Patents

Literature

3756 results about "Produced water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Produced water is a term used in the oil industry to describe water that is produced as a byproduct along with the oil and gas. Oil and gas reservoirs often have water as well as hydrocarbons, sometimes in a zone that lies under the hydrocarbons, and sometimes in the same zone with the oil and gas.

Treating produced waters

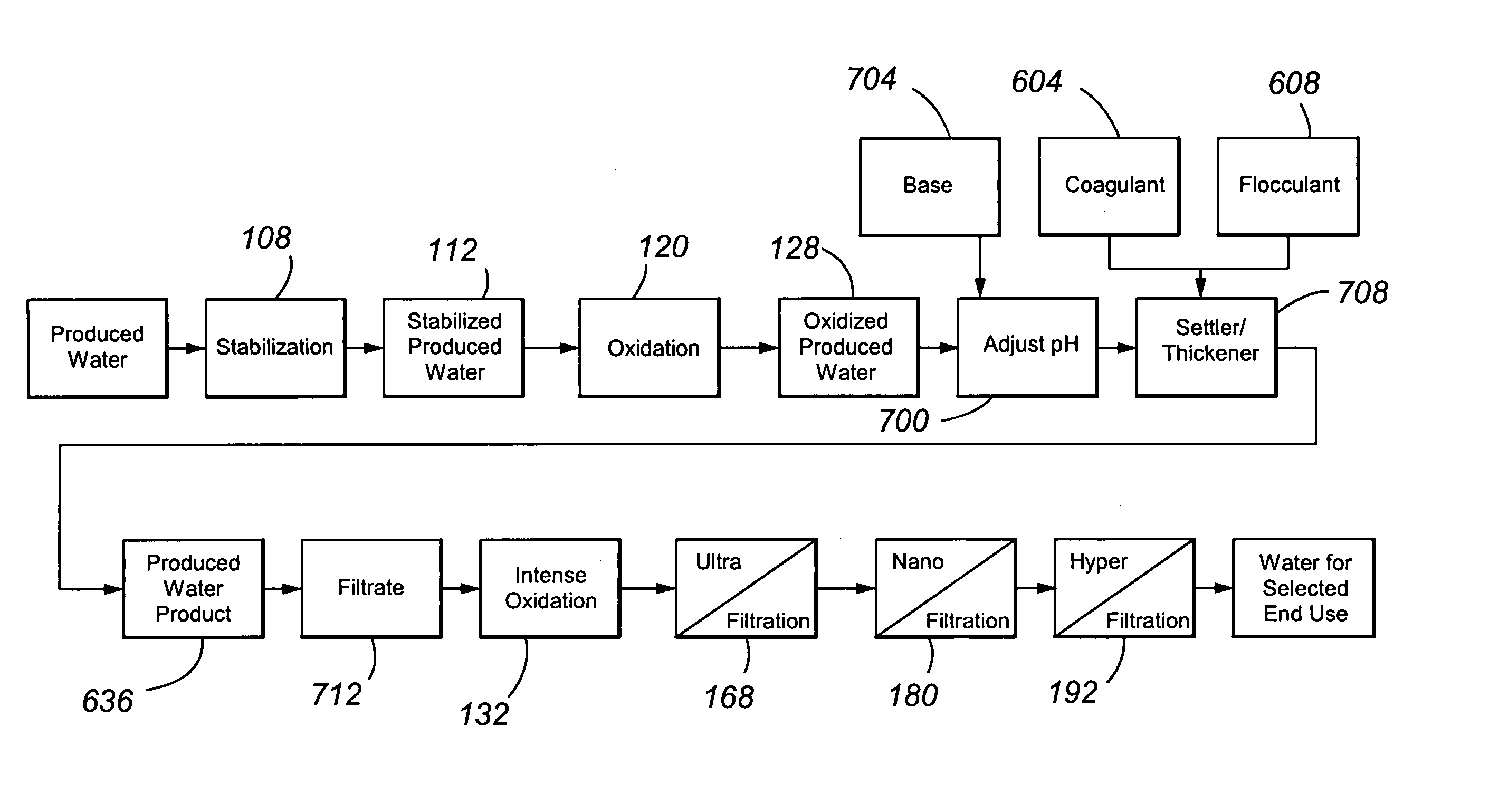

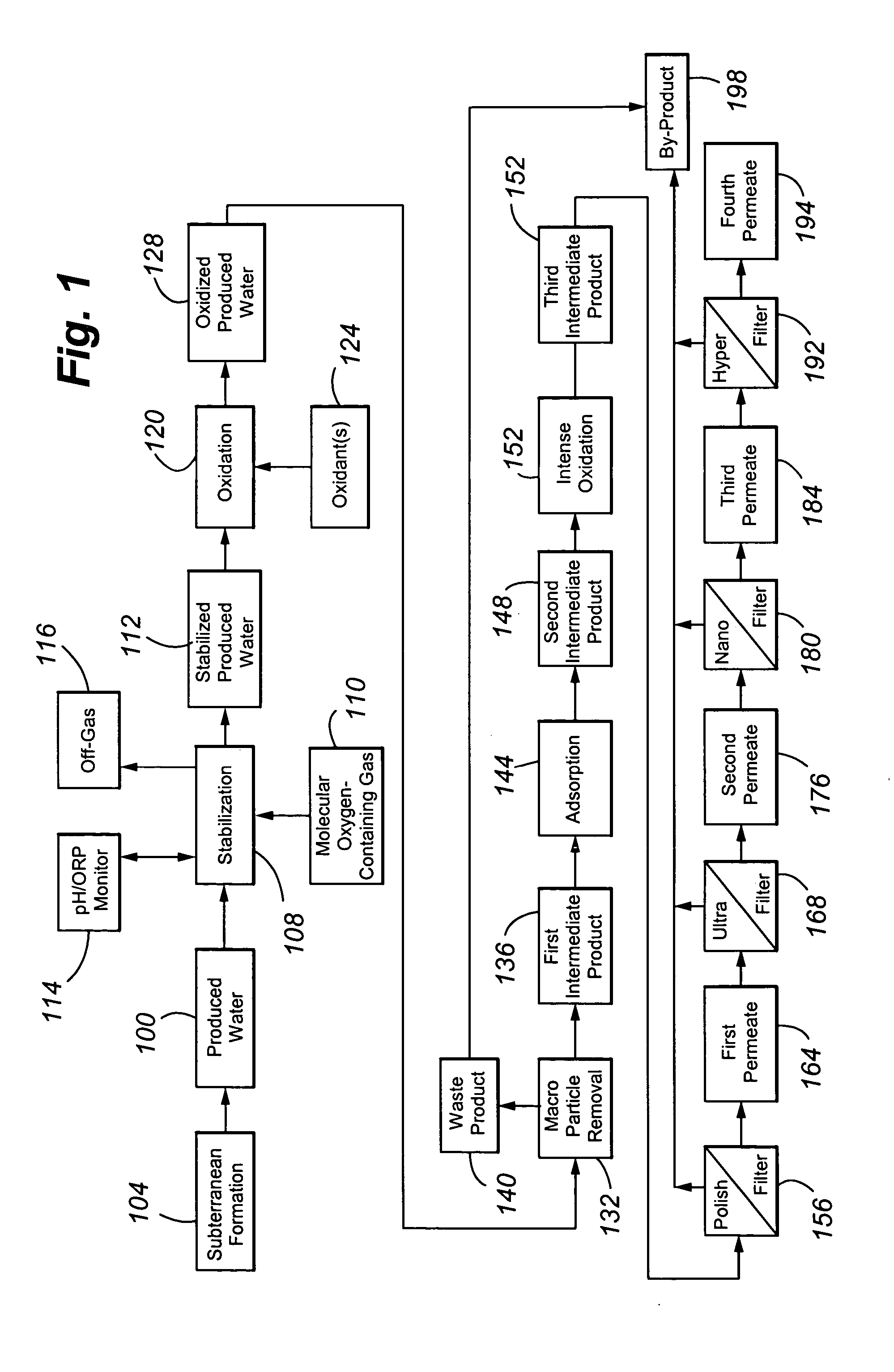

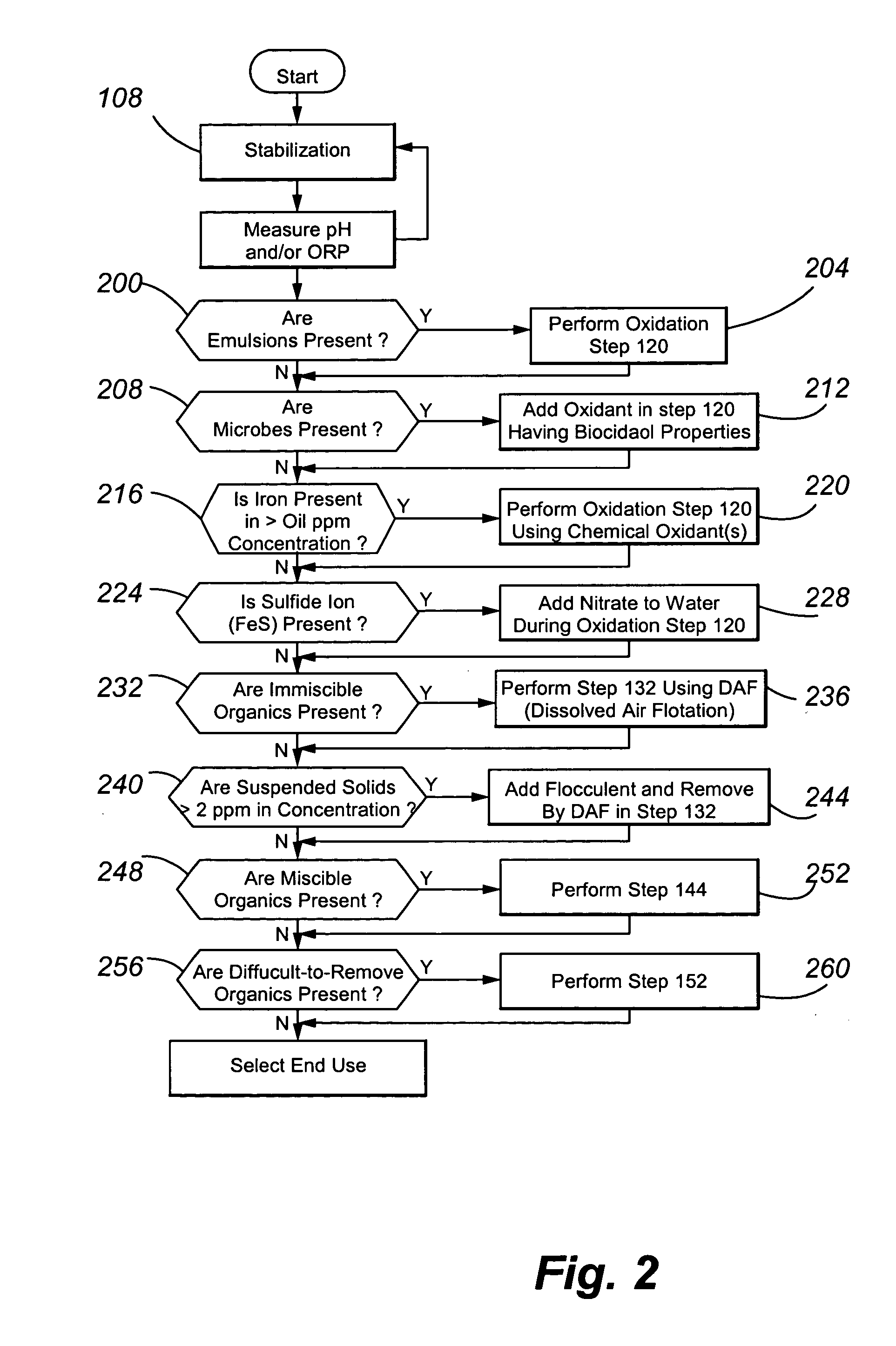

InactiveUS20070102359A1Complicate purificationIncrease ratingsUltrafiltrationTreatment involving filtrationEmulsionUnit operation

The present invention is directed to various sets of unit operations for treating aqueous effluents and logic for designing and effecting the treatment. The unit operations include stabilization of subterranean waters, sequential oxidation steps to alter selected target materials, oxidation to break up emulsions prior to removal of the emulsion components, and intense oxidation to break up difficult-to-remove organic target materials.

Owner:HW PROCESS TECH

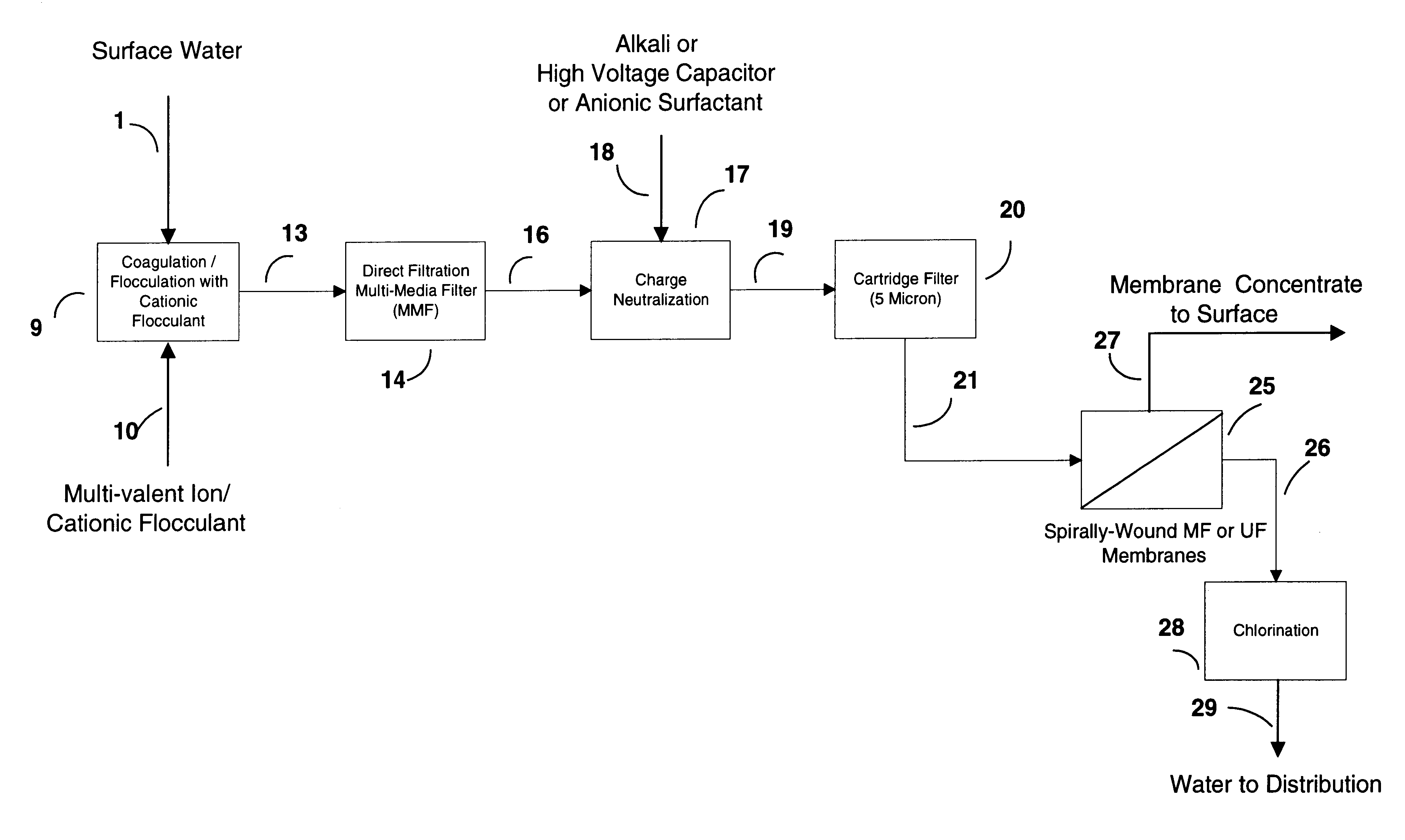

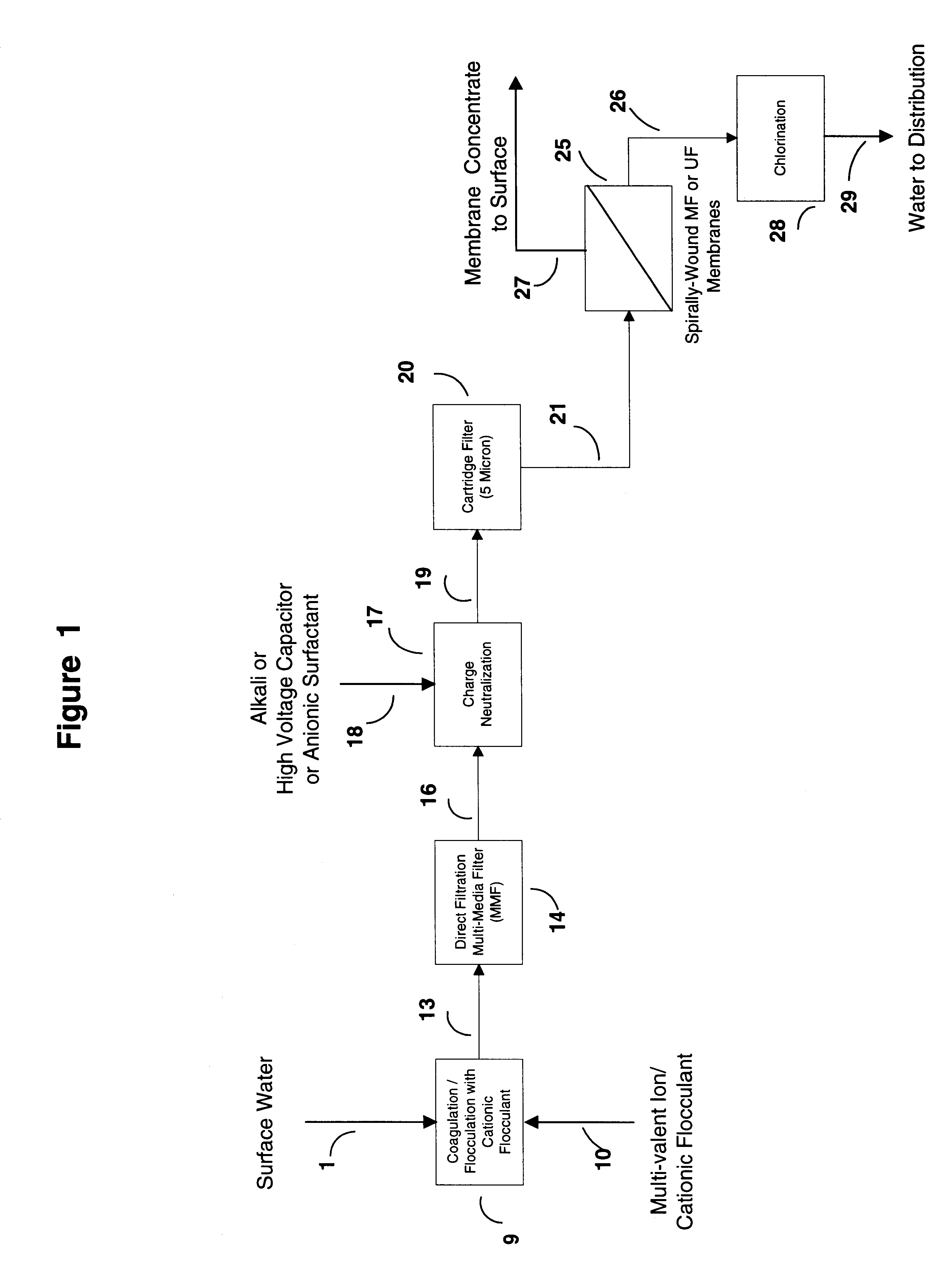

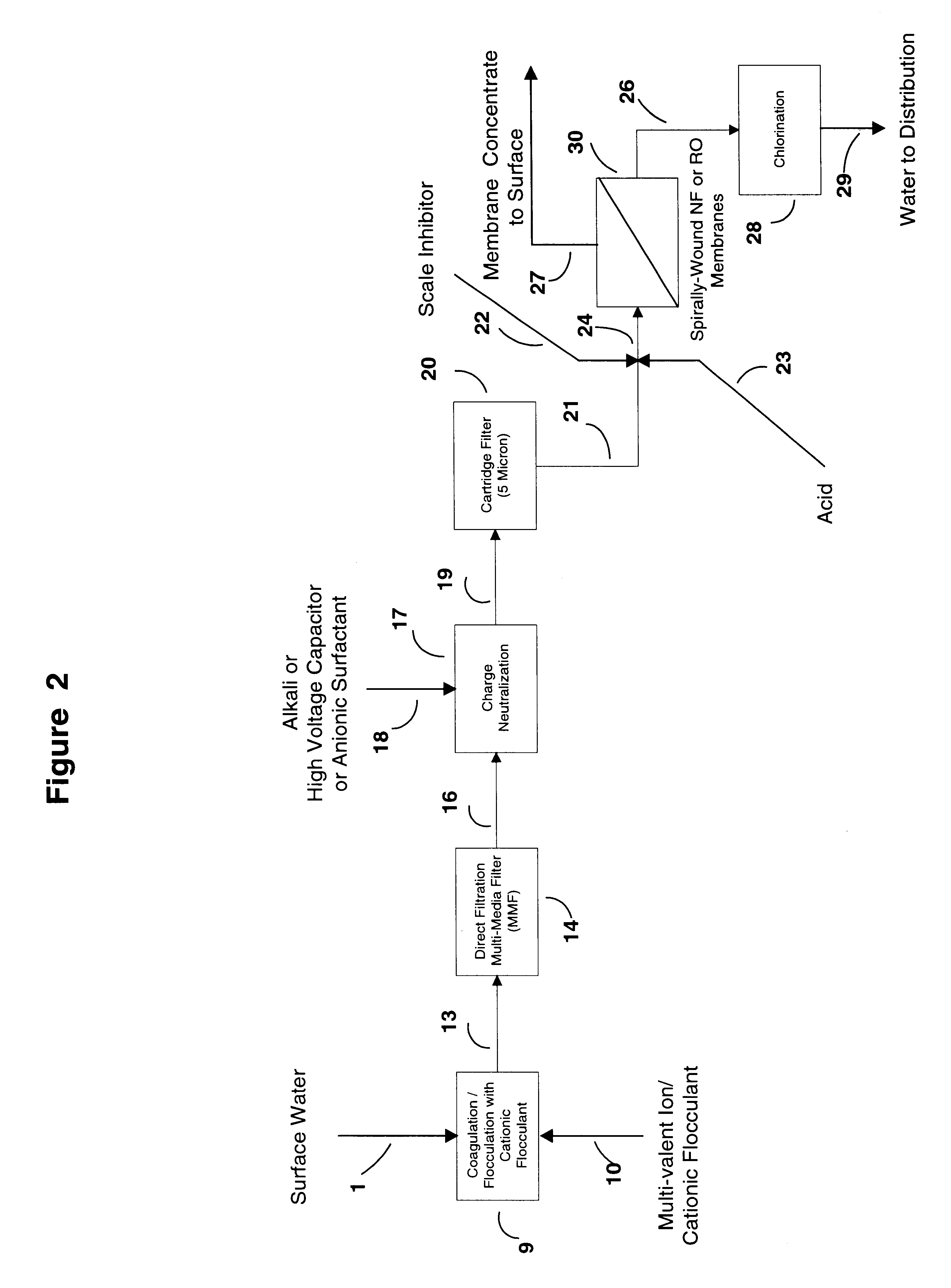

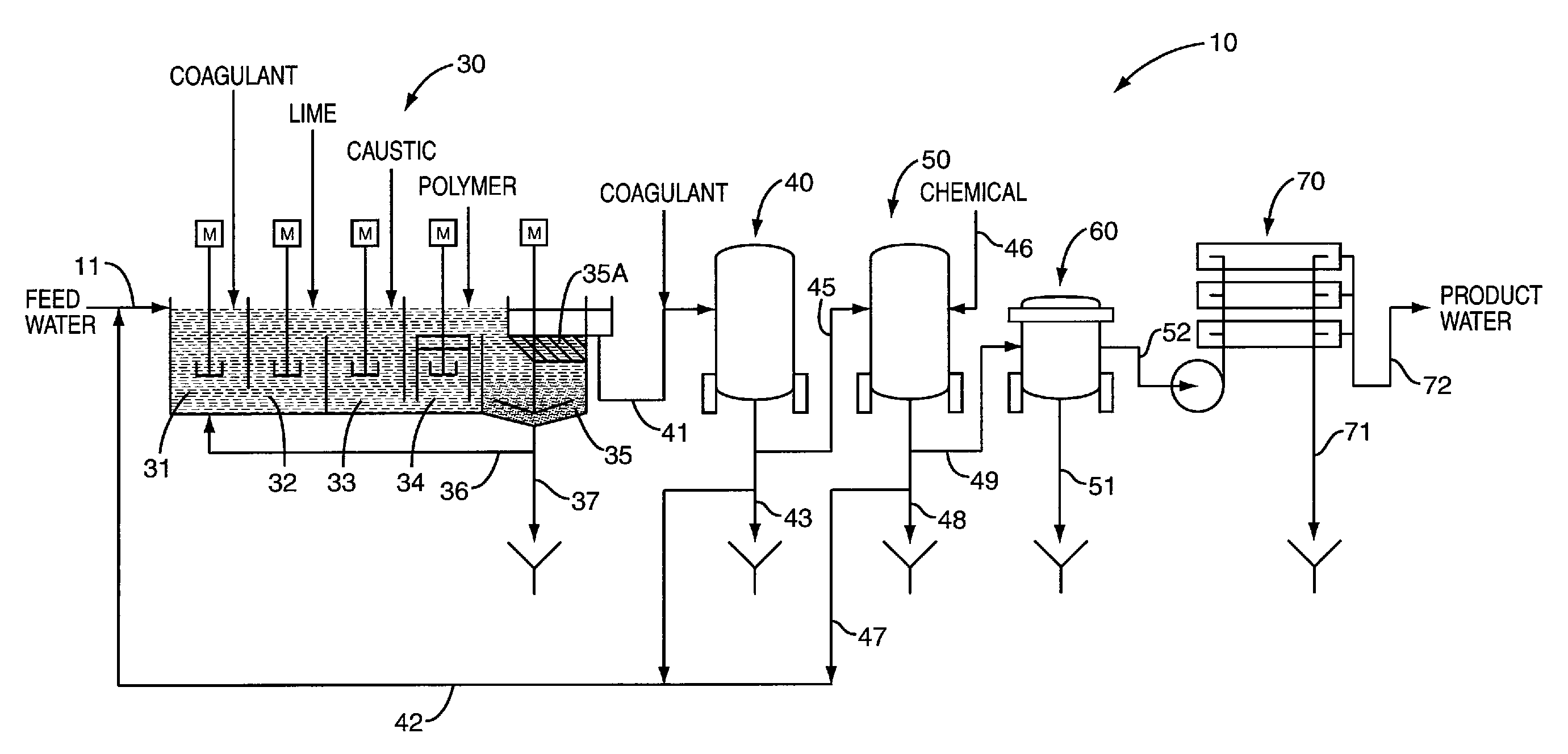

Water treatment process for membranes

InactiveUS6416668B1Effective and safe and reliable to produceCapital and operating costMembranesUltrafiltrationZeta potentialFiltration

