Patents

Literature

1533 results about "Electronic industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

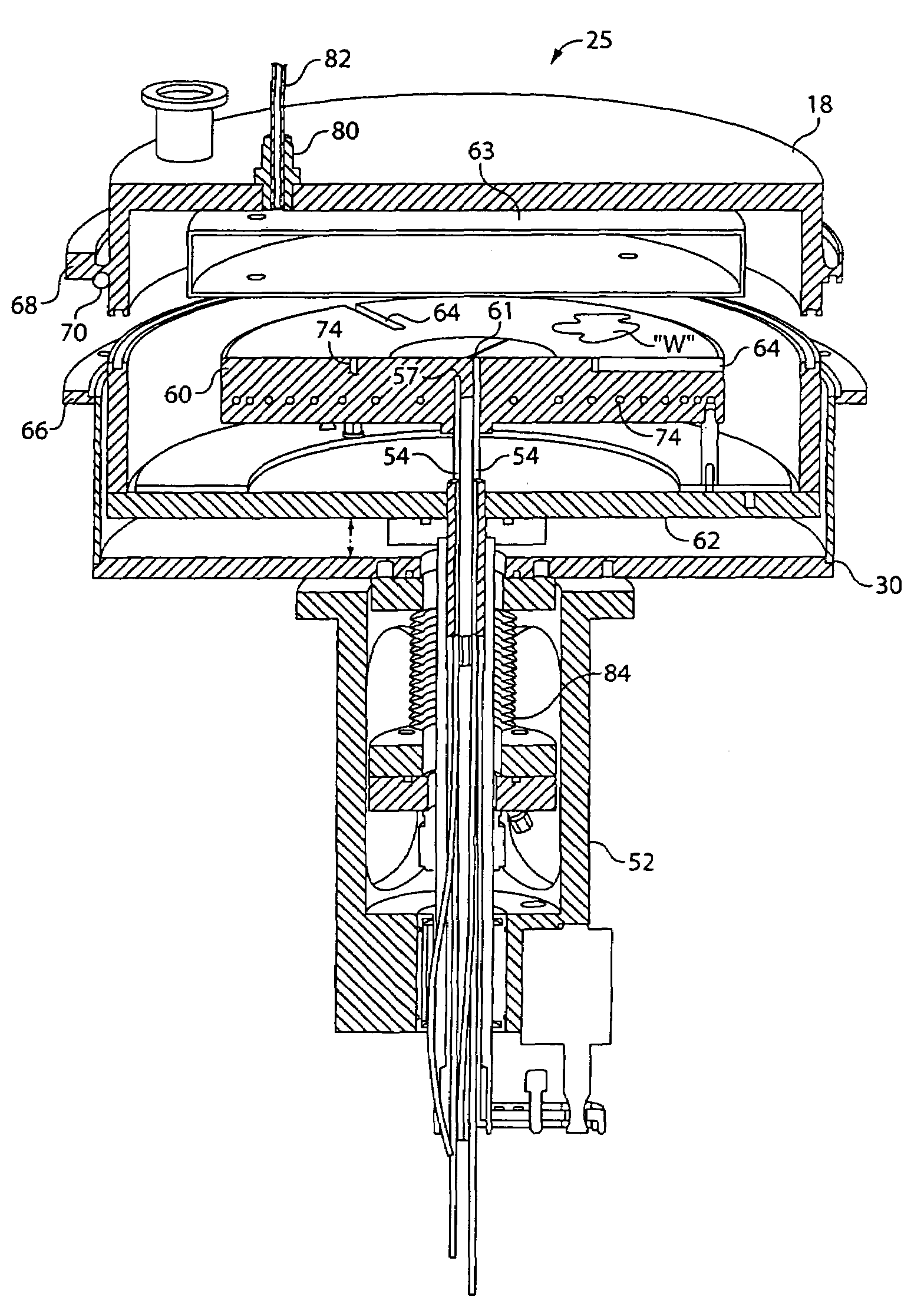

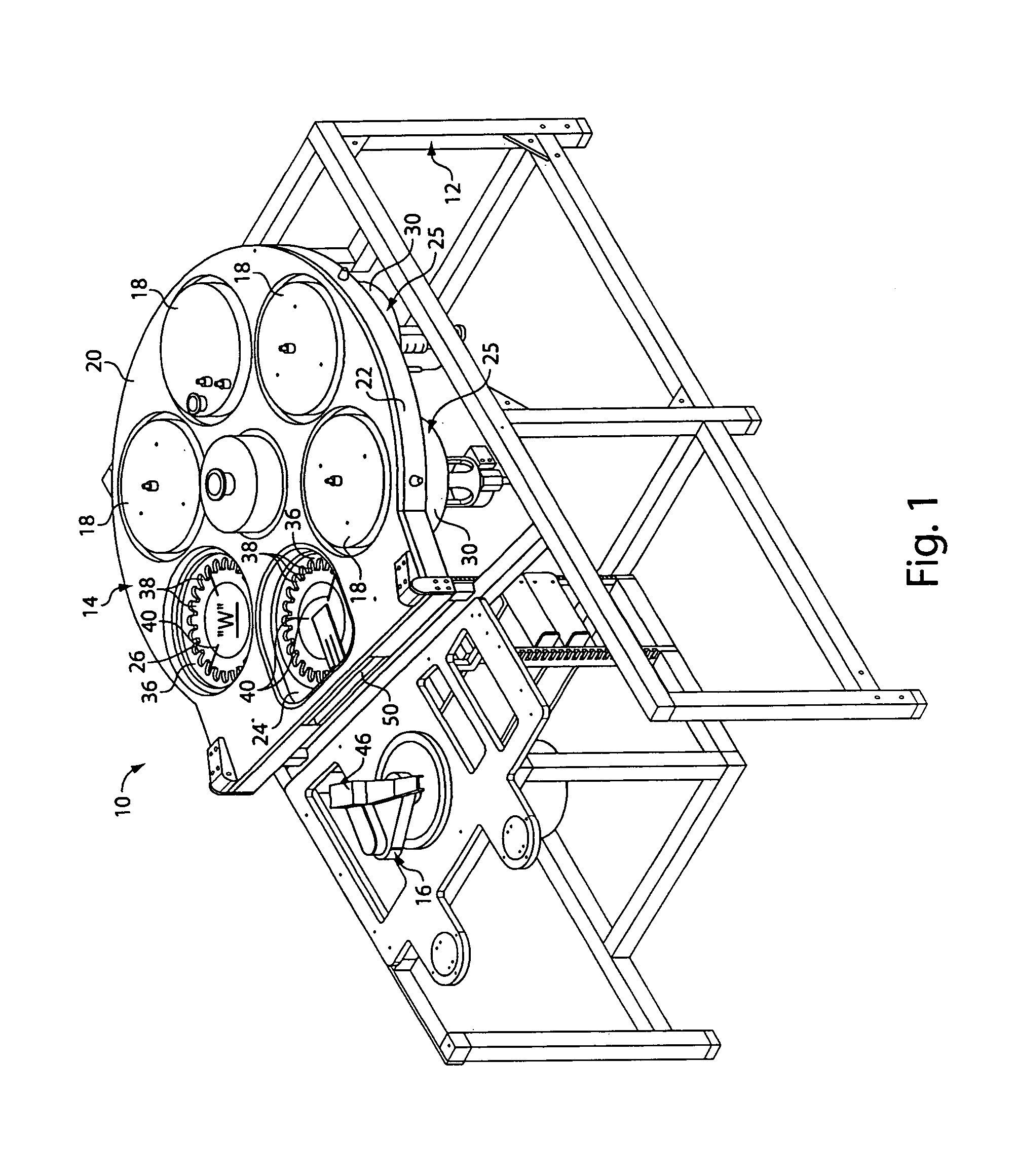

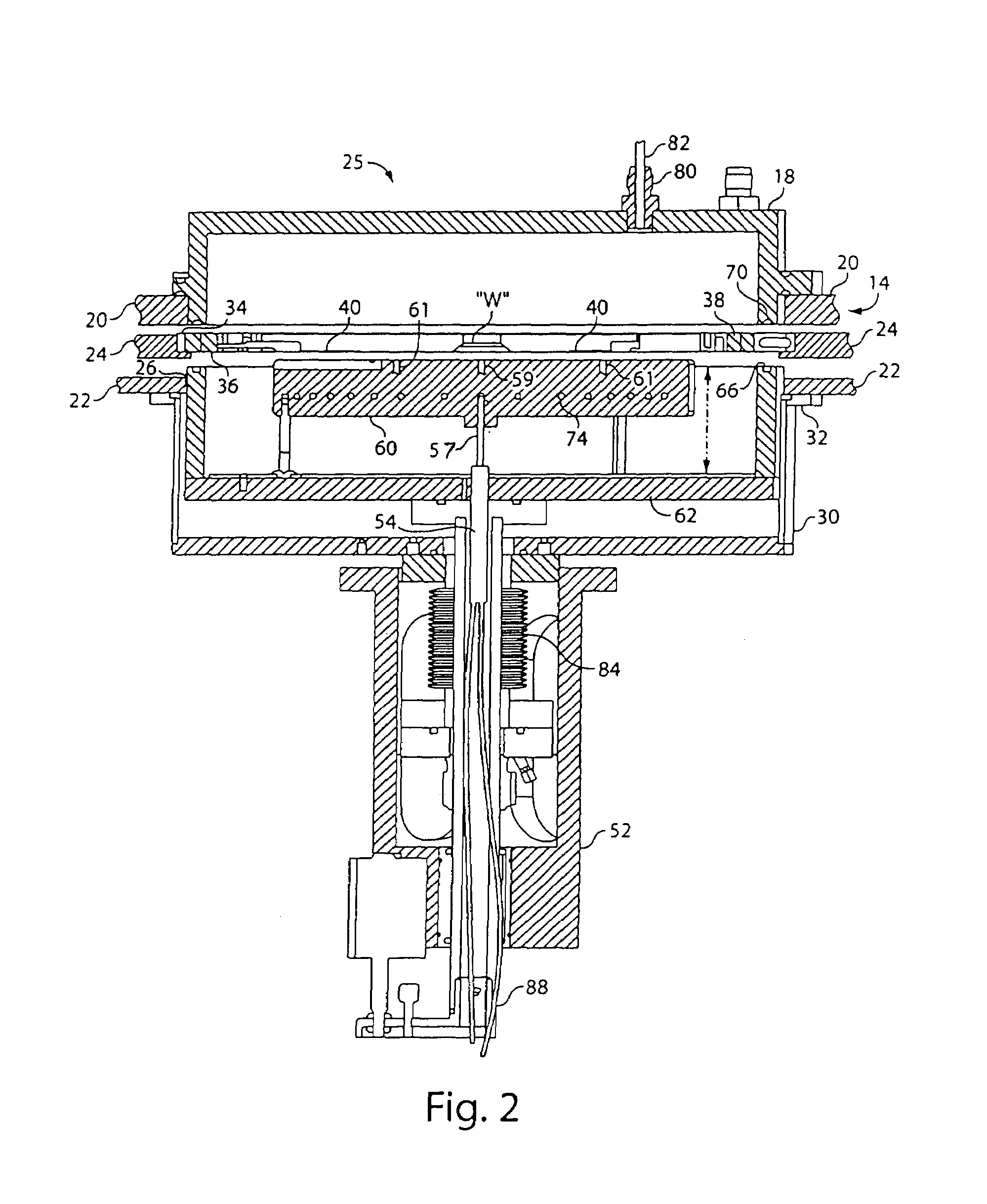

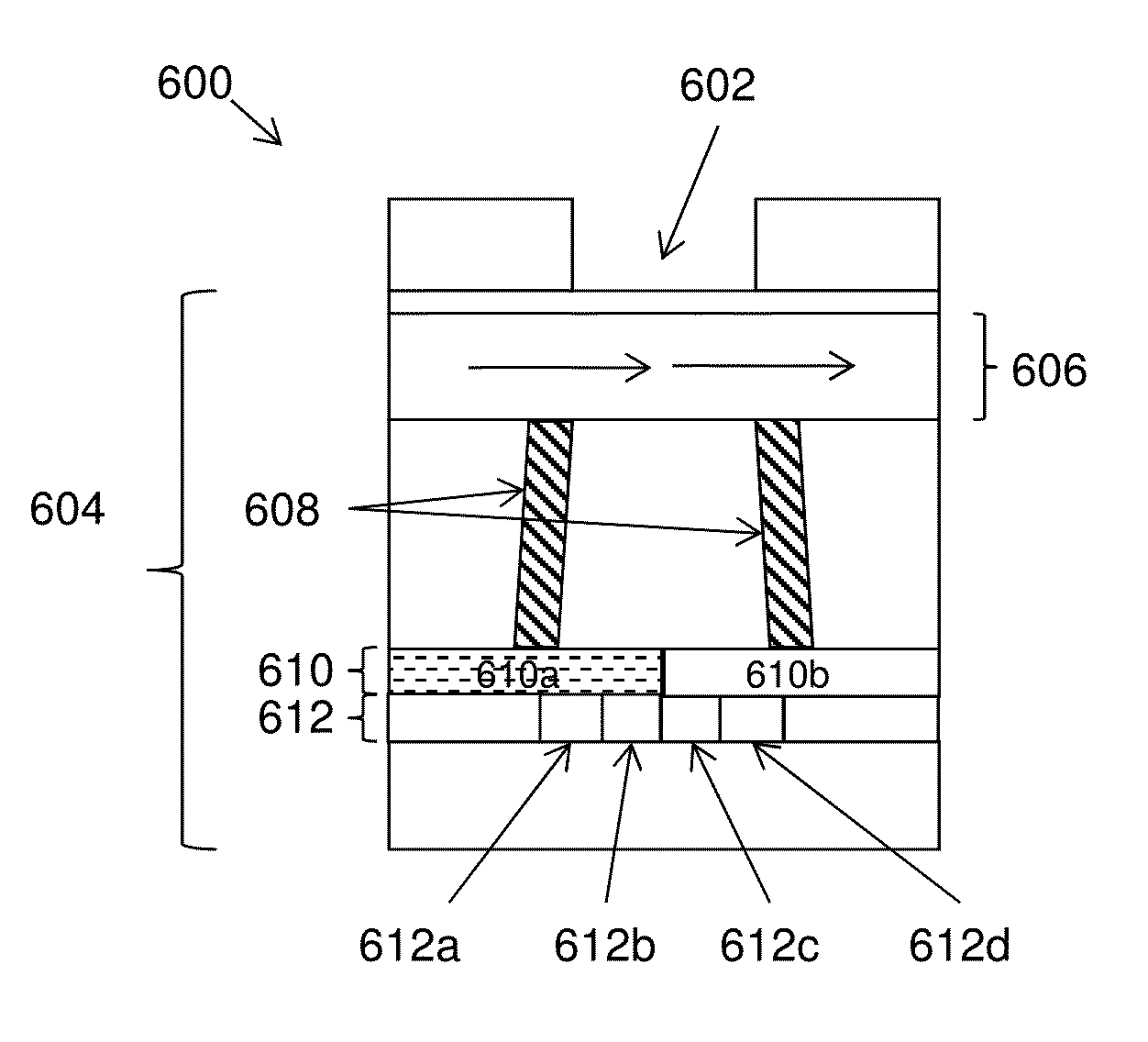

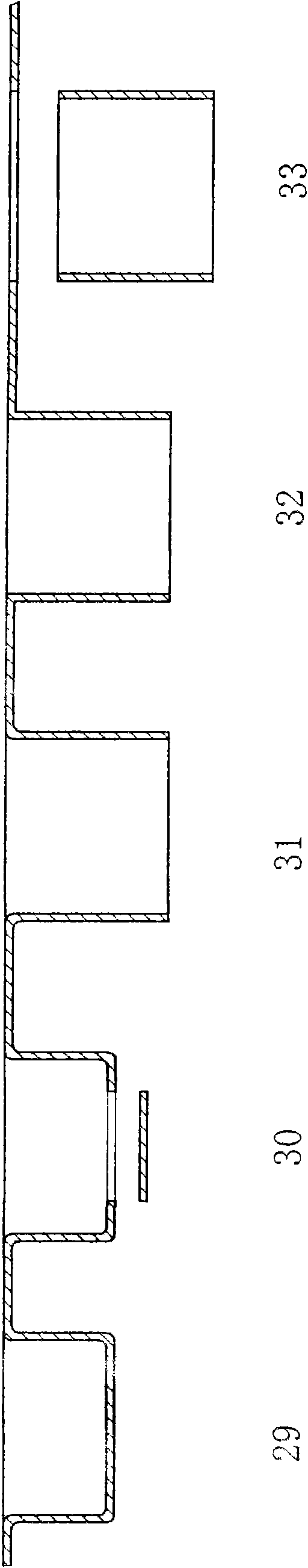

Isolation chamber arrangement for serial processing of semiconductor wafers for the electronic industry

InactiveUS7008879B2Simplifies loading and unloadingOptimization mechanismSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingBiochemical engineeringComputer module

