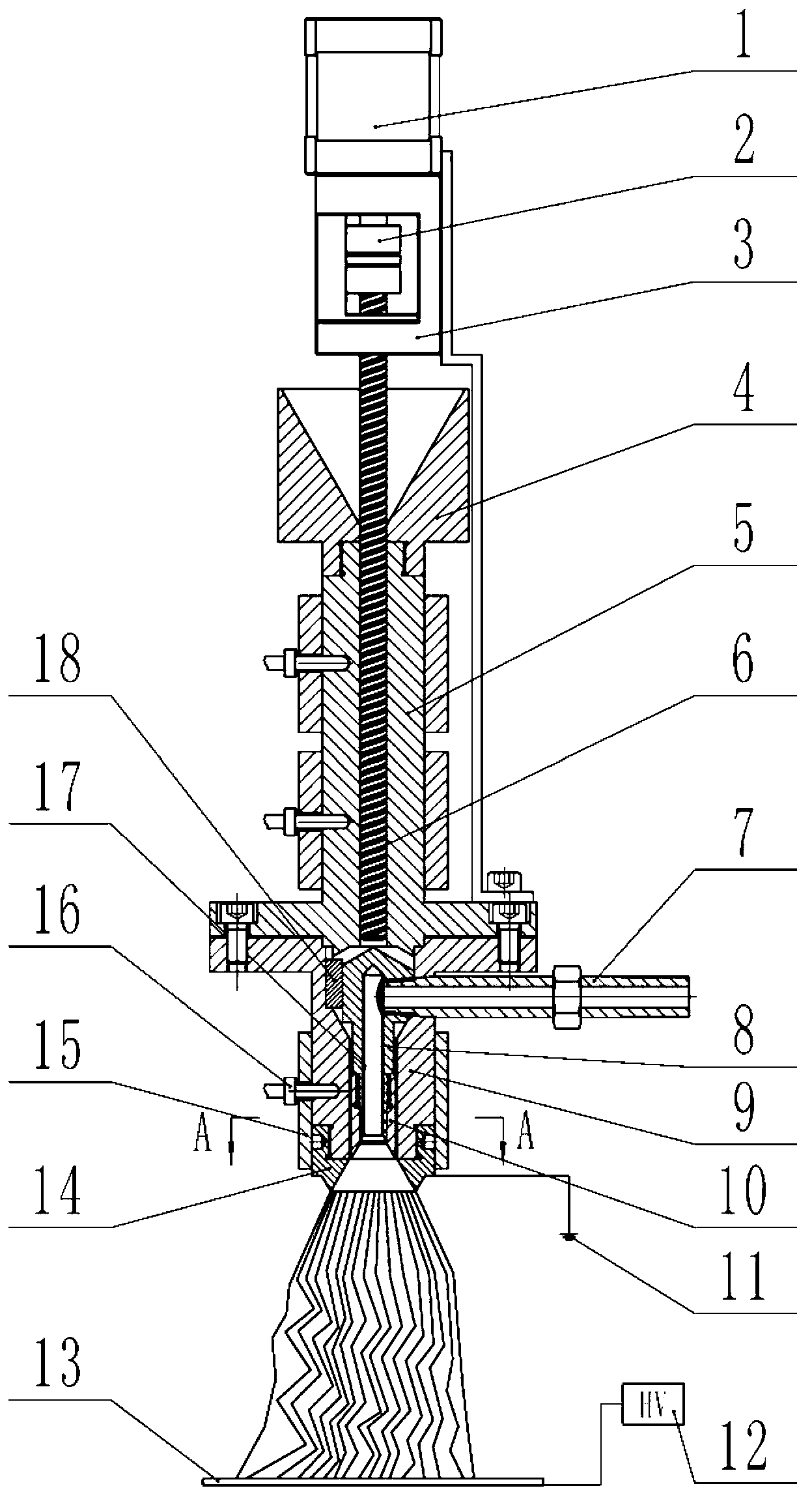

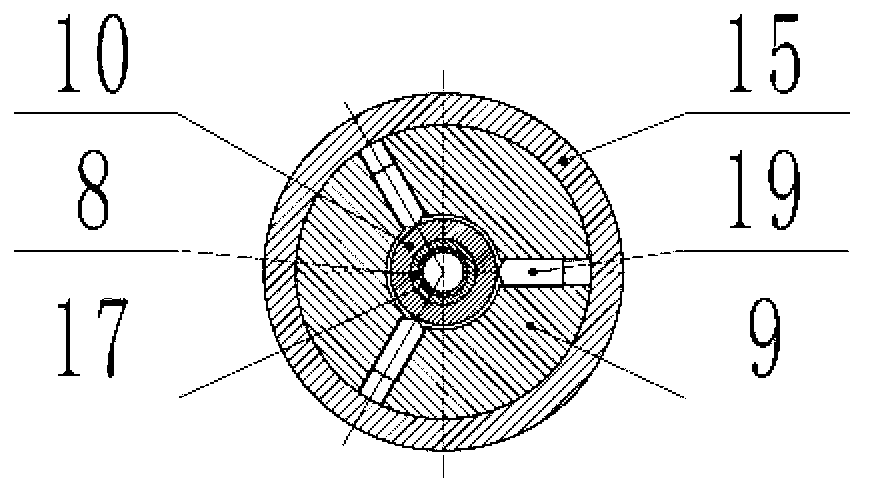

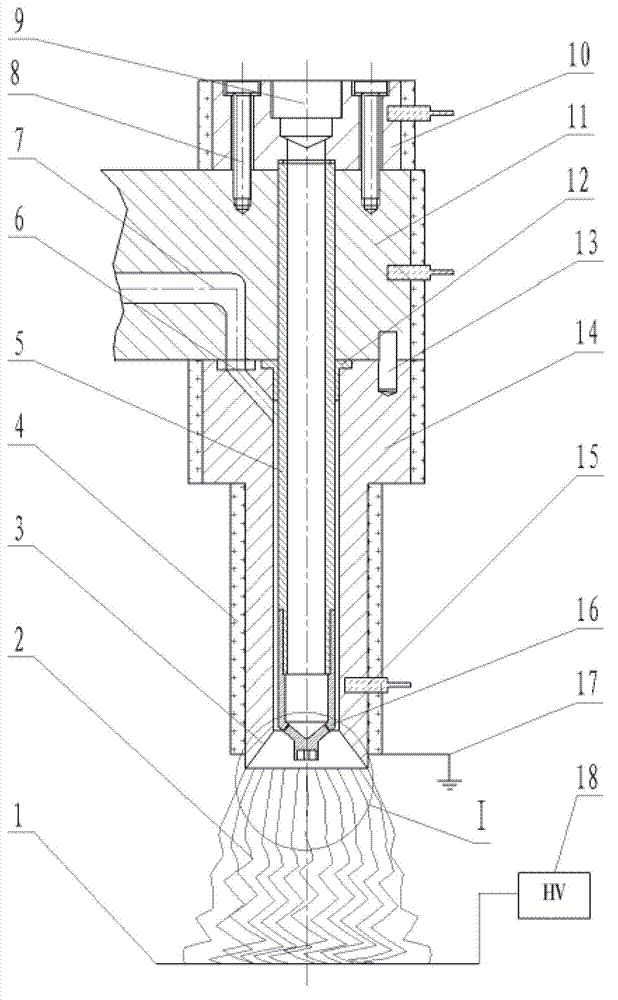

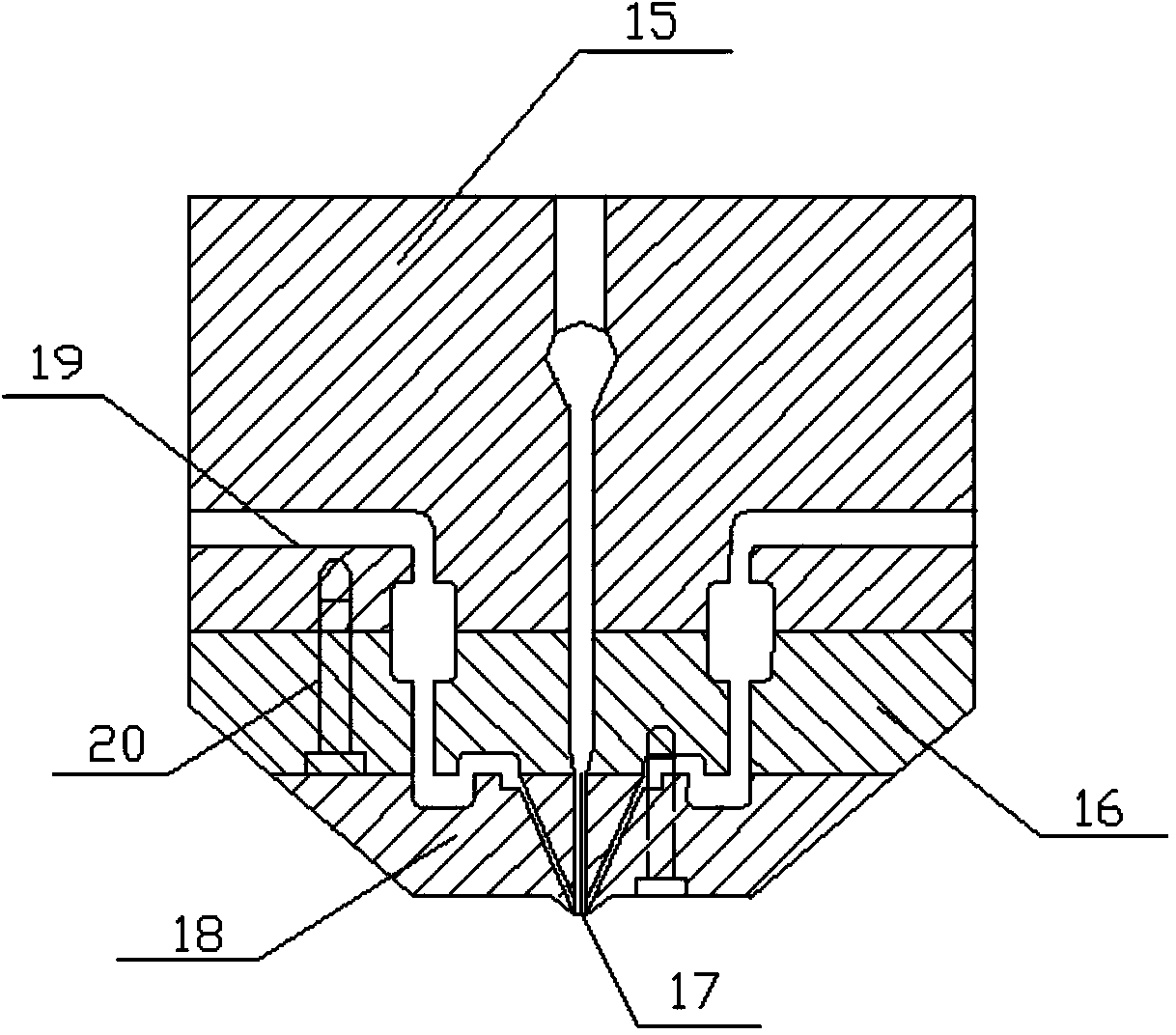

Differential melt-electrospinning jet head

The invention discloses a differential metl-electrospinning jet head and belongs to the field of electrostatic spinning. The differential metl-electrospinning jet head mainly comprises a hopper, a charging barrel, a jet head body, an internal cone-shaped jet head, an airflow channel air inlet pipe, an airflow channel standpipe, an airflow channel insulating layer, a jet head inner body, a button, a jackscrew, a heating device, a temperature sensor, a screw rod, a coupler, a servomotor, a motor support, a grounding electrode, a receiving electrode plate and a high-voltage electrostatic generator. The differential metl-electrospinning jet head adopts a center-feeding and side-air-intake manner, ensures uniform melt circumferential distribution through the adjustment of the jackscrew, adopts the inner cone-shaped jet head, and can spin dozens of filaments through a single jet head, thereby achieving high spinning efficiency; and by the aid of hot air, the melt layer on the inner cone surface can be blown thinner, the filaments can be drawn, and a heat insulation role can be played on the environmental temperature to slow down cooling of the filaments and prolong the filament drawing time. Therefore, the spun filaments are thinner. The differential metl-electrospinning jet head has the advantages of simple structure, capability of spinning thin fibers and high spinning efficiency.