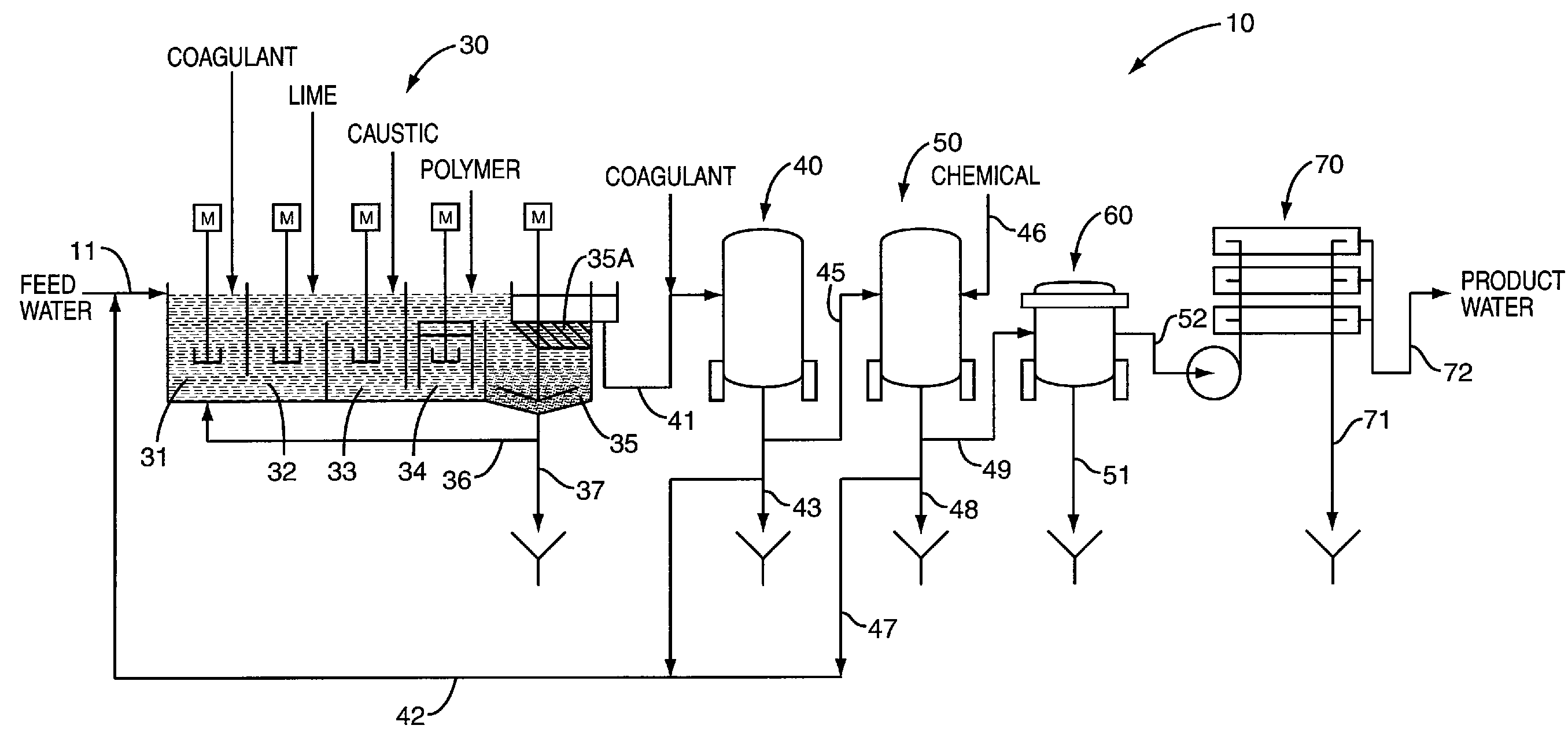

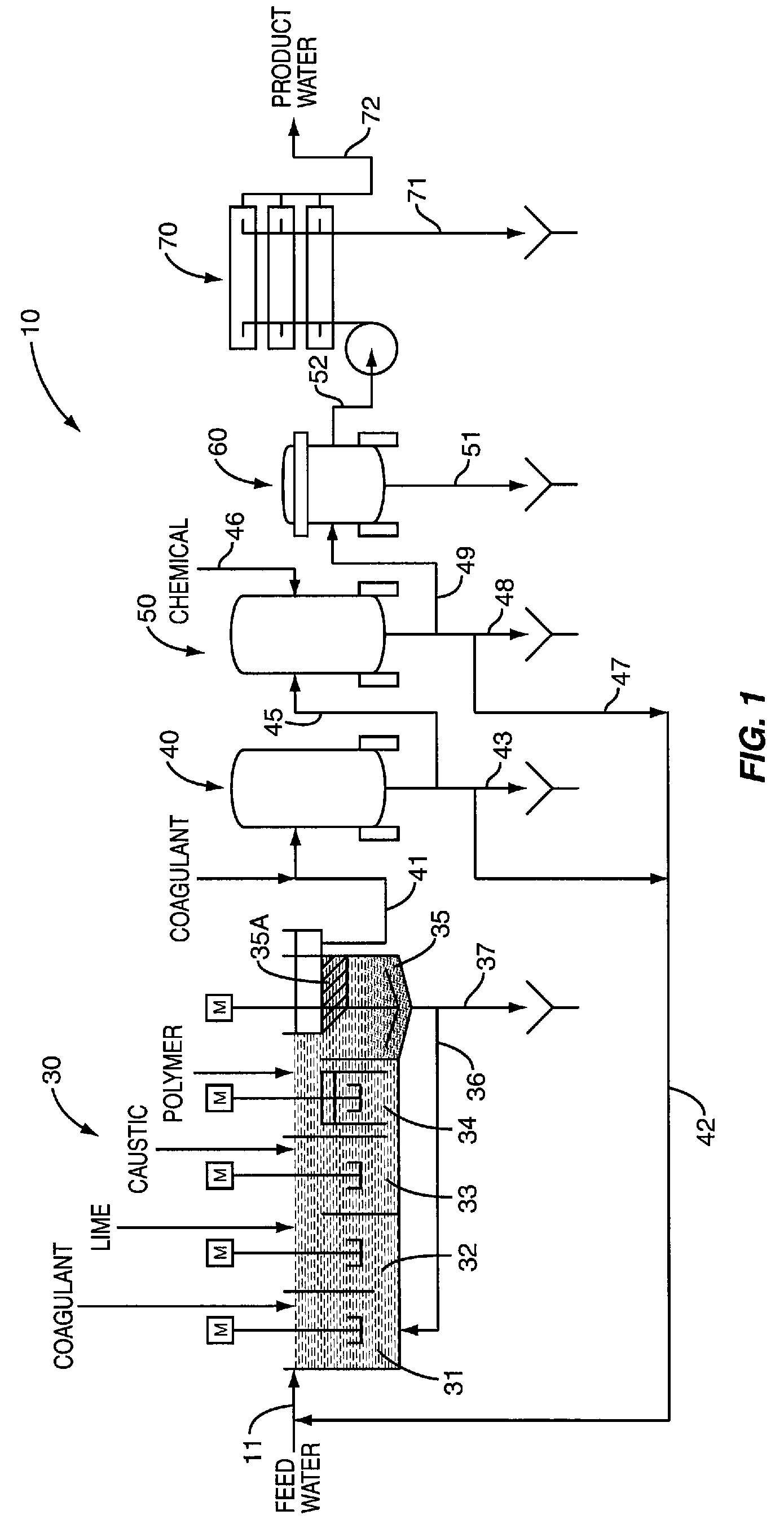

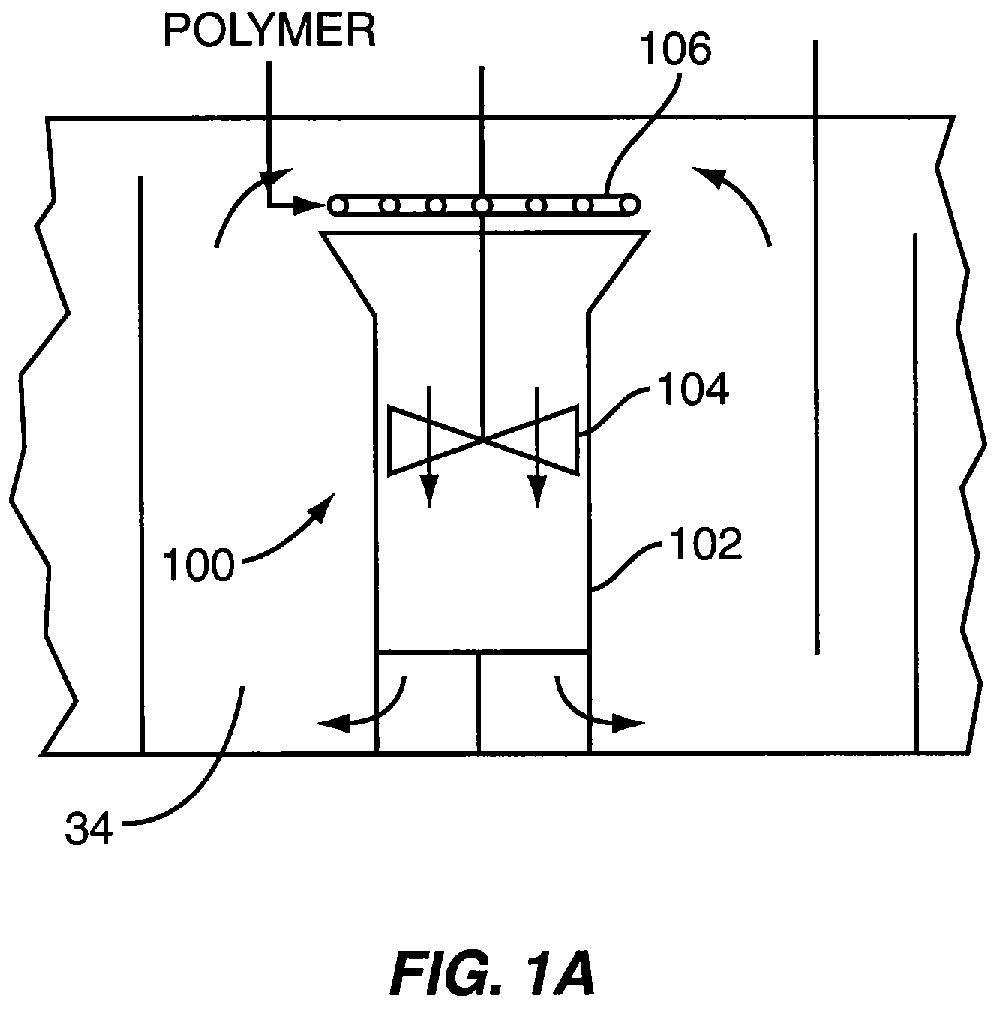

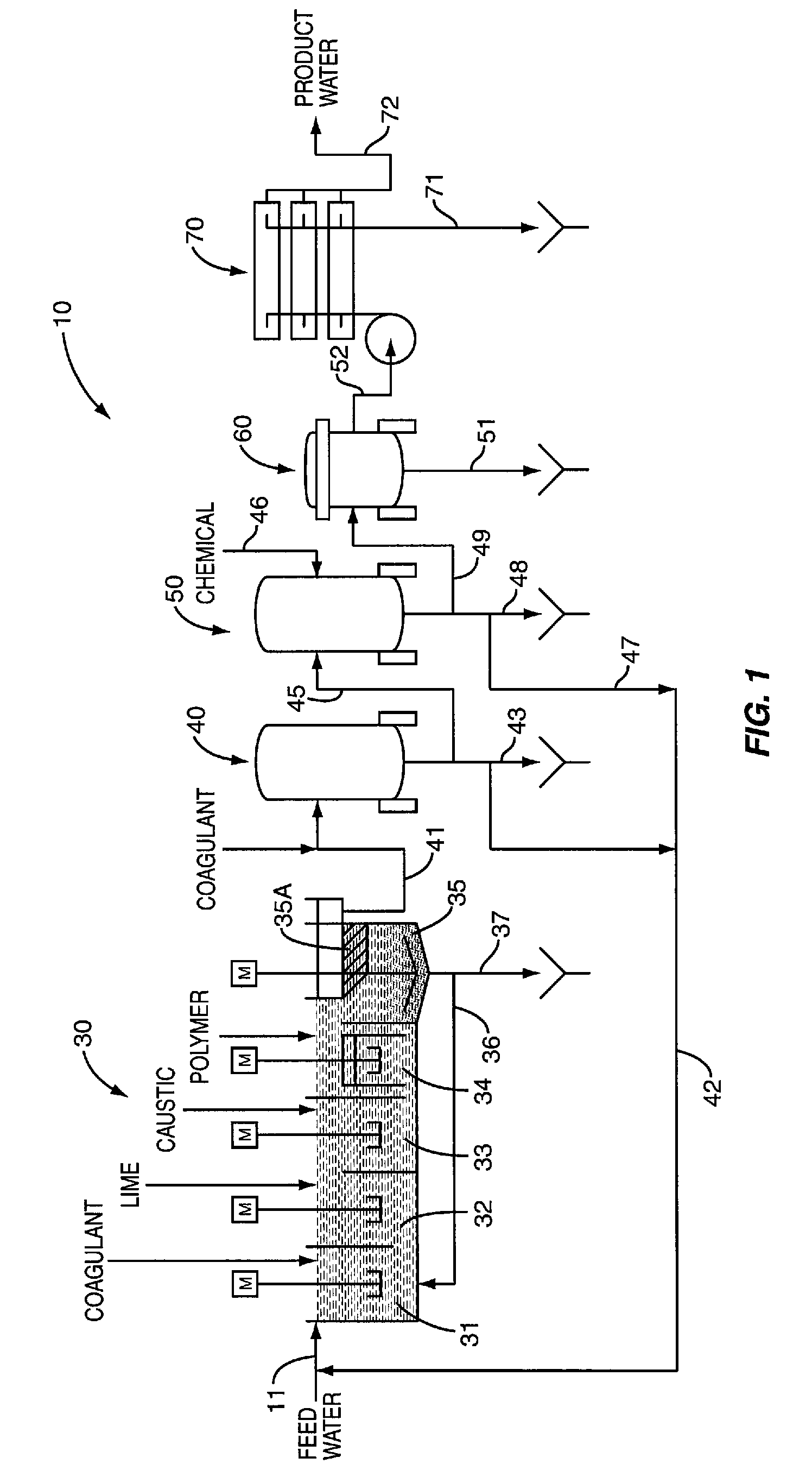

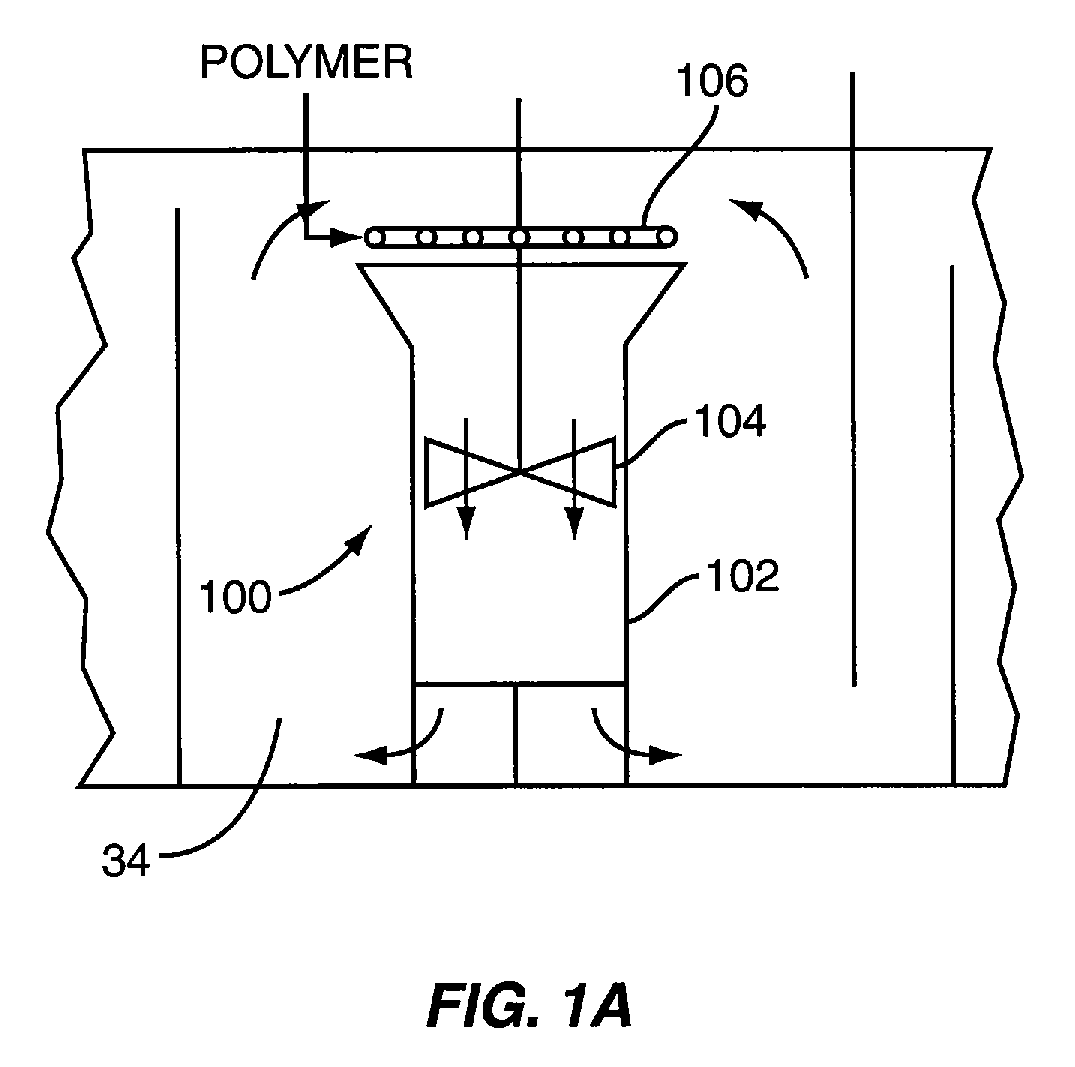

This invention discloses a cost-effective process for separating contaminants and a wide-range of fouling material from surface water, ground water and from industrial effluents. Having undergone effective pre-treatment, the water can be purified further by using high-surface area spirally wound micro-filtration (MF), ultra-filtration (UF), nano-filtration (NF) or reverse osmosis (RO) membranes. High-quality potable water free from pathogen and other contaminants is thus produced at low-cost from the pre-treated surface water and ground-water. Conversely, pre-treated industrial effluents are further purified at a relatively low-cost using NF or RO membranes, thus producing water suitable for recycle or surface discharge. The process of this invention uses cationic inorganic and / or polymeric flocculants to coagulate and flocculate the water-borne colloidal matter (e.g. clays, iron hydroxides, naturally occurring matter (NOM's), etc.), followed by filtration using a multi-media filter, charge neutralization and reversal and final filtration using a 5-micron cartridge filter. These pre-treatment steps provides a good quality water having a low Silt Density Index and a significant negative zeta potential, thereby ensuring against irreversible chemical fouling of the spirally-wound membranes.

Owner:AL SAMADI RIAD A

Nonwovens produced from multicomponent fibers

InactiveUS20080311815A1Reduce blockingReduce fusionNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceSlurry

A water non-dispersible polymer microfiber is provided comprising at least one water non-dispersible polymer wherein the water non-dispersible polymer microfiber has an equivalent diameter of less than 5 microns and length of less than 25 millimeters. A process for producing water non-dispersible polymer microfibers is also provided, the process comprising: a) cutting a multicomponent fiber into cut multicomponent fibers; b) contacting a fiber-containing feedstock with water to produce a fiber mix slurry; wherein the fiber-containing feedstock comprises cut multicomponent fibers; c) heating the fiber mix slurry to produce a heated fiber mix slurry; d) optionally, mixing the fiber mix slurry in a shearing zone; e) removing at least a portion of the sulfopolyester from the multicomponent fiber to produce a slurry mixture comprising a sulfopolyester dispersion and water non-dispersible polymer microfibers; and f) separating the water non-dispersible polymer microfibers from the slurry mixture. A process for producing a nonwoven article is also provided.

Owner:EASTMAN CHEM CO

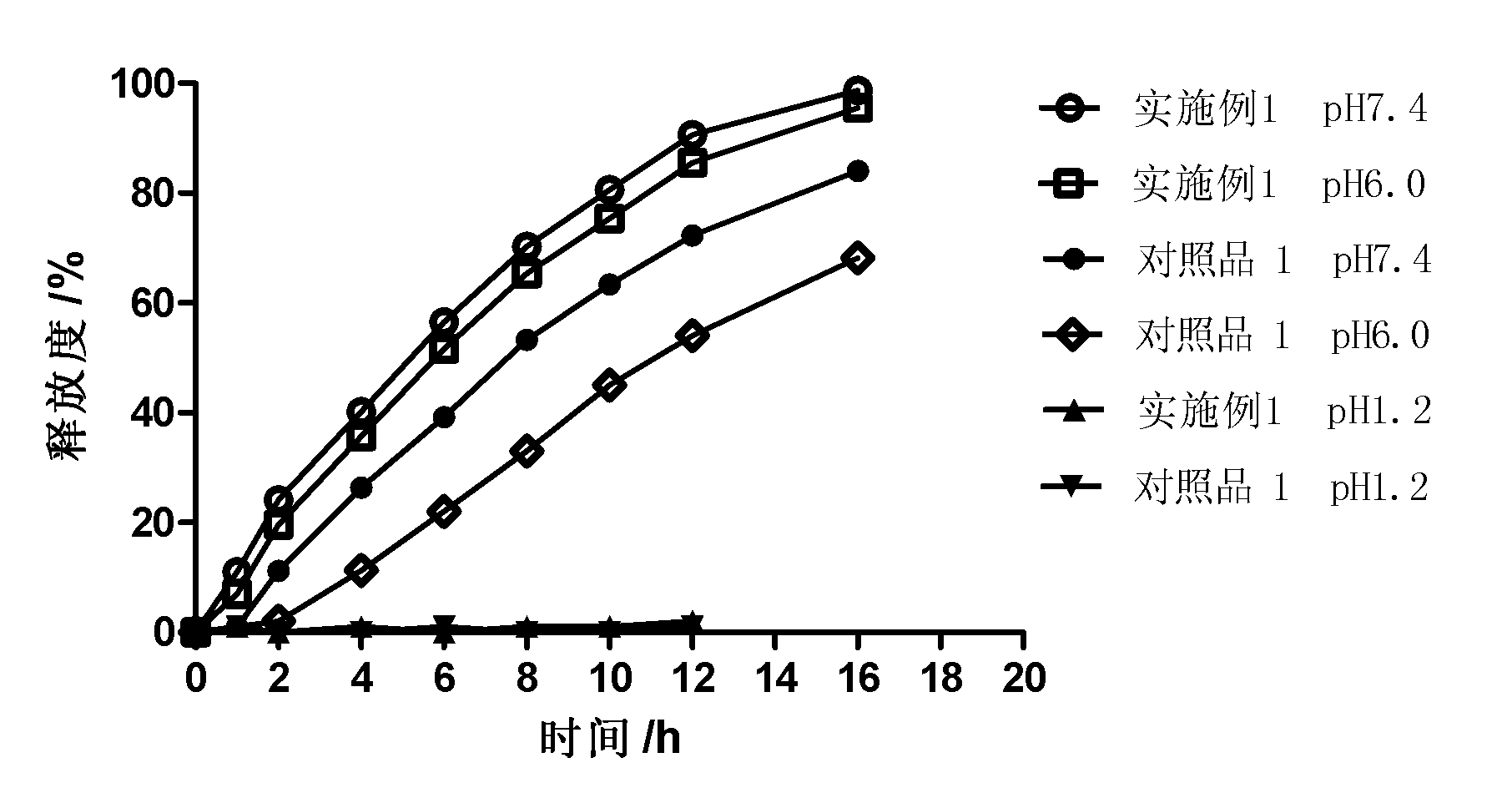

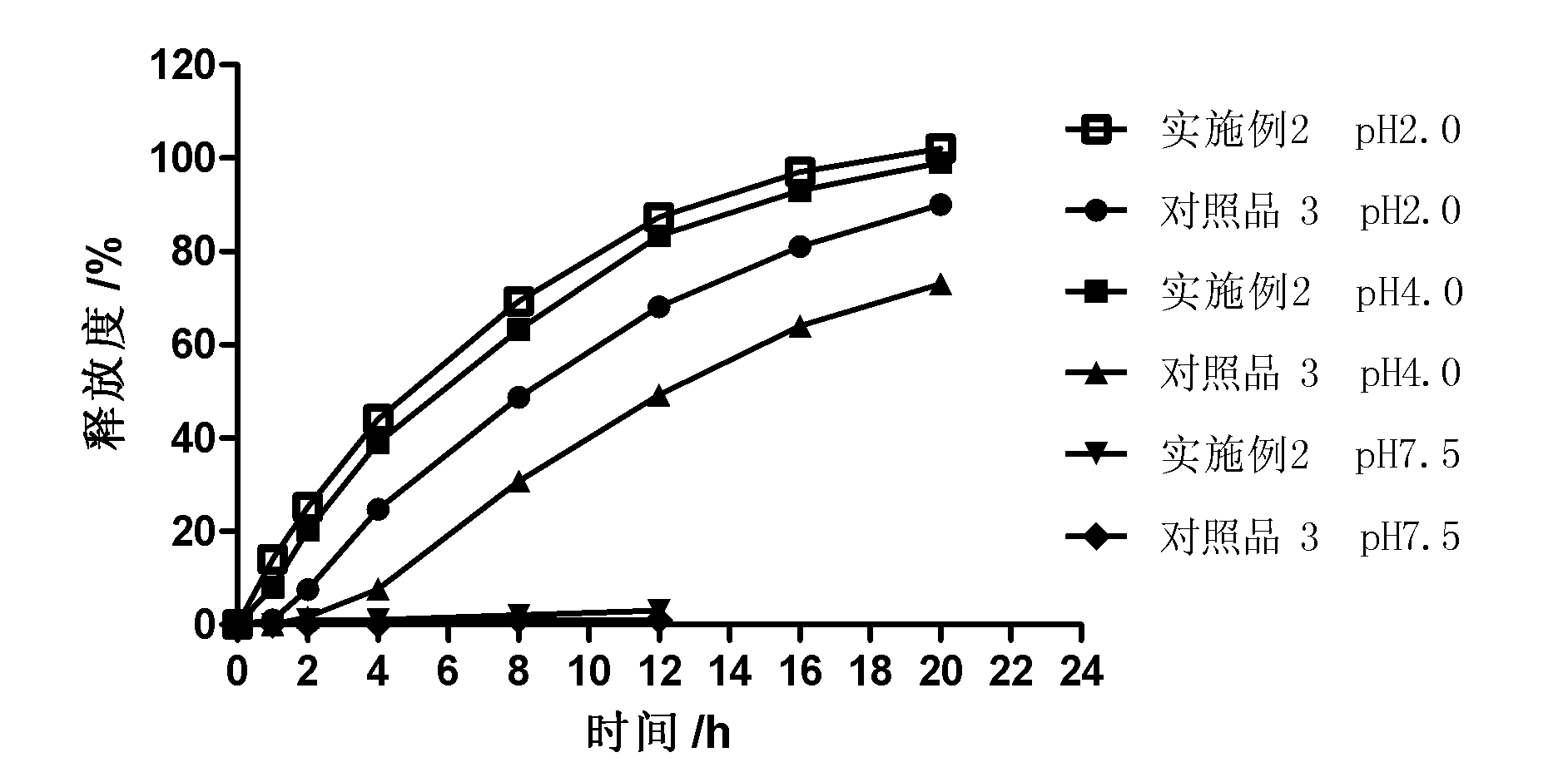

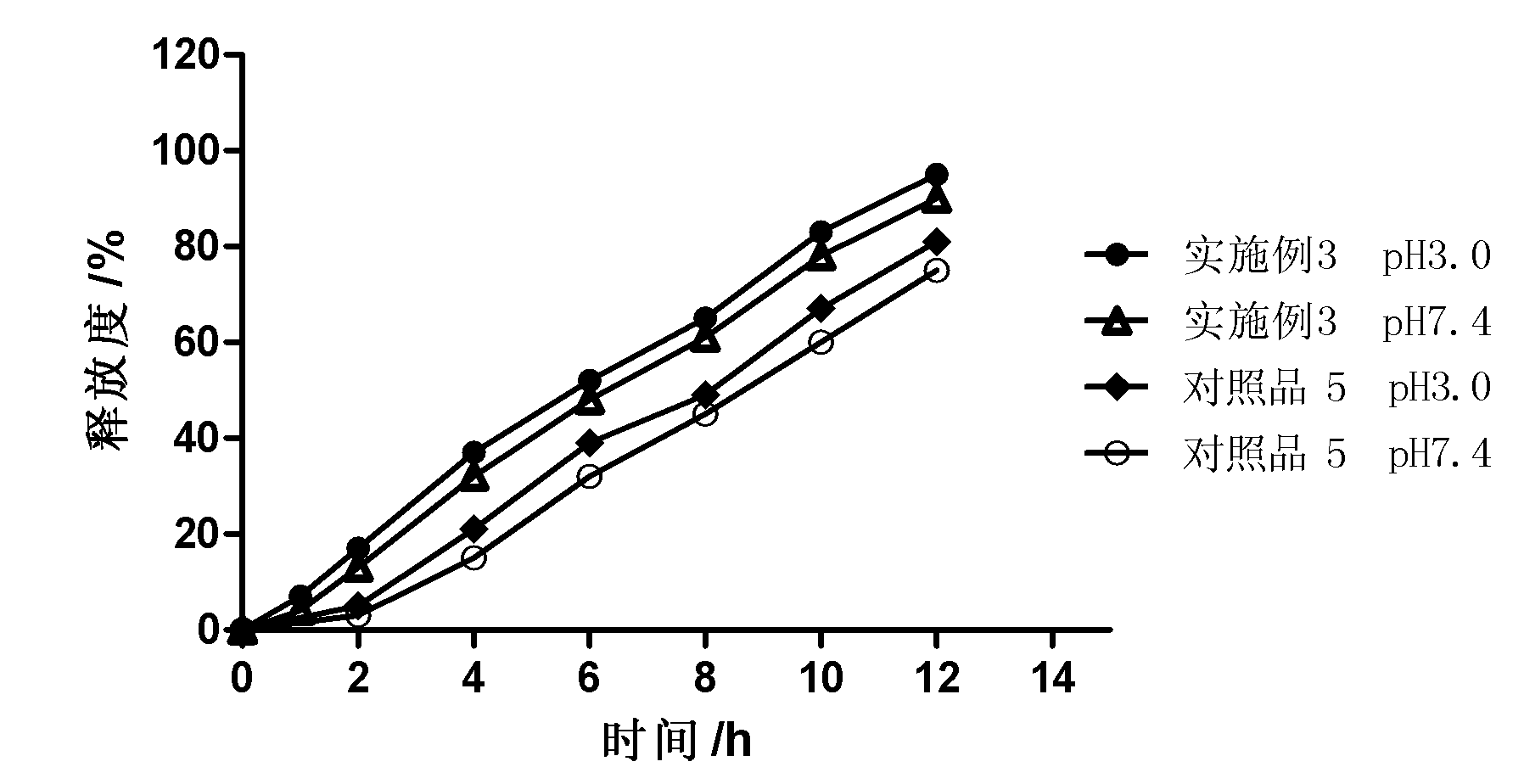

Controlled release preparation

InactiveCN101987081AImprove stabilityRelease impact mitigationInorganic non-active ingredientsSuppositories deliveryParticulatesChemical reaction

The invention discloses a controlled release preparation with improved performance. The controlled release preparation comprises a core containing medicament and a controlled release film covering the outside of the core and being almost insoluble in water as well as stomach and intestines digestive juice. The controlled release film comprises particulate matters of a water soluble medicinal additive, the water-soluble medicinal additive is covered by a polymer film which can be soluble in the stomach and / or intestines digestive juice but almost insoluble in water, the polymer and the medicinal additive can not produce chemical reaction or can produce chemical reaction but do not produce water-insoluble non-gaseous products and the pharmaceutically unacceptable products, and the amount of the polymer is no more 700% of that of the medicinal additive. The invention also discloses a preparation method of the controlled release preparation. The controlled release preparation has the advantages of improved medicament release reproducibility, reduced medicament release lag time, accelerated medicament release and improved bioavailability, can realize located controlled release, delayed controlled release and interval type or pulse type controlled release of the medicament in the gastrointestinal tract, and the like.

Owner:钟术光

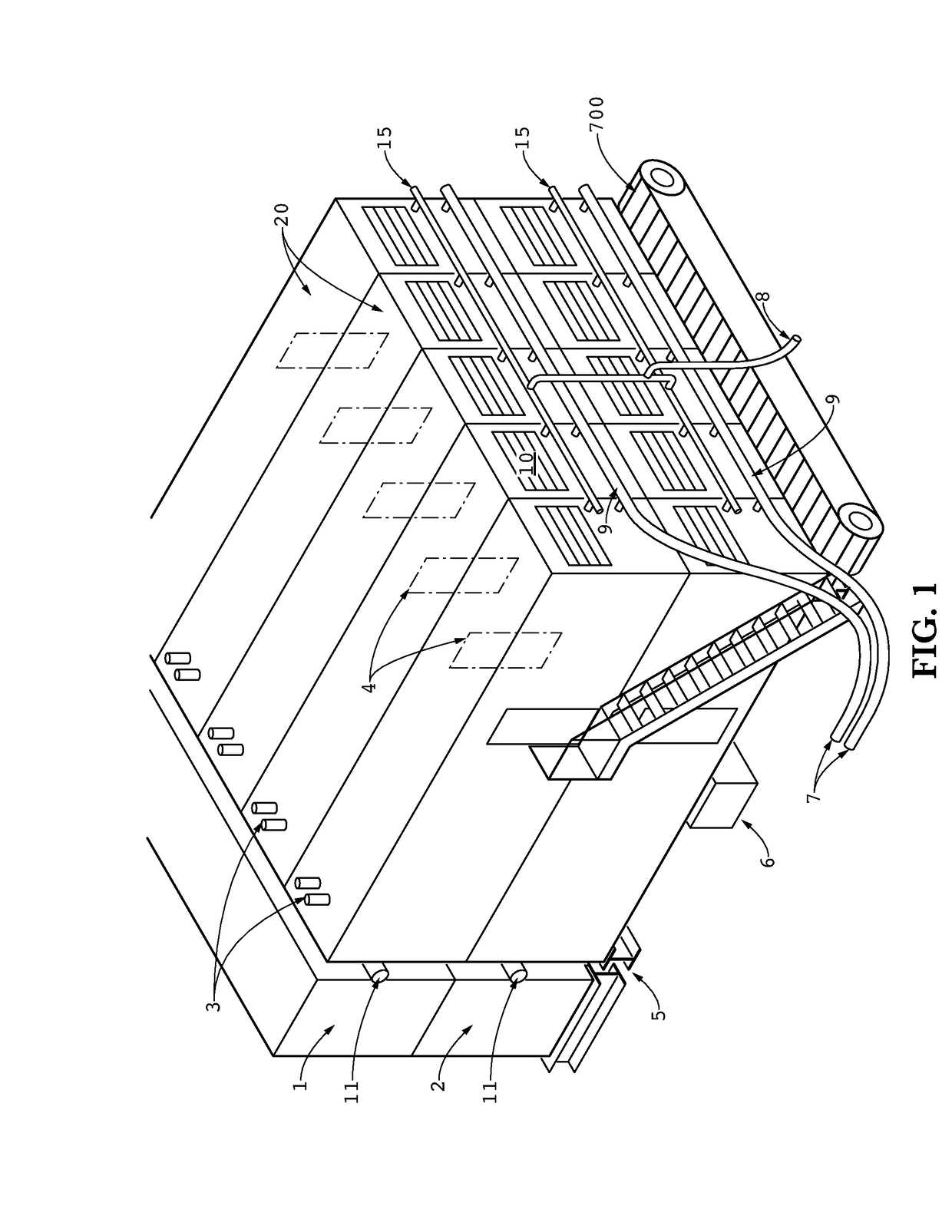

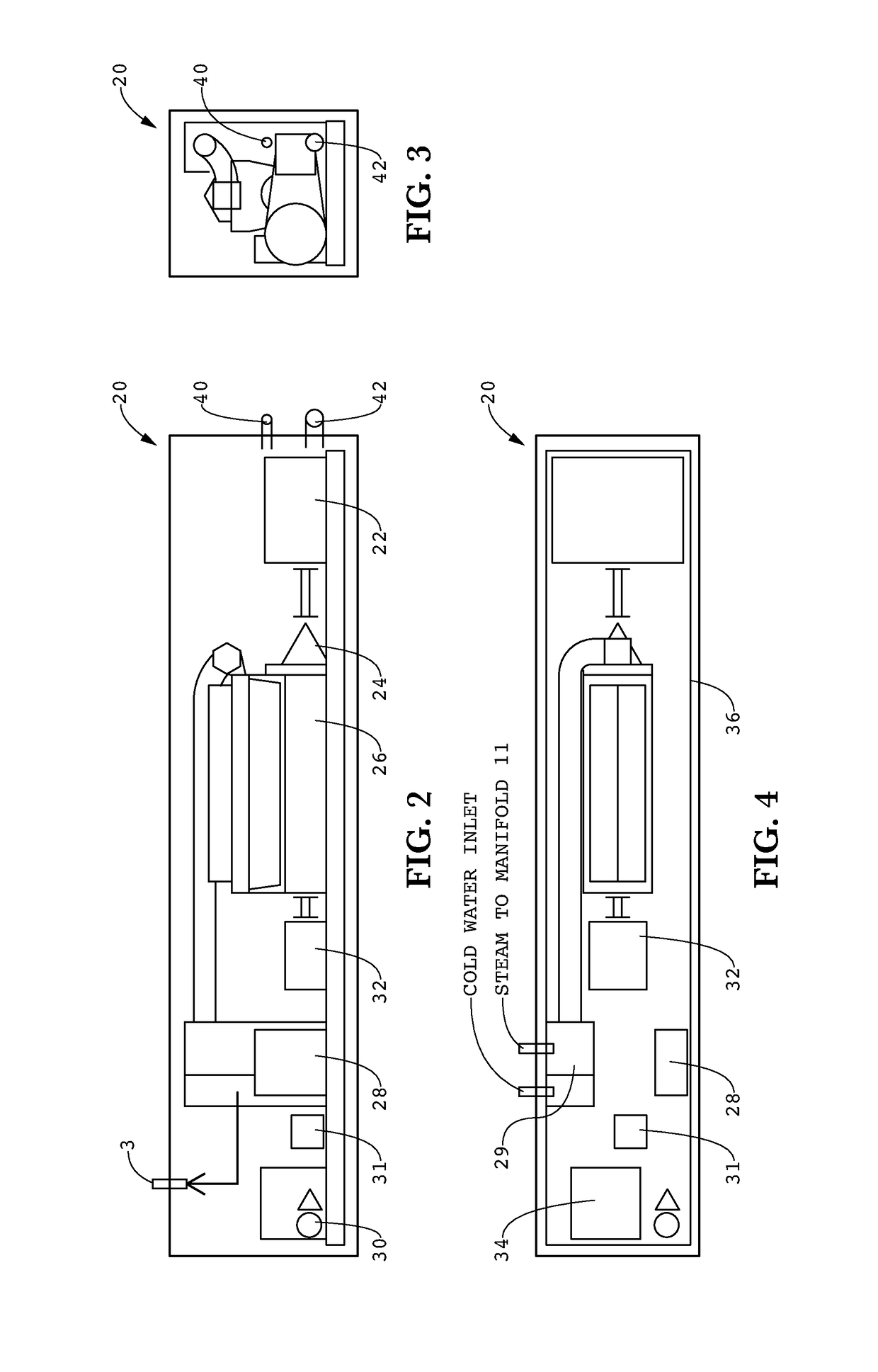

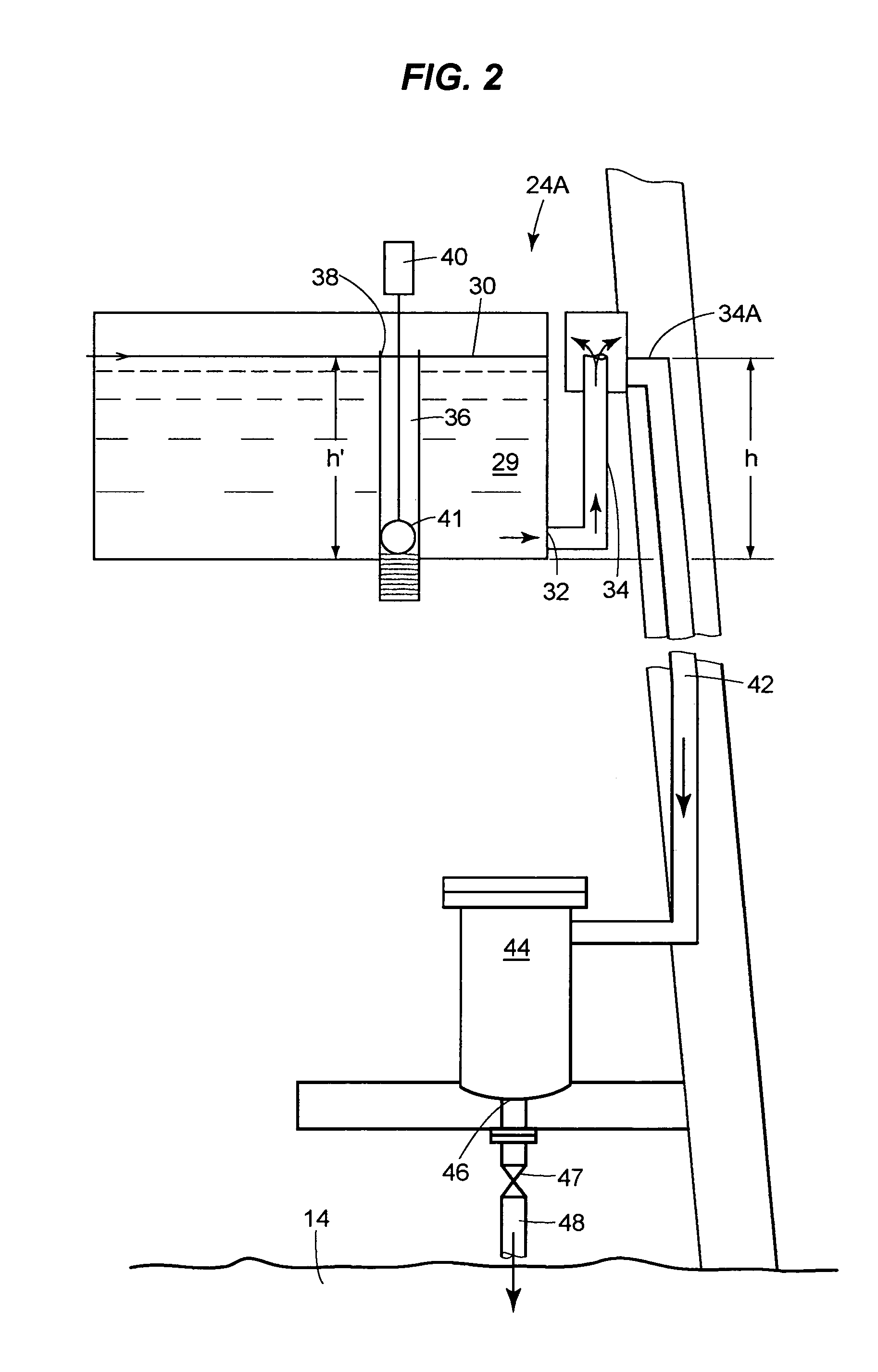

Hydraulic fracturing system and method

ActiveUS9840897B2Multiple-effect/fractional condensationSteam/vapor condensersDistilled waterHydraulic fracturing

Disclosed herein is a fracturing unit for hydraulic fracturing having an engine and a fracturing pump connected to the engine through a variable speed torque converter. Also disclosed is a hydraulic fracturing system using multiple fracturing units which are sized similar to ISO containers. A hydraulic fracturing system may also force flow back water, produced water, or fresh water through a heat exchanger so that heat from the fracturing engines can be transferred to these liquids in order to vaporize them. A force cooled fractioning unit then can accept the vapor / steam in order to condense the various components and produce distilled water for re-use in the fracturing process or for release into the environment.

