Patents

Literature

1262results about How to "Uniform pore size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

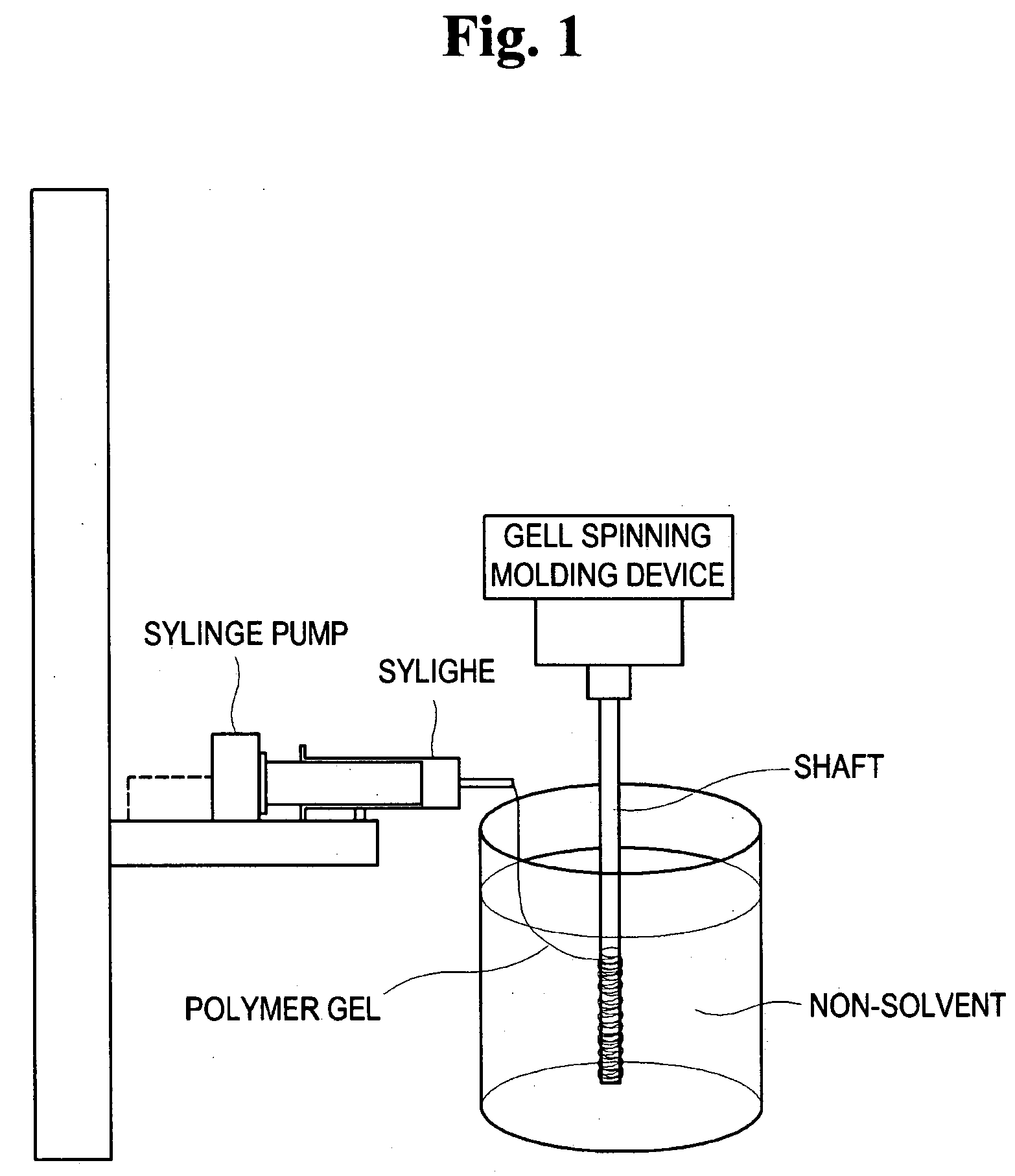

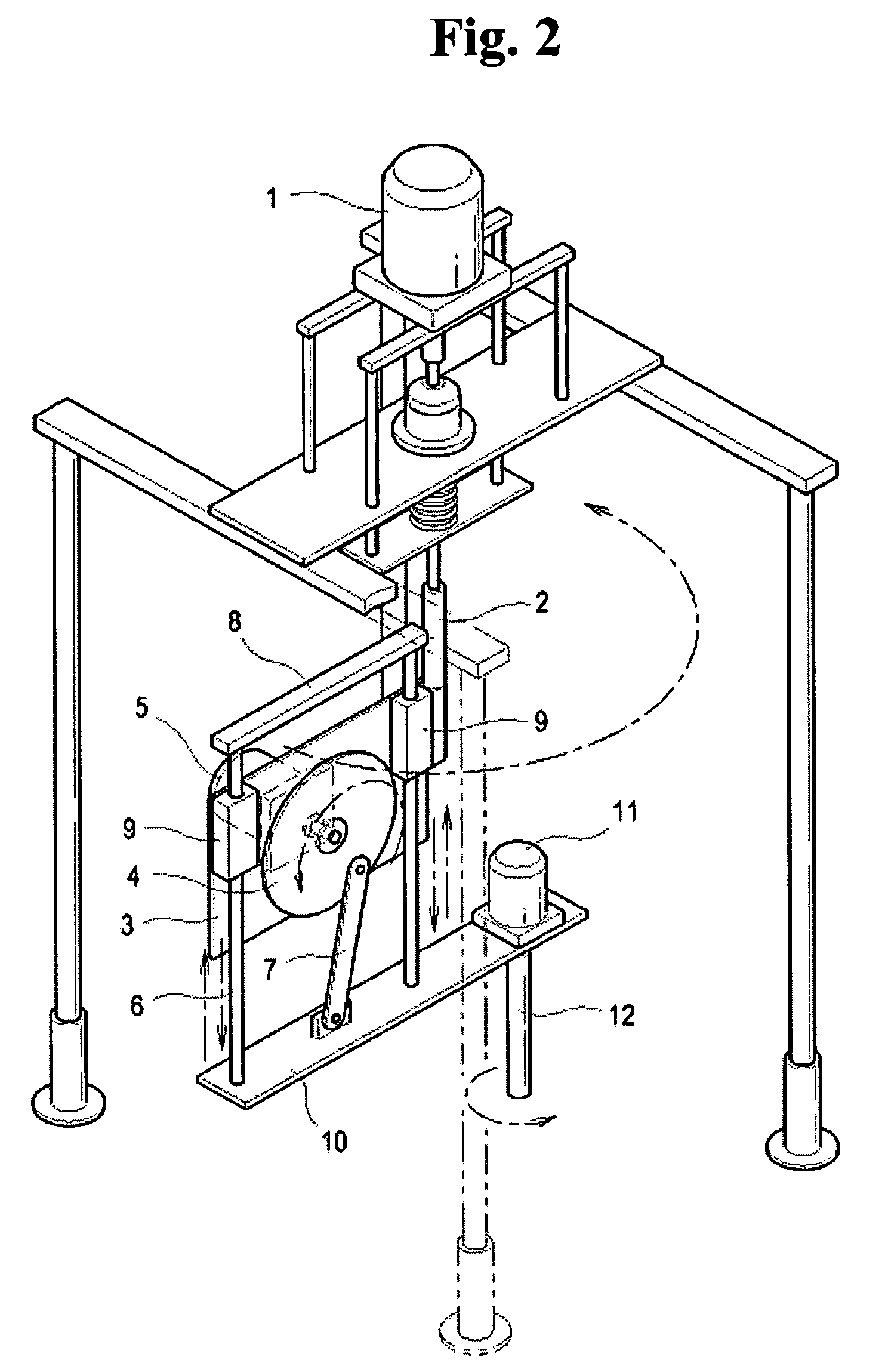

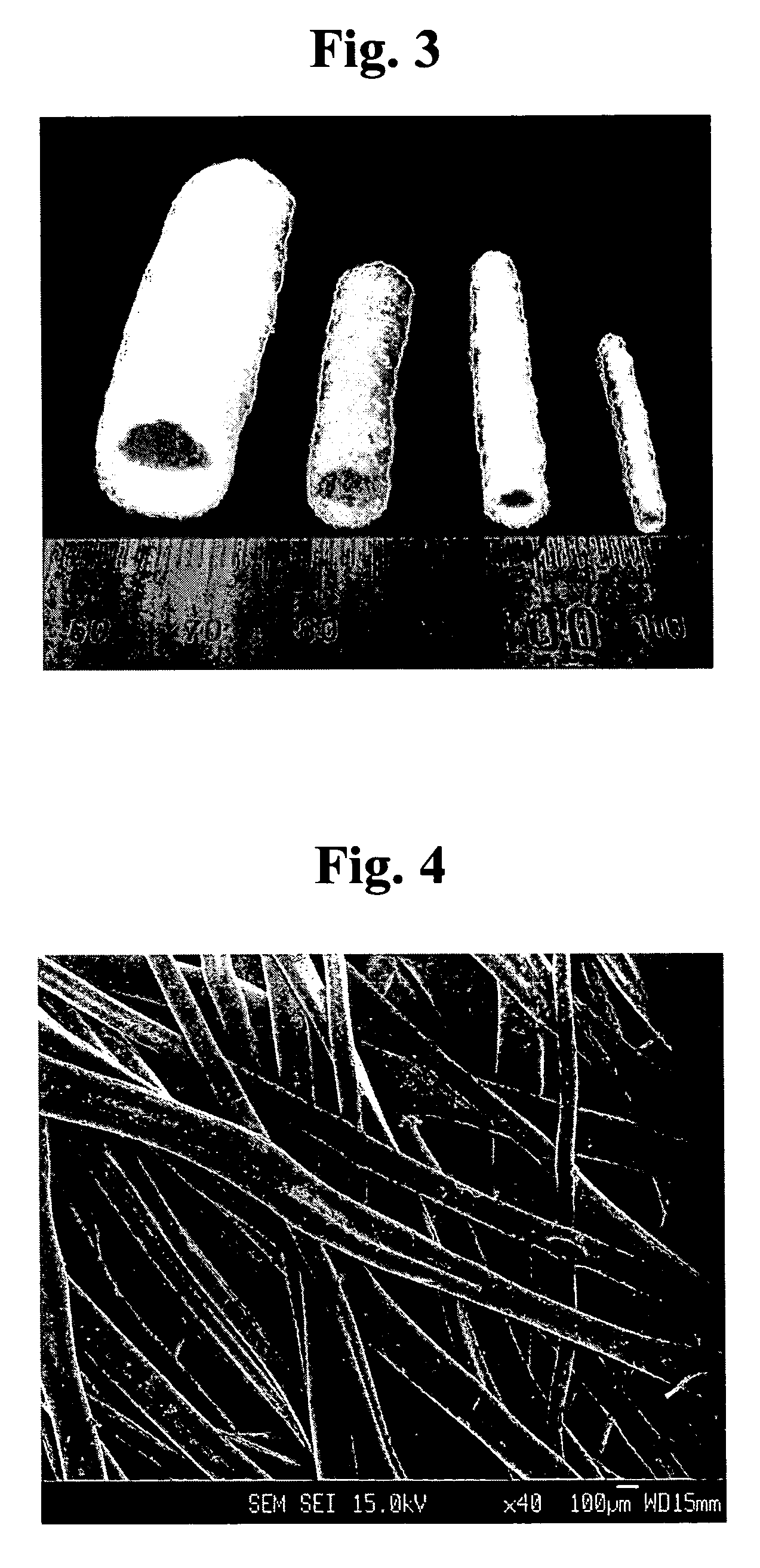

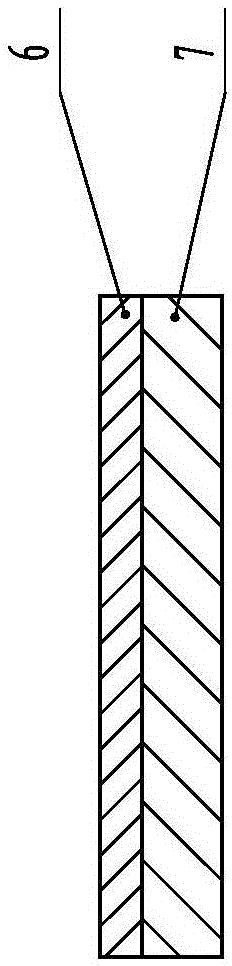

Method for preparing porous polymer scaffold for tissue engineering using gel spinning molding technique

InactiveUS20070009570A1Uniform pore sizeImprove interconnectivitySuture equipmentsCeramic shaping apparatusPolymer scienceSpinning

The present invention relates to a method of preparing a porous polymer scaffold for tissue engineering using a gel spinning molding technique. The method of the present invention can prepare a porous polymer scaffold having a uniform pore size, high interconnectivity between pores and mechanical strength, as well as high cell seeding and proliferation efficiencies, which can be effectively used in tissue engineering applications. Further, the method of the present invention can easily mold a porous polymer scaffold in various types such as a tube type favorable for regeneration of blood vessels, esophagus, nerves and the like, as well as a sheet type favorable for regeneration of skins, muscles and the like, by regulating the shape and size of a template shaft.

Owner:KOREA INST OF SCI & TECH

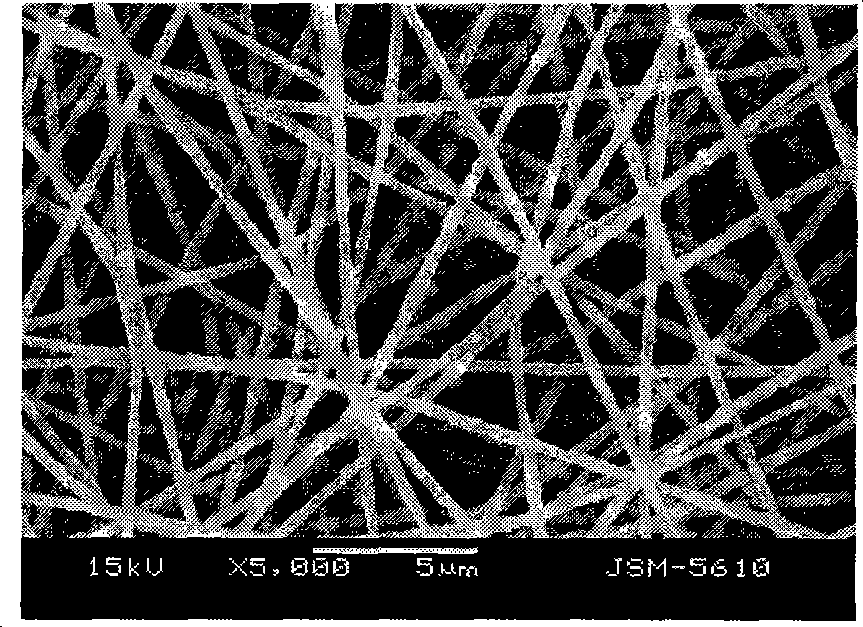

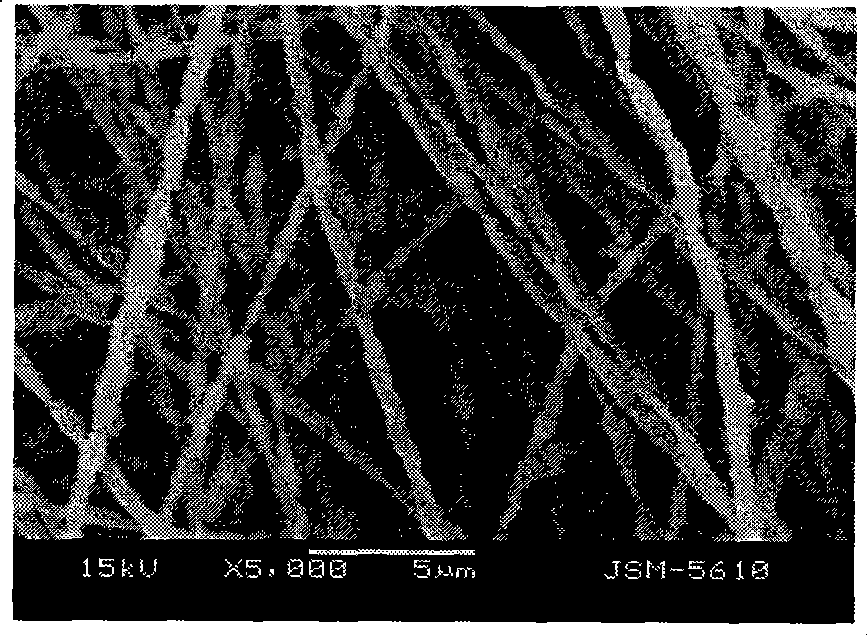

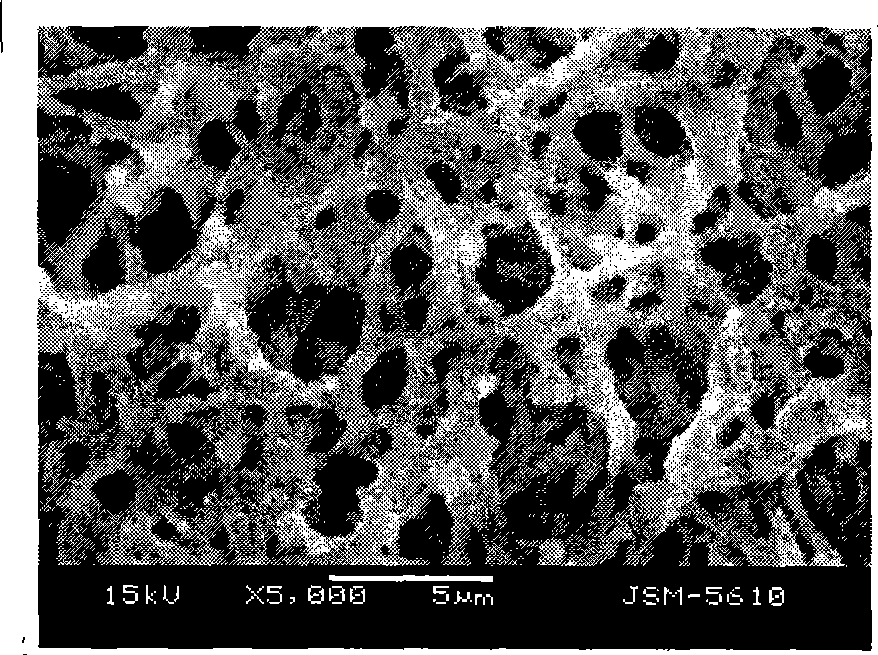

Preparation method of polytetrafluoroethylene superfine fiber porous membrane

InactiveCN101530750AUniform pore sizeHigh porositySemi-permeable membranesHigh concentrationVoid ratio

The invention discloses a preparation method of polytetrafluoroethylene superfine fiber porous membrane. In the method, high concentration polytetrafluoroethylene aqueous emulsion is mixed with matrix polymer uniformly to prepare spinning solution. With the effect of high voltage electric field, polytetrafluoroethylene / matrix polymer composite superfine fiber porous membrane with the diameter of 100 nm to 2 [mu]m is obtained by electrostatic spinning, and then polytetrafluoroethylene superfine fiber porous membrane is formed at the conditions of sintering temperature being 330 to 500 DEG C and the sintering time lasting 30s to 5min so that the aperture diameter is 100 nm to 10 [mu]m and the porosity is 50% to 80%. The polytetrafluoroethylene superfine fiber porous membrane prepared by using the method has uniform aperture diameter and high porosity, and can be widely applied to filter material. Compared with the existing technology, the preparation method has the characteristics of simple processing technology, short process and low cost.

