Patents

Literature

3352results about "Reversed direction vortex" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

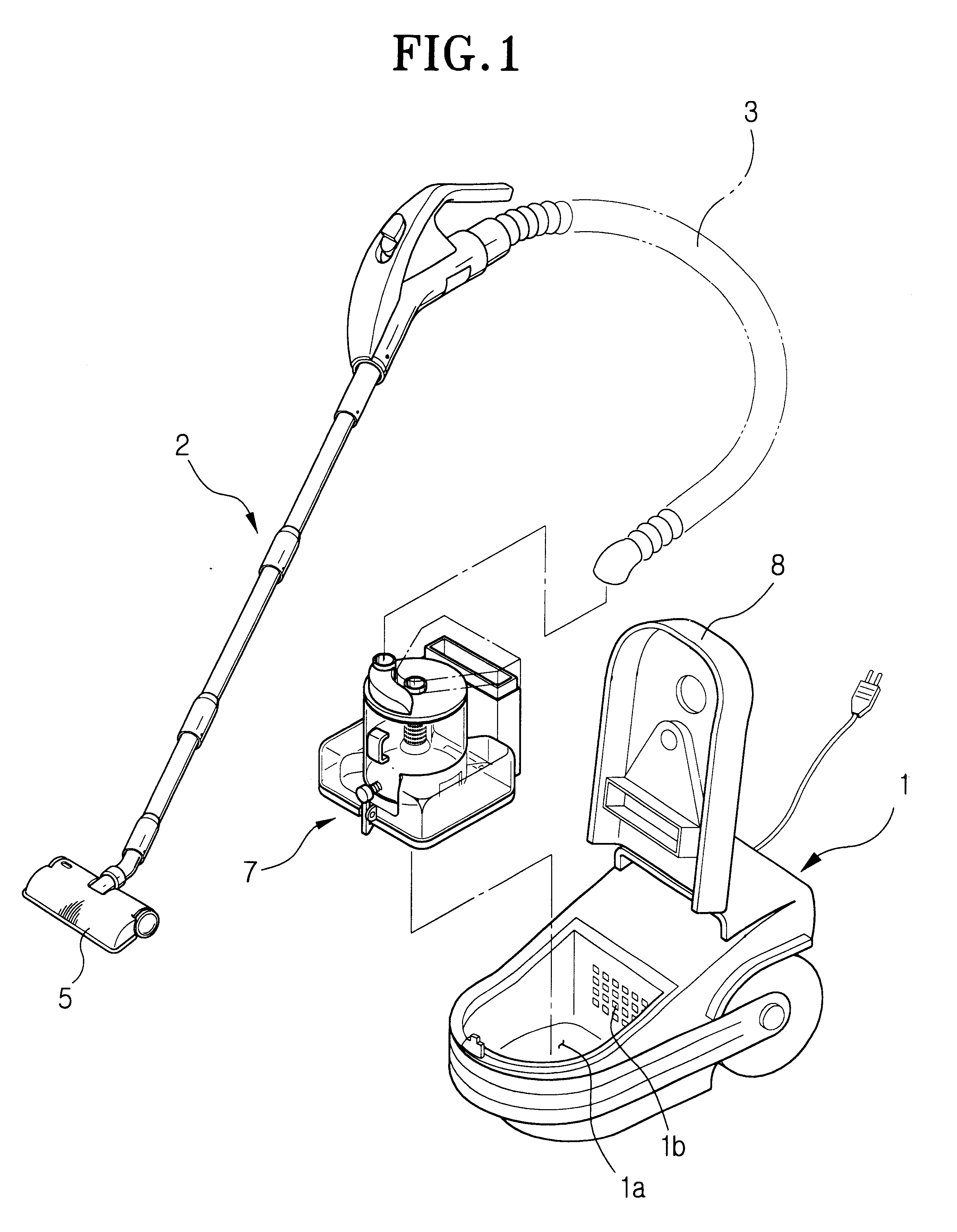

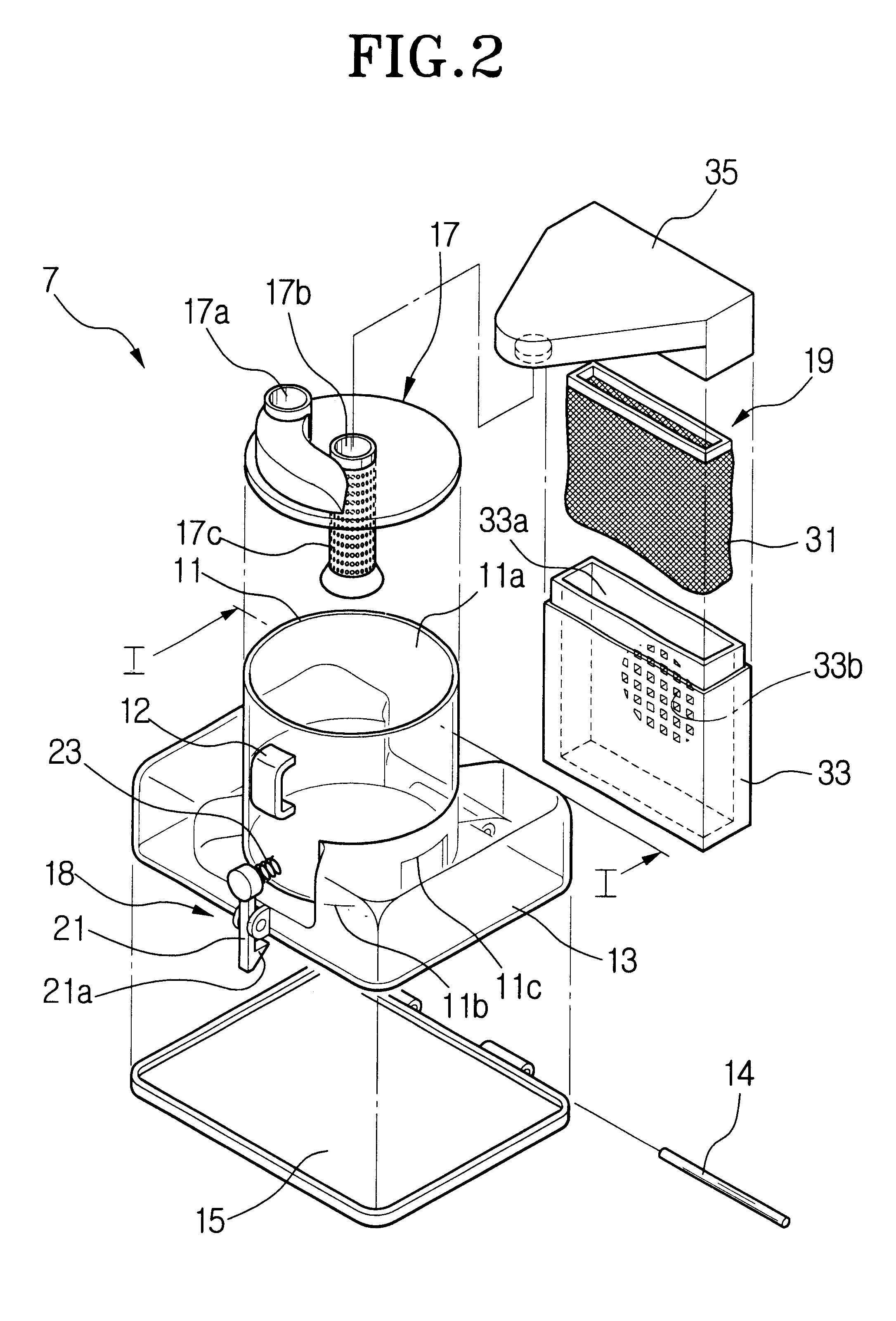

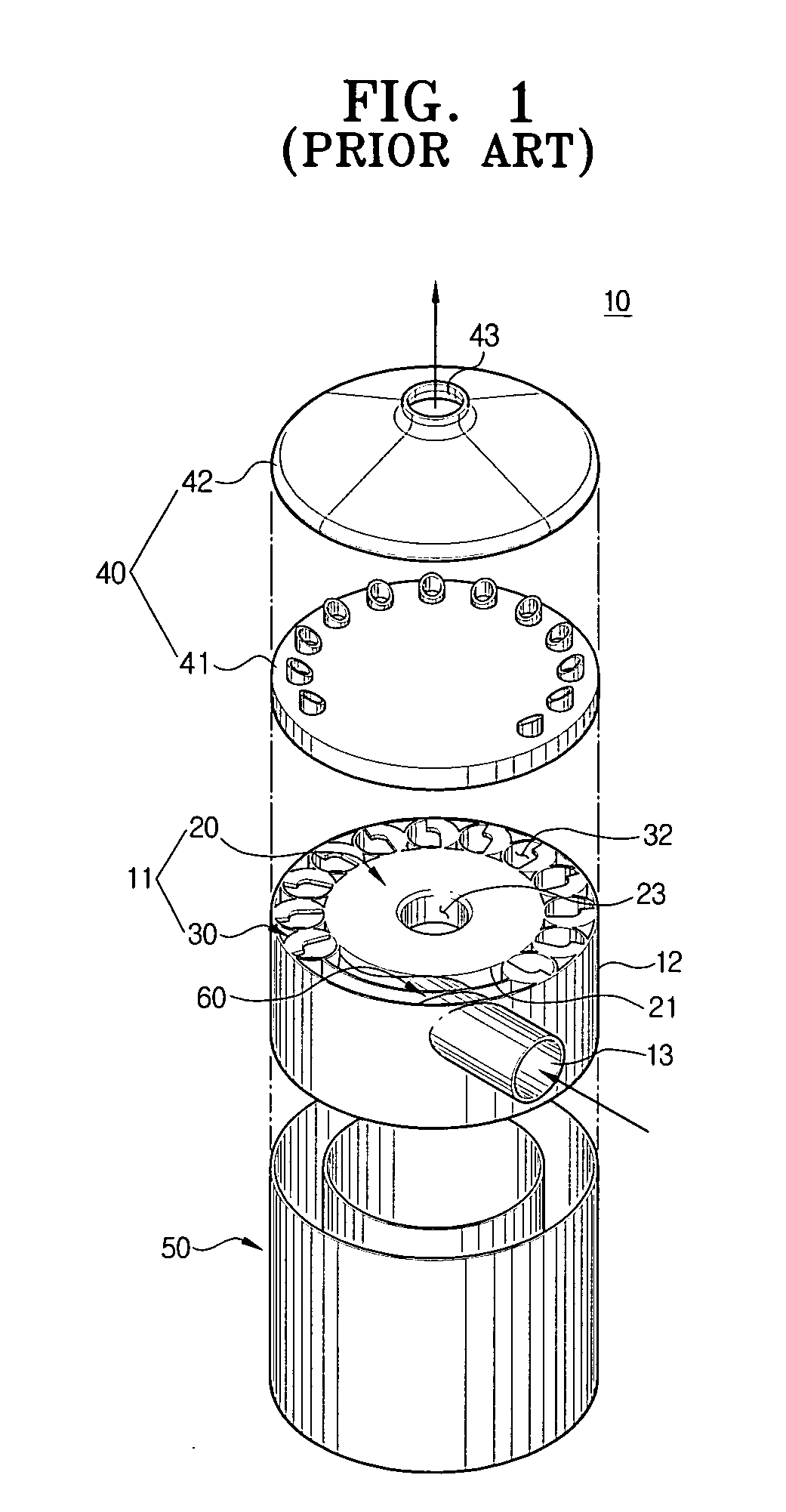

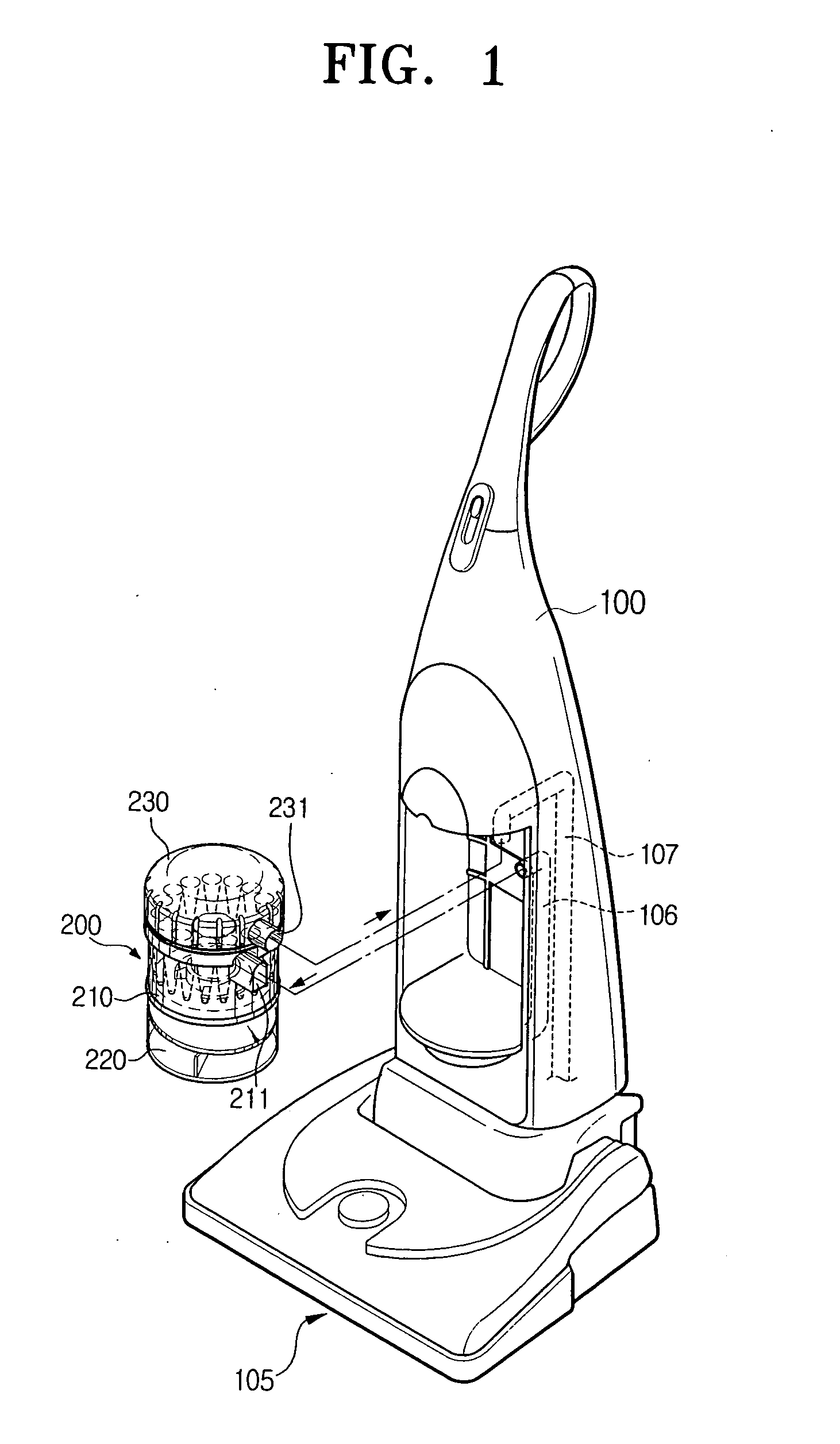

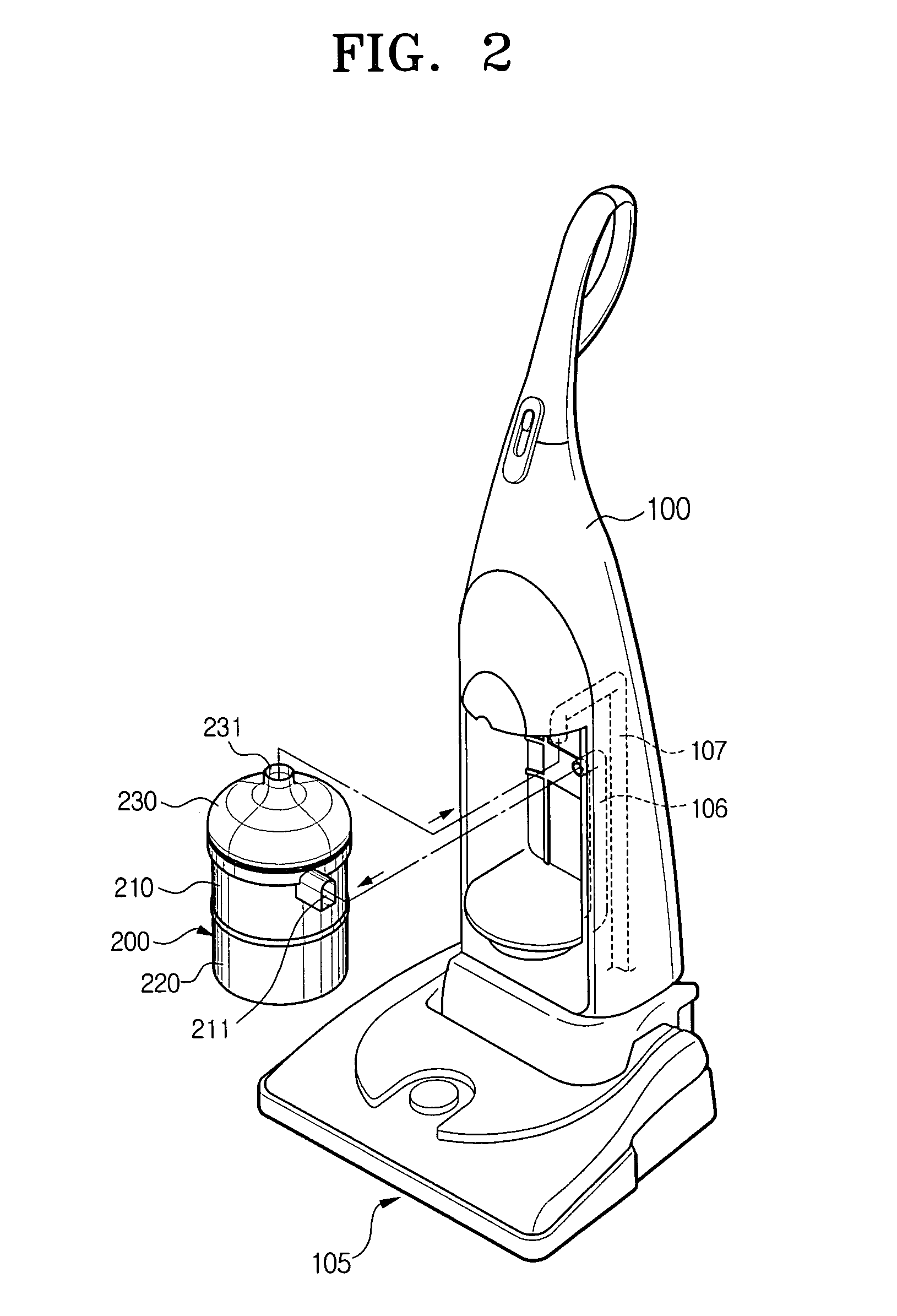

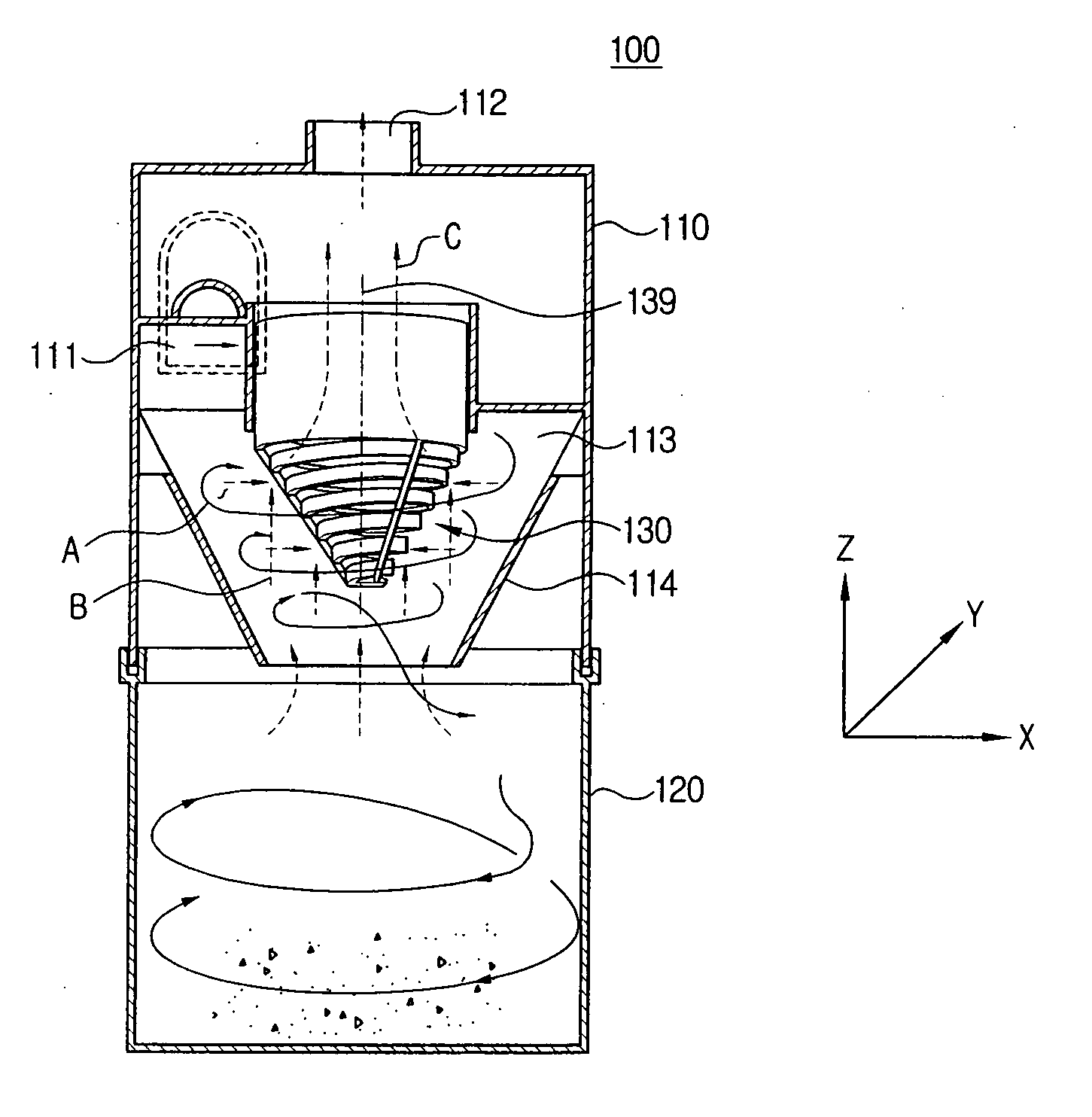

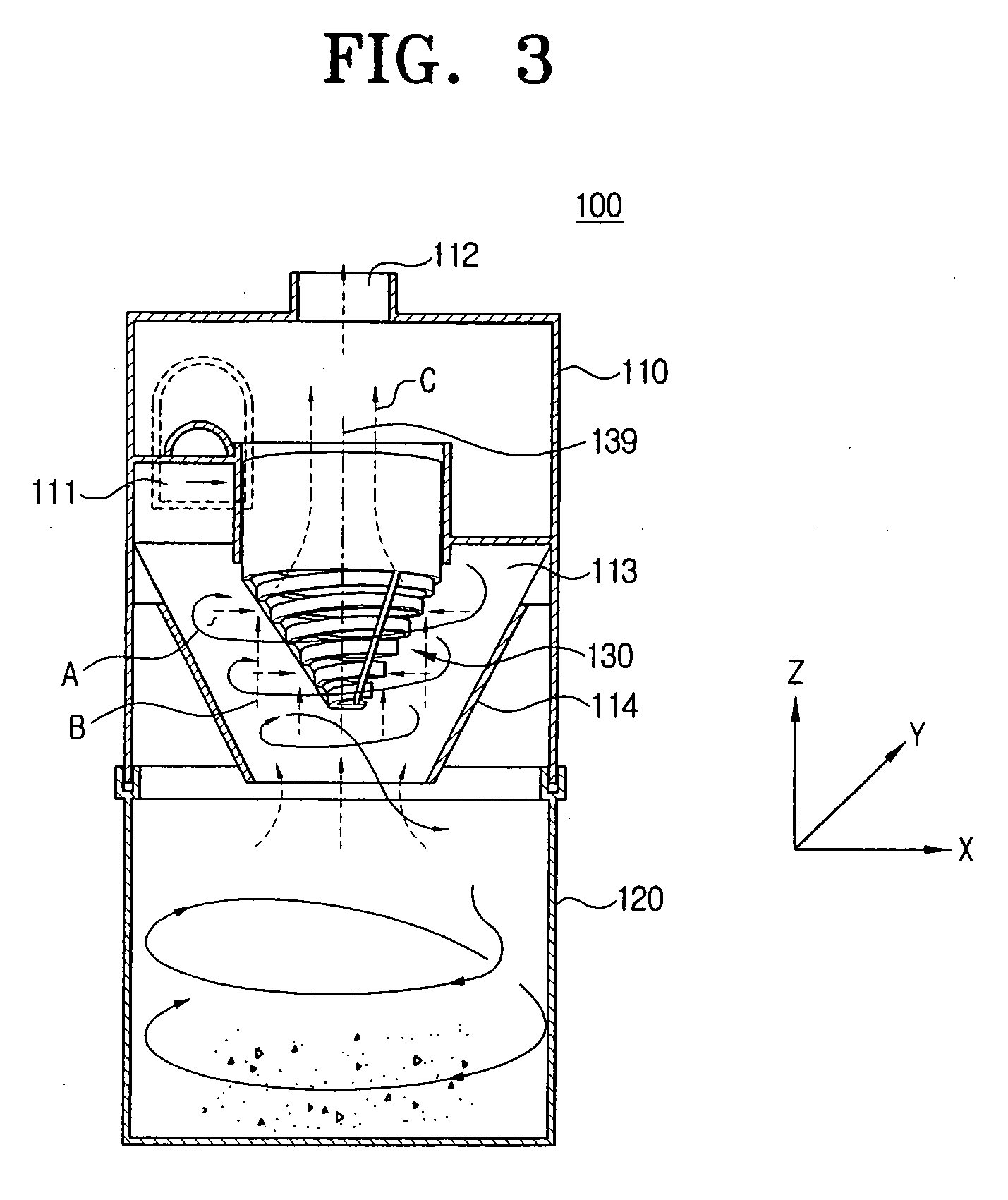

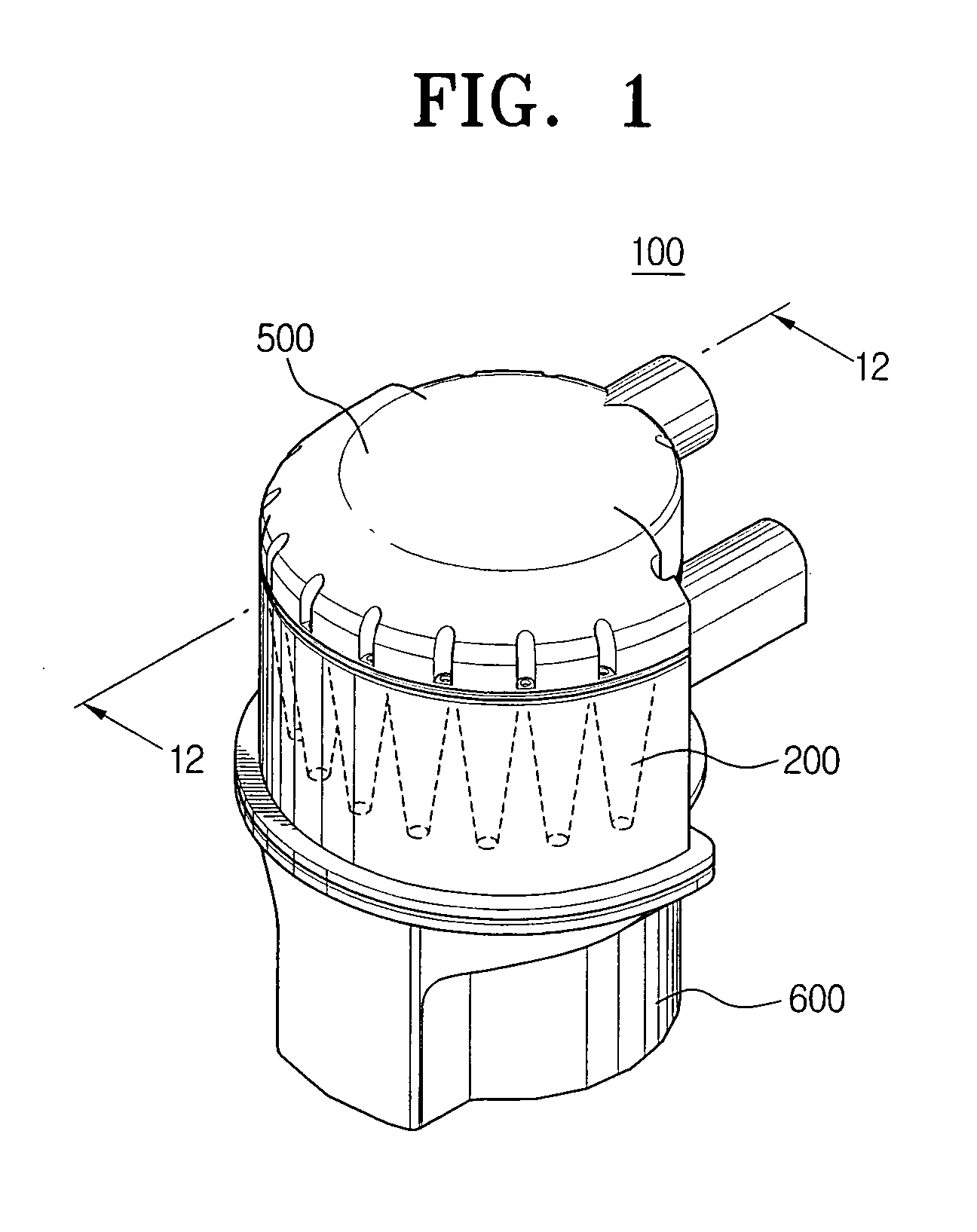

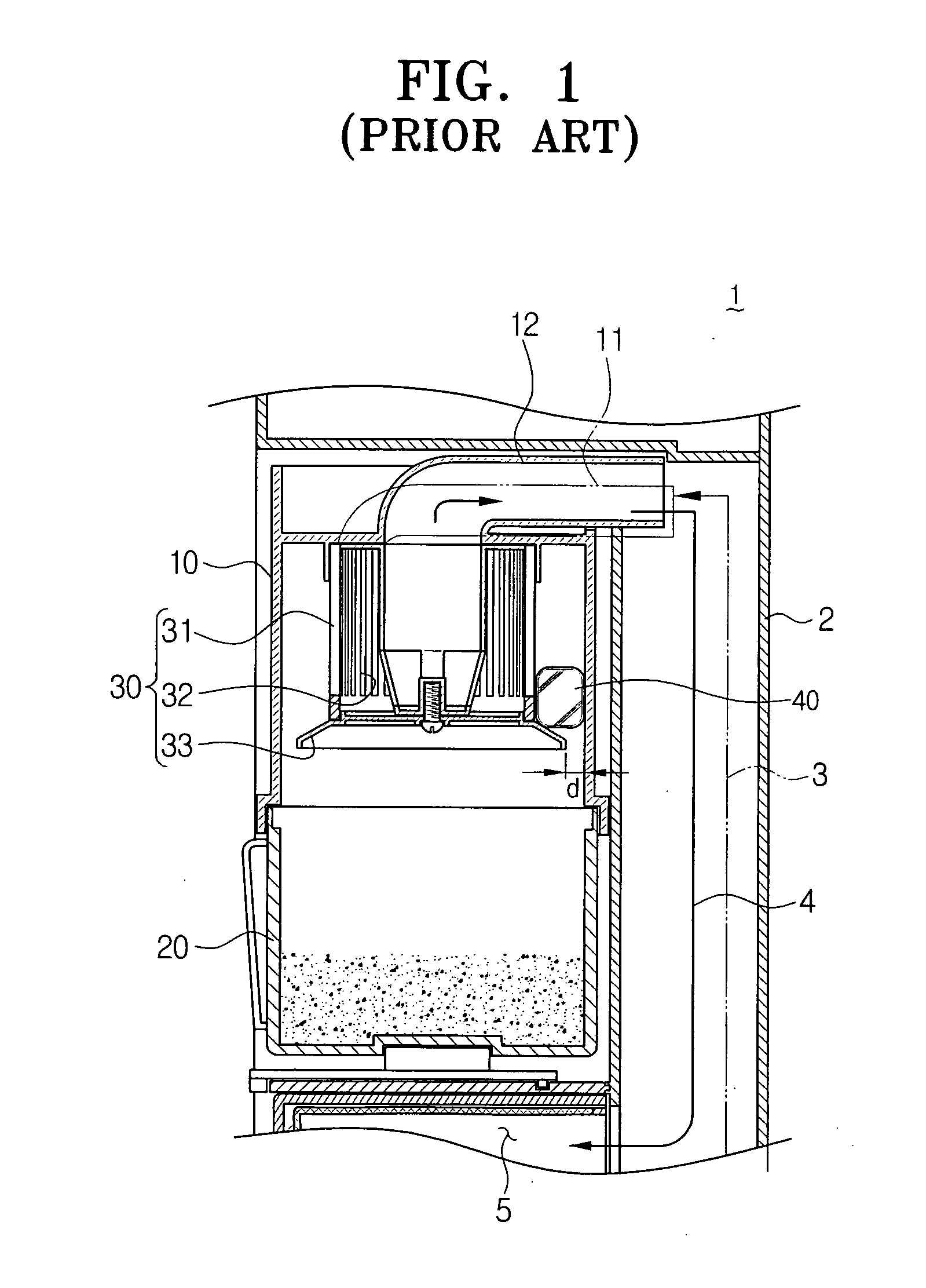

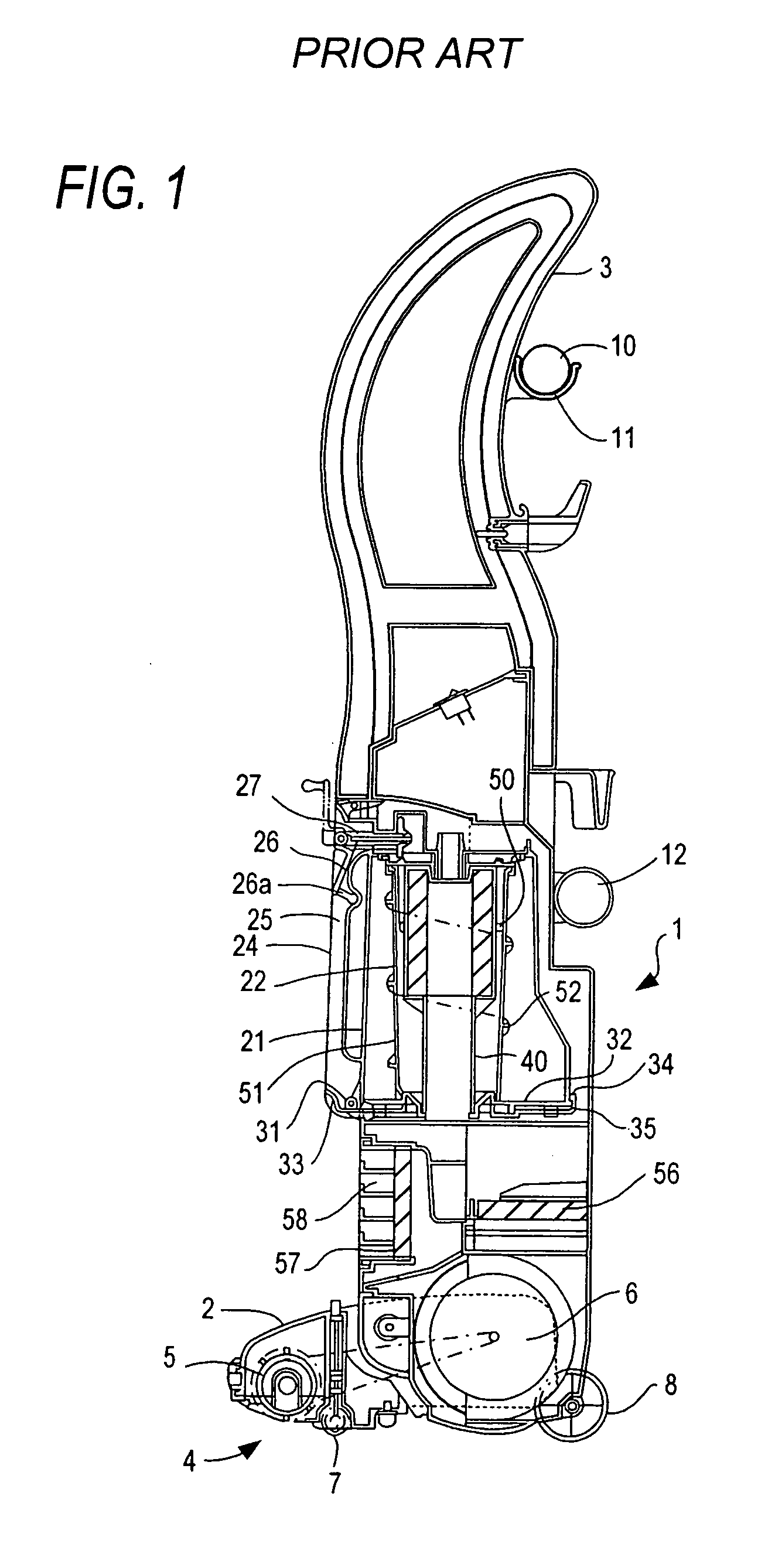

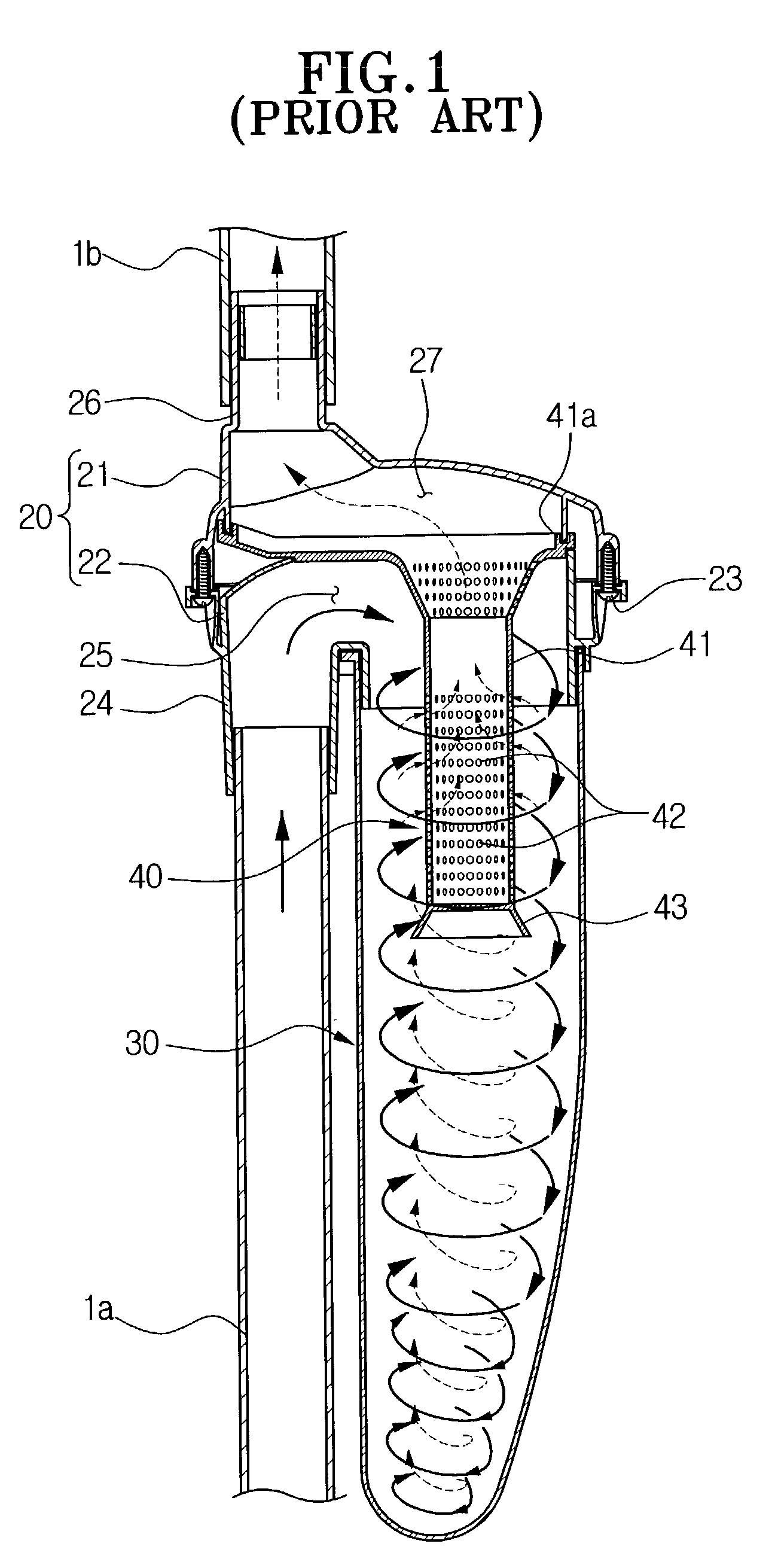

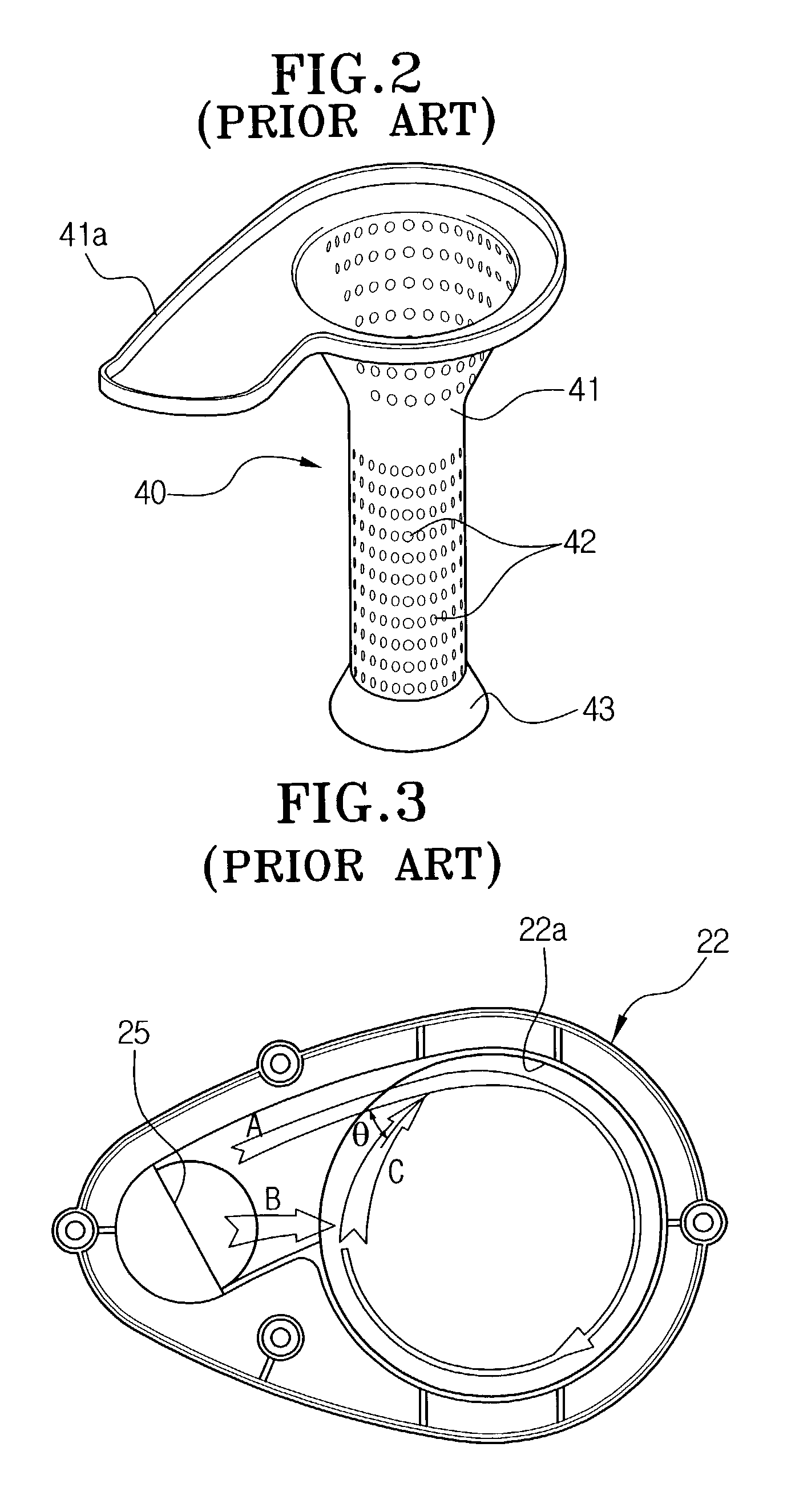

Vacuum cleaner having a cyclone type dust collecting apparatus

A vacuum cleaner includes a cleaner body, a suction brush, through which air and contaminants are drawn in, and a cyclone type dust collecting device. The cleaner body has a motor driving chamber and a dust collecting chamber in communication with the motor driving chamber. The cyclone type dust collecting device is mounted in the dust collecting chamber and separates by centrifugal force the contaminants from the air. The cyclone type dust collecting device includes a hollow cylindrical cyclone body having an open top, a closed bottom, and a contaminant outlet. The open top allows air and contaminants into the cyclone body, where the contaminants are separated from the air by centrifugation. The contaminants are then discharged from the cyclone body through the contaminant outlet. The cyclone type dust collecting device further includes a contaminant receptacle for collecting the contaminants discharged through the contaminant outlet, a base member hingedly connected to the contaminant receptacle, and a cover for covering the top of the cyclone body. The cover has an air inlet passage, through which air and contaminants drawn in through the suction brush enter into the cyclone body, an air outlet passage, through which the air is discharged from the cyclone body, and a contaminant separating grill. The grill extends downward from the air outlet passage into the cyclone body and has a plurality of fine holes.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