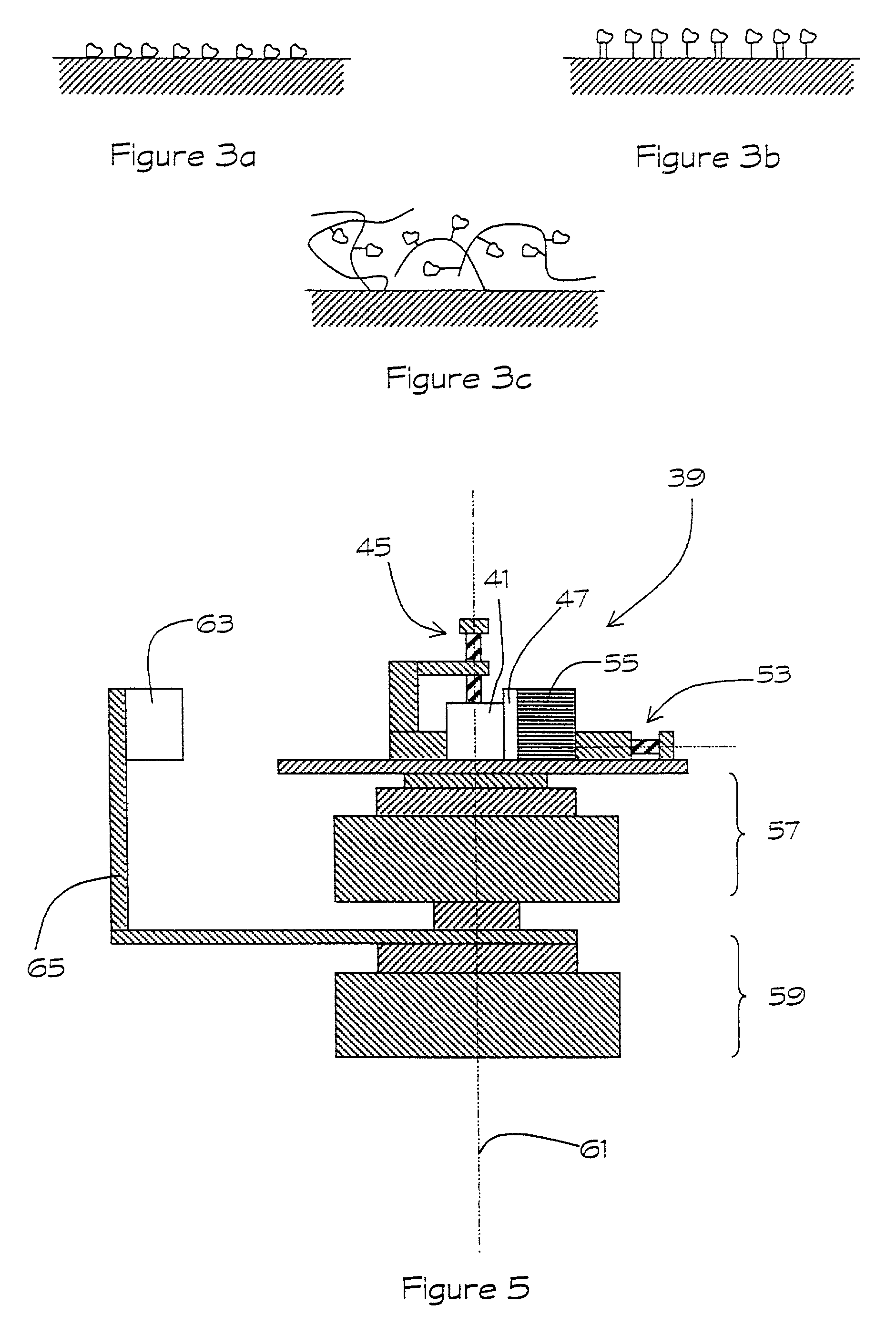

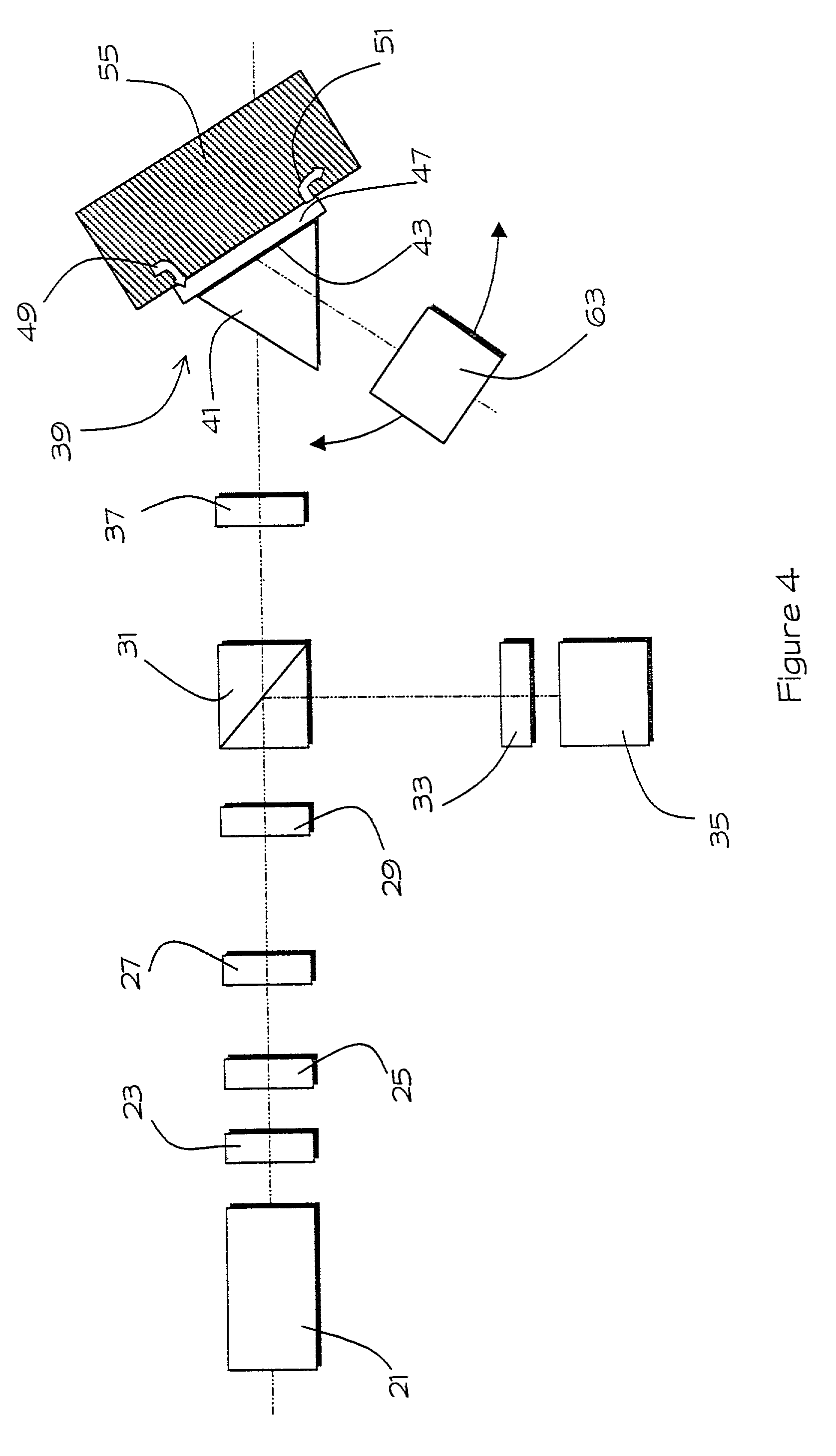

An apparatus for the treatment of semiconductor wafers, comprising a supportive frame and a process table arranged on the supportive frame. The process table comprises a stationary upper platen and a stationary lower plate. An intermediate indexing plate is rotatively arranged between the upper platen and the lower plate. At least one wafer support pin is attached to the indexing plate for the support of a wafer by the indexing plate. An upper housing is arranged on the upper platen and an outer lower housing is arranged on the lower plate. A displacable lower isolation chamber is disposed within the outer lower housing, being displacable against the indexing plate to define a treatment module between the upper housing and the lower isolation chamber in which the wafer is treated. A wafer supporting treatment plate is arranged within the lower isolation chamber, for controlled rapid treatment of a wafer within the treatment module.

Owner:SEMLGEAR INC

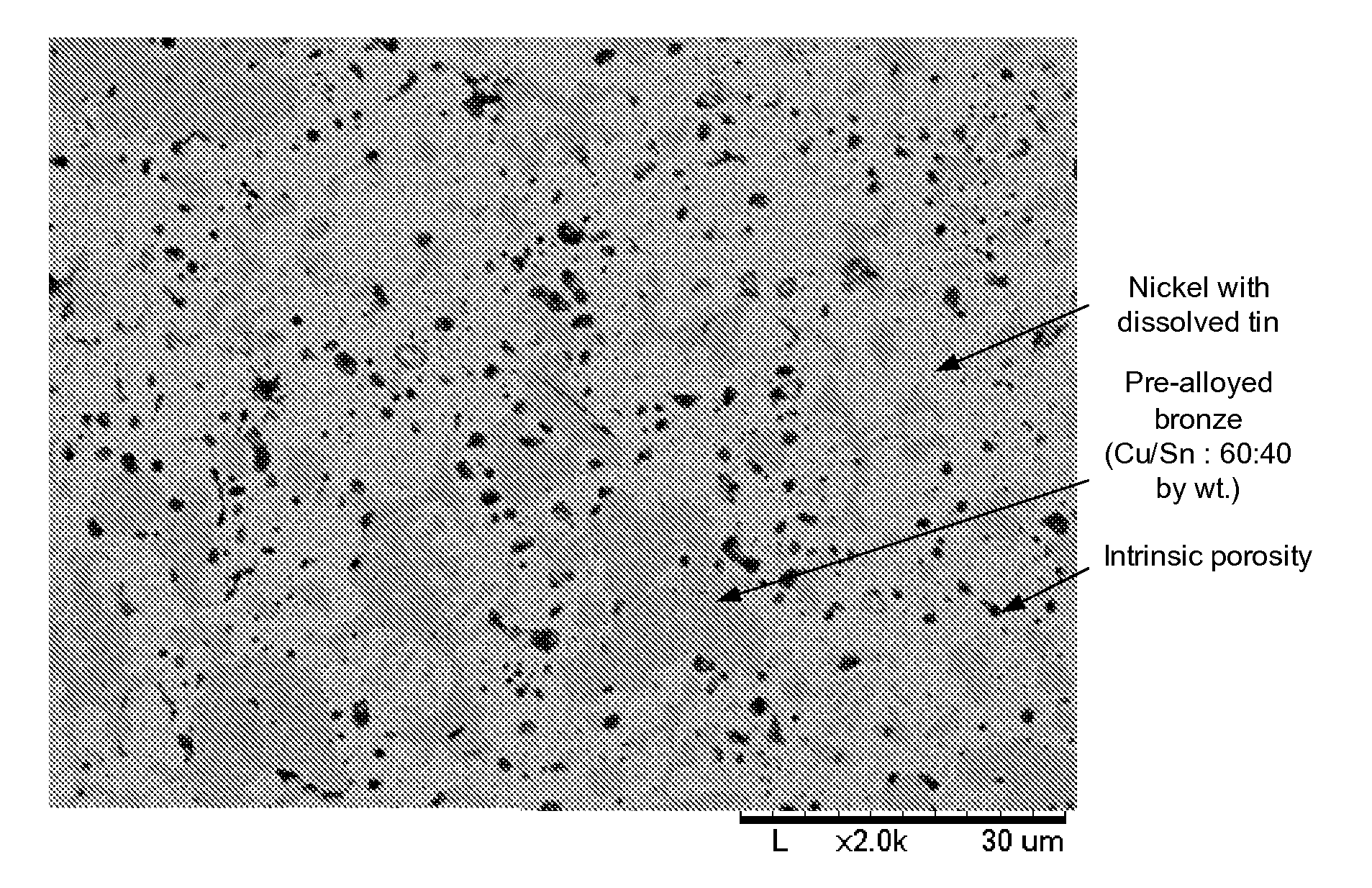

Abrasive Slicing Tool for Electronics Industry

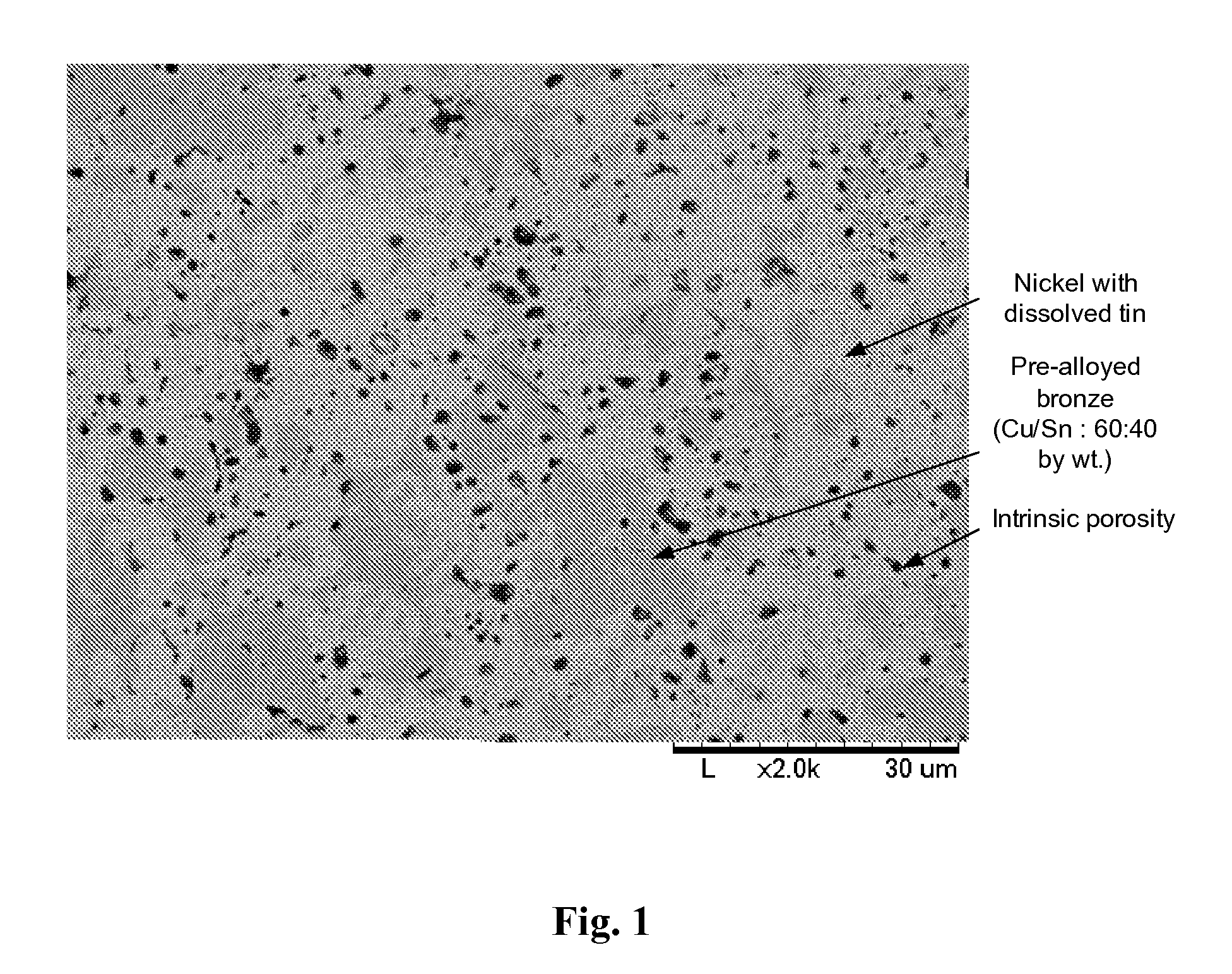

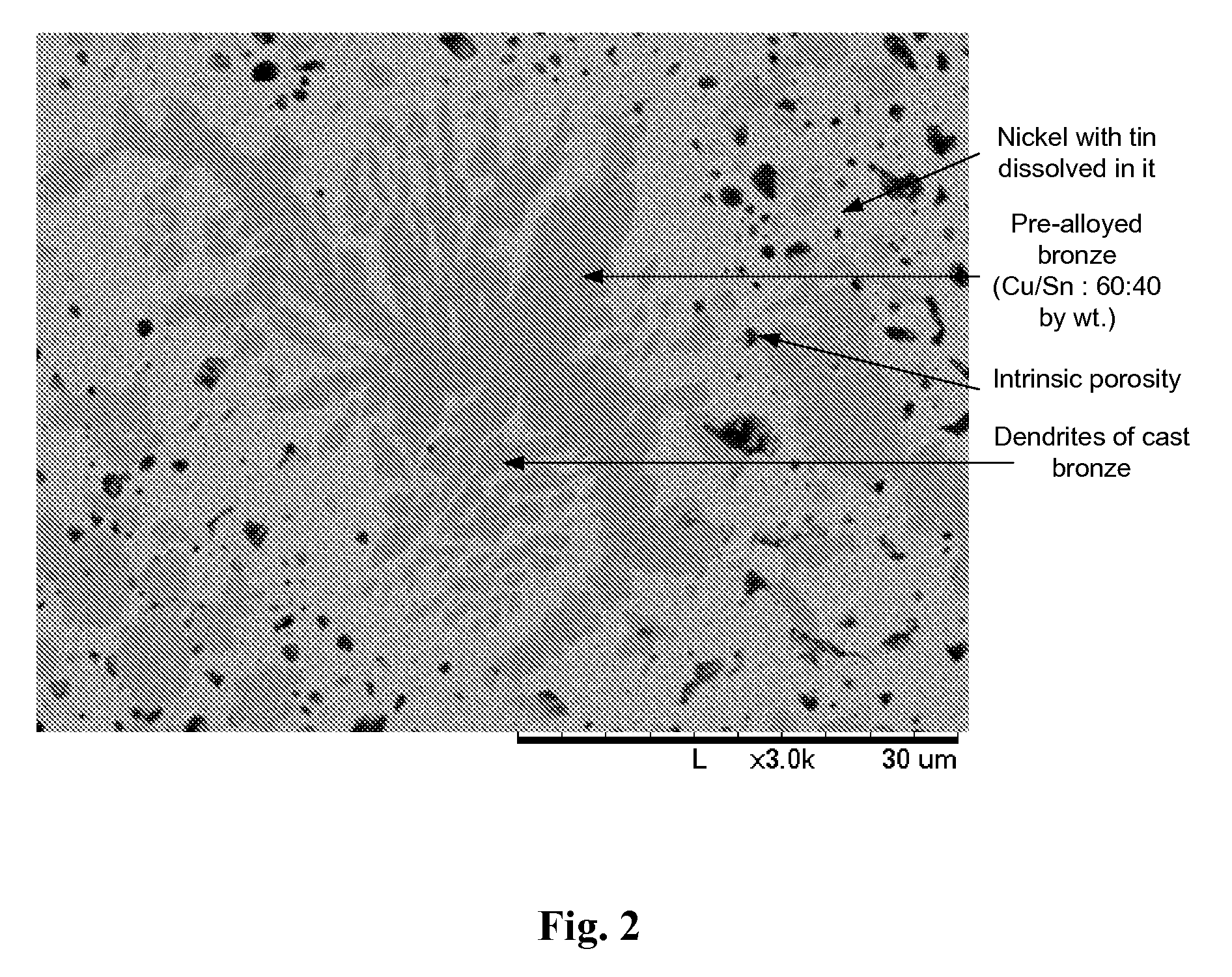

InactiveUS20100000159A1Superior wheel stiffnessProlong lifePigmenting treatmentOther chemical processesPorosityElectronic industry

A bond matrix for metal bonded abrasive tools includes a metal bond system, porosity and an optional filler. Tools according to embodiments of the invention exhibit long tool life, produce an acceptable quality of cut and can have self-dressing properties. The bond matrix can be used, for example, in abrasives tools configured for the electronics industry, such as 1A8 wheels for slicing ball grid arrays (BGAs) and other such slicing operations.