Owner:ZHEJIANG SCI-TECH UNIV

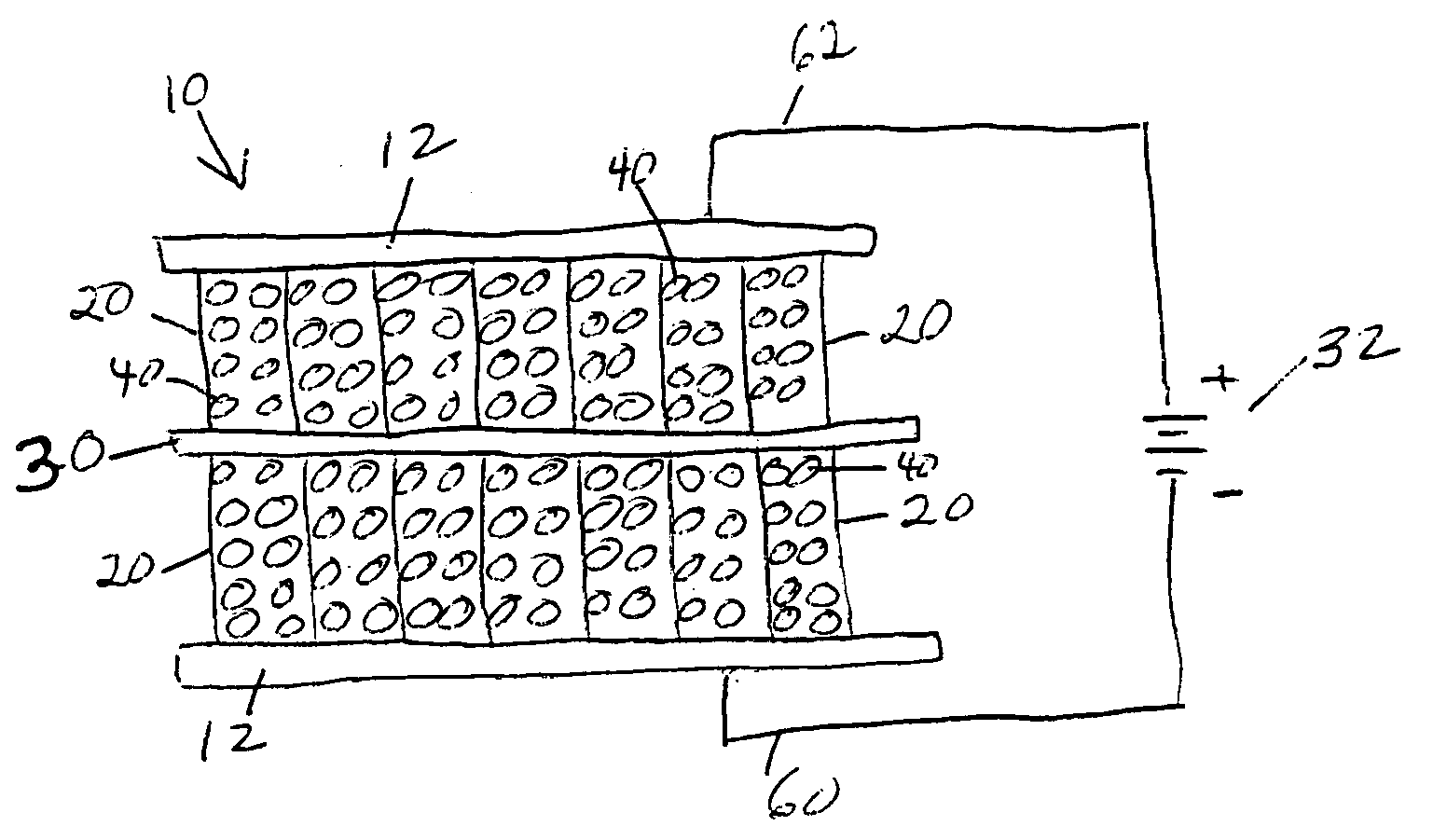

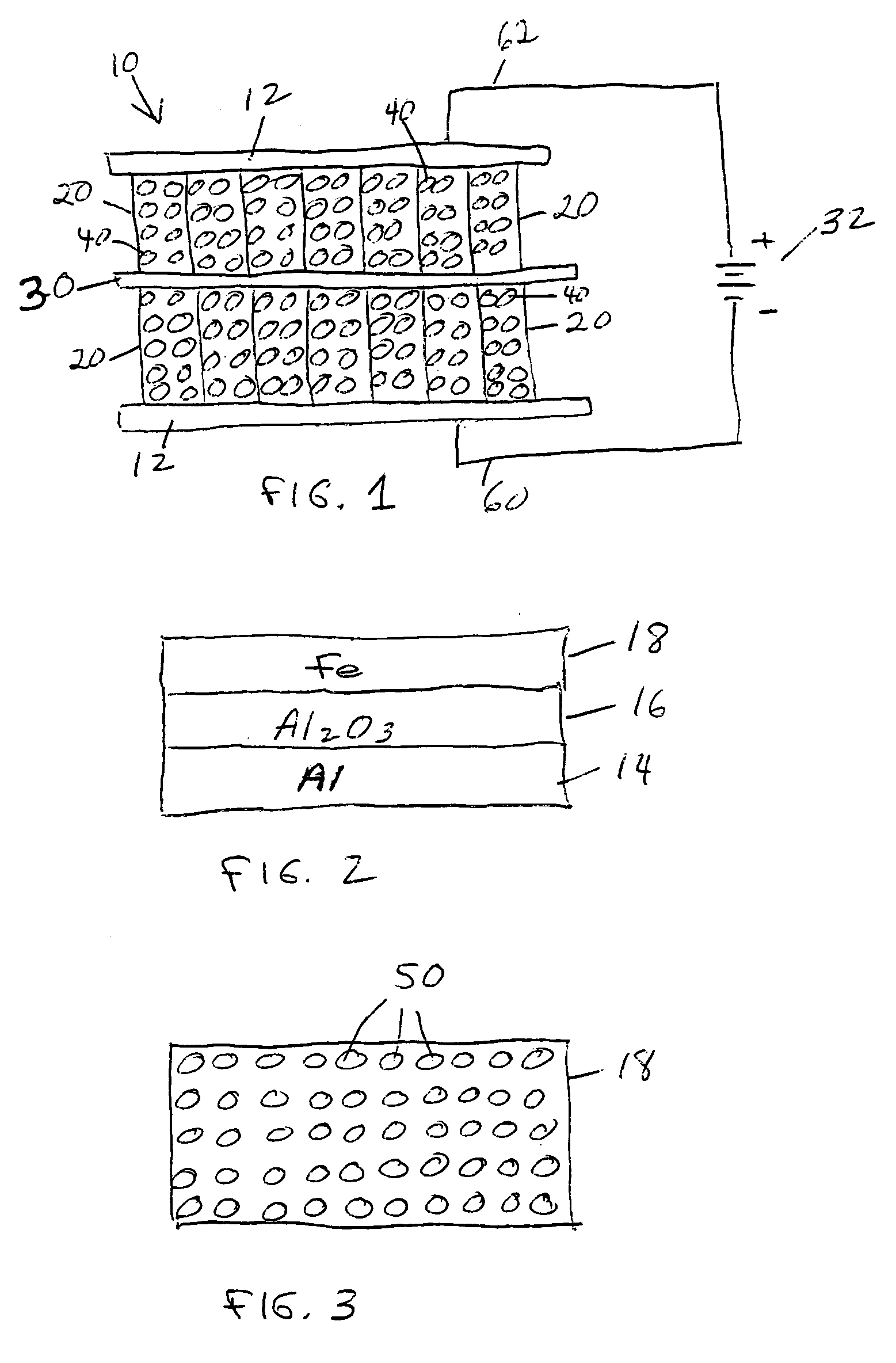

Engineered structure for charge storage and method of making

InactiveUS20070258192A1High capacitanceHigh immunityMaterial nanotechnologyHybrid capacitor separatorsIonEngineering

Engineered structure for charge storage. An electrolyte is disposed between two electrically conducting plates, each plate serving as a base for an aligned array of electrically conducting nanostructures extending from the surface of each plate into the electrolyte. The nanostructures have diameter and spacing comparable to the dimension of an ion of the electrolyte. An electrically insulating separator is disposed between the two plates. A CVD process (or other processes yielding similar results) is used to make the aligned array of electrically conducting nanostructures.

Owner:MASSACHUSETTS INST OF TECH

Nonaqueous electrolyte solution secondary battery separator and nonaqueous electrolyte solution secondary battery using the same

ActiveUS20060127753A1Improve battery performanceImprove cycle performanceCell electrodesSecondary cellsPhysical chemistryPore diameter

An object of this invention is to improve battery performance such as a rate capability of a nonaqueous electrolyte solution secondary battery using a separator constituting a thermoplastic resin-based porous film containing a filler. This invention provides a nonaqueous electrolyte solution secondary battery separator which is formed from a porous film containing a thermoplastic resin and a filler contained in the thermoplastic resin and has a ratio of an average pore diameter (μm) to a maximum pore diameter (μm) defined by ASTM F316-86 of 0.6 or more as well as relates to a nonaqueous electrolyte solution secondary battery using this separator.

Owner:MITSUBISHI CHEM CORP

Polyimide foam and method of producing the same

The invention discloses polyimide foam and a preparation method thereof. Aromatic dianhydride and / or aromatic acid ester, alcohol with low molecular, a catalyst and a surface active agent are mixed proportionally in a polar solvent and react so as to form foam precursor solution. The foam precursor solution and isocyanate react in a mould and freely foam into a foam intermediate. The intermediate is solidified by microwave radiation or / and oven heating to obtain solid polyimide foam. The preparation process has short path, simple technology, good stability for storage of the foam precursor solution, adaptation to processing technologies of pouring, spray coating, extrusion, and the like, no occurrence of defects of cracked foam, foam combination, subsidence and incomplete amination, low preparation cost as well as uniform hold diameter and stable performance of the solid polyimide form, and is convenient for popularization and application.

Owner:BEIJING RADIATION APPL RES CENT

Lithium-ion battery diaphragm and preparation method thereof

InactiveCN105140451AUniform pore sizePorosity is easy to controlCell component detailsPorous coatingPorous substrate

The invention discloses a lithium-ion battery diaphragm. The lithium-ion battery diaphragm is prepared by coating the upper surface and the lower surface of a porous base material with one or more porous coatings, wherein the thickness of the porous base material is 4-80 microns; the porosity of the porous base material is 30%-90%; and each porous coating comprises the following raw materials in parts by weight: 30-100 parts of a polymer material, 0-70 parts of inorganic powder and a surface treating agent and 0-50 parts of a compatibilizer. The invention further discloses a preparation method of the lithium-ion battery diaphragm. The battery diaphragm disclosed by the invention is controllable in pore size and porosity and uniform in pore size; the finished diaphragm product is high in high-grade rate, good in wettability and high in safety; and the diaphragm is good in heat resistance, and has a thermal closing function.

Owner:郑少华

Method for preparing low density polypropylene foam section or beads by two-step extrusion molding

The invention discloses a method for a preparing low density polypropylene foam section or beads by two-step extrusion molding, which comprises the following steps that: expandable master batch is prepared from 30 to 80 portions of polypropylene, 10 to 40 portions of foaming agent, 0 to 15 portions of foaming accelerant, 0 to15 portions of dispersant and 0 to 10 portions of nucleating agent at a temperature below the decomposition temperature of the foaming agent and above a viscous flow temperature of the polypropylene; 20 to 99 portions of polypropylene with high melt strength, 0 to 70 portions of common polypropylene and 1 to 10 portions of expandable master batch are plasticizated and extruded together; supercritical gas is added to perform the blending of the plasticizated and extruded mixture; and the product obtained is made to generate foamcores in a foaming nucleation apparatus to form the section or beads finally. A chemical foaming agent is partially decomposed and foamed during the plasticization and extrusion, so that the viscosity of fused mass is reduced, the dissolution and dispersion of the supercritical gas are facilitated, and a problem that a foam imploding is likely to happen in a secondary forming process so as to influence the quality and appearance of secondarily formed product is solved as the chemical foaming agent retained in molding beads can be decomposed and foamed again during the secondary processing.

Owner:SICHUAN UNIV

Composite stacked and coated lithium ion battery diaphragm and preparation method thereof

ActiveCN104393217AHigh strengthImprove heat resistanceCell seperators/membranes/diaphragms/spacersViscous flowLithium-ion battery

The invention relates to a composite stacked and coated lithium ion battery diaphragm and a preparation method thereof. The diaphragm is a porous diaphragm which is prepared by mixing one or many kinds of coating sizing agents and is provided with a layer or multiple layers of structures; the porous diaphragm comprises the following components in parts by weight: 30-100 parts of a polymeric material, 0-70 parts of inorganic powder bodies and a surface treating agent thereof, and 0-50 parts of a compatibilizer; the polymeric material at least selects and uses two kinds of polymeric materials, one kind of the polymeric materials is a thermoplastic material of which the melting point or the viscous flow temperature is 100-150 DEG C, and the other kind of the polymeric materials is a thermoplastic material or a thermosetting material of which the melting point or the viscous flow temperature is higher than or equivalent to that of the thermoplastic material of which the melting point or the viscous flow temperature is 100-150 DEG C. The composite stacked and coated lithium ion battery diaphragm provided by the invention is uniform in bore diameter, good in wettability, favorable in heat resistance and good in hot melting and closing function, and the preparation method for the composite stacked and coated lithium ion battery diaphragm is simple in technology, wide in the material selecting range, and controllable in the micropore forming condition.

Owner:HORIZON SPECIALTY MATERIAL

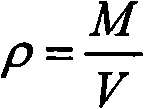

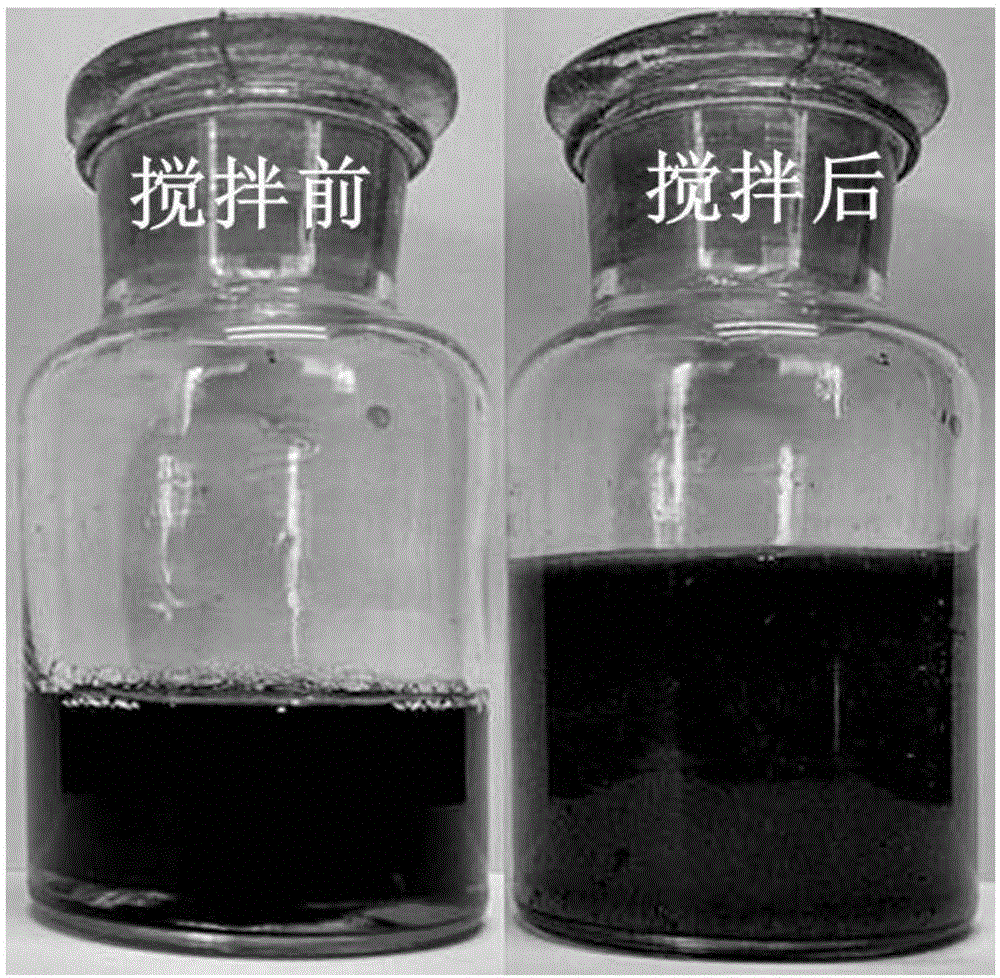

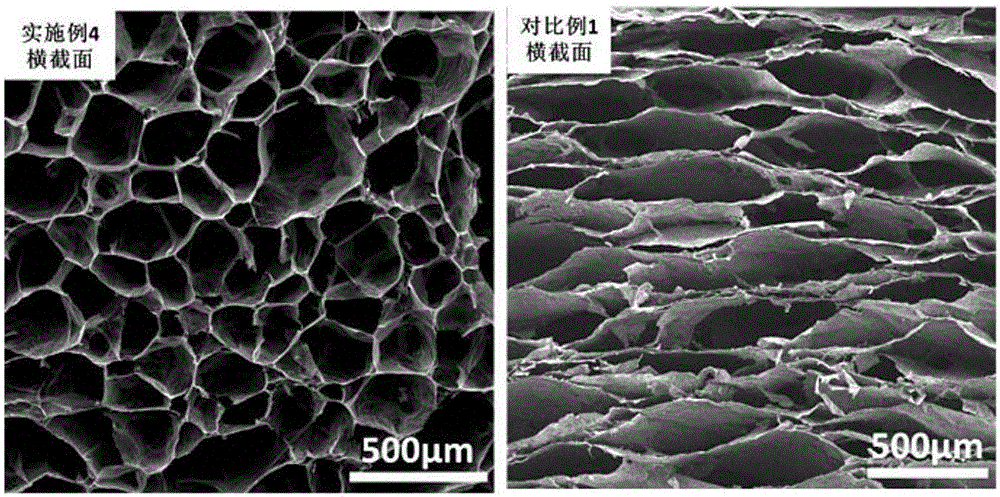

Method for preparing isotropic superelastic graphene aerogel

The invention provides a method for preparing isotropic superelastic graphene gasgel. The method comprises the following steps: firstly, stirring and mixing an oxidized graphene aqueous dispersion, a reducing agent and sodium dodecyl sulfate (SDS) at low speed, and then stirring at high speed; heating, freezing, melting at room temperature, washing with ethanol and drying at atmospheric pressure to obtain the isotropic superelastic graphene aerogel. The method provided by the invention has the advantages of simple process and is suitable for industrial production, and the obtained graphene aerogel is isotropic, has uniform cell size, and has excellent compression recovery and good electrochemical performance.