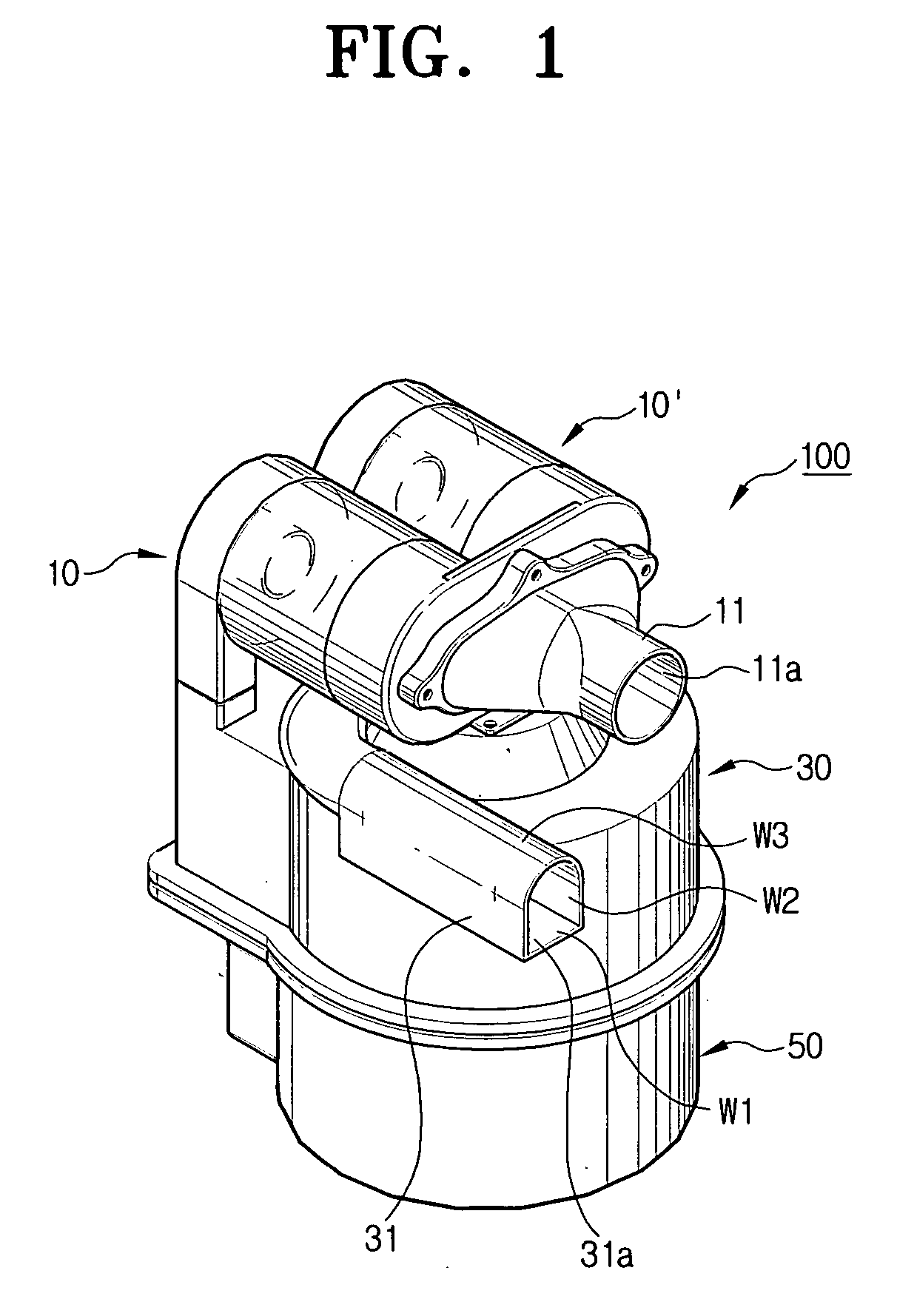

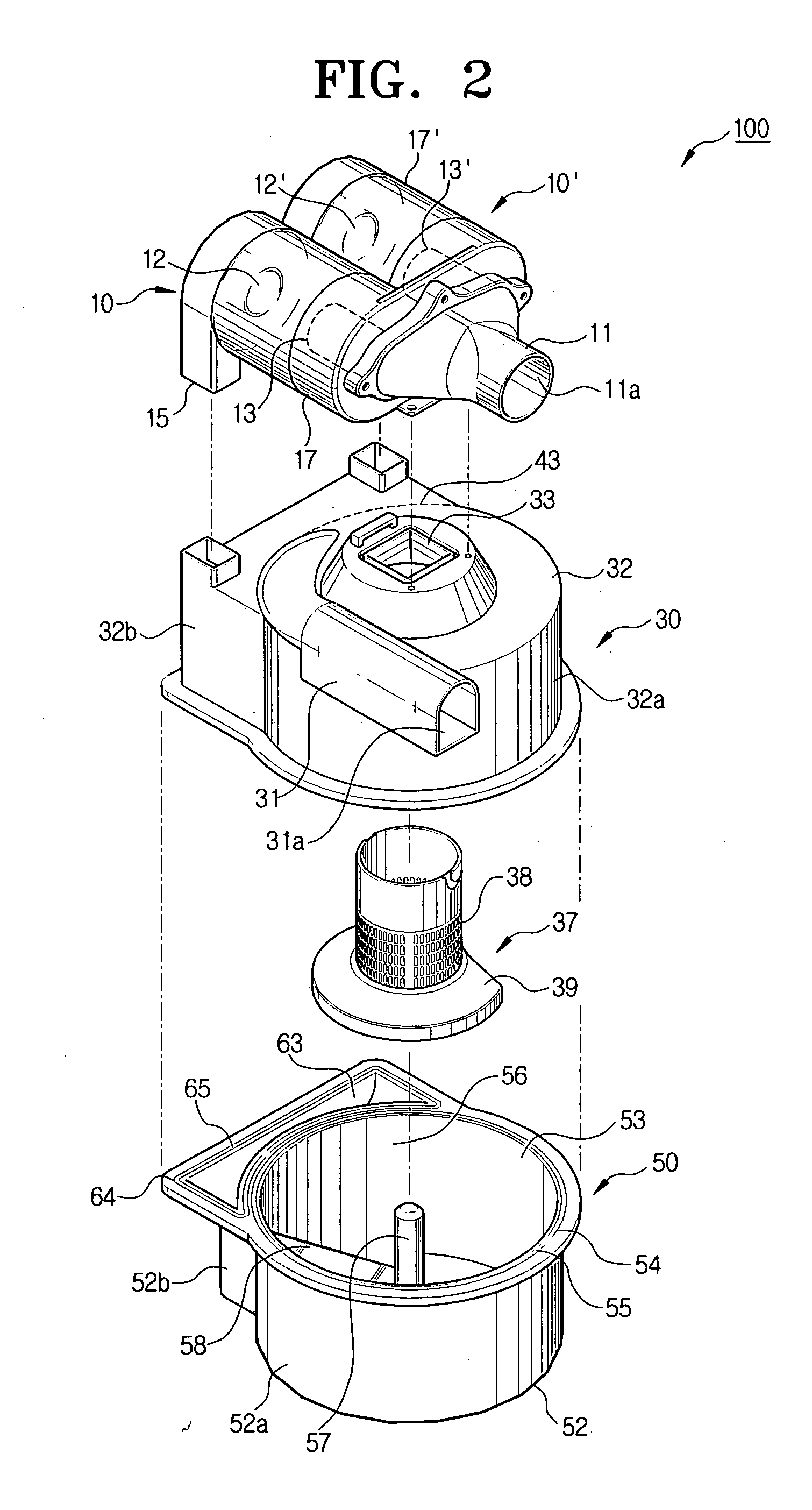

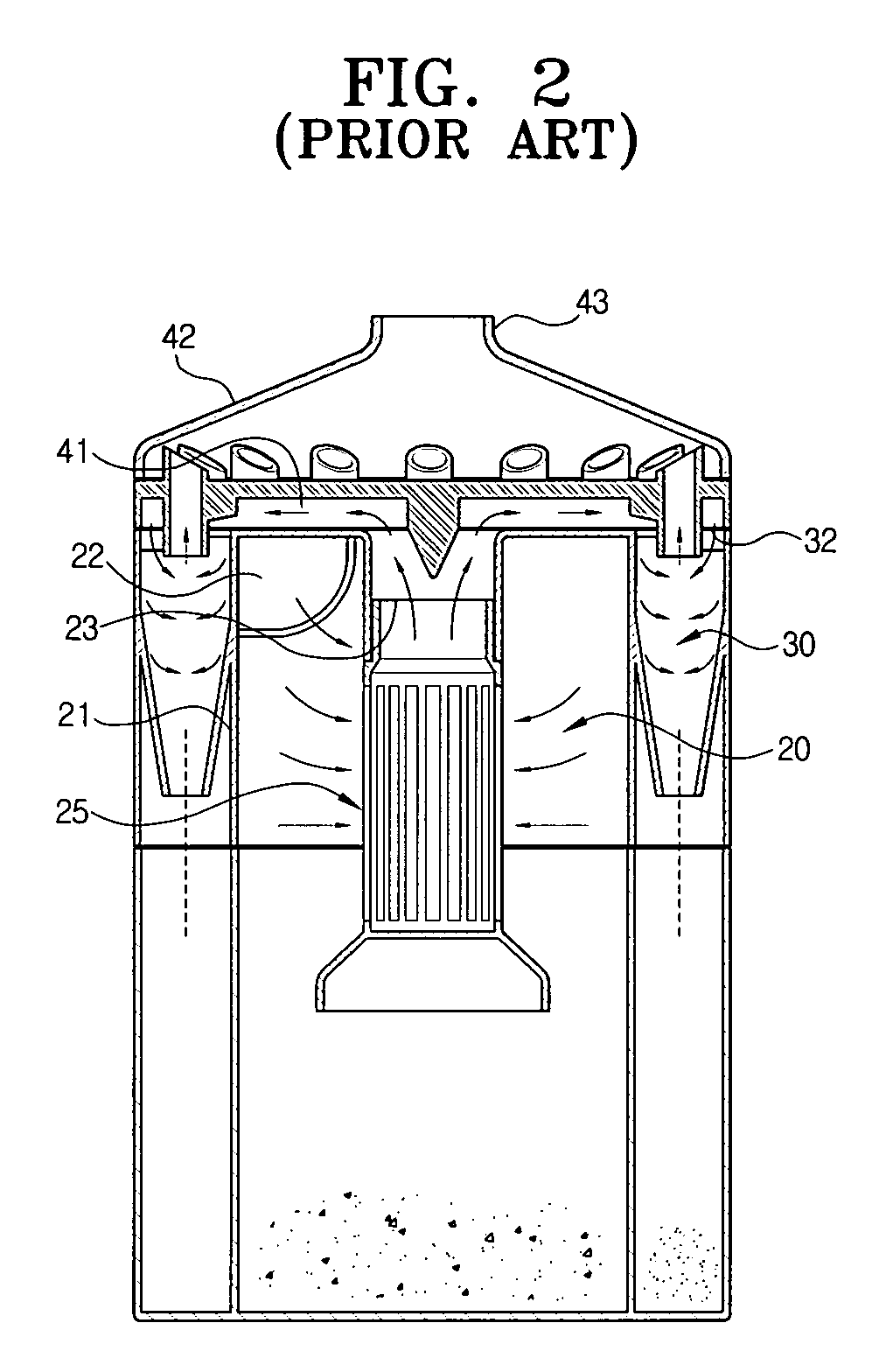

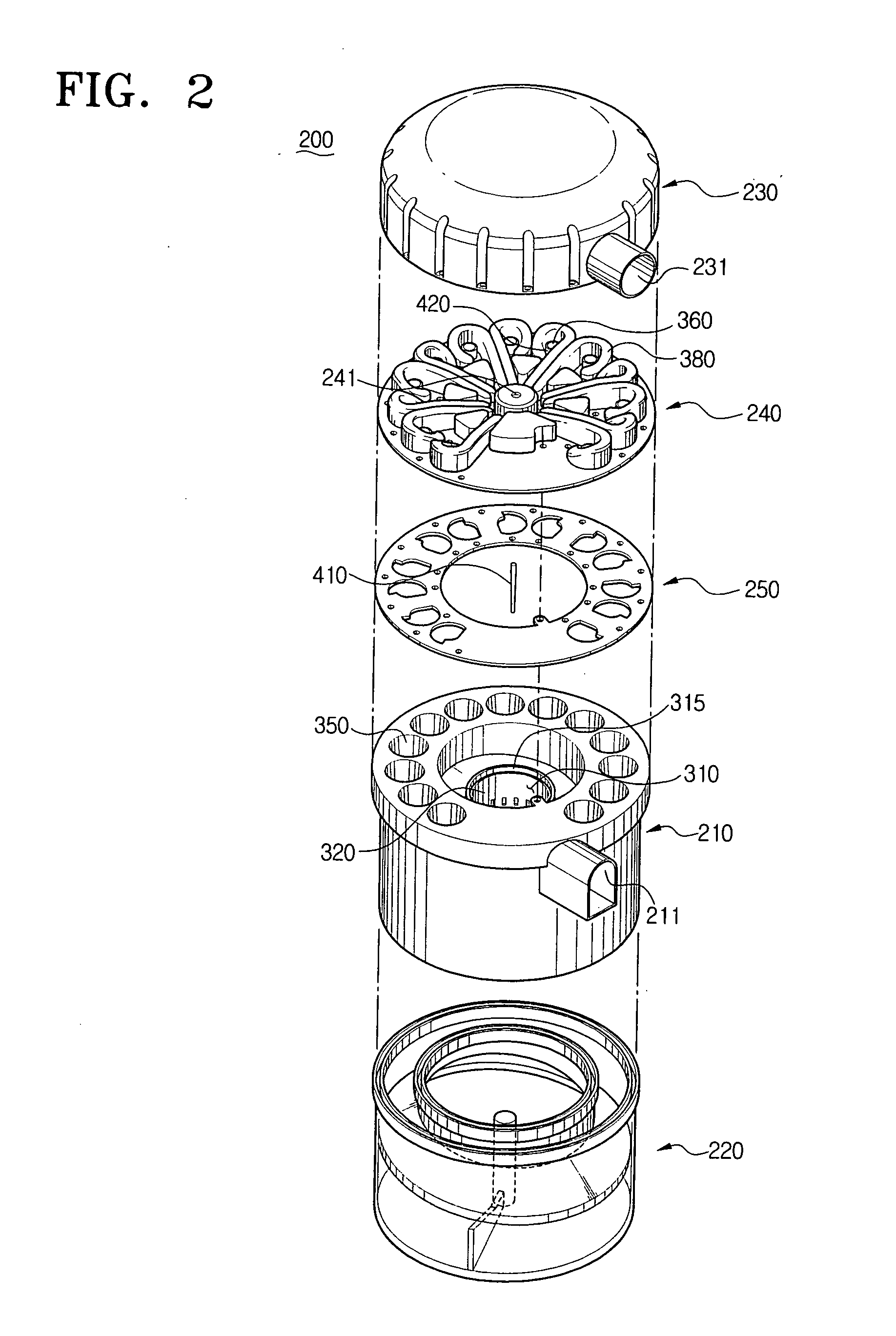

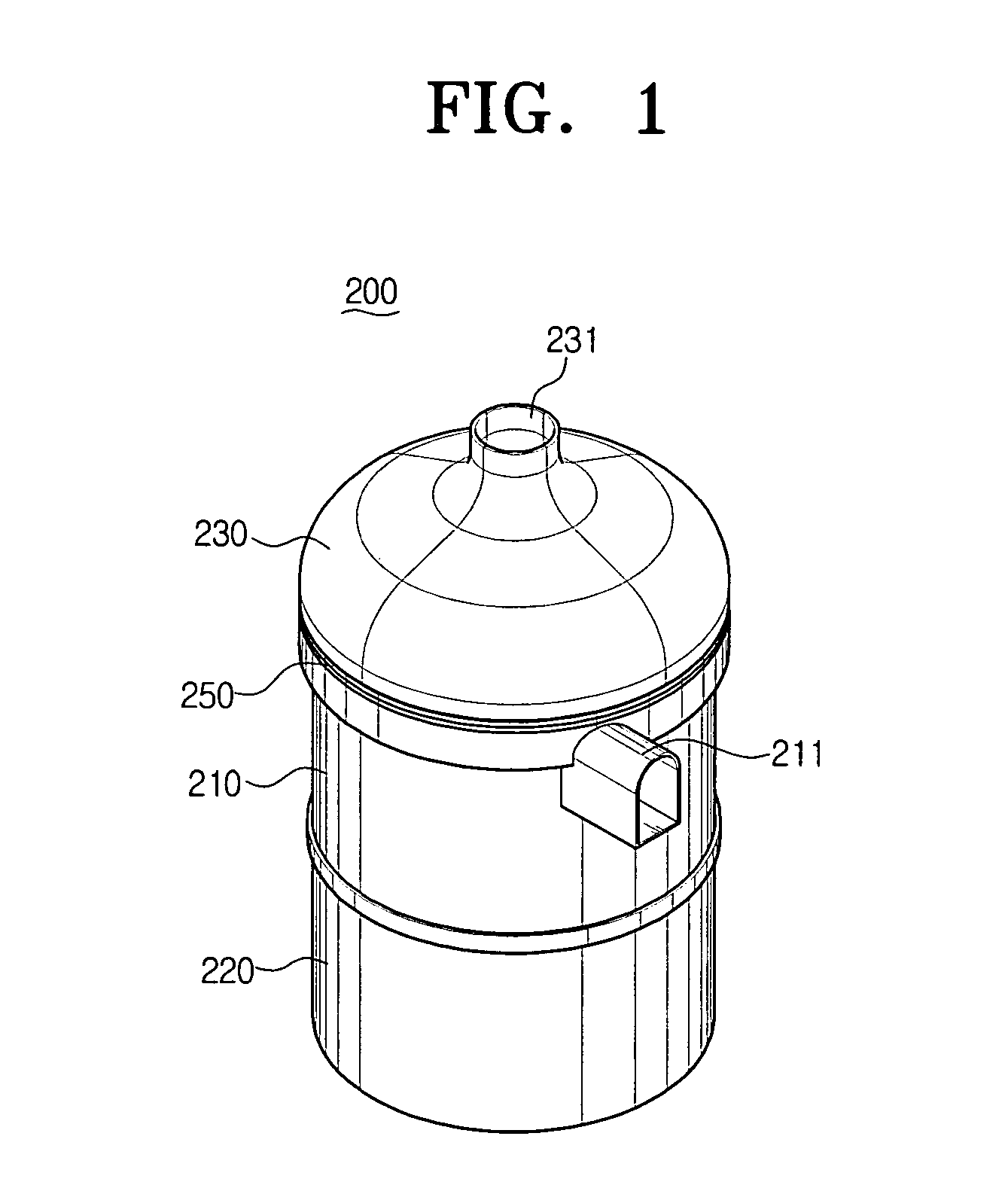

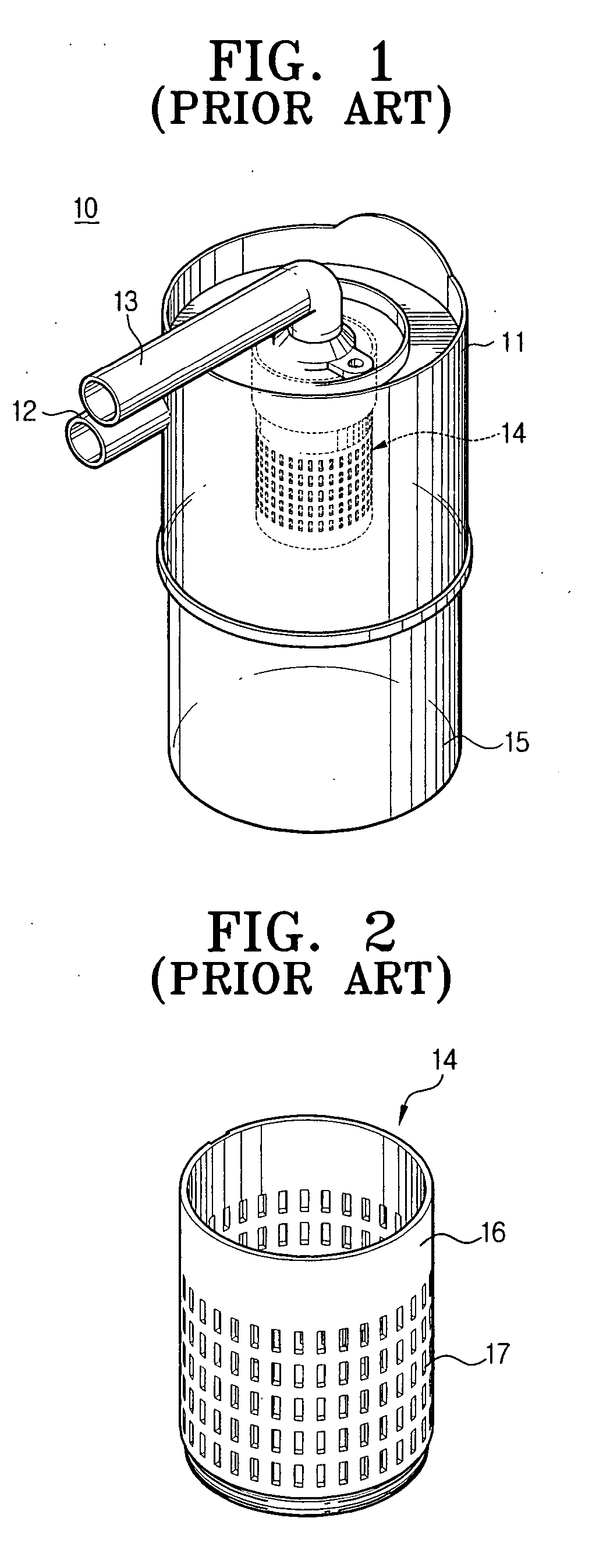

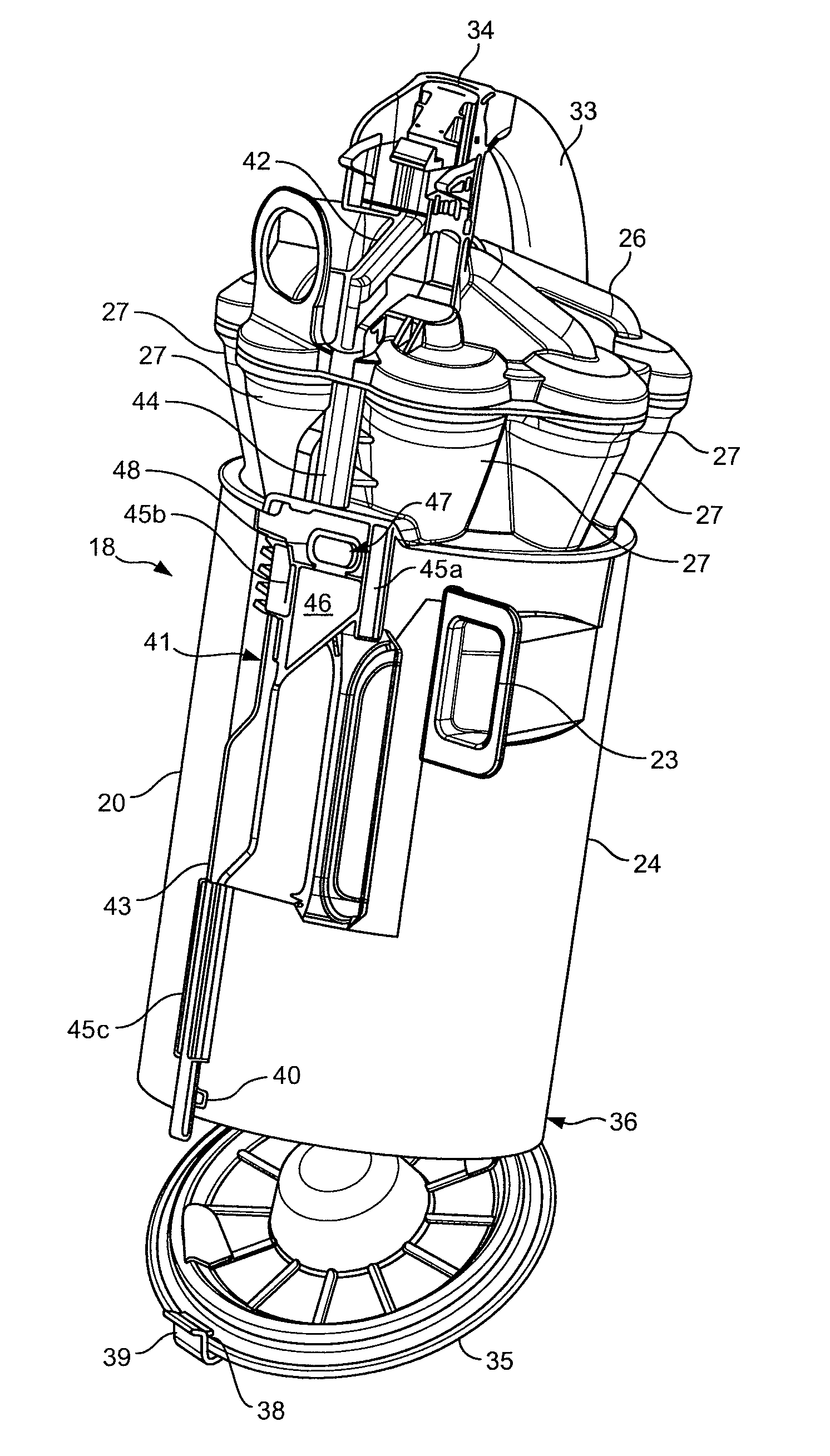

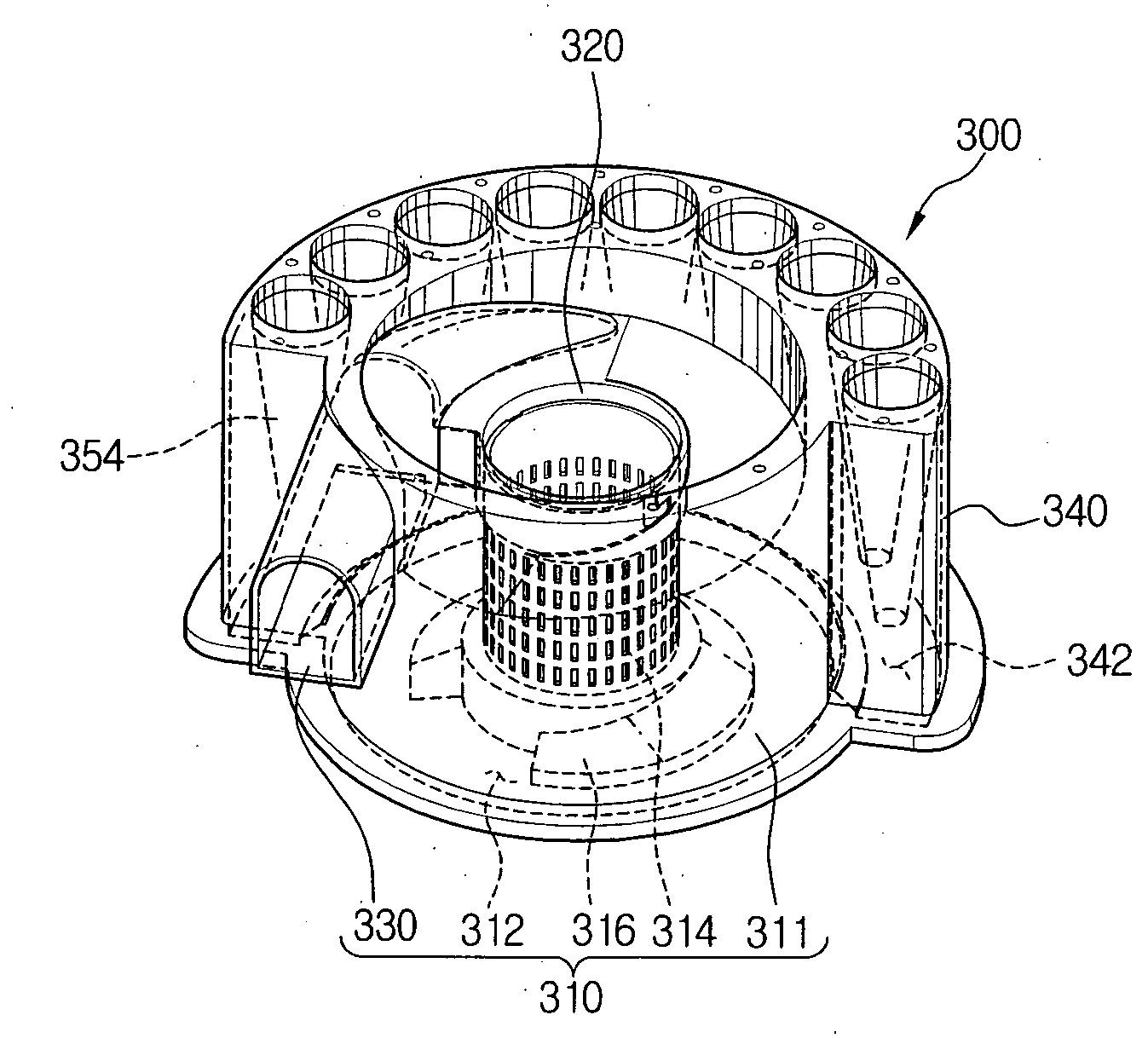

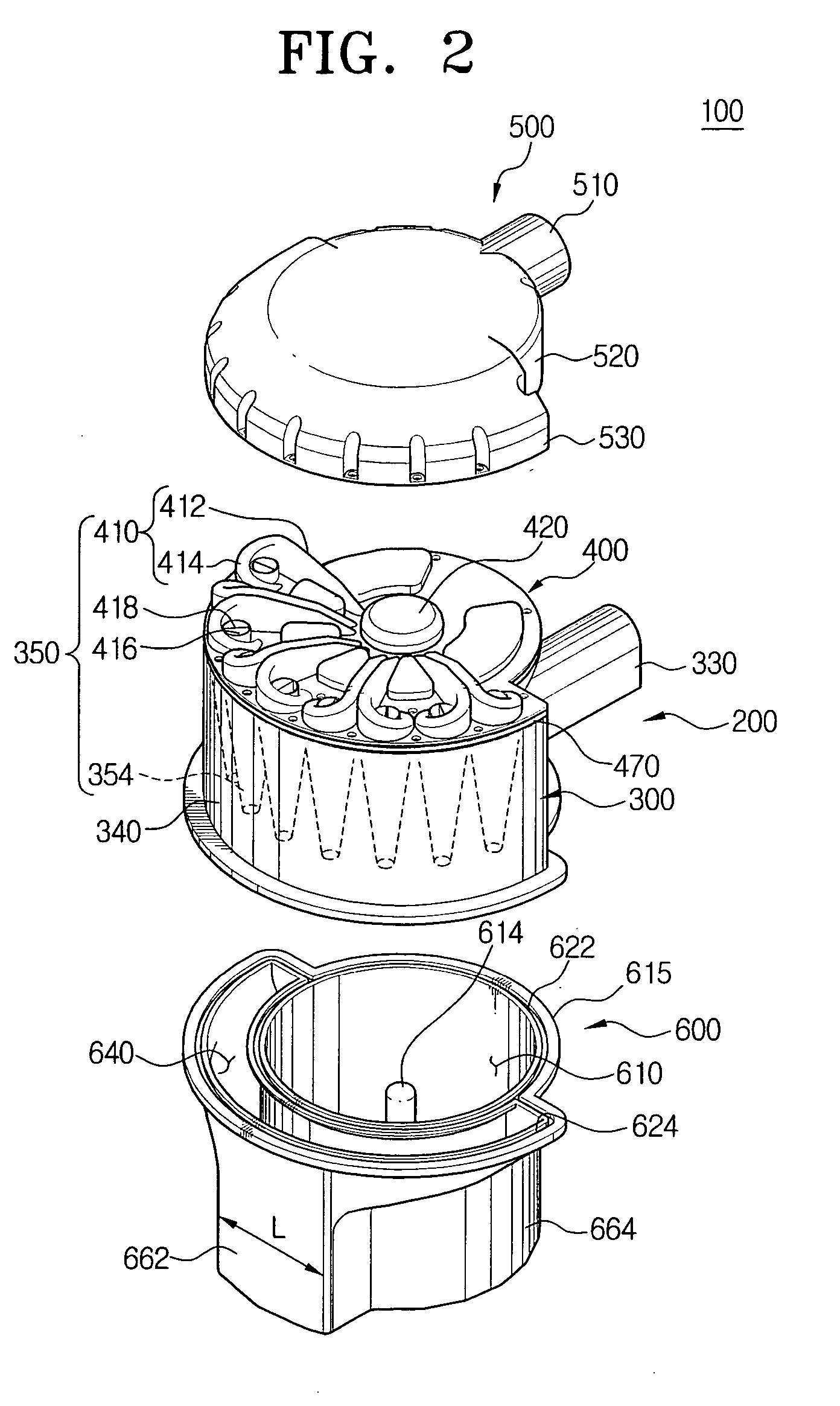

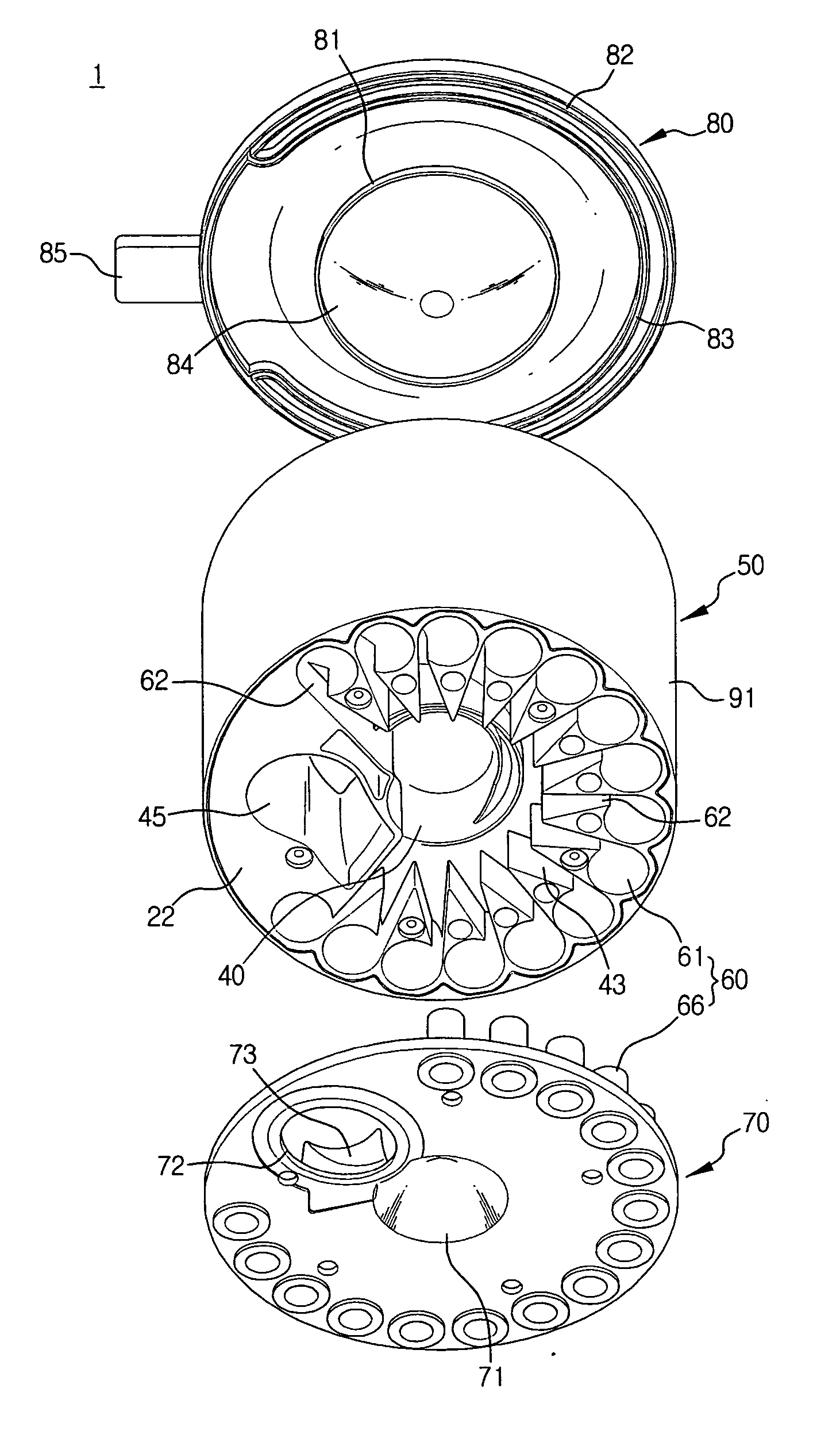

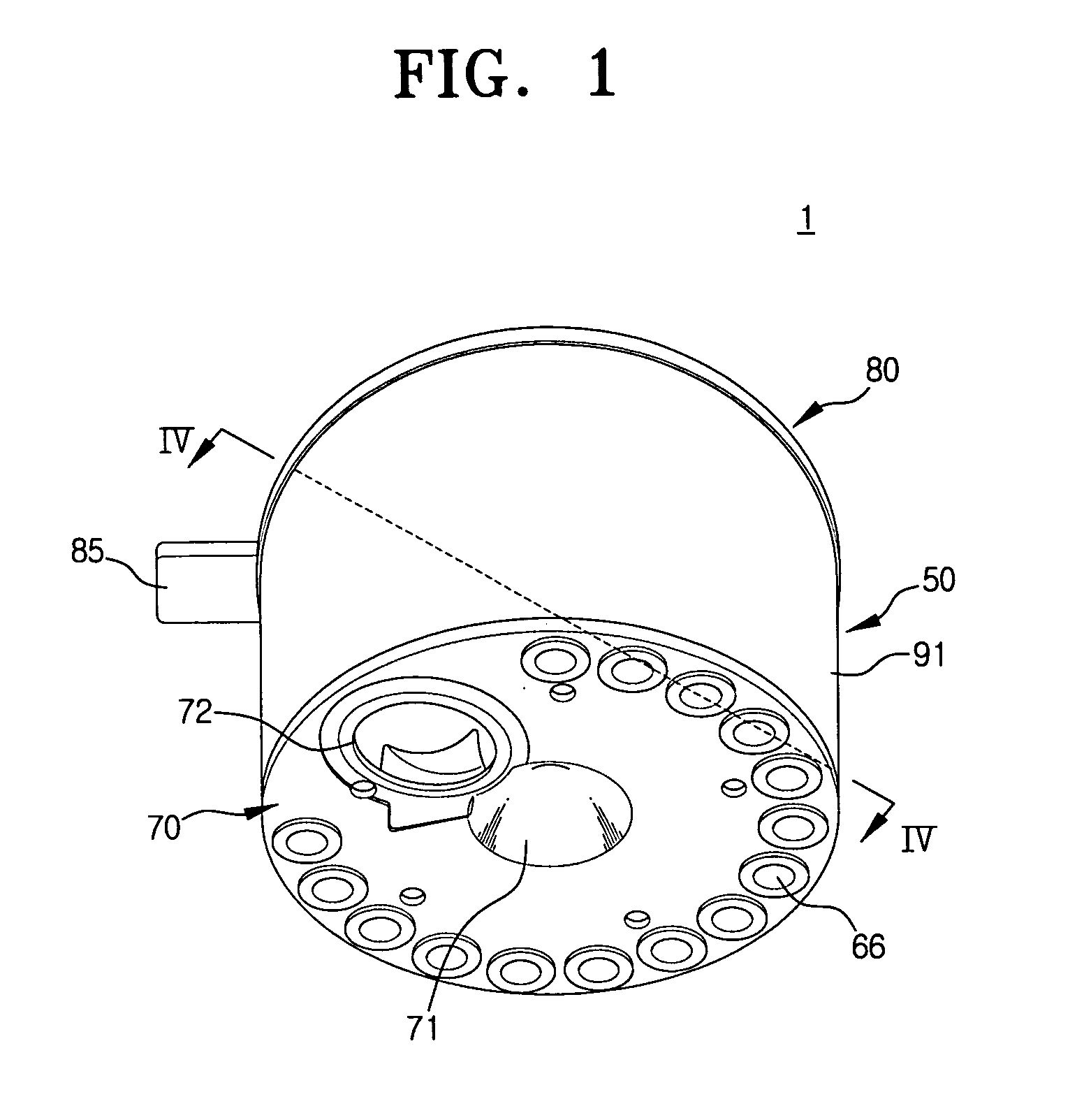

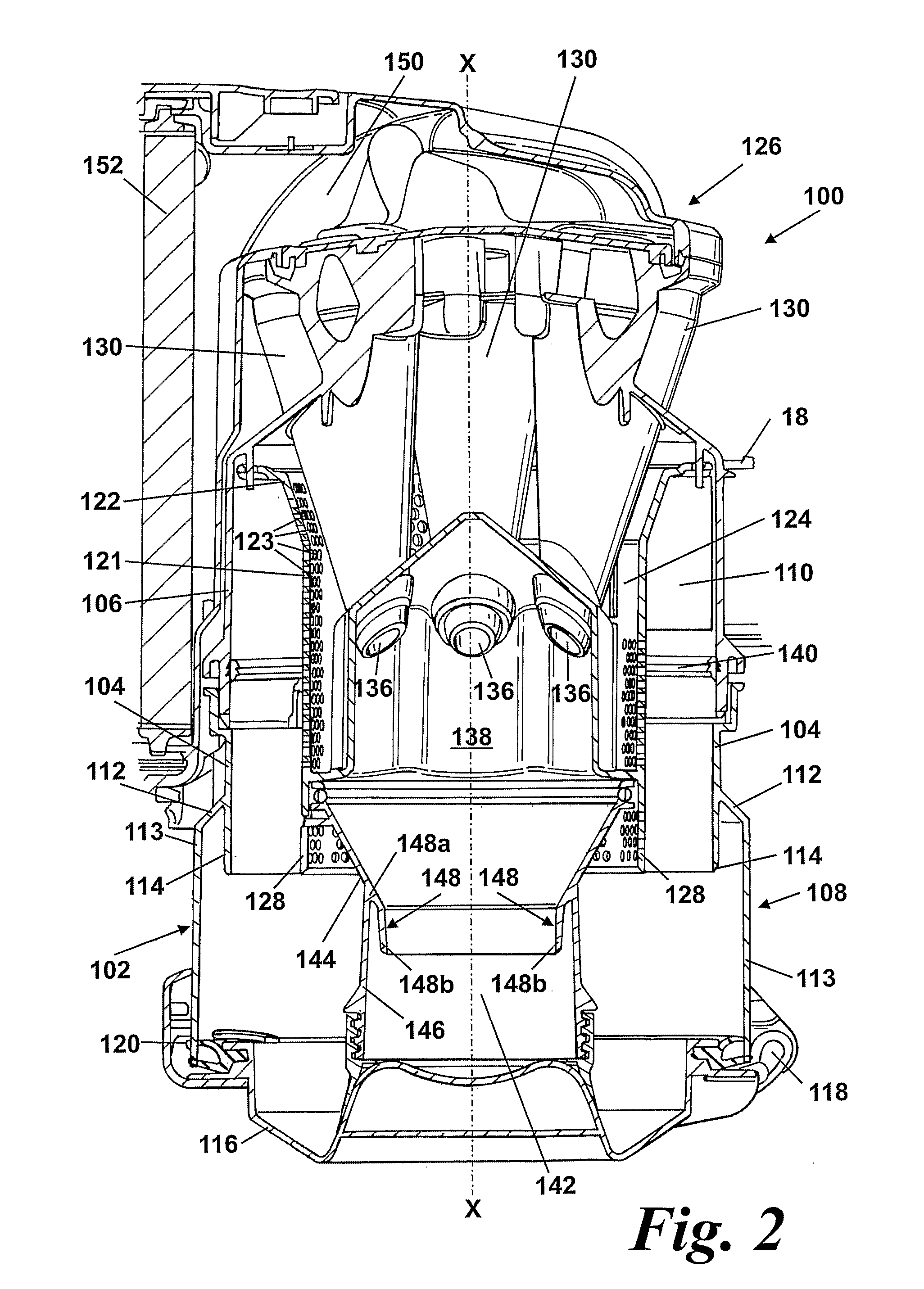

Multi cyclone vessel dust collecting apparatus for vacuum cleaner

A multi cyclone vessel dust collecting apparatus comprises a first cyclone vessel for centrifugally separating contaminants from drawn in air; a plurality of a second cyclone vessels configured on the first cyclone vessel; and a contaminant collecting unit attached to a bottom portion of the first cyclone vessel. Each