Patents

Literature

1279 results about "Tungsten alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

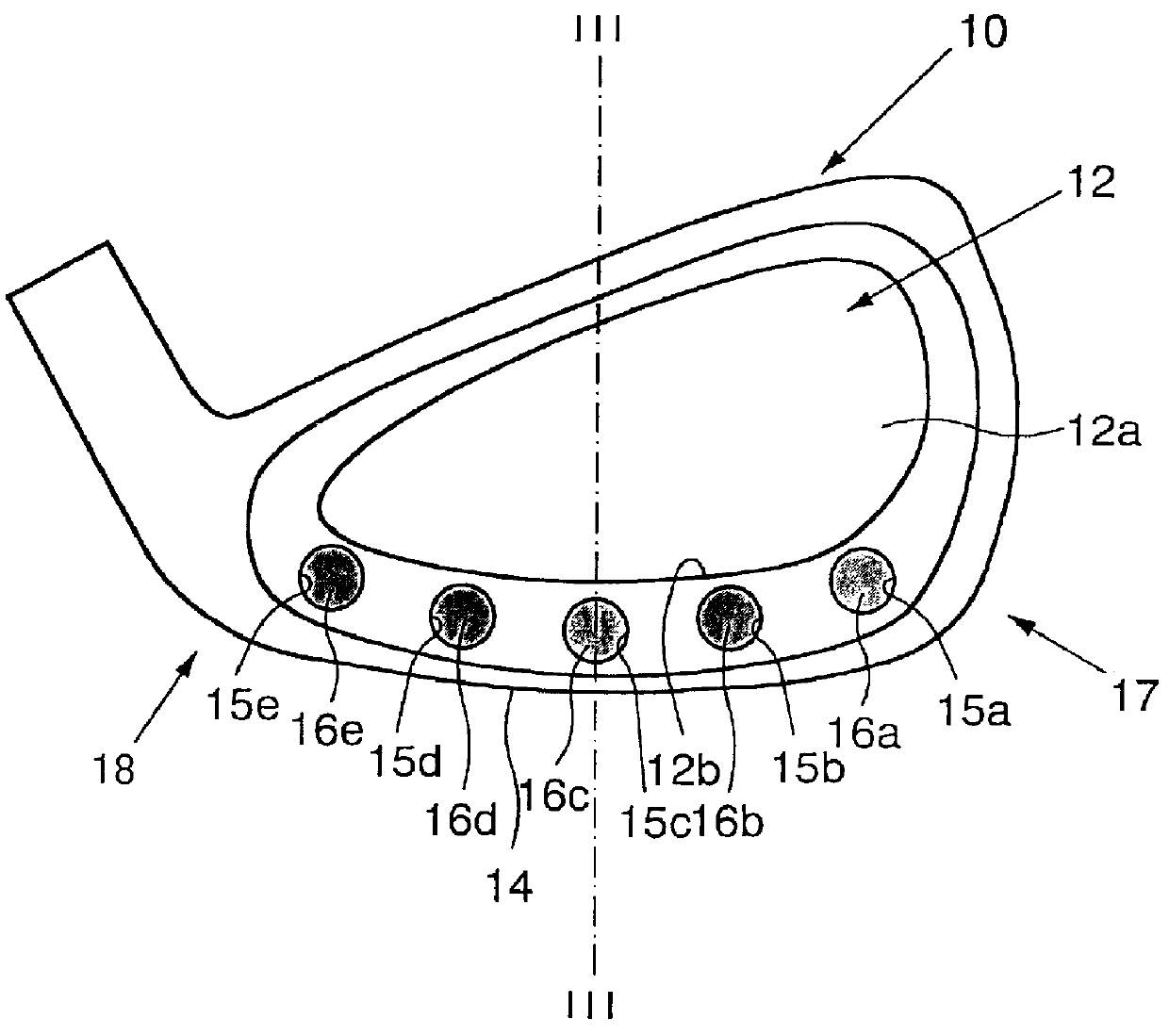

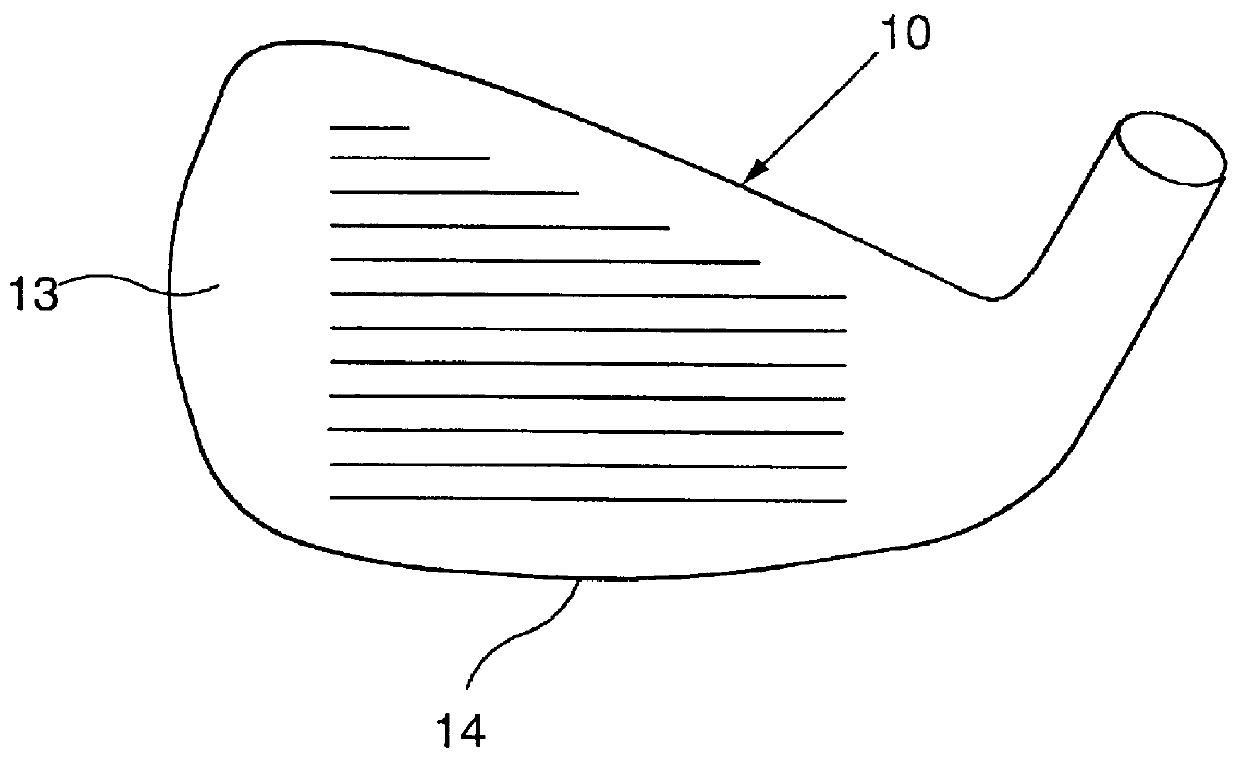

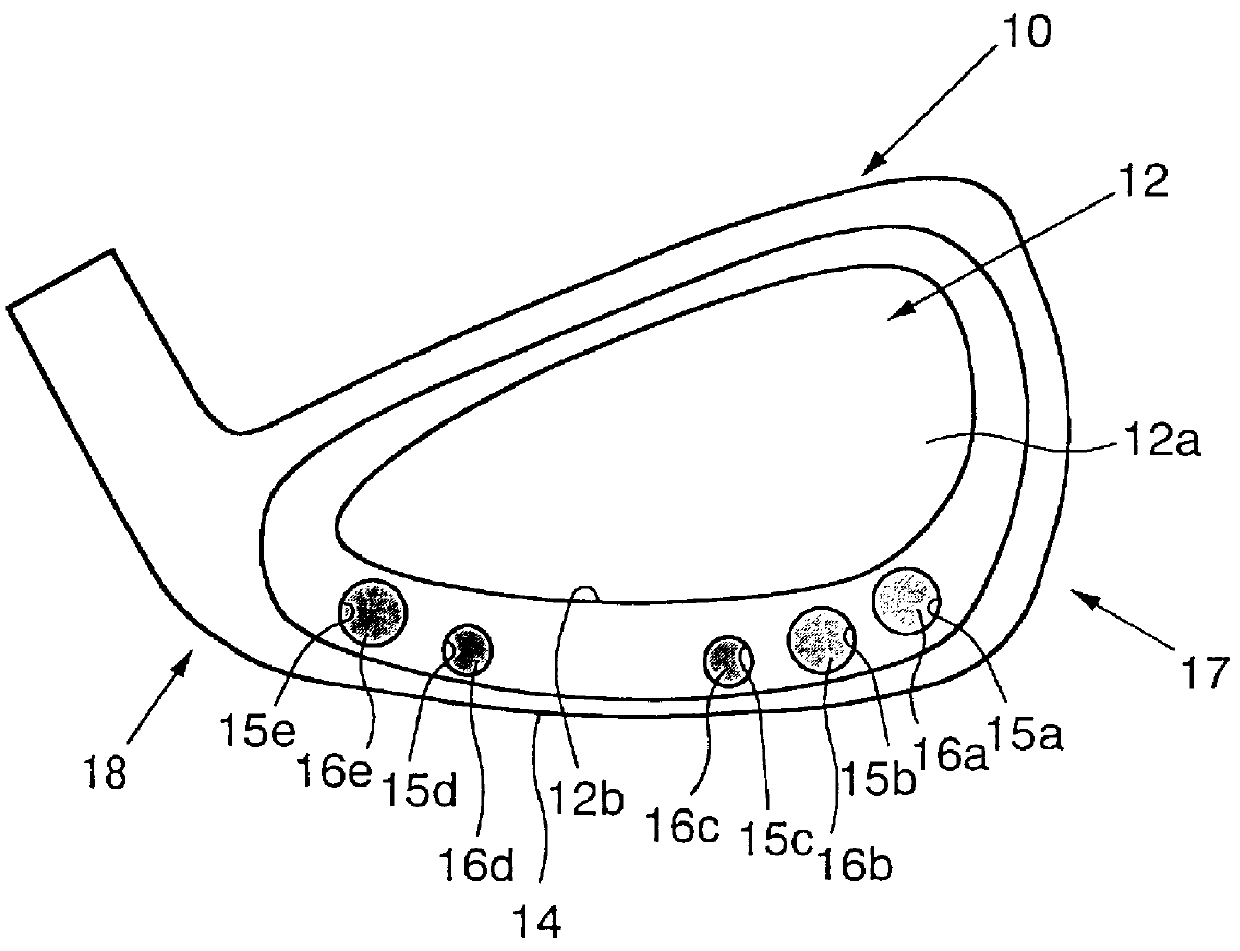

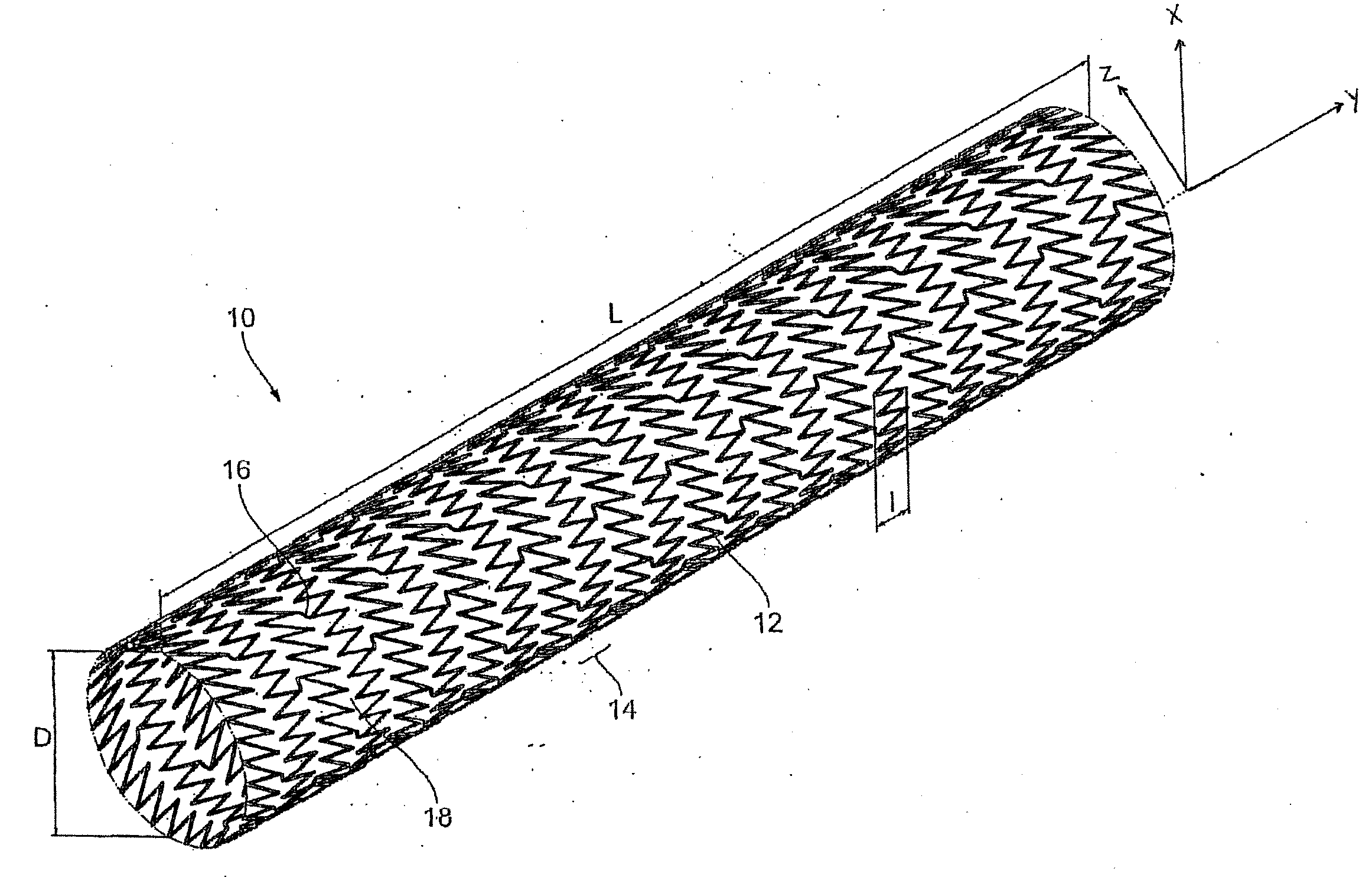

Iron golf club head including weight members for adjusting center of gravity thereof

An iron golf club head comprised of a head body 10 made of light metal such as titanium and containing a plurality of weight members 16. The head body 10 includes a front surface 13, a rear surface 13a, a cavity 12 disposed at the rear surface 13a, and a plurality of holes 15 disposed in the head body 10 at the rear surface 13a between a lower side wall 12b of the cavity 12 and a sole 14 of the head body 10 at predetermined intervals between a toe part 17 and a heel part 18. The center axis of each hole 15 is oriented substantially parallel to the sole 14 of the head body 10. The weight members 16 are press-inserted into the holes 15 in a direction going toward the front surface 13 of the head body 10 to a predetermined depth. Each weight member 16 is made of a material having a heavier specific weight than the light metal used for the aforesaid head body 10. Tungsten or tungsten alloy can be used as the material for the weight members 16. The combined weight of the weight members 16 does not exceed forty percent of the weight of the entire head.

Owner:YONEX CO LTD

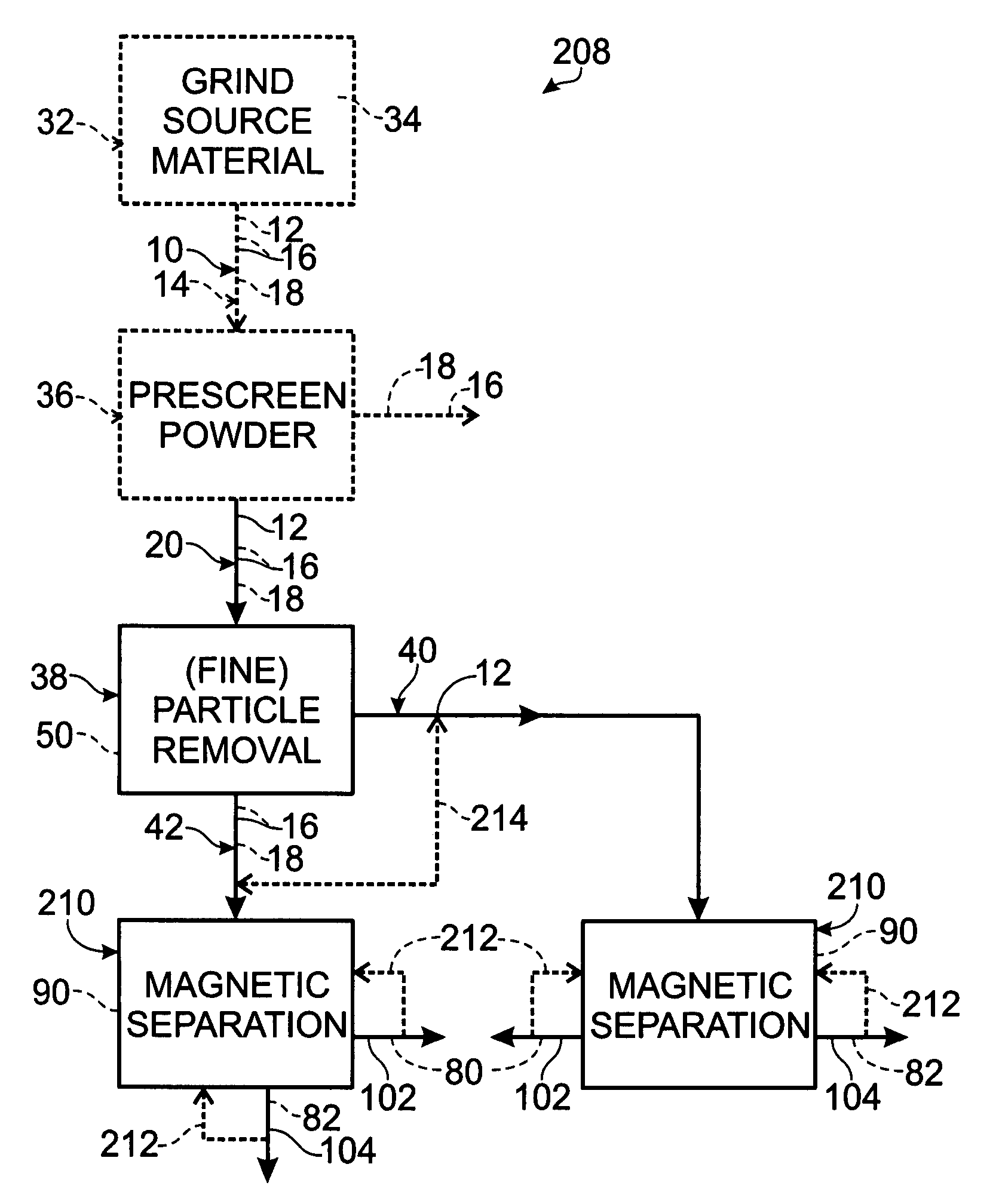

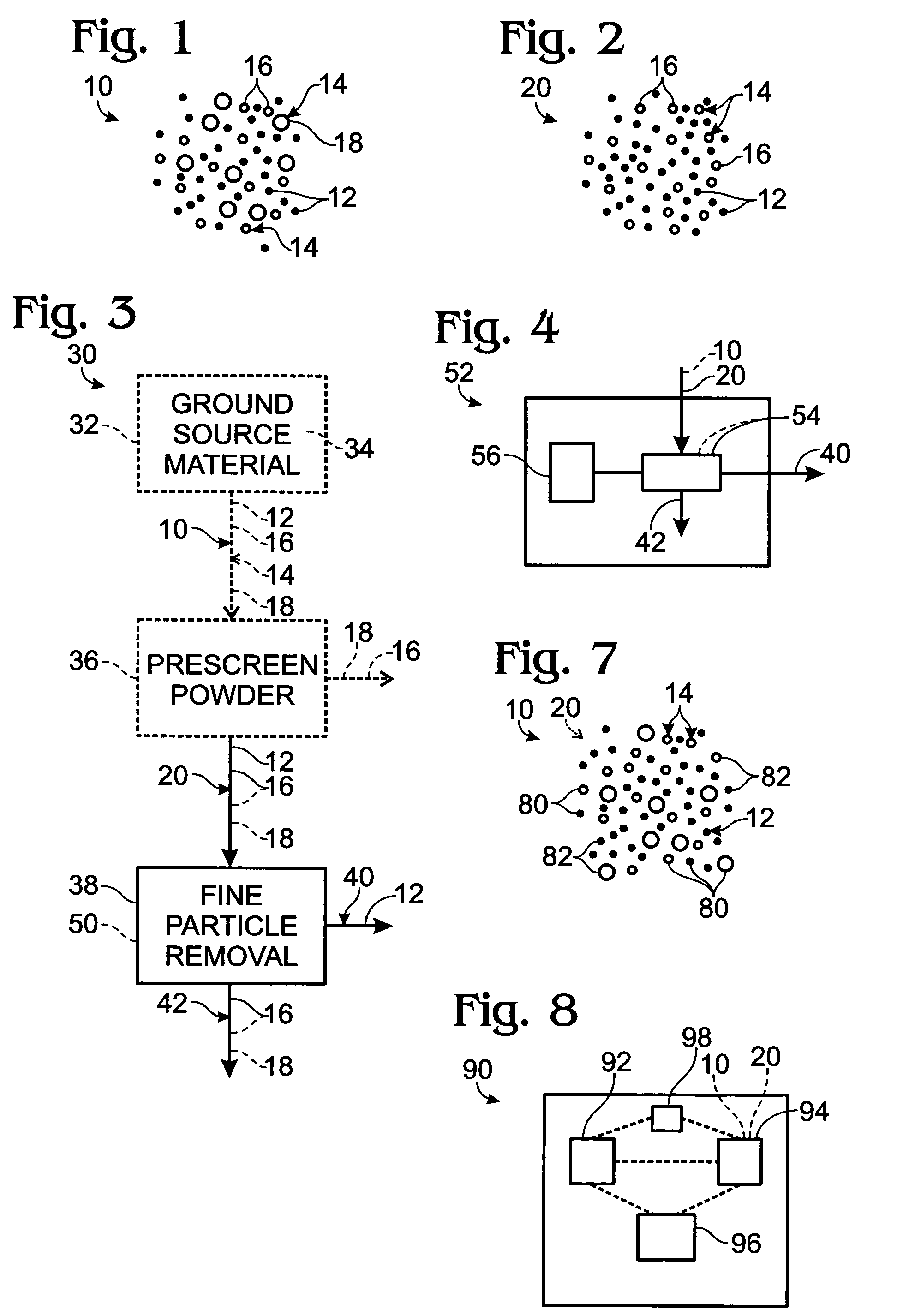

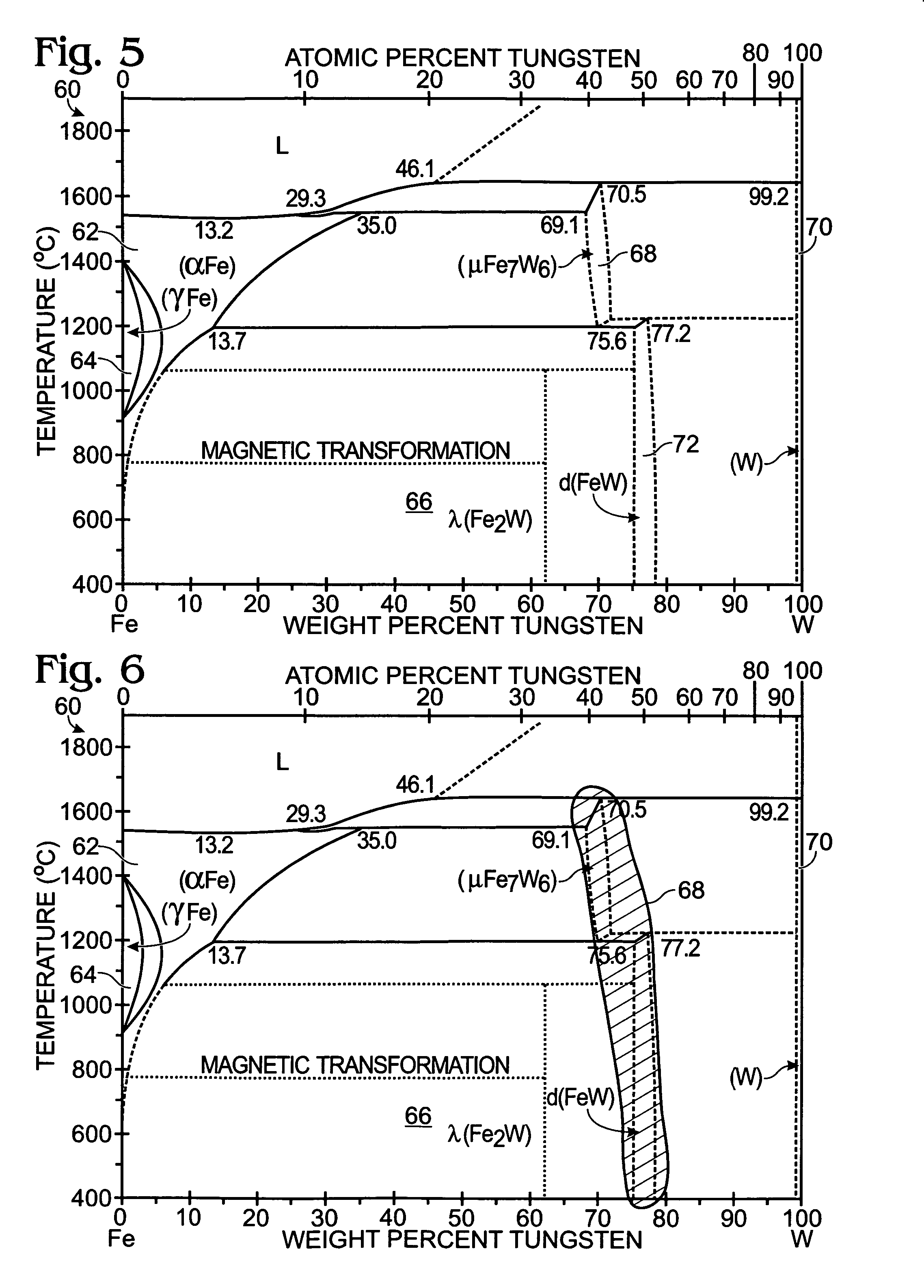

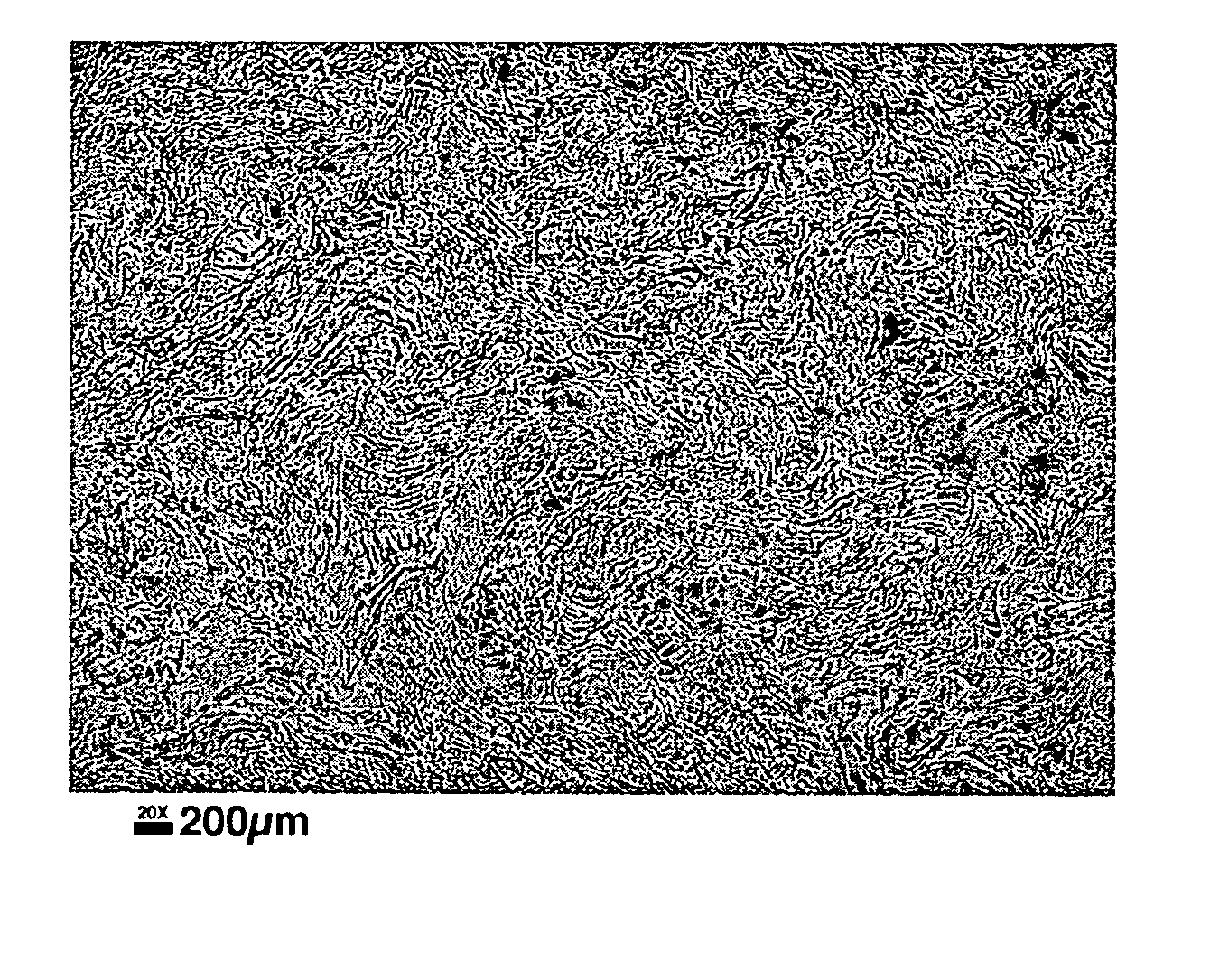

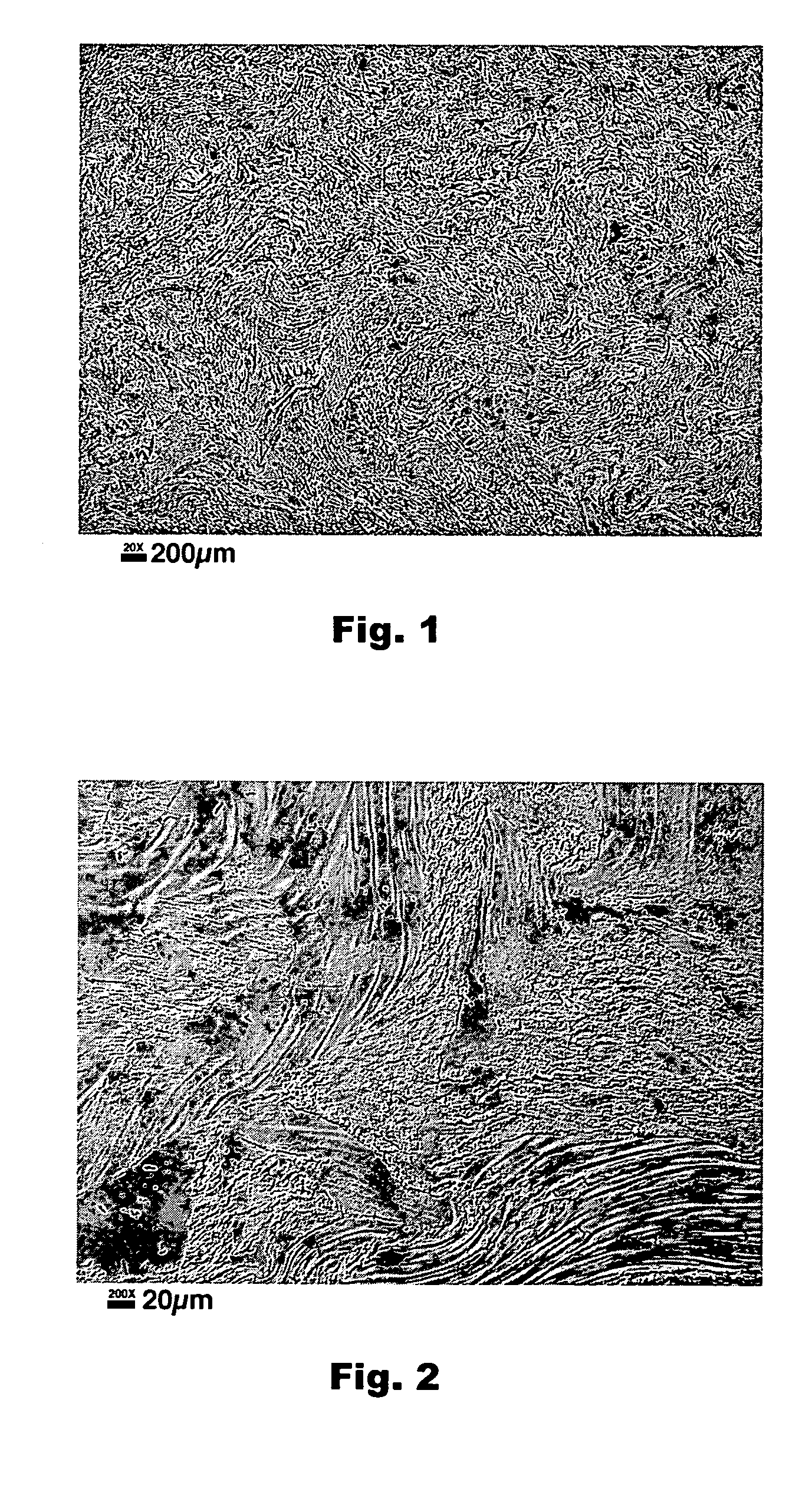

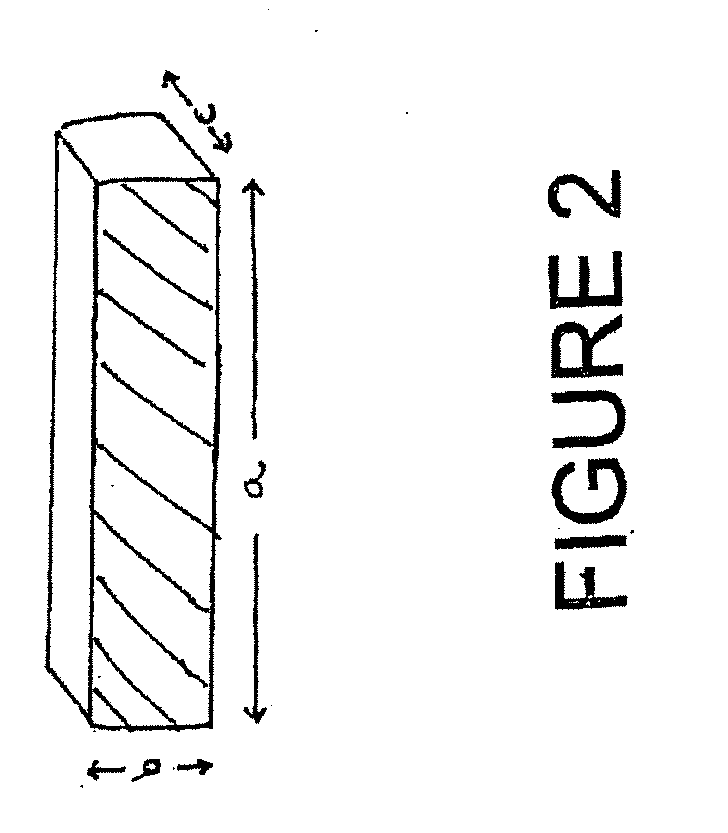

System and method for processing ferrotungsten and other tungsten alloys, articles formed therefrom and methods for detecting the same

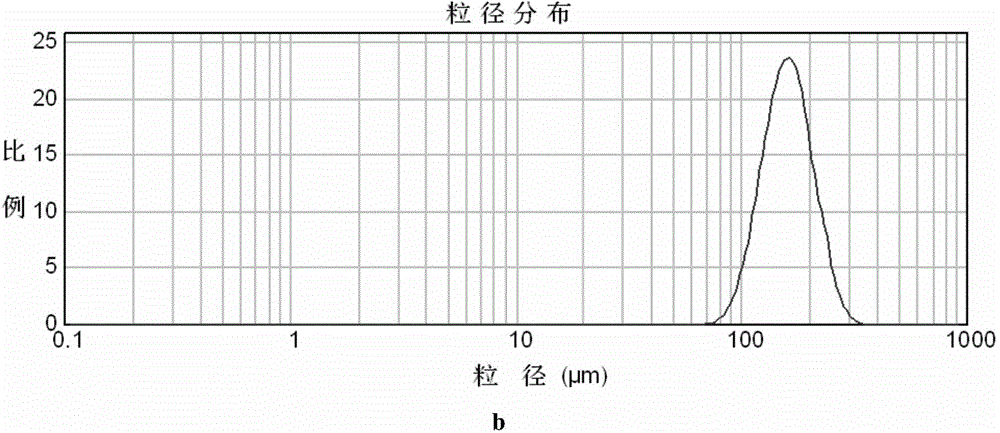

Systems and methods for refining or otherwise processing tungsten alloys, including ferrotungsten powder and articles formed therefrom, and methods for detecting the presence of the same. The methods include at least one of magnetically-separating and particle-size-separating ferrotungsten or ferrotungsten-containing powder. In some embodiments, powder may be separated to remove fine particles, and optionally to separate the remaining particles into fractions containing selected particle size distributions. The powder additionally or alternatively may be separated into at least magnetic and non-magnetic fractions. In some embodiments, portions of two or more size and / or magnetism fractions are mixed to provide a ferrotungsten-containing feedstock. Selected fractions resulting from the size and magnetism separation steps may be utilized to provide a ferrotungsten-containing feedstock from which articles are produced and which may include additional components.

