Patents

Literature

453 results about "Spreadability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In media studies, spreadability is the wide distribution and circulation of information on media platforms. The term was coined by Henry Jenkins in the book Spreadable Media. Spreadability contrasts with the "stickiness" of aggregating media in centralized places.

Color-changing wallpaper adhesive primer/activator

InactiveUS6894095B2Speed up the flowGood spreadabilityNon-macromolecular adhesive additivesControlling laminationAdhesiveColor changes

Adhesives and primer compositions that include water, a polymer and a pH indicator. The adhesives and primers have a visually-detectable color when wet, and preferably dry to a clear or transparent film, while having good flow and spreadability. The adhesives and primers provide a visual indication of wetness by including a pH indicator such that when the composition is wet, the pH indicator is colored such that the color and the intensity of the color provides a visual indication of wetness; sufficiency of thickness; and uniformity of application of the adhesive or primer.

Owner:ROMAN DECORATING PRODS

Long lasting liquid color compositions

Embodiments include a liquid colorant composition having an acrylates / octylacrylamide copolymer, a cellulose material, alcohol and a colorant. The cellulose material may be hydroxypropylcellulose. Isostearyl alcohol and silica may be included in the composition to enhance properties such as the spreadability and feel of the composition on the lips. Additional additives such as fragrance and botanical extracts may also be added. Such compositions can be easily applied to the lips and offer long wear characteristics.

Owner:FISHMAN YORAM

Method of drying an absorbent polymer with a surfactant

InactiveUS20070123624A1Improved pumpability and spreadabilityImprove drying efficiencyTransportation and packagingMixingPolymer scienceAcid value

A method of drying an absorbent polymer includes providing the absorbent polymer. A surfactant having a C10 to C24 ester group is incorporated with the absorbent polymer. An acid value of the surfactant is increased to further increase drying efficiency of the absorbent polymer. More specifically, after increasing the acid value of the surfactant, the absorbent polymer exhibits improved pumpability and spreadability, as compared to absorbent polymers including the surfactant without having the acid value of the surfactant increased.

Owner:OTTEN JAY +2

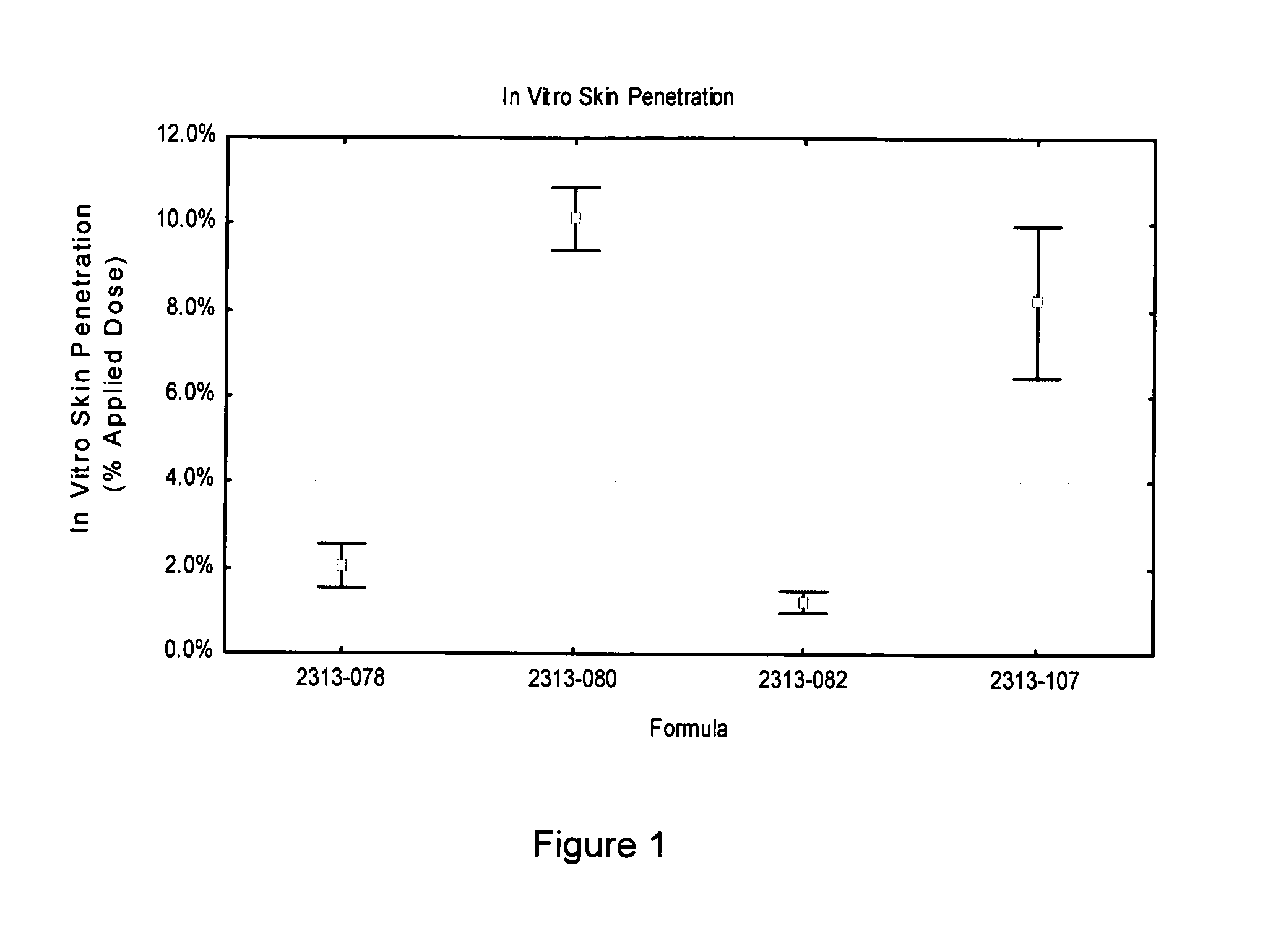

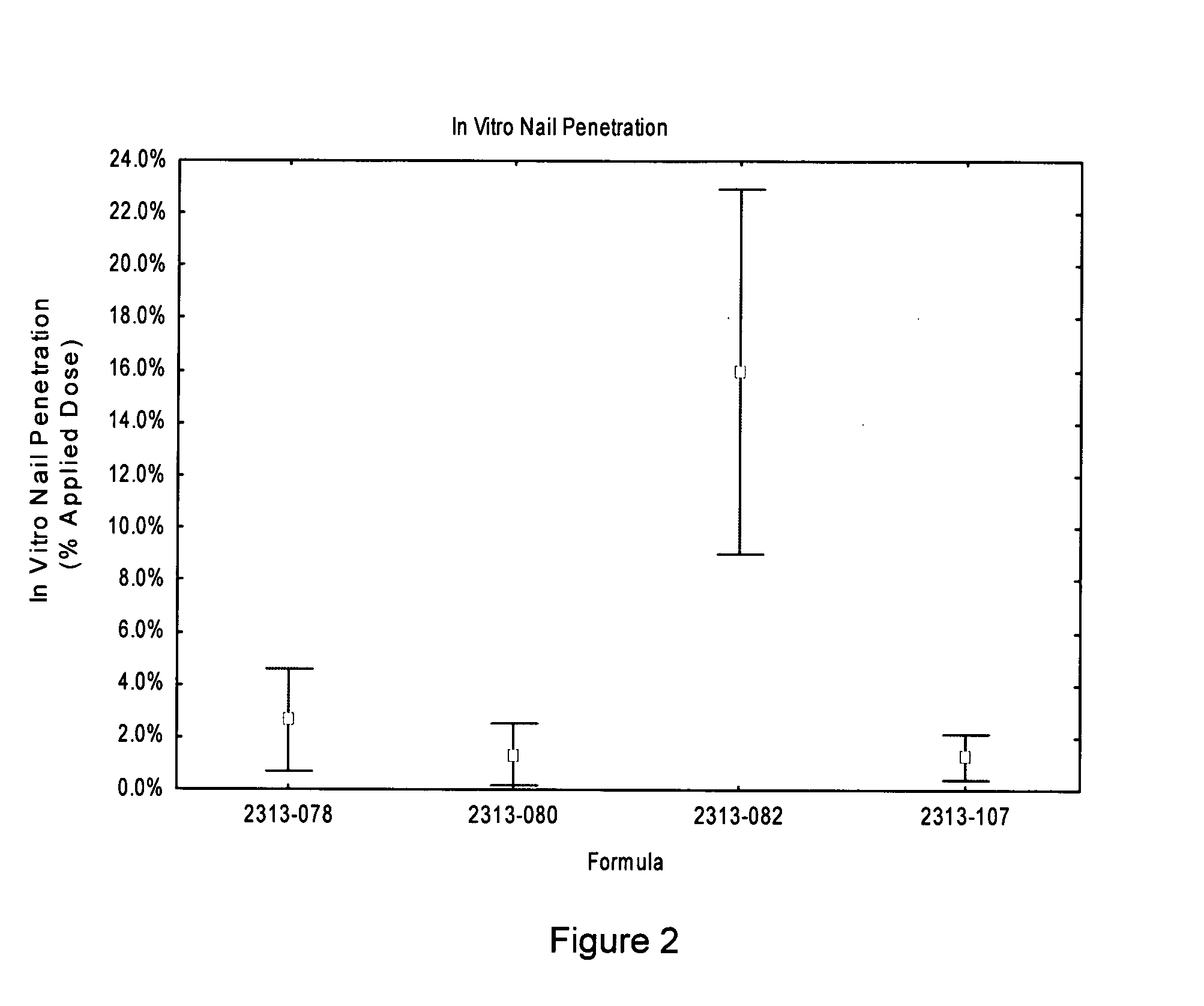

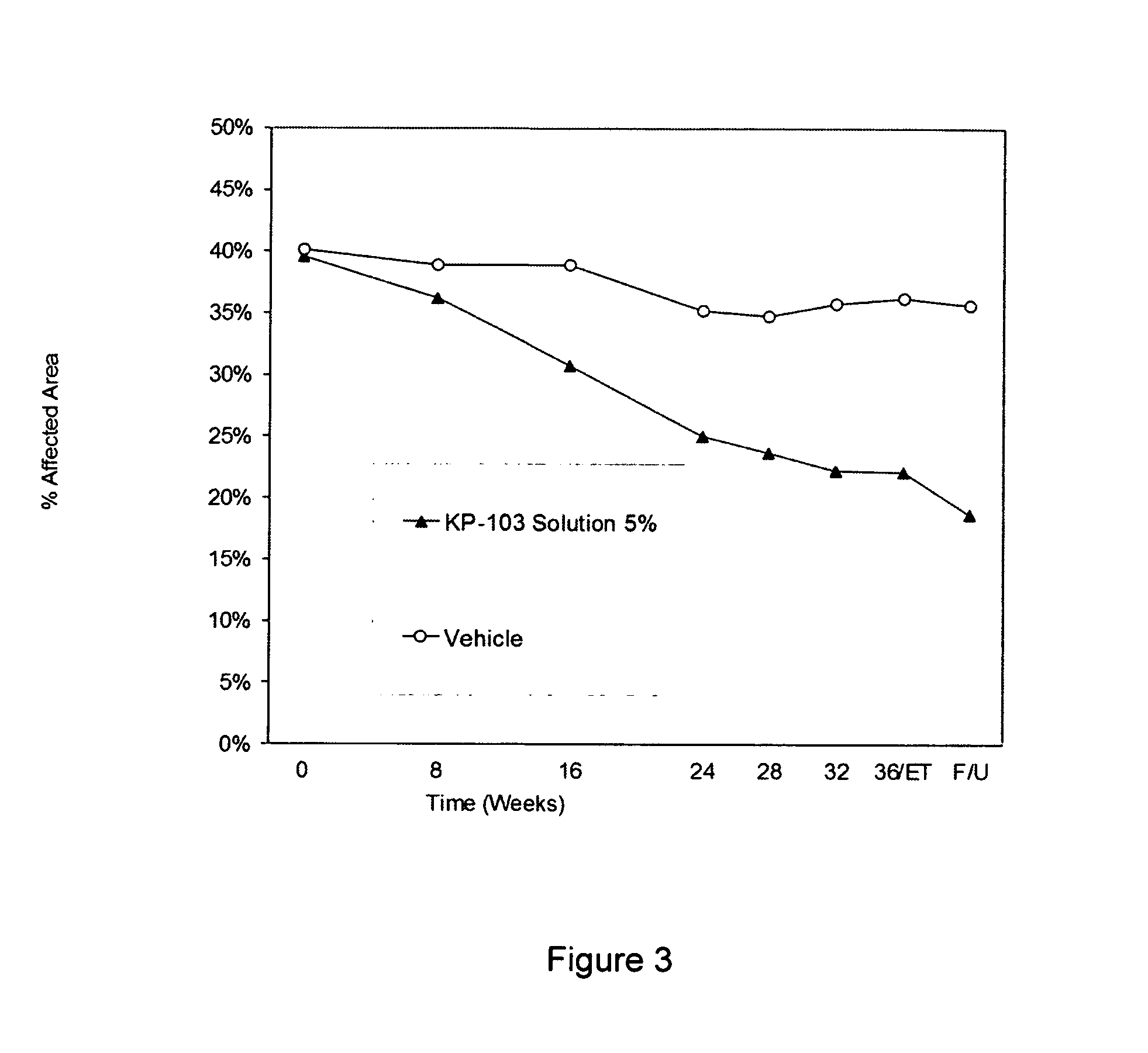

Compositions and methods for treating diseases of the nail

Methods and compositions for treating disorders of the nail and nail bed. Such compositions contain a vehicle in which all components of the composition are dissolved, suspended, dispersed, or emulsified, a non-volatile solvent, a wetting agent, and a pharmaceutically active ingredient that is soluble in the non-volatile solvent and / or a mixture of the vehicle and the non-volatile solvent, which composition has a surface tension of 40 dynes / cm or less and has continuing spreadability, and which composition is effective in treating a disorder of the nail or nail bed.

