Patents

Literature

254results about How to "Lower overall flow resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

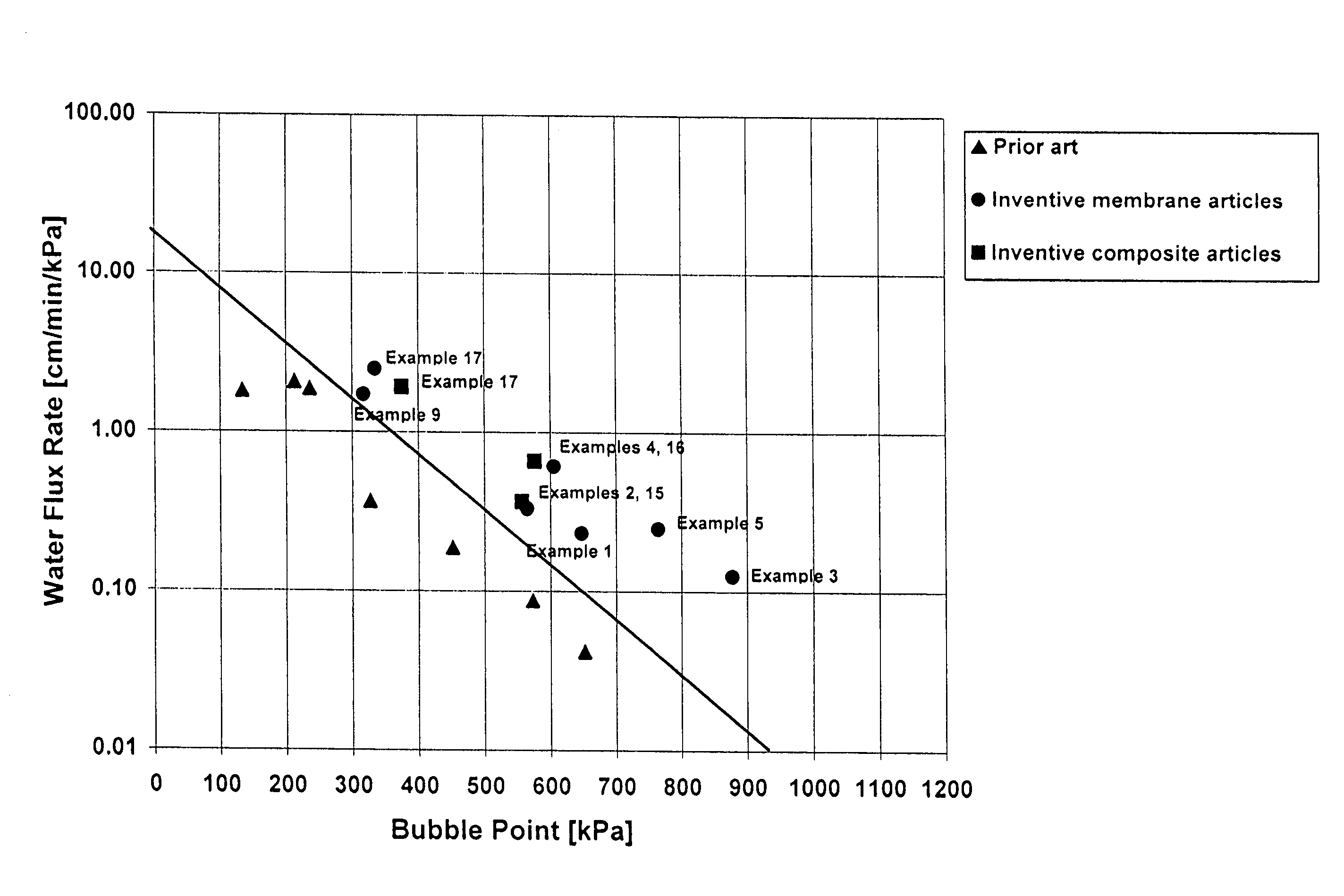

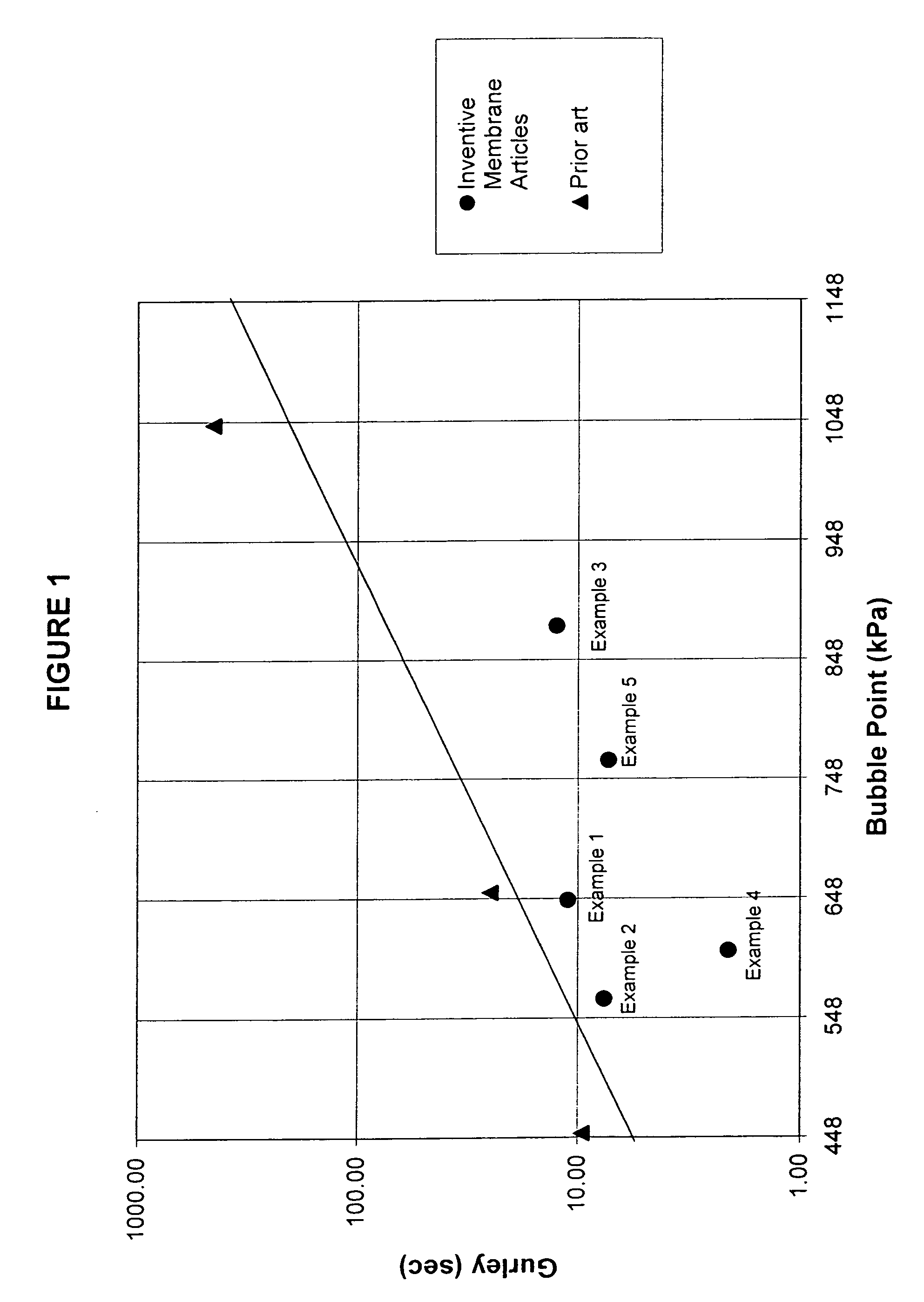

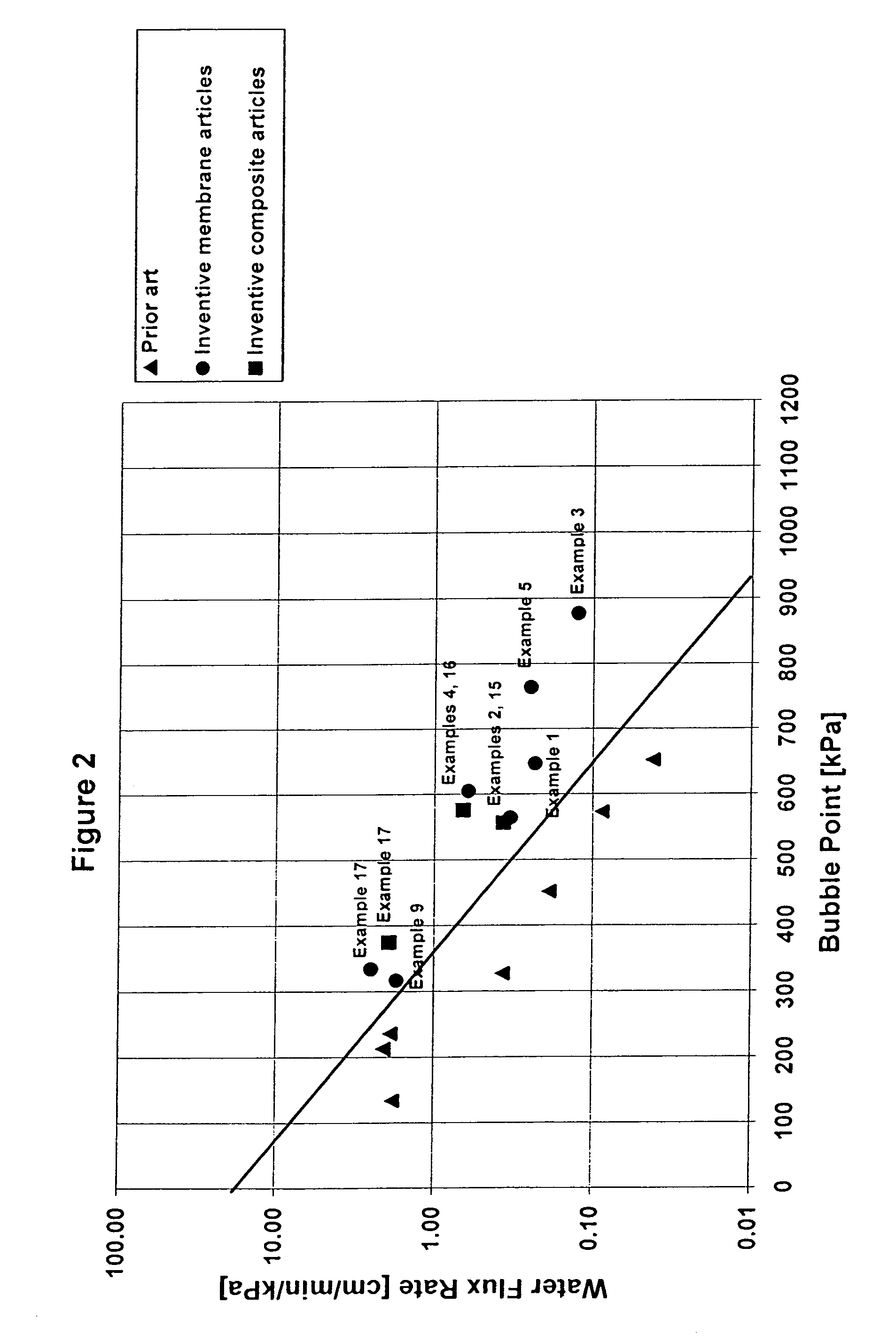

Porous PTFE materials and articles produced therefrom

ActiveUS7306729B2High strengthLower overall flow resistanceMembranesSemi-permeable membranesFlow resistivityFiltration

Novel porous PTFE membranes are described possessing a unique combination of high strength, low flow resistance, and small pore size. Additionally, unique constructions with superior filtration and venting properties incorporating porous PTFE membranes are described.

Owner:WL GORE & ASSOC INC

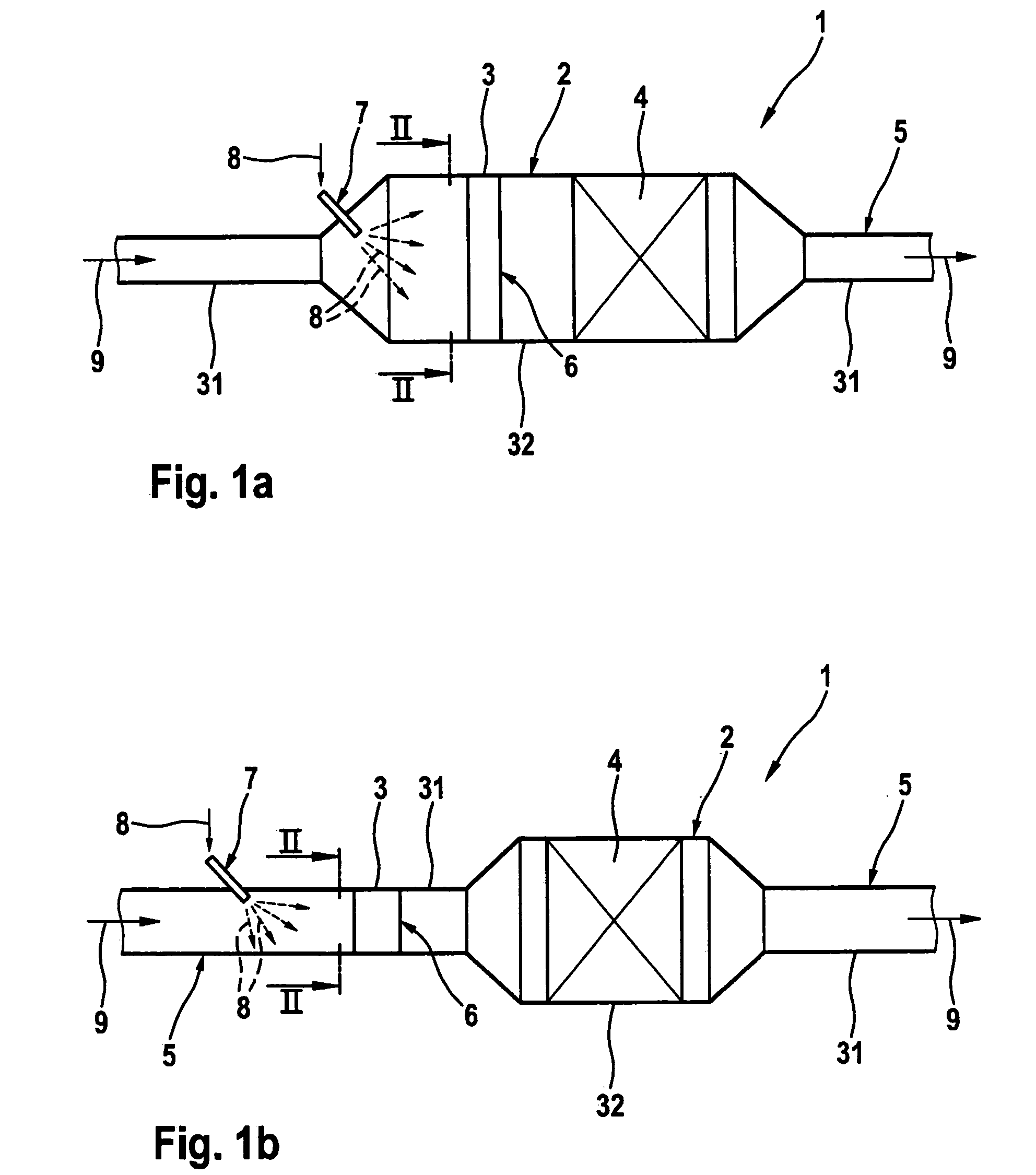

Static mixer and exhaust gas treatment device

InactiveUS7793494B2Design economyIntense mixing effect and vaporization effectInternal combustion piston enginesFlow mixersExhaust fumesEngineering

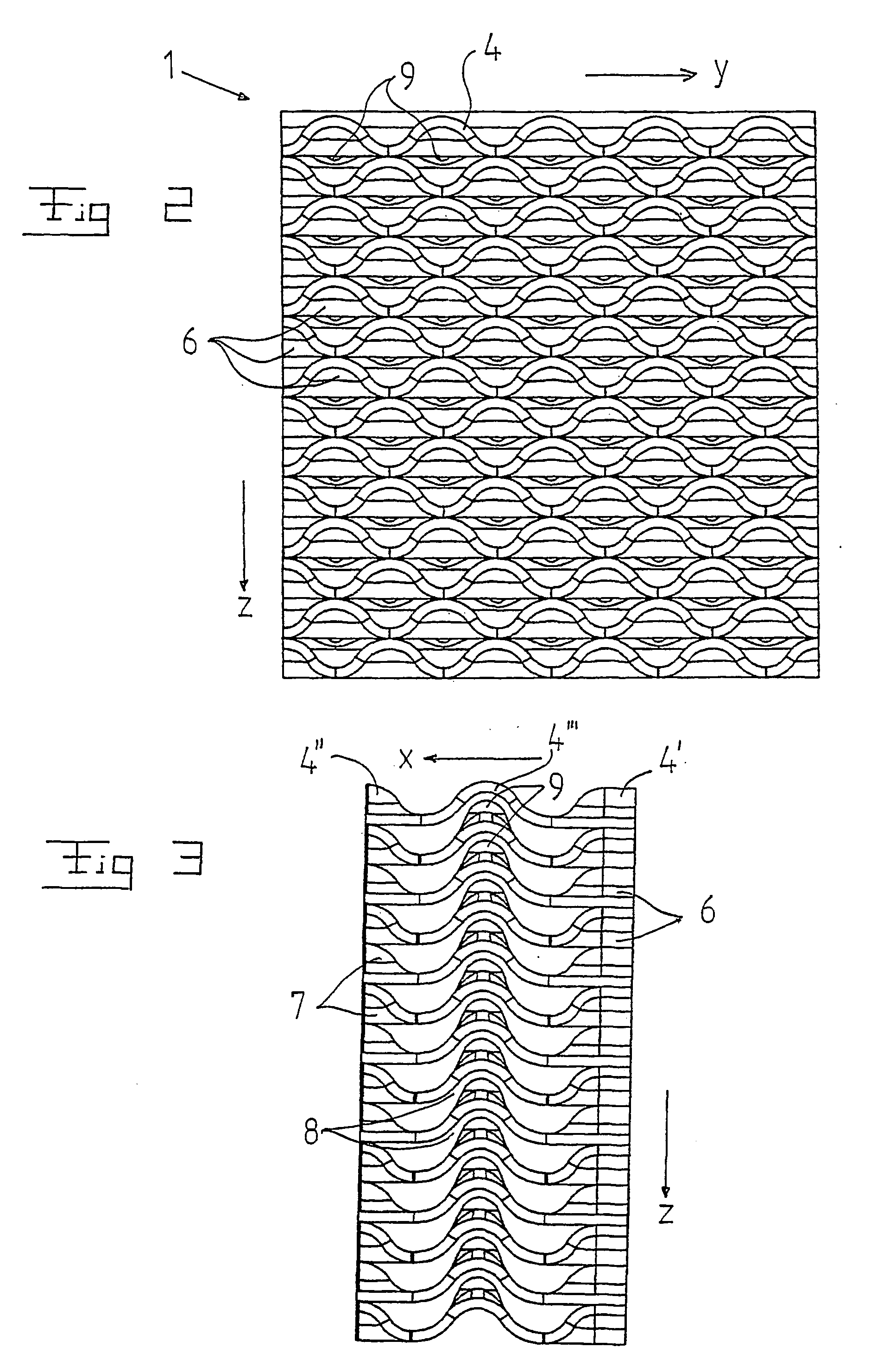

The invention relates to a static mixer for an exhaust system of an internal combustion engine. The mixer has a wall structure that is arranged across the directional of flow in a pipe and has several layers of a corrugated sheeting material laying across one another in the direction of flow. The cells through which the flow can pass in the direction of flow are provided between the sheeting material of neighboring layers. The sheeting material has baffles for all or several of the cells. The baffles are arranged on the sheeting material so that they are arranged on their outgoing flow side in the case of said cells and extend in the direction of flow and across it.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

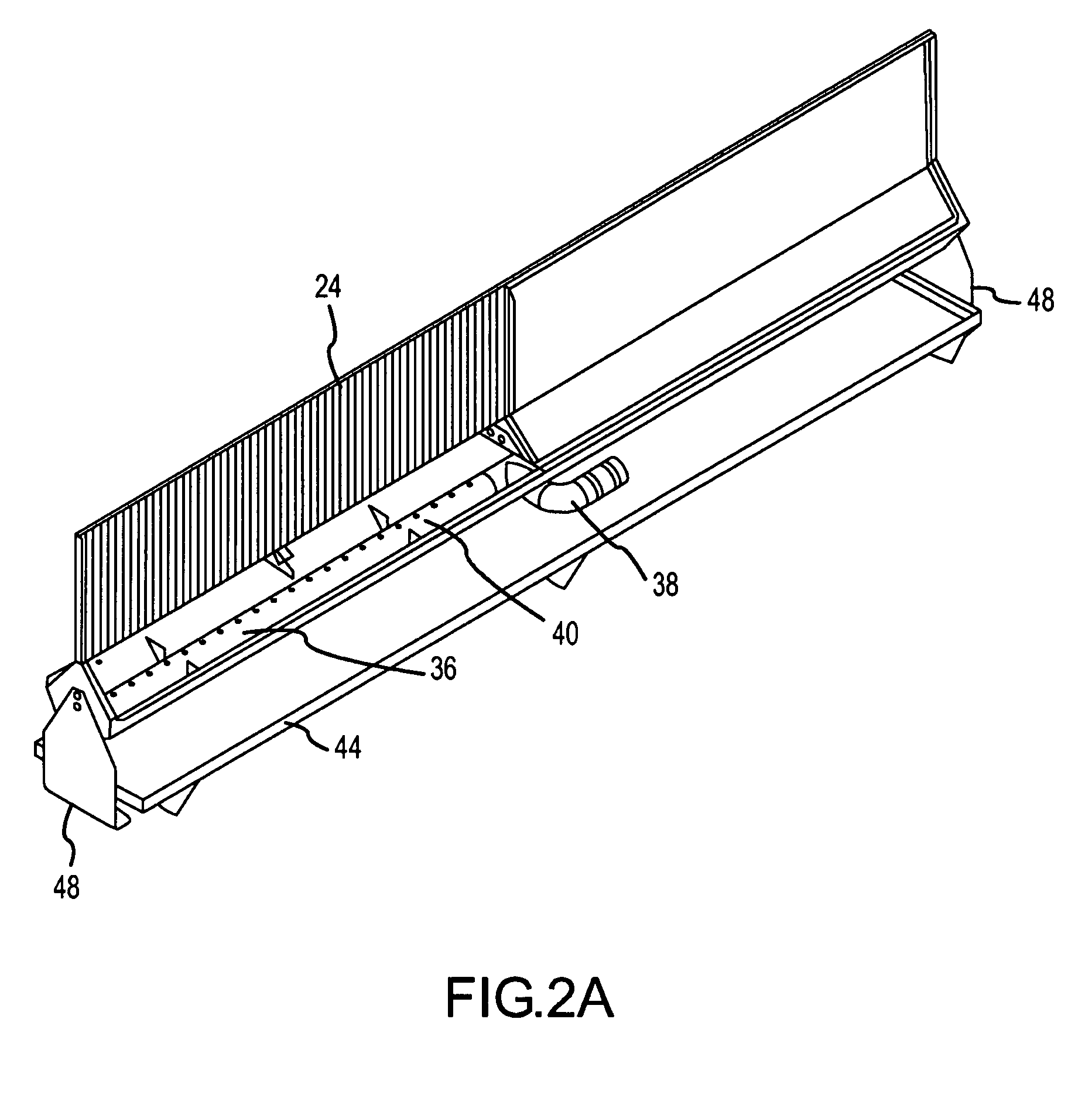

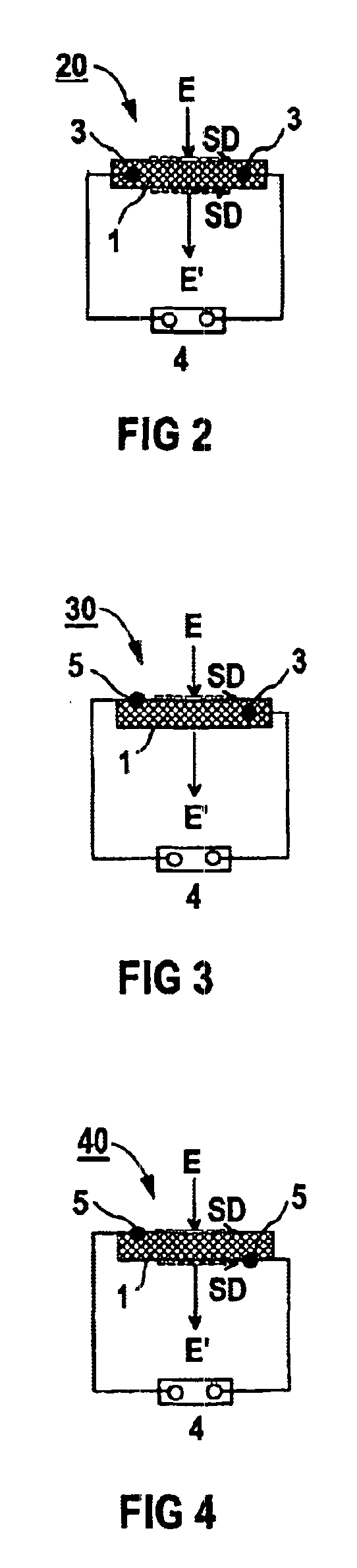

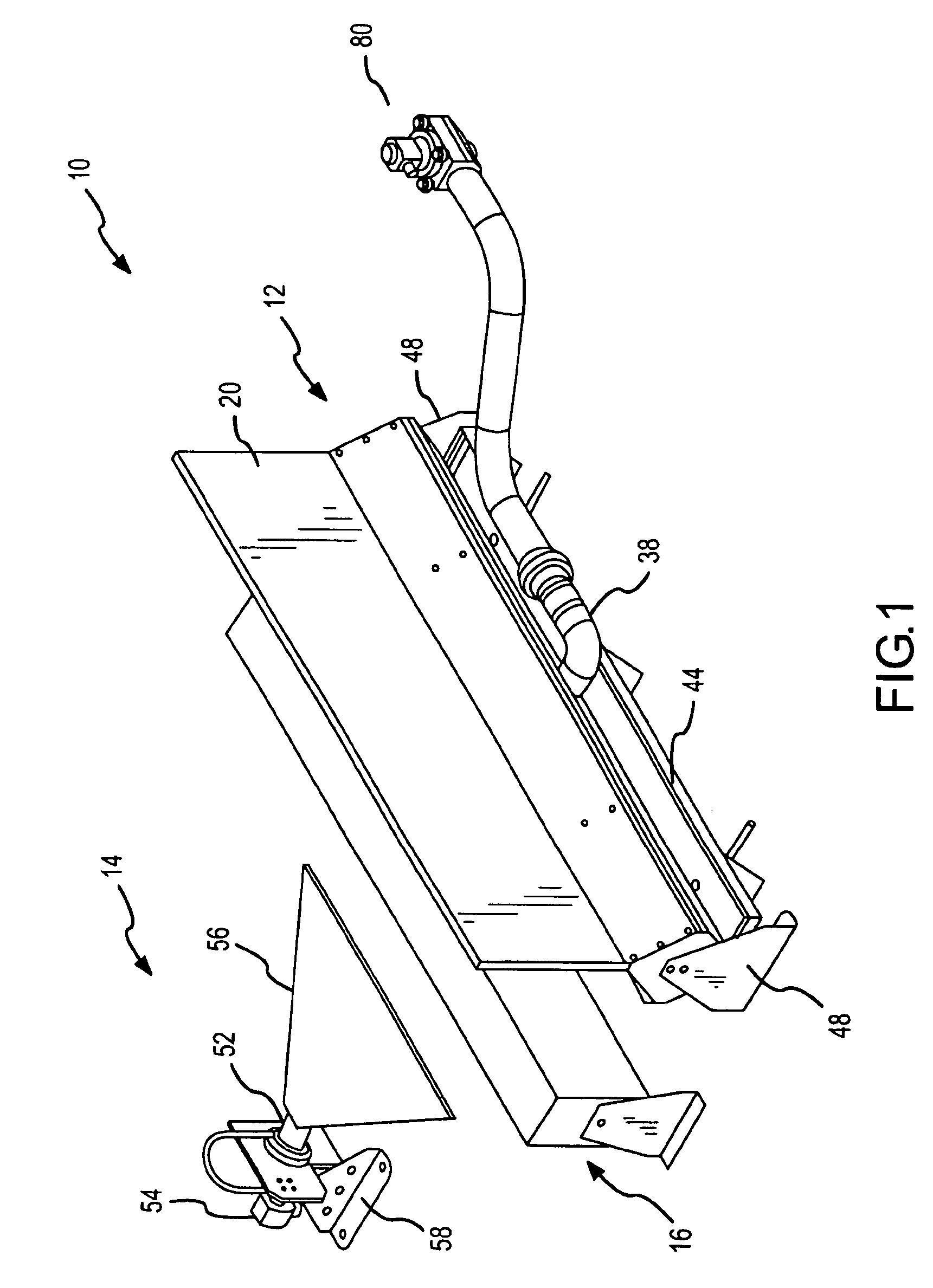

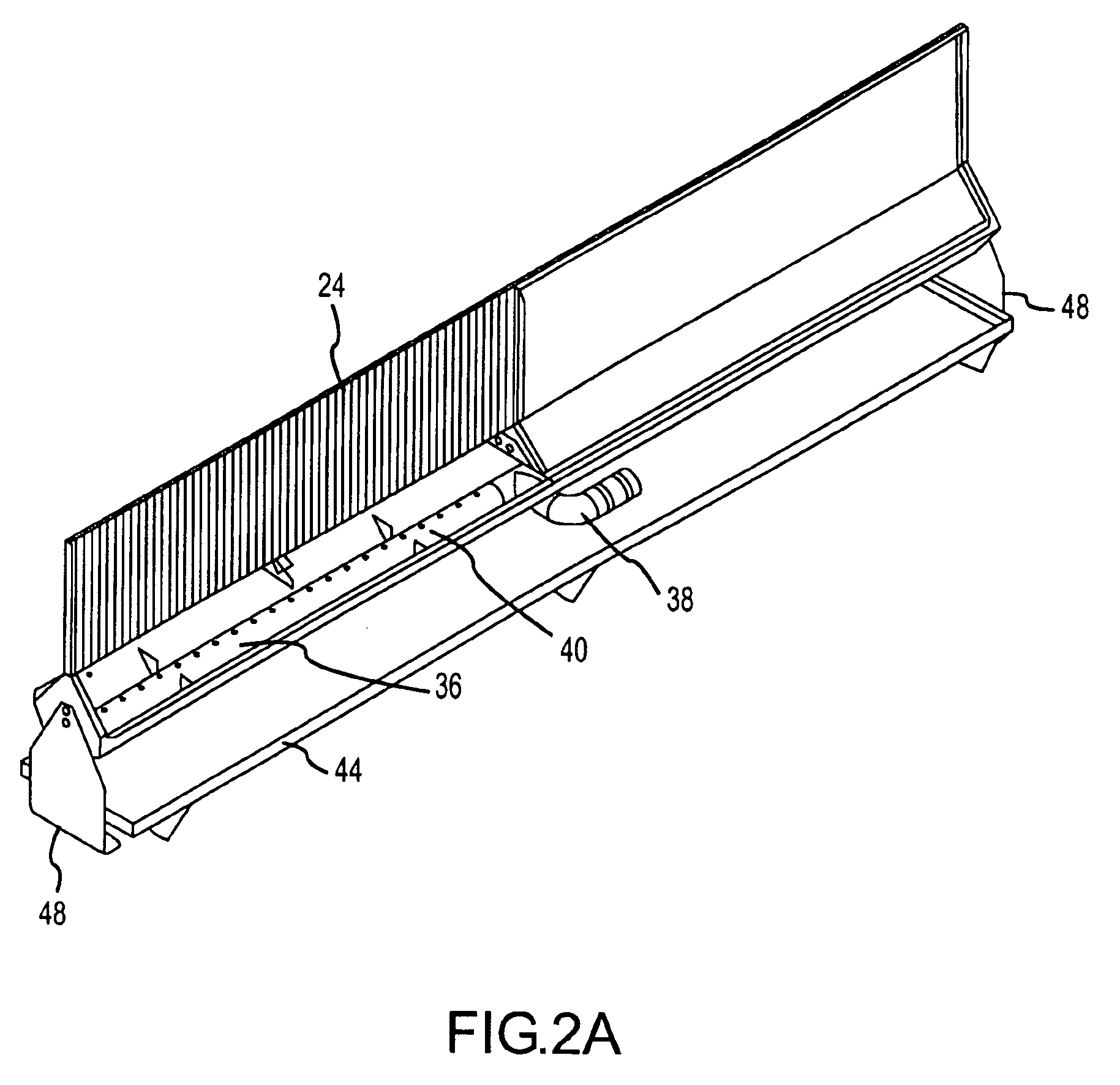

Apparatus for producing a fire special effect

InactiveUS6953401B2Eliminate and substantially reduce any gapUniform densityShow cabinetsAmusementsEngineeringSpecial effects

In one embodiment, the present invention provides a device for producing a fire special effect that is suitable for applications in which the viewers of the simulated flame are able inspect the device from relatively close range and / or from a number of perspectives. For example, the device can be used as a torchiere or wall sconce.