Owner:LARSON KEVIN

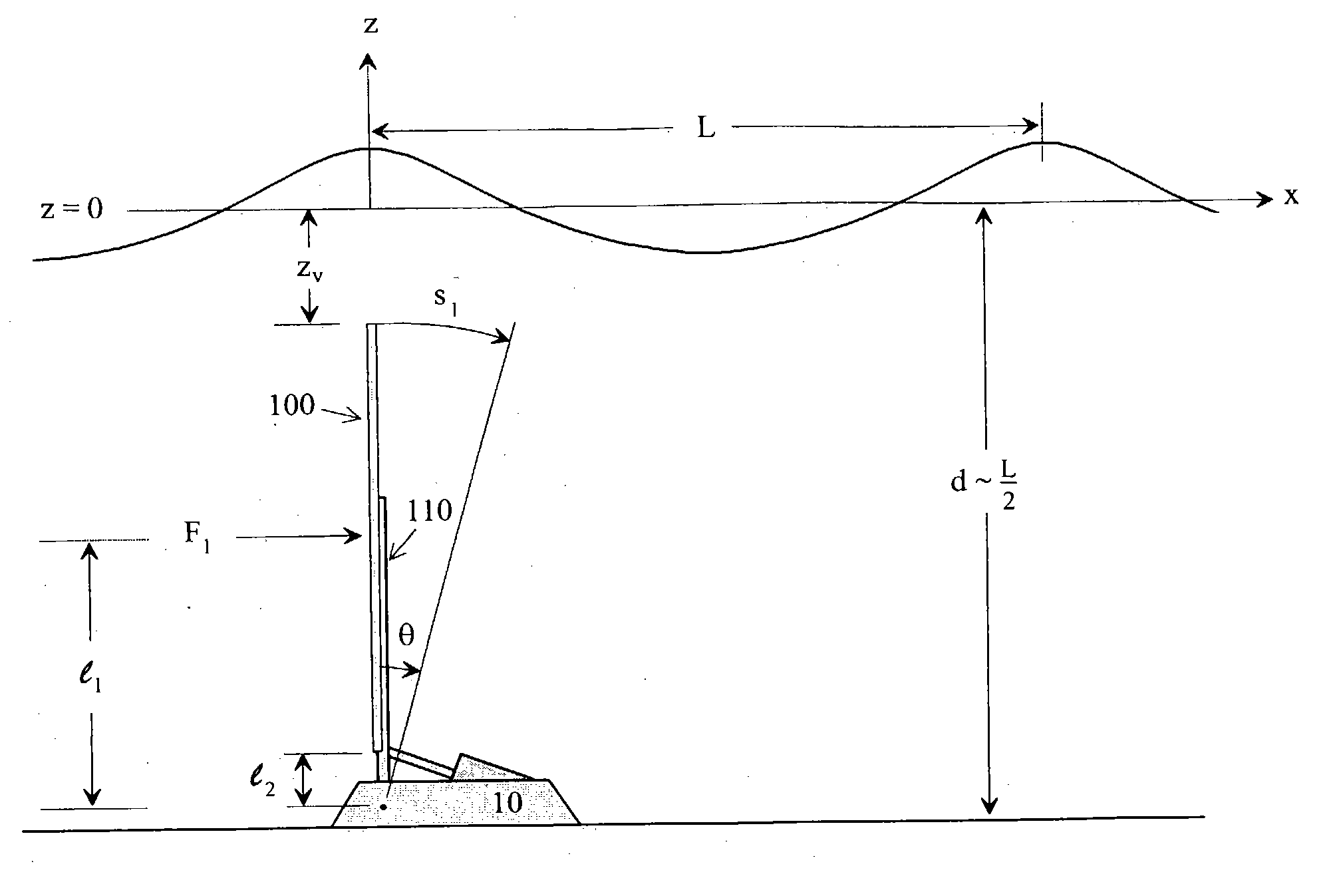

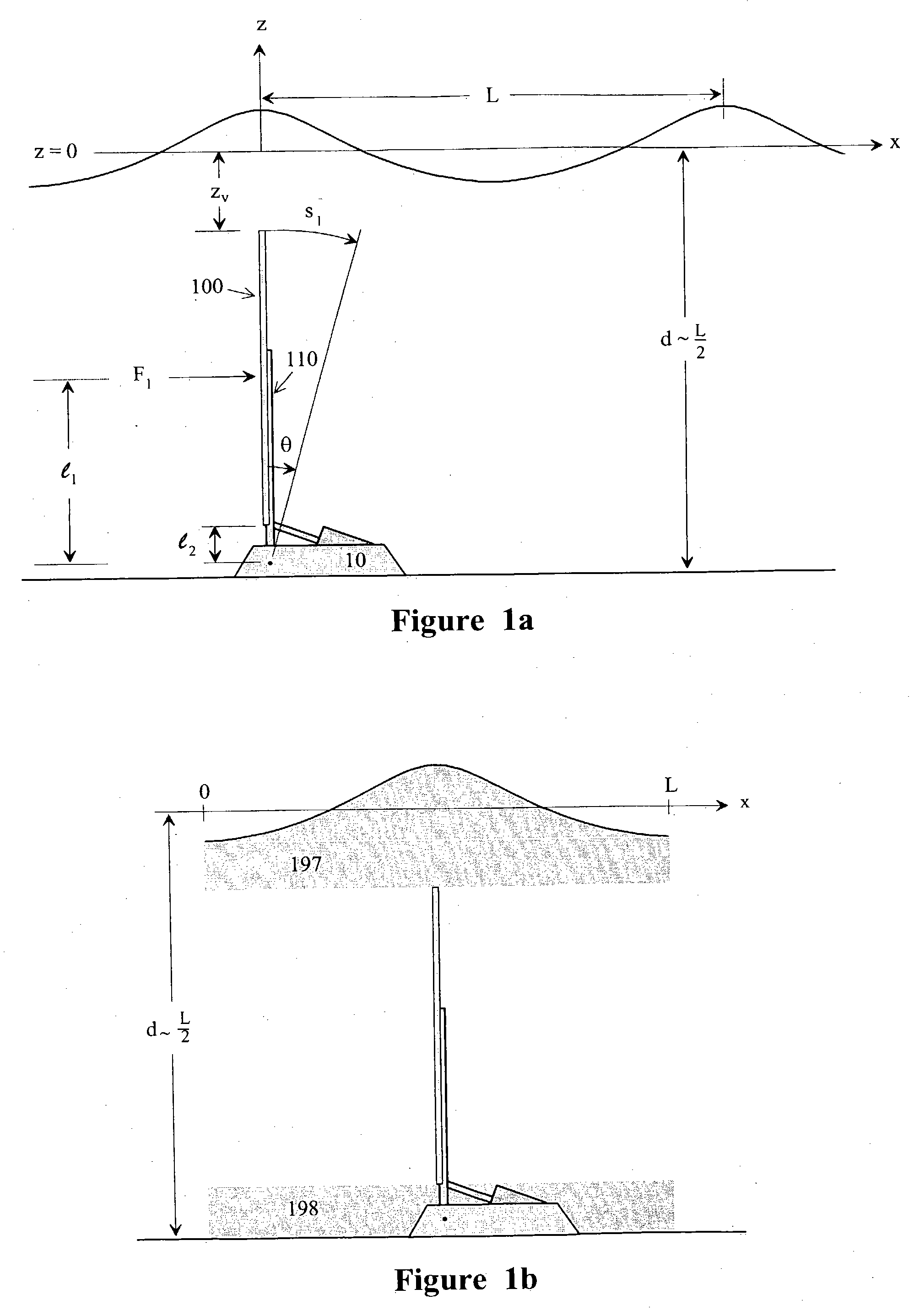

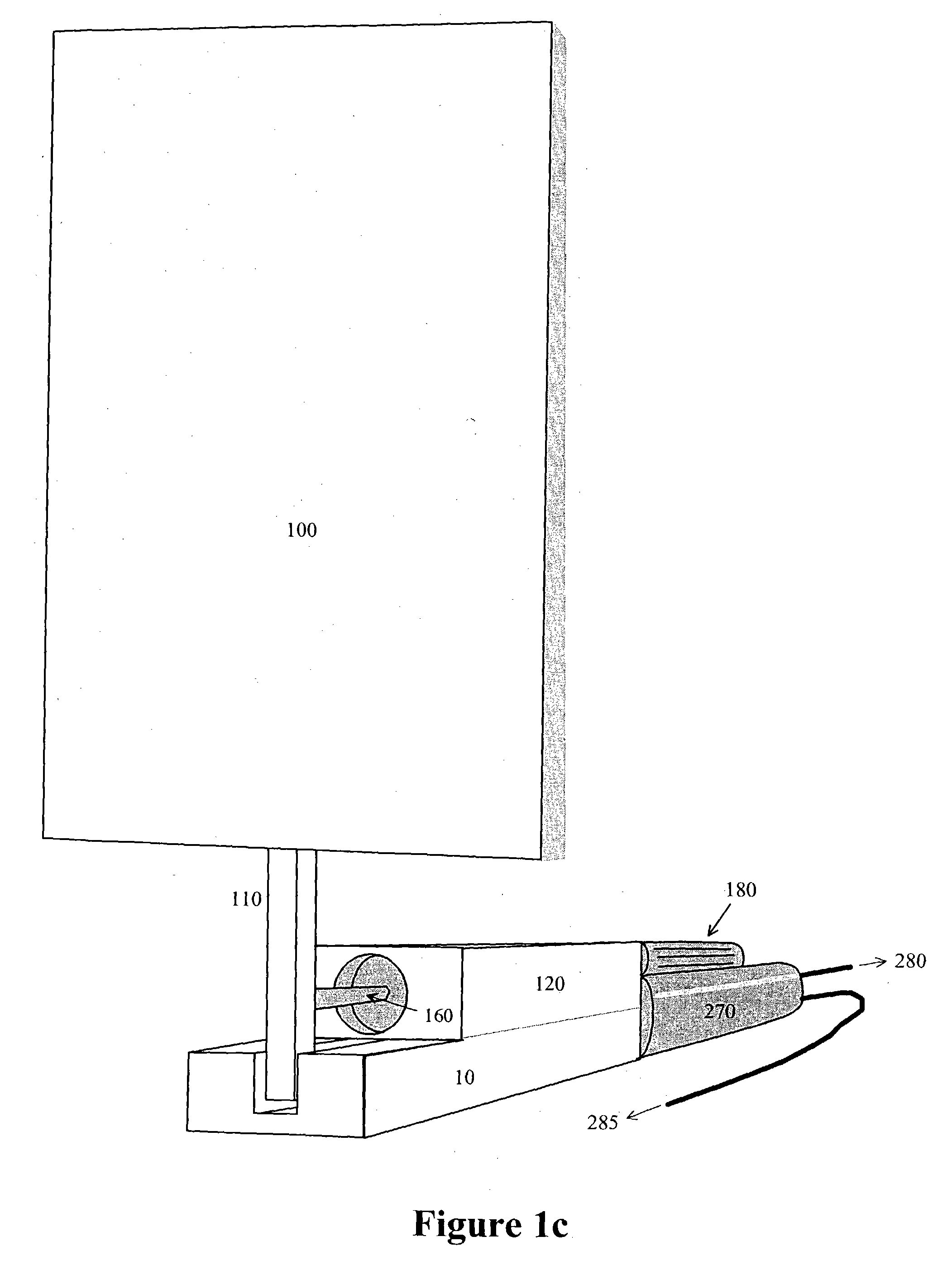

Wave energy conversion device for desalination, ETC

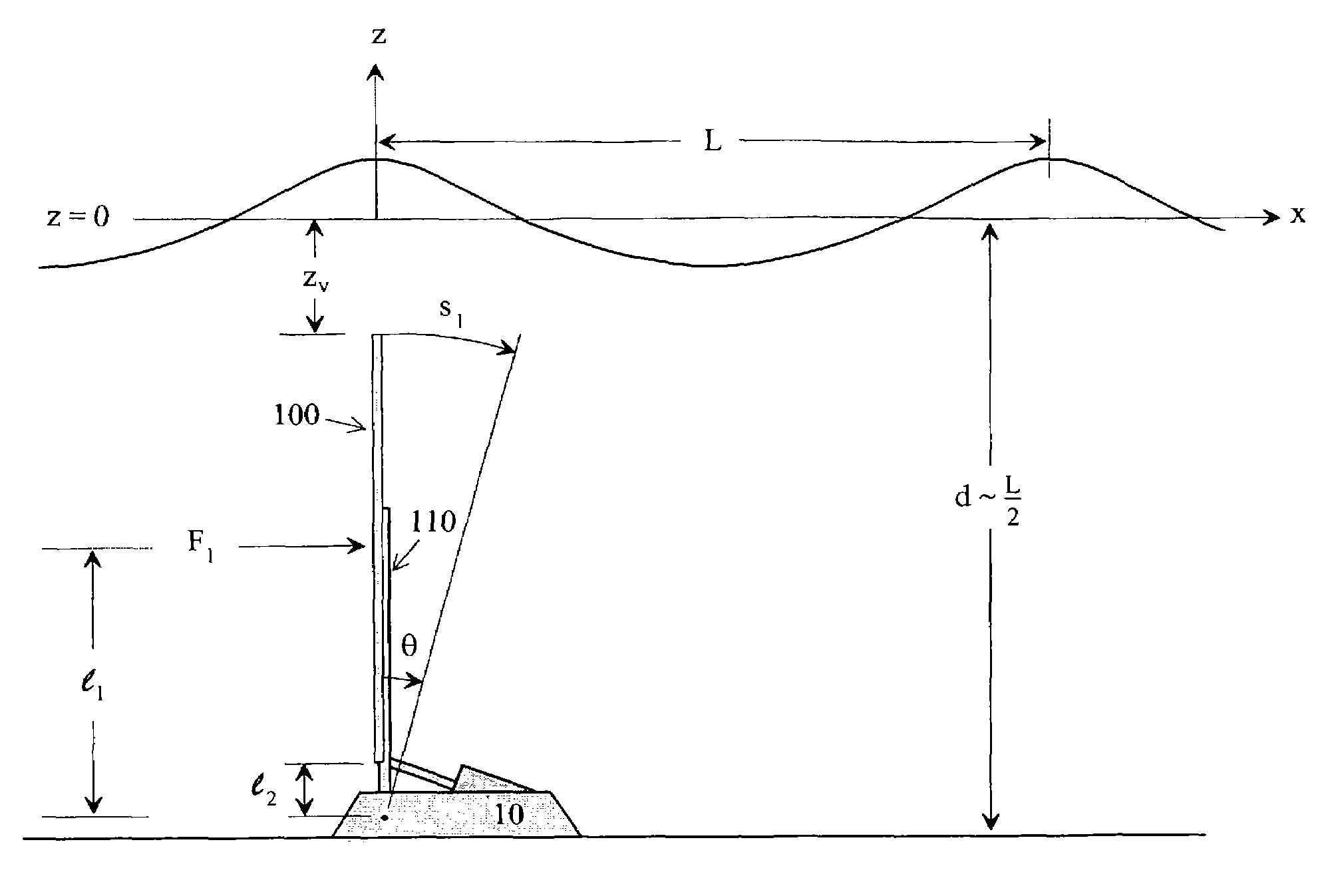

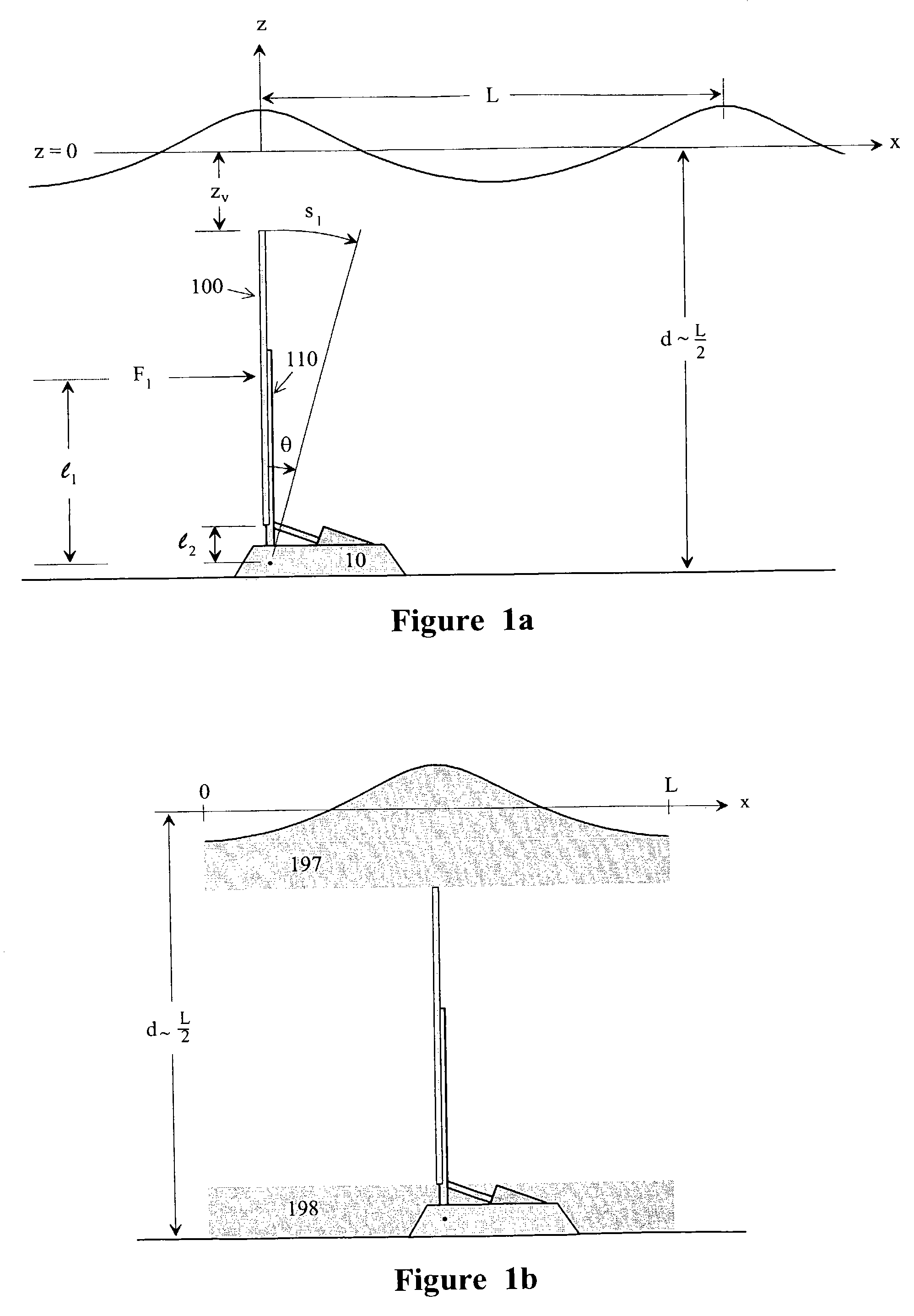

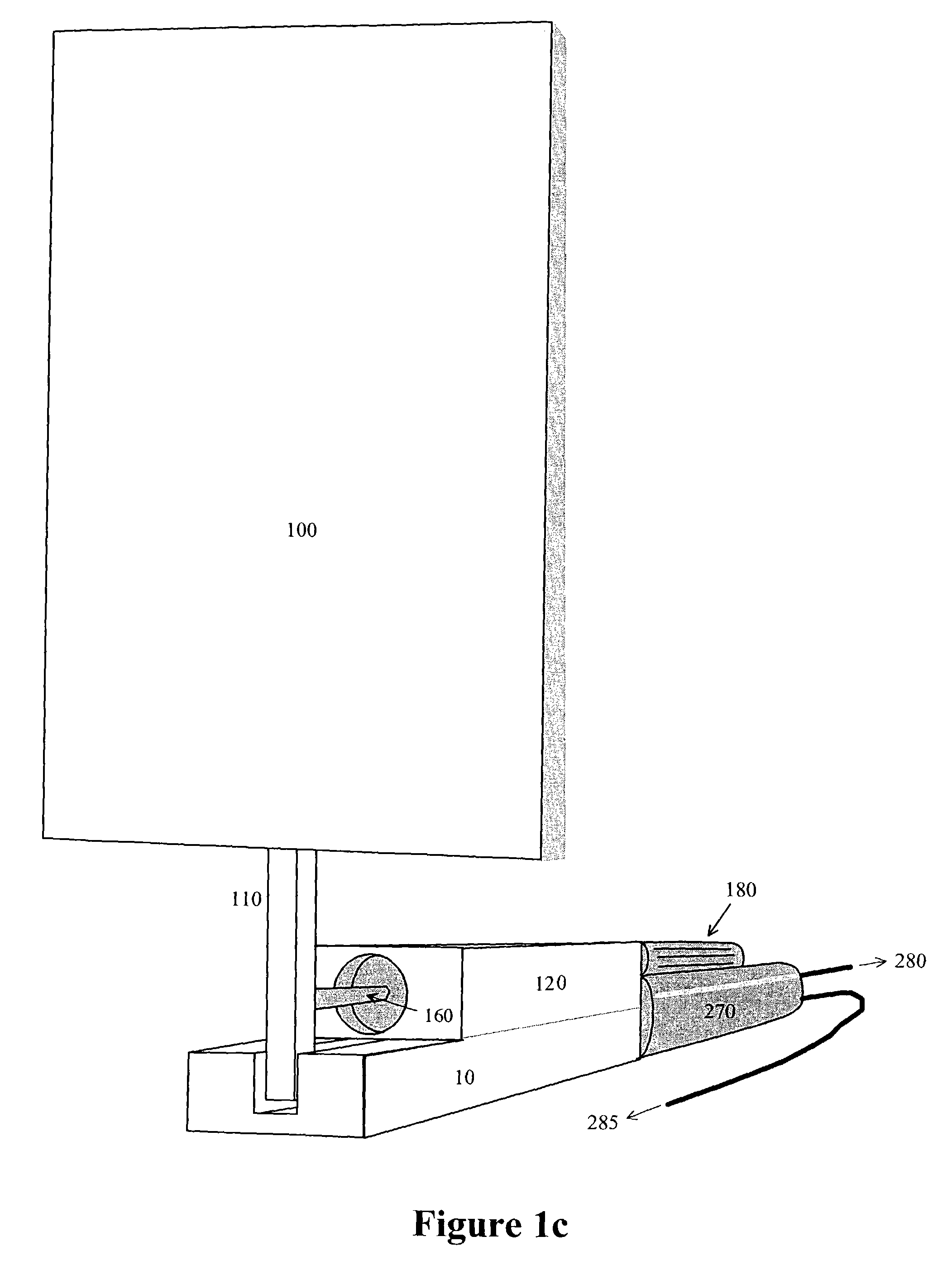

InactiveUS7023104B2Improve efficiencyEasy to operateWind motor controlGeneral water supply conservationWater qualityEngineering

An impulse-type “wave motor” employs a seabed-mounted or supported structure mounting a wave energy absorbing panel on a hinged lever arm for reciprocation motion to obtain optimal absorption of wave energy from wave motion in the sea. For deepwater wavelengths of L, the panel is optimally positioned in a region within L / 2 depth from the sea surface. The panel motion is coupled by a connecting rod to a fluid pump which generates a high-pressure fluid output that may be used to drive a reverse osmosis desalination unit or to produce other useful work. Seawater or brackish water may be desalinated through reverse osmosis membranes to produce water quality for consumption, agricultural, or other uses. The submerged operating environment of the device in a region of one-half the design wavelength provides the maximum available energy flux and forced oscillations. The pump may be of the positive-displacement piston type, plunger type, or multi-staging driver type, or a variable volume pump.

Owner:KOBASHIKAWA ALVIN +1

Method for treating wastewater or produced water

ActiveUS7815804B2Reduce hardnessReduce dissolved solidWaste water treatment from quariesGeneral water supply conservationWastewaterIon exchange

A method or process for treating wastewater containing high organics, silica, boron, hardness, and suspended and dissolved solids. The method includes degasifying the wastewater for the removal of dissolved gases and thereafter chemically softening the wastewater. After the chemical softening step, the wastewater is directed through a media filter or membrane which removes additional solids and precipitants. Thereafter the wastewater is directed through a sodium ion exchange that further softens the wastewater. The effluent from the ion exchange is directed through a cartridge filter and the effluent from the cartridge filter is directed through one or more reverse osmosis units. At a selected phase of the process, prior to the wastewater reaching the reverse osmosis unit or units, the pH of the wastewater is raised and maintained such that the pH of the wastewater reaching a reverse osmosis unit is at a pH greater than 10.5.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

Method for removing oil from water coalescing in a polymer particle/fiber media

ActiveUS7297279B2Increase the liquid flow rateBig contactLiquid suspension thickening by filtrationSolid sorbent liquid separationFiberWater flow

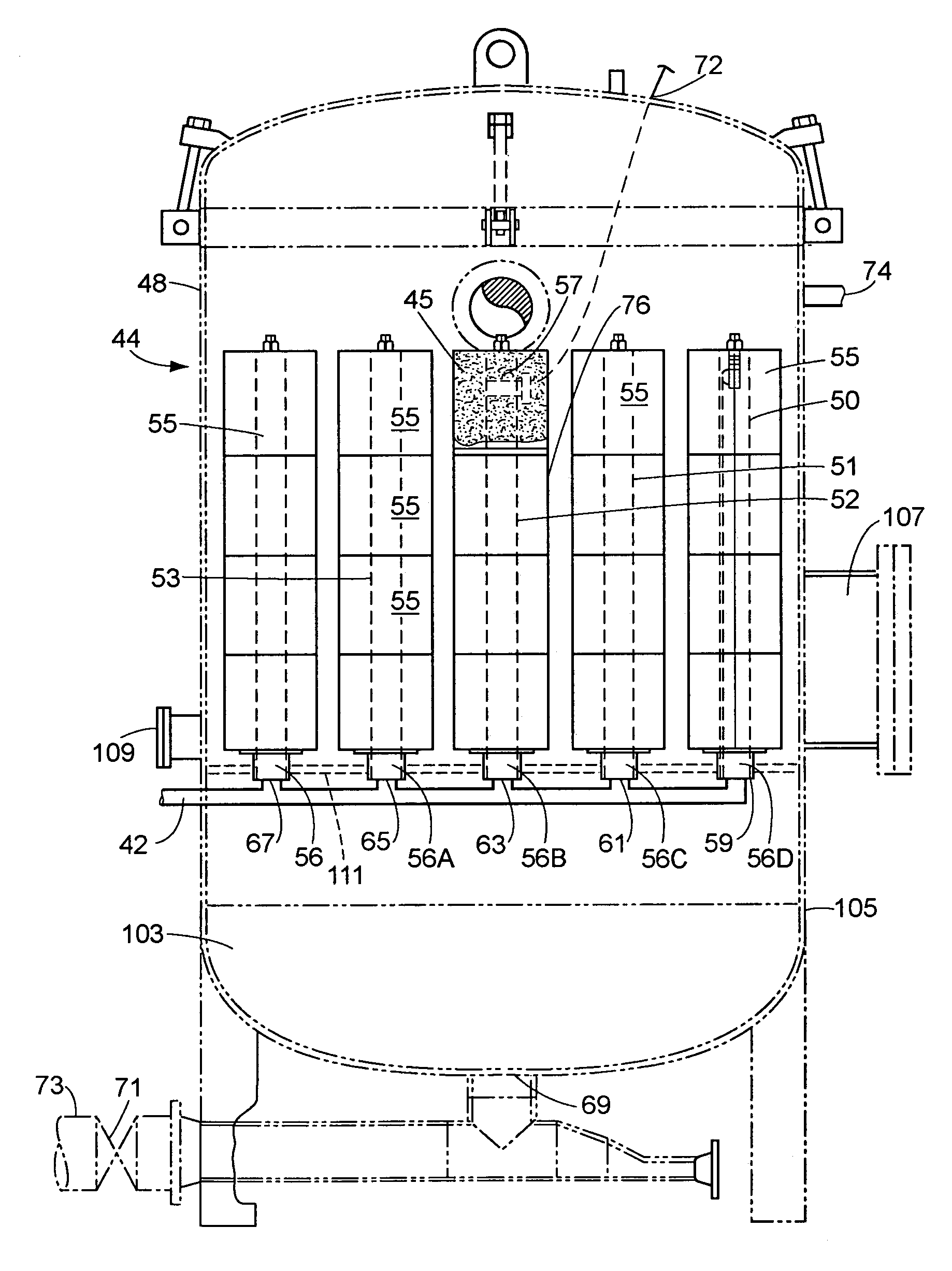

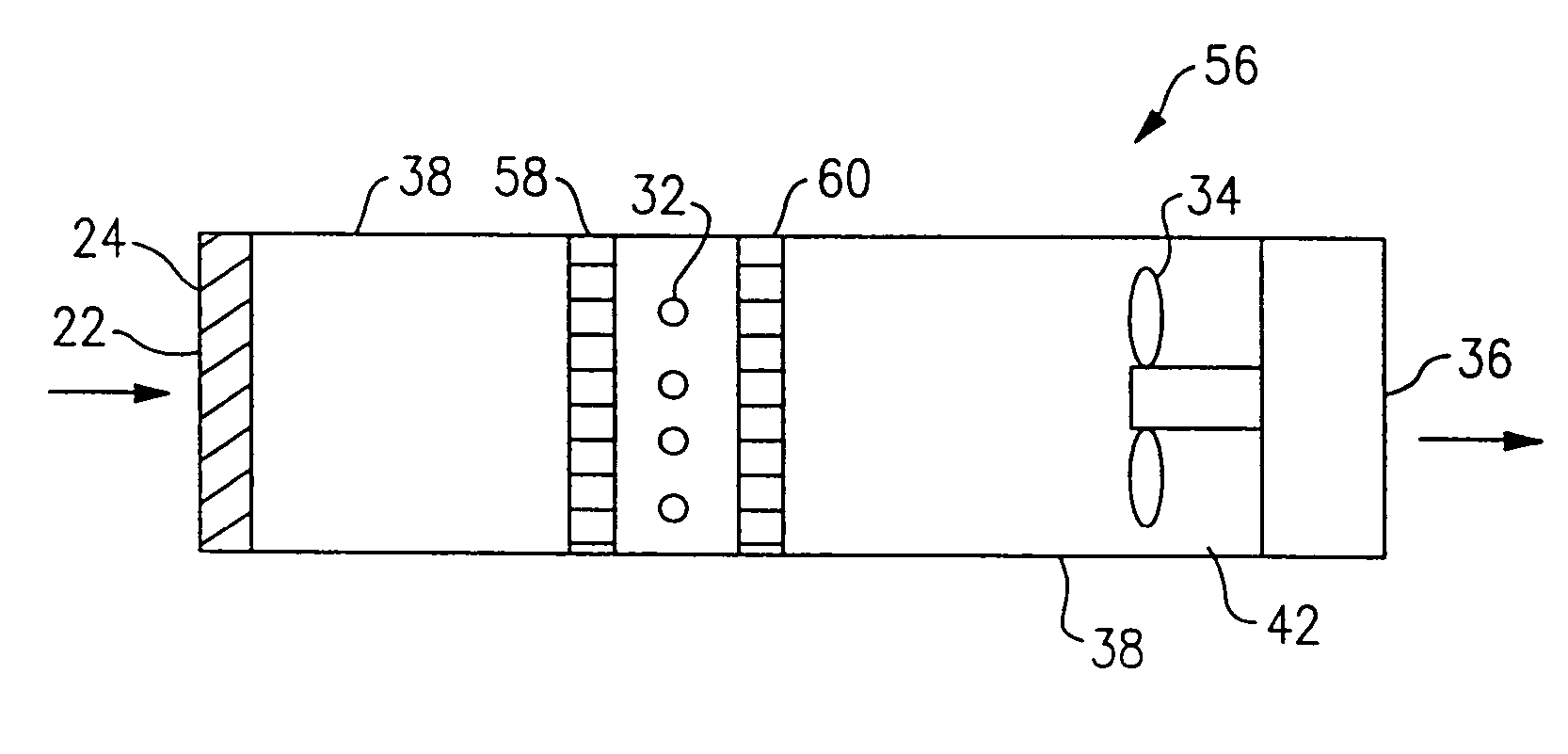

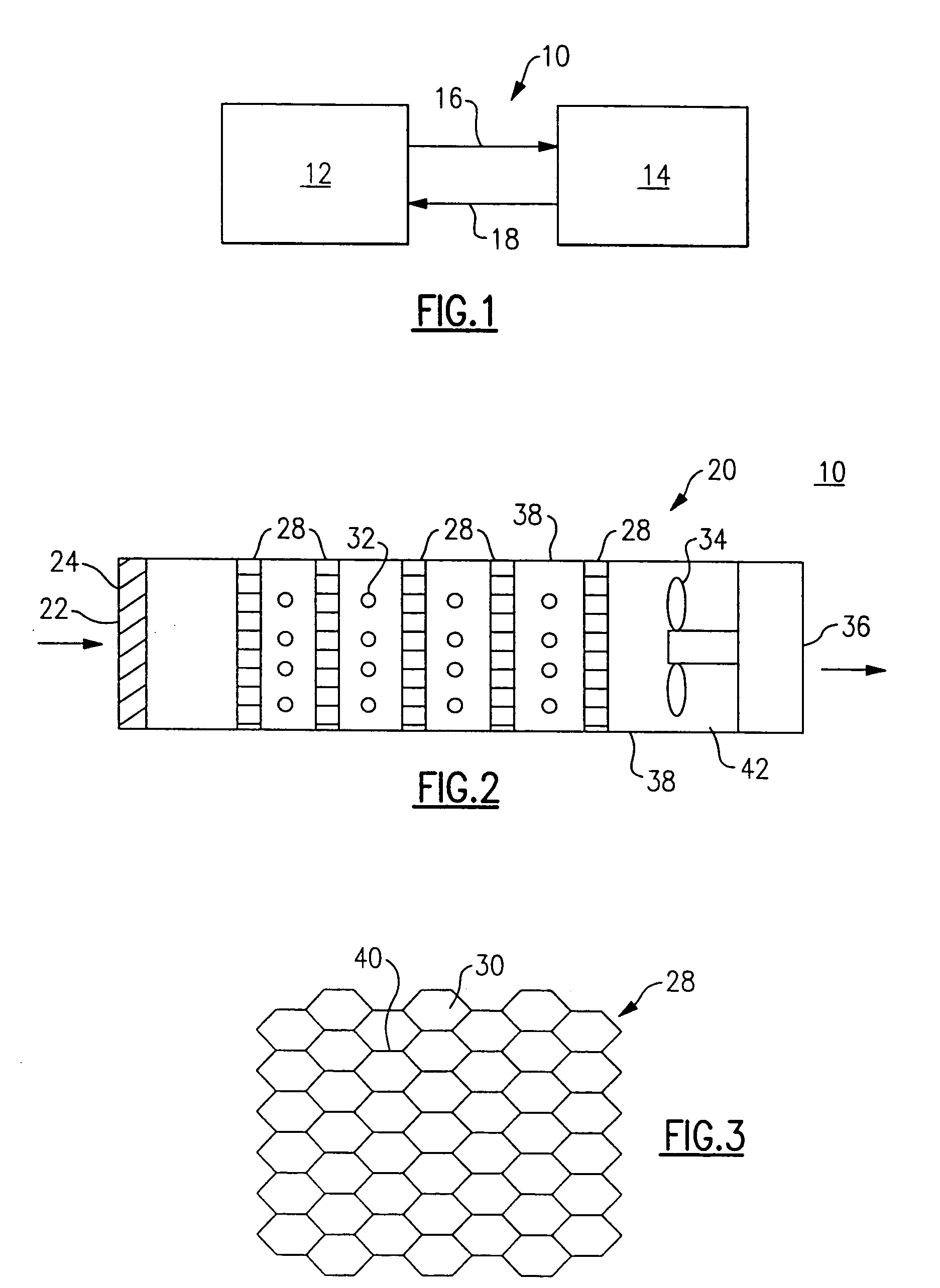

Apparatus in fluid communication with a water leg portion of a hydrocarbon-contaminated water, e.g., a water leg portion of a produced water stream or an offshore drilling or production platform sump tank for conveying water, separated from oil, into contact with non-woven fiber / particulate polymer coalescing media-containing canisters such that the hydrocarbon droplets and other organic material droplets commingled with the sump tank or produced water will be coalesced by passage through the coalescing media. The canisters preferably are provided in a plurality of stacks in each vessel. Solids that do not pass through the canisters are accumulated at the bottom of the vessel and easily drained through a drain port. The water and hydrocarbons will pass through the coalescing media within the canisters and will be separated easily from each vessel, e.g., by gravity separation, sot that the water can be conveyed back to the ocean water without contamination.

Owner:AMCOL INTERNATIONAL CORPORATION

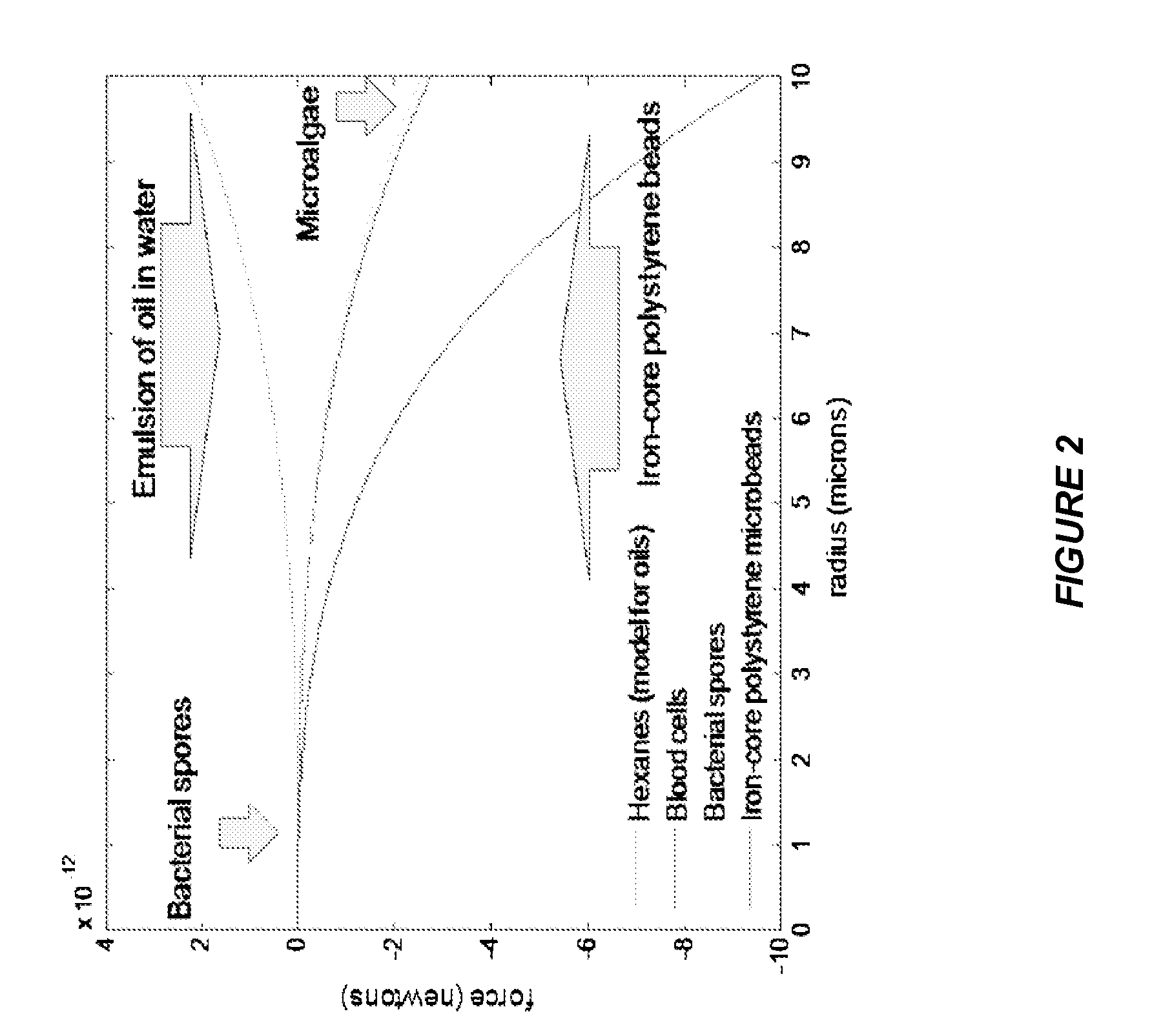

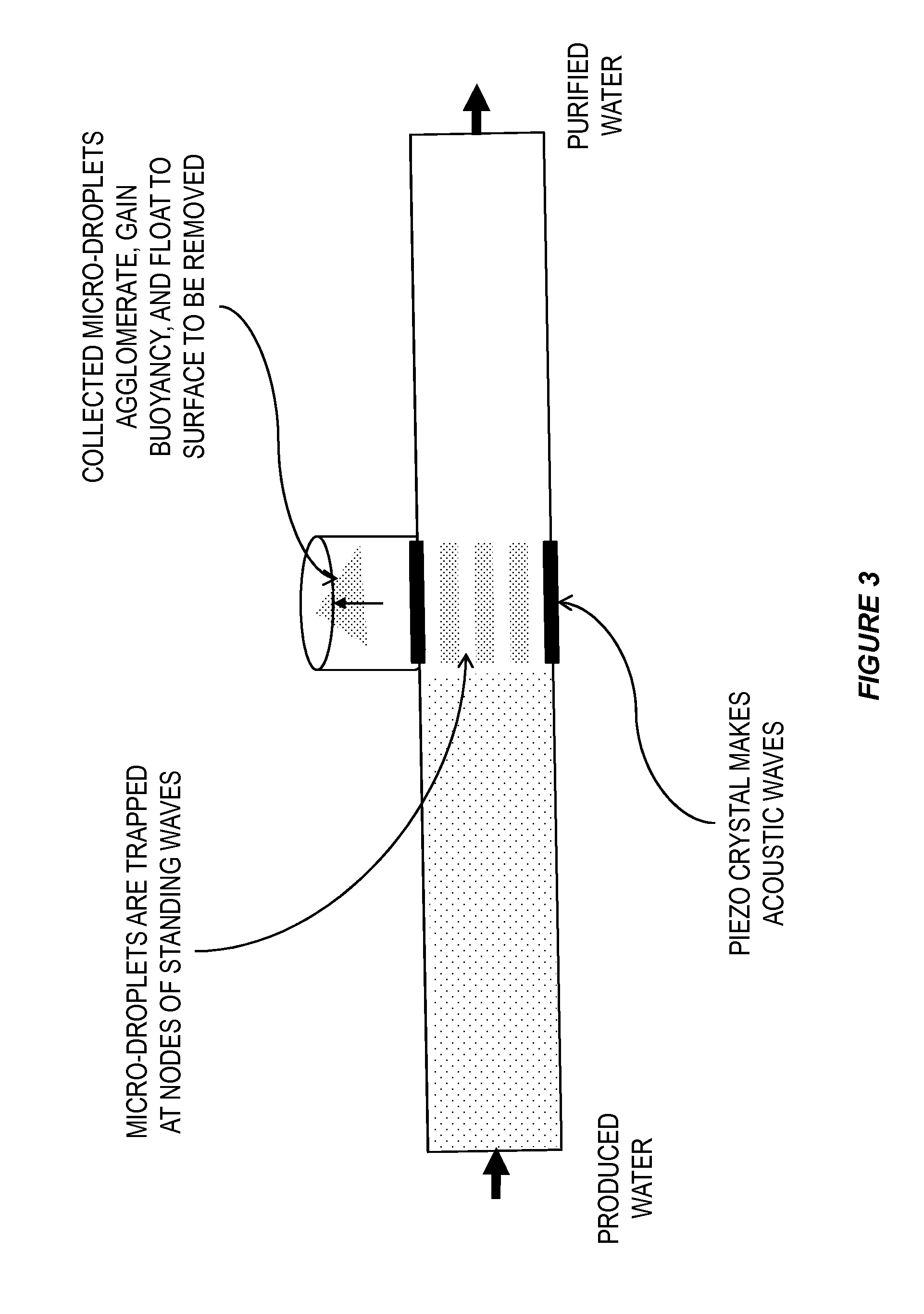

Ultrasound and Acoustophoresis Technology for Separation of Oil and Water, with Application to Produce Water

InactiveUS20110278218A1Maximize acoustic energy transferAvoid enteringWaste water treatment from quariesFatty/oily/floating substances removal devicesEmulsionResonance

Several prototype systems are described for separating oil and water from emulsions. The systems operate at ultrasonic resonance and are thus low power. Each system contains one or more acoustic transducers operating in the 100 kHz to 5 MHz range. Each system contains flow input for the emulsion and two or more flow outputs for the separated oil and water. Existing prototypes operate from 200 mL / min to >15 L / min. Each uses low power in the range of 1-5 W.

