Patents

Literature

430results about How to "Appropriate viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Topical composition

ActiveUS20080234239A1Improve solubilityImprove permeabilityOrganic active ingredientsBiocideChemical compositionDermatology

A composition suitable for topical application comprising a continuous phase and at least one discontinuous phase, said composition comprising at least one polyaphron dispersion, at least one vitamin D or vitamin D analogue and at least one corticosteroid.

Owner:MC2 THERAPEUTICS LTD

Personal care article for sequentially dispensing compositions with distinct fragrance characters

InactiveUS20090029900A1High viscosityAppropriate viscosityCosmetic preparationsToilet preparationsFlavorProximate

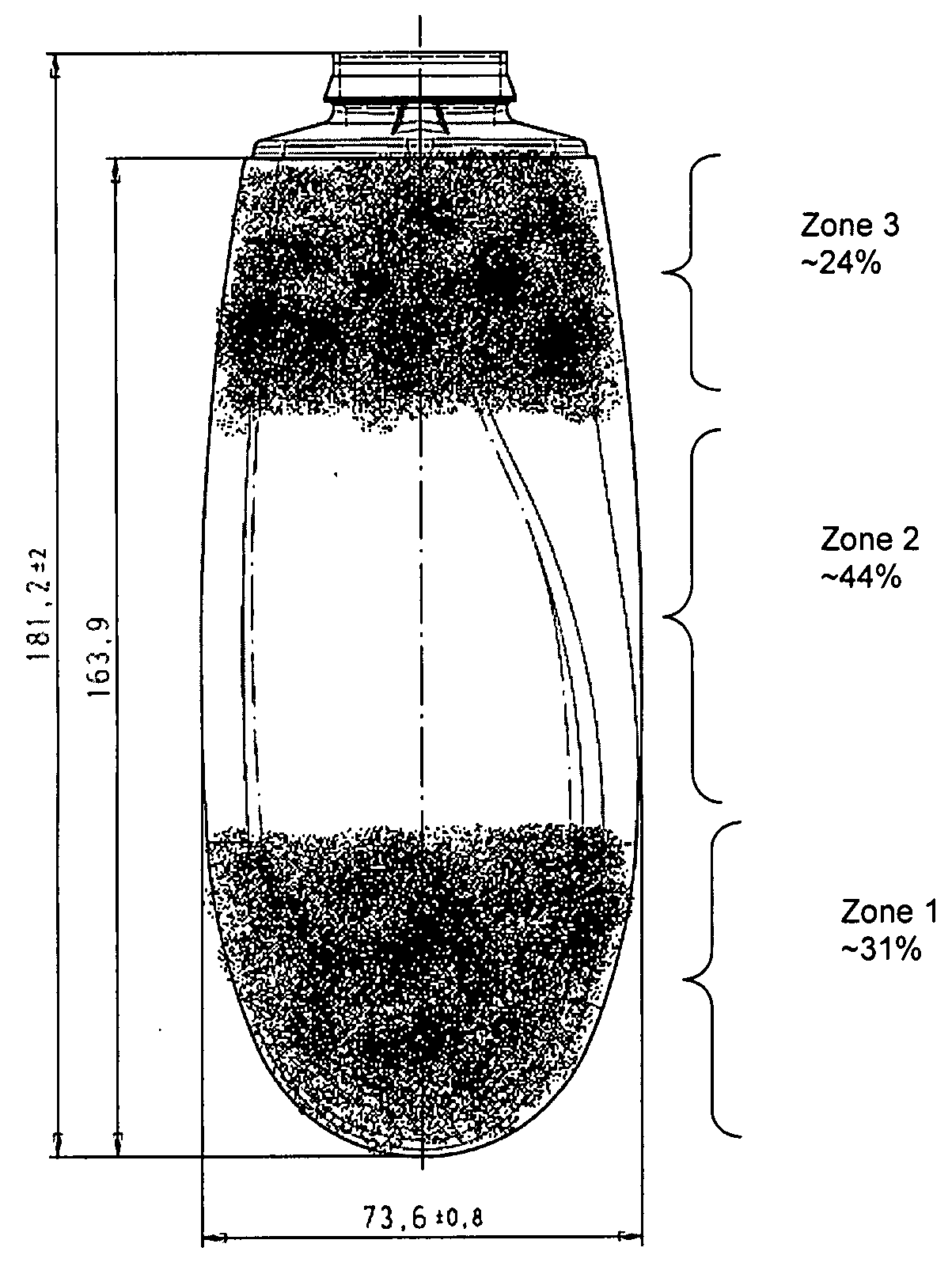

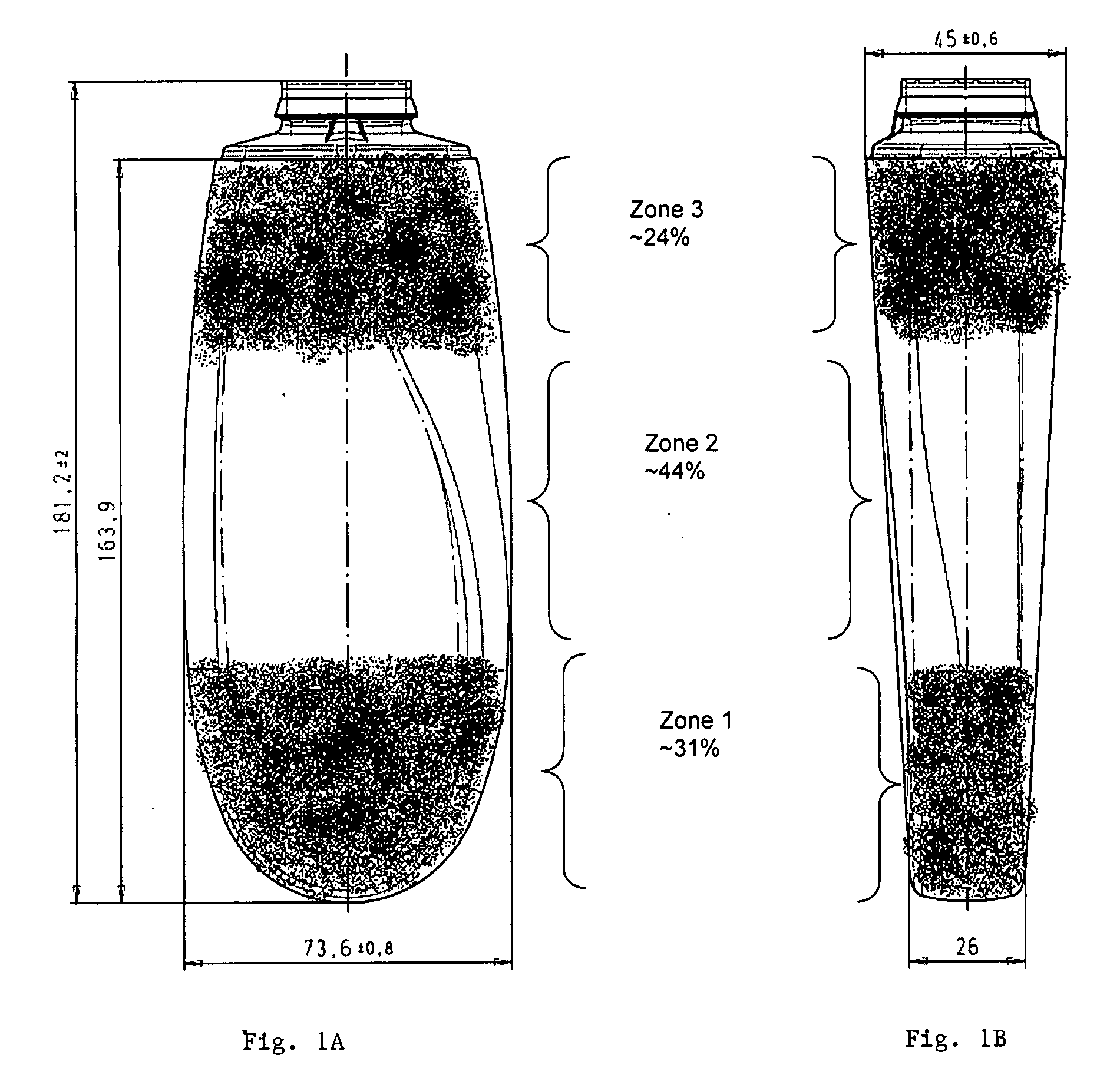

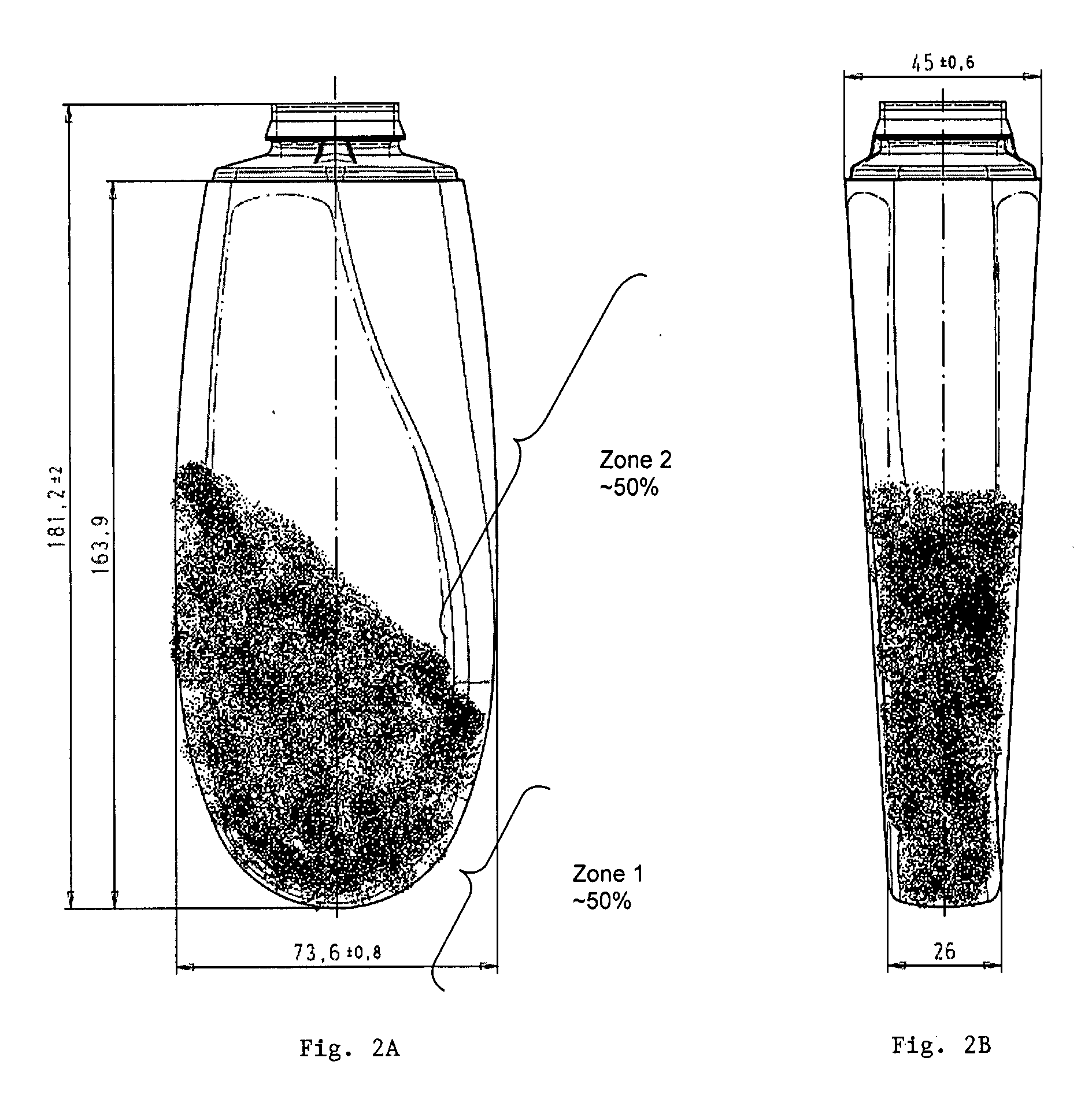

The present invention relates to a personal care article that comprises a single chamber package and a liquid personal care product. The package comprises a dispensing orifice, a first zone proximate to the dispensing orifice and a second zone distal to the dispensing orifice. The liquid personal care product comprises a first personal care composition substantially disposed within the first zone and the second personal care composition substantially disposed within the second zone. The first composition comprises a first fragrance character and the second composition comprises a second fragrance character; wherein the first fragrance character is distinct from the second fragrance character.