Owner:QINGDAO UNIV OF SCI & TECH

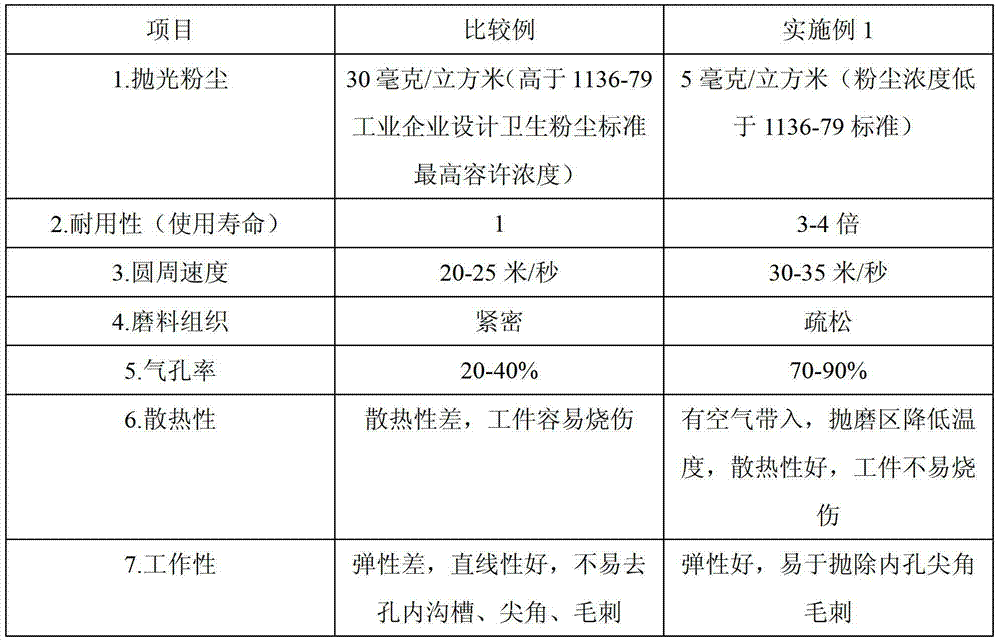

Polyvinyl alcohol-polyurethane elastic buffing wheel and preparation method thereof

InactiveCN103395011AUniform cellsNo stuffingAbrasion apparatusGrinding devicesWater bathsDistilled water

The invention discloses a polyvinyl alcohol-polyurethane elastic buffing wheel and a preparation method of the polyvinyl alcohol-polyurethane elastic buffing wheel. The preparation method comprises the steps that firstly, polyvinyl alcohol is mixed with distilled water, and the mixture is dissolved for 20-30 minutes under the condition of 50-95 DEG C water bath and at the rotation speed of 400-600r / min to obtain a polyvinyl alcohol aqueous solution; then, the polyvinyl alcohol aqueous solution is heated up to 30-100 DEG C, grinding materials are firstly added into the polyvinyl alcohol aqueous solution, after the mixture of the grinding materials and the polyvinyl alcohol aqueous solution is stirred and mixed evenly at the rotation speed of 400-600r / min, polyurethane pre-polymers, catalysts and air hole generating agents are added, and all the components are stirred and mixed evenly at the rotation speed of 400-600r / min and react for 5-10min; solidification is conducted for 2-4h under the condition of 30-100 DEG C, and then the buffing wheel which is good in elasticity, good in water resistance, good in heat-dissipating performance and high in mechanical strength is obtained. The elastic buffing wheel is even in foam hole, good in abrasion resistance and grinding force, not prone to deforming or curling in humid environment and applicable to long-time grinding work.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of medical porous titanium and titanium alloy

InactiveCN102747245AImprove efficiencyGood mechanical propertiesProsthesisThermal insulationRepair material

The invention discloses a preparation method of medical porous titanium and titanium alloy, which comprises the following steps: proportionally preparing titanium powder, alloy element powder and pore forming agent powder according to needs; carrying out ball milling, mixing and mechanical pressing by a powder metallurgy blank making technique to obtain a blank; putting the blank in a thermal insulation barrel, and putting the thermal insulation barrel into a microwave sintering furnace; and after vacuumizing the furnace chamber to a vacuum degree of 0.1Pa, charging argon with the purity of 99.999% to form cyclic protection, controlling the output power of the microwave sintering furnace at 0.5-3kW, heating to the sintering temperature of 800-1200 DEG C at the heating rate of 5-40 DEG C / minute, keeping the temperature for 5-30 minutes, shutting down the microwave source, and carrying out furnace cooling to obtain the medical porous titanium and titanium alloy. The invention has the advantages of simple preparation method, short sintering period, high efficiency, low sintering temperature and low energy consumption; and the sintered porous titanium and titanium alloy have excellent mechanical properties, and can be used as alternate repair material for bones, joints, artificial radix dentis and other hard tissues.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

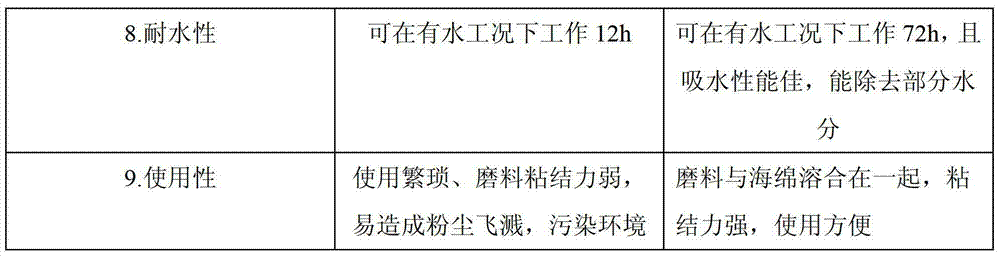

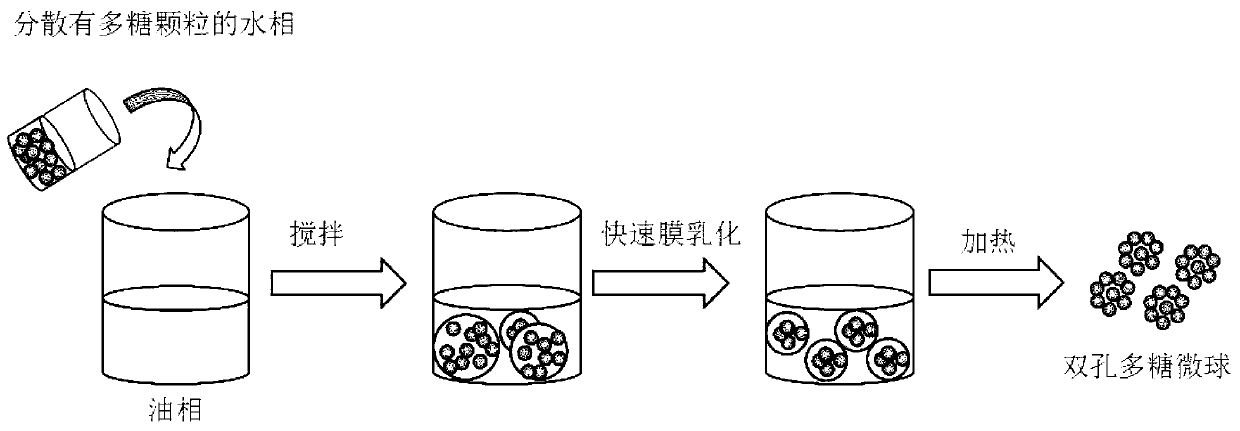

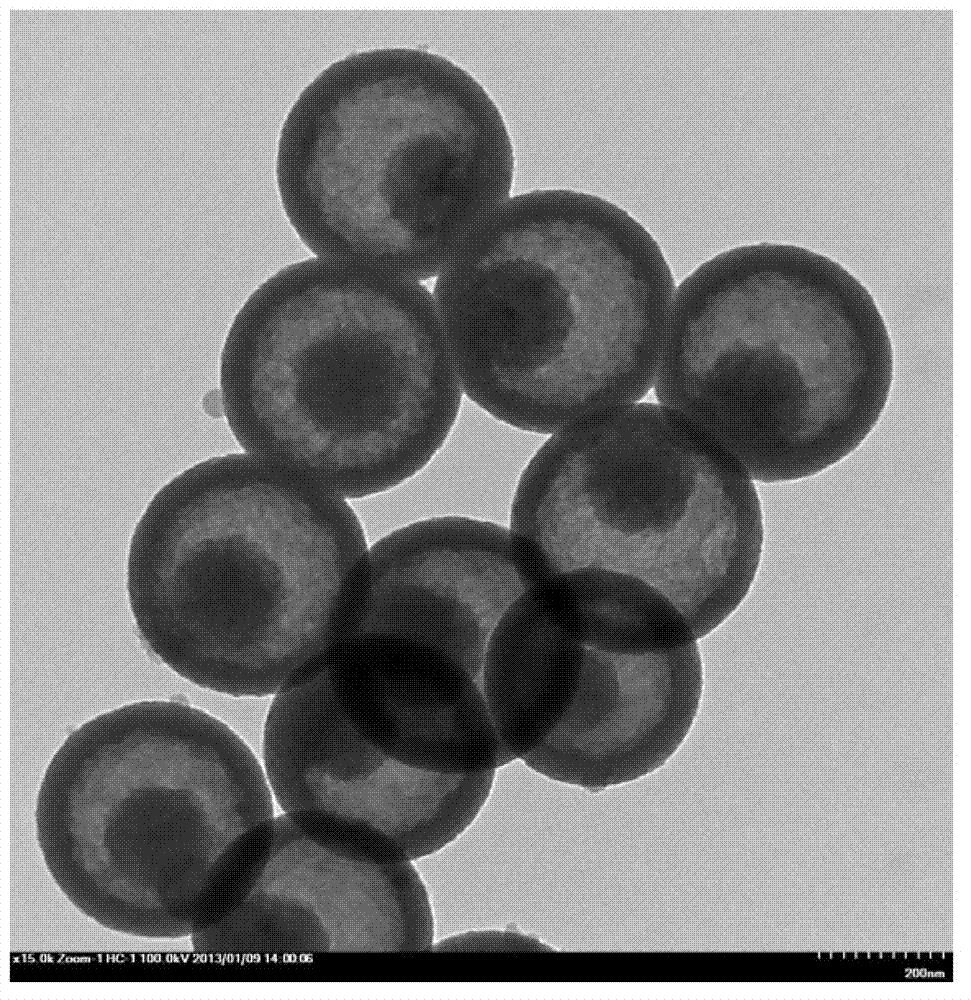

Dual-hole polysaccharide microspheres, preparation method and purpose thereof

ActiveCN103341172ASimple processAvoid removal stepsCosmetic preparationsToilet preparationsMembrane emulsificationMicrosphere

The invention relates to dual-hole polysaccharide microspheres, a preparation method and a purpose thereof. The microspheres are formed by a plurality of stacked polysaccharide particles with small particle sizes, with an average particle size of the microspheres being 500 nm to 500 [mu]m; and comprises gel pores containing the polysaccharide as well as macroporous dual-hole structure formed by gaps among the polysaccharide particles. The preparation method of the microspheres comprises dispersing the polysaccharide particles in a water phase and then in an oil phase to form water in oil emulsion, heating the emulsion, and stirring to obtain the dual-hole polysaccharide microspheres. Furthermore, according to the preparation method, together with a membrane emulsification technology, the dual-hole polysaccharide microspheres with uniform particle size distribution can be prepared, with an average particle size range being 500 nm to 100 [mu]m and a particle size distribution coefficient being less than 20 %. The dual-hole polysaccharide microspheres provided by the invention are suitable for being used as separation mediums for separating biomacromolecules, biologically active material carriers, etc.

Owner:SENHUI MICROSPHERE TECH SUZHOU CO LTD

Adsorbent for exhaust gas purification

InactiveUS20020016252A1High HC desorption temperatureHigh acidic hydrothermal resistanceAluminium compoundsGas treatmentHydrocotyle bowlesioidesSorbent

