Patents

Literature

206results about How to "Improve dirt holding capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for water filtration

InactiveUS20090045135A1Great hydraulic resistancePromote circulationTreatment using aerobic processesTreatment involving filtrationNatural sourceSuspended particles

This is a method of filtration of a liquid comprising steps of sequential filtration of said liquid through at least one deep bed medium producing at least one first filtrate followed by at least one membrane medium filtration producing at least one second filtrate, wherein said membrane medium is at least periodically within said deep bed media Many types of deep bed and membrane media can be used. The domain of using contact clarification (direct filtration) can be expanded towards greater solids concentration. Operation and backwash, is simplified, continuous filtration becomes possible. Water can be water from natural source water, process water, wastewater, aqueous or non-aqueous suspensions, emulsions, solutions. Treatment can include mechanical interception of suspended particles, chemical, physical chemical, electrochemical, and biological processes. In water and wastewater processing, control over suspended solids, BOD, COD, nitrogen and phosphorus compounds, bacteria and viruses, heavy metals, color, and other constituents can be dramatically improved as compared to conventional processes. The method can be accommodated in new and modified existing treatment systems.

Owner:KHUDENKO ENG

Method for water filtration

InactiveUS7553418B2Simple in-situ restoration of membrane surfaceEfficient removalTreatment using aerobic processesTreatment involving filtrationNatural sourceSuspended particles

This is a method of filtration of a liquid comprising steps of sequential filtration of said liquid through at least one deep bed medium producing at least one first filtrate followed by at least one membrane medium filtration producing at least one second filtrate, wherein said membrane medium is at least periodically within said deep bed media Many types of deep bed and membrane media can be used. The domain of using contact clarification (direct filtration) can be expanded towards greater solids concentration. Operation and backwash, is simplified, continuous filtration becomes possible. Water can be water from natural source water, process water, wastewater, aqueous or non-aqueous suspensions, emulsions, solutions. Treatment can include mechanical interception of suspended particles, chemical, physical chemical, electrochemical, and biological processes. In water and wastewater processing, control over suspended solids, BOD, COD, nitrogen and phosphorus compounds, bacteria and viruses, heavy metals, color, and other constituents can be dramatically improved as compared to conventional processes. The method can be accommodated in new and modified existing treatment systems.

Owner:KHUDENKO ENG

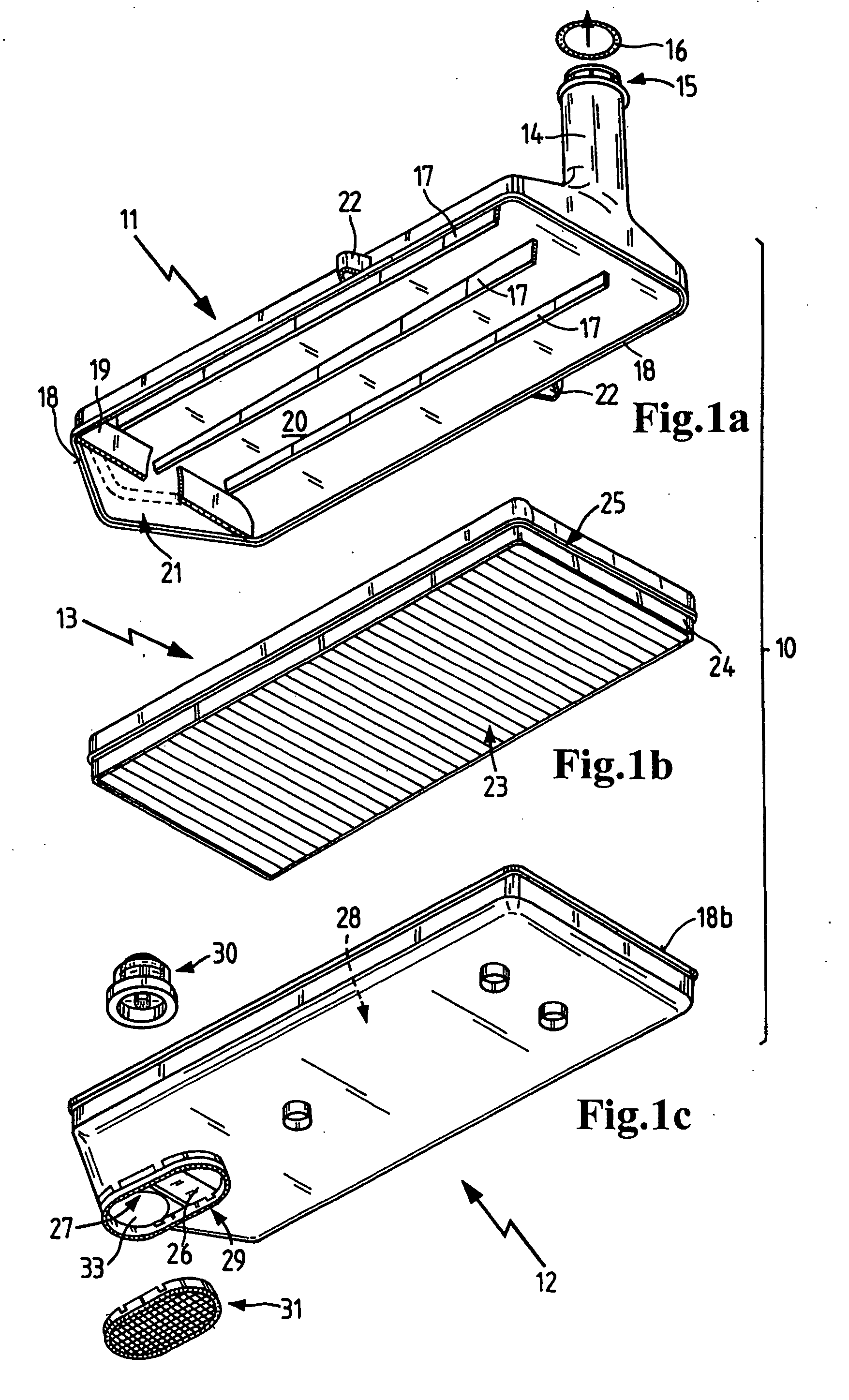

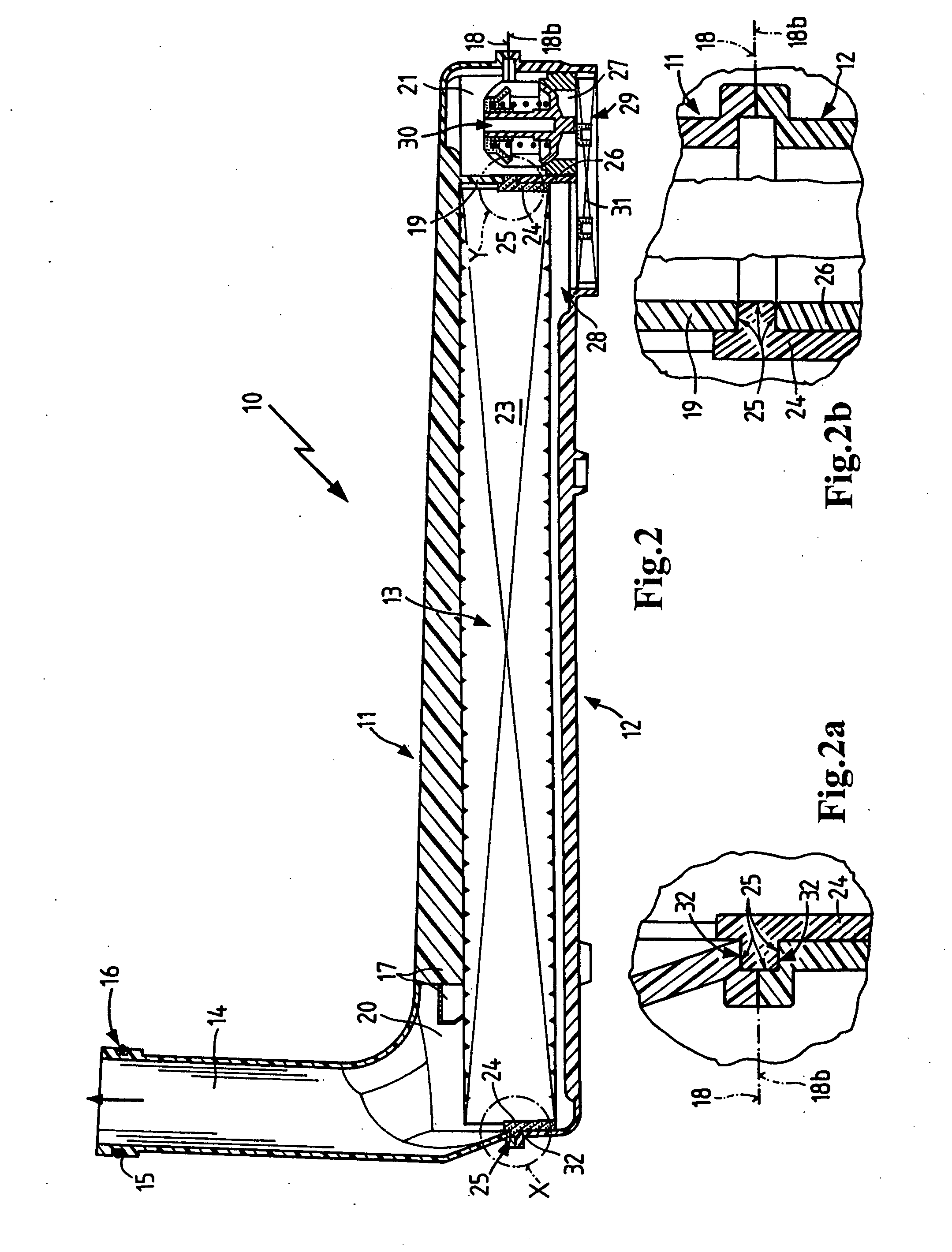

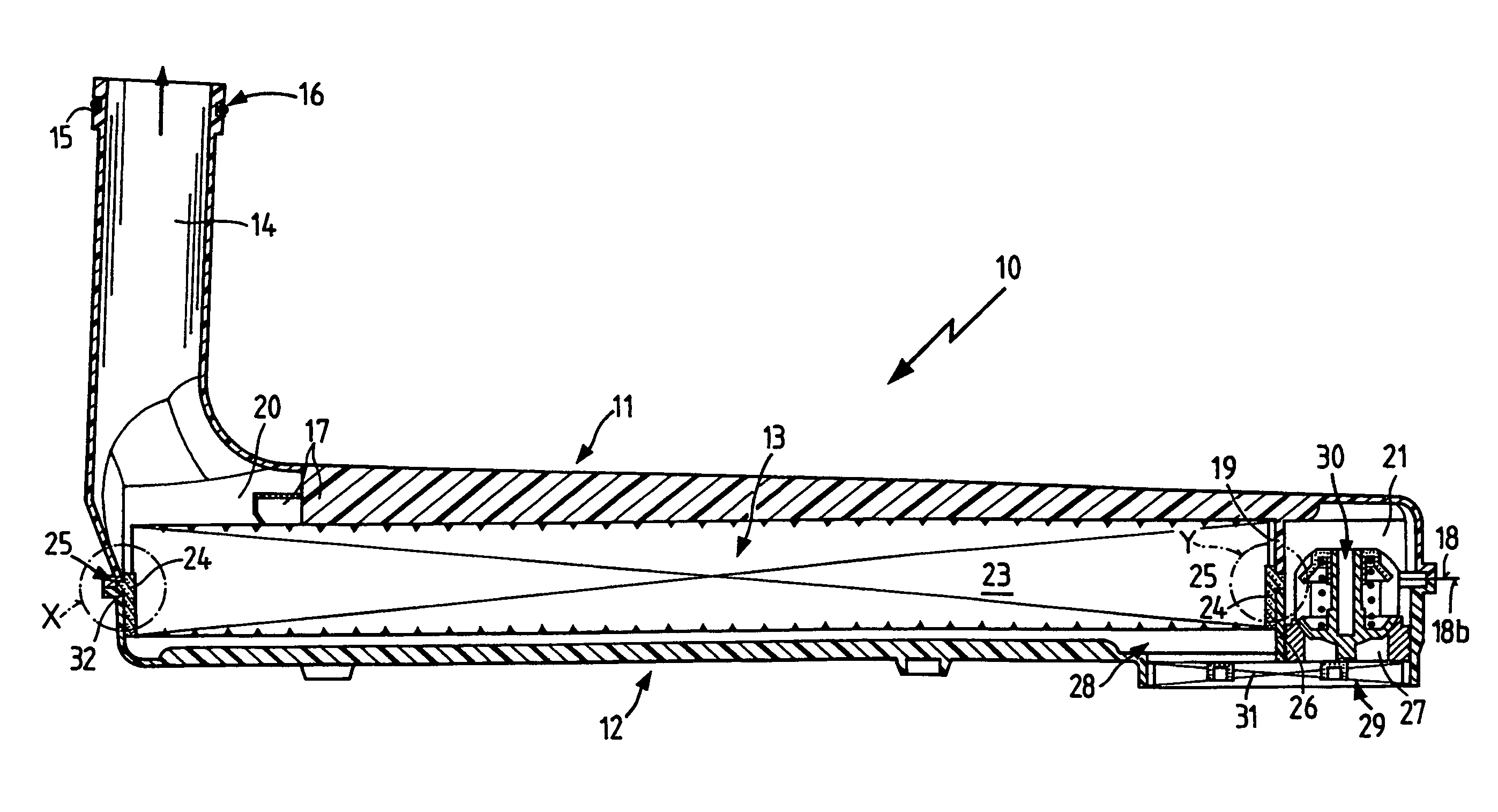

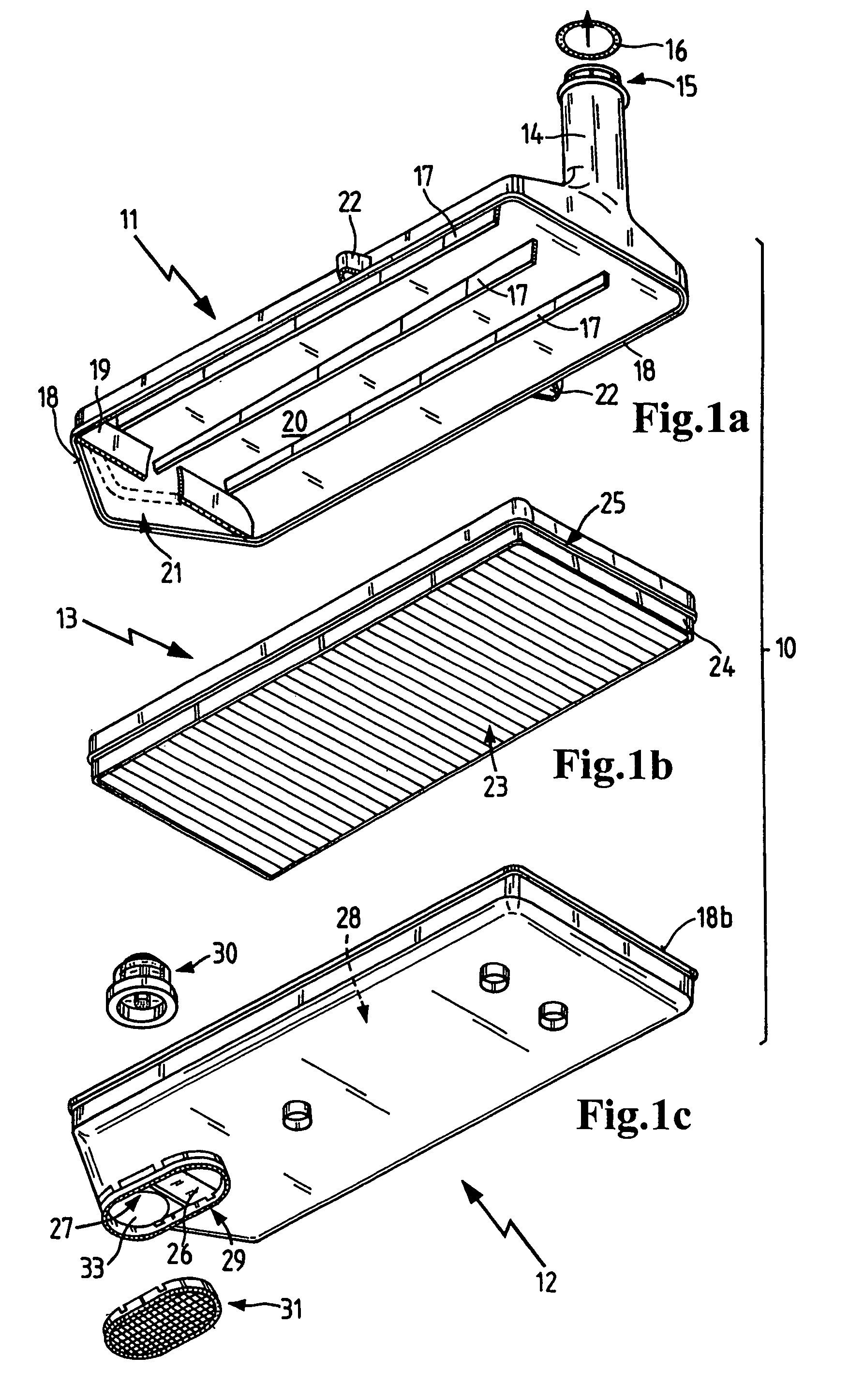

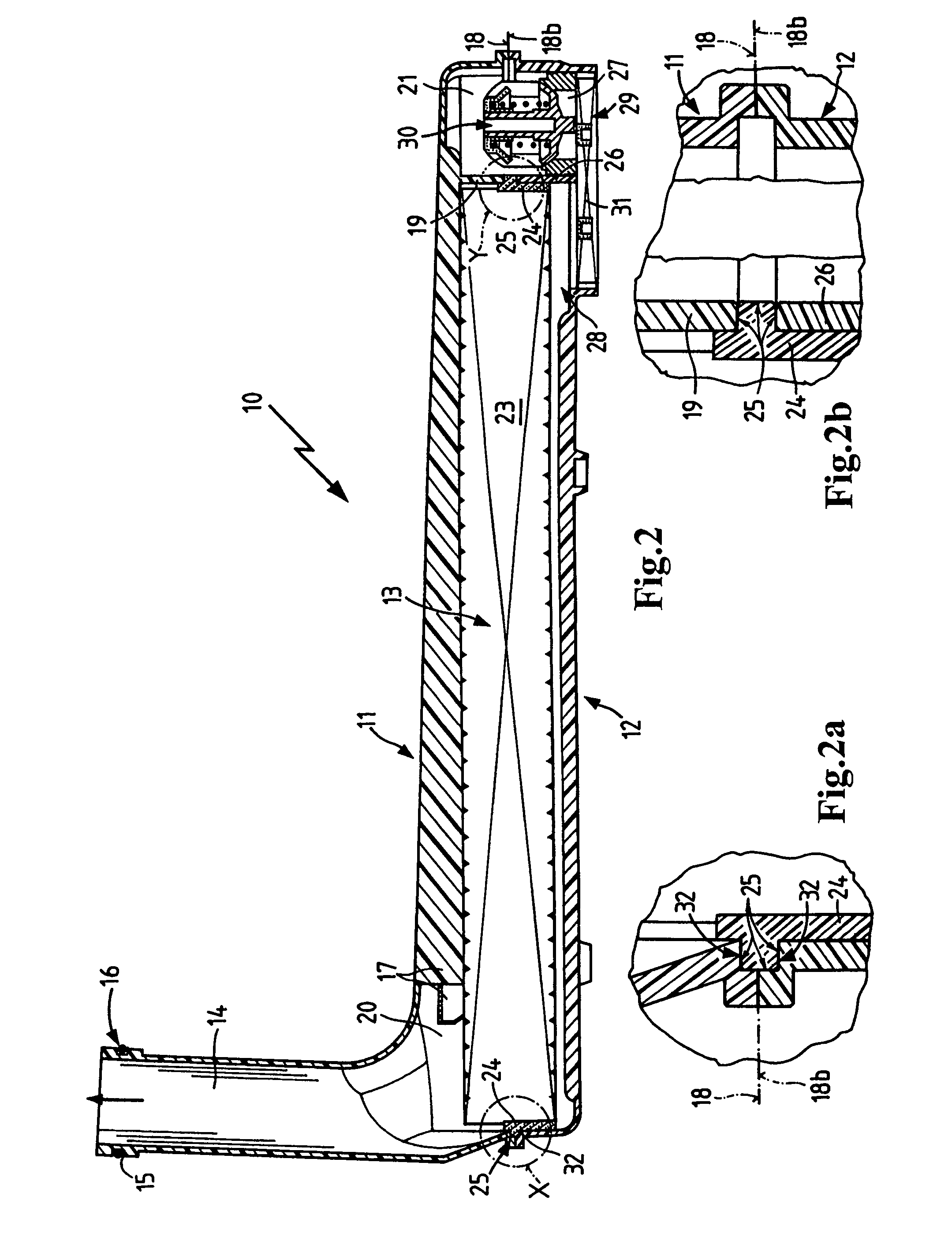

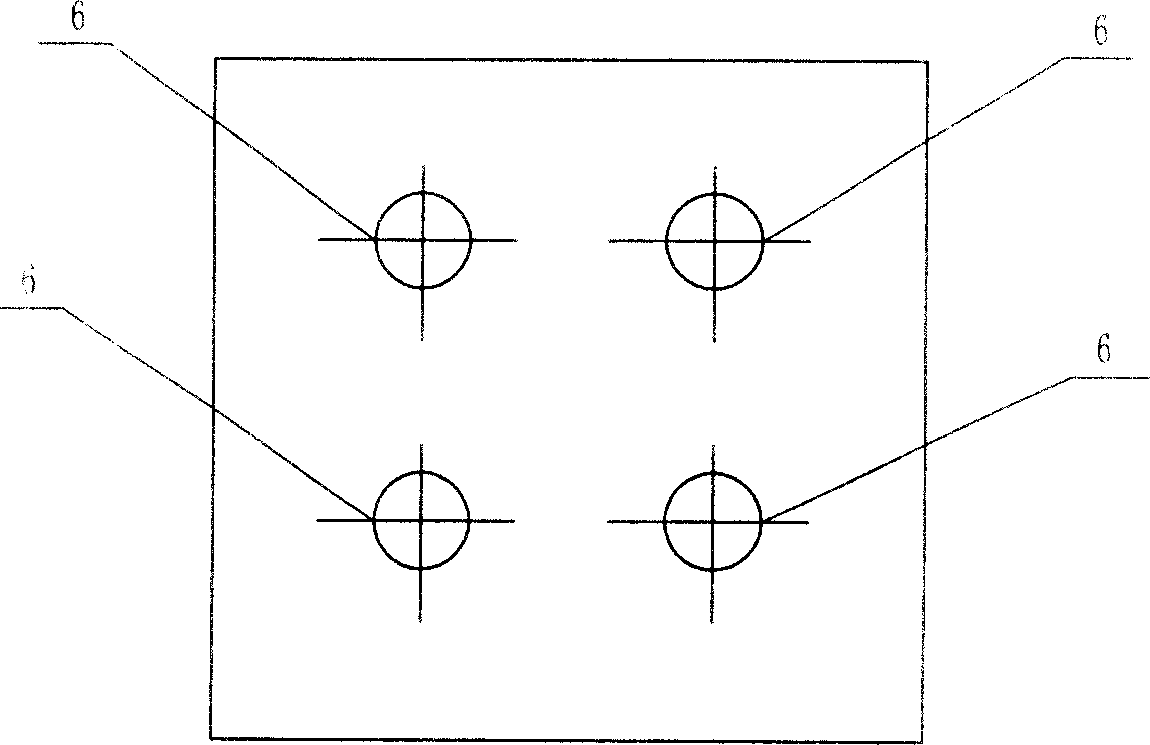

Oil filter unit

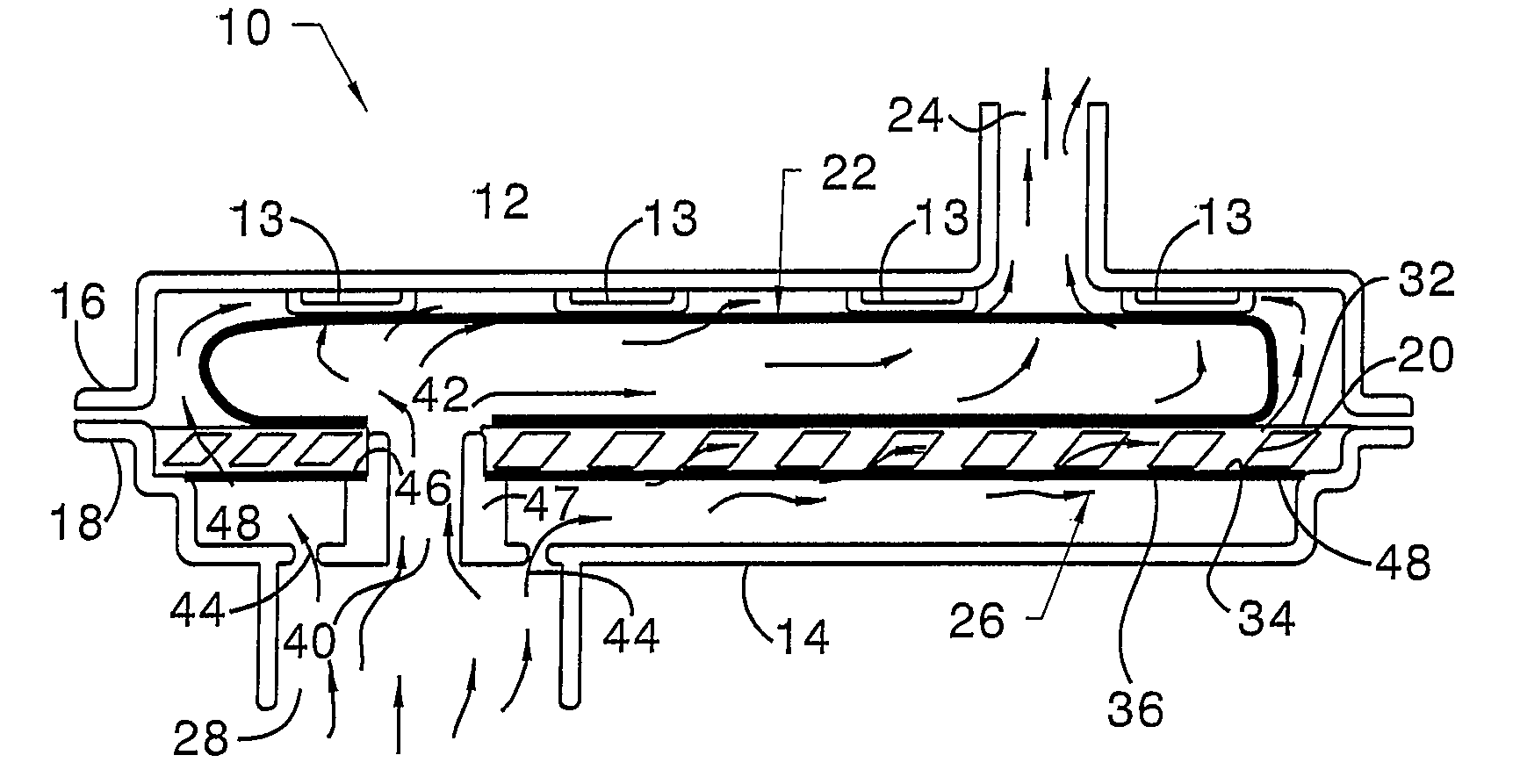

ActiveUS20060180541A1Reduce differential pressureImprove dirt holding capacityLoose filtering material filtersCartridge filtersAutomatic transmissionFilter media

An oil filter unit for arrangement in the oil sump of an oil circuit, particularly in an automatic transmission. The oil filter unit has a multi-part filter housing with a filter chamber disposed therein such that an oil inlet and an oil outlet communicate with the filter chamber. A filter element is sealingly mounted in the housing between the oil inlet and the oil outlet. The filter element has a pleated filter medium, which is sealingly enclosed by a frame, and the frame has seal contours designed to cooperate with the contours of the filter housing.