Owner:BAUSCH HEALTH IRELAND LTD

Electrode composition for inkjet printing, and electrode and secondary battery prepared using the electrode composition

InactiveUS20110111292A1Improve cycle lifeConductive materialActive material electrodesSolventSpreadability

An electrode composition for inkjet printing includes an electrode active material, a binder resin, and a solvent. An electrode and a secondary battery prepared by using the electrode use the printed electrode composition. A precise electrode pattern is formed by using an inkjet printing method since spreadability of the electrode composition is excellent. The secondary battery is a micro-thin type having increased electrode capacity and increased cycle lifespan which is prepared since coherence between the electrode composition and a current collector is excellent.

Owner:SAMSUNG ELECTRONICS CO LTD

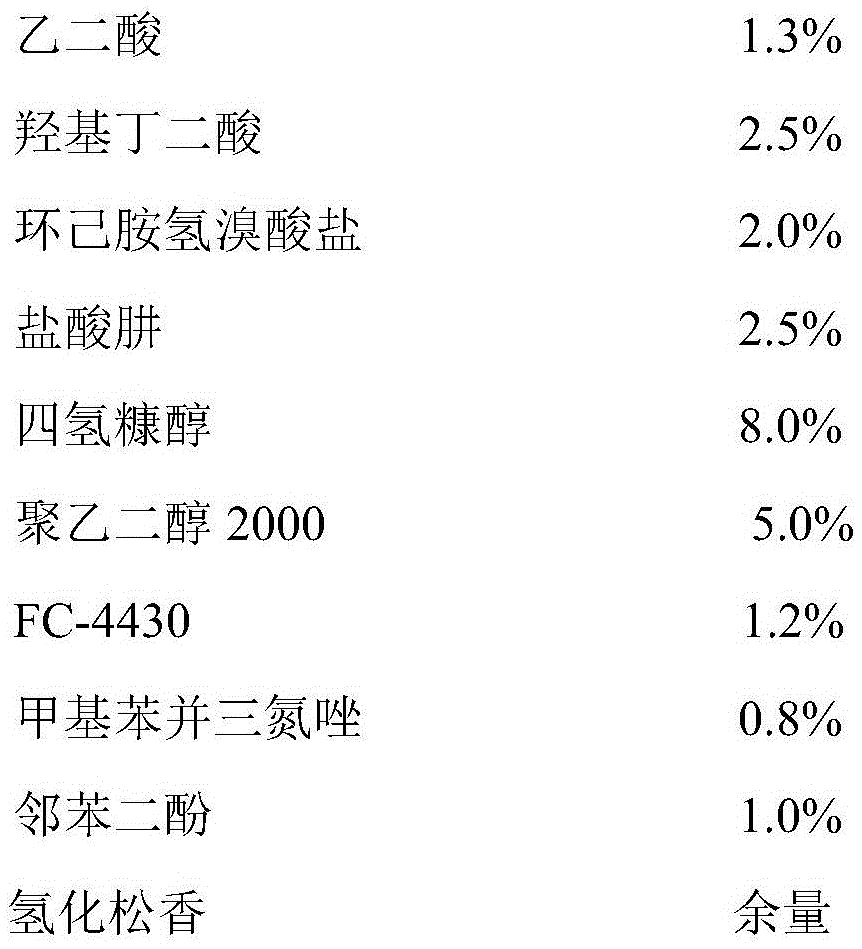

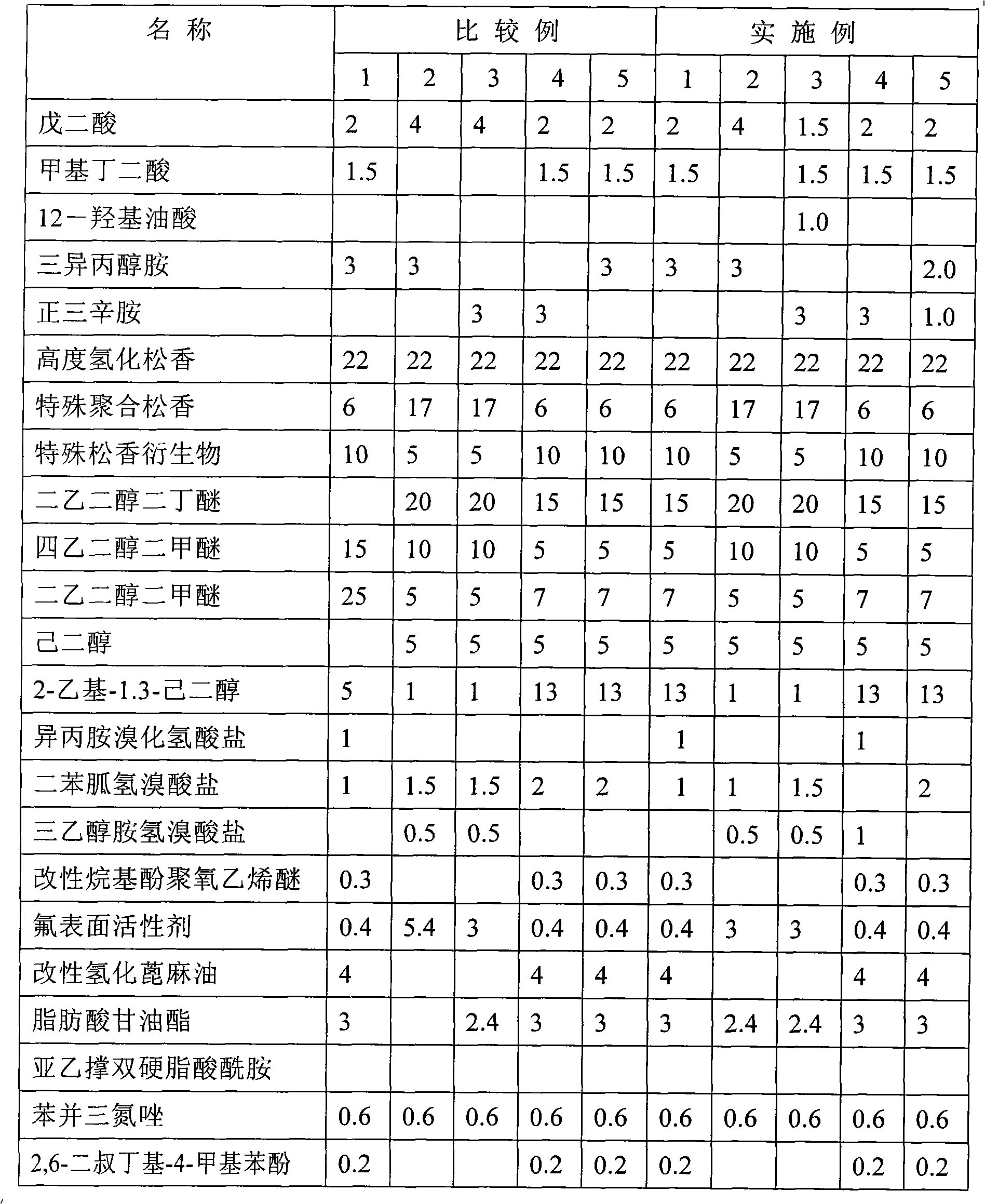

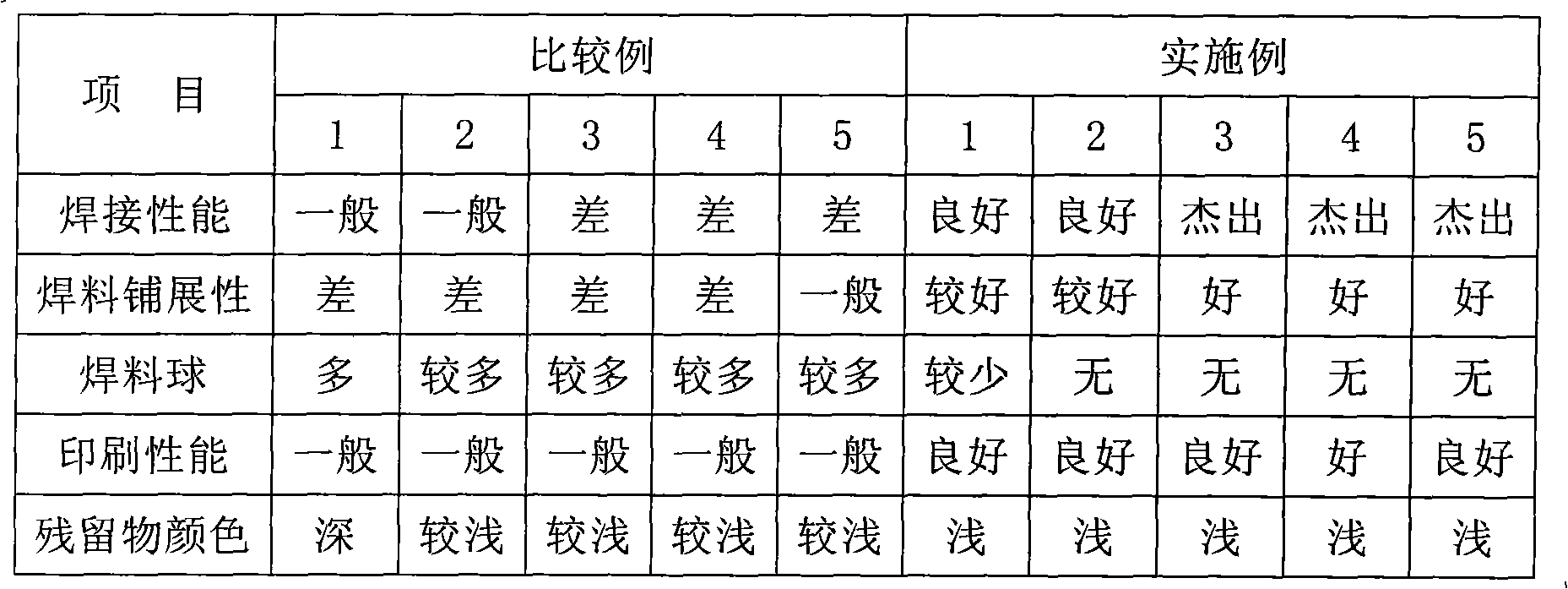

Low solid content halogenide-free water-based type cleaning-free scaling powder

InactiveCN101327552AHigh activitySolve the defect of insufficient wettabilityWelding/cutting media/materialsSoldering mediaWater basedAviation

The present invention relates to a medium-and-high-activity, low-solid-content halideless water-based type wash-free soldering flux which is applicable to the spraying process, the foaming process and the dipping process. The soldering flux is composed of the following weight proportions of substances: 1 percent to 4 percent of promoting agent, 0.5 percent to 1.5 percent of filmerformer, 20 percent to 40 percent of latent solvent, 0.1 percent to 2 percent of wetting agent and 0.01 percent to 0.1 percent of corrosion inhibitor, and the rest is deionized water. The soldering flux of the present invention does not contain halogen and colophony; soldering material can have good spreadability; a PCB board can have good solder permeability; soldering spots are plump and shiny; the surface of the soldered PCB board has no visible residues and is not eroded, and the surface insulation resistance is high; under the normal temperature, the soldering flux does not absorb moisture and cannot be decomposed, and a washing process can be omitted. Since the deionized water is used as solvent, the soldering flux does not contain any volatile organic substance, so the soldering flux cannot be ignited and does not explode, and therefore the soldering flux is environment-friendly. The soldering flux is applicable to the wave-soldering or dip-soldering production line of various printed boards in the fields of communication, aviation, computers, etc.

Owner:DONGGUAN YONGAN TECH

Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal and preparation method thereof

InactiveCN102319963AReduce brittlenessImprove surface activityWelding/cutting media/materialsSoldering mediaSlagAlloy

The invention relates to an Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal and a preparation method thereof. The components of the aluminum-based brazing filler metal are 7 to 13 percent by weight of Si, 5 to 11 percent by weight of Cu, 4 to 11 percent by weight of Zn, 1 to 6 percent by weight of Sn, 1 to 3 percent by weight of Ni, 0.02 to 0.3 percent by weight of Ce, 0.01 to 0.1 percent by weight of Sr, 0.01 to 0.2 percent by weight of Zr and the balance of Al. The process flow for preparing the aluminum-based brazing filler metal is that: pure aluminum is added into a graphite crucible and covered by flux for aluminum under the condition of 800 DEG C to 900 DEG C, and slag is removed after melting; the aluminum-based intermediate alloy of high-melting point elements and flux for aluminum are added at the same time, and melting, stirring and slag removal are carried out; the aluminum-based intermediate alloy of low-melting point elements is added under the protection of nitrogen, and melting and stirring are carried out; the mixture of argon and hexachloroethane is added to carry out refining, and standing and slag removal are carried out; the intermediate alloy of trace elements is added, and melting and stirring are carried out; secondary refining and slag removal are carried out; and under the protection of nitrogen, casting formation is carried out. The Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal has the advantages of low melting point, high strength, high toughness, high corrosion-resistant property and good wetting property and spreadability.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