of a plurality of the second cyclone vessels are parallel to each other. The center axis line of air rotation movement of the second cyclone vessel is substantially perpendicular to that of the first cyclone vessel. The contaminants collecting unit comprises a body which can be used as a handle.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

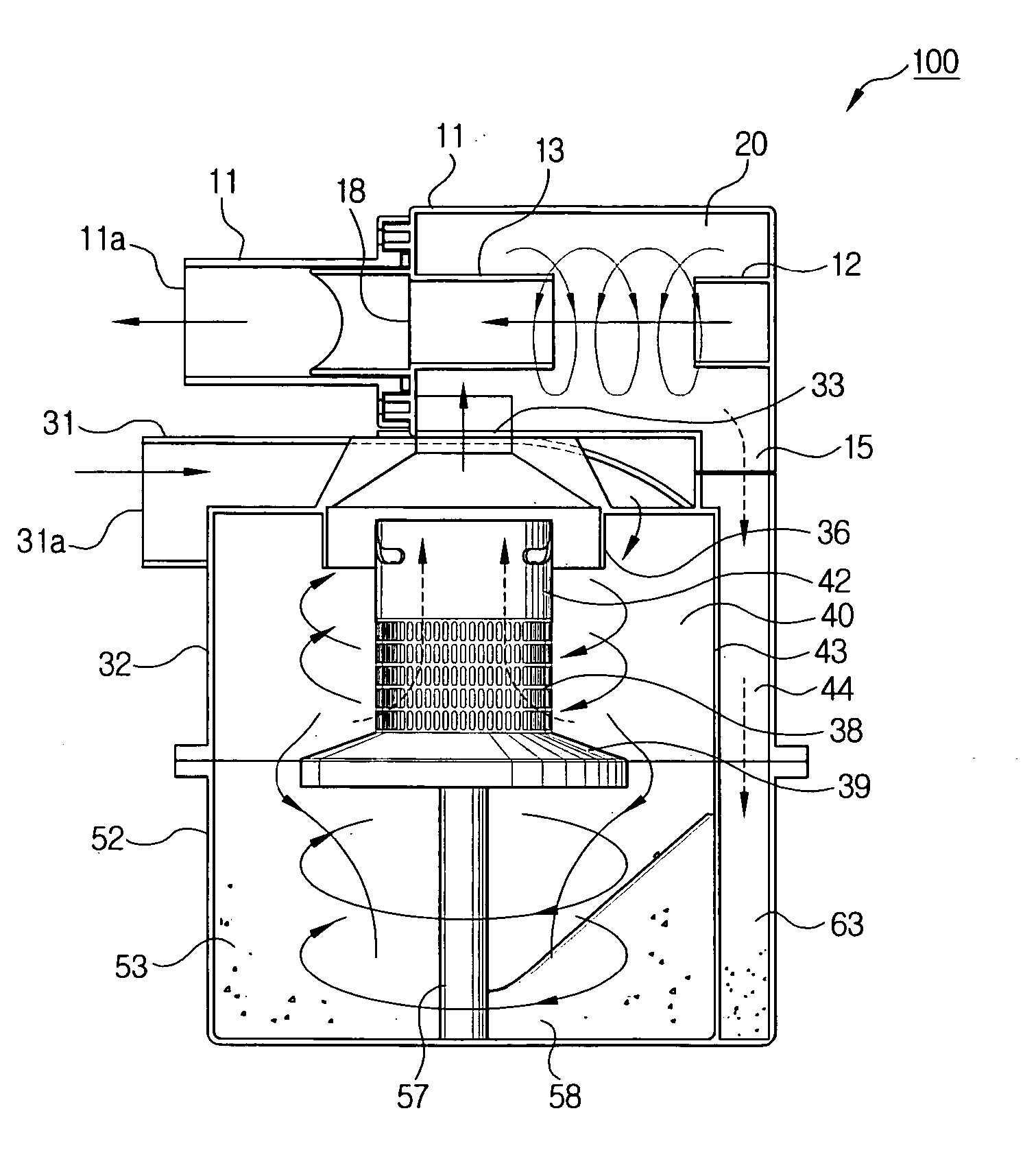

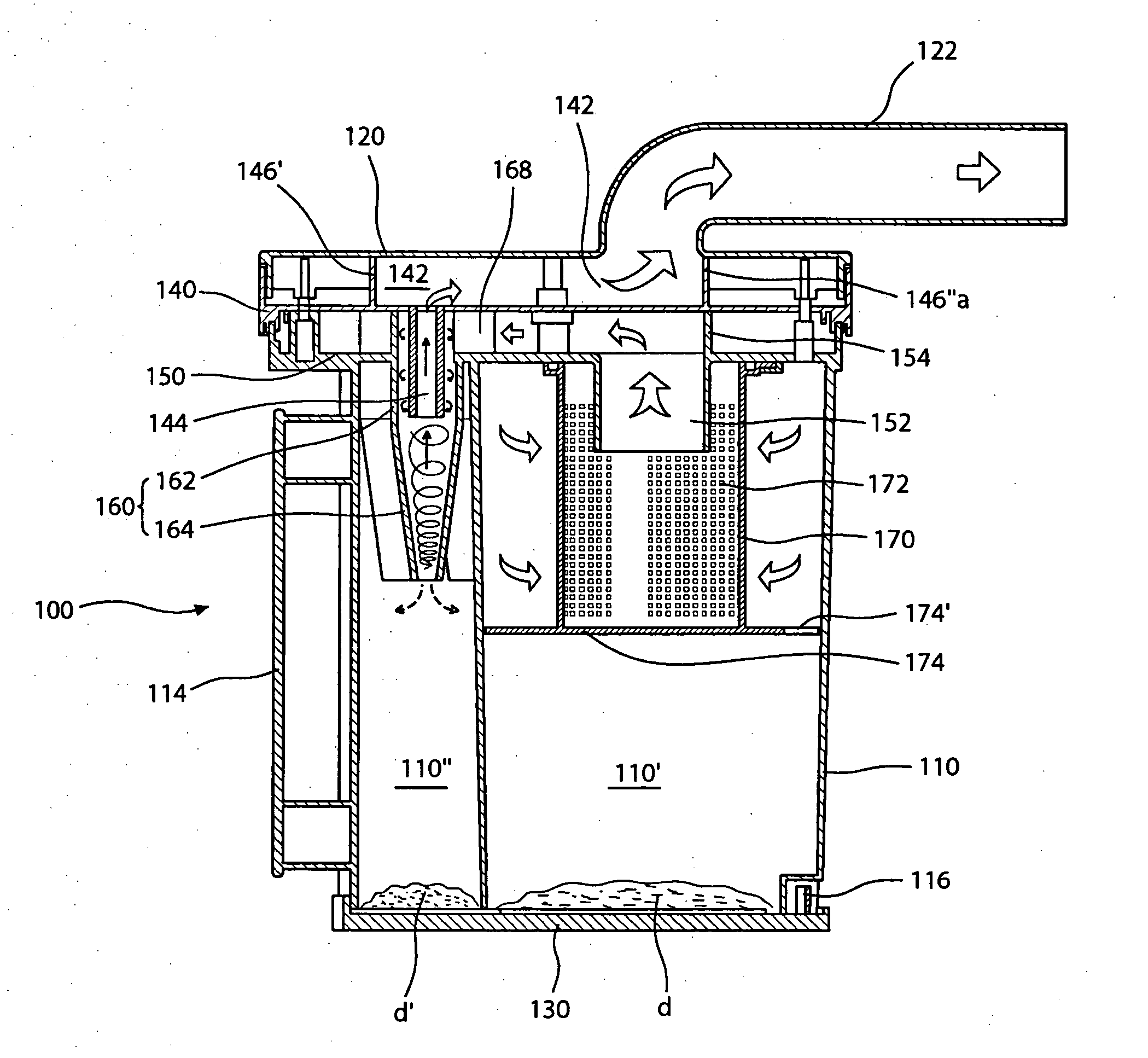

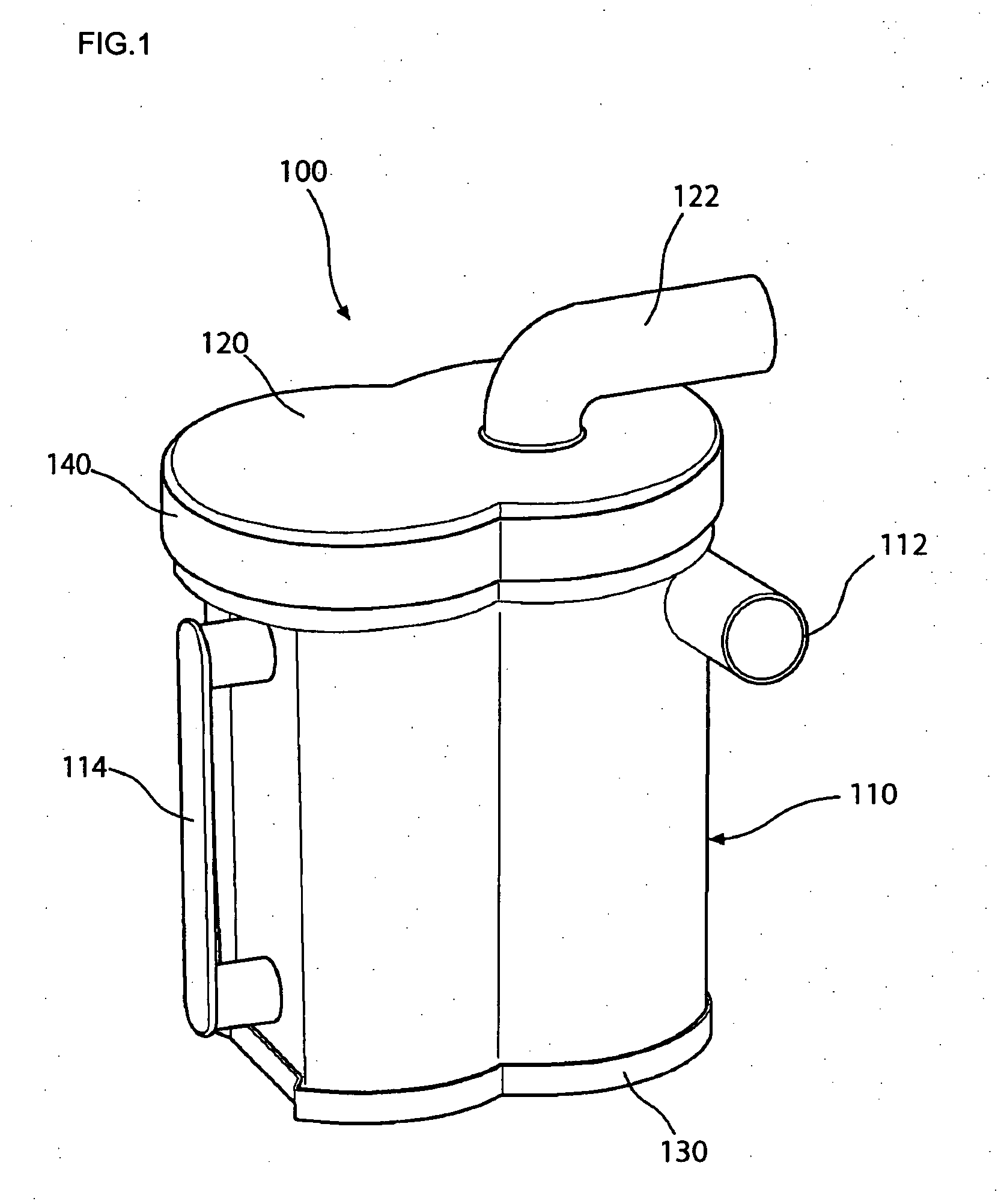

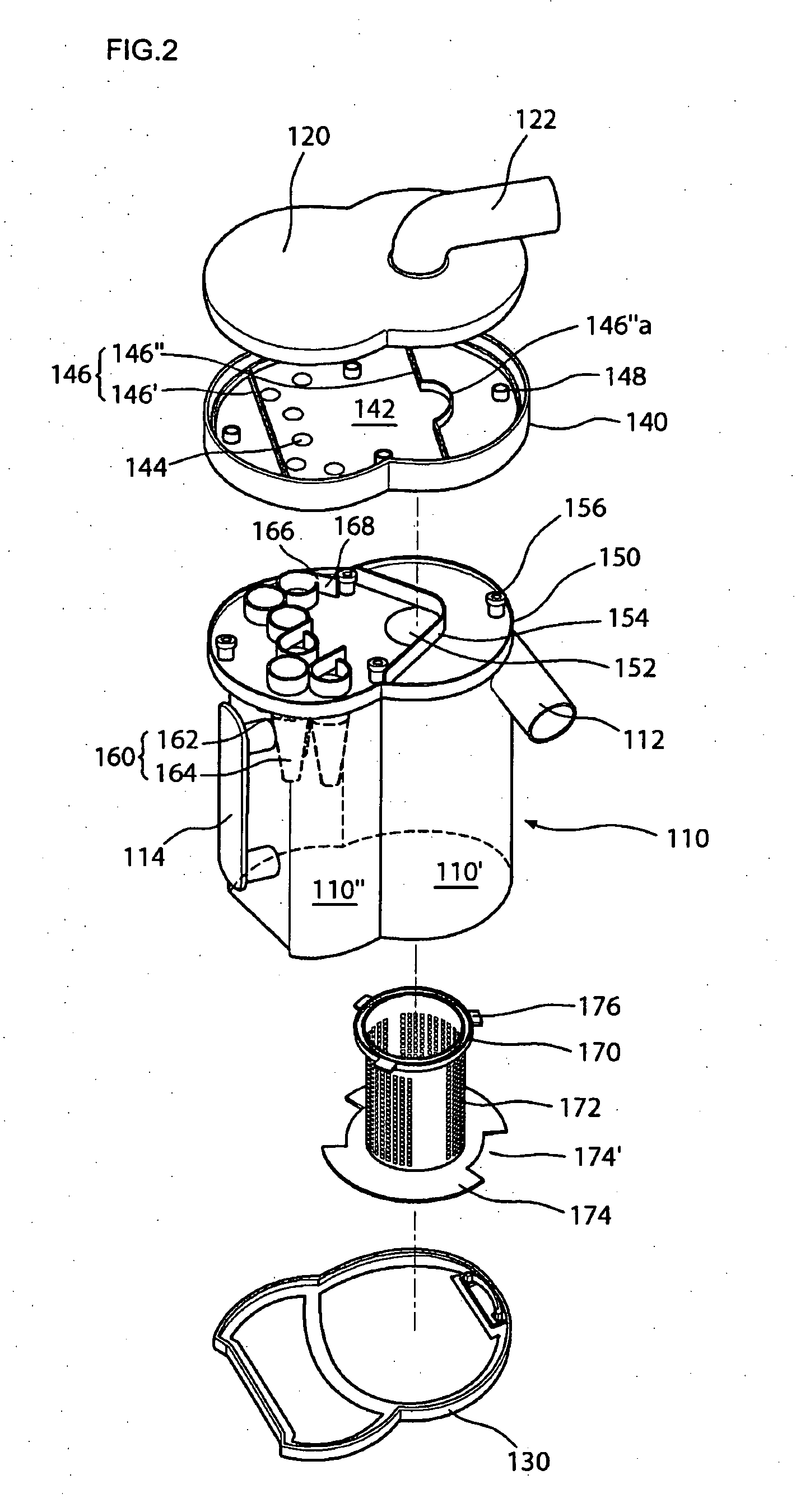

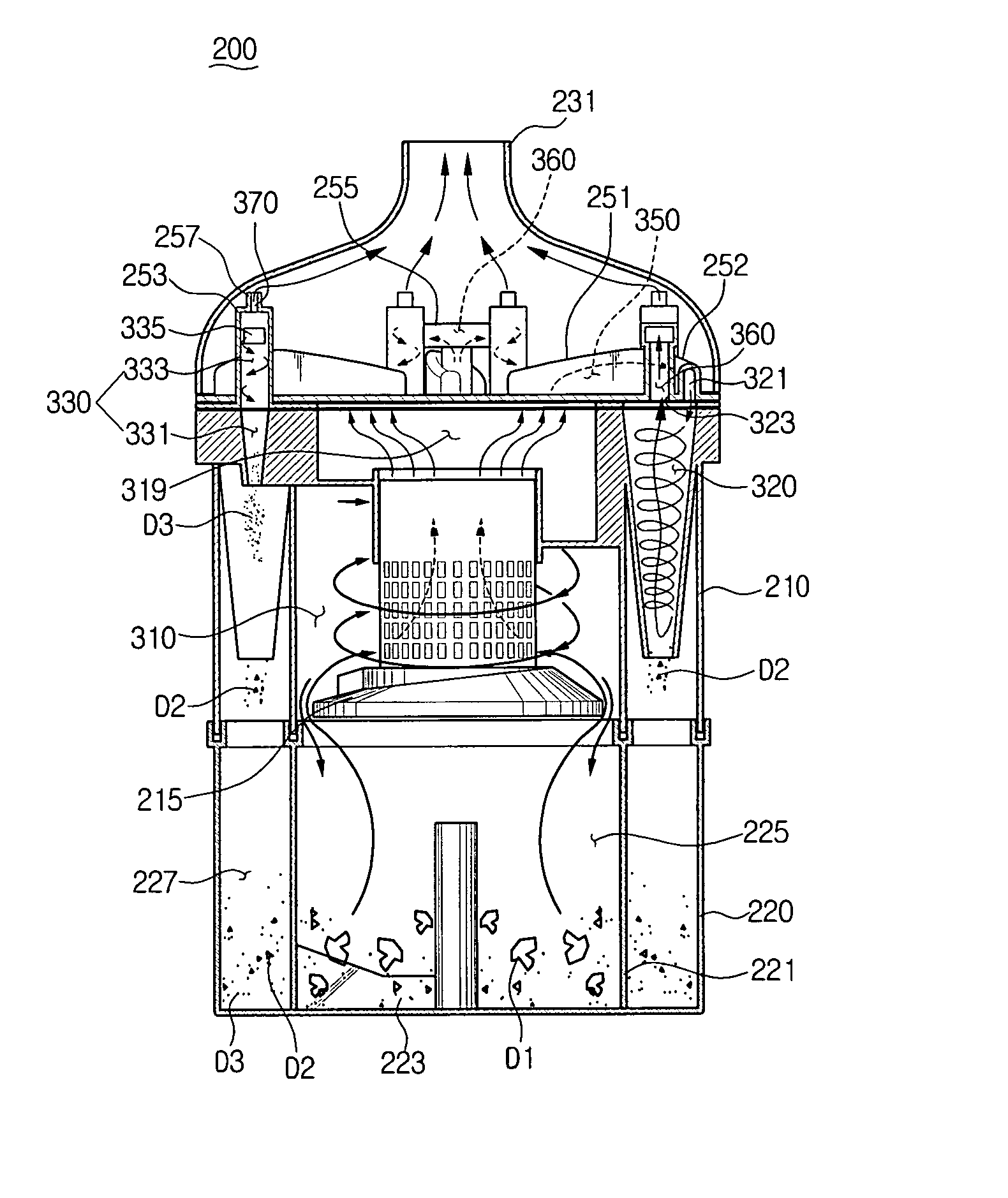

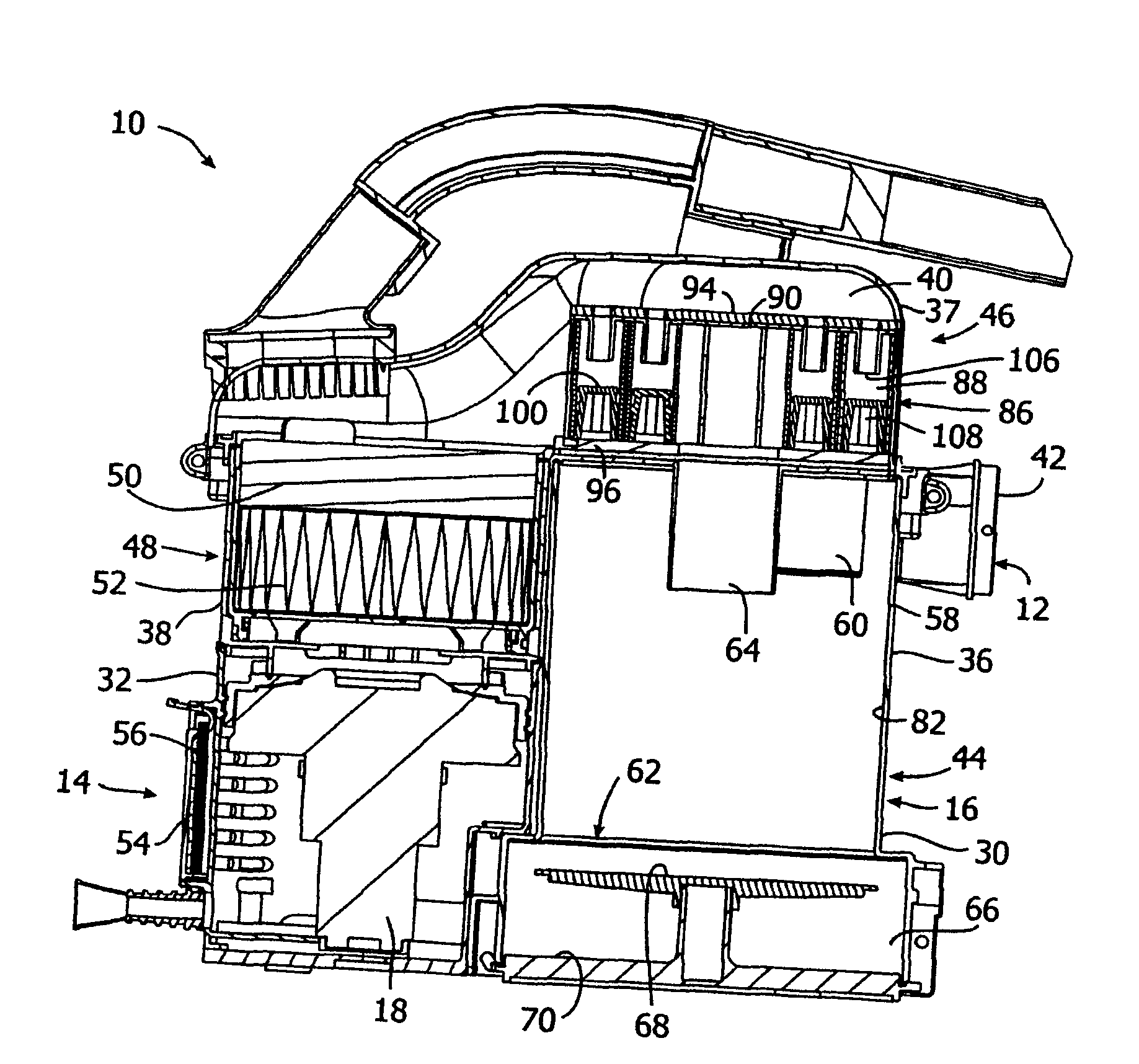

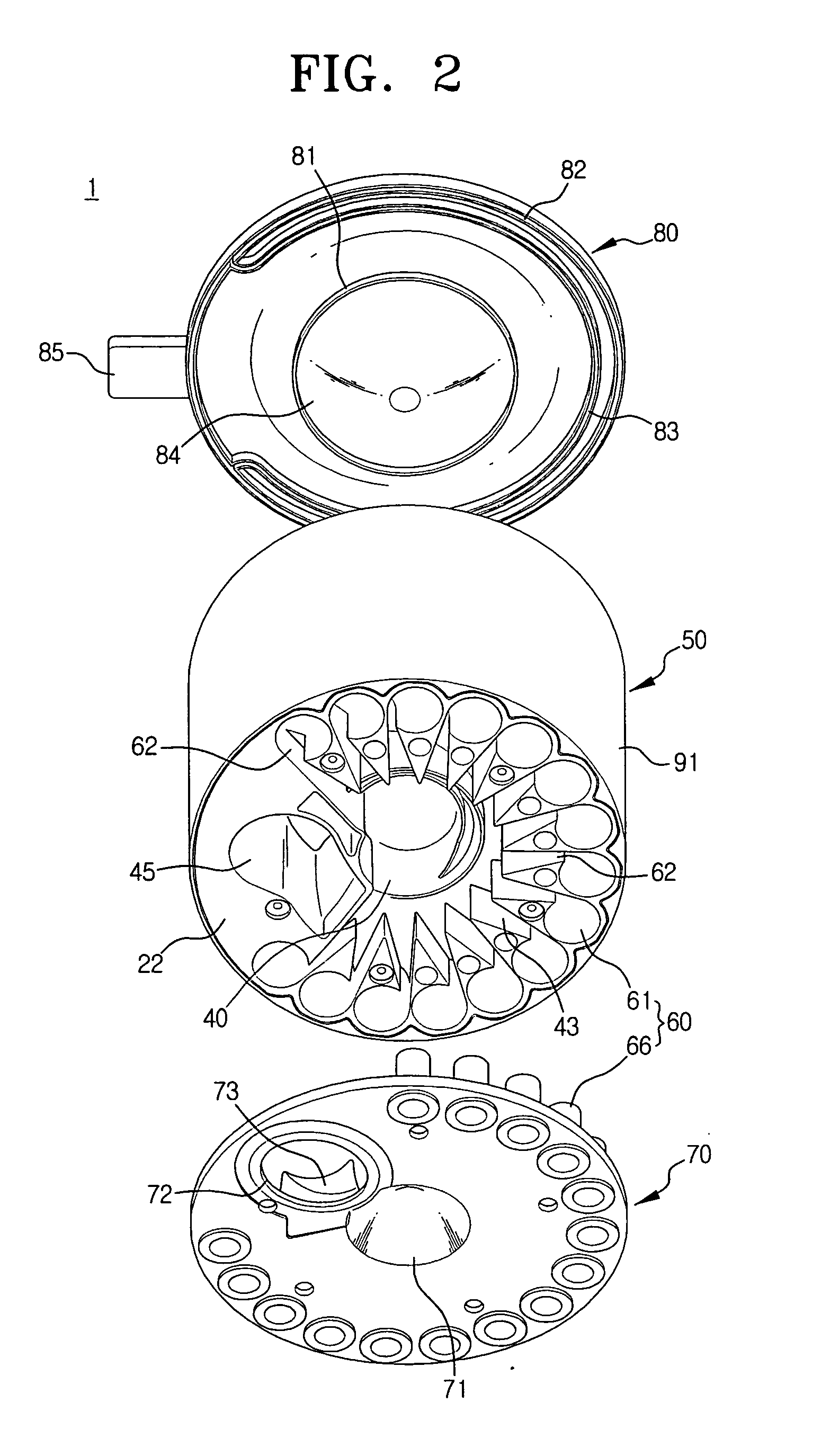

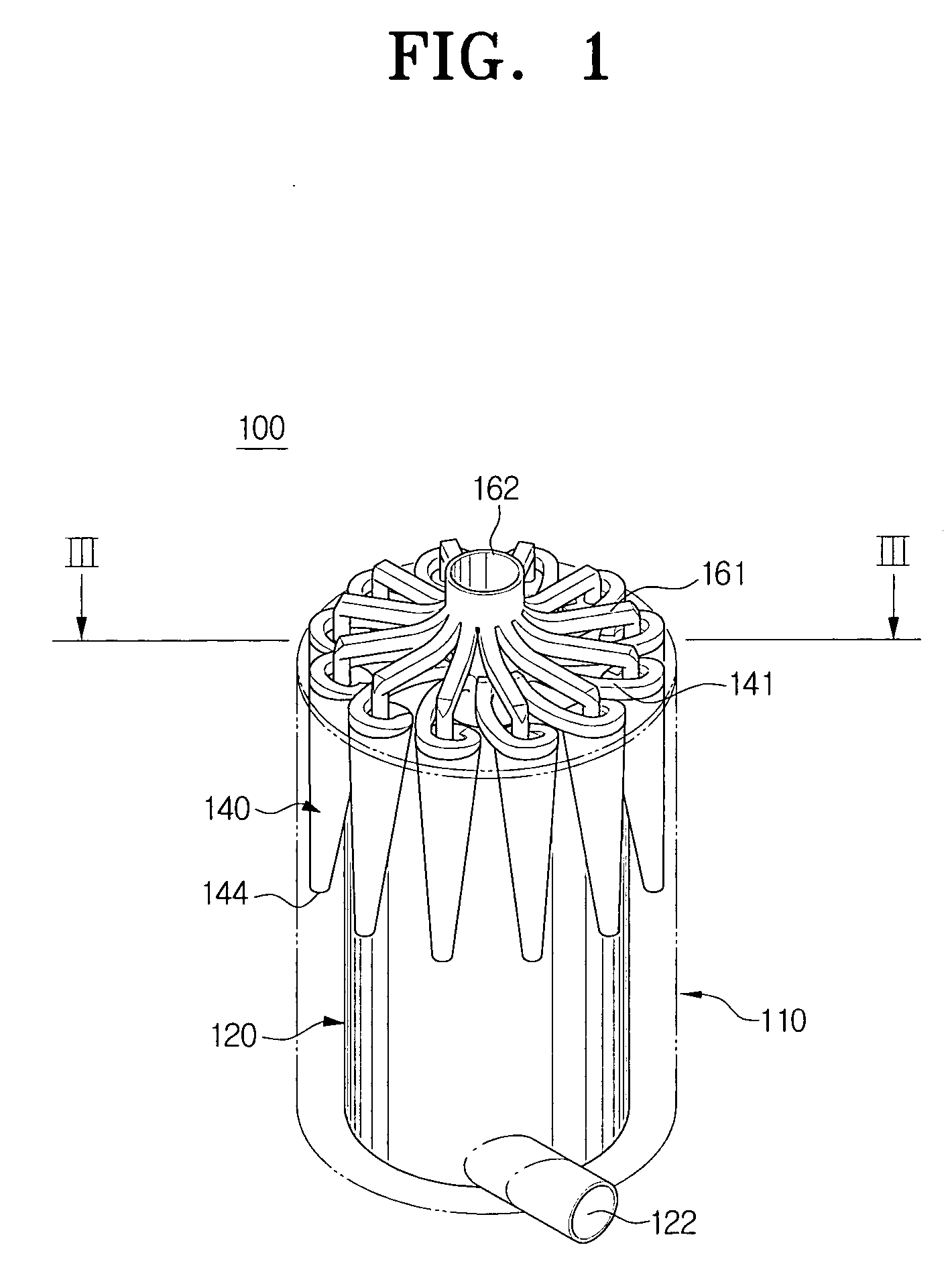

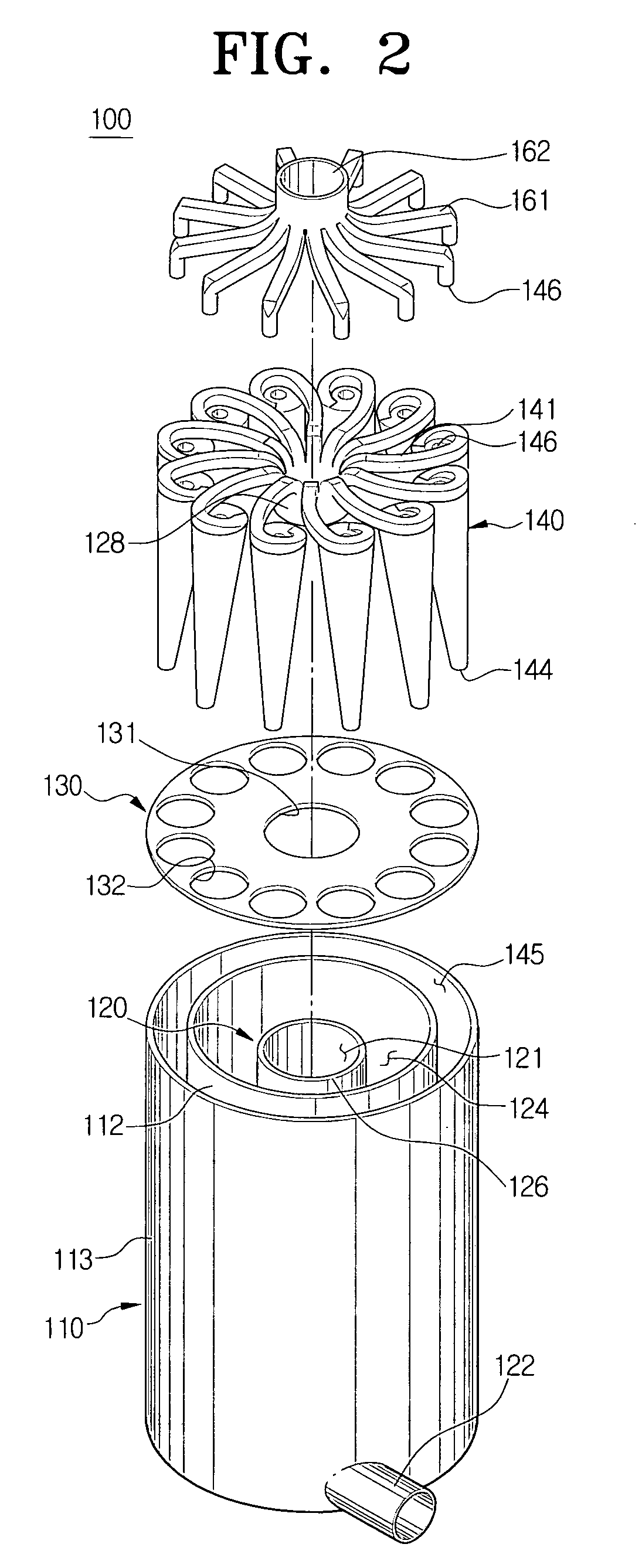

Multi cyclone dust-collecting apparatus

InactiveUS20060254226A1Improve efficiencyIncrease the number ofReversed direction vortexSuction cleanersCycloneEngineering

