Patents

Literature

2098results about How to "Uniform density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

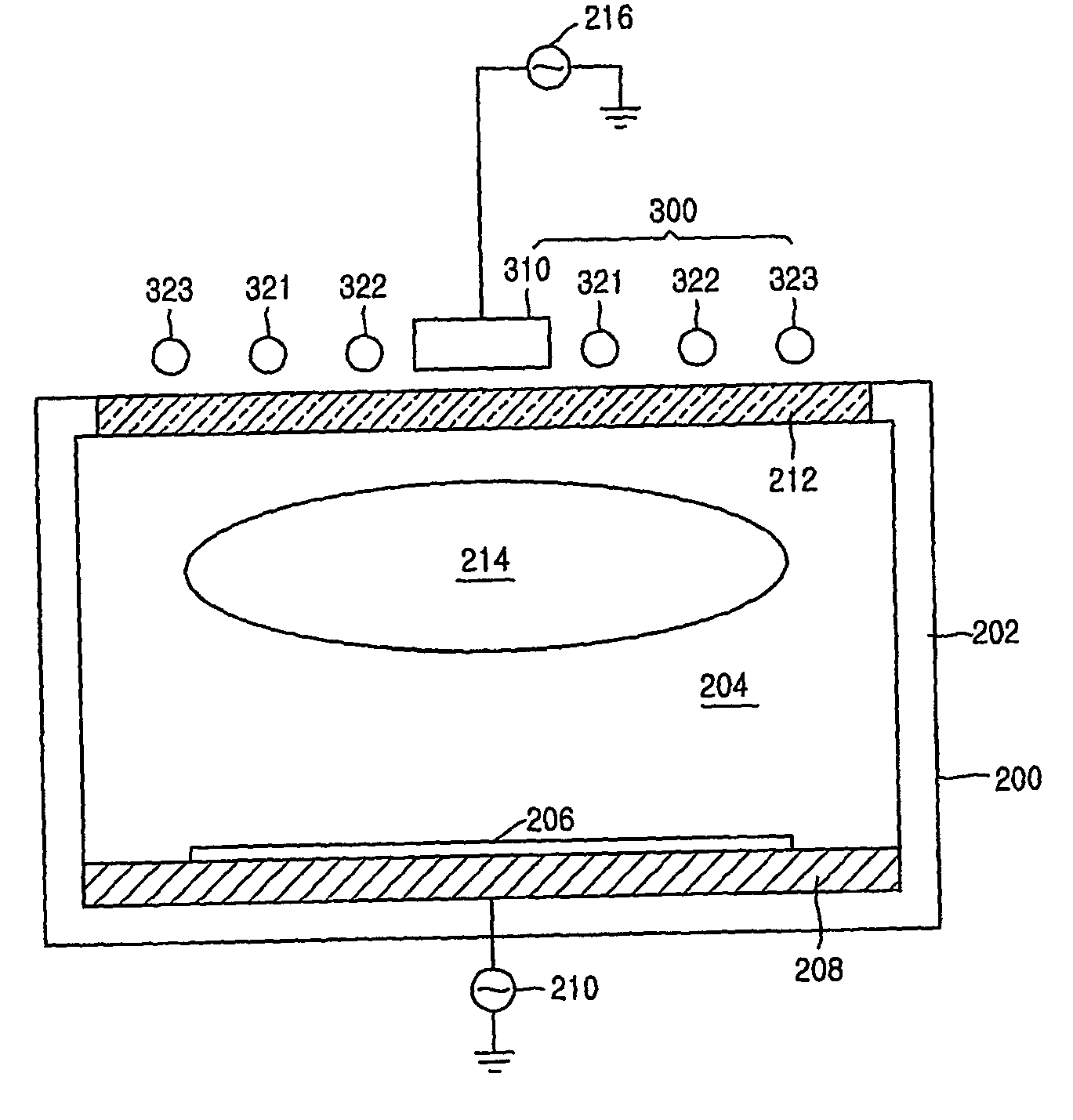

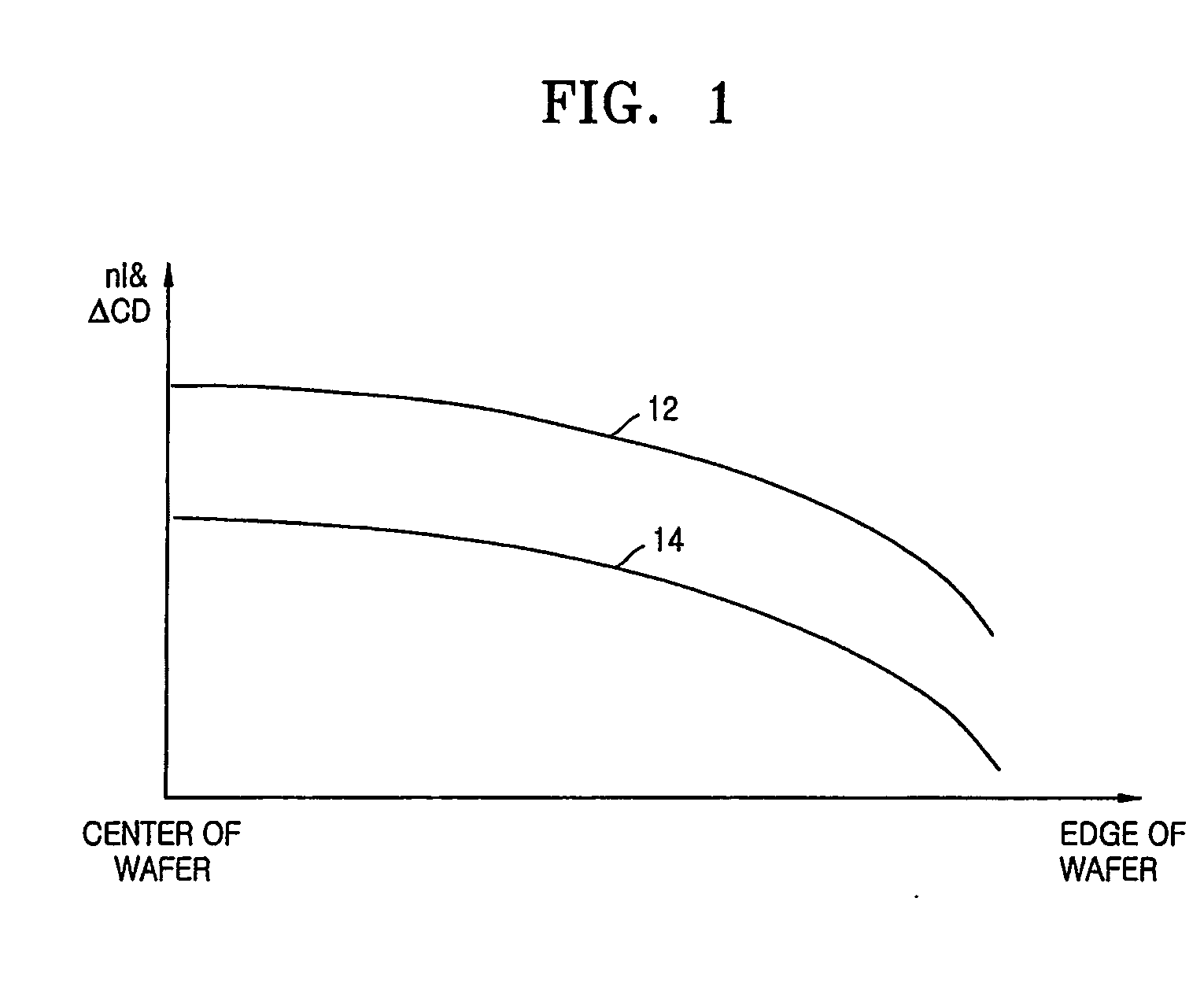

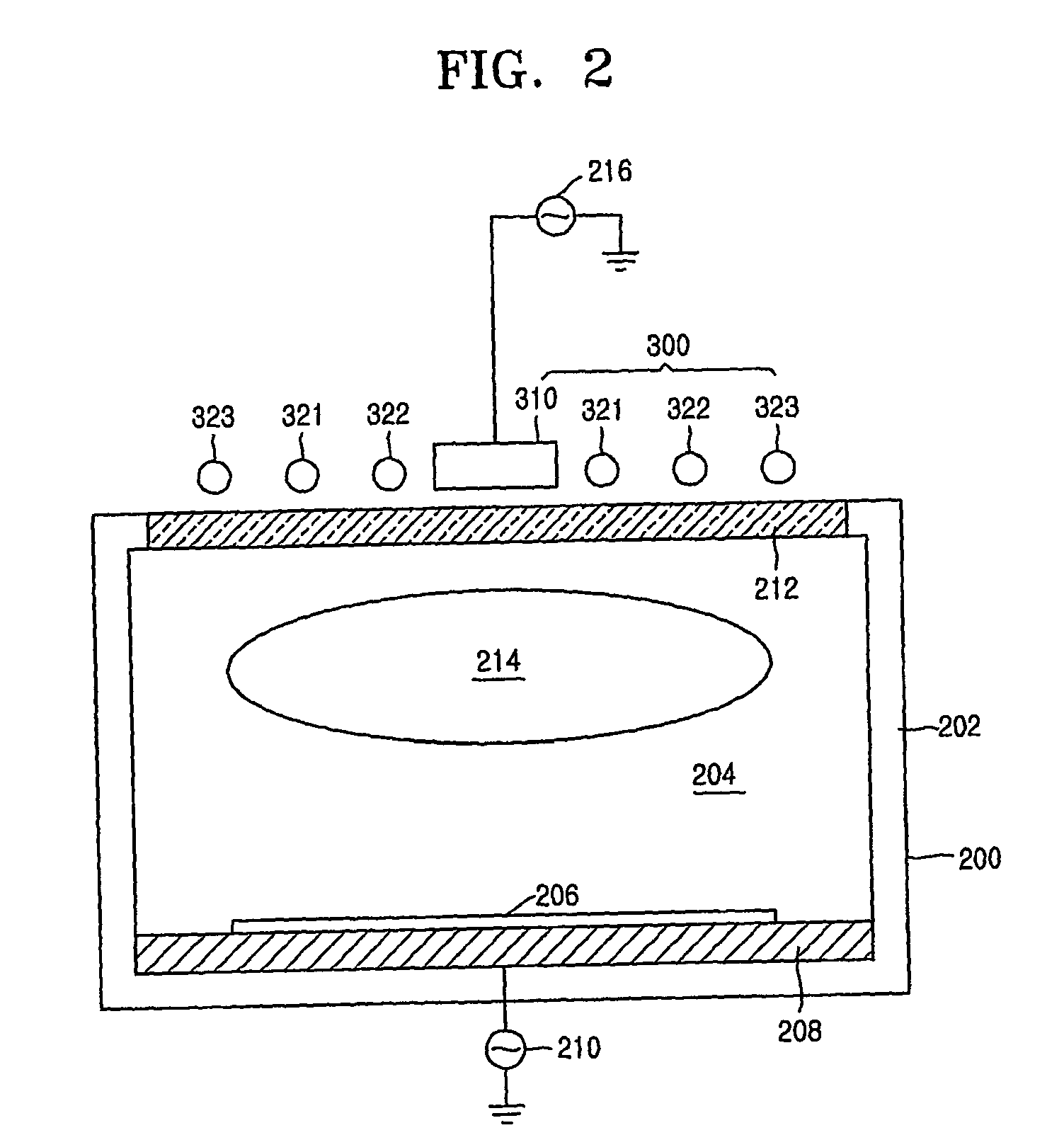

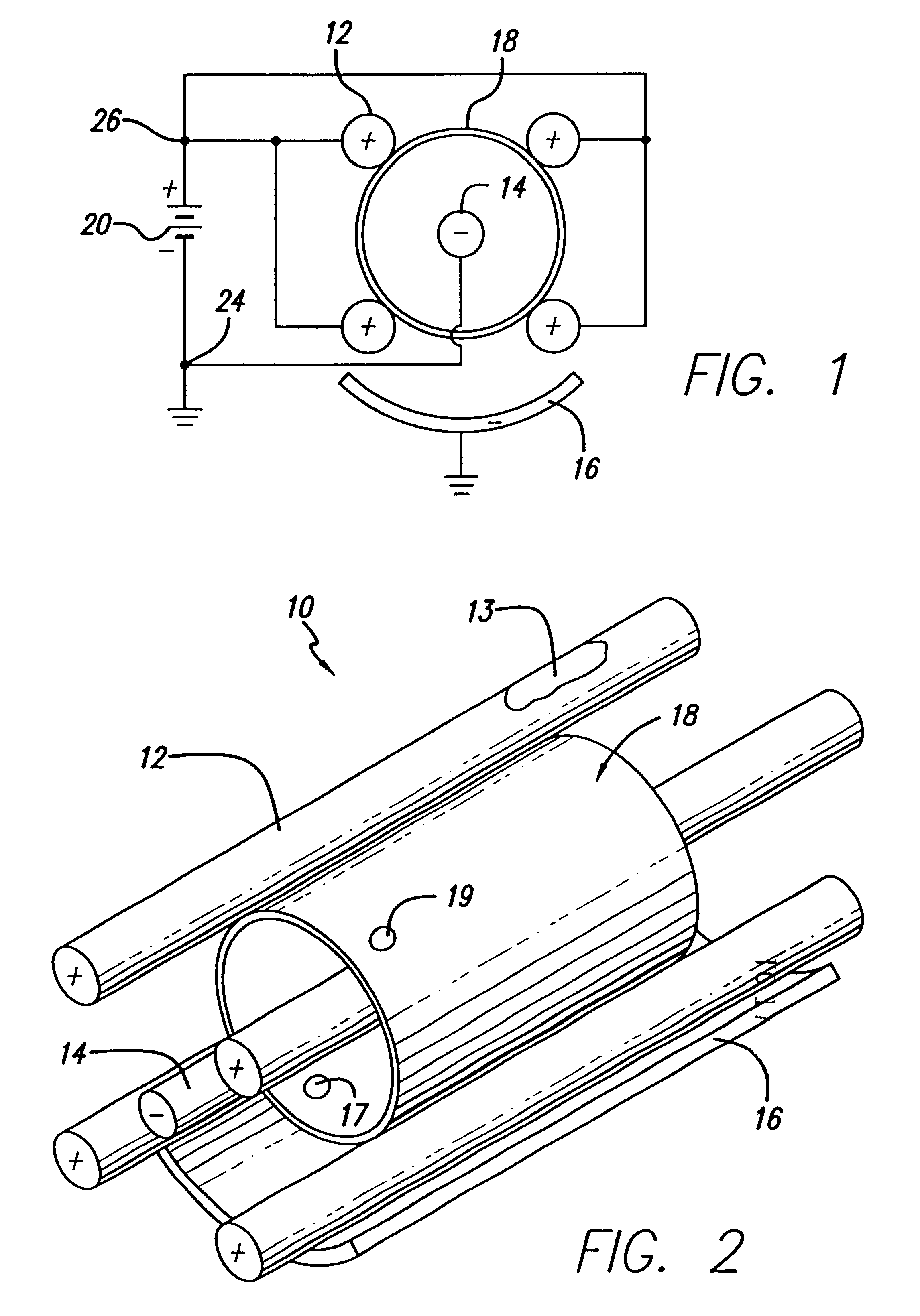

Adaptive plasma source for generating uniform plasma

InactiveUS20070084405A1Uniform plasma densityReduces plasma densityElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringRadio frequency

There is provided an adaptive plasma source, which is arranged at an upper portion of a reaction chamber having a reaction space to form plasma and is supplied with RF (radio frequency) power from an external RF power source to form an electric field inside the reaction space. The adaptive plasma source includes a conductive bushing and at least two unit coils. The bushing is coupled to the RF power source and arranged at an upper central portion of the reaction chamber. The at least two unit coils are branched from the bushing and surround the bushing in a spiral shape and have the number of turns equal to a×(b / m), where a and b are positive integers and m is the number of the unit coils.

Owner:ADAPTIVE PLASMA TECH

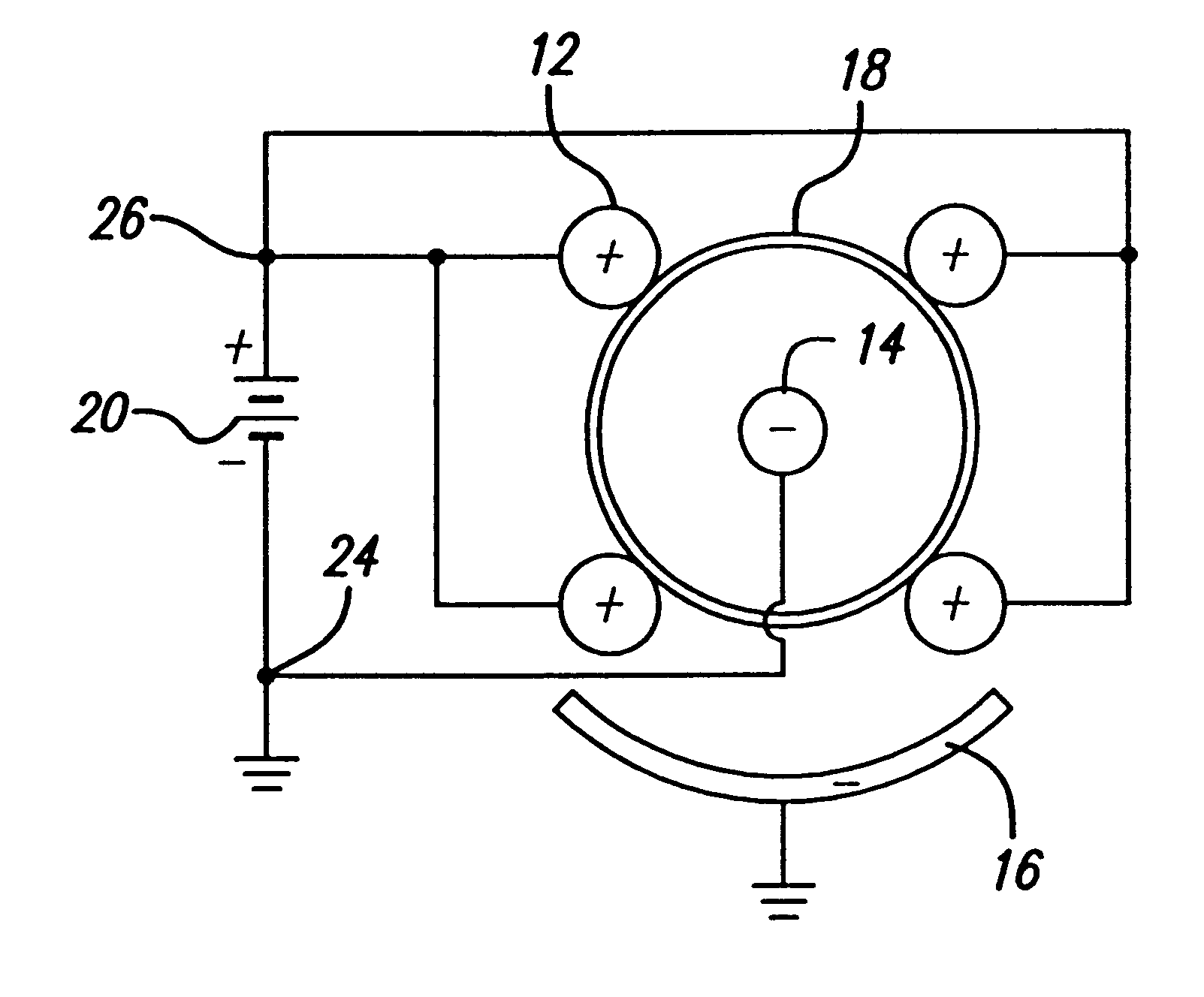

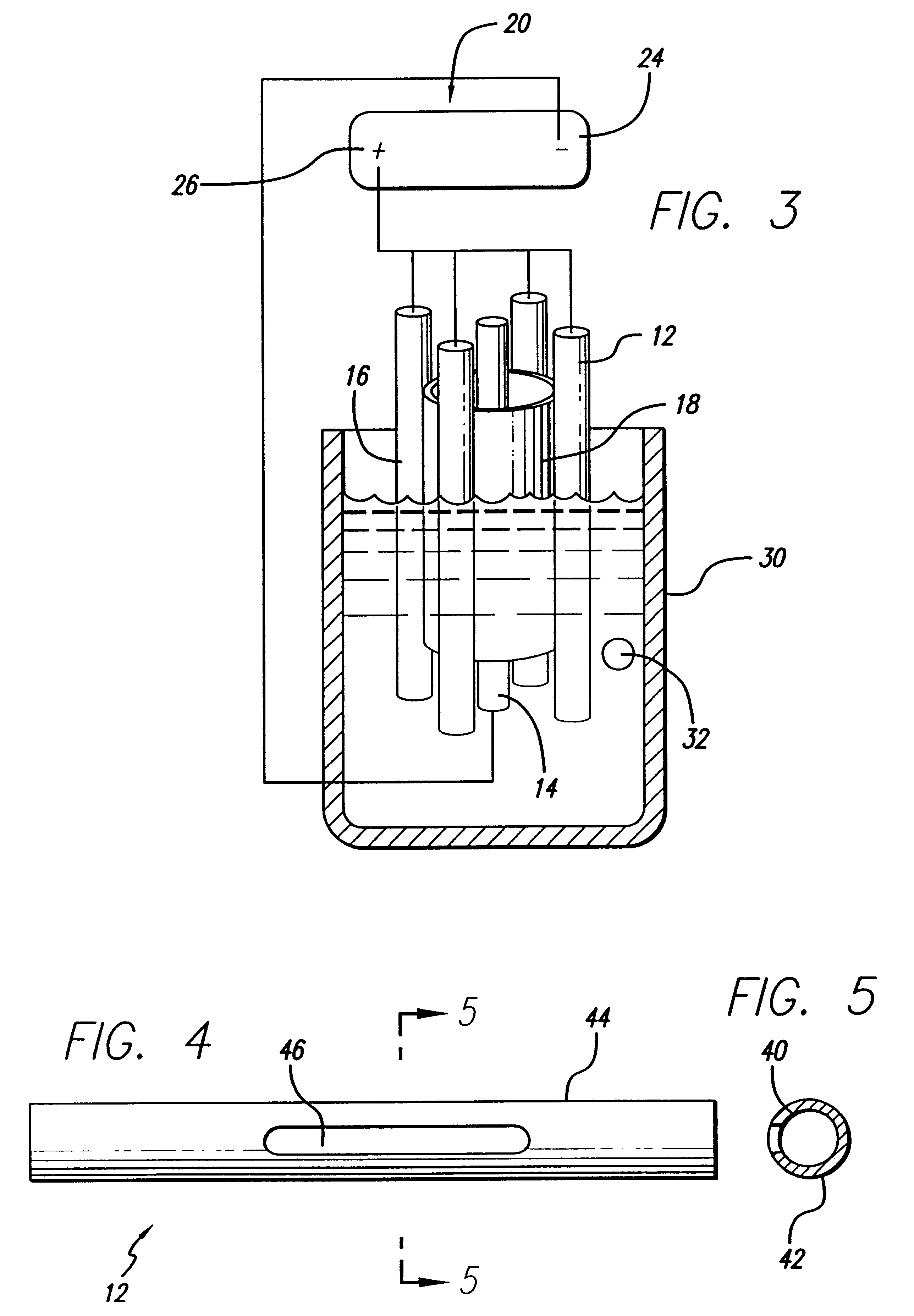

Electro-polishing fixture and electrolyte solution for polishing stents and method

An electro-polishing fixture for polishing stents which incorporates multiple anodes in contact with the stent and a center cathode disposed coaxially within the interior of the stent and a curved exterior cathode disposed about the perimeter of the stent. The invention further includes an electrolyte solution adapted for polishing stents composed of nickel-titanium alloy and a method of using the electrolyte in combination with the electro-polishing fixture.

Owner:ABBOTT CARDIOVASCULAR

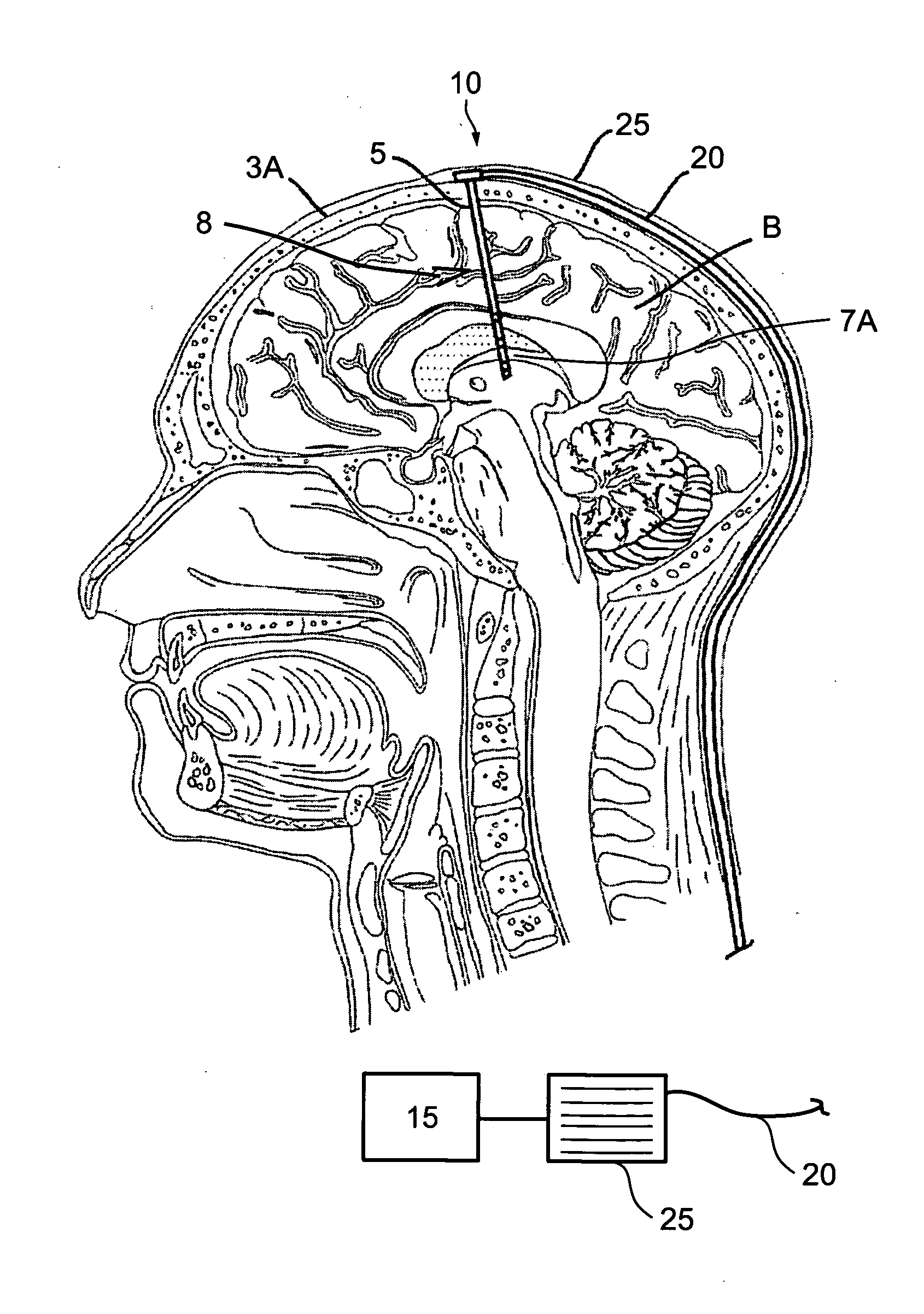

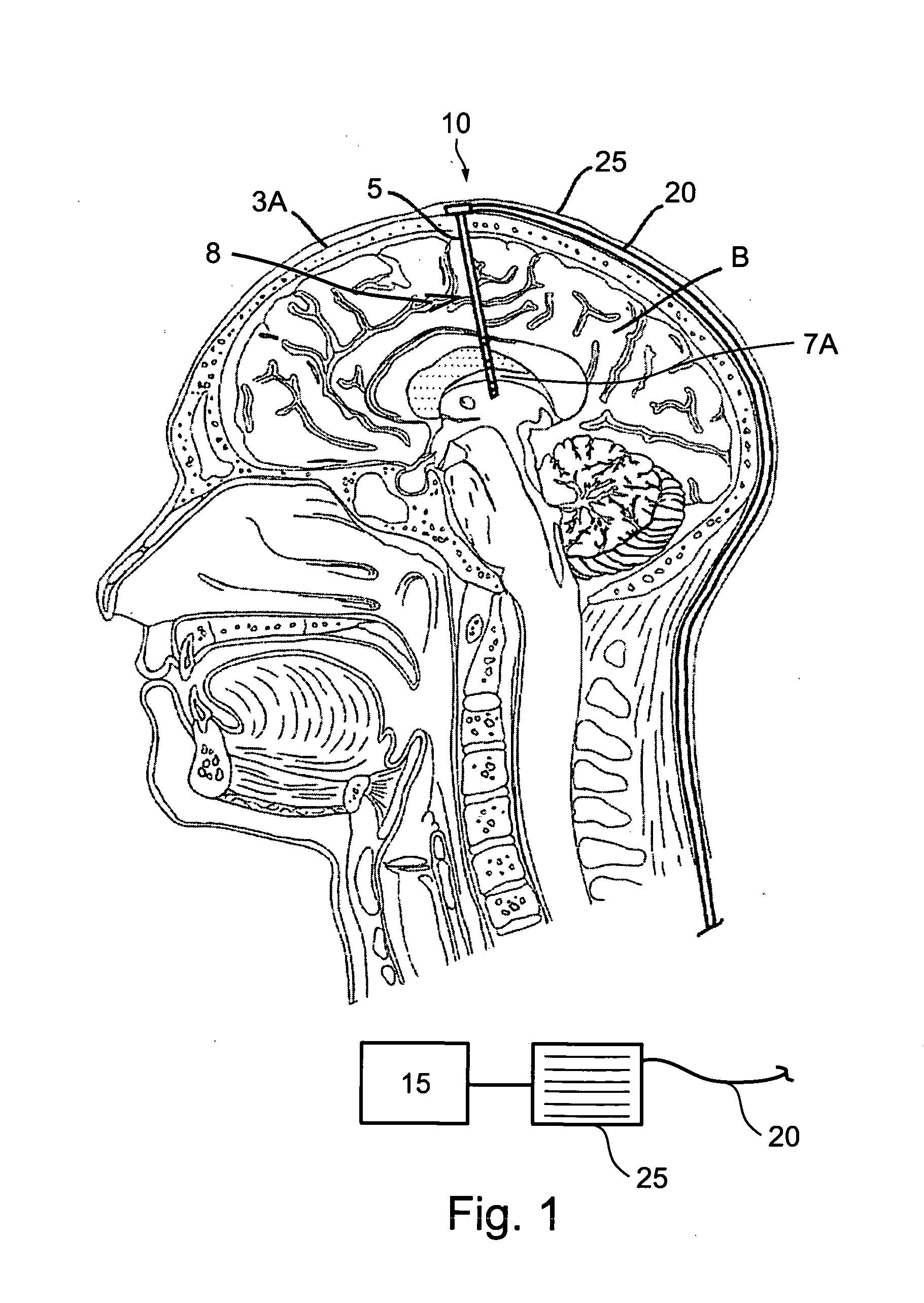

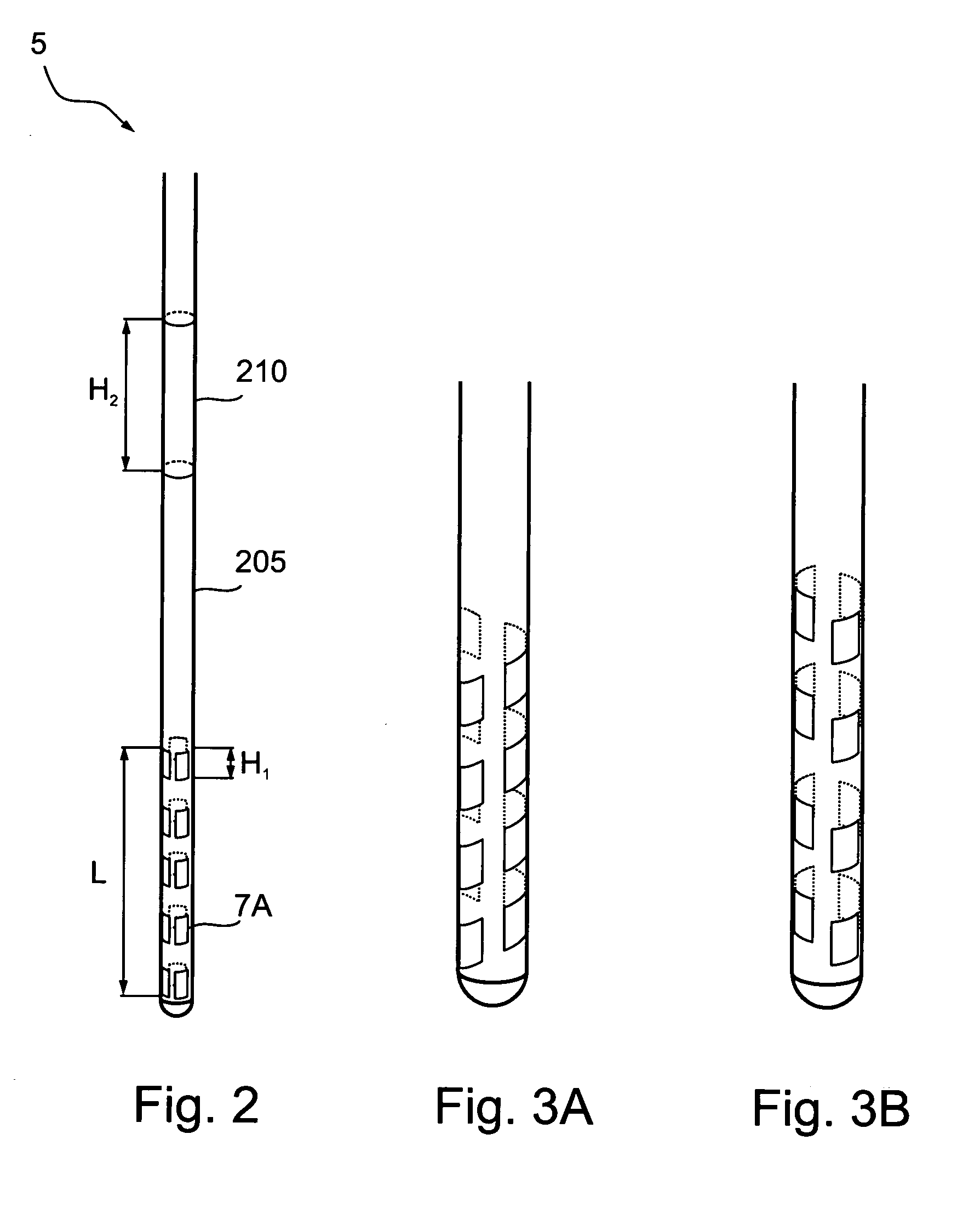

Directional stimulation of neural tissue

ActiveUS20080215125A1Quality improvementReduce inductionHead electrodesExternal electrodesNervous tissueElectrical control

A multi-contact electrode for neural tissue stimulation is described. The electrode has an axis and includes a plurality of electrodes going along the axis. Each electrode ends with a contact, and at least one of the contacts has an internal edge, resulting in non-uniform electrical properties throughout the contact surface facing the tissue. Also described are methods of making an electrical contact with an internal edge, and methods and systems for characterizing internal edge.

Owner:ALPHA OMEGA NEURO TECH

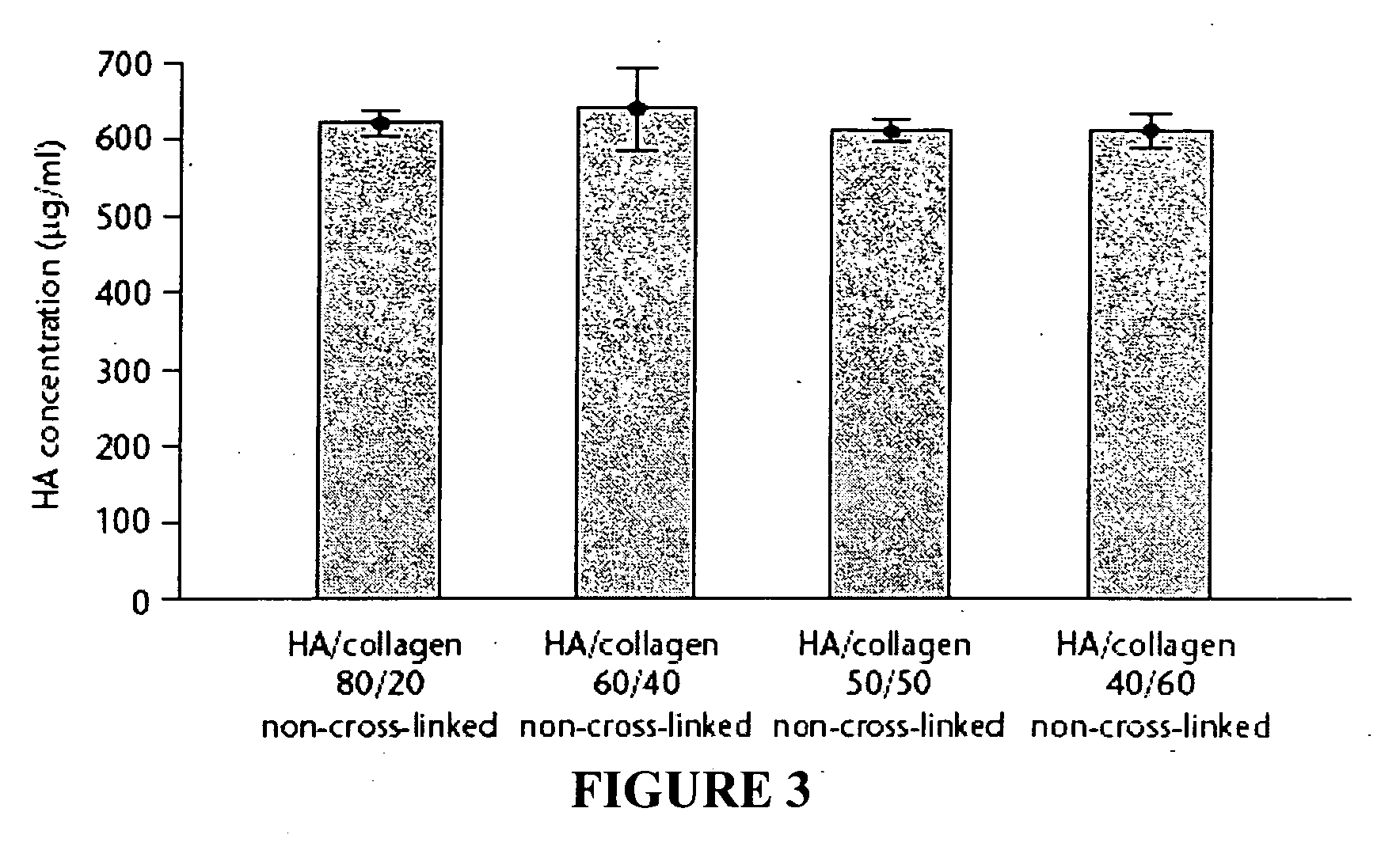

Method for producing cross-linked hyaluronic acid-protein bio-composites

InactiveUS20060189516A1Uniform densityUniform porosityPeptide/protein ingredientsSkeletal disorderCross-linkFiber

This invention is concerned with a new method for producing cross-linked hyaluronic acid—protein bio-composites in various shapes. In the present process, a polysaccharide solution and a protein solution are mixed under moderate pH values in presence of salts to form a homogenous solution, which can be processed into various shapes, such as membrane, sponge, fiber, tube or micro-granular and so on. After then, the homogenous solution is subjected to a cross-linking reaction in organic solvent containing weak acid to produce an implantable bio composite material having excellent bio-compatibility, biodegradability, prolonged enzymatic degradation time, and good physical properties.

