Patents

Literature

3120 results about "Microfiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

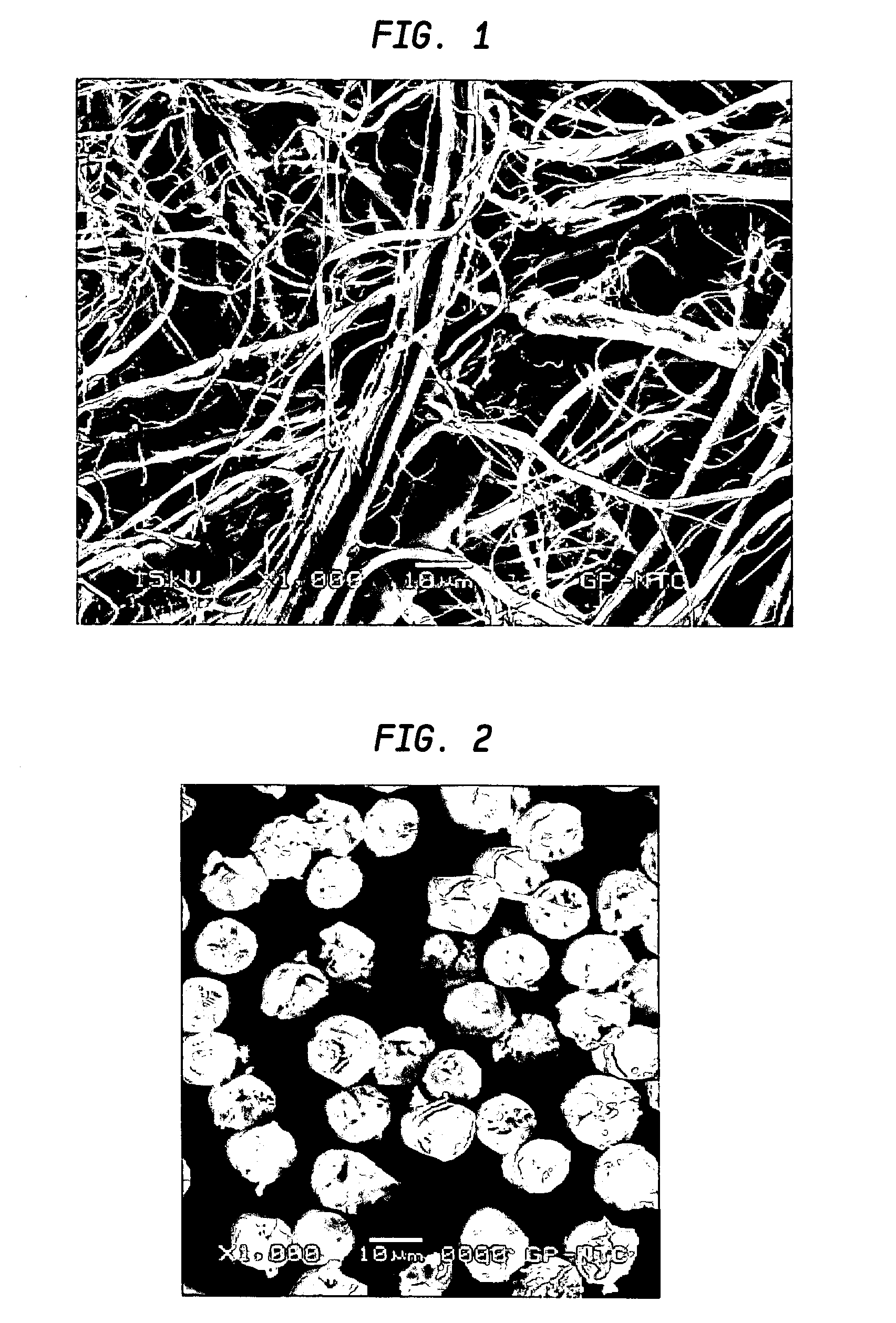

Microfiber (or microfibre) is synthetic fiber finer than one denier or decitex/thread, having a diameter of less than ten micrometres. This is smaller than the diameter of a strand of silk (which is approximately one denier), which is itself about 1/5 the diameter of a human hair.

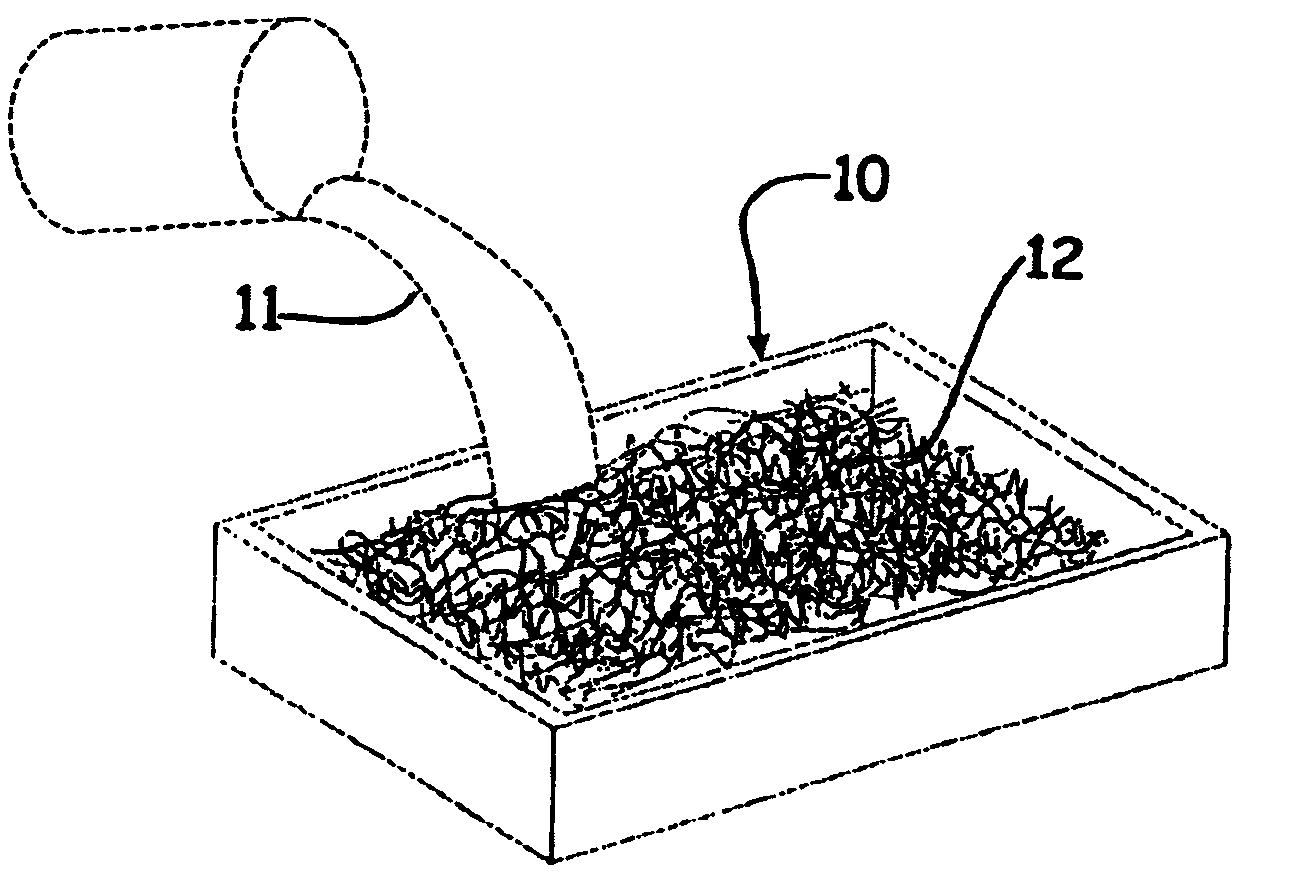

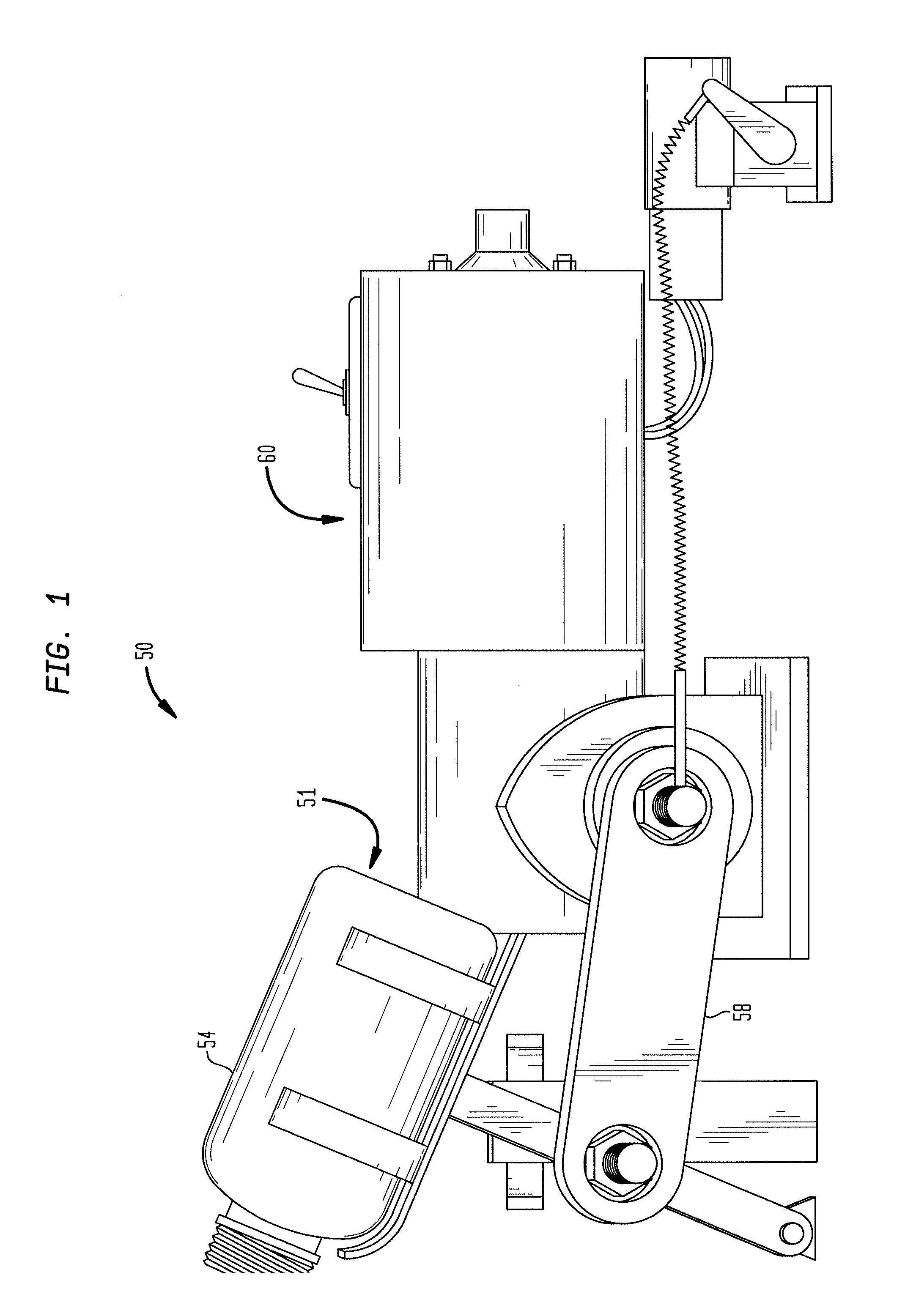

Fine particle liquid filtration media

The present invention provides a filter media comprising (a) a nonwoven composite material comprising a stabilized mixture of thermoplastic microfibers and at least about 50%, by weight, of a secondary fibrous material such as pulp or polymeric staple fibers; (b) a first outer nonwoven web comprising a substantially uniform nonwoven web of autogenously bonded multicomponent fibers; and (c) a second outer nonwoven web wherein the nonwoven composite material is positioned between the first outer nonwoven web and second outer nonwoven web. The filter material is well suited to filtering liquid borne particulate matter ranging in size from 5.mu. to about 25.mu..

Owner:KIMBERLY-CLARK WORLDWIDE INC

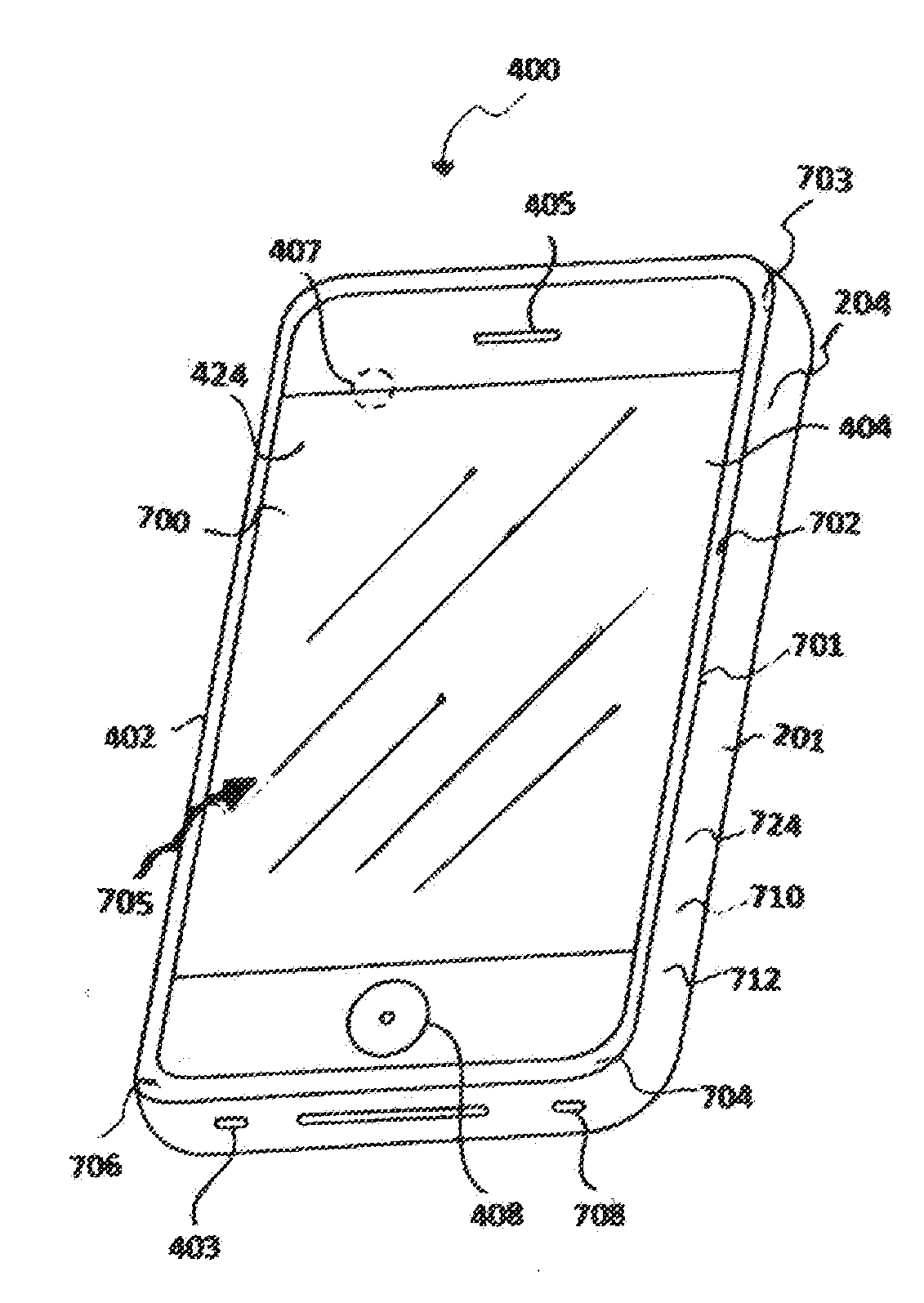

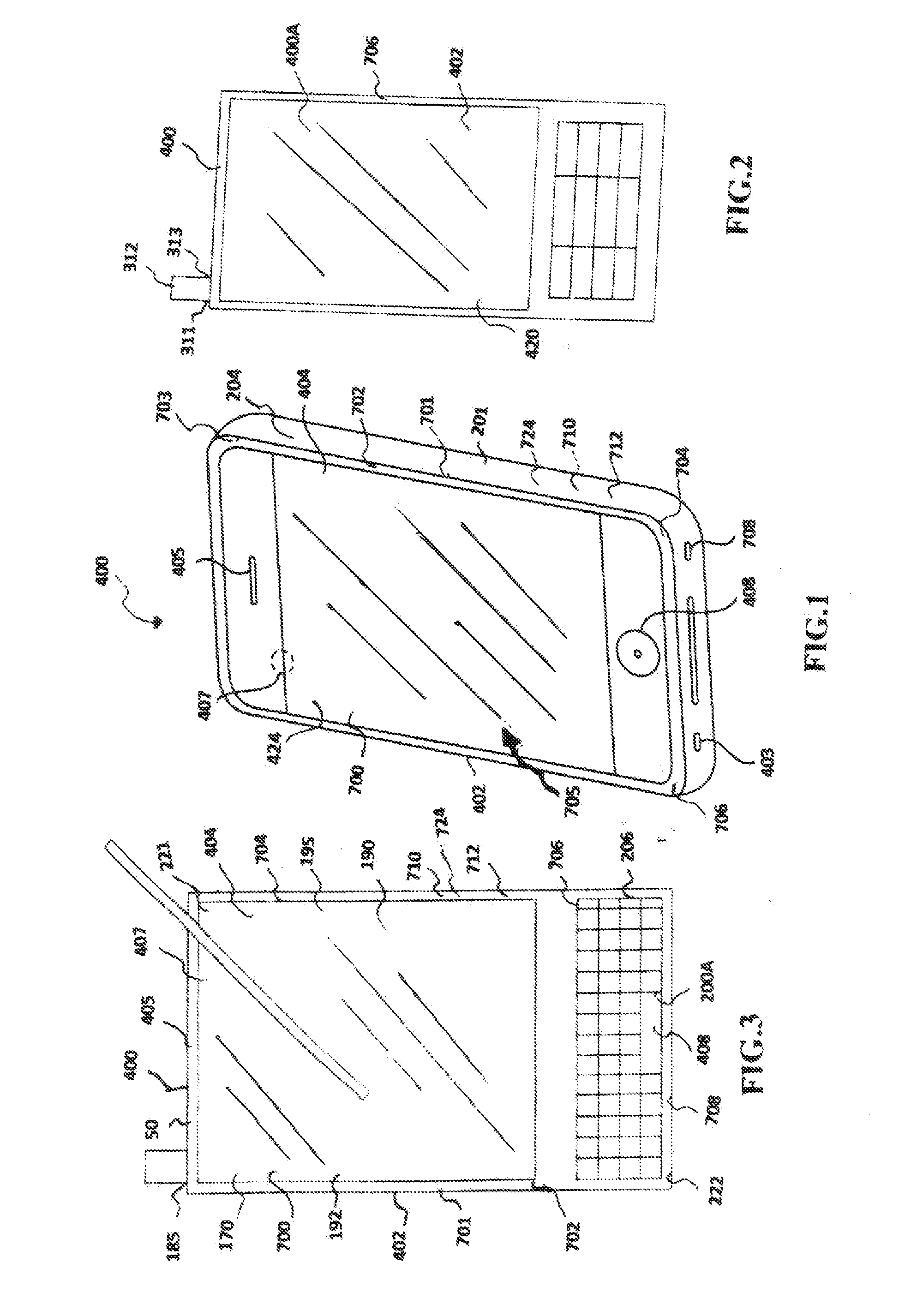

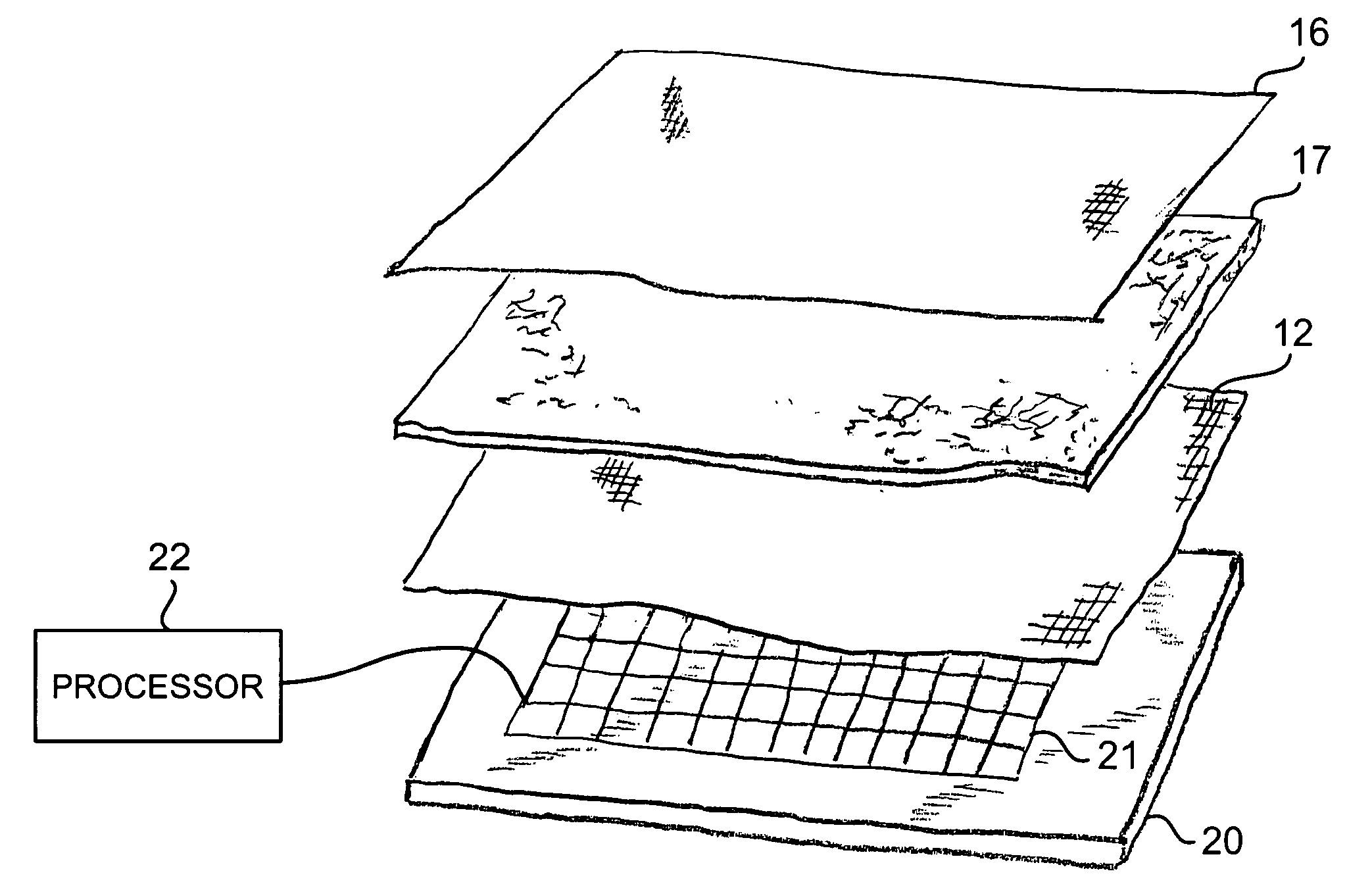

Energy harvesting computer device in association with a communication device configured with apparatus for boosting signal reception

ActiveUS20130157729A1Improve consumer electronics hybrid consumer electronics performanceLow densityMaterial nanotechnologyEnergy efficient ICTCellular telephoneCommunication device

Disclosed embodiments comprise an energy harvesting computer device in association with a communication device comprising interactive user interface operatively configured with CMOS multiple antennas on chip for boosting signal receptions and for providing faster data transmission speed. Disclosed embodiment encompasses three modes of communications—the Cell phone, wireless Internet applications, and Global communication and media information. Embodiments provide communication apparatus operable to enhance mobile communication efficiency with touch sensitive display comprising energy harvesting platform in communication with a charging circuit board configured with memories, processors, sensors, and modules. Embodiments further provide a gaming device, a wireless media device configured with touch pads comprising sensors being embedded in silicon substrate and fused in nano-fiber / microfiber material having excellent electrical characteristics. Certain embodiments provide communication apparatus configured for voice enabled applications comprising human voice auditory operable to convert text into voice auditory and / or voice auditory into text applications.

Owner:TABE JOSEPH AKWO

Electrically conductive polymer composition

InactiveUS6184280B1Sufficient electrical conductivityImprove polymer propertiesOther chemical processesConductive materialPolymer scienceCarbon fibers

An electrically conductive polymer composition comprises a moldable organic polymer having hollow carbon microfibers and an electrically conductive white powder uniformly dispersed therein, the carbon fibers being present in an amount of 0.01 wt. % to less than 2 wt. % and the electrically conductive white powder being present in an amount of 2.5-40 wt. %, each percent range based on the total weight of the composition, the amounts of carbon microfibers and white powder being sufficient to simultaneously impart the desired electrical conductivity to the composition and white pigmentation to the composition.

Owner:MITSUBISHI MATERIALS CORP +1

Electret filter media

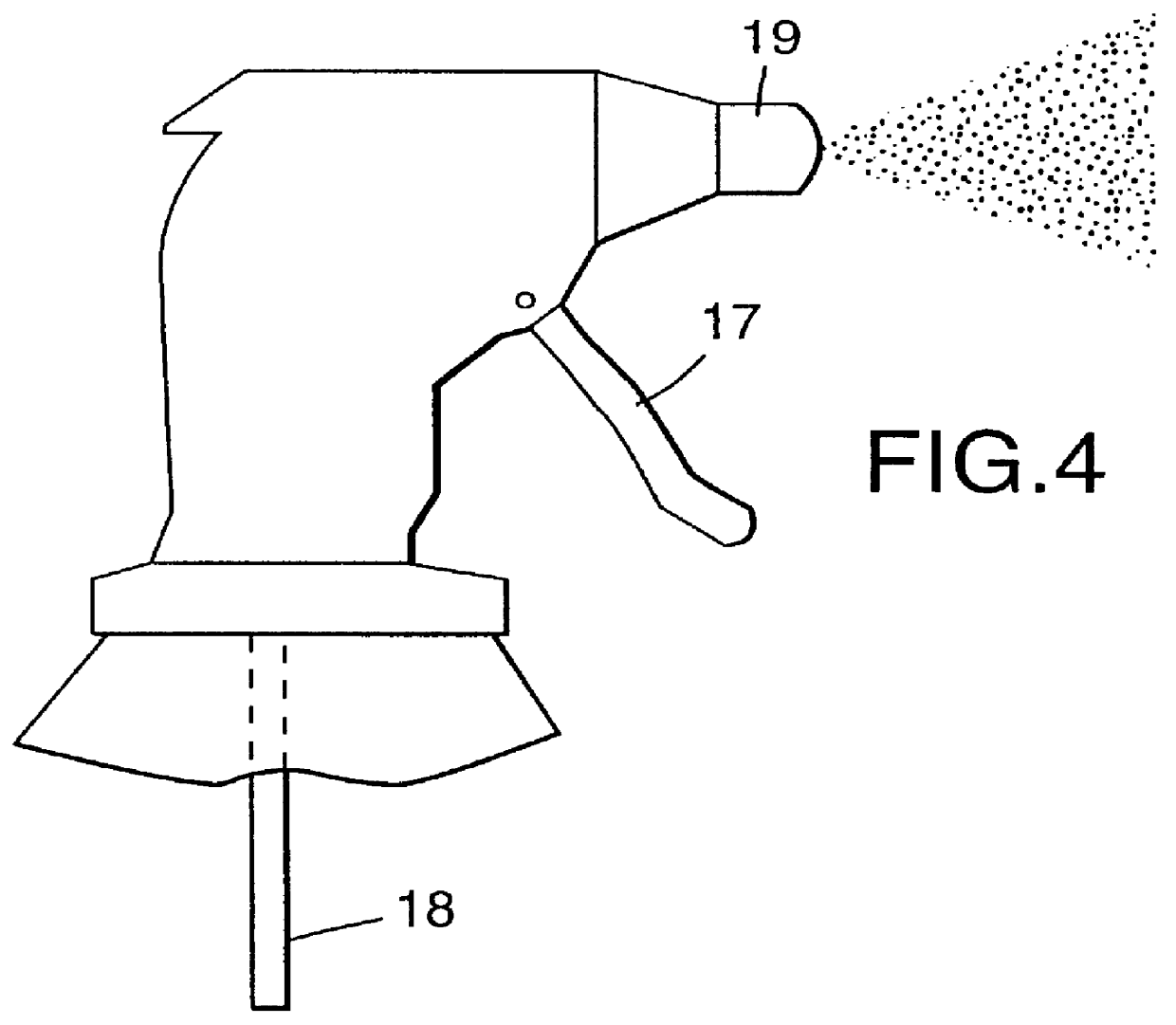

InactiveUS6119691AReduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersMicrometerFilter media

An electret filter media, and mask, that is made of a nonwoven web of thermoplastic microfibers. The thermoplastic microfibers are of substantially the same composition, are nonconductive, and have an effective fiber diameter less than about 15 micrometers. The nonwoven web also has sufficient unpolarized trapped charge to exhibit an initial filtration quality factor of at least 0.31 when measured under the DOP Penetration and Pressure Drop Test.

