Patents

Literature

125 results about "Electrospun nanofiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

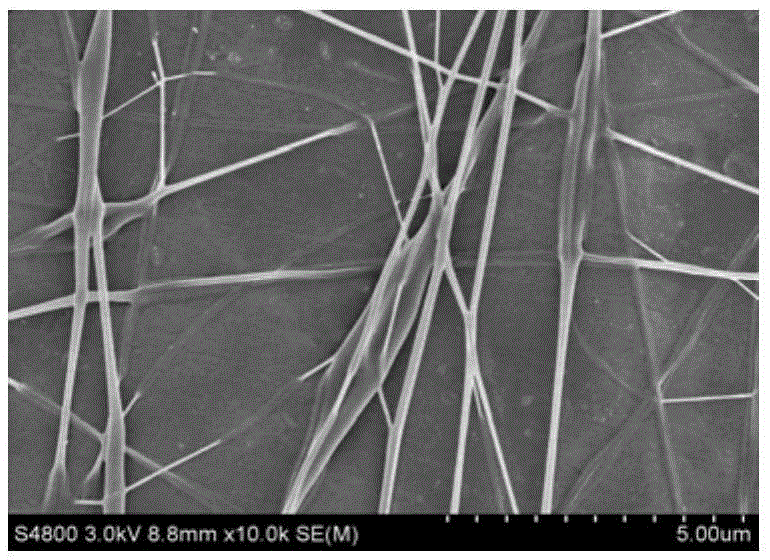

Method for manufacturing electrospun nanofiber gas filtering material in mass manner

InactiveCN105133187AIncrease productionGood breathability and moisture permeabilitySemi-permeable membranesFilament/thread formingFiberElectrospun nanofiber

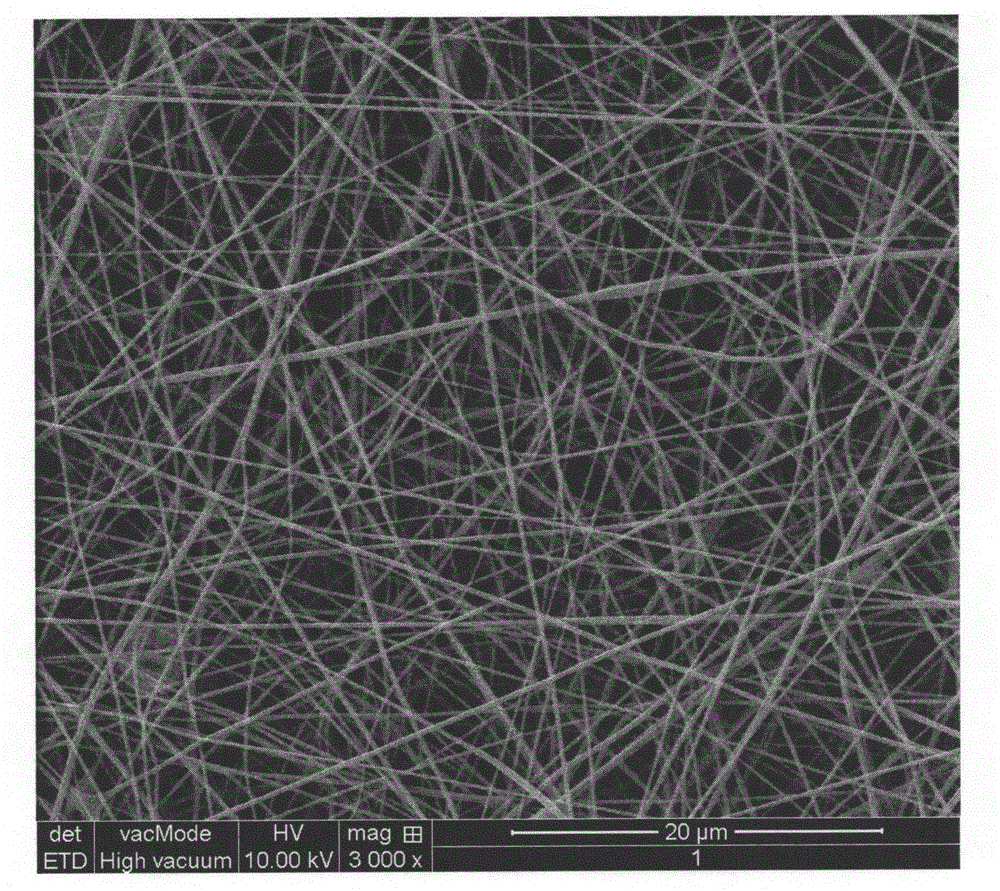

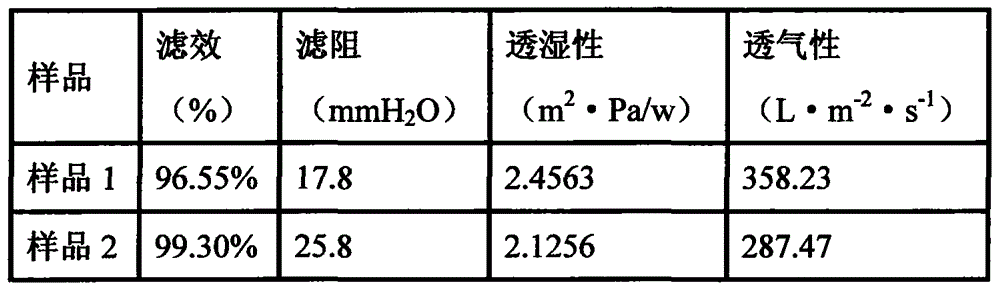

The invention discloses a method for manufacturing an electrospun nanofiber gas filtering material in a mass manner by using an umbrella-shaped electrostatic spinning sprayer. The method comprises: dissolving a high-molecular polymer in a solvent, mixing to obtain an even solution; using the spinning solution in electrostatic spinning to obtain a nanofiber membrane; combining the nanofiber membrane with a non-woven fabric, manufacturing non-woven fabric / nanofilm / non-woven fabric composite film; performing ultrasonic bonding on the non-woven fabric / nanofilm / non-woven fabric composite film, to manufacture a filtering material. The manufacturing method is convenient and fast, and can realize small-batch production. Filtering efficiency of the obtained filtering material reaches up to 99.55%, filtering resistance is 150-200 Pa, gas permeability reaches 355L.m<-2>.s<-1>, and moisture-penetrability reaches 9.6 m<2>.Pa / w, that is, the material has good gas permeability and moisture penetrability, and the method has very good application prospect in the field of air filtering.

Owner:DONGHUA UNIV +1

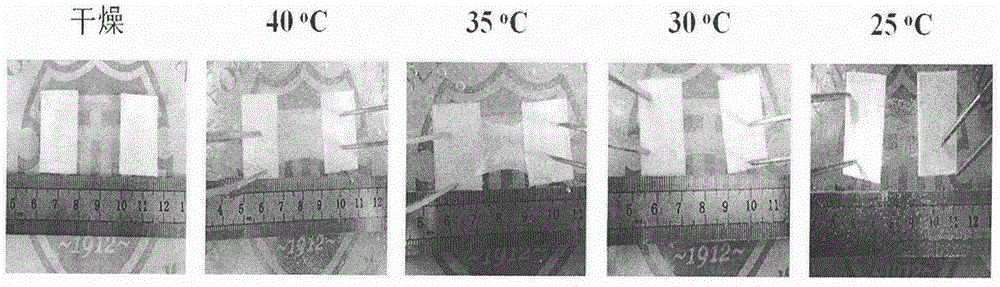

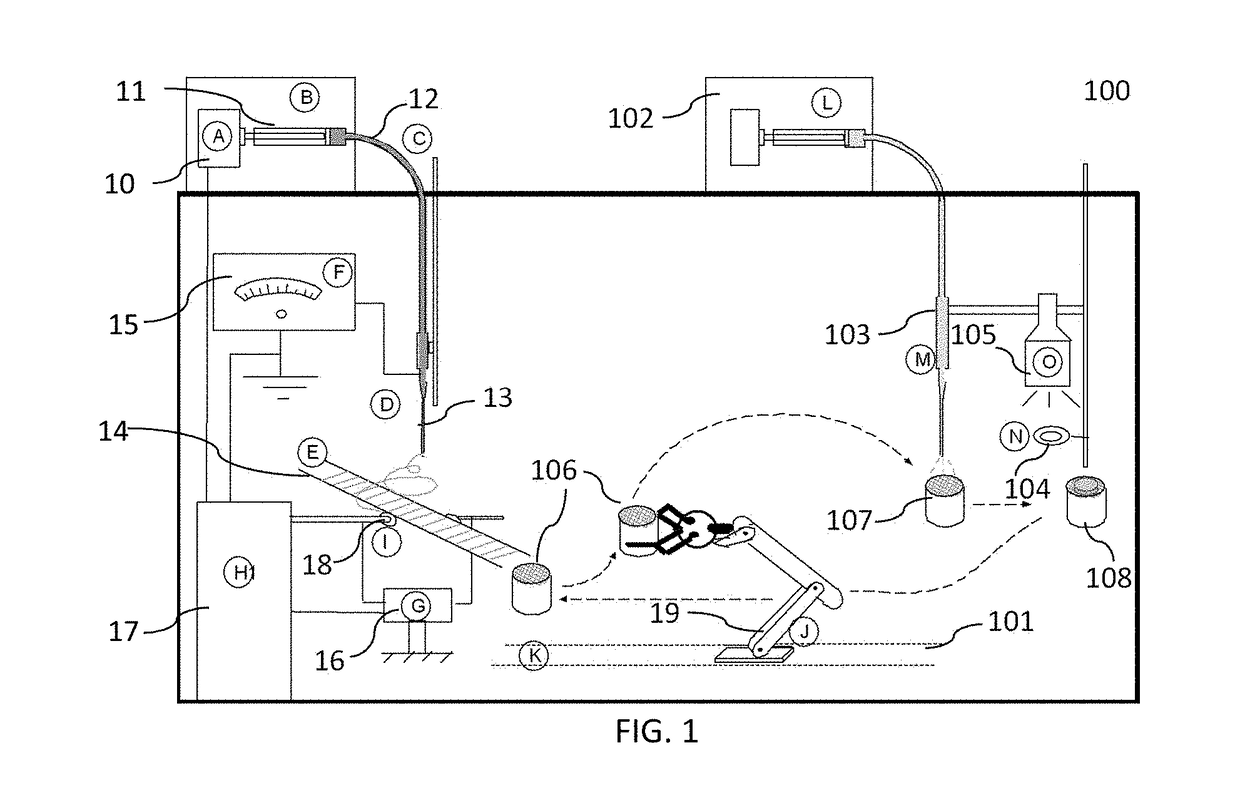

Multiple response type filtration-controllable electrospun nanofiber membrane and preparation method thereof

ActiveCN106319759AAchieving Smart SeparabilityFlux controlNon-woven fabricsElectrospun nanofiberFiber

The invention relates to a multiple response type filtration-controllable electrospun nanofiber membrane and a preparation method thereof. Nanofibers are composed of electrostatic spinning thermosensitive and pH responsive polymers and solvents, and the multiple response type filtration-controllable electrospun nanofiber membrane is formed by putting a prepared mixed solution in an injector and then spinning of an electrostatic spinning apparatus. The multiple response type filtration-controllable electrospun nanofiber membrane and the preparation method thereof have the advantages that since smart response of the thermosensitive and pH responsive polymers in the spinning solution is combined with the advantages of large specific area, high porosity and loose and porous performance of the nanofibers, controllable filtration of air is achieved; the preparation method is simple and easy to implement, low in production cost, high in interception efficiency, low in resistance, rapid in filtration reaction, high in treatment efficiency, reusable and capable of achieving smart separability of the nanofiber membrane and can be applied to the fields such as filtration and adsorption, drug delivery, chemical separation, sensing drive and tissue engineering.

Owner:TIANJIN POLYTECHNIC UNIV

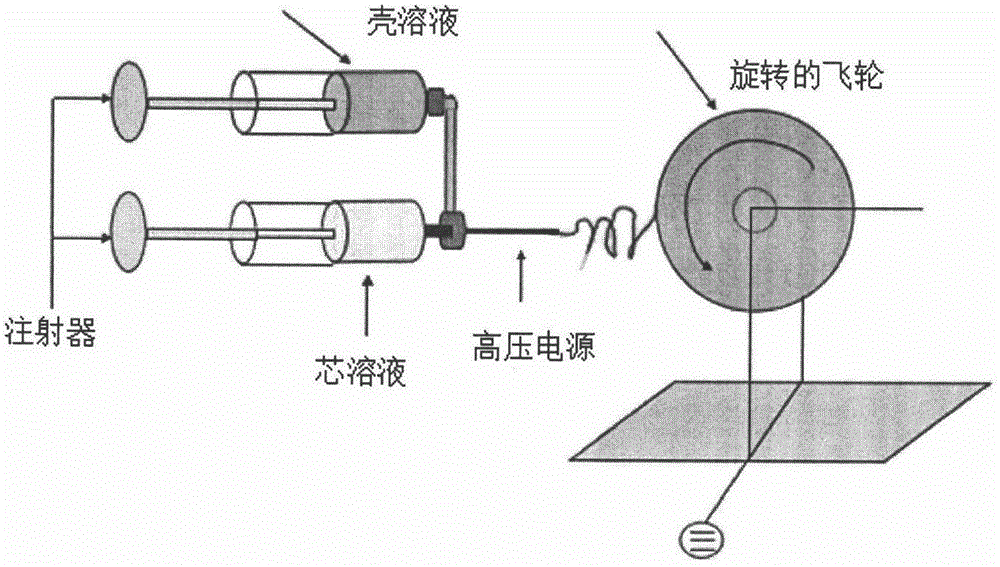

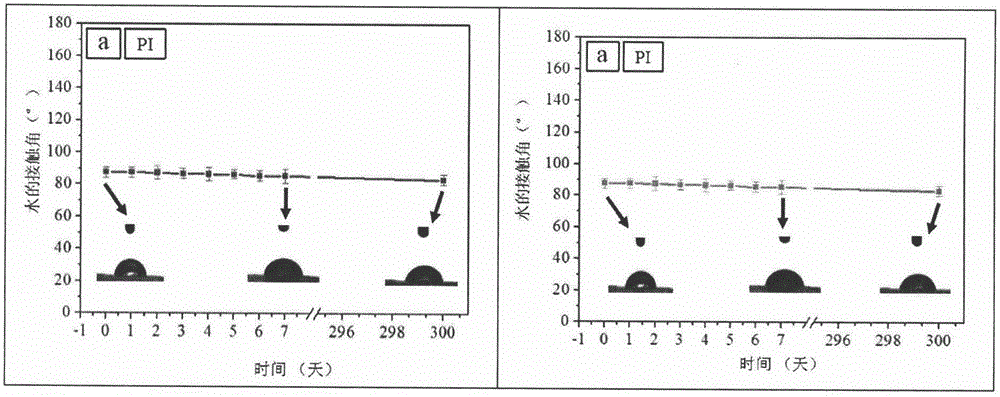

Efficient electrostatic spinning oil-water separation fiber membrane

InactiveCN105603637AEasy to separateImprove separation efficiencyFatty/oily/floating substances removal devicesElectro-spinningFiberSilica nanoparticles

The invention discloses a preparation method of an efficient electrostatic spinning oil-water separation fiber membrane. The preparation method includes the steps that polyamic acid (PPA) is synthesized, a PPA nanofiber membrane is prepared in an electrospinning mode, and the PPA nanofiber membrane is imidized into a polyimide membrane (PI); a cellulose acetate (CA) nanofiber membrane is prepared; coaxial electrospinning is carried out on CA-PAA, and a product is imidized into CA-PI; benzoxazine monomers (BAF-tfa) are synthesized; in-situ immobilization is performed on the CA, PI and CA-PI nanofiber membranes with BAF-tfa and BAF-tfa / silica nanoparticles (SiO2NPs); an oil-water separation experiment is carried out. The preparation method has the advantages that by carrying out surface modification on the fiber membranes, the CA-PI nanofiber membrane which is biodegradable, low in cost, large in oil-water separation flow and high in separation efficiency is obtained; the high-performance membrane material has broad application prospects in oil-water separation, sewage treatment and deepwater oil leak.

Owner:NANJING FORESTRY UNIV

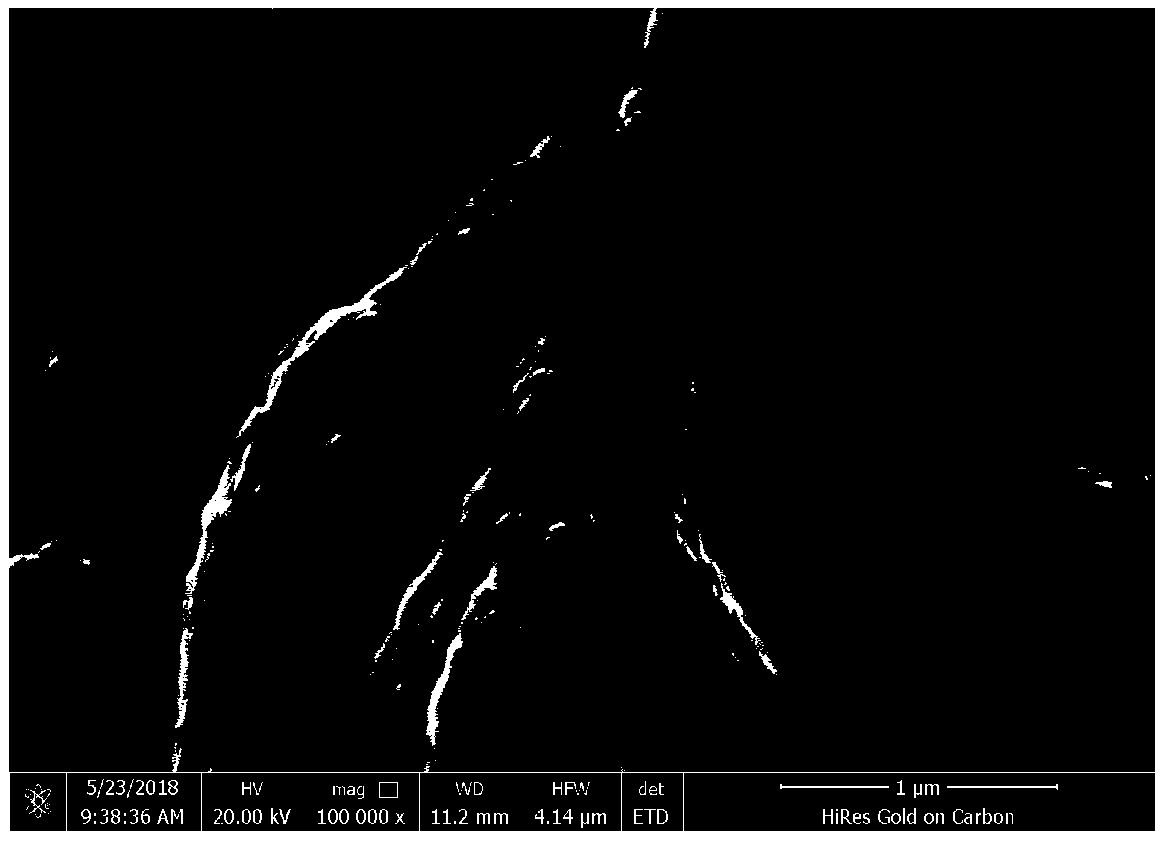

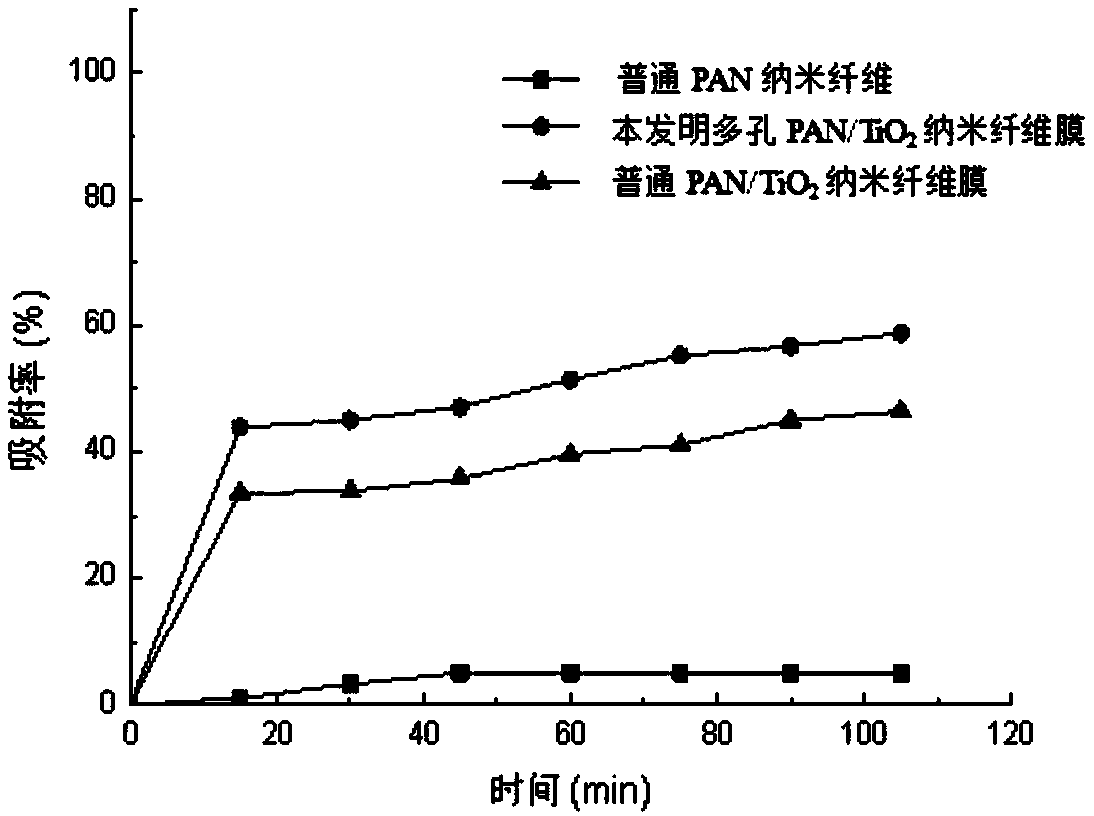

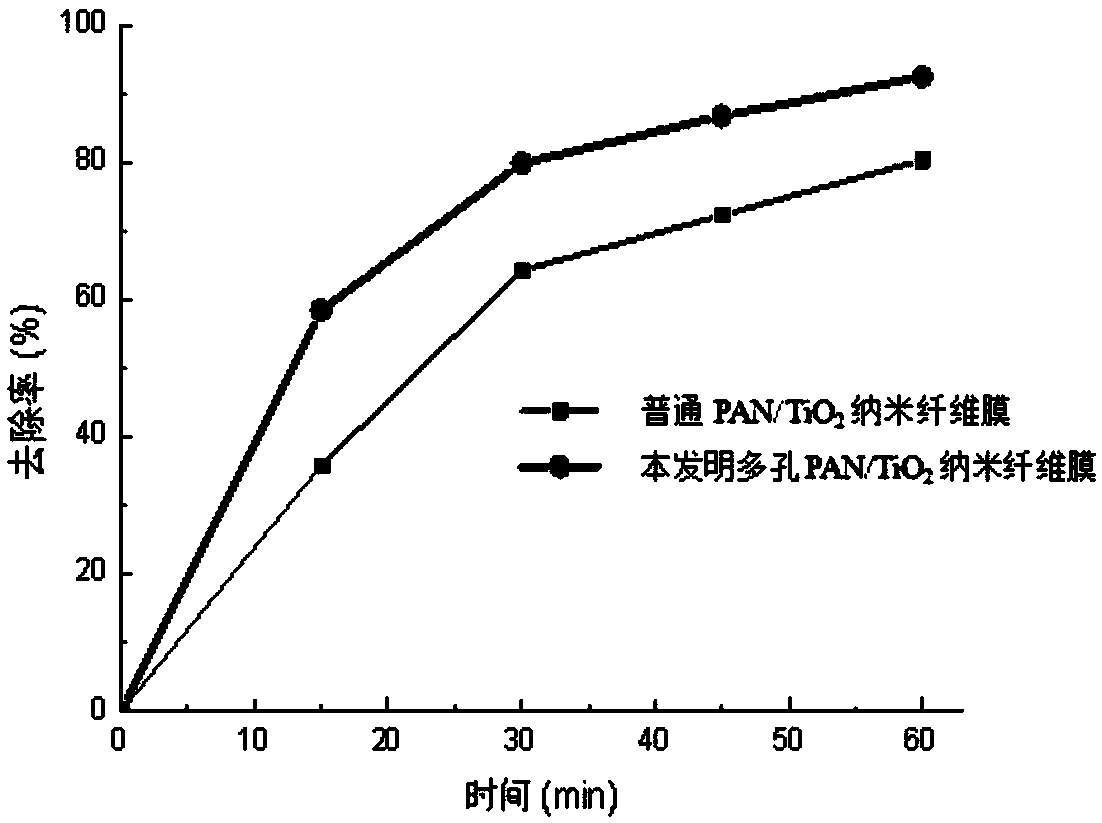

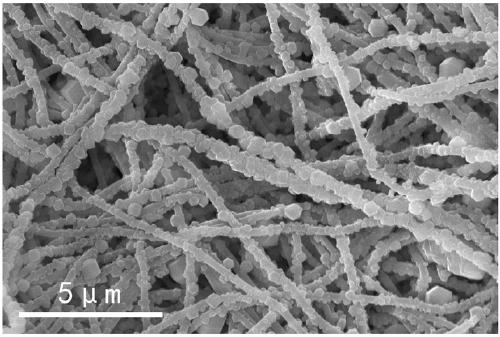

Porous supported electrospun nano photocatalytic fiber membrane and preparation method thereof

ActiveCN108842304ASolve the adsorption problemSolve removalLiquid/gas/vapor removalMonocomponent synthetic polymer artificial filamentPorosityElectrospinning

The invention relates to a porous supported electrospun nano photocatalytic fiber membrane and a preparation method thereof. According to the preparation method, nano titanium dioxide, polyacrylonitrile (PAN) and polyvinylpyrrolidone (PVP) are dissolved in a solvent to obtain an electrospinning solution, a nano photocatalytic fiber membrane loaded with the nano titanium dioxide is obtained throughelectrospinning, and after water treatment is carried out on the nano photocatalytic fiber membrane, the PVP is dissolved out to obtain the porous supported electrospun nano photocatalytic fiber membrane. The porous supported electrospun nano photocatalytic fiber membrane and the preparation method thereof have the advantages that the method is simple, the operation is easy, the cost is low, theprepared photocatalytic fiber membrane has the characteristics of high porosity and large specific surface area, the contact area between the photocatalytic fiber membrane and reactant is effectivelyincreased, the photocatalytic degradation efficiency is increased, the photocatalytic efficiency reaches up to 90% or above, the removal rate of methylene blue can reach up to 93% or above, electrospun nanofiber serves as a carrier to fix the photocatalyst titanium dioxide, thereby preventing the catalyst from being lost and recycling the catalyst, and the photocatalytic effect is permanent.