Owner:BEIJING UNIV OF CHEM TECH

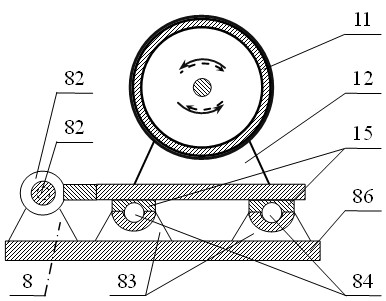

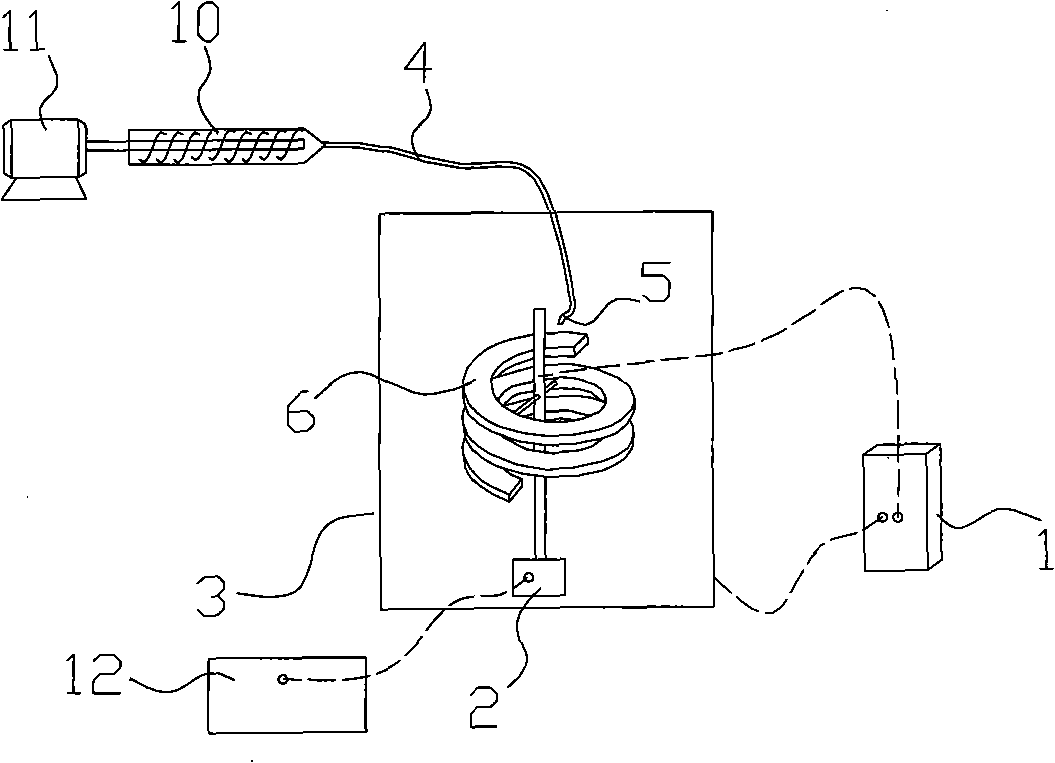

High-speed preparation device and process of centrifugal electrostatic spinning nanometer twisted yarns

ActiveCN103409861AAchieving Orientation ControllabilityIncrease elasticityFilament/thread formingContinuous wound-up machinesFiberYarn

The invention discloses a high-speed preparation device of centrifugal electrostatic spinning nanometer twisted yarns. The high-speed preparation device mainly comprises a feed extrusion device, a motor, an electromagnetic heating coil, a bearing, a conical ring perforated electrode, a centrifugal rotating umbrella-type spray head, an air compressor, a cyclone vacuum generator, a roller receiving device, a high-voltage electrostatic generator, a synchronous toothed belt and a rack, wherein the motor drives the centrifugal rotating umbrella-type spray head to rotate at high speed; the electromagnetic heating coil is in non-contact connection with the centrifugal rotating umbrella-type spray head and is heated through radiation; the feed extrusion device is used for supplying feed to the centrifugal rotating umbrella-type spray head through a hole in the center of the centrifugal rotating umbrella-type spray head; the conical ring perforated electrode is fixed at the middle position of the center of the rack. The high-speed preparation device is combined with an electrostatic spinning technology and a centrifugal spinning technology; a rotating airflow is formed in a chamber by the combined use of the air compressor and the cyclone vacuum generator to guide fiber to form twisted yarns, so that the orientation controllability of nanofiber is achieved; conditions are created for industrial application of the nanofiber in the specific industries, such as water treatment.

Owner:BEIJING UNIV OF CHEM TECH

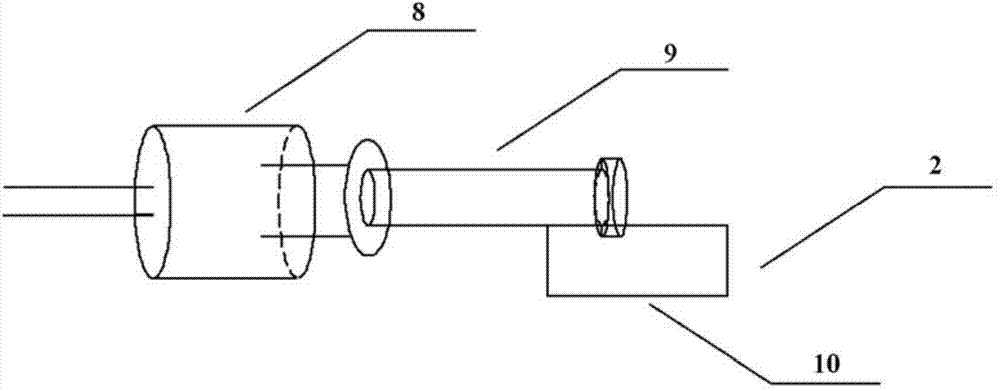

Method and device for evaluating pilling resistance of yarn by on-line inlet and outlet measurement mode

InactiveCN102323120ARepresentativeMeasurement is highly targetedPreparing sample for investigationMaterial analysis by optical meansYarnTest sample

The invention relates to a method and a device for evaluating the pilling resistance of a yarn by an on-line inlet and outlet measurement mode. The method comprises the steps of input pre-evaluation, uniform winding forming, preparation of a test sample by carrying pressurizing friction, stable backing-off and on-line measurement, comparison and evaluation. The device comprises a yarn supply and recovery device, a yarn pilling condition measurement device and a winding friction mechanism. The yarn pilling condition measurement device comprises a capacitor plate, a static electricity generation device and a yarn hairness measurement system. The static electricity generation device comprises a prepositive static electricity generator and a post static electricity generator. The prepositive static electricity generator and the post static electricity generator are respectively arranged at both sides of the yarn hairness measurement system. The capacitor plate is arranged at the rear sideof the post static electricity generator. The winding friction mechanism comprises a winding drum. The separation position of the unwound yarn and the winding drum is provided with a backing-off tension measurement mechanism. The winding friction mechanism is connected with a reciprocating mechanism. In the invention, the yarn is used for directly testing and panel knitting is not used; and by taking a base yarn as the contrast, the method and the device are more accurate.