Owner:FLODESIGN SONICS

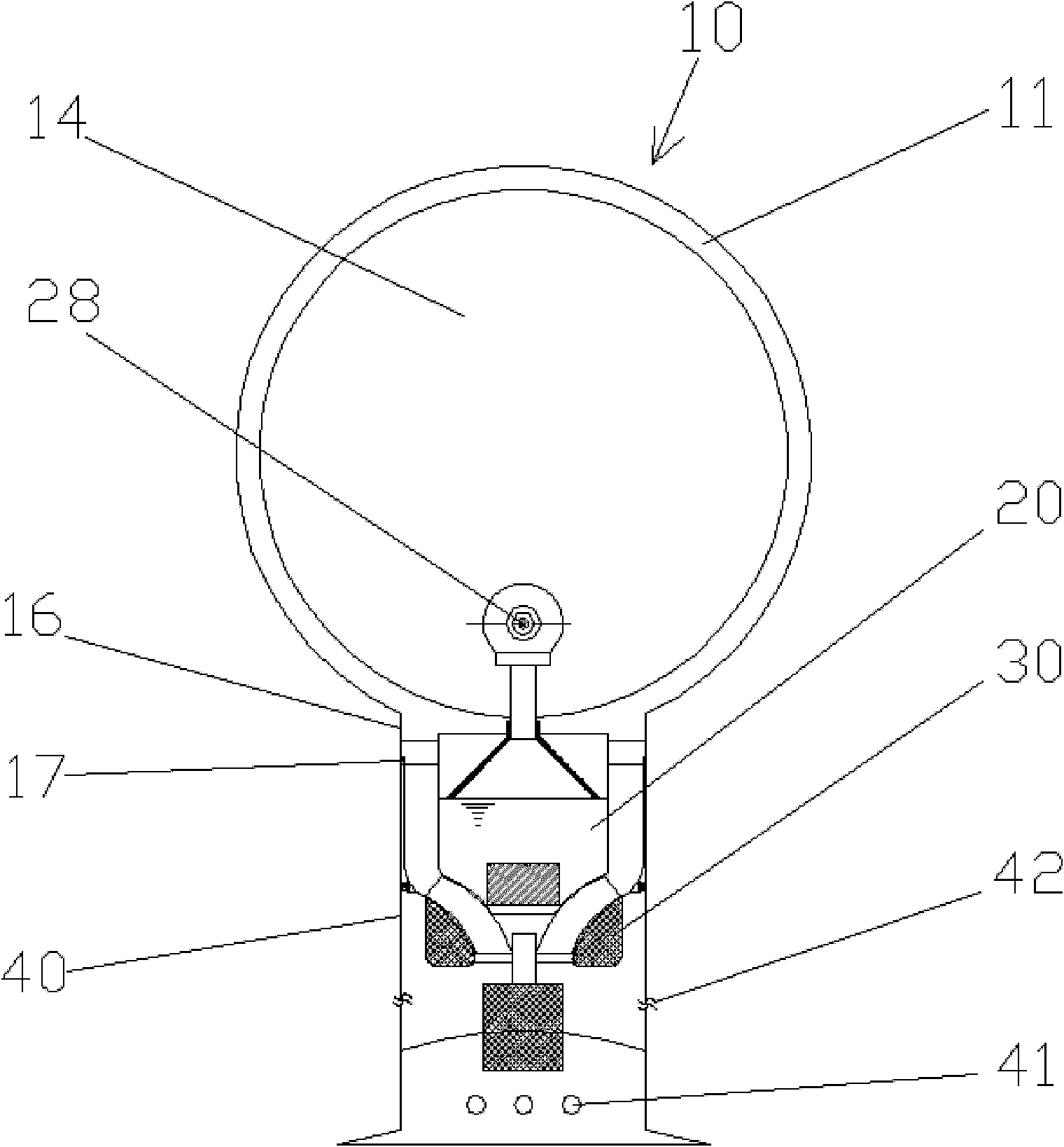

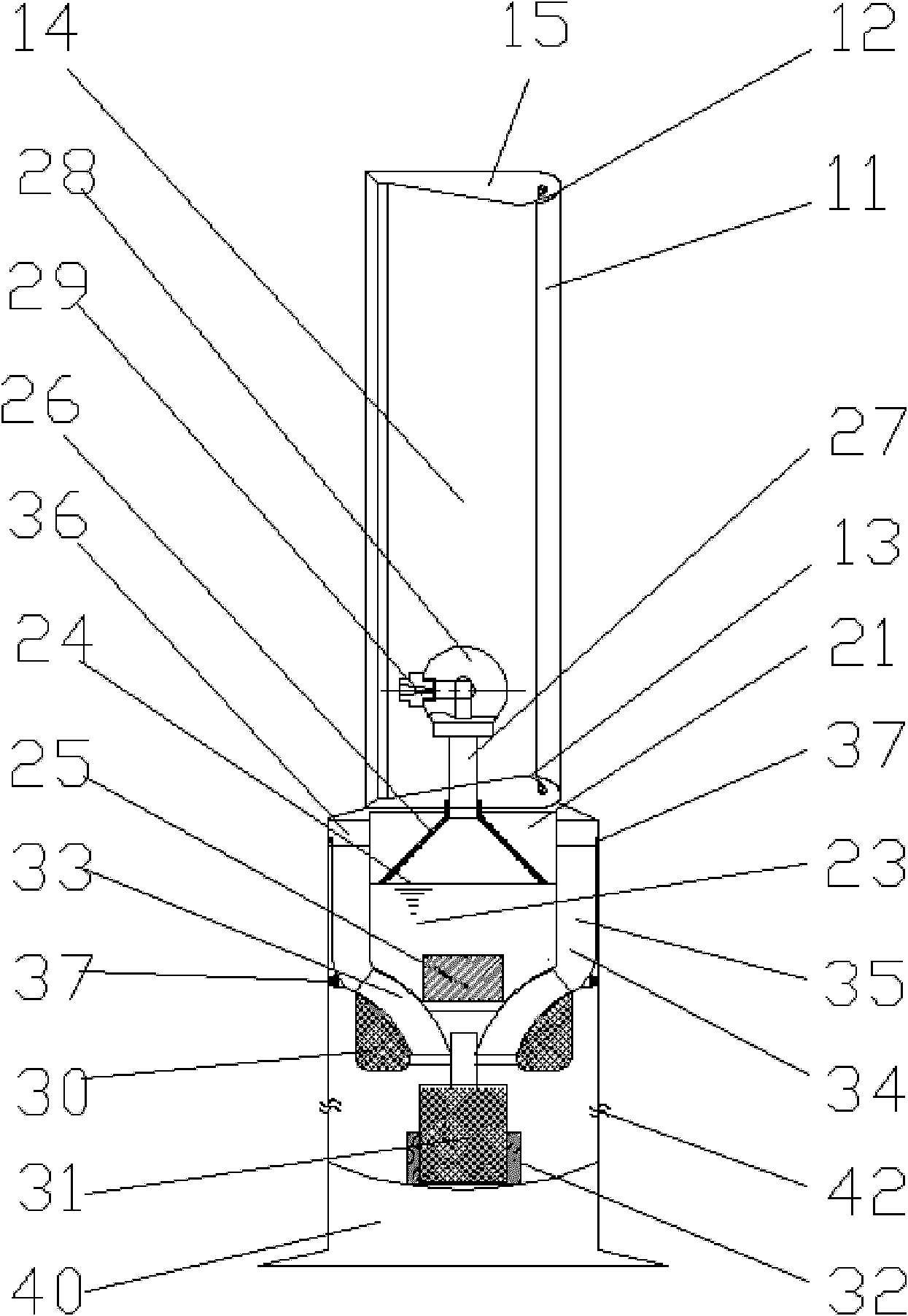

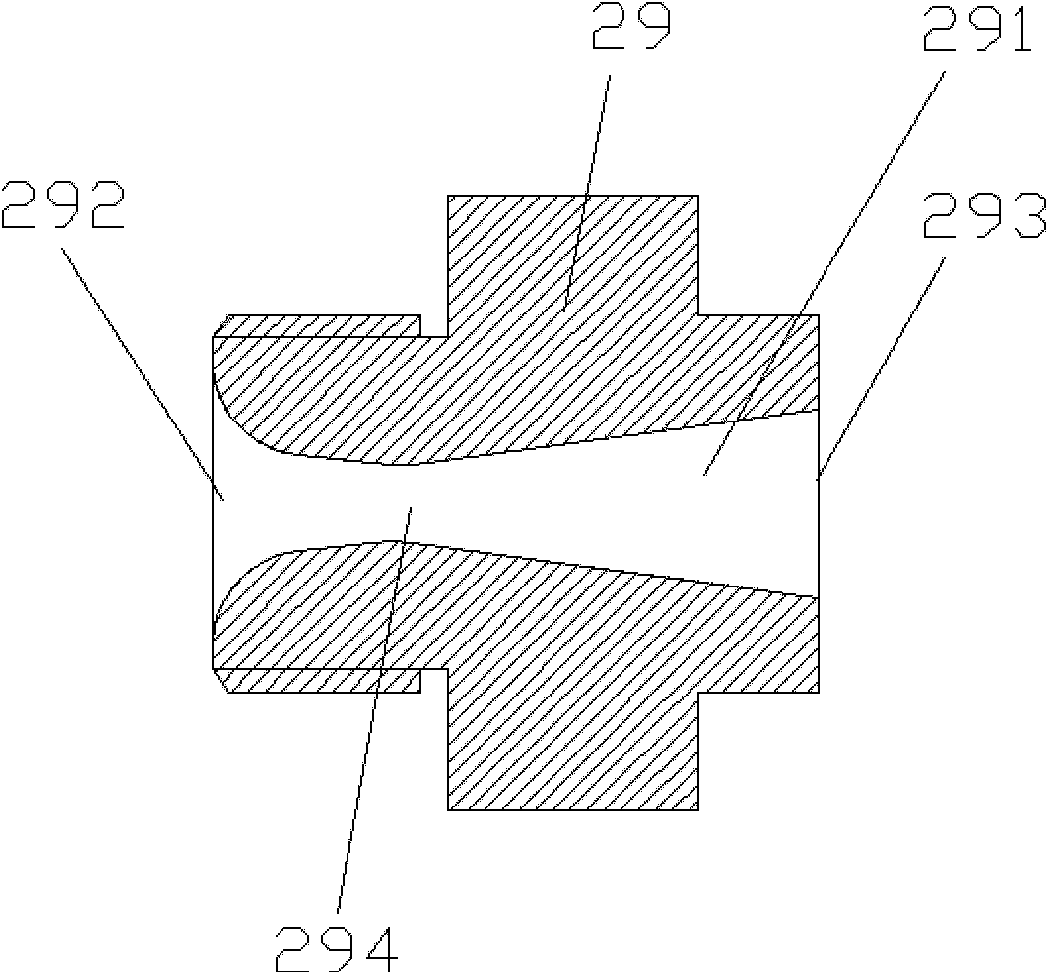

Ventilation device

InactiveCN102095236APromote absorptionImprove cooling effectLighting and heating apparatusJet pumpsWater vaporEngineering

The invention discloses a ventilation device, which aims to solve the problem that the conventional ventilation device does not have an air adjusting function. The device comprises a pedestal, a high-speed air blower and an annular ejector, wherein the high-speed air blower is arranged at the bottom of the pedestal; the annular ejector is arranged at an air outlet of the high-speed air blower and is fixed on the pedestal; and the air inlet or the air outlet of the high-speed air blower is provided with a vapor generator which is fixed on the pedestal for producing water vapor. In the ventilation device, the water vapor is produced through the vapor generator and is ejected through an atomization nozzle at a high speed to produce fog of smaller granularity, so that a hot air flow can more easily absorb the latent heat of vaporization, and the ventilation device has a humidification effect and a heat absorption and temperature reduction effect on a large amount of hot air sucked by the annular nozzle, and brings comfortable cool air similar to air on the shore of a lake or a sea to the surrounding environment. In the ventilation device, an external circulating device is not required to be mounted, so the cost is low; the space is not required to be closed, so that air convection is guaranteed; and the ventilation device is more energy-saving in the same temperature reduction range compared with a fan and an air conditioner, and can be used conveniently and safely.

Owner:曾小颖 +1

Wave energy conversion device for desalination, ETC

InactiveUS20040007881A1Minimize exposureLow profileWind motor controlGeneral water supply conservationWater qualityWave motor

An impulse-type "wave motor" employs a seabed-mounted or supported structure mounting a wave energy absorbing panel on a hinged lever arm for reciprocation motion to obtain optimal absorption of wave energy from wave motion in the sea. For deepwater wavelengths of L, the panel is optimally positioned in a region within L / 2 depth from the sea surface. The panel motion is coupled by a connecting rod to a fluid pump which generates a high-pressure fluid output that may be used to drive a reverse osmosis desalination unit or to produce other useful work. Seawater or brackish water may be desalinated through reverse osmosis membranes to produce water quality for consumption, agricultural, or other uses. The submerged operating environment of the device in a region of one-half the design wavelength provides the maximum available energy flux and forced oscillations. The pump may be of the positive-displacement piston type, plunger type, or multi-staging driver type, or a variable volume pump.

Owner:KOBASHIKAWA ALVIN +1

Method of using controlled release tracers

Fluids produced from a fractured subterranean formation may be monitored by pumping into the well a fracturing fluid which contains a tracer. The method may be used to monitor produced hydrocarbons as well as produced water. The tracer may also be used in a sand control, frac pack or acid fracturing operation. The tracer is a component of a composite where it may be immobilized within a matrix (such as an emulsion) or porous particulate, onto a support or compressed with a binder into a solid particulate. The tracer may be slowly released from the composite.

Owner:BAKER HUGHES INC

Produced water treatment method and apparatus

InactiveUS20080156709A1Improve filtration efficiencyEnhanced cavitationUltrafiltrationLoose filtering material filtersCavitationWaste collection

The present invention discloses a method and apparatus for separating particles and dissolved matter from a produced water fluid stream. Specifically, the present invention includes a first pressure source which transports untreated produced water or contaminated aqueous fluid into a separator annulus with a filter element disposed therein. The untreated fluid is placed under appropriate pressure sufficient to produce turbulent flow, increased particle kinetics and / or cavitation allowing the desired fluid to penetrate and pass into and through the filter media. The treated fluid is then transported to a collection tank. The contaminant matter retained by the filter media may be removed by the nearly instantaneous reverse pressurization of the separator annulus by a second pressure source thereby removing the contaminant particles away from contact with the filter media, and which may then be transported to a waste collection tank or a separator for further treatment.

Owner:TERVITA +1

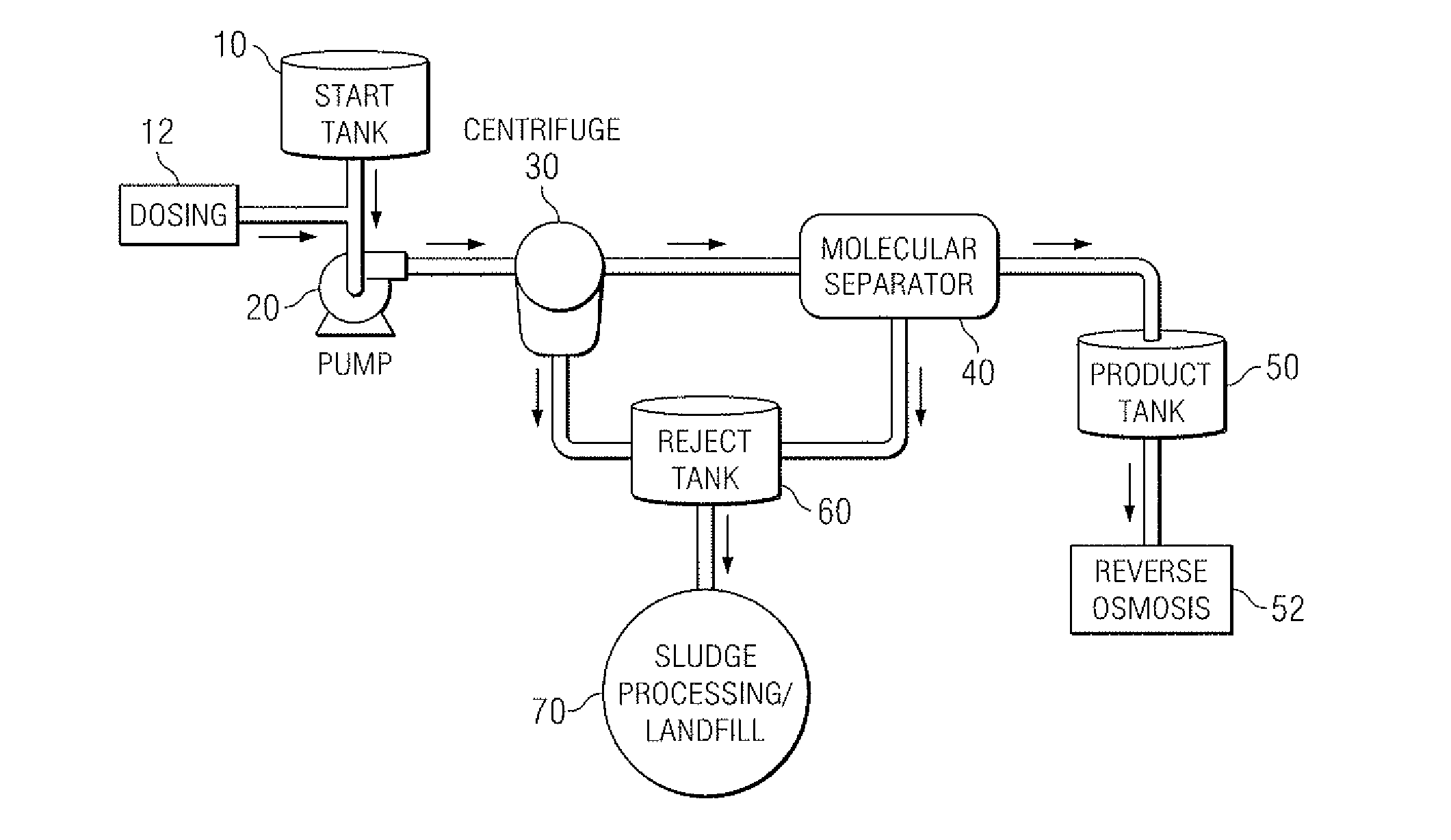

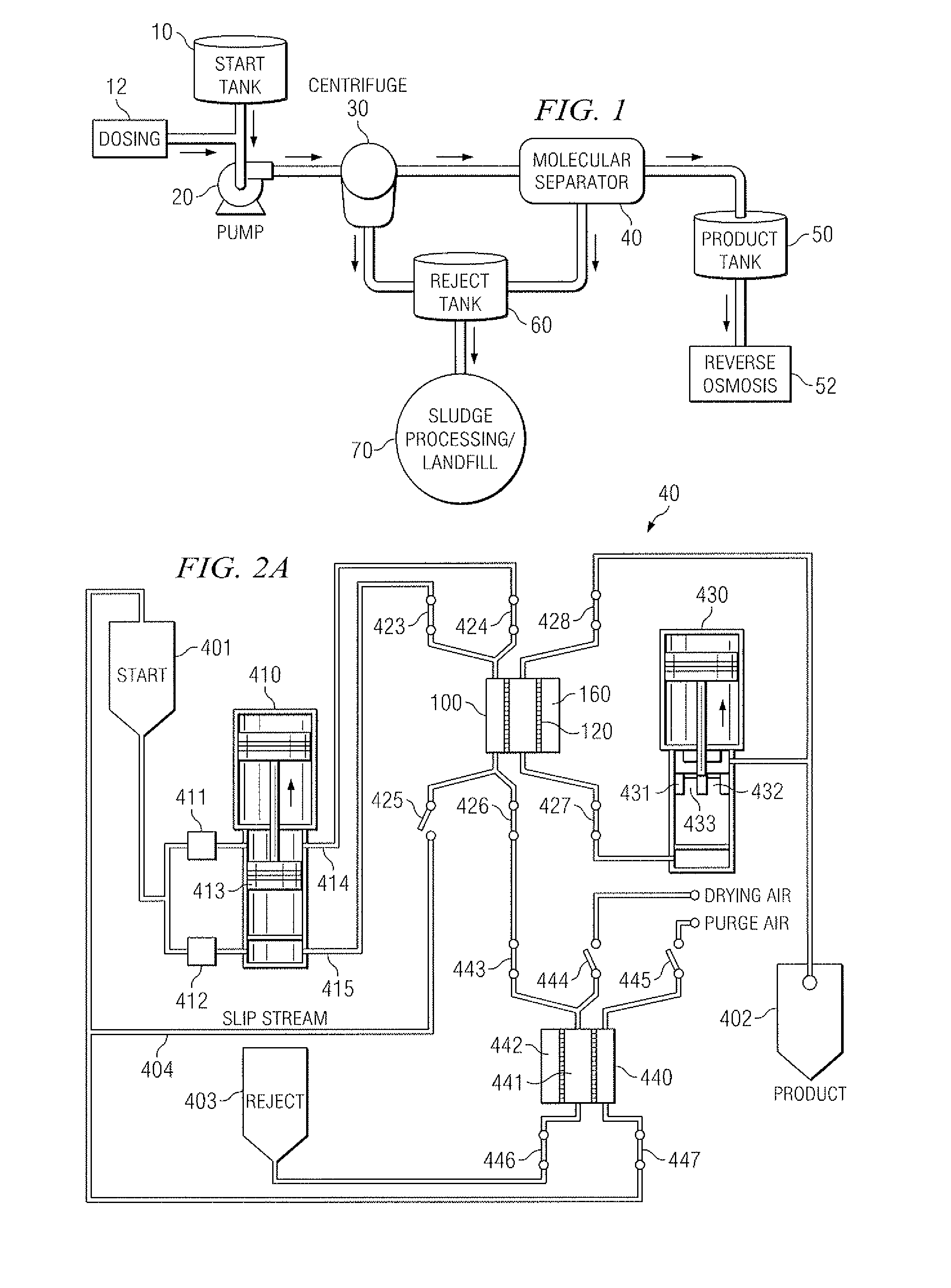

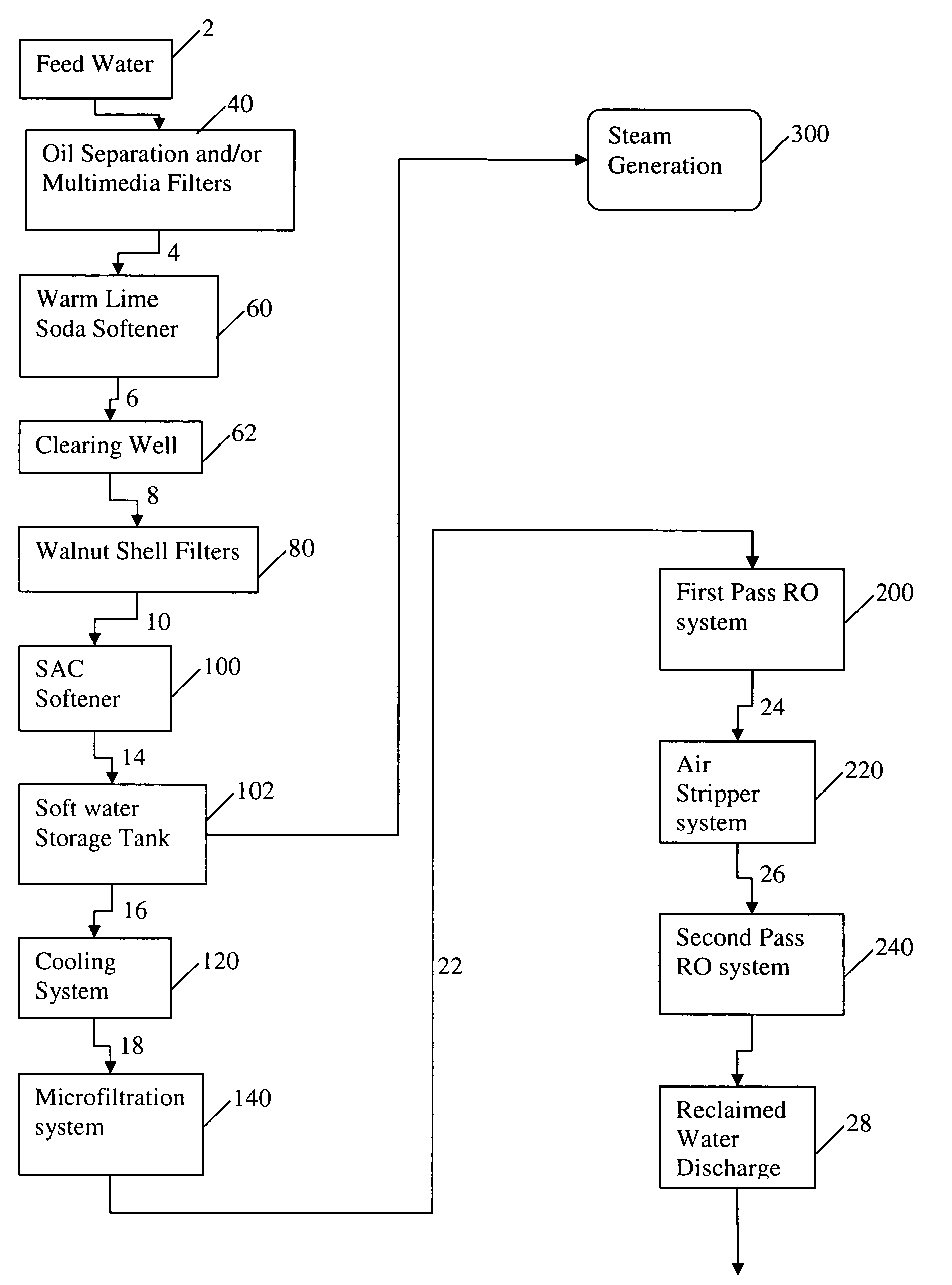

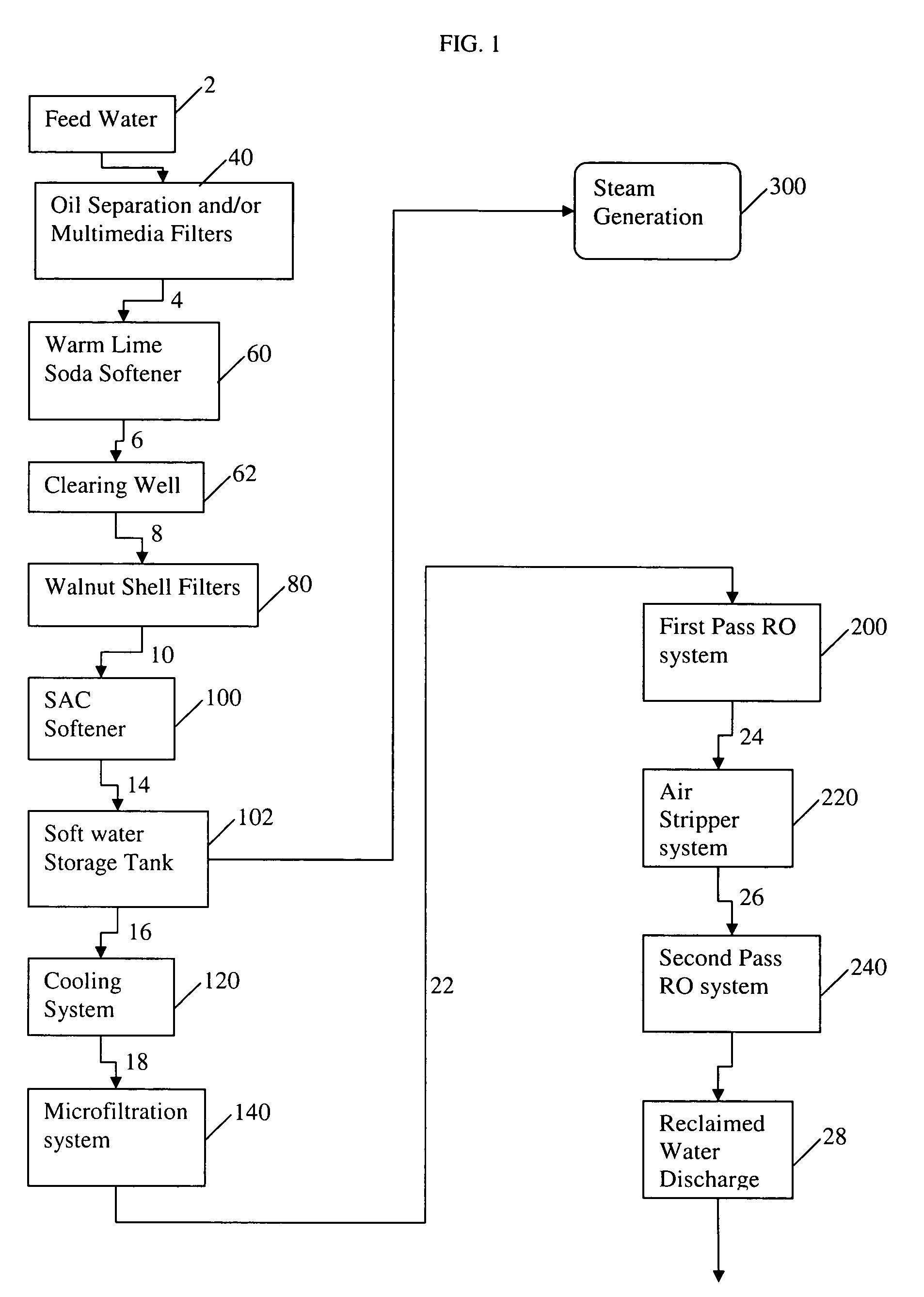

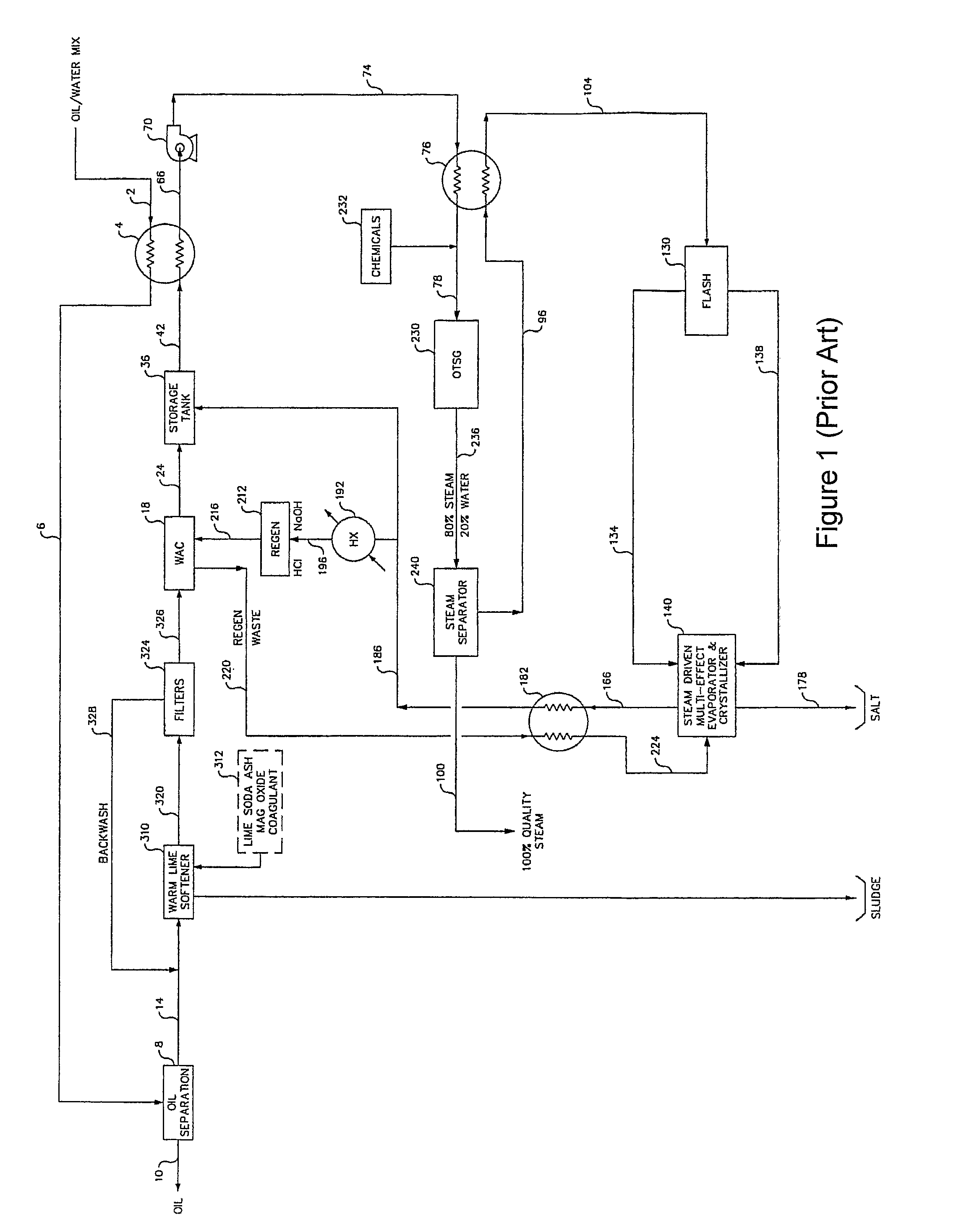

Water treatment process for oilfield produced water

ActiveUS7520993B1Minimize continued precipitationLiquid separation auxillary apparatusUsing liquid separation agentSludgeTreatments water

The invention relates to a method and system for treating an aqueous liquid containing dissolved minerals and dissolved hydrocarbons. Method steps and apparatus for treating a waste water feed stream are disclosed which utilize a warm lime softening system in fluid communication with the waste water feed stream, wherein sludge from the warm lime softening system is recycled to improve lime utilization and enhance silica and boron removal without the addition of an external source of magnesium. In addition, a microfiltration system and / or an air stripper system may be used in fluid communication with at least one reverse osmosis system to produce a treatment water that meets state and federal guidelines for surface discharge.

Owner:WATER & POWER TECH

Process for producing water-absorbing resin

InactiveUS20050085604A1Prevent discolorationNo discolorationAbsorbent padsBaby linensPolymer scienceProduced water

A process for preparing a water-absorbent resin made from an α,β-unsaturated carboxylic acid as an essential monomer characterized in that the process comprises allowing a metal chelating agent to be present at any step in the process in an amount of 0.001 to 6 parts by weight, based on 100 parts by weight of the α,β-unsaturated carboxylic acid; and adding a reducing agent or an oxidizing agent thereto in an amount of 0.001 to 6 parts by weight, based on 100 parts by weight of the α,β-unsaturated carboxylic acid before initiation of drying and / or during drying of a gelated product containing a water-absorbent resin obtained by polymerization.