A multi cyclone dust-collecting apparatus including a dust-collecting housing; a first cyclone; a plurality of secondary cyclones; and a cover unit is provided. The dust-collecting housing has a suction pipe, which draws in ambient air. The first cyclone is disposed in the dust-collecting housing and has a first inlet port formed on a lower portion thereof to fluidly communicate with the suction pipe. The first inlet port and an air outlet port of the first cyclone have the same axis. The plurality of secondary cyclones are arranged outside the first cyclone at a predetermined interval and disposed in the dust-collecting housing. The cover unit guides the air discharged from the first cyclone to the respective secondary cyclones, filters again the air separated out from the dirt particles in the secondary cyclones, and discharges cleaned air outwardly.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

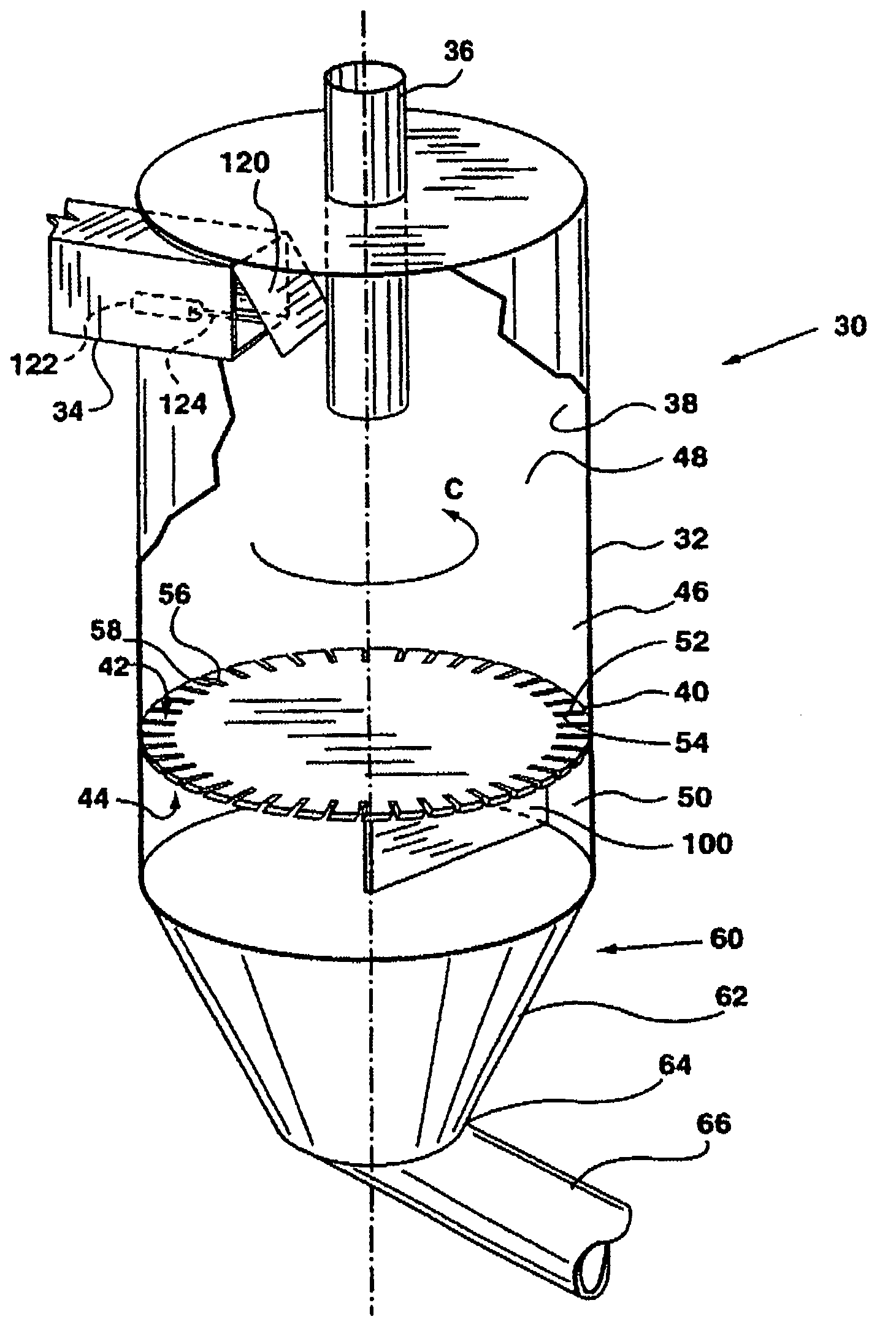

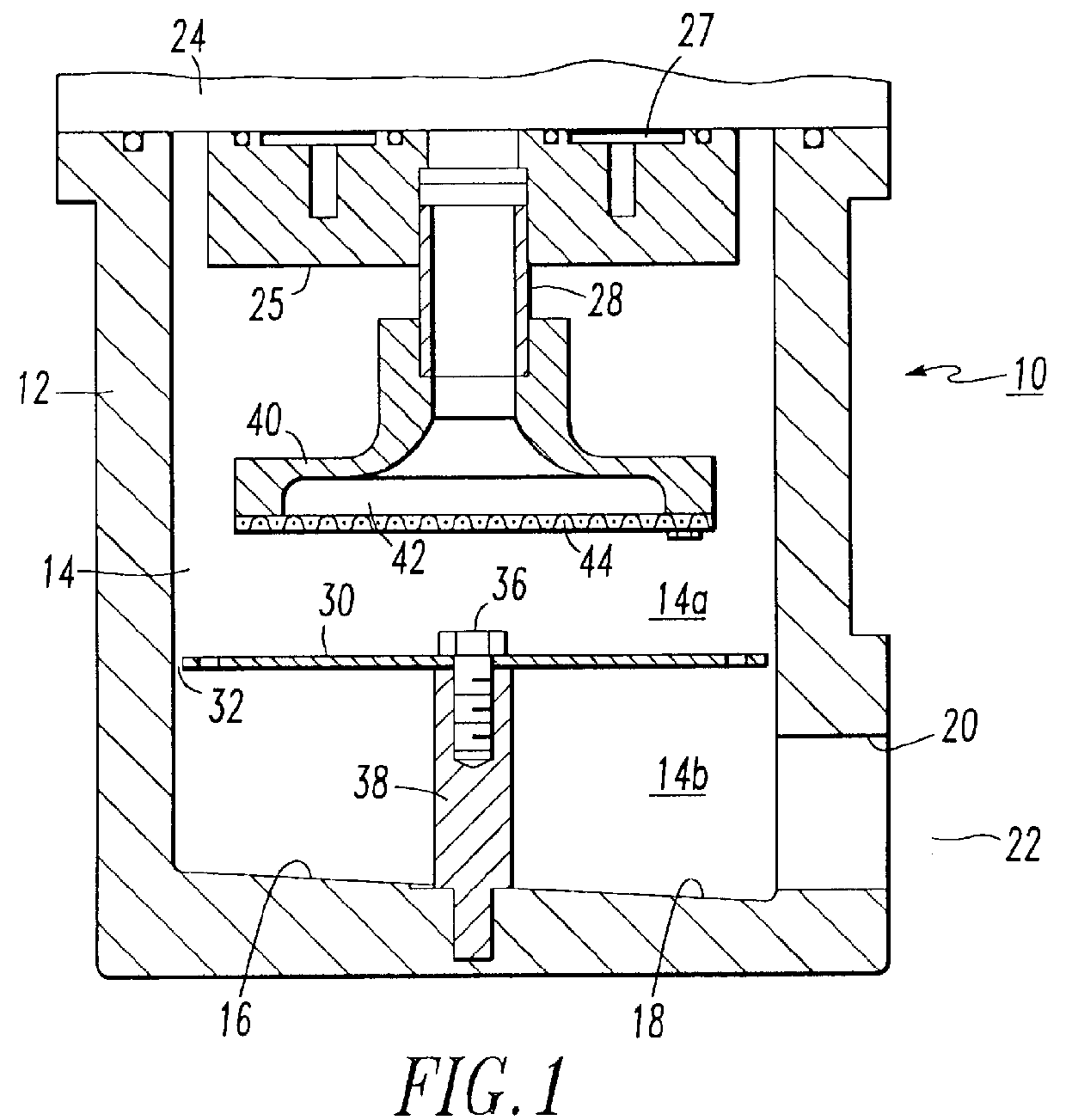

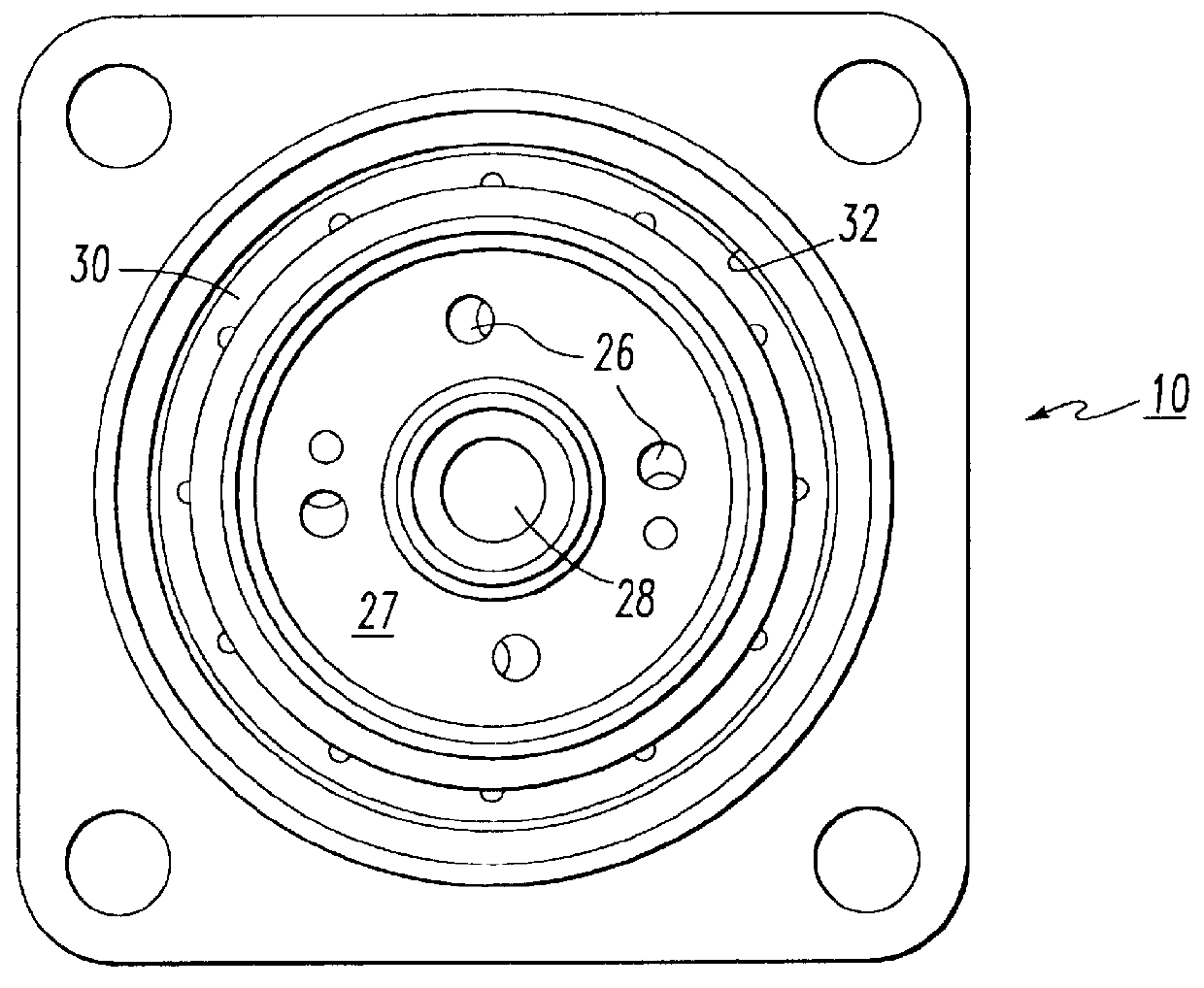

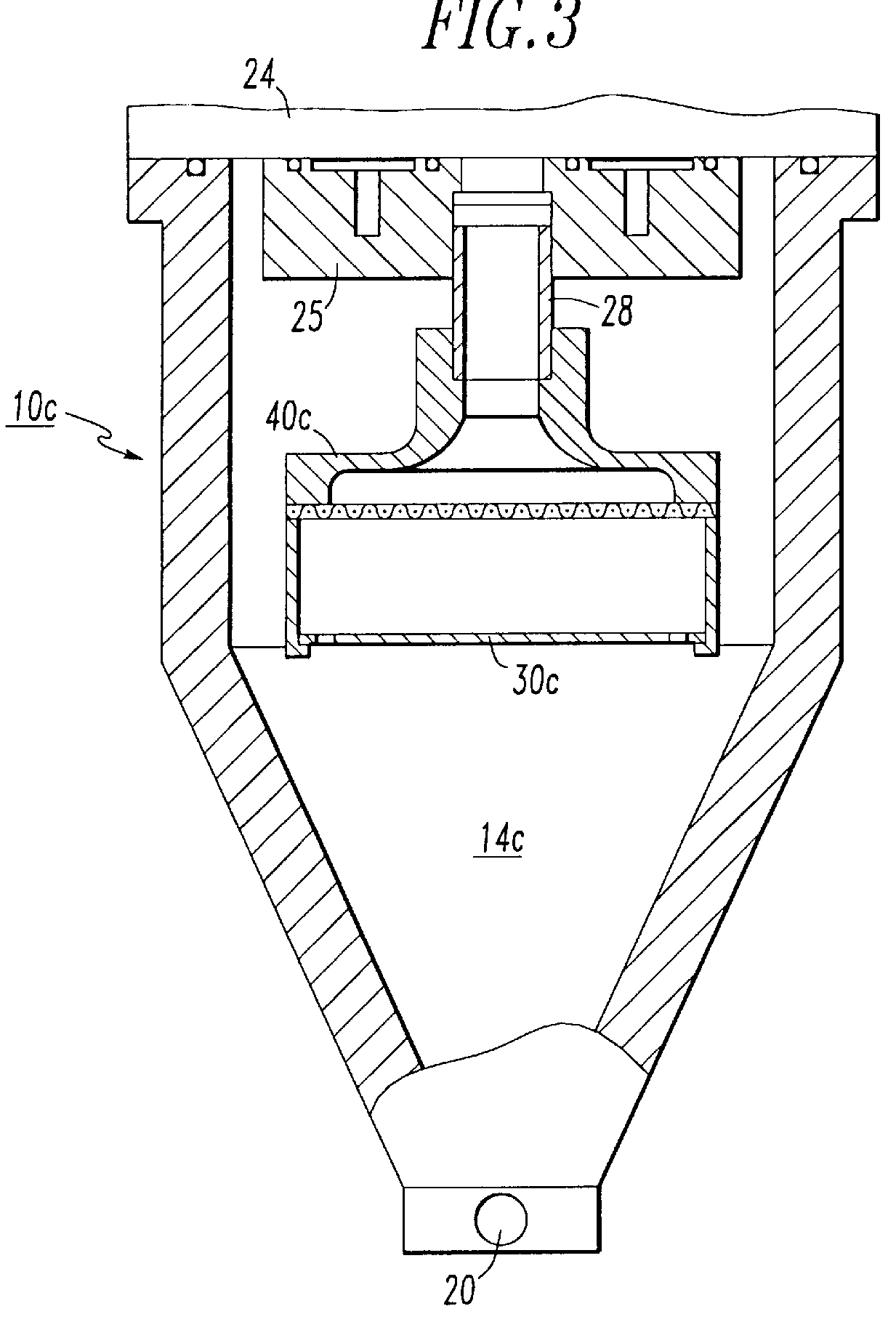

Apparatus and method for separating particles from a cyclonic fluid flow

InactiveUS6874197B1Improve efficiencyPrevent reentrainmentCleaning filter meansSuction filtersEngineeringParticle separation

A particle separation member (40) is provided for use with a cyclone separator (30). The particle separation member (40) divides the separator (30) into a cyclone chamber (46) and a particle receiving chamber (50). The cyclone chamber (46) and the particle receiving chamber (50) communicating via a plurality of apertures (52) in the particle separation member (40).

Owner:OMACHRON INTPROP

Dust collection assembly of vacuum cleaner

InactiveUS20060137304A1Improve dust removal efficiencyEasy constructionCombination devicesSuction filtersCycloneForeign matter

A dust collection assembly of a vacuum cleaner is provided. The dust collection assembly includes a dust collecting box, a filter, a flow guide unit, an exhaust guider, and an upper cover. The dust collecting box and the flow guide unit are integrally formed in a single body. The dust collecting box includes a first and second dust collecting spaces for collecting foreign objects. The filter is disposed in the inside of the dust collecting space to primarily filter foreign objects during operation of a cyclone. The flow guide unit guides airflow and has small cyclones integrally formed therein, for secondarily filtering the foreign objects in air. The exhaust guider guides airflow and has a plurality of discharge holes through which air filtered by the small cyclone flows. The upper cover is disposed on the upper side of the exhaust guider.

Owner:LG ELECTRONICS INC

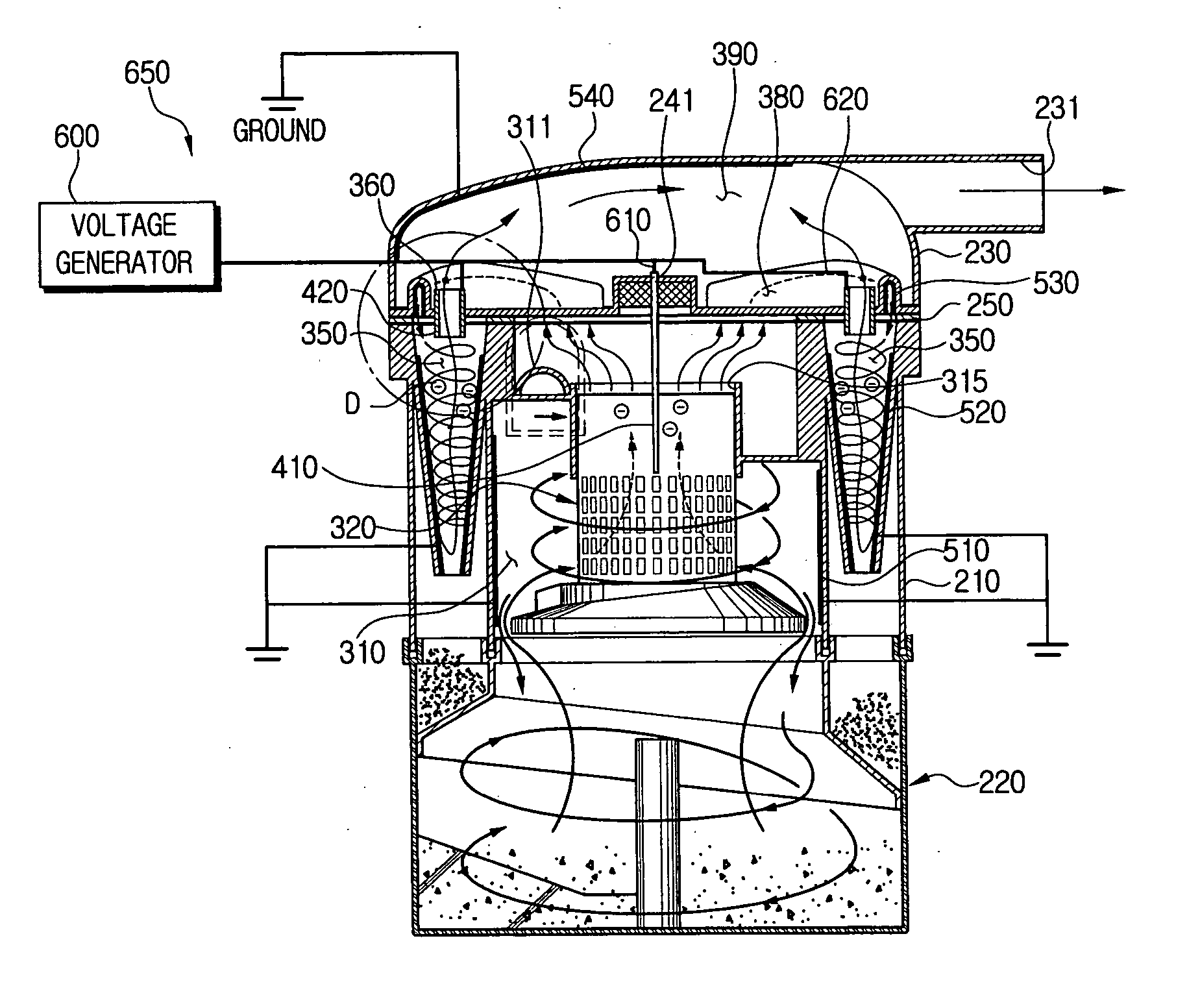

Cyclone dust collecting device for vacuum cleaner

InactiveUS20060278081A1Separation efficiency can be improvedIncreased durabilityCleaning filter meansSuction filtersCorona dischargeConductive materials

A cyclone dust collecting device using a corona discharge is provided. The cyclone dust collecting device includes a cyclone chamber rotating air drawn in from the outside to separate contaminants from the air, a discharge pipe guiding the air separated from the contaminants to the outside of the cyclone chamber and including a discharge electrode part with at least a part made of a conductive material and a power supply unit supplying a power to the discharge electrode part for the discharge electrode part to perform a corona discharge.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Cyclone dust separating apparatus for vacuum cleaner and vacuum cleaner having the same

ActiveUS20060230724A1Improved contaminant separation efficiencySmall sizeSuction filtersReversed direction vortexCycloneEngineering

A cyclone dust separating apparatus has a first cyclone chamber for separating particles from the externally-drawn fluid by centrifugal force, one or more second cyclone chambers for separating particles from the fluid discharged from the first cyclone chamber by centrifugal force, and one or more third cyclone chambers for separating particles from the fluid discharged from the second cyclone chambers, and causing the fluid to be discharged out via a discharge passage. The second and the third cyclone chambers are arranged in radial relation with respect to the first cyclone chamber, and thus, surround the first cyclone chamber. Therefore, the cyclone dust separating apparatus provides multi-stage centrifugal cleaning process and improved cleaning efficiency, while remaining compact-sized.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

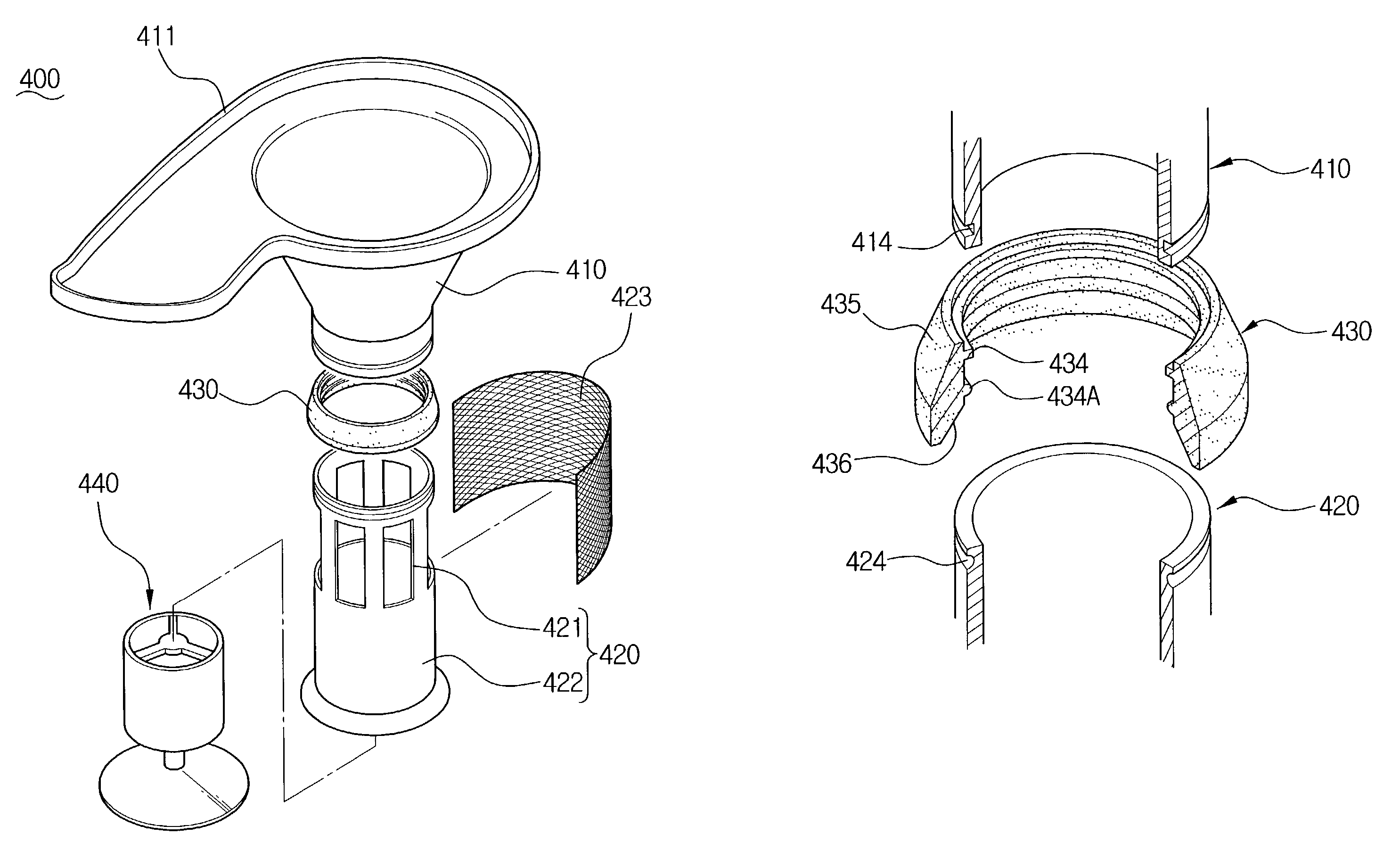

Filter assembly and cyclone dust collecting apparatus having the same

InactiveUS20060236663A1Improve suction capacityImprove liquidityCleaning filter meansCombination devicesCyclonePerpendicular direction

A filter assembly and a cyclone dust collecting apparatus using the same are provided. The filter assembly is employed by a cyclone dust collecting apparatus which centrifugally separates contaminant from drawn-in air to remove the contaminant and filters and discharges the air and has a filter part, and an air path. The air path is formed in the filter part to guide the air into the filter part and enables the air to flow in a three-dimensional direction, in other words, in a perpendicular direction to a central axis of the filter part, simultaneously flow in a parallel direction with the central axis of the filter part.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Adsorption Desulfurization Process for Hydrocarbons and a Reaction Apparatus Therefor

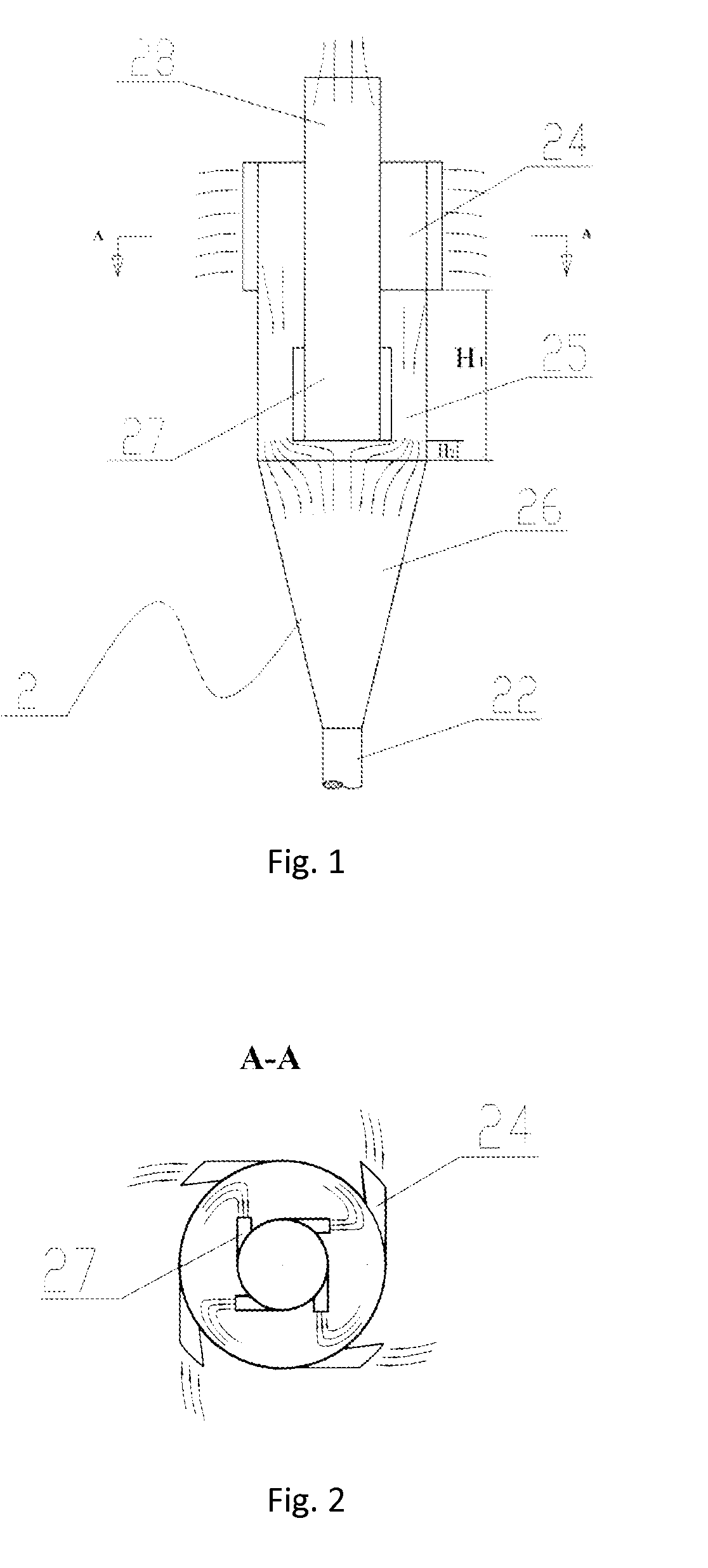

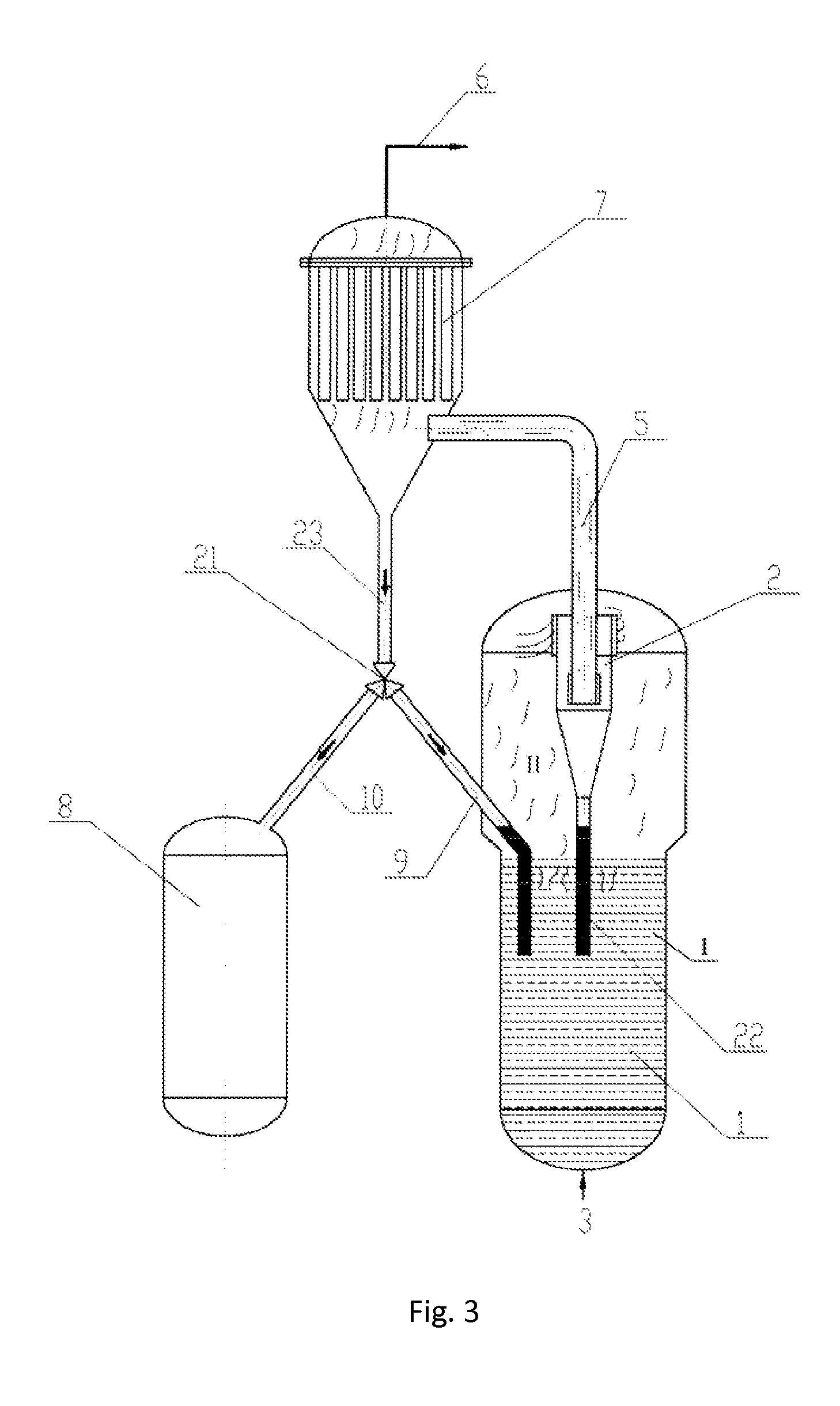

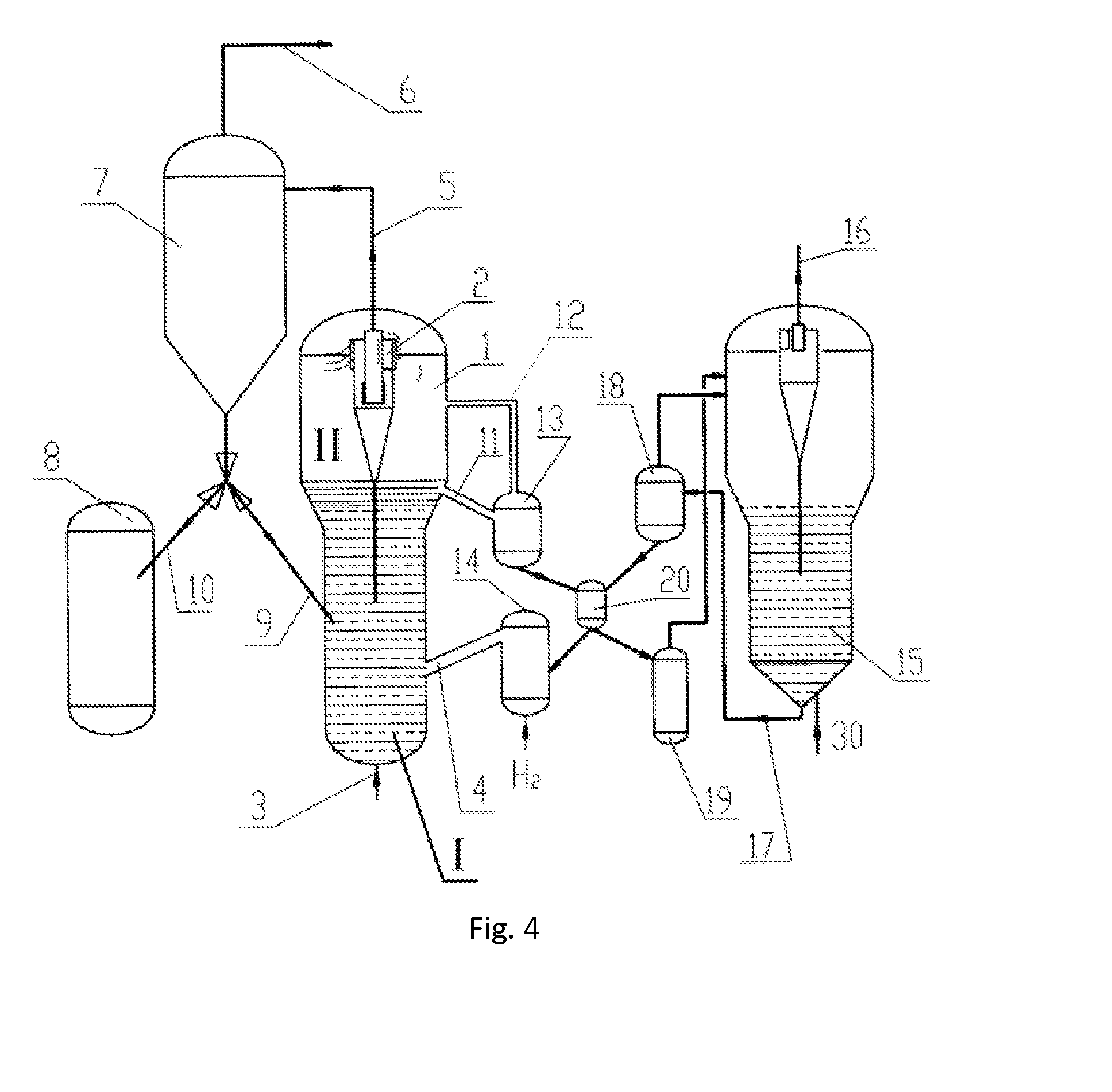

ActiveUS20140121438A1Efficient removalReduce flow rateReversed direction vortexHydrocarbonsFluidized bedStraight tube

The present invention relates to an airflow particle sorter, comprising: a top-sealed sorter main body, a discharge port, an outtake tube and at least one directing-intake port; the inner space of the sorter main body, from the above to the bottom, includes, a straight tube zone and a cone zone, the conical bottom of the cone zone is connected to the straight tube zone; the discharge port is located at the bottom of the cone zone; the directing-intake port is installed in the upper part of the straight tube zone in a tangential direction of the straight tube zone, and is communicated with the inner space of the sorter main body; the outtake tube is hermetically inserted into the top of the sorter main body, and extends downwardly to the lower part of the straight tube zone, and the outtake tube has a sealed bottom end; the lower part of the outtake tube is installed with at least one directing-outtake port, which communicates the outtake tube with the inner space of the sorter main body, the directing-outtake port is installed in a tangential direction of the outtake tube. The present invention further relates to a fluidized bed reactor and an adsorption desulfurization reaction apparatus as well as an adsorption desulfurization process.