Owner:XI'AN POLYTECHNIC UNIVERSITY

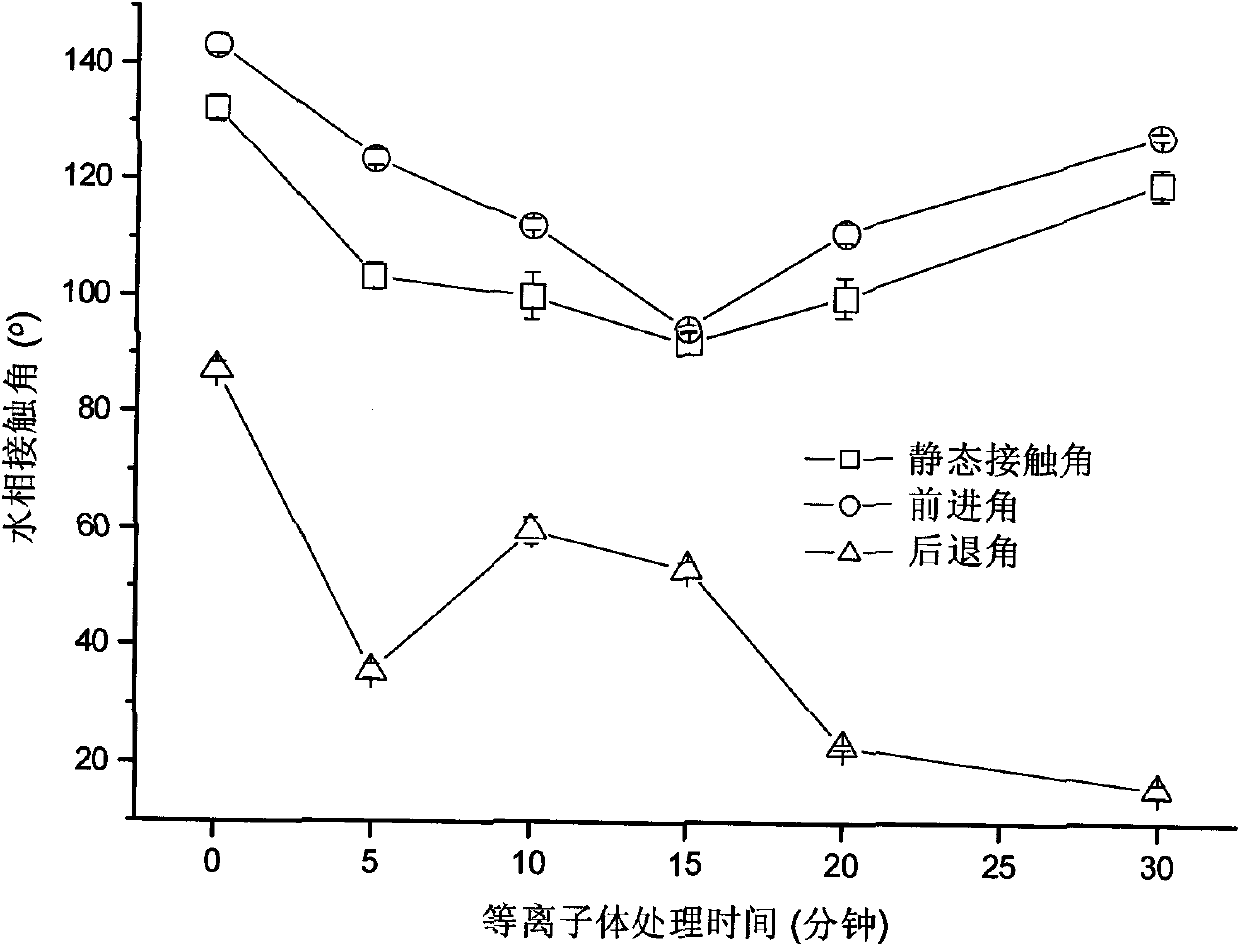

Method for preparing bioactive poly(lactic-co-glycolic acid)/collagen/hydroxyapatite composite fiber membrane for bone repair

The invention discloses a method for preparing a bioactive poly (lactic-co-glycolic acid) / collagen / hydroxyapatite composite fiber membrane for bone repair. The method comprises the following steps of: treating a poly (lactic-co-glycolic acid) electrospun nanofiber membrane by using plasma, coating collagen, and immersing the poly (lactic-co-glycolic acid) electrospun nanofiber membrane into a simulated human physiologic body fluid to mineralize to obtain the poly (lactic-co-glycolic acid) / collagen / hydroxyapatite composite fiber membrane. The preparation method of the invention has the advantages of simpleness, high speed and wide material sources. By adopting the method of plasma treatment and coating, the highly-bionic nanofiber composite membrane is prepared by the steps of introducing collagen with osteocyte epimatrix into the poly (lactic-co-glycolic acid) electrospun nanofiber membrane and depositing active hydroxyapatite onto the fiber membrane, thereby obtaining. The composite fiber membrane has the advantages of favorable combination properties and convenient operation, can effectively promote the capabilities of adherence, growth and calcification osteogenesis of osteoblasts and stem cells, and is hopeful to become an ideal active bracket for bone repair.

Owner:无锡贝迪生物工程股份有限公司

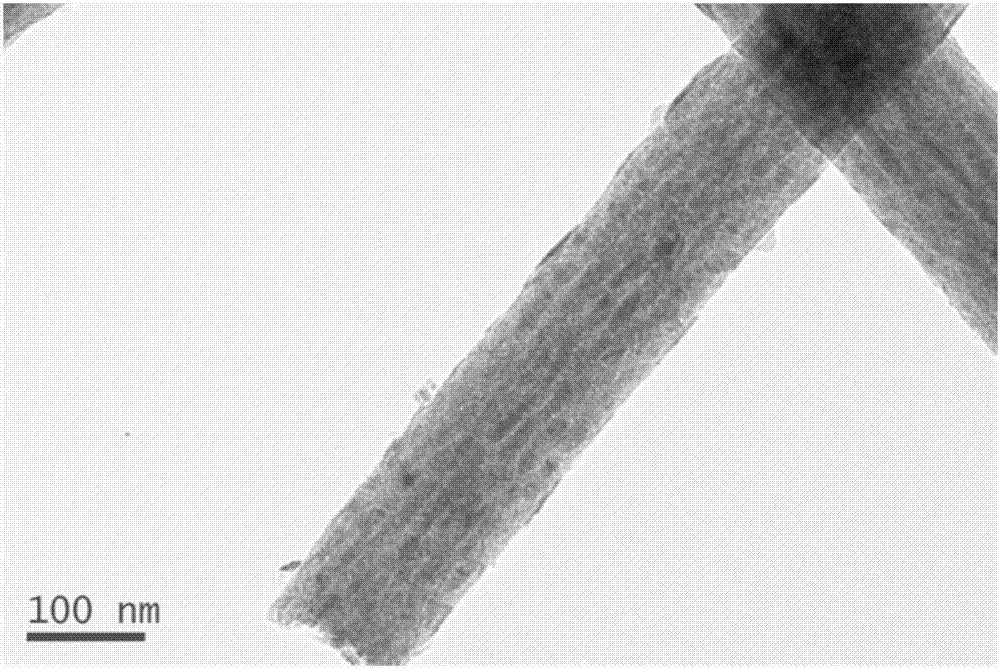

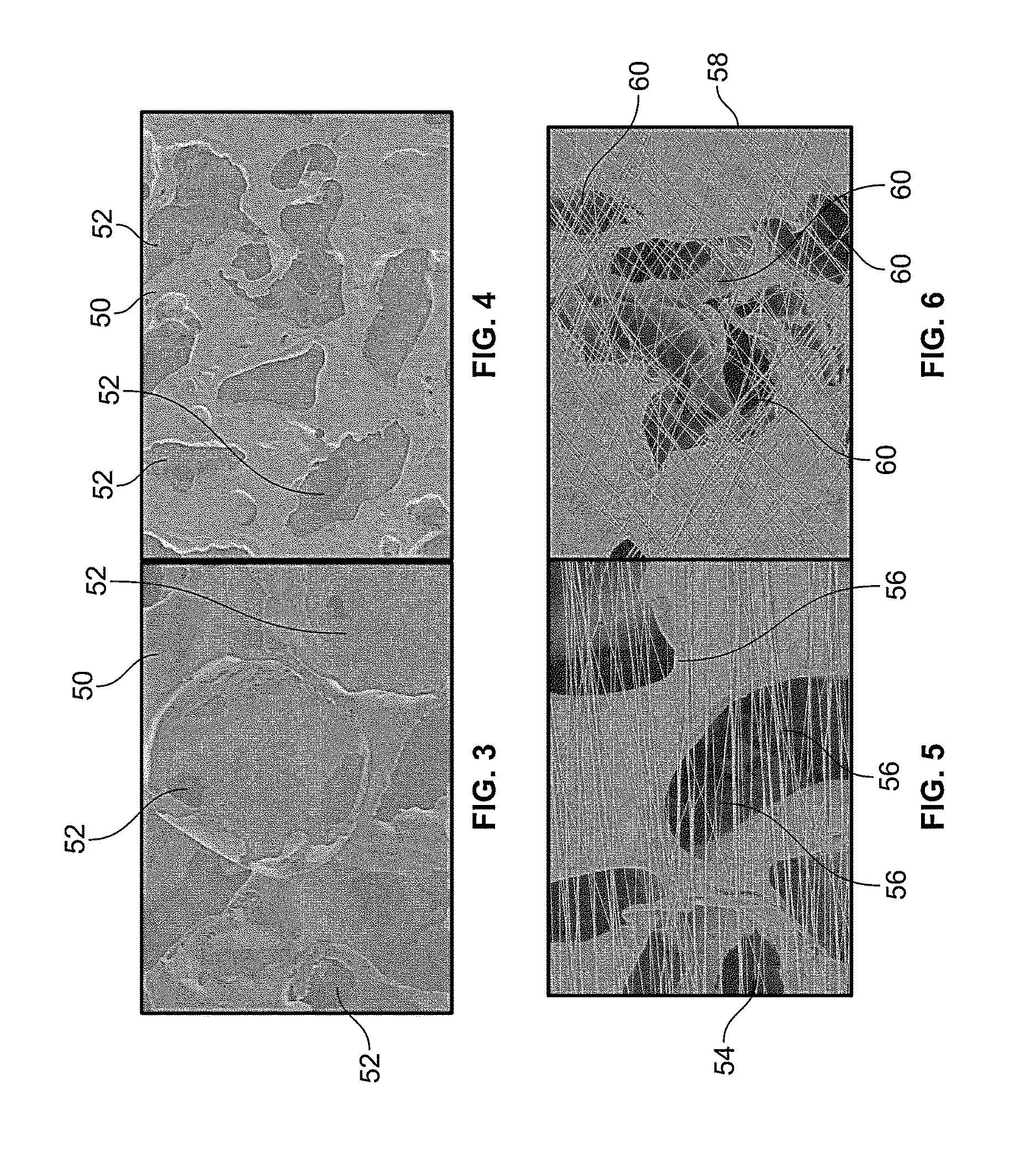

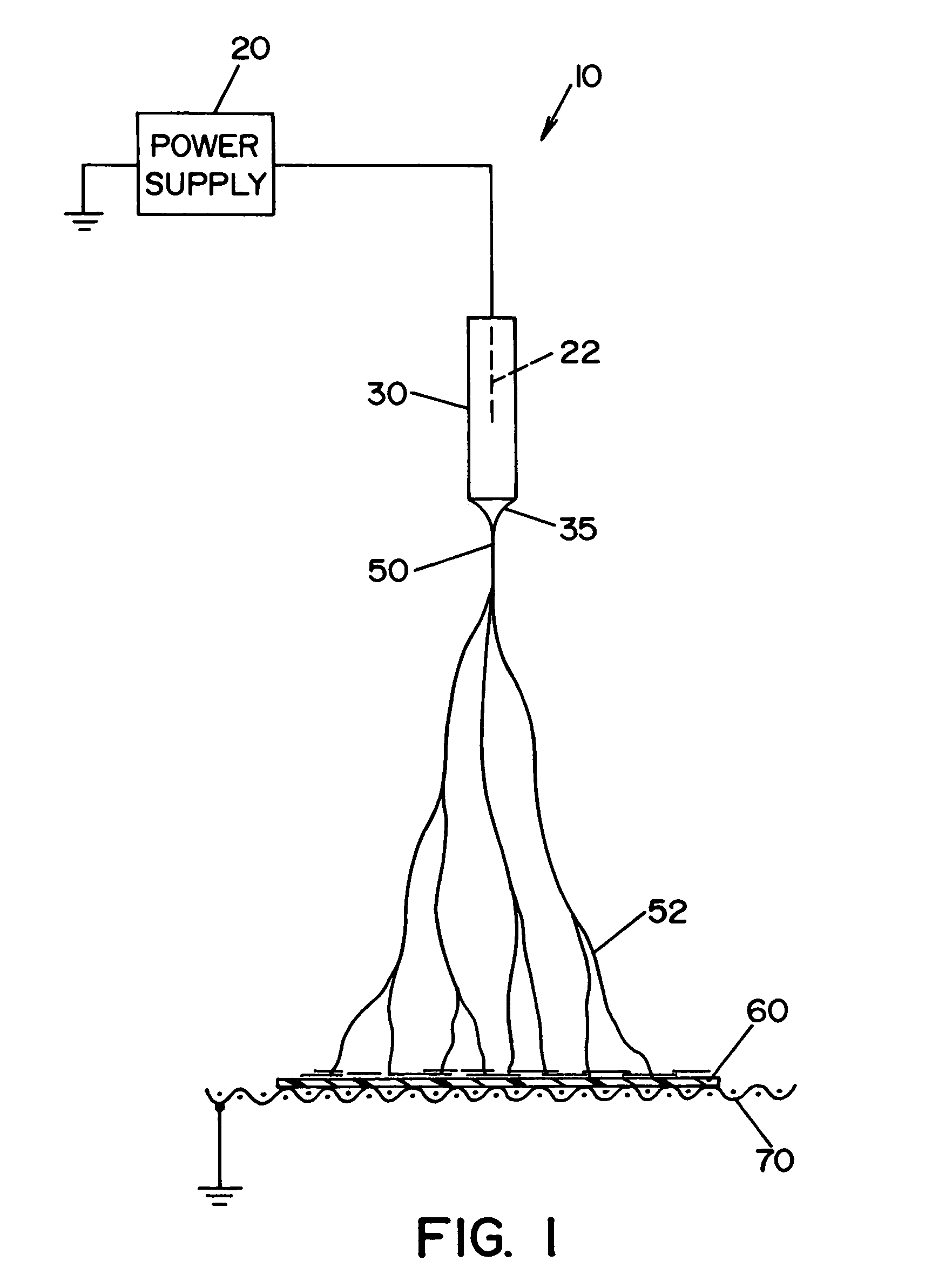

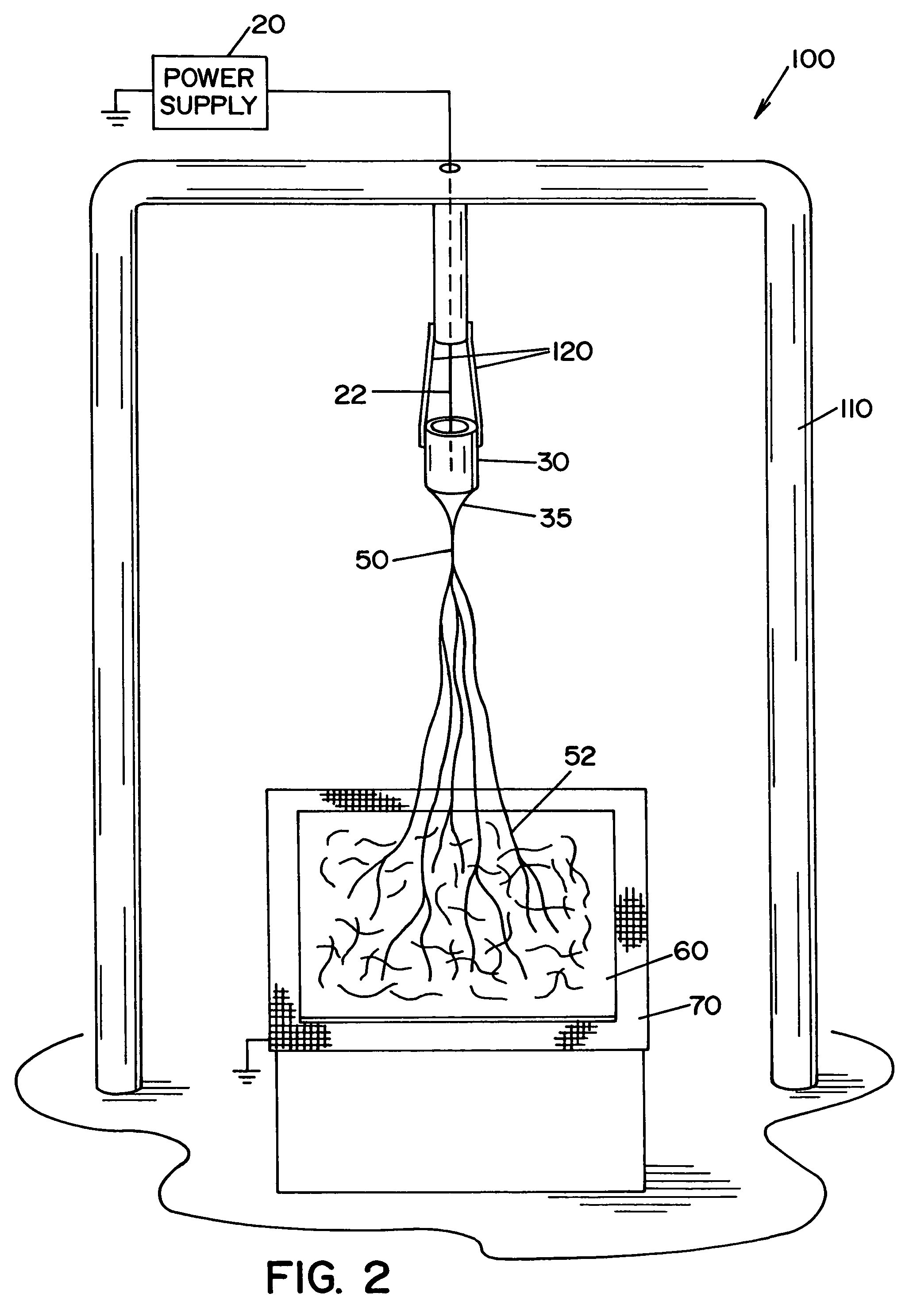

Carbon and electrospun nanostructures

The present invention is directed to the production of nanostructures, e.g., single wall carbon nanotubes (“SWNT”) and / or multi-wall carbon nanotubes (“MWNT”), from solutions containing a polymer, such as polyacrylonitrile (PAN). In particular, the invention is directed to the production of nanostructures, for example, SWNT and / or MWNT, from mixtures, e.g., solutions, containing polyacrylonitrile, polyaniline emeraldine base (PANi) or a salt thereof, an iron salt, e.g., iron chloride, and a solvent. In one embodiment, a mixture containing polyacrylonitrile, polyaniline emeraldine base or a salt thereof, an iron salt, e.g., iron chloride, and a solvent is formed and the mixture is electrospun to form nanofibers. In another embodiment, the electrospun nanofibers are then oxidized, e.g., heated in air, and subsequently pyrolyzed to form carbon nanostructures.