Owner:TECHNIFEX PRODS

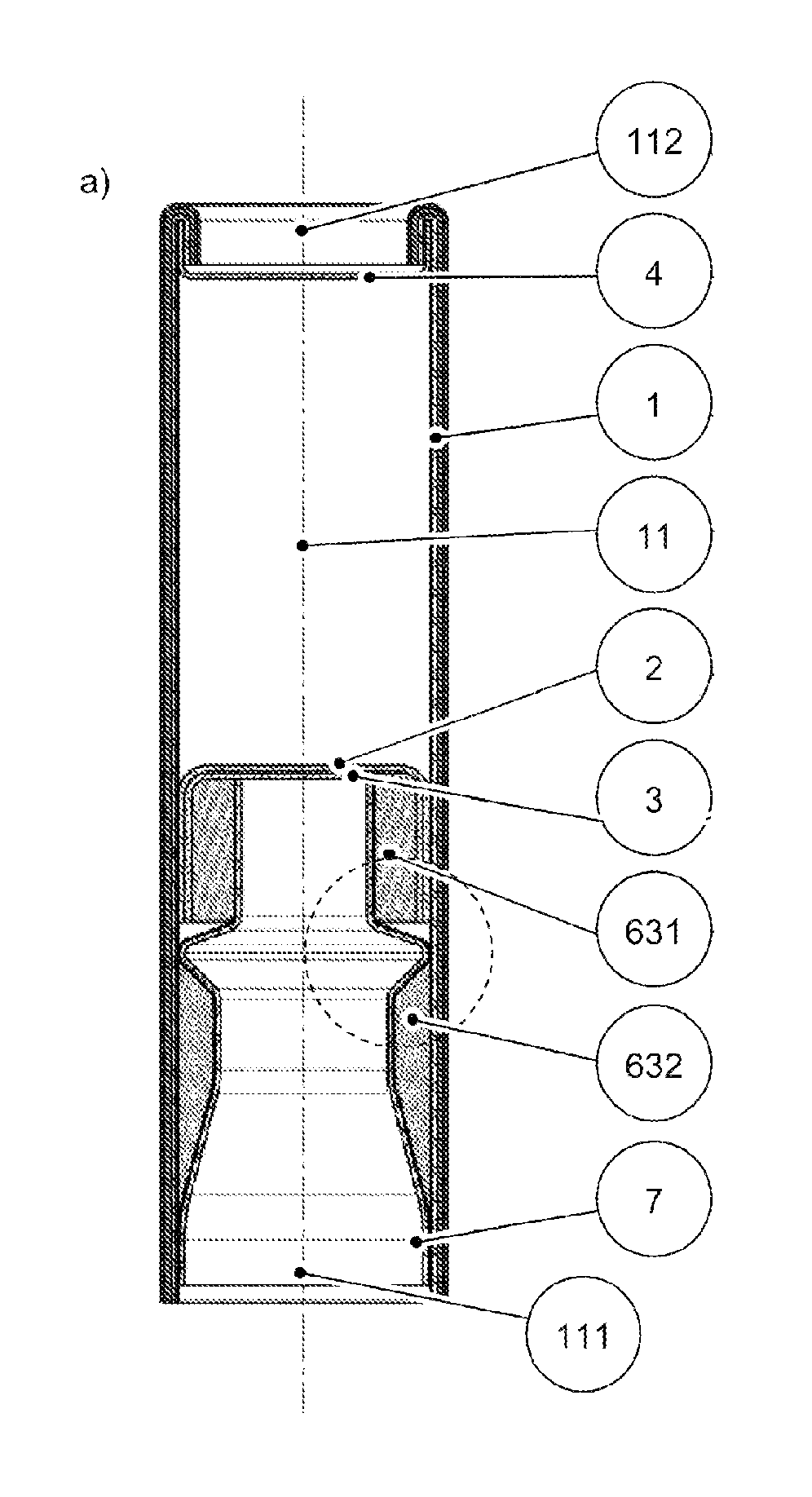

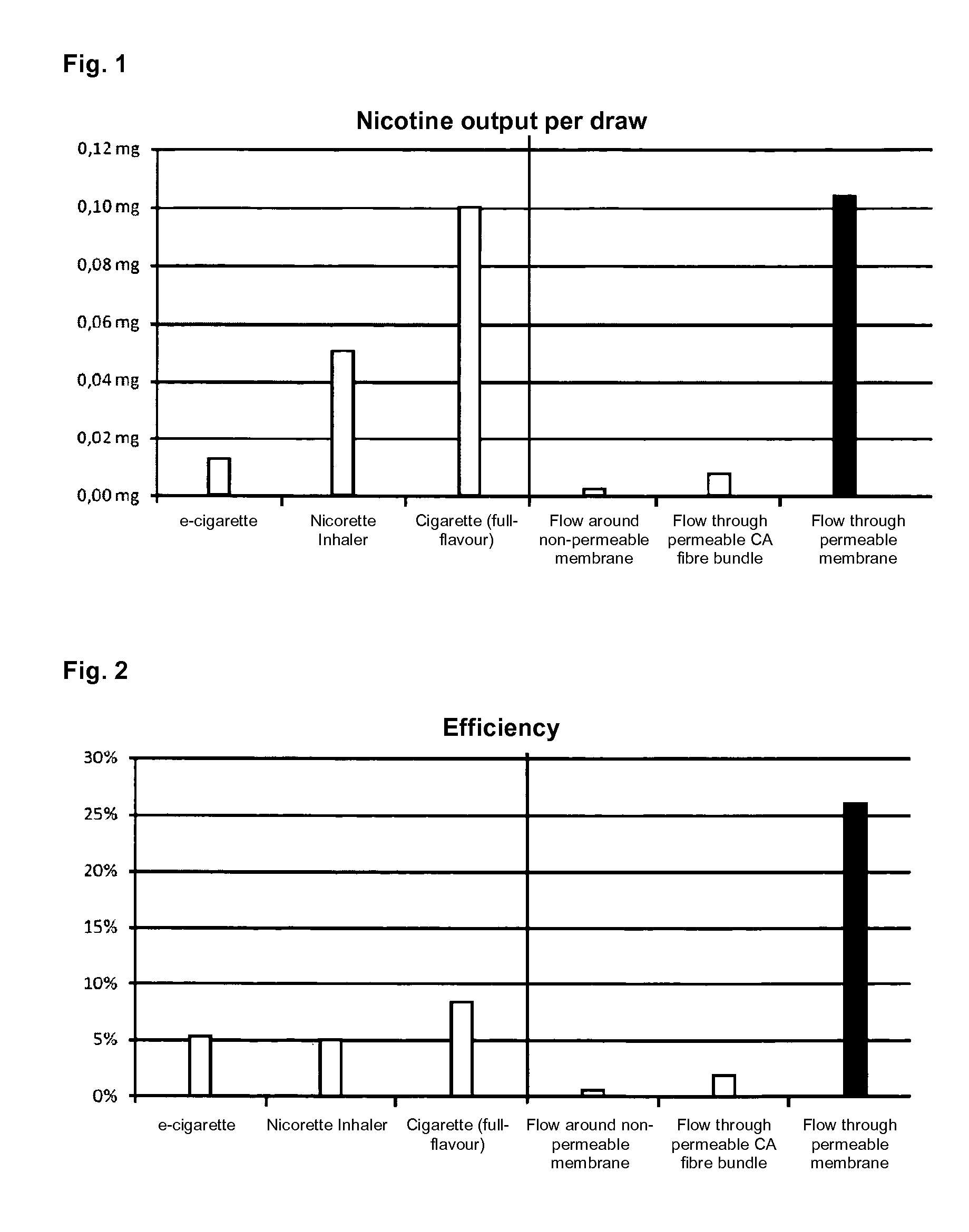

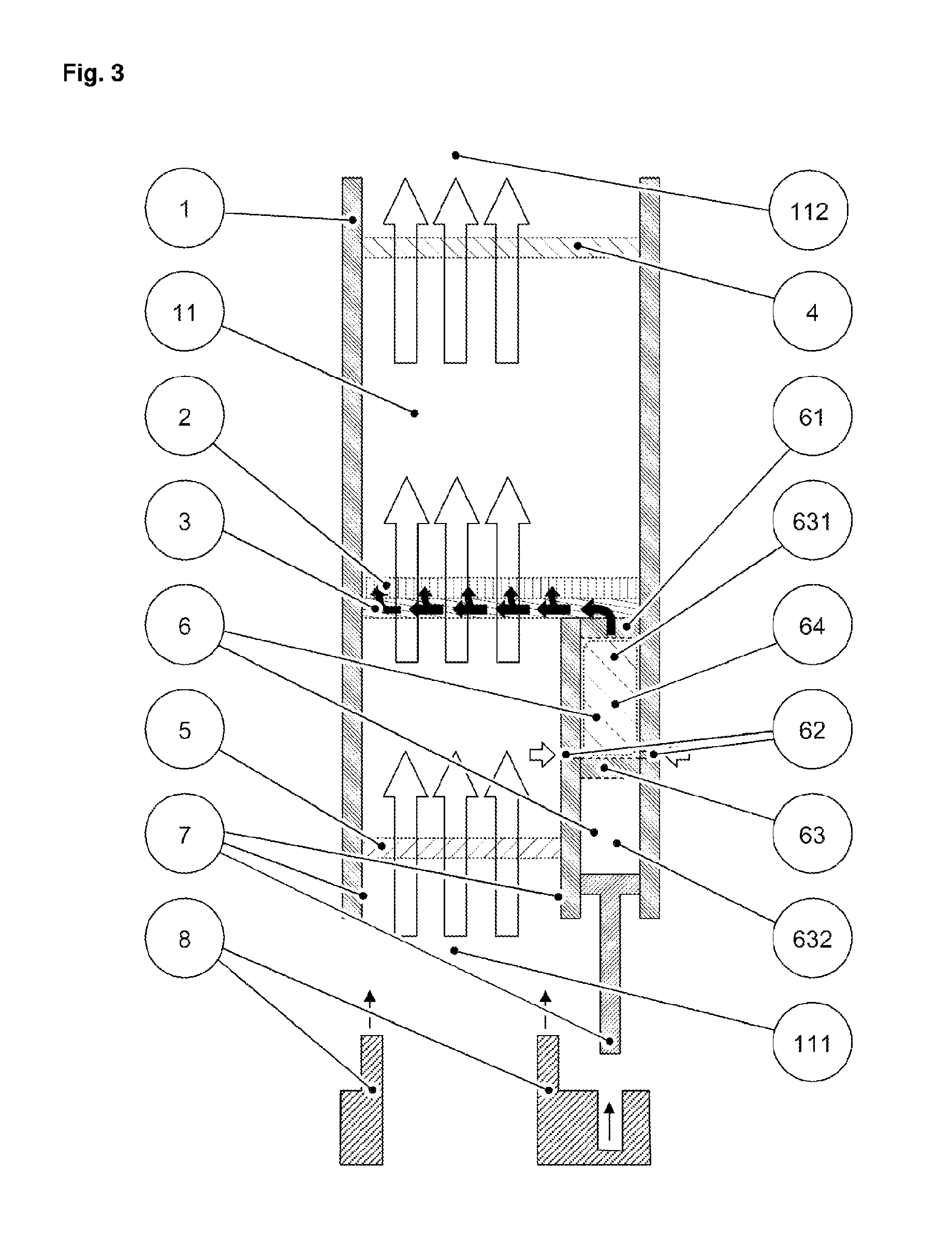

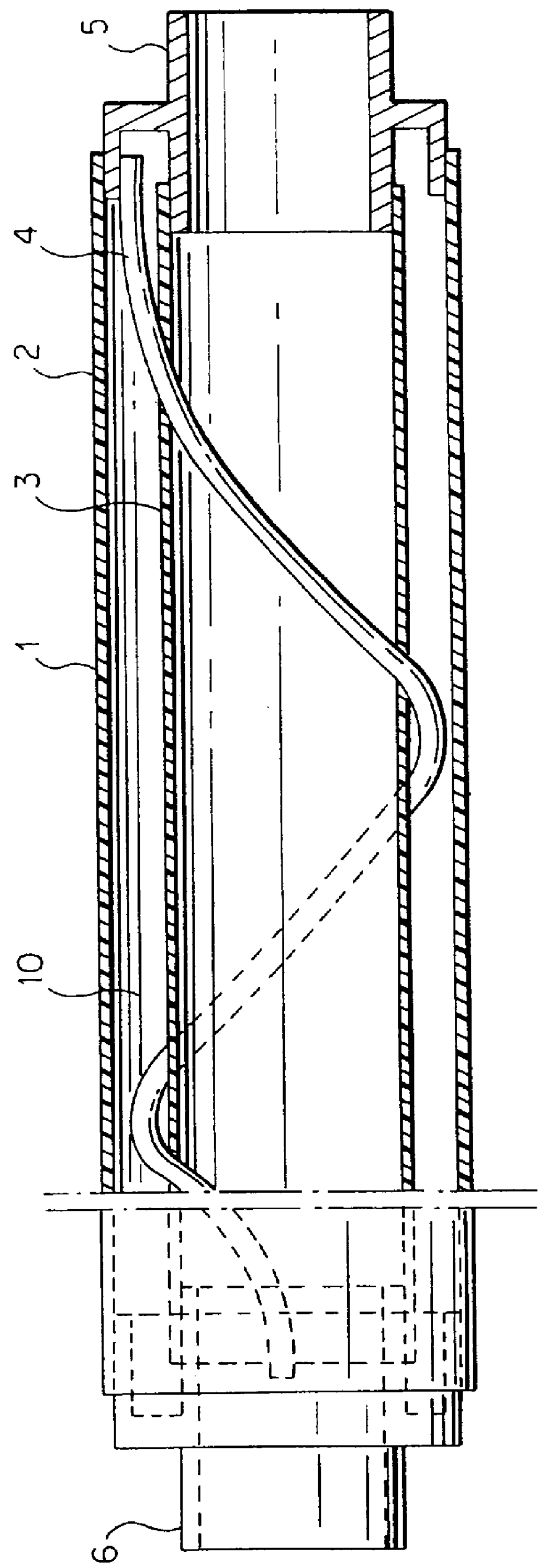

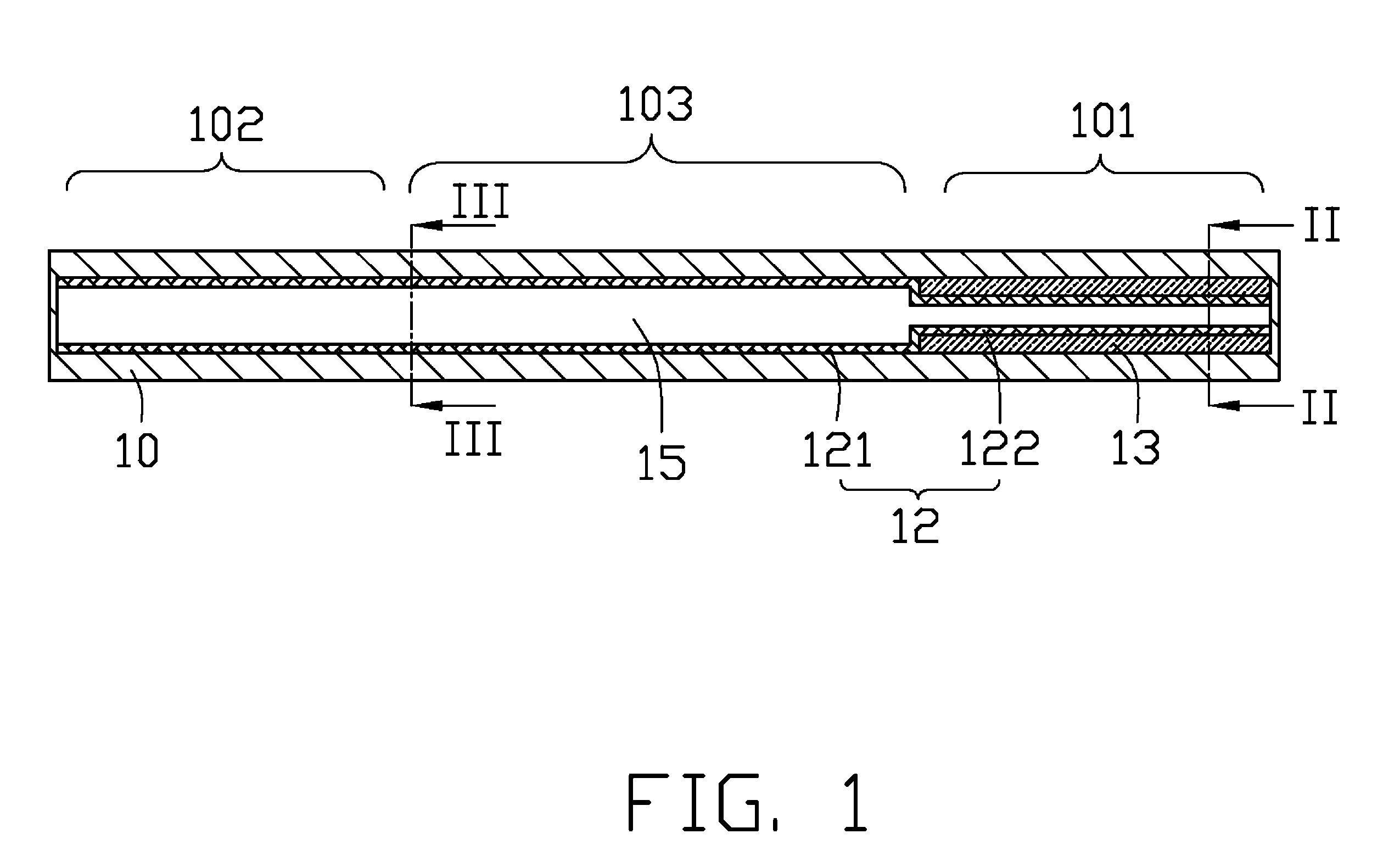

Smokeless cigarette substitute product

ActiveUS20120111346A1Big ratioLower overall flow resistanceRespiratorsTobacco smoke filtersThermal energyChemistry

Method and device for volatilising active and / or aroma materials for the purpose of releasing an inhalable aerosol, wherein a fluid flows through a flow channel (11) in a preferably cylindrical hollow body (1) and wherein the fluid in this flow channel entirely or in part flows through at least one vaporiser membrane (2), wherein the at least one vaporiser membrane has been and / or is wetted with a substance containing an active and / or aroma material to be vaporised and wherein the fluid additionally containing thermal energy vaporises this substance on flowing through the vaporiser membrane and supplies it to the fluid stream.

Owner:PHILIP MORRIS PROD SA

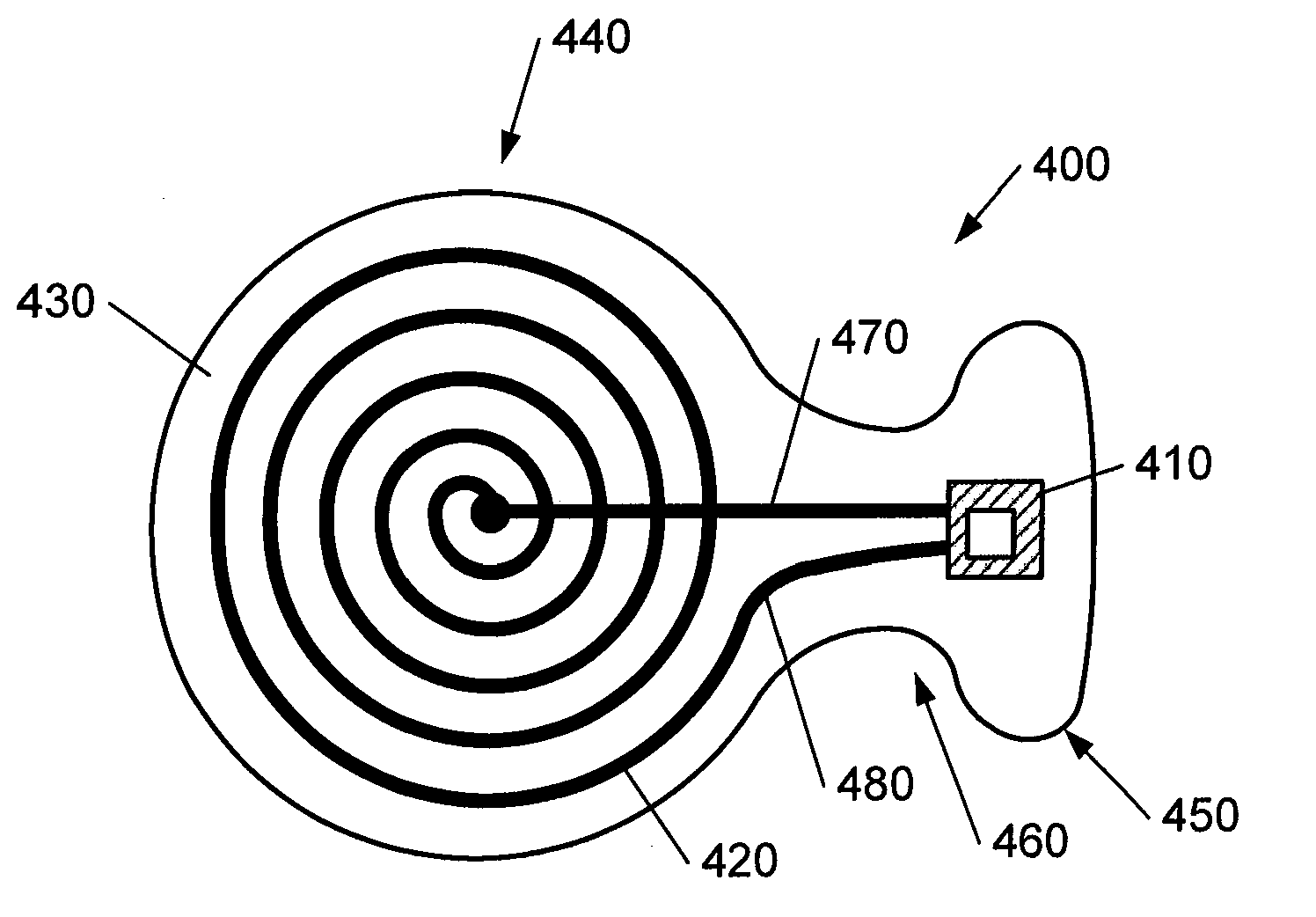

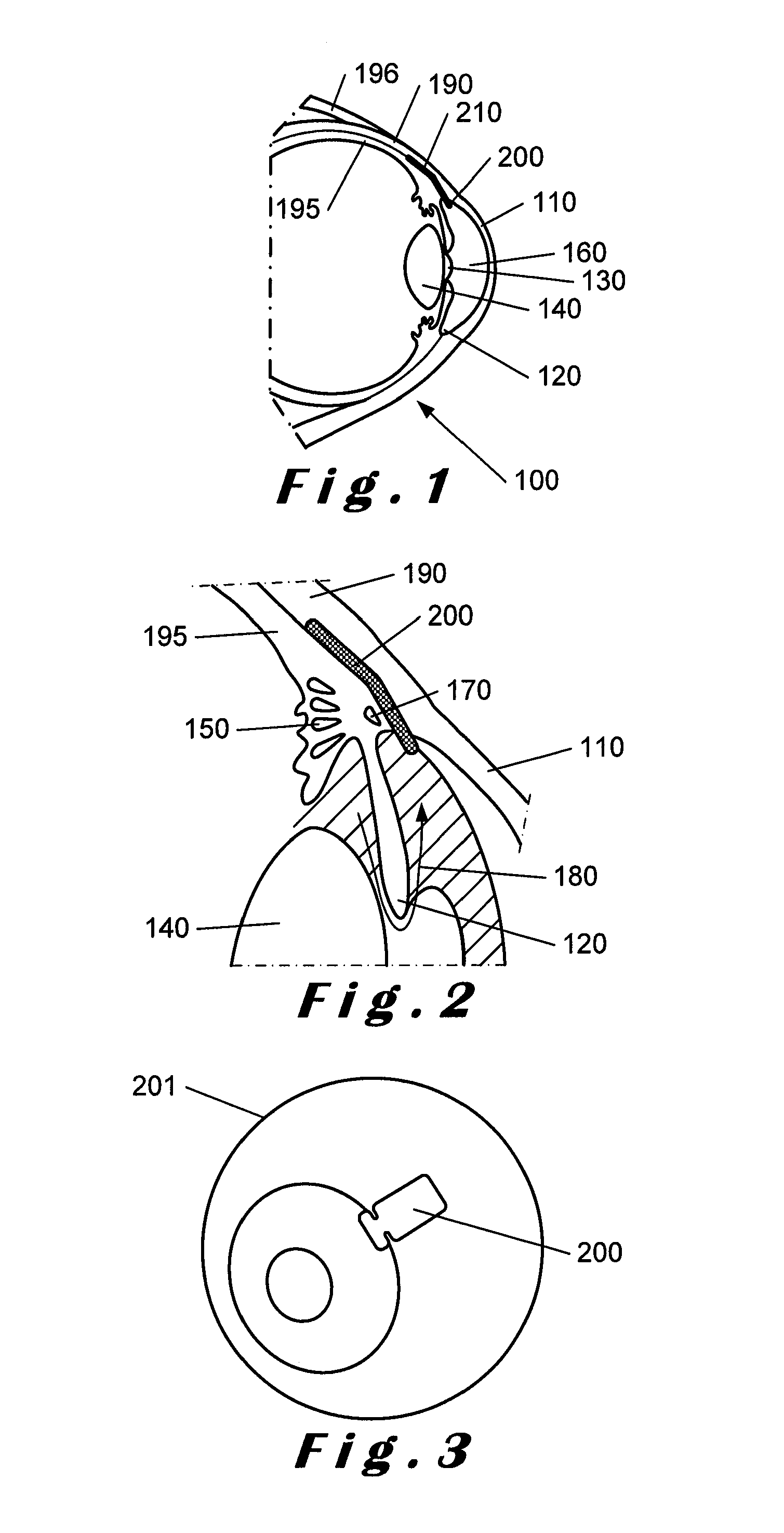

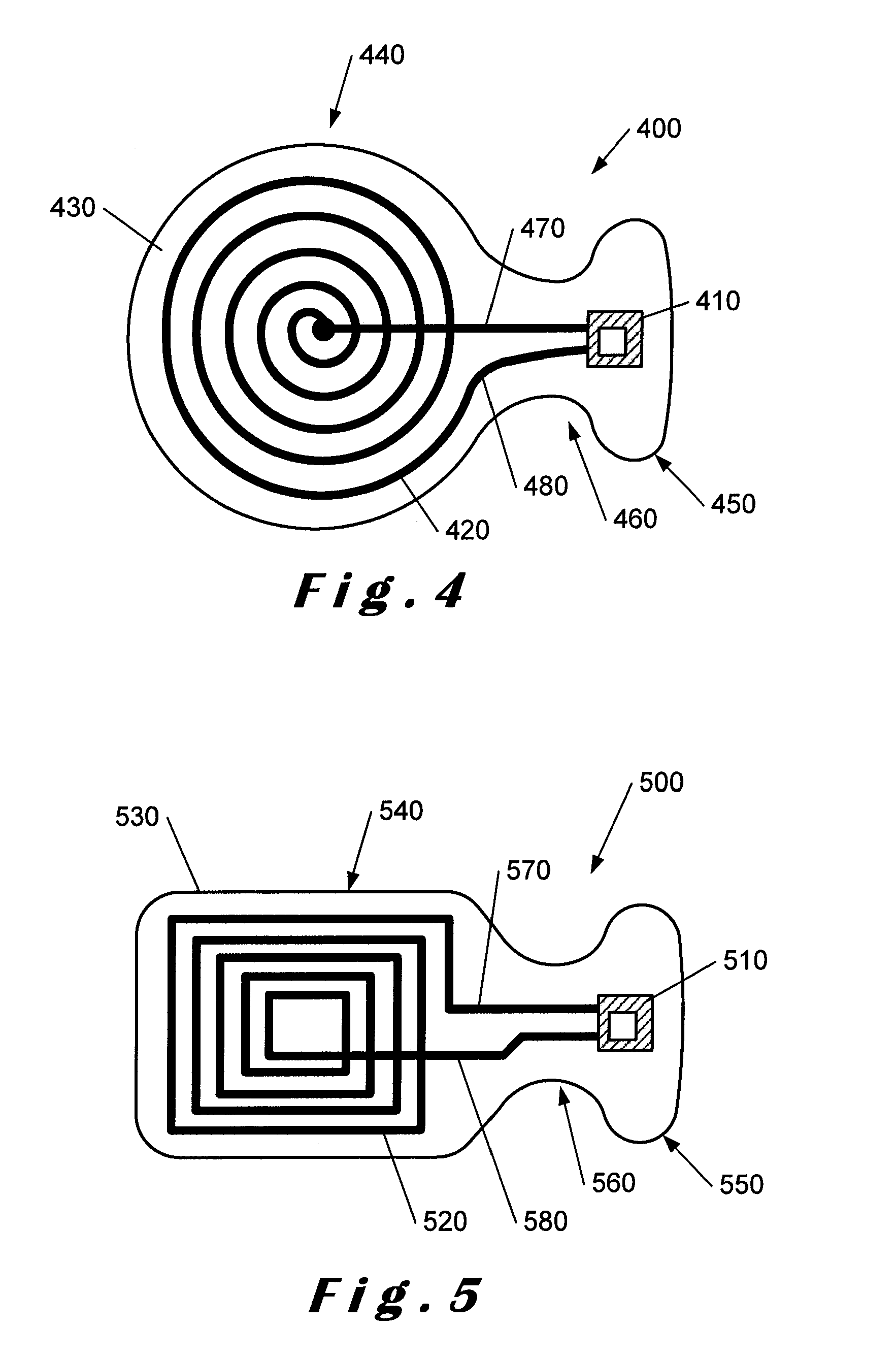

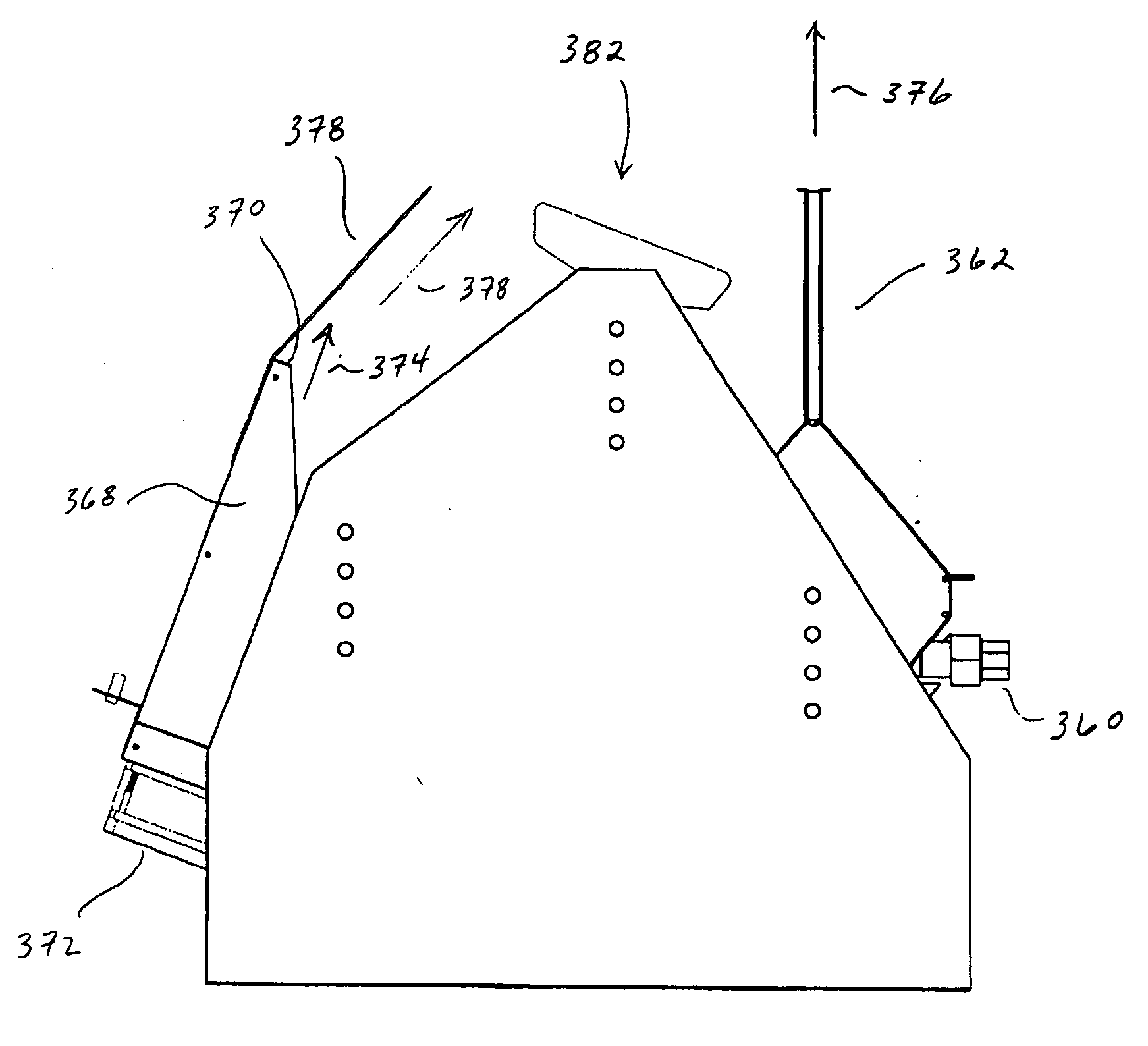

Device and method for glaucoma management and treatment

ActiveUS20120302861A1Readily conform to eye contourMinimize traumaEye surgeryDiagnostic recording/measuringAqueous humourIOPS

Described herein is a device for glaucoma treatment and monitoring that comprises a combination of an intraocular pressure (IOP) sensor and a glaucoma drainage device. The device comprises an IOP sensor and an inductive antenna mounted within a porous biocompatible material that forms the drainage path. The IOP sensor is mounted in a footplate portion of the device and is mountable in the anterior chamber of an eye. The footplate portion is connected to a body portion that houses the spiral antenna by a neck portion which retains the footplate portion in a suitable position within the anterior chamber. Due to its size, the footplate portion housing the IOP sensor can readily be inserted into the anterior chamber with the body portion housing the spiral antenna located outside of the anterior chamber in a sub-scleral space to disperse the aqueous humour.

Owner:ISTAR MEDICAL

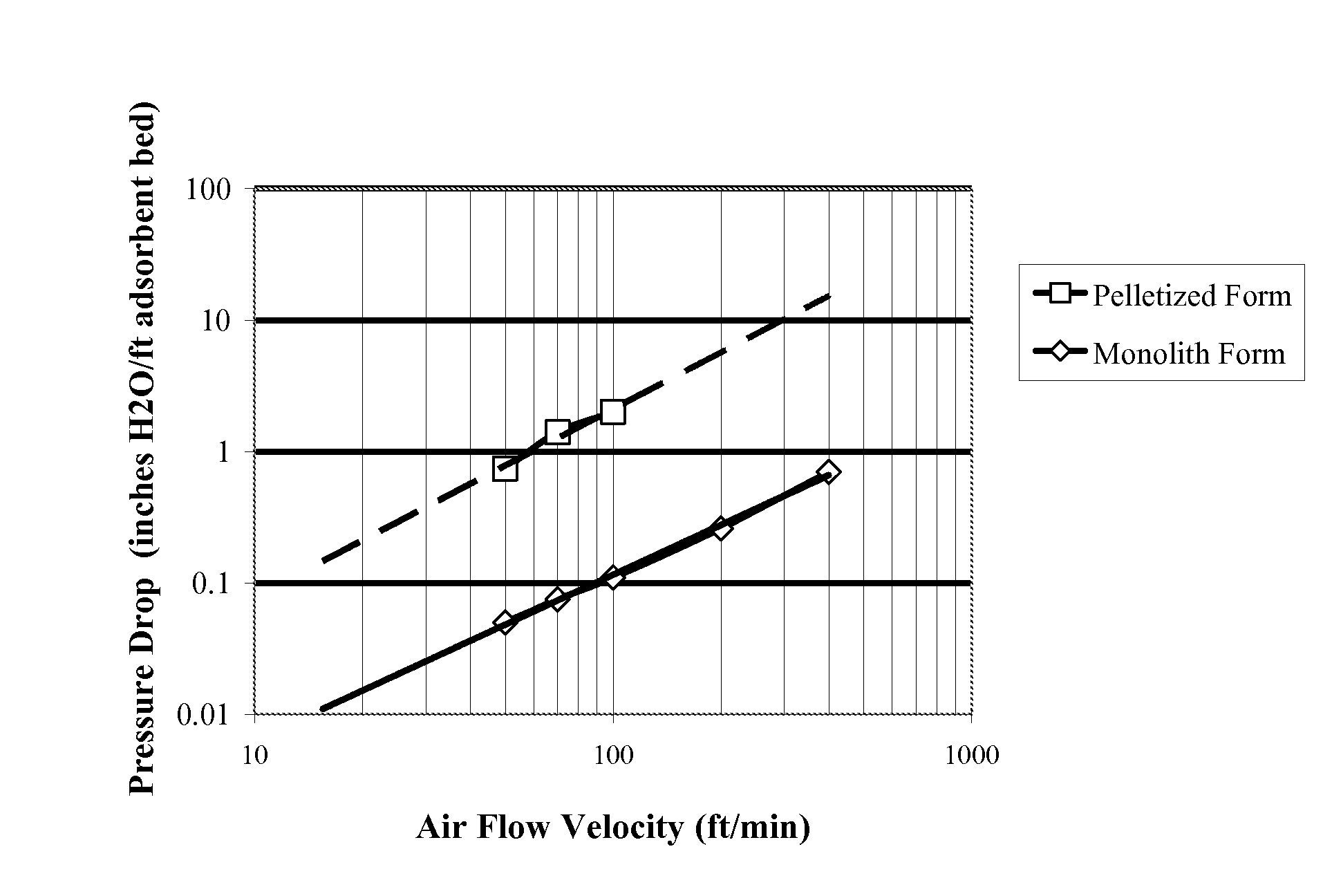

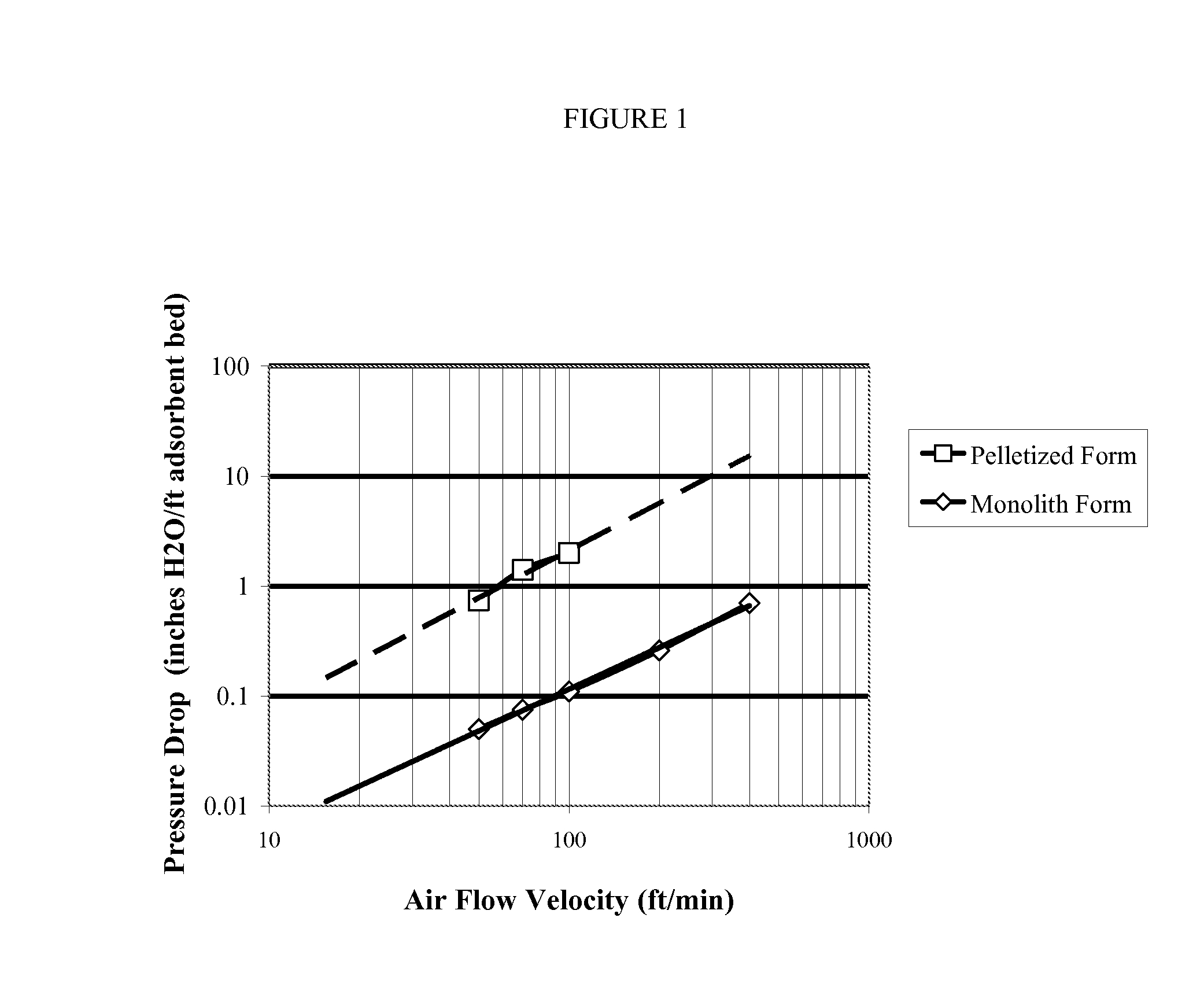

Impregnated Monoliths

InactiveUS20080236389A1Lower overall flow resistanceImprove adsorption capacityGas treatmentLayered productsAlkaline earth metalHoneycomb

The present invention relates to adsorbent honeycomb monoliths and other porous monoliths impregnated with alkaline and / or caustic salts of alkaline metal or alkaline earth metal. The impregnated monoliths have high adsorption capacity and low flow resistance, yet with minimized flammability, suitable for use in removal of acidic, malodorous and / or harmful gases.