Owner:AMICK FAMILY REVOCABLE LIVING TRUST

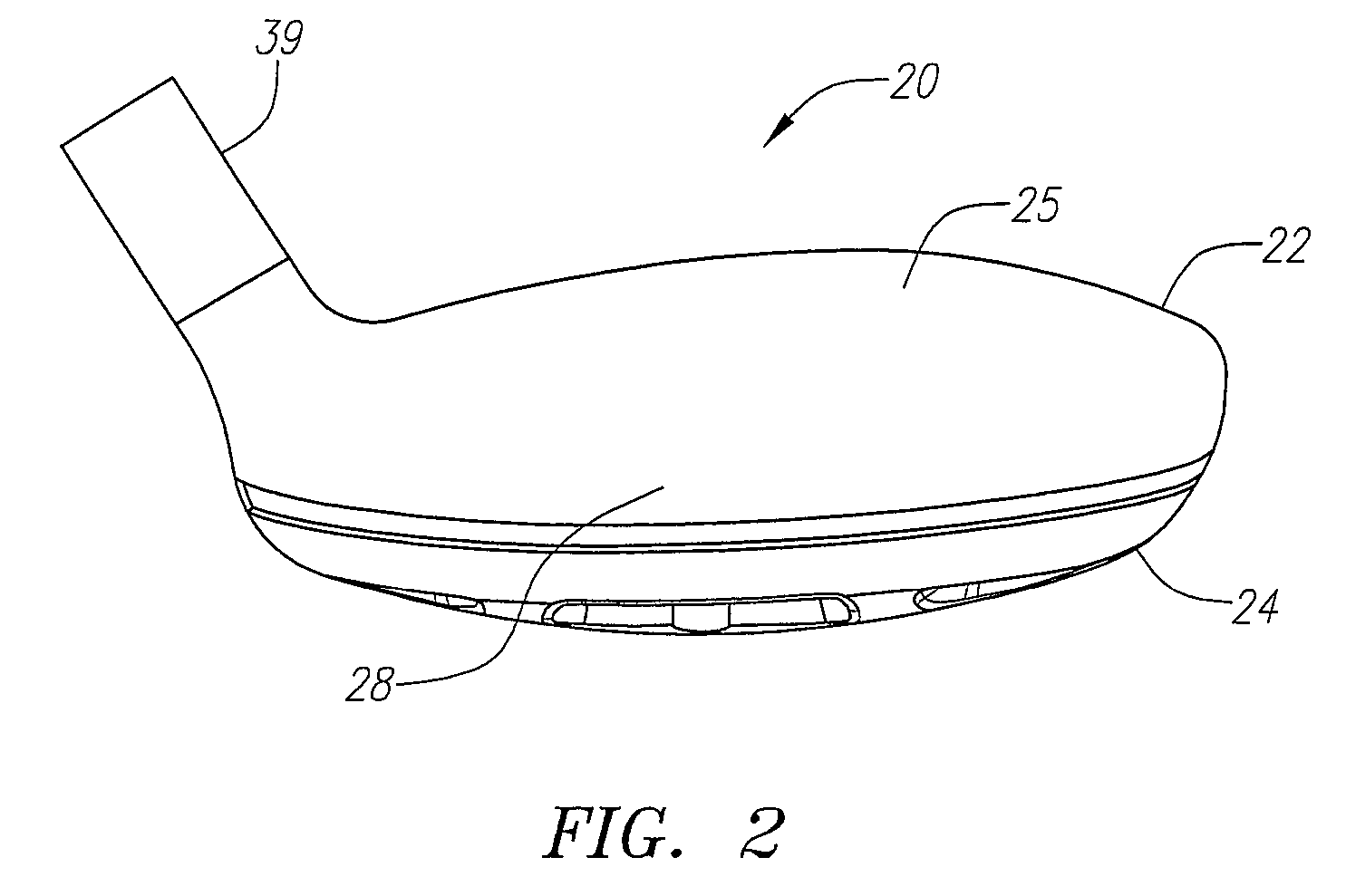

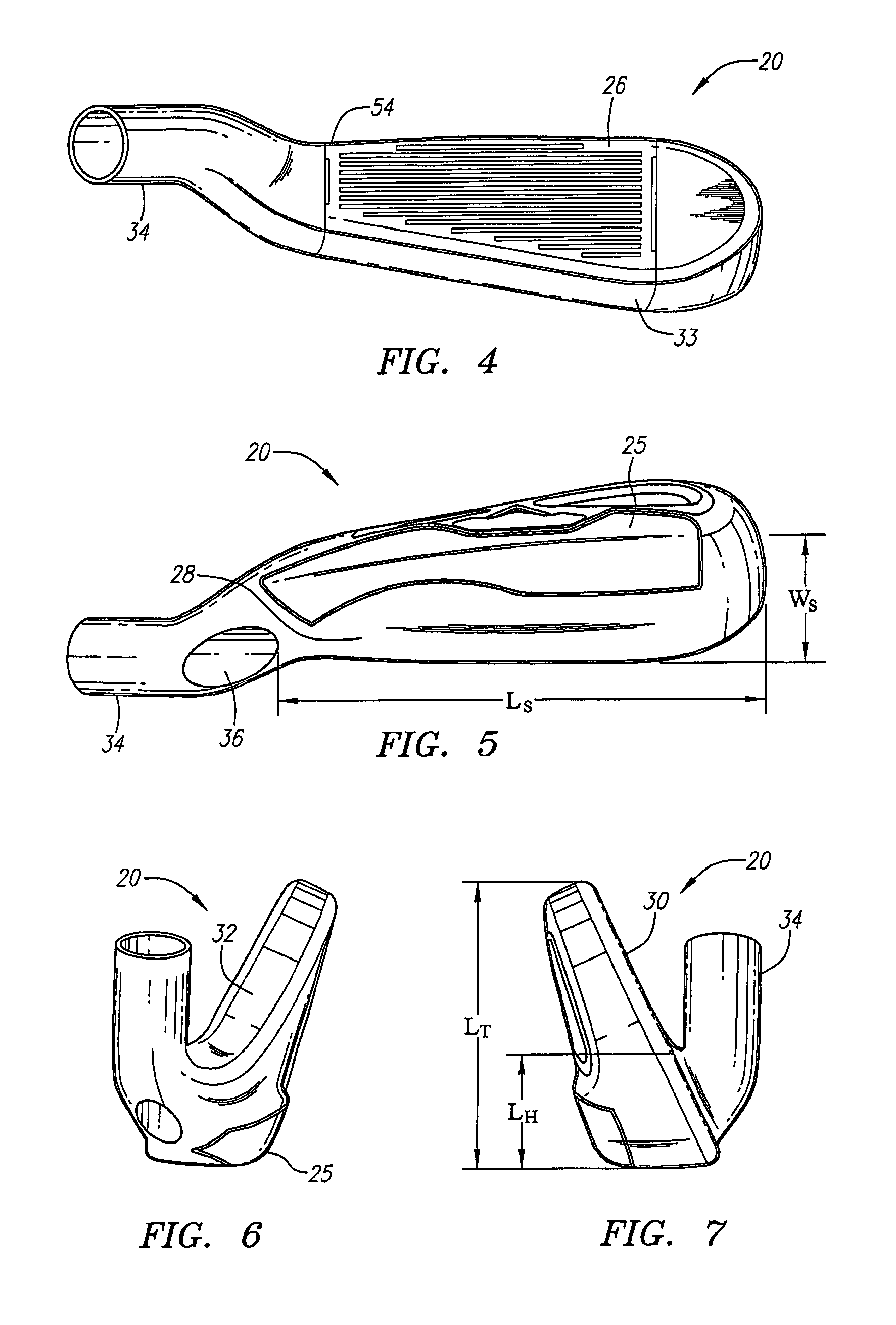

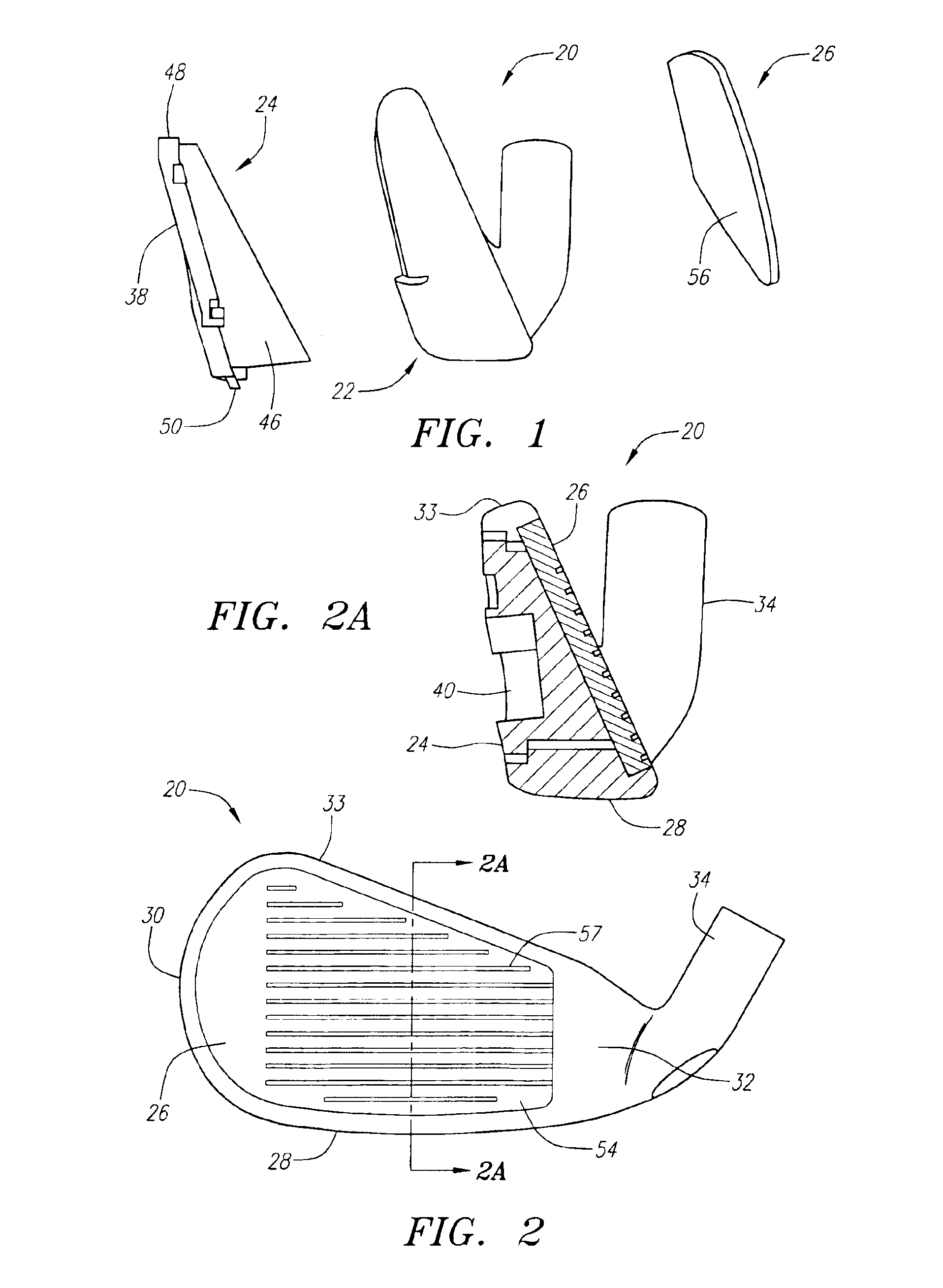

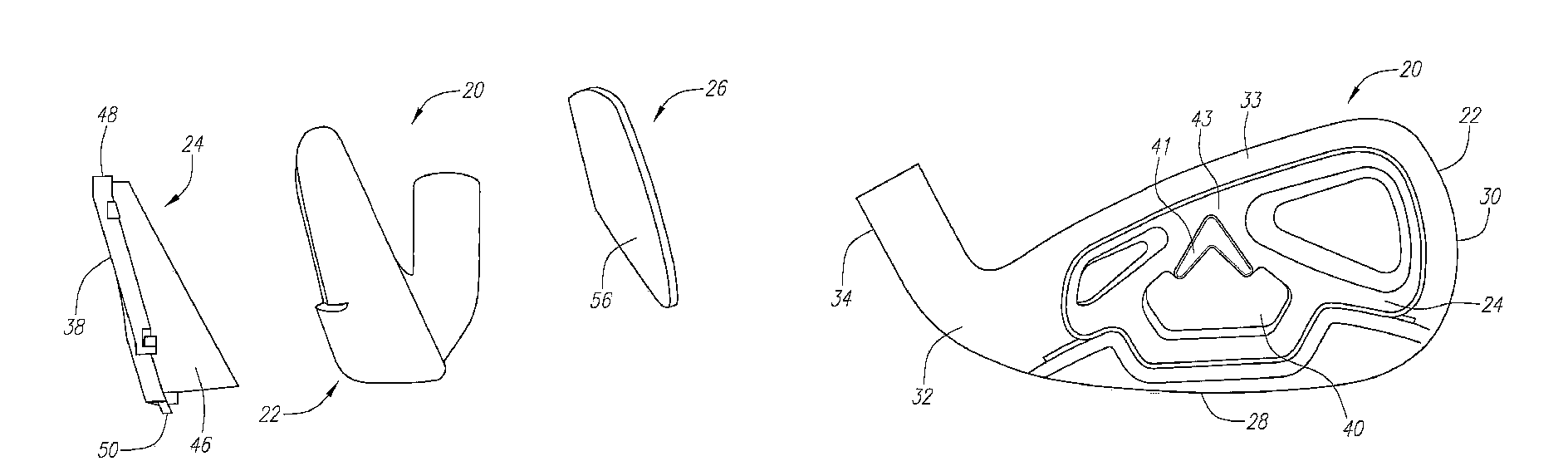

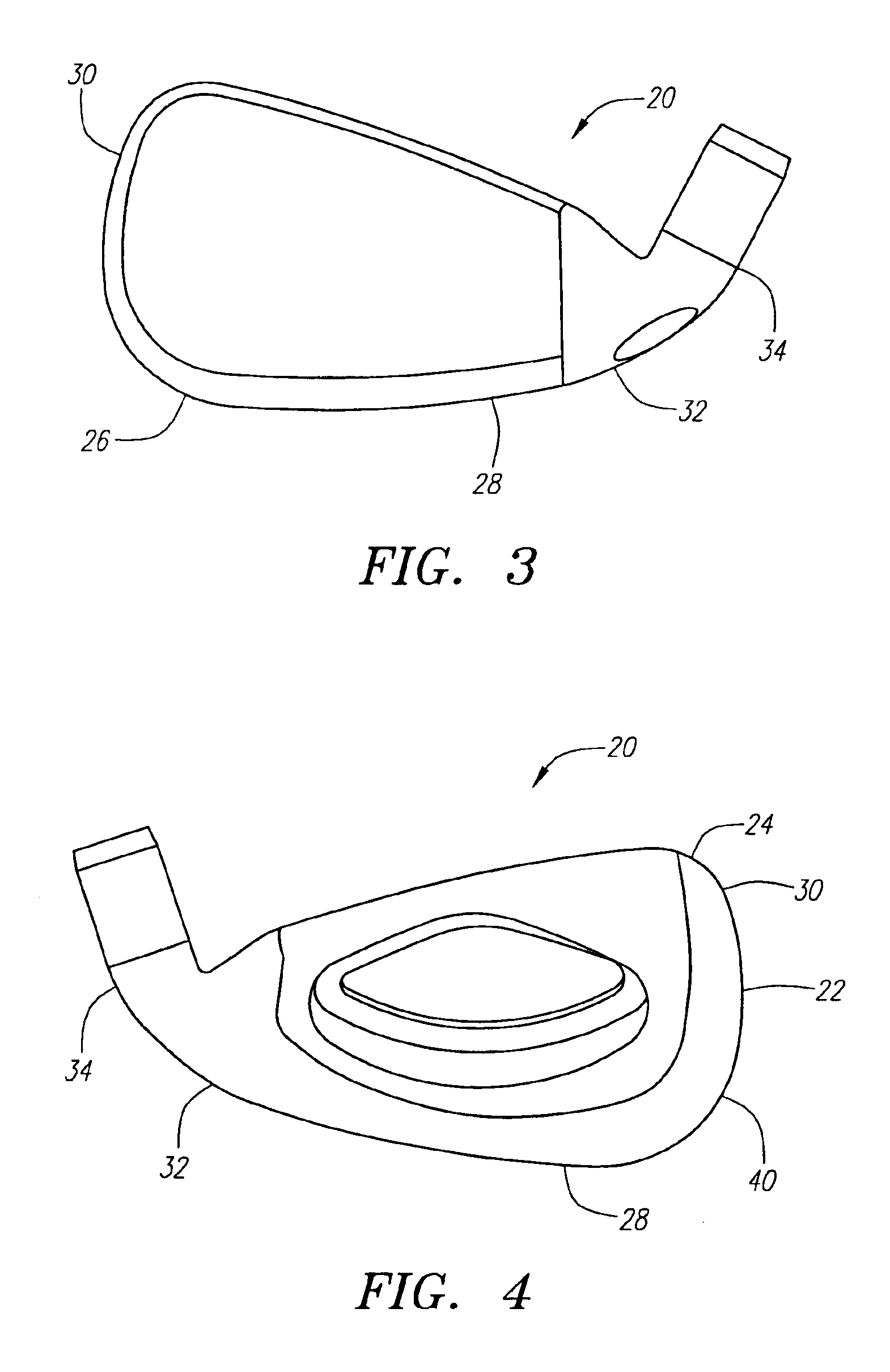

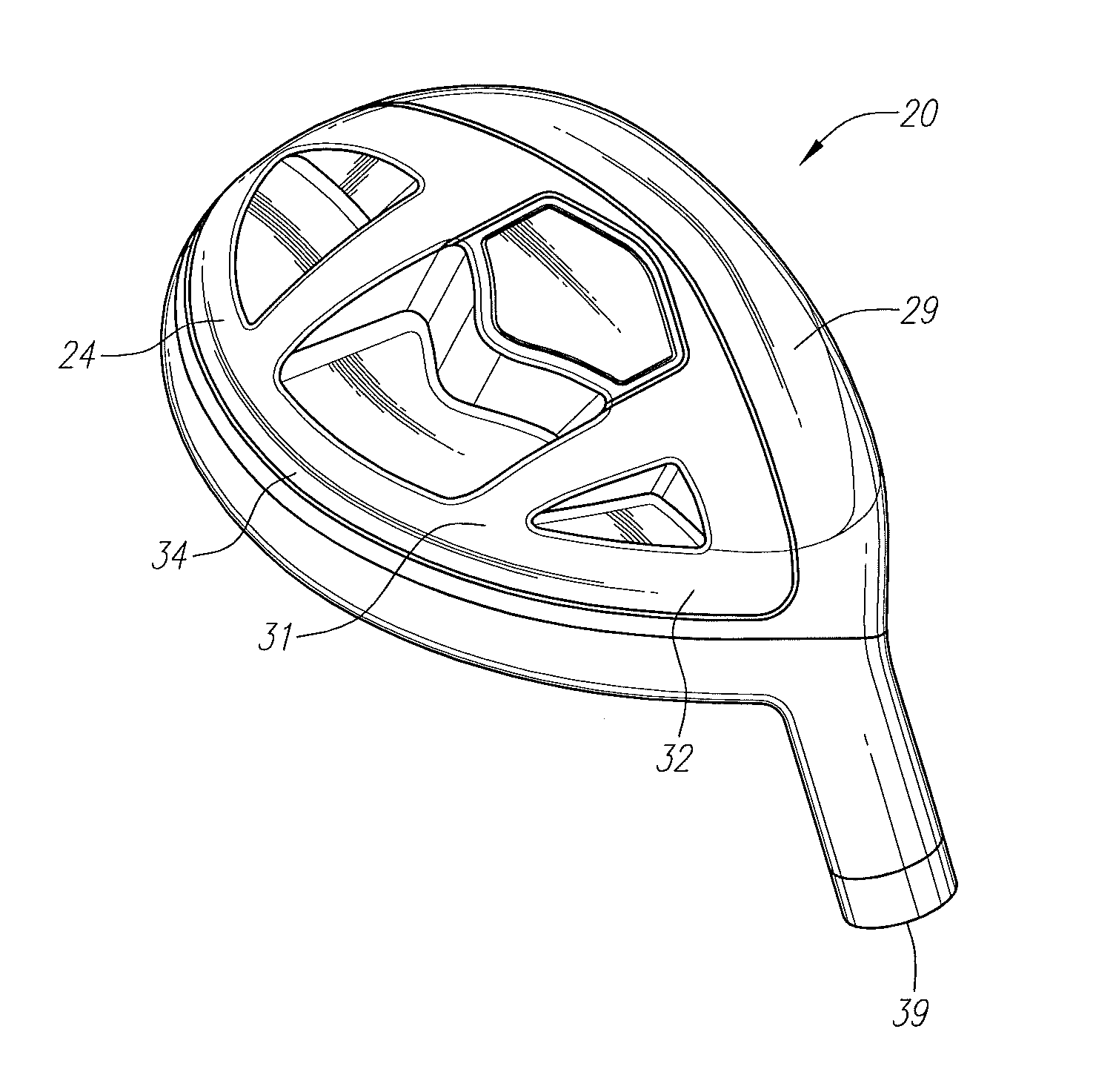

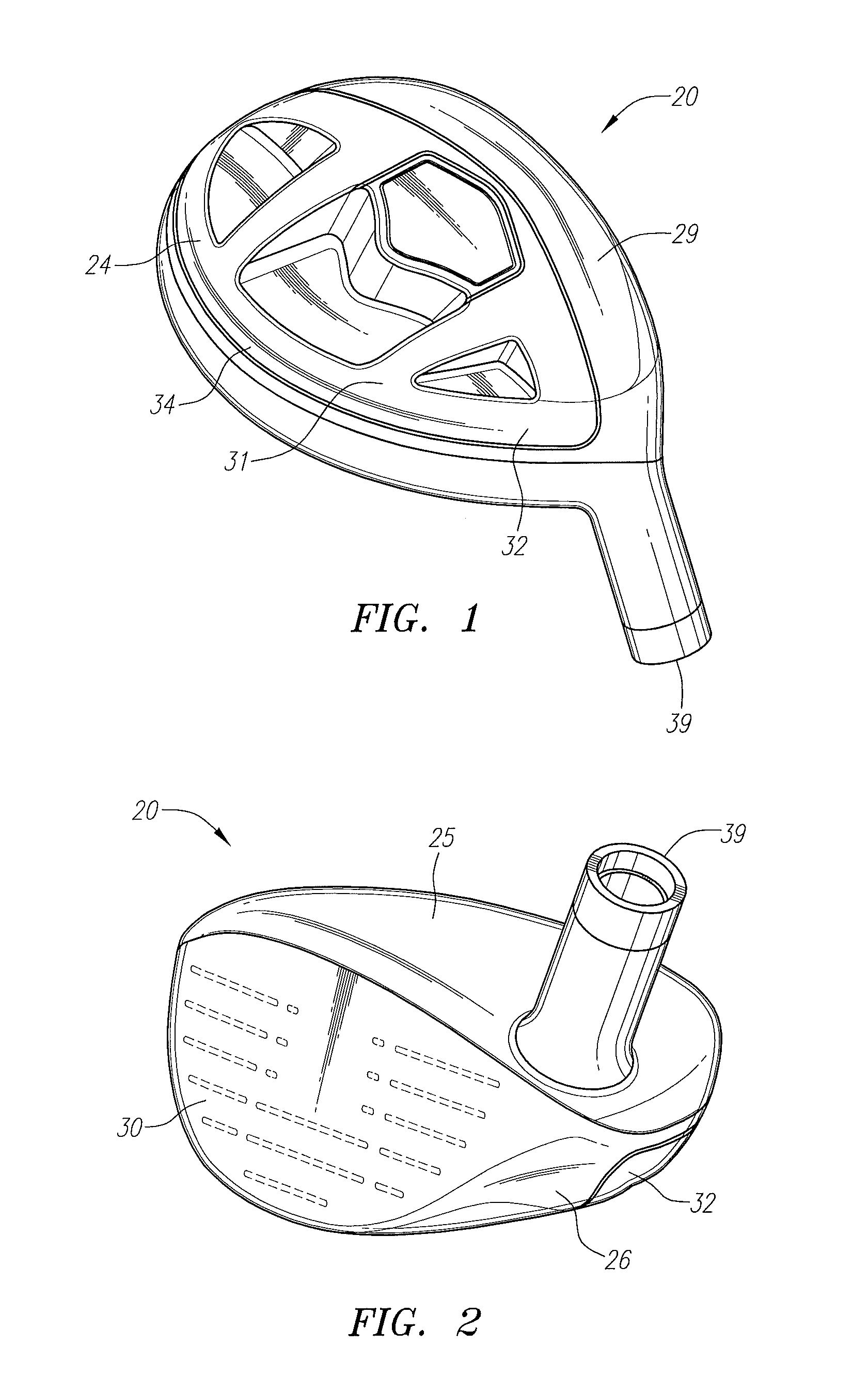

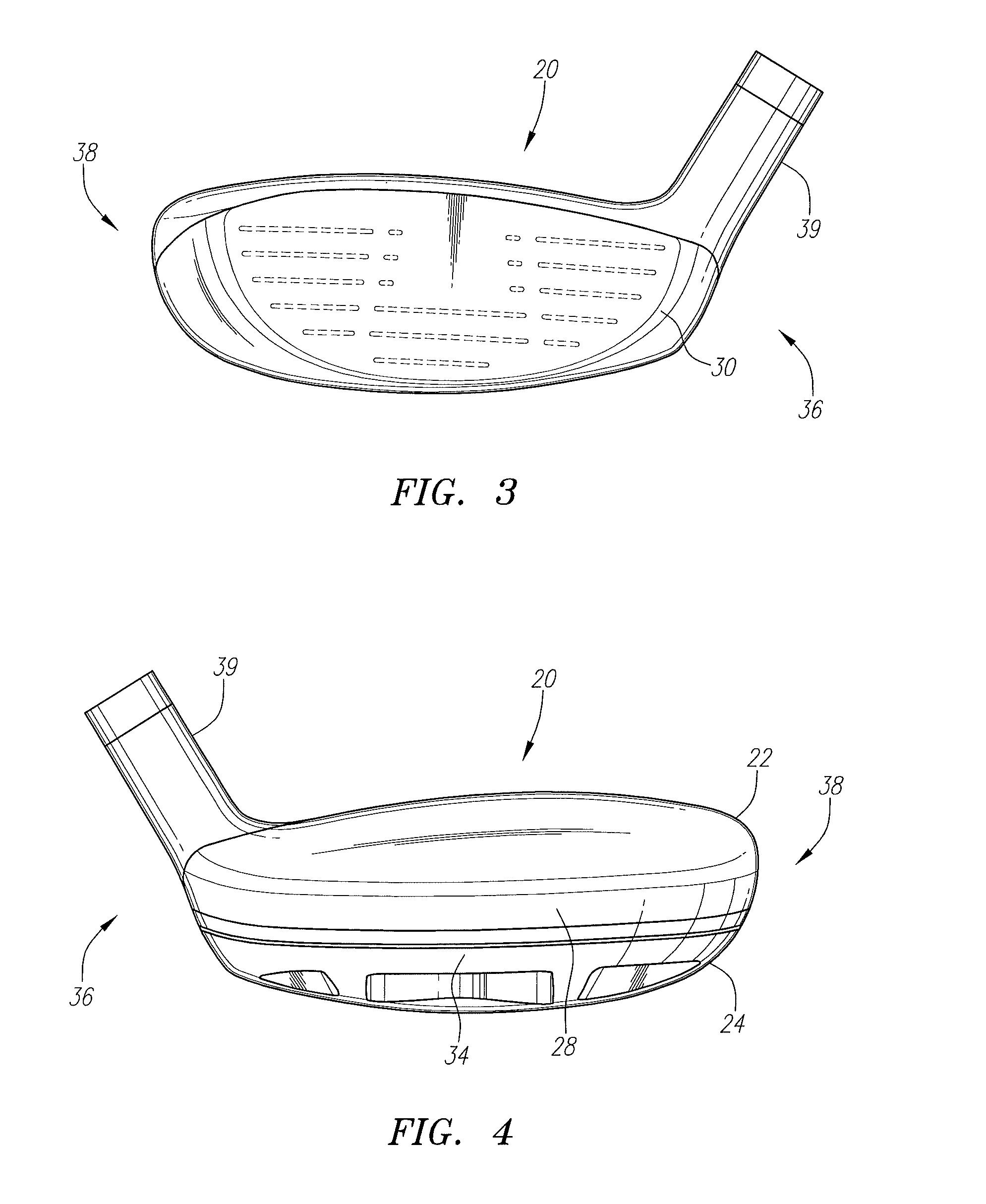

Golf club head with tungsten alloy sole applications

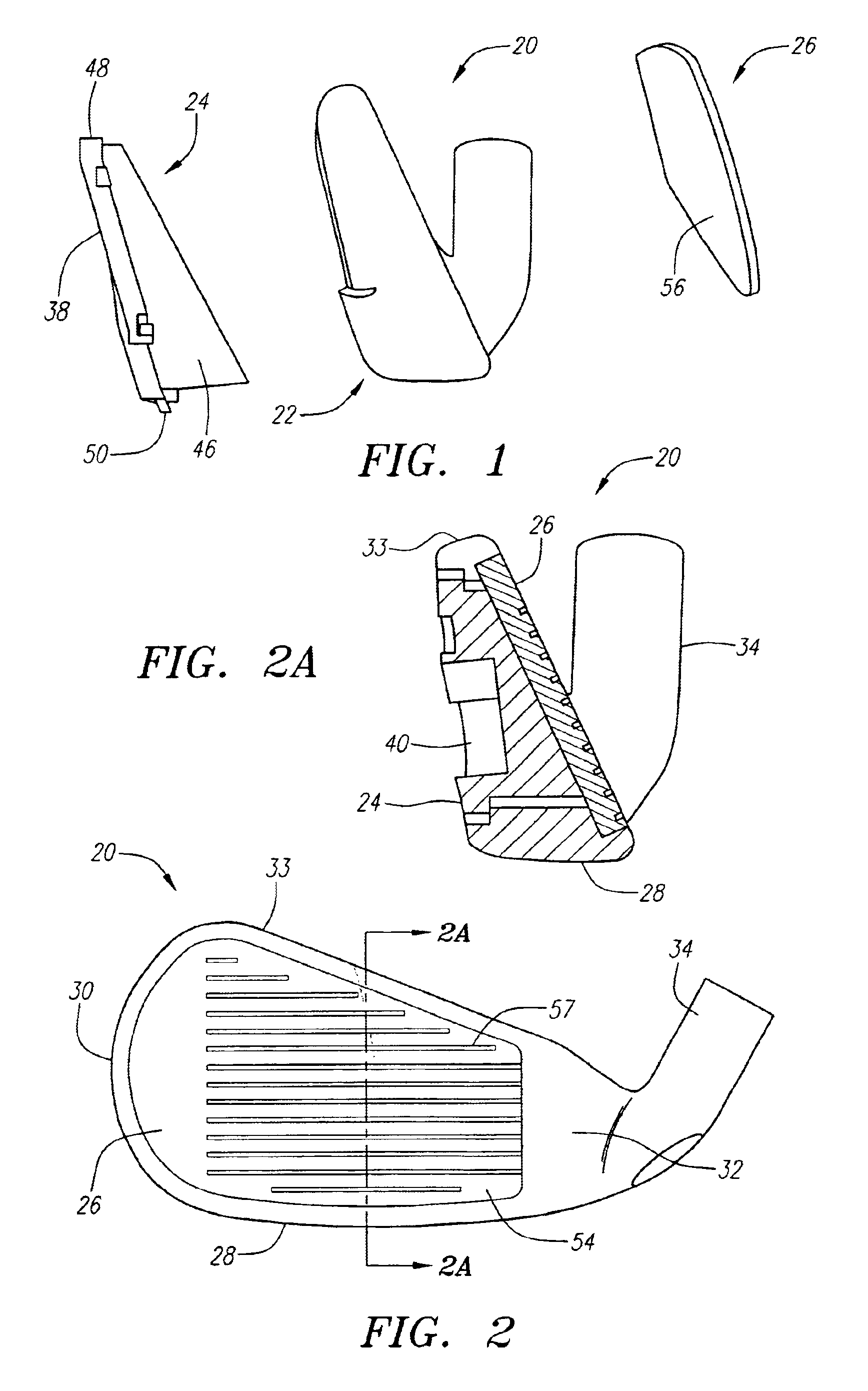

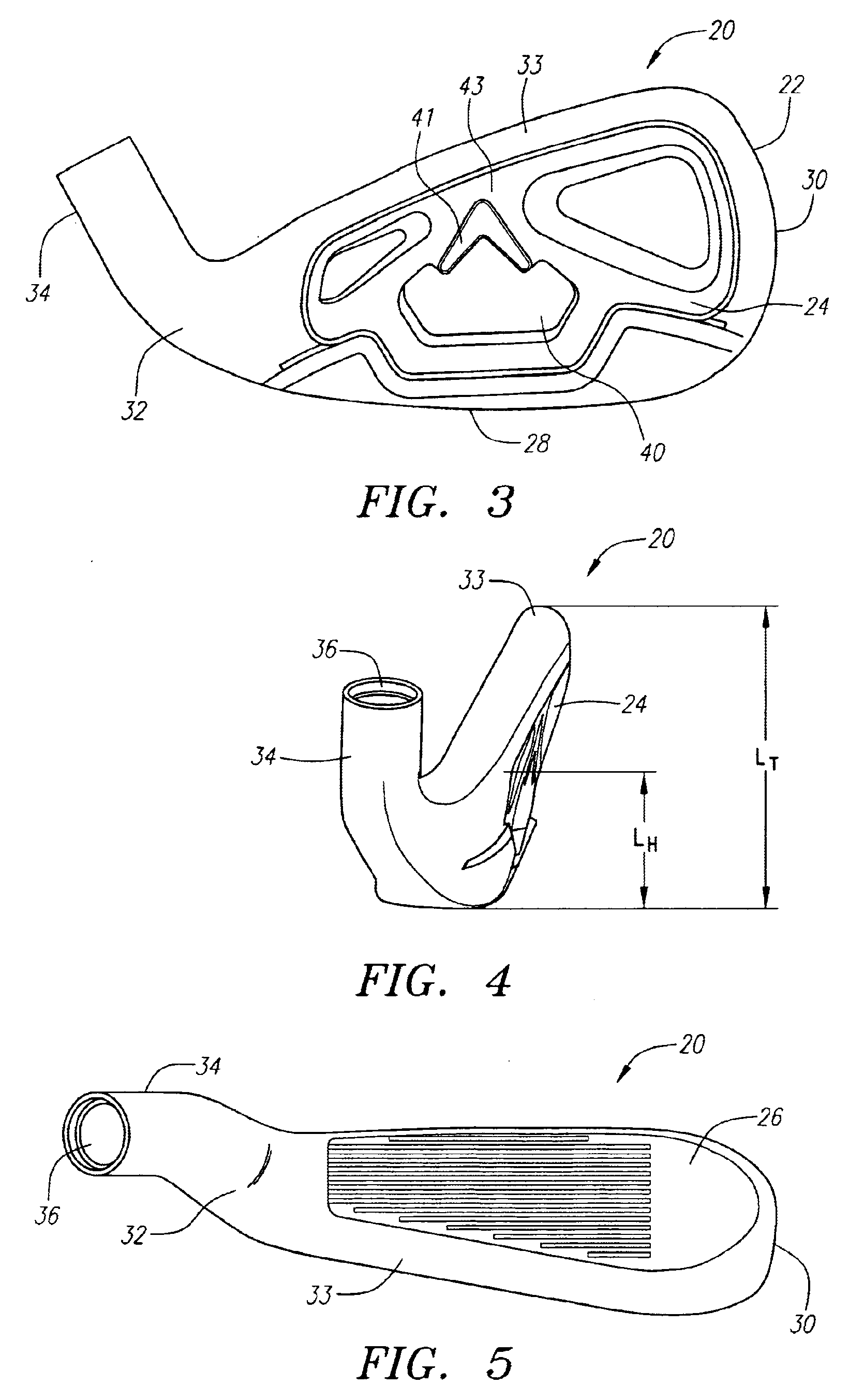

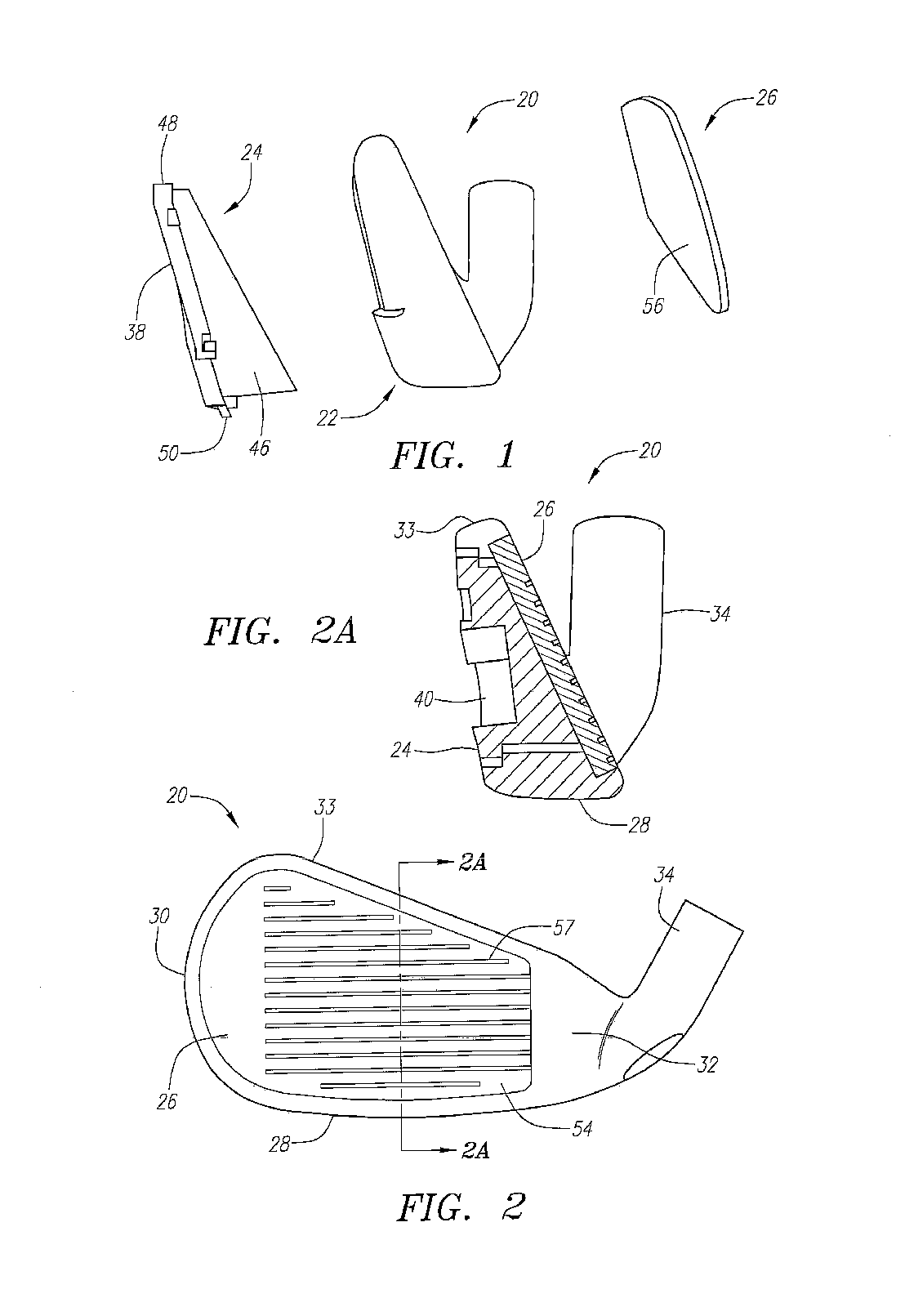

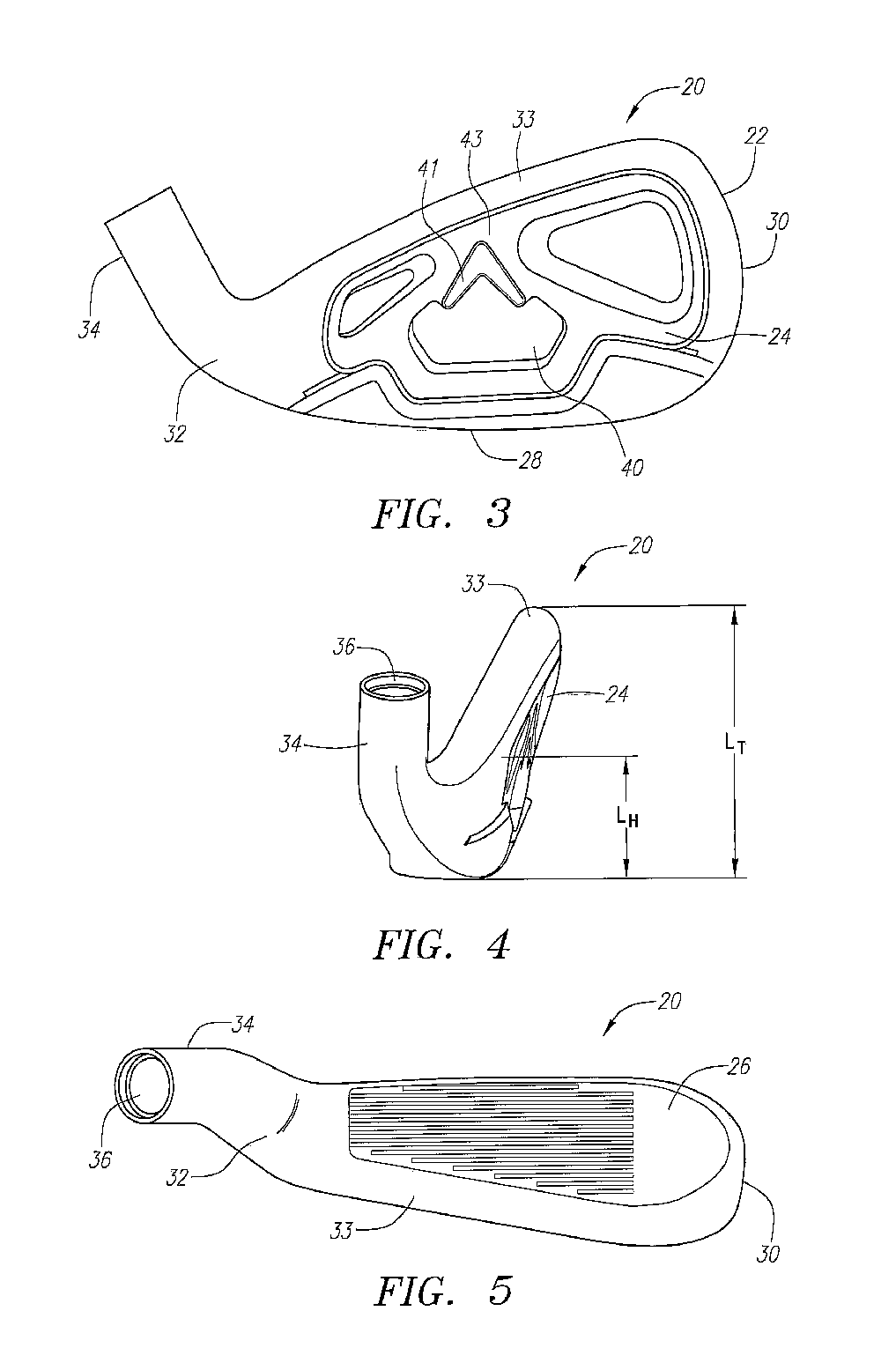

A wood-type golf club head (20) with a main body (22) and a minor body (24) is disclosed herein. The main body (26) has a front portion (30), a crown portion (25), a partial toe portion (27), a partial heel portion (26), a partial rear portion (28) and a partial sole portion (29). The minor body (24) preferably has a sole wall (31), a partial toe wall (33), a partial heel wall (32) and a partial rear wall (34). The minor body (24) is preferably welded to the main body (22). The minor body (24) preferably has a mass ranging from 80 grams to 110 grams. The minor body (24) is preferably from 50 weight percent to 35 weight percent of the total mass of the wood-type golf club head (20).