Owner:THE PROCTER & GAMBLE COMPANY

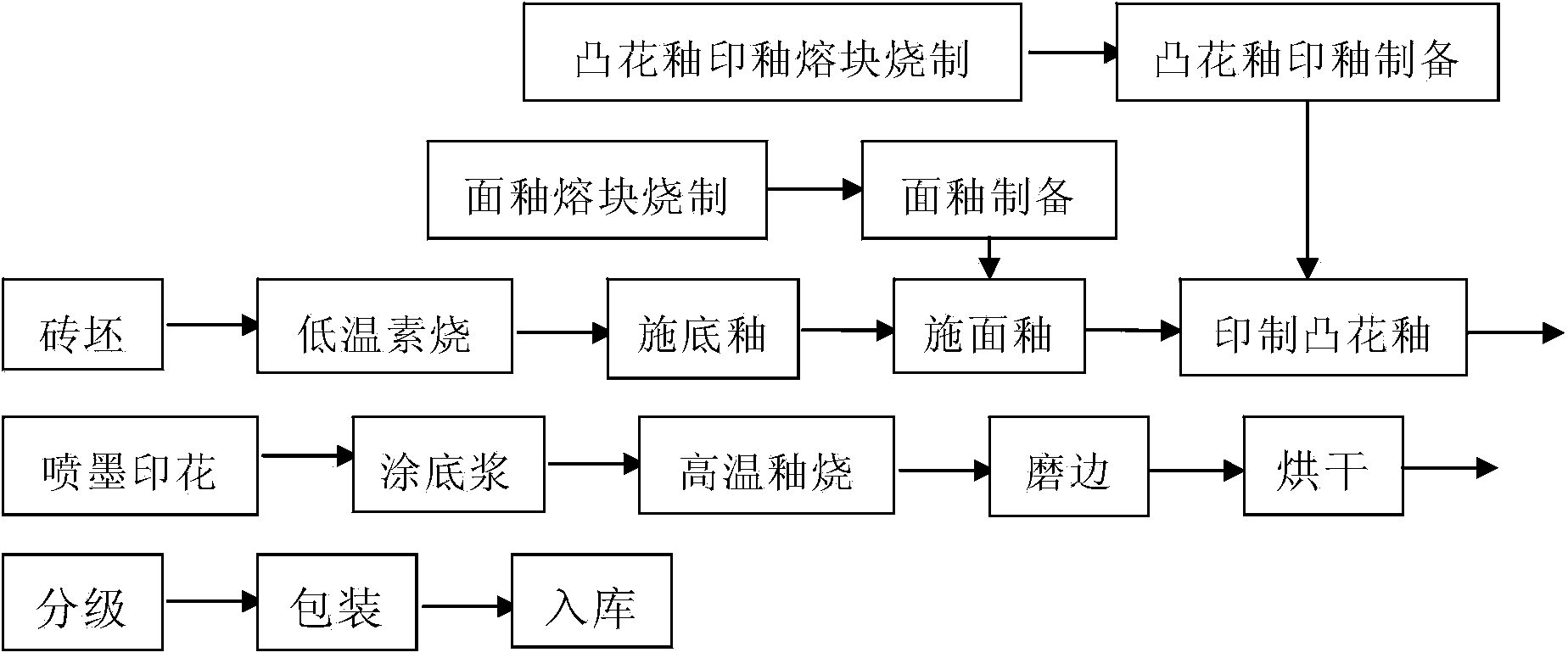

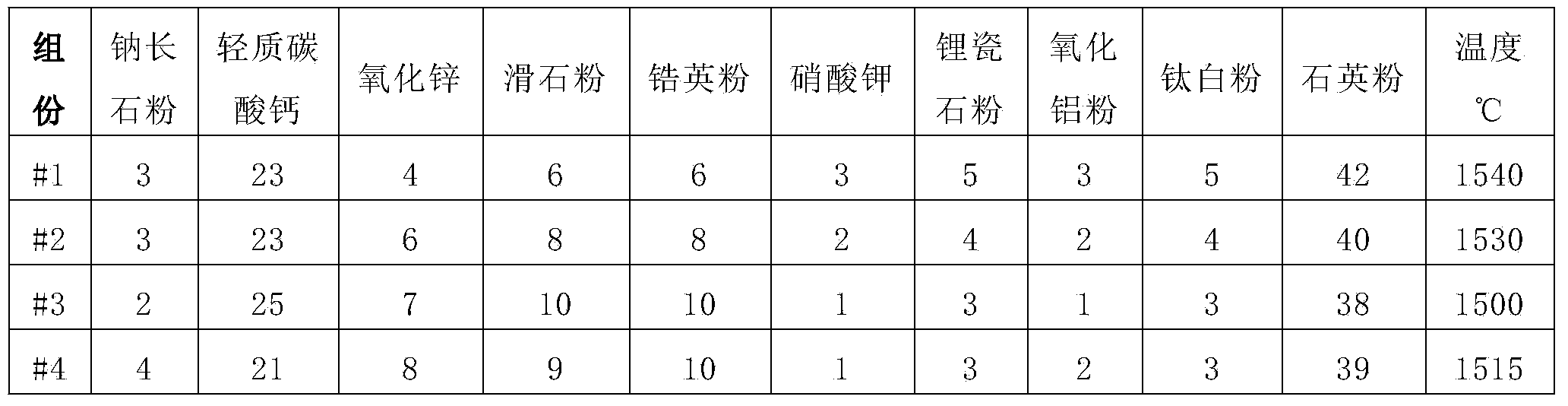

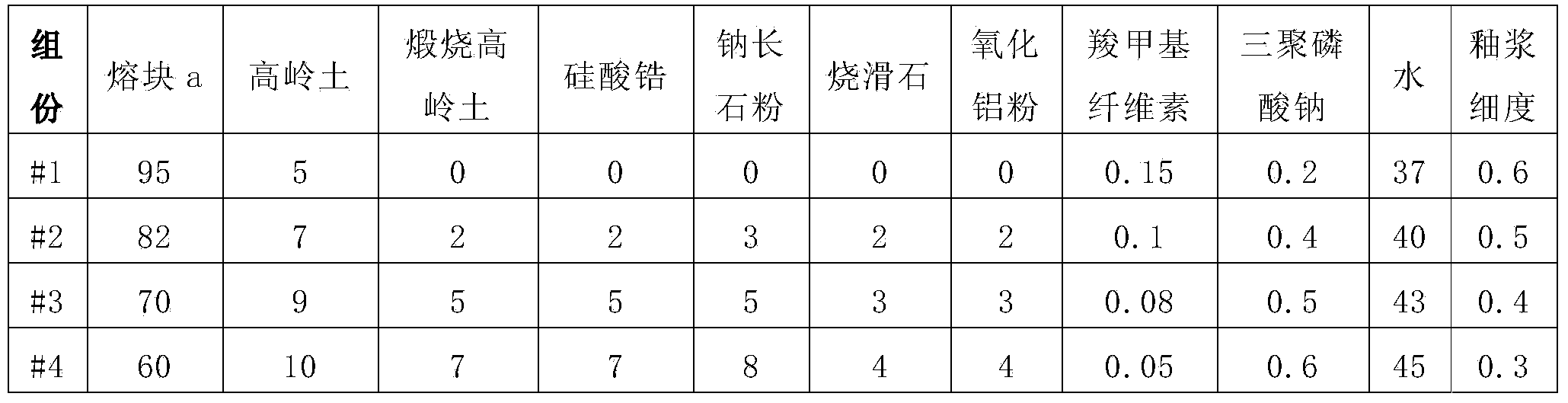

Glazed tile with wallpaper or bark-shaped surface and concave and convex effect and preparation method

The invention discloses glazed tile with wallpaper or bark-shaped surface and concave and convex effect and a preparation method. According to the invention, a product which is a glazed tile with wallpaper or bark-shaped surface and concave and convex effect is obtained by optimizing the composition of an overglaze frit and an overglaze formula, as well as the composition of a convex fancy glaze printed glaze frit and a convex fancy glaze printed glaze formula, printing the convex fancy glaze printed glaze on a green body coated with underglaze and overglaze through a special rubber roller or screen printing plate, and then enabling patterns of convex fancy glaze to keep original printing appearance after being fired at a high temperature and protrude on the surface of inkjet patterns through inkjet printing and high-temperature firing. Further, by mixing with optimized ceramic rubber roller printing ink, through the special rubber roller with optimized design or the screen printing plate with optimized mesh count, the surface gloss of the obtained glazed tile with wallpaper or bark-shaped surface and concave and convex effect is 15-40, the convex fancy glaze has good performance, the protruding height is greater than or equal to 0.8mm, and the convex fancy glaze does not adsorb pollution, so that the decorative patterns formed by inkjet printing are not damaged, and the disadvantage of single decoration style of an existing glazed tile is overcome.

Owner:GUANGDONG WINTO CERAMICS +3

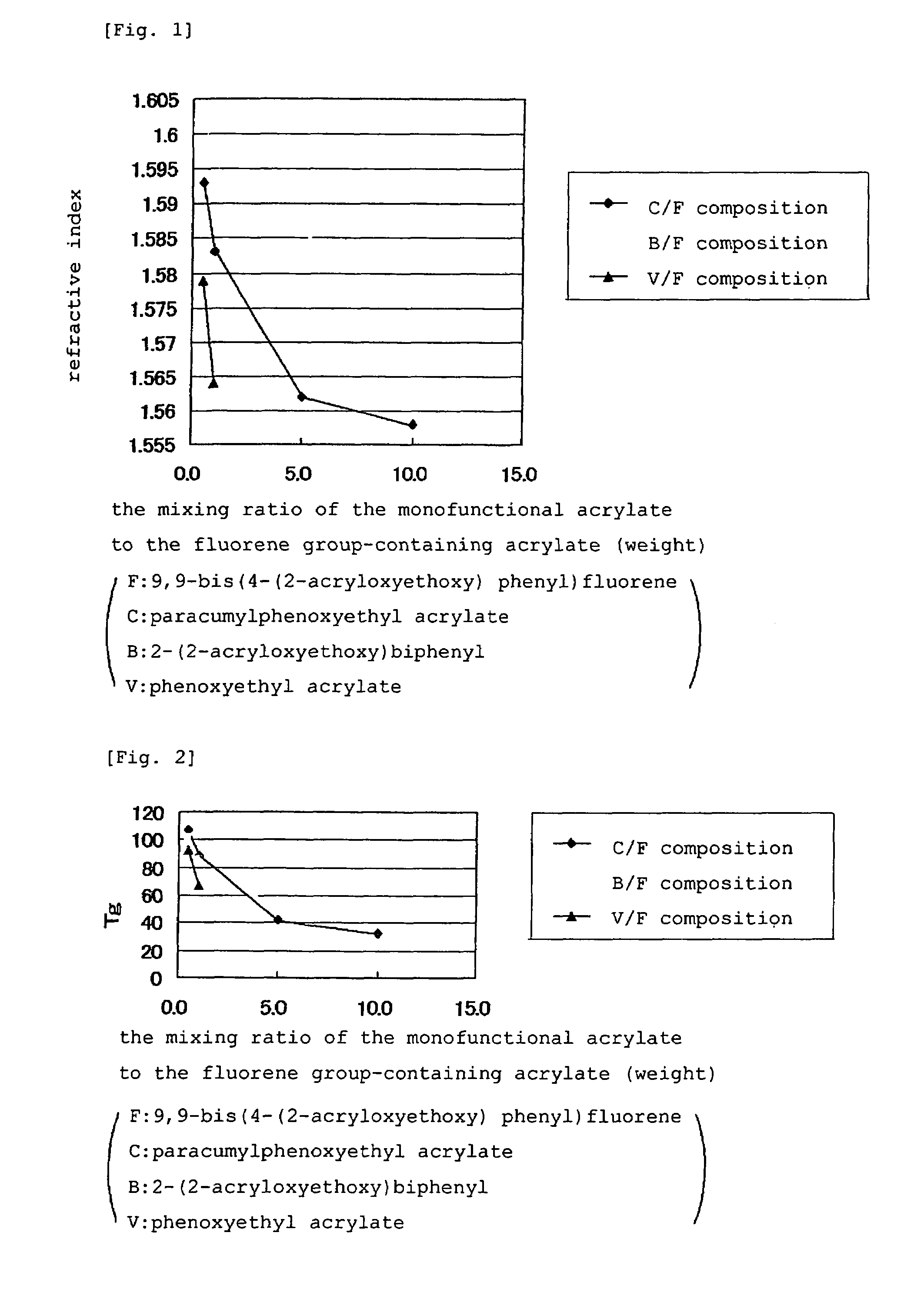

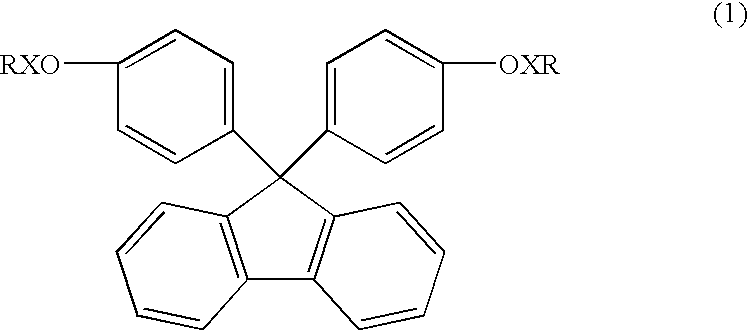

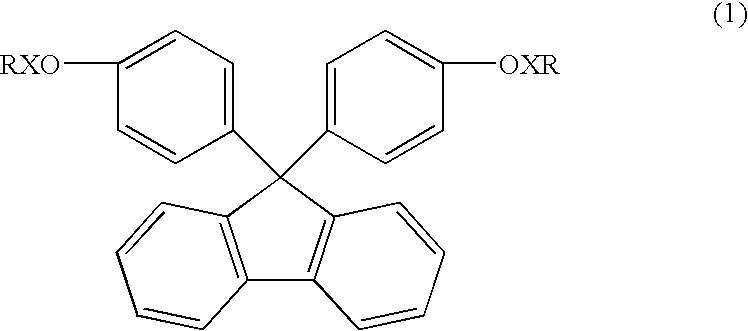

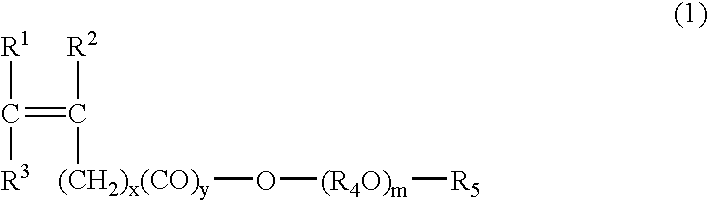

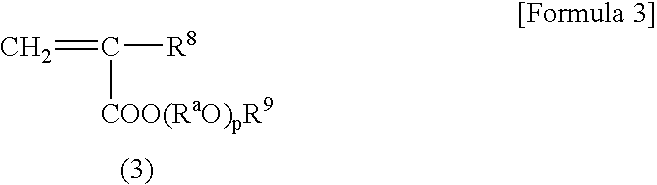

Curable resin composition

A resin composition having a viscosity suitable for encapsulating optical devices such as light-emitting devices is provided. Specifically, the cured product of the resin composition has a refractive index greater than or equal to that of epoxy resins, exhibits excellent heat resistance and light resistance, and has thermal stress relaxation properties. The curable resin composition contains a fluorene group-containing acrylate or methacrylate represented by the following formula and a specific monofunctional acrylate or methacrylate:wherein X is —(CH2CH2O)n— or —(CH2CH2O)—CH2CH(OH)CH2O— with n being 1 to 5 and R is an acrylic or methacrylic group.