Owner:PHYSICAL SCI

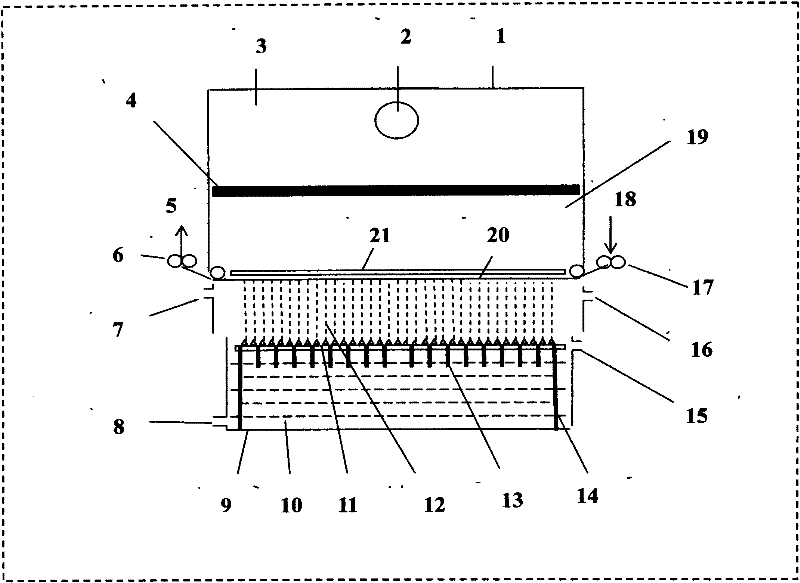

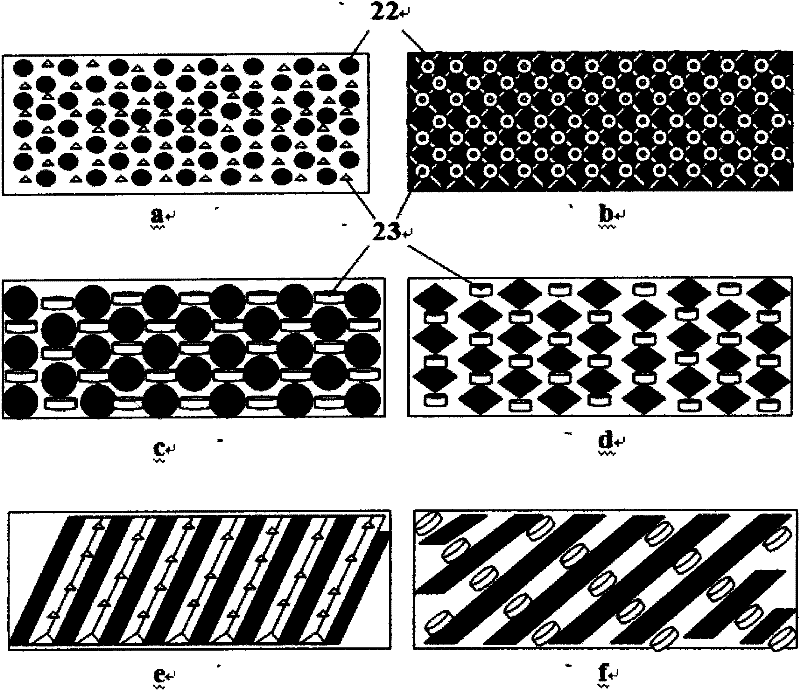

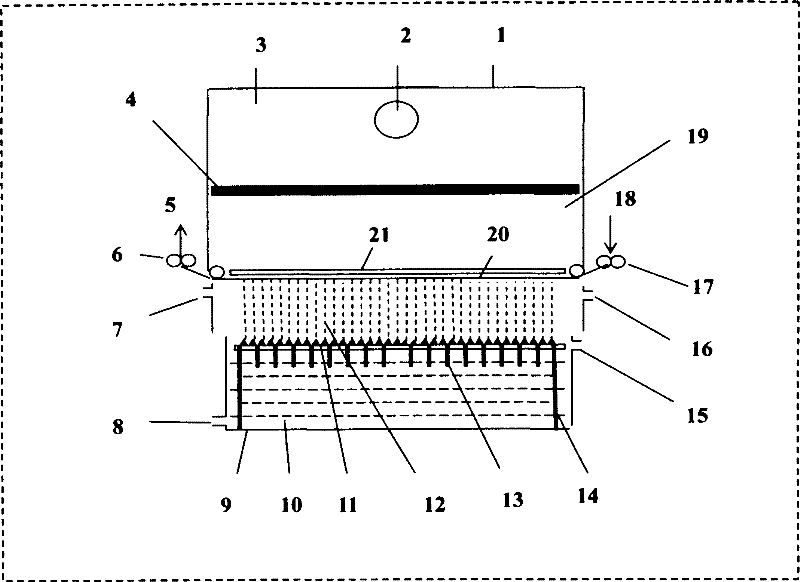

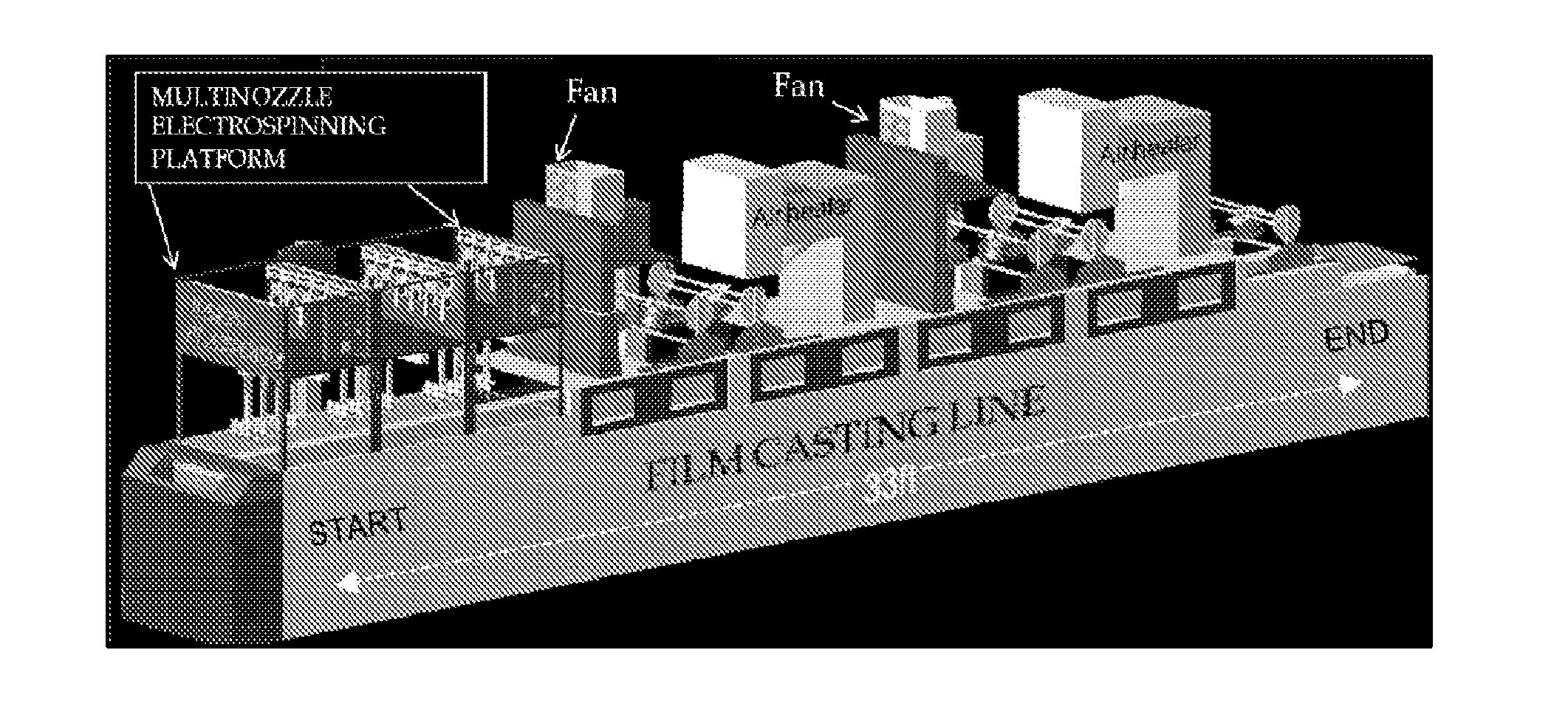

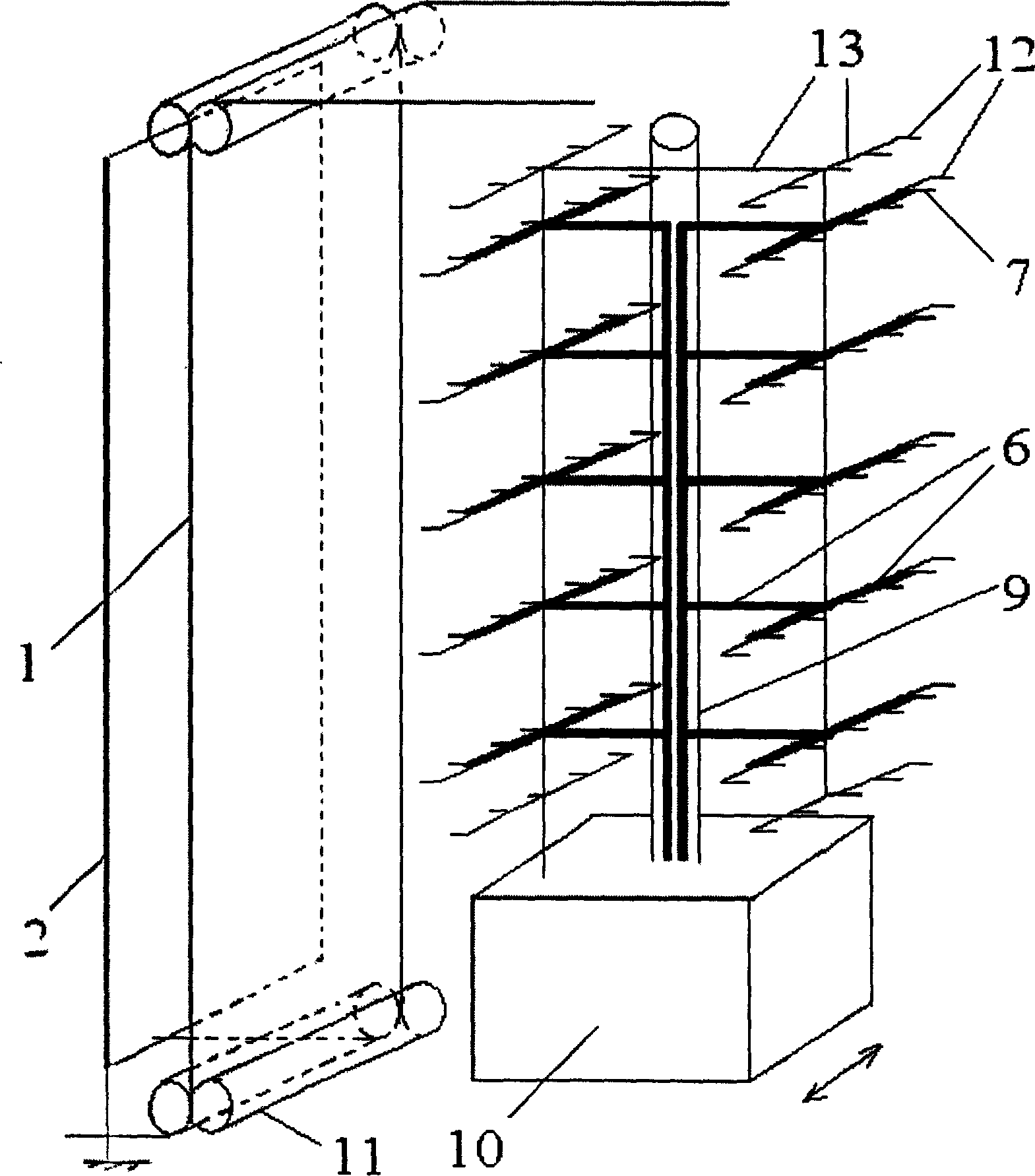

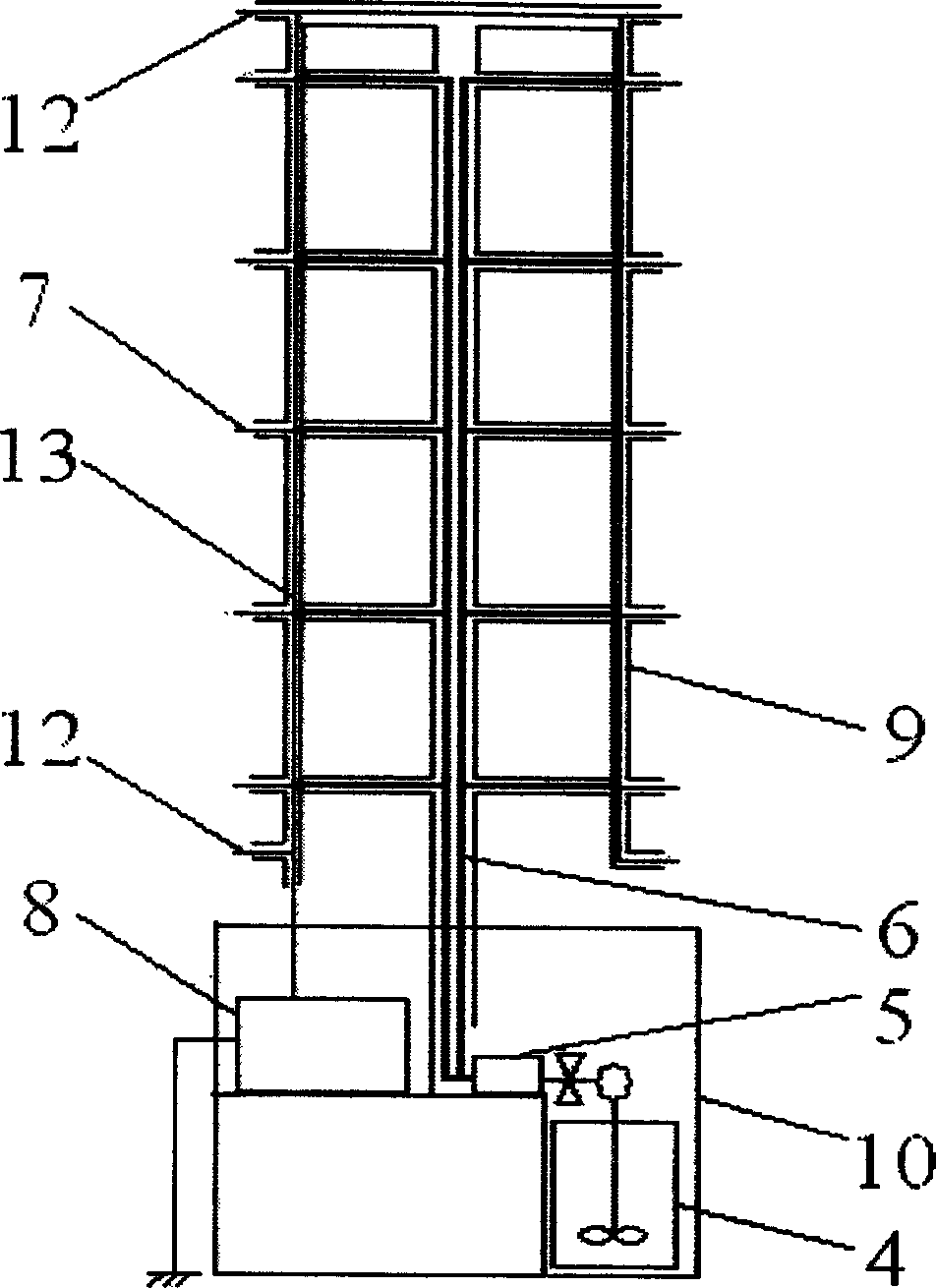

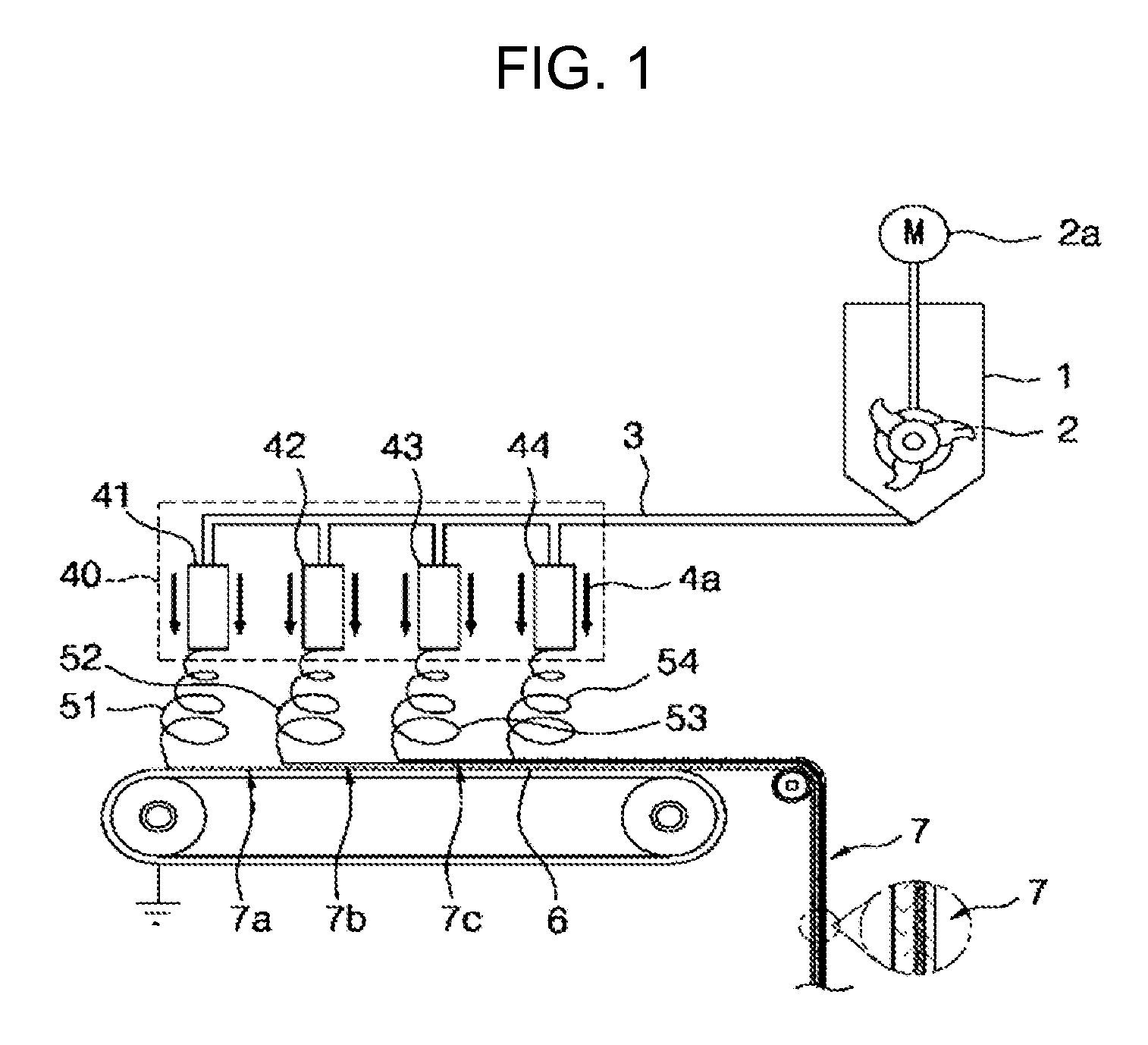

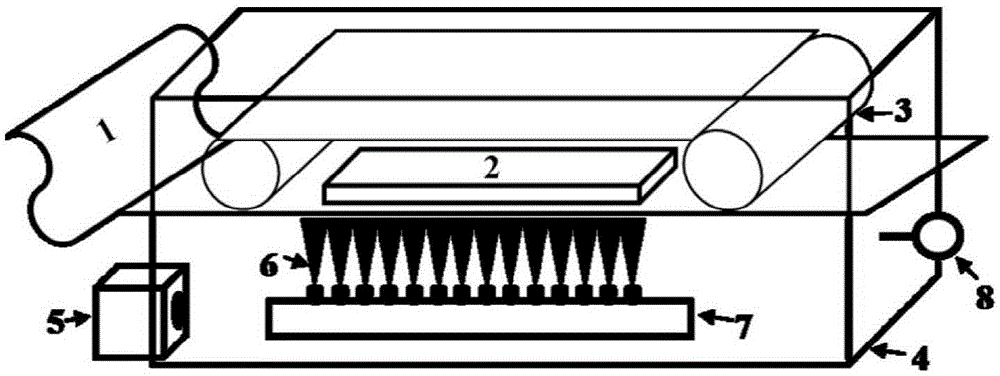

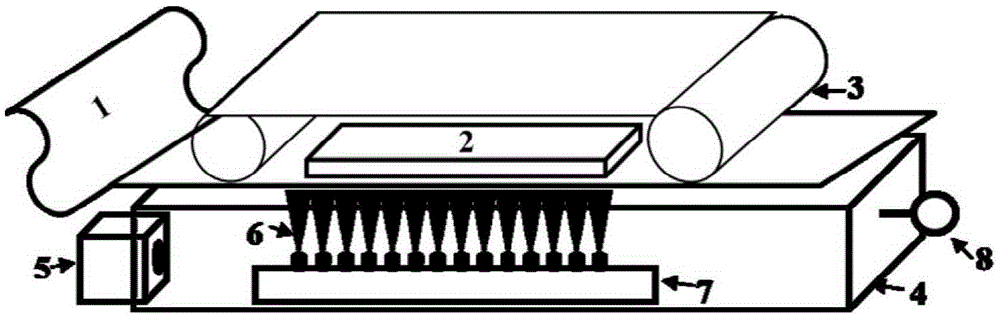

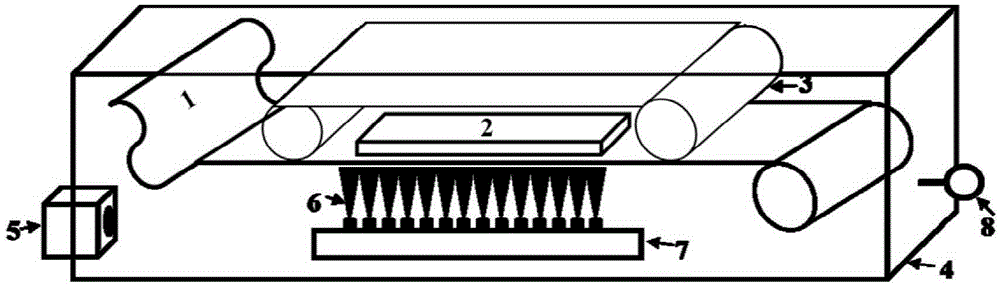

Continuous mass production method and continuous mass production equipment for electrospun nanofiber membranes

InactiveCN102650095AImprove driftOvercoming electrostatic repulsionFilament/thread formingNon-woven fabricsElectrospun nanofiberNanofiber

The invention relates to a continuous mass production method and continuous mass production equipment for electrospun nanofiber membranes. The method comprises the following steps: (1), electrified electrodes are kept in a vibrating state to drive polymer liquor to a plurality of protrusions on the upper surfaces of the electrified electrodes, so as to form a Taylor cone, and ensure that the whole upper surfaces become spinning surfaces, which obtains high spinning production capacity; (2), air in the space between two electrodes is sucked to the back side of a counter electrode to generate an air flow, so that stressed drift of nanofiber is accelerated, and the nanofiber is sucked to be laid on a continuous receiving screen to form a membrane; and (3) the air flow is heated dry hot air. The equipment comprises a polymer container, the vibrating electrified electrodes, the continuous receiving screen, the counter electrode and a negative pressure chamber, wherein the upper surfaces of the vibrating electrified electrodes are approximately in accordance with the liquid level; the counter electrode is made of a metal mesh or a porous metal plate; the negative pressure chamber comprises a hood, a rear air chamber, a balancing plate and an air suction pump; each vibrating electrified electrode is a metal mesh-shaped plane or a porous metal flat plate; innumerous holes and innumerous small protrusions are formed on the plane; and the small protrusions are regularly arranged and higher than the plane. The invention facilitates mass production of the electrospun nanofiber membranes.

Owner:谢维

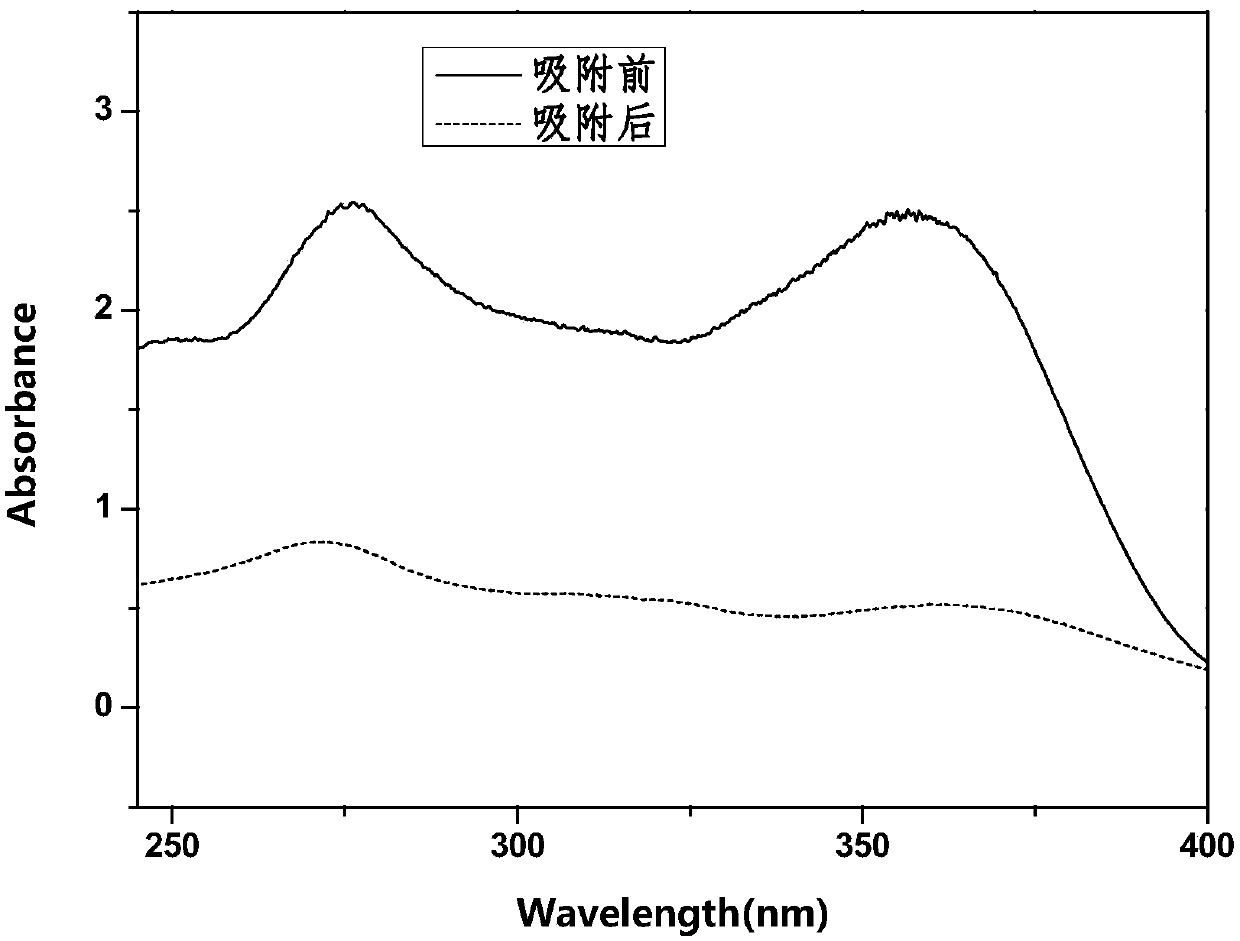

Preparation method and application of polydopamine modified ZIF-8 functionalized nanofiber membrane

PendingCN109577005AImprove hydrophilicityPromote growthOther chemical processesFibre typesNanofiberNanofibrous membrane

The invention relates to a preparation method of a polydopamine modified ZIF-8 functionalized nanofiber membrane and application of the membrane in antibiotic adsorption. The functionalized nanofibermembrane is prepared through the electrospinning technology and a conventional solution method, polyacrylonitrile serves as a base, the surface of the polyacrylonitrile is wrapped with polydopamine toimprove the polydopamine, so that ZIF-8 crystal particles easily grow on the outermost layer of the polyacrylonitrile. The obtained polydopamine modified ZIF-8 functionalized nanofiber membrane can effectively adsorb tetracycline antibiotics from an aqueous solution, and the obtained polydopamine modified ZIF-8 functionalized nanofiber membrane has excellent recycling ability. The preparation process is simple and feasible, raw materials are easy to obtain and environmentally friendly, the cost is low, and the method has good application prospects.

Owner:JILIN UNIV

Dental compositions based on nanofiber reinforcement

A dental material using nano material that will serve as reinforcement and will enhance mechanical properties with minimal sacrifice in other properties including processability of a dental material. The dental material may be used as a filling, restorative, cement, liner, adhesive or primer. This is achieved by combining several polymerizable monomers and / or oligomers, a polymerization initiator, at least one hyperbranched additive and at least one of an electrospun nanofiber, an electrospun nanosphere or a hyperbranched macromolecule. The hyperbranched additive may be hyperbranched molecules, dendridic molecules (such as dendrimers). In a preferred embodiment a caged silica (such as POSS) is used for a caged macromolecule. The material may also include nanoclay or traditional composite fillers. The material may optionally include accelerators (such as DEHPT), cross linkers or pigment

Owner:PREMIER DENTAL PRODS +1

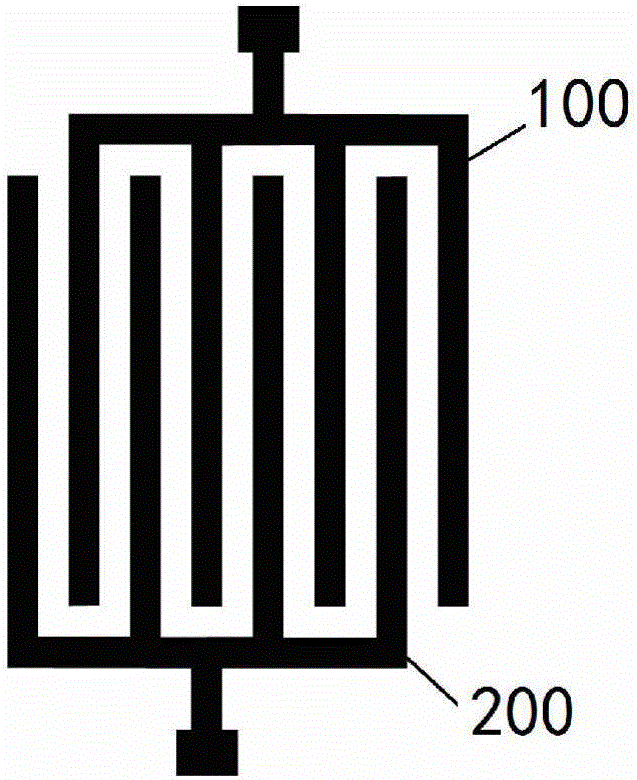

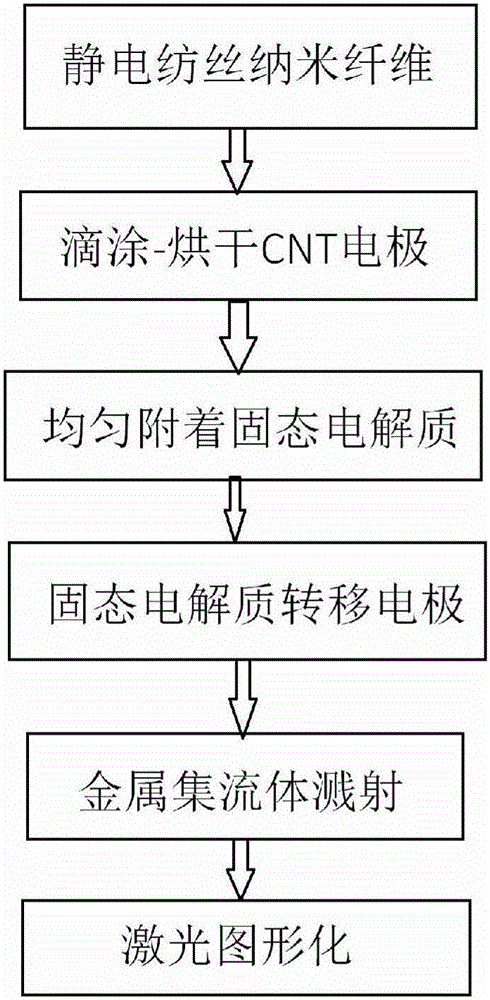

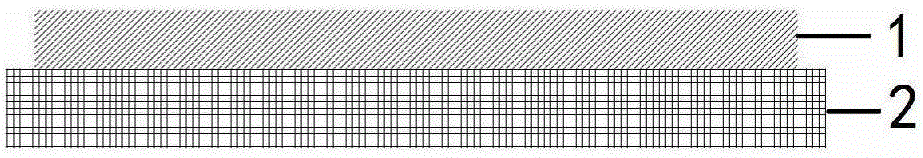

A freestyle miniature supercapacitor based on laser graphics and a manufacturing method thereof

ActiveCN106449134AReduce thicknessSimple structureMaterial nanotechnologyHybrid capacitor electrodesSolid state electrolyteElectrospun nanofiber

A freestyle miniature supercapacitor based on laser graphics and a manufacturing method thereof belong to the technical field of micro-power energy storage. The structure is composed of a solid electrolyte, a flexible electrode and a metal current collector from the bottom up. Carbon nanotubes are dispensed on electrospun nanofibers to obtain the flexible electrode. The present invention proposes the freestyle miniature supercapacitor which uses a planar interdigitated electrode. Compared with a conventional supercapacitor in a sandwich structure, the freestyle miniature supercapacitor has a much lower device thickness, higher device flexibility, and can be better integrated with flexibly electronic devices. Meanwhile, through use of the advantages of the high specific surface area and high conductivity of the electrospun nanofibers and the carbon nanotubess, the light and stable flexible electrode is manufactured to further improve the energy and power density. Compared with other miniature supercapacitors, the freestyle miniature supercapacitor of the invention has the much lower device thickness in a novel electrolyte transfer mode without any additional substrate, and the damage which may be brought for complex transfer technology can be avoided.