Owner:TOPGOLF CALLAWAY BRANDS CORP

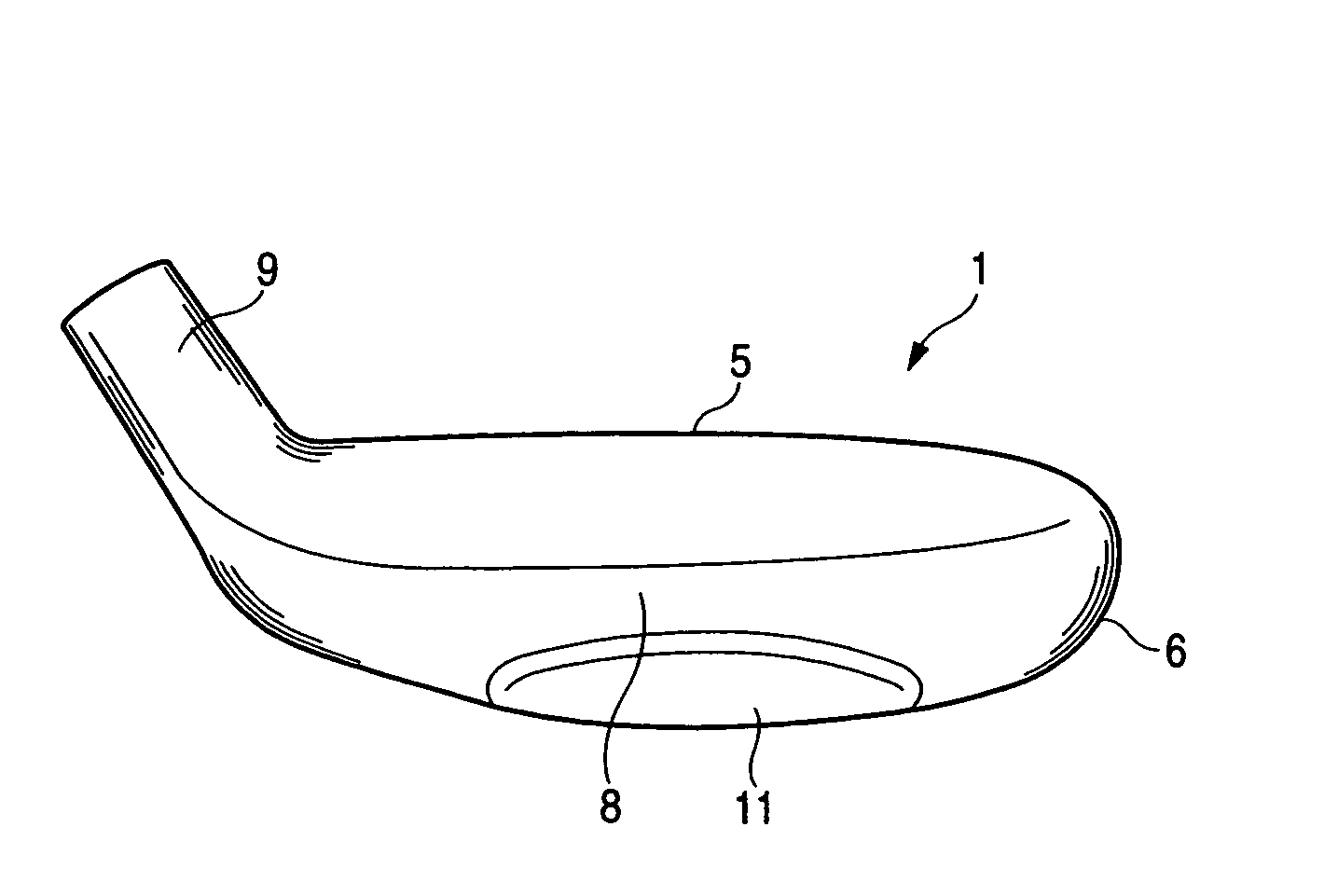

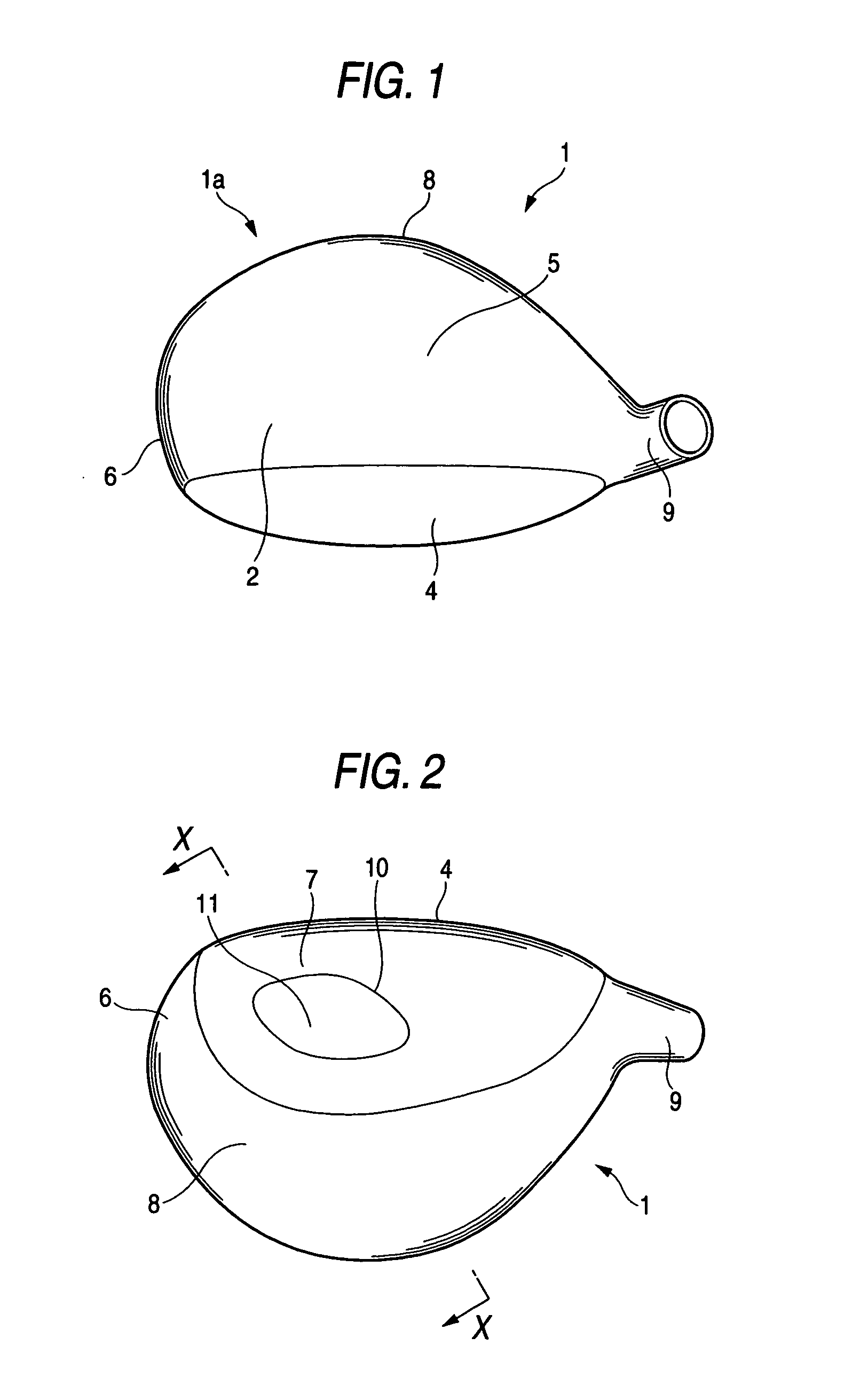

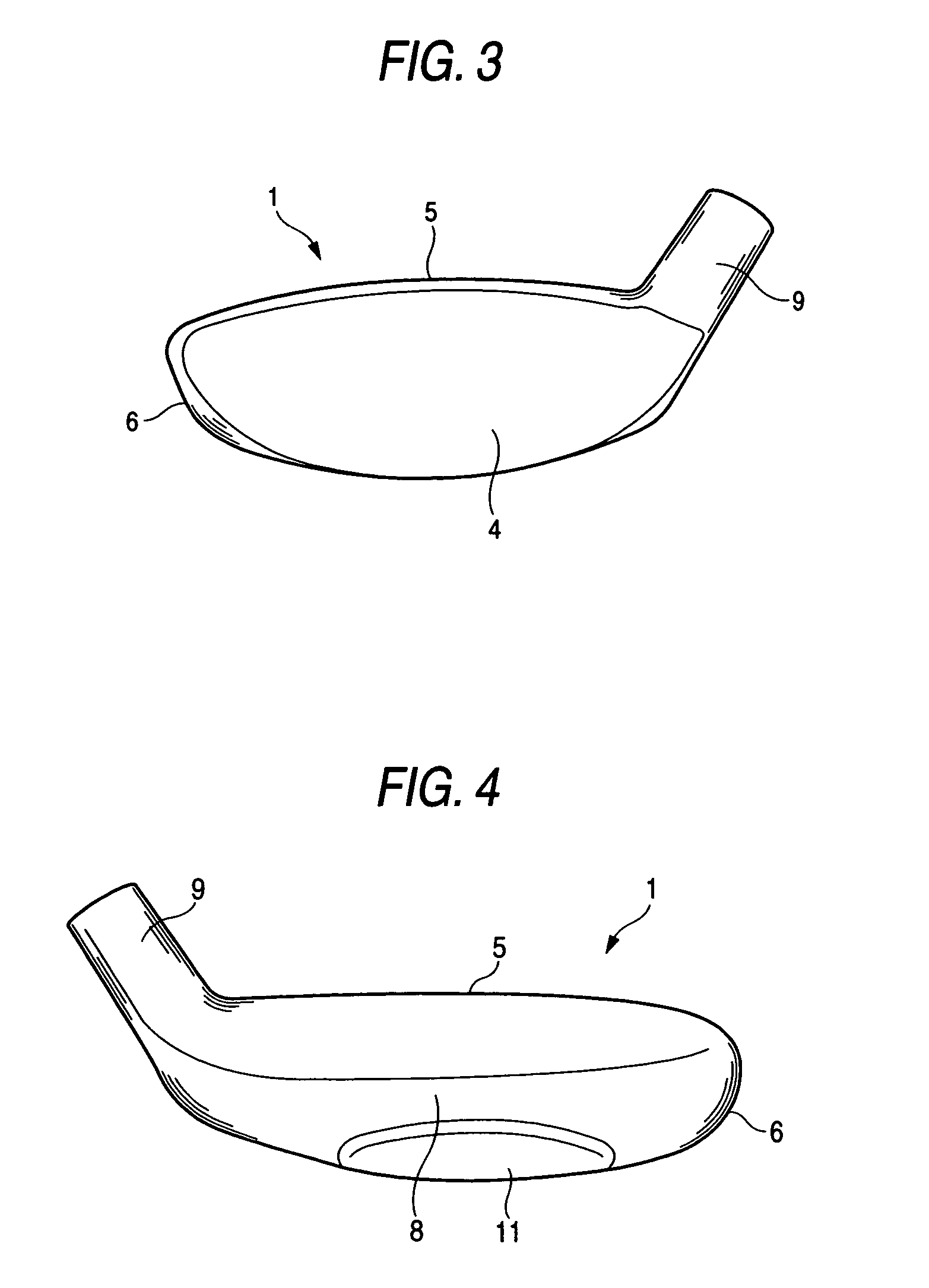

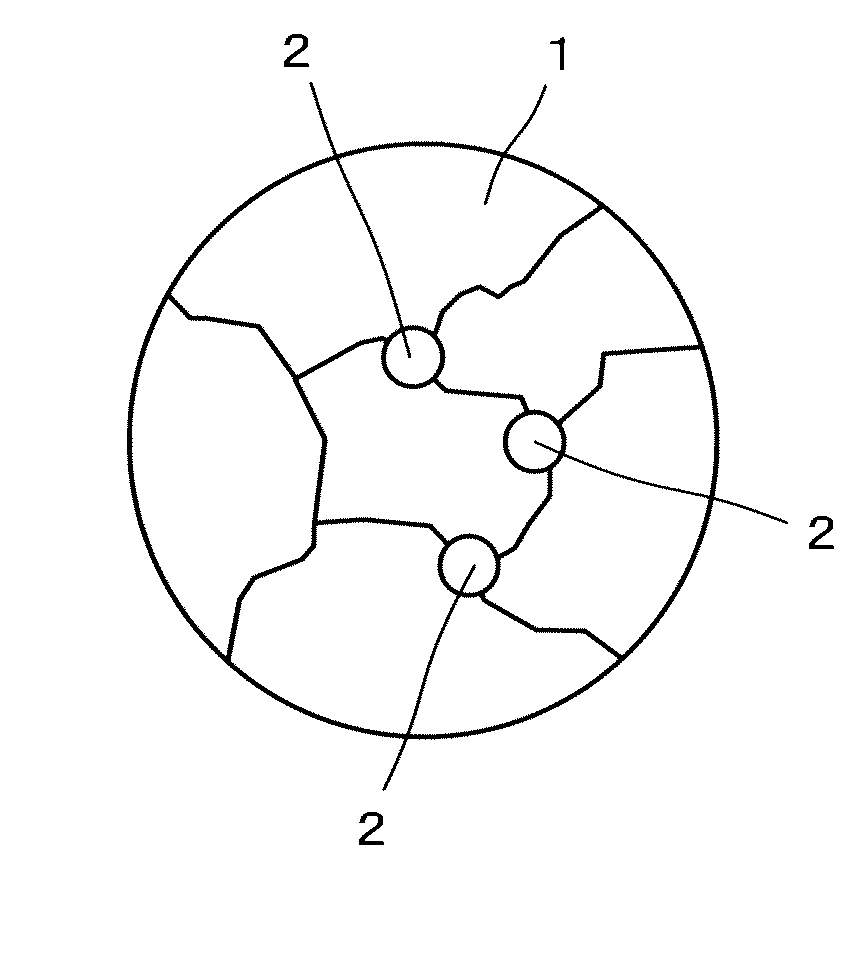

Golf club head

InactiveUS7326472B2Increase production capacityAccurate settingThin material handlingGolf clubsEngineeringGolf Ball

A head body of a golf club head has a hollow portion defined by an outer wall. An opening portion is provided in a part of the head body. A small tungsten alloy piece having a shape fittable to the opening portion so as to cover the opening portion is fixedly attached to the opening portion by welding. The golf club head defines the opening portion in a part of the metal head body and has the small tungsten alloy piece fitted and joined to the opening portion by welding so that the golf club head can be reduced in weight because of provision of the hollow portion. Since the small tungsten alloy piece is joined to the opening portion by welding, difficult plastic forming is not required particularly, and the weight can be adjusted easily and accurately.