Owner:MANN HUMMEL GMBH

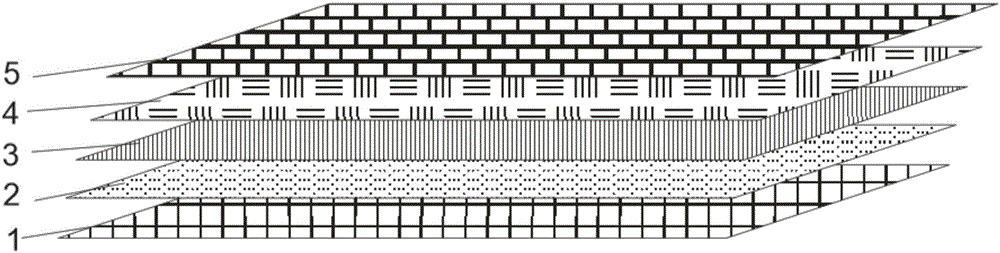

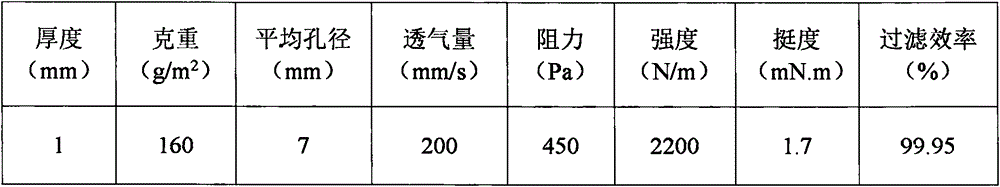

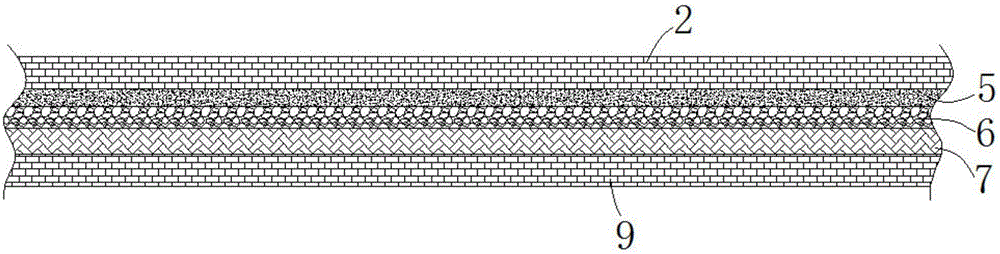

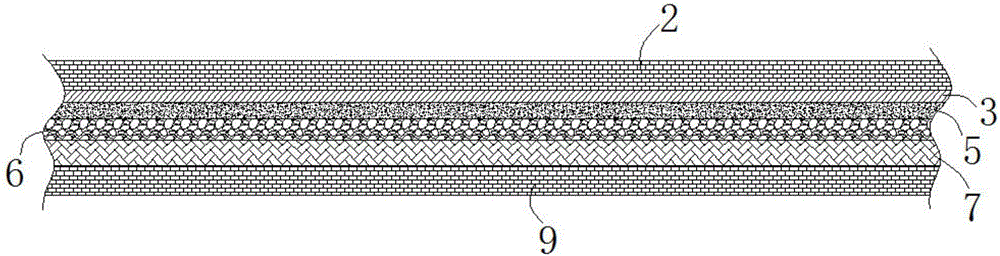

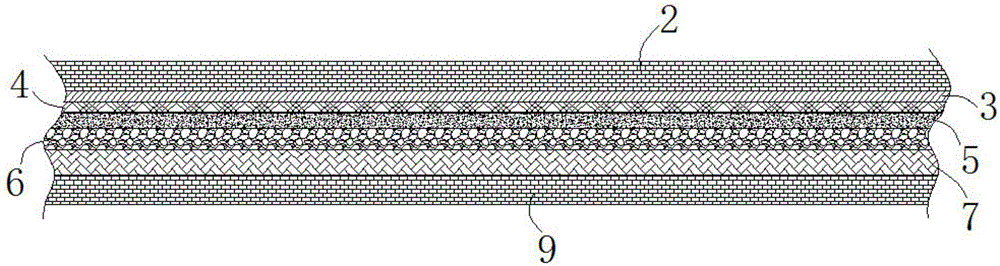

Preparation method of multilayer-structure nano fiber composite membrane for filtering particulates in air

InactiveCN106541683AHigh particle filtration efficiencyImprove dirt holding capacityDispersed particle filtrationSynthetic resin layered productsFiberParticulates

The invention relates to the technical field of manufacturing of fiber composite membranes, particularly a preparation method of a multilayer-structure nano fiber composite membrane for filtering particulates in air. The preparation method comprises the following steps: (1) sequentially spinning a first nano fiber membrane layer to nth nano fiber membrane layer onto a matrix by electrostatic spinning, wherein n is a whole number ranging from 1 to 50; (2) covering a nano fiber membrane protective layer on the upper surface of the nth nano fiber membrane layer and the exposed surfaces of all the nano fiber membrane layers to obtain a semifinished product; and (3) compounding the semifinished product to obtain the product. The method can enhance the uniformity and mechanical properties of the filter membrane, and can also enhance the barrier efficiency of the filter membrane for particulates and relatively lower the air drag.

Owner:东莞巨微新材料科技有限公司 +2

Nonwoven fibrous mat for MERV filter and method

InactiveUS20070271889A1Low costEliminate needNon-fibrous pulp additionNatural cellulose pulp/paperPolyesterFiber

Wet laid, nonwoven, fibrous mats suitable for making MERV 6 or higher, filters, and methods of making the nonwoven mats filter media are disclosed. The mats include a blend comprising a major portion of glass fibers, a minor portion of man-made polymer fibers, such as polyester fibers and about 0-30 wt. percent of chemically cross linked bleached Kraft pulp the fibers, and optionally fully bleached softwood Kraft pulp, the fibers being bound together with a cured binder having a Tg in the range of about minus 30 to about 50 degrees C. The mats are pleated prior to assembling the filter in conventional manner. The only fibrous mat in the filters is wet laid fibrous nonwoven mat and the pleated filter media needs no other means of support in the filter frame.

Owner:JOHNS MANVILLE CORP

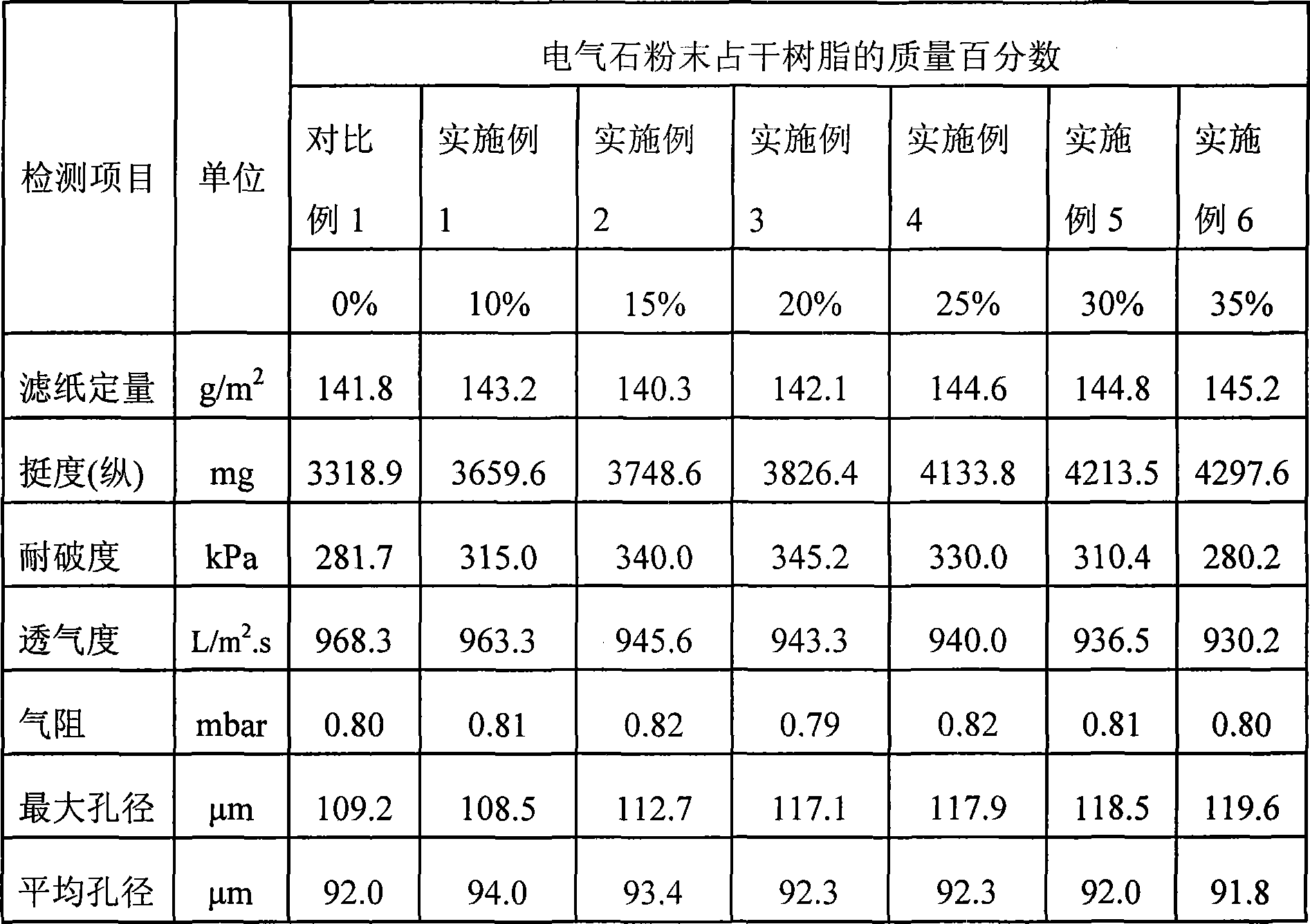

Filter paper of air filter for saving fuel and method for manufacturing same

ActiveCN101392703AReduce resistanceEasy to useWater-repelling agents additionMachines/enginesWater basedFuel conservation

The invention provides filter paper of an air filter of fuel conservation and a manufacture method thereof. The filter paper consists of base paper and a sizing agent which is coated on a single side or double sides of the base paper gram weight of between 110 and 160 gram / meter<2>, and water-base resin (butt) is 5 to 30 percent of mass of the base paper. The sizing agent comprises the following components in weight percentage: 2 to 20 percent of the water-base resin (butt), 1 to 20 percent of powder functional material, and 60 to 80 percent of water. The powder functional material is more than one of tourmaline ore powder with far infrared emitting property and releasing anion property, molten mass powder of rare-earth zirconium oxide and alumina, molten mass powder of rare-earth zirconium oxide, titanium oxide or rare-earth zirconium oxide, zinc oxide and the like. With the filter paper, fuel can be saved by 3 to 10 percent, but power of the engine is increased by 5 to 20 percent; noise of the engine is reduced by over 10 decibels, and exhaust emission pollutants are reduced by over 10 to 30 percent.

Owner:湖北国鼎华明纳米新材料有限公司

Synthetic filter material, filter-paper-free metal-free synthetic filter element, manufacturing method of filter element, and filter

InactiveCN103590874AStrong impact resistanceHigh temperature resistantPressure lubricationLubricant mounting/connectionFiberMineral particles

The invention provides a synthetic filter material synthesized through inter-amalgamation and lamination of multi-fiber filter materials and wood or mineral particle filter materials, a filter element and manufacturing method thereof, and an oil filter matched with an internal combustion engine. The filter element is free of filter paper and a metal support frame, the filter element frame and the cover plates of the filter element are made of modified nylon materials, the whole sealed filter element is formed through ultrasonic welding, the filter material is filled between 3-8 groups of blades and the frame, and the filter element does not fracture and deform after 20,000 times of impact of pulse anti-fatigue detection under the pressure of 1.6MPa. The filter element is stable and solid in structure, high-temperature and high-pressure engine oil resistance of the filter element is enhanced, the synthetic material of the filter element can filter impurities such as metal abrasive dust and carbon powder generated during combustion of an engine and mixed into the engine oil, and gel gradually generated by the engine oil to the maximum extent, the plant particle filter materials of the filter element contain antioxidant which releases slowly and can perform oxidation-reduction on online engine oil, the replacement mileage of the lubricating engine oil and the oil filter is prolonged to 30,000-100,000 kilometers, and emission of harmful tail gas is reduced.

Owner:沃卡瑞(天津)贸易有限公司

Nonwoven fibrous mat for MERV filter and method

InactiveUS7582132B2Low costEliminate needNon-fibrous pulp additionNatural cellulose pulp/paperPolyesterCross-link

Wet laid, nonwoven, fibrous mats suitable for making MERV 6 or higher, filters, and methods of making the nonwoven mats filter media are disclosed. The mats include a blend comprising a major portion of glass fibers, a minor portion of man-made polymer fibers, such as polyester fibers and about 0-30 wt. percent of chemically cross linked bleached Kraft pulp the fibers, and optionally fully bleached softwood Kraft pulp, the fibers being bound together with a cured binder having a Tg in the range of about minus 30 to about 50 degrees C. The mats are pleated prior to assembling the filter in conventional manner. The only fibrous mat in the filters is wet laid fibrous nonwoven mat and the pleated filter media needs no other means of support in the filter frame.

Owner:JOHNS MANVILLE CORP

Water treating process and apparatus for cellulose fiber hydro-entangling process

InactiveCN101066814AEfficient removalGuaranteed cleanlinessMultistage water/sewage treatmentWaste water treatment from textile industryWater savingWater quality

The present invention relates to is water treating process and apparatus for cellulose fiber hydro-entangling process. The water treating apparatus includes a high pressure pump, a police filter set between the high pressure pump and the hydro-entangling machine, a vacuum sucker, an efficient superficial air floating tank, a sand filter, a precise tubular filter and a bag filter. During the production, only bactericide is added to the air floating tank and the sewage tank regularly, and no flocculant and coagulant aid are needed. The present invention has high automation, low cost, water saving and short water treating period.

Owner:DONGHUA UNIV +1

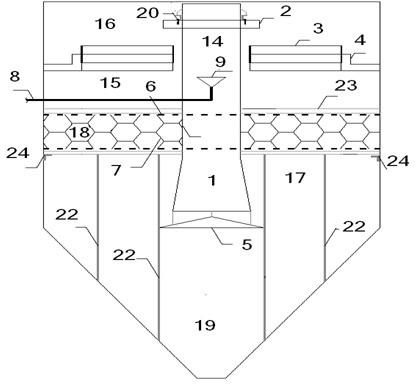

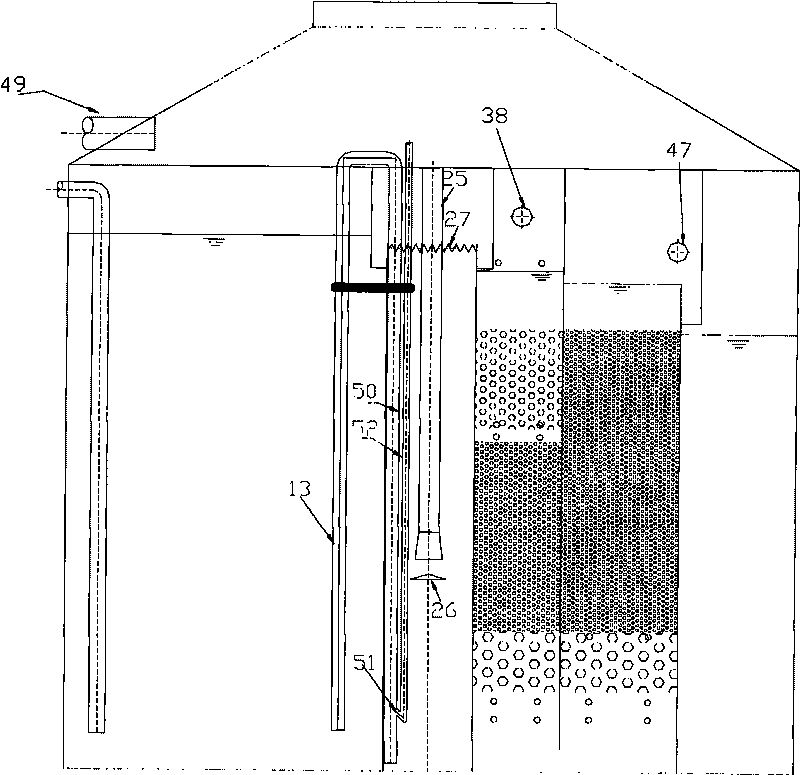

Vertical-flow type settling pond

InactiveCN102180570AExtended backwash cycleGood biological treatment effectMultistage water/sewage treatmentWater dischargeSludge

The invention relates to a vertical-flow type settling pond for sewage treatment, comprising a water feeding area, a water feeding pipe, an overhaul area, a water collecting area, a filtering area, a settling area, a sludge collecting area and a water discharging pipe. The water feeding area extends from the top of the settling pond into the lower part of the settling pond, the water feeding area is provided with the water feeding pipe, the overhaul area, the water collecting area, the filtering area and the settling area are sequentially arranged around the water feeding area from the top down, the sludge collecting area is communicated with the lower part of the settling area, a water collector which can be regulated according to the water level is arranged in the water collecting area, and the water collector is communicated with the water discharging pipe; and the water collecting area further comprises a filtering water buffering section arranged at the lower part of the water collector. Due to the existence of the filtering water buffering section, water after filtered in the filtering area firstly enters into the filtering water buffering section to be buffered and then enters into the water collector, thus the uniform water discharge at an water discharge part still can be ensured due to the action of the filtering water buffering section even though filtering materials or biological fillers are aggregated.

Owner:BEIJING MUNICIPAL ENG PROFESSIONAL DESIGNINST

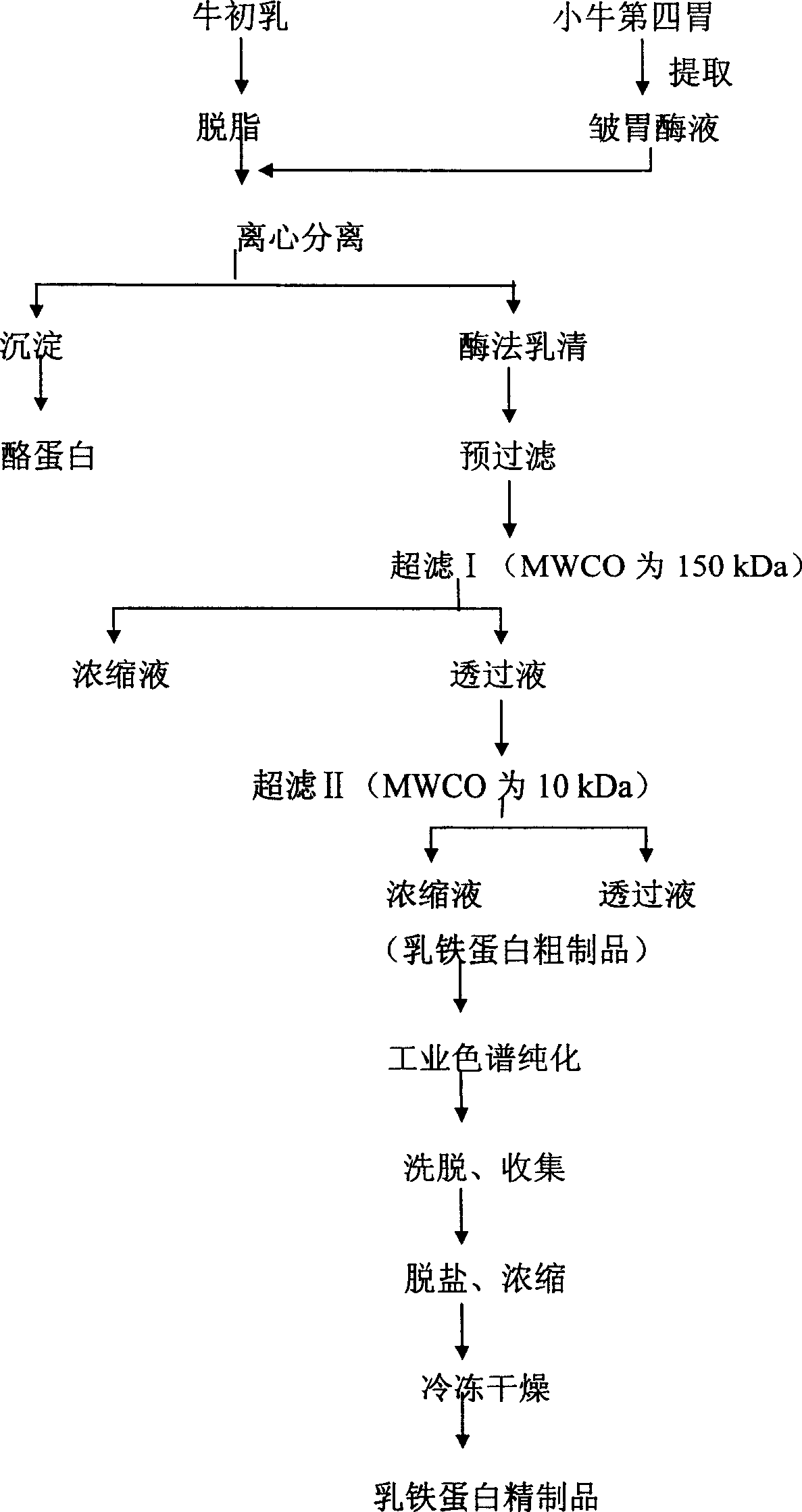

Method for inductrialized separation of purified lactoferrins from cattle colostrum

InactiveCN1849903AHigh clarityReduce co-precipitationAnimal proteins working-upLactoferrinMilk products

The present invention relates to a method for industrial separation and purification of lactoferrin from beestings. It is characterized by that it uses beestings defatted serum as raw material, adopts enzyme method to remove casein and utilizes combination of membrane separation technique and industrial chromatographic technique to separate out lactoferrin whose purity is above 90% from beestings.