Owner:SUMITOMO SEIKA CHEM CO LTD

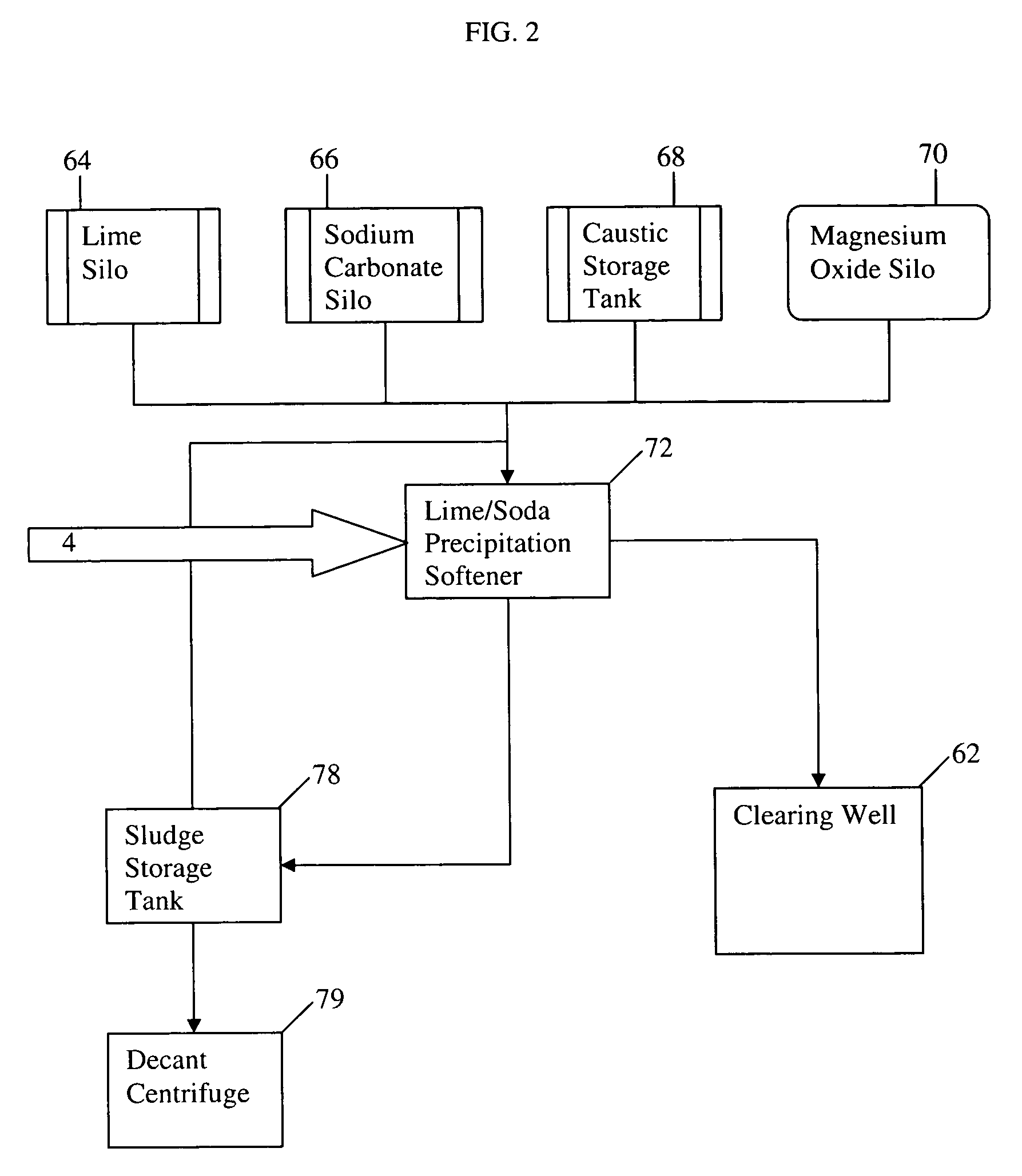

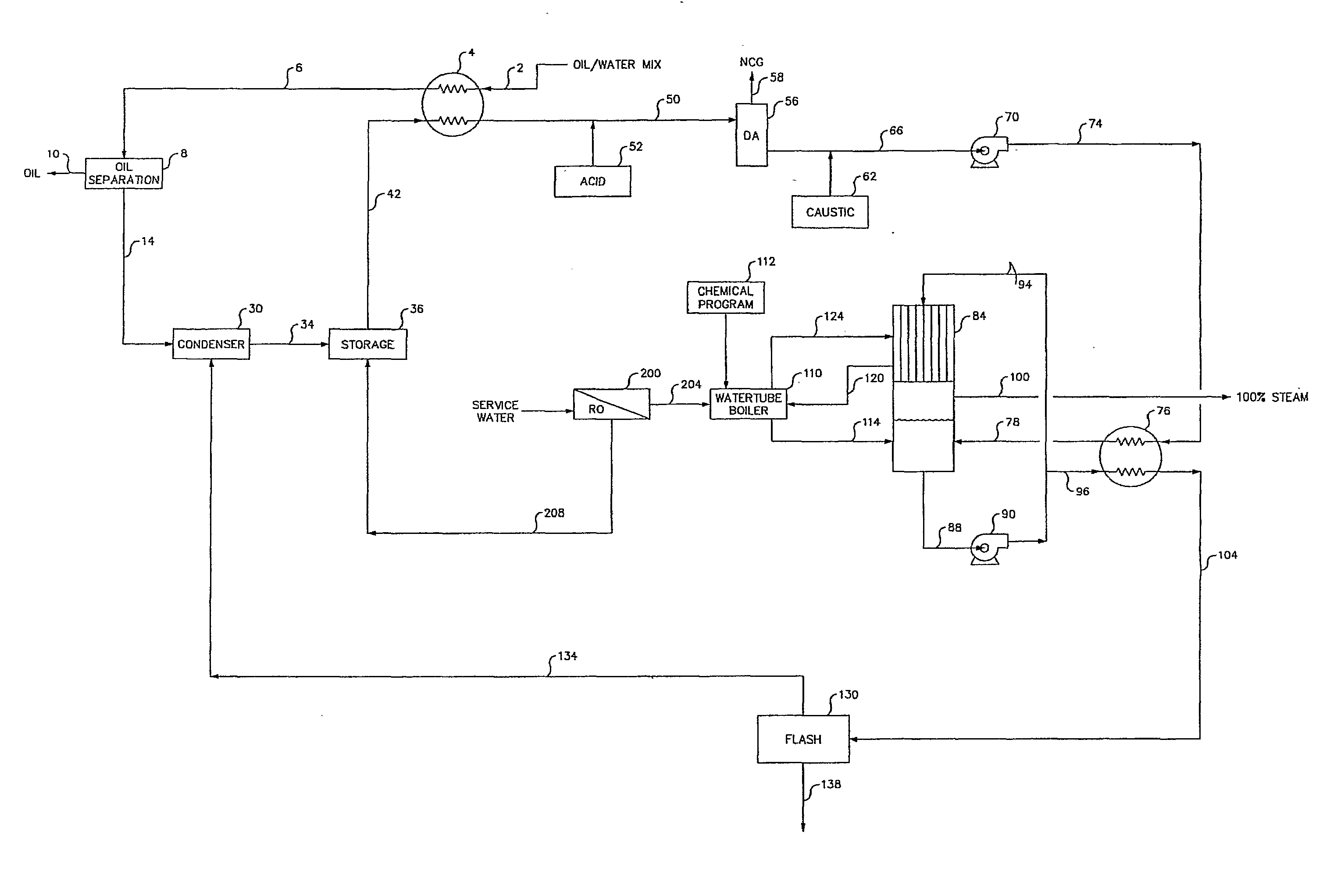

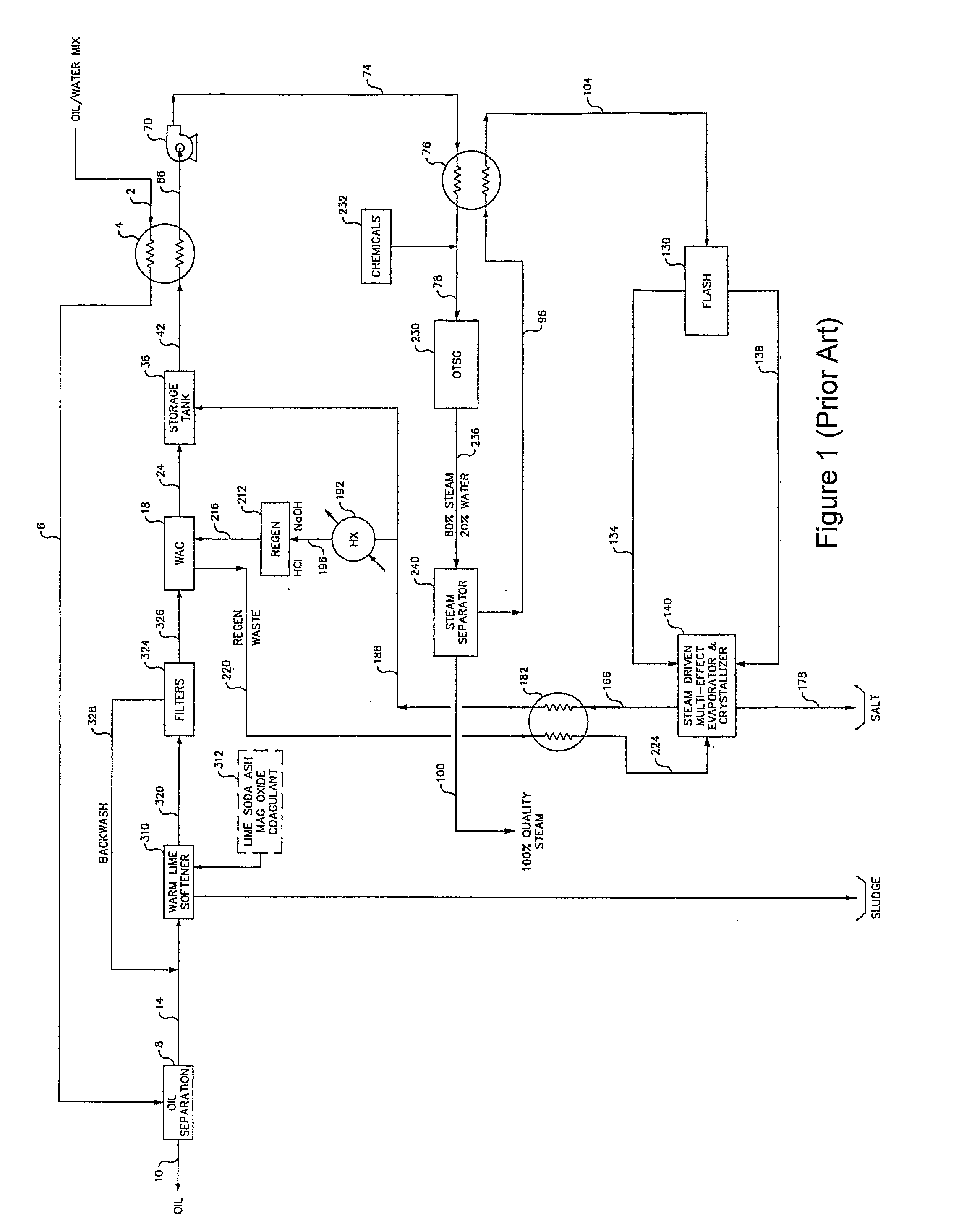

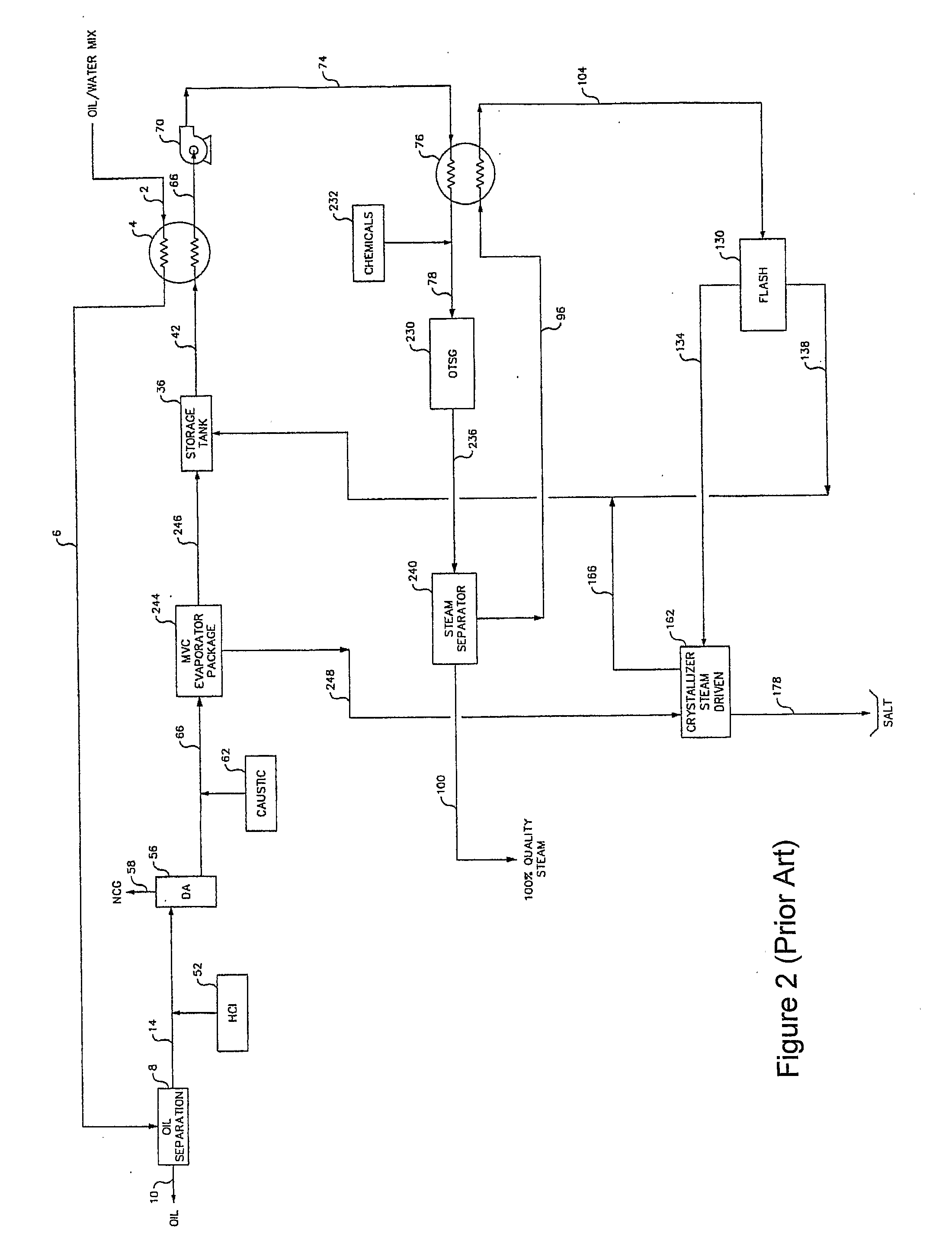

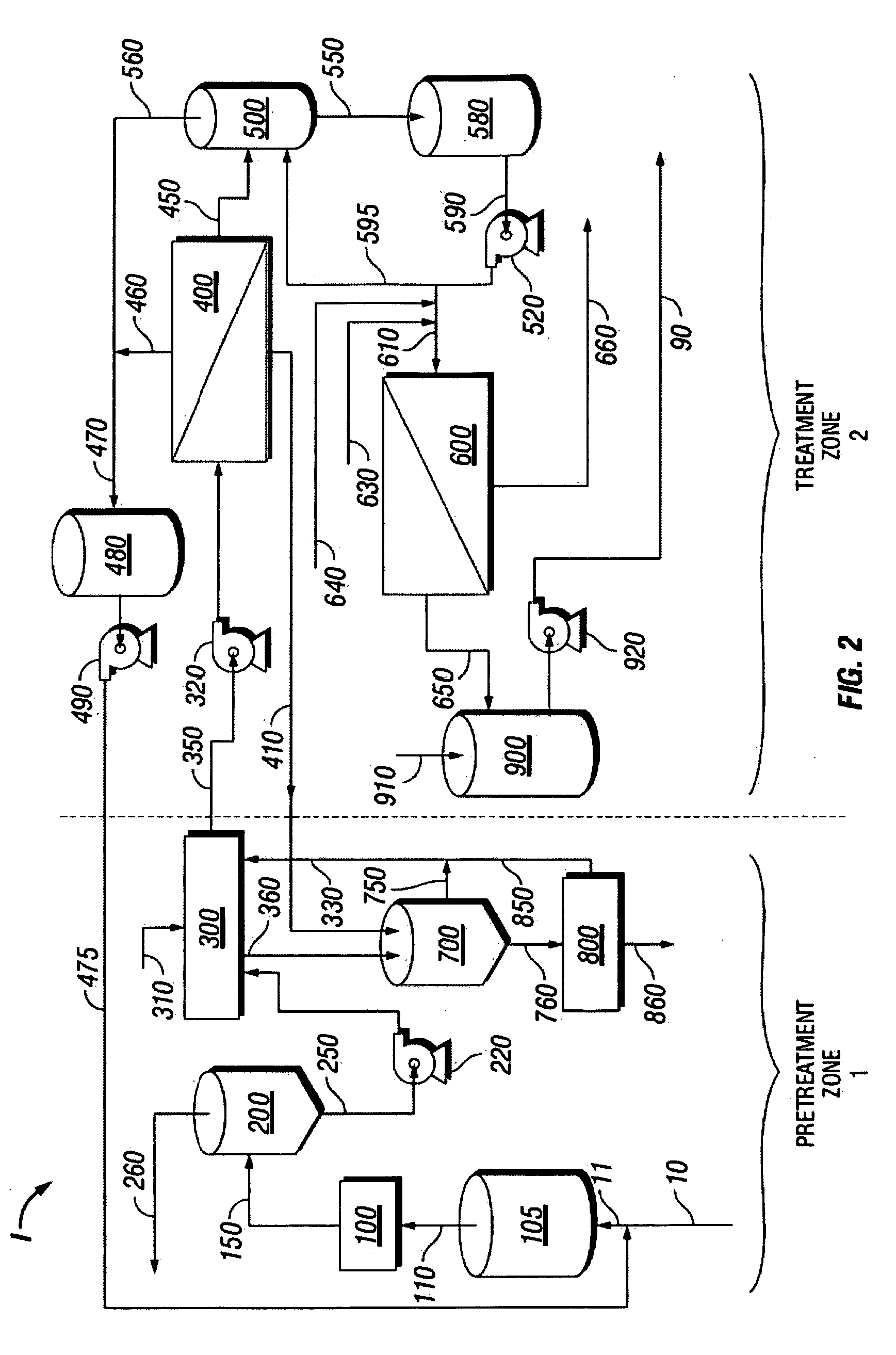

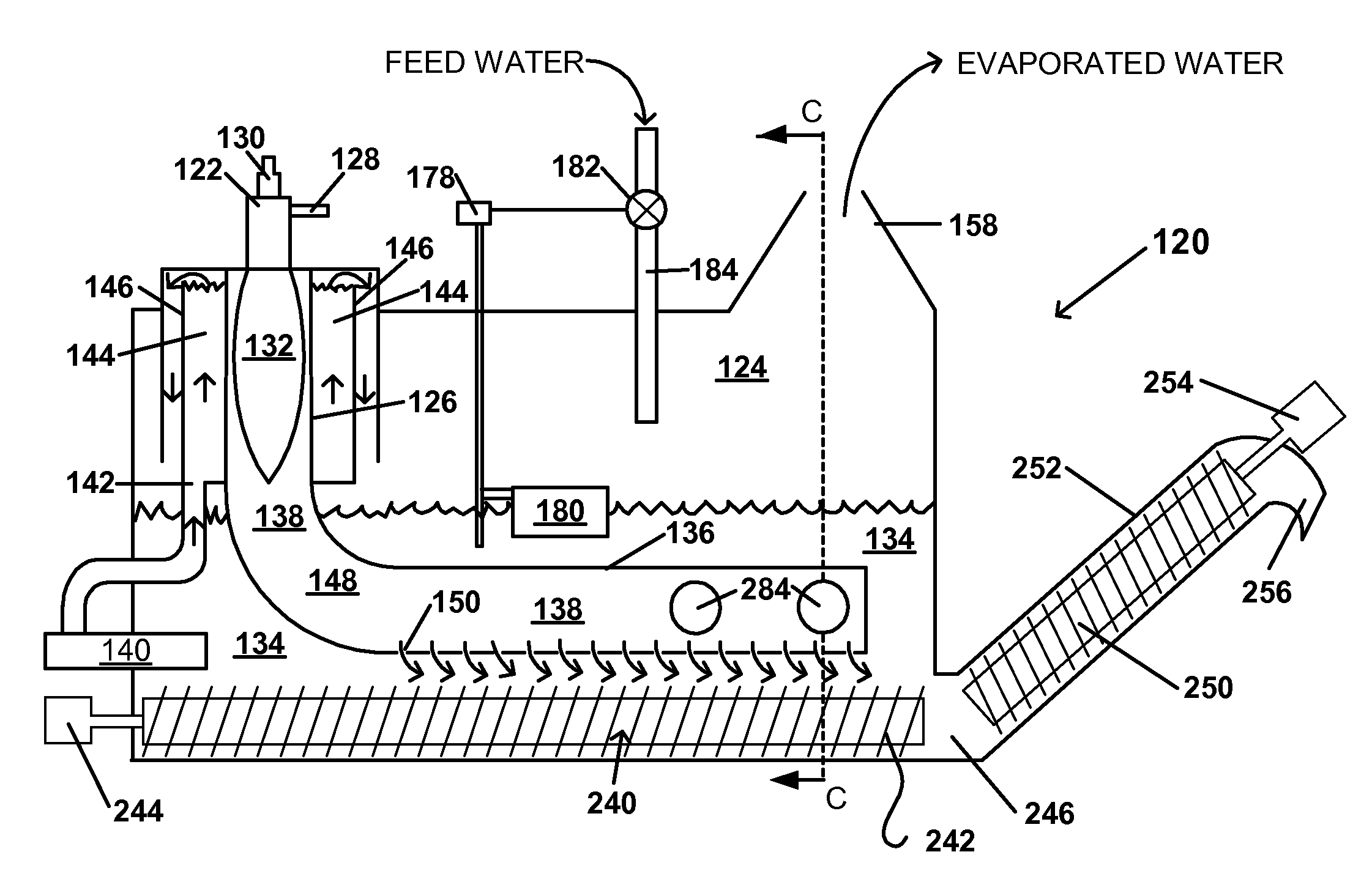

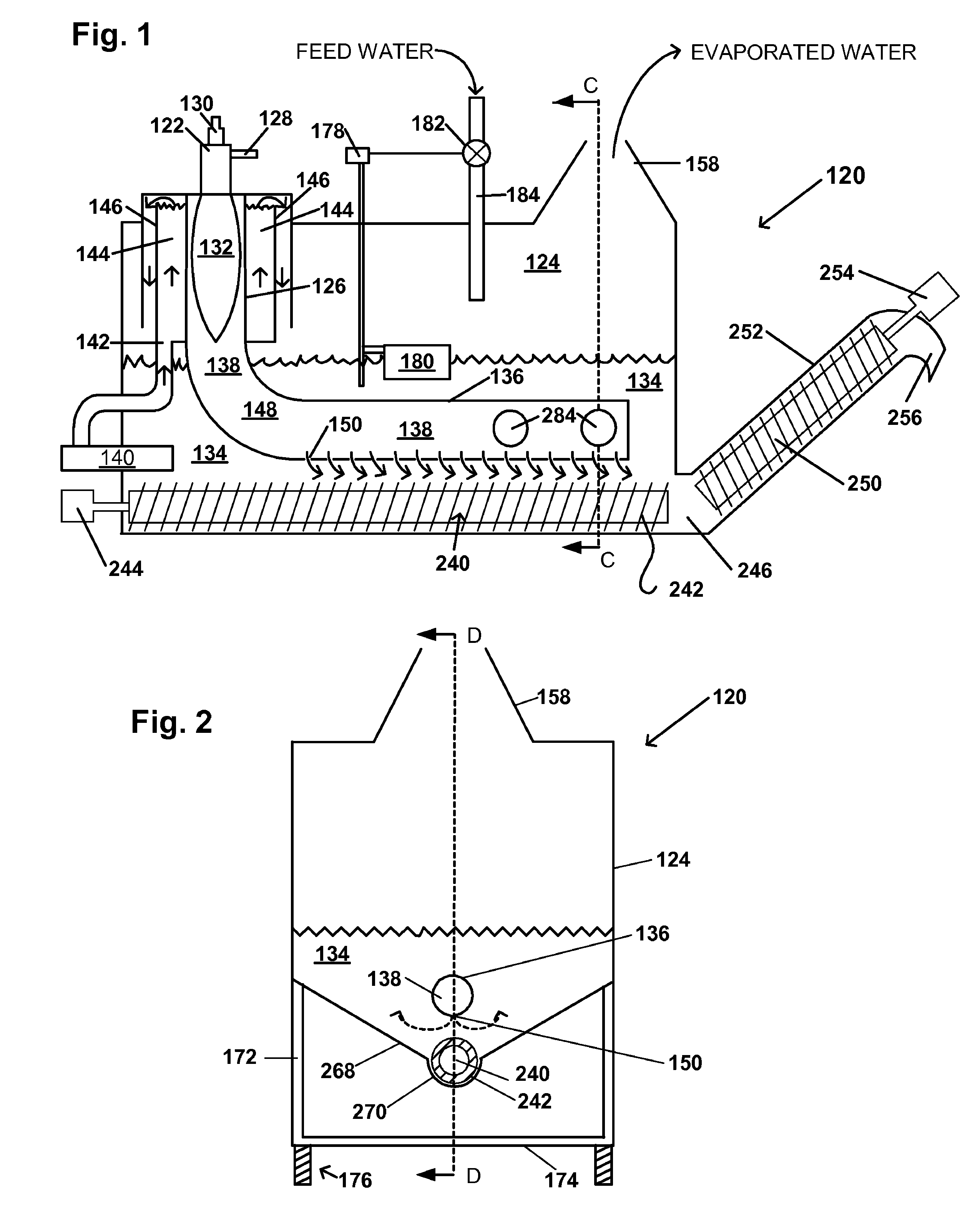

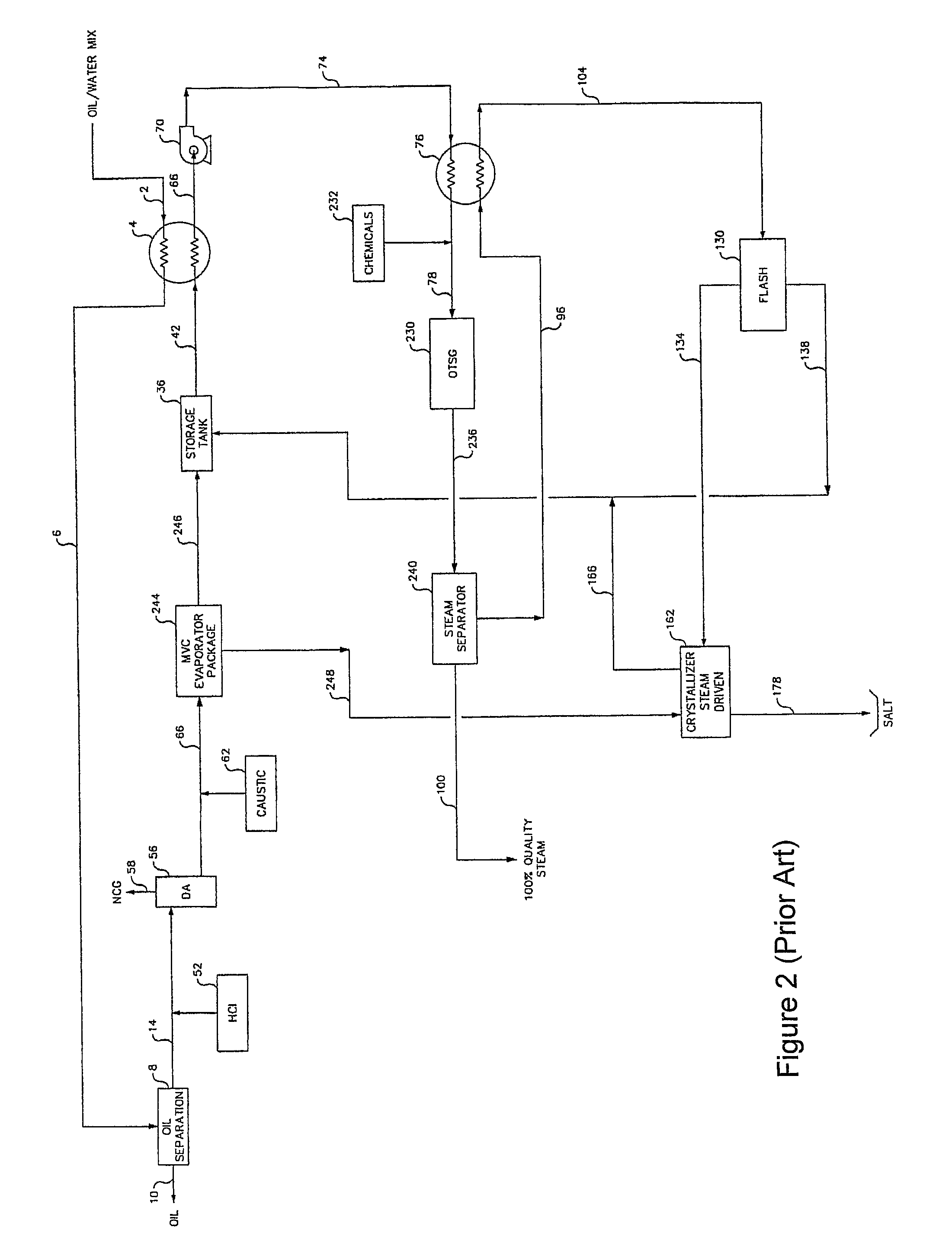

Method for Production of High Pressure Steam from Produced Water

InactiveUS20080110630A1Average power consumptionMinimize waste generationDrying using combination processesSolid sorbent liquid separationChemical treatmentDistillation

An evaporation based method for generation of high pressure steam from produced water in the heavy oil production industry. De-oiled produced water is processed through a high pH / high pressure evaporator driven by a commercial watertube boiler. The vapor produced by the evaporator is suitable for the steam assisted gravity drainage (SAGD) method being utilized by heavy oil recovery installations, without the use of once through steam generators that require extensive chemical treatment, and without requiring atmospheric distillation, which requires high power consuming compressors. Evaporator blowdown may be further treated in a crystallizing evaporator to provide a zero liquid discharge (ZLD) system and, with most produced waters, at least 98% of the incoming produced water stream can be recovered in the form of high pressure steam.

Owner:AQUATECH INT LLC

Method for Treating Wastewater or Produced Water

ActiveUS20080135478A1Reduce hardnessReduced silica concentrationWaste water treatment from quariesGeneral water supply conservationWastewaterIon exchange

A method or process for treating wastewater containing high organics, silica, boron, hardness, and suspended and dissolved solids. The method includes degasifying the wastewater for the removal of dissolved gases and thereafter chemically softening the wastewater. After the chemical softening step, the wastewater is directed through a media filter or membrane which removes additional solids and precipitants. Thereafter the wastewater is directed through a sodium ion exchange that further softens the wastewater. The effluent from the ion exchange is directed through a cartridge filter and the effluent from the cartridge filter is directed through one or more reverse osmosis units. At a selected phase of the process, prior to the wastewater reaching the reverse osmosis unit or units, the pH of the wastewater is raised and maintained such that the pH of the wastewater reaching a reverse osmosis unit is at a pH greater than 10.5.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

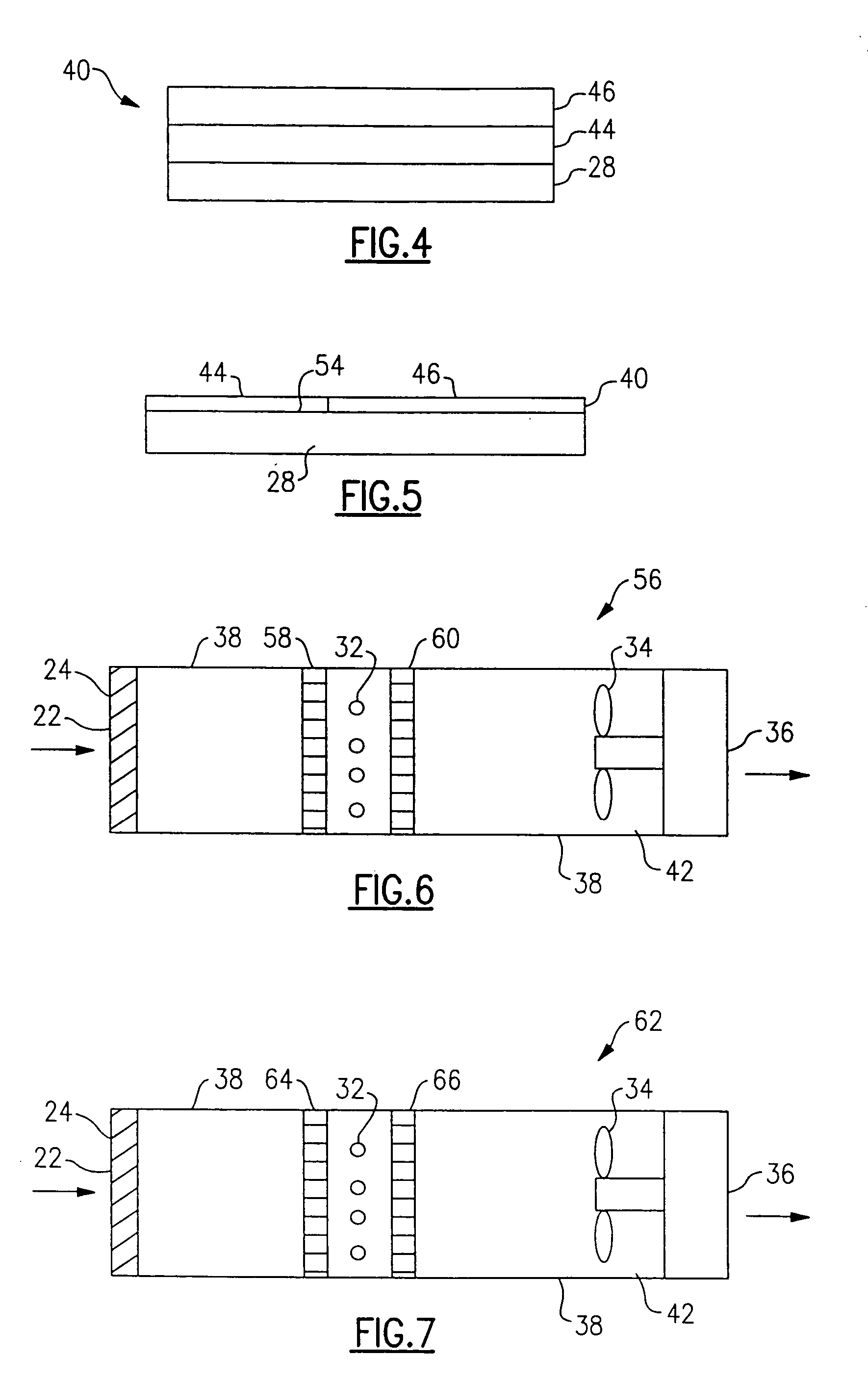

Bifunctional layered photocatalyst/thermocatalyst for improving indoor air quality

InactiveUS20050129591A1Lower energy barrierMechanical apparatusAir-treating devicesIndoor air qualityBifunctional

A photocatalytic / thermocatalytic coating includes an inner layer of metal / titanium dioxide or metal oxide / titanium dioxide that is applied on a honeycomb and an outer layer of titanium dioxide or metal oxide doped titanium dioxide applied on the inner layer. The inner layer of can be gold / titanium dioxide, platinum / titanium dioxide, or manganese oxide / titanium dioxide. The outer layer of titanium dioxide or metal oxide doped titanium dioxide oxides volatile organic compounds to carbon dioxide, water, and other substances. As the outer layer is thin and porous, the contaminants in the air can diffuse through the outer layer and adsorb onto the inner layer. When photons of the ultraviolet light are absorbed by the coating, reactive hydroxyl radicals are formed that oxidize the contaminant to produce water, carbon dioxide, and other substances.