Owner:SONY CORP +1

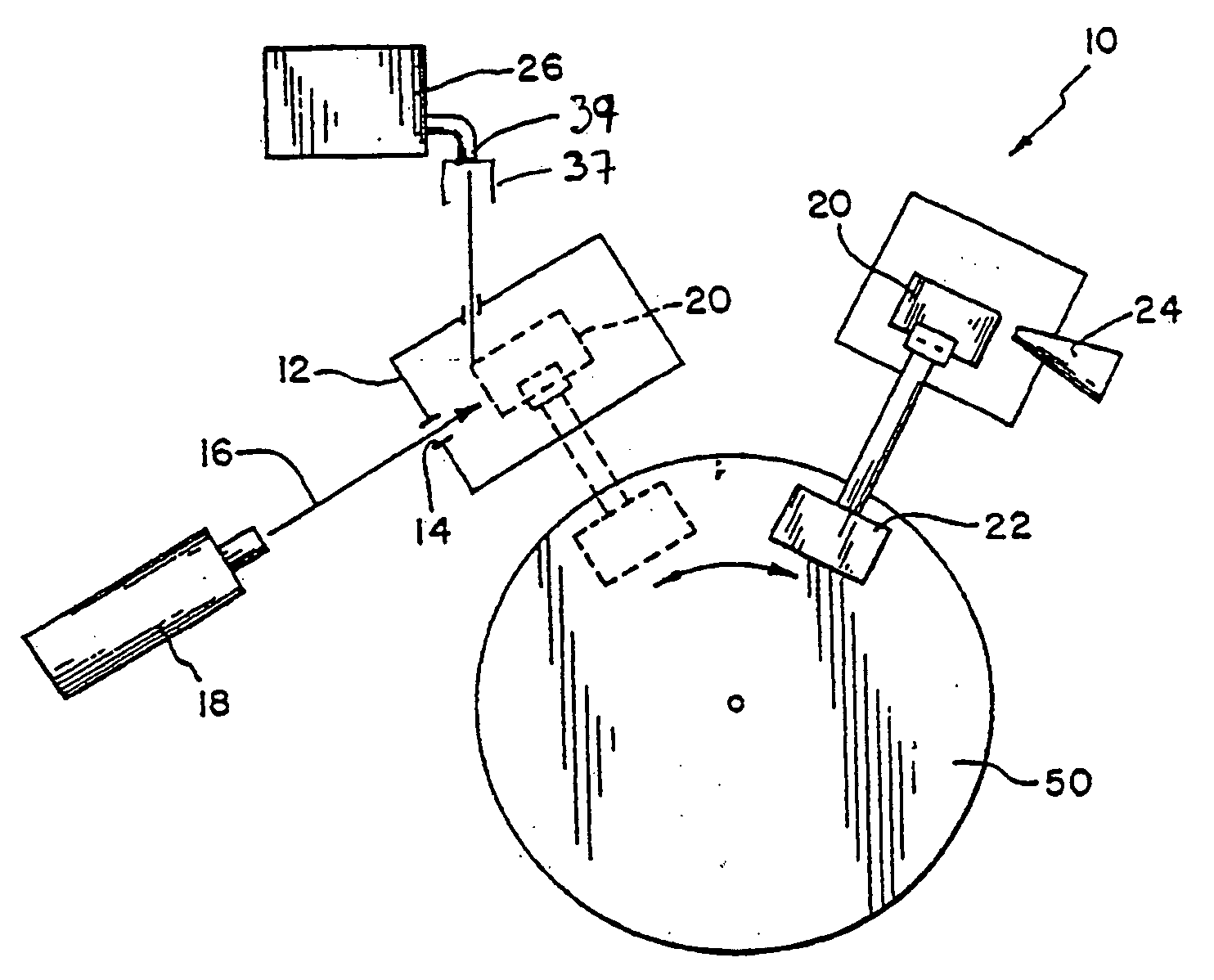

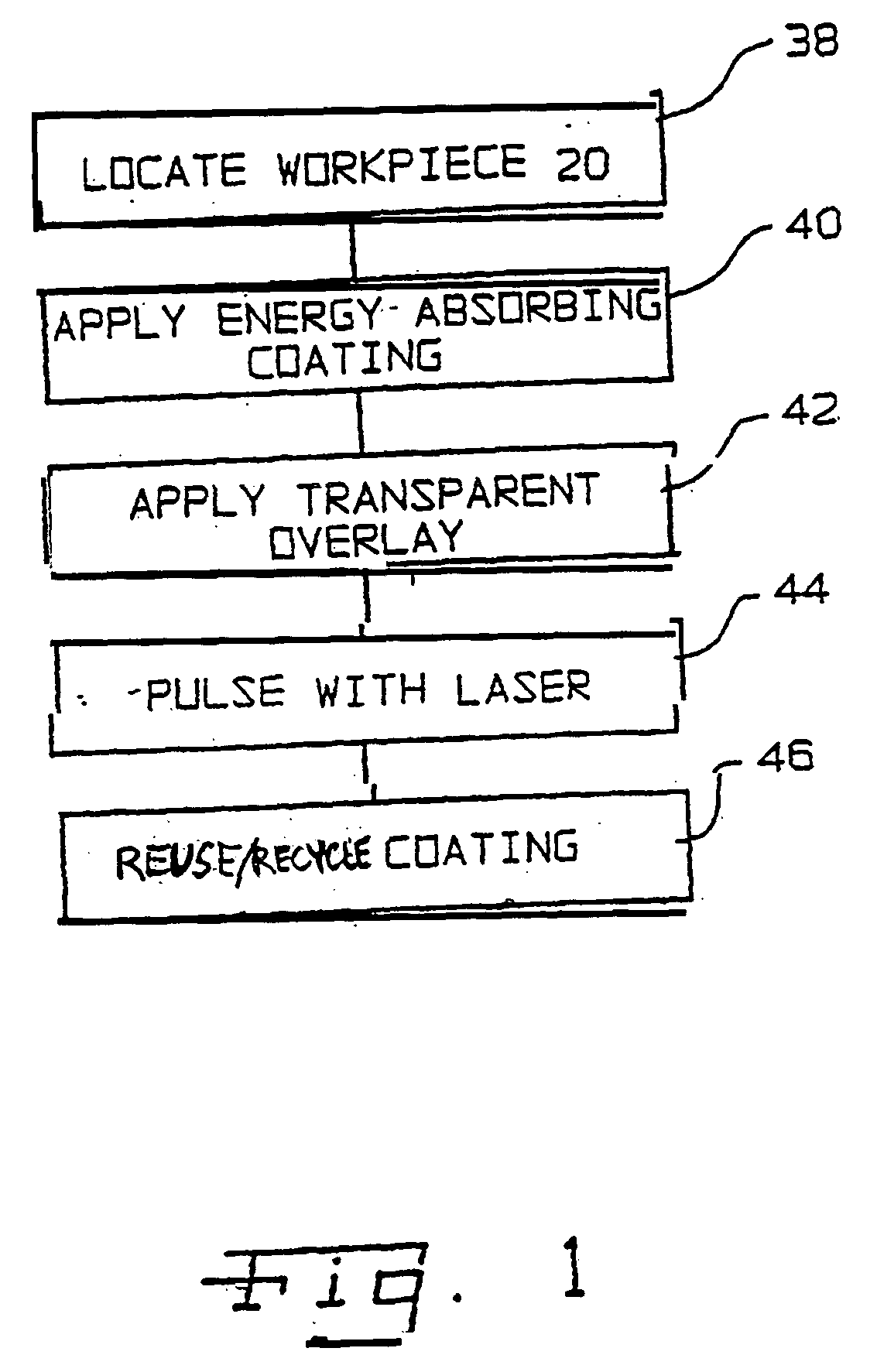

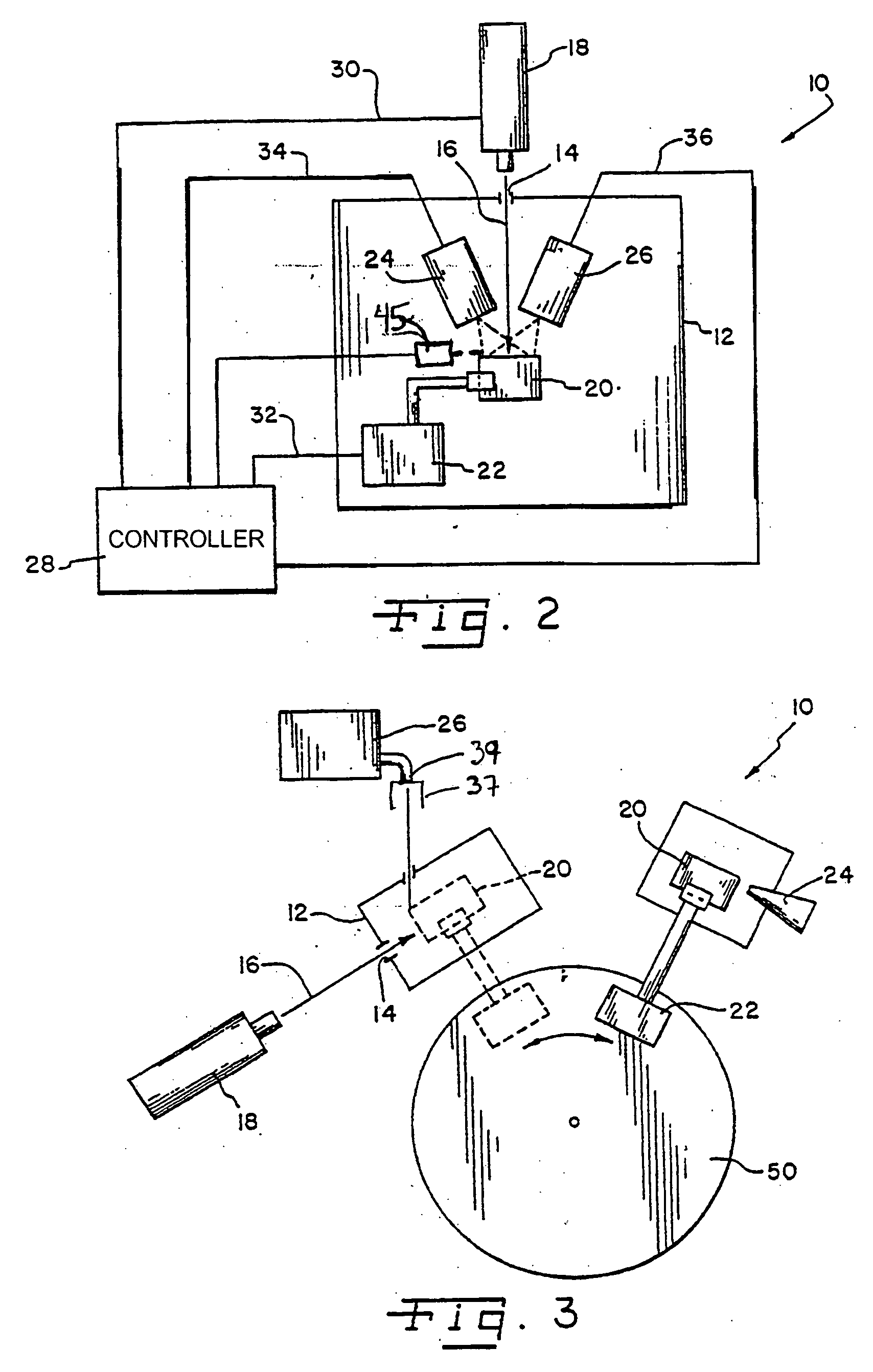

Laser peening process and apparatus using a liquid erosion-resistant opaque overlay coating

InactiveUS20050045607A1Allow useIncrease displacementLaser beam welding apparatusDissolutionLaser peening

The invention relates to a method and apparatus for improving properties of a solid material by providing shockwaves there through. Laser shock processing is used to provide the shockwaves. The method includes applying a liquid energy-absorbing overlay, which is resistant to erosion and dissolution by the transparent water overlay and which is resistant to drying to a portion of the surface of the solid material and then applying a transparent overlay to the coated portion of the solid material. A pulse of coherent laser energy is directed to the coated portion of the solid material to create a shockwave. Advantageously, at least a portion of the unspent energy-absorbing overlay can be reused in situ at a further laser treatment location and / or recovered for later use.

Owner:LSP TECH INC

Method for preparing porous ceramic filter membrane by low-temperature sintering

InactiveCN104587846AImprove stabilityAppropriate viscositySemi-permeable membranesVacuum pressureHigh intensity

The invention discloses a method for preparing a porous ceramic filter membrane by low-temperature sintering. The method comprises the following steps: mixing and stirring ceramic aggregate particles, a sintering aid, deionized water, a dispersant and a defoamer, then carrying out vacuum pressure maintaining to remove a gas in the obtained filter membrane layer slurry; soaking a support body material in the filter membrane layer slurry, then obtaining a membrane layer on the support material by a pulling method, and then sintering at 700-1070 DEG C to obtain the porous ceramic filter membrane. According to the method, the porous ceramic membrane product which is high in strength, resistant to wear and corrosion, long in life and low in cost is obtained by optimally proportioning the sintering aid, the dispersant and the defoamer, preparing the ceramic membrane layer slurry system with high stability and proper viscosity, regulating the pulling method of the ceramic support body with a high porosity and a large hole diameter in the prefabricated membrane layer slurry system, thereby obtaining a uniform and asymmetrical porous ceramic membrane blank on the whole surface of a specified position of the support body material, and finally drying stage by stage and rapidly sintering at a low temperature of 1100 DEG C so as to obtain a porous ceramic filter membrane product with high intensity, abrasion resistance, corrosion resistance, long service life and low cost.

Owner:CHANGAN UNIV

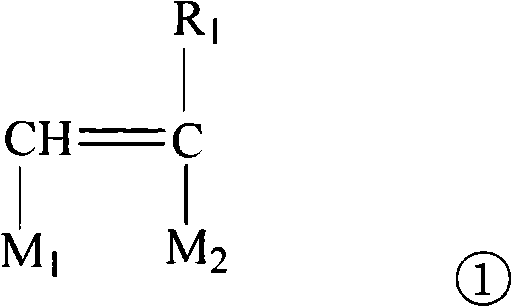

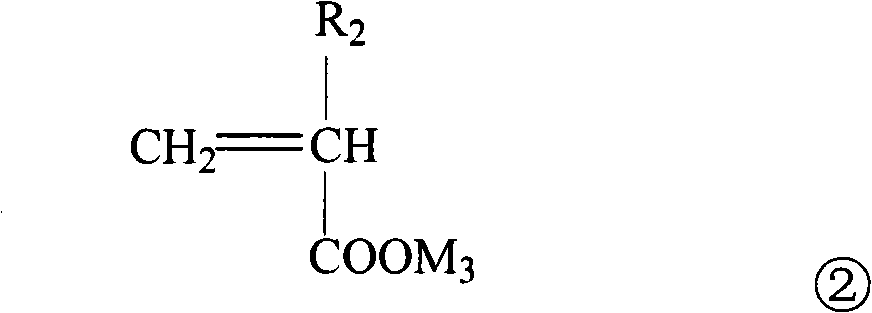

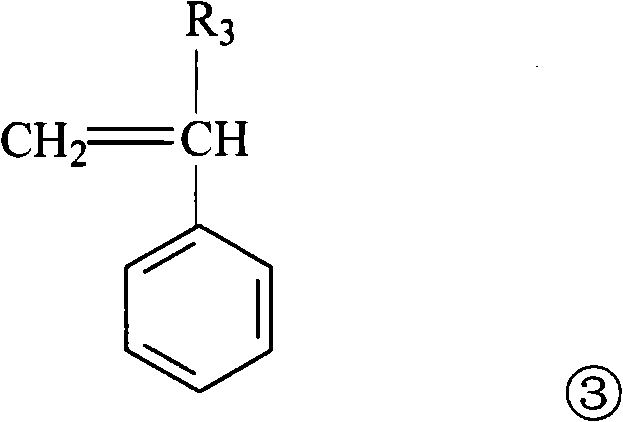

Method for preparing aqueous polyurethane-acrylate composite emulsion

The invention discloses a method for preparing aqueous polyurethane-acrylate composite emulsion. The method comprises the following steps of: synthesizing aqueous polyurethane prepolymer by using dihydric alcohol polymer, diisocyanate and hydrophilic chain extender in the absence of a metal catalyst and an organic solvent, blocking ends of the prepolymer by using a vinyl compound, then neutralizing the polymer, dripping water into the polymer to perform self-emulsification, extending the chain to obtain aqueous polyurethane dispersion, and dripping initiator dissolved acrylate monomer into the dispersion in the absence of additional emulsifier to perform polymerization so as to obtain the aqueous polyurethane-acrylate composite emulsion with high solid content. The solid content of the composite emulsion is over 45 percent; and the preparation process does not use any solvent or metal catalyst, has no pollutant discharge, and is a pollution-free production process. The obtained environmentally-friendly aqueous polyurethane-acrylate composite emulsion with high solid content can be used as adhesive, coating and the like.

Owner:GUANGDONG RITOP FINE CHEM

Aluminum soldering paste

InactiveCN102764938AEasy to apply and adhereAppropriate viscosityWelding/cutting media/materialsSoldering mediaOrganic solventSolder paste

The invention discloses an aluminum-based alloy soldering paste suitable for an aluminum-stainless steel and aluminum-aluminum alloy soldering connection batch production technology aiming at the requirement of high-efficiency soldering technology. The soldering paste consists of the following components by weight percent: 1) 50-65% of aluminum-based alloy soldering material powder, 2) 10-25% of fluoroaluminate soldering flux, 3) 3-10% of tackifier, 4) 2-10% of thickening agent, 5) 10-30% of organic solvent, and 6) 0.05-0.50% of stabilizing agent. The soldering paste provided by the invention has moderate viscosity and soldering flux which is in accurate proportion, and is extremely suitable for workpieces with irregular weld joint shapes and complex structures; the soldering paste can be very simply and conveniently coated on the part of a welding element, which is required for soldering joint; working procedures such as auxiliary positioning, soldering flux coating and brushing are not required like plate-shaped or silk-shaped soldering materials; the soldering production technology is simplified; the labor cost is lowered; and the product quality and production efficiency are improved.