Owner:NGK INSULATORS LTD

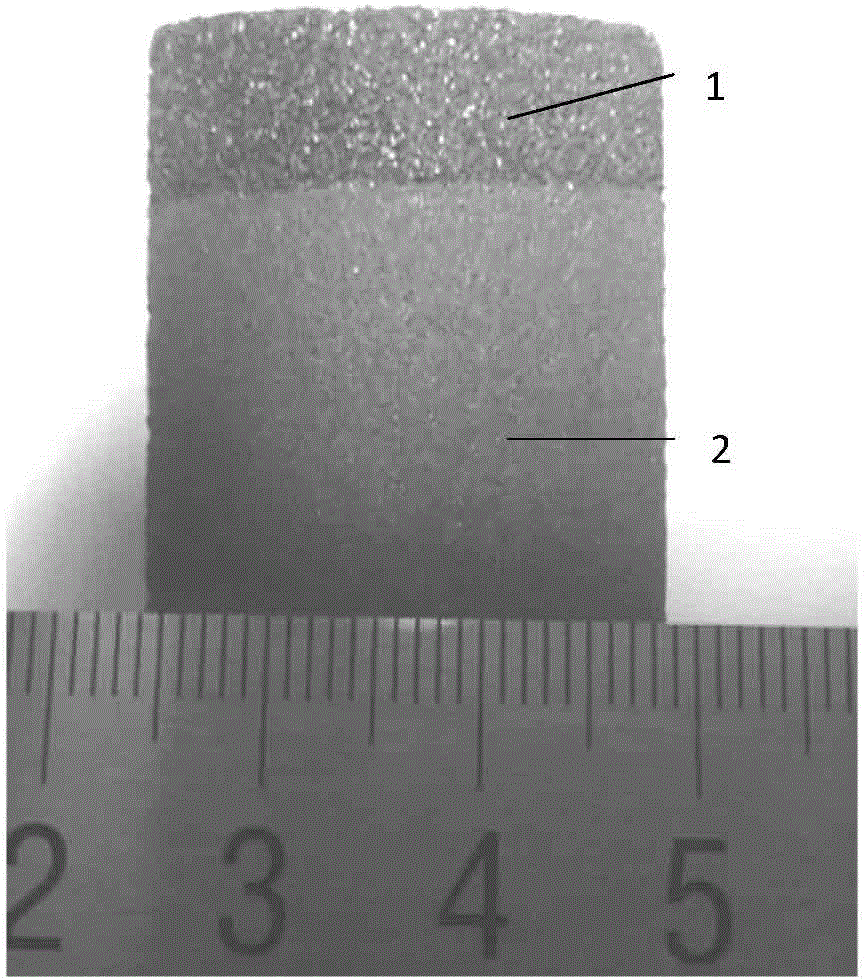

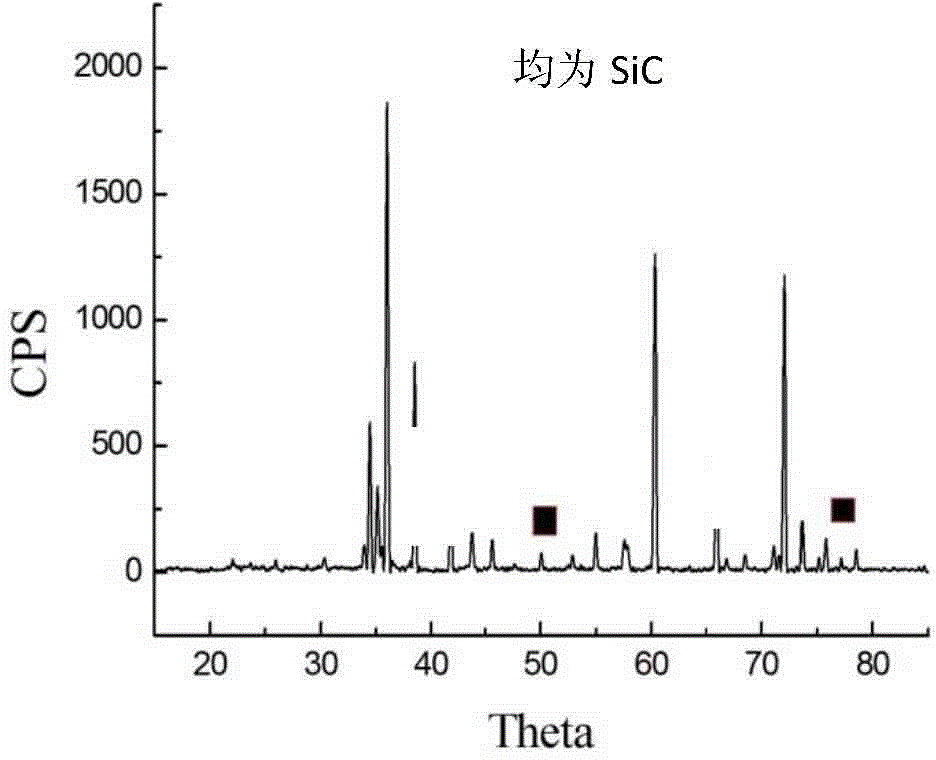

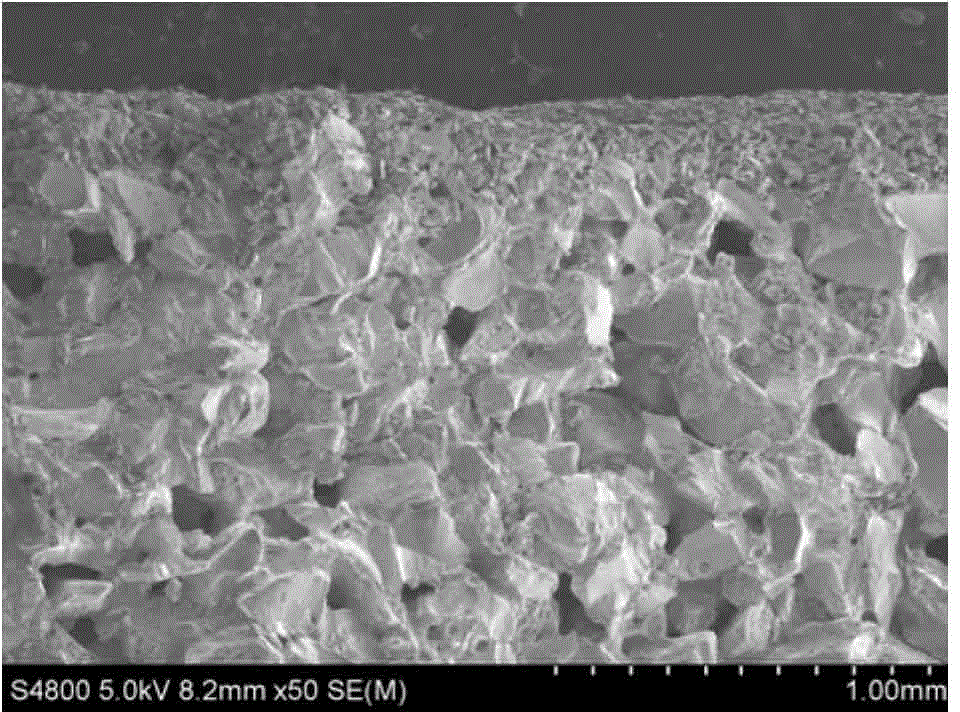

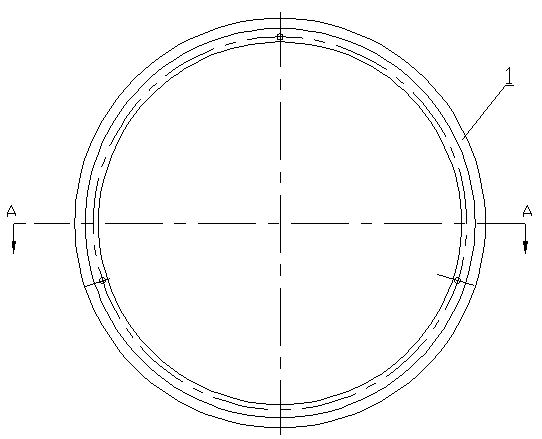

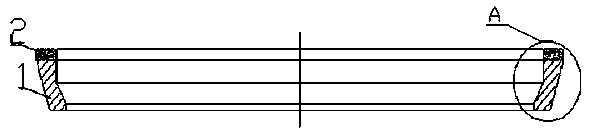

Silicon carbide porous ceramic filter and manufacturing method thereof

The invention relates to a silicon carbide porous ceramic filter and a manufacturing method thereof, in particular to a filter material for high-temperature liquid or gaseous fluid. The ideal silicon carbide porous ceramic filter has the advantages of gradient pore structure, low sintering temperature, high use temperature, high porosity factor, low pressure drop, large geometric surface area, zigzag flow path, high intensity, long service life, low production cost, easy regeneration and repeated use. Moreover, the filter is formed by compounding and sintering a plurality of layers of ceramic materials of different pore structures, and comprises a main body billet layer, a transition compound film layer and a surface compound film layer. Therefore, the filter is suitable for filtration and purification of various high-temperature and low-temperature fluids such as molten metal, high-temperature flue gas, coking gas and automobile exhaust.

Owner:淄博鑫拓耐火材料有限公司

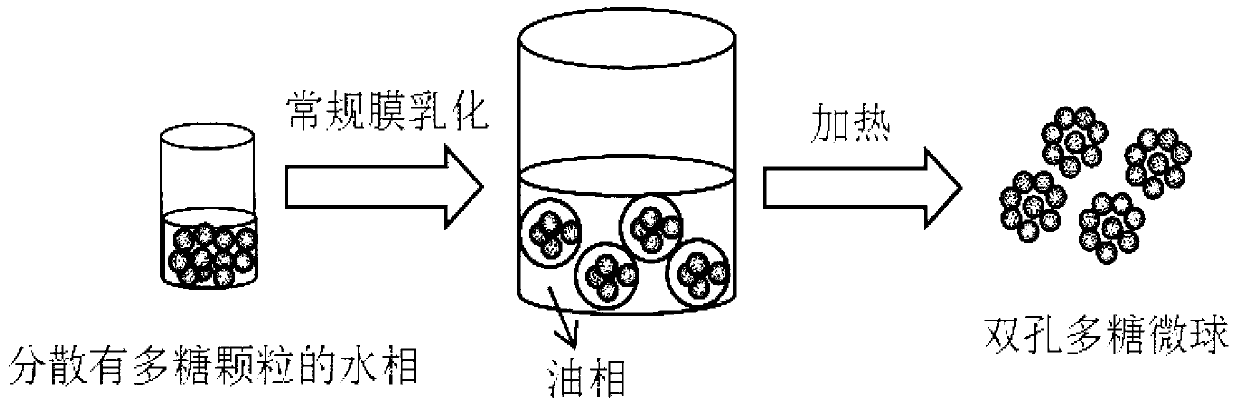

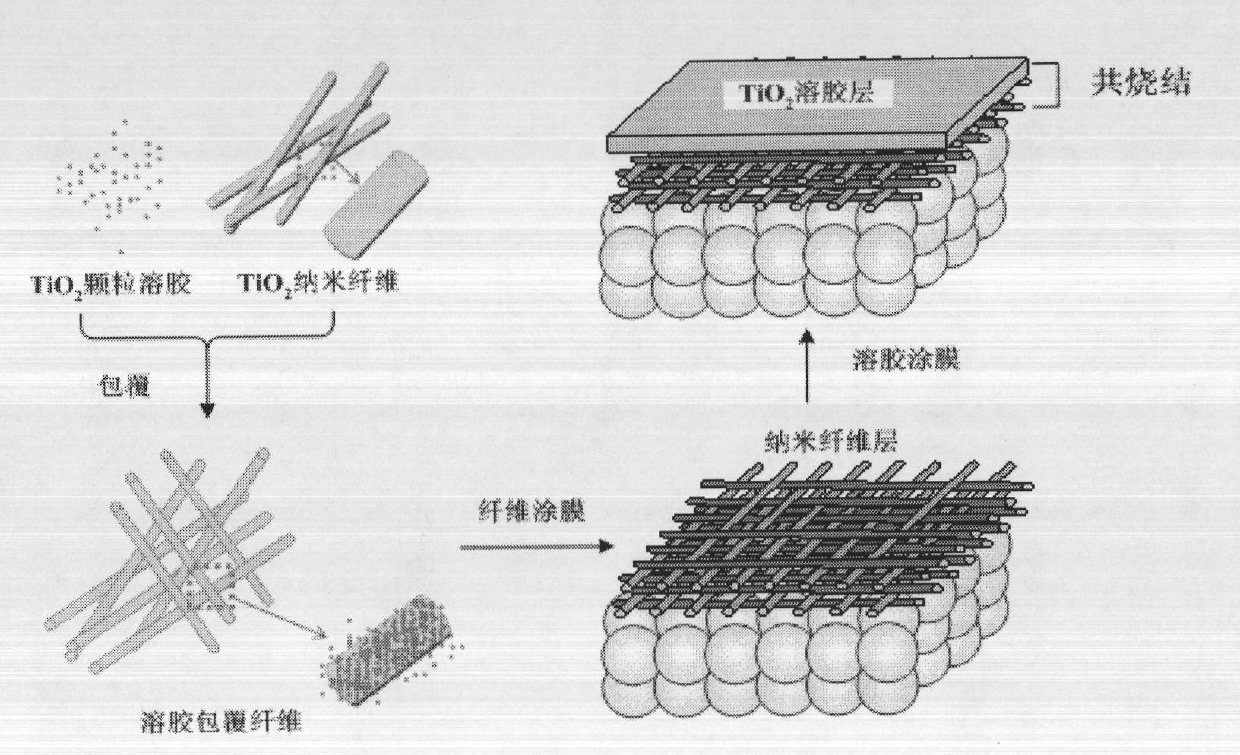

Asymmetrically-structural ceramic ultrafiltration membrane and preparation method thereof

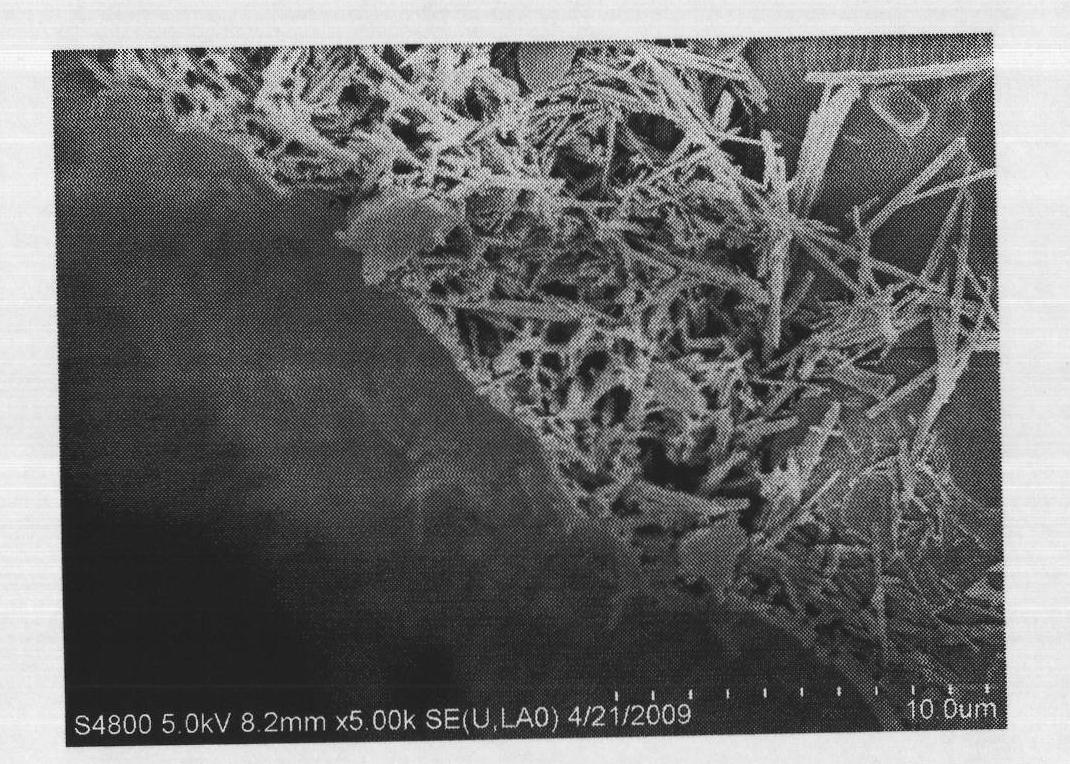

ActiveCN101791524AHigh porosityUniform pore sizeSemi-permeable membranesUltrafiltrationDefoaming Agents

The invention relates to an asymmetrically-structural ceramic ultrafiltration membrane and a preparation method thereof, wherein the preparation method thereof comprises the steps: dispersing one-dimensional fibrous material in sol and sufficiently mixing the material with the gel; by adding deionized water, controlling the weight ratio of gel particle to fiber in membrane preparing solution in a range from 0.01 to 0.4, adjusting pH value of the solution, adding dispersing agent, thickening agent and defoaming agent to formulate the membrane preparing solution, coating membrane on a porous support body and drying the porous support body to form a transition layer; coating the gel-containing membrane preparing solution on the surface of the transition layer, air-drying, oven-drying and roasting the wet membrane, and naturally cooling the membrane to result in the asymmetrically-structural ceramic ultrafiltration membrane. Since the transition layer is composed of fiber and sintering is promoted through the gel, resistance of the transition layer is advantageously lessened and interior combination strength of the transition layer is enhanced; the fiber-constructed transition layer divides large pores into small pores to provide larger total porosity and flowing pore channel, thus high permeation flux is maintained while high selectivity is obtained.

Owner:NANJING UNIV OF TECH

Method for preparing nanometer carbon fiber/foam coal through taking coal liquefaction residues as raw materials

The method for preparing nanometer carbon fiber / foam coal through taking coal liquefaction residues as raw materials belongs to the scientific and technological field of coal materials of the scientific and technological branch of inorganic non-metallic materials. The method takes the coal liquefaction residues as the coal source of the foam coal, and compounds metallic / foam coal compound materials through the supercritical foaming method or the formwork method, and prepares the nanometer carbon fiber / foam coal compound materials through the chemical vapor deposition of organic matter. The method fully utilizes the characteristics of metallic accelerating agent containing abundant coal organic matter, iron-contained compound and the like in the coal liquefaction residues, and prepares metallic / foam coal compound materials, and the nanometer carbon fiber completely covers on the surface of the foam coal after the chemical vapor deposition. The novel nanometer carbon fiber / foam compound materials have the structural characteristics of solid foam and hollow nanometer carbon fiber. And the method is expected to be used in the fields of catalyzer and a catalyzer carrier, a fuel battery electrode material, high-effective sorbent of a fixed bed reactor and the like.