Owner:CARRIER CORP

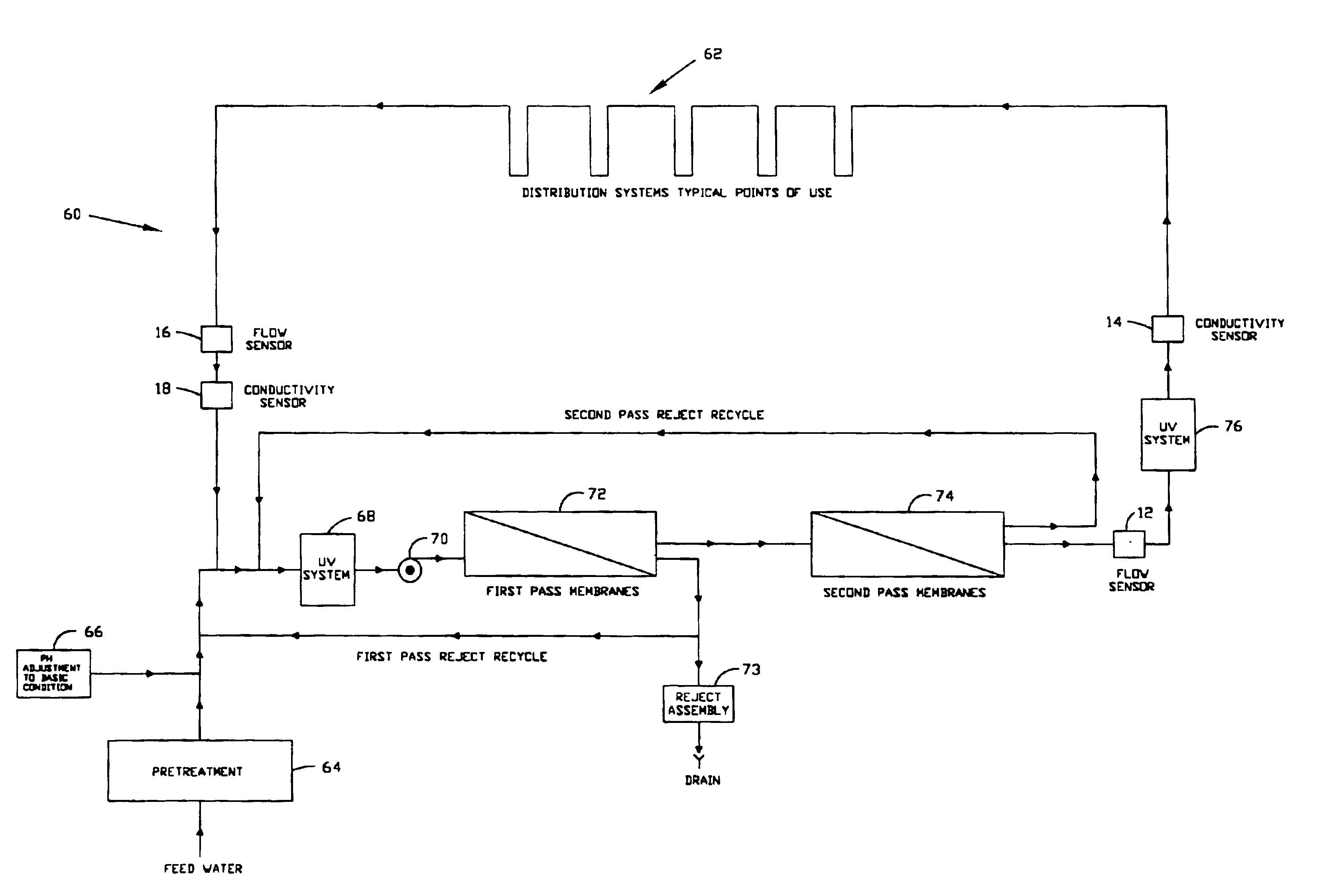

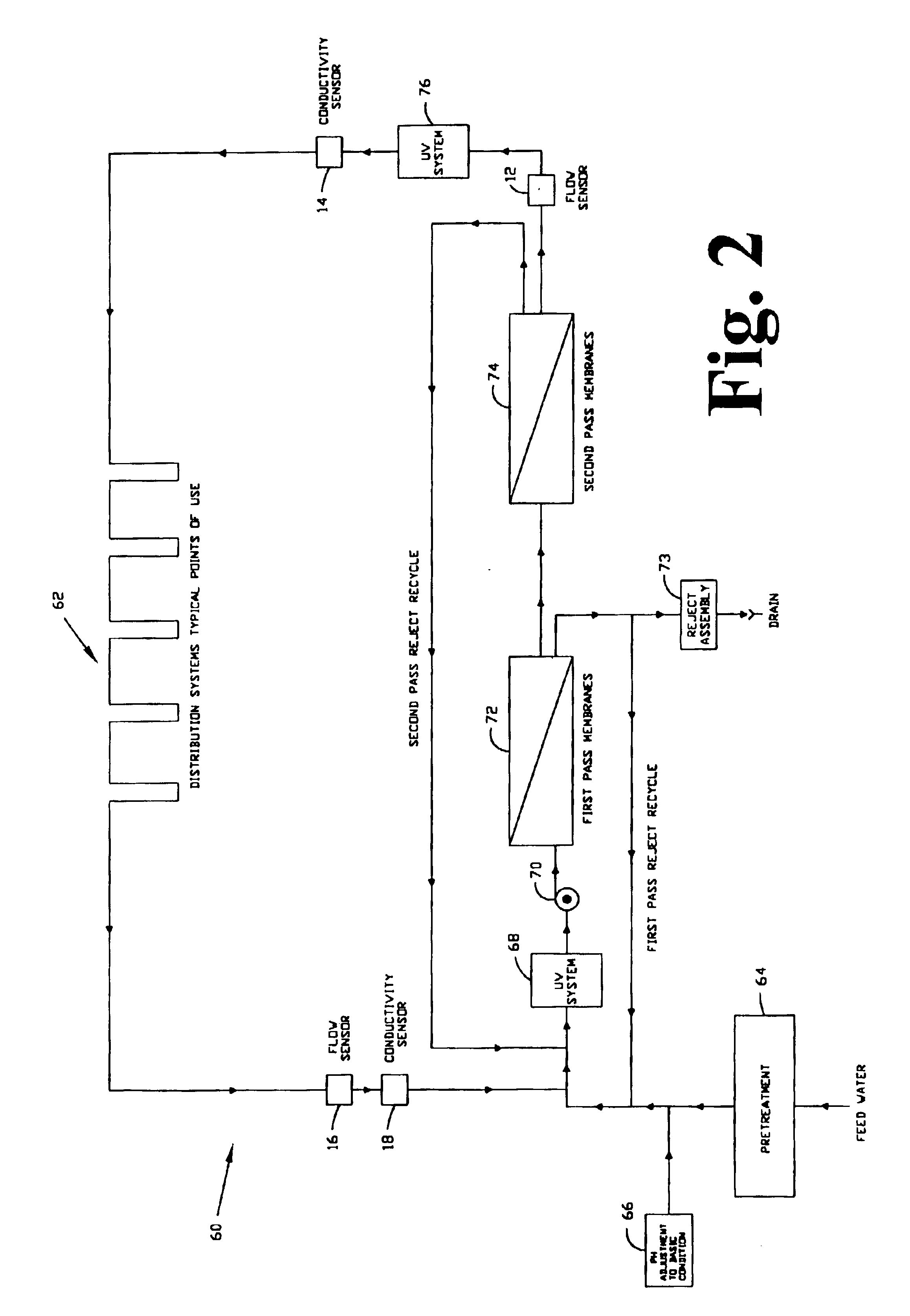

Apparatus and method for producing purified water having microbiological purity

InactiveUS6908546B2Reduce capital cost investmentReduce operating costsMembranesOther chemical processesNO storageReverse osmosis

A process is provided to produce water that will meet the specifications of the United States Pharmacopeia Inc. for Purified Water and Water for Injection, and water for dialysis as circumscribed by the American Association for Advancement of Medical Instrumentation (AAMI). The system has no storage tanks where stagnant water will be fouled by biofilm colonizing the tank surface. Water is circulated throughout the purification system and drawn as required, on demand. The water is purified and used immediately or recycled and repurified to ensure quality. Sanitation of the purification system, maintaining microbiological purity and cleaning is done by controlling the pH so that it is normally acidic by maintaining a high carbon dioxide concentration in solution, the carbon dioxide being allowed to pass into the permeate from a reverse osmosis membrane assembly used to purify the water.

Owner:BONOMICS LTD

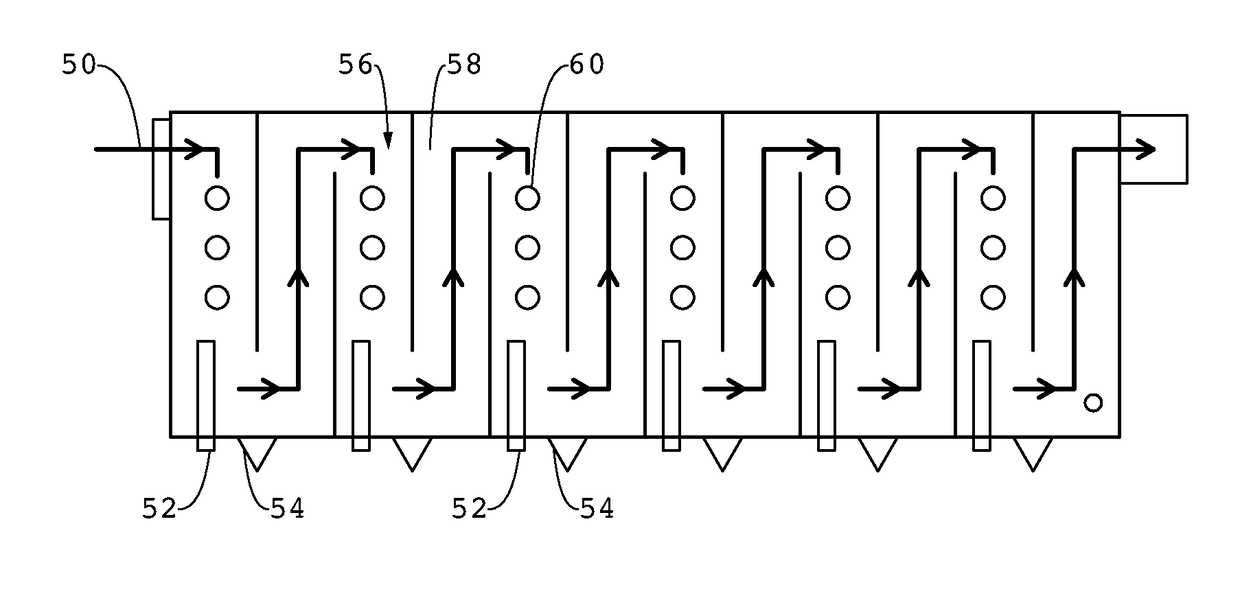

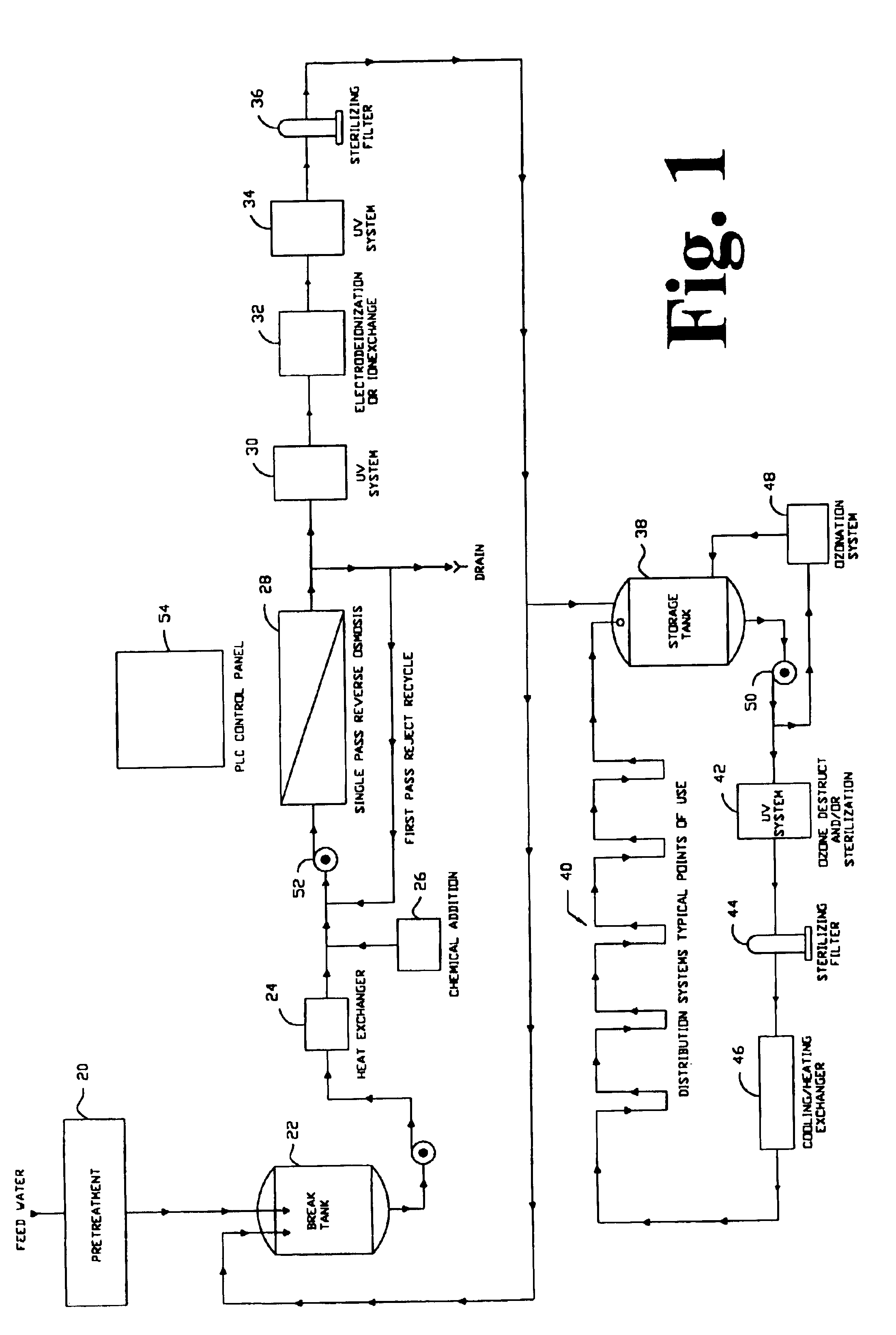

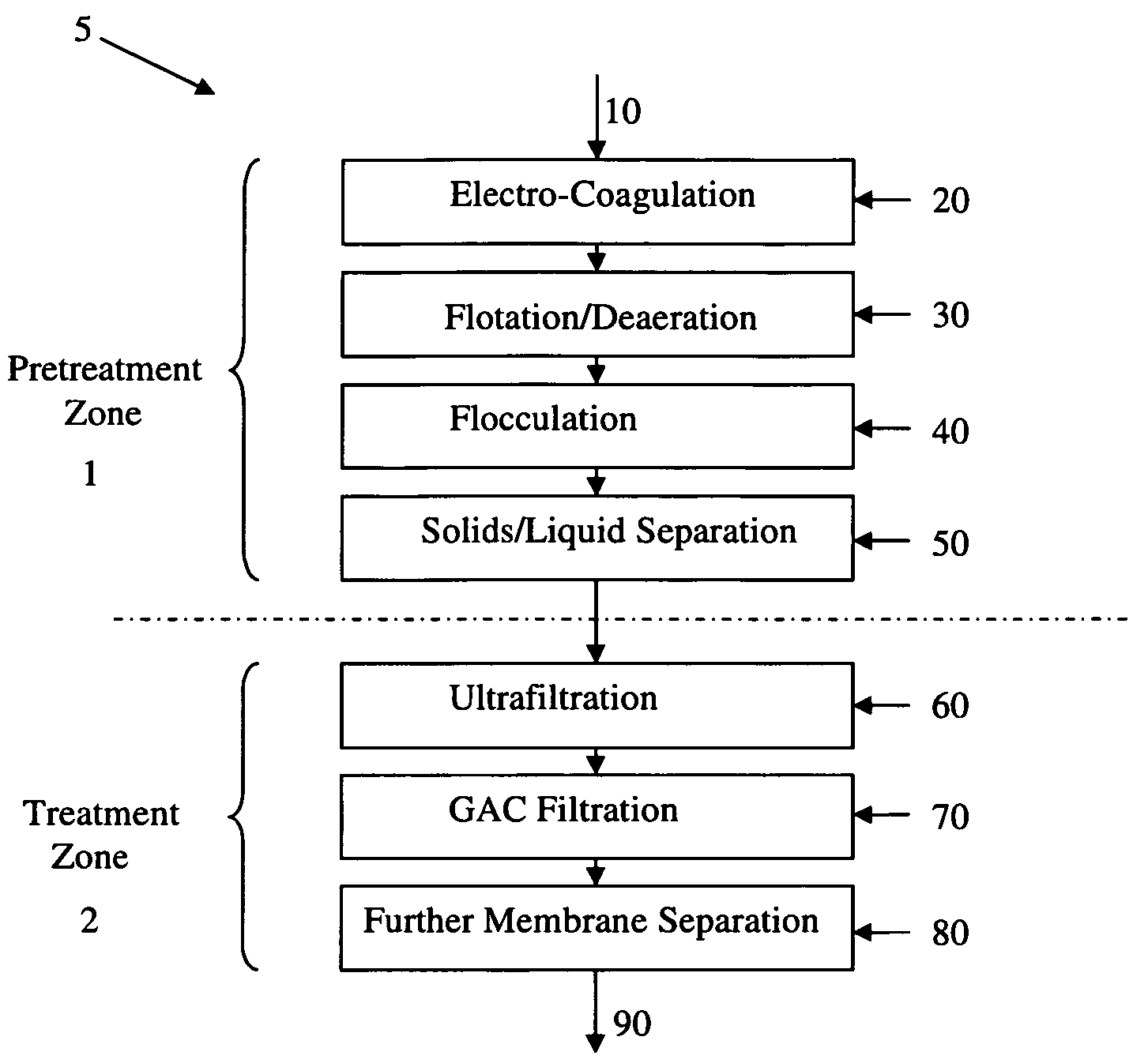

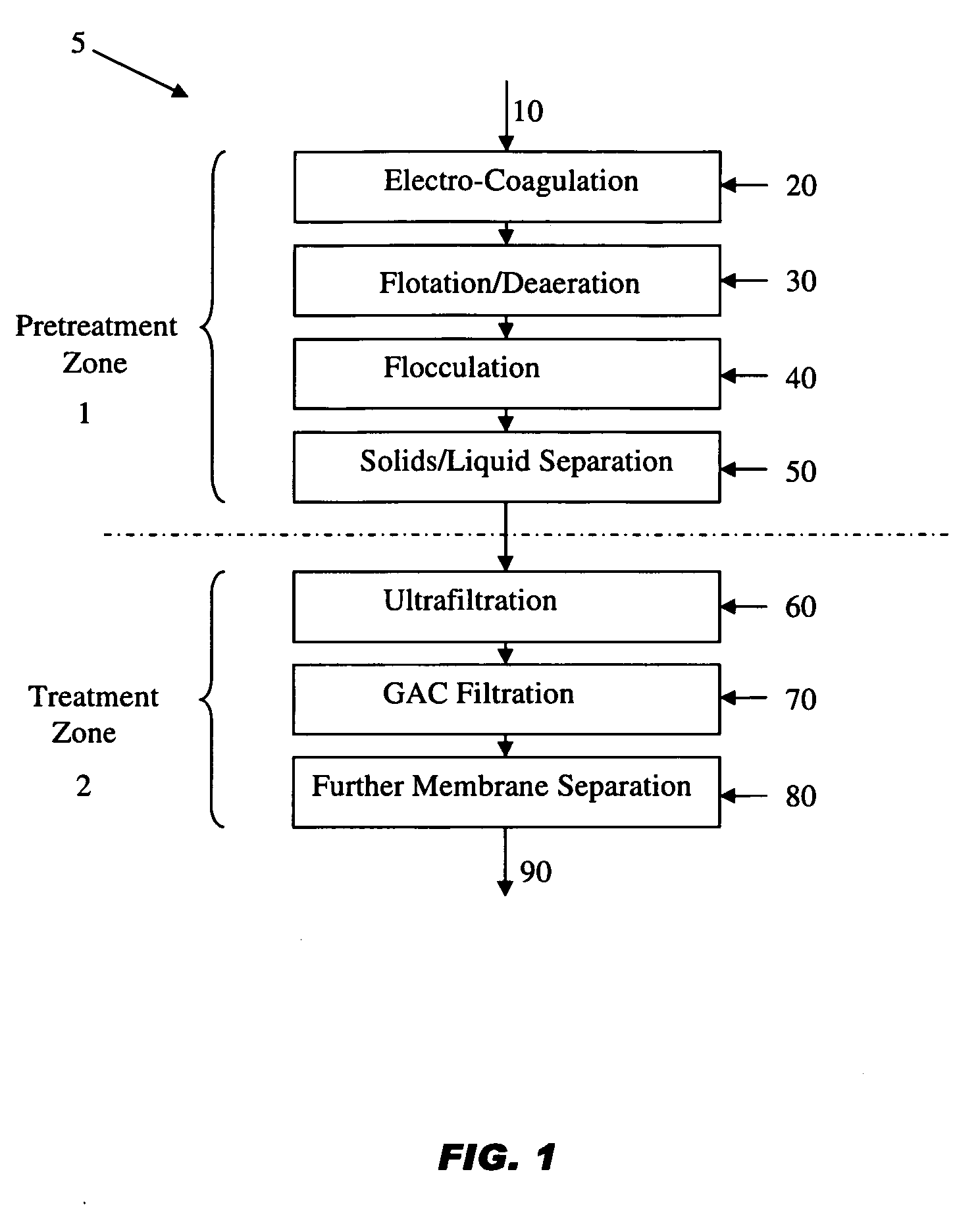

Treatment process and system for wastewater, process waters, and produced waters applications

A method for the removal of contaminants from a contaminated water stream, by pretreating the contaminated water stream to yield a pretreated water stream, wherein pretreating comprises passing the contaminated water stream to at least one electrocoagulation cell wherein coagulation of contaminants is promoted, yielding an electrocoagulated stream; and separating coagulated contaminants from the electrocoagulated stream.An electrocoagulation reactor comprising a plurality of electrodes positioned parallel to each other and provided with a means of energizing each electrode; a fluid inlet for an inlet stream comprising contaminated water; a fluid outlet for an outlet stream comprising electrocoagulated products; a flow distributor system; and a gas distribution system for injecting a gas into the electrocoagulation reactor. An electrocoagulation system for treating a contaminated water stream, the system comprising at least one electrocoagulation reactor.

Owner:ITS ENGINEERED SYST

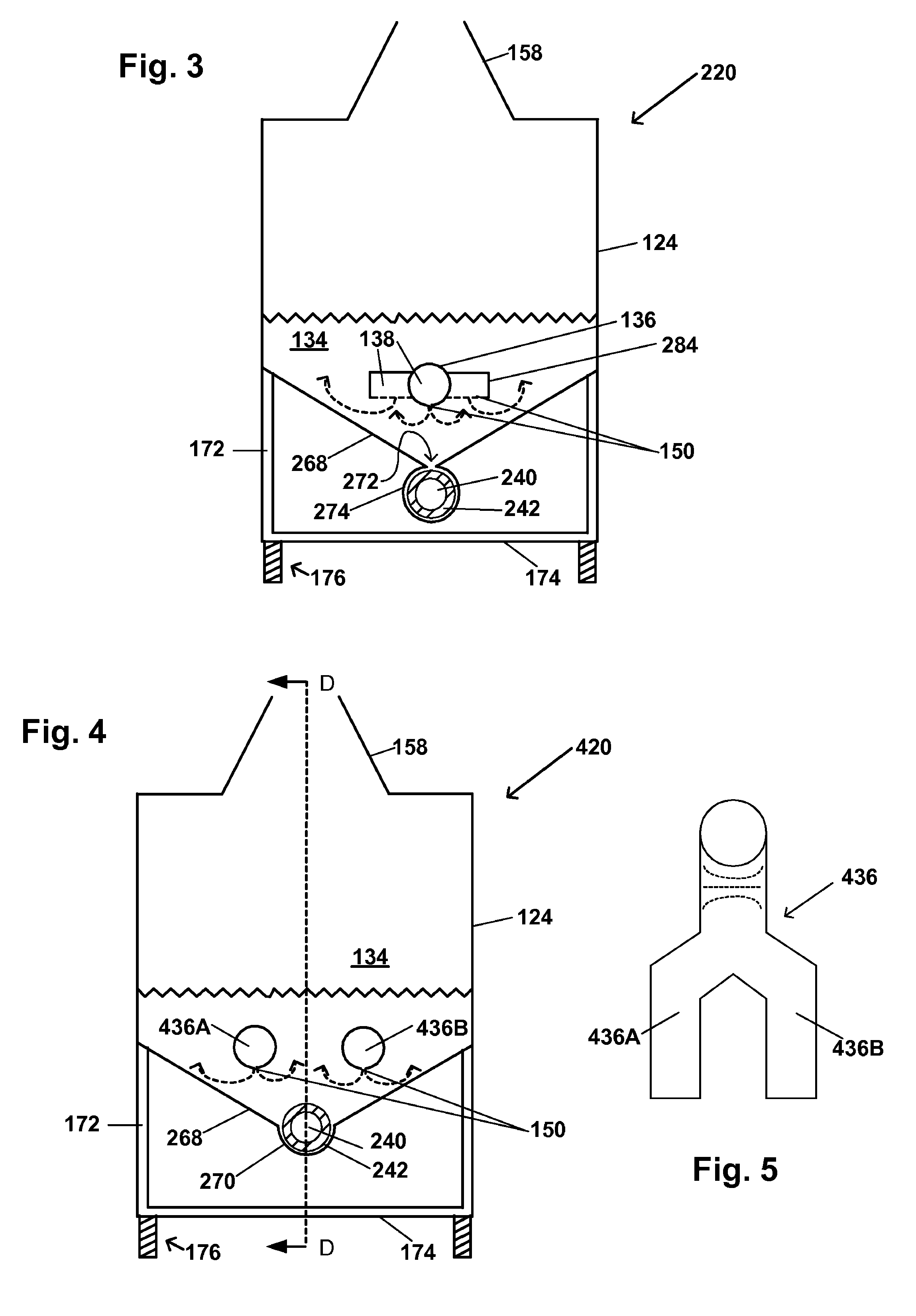

Submerged combustion disposal of produced water

InactiveUS7845314B2Easy to handleEasy disposalBoiler cleaning apparatusSedimentation separationCombustion systemCombustion chamber

The present invention relates to a method of disposing of produced water and to a produced water disposal apparatus including a container for receiving and holding produced water; and a burner having a combustion chamber, wherein at least a portion of the combustion chamber is submerged in the water and the submerged portion of the combustion chamber comprises a sparger tube through which combustion gases emerge into, mix with and agitate the water. The present invention further relates to a mechanism for removing debris from the produced water disposal apparatus. In one embodiment, heat is supplied from an externally operated combustion system, rather than the submerged combustion. In one embodiment, the apparatus provides a concentrator, in which a solute can be removed and recovered from an aqueous medium containing the solute.

Owner:TDU LLC

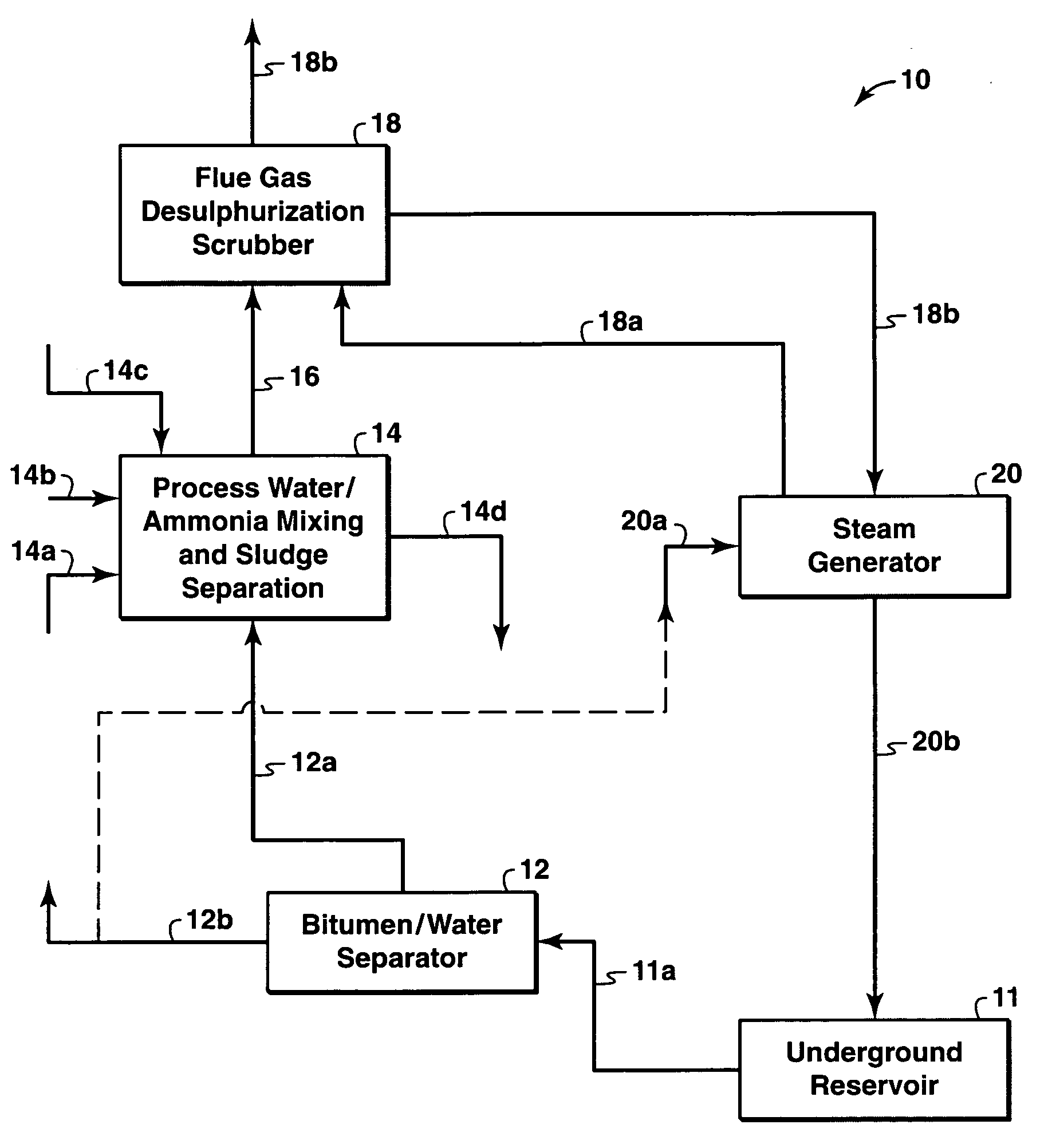

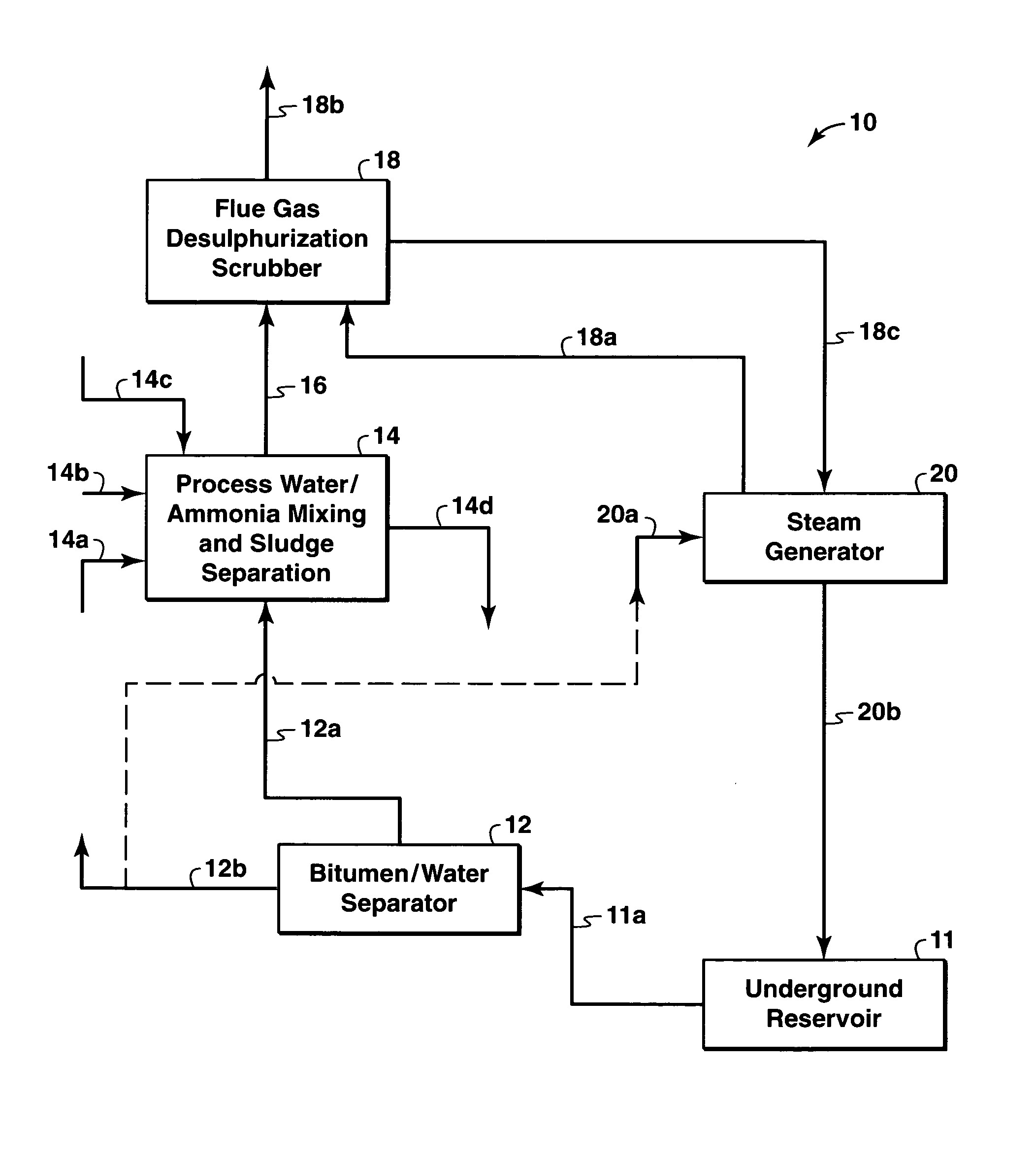

Integrated water treatment and flue gas desulfurization process

A water stream containing hardness minerals is subjected to a water treatment process using an alkali agent to precipitate the hardness minerals and to produce a softened water stream is used to create an integrated water treatment and flue gas desulfurization process. Thereafter, the softened, alkaline water stream is utilized in a scrubber to scrub a flue gas containing sulfur dioxide to produce a sulfur-lean flue gas. The invention may be applied to a steam-based bitumen recovery operation where bitumen, sour produced gas or other sulfur containing fuels are burned for producing steam for bitumen recovery. More specifically, the associated produced water from the bitumen recovery process may be softened for re-use and for utilization as a scrubbing agent for high-sulfur containing flue gas arising from the steam generators. The process provides an economically favorable process while minimizing waste disposal requirements.

Owner:EXXONMOBIL UPSTREAM RES CO

Acrylic acid composition and its production process, and process for producing water- absorbent resin using this acrylic acid composition, and water-absorbent resin

InactiveUS20040110914A1Improve productivityHigh propertyAbsorbent padsBaby linensProduction ratePolymer science

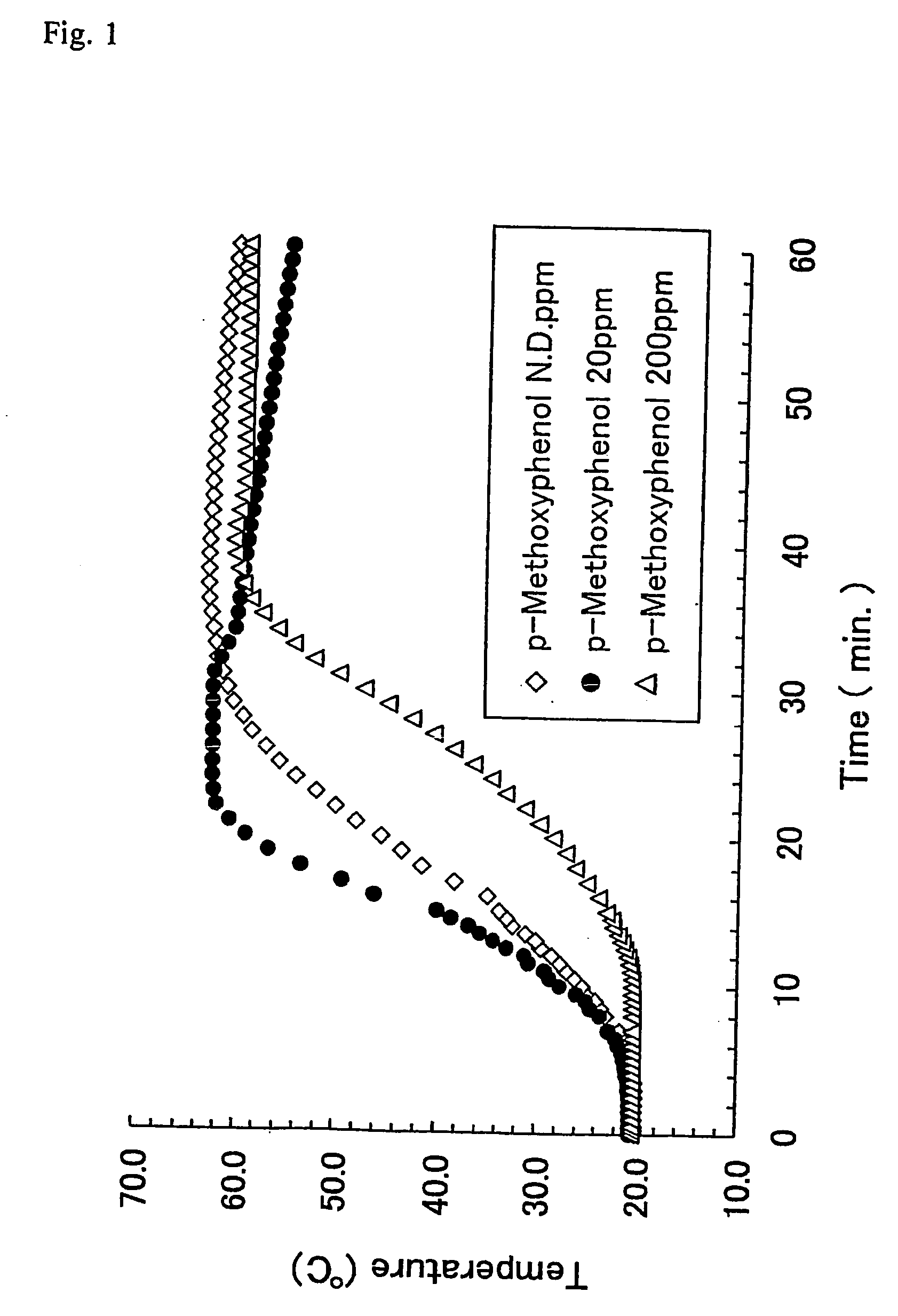

In order to produce inexpensively with high productivity a water-absorbent resin of which: the residual monomer content and the water-extractable content are both low, and the properties are high, and the colorability is low; there is provided a process for producing a water-absorbent resin, which is a process for producing a crosslinked water-absorbent resin by polymerizing a monomer component including acrylic acid and / or its salt in a major proportion wherein the acrylic acid is a product obtained by catalytic gas phase oxidation of propylene and / or propane, with the process being characterized by comprising the steps of: preparing the monomer component from an acrylic acid composition that includes the unneutralized acrylic acid and a methoxyphenol and has a methoxyphenol content of 10 to 160 ppm by weight (based on the unneutralized acrylic acid); and then carrying out radical and / or ultraviolet polymerization of the resultant monomer component.