Owner:SAINT GOBAIN ABRASIVES INC +1

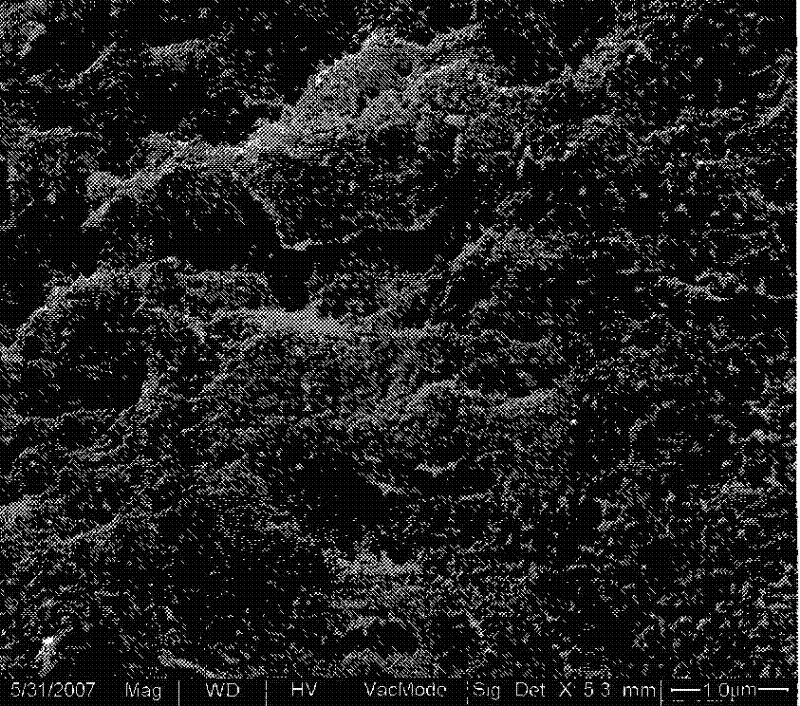

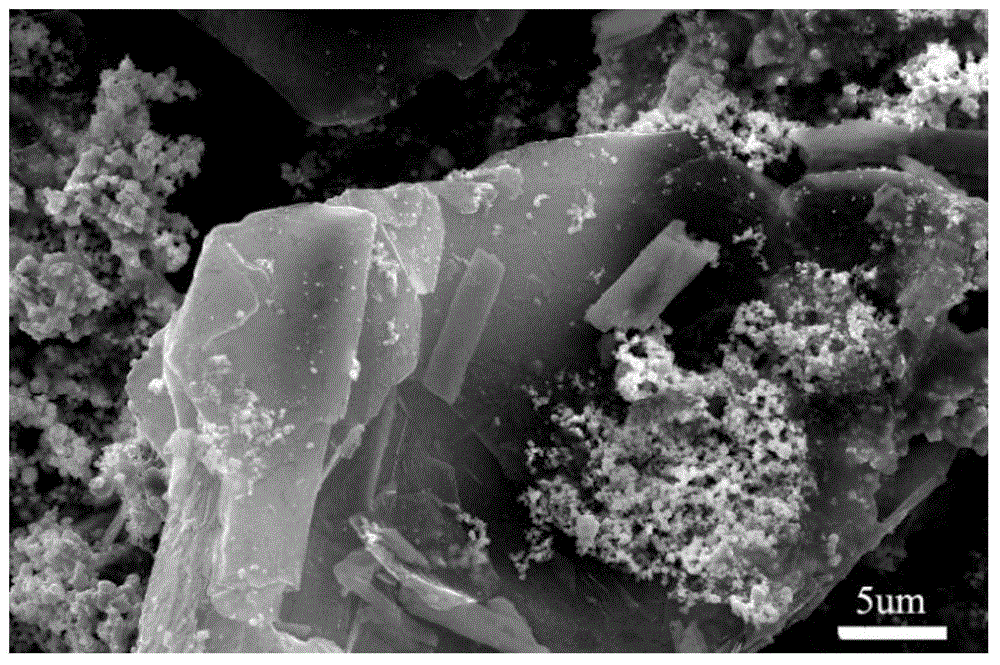

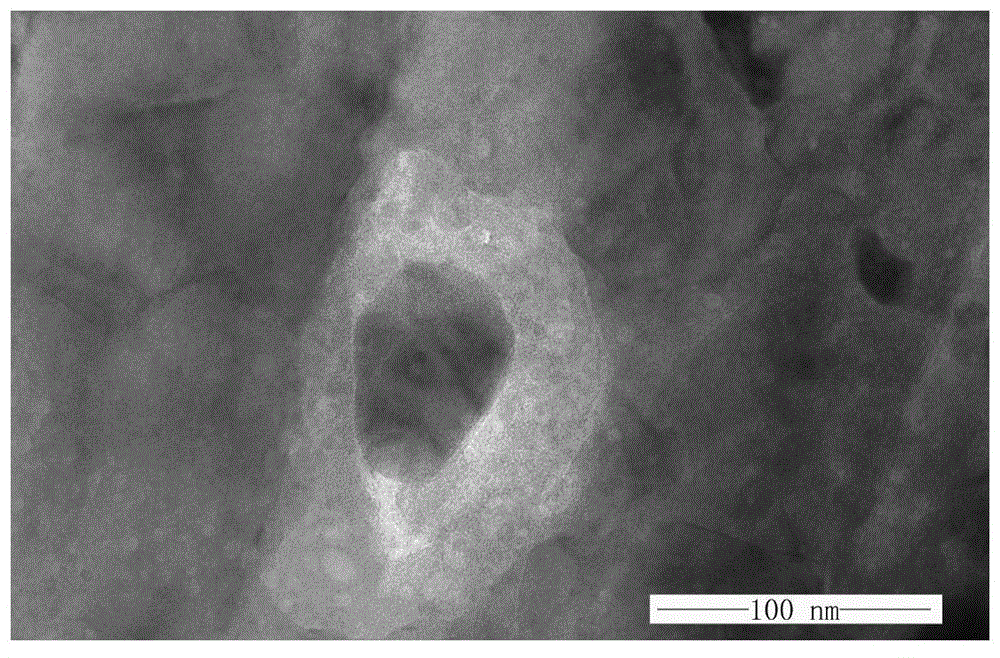

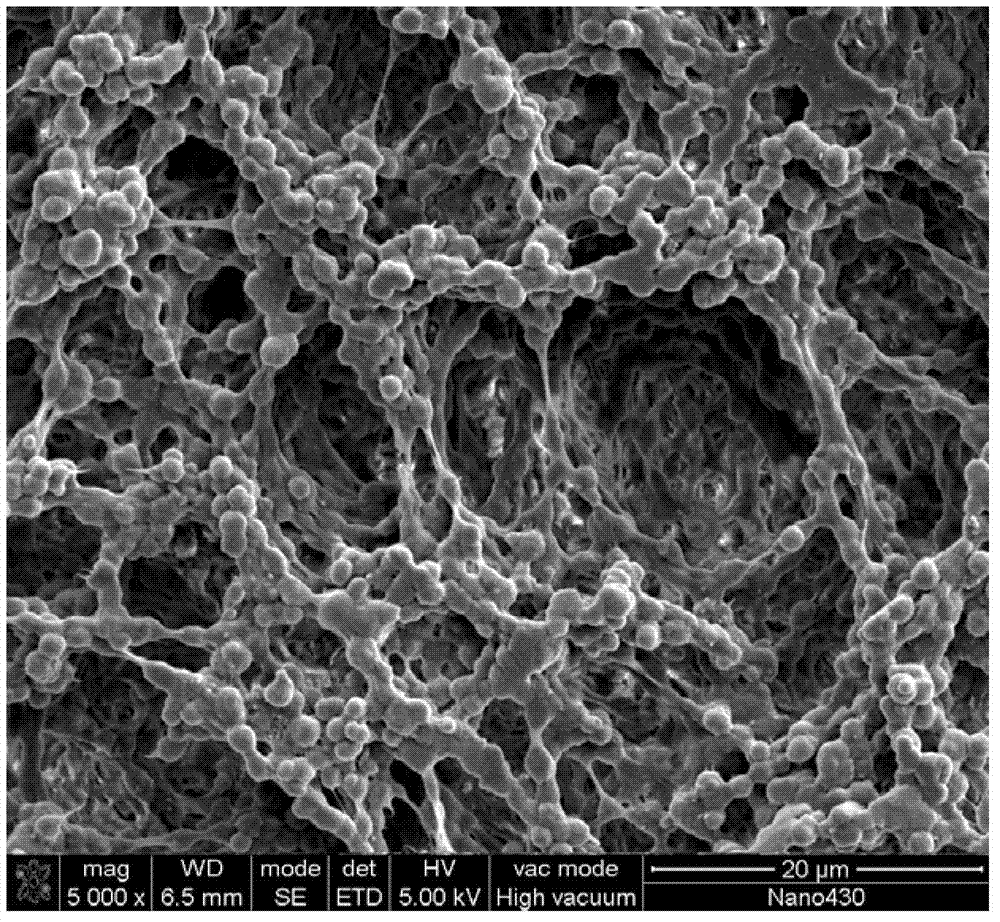

Method for preparing graphene-carbon nano tube hybrid composite

InactiveCN101734650ALow costIncrease stiffnessNanostructure manufactureChemical industryCarbon nanotube

The invention provides a method for preparing a graphene-carbon nano tube hybrid composite and relates to a method for preparing a functional high molecular material and a device thereof. The method comprises the following steps of: carrying out the stirring and sonic oscillation treatment on graphene and carbon nano tubes to preform an entangled network structure, thoroughly mixing the entangled network structure and polymer particles, and thus obtaining an uniformly-mixed system in which the graphene-carbon nano tube network is coated on the surfaces of the polymer particles after removing the solvent; and putting the uniformly-mixed system in a mould, hot-compacting, and obtaining the graphene-carbon nano tube hybrid composite after cooling and demoulding. By mingling the graphene and the carbon nano tubes in advance to form the communicated network structure, the method realizes the advantage complementation of the graphene and carbon nano tube structures and enables the hybrid composite to have favorable electric conduction and heat conduction properties. The method can be widely used in the fields such as aviation, transportation and communication, electronic industry, civil facilities, construction, chemical industry and the like, can be produced in the industrial scale, and has the advantages of low cost and environmental friendliness.

Owner:SHENYANG JIANZHU UNIVERSITY

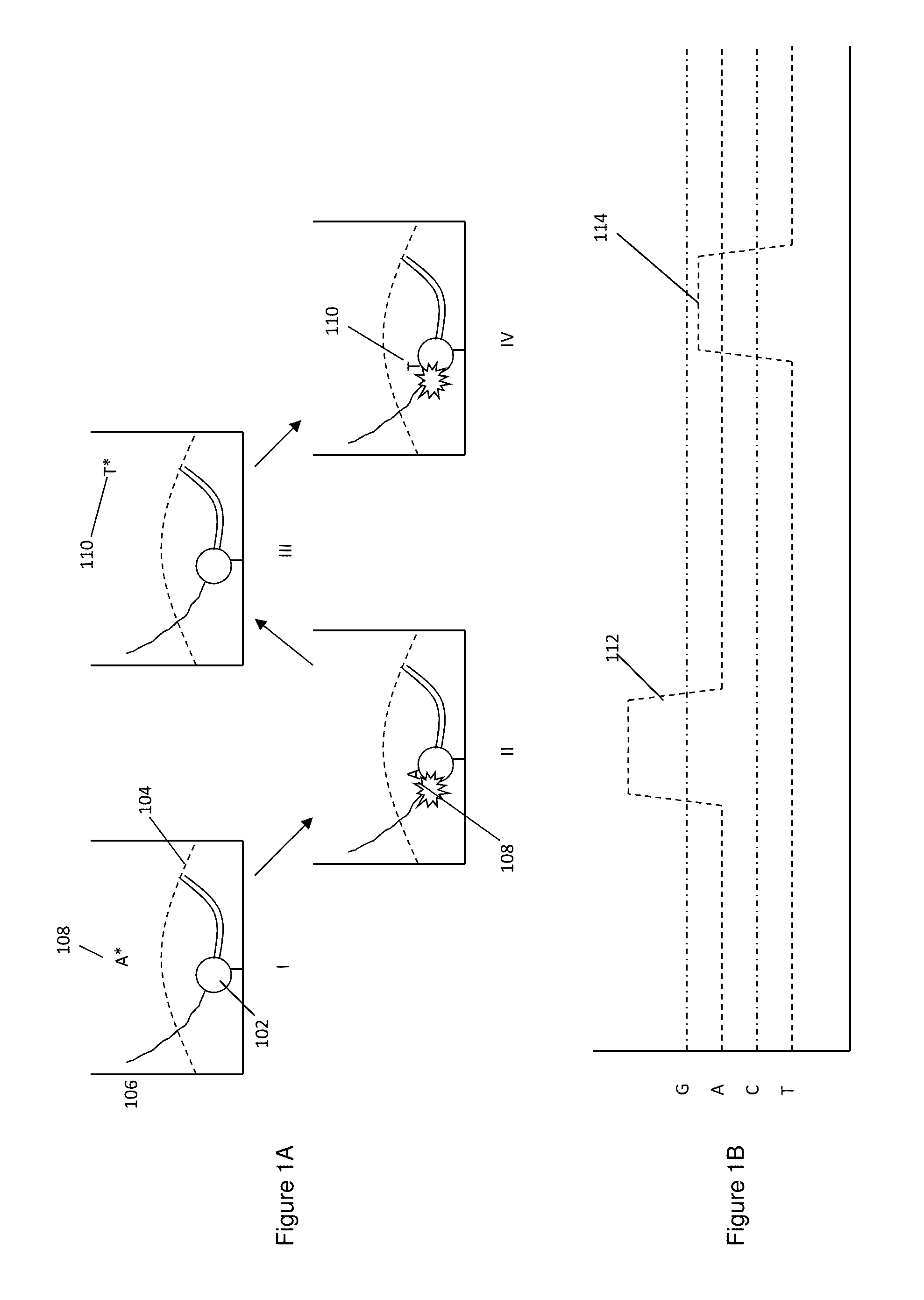

Arrays of integrated analytical devices and methods for production

Arrays of integrated analytical devices and their methods for production are provided. The arrays are useful in the analysis of highly multiplexed optical reactions in large numbers at high densities, including biochemical reactions, such as nucleic acid sequencing reactions. The integrated devices allow the highly sensitive discrimination of optical signals using features such as spectra, amplitude, and time resolution, or combinations thereof. The arrays and methods of the invention make use of silicon chip fabrication and manufacturing techniques developed for the electronics industry and highly suited for miniaturization and high throughput.