Owner:DALIAN UNIV OF TECH

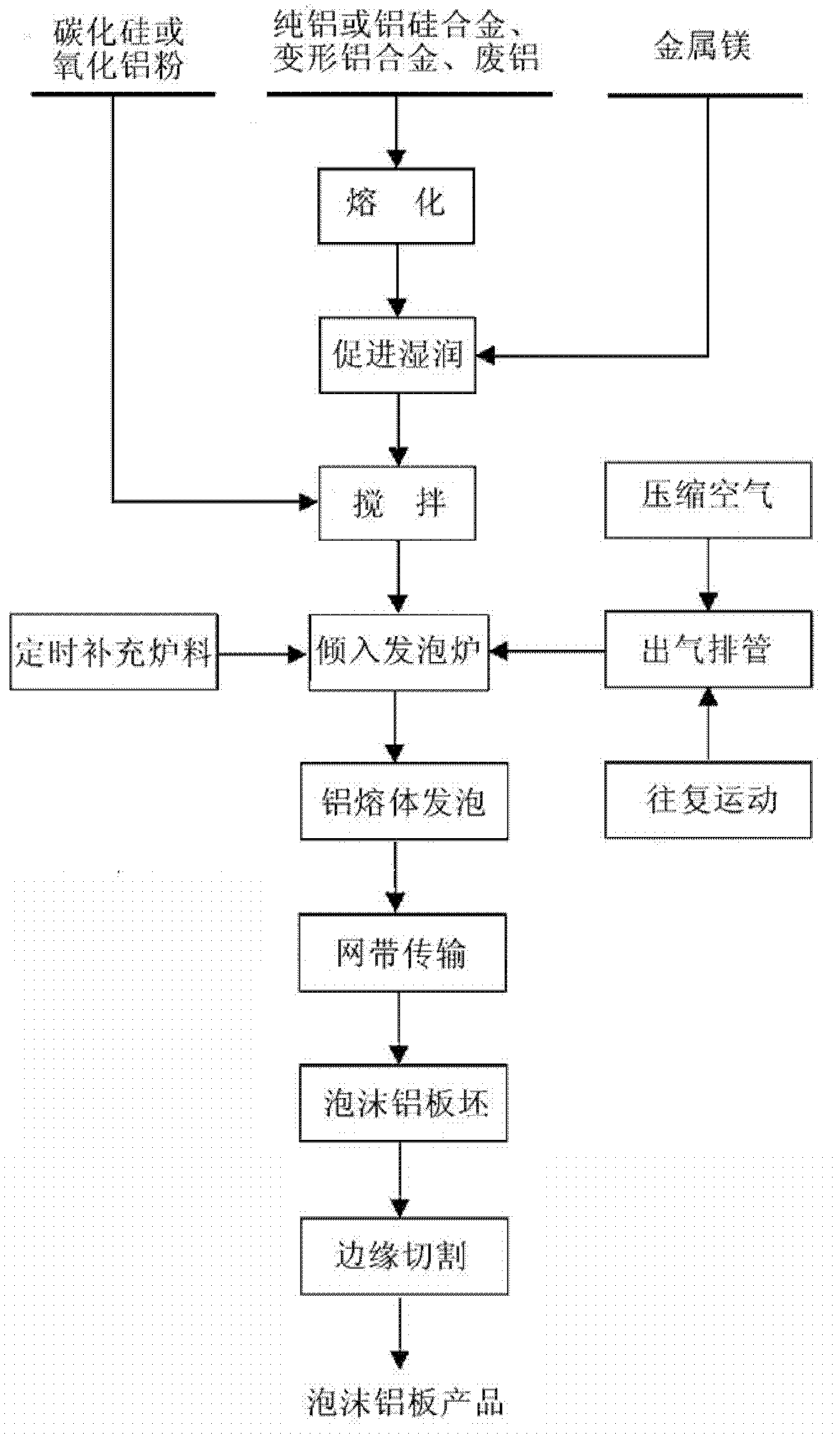

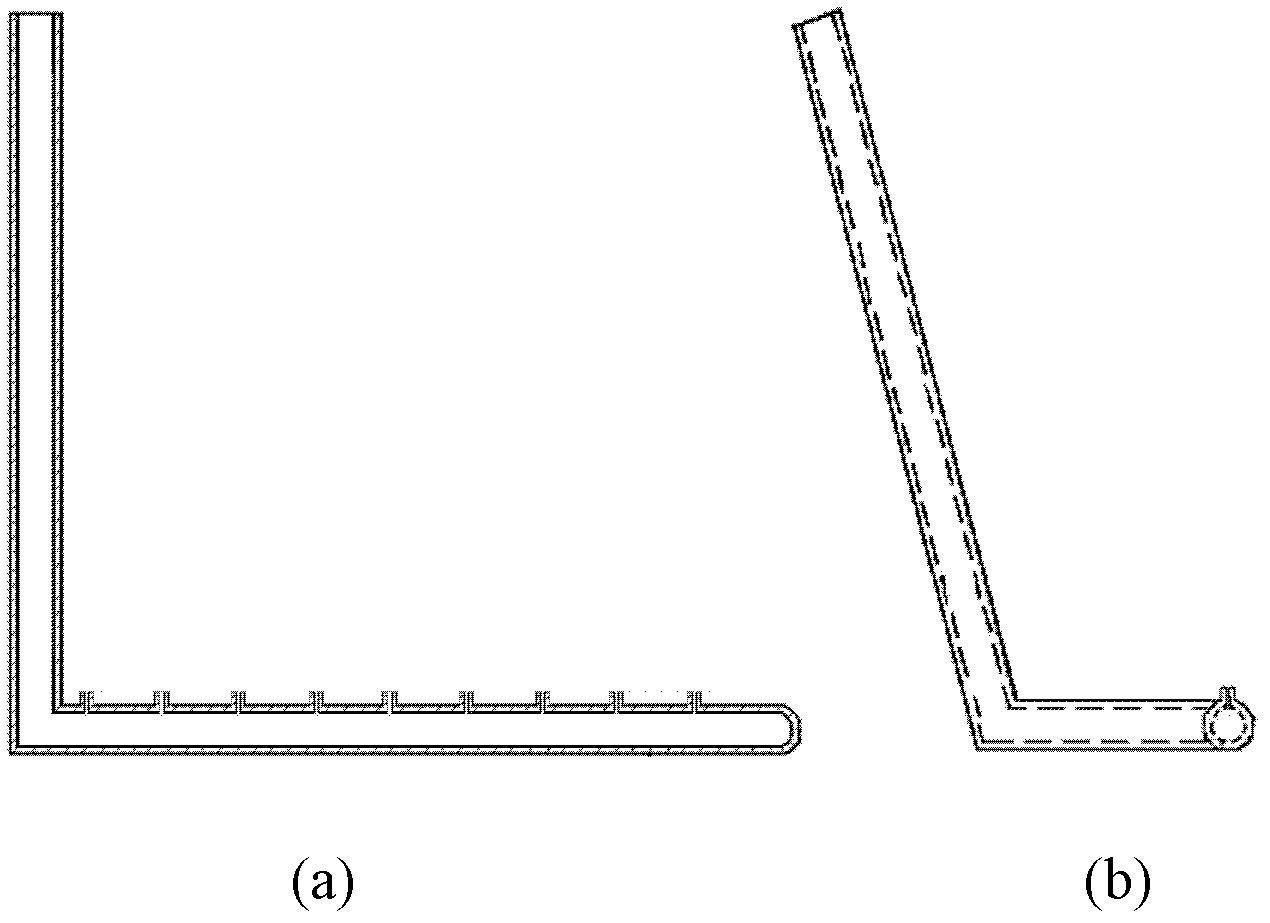

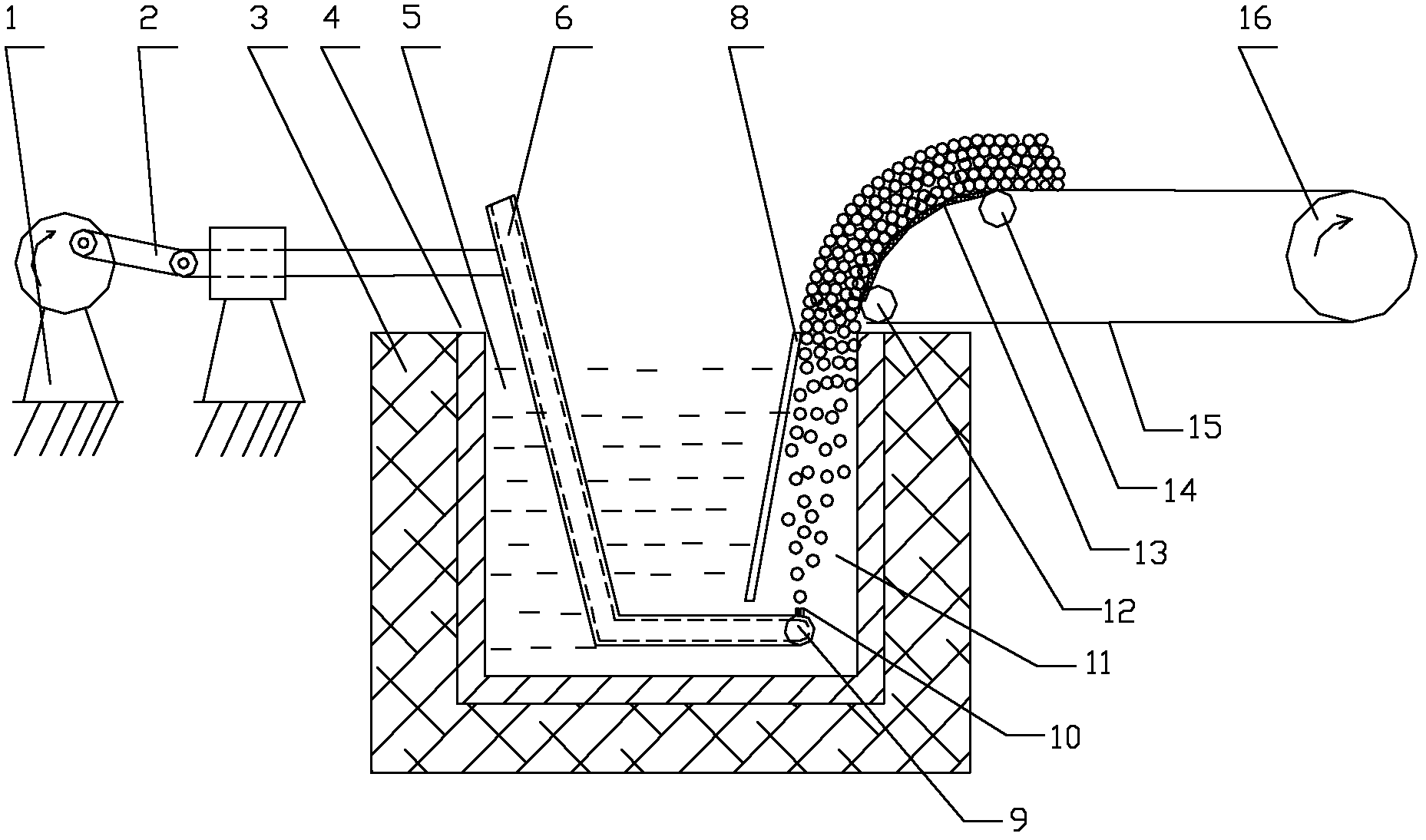

Process and apparatus for continuous production of closed-cell aluminum foam with blowing foaming

The invention relates to a process and an apparatus for continuous production of a closed-cell aluminum foam through blowing foaming. The process comprises the following steps: melting a raw material, adding with a ceramic tackifier and a moistening promoter, stirring to obtain molten aluminum with uniform component, carrying out continuous foaming with the apparatus for the continuous productionof the closed-cell aluminum foam with blowing foaming to obtain a molten aluminum foam with uniform foam size, and controllable density and productivity, and producing a foamed aluminum board by going through a net belt and transmitting with an arc transition mechanism and cutting. The apparatus is characterized in that: a simple crank link mechanism is adopted to realize the reciprocating motion of a horizontal outlet duct, and the arc transition mechanism allows the ascending lifting of the molten aluminum foam to be changed into horizontal transmission. According to the invention, the process and the apparatus are simple, the operation control is accurate, and a purpose that the pore size and the density of foamed aluminum products can be accurately controlled at a high efficiency anda low cost is realized because the foam size of the molten aluminum is adjusted by changing the frequency of the reciprocating motion of the outlet duct, the pressure and the flow of a compressed gasand the diameter of outlet micropores.

Owner:ANHUI NEOFOUND TECH

Modified polyimides foam and preparation thereof

The invention discloses modified polyimide foam and a preparation method thereof. The preparation method comprises the following steps: aromatic dianhydride and / or aromatic acid ester, siloxane with active terminal group, low molecular alcohol, a catalyst and a surface active agent are mixed into a polar solvent according to proportion and react to form foaming precursor solution which reacts with isocyanate to form foaming intermediate solution; and the foaming intermediate solution carries out foaming freely in a mold and forms a modified foaming intermediate which is radiated by microwave or / and heated and cured in an oven, and then the solid polyimide foam is obtained. The method has short route of preparation process and simple technique; the foaming precursor solution has good stability of storage, is suitable for the processing techniques of casting, painting, extruding and the like, and the defects of broken foam, parallel foam, depression and incomplete imidizate of materials do not occur; the polyimide foam has even aperture, high stability, low rigidity, good flexibility and good processability; and the preparation cost is low, thus being convenient to promotion and application.

