Device for preparing electrospun nanofiber yarns by using rotary collector and preparation method thereof

A technology of nanofiber and rotary collection, which is applied to spinning machines, fiber processing, open-end spinning machines, etc., and can solve problems such as reducing yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

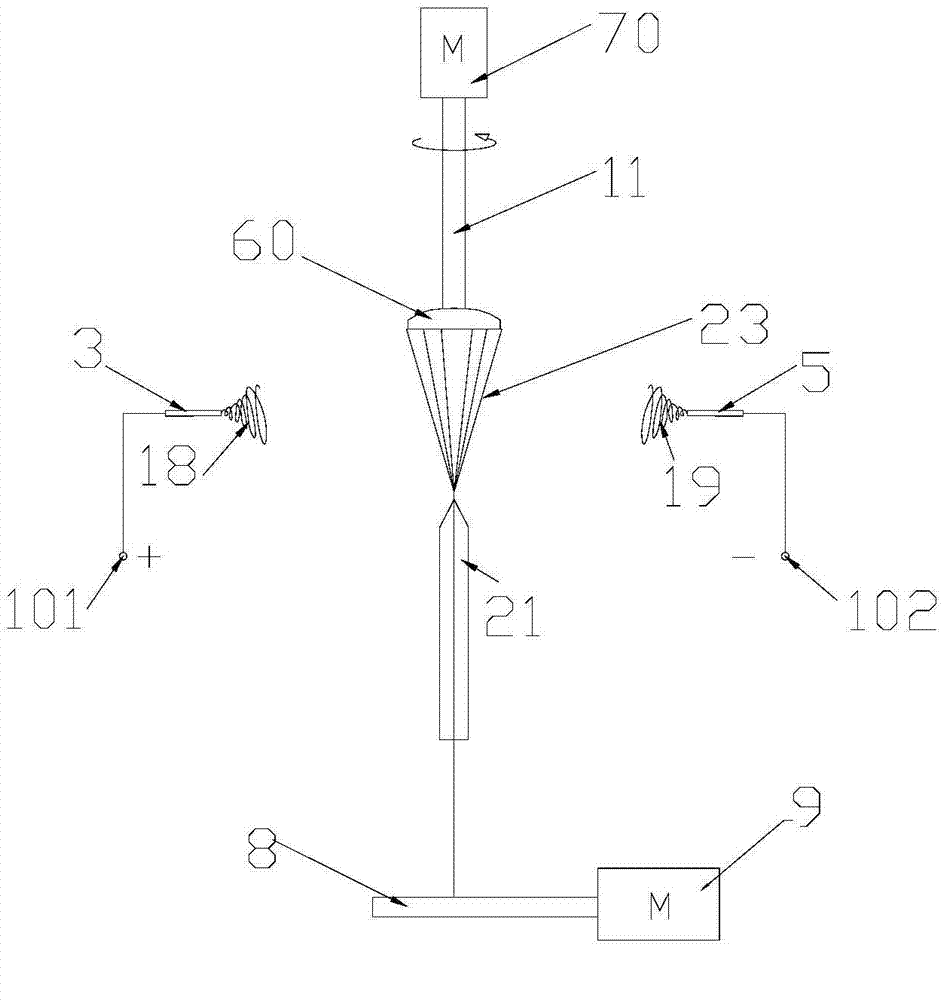

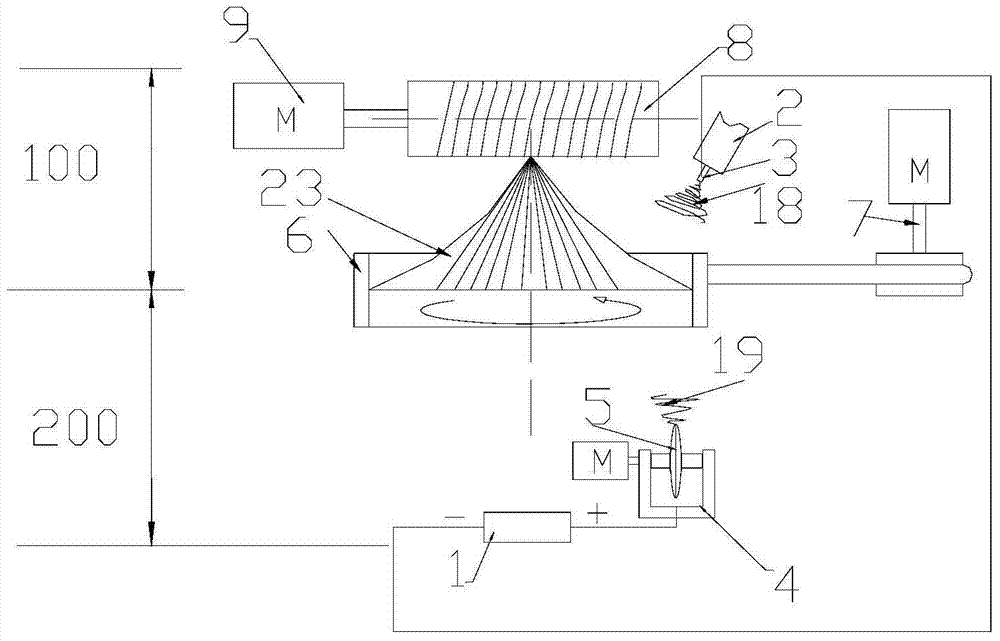

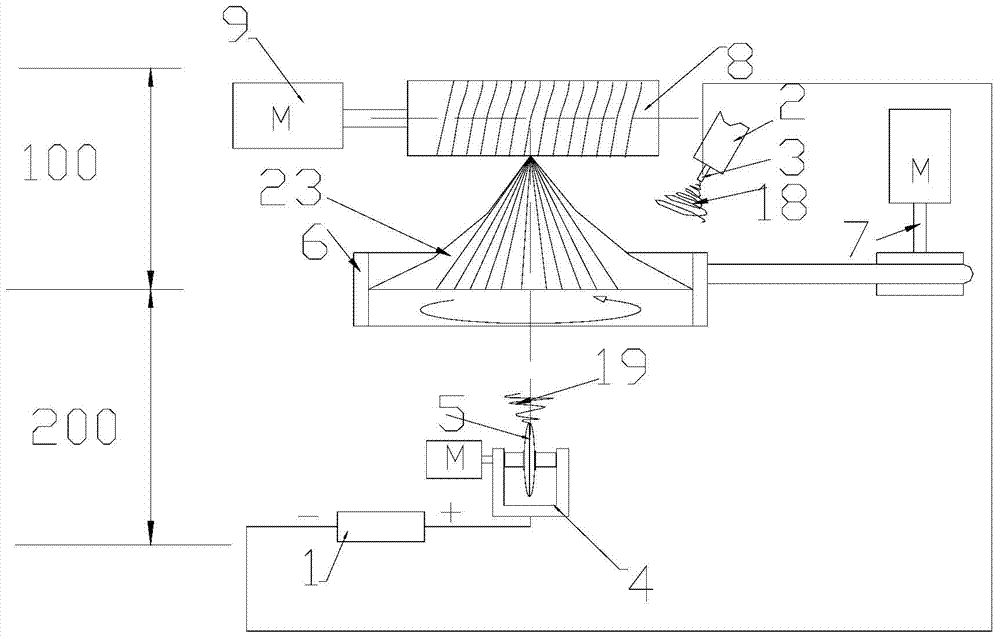

[0101] Such as Figure 2-4 As shown, the rotating collector prepares the electrospinning nanofiber yarn device, including: high voltage power supply 1, negative electrode solution tank 2, negative electrode spinning head 3, positive electrode solution tank 4, positive electrode spinning head 5, hollow collector 6, hollow collecting Drive device 7, winding device 8.

[0102] The negative and positive stages of the high voltage power supply 1 are respectively connected to the negative spinning head 3 and the positive spinning head 5; the negative solution tank 2 and the positive solution tank 4 supply liquid to the negative spinning head 3 and the positive spinning head 5 respectively.

[0103] Such as Figure 2-4 As shown, the collector transmission device 7 is connected to the hollow collector 6 and is arranged above the positive electrode solution tank 4 and the positive electrode spinning head 5 .

[0104] Such as Figure 2-4 As shown, the winding device 8 is connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com