Owner:PACIFIC BIOSCIENCES

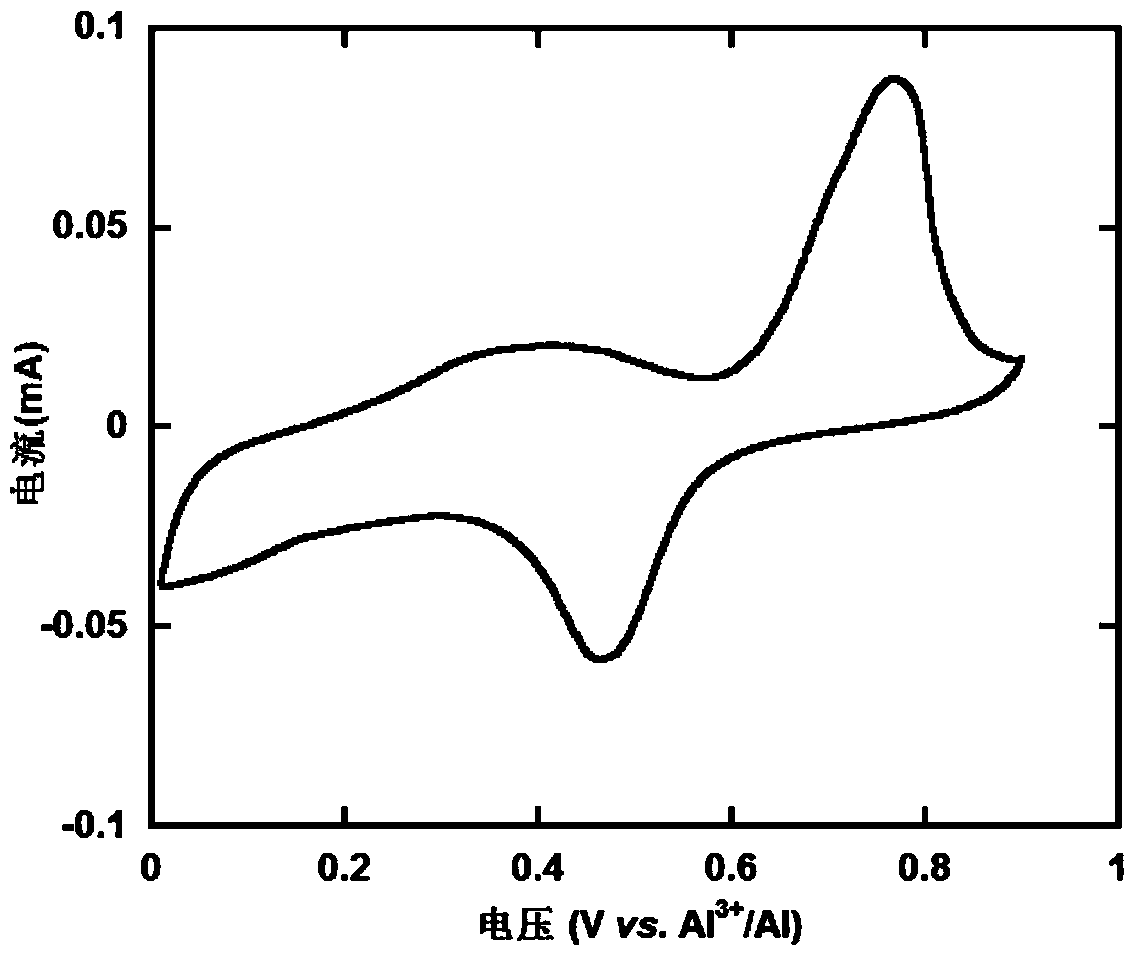

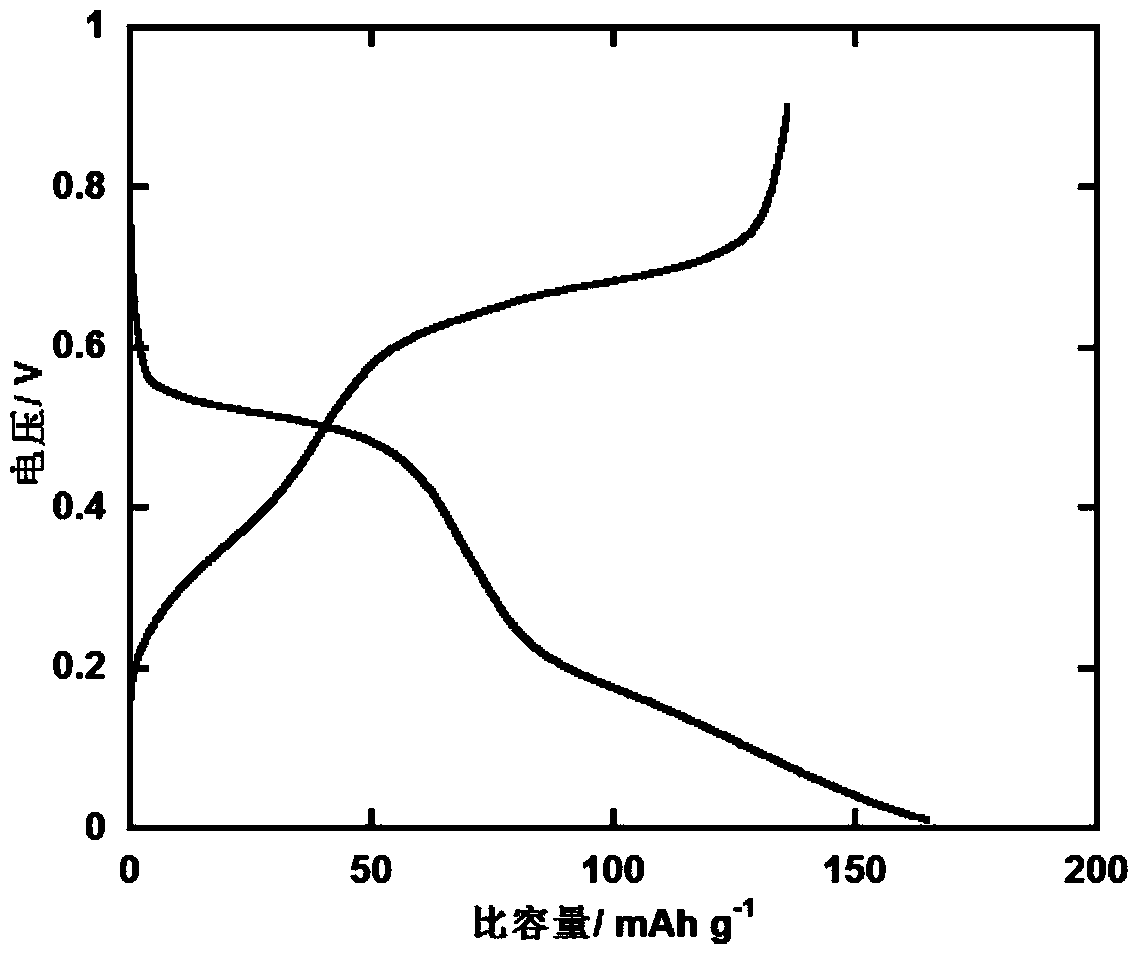

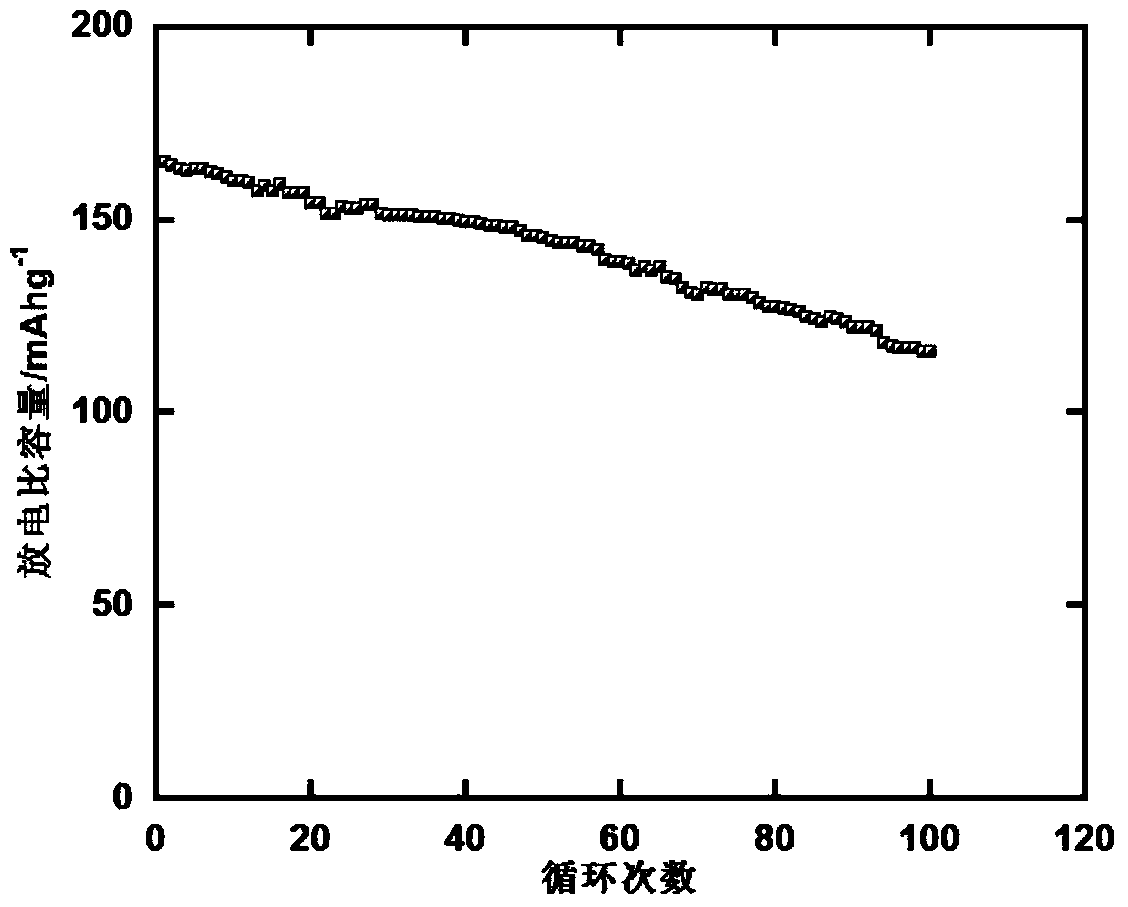

Rechargeable aluminum ion cell and preparation method thereof

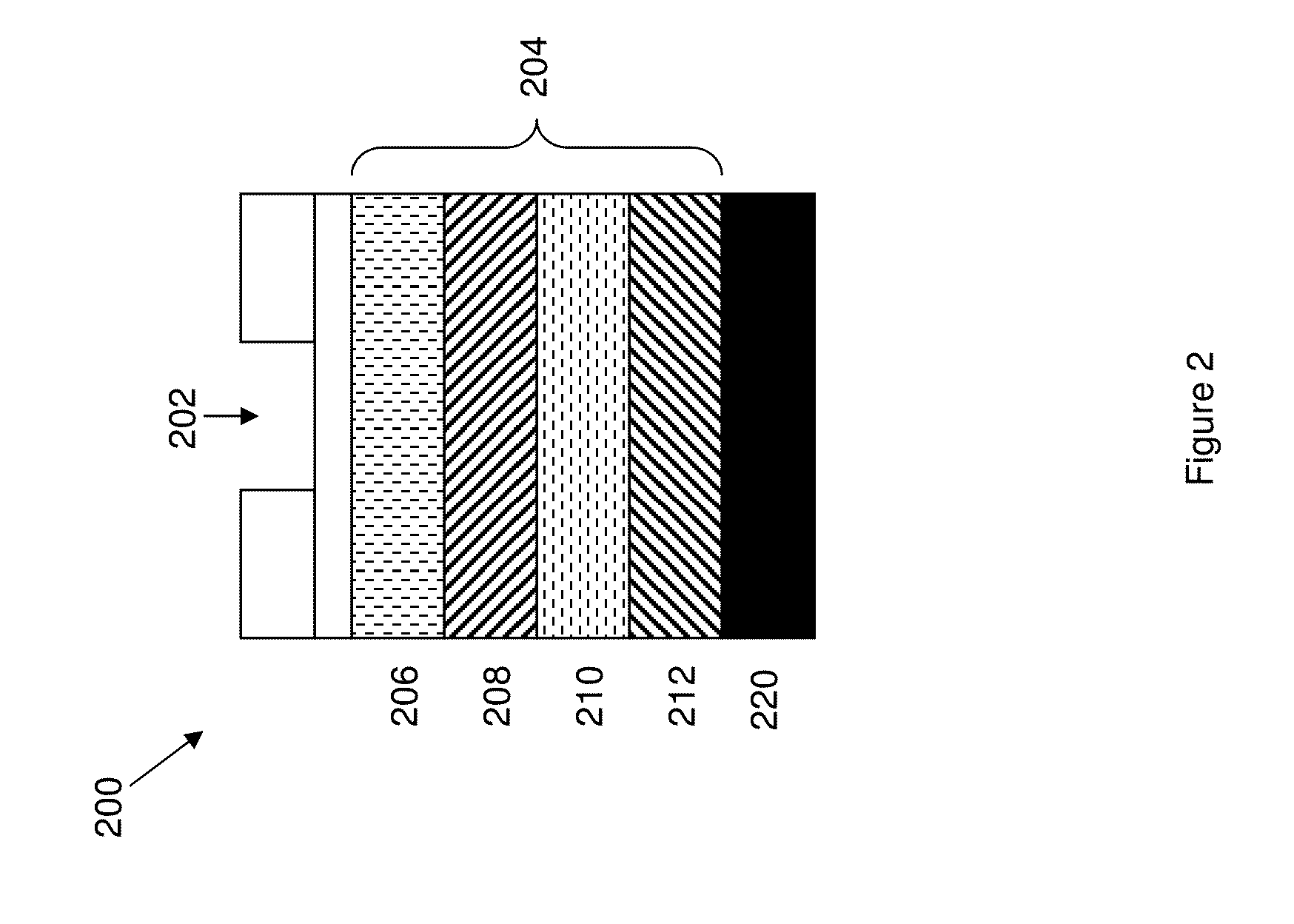

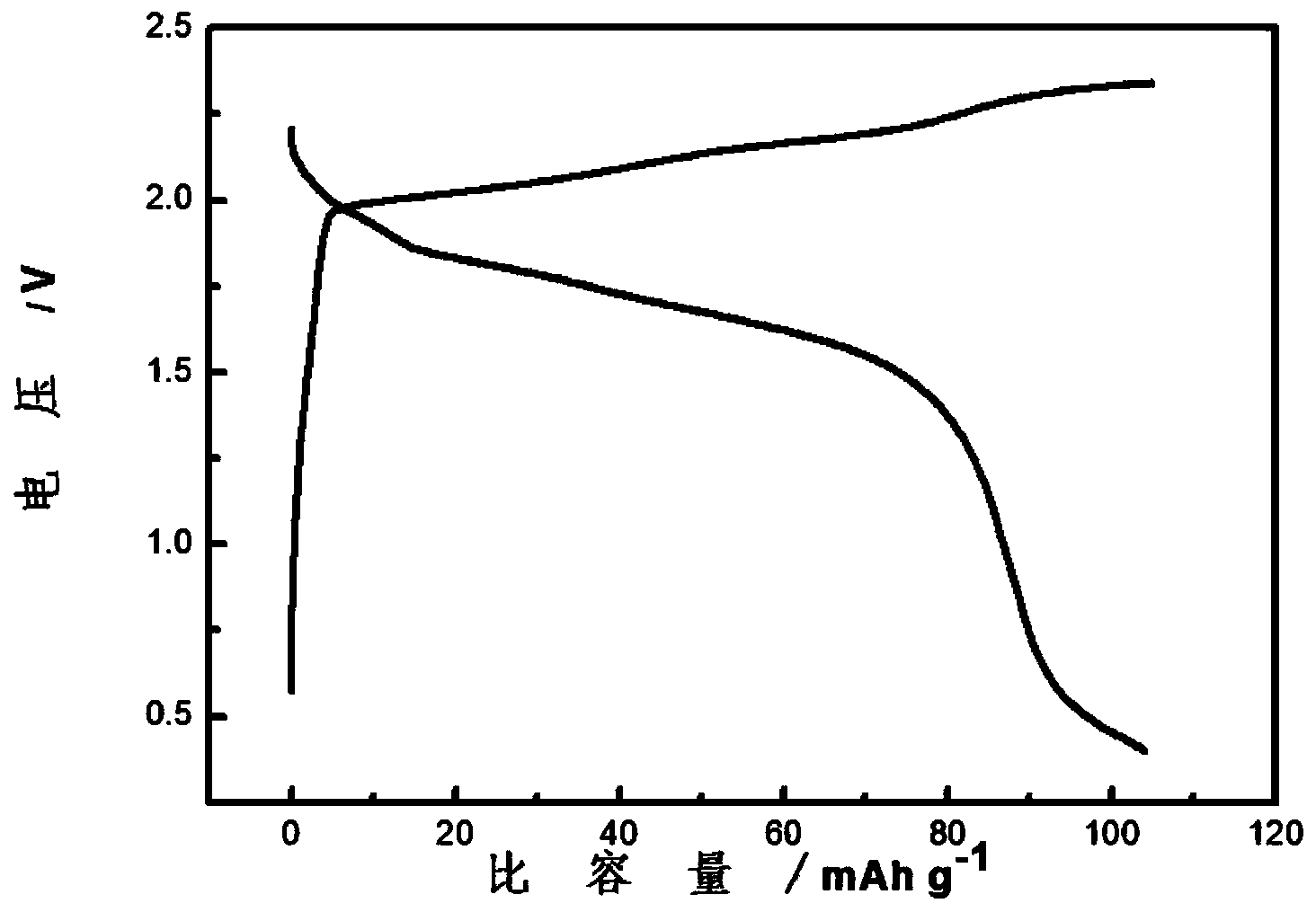

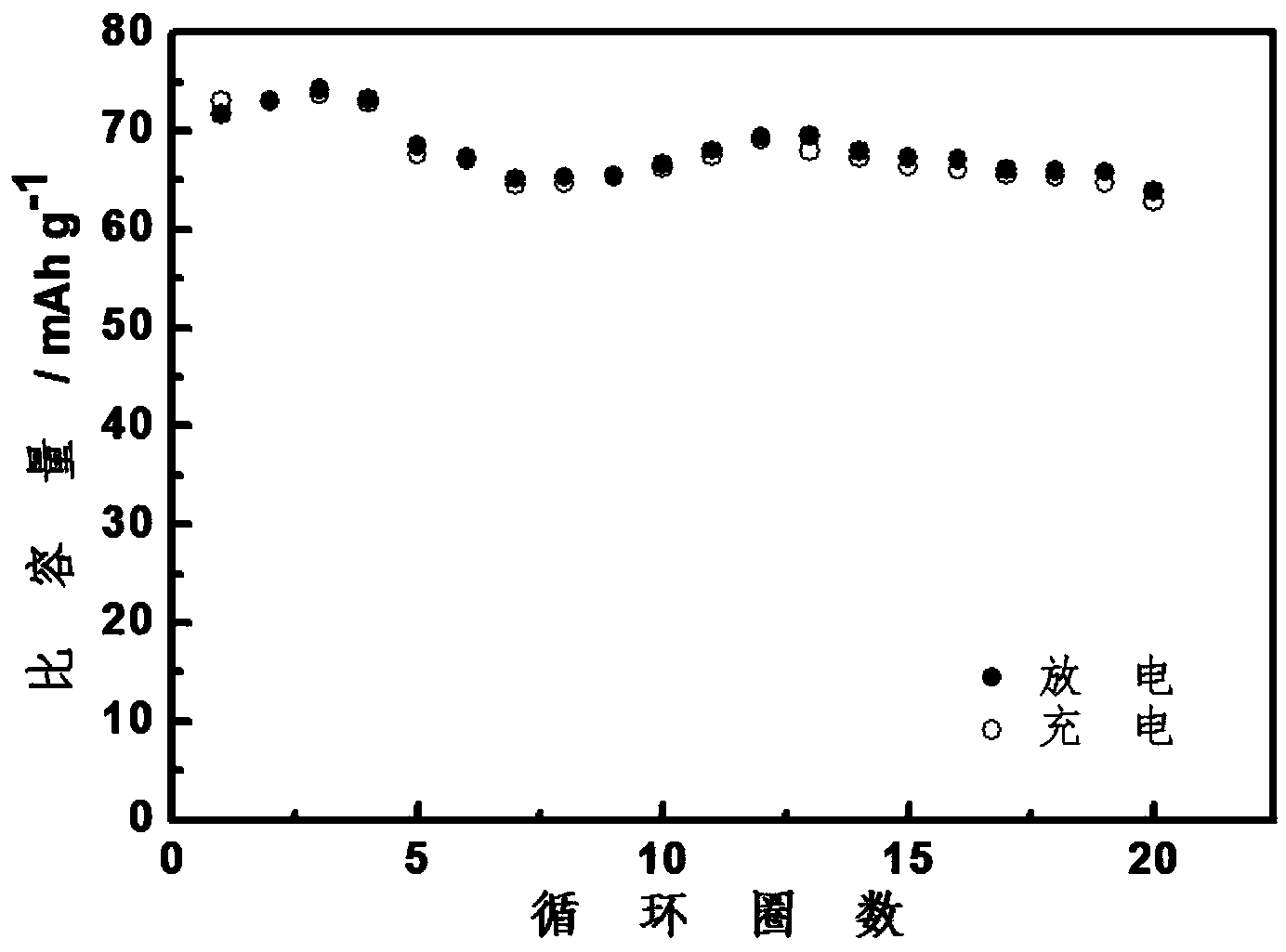

InactiveCN104241596AImprove conductivityImprove thermal stabilityCell electrodesElectrolyte accumulators manufactureAluminum IonMetal foil

The invention discloses a rechargeable aluminum ion cell and a preparation method thereof and belongs to the field of energy reutilization. The cell comprises an anode, a cathode, a liquefied aluminum ion electrolyte and a diaphragm material, wherein the anode is made of graphite structure carbon material; the cathode is made of highly pure aluminum; the liquefied aluminum ion electrolyte is formed by mixing anhydrous aluminum chloride and 3-methyl imidazole compound; the molar ratio between the anhydrous aluminum chloride and the 3-methyl imidazole compound is from 1.1:1 to 1.6:1. The preparation process of the cell comprises the following steps: processing the graphite structure carbon material into laminar shapes; fixing the anode material with inertial metal foil as a current collector and covering the anode with the diaphragm material; washing highly pure aluminum cutting piece as the cathode; preparing the liquefied aluminum ion electrolyte which contains A13 plus ion capable of freely moving. The anode, the cathode and the liquefied aluminum ion electrolyte are assembled in a glove box to form the cell; the cell has the characteristics of high capacity and good circulating stability and is applicable to multiple fields such as electronic industry, communication industry and electric automobile.

Owner:UNIV OF SCI & TECH BEIJING +1

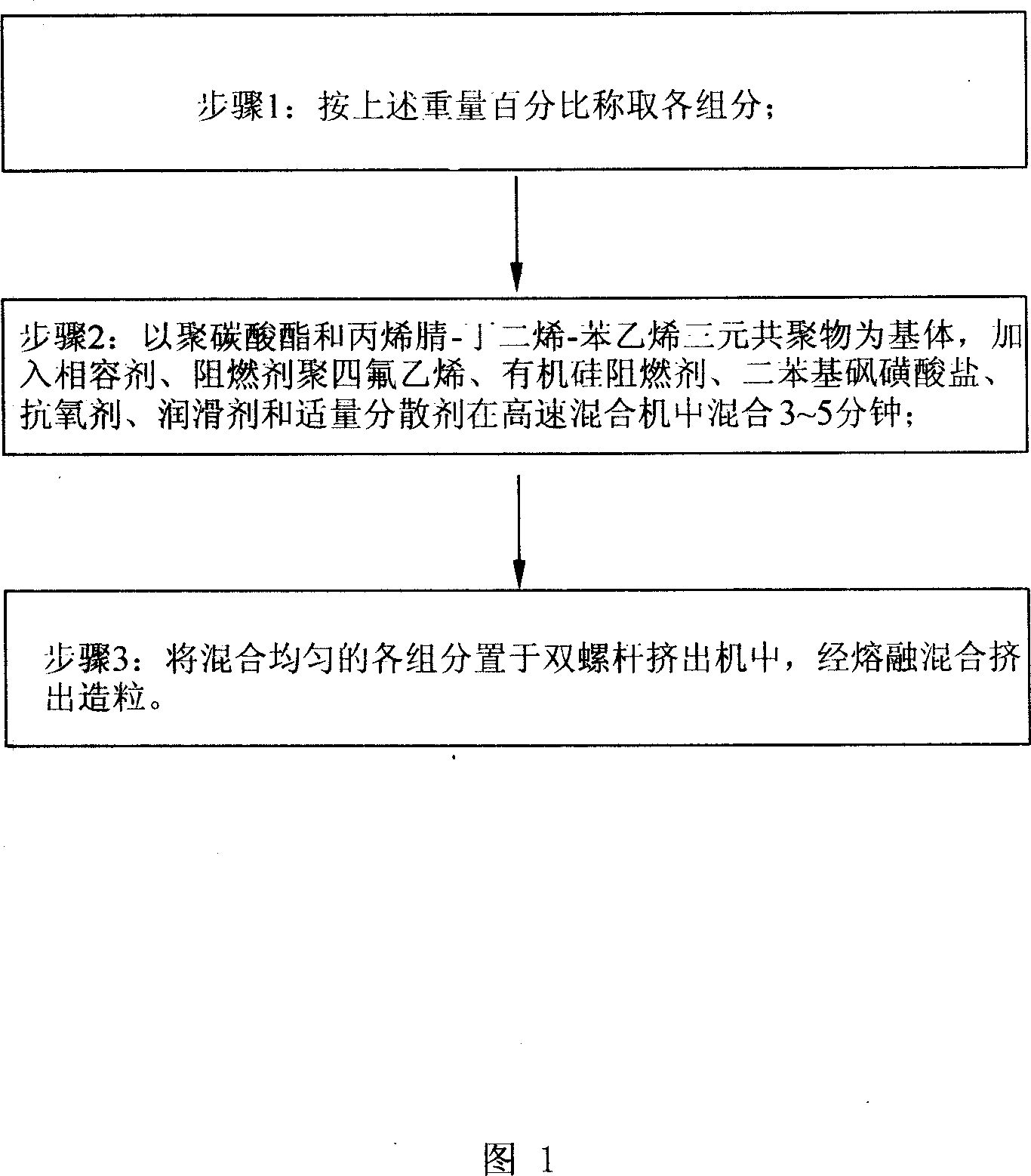

Fire retardant PC/ABS alloy material without halide and phosphate and its prepn process

The fire retardant PC / ABS alloy material without halide and phosphate consists of polycarbonate 65.5-91.2 wt%, acrylonitrile-butadiene-styrene ternary copolymer 6-17 wt%, compatilizer 1.0-4.0 wt%, fire retardant PTFE 0.3-1.5 wt%, organosilicon fire retardant 1.0-8.0 wt%, diphenyl sulfone sulfonate 0.1-1.0 wt%, antioxidant 0.1-1.0 wt% and lubricant 0.2-2.0 wt%. The present invention also provides the preparation process of the alloy material. The alloy material is environment friendly, and may be applied widely in automobile industry, electronic industry, electric industry and mechanical industry.