Owner:DONGHUA UNIV

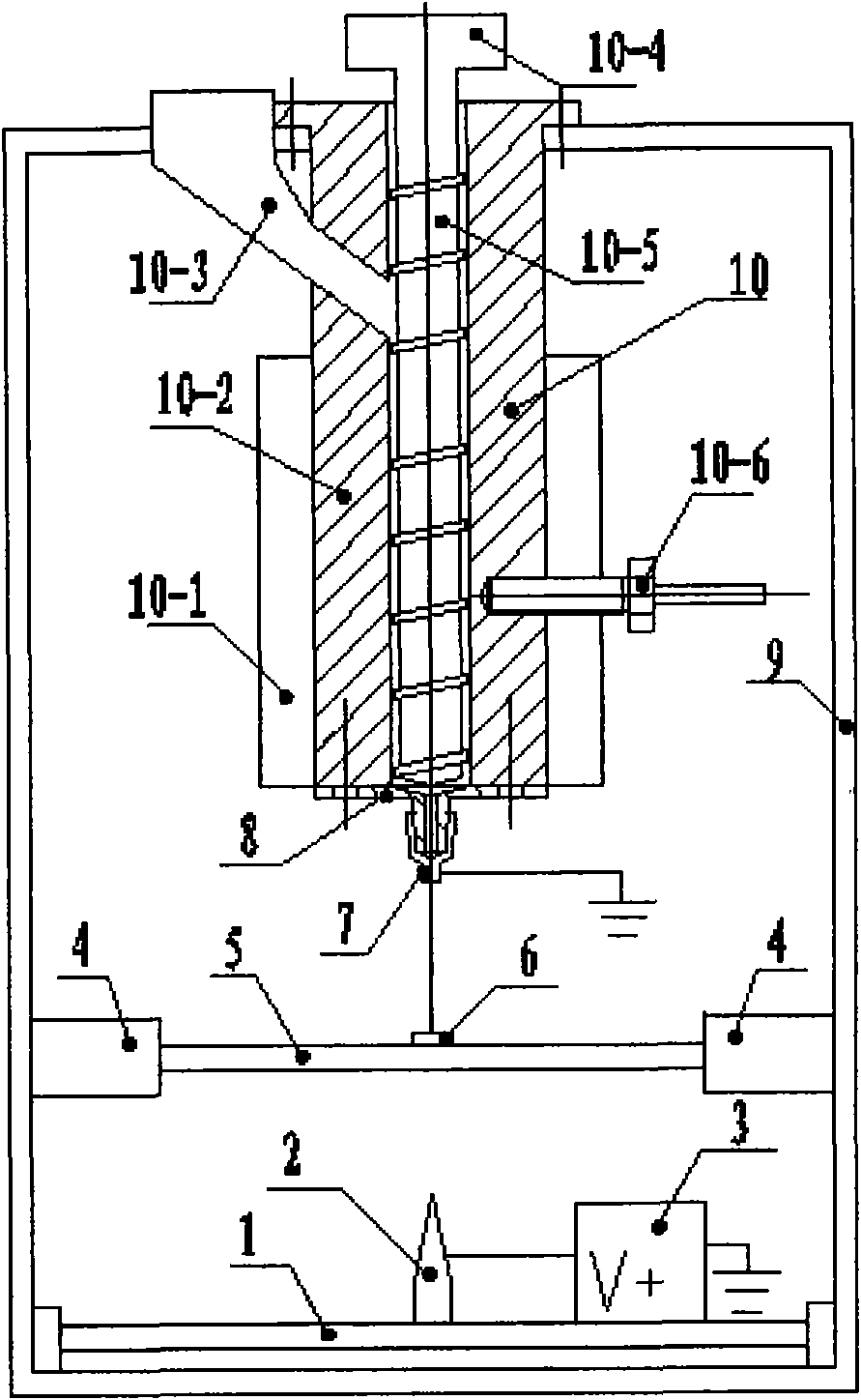

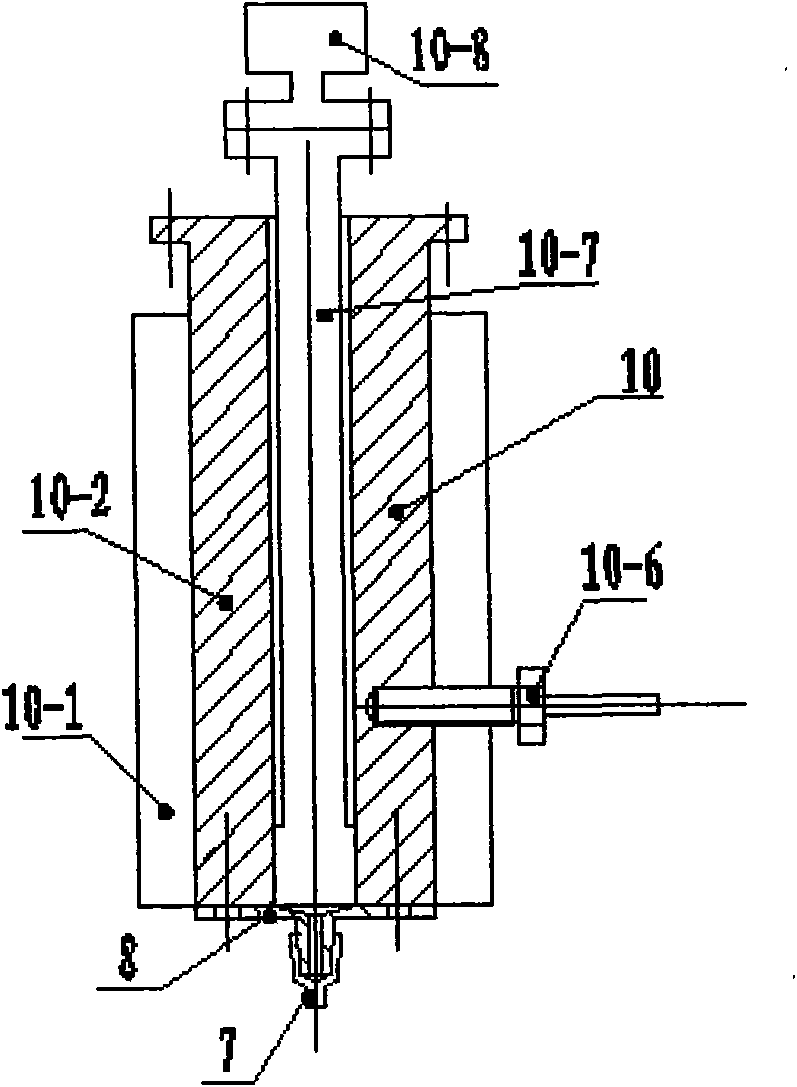

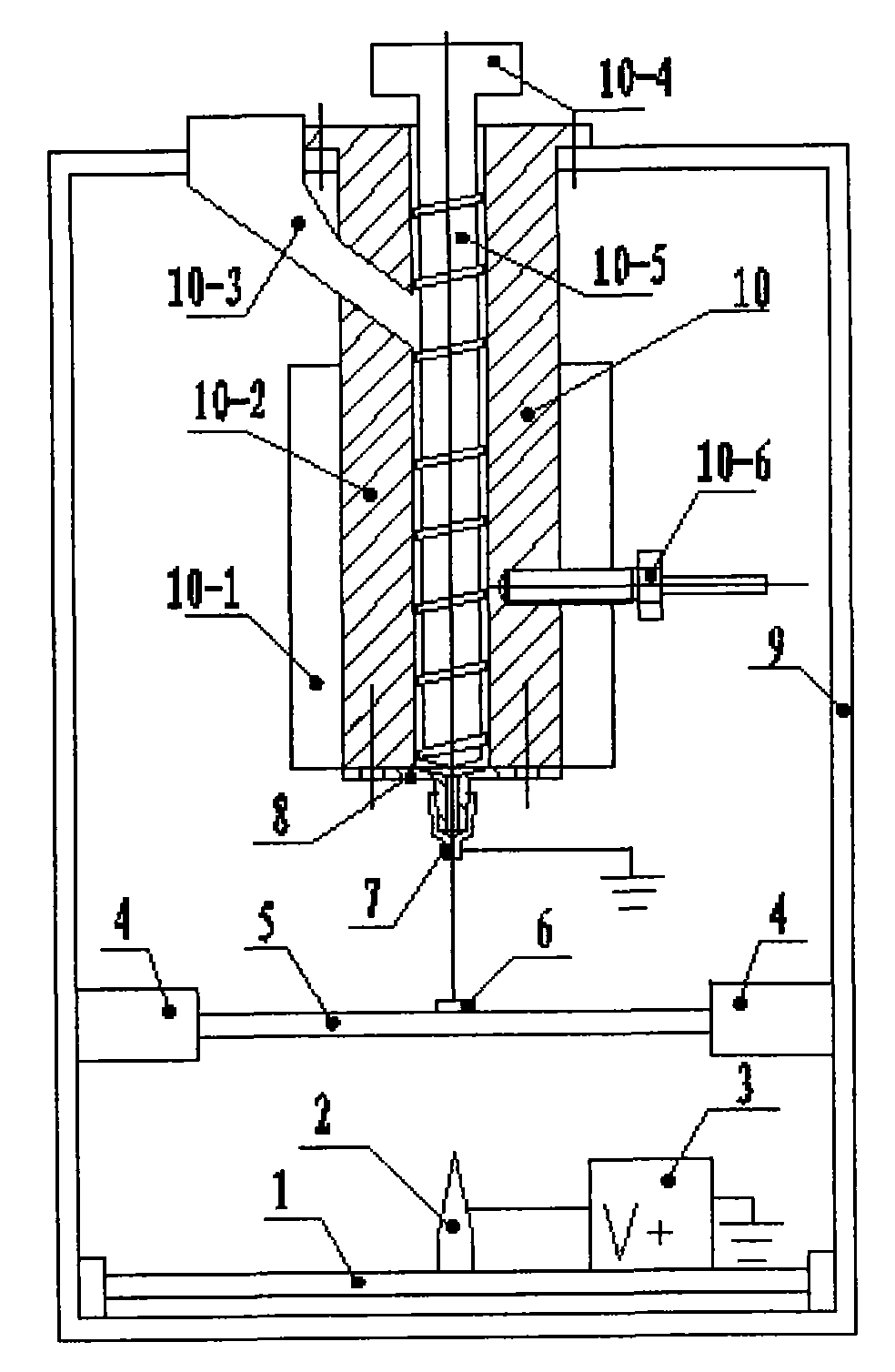

Method and device for rapid forming by combining electrostatic spinning technique

ActiveCN101837642AAddressing Shortfalls in the Production of Tiny PartsHigh precisionFilament/thread formingMedia controlsFiber

The invention provides a rapid forming method combining an electrostatic spinning technique and a device. The method comprises the following steps of: adding a spinning medium into a spinning medium control device, and adjusting the flow of the spinning medium to ensure that the spinning medium uniformly flows out of the tail end of a capillary tube; inputting a plane program of a product platform into a computer, and raising the product platform to a working position; raising a point electrode saddle, and adjusting the height of the point electrode saddle and an output voltage of an electrostatic generator according to requirements on the size of silks ejected by the capillary tube; and when the adjustment is stable, cleaning the product platform, and then starting the electrostatic generator, a product platform motion system and a computer running program to stack fused fibers into needed shapes on the product platform. The electrostatic spinning technique is applied to the rapid forming method, has a significant effect on production of micro parts, and has quick forming speed, flexible processing control and wider adaptation range for the production of quick forming products with general sizes.