Owner:CHINA PETROCHEMICAL CORP +1

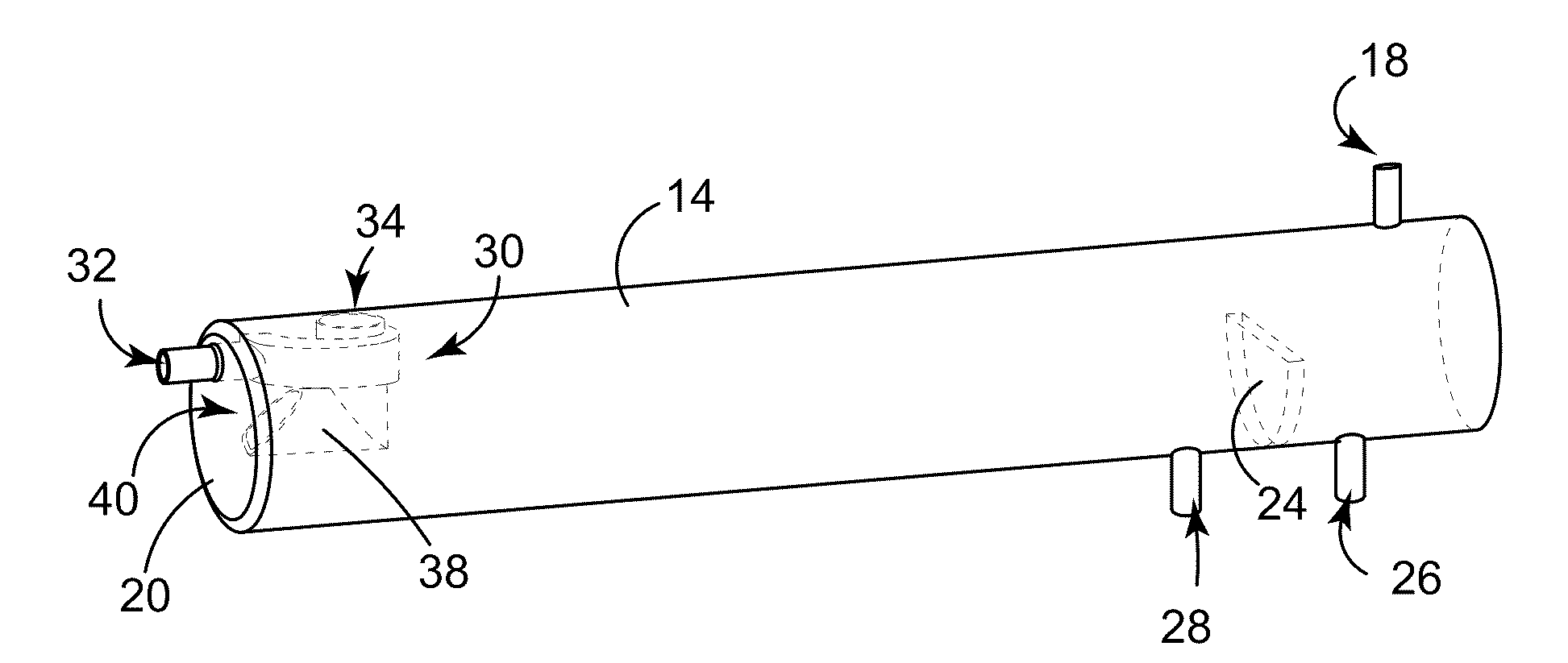

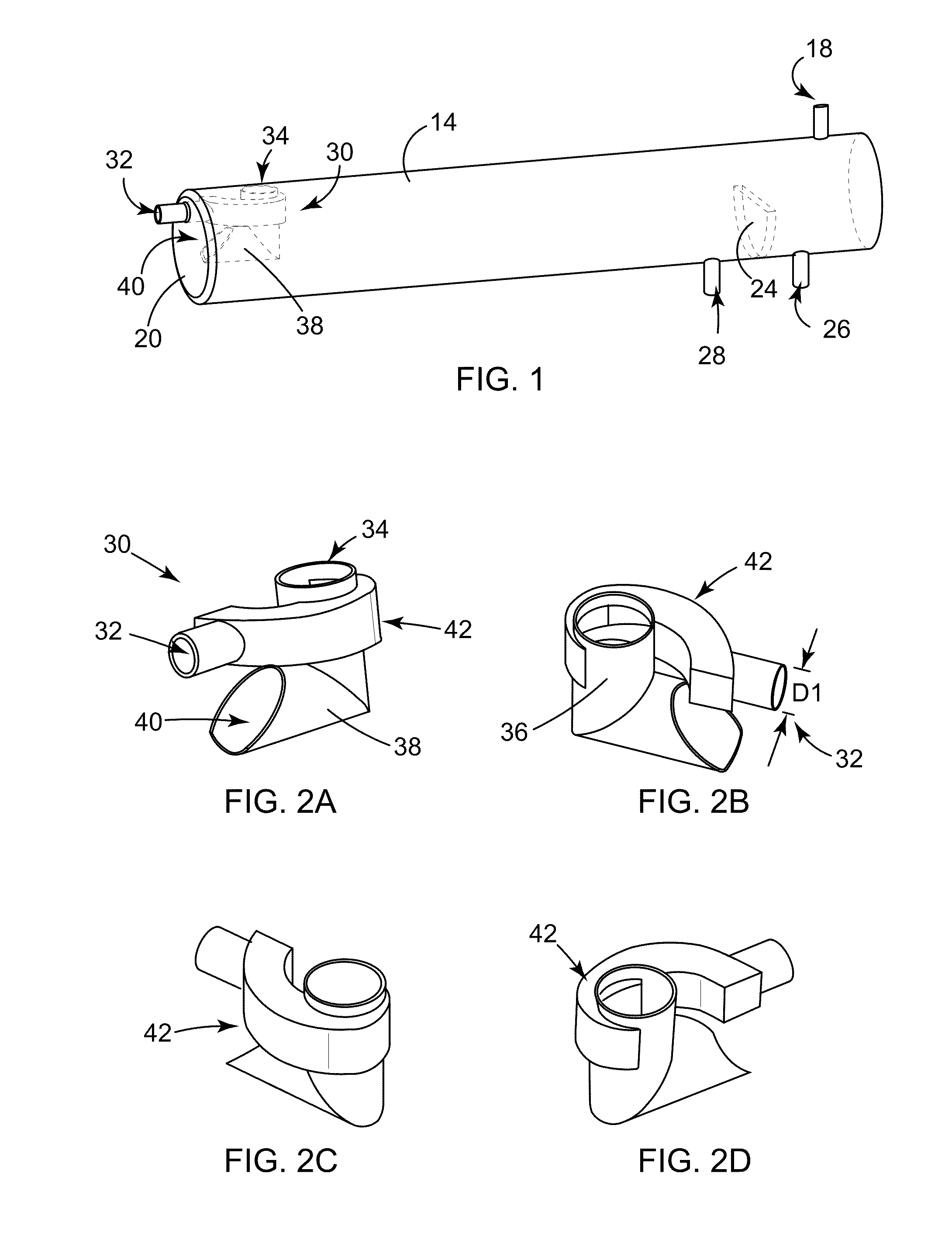

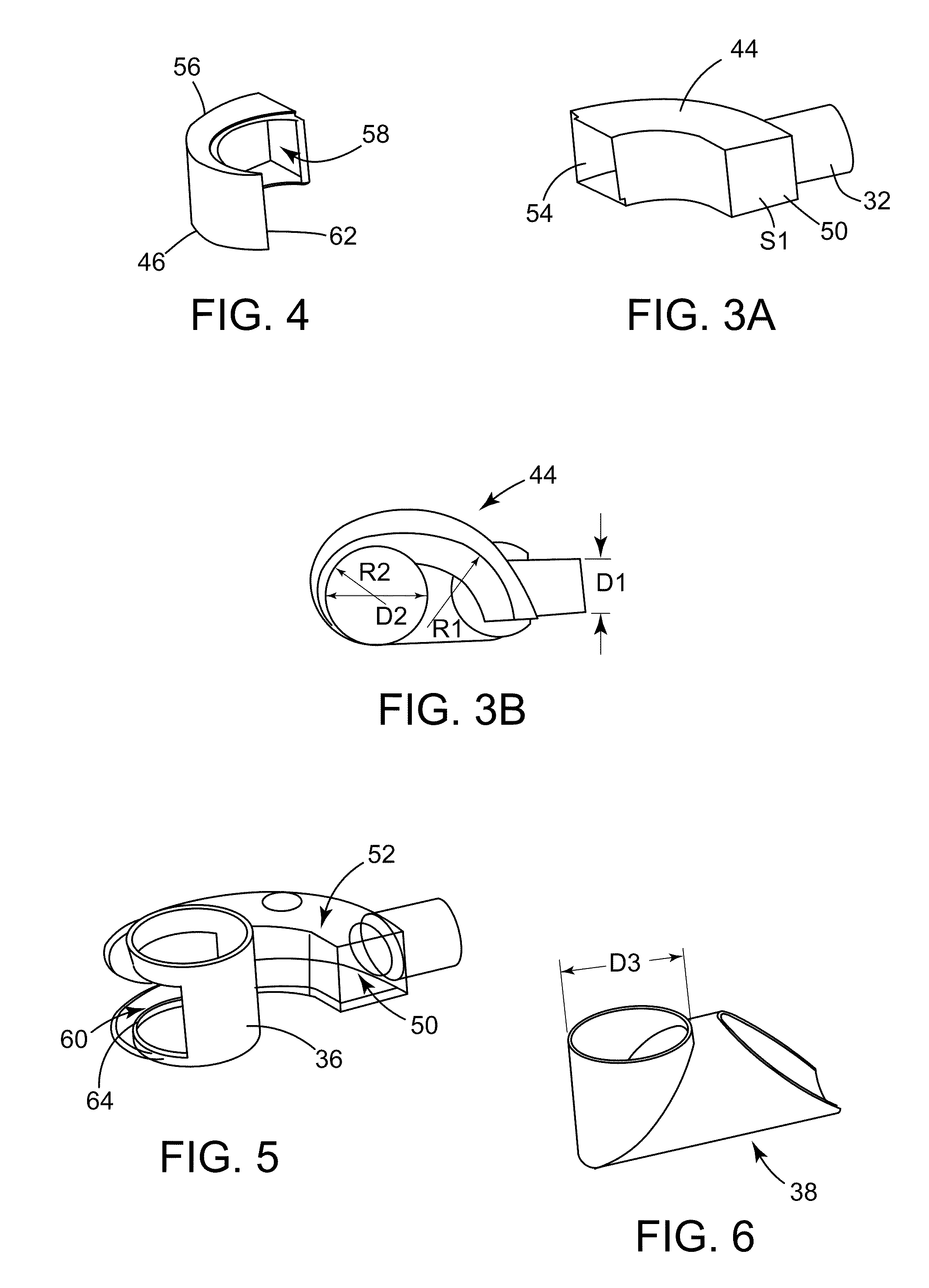

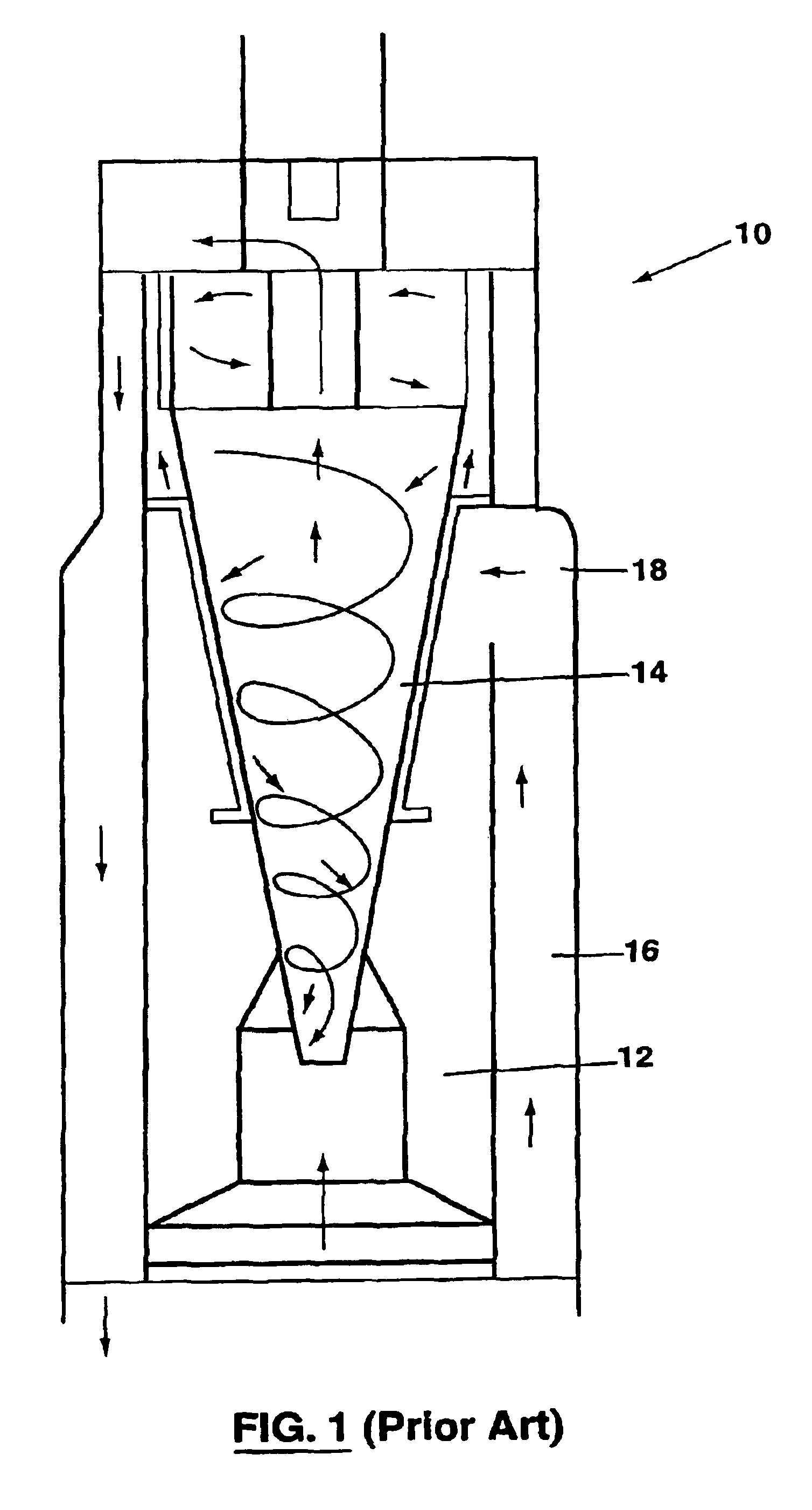

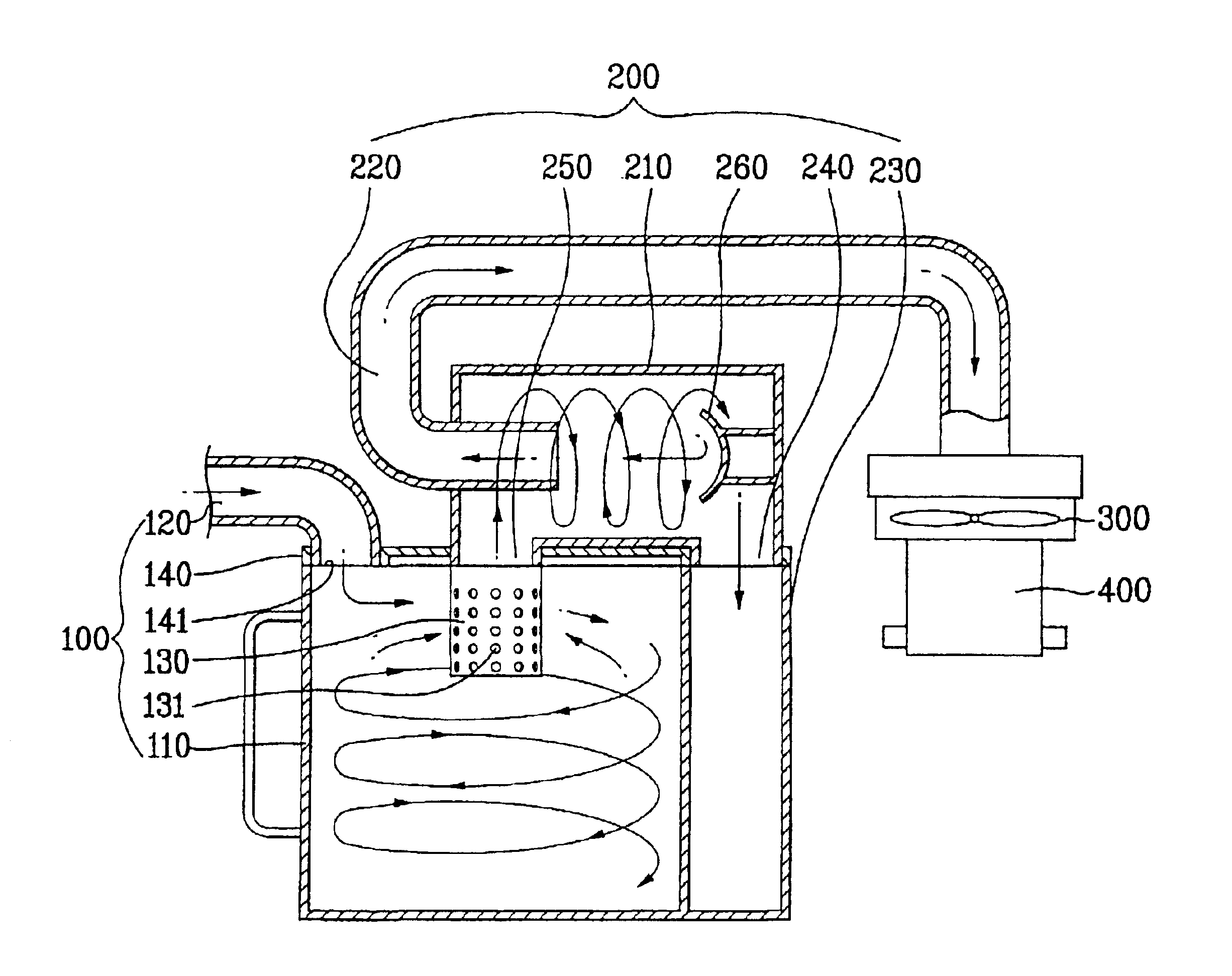

Apparatus for separation of gas-liquid mixtures and promoting coalescence of liquids

ActiveUS20110247500A1Reduce momentumPromote droplet coalescenceLiquid degasificationReversed direction vortexChemical physicsOil separation

Provided herein is a conditioning apparatus that includes a geometrical configuration having an inlet flow deceleration conduit and a cyclonic tube to effectuate both liquid-gas separation and droplet coalescence. The apparatus is typically positioned at the inlet of a separator vessel used for removing water and gas from extracted crude oil containing entrained water and gas. The apparatus promotes droplet coalescence and gas separation for mixed fluids flowing into an existing water and oil separation device.

Owner:SAUDI ARABIAN OIL CO

Cyclonic separating apparatus for vacuum cleaner which is capable of separately collecting water from dust

InactiveUS20060162298A1Easy to separatePreventing dispersion and subsequent backflowCombination devicesAuxillary pretreatmentInterior spaceCyclonic separation

A cyclonic separating apparatus for a vacuum cleaner that can separately collect dust and water. The cyclonic separating apparatus includes: a cyclone body having an air inlet passage and an air discharge passage; a dust receptacle connected to a lower end of the cyclone body; and a screen dividing the cyclone body and interior space of the dust receptacle into a first chamber and a second chamber, the screen having a plurality of passing holes, wherein drawn air rotates in the first chamber and water separated from the air moves to the second chamber through the passing holes.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

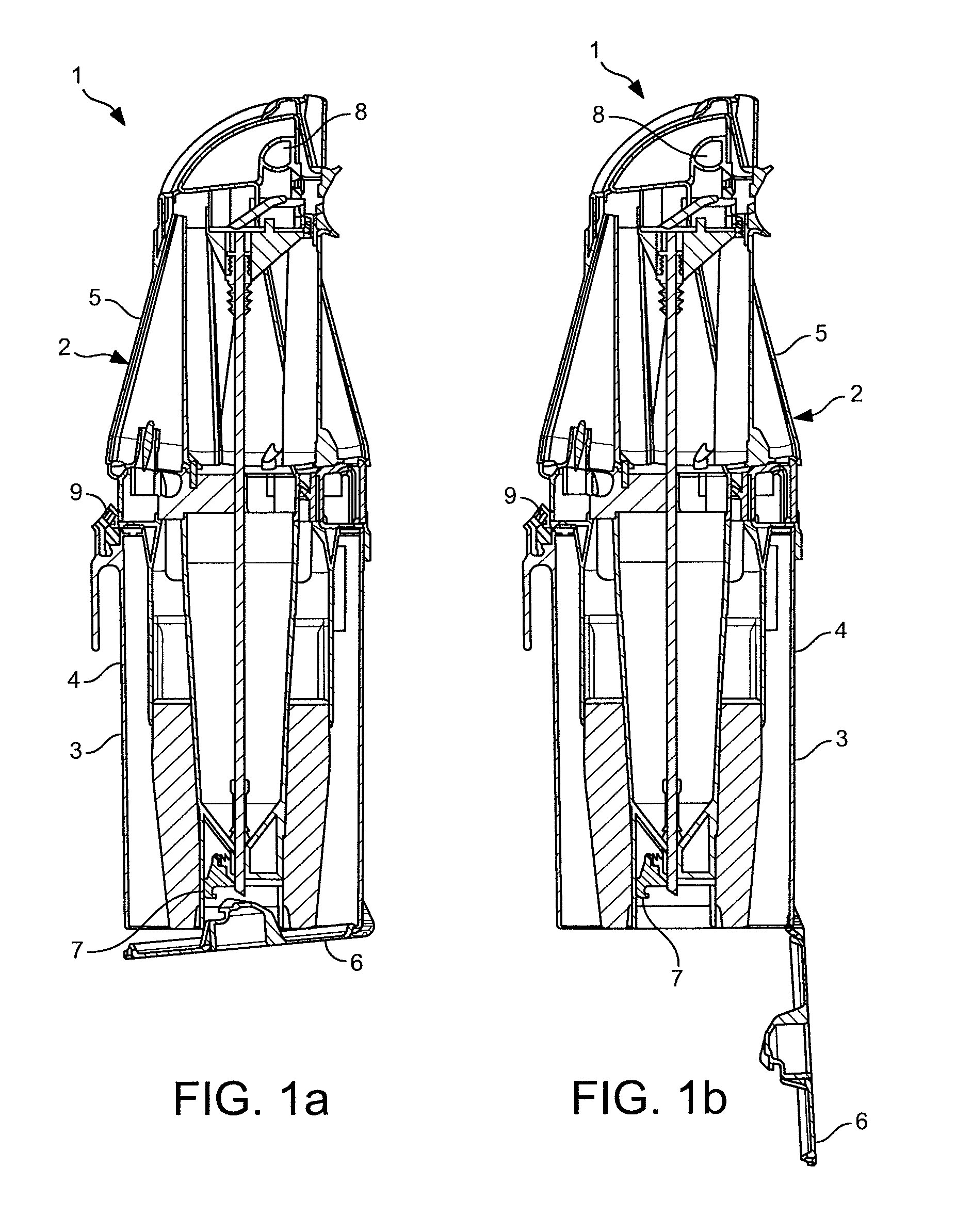

Separating apparatus for a cleaning appliance

A separating apparatus for a cleaning appliance, such as a vacuum cleaner, includes a separator for separating dirt and dust from a fluid flow and a collecting chamber arranged to collect dirt and dust separated by the separator. A first catch for opening a closure member on the collecting chamber is provided, with first releasing means for releasing this catch. There is also provided a second catch for releasing the collecting chamber from the separator and second releasing means for releasing the second catch. The second releasing means is inaccessible when the first catch is engaged. A cover associated with the first releasing means obscures the second releasing means until the first catch has been released. The invention prevents the user from accidentally releasing the collecting chamber from the separator when it was the user's intention simply to empty dirt and dust from the collecting chamber.

Owner:DYSON TECH LTD

Apparatus and method for separating particles from a cyclonic fluid flow

InactiveUS20060137314A1Prevent reentrainmentEfficient separationCleaning filter meansCombination devicesParticle separationPhysics

A particle separation member is provided for use with a cyclone separator. The particle separation member divides the separator into a cyclone chamber and a particle receiving chamber. The cyclone chamber and the particle receiving chamber communicating via a plurality of apertures in the particle separation member.