Owner:SHENZHEN KEJU NEW MATERIAL

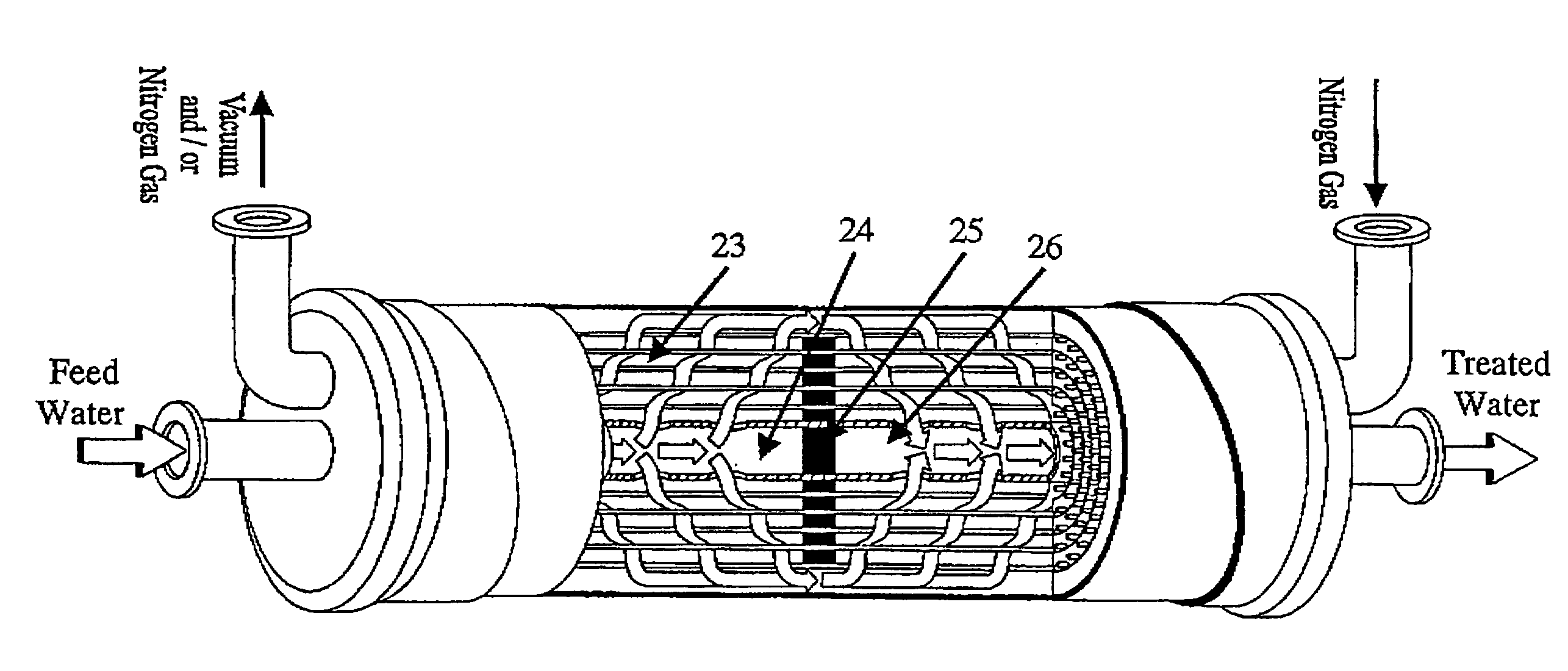

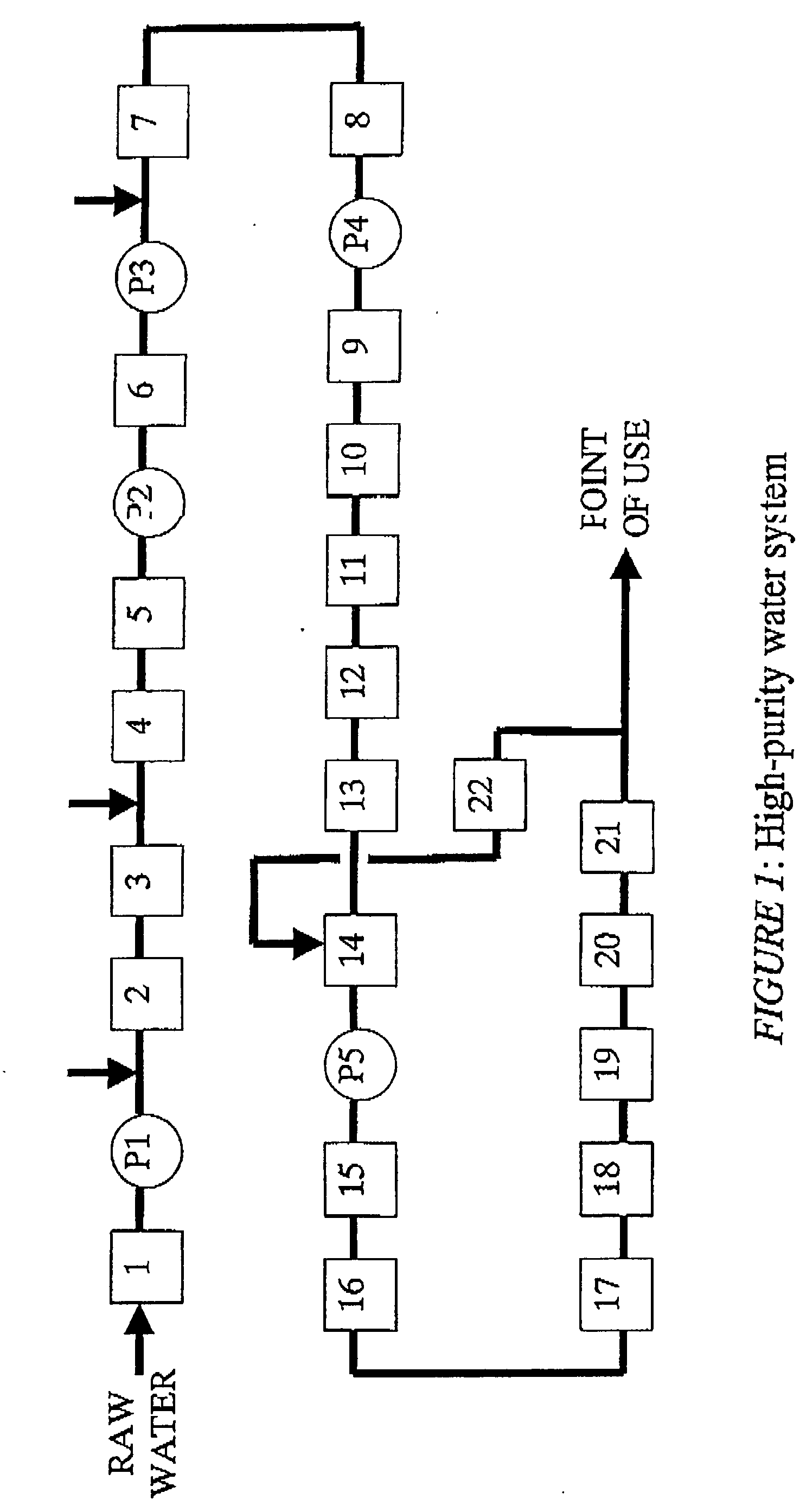

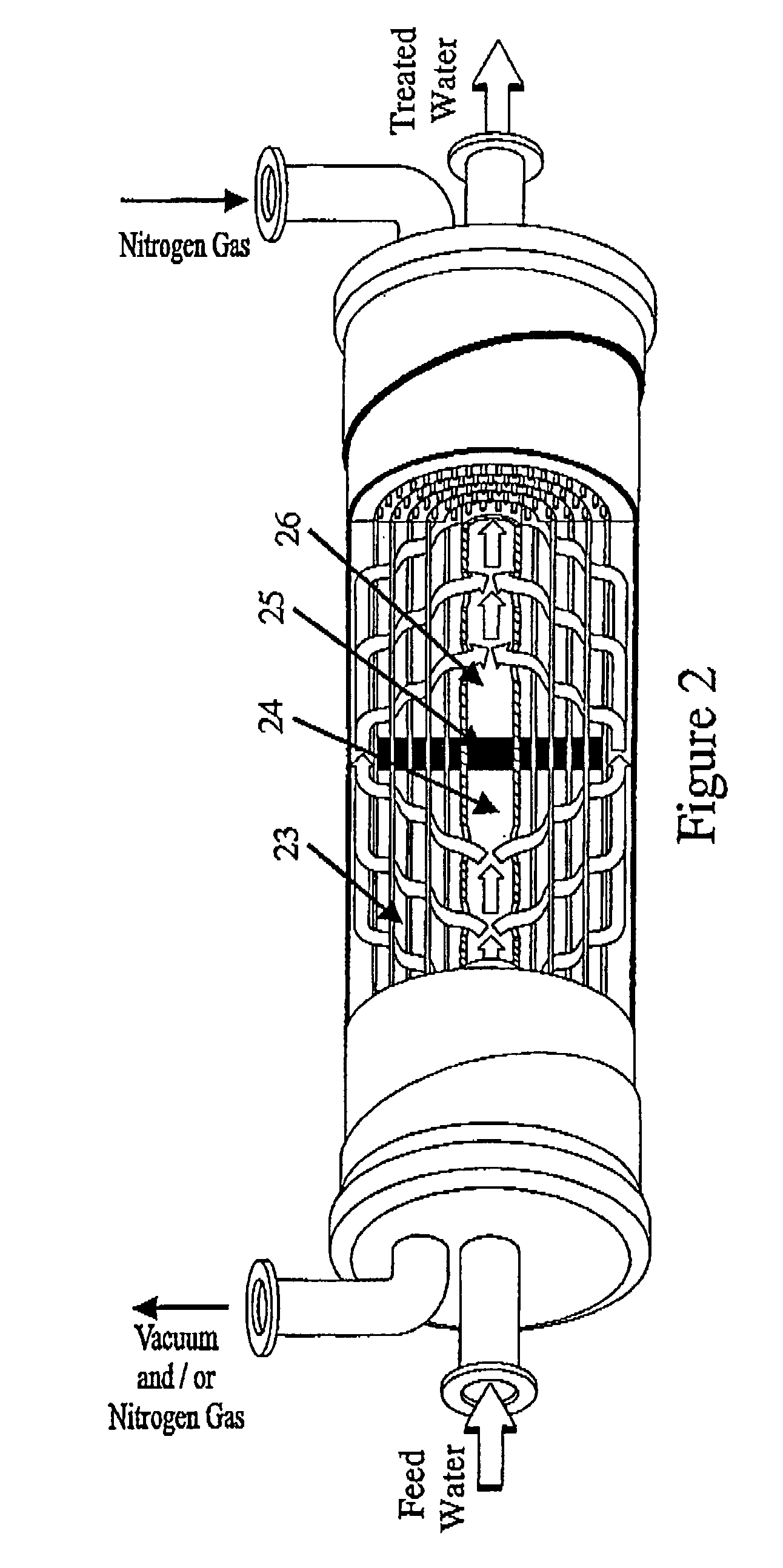

Method of removing organic impurities from water

InactiveUS20040050786A1Improves organic removal efficiencyLow flux rateTreatment involving filtrationSolid sorbent liquid separationWater useElectronic industry

In addition to health implications, trihalomethanes (THMs) poses a challenge to the electronic industry where such impurities cannot be tolerated. A process is provided for removing THMs from high-purity water used in the electronic industry. The method of the invention comprises contacting the high-purity water with a membrane degassifier, preferably operating at a temperature exceeding 45° C.

Owner:EVOQUA WATER TECH PTE LTD

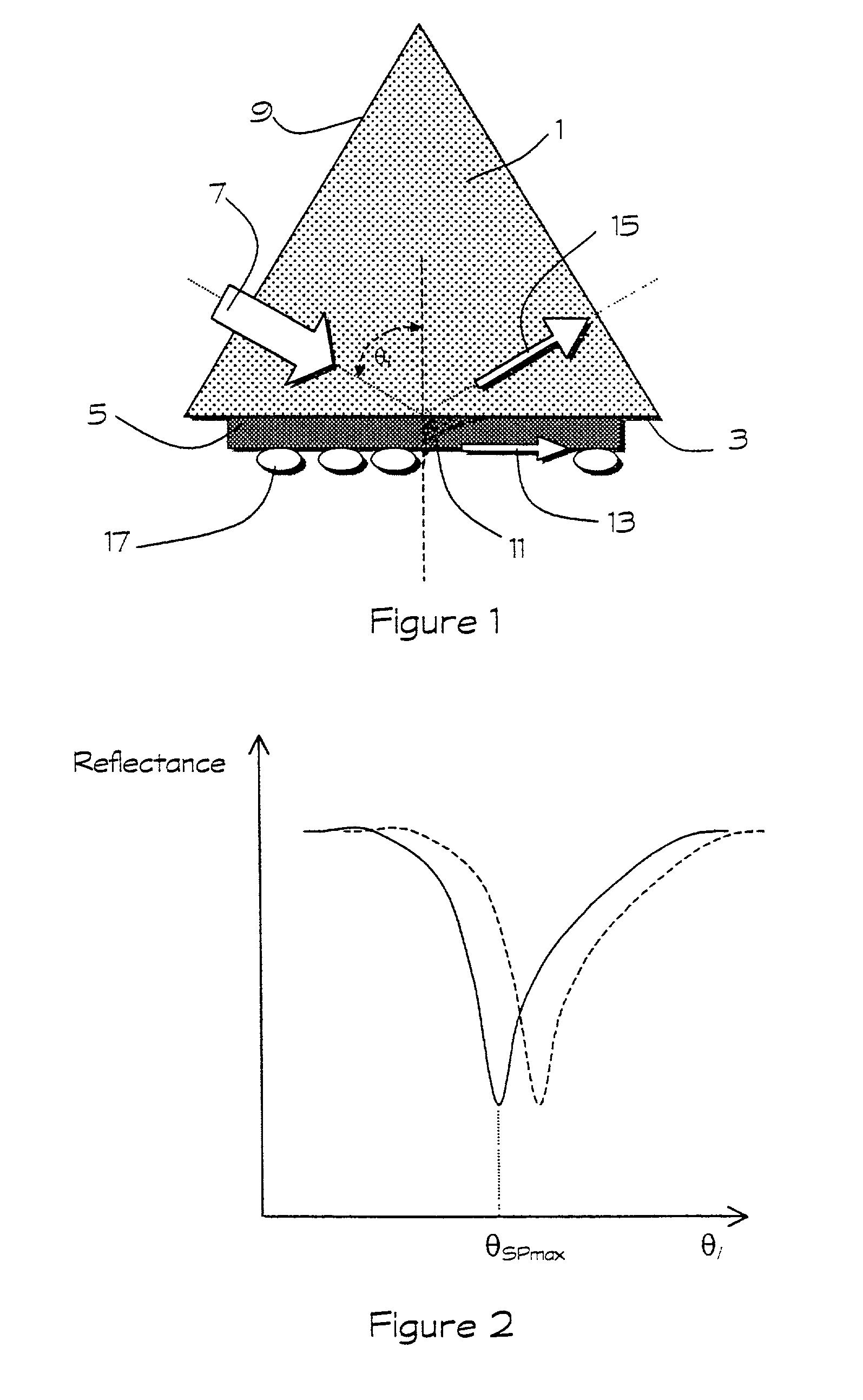

Detection of pyrogen and other impurities in water

InactiveUS20010040130A1Improve stabilityHigh sensitivityIon-exchanger regenerationScattering properties measurementsRefractive indexAmoebocyte lysate

High purity water, particularly that intended for the pharmaceutical or electronics industry, is analyzed for the presence of pyrogen or other impurities by causing the water to come into contact with a direct affinity sensor, which may be a surface plasmon resonance (SPR) device or other sensor relying on an evanescent wave phenomenon. A property of the surface-refractive index in the case of SPR-changes on the binding of impurity, thereby enabling impurity to be detected. The invention overcomes the cumbersome nature and batch-to-batch variability of the conventional in vivo tests as well as the in vitro Limulus Amoebocyte Lysate (LAL) assay and for the first time allows the continuous or real time monitoring of high purity water for pyrogen.

Owner:THE LORCH FOUND +1

Tungsten alloy composite plating coat material and manufacturing method thereof

InactiveCN101210305AImprove wear resistanceImprove corrosion resistanceMetallic material coating processesFiberMining industry

The invention relates to a tungsten alloy composite coating material and a manufacture method. The tungsten alloy composite coating material is a multi-phase composite structure material composed of a tungsten alloy and a large number of particles or fibers dispersed in the tungsten alloy. The tungsten alloy composite coating contains tungsten of 5 to 98wt% and particles or fibers of 0.05 to 80wt%, and the diameter of the particle or the fiber is 3nm to 5 micrometer. The coating has low internal stress, excellent normal-temperature and high-temperature hardness and abrasion resistance, excellent high-temperature oxidization resistance and excellent corrosion resistance. The tungsten alloy composite coating has important use in machinery industry, chemical and medicine industry, metallurgy industry, aerospace industry, weapons and ammunitions, petroleum exploitation, mining industry, electronic industry, etc, and is particularly suitable for the occasions with high-temperature strength and high corrosion resistance.

Owner:CHENGDU SHENJIA MACHINERY MFG +2

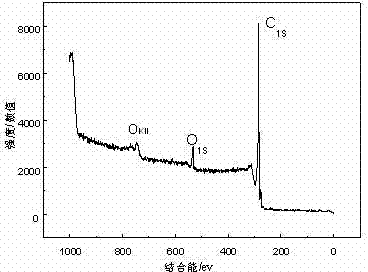

Graphene reinforced lead-free solder and preparation method thereof

ActiveCN102581504ADoes not damage the structureGood dispersionWelding/cutting media/materialsSoldering mediaGrapheneElectronic industry

The invention discloses a graphene reinforced lead-free solder, which comprises, by weight parts, graphene and lead-free solder base body of the ratio of 0.75-1.75:50000. The preparation method includes: by means of process of powder metallurgy, disposing the graphene into absolute ethyl alcohol according to proportion, vibrating ultrasonically, milling and drying the absolute ethyl alcohol with the graphene, mixing and stirring the absolute ethyl alcohol and the lead-free solder base body, pressing the same into a blank, sintering the blank at the temperature of 175 DEG C under the protective atmosphere of high-purity argon, extruding the same into a bar with the diameter of 6mm, and preparing the graphene reinforced lead-free solder. The graphene reinforced lead-free solder can meet the requirements of environmental protection and reliable welding, substitutes for conventional stannum-lead solder, has higher and more reliable mechanical performance than lead-free solder in the prior art, can be used as connection materials for oversized integrated circuits and is a composite material according with development trends of the modern electronic industry.

Owner:TIANJIN UNIV

Ultraviolet crosslinking and curing EVA (ethylene vinyl acetate copolymer) optical adhesive film and preparation method thereof

ActiveCN103525319AShort operating timeLess investmentNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceUltraviolet

The invention relates to an ultraviolet crosslinking and curing EVA (ethylene vinyl acetate copolymer) optical adhesive film and a preparation method thereof. The ultraviolet crosslinking and curing EVA optical adhesive film takes EVA or a mixture of the EVA and an EVA-modified graft polymer as a base material; in the mixture, the weight ratio of the EVA to the EVA-modified graft polymer is 1: 0-0.2; and according to 100 parts of the of the base material by total weight, the EVA optical adhesive film further comprises the following raw materials in part by weight: 0.1-5 parts of photoinitiator, 0.1-5 parts of multifunctional crosslinking agent, 0.1-1 part of antioxidant, 0.1-1 part of light stabilizer, 0.1-2 parts of coupling agent and 0.1-10 parts of bonding resin. The preparation method is short in operating time, small in required equipment investment, simple in process, convenient in operation and maintenance, energy-saving, environment-friendly and high in production efficiency; the production cost is reduced; the ultraviolet crosslinking and curing EVA optical adhesive film is low in defective ratio and excellent in mechanical properties; and during use, the ultraviolet crosslinking and curing EVA optical adhesive film can be crosslinked and adhered through radiation of specific ultraviolet, so that optical adhesive OCA and liquid optical adhesive LOCA for adhering a display in the traditional electronic industry can be replaced.

Owner:GUANGZHOU HUICHI GLASS TECHNICAL CO LTD

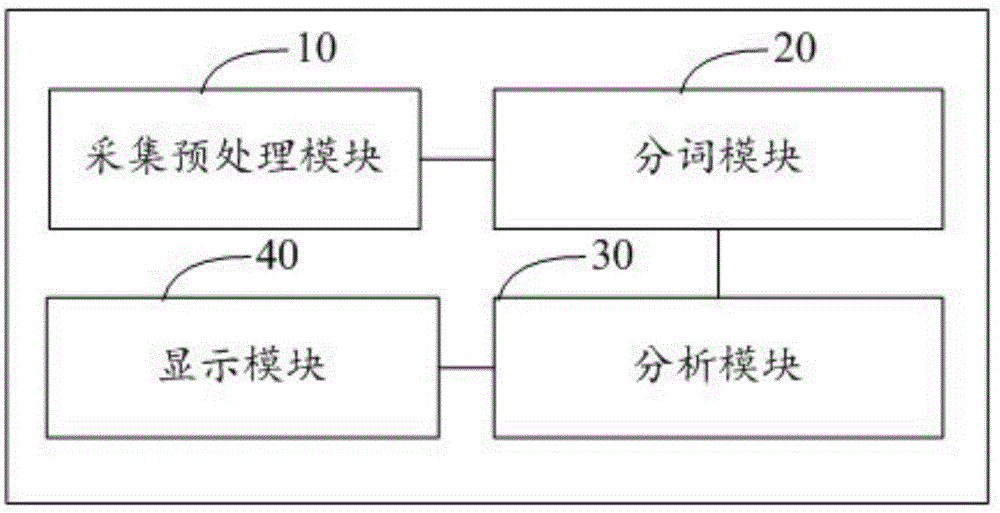

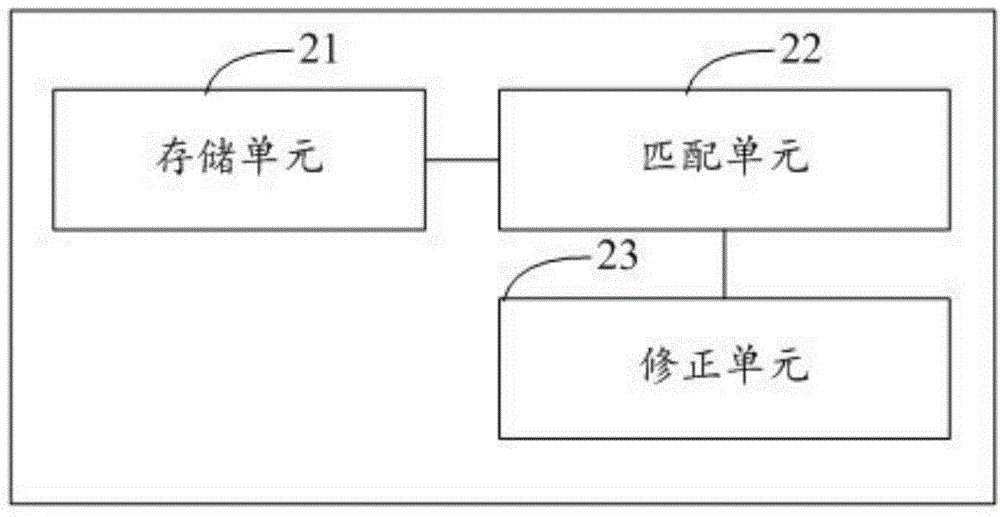

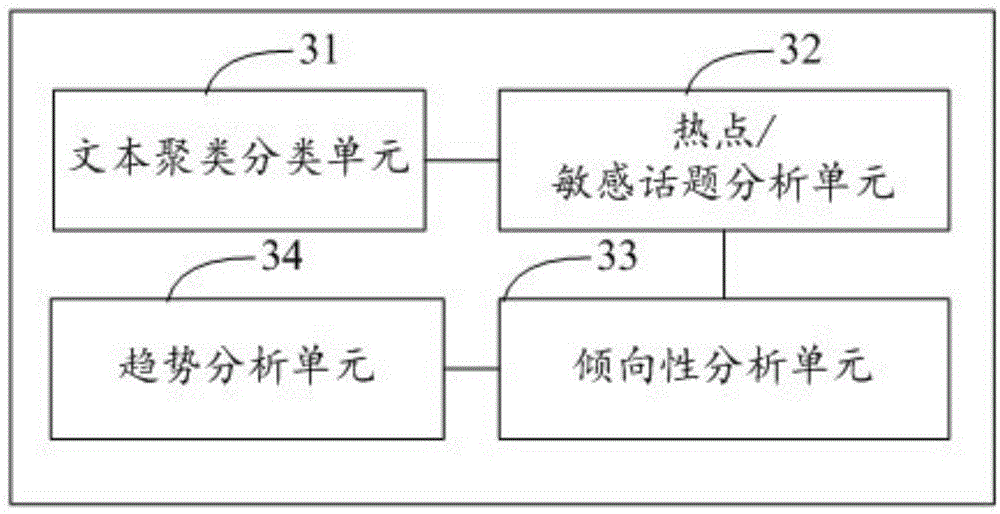

System and method for analyzing vertical public opinions based on industry

InactiveCN104573016AEffective sentiment analysisImprove accuracyWeb data indexingRelational databasesThe InternetTopic analysis

A system for analyzing vertical public opinions based on an industry comprises an acquisition and pre-treatment module for acquiring and pre-treating Internet information relevant to the consumer electronics industry and obtaining the formative information of the consumer electronics industry based on documents; a word segmentation module for matching words by means of a character string matching algorithm, and obtaining work segmentation results by amending the matching results in a word segmentation method based on understanding and statistics; an analysis module for performing document clustering and classification on the word segmentation results according to the frequency and similarity of keywords in the word segmentation results of the documents, and for obtaining analyzed and processed information after hotspot / sensitive topic analysis, orientation analysis and trend analysis to the clustered and classified results; and a display module for pushing the analyzed and processed information to users. The invention further provides a method for analyzing vertical public opinions based on an industry.