Owner:JIANGNAN UNIV

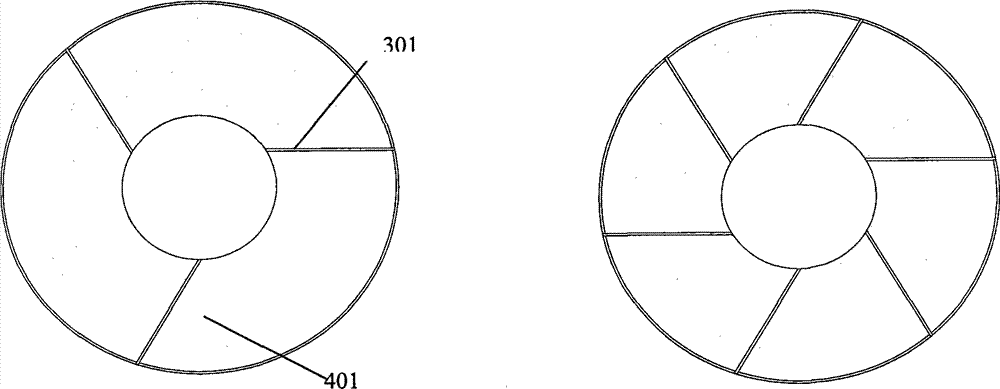

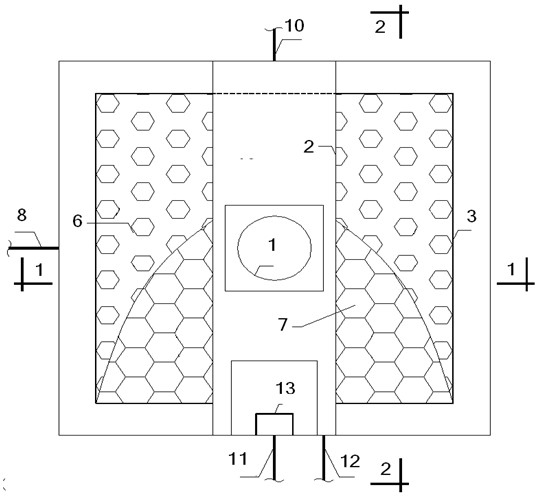

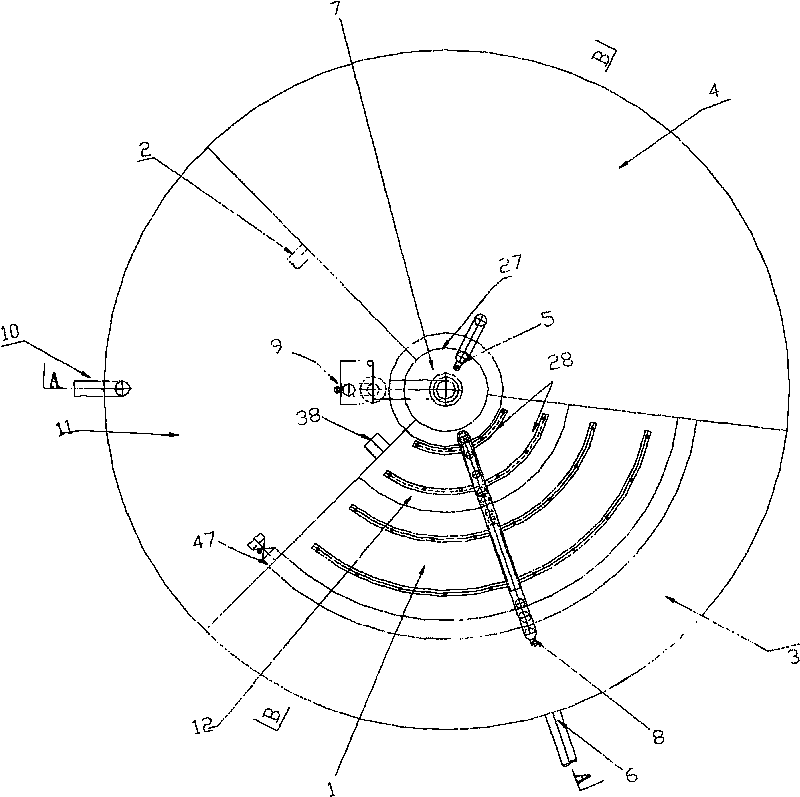

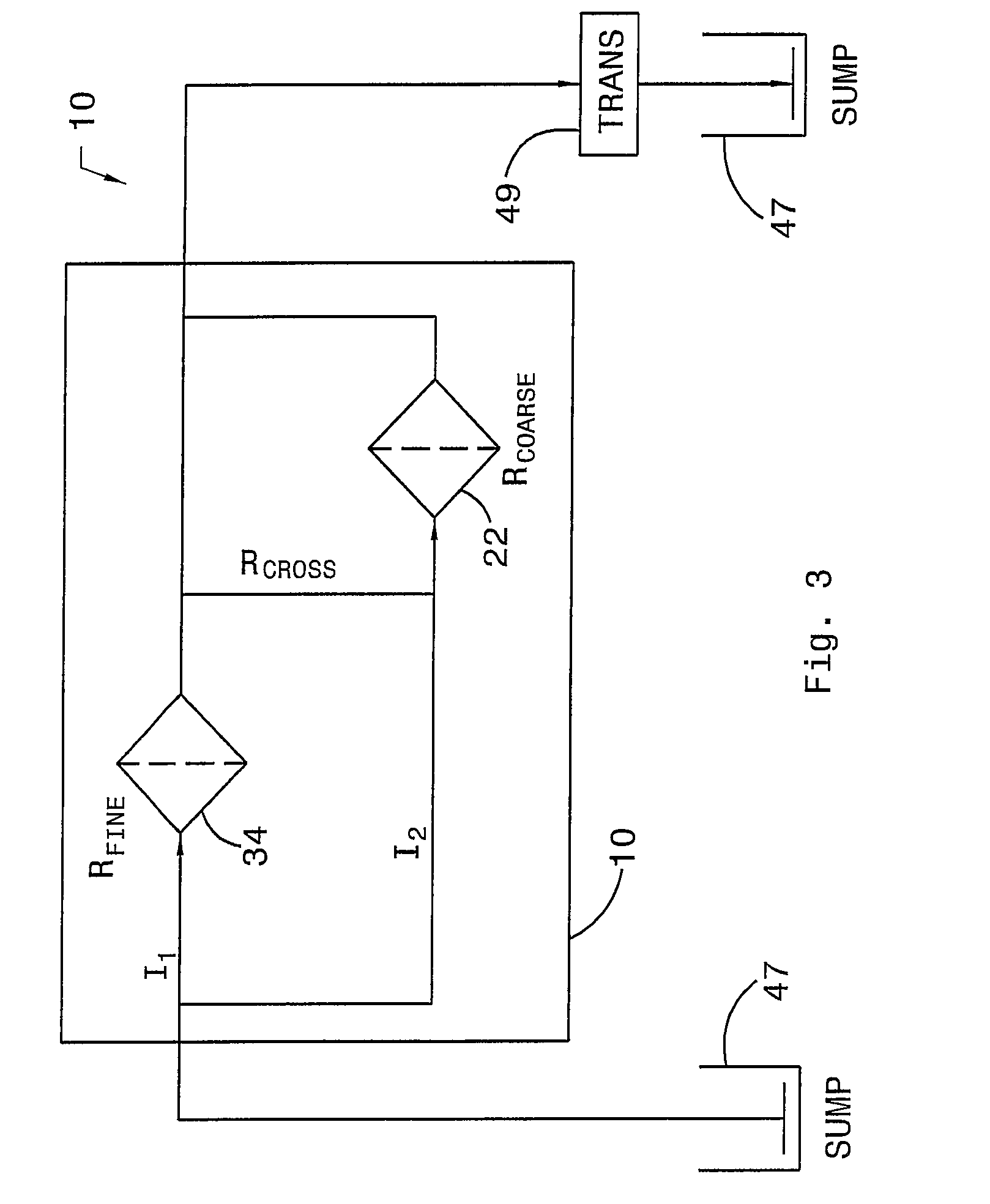

Integrated A/O bacteria filter device for treating dispersed wastewater

ActiveCN101723560ARealize integrationCompact structureTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSludgeWastewater

The invention relates to an integrated A / O bacteria filter device for treating dispersed wastewater, which has a cylindrical structure in shape. The center of the integrated A / O bacteria filter device is provided with a cylindrical erect flow primary settling tank, a baffle wall is arranged between an inner cylinder body and an outer cylinder body, and a space is divided into an adjusting tank, a hypoxia bacteria filter, an aerobe filter, a clear water tank and a mud storage tank. The aerobe filter and the clear water tank are in a concentric circle arc structure. Wastewater in the adjusting tank is lifted into the primary settling tank through an air lifter, the settled wastewater and recycled nitrification liquor are together distributed into the hypoxia bacteria filter for denitrification, the bottom and the middle part of the hypoxia bacteria filter are provided with backwashing pipelines which can realize subsection washing; the hypoxia bacteria filter is communicated with the bottom of the aerobe filter, the denitrified wastewater overflows from the surface into the clear water tank for outputting after organic matters are removed and nitrification is carried out in the aerobe filter. The backwashing wastewater of the device flows into the adjusting tank per se, and mud in the primary settling tank is lifted into the mud storage tank through the air lifter. The invention has the advantages of less investment, little operation cost, longer mud discharge period and convenient management, thereby being suitable for treating the dispersed wastewater in countryside.

Owner:TONGJI UNIV

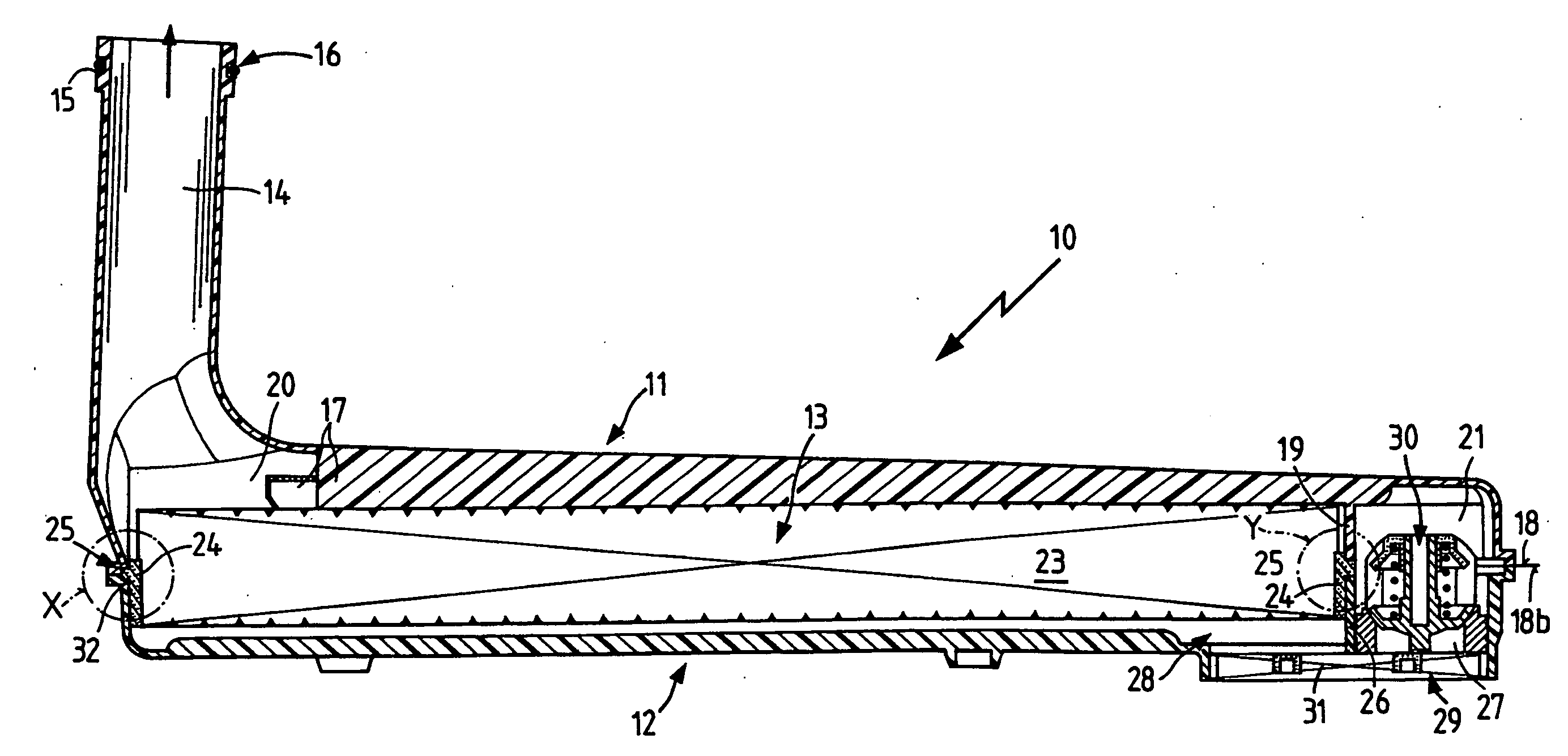

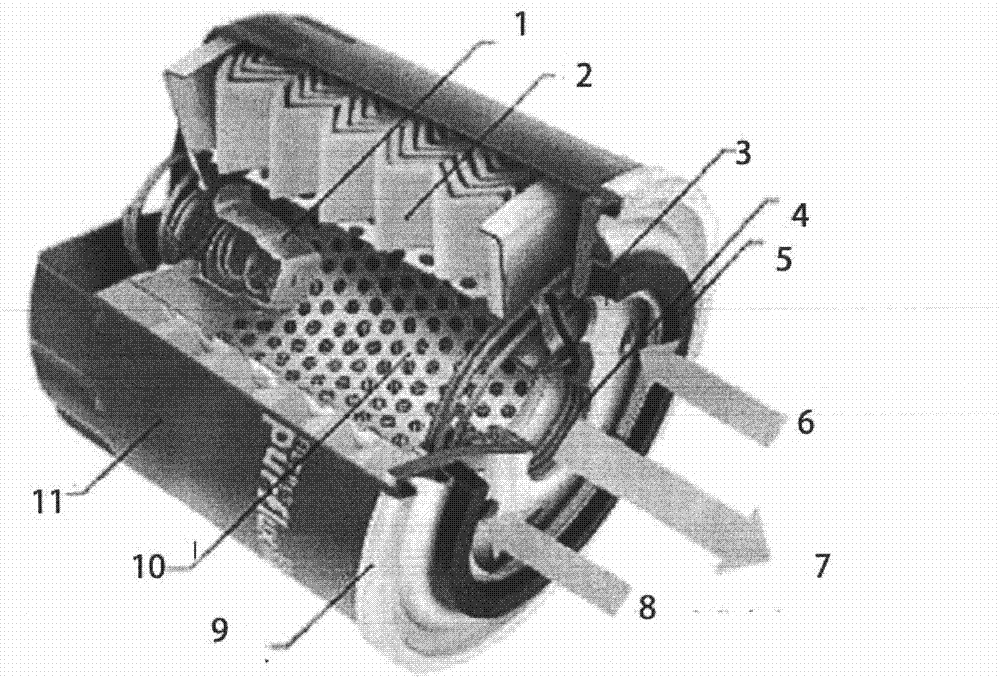

Oil filter unit

ActiveUS7845500B2Reduce differential pressureImprove dirt holding capacityLoose filtering material filtersCartridge filtersAutomatic transmissionFilter media

An oil filter unit for arrangement in the oil sump of an oil circuit, particularly in an automatic transmission. The oil filter unit has a multi-part filter housing with a filter chamber disposed therein such that an oil inlet and an oil outlet communicate with the filter chamber. A filter element is sealingly mounted in the housing between the oil inlet and the oil outlet. The filter element has a pleated filter medium, which is sealingly enclosed by a frame, and the frame has seal contours designed to cooperate with the contours of the filter housing.

Owner:MANN HUMMEL GMBH

Composite nuclear track membrane and preparation method thereof

ActiveCN104001429AImprove surface hydrophilicityHigh mechanical strengthSemi-permeable membranesPolyesterVolumetric Mass Density

The invention discloses a composite nuclear track membrane and a preparation method thereof. The composite nuclear track membrane comprises a polyester nuclear track membrane or a polycarbonate nuclear track membrane, wherein a porous cellulose acetate membrane is composited on one surface of the polyester nuclear track membrane or the polycarbonate nuclear track membrane so as to form the composite nuclear track membrane of which the thickness is 67-160 microns, the aperture of the polyester nuclear track membrane or the polycarbonate nuclear track membrane is 1-10 microns, the pore density of the polyester nuclear track membrane or the polycarbonate nuclear track membrane is 2*10<5> / cm<2>-2*10<7> / cm<2>, and the thickness of the polyester nuclear track membrane or the polycarbonate nuclear track membrane is 7-25 microns. The composite nuclear track membrane has the advantage that the surface hydrophilicity is good, the mechanical strength is high, the membrane thickness is moderate, the automatic operation can be realized easily, the flux of the filtering liquid is high, and the assimilative capacity is strong; the composite membrane is an integer, is not layered and is suitable for fabricating roll type filter cores; the porous cellulose acetate membrane composited on the nuclear track membrane is taken as a pre-filtering layer or a support layer of the nuclear track membrane, so that the problems about mechanical strength and thickness of the membrane are solved, and meanwhile, the a pre-filtering problem of the membrane is solved.