Owner:江门市盈盛焊接材料科技有限公司

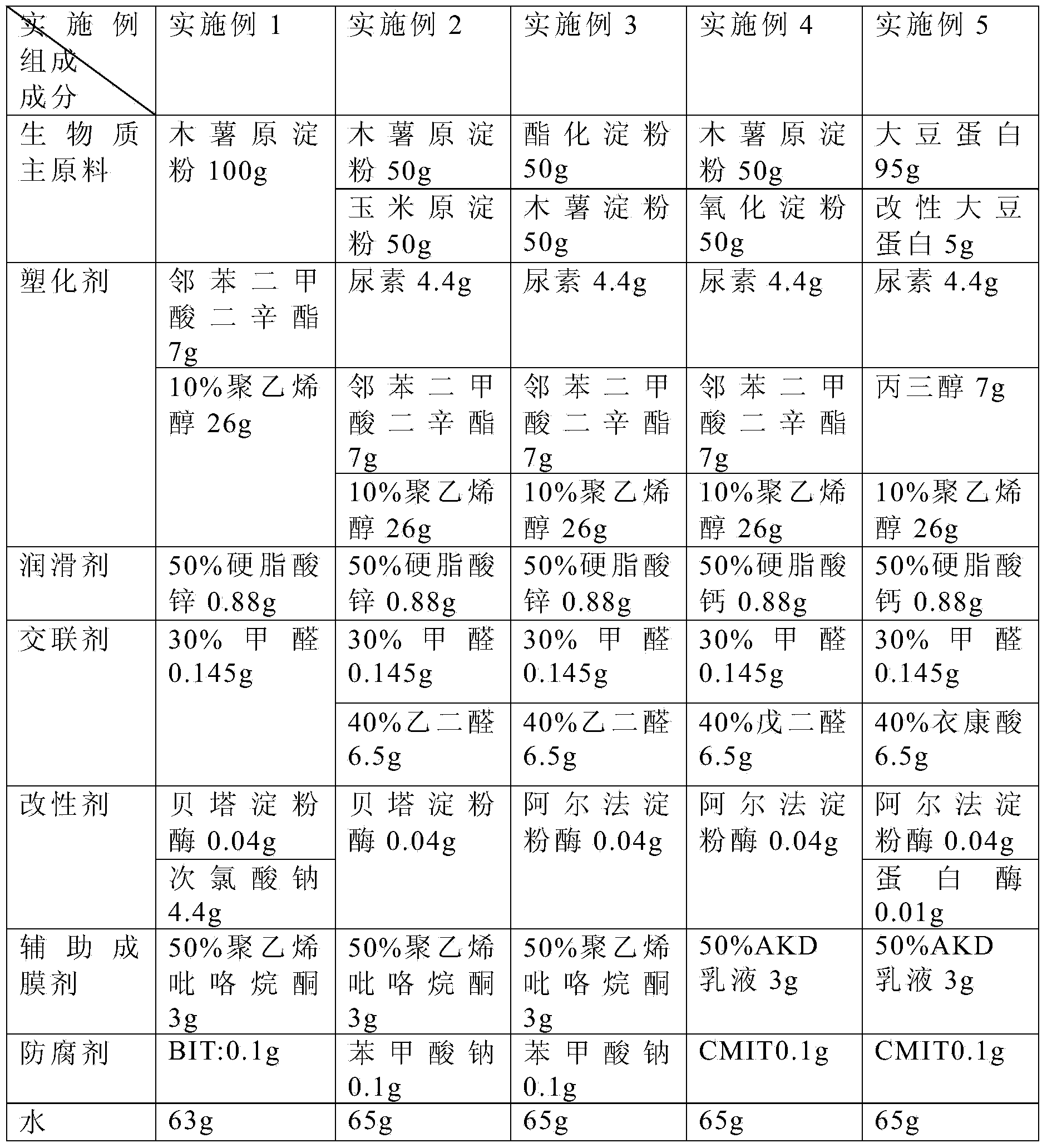

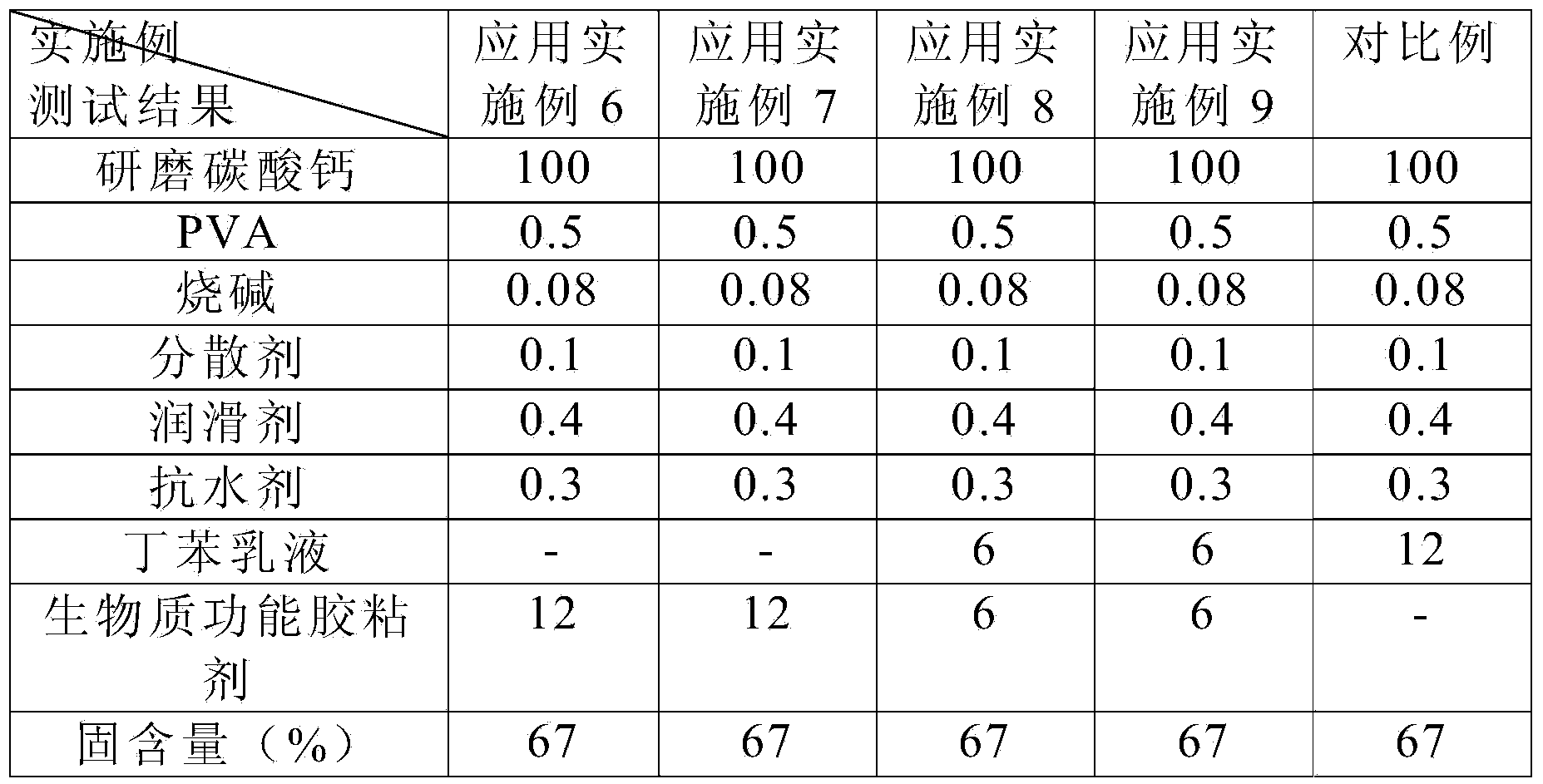

Starch based biomass functional adhesive and preparation method thereof

InactiveCN104164199AReduce manufacturing costHigh economic valueNon-macromolecular adhesive additivesProtein adhesivesAdhesivePlasticizer

The invention relates to a starch based biomass functional adhesive and a preparation method thereof, and is particularly applied to the field of papermaking. The biomass functional adhesive comprises the following components: 30-45% of a biomass main raw material, 5.5-22.5% of a plasticizer, 0.55-3.5% of a lubricant, 0.55-5.5% of a crosslinking agent, 0.01-5.5% of a modifier, 0.55-5.5% of an auxiliary film-forming agent, 0.1-0.55% of a preservative, 0.01-5.5% of a pH regulator and the balance of water. The preparation method is as follows: adding the biomass main raw material, the modifier and the water into a reaction kettle, heating to 60 to 100 DEG C for reaction; performing digestive treatment; adding the lubricant, the plasticizer and the crosslinking agent for reaction at 60 to 90 DEG C, then adding the preservative, adding the pH regulator and the auxiliary film-forming agent, mixing, discharging and filtering to obtain the biomass functional adhesive. The biomass functional adhesive has low cost and excellent adhesive performance.

Owner:NINGBO JIAHUA NEW MATERIAL TECH CO LTD

Oil base and external preparation containing same

ActiveUS20070269470A1Appropriate hardnessAppropriate spreadabilityCosmetic preparationsBiocideGlycerolHydroxystearic Acid

[Problems to be Solved] To provide an oil base having appropriate hardness and viscosity and excellent spreadability, a process for producing same, and a cosmetic material containing the oil base [Solution means] The oil base of the present invention is an oil base containing an ester condensate obtained by a reaction between polyglycerol, 12-hydroxystearic acid, and hydrogenated dimer acid, the oil base having a three-dimensional network structure in which hydrogenated dimer acid is condensed with a hydroxyl group of each of the polyglycerol and 12-hydroxystearic acid.

Owner:KOKYU ALCOHOL KOGYO

Method for preparing polymer ceramic dispersants

InactiveCN101274242AAppropriate viscosityImprove liquidityTransportation and packagingMixingPolymer sciencePolyethylene glycol

The invention discloses a preparation method of a polymer ceramic dispersant, which is characterized in that polyethylene glycol and maleic anhydride are uniformly mixed and polymerized to obtain a semi-esterification product; the semi-esterification product, vinyl monomer and water are uniformly mixed to carry out free radical polymerization under the inducement of initiating agent so as to obtain the polymer ceramic dispersant. The product prepared by adopting the invention has excellent dispersion dilution effect and grinding-aid effect on the ceramic slurry, improves the billet strength and the billet yield, thus reducing the production cost; meanwhile, the indexes such as the density and the folding resistance strength, etc. of the ceramic product are greatly reinforced. Furthermore, the product can be also used for the dispersion of dye and coating, etc.

Owner:SHAANXI UNIV OF SCI & TECH

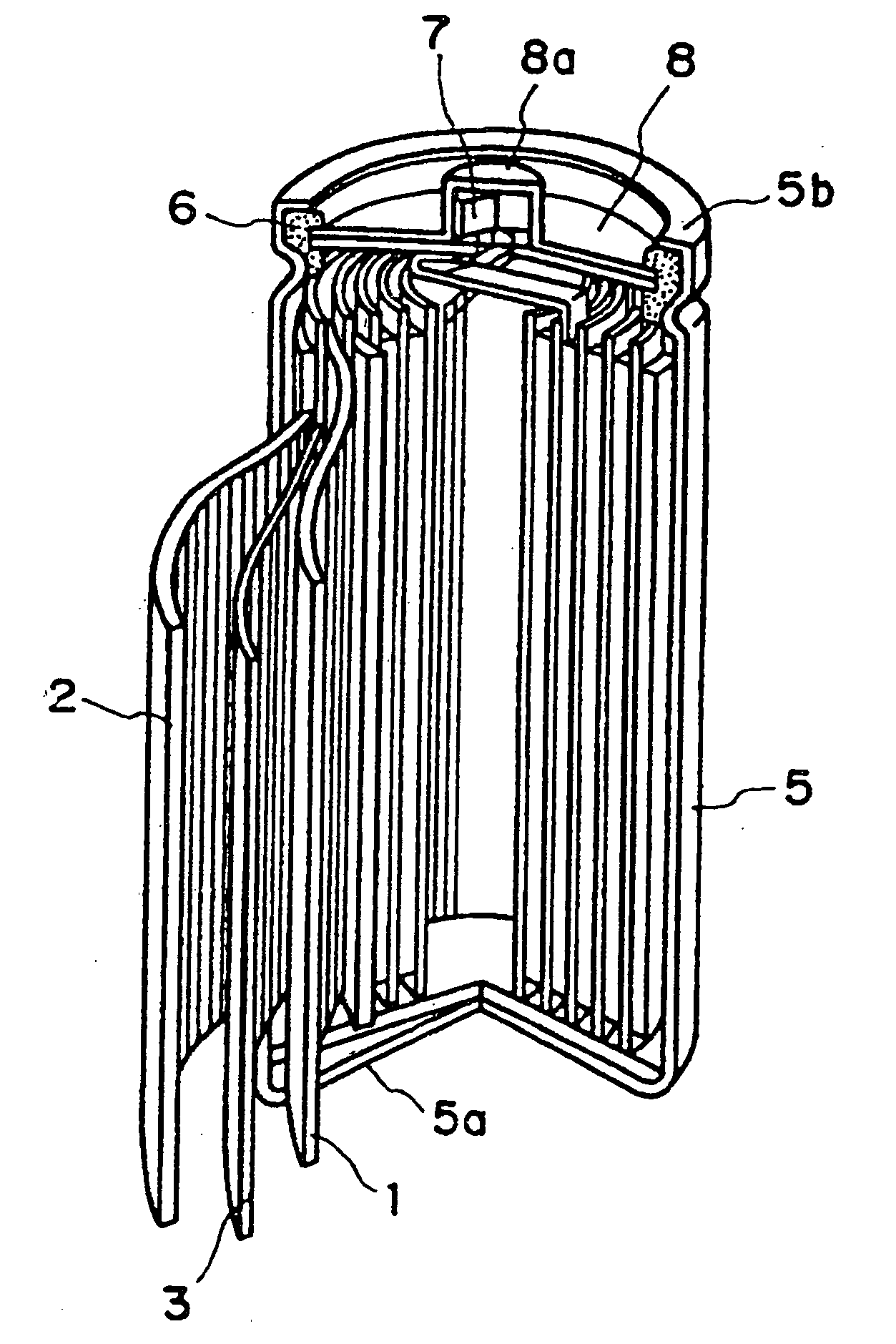

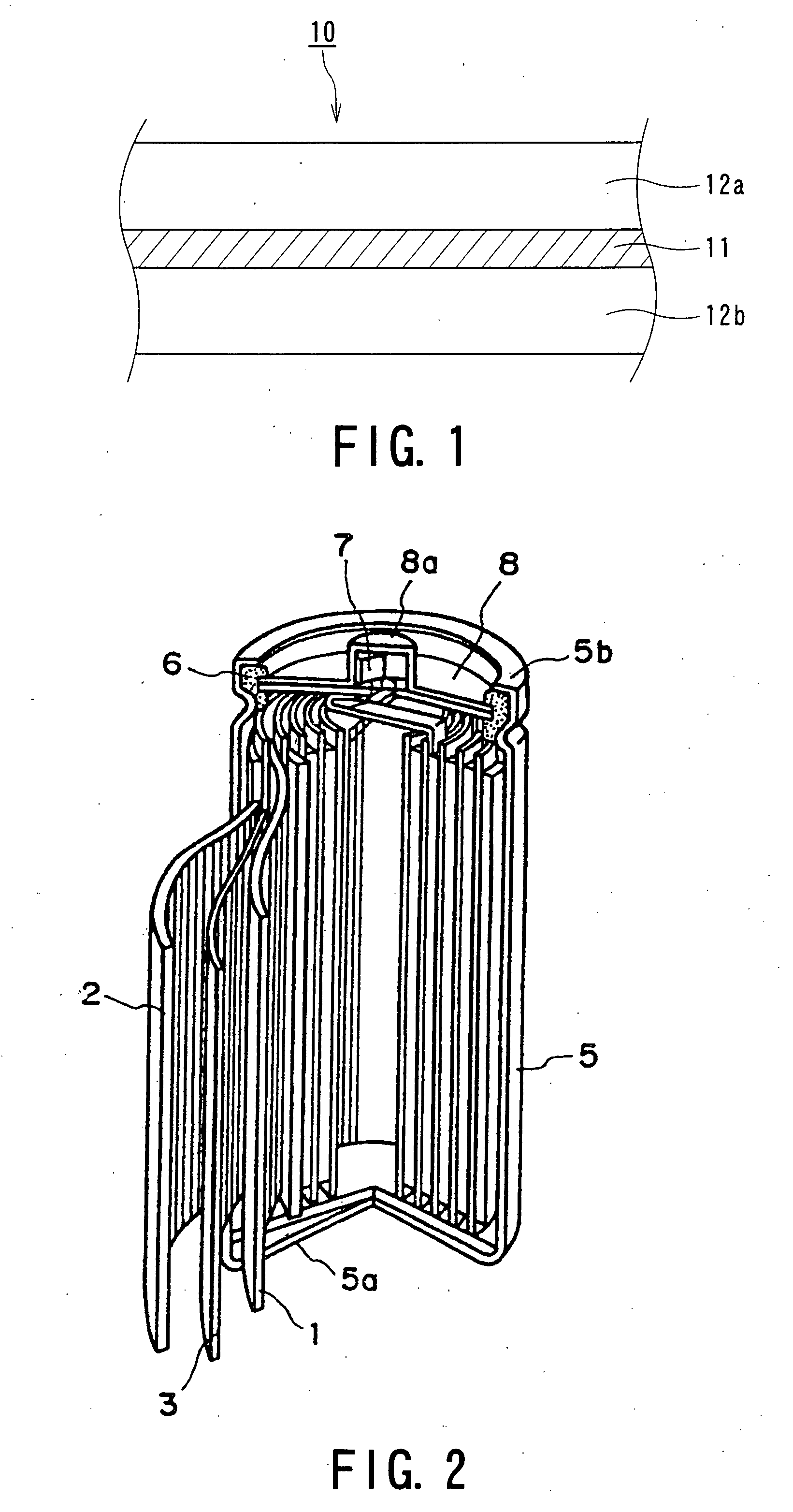

Vinylidene Fluoride Based Core-Shell Type Polymer and Use Thereof in Nonaqueous Electrochemical Device

InactiveUS20080131776A1Increase flexibilityIncrease resistanceNon-aqueous electrolyte accumulatorsHybrid capacitor electrodesComposite electrodePolymer science

A core / shell polymer (A), comprising: a rubbery core comprising a crosslinked vinylidene fluoride copolymer (a) having a vinylidene fluoride content of 30-90 wt. % and a shell comprising a vinylidene fluoride polymer (b) having a vinylidene fluoride content which is larger than in the crosslinked vinylidene fluoride copolymer (a) and at least 80 wt. %, in a weight ratio (a) / (b) of 30 / 70-90 / 10. The vinylidene fluoride-based core / shell polymer (A) is excellent in mechanical properties including flexibility and resistance to nonaqueous electrolytic solutions, is capable of forming a composite electrode layer showing excellent flexibility and adhesion to an electroconductive substrate in combination with a powder active substance and is therefore suitable for use as a binder for nonaqueous electrochemical devices.

Owner:KUREHA KAGAKU KOGYO KK

Quantum dot ink used for ink-jet printing and preparation method thereof

The invention discloses quantum dot ink used for ink-jet printing and a preparation method thereof. The quantum dot ink comprises the following ingredients in parts by weight: 5-20% of quantum dot and 80.0-95.0% of solvent, wherein the solvent comprises at least one alkane and / or arene organic solvent and at least one small molecule ether organic solvent, and the dosage of the small molecule ether organic solvent is 1.0-80.0% of the total weight of the solvent. The quantum dot ink has proper viscosity and surface tension, the requirement of an ink-jet printer on membrane performance can be met, and the ink-jet printing way of a quantum dot luminescent layer is realized. Through the ink-jet printing method, the quantum dot luminescent layer with a pixel dot matrix is formed by deposition; meanwhile, through post-processing, organic substances in the quantum dot luminescent layer prepared by printing can volatilize, so that the electric charge transmission of the quantum dot luminescent layer can be conveniently carried out, starting voltage is lowered, and therefore, electrons and cavities can carry out compound radiation luminescence.

Owner:TCL CORPORATION

Micro slag gas protection flux-cored wire suitable for electric arc additive manufacturing of die

ActiveCN106077992ANo flowWell formedArc welding apparatusWelding/cutting media/materialsLiquid metalMagnesite

The invention relates to a micro slag gas protection flux-cored wire suitable for electric arc additive manufacturing of a die. The flux-cored wire is formed by wrapping a powder core with a steel strip and comprises a component A, a component B and a component C. The component A comprises, by weight, 30-45% of rutile, 4-7% of cryolite, 8-14% of fluorite, 10-20% of marble, 8-14% of magnesite, 8-14% of potassium titanate and 10-22% of albite. The component B comprises, by weight, 5-20% of aluminum magnesium alloy, 5-15% of ferrotitanium, 26-40% of nickel, 8-20% of molybdenum, 12-24% of chrome, 10-18% of 45# silicon iron and 10-28% of manganese. The component C is composed of iron powder and impurities. After the flux-cored wire is welded, a micro amount of molten slag is formed and thinly and uniformly covers the surface of deposited metal, the molten slag cocks and falls off automatically after cooling, and multilayer welding can be achieved without slag removing; and in addition, weld spatter hardly appears, electric arcs are stable, molten metal does not flow, the appearance is attractive, excellent welding technological performance is achieved, and the deposited metal has good comprehensive mechanical performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Cyanate resin for hot-melt prepregs and preparation method thereof

The invention relates to a cyanate resin for hot-melt prepregs and a preparation method thereof, belonging to the technical field of hot-melt prepregs. The cyanate resin is composed of 60-95 parts of modified cyanate resin and 5-40 parts of toughener. The cyanate resin for hot-melt prepregs has the advantages of simple technique and no solvent volatilization, and is suitable for industrial production. A hot-melt process can be adopted to prepare the prepreg. The prepreg has favorable manufacturability and long storage period. The prepared cyanate resin fiber composite material has the advantages of higher comprehensive mechanical properties, favorable heat resistance and favorable radiation resistance, can widely satisfy the requirements for high-performance aerospace structure materials, and has favorable application prospects.