Owner:WUHAN TIPDM INTELLIGENT TECH

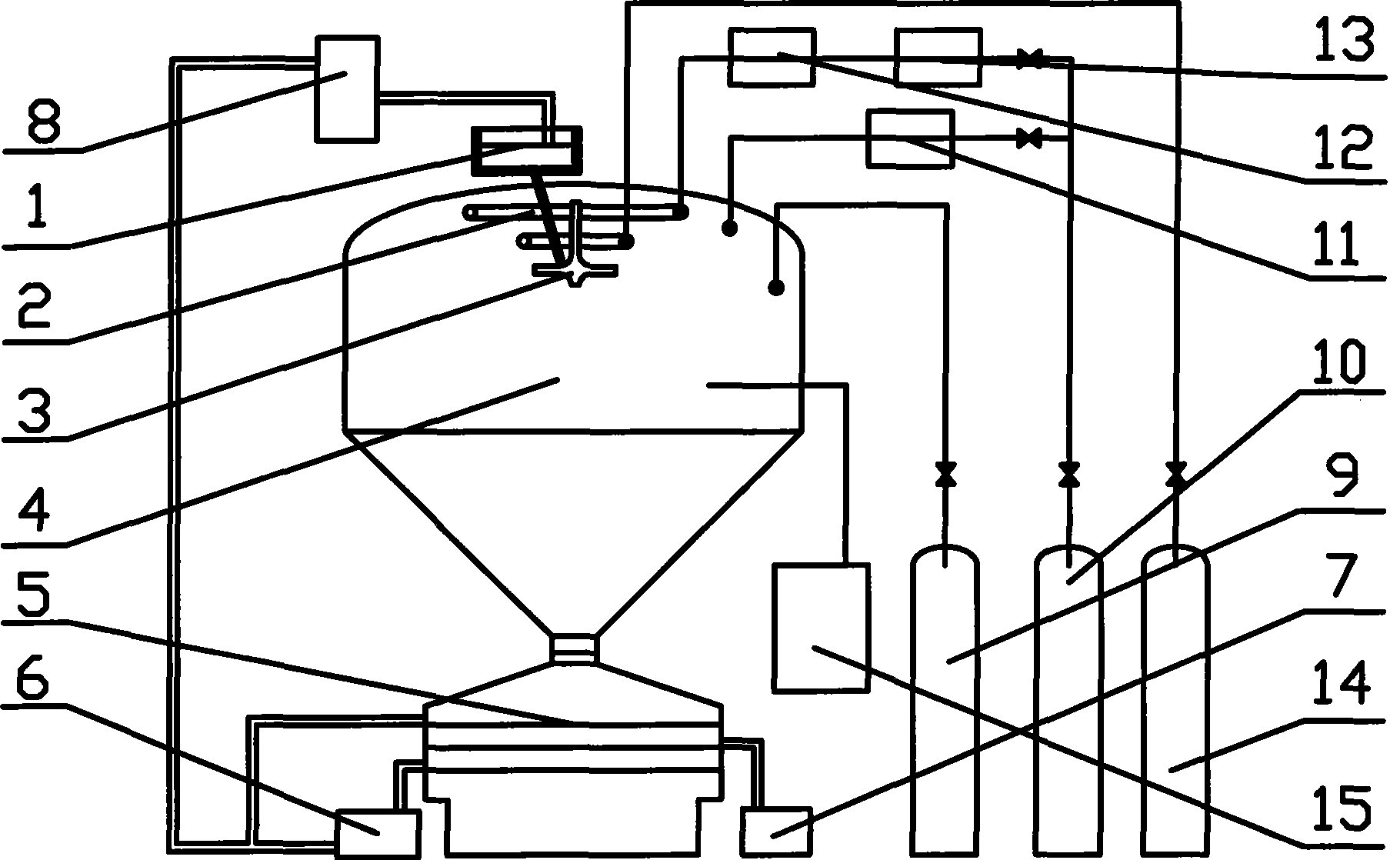

Preparation method of continuous high quality soldering powder

The invention discloses a method for preparing alloy powder, more particularly relates to a method for continuously preparing high-quality tin alloy welding powder. The invention is characterized in that an atomizing chamber is vacuumed, then inert protection gas is filled into the atomizing chamber; the tin alloy material is melted in a melting furnace, and then is controlled to be atomized in the atomizing chamber; after being cooled, the tin alloy material is solidified into tin alloy powder grain; by the sieving of the equipment, the needed product is obtained; products not meeting the requirements is melted and prepared again. The invention has the advantage that the quality of tin alloy powder is greatly improved by optimizing producing condition; the surface chemical property is improved; the productive labor cost can be greatly lowered; high priority is given to environmental protection in the process of realizing a circular production process. Products prepared by the method can be widely applied to encapsulation and circuit board welding material in electronic industry.

Owner:HUIJIN ATOMIZING SCI

Heat and flame resistant nylon composite

InactiveCN101735601AImprove flame retardant performanceImprove mechanical propertiesNylon materialNitrogen

The invention relates to heat and flame resistant nylon composite belonging to the filed of the electrical and electronic material. The heat and flame resistant nylon composite is characterized by comprising phosphorus flame retardant, nitrogen flame retardant, inorganic synergist, filler and auxiliary agent facilitating the processing and stabilizing. Due to the synergistic effect of the phosphorus flame retardant, the nitrogen flame retardant and the inorganic synergist, the nylon has the flame resistance, mains the mechanical performance, the thermal performance and the electrical insulating performance and can pass the test of the glow wire at 850 DEG C, and the problems that the defect of the nylon product is increased and the mechanical performance and the electrical insulating performance of the nylon produce are decreased due to the large consumption of the phosphorus flame retardant are solved. The heat and flame resistant nylon composite has good flame resistance, mechanical performance, thermal performance and electrical insulating performance and is mainly applied to the electrical and electronic industry.

Owner:SINOPLAST NEW MATERIAL

Aluminium ion battery and preparation method thereof

InactiveCN103825045AImprove securityImprove insulation performanceCell electrodesFinal product manufactureAluminum IonAluminium-ion battery

The invention relates to an aluminium ion battery and a preparation method thereof and belongs to the field of aluminium ion batteries and preparation thereof. The aluminium ion battery comprises a positive electrode, a negative electrode and an aluminium ion electrolyte, wherein the positive electrode is made of transition metal oxide; the negative electrode is made of high purity aluminium; the battery comprises a diaphragm material when the aluminium ion electrolyte is in a liquid state. Since abundant aluminium elements are stored, the cost for the ion battery is greatly reduced; the safety performance is improved; the transition metal oxide is applicable to hypervalent ion batteries due to relative stability under the variable valence states and different valence states. The ion liquid serves as the electrolyte for the hypervalent ion battery, so that aluminium ion is high in conductivity, good in heat stability, broad in electrochemical window and high in chemical stability and almost incapable of reacting with the positive electrode materials, the negative electrode materials, a current collector, a binder and a diaphragm in a battery system and capable of maintaining the liquid state in a board temperature range. The aluminium ion battery can be applied to various fields, such as electronic industries, communication industries and electric vehicles and the like.

Owner:UNIV OF SCI & TECH BEIJING

Glass cleaning agent composite for electronic industry

InactiveCN1482223AEasy to cleanRaw materials are easy to getInorganic non-surface-active detergent compositionsSodium bicarbonateSodium metasilicate

The electronic industrial glass cleaning agent composition belongs to the field of electronic industrial cleaning technology. The cleaning agent consists of sodium metasilicate, sodium hydroxide, sodium carbonate, sodium bicarbonate, Pluronic polyol, CMC, fluoric surfactant, complexing agent, defoaming agent and deionized water. It is used to clean substrate glass and coated conducting glass. During the cleaning, the cleaning agent in 1-5 % is compounded with deionized water in 95-99 % to compound the cleaning liquid for showering or ultrasonic cleaning to eliminate pollutant on glass fastcompletely. It is used to replace strong acid and strong alkali cleaning agent and has no damage to glass surface and no corrosion to ITO film. The cleaning agent has no bad smell, no toxicity and no corrosion, and is safe, reliable, environment friendly and low in cost.

Owner:SHANDONG UNIV

Preparation method of multidimensional hybrid composite of glass fibre/ grapheme- carbon nano tube/ epoxy resin

InactiveCN102304274AIncreased interlaminar shear strengthImprove interface strengthCarbon nanotubeResin matrix

The invention relates to a preparation method of multidimensional hybrid composite of glass fibre / grapheme-carbon nano tube / epoxy resin. In the method, after grapheme-carbon nano tube network structure is subjected to surface carboxylation, diamine or polyamine is introduced on the grapheme-carbon nano tube network structure; the grapheme-carbon nano tube connected with the amino is modified by micromolecule aromatic polybasic anhydride compound to prepare the carbon nano tube carried with an anhydride group; the grapheme-carbon nano tube is dispersed in the epoxy resin matrix by ultrasonic oscillation and high-speed stirring; organic acid anhydride curing agent is adopted for curing; and the obtained epoxy resin polymer containing the grapheme-carbon nano tube serves as the matrix to be compounded with glass fiber processed by silane coupling agent to form a multifunctional hybrid composite structure connected by covalent bonds. The multidimensional hybrid composite is convenient to prepare, the application range of the glass fiber, the grapheme, the carbon nano tube and the epoxy resin is widened, so that the hybrid composite can be widely applied on the aspects of aerospace, traffic transportation, electronic industry, civil facilities, building, chemical engineering and the like, can be industrially produced on a large scale, has low cost and is friendly to environment.

Owner:TONGJI UNIV

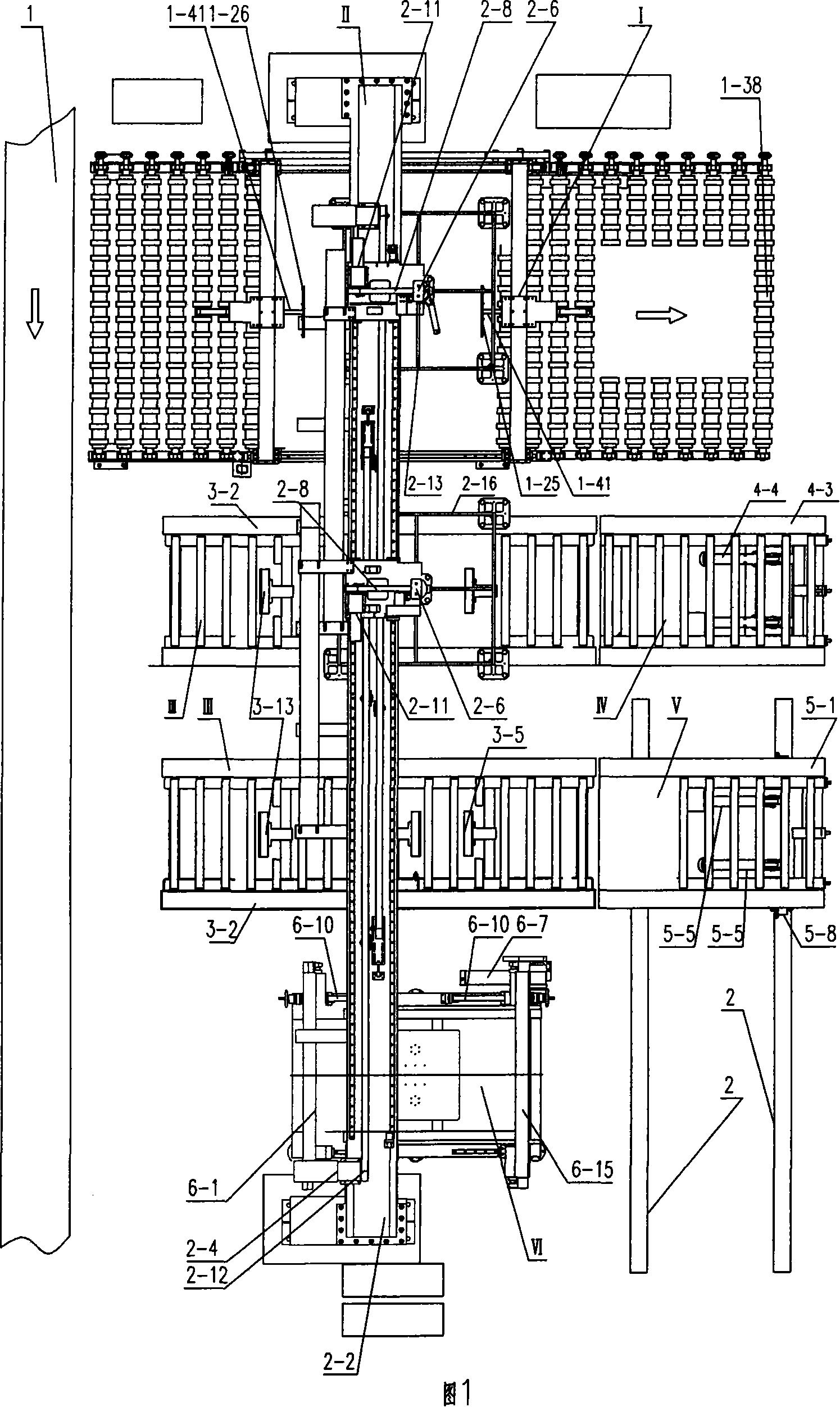

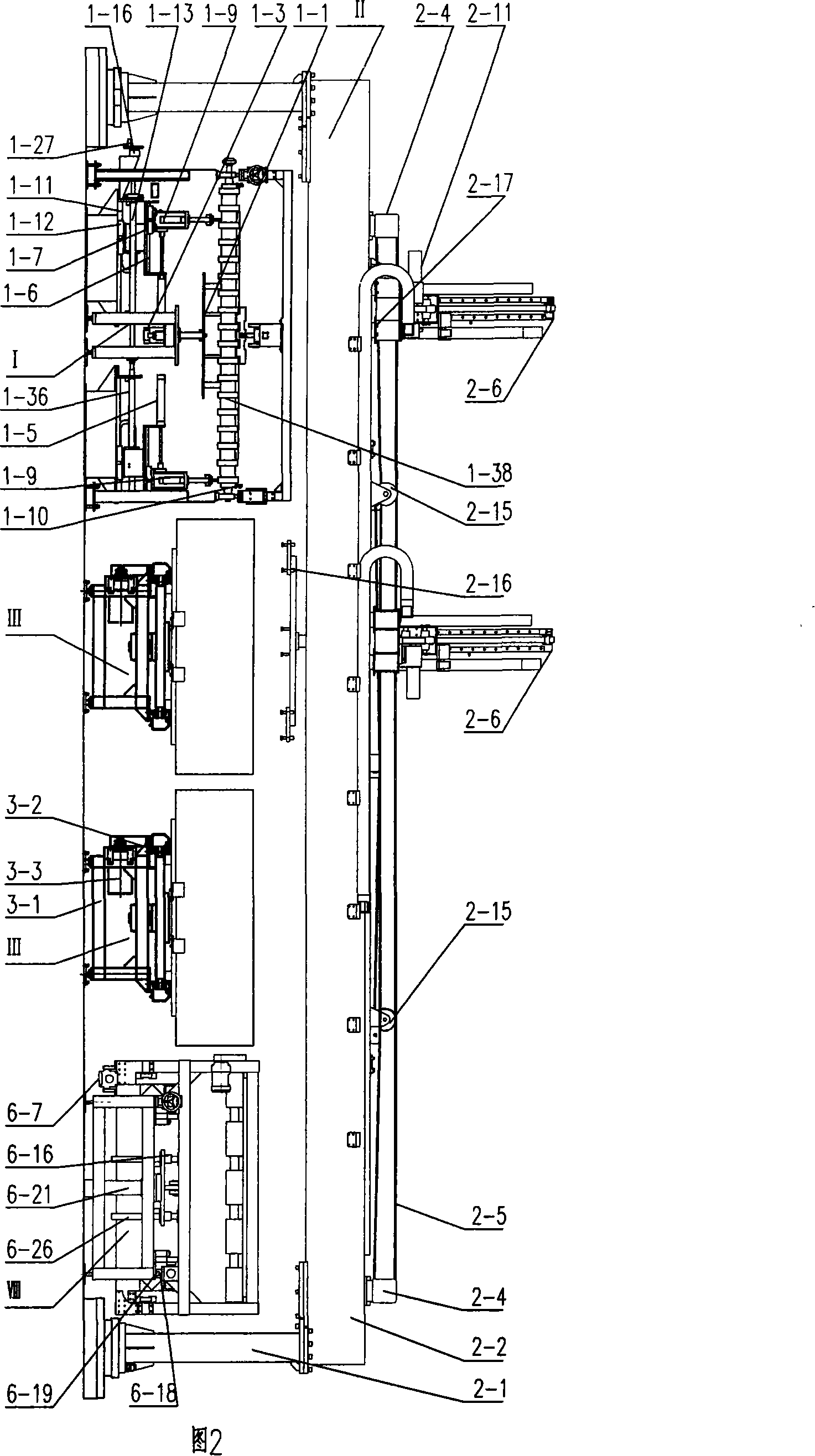

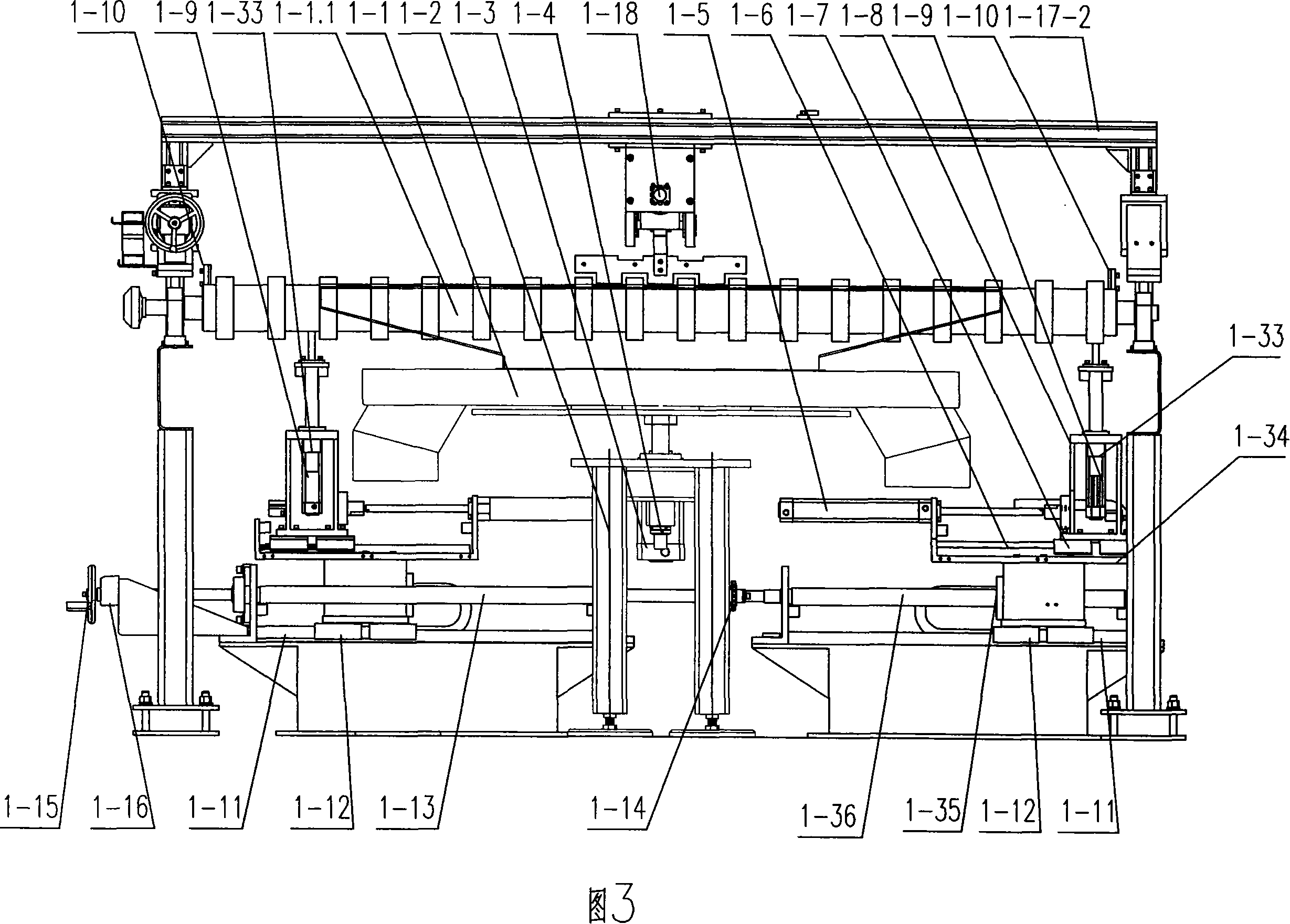

Automatic sheet-fetching system of ultra-thin glass

ActiveCN101139015ATimely crawlSolve the key technical problems of offlineRegistering devicesCharge manipulationEngineeringThin glass

The present invention discloses a ultra-thin glass automatic slicing system and comprises a glass transmission branch, a clean transportation robot and a packing box fixed turnover unit as well as a glass centering positioning unit, a packing box transmission positioning unit, a packing box moving turnover unit and a septum paper supplying unit. A glass transmission main line is vertical to the glass transmission branch and the glass centering positioning unit is arranged above and below the glass transmission branch; two packing box transmission positioning units are arranged in parallel with the glass transmission branch, wherein, the terminal of the packing box transmission positioning unit arranged close to the glass transmission branch is provided with the packing box fixed turnover unit; the terminal of the packing box transmission positioning unit far away from the glass transmission branch is provided with the packing box moving turnover unit; the septum paper supplying unit is arranged in parallel to the packing box transmission positioning unit; the present invention can meet the quality standard of glass in electronic industry and packing requirement of ultra-thin glass storage and transmission at the same time, and improve yield and packing quality of ultra-thin float glass.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

Preparation method of high-thermal conductivity graphene-Sn-Ag composite brazing filler metal

ActiveCN104400247AImprove performanceSolve reunionWelding/cutting media/materialsSoldering mediaDensity differenceCvd graphene

The invention discloses a preparation method of a high-thermal conductivity graphene-Sn-Ag composite brazing filler metal, ad relates to a preparation method of a high-thermal conductivity composite brazing filler metal. The preparation method has the following purposes: the problem of graphene floating and agglomeration in the preparation and application process of the composite brazing filler metal is solved by reducing a greater density difference between graphene and an Sn-Ag brazing filler metal matrix through plating a metal on the graphene; meanwhile, the graphene is dispersed more uniformly in the brazing filler metal matrix; and the reliability of sealing and brazing is improved by improving the heat conductivity of the composite brazing filler metal through adding the graphene. The method comprises the following steps: (1) the metal is plated on the graphene; and (2) the ball milling, the mixing and the medium-temperature smelting are performed for the metal-plated graphene and the Sn-Ag brazing filler metal to obtain the high-thermal conductivity composite brazing filler metal. The prepared composite brazing filler metal is high in thermal conductivity, has a higher wettability compared with a traditional Sn-Ag brazing filler metal, and is a composite brazing filler metal accordant with the present development tendency of an electronic industry as a connecting material of traditional large-scale integrated circuits.