Owner:BRIDGESTONE SPORTS

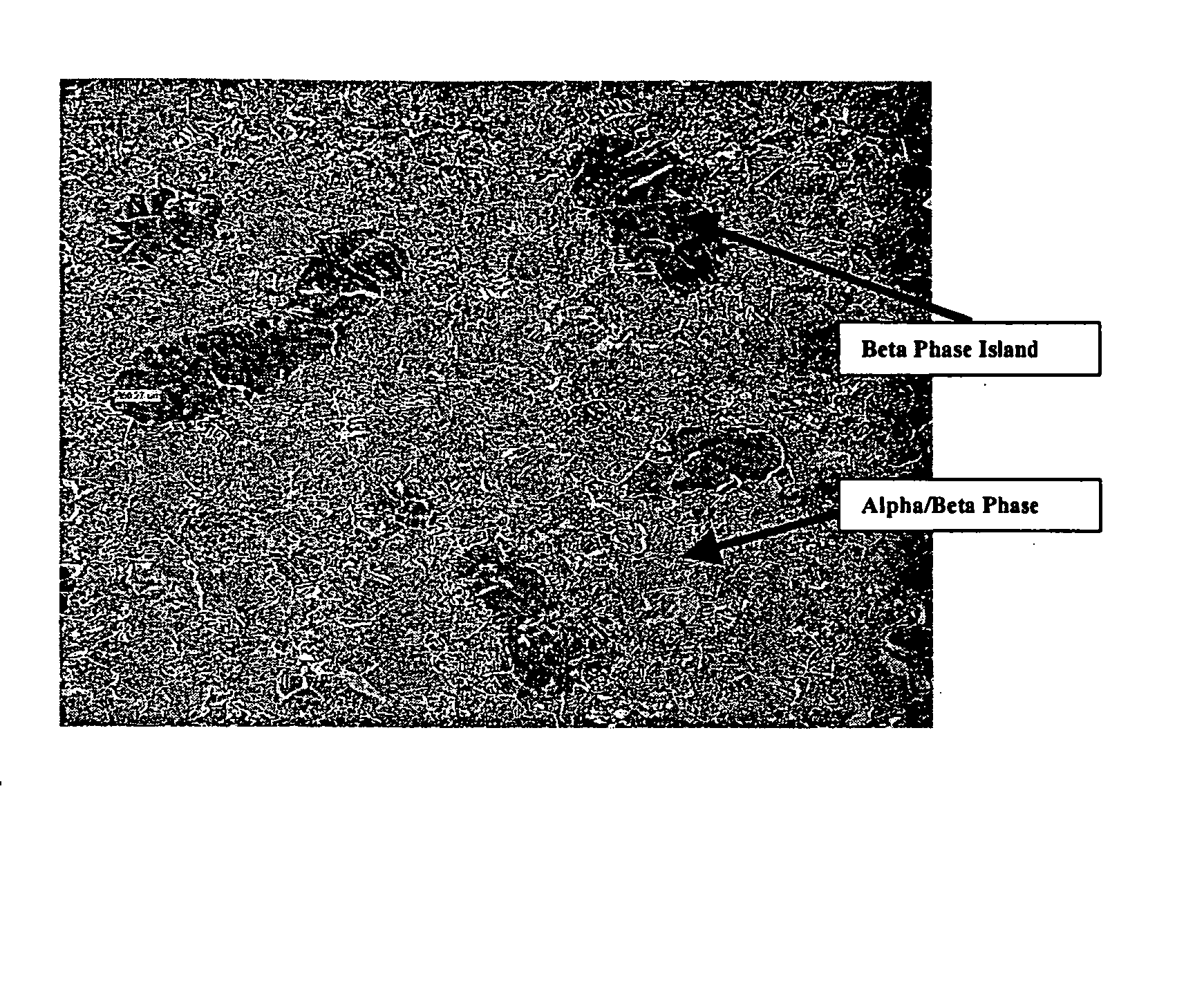

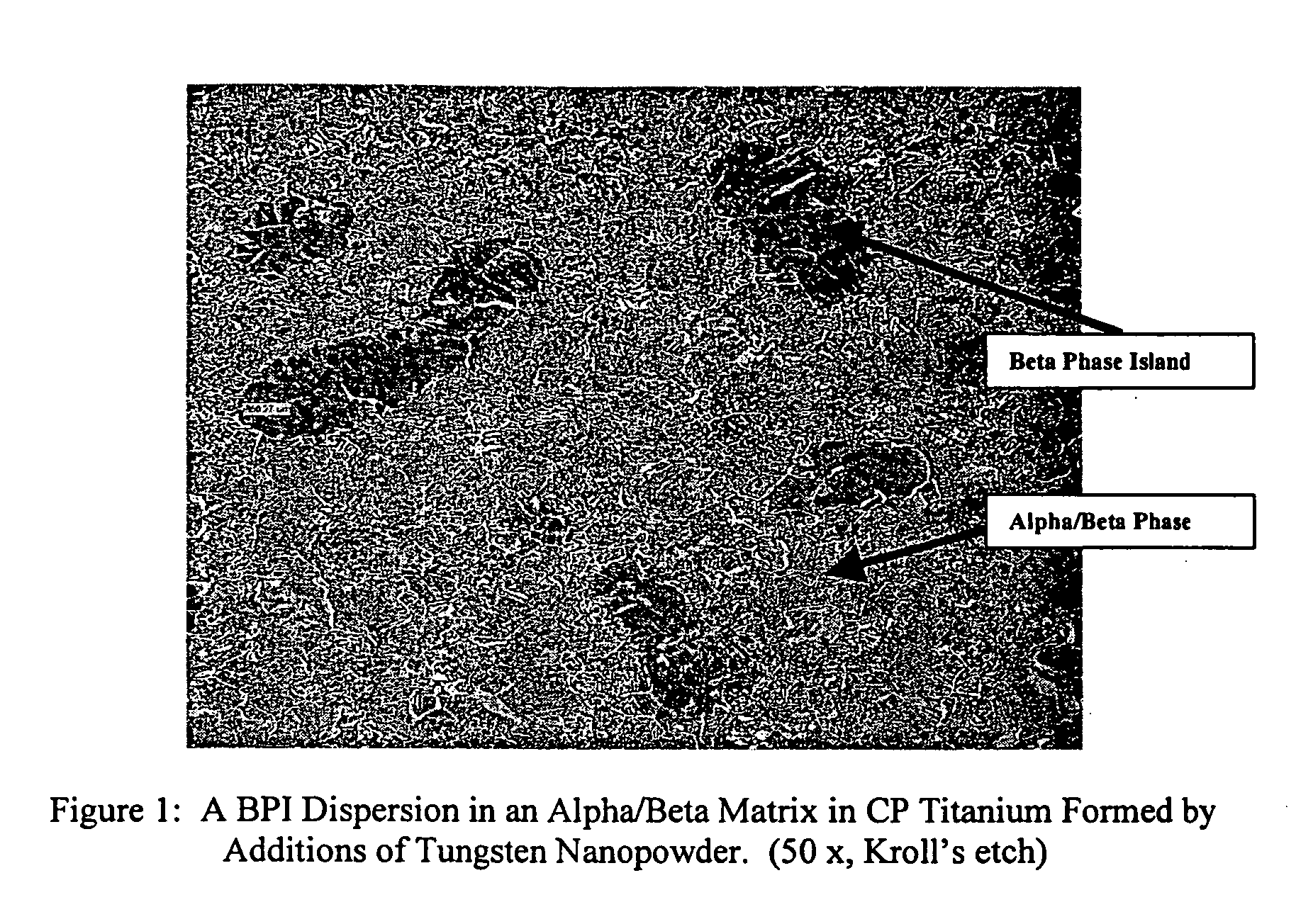

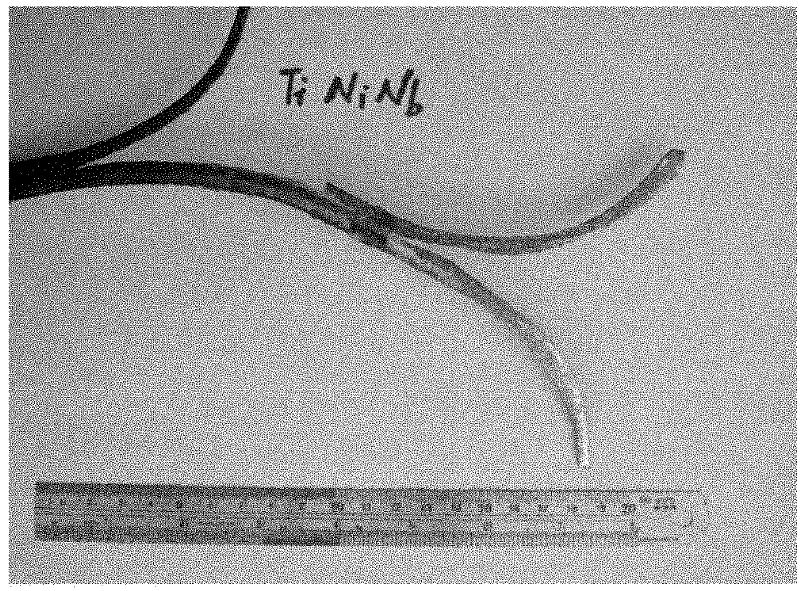

Titanium tungsten alloys produced by additions of tungsten nanopowder

Disclosed herein are titanium-tungsten alloys and composites wherein the tungsten comprises 0.5% to 40% by weight of the alloy. Also disclosed is a method of making such alloys and composites using powders of tungsten less then 3 μm in size, such as 1 μm or less. Also disclosed is a method of making the titanium alloy by powder metallurgy, and products made from such alloys or billets that may be cast, forged, or extruded. These methods of production can be used to make titanium alloys comprising other slow-diffusing beta stabilizers, such as but not limited to V, Nb, Mo, and Ta.

Owner:DYNAMET TECH

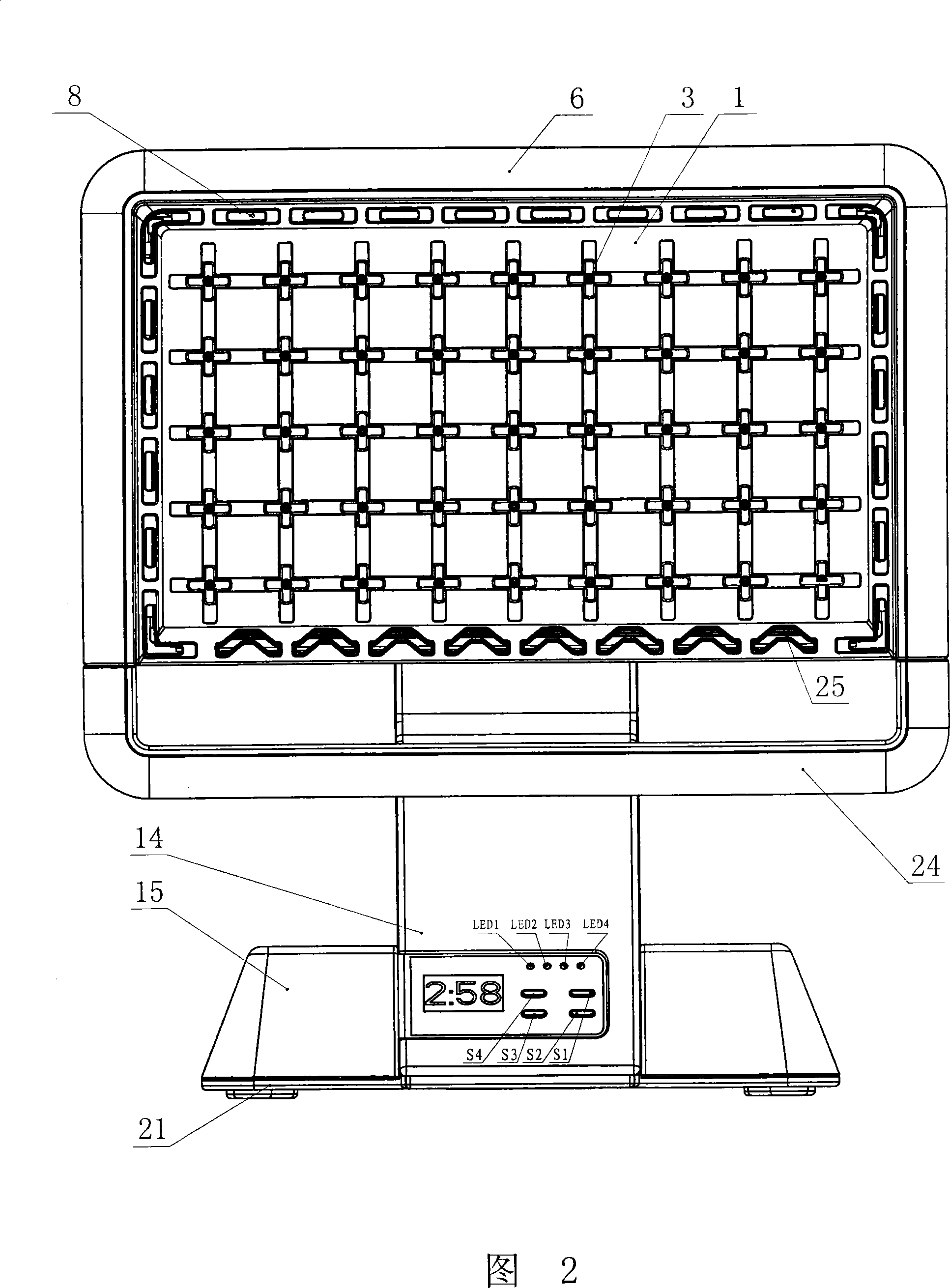

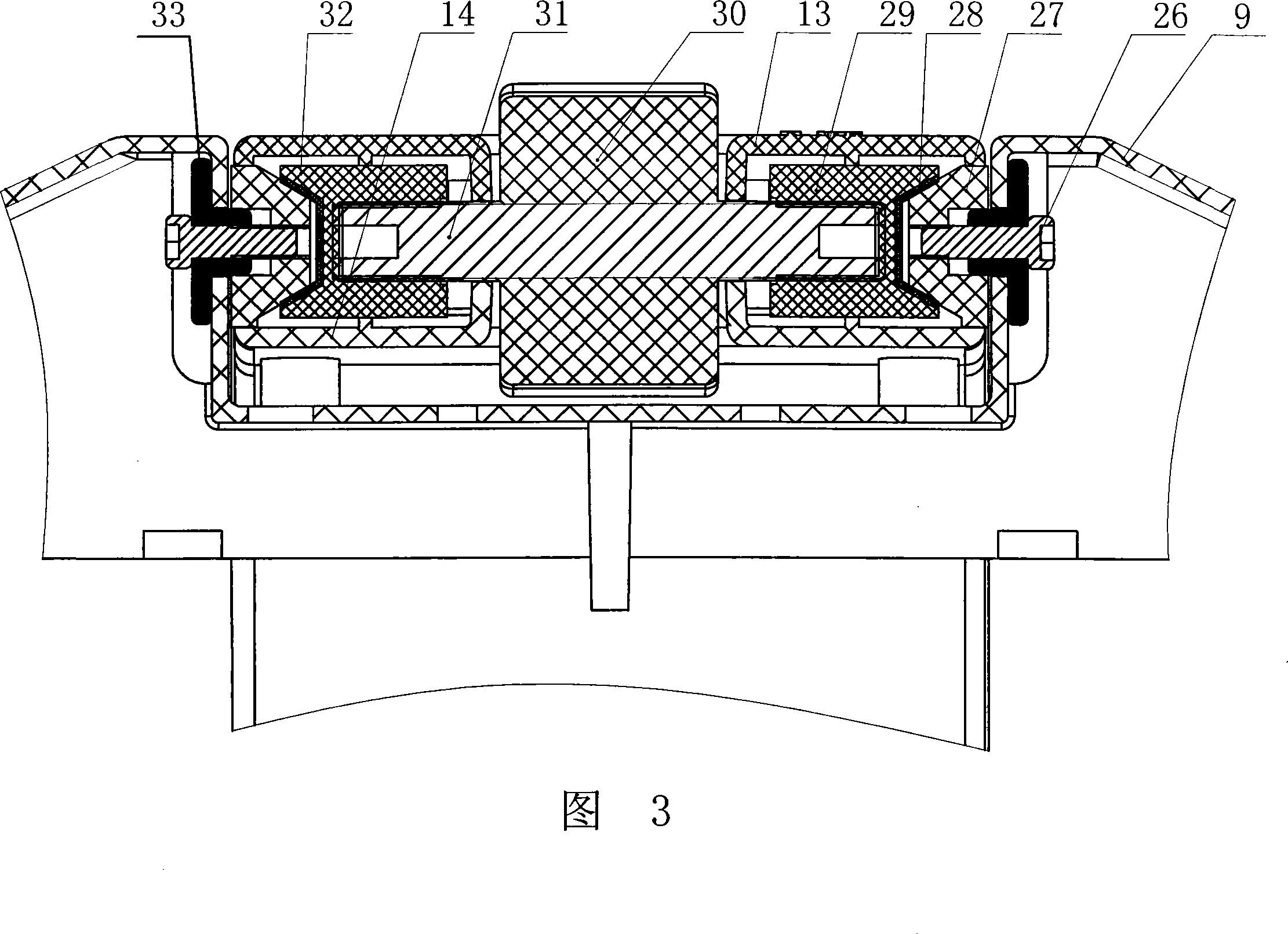

Iron golf club

InactiveUS7338387B2Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityMetallic materials

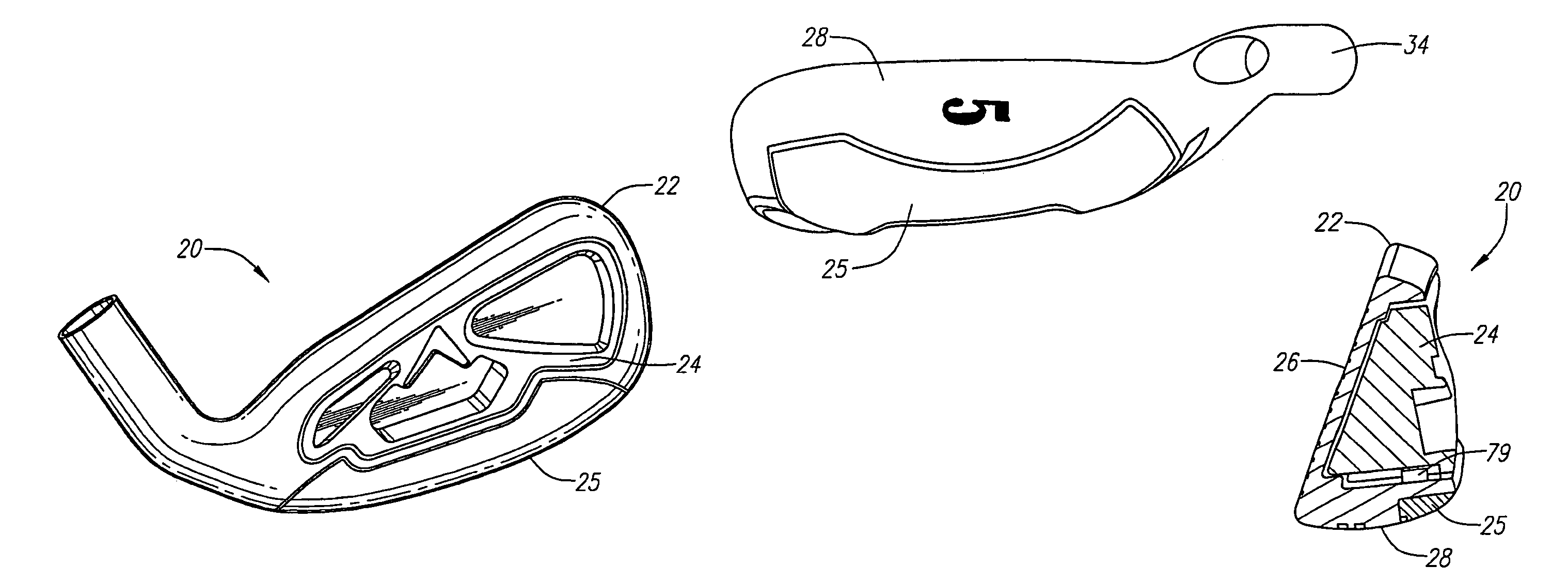

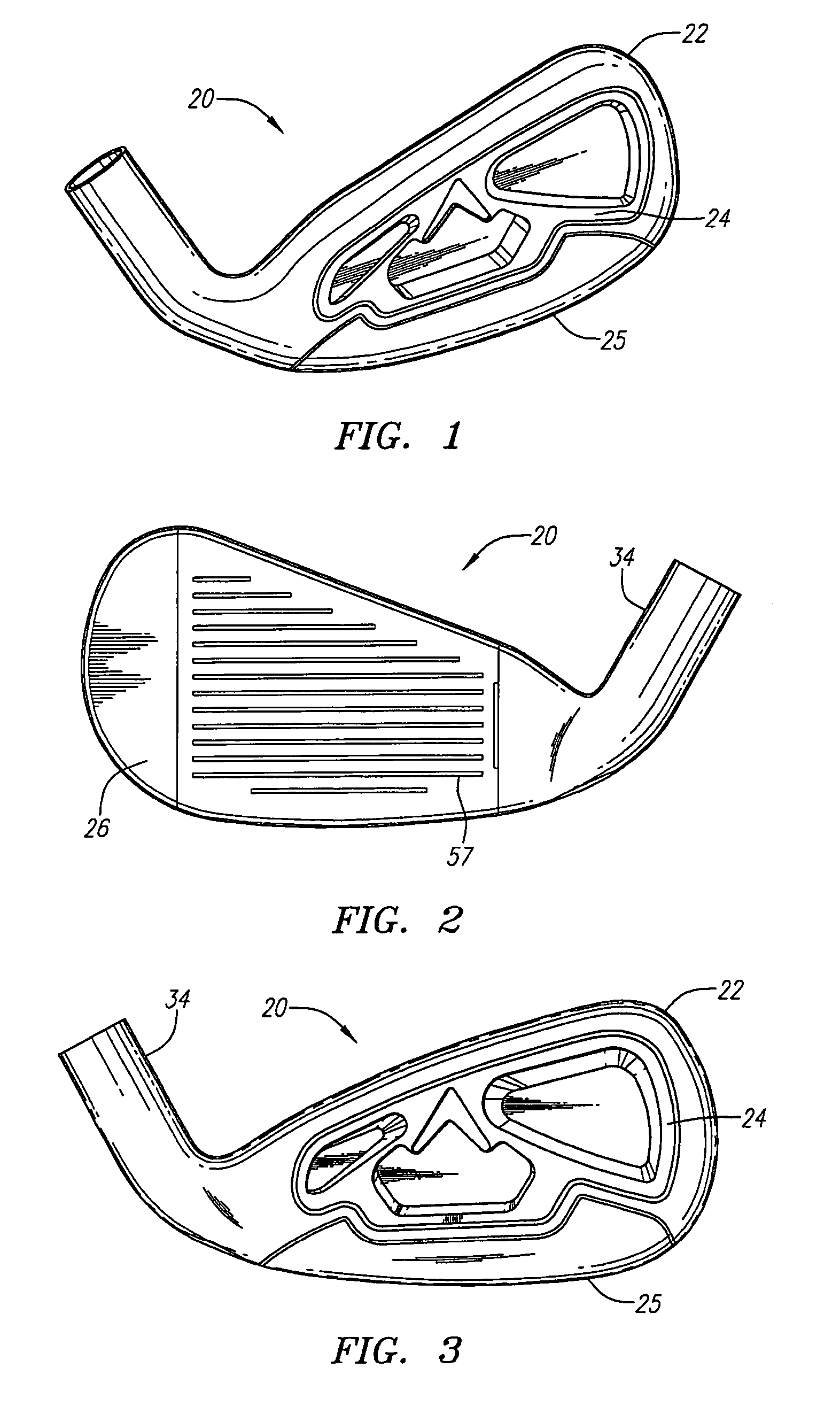

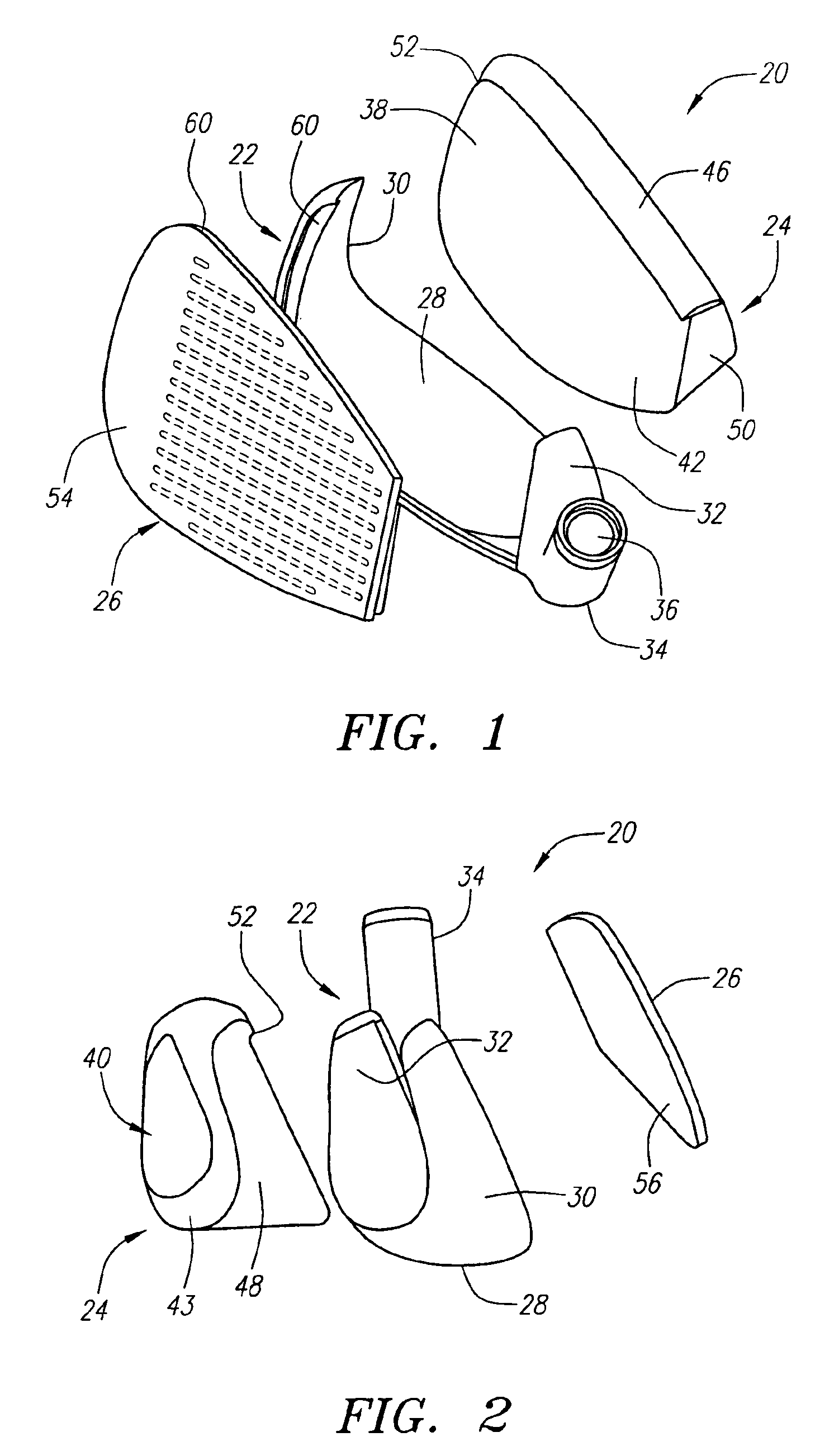

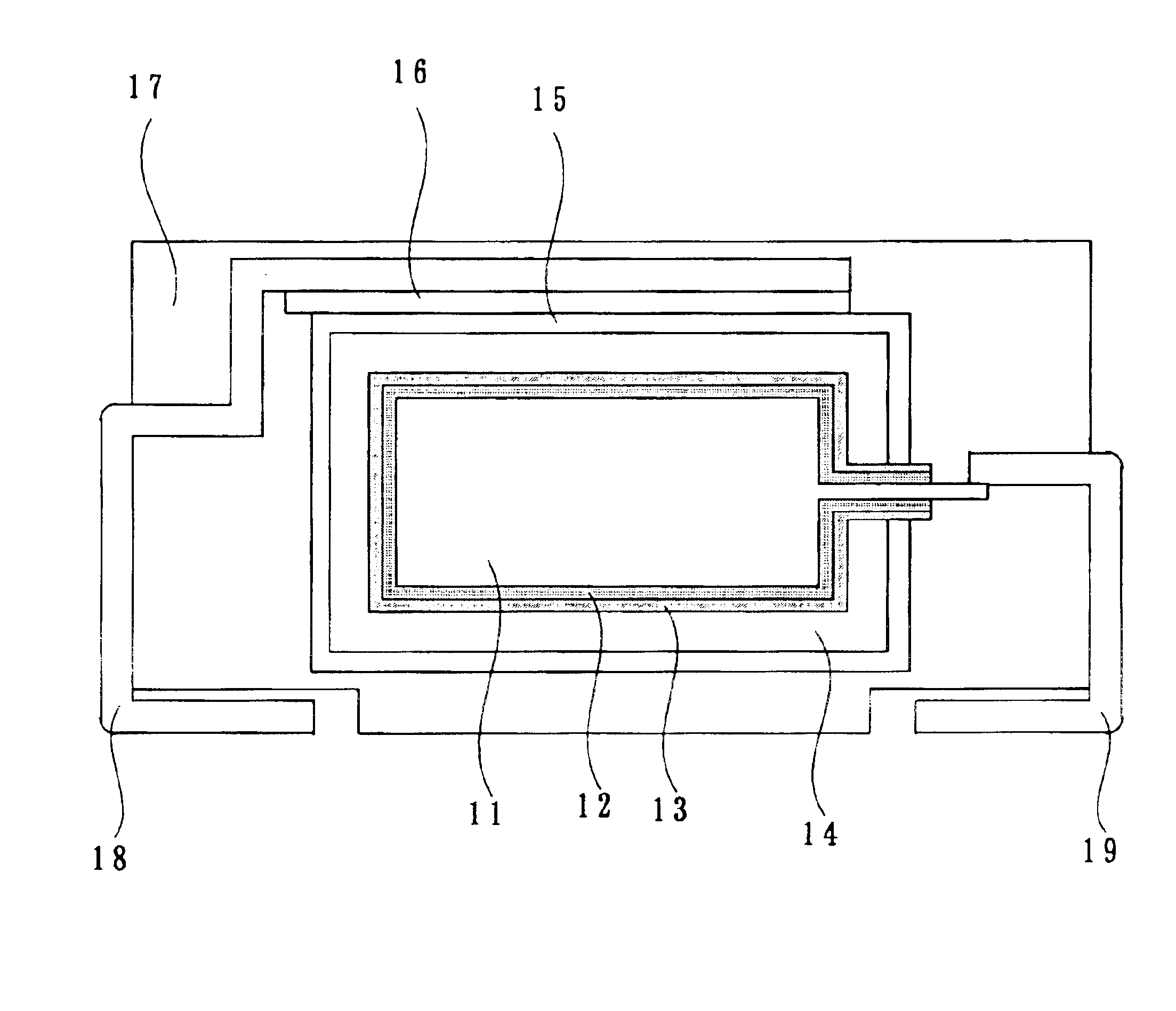

The iron golf club head (20) of the present invention is preferably composed of three main components: a main body (22), a central member (24) and a mass member (25). The Mass member (25) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The main body (22) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx, and a low center of gravity.

Owner:TOPGOLF CALLAWAY BRANDS CORP

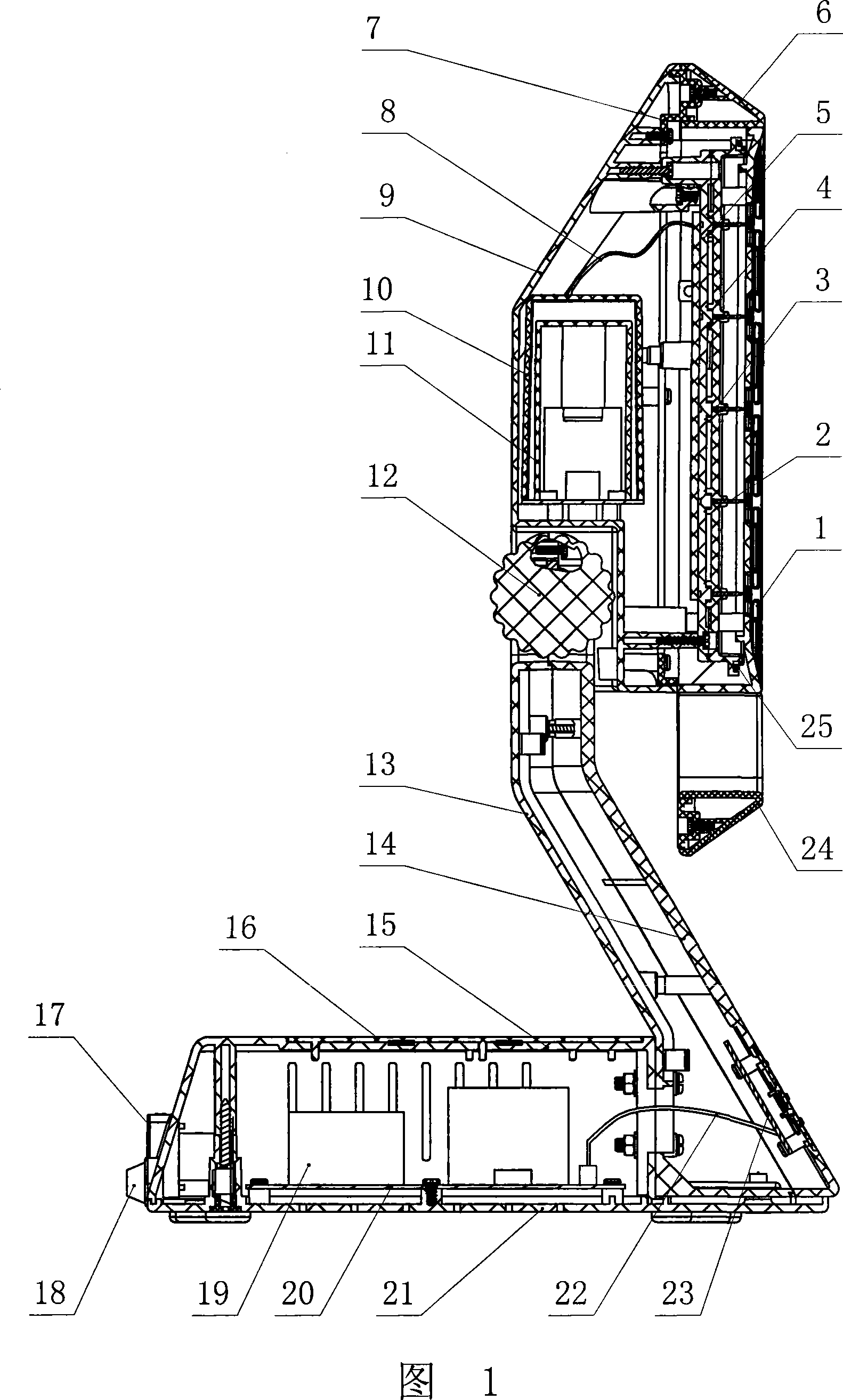

Negative ion generating device

ActiveCN101214390AQuality improvementLarge particle sizeDeodrantsCorona dischargeFiberHigh concentration

An anion generator includes a base and a shell assembled on the base, needle stripes of homopolar spray points vertically lined with equal spacing fixed between a partition plate and a window grating, and a control circuit. The technical proposal is that the shell consists of a rear shell and a front shell; the window grating is moveably connected with the rear shell; the homopolar tungsten alloy spray points vertically lined with equal spacing are fixed between the needle stripes and press plates through the one-off sealing and packaging technique; the carbide fibre fixed on the needle stripes is communicated with the small high voltage blocks; a closed carbide fibre ring is arranged in a circular slot on the circumference of the needle stripes; the high voltage block assembly components fixed in the shell are sealed and packaged in a shield screen; the base and the shell are hinged together by a rotary positioning device. The invention has the advantages of reasonable structure design, convenience in adjustment and positioning, good transmission direction of the anion, high concentration and small grain size of the generated anion, large output quantity within unit time and obvious improvement of the air quality, thus obviously improving the curative effect of diseases and the air purification efficiency, and obviously extending the service life.