Owner:MEADWESTVACO CORP

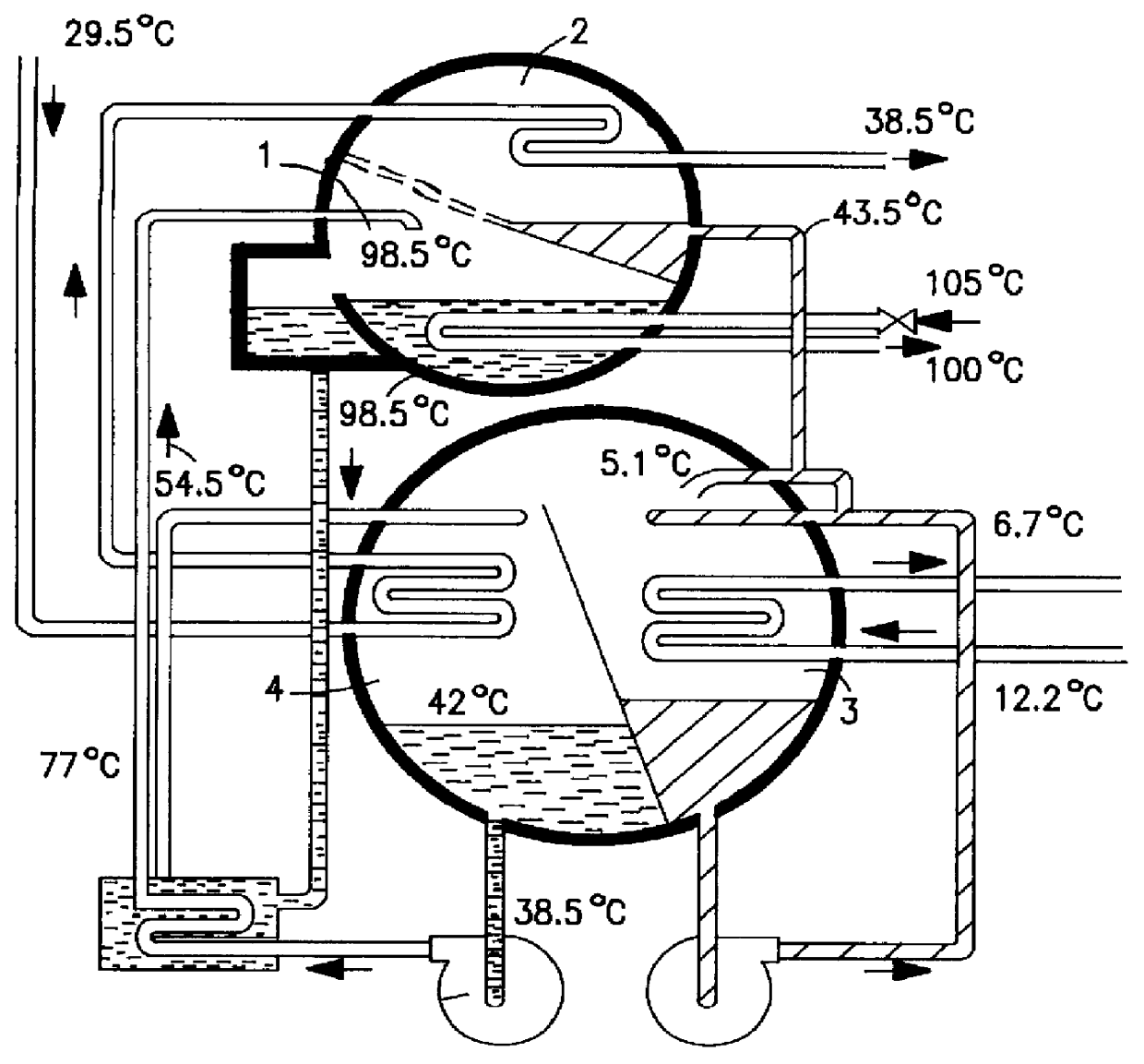

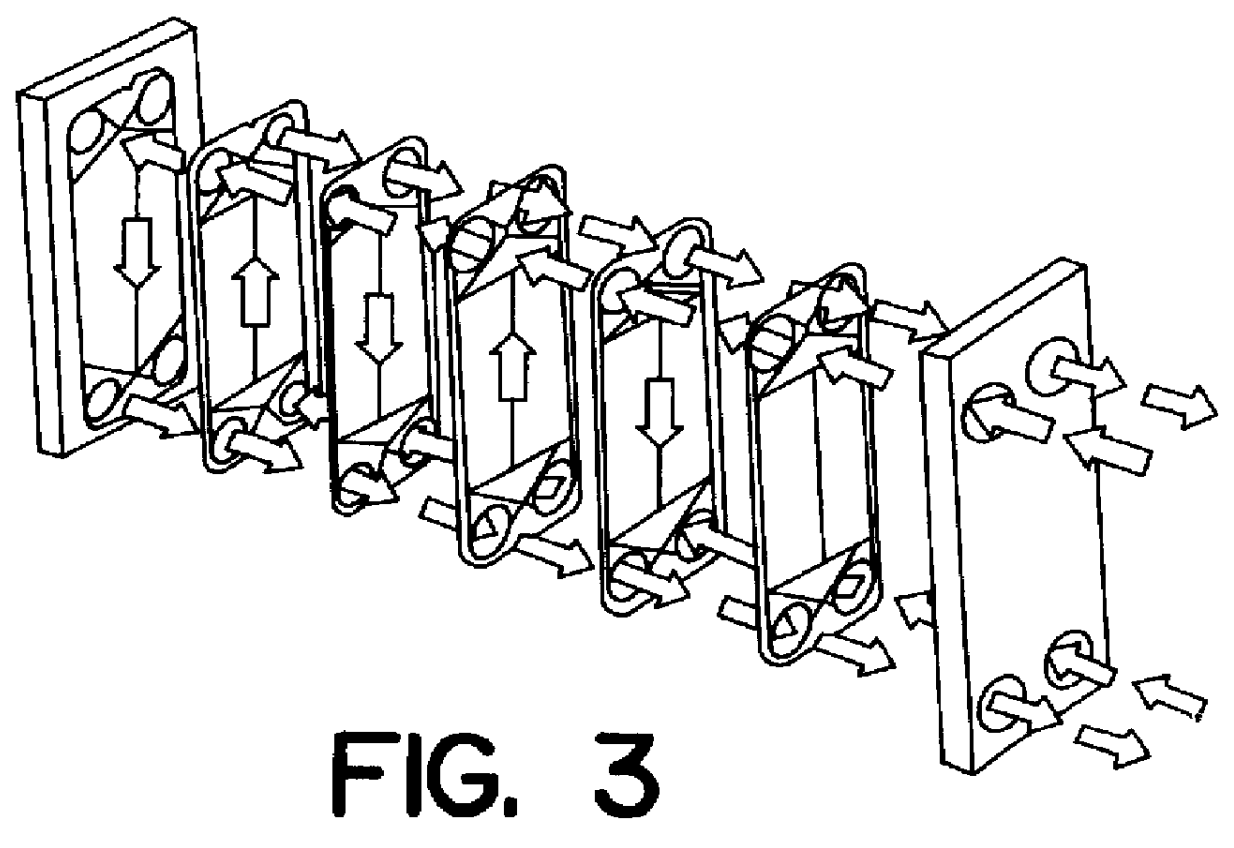

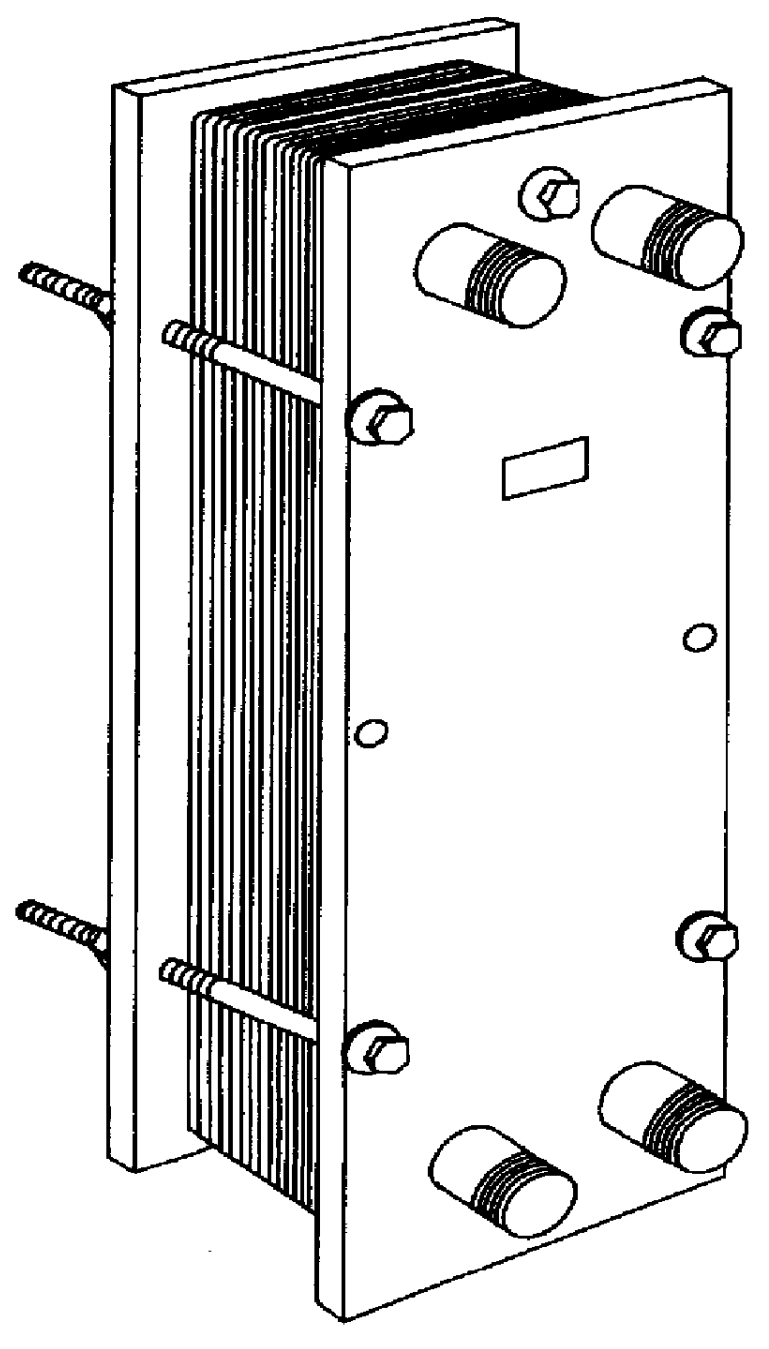

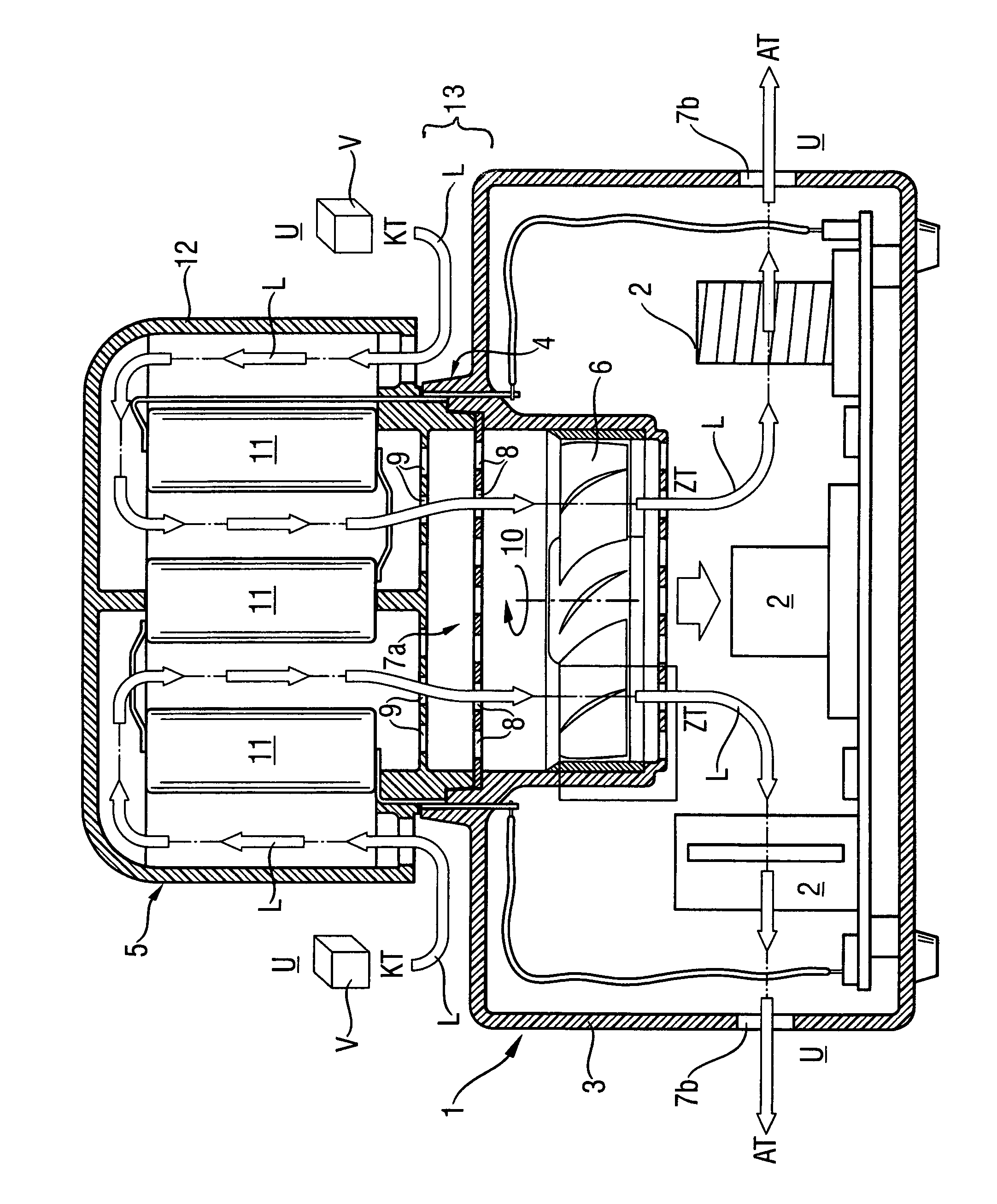

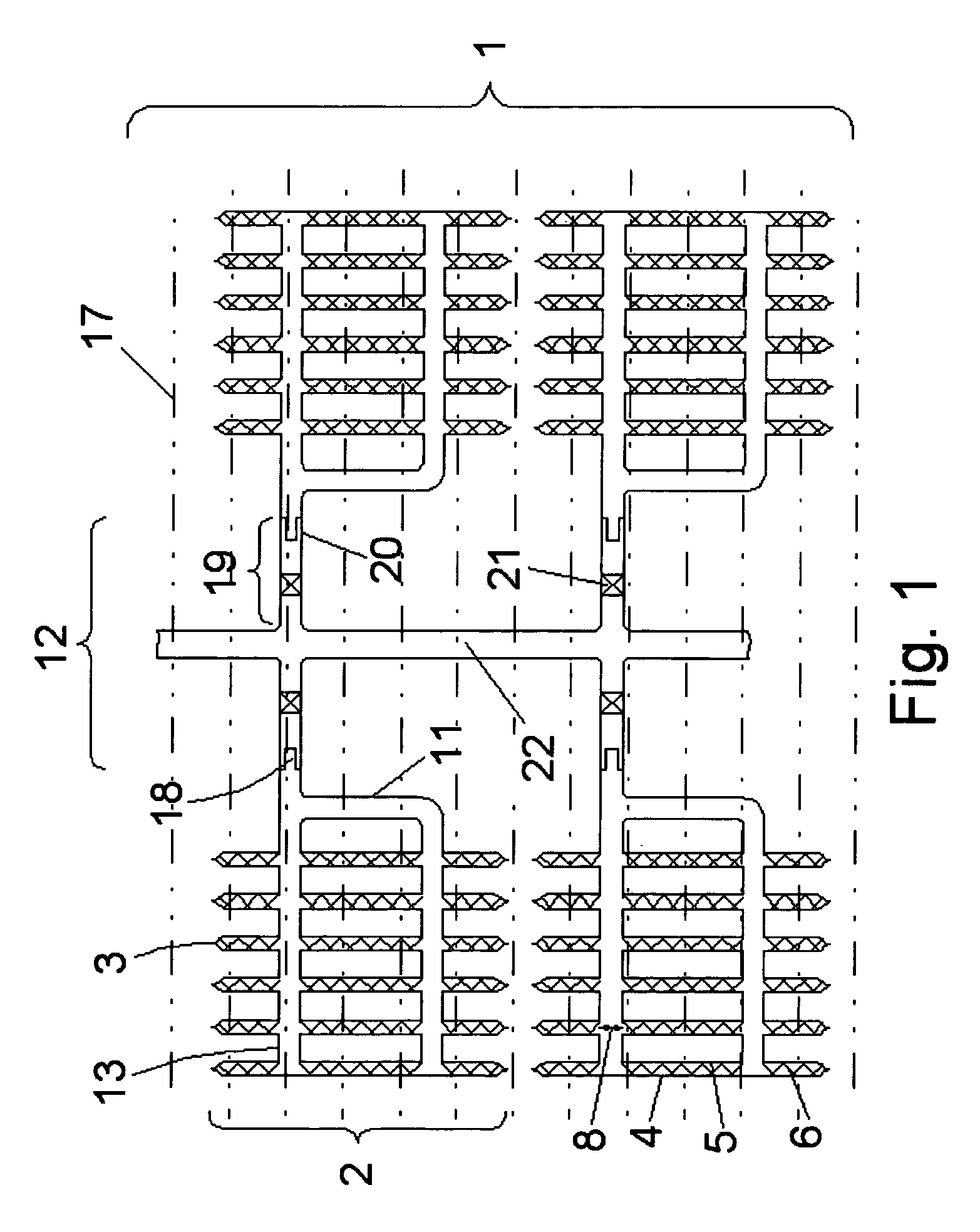

Arrangement for transferring heating and cooling power

InactiveUS6158238ALow flow resistanceReduce distanceEnergy efficient heating/coolingClimate change adaptationPlate heat exchangerEngineering

PCT No. PCT / FI97 / 00515 Sec. 371 Date Mar. 31, 1999 Sec. 102(e) Date Mar. 31, 1999 PCT Filed Sep. 3, 1997 PCT Pub. No. WO98 / 10233 PCT Pub. Date Mar. 12, 1998An apparatus for transferring heating and cooling power by means of two heat transfer media, wherein at least one of the heating media is arranged to be evaporated or condensed. To reduce the need for space, the apparatus includes a shell (3) inside which at least one plate heat exchanger (1,2) is arranged loosely, flow slots (19) of the heat exchanger being arranged to be completely or mainly open towards the shell (3) in such a manner that the evaporating or condensing heat transfer medium can flow to the plate heat exchanger or from the plate heat exchanger from different sides of the plate heat exchanger on the whole length of that slot (19) which is open.

Owner:ABB POWER +1

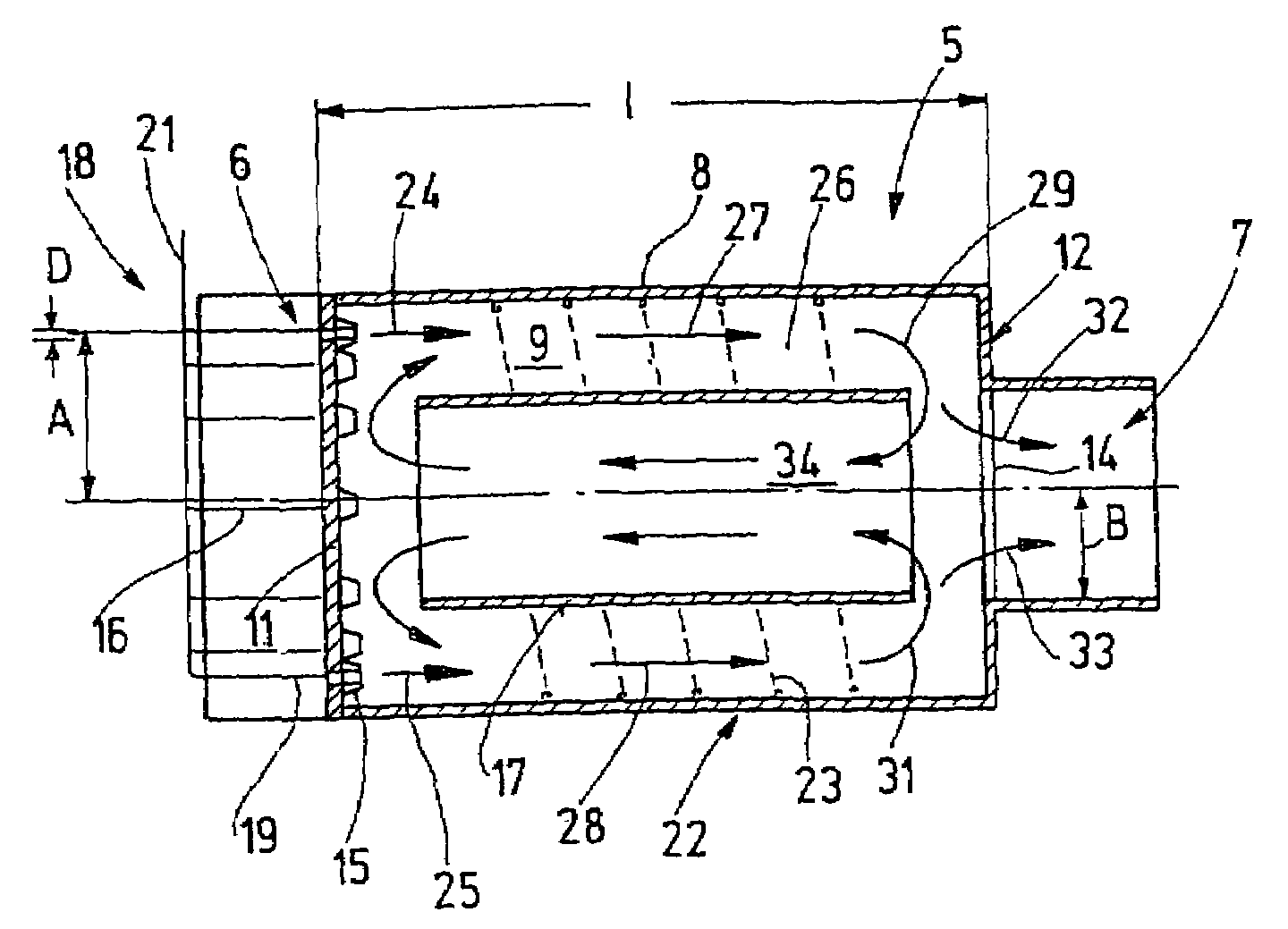

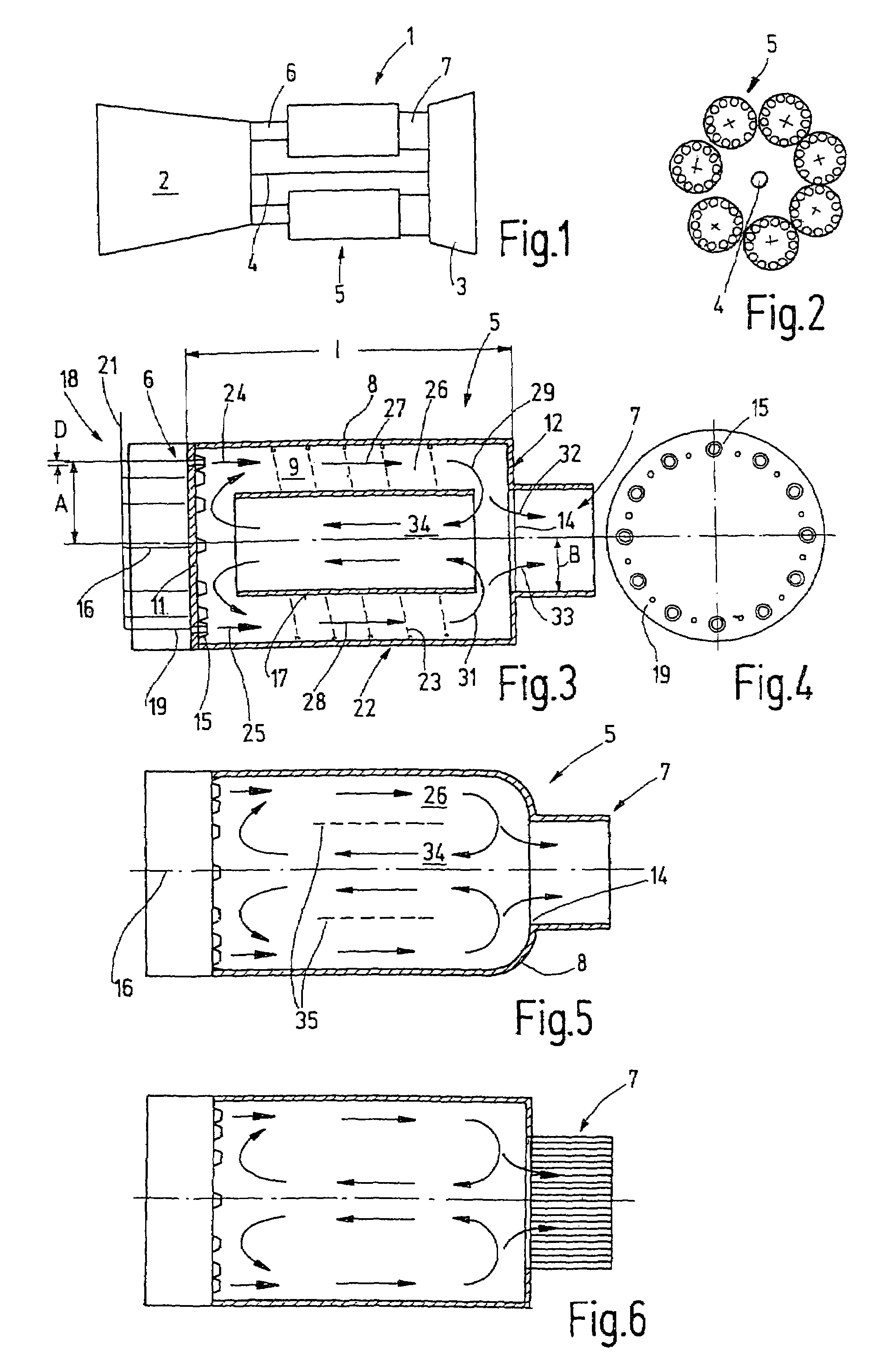

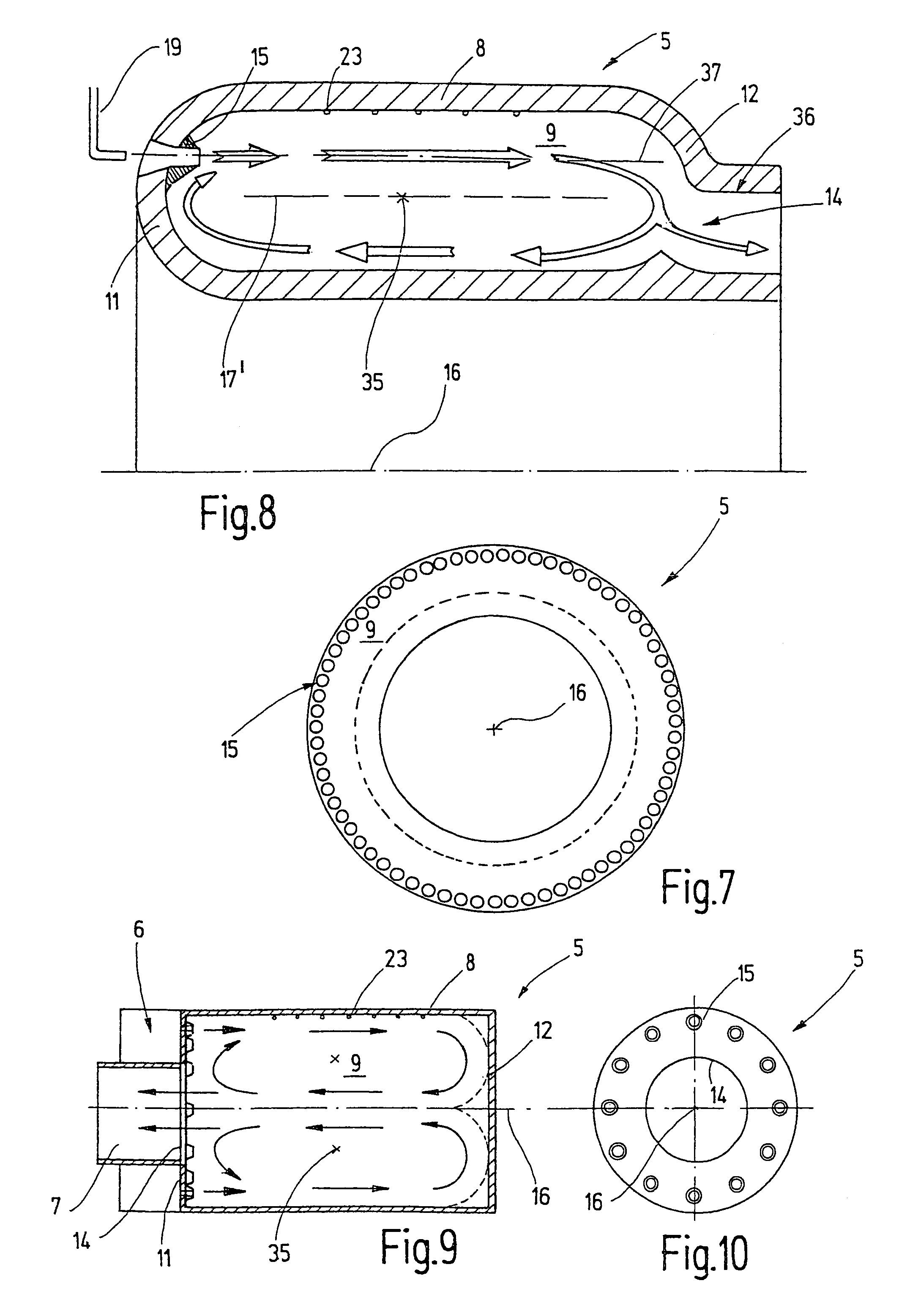

Combustion chamber with flameless oxidation

InactiveUS7062917B2Lower overall flow resistanceIncreased pressure lossContinuous combustion chamberGas turbine plantsInterior spaceCombustion chamber

A combustion chamber (5) for a gas turbine is adapted for flameless oxidation of fuels. This circulation flow has an internal space (9) in which a large-volume circulation flow is established. To this end, the combustion chamber supplies a hot exhaust stream to the introduced air, the mass flow rate of which exceeds the fresh air stream. The fresh air and the fuel are fed to the combustion chamber in the same direction, roughly parallel to the wall.

Owner:WS WARMEPROZESSTECHN

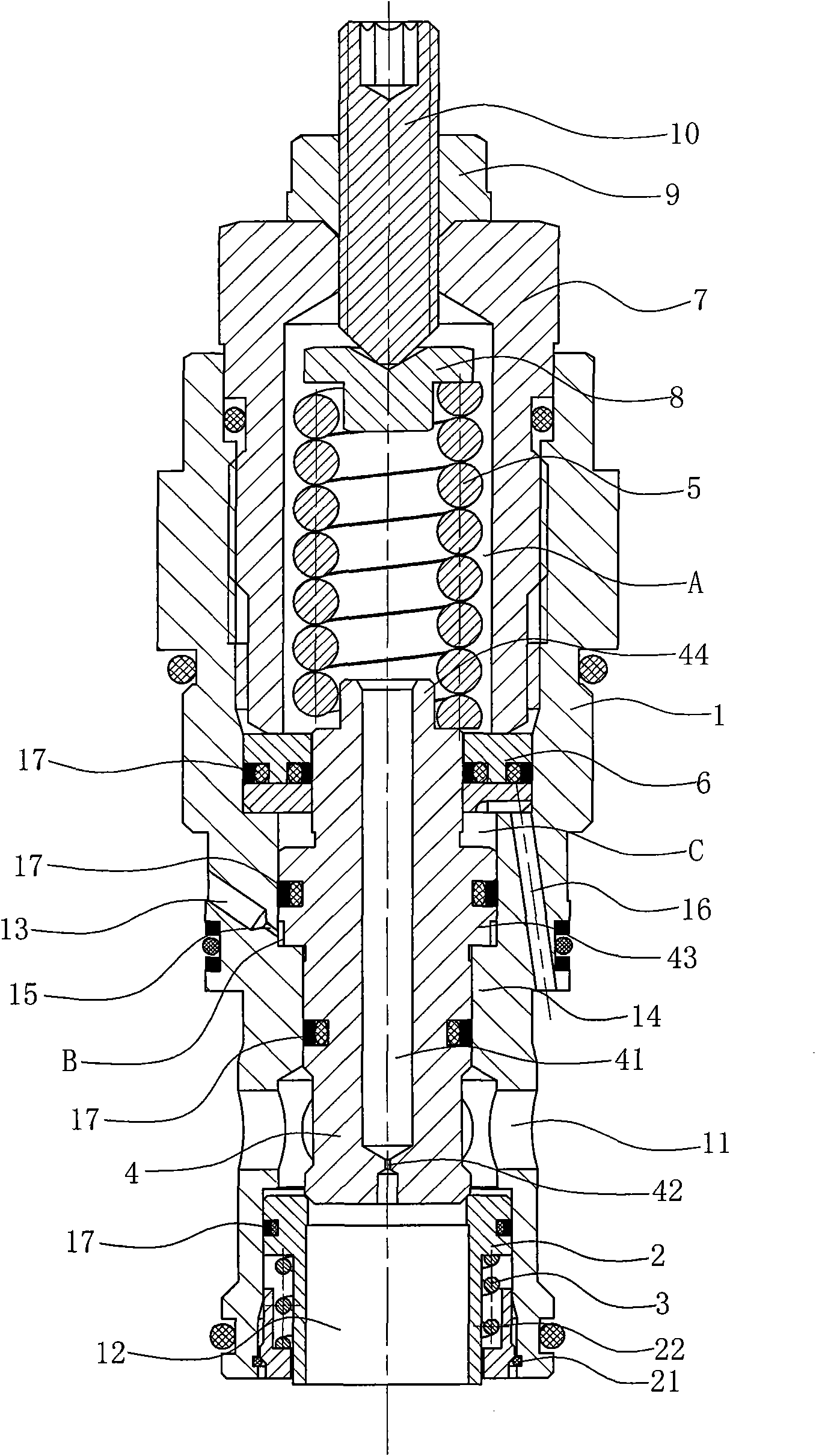

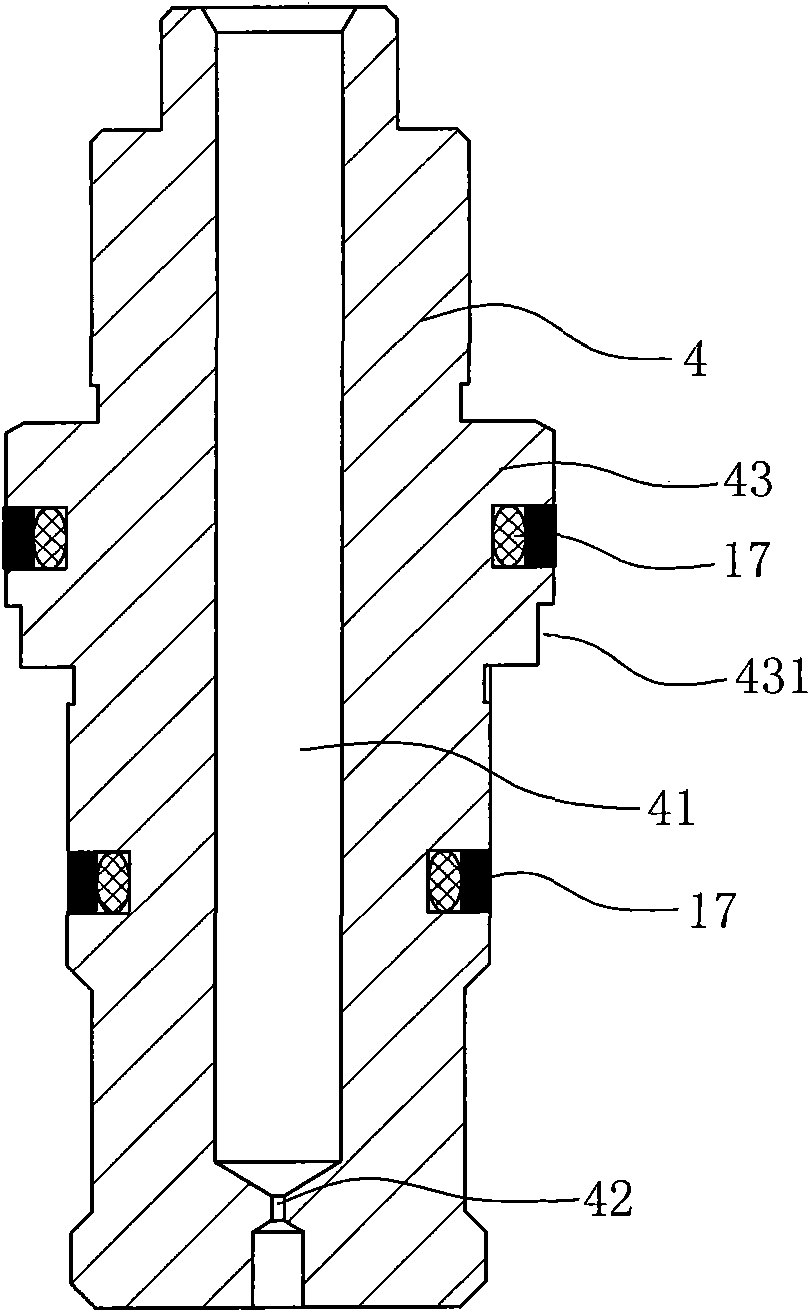

Plug-in type balance valve

InactiveCN101634317AReduce heat treatment requirementsReduce material requirementsServomotor componentsShoulder BladesThermal treatment

The invention relates to a plug-in type balance valve which comprises a valve body, a one-way valve core and a balance valve core, wherein a first oil opening, a second oil opening and a third oil opening are arranged on the valve body; the one-way valve core is arranged at the second oil opening and pushed by a first spring to maintain the trend of axial upward shift; the balance valve core is installed in the valve body and can be matched with a valve opening of the one-way valve core, and a second spring is arranged in a spring cavity of the valve body; the upper part in the balance valve core is provided with an axial passage and a first damping hole; the middle position of the balance valve core is provided with an axial convex shoulder; an annular notch is arranged on the periphery surface of the axial convex shoulder; the inner wall of the valve body is provided with an annular inner shoulder blade; an oil inlet cavity is formed among the annular notch, the inner wall of the valve body and the annular inner shoulder blade; and the third oil opening is communicated with the oil inlet cavity by a second damping hole on the side wall of the valve wall. The balance valve core and the one-way valve core are in an integral structure, and the structure is simple; the balance valve core and the one-way valve core are relatively independent on the relative position relationship, the assembly is convenient, and the requirements on heat treatment and materials of the balance valve core are lowered.

Owner:NINGBO HANSHANG HYDRAULIC

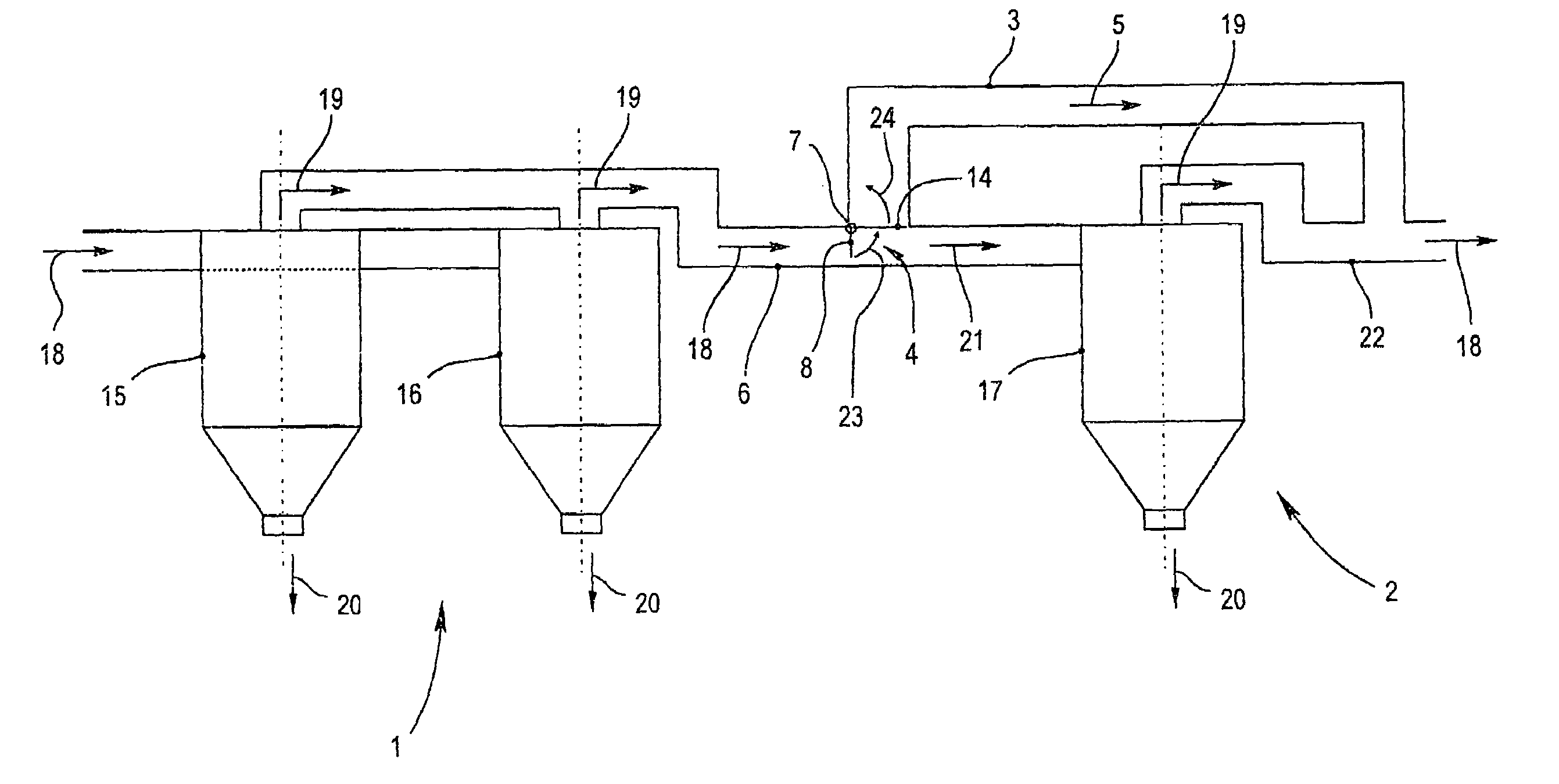

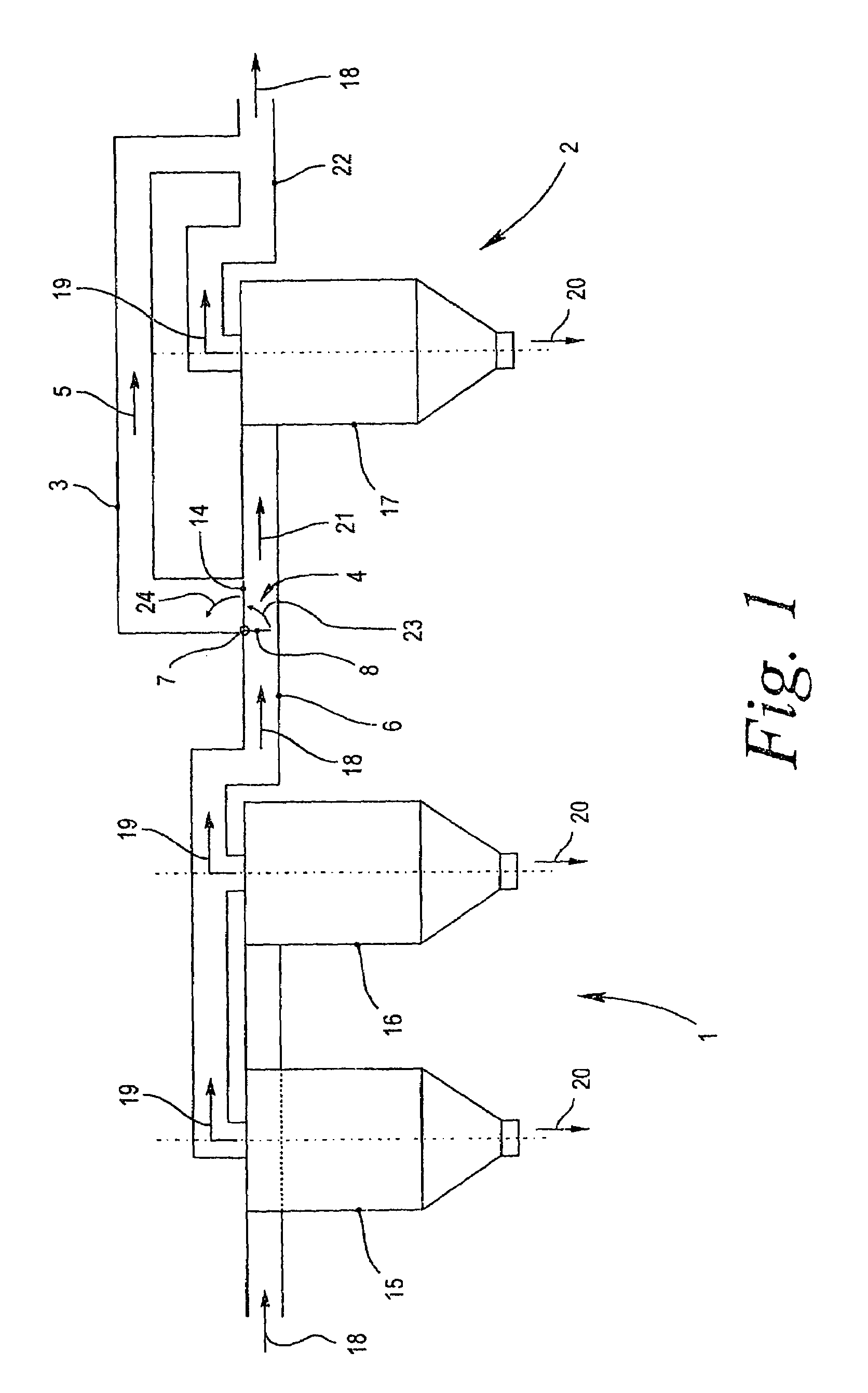

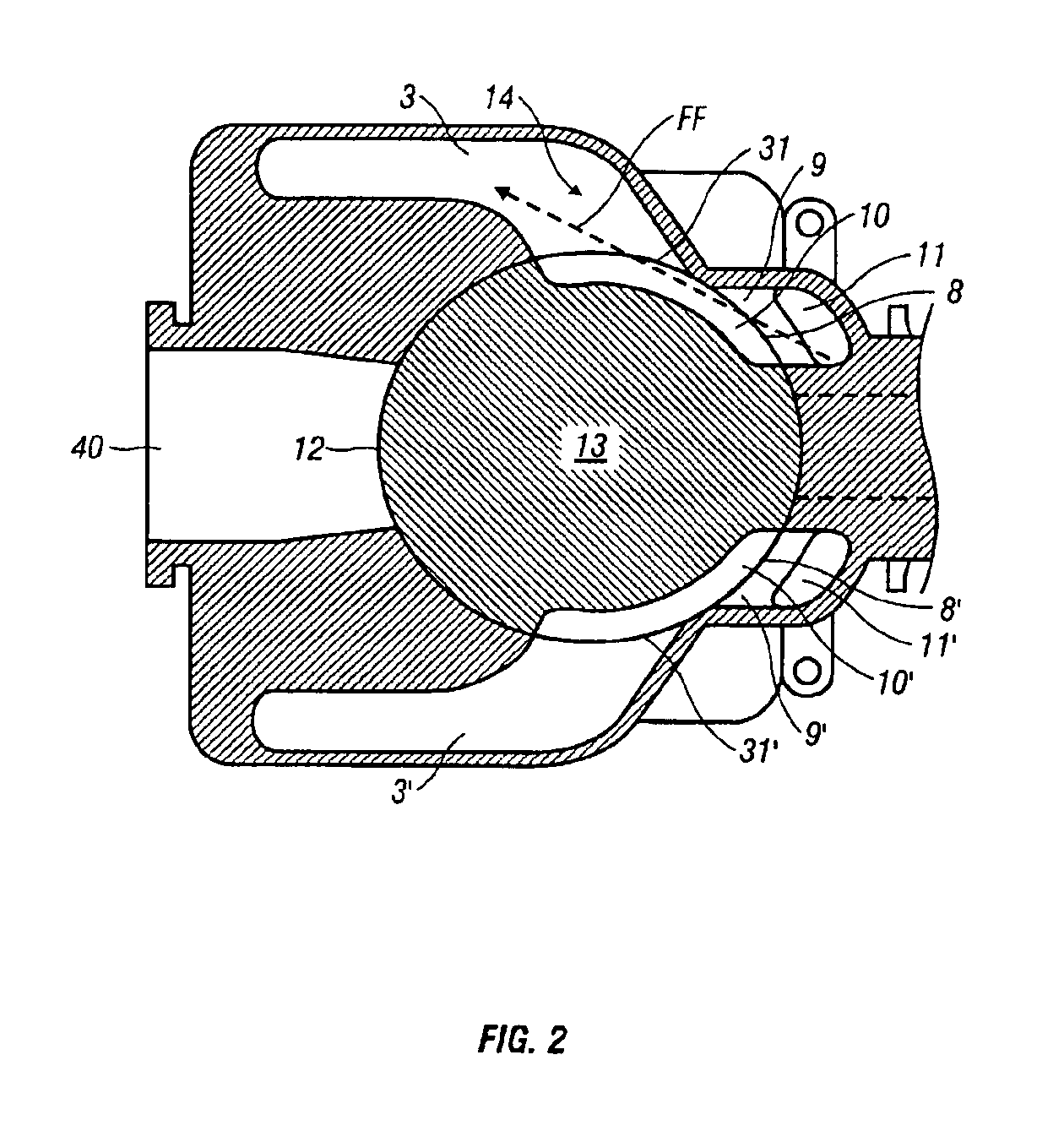

Cyclone separator

InactiveUS7159723B2Easy to separateWide range of operationsReversed direction vortexDispersed particle separationCycloneEngineering

A cyclone separator including an initial cyclone arrangement (1) arranged first in relation to a flow direction (18) through the separator; a second cyclone arrangement (2) connected in series with the initial cyclone arrangement; a bypass channel (3) bypassing the second cyclone arrangement (2), and a volumetric flow controlled valve device (4) for selectively directing a partial stream (5) through the bypass channel (3).