Owner:OMACHRON INTPROP

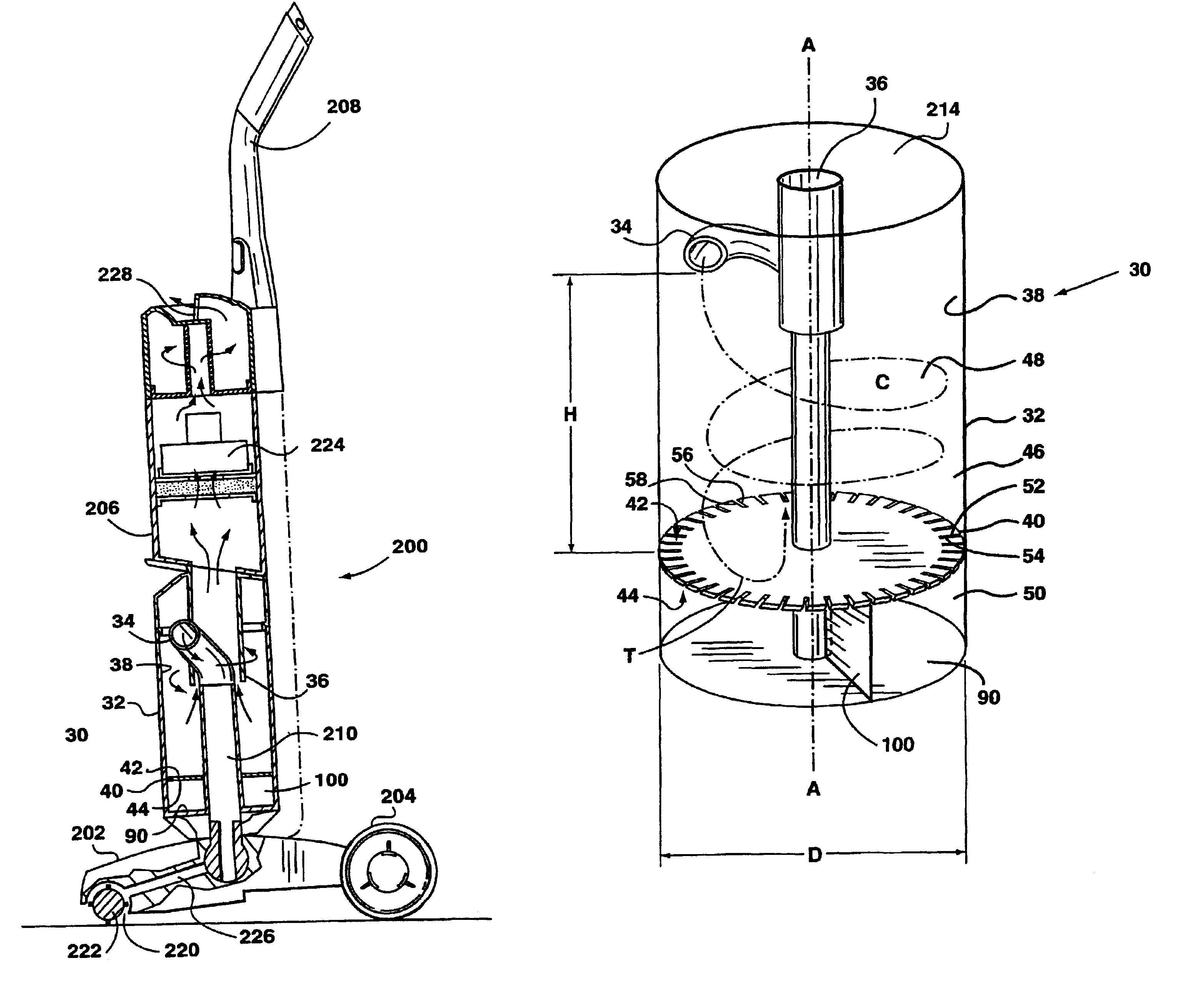

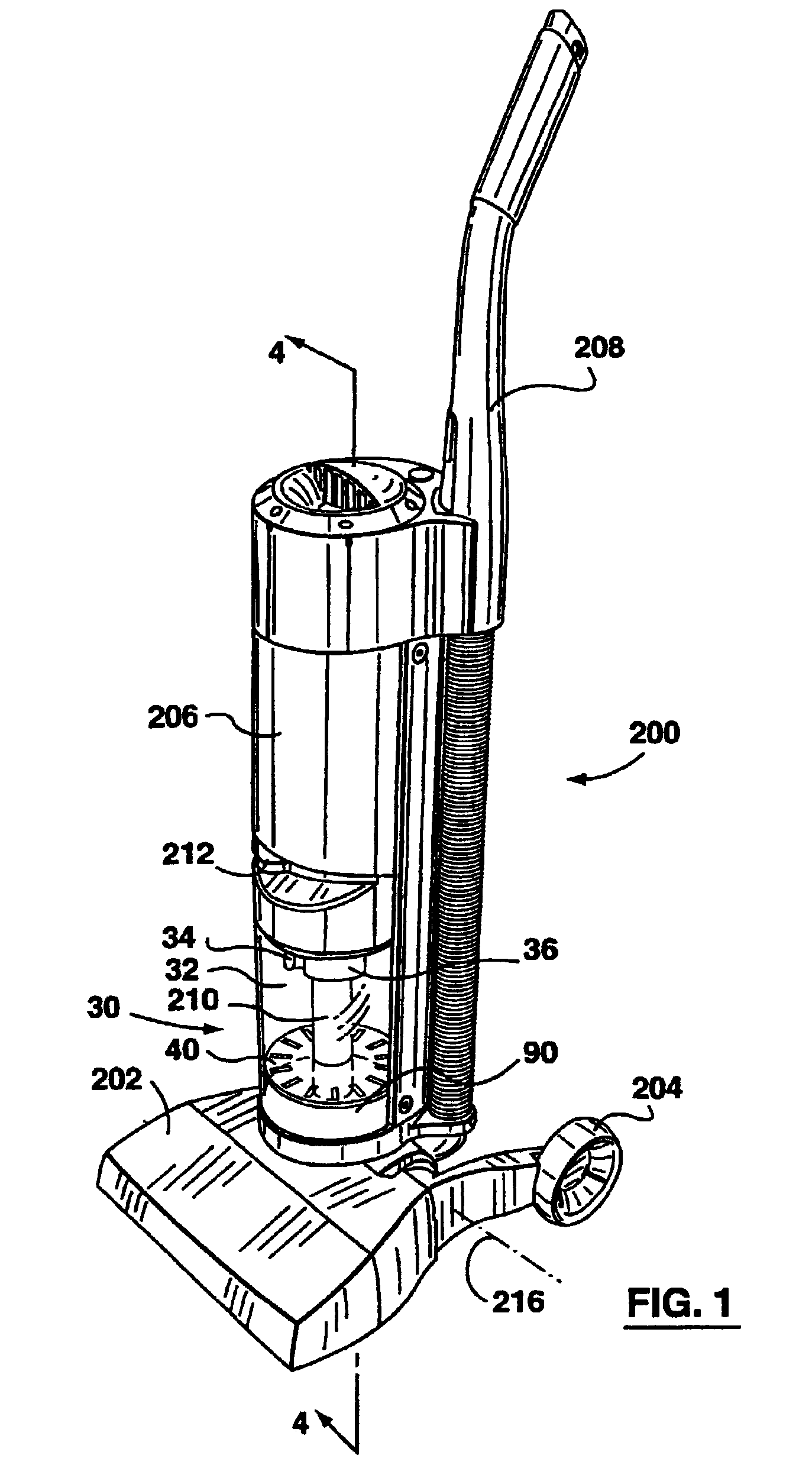

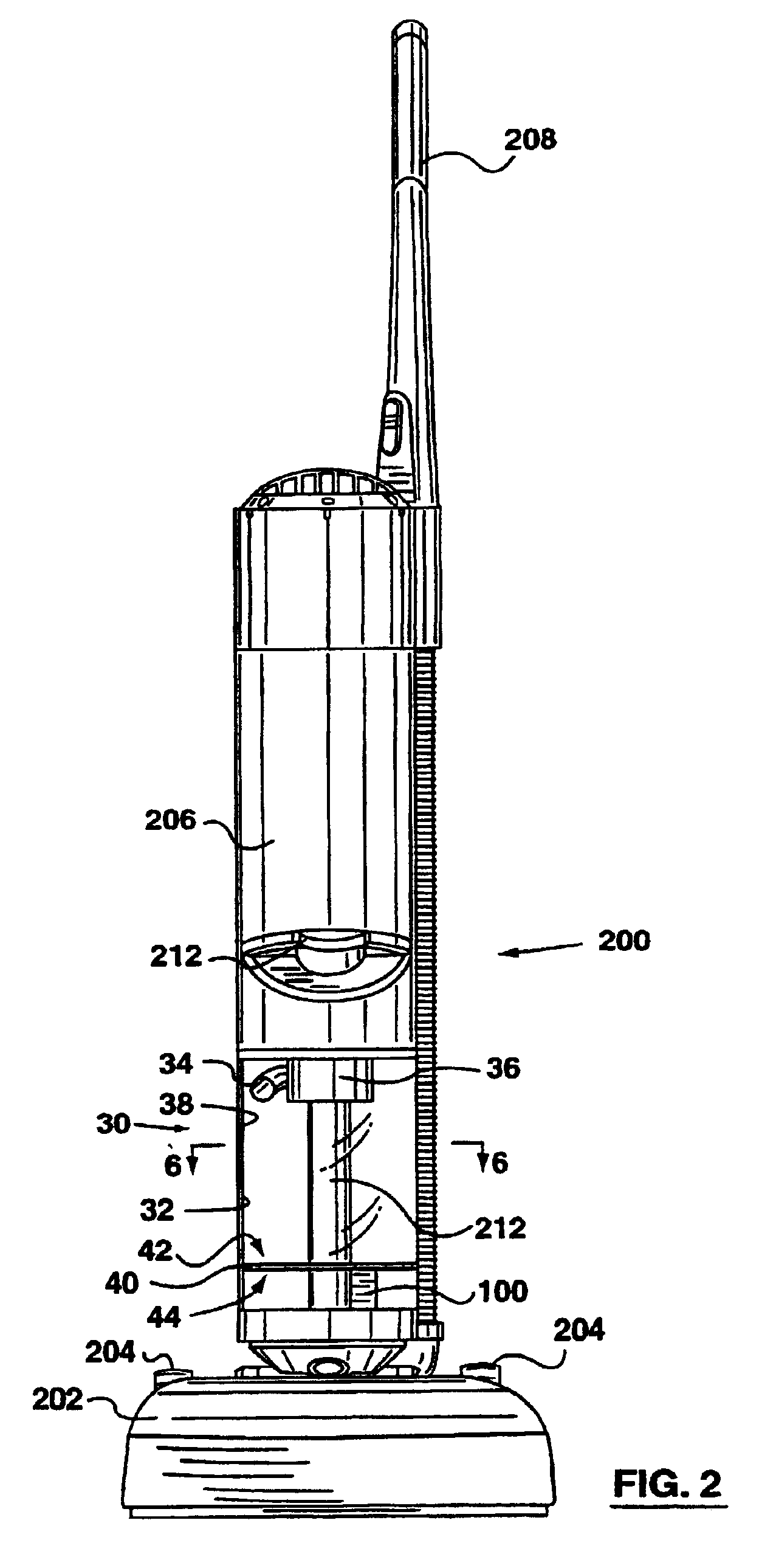

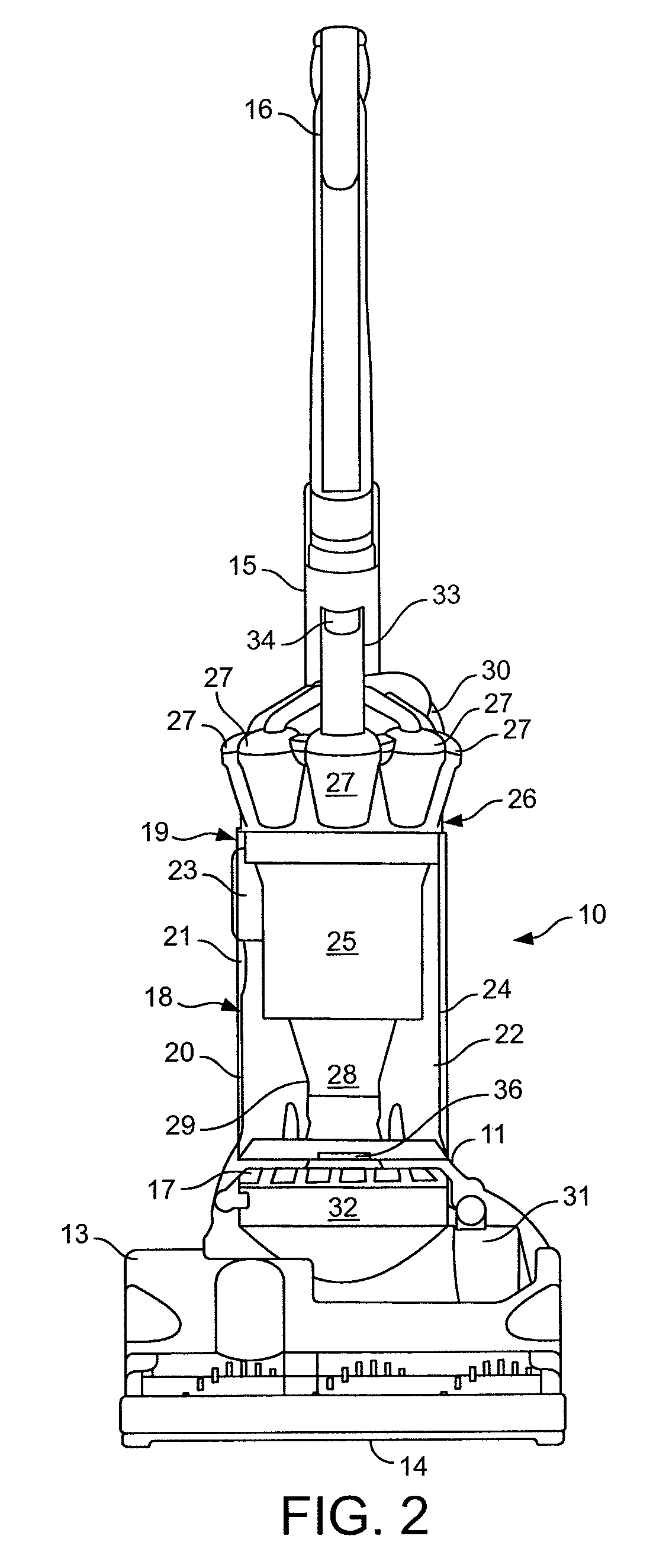

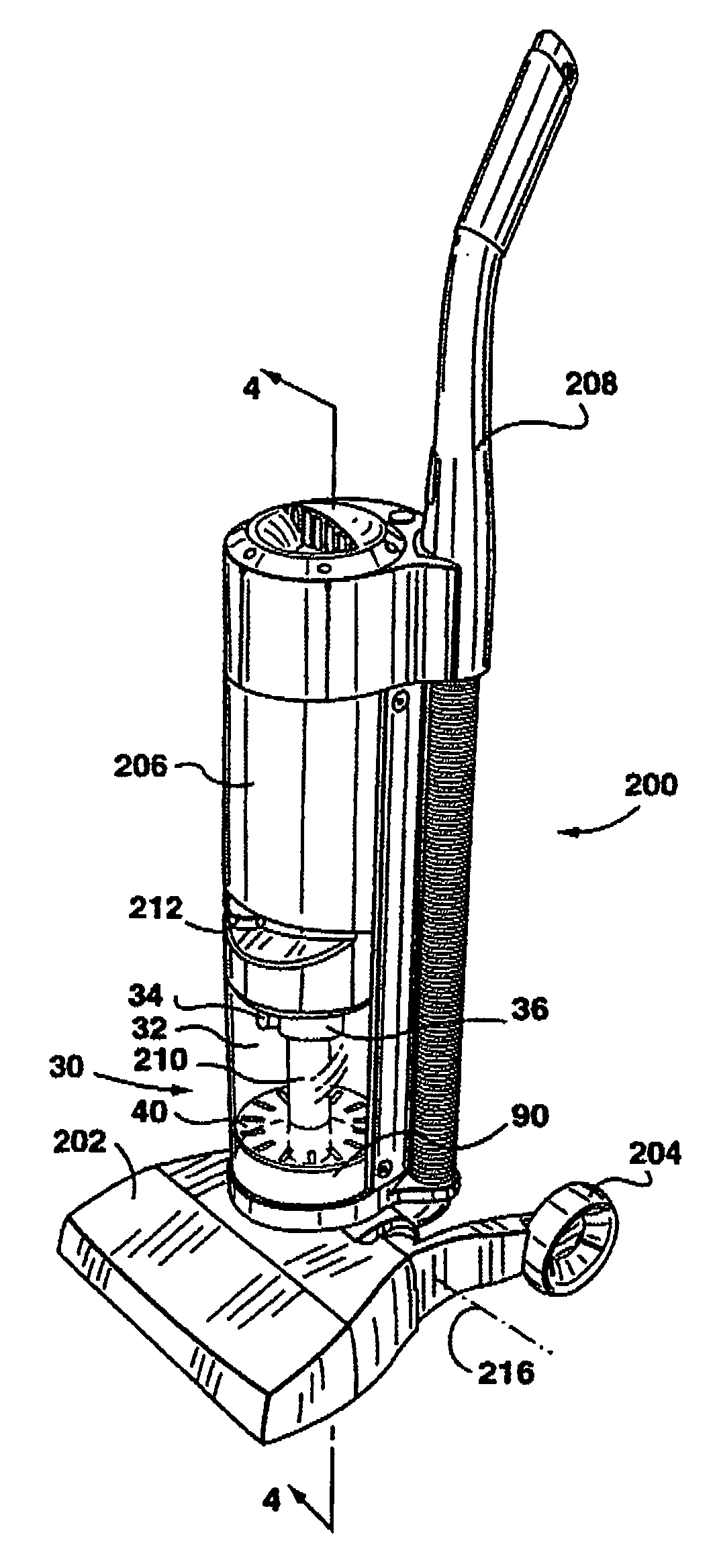

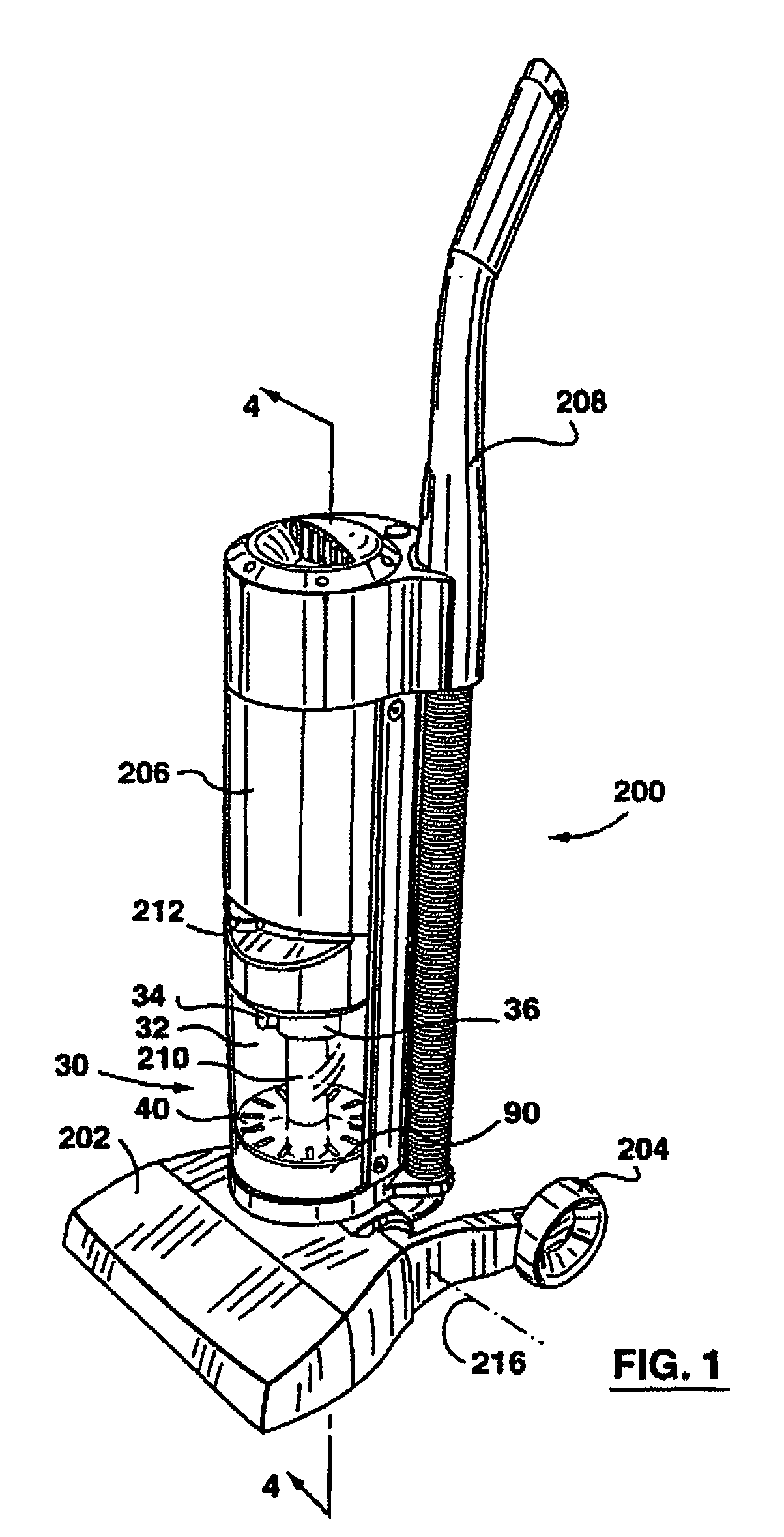

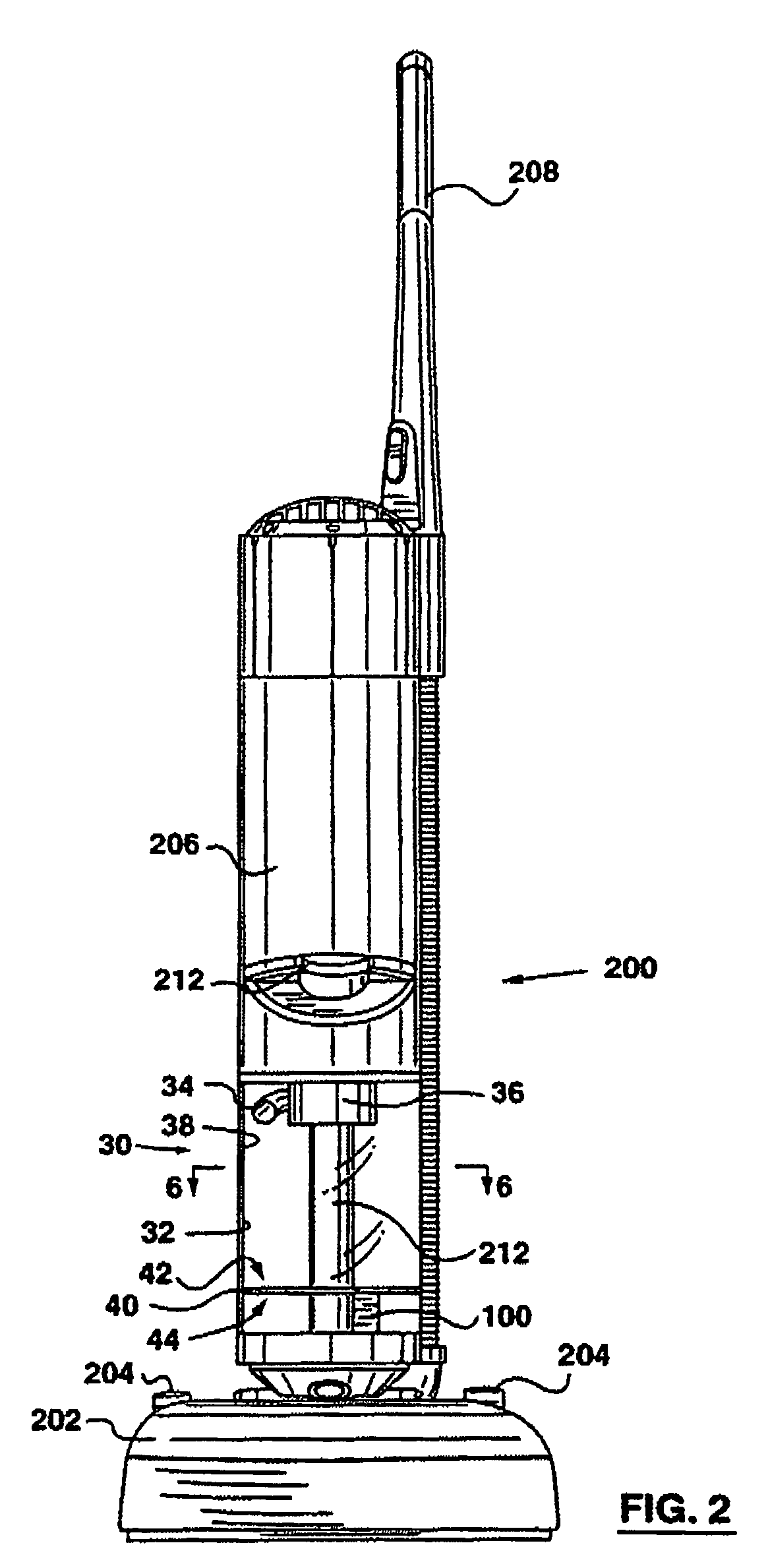

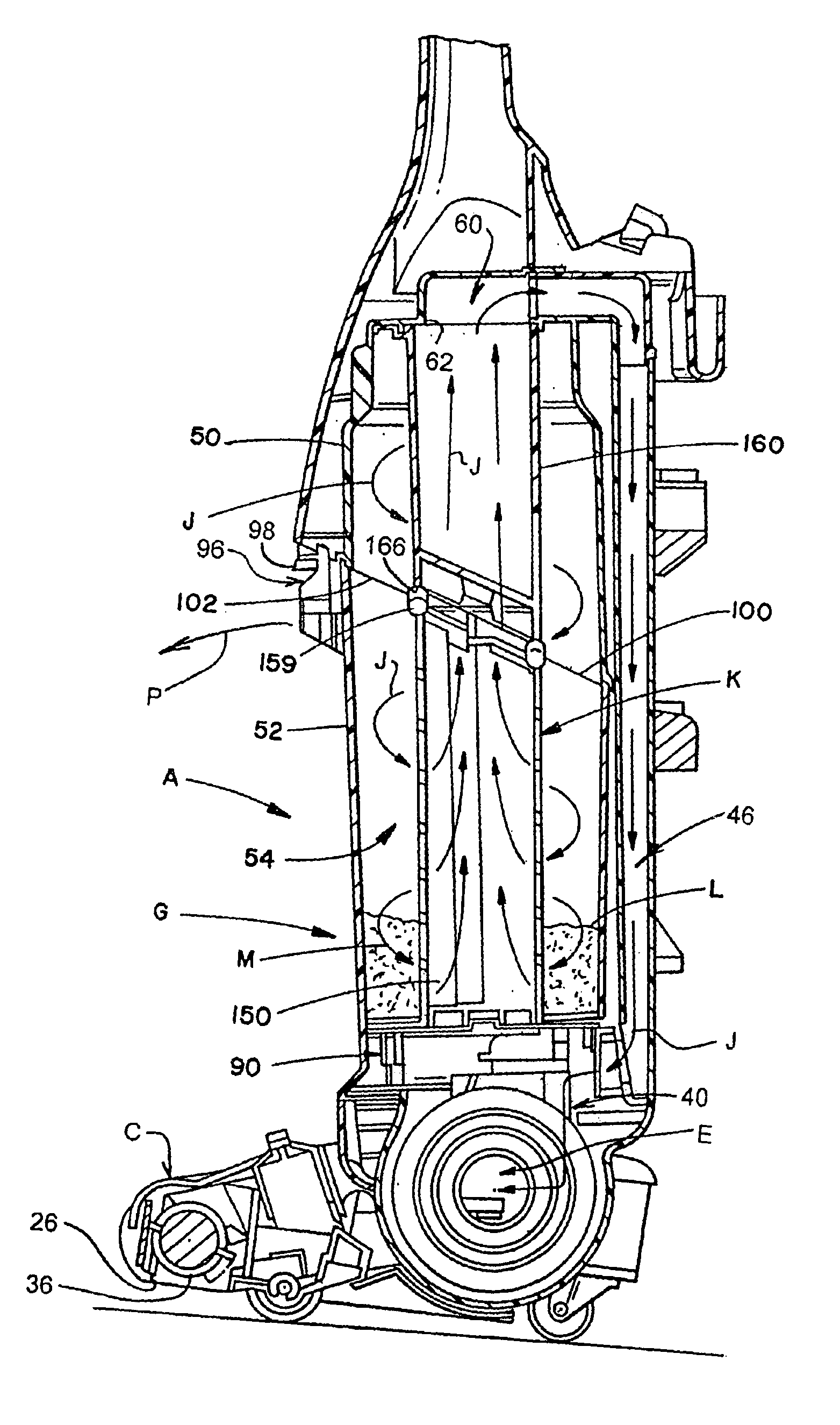

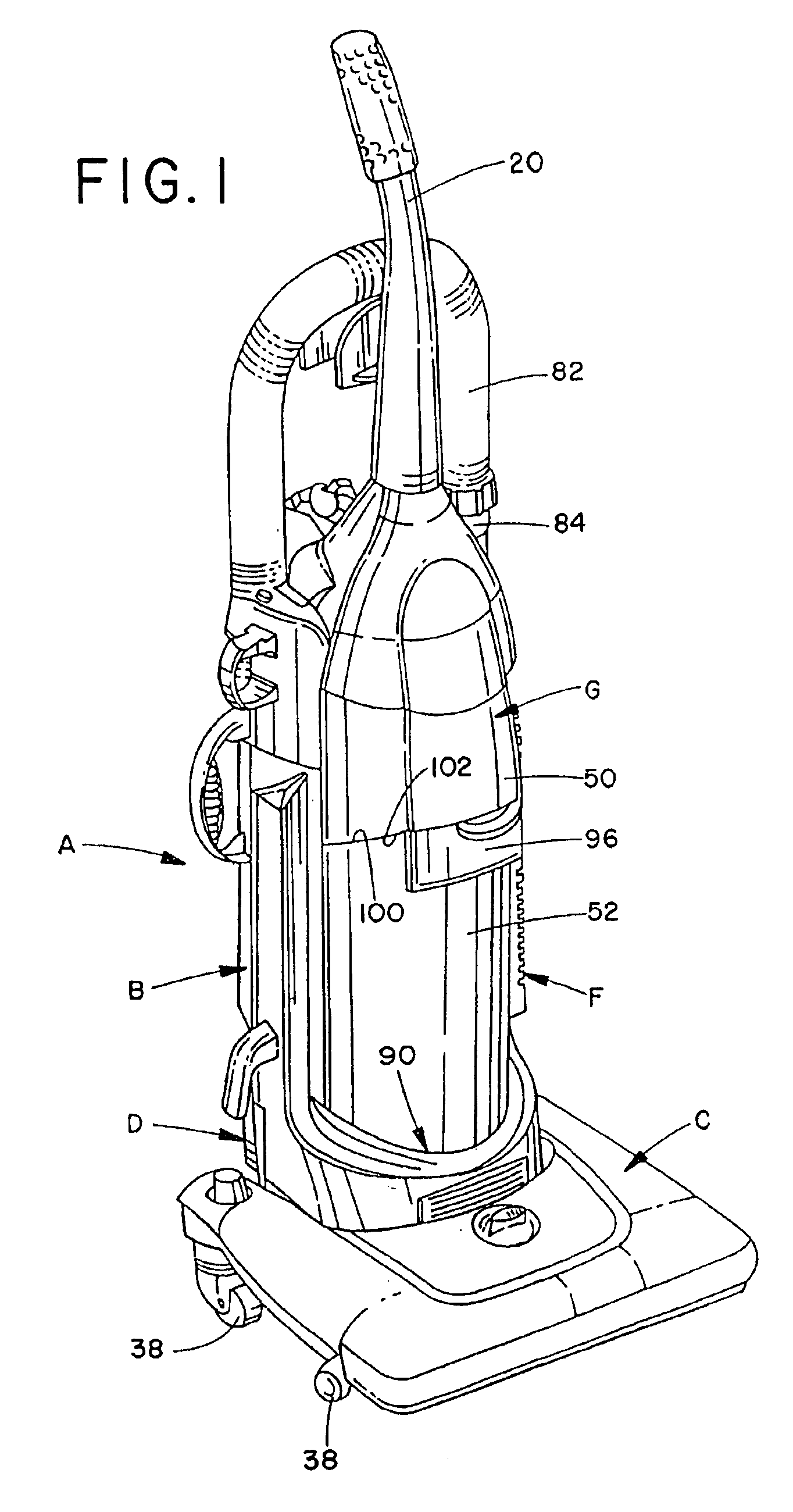

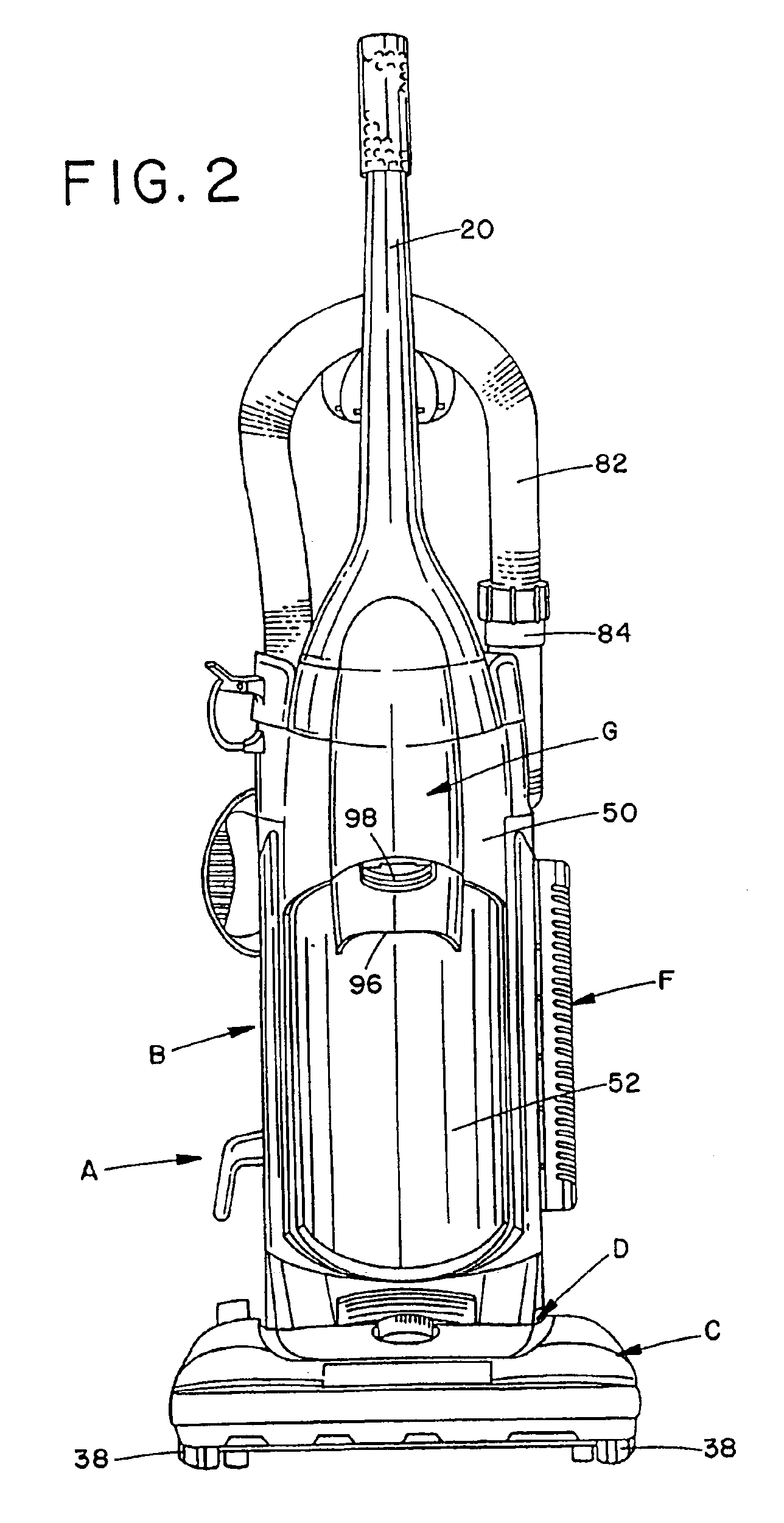

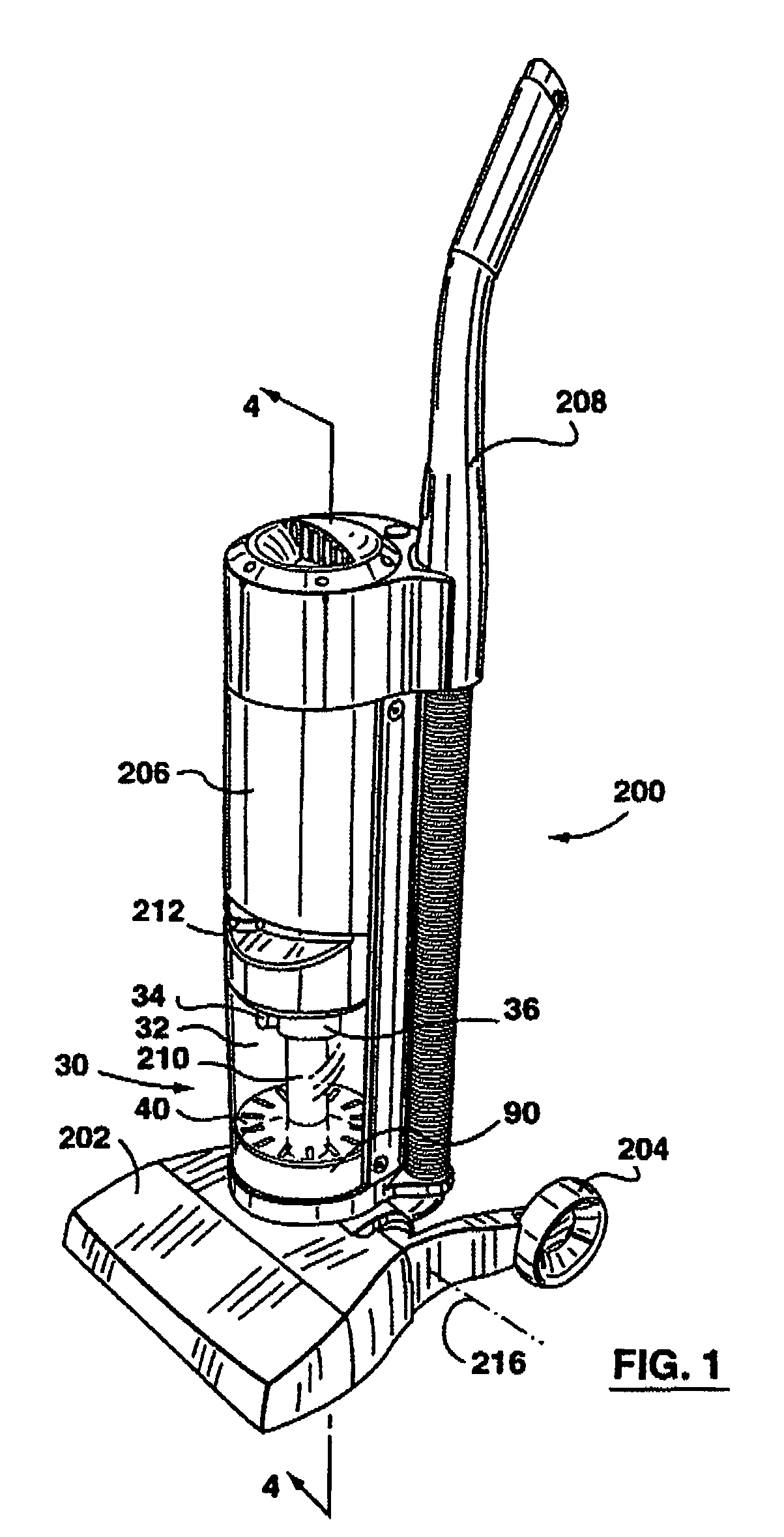

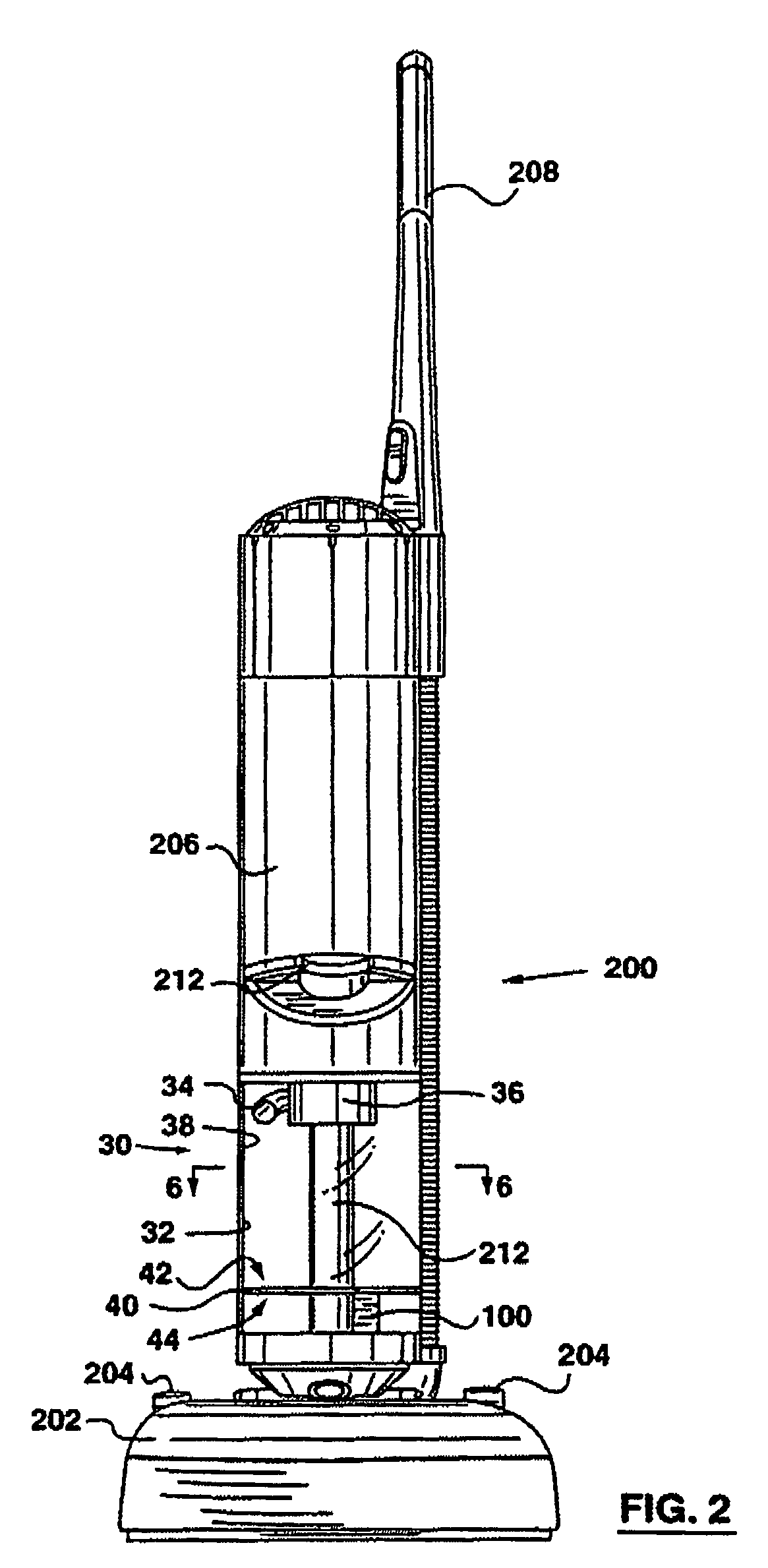

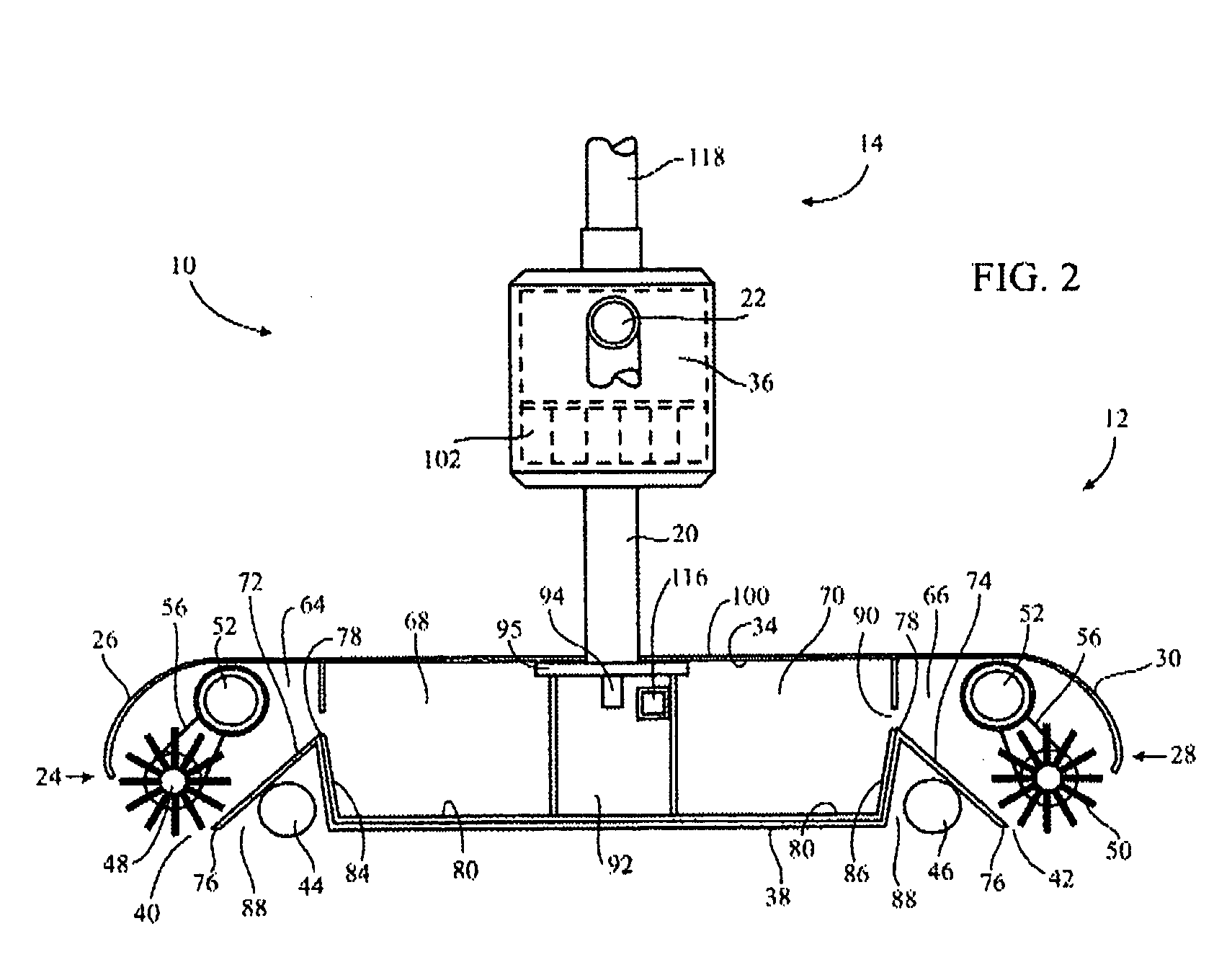

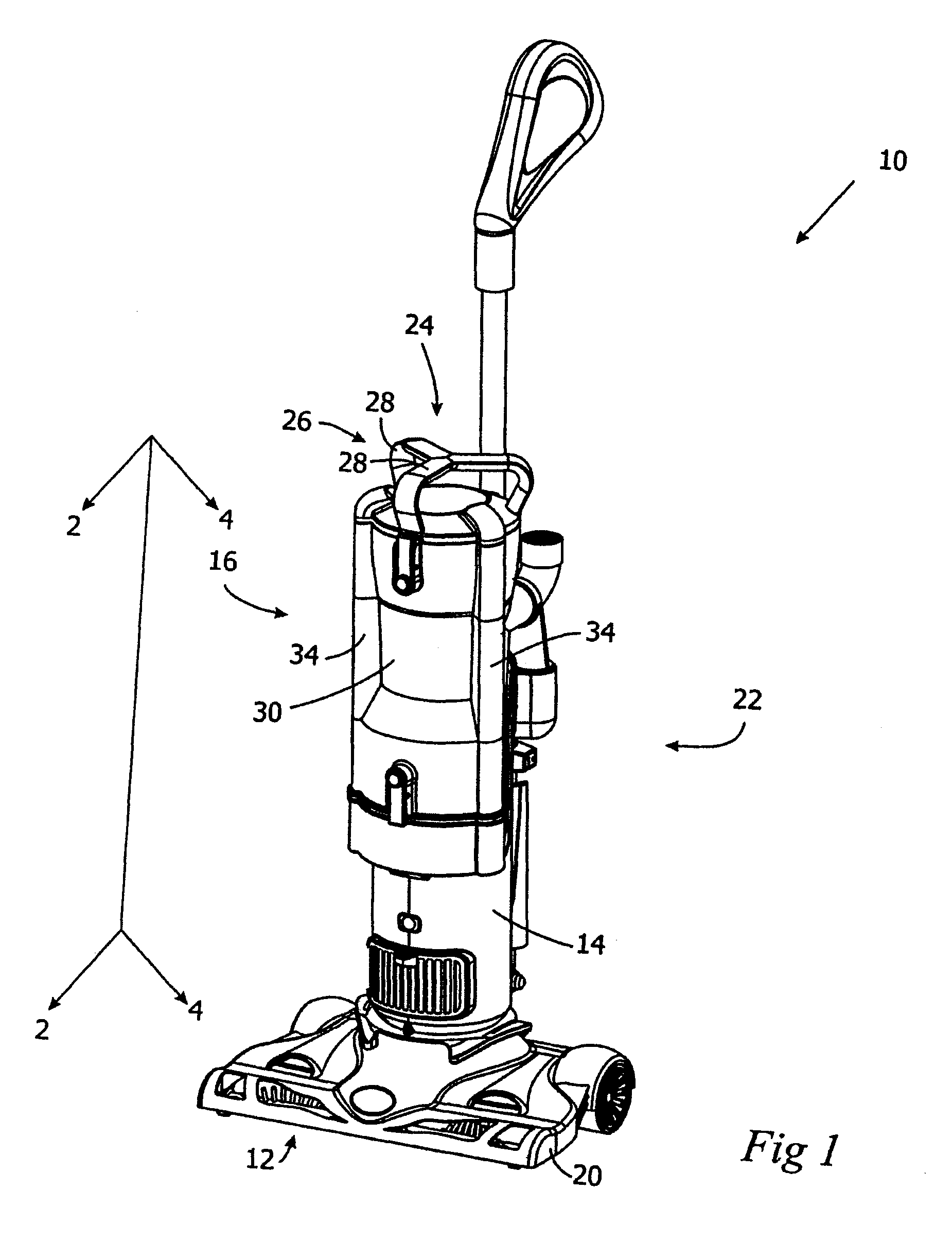

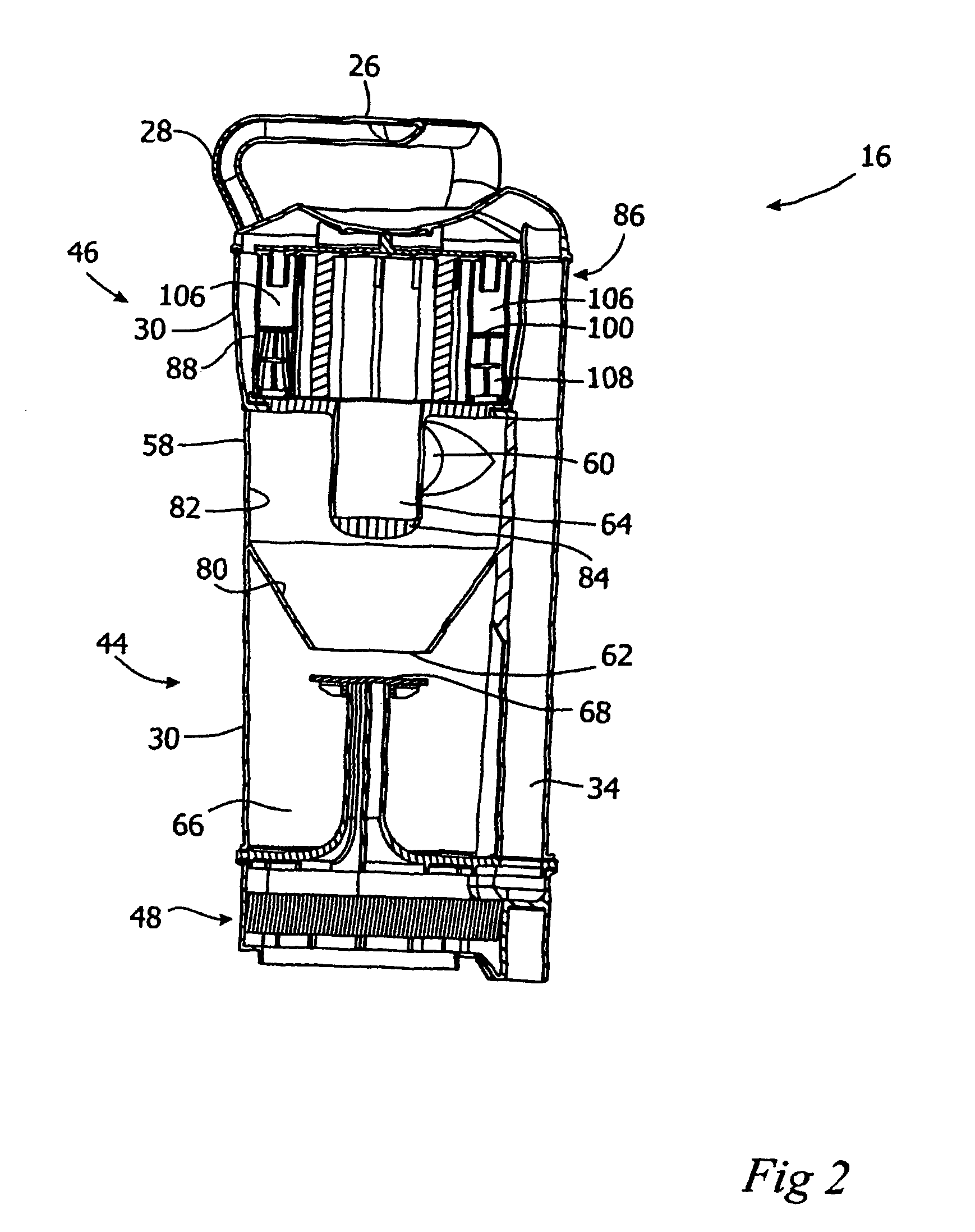

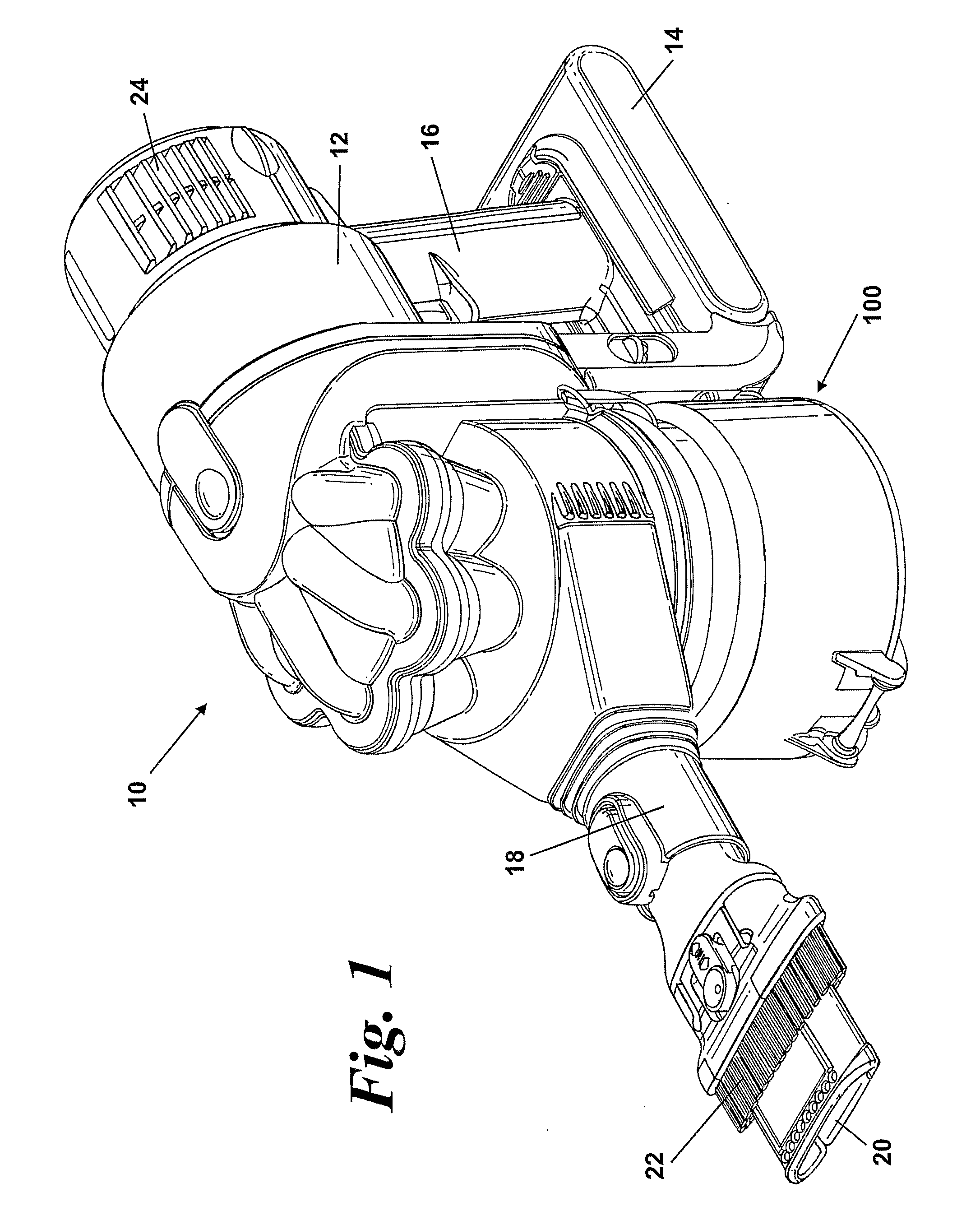

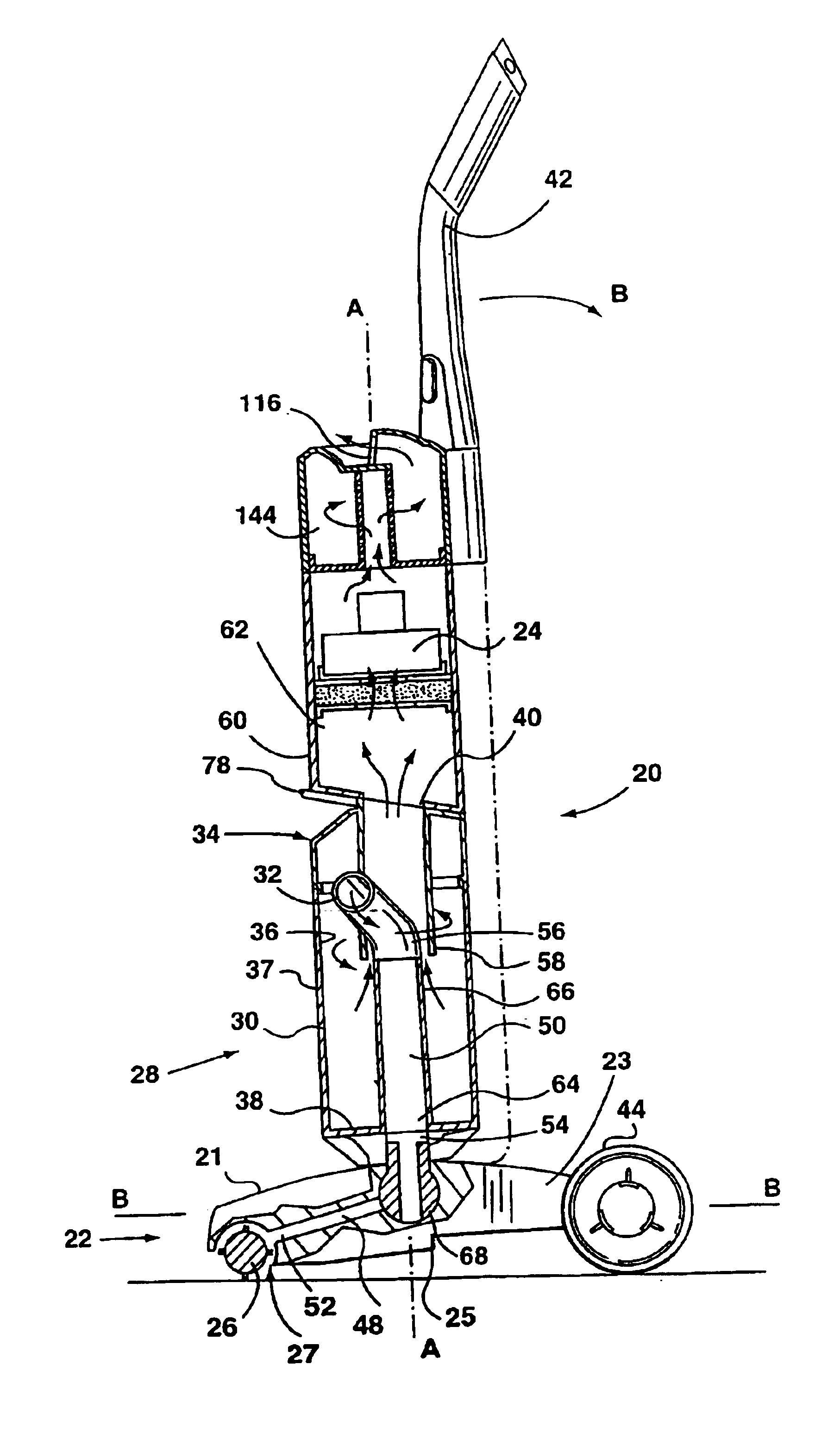

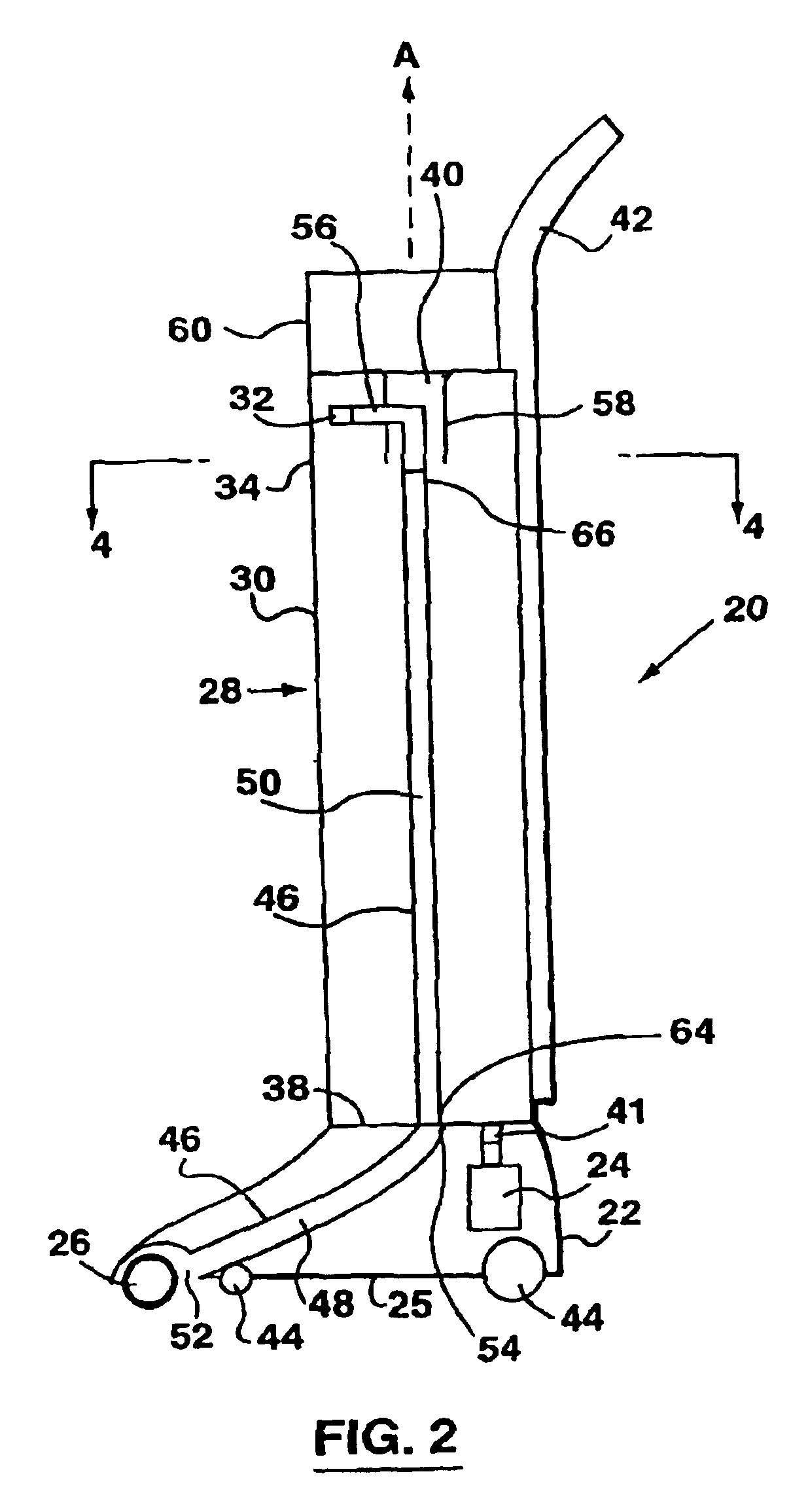

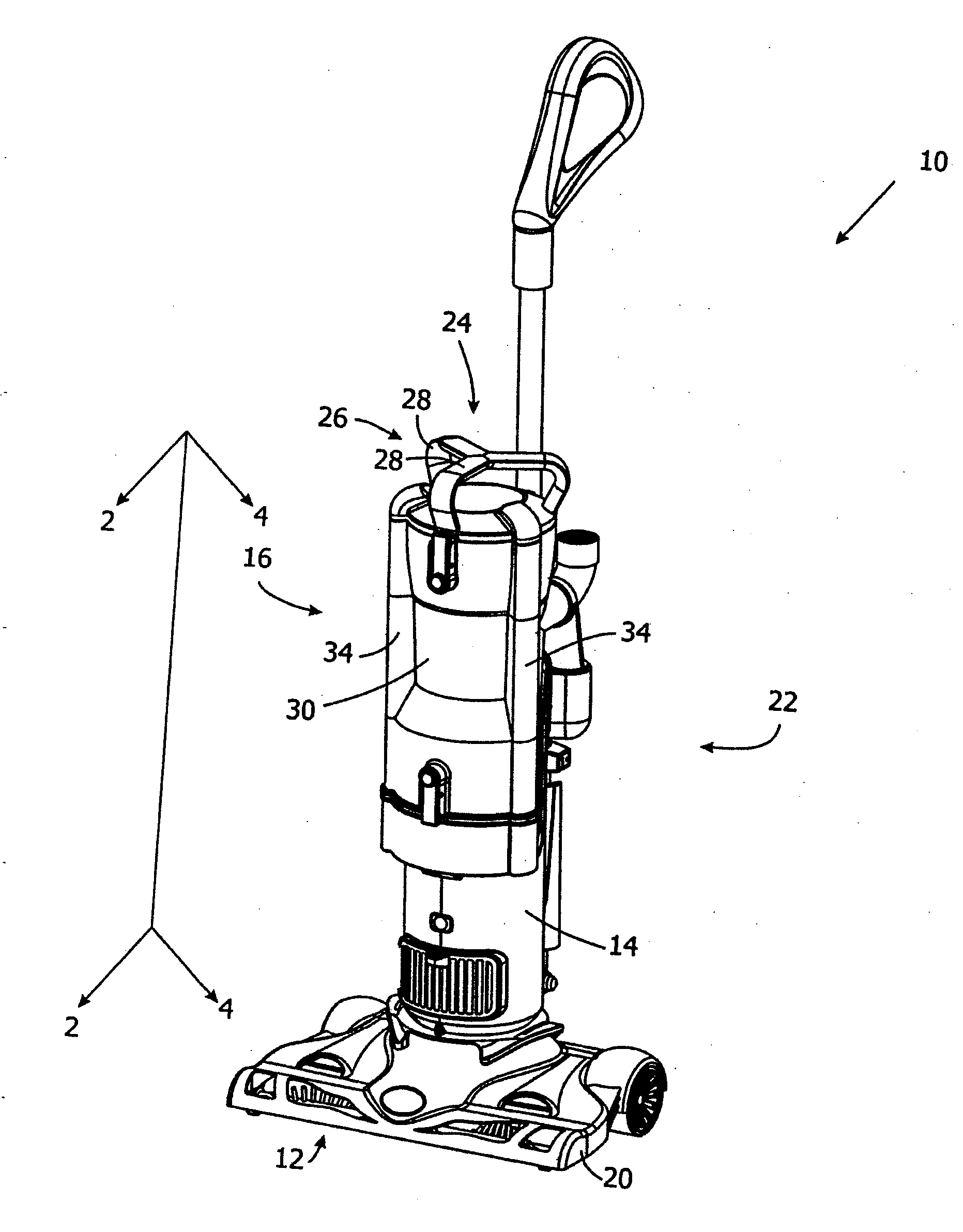

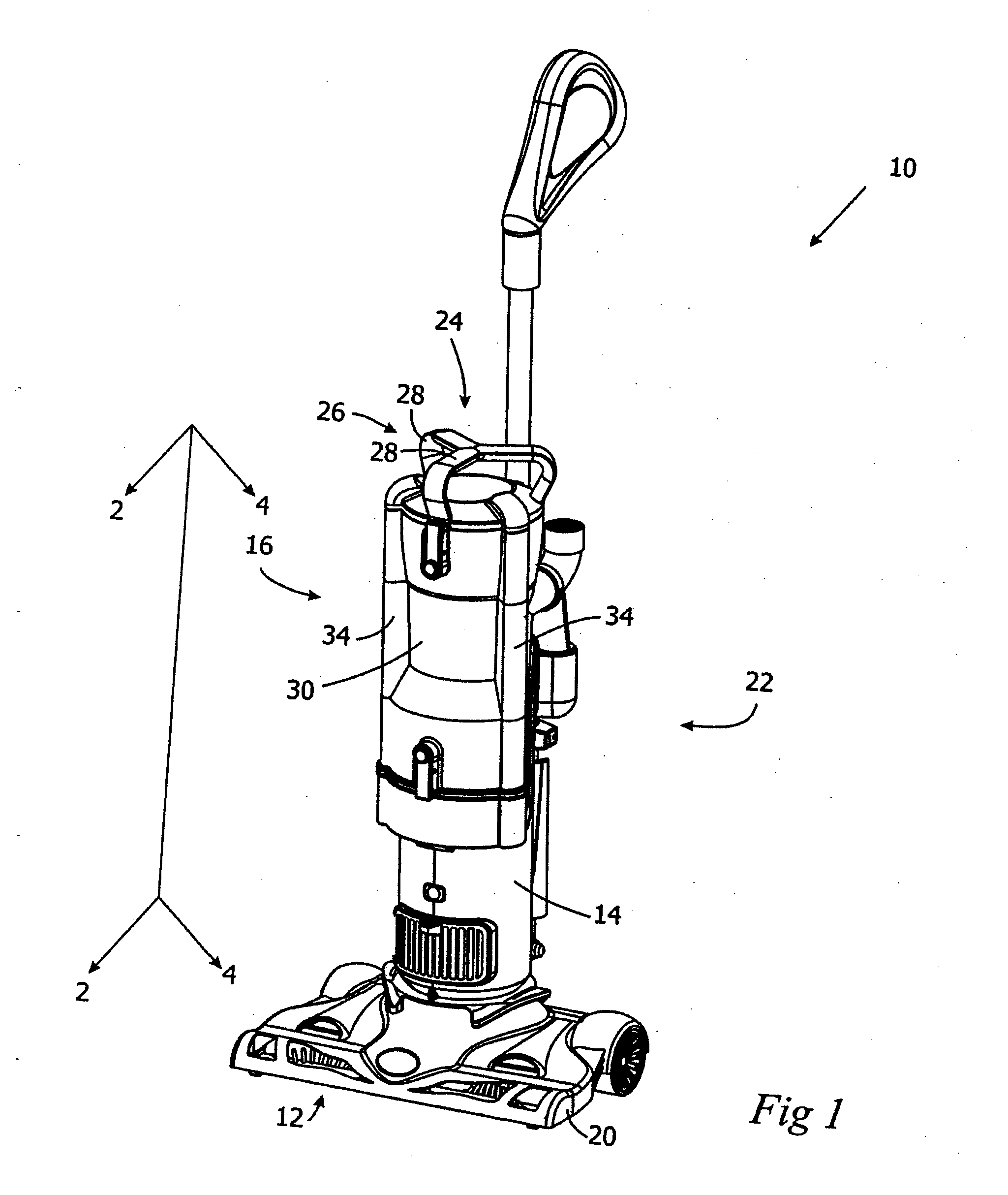

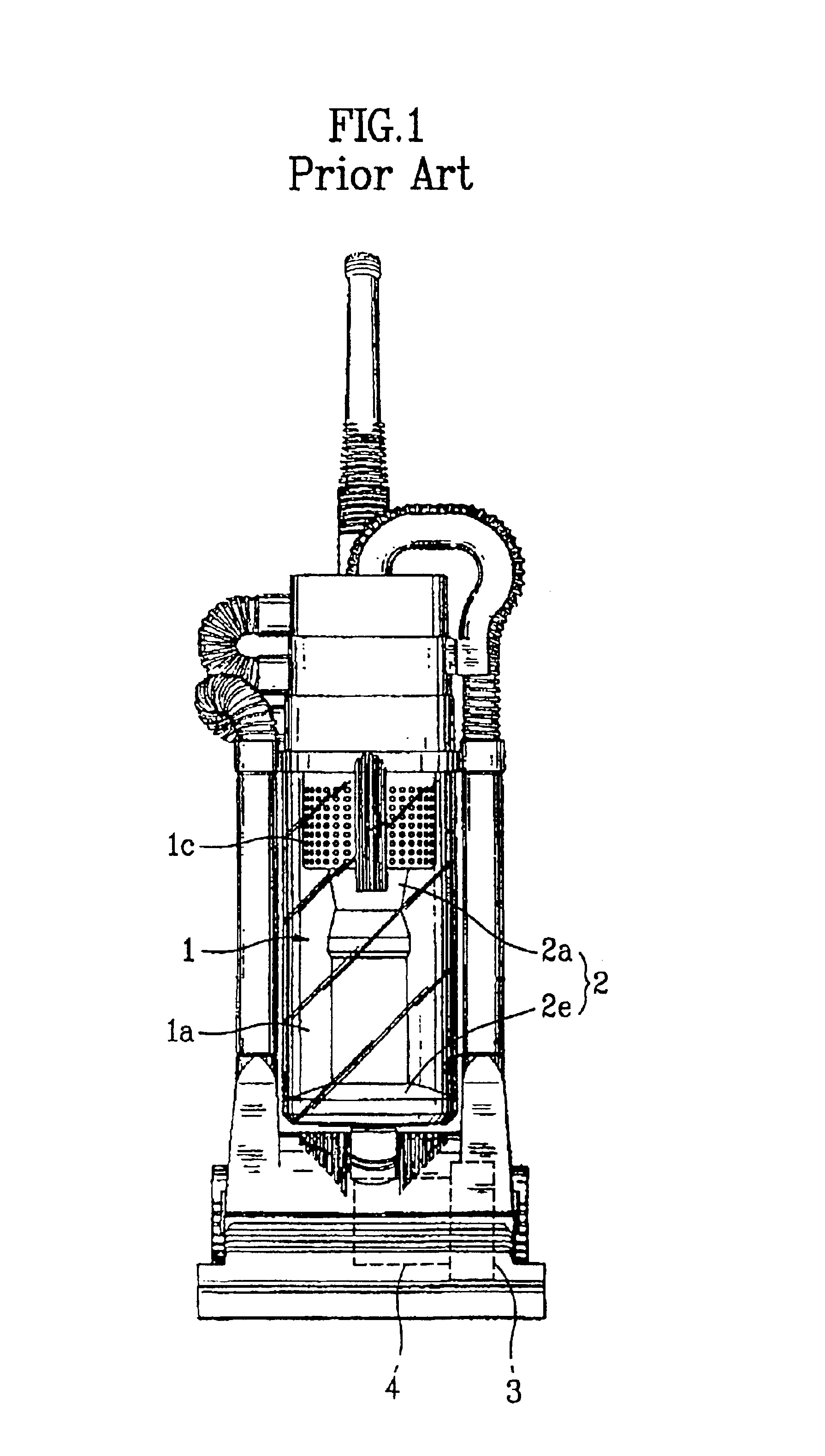

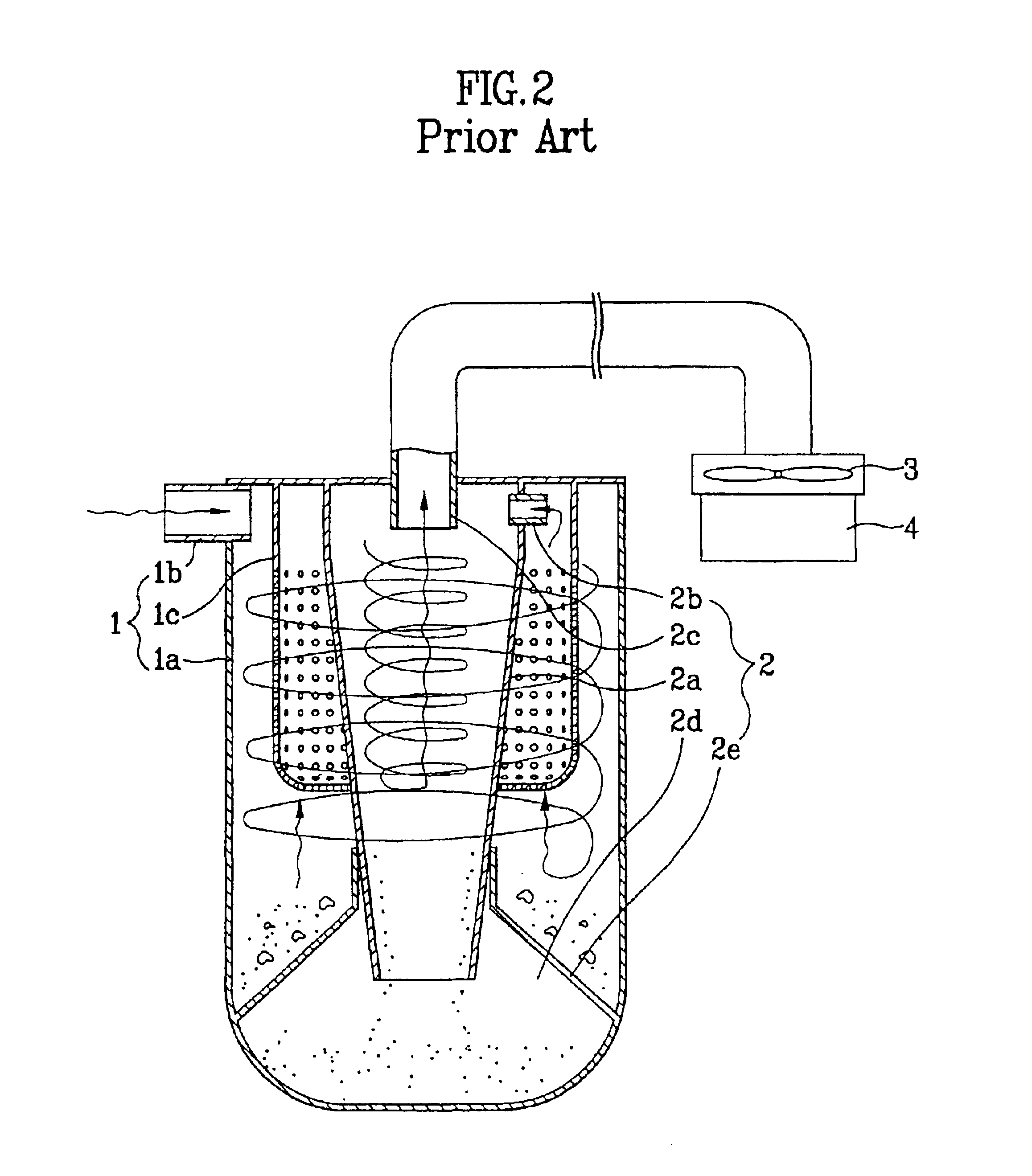

Upright vacuum cleaner with cyclonic airflow

InactiveUS6848146B2Easily and conveniently emptied dirt cupEffective filteringCleaning filter meansCombination devicesHEPACyclone

A vacuum cleaner includes a first housing defining a cyclonic airflow chamber and a second housing defining a main suction opening that is in communication with an inlet of the cyclonic chamber. A suction source has a suction airstream inlet in communication with an outlet of the cyclonic chamber, and establishes a suction airstream that enters said main suction opening, passes through said cyclonic chamber, and passes to an outlet of said suction source. A substantial portion of particulates entrained in the suction airstream are separated therefrom when said suction airstream moves in a cyclonic fashion through the cyclonic chamber. A main filter assembly, preferably including filter medium comprising polytetrafluoroethylene (PTFE), is located in the cyclonic chamber so that a suction airstream moving from the main suction opening to the inlet of said suction source by way of the cyclonic airflow chamber passes through the filter medium thereof after said airstream moves in a cyclonic fashion within the cyclonic airflow chamber to remove residual particulates from the suction airstream before it leaves the cyclonic chamber. A HEPA filter can be provided to filter the suction airstream exhausted through the outlet of the suction source prior to the airstream being discharged from the vacuum.

Owner:ROYAL APPLIANCE MFG

Cyclone vessel dust collector and vacuum cleaner having the same

InactiveUS20050252180A1Small sizeLarge amount of dust collectionCleaning filter meansSuction filtersCycloneMarine engineering

Disclosed are a cyclone vessel dust collection and a vacuum cleaner including the same. The cyclone vessel dust collector comprises a cyclone vessel main-body including a primary cyclone vessel unit for separating dusts from dust containing air, and one or more secondary cyclone vessel units for separating dusts from the air passing through the primary cyclone vessel unit, the secondary cyclone vessel units being arranged to surround at least a part of the primary cyclone vessel unit; and a dirt collection bin for receiving dusts or the like separated by the cyclone vessel main-body, wherein the cyclone vessel main-body has an outer circumference with a non-constant radius. Therefore, the cyclone vessel dust collector can have a dust collection capability of large capacity with a small size.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Cyclone dust collecting apparatus having contaminants counterflow prevention member