Owner:BEIJING RADIATION APPL RES CENT

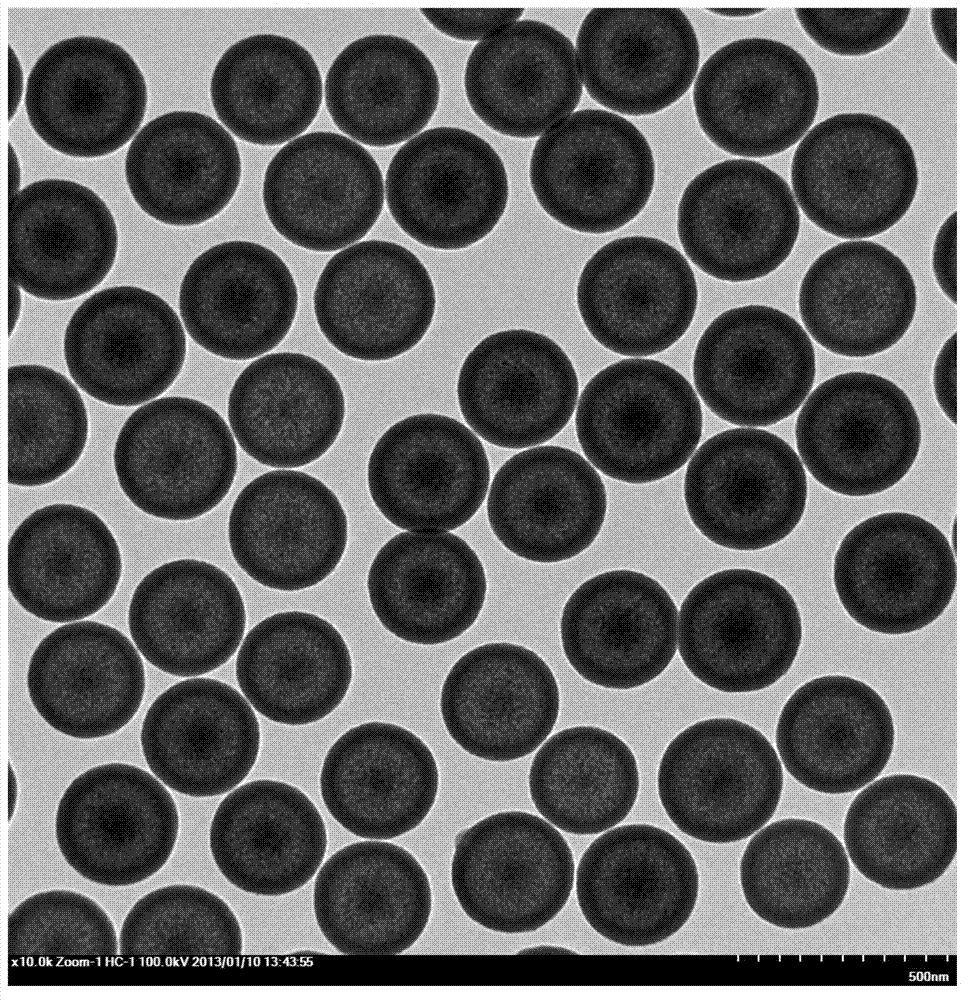

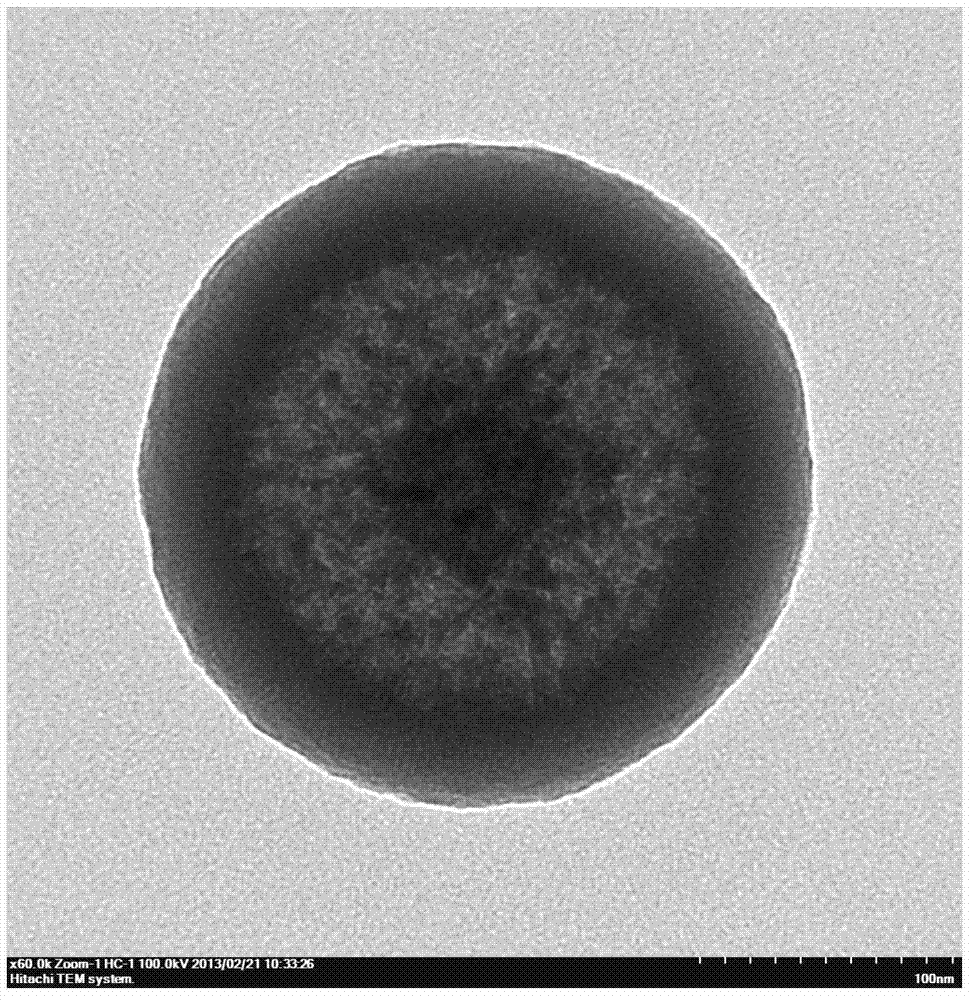

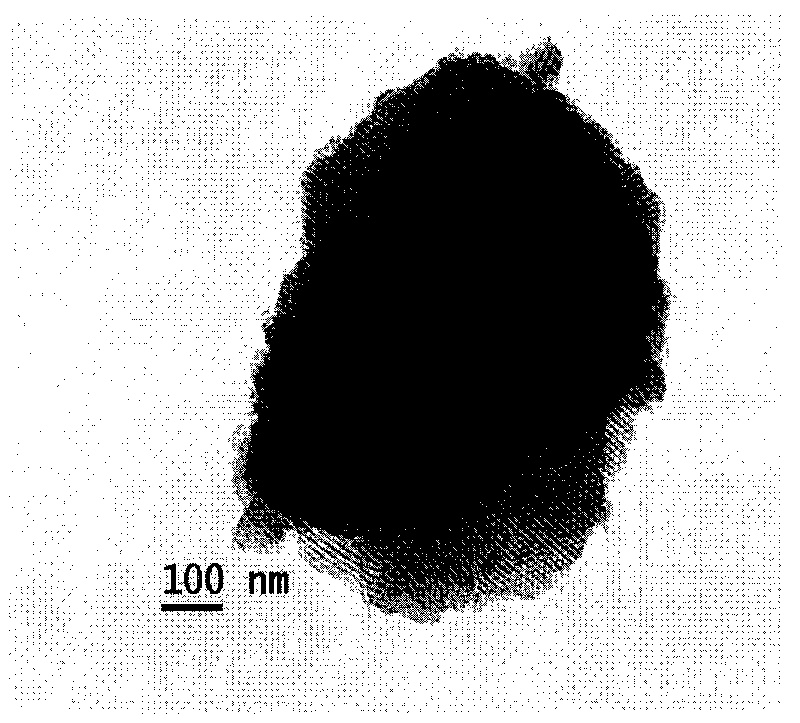

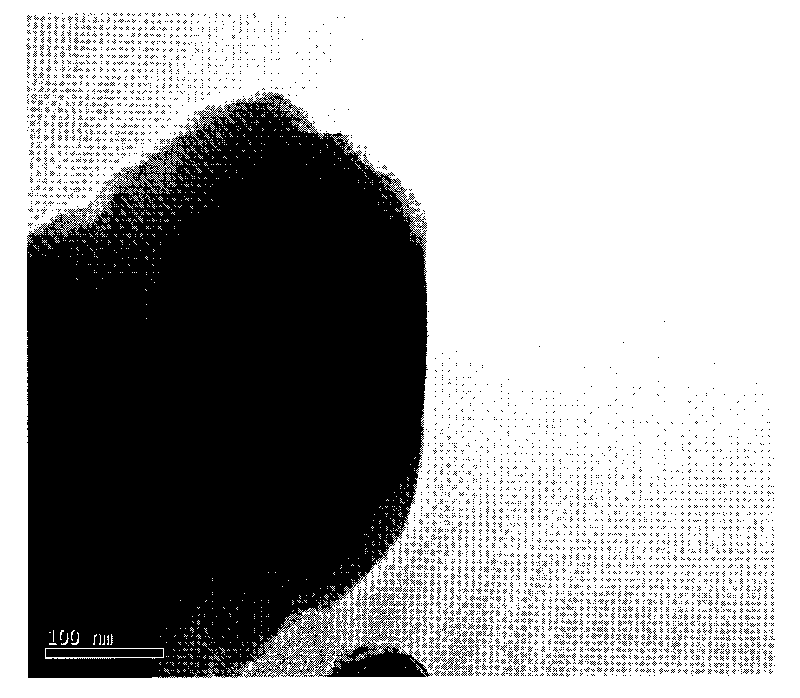

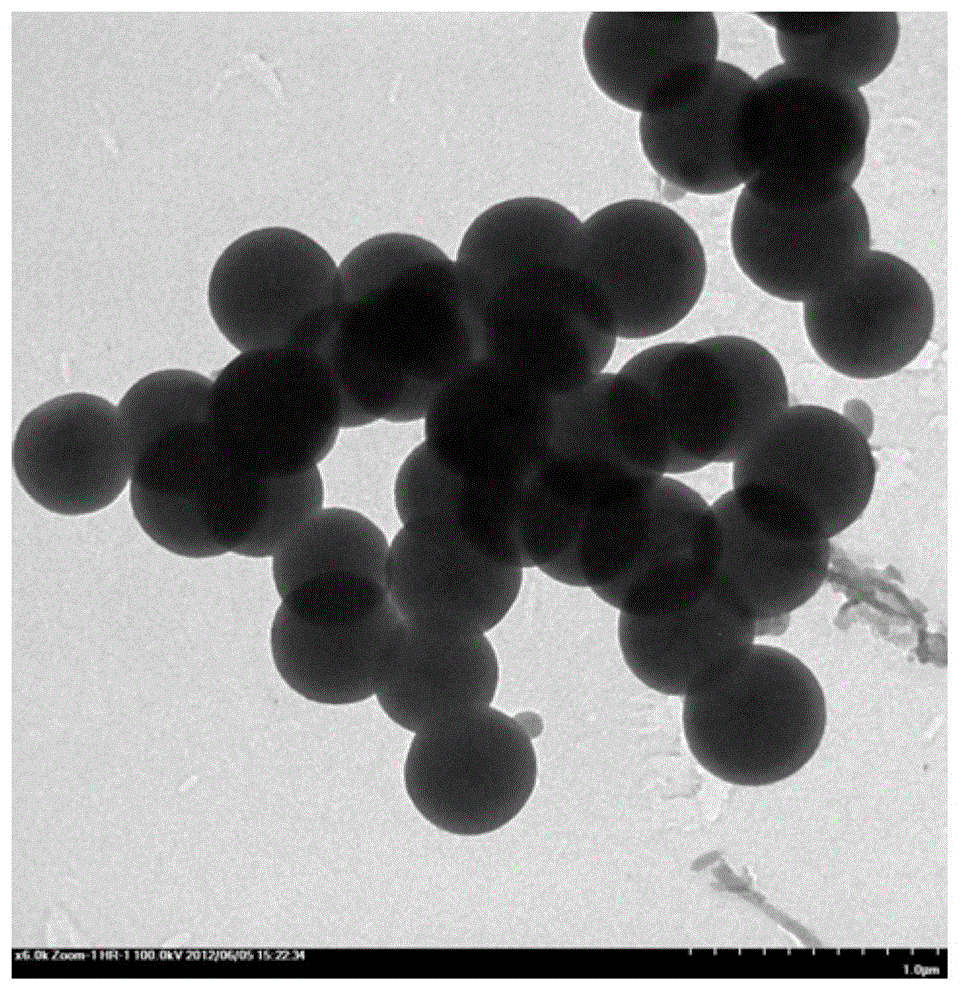

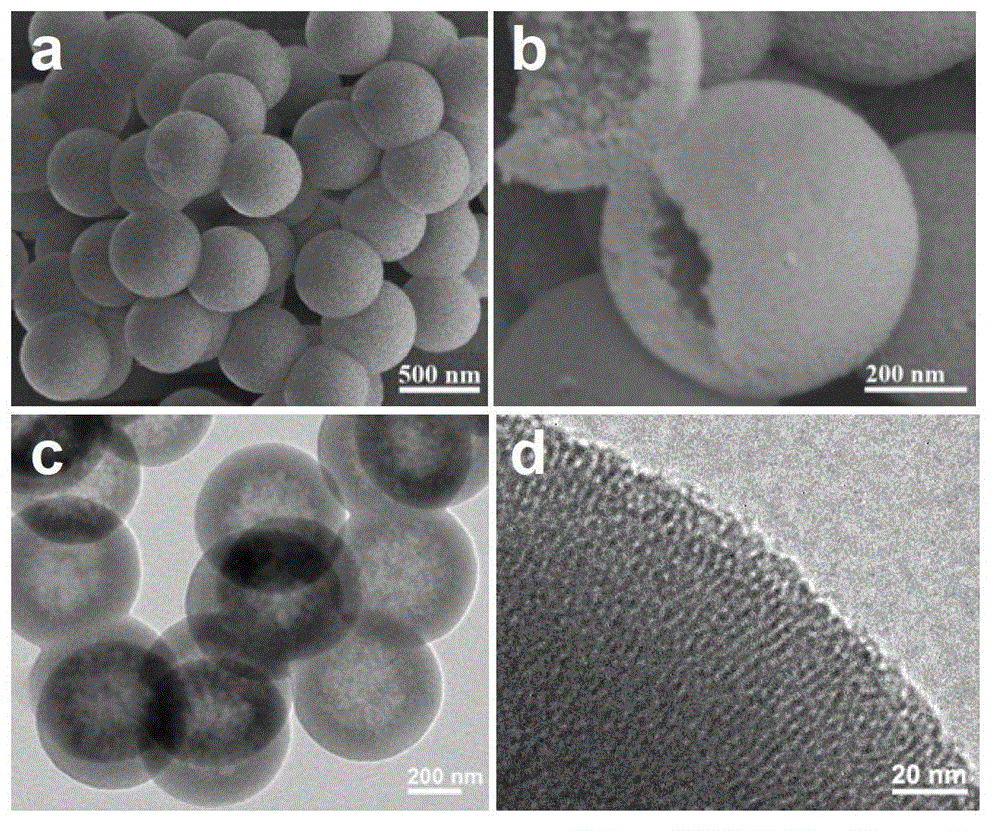

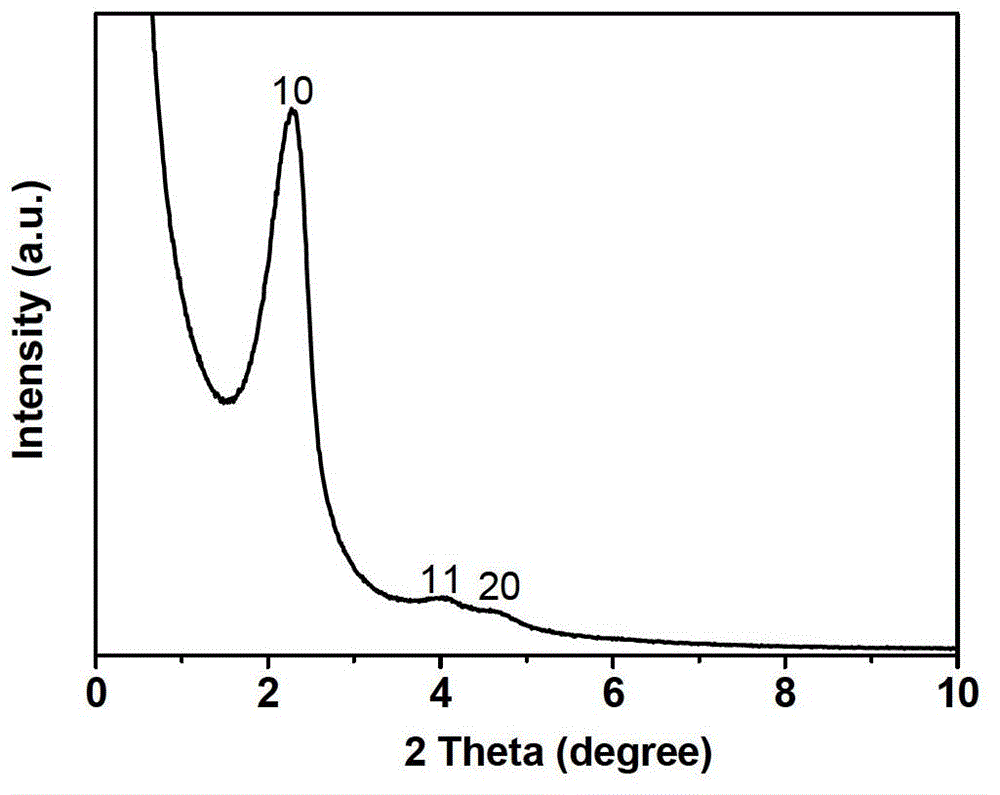

Mesoporous silica with yolk-shell structure and preparation method thereof

The invention discloses mesoporous silica with a yolk-shell structure and a preparation method thereof. The morphology of the mesoporous silica is of spherical bodies. The spherical body has a mesoporous core and a mesoporous shell. A cavity structure is between the mesoporous core and the mesoporous shell. Mesoporous silica balls have high specific surface area, uniform and adjustable particle size and uniform pore size. The preparation method of the mesoporous silica includes: dissolving a surface active agent in a mixed solution of ethanol, ammonia and water, adding two silica precursors into the mixed solution under heating and stirring conditions, transferring the obtained spherical silica into water after reacting for a period, etching to remove intermediate loose layers of silica balls, finally removing the surface active agent to obtain mesoporous silica products having the yolk-shell structure. The preparation method of the present invention has the characteristics of simple process, low cost, and environmental protection. The prepared mesoporous silica has great application potential in medical imaging, drug delivery and other fields.

Owner:NANJING GENERAL HOSPITAL NANJING MILLITARY COMMAND P L A

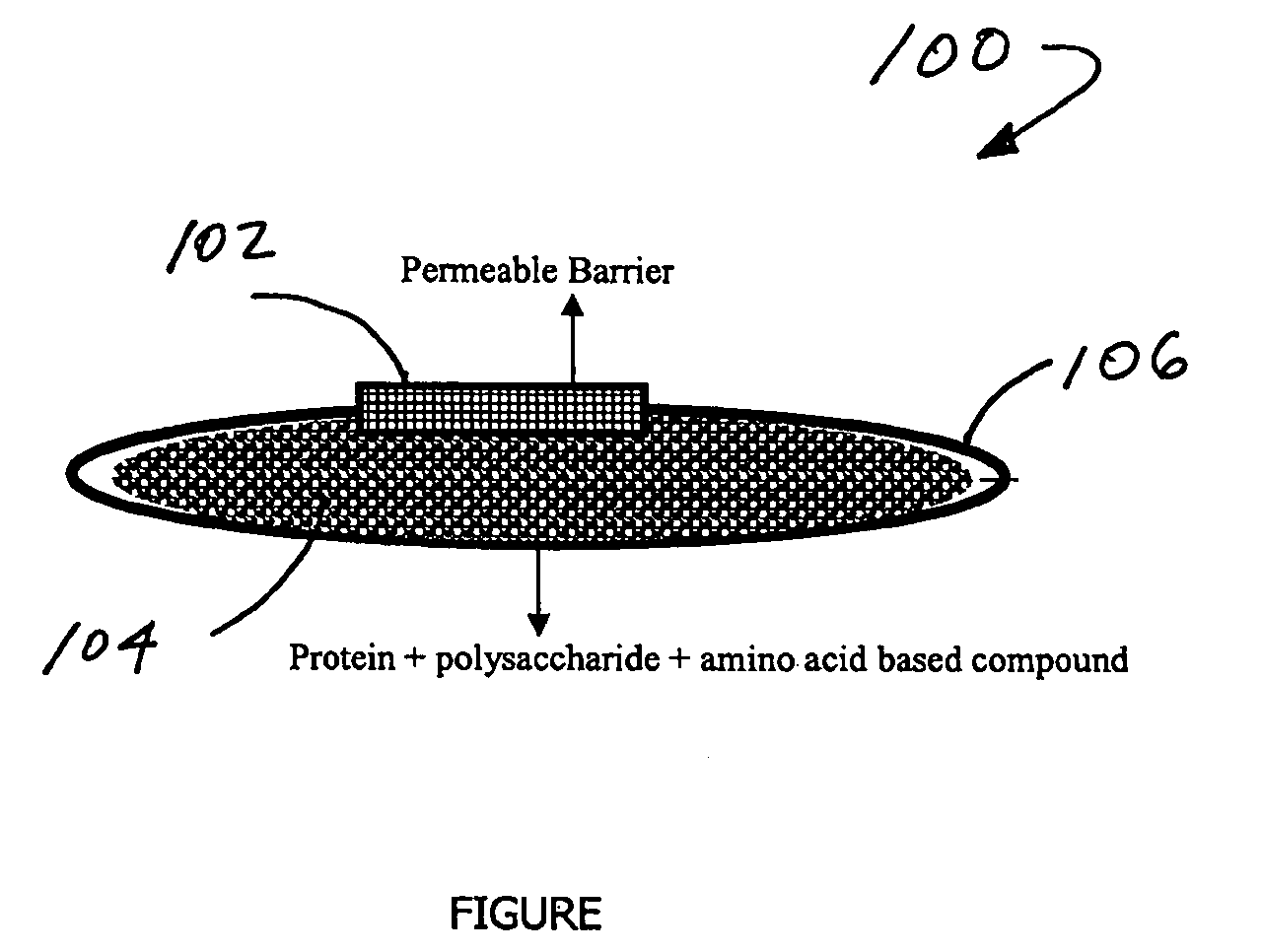

Stabilization of biologically active proteins with mixtures of polysaccharides and amino acid based compounds

InactiveUS20060024346A1Uniform pore sizeReduce concentrationOrganic active ingredientsBiocideActive proteinCompound (substance)

The invention provides heat stable aqueous solutions or gels comprising a biologically active protein and a stabilizing effective amount of a mixture of a polysaccharide and an amino acid based compound. The invention also discloses stabilized solutions or gels suitable for use in an implantable drug delivery device at body temperature, and a device containing the stabilized solution or gels.