Owner:MANN HUMMEL GMBH

Flexible tube device

InactiveUS6105620AImprove adaptabilityCostHeat exhanger conduitsPipe elementsBending forceBiomedical engineering

Owner:HABERL JOHANN

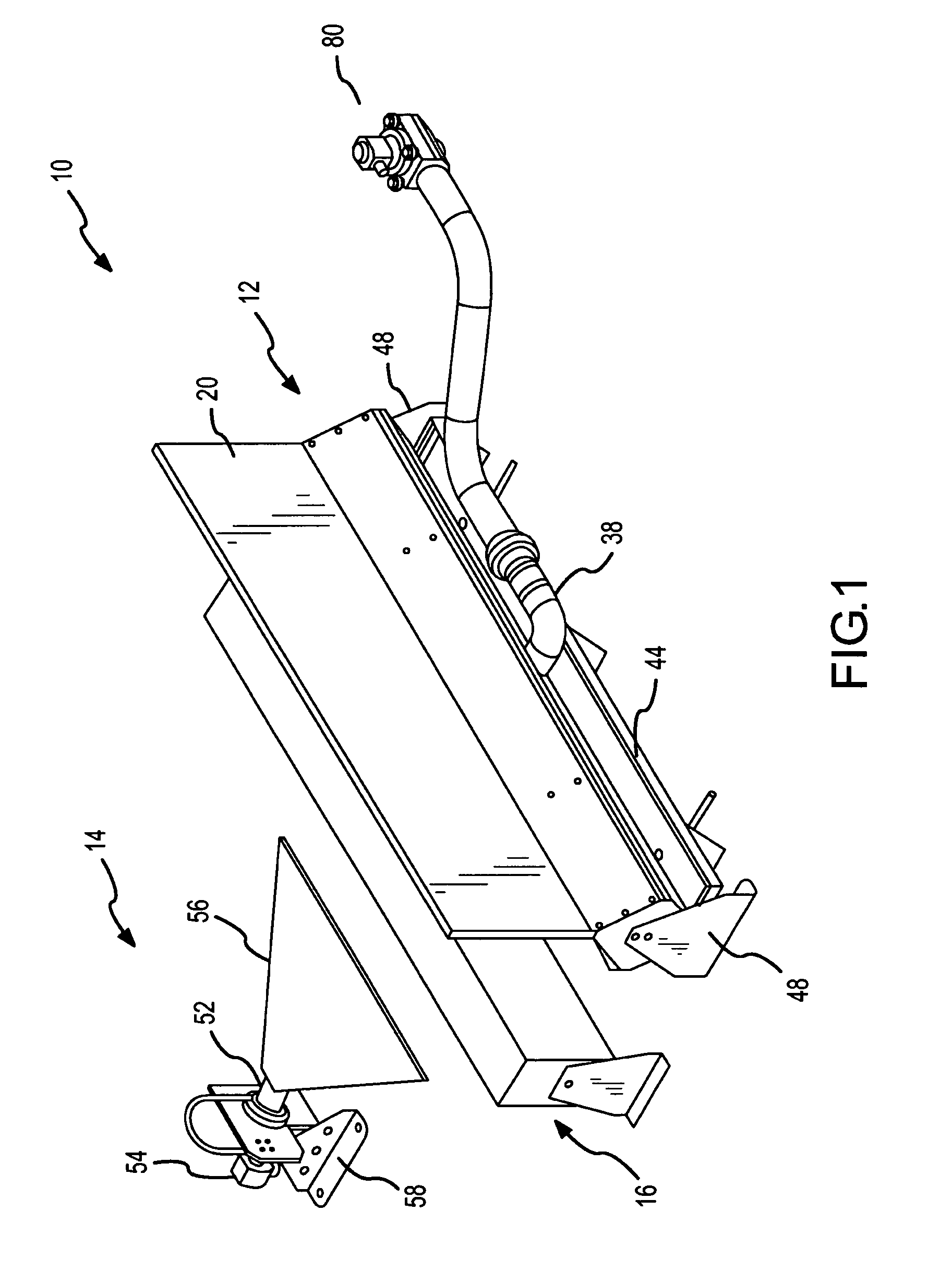

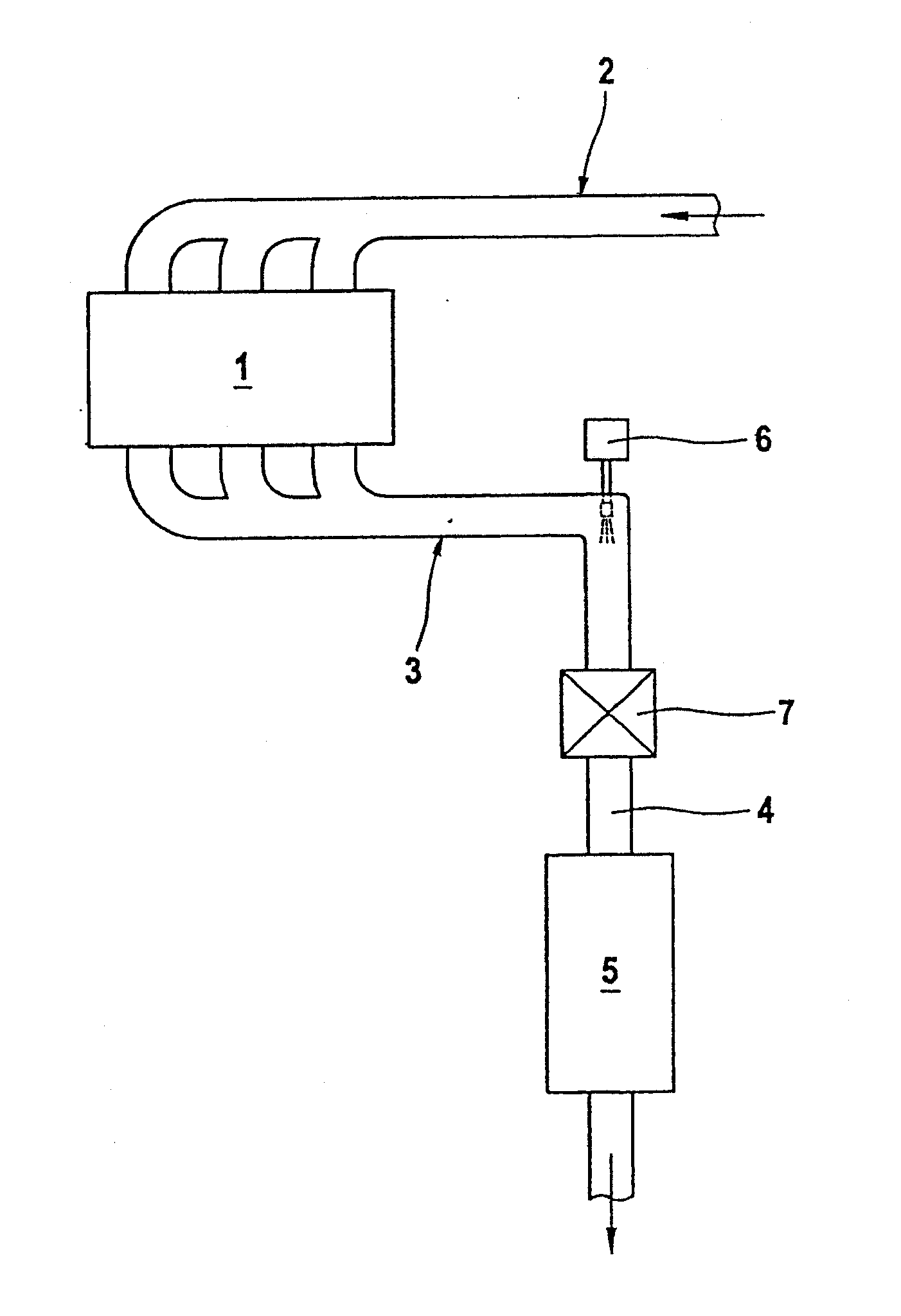

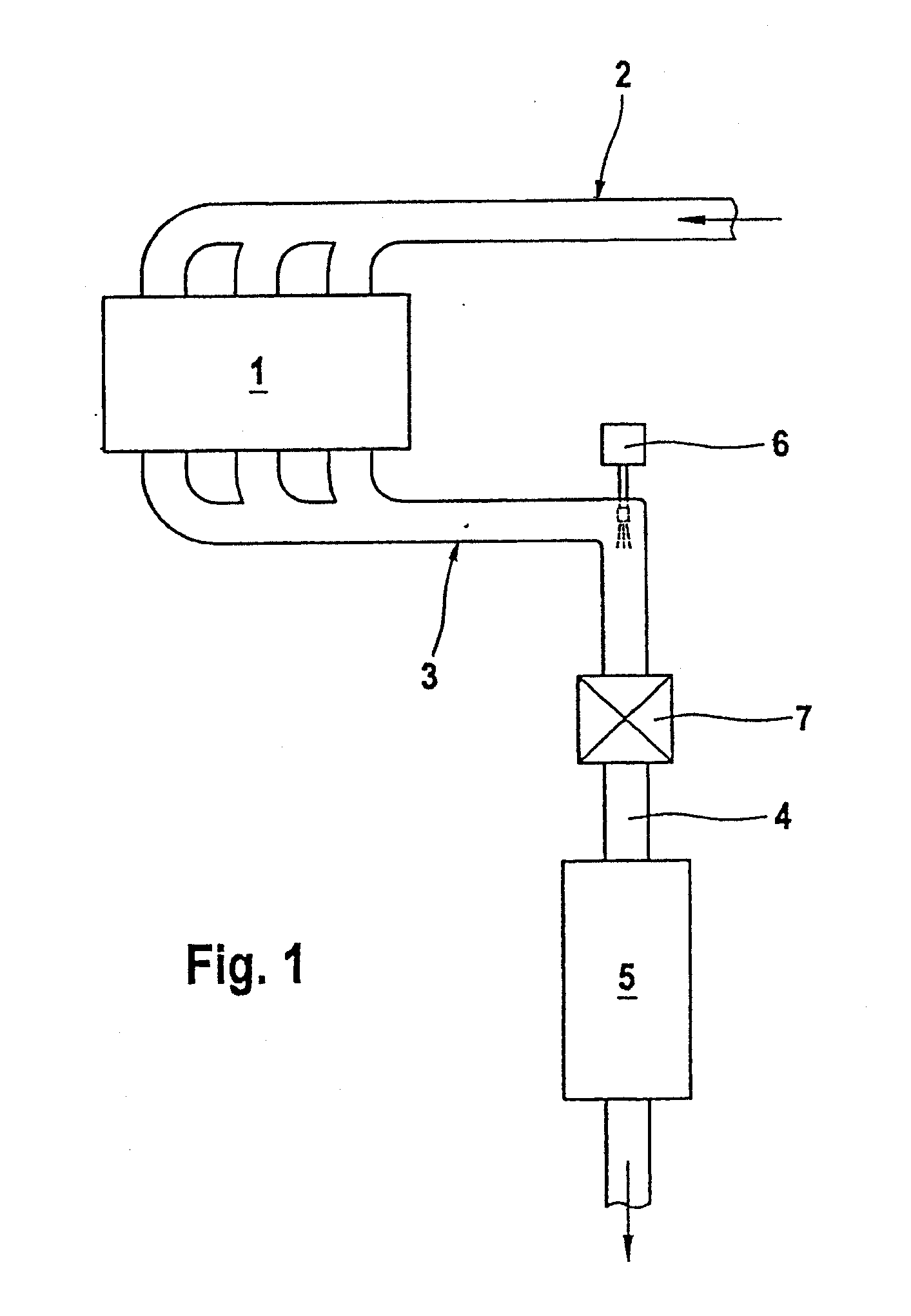

Method for reducing particle emissions containing carbon of diesel motors and corresponding system

InactiveUS6938409B2Improve the level ofIncrease probabilityInternal combustion piston enginesExhaust apparatusElectricityNitrogen oxide

Exhaust gas amitted from a diesel engine flows through a ceramic soot filter in which particles contained in the exhaust are deposited and oxidized to regenerate the filter. The filter is regenerated by non-thermal, electric surface creeping discharge on filter surfaces covered with particles. In addition, nitrogen oxides may be reduced by selective catalytic reduction. The system is designed to ensure operation reliability and environmental compatibility.

Owner:CONTINENTAL AUTOMOTIVE GMBH

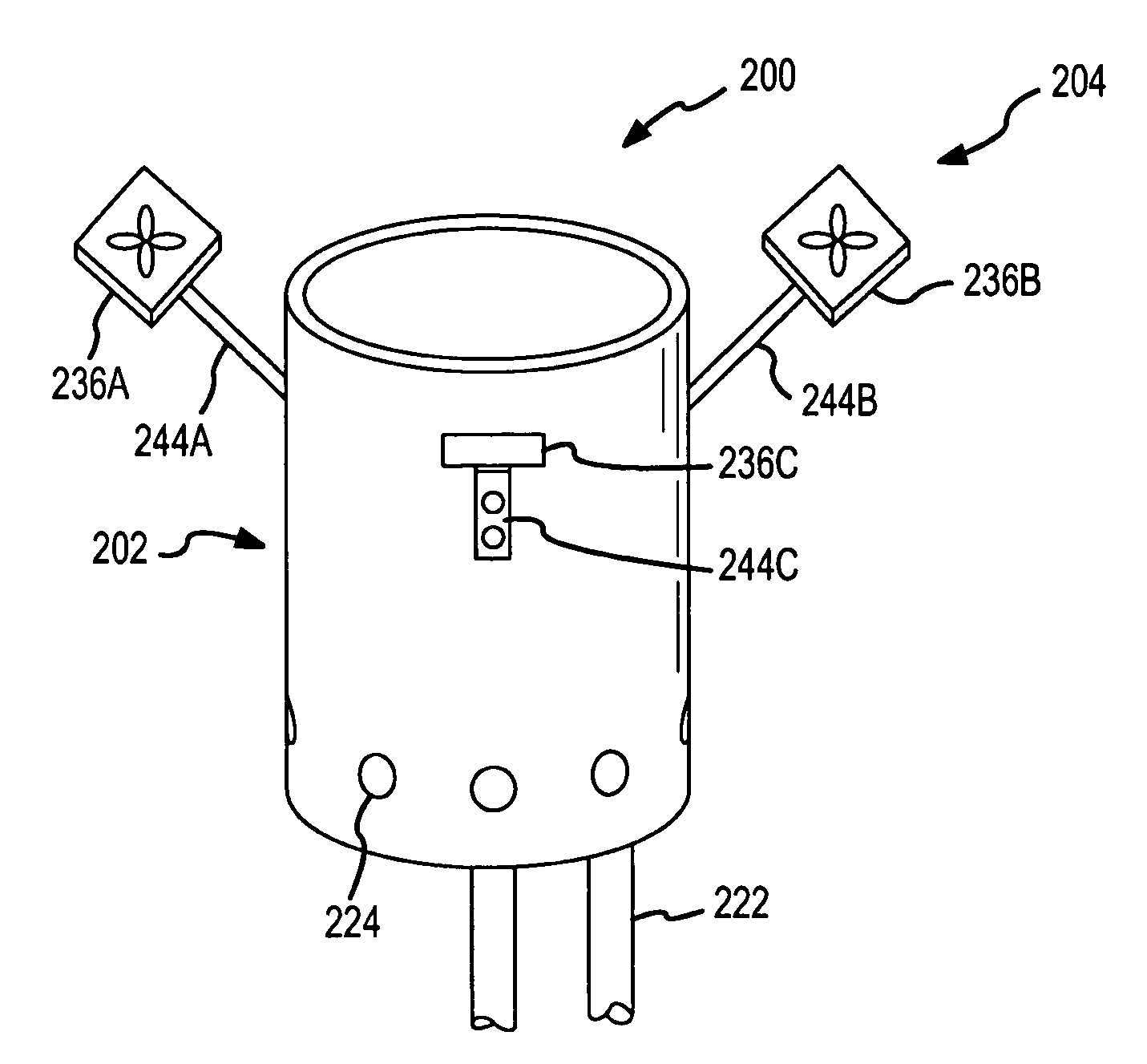

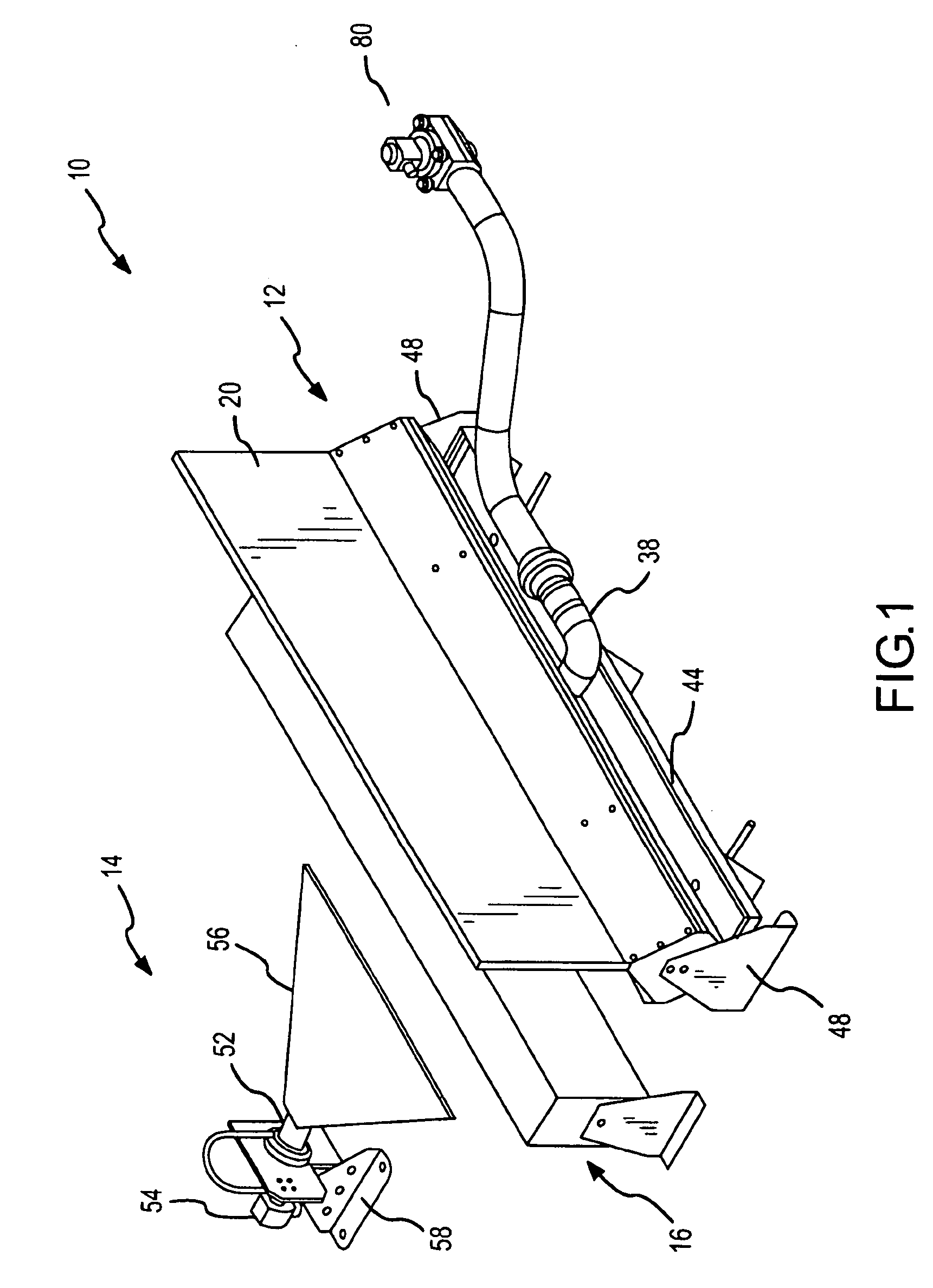

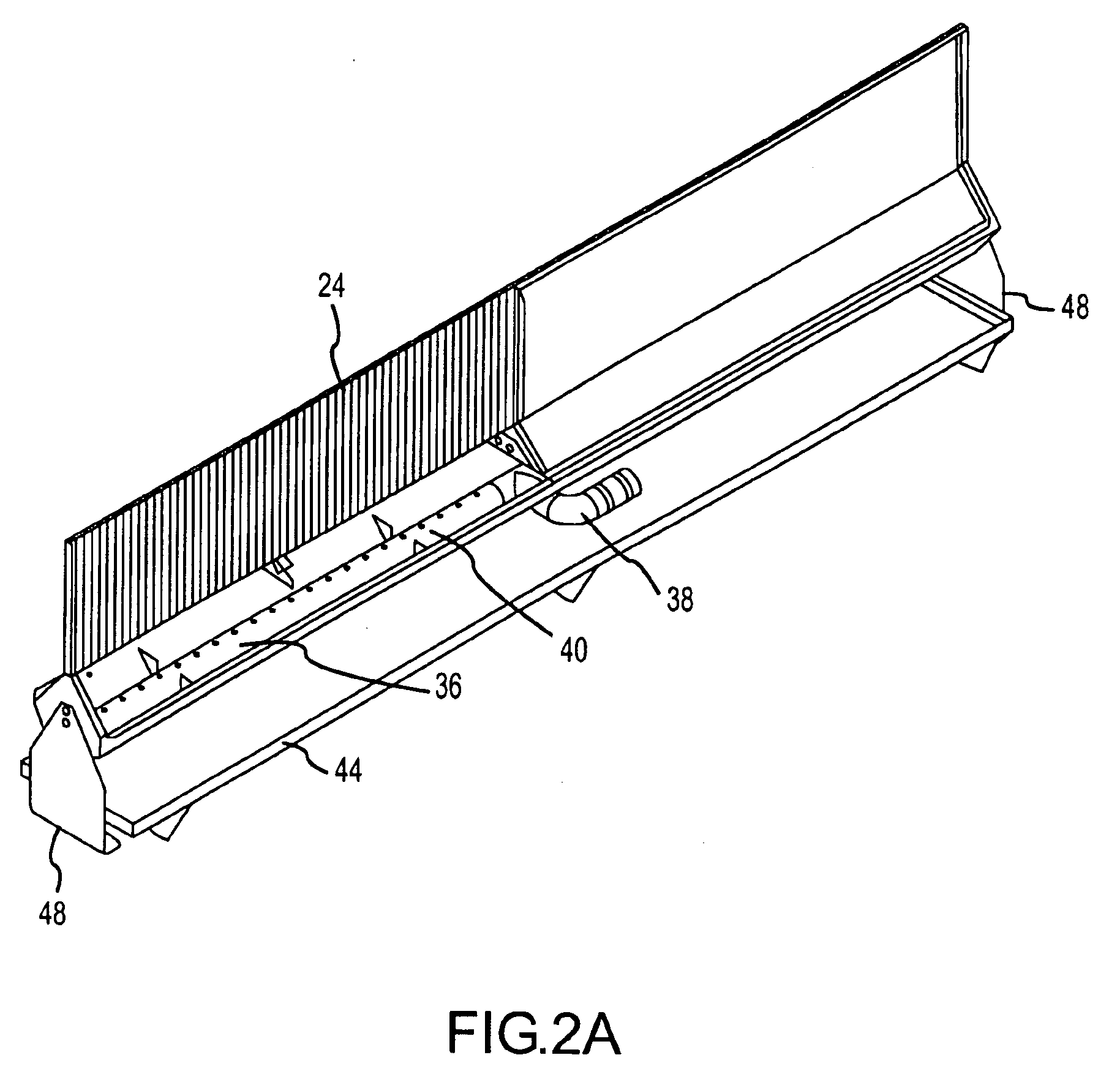

Apparatus for producing a fire special effect

ActiveUS7762897B2Eliminate and substantially reduce any gapUniform densityShow cabinetsPoint-like light sourceEngineeringLED lamp

The present invention provides a device for producing a fire special facilitates a more compact device. In one embodiment, the device comprises a steam curtain generator for directing received steam to an outlet slot that directs the steam into the ambient atmosphere such that the steam is flowing in a substantially a first direction to produce a curtain of steam, fan that is oriented so as to produce a flow of air in a direction that is substantially parallel to the flow of a steam curtain, a deflector for redirecting the flow of air produced by the fan towards the steam curtain, an adjustable agitator for causing turbulent flow in the stream of air directed towards a steam curtain, and an LED light for producing light that is projected onto a steam curtain.

Owner:TECHNIFEX PRODS

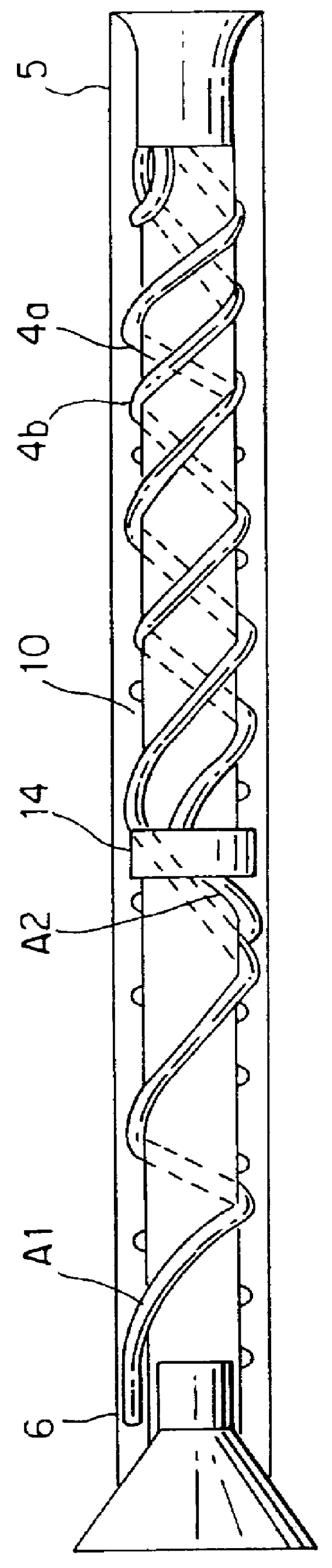

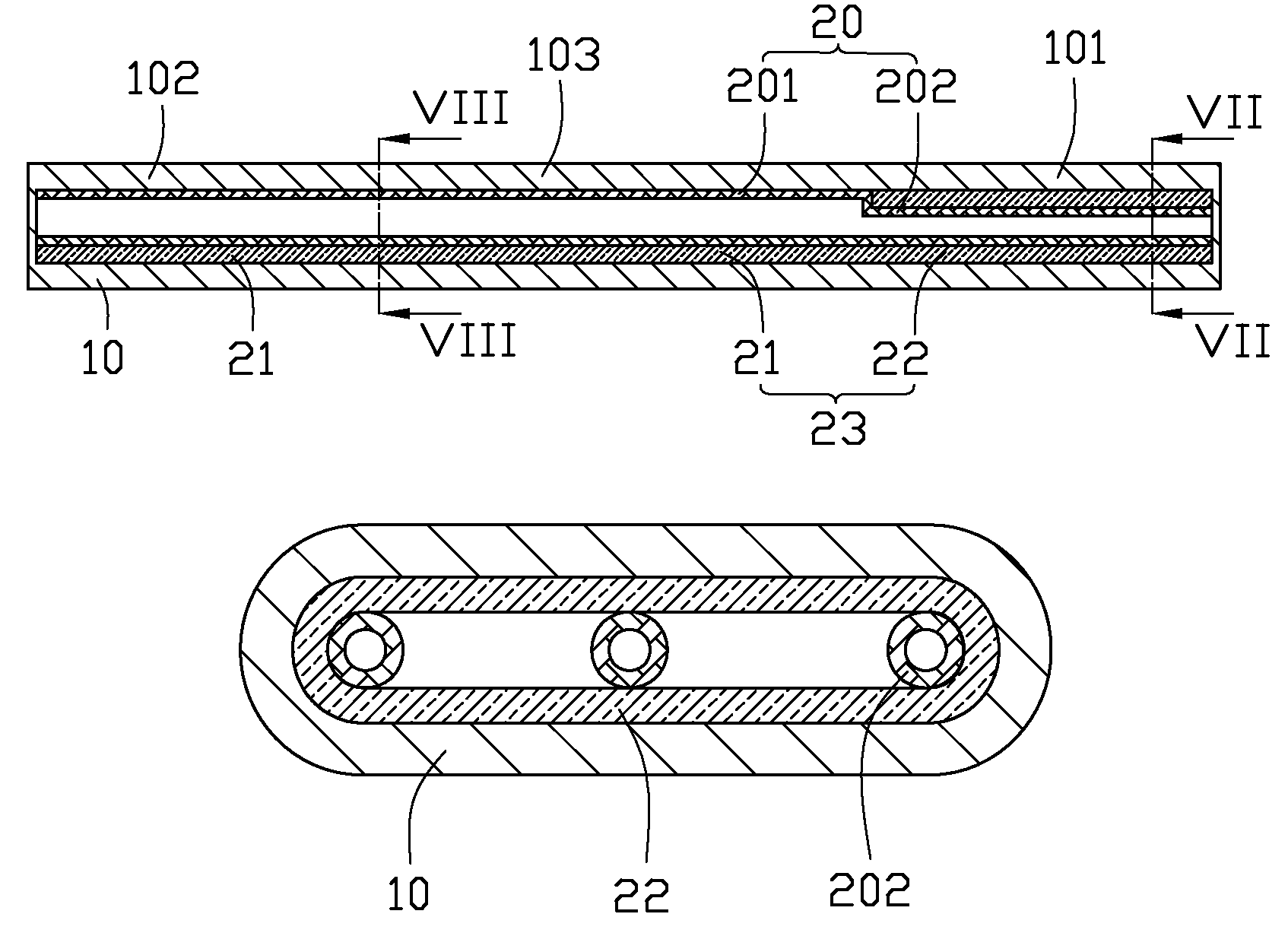

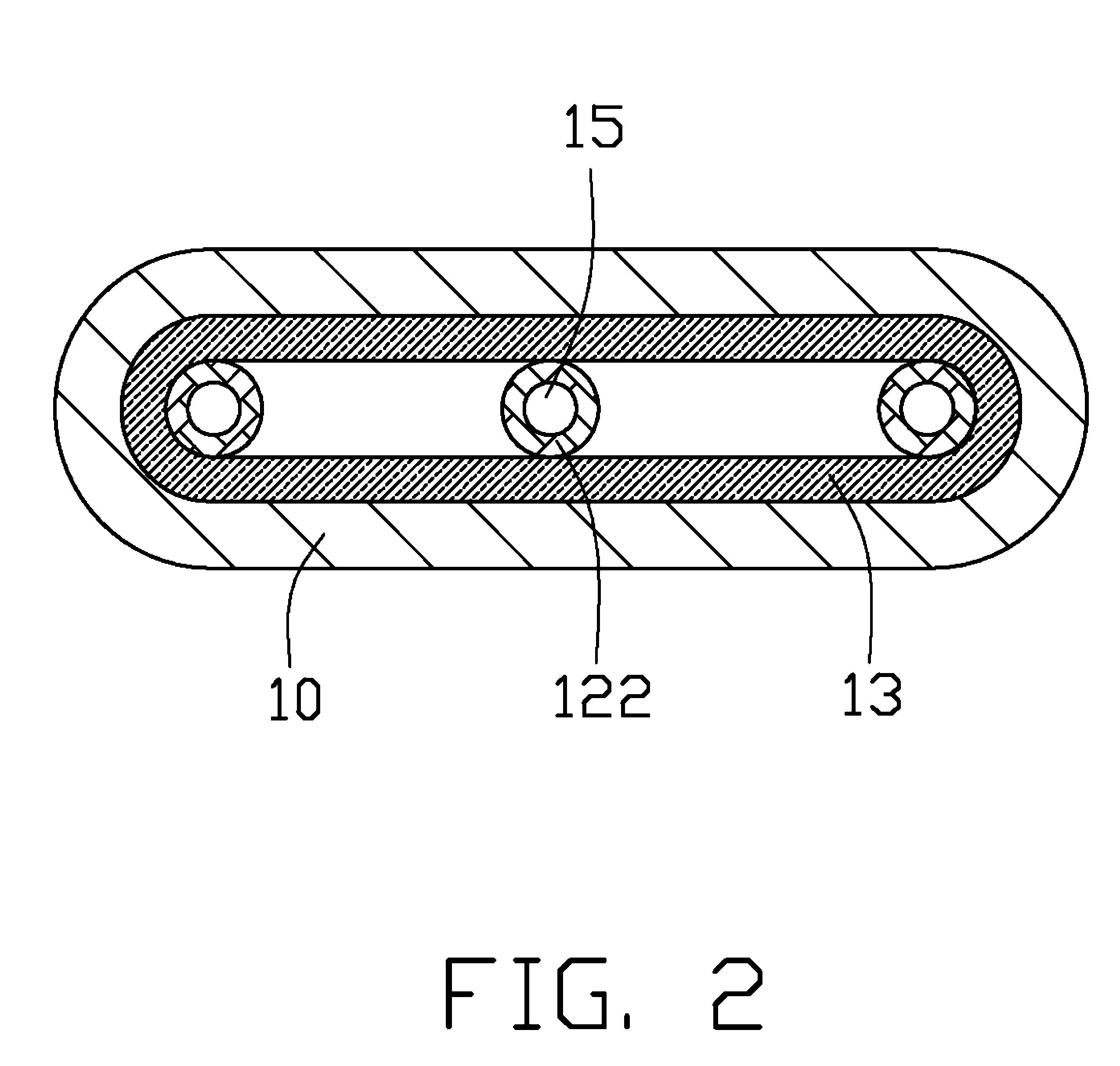

Heat pipe with composite wick structure

InactiveUS7845394B2Lower overall flow resistanceReduce heat transferSolid-state devicesIndirect heat exchangersMechanical engineeringHeat pipe

A heat pipe includes an elongated casing (10), a wick (13), at least one artery mesh (12), and working medium filling in the casing. The casing has an evaporating section (101) and a condensing section (102). The wick is disposed on an inner wall of the evaporating section. The at least one artery mesh includes a large portion (121) and a small portion (122) with an outer diameter smaller than that of the large portion. The small portion is located within and contacts with the wick, and the large portion contacts with the inner wall of the condensing section of the casing. The working medium saturates the wick and the at least one artery mesh.