Owner:IND TECH RES INST

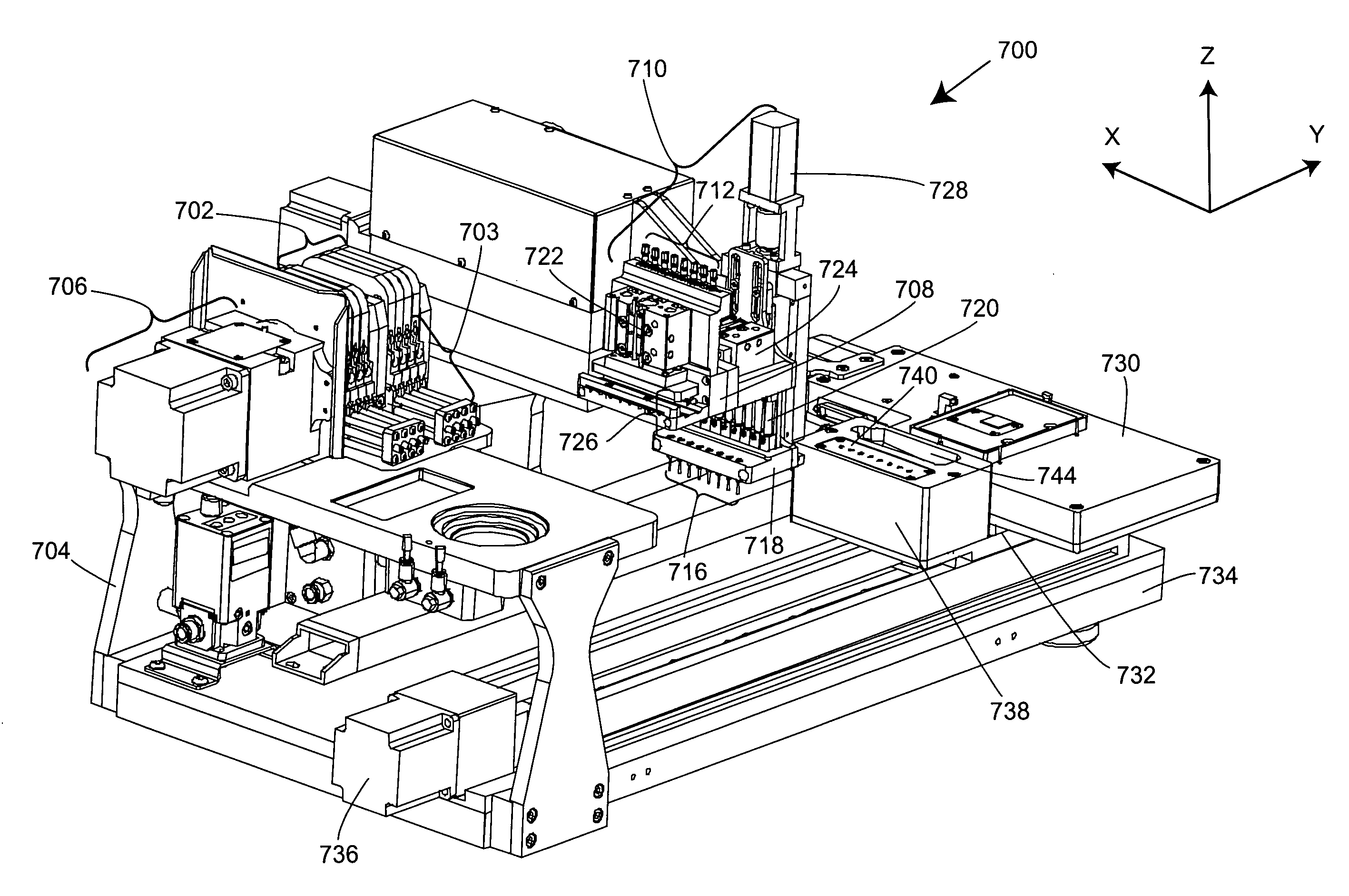

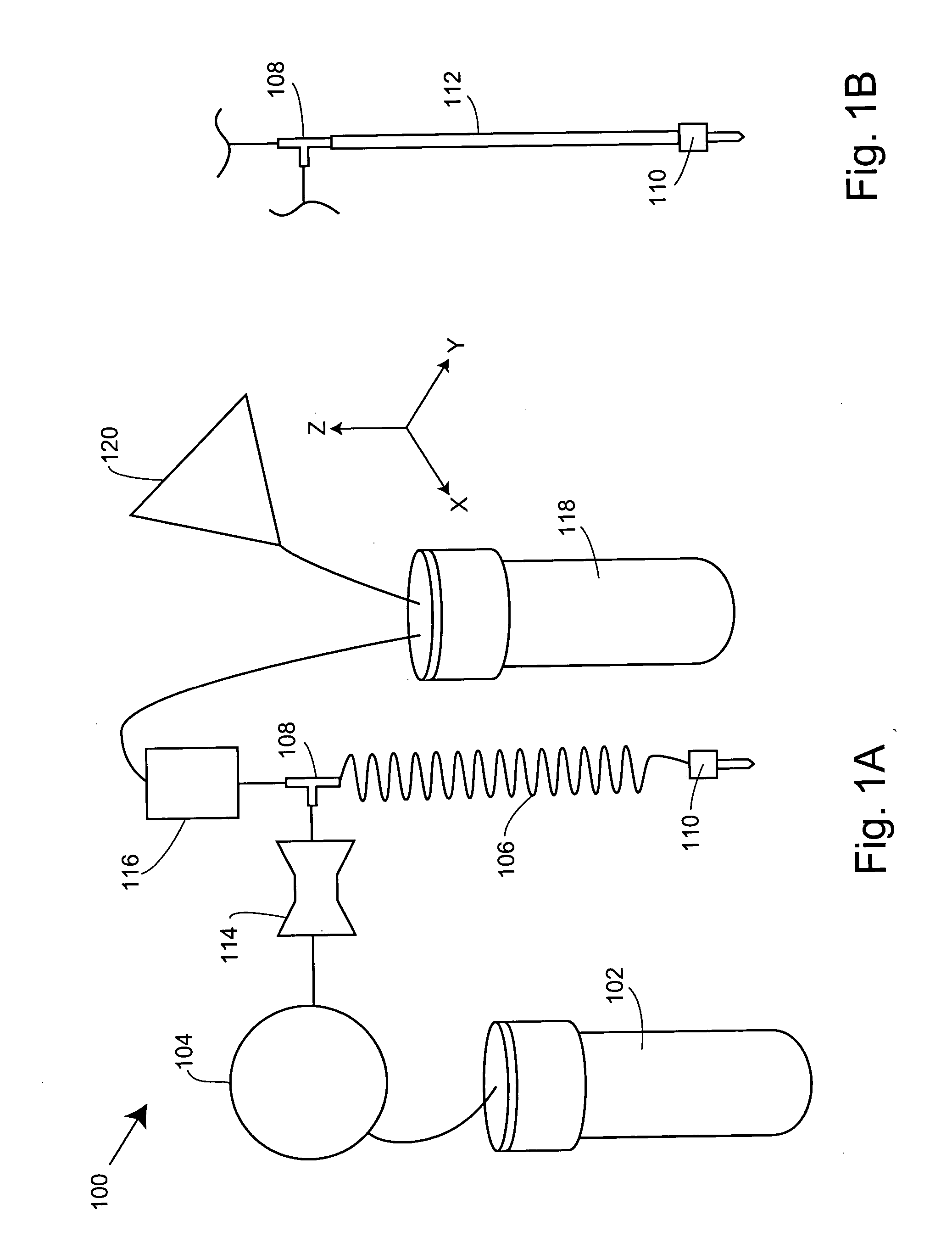

Dispensing systems, software, and related methods

InactiveUS20060002824A1Minimize disruptionReduce foamingAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionPeristaltic pumpSubstrate surface

The present invention provides dispensing systems that include peristaltic pumps and other pressure sources for the efficient delivery of accurate volumes of fluidic materials into the wells of multi-well containers or onto substrate surfaces. These systems are typically configured to dispense volumes of fluid having substantially uniform densities. Related computer program products and methods of dispensing fluidic materials are also provided.

Owner:IRM

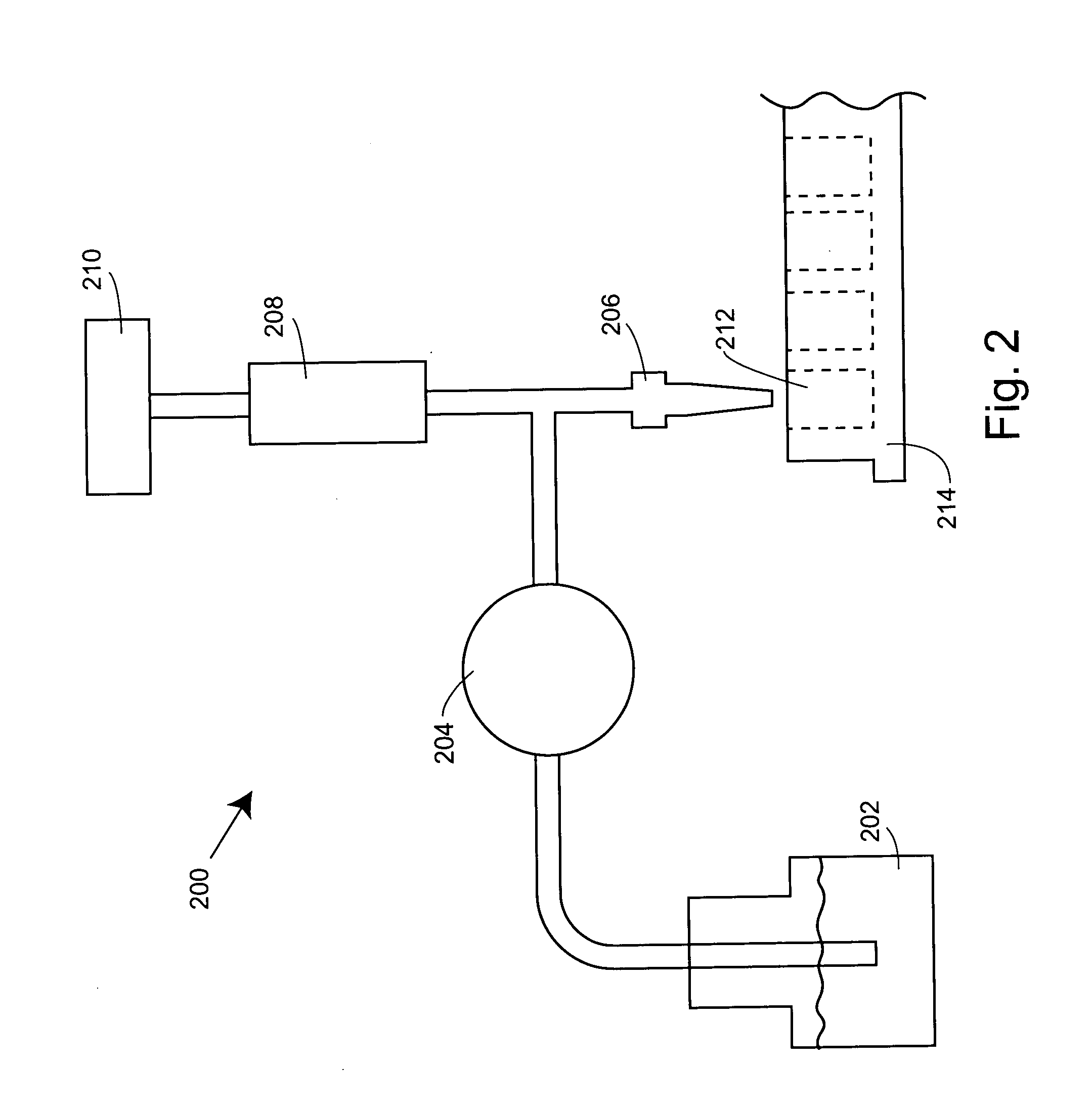

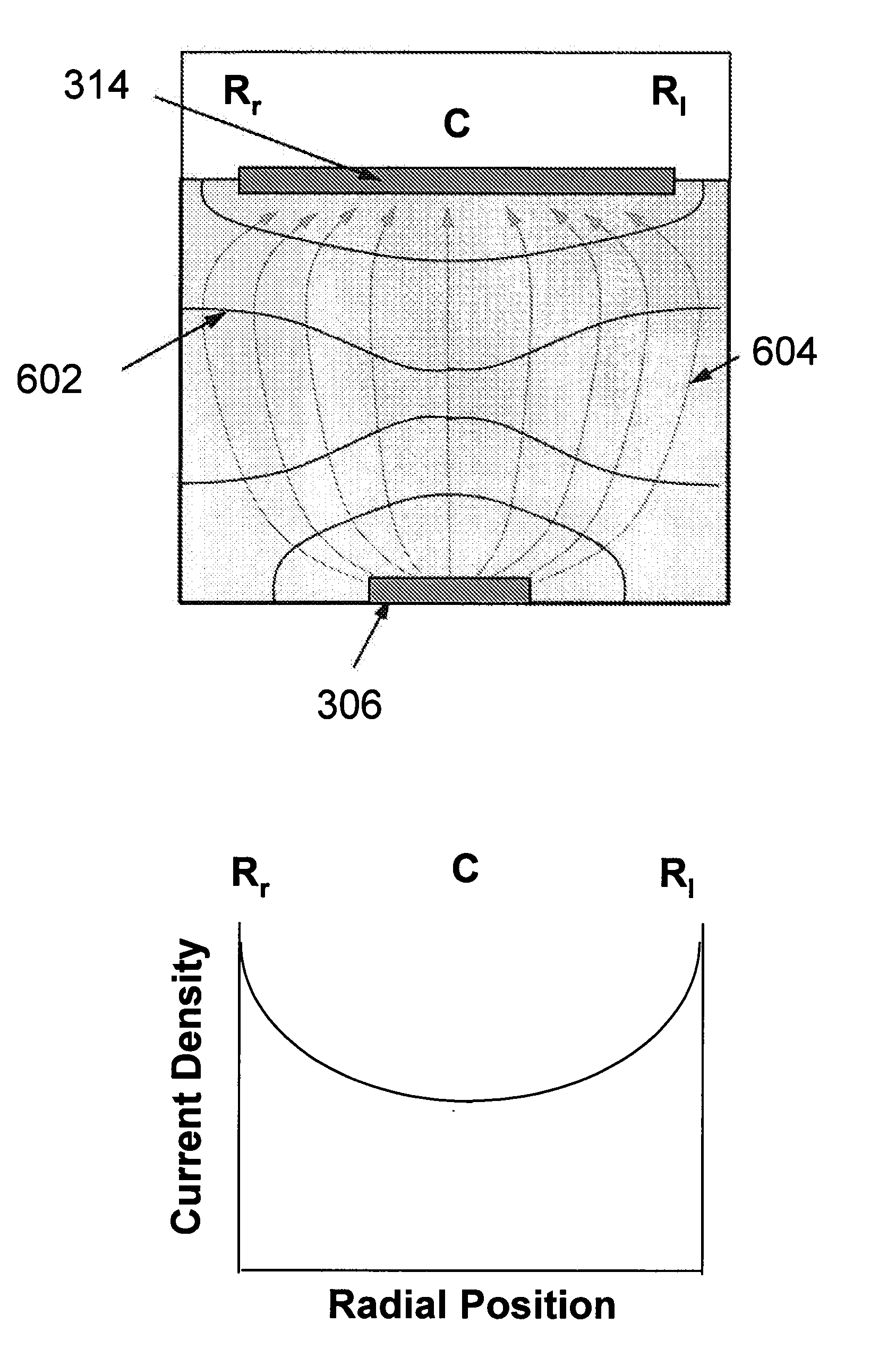

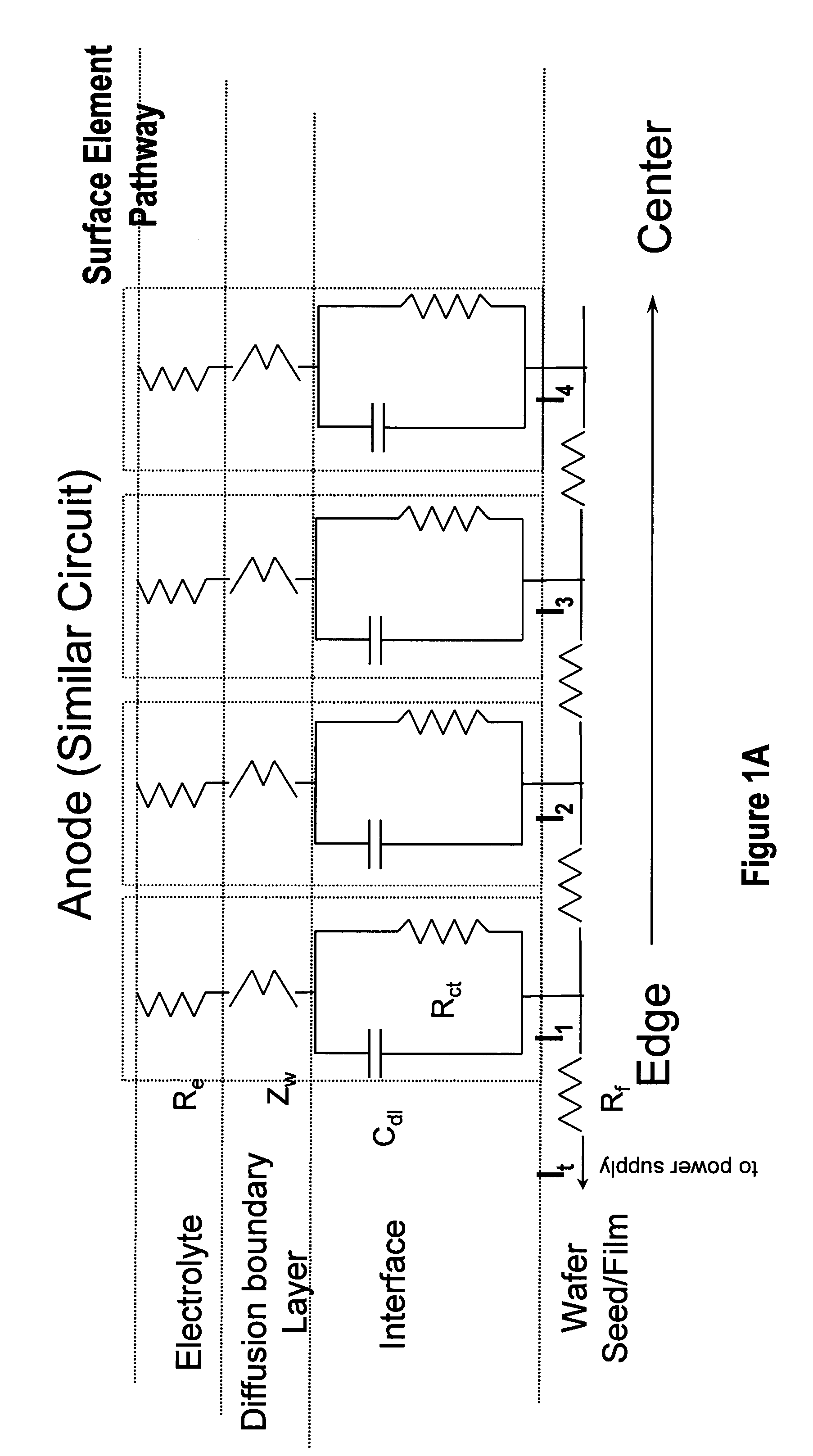

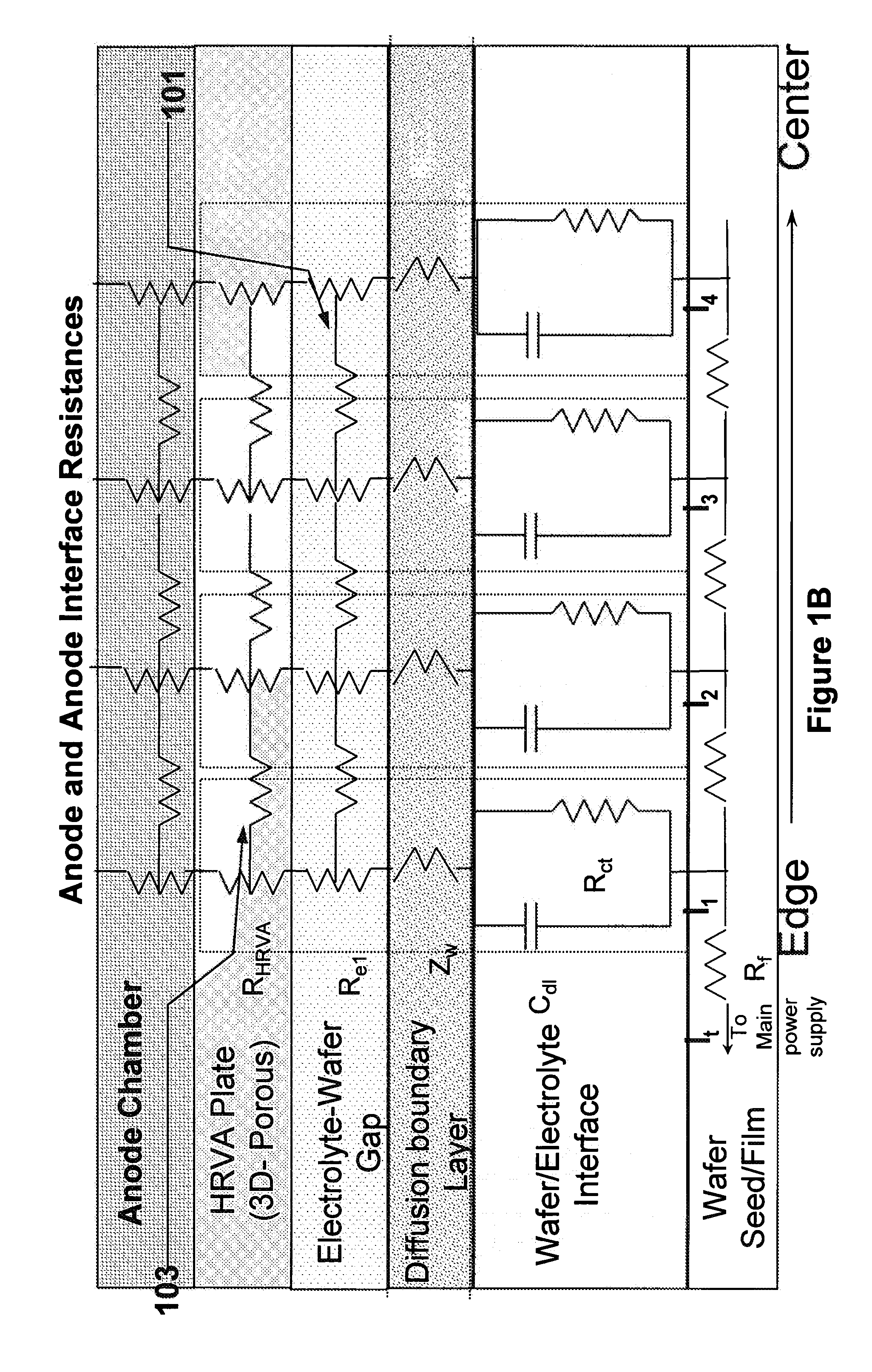

Method and apparatus for electroplating

An apparatus for electroplating a layer of metal onto the surface of a wafer includes an ionically resistive ionically permeable element located in close proximity of the wafer and an auxiliary cathode located between the anode and the ionically resistive ionically permeable element. The ionically resistive ionically permeable element serves to modulate ionic current at the wafer surface. The auxiliary cathode is configured to shape the current distribution from the anode. The provided configuration effectively redistributes ionic current in the plating system allowing plating of uniform metal layers and mitigating the terminal effect.

Owner:NOVELLUS SYSTEMS

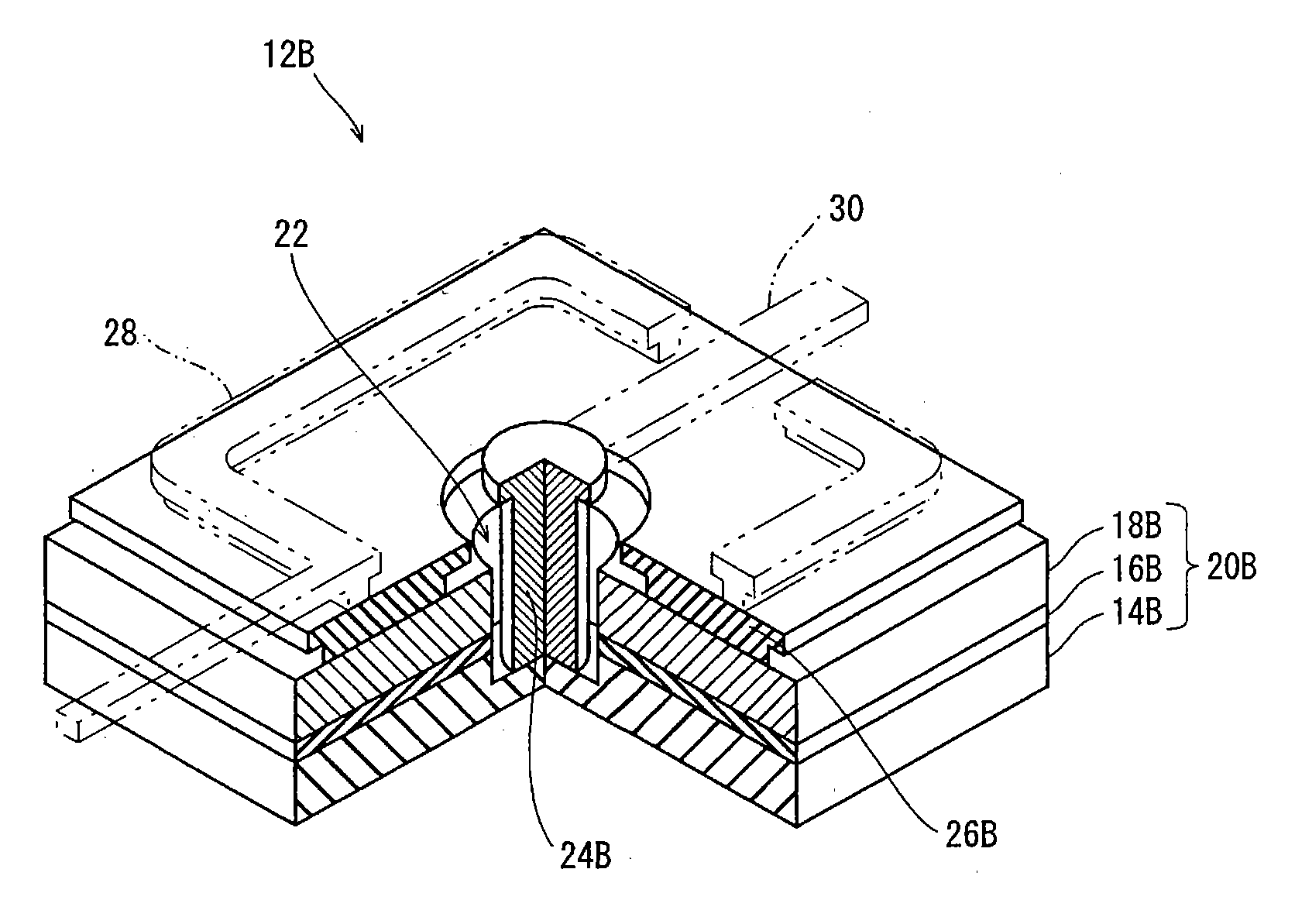

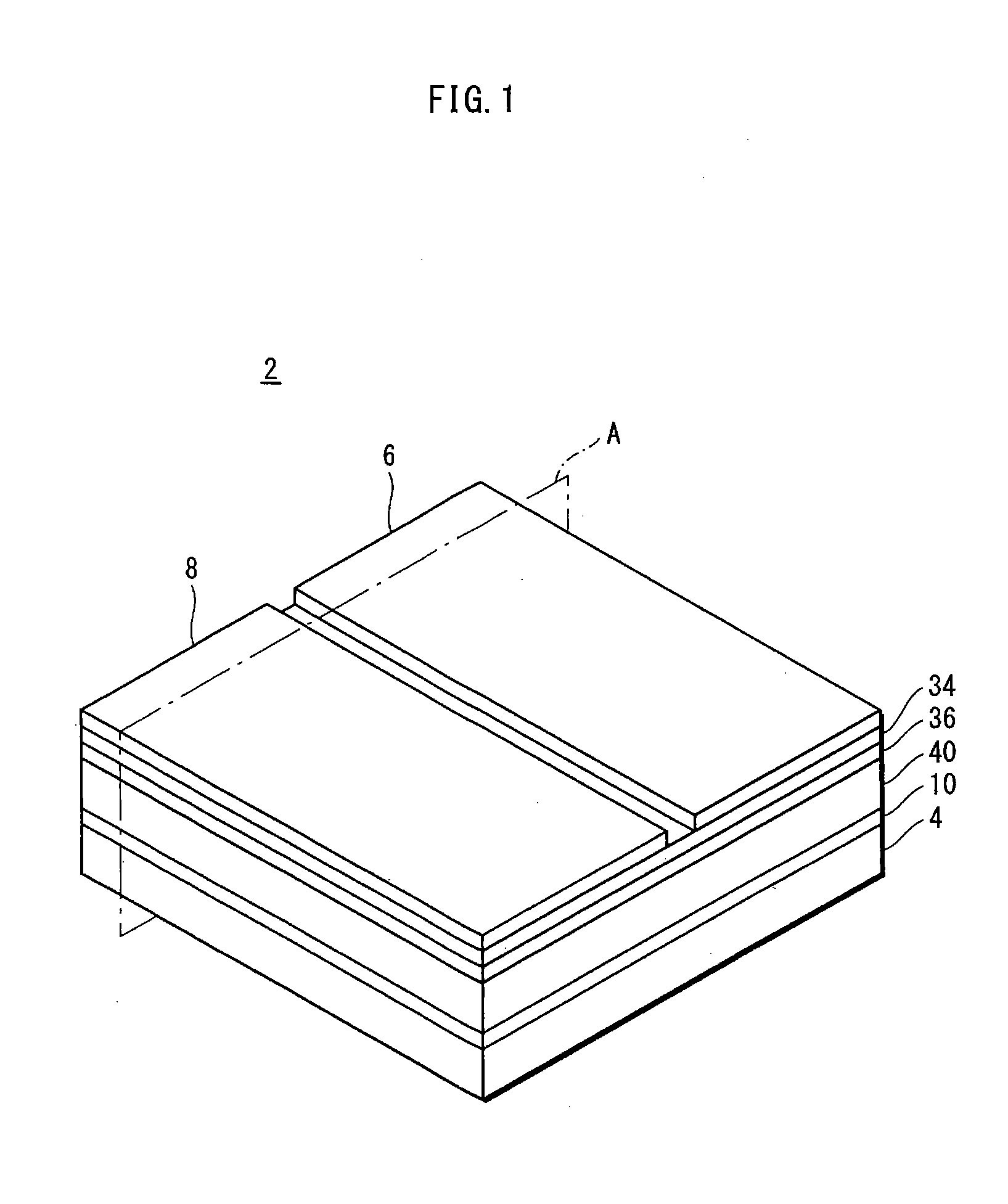

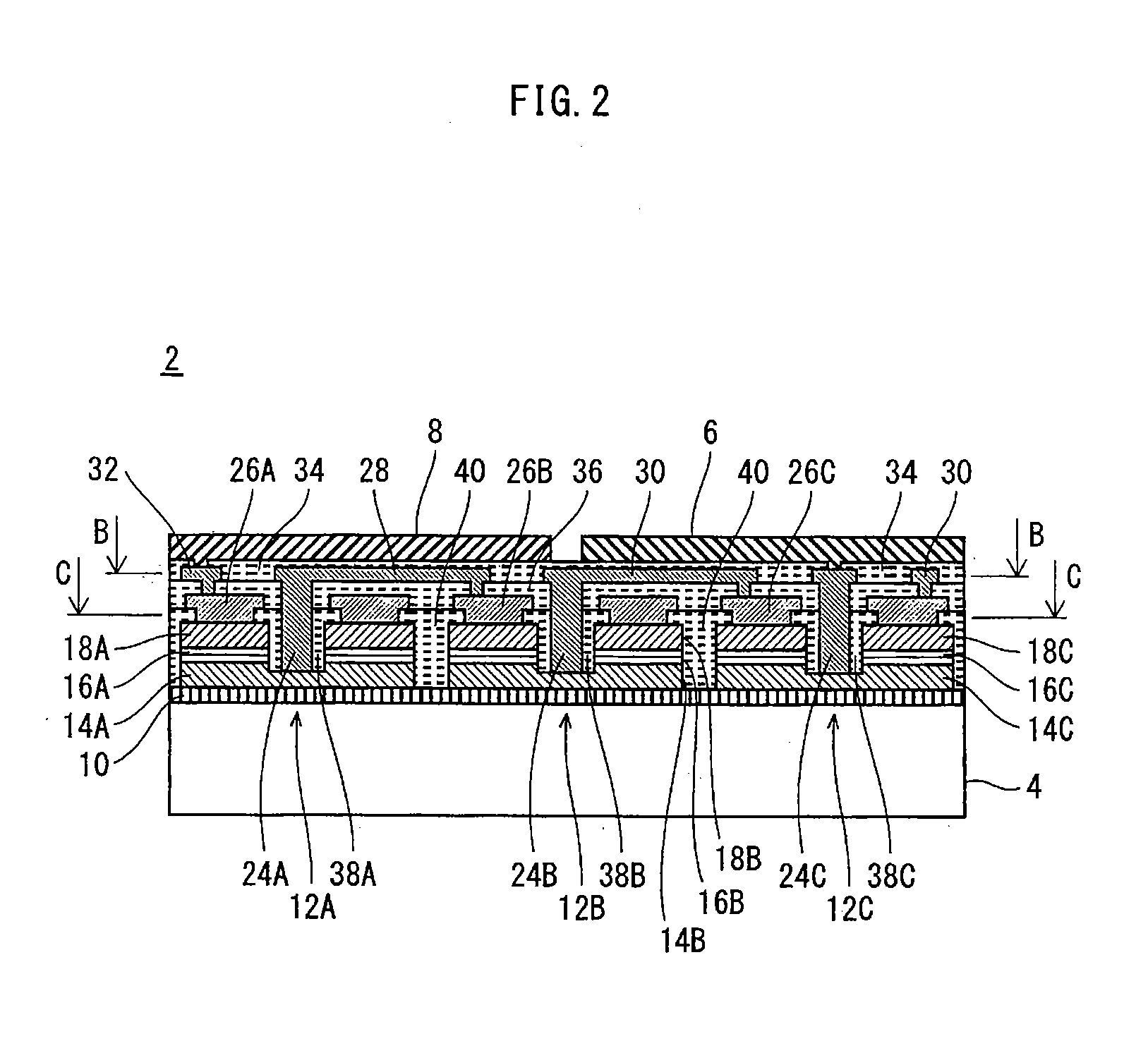

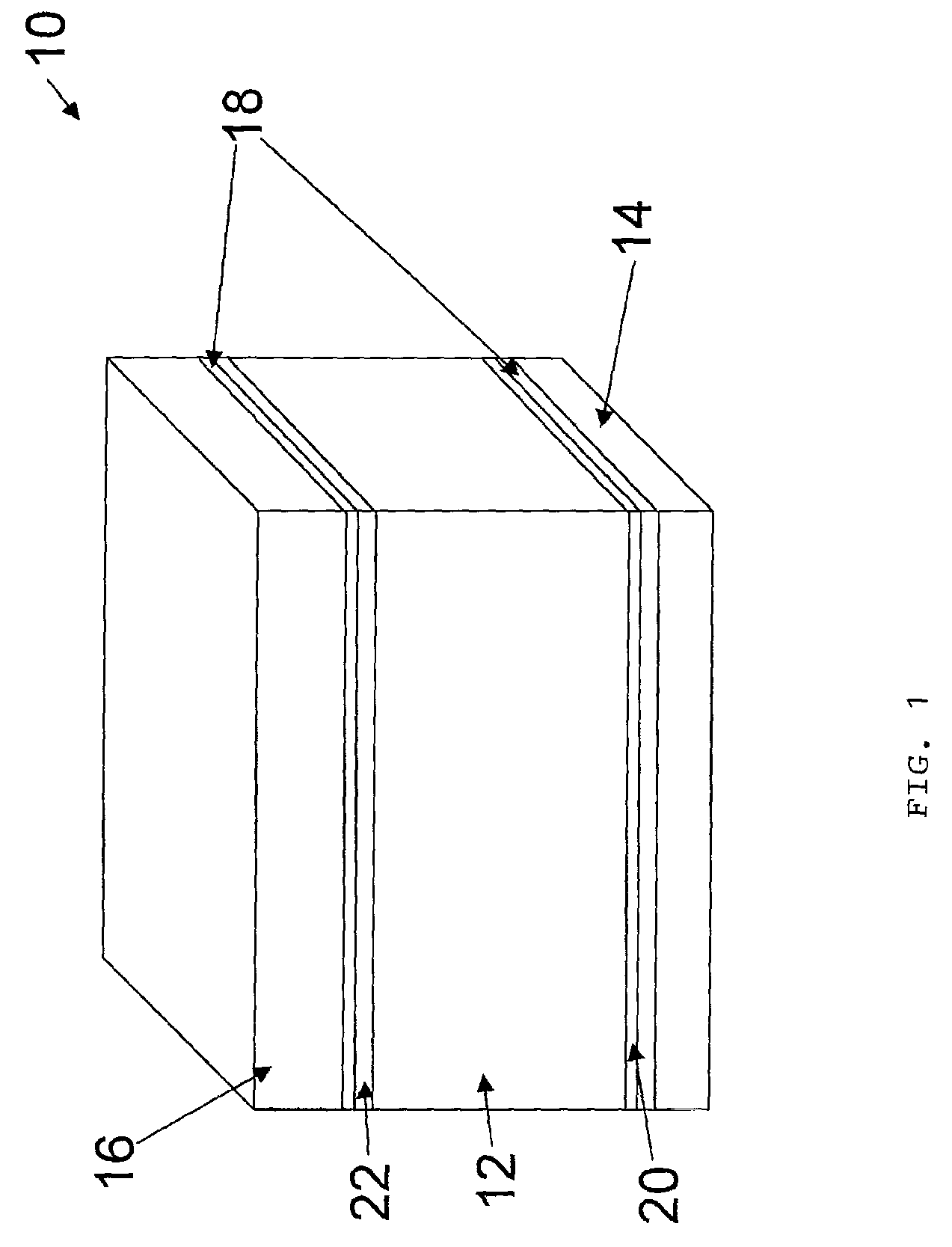

Semiconductor light-emitting device, light-emitting module, and illumination device

ActiveUS20110266579A1Improve luminous efficiencySpeed up the flowPoint-like light sourceSolid-state devicesEngineeringLight emitting device

A semiconductor light-emitting device having a substrate on which a semiconductor multilayer film is disposed, the semiconductor multilayer film having a layered structure in which a first conductive layer, a light-emitting layer and a second conductive layer are layered above the substrate from bottom to top in the stated order, and being divided into portions by grooves extending perpendicular to the substrate, each portion having a diode structure and serving as a light-emitting element 12, each light-emitting element 12 having a hole 22 in a central portion thereof in plan view, the hole 22 penetrating through the second conductive layer 18 and the light-emitting layer 16 and reaching the first conductive layer 14, and comprising: a first electrode 24 inserted in the hole 22 and having a columnar shape, one end thereof being connected to the first conductive layer 14 at the bottom of the hole 22, and the other end protruding from an opening of the hole 22; and a second electrode 26 formed on the second conductive layer 18 and having an annular shape surrounding the opening of the hole 22.