Owner:柏学红

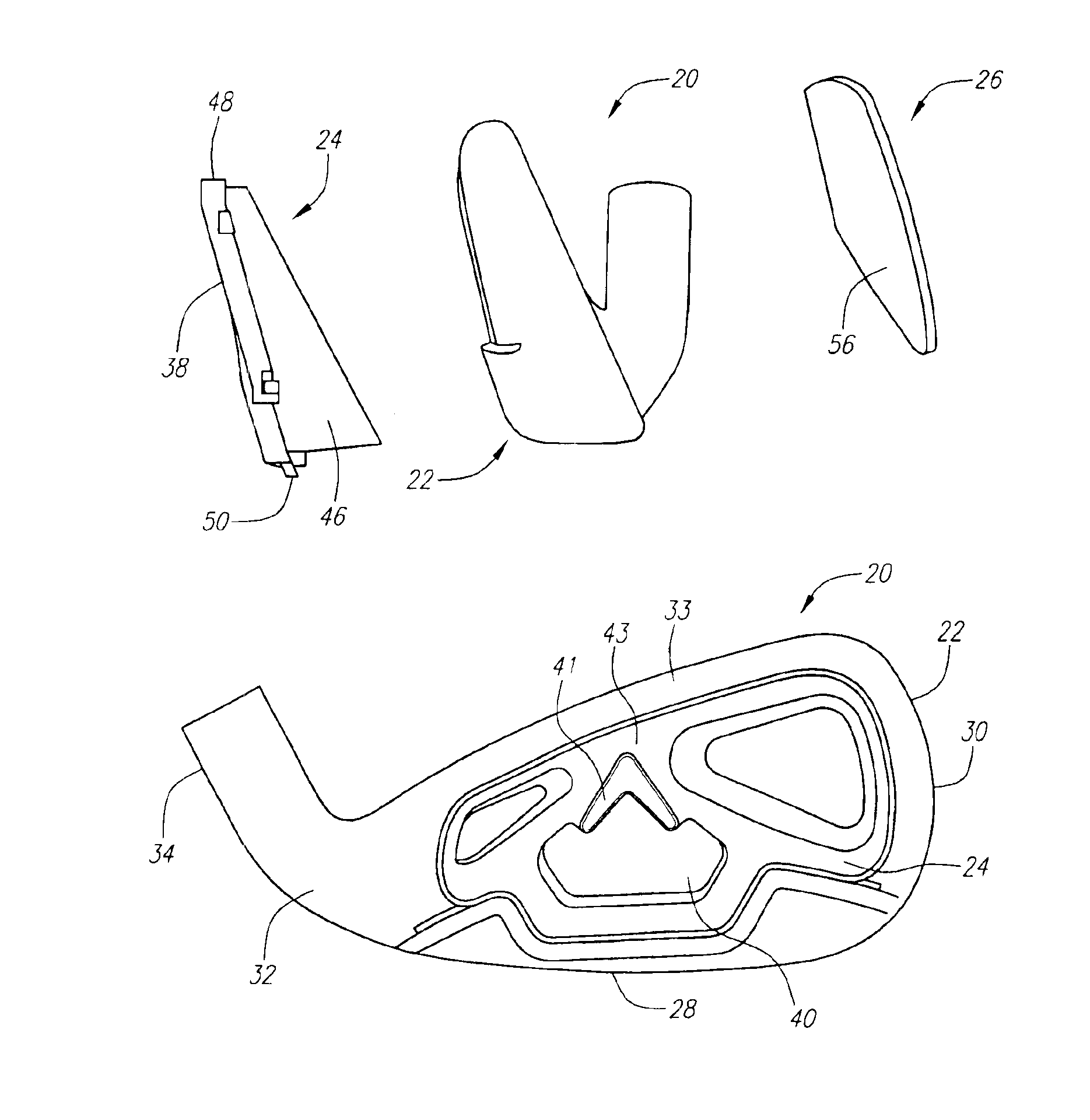

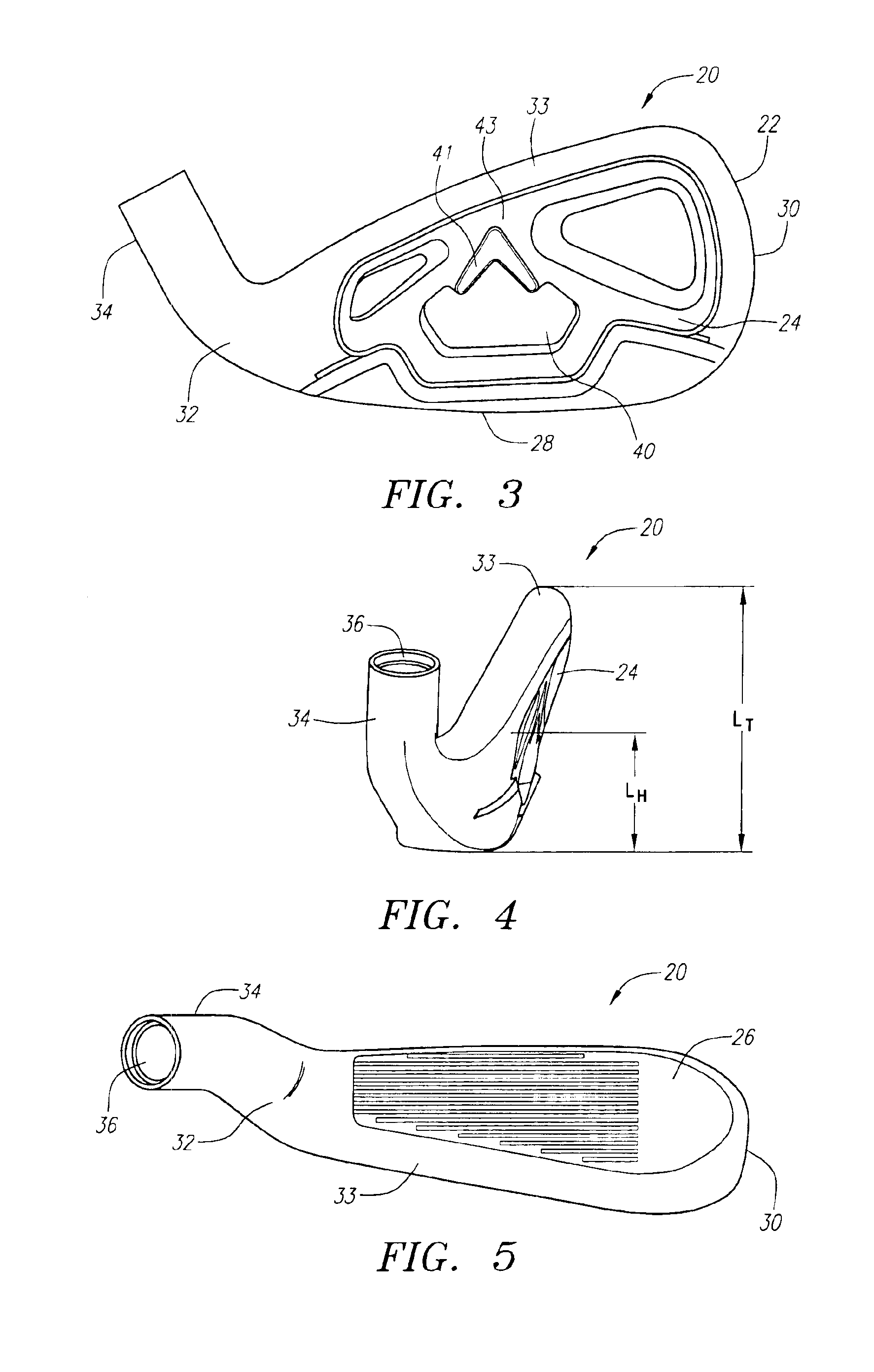

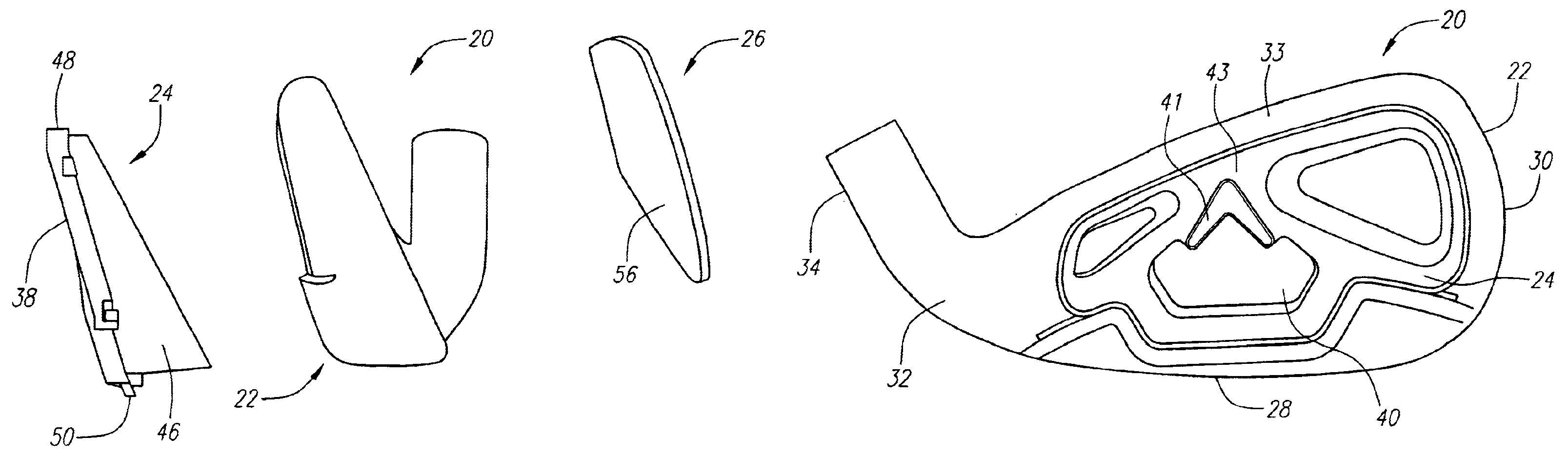

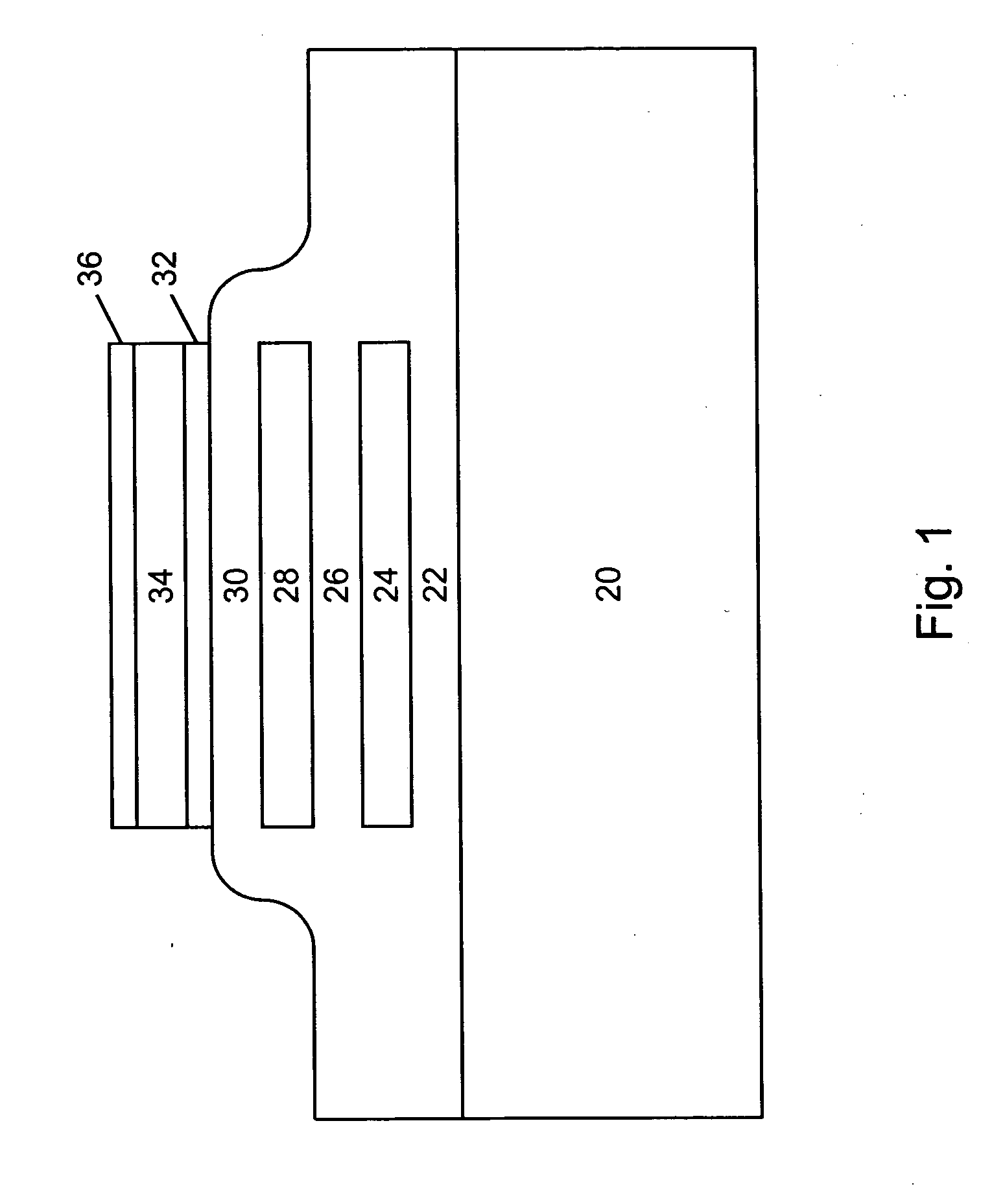

Iron golf club with nanocrystalline face insert

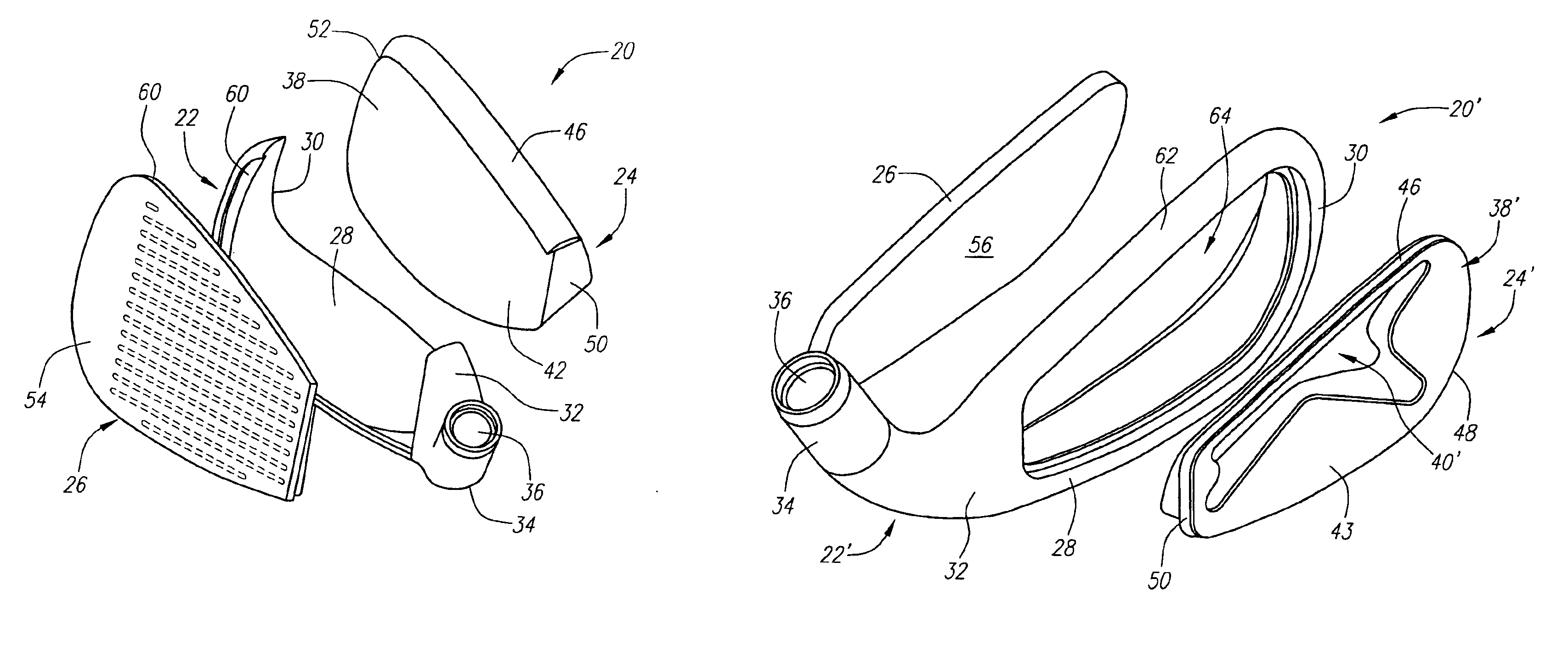

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a nanocrystalline plated face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a non-metal material plated with a nanocrystalline material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

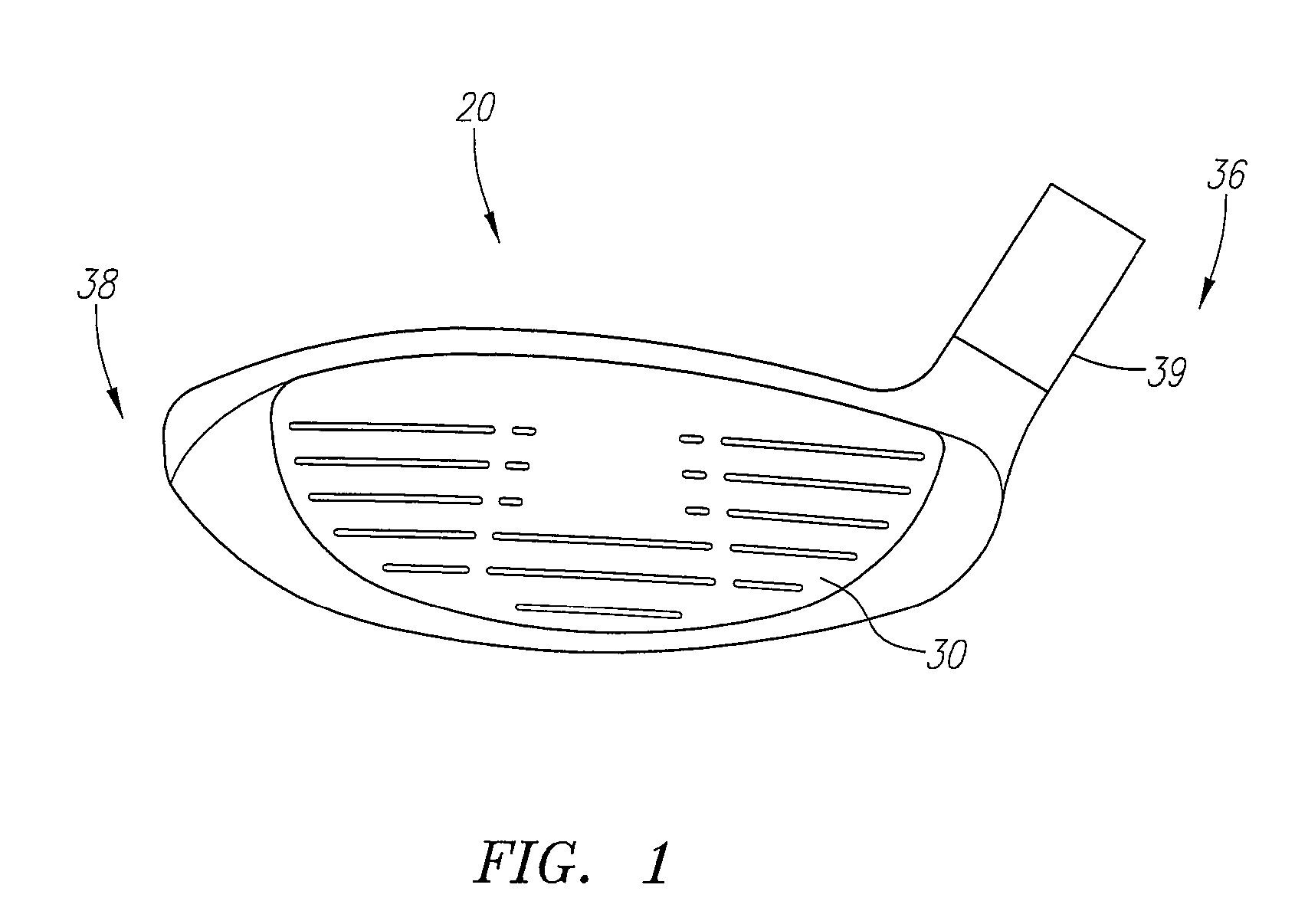

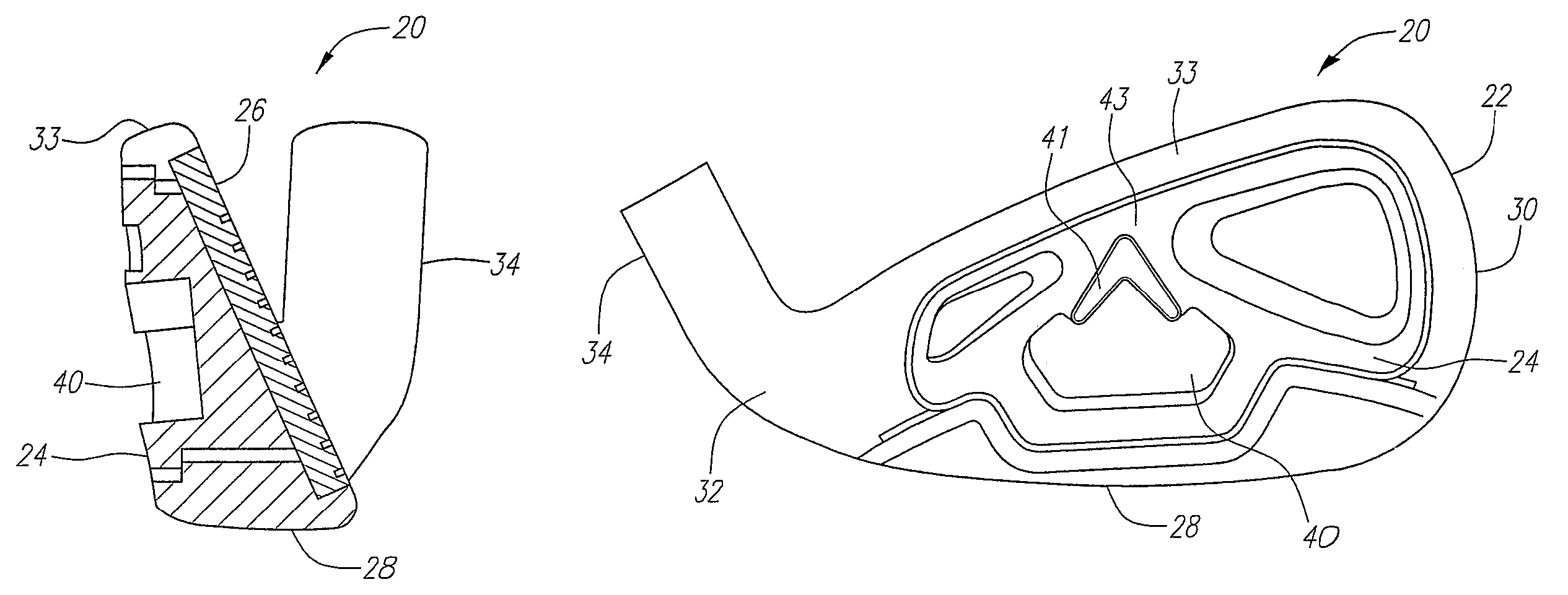

Iron golf club head

InactiveUS6887164B2Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityMetallic materials

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

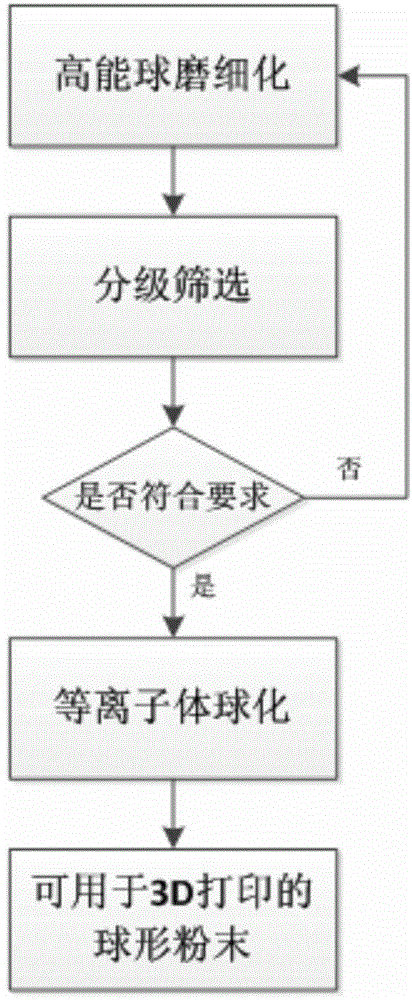

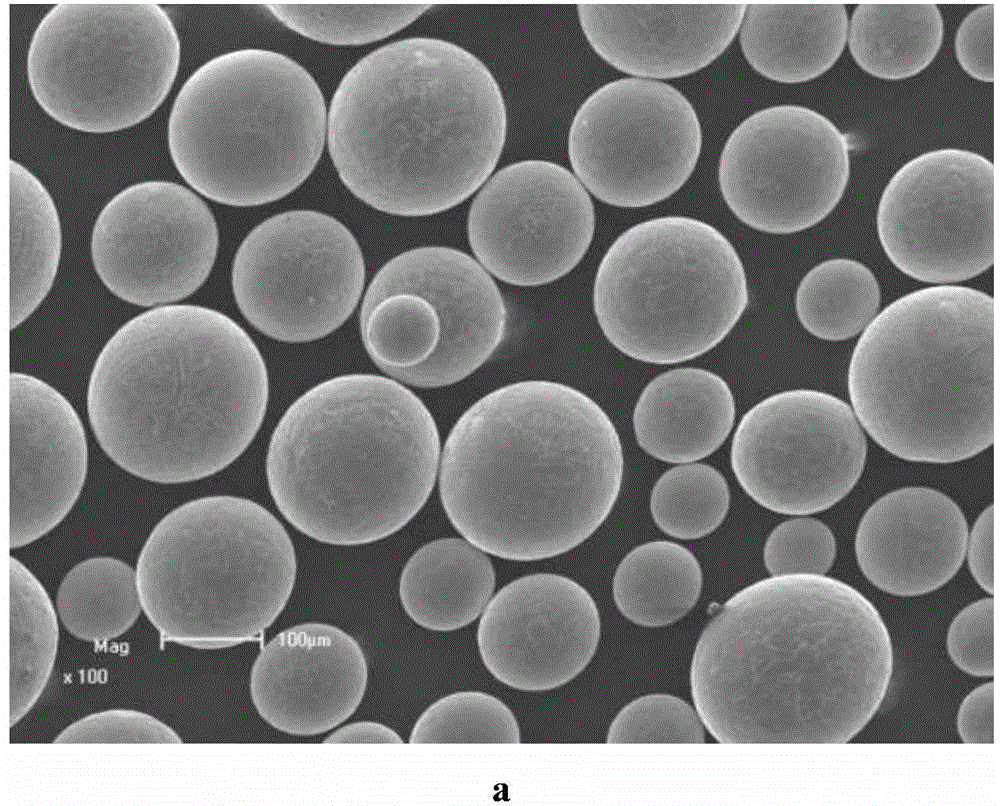

Method for preparing spherical powder material used for three-dimensional printing

The invention discloses a method for preparing a spherical powder material used for three-dimensional printing. The method includes the steps of raw material selecting, high-energy ball milling and radio-frequency plasma spherizing. Selected raw materials are metal or alloy powder in the step of raw material selecting; the step of high-energy ball milling is carried out under the argon shielding condition, petroleum ether serves as the ball milling medium, and the metal or alloy powder is aluminum alloy powder, or titanium alloy powder, or nickel-base alloy powder, or stainless steel powder or tungsten alloy powder; according to the step of radio-frequency plasma spherizing, the total gas flow is 100 L / min-200 L / min, the input power of plasma is 50 kW-100 kW, the negative pressure of a gas outlet of a system is minus 1000 Pa-minus 2000 Pa, and the powder conveying amount is 50 g / min-150 g / min. The manufactured spherical powder is high in sphericity degree, even in granularity, low in oxygen content and good in liquidity, has few defects and is suitable for three-dimensional printing. The method for preparing the spherical powder material used for three-dimensional printing has the advantage that the process is accurate and controllable.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

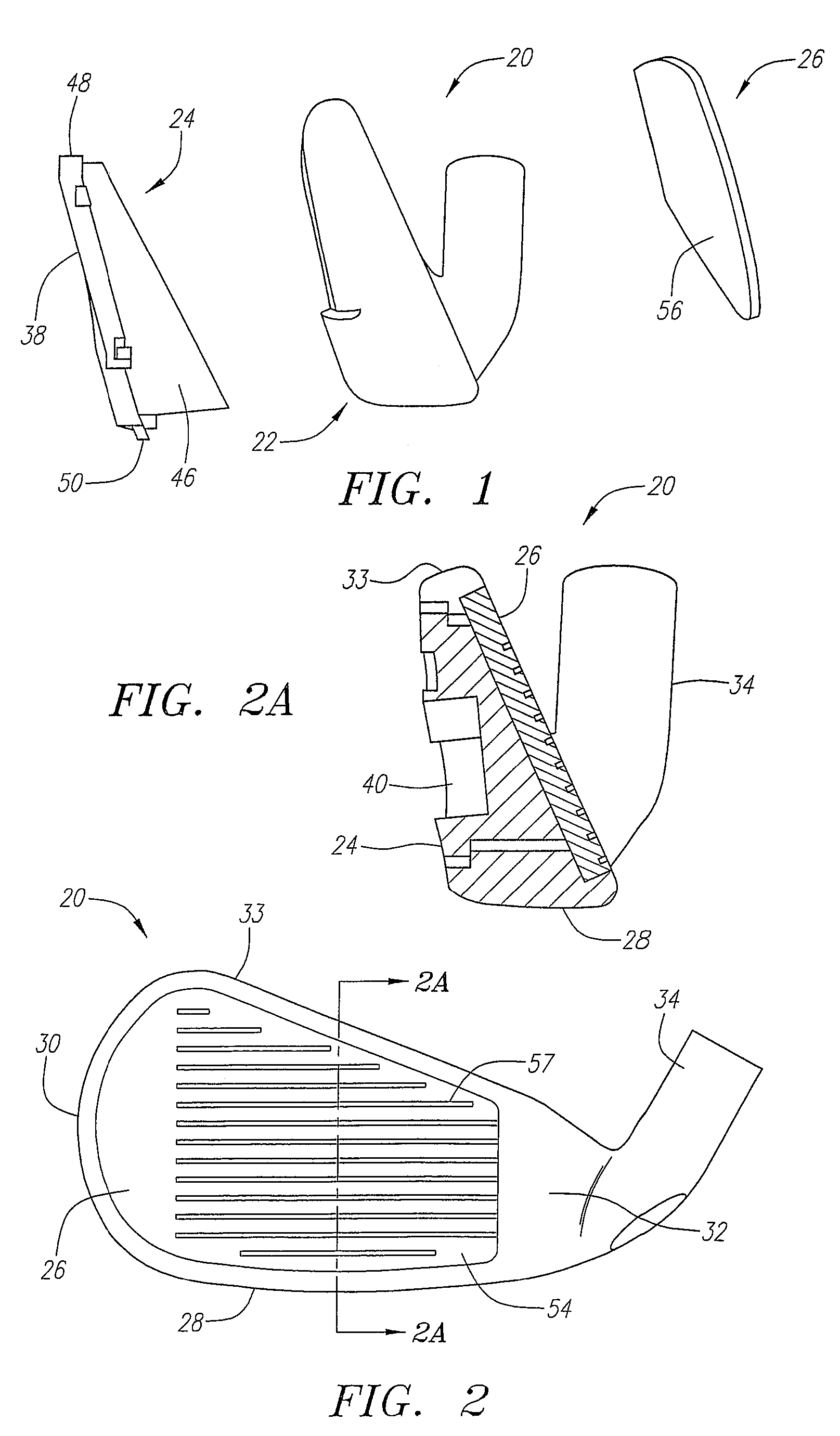

Iron golf club

InactiveUS6857973B2Lower center of gravityHigh moment of inertiaGolf clubsHigh densityMetallic materials