Owner:天津理源科技有限公司

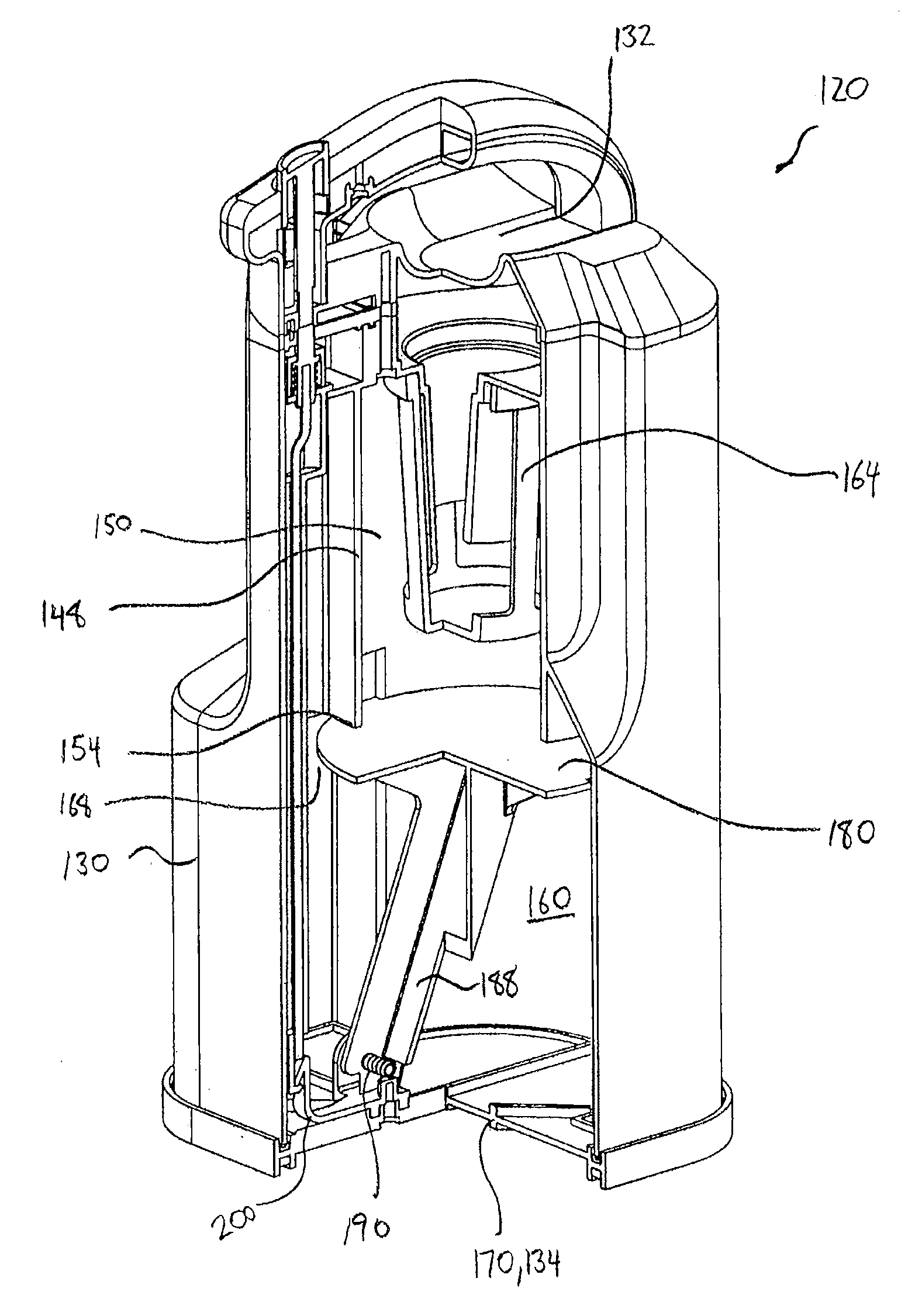

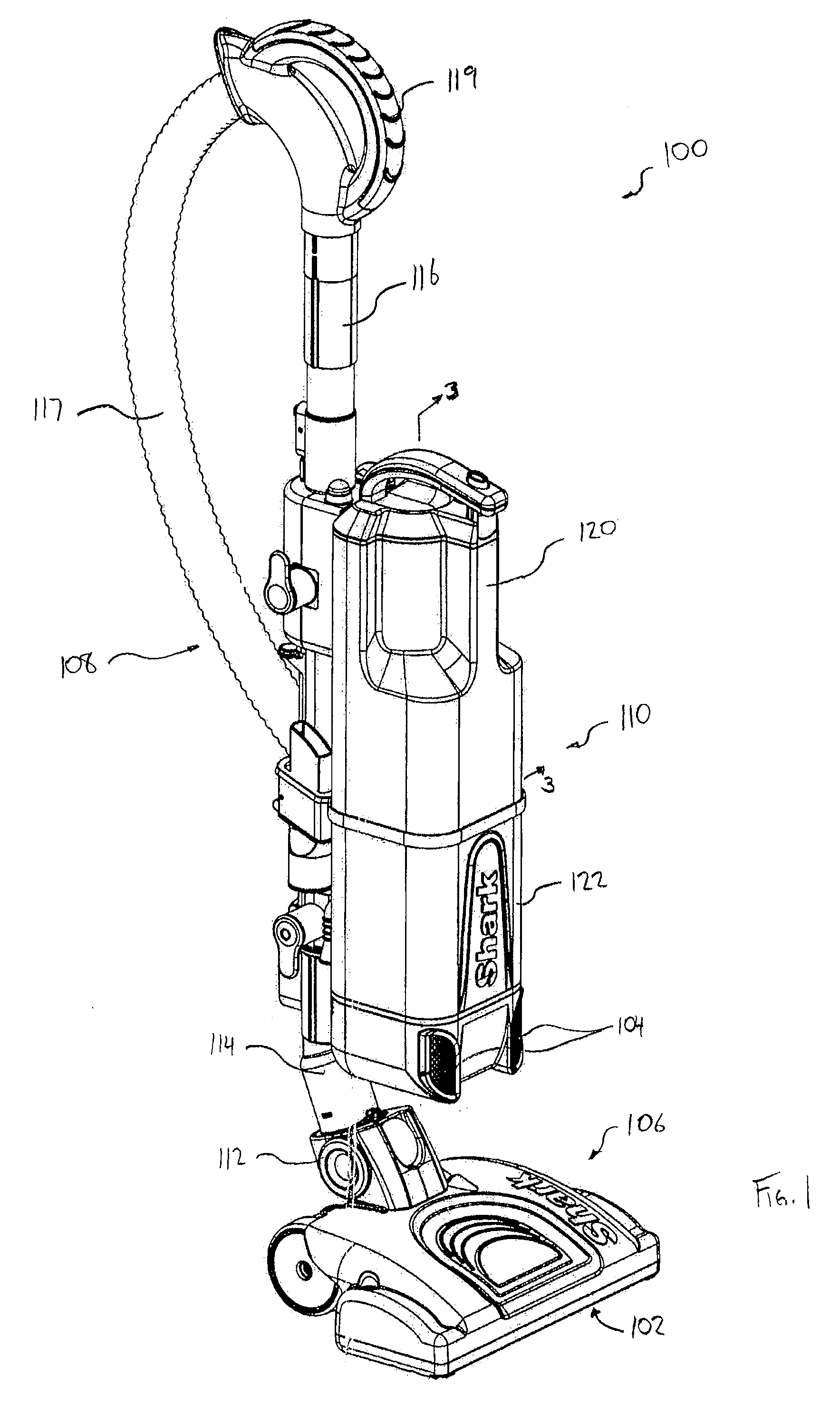

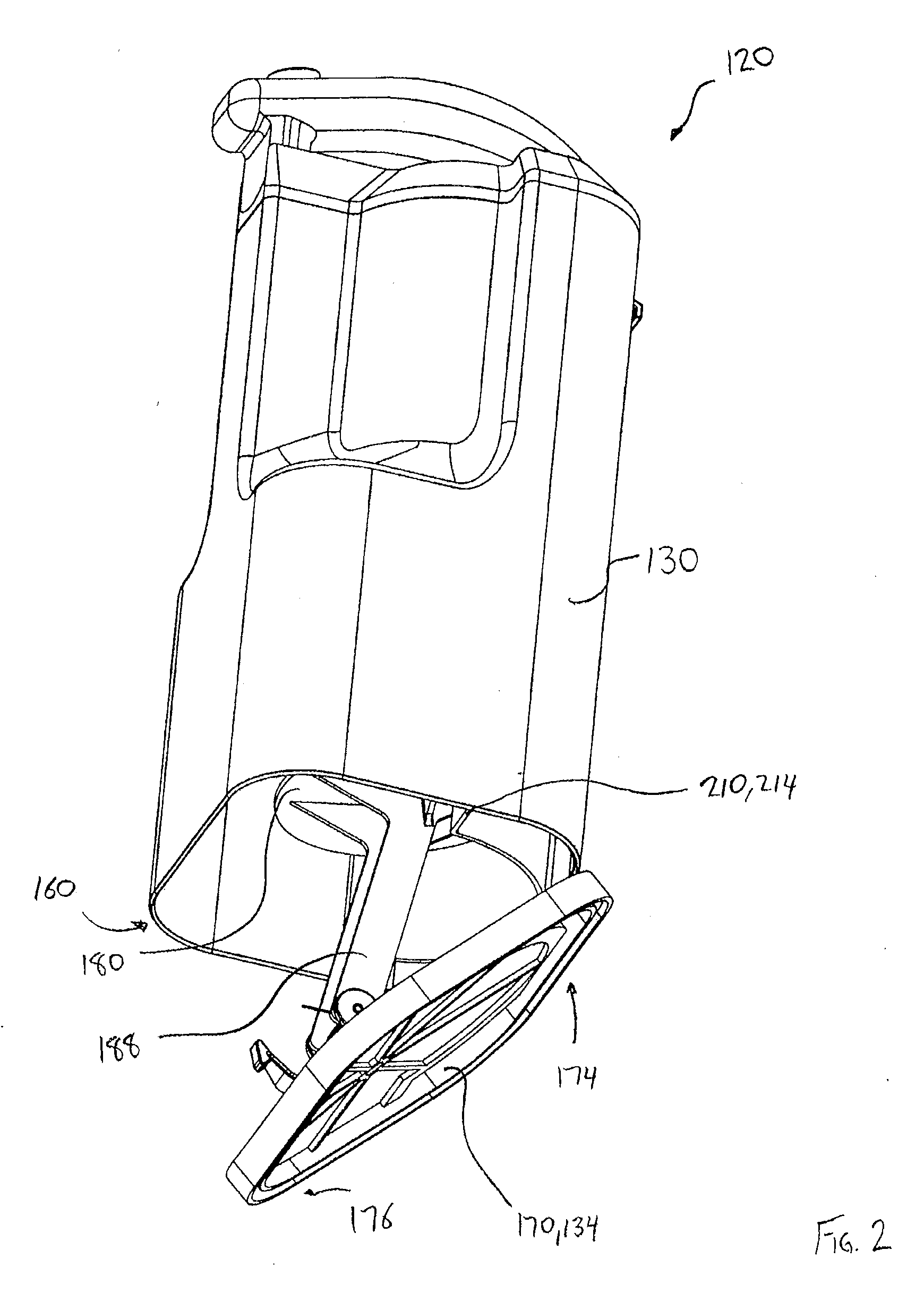

Cyclone construction for a surface cleaning apparatus

ActiveUS20120311979A1Improve dirt holding capacityReduce hand weightCombination devicesLiquid degasificationCycloneSurface cleaning

A cyclone for a surface cleaning apparatus has spaced apart and opposed first and second cyclone chamber end walls and a cyclone chamber sidewall extending therebetween. At least one of the first cyclone chamber end wall and the second cyclone chamber end wall is openable so as to provide access to the cyclone chamber. An opening extends along only a portion of the perimeter of the cyclone chamber sidewall and is positioned adjacent the second cyclone chamber end wall, the opening defining the dirt outlet whereby dirt exiting the cyclone chamber via the dirt outlet travels in a generally outwardly direction to an exterior dirt collection chamber.

Owner:OMACHRON INTPROP

Suction filter for automatic transmission fluid

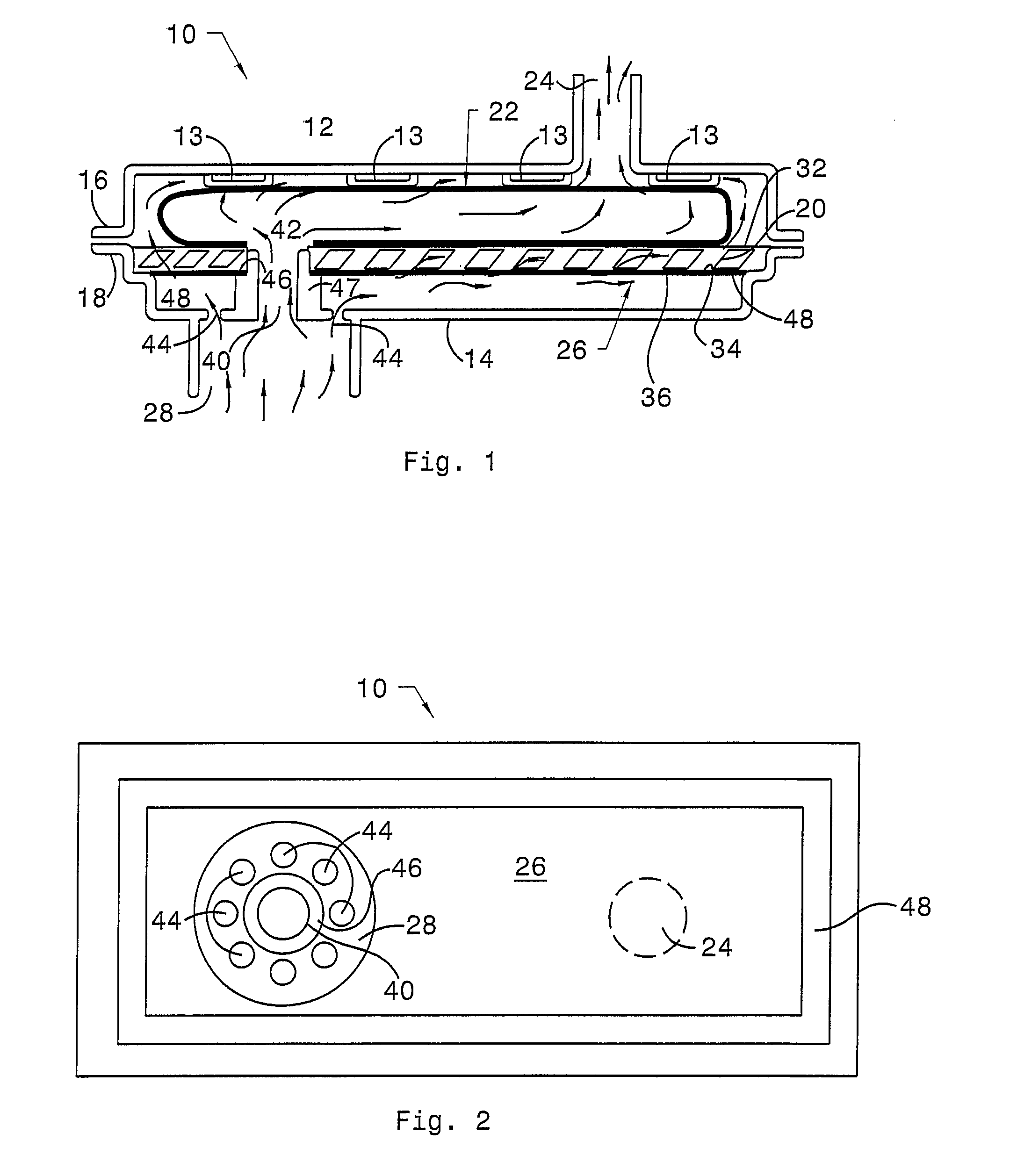

ActiveUS7998347B2High bulk densityLow costWater/sewage treatmentMultistage water/sewage treatmentMedia filterWaste management

An assembly for filtering contaminants from automatic transmission fluid includes a housing including a first inlet and a second inlet, through which fluid enters the housing, and an outlet, through which fluid exits the housing; a first media filter located within the housing in a first fluid flow path between the first inlet and the outlet; and a second media filter located within the housing in a second fluid flow path between the second inlet and the outlet.

Owner:FORD GLOBAL TECH LLC

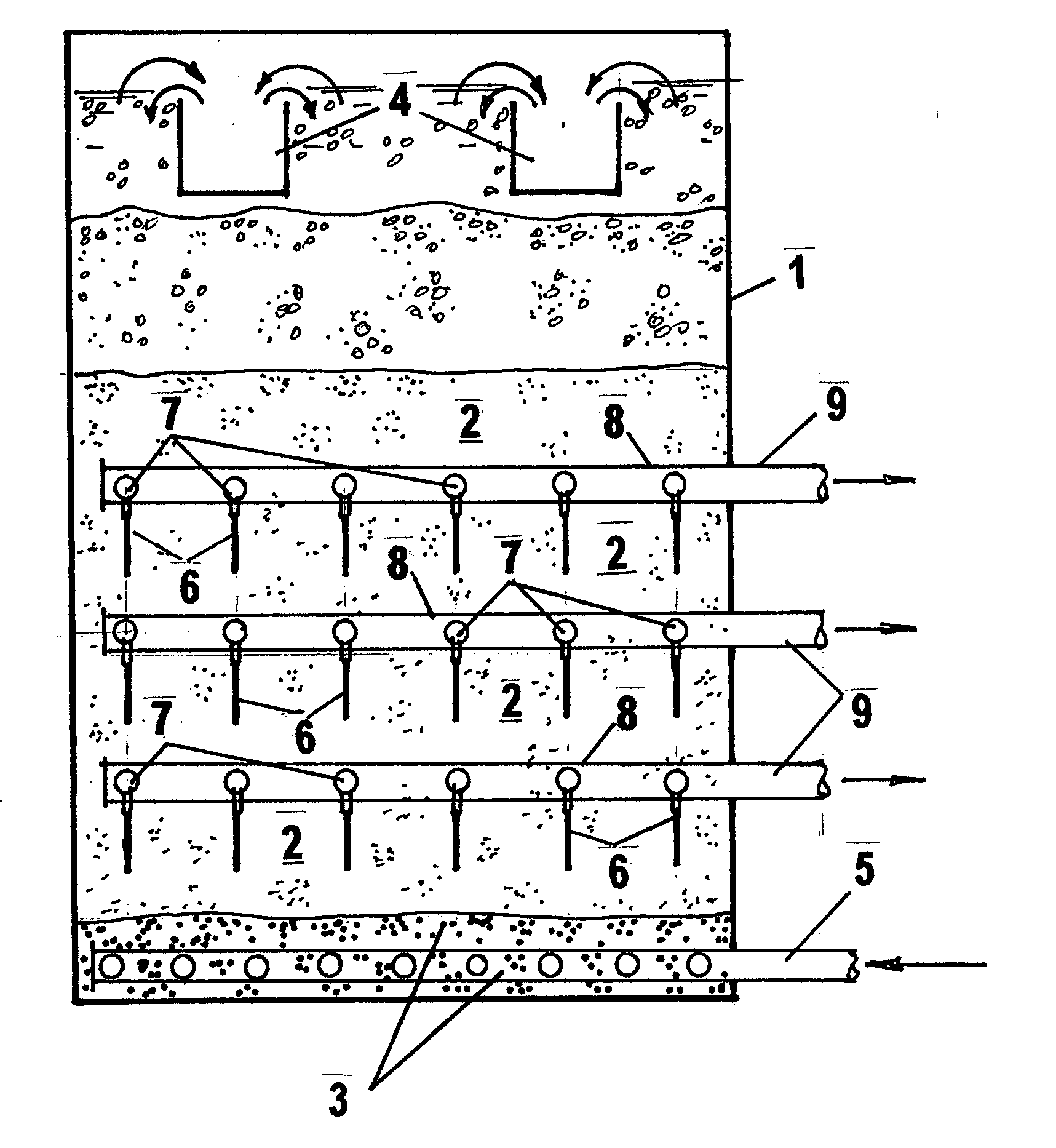

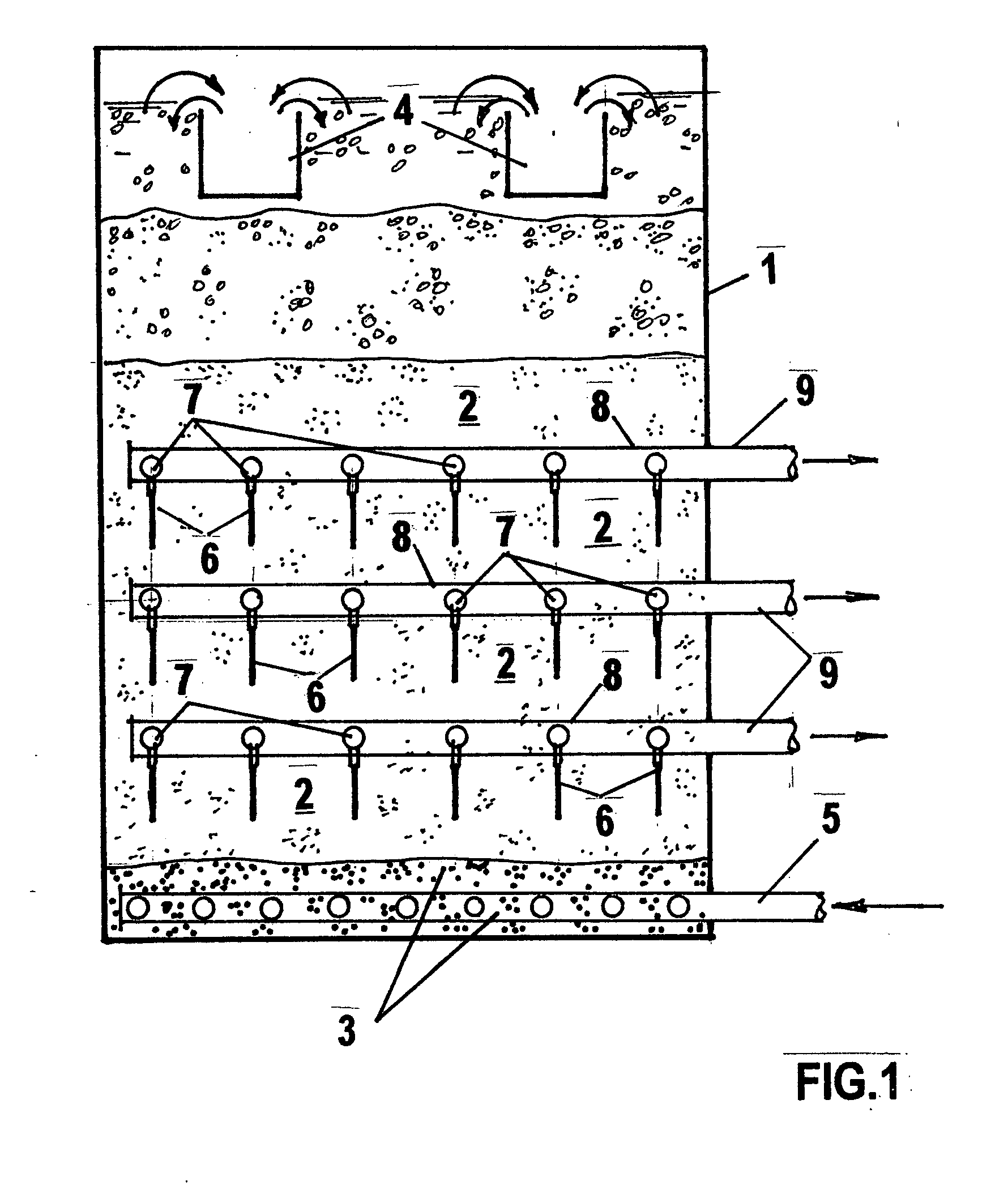

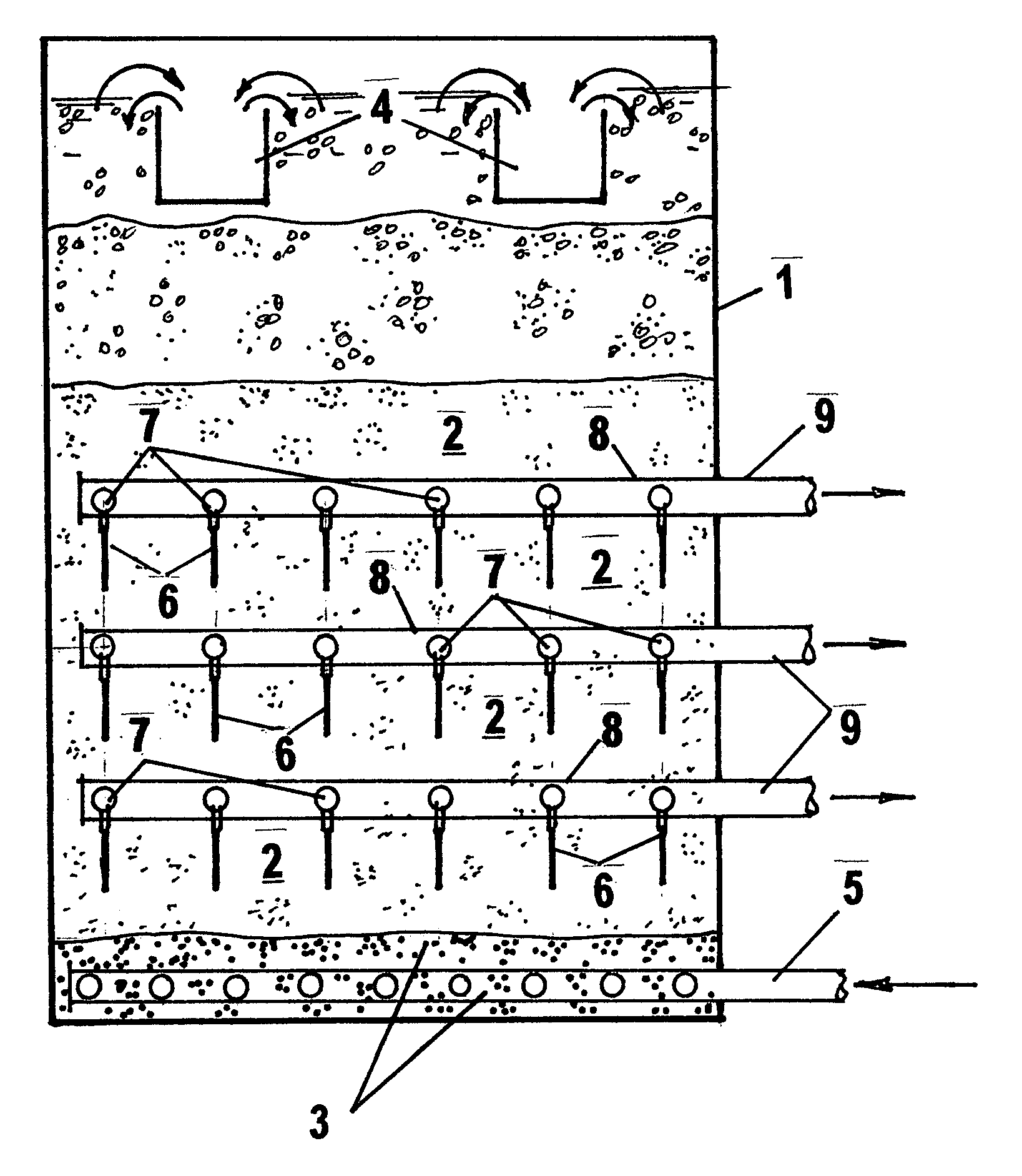

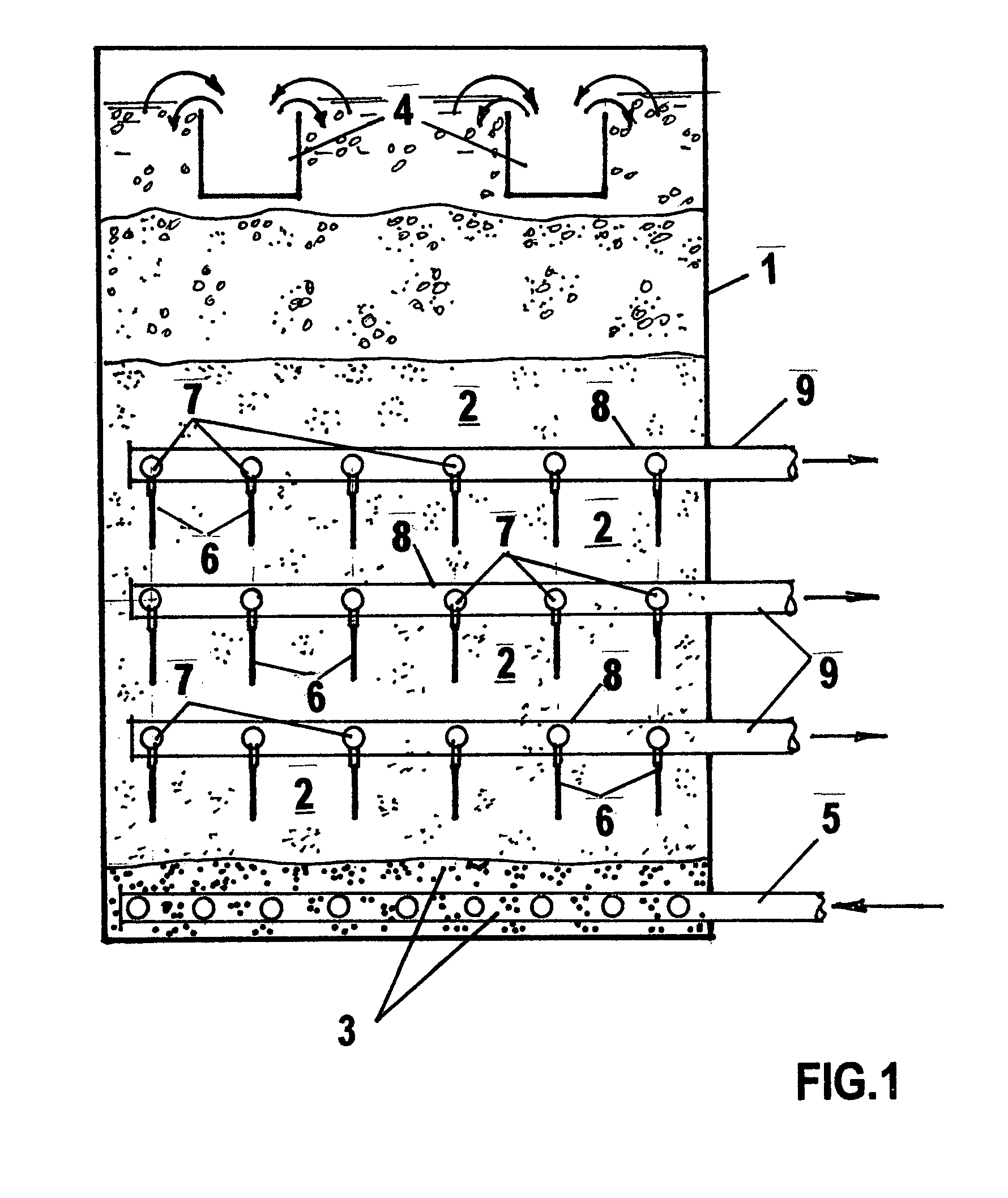

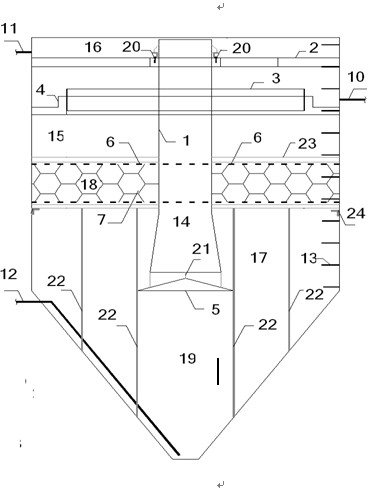

Biological reactor with internal circulating double filtering

InactiveCN1693230AImprove dirt holding capacityIncrease shock loadTreatment using aerobic processesSustainable biological treatmentActivated sludgeWater quality

A bioreactor with internal with internal circulation and dual filters for treating sewage is composed of water distributing chamber with water distributor, bearing plate, bearing layer, fitlering layer and cyclic aerating cylinder with filter-water outlet unit. The sewage is circulating through said water distributor, cycle aerating cylinder and filter layer, and is filtered by filter layer and the filter-water outlet unit.