Owner:3M CO

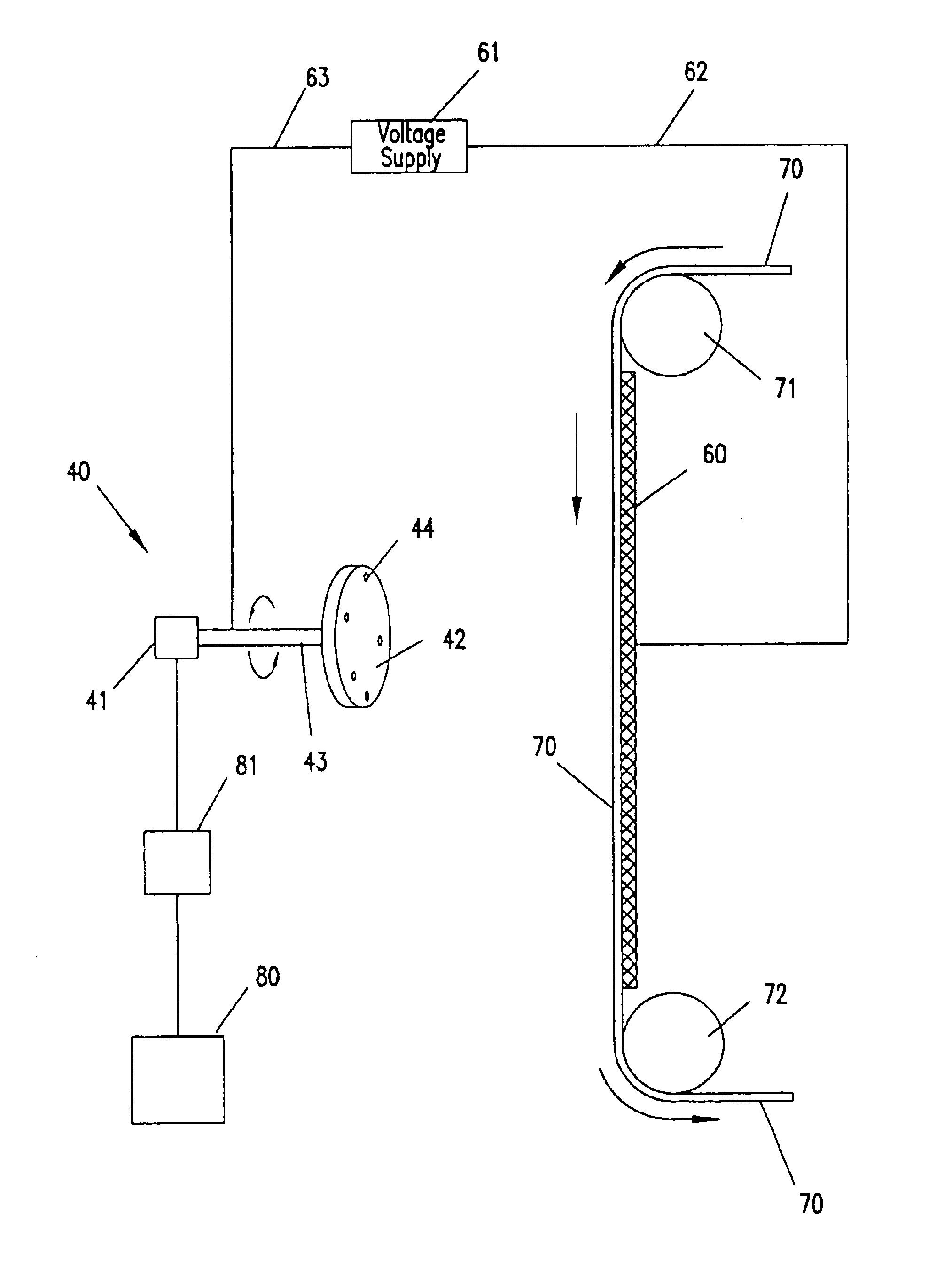

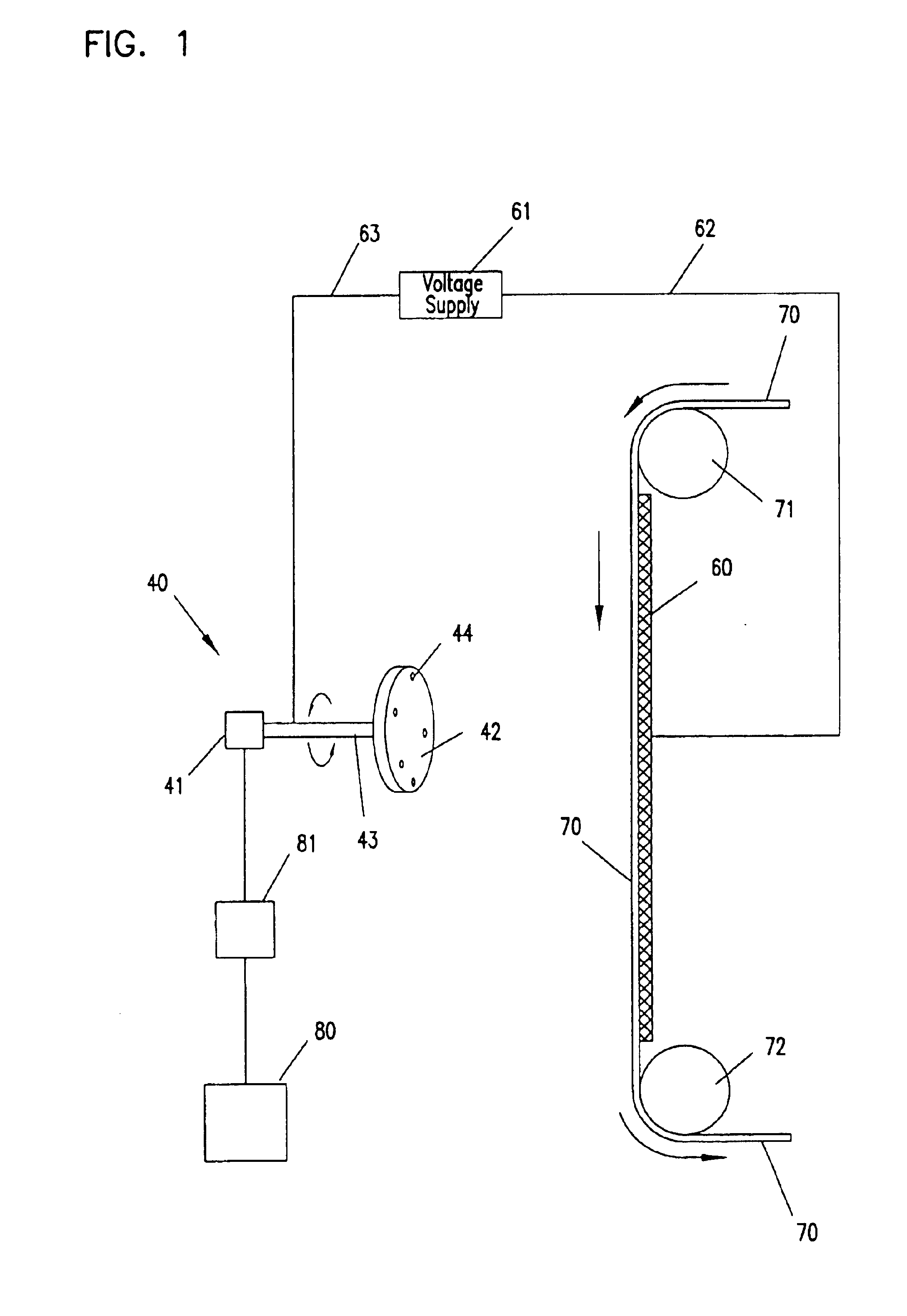

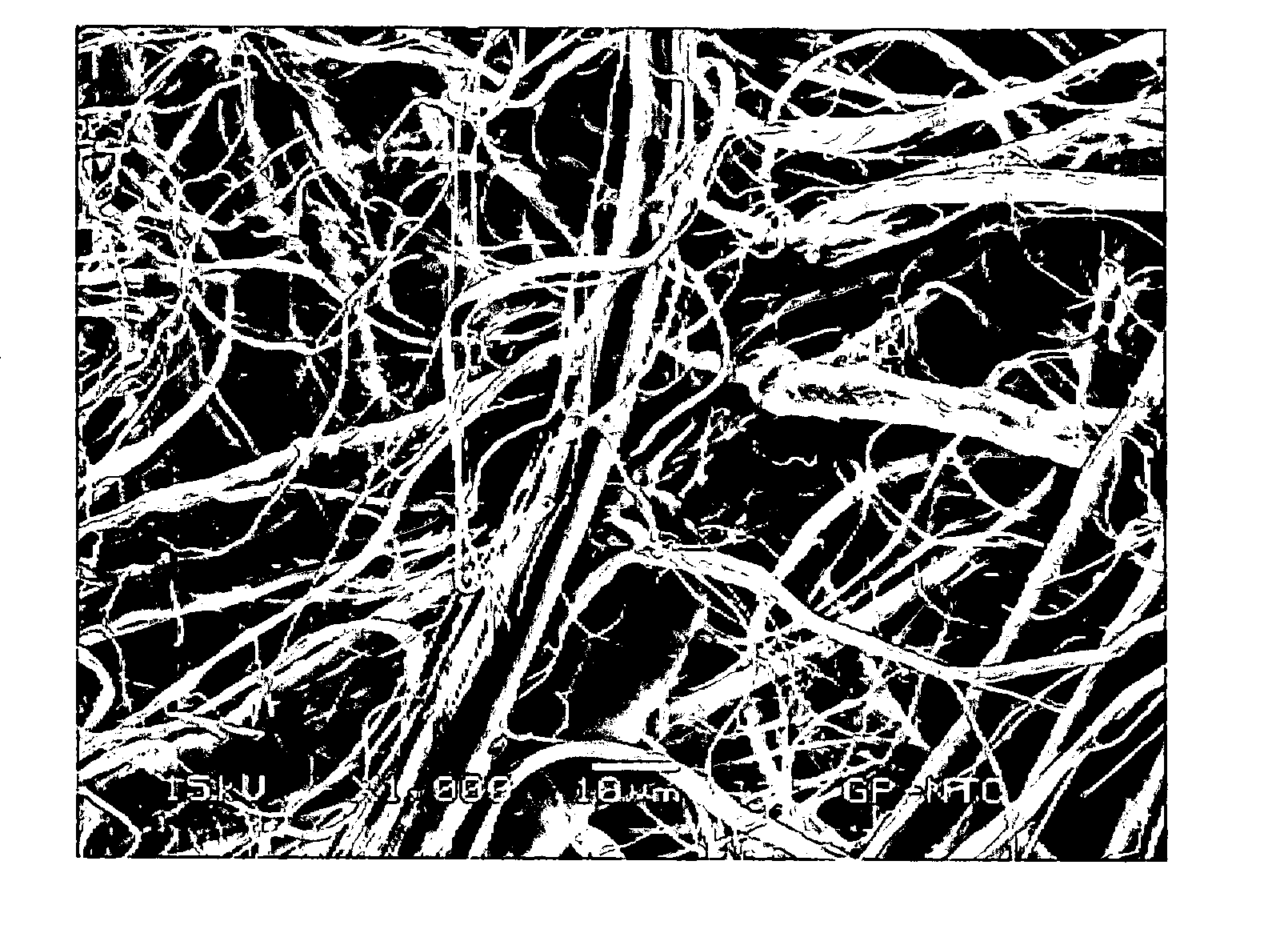

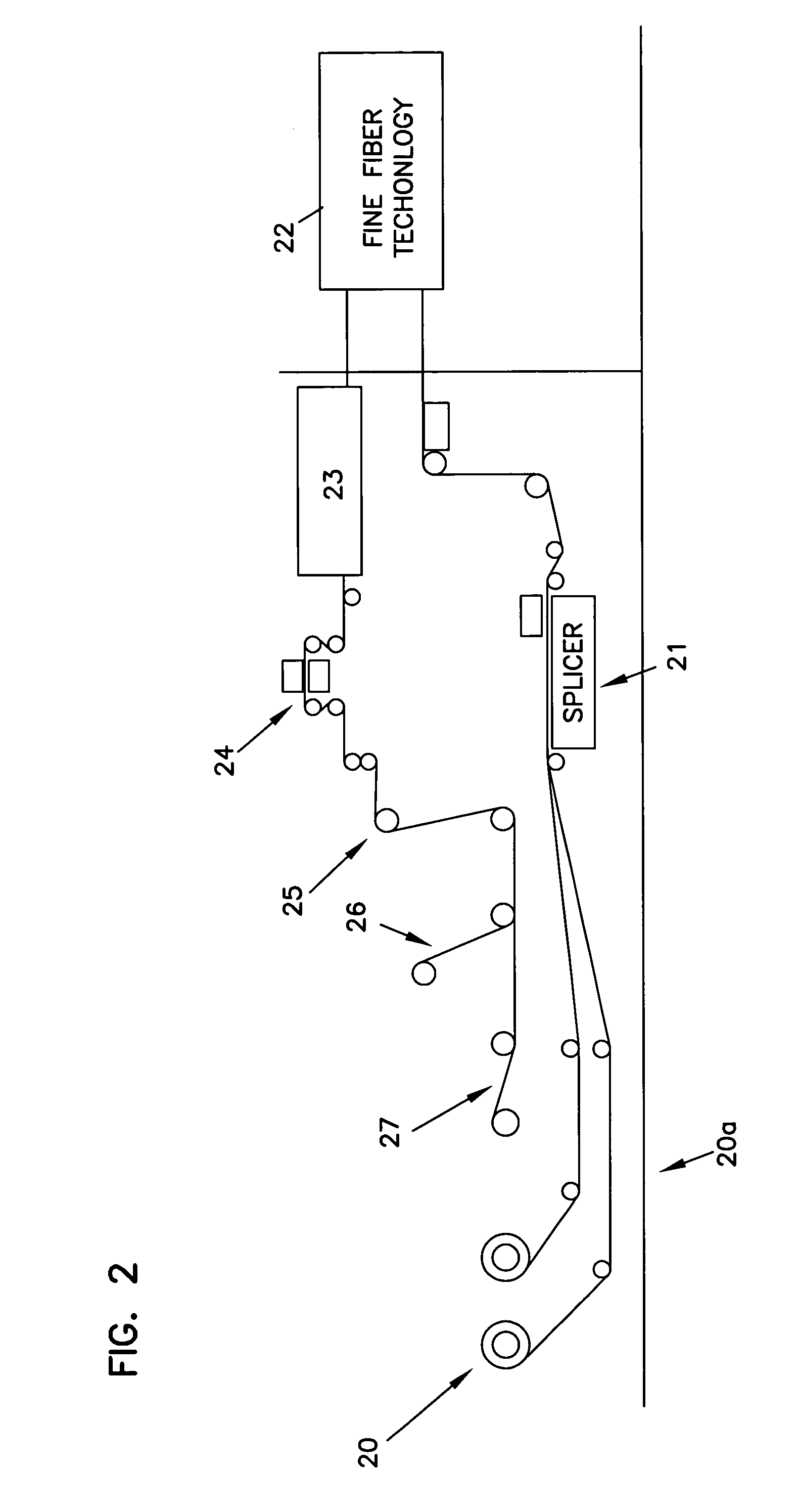

Process if making fine fiber material

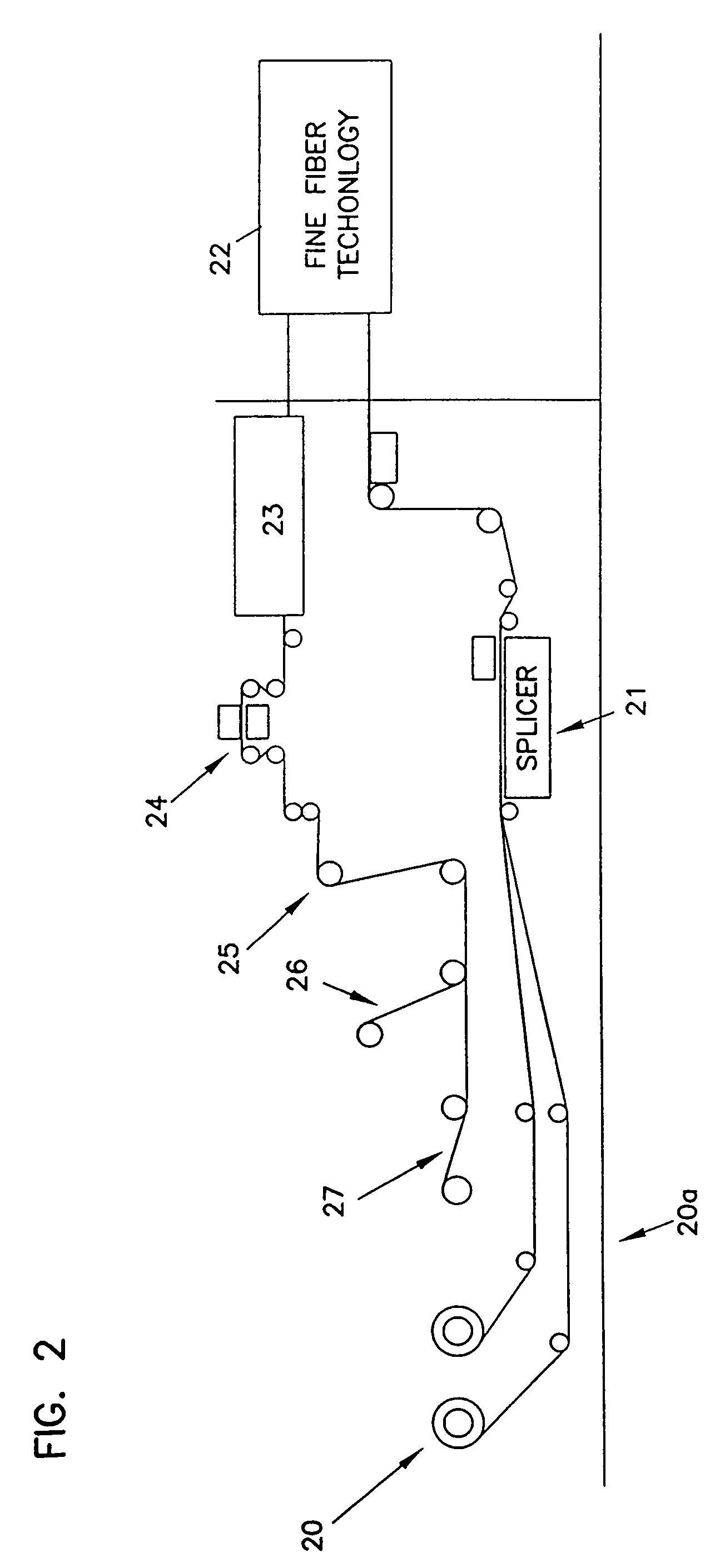

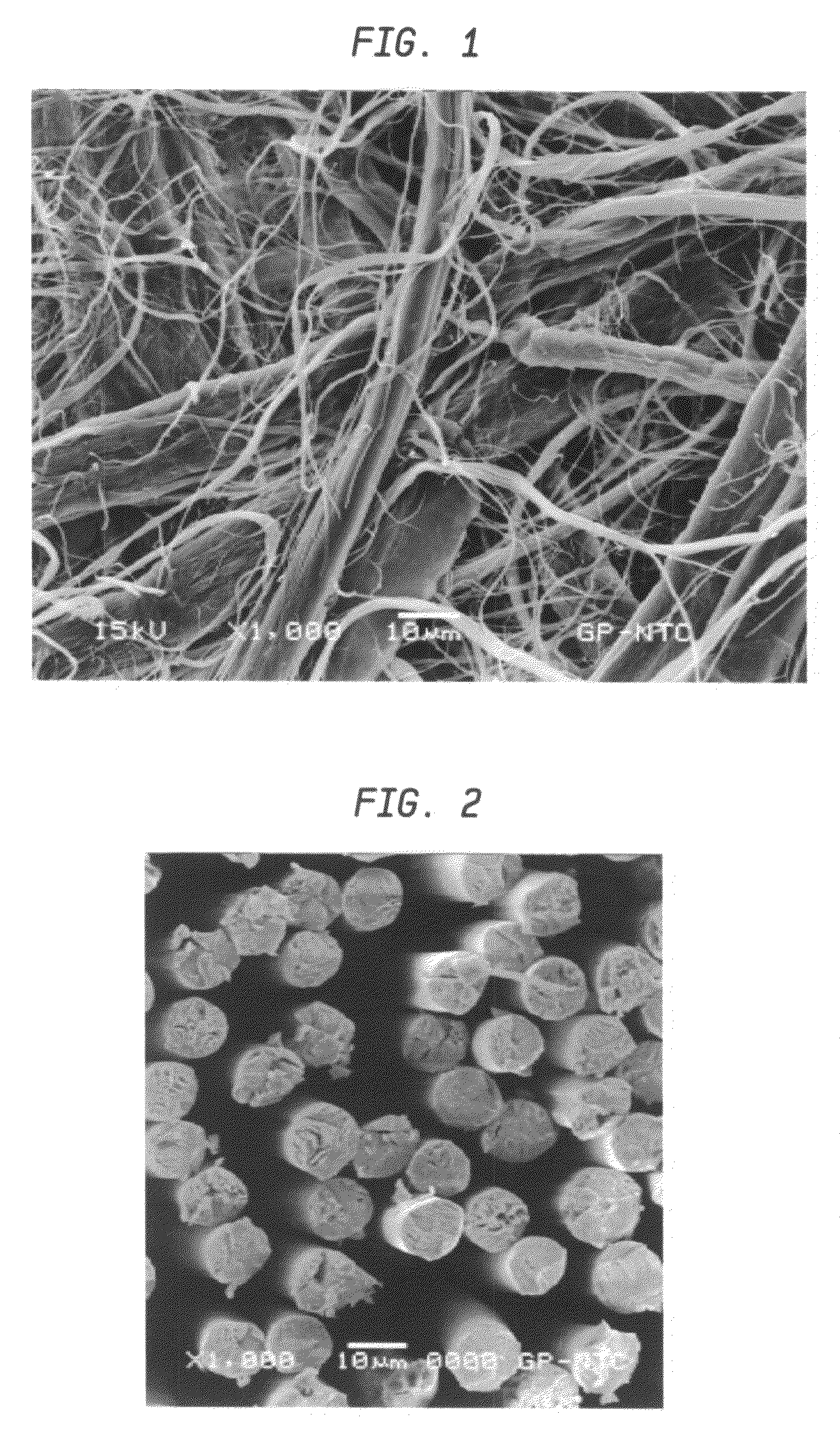

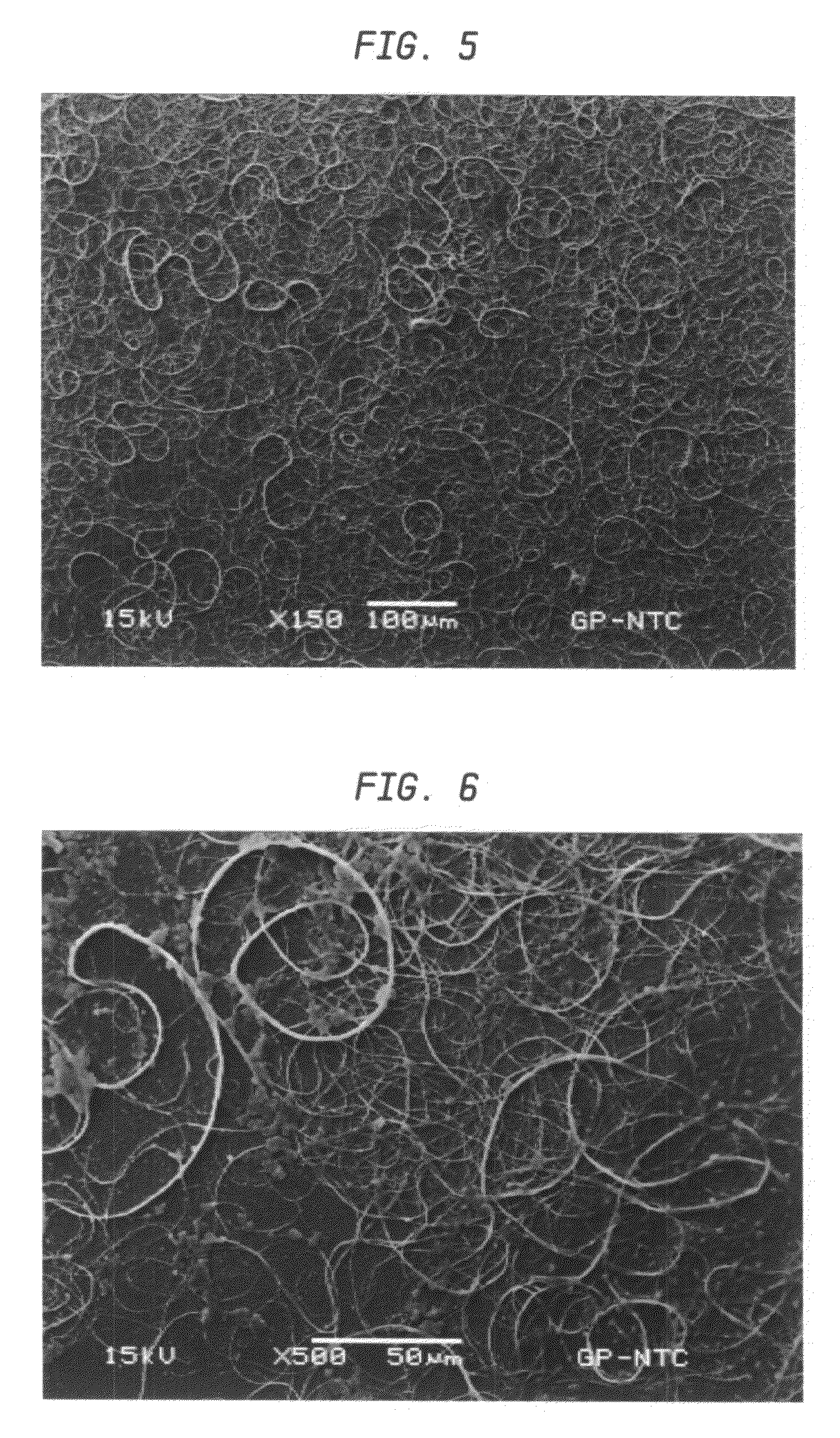

Improved polymer materials and fine fiber materials can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

Electret filter media and filtering masks that contain electret filter media

InactiveUS6783574B1Reduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersFilter mediaRespiratory mask

Electret filter media comprising a nonwoven web of thermoplastic nonconductive microfibers having trapped charge, said charge provided by (1) subjecting the nonwoven web to a corona treatment, followed by (2) impingement of jets of water or a stream of water droplets on the web at a pressure sufficient to provide the web with filtration enhancing electret charge and (3) drying the web. This electret filter media may be used in a respiratory mask to provide extraordinarily good filtration properties.