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

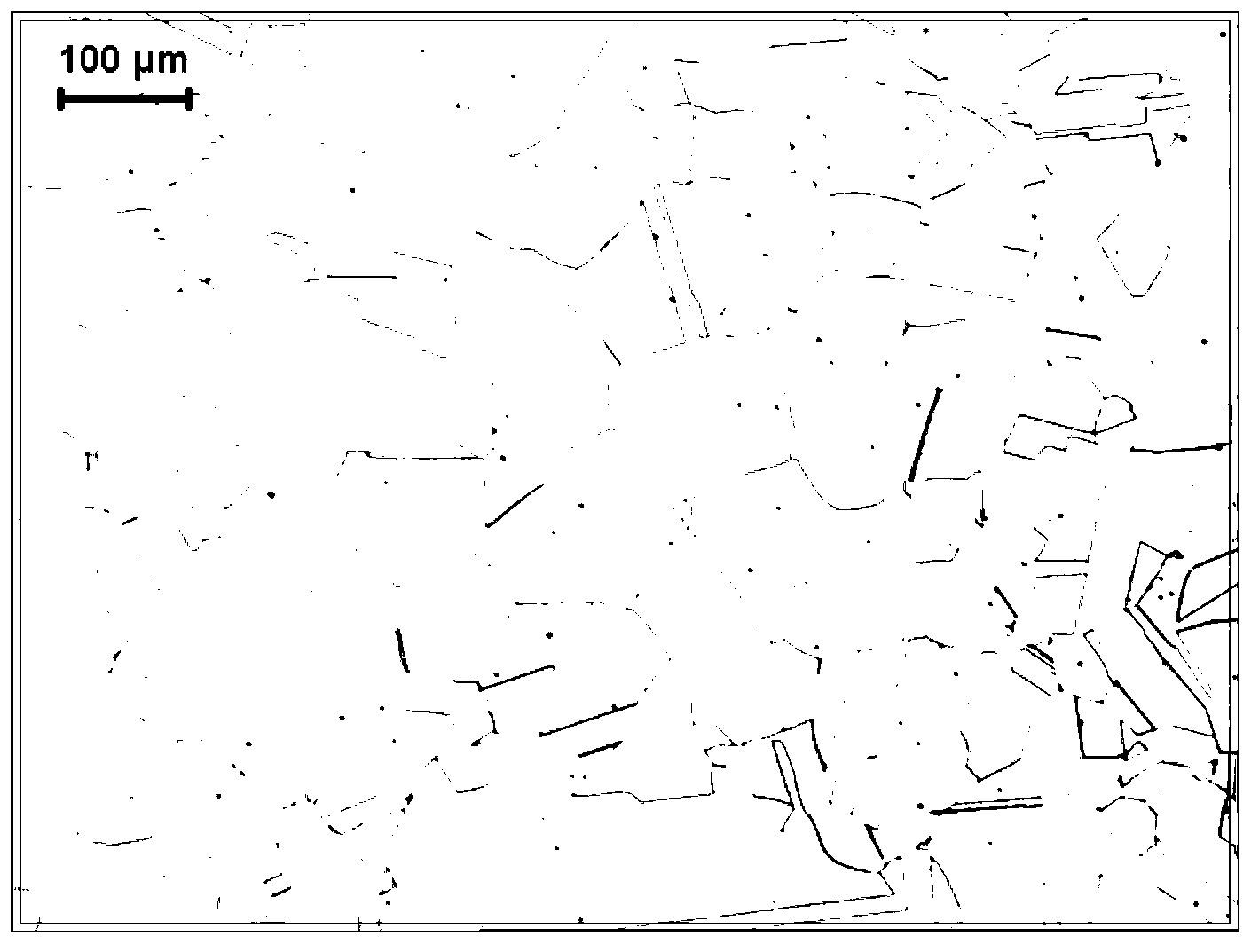

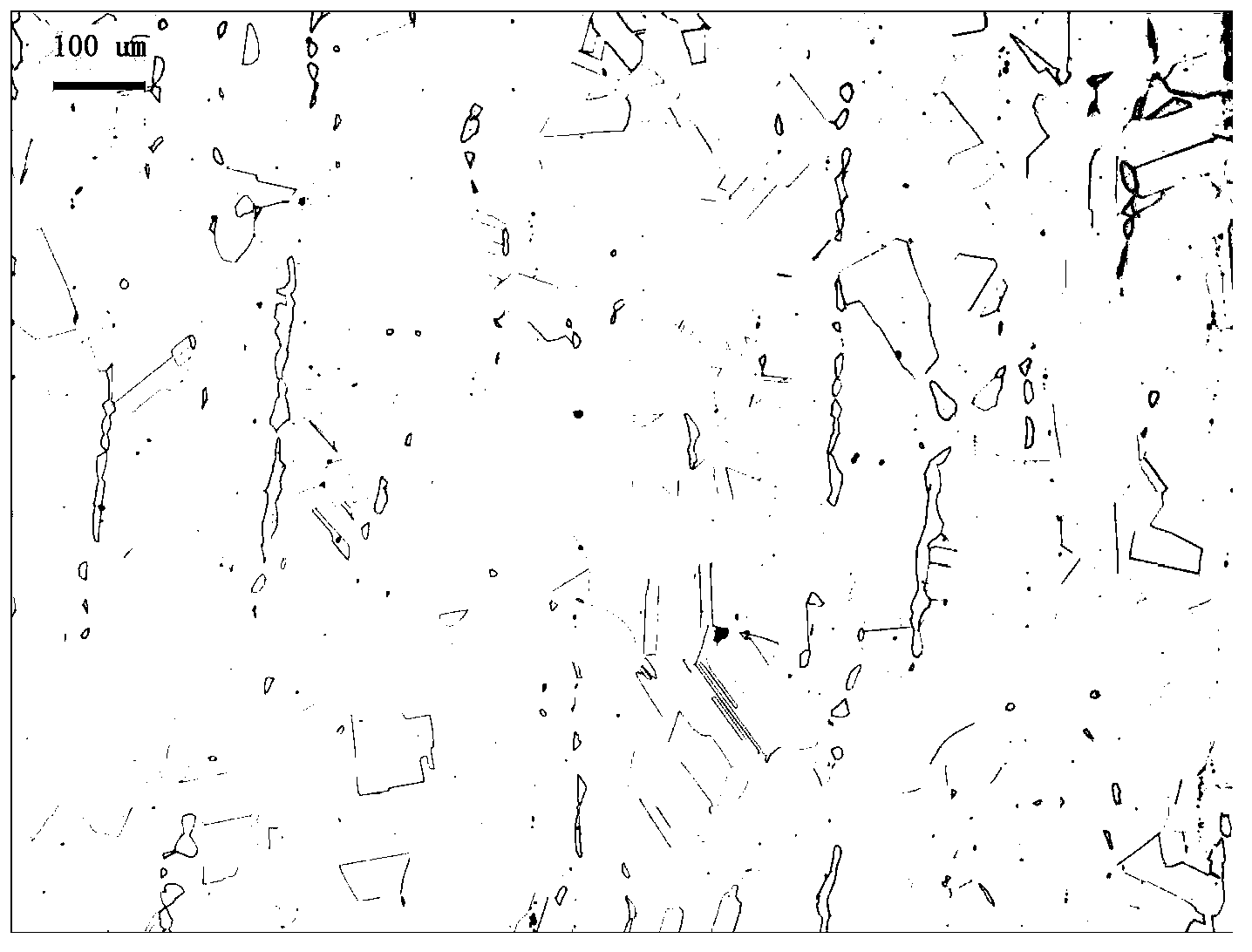

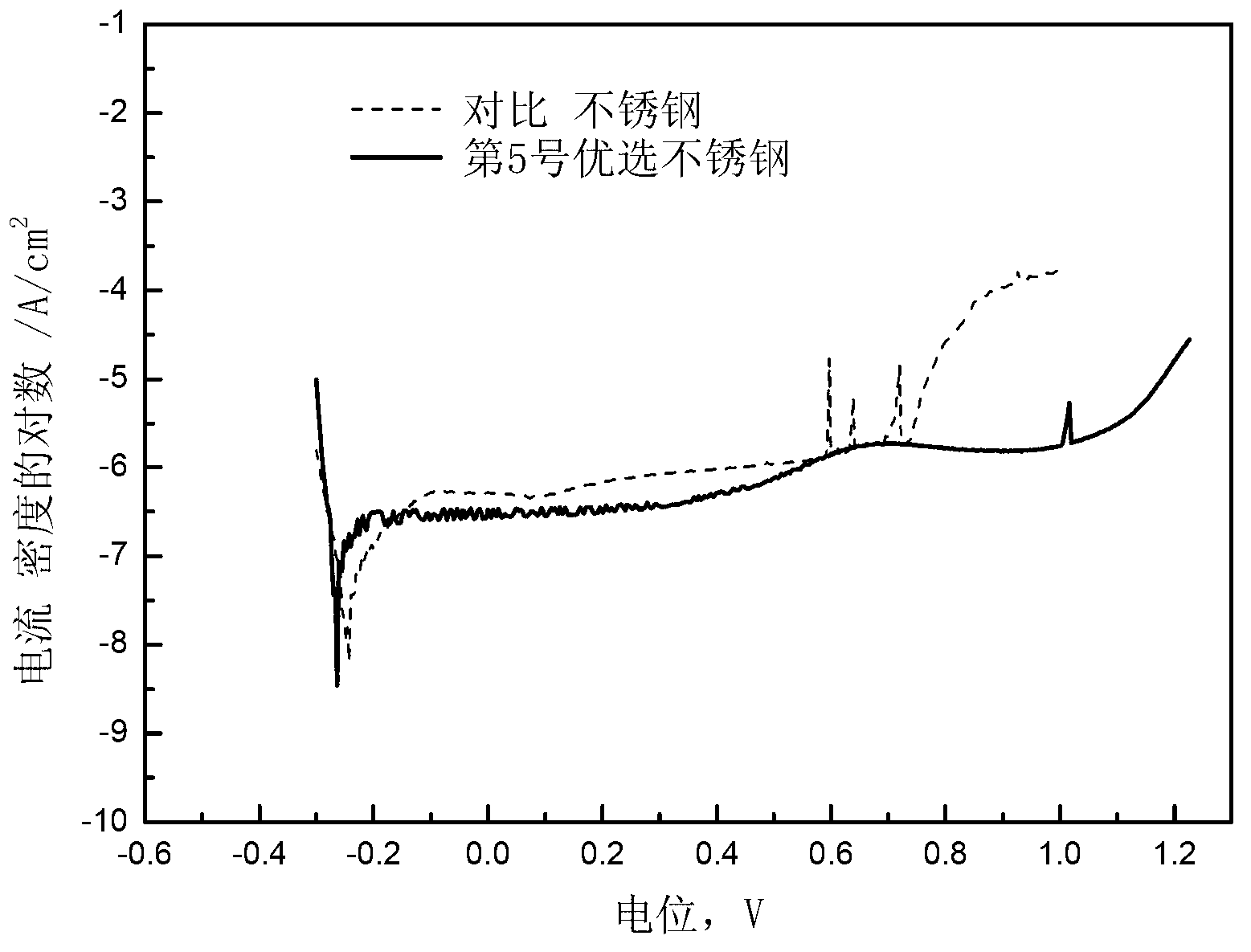

High-nitrogen austenitic stainless steel for vascular stent and application thereof

The invention provides a high-nitrogen austenitic stainless steel material for a vascular stent, which comprises the following chemical components in percentage by weight: 16-20% of Cr, 12-20% of Mn, 1-3% of Mo, 0.5-2% of Cu, no more than 0.05% of Ni, 0.7-1.2% of N, 0.5-8% of W, 0.05-0.5% of RE, no more than 0.08% of C, 0.3-4% of Si, no more than 0.010% of S, no more than 0.02% of P and the balance of Fe, wherein RE is a rare-earth element. The high-nitrogen stainless steel provided by the invention is mainly used for vascular stent processing; the elements of copper, nitrogen and rare earth are added to increase the blood compatibility of the stainless steel; and the tungsten alloy is added to increase the density of the stainless steel. The stainless steel has excellent visibility under X rays, contains no potential toxic element nickel, can be used in the aspects of surgical implants, medical appliances, food and catering appliances, jewelry and other stainless steel products which are always in contact with a human body, and can also be used in the fields of chemical engineering, environment protection and the like.

Owner:ZHONGKE YIAN MEDICAL TECH BEIJING CO LTD

Iron golf club

InactiveUS7220189B2Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityMetallic materials

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

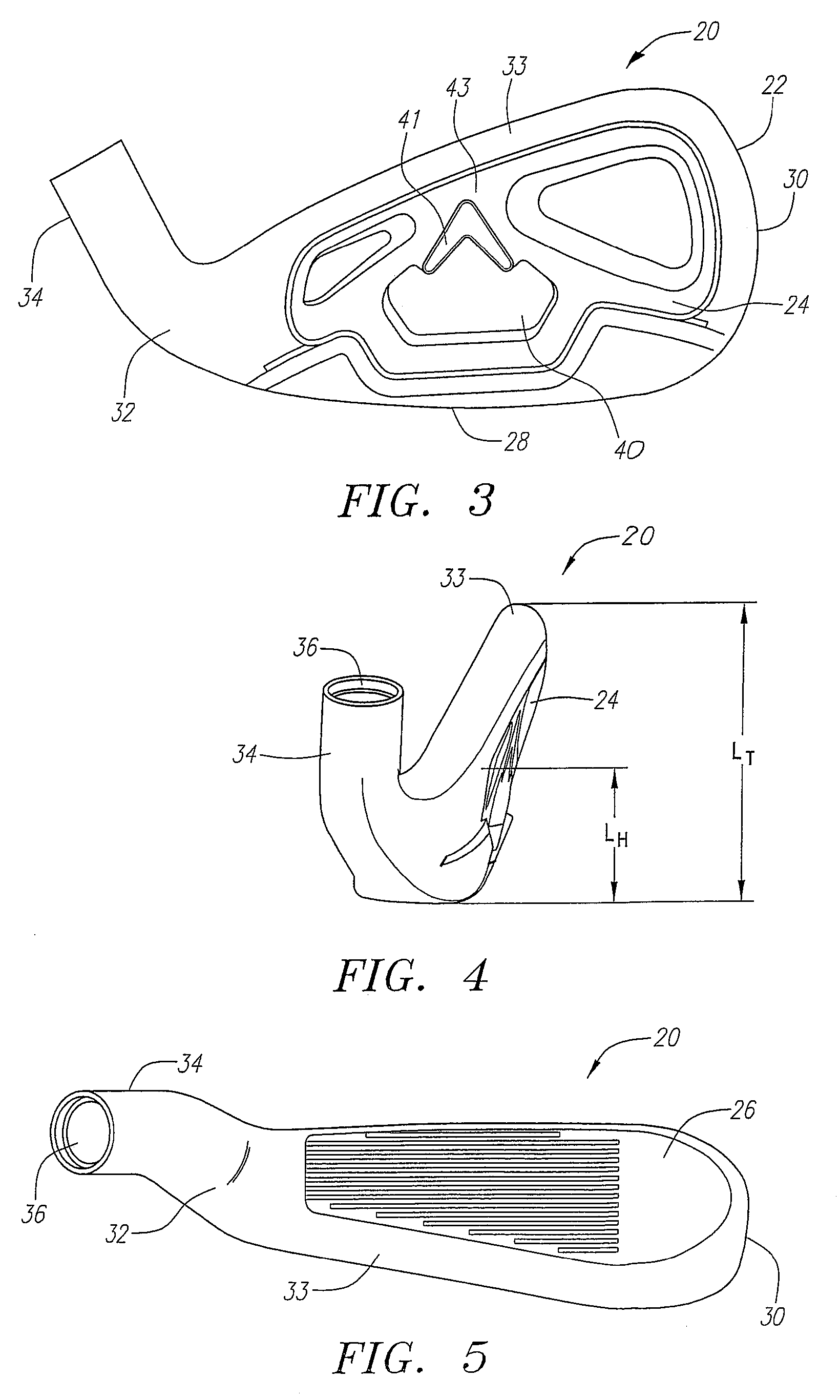

Iron golf club

InactiveUS6863625B2Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityMetallic materials

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

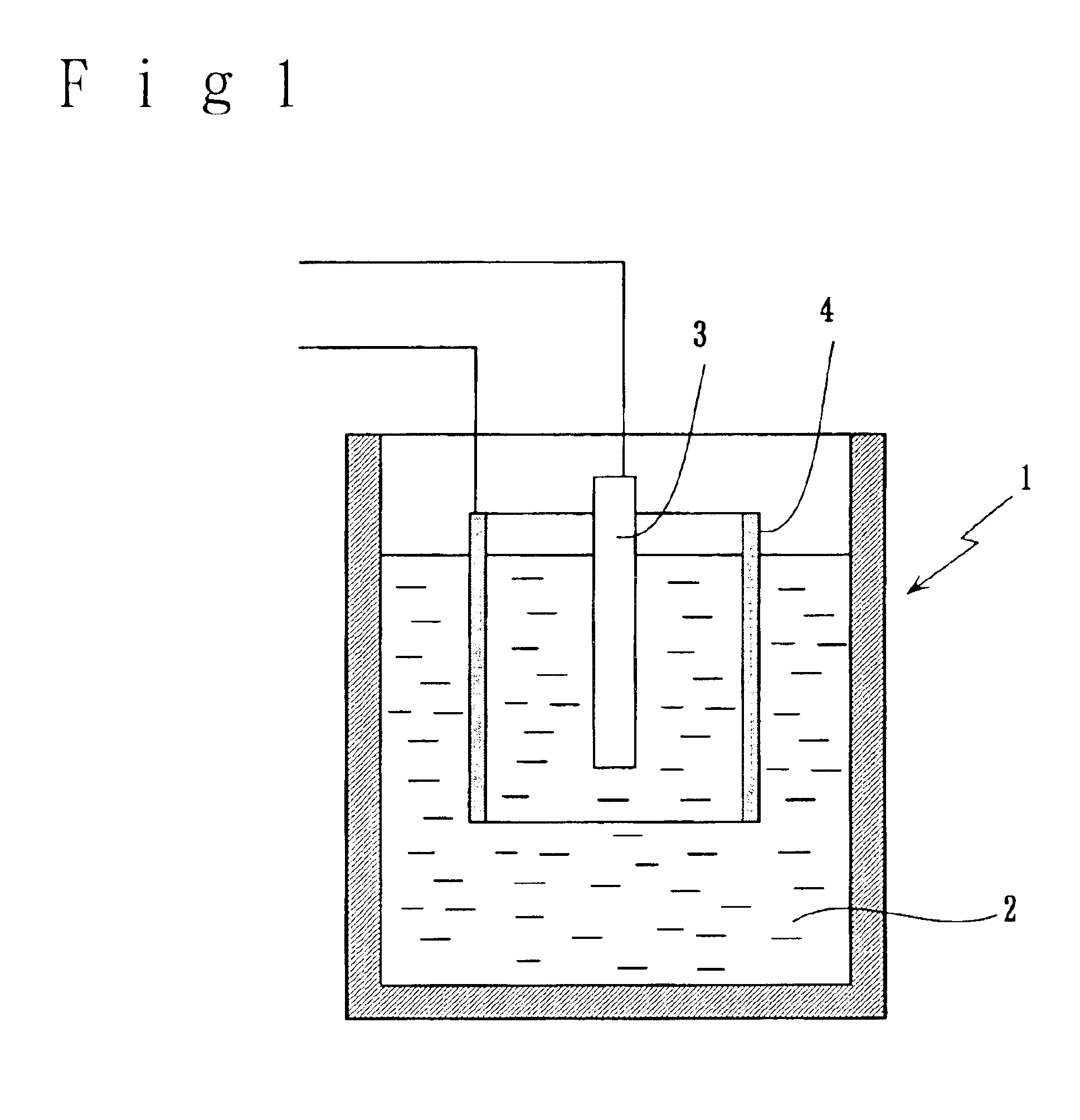

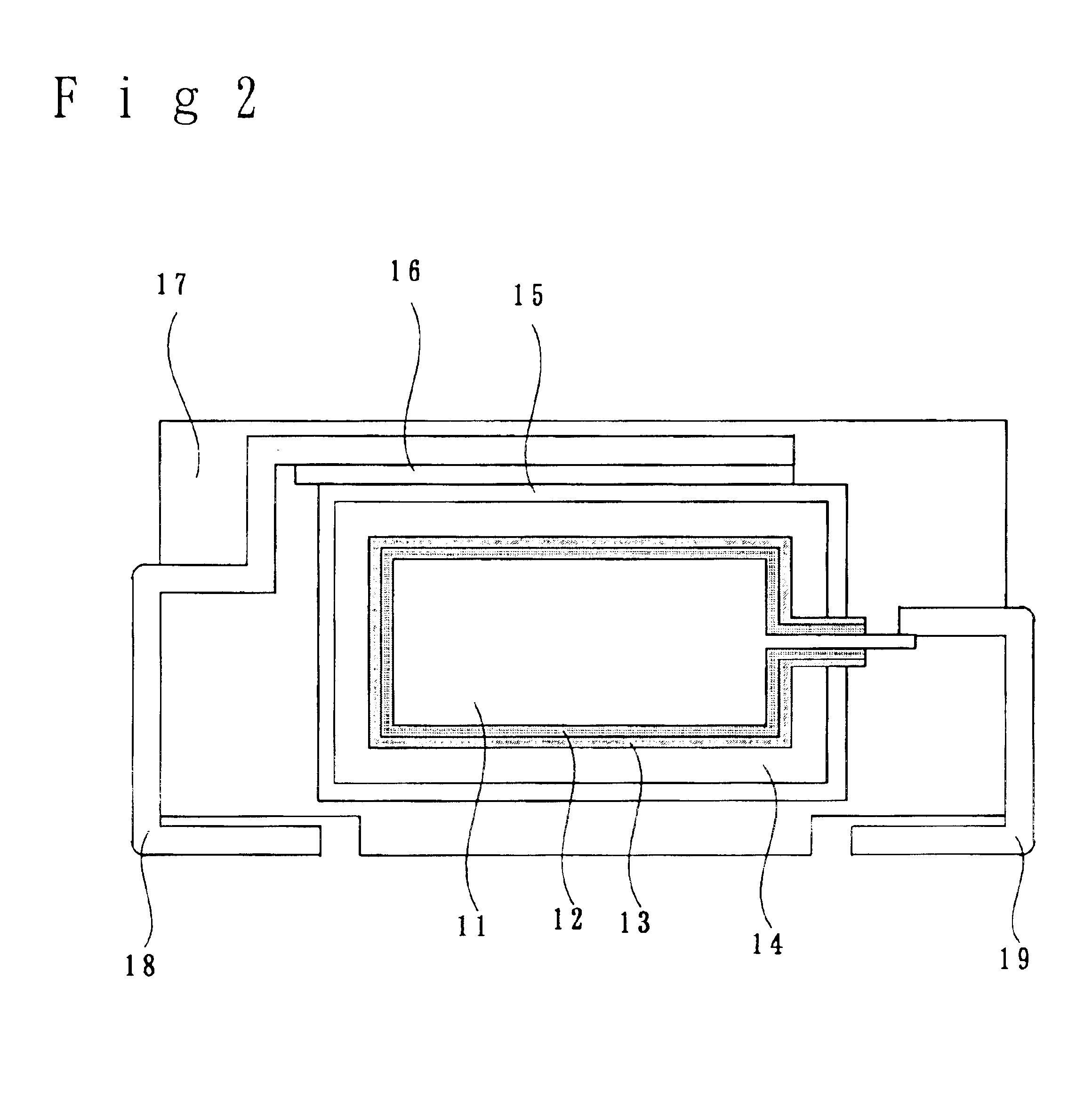

Electrolytic capacitor and a fabrication method therefor

InactiveUS6876083B2Avoid excessive leakage currentAvoid excessive currentTransistorSolid electrolytic capacitorsElectrolytic capacitorNiobium alloy

An electrolytic capacitor including one type of electrode selected from a group consisting of an electrode of at least one type of alloy selected from a group consisting of niobium alloy, titanium alloy, and tungsten alloy, an electrode of mixed sinter of niobium and aluminum, or a fluorine-doped electrode of niobium or niobium alloy and on a surface of each electrode a dielectric layer is formed by anodizing the electrode.

Owner:SANYO ELECTRIC CO LTD

Titanium-tungsten alloy based mirrors and electrodes in bulk acoustic wave devices

Titanium-tungsten alloy based mirrors and electrodes in bulk acoustic wave devices simplify processing by eliminating the need for adhesion, barrier and seed layers, and preserve the advantages of tungsten layers. Alternate layers of high and low acoustic impedance materials are use, wherein the high acoustic impedance layers are titanium-tungsten alloy layers, preferably deposited by physical vapor deposition, and isotropically patterned with a wet etch. SiO2 is preferably used for the low acoustic impedance layers, though other low acoustic impedance materials may be used if desired. Electrodes and loads may also be a Titanium-tungsten alloy. Titanium-tungsten alloys in the range of 3 to 15 percent of titanium by weight are preferred.

Owner:MAXIM INTEGRATED PROD INC

High-hardness hypereutectic high chromium, manganese, molybdenum and tungsten alloy wear resistant steel material and use thereof

The invention discloses a high-hardness hypereutectic high Cr-Mn-Mo-tungsten alloy abrasion-resistant steel and iron material which adopts multivariant alloying and has the advantages of good hardenability, high hardness, better abrasion-resistance and wear resistance, and the like compared with the prior high-chromium cast iron especially the addition of C, Cr, Mn, Mo and tungsten, thereby enlarging the application range of materials. The invention is suitable for preparing wearing and corrosive wearing parts, in particular to parts used for impacting corrosive wearing working conditions.

Owner:JINAN UNIVERSITY

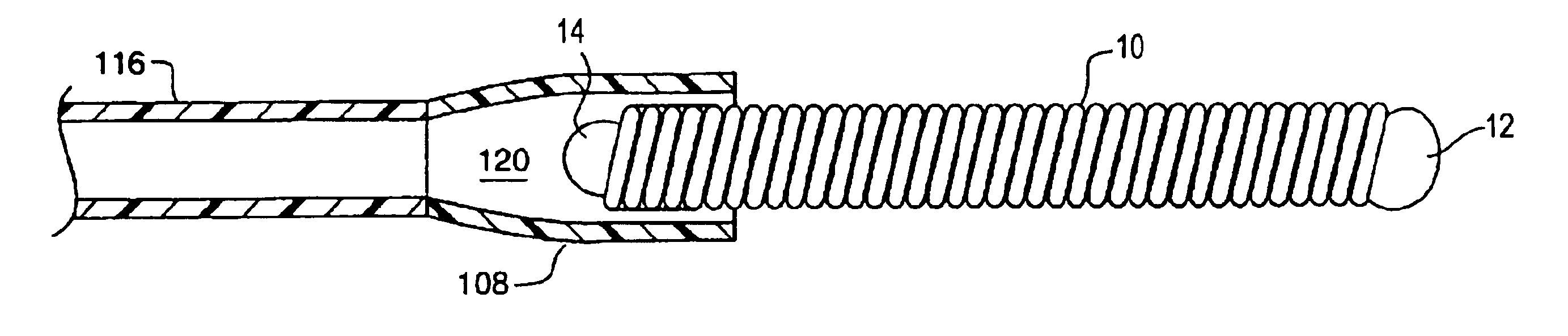

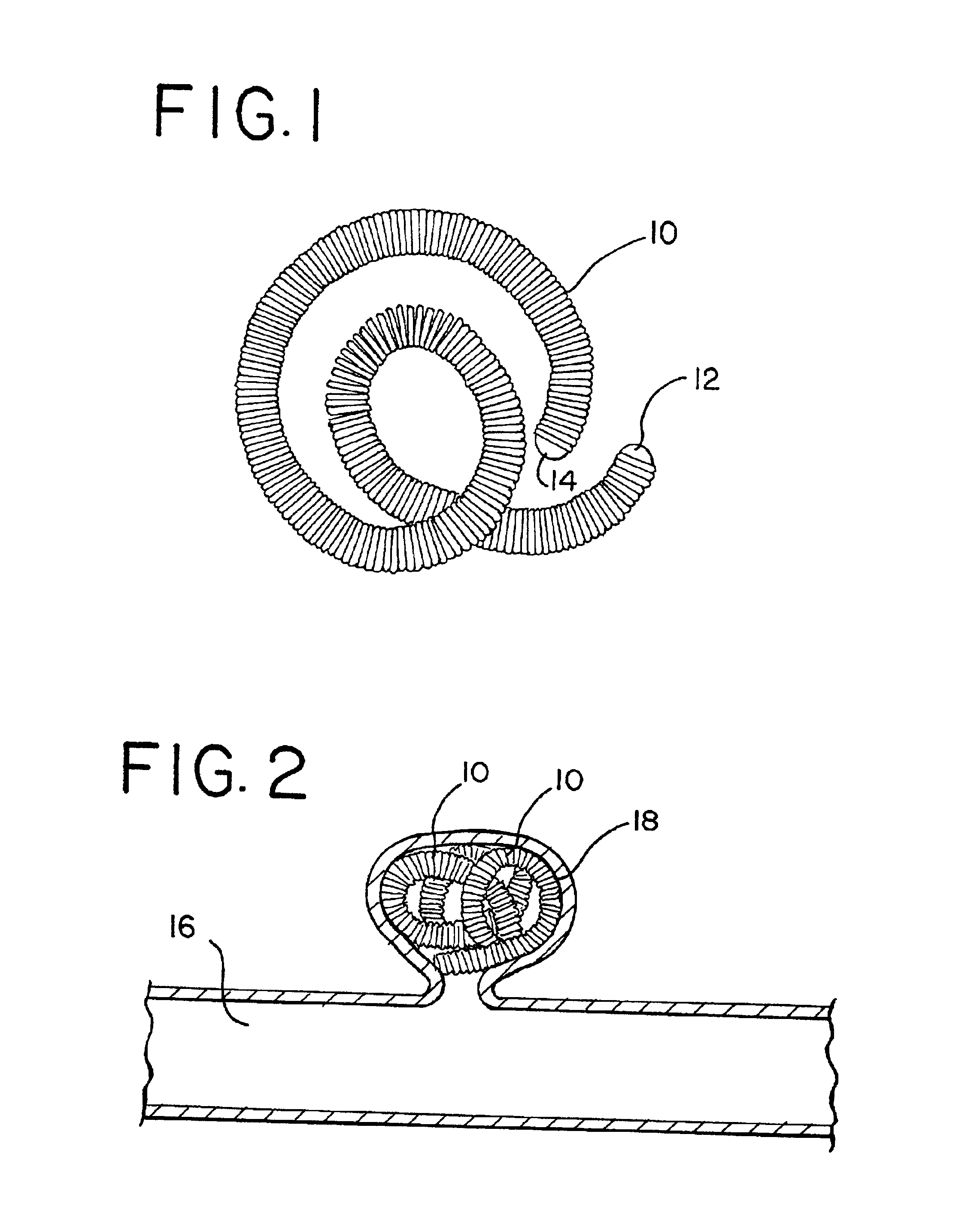

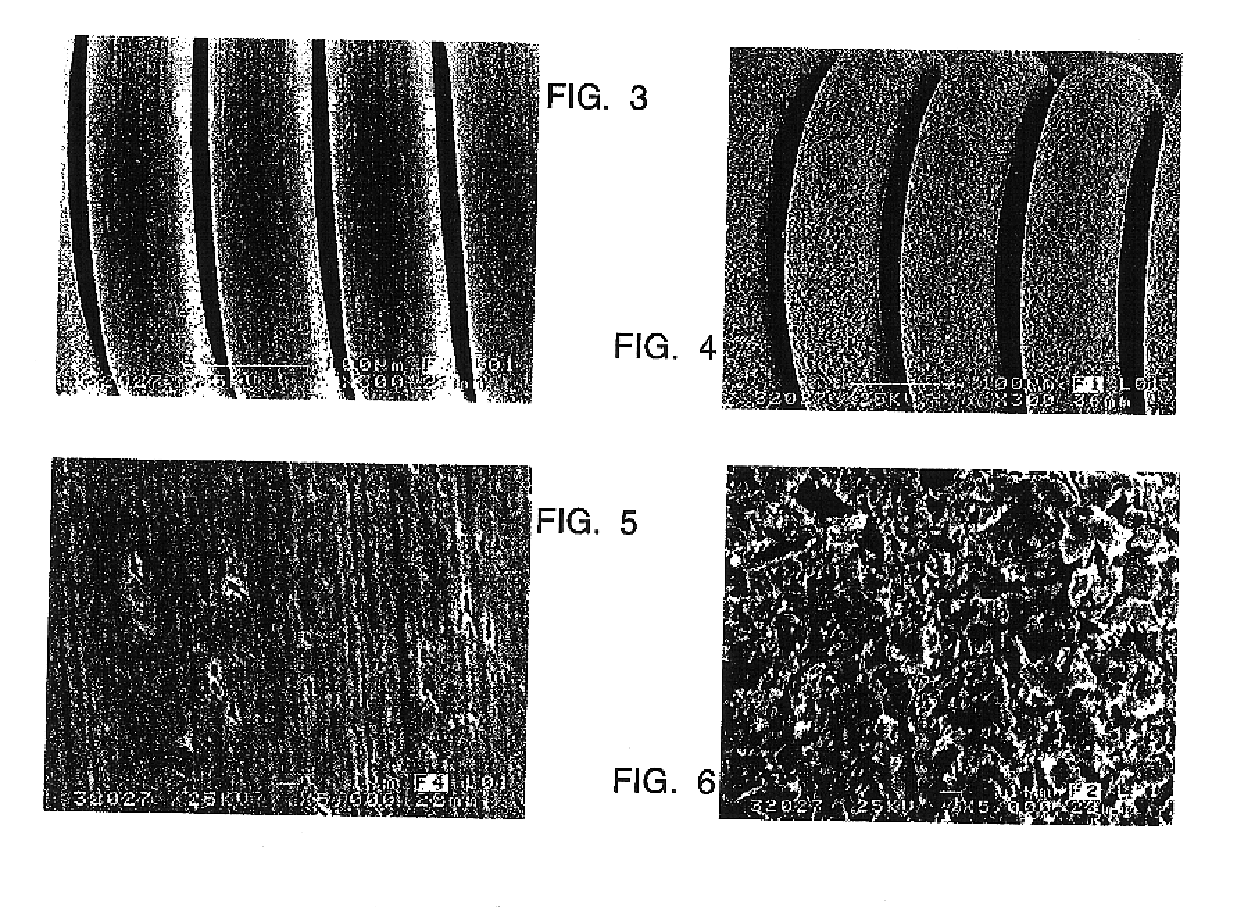

Occluding vasculature of a patient using embolic coil with improved platelet adhesion

InactiveUS6953468B2Improved platelet adhesionGood coagulationDilatorsTissue regenerationPlatinumRadiology

A method as provided for occluding the vasculature of a patient. The method comprises the steps of providing a plurality of embolic coils having a textured surface. The embolic coils are introduced into the patient's vasculature. In this manner, the textured surface provides improved platelet adhesion compared to a non-textured surface, to promote clotting. In the illustrative embodiment, the embolic coil comprises a platinum-tungsten alloy wire and the texturing is performed by abrasion or sandblasting to provide substantially uniform roughness comprising pockets having diameters of about 0.125 microns to about fifty microns and depths of about 0.25 microns to about twenty microns.