Owner:PANASONIC CORP

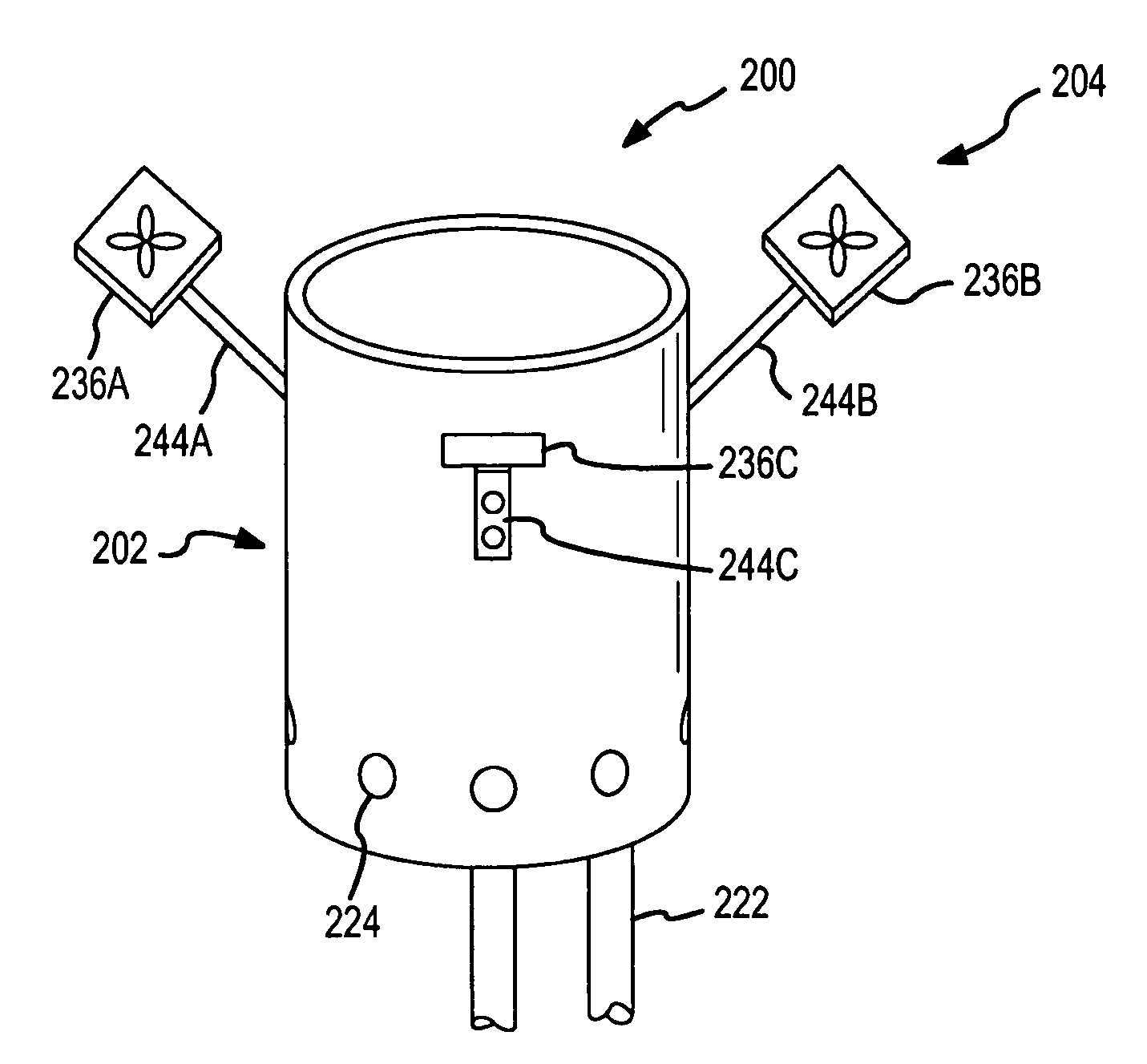

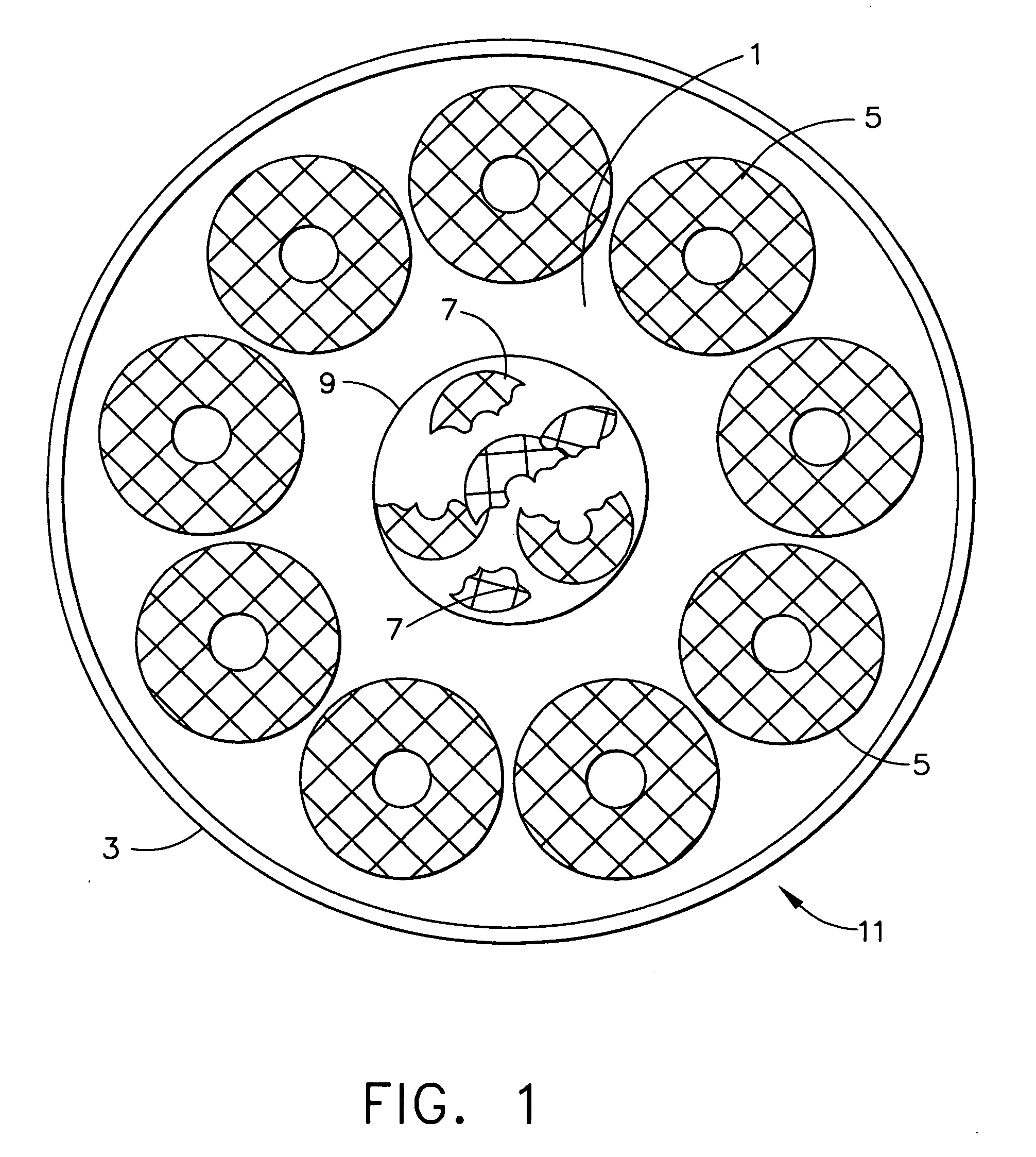

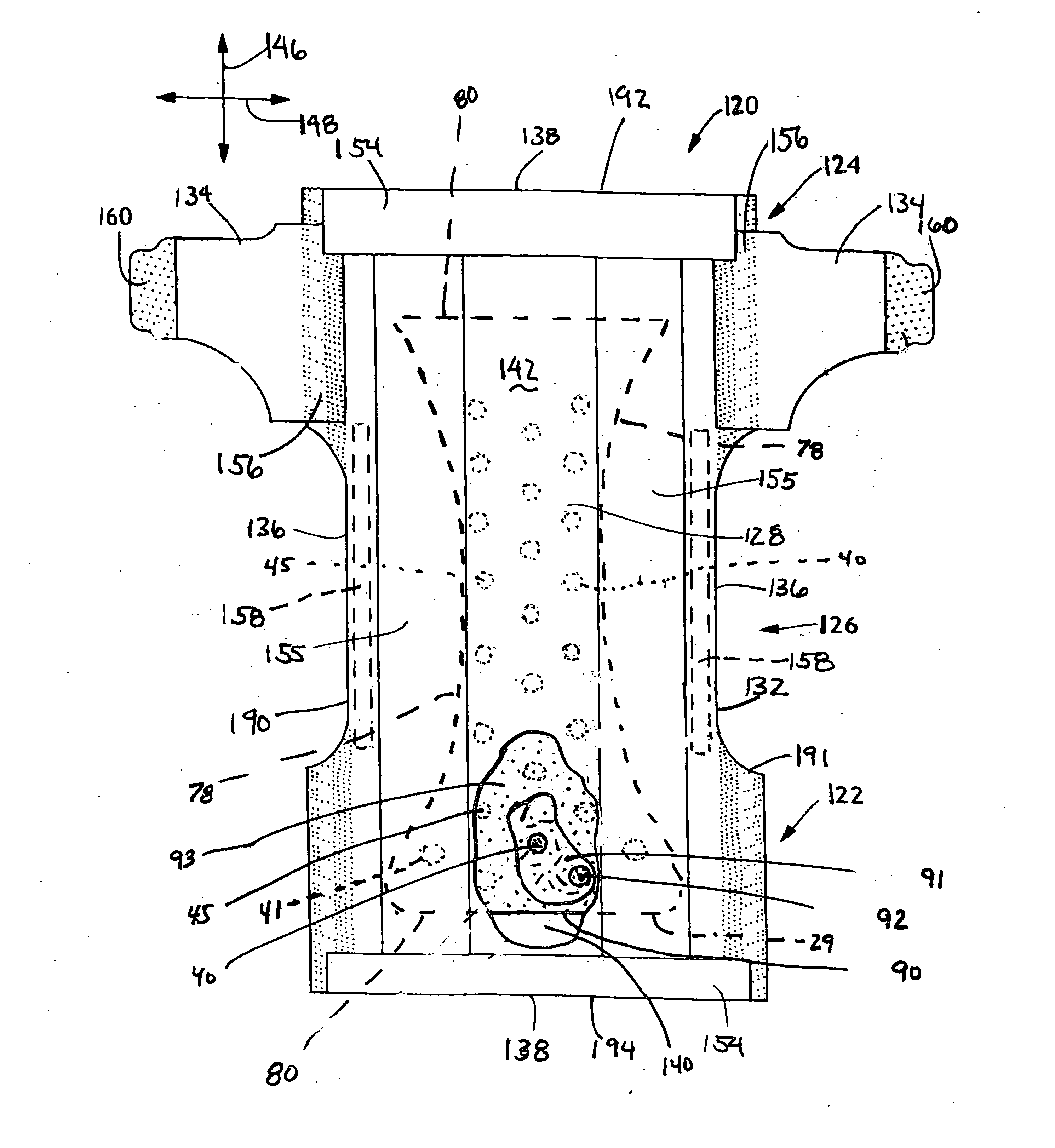

Apparatus for producing a fire special effect

InactiveUS6953401B2Eliminate and substantially reduce any gapUniform densityShow cabinetsAmusementsEngineeringSpecial effects

In one embodiment, the present invention provides a device for producing a fire special effect that is suitable for applications in which the viewers of the simulated flame are able inspect the device from relatively close range and / or from a number of perspectives. For example, the device can be used as a torchiere or wall sconce.

Owner:TECHNIFEX PRODS

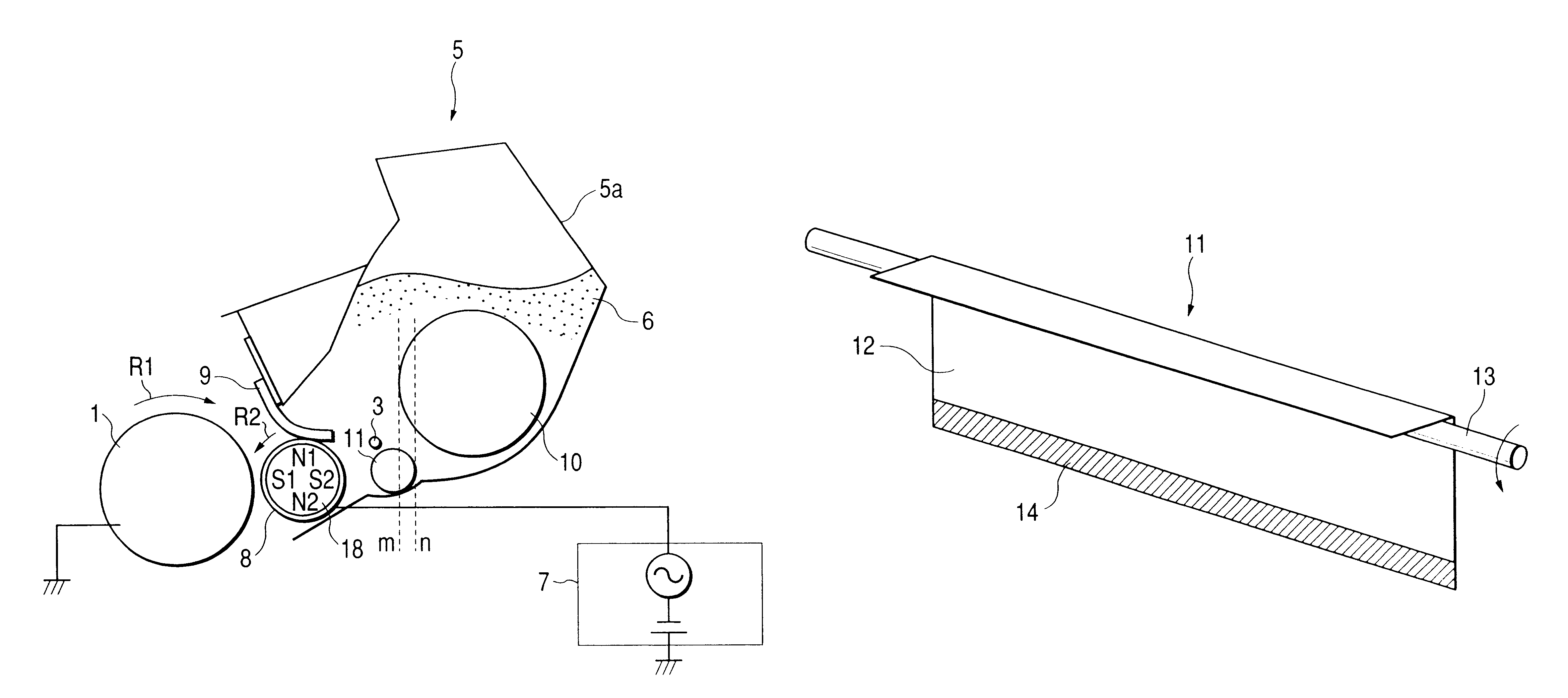

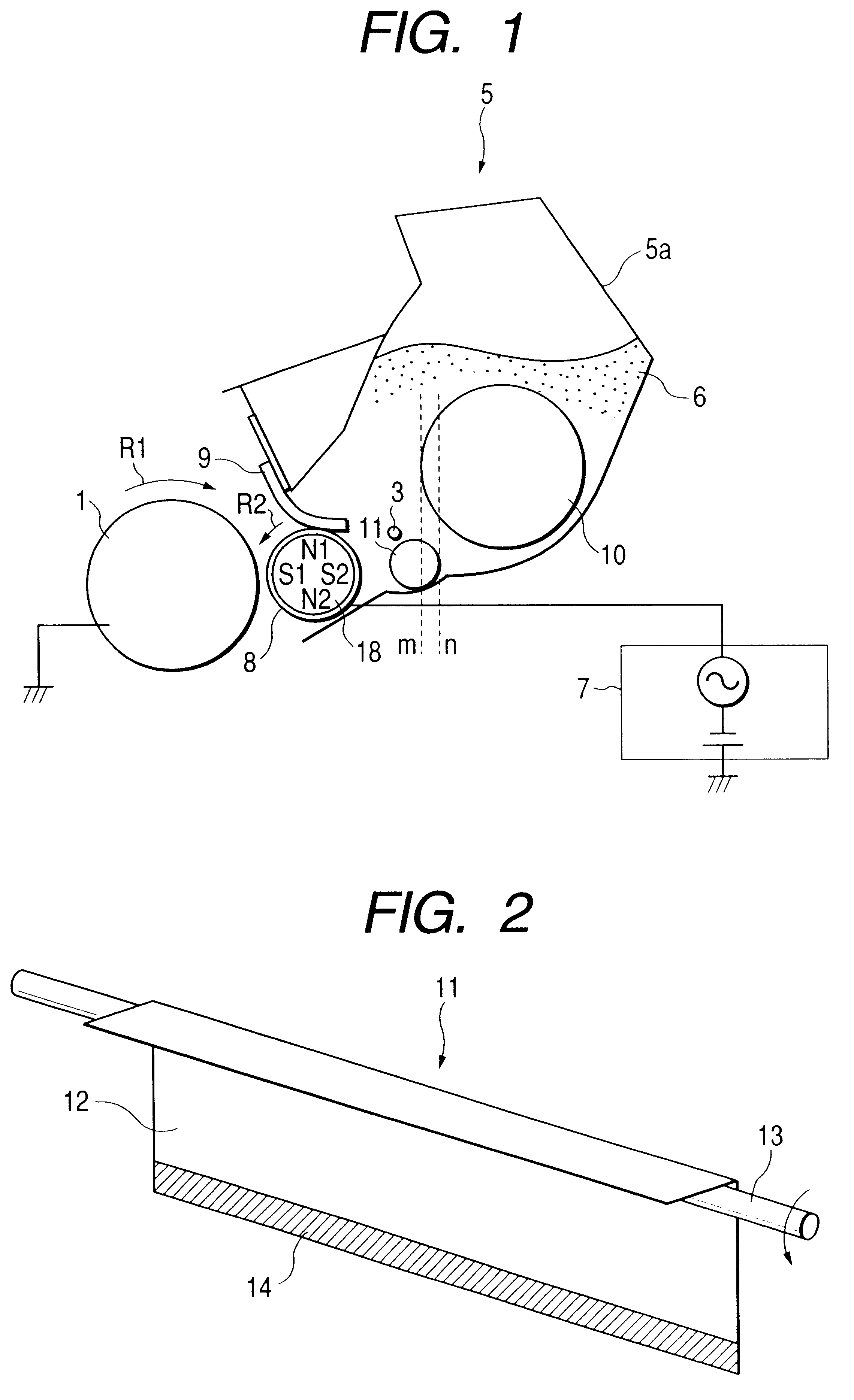

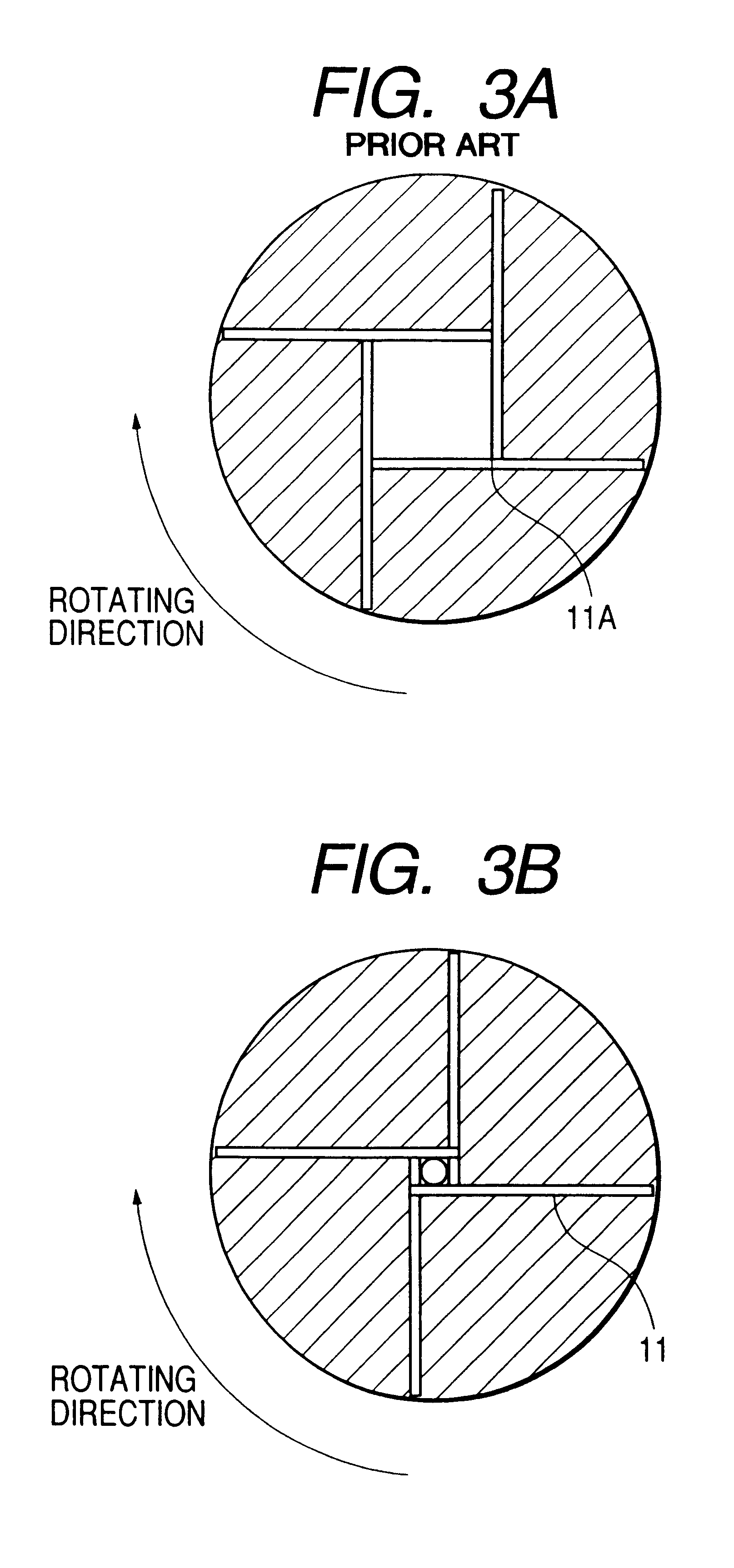

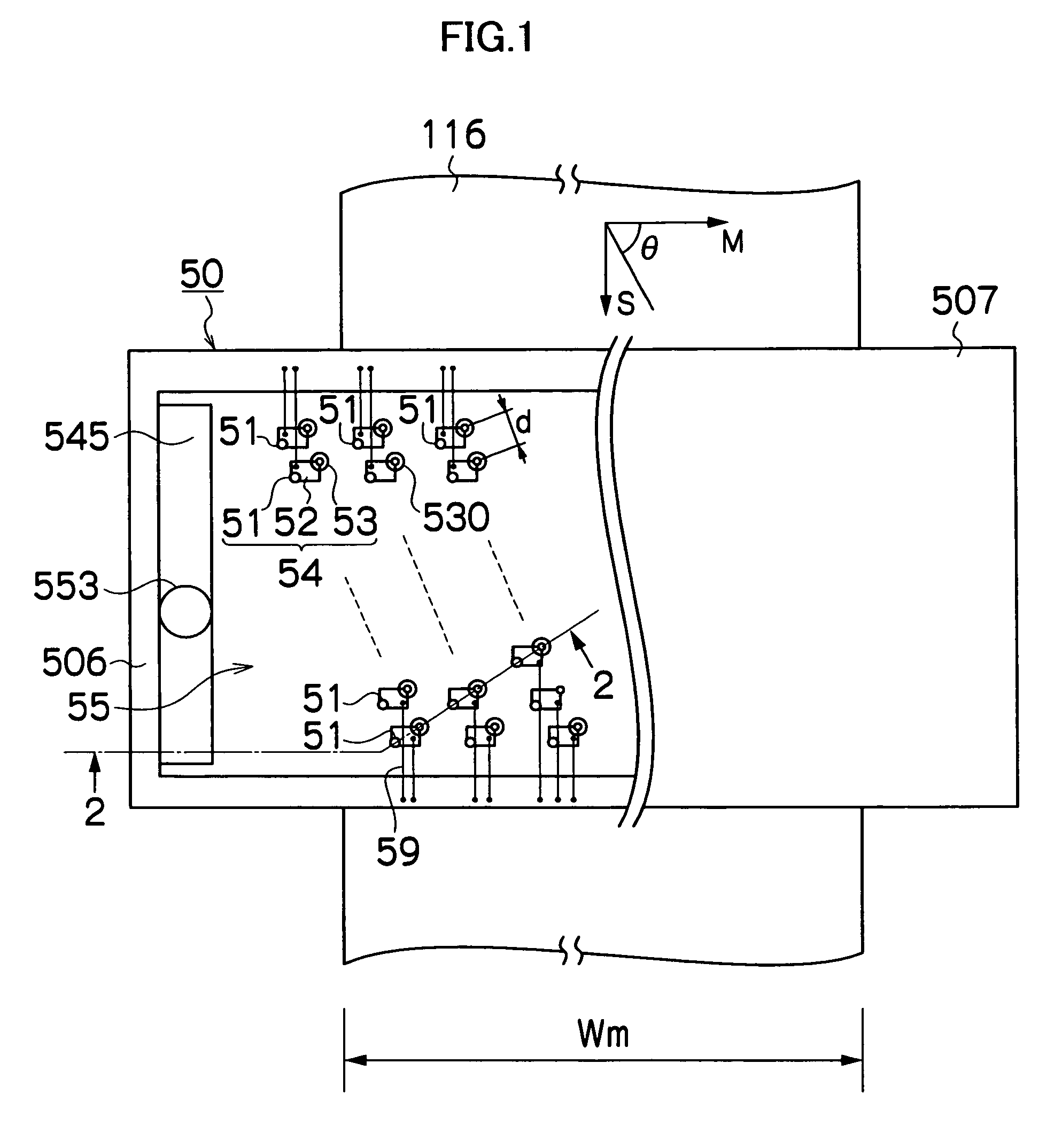

Agitating member, developing apparatus and process cartridge

InactiveUS6337964B2Sufficient forceDeterioration of a toner can be preventedDevelopersElectrographic process apparatusEngineeringImaging equipment

An agitating member for agitating a developer includes a metal shaft, a plate member joined to the metal shaft, and a sheet member joined to the plate member, the sheet member being free to curve. A developing apparatus includes a developer bearing member bearing a developer thereon, a developer container containing the developer therein, and the above-described agitating member provided in the developer container for agitating the developer and supplying it to the developer bearing member. A process cartridge detachably attachable to the main body of an image forming apparatus, includes an electrophotographic photosensitive member and the above-described developing apparatus.