Owner:HON HAI PRECISION IND CO LTD

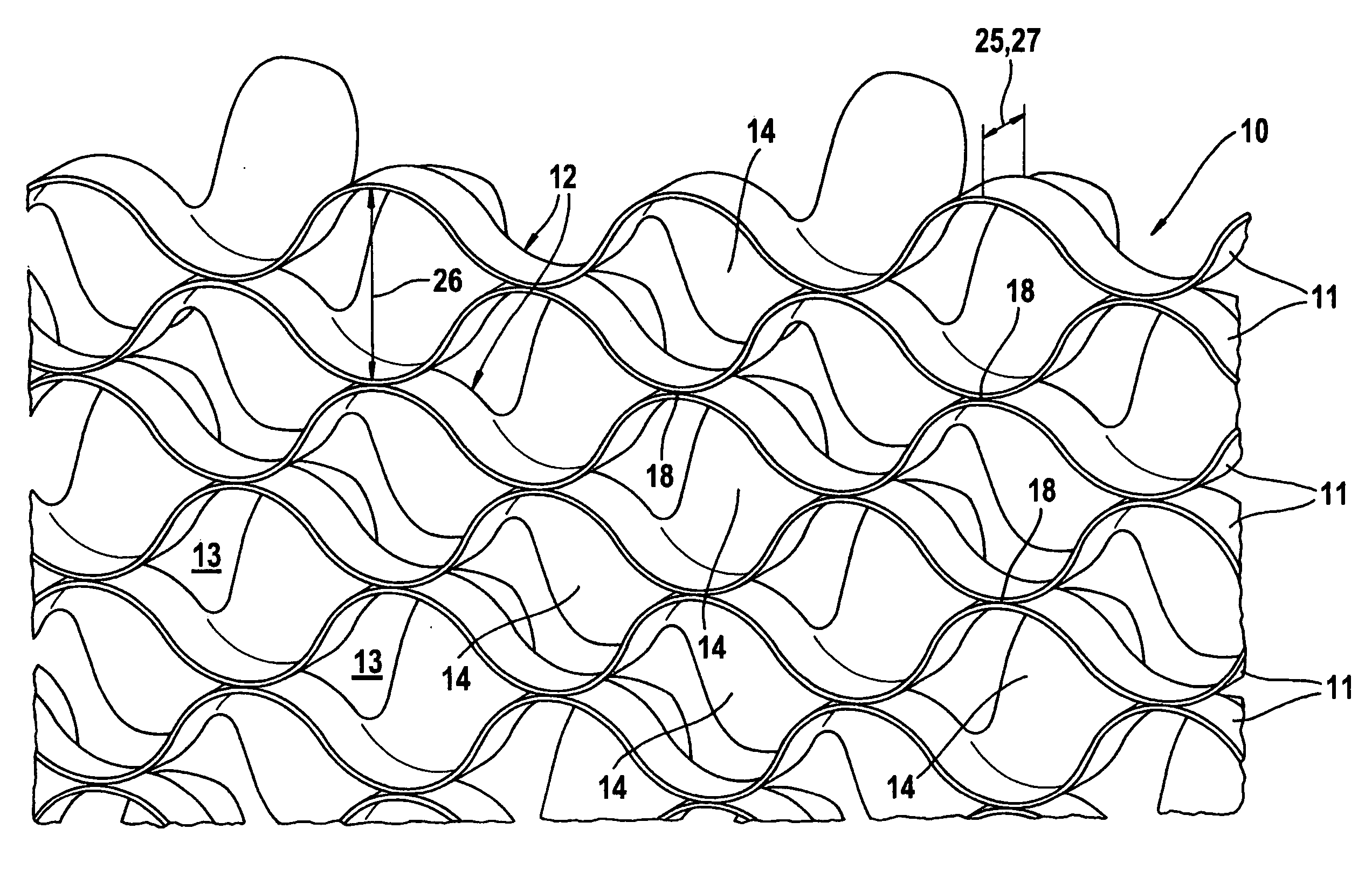

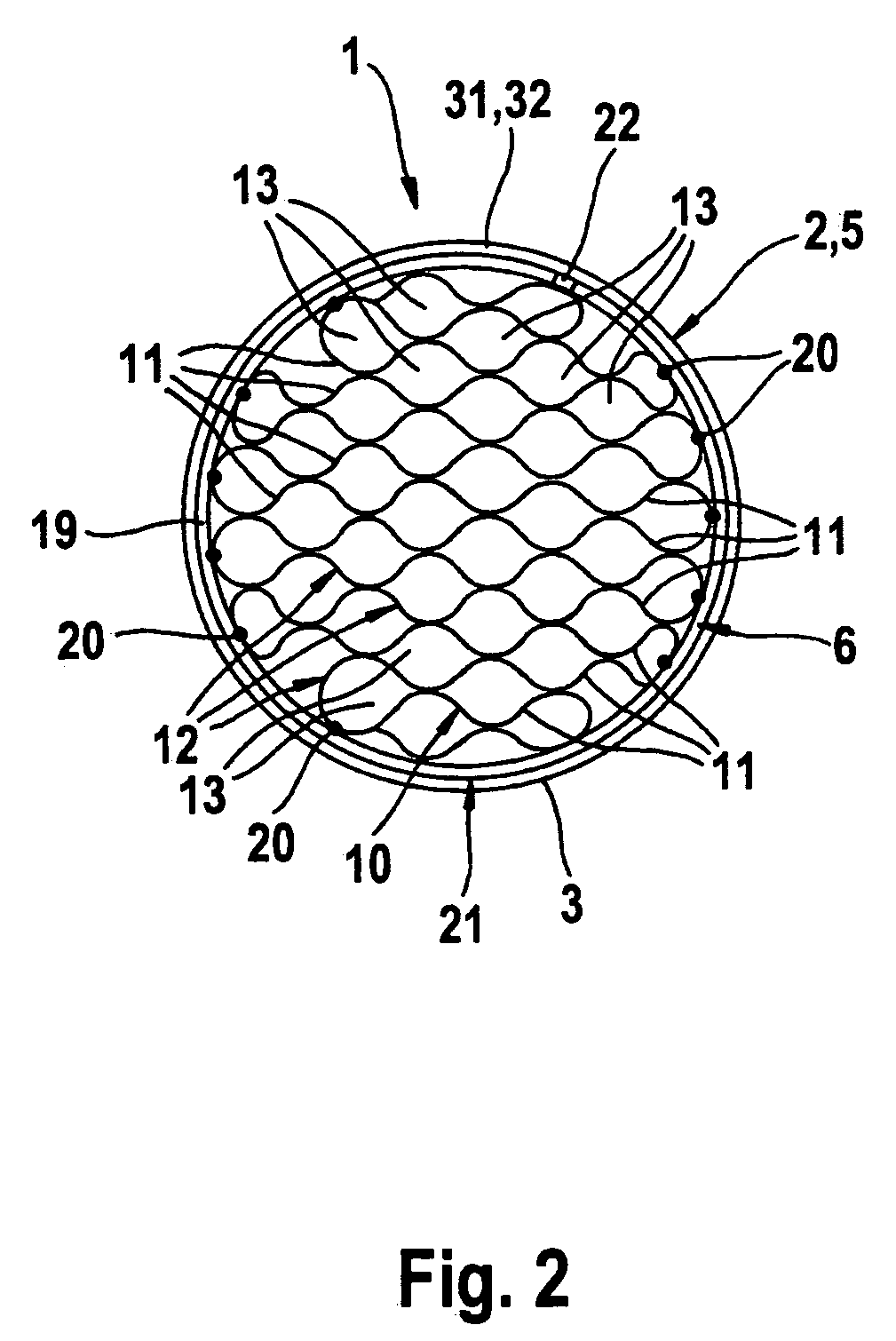

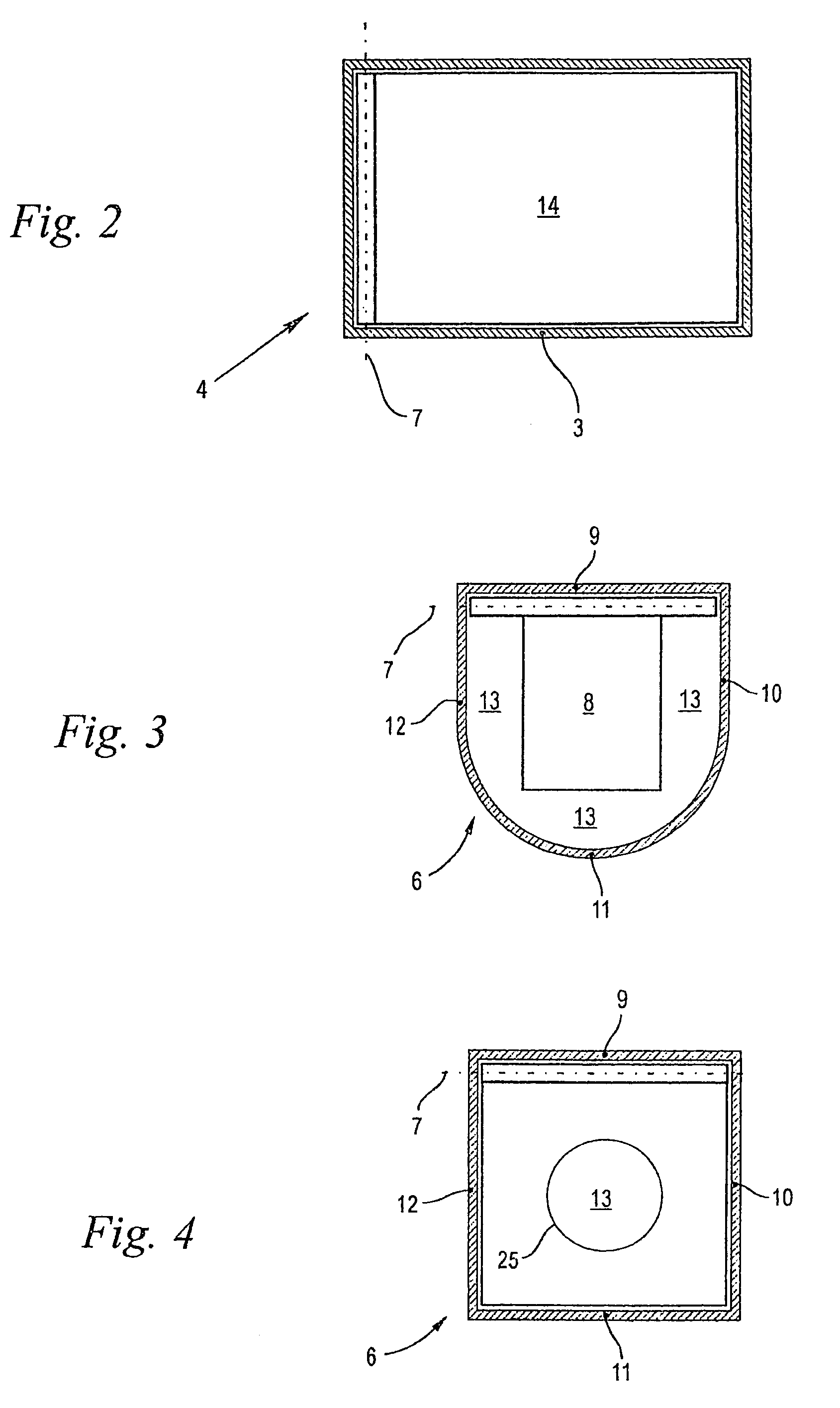

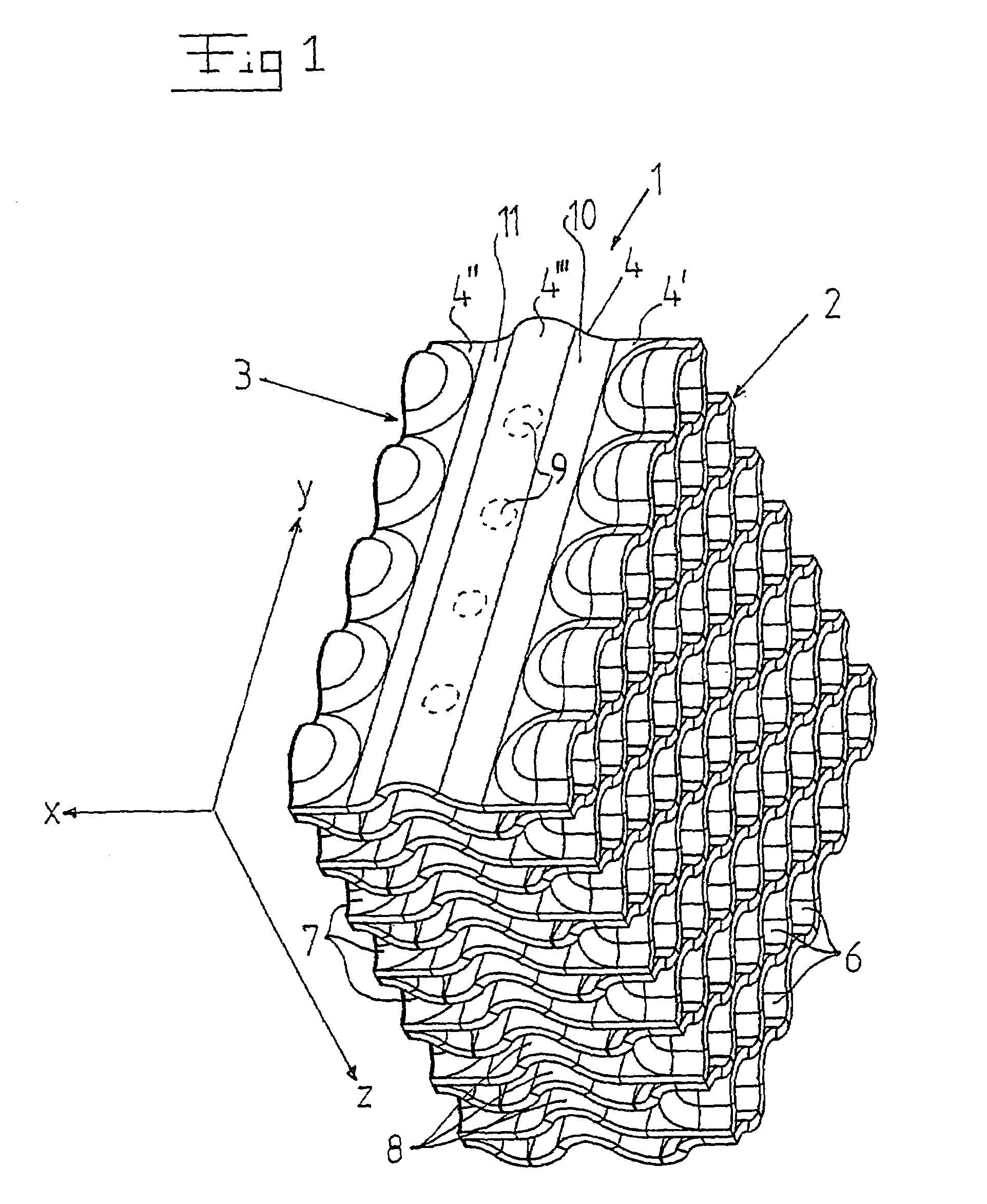

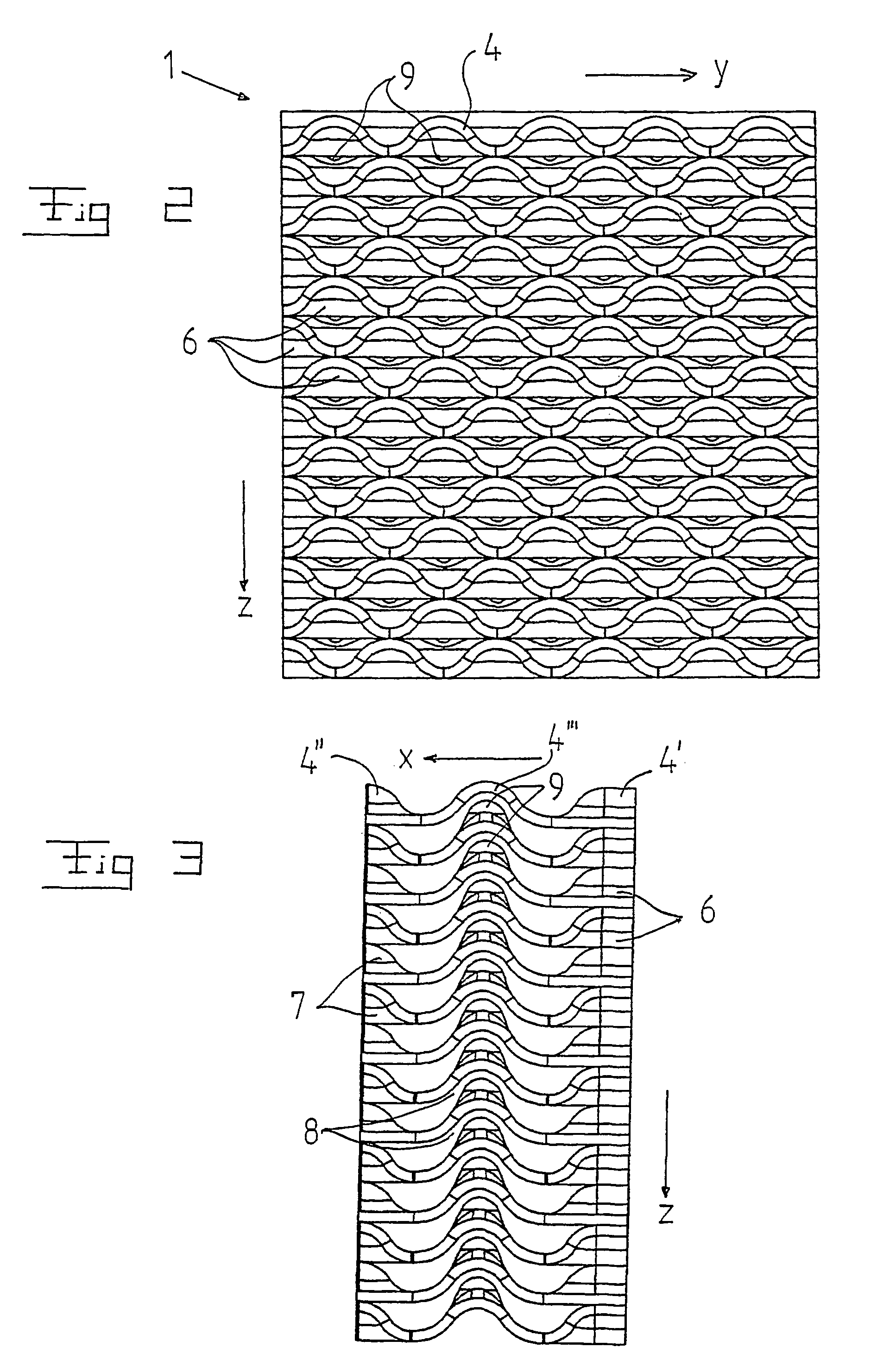

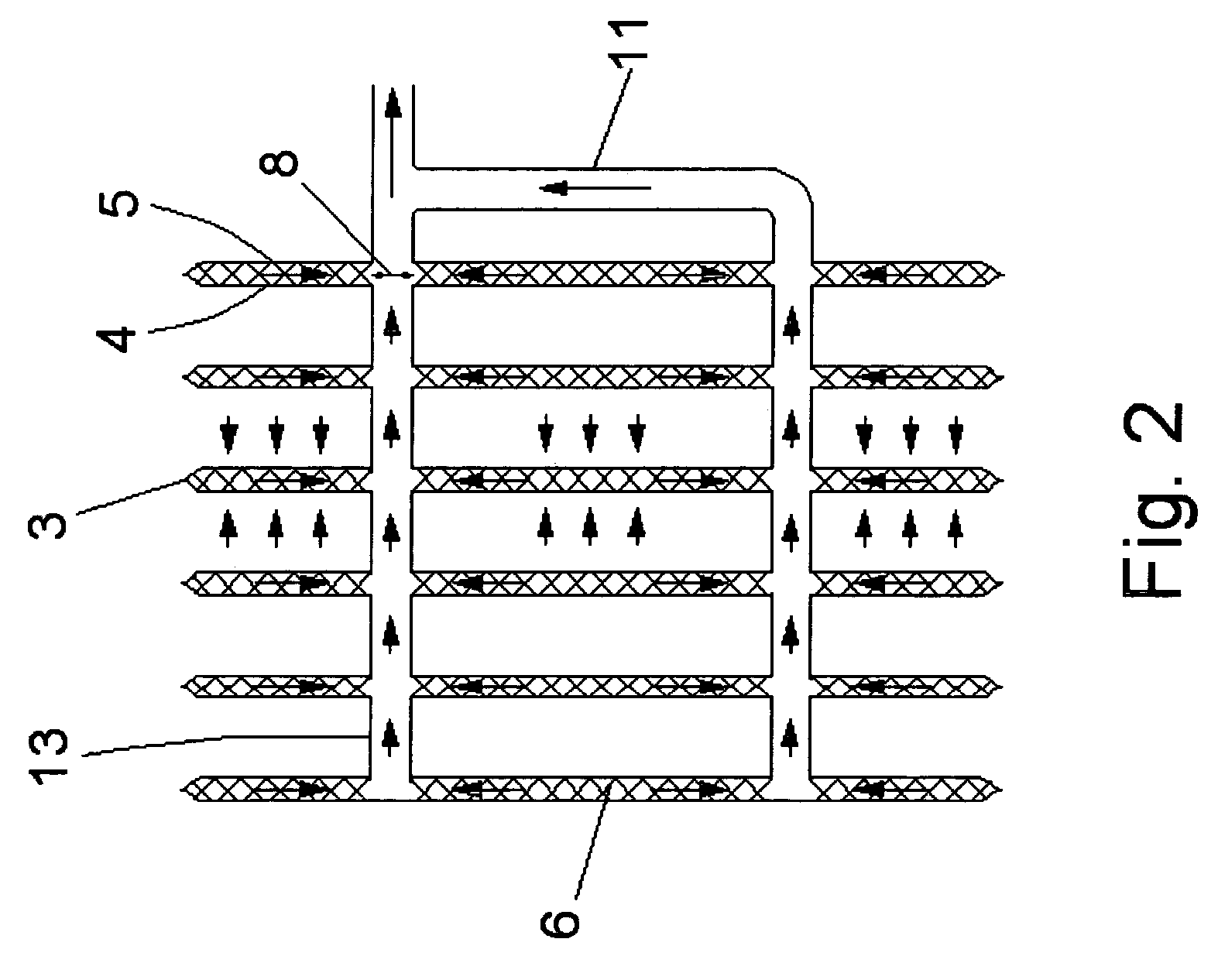

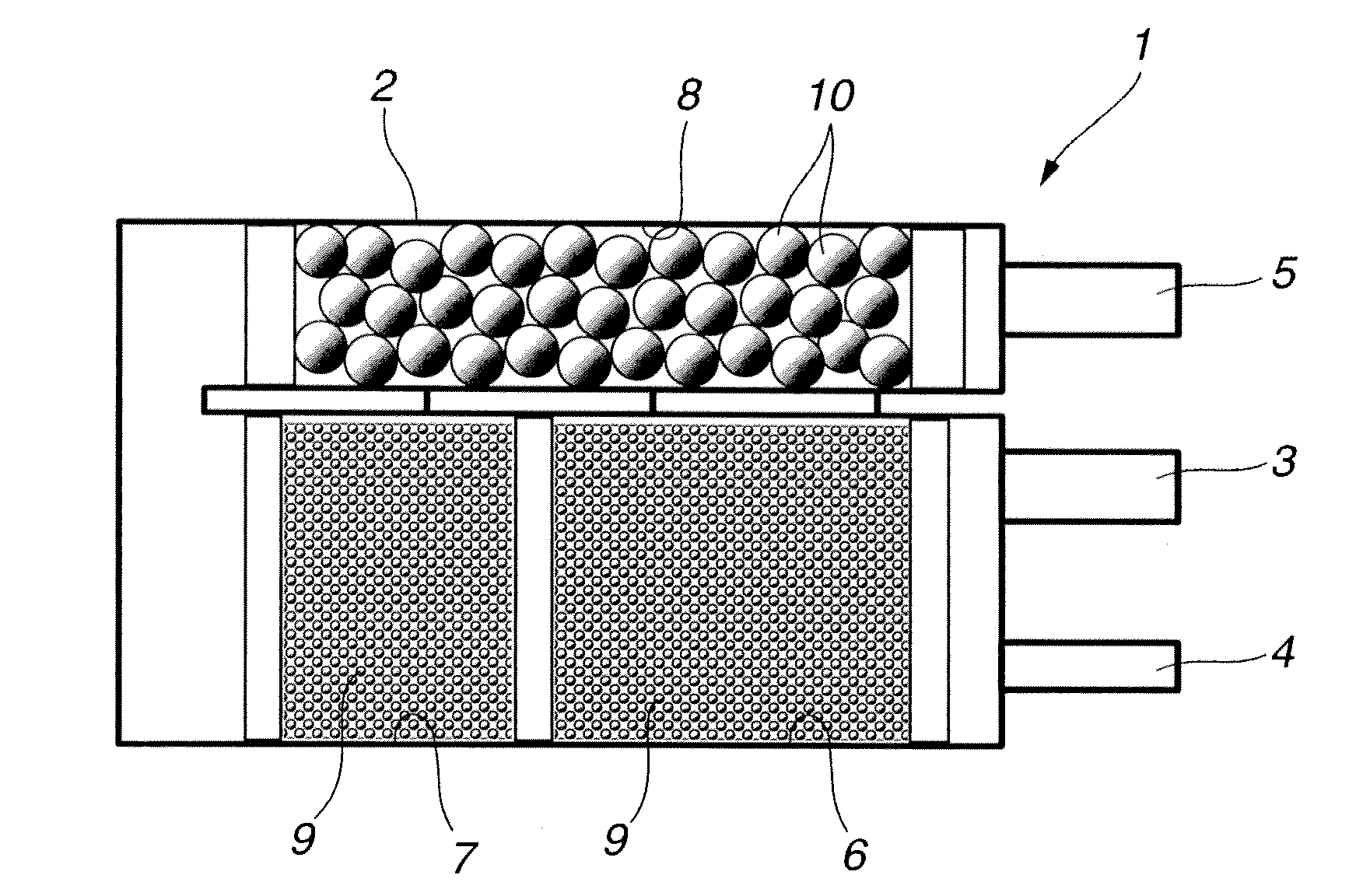

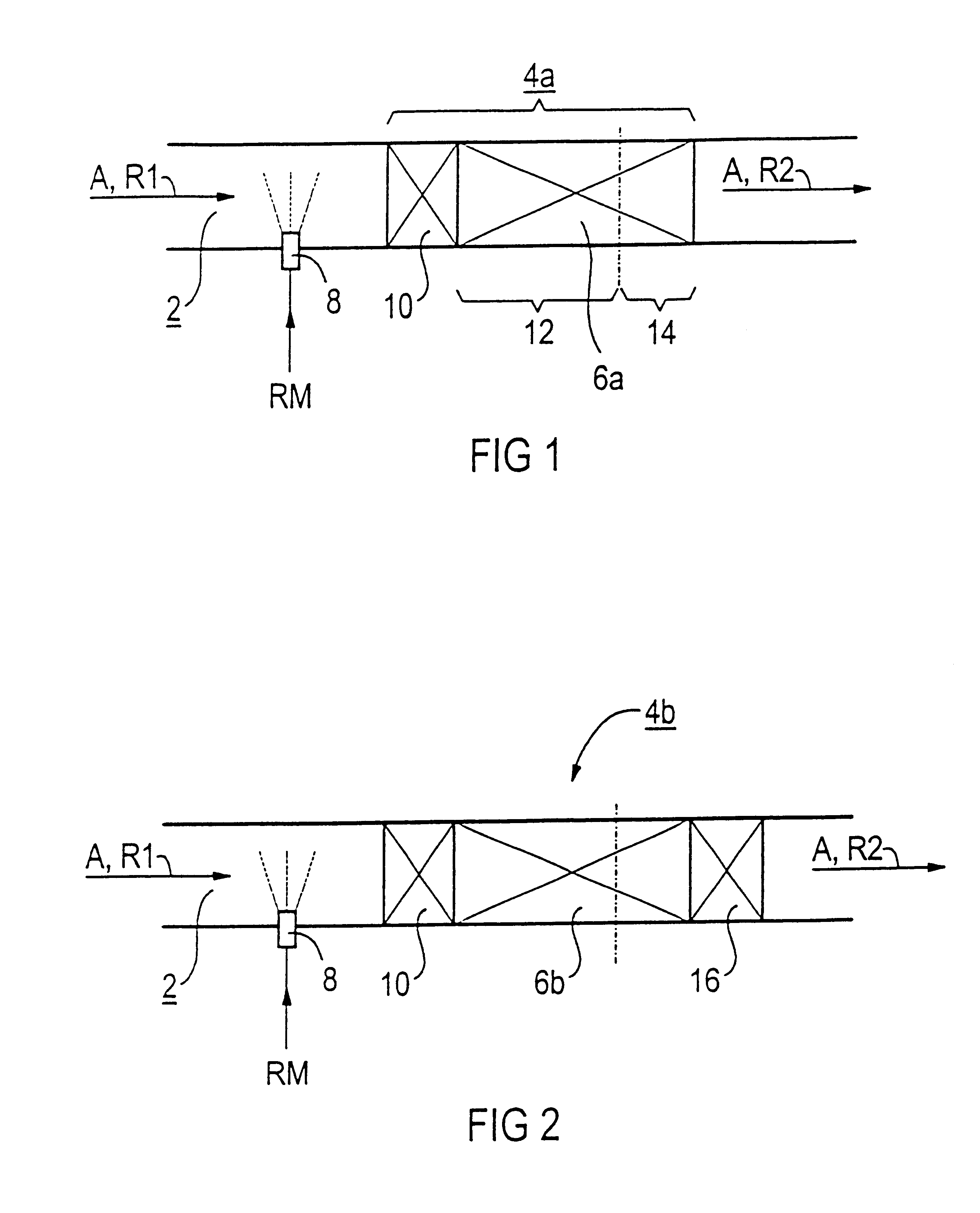

Filter for cooling water in a light water cooled nuclear reactor

InactiveUS7149272B2Lower overall flow resistanceLow costNuclear energy generationFuel element assembliesNuclear reactor coreNuclear plant

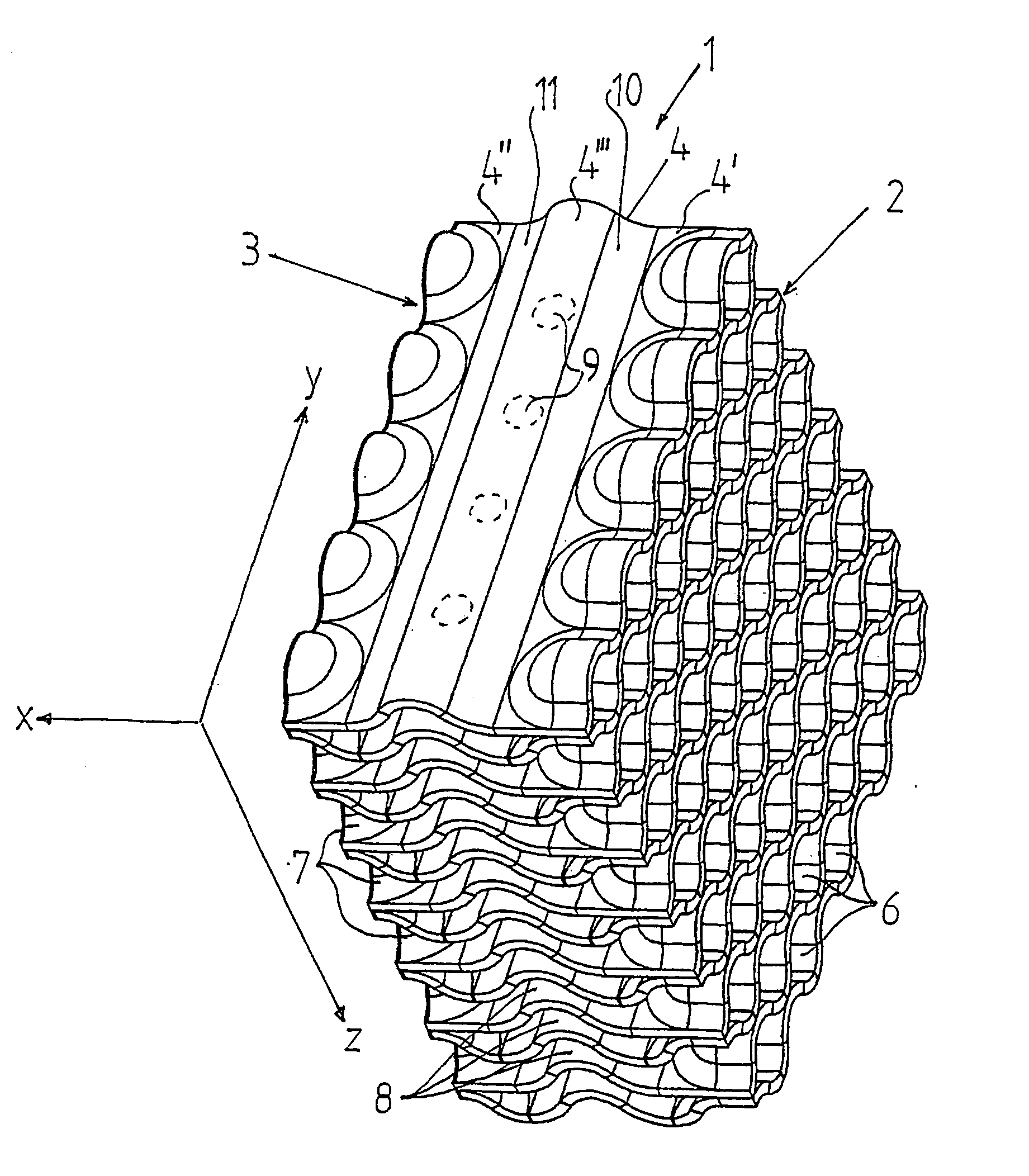

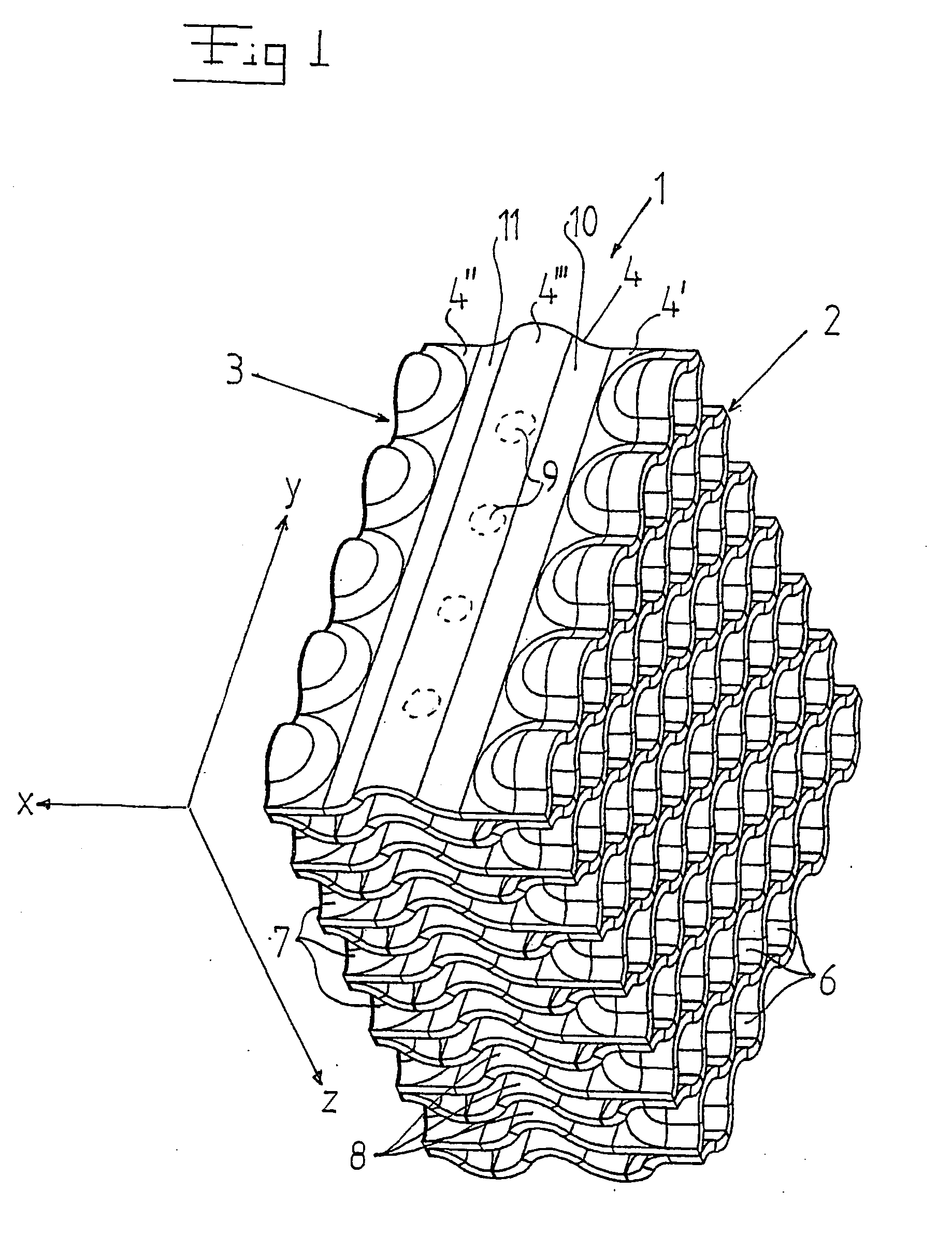

The invention refers to a filter (1) for separating particle from cooling water in a nuclear plant, and a fuel assembly with such a filter. The filter has an inlet end (2) and an outlet end (3) and permits through-flow of the cooling water in a main flow direction (x). The filter includes a number of sheets (4) extending in the flow direction from the inlet end to the outlet end. The sheets are arranged beside each other and form passages for the cooling water. The sheets include a first portion (4′) extending from the inlet end (2), a second portion (4″) extending from the outlet end (3), and a third portion (4′″) extending between the first portion (4′) and the second portion (4″). The sheets (4) have along the first portion continuous wave-shape extending in a direction (y) transversally to the flow direction (x) and along the third portion a continuous wave-shape extending in the flow direction (x).

Owner:WESTINGHOUSE ELECTRIC SWEDEN

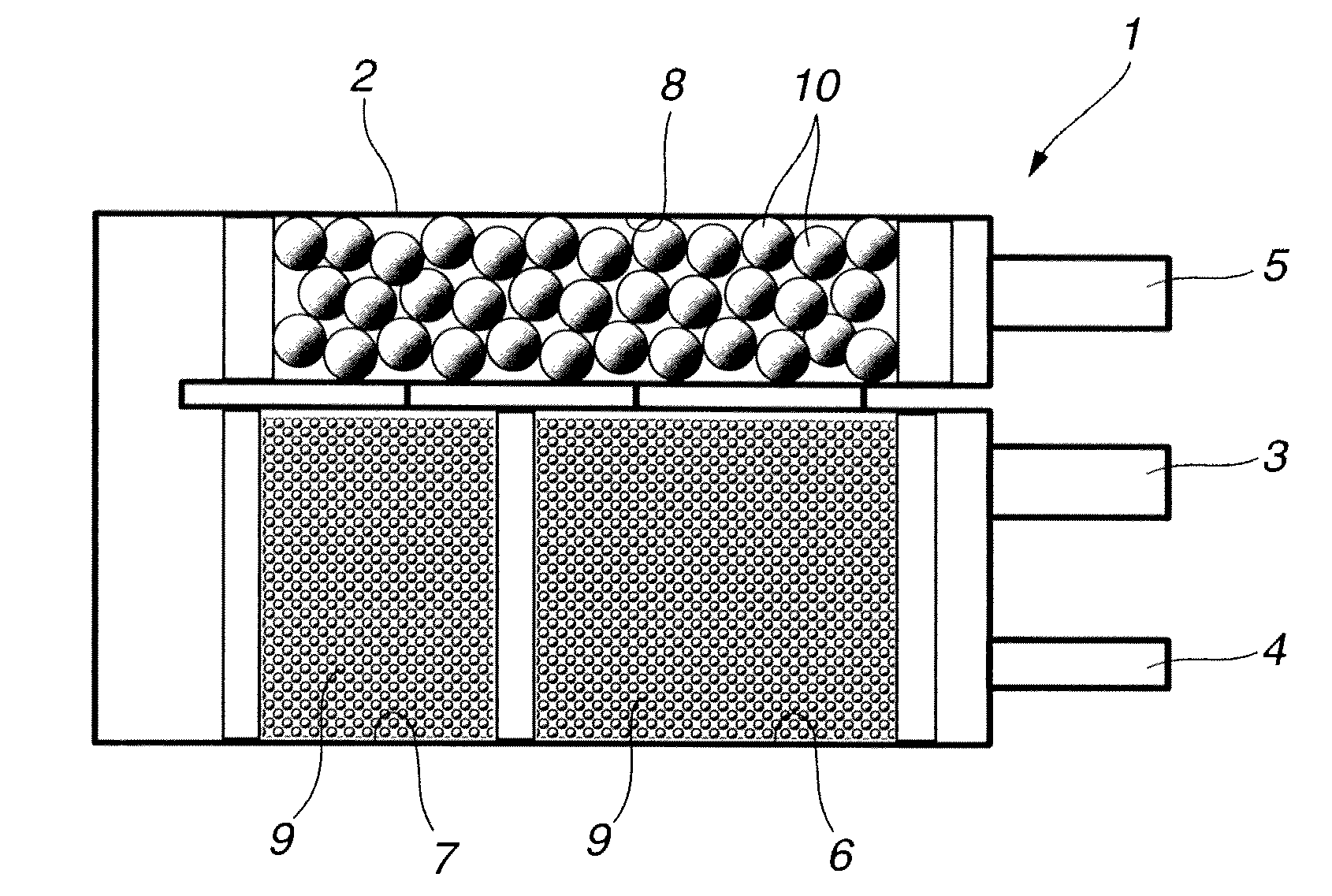

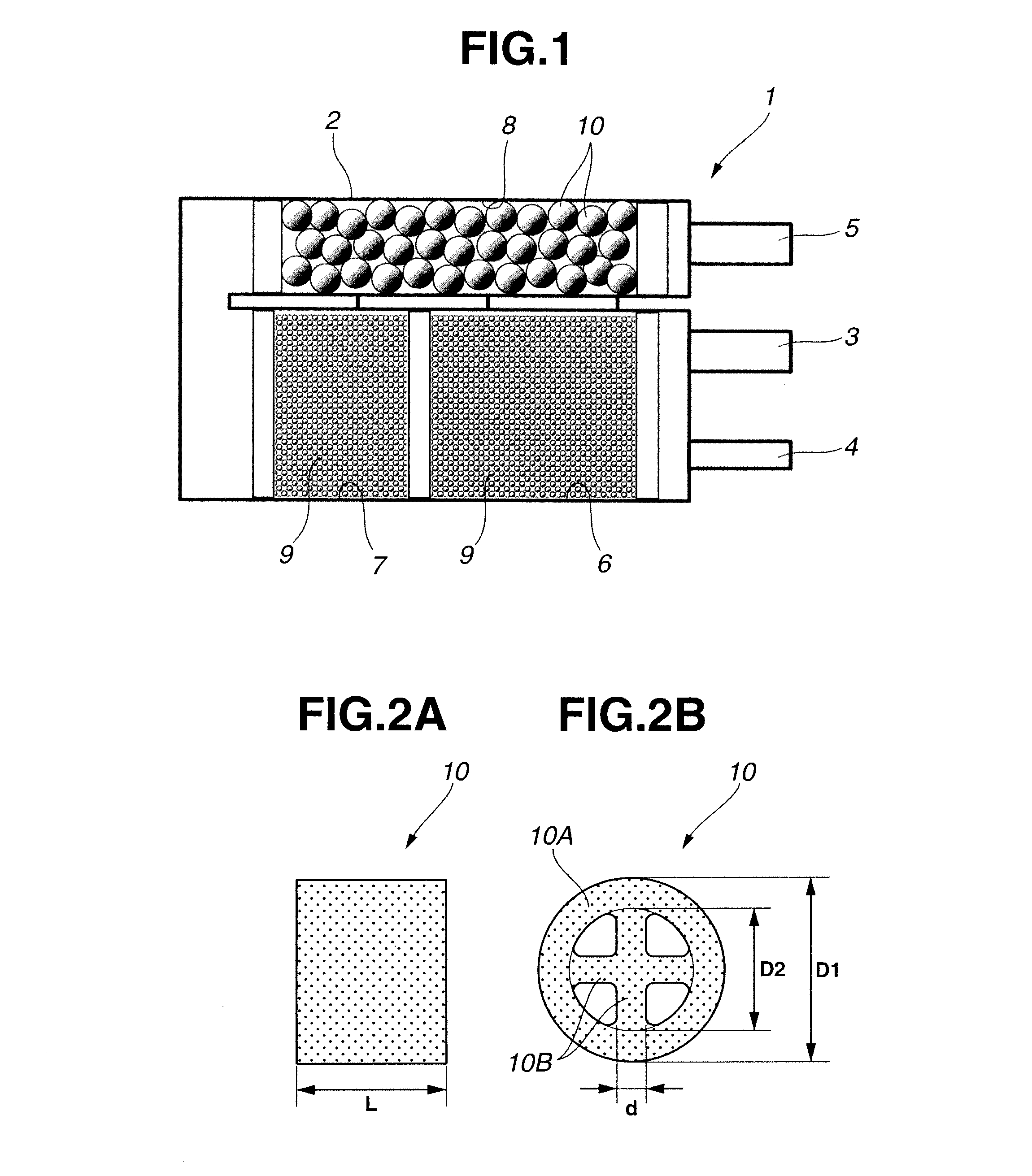

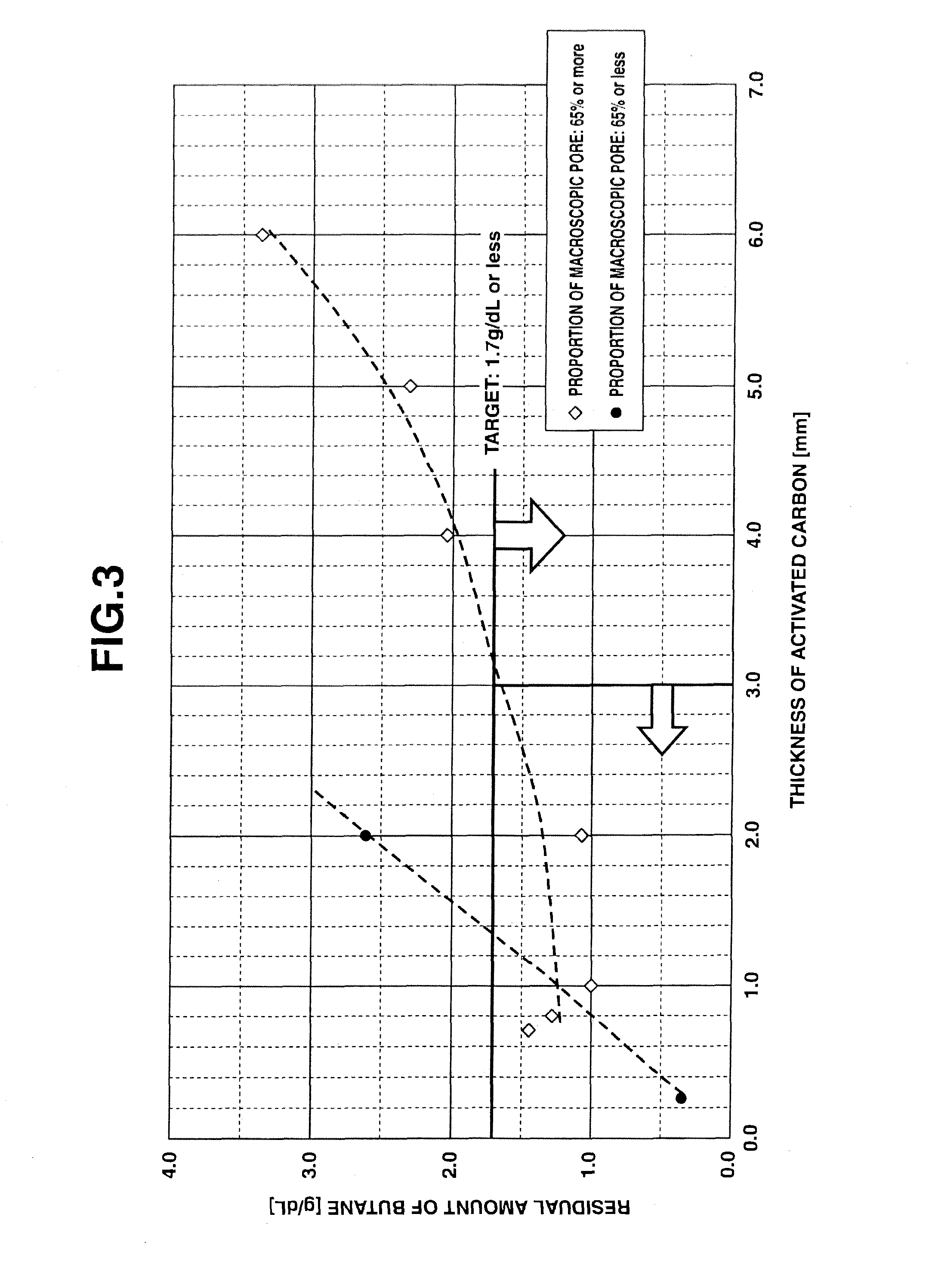

Adsorbent for canister, and canister

ActiveUS9174195B2Small flow resistanceCanister can be kept lowGas treatmentNon-fuel substance addition to fuelActivated carbonSorbent