Owner:BATTELLE MEMORIAL INST

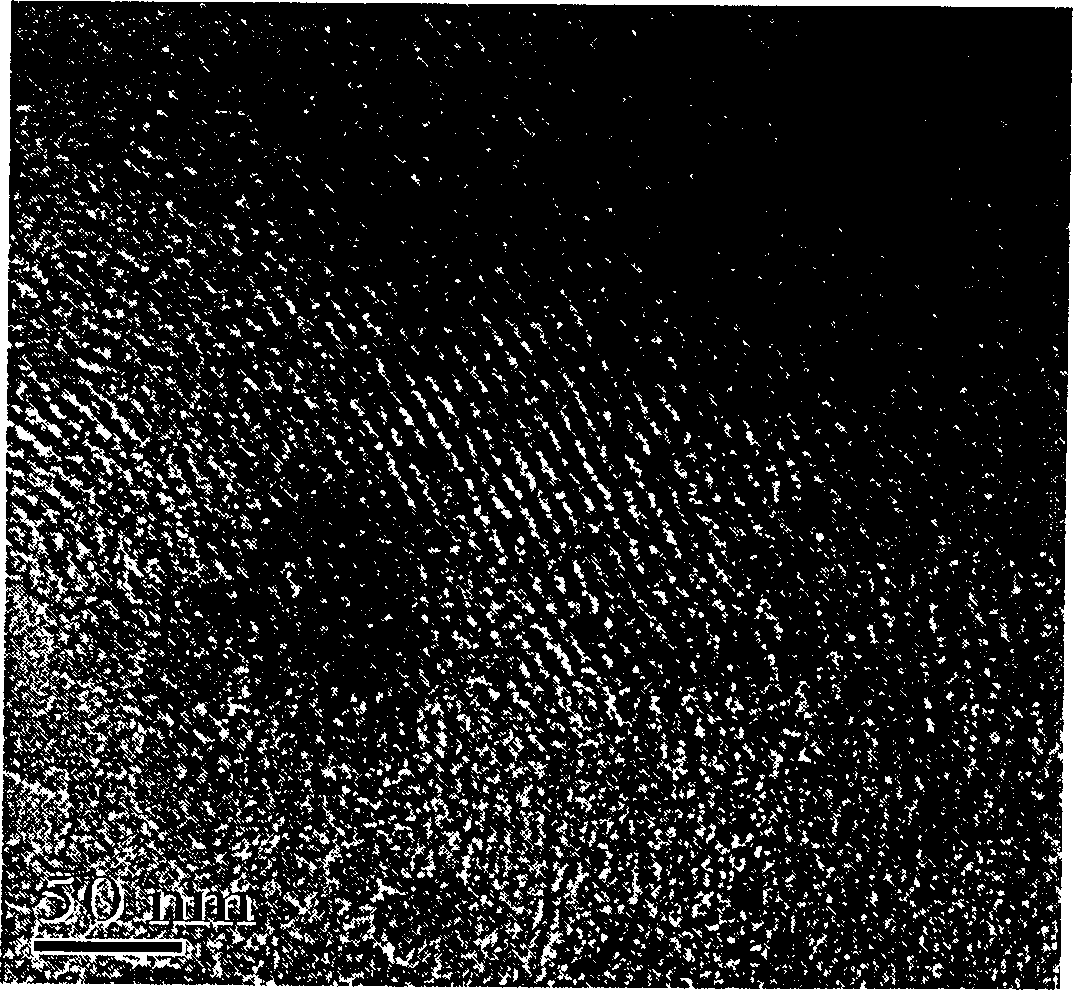

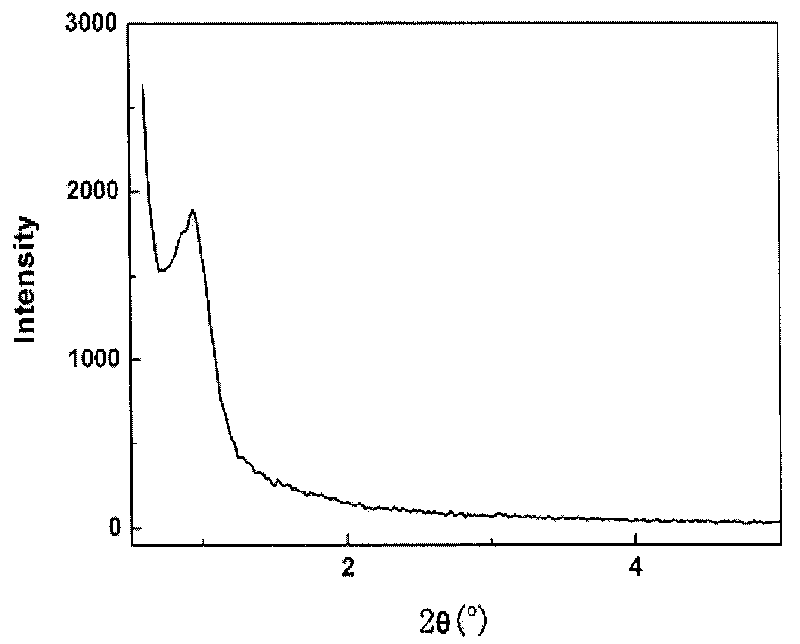

Method for preparing iron/nitrogen-codoped ordered mesoporous carbon material

ActiveCN106517136AImprove wettabilityImprove electrochemical performanceCarbon preparation/purificationEtchingReaction temperature

The invention provides a method for preparing an iron / nitrogen-codoped ordered mesoporous carbon material. The method comprises the following steps: taking a triblock copolymer F127 as a template, under acidic condition, a silicon source-tetraethoxysilane, a carbon source-phenolic resin, a nitrogen source 1-urea, a nitrogen source 2-pyrroles monomer and an iron source-ferric trichloride are added, the micelle having a three-dimensional porous structure is synthesized with one step by a solvent volatilization induction self-assembly method, and the ordered mesoporous carbon material is obtained through high temperature carbonization and hydrofluoric acid etching. The method of the ordered mesoporous carbon material has the advantages of simple operation, low reaction temperature, and controllable condition, the prepared ordered mesoporous carbon material has the ordered three-dimensional tunnel structure, high specific surface area and excellent electrochemistry performance, and has good application prospect in the field of electrochemistry.

Owner:QINGDAO UNIV OF SCI & TECH

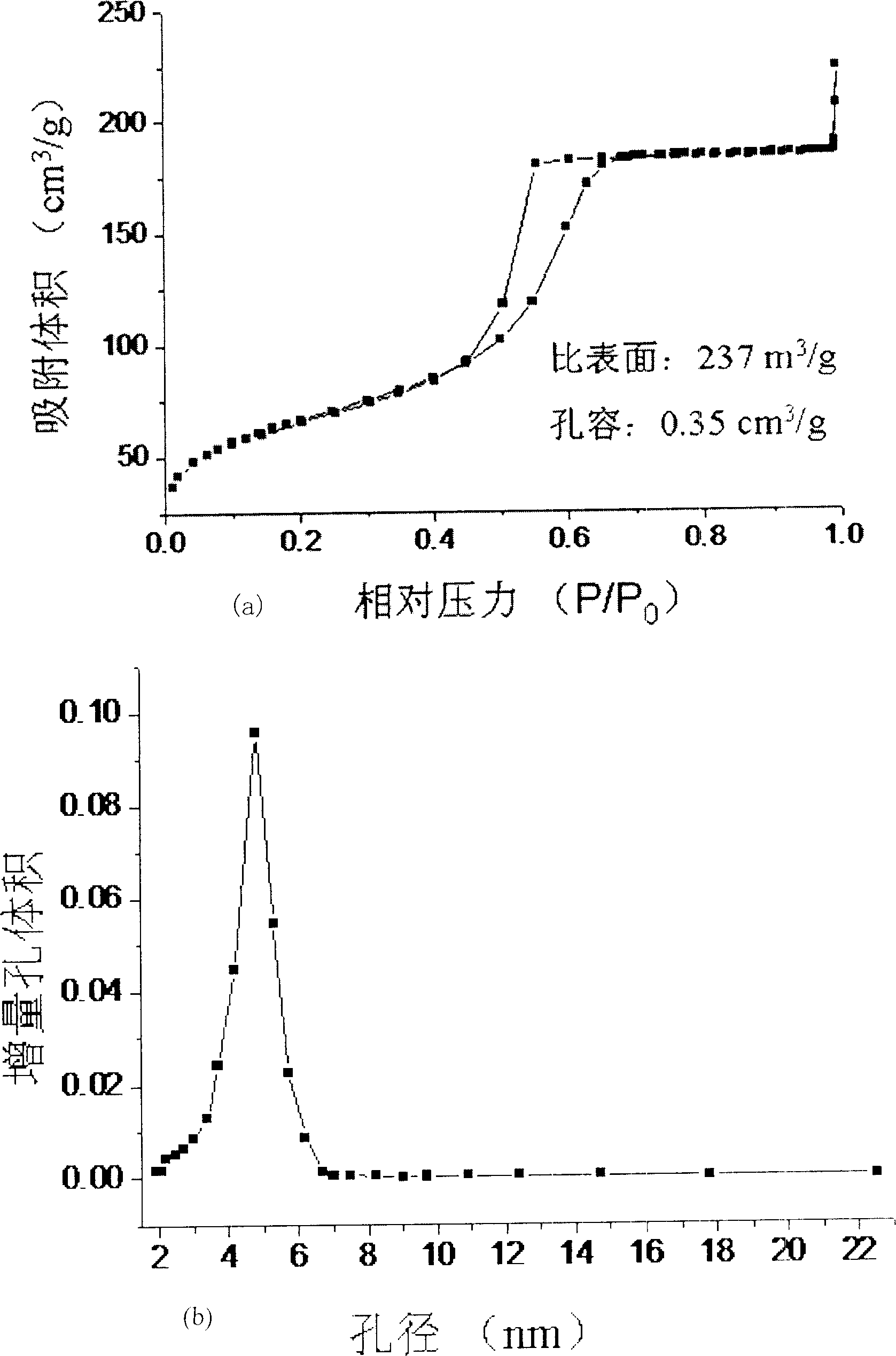

Mesoporous biological glass fiber material and its prepn and application

InactiveCN1887361AMild reaction conditionsEasy to operateGlass making apparatusCoatingsBone tissue engineeringBiocompatibility Testing

The present invention belongs to the field of biomedical material technology, and is especially one kind of mesoporous biological glass fiber material with bone repairing bioactivity and its preparation process. The mesoporous biological glass fiber material is prepared through spraying sol in controlled viscosity by means of template of surfactant. It has controllable composition, has the main components of SiO2, CaO and P2O5 and may have also TiO2, MgO, etc. added. It has controllable mesoporous structure of pore size 1-30 nm, specific surface area 100-1000 sq m / g, pore volume 0.3-1.5 cu cm / g. It possesses controllable macroscopic fiber shape, excellent osteogenesis activity and cell activity, and excellent biocompatibility and degrading performance. Therefore, the mesoporous biological glass fiber material may be used as bone repairing filler material and rack material.

Owner:FUDAN UNIV

Ordered nanostructure sulphur/mesoporous carbon composite material for anode of lithium ion battery

InactiveCN101728538AIncrease capacityGood dispersionElectrode carriers/collectorsSulfurConductive materials

The invention relates to an ordered nanostructure sulphur / mesoporous carbon composite material for anode of a lithium ion battery; the composite material is formed by taking the ordered carbon-based mesoporous material as a carrier and loading nanometer sulphur in porous channels; the composite material is sulphur-mesoporous carbon composite material which has high sulphur content, good dispersibility, high capacity and good stability, thereby overcoming the disadvantages of electricity-conducting material, finding good carrier material for the lithium-sulphur batteries and opening up new application field for the mesoporous material; the method in the invention has the advantages of low preparation process and low cost.

Owner:SHANGHAI UNIV

Preparation method of ordered mesoporous silica microspheres with hollow structures

InactiveCN102718225ALow equipment requirementsLow costMaterial nanotechnologySilicaMicrosphereMesoporous silica

The invention discloses a preparation method of ordered mesoporous silica microspheres with hollow structures. The preparation method comprises the following steps: firstly, dissolving a cationic surface active agent in mixed solution of ethanol and water, sequentially adding ammonia water and a silicon source in the mixed solution under the conditions of heating and mixing, and reacting for a period of time to obtain solid silica microspheres; washing the obtained silica, transferring the silica into water for etching, and reacting for a period of time to obtain hollow silica microspheres; and finally, collecting the hollow silica, and obtaining products of ordered mesoporous silica microspheres with hollow structures by drying and roasting. In the preparation method, a sacrificial hard template or an emulsion template does not need to be prepared in advance. The preparation method has the characteristics of simple technological process, mild reaction conditions, low cost, and environmental friendliness; and the prepared hollow mesoporous silica microspheres have great application potential in ultrasonic imaging, drug delivery and other biomedical fields.

Owner:NANJING GENERAL HOSPITAL NANJING MILLITARY COMMAND P L A

Method for preparing porous ceramic filter membrane by low-temperature sintering

InactiveCN104587846AImprove stabilityAppropriate viscositySemi-permeable membranesVacuum pressureHigh intensity

The invention discloses a method for preparing a porous ceramic filter membrane by low-temperature sintering. The method comprises the following steps: mixing and stirring ceramic aggregate particles, a sintering aid, deionized water, a dispersant and a defoamer, then carrying out vacuum pressure maintaining to remove a gas in the obtained filter membrane layer slurry; soaking a support body material in the filter membrane layer slurry, then obtaining a membrane layer on the support material by a pulling method, and then sintering at 700-1070 DEG C to obtain the porous ceramic filter membrane. According to the method, the porous ceramic membrane product which is high in strength, resistant to wear and corrosion, long in life and low in cost is obtained by optimally proportioning the sintering aid, the dispersant and the defoamer, preparing the ceramic membrane layer slurry system with high stability and proper viscosity, regulating the pulling method of the ceramic support body with a high porosity and a large hole diameter in the prefabricated membrane layer slurry system, thereby obtaining a uniform and asymmetrical porous ceramic membrane blank on the whole surface of a specified position of the support body material, and finally drying stage by stage and rapidly sintering at a low temperature of 1100 DEG C so as to obtain a porous ceramic filter membrane product with high intensity, abrasion resistance, corrosion resistance, long service life and low cost.

Owner:CHANGAN UNIV

Peripheral edge grinding wheel for machining PCBN (polycrystalline cubic boron nitride) blades

InactiveCN103753413AEvenly distributedUniform pore sizeBonded abrasive wheelsGrinding devicesLithium hydroxideBoron nitride

The invention discloses a peripheral edge grinding wheel for machining PCBN (polycrystalline cubic boron nitride) blades. The peripheral edge grinding wheel comprises a grinding wheel matrix and a grinding material layer. The grinding material layer is positioned on the grinding wheel matrix and is made of raw materials including, by weight, 44-65% of diamond, 22.5-40.5% of ceramic bonding agents, 0.5-10% of pore forming agents and 5-10% of phenolic resin liquid; the ceramic bonding agents are made of raw materials including, by weight, 40-60.5% of silicon dioxide, 5.5-17% of alumina, 25-35% of boric acid, 2-7% of sodium carbonate, 8-11% of lithium hydroxide and 2-6% of calcium oxide; pore forming agents are alumina hollow balls. The peripheral edge grinding wheel has the advantages of good sharpness, high grinding quality and long service life.

Owner:江苏赛扬精工科技有限责任公司

Hydrogels and hydrogel arrays made from reactive prepolymers crosslinked by [2 + 2] cycloaddition

InactiveUS20020115740A1Uniform pore sizeImprove controlThin material handlingPrepolymerPhotochemistry

Reactive prepolymers incorporating [2+2] photoreactive sites are synthesized. Upon exposure to UV light, these prepolymers undergo [2+2] cycloaddition to crosslink. When crosslinked, the reactive prepolymers form a hydrogel. Selective hydrogel formation is provided through selective exposure of the reactive prepolymer to UV light. Supports and other molecules may be attached or incorporated into the hydrogel through [2+2] cycloaddition with uncrosslinked [2+2] photoreactive sites present in the hydrogel.