Owner:CANON KK

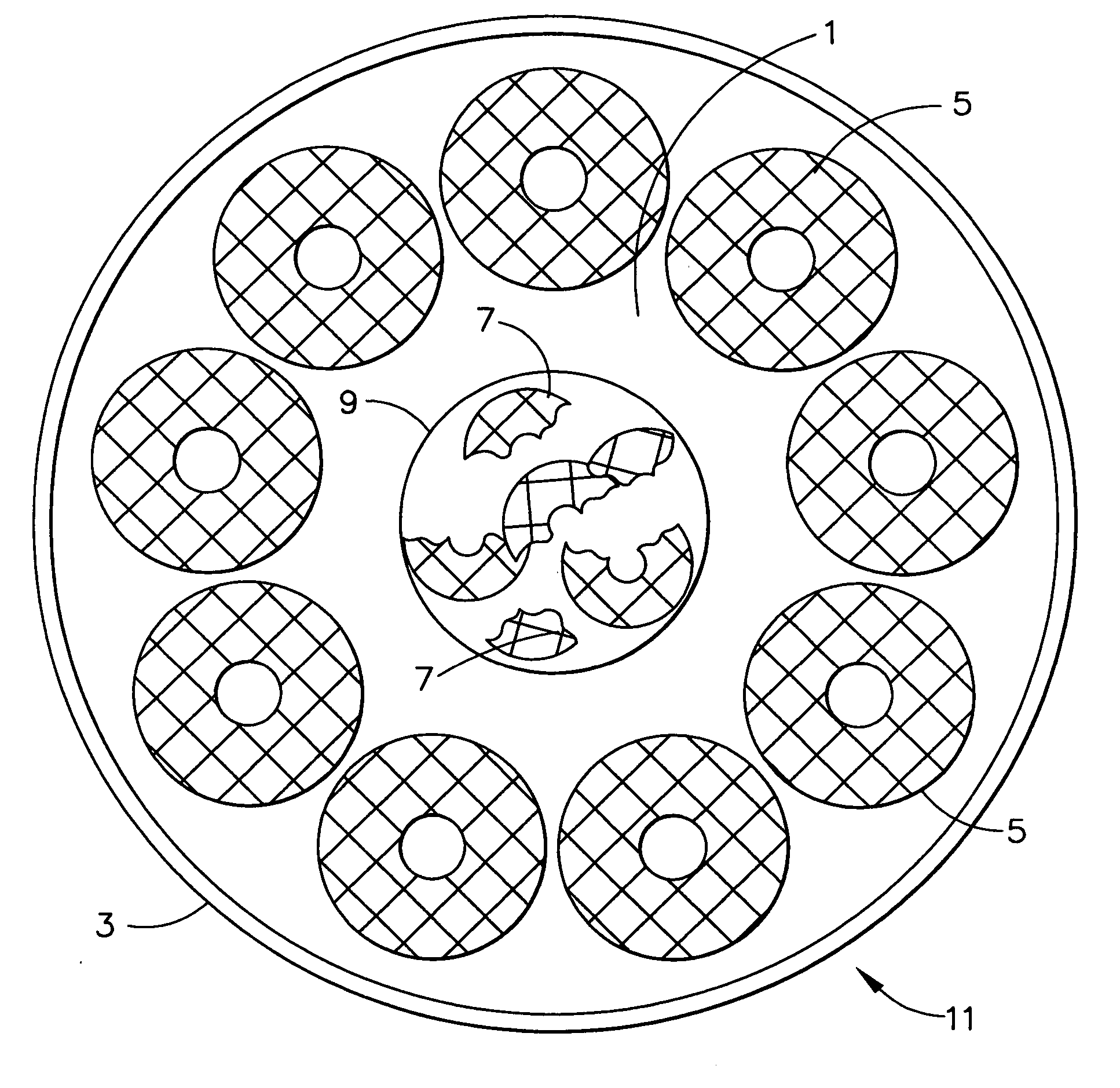

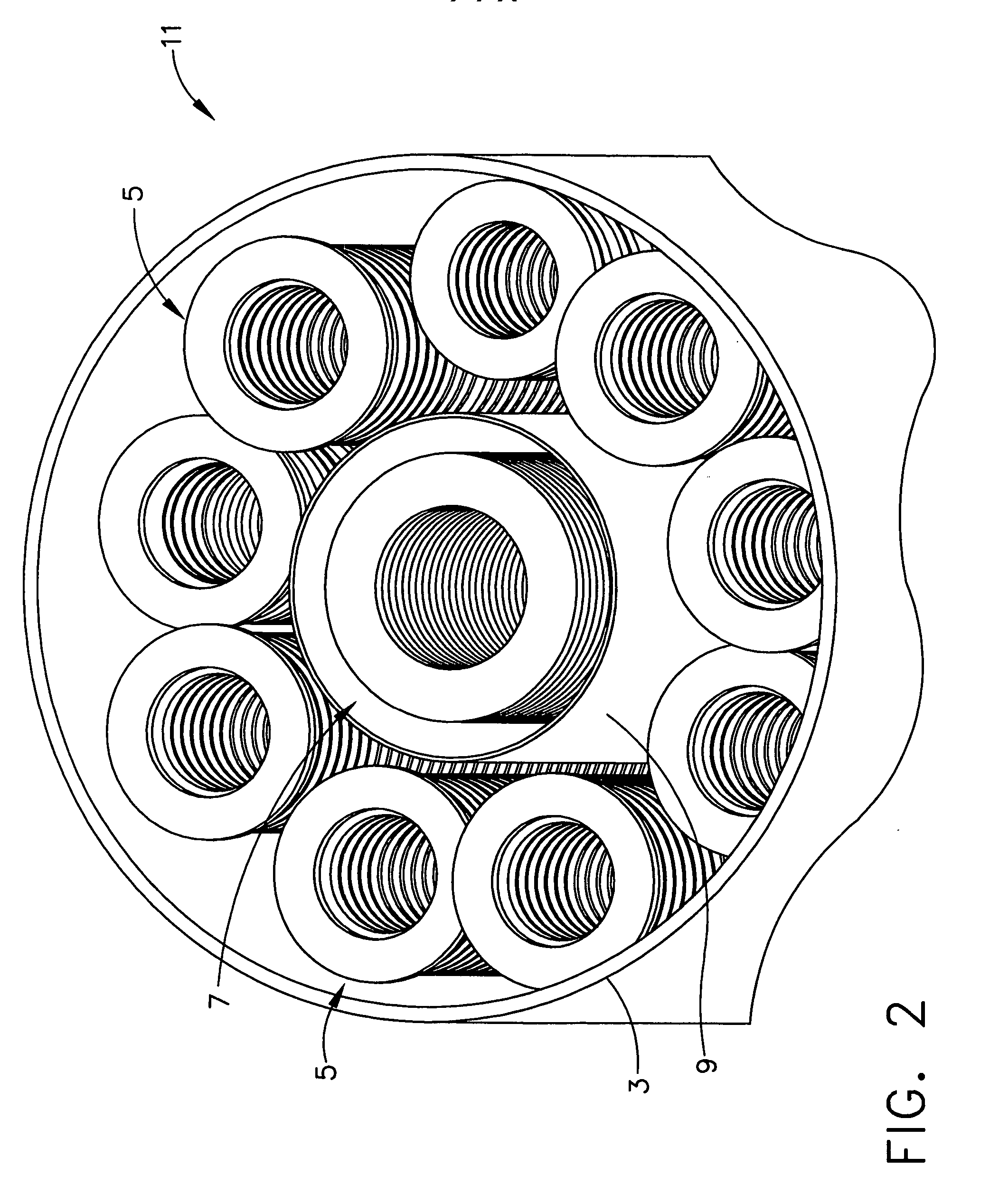

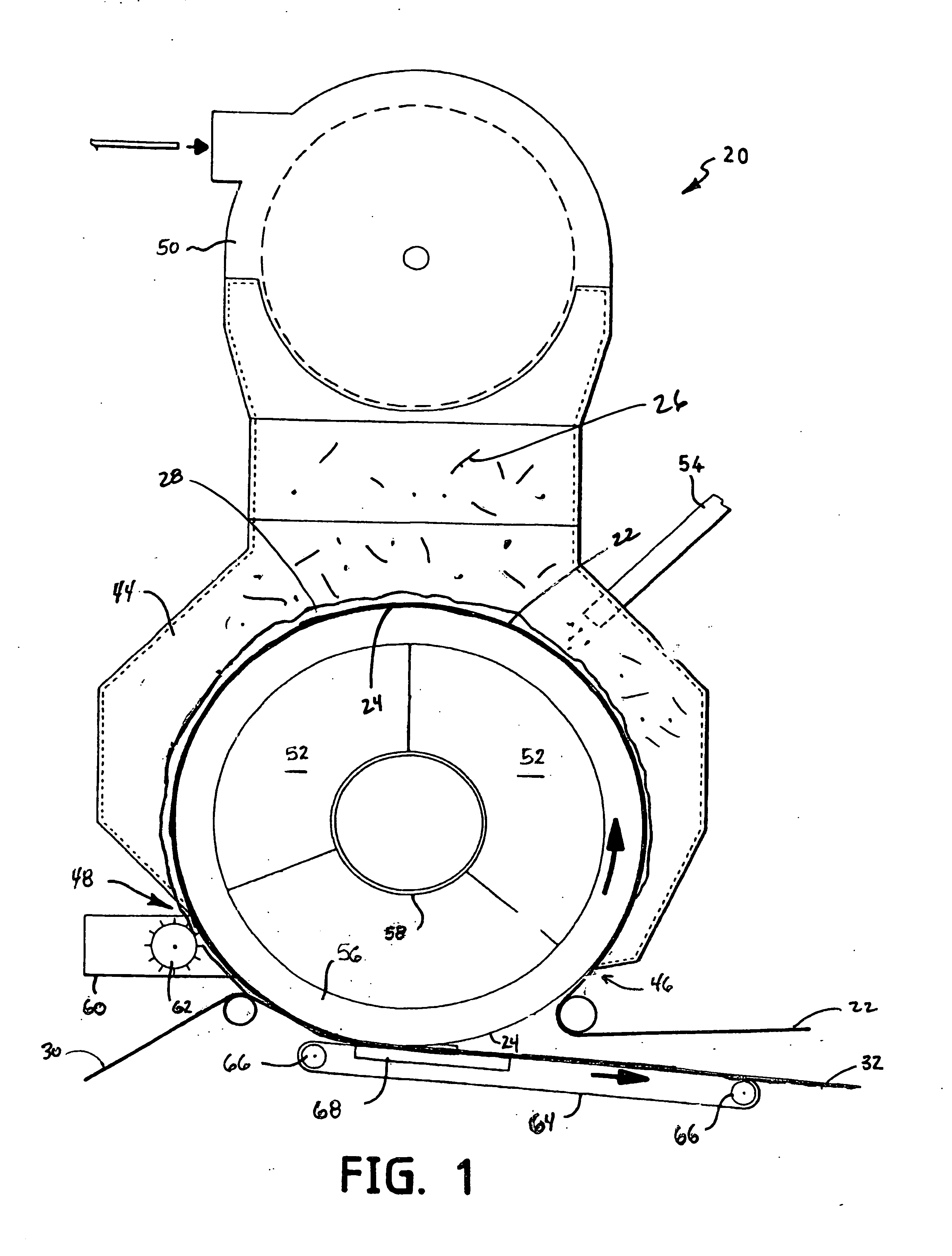

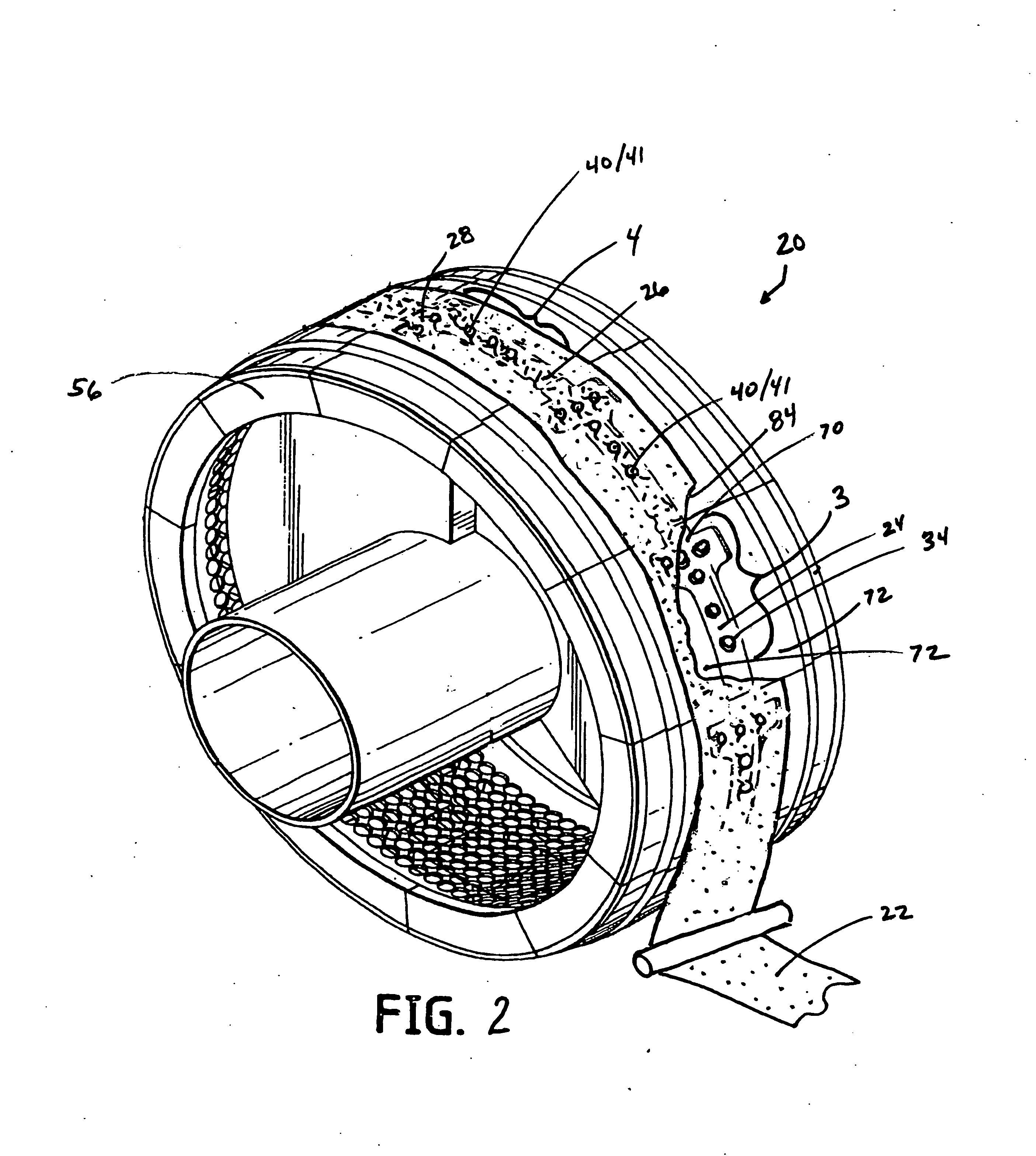

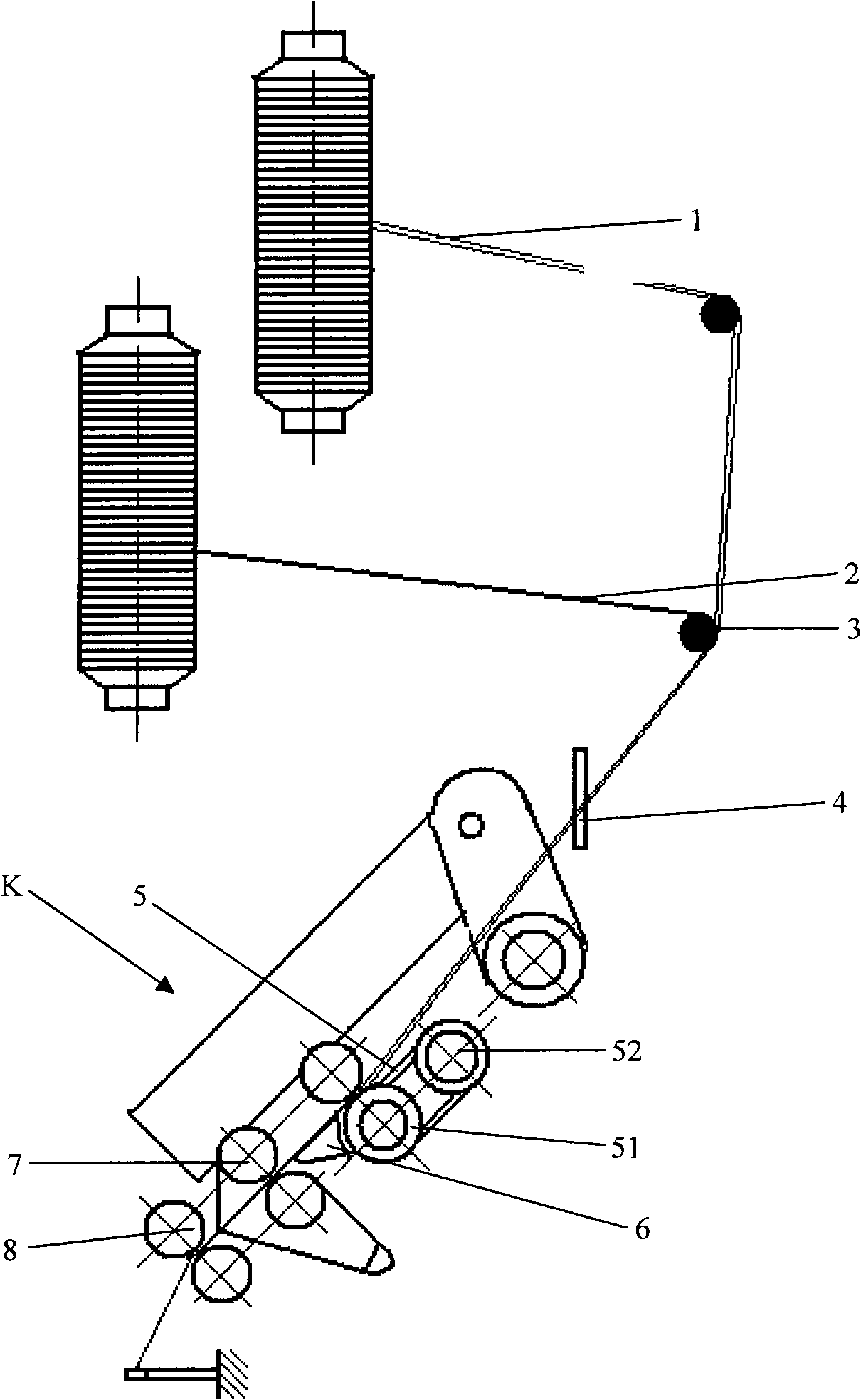

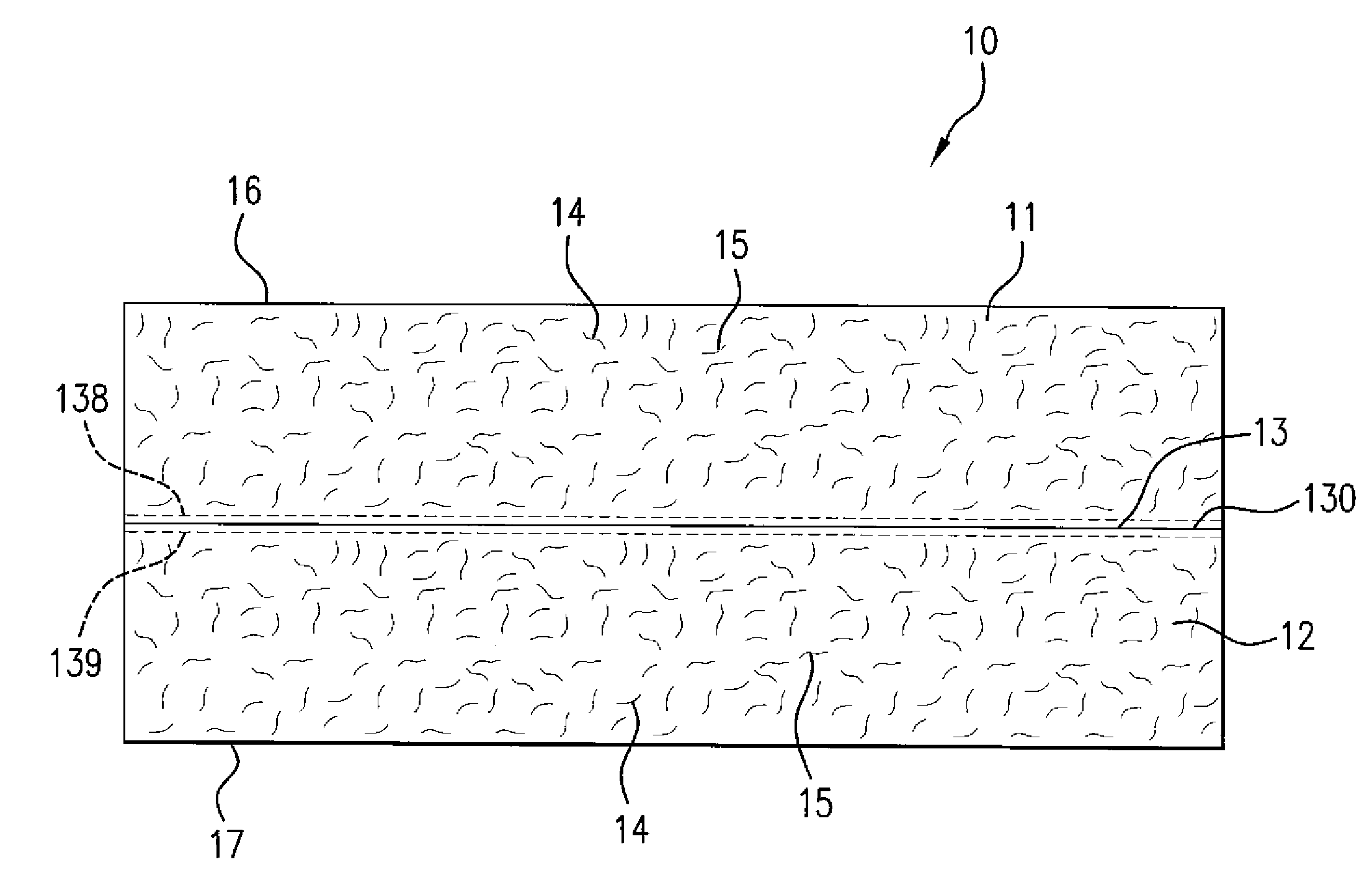

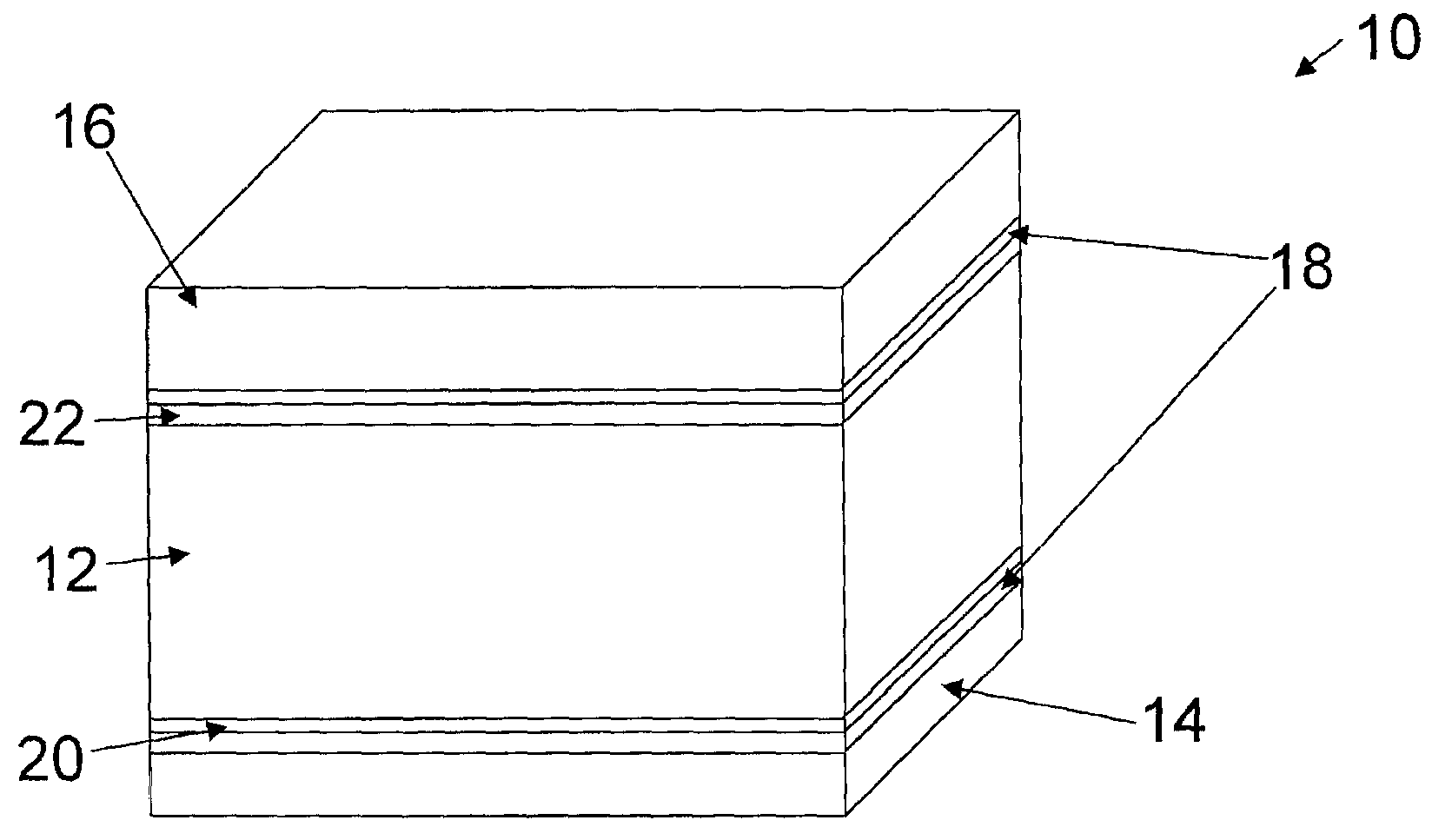

Chemical vapor deposition apparatus and method

InactiveUS20060046059A1High densityGreat and uniform weightLayered productsChemical vapor deposition coatingCarbon compositesCircular disc

Apparatus such as a furnace muffle (11) for use in a CVI / CVD furnace. The apparatus includes a bottom (12), a top (13), and an outer wall (3) defining an interior space (1) in the apparatus, and a passive heat distribution element (7, 9) located within the interior space (1) and apart from the outer wall (3). Preferably, the bottom (12) and top (12) include perforated plates and the outer wall (3) is cylindrical in shape and all are made of graphite or carbon-carbon composite material and the passive heat distribution element (7, 9) is cylindrical in shape and includes graphite or carbon-carbon composite discs having no spacers therebetween. Also, a method for densifying a porous carbon preform (5), which method includes the steps of: (a) providing the apparatus (11); (b) charging the apparatus (11) with a plurality of stacks of annular porous carbon preforms (5), the preforms being separated from one another by spacers (15); (c) locating the charged apparatus (11) in a furnace at a temperature in the range of 950-1100° C. and a pressure in the range of 5-40 torr; and (d) circulating a natural gas reactant blended with up to 15% propane through the apparatus for 150-900 hours. Also, a batch of carbon-carbon composite preforms made by the method, wherein the density of the batch of preforms is at least 0.5 g / cc higher than the density of a batch of preforms made by an otherwise identical process in which the apparatus does not contain a passive heat distribution element located within its interior. The preforms may be configured as aircraft landing system brake discs or racing car brake discs.

Owner:HONEYWELL INT INC

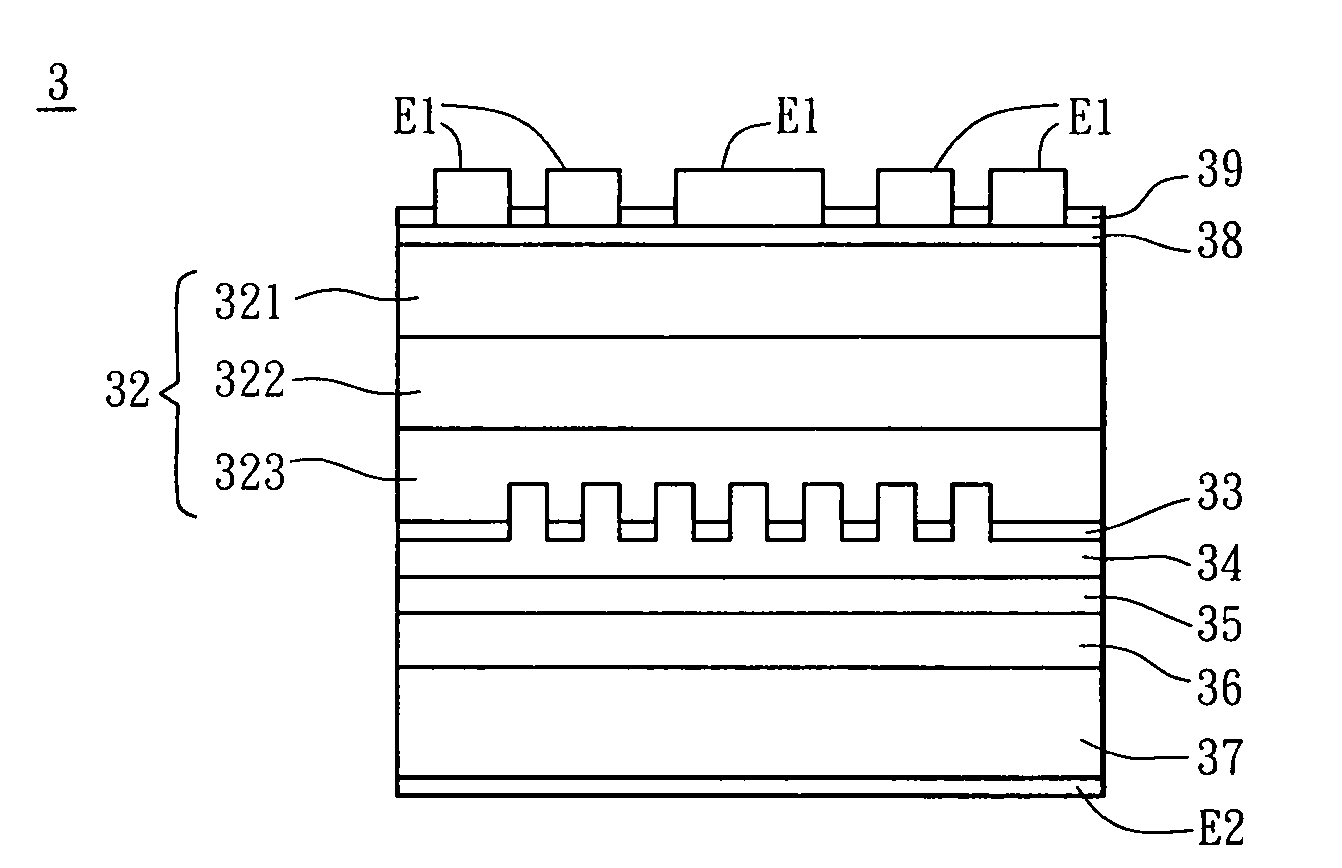

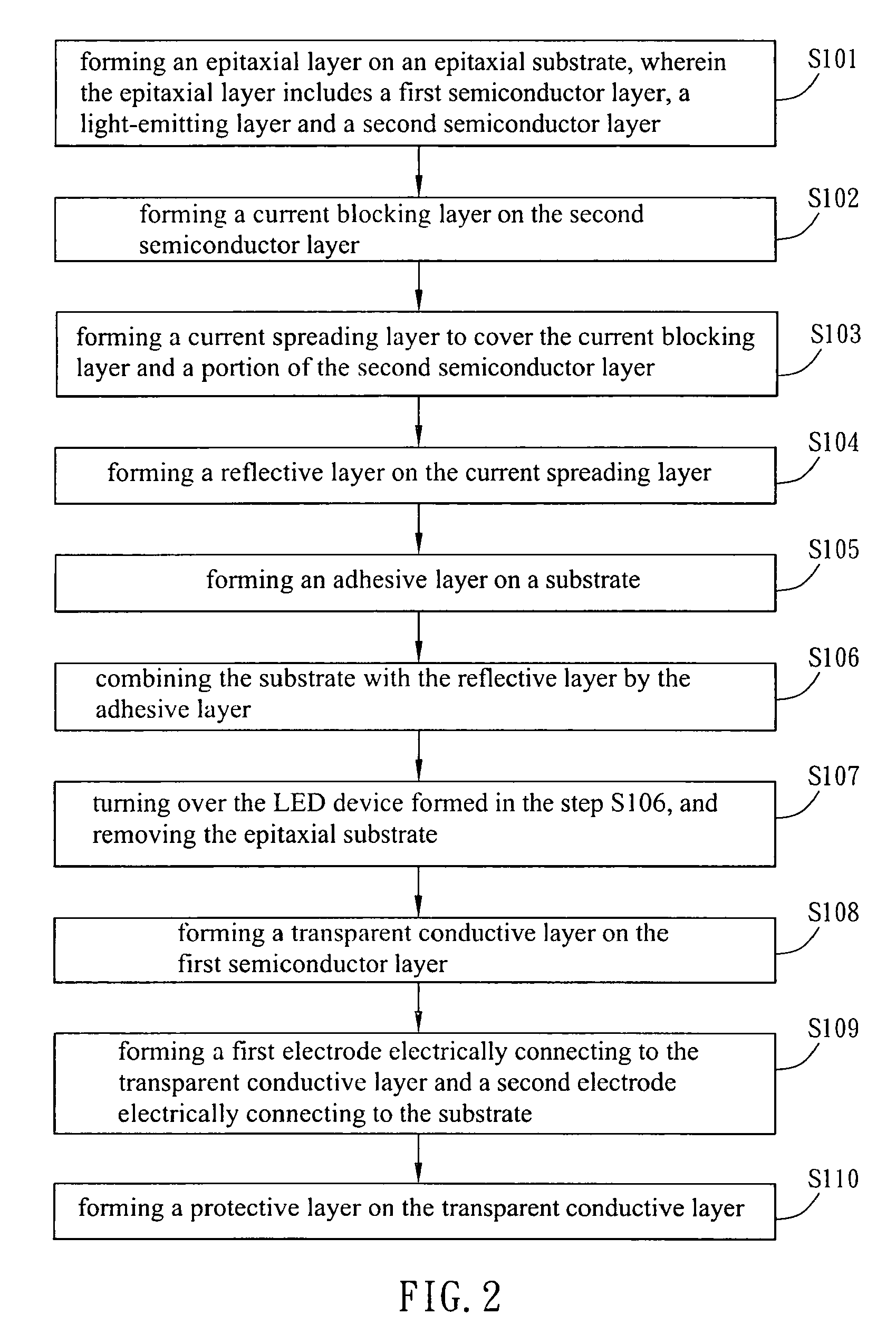

Light-emitting diode device and manufacturing method thereof

ActiveUS20090152583A1Improve lighting efficiencyUniform densitySemiconductor/solid-state device manufacturingSemiconductor devicesBlocking layerEngineering

A light-emitting diode device includes an epitaxial layer, a current blocking layer and a current spreading layer. The current blocking layer is disposed on one side of the epitaxial layer and contacts with a portion of the epitaxial layer. The current spreading layer is disposed on one side of the epitaxial layer and contacts with at least a portion of the current blocking layer.

Owner:DELTA ELECTRONICS INC

Stabilized absorbent composite

Owner:KIMBERLY-CLARK WORLDWIDE INC

Bipolar plate for fuel cell and method for production thereof

InactiveUS20040247978A1Low costSimple structureFinal product manufactureDecorative surface effectsFuel cellsMetal alloy

In a bipolar plate for a fuel cell including a metal substrate and a metallic coating formed on at least part of a surface of the metal substrate, the durability or the resilience is elevated by suitably selecting a material or a shape of the metal substrate and / or the metallic coating. The material of the metal substrate includes one or more of metals or metal alloys selected from a group consisting of iron, nickel, alloys thereof and stainless steel; and the metallic coating includes a combination of conductive platinum-group metal oxides. The metal substrate may be a thermally oxidized substrate, and the metallic coating may be a conductive oxide. Further, the metallic coating may be a metallic porous element or a metallic porous element having a passivity prevention layer on the surface thereof.

Owner:FURUYA KINZOKU KK

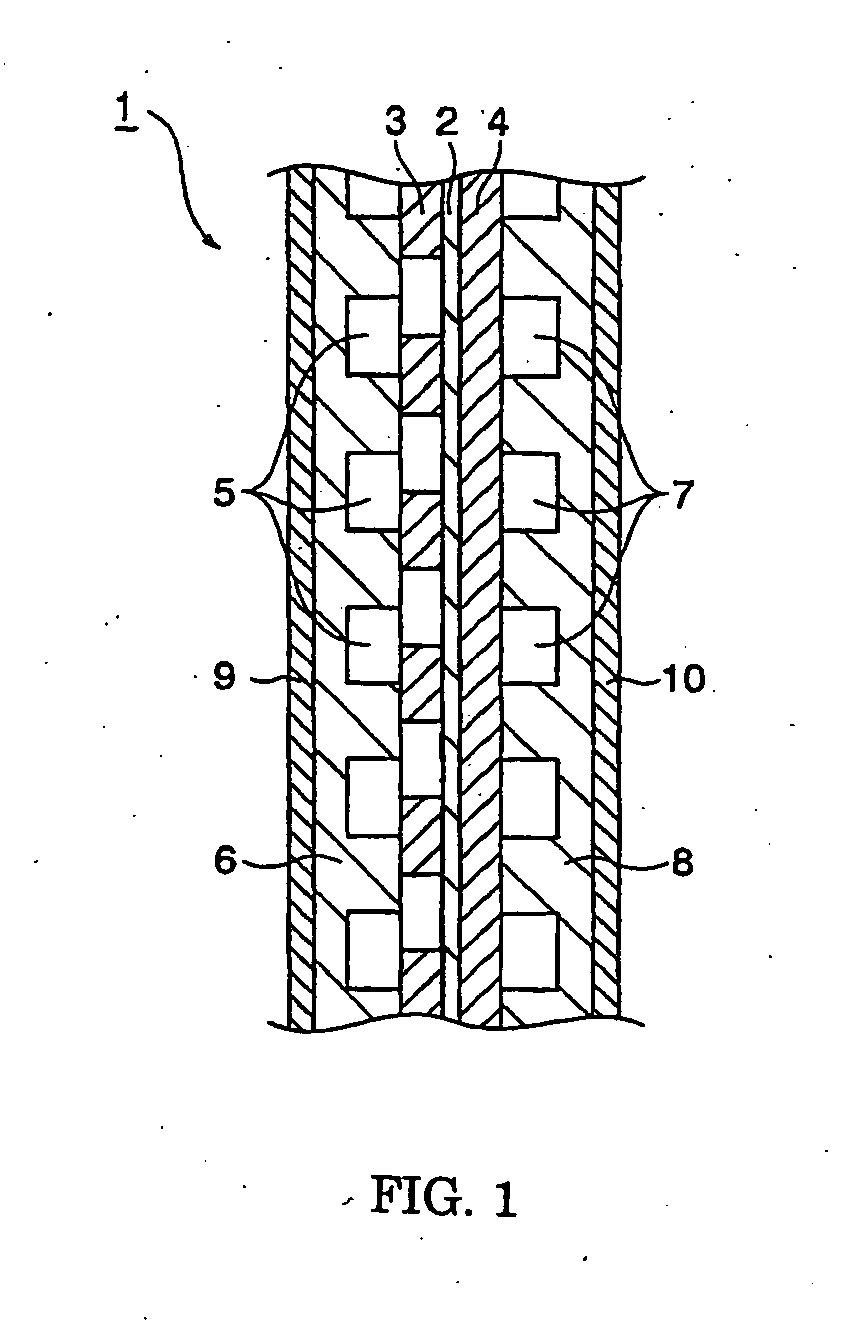

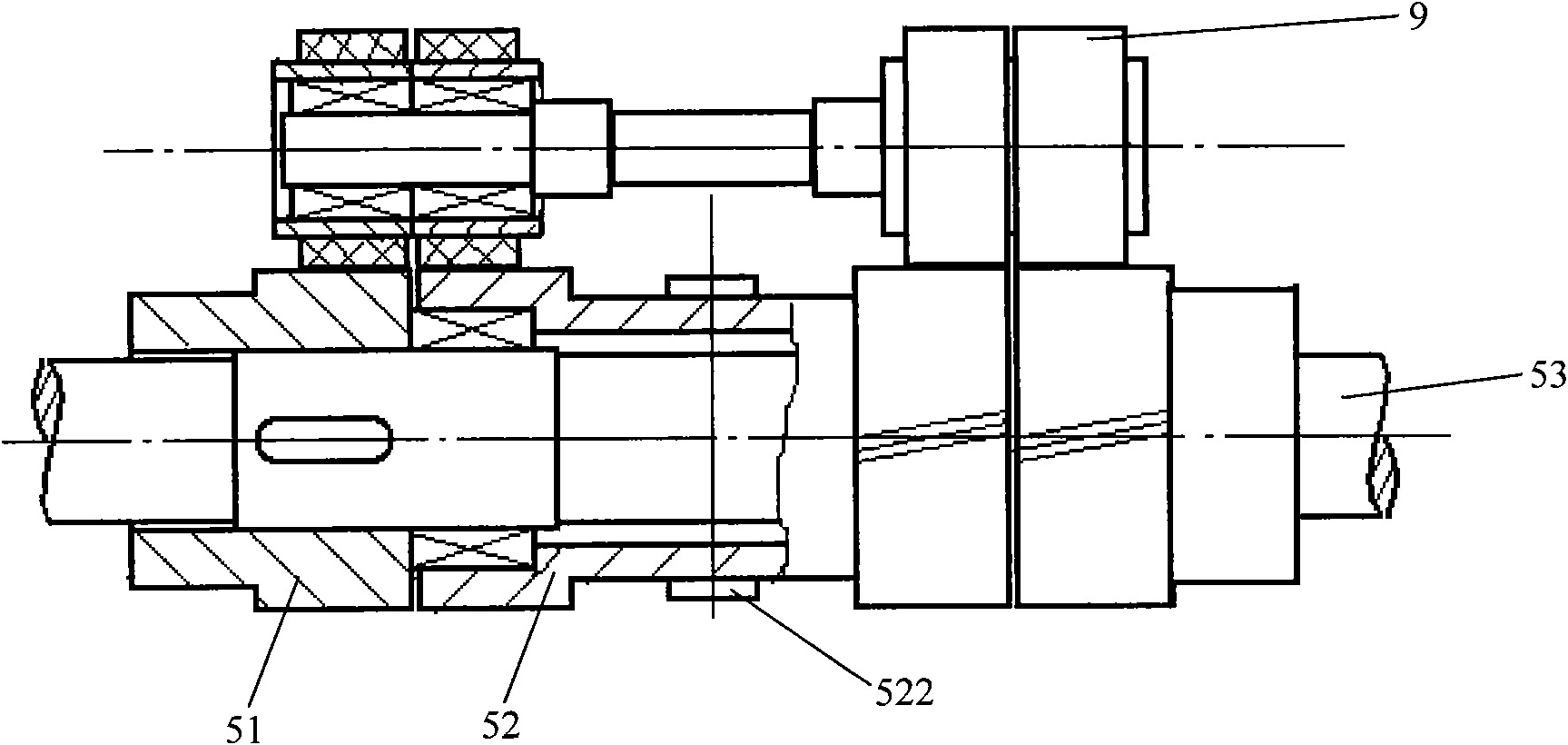

Ring spinning method and device of equi-linear density space dyed yarn

The invention relates to ring spinning method and device of equi-linear density space dyed yarn. The method comprises the following steps of: respectively feeding a fiber strip group (A) with the linear density tex T(A) and a fiber strip group (B) with the linear density tex T(B) into a fixed rear roller and a loop rear roller on a rear roller shaft through yarn guiding rods and grids; and feeding the fiber strip group (A) and the fiber strip group (B) with constant feeding quantity sum into a rear drawing region in any period of time under the process requirement that the feeding speeds of the fiber strip group (A) and the fiber strip group (B) vary with stages by adopting a speed coupling uniform feeding control method. After the strip collection of a strip collector, fiber strips are fed into a middle roller in different drawing ratios, converged in a front drawing region of a spinning machine, drawn and output by a front roller and twisted into equi-linear density space dyed yarn.