Owner:BEIJING UNIV OF CHEM TECH

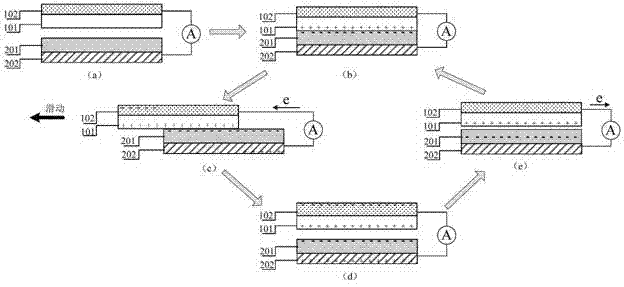

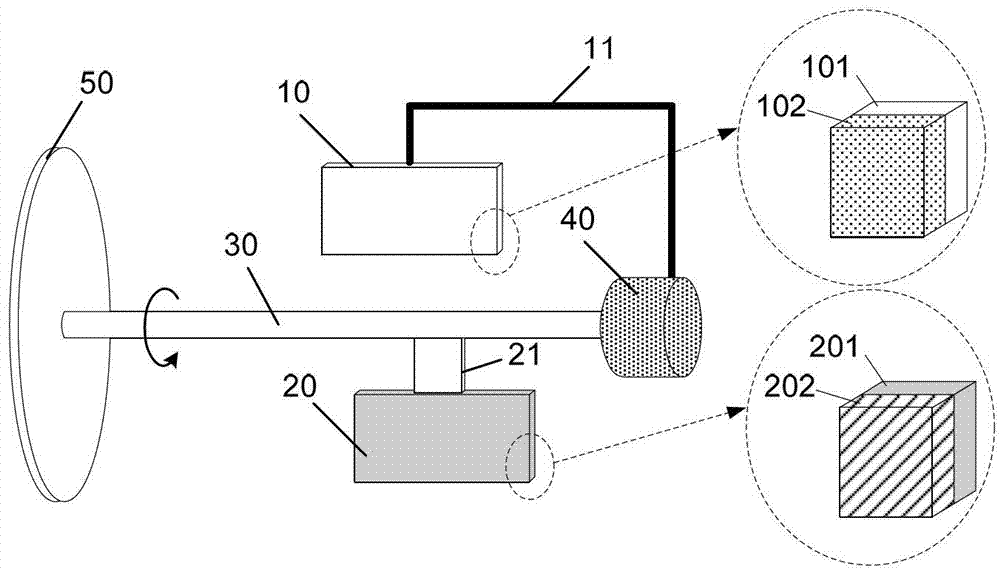

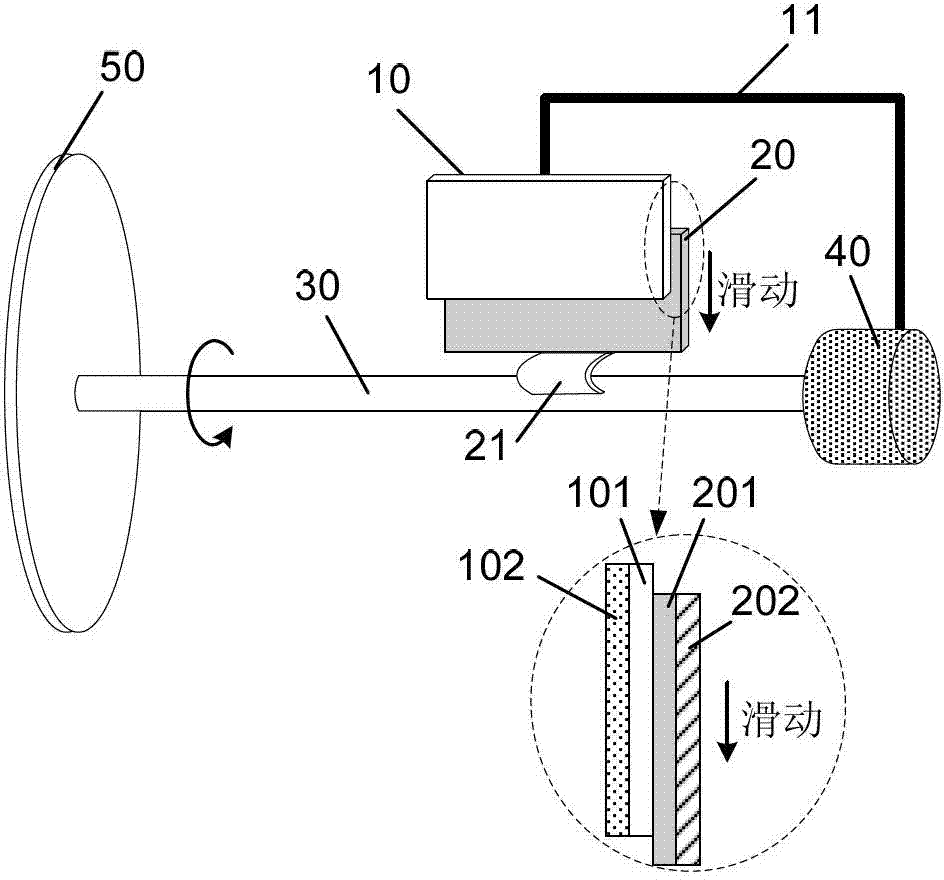

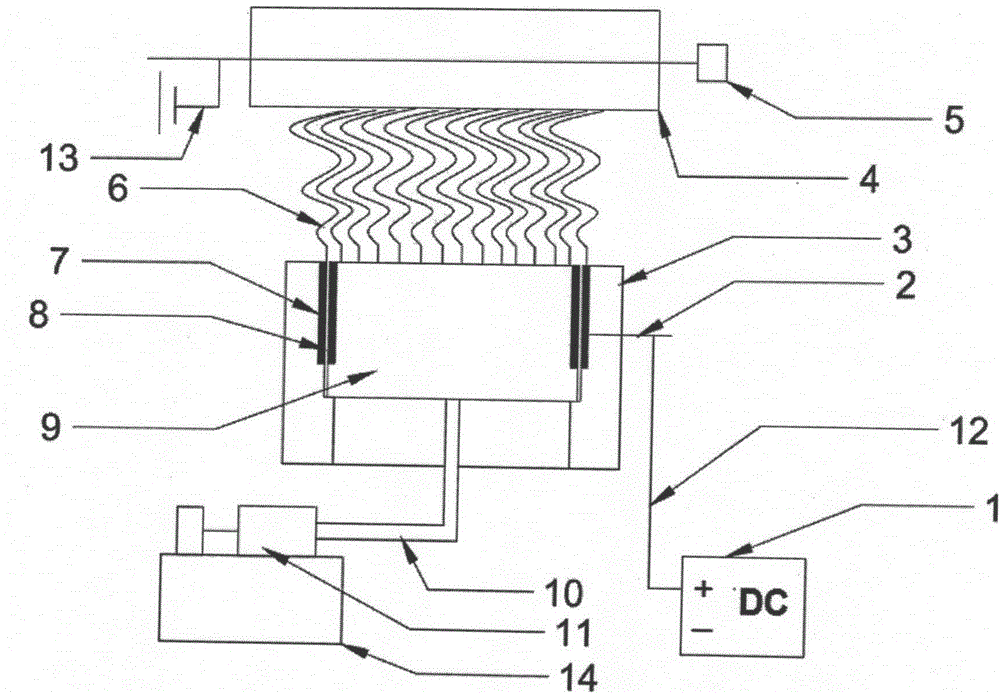

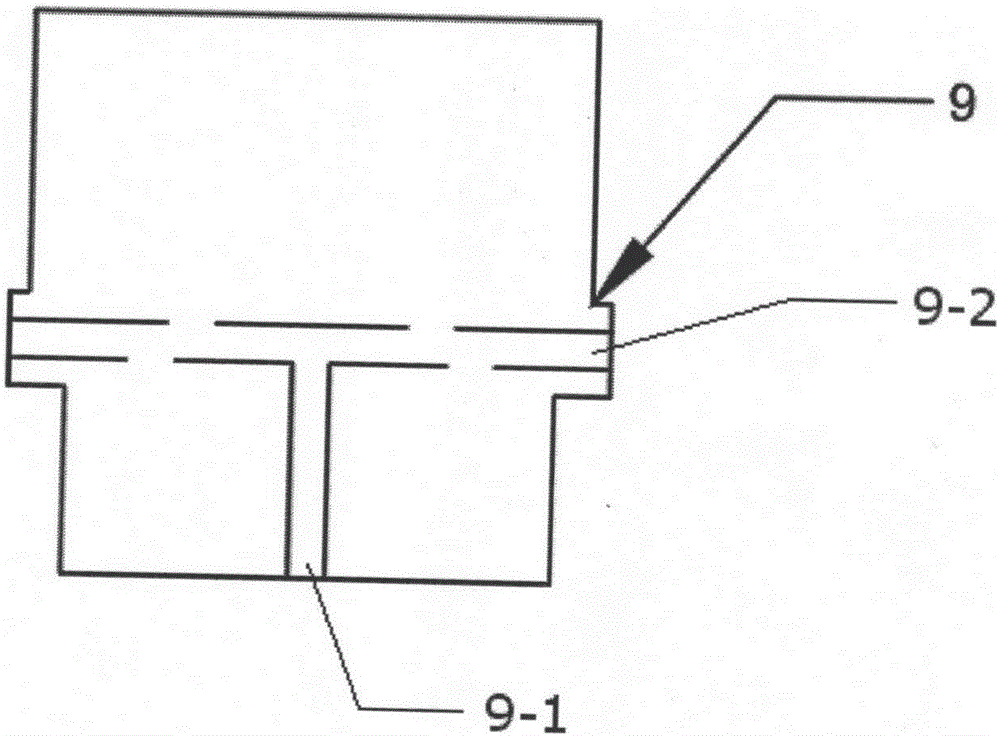

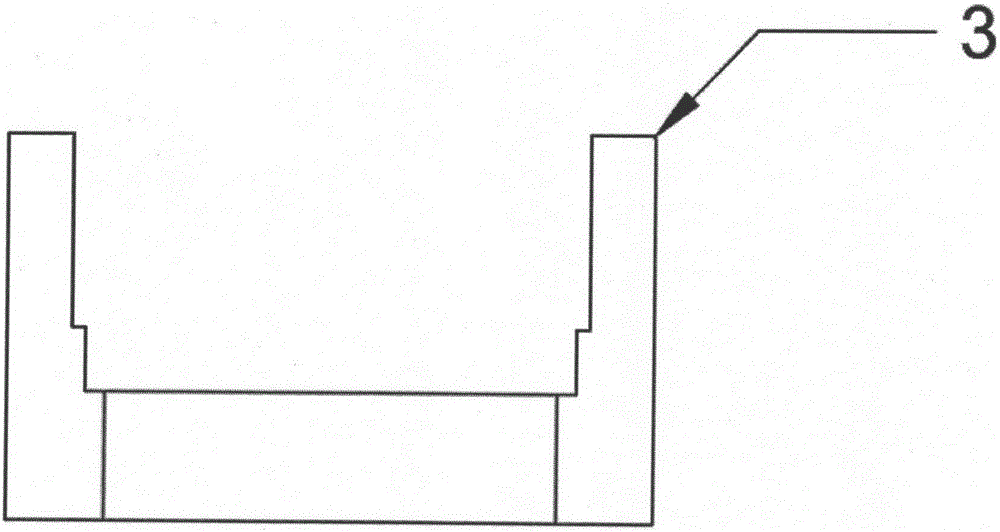

Rotary electrostatic generator

ActiveCN103780129ARealize the collectionEfficient use ofBatteries circuit arrangementsElectric powerElectric signalCapacitor

The invention provides a rotary electrostatic generator, which comprises a power collecting component, a stator, a stator supporting member, a rotor, a rotor supporting member, a rotating shaft and a bearing, wherein the power collecting component is fixed on the rotating shaft, the rotating shaft, the rotor supporting member fixed on the rotating shaft and the rotor connected to the rotor supporting member are driven to rotate together by an external force, the rotor and the stator are enabled to be contacted with or separated from each other periodically, relative sliding friction is generated between a first friction layer and a second friction layer on the contact surface, and the friction area is changed, thereby being capable of generating electric signals and outputting the electric signals to an external circuit. The electric signal output not only can act as a power supply to drive electronic devices such as an LED, an LCD and the like or charge energy storage devices such as a lithium battery, a capacitor and the like, but also can be used for detecting the flow rate of a fluid in real time.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