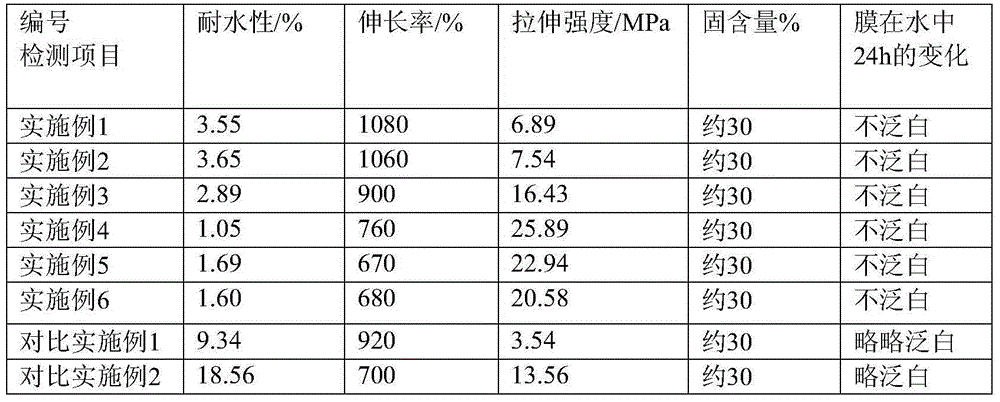

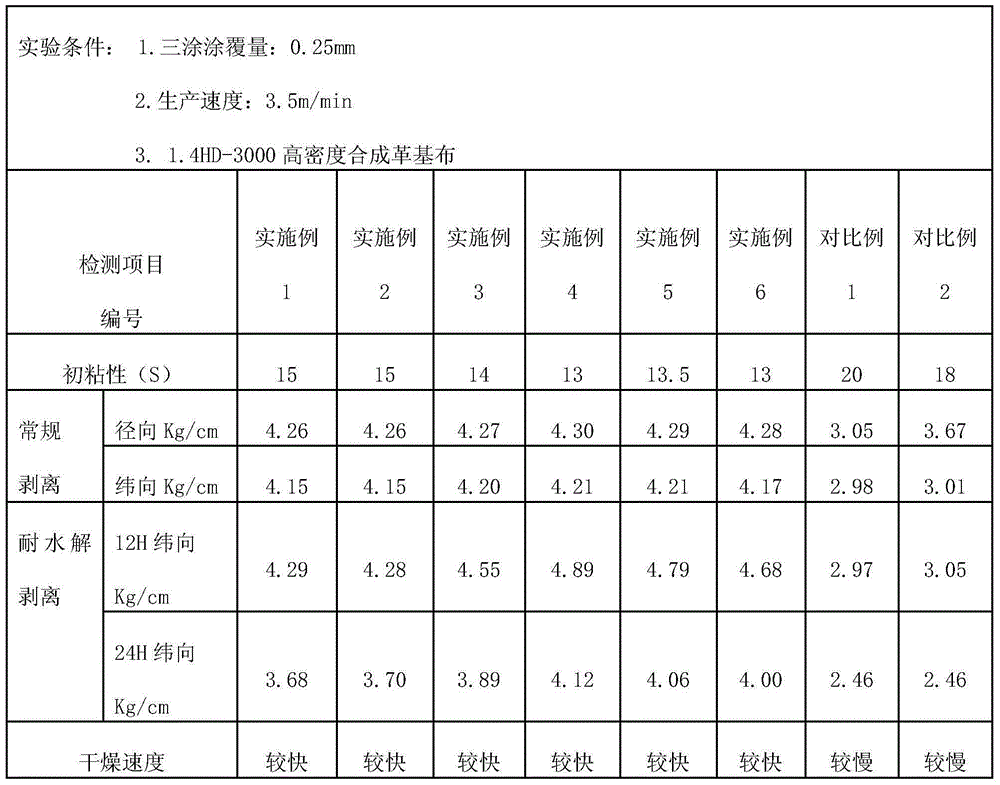

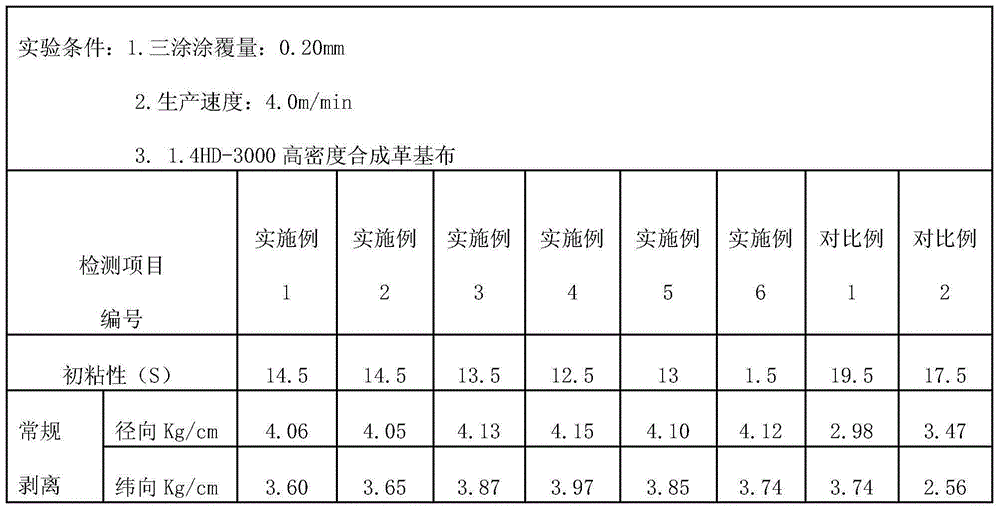

Synthetic leather binding agent and preparation method thereof

ActiveCN105062403AGood light fastnessImprove initial tack performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAlcohol

The invention provides a synthetic leather binding agent and a preparation method thereof. The synthetic leather binding agent is mainly prepared from polyhydric alcohol, diisocyanate, catalysts, epoxy resin and the like. According to the synthetic leather binding agent and the preparation method thereof, chemical modification is conducted on waterborne polyurethane through the epoxy resin, the high degree of branching of the epoxy resin is introduced into a main chain of polyurethane, and the initial adhesion, the peel strength, the drying rate and the water resistance of a dispersion liquid film are improved. The synthetic leather binding agent prepared through the method has good environment protectability. Dispersion liquid has the advantages of being high in initial adhesion, good in peel strength, high in drying rate and excellent in water resistance. Meanwhile, the good levelling property and spreadability are achieved. The using condition of the synthetic leather binding agent is met.

Owner:SHANDONG TIANQING TECH DEV

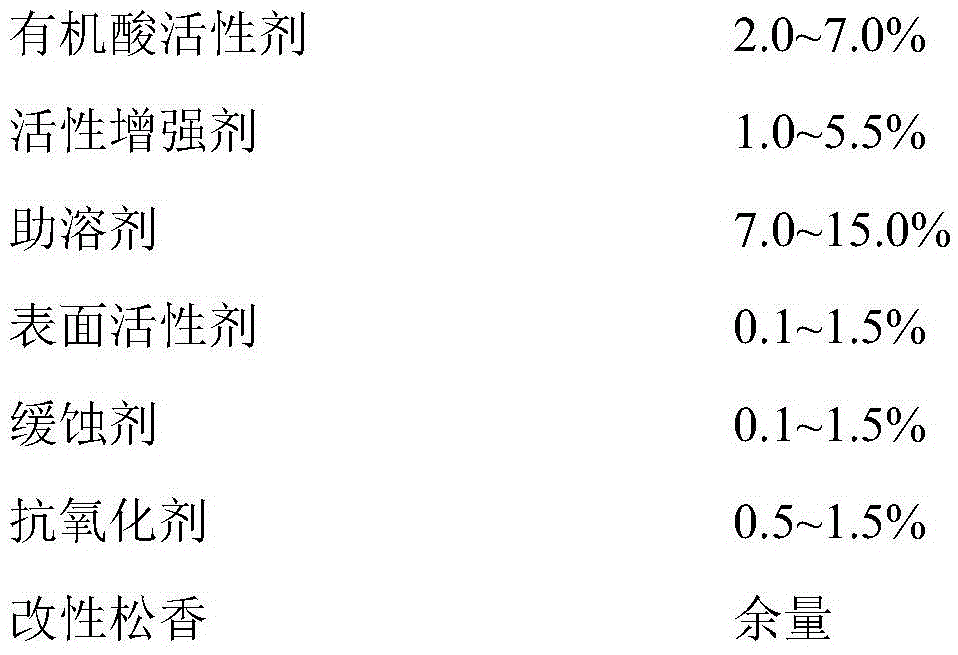

High-performance tin wire soldering flux for automatic tin soldering and preparation method of high-performance tin wire soldering flux

ActiveCN105458552ASuccessful realization of automatic solderingFast tinningWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceOrganic acid

The invention relates to a high-performance tin wire soldering flux for automatic tin soldering and a preparation method of the high-performance tin wire soldering flux. The high-performance tin wire soldering flux is prepared from the following components in percentage by weight: 2.0-7.0% of an organic acid active agent, 1.0-5.5% of an activity enhancer, 7.0-15.0% of a solubilizer, 0.1-1.5% of a surfactant, 0.1-1.5% of an inhibitor, 0.5-1.5% of an antioxidant, and the balance being modified rosin. A tin wire made by adopting the soldering flux disclosed by the invention has the characteristics of high tin plating speed, good spreadability, low empty soldering and false soldering rate, high insulation resistance after soldering, and the like; the soldering flux is particularly suitable for automation tin soldering for assembling of electronic parts and components in specific structures, printed circuit boards in specific structures and the like, and can be widely applied for the automatic tin soldering of batteries, instruments, meters and various in-home electric appliances in the electronic / electrical industry; the production efficiency is easy to improve, and the production cost is reduced.

Owner:SHENZHEN XINGHONGTAI TIN +1

Foaming hair care composition

InactiveUS20170087068A1Reduced wet conditioningReduced spreadabilityCosmetic preparationsHair cosmeticsVolumetric Mass DensityPolymer chemistry

Disclosed is a hair care composition comprising: a high melting point fatty compound; a cationic surfactant system; an aqueous carrier; and a propellant; wherein the composition has a foam density of at least about 0.3, and wherein the composition has a foam collapse resistance value of at least about 1.5 kg·m·s−2 [N]. This foaming hair care composition provides improved wet conditioning, spreadability and / or even deposition.

Owner:THE PROCTER & GAMBLE COMPANY

Multi-vegetable-oil-containing infantile eczema care cream

InactiveCN106361599ANon-irritatingLong-term stabilityCosmetic preparationsToilet preparationsWaxVegetable oil

The invention discloses a multi-vegetable-oil-containing infantile eczema care cream. The infantile eczema care cream is proportionally prepared from the following raw materials by a conventional cream preparation method: 10-30% of shea butter, 1-5% of camellia seed oil, 5-10% of Moringa oleifera seed oil, 1-5% of lanolin, 1-5% of Calm Yang (WAX), 0.5-1.0% of dendrobe / Tremella fuciformis extract and 1-5% of Calm Yang. The infantile eczema care cream can improve the skin, is nonirritating and safe for the skin, is mild, moisturizing and not oily, has favorable spreadability, has favorable itching relieving effects after use, and has favorable relieving effects on multiple skins.