Owner:陈伟雄

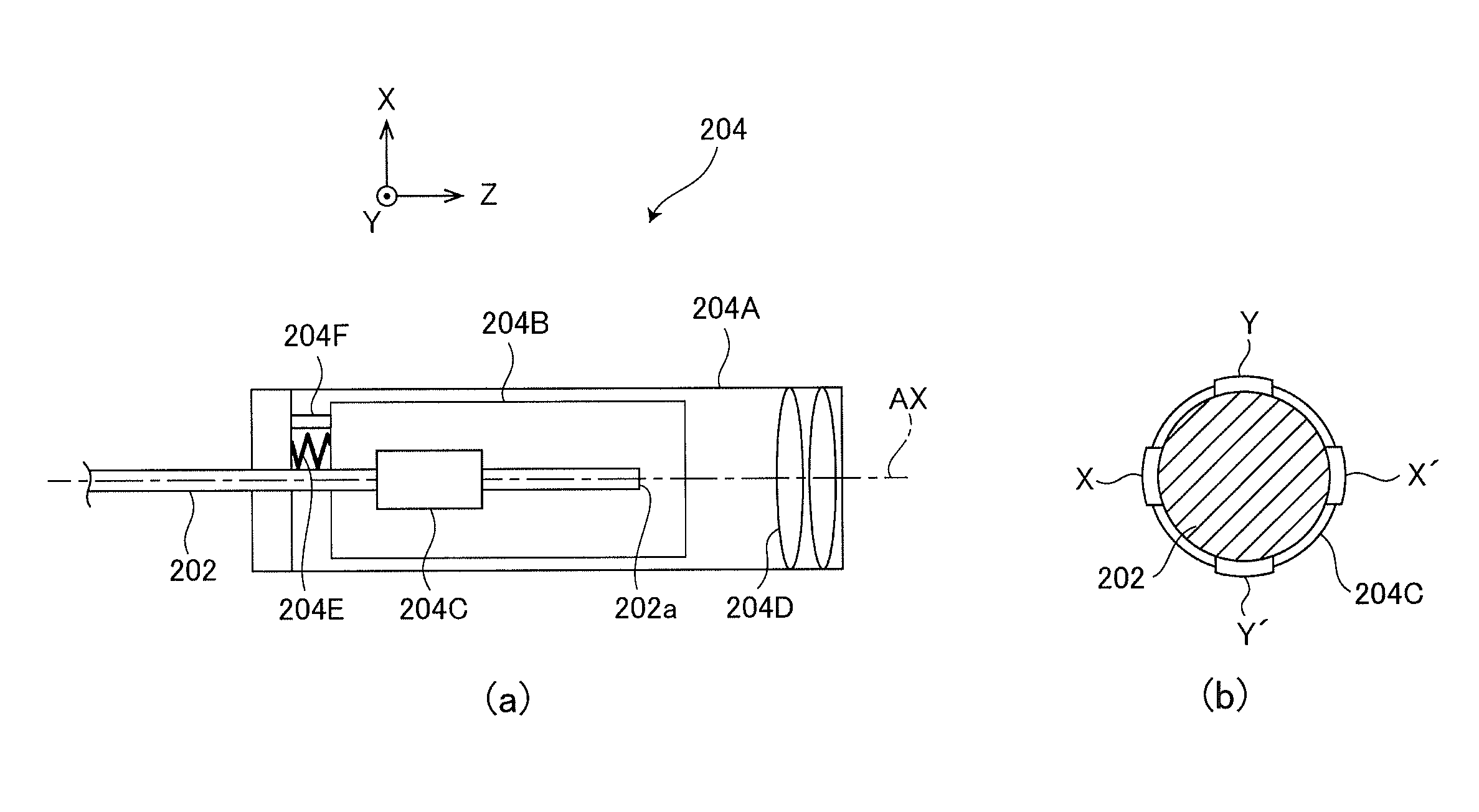

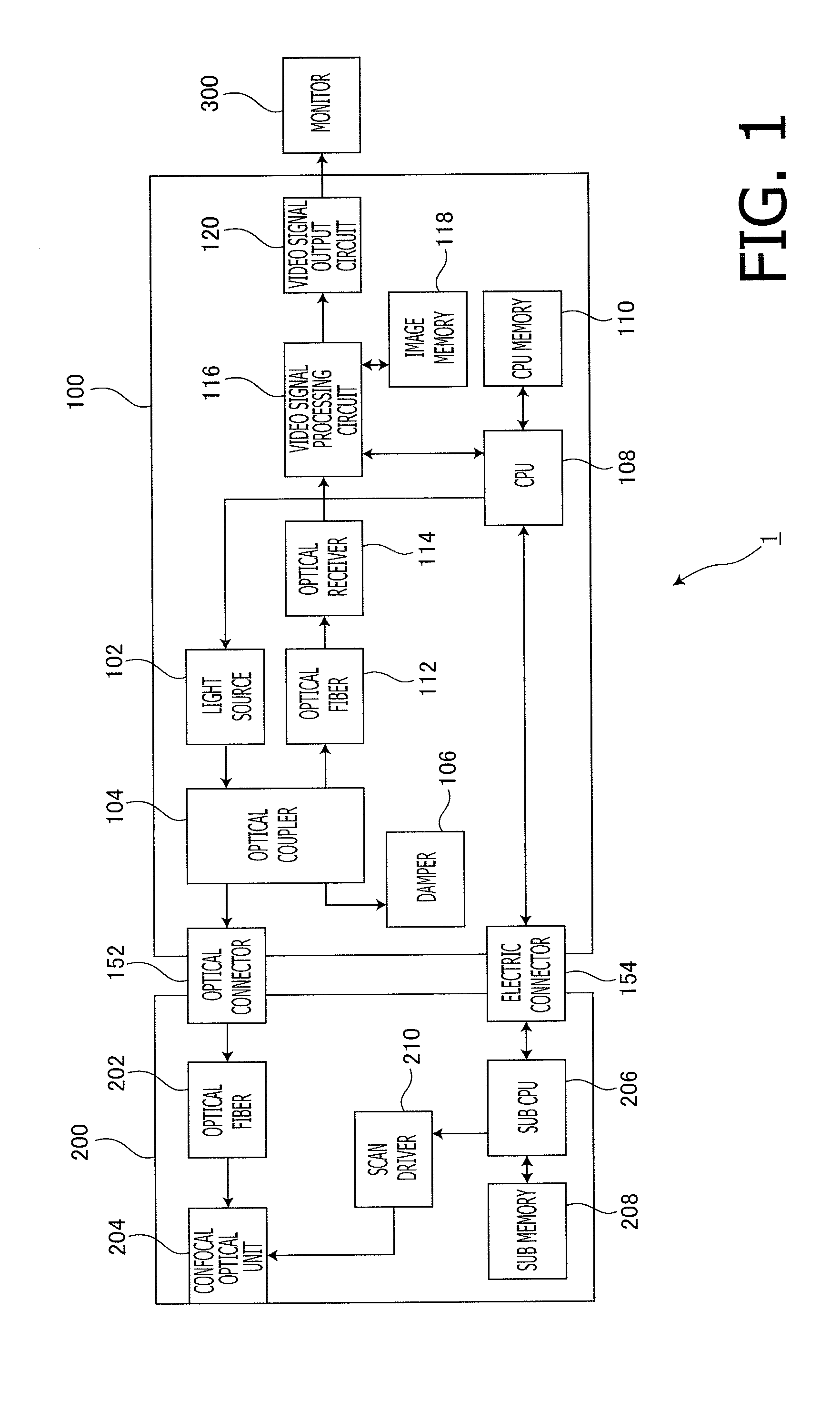

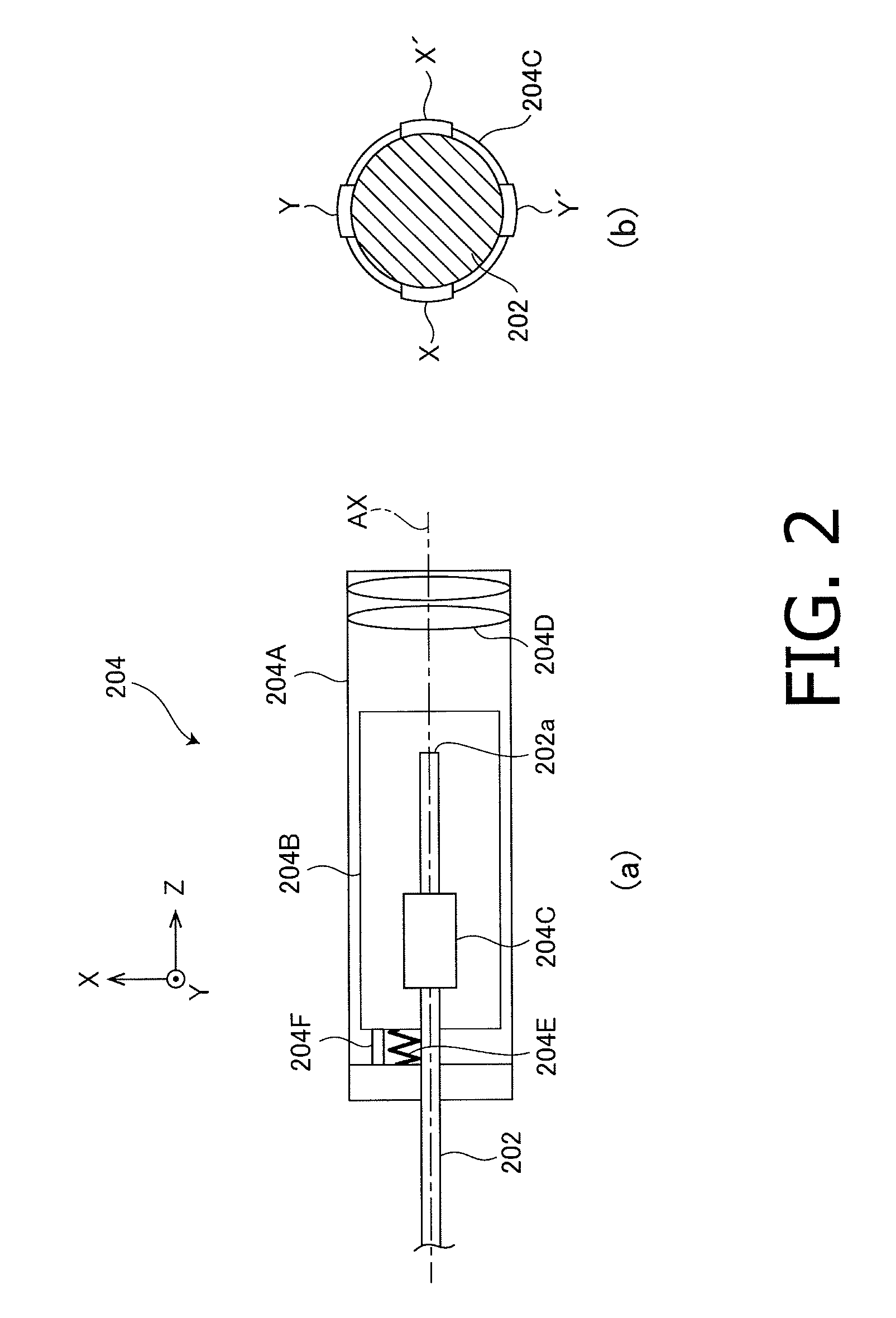

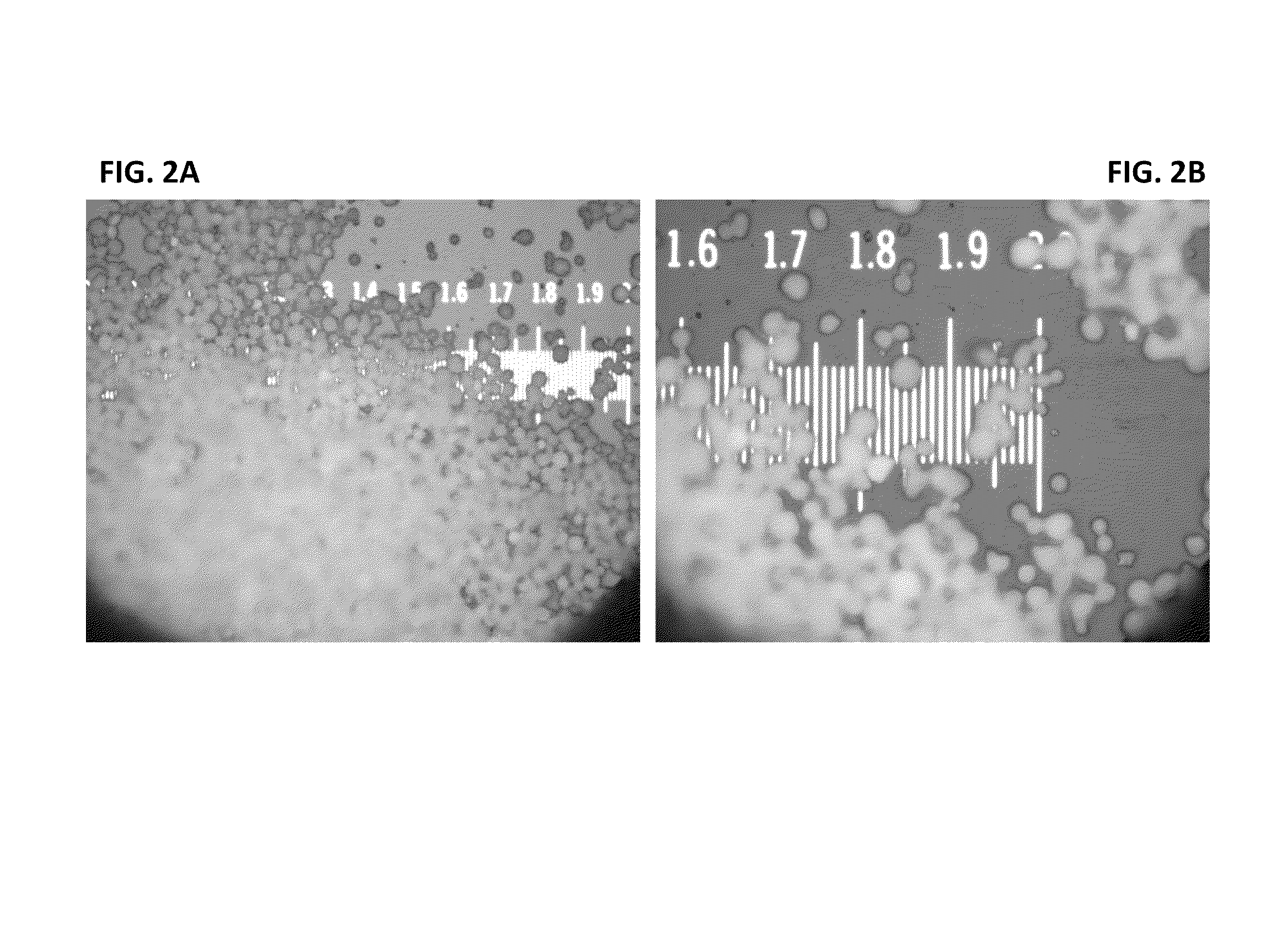

Scanning confocal endoscope system

A scanning confocal endoscope system is configured by: a point source that scans on a subject with excitation light by periodically moving in a two-dimensional plane; a point source control means that controls the point source so that irradiation density of the excitation light becomes smaller than or equal to predetermined density over a whole scanning area; a confocal pinhole arranged at a position conjugate with a converging point of the excitation light; an image signal detection means that detects an image signal by receiving fluorescence emitted from the subject being excited by the excitation light via the confocal pinhole; and an image generation means that generates a confocal image using the detected image signal.

Owner:HOYA CORP

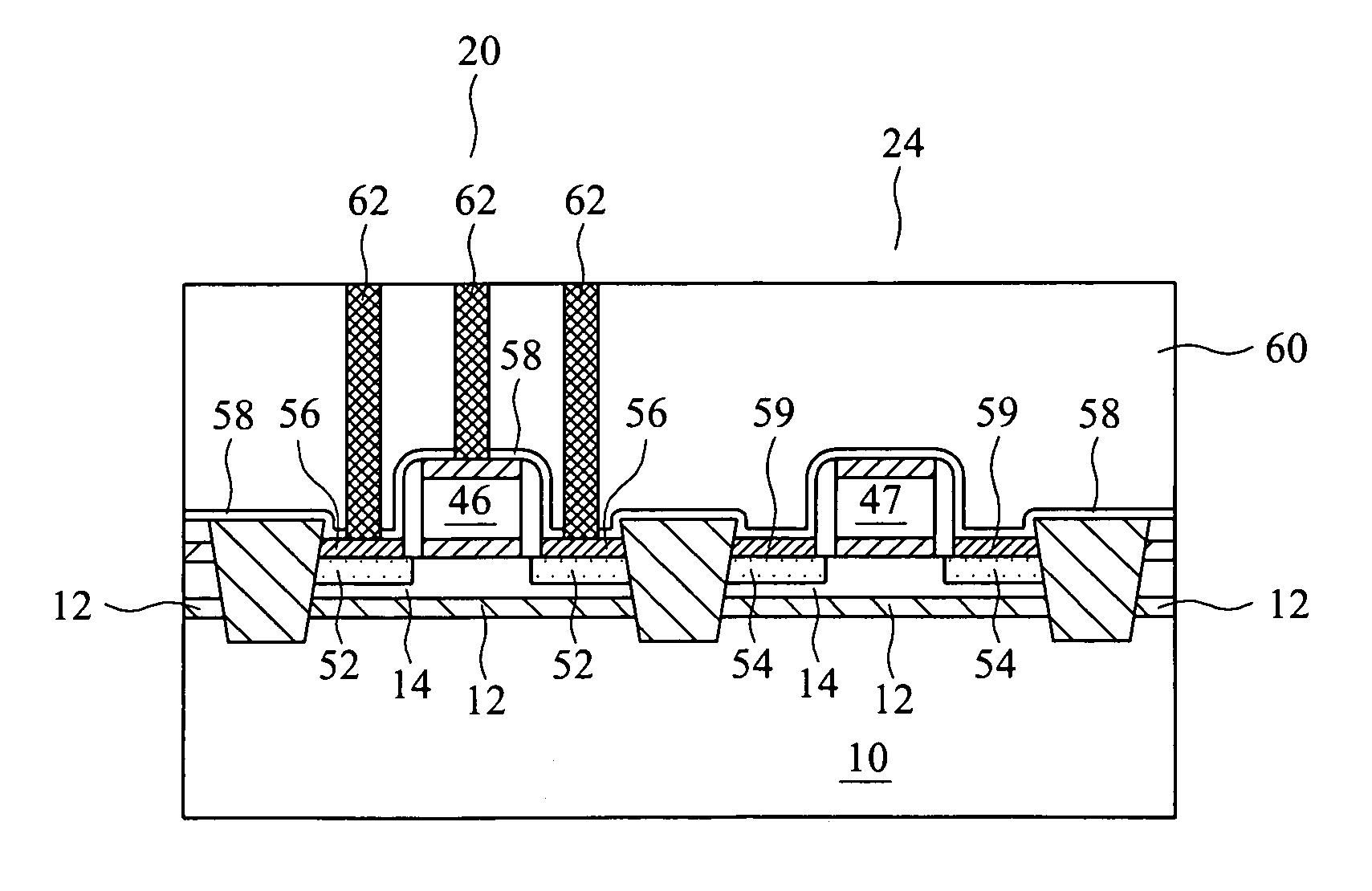

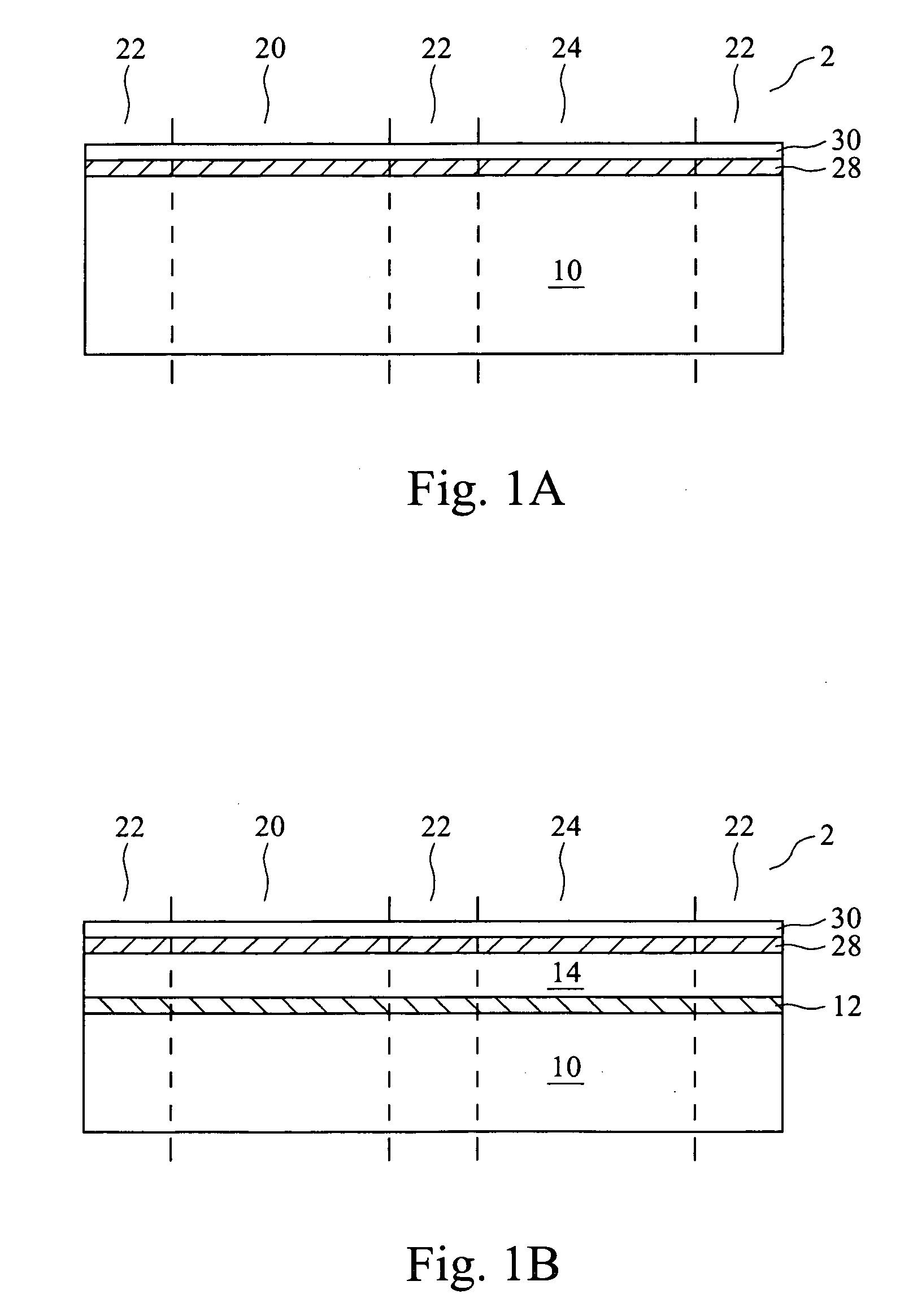

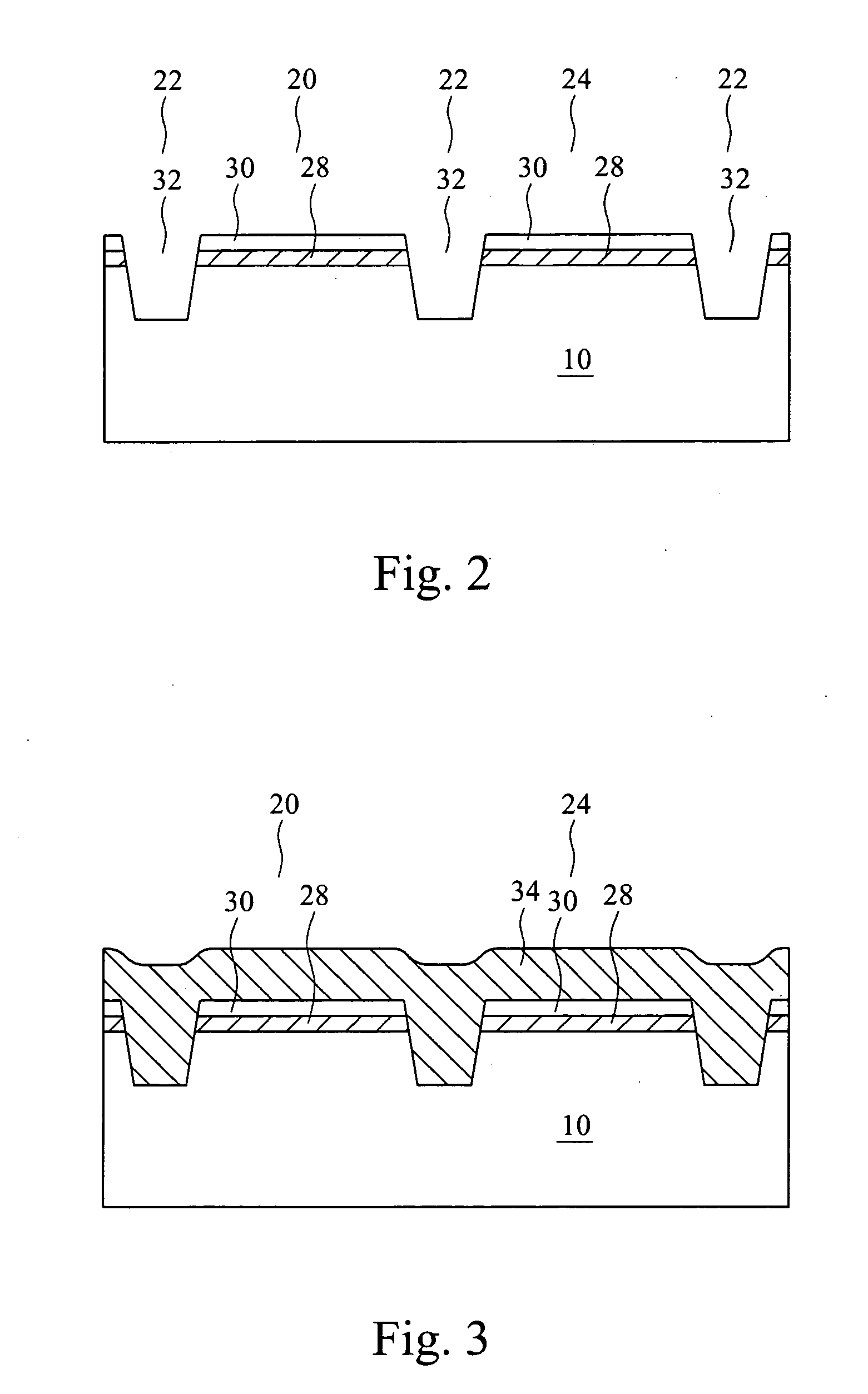

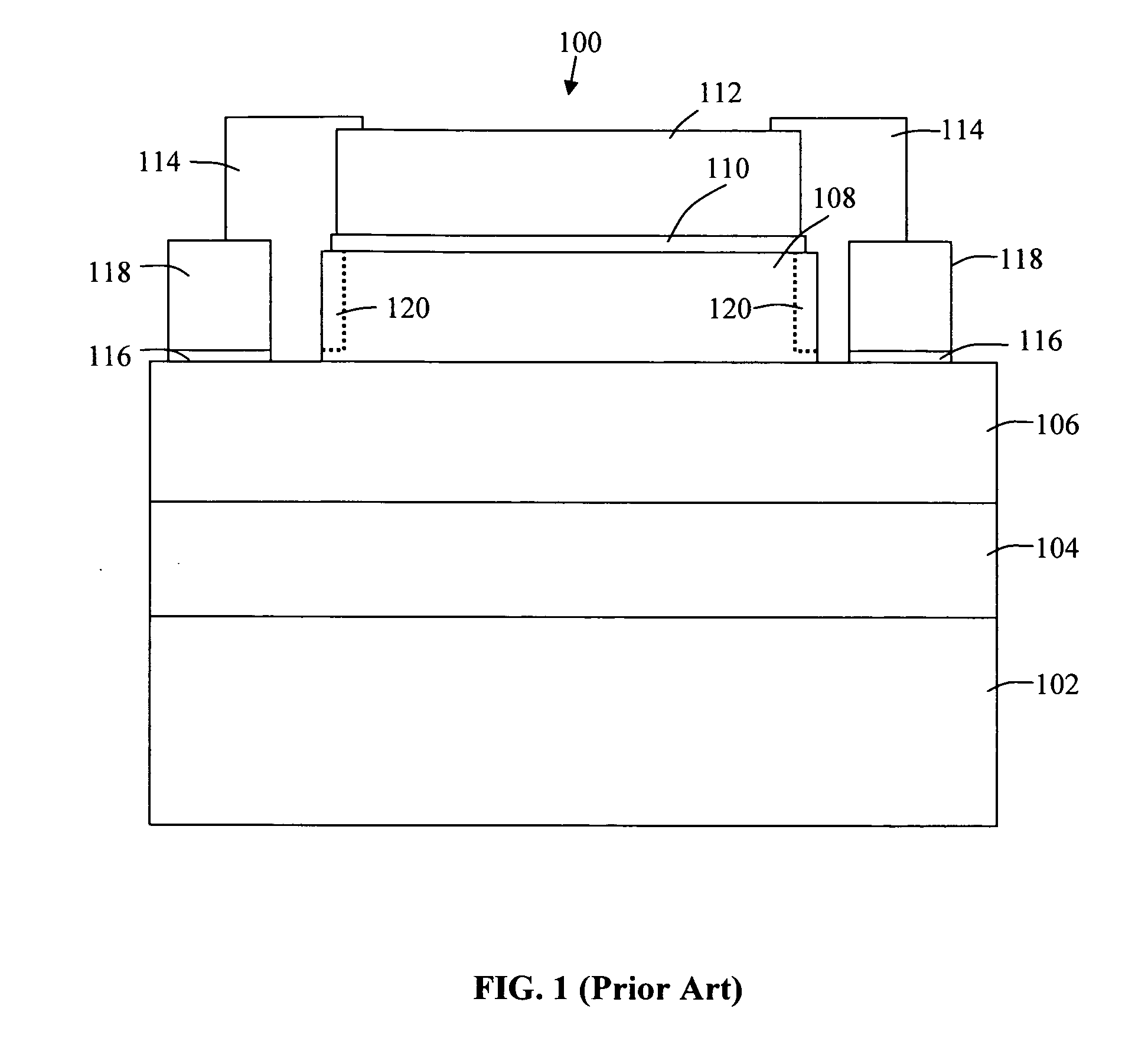

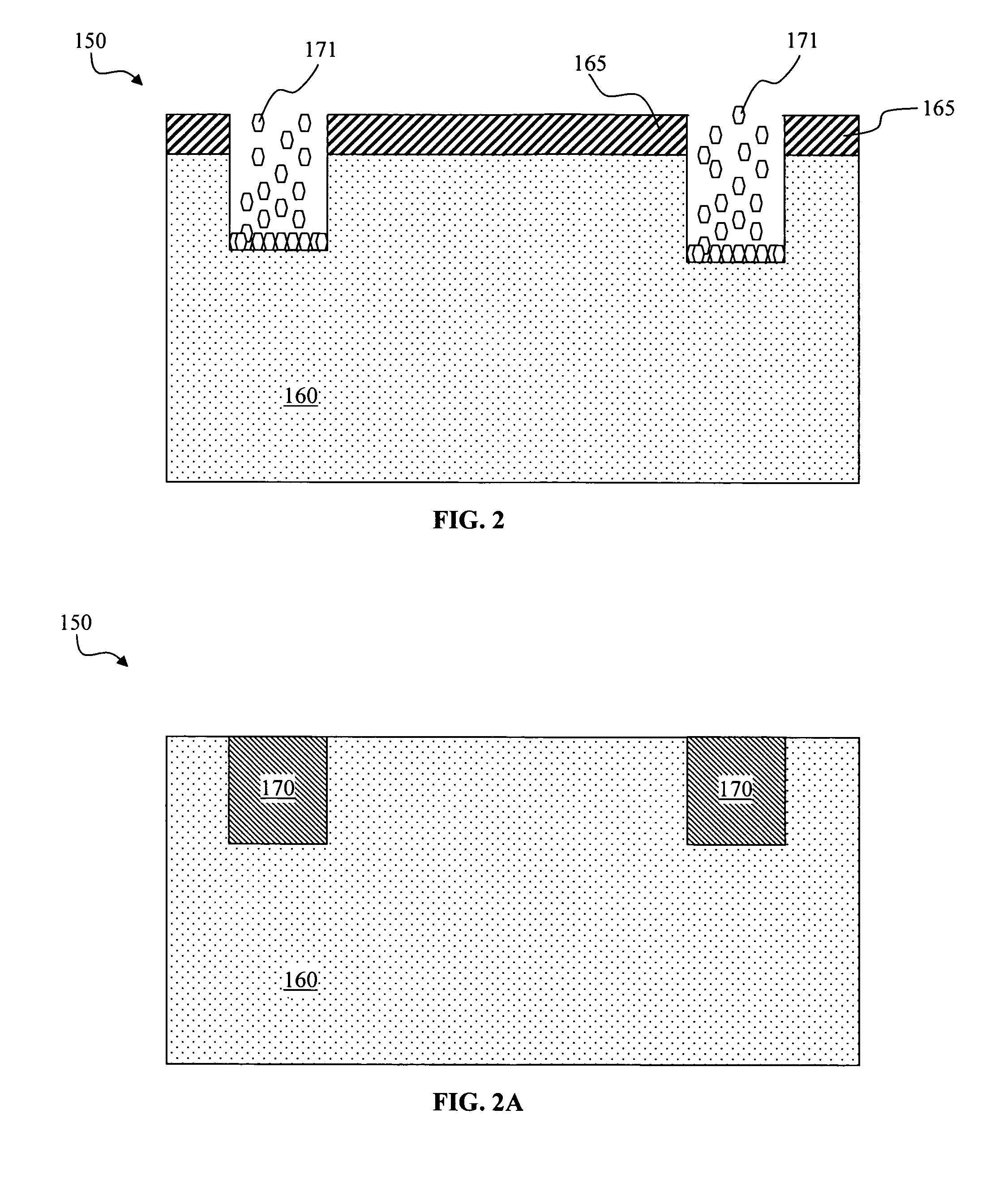

Pattern loading effect reduction for selective epitaxial growth

InactiveUS20060228850A1Reduce Pattern Loading EffectPattern density is uniformSemiconductor/solid-state device manufacturingSemiconductor devicesCrystallographyMaterials science

A method of reducing the pattern-loading effect for selective epitaxial growth. The method includes the steps of: forming a mask layer over a substrate; forming an isolation region in the substrate isolating an active region and a dummy active region; removing at least a portion of the mask layer in the active region and thus forming a first opening, the substrate being exposed through the first opening; removing at least a portion of the mask layer in the dummy active region and thus forming a second opening, the substrate being exposed through the second opening; and performing selective epitaxial growth simultaneously on the substrate in the first opening and second openings. By introducing the second opening wherein epitaxial growth occurs, the pattern density is more uniform and thus the pattern-loading effect is reduced.

Owner:TAIWAN SEMICON MFG CO LTD

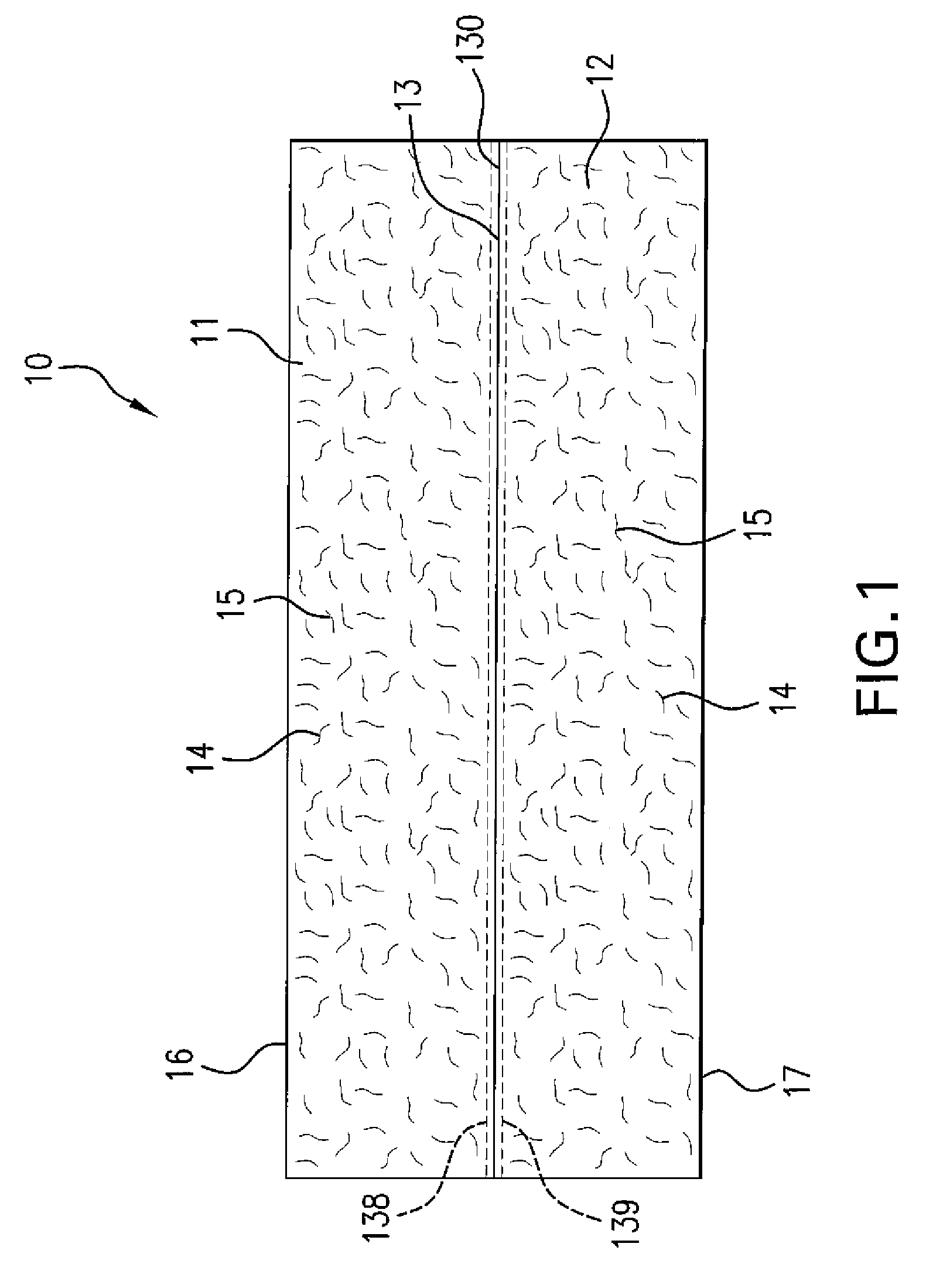

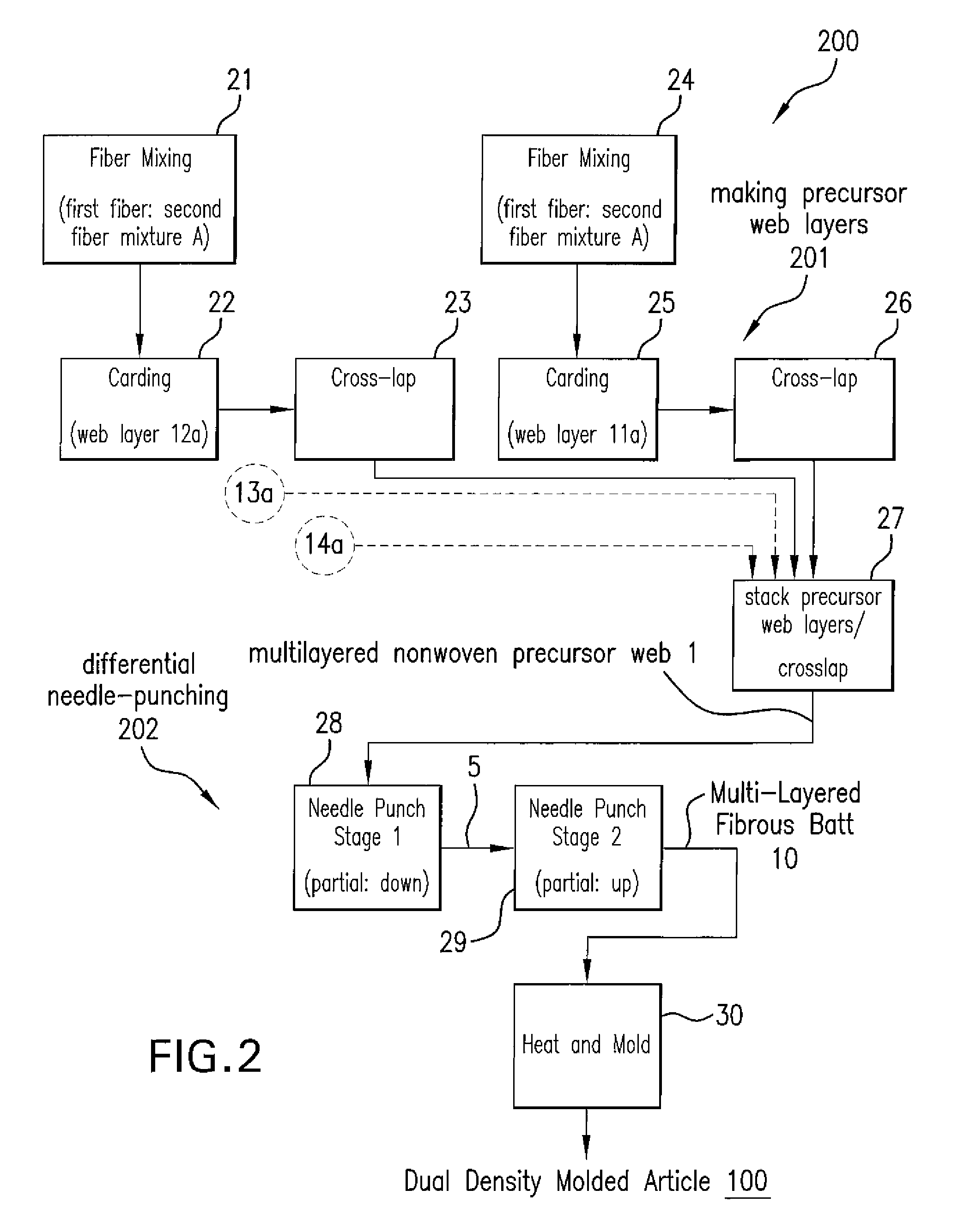

Nonwoven multilayered fibrous batts and multi-density molded articles made with same and processes of making thereof

InactiveUS7928025B2Reduce complexityLow costSynthetic resin layered productsNeedling machinesFiberNeedle penetration