Owner:NIPPON SHOKUBAI CO LTD

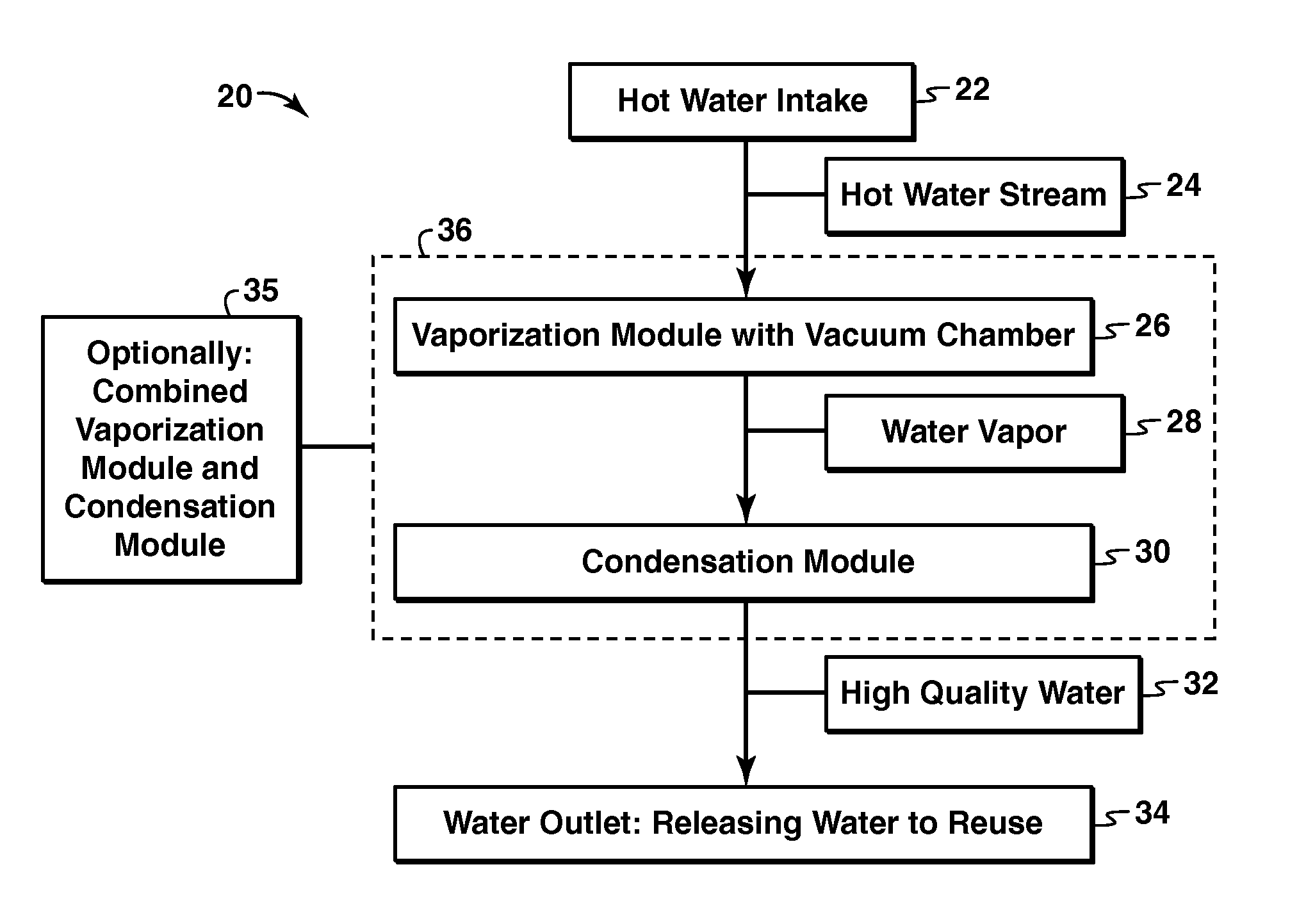

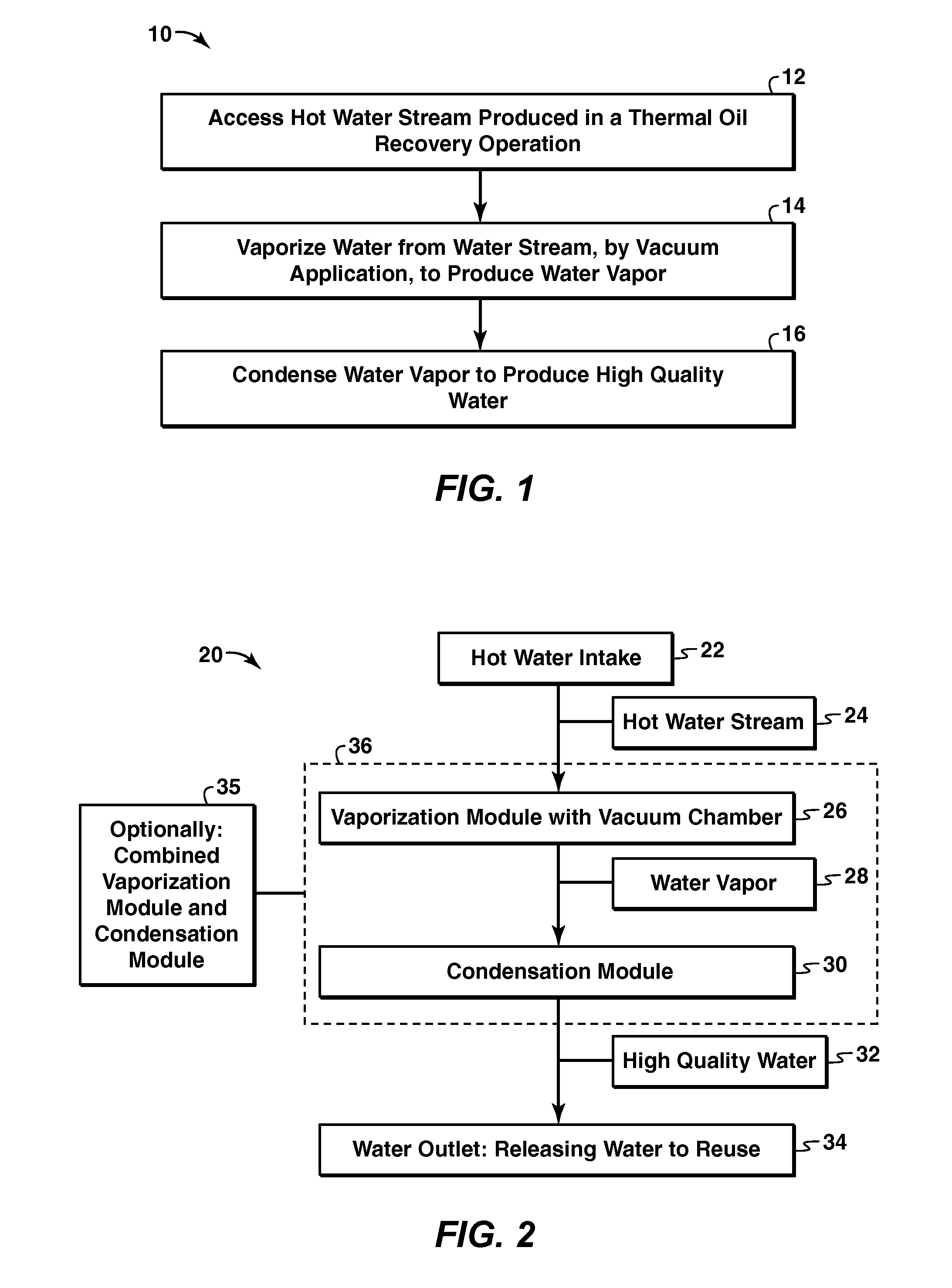

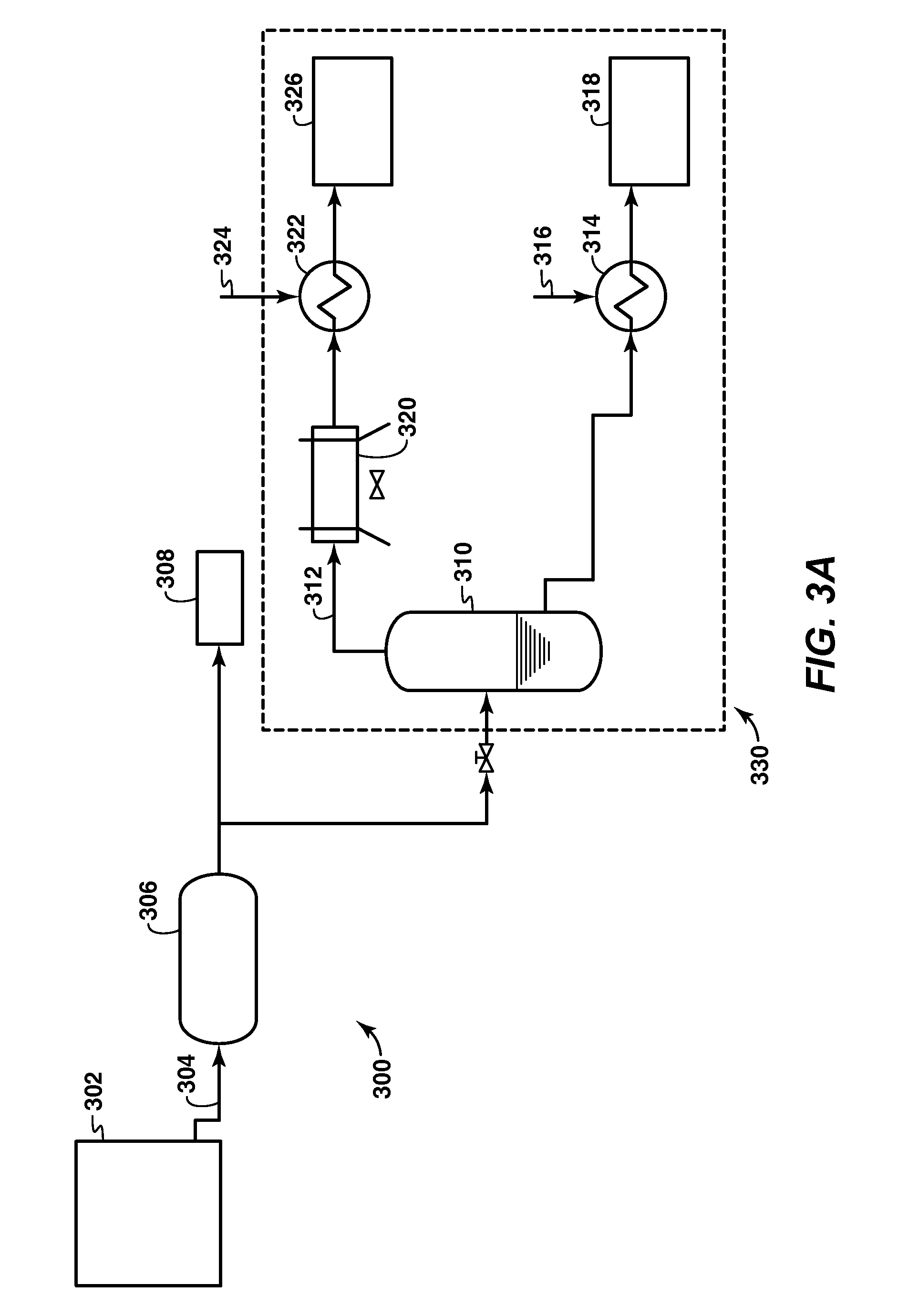

Recovery of high water from produced water arising from a thermal hydrocarbon recovery operation using vaccum technologies

InactiveUS20100282593A1High purityImprove purification effectAuxillariesEvaporation with vapour compressionWater flowVaporization

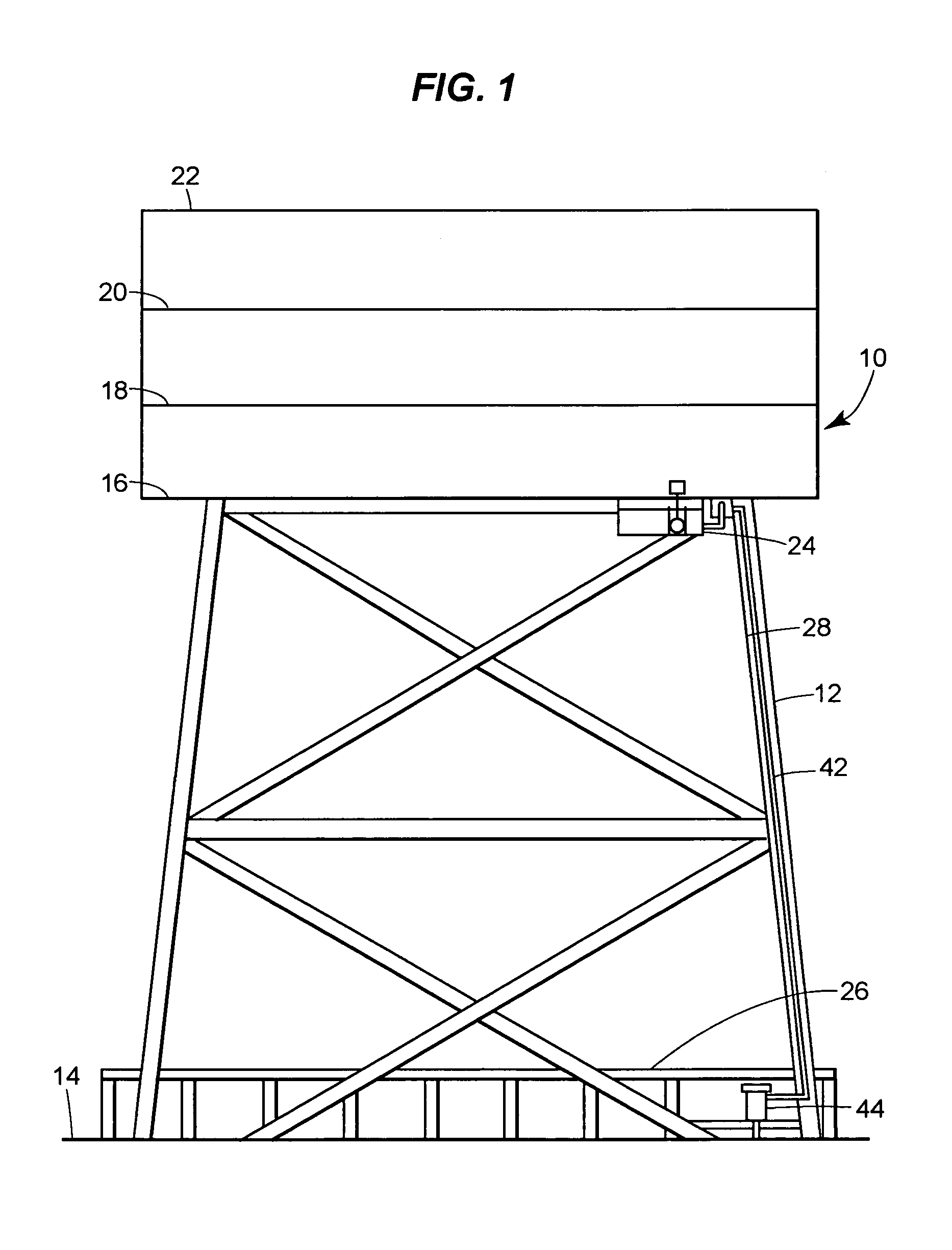

A method for reducing and re-using waste heat and water resulting from thermal hydrocarbon recovery operations involving accessing a hot water stream produced in a thermal hydrocarbon recovery operation; vaporizing water from the water stream by applying a vacuum, thereby producing water vapor; and condensing the water vapor to produce high quality water. A system is described including a hot water intake interfacing with a hot water stream from a thermal hydrocarbon recovery operation; a vaporization module receiving the hot water stream from the hot water intake, comprising a vacuum chamber in which a vacuum is applied to produce water vapor from the hot water stream; a condensation module in which water vapor produced in the vaporization module is condensed to form high quality water; and a water outlet for releasing the high quality water from the condensation module for re-use within the thermal hydrocarbon recovery operation.

Owner:EXXONMOBIL UPSTREAM RES CO

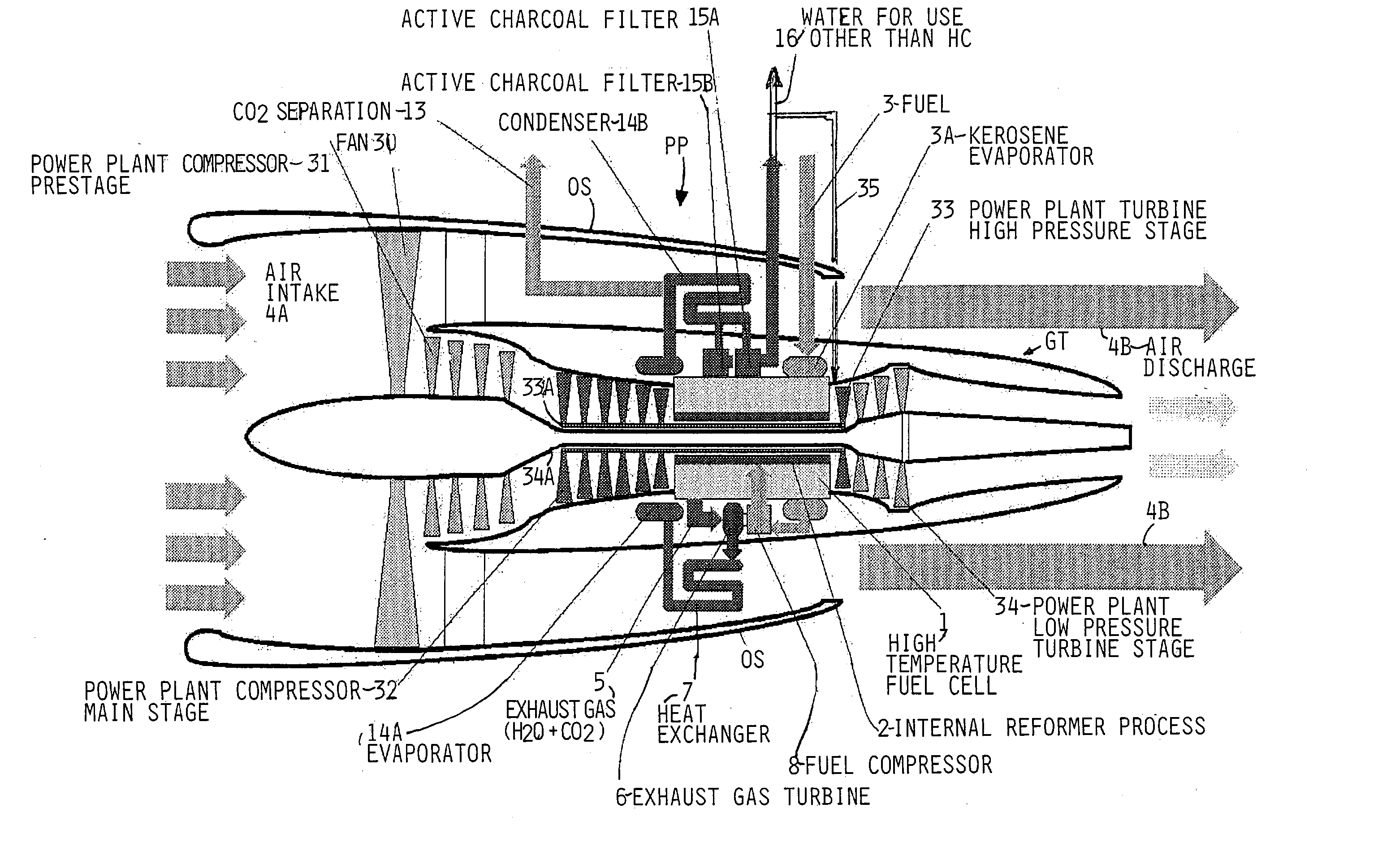

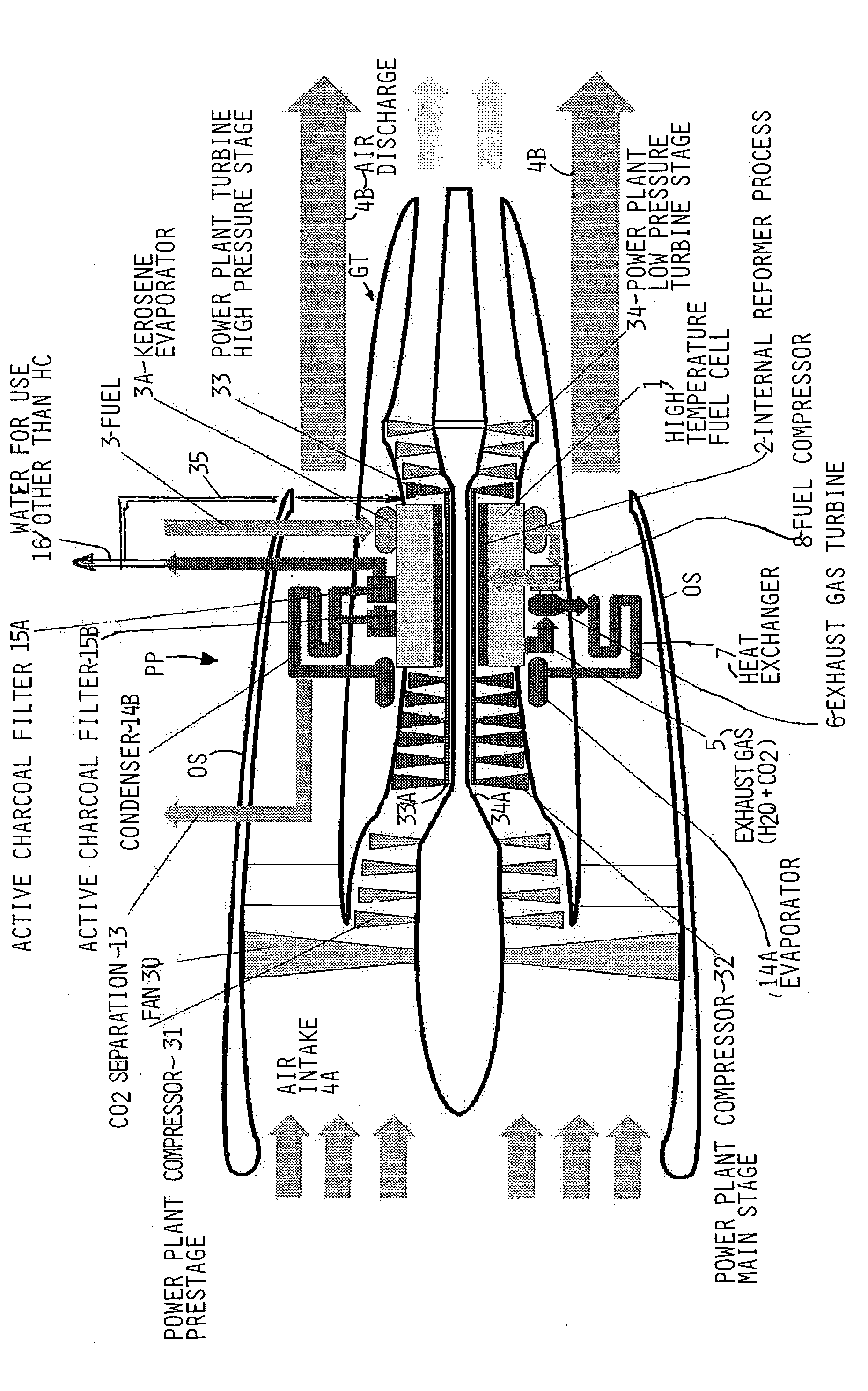

Apparatus for producing water onboard of a craft driven by a power plant

InactiveUS20040040312A1Improve overall utilizationFlexibility in distributionFuel cells groupingFuel cell auxillariesCombustion chamberEngineering

Water is generated onboard of a craft such as an aircraft or in a self-contained stationary system by partially or completely integrating a water generating unit into a power plant of the craft or system. The water generating unit includes one or more high temperature fuel cells which partially or completely replace the combustion chamber or chambers of the power plant. A reformer process is integrated into the high temperature fuel cell which is arranged between, on the one hand, a fan (30) and power plant compressor stages (31, 32) and, on the other hand, power plant turbine stages (33, 34). These power plant stages may be provided in such redundant numbers that safety and redundancy requirements are satisfied.

Owner:AIRBUS OPERATIONS GMBH

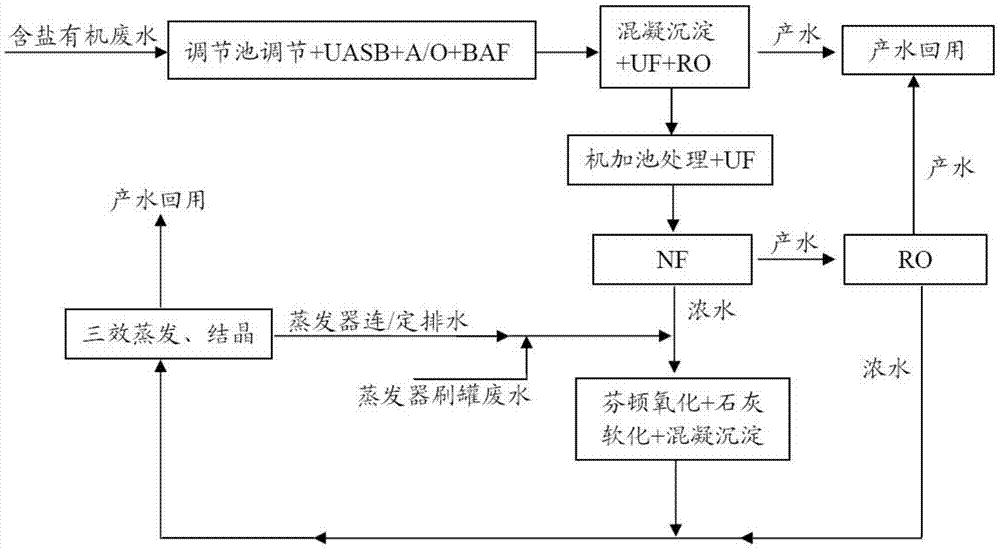

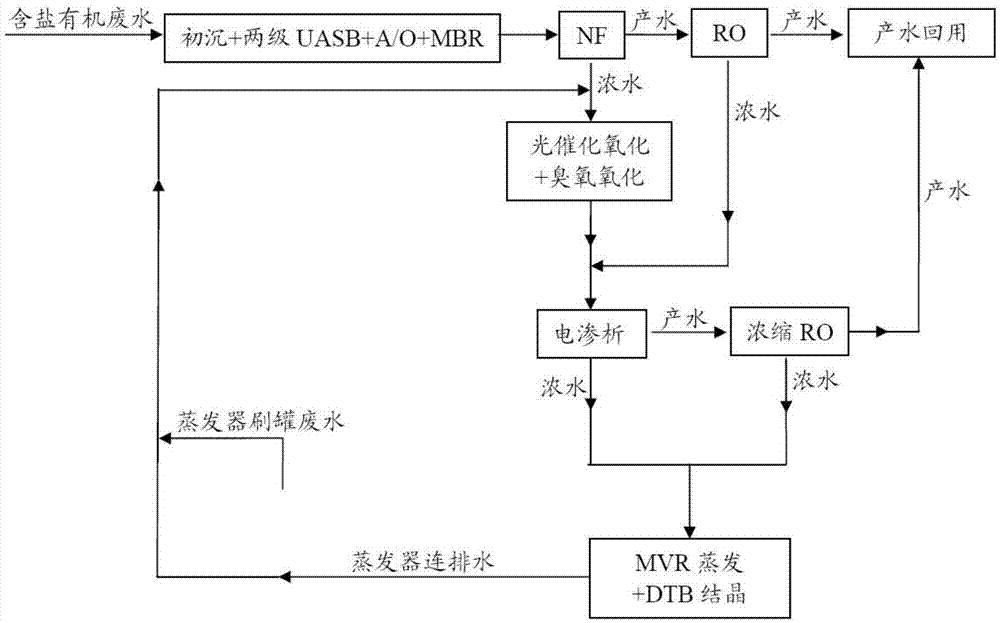

Zero-discharge treatment method of salt-containing organic wastewater

InactiveCN105439395AEasy to handleEfficient reuseTreatment using aerobic processesTreatment involving filtrationEvaporationOrganic matter

The invention provides a zero-discharge treatment method of salt-containing organic wastewater. The method comprises the following steps that biochemical treatment and filtering treatment are performed on wastewater; then, membrane concentration is performed; pure-water-producing high-organic-matter-content membrane concentration concentrated water and optional low-organic-matter-content membrane concentration concentrated water are obtained; the high-organic-matter-content membrane concentration concentrated water is used for high-grade oxidation treatment; high-grade oxidation produced water is used for regulation treatment to obtain high-grade oxidation outlet water; the obtained high-grade oxidation outlet water is subjected to evaporation treatment; or the obtained high-grade oxidation outlet water and the low-organic-matter-content membrane concentration concentrated water are mixed under the condition that the low-organic-matter-content membrane concentration concentrated water exists in the step, and then, the evaporation treatment is carried out; external discharge concentration liquid of an evaporator and / or high-salt-content high-organic-matter-content wastewater discharged during the tank brushing of the evaporator are conveyed back into a high-grade oxidation treatment unit; after the liquid is mixed with the high-organic-matter-content membrane concentration concentrated water, the high-grade oxidation treatment is carried out. The wastewater treatment method is stable and reliable; the long-period and stable operation of an evaporation system can be ensured; the zero discharge of the industrial wastewater is realized.