Owner:FUJIAN MENGJIAOLAN DAILY CHEM

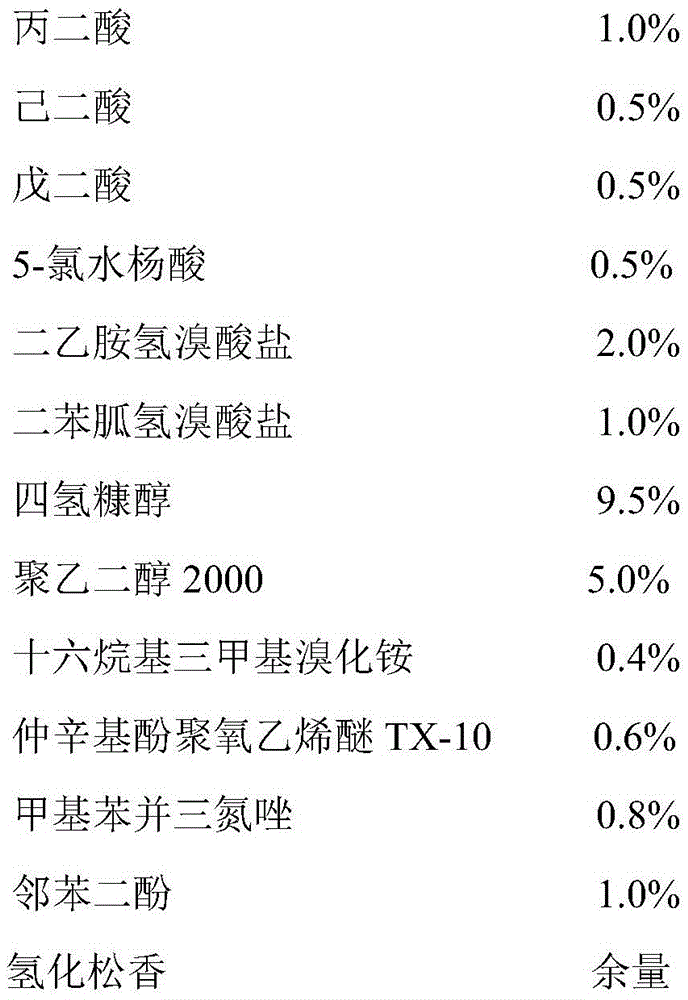

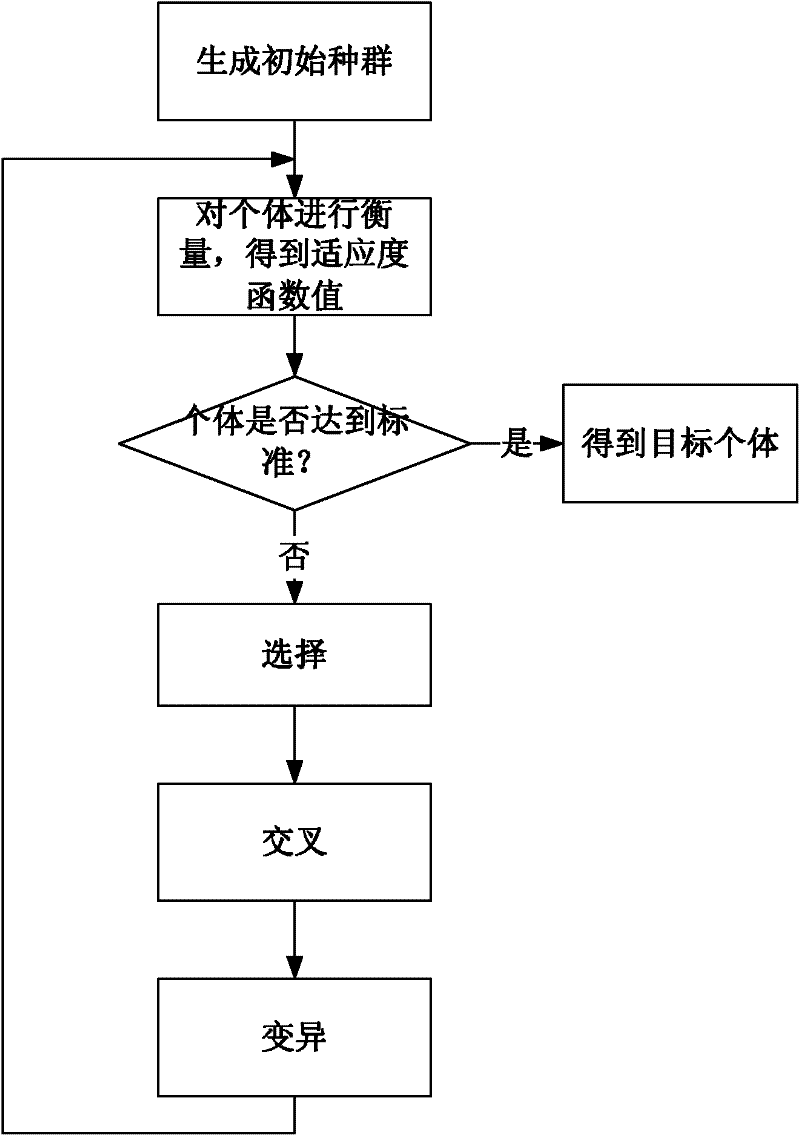

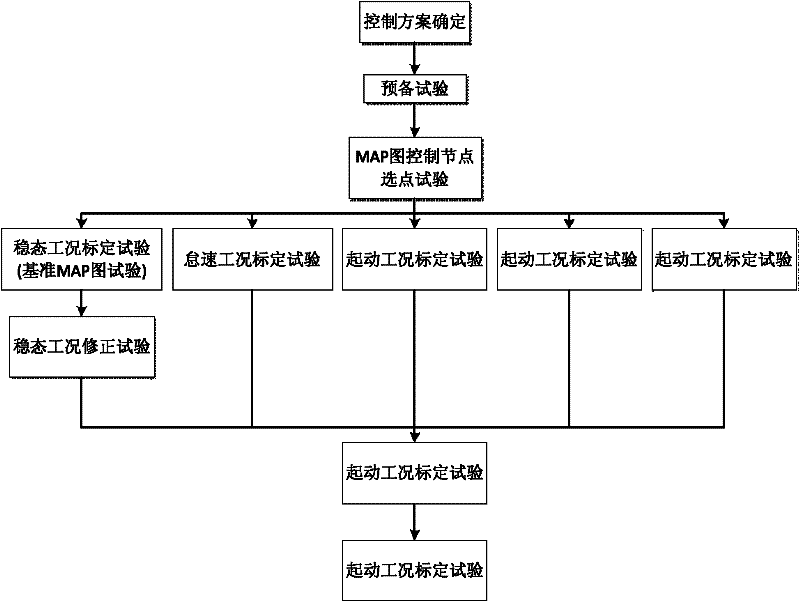

Automatic calibration parameter optimization method of engine based on genetic algorithm

InactiveCN102337979AStrong automationImprove objectivityElectrical controlMachines/enginesAlgorithmMetapopulation