Owner:魏刚 +2

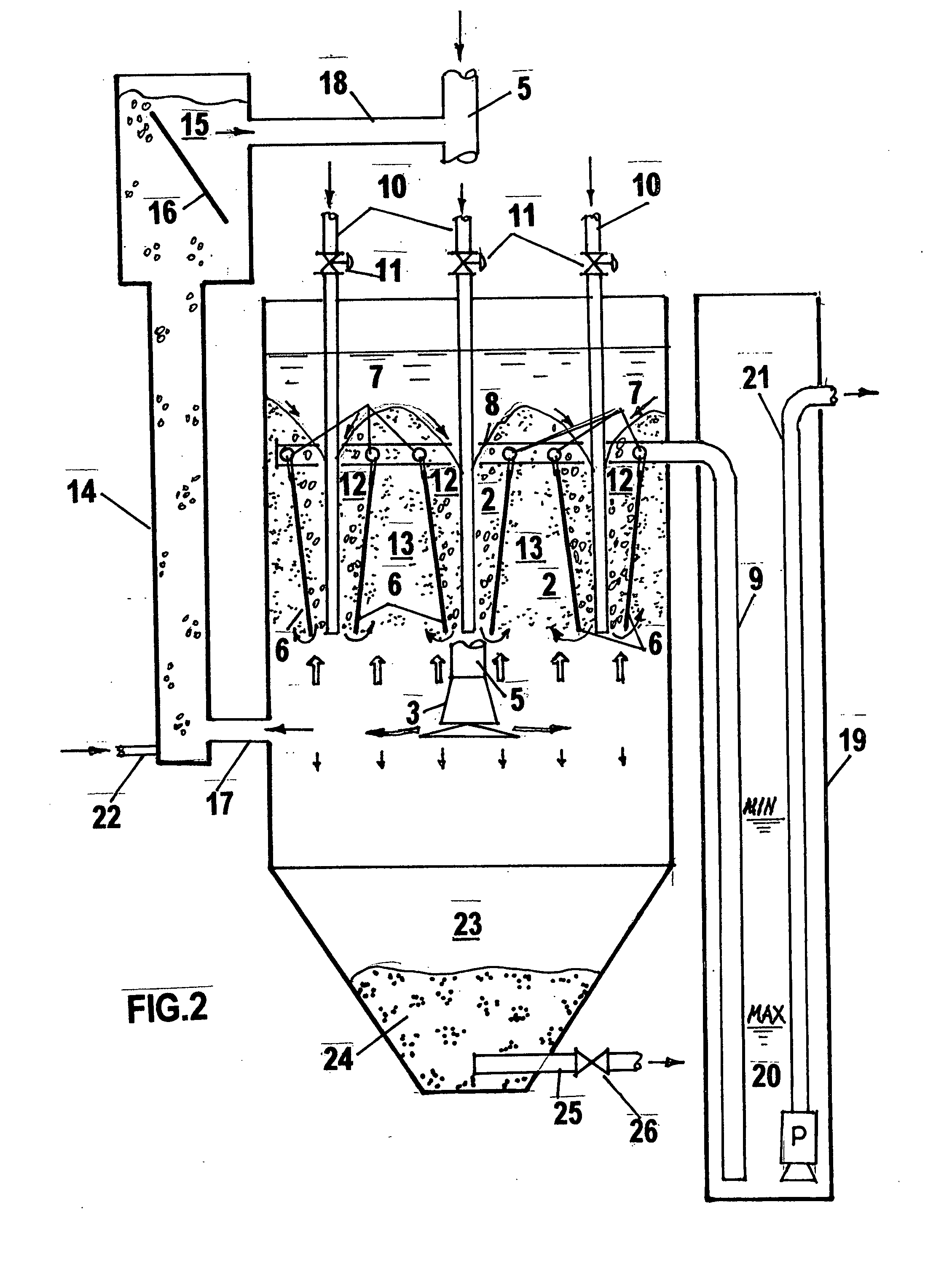

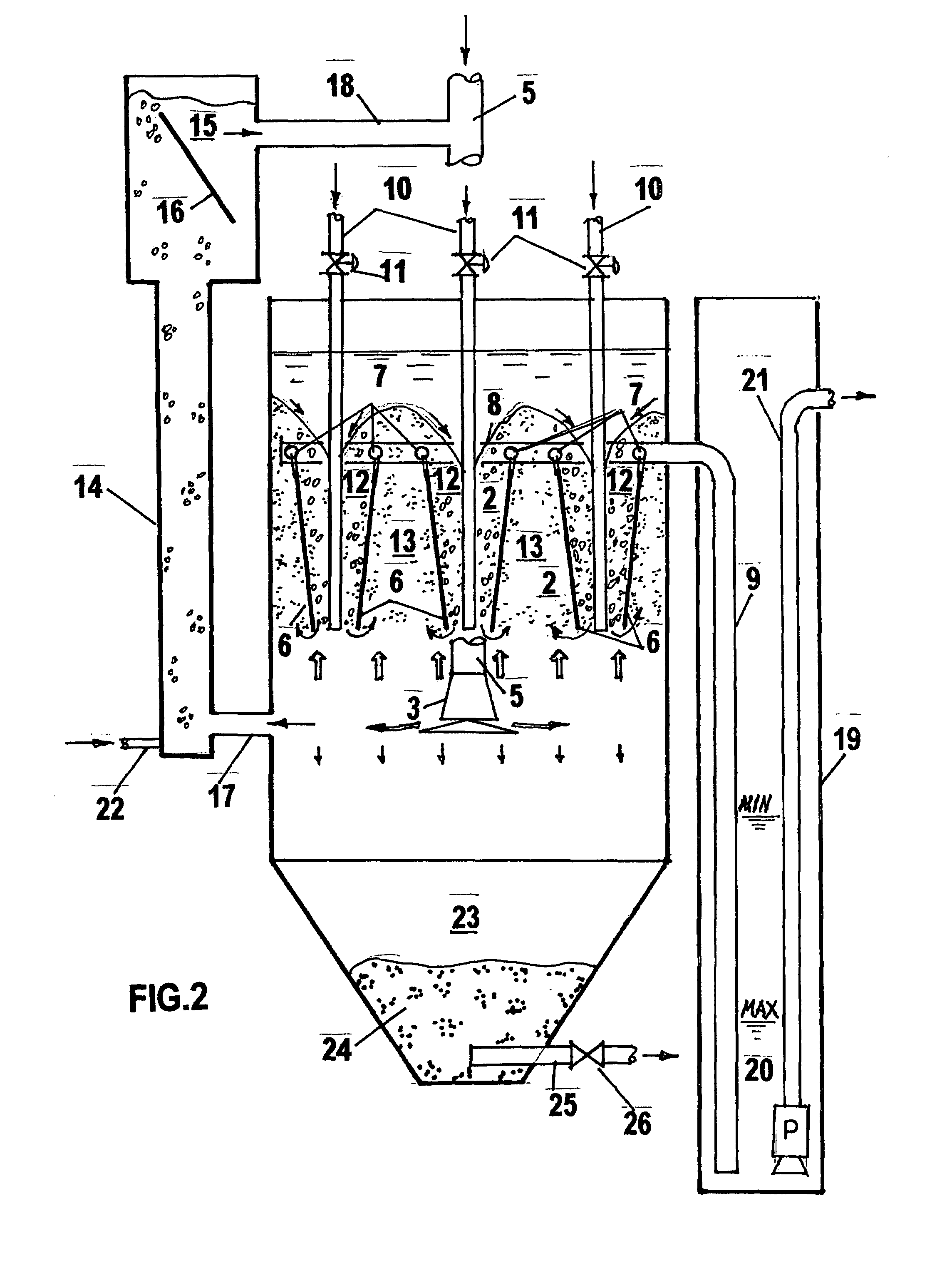

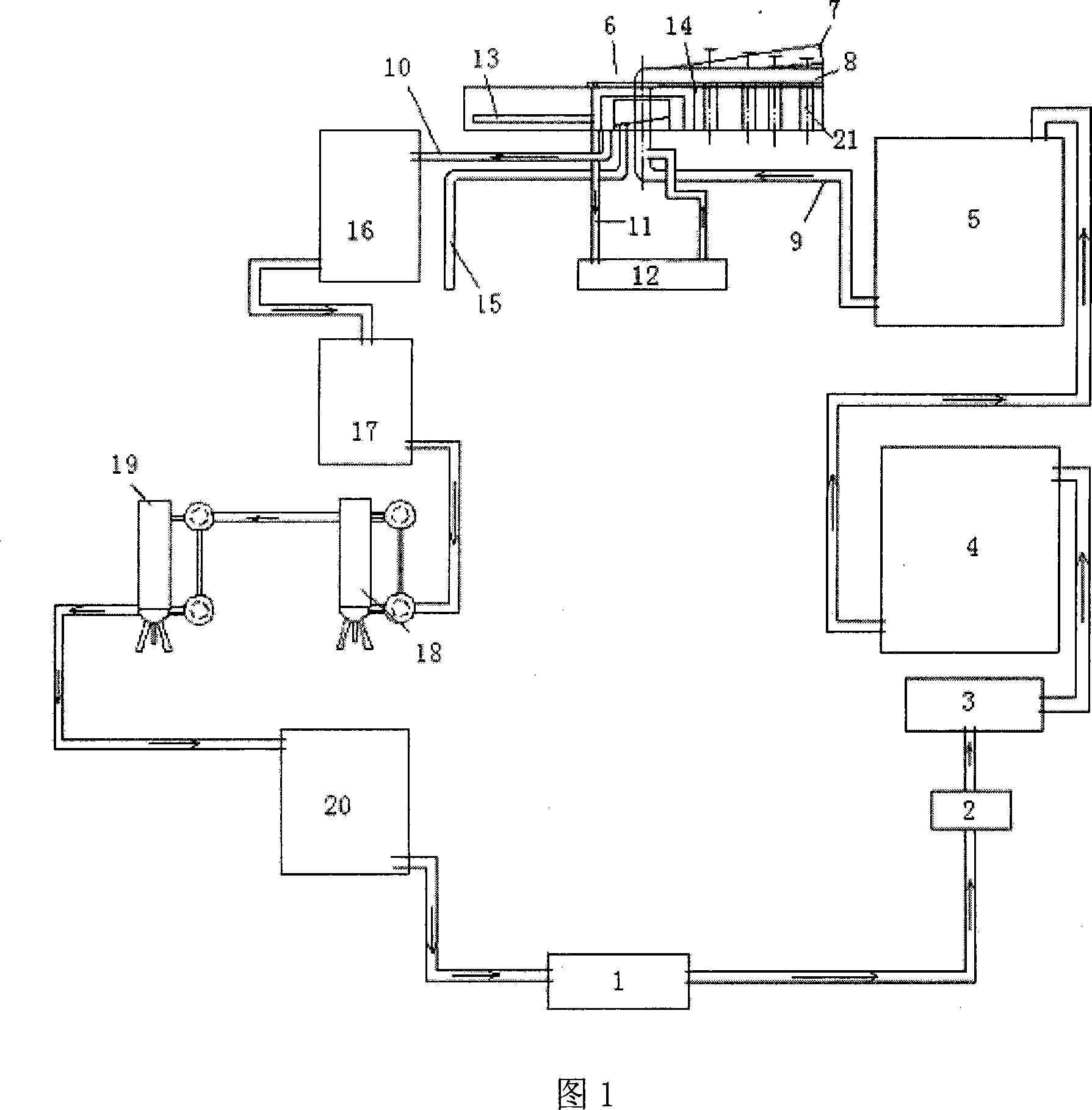

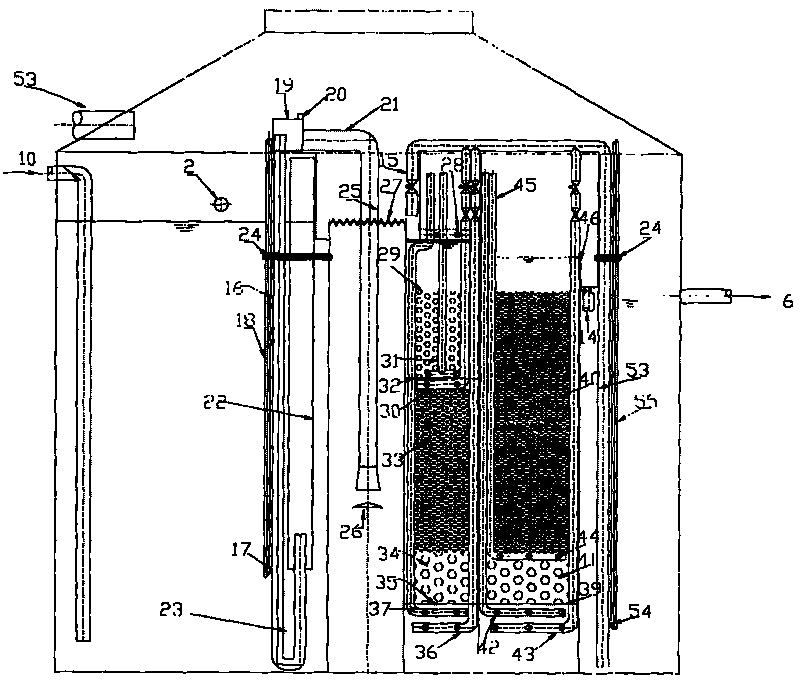

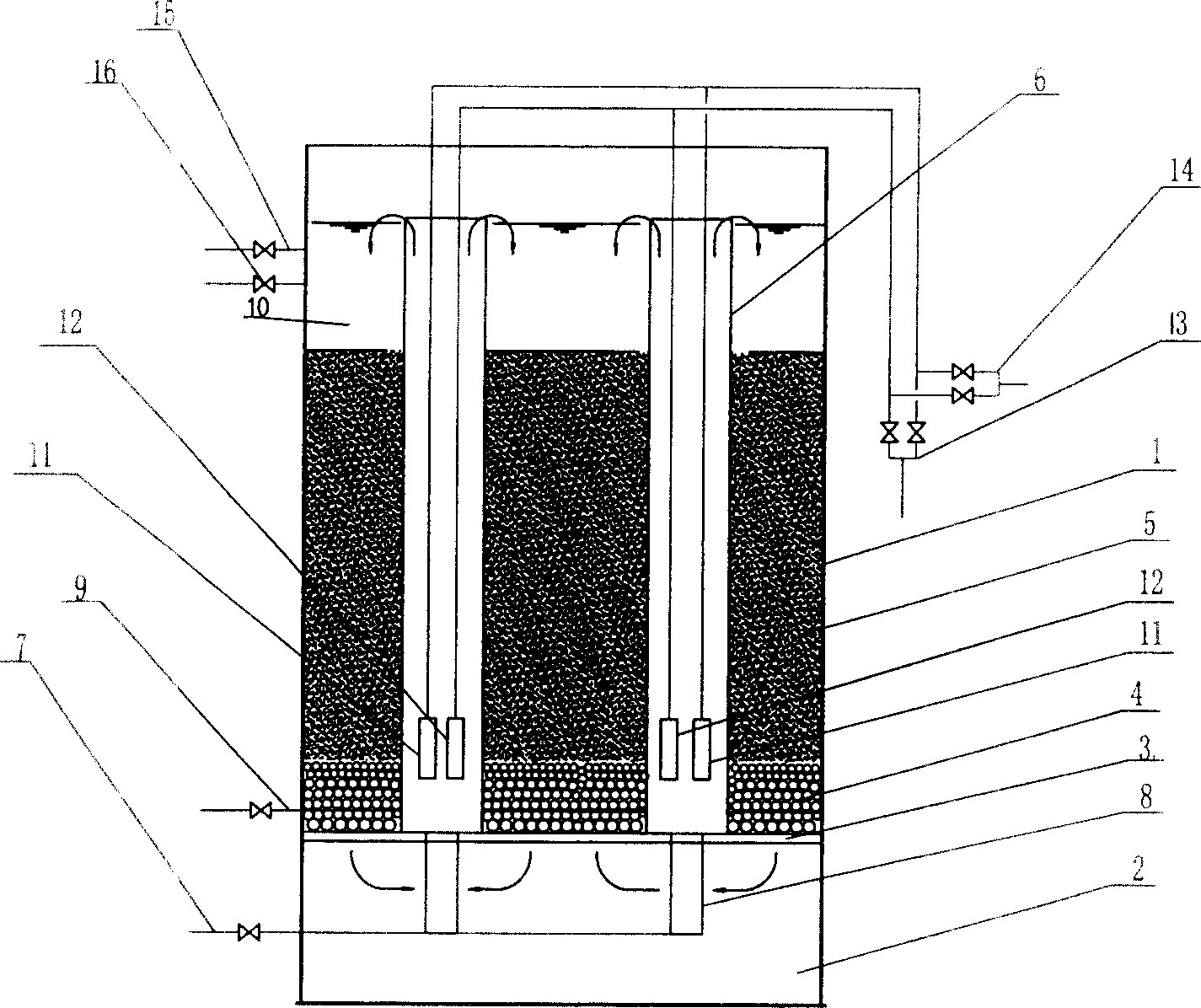

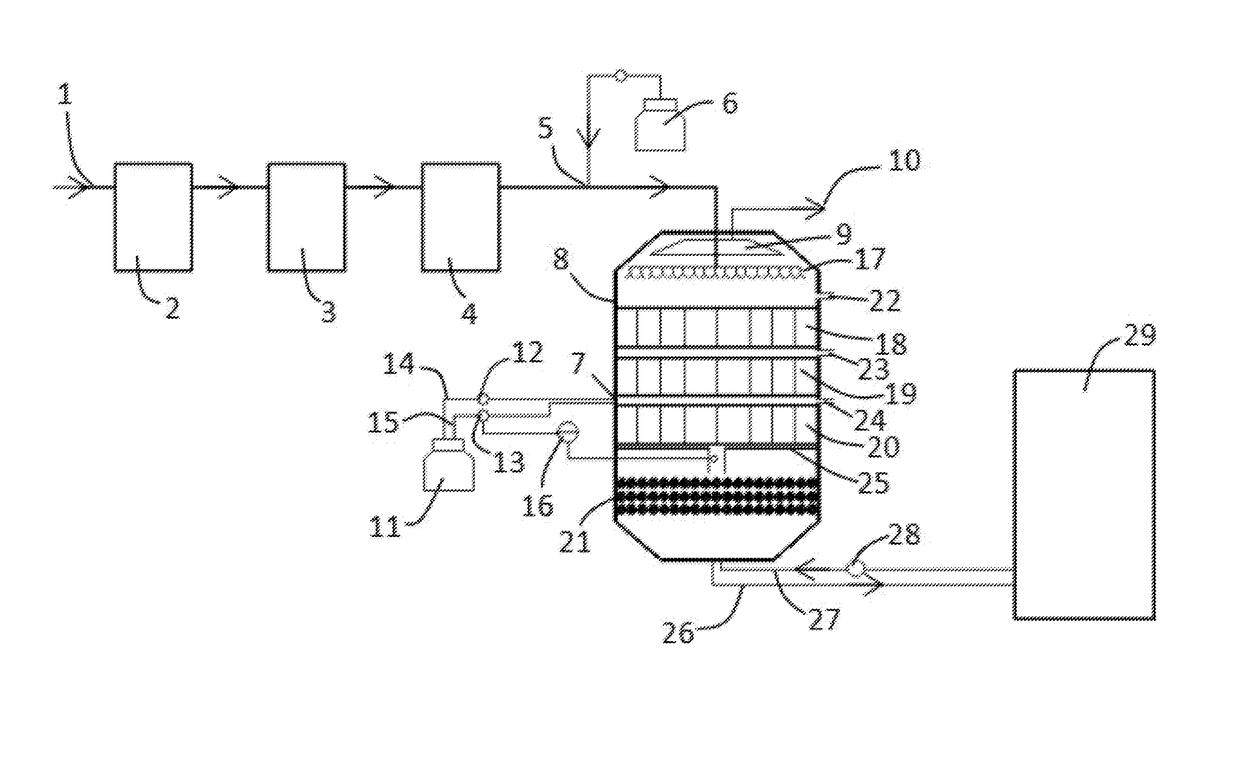

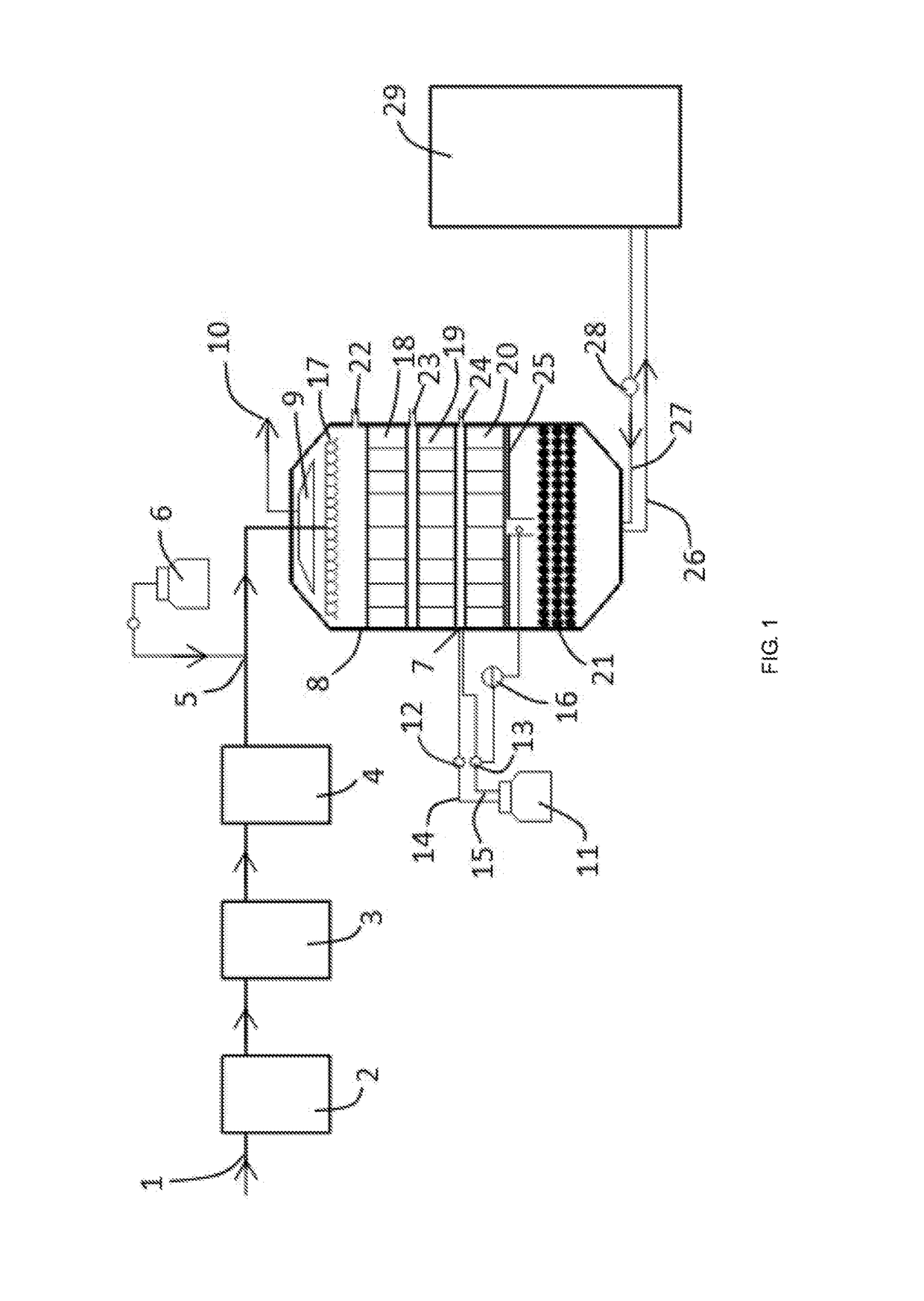

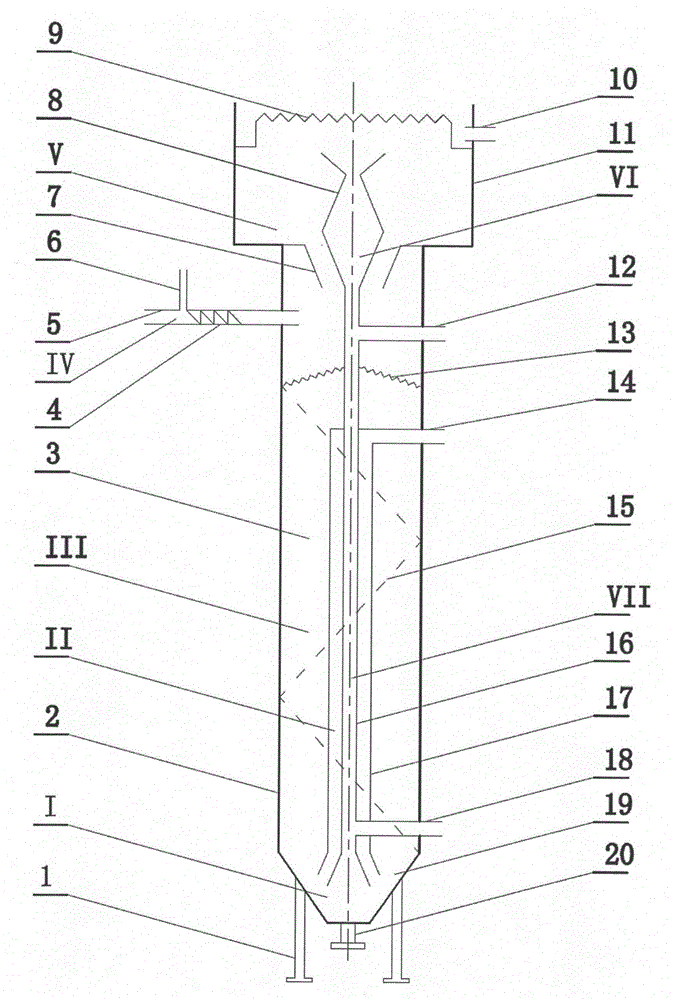

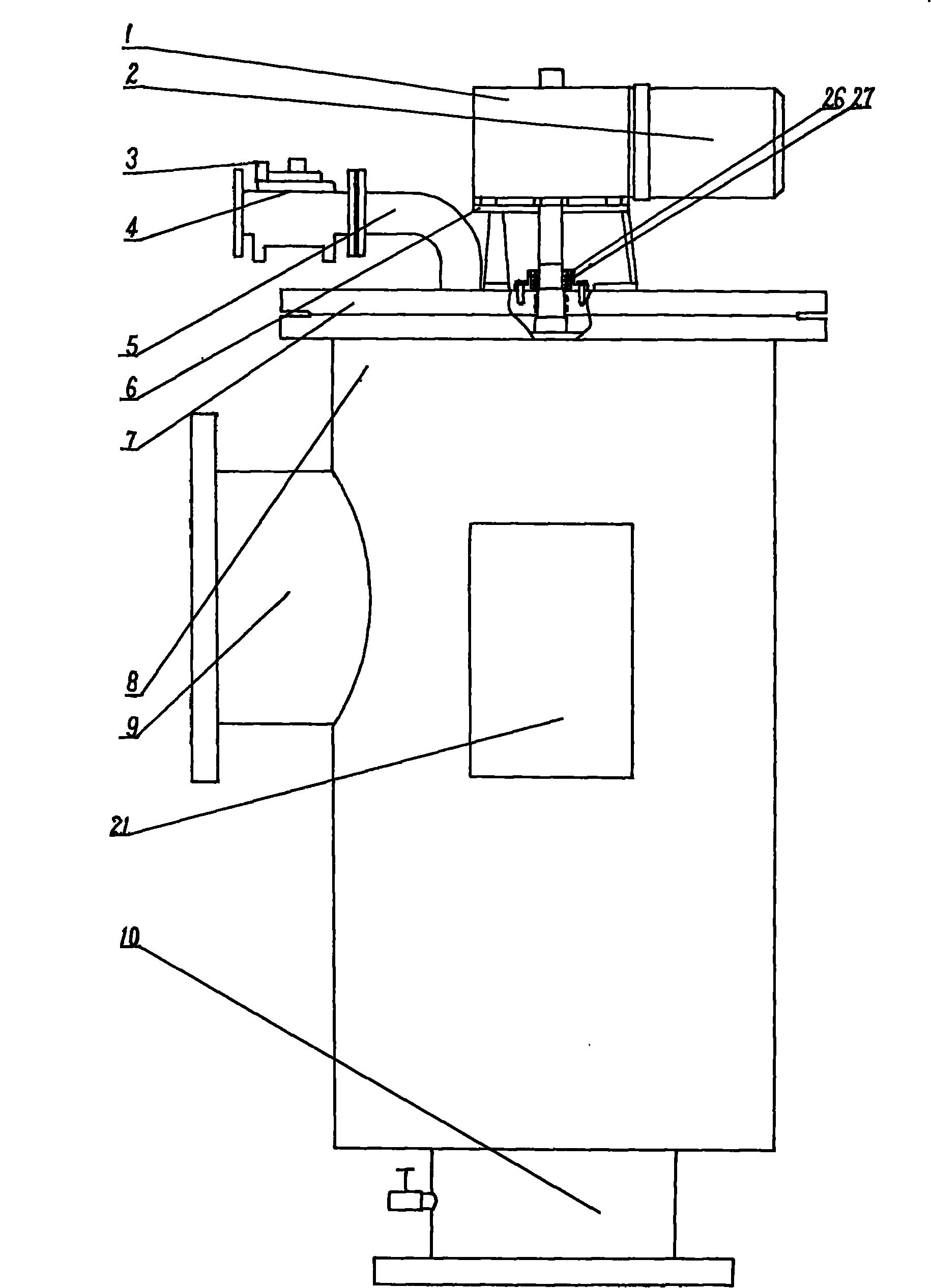

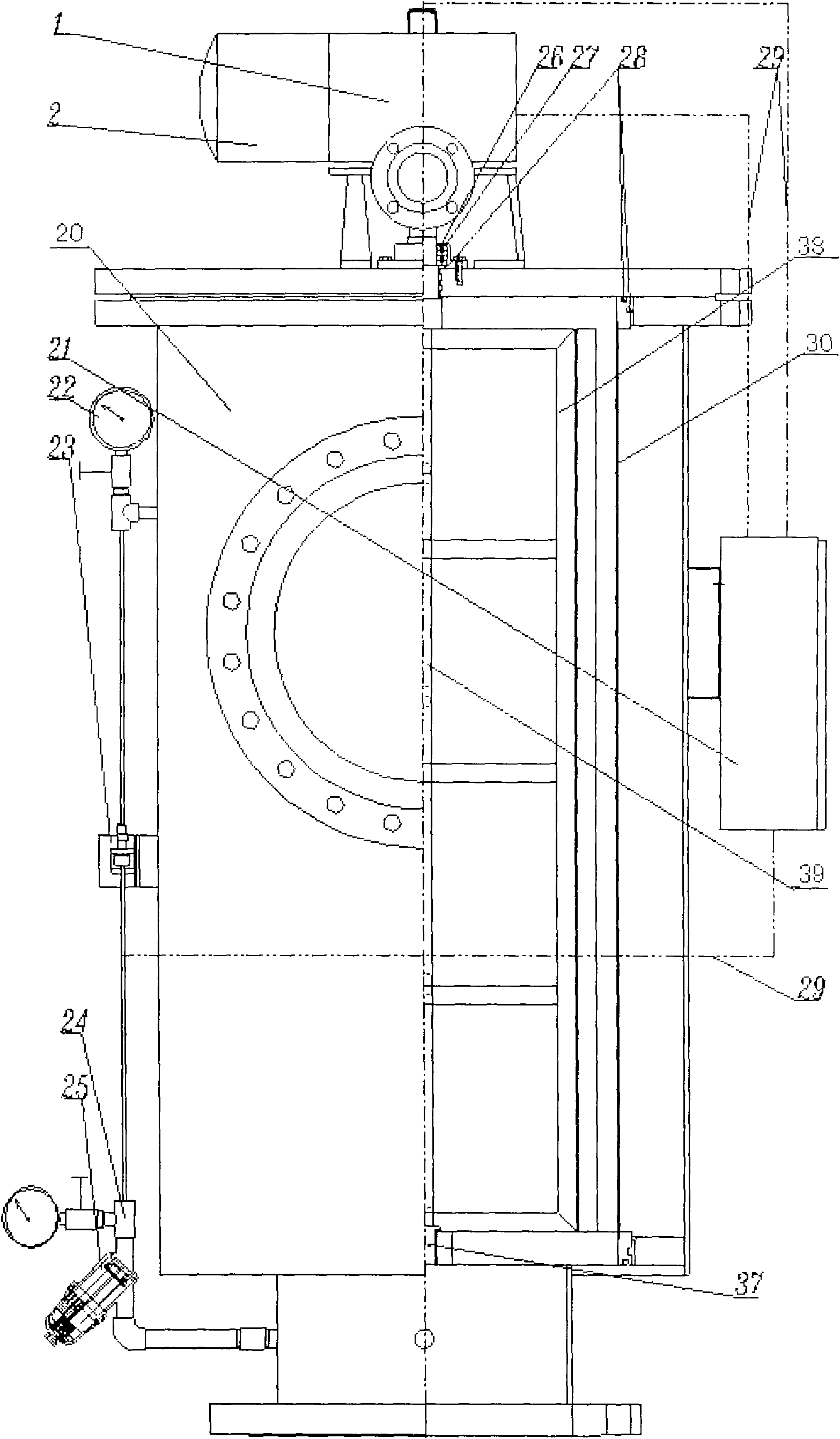

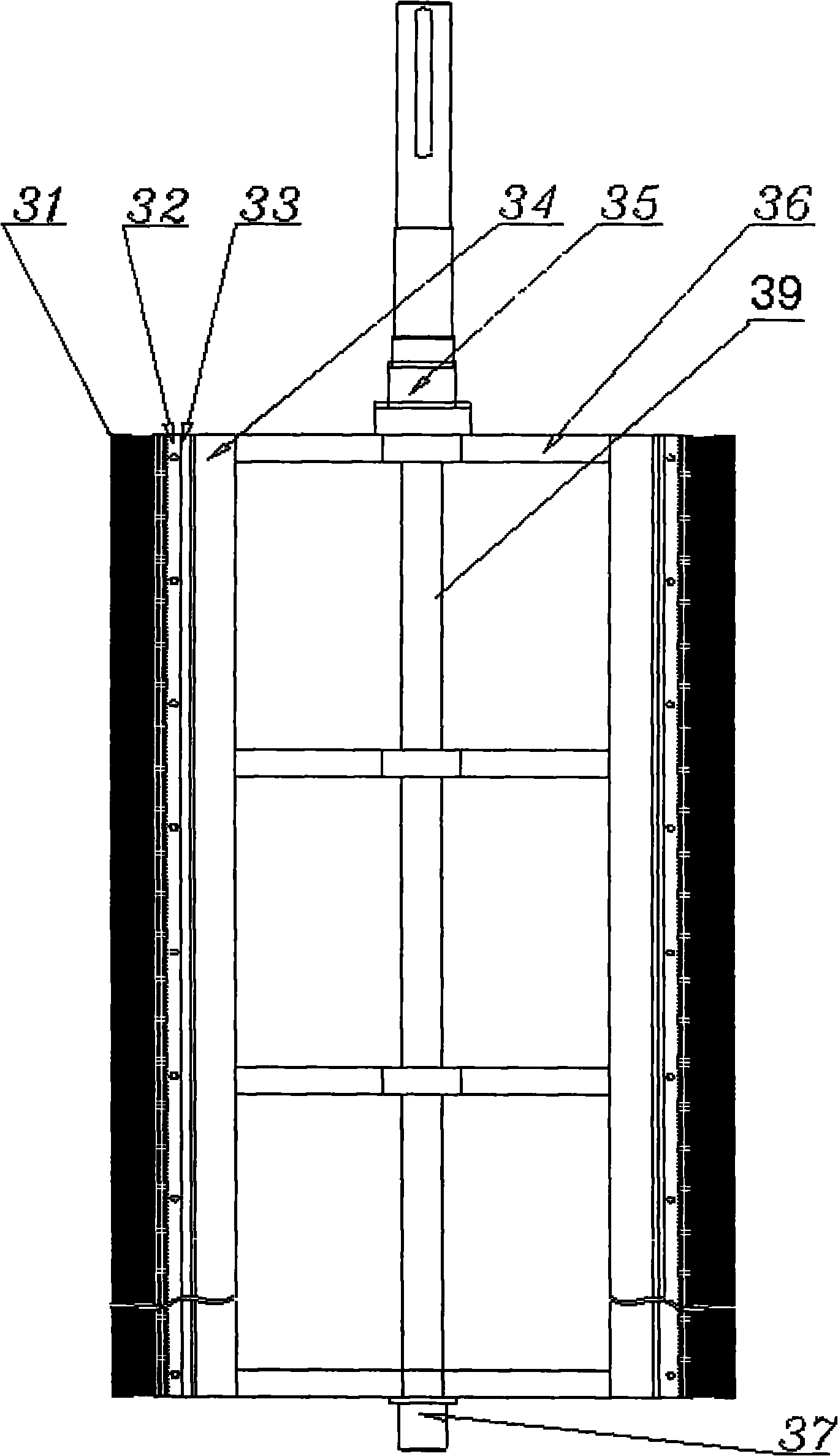

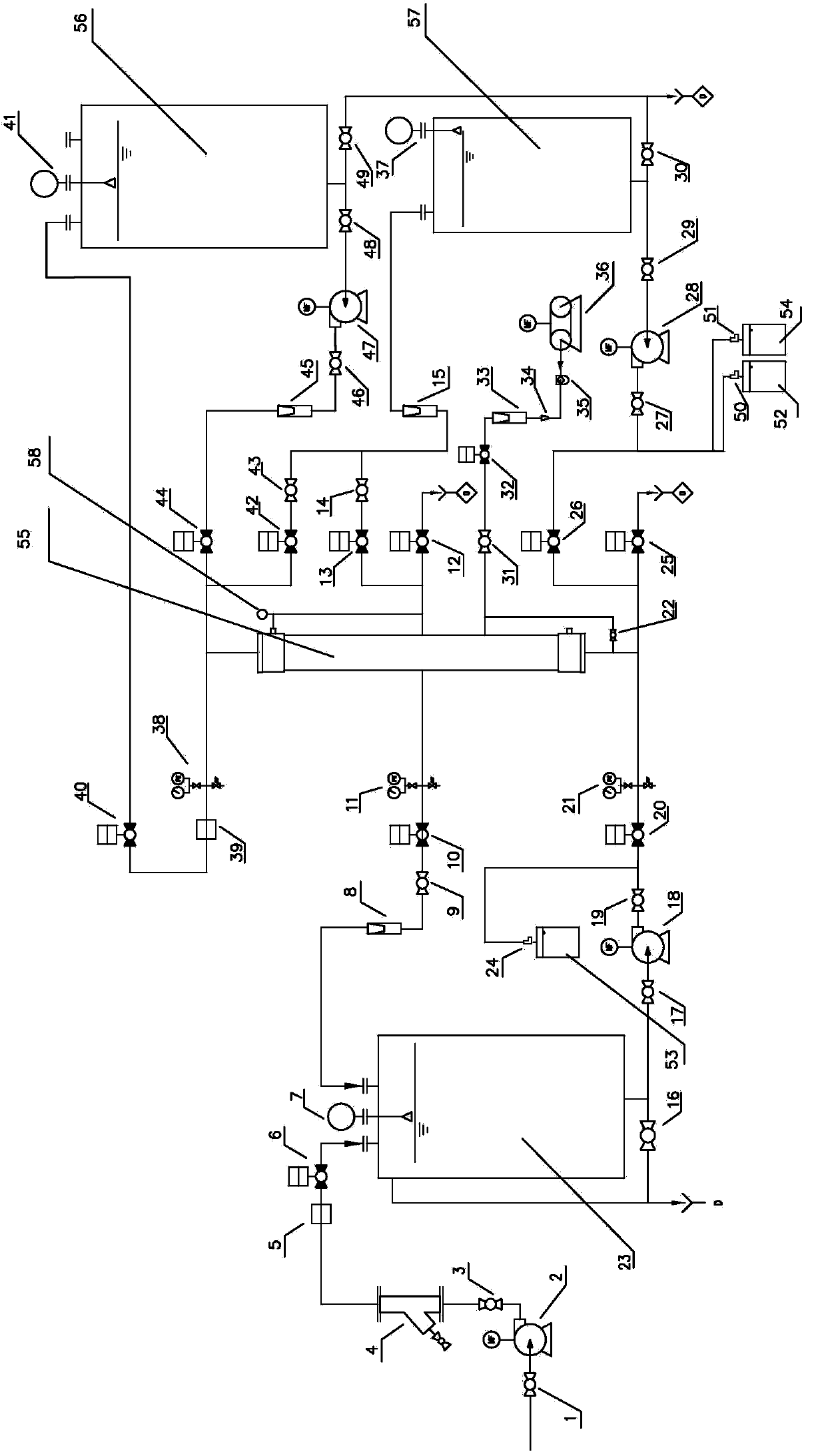

Apparatus for sewage deep denitrification with high pollutant carrying capacity and low energy consumption, and method for running the same

ActiveUS20180099885A1Reduce backwash timesStable water-bearing layerWater treatment parameter controlTreatment using aerobic processesChemical storageBiological filter

The invention discloses an apparatus for sewage deep denitrification with high pollutant carrying capacity and low energy consumption and a method for running the same, characterized in that: the apparatus mainly includes a settling tank, an electrodialysis device, a pH adjusting tank, a first chemical storage tank, a biofilters a second chemical storage tank, a redox potential measuring device, a backwash pump, and a clean water tank, wherein the biofilter is provided with, a gas collecting device, an uniform water distributor, a first filter bed, a second filter bed, a third filter bed, and a fourth filter bed sequentially from up to down, a second dosing port is arranged underneath the second filter bed, and the second chemical storage tank is communicated to the second dosing port respectively through a first flow path and a second flow path.

Owner:NANJING UNIV

Three-layer composite filter paper and preparation method thereof

InactiveCN105970715AReasonable adjustment of filtration efficiencyReasonable adjustment of filter resistanceNon-fibrous pulp additionPaper/cardboardGlass fiberSlurry