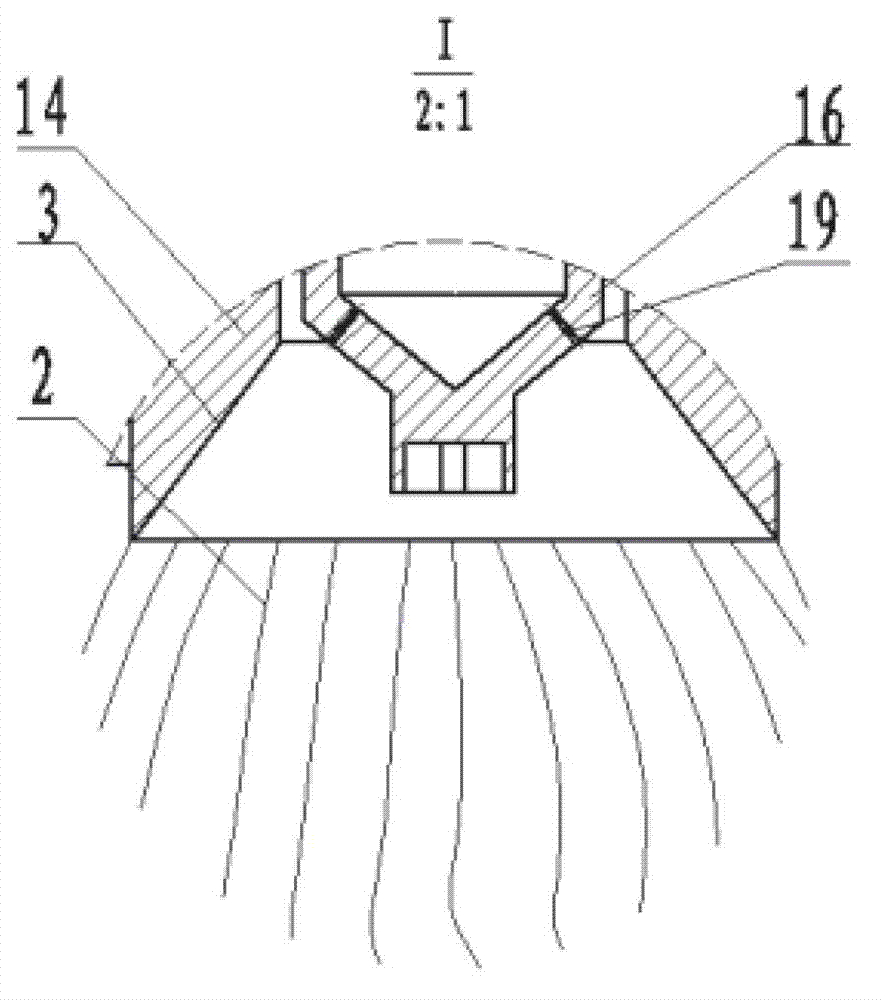

Airflow assisted internal conical surface distributed electrostatic spinning nozzle

ActiveCN102864502AEvenly distributedPromote aggregationSpinnerette packsFilament/thread formingFiberElectrospinning

The invention discloses an airflow assisted internal conical surface distributed electrostatic spinning nozzle which belongs to the field of electrostatic spinning and mainly comprises a receiving plate, an electrical heating device, an airflow guide column, a screw, a gas interface block, a distributing plate, a chocked flow block, an internal conical surface nozzle body, a nozzle body locating pin, a temperature sensor, an airflow nozzle, a grounding electrode and a high-pressure electrostatic generator, wherein the side surface of the upper end of the internal conical surface nozzle body is provided with a spinning medium inlet and is used for being connected with a distributing plate runner, and a gap between the internal conical surface nozzle body and the airflow guide column is used for guiding a spinning medium so that the spinning medium is uniformly distributed on the internal conical surface on the lower end of the internal conical surface nozzle body. By adopting uniform distribution of an internal conical surface structure, and using a thinning effect of airflow on the internal conical surface to the spinning medium, a high-speed stretching role of airflow to jet flow, and a keeping function of hot airflow residual heat to environment temperature, the problems of fiber refining and high-efficiency spinning are well solved, and a plurality of nozzles can be used as a basis assembly of the melt electrostatic spinning industrialization through different forms of expansion combinations.

Owner:BEIJING UNIV OF CHEM TECH

Medicinal coating production for vascular stand and electrostatic spraying apparatus

InactiveCN1644184AImprove atomization rateIncrease profitSurgeryPretreated surfacesElectricitySpray nozzle

A process for preparing the coated medicine layer on the scaffold of blood vessel includes such steps as washing said scaffold, drying, proportionally mixing medicine with polymer carrier to obtain coating, connecting the scaffold to ground, high-pressure atomizing of said coating electrically charging the atomized coating by electrostatic generator, adsorbing the charged coating onto surface of scaffold under the action of electric field and high pressure, drying and disinfecting. Its electrostatic spray apparatus is composed of power source, changeover valve, high-pressure pump, coating container, filtering, electrostatic generator and spray gun with nozzle connected to said electrostatic generator.

Owner:DALIAN UNIV OF TECH

High-efficiency needleless coaxial electrostatic spinning device and method

ActiveCN103572388AAvoid easy cloggingSolve easy blockageFilament/thread formingInfusion catheterElectrospinning

The invention relates to a high-efficiency needleless coaxial electrostatic spinning device and method. The high-efficiency needleless coaxial electrostatic spinning device comprises a step-shaped needleless spinneret, a liquid feed system, a solution recovery tank, a receiving board and a high-voltage electrostatic generator. The liquid feed system comprises a propeller, an insulating rod and solution storing containers. A cylindrical hollow portion is arranged in the center of the step-shaped needleless spinneret, wherein two infusion catheters with different diameters are concentrically arranged at the cylindrical hollow portion in the axial direction; the two infusion catheters with different diameters are connected with the shell solution storing container and the core solution storing container respectively; the solution recovery tank is arranged at the bottom of the step-shaped needleless spinneret. According to the method, the high-efficiency needleless coaxial electrostatic spinning device is used for spinning. The step-shaped needleless spinneret of the high-efficiency needleless coaxial electrostatic spinning device can avoid the phenomenon that a pinhead is blocked, and is easy to clean and good in stability. The electrostatic spinning method effectively improves production efficiency of core-shell structure nanofiber and can realize continuous and large-scale production of the core-shell structure nanofiber.

Owner:HENAN XINYE TEXTILE

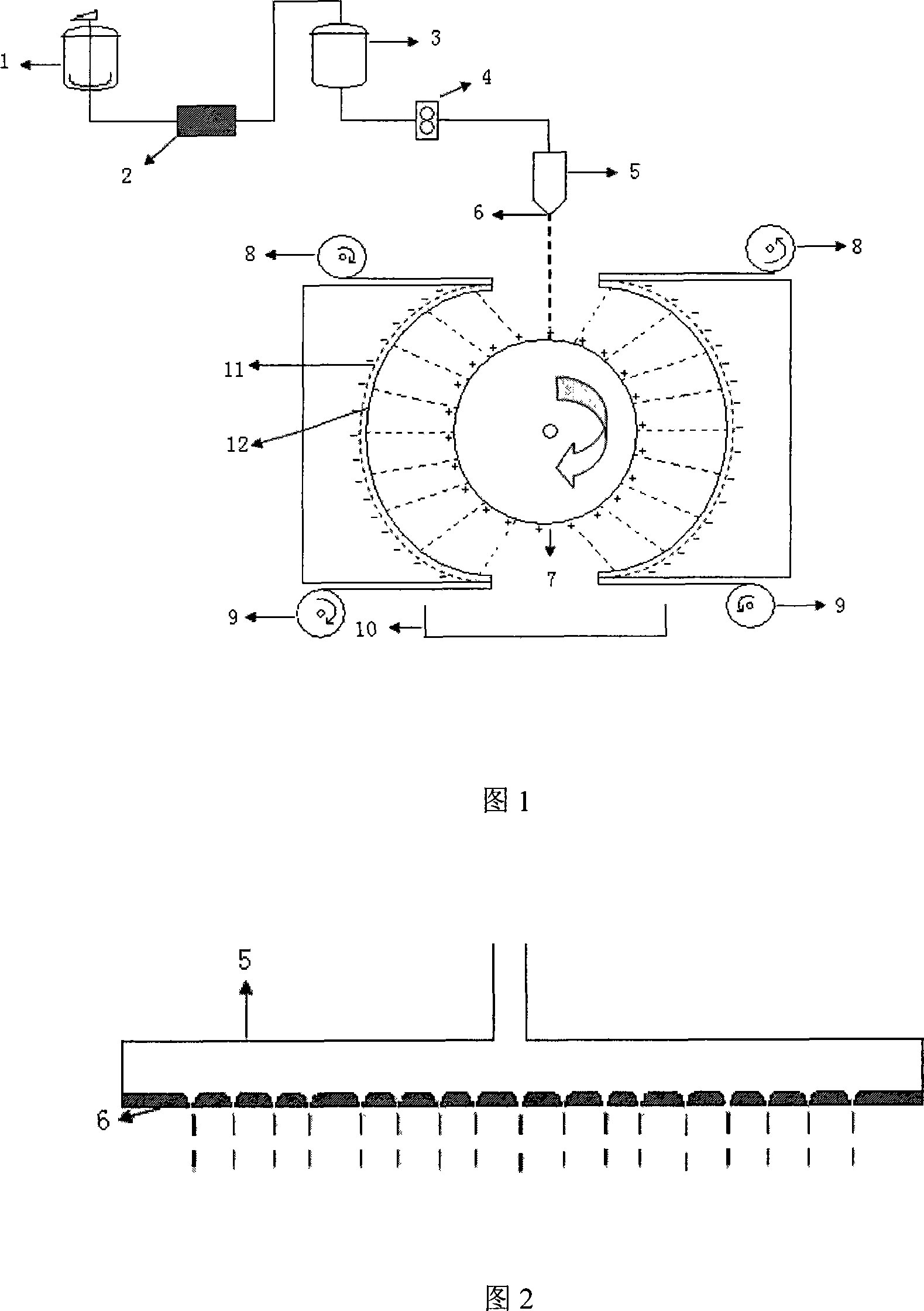

Device and method for preparing highly effective continuous electrostatic spinning nano fibre felt

InactiveCN101215762AGuaranteed continuous supplyEasily overcome surface tensionSpinning head liquid feederFilament/thread formingFiberLiquid storage tank

The invention relates to a preparing device of a high-effective continuous-type electro-spin nanometer fiber felt, the invention comprises a fluid supply system, a metal roller, a receiving device and a spinning fluid recycling groove. The process for preparing comprises firstly, preparing polymer spinning fluid with correct concentration in a dissolution kettle, temporarily storing in a liquid storage tank after passing through a filter, secondly, connecting the metal roller and the positive electrode of a high-pressure electrostatic generator, applying correct electrostatic pressure, leading an aluminium screen cloth to connect ground, thirdly, leading the metal roller to rotate in correct rotary speed, fourth, starting a measuring pump, feeding spinning liquid from the liquid storage tank to an even allotter, leading the spinning liquid to be evenly allocated to a spraying hole on the front end of the even allotter, sputtering from the spraying hole to the surface of a rotating metal roller to form Taylor awl, fifthly, leading a coiling drum to rotate to drive a fiber receiving net to move, and continuously receiving nanometer fiber felt. The process for preparation of the nanometer fiber felt of the invention has high production efficiency, which is suitable for scale production of electro-spinning.