Owner:3M CO

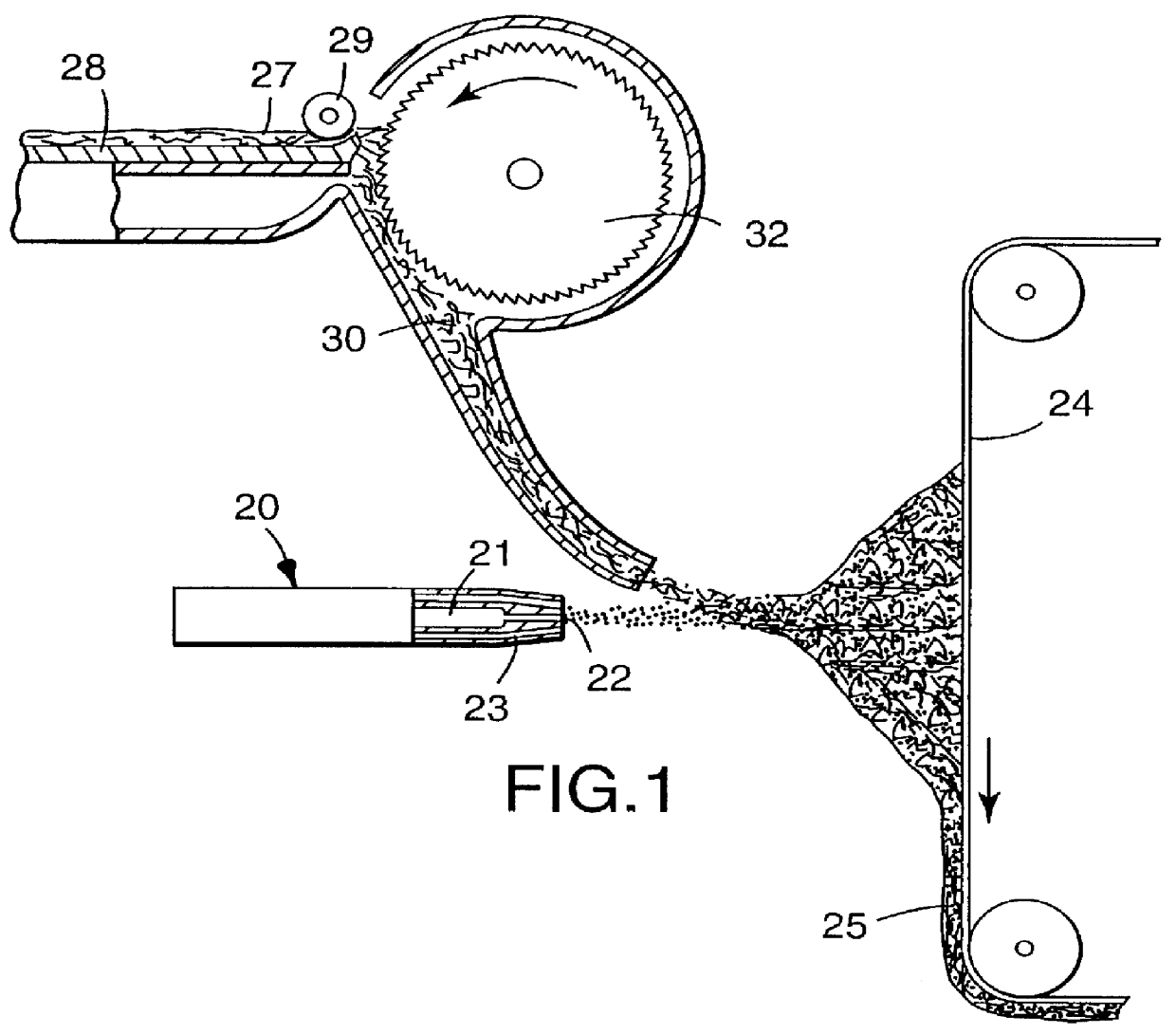

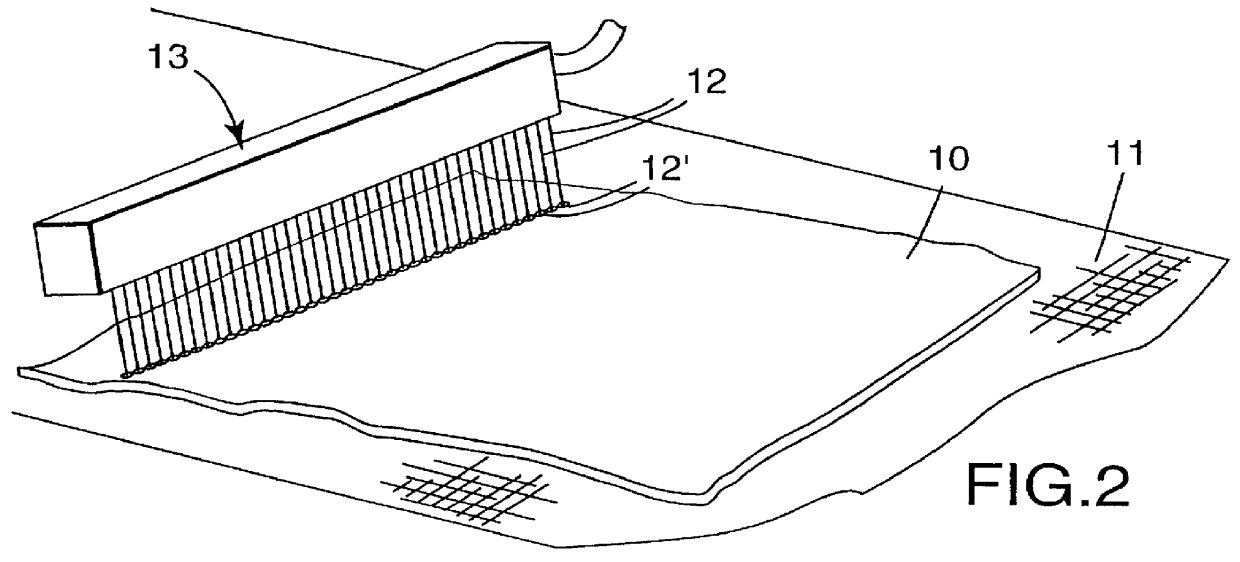

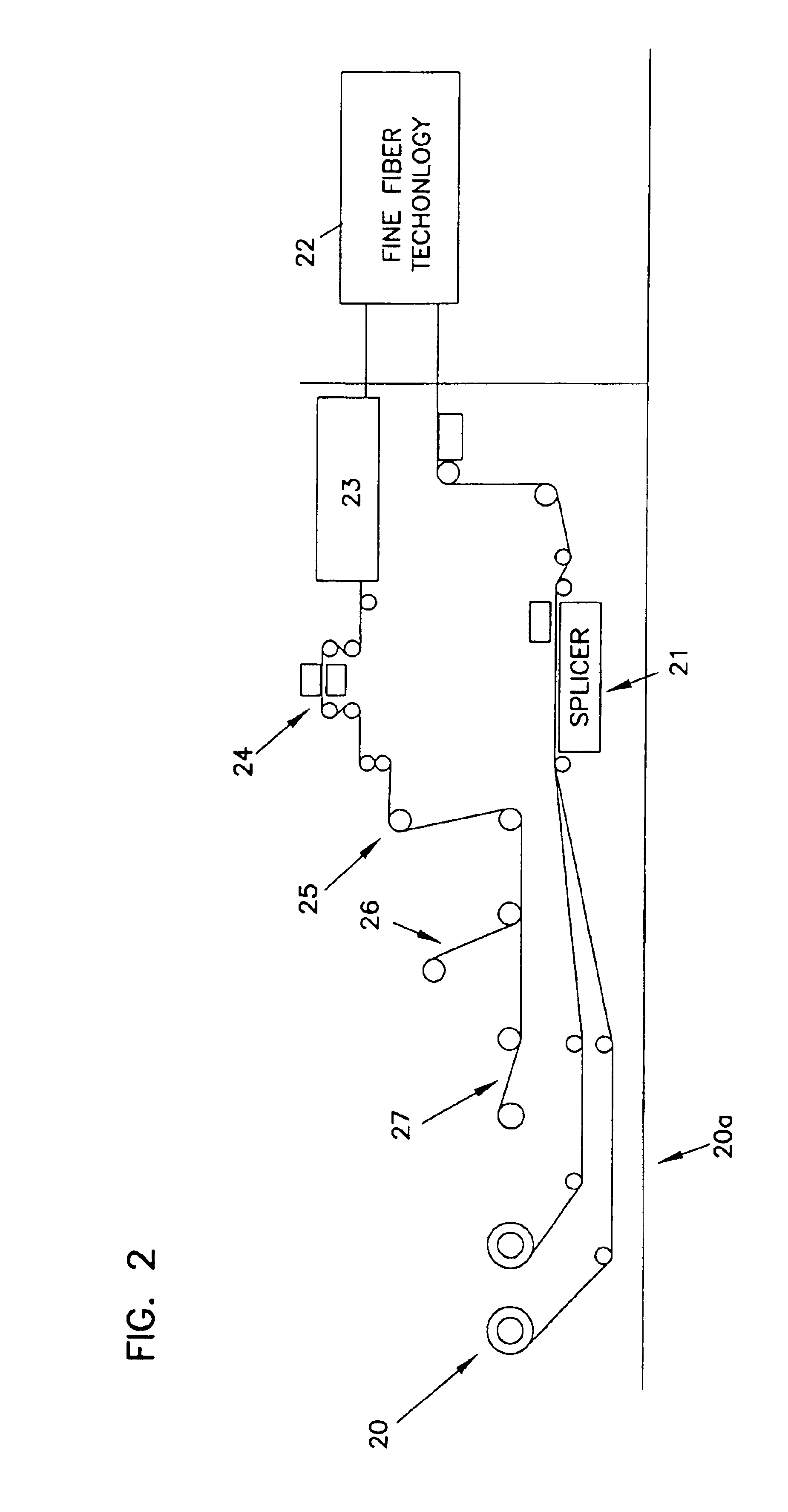

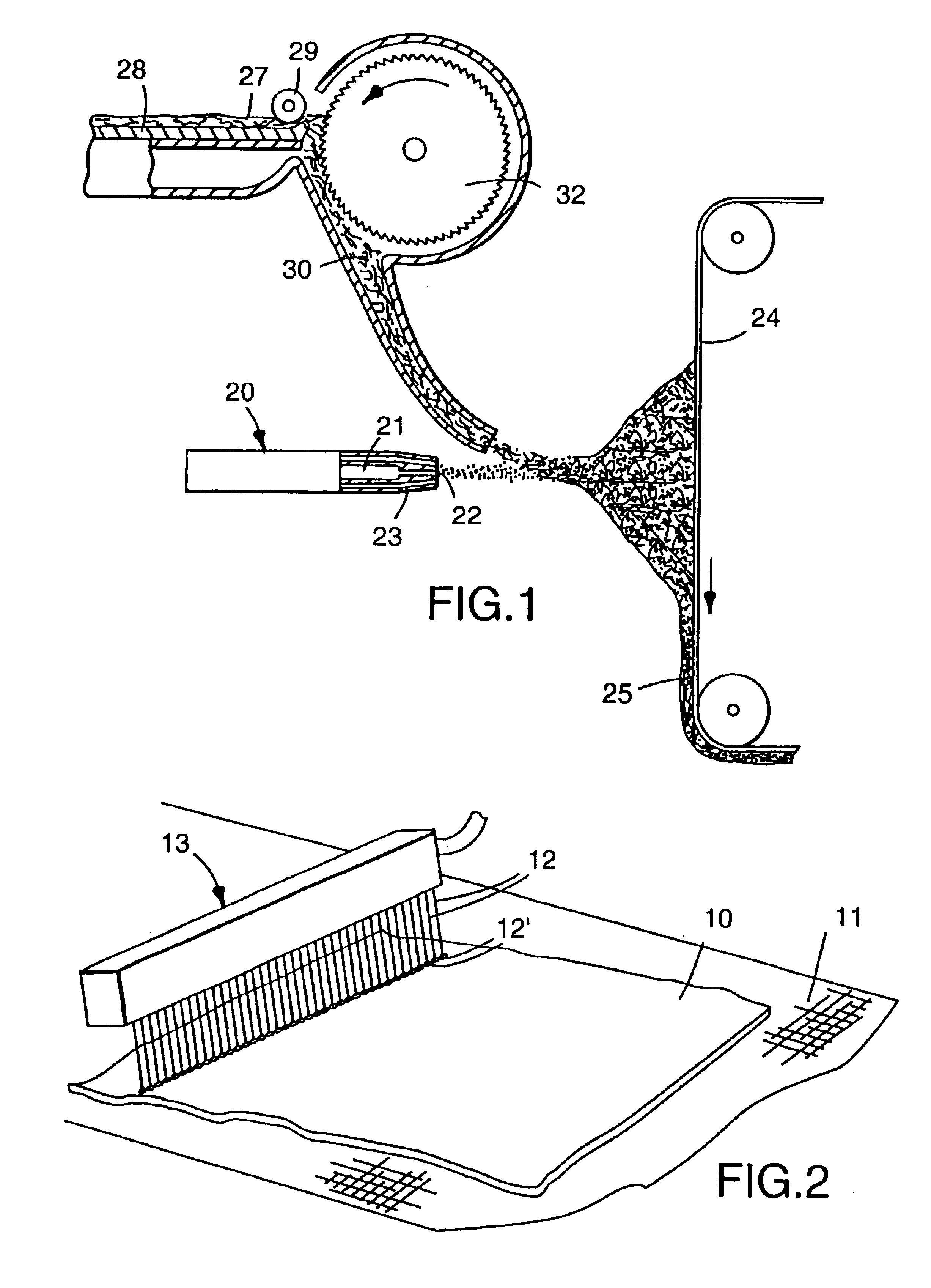

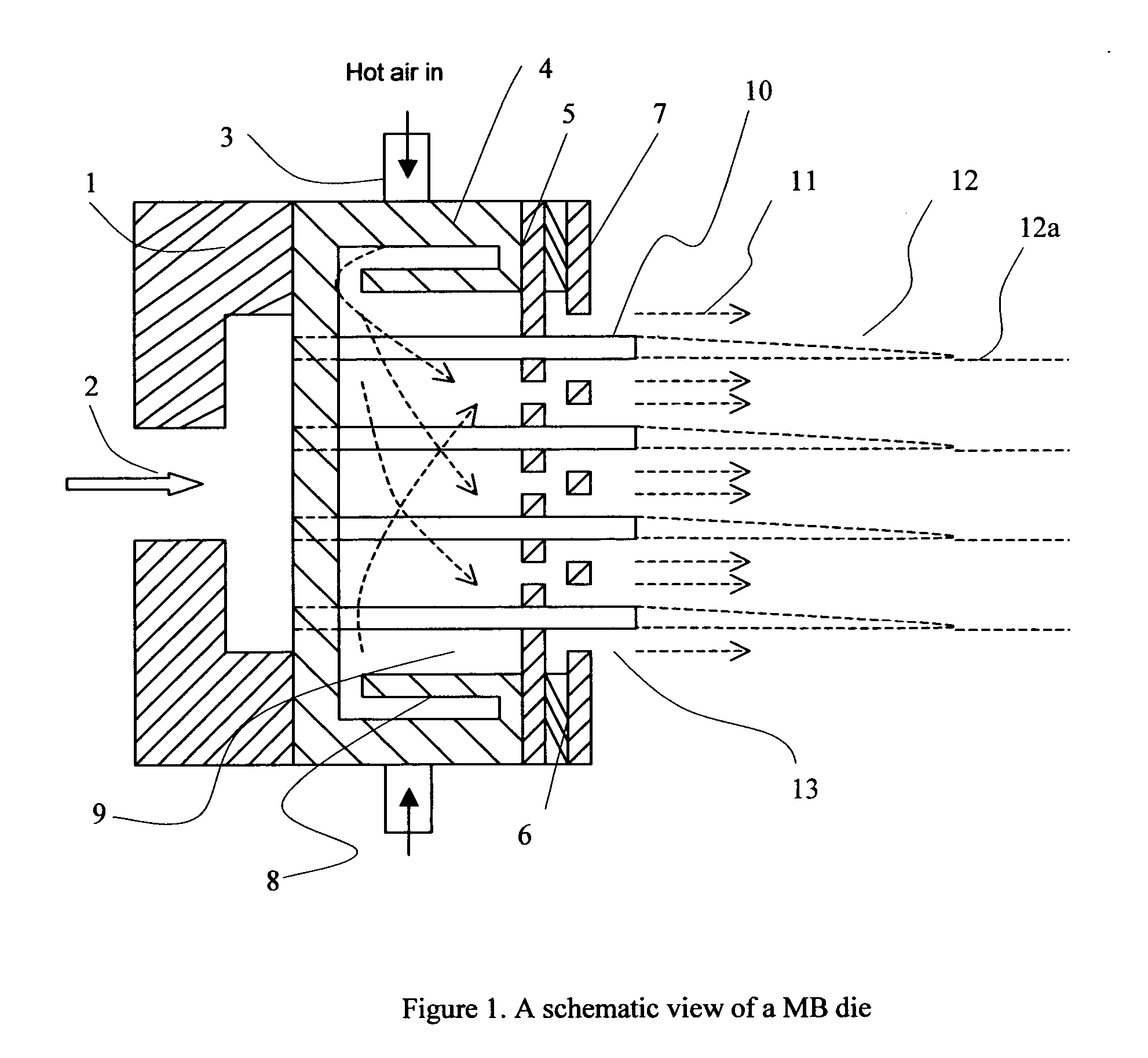

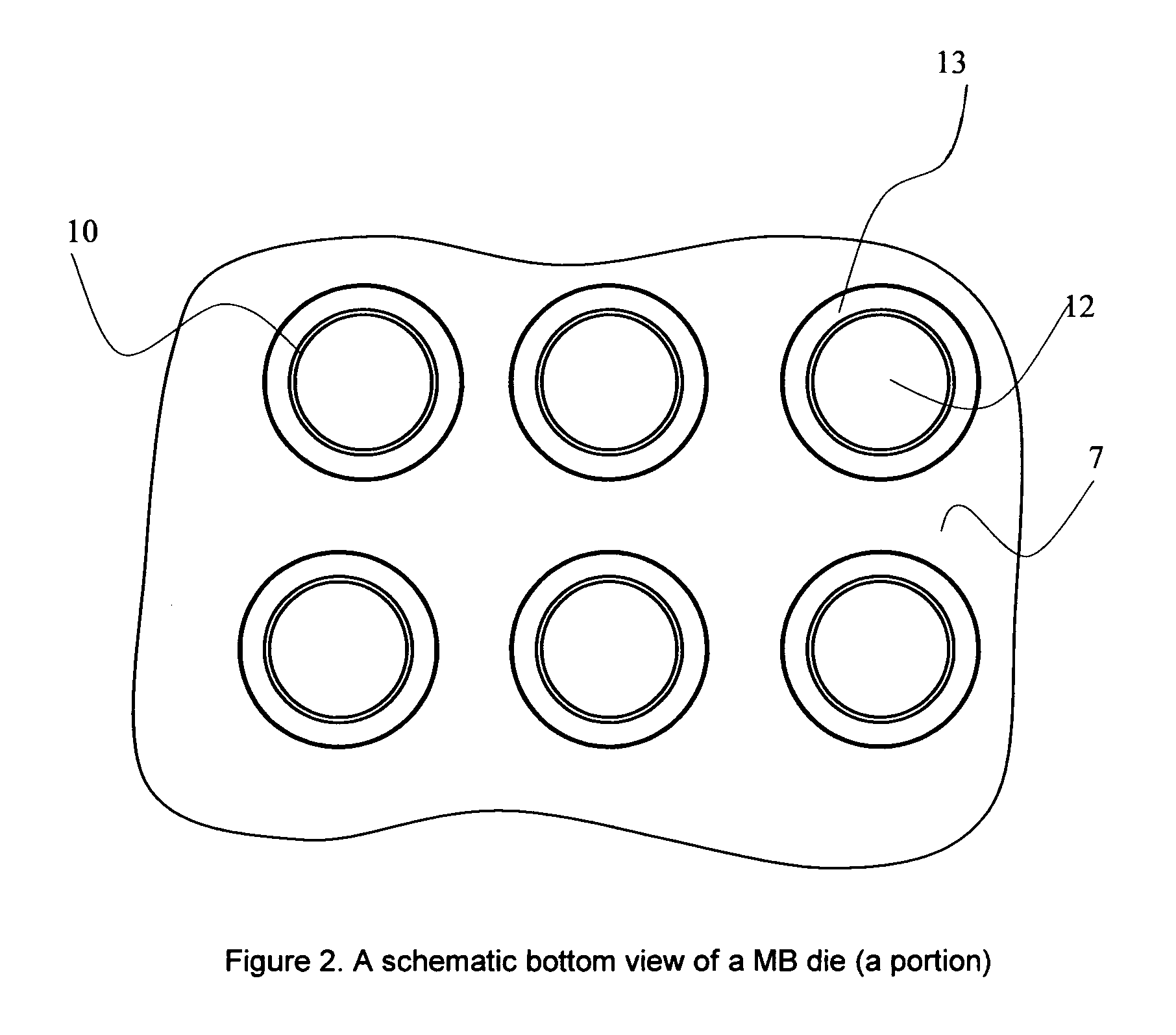

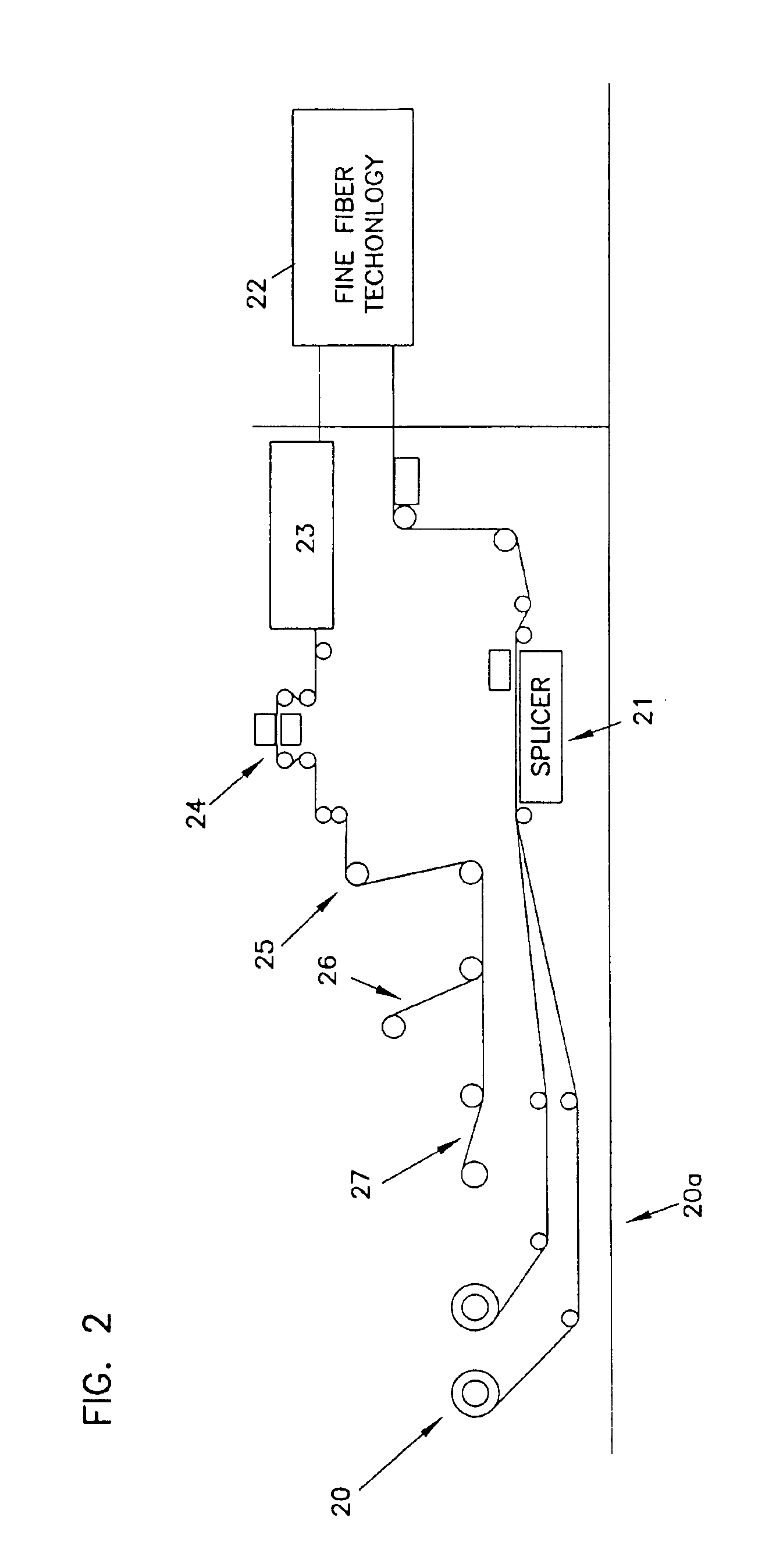

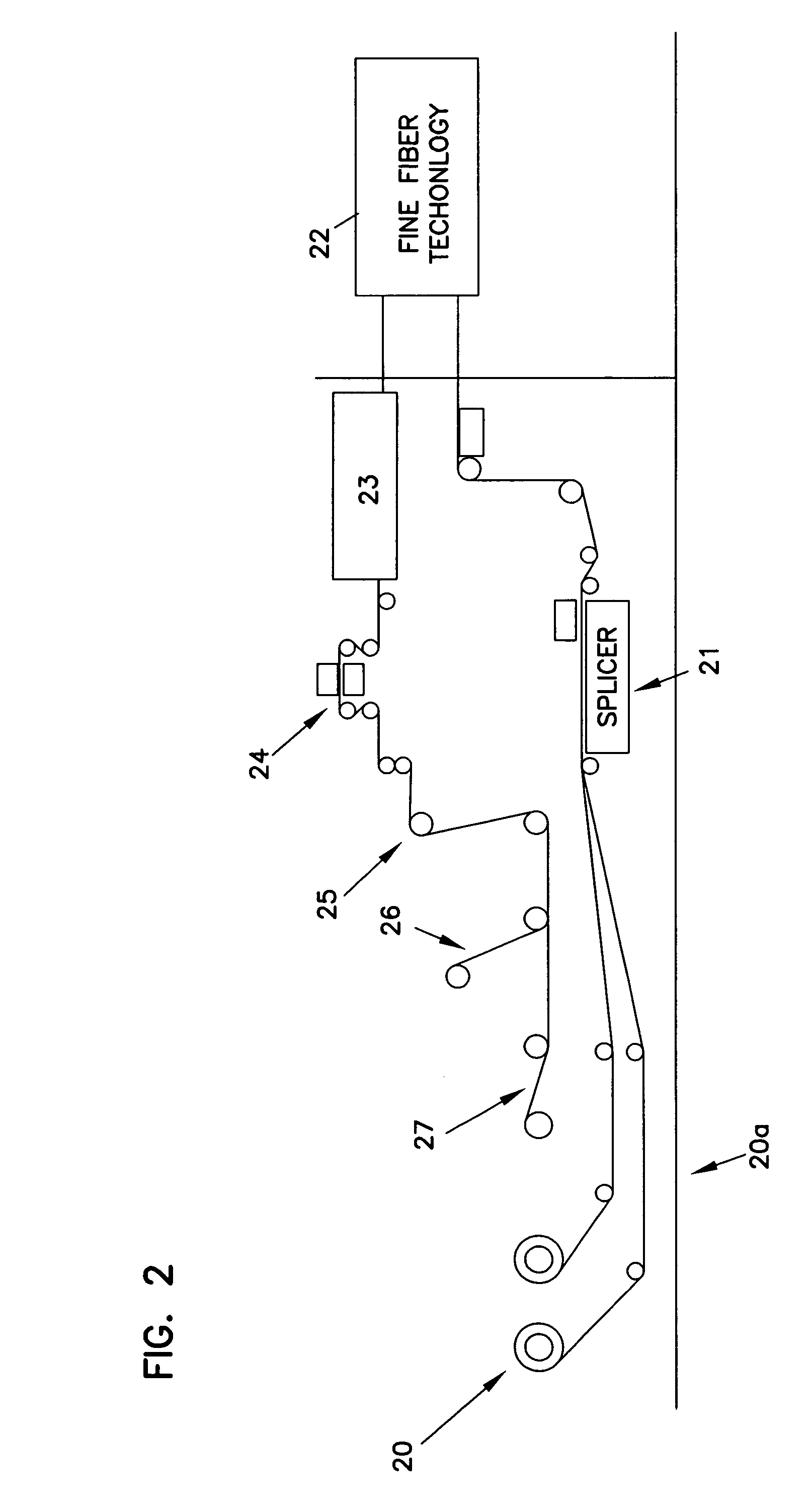

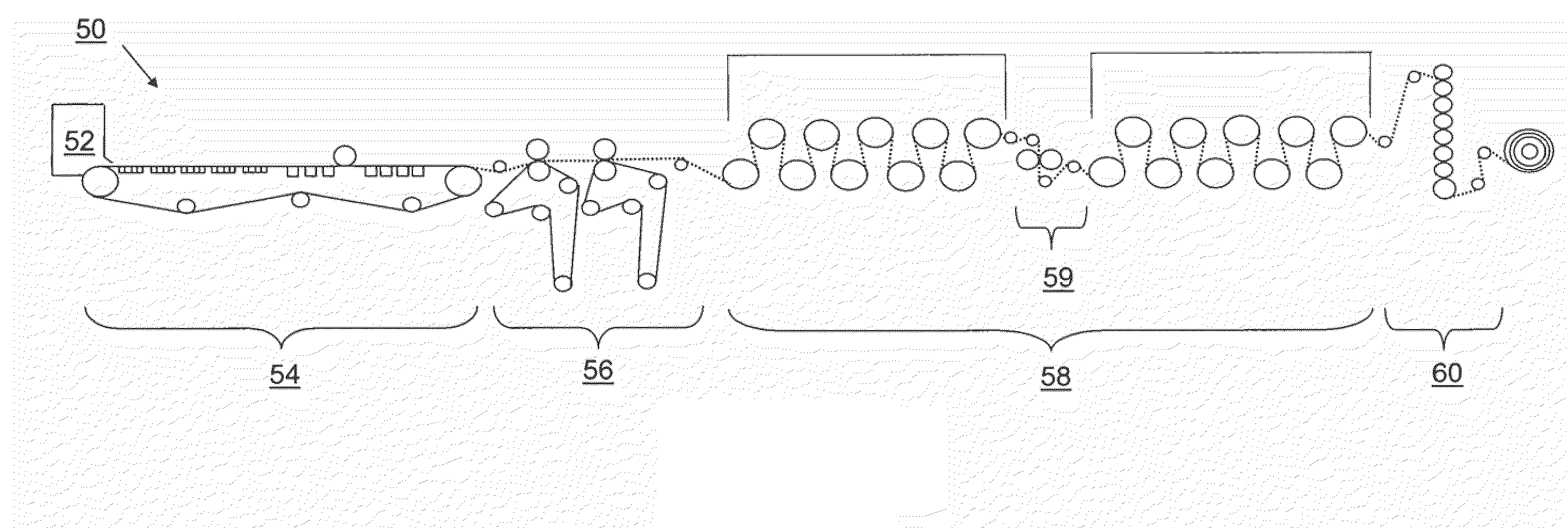

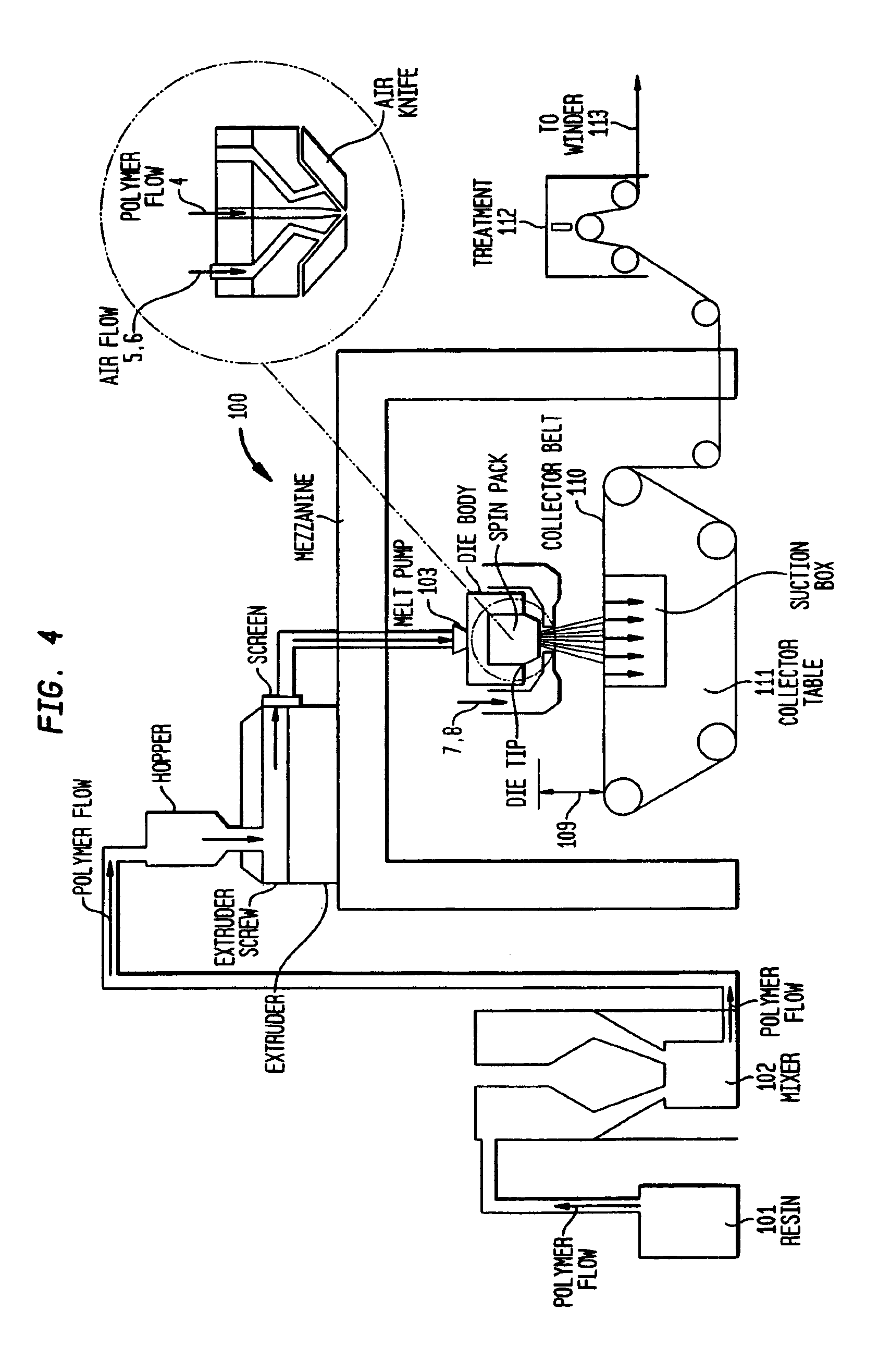

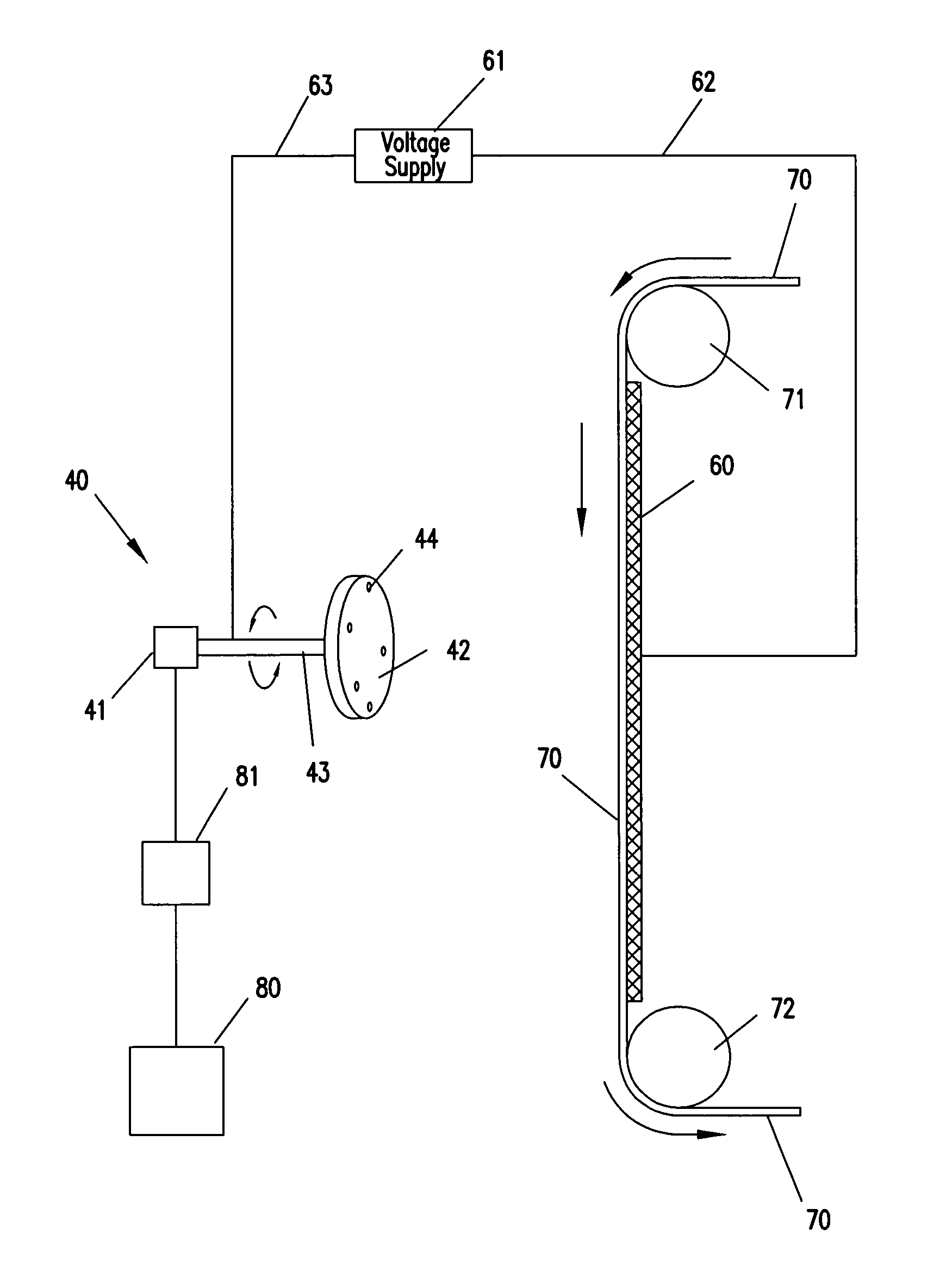

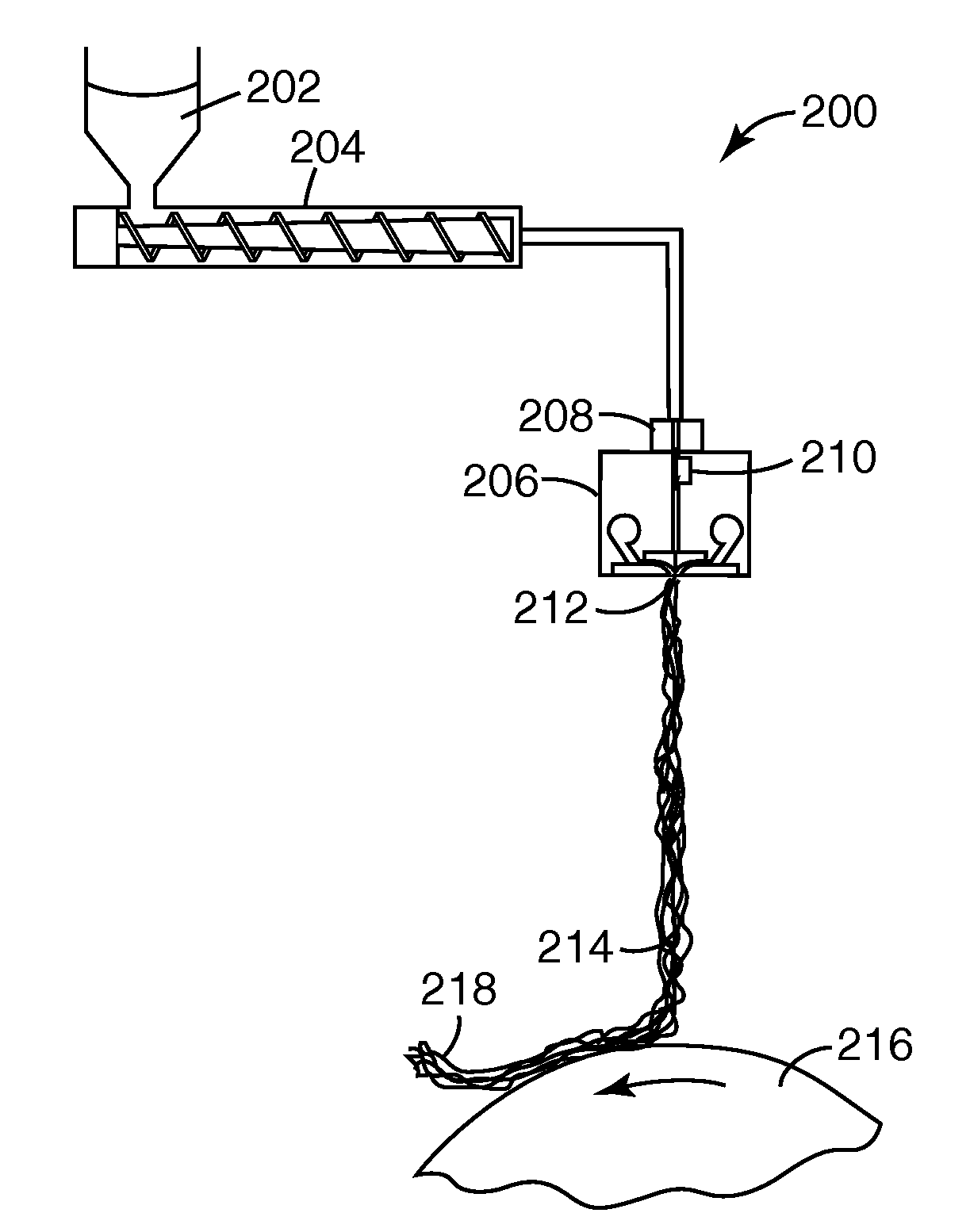

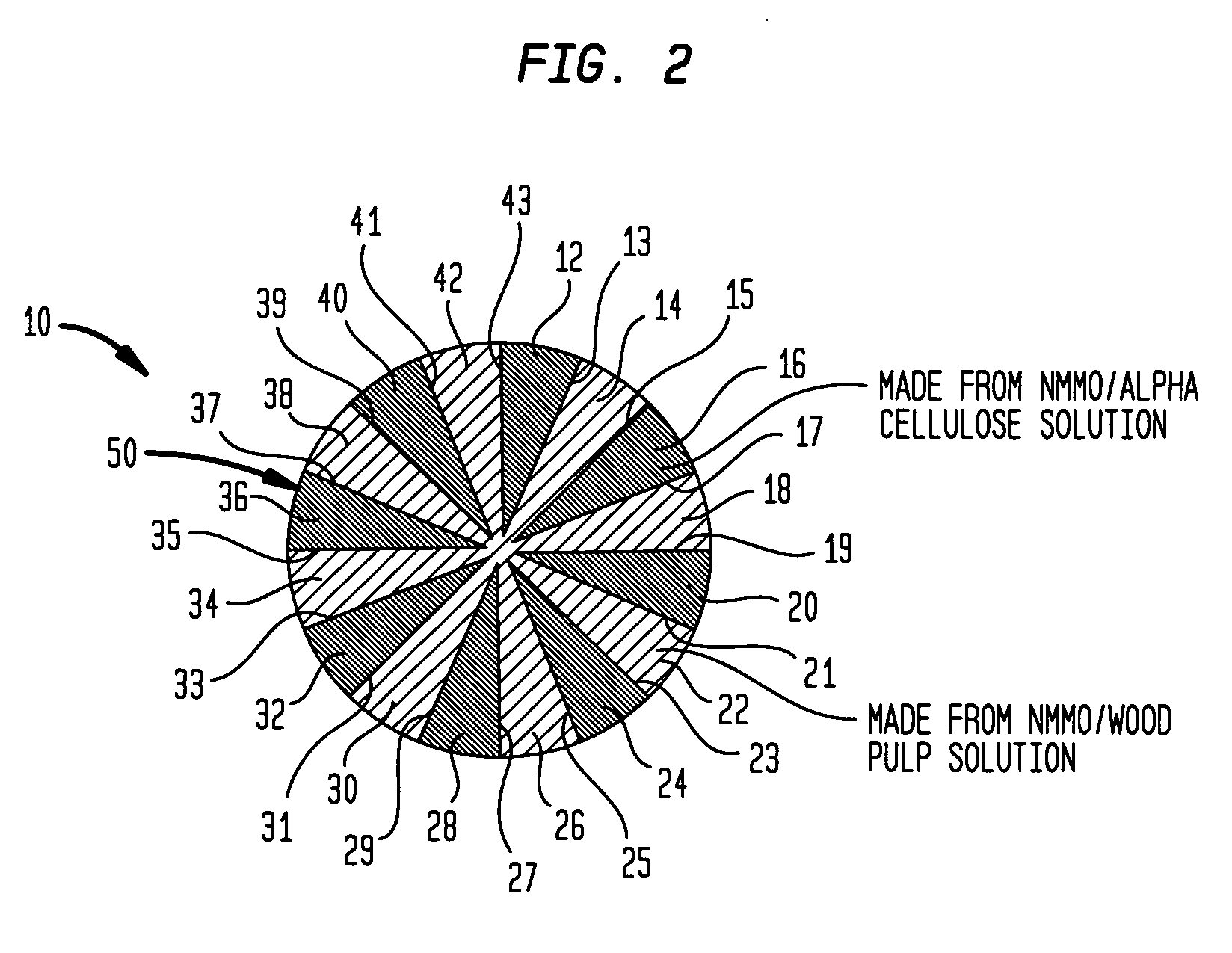

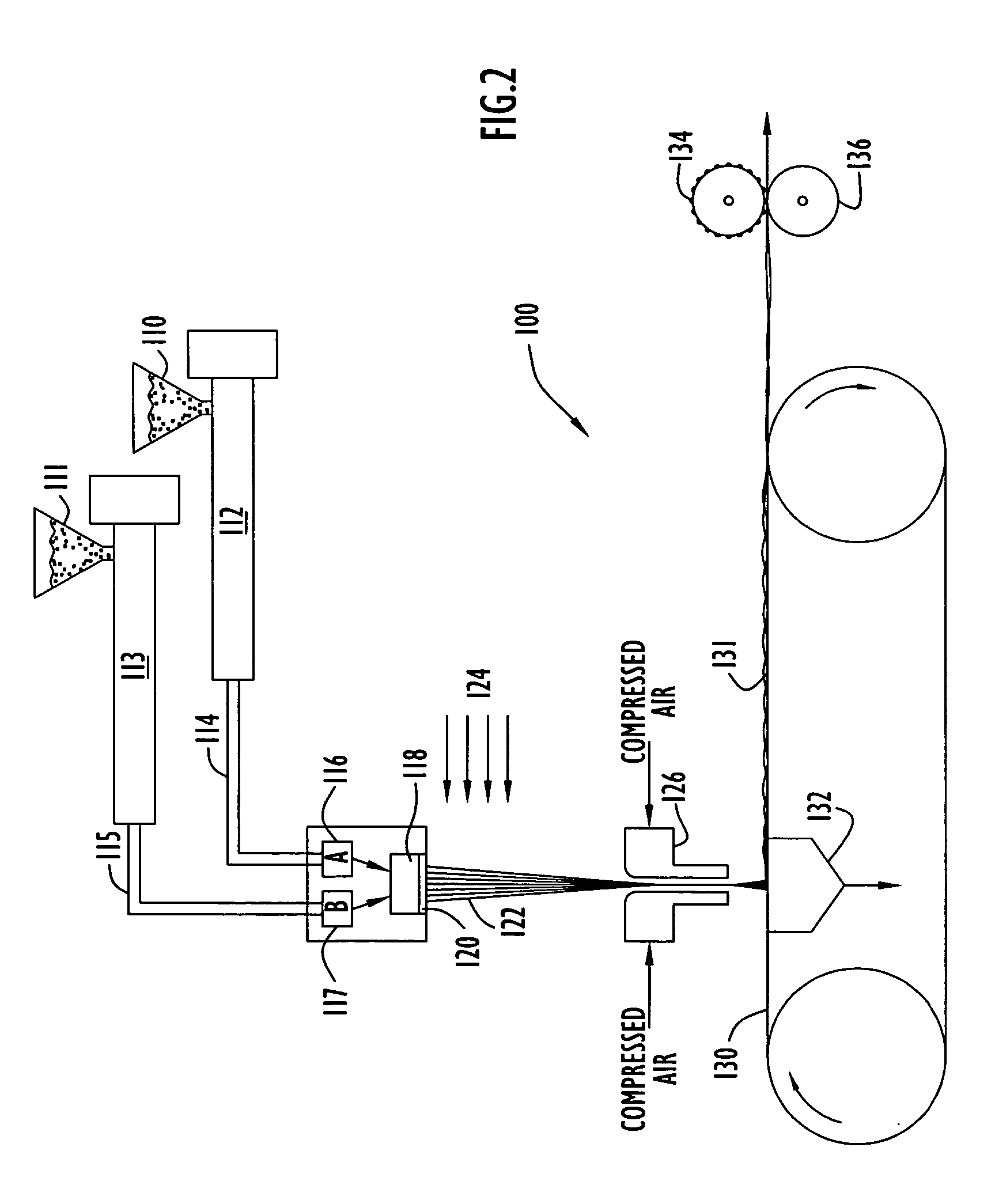

Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby

InactiveUS20050056956A1Artificial filament washing/dryingLoose filtering material filtersNon solventEngineering

This invention relates to a process of melt blowing a cellulose solution through a concentric melt blown die with multiple rows of spinning nozzles to form cellulosic microfiber webs with different web structures. The process comprises the steps of (a) extruding a cellulose solution (dope) through a melt blown spinneret with multiple rows of spinning nozzles; (b) drawing each individual extrudate filament to fine fiber diameter by its own air jet; (c) coagulating and entangling the fine fibers