Owner:MAHLE JAPAN LTD +1

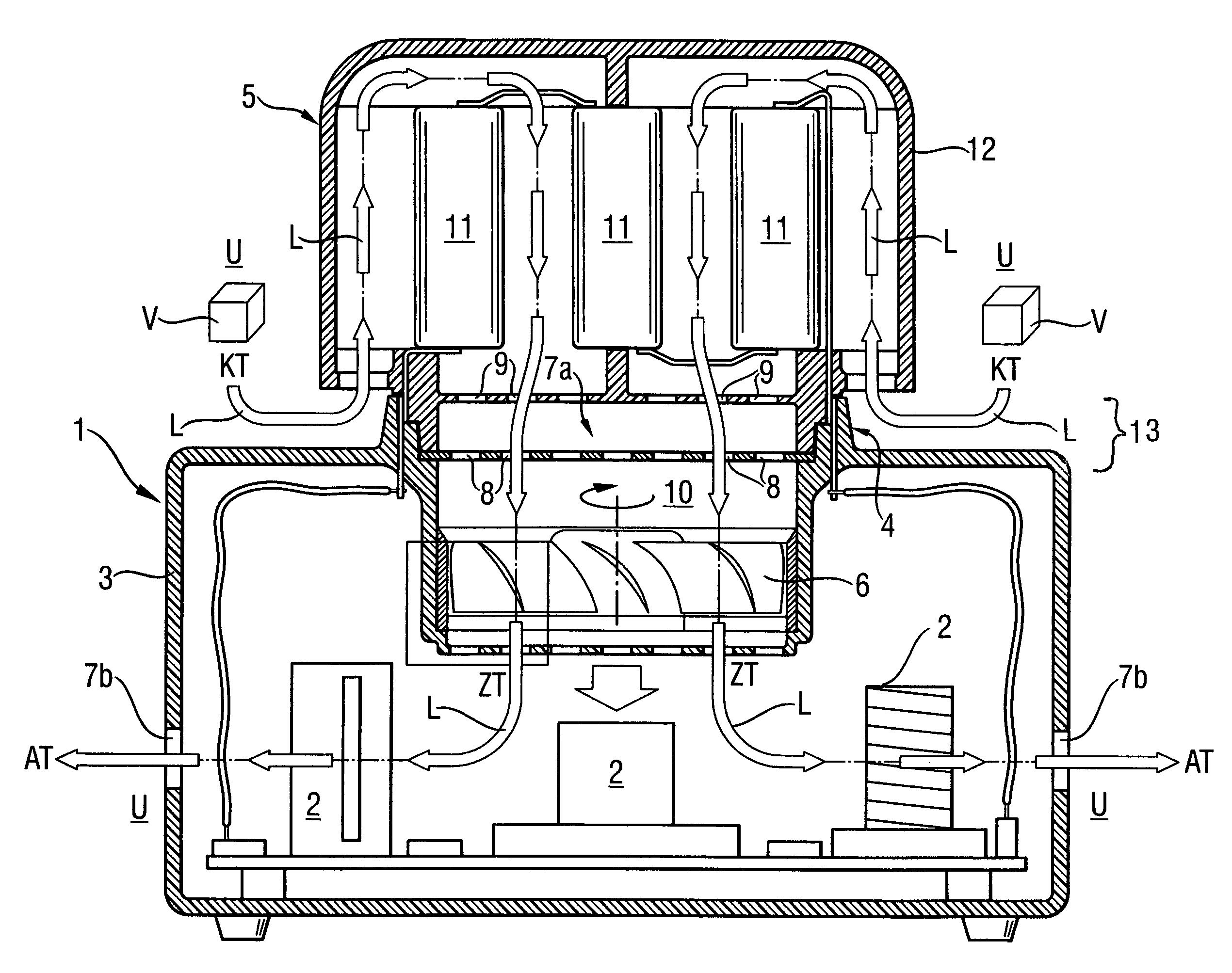

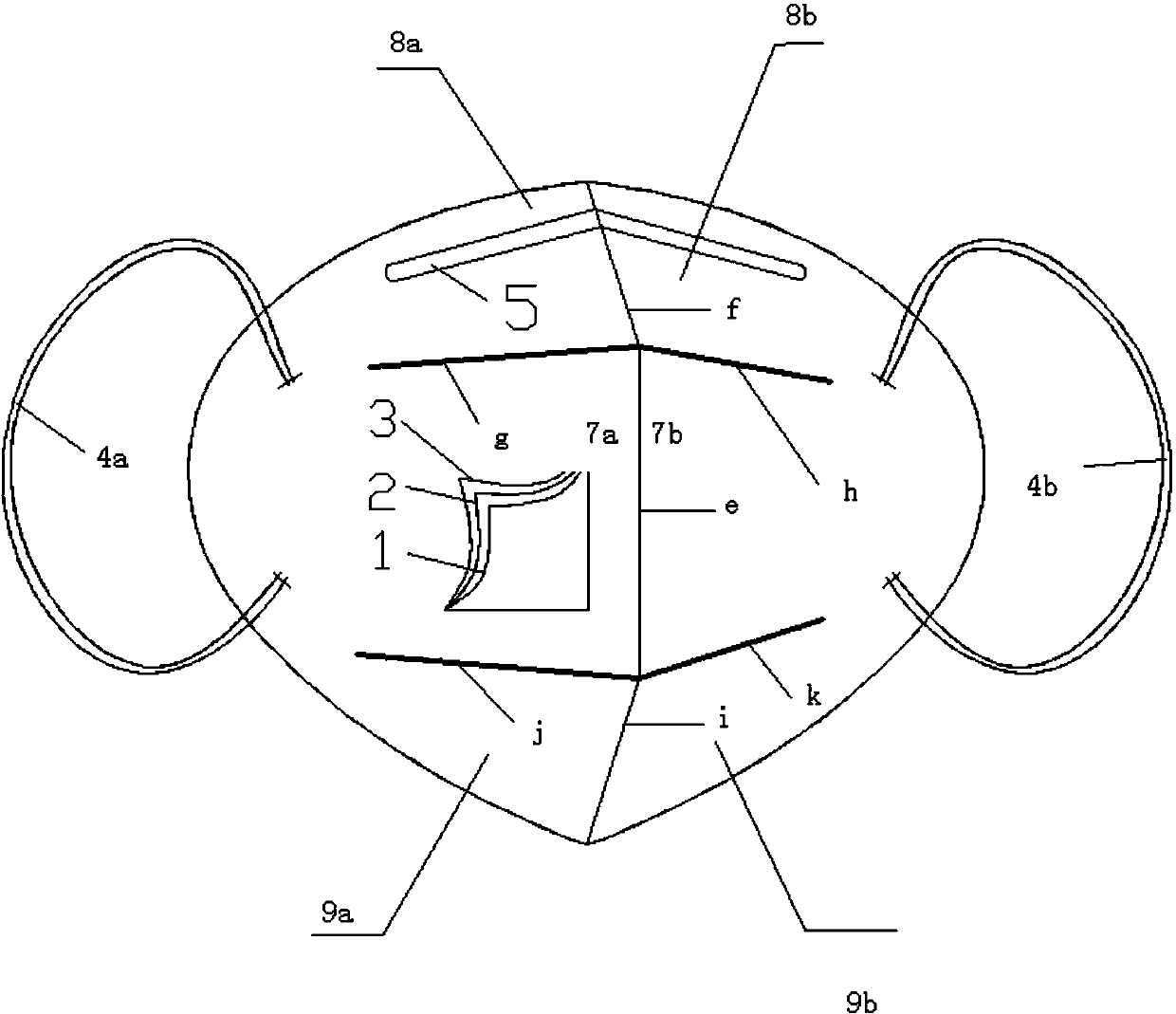

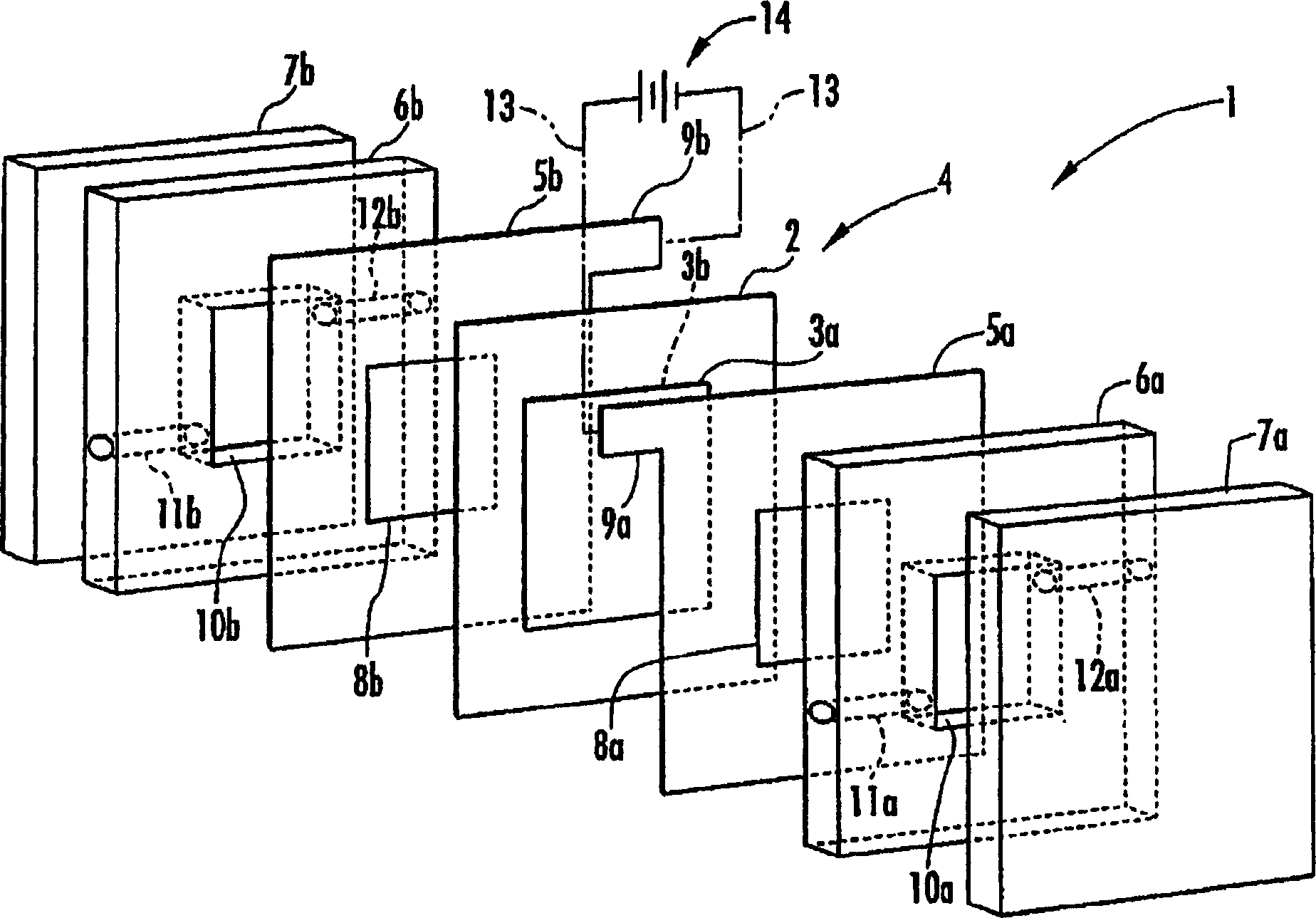

Storage battery charging station

InactiveUS6967464B2Improve cooling effectLower overall flow resistanceBatteries circuit arrangementsSecondary cells charging/dischargingElectricityAir volume

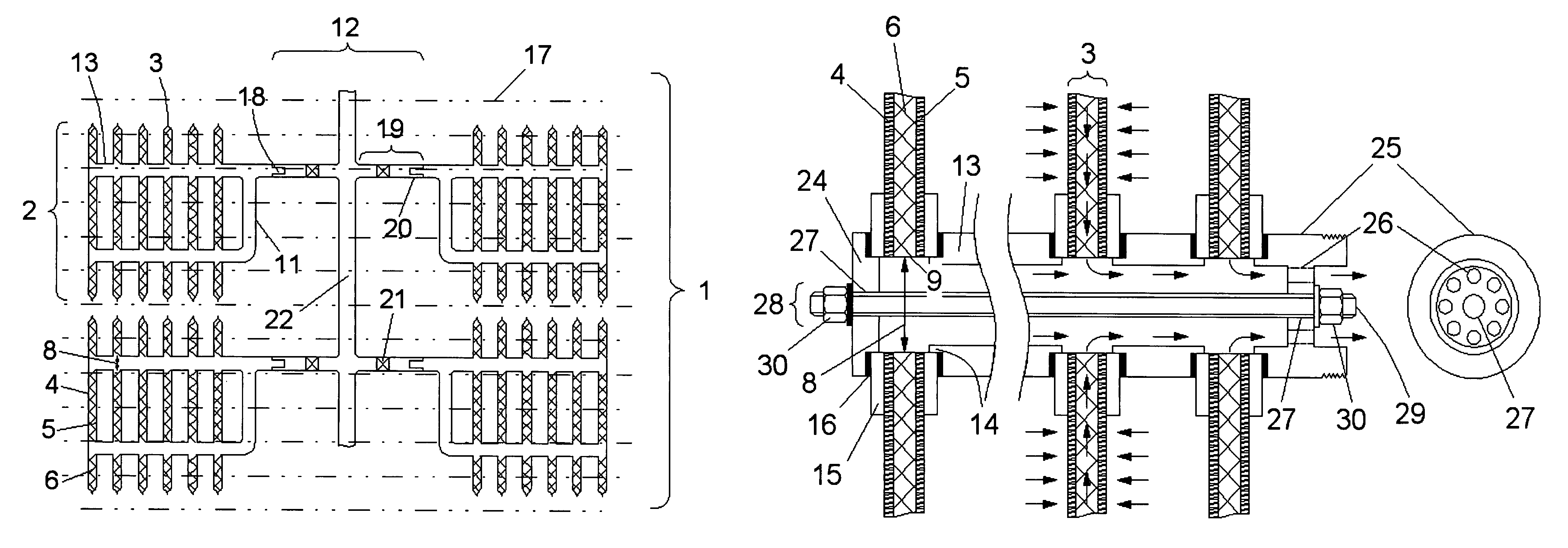

A charging station (1) for a rechargeable battery (5) that can be electrically and physically connected to the rechargeable battery (5). The charging station (1) has charger electronics (2) in a charger housing (3) and an electrical and physical contact interface (4) for the battery (5). An air blower (6) producing an air current (L) through two air vents (7a, 7b) is arranged in the charger housing (3). The air vent (7a) of the physical contact interface (4) is spatially associated with the battery (5) and the charger electronics (2) is arranged in the air current (L) to transfer heat. In the cooling process, in a first stage, an air volume (V) at cooling temperature CT is moved past the battery to transfer heat into and onto the battery and, in a second stage, the air volume (V) at an intermediate temperature IT>CT permeates the charger housing (2) containing the charging electronics (2.).

Owner:HILTI AG

Elastic connecting duct

InactiveUS20050045138A1Prevents any short circuitReduce weightCombustion enginesAir intakes for fuelAir filterEngineering

A one-piece elastic connecting duct for disposition between any air filter and an internal combustion engine of a manually operated implement, such as a power saw, a cut-off machine, or the like, is provided. The connecting duct comprises a first conduit for fuel / air mixture, and a second conduit for largely fuel-free air.

Owner:ANDREAS STIHL AG & CO KG

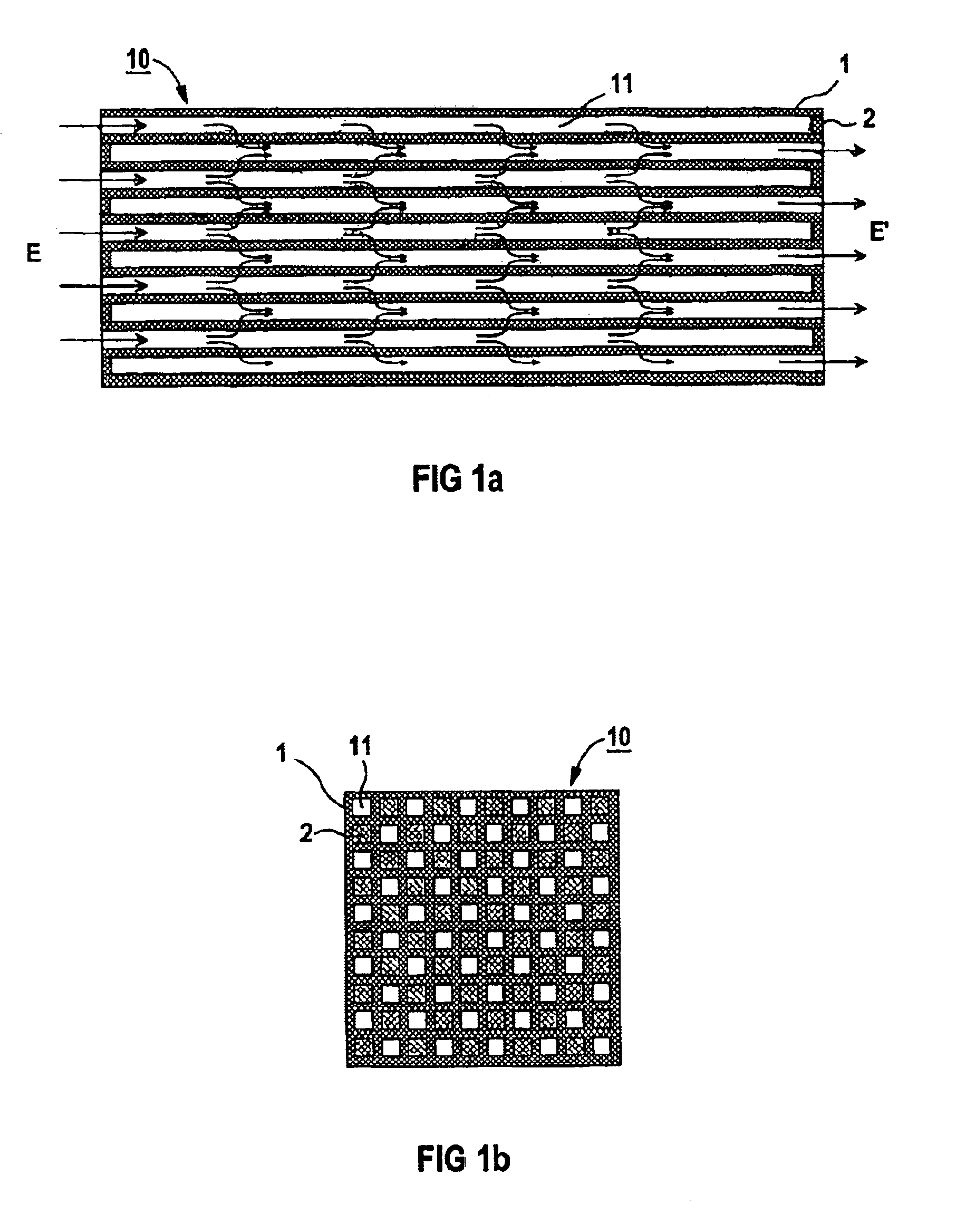

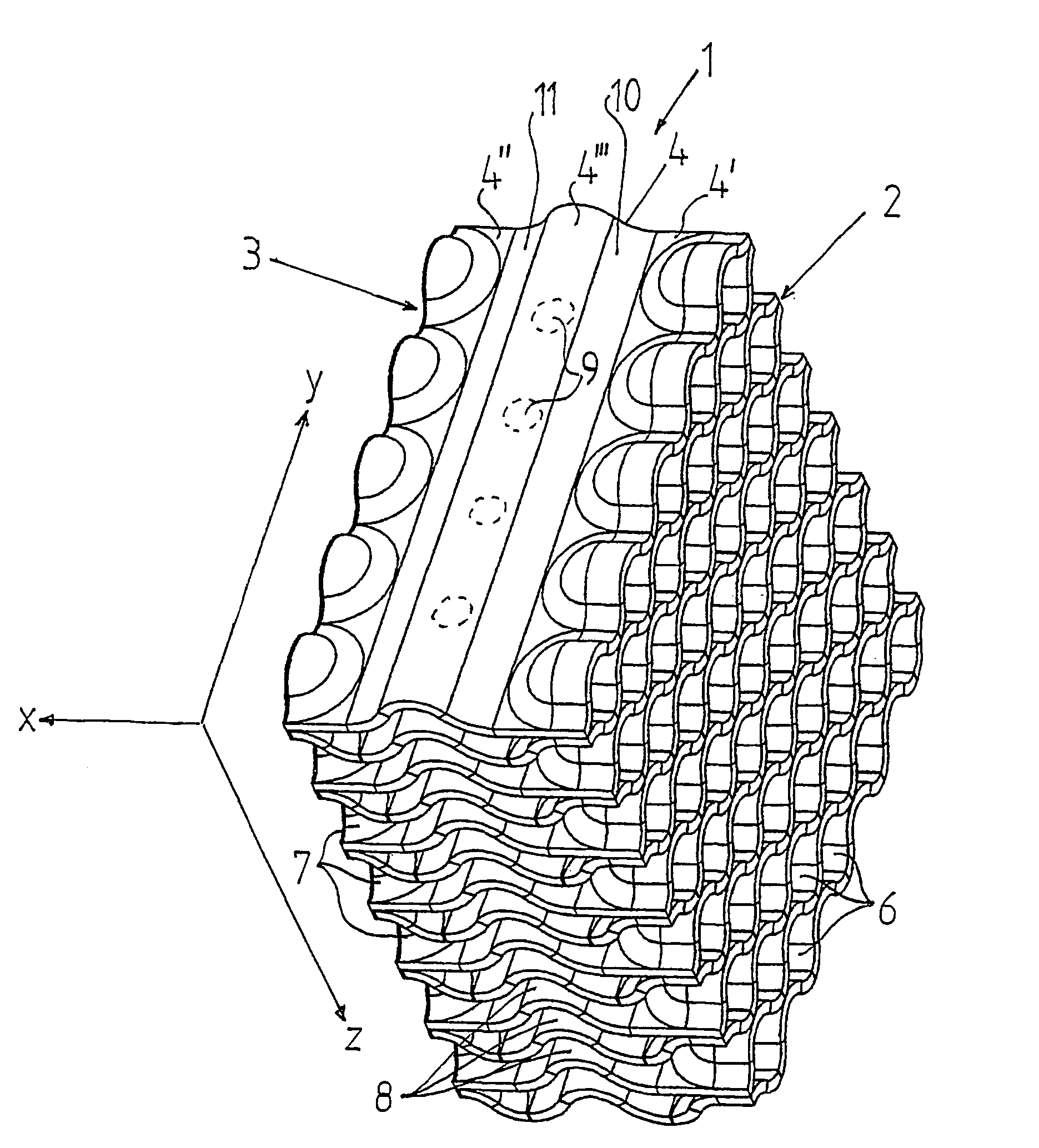

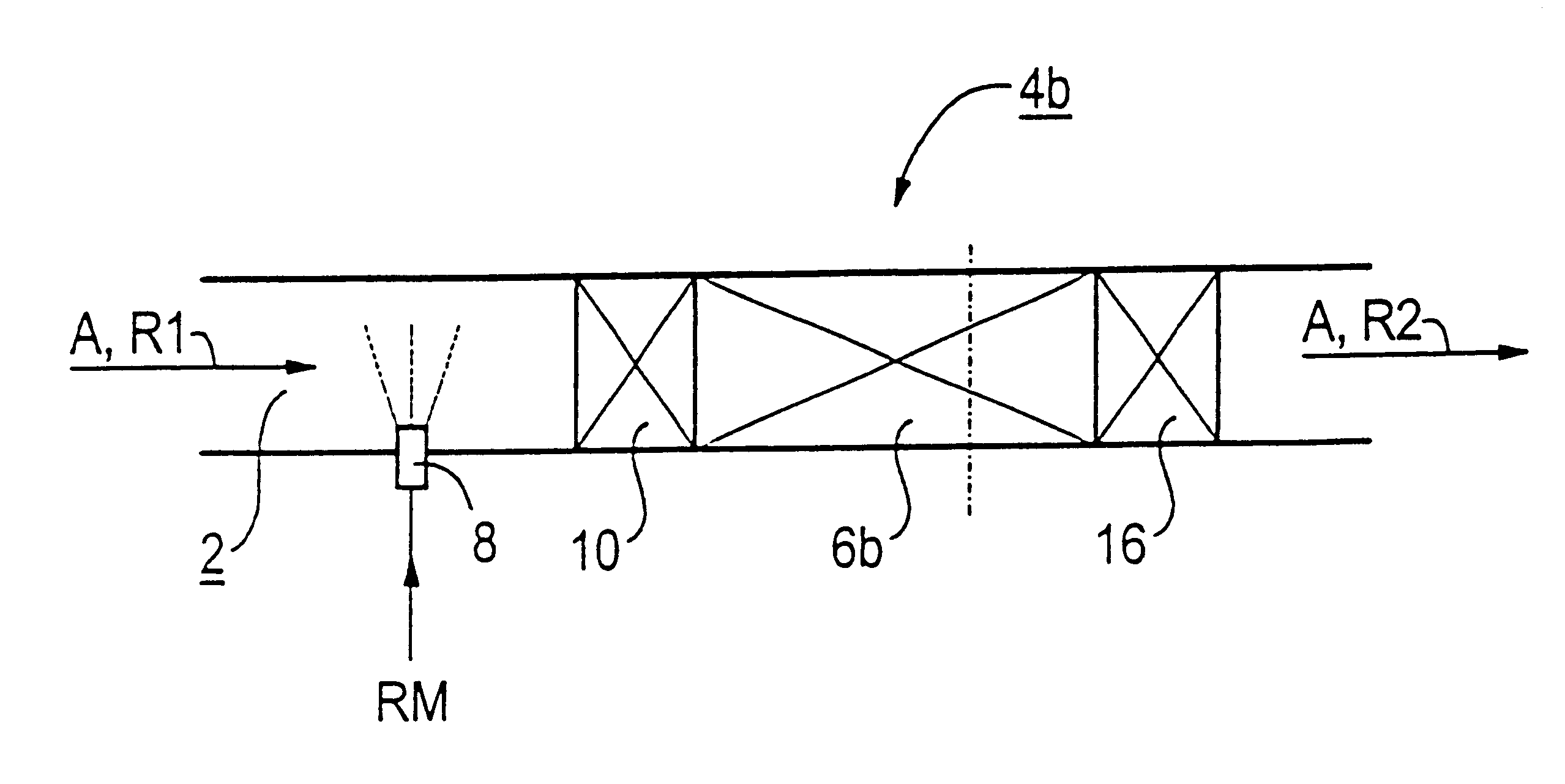

Filter for cooling water in a light water cooled nuclear reactor

InactiveUS20040076253A1Lower overall flow resistanceEfficient captureNuclear energy generationFuel element assembliesNuclear plantNuclear reactor core

The invention refers to a filter (1) for separating particle from cooling water in a nuclear plant, and a fuel assembly with such a filter. The filter has an inlet end (2) and an outlet end (3) and permits through-flow of the cooling water in a main flow direction (x). The filter includes a number of sheets (4) extending in the flow direction from the inlet end to the outlet end. The sheets are arranged beside each other and form passages for the cooling water. The sheets include a first portion (4') extending from the inlet end (2), a second portion (4'') extending from the outlet end (3), and a third portion (4''') extending between the first portion (4') and the second portion (4''). The sheets (4) have along the first portion continuous wave-shape extending in a direction (y) transversally to the flow direction (x) and along the third portion a continuous wave-shape extending in the flow direction (x).

Owner:WESTINGHOUSE ELECTRIC SWEDEN

Apparatus for filtering substances out of liquids

ActiveUS7892430B2Simple and inexpensive to produceLower overall flow resistanceMembranesSemi-permeable membranesDifferential pressureBiomedical engineering

Apparatus for filtering liquids, comprising flat membrane pockets arranged parallel and means for pressure-tight connection of the membrane pockets to one another and for coupling an extraction means. The membrane pocket includes a drainage element, which is joined surface-to-surface to two membranes and is enclosed in a pressure-tight manner at the edge. Adjacent membrane pockets are connected to one another and to the extraction means via one or more outflow bores and associated lines. The outflow bores are arranged in such a way that the transmembrane differential pressure drops only slightly over the surface of the membrane pocket.

Owner:MICRODYN NADIR

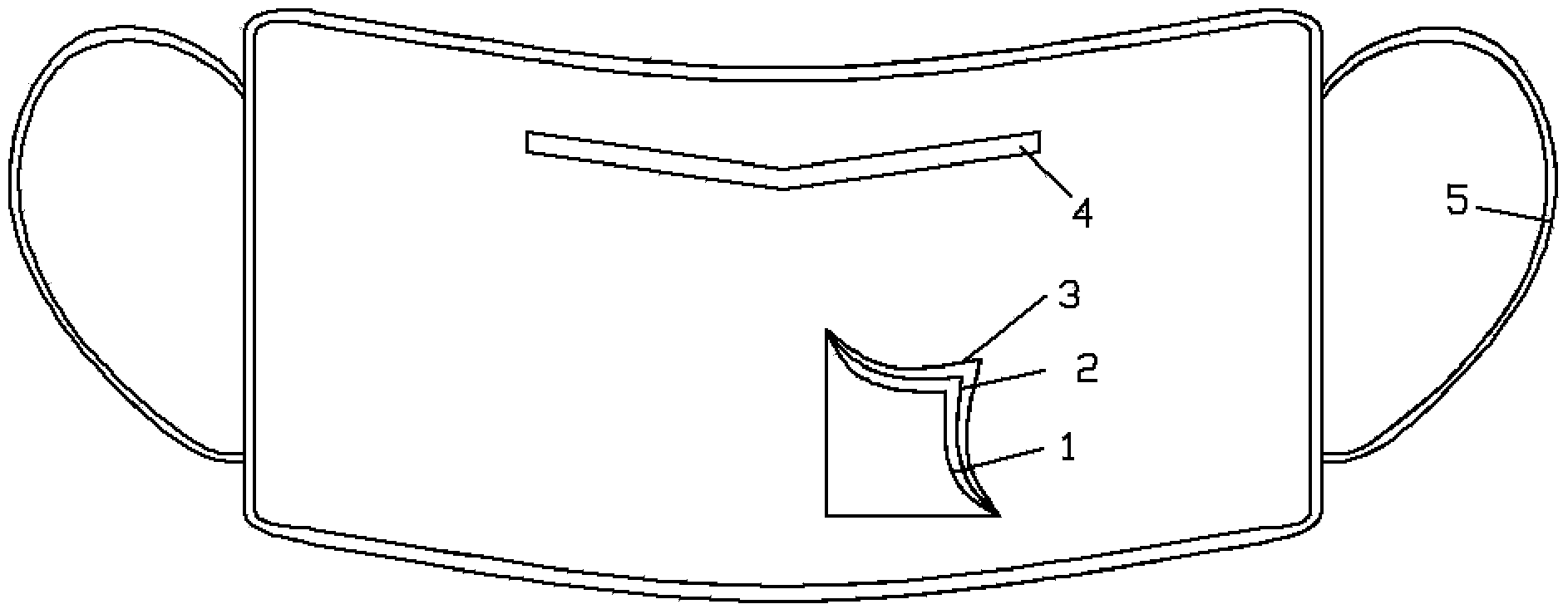

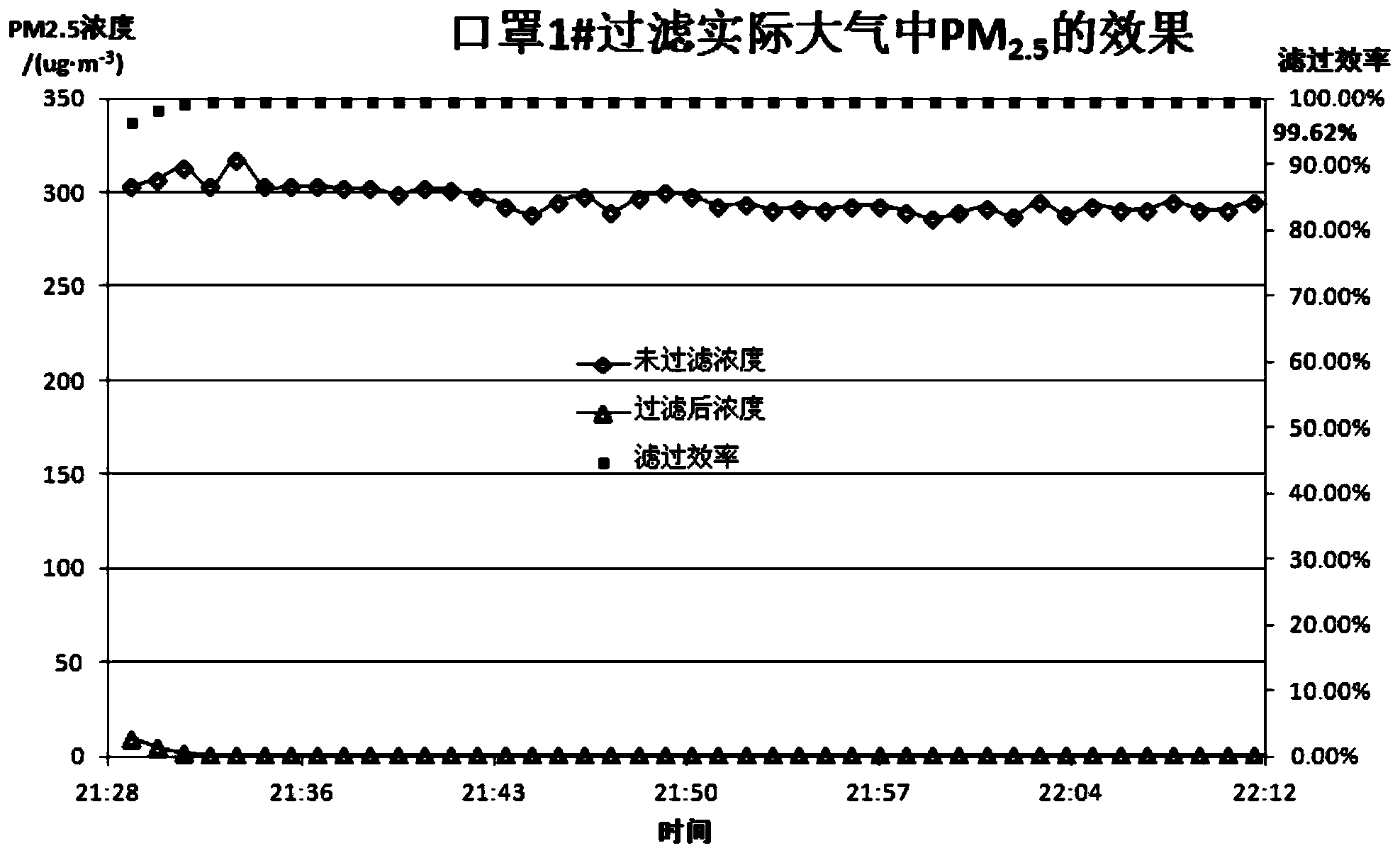

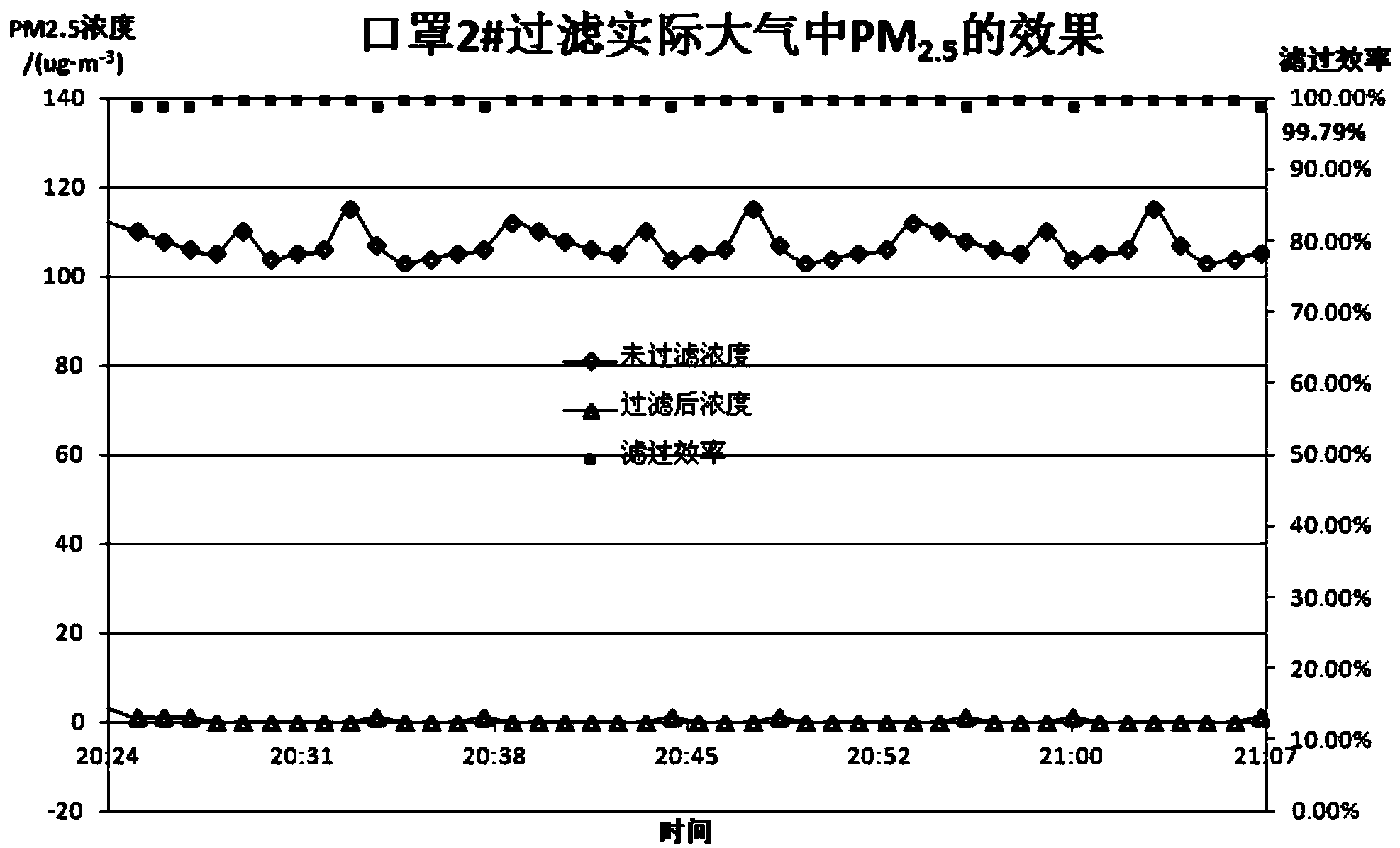

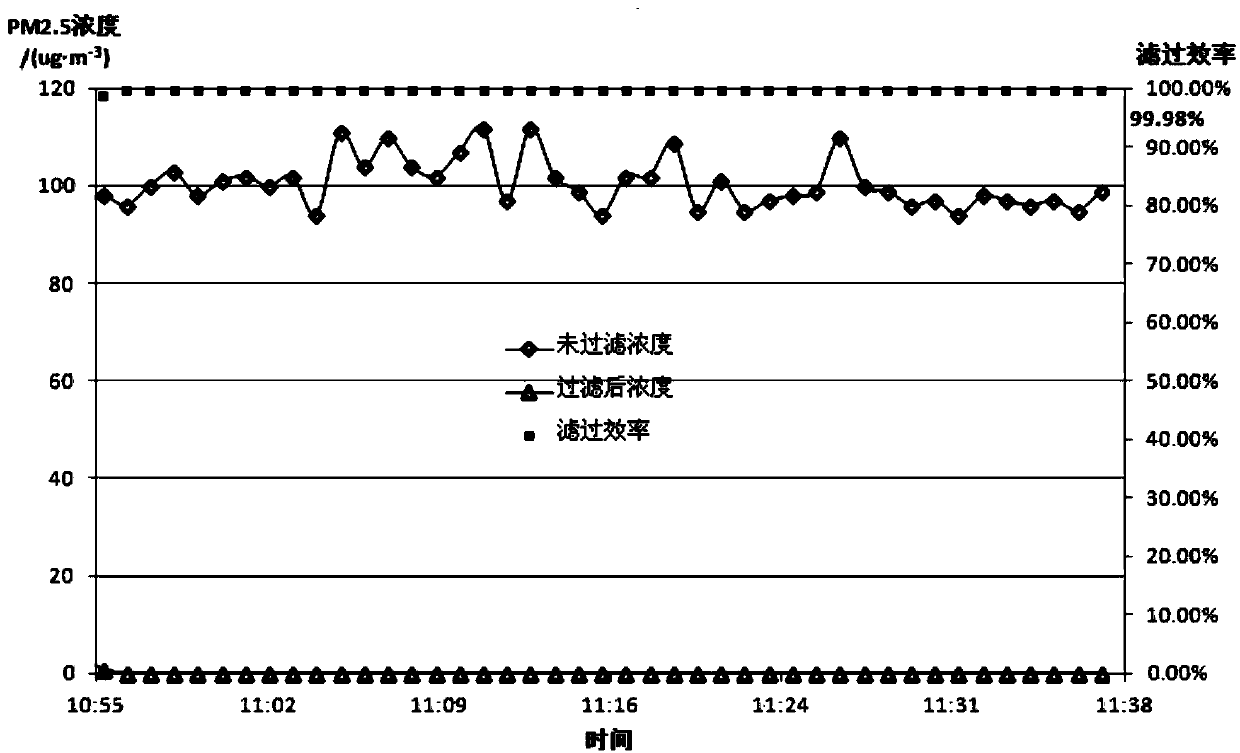

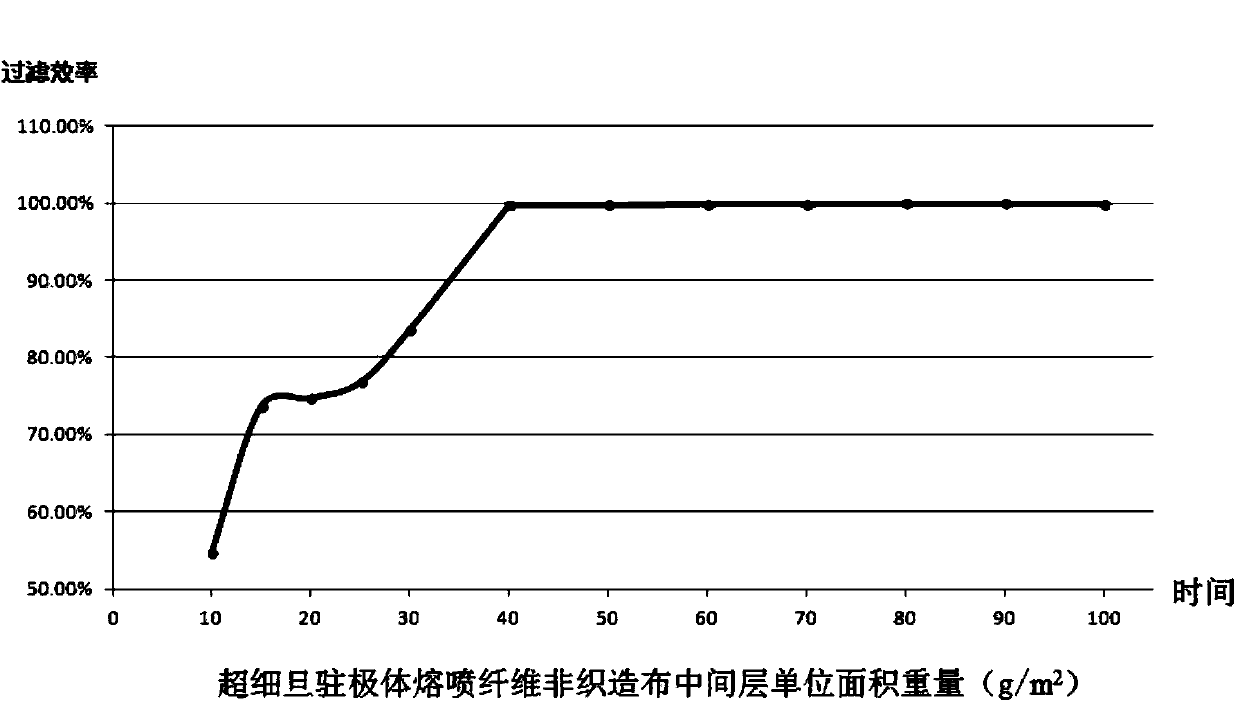

Planar mask for efficiently filtering PM 2.5

InactiveCN103637431AGood wearing feelingGood air permeabilityProtective garmentWoven fabricEngineering

The invention relates to a planar mask for efficiently filtering PM 2.5. The planar mask comprises a mask body used for covering the mouth and the nose of a wearer. A pair of ear hooking portions are formed on the two sides of the mask body in an extending mode and used for being hooked on the ears of the wearer. The mask body is of a three-layer structure in a stacked mode, and the three-layer structure comprises a polypropylene fiber spunbonded non-woven fabric outer layer, a superfine fiber electret melt-blown non-woven fabric middle layer and a polypropylene fiber spunbonded non-woven fabric inner layer in sequence from outside to inside. The weight per unit area of the superfine fiber electret melt-blown non-woven fabric middle layer is 20-60g / m<2>. The planar mask for efficiently filtering the PM 2.5 has the advantages of being high in filtration rate and low in choked flow, has prominent obstruction and capturing capability for the PM 2.5 and is good in breathability, low in weight, comfortable to wear and high in PM 2.5 filtering efficiency in high level. The filtering efficiency can reach up to more than 99%, the weight is low, and breathability and comfortable sensation of the mask are ensured at the same time.