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

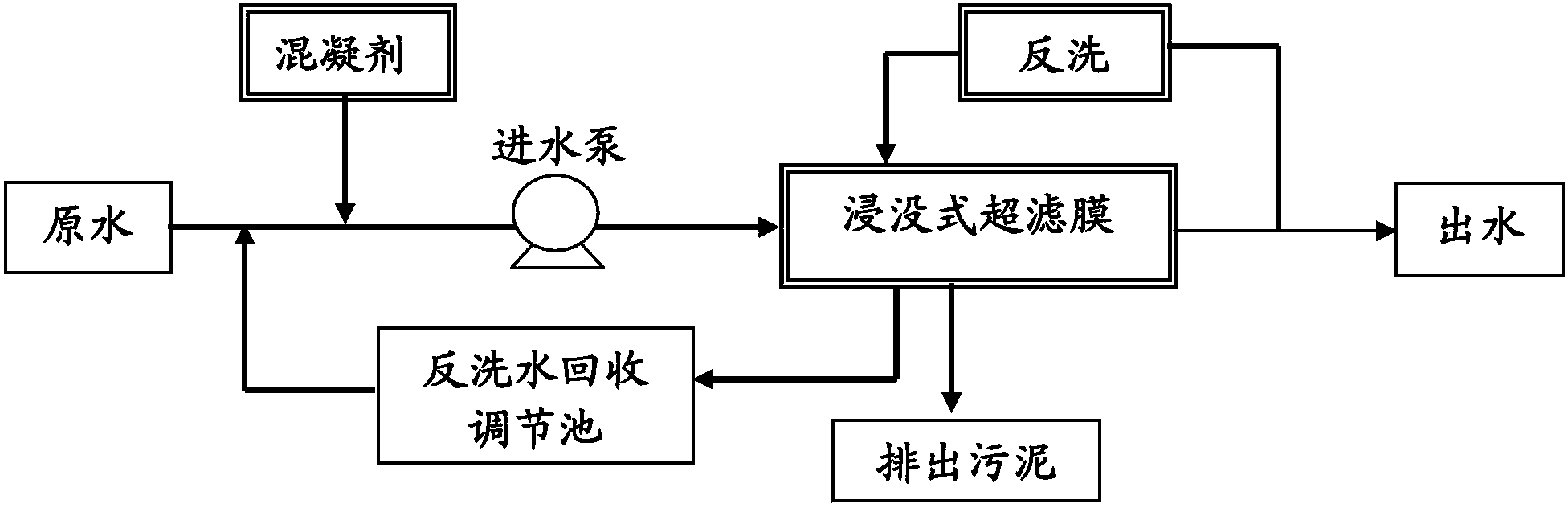

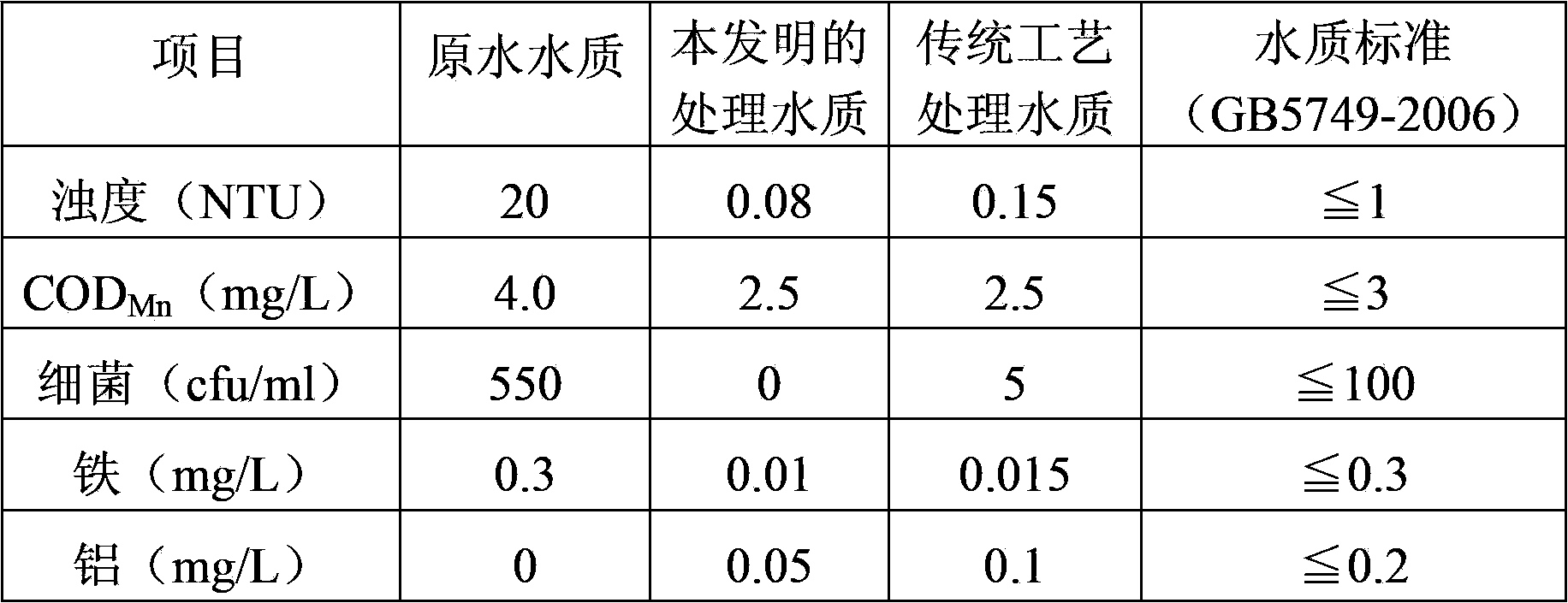

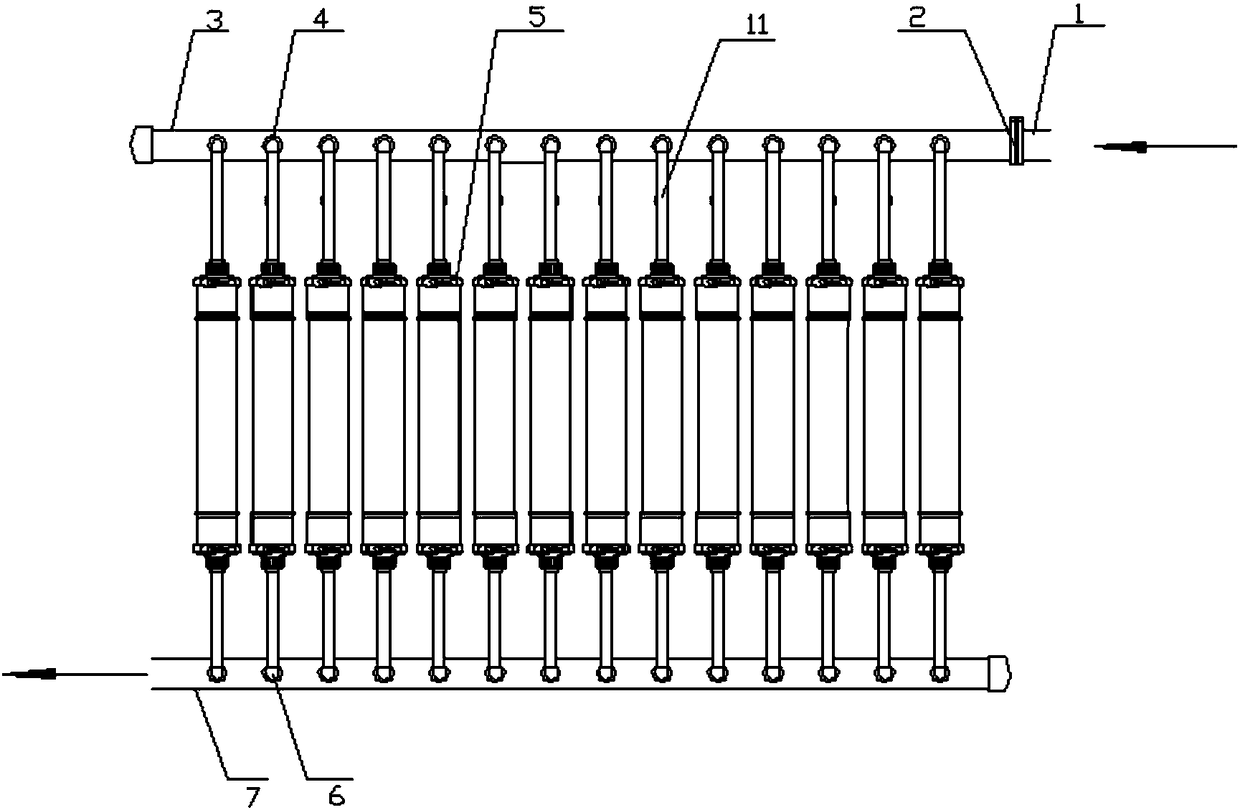

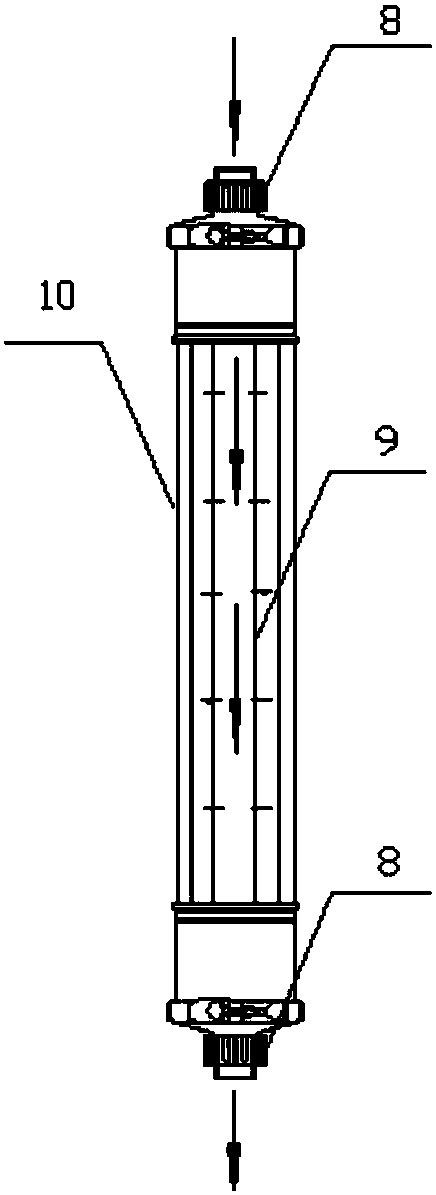

Immersion type ultra-filtration system

InactiveCN103566762ASimple processThe project occupies a small areaUltrafiltrationWater/sewage treatment bu osmosis/dialysisUltrafiltrationChemistry

The invention discloses an immersion type ultra-filtration system. According to the immersion type ultra-filtration system, a coagulant is added into a water suction opening of an immersion type ultra-filtration membrane water inlet pump; raw water added with the coagulant enters an immersion type ultra-filtration membrane tank to be filtered. According to the immersion type ultra-filtration system, a combined process of online coagulation and an immersion type ultra-filtration membrane is adopted; meanwhile, ultra-filtration membrane backwashing water returns back to a raw water pipeline to be recycled. A sludge discharging groove is formed in the bottom of the immersion type ultra-filtration system so that sludge can be discharged at fixed period to ensure the stable operation of immersion type ultra-filtration. According to the system, the recycling of the ultra-filtration backwashing water is realized on the basis of not additionally arranging a treatment structure, so that the recycling rate of the whole system is improved, and the initial investment and the operation cost of the system are reduced.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

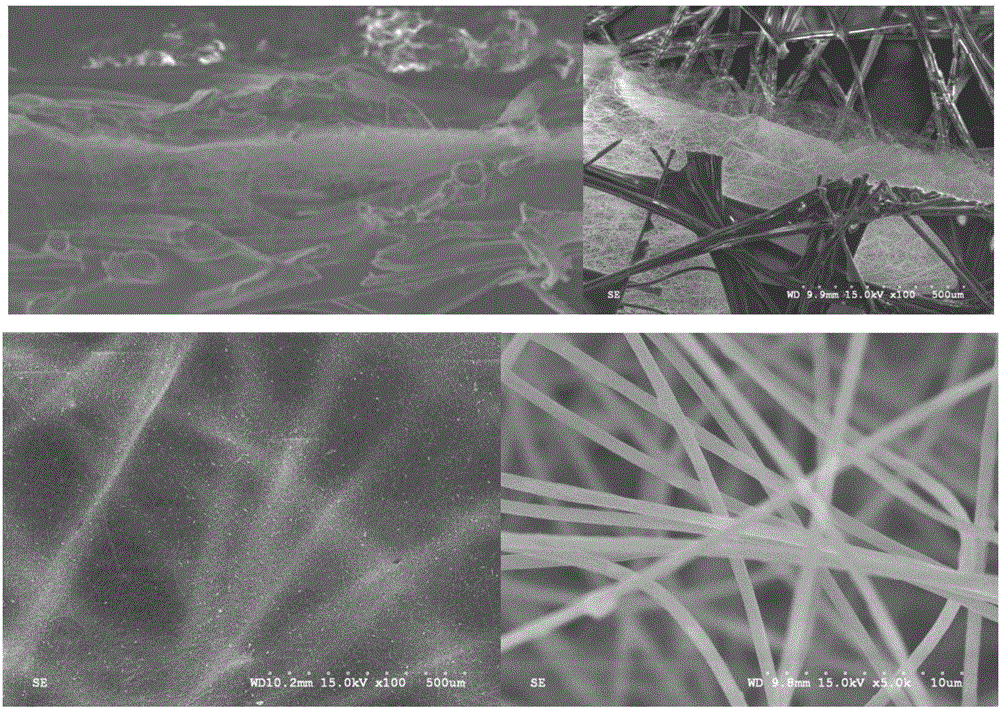

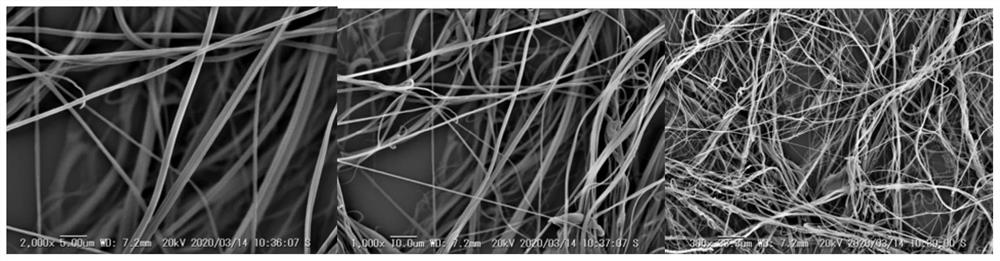

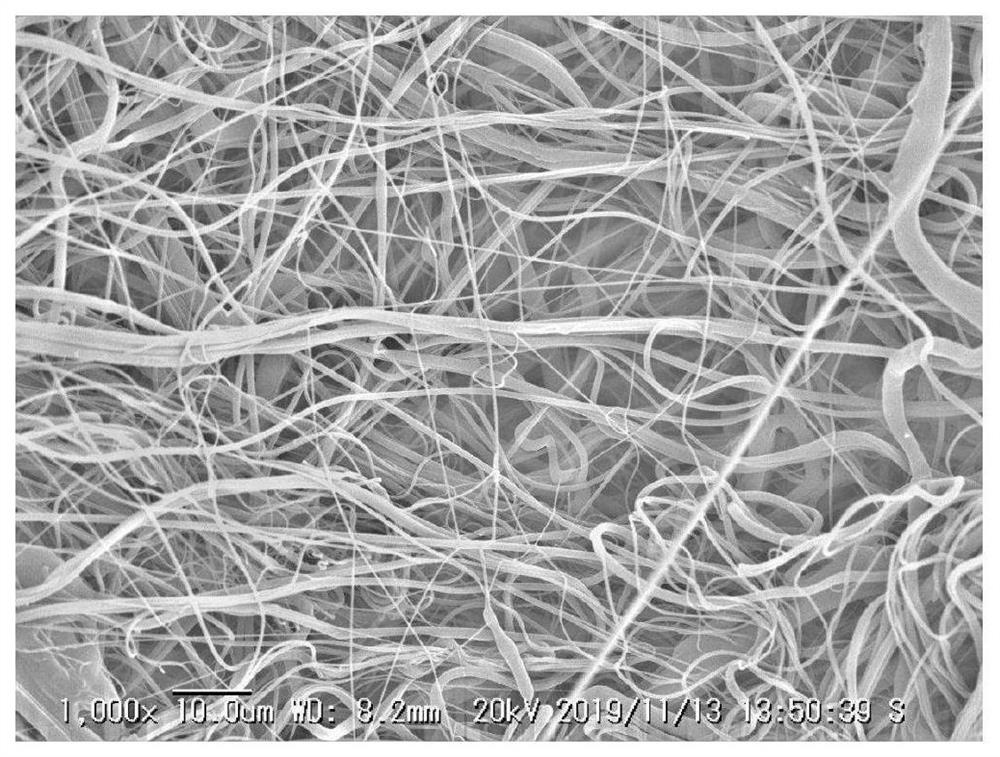

Deep filter element with crude and fine fiber mixed structure and preparation method of deep filter element

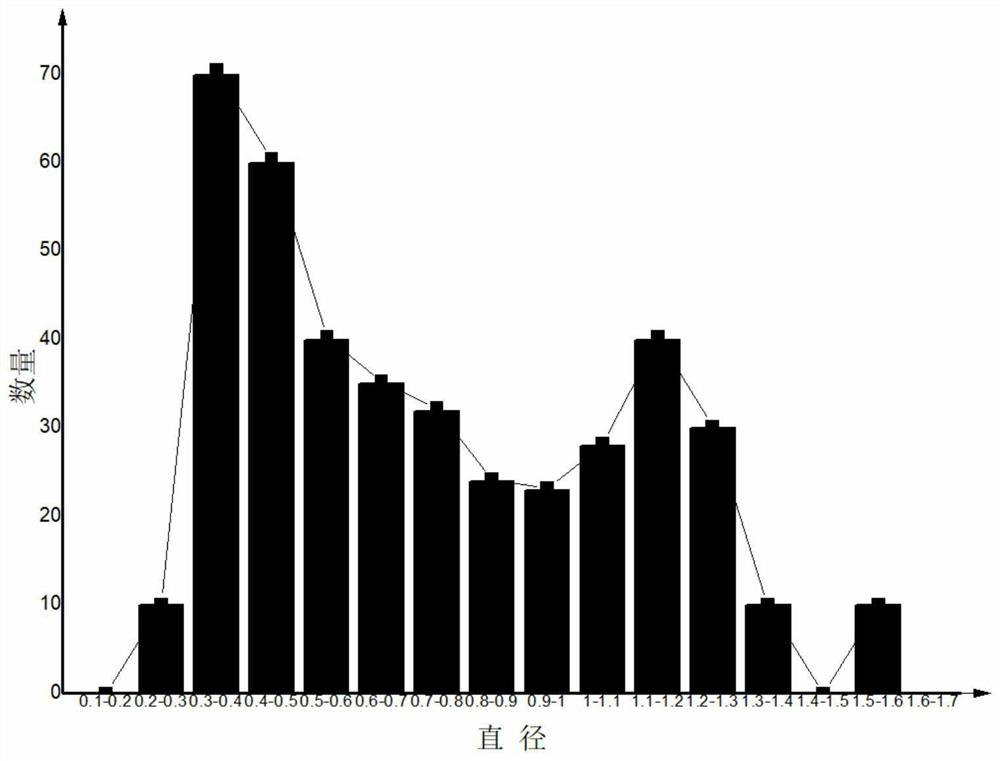

PendingCN111603846AEnsure structural stabilityDoes not increase filter resistanceMembrane filtersMelt spinning methodsCrude fibreFiber diameter

The invention discloses a deep filter element with a crude and fine fiber mixed structure. The deep filter element at least comprises two filtering layers; each filtering layer comprises a crude fiberset and a fine fiber set which are interwoven with each other; the average diameter of the crude fiber set of each filtering layer is reduced from the outer side to the inner side; the average diameter of the fine fiber set of each filtering layer is reduced from the outer side to the inner side; the fiber diameter of the fine fiber set of the innermost filtering layer is not larger than 1 micrometer; the fiber diameter of the crude fiber set of the outermost filtering layer is not smaller than 5 micrometers. The invention further discloses a preparation method of the deep filter element withthe crude and fine fiber mixed structure. The preparation method comprises the following steps of: 1) melt spinning; and 2) receiving a finished screen. The crude coarse fiber sets play a role in bonding the fine fiber sets and play a role in supporting, and therefore, the filter element is prevented from being compressed in a using process, and a dirt containing amount is increased, the fine fiber sets play a role in filtering and intercepting, so that filtering precision is improved, and the filter element has the functions of high filtering precision, high dirt containing capacity and longservice life and is good in filtering effect.

Owner:HANGZHOU COBETTER TECH CO LTD

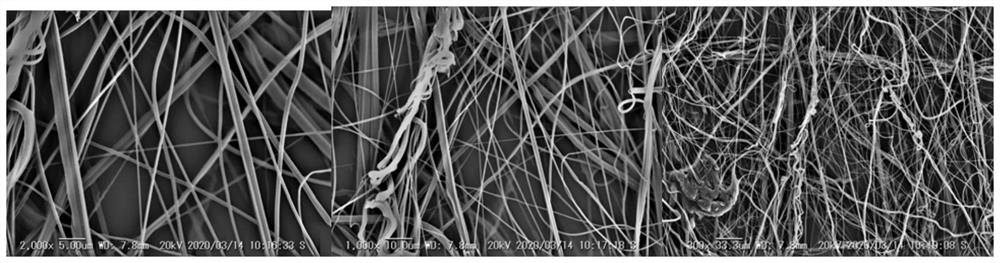

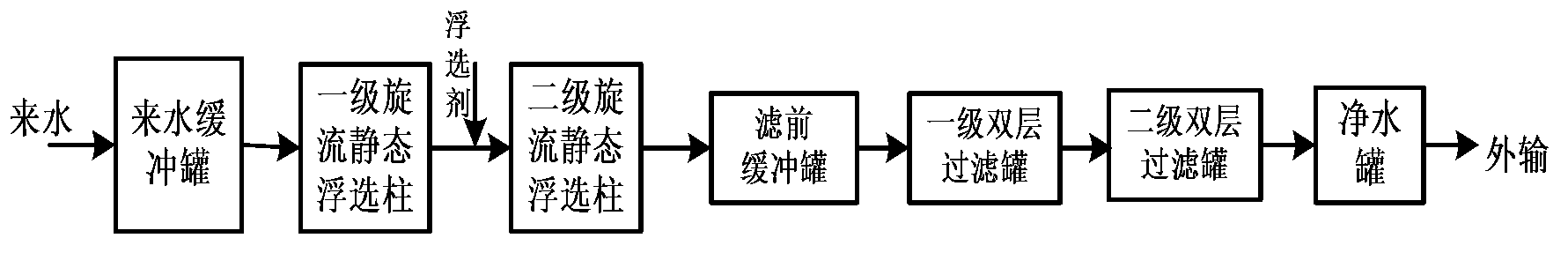

Oilfield poly-surfactant flooding sewage treatment process

InactiveCN103011474AShorten oil-water separation timeShort stayMultistage water/sewage treatmentFilter materialOil field

The invention discloses an oilfield poly-surfactant flooding sewage treatment process, solving the problems that the conventional settling and filtering process is long in running time, large in floor area, high in investment cost and the like. The oilfield poly-surfactant flooding sewage treatment process comprises the following specific steps: 1, performing stabilizing regulation on water quality and water amount of inflowing water by using an inflowing water buffer tank; 2, removing oil slick and most of dispersed oil from water by using a primary swirling static flotation column; 3, mixing outflowing water obtained in the step 2 with a flotation agent through a pipeline, entering a secondary swirling static flotation column, and further removing the dispersed oil, emulsified oil and suspended solids from water; and 4, sending the sewage treated in the step 3 into a two-stage double-filtering material filter, filtering till and the treated sewage reaches a pouring standard for a high-permeability strata, namely the oil content is less than or equal to 20mg / L, the suspended solid content is less than or equal to 20mg / L and the median particle size is less than or equal to 5 microns. By the oilfield poly-surfactant flooding sewage treatment process, the oil removing time is greatly shortened, the floor area is reduced, only a little of flotation agent is added in a running process, the maintenance is simple, and the outflowing water is stable and qualified.

Owner:PETROCHINA CO LTD +2

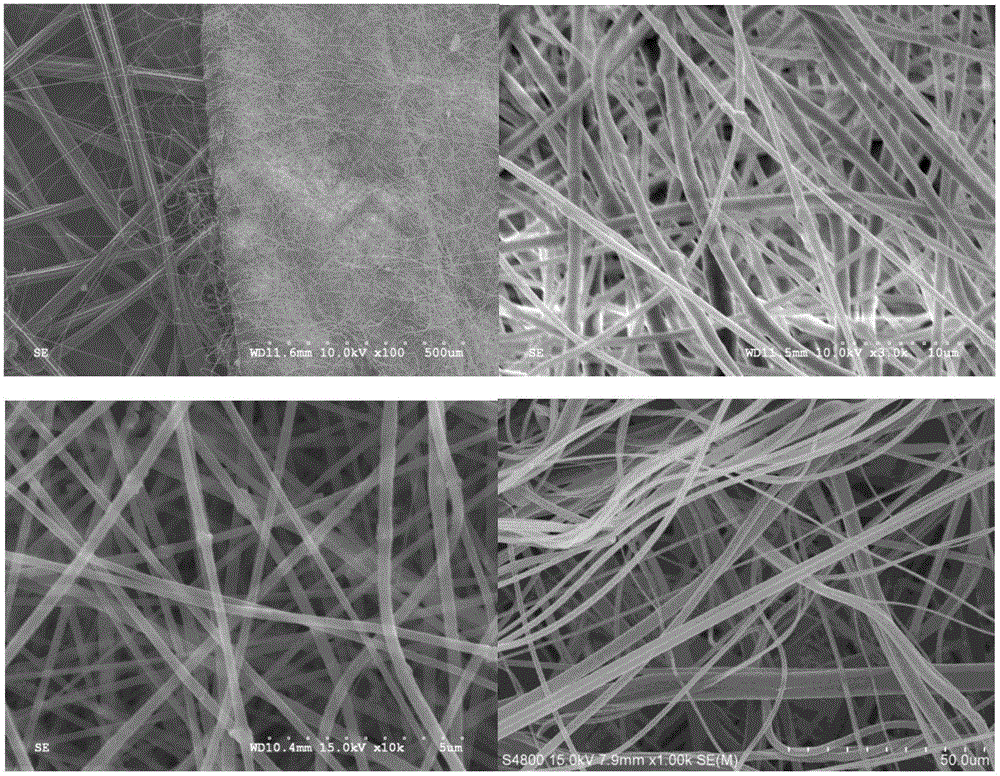

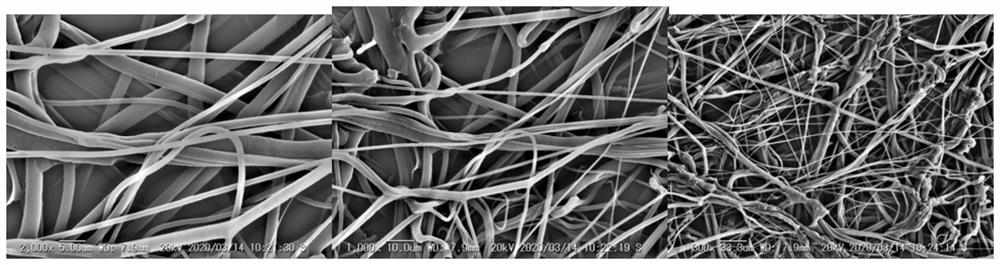

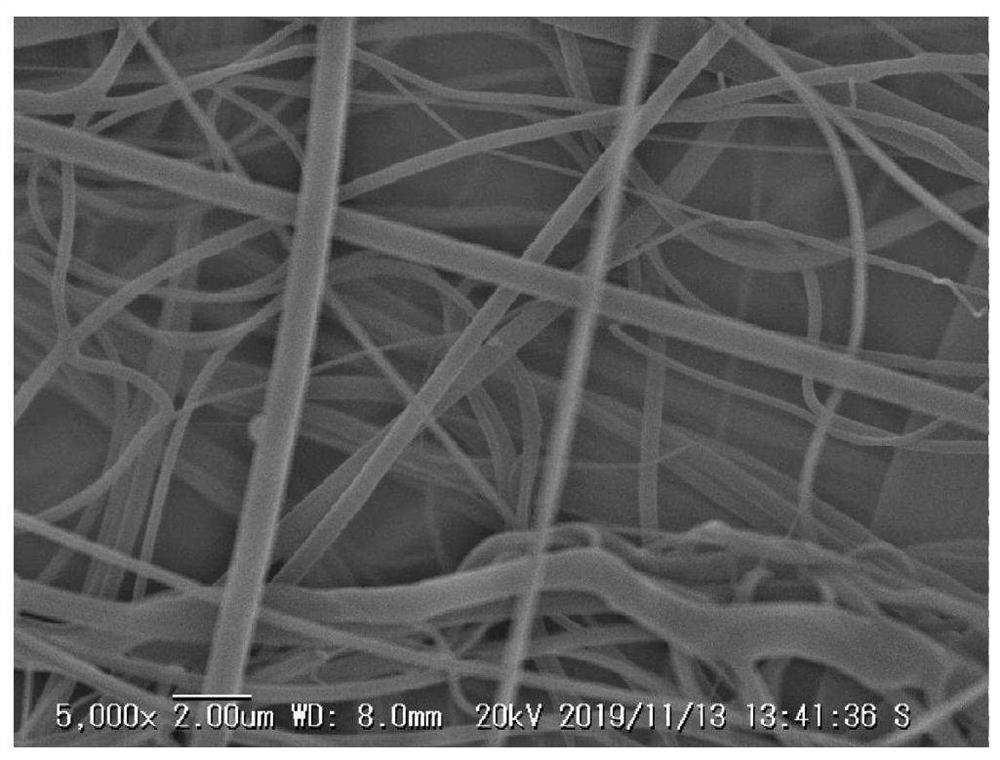

Melt-blowing filter medium with nano/micron fiber interlocked structure and preparation method for melt-blowing filter medium

ActiveCN111607900AImprove dirt holding capacityHigh filtration precisionFilament/thread formingConjugated synthetic polymer artificial filamentsPolymer scienceNanofiber

The invention discloses a melt-blowing filter medium with a nano / micron fiber interlocked structure. The melt-blowing filter medium with the nano / micron fiber interlocked structure comprises at leasta nano fiber set and a micro fiber set. The fiber diameter of the nano fiber sets is smaller than 1 micrometer, the nano fiber set comprises multiple nano fiber combinations with the diameters changing in a gradient mode, and fibers in each nano fiber combination are interwoven or fibers in all the nano fiber combinations are interwoven. The fiber diameter of the micron fiber set is greater than 1micrometer, the micron fiber set comprises a plurality of micron fiber combinations with the diameters changing in a gradient mode, and fibers in each micron fiber combination are interwoven or fibers in all the micron fiber combinations are interwoven. The nano fiber set and the micro fiber set are formed by melt-blowing a mixture consisting of at least two polymers of the same or different meltindices. The invention further discloses a preparation method for the melt-blowing filter medium. The preparation method comprises the following steps: 1) raw material mixing, 2) melt spinning, and 3) receiving and molding. Through the combination of the nano fiber set and the micron fiber set, a favorable filtering effect is achieved, the contaminant carrying capacity is improved, the filter pressure resistance is reduced, and the filtering effect is excellent.