with a series of pressured hydro needling jets of recycling solution of the mixture of cellulose solvent and non-solvent in the spin-line; (d) collecting the stream of microfibers, air and needling jets on a moving collecting surface to form cellulosic fiber web; (e) hydro-entangling the said pre-bonded web downstream with at least one set of hydro needling jets of recycling solvent / non-solvent solution for forming well bonded nonwoven web; (f) regenerating the fine fibers in at least one bath for at least 5 seconds; (g) further regenerating and washing the fine fibers in another bath for at least 5 seconds; (h) pinching the well bonded melt blown cellulosic nonwoven with pressure rollers to remove major portions of the non-solvent; (i) drying the nonwoven web by heat, or vacuum or both, and (j) winding the nonwoven web into rolls.

Owner:BIAX FIBERFILM CORP

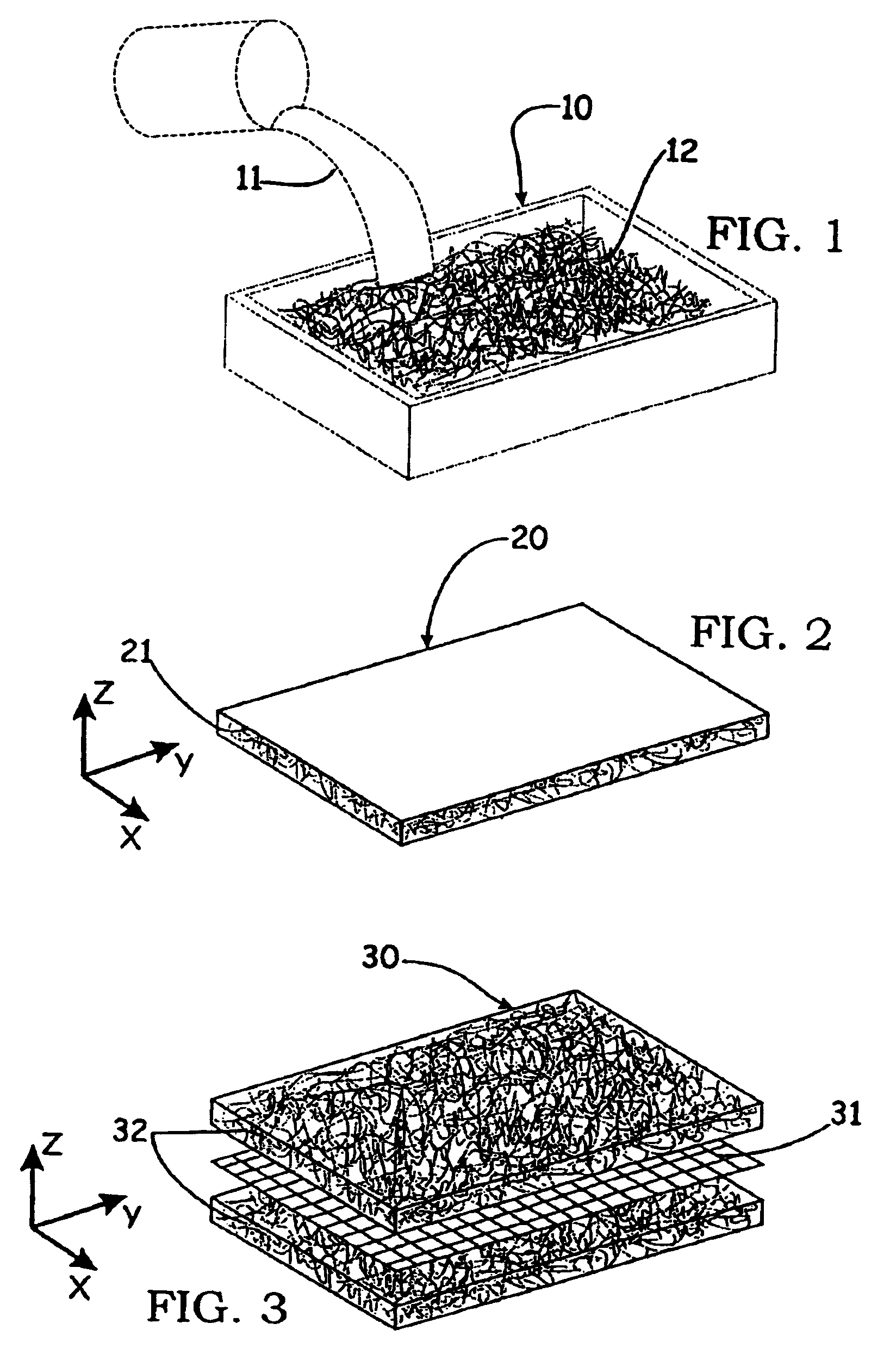

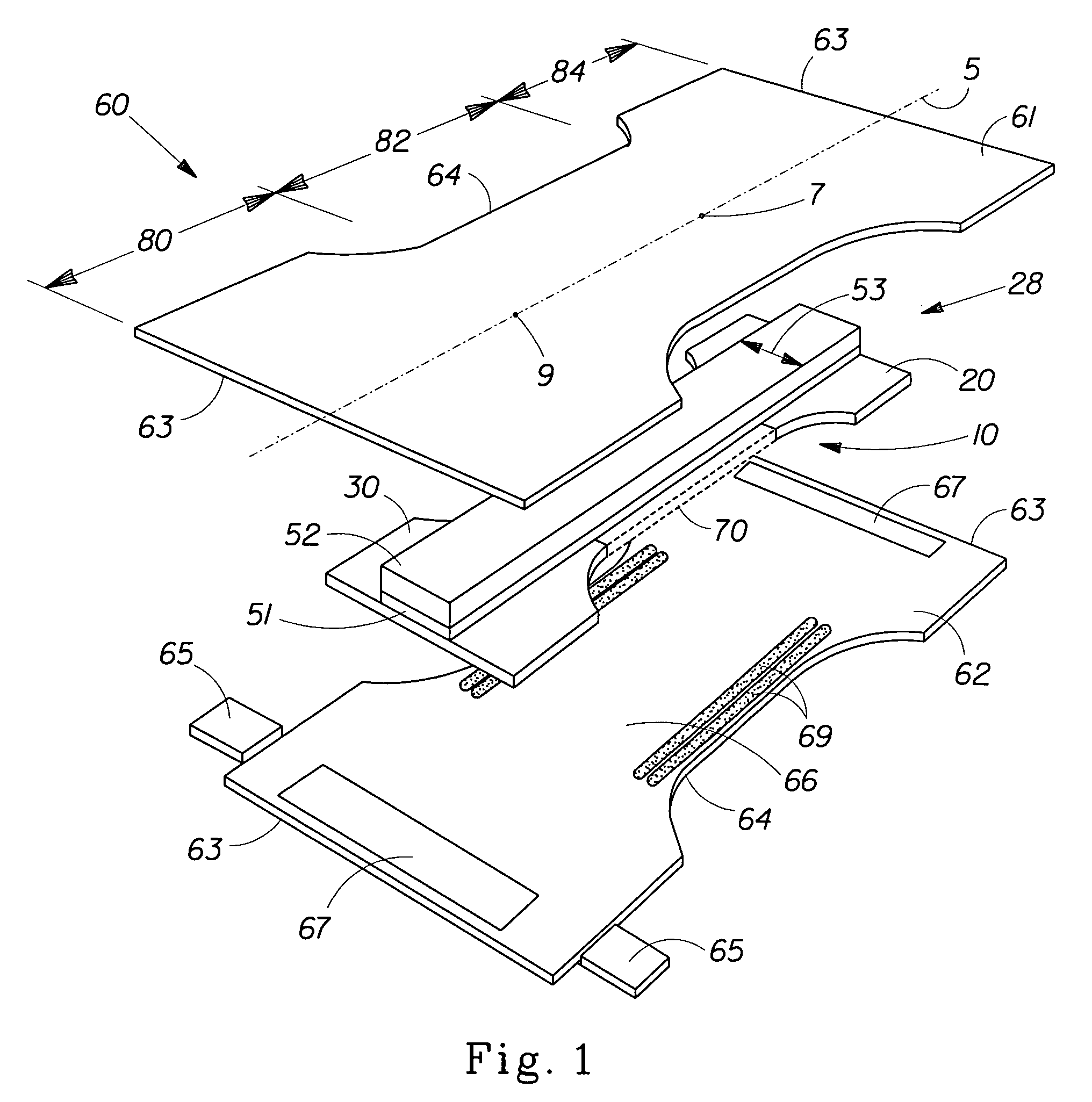

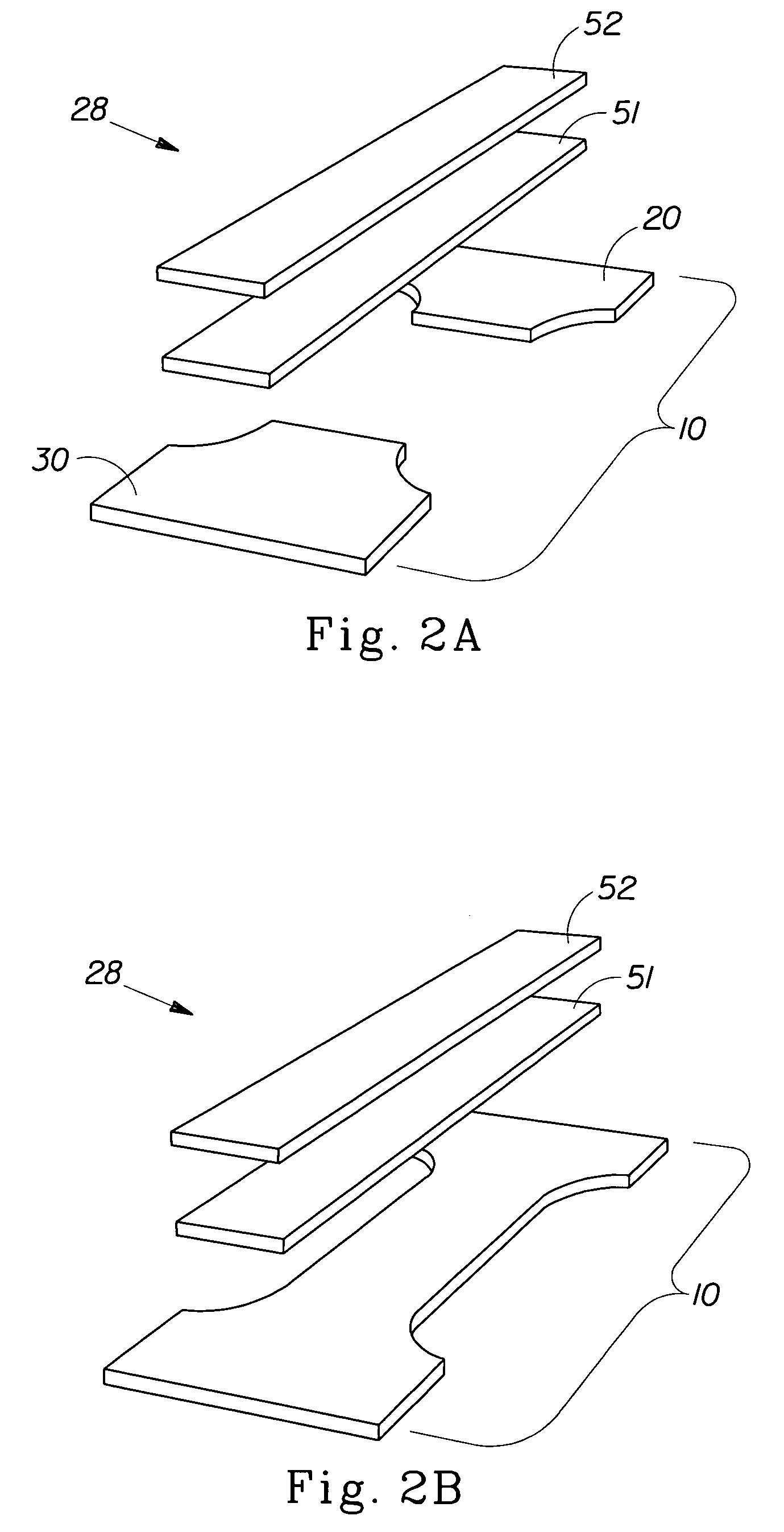

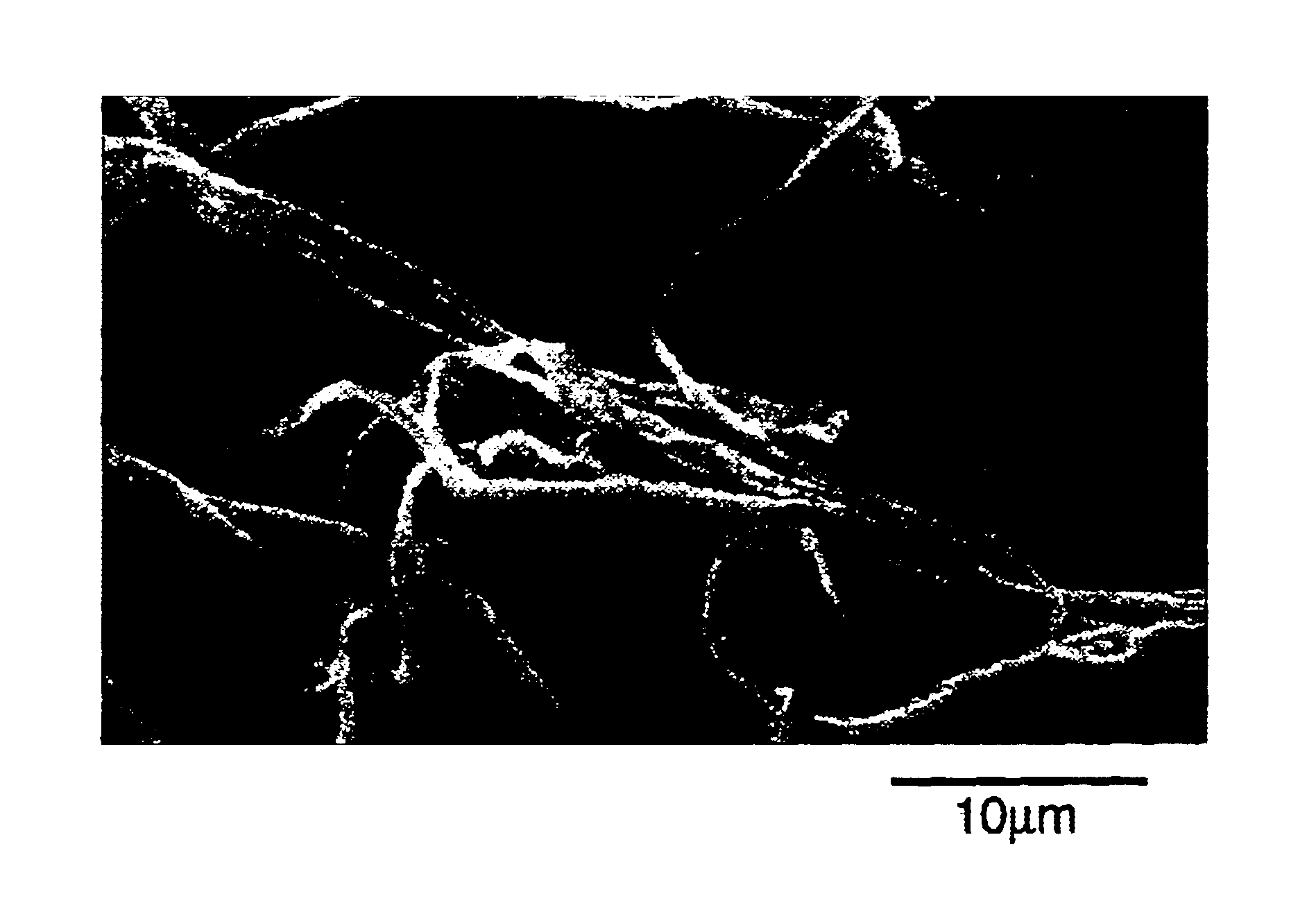

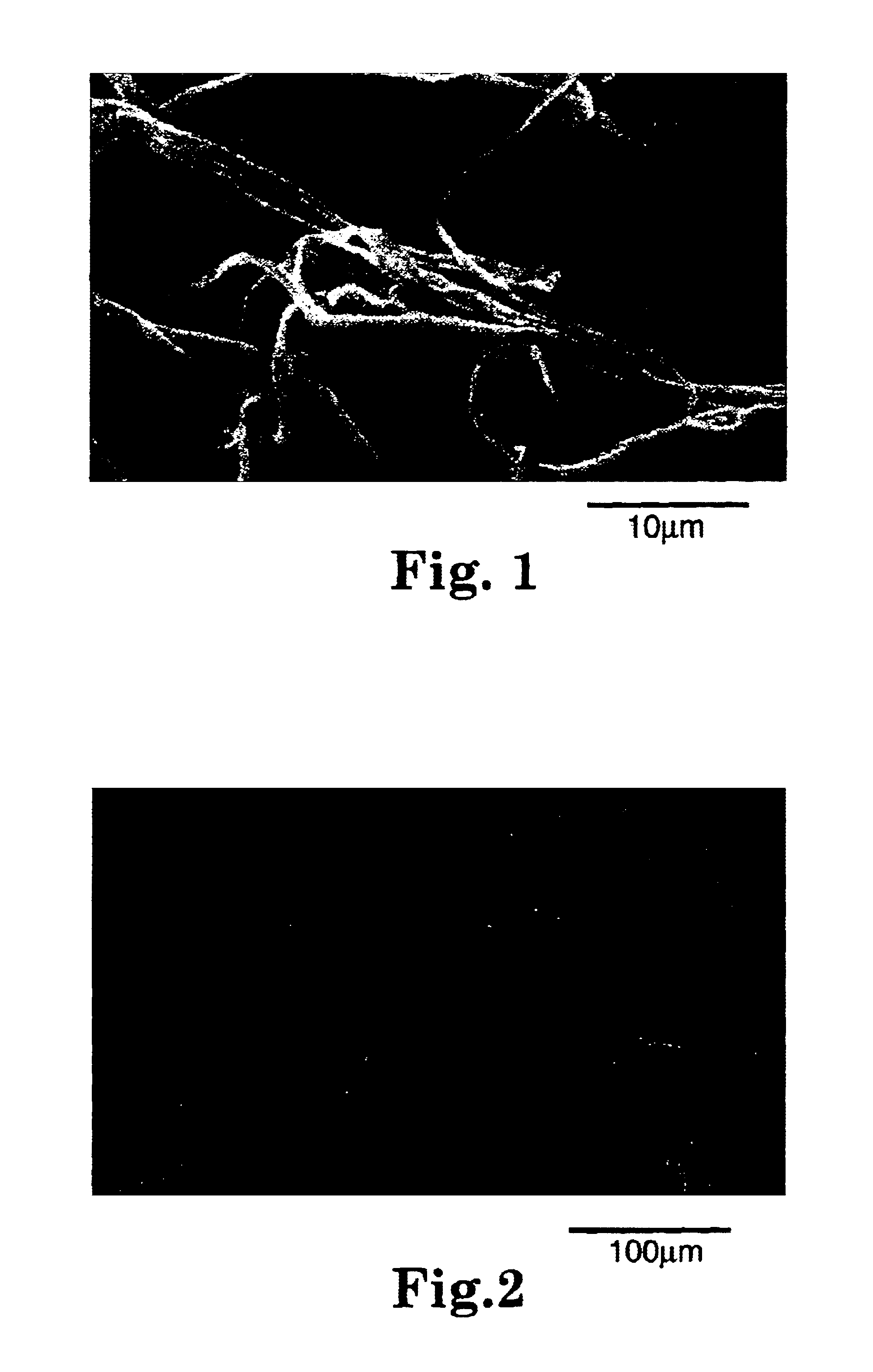

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

InactiveUS6924028B2Simple materialSubstantial surface loadingCombination devicesMaterial nanotechnologyPolymer scienceNanofiber