Owner:CODMAN & SHURTLEFF INC

Tungsten alloy composite plating coat material and manufacturing method thereof

InactiveCN101210305AImprove wear resistanceImprove corrosion resistanceMetallic material coating processesFiberMining industry

The invention relates to a tungsten alloy composite coating material and a manufacture method. The tungsten alloy composite coating material is a multi-phase composite structure material composed of a tungsten alloy and a large number of particles or fibers dispersed in the tungsten alloy. The tungsten alloy composite coating contains tungsten of 5 to 98wt% and particles or fibers of 0.05 to 80wt%, and the diameter of the particle or the fiber is 3nm to 5 micrometer. The coating has low internal stress, excellent normal-temperature and high-temperature hardness and abrasion resistance, excellent high-temperature oxidization resistance and excellent corrosion resistance. The tungsten alloy composite coating has important use in machinery industry, chemical and medicine industry, metallurgy industry, aerospace industry, weapons and ammunitions, petroleum exploitation, mining industry, electronic industry, etc, and is particularly suitable for the occasions with high-temperature strength and high corrosion resistance.

Owner:CHENGDU SHENJIA MACHINERY MFG +2

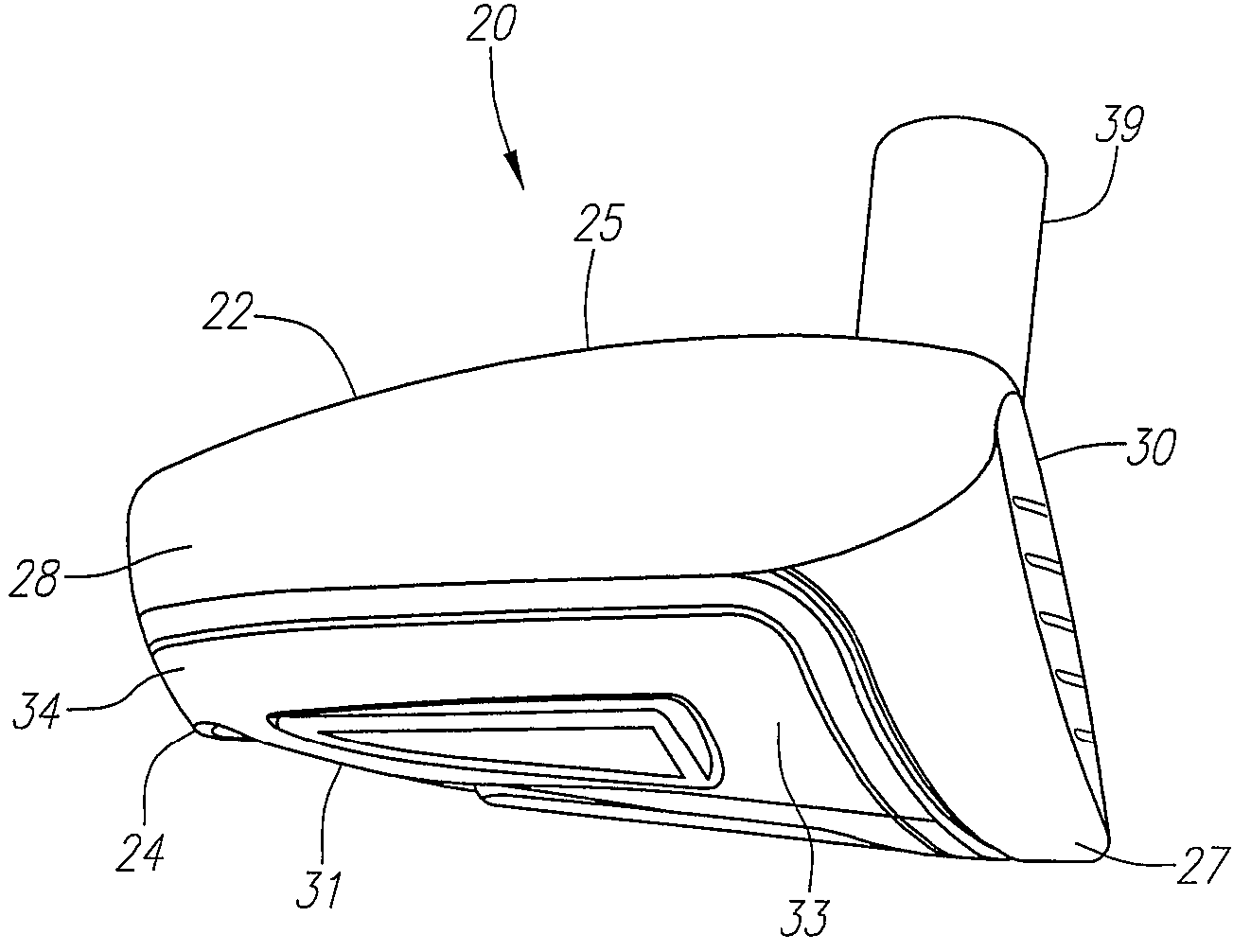

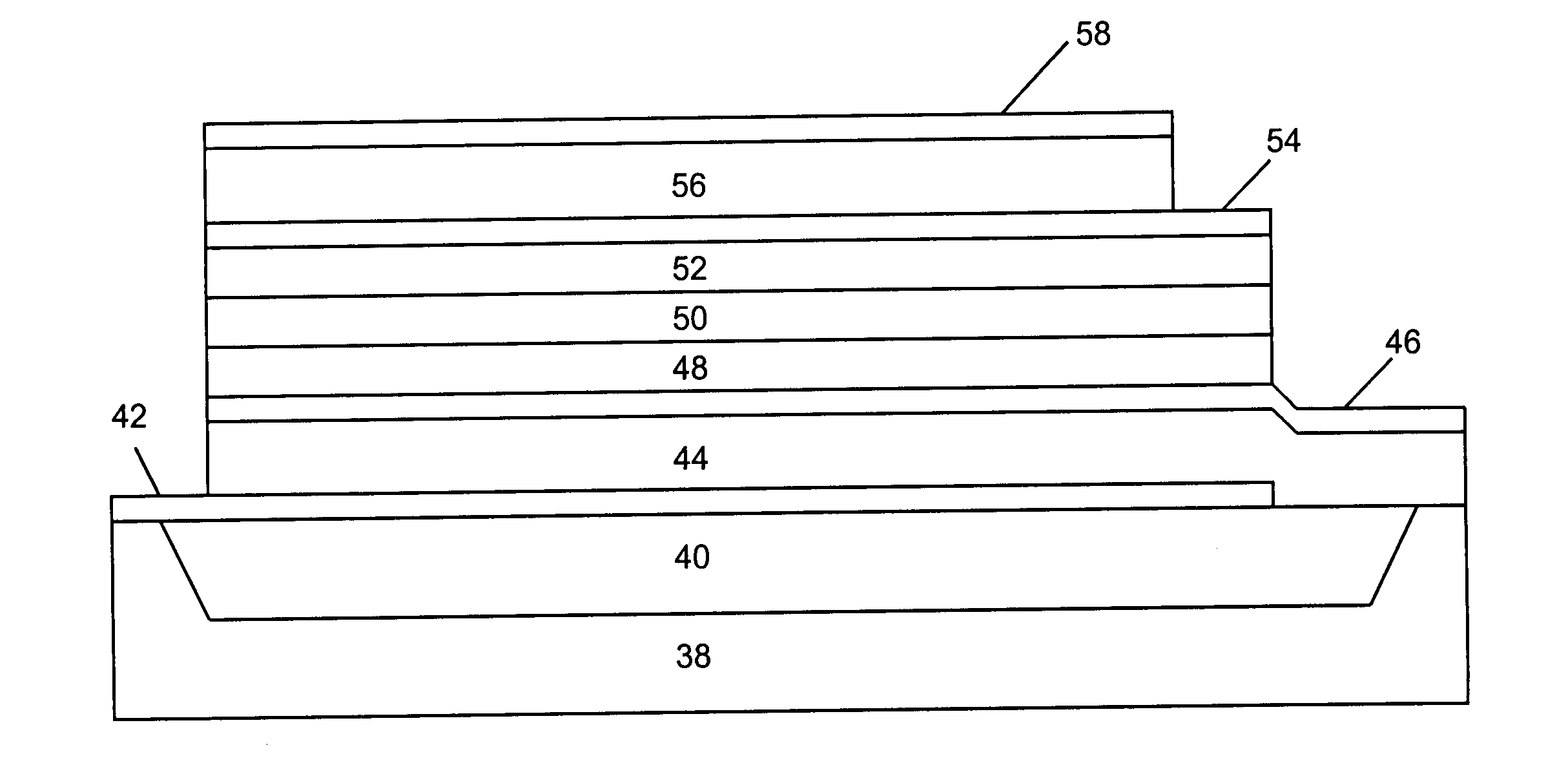

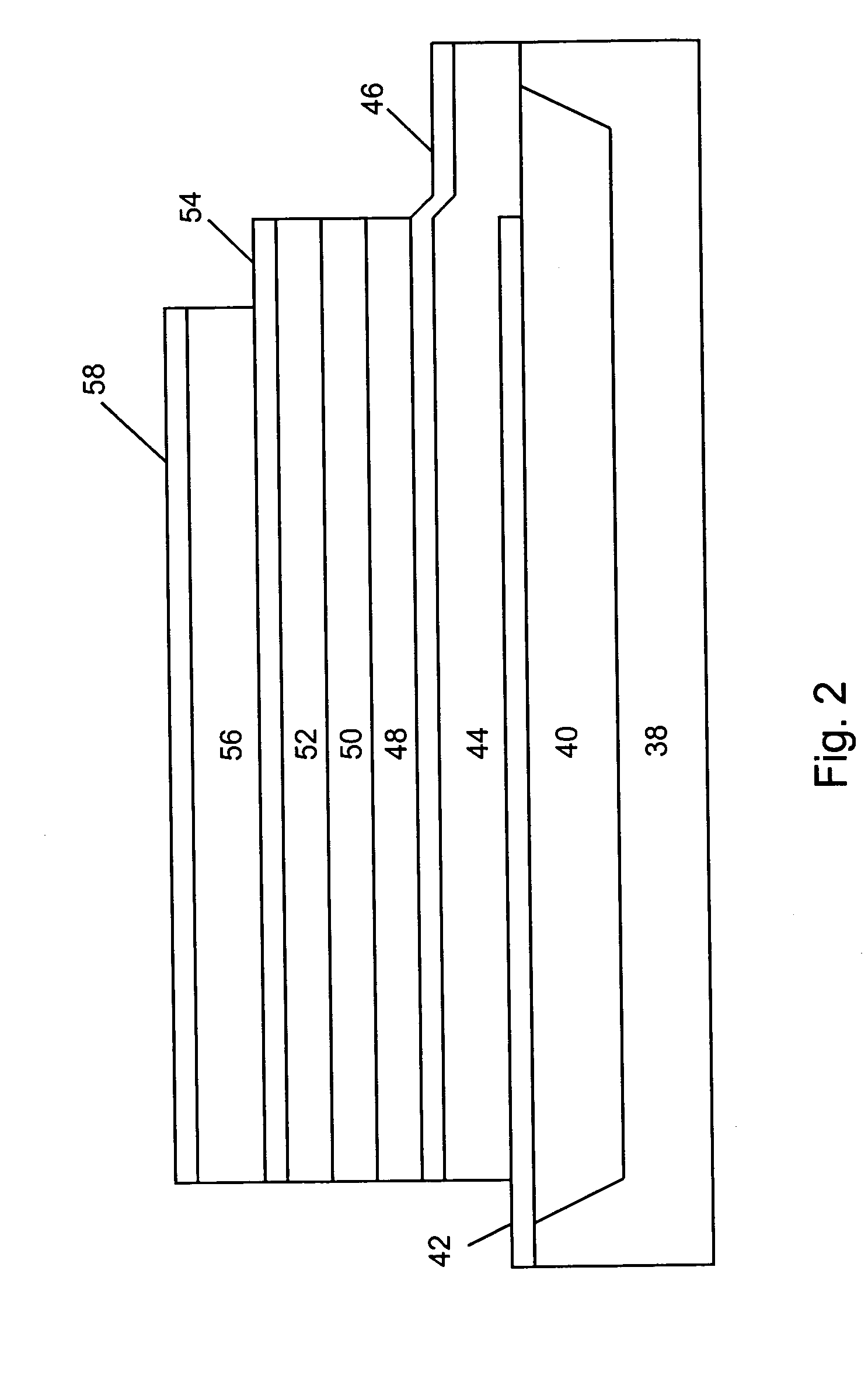

Golf club head with tungsten alloy sole component

A hybrid wood-type golf club head (20) with a main body (22) and a minor body (24) is disclosed herein. The main body (26) has a front portion (30), a crown portion (25), a partial toe portion (27), a partial heel portion (26), a partial rear portion (28) and a partial sole portion (29). The minor body (24) preferably has a sole wall (31), a partial toe wall (33), a partial heel wall (32) and a partial rear wall (34). The minor body (24) is preferably welded to the main body (22). The minor body (24) preferably has a mass ranging from 80 grams to 130 grams. The minor body (24) is preferably from 55 weight percent to 35 weight percent of the total mass of the wood-type golf club head (20).

Owner:TOPGOLF CALLAWAY BRANDS CORP

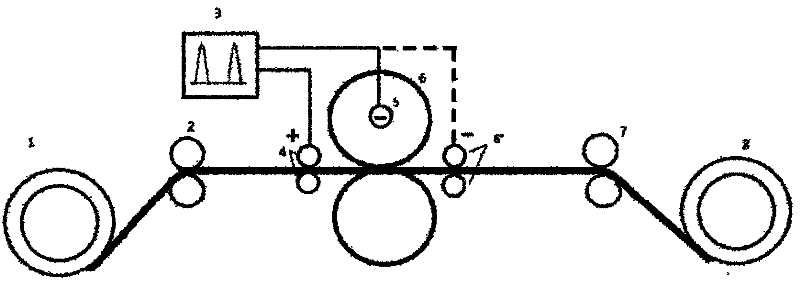

Method and system for rolling difficult-to-machine metal material by combining electro-plasticity with temperature plasticity

InactiveCN102172620ARaise the barrierInternal electron movement intensifiesTemperature control deviceMetal rolling arrangementsHigh energyCrystallographic defect

The invention relates to a method for rolling a difficult-to-machine metal material by combining electro-plasticity with temperature plasticity. The method comprises the following steps of: preheating a roller to the recovery temperature of a machined metal material and lower than the recrystallization temperature of the metal material; and inputting high-energy pulse current into a machining section of the moving metal material, performing electro-plastic treatment under the actions of the thermal effect and non-thermal effect of the metal material, and feeding the machining section into the preheated roller for rolling by combining electro-plasticity with temperature plasticity. In the rolling process, electro-plasticity and temperature plasticity are combined and unbalanced kinetic energy produced by the material due to the rise of atomic potential energy and strong electric stimulation of pulse current under heating condition is fully utilized, so that movement of crystal defects such as diffusion, dislocation and the like of atoms is facilitated, the internal microstructure of the metal material is improved, a tissue which is beneficial to enhancing of intensity and toughness (plasticity) is formed, and the plasticity of the material at low temperature is enhanced. The method is suitable for rolling difficult-to-machine metal materials such as magnesium alloys, nickel-titanium alloys, tungsten alloys and the like.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

Probe needle material, probe needle and probe card each using the same, and inspection process

ActiveUS20100194415A1Maintain contact stabilityNot abraded heavilyElectrical measurement instrument detailsElectrical testingProbe cardHafnium

Disclosed is a probe needle material used for producing a probe needle which is used in contact with an inspection object to inspect electrical characteristics of the inspection object, comprising not less than 0.1% by volume but not more than 3.5% by volume of at least one compound selected from the group consisting of titanium boride, zirconium boride, hafnium boride, niobium boride, tantalum boride, chromium boride, titanium carbide, zirconium carbide, hafnium carbide, vanadium carbide, niobium carbide, tantalum carbide, zirconium oxide, hafnium oxide and chromium oxide and the balance of a tungsten alloy mainly consisting of tungsten.

Owner:KK TOSHIBA +1

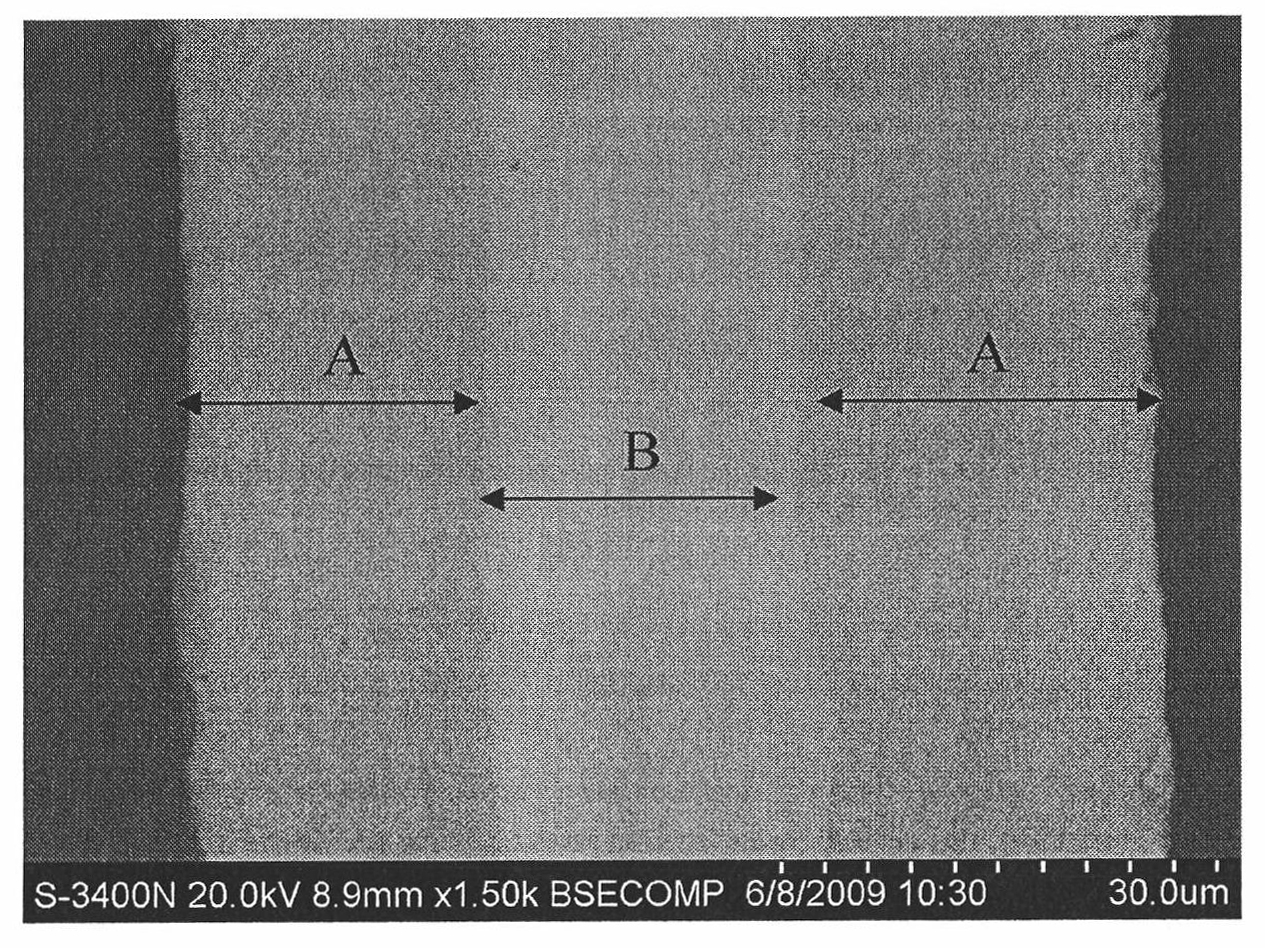

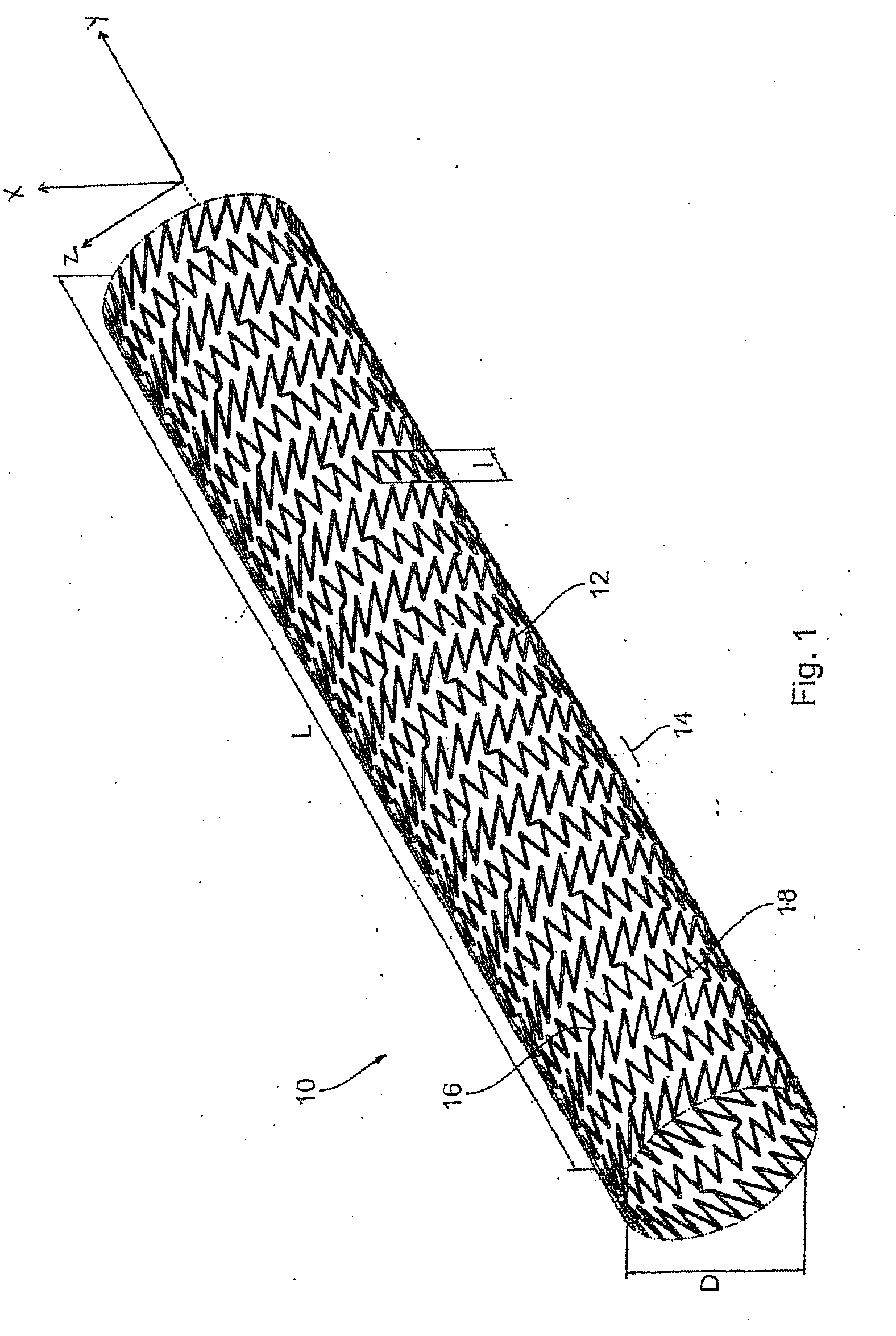

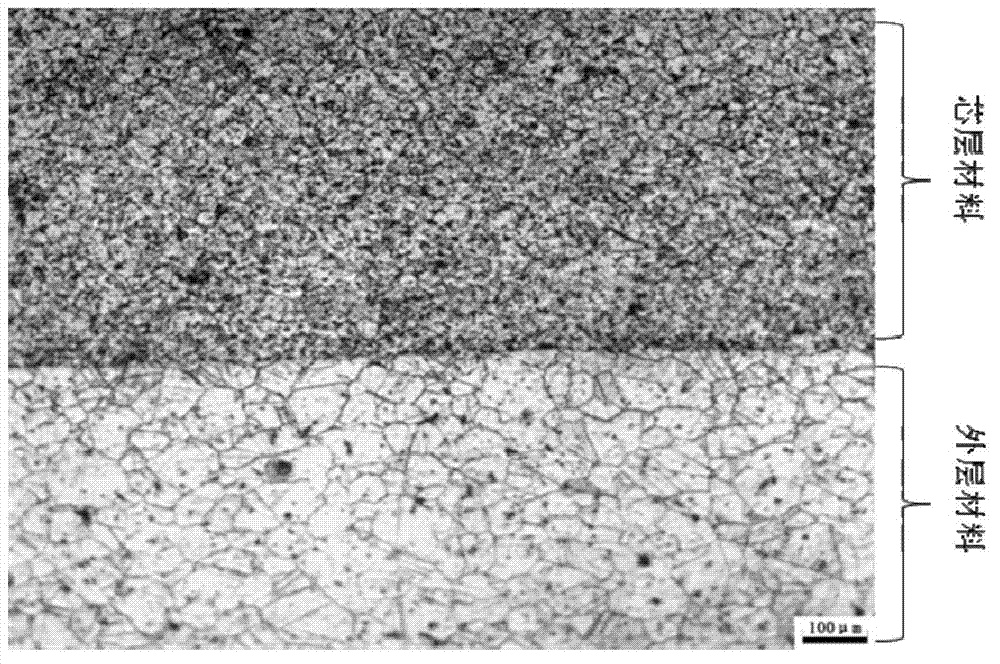

Tungsten titanium target material with high purity and high tungsten-rich phase, and preparation method thereof

ActiveCN101748365AUniform densityHigh strengthVacuum evaporation coatingSputtering coatingHigh densityRefractory

The invention relates to a refractory alloy tungsten titanium target material and a preparation method thereof, in particular to a tungsten titanium target material with high purity and high content of tungsten-rich phase, and a hot-pressing preparation method thereof, which belongs to the technical field of refractory alloy target materials. The method prepares high-density tungsten alloy targetmaterial by taking high-purity W powder and Ti powder, as well as high-purity Mo, Cr, Ta, Nb and other additive metal powder as raw materials and adopting a high-temperature high-pressure hot-pressing molding process, wherein the relative density of the target material reaches 95 to 99 percent, and the content of tungsten-rich phase reaches 80 to 93 percent. Relative to the prior art, the method adds part of high-purity Nb, Mo, Cr, Ta and other metal powder while mixing materials so as to stabilize the tungsten-rich phase in alloy, increase the content of the tungsten-rich phase in the alloy and improve the using quality of the target material.