Owner:PEKING UNIV

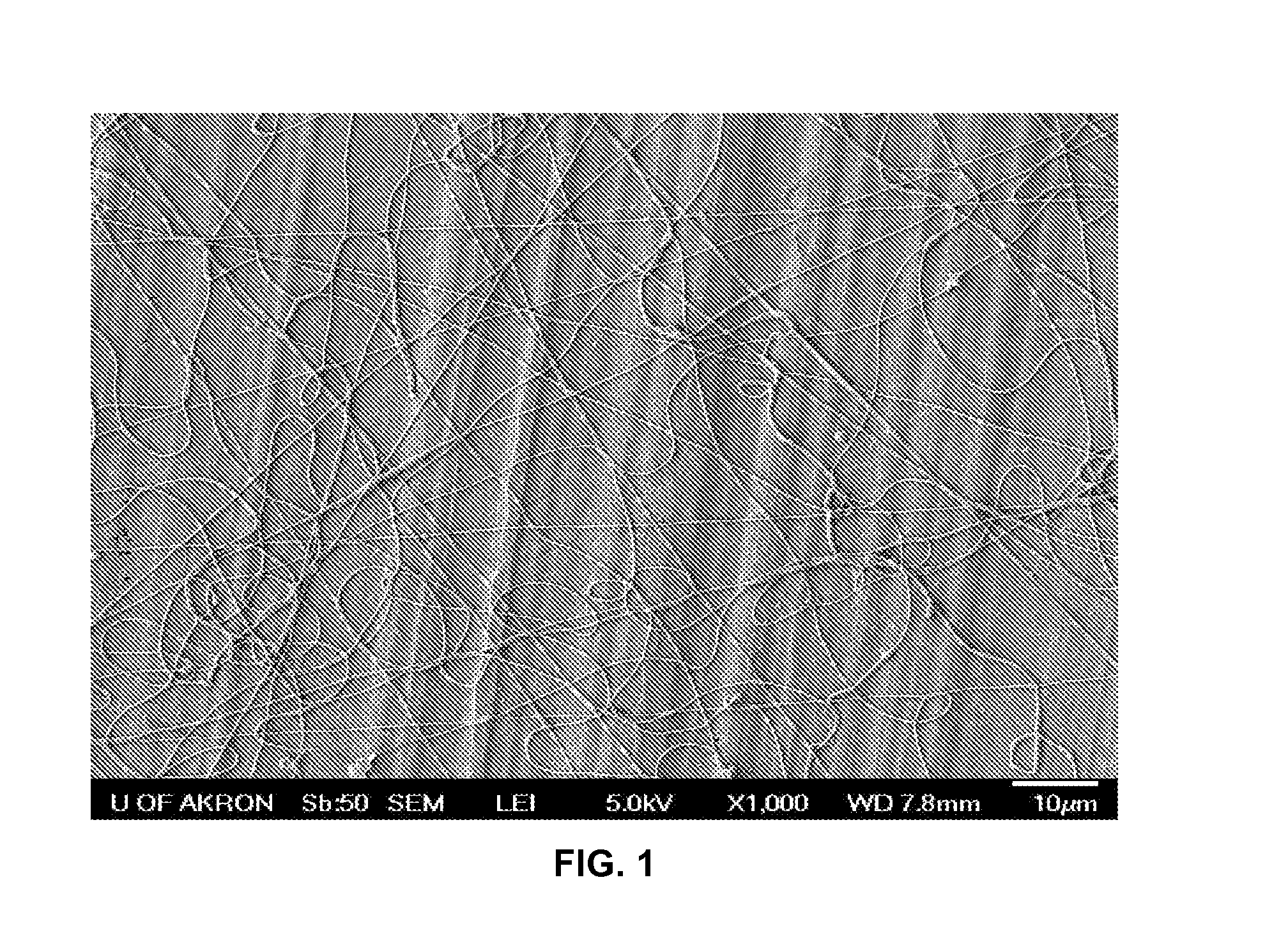

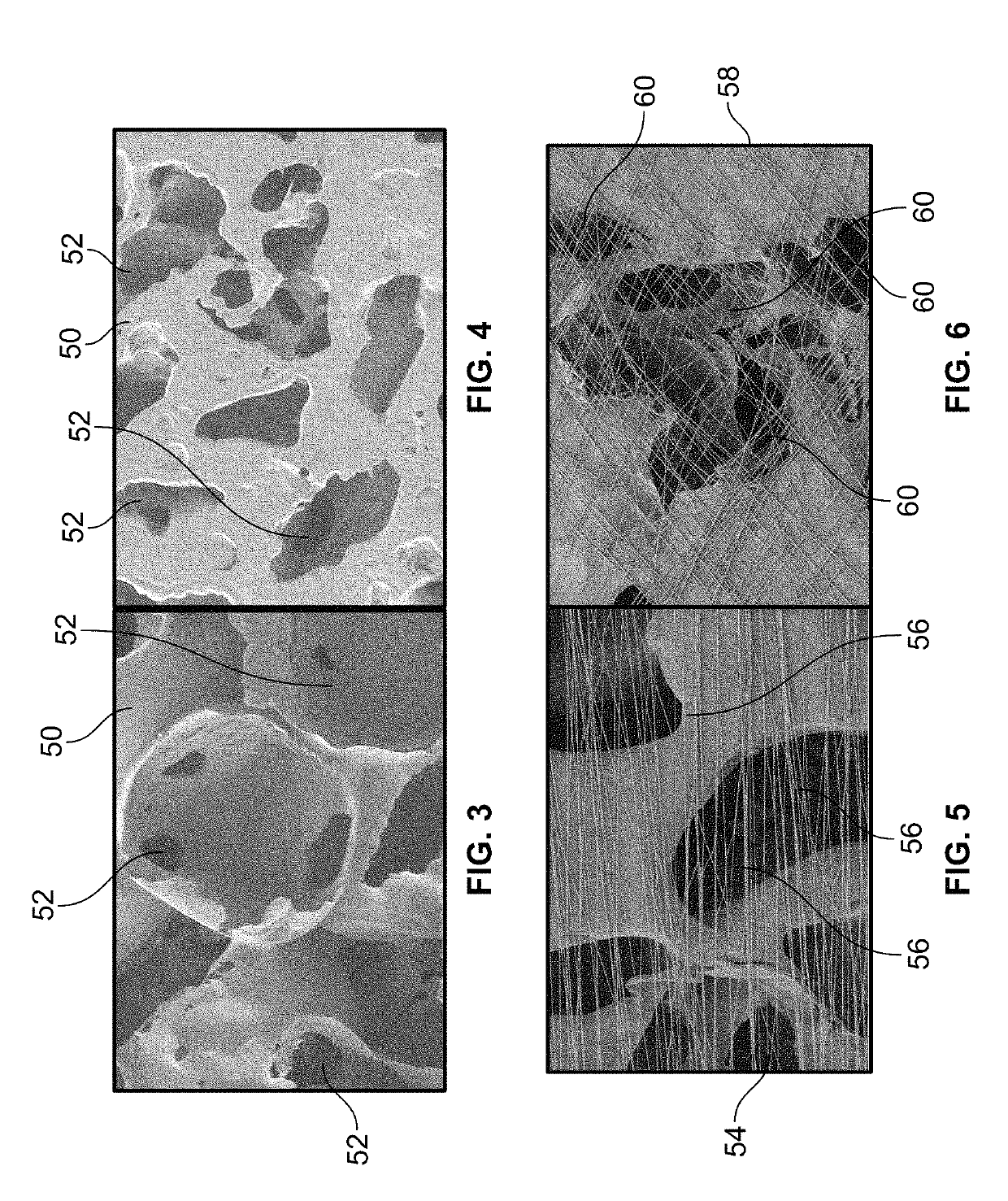

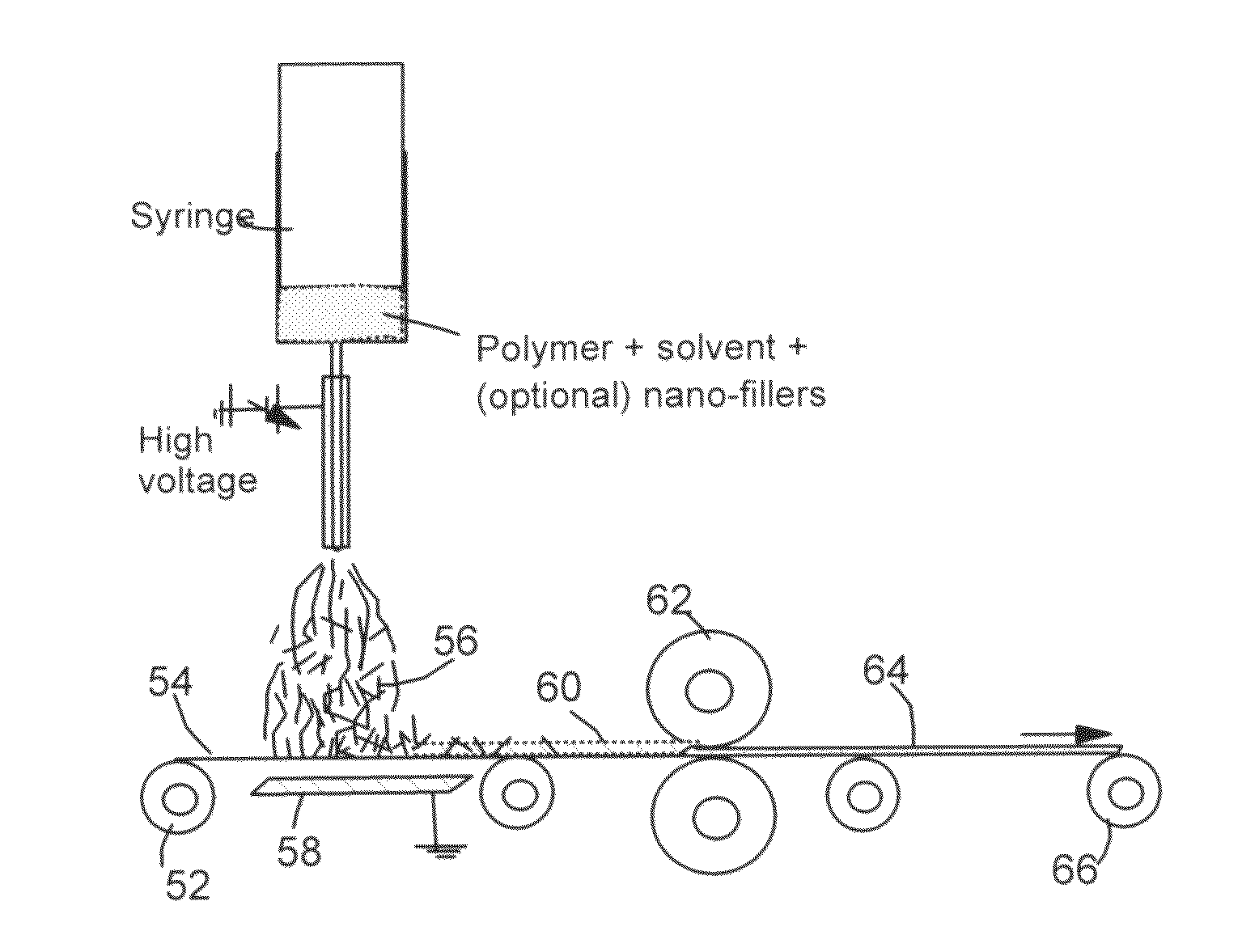

Manufacturing of multifunctional electrically conductive/transparent/flexible films

The present invention relates to a method for producing flexible, stretchable transparent and highly electrically conducting hybrid polymer films comprising electrically conductive electrospun nanofibers embedded in solution cast dielectric polymer films. In one embodiment, the present invention utilizes an electrically conductive nanofiber, or nanofiber structure, that is embedded in a suitable polymer film. In one embodiment, the electrically conductive nanofiber, or nanofiber structure, can be electrospun from a suitable polymer solution that contains a suitable amount of, for example, at least one conductive material. In one embodiment, the flexible polymer film portion of the present invention can be formed from poly(methyl methacrylate) (PMMA) or polyimide. In another embodiment, the present invention relates to flexible polymer films that have conductive structures embedded therein, wherein the flexible polymer film portion is form via a casting process to produce transparent films from, for example, polycarbonate, polyurethane and / or cyclopolyolefin polymer compositions.

Owner:THE UNIVERSITY OF AKRON

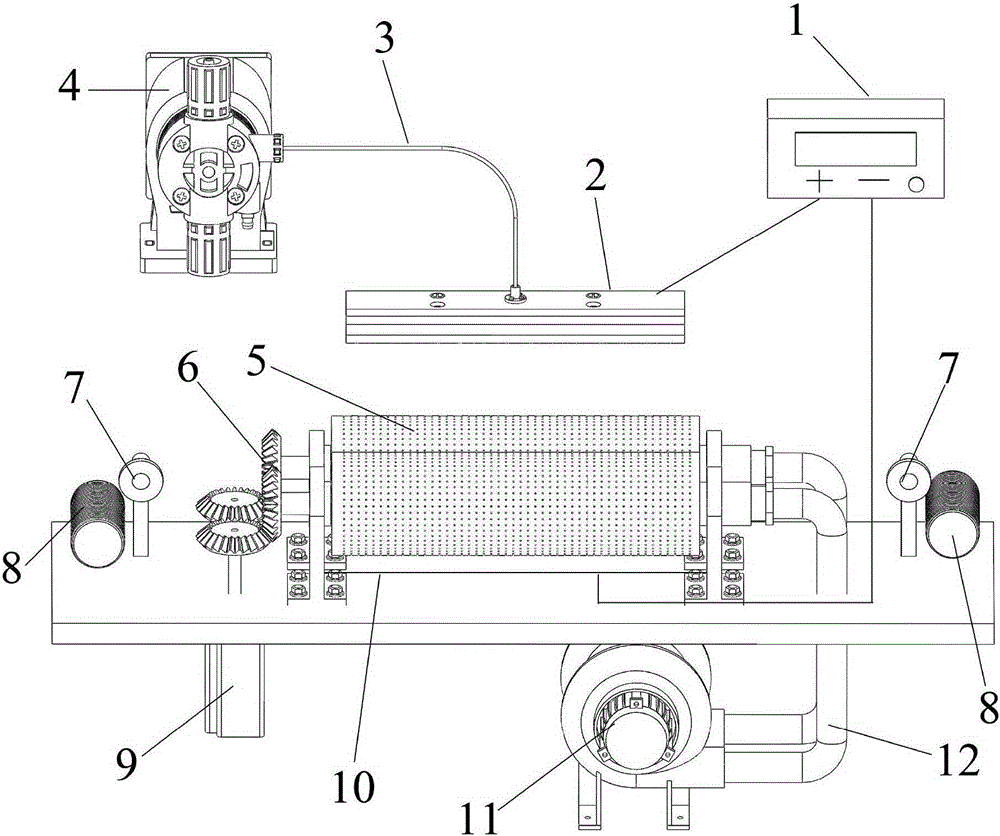

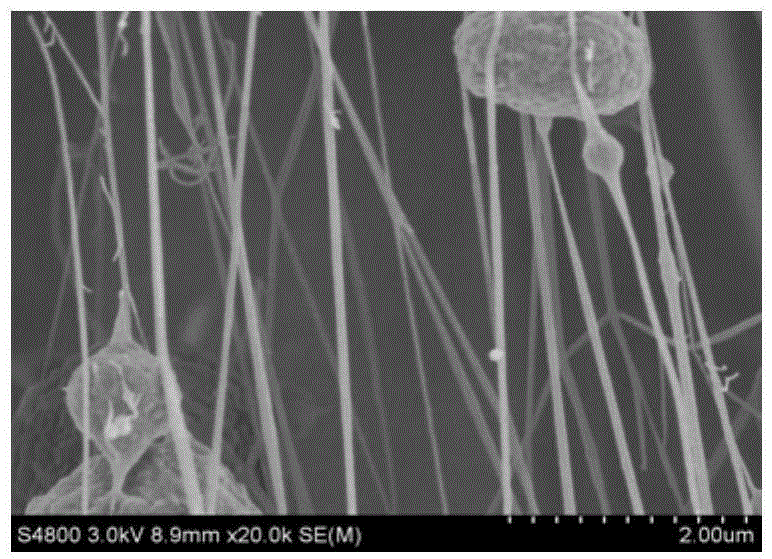

Multi-jet friction yarn-forming apparatus of electrostatic spinning nano fiber and manufacturing method thereof

ActiveCN105220246AIncrease productionMeet the scaleFilament/thread formingYarnYarnElectrospun nanofiber

The invention provides a multi-jet friction electrostatic spinning yarn-forming apparatus, which mainly comprises a spinner, a friction rod, a metal rod, a yarn guiding device and a winding device, wherein the spinner is constituted of a plurality of air chambers that are arranged symmetrically to a solution chamber and symmetrically along two sides of the solution chamber; a group of spinning holes arranged along the same axis are set below the solution chamber; the spinner is connected to a positive electrode of a high-voltage generator; two parallelly arranged metal friction rods are set below the spinner; one end of each of the two friction rods is connected to a motor through a wheel gear and the other end of each of the two friction rods is connected to a vortex blower through an air suction pipe; the metal rod connected to a negative electrode of the high-voltage generator is set below the friction rod; and two ends of the friction rod are respectively connected to the yarn guiding device and the winding device. According to the invention, the manufacturing process is simple; the nano fiber yarn production is high; the apparatus provided herein is suitable for various high polymer spinning solutions; and the apparatus provided herein can satisfy large-scale and continuous manufacture for nano fiber yarns.

Owner:河南中纤新材料科技有限公司

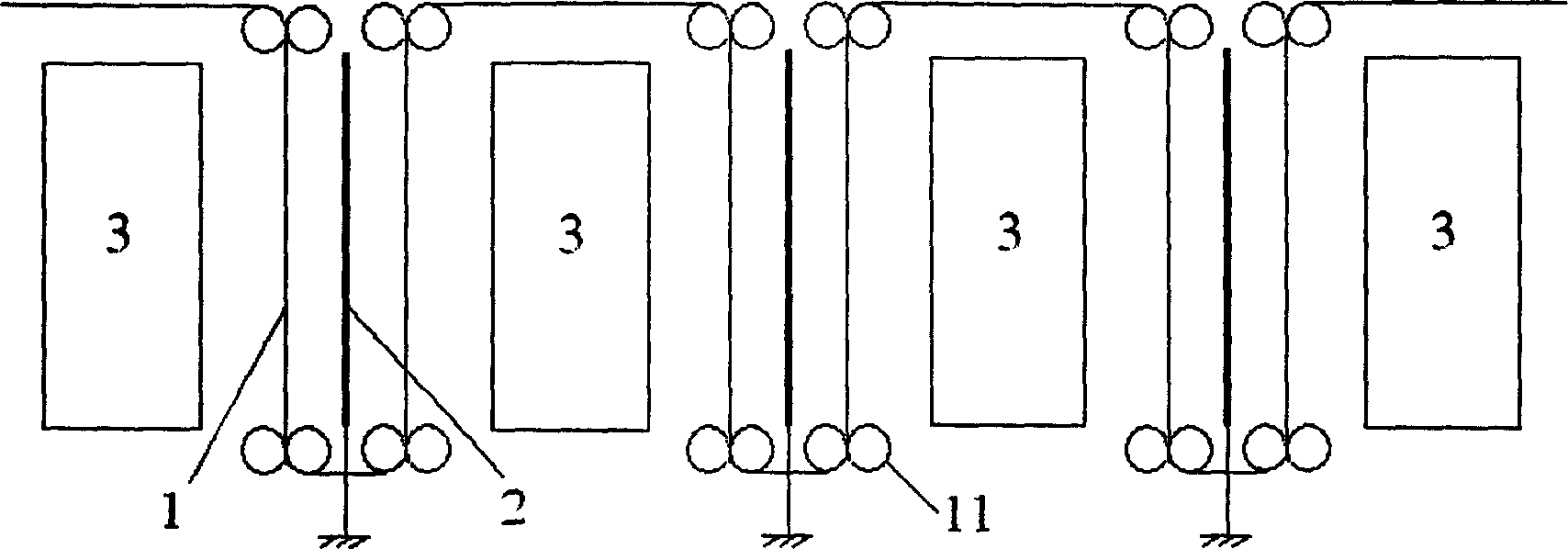

Device and method for preparing combined continuous electro-spinning nano fibrous membrane

InactiveCN1664182AEvenly distributedImprove uniformityFilament/thread formingElectrospun nanofiberFiber

Kockdown series electricity spin nanometre fiber membrane produce set is a preparation method .The set constitute with series incept net (1), electricity spin unit (2). The metal net lay the facing of a quilt of erect part of series incept net parallel, electricity spin unit lay the face of erect part of series incept symmetry with metal net. Series incept drive by drive roller, move up and down, electricity spin unit keep the distance with series incept net and move landscape orientation. The high polymer liquor is pumped with computation transfusion from liquid tank. And transport to line electricity spin spray, throw the same or adverse direct current to electricity spin spray of close electricity spin unit by high voltage set. The high polymer liquor of spray head sprays silk under the function of electric field, forming nanometre fibre. This method let the nanometre fibre no easy dissipate, nanometre fibre membrane equality well.

Owner:SOUTHEAST UNIV

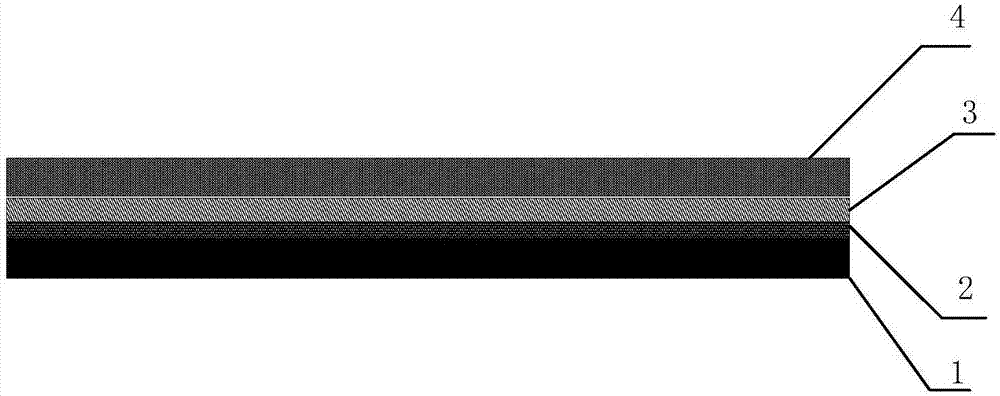

Lithium battery diaphragm for power battery and preparation method thereof

InactiveCN106935772AExcellent heat shrinkage resistanceAvoid large area short circuitLi-accumulatorsCell component detailsElectrospun nanofiberElectrical battery

The invention provides a lithium battery diaphragm for power vehicles. The diaphragm has four layers, the layers are respectively from bottom to top a base diaphragm, a nanometer flame retarding layer, an electrospun nanofiber layer and a thermal closed layer, wherein the base diaphragm is a PET nuclear pore membrane with a thickness of 5 microns-20 microns, the nano meter flame retardant layer is a flame retardant ceramic slurry with a thickness of 0.5 micron-10 microns, the thickness of the electrospun nano-fiber layer is 2 microns-5 microns, and the heat closed layer is a heat-resistant epoxy resin with a thickness of 5 microns-10 microns. The invention also provides a preparation method of the lithium battery diaphragm; the heat-resistance and shrinkage performance of the prepared lithium battery diaphragm can be greatly improved, the thermal stability and thermal closed property are significantly improved, and the security is very good.

Owner:湖南中智优库科技有限公司

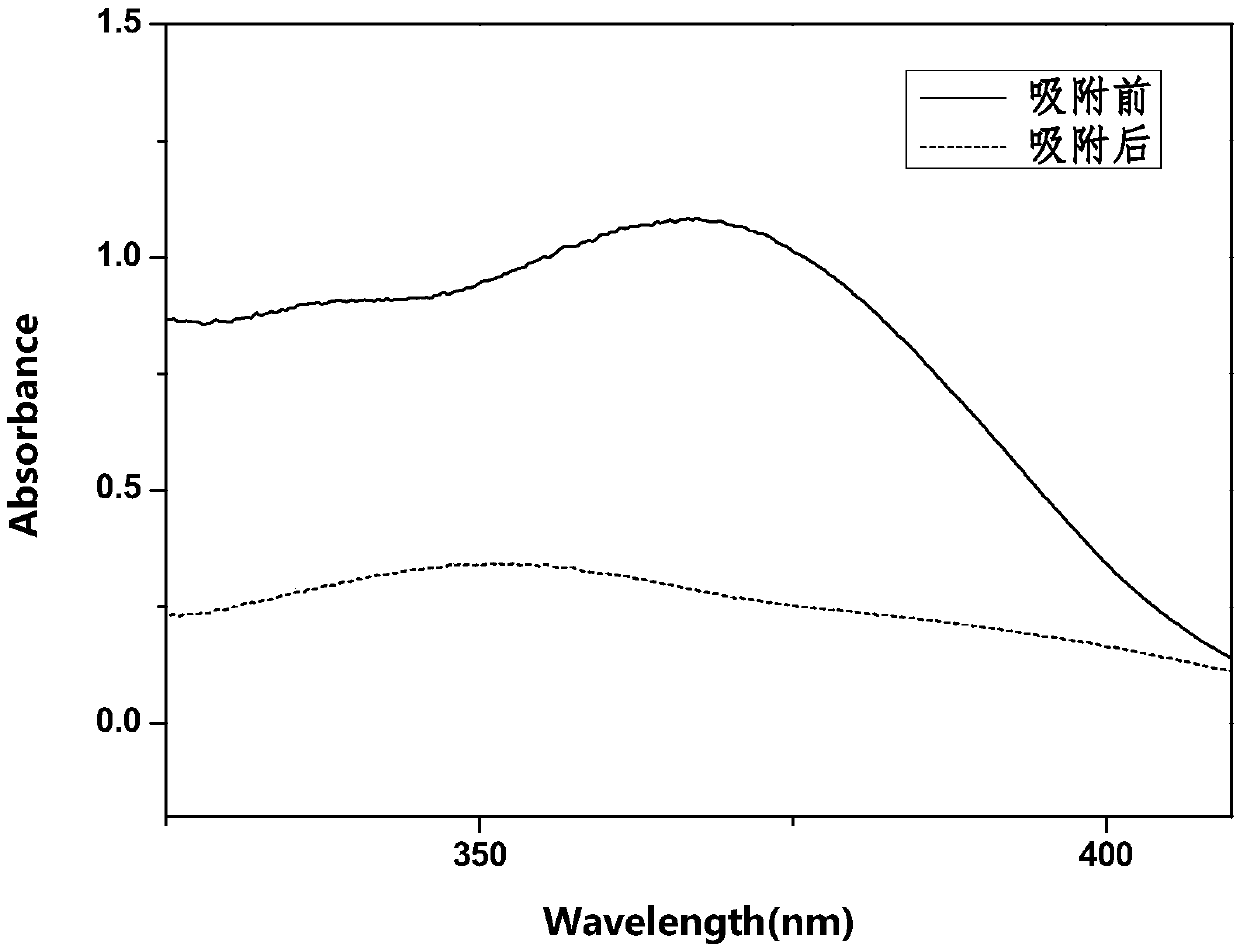

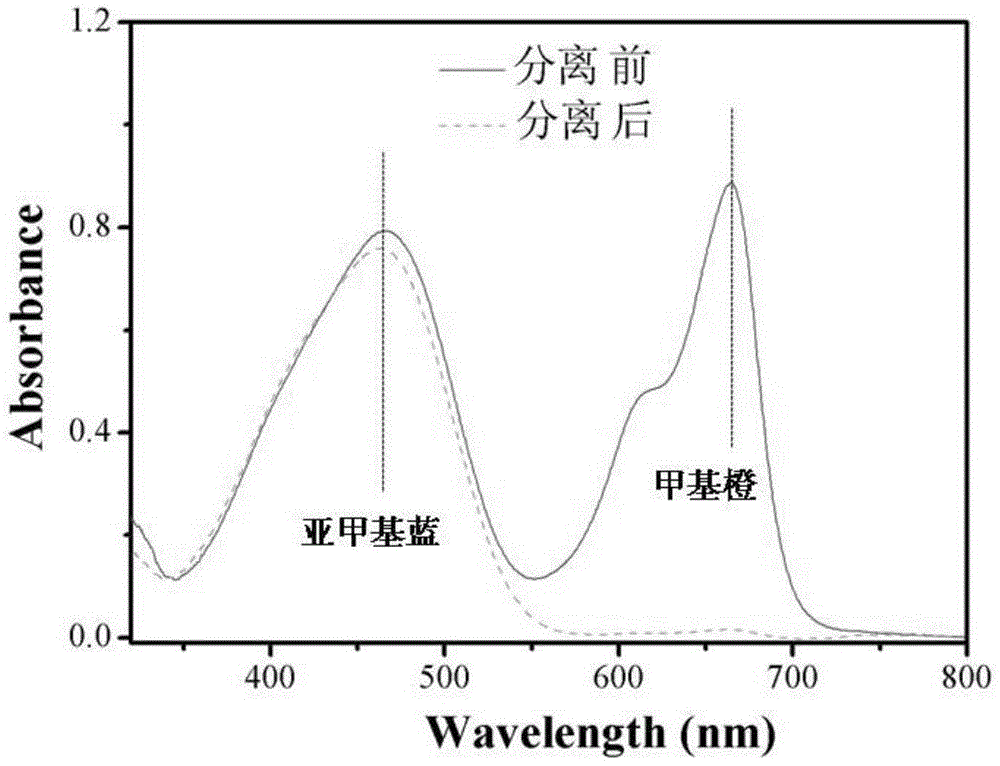

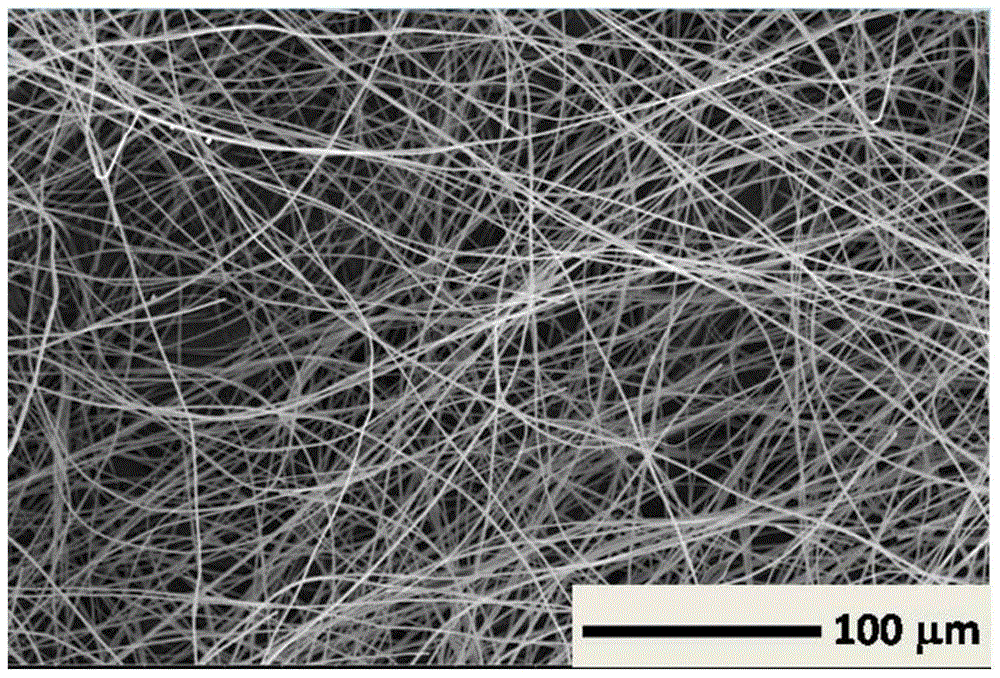

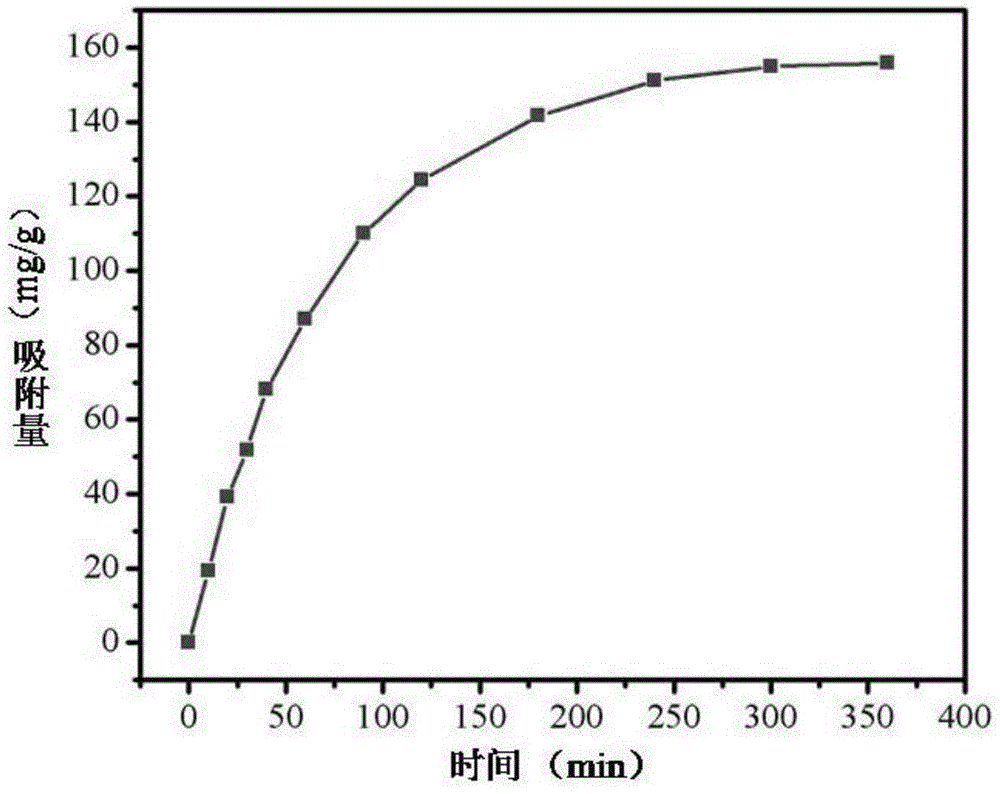

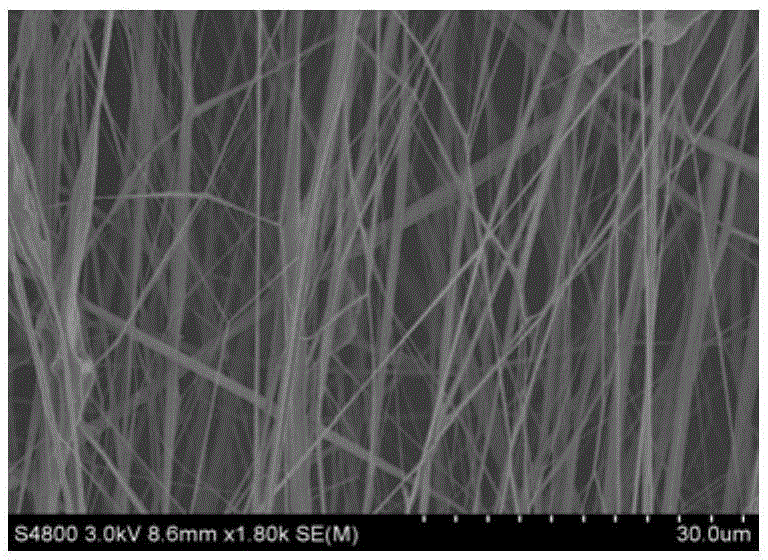

Beta-cyclodextrin-based nanometer fiber film, preparation method thereof, and application of beta-cyclodextrin-based nanometer fiber film to dye adsorption and separation