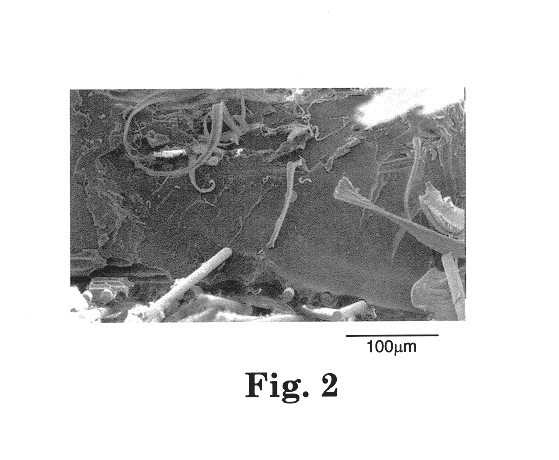

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

Air filter with fine fiber and spun bonded media

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

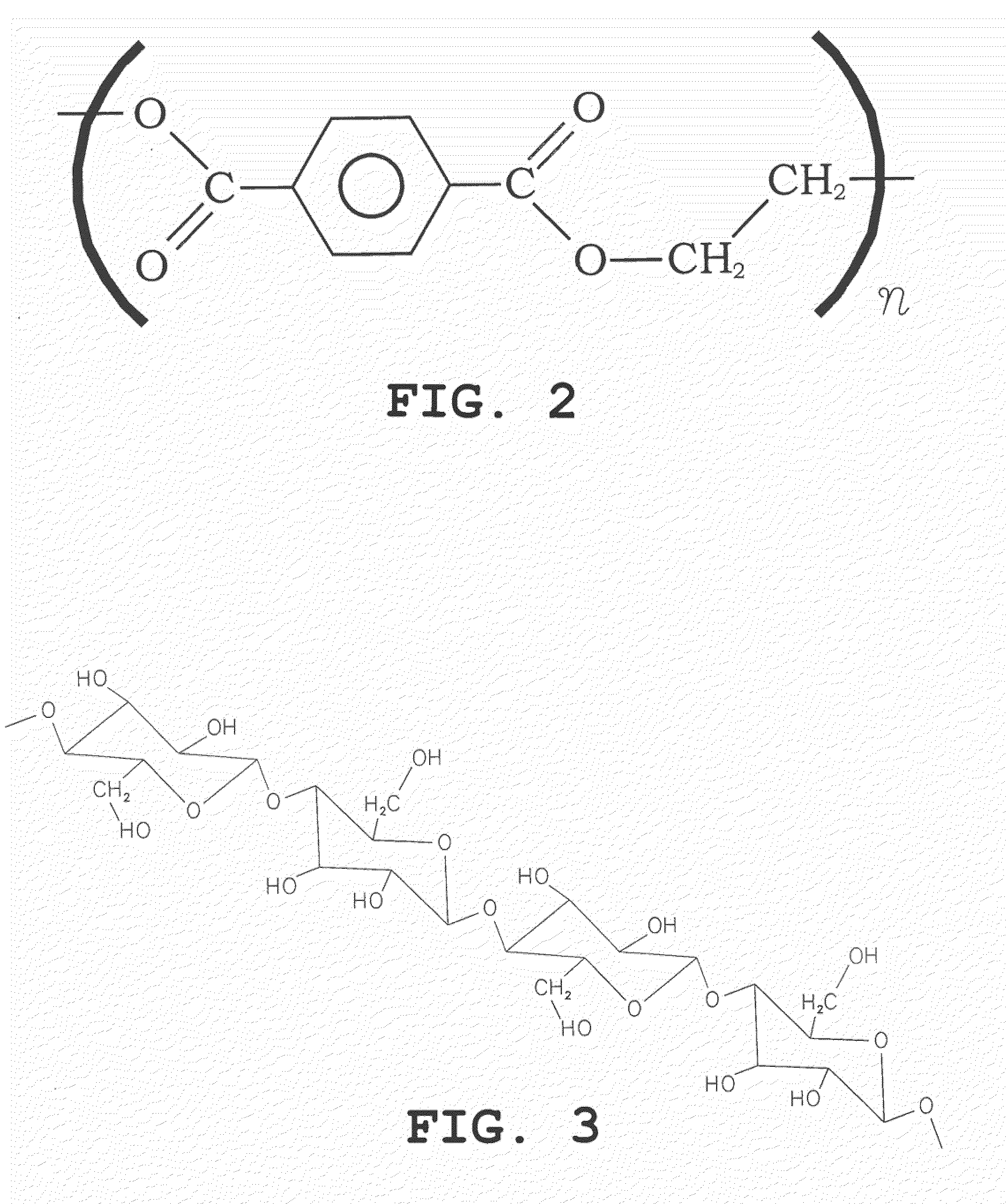

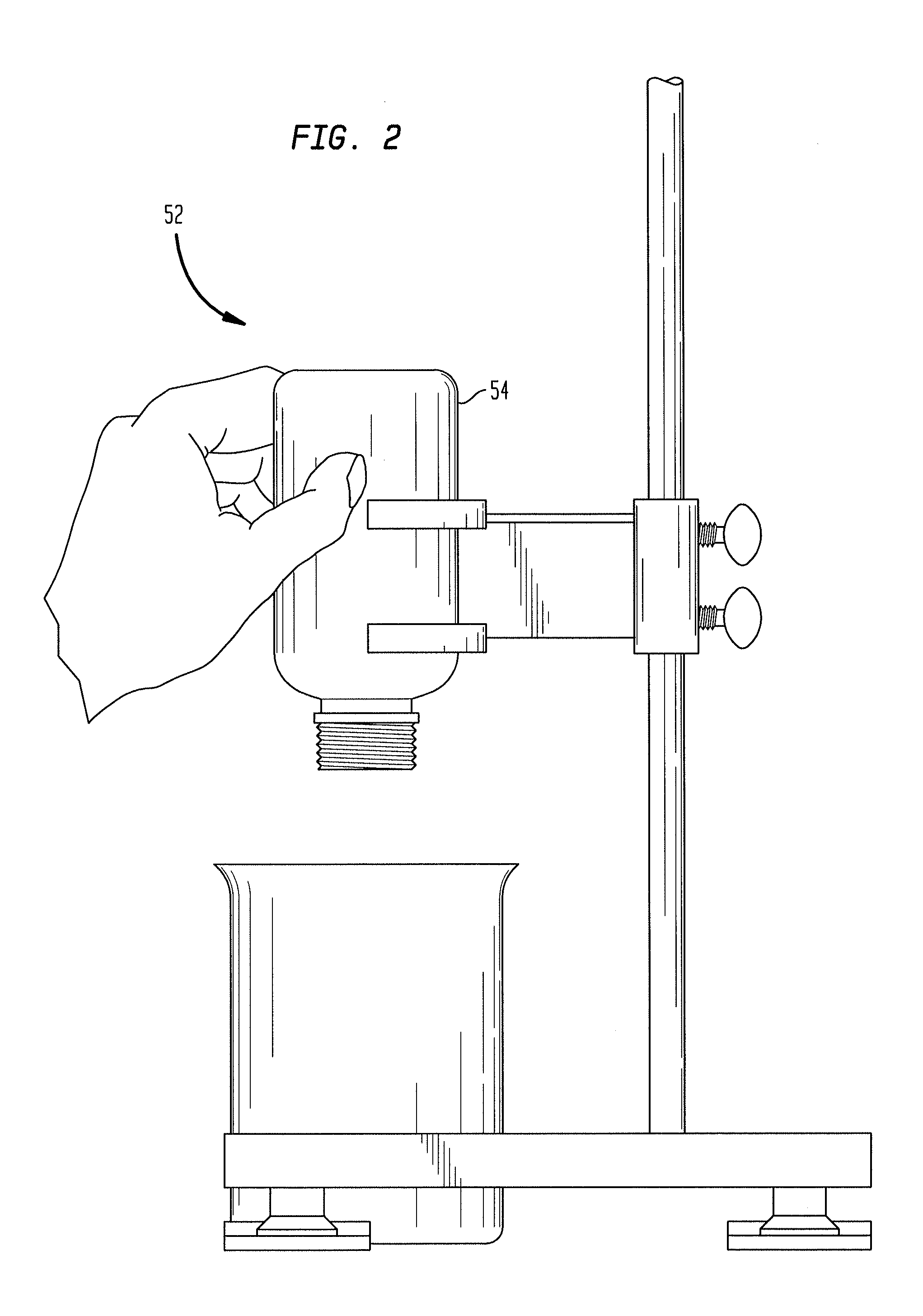

Nonwovens produced from multicomponent fibers

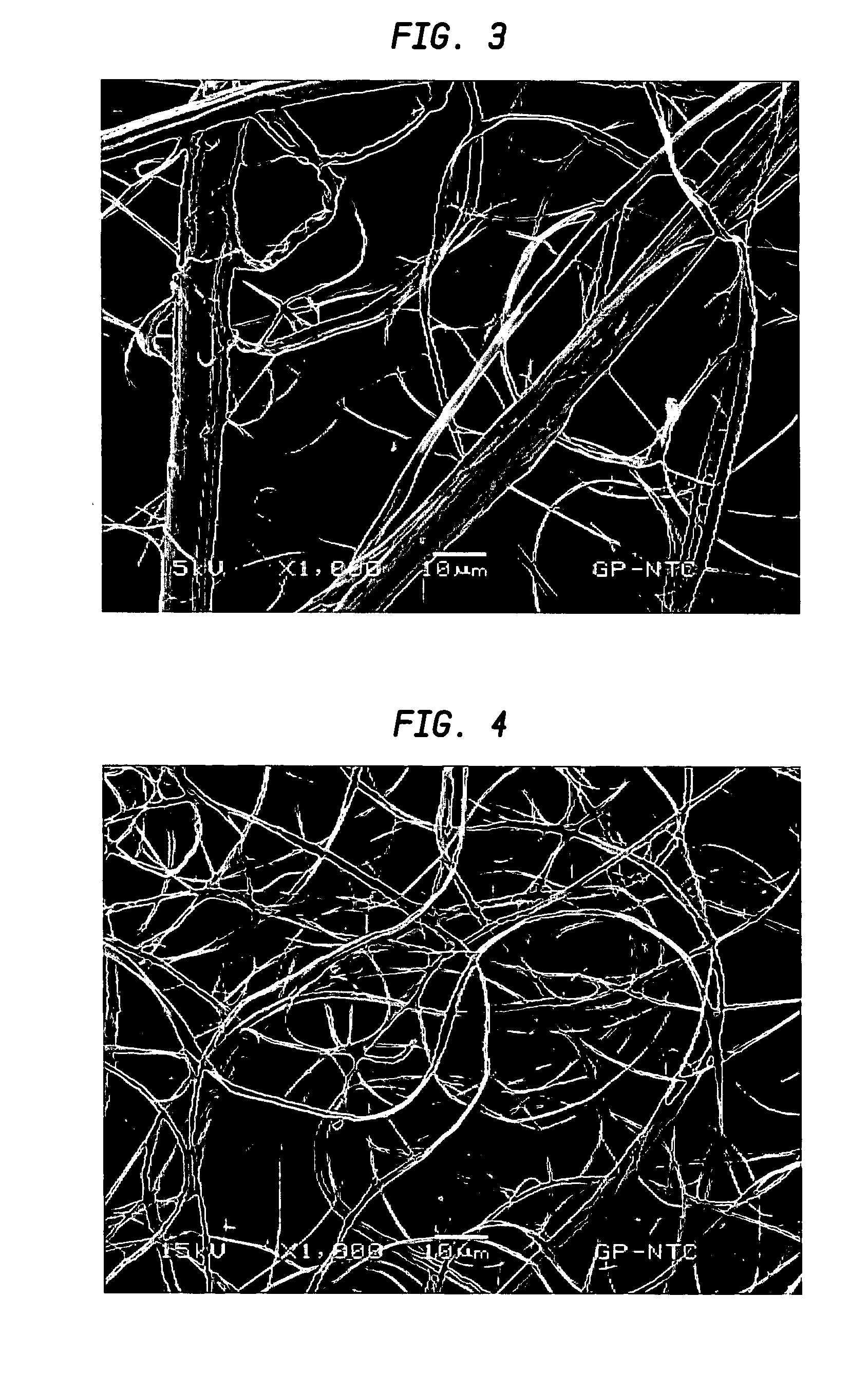

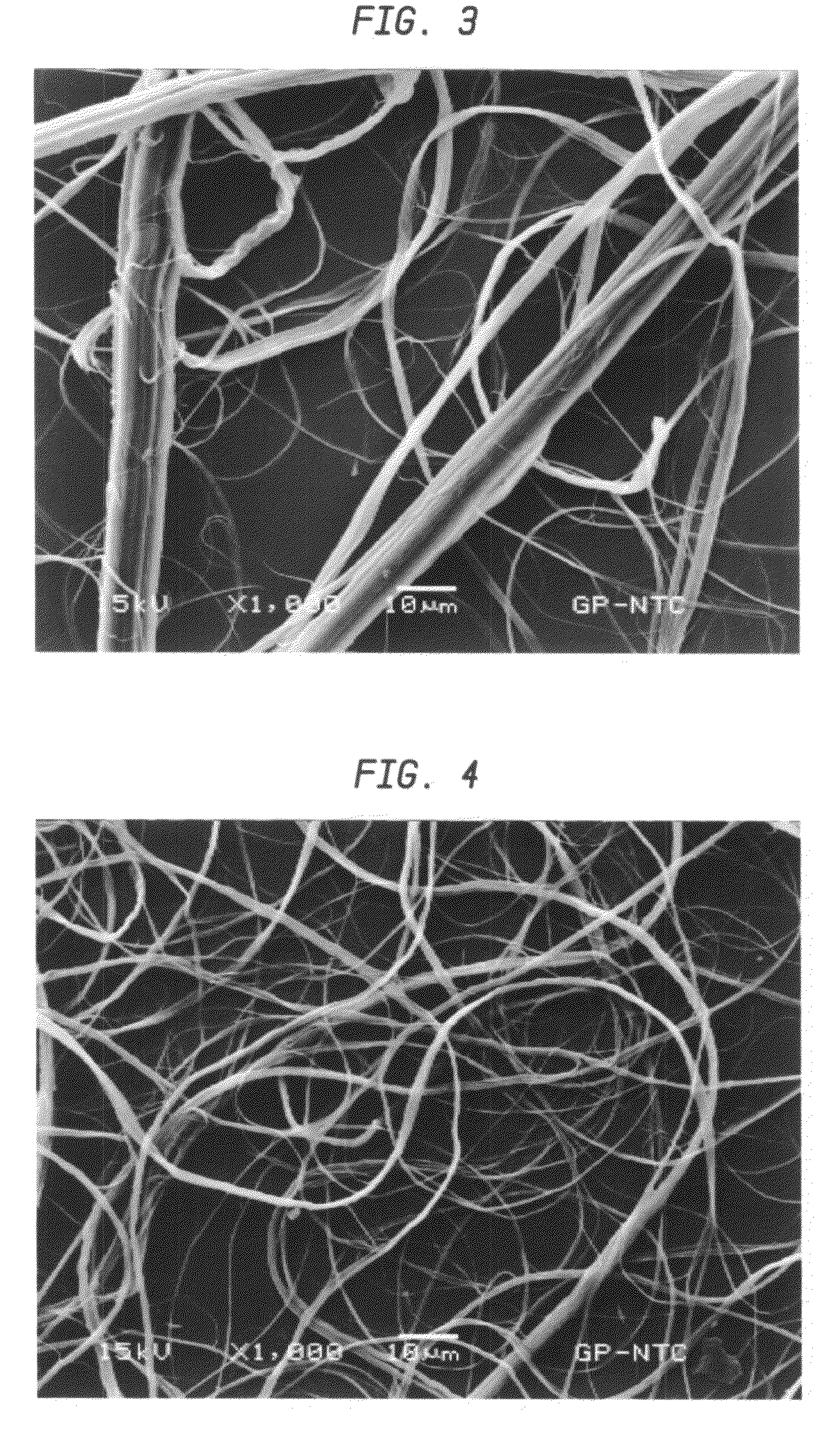

InactiveUS20080311815A1Reduce blockingReduce fusionNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceSlurry

A water non-dispersible polymer microfiber is provided comprising at least one water non-dispersible polymer wherein the water non-dispersible polymer microfiber has an equivalent diameter of less than 5 microns and length of less than 25 millimeters. A process for producing water non-dispersible polymer microfibers is also provided, the process comprising: a) cutting a multicomponent fiber into cut multicomponent fibers; b) contacting a fiber-containing feedstock with water to produce a fiber mix slurry; wherein the fiber-containing feedstock comprises cut multicomponent fibers; c) heating the fiber mix slurry to produce a heated fiber mix slurry; d) optionally, mixing the fiber mix slurry in a shearing zone; e) removing at least a portion of the sulfopolyester from the multicomponent fiber to produce a slurry mixture comprising a sulfopolyester dispersion and water non-dispersible polymer microfibers; and f) separating the water non-dispersible polymer microfibers from the slurry mixture. A process for producing a nonwoven article is also provided.

Owner:EASTMAN CHEM CO

Hydraulically-Formed Nonwoven Sheet with Microfibers

InactiveUS20100272938A1Non-fibrous pulp additionNatural cellulose pulp/paperNonwoven fabricMedical device

In a first embodiment, a hydraulically-formed nonwoven sheet, a package comprising such sheet, a method of packaging a medical device using a package with such sheet and a method of manufacturing such sheet are provided. This nonwoven sheet comprises first and second non-cellulosic polymeric fibers. The first non-cellulosic polymeric fibers have an average diameter less than about 3.5 micron, an average cut length less than about 3 millimeters and an average aspect ratio of about 400 to about 2000; the second non-cellulosic polymeric fibers have an average diameter greater than about 3.5 micron and an average aspect ratio of about 400 to about 1000. In a second embodiment, a hydraulically-formed nonwoven sheet is provided. This nonwoven sheet comprises binding material, non-cellulosic polymeric fibers and cellulosic based materials. The non-cellulosic polymeric fibers have an average diameter less than about 3.5 micron, an average cut length less than about 3 millimeters and an average aspect ratio of about 400 to about 2000. The second nonwoven sheet has a bacterial filtration efficiency of at least about 98%.

Owner:BEMIS COMPANY INC

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

Owner:DONALDSON CO INC

Filter media

InactiveUS6858057B2Lower performance requirementsEnhanced filtration performance characteristicCombination devicesOther chemical processesFilter mediaEngineering

A filter media comprising a synthetic microfiber polymer fine fiber web wherein the diameter of the fibers is between about 0.8 to about 1.5 microns. The filter media is acceptable for use in ASHRAE applications. Constructions with a low DP backing, support or prefilter layers of coarse fiber provide large area filter webs of high efficiency and a stable and high threshold value of alpha above eleven.