Owner:HARBIN INST OF TECH

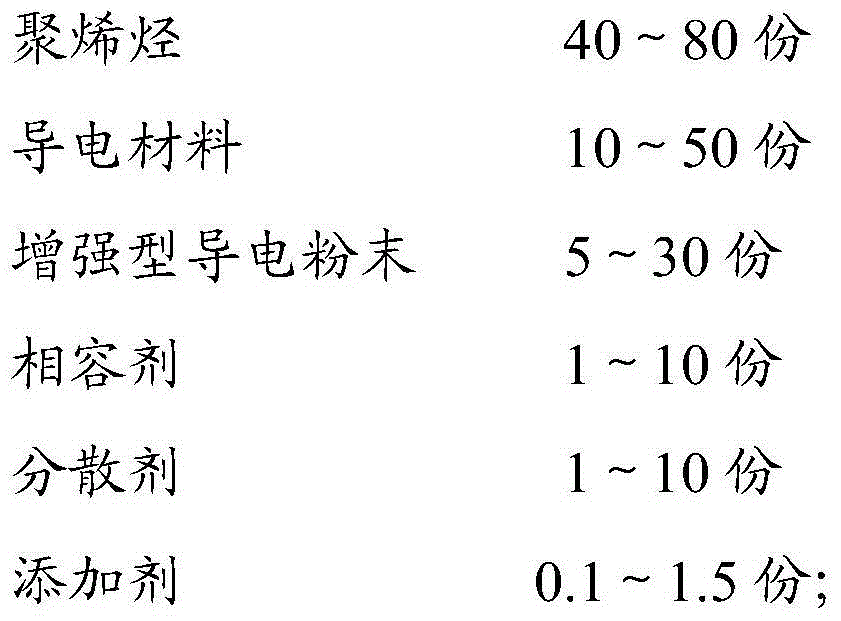

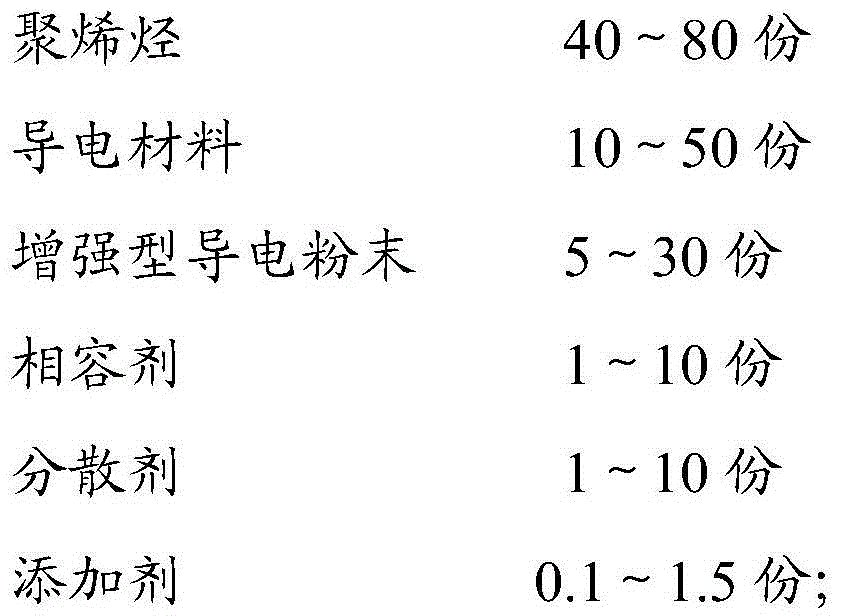

Permanently anti-static polyolefin master batch and preparation method thereof

The invention belongs to the technical field of high polymer materials, and particularly relates to a permanently anti-static polyolefin master batch and a preparation method thereof. The polyolefin master batch is prepared from the following components in parts by weight: 40-80 parts of polyolefin, 10-50 parts of conductive polymer or a composite material thereof, 5-30 parts of reinforcing conductive powder or fiber, 1-10 parts of a compatilizer, 1-10 parts of a dispersing agent, and 0.5-1.5 parts of other additives; the preparation method comprises the following steps: mixing the materials uniformly, then adding the mixture into a co-rotating twin screw extruder with a length to diameter ratio of 36-48, and extruding and pelletizing to obtain the product. The polyolefin master batch is good in dispersibility and compatibility; the good appearance, mechanical properties and stability of polyolefin can be maintained while the excellent anti-static effect can be achieved; the polyolefin master batch can be widely applied to membrane blowing, extrusion, blow molding and injecting molding products, and promotes the high-speed development of the electronic industry, the petroleum industry, the weapon industry and the military field in China.

Owner:DONGGUAN DICOLORS PLASTIC & METAL

Method for preparing halogen-free flame-proof polylactic acid

InactiveCN101260227AMeet environmental protection requirementsImprove flame retardant performanceJet aeroplaneMolecular materials

The invention belongs to the high molecular material technical field, and in particular relates to a preparation method of halogen-free fire-retarding poly lactic acid. The preparation method comprises the following steps: firstly, fire retardant, fire-retarding auxiliary agent and antioxidant are stirred according to a certain proportion to obtain fire-retarding mixture; then, poly lactic acid, the fire-retarding mixture, compatibilizer and coupling agent are mixed according to a certain proportion and are fused and mixed; and finally, the materials are made into fire-retarding poly lactic acid after cooling, pelleting and drying. The fire-retarding poly lactic acid, which has excellent fire-retarding performance and less fused dripping and can pass UL94 grade testing, can be used in fields such as airplane, automobile and electronic industry, which have strict requirements on material fire-retarding performance.

Owner:TONGJI UNIV

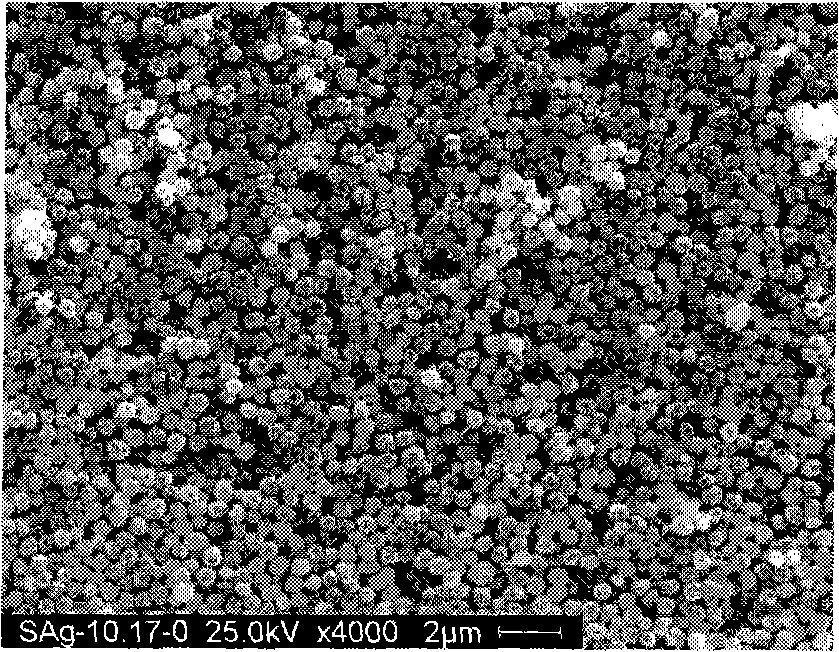

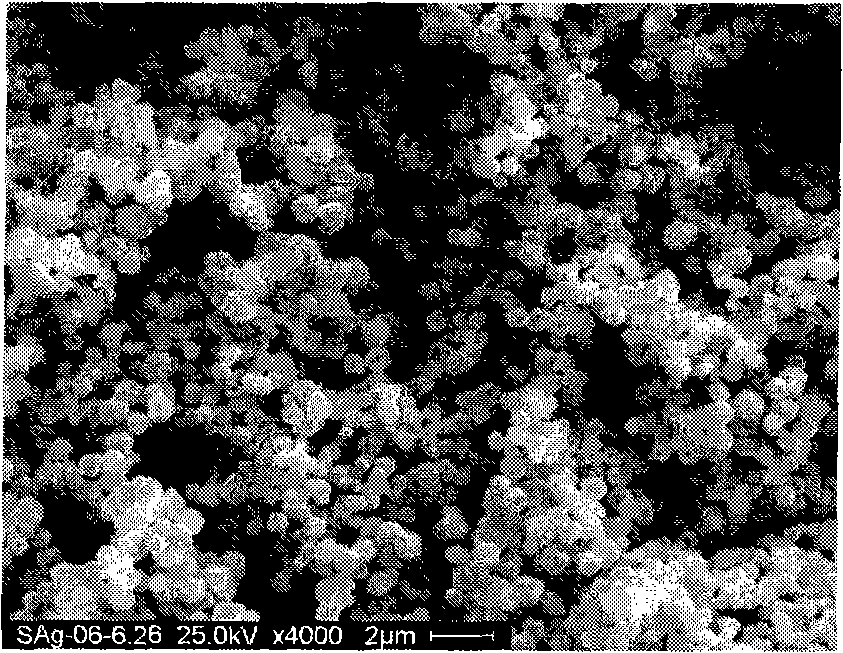

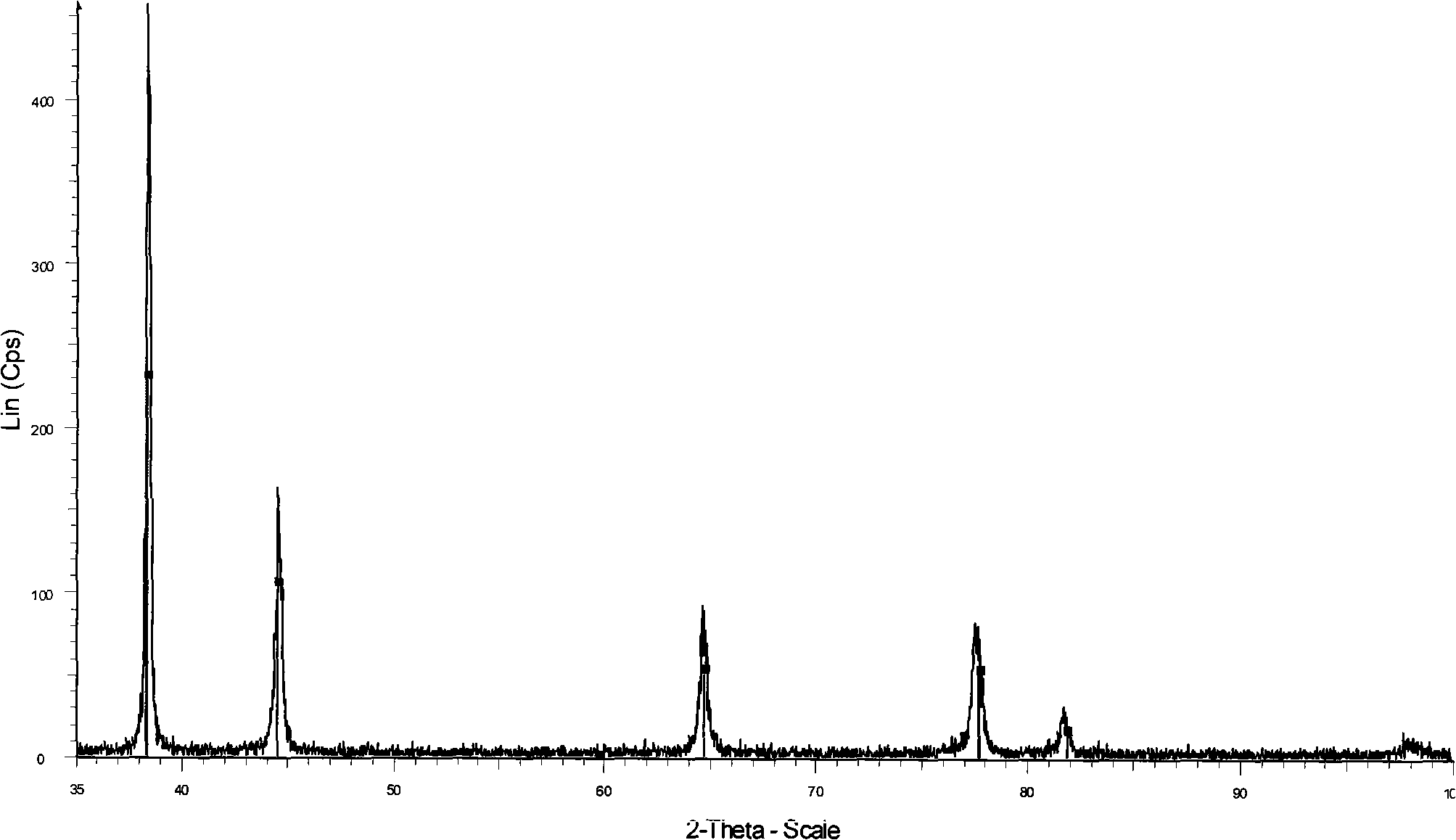

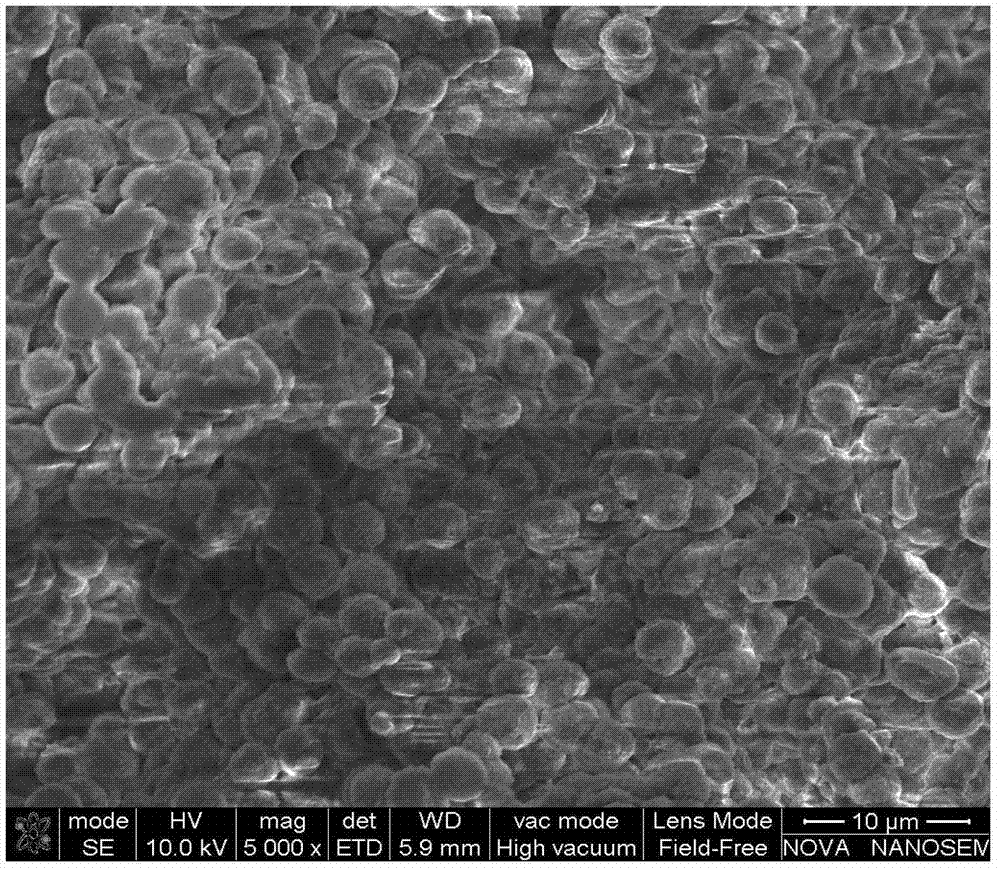

Preparation of high dispersed superfine spherical silver powder for conductive silver slurry

A preparation method of high-dispersion ultra-fine spherical silver powder used for conductive silver paste relates to a preparation method of ultra-fine spherical silver powder, in particular to the preparation method of the high-dispersion ultra-fine spherical silver powder for the conductive silver paste in the electronic industry. The preparation method is characterized in that silver ammonia solution is dropped in a reduction system which consists of a reducing agent of formaldehyde, a dispersant of polyvinyl alcohol PVA and sodium hydroxide solution, thus obtaining high-dispersion ultra-fine silver powder slurry, and the high-dispersion ultra-fine spherical silver powder with the particle size range of 0.3 to 1.0Mum can be obtained by solid-liquid separation and drying. The method of the invention has simple and feasible process flow, low production cost, less equipment investment, stable and reliable process conditions, small particle size of the product silver powder, narrow distribution range, high yield and easy realization of industrial mass production.