Owner:AVINTIV SPECIALTY MATERIALS INC +1

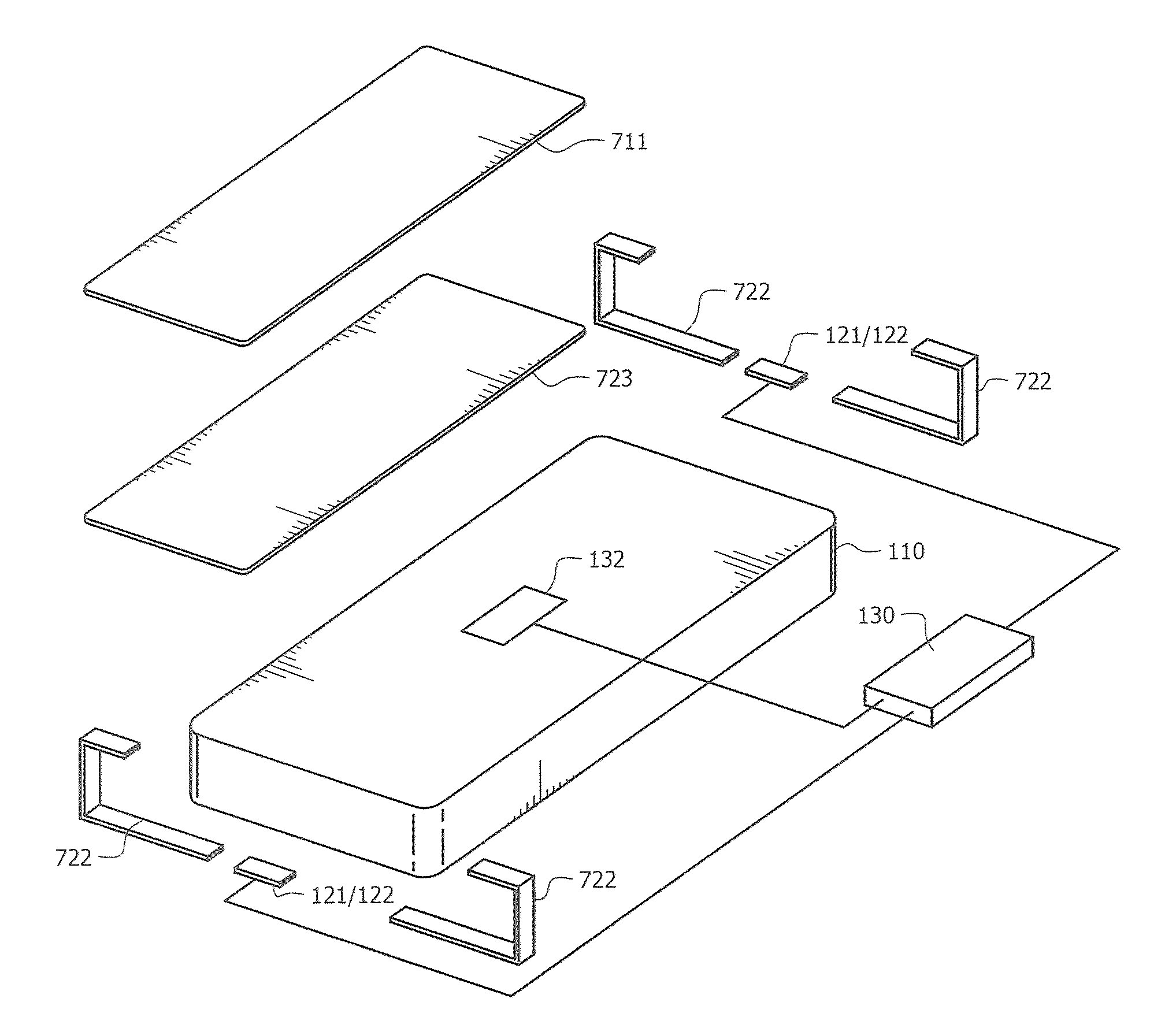

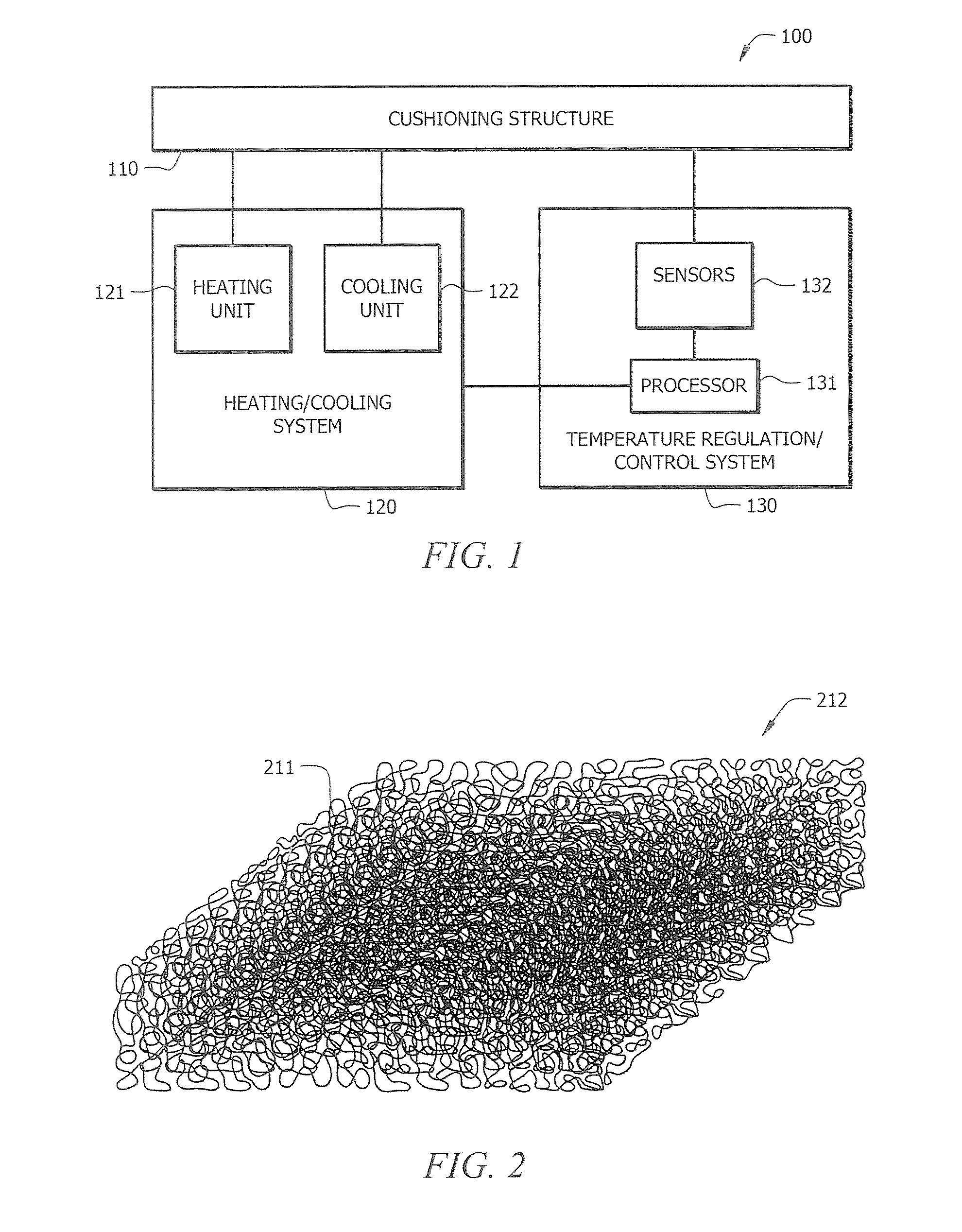

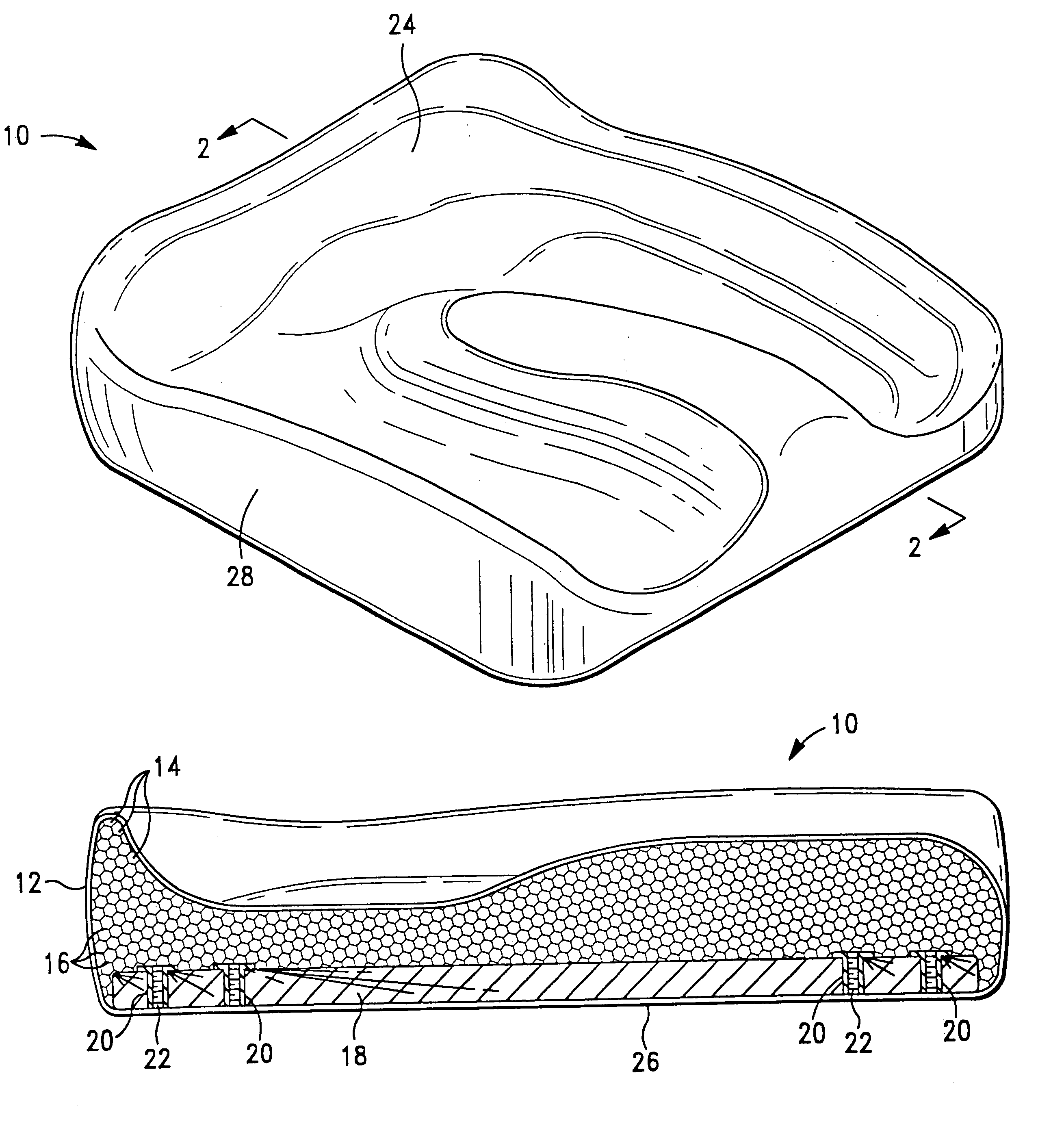

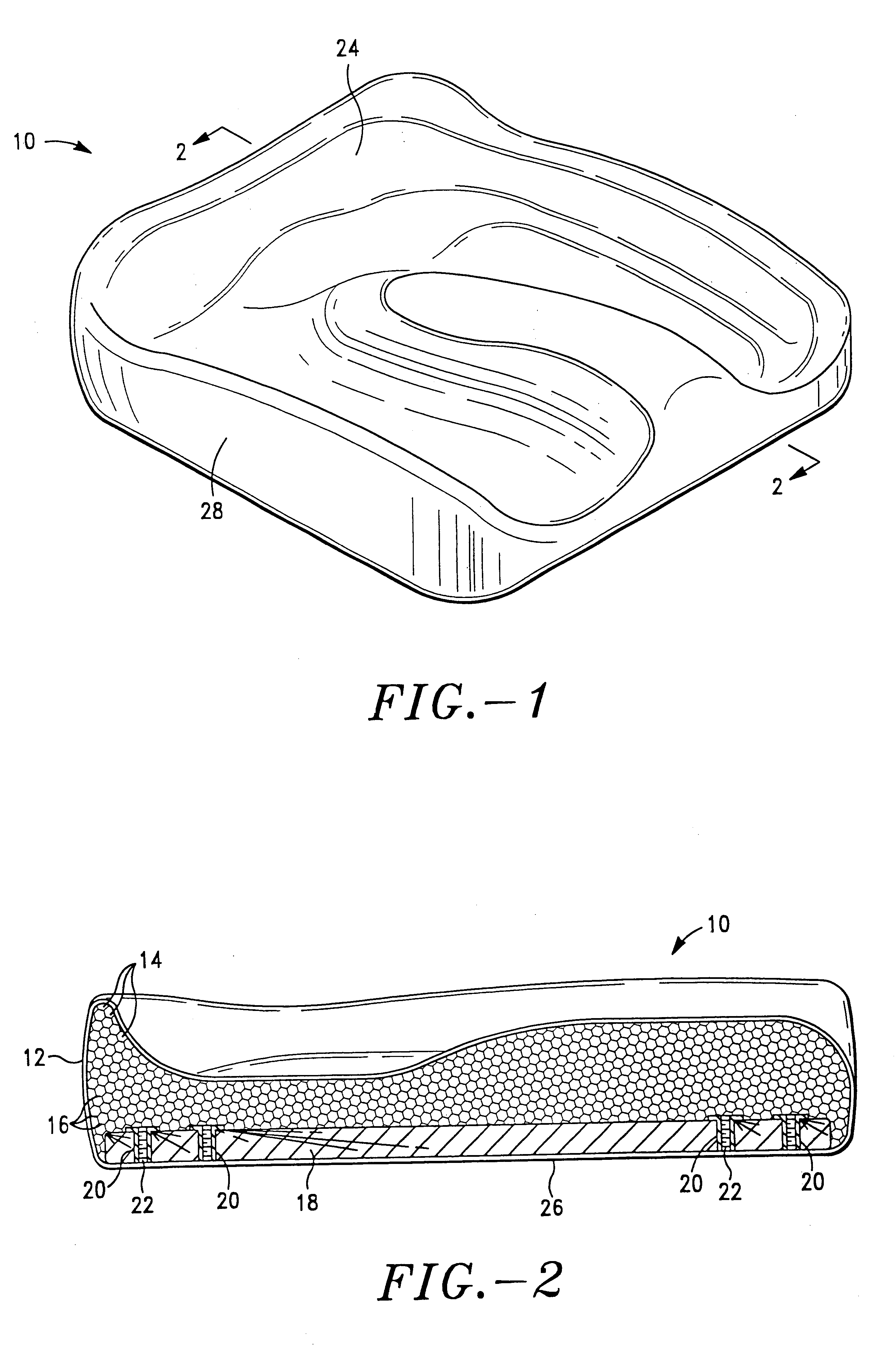

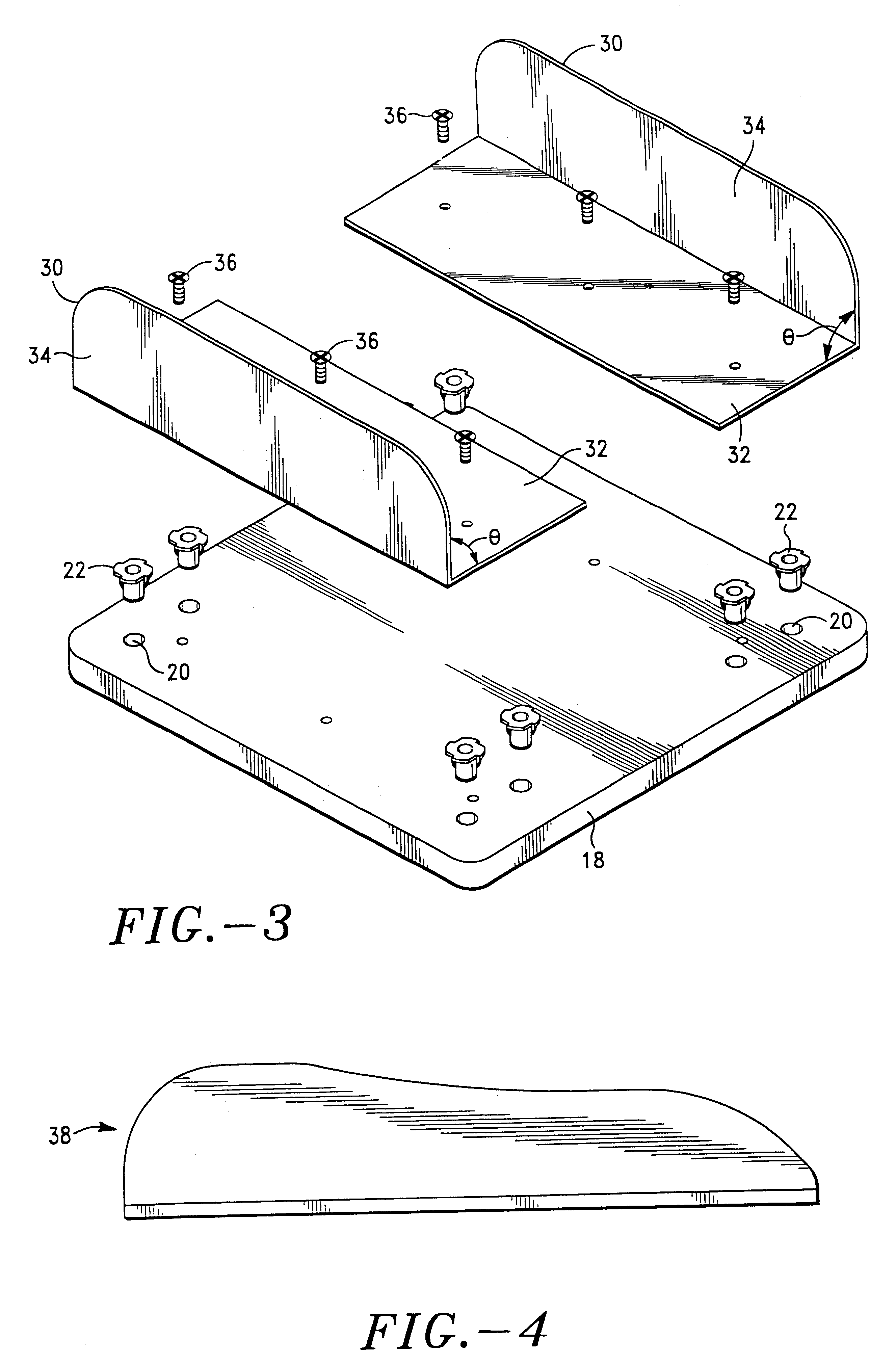

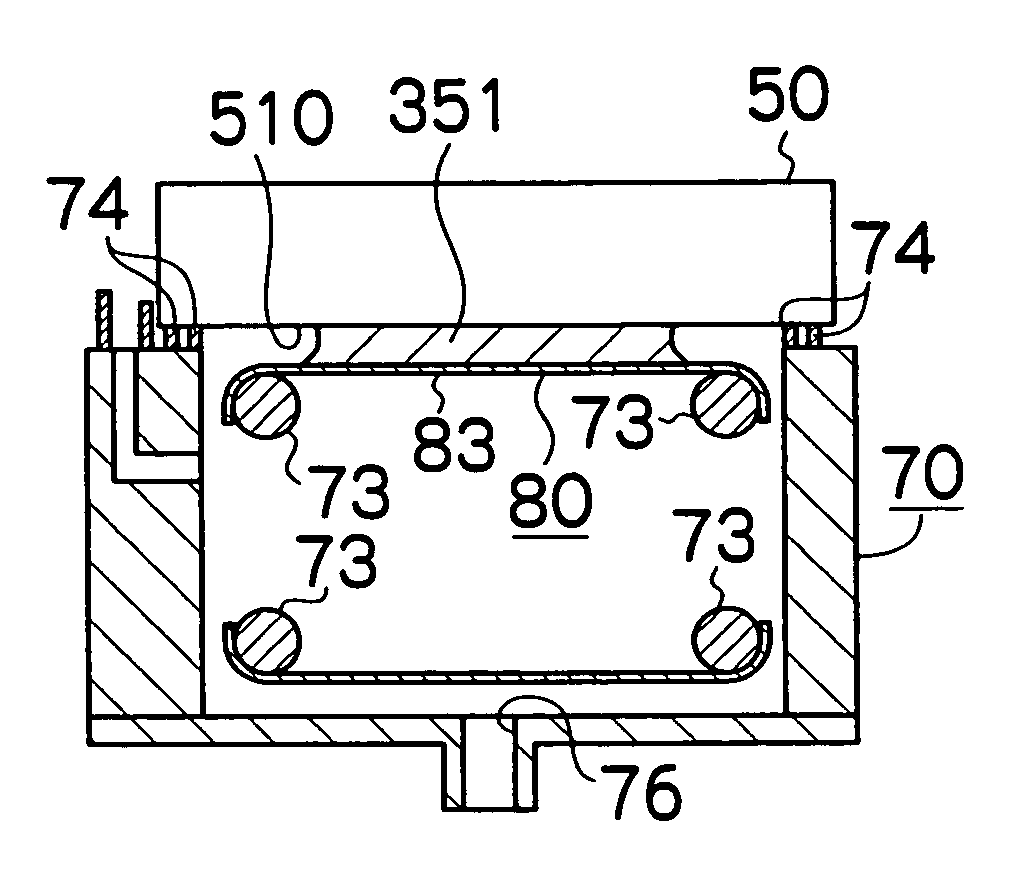

Systems and methods providing temperature regulated cushion structure

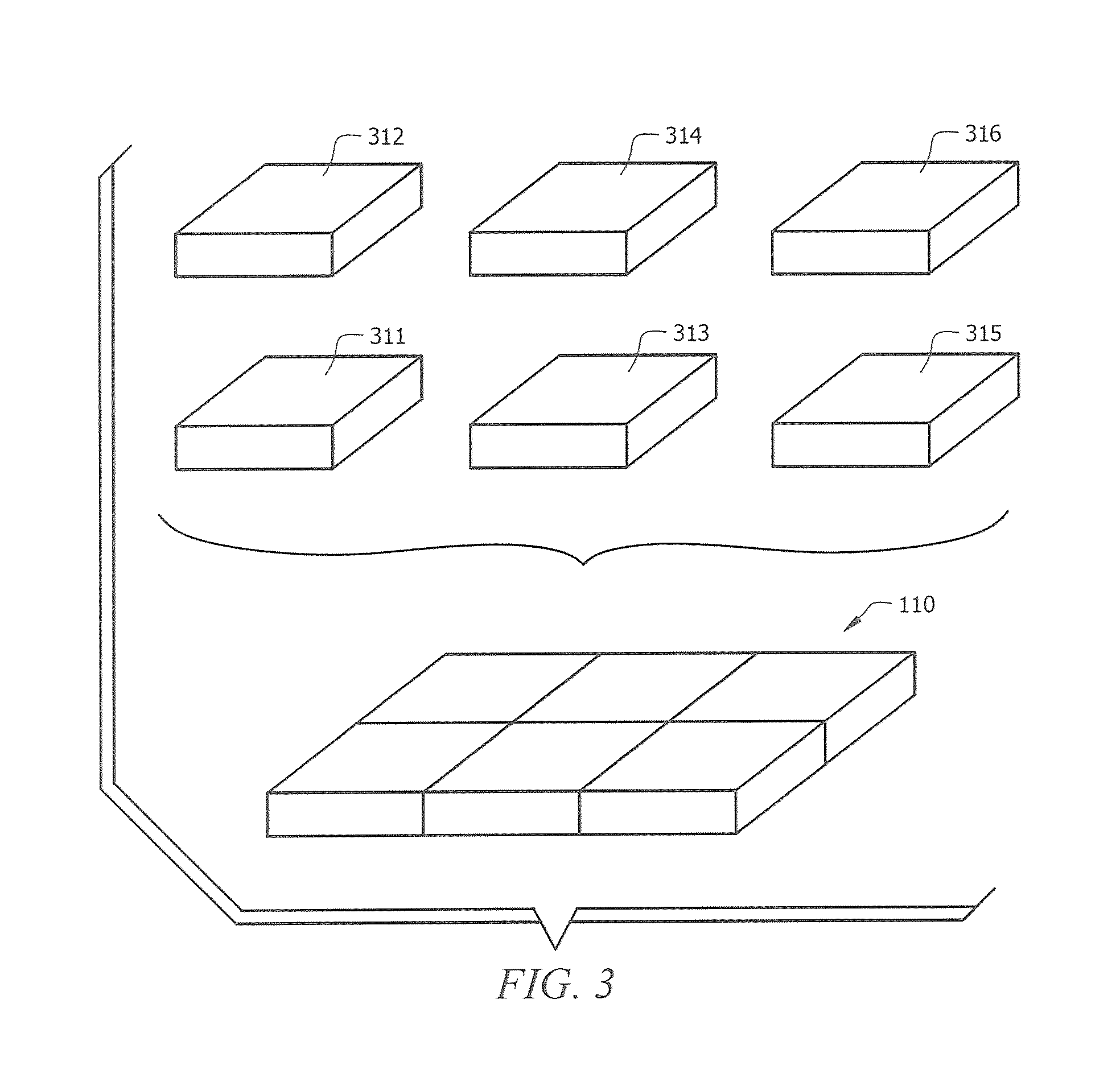

InactiveUS20110041246A1Reduce weightUniform densityStuffed mattressesElectric heatingCushioningModularity

Systems and methods in which temperature regulated cushioning systems are provided in hygienic, convenient configurations are shown. Embodiments provide heating and cooling to provide temperature regulation adapted for human comfort and / or therapeutic effects. Heating and cooling systems implemented with respect to cushioning systems are configured to provided desired temperature regulation for the cushioning system when in use while facilitating hygienic cleaning of the cushioning system. Cushioning structure is preferably adapted to be low weight and to facilitate desired temperature regulation while providing a structure which passively supports and cushions expected loads. Cushion media utilized according to embodiments is modular, such as may comprise a plurality of smaller blocks adapted to cooperate to form a larger cushioning structure. A frame system is utilized according to embodiments to facilitate a desired cooperative arrangement of individual cushion media components and / or to provide various cushioning structure configurations using the cushion media.

Owner:HONG KONG APPLIED SCI & TECH RES INST

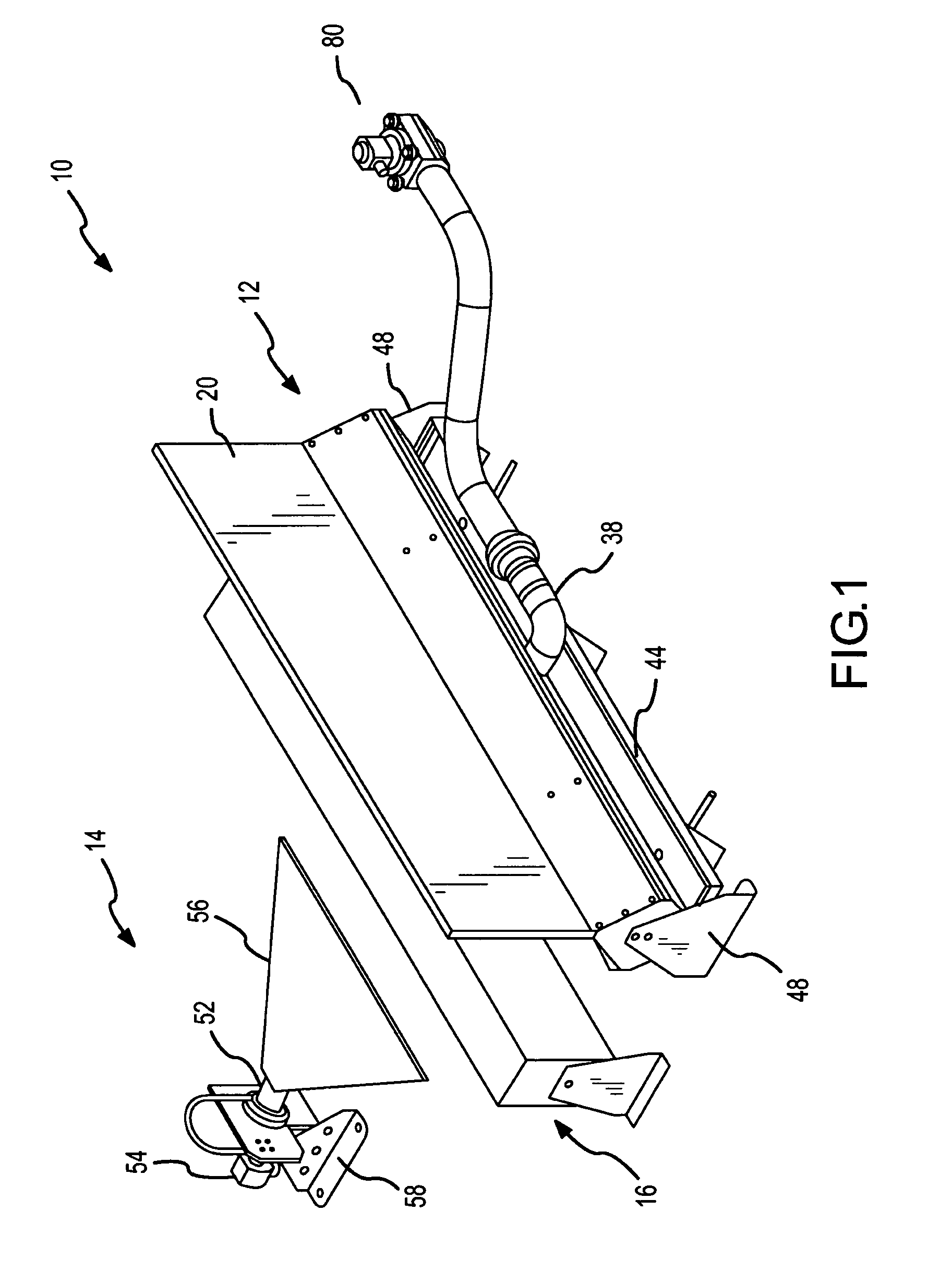

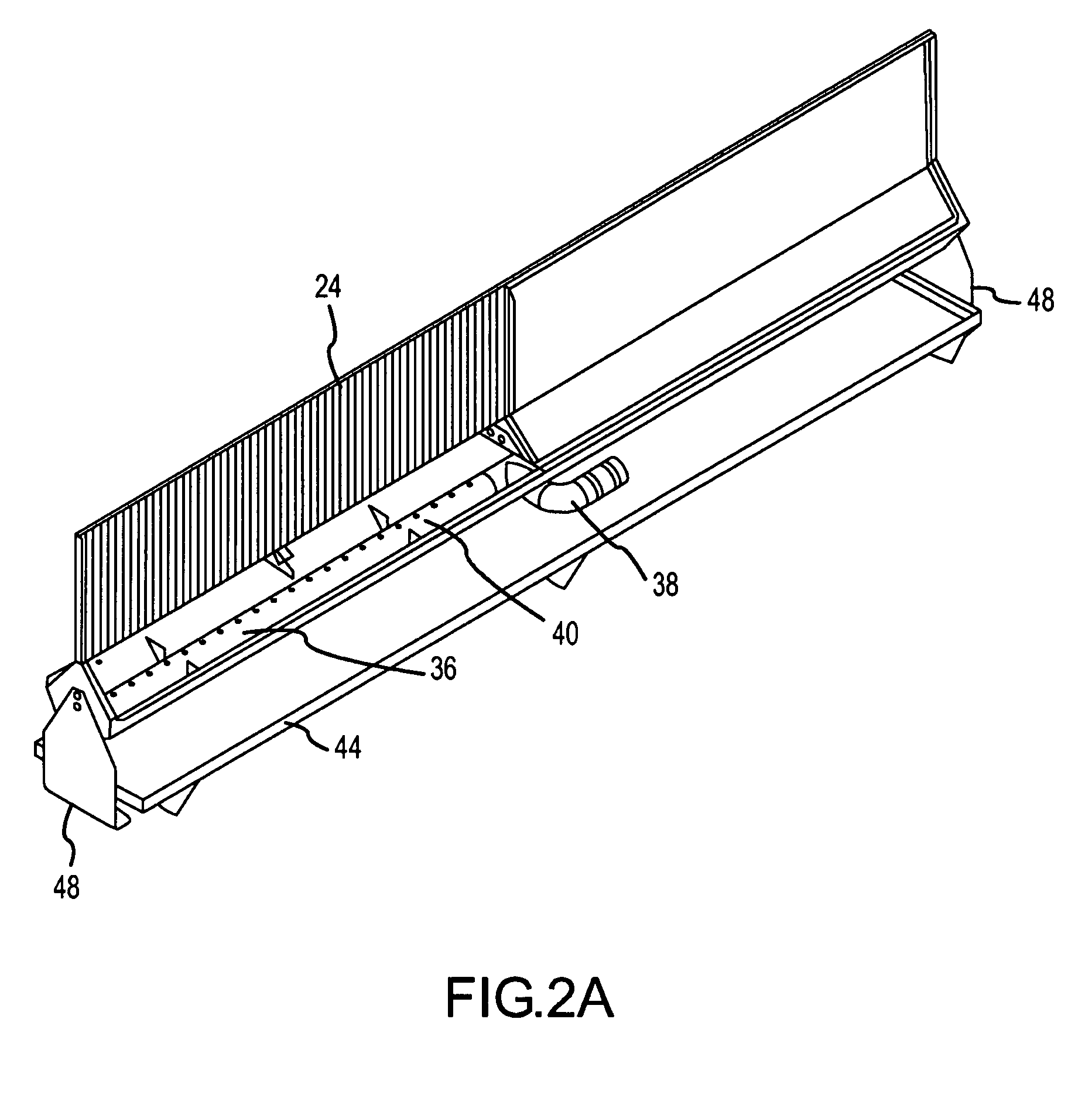

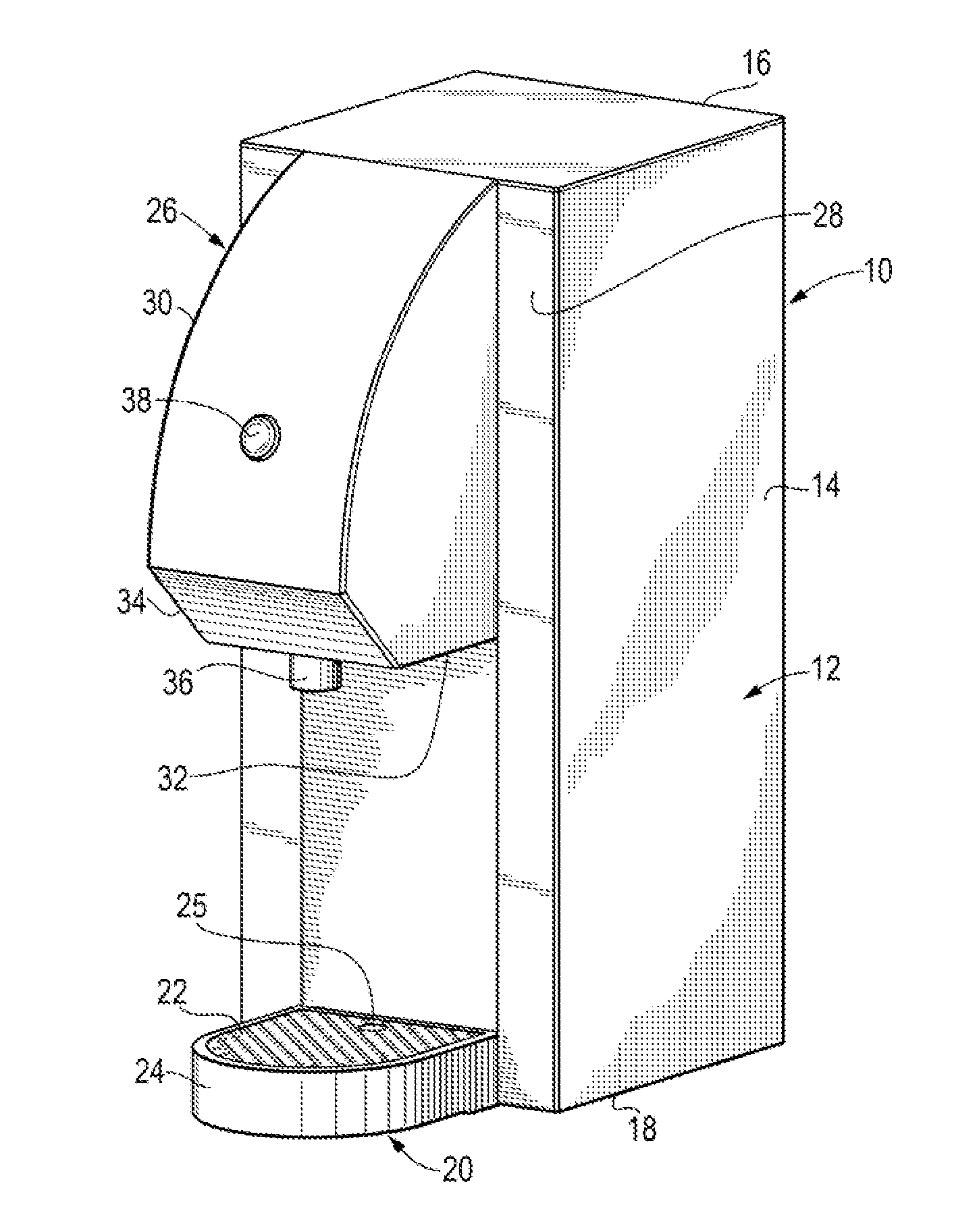

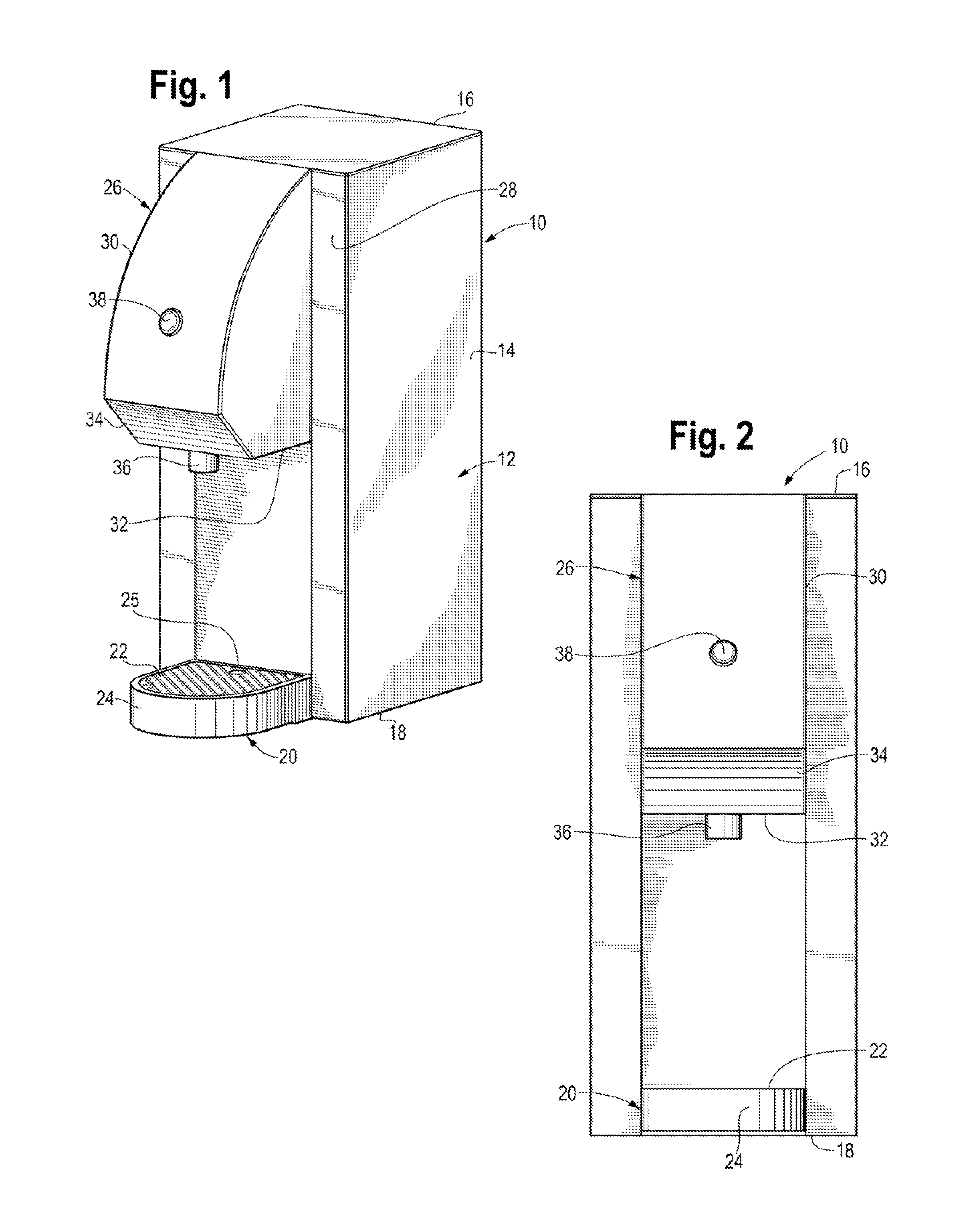

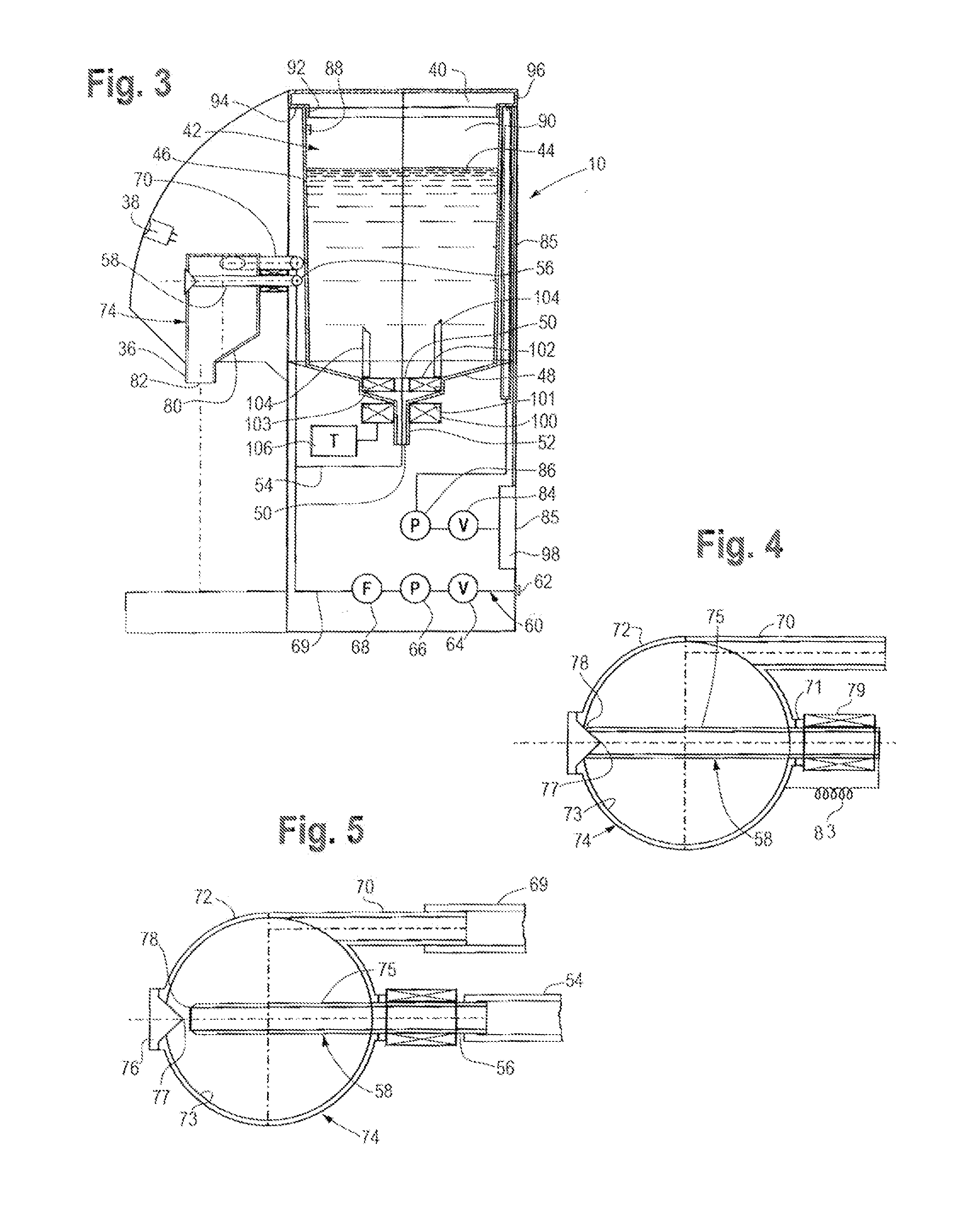

Liquid beverage concentrate mixing beverage dispenser and method

ActiveUS8881948B1Easy maintenanceUniform viscosityBeverage vesselsLiquid transferring devicesNitrogenEngineering

An automated mixing drink dispenser (10) establishes a preselected feed rate of concentrate from a concentrate hopper (42) and ratio of concentrate to mixing water fed into a mixing chamber (42) through the Venturi effect created by swirling water fed into a mixing chamber (42) at a preselected water pressure (66) and preselected regulated flow rate (68) associated with the preselected feed rate of the concentrate. Concentrate is fed to a mixing chamber (42) from a concentrate hopper (42) having an open drain hole (50) openly connected to the mixing chamber (42). A stirring mechanism (106, 100, 101, 102, 104) mechanically mixes the concentrate within the concentrate hopper (42) to maintain a uniform density and viscosity and a gas pressure mechanism (92, 94, 96, 86) maintains a uniform head pressure of concentrate to facilitate maintenance of the preselected concentrate flow rate over time. Nitrogen gas in air is pumped through a nitrogen passing filter to fill the space (90) above the concentrate to both maintain head pressure and to reduce deterioration of the concentrate due to interaction with oxygen.

