Preparation method of polytetrafluoroethylene superfine fiber porous membrane

A polytetrafluoroethylene and ultra-fine fiber technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of complex production process, many influencing factors, large melt viscosity, etc. , the effect of short process and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

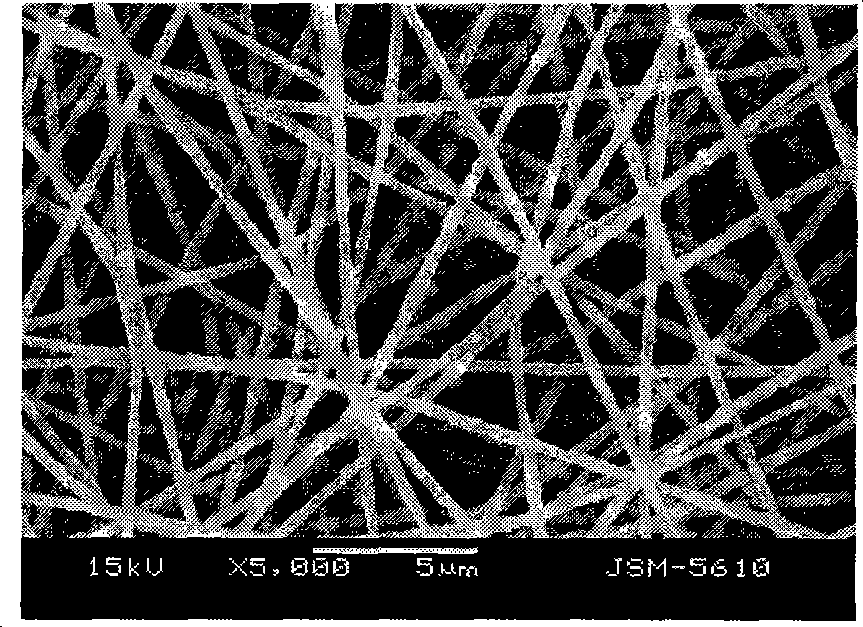

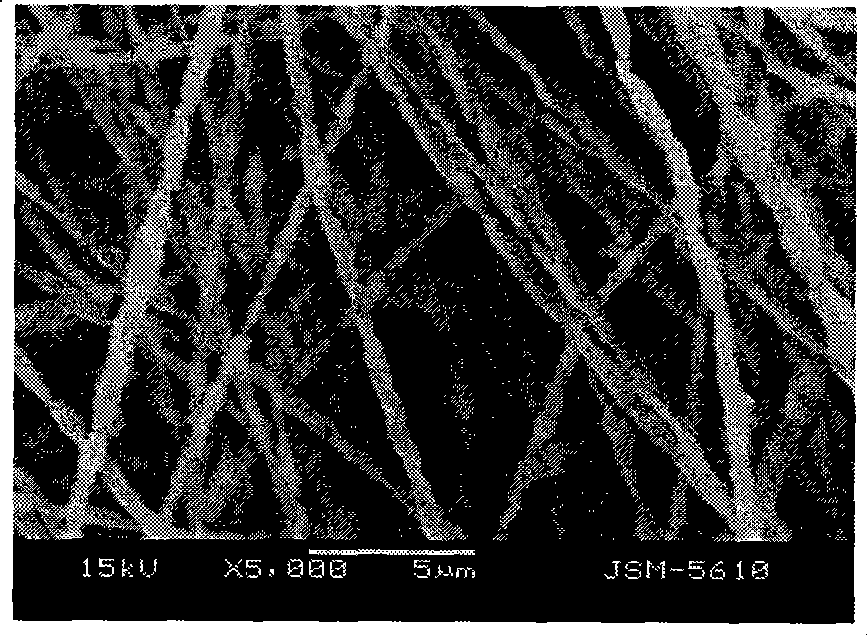

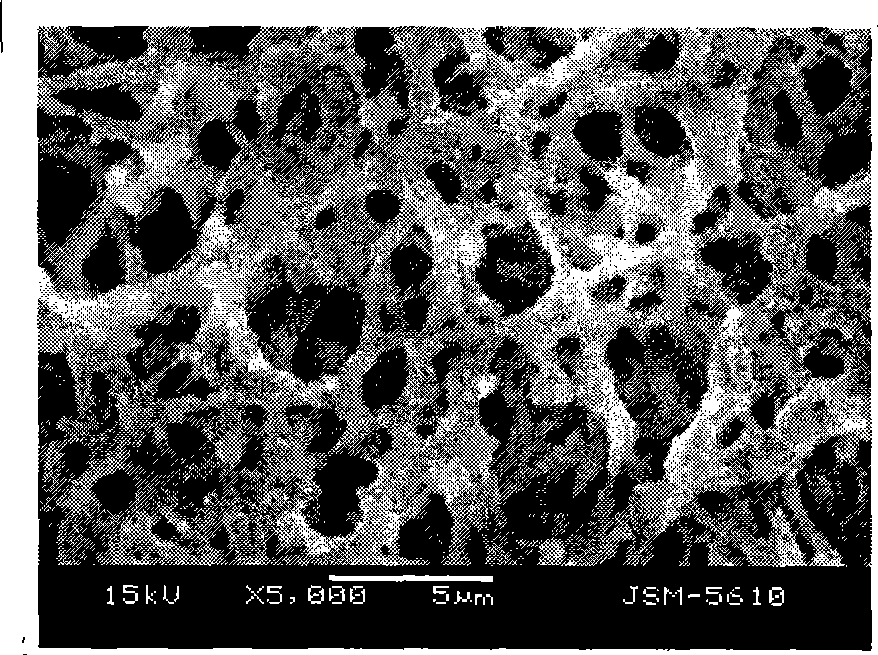

[0027] Dissolve 1.56g of polyvinyl alcohol in 12.37ml of water at 90°C, then mix evenly with 6.07g of high-concentration polytetrafluoroethylene aqueous emulsion to form a solid content of 26%, the mass ratio of polytetrafluoroethylene to polyvinyl alcohol It is a 70:30 spinning solution. Then add it to the liquid storage tank, transport it to the spinneret through a micrometering pump, connect the spinneret to the high-voltage positive electrode, control the distance between the spinneret and the receiving device at 15cm, the liquid flow rate is 0.01ml / min, and the voltage is 15kV. Electrospinning obtains Polytetrafluoroethylene / polyvinyl alcohol composite superfine fiber porous membrane is observed with a scanning electron microscope (see attached figure 1 ). The obtained composite microfiber porous membrane was sintered at a temperature of 390° C. for 2 min to remove polyvinyl alcohol to obtain a brown polytetrafluoroethylene ultrafine fiber porous membrane, which was obse...

Embodiment 2