ActiveCN105220362AIncrease contentImprove adsorption capacityNon-woven fabricsArtifical filament manufactureFiberCell separation

The invention relates to a beta-cyclodextrin-based nanometer fiber film, a preparation method thereof, and application of the beta-cyclodextrin-based nanometer fiber film to dye adsorption and separation. The nanometer fiber dye adsorption and separation film is prepared by combining the electrospinning technology with the in-situ thermo-crosslinking method. The beta-cyclodextrin-based nanometer fiber film is prepared from body beta-cyclodextrin, crosslinking agent citric acid and polyacrylic acid which plays a role of crosslinking agents while assisting in spinning macromolecules. A crosslinking reaction happens between hydroxide radicals of beta-cyclodextrin and carboxyl of citric acid and polyacrylic acid to form ester bonds, and therefore the ester bonds are connected to form a three-dimensional crosslinked structure. The beta-cyclodextrin-based electrospinning nanometer fiber film obtained through the method can effectively separate positive ion and negative ion mixed solutions; the obtained beta-cyclodextrin-based electrospinning nanometer fiber film is high in recycling capacity. The preparation process is simple and easy to implement, raw materials can be easily obtained, friendliness to the environment is achieved, cost is low, and good application prospects are achieved.

Owner:吉林省贞靓科技有限公司

Preparation method of high-adsorbability cellulose diacetate composite electrostatic spinning nanofiber ordered porous film

ActiveCN105396563ACreate pollutionSmall fiber diameterOther chemical processesDispersed particle filtrationElectrospun nanofiberPolymer science

The invention discloses a preparation method of a high-adsorbability cellulose diacetate composite electrostatic spinning nanofiber ordered porous film. The preparation method comprises the following steps: dissolving cellulose diacetate and polycaprolactone, or cellulose diacetate and a lactic acid-glycolic acid copolymer, or cellulose diacetate and polyvinylpyrrolidone into an organic solvent so as to prepare a spinning solution, and preparing the cellulose diacetate composite electrostatic spinning nanofiber ordered porous film by adopting an electrostatic spinning method. The method disclosed by the invention is simple, and cannot pollute the environment in the preparation process. The prepared cellulose diacetate composite electrostatic spinning nanofiber ordered porous film has tiny fiber diameter, good pore diameter and order degree, is good in dry and wet state adsorption performances, is high in water absorption, can be applied to the flue gas and tobacco industry of the dry state and wet state adsorption and filtration separation industry, is wide in market application prospect, and has relatively high application value.

Owner:ZHEJIANG UNIV

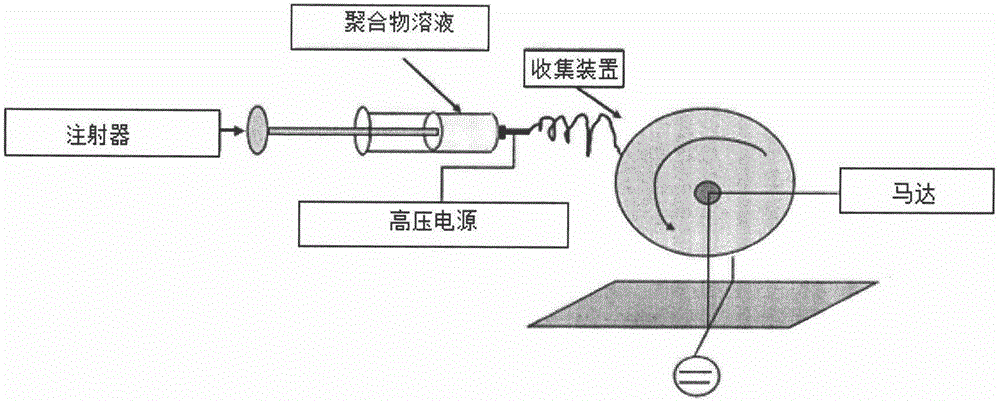

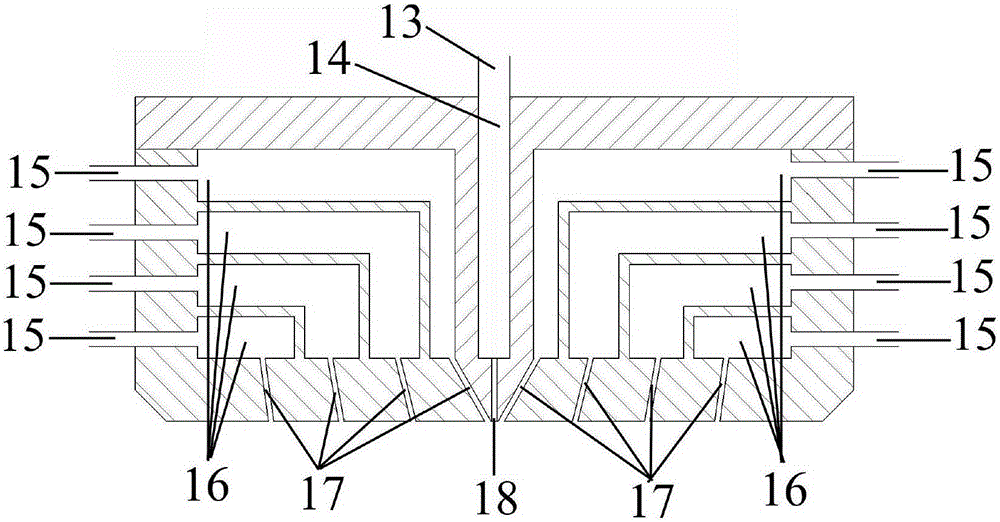

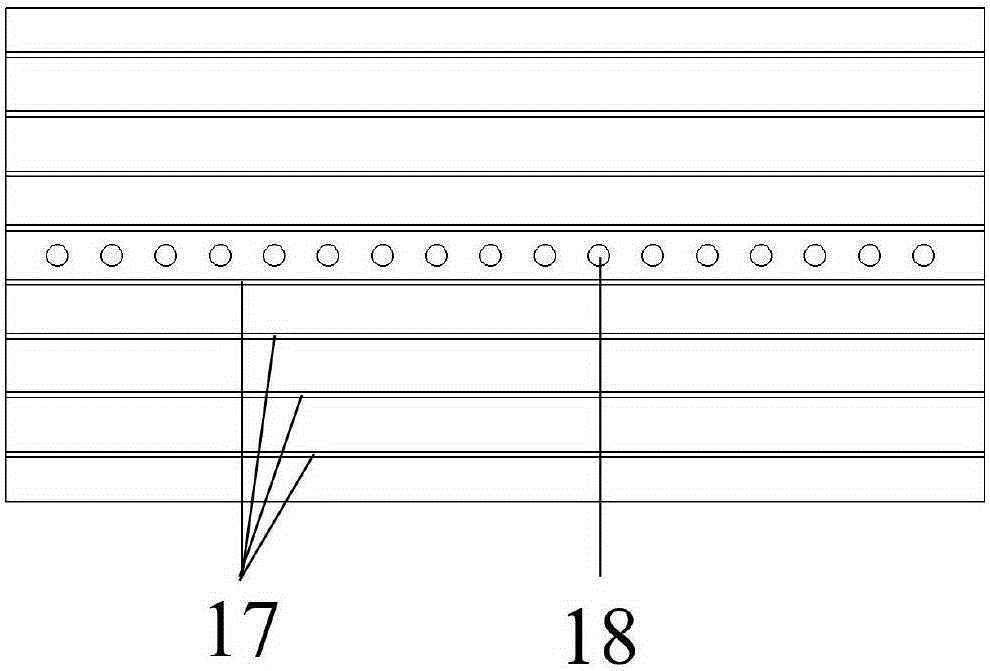

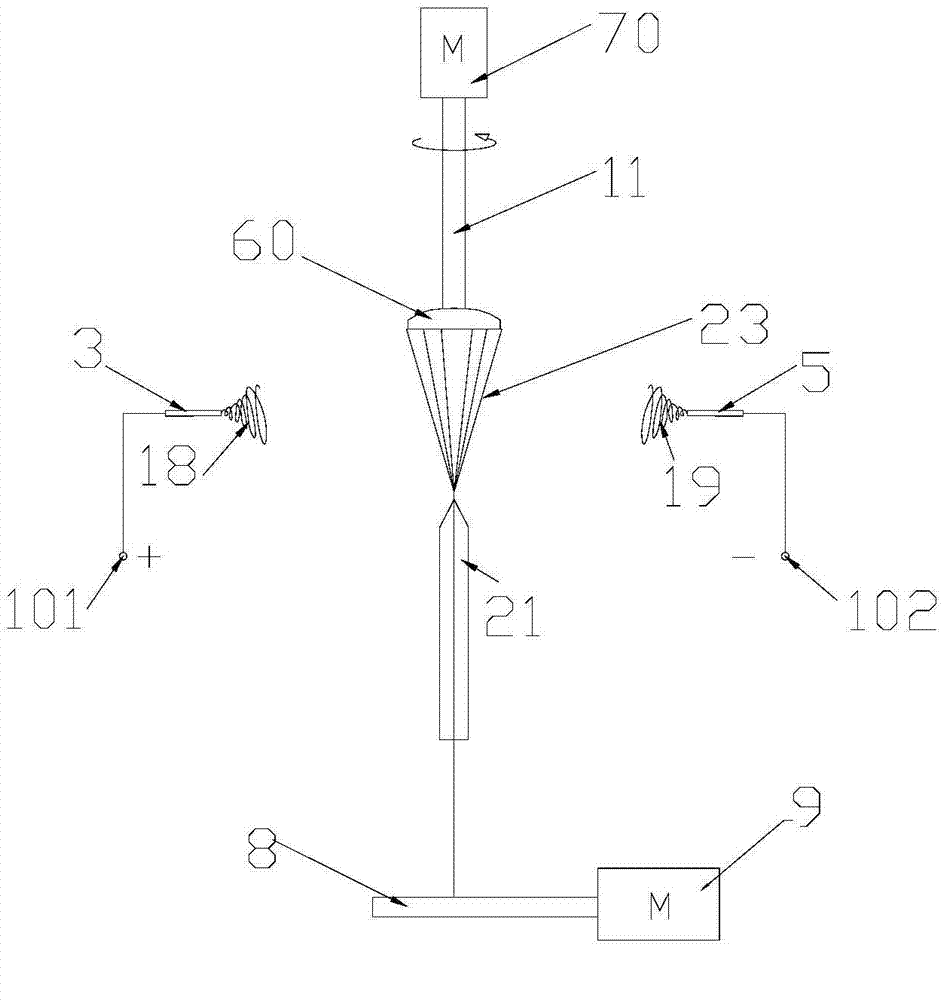

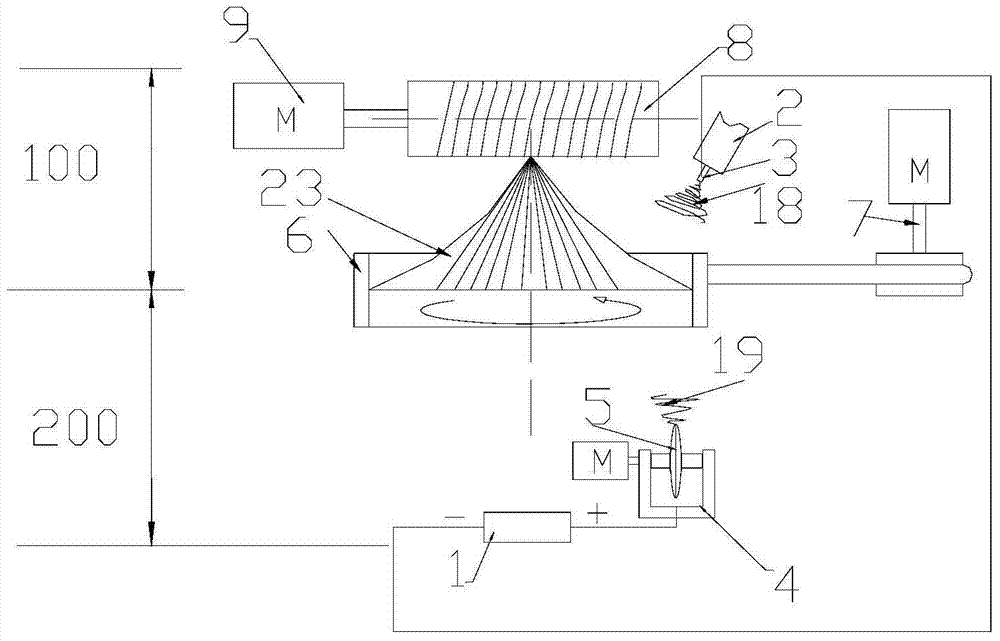

Device for preparing electrospun nanofiber yarns by using rotary collector and preparation method thereof

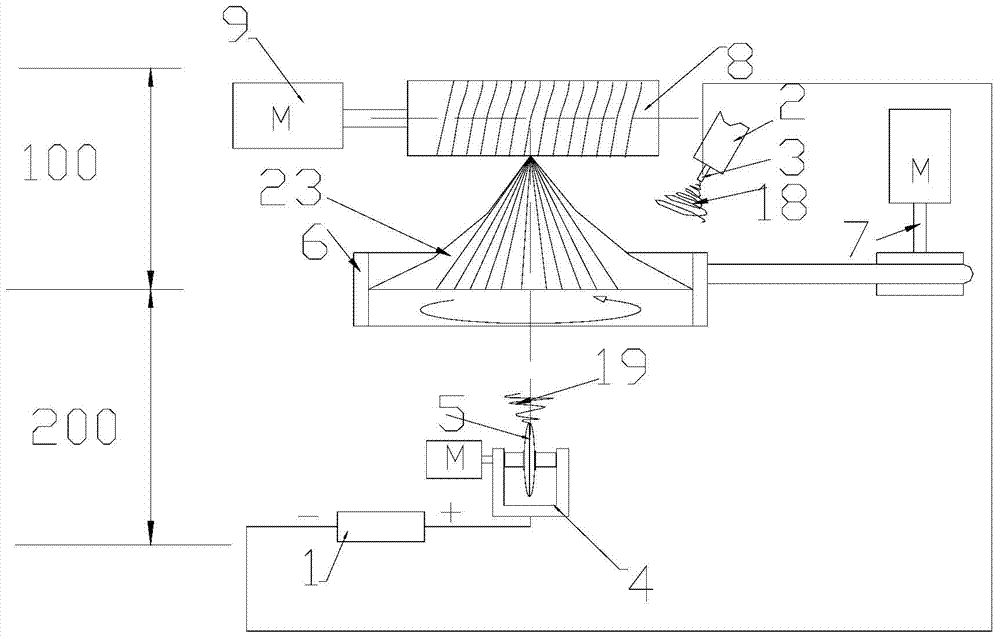

The application relates to a device for preparing electrospun nanofiber yarns by using a rotary collector. The device comprises a high-voltage power supply (1), a negative solution tank (2), a negative spinning head (3), a positive solution tank (4), a collection transmission device (7), a hollow collector (6), a winding transmission device (9) and a winding device (8), wherein the negative electrode and positive electrode of the high-voltage power supply (1) are respectively connected with a negative spinning head (3) of the negative solution tank (2) and a positive spinning head of the positive solution tank (4). The device has the advantages that spinning liquid is provided for the negative spinning head (3) and a positive spinning head (5) from the negative solution tank (2) and the positive solution tank (4); under the action of high voltage, the spinning liquid is transformed into a nano fiber by a fiber generator, an upward fiber cone is formed above the hollow collector (6), the nano fiber yarns are pulled out of the vertex of the fiber cone and are twisted, wound and collected by rotation of the hollow collector (6), and finally are collected into continuous nano fiber yarns by the winding device (8). The nano fiber yarns have strong mechanical strength and can be used for producing various nano-fiber textiles.

Owner:SHANGHAI YUNTONG NANO MATERIALS TECH CO LTD

Electrospun Nanofibrous Membranes and Disposable Glucose Biosensor

ActiveUS20160153025A1Low costHigh sensitivityImmobilised enzymesBioreactor/fermenter combinationsCross-linkFiber

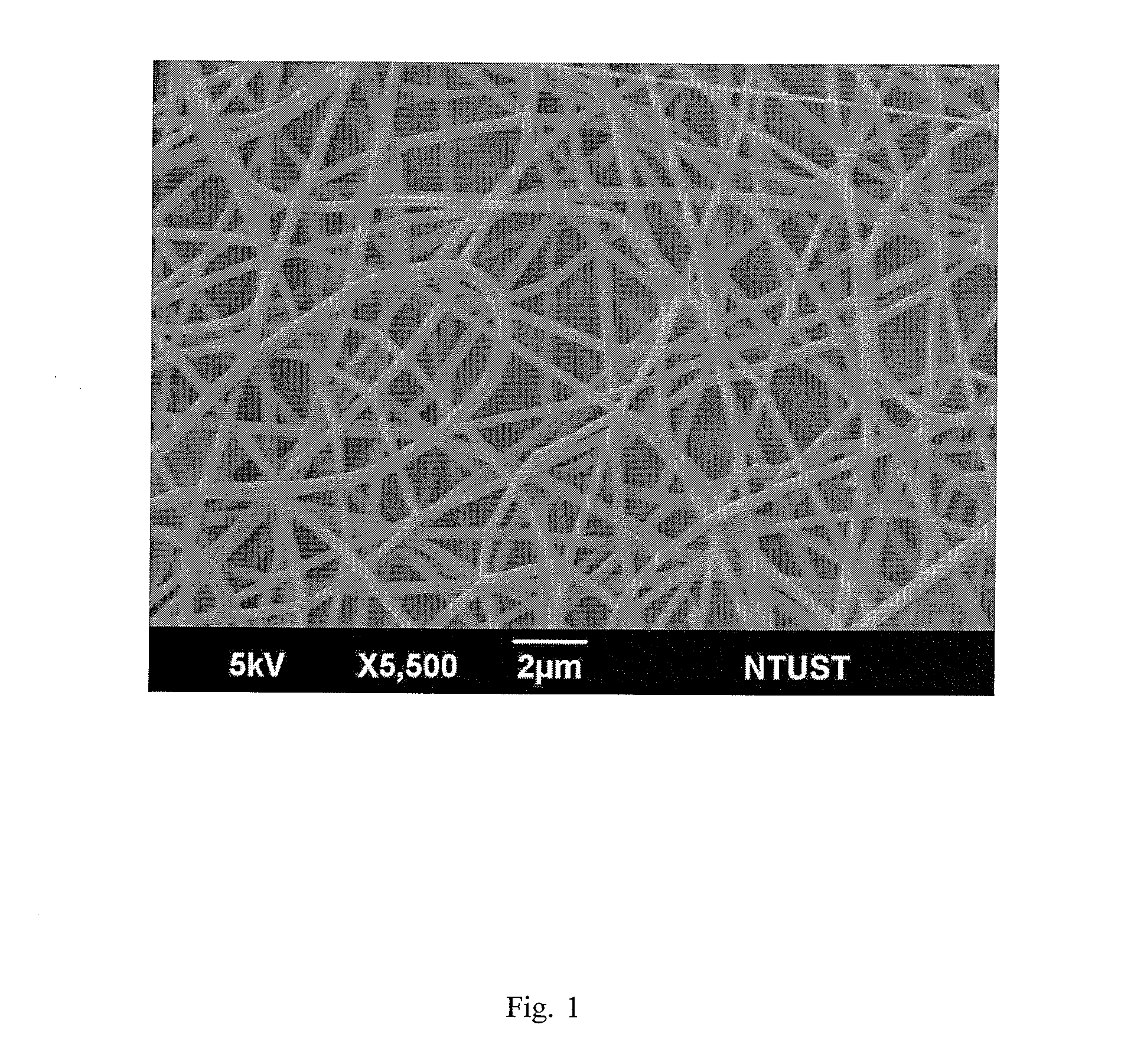

An electrospun nanofibrous membrane being sheet like and being formed by comprising multiple glucose oxidase / potassium hexacyanoferrate (III) modified electrospun nanofibers, wherein the glucose oxidase / potassium hexacyanoferrate (III) modified electrospun nanofibers are PVA electrospun nanofibers containing glucose oxidase and potassium hexacyanoferrate (III) homogeneously dispersed therein; and the glucose oxidase / potassium hexacyanoferrate (III) modified electrospun nanofibers are PVA electrospun nanofibers and are cross-linked by glutaraldehyde vapor with ultrasonic energy assistance. In the present invention, graphene modified PVA / GOx electrospun membranes were prepared to examine the immobilization mechanism between graphene and GOx. The electrochemical measurement results show that the sensitivities increased with increasing graphene concentrations up to 20 ppm. The highest sensitivity recorded 38.7 μA / mM was for a PVA / GOx membrane with 20 ppm graphene representing a 109% increase over a membrane made without graphene.

Owner:NAT TAIWAN UNIV OF SCI & TECH

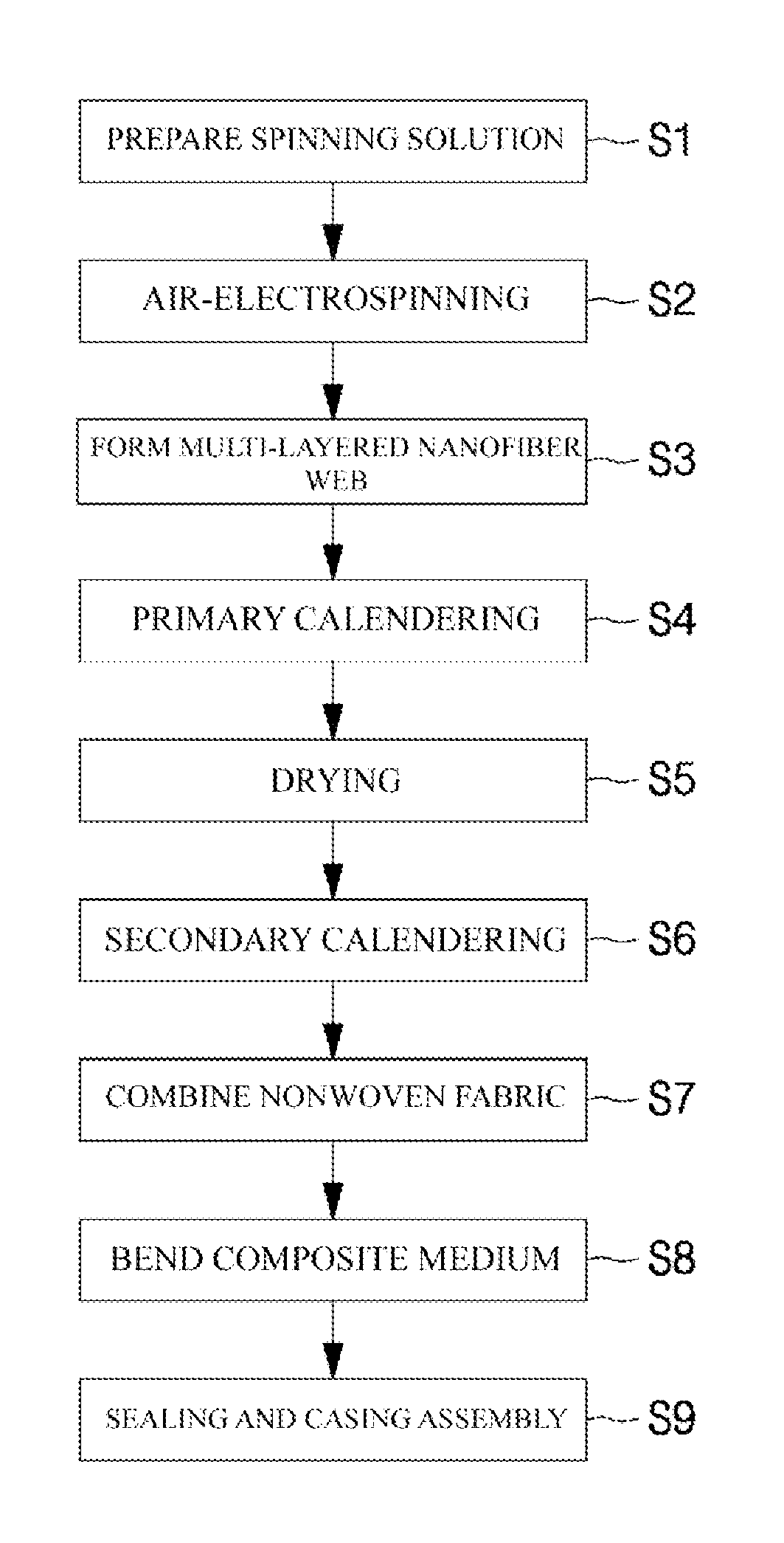

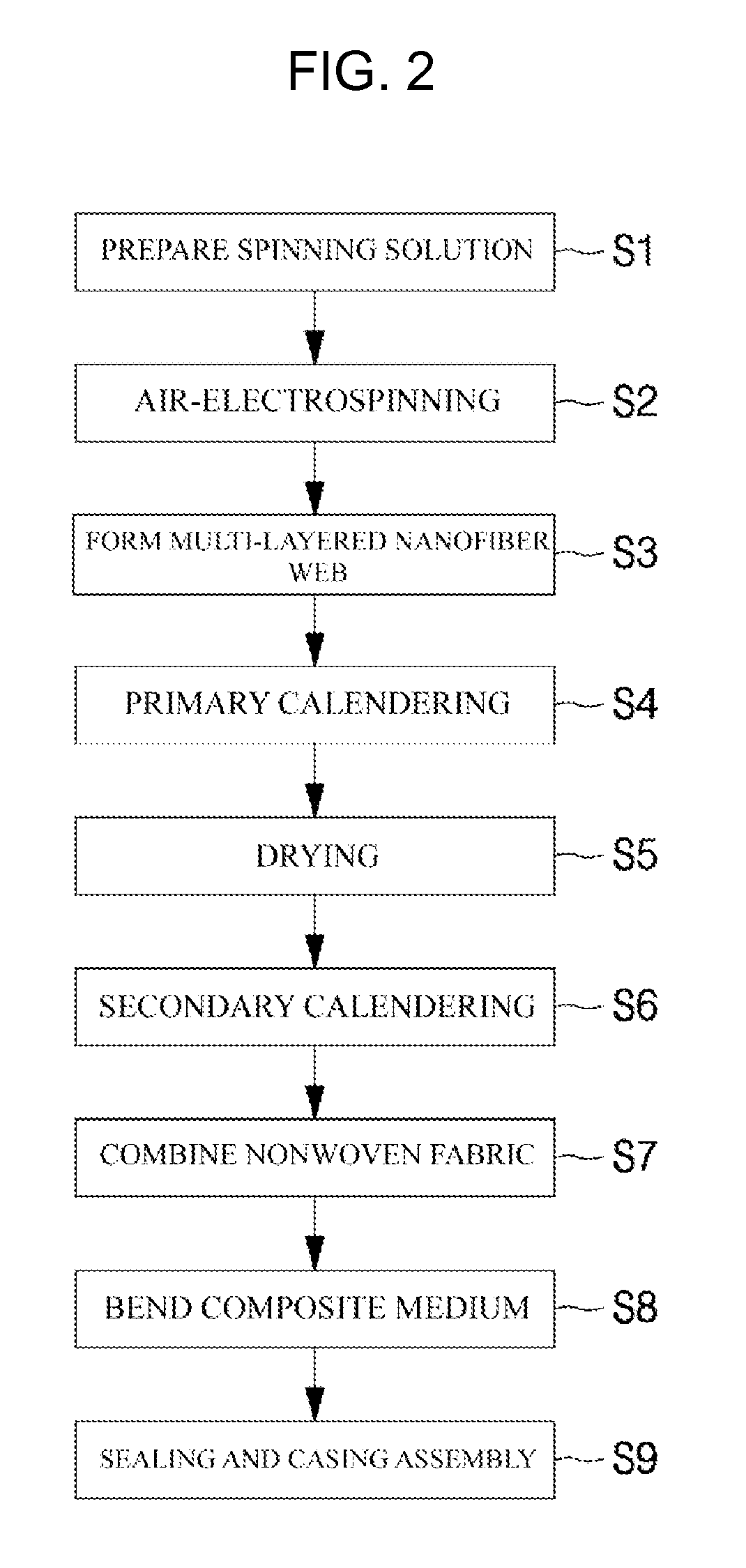

Filter media for a liquid filter using an electrospun nanofiber web, method for manufacturing same, and liquid filter using same

ActiveUS9220998B2Increased durabilityMaximize efficiencySemi-permeable membranesNanotechElectrospun nanofiberNanofiber

Provided is a filter medium for a liquid filter, having a three-dimensional micropore structure of a multi-layered structure using a multilayer nanofiber web that is obtained by performing air-electrospinning, to thus be thin but have high efficiency and long life, a method of manufacturing the filter medium using the multilayer nanofiber web, and a liquid filter using the filter medium. The filter medium for a liquid filter, includes: a nanofiber web that is made by stacking nanofibers that are obtained by air-electrospinning a fibrous polymer material and that have micropores; and a supporter that is inserted and combined onto one surface or in an inner portion of the nanofiber web.