Owner:长春长光宇航复合材料有限公司

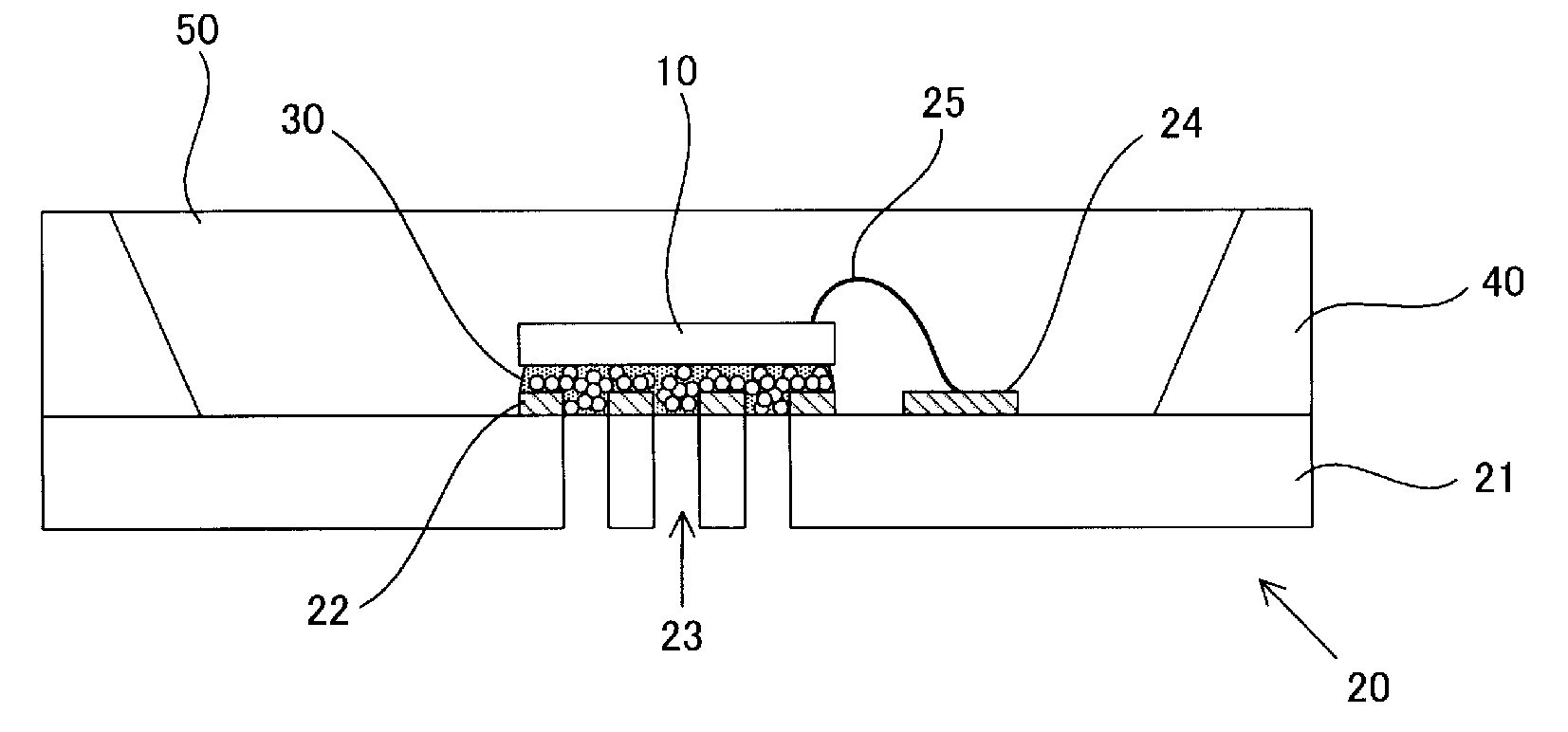

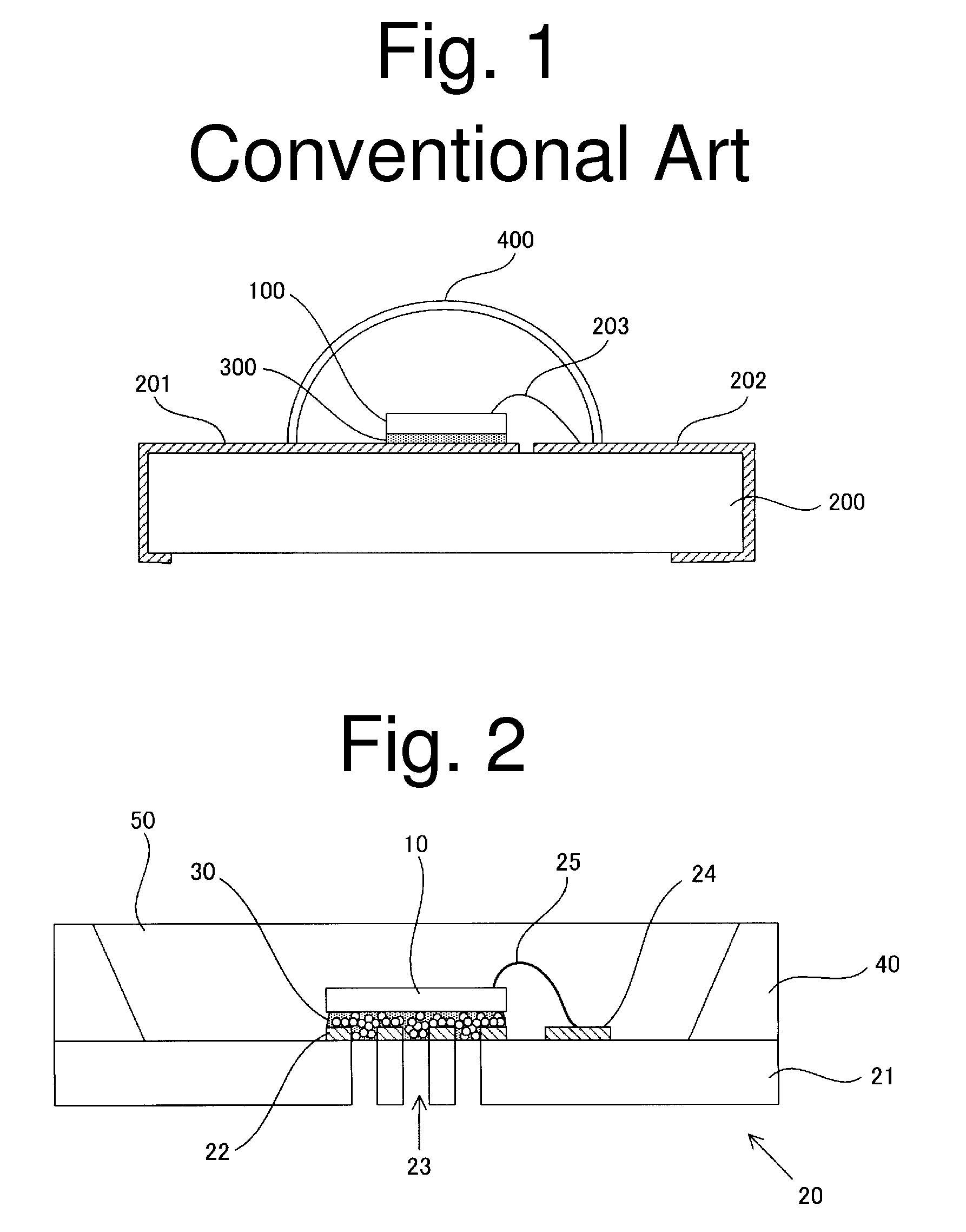

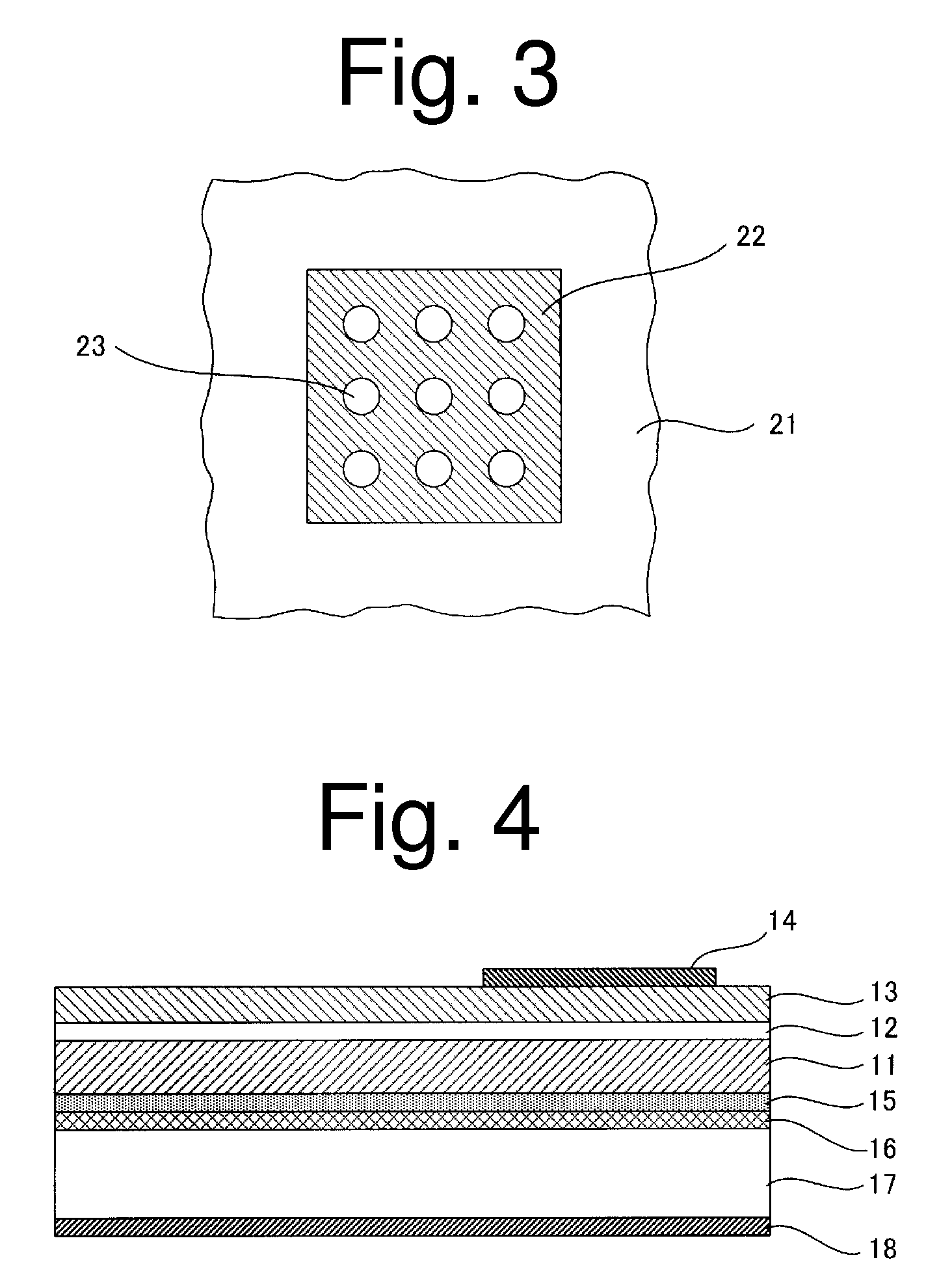

Optical semiconductor apparatus and method for producing the same

InactiveUS20100123162A1Treatment time be reducePrevent reoxidationSolid-state devicesSemiconductor/solid-state device manufacturingSolder pasteEngineering

An optical semiconductor apparatus can be configured by mounting an optical semiconductor element on a package substrate using a solder paste. The optical semiconductor apparatus can include a package substrate and a metal die pad formed on the substrate, and an optical semiconductor element bonded to the die pad with a solder material. The substrate can be made of a ceramic base material. A plurality of through holes can be formed in the substrate so that the through holes penetrate both the substrate base material and the die pad. Each of the through holes can have an inner surface where the ceramic base material is exposed. Each through hole can have an opening diameter greater than or equal to 40 μm and less than or equal to 100 μm. The plurality of through holes can be formed such that the total area of the openings of the through holes is 50% or less of the bonded area between the optical semiconductor element and the die pad including the through holes covered with the solder material. The through holes can be covered with the solder material at the upper end thereof where the optical semiconductor element and the die pad are bonded to each other.

Owner:STANLEY ELECTRIC CO LTD

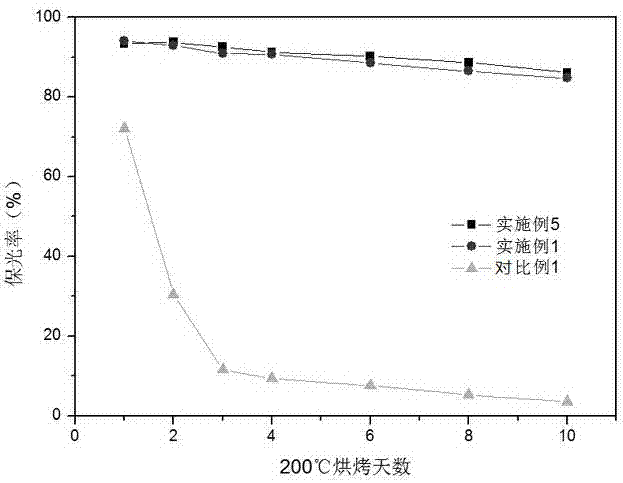

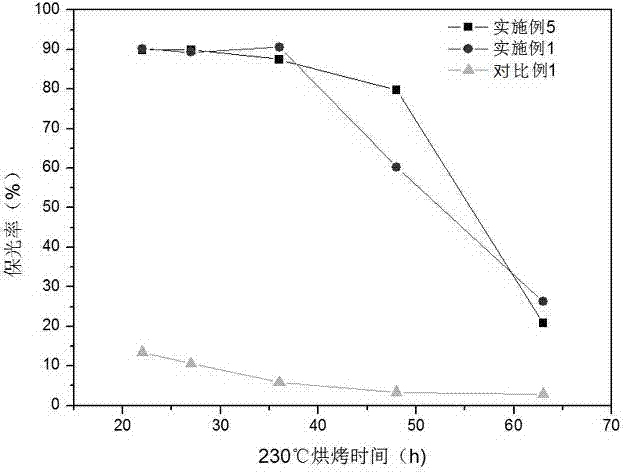

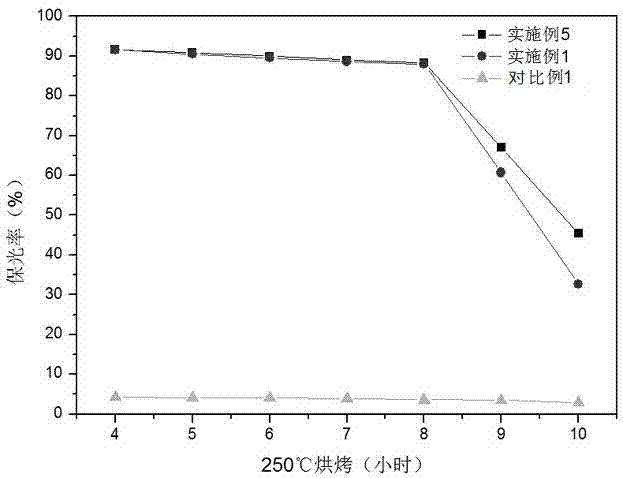

Pure polyester resin for TGIC cured high temperature resistant powder coatings, and preparation method thereof

ActiveCN104292441ASuitable glass transition temperatureAppropriate viscosityPowdery paintsPolyester coatingsGlass transitionMonomer

The invention discloses a pure polyester resin for TGIC cured high temperature resistant powder coatings. The acid value, the glass transition temperature, the softening point and the 200DEG C melt viscosity of the pure polyester resin are 30-35mgKOH / g, 70-78DEG C, 112-118DEG C and 15000-20000mPa.s respectively. The pure polyester resin is obtained through a melt condensation polymerization reaction of monomers comprising 33-38mass% of diol, 58-65mass% of aromatic dibasic acid, and 1.5-5mass% of polyol. The invention also discloses a preparation method of the pure polyester resin. The pure polyester resin has a high glass transition temperature and is suitable for a TGIC curing system, and powder coatings prepared by using the pure polyester resin have the advantages of excellent heat resistance, and no gloss loss and high gloss retention of coating layers baked at 270DEG C for 2h or baked at 300DEG C for 0.5h.