Owner:FOOD EQUIP TECH

Lithium-sulfur battery

InactiveCN107665966ALower internal resistanceImprove cycle performanceCell seperators/membranes/diaphragms/spacersCell electrodesLithium–sulfur batteryPolymer

The invention discloses a lithium-sulfur battery adopting a multi-layer composite separator. The multi-layer composite separator is characterized in that one side surface of a substrate separator is coated with a polymer layer A, the other side surface of the substrate separator is coated with an inorganic solid material layer and a polymer layer B, and the inorganic solid material layer is located between the substrate separator and the polymer layer B. The mechanical strength of the separator can be improved by the inorganic solid material layer, when a ceramic material with a lithium ion conduction function is used, the ionic conductivity of the separator can be improved effectively, and a polarization effect in charge-discharge processes is reduced. An electrolyte of the lithium-sulfurbattery contains an additive, therefore, interface state of a cathode, an anode and the separator is improved, charge-discharge current on the lithium anode surface is more uniform, activity of the lithium anode in the lithium anode can be reduced effectively, possibility of formation of lithium dendrites is reduced greatly, and use stability of the lithium anode is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

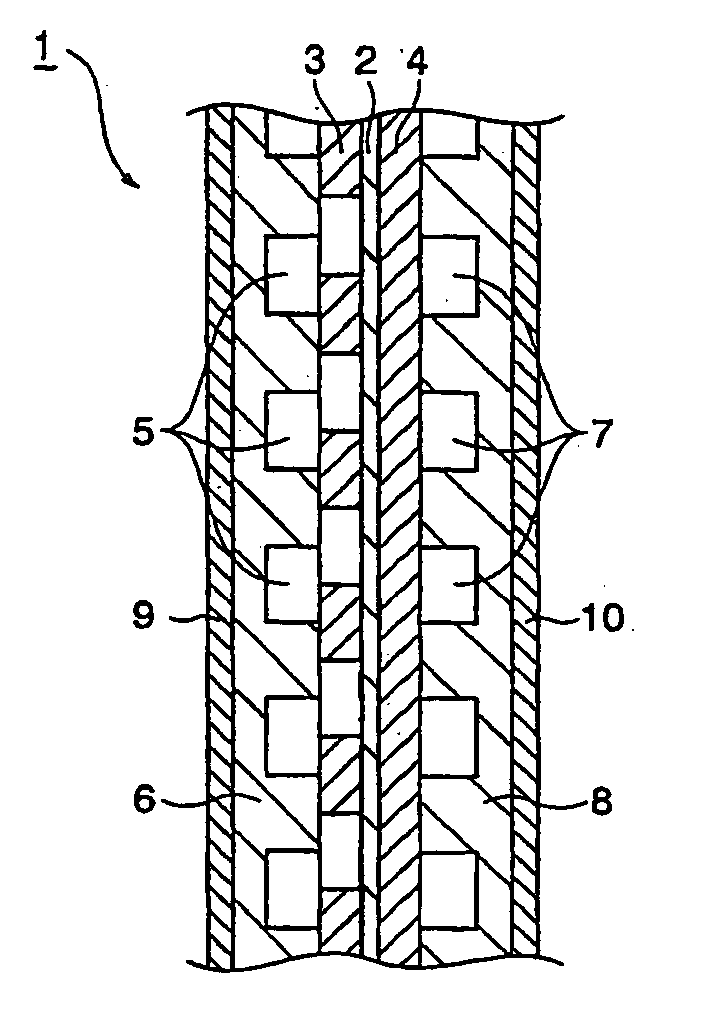

Separator for lithium ion secondary battery, method for manufacture thereof, and lithium ion secondary battery

ActiveUS20110171535A1Less fluctuationUniform densityMaterial nanotechnologyPretreated surfacesLithiumInorganic particle

Disclosed are a separator for lithium ion secondary batteries, having an inorganic layer formed from inorganic particles, characterized in that the inorganic particles have a particle diameter distribution in which the 50% cumulative particle diameter D50 is in the range of 100 nm to 500 nm, the 10% cumulative particle diameter D10 is 0.5D50 or more, and the 90% cumulative particle diameter D90 is 2D50 or less; a method for manufacturing the separator; and a lithium ion secondary battery using the separator. When the separator is used, there can be produced a lithium ion secondary battery in which a short circuit caused by contraction or melting can be definitely prevented, as well as the current density applied to the electrodes during charging and discharging is uniform so that charging and discharging can be efficiently achieved.

Owner:NIPPON BAIRIIN

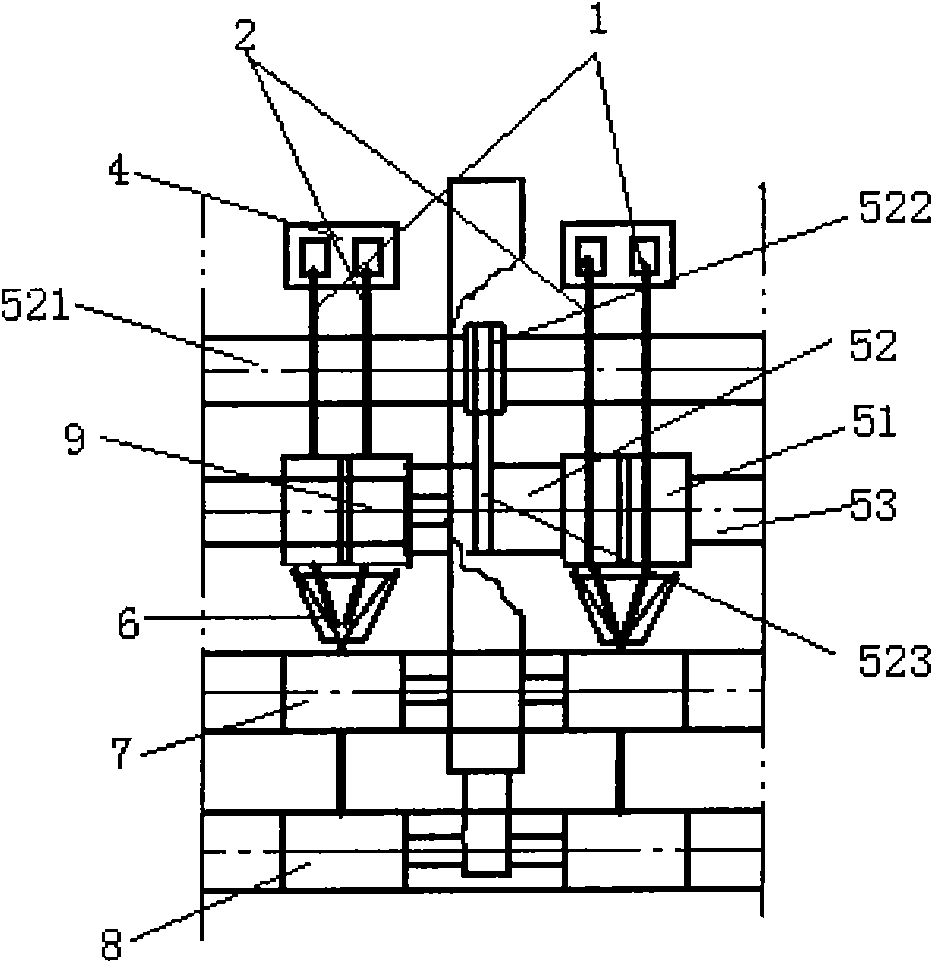

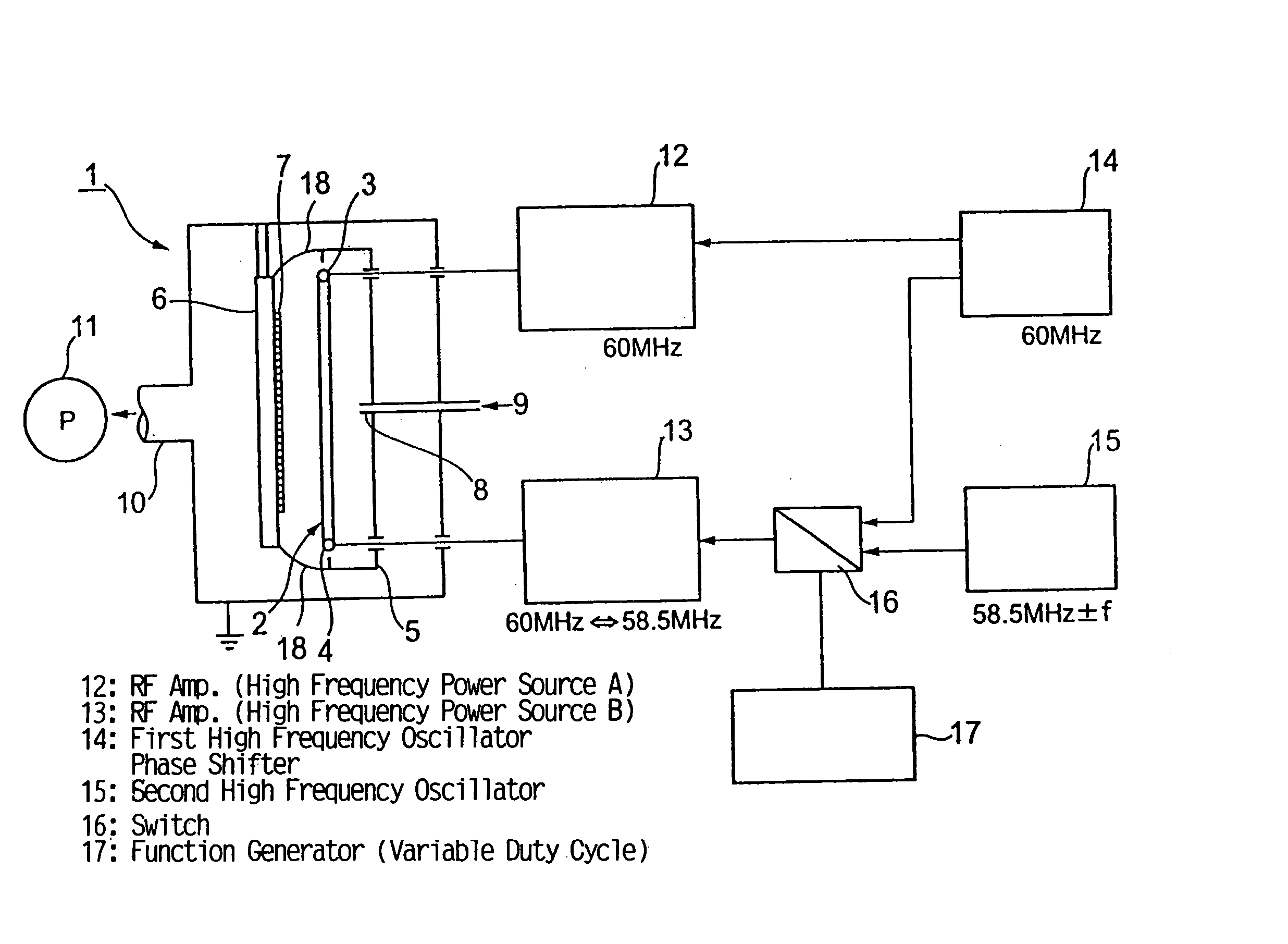

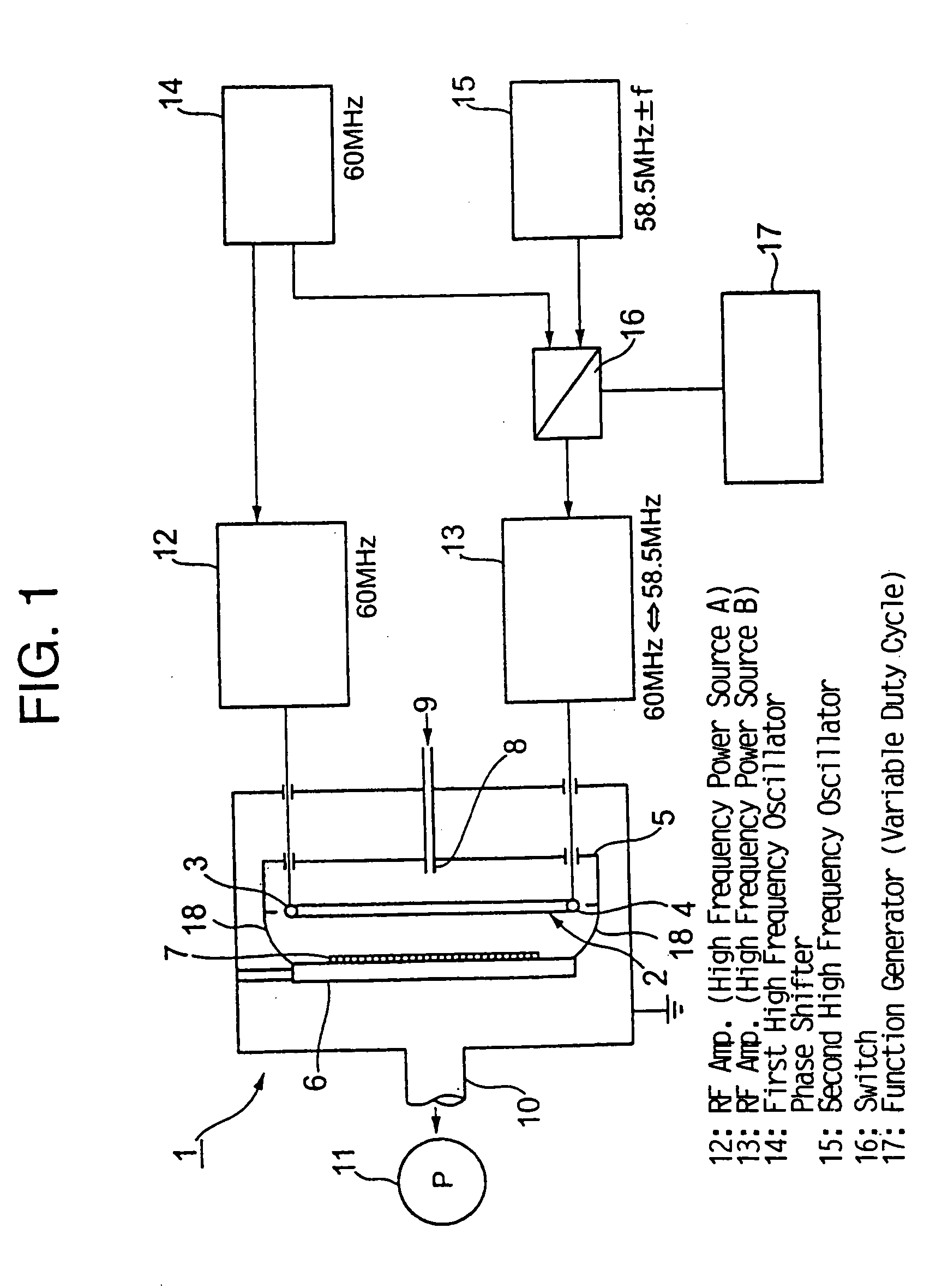

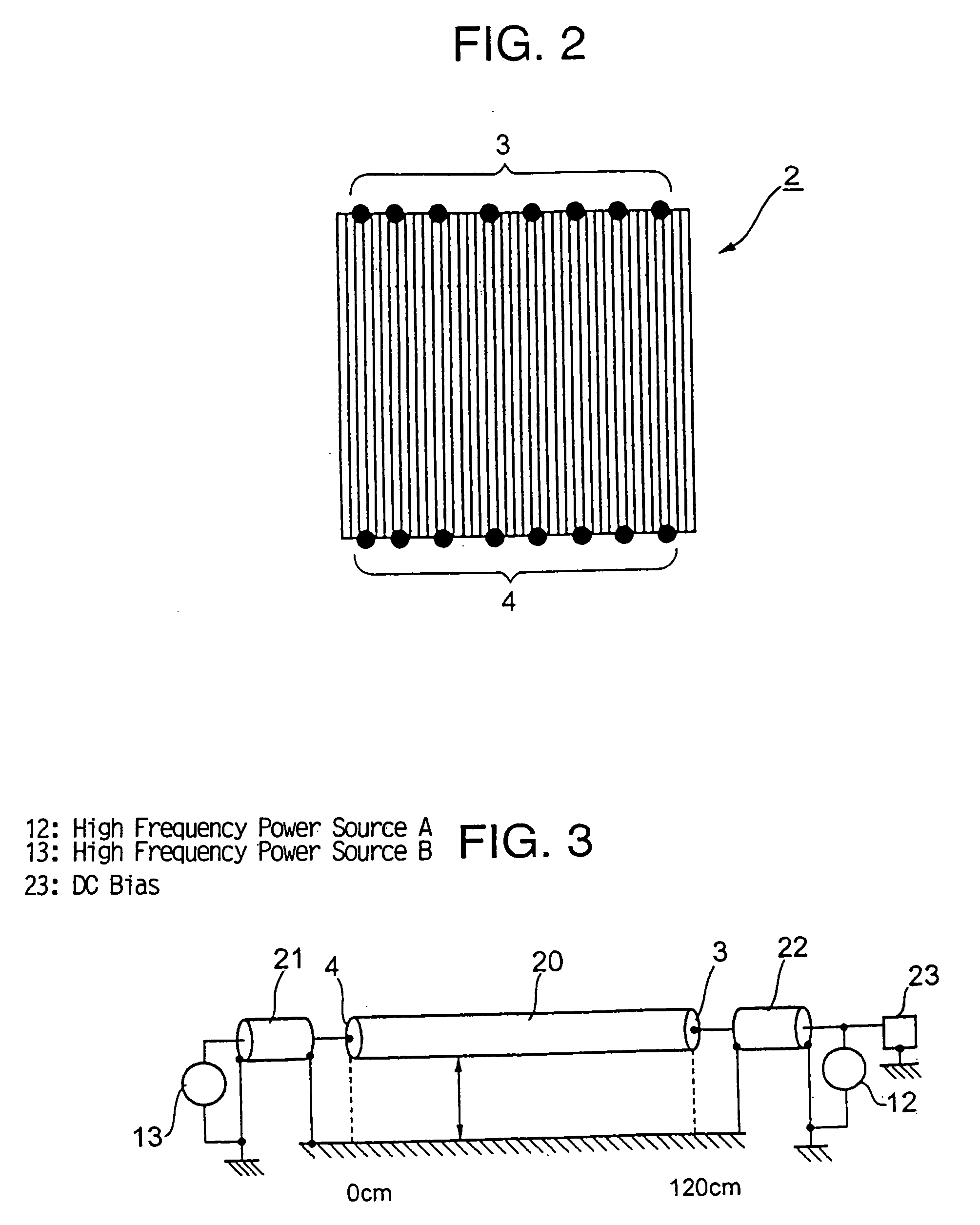

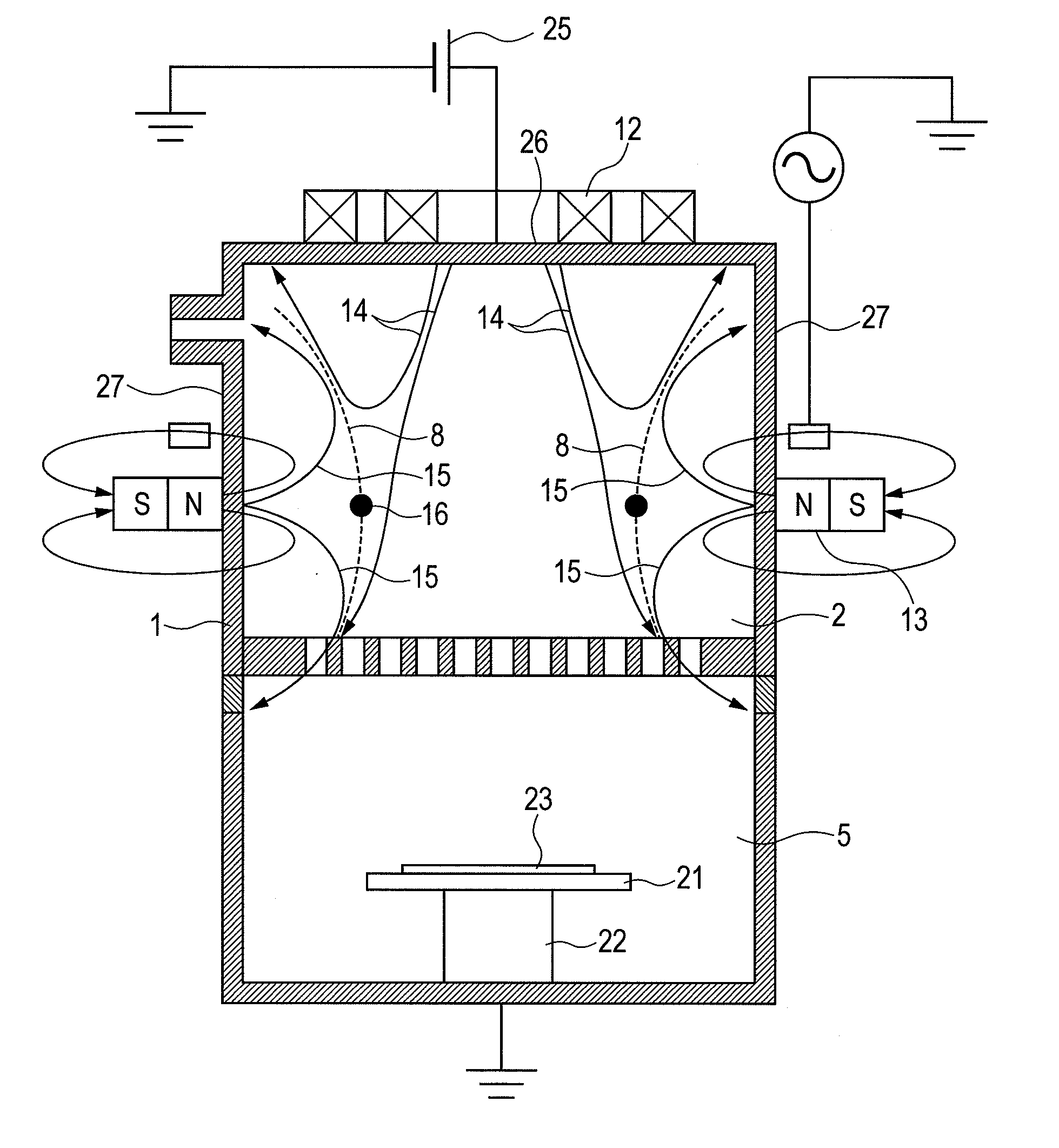

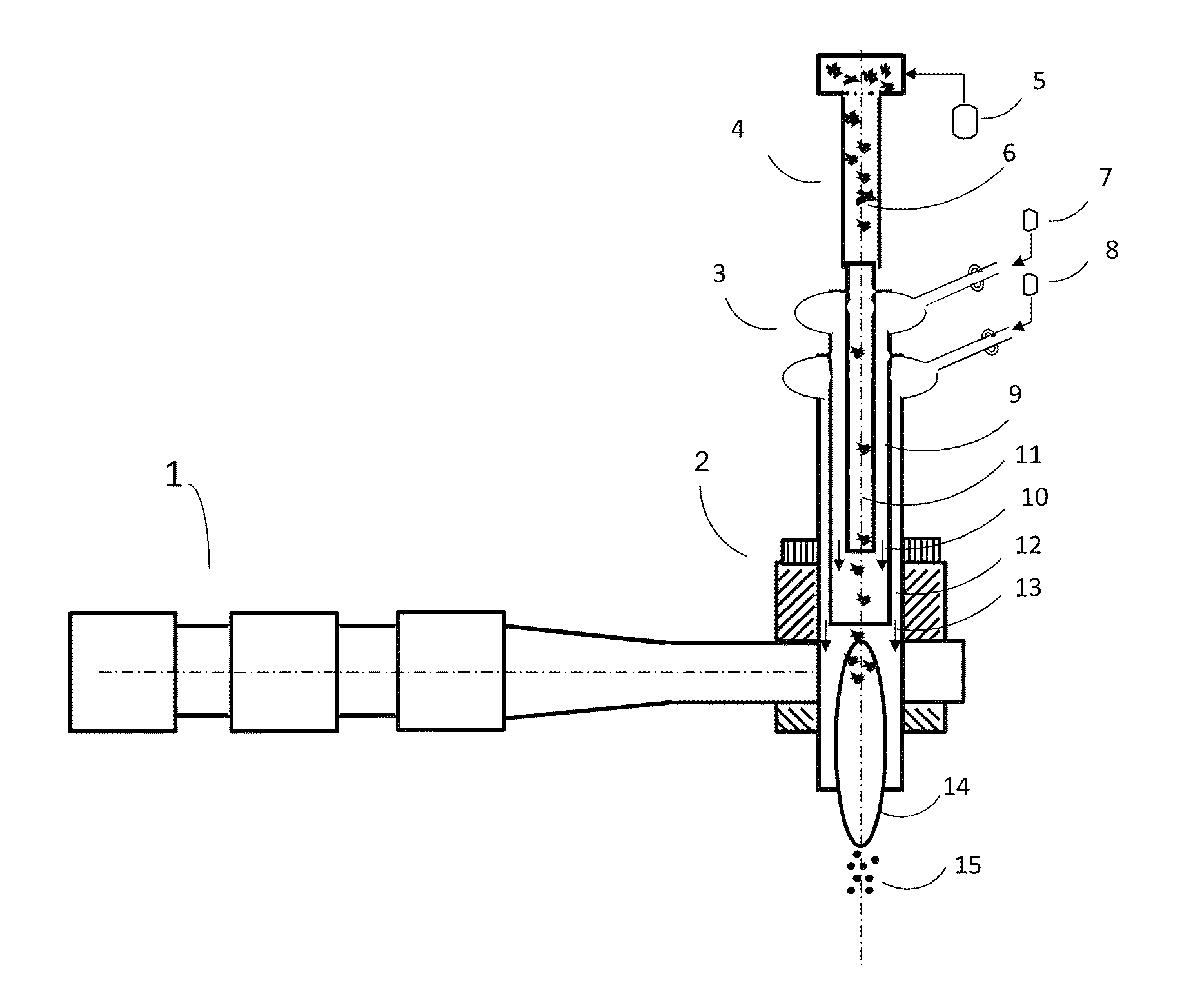

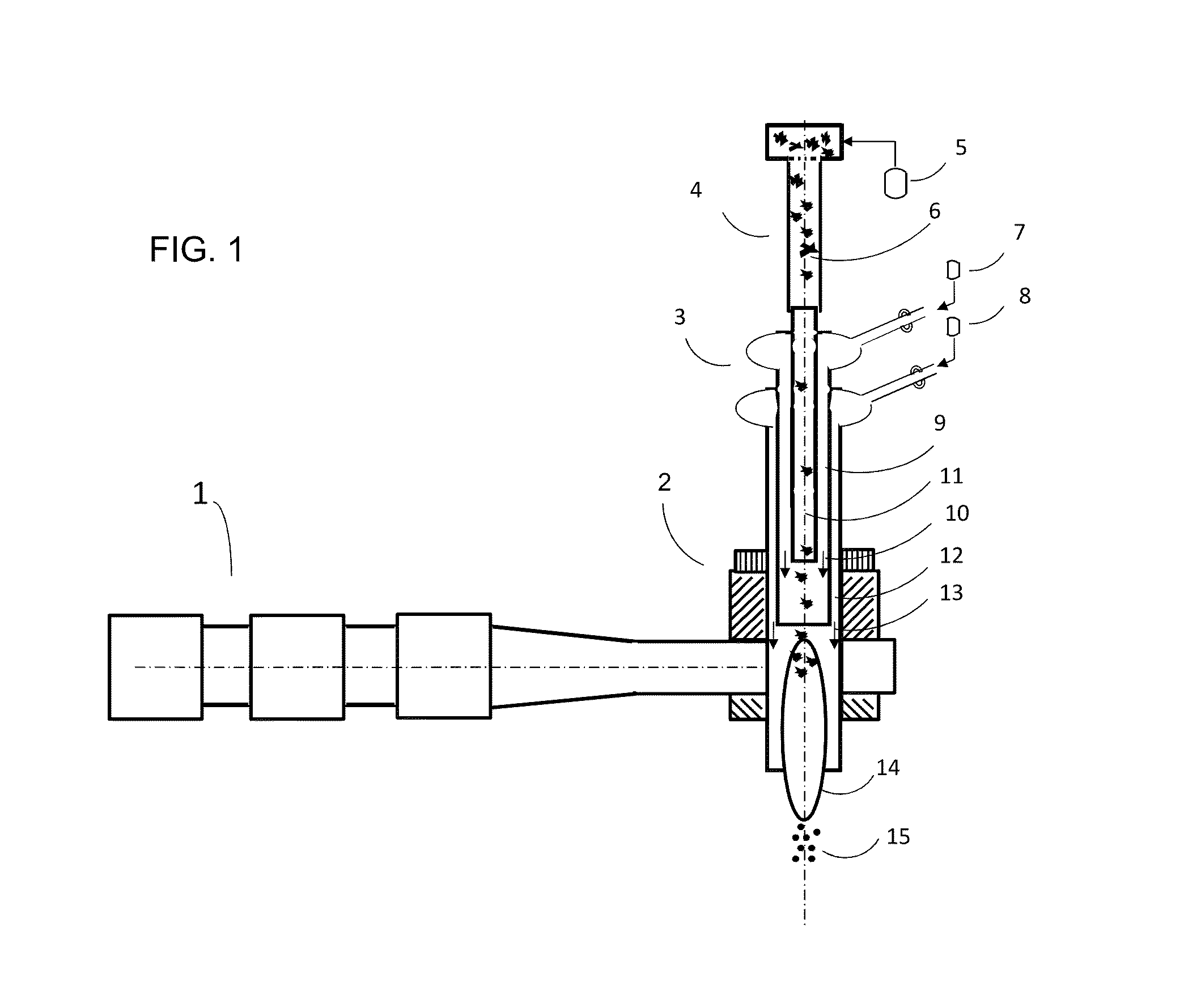

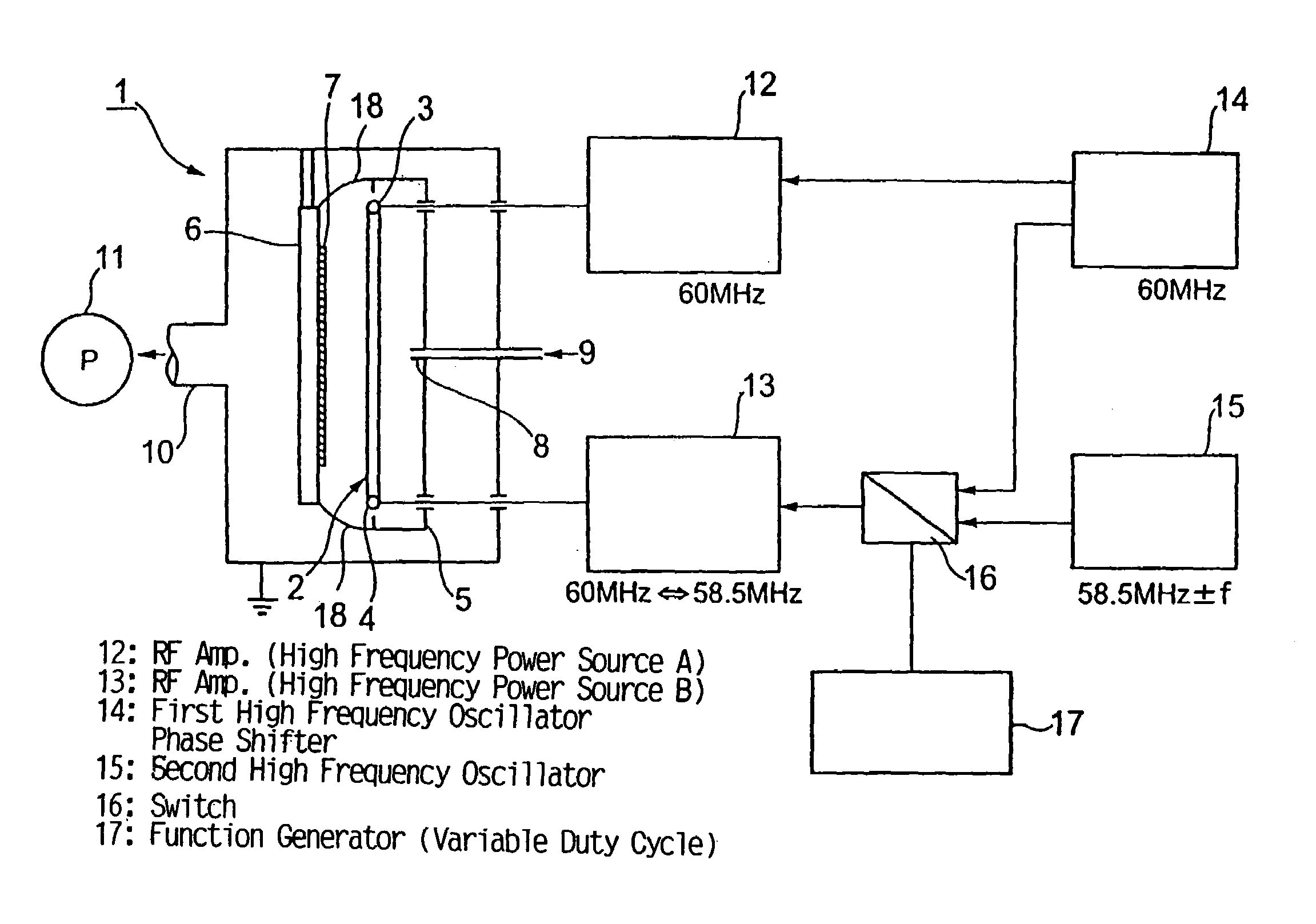

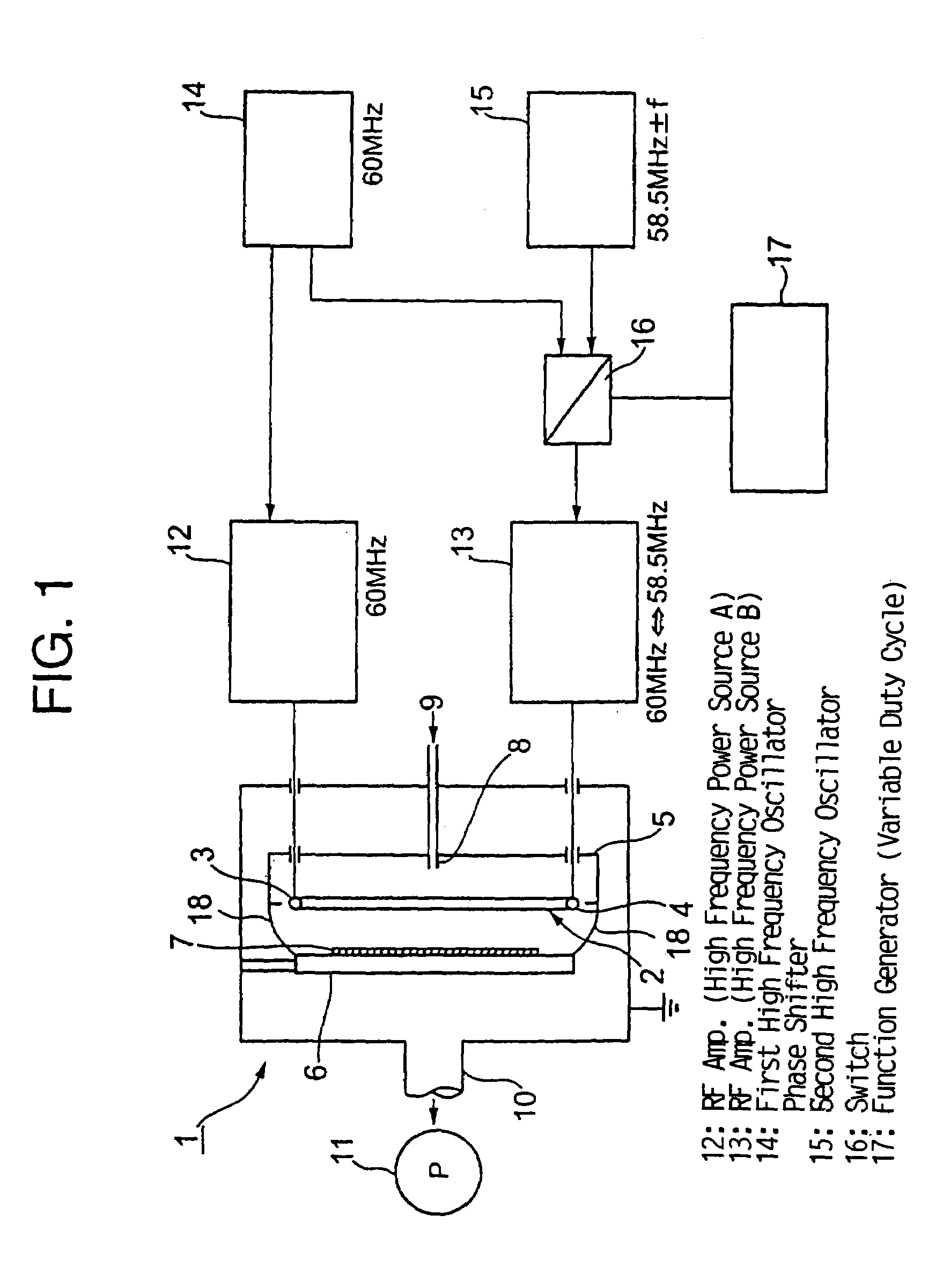

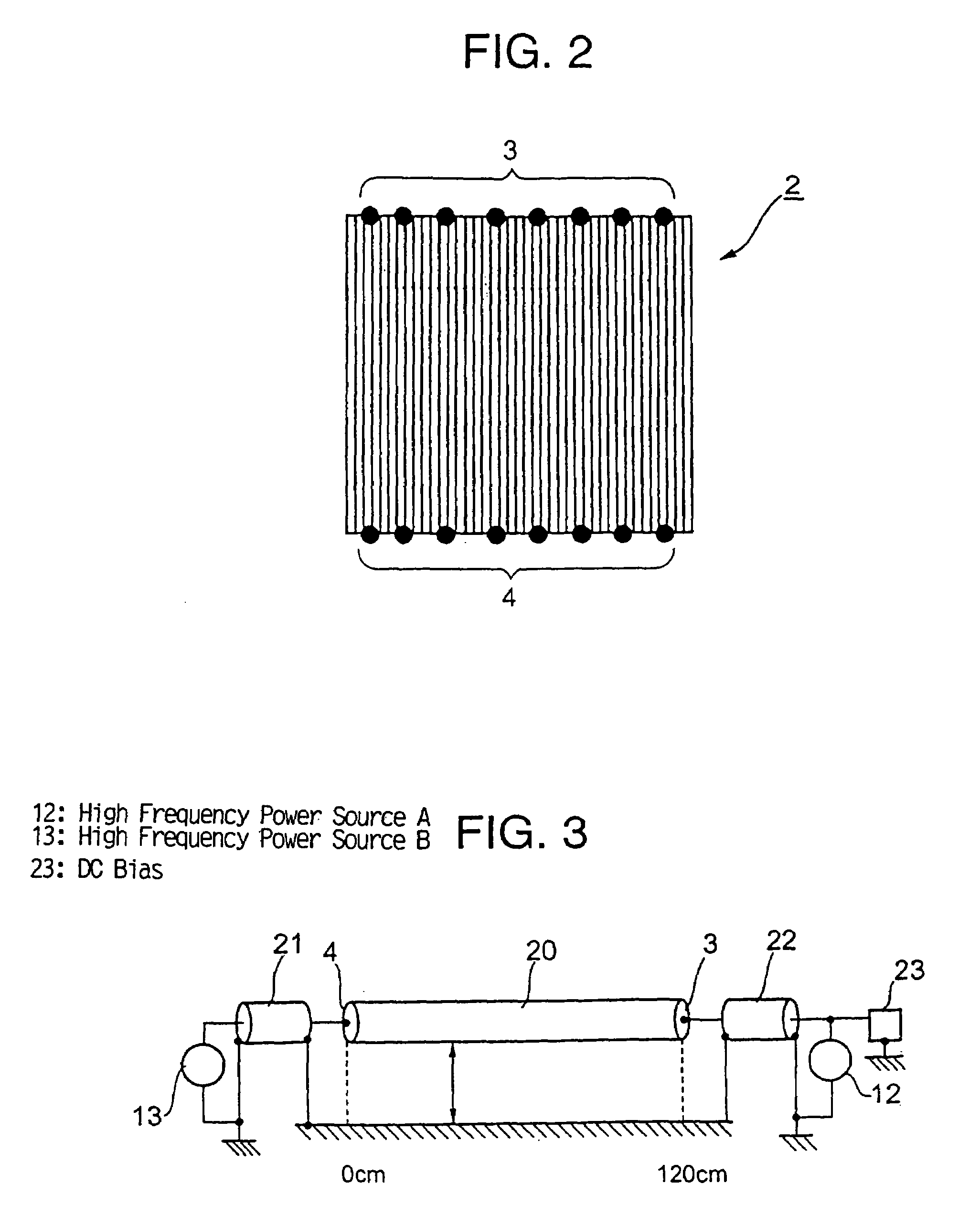

Method and device for generating uniform high-frequency plasma over large surface area used for plasma chemical vapor deposition apparatus

InactiveUS20050255255A1Reduce power lossIncrease rangeElectric discharge tubesChemical vapor deposition coatingPhysicsVery high frequency

This invention relates a plasma generation device for generating plasma uniformly over a large surface area by very high frequency (VHF), which is installed in a plasma chemical vapor deposition apparatus. The present invention installs a first and a second power supply section on both ends of the discharge electrode installed in plasma chemical vapor deposition apparatus, which are supplied with alternate cycles: the first cycle wherein the first and second power supply sections receive high frequency waves at the same frequency, and a second cycle wherein different high frequency waves are received. In this manner, the state of plasma generation may be varied in each cycle, and when averaged over time, it makes possible uniform plasma generation over a large surface area.