InactiveUS20060168922A1Prevent backflowCombination devicesAuxillary pretreatmentEngineeringPollutant

A cyclone dust collecting apparatus comprises a deformable contaminants counterflow prevention member mounted to within 10 to 12 mm of the inner surface of the cyclone dust collecting apparatus. The deformable contaminants counterflow prevention member is soft enough to be elastically transformed to allow large contaminants to be drawn past it and drop into a dust collecting apparatus yet resilient enough so that it returns to its original shape after a large contaminant is passed.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Apparatus and method for separating particles from a cyclonic fluid flow

InactiveUS7449040B2Prevent reentrainmentEfficient separationCleaning filter meansCombination devicesParticle separationPhysics

A particle separation member is provided for use with a cyclone separator. The particle separation member divides the separator into a cyclone chamber and a particle receiving chamber. The cyclone chamber and the particle receiving chamber communicating via a plurality of apertures in the particle separation member.

Owner:OMACHRON INTPROP

Dirt container for a surface cleaning apparatus and method of use

InactiveUS20050115409A1Efficient removalReduce the amount requiredCombination devicesAuxillary pretreatmentSurface cleaningEngineering

A dirt container for a surface cleaning apparatus is constructed from an air impermeable material and exterior walls of sufficient rigidity to maintain the shape of the dirt container. The dirt container may be supplied in a disassembled condition and assembled by a consumer prior to use.

Owner:POLAR LIGHT

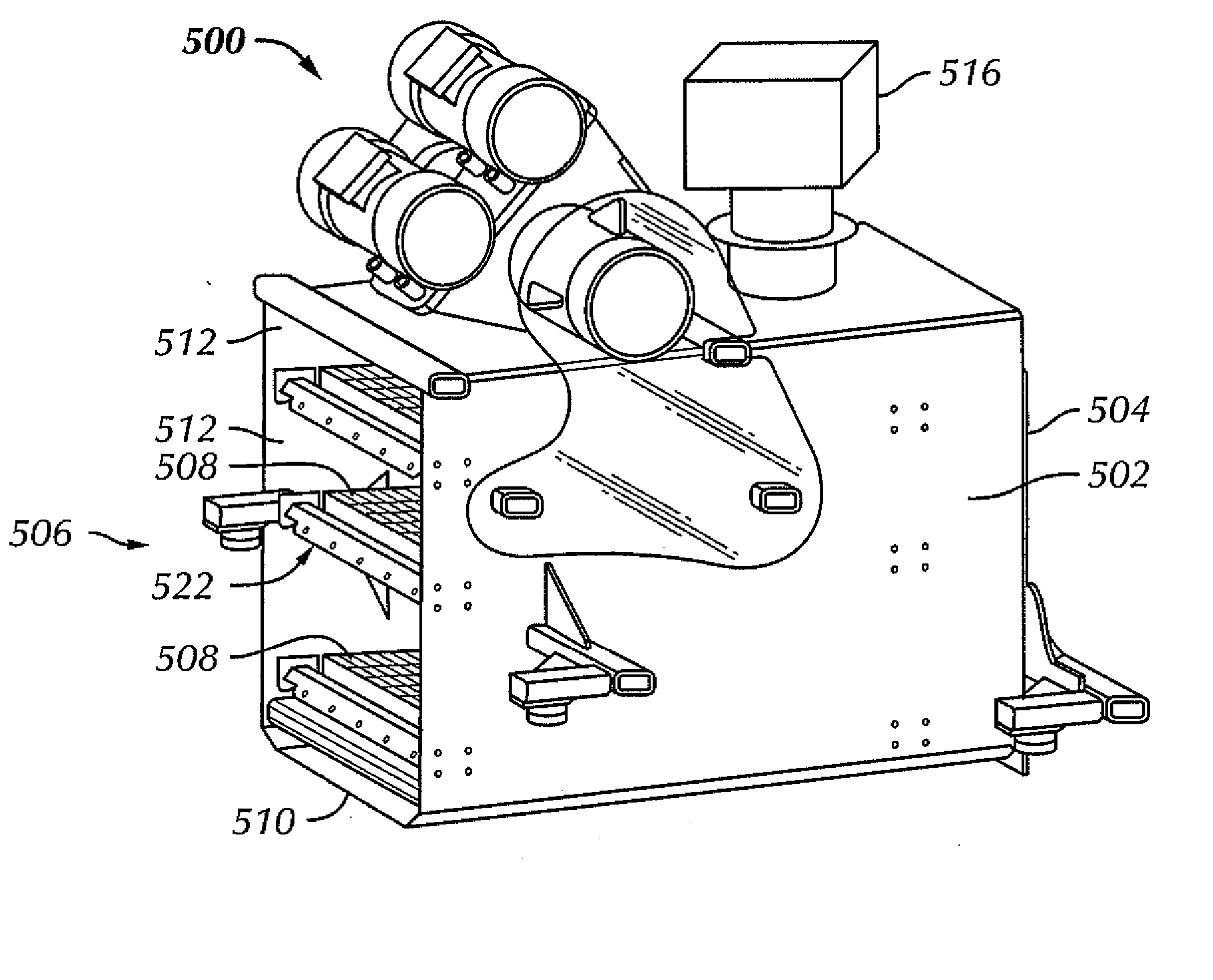

Cyclonic array such as for a vacuum cleaner

InactiveUS7867308B2Reliable and easy to manufactureEasy to disassembleCleaning filter meansCombination devicesCycloneSurface cleaning

A cyclonic cleaning stage for a, e.g., surface cleaning apparatus is provided. The cyclonic cleaning stage comprises a plurality of cyclones, which are integrally molded as a single body. Each cyclone has a cyclone body having an upper end, a lower end, a cyclone inlet, and a cyclone outlet. Each cyclone inlet has a top. A separately molded upper cover is mounted to the top of the single body at the upper ends. A separately molded lower cover is mounted on the single body at the lower ends of the cyclones.

Owner:OMACHRON INTPROP

Cyclonic bagless vacuum cleaner with slotted baffle

A dirt separation and collection container suitable for use in a bagless vacuum cleaner including two dirt separation and collection zones is provided. Dirty air enters the mid-section of the device and enters a first stage dirt separation zone including a cylindrical baffle spaced inwardly from the outer wall of the device with an inclined slot to allow coarse dirt particles and fibers to pass through and collect at the base of the outer wall of the device. The spinning air is then fed into a second stage conical separator for separating fine dirt particles and collecting them in an inner substantially cylindrical collection chamber. Air exits the conical separator and device opposite the cone opening before being drawn to the suction source. Elements may be oriented upwardly or downwardly depending upon the configuration of the housing for receiving the dirt separation and collection device.