Owner:GE HEALTHCARE BIO SCI CORP

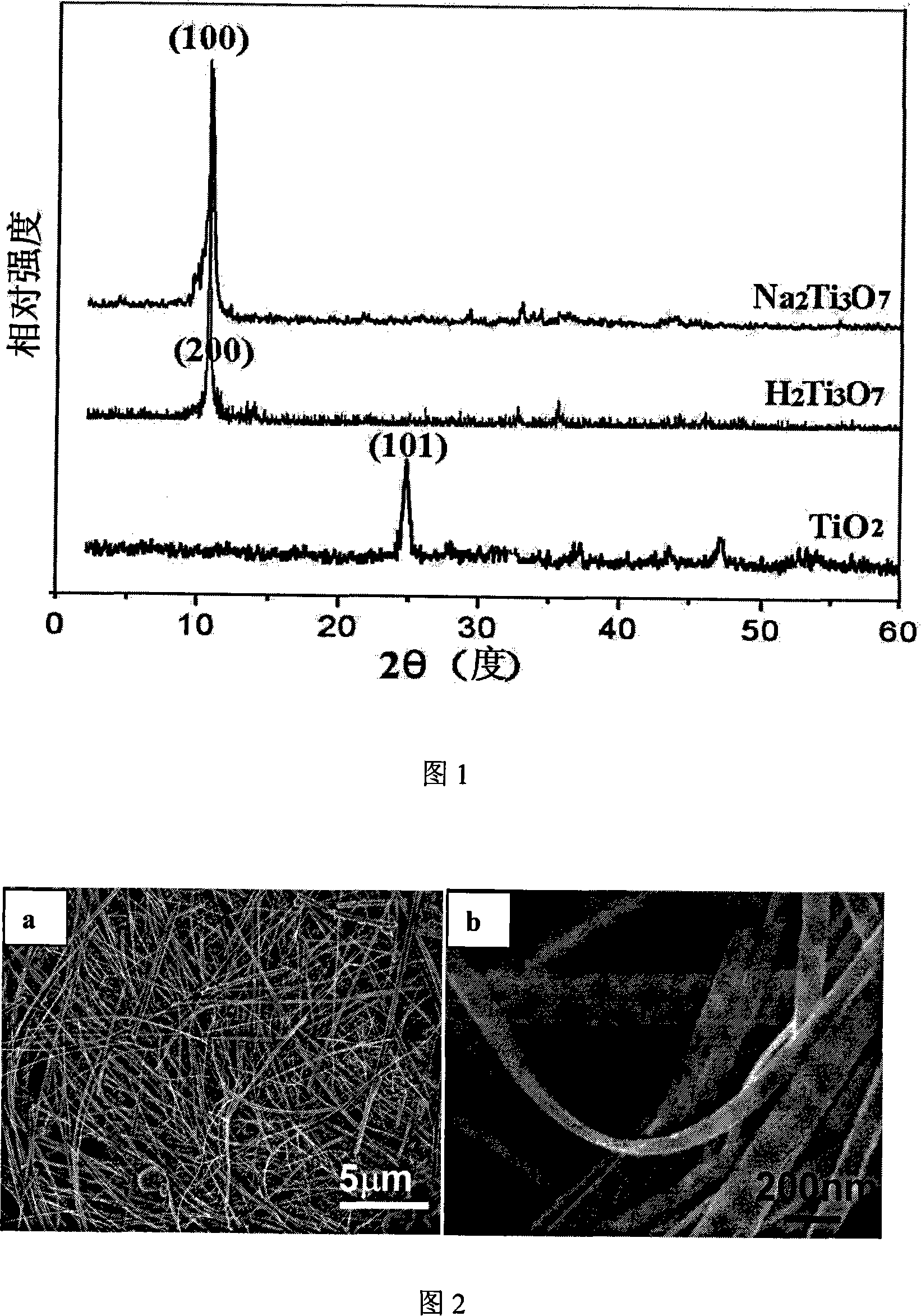

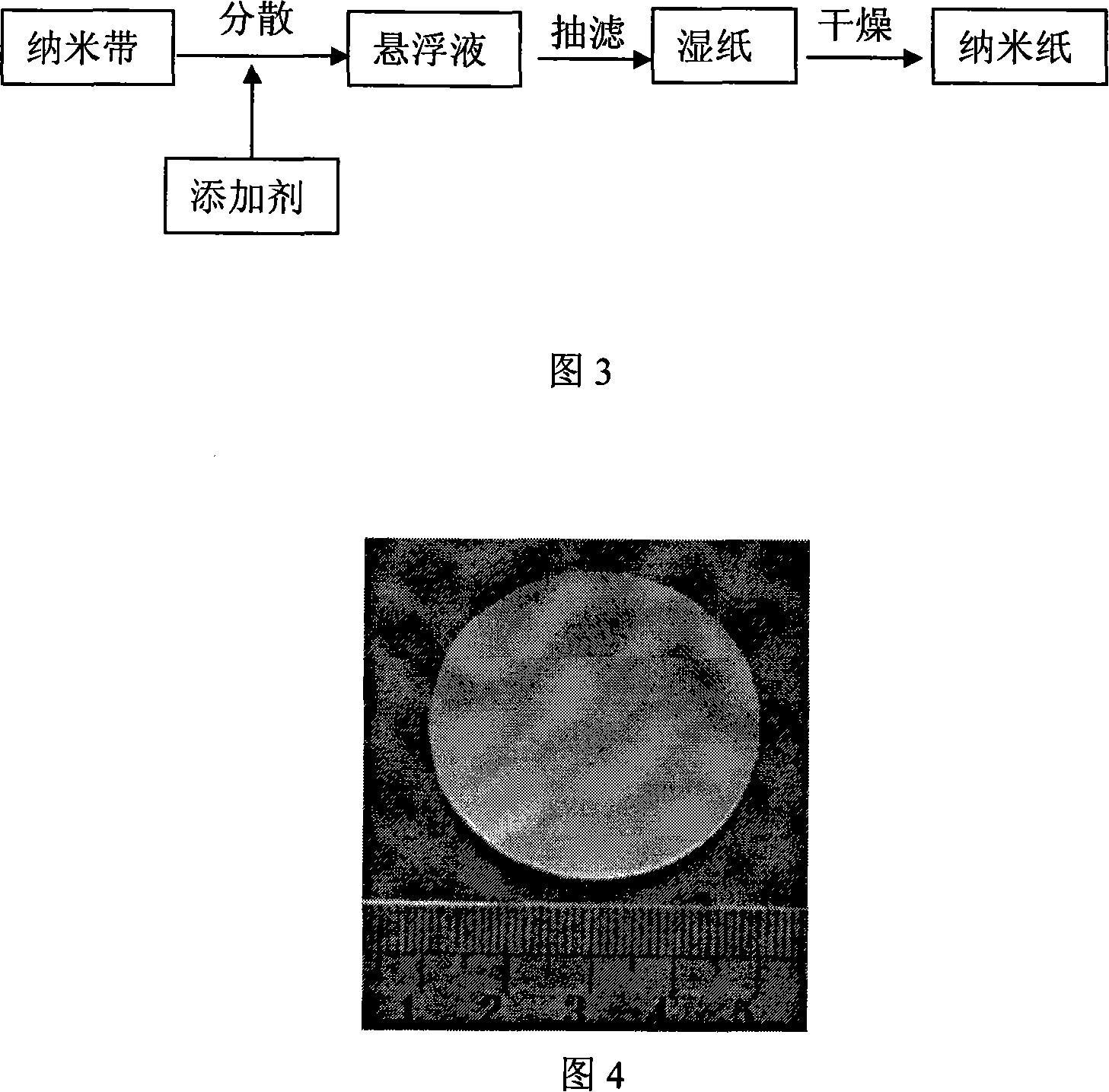

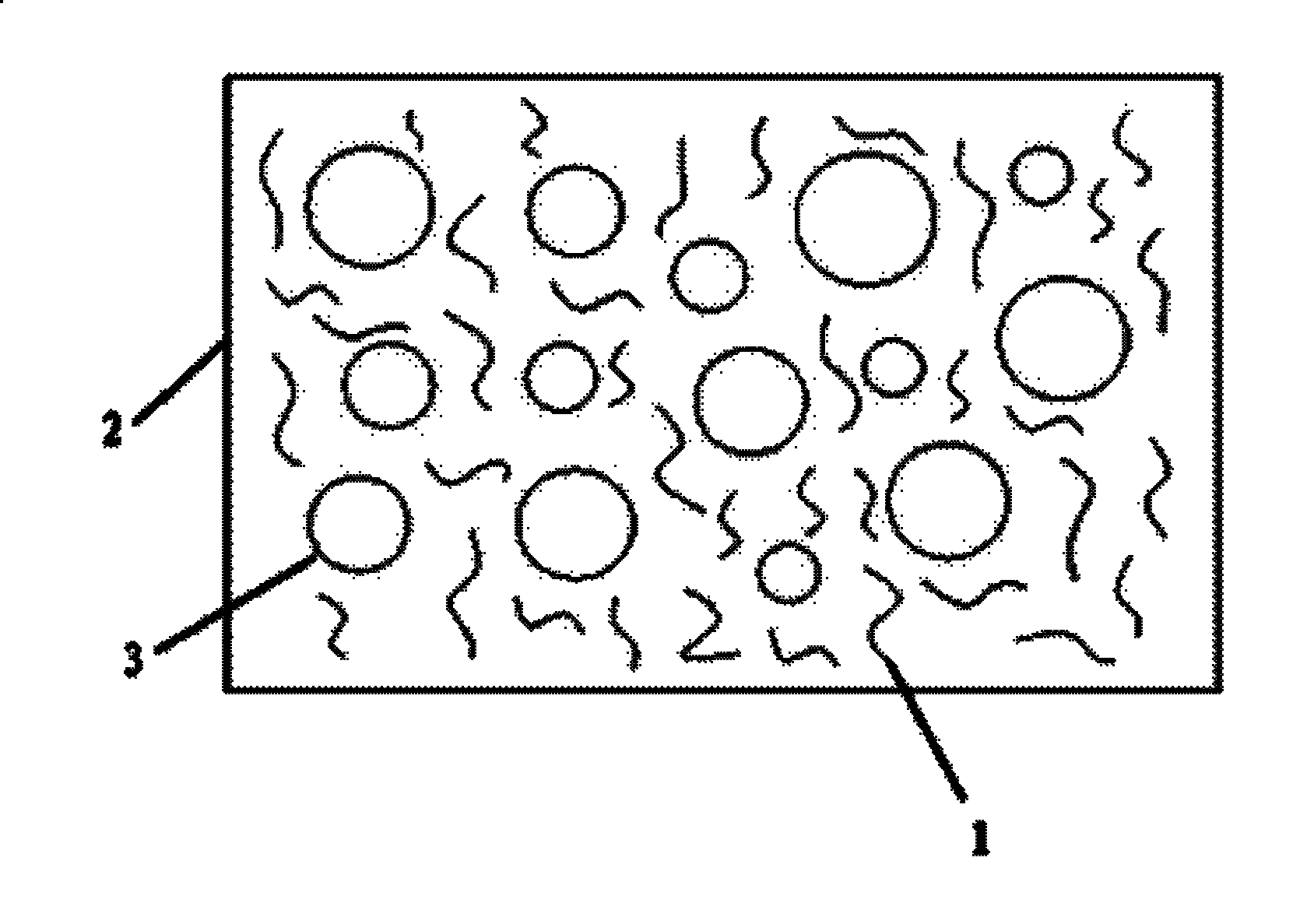

Titanium dioxide nano paper and preparation method thereof

InactiveCN101126213ALess fiberUniform pore sizeSpecial paperReinforcing agents additionPhotocatalysisTitanium dioxide

Owner:SHANDONG UNIV

Method for preparing hydrophilic porous membrane

InactiveCN101862604AStable structureUniform pore sizeSemi-permeable membranesPolymer sciencePolyvinyl alcohol

The invention provides a method for preparing a hydrophilic porous membrane. The method comprises the following steps of: preparing a polymer membrane by using a known blending modification method, wherein a membrane forming polymer is one of polyvinylidene fluoride, polysulfone, polyether sulphone, polrvinyl chloride, polyamide or polyacrylonitrile; a modification additive is one of or a mixture of more of polyvinylpyrrolidone, polyvinylpyrrolidone copolymer, polyethylene glycol, polypropylene glycol, polyvinyl alcohol, polyacrylic acid or polyelectrolyte; and then performing chemical crosslinking or radiation crosslinking treatment on the prepared polymer membrane to obtain the porous membrane with stable hydrophilicity. The prepared porous membrane has more uniform bore diameters, and the membrane flux is higher than that of the unprocessed membrane by 2 to 10 times.

Owner:XIAMEN LEEBAM MEMBRANE TECH

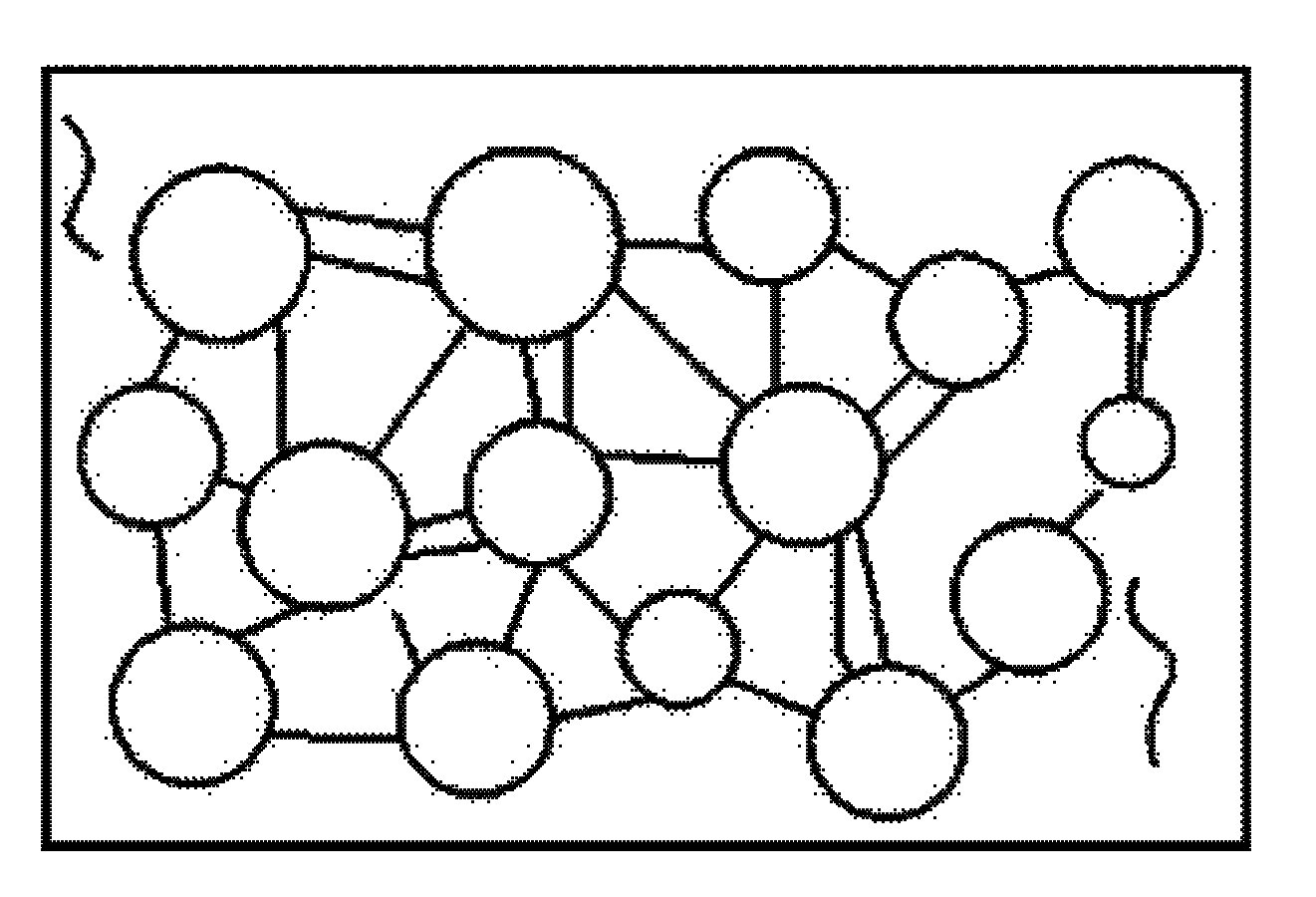

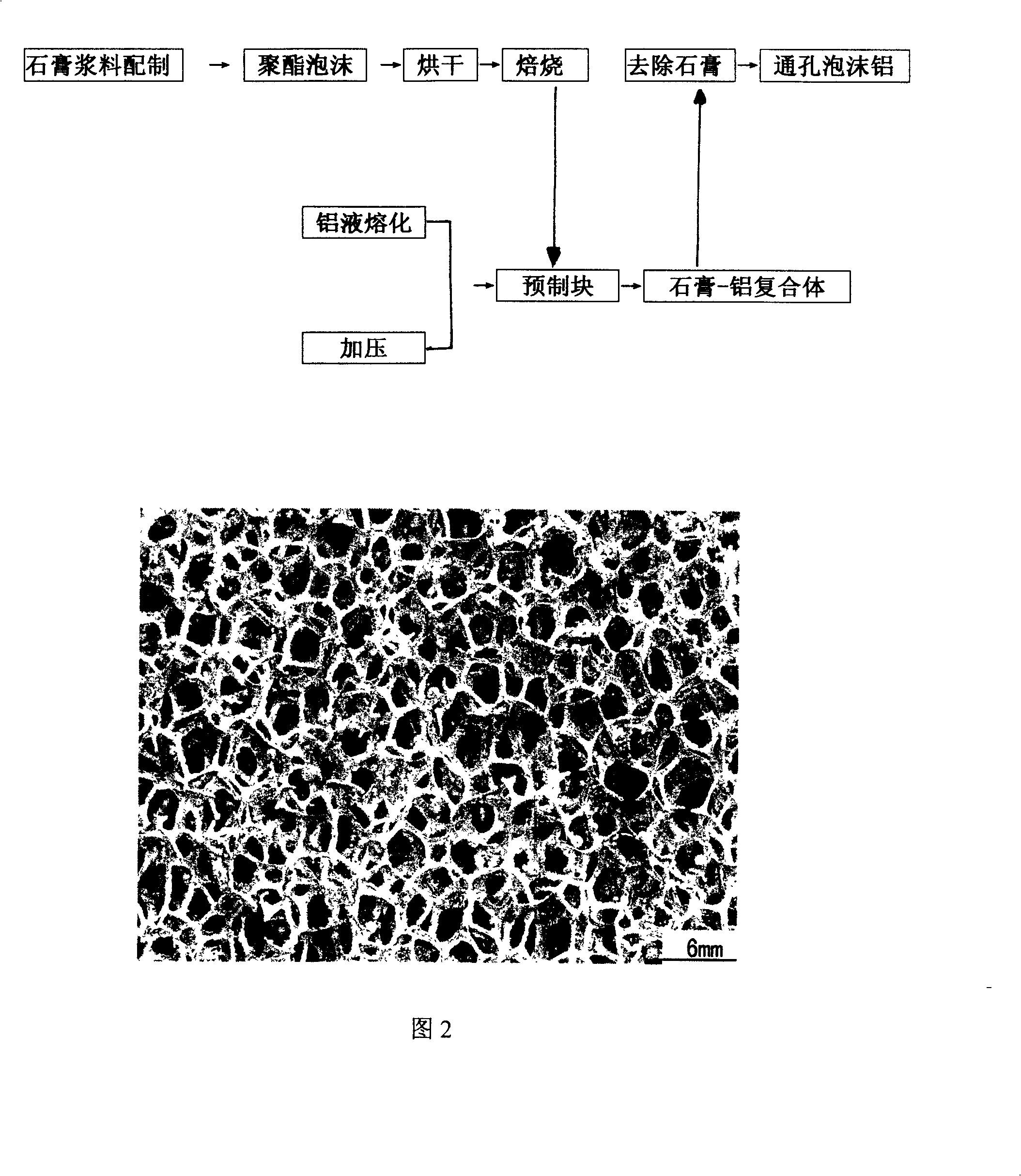

Method for preparing through-hole foamed metal of high factor of porosity

The invention discloses a process for preparing high porosity through hole foamed metal, which is characterized in that: the process selects a material with a foam structure as a parent material, the parent material is provided with three-dimensional through holes which are then filled with powdery slurries dissolvable in water or other solvents, the slurries are dried and hardened to form a prefabricated model, then the parent material is gasified and decomposed after calcinations, then the prefabricated model is positioned in a mold and poured with liquid metal, the liquid metal is filled in the holes of the prefabricated model, powder materials in a forming block are dissolved and removed after cooling, thereby the foamed metal of three-dimensional network through holes is obtained. The foamed aluminum gained in the invention has a three-dimensional network structure with holes communicated with one another, and the porosity and aperture can be adjusted in the range of between 80 percent and 98 percent and between 0.5 and 5mm respectively.

Owner:INST OF SOLID PHYSICS ACAD SINICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Hydrogels and hydrogel arrays made from reactive prepolymers crosslinked by [2 + 2] cycloaddition Hydrogels and hydrogel arrays made from reactive prepolymers crosslinked by [2 + 2] cycloaddition](https://images-eureka.patsnap.com/patent_img/84476dcb-3f78-4fc6-82cf-657b7a3ecb4b/US20020115740A1-20020822-C00001.png)

![Hydrogels and hydrogel arrays made from reactive prepolymers crosslinked by [2 + 2] cycloaddition Hydrogels and hydrogel arrays made from reactive prepolymers crosslinked by [2 + 2] cycloaddition](https://images-eureka.patsnap.com/patent_img/84476dcb-3f78-4fc6-82cf-657b7a3ecb4b/US20020115740A1-20020822-C00002.png)

![Hydrogels and hydrogel arrays made from reactive prepolymers crosslinked by [2 + 2] cycloaddition Hydrogels and hydrogel arrays made from reactive prepolymers crosslinked by [2 + 2] cycloaddition](https://images-eureka.patsnap.com/patent_img/84476dcb-3f78-4fc6-82cf-657b7a3ecb4b/US20020115740A1-20020822-C00003.png)