Owner:AMOGREENTECH CO LTD

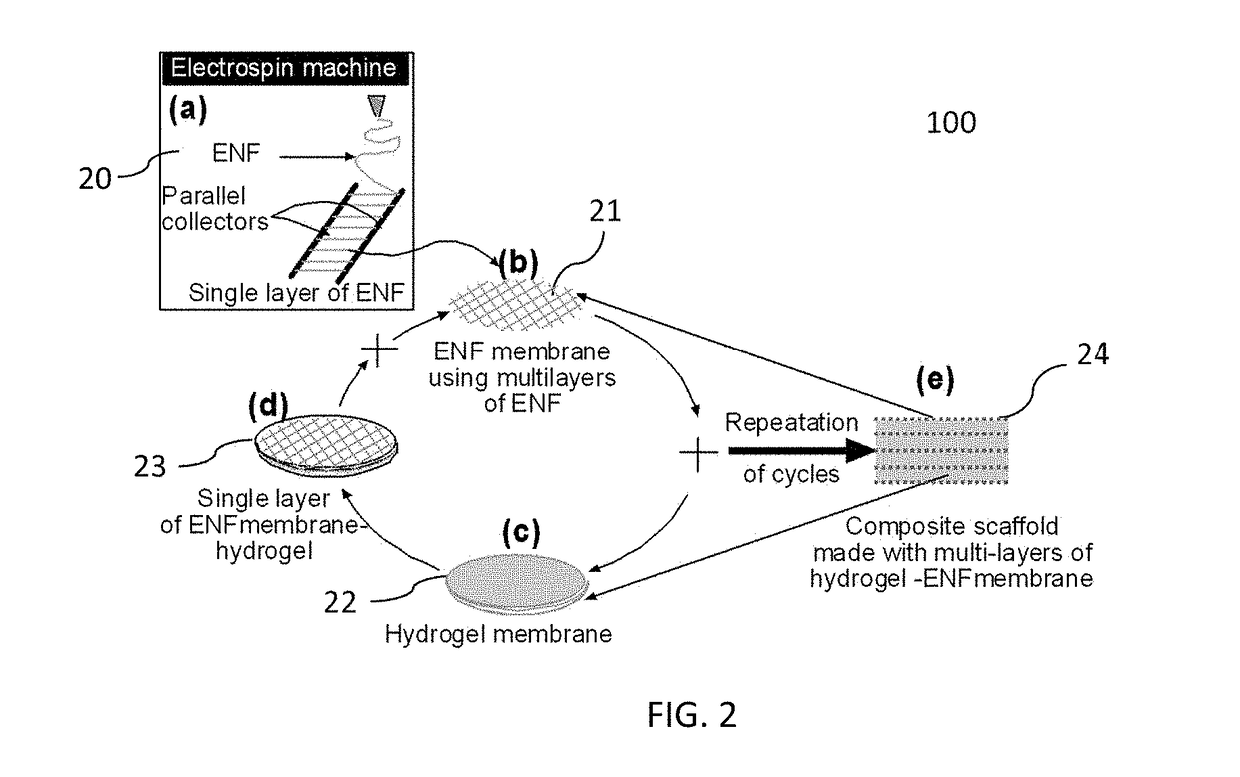

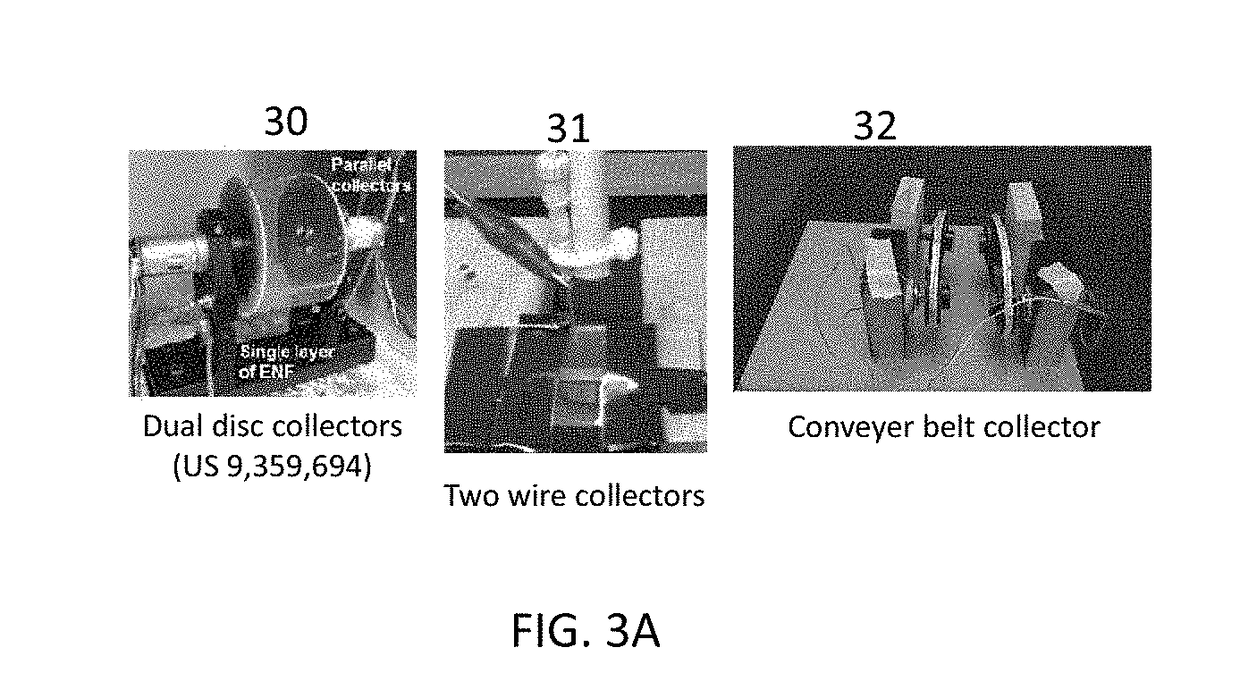

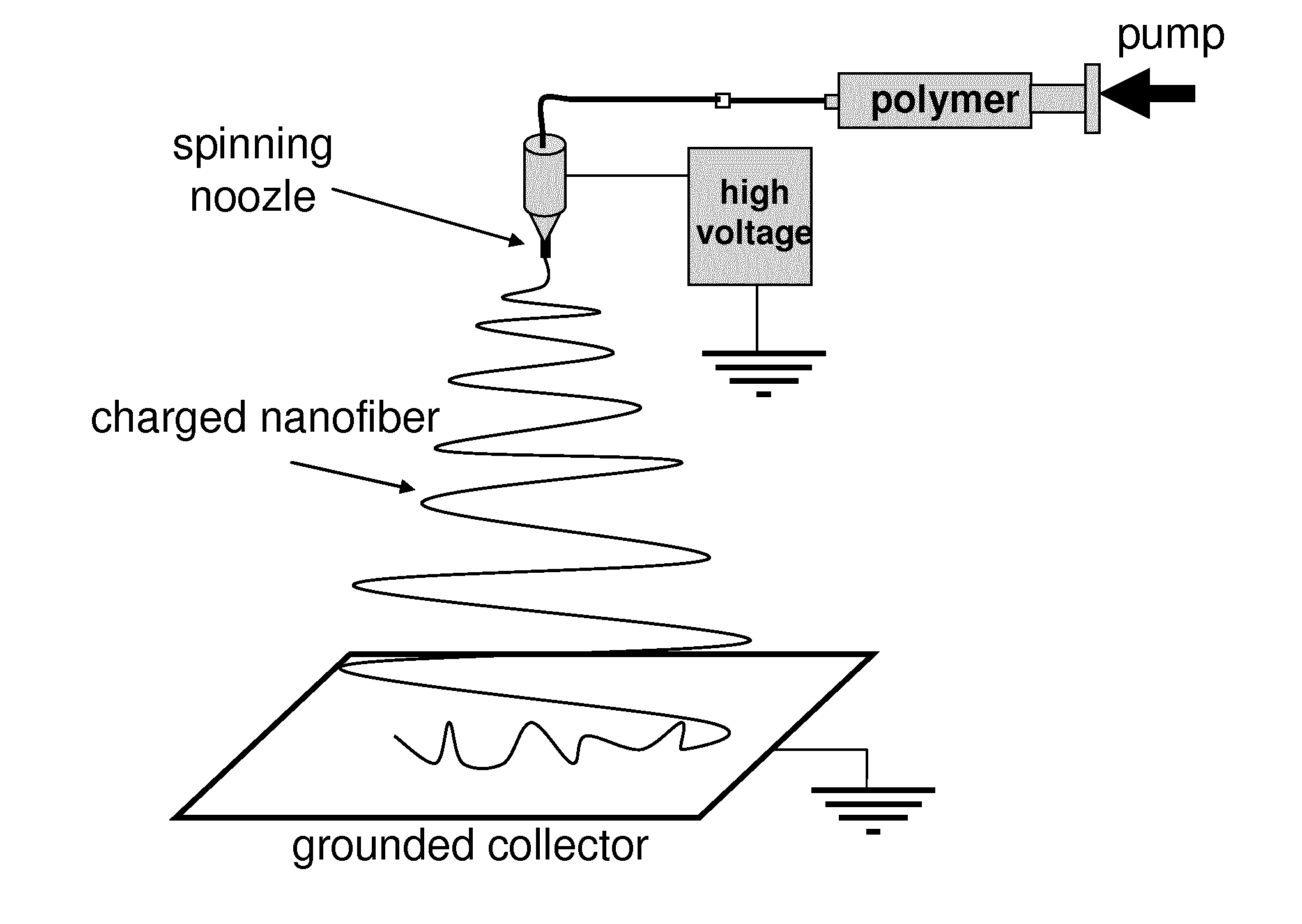

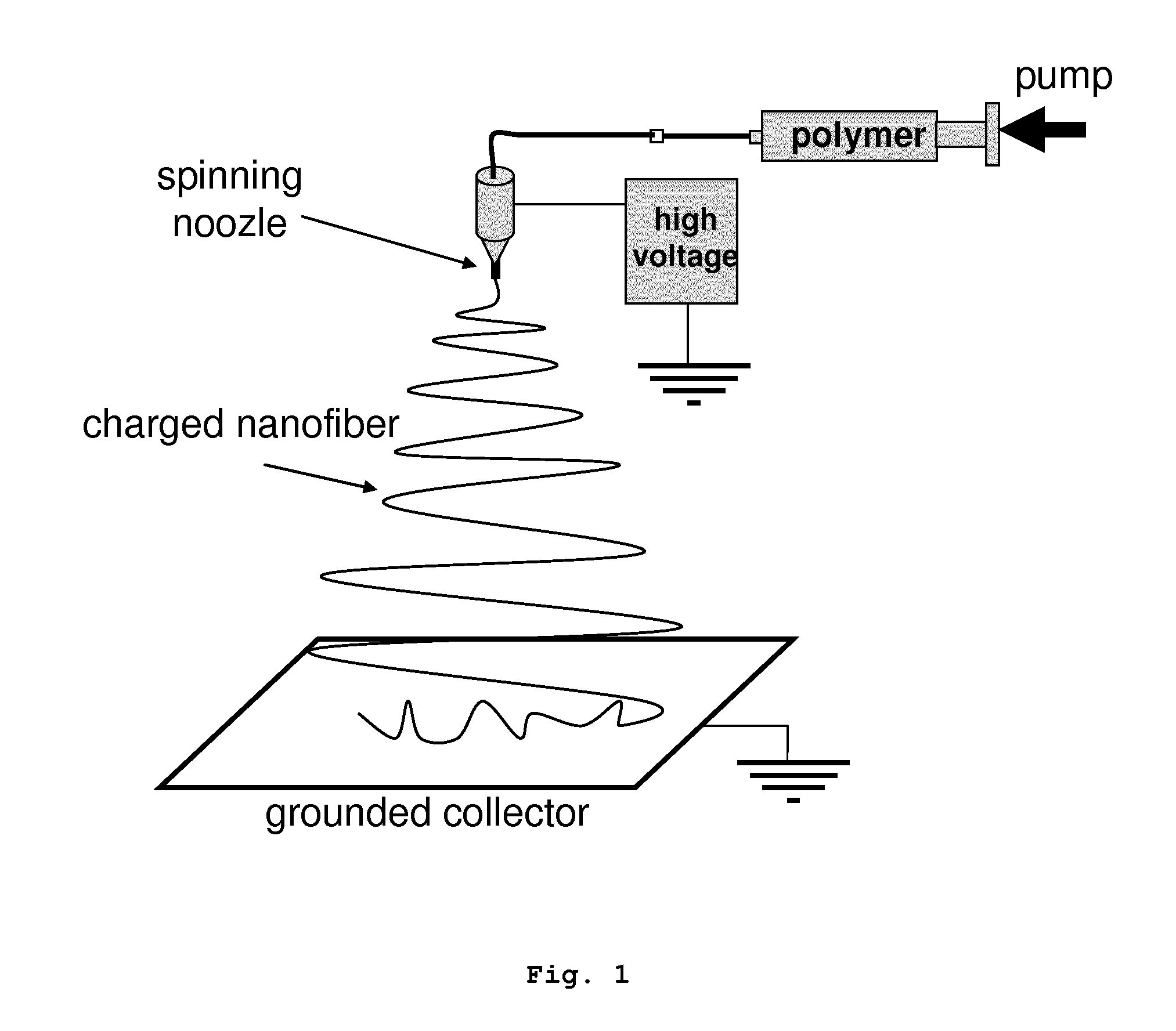

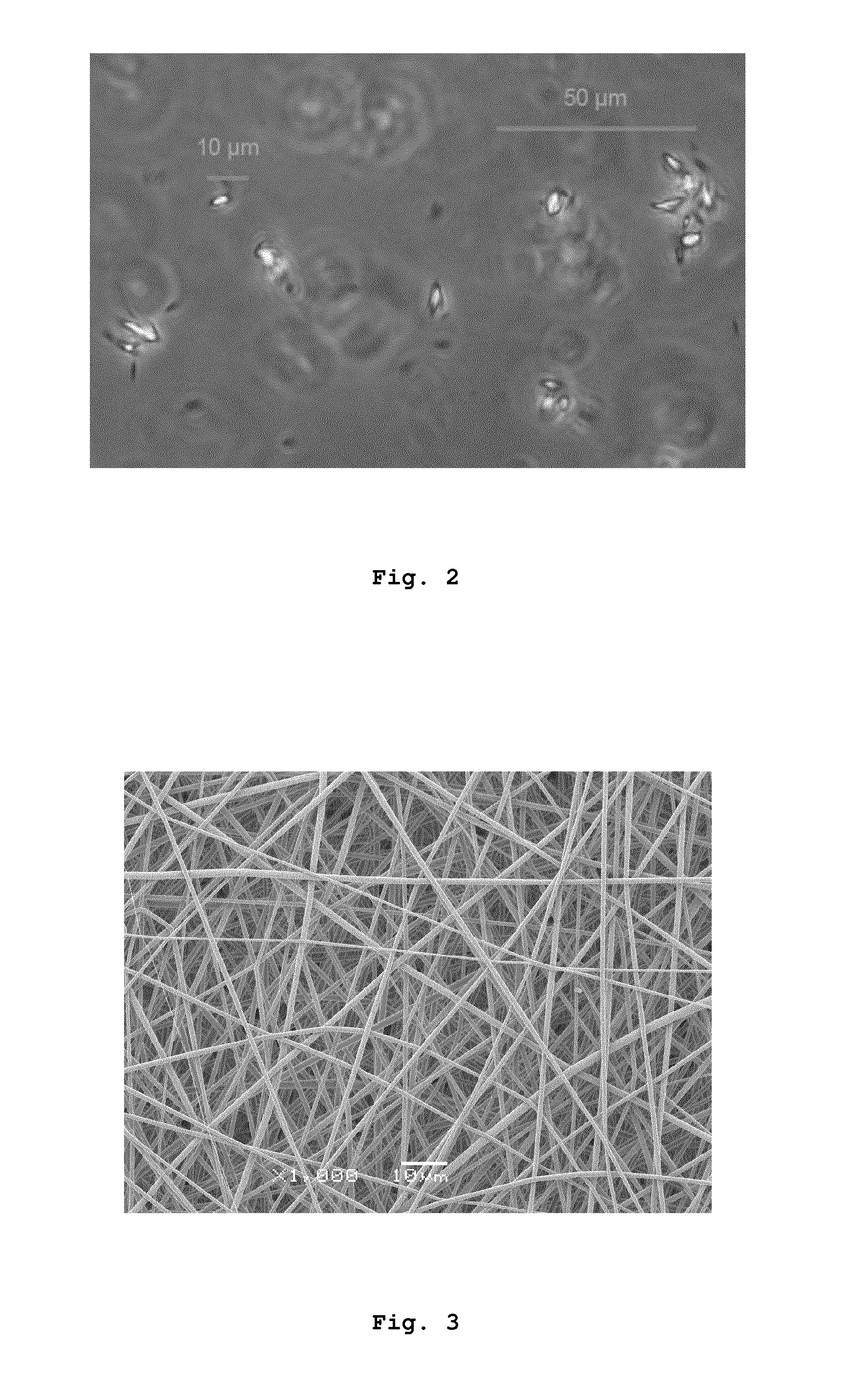

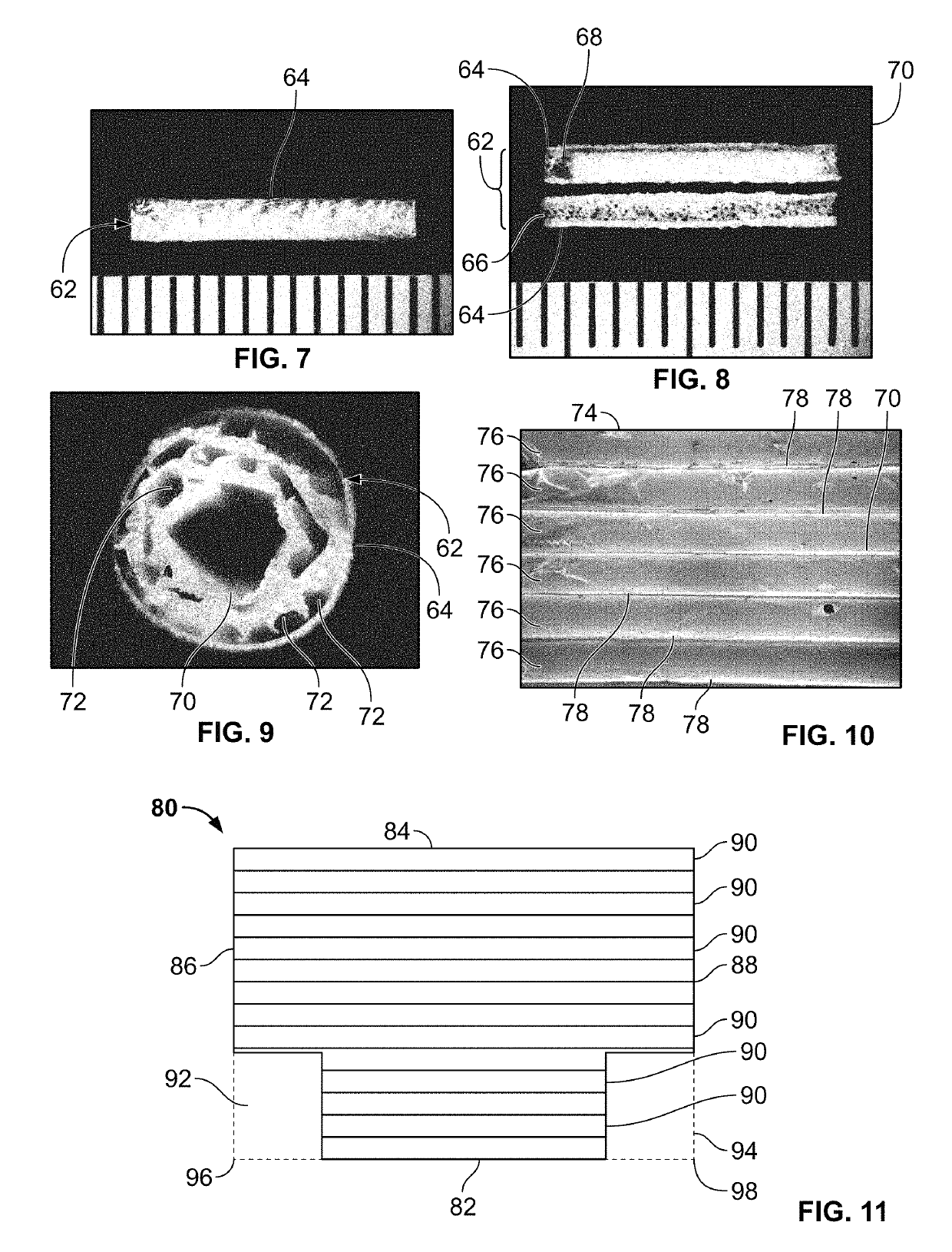

Process to create 3D tissue scaffold using electrospun nanofiber matrix and photosensitive hydrogel

ActiveUS20170239388A1High mechanical strengthProfitable/superior microstructureFibre typesEpidermal cells/skin cellsElectrospun nanofiberPolymer science

A process providing a method to create 3D scaffolds using nano-scale fibers, comprising: deposition and alignment of a plurality of electrospun fiber layers on a substrate; application of a photosensitive biomedical polymer liquid to each fiber layer deposited on said substrate; deposition and cross-alignment of a plurality of electrospun fiber layers on said substrate; retaining said polymer liquid in place using said cross-aligned fiber layers; curing said polymer liquid on top of each fiber layer using UV light.