Owner:MITSUBISHI HEAVY IND LTD

Carbon foam structural insulated panel

InactiveUS7785712B2High strengthEasy to processLayered productsThin material handlingVolumetric Mass DensityCompressive strength

A structural insulated panel, which includes a carbon foam core having a high ratio of compressive strength to density, desirable fire retardant properties, and resistance to environmental stress. The carbon foam structural insulated panel also includes a first layer and a second layer bound to a first surface and second surface of the carbon foam core. Applications of the carbon foam structural insulated panel include structural and fire retardant elements of residential and commercial buildings, aircraft and also watercraft.

Owner:GRAFTECH INT HLDG INC

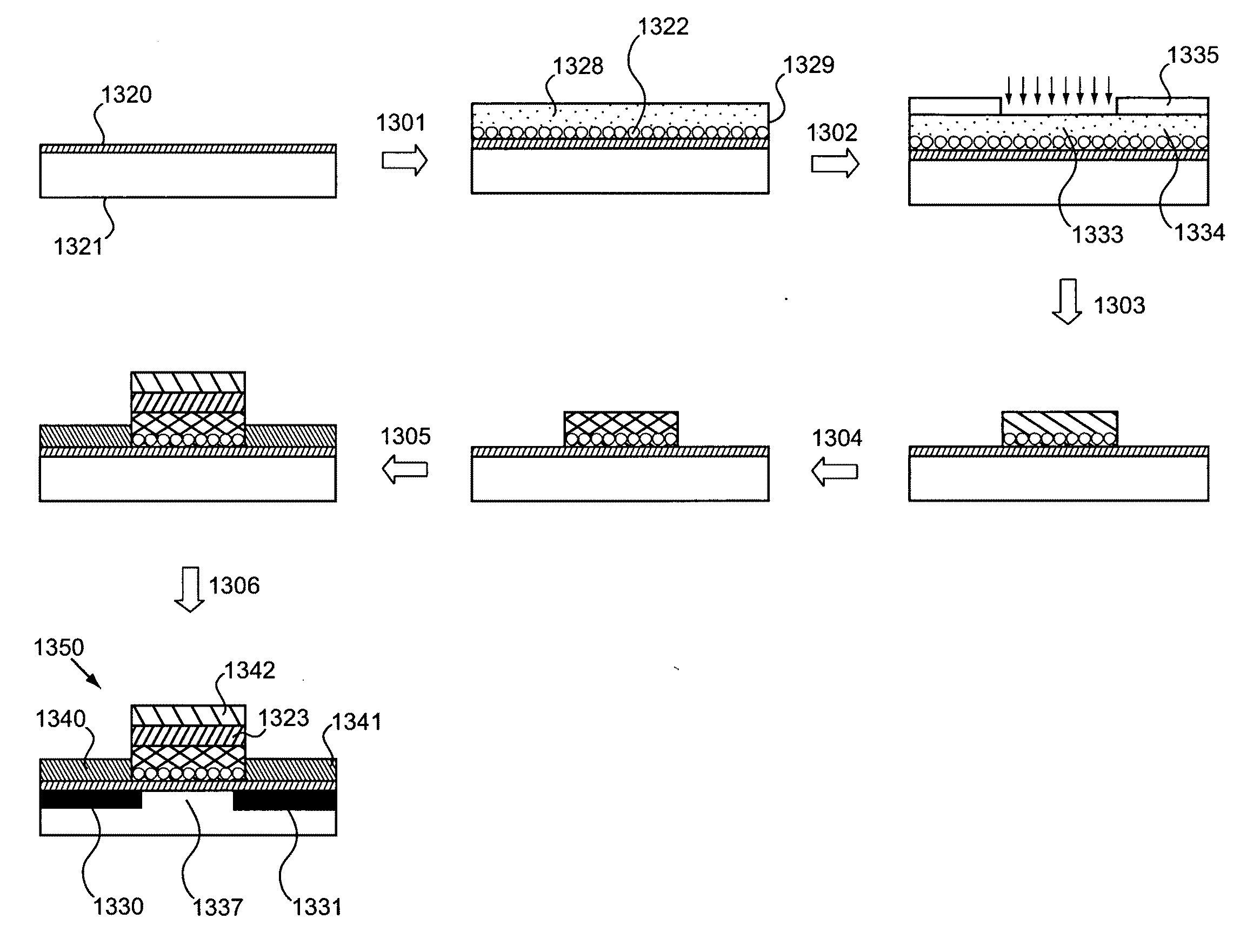

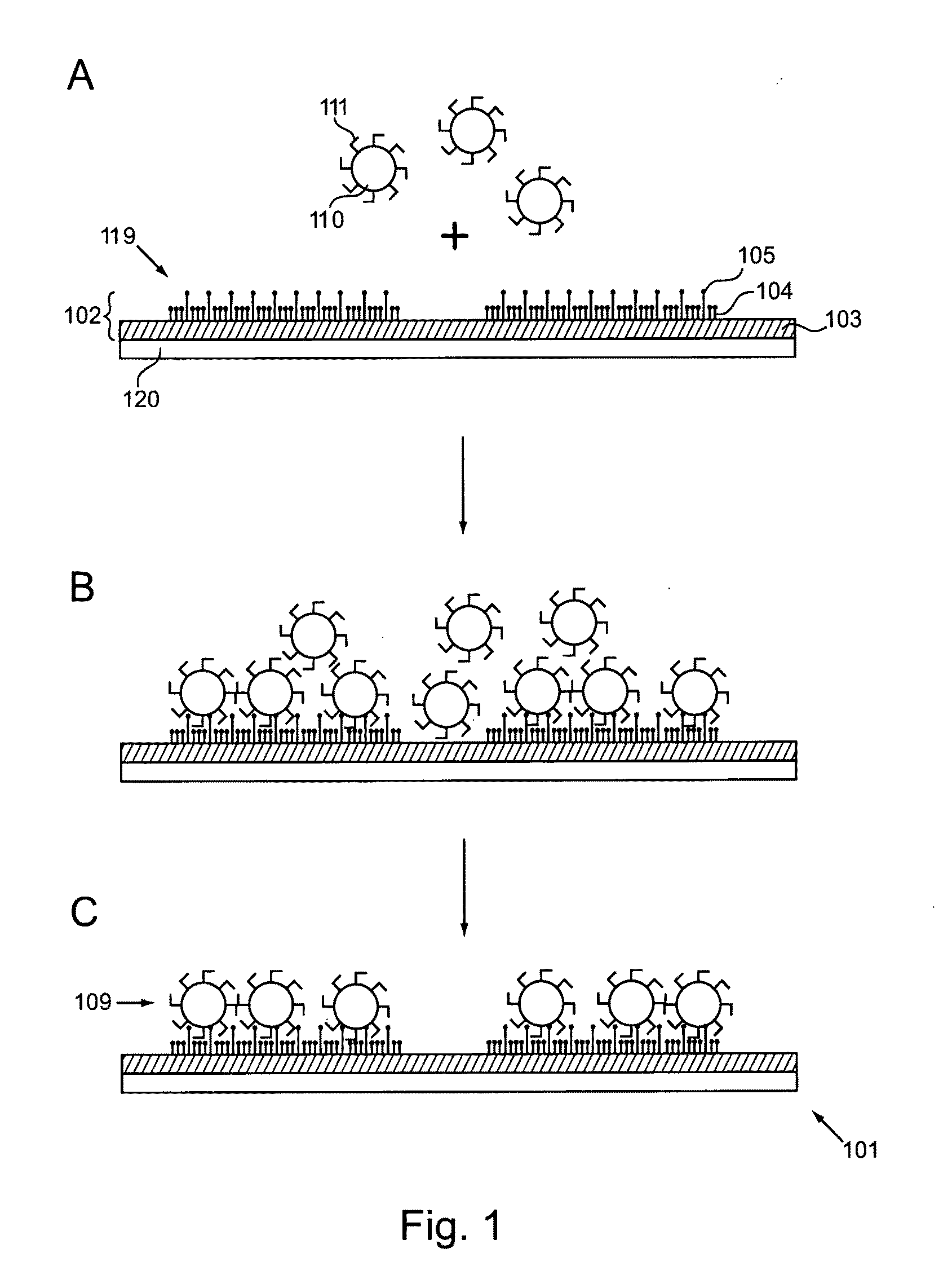

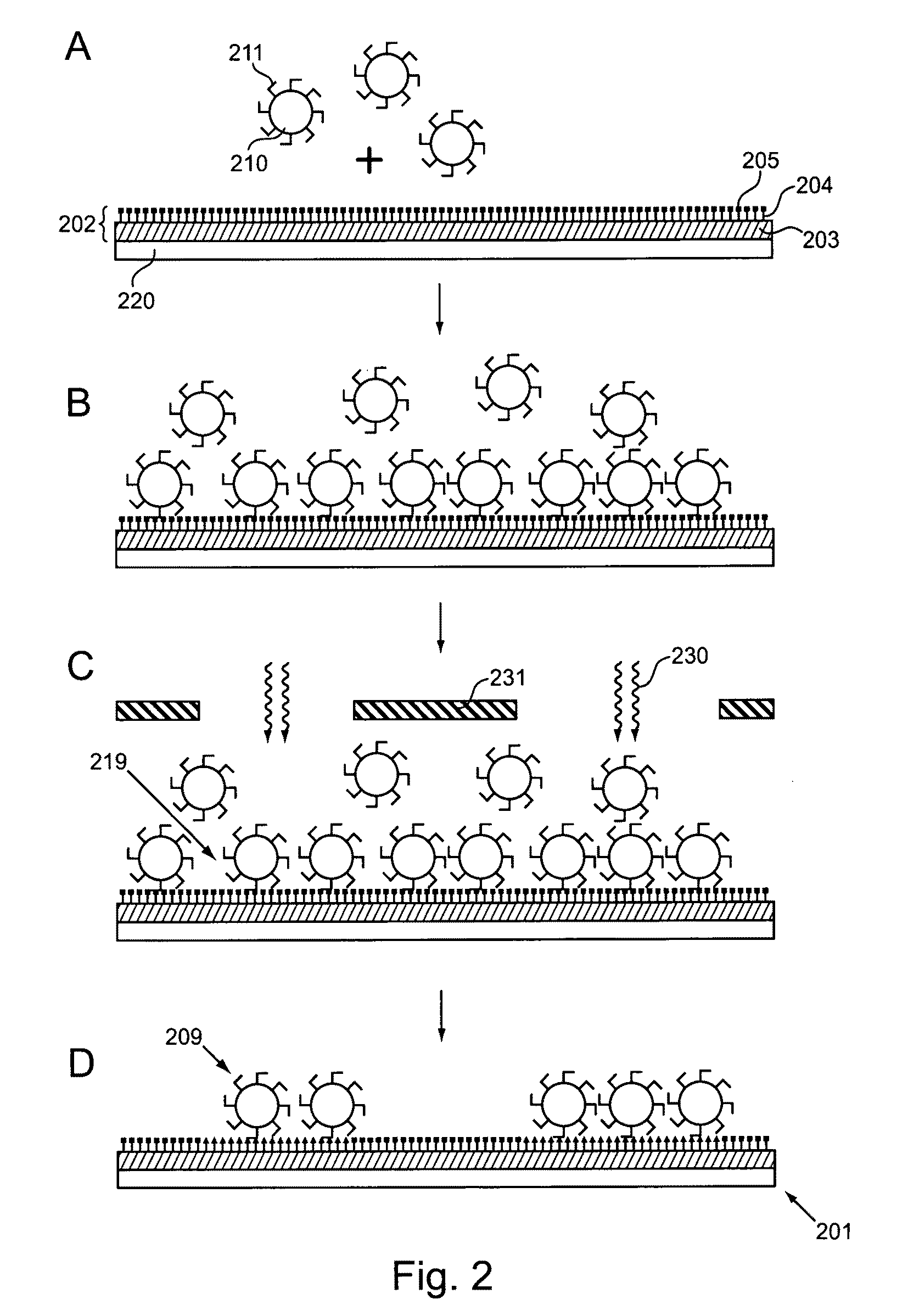

Methods and devices for forming nanostructure monolayers and devices including such monolayers

InactiveUS20100155786A1Fuse protectionHigh densityMaterial nanotechnologyNanoinformaticsResistDielectric

Methods for forming or patterning nanostructure arrays are provided. The methods involve formation of arrays on coatings comprising nanostructure association groups, formation of arrays in spin-on-dielectrics, solvent annealing after nanostructure deposition, patterning using resist, and / or use of devices that facilitate array formation. Related devices for forming nanostructure arrays are also provided, as are devices including nanostructure arrays (e.g., memory devices). Methods for protecting nanostructures from fusion during high temperature processing are also provided.

Owner:WODEN TECH INC

Molded cushion and method of making the same

InactiveUS6611980B2Fairly softUniform textureSofasWheelchairs/patient conveyanceAdhesiveShell molding

The present invention is directed to a custom-contoured cushion for a wheelchair or other seating device and a method of making the same. In one embodiment, the novel custom-contoured cushion is comprised of a stretchable bag filled with soft and resilient closed-cell foam pellets adhered together by and / or embedded within an elastomeric polymerizable adhesive. The pellets do not absorb a significant amount of the adhesive and, after molding, remain sufficiently soft and resilient to provide a comfortable and durable cushion.Alternatively, the cushion contains soft and resilient pellets, but does not contain the elastomeric polymerizable adhesive. In the first embodiment, the custom-molded, custom-contoured cushion is made by mixing the pellets with the adhesive to form a pellet / adhesive mixture, positioning the user on a bag filled with the pellet / adhesive mixture, molding the mixture around the user to provide cushioning around the user's seating surface, and allowing the adhesive to cure. The pellets and adhesive may either be added to the bag separately and mixed within the has, or may be mixed outside the bag, after which the pellet / adhesive mixture is added to the bag.

Owner:WEMPE PATRICK L

Liquid ejection apparatus and liquid agitation method

InactiveUS7677690B2Agitated efficiently and satisfactorilyEjected stablyPrintingLiquid jetDevice form

A liquid ejection apparatus which ejects liquid toward a prescribed medium is provided. The apparatus includes a liquid ejection head which has an ejection port ejecting liquid, and an energy application element applying energy to the liquid to be ejected from the ejection port; and a liquid receiving device which is opposite to the ejection port and receives the liquid ejected from the ejection port. The liquid received by the liquid receiving device forms a liquid pool between the liquid receiving device and the ejection port and the liquid is agitated by a driving device which applies a drive signal to the energy application element.

Owner:FUJIFILM CORP

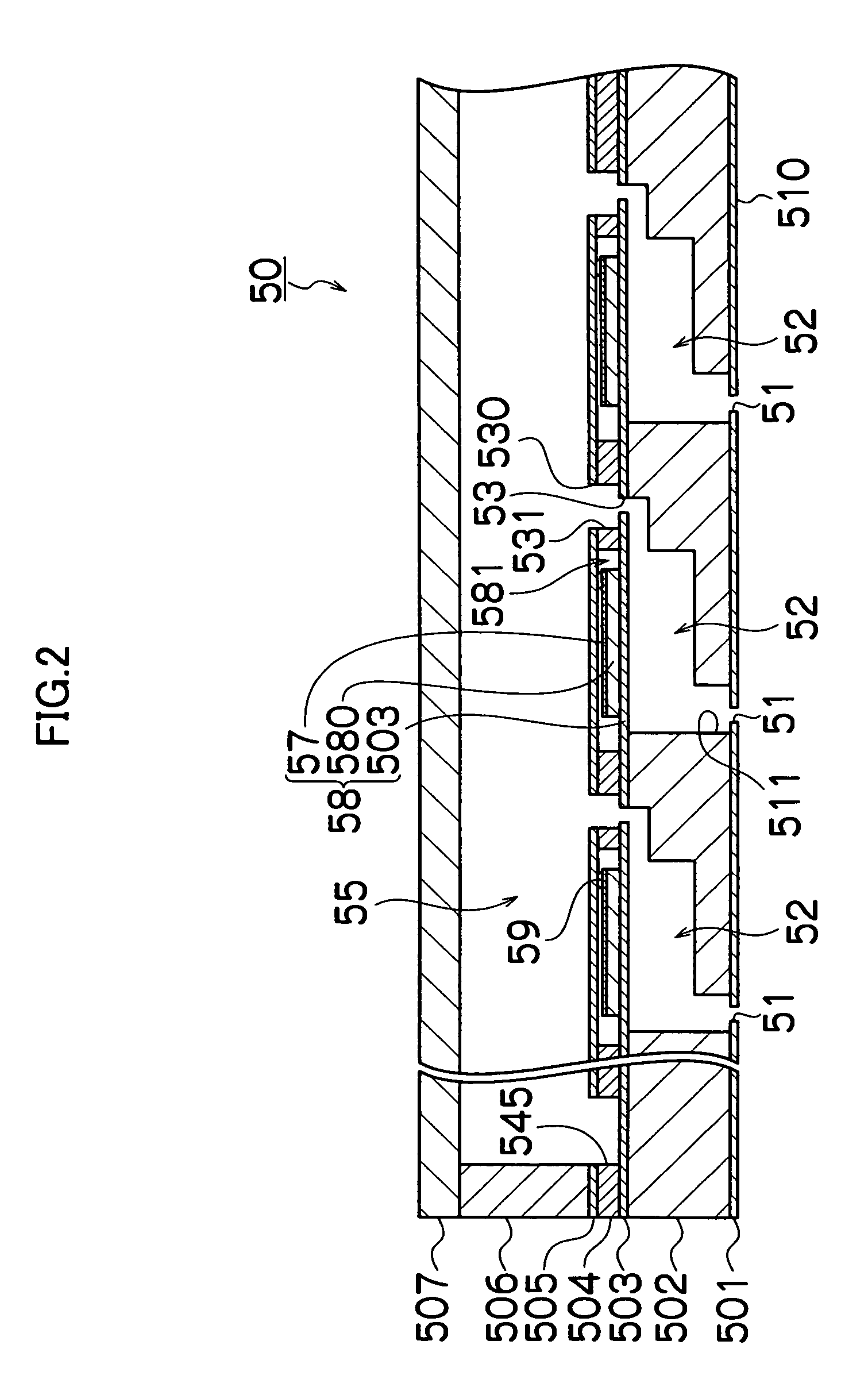

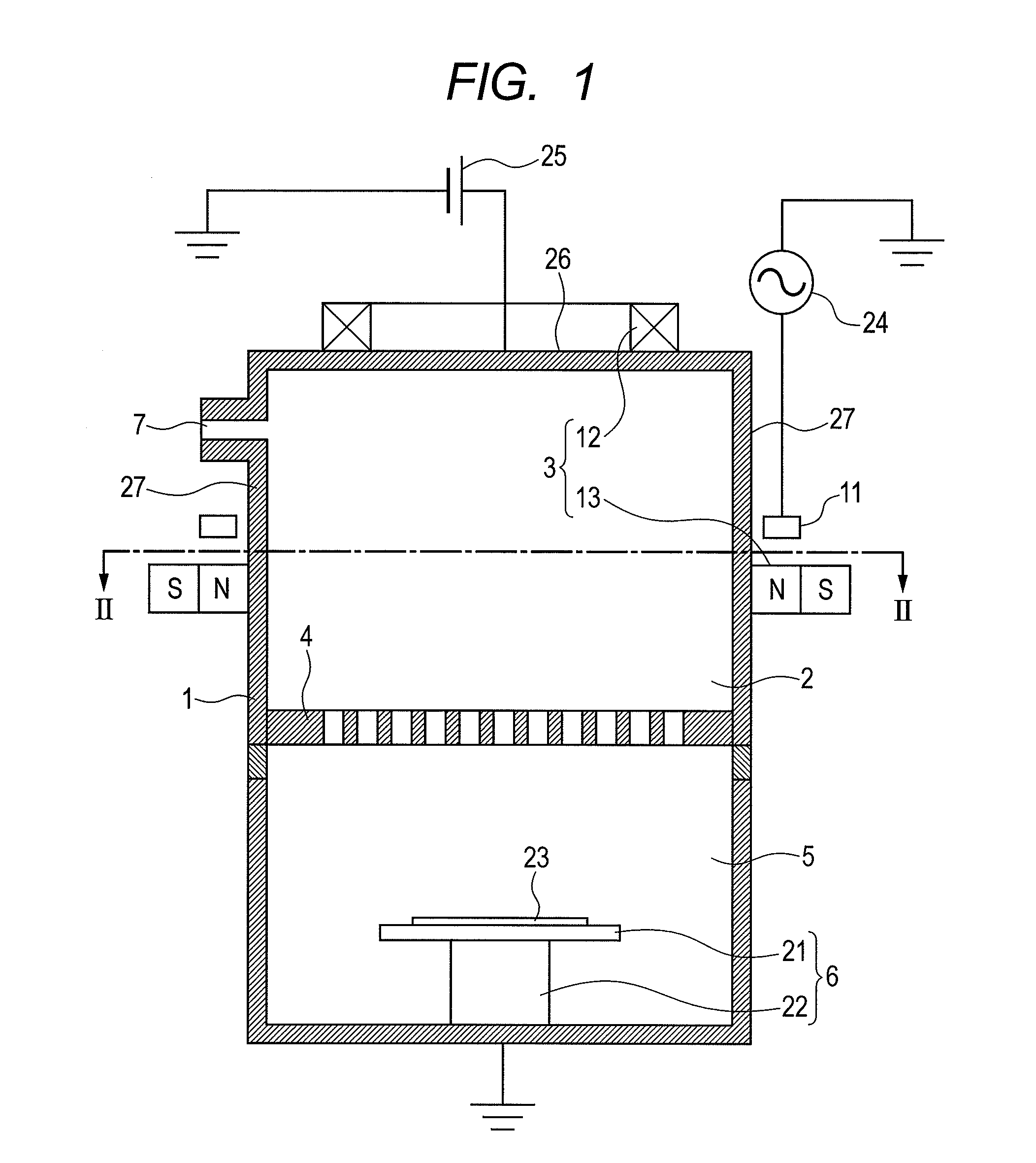

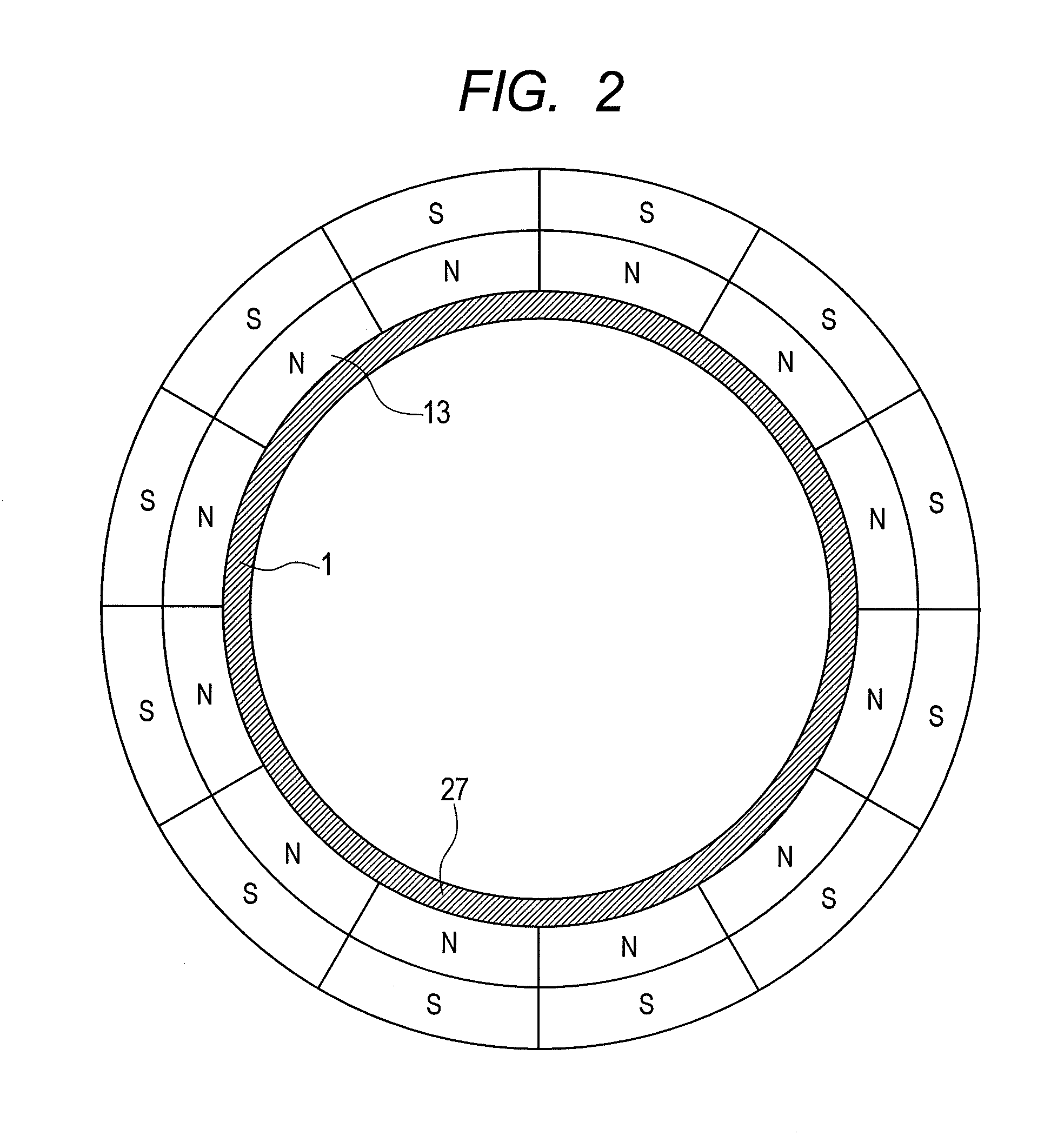

Plasma processing device, plasma processing method and method of manufacturing element including substrate to be processed

ActiveUS20110309050A1Fast processingOptimizationElectric discharge tubesDecorative surface effectsElectrical polarityEngineering

The present invention provides a plasma processing device and a plasma processing method that can easily adjust plasma density distribution while making the plasma density uniform, and a method of manufacturing an element including a substrate to be processed. In an embodiment of the present invention, the inside of a vacuum vessel (1) is divided by a grid (4) having communication holes into a plasma generation chamber (2) and a plasma processing chamber (5). On the upper wall (26) of the plasma generation chamber (2), magnetic coils (12) are arranged such that magnetic field lines within the vacuum vessel (1) point from the center of the vacuum vessel (1) to a side wall (27), and, outside the side wall (27) of the plasma generation chamber (2), ring-shaped permanent magnets (13) are arranged such that a polarity pointing to the inside of the vacuum vessel (1) is a north pole and a polarity pointing to the outside of the vacuum vessel (1) is a south pole.

Owner:CANON ANELVA CORP

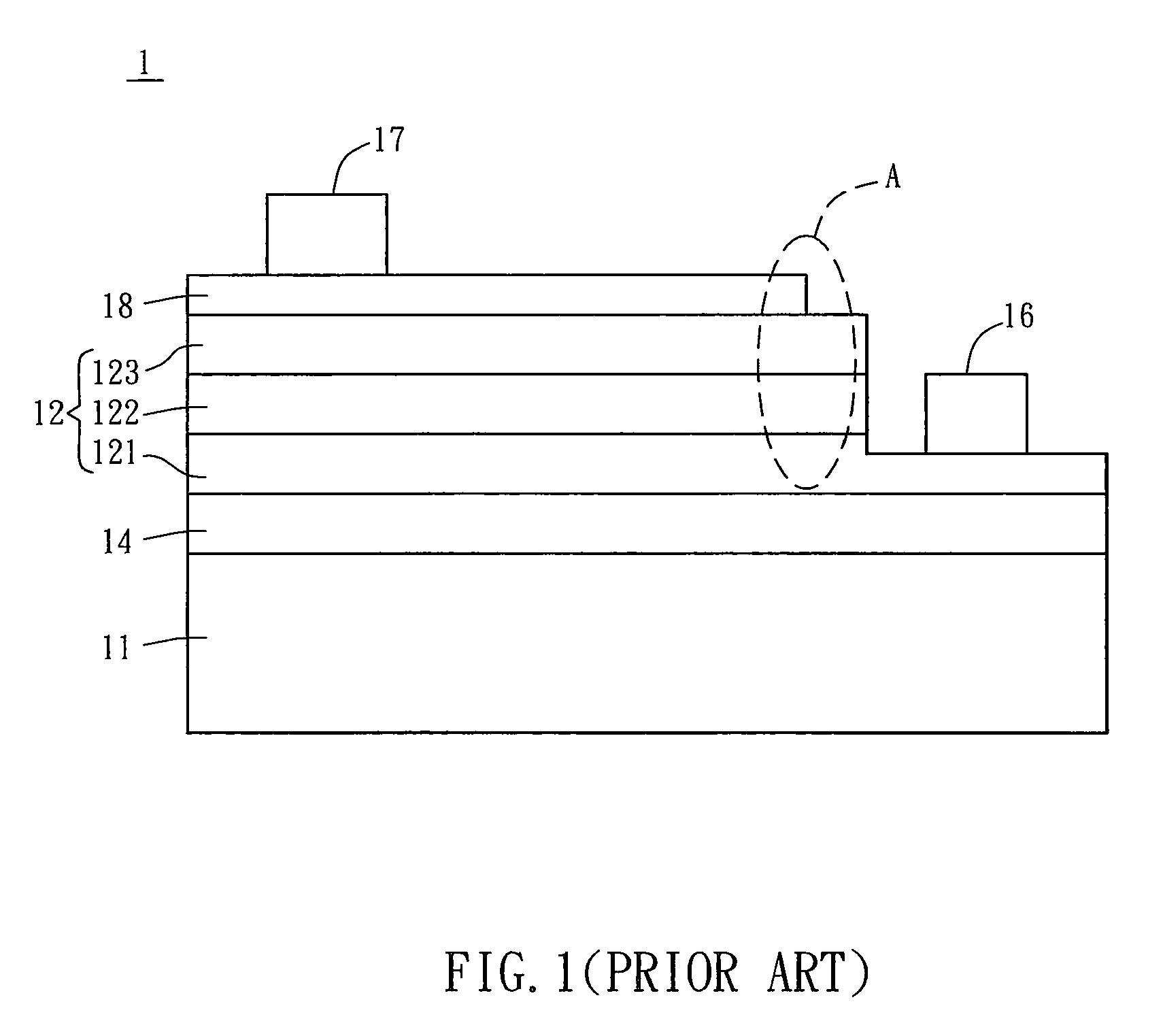

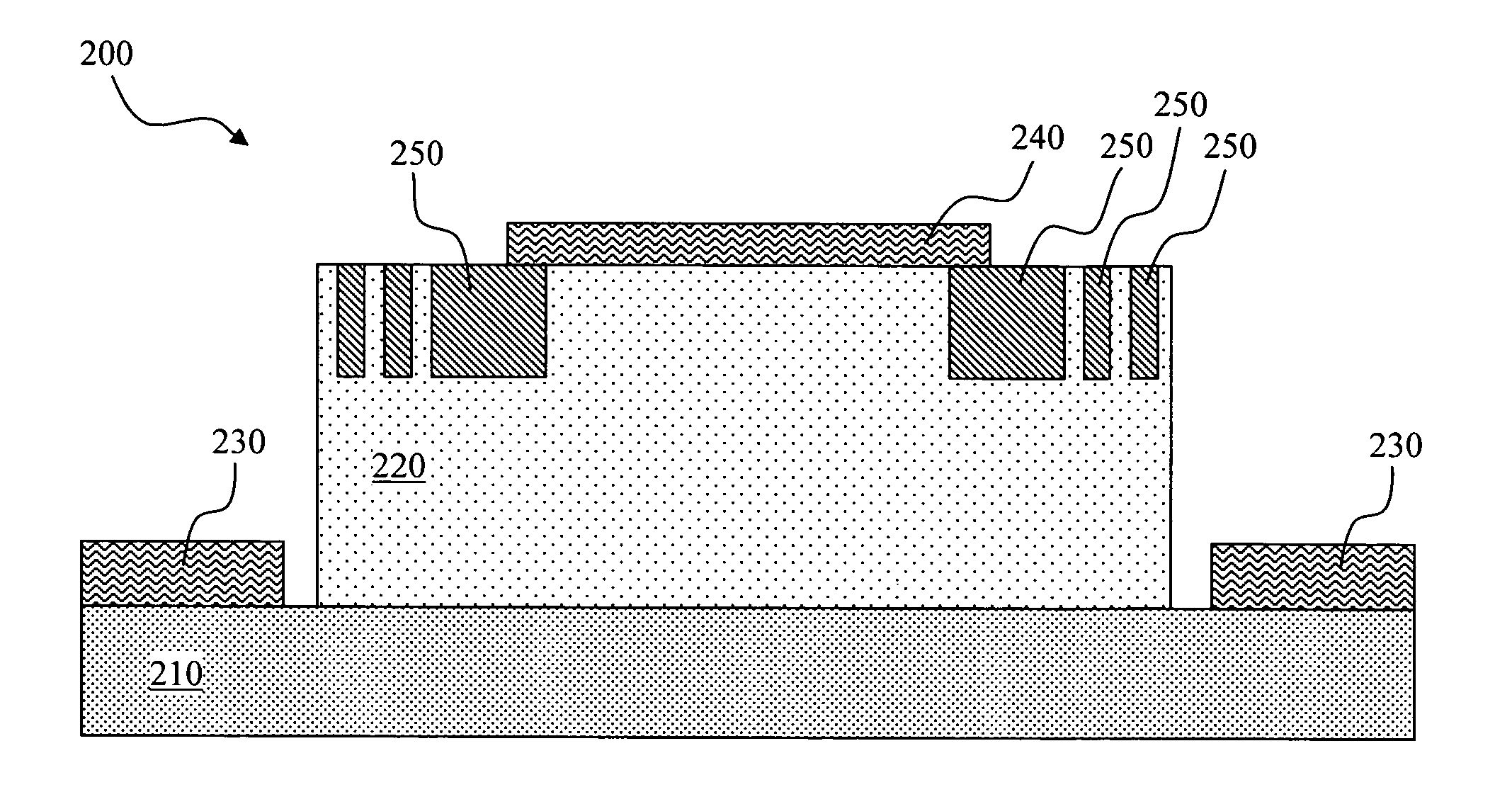

Gallium nitride semiconductor device with improved termination scheme

ActiveUS20110101369A1Uniform densityImproved termination structureSemiconductor/solid-state device manufacturingDiodeGallium nitrideSemiconductor

This invention discloses a gallium nitride based semiconductor power device disposed in a semiconductor substrate. The power device comprises a termination area disposed at a peripheral area of the semiconductor power device comprises a termination structure having at least a guard ring disposed in a trench filled with doped gallium-based epitaxial layer therein.

Owner:ALPHA & OMEGA SEMICON INC

Method and device for generating uniform high-frequency plasma over large surface area used for plasma chemical vapor deposition apparatus

InactiveUS7205034B2Increase plasma densityLow densityElectric discharge tubesChemical vapor deposition coatingEngineeringChemical vapor deposition

A plasma generation device for generating plasma uniformly over a large surface area by very high frequency (VHF), which is installed in a plasma chemical vapor deposition apparatus. A first and a second power supply section are installed on both ends of the discharge electrode installed in a plasma chemical vapor deposition apparatus, and are supplied with alternate cycles: the first cycle wherein the first and second power supply sections receive high frequency waves at the same frequency, and a second cycle wherein different high frequency waves are received. In this manner, the state of plasma generation may be varied in each cycle, and when averaged over time, it makes possible uniform plasma generation over a large surface area.

Owner:MITSUBISHI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com