Owner:HANGZHOU COBETTER TECH CO LTD

Online detachable large-flow filter

InactiveCN108854212ALow investment costReduce replacement costsStationary filtering element filtersInlet valveWater diversion

The invention discloses an online detachable large-flow filter, belonging to the field of water treatment. The online detachable large-flow filter is formed by a plurality of single filter pipes whichare connected in parallel, and the two ends of each filter pipe are connected between a water inlet pipeline and a water outlet pipeline by means of water diversion pipelines; the connecting parts ofthe two ends of each filter pipe and the water diversion pipelines are separately provided with a filter element disassembly rotary knob; the connecting part between each water diversion pipeline andthe water inlet pipeline is provided with a water inlet valve, and the connecting part between each water diversion pipeline and the water outlet pipeline is provided with a water outlet valve. According to the online detachable large-flow filter, the investment cost and the replacement cost are reduced, the filter area is enlarged, the pollutant-holding capacity is enhanced, the service life isprolonged and the maintenance cost is lowered; equipment can be operated continuously, and the use of other filter elements is not affected when one filter element is replaced; the online detachable large-flow filter is convenient to replace, and does not need very professional knowledge and special disassembly tools; the online detachable large-flow filter is high in degree of automation, simpleto manage and labor-saving.

Owner:NANJING GUONENG ENVIRONMENTAL PROTECTION ENG

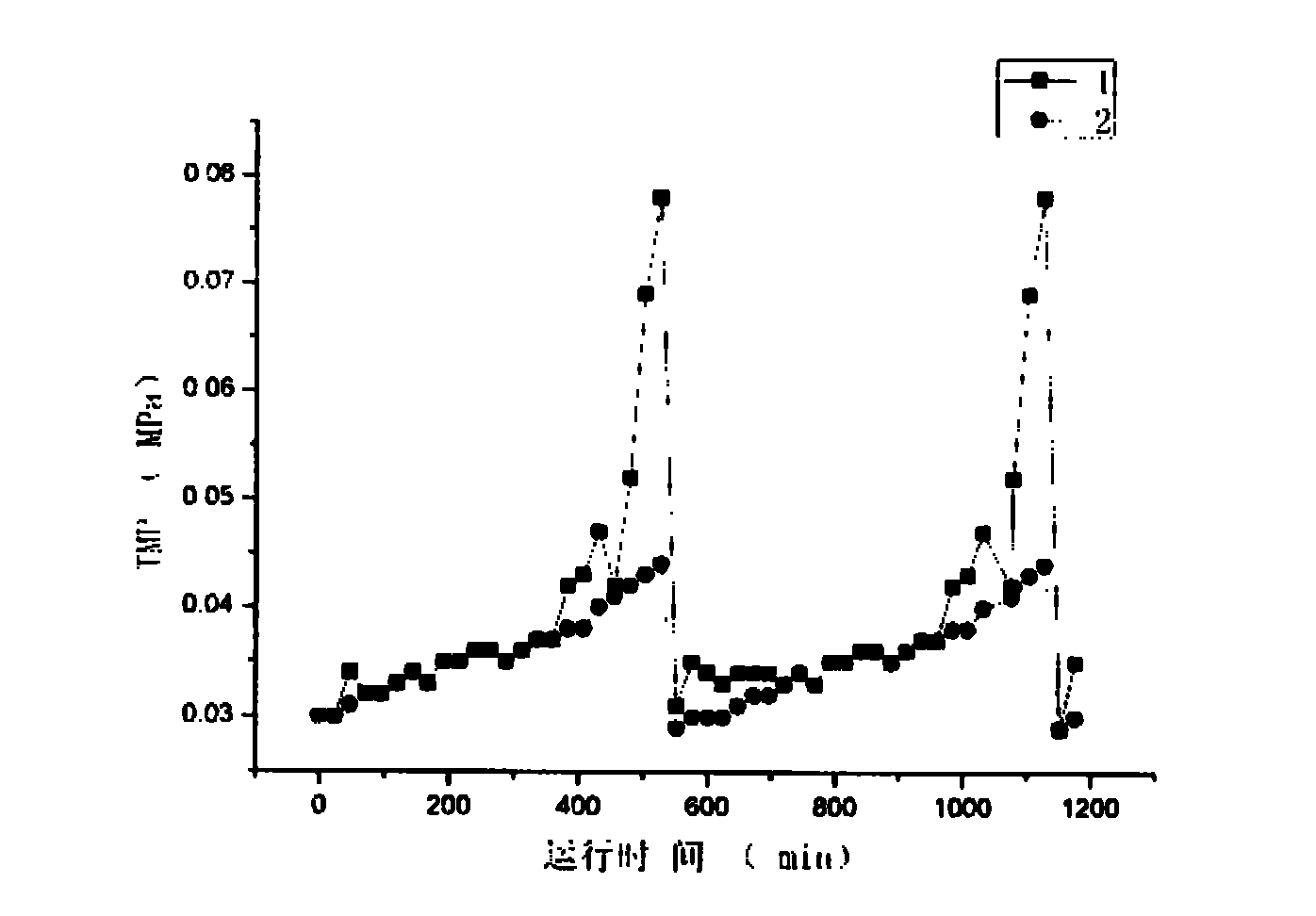

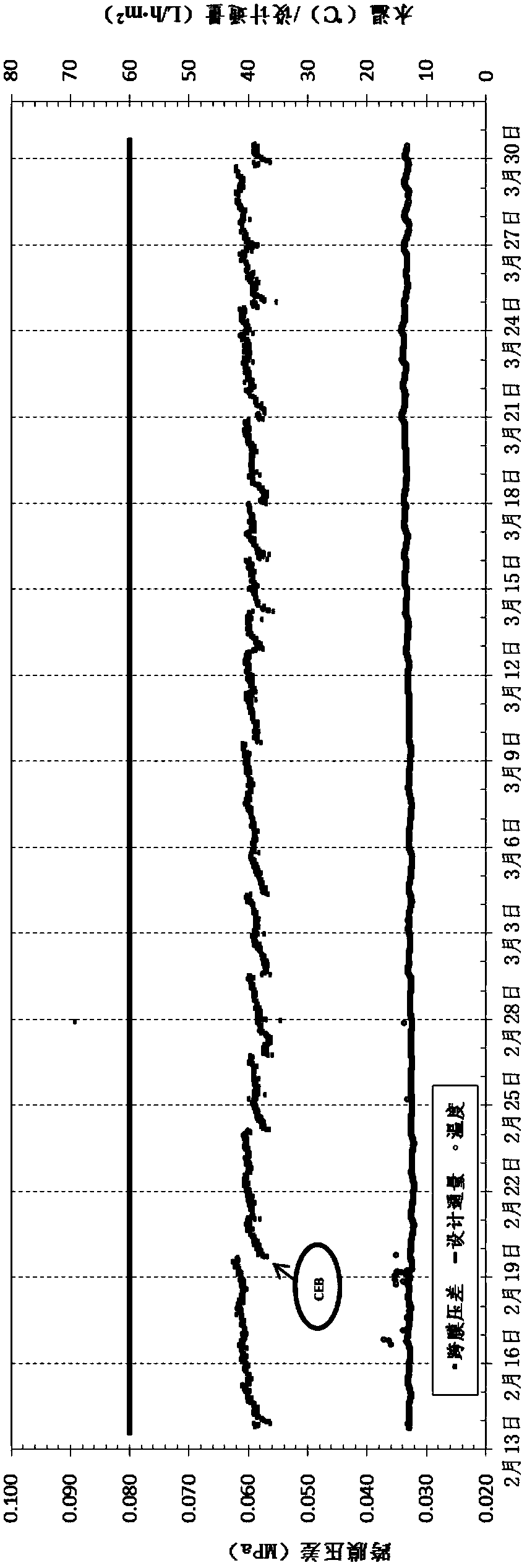

Separating membrane pollution controlling and cleaning method

InactiveCN103316592ASmall fluxImprove throughputSemi-permeable membranesParticulatesChemical physics

The invention provides a separating membrane pollution controlling and cleaning method, comprising: adding particles in a filtration circulating system as a micro-filtration medium, locally implementing porous loosened sedimentary deposit on a membrane surface of a membrane assembly, and implementing active control of a sedimentary deposit structure by load capacity and deposition density of the particles on the surface of the separating membrane; and after sewage is filtrated, collecting the micro-filtering medium backing to a system for reusing. Aiming at an ultramicro filter membrane or a membrane distillation system, the method cancels pre-stage multimedium filtration, and provides a micro-medium locally-filtrating process. By multi-medium auxiliary filtration effect of particles, the method raises a dirt accepting capability of the system, delays membrane pollution, prolongs a membrane cleaning period, and is intended to solve problems that difference of initial flux of different membranes is big, balance flux is similar, and membrane usefulness cannot fully be performed. By selection of multimedium particle sizes of the particles, the method implements auxiliary filtration layer structure control, combines a chemical separating process and design of a membrane material surface pollution layer structure, and implements the membrane filtration process of high flux.

Owner:TIANJIN POLYTECHNIC UNIV

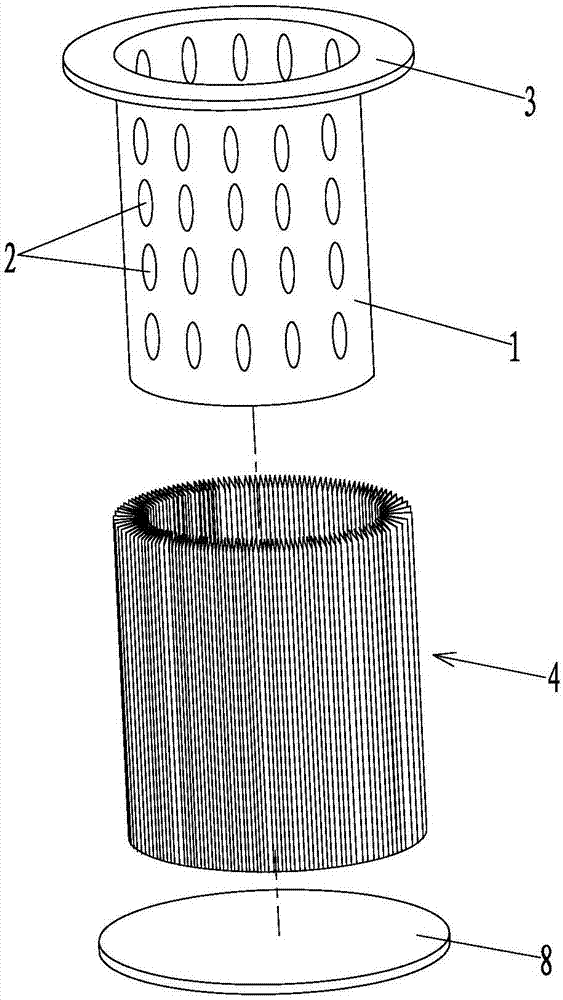

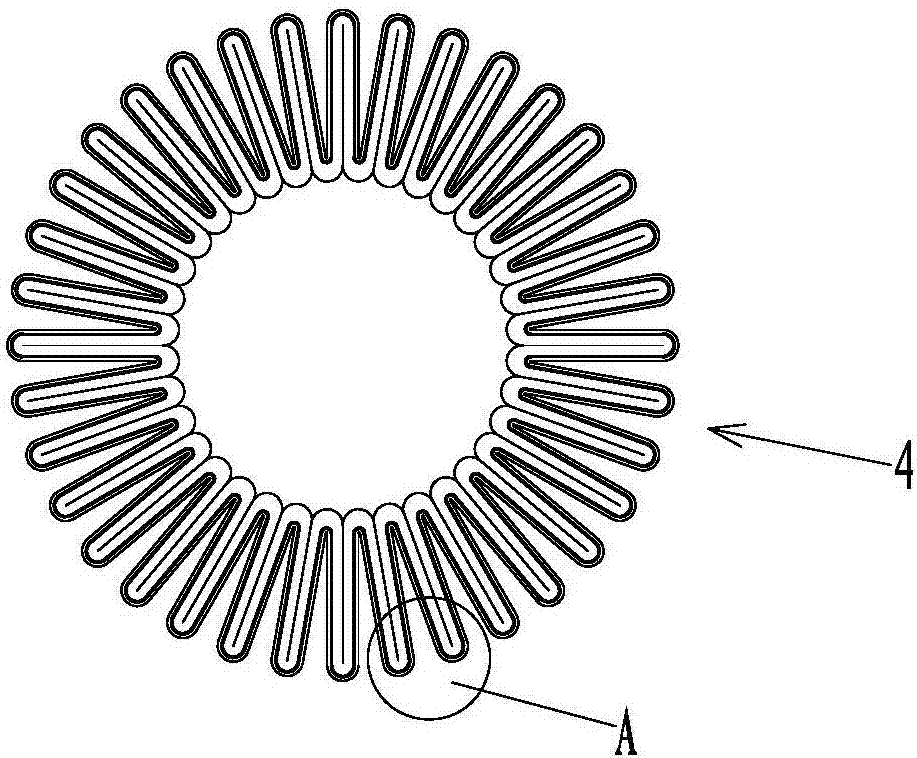

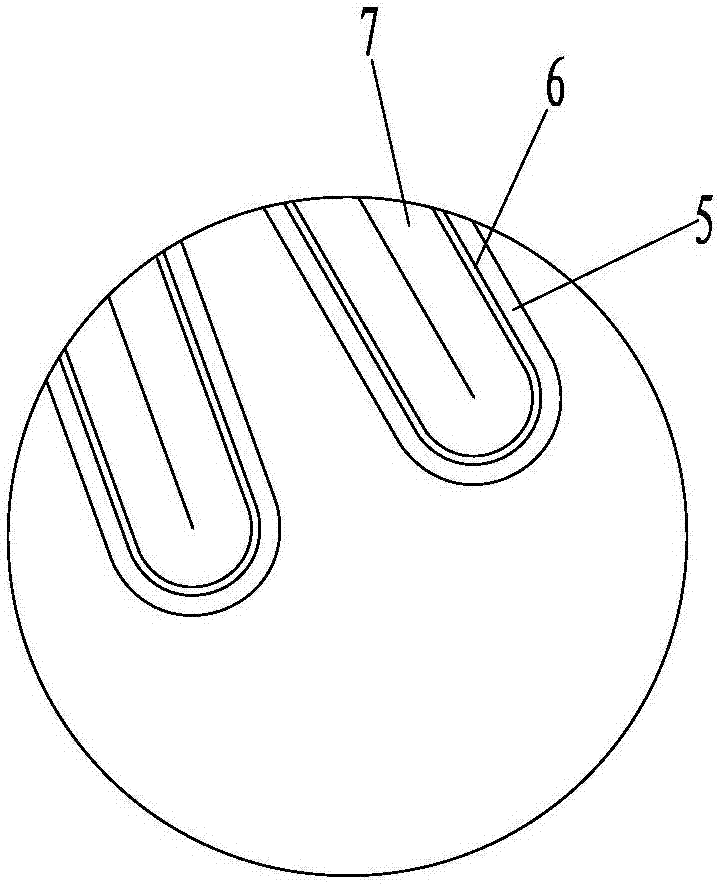

Folding filter core structure, filter cylinder device and machining method of filter cylinder device

InactiveCN107029474ASimple methodSimplify the assembly processMembrane filtersFiltration circuitsFiltrationBiochemical engineering

A folded filter element structure, a filter cartridge device and a processing method thereof, the folded filter element structure includes a filter element frame, the filter element frame is connected with a ring-shaped folded filter element, the lower end of the filter element frame is provided with a lower cover; the filter cartridge device includes a filter cartridge and a The pleated filter element structure; during processing, one or more materials in the nuclear pore fine filter membrane, non-woven fabric, and nuclear pore coarse filter membrane are compositely welded together, and folded or not folded in half along the width direction and placed in parallel, and then along the The stretching direction is folded into a louver shape, and its two ends are sealed and welded to form a ring-shaped folded filter element; the folded filter element is placed on the filter element frame, and then the upper and lower edges of the folded filter element are welded to the upper and lower covers to form a sealed body; put the sealed body Insert it into the frame of the filter cartridge so that the upper and lower covers fit closely with the inner wall of the frame of the filter cartridge. The filter element of the present invention is self-contained, easy to replace, low in production cost, long in service life, has increased effective filtering area of the filter element, strong dirt holding capacity, improved filtering efficiency, reduced replacement frequency, more convenient use and wide application range.

Owner:上海谷奇核孔膜科技股份有限公司

Helical flow dephosphorization reactor

ActiveCN104478121AEnhanced plug flowImprove performanceWater contaminantsTreatment involving filtrationWater dischargeEnvironmental engineering

The invention provides a helical flow dephosphorization reactor. The helical flow dephosphorization reactor comprises a pre-backwashing zone, a gas stripping lifting zone, a water discharging zone, a filtering zone, a water feeding zone, a backwashing zone and a solid-liquid separation zone from bottom to top; the pre-backwashing zone comprises an inverted bench body, and an escape tube is arranged below the inverted bench body; the gas stripping lifting zone comprises a gas stripping tube, and the lower end of the gas stripping tube is provided with a gas stripping gas inlet tube; the water discharging zone comprises a filtered water collecting tube, and the filtered water collecting tube is coaxially arranged outside the gas stripping tube; the filtering zone comprises a lower cylinder, and the lower cylinder is coaxially arranged outside the filtered water collecting tube; the water feeding zone comprises a water feeding tube, and the water feeding tube is connected with the upper end of the lower cylinder; the backwashing zone comprises a backwashing air tube, the backwashing air tube is connected with the upper end of the gas stripping tube, and an efficient stripping tube is connected with the top of the gas stripping tube; and the solid-liquid separation zone comprises an upper cylinder, and the upper cylinder is connected with the top of the lower cylinder. The reactor has the advantages of continuous running, tending towards a laminar flow state, small dead zone area, high filtering and backwashing efficiency, reasonable and concise structure, convenient processing and convenient popularization application.

Owner:浙江沃乐科技有限公司

Bulk flow and self-cleaning net type filter

InactiveCN102039065AHigh degree of automationFiltration flow is largeStationary filtering element filtersControl systemSewage

The present invention relates to a bulk flow and self-cleaning net type filter comprising a tank body, a power system, a control system and a filter chamber. The bottom of the tank body is provided with a water inlet, one side of the tank body is provided with a water outlet, and the top of the tank body is provided with a sewage draining exit and a power system, and a filter chamber connected with the power system, the control system and the water outlet respectively is arranged inside the tank body. The filter is characterized in that the filter chamber comprises a cuneate filter canister and a rotating stainless steel wire brush unit arranged in the cuneate filter canister; the cuneate filter canister is connected with the water inlet; the rotating stainless steel wire brush unit comprises central upper, middle and lower wire brush shafts that are connected to each other, and three sets of steel wire brushes that are arranged at the central brush shafts vertically; the upper and lower shafts of the wire brush are connected with the top and the bottom of the filter chamber respectively; every two steel wire brushes are at a 120 DEG angle to each other. The filter is advantageous in simple structure, sensitive self-cleaning control system and excellent sewage draining effect.

Owner:GANSU DAYU WATER SAVING

Bittern or seawater ultrafiltration pre-treatment process and system

ActiveCN104211203AReduce refining costsSimple refining processReverse osmosisWater/sewage treatment bu osmosis/dialysisUltrafiltrationSeawater

The invention discloses a bittern or seawater ultrafiltration pre-treatment process and system. The bittern or seawater ultrafiltration pre-treatment process and system can provide filtered water meeting water feeding requirements of nanofiltration. Every process cycle of the bittern or seawater ultrafiltration pre-treatment process sequentially comprises a filtering step, a water producing step, a cleaning step and a discharging step, wherein the cleaning step comprises processes including gas wiping, gas-water backwashing and gas exhausting. Bittern or seawater is filtered through a cartridge filter and precisely-filtered liquor is filtered through a ultrafilter membrane filtering device to produce water; the gas exhausting process comprises that, during a membrane module exhaust process, oilless compressed air is inlet to the water inlet side of membrane yarns, and compressed air and water are mixed and oscillated to act on the surface of the membrane yarns; during the gas exhaust process, the water level decreases continuously, the gas-water washing strengths of the cross sections at different horizontal heights change, so that the membrane yarns can be cleaned from top to bottom. The bittern or seawater ultrafiltration pre-treatment process enables the bittern and seawater to be treated in a membrane filtering mode, thereby reducing the purification cost and simplifying the purification process, and through stable water output, prolongs the service life of nanofiltration membranes and guarantees stable operation of a nanofiltration system.

Owner:TIANJIN MOTIMO MEMBRANE TECH +1

Multilayer fiber composite filter material

ActiveCN105749622AAvoid wastingIncrease the cost of useSynthetic resin layered productsMembrane filtersComposite filterFilter material

The invention relates to a multilayer fiber composite filter material.The multilayer fiber composite filter material is sequentially provided with an inner supporting layer, a polypropylene superfine fiber layer, a fine fiber glass fiber layer, a crude fiber glass fiber layer and an outer supporting layer from inside to outside.According to the multilayer fiber composite filter material, fiber filter layers of multiple dimensions and mesh numbers are composited together from outside to inside from coarse filtering to fine filtering, so that the filtering capacity of the filter material is distributed in gradient, particles of different dimensions are effectively intercepted in a segmented mode, it can be avoided that a filter screen small in mesh is used for filtering large-particle matter, and consequently a filter material is wasted, the use cost of the filter material is reduced, the filter efficiency of the filter material is improved, the service life of the filter material is prolonged, and the pollution load capable of being contained by the filter material is increased.

Owner:BEIJING ALL OF FILLER TECH DEV CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com