Owner:DONGHUA UNIV

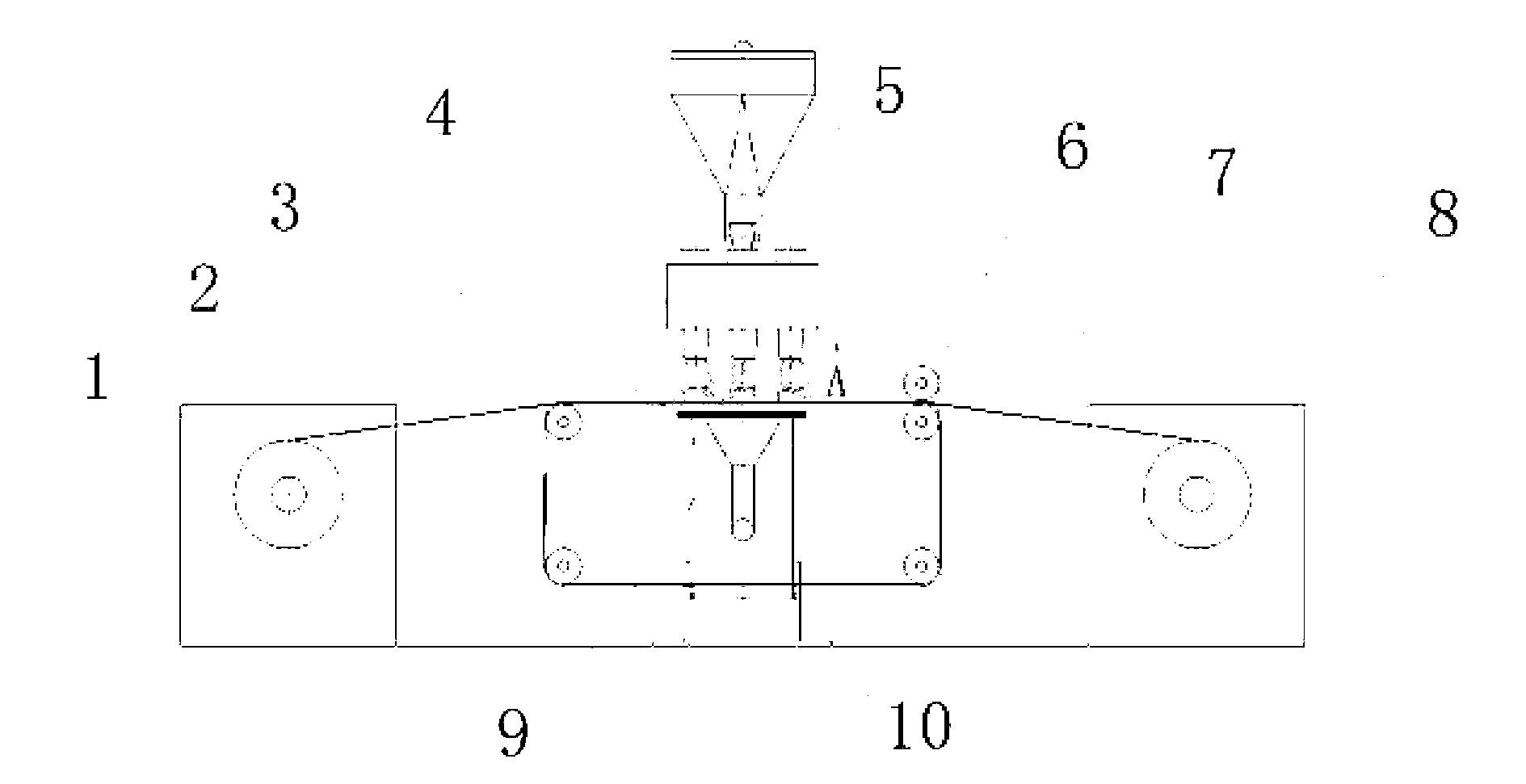

Device and process for mass production of nanometer fiber by melt electro-spinning method

ActiveCN102839431AMelt thinningFlexible arrangementSpinnerette packsFilament/thread formingMelt blowingNanofiber

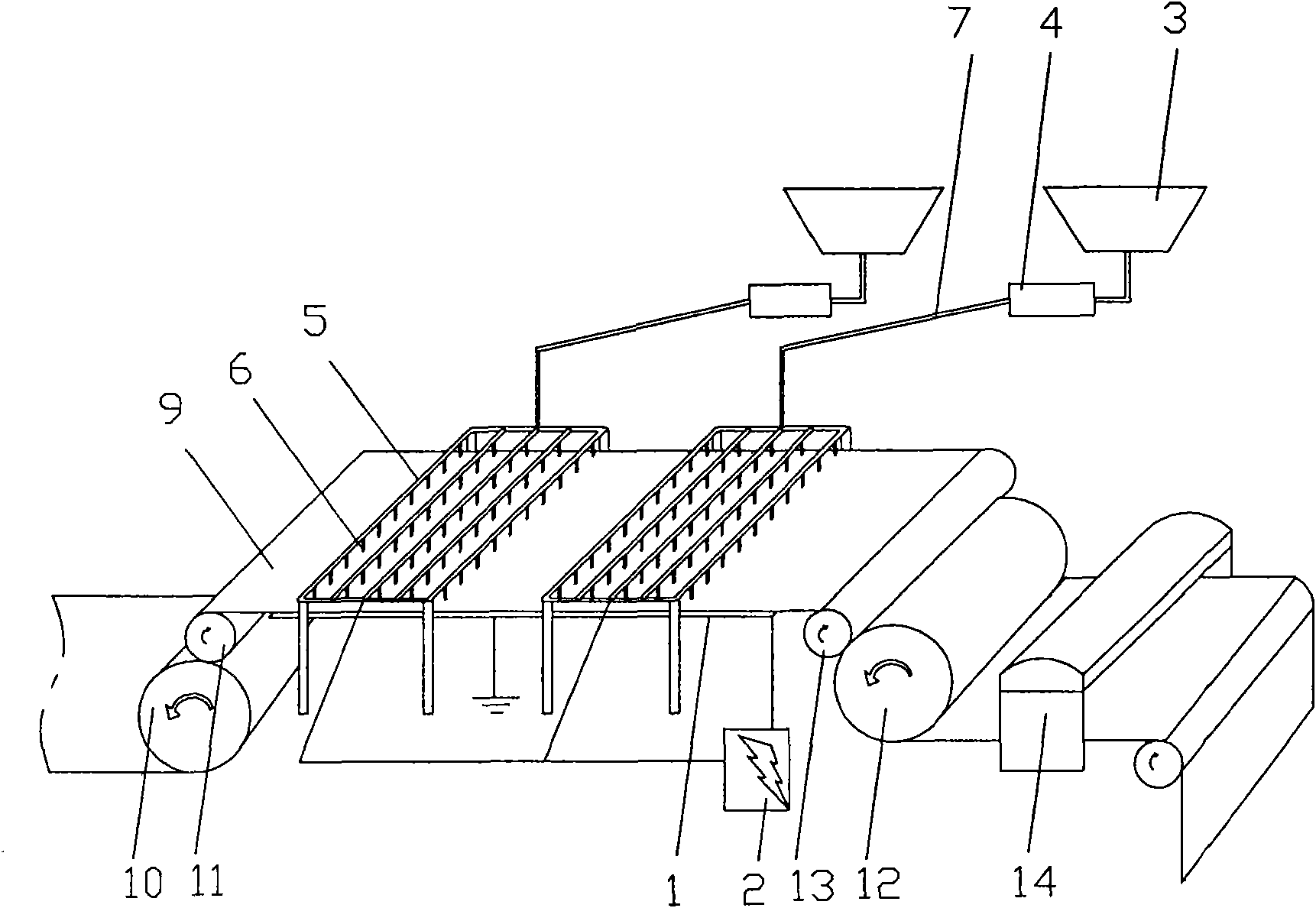

The invention relates to a device and a process for mass production of nanometer fiber by a melt electro-spinning method, belonging to the field of electro-spinning. The device mainly comprises a base fabric unwinding device, a conveyor belt device, a high-voltage electrode net, a spinning die head assembly, a melt body metering pump, a static removal roller, base fabric, a base fabric winding device, a hot wind return path, an electrode net insulation support, a melt body transmission device, a high-voltage static generator and an air heating system, wherein by the application of a primary division runner in the spinning die head assembly, primary division and accurate partition temperature control of a melt body can be realized; with the creation of a nozzle on an airflow-assisted inner conical face and the assistance of high-speed hot air, secondary division thinning of a melt body layer is realized; by the whole device and the corresponding process, the problems of thick fiber and low yield of the traditional melt body spinning device and process are solved, the device and the process can substitute a melt blowing method to be the main production device and process for production of non-woven materials, and a new path is provided for the production of hundred-nanometer fiber products.

Owner:BEIJING UNIV OF CHEM TECH

Sorting device convenient to classify express packages

ActiveCN108657800AEasy to classifyEasy to pack and transportConveyorsCleaningSurface mountingPortal frame

The invention discloses a sorting device convenient to classify express packages. The sorting device comprises a conveyor; a conveying belt is mounted on the upper surface of the conveyor; an arc block is fixedly mounted on the side, near the conveying belt, of the upper surface of the conveyor; an electrostatic generator is embedded in the conveyor; a cleaning roller is embedded in the upper side, near the electrostatic generator, in the conveyor; a fixed plate is fixedly mounted on one side of the conveyor; an express outlet box is fixedly mounted on the other side of the conveyor; and portal frames are fixedly mounted on the side, near the arc block, of the upper surface of the conveyor. Through the portal frames with different heights, the express packages can be classified and sortedaccording to the heights thereof, so that the express packages in the same regions can be conveniently transported; through a push plate and the arc block, the damage problem of the express packages caused by long-time friction with the conveyor can be prevented; and the electrostatic generator and the cleaning roller can clean the conveying belt during working of the conveyor.