Owner:ZHEJIANG UNIV

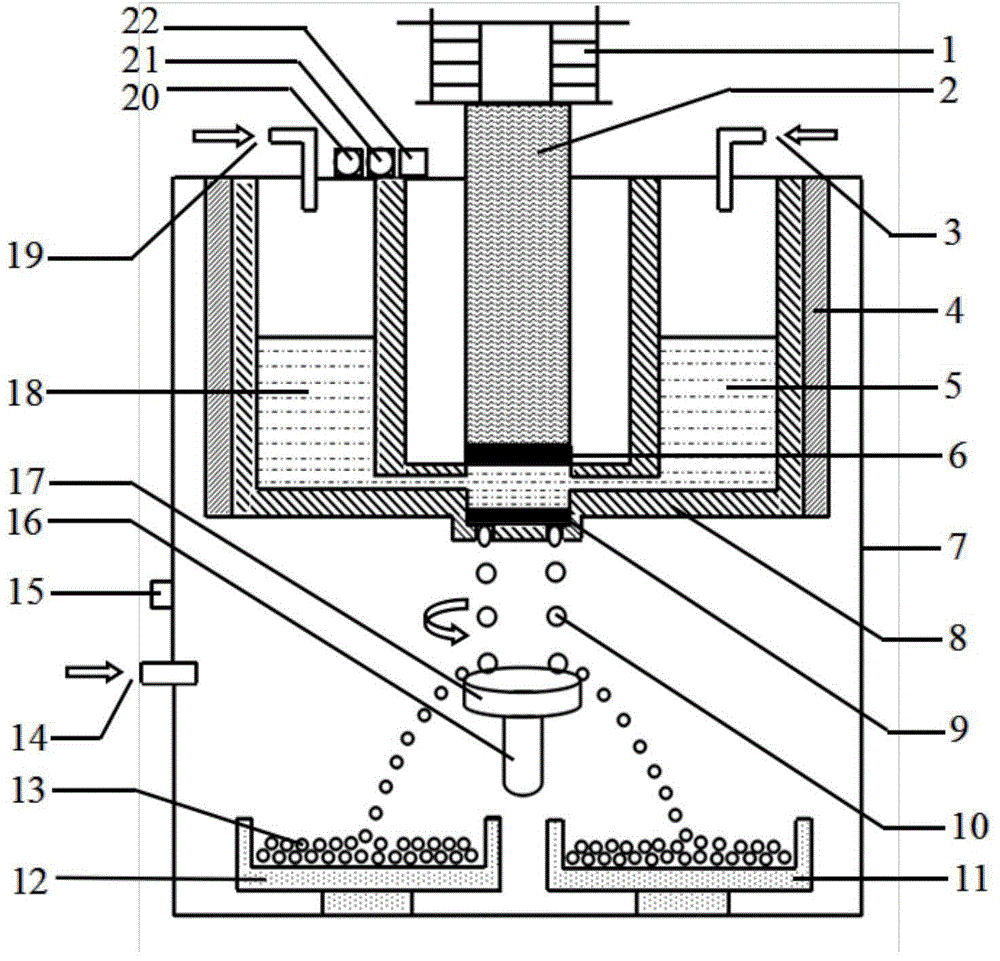

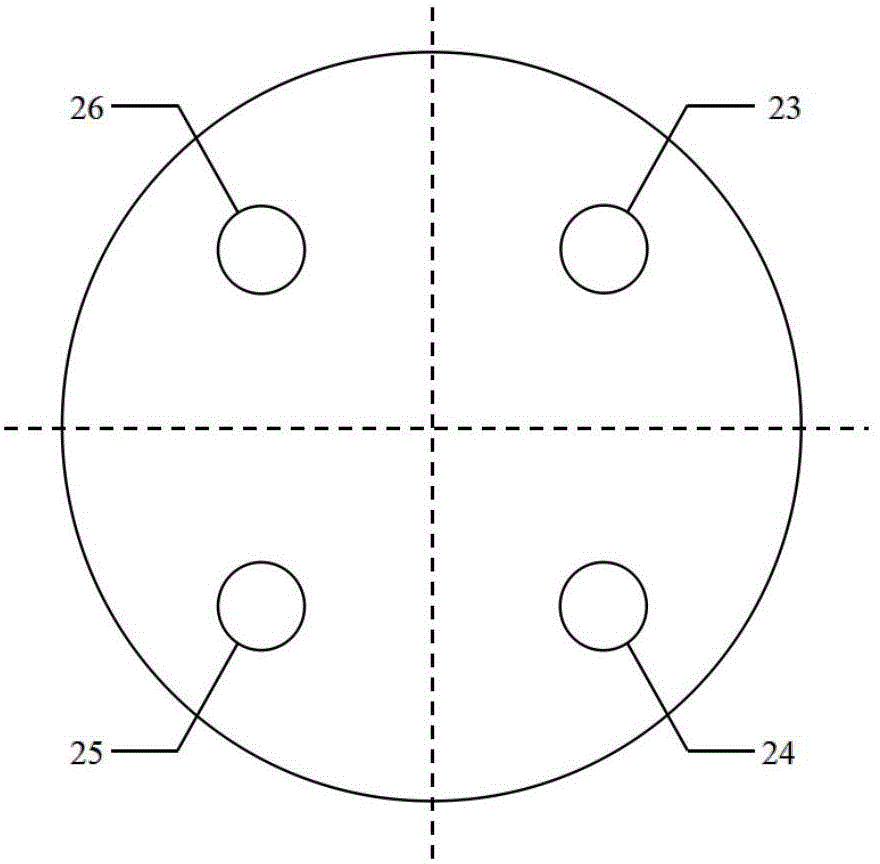

High efficiency superfine spherical metal powder preparation method and device

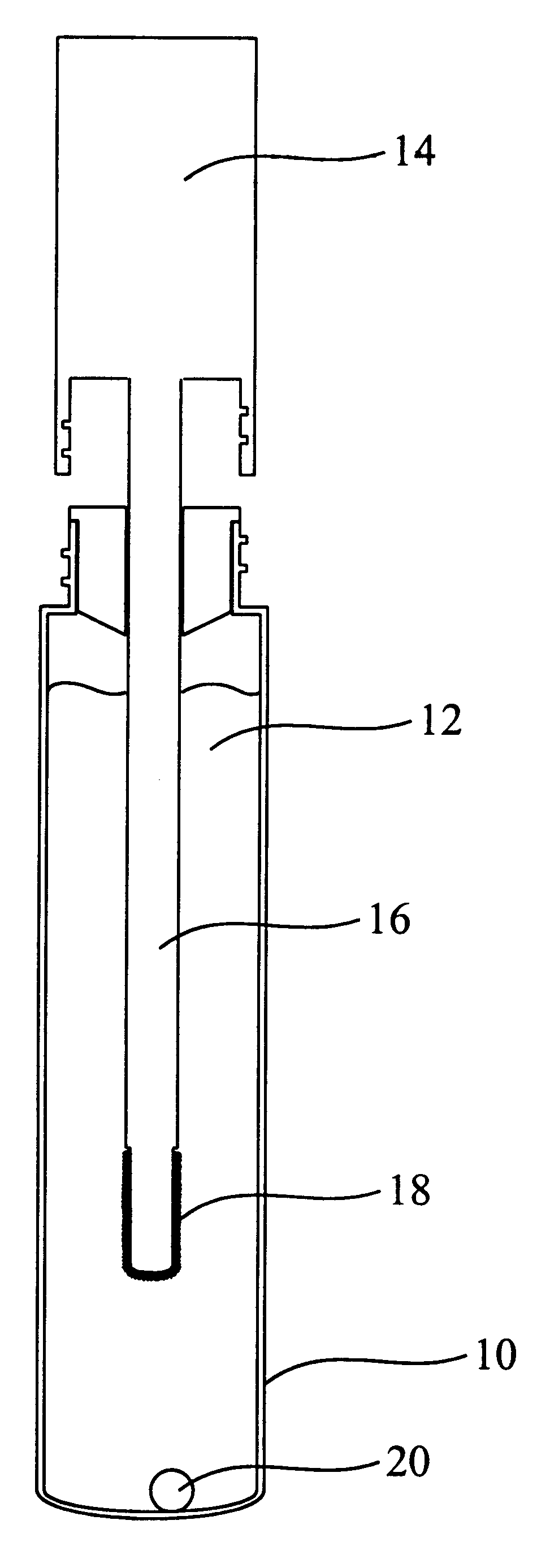

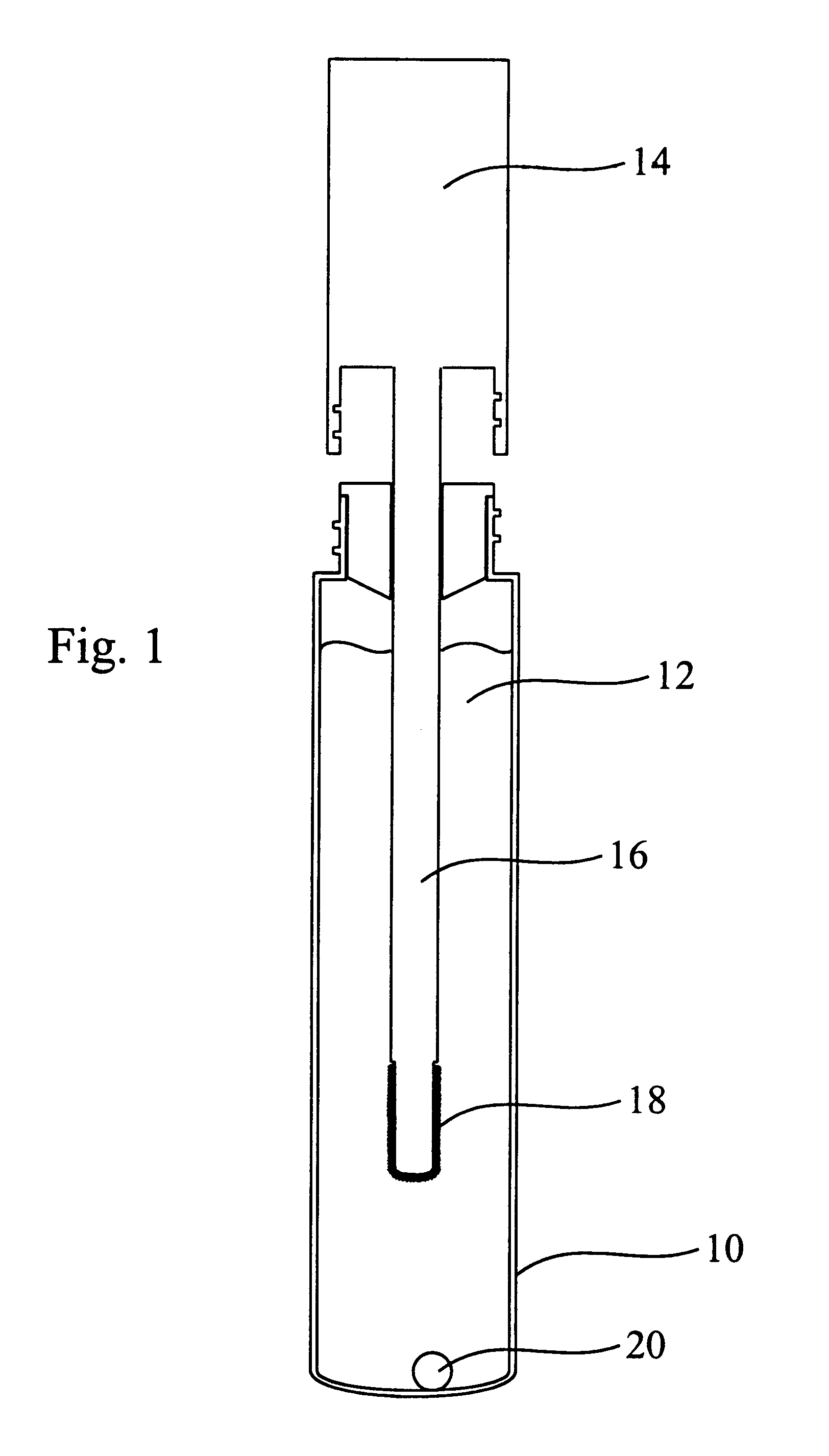

The invention discloses a high-efficiency superfine spherical metal powder preparation device, which comprises a shell, a crucible and a powder collecting area, and is characterized in that the crucible is in a circular structure that the inside and the outside are nested, the bottom of the inner accommodating cavity of the crucible and the bottom of the outer accommodating cavity of the crucible are provided with central holes which are through; a space used for flowing molten metal is arranged between the bottom of the inner accommodating cavity and the bottom of the outer accommodating cavity; a tabletting is arranged above the central hole of the inner accommodating cavity, and a drive rod contacts with the tabletting; the central hole bottom of the outer accommodating cavity is provided with a gasket with a hole; the powder collecting area comprises a catch tray and a rotating disk, wherein the catch tray is arranged on the bottom of the shell and the rotating disk is arranged above the catch tray and is connected with a motor. The invention further discloses a method of preparing the superfine spherical metal powder, the method mainly combines a pulse microcellular injection method and a centrifugal atomization method, and the superfine spherical metal powder meeting the usage requirements that the grain size distribution range is narrow, the sphericity is high, the spreadability and the mobility are good, and the production efficiency is high can be prepared.

Owner:DALIAN UNIV OF TECH

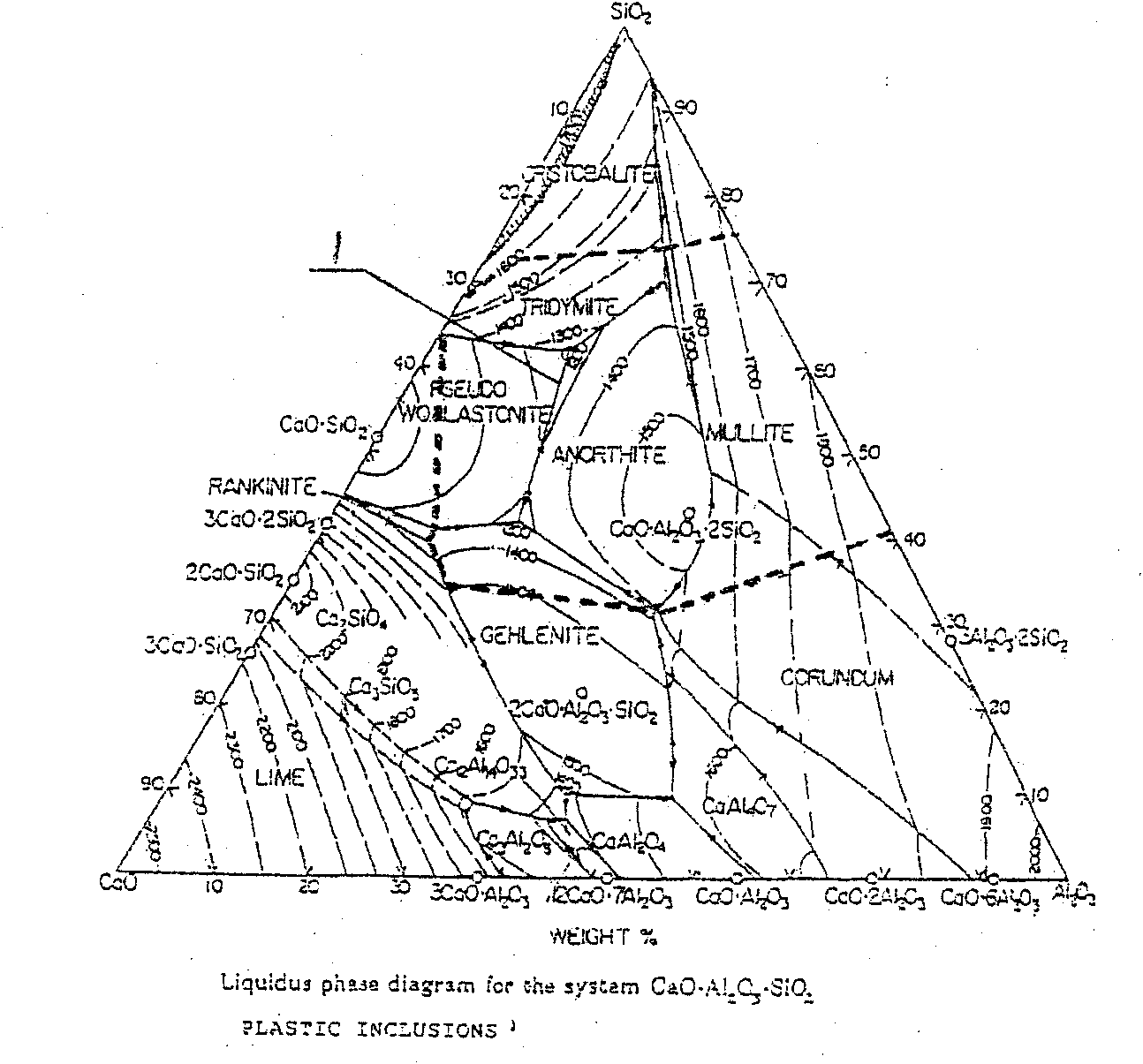

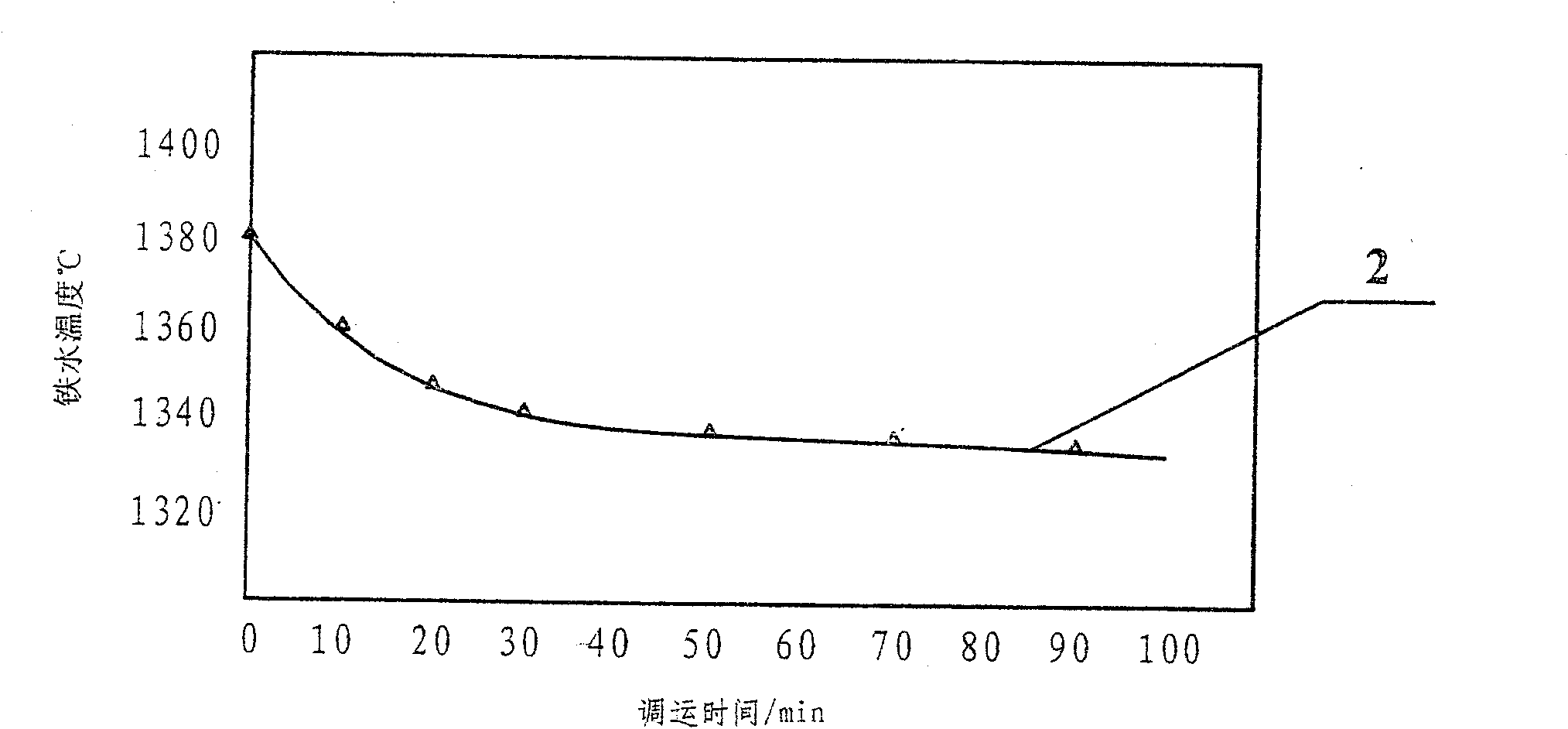

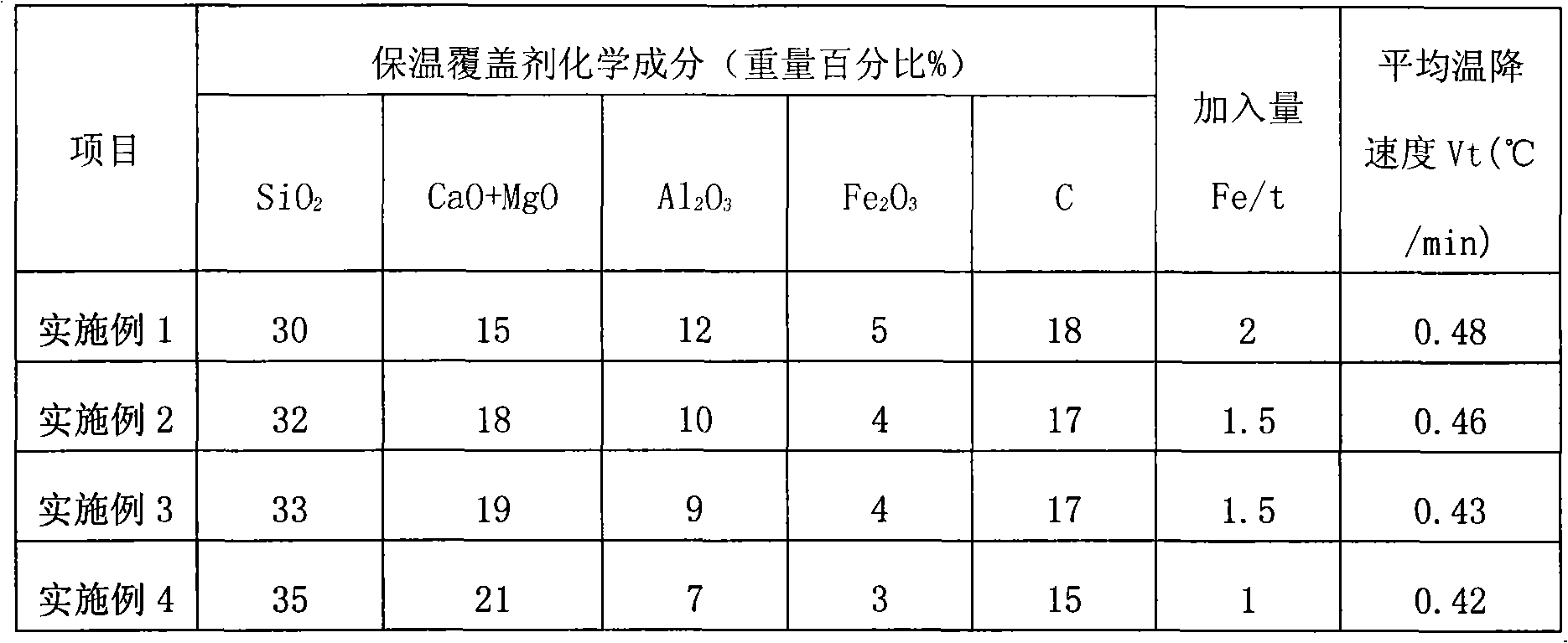

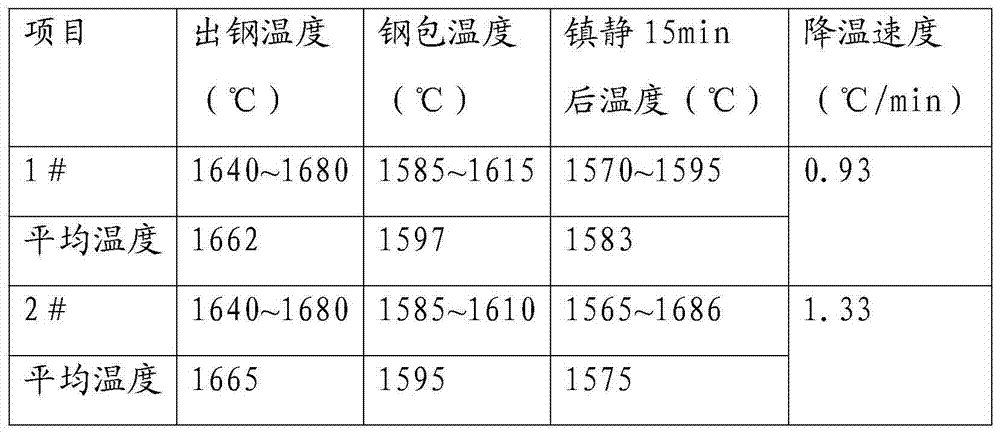

Granular heat-preserving covering flux for hot metal in steelmaking

InactiveCN101787413AConducive to slag cleaning operationImprove adsorption capacityProcess efficiency improvementSteelmakingImpurity