Owner:UNIVERSITY OF CENTRAL OKLAHOMA

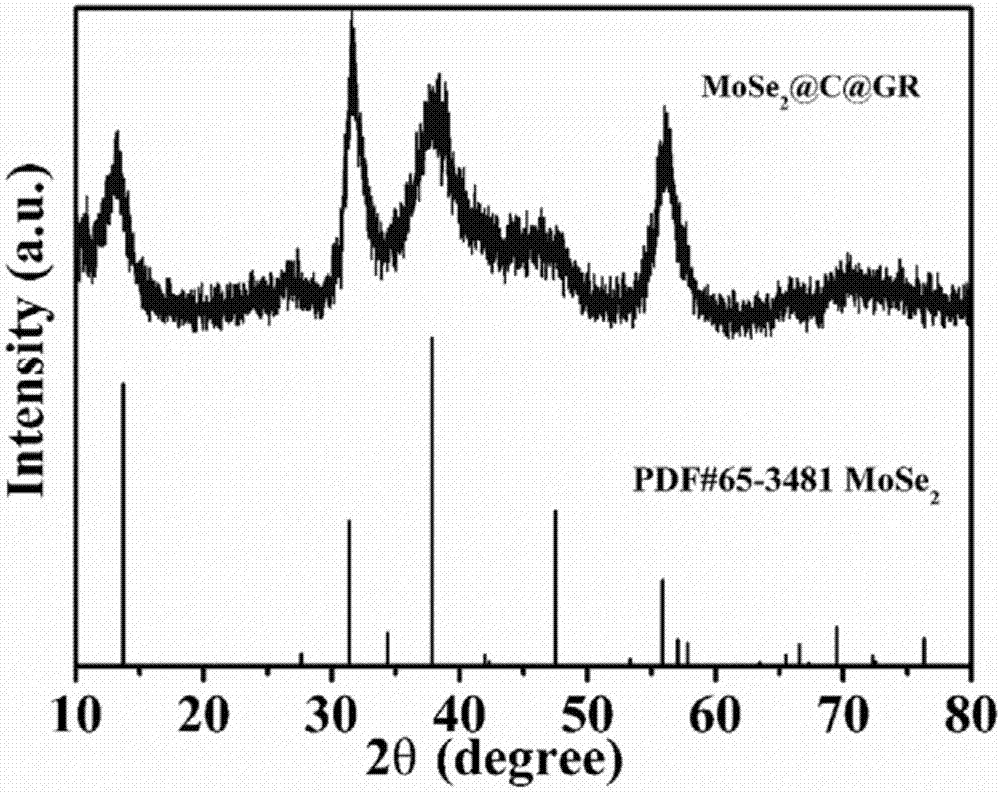

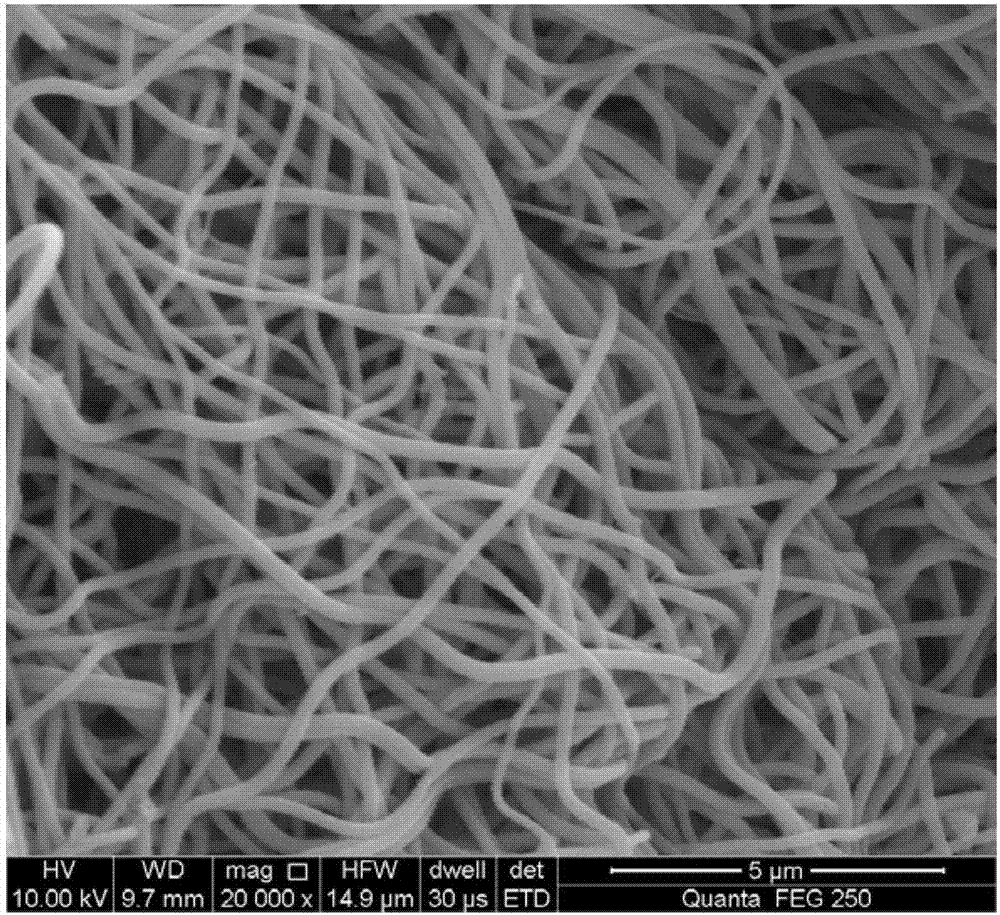

Carbon-coated MoSe2/graphene electrospun nanofibers and preparation method thereof

ActiveCN107170974AInhibition of volume expansionImprove performanceCell electrodesElectrospun nanofiberFiber

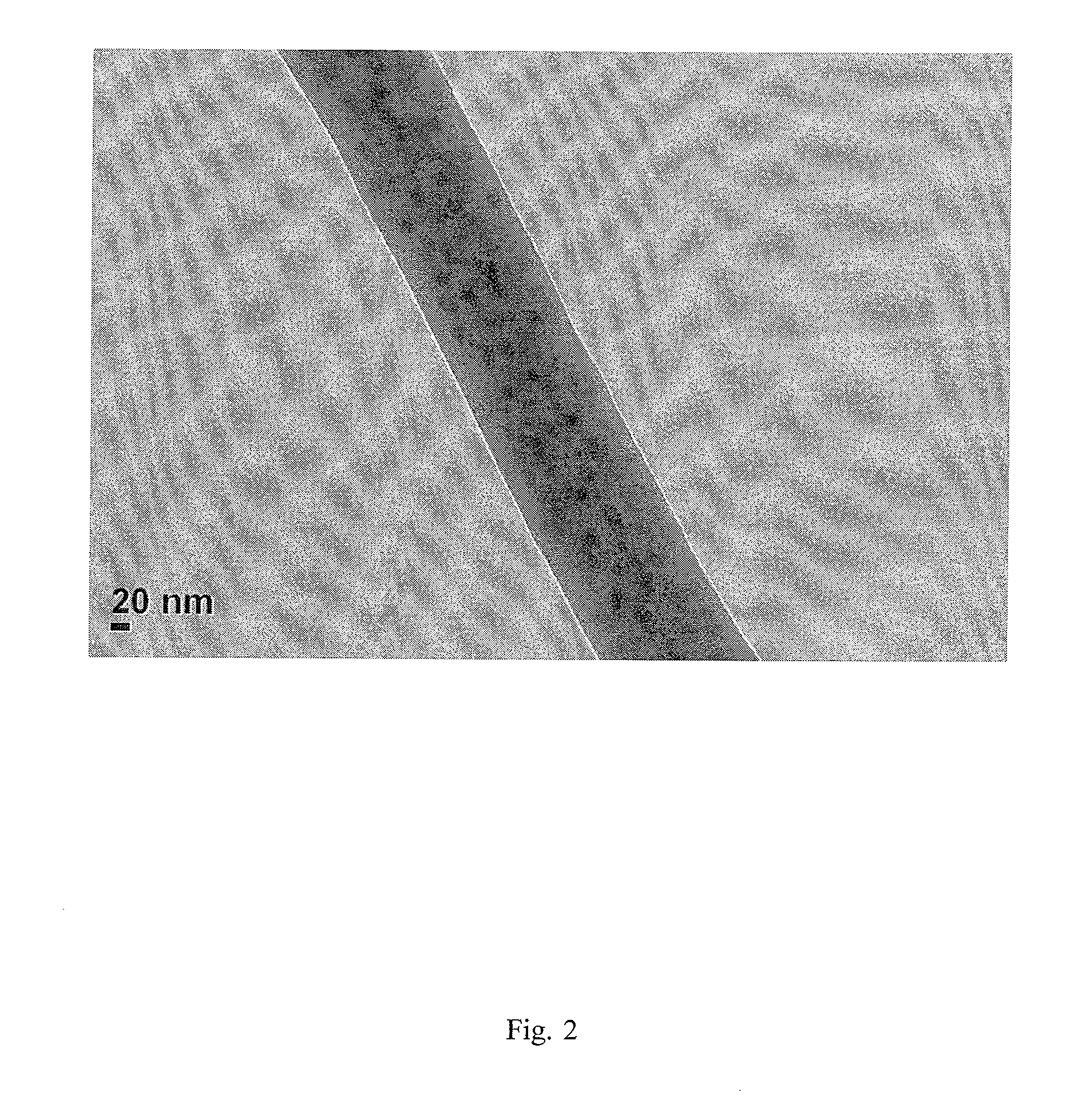

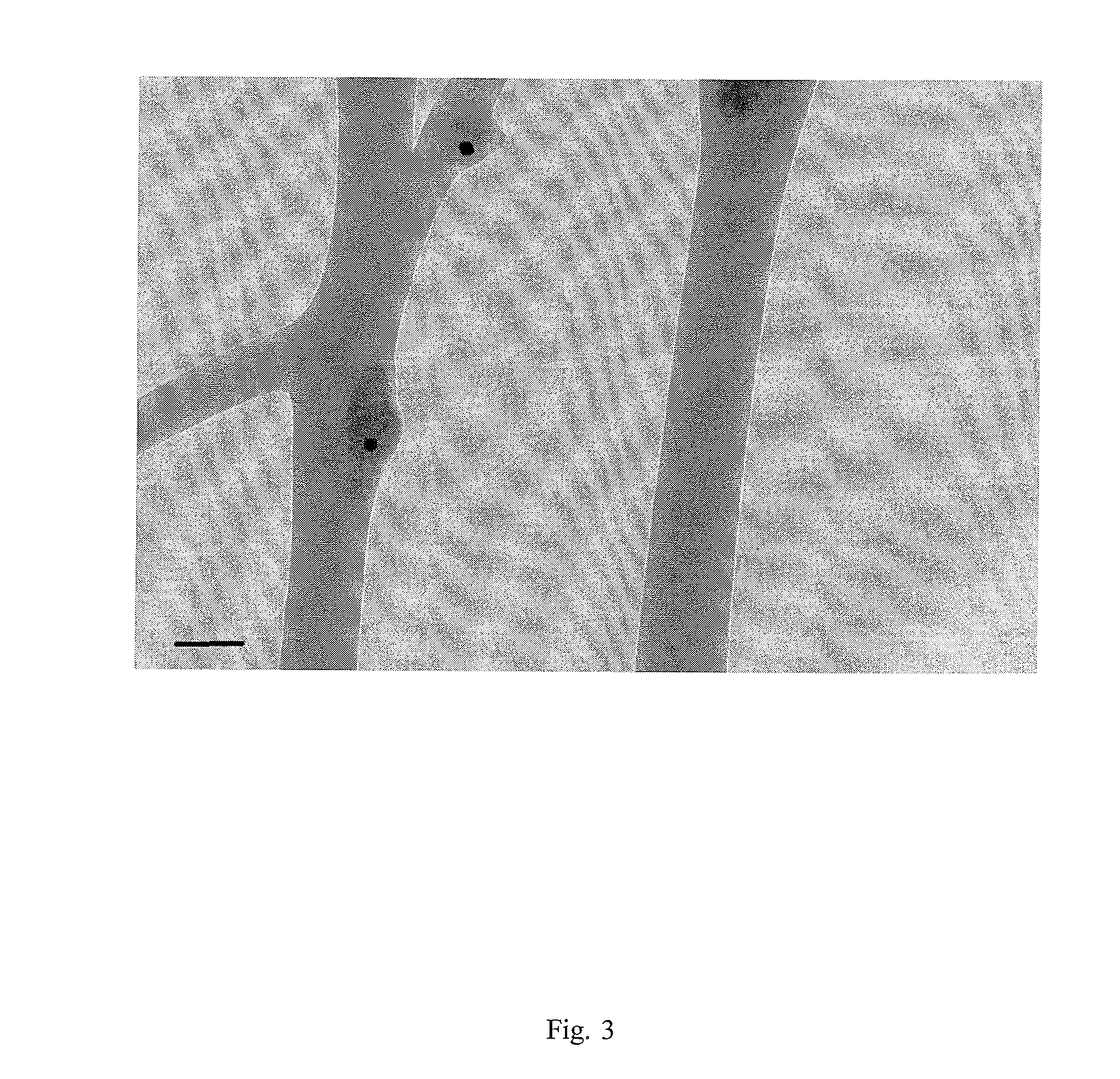

The invention relates to carbon-coated MoSe2 / graphene nanofibers prepared by electrospining and a preparation method thereof. The nanofibers are composed of coated carbon, MoSe2 and graphene. The preparation method comprises the following steps: dissolving water soluble molybdenum salt and a high polymer in a mixed solution of deionized water and ethylene glycol, heating the mixed solution till a stable transparent sol is formed, adding the graphene into the molybdenum salt solution to form an electrospining solution; electrospining the electrospining solution to obtain hybridized fibers; and then vacuum sintering the hybridized fibers obtained in the step 2 and zero valent selenium powder in a tubular furnace to obtain a carbon-coated MoSe2 / graphene nanofiber material. The fibers are uniform in shape and length, and MoSe2 crystals are uniformly distributed in the fibers and are coated by amorphous carbon; and the graphene as a conductive network is uniformly distributed in the fibers. According to the carbon-coated MoSe2 / graphene nanofibers provided by the invention, the raw materials are easily available, the preparation process is simple and controllable reaction conditions are mild, and the obtained product has a relatively high specific surface area, excellent conductivity and structural stability and can be used as an ideal lithium / sodium ion battery cathode material and a high performance electrocatalytic material.

Owner:CENT SOUTH UNIV

Nonwoven membrane as a drug delivery system

The invention defines a nonwoven membrane for the controlled and sustained release of a therapeutic or cosmetic active agent in the area of the body to be treated. This nonwoven membrane comprises one single type of biocompatible electrospun nanofibers and microparticles of at least one therapeutic or cosmetic active agent which are entangled between the nanofibers, the active agent having a low water solubility.

Owner:UNIV POLITECNICA DE CATALUNYA +1

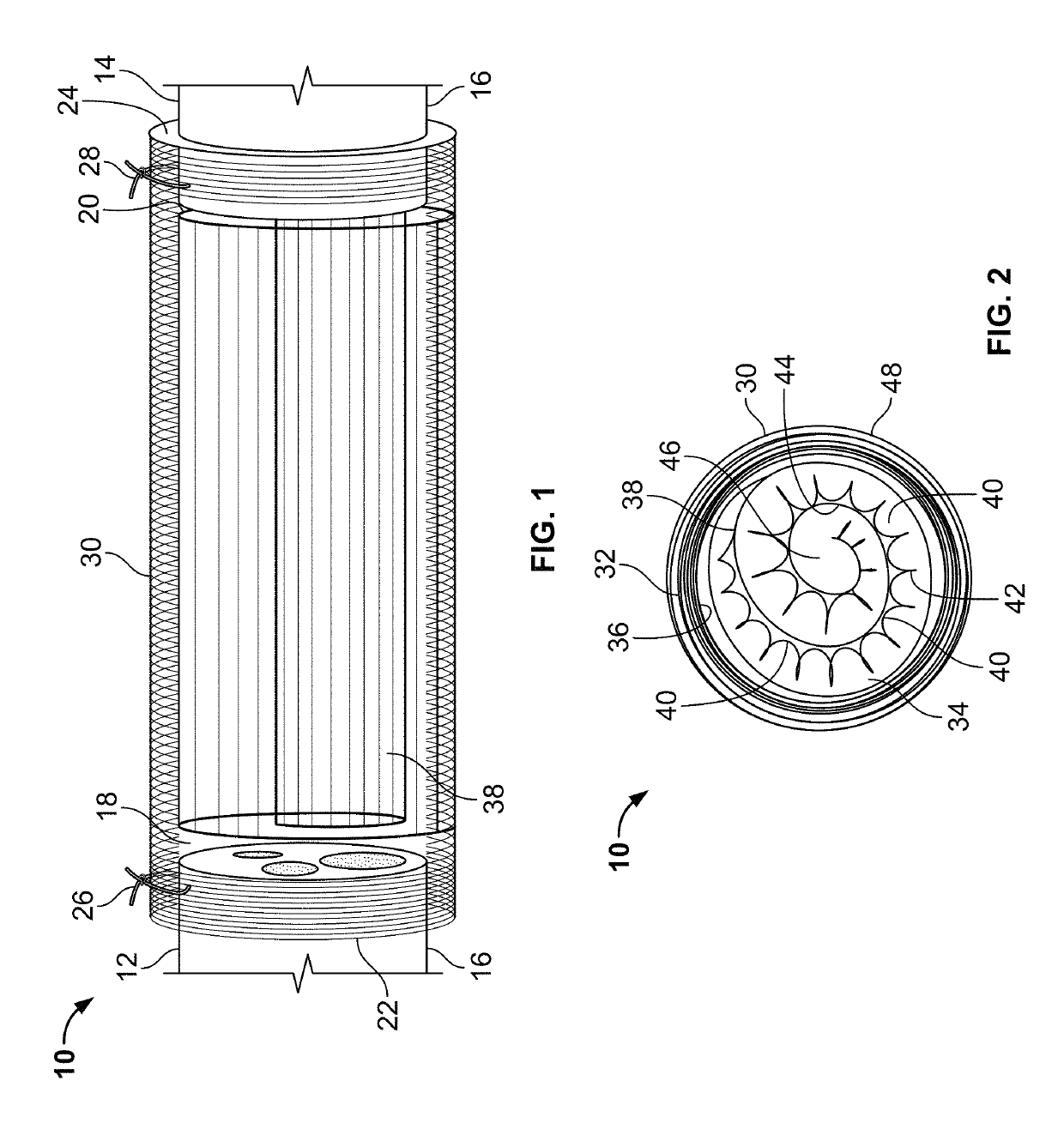

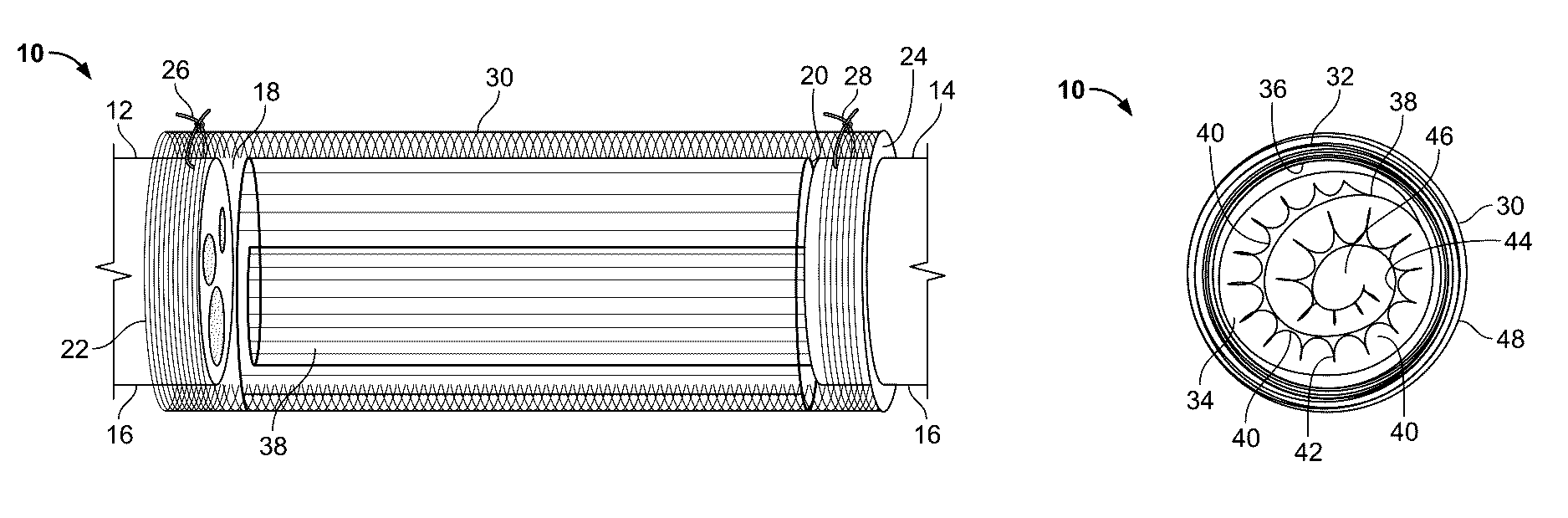

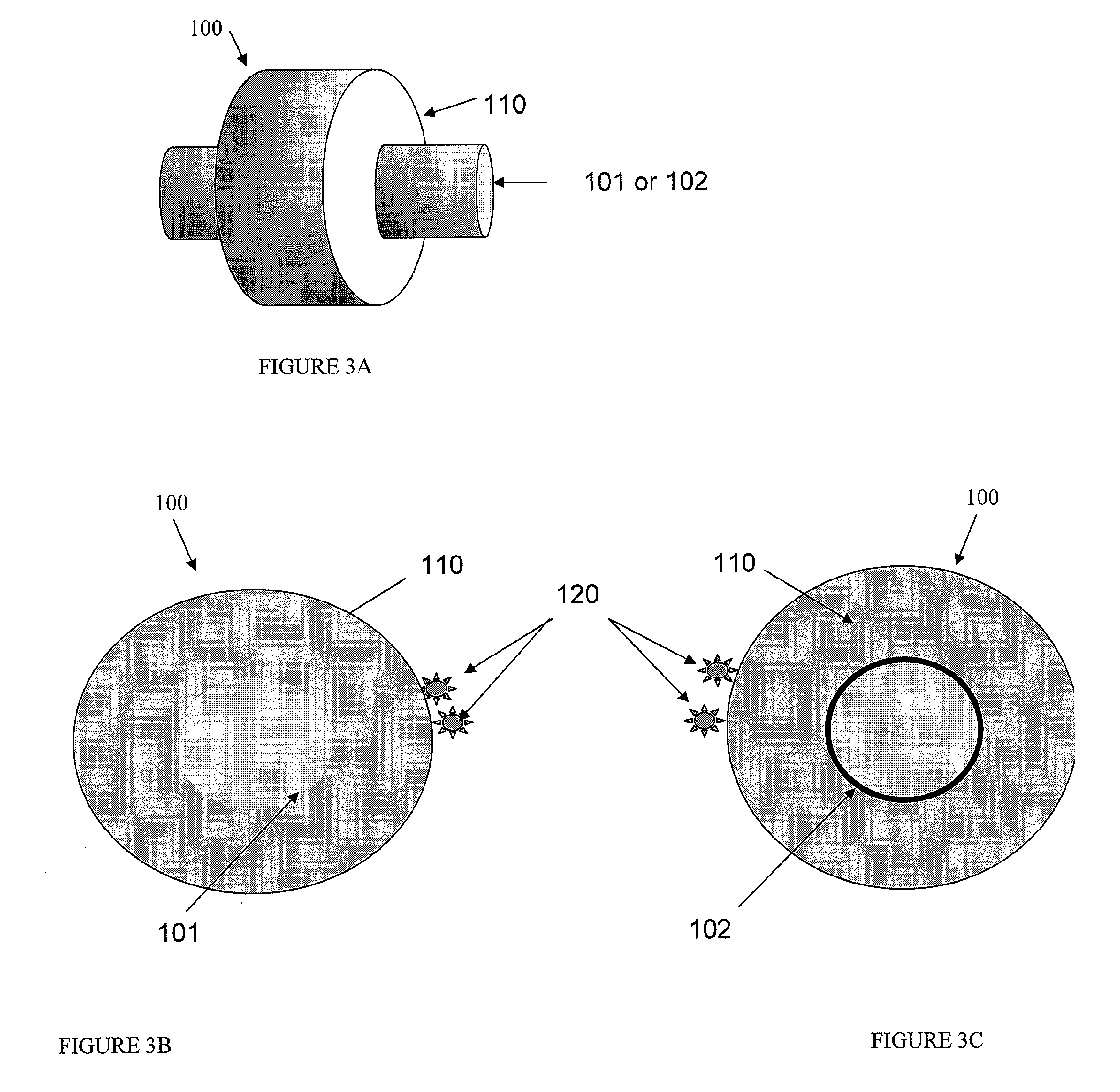

Implantable nerve guidance conduits having polymer fiber guidance channel

ActiveUS10363041B2Promote regenerationRestore function to of injurySurgeryPharmaceutical delivery mechanismFiberElectrospun nanofiber

A nerve guidance conduit includes one or more guidance channels formed as porous polymeric structures. The guidance channels are within an outer tubular structure that includes randomly-oriented nanofibers. The guidance channels may have electrospun nanofibers on their inner and outer surfaces in a parallel alignment with the guidance channels. Such aligned nanofibers may also be present on the inner surface of the outer tubular structure. The outer surfaces of the guidance channels and the inner surface of the tubular structure define additional guidance channels. Such a nerve guidance conduit provides augmented surface areas for providing directional guidance and enhancing peripheral nerve regeneration. The structure also has the mechanical and nutrient transport requirements required over long regeneration periods.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

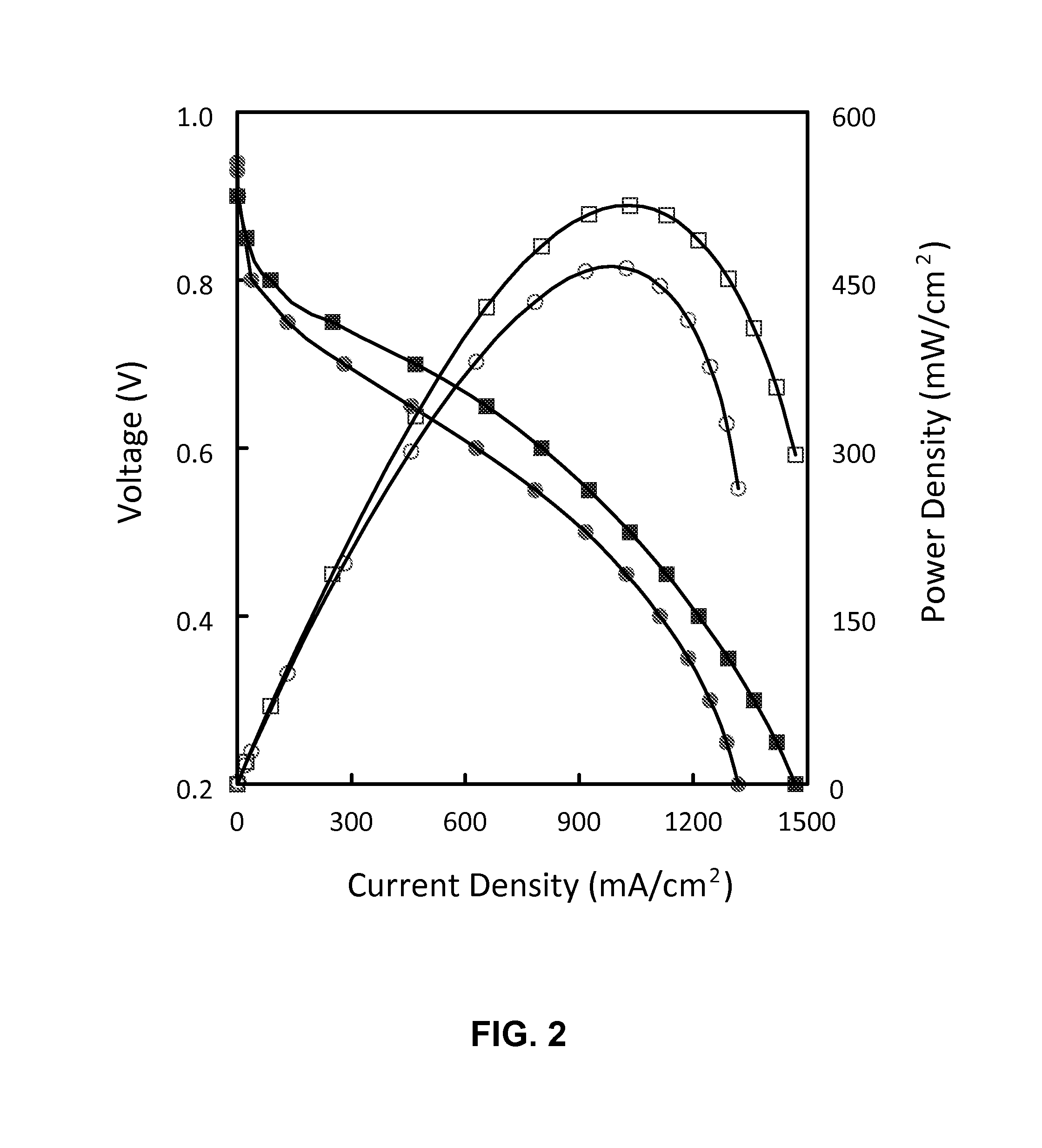

Nanofiber membrane-electrode-assembly and method of fabricating same

In one aspect of the present invention, a fuel cell membrane-electrode-assembly (MEA) has an anode electrode, a cathode electrode, and a membrane disposed between the anode electrode and the cathode electrode. At least one of the anode electrode, the cathode electrode and the membrane is formed of electrospun nanofibers.