[0029] Dissolve 2.2g of polyvinyl alcohol in 14.13ml of water at 90°C, then mix evenly with 3.67g of high-concentration polytetrafluoroethylene aqueous emulsion to form a solid content of 26%, the mass ratio of polytetrafluoroethylene to polyvinyl alcohol It is a 50:50 spinning solution. Then add it to the liquid storage tank, transport it to the spinneret through a micrometering pump, connect the spinneret to the high-voltage positive electrode, control the distance between the spinneret and the receiving device at 15cm, the liquid flow rate is 0.01ml / min, and the voltage is 15kV. Electrospinning obtains Polytetrafluoroethylene / polyvinyl alcohol composite microfiber porous membrane. The obtained composite ultrafine fiber porous membrane was sintered at a temperature of 390° C. for 2 minutes to remove polyvinyl alcohol to obtain a brown polytetrafluoroethylene ultrafine fiber ene porous membrane.

Embodiment 3

[0031] Dissolve 1.56g of polyvinyl alcohol in 12.37ml of water at 90°C, then mix evenly with 6.07g of high-concentration polytetrafluoroethylene aqueous emulsion to form a solid content of 26%, the mass ratio of polytetrafluoroethylene to polyvinyl alcohol It is a 70:30 spinning solution. Then add it to the liquid storage tank, transport it to the spinneret through a micro-metering pump, connect the spinneret to the high-voltage positive electrode, control the distance between the spinneret and the receiving device at 14cm, the liquid flow rate is 0.008ml / min, and the voltage is 17kV. Electrospinning obtains Polytetrafluoroethylene / polyvinyl alcohol composite microfiber porous membrane. The obtained composite ultrafine fiber porous membrane was sintered at a temperature of 390° C. for 2 minutes to remove polyvinyl alcohol, and a brown polytetrafluoroethylene ultrafine fiber porous membrane was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com