Owner:DATANG INT CHEM TECH RESINST

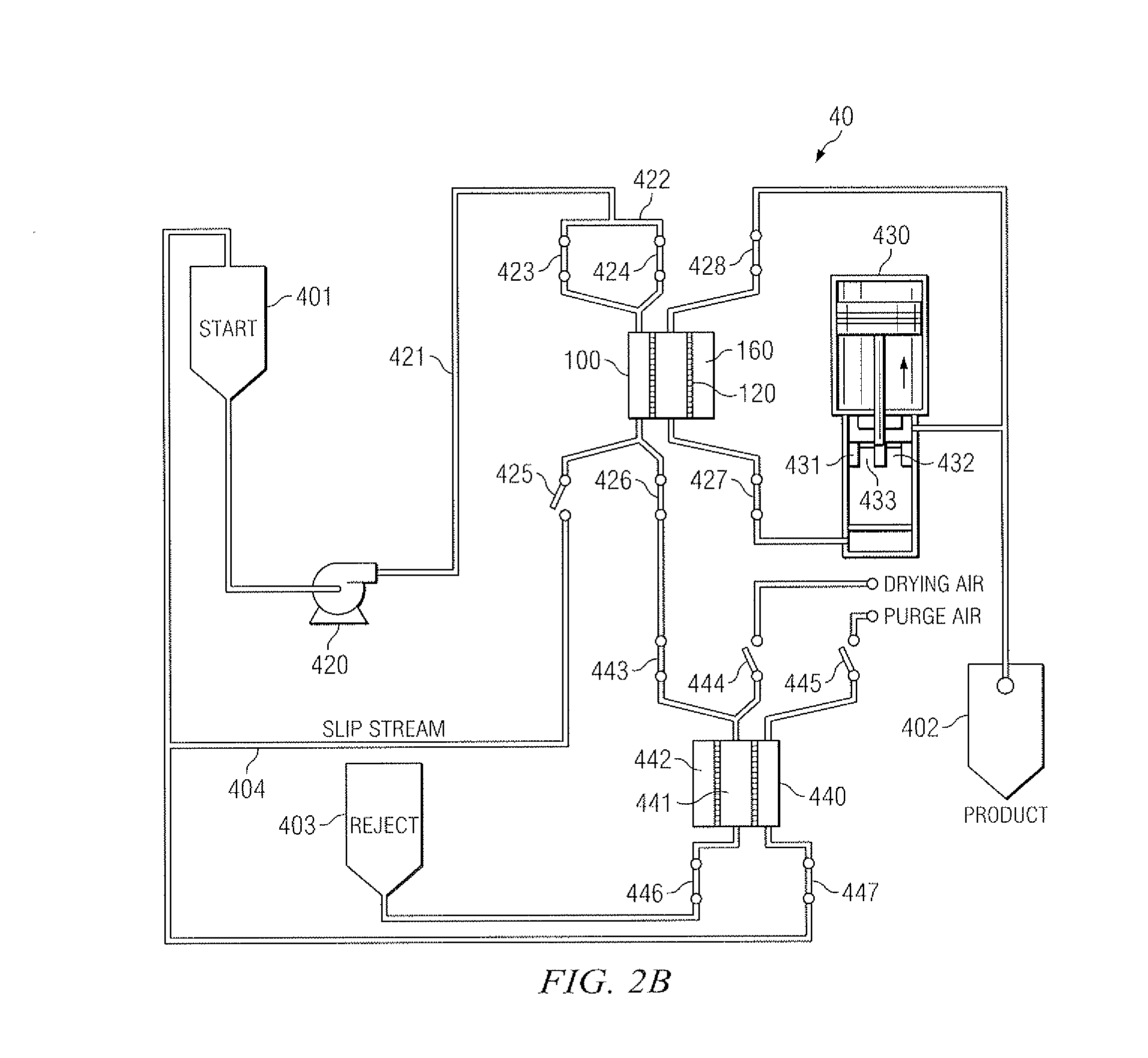

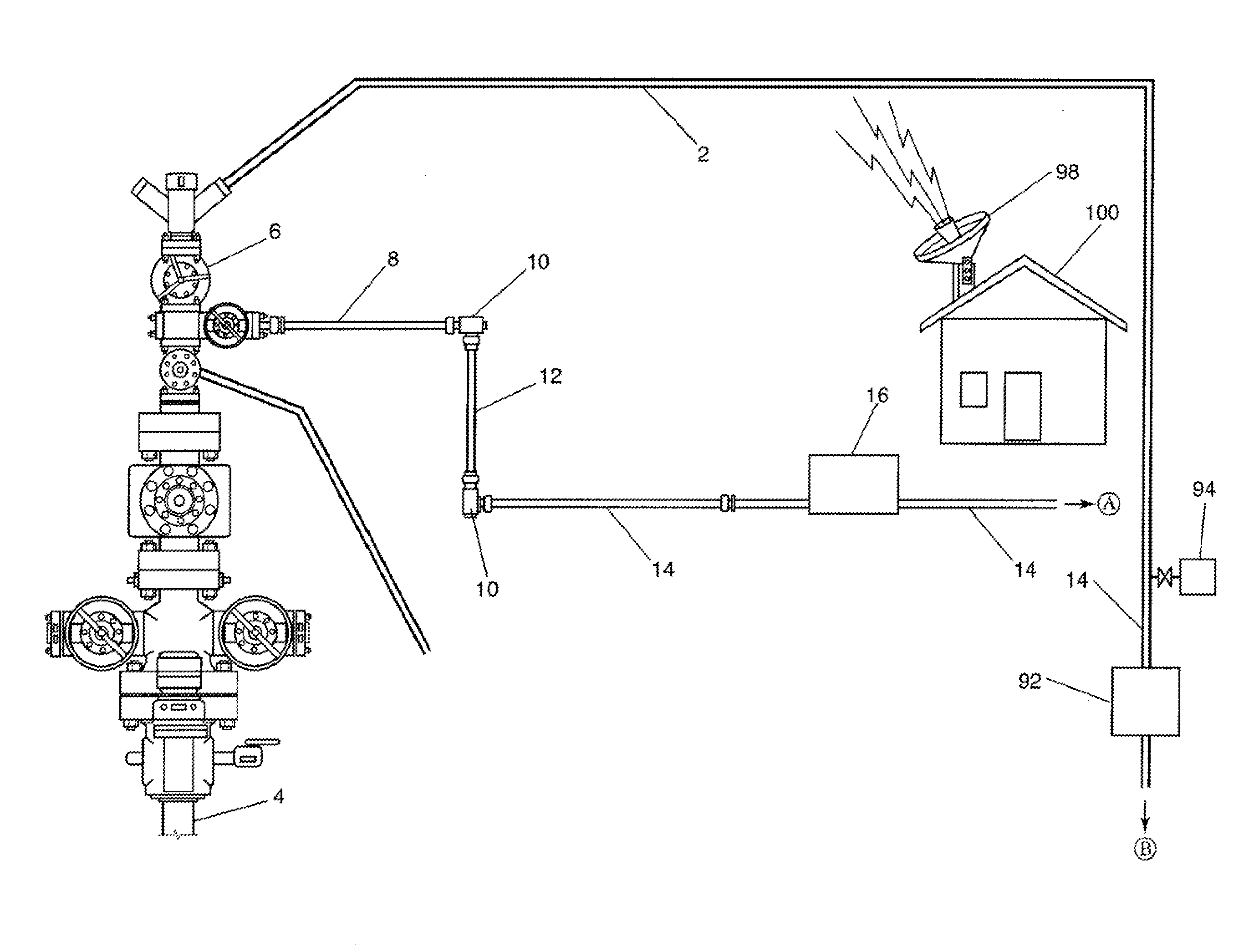

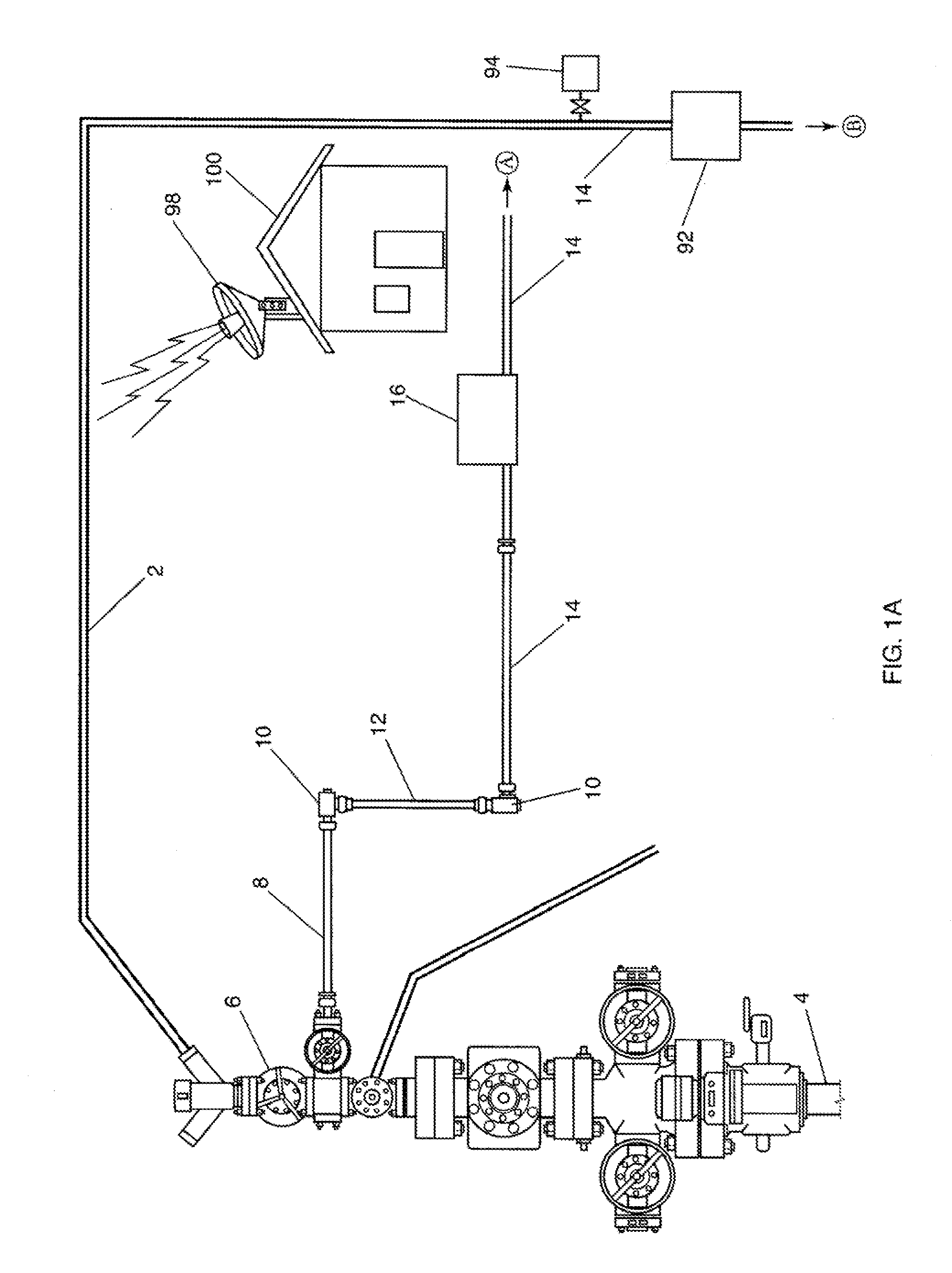

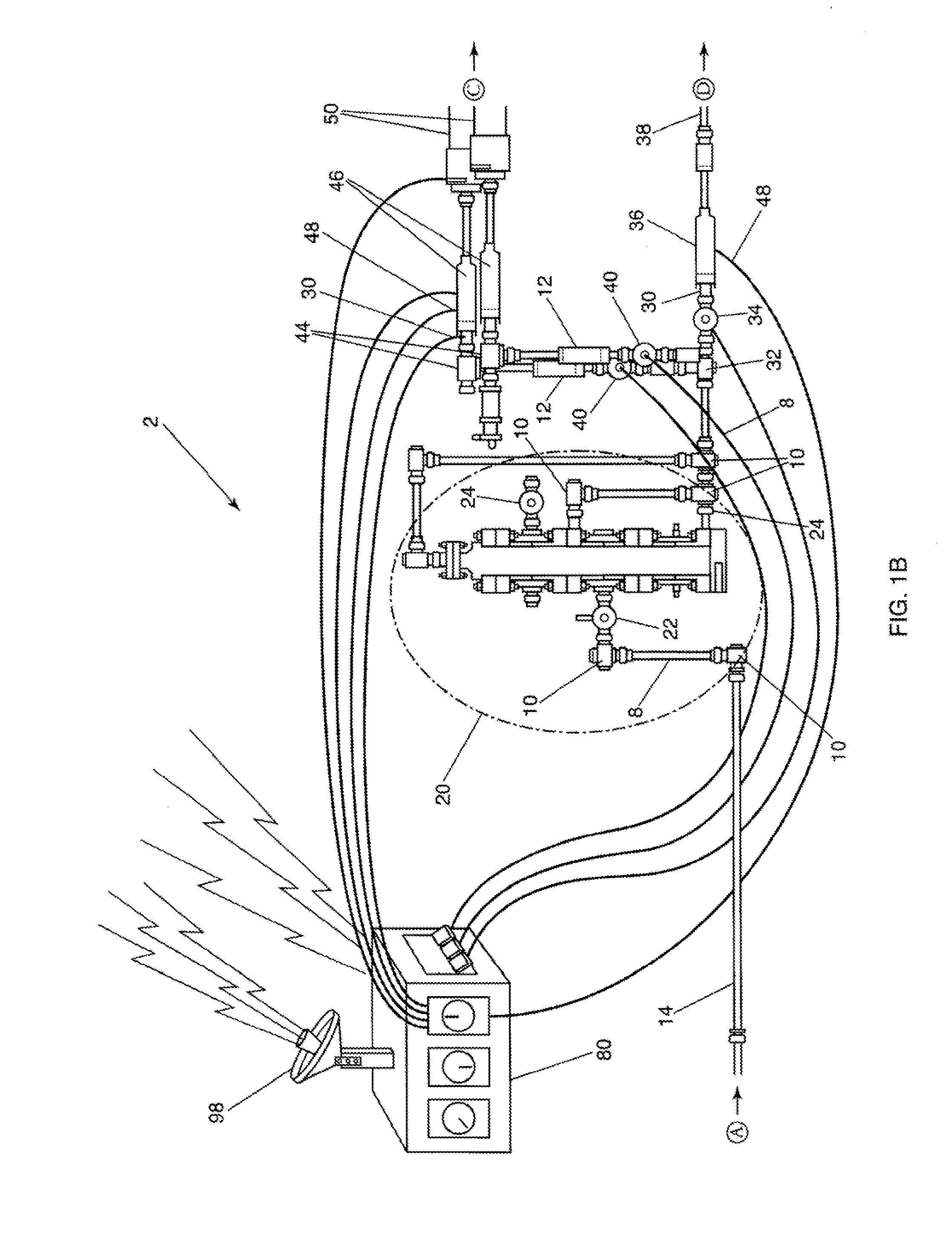

Automated closed loop flowback and separation system

InactiveUS20100206560A1Realize automatic adjustmentSurveyDrilling rodsAutomatic controlHuman–machine interface

An automated closed loop flowback and separation system that allows automated control and remote operation of a flowback operation from a safe distance without any fluid or gas release to the atmosphere. Four-phase separation tanks allow the transport gas, well bore cuttings, produced oil, and produced water to be automatically separated and transported through process piping for reuse or sale, eliminating the need for auxiliary equipment. Flow measurement instruments, pressure transmitters, and level transmitters work in conjunction with an automated blast choke to send data to a programmable logic controller for use in calculating the erosion status of the choke restriction and adjusting the choke to compensate. The programmable logic controller works with a touch-screen or similar human-machine interface to allow remote monitoring and control or automated control of the system. The automated blast choke can vary the choke restriction opening based on the pressure differential and flow rate conditions.

Owner:CANADIAN FRACMASTER

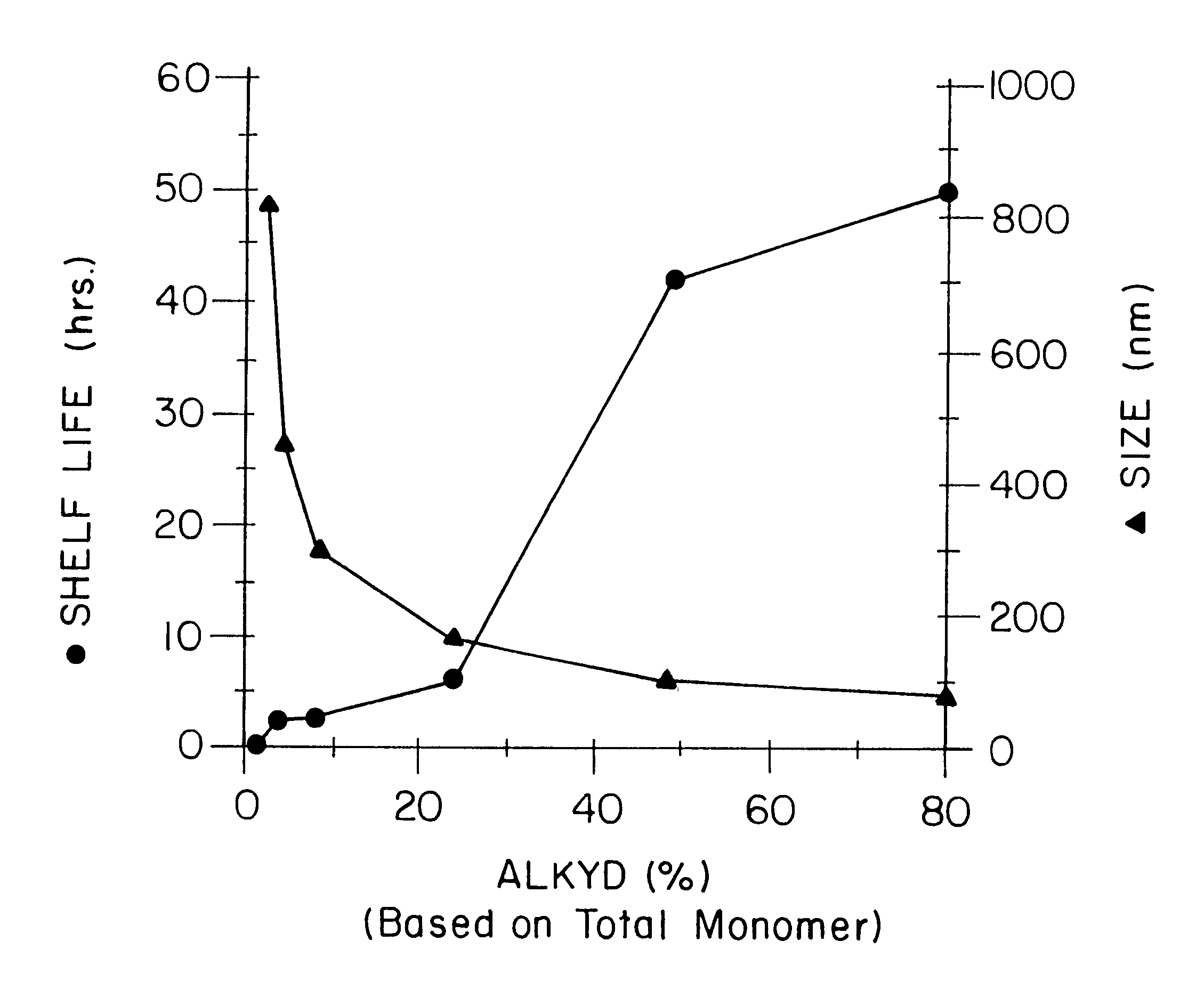

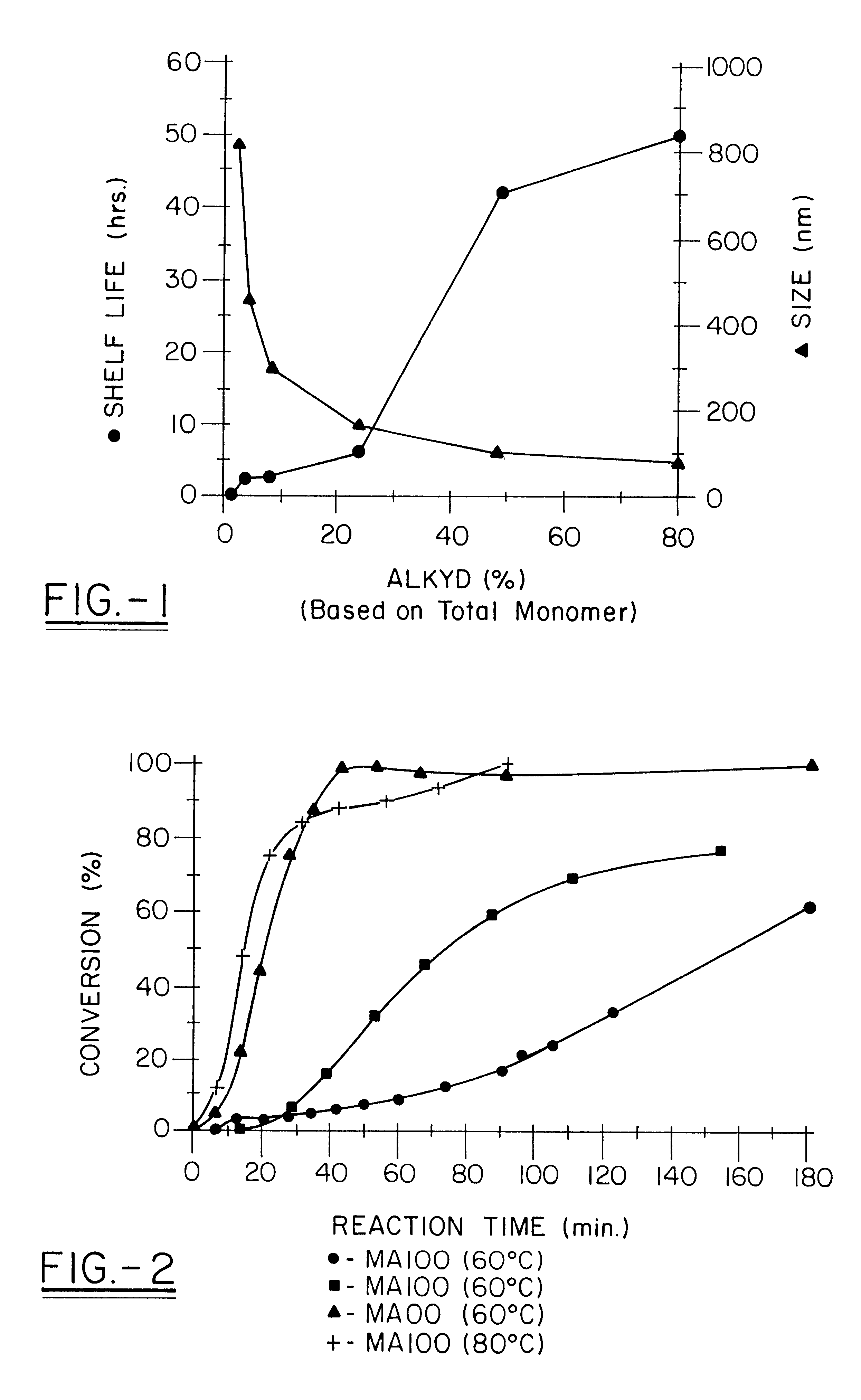

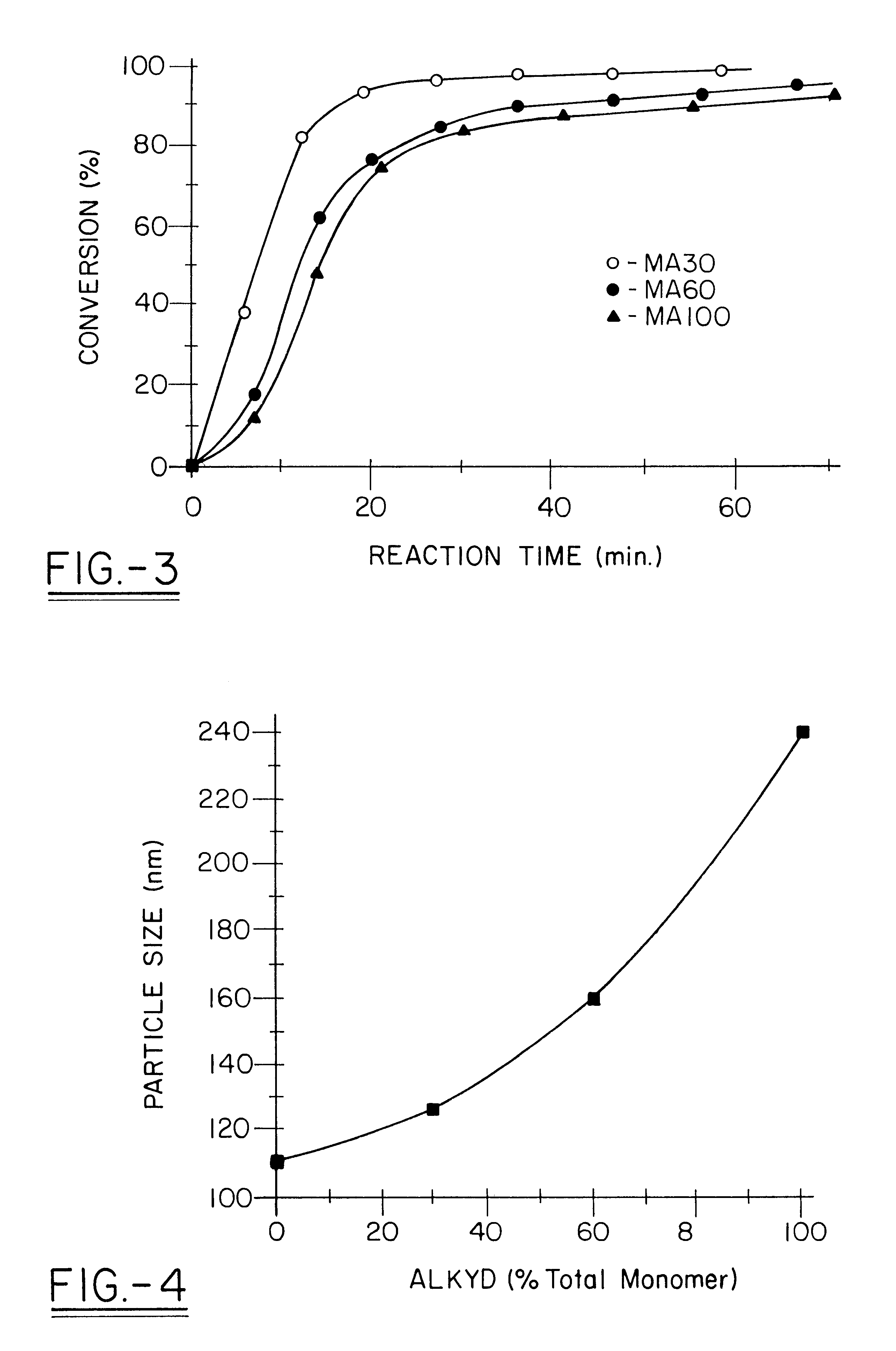

Water-borne alkyd coatings by miniemulsion polymerization

A distinctive graft copolymer is made by dissolving an alkyd resin in various vinyl monomers (methyl methacrylate, styrene, etc.). The monomer / alkyd solution is then miniemulsion polymerized to form a latex consisting of submicron particles of polymer with the alkyd grafted onto the polymer backbone. The latex can be applied to a substrate, which on drying forms a polymeric film with good film properties. The latex can be used in a latex paint formulation in place of an acrylate, acetate or styrene-divinyl benzene latex. In this way it is possible to produce water-borne alkyd coatings which combine the film hardness properties of an oil-based alkyd coating with easy application and cleanup. The coating will beneficially lack organic solvent exposure of typical standard latex coatings.

Owner:GEORGIA TECH RES CORP

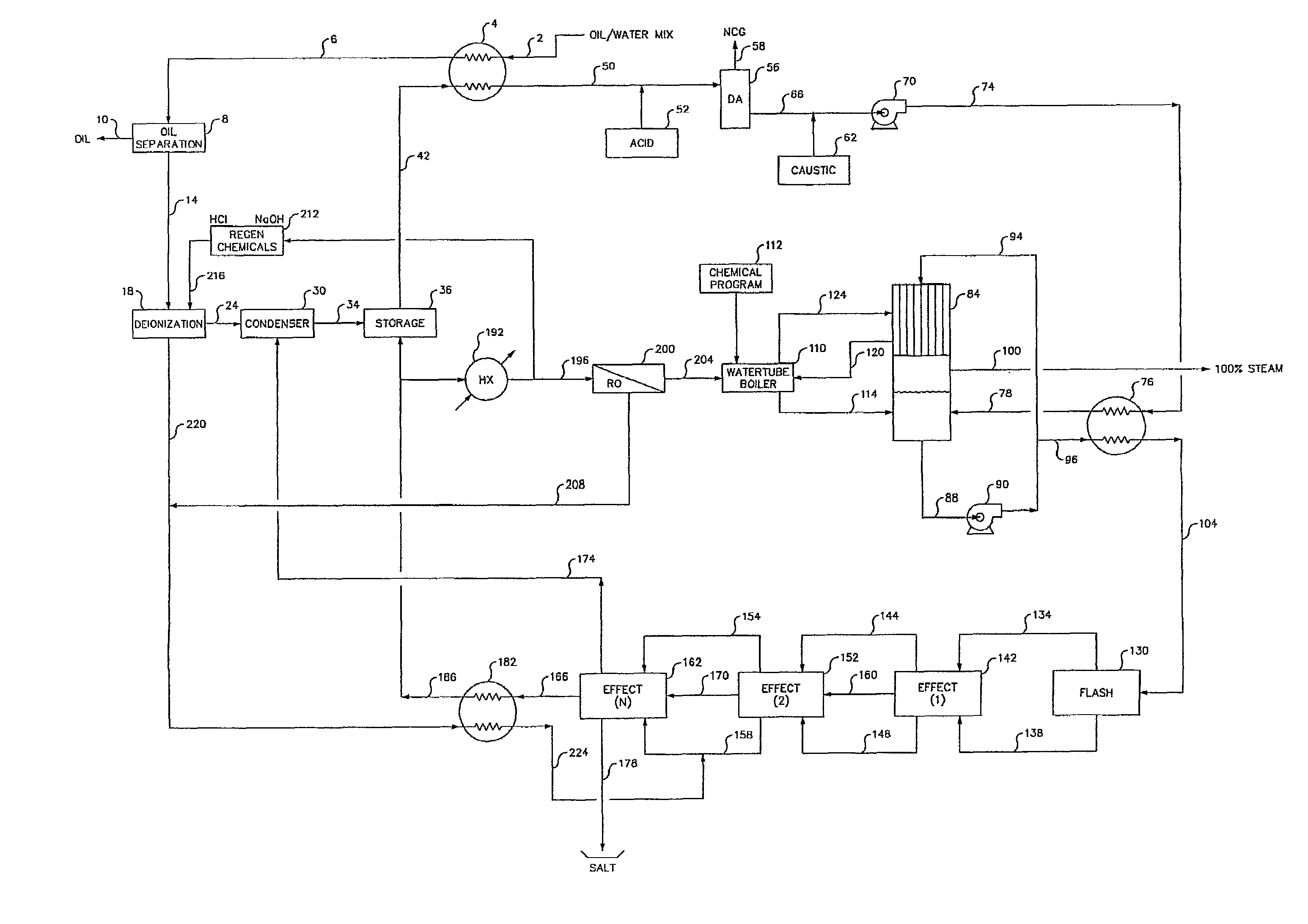

Method for production of high pressure steam from produced water

InactiveUS7591309B2Drying using combination processesSolid sorbent liquid separationChemical treatmentWater flow

An evaporation based method for generation of high pressure steam from produced water in the heavy oil production industry. De-oiled produced water is processed through a high pH / high pressure evaporator driven by a commercial watertube boiler. The vapor produced by the evaporator is suitable for the steam assisted gravity drainage (SAGD) method being utilized by heavy oil recovery installations, without the use of once through steam generators that require extensive chemical treatment, and without requiring atmospheric distillation, which requires high power consuming compressors. Evaporator blowdown may be further treated in a crystallizing evaporator to provide a zero liquid discharge (ZLD) system and, with most produced waters, at least 98% of the incoming produced water stream can be recovered in the form of high pressure steam.

Owner:AQUATECH INT LLC

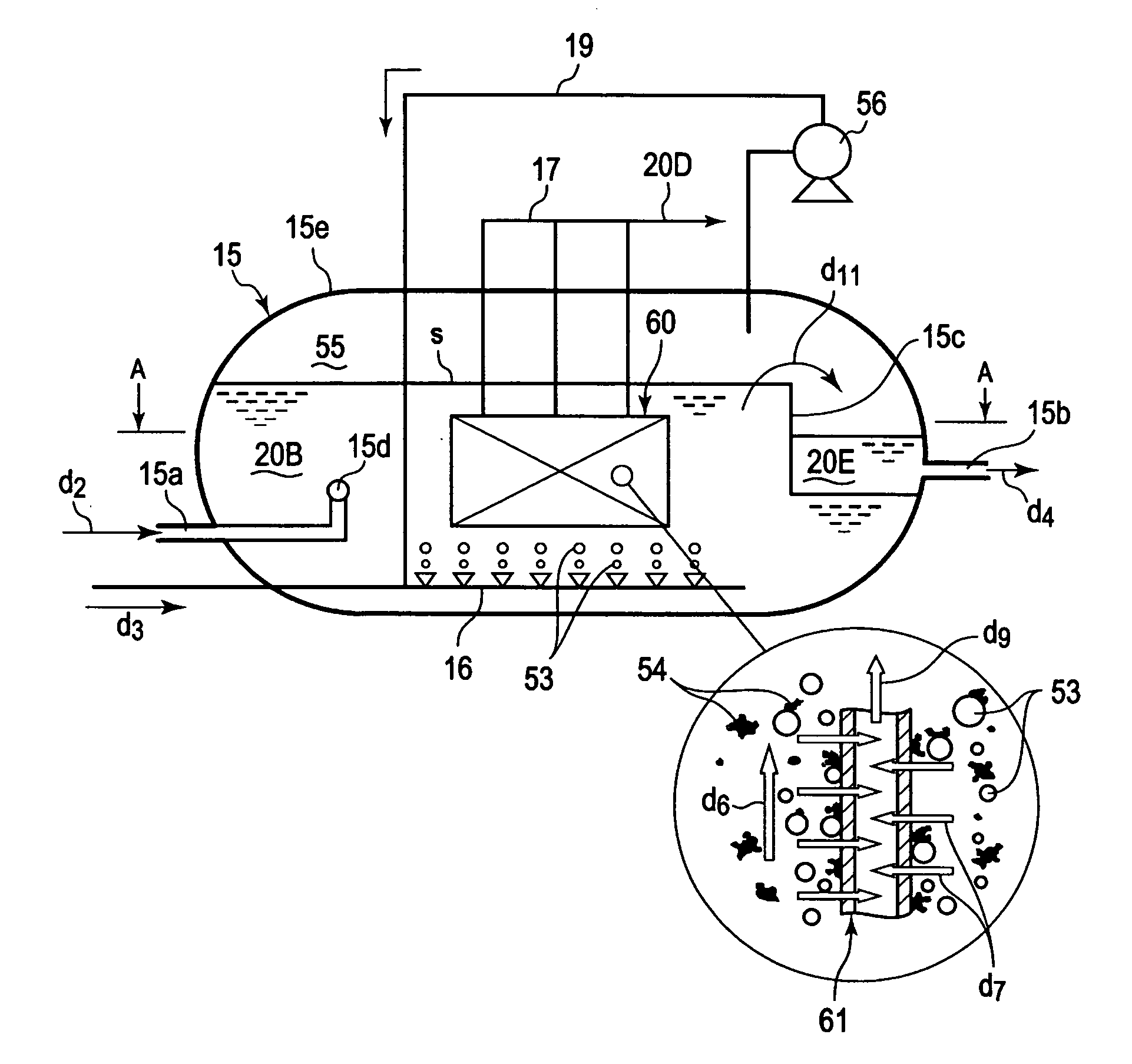

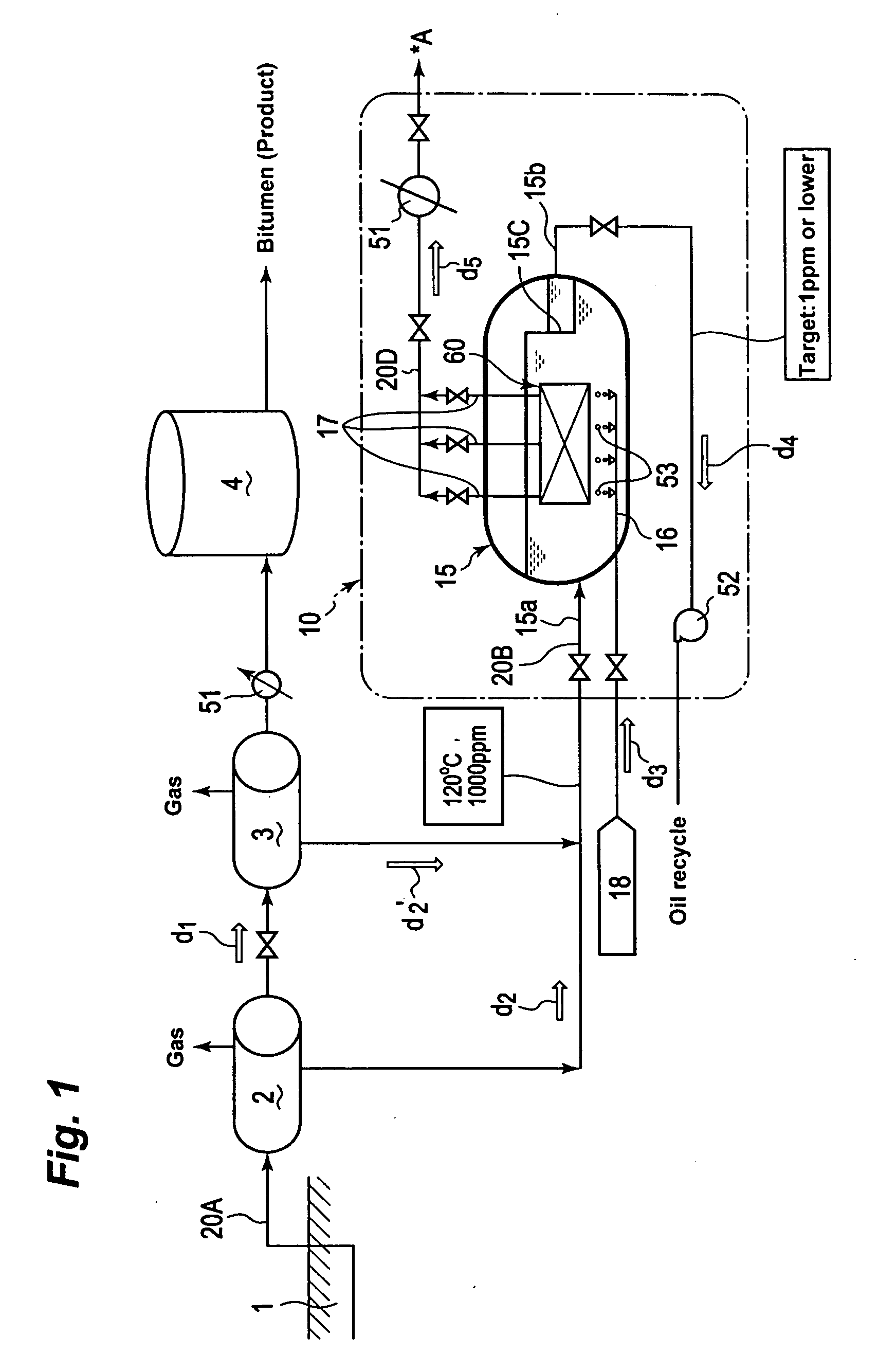

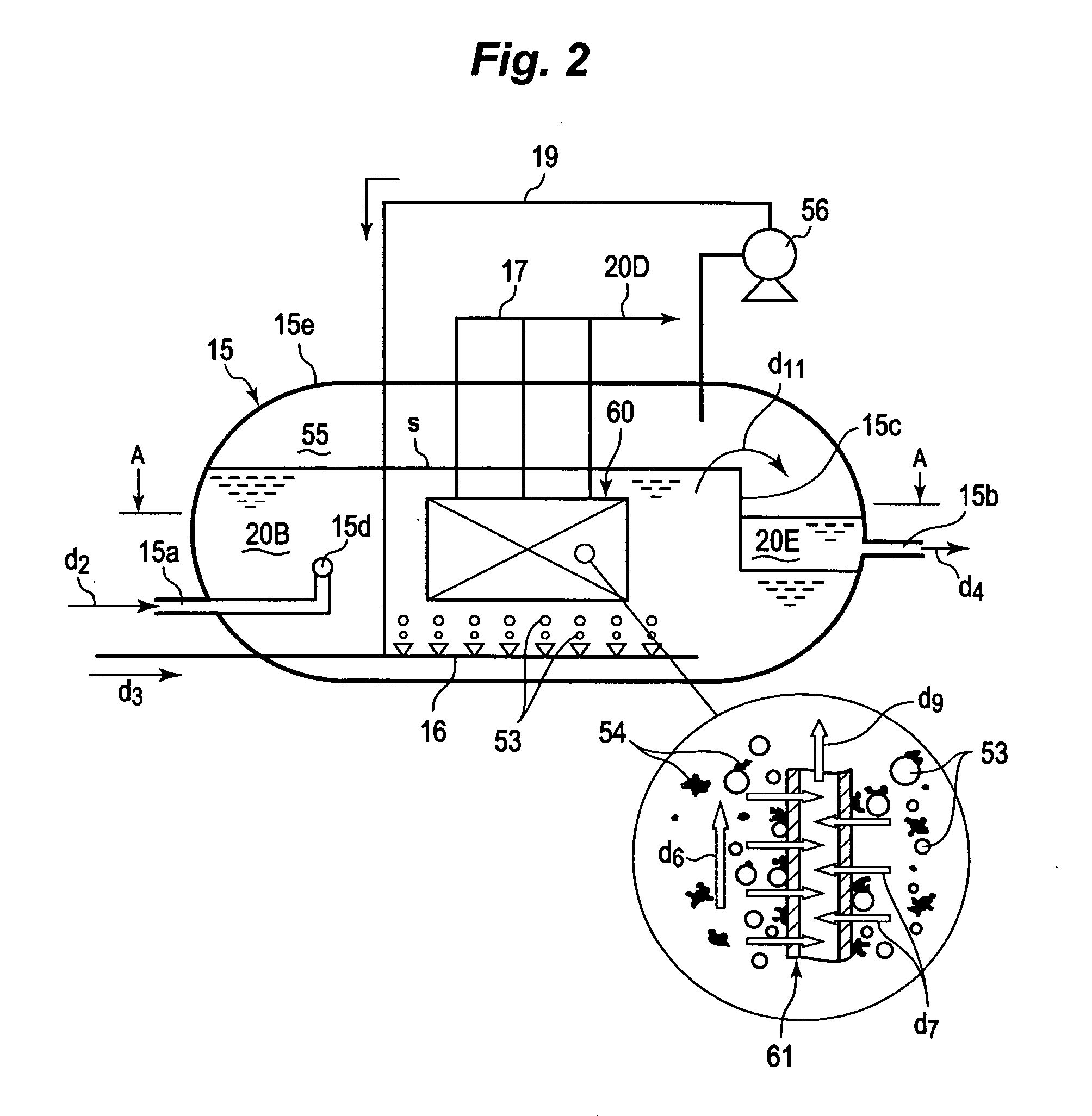

Apparatus of produced water treatment, system and method of using the apparatus, and method of water reuse by using the same

An apparatus of produced water treatment, to be adopted in an in-situ recovery method of producing bitumen from oil sand, the apparatus capable of removing the oil from produced water, the produced water of being left by separating the bitumen from bitumen-mixed fluid having been recovered from the oil sand, the apparatus having: a vessel for receiving the produced water; a submerge type filtration membrane module, installed in the vessel, for filtering the produced water in the condition of the membrane being submerged in the produced water; and a bubble generator for generating bubbles to be forwarded toward the submerged filtration membrane in the produced water.

Owner:TOYO ENG CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com