The invention discloses a granular heat-preserving covering flux for hot metal in steelmaking, and relates to a treatment agent added into a ladle for preserving heat on the surface of hot metal for steelmaking. The granular heat-preserving covering flux is characterized in that: the heat-preserving covering flux is prepared from expanded vermiculite, wollastonite, bauxite, iron ore concentrate and coke powder, and comprises the following components in percentage by weight: 30 to 35 percent of SiO2, 15 to 21 percent of (CaO+MgO), 7 to 12 percent of Al2O3, 3 to 5 percent of Fe2O3, 15 to 20 percent of C, and the balance of impurities; and the raw materials are ground, sieved, mixed, mixed and stirred, dried, cooled, and weighed and packaged at normal temperature and normal pressure. The granular heat-preserving covering flux has the advantages that: the granular heat-preserving covering flux has good slagability and spreadability, is conveniently adsorbed by inclusion, contains a heat-generating agent and an oxygen supplying agent so as to facilitate melting per se and reduce iron sticking and ladle sticking; the expanded vermiculite and the wollastonite regulate components of the heat-preserving covering flux, and have expanding and heat insulating functions, and good heat preservation property; the MgO regulates the alkalinity and reduces the adhesion of the heat-preserving covering flux with a ladle lining so as to facilitate cleaning slag in the ladle; and the heat-preserving covering flux is granular and greatly reduces dust pollution.

Owner:马鞍山中冶钢铁冶金高新技术有限公司

Personal care composition with improved spreadability

A stable personal care composition in the form of a substantially anhydrous oil matrix having improved spreadability that may comprise a hydrocarbon wax, a polar oil, and a non-emulsifying silicone elastomer. The weight ratio of the hydrocarbon wax to the polar oil is from about 0.01 to about 0.5. The personal care composition may exhibit a spreadability of 1.0 kg to about 5.0 kg and a hardness of about 3 g to about 120 g

Owner:THE PROCTER & GAMBLE COMPANY

Lead-free soldering paste

ActiveCN102000927AExtended active timeImprove flux performanceWelding/cutting media/materialsSoldering mediaFatty acid glycerol estersSolvent

The invention discloses a lead-free soldering paste with favorable welding performance, printing performance and spreadability and fewer welded residues. The lead-free soldering paste is formed by mixing 8-20 percent by weight of soldering flux and 80-92 percent by weight of SnAgCu series solder powder. The soldering flux comprises the components: 38-44 percent by weight of colophony, 6.5-7.0 percent by weight of activating agent, 41-45 percent by weight of organic solvent and 2.4-7.0 percent by weight of thixotropic agent, wherein the activating agent comprises halogen composite salt, dicarboxylic acid and alcohol amine salt; the organic solvent is formed by matching solvent with high boiling point being more than 220DEG C and solvent with low boiling point being less than 220DEG C; the thixotropic agent comprises one or two of daiamid, hydrogenated castor oil, fatty glyceride and N, N-ethylene distearate; and the SnAgCu series solder powder is formed by mixing 96.5-99.0 percent by weight of Sn powder, 0.3-3.0 percent by weight of Ag powder and 0.5-0.7 percent by weight of Cu powder. The invention is applicable to the surface mounted process in the electronic industry.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

Low-melting-point and high-strength aluminum-based brazing filler metal and preparation method thereof

InactiveCN102000924AReduce brittlenessReduce surface tensionWelding/cutting media/materialsSoldering mediaNitrogen gasToughness

The invention discloses a low-melting-point and high-strength aluminum-based brazing filler metal and a preparation method thereof. The brazing filler metal consists of the following components in percentage by mass: 6 to 13 percent of Si, 6 to 13 percent of Cu, 1 to 3 percent of Ni, 0.01 to 0.1 percent of Sr, 0.01 to 0.2 percent of Ti, 0.01 to 0.2 percent of Y and the balance of Al. The preparation method comprises the following steps of: weighing each component; adding the components into a graphite crucible melting furnace according to a certain sequence; melting and then refining twice, wherein argon gas and hexachloroethane are used as refining agents during the refining; introducing the hexachloroethane from bottom of solution by the argon gas, wherein the introduction pressure of the argon gas is 5 to 7KPa; and continuously casting solution which is subjected to the second refining process under the protection of nitrogen gas as required or performing gas atomization to form the aluminum-based brazing filler metal in different forms. The aluminum-based brazing filler metal prepared by the method has the superior characteristics of low melting point, high strength, toughness, wettability and spreadability and the like.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

Color-changing wallpaper adhesive primer/activator

Adhesives and primer compositions that include water, a polymer and a pH indicator. The adhesives and primers have a visually-detectable color when wet, and preferably dry to a clear or transparent film, while having good flow and spreadability. The adhesives and primers provide a visual indication of wetness by including a pH indicator such that when the composition is wet, the pH indicator is colored such that the color and the intensity of the color provides a visual indication of wetness; sufficiency of thickness; and uniformity of application of the adhesive or primer.