Owner:有研资源环境技术研究院(北京)有限公司

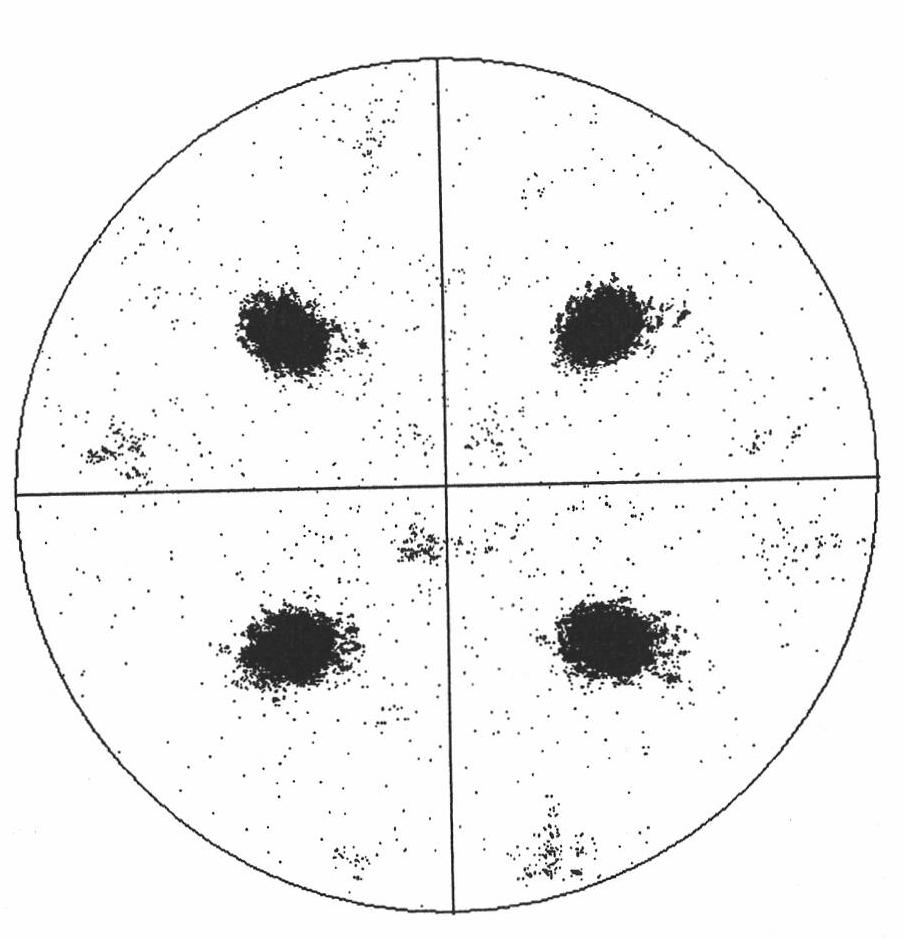

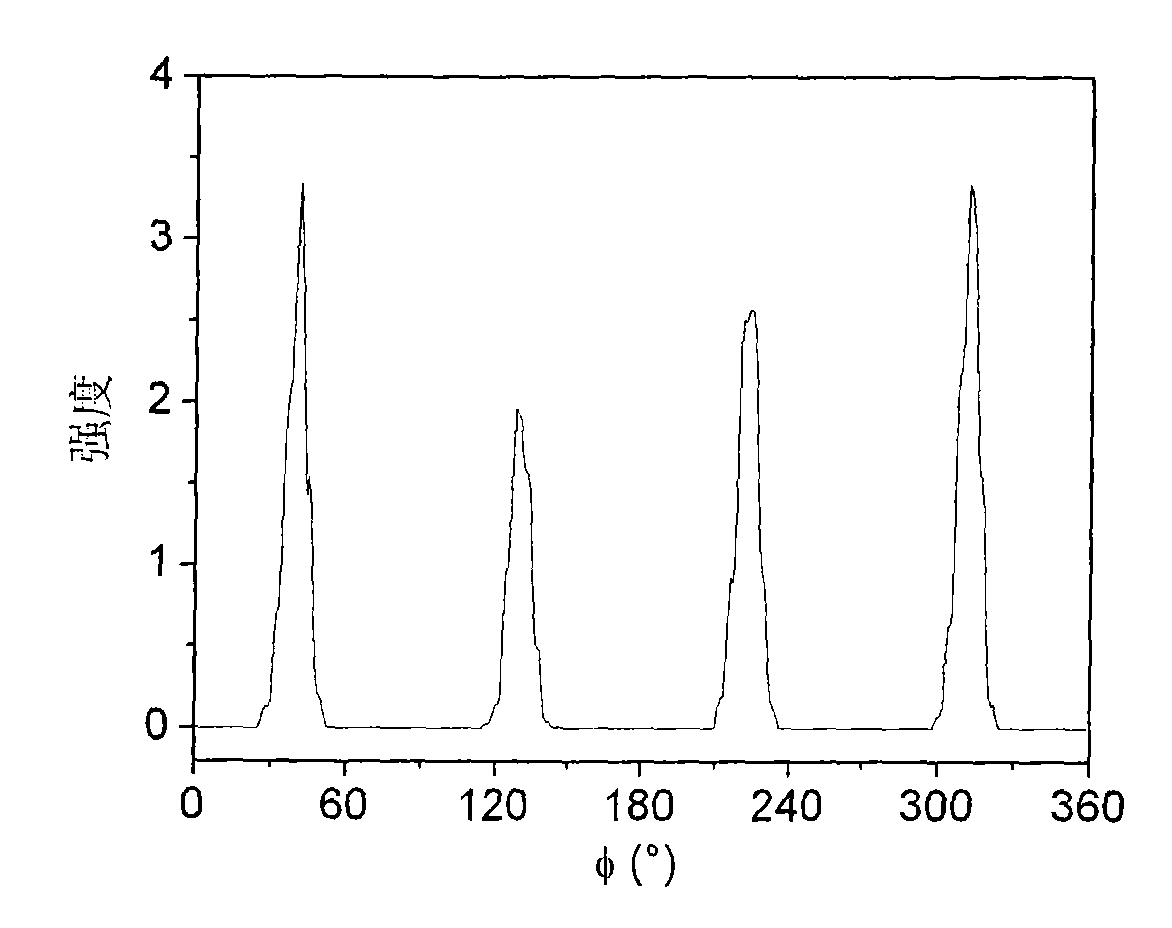

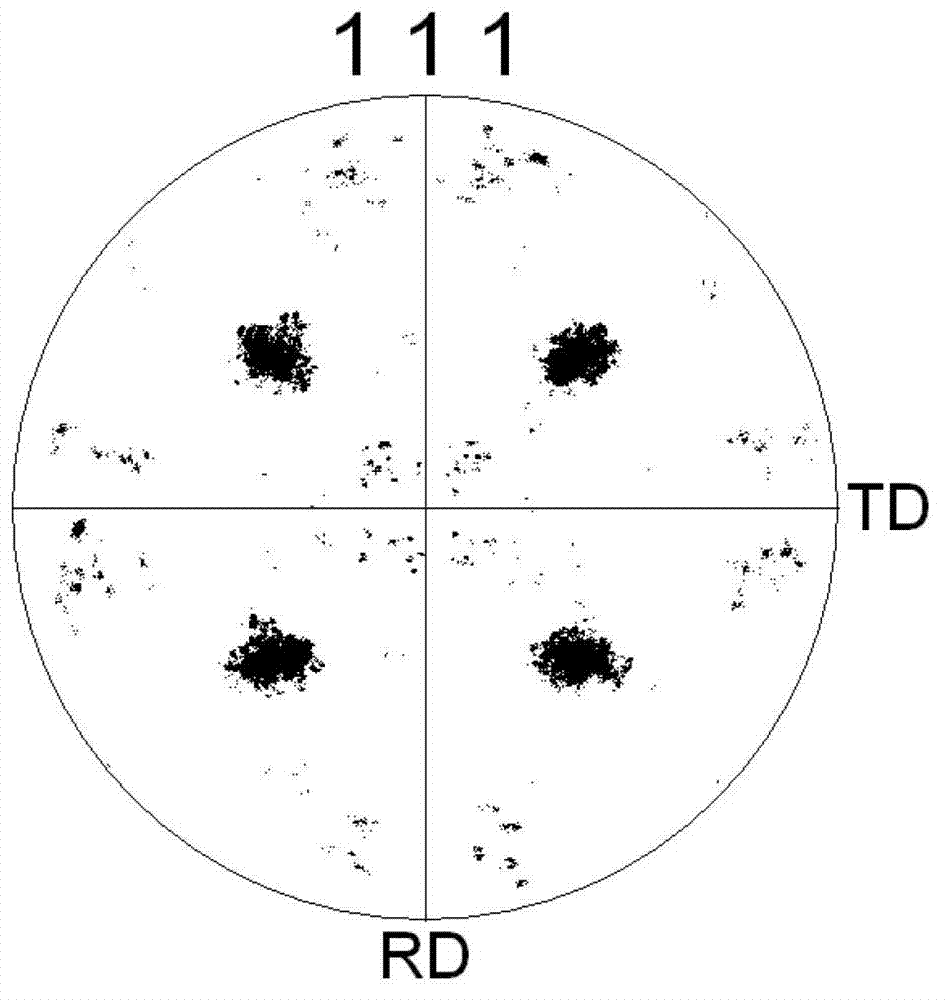

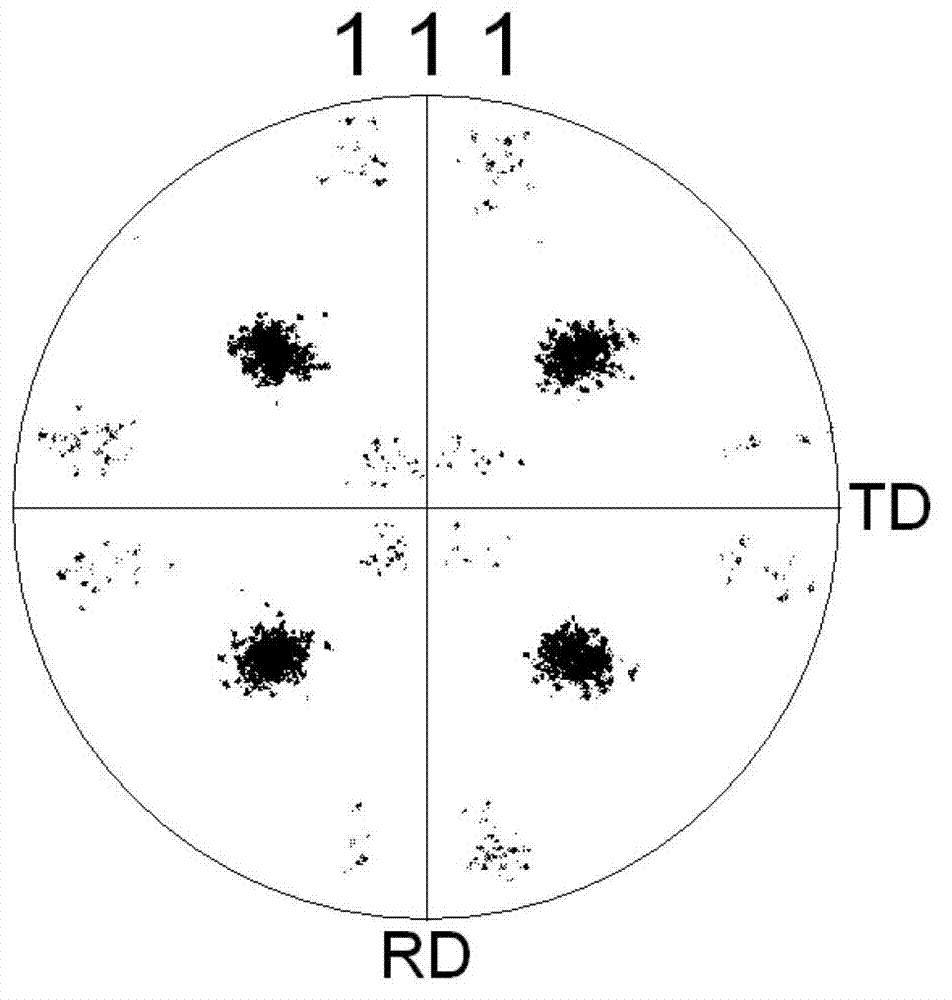

Non-magnetic cube texture Cu-based alloy composite base band and preparation method thereof

InactiveCN101786352AHigh mechanical strengthNo Magnetic GuaranteeMetal rolling arrangementsMetal layered productsSurface layerMold filling

The invention discloses a non-magnetic cube texture Cu-based alloy composite base band. The non-magnetic cube texture Cu-based alloy composite base band is prepared by compositing surface layers and a core layer and has the structure of surface layer, core layer and surface layer, wherein each surface layer is copper-nickel alloy in which the weight percentage of nickel is less than 50 percent; and the core layer is nickel-tungsten alloy in which the atomic percentage of tungsten is between 9 and 12 percent. A preparation method by using powder metallurgy comprises the following steps: (1) initial powder mixing and mold filling; (2) compressing and sintering of a composite green compact; (3) deforming and rolling of the sintered composite bullet; and (4) recrystallizing heat treatment for a cold rolling base band. The preparation method improves the mechanical strength of the whole base band and simultaneously ensures the non-magnetic performance of the whole base band; and the composite base band has high yield strength.

Owner:BEIJING UNIV OF TECH

Preparation method of nano yttrium oxide dispersion strengthening tungsten alloy

The invention provides a preparation method of a nano yttrium oxide dispersion strengthening tungsten alloy and belongs to the field of the manufacturing of powder used for powder metallurgy. The preparation method mainly comprises the following steps of: dissolving yttrium nitrite (Y(NO3)3.6H2O) in ethyl alcohol, and carrying out ball milling and mixing on yttrium nitrite and ammonium paratungstate (APT); after wet powder is dried by distillation, calcining for 20-150 minutes at the temperature of 400-900 DEG C to obtain nano yttrium oxide dispersion strengthening tungsten powder; then reducing by H2 for 30-150 minutes at the temperature of 600-1000 DEG C to prepare the nano yttrium oxide dispersion strengthening tungsten powder; and mixing 0.1-1% of Ni as an activated sintering agent, and carrying out compression moulding and H2 gas shield sintering or vacuum or HIP (hot isostatic pressing) sintering, so that the nano yttrium oxide dispersion strengthening tungsten alloy can be prepared. The preparation method provided by the invention has the advantages that the density can be 18.28-19.2g / cm<3>, and a yttrium oxide dispersed phase is fine and is uniformly distributed in tungsten crystal particles.

Owner:UNIV OF SCI & TECH BEIJING

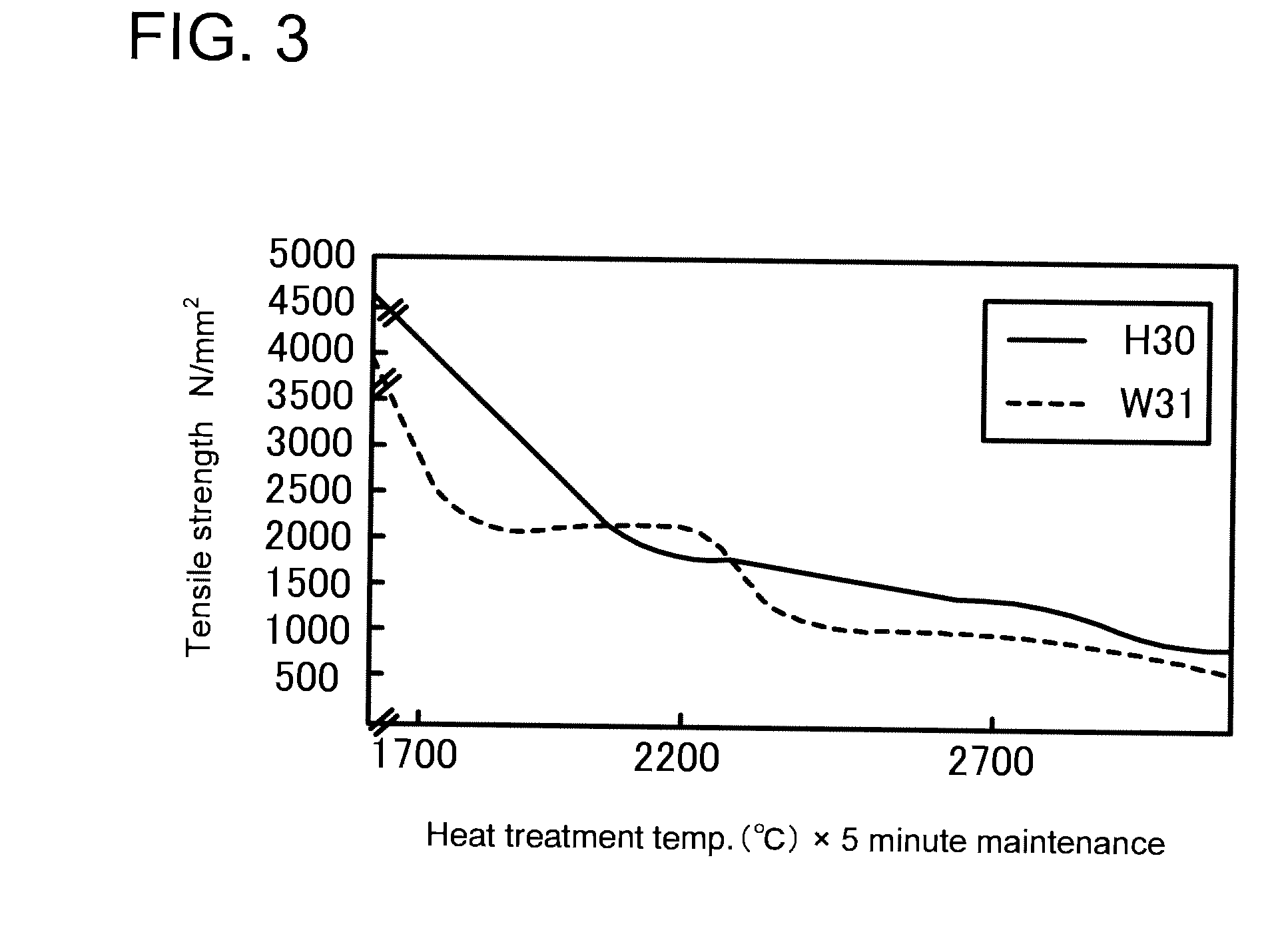

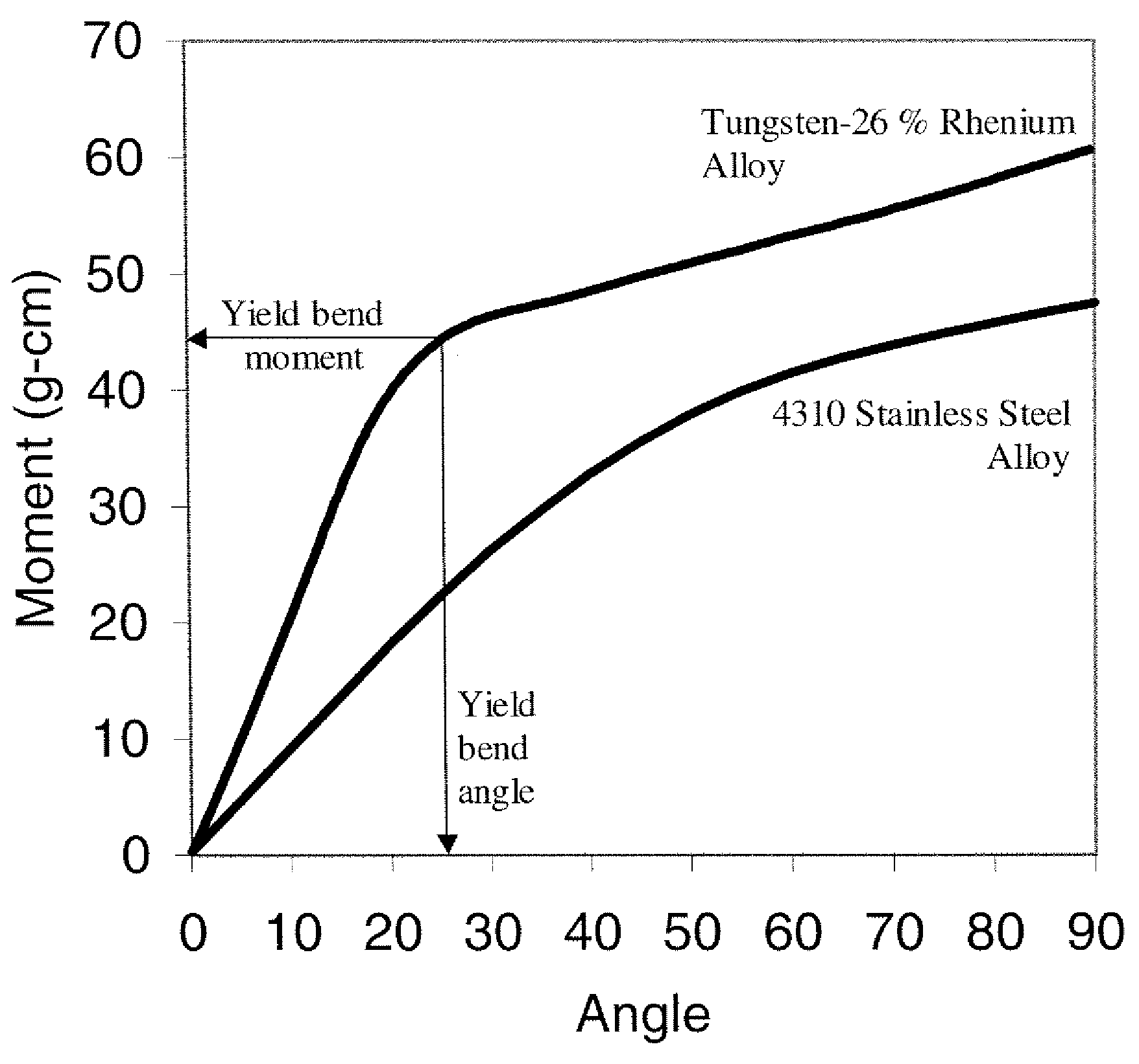

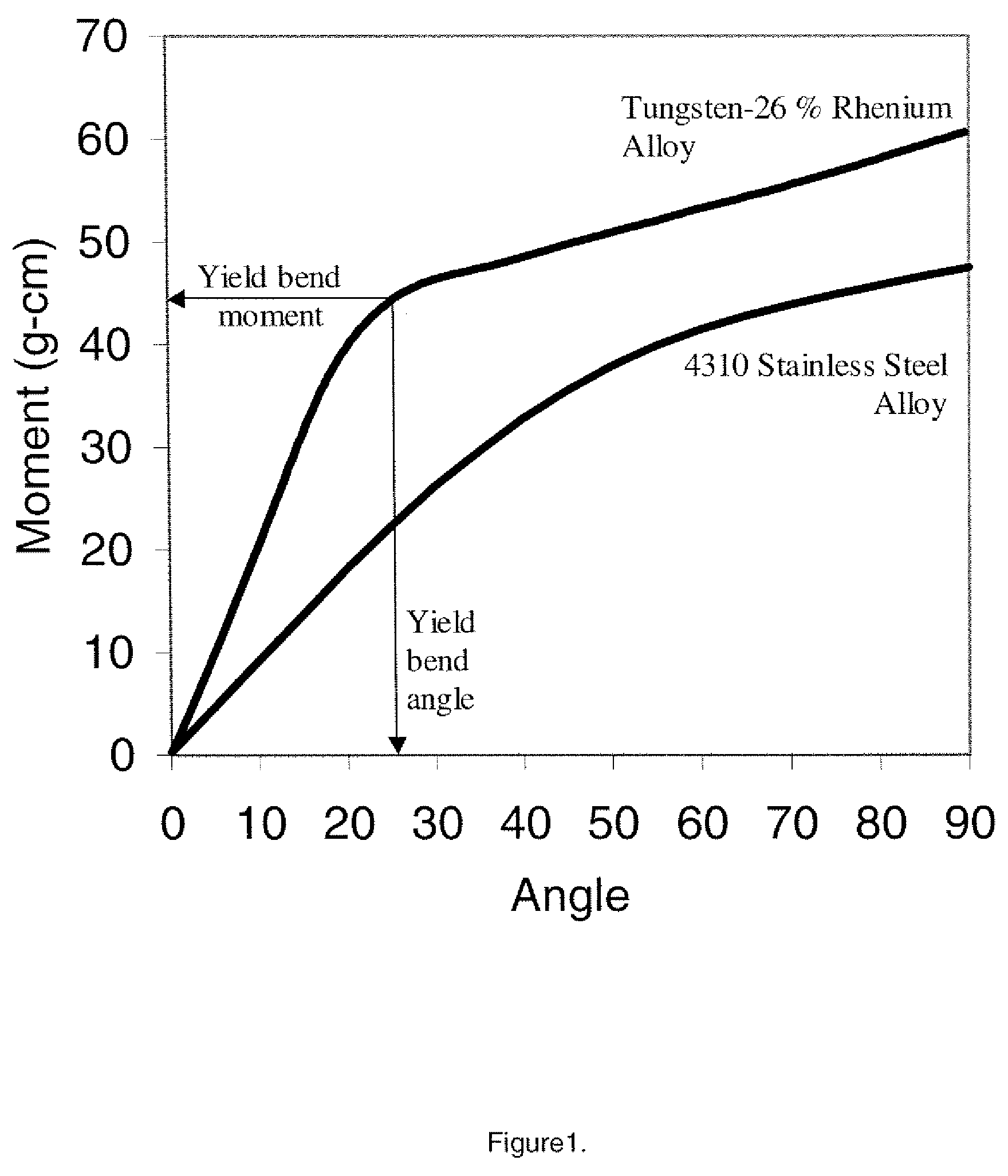

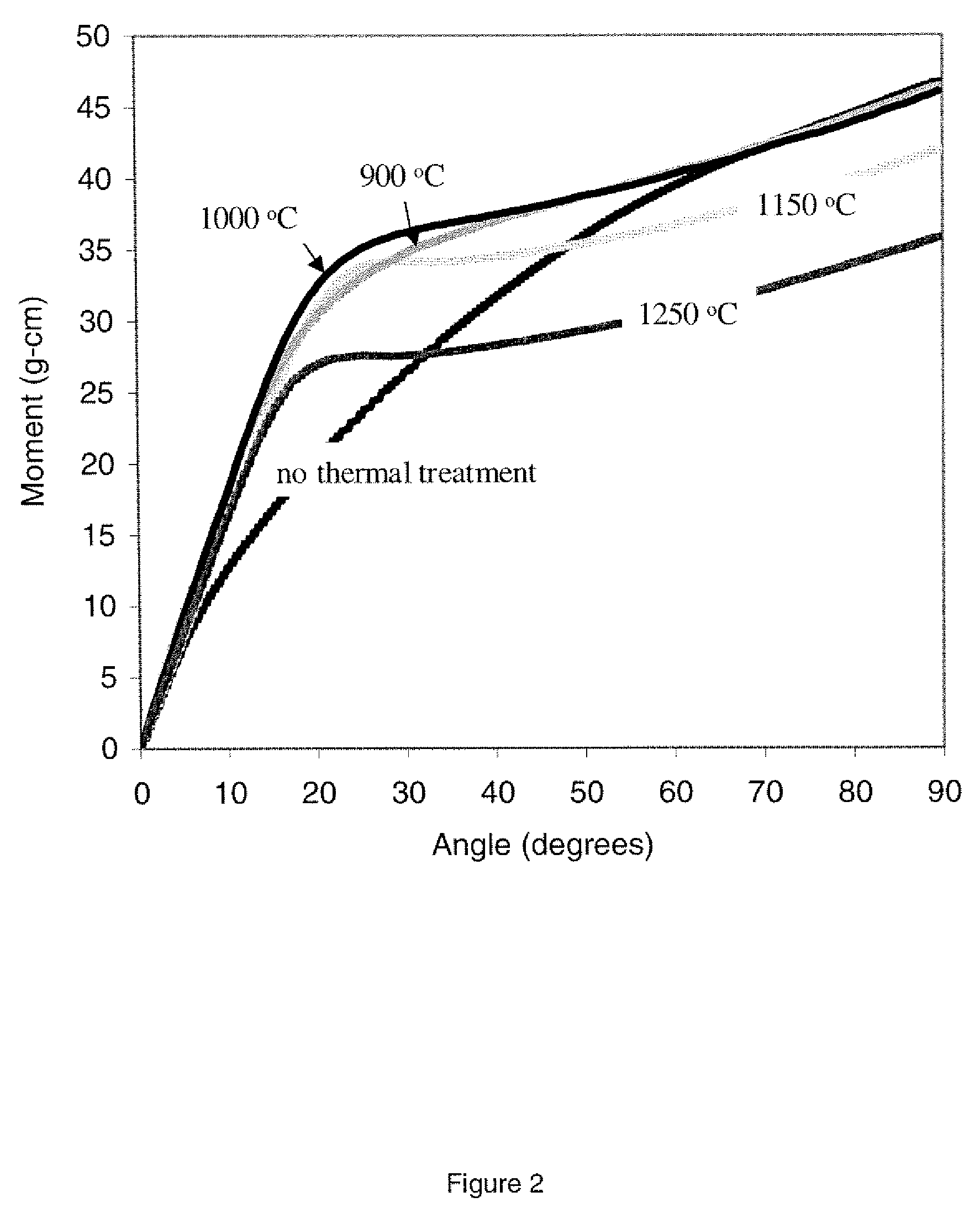

Tungsten alloy suture needles

A method for making a curved tungsten alloy suture needle comprising the step of heating tungsten alloy needle blanks or a tungsten alloy suture needle to a temperature below the recrystallization temperature of the alloy. The tungsten alloy suture needles described herein have a desirable combination of stiffness, strength, ductility, and surface color.

Owner:ETHICON INC

Specially configured and surface modified medical device with certain design features that utilize the intrinsic properties of tungsten, zirconium, tantalum and/or niobium

InactiveUS20100305682A1Good physical propertiesIncrease success rateStentsSurgeryNiobiumSpecial geometry

Owner:MICO INNOVATIONS

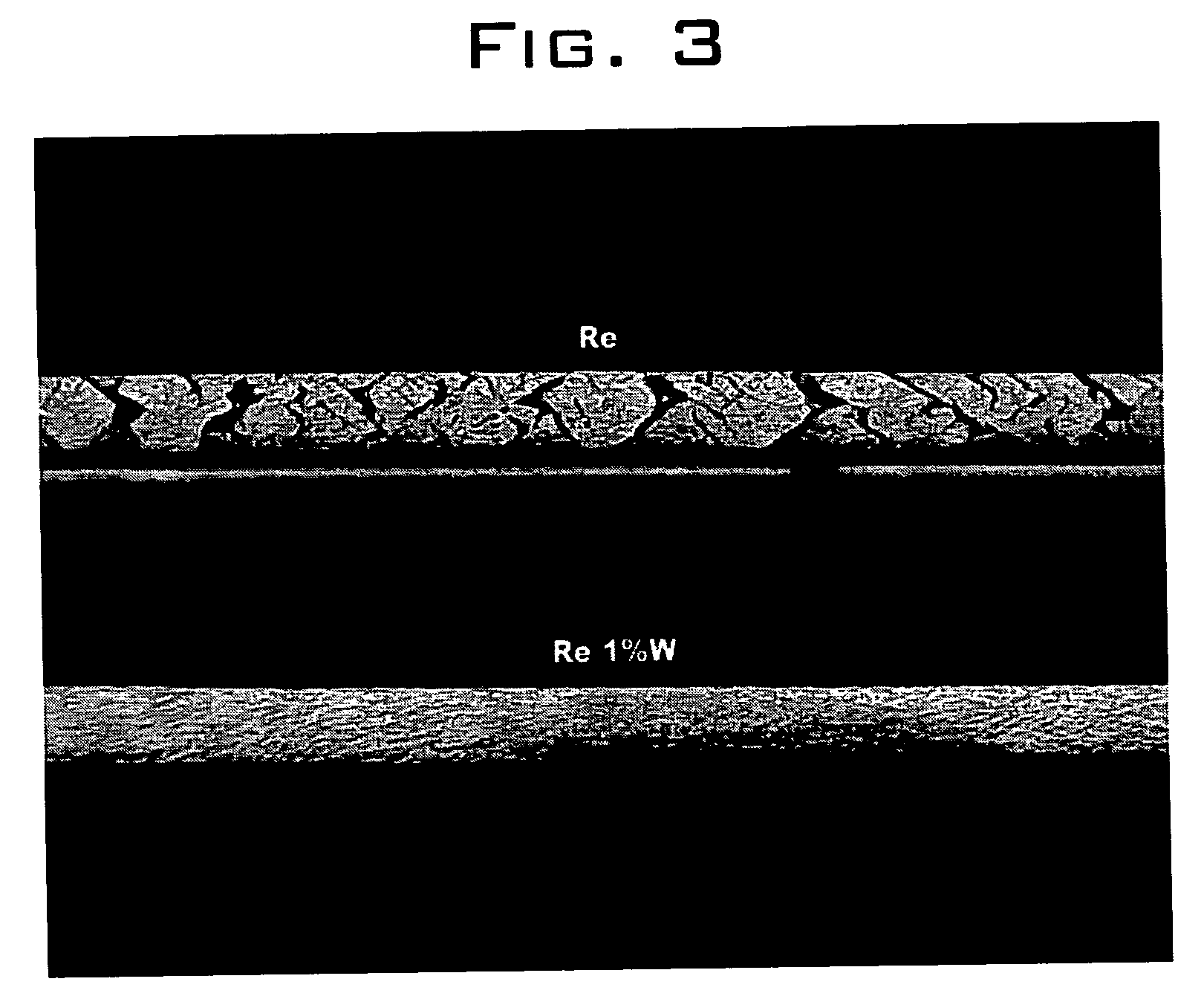

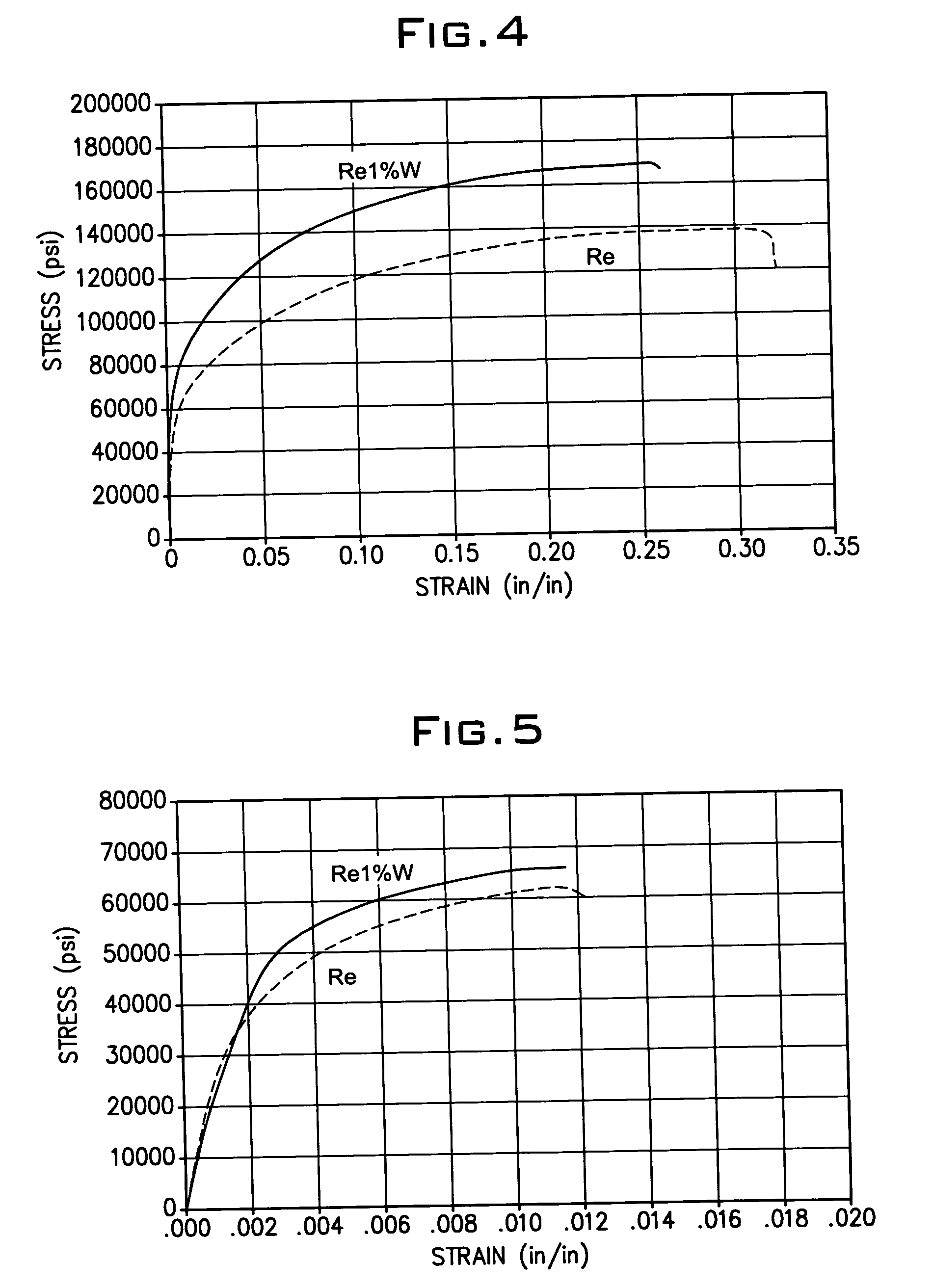

Binary rhenium alloys

InactiveUS20050238522A1Improve mechanical propertiesLoss in ductilityTransportation and packagingMetal-working apparatusRheniumMetal powder

Rhenium-tungsten alloys including rhenium and from about 0.025% to less than about 10% by weight tungsten. The rhenium-tungsten alloys are formed by a process that includes coating rhenium metal powders with a liquid including a tungsten compound, drying the coated rhenium powder, compressing the dried coated powder to form a compact, and then sintering the compact to form the rhenium-tungsten alloy. The rhenium-tungsten alloys according to the invention exhibit mechanical properties that are superior to high-purity rhenium metal without a loss in ductility.

Owner:RHENIUM ALLOYS

Low-magnetism or magnetism-free and high-strength Ni-W alloy composite base band and preparation method thereof

ActiveCN102756512AAchieve associativityImprove bindingMetal layered productsTungsten atomAlloy composite

The invention provides a low-magnetism or magnetism-free and high-strength Ni-W alloy composite base band and a preparation method thereof, belonging to the technical field of a high-temperature super-conductive coating conductor texture metal base band. According to the Ni-W alloy composite base band disclosed by the invention, a surface layer is a Ni-W alloy with high W content and the atom percentage content of the W is 7.5-9.3%; and a core layer is a nickel-tungsten alloy with the tungsten atom percentage content of 9.3-12%. The preparation method comprises the following steps of sequentially placing a high-W-content Ni-W alloy blank ingot (A) which is prepared by a smelting method and has the atom percentage content of the W of 7.5-9.3%, and Ni-W mixed powder (B) with the atom percentage content of the W of 9.3-12% into a mould according to the sequence of A-B-A; utilizing a discharge plasma sintering technology to sinter to obtain a composite blank ingot; then, carrying out hot rolling and carrying out cold rolling treatment on a hot rolling blank ingot; and then, crystallizing and annealing, carrying out cold rolling to obtain the composite base band, and re-crystallizing and annealing the base band under the protection of Ar / H2 mixed gas to obtain the Ni-W alloy composite base band. The composite base band has the advantages of high strength, low magnetism or no magnetism and strong cubic structure, and can further meet the requirement of further improving the performance of an YBCO (Yttrium Barium Copper Oxide) coating conductor.

Owner:深创超导(深圳)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com