Owner:HOLLINGSWORTH VOSE

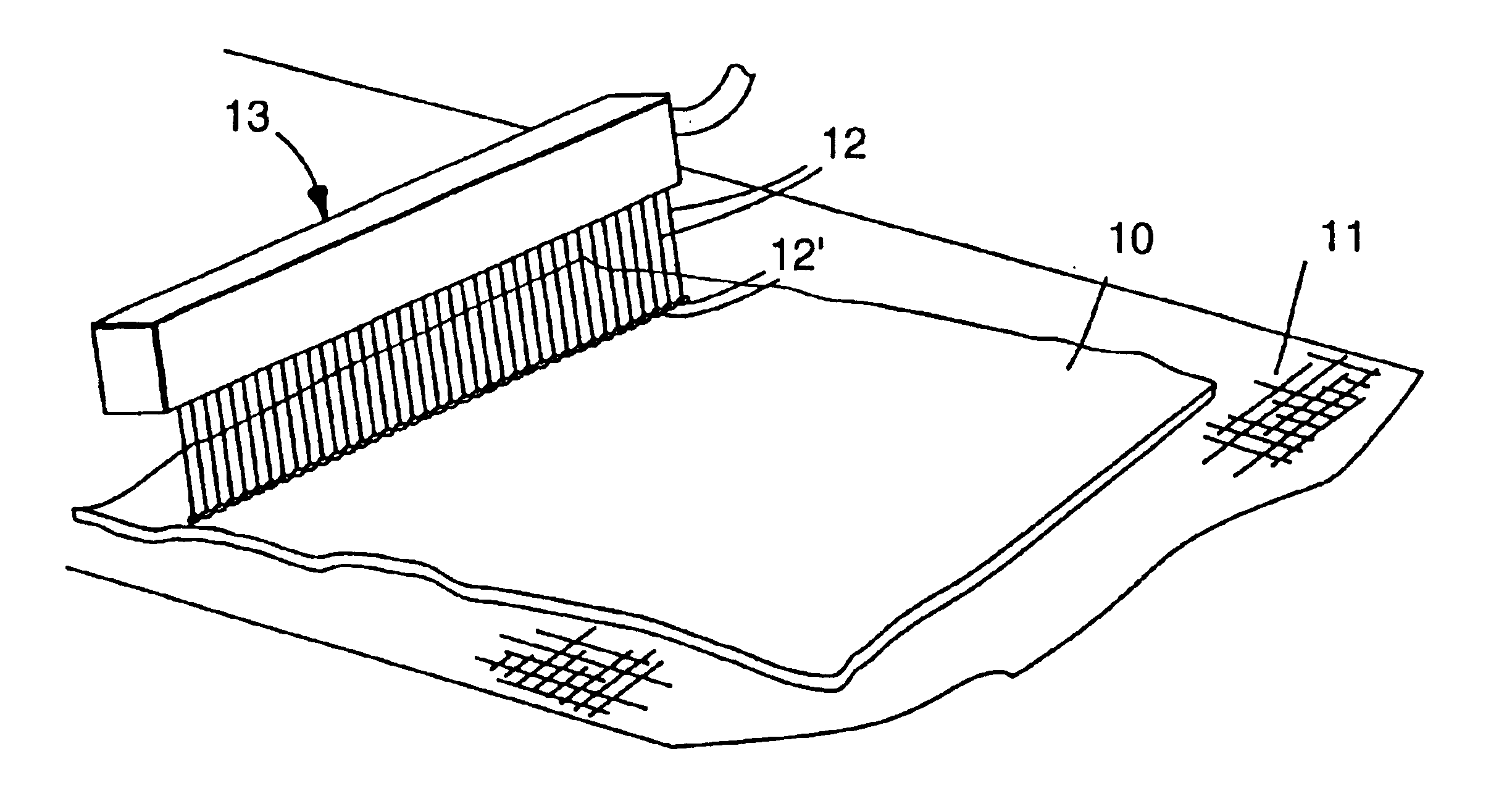

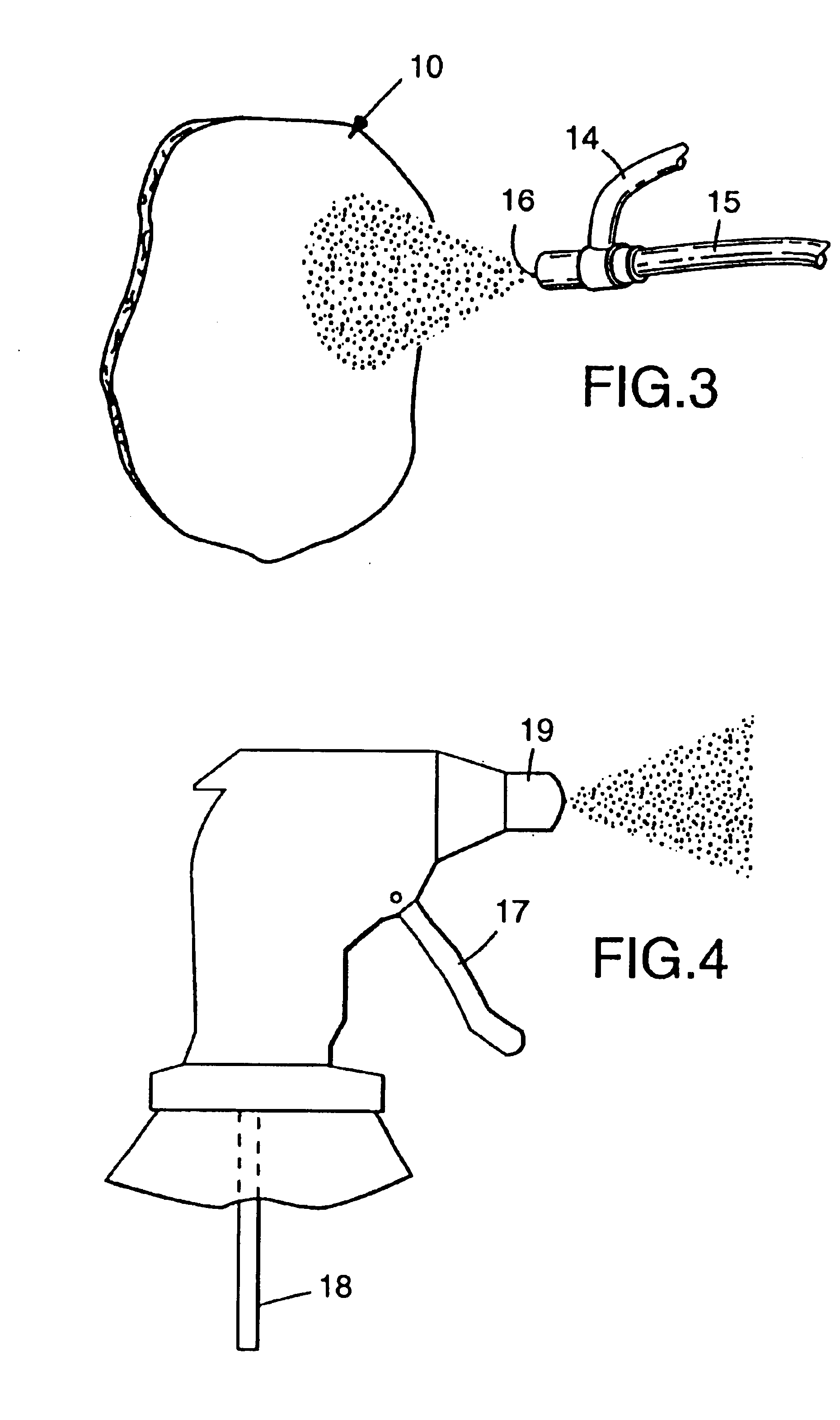

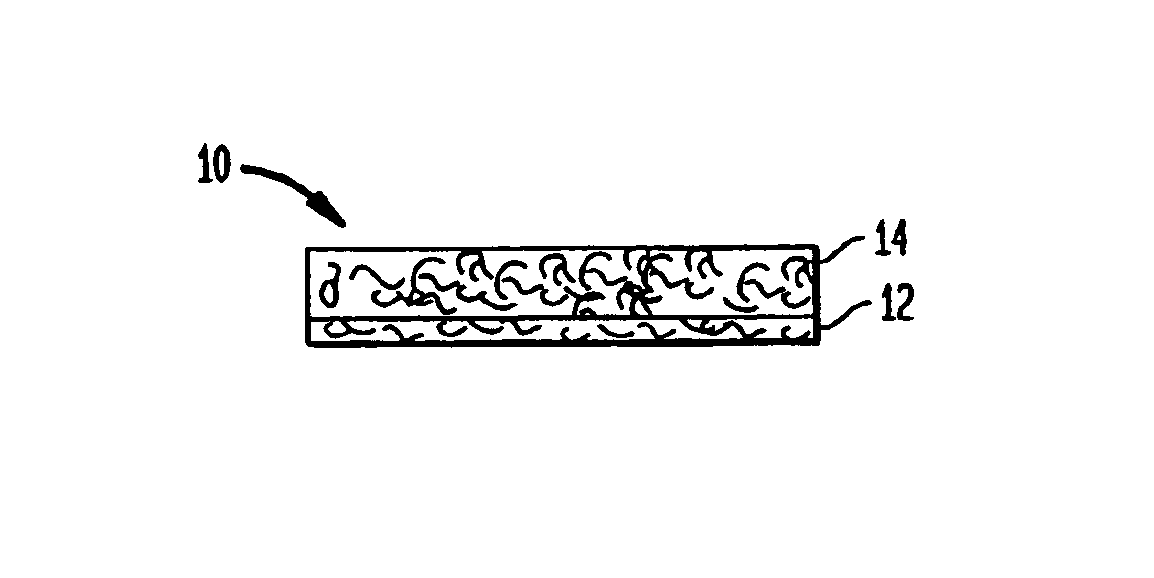

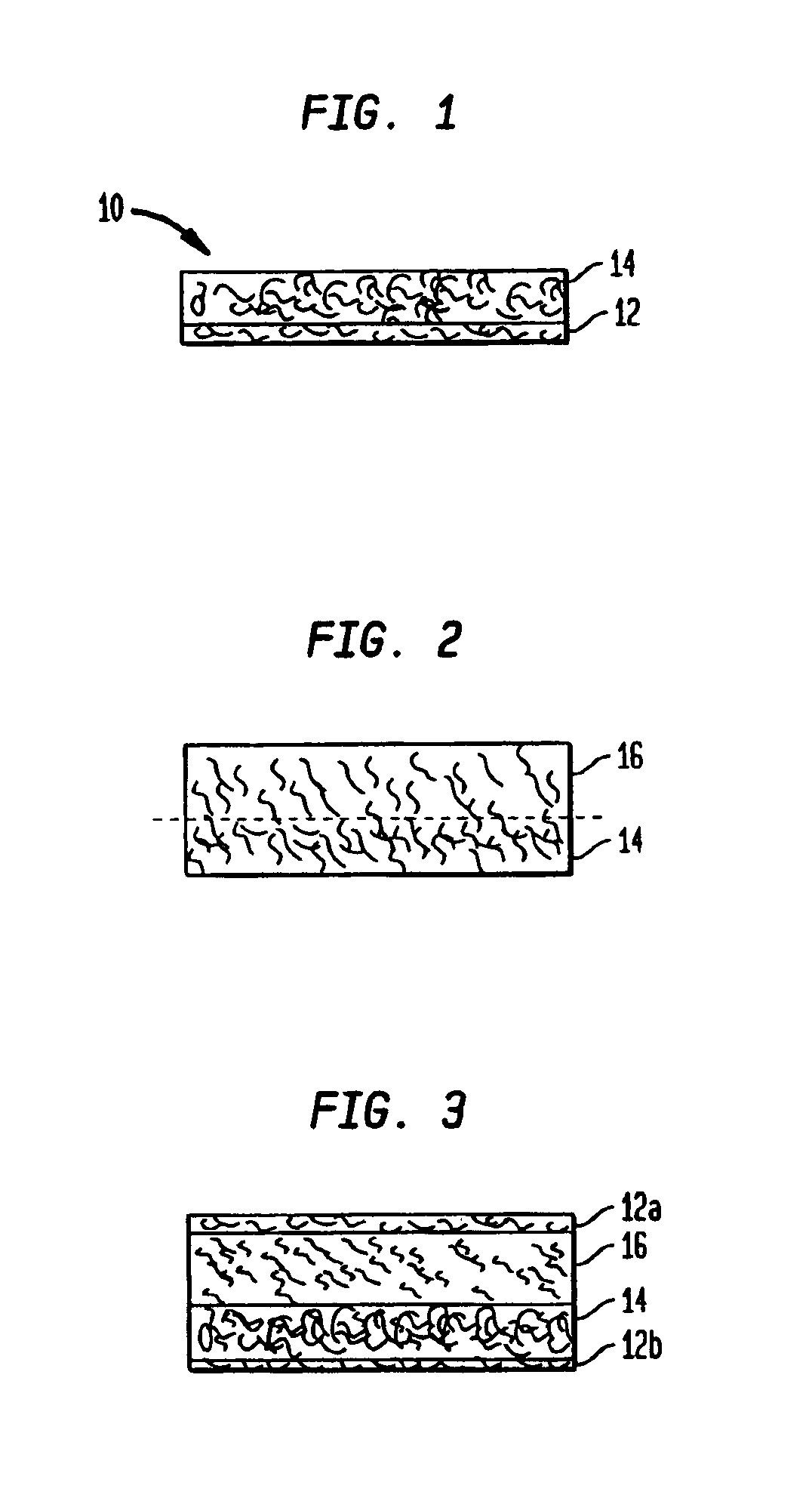

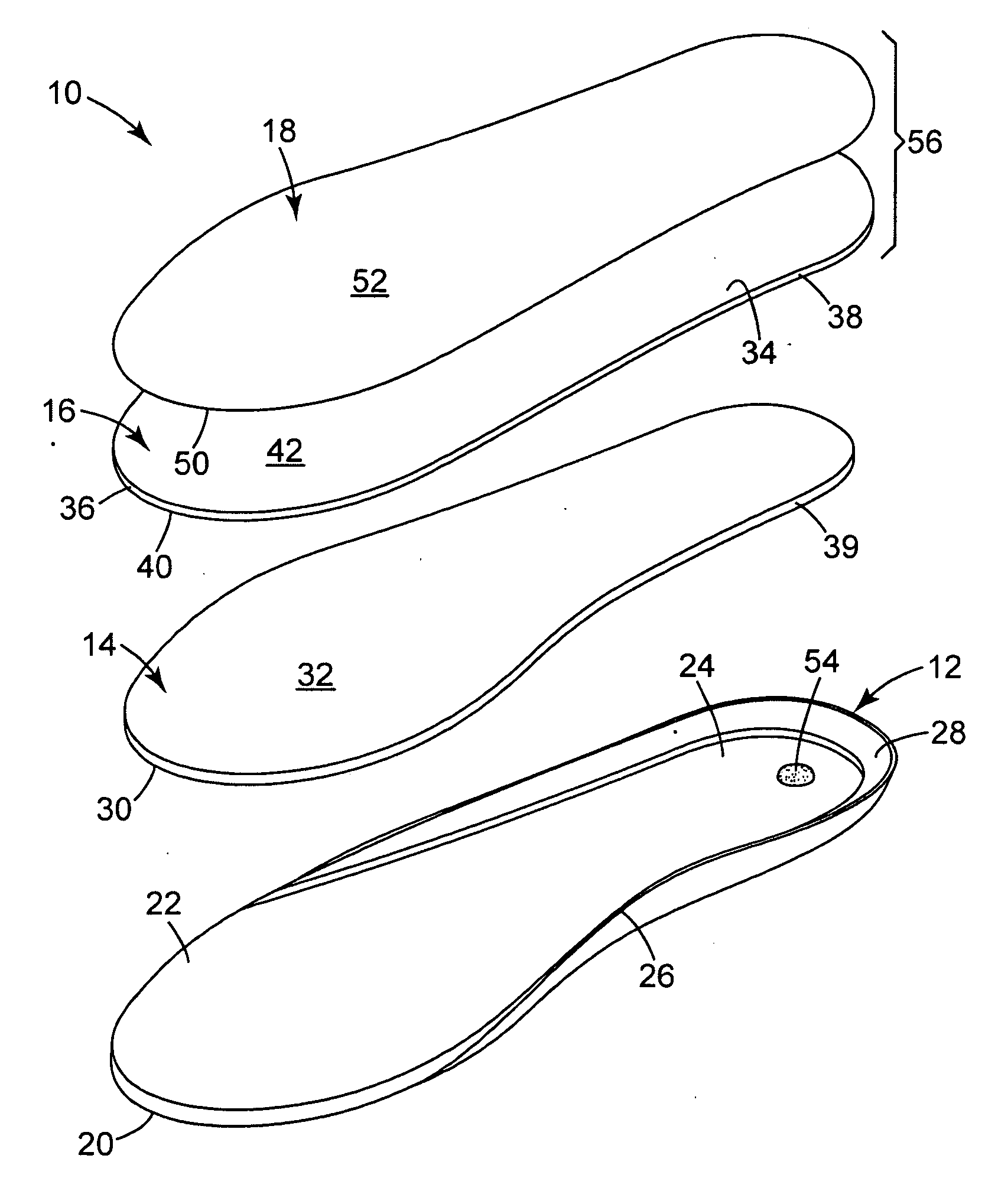

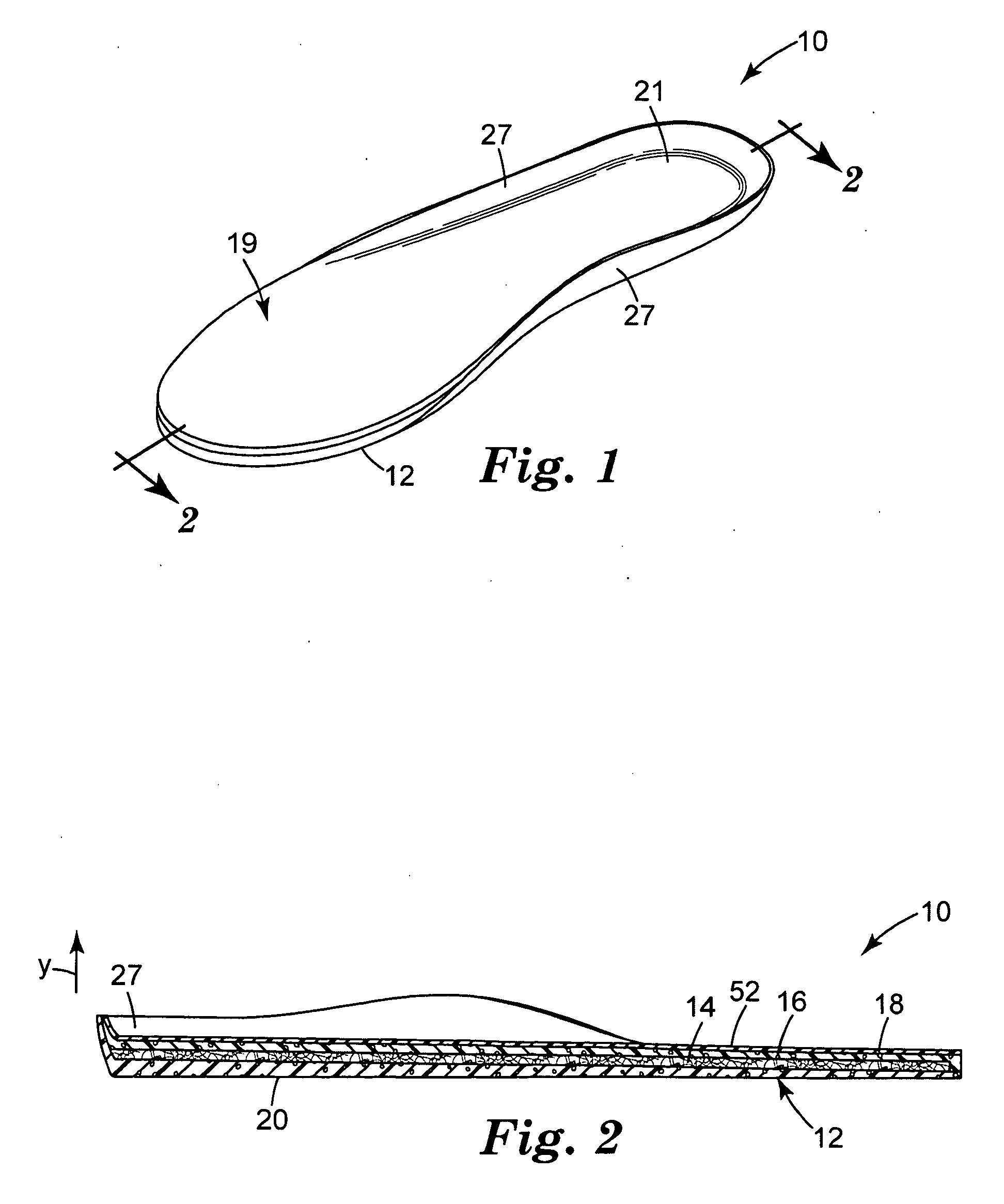

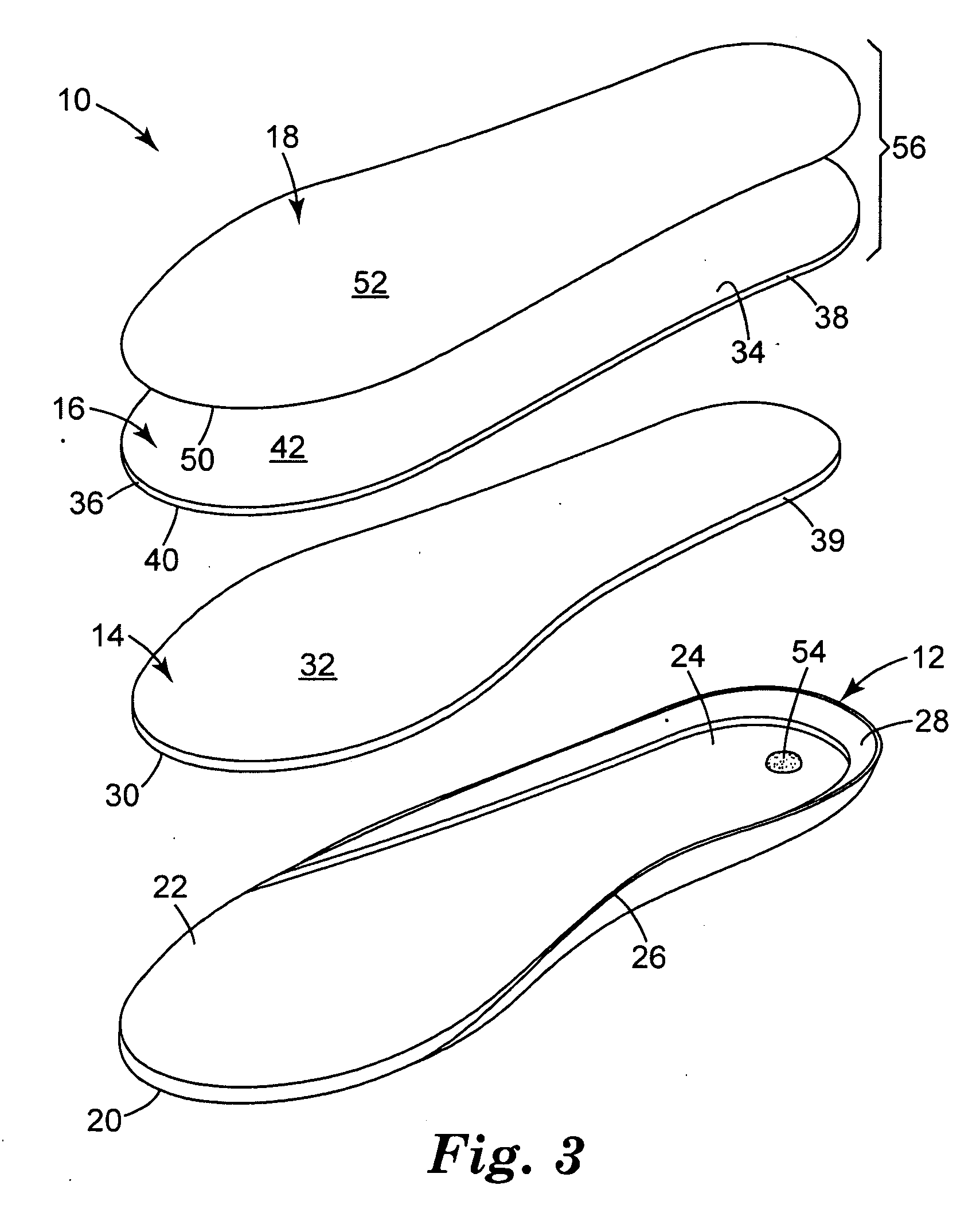

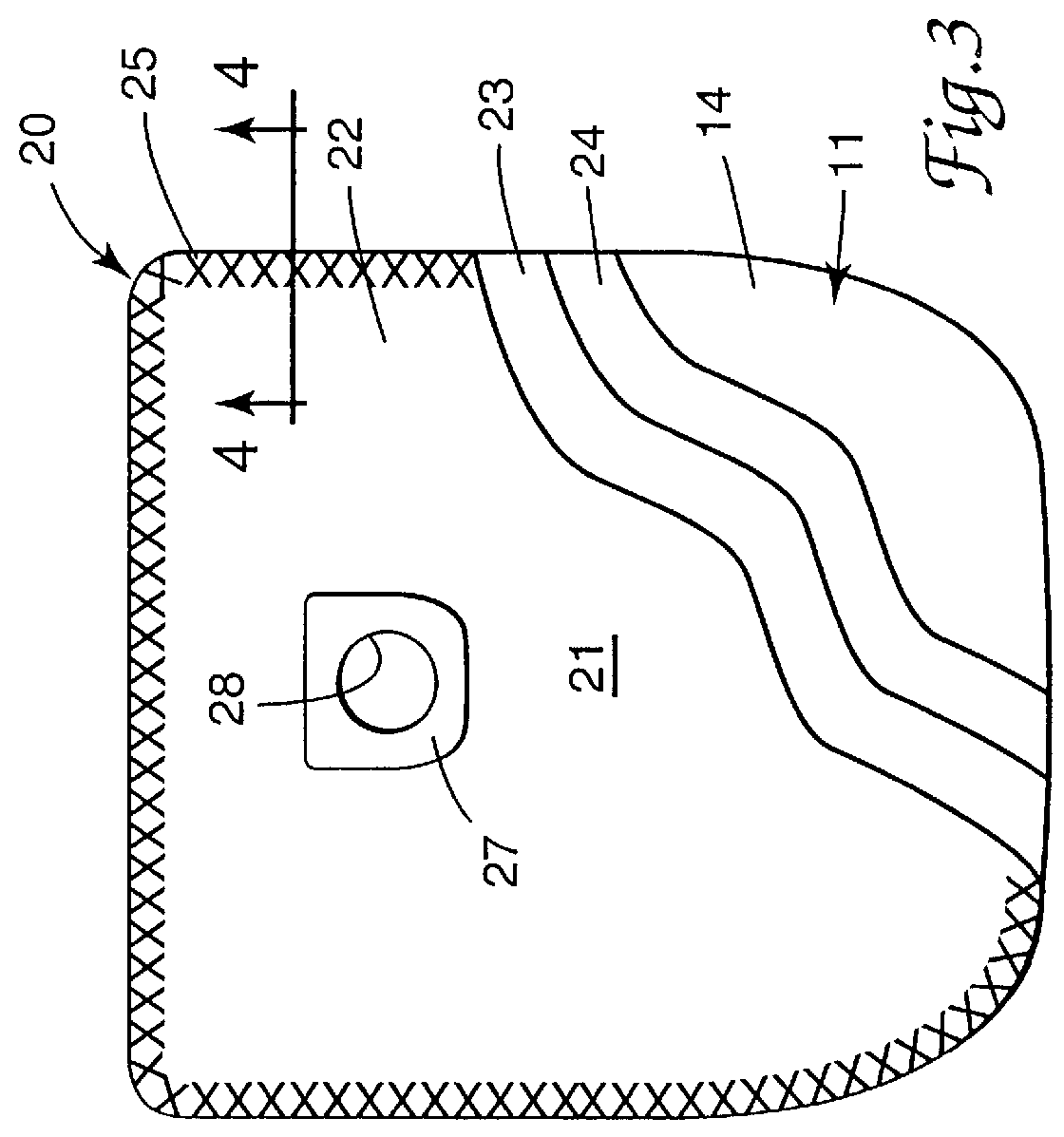

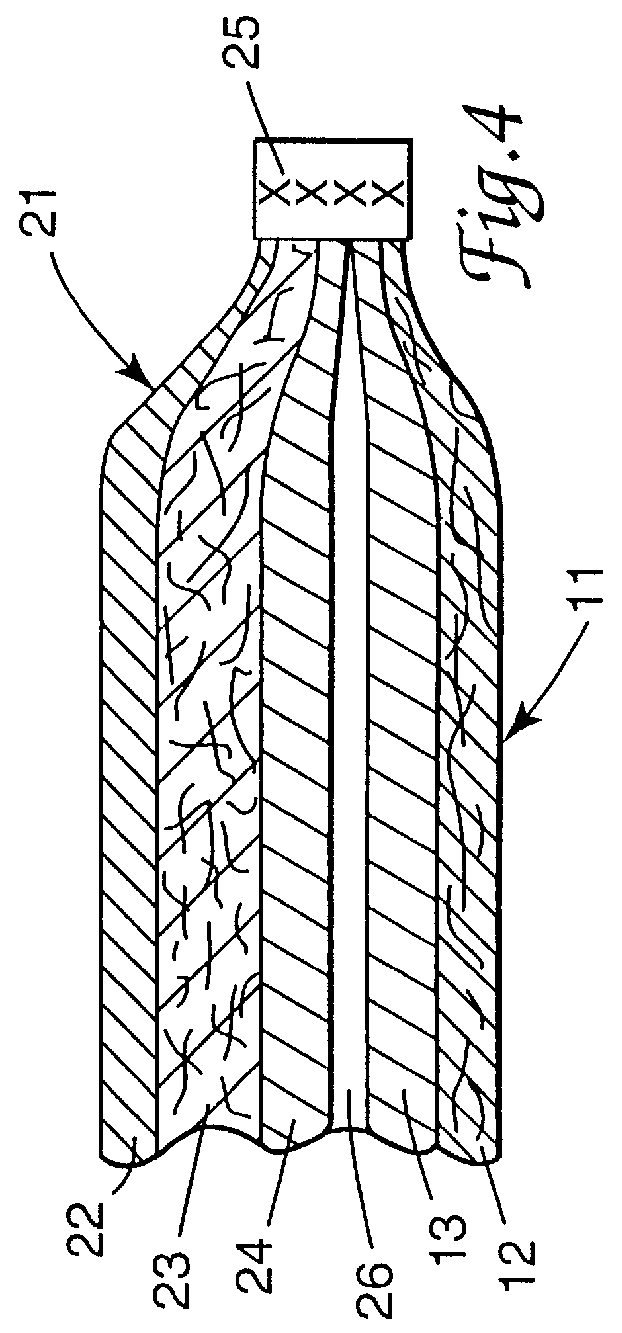

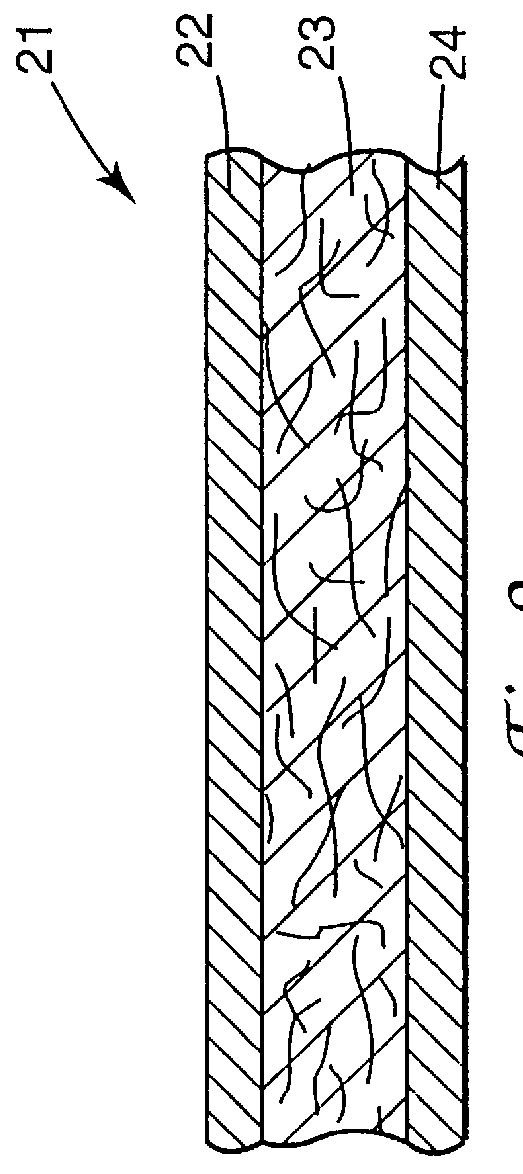

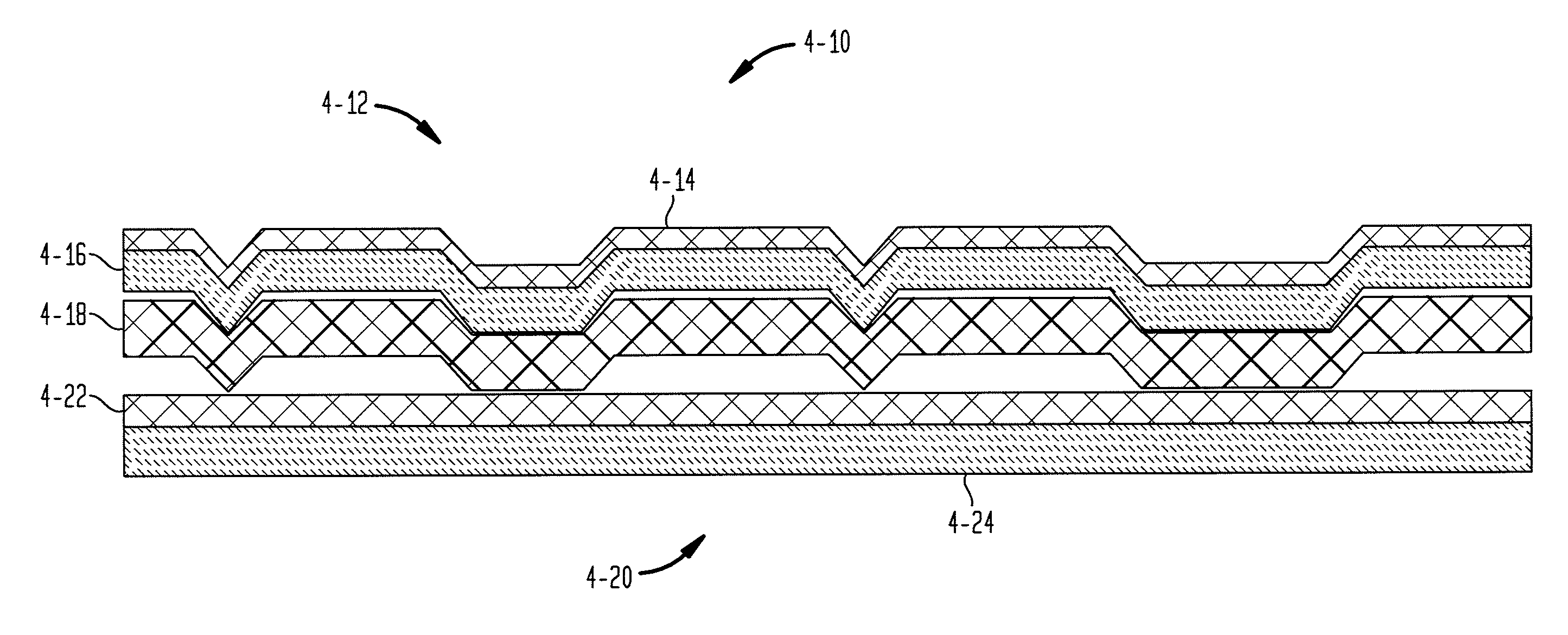

Molded insulated shoe footbed and method of making an insulated footbed

A shoe footbed 10 made by first molding a shape-retaining layer 12 into a contoured condition. After the shape-retaining layer 12 has been molded, a layer of thermal insulation 14 is placed on top of the molded layer 12. A conforming layer 16 and a fabric top layer 18 may be placed over the thermal insulation 14 and the shape-retaining layer 12. The inventive method of manufacture is particularly suited for making insulated footbeds that contain nonwoven webs of polymeric microfiber because damage to the fibrous web from heat and compression may be avoided.

Owner:3M INNOVATIVE PROPERTIES CO

Aerogel composite with fibrous batting

InactiveUS7078359B2Improve thermal efficiencyMinimized volumeShielding materialsCeilingsUltrasound attenuationPliability

Aerogel composite materials having a lofty fibrous batting reinforcement preferably in combination with one or both of individual short randomly oriented microfibers and conductive layers exhibit improved performance in one or all of flexibility, drape, durability, resistance to sintering, x-y thermal conductivity, x-y electrical conductivity, RFI-EMI attenuation, and / or burn-through resistance.

Owner:ASPEN AEROGELS INC

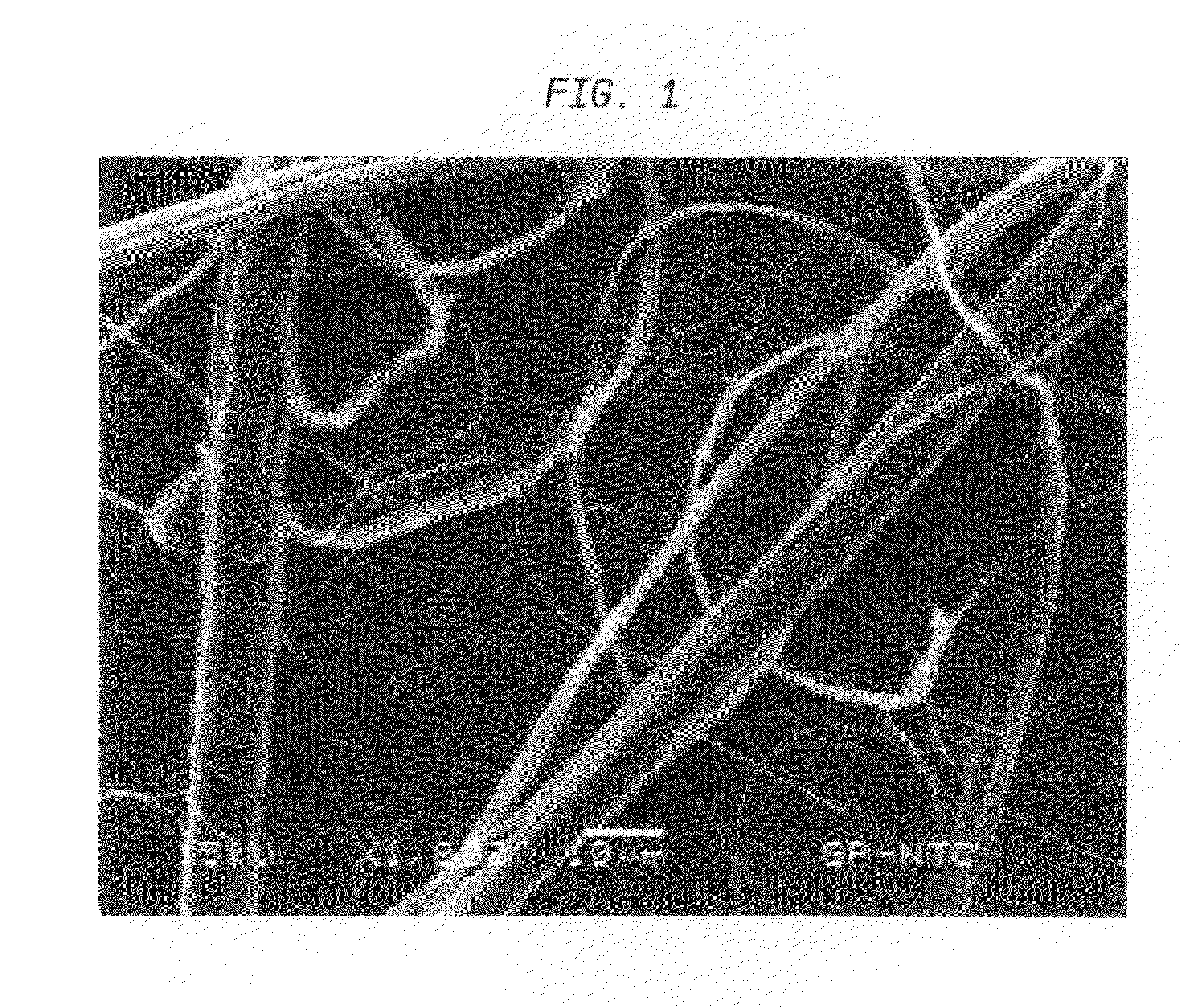

Absorbent sheet having regenerated cellulose microfiber network

ActiveUS20070224419A1High wet/dry tensile ratioImprove consistencyNon-fibrous pulp additionPaper after-treatmentPolymer sciencePapermaking

An absorbent paper sheet for tissue or towel includes from about 99 percent to about 70 percent by weight of cellulosic papermaking fiber and from about 1 percent to about 30 percent by weight fibrillated regenerated cellulose microfiber which was regenerated form a cellulosic dope utilizing a tertiary amine N-oxide solvent or an ionic liquid. Fibrillation of the microfiber is controlled such that it has a reduced coarseness and a reduced freeness as compared with unfibrillated regenerated cellulose microfiber from which it is made and provides at least one of the following attributes to the absorbent sheet: (a) the absorbent sheet exhibits an elevated SAT value and an elevated wet tensile value as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (b) the absorbent sheet exhibits an elevated wet / dry CD tensile ratio as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (c) the absorbent sheet exhibits a lower GM Break Modulus than a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber; or (d) the absorbent sheet exhibits an elevated bulk as compared with a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber. In some embodiments, the pulp is pre-treated with debonder to enhance the wet / dry CD tensile ratio of the sheet.

Owner:GPCP IP HLDG LLC

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

Disposable absorbent articles comprising non-biopersistent inorganic vitreous microfibers

An absorbent article having a distribution member comprising non-biopersistent inorganic vitreous microfibers. The microfibers have an average effective diameter between about 0.1 micron and about 6 microns and are arranged in a fibrous assembly having a basis weight between about 40 g / m2 and about 350 g / m2 and a density between about 0.04 g / m3 and about 0,25 g / m3. In preferred embodiments, the fibrous assembly can vertically wick a 0.9% saline solution to a height of 5 cm in less than about 5 minutes.

Owner:THE PROCTER & GAMBLE COMPANY

High Softness, High Durability Bath Tissue Incorporating High Lignin Eucalyptus Fiber

ActiveUS20130029106A1Less-wet lintOffsetting costsCellulosic pulp after-treatmentNon-fibrous pulp additionCellulose fiberMaterials science

A cellulosic tissue includes cellulosic fibers selected from the group consisting of chemically pulped fibers and mechanically pulped fibers, the cellulosic fibers have from about 10% to about 50% by weight eucalyptus fibers having a lignin content of at least about 20% by weight, and from about 3% to about 10% by weight regenerated cellulosic microfibers.

Owner:GPCP IP HLDG LLC

Aliphatic polyester microfibers, microfibrillated articles and use thereof

InactiveUS6890649B2Increase surface areaUseful applicationEngine sealsFilament/thread formingPolyesterParticulates

The present invention relates to aliphatic polyester microfibers, films having a microfibrillated surface, and methods of making the same. Microfibers of the invention can be prepared by imparting fluid energy, typically in the form of high-pressure water jets, to a highly oriented, highly crystalline, aliphatic polyester film to liberate microfibers therefrom. Microfibrillated films of the invention find use as tape backings, filters for particulate contaminants, such as face masks and water or air filters, fibrous mats, such as those used for removal of oil from water and those used as wipes, and thermal and acoustical insulation. Microfibers of the invention, when removed from the film matrix may be used in the preparation of woven or nonwoven articles and used as wipes for the removal of debris or dust from a surface. The microfibers and microfibrillated articles of the invention may be biodegradable, rendering them useful for geotextiles.

Owner:3M INNOVATIVE PROPERTIES CO

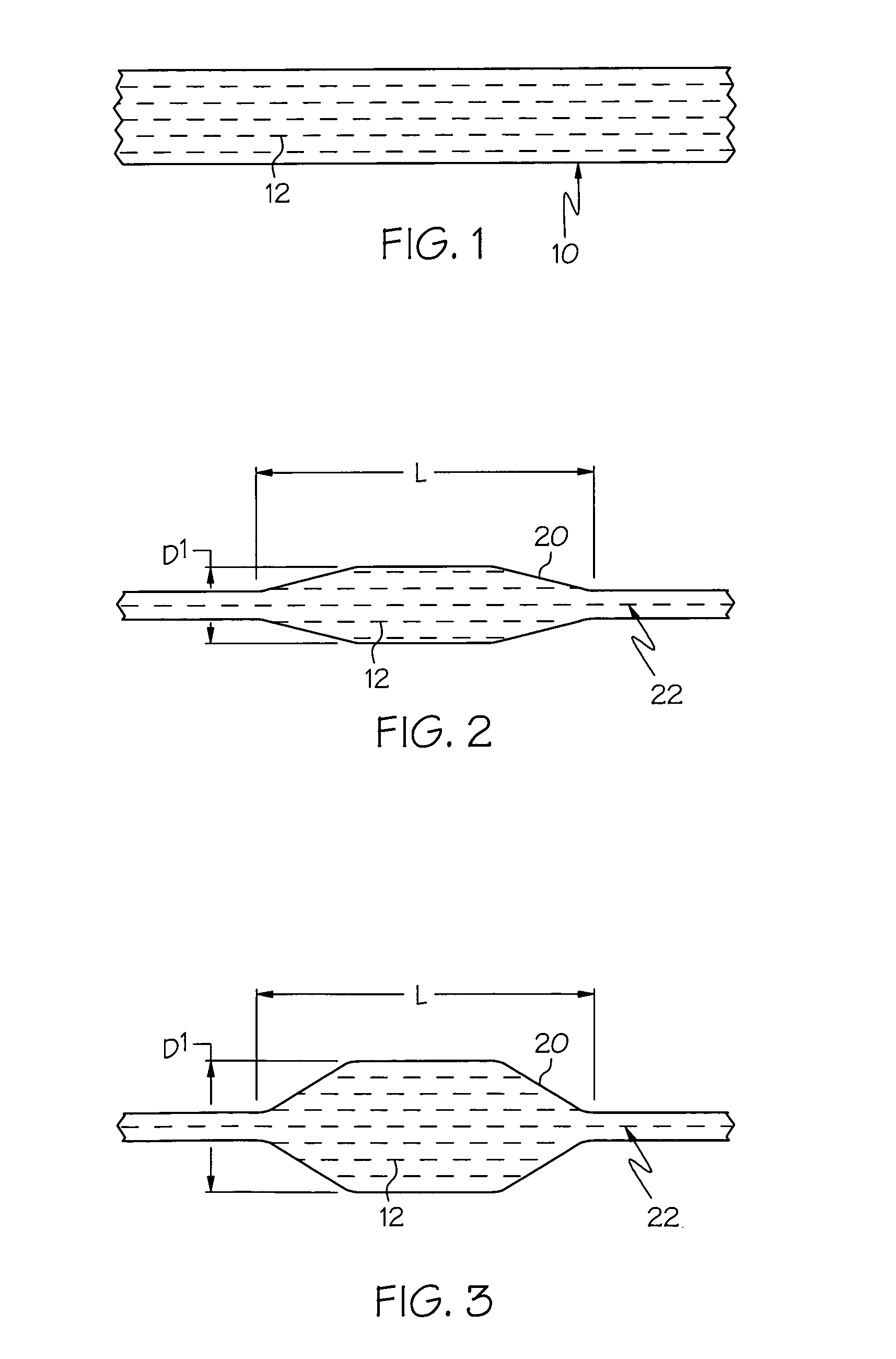

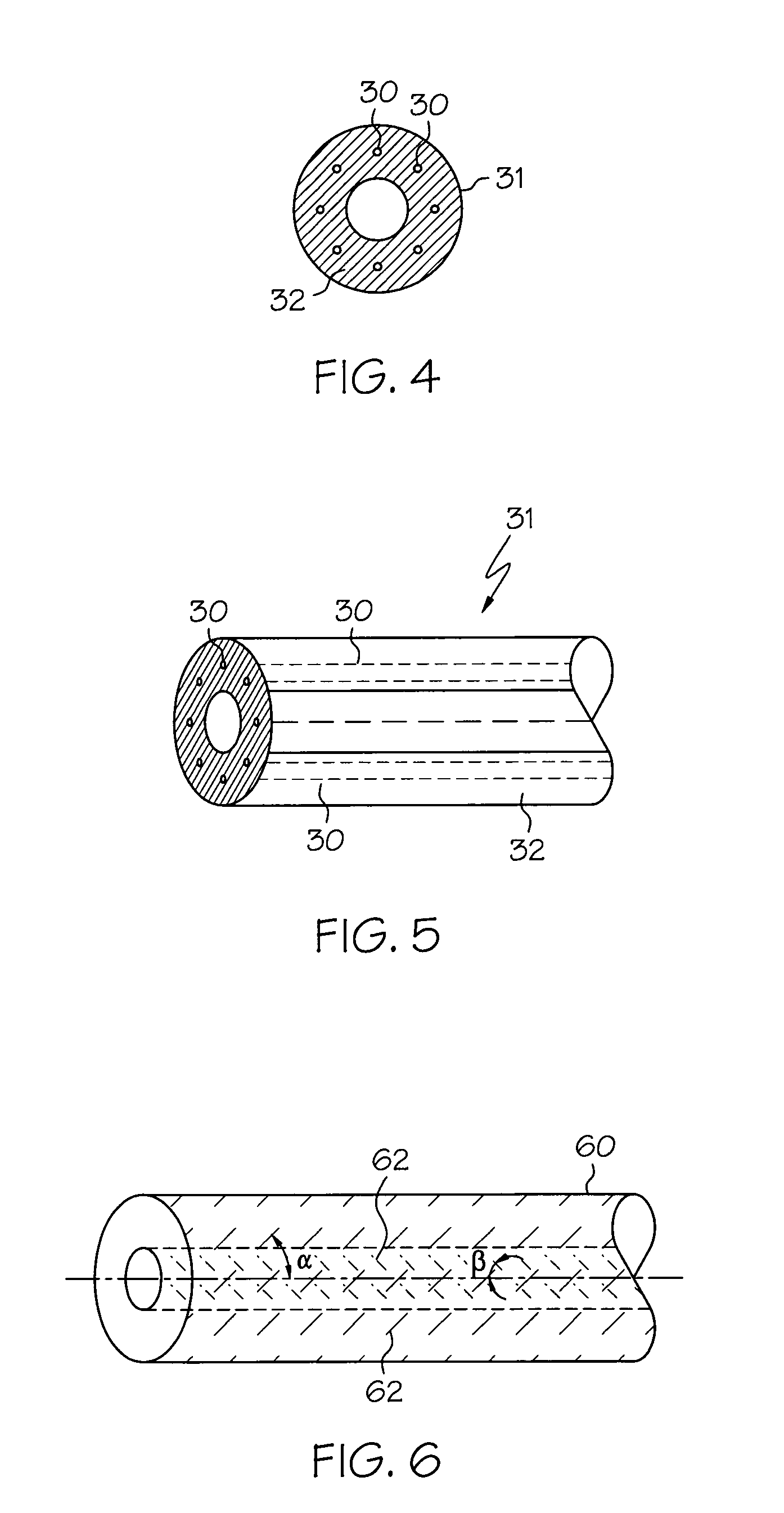

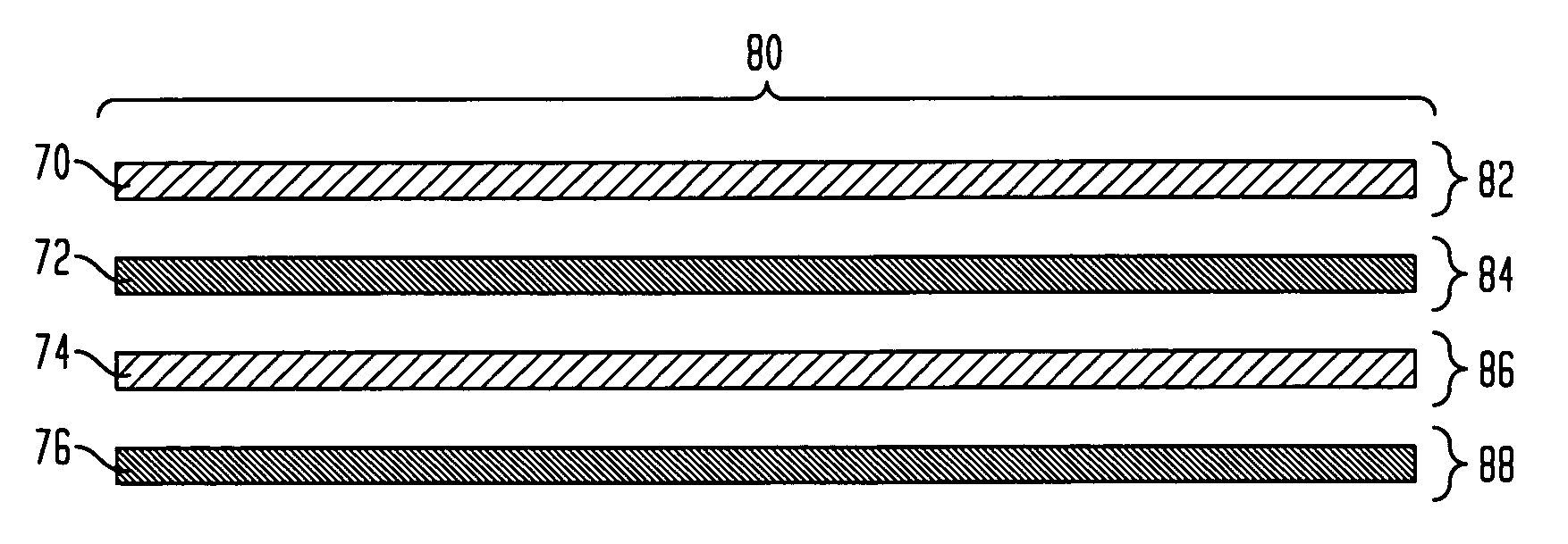

Dimensionally stable balloons

InactiveUS6977103B2Minimal longitudinalIncrease heightSurgeryMedical devicesUltimate tensile strengthMaterials science

An inflatable medical balloon comprises a polymer matrix material and a plurality of fibers distributed in the matrix material. The plurality of fibers operatively adhere to the matrix material and provide reinforcement thereof. The fibers may be parallel or angularly oriented relative to the longitudinal balloon axis, and may be helically disposed thereabout. The fibers may be composed of material which has a greater tensile strength than the matrix material. The fibers may be microfibers formed by phase separation of a melt blend material during extrusion or polymer cores coextruded with the matrix material and surrounded thereby. The balloon may be formed of alternating layers of fiber-free polymer and layers of fiber-containing polymer.