Owner:JINCHUAN GROUP LIMITED

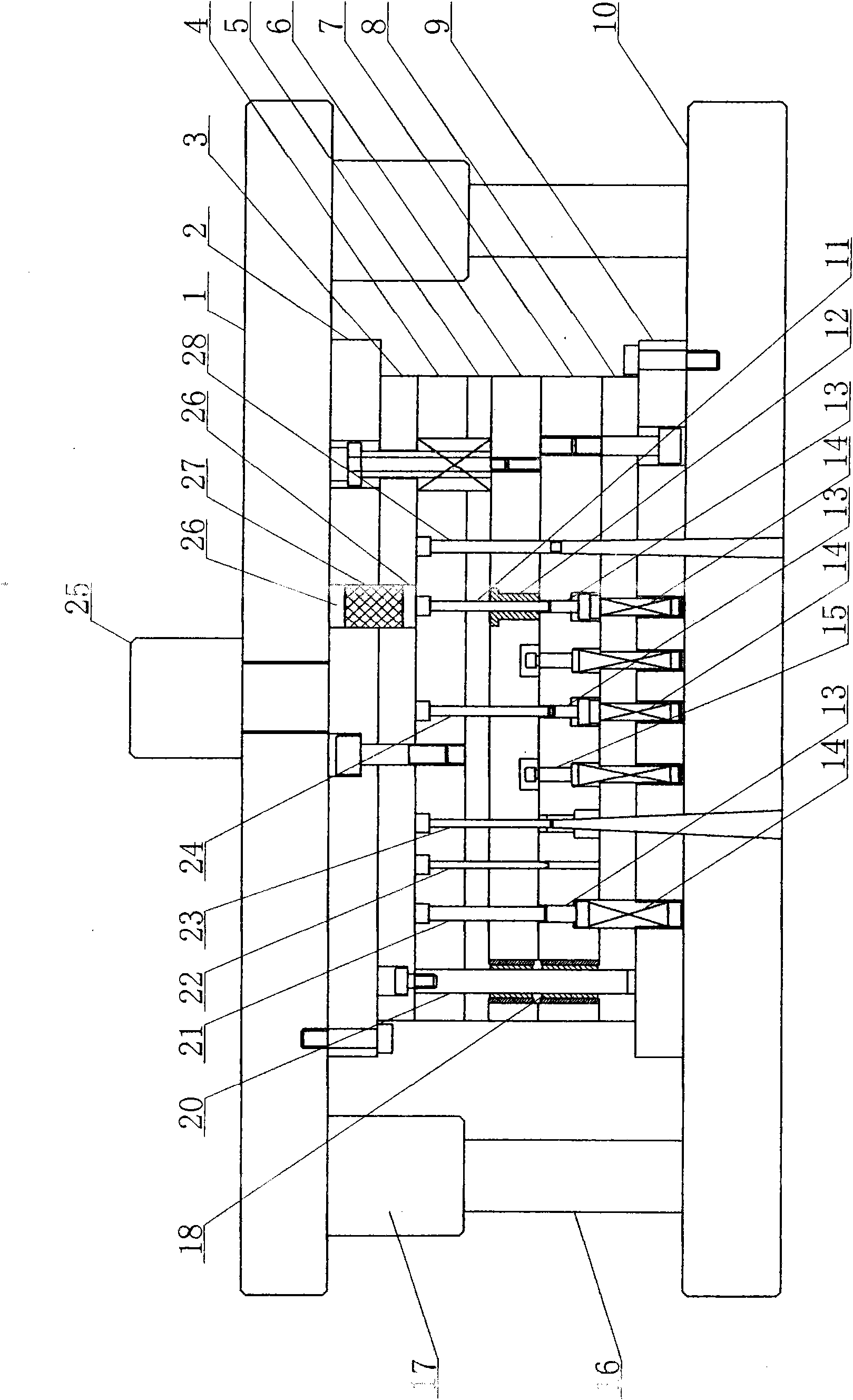

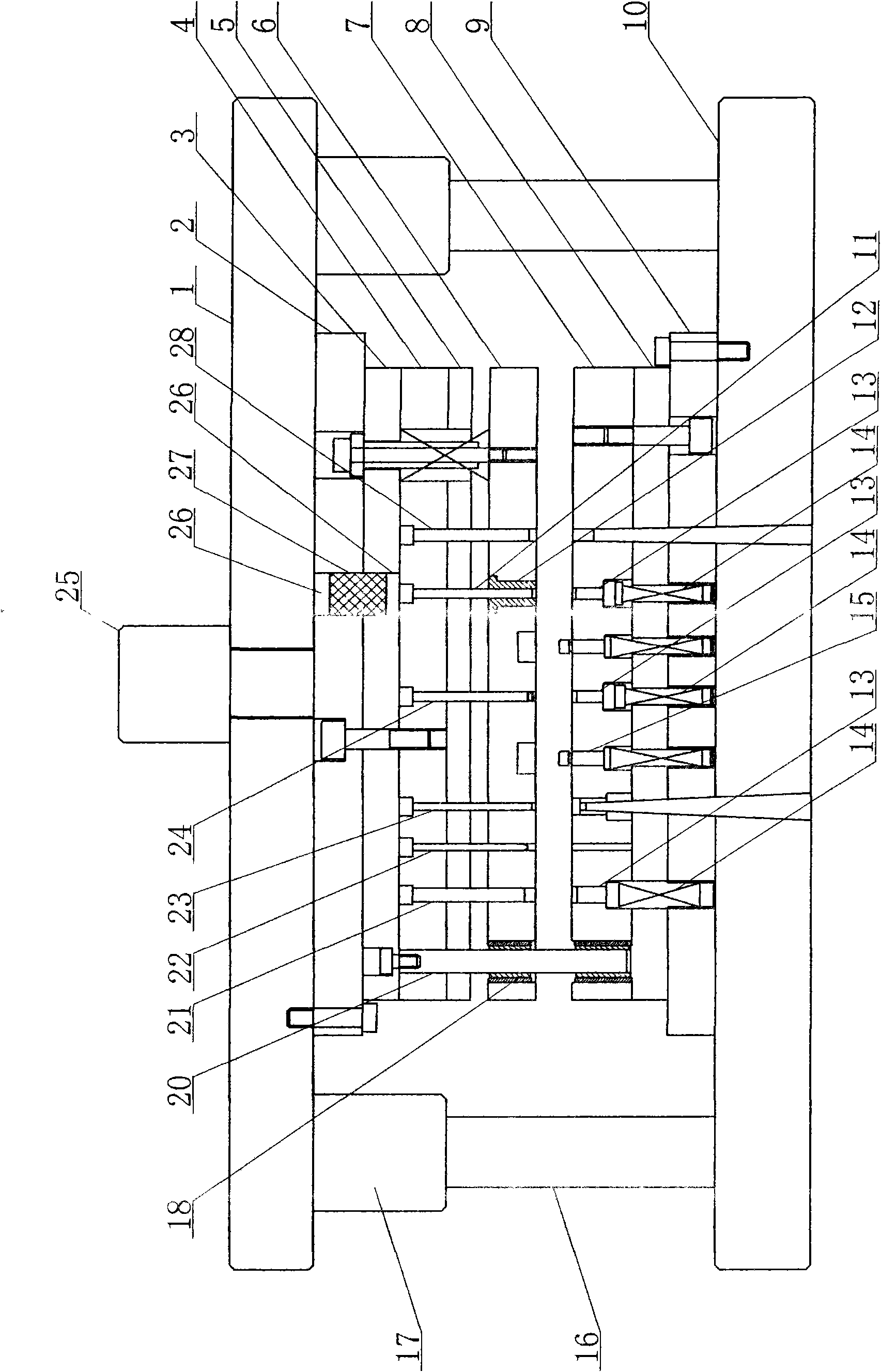

Method for producing thin-wall metal circular ring and grading stamping mould used therefor

ActiveCN101767164AIncrease productivityUniform wall thicknessShaping toolsPunchingElectronic industry

The invention discloses a method for producing a thin-wall metal circular ring, which comprises the steps of deep-drawing, punching, turning up, shaping and blanking plate materials or strip-shaped materials on a grading stamping mould. The grading stamping mould used for implementing the method mainly comprises an upper mould part and a lower mould part, wherein a deep-drawing male mould, a punching male mould, a turning-up male mould, a shaping male mould and a blanking male mould are arranged on the upper mould part sequentially; the male moulds all pass through a discharging plate; an annular convex part is arranged on the part, which surrounds the shaping male part, of the discharging plate; a deep-drawing female mould, a punching female mould, a turning-up female mould, a shaping female mould and a blanking female mould are arranged on the lower mould part sequentially; and spring-ejecting parts are arranged in the cavities of the deep-drawing female mould, the turning-up female mould and the shaping female mould. The method solves the technical problems of low processing precision and low production efficiency of the metal circular ring with two straight end faces. The method has a simple structure and is widely applied to the production manufacturing industry of the metal circular ring in electronic industry.

Owner:WEIFANG YUYUAN ELECTRONICS CO LTD

Process for preparing nano gold particle materal

InactiveCN1554503AImproved size distribution rangePrecise size controlPolyvinyl alcoholGold particles

The preparation process of nano gold particle material includes the following steps: preparing mixed water solution of HAuCl4, protecting agent and acetone in the weight ratio of 1 to 10-10000 to 100-1500, with the protecting agent being one of polyglycol, PVA and PVP; and irradiating the mixed water solution with ultraviolet ray of wavelength 254-400 nm to complete the reduction reaction to obtain nano gold particle. The said technological process is simple, and can produce pure nano gold particle with controllable size and narrow size distribution range. The produced nano gold particle may be used in biomedicine, electronic industry and fine chemical industry.

Owner:KUNMING INST OF PRECIOUS METALS

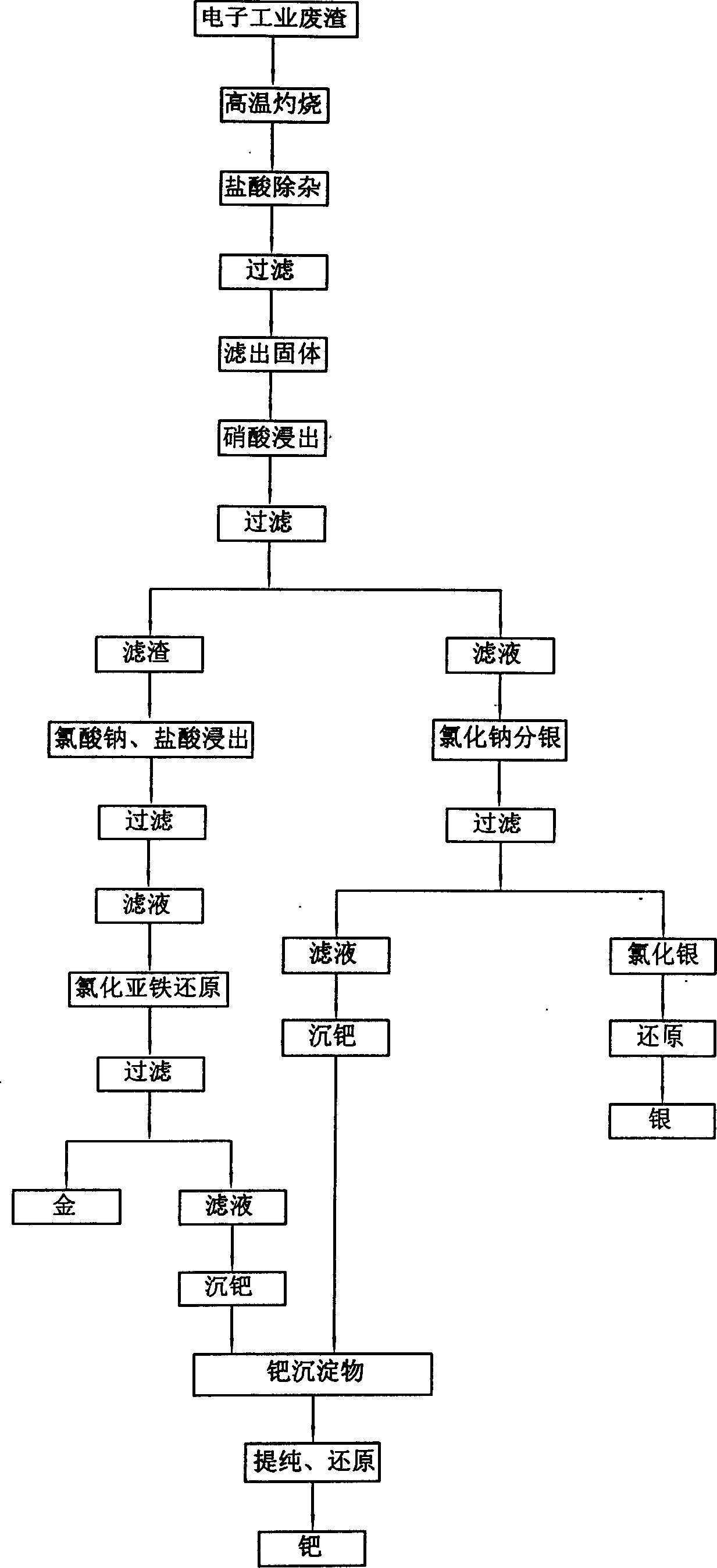

Technological process for extracting gold, silver and palladium from electronic industry waste

InactiveCN1603432AEfficient extractionAvoid interferenceProcess efficiency improvementHydrometallurgyOrganic matter

The invention discloses a kind withdraws golden, the silver, the arrowhead used in ancient times technique from the electronics industry waste residue, he solved the organic matter to withdraw the process to the precious metal the disturbance, realized the minute using the hydrometallurgy technology step to withdraw golden, the silver, the arrowhead used in ancient times goal. The technique has the operating environment well, the cost is inexpensive, the precious metal first experience higher merit which withdraws.

Owner:NANJING UNIV

Single-component epoxy resin conductive silver adhesive composition and preparation method thereof

ActiveCN104017529AReduce viscosityImprove stabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxySolvent

The invention belongs to the technical field of epoxy resin adhesives, and particularly discloses a single-component epoxy resin conductive silver adhesive composition and a preparation method thereof. The composition contains the following components in parts by weight: 10-25 parts of epoxy resin, 1-5 parts of diluter, 0.5-3 parts of toughening agent, 0.5-3 parts of enhancer, 0.5-3 parts of solvent, 0.5-3 parts of coupling agent, 0.5-3 parts of anti-aging agent, 1-5 parts of curing agent, 0.2-1 part of accelerator and 30-35 parts of silver powder. The preparation method of the composition comprises the following steps: thoroughly and uniformly mixing all the components except silver powder at 20-35 DEG C, adding the silver powder, thoroughly and uniformly mixing, and carrying out vacuum degassing under stirring conditions to obtain the finished epoxy resin conductive adhesive composition product. The composition has the advantages of low viscosity, favorable condensate strength, high adhesive force, low volume resistivity, high heat conductivity, long shelf life, favorable long-term weather resistance and stable electric properties, and can be widely used in electronic industry and other conductive adhesive industries.

Owner:江苏矽时代材料科技有限公司

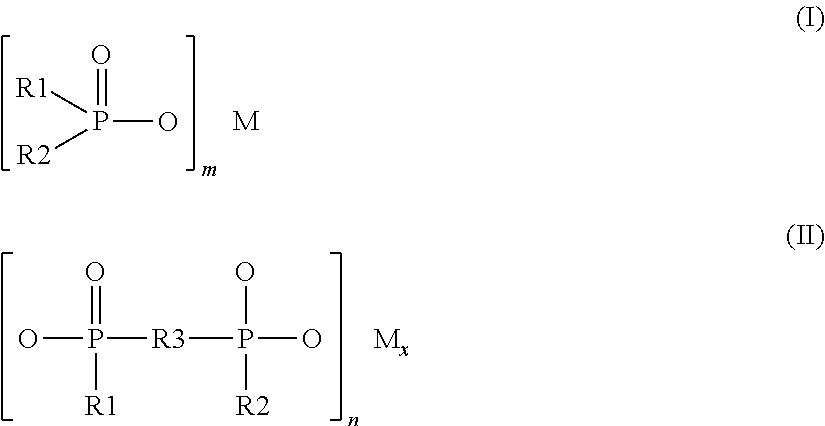

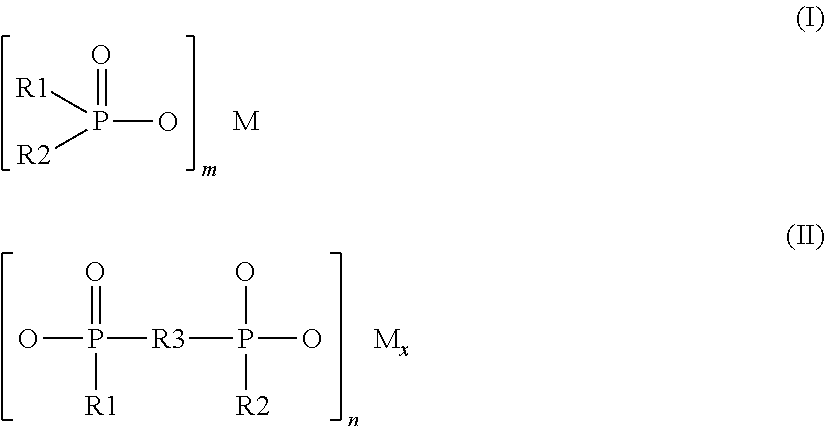

Flame-protected, partially aromatic polyamide molding compounds

ActiveUS20120083558A1Reduce the amount requiredGroup 5/15 element organic compoundsSynthetic resin layered productsThermoplasticPolyamide

The invention relates to a flame-retardant polyamide molding composition based on semicrystalline polyamides. This polyamide molding composition is based on(A) from 30 to 92% by weight of at least one aliphatic or semiaromatic, semicrystalline polyamide with melting point (Tm) in the range from 240° C. to 340° C.;(B) from 0 to 50% by weight of at least one filler and reinforcing agent;(C) from 8 to 18% by weight of at least one halogen-free flame retardant;(D) from 0 to 2.0% by weight of at least one barium carboxylate;(E) from 0 to 5% by weight of at least one additive;wherein the percentages by weight of components (A) to (E) give a total of 100%, and with the proviso that if the proportion of component (D) is in the range from 0 to 0.1% by weight the halogen-free flame retardant of component (C) is based on a barium phosphinate. The invention further relates to the use of barium carboxylate in a polyamide molding composition using a halogen-free flame retardant for inhibiting corrosive action during processing. The molding compositions comply with fire-protection class UL 94 V-0, and have no, or only slight, corrosive action with respect to the machine components used in thermoplastic processing, and exhibit good mechanical properties. They are suitable for producing, in particular, thin-walled moldings for the electrical and electronics industry, examples being housings, housing components, and connectors.

Owner:EMS PATENT AG

Method for preparing natural fiber/polylactic acid composite material with anti-flaming function

InactiveCN101260228AImprove flame retardant performanceReduce generationMolecular materialsNatural fiber

The invention belongs to the high molecular material modification technical field, and in particular relates to a preparation method of natural fiber / poly lactic acid composite material with fire-retarding performance. The preparation method comprises the following steps: the surface modification and the fire-retarding modification of natural fiber are completed to improve the interface combination degree and the fire-retarding performance between the natural fiber and a poly lactic acid matrix; and then, the modified natural fiber is combined with poly lactic acid and fire retardant, thereby obtaining natural fiber-reinforced poly lactic acid composite material with excellent fire-retarding performance, mechanical property and full biodegradation. The poly lactic acid composite material, which can pass the fire-retarding testing in accordance with the standards of Federal Aviation Administration (FAA) and UL94V-O grade testing, can be used in fields such as airplane, automobile and electronic industry, which have strict requirements on material fire-retarding performance and mechanical property.

Owner:TONGJI UNIV

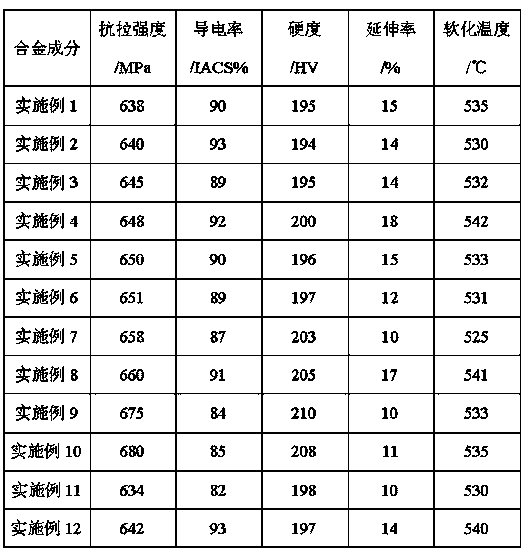

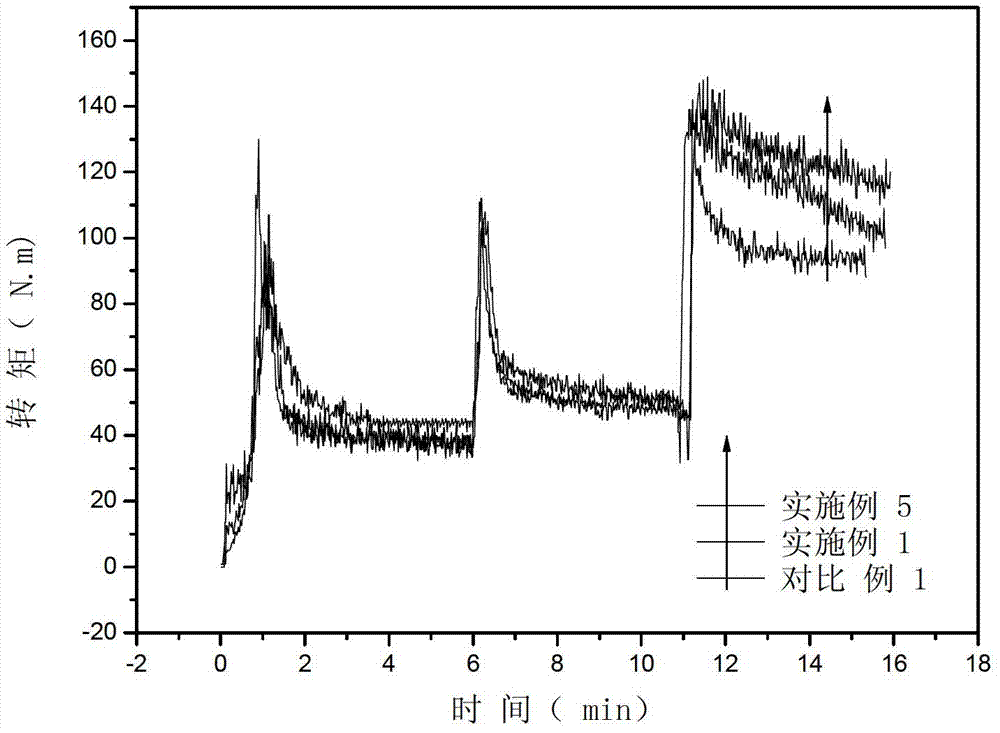

High-strength, high-conductivity and high-extensibility rare earth copper alloy and preparation method thereof

A high-strength, high-conductivity and high-extensibility rare earth copper alloy and a preparation method thereof are disclosed. The alloy is composed of following components in percentage by weight: 0.5 to 1.5% of chromium, 0.3 to 0.5% of zirconium, 0.1 to 0.3% of nickel, 0.2 to 0.5% of titanium, 0.2 to 0.4% of manganese, 0.02 to 0.15% of rare earth elements and the balance of copper and inevitable impurity elements, wherein the rare earth elements are one or two elements of erbium and lanthanum. The preparation method comprises following steps: preparing intermediate alloy, smelting, moulding, casting, treating solid solution, drawing to deform, performing an aging treatment, and a cold rolling treatment. The components and the ratio of the components are limited to let each component have a combined action, thus the comprehensive properties of the alloy material are prominently improved: the extension strength is larger than 630 MPa, the hardness is larger than 190 HV, the ductility is larger than 10%, the conductivity is larger than 80%IACS, and the softening temperature is larger than 520 DEG C; and the rare earth copper alloy can satisfy the requirements of materials in the electronic industry such as lead frame on copper alloy performances.

Owner:HENAN UNIV OF SCI & TECH

Dynamic vulcanized fluoroplastic/fluororubber/silicone rubber thermoplastic elastomer and preparation method thereof

The invention discloses a dynamic vulcanized fluoroplastic / fluororubber / silicon rubber thermoplastic elastomer and a preparation method thereof. The thermoplastic elastomer comprises the following raw materials in parts by mass: 10-80 parts of fluoroplastic, 5-80 parts of fluororubber, 5-85 parts of silicone rubber, 1-10 parts of acid acceptor, 1-20 parts of interfacial modifier, 0.1-5 parts of cross-linking agent and 0.1-10 parts of cross-linking aid. The preparation method comprises the following steps of: uniformly mixing the fluoroplastic, the fluororubber, the acid acceptor, the silicon rubber and the interfacial modifier at 175-330 DEG C; and adding the cross-linking agent and the cross-linking aid under a high-speed shear condition to carry out dynamic vulcanization on rubber to obtain the thermoplastic elastomer. The fluoroplastic / fluororubber / silicon rubber thermoplastic elastomer has high mechanical strength, has the characteristics of excellent high-temperature and low-temperature resistance, chemical resistance, oil resistance, capability of repeated processing and the like and can be widely applied to the fields of aerospace industry, automobile industry, information and electronics industry, chemical industry, new energy resources, electric power industry, environmental protection and the like.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com