Owner:ROMAN DECORATING PRODS

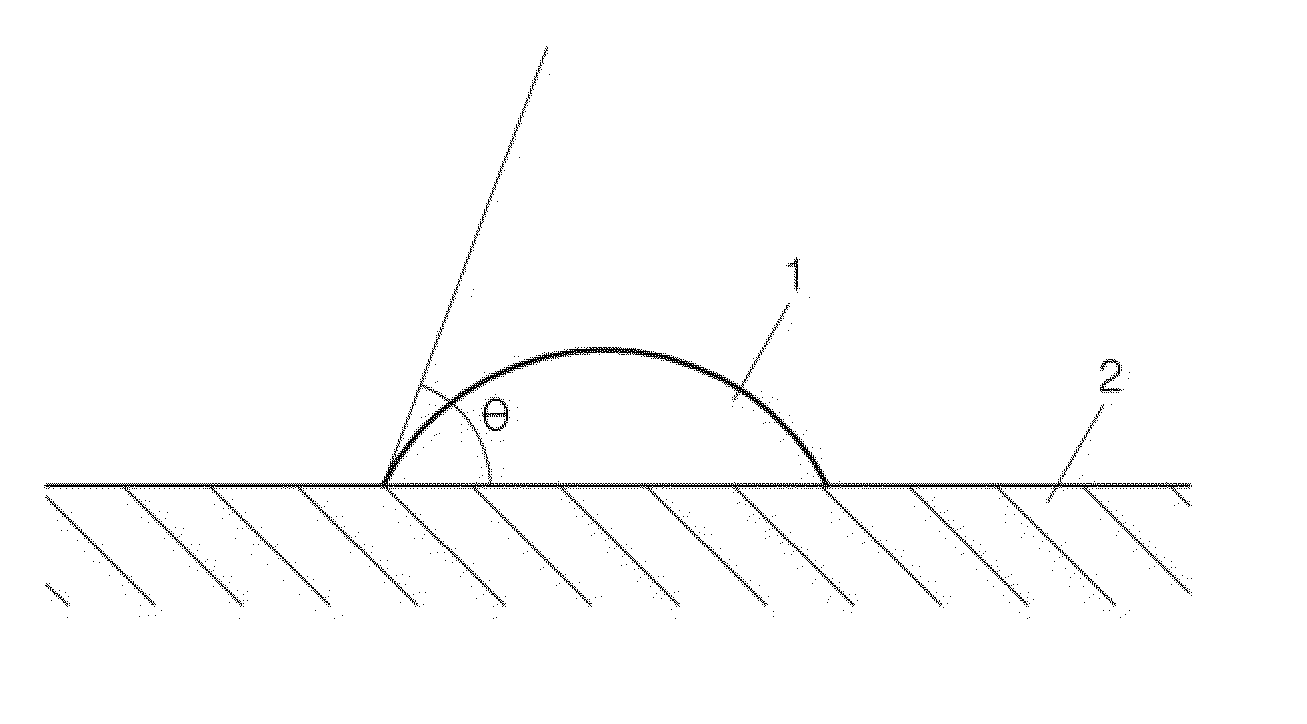

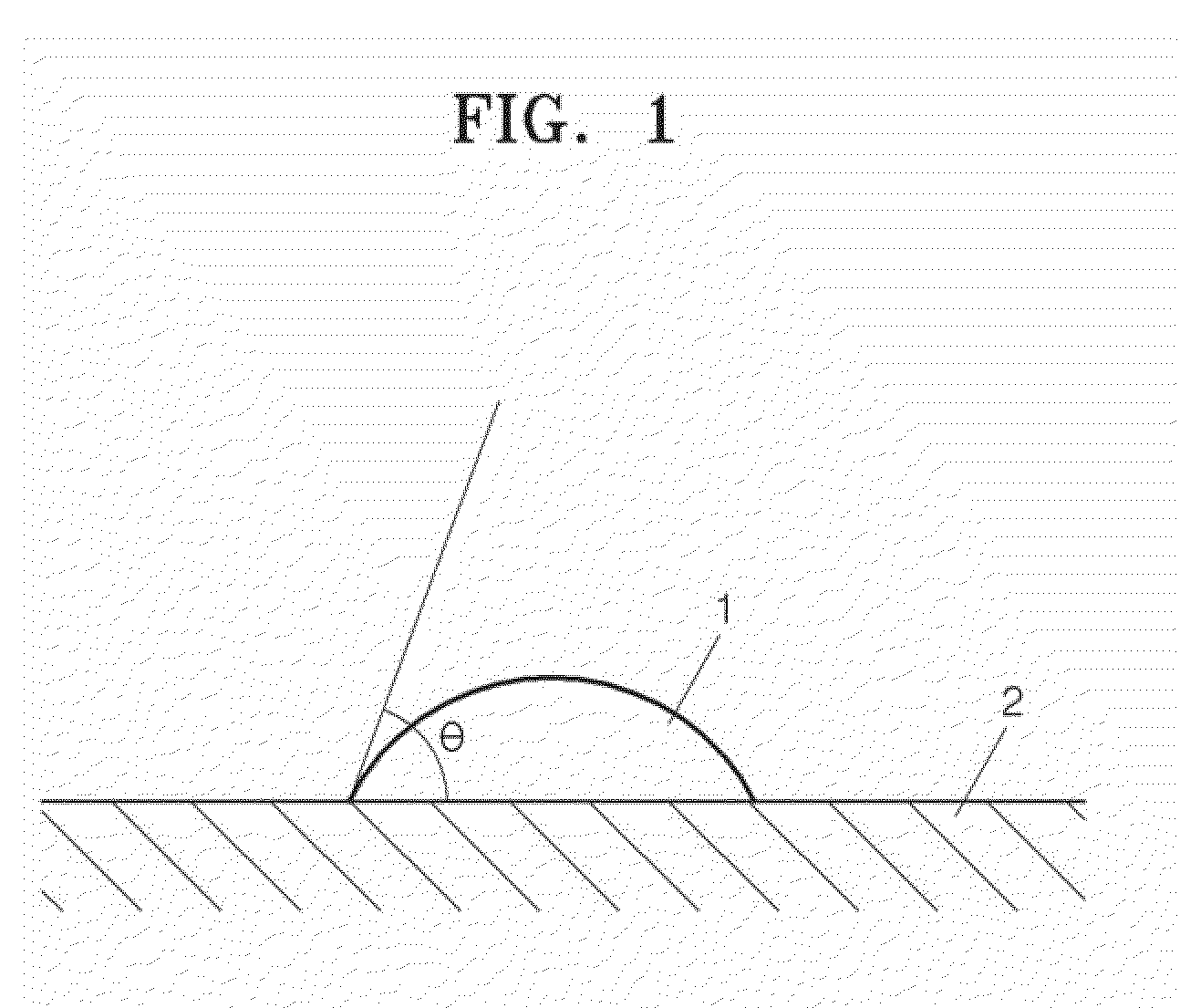

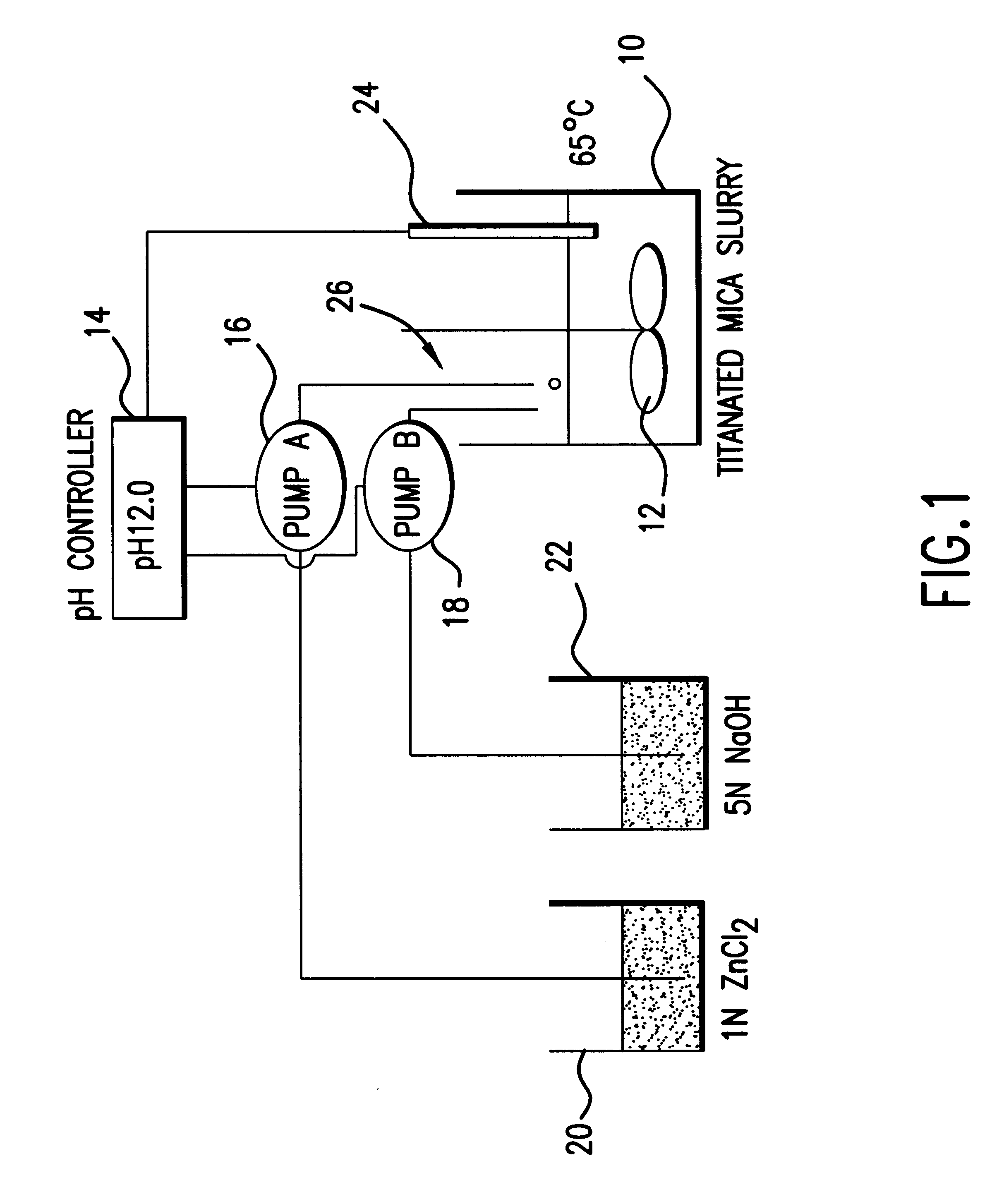

Zinc oxide-coated material and fatty acid-solidifying powder and external preparation for skin each made by using the material

InactiveUS6242092B1Higher cosmetic durabilityImproved cosmetic durabilityCosmetic preparationsBody powdersFatty acidMaterials science

An object of the present invention is to provide a powder and an external preparation for skin using the same which has good spreadability and does not spoil fatty acid-solidity ability of zinc oxide.A zinc oxide-coated material characterized as coating an amorphous state of zinc oxide on a substrate.

Owner:SHISEIDO CO LTD

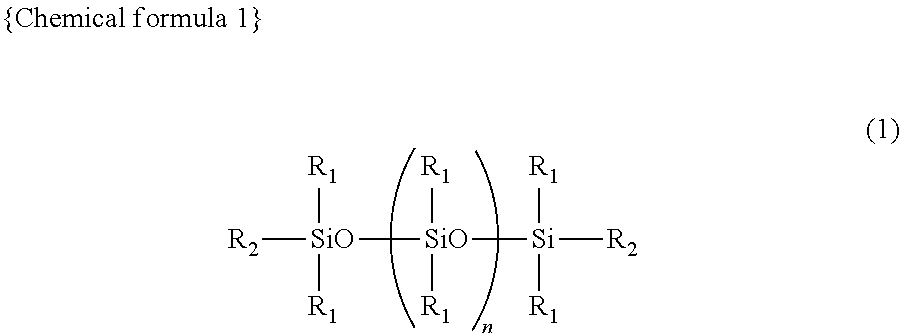

Oil-In-Water Emulsion-Type Hair Cosmetic

InactiveUS20110318295A1Promote absorptionGood spreadabilityCosmetic preparationsHair cosmeticsMass ratioOil phase

{Object} To provide an oil-in-water emulsified hair cosmetic of the present invention manifests good absorption and spreadability into the hair, doesn't cause dripping during use, and yet has an aesthetic appearance of transparent or semi-transparent gel despite the fact that it has a high mending effect and a rich sensation as is found in oil-based hair care agents.{Means to achieve the object} (a) Silicones chosen from high polymer silicone that is gum-like or has a viscosity of 1 million cs or higher, silicone with both ends hydroxy-modified, amino-modified silicone, ammonium-modified silicone, and polyalkylene glycol-modified silicone: 0.1-10 wt %, (b) Dimethylpolysiloxane having a viscosity of 100 cs or less: 0.5-79 wt %, (c) Polyhydric alcohol: 1-25 wt %, and (d) Hydrophilic surfactant: 1-10 wt % are blended in, the blend ratio of the oil phase is made to be 50-80 wt %, and the blend ratio (mass ratio) between (a) and (b) is made to be (a):(b)=1:5-1:100.[Selected drawings] None

Owner:SHISEIDO CO LTD

Color-changing wallpaper adhesive primer/activator

Adhesives and primer compositions that include water, a polymer and a pH indicator. The adhesives and primers have a visually-detectable color when wet, and preferably dry to a clear or transparent film, while having good flow and spreadability. The adhesives and primers provide a visual indication of wetness by including a pH indicator such that when the composition is wet, the pH indicator is colored such that the color and the intensity of the color provides a visual indication of wetness; sufficiency of thickness; and uniformity of application of the adhesive or primer.

Owner:ROMAN DECORATING PRODS

Low-emission aqueous dispersion adhesive

The invention is a low-emission dispersion adhesive based on polyacrylates with an addition of a tall oil resin modified by carboxy groups. The adhesive is distinguished by especially low emissions and otherwise its properties are equally as good, especially in terms of spreadability, initial tack and open time, as those of an adhesive containing balsam resin. The adhesive is very suitable for bonding floor coverings.

Owner:ARIZONA CHEM CO

Novel brazing flux used for stainless steel and aluminum brazing

InactiveCN103521942AEasy to prepareLow costWelding/cutting media/materialsSoldering mediaCopper fluoridePotassium

The invention relates to brazing flux used for brazing, in particular to novel brazing flux used for stainless steel and aluminum brazing. The composition of the brazing flux comprises potassium fluoroaluminate+potassium hexafluoroaluminate (KA1F4+K3A1F6) eutecticum, zinc fluoride (ZnF2), copper fluoride (CuF2), and stannic fluoride (SnF4). The novel brazing flux is free of corrosion, and ingredient preparation is simple and convenient, so that production cost is low. Under high temperature, the madefaction and the spreadability of the brazing flux are favorable to the madefaction and the spreadability of brazing filler metal. Welded products are thin in welding joint, high in strength, free of cold solder joints, free of brazing filler metal stacking, and small in residue of brazing flux after welding. Moreover, the residue is easy to clean up. The novel brazing flux used for stainless steel and aluminum brazing is low in cost, simple in preparation, and high in practical value.

Owner:QINGDAO SHENGJIA INFORMATION TECH

Personal Wash Compositions Comprising Specific Blends of Saturated (Hydrogenated) Oil to Unsaturated Triglyceride Oils

ActiveUS20100210500A1Improve balanceIncrease depositionCosmetic preparationsHair removalTG - TriglycerideUnsaturated Oils

The present invention provides personal wash compositions where blends of triglyceride oils are specifically formulated to provide functional benefits. Specifically when formulated to have specific blend of saturated to unsaturated oils, perfect balance between, on the one hand, spreadability and deposition and, on the other hand, retention of excellent framing, is achieved.

Owner:CONOPCO INC D B A UNILEVER

ASP medium thickness slab high drawing speed plate blank low-carbon steel continuous casting functional protective material

The invention discloses an ASP medium thickness slab high drawing speed plate blank low-carbon steel continuous casting functional protective material which comprises the components by weight percent:1.0-1.5% of Li2O, 3.0-5.0% of MgO, 0.7-1.5% of Fe2O3, 0.93-0.97% of CaO / SiO2 and the rest of SiO2, CaO, Al2O3, Na2O, F and K2O. The material solves the problems that high drawing speed plate blank continuous casting low-carbon steel has a thin liquid slag layer, poor lubrication, breakout by sticking, casting blank surface slag inclusion and sticky residue quality in the prior art. Protective slag has good spreadability, heat preservation and melting property in a crystallizer; the four sides inside the crystallizer are stable and even in capacity of heat transmission; the thickness of the liquid slag layer is 8-12mm; furthermore, the protective material has fewer slag strips, good lubricating property of the protective slag, prevents the breakout by sticking, and has no slag inclusion and sticky residue on the surface of casting blank as well as good casting blank surface quality.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

Thermal-insulation cover agent and preparation method thereof

The invention provides a thermal-insulation cover agent. The thermal-insulation cover agent is characterized in that the thermal-insulation cover agent is composed of, by mass, 25%-45% of silicon oxide, 18%-35% of aluminum oxide, 13%-28% of calcium oxide, 2%-15% of ferric oxide, 2%-5% of carbon, 2%-5% of magnesium oxide, 1.2%-4% of expanding agents, 2.6%-5% of heat generating agents, and the balance is aluminum. The invention further provides a preparation method of the thermal-insulation cover agent. The preparation method includes the following steps of ingredient weighing, mother liquor preparation, pulping, pelleting, drying and screening. The thermal-insulation cover agent has the advantages of being good in spreadability and thermal insulation performance, and capable of reducing molten steel temperature drop speed, avoiding secondary oxidation from happening on the surface of molten steel and greatly reducing pollution to operation environment.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

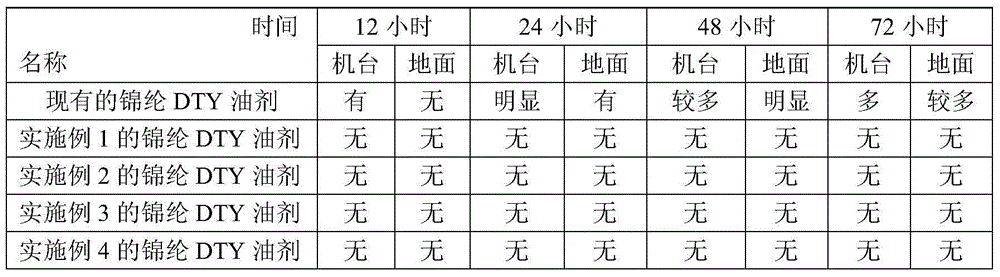

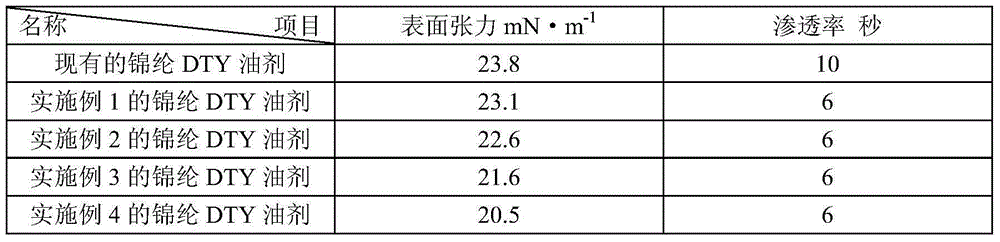

Chinlon DTY oiling agent with efficient permeability and splashing prevention property and preparation method of oiling agent

The invention provides a chinlon DTY oiling agent with efficient permeability and splashing prevention property. The oiling agent is prepared from the following components according to weight percent: 6-12% of emulsifier, 3-8% of collecting agent, 2-5% of antistatic agent, 0.5-1.5% of efficient penetrant, 0.5-1.5% of splashing prevention agent and 72-88% of smoothing agent. The chinlon DTY oiling agent with efficient permeability and splashing prevention property, provided by the invention, is transparent, steady, and good in spinnability; the surface tension of the oiling agent is small, the spreadability is good, the permeability is strong, and oiling is quick and uniform; intermolecular attraction of the oiling agent is strong, so that the oiling agent cannot be thrown away by a machine running at high speed and splash; since the oiling amount of the fiber surface is ensured, high speed elasticity enhancement is facilitated, and the quality of fiber is guaranteed.

