Bittern or seawater ultrafiltration pre-treatment process and system

A pretreatment and brine technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problems of complex brine water quality and no brine, and shorten sewage discharge Time, effluent stability, and the effect of reducing pollutant content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

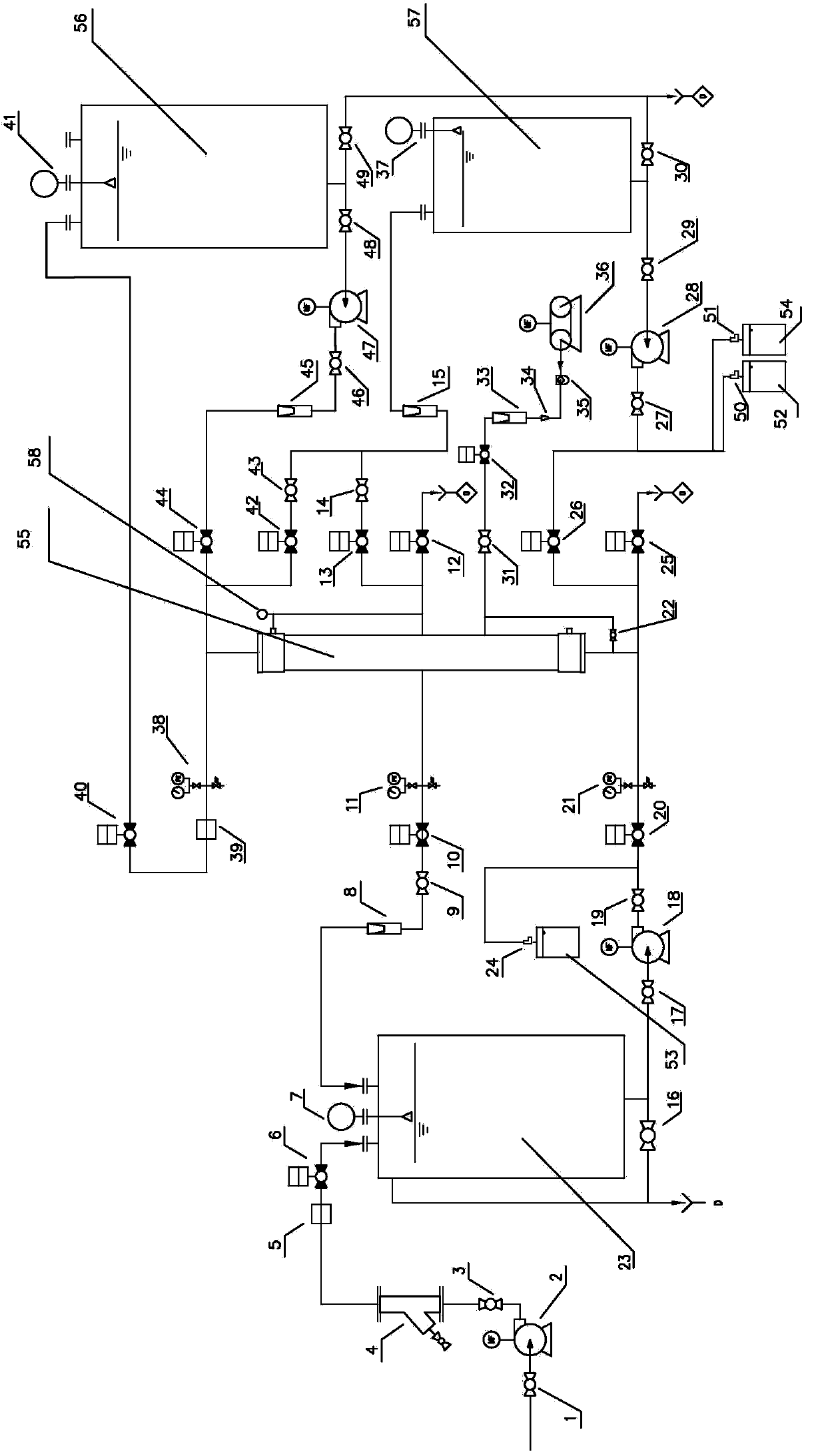

[0038] The schematic diagram of the brine or seawater ultrafiltration pretreatment system of the present invention is as follows figure 1 As shown, it includes a water inlet device, an ultrafiltration membrane filtration device 55, a buffer water tank 56, a backwash device, a cleaning device, an air supply device, a backflow device and a dosing device; the ultrafiltration membrane filtration device 55 adopts a hollow fiber external pressure Column ultrafiltration membrane module. The ultrafiltration membrane filtration device 55 can be composed of multiple sets of hollow fiber external pressure column ultrafiltration membrane modules connected in parallel according to actual needs.

[0039] The water inlet device includes a manual valve 1 before the water supply pump, 2, a manual valve 3 behind the water supply pump, a raw water tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com