Owner:GUANGZHOU KINTE IND

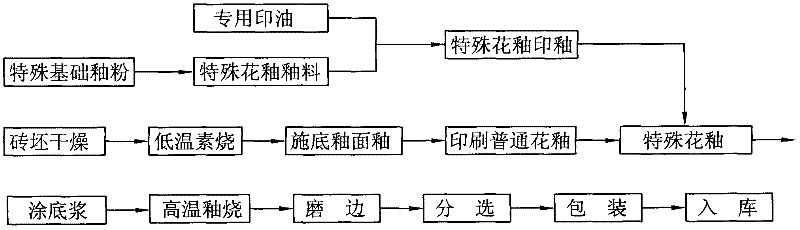

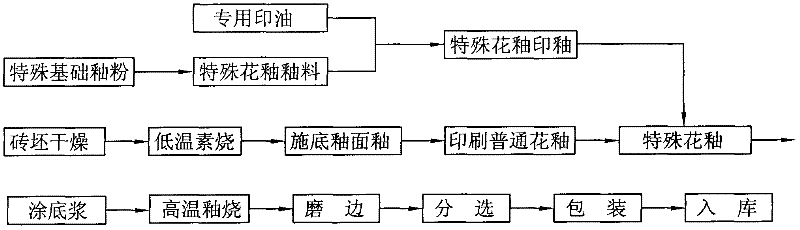

Preparation method and intermediate product of optical relievo illusion glazed brick

The invention relates to a preparation method of an optical relievo illusion glazed brick, which comprises the following steps: A. preparation of special basic glaze powder; B. preparation of special fancy glaze material; C. preparation of special fancy glaze printing glaze; D. special fancy glaze printing; and E. product firing system. By optimizing the compositions of the special basic glaze powder, special fancy glaze material, printing oil and special fancy glaze printing glaze as well as the firing technique and the like, optimized special rubber rollers or printing silk screen plate with optimized meshes can be used for printing the special fancy glaze on the base glaze, surface glaze and common fancy glaze green body, and the green body is fired at high temperature, so that the special fancy glaze pattern sinks into the common surface glaze and fancy glaze. The obtained product does not have the special fancy glaze pattern when viewed from the front side, but has the clear delicate pattern with relievo illusion effect when viewed from the lateral side, thereby achieving the dreamy illusion effect. The special fancy glaze has favorable transparency, does not destroy the original decorative pattern, and overcomes the defect of single decorative style in the existing glazed brick.

Owner:GUANGDONG WINTO CERAMICS +1

Crack-resistant waterborne coating

ActiveCN106433442ASuitable mechanicalAppropriate viscosityPolyurea/polyurethane coatingsCrack resistanceDodecylsulfonic acid

The invention discloses a crack-resistant waterborne coating which comprises the following raw materials in parts by weight: 60-80 parts of a modified polyurethane emulsion, 20-30 parts of an acrylic emulsion, 15-25 parts of a pigment, 10-20 parts of a filler, 3-5 parts of 2,2,4-trimethyl-1,3-pentanediolmono(2-methylpropanoate), 4-5 parts of sodium dodecyl sulfate, 0.2-0.4 part of a flatting agent, 0.1-0.2 part of an emulsifying agent OP-10, 0.1-0.2 part of a de-foaming agent, 0.2-0.4 part of a wetting agent 265, 0.2-0.4 part of sodium carboxymethyl cellulose, 0.6-0.8 part of gamma-(2,3-epoxypropoxy) mercaptopropyltrimethoxysilane, 0.2-0.4 part of a mildew preventive and 10-18 parts of water. The crack-resistant waterborne coating disclosed by the invention has good toughness, impact performance, crack resistance and bonding performance.

Owner:安徽琮玥工程项目管理有限公司

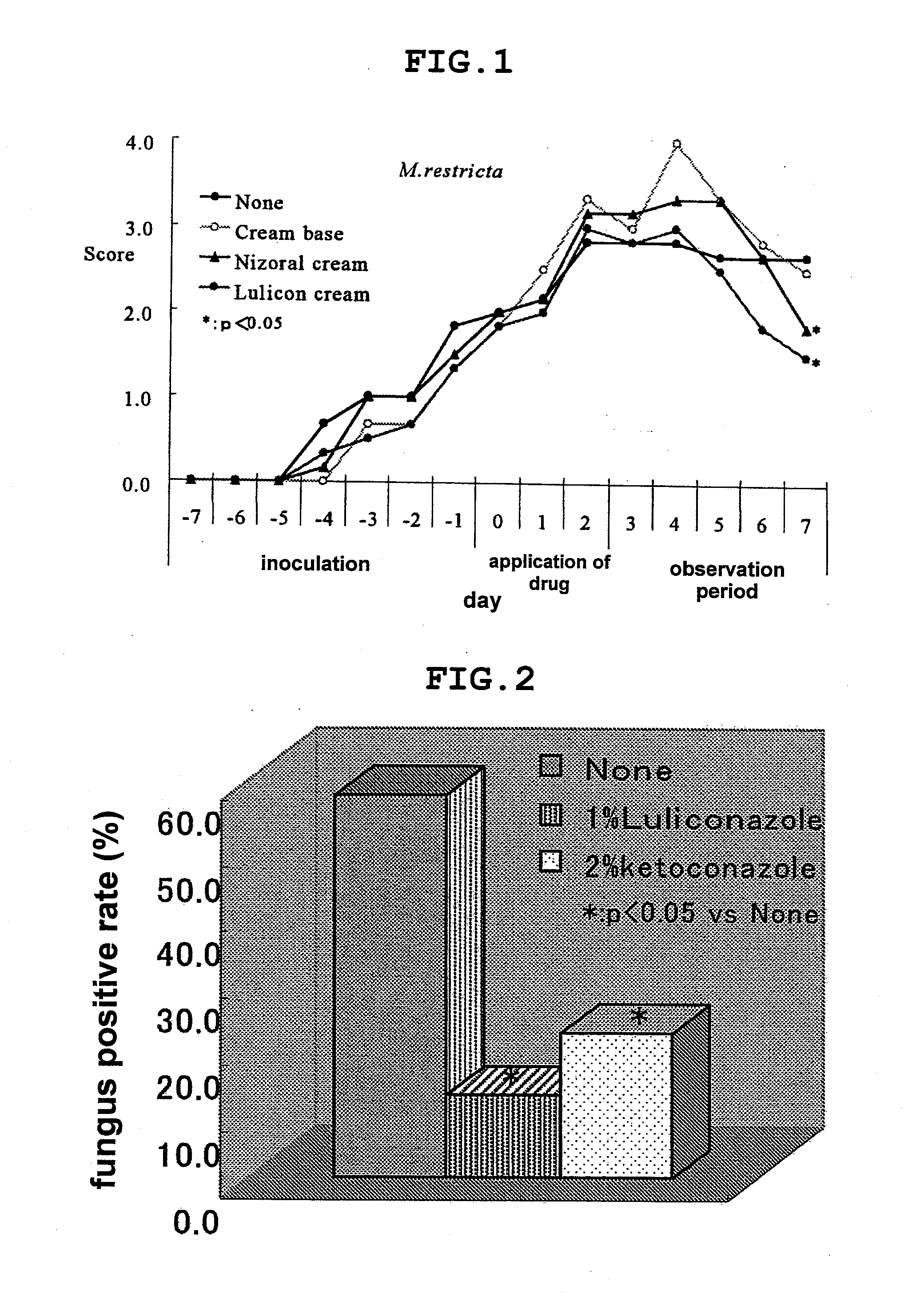

Agent for fungal dermatitis

InactiveUS20100249202A1Improve antifungal effectEfficient use ofOrganic active ingredientsBiocideBULK ACTIVE INGREDIENTActive ingredient

The invention relates to a therapeutic agent for fungal dermatitis, containing luliconazole or a pharmaceutically acceptable salt thereof as an active ingredient, and a composition for the treatment of fungal dermatitis, containing luliconazole or lanoconazole in a substantially dissolved state as an active ingredient.

Owner:NIHON NOHYAKU CO LTD

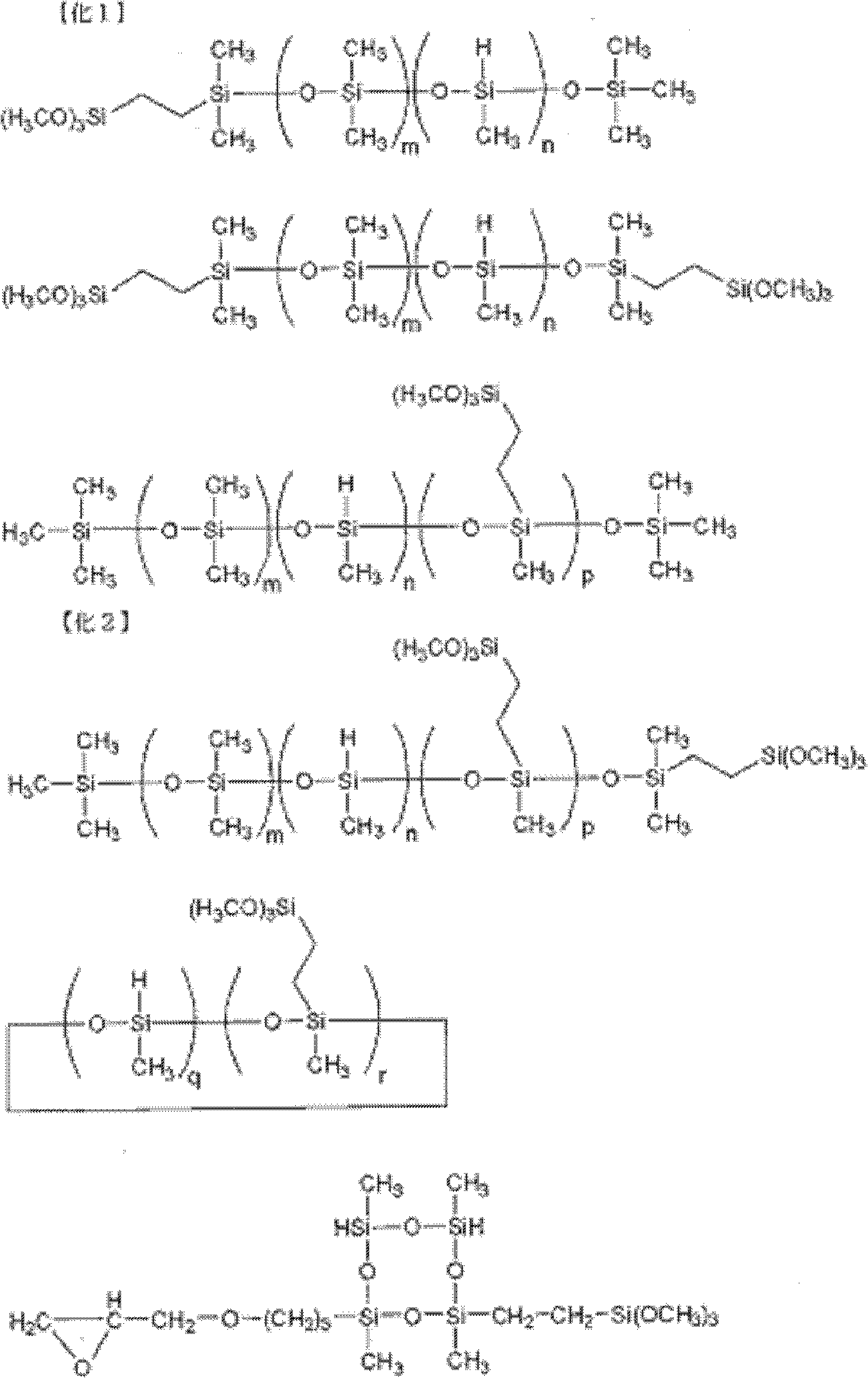

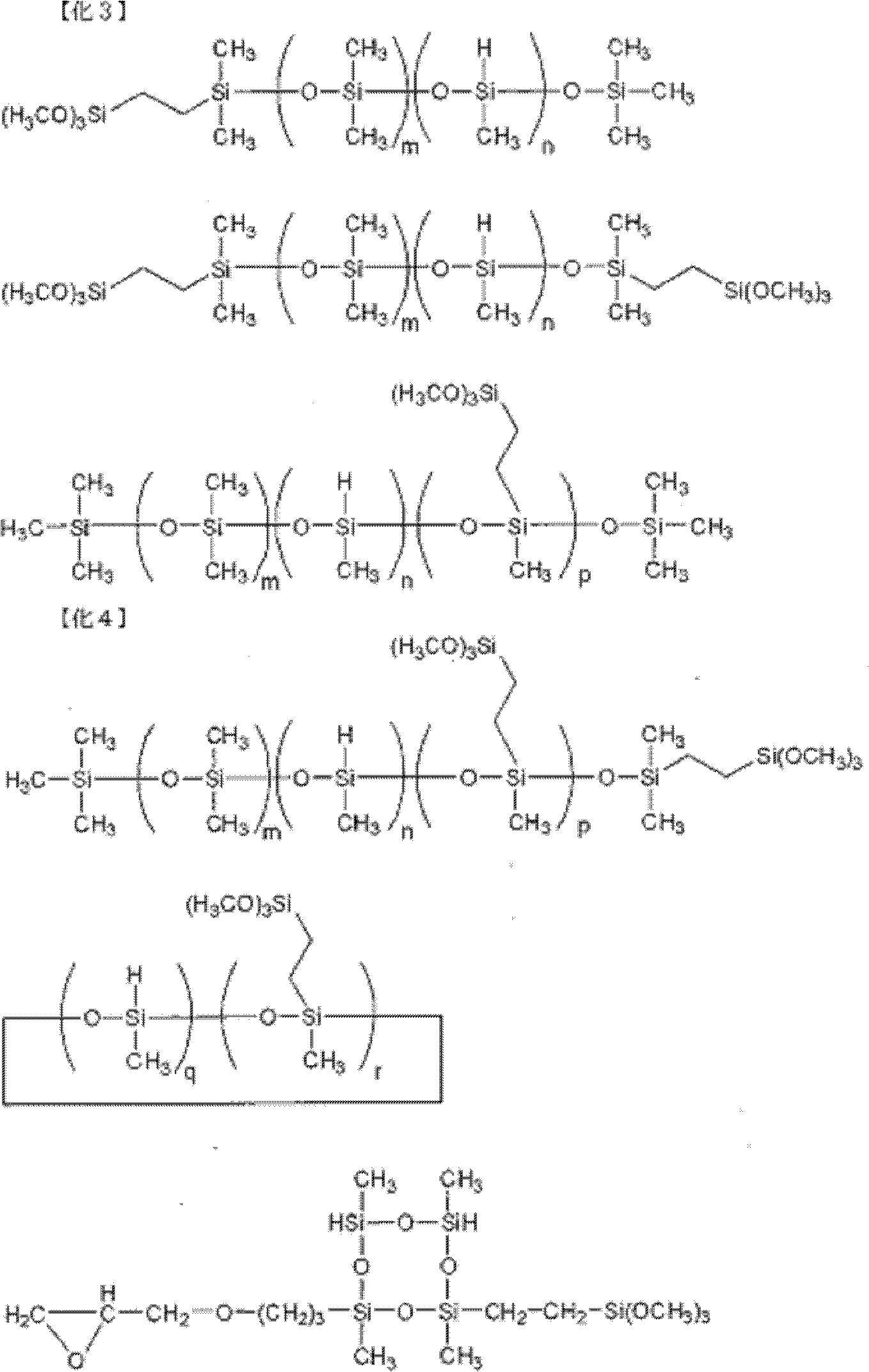

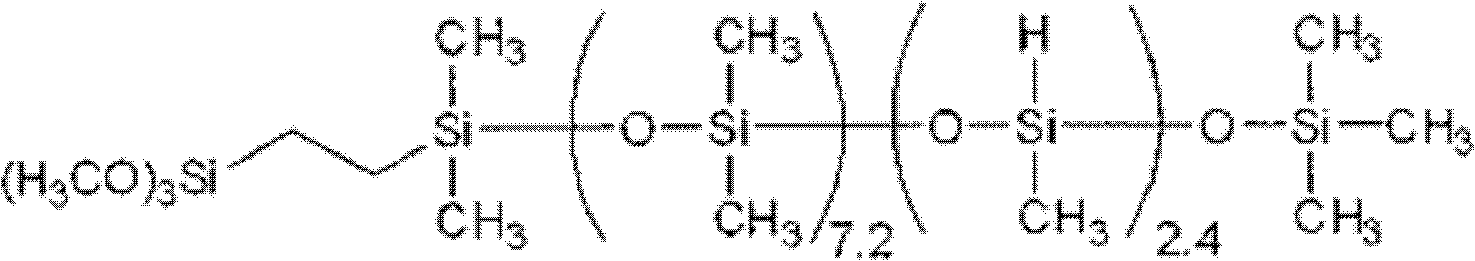

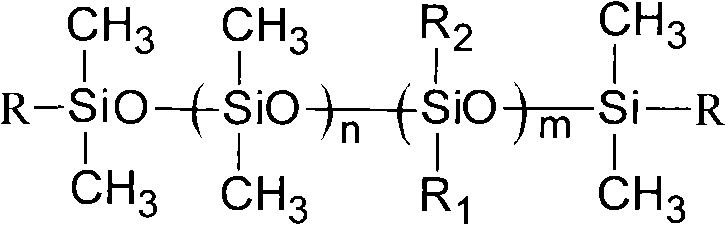

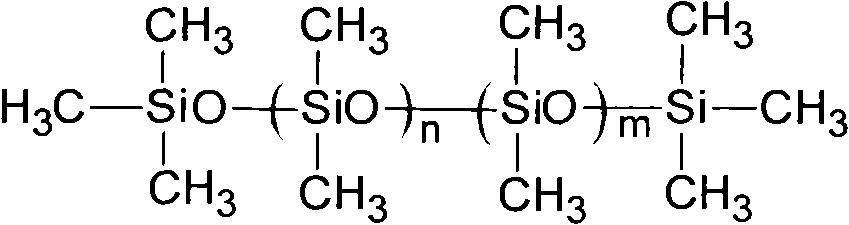

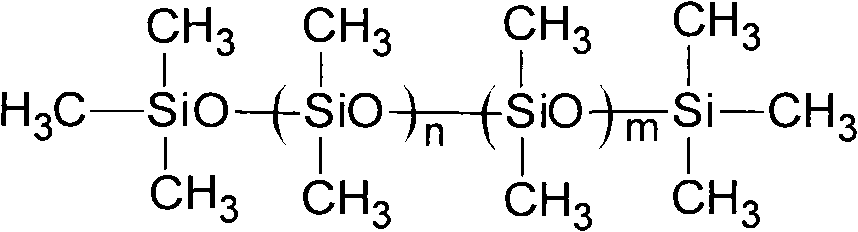

Addition solidifying type organosilicone composition and photosemiconductor apparatus using the same