Owner:SHANDONG UNIV

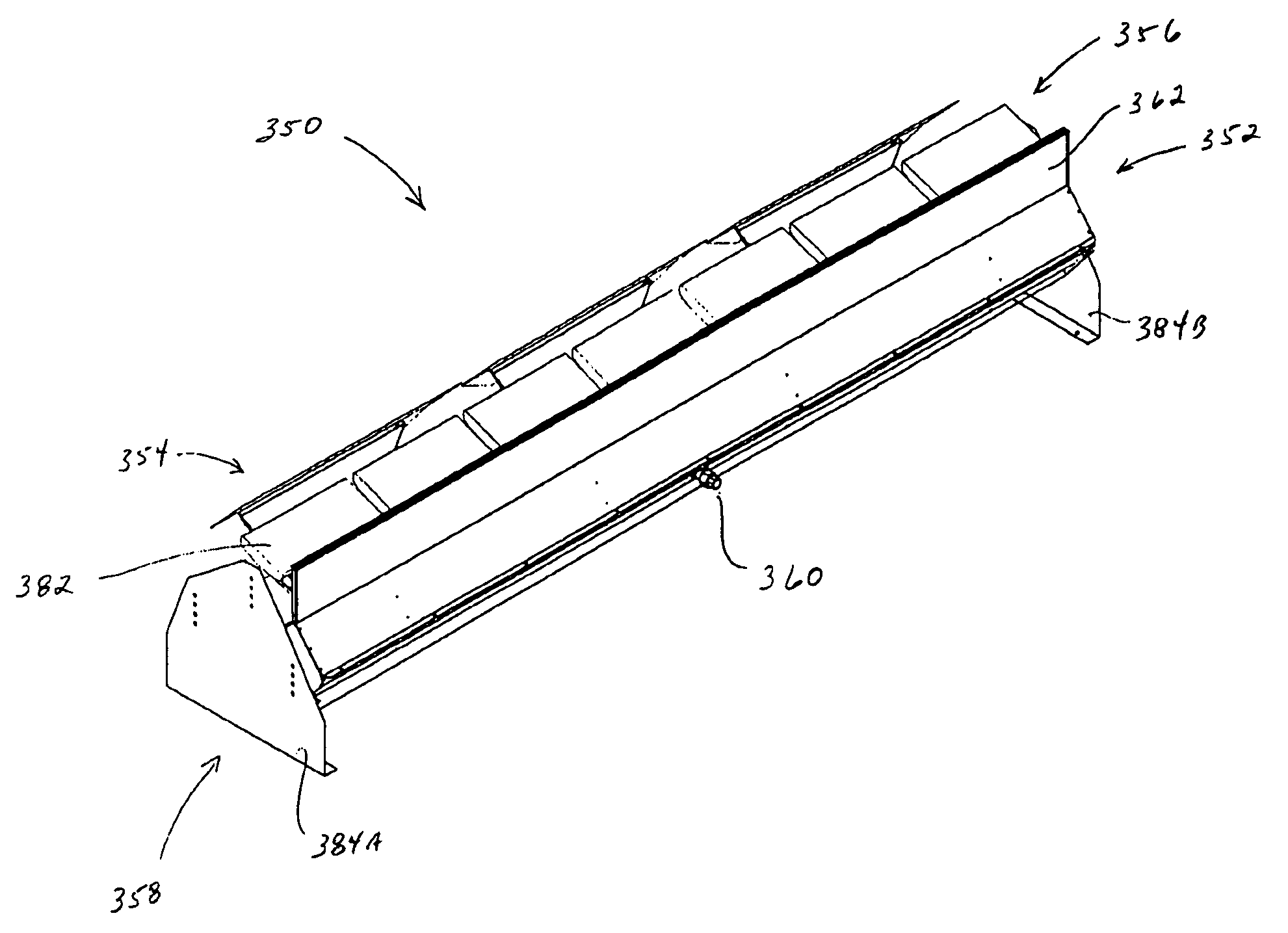

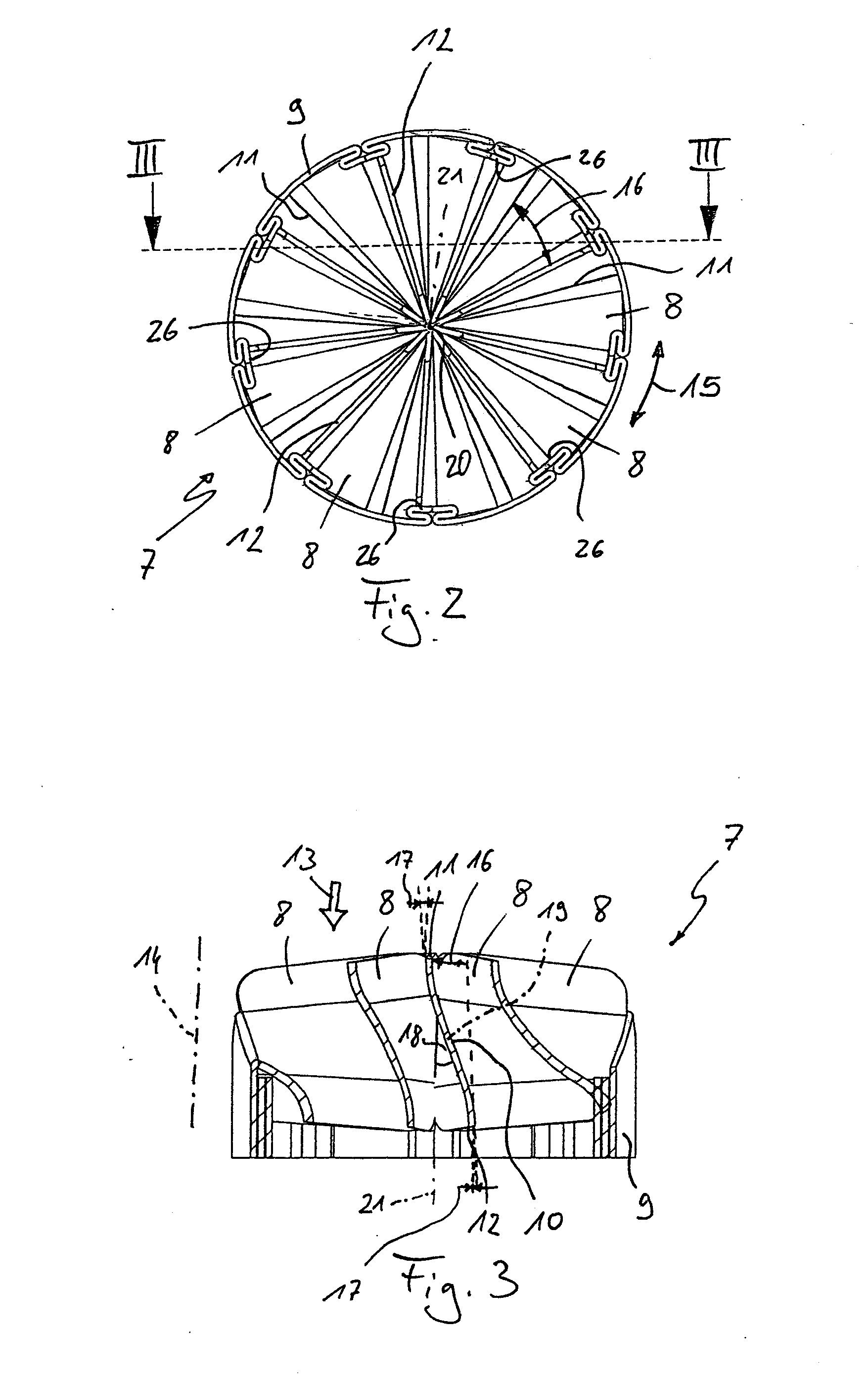

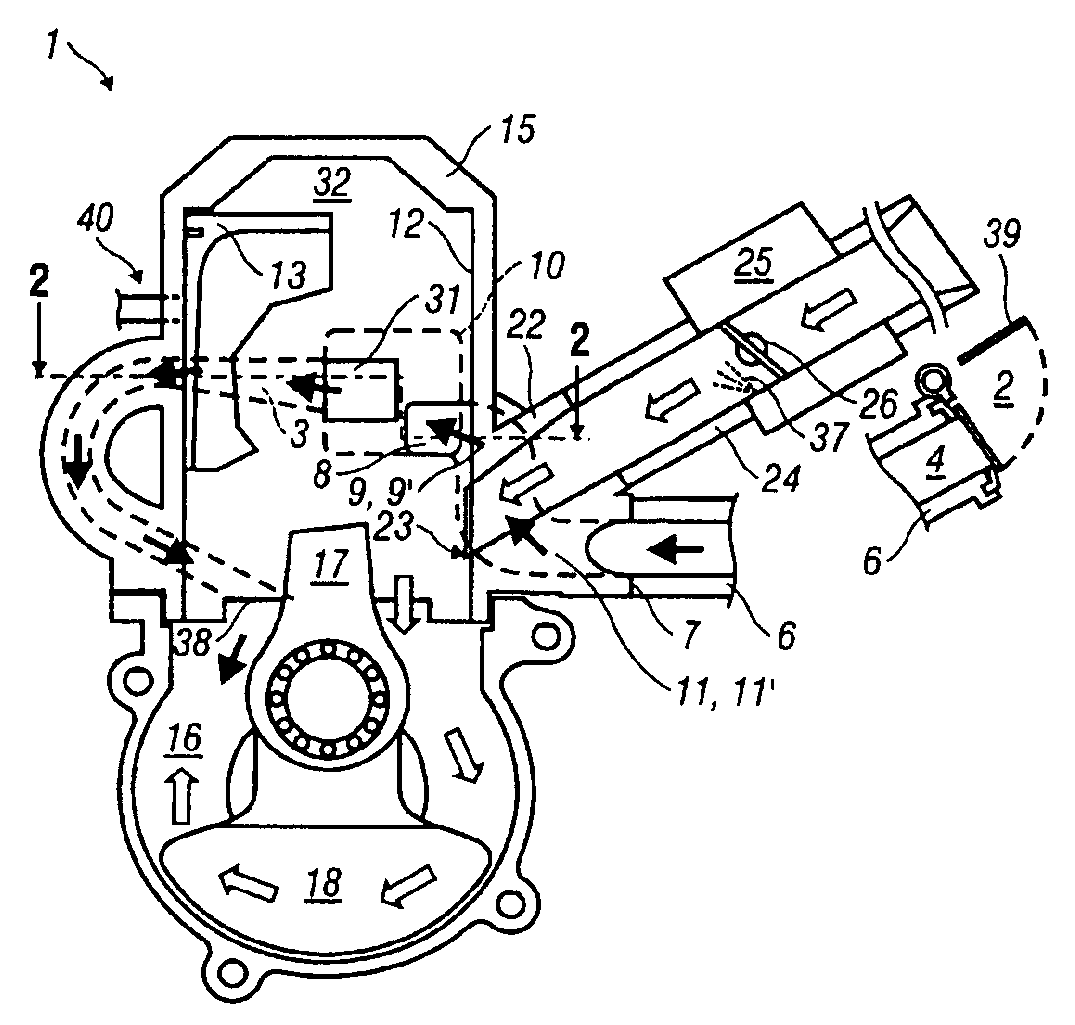

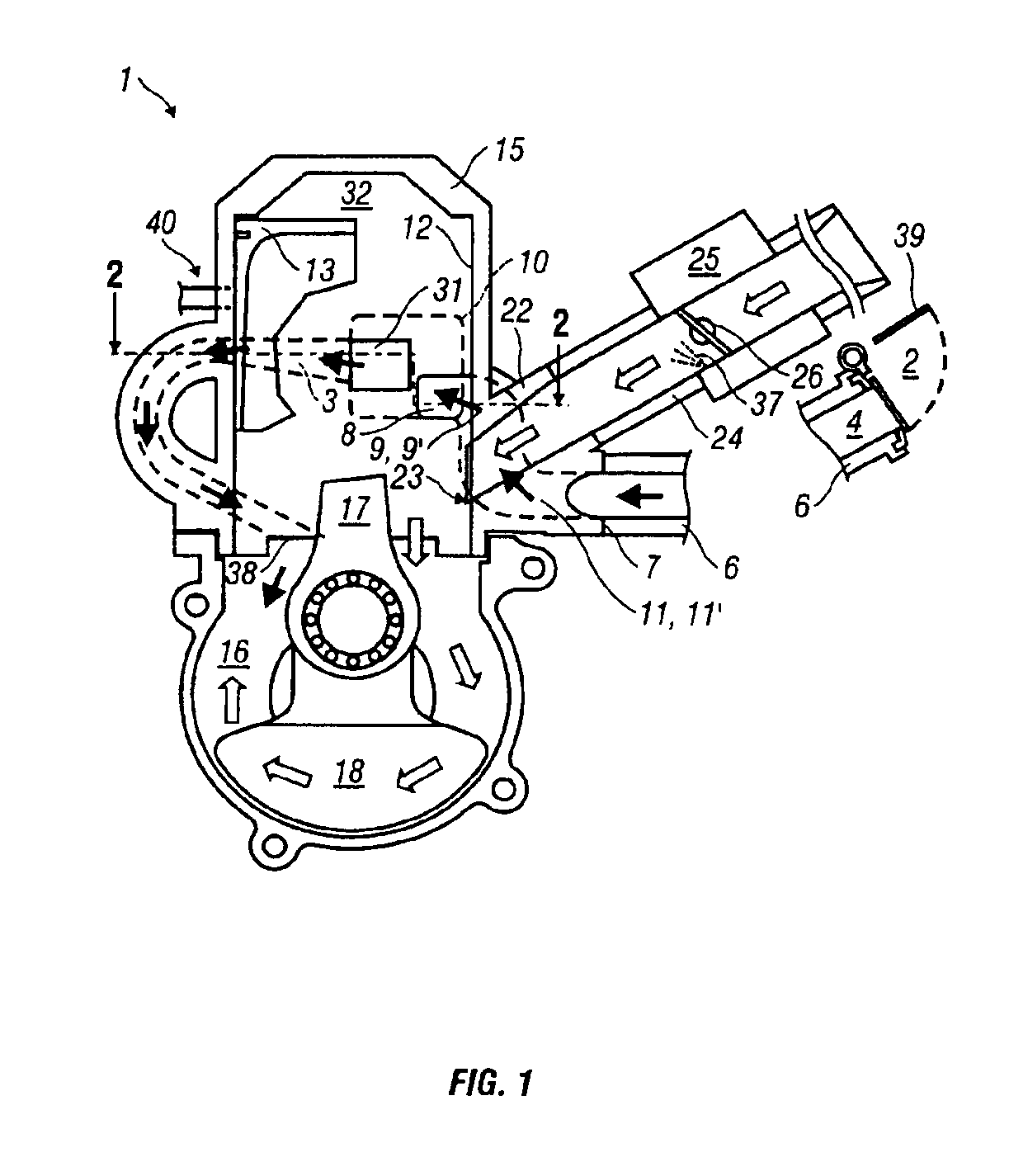

Mixing and/or evaporating device

ActiveUS20110016856A1Small sizeSufficient opaquenessInternal combustion piston enginesFlow mixersLeading edgeInternal combustion engine

A mixing and / or evaporating device (7) is provided through which exhaust gas can flow axially. The mixing and / or evaporating device (7) is arranged in an exhaust gas-carrying line of an exhaust system of an internal combustion engine, especially of a motor vehicle, with a plurality of blades (8), which are arranged distributed in the circumferential direction and which project inwardly from an outer wall (9). Each blade (8) has a profile (10) at least in an area adjoining the outer wall (9) in the axial direction (14), in which profile a discharge edge (12) has an offset (16) in the circumferential direction (15) in relation to the leading edge (11). A reduction of the flow resistance of the device (7) can be achieved if the profile (10) has an angle of incidence (17) each in relation to the axial direction (14) at the leading edge (11) and at the discharge edge (12), which angle is in a range of −10°, inclusive to +10°, inclusive.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

Apparatus for producing a fire special effect

ActiveUS20060275721A1Eliminate and substantially reduce any gapUniform densityShow cabinetsPoint-like light sourceEngineeringSpecial effects

The present invention provides a device for producing a fire special facilitates a more compact device. In one embodiment, the device comprises a steam curtain generator for directing received steam to an outlet slot that directs the steam into the ambient atmosphere such that the steam is flowing in a substantially a first direction to produce a curtain of steam, fan that is oriented so as to produce a flow of air in a direction that is substantially parallel to the flow of a steam curtain, a deflector for redirecting the flow of air produced by the fan towards the steam curtain, an adjustable agitator for causing turbulent flow in the stream of air directed towards a steam curtain, and an LED light for producing light that is projected onto a steam curtain.

Owner:TECHNIFEX PRODS

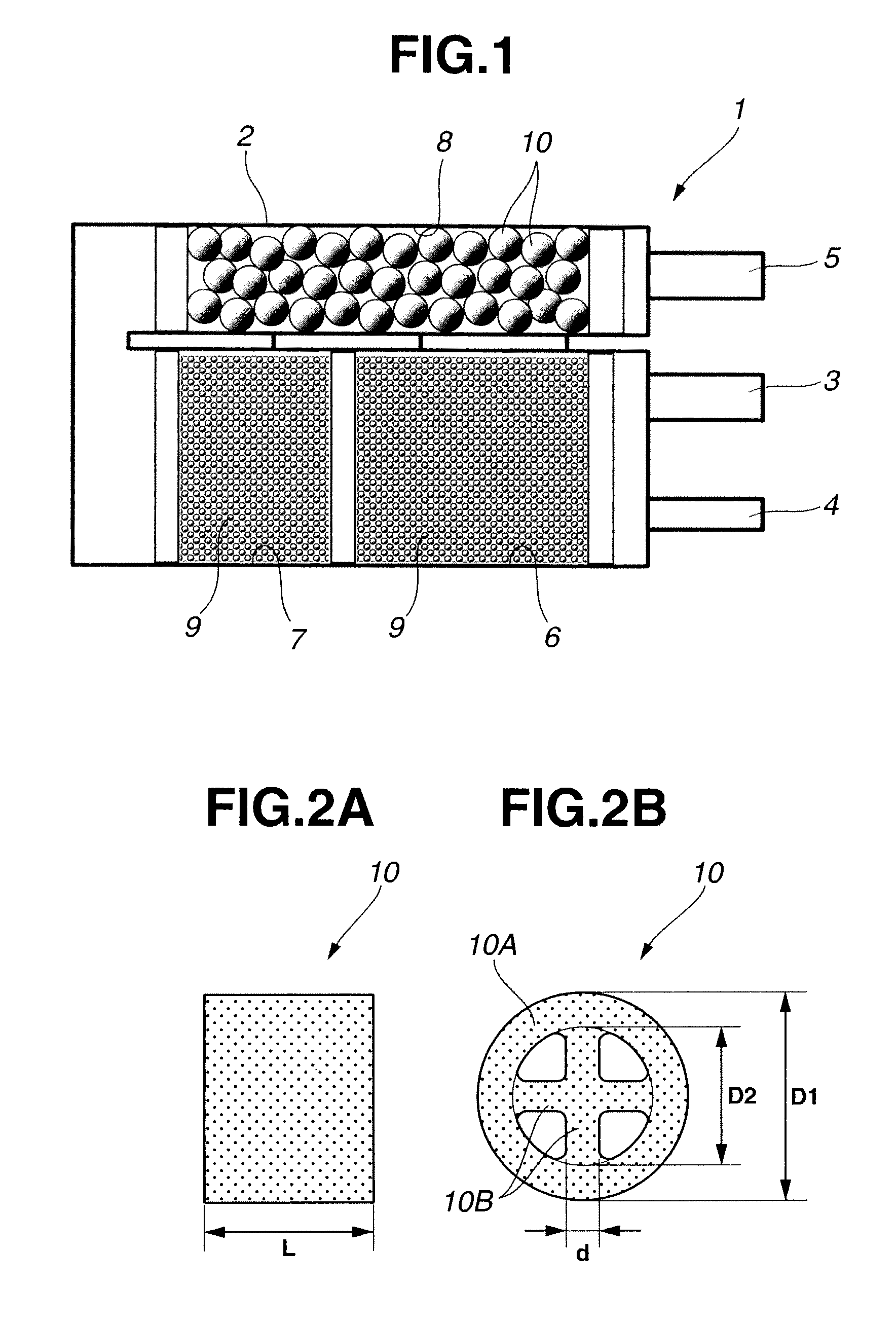

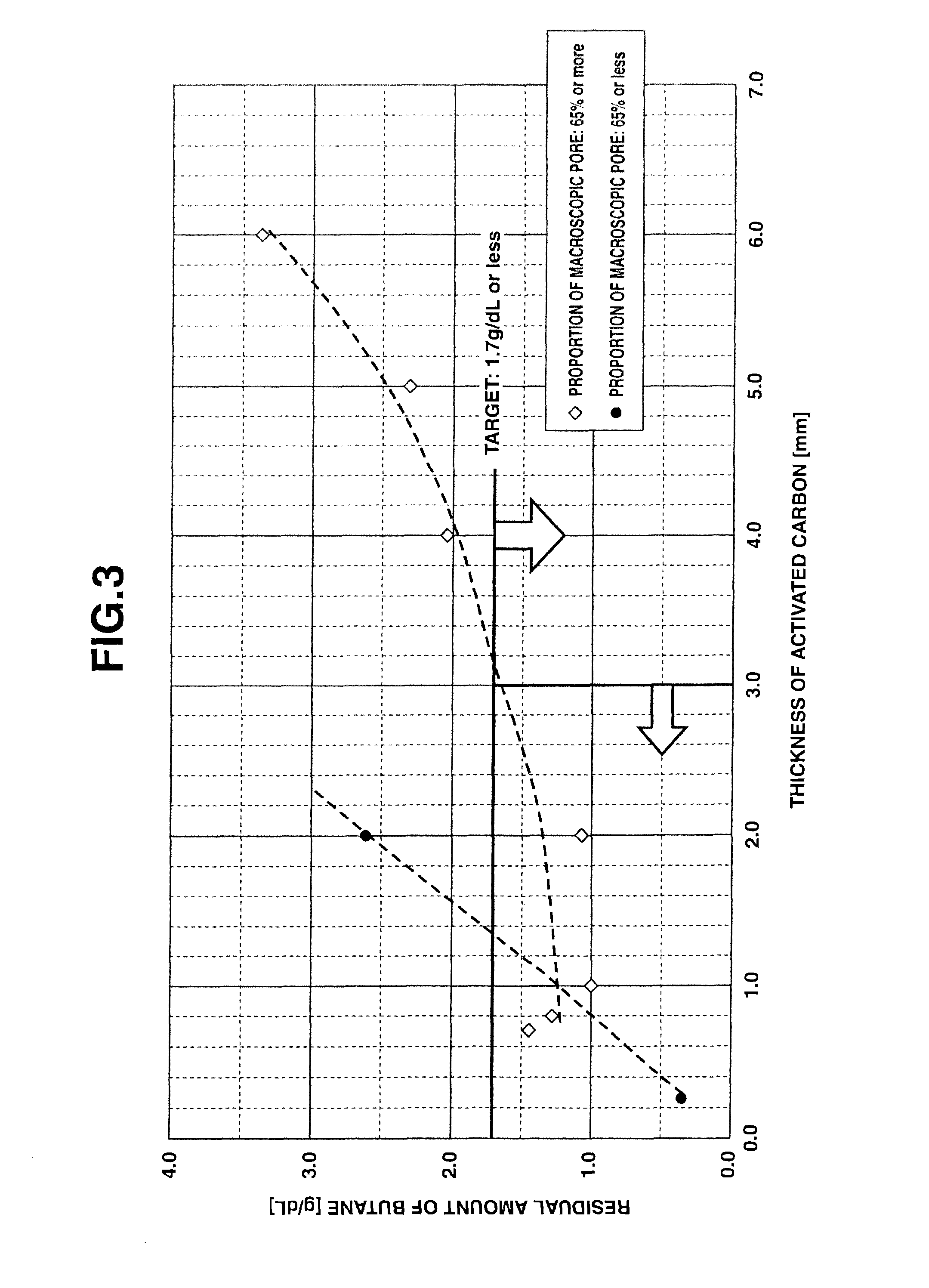

Adsorbent for canister, and canister

ActiveUS20140124385A1Decrease resistance to flowSmall flow resistanceGas treatmentNon-fuel substance addition to fuelActivated carbonSorbent

To obtain adsorbent (10), meltable core which melts away during baking and binder are added to powdery activated carbon having microscopic pore whose size is less than 100 nm together with water and mixed together, then this mixture is molded into hollow cylindrical shape whose outside diameter is 4˜6 mm and baked. Although macroscopic pore whose side is 100 nm or more is formed by the meltable core, proportion of volume of the macroscopic pore to volume of the microscopic pore is adjusted to 65%˜150%. The adsorbent (10) has shape in cross section formed from cylindrical wall (10A) and cross-shaped radial wall (10B), and thickness of each part is within a range of 0.6˜3 mm. The adsorbent (10) of the present invention can satisfy adsorbing / desorbing performance of fuel vapor, flow resistance as a canister and strength of the adsorbent at the same time.

Owner:MAHLE JAPAN LTD +1

Method and device for reducing the number of particles in an exhaust gas

InactiveUS6941742B1Improve efficiencyEffective level of separationCyanogen compoundsNitrogen compoundsCatalytic oxidationSulfur trioxide

To reduce the number of particles in an exhaust gas (A), in particular in the exhaust gas (A) from an internal-combustion engine, sulfur dioxide SO2 which is contained in the exhaust gas (A) is at least partially catalytically oxidized, in the presence of ammonia NH3 in a catalytic converter system having a catalytic activity which increases in the direction of flow, to form sulfur trioxide SO3. The simultaneous presence of sulfur trioxide SO3 and ammonia NH3 in the exhaust-gas stream which is brought about in this way results in an agglomeration of the small and very small particles and reduction in the number thereof.

Owner:SIEMENS AG

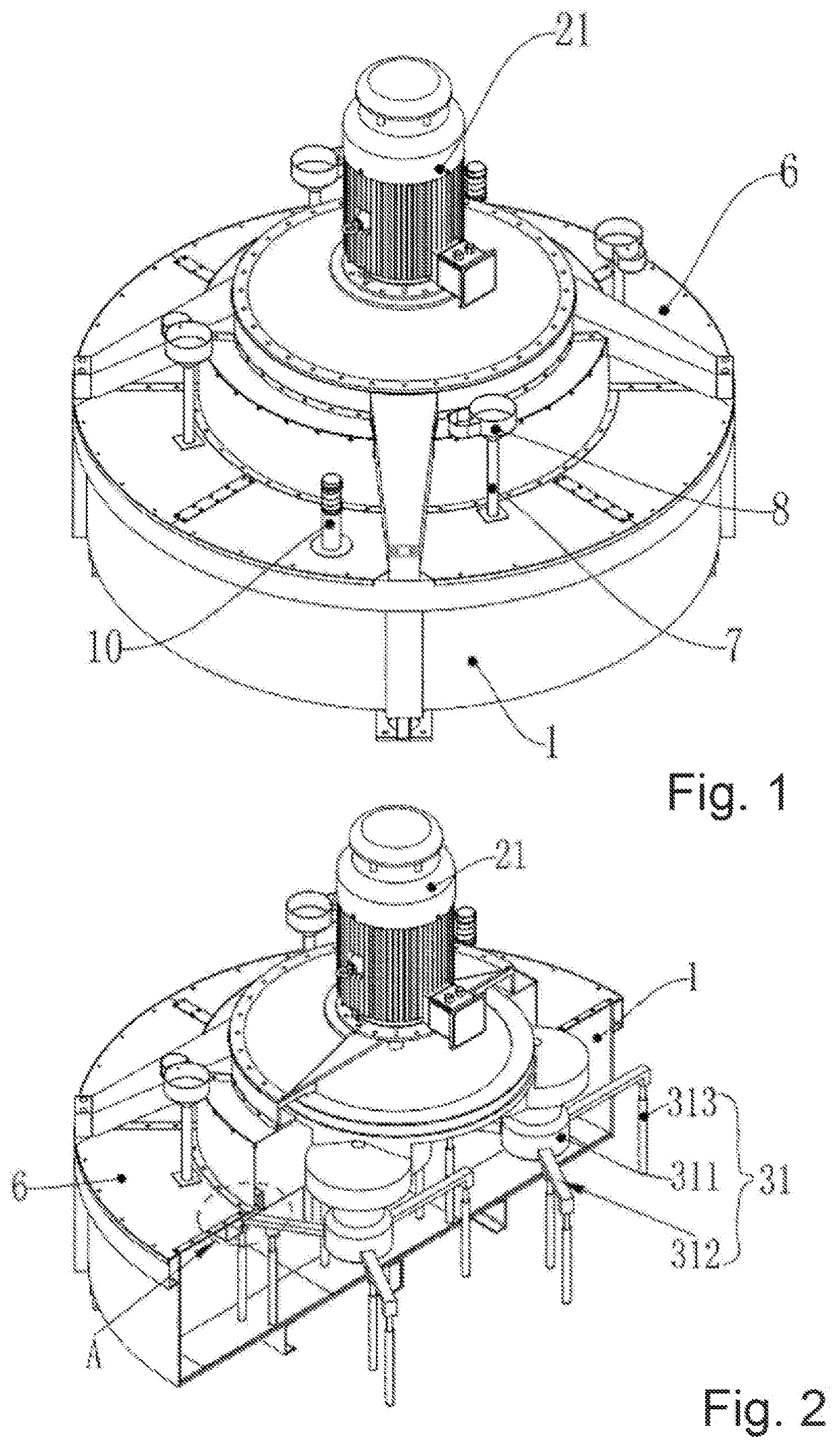

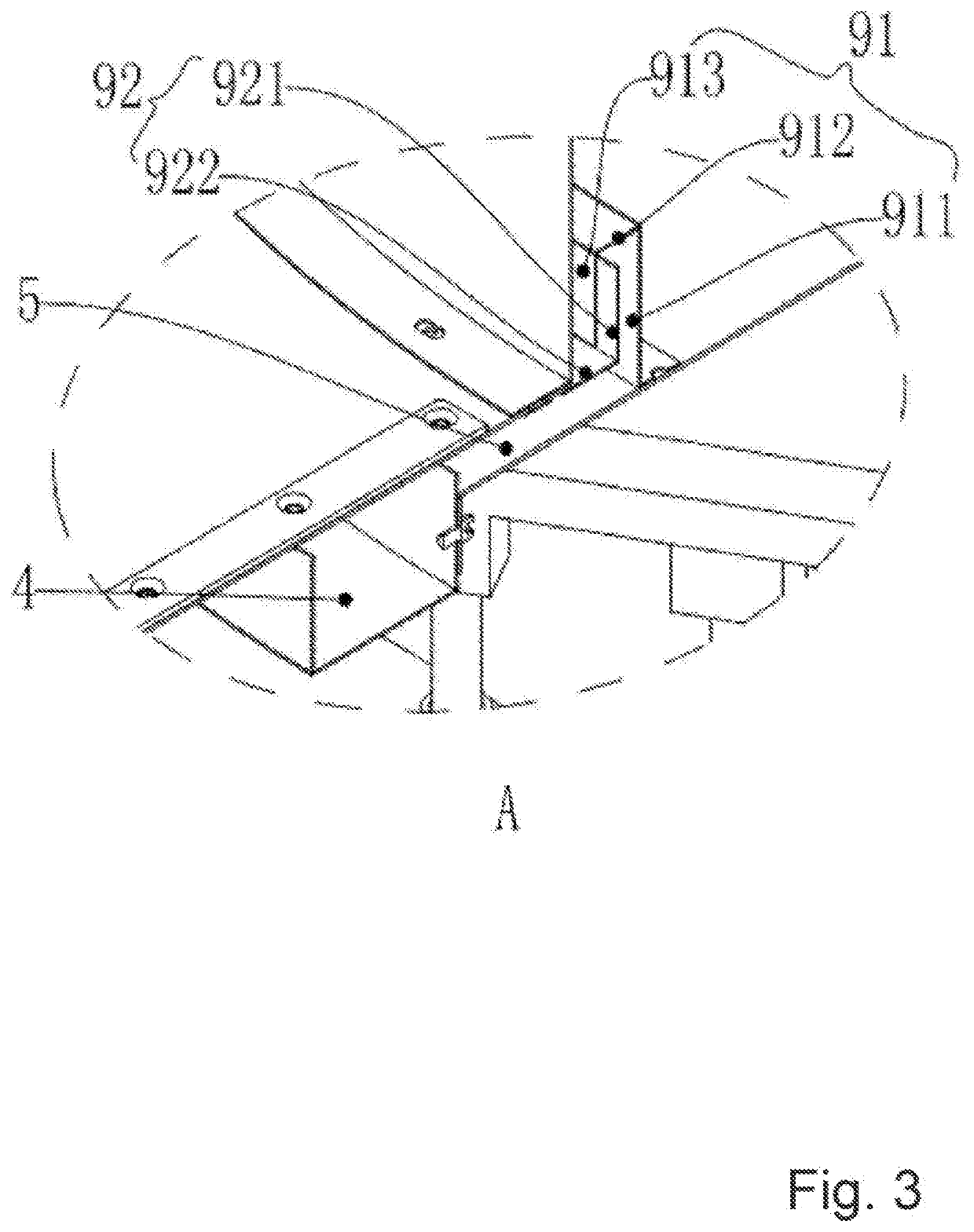

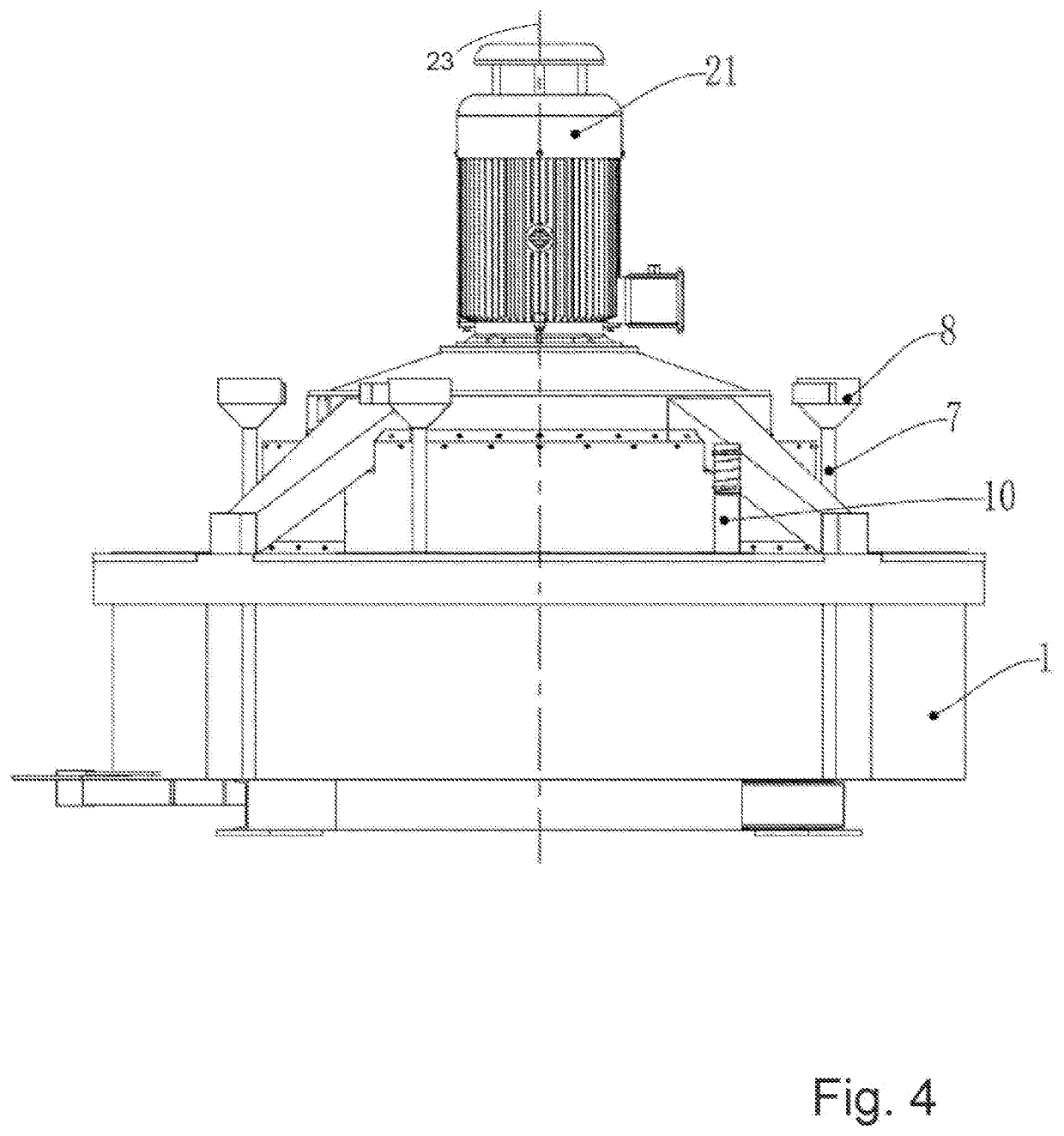

Mixer for synthetic quartz

InactiveUS20200261871A1Easy to cleanSmall flow resistanceRotary stirring mixersMixing operation control apparatusEngineeringMixing tank

A mixer for synthetic quartz includes a mixing barrel (1), a power transmission system (2), a mixing system (3), and multiple material receiving receptacles (4). The power transmission system is provided above the mixing tank. The mixing system is provided inside the mixing tank. The power transmission system is used to drive the mixing system to move. An opening is arranged at each of two ends of the material receiving receptacle. The multiple material receiving receptacles (4) are arranged at a top portion of the mixing tank, and end portions of two adjacent material receiving receptacles are spaced apart from each other without contact there between. A resin experiences low flow resistance in the material receiving receptacle, and thus can fall smoothly without accumulating in the material receiving receptacle. Moreover, the material receiving receptacle can be cleaned easily.