Owner:BOSTON SCI SCIMED INC

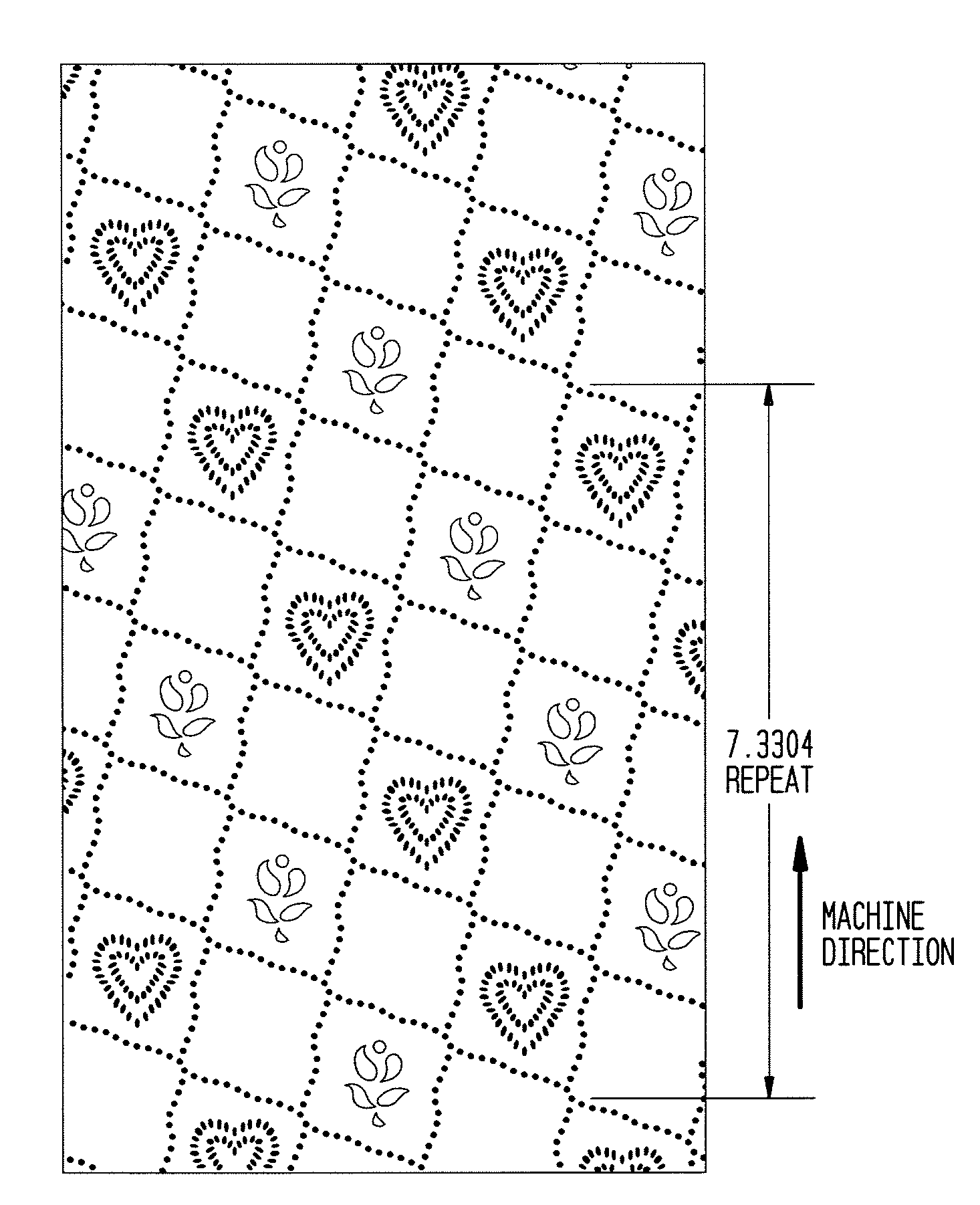

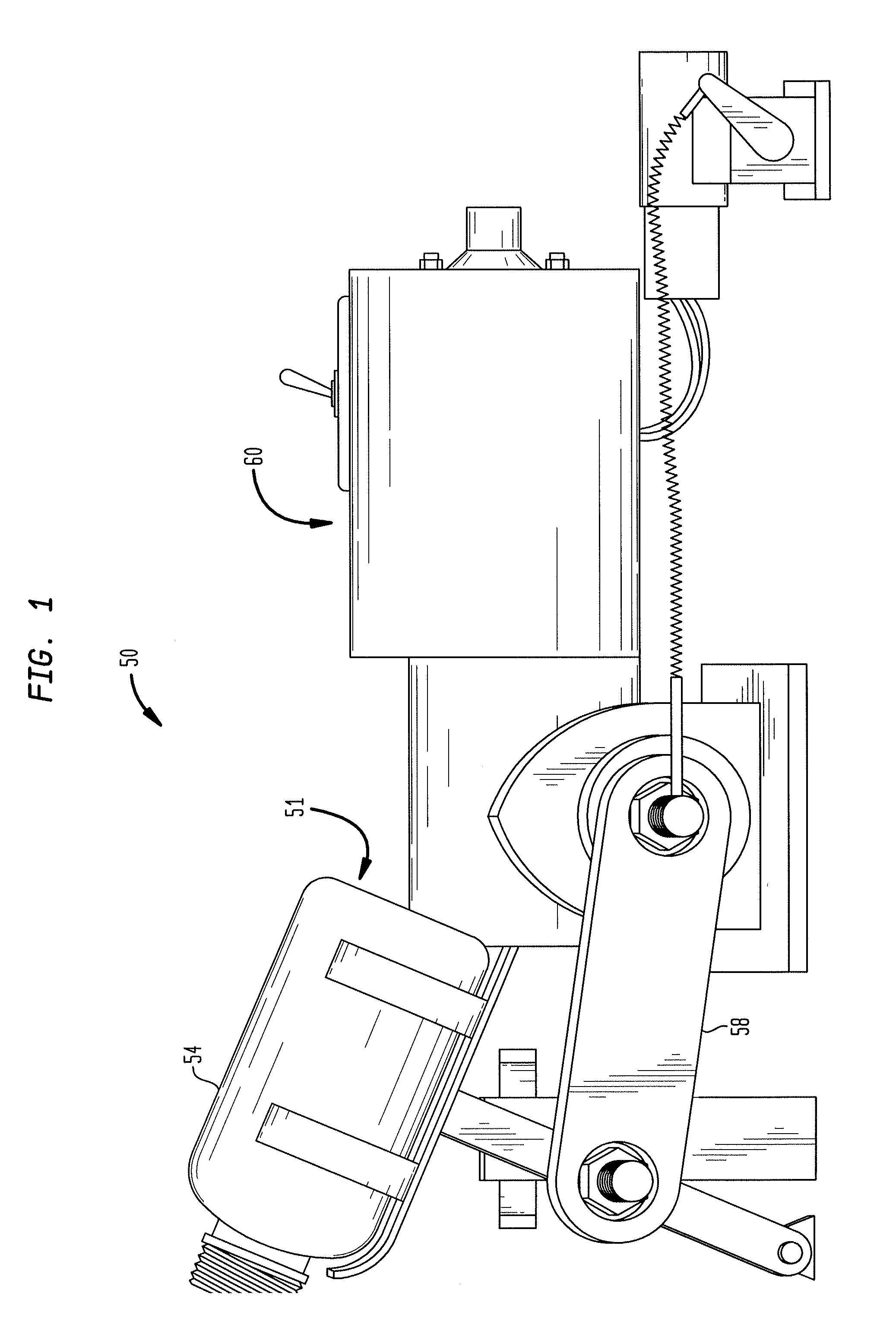

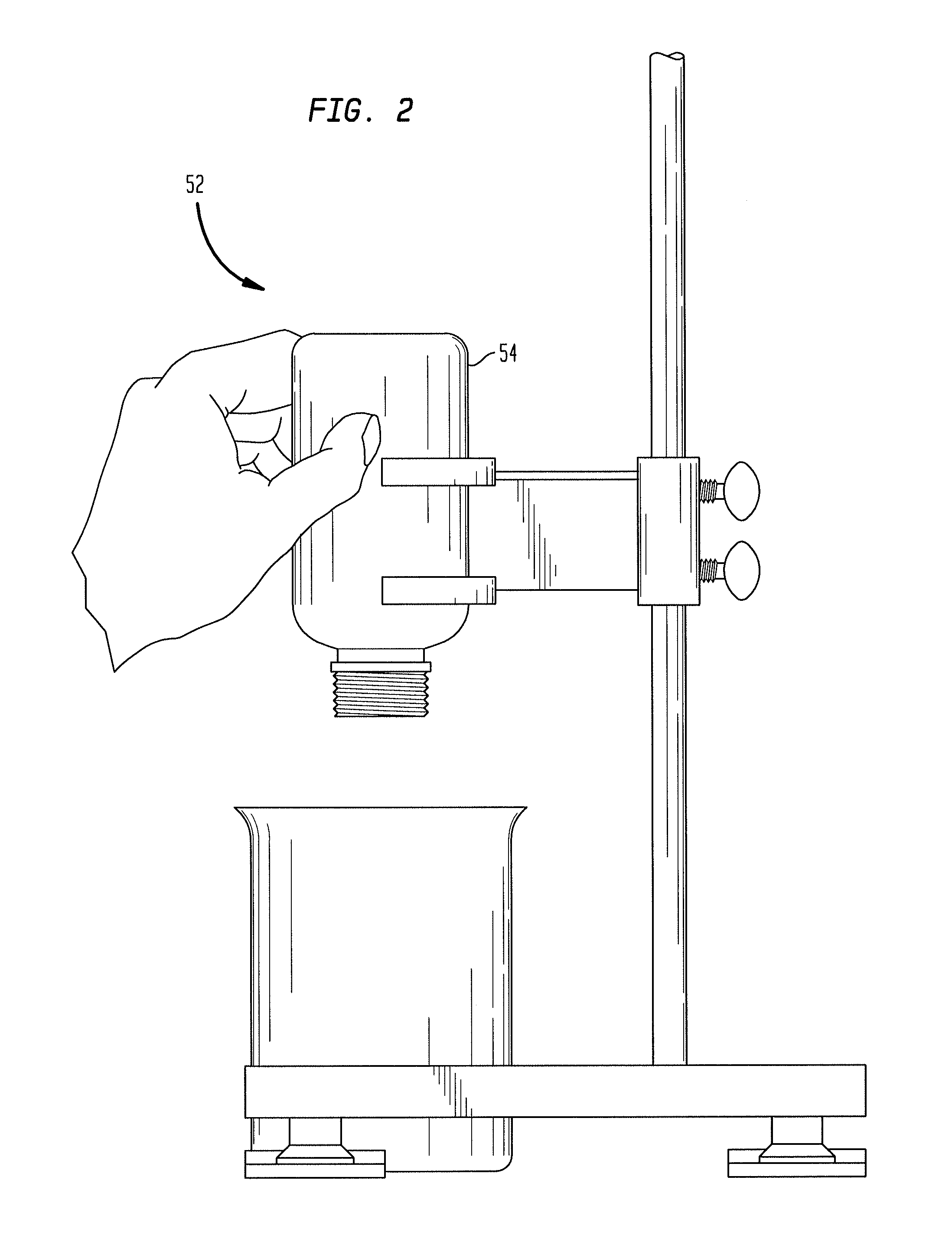

Dual media vacuum filter bag

There is provided a vacuum cleaner filer bag including at least two sidewalls which sidewalls are joined by seams. At least one first sidewall comprises a film laminate of a heat sealable film layer and a film support layer. At least one second sidewall comprises a filter laminate comprising at least a synthetic fiber filter layer and synthetic fiber support layer where the at least one first sidewall is joined to adjacent sidewalls by thermal seams. The filter layer is preferably a high efficiency microfiber filter media which provides HEPA level performance for the vacuum cleaner bag.