ActiveCN102757649AAppropriate viscosityExcellent ejectionSemiconductor devicesOptical reflectionFumed silica

The invention provides an addition solidifying type organosilicone composition having proper viscosity (ejecting property), nonliquidity (shape stability when being heated for solidification), and excellent optical reflection, and a photosemiconductor apparatus using the same. The addition solidifying organosilicone composition is particularly applicable to the reflecting material of the LED with self-adhesiveness. The self-adhesiveness addition solidifying type organosilicone composition applicable to photosemiconductor apparatus comprises the following procedures: (A) one molecule comprises at least two organopolysiloxanes of alkenyl bonded with the silicon atom, 100 parts by mass; (B) one molecule comprises at least two hydrogen atoms bonded with silicon atoms and at least one organic polysiloxane of the alkoxy, with the general Si-H-yl number being 1.4-5.0 times of the general alkene-yl number of the component (A); (C) fumed silica, relative to 100 parts by mass of the components (A) and (B), has 8 to 30 parts by mass; (D) white pigment; and (E) solidifying catalyst.

Owner:SHIN ETSU CHEM IND CO LTD

Cement additive

To provide a cement admixture which makes it possible to: enhance slump maintaining capability; maintain fluidity; and provide a cement composition and the like having an appropriate viscosity for handling at the place where the composition and the like is handled. A cement admixture comprising an alkylene oxide adduct comprising a compound having 3 or more active hydrogens and an oxyalkylene group added to the compound, wherein an average molar number of addition of the oxyalkylene group relative to 1 mole of the active hydrogen is 100 mole or more.

Owner:NIPPON SHOKUBAI CO LTD

Silicone oil electric force compound grease and preparation method thereof

InactiveCN102024505AImprove high temperature resistanceImprove low temperature resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicone oilMetal powder

The invention discloses electric force compound grease and a preparation method thereof. The silicone oil electric force compound grease mainly comprises silicon oil, white carbon black and conductive metal powder, wherein the white carbon black is subject to surface treatment with a lipophilic processing agent. The silicone oil electric force compound grease comprises the following components in parts by weight: 100 parts of silicon oil, 20-33 parts of precipitated silica subject to the surface treatment with the lipophilic processing agent, 65-90 parts of conductive metal powder, 0-2 parts of stabilizing agent and 0-2 parts of anti-oxygen agent, or the silicone oil electric force compound grease is also composed of the following components in parts by weight: 100 parts of silicon oil, 10-15 parts of fumed silica subject to the surface treatment with the lipophilic processing agent, 65-90 parts of conductive metal powder, 0-2 parts of stabilizing agent and 0-2 parts of anti-oxygen agent. The silicone oil electric force compound grease disclosed by the invention has the advantages of high dropping point temperature, good attachment property, stable rationalizing property, long service life and good economic property.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +2

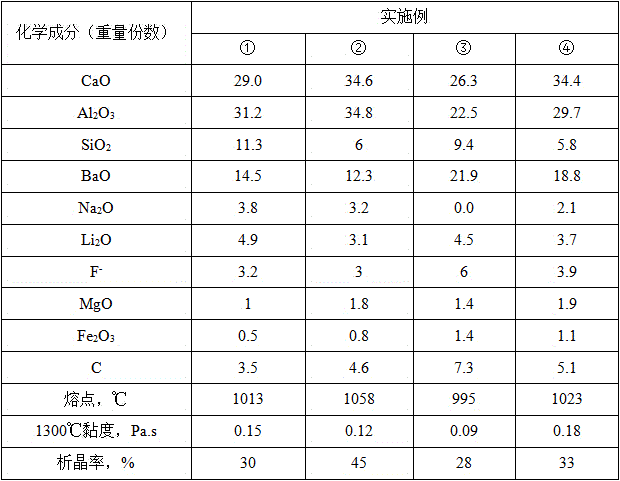

Crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of crystallizer covering slag

The invention provides a crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of the crystallizer covering slag. The covering slag is prepared from the following components in parts by weight: 20-38 parts of CaO, 20-35 parts of Al2O3, 5-18 parts of SiO2, 10-22 parts of BaO, 2-7 parts of Li2O, 5-12 parts of F<->, 1-4 parts of MgO, 2-8 parts of C and Fe2O3 which is less than or equal to 2 parts. According to the preparation method disclosed by the invention, wollastonite, limestone, quartz sand, fluorite, bauxite, barium carbonate, magnesia, soda, lithium carbonate and carbonaceous materials are used as raw materials, and the covering slag is prepared through the following steps of: calculating of consumption, melting, smashing, fine grinding, drying and granulation. The covering slag disclosed by the invention has the characteristics of being low in reactivity and good in property stability, the lubrication and the thermal transmission of casting blanks can be effectively coordinated and controlled, the smooth performing of the continuous casting process of the high-manganese high-aluminum steel can be guaranteed, high-manganese high-aluminum steel continuous casting blanks with excellent surface quality are cast, and multi-heat continuous casting can be realized.

Owner:CHONGQING UNIV

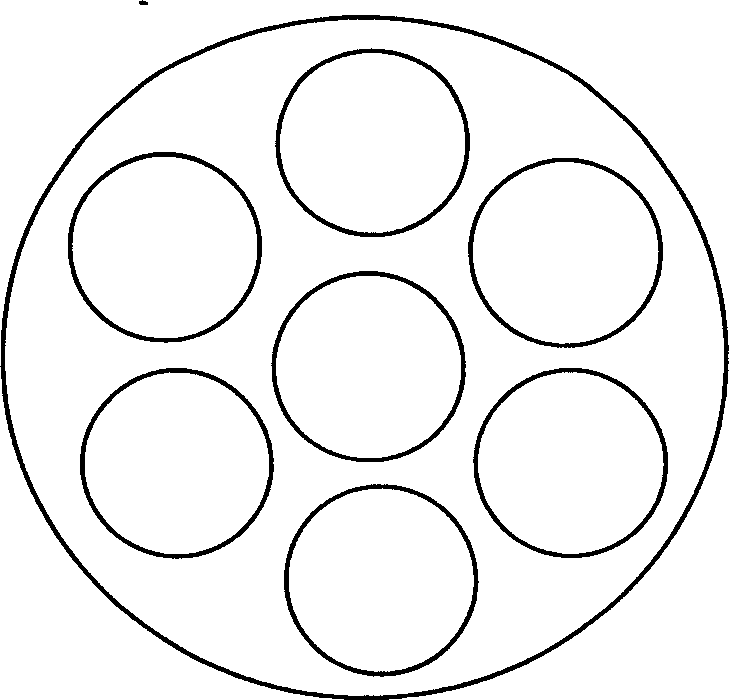

Fibre membrane with porous structure and production thereof

InactiveCN1680007AHigh mechanical strengthDoes not reduce water permeabilitySemi-permeable membranesSewage treatmentFiber

A fibrous membrane with porous cross-section structure features that the number of pores is 5,7 or 9, the pore wall shows five-layer bidirectional asymmetric structure consisting of external compact layer, finger pore supporting layer, sponge layer containing micropores, finger pore layer and internal compact layer, and its water permeability is 100-900 L / sq.m.h. Its preparing process is also disclosed.

Owner:DONGHUA UNIV

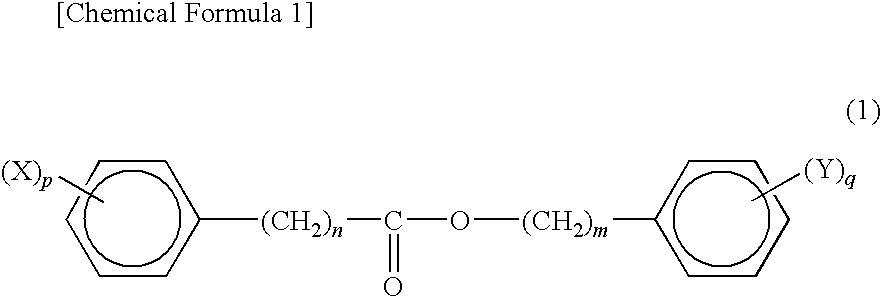

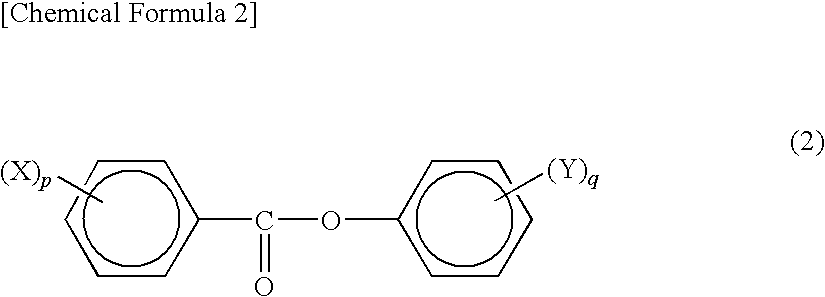

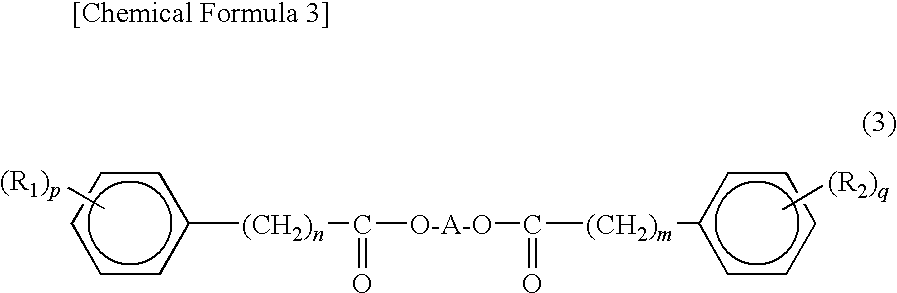

Hydraulic fluid and hydraulic system

ActiveUS20100130394A1High bulk modulusImprove the lubrication effectOrganic chemistryLiquid carbonaceous fuelsHydraulic circuitEngineering

A hydraulic fluid of the present invention contains, as a base oil, an ester having two or more ring structures, the two or more ring structures being at least one selected from an aromatic ring and a saturated naphthenic ring. Particularly, the hydraulic fluid contains an ester having two or more aromatic rings as the base oil. The hydraulic fluid has low energy loss due to compression and exhibits excellent responsiveness when being used in a hydraulic circuit. Consequently, the hydraulic fluid realizes energy-saving, high-speed operation and high precision of control in the hydraulic circuit.

Owner:IDEMITSU KOSAN CO LTD

Rice flour for steamed meat and preparation method

A rice flour used for steaming pork to make the steamed pork have a certain adhesion for shaping, additional small and taste and rich nutrients is prepared from the clean rice, parched rice, flavouring and parched seeds of plant (peanut, soybean, sesame and sunflower).