Owner:TAICANG LONGFANG OIL CO LTD

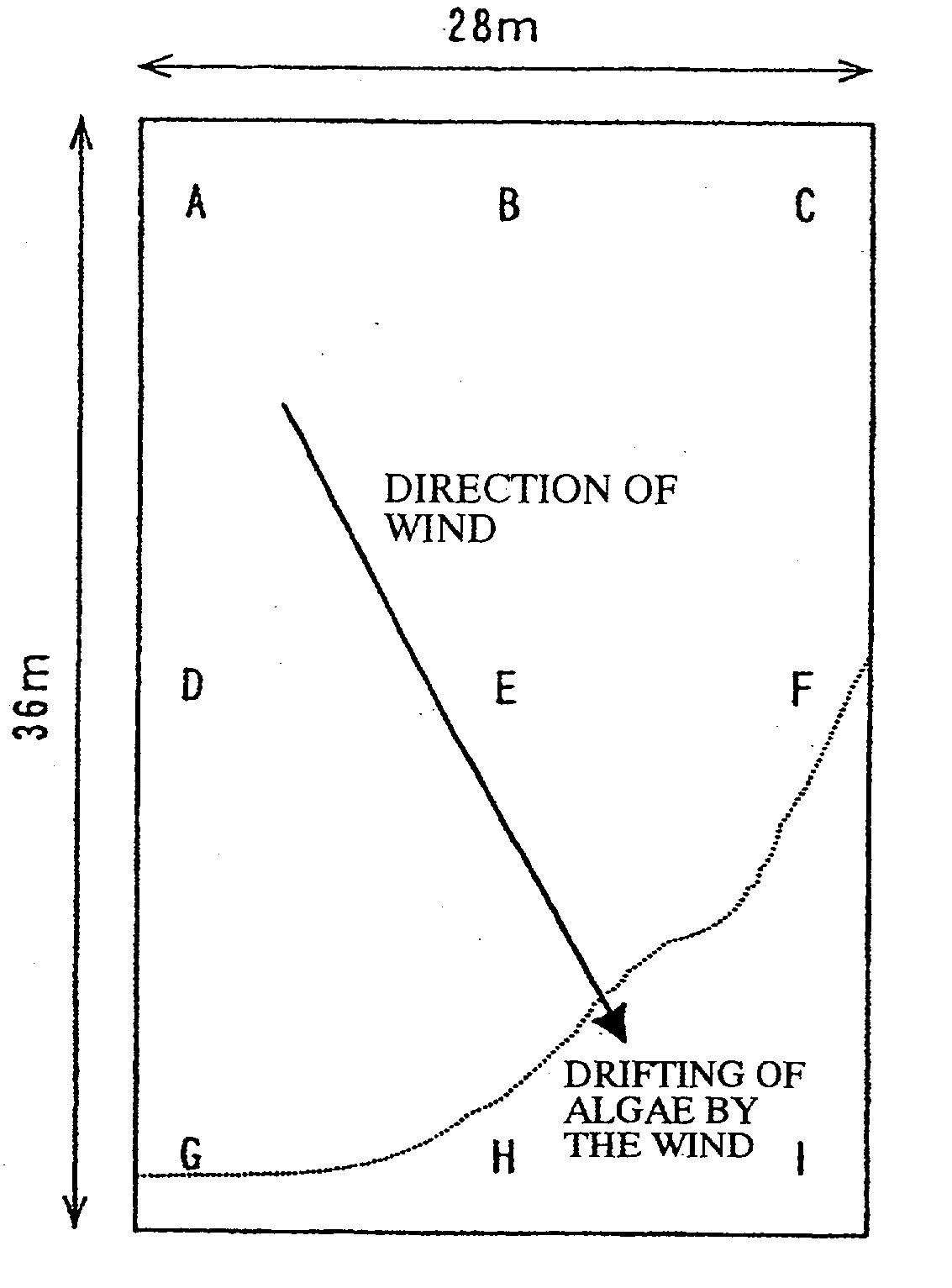

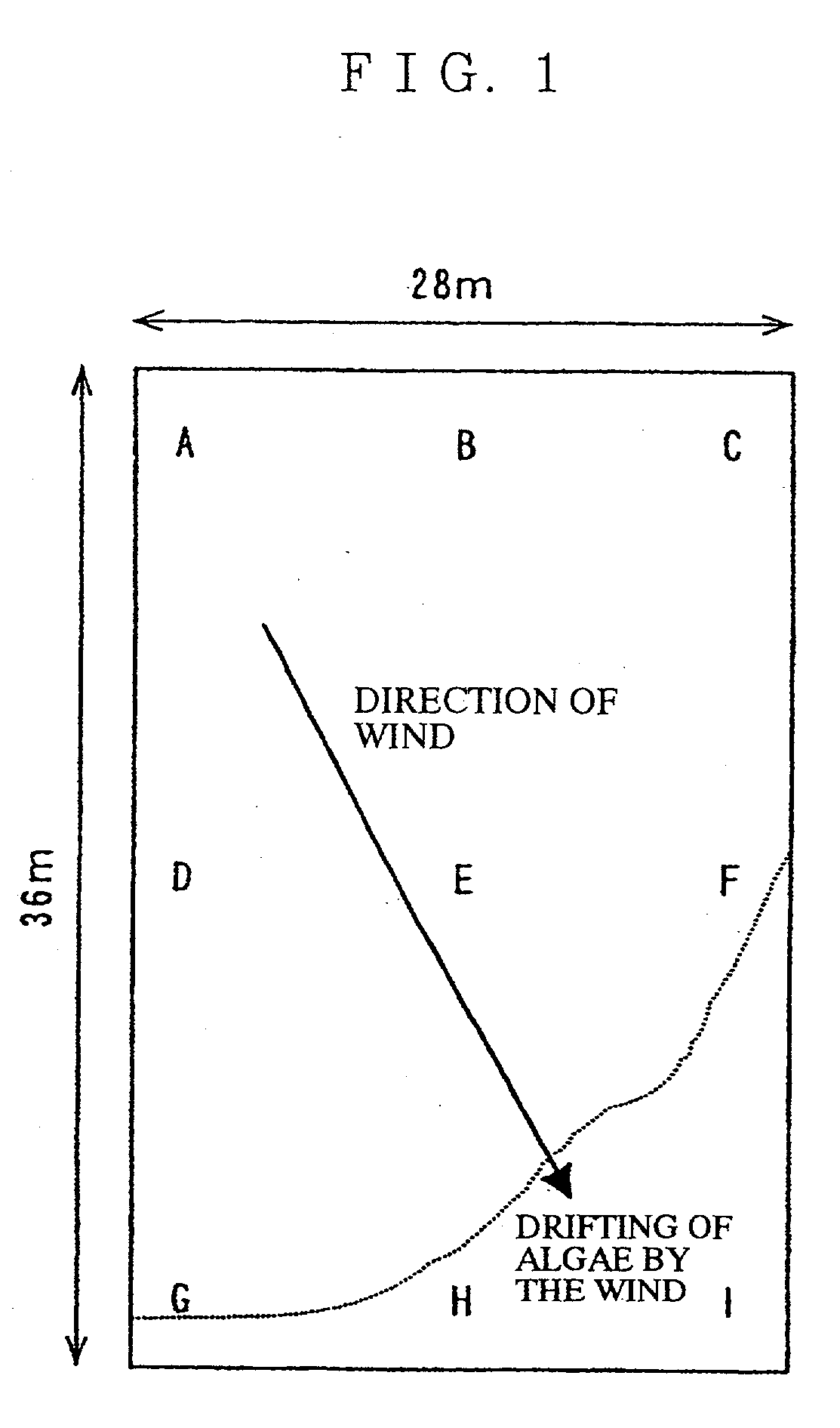

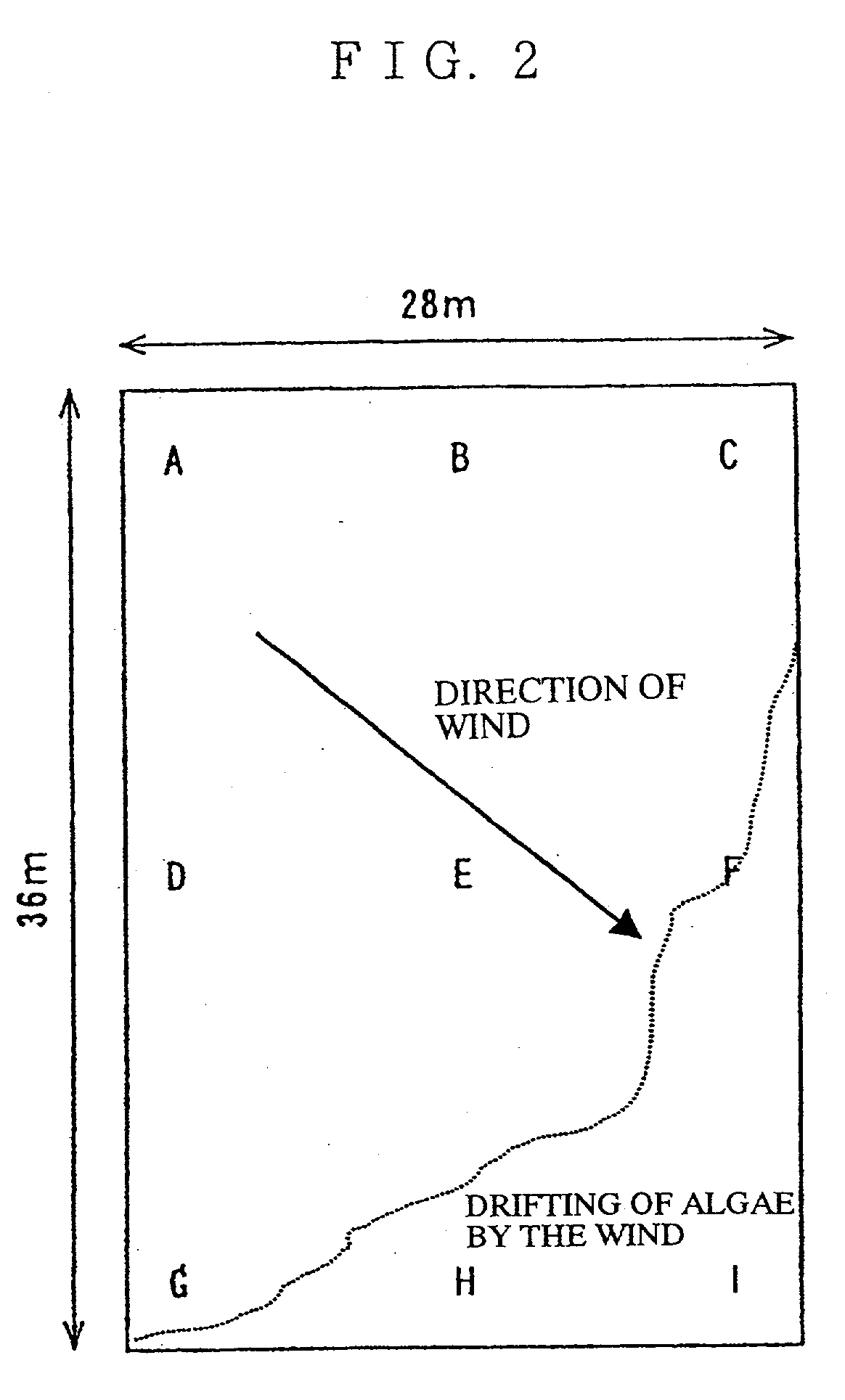

Uniformly spreadable granular agricultural chemicals formulation and method for scattering (applying) thereof

InactiveUS20040011262A1Good spreadabilityDesired effectBiocideFertiliser distributersTreatment effectBULK ACTIVE INGREDIENT

An object of the present invention is to provide a uniformly spreadable granular agricultural chemical formulation and to establish a method of scattering (applying) the formulation under the assumption that the spreadability of the agrochemically active ingredient is satisfactory so that the expected treatment effect of the agricultural chemicals can be obtained by local application even when algae are drifted by the wind and cover the surface of the water of the paddy field. A uniformly spreadable granular agricultural chemicals formulation which contains an agrochemically active ingredient, has a particle-size distribution such that 80% or more of the granules have a particle diameter of 3 mm or more, and has floatability on the water surface, and breaks down on the water surface within 30 minutes is obtained, and a method of scattering (applying) the above formulation on 5% to 50% of the total area of the paddy field applied from a levee at a distance of 1 m or more.

Owner:KUMIAI CHEM IND CO LTD

Washing-free lead-free halogen-free tin soldering paste

InactiveCN101780606ASuitable for surface mount requirementsMeet surface mount requirementsWelding/cutting media/materialsSoldering mediaParaffin waxOrganic acid

The invention discloses a washing-free lead-free halogen-free tin soldering paste, which is formed by mixing 10 to 12.5 percent of colophony-based flux cream and 88 to 89.5 percent of lead-free tin soldering powder, wherein the lead-free tin soldering powder consists of 0 to 3.5 percent of silver, 0.3 to 0.9 percent of copper and tin, the colophony-based flux cream comprises the following components: 2 to 15 percent of organic acid activating agent, 20 to 25 percent of organic solvent, 3 to 5 percent of polyethyleneglycol 2000, 0 to 3 percent of paraffin wax, 3 to 5 percent of hydrogenated castor oil, 2 to 4 percent of surface active agent, 3 to 6 percent of inhibiter, and the rest is modified colophony. The alloy powder is free from containing lead, and the flux cream is free from containing halogen, so the tin soldering paste favors the environment protection, has fewer residues after the soldering, is free from being washed, and has good spreadability of the welding flux. The copper mirror is free from penetration after being welded with the prepared soldering paste. The encapsulation requirement of the top-grade precise electronic product can be satisfied.

Owner:深圳市唯特偶新材料股份有限公司

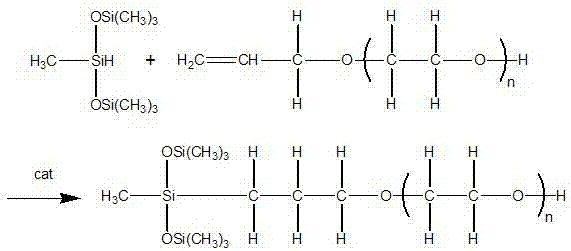

Preparation method of polyether modified siloxane

InactiveCN102225947AHigh activityImprove the mixing effectSilicon organic compoundsTransportation and packagingHydrogenOrganic solvent

The invention discloses a synthesis of organosilicon surfactant (polyether modified siloxane), comprising a solvent-free reaction of terminal allyl polyoxyethylene ether (molecular weight: 456-500) with heptamethyl trisiloxane by using chloroplatinic acid (speier catalyst) as catalyst. The catalyst used in the invention has high reactive activity for catalyzing organosilicon, and active hydrogen has high conversion rate, the use of benzene organic solvent is prevented, so that the preparation process is nontoxic and no pollution. The prepared polyether modified siloxane is clear and transparent, and has good wetability and spreadability.

Owner:南通德益化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com