Owner:VEEGOO TECH CO LTD

PM2.5C type mouth mask efficient in filtering

The invention relates to a PM2.5C type mouth mask efficient in filtering. The mouth mask comprises a mouth mask body, and the two sides of the mouth mask body extend out to form a pair of portions hung on ears. The mouth mask body comprises a left mouth and nose piece portion, a right mouth and nose piece portion, a left nose bridge piece portion, a right nose bridge piece portion, a left jaw piece portion and a right jaw piece portion, wherein the edge of the left nose bridge piece portion and the edge of the right nose bridge piece portion are combined, the mouth mask body is of a three-layer structure to form a laminated shape, and the weight of a middle layer made of ultra-fine electret melt-blown fiber non-woven cloth per unit area is 20-60g / m2. The PM2.5C type mouth mask efficient in filtering integrates air permeability, weight, wearing comfort and PM2.5 filtering efficiency of a mouth mask at a high level. The PM2.5 filtering efficiency of the mouth mask can reach more than 99% at most, the mouth mask is low in weight, and air permeability and comfort of the mouth mask are guaranteed at the same time. Water mist is prevented from being generated on lenses, warm air is prevented from accumulating on the inner side of the mouth mask, and bacteria are prevented from growing.

Owner:SHANDONG UNIV

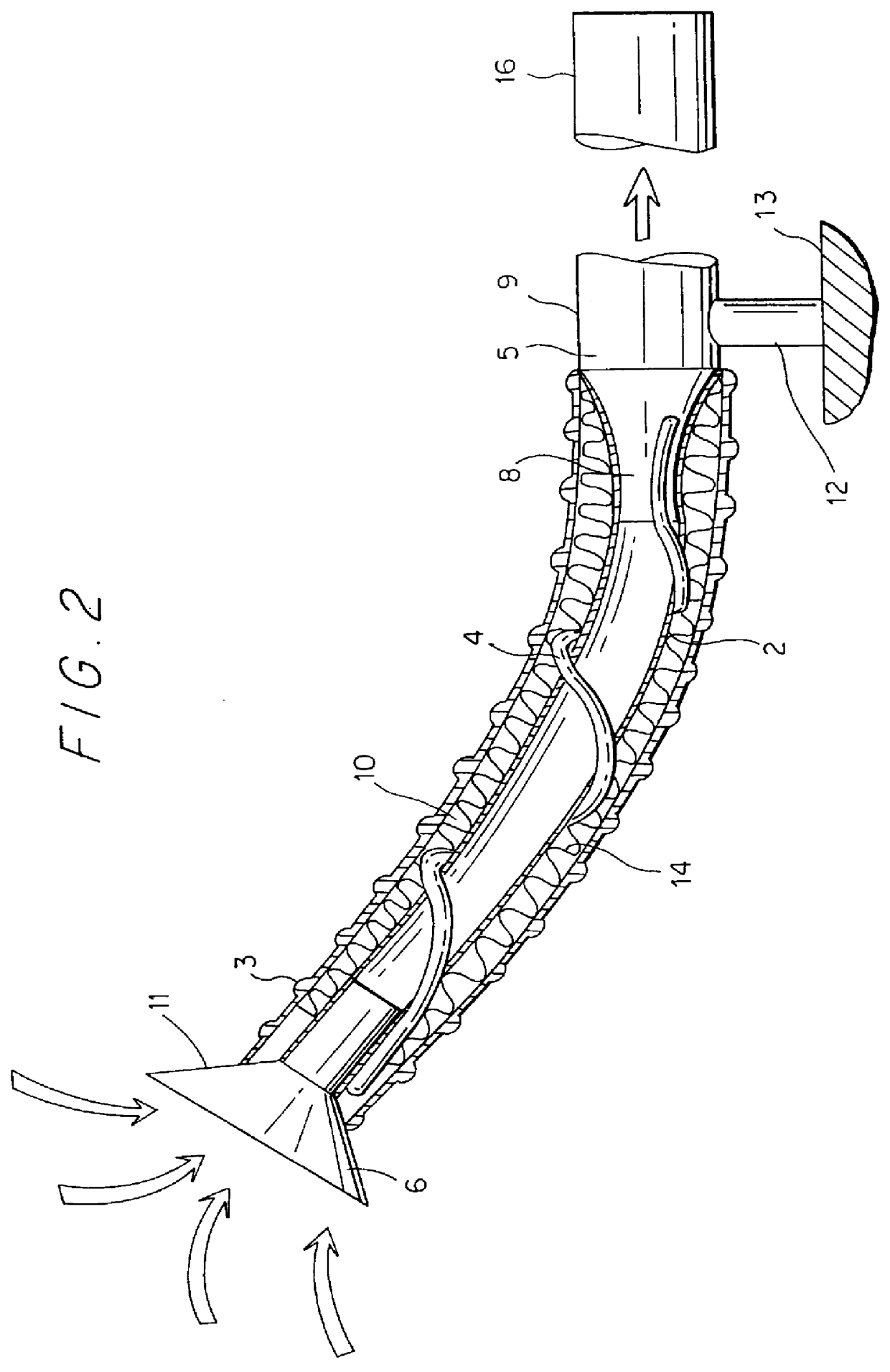

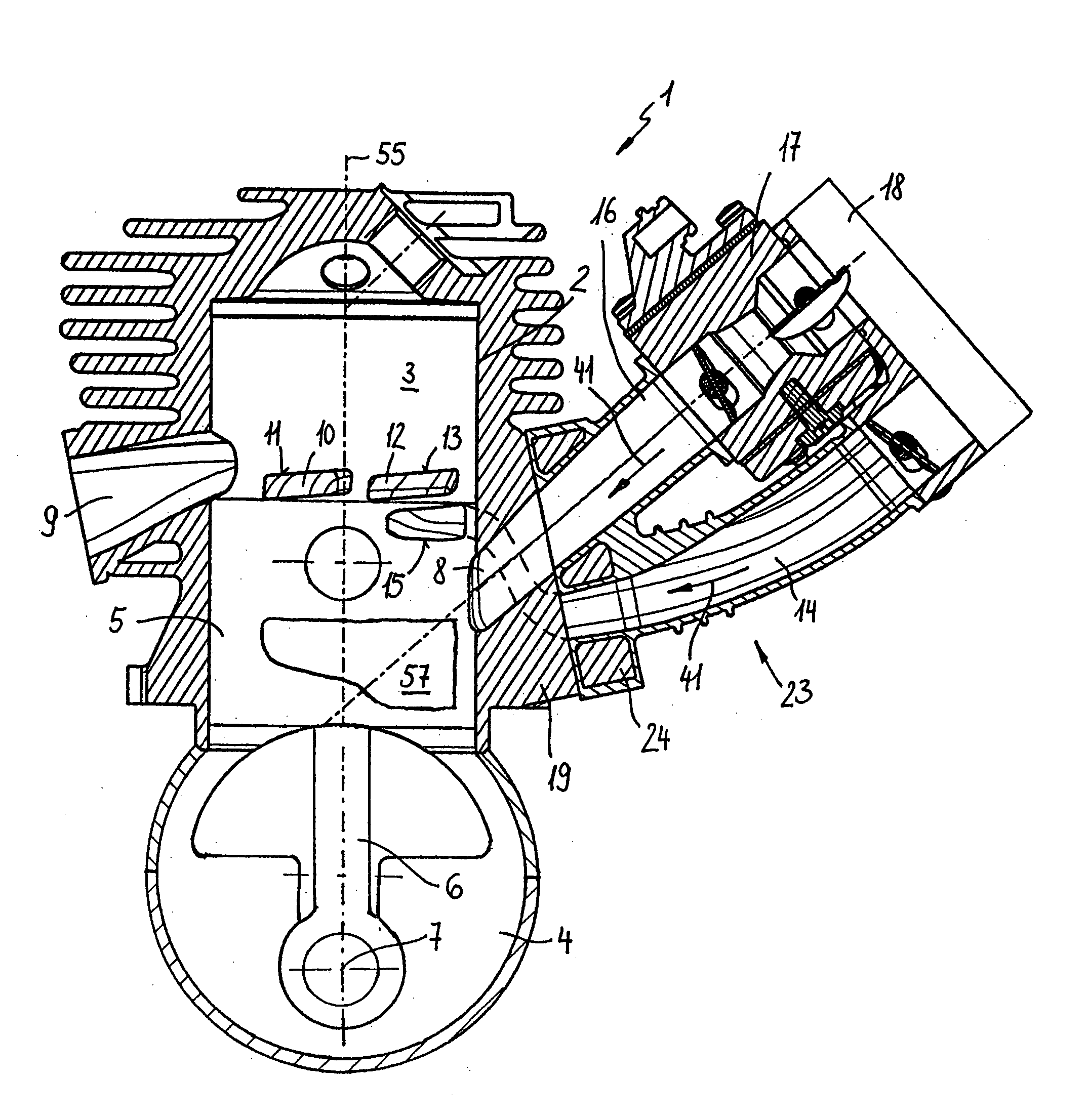

Two-stroke internal combustion engine

InactiveUS7082910B2Shorten the lengthSmall sizeCylinder headsCombustion enginesThrottle controlTop dead center

Crankcase scavenged two-stroke internal combustion engine (1), in which a piston ported air passage is arranged between an air inlet (2) and the upper part of a number of transfer ducts (3, 3′). The air passage is arranged from an air inlet (2) equipped with a restriction valve (4), controlled by at least one engine parameter, for instance the carburetor throttle control. The air inlet extends via at least one connecting duct (6, 6′) to at least one connecting port (8, 8′) in the engine's cylinder wall (12). The connecting port (8, 8′) is arranged so that it in connection with piston positions at the top dead center is connected with flow paths (10, 10′) embodied in the piston (13), which extend to the upper part of a number of transfer ducts (3, 3′). Each flow path through the cylinder and piston is to a great extent arranged in the cylinder's lateral direction, on the one hand in that the connecting port (8, 8′) and adjacent scavenging port (31, 31′) of the cylinder are shifted sideways in relation to each other along the periphery of the cylinder wall (12), and on the other hand in that the transfer ducts (3, 3′) of the cylinder are running essentially in the cylinder's lateral direction away from each transfer port (31, 31′) respectively, i.e. tangentially in relation to the circumference of the cylinder wall (12).

Owner:HUSQVARNA AB

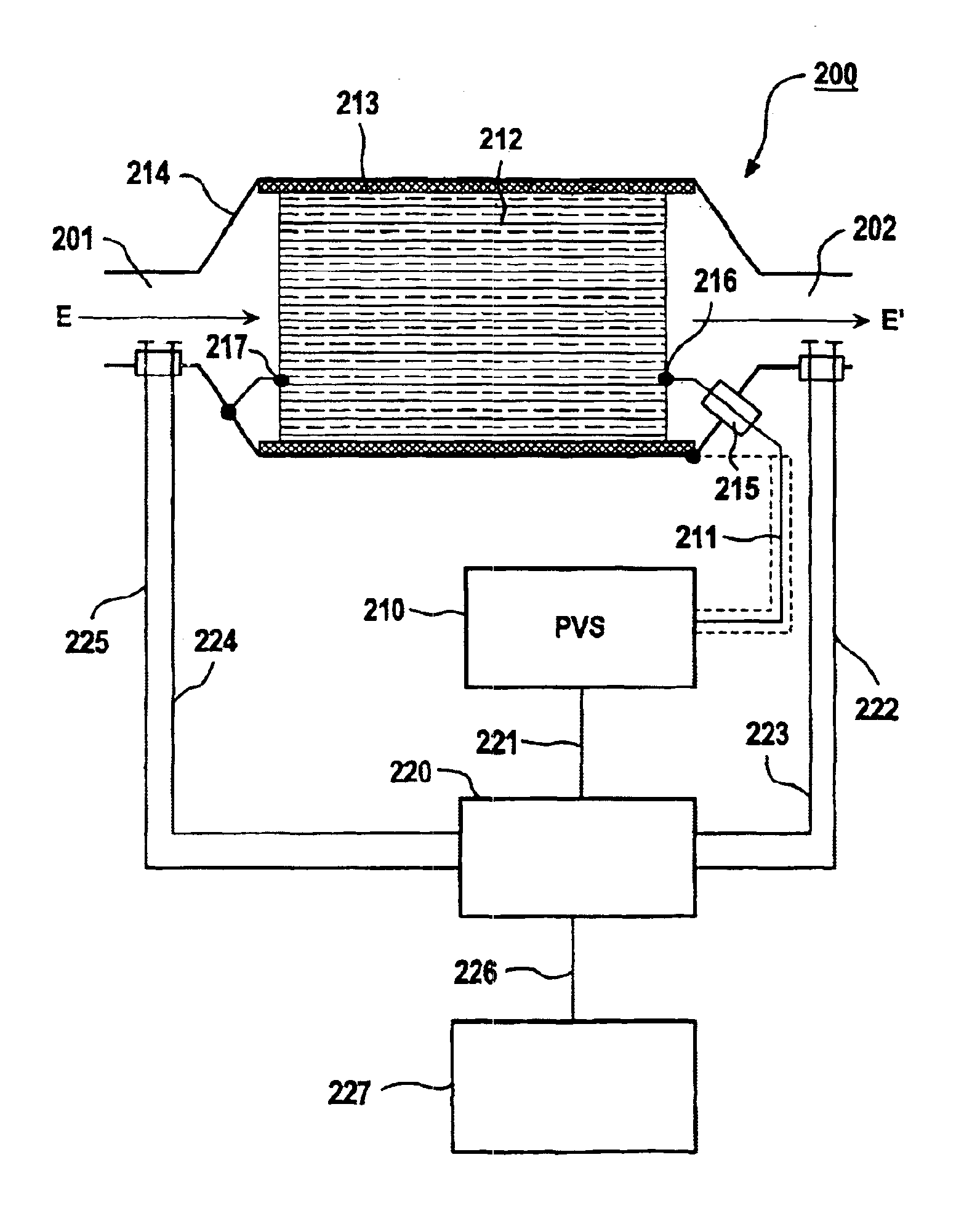

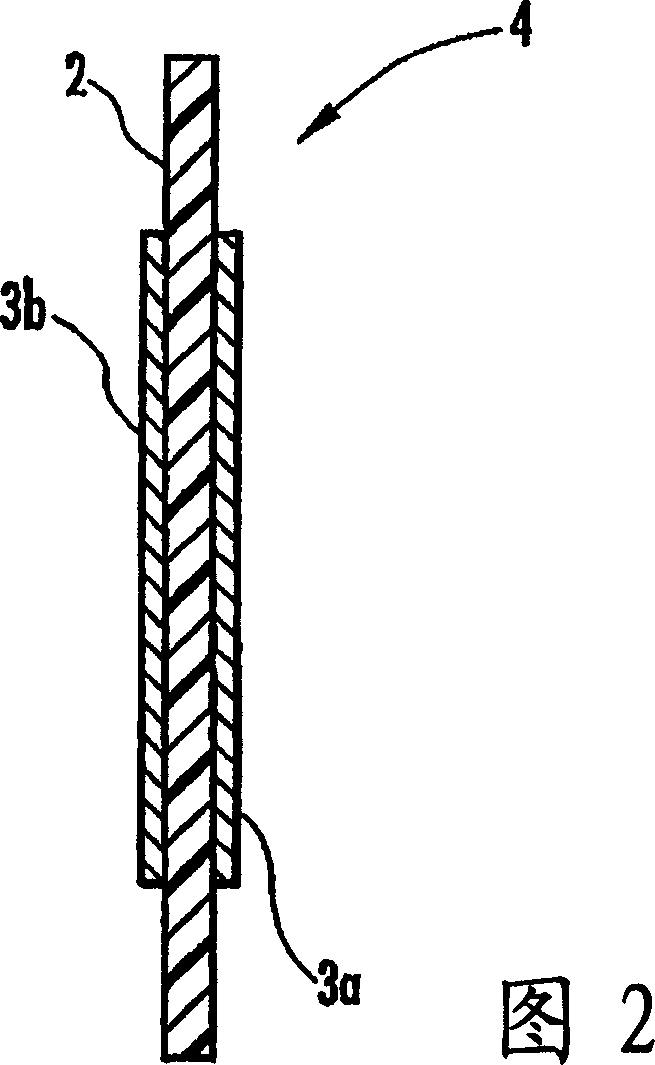

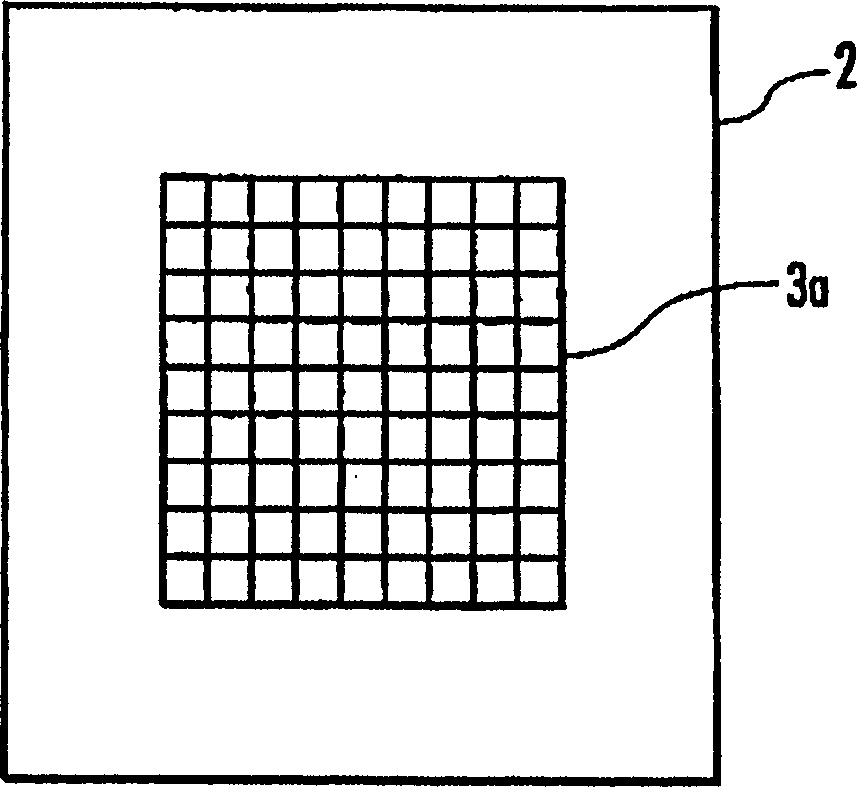

Electrolysis vessel and apparatus for generating electrolyzed water

InactiveCN1878729ALower overall flow resistanceLower resistanceCellsWater/sewage treatment by electrochemical methodsConductive pasteElectrolysed water

Disclosed are an electrolysis vessel and an apparatus for generating electrolyzed water which are small in size, excellent in electrolysis efficiency, and enable to reduce the anion concentration in the acidic electrolyzed water. The electrolysis vessel comprises electrolysis chambers (10a, 10b) arranged opposite to each other with an ion-permeable separating membrane (2) interposed between, raw material water supply means (11a, 11b), electrodes (3a, 3b) so arranged as to have the separating membrane (2) between them, and electrolyzed water taking-out means (12a, 12b). The separating membrane (2) is an anion permeable membrane, and the electrodes (3a, 3b) are formed on respective sides of the anion permeable membrane (2) in an appressed manner, while leaving a portion of the anion permeable membrane (2) exposed. Only raw material water supplied to the cathode side electrolysis chamber (10b) contains an electrolyte. The electrodes (3a, 3b) are porous bodies and contain an electrode base composed of a powder titanium compound such as TiC or TiN, a catalyst such as platinum black or iridium black, and a binder such as PVA. The electrodes (3a, 3b) may have a mesh-like shape or a comb-like shape, and are formed by applying a conductive paste containing a conductive powder on respective sides of the anion permeable membrane (2) and heating or pressurizing the thus-applied paste.

Owner:HONDA MOTOR CO LTD

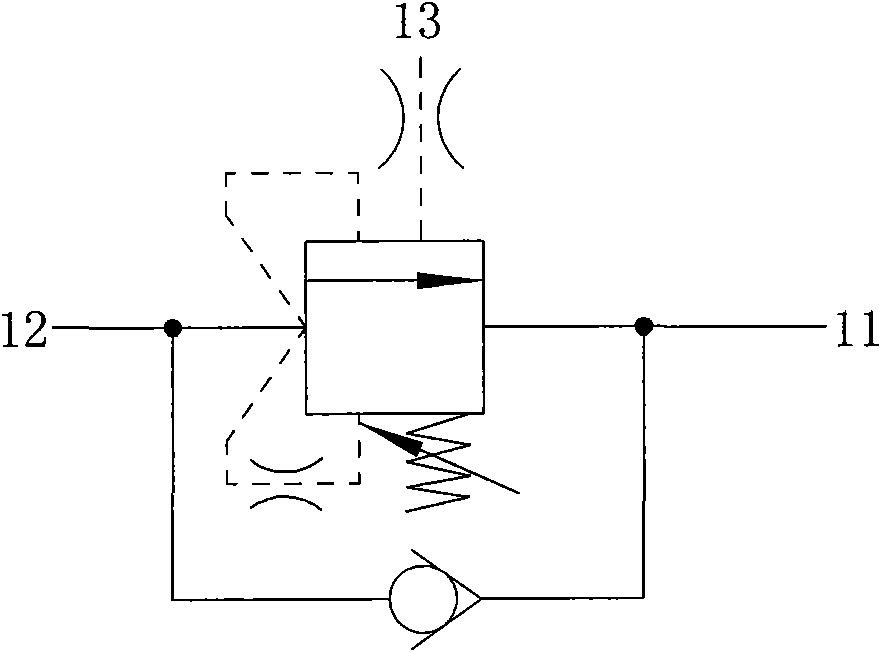

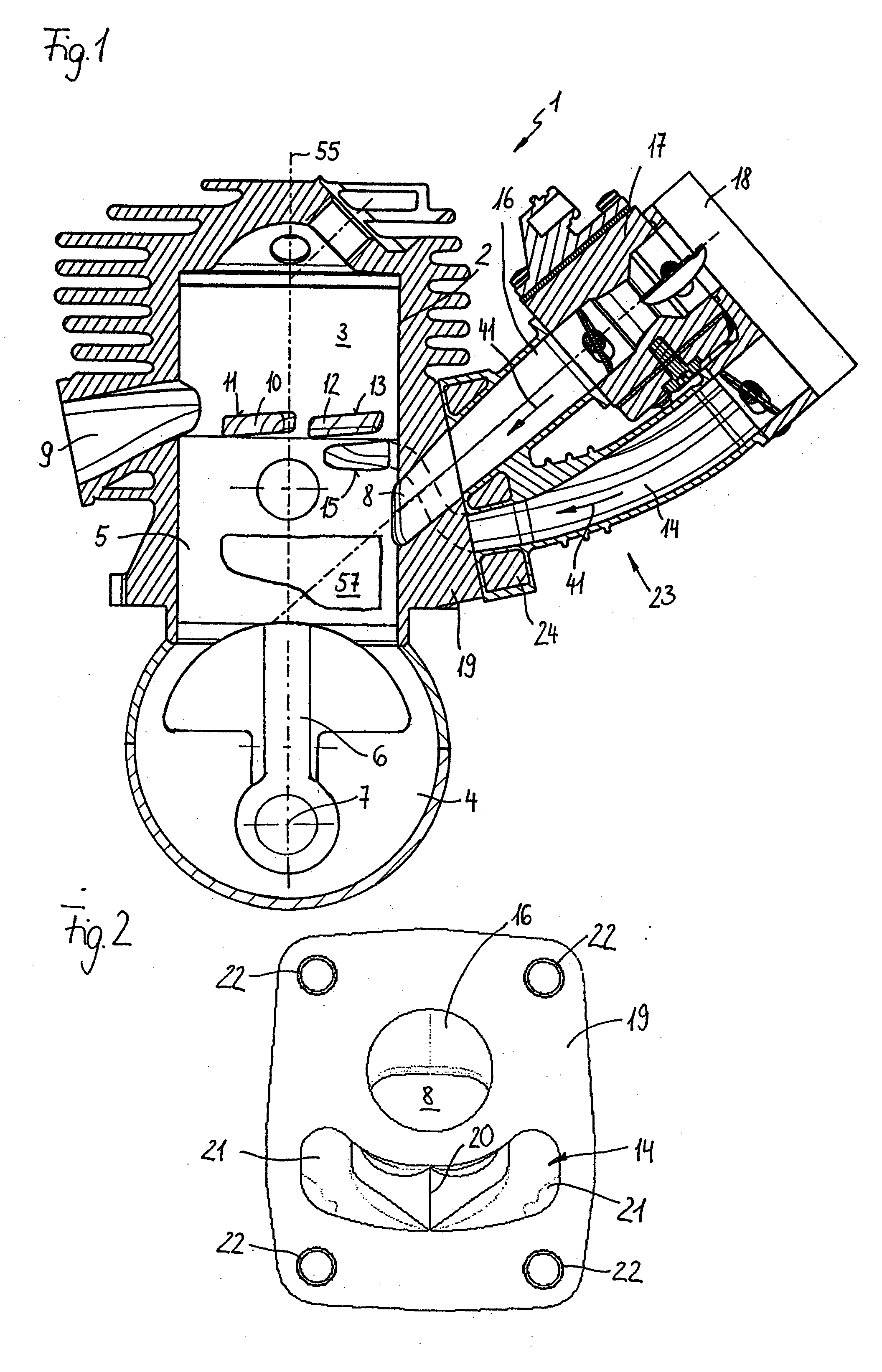

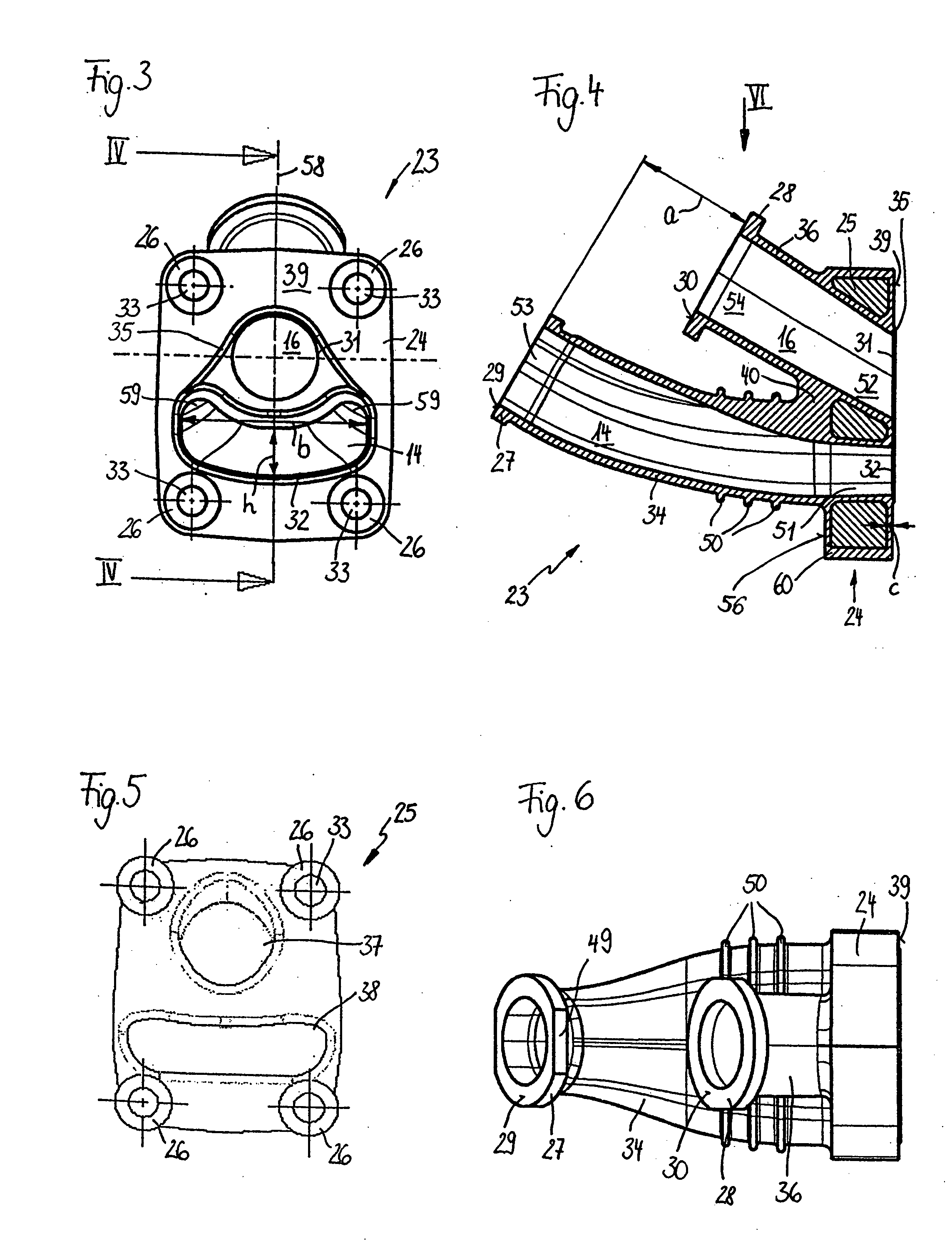

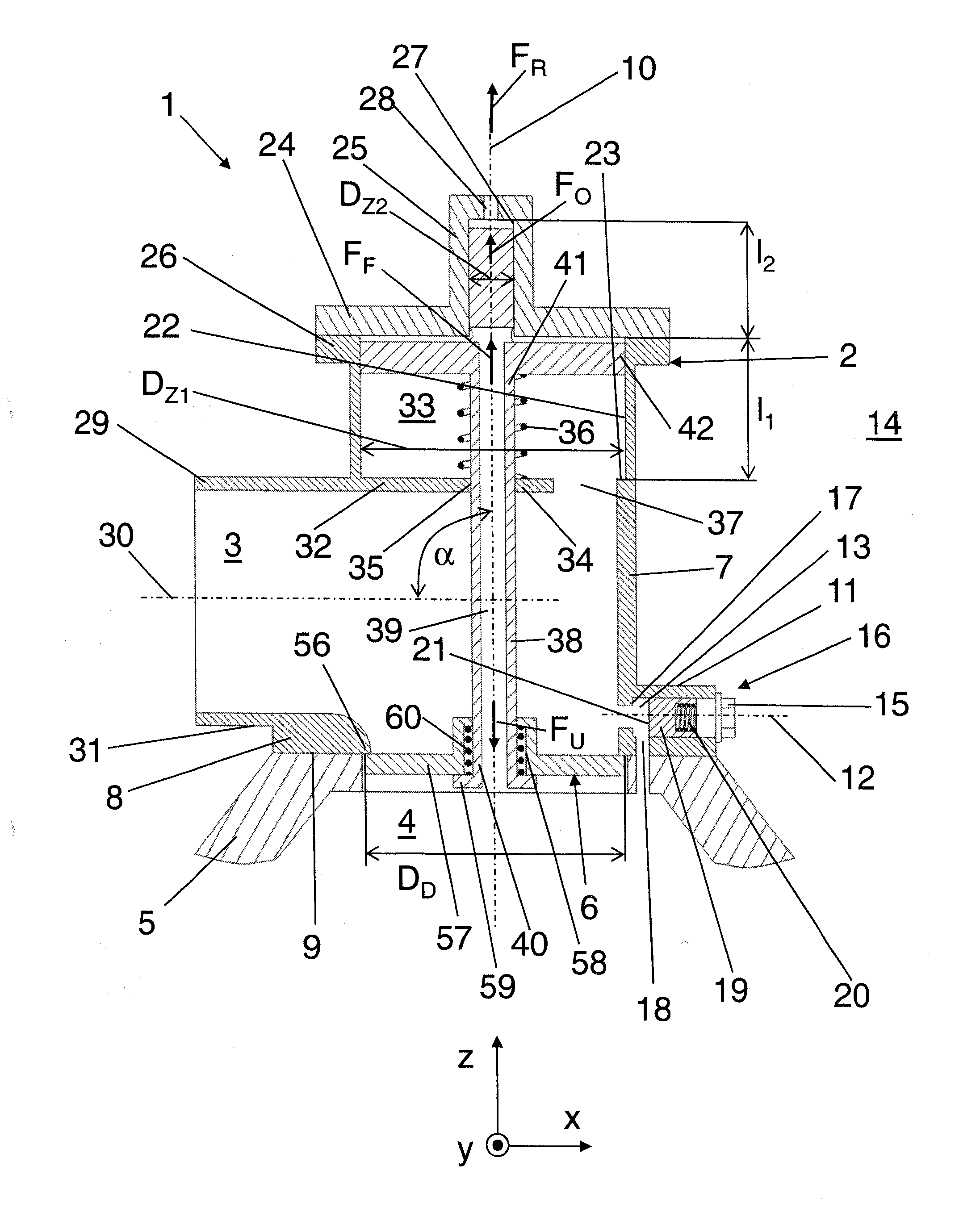

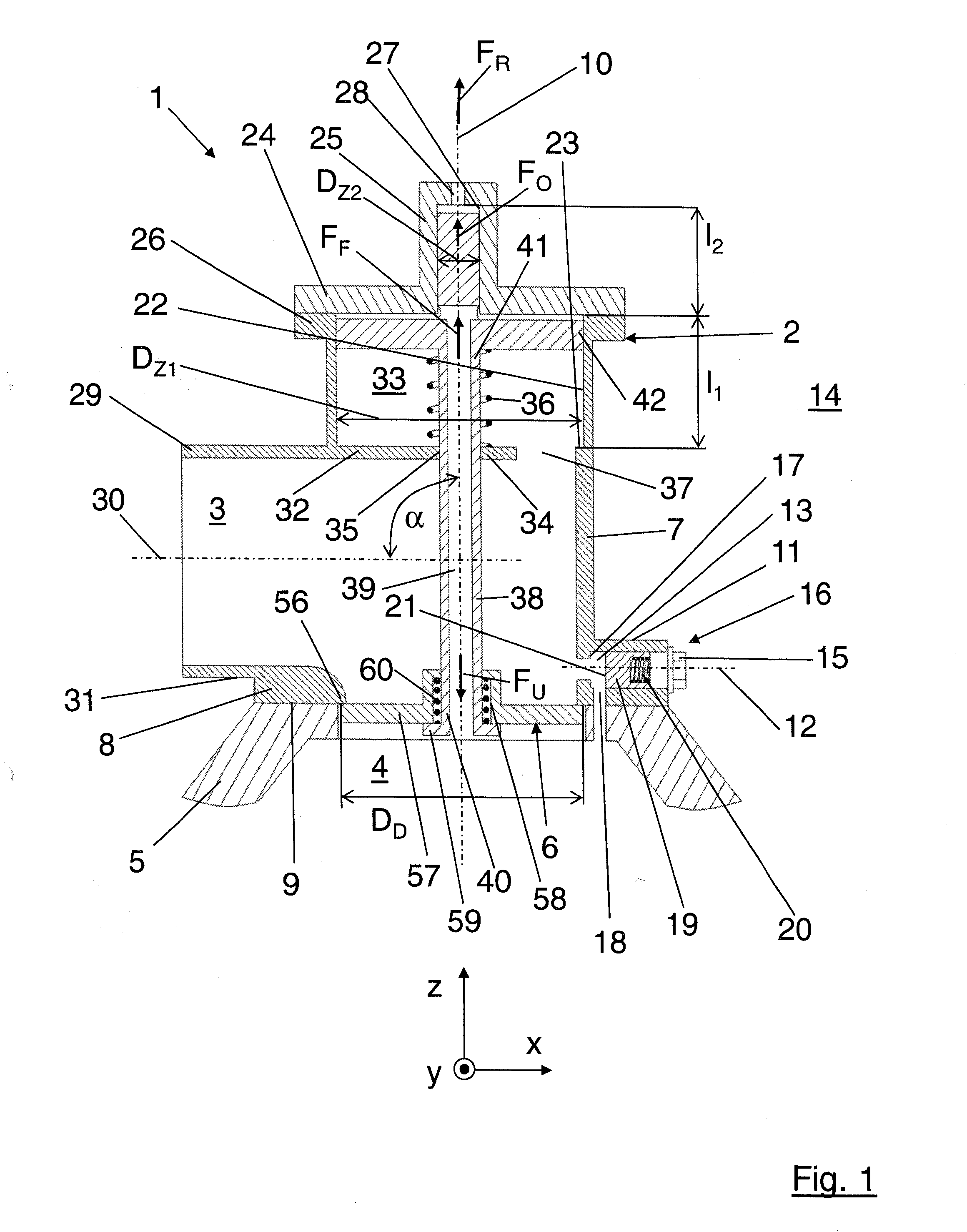

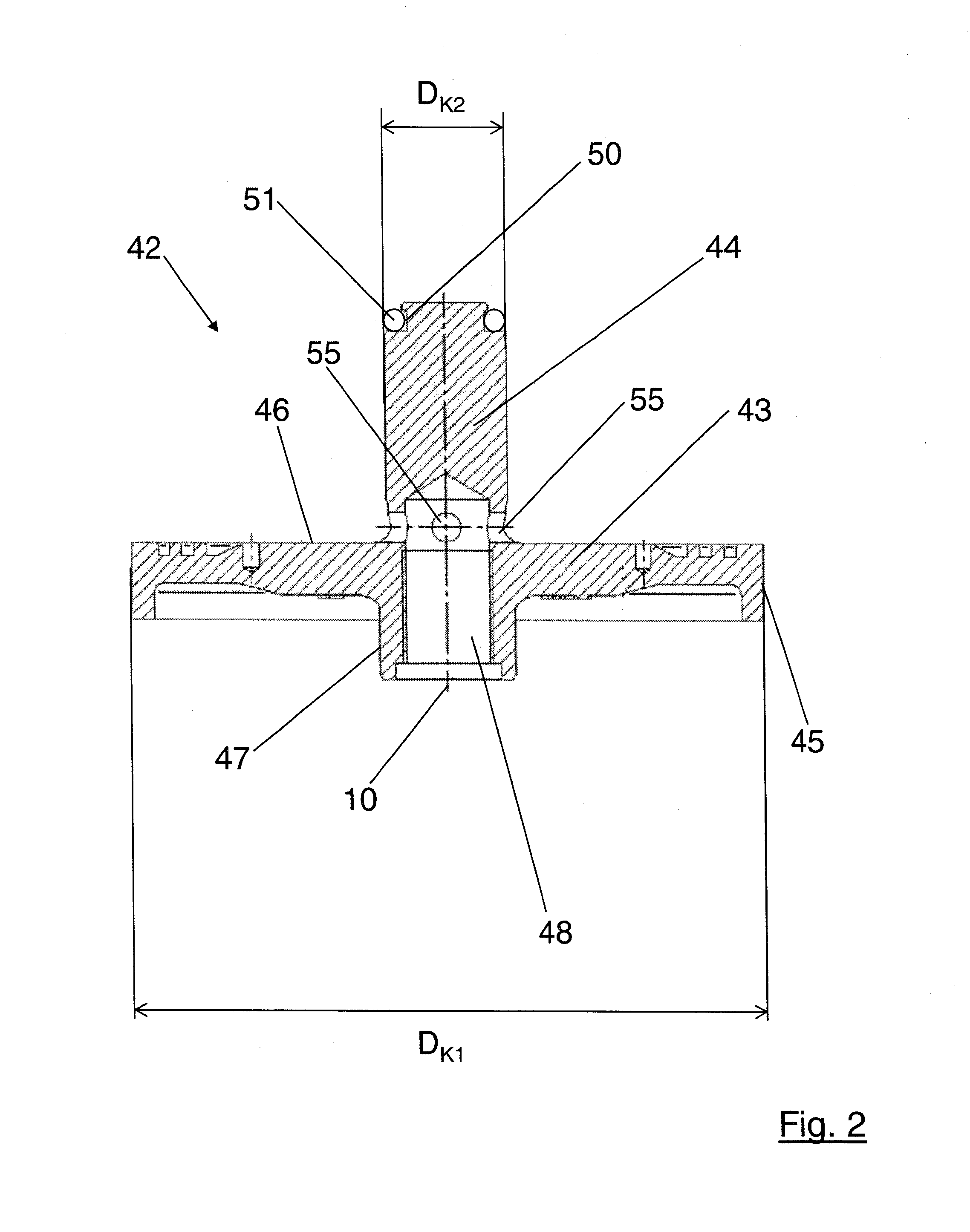

Gas Inlet Valve for a Compressor, Compressor Comprising a Gas Inlet Valve of This Type and Method for Operating a Compressor Comprising a Gas Inlet Valve of This Type

ActiveUS20130136638A1Reliably flowExtended service lifeOscillating piston enginesCheck valvesInlet valveEngineering

A gas inlet valve (1) for a compressor (64), comprising: a housing (2); a valve device (6) arranged between a gas inlet portion (3) and a gas outlet portion (4), a valve body (57) resting against a valve seat (56) in a sealing manner when the valve device (6) is in a closed operating state, and the valve body (57) being lifted from the valve seat (56) when the valve device (6) is in an open operating state; a piston device (42) which comprises a first piston portion (43) and a second piston portion (44) which is different from the first piston portion (43), the first piston portion (43) being displaceably guided in a first cylinder portion (22) of the housing (2) and the second piston portion (44) being displaceably guided in a second cylinder portion (27) of the housing (2) which is different from the first cylinder portion (22); and a piston rod (38) which is displaceably mounted in the housing (2) and mechanically couples the valve body (57) of the valve device (6) to the piston rod (38), a fluid line (39) putting a first cylinder chamber (49) of the first cylinder portion (22) in operative fluid communication with the gas outlet portion (4), it being possible to apply a control pressure to a second cylinder chamber (52) of the second cylinder portion (27) in order to lift the valve body (57) from the valve seat (56). A rotary compressor comprising a gas inlet valve (1) of this type and a method for operating a compressor (64), in particular a rotary compressor, comprising a gas inlet valve (1) of this type.

Owner:KAESER KOMPRESSOREN SE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com