Owner:成都孔师傅食品有限公司

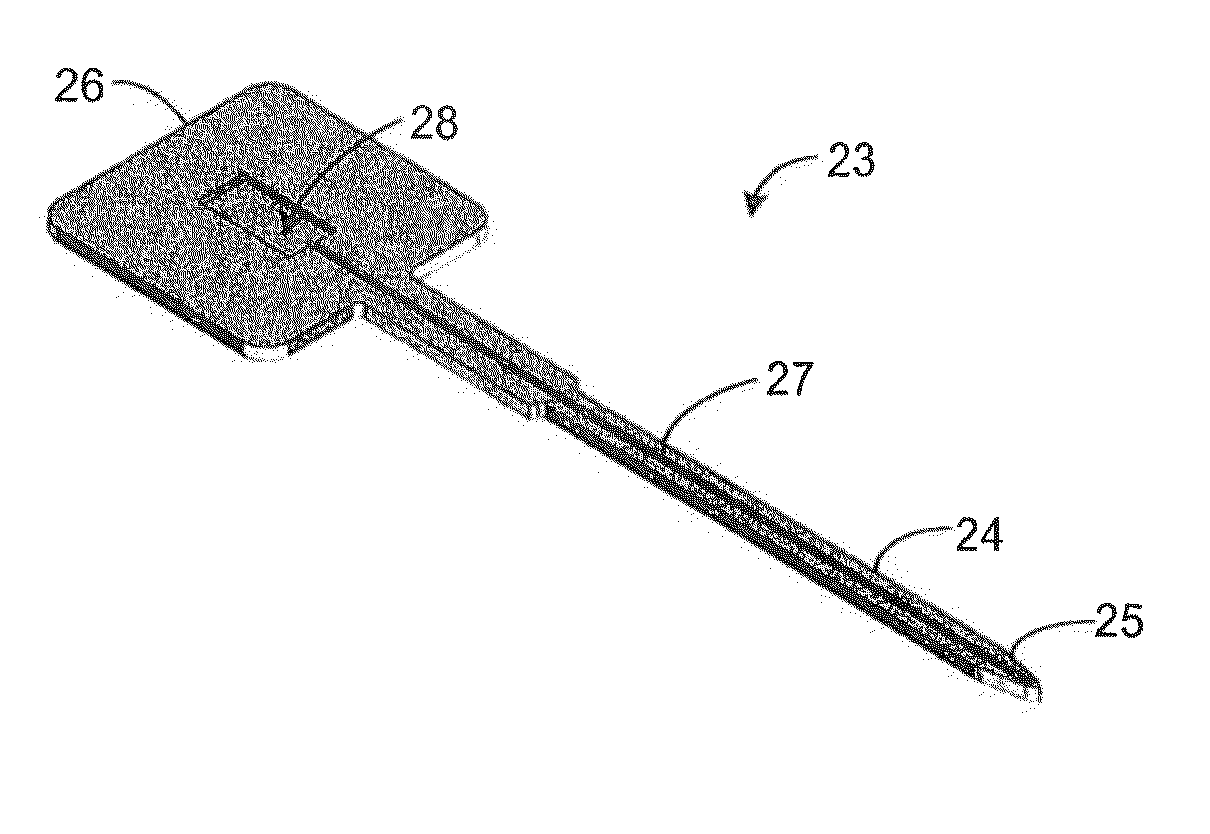

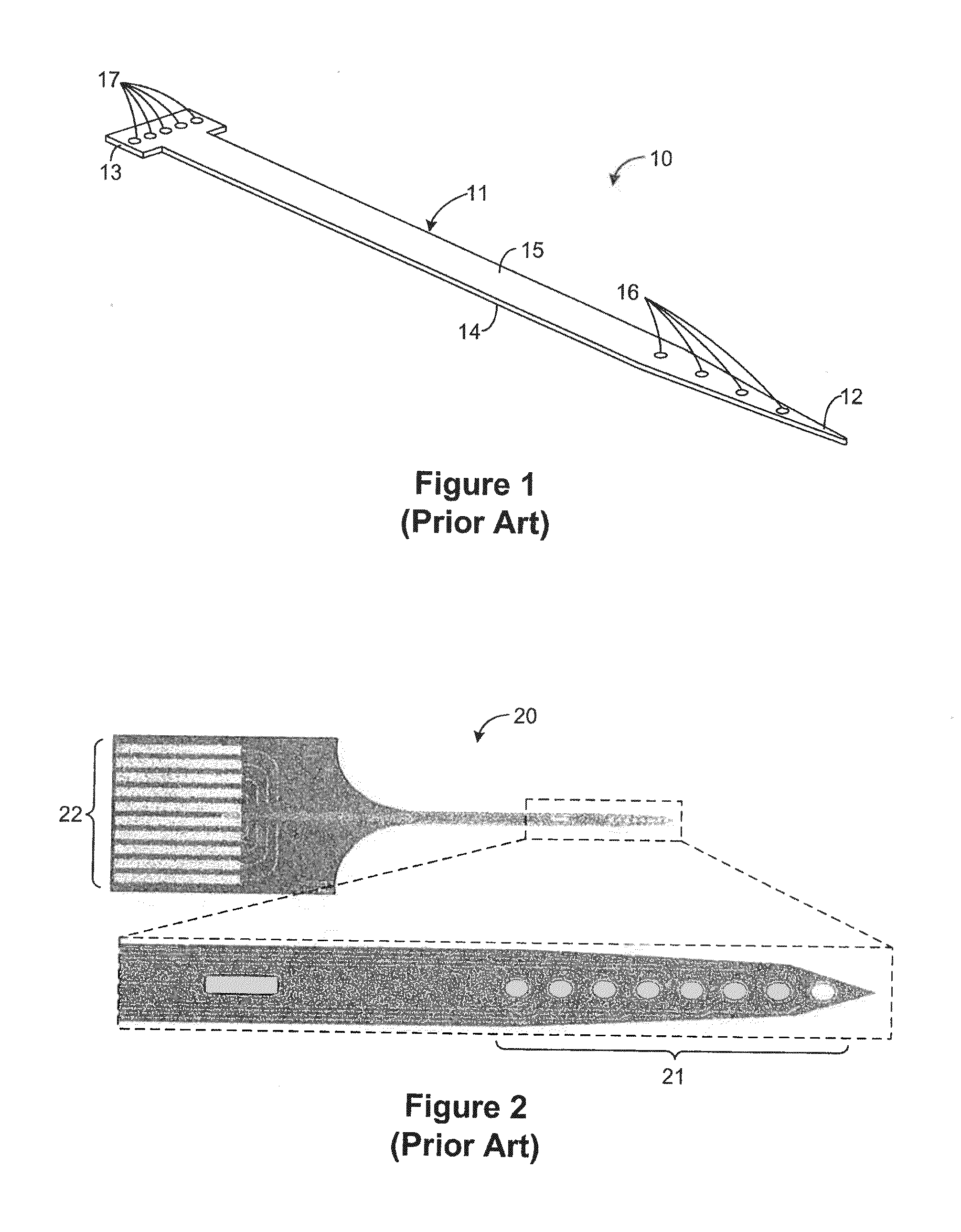

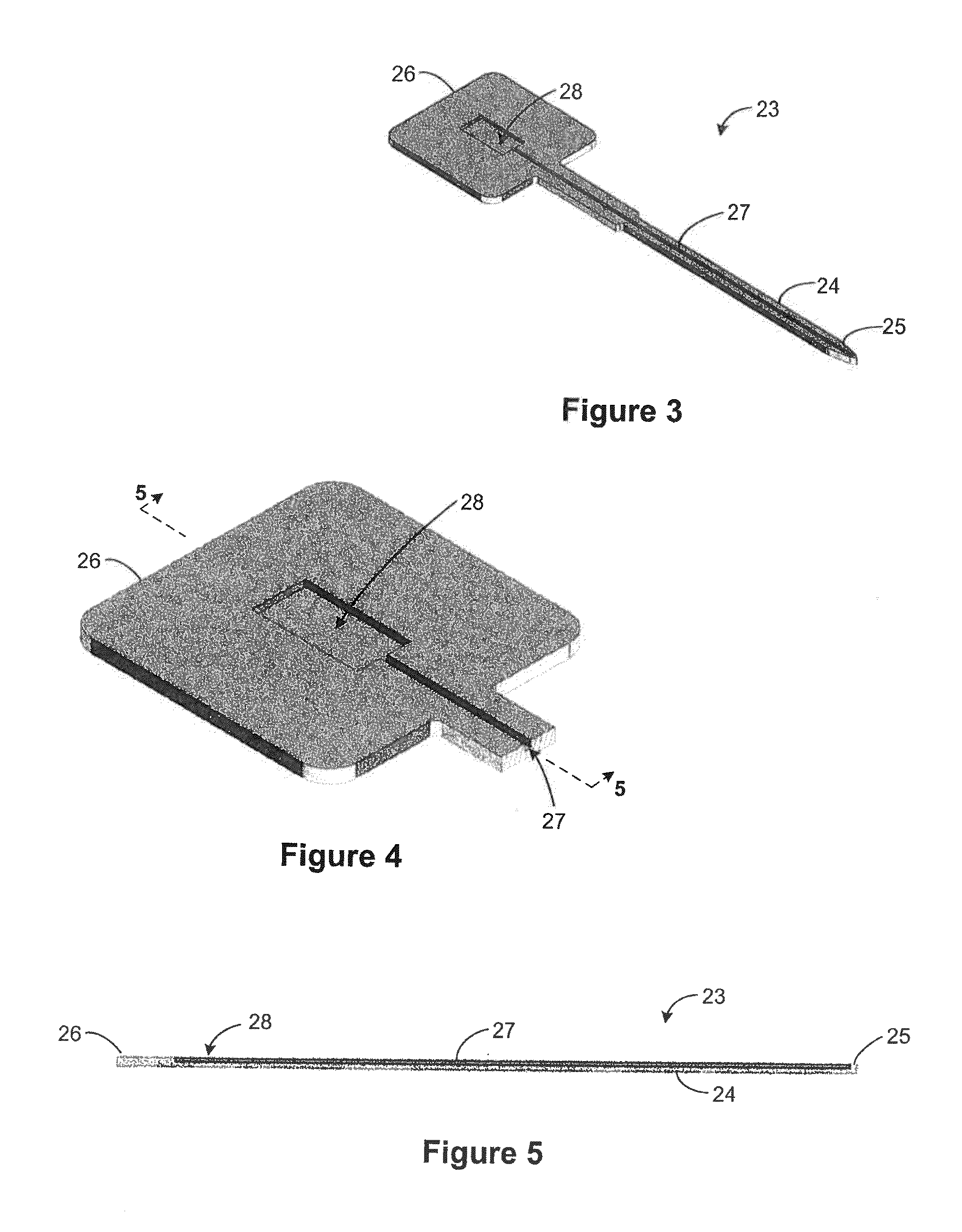

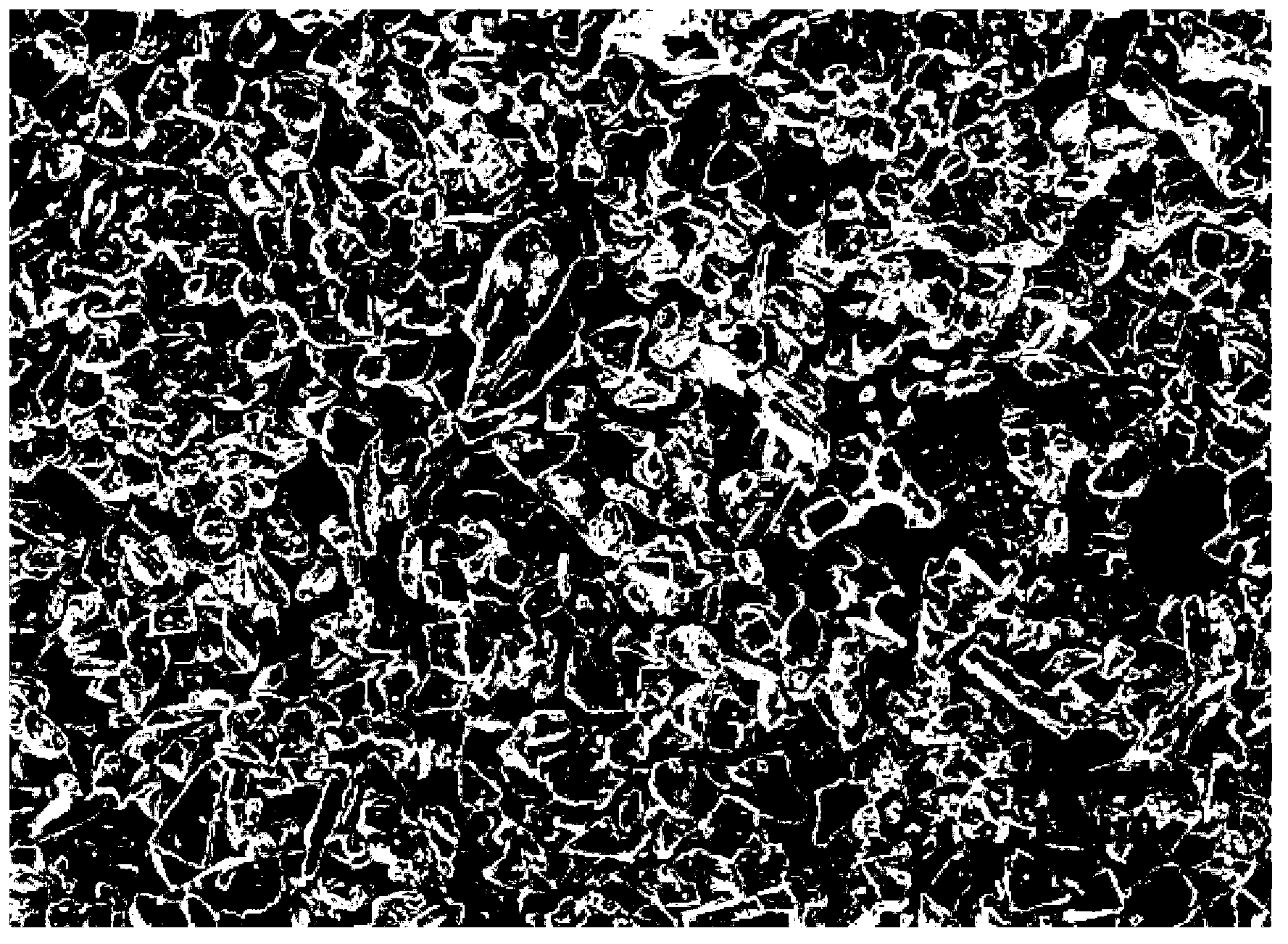

Rigid stiffener-reinforced flexible neural probes, and methods of fabrication using wicking channel-distributed adhesives and tissue insertion and extraction

ActiveUS20140378993A1Accurate and repeatable alignmentAccurate and repeatable and attachmentSpinal electrodesAdhesive processesAdhesiveCapillary Tubing

A stiffener-reinforced microelectrode array probe and fabrication method using wicking channel-distributed adhesives which temporarily adheres a flexible device onto a rigid stiffener for insertion and extraction. Assembly is by dispensing a liquid adhesive into a narrow open groove wicking channel formed on the stiffener so that the adhesive is wicked along and tills the channel by capillary action, and adhering the adhesive-filled bonding side of the elongated section of the rigid substrate to a flexible device.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Magnesium alloy rare earth compound flux and its production method

The present invention provides a magnesium alloy rare earth compound flux and its production method. Its composition includes (wt%) 40-55% of magnesium chloride, 15-25% of potassium chloride, 12-25% of sodium chloride, 1-6% of calcium chloride, 5-15% of calcium fluoride, 1-8% of barium chloride and 3-10% of rare earth activator. Said ivnention flux has high activity, proper melting point, density, viscosity and surface tension, and can greatly raise mechanical property of magnesium alloy and corrosion resistance.

Owner:SHANGHAI HAOHUA MOLD

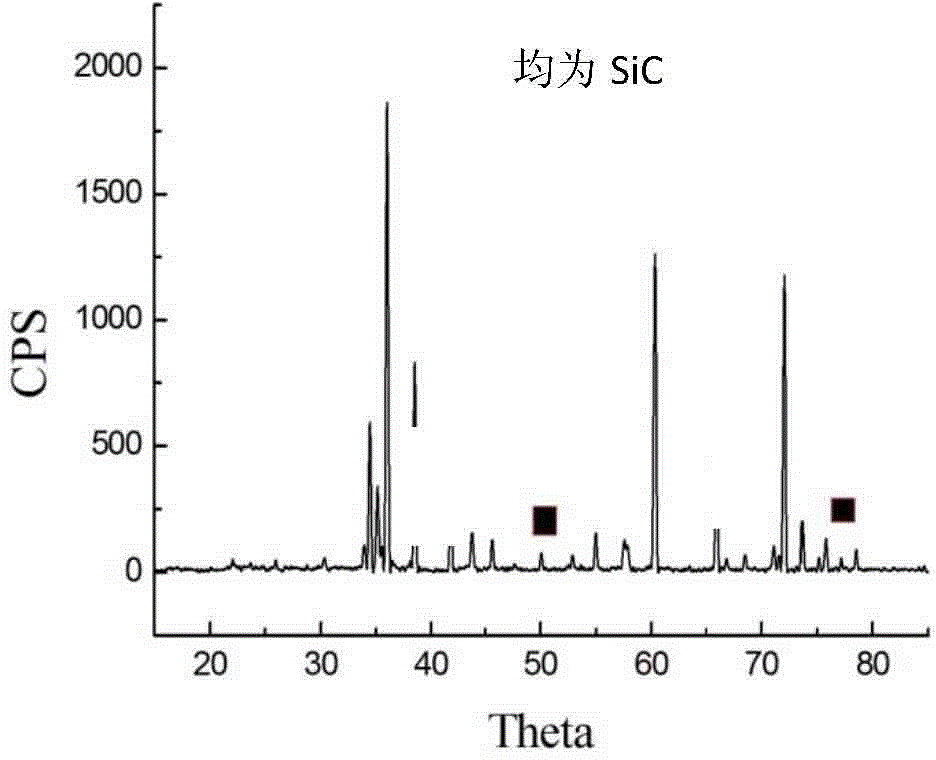

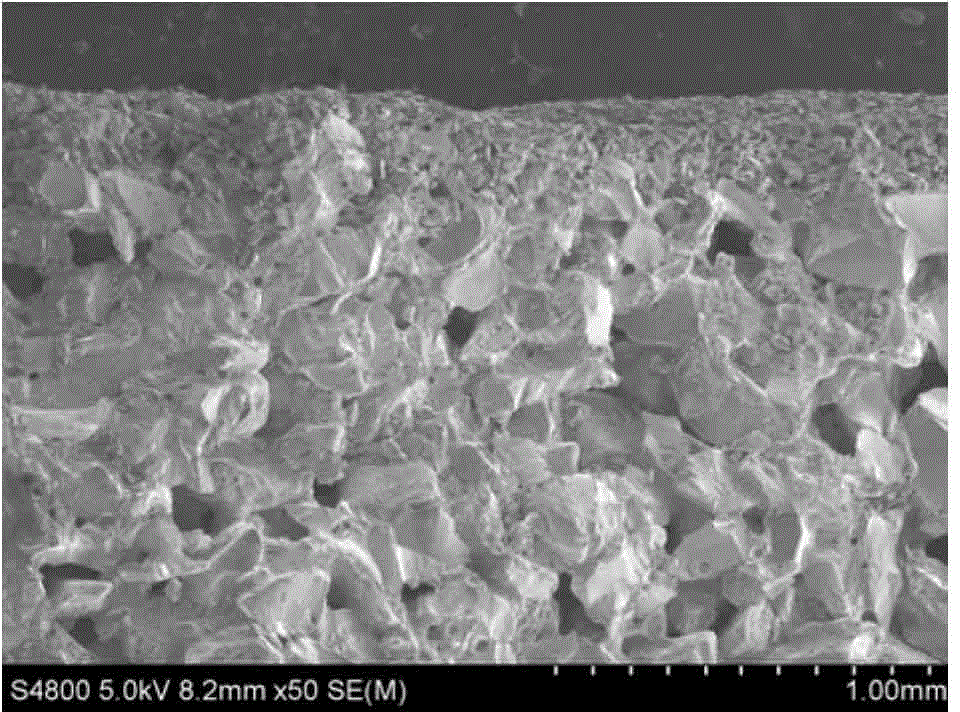

Coating method of silicon carbide ceramic membrane for high-temperature filtration

The invention discloses a coating method of a silicon carbide ceramic membrane for high-temperature filtration. The method comprises the following steps: preparing an inorganic silicon carbide membrane slurry material which is stable, good in dispersibility and excellent in membrane-forming property by utilizing one or multiple solvents of glycerol, propylene glycol, ethanol, ethylene glycol and triethylene glycol; coating the filtering membrane by utilizing the air spraying technology; and performing heat treatment, thereby preparing the silicon carbide ceramic membrane which is uniform and integrated, controllable in thickness and large in size. Based on the reasonable design of a ceramic bonding agent for the filtering membrane, the chemical stability and the bonding strength of the filtering membrane are improved. The prepared silicon carbide ceramic membrane is simple in preparation process and easy in membrane-forming condition control, realizes reduction in cost and is convenient for industrialized production. The composite filtering material obtained by sintering at high temperature is suitable for the filtration purification of high-temperature fluids such as molten metal, high-temperature flue gas and the like.

Owner:HAINAN UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com