Jet yarn spinning device for electrostatic spun nano fiber and preparing method

A nanofiber, air-jet spinning technology, applied in fiber processing, textiles and papermaking, spinneret assemblies, etc., can solve the problem that nanofiber yarns cannot be obtained stably and continuously, fibers cannot be well oriented, lack stability, Continuity and other problems, to achieve the effect of simple structure, high production efficiency, and avoidance of blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

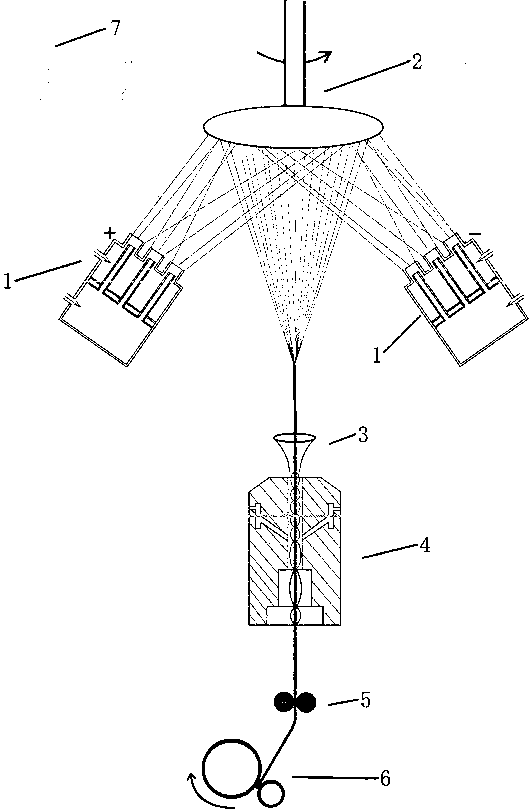

[0031] Depend on figure 1 , image 3 and Figure 4 As shown, an air-jet spinning device for electrospinning nanofibers includes a spinning device 1, a gathering device 2, a bundler 3, a nozzle twister 4, a yarn drawing roller 5, a winding mechanism 6 and a high-voltage electrostatic generator 7.

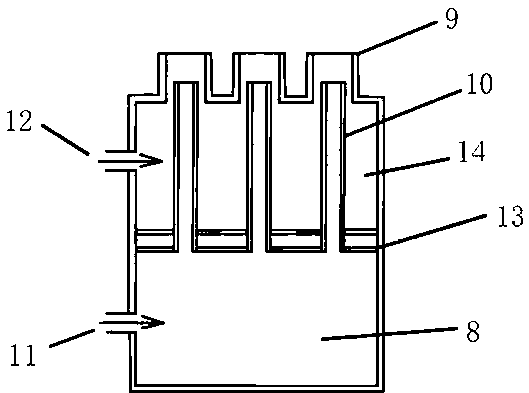

[0032] The spinning device 1 is formed by connecting an air chamber 8 with an air inlet 11 on one side and a solution chamber 14 with a liquid inlet 12 on one side through an intermediate connecting body 13. The air chamber 8 and the solution chamber 14 are cylindrical. A vertically upward air spray pipe 10 is arranged on the intermediate connecting body 13 , and a vertically upward spinneret 9 is arranged on the solution chamber 14 . The number of spinnerets 9 and air jets 10 is 5, arranged in concentric circles, with 1 in the center and 4 on the sides. Each spinneret 9 corresponds to a concentric air jet 10 for ventilation, and the air jets 10 The height is lower than the upper...

Embodiment 2

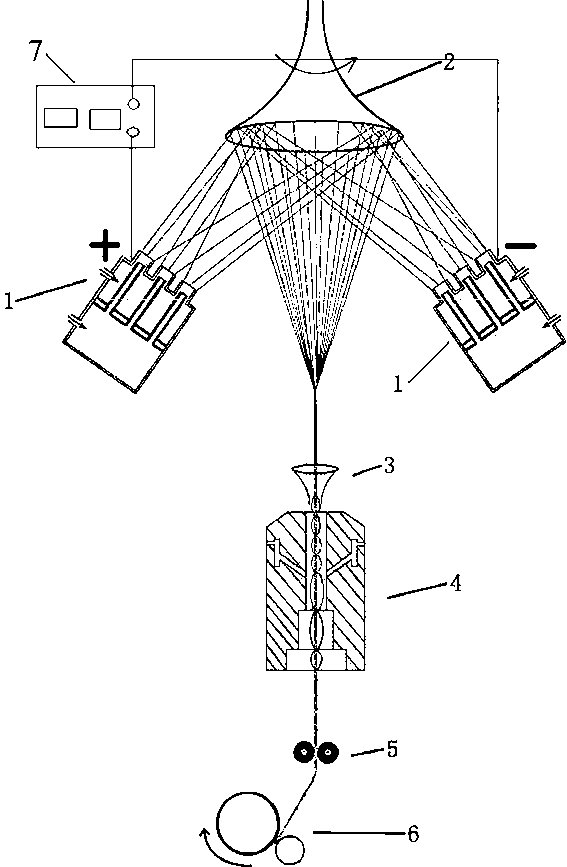

[0045] Depend on figure 2 , image 3 and Figure 4 As shown, an air-jet spinning device for electrospinning nanofibers includes a spinning device 1, a gathering device 2, a bundler 3, a nozzle twister 4, a yarn drawing roller 5, a winding mechanism 6 and a high-voltage electrostatic generator 7.

[0046] The spinning device 1 is formed by connecting an air chamber 8 with an air inlet 11 on one side and a solution chamber 14 with a liquid inlet 12 on one side through an intermediate connecting body 13. The air chamber 8 and the solution chamber 14 are cylindrical. A vertically upward air spray pipe 10 is arranged on the intermediate connecting body 13 , and a vertically upward spinneret 9 is arranged on the solution chamber 14 . The number of spinnerets 9 and air jets 10 is 9, arranged in concentric circles, with 1 in the center and 8 on the sides. Each spinneret 9 corresponds to a concentric air jet 10 for ventilation, and the air jets 10 The height is lower than the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com