Owner:磐安县天诚科技有限公司

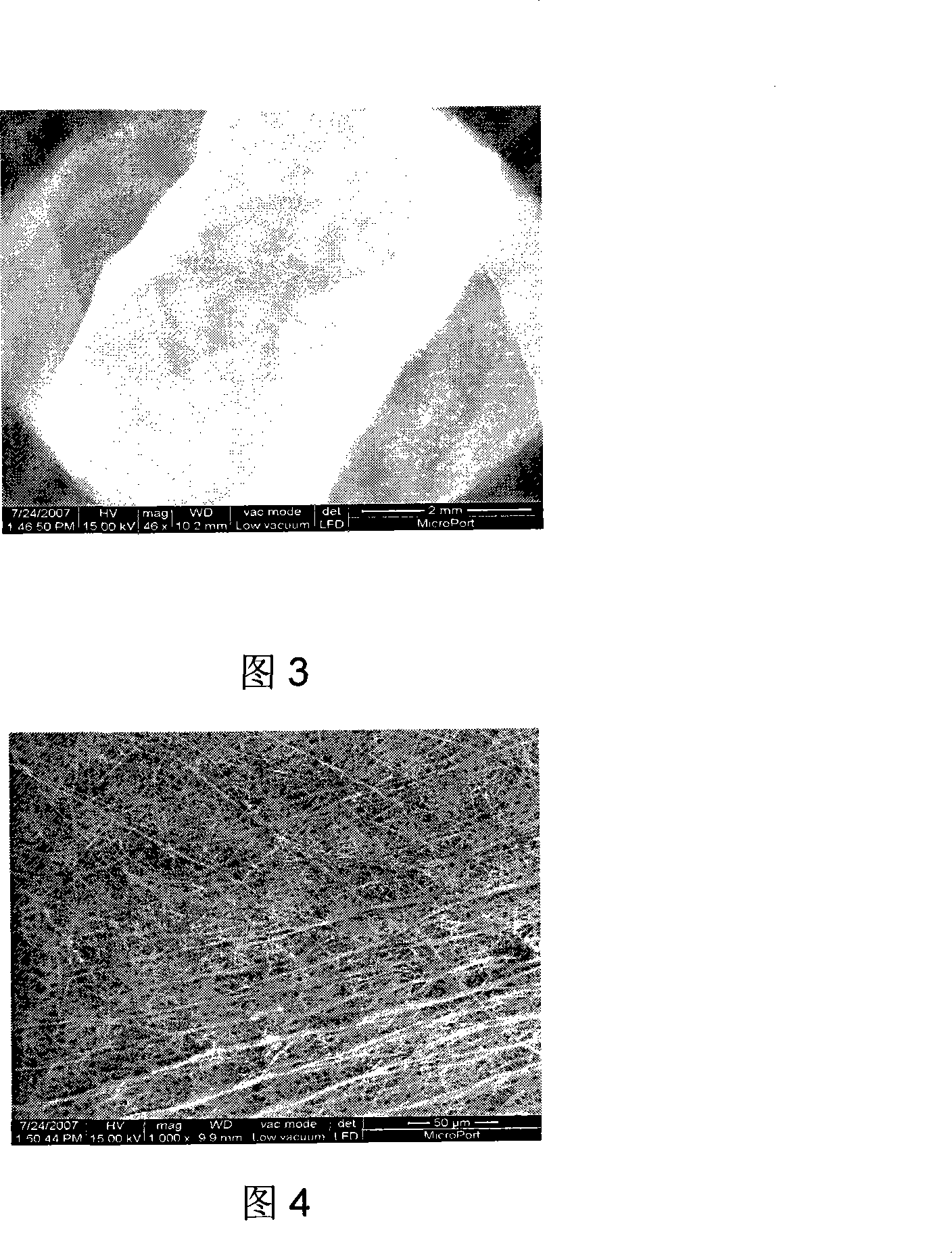

Preparation method of shell core fibre tectorial membrana endovascular stent

The invention relates to a preparation method of a shell core fiber covered endovascular stent graft. The steps are as follows: firstly, a polymer is dissolved in adaptive dissolvent to obtain solution with a certain concentration; secondly, medicine or an artificial polymer and medicine, and a bio-active element are dissolved in the adaptive dissolvent to obtain solution or suspension liquid; thirdly, the solution of the polymer and the medicine or the solution or suspension liquid of the medicine or bio-active element are respectively filled in two injectors, the speed of a micro injection pump, the voltage of an electrostatic generator and the distance of a receiving device are adjusted, fiber is obtained through the static spinning preparation, and the fiber is received as a tube shape or film shape structure; fourthly, the endovascular stent graft is fixed on a revolution axle, through the revolution of the endovascular stent graft, the static spinning fiber are directly received as fibrous membrane covered on the endovascular stent graft. The invention can effectively prevent smooth muscle cells from hyperplasia in the stent graft or from narrowing in the stent graft caused by the other functions, and the shell core fiber for the medicine loading can slowly release the medicine to attain the purpose of curing.

Owner:DONGHUA UNIV

Non-nozzle continuous electrostatic spinning system

InactiveCN101275298AIncrease centrifugal forceAvoid electric field interferenceFilament/thread formingEngineeringElectrostatic generator

The invention discloses a non showerhead continuously electrostatic spinning system, which includes a liquid feeding apparatus, a rotating component, a receiving apparatus and an electrostatic generator, wherein, the liquid feeding apparatus provides liquid for the rotating component, the rotating component is connected to a driving mechanism in transmission, the receiving apparatus faces to the rotating component, one pole of the electrostatic generator is electrically connected to the receiving apparatus, and the other pole is electrically connected to at lest one of the liquid feeding apparatus and the rotating component. The inventive spinning system has good product quality and high efficiency.

Owner:SOUTH CHINA UNIV OF TECH

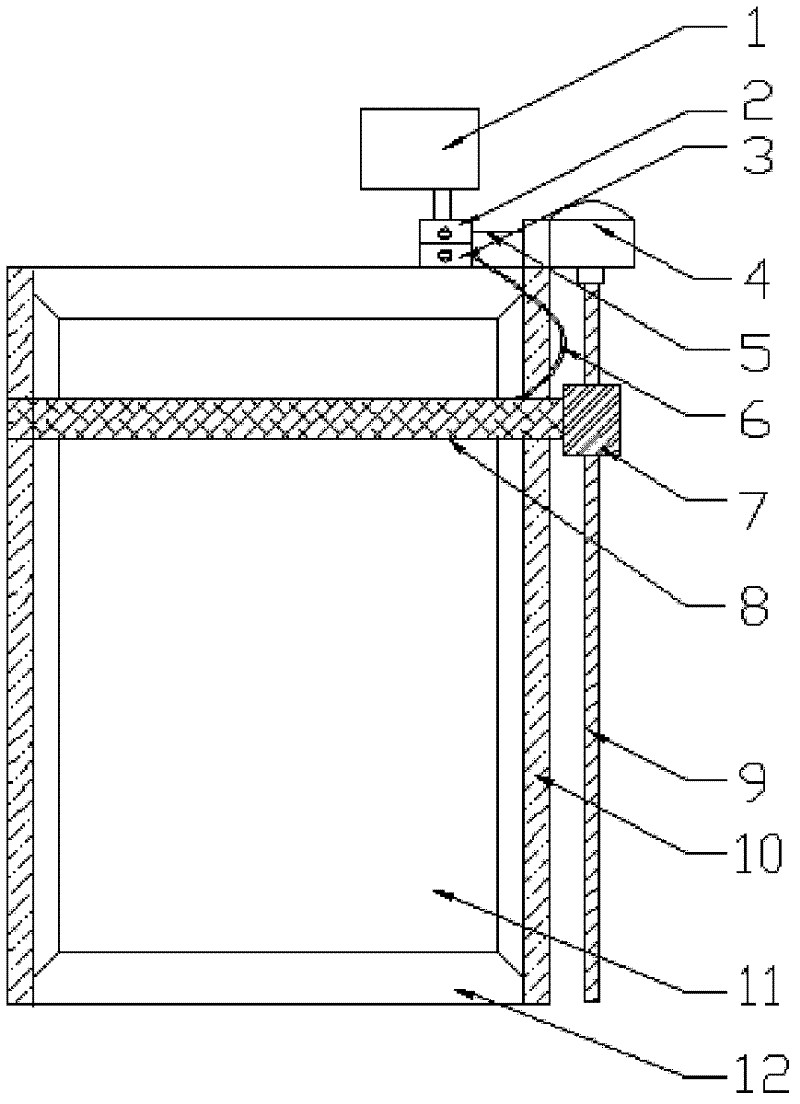

Automatic dust removing device for solar cell assembly

InactiveCN102416393AExtended service lifeAvoid hot spotsFlexible article cleaningEngineeringMaterial resources

The invention discloses an automatic dust removing device for a solar cell assembly. The dust removing device comprises a direct-current motor power supply switch, a direct-current motor, a ball screw, a linear guide rail and an electrostatic brush, wherein the electrostatic brush comprises an electrostatic generator and fan power supply switch, an electrostatic brush cover, a vent, an electrostatic generator, a fan, an electrostatic net, a dust absorption brush and a dust storage chamber; and the electrostatic brush moves up and down on the surface of the assembly during working and absorbs dust by using electrostatic effect, so that the purpose of removing the dust is fulfilled. The device has high automation degree and high work efficiency, saves a large amount of manpower and material resources, and can effectively remove the dust on the surface of the assembly so that the solar radiation intensity on the surface of the assembly is maximum and normal power output of the assembly is ensured; and through the device, hot spot effect in the assembly can be avoided, the assembly is protected, and the service life of the assembly is prolonged.

Owner:WORLDWIDE ENERGY & MFG NANTONG

Double-circular-ring-shaped slit type electrostatic spinning device and method

InactiveCN105821497ARealize automatic and precise supplyRealize industrial preparationFilament/thread formingFiberCollection system

The invention discloses a double-circular-ring-shaped slit type electrostatic spinning device and method. The electrostatic spinning device comprises a liquid supply system, a double-circular-ring-shaped slit type nozzle system and a nano fiber collection system. The electrostatic spinning method comprises the following steps of: starting a microinjection pump to enable a solution to flow into a slit between an inner ring and an outer ring through a micro-channel in an inner core; adjusting the flow of the solution to enable a liquid surface of the solution to fully overflow in the slit, but not flow out; starting a speed regulating motor to enable a metal roller to rotate normally; starting a high-voltage electrostatic generator and slowly increasing voltage; when the voltage exceeds a certain value, forming a plurality of jet flows in the slit; in a process that the jet flows fly to the metal roller, volatilizing a solvent and curing a high polymer to form nano fibers which are deposited on the metal roller; and rotating the metal roller to collect the nano fibers. By adopting the microinjection pump and the liquid supply system, a high polymer solution can be automatically and accurately supplied, and the solution is sufficiently and efficiently utilized, so that the yield of the nano fibers is improved and continuous preparation of the nano fibers is realized.