Owner:3M INNOVATIVE PROPERTIES CO

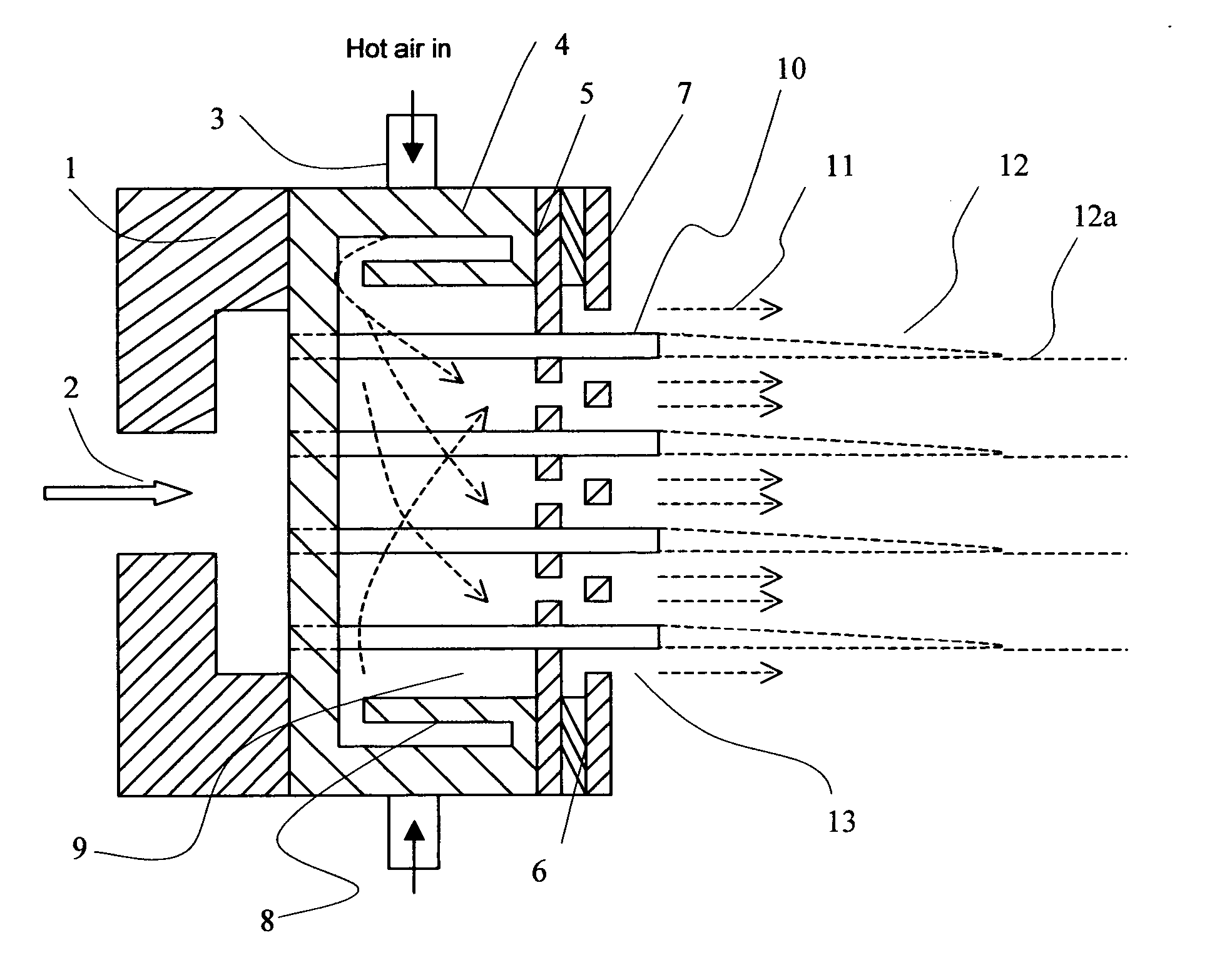

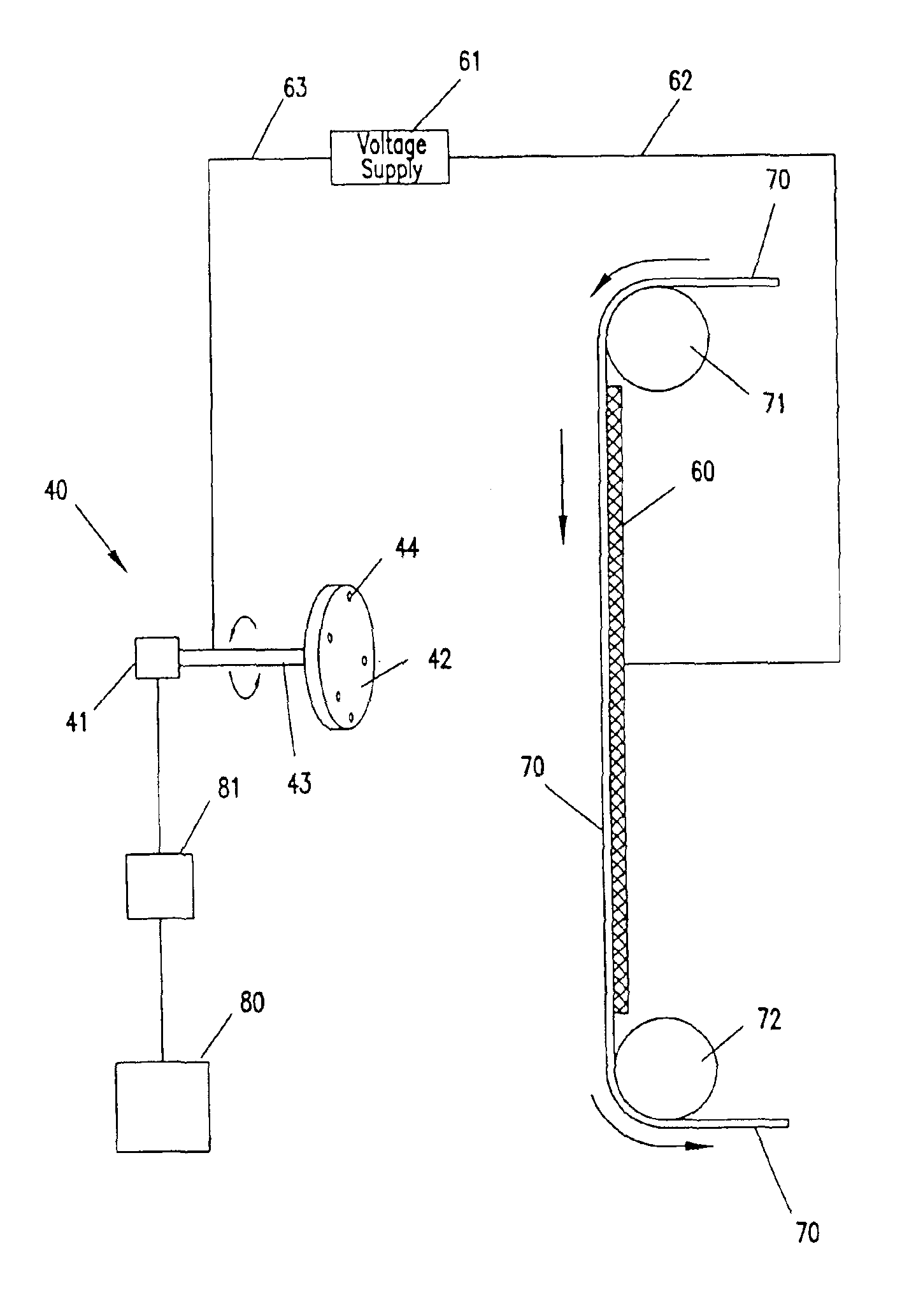

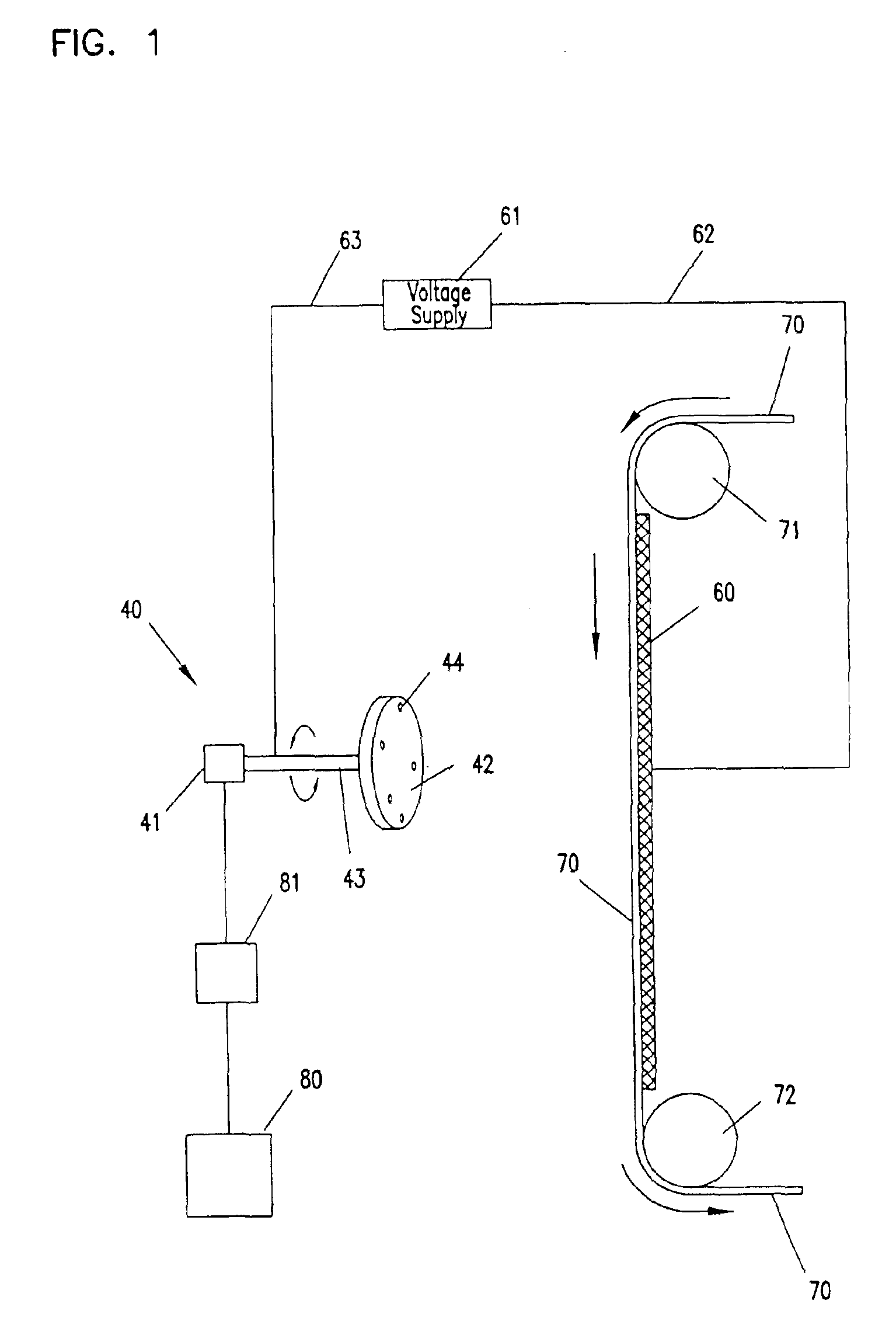

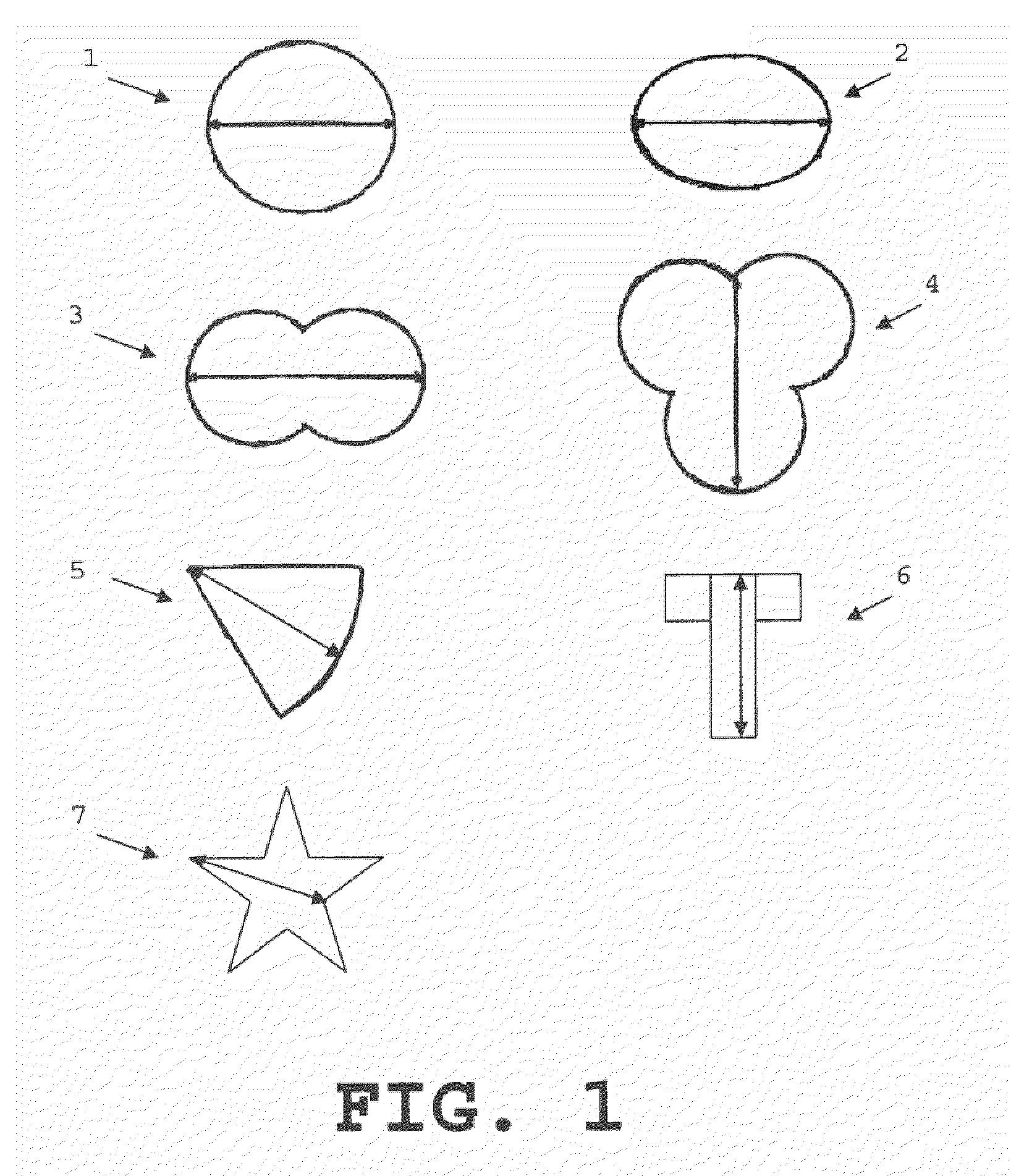

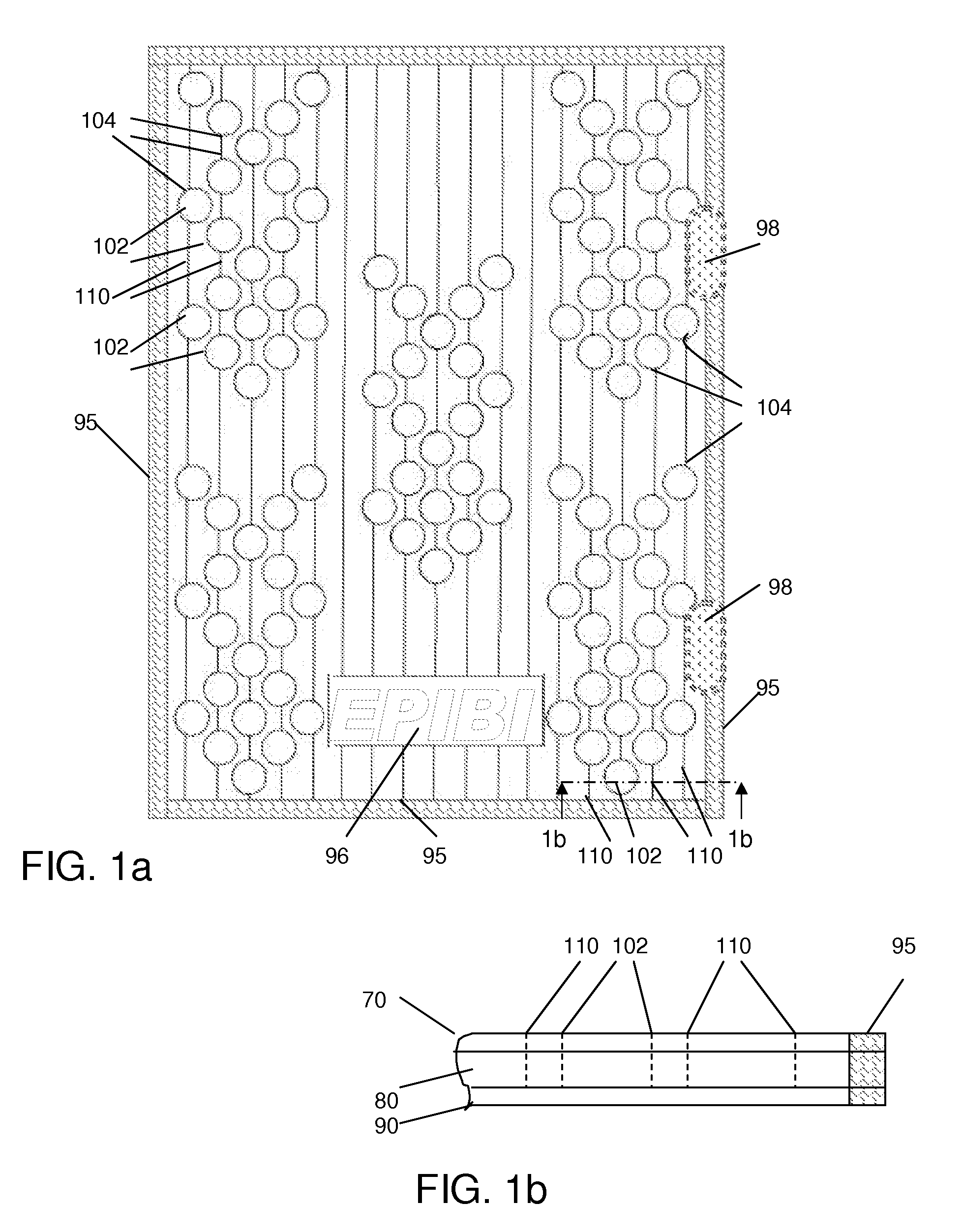

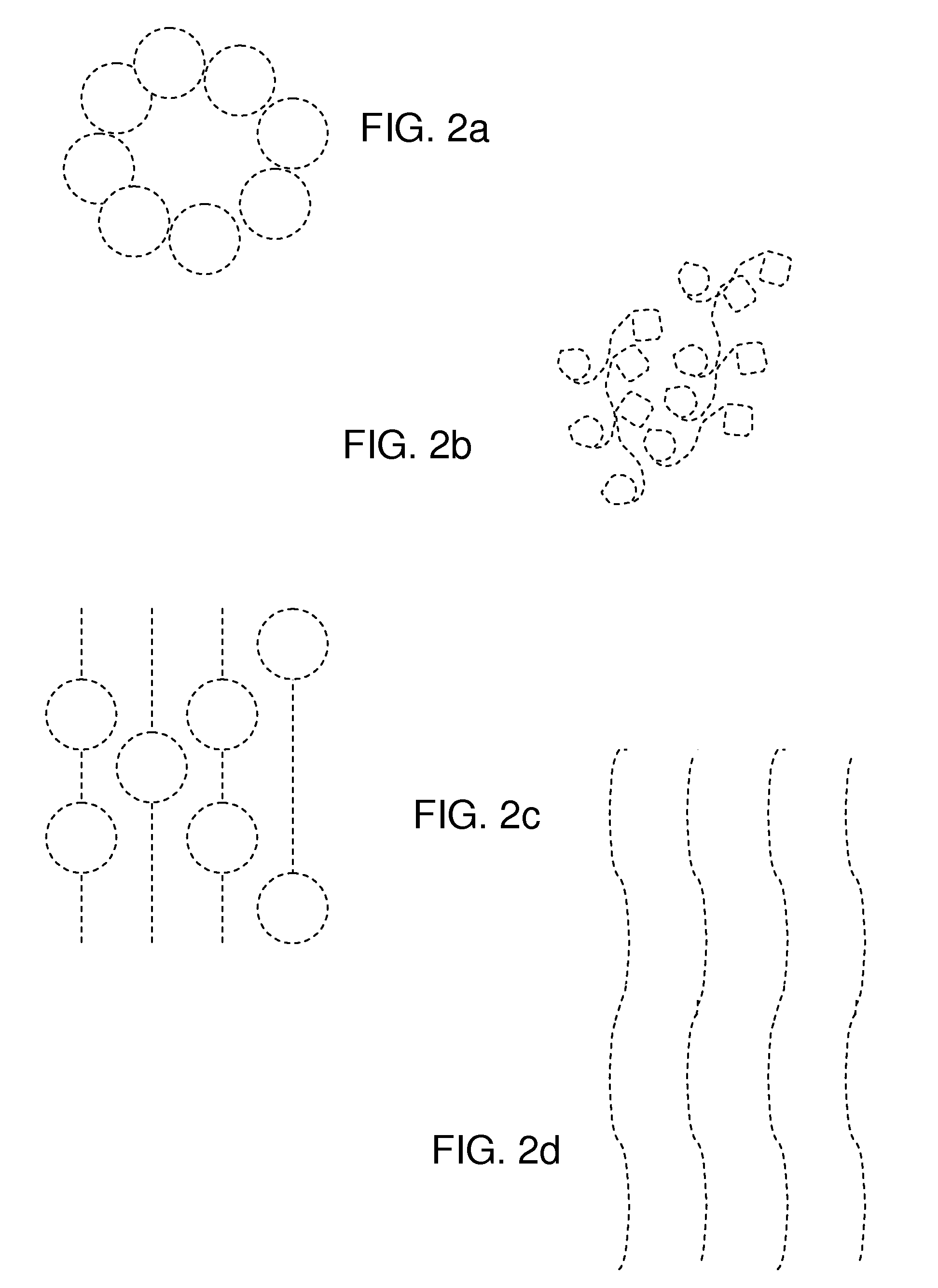

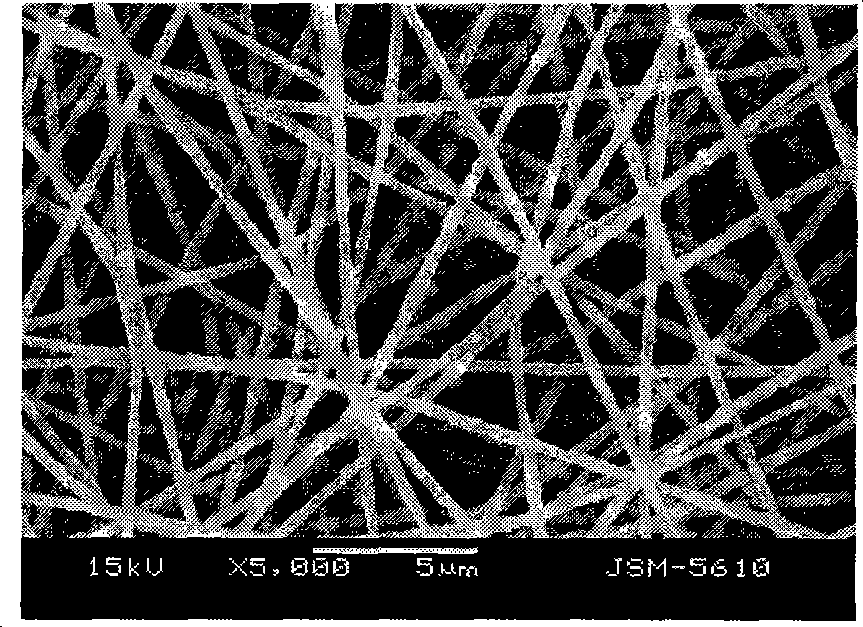

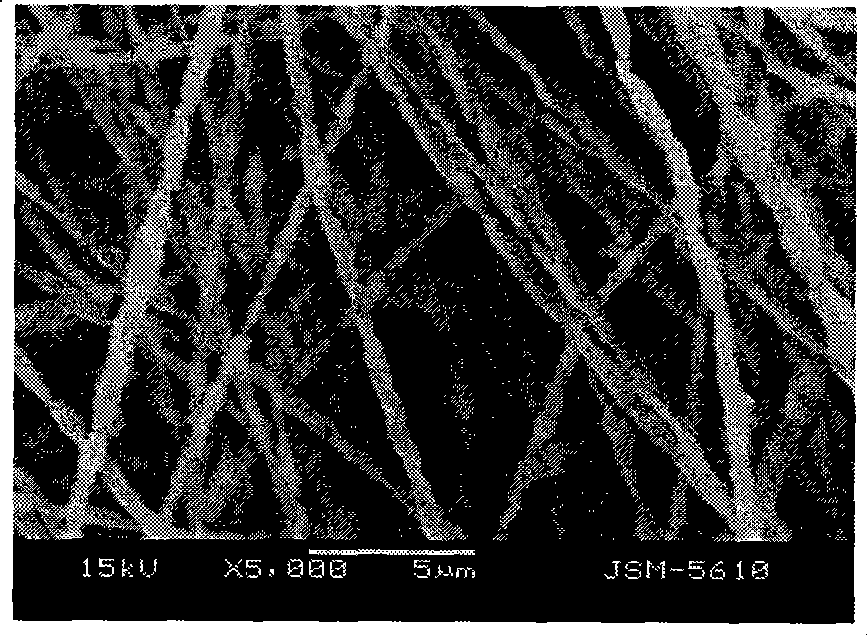

Monocomponent Monolayer Meltblown Web And Meltblowing Apparatus

ActiveUS20080026659A1Good molding effectIncrease fiber surface areaDispersed particle filtrationMagnetic materials for record carriersPolymer scienceRespirator

A porous monocomponent nonwoven web contains a bimodal mass fraction / fiber size mixture of intermingled continuous microfibers and larger size fibers of the same polymeric composition. There are at least five times as many microfibers as larger size fibers, and a histogram of the mass fraction of fibers vs. fiber size exhibits a larger size fiber mode greater than 10 μm. The web may be made by flowing fiber-forming material through a die cavity having larger size orifices and at least five times as many smaller size orifices to form filaments, attenuating the filaments into fibers and collecting the attenuated fibers to form the nonwoven web. The web is especially well suited to the manufacture of self-supporting three dimensional articles such as molded cup-shaped respirators and pleated air filters.

Owner:3M INNOVATIVE PROPERTIES CO

Composite articles reinforced with highly oriented microfibers

InactiveUS6630231B2Improve toughnessHigh strengthLamination ancillary operationsLayered product treatmentMaterial typePolymer science

A composite formed of a polymer matrix phase having a reinforcement phase including polymeric microfibers. The microfibers are preferably formed of a highly oriented polymer, having a high modulus value and a large surface area. The large surface area can serve to tightly bind the microfibers to the polymer matrix phase. The microfibers can be provided as a fully- or partially-microfibrillated film, as a non-woven web of entangled microfibers, or as a pulp having free fibers. The microfibers can be embedded in, or impregnated with, a polymer or polymer precursor. Some composite articles are formed from thermoset resins cured about a highly oriented polypropylene microfiber reinforcement phase, providing a strong, tough, moisture resistant article. One composite includes a matrix and reinforcement formed of the same material type and having substantially equal refractive indices, allowing the composite to be optically clear.

Owner:3M INNOVATIVE PROPERTIES CO

High Softness, High Durability Bath Tissues With Temporary Wet Strength

ActiveUS20130029105A1Improve tissue performanceGood flexibilityPersonal careReinforcing agents additionWet strengthCalipers

Owner:GPCP IP HLDG LLC

Absorbent sheet having regenerated cellulose microfiber network

An absorbent paper sheet for tissue or towel includes from about 99 percent to about 70 percent by weight of cellulosic papermaking fiber and from about 1 percent to about 30 percent by weight fibrillated regenerated cellulose microfiber which was regenerated form a cellulosic dope utilizing a tertiary amine N-oxide solvent or an ionic liquid. Fibrillation of the microfiber is controlled such that it has a reduced coarseness and a reduced freeness as compared with unfibrillated regenerated cellulose microfiber from which it is made and provides at least one of the following attributes to the absorbent sheet: (a) the absorbent sheet exhibits an elevated SAT value and an elevated wet tensile value as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (b) the absorbent sheet exhibits an elevated wet / dry CD tensile ratio as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (c) the absorbent sheet exhibits a lower GM Break Modulus than a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber; or (d) the absorbent sheet exhibits an elevated bulk as compared with a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber. In some embodiments, the pulp is pre-treated with debonder to enhance the wet / dry CD tensile ratio of the sheet.

Owner:GPCP IP HLDG LLC

Devices for prevention of pressure ulcers

InactiveUS20090070939A1Avoid pressure soresMinimal puckeringStuffed mattressesSpring mattressesInter layerSkin contact

A support surface, such as an underpad, for preventing pressure sores in a patient is a multi-layer textile assembly having a skin contact layer formed from a fabric of synthetic filament yarns woven to provide air permeability and moisture vapor permeability and having a thickness of less than 1 mm. An absorbent middle layer is formed from a breathable microfiber fabric woven to provide for moisture transition from an upper surface of the middle layer to a bottom surface of the middle layer. The skin contact layer and the middle layer are stitched together using a stitching pattern optimized to produce an open pattern with minimal puckering. A bottom layer is formed from a breathable, waterproof fabric woven from synthetic yarn to produce a moisture vapor transfer rate within the range of 5,000 to 20,000 grams per meter squared per 24 hours. The three layers are attached together around their outer edges.

Owner:PERSIMMON SCI

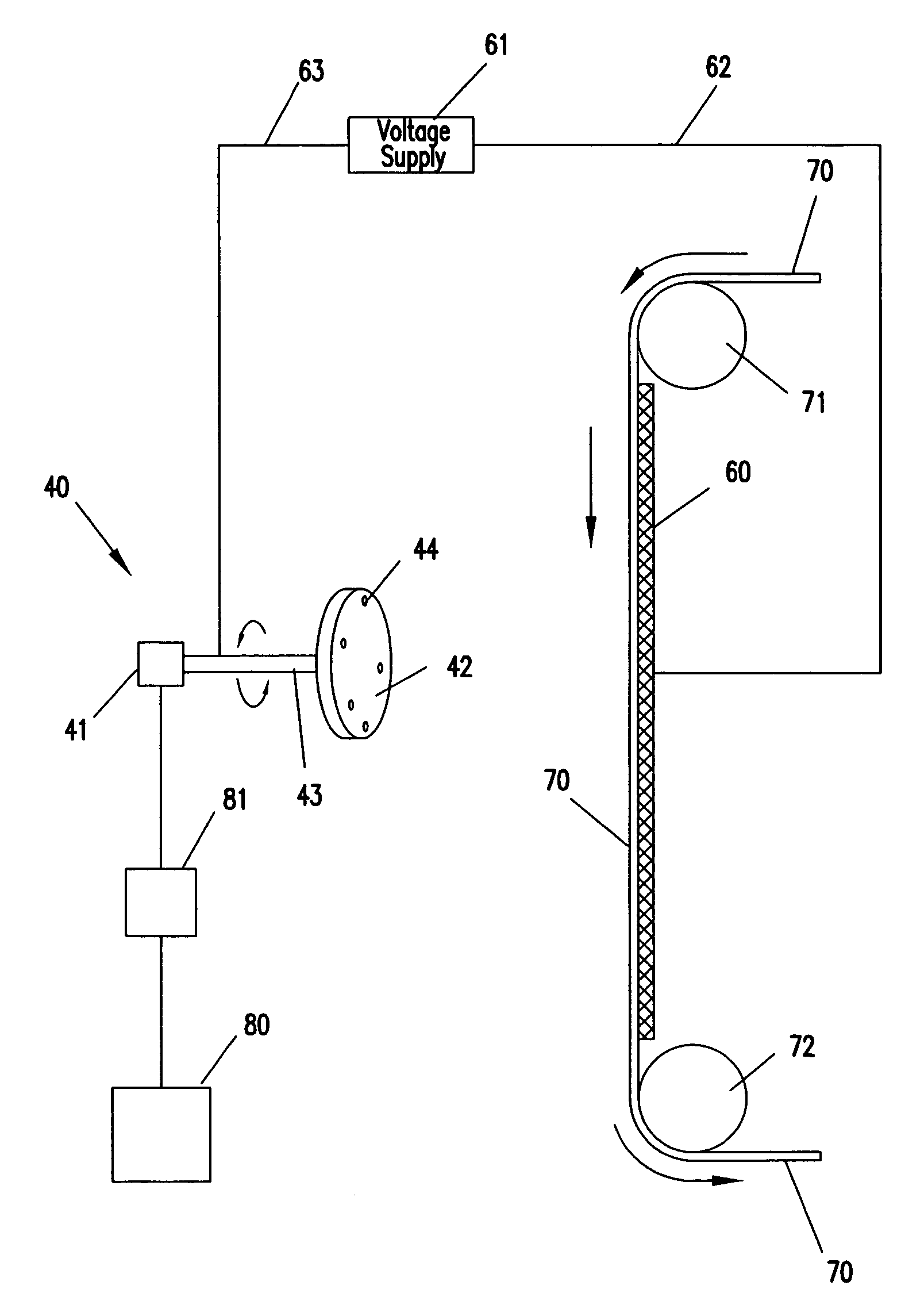

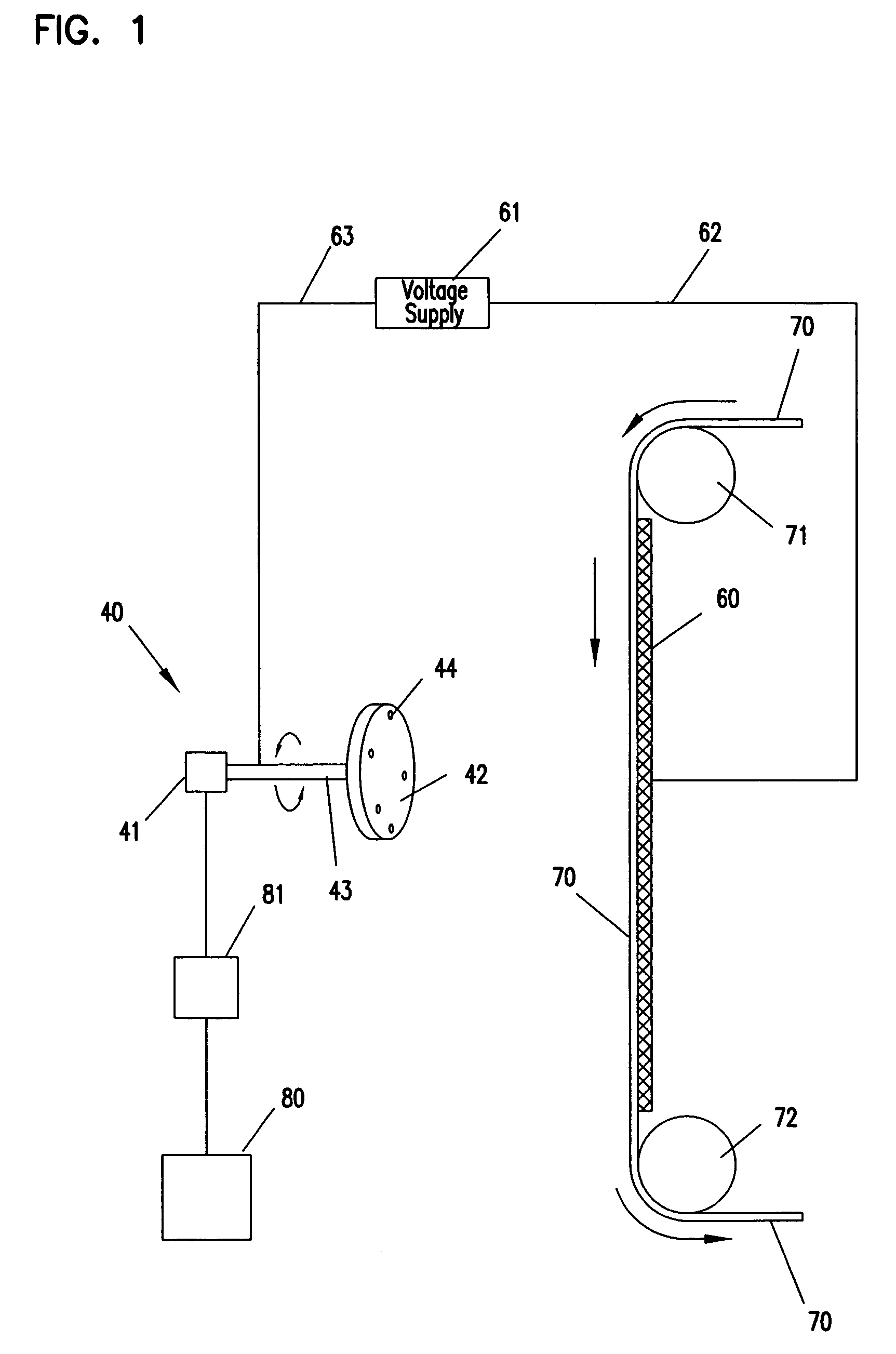

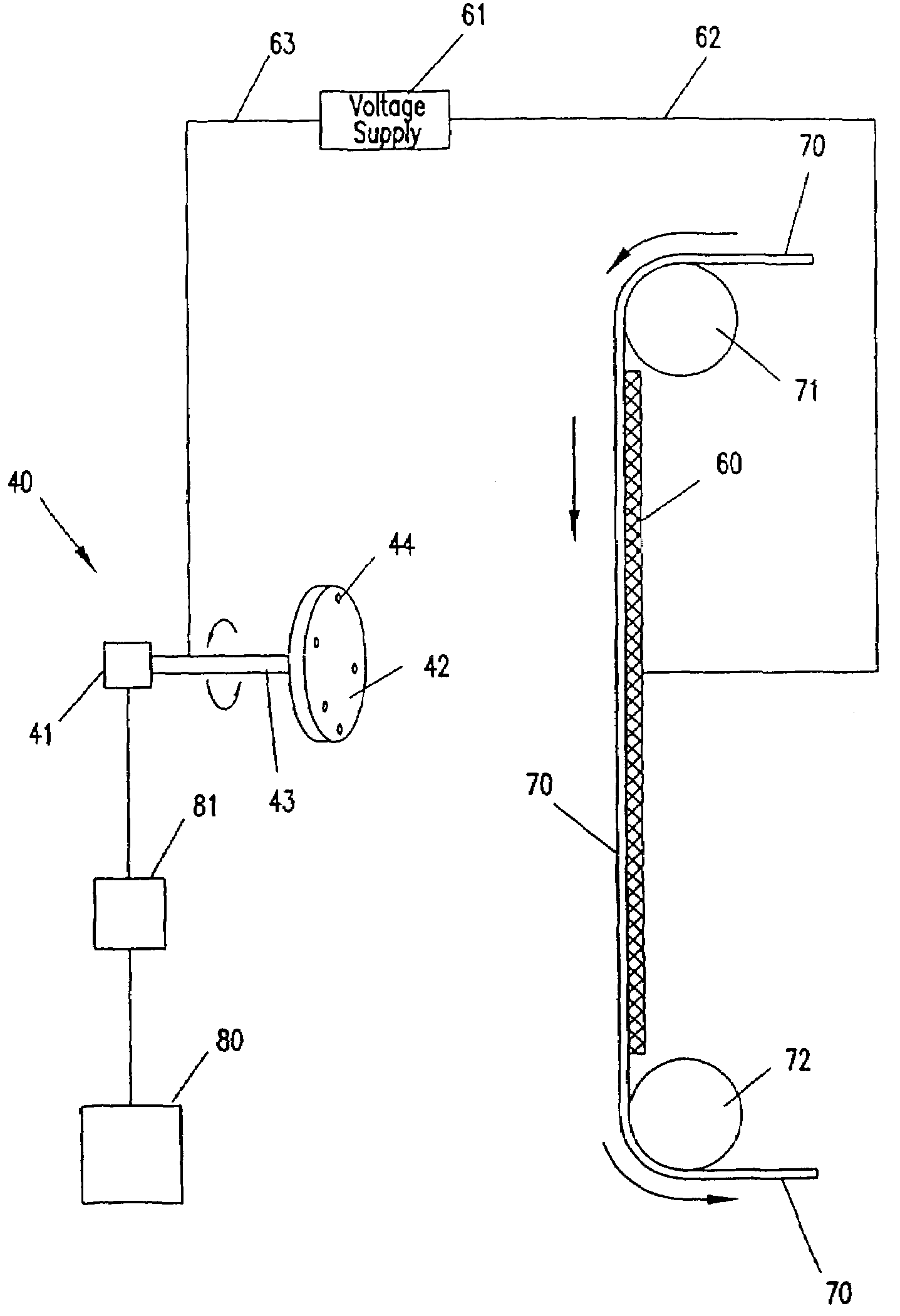

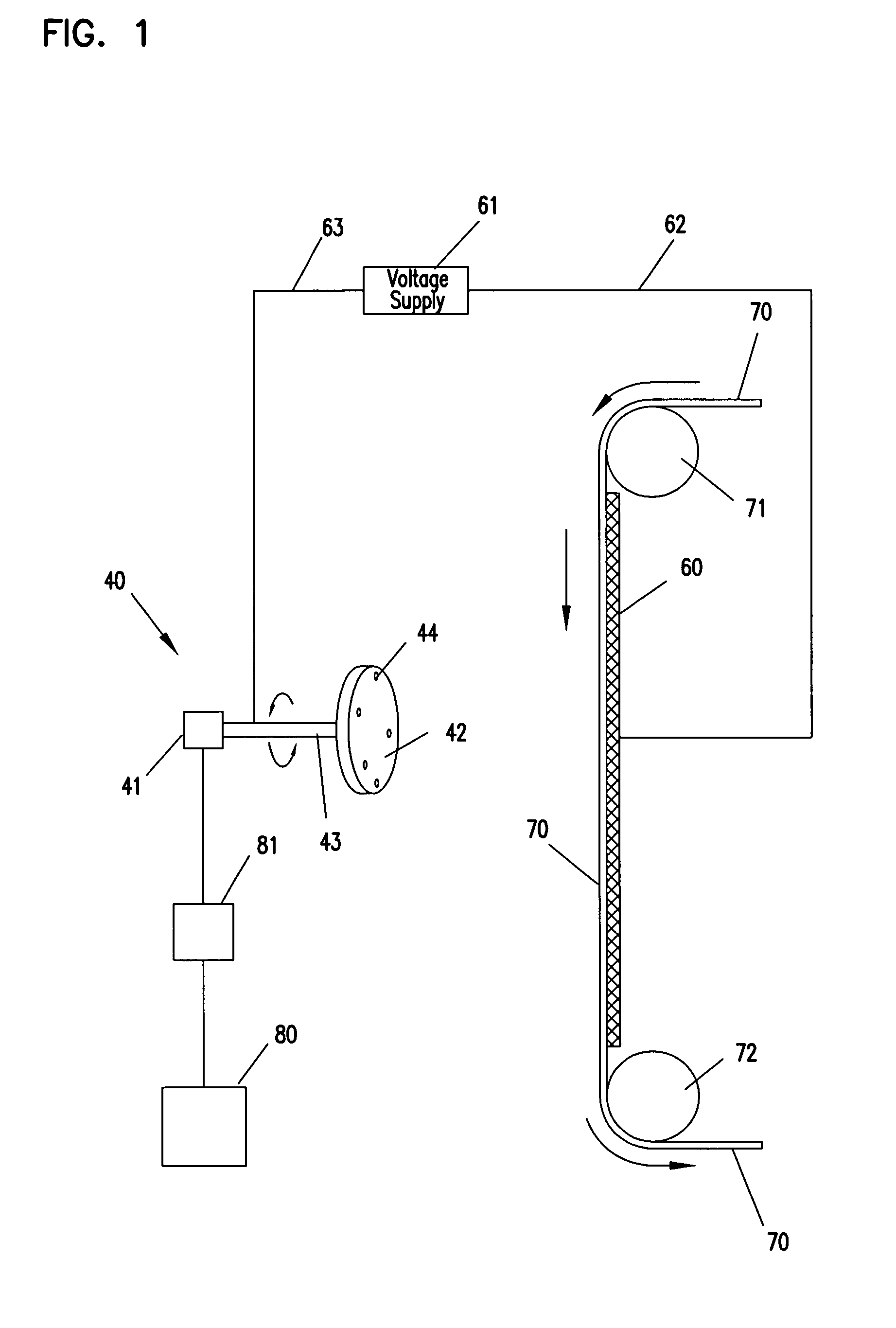

Preparation method of polytetrafluoroethylene superfine fiber porous membrane

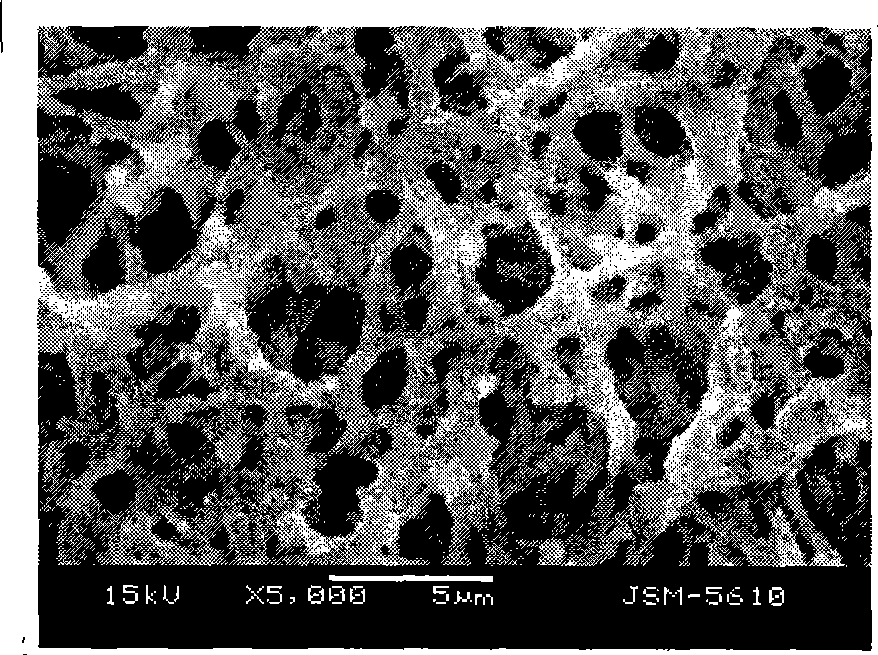

InactiveCN101530750AUniform pore sizeHigh porositySemi-permeable membranesHigh concentrationVoid ratio

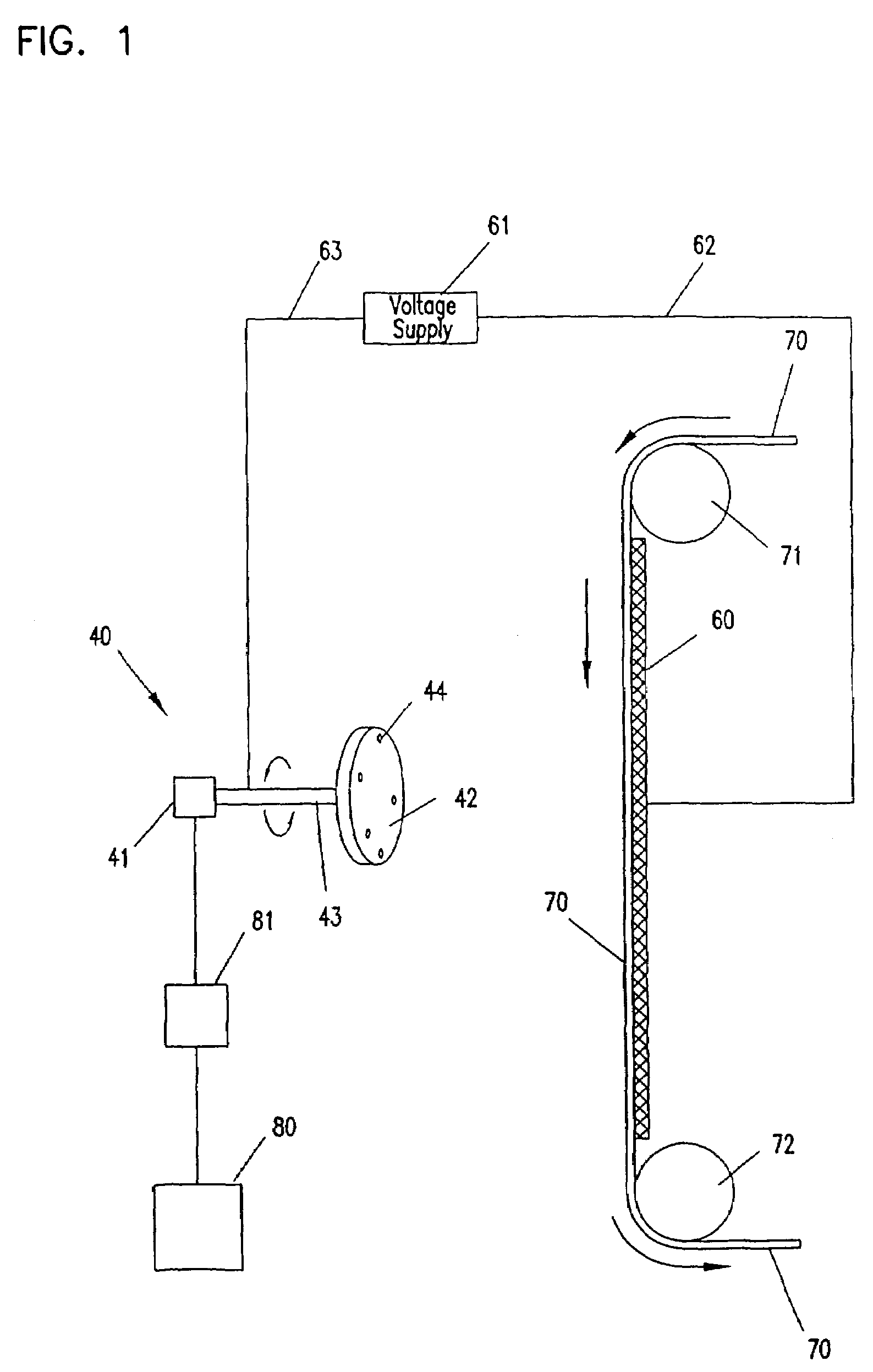

The invention discloses a preparation method of polytetrafluoroethylene superfine fiber porous membrane. In the method, high concentration polytetrafluoroethylene aqueous emulsion is mixed with matrix polymer uniformly to prepare spinning solution. With the effect of high voltage electric field, polytetrafluoroethylene / matrix polymer composite superfine fiber porous membrane with the diameter of 100 nm to 2 [mu]m is obtained by electrostatic spinning, and then polytetrafluoroethylene superfine fiber porous membrane is formed at the conditions of sintering temperature being 330 to 500 DEG C and the sintering time lasting 30s to 5min so that the aperture diameter is 100 nm to 10 [mu]m and the porosity is 50% to 80%. The polytetrafluoroethylene superfine fiber porous membrane prepared by using the method has uniform aperture diameter and high porosity, and can be widely applied to filter material. Compared with the existing technology, the preparation method has the characteristics of simple processing technology, short process and low cost.

Owner:ZHEJIANG SCI-TECH UNIV

Method of making regenerated cellulose microfibers and absorbent products incorporating same

ActiveUS20080173419A1High yieldLow costNon-fibrous pulp additionElectric discharge heatingPolymer sciencePersonal Care Product

A method of making regenerated cellulose microfibers includes forming segmented fibers with multiple longitudinally-extending segments of slightly different composition such that there is defined splittable interfaces between juxtaposed segments of the fibers which are then split into microfibers at yields of greater than 50%. Fibers so produced may be incorporated into absorbent sheet with other papermaking fibers to provide strength, softness, bulk and absorbency to tissue, towel, and personal care products.

Owner:GPCP IP HLDG LLC

Methods and apparatus for forming ultra-fine fibers and non-woven webs of ultra-fine spunbond fibers

ActiveUS20050032450A1Filament/thread formingPaper/cardboard layered productsMolten statePolymer science

A nonwoven web product including ultra-fine fibers is formed utilizing a spunbond apparatus that forms multicomponent fibers by delivering first and second polymer components in a molten state from a spin pack to a spinneret, extruding multicomponent fibers including the first and second polymer components from the spinneret, attenuating the multicomponent fibers in an aspirator, laying down the multicomponent fibers on an elongated forming surface disposed downstream from the aspirator to form a nonwoven web, and bonding portions of at least some of the fibers in the nonwoven web together to form a bonded, nonwoven web product. The multicomponent fibers can include separable segments such as islands-in-the-sea fibers, where certain separated segments become the ultra-fine fibers in the web product. In addition, carbon tubular fibers can be formed by extruding islands-in-the-sea fibers including polyacrylonitrile or pitch sheath segments in the fibers, separating the segments of the fiber, and converting the polyacrylonitrile or pitch to carbon by a carbonization process.

Owner:HILLS CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com