Owner:VANDERBILT UNIV

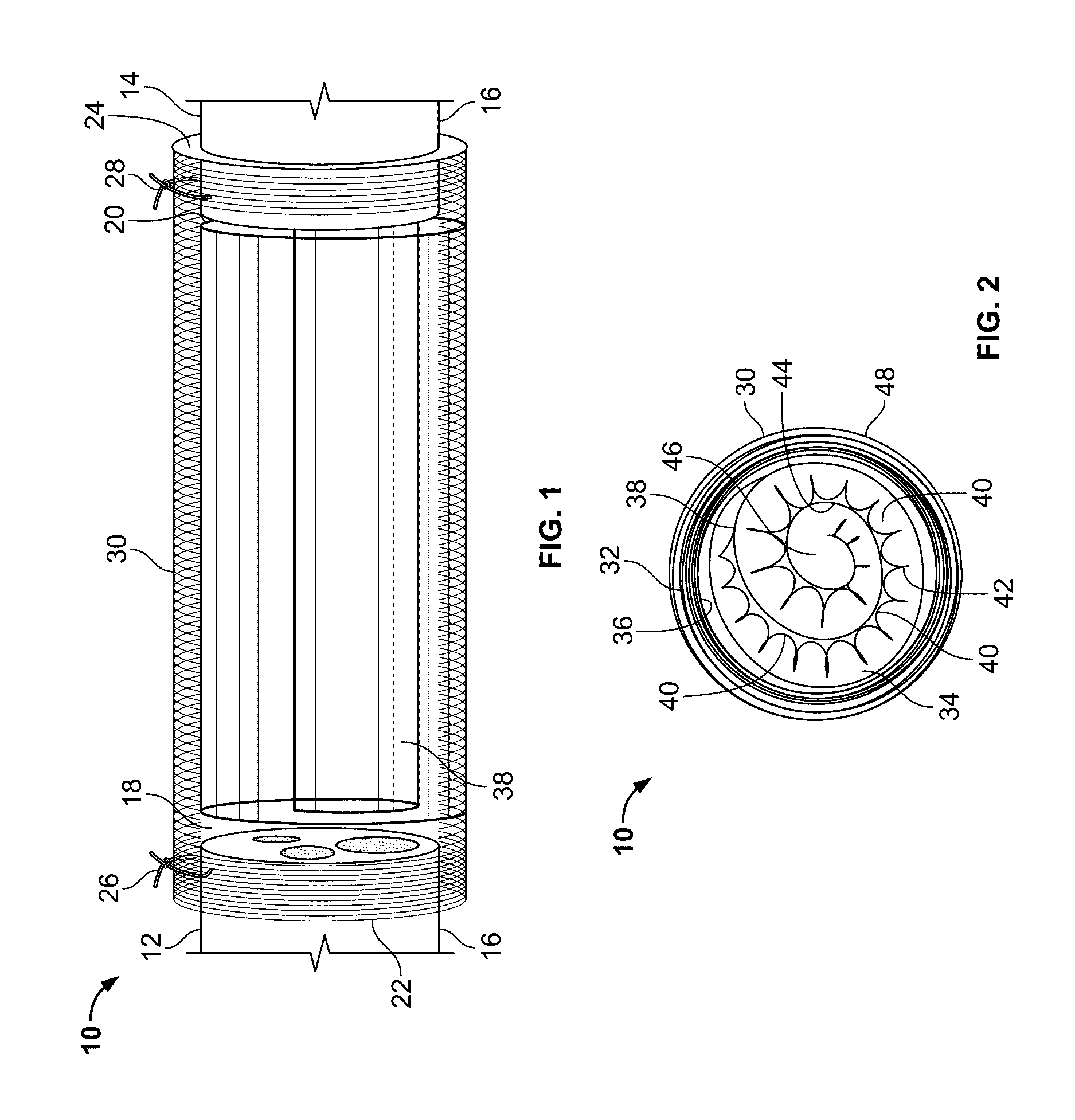

Implantable nerve conduit having a polymer fiber spiral guidance channel

ActiveUS9585666B2Increase surface areaShorten the length of timeSurgeryPharmaceutical delivery mechanismFiberElectrospun nanofiber

A nerve guidance conduit includes a spiral structured porous sheet decorated with channels on its surface and electrospun nanofibers in a parallel alignment with the channels and an outer tubular structure including randomly-oriented nanofibers. Such a structure provides augmented surface areas for providing directional guidance and augmented surfaces for enhancing and peripheral nerve regeneration. The structure also has the mechanical and nutrient transport requirements required over long regeneration periods. To prepare a nerve guidance conduit, porous polymer sheet is prepared by a solvent casting method while using a template of thin rods to form parallel channels on a surface of the sheet. Aligned nanofibers are deposited on the sheet parallel to the channels. The polymer sheet is then wound to form a spiral structure. A dense layer of randomly-oriented nanofibers may be deposited on the outside of the spiral.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

Indicator device having an active agent encapsulated in an electrospun nanofiber

ActiveUS7569359B2Avoid separationBioreactor/fermenter combinationsBiological substance pretreatmentsElectrospun nanofiberActive agent

An indicator device for determining the efficacy of an antimicrobial treatment process. The indicator device includes an active agent encapsulated in an encapsulation component. The encapsulation components preferably takes the form of an electrospun nanofiber including a polymer.

Owner:AMERICAN STERILIZER CO

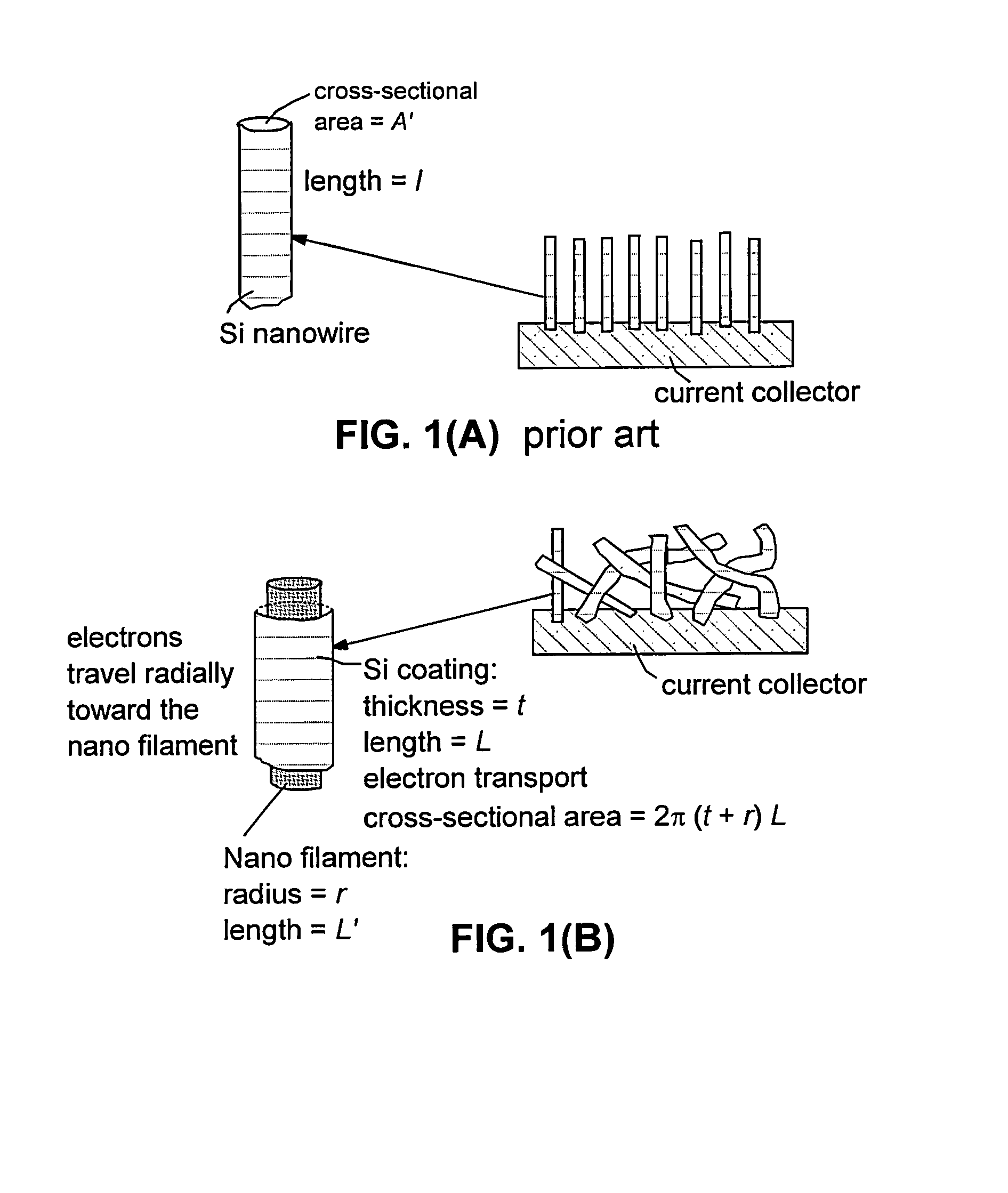

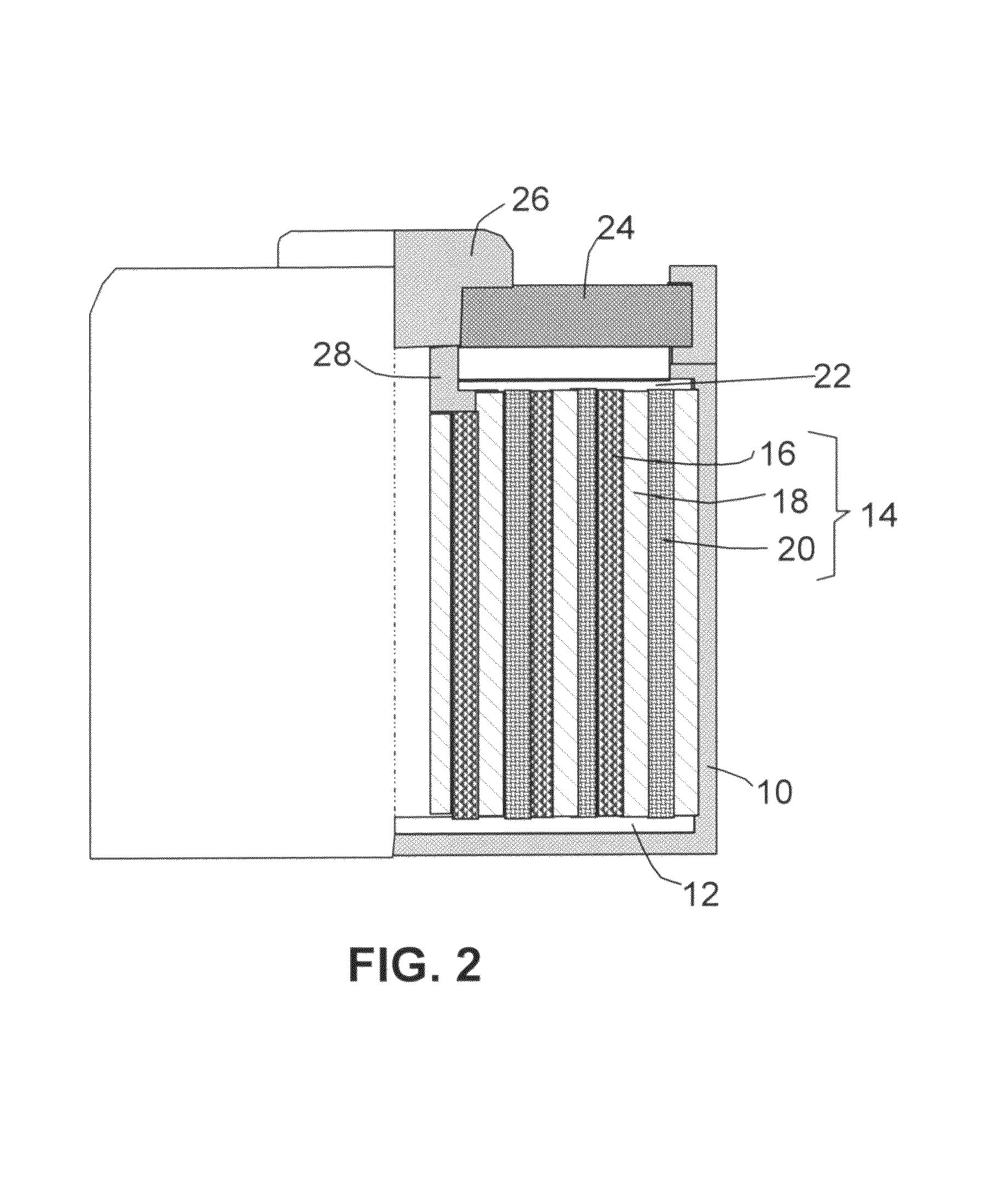

Method of producing hybrid nano-filament electrodes for lithium metal or lithium ion batteries

ActiveUS8906447B2High reversible capacityLower internal resistanceElectrochemical processing of electrodesElectrode thermal treatmentElectrospun nanofiberElectrical battery

Disclosed is a method of producing a hybrid nano-filament composition for use in a lithium battery electrode. The method comprises: (a) providing an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a porous network of electrically conductive filaments, wherein the filaments comprise electro-spun nano-fibers that have a diameter less than 500 nm (preferably less than 100 nm); and (b) depositing micron- or nanometer-scaled coating onto a surface of the electro-spun nano-fibers, wherein the coating comprises an electro-active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 10 μm (preferably less than 1 μm). The same method can be followed to produce an anode or a cathode. The battery featuring an anode or cathode made with this method exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

A kind of high wear-resisting and anti-stripping electrostatic spinning nanofiber composite filter material and its spinning method

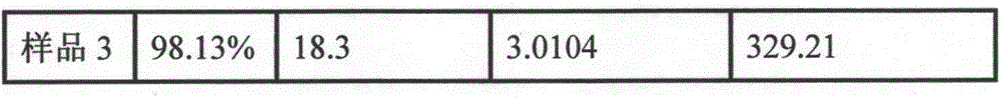

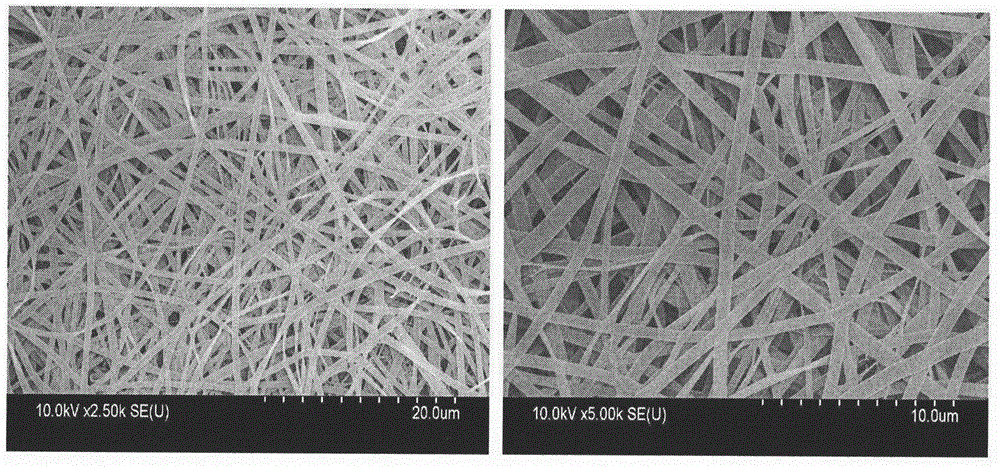

ActiveCN104028047BCompact structureSimple processSynthetic resin layered productsLaminationElectrospun nanofiberSpinning

The invention relates to a high-wear-resistant anti-stripping electrostatic spinning nanofiber composite filter material and a spinning method thereof. The preparation method comprises the following step: in the electrostatic spinning process, performing one-step forming by controlling and regulating the solvent concentration / pressure difference / melting points of two different polymers / an electrostatic spray solvent, so as to obtain dense three-dimensional arc-hole structural composite filter material fully adhered to fiber lapping points, wherein the gram weight of a fiber layer is 0.01 to 30 g / m<2>, the wear resistance of the composite filter material is 600 to 3,000 circles, the anti-stripping intensity is 5 to 100 MPa, the filter efficiency to 0.008-2-mircon particles reaches more than 99.99%, the resistance pressure drop is below 25 Pa, and the clogging capacity is 100 to 3,000 g / m<2>. The spinning method has the advantages of simple preparation process and low cost, and the prepared composite filter material has wide application prospects in the fields of engine filtration, air compressor filtration, gas turbine filtration, indoor air purification and filtration, high-efficiency filtration and the like.

Owner:SHANGHAI XUNJIANG TECH CO LTD

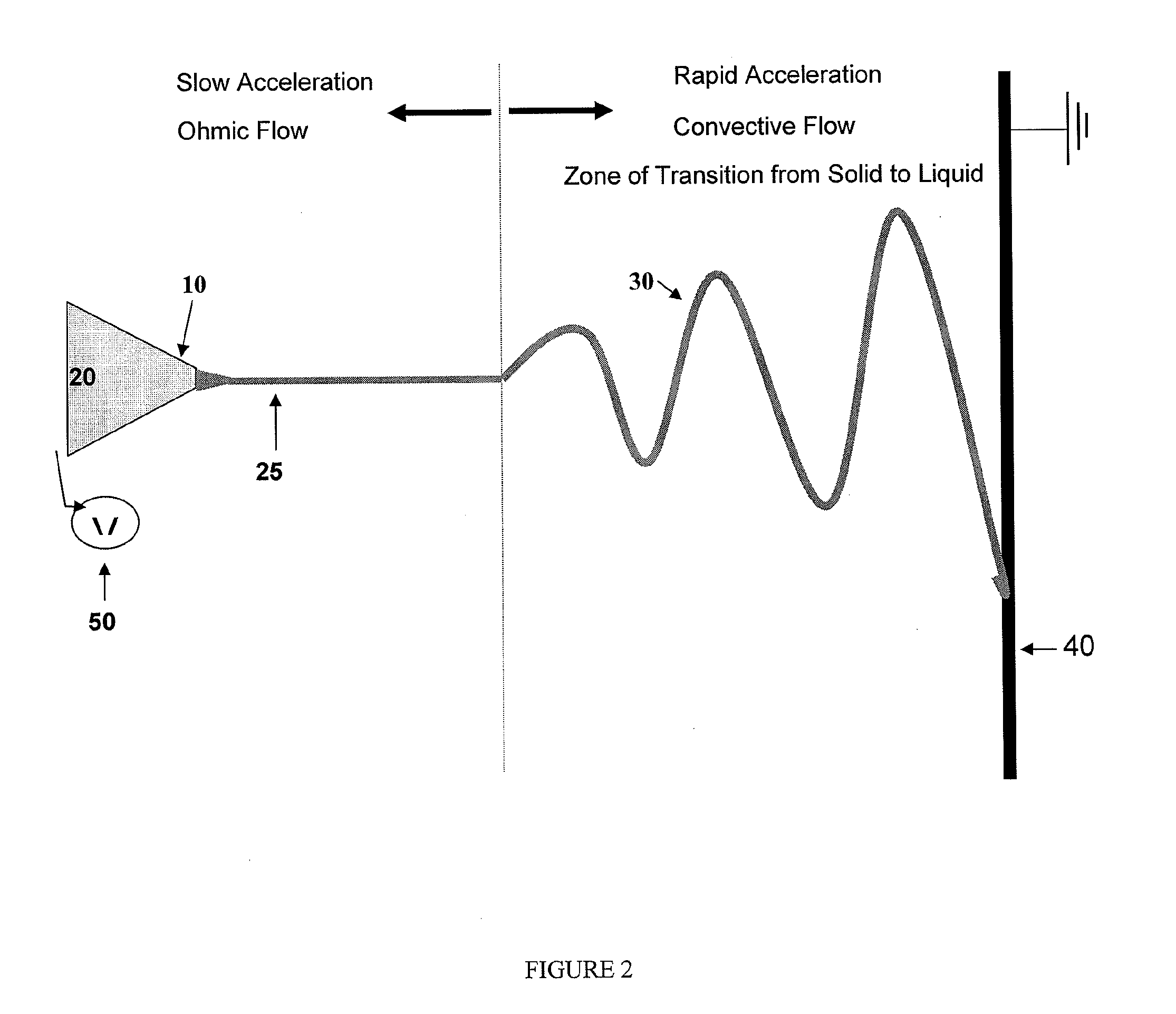

Electrospun Fiber Pre-Concentrator

The present disclosure relates, in some embodiments, to pre-concentrator compositions, devices, systems, and / or methods for concentrating small quantities of chemical or biological compounds, e.g., CBRNE compounds. A pre-concentrator of the disclosure may be operable to releasably bind and concentrate CBRNE compounds. In some embodiments, a pre-concentrator may comprise a 3-D structure of electrospun nanofibers, that comprise at least one polymer, one conducting agent and at least one chemical-specific functional group and / or biological-specific moiety configured to selectively bind to a CBRNE compound. Bound compounds may be released and detected. Pre-concentrator devices and systems operable to bind, concentrate, and / or detect one or more CBRNE compounds are described. Devices and systems of the disclosure may be configured to concentrate and detect multiple compounds. Methods for synthesizing pre-concentrators as well as methods for concentrating, detecting and identifying compounds of interest are also set forth.

Owner:RAYTHEON CO

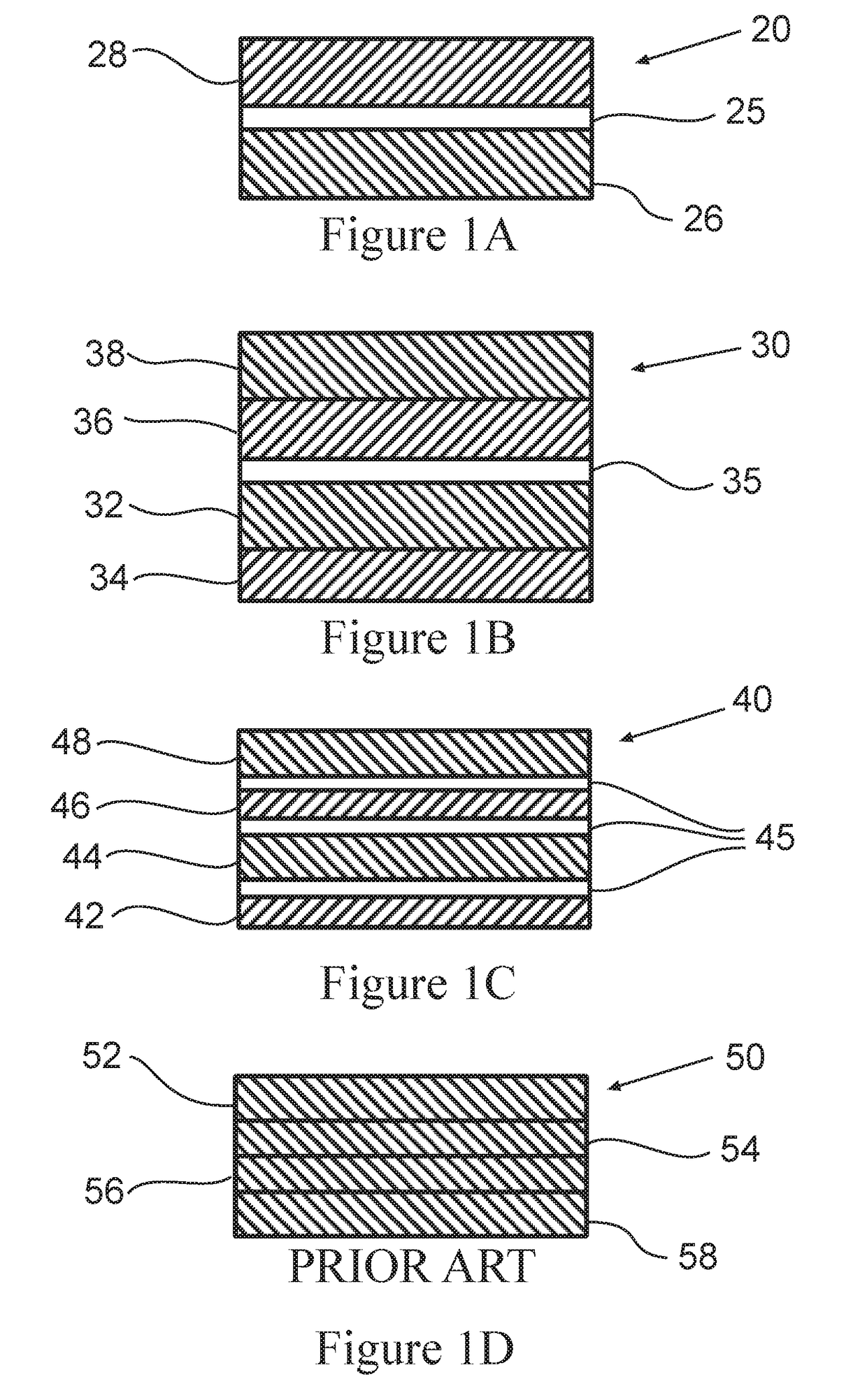

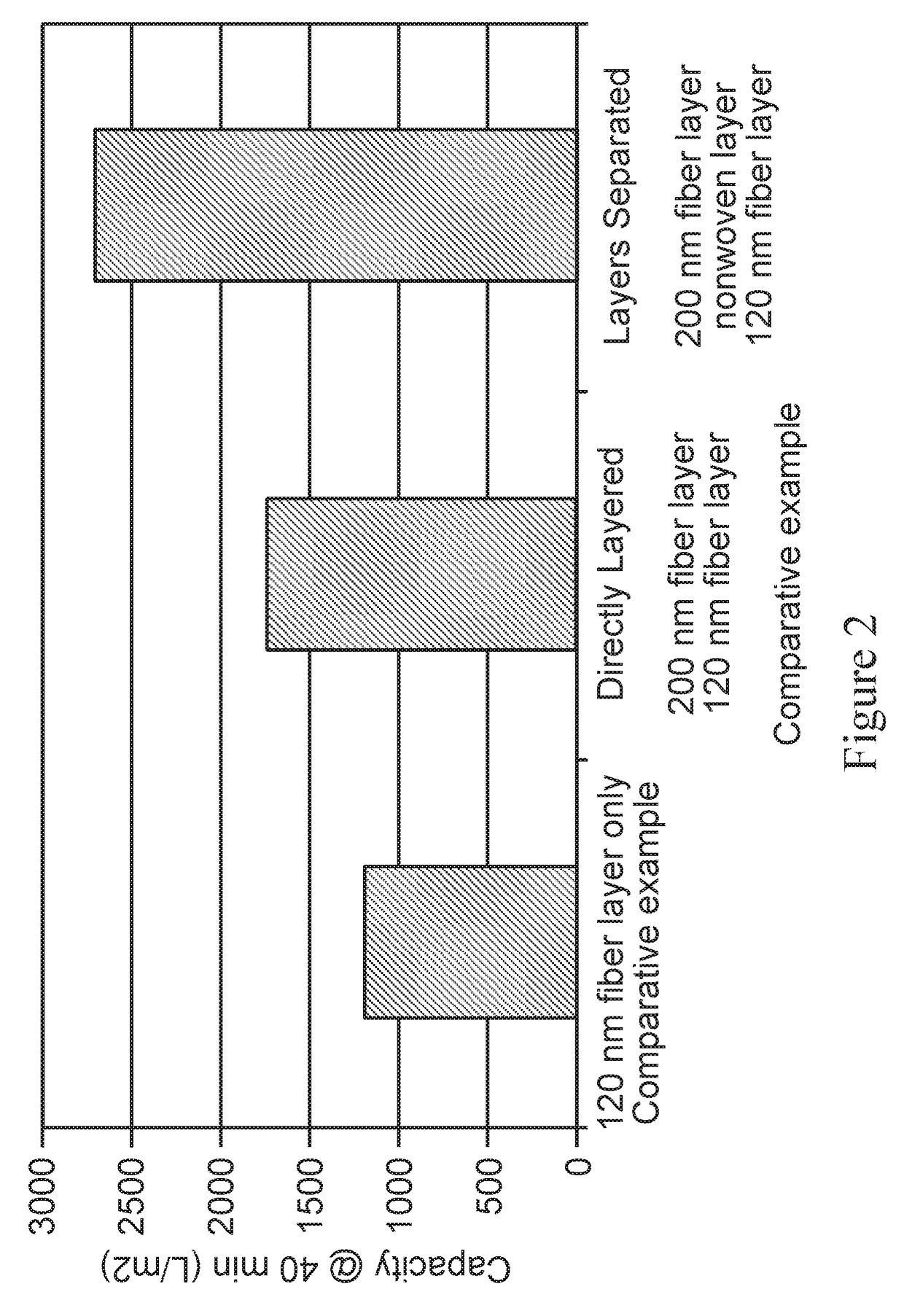

Filter structure with enhanced dirt holding capacity

PendingUS20170173509A1Improve dirt holding capacityMembrane filtersFiltration separationElectrospun nanofiberComposite media

A fluid filtration device containing a composite filter media having a coarse porous polymeric nonwoven interlayer located between first and second polymeric fiber containing filter mats. The fiber diameters of the fibers in the first and second filter mats are different from each other, and each filter mat has a different pore size rating. The first and second polymeric fibers in the filter mats can be electrospun nanofibers. The interlayer has a coarser pore size when compared to the either the first or second filter mats, such that the resulting composite media has an increased dirt holding capacity compared to filter layers that are layered directly over each other without the presence of a coarse interlayer therebetween.

Owner:MILLIPORE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com