Owner:DONGHUA UNIV

Automatic control multi-spray-head electrostatic spinning equipment

InactiveCN102776582AEasy to adjustAffect qualitySpinnerette packsFilament/thread formingFiberAutomatic control

The invention provides automatic control multi-spray-head electrostatic spinning equipment, which comprises a high-voltage electrostatic generator, a receiving device and a lifting device and is characterized by also comprising an automatic control box, a dustproof transverse moving slide table, a multi-passage precise liquid supply pump and a self-cleaning type multi-spray-head device, wherein data interfaces of multi-passage precise liquid supply pump, the dustproof transverse moving slide table and the receiving device are respectively connected with the automatic control box, an injector is fixedly arranged at the multi-passage precise liquid supply pump, the self-cleaning type multi-spray-head device is connected with the front end of the injector, a bakelite plate covered with a conducting wire is fixedly arranged on a spinning head, a conducting clamp post is fixedly arranged on the bakelite plate covered with the conducting wire, and the high-voltage electrostatic generator is connected with the conducting clamp post. The automatic control multi-spray-head electrostatic spinning equipment has the advantages that the precision, integration and automation degree is high, the operation is simple, convenient, safe and fast, the production efficiency is high, and wide application prospects are realized in the industrial aspect of nanometer fibers.

Owner:DONGHUA UNIV

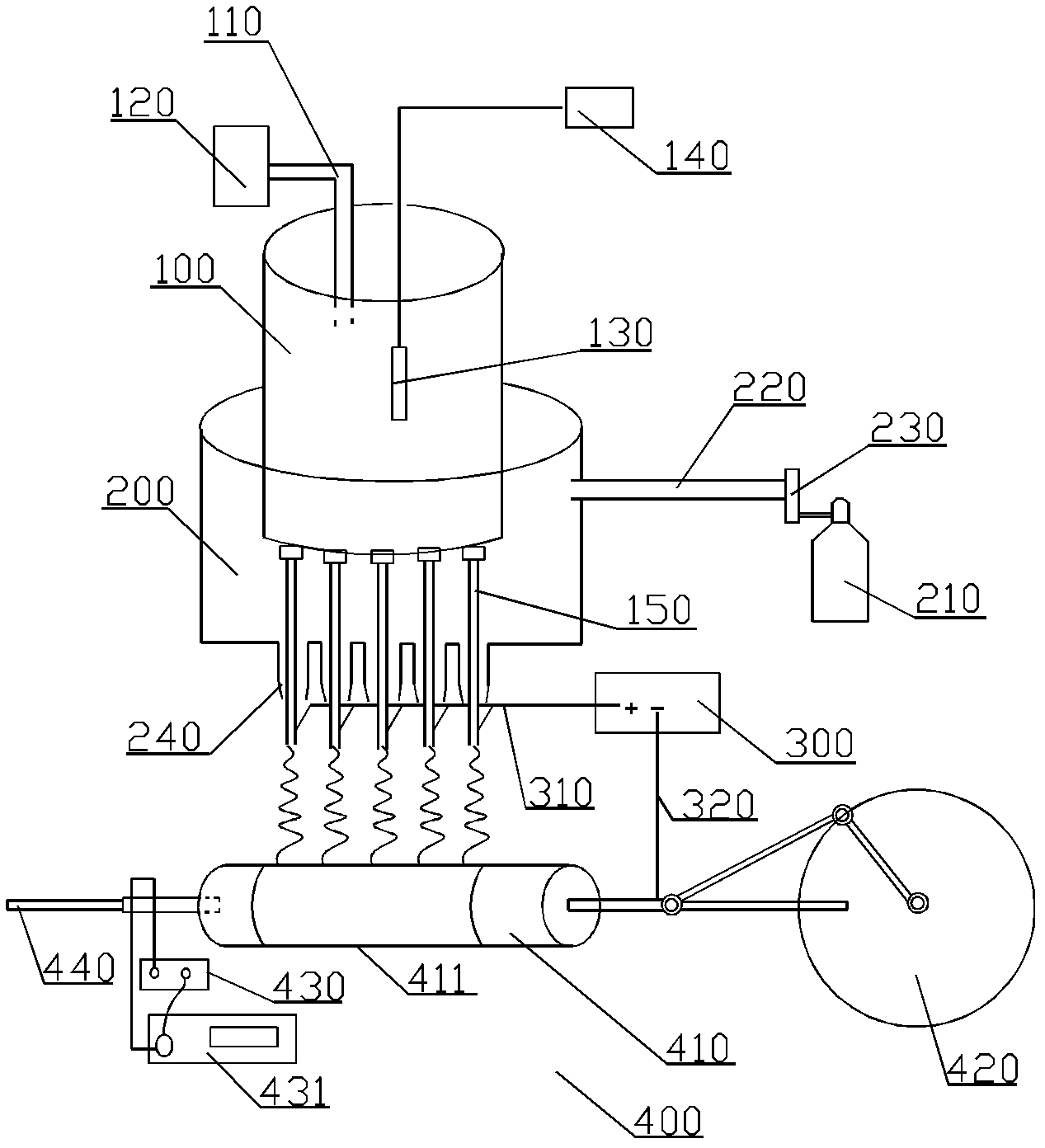

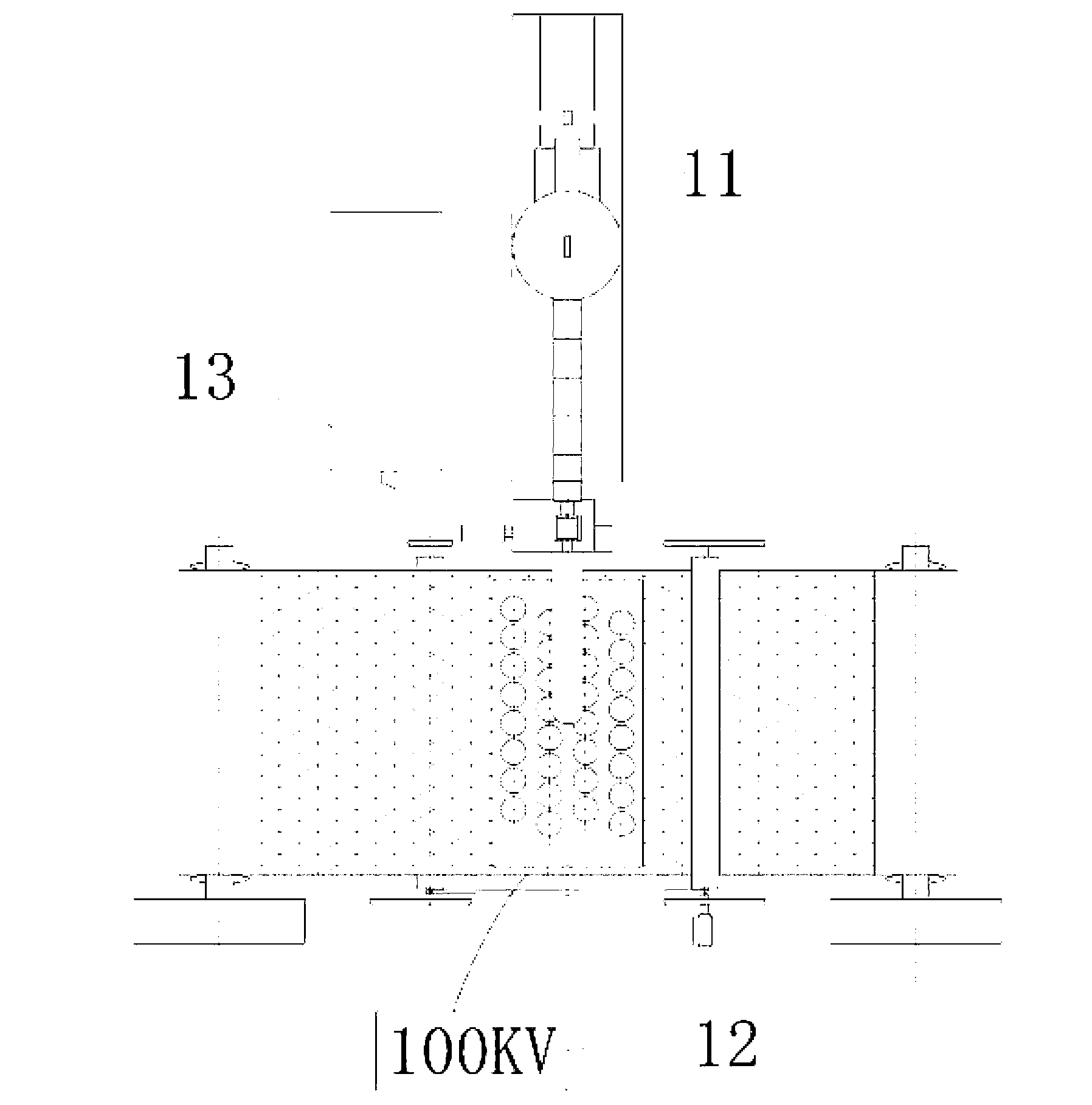

Differential melt electro-blowing spinning device and technology for preparing nanofibers in batches

ActiveCN103451754ARealize industrial productionRealize batch preparationFilament/thread formingNon-woven fabricsFiberSpinning

The invention discloses a differential melt electro-blowing spinning device and technology for preparing nanofibers in batches, and belongs to the field of electrostatic spinning. The device mainly comprises an extruder, a filter screen, a melt metering pump, a spinning manifold, an airflow heating device, an air compressor, an upper plate electrode, a lower plate electrode, a high-voltage electrostatic generator, a guide air knife, a hot rolling device, a receiving device, a screen spreading belt and an air draft system. An outlet of the extruder is connected with the filter screen, and the melt metering pump is connected between the filter screen and the spinning manifold through a flange. Airflow is divided into two portions through a flow divider to be connected to the spinning manifold; after melt is divided and guided in flow through the spinning manifold, a thin uniform-flowing melt layer is obtained at the lower end of a wavy flow guide plate; under the high-voltage electrostatic action, the melt layer forms a plurality of Taylor cones in a self-organization manner, the Taylor cones are stretched and split continuously under the conditions of high-speed airflow and high-voltage electrostatics, and superfine fibers are formed at the receiving end of the screen spreading belt by means of curing. By the aid of the device and technology, difficulties of high viscosity of polymers, low yield, complicated devices and the like are overcome, and industrial production of differential melt electro-blowing spinning can be achieved.

Owner:BEIJING UNIV OF CHEM TECH

Electrostatic spinning machine

InactiveCN1908255AReduce processing stepsAvoid lack of assemblyFilament/thread formingState of artElectrospinning

The invention relates to static spinning machine, which comprises: a high-voltage system, a material supplier, an ejection height adjuster, and a collector, wherein said power system is formed by high-voltage direct-current static generator, an anode and a cathode; the supplier is formed by a cup support, a micro ejection pump, and an ejector; the adjuster comprises a group of worm systems integrated with the liquid storage cup, while one end of it fixes the liquid storage cup and another end has the worm wheel meshed with worm, to slide along the trapeze groove at the side edge of worm groove; and the collector can be metallic plate shape, mesh shape and tube shape.

Owner:FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com