Owner:SHARKNINJA OPERATING LLC

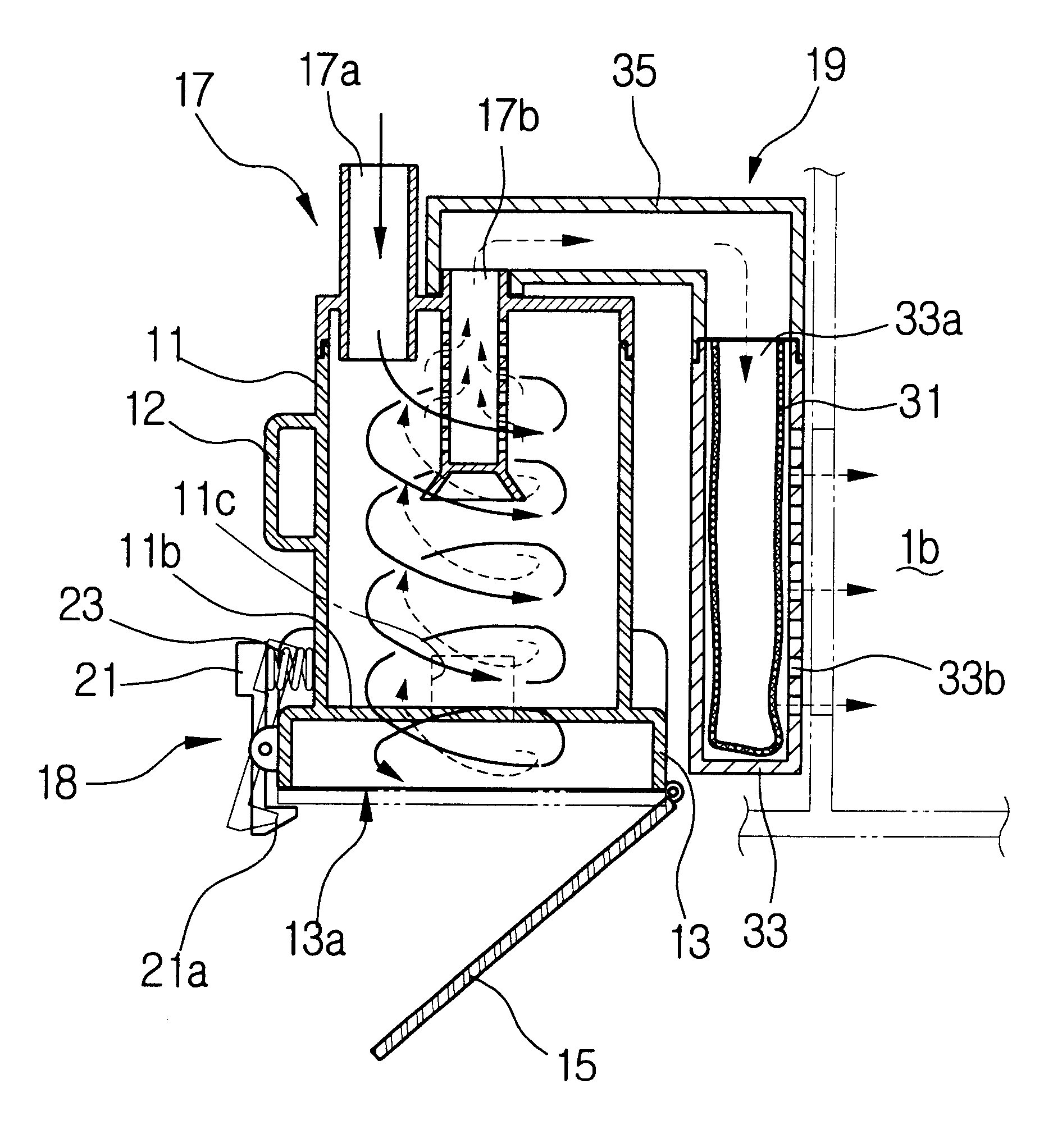

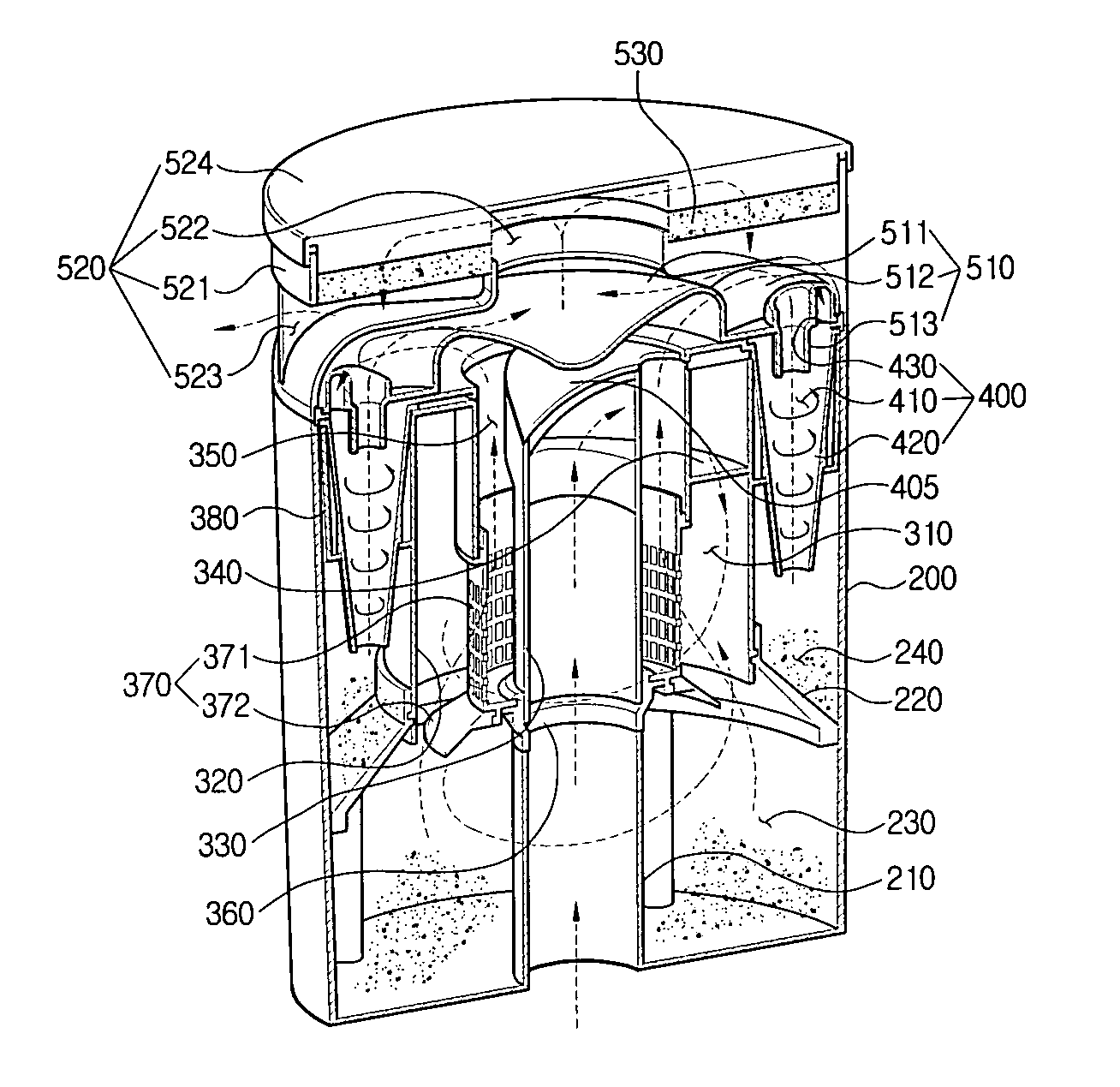

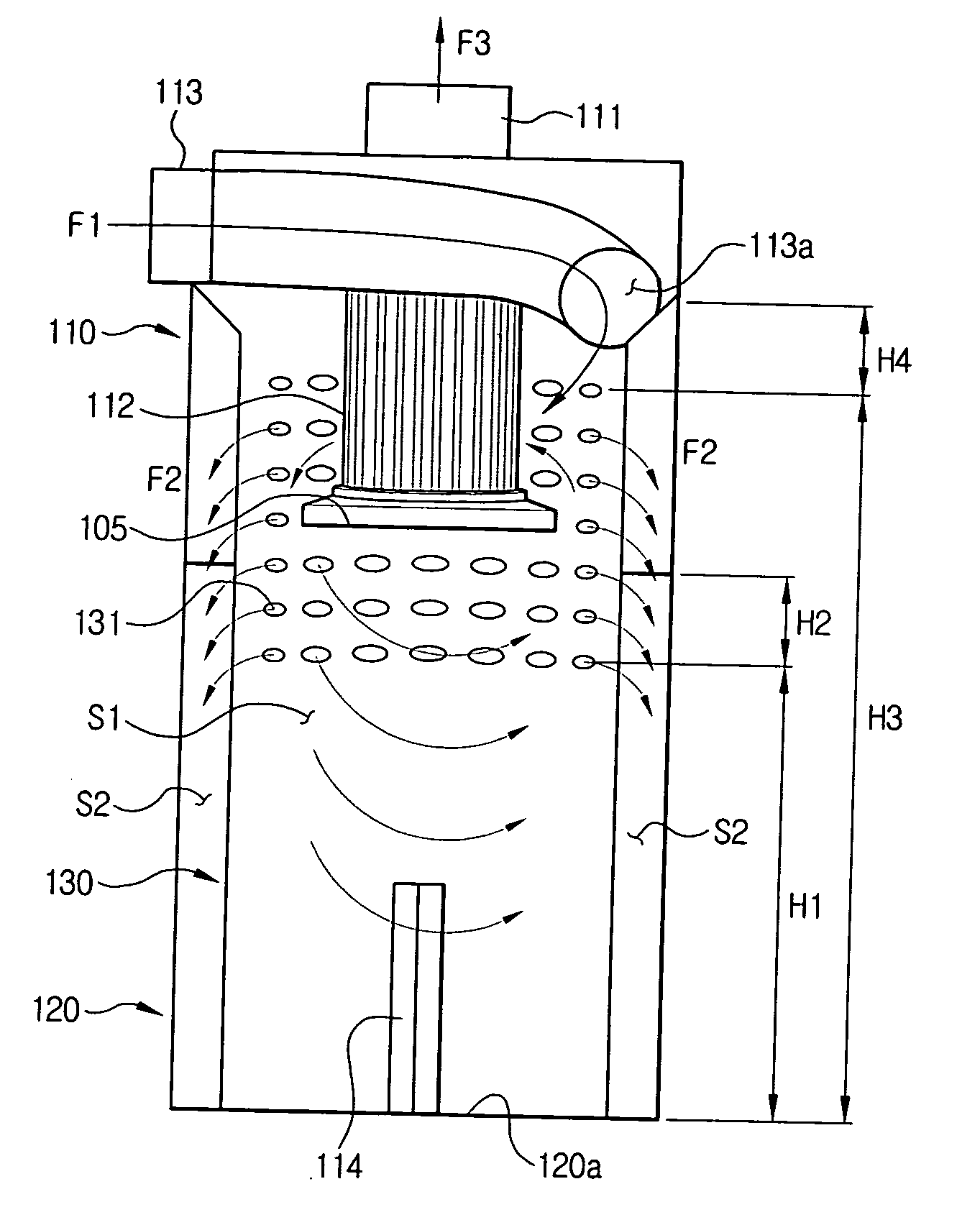

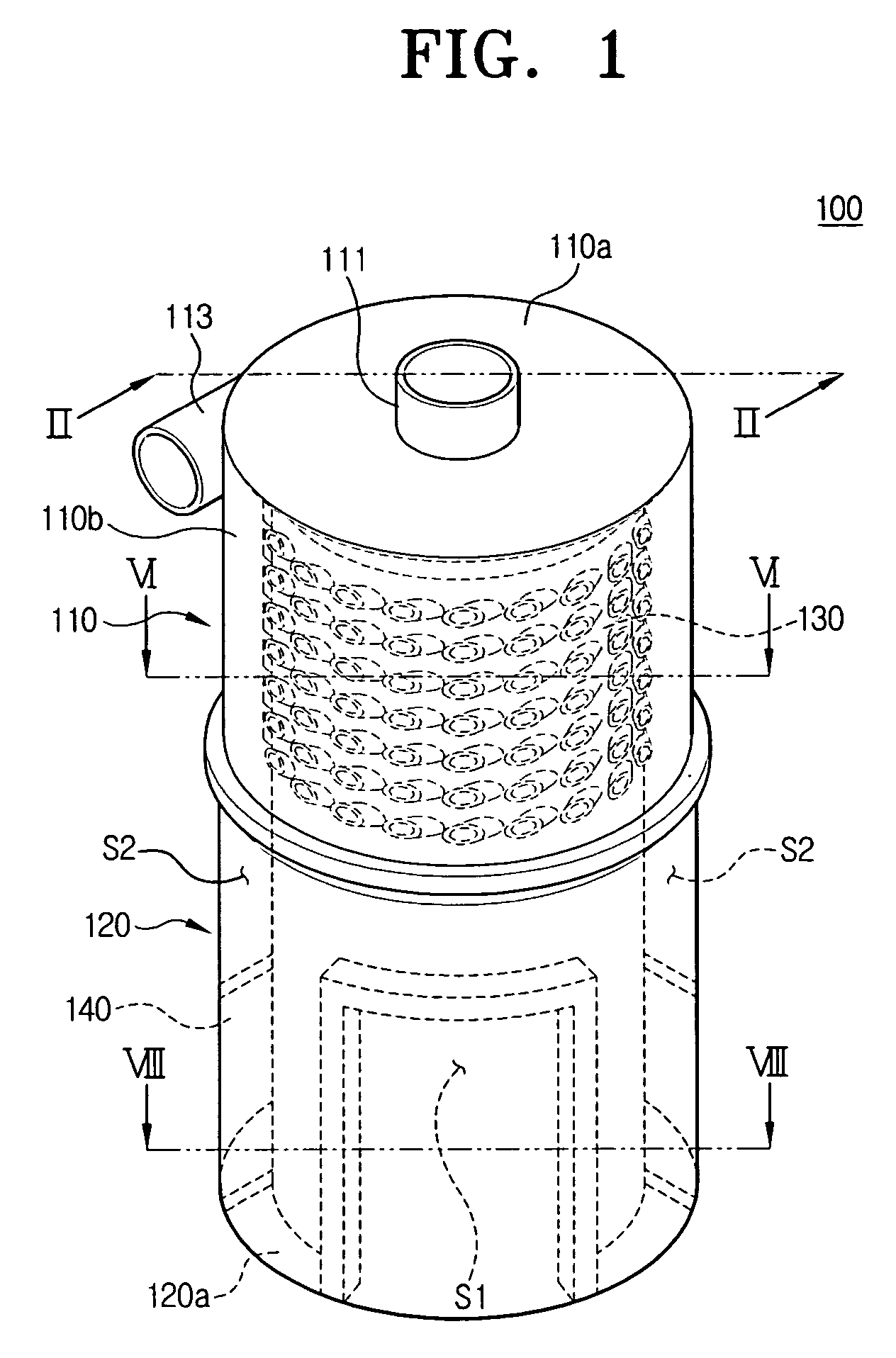

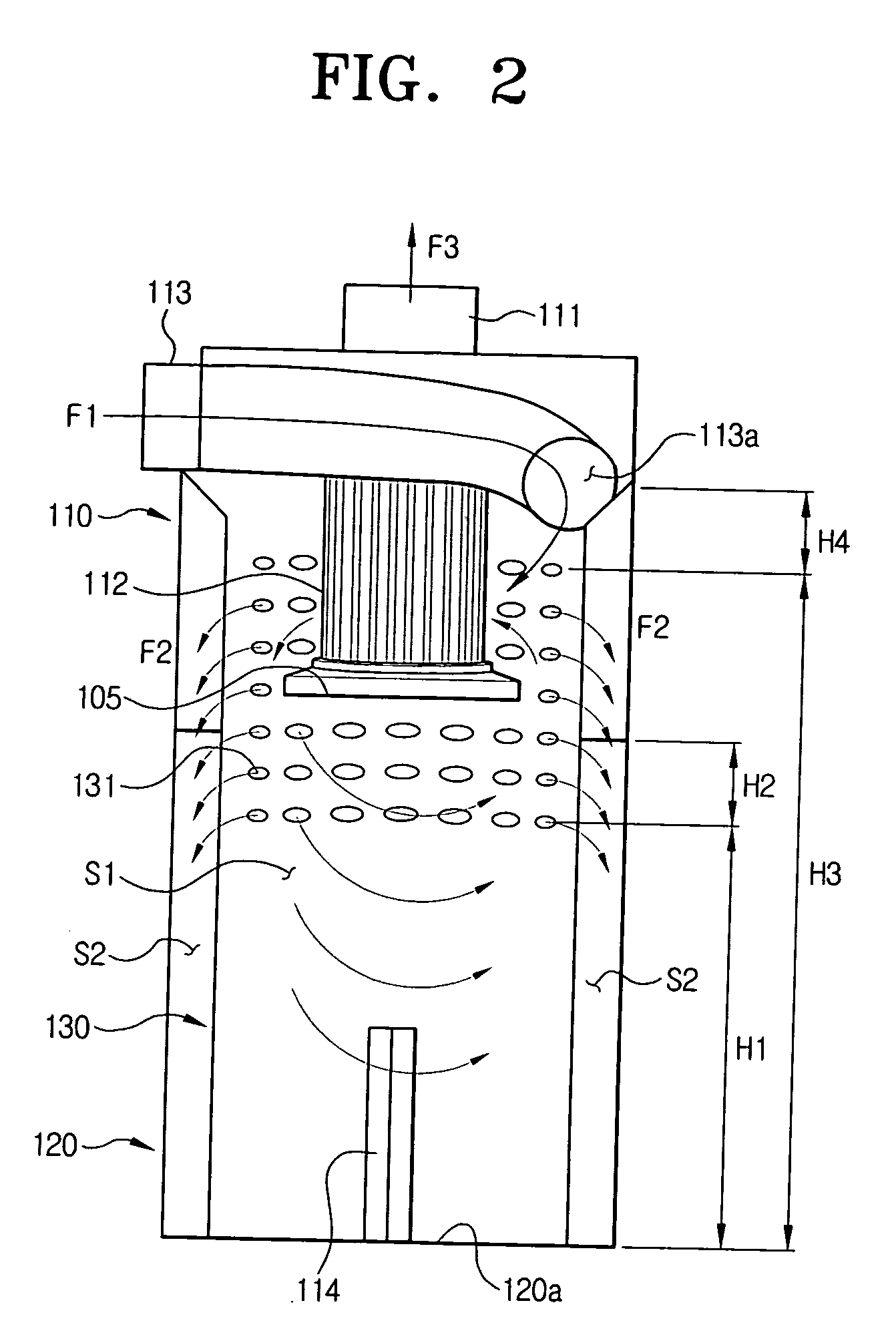

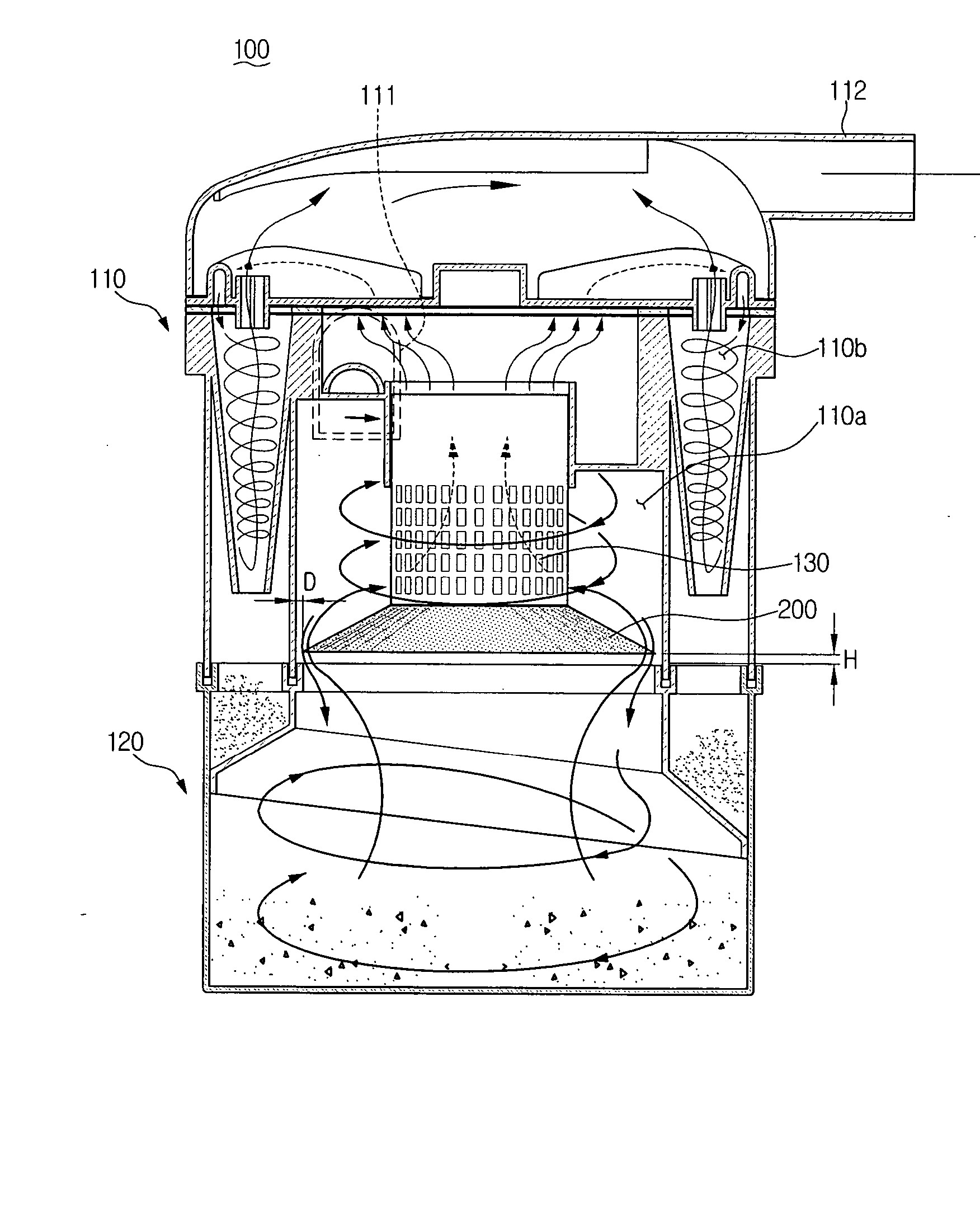

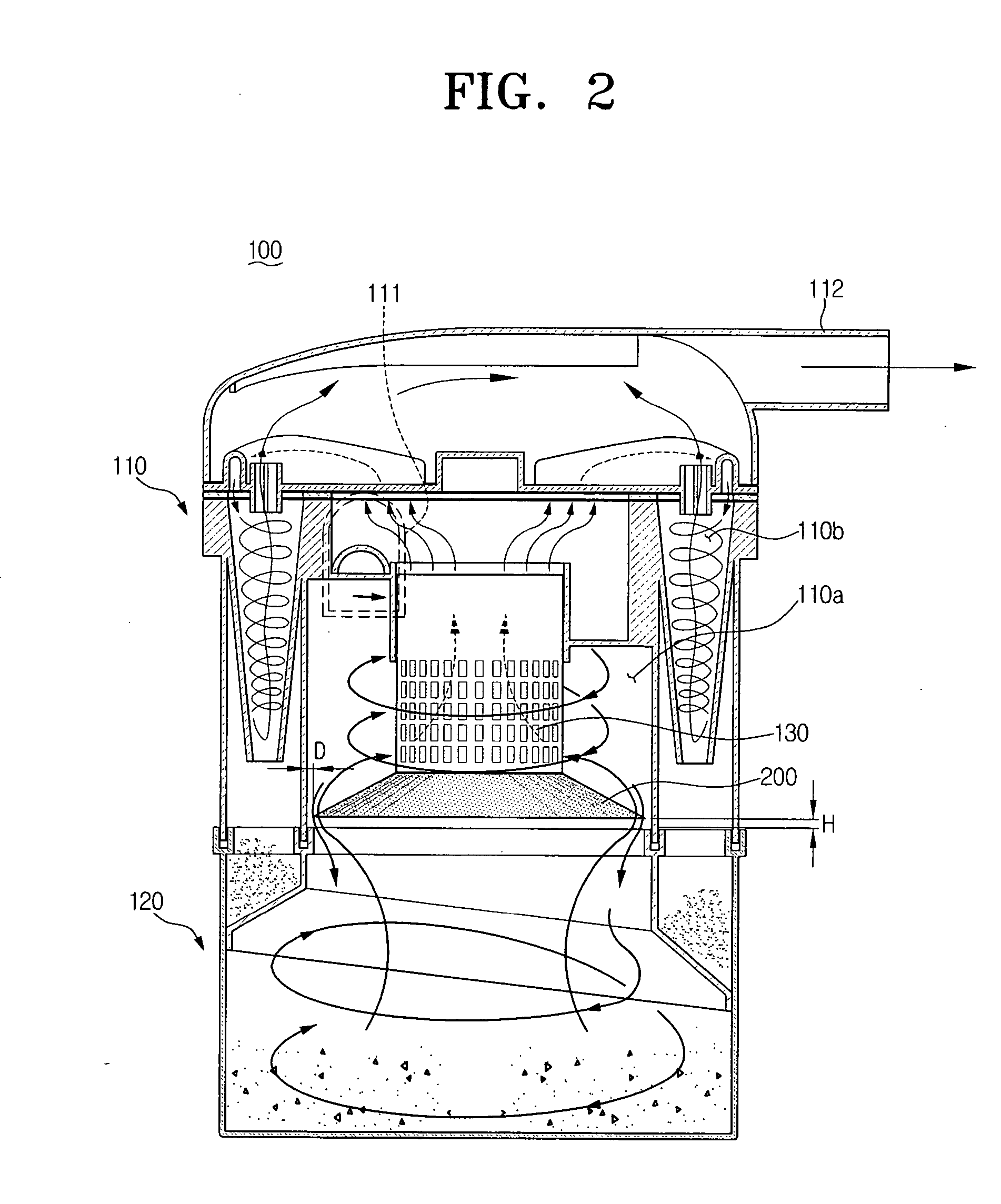

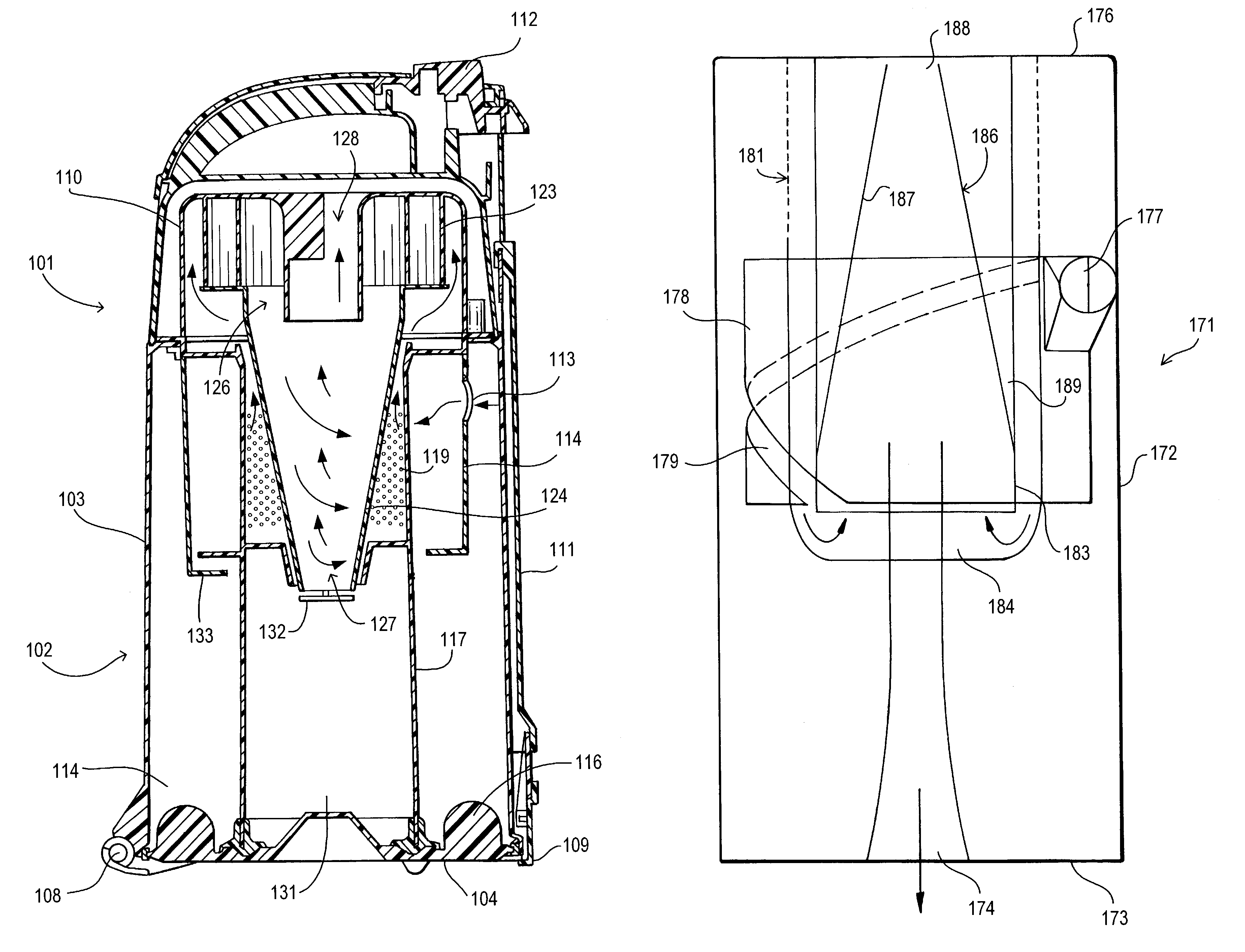

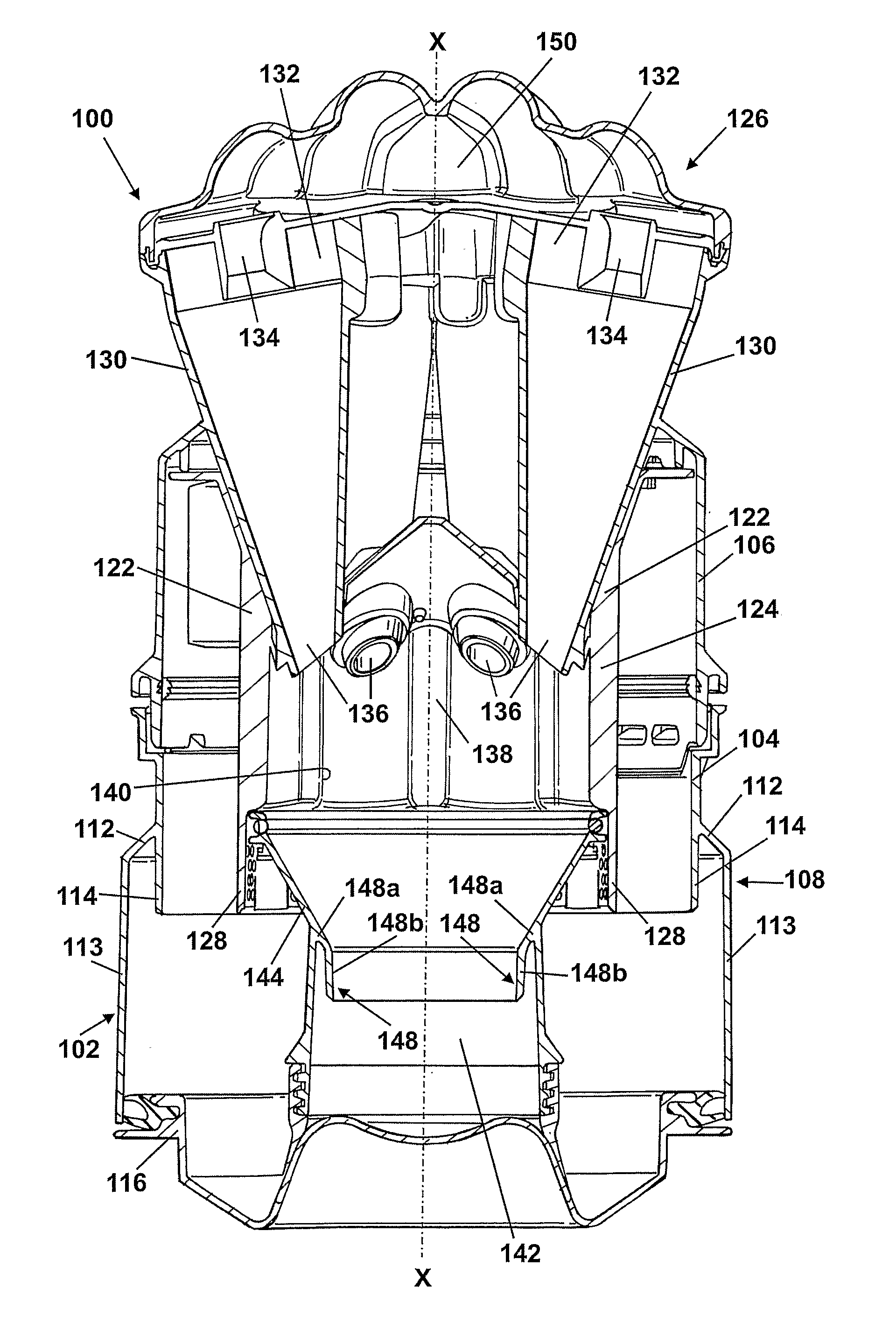

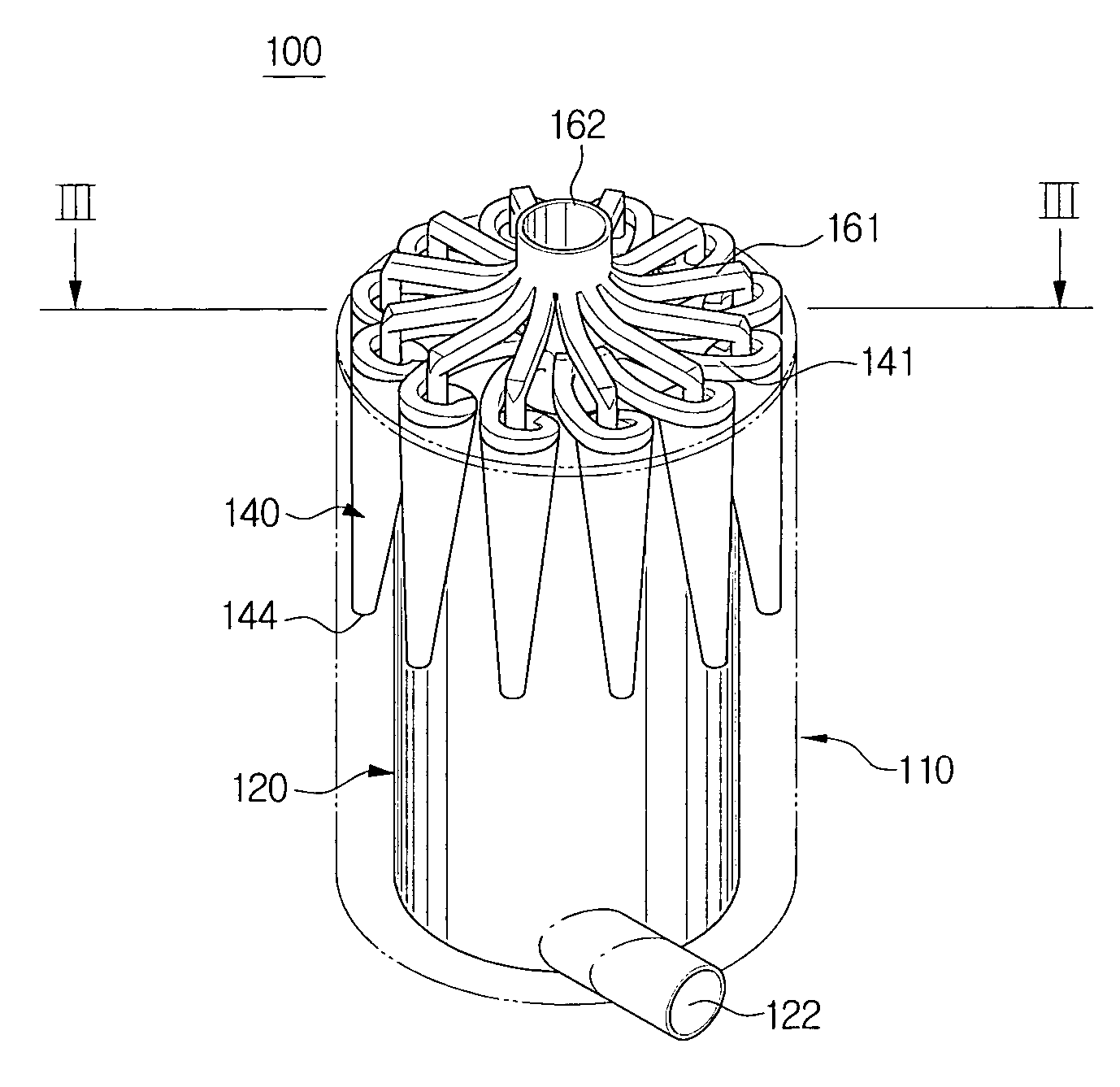

Multi-cyclone dust collector for vacuum cleaner and dust collecting method

InactiveUS20070079584A1Improve dust collection efficiencyProblem and drawbackReversed direction vortexSuction cleanersCycloneCyclonic spray scrubber

The present invention relates to a multi-cyclone dust collector for a vacuum cleaner and dust collecting chamber. The multi-cyclone dust collector includes a first cyclone unit having a first cyclone body and a first dust collecting chamber, the first cyclone body taking dust-laden air entering through an under portion thereof and forming a first upwardly whirling air current so as to separate contaminants centrifugally from the dust-laden air, the first dust collecting chamber collecting contaminants discharged from the first cyclone body; and a second cyclone unit wrapping around at least a portion of the first dust collecting chamber, sucking semi-clean air discharged from the first cyclone unit through an under portion thereof, taking the sucked semi-clean air and forming a second upwardly whirling air current so as to separate contaminants centrifugally from the semi-clean air.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Cyclonic separating apparatus

InactiveUS20090313958A1Reduces risk of re-entrainmentMinimize impactCombination devicesSuction filtersCycloneCyclonic separation

A cyclonic separating apparatus for separating particles from a dirt-laden airflow includes a cyclone for separating and collecting dirt and dust from the dirt-laden airflow. The cyclone has an air inlet, an air outlet, a longitudinal axis and a wall. The wall includes a first portion and a second portion spaced farther from the longitudinal axis than the first portion, the first and second portions being spaced along the longitudinal axis. The cyclone also includes at least one lip extending from the first portion of the wall into a portion of the cyclone surrounded by the second portion of the wall. By providing a cyclone with a wall having two portions of different sizes and a lip extending from the portion with the smaller size into the portion with the larger size, the risk of blockages due to re-entrainment and movement of dirt and dust within the cyclonic separating apparatus is reduced.

Owner:DYSON TECH LTD

E-1 air dryer liquid separator with baffle

In a centrifugal separator for separating a liquid from a compressed gas, a baffle is provided to separate the centrifugal chamber into an upper sub-chamber and a lower sub-chamber but does not contact the walls of the chamber thereby being insufficient to prevent downward flow of separated liquid along the interior wall of the two sub-chambers, and insufficient to prevent flow of compressed gas from one sub-chamber to the other sub-chamber, the baffle nevertheless being sufficient to prevent turbulent gas flow in the lower sub-chamber when collected liquid is drained therefrom.

Owner:WESTINGHOUSE AIR BRAKE CO

Air flow passage for a vacuum cleaner

InactiveUS6902596B2Reduce back pressureImprove performanceCleaning filter meansSuction filtersCycloneCyclonic separation

A vacuum cleaner is provided having improved pressure loss characteristics. A fluid supply conduit in flow communication with an inlet to a cyclone is integrally formed as part of a cyclone bin. The present invention may be adapted for use with cyclonic separation devices of all types, including single- and multi-stage cyclonic separators.

Owner:OMACHRON INTPROP

Cyclone-type dust-collecting apparatus for vacuum cleaner

InactiveUS6968596B2Easy maintenanceImproves stability and directionalityCleaning filter meansCombination devicesCycloneEngineering

A cyclone-type dust-collecting apparatus for a vacuum cleaner comprises a conically shaped grill assembly disposed at the air outflow port of a cyclone body. The grill assembly includes a grill portion and prevents reverse flow of dust and dirt from the cyclone body. The grill assembly members are easily separable to allow a user to easily remove the dirt collected in the grill portion by simply separating the second grill member from the connection member and washing the second grill member with water.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Cyclone dust separating apparatus

ActiveUS20060230726A1Improve cleaning efficiencyReduce lossesCleaning filter meansSuction filtersCycloneEngineering

A cyclone dust separating apparatus for separating dust from external air drawn in thereto and discharging the separated dust, comprises at least one first cyclone body having a tubular shape and forming a first cyclone chamber where the external air is rotated; and at least one second cyclone body forming a second cyclone chamber where the air discharged from the first cyclone chamber is rotated again to separate dust, wherein the external air is drawn in through a lower end of the first cyclone chamber and discharged through an upper end of the first cyclone chamber, and the air discharged from the first cyclone chamber is drawn in through an upper end of the second cyclone chamber and discharged through an upper end of the second cyclone chamber.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Cyclonic array such as for a vacuum cleaner

InactiveUS20080172995A1Easy to disassembleEasy to cleanCleaning filter meansCombination devicesCycloneSurface cleaning

A cyclonic cleaning stage for a, e.g., surface cleaning apparatus is provided. The cyclonic cleaning stage comprises a plurality of cyclones, which are integrally molded as a single body. Each cyclone has a cyclone body having an upper end, a lower end, a cyclone inlet, and a cyclone outlet. Each cyclone inlet has a top. A separately molded upper cover is mounted to the top of the single body at the upper ends. A separately molded lower cover is mounted on the single body at the lower ends of the cyclones.

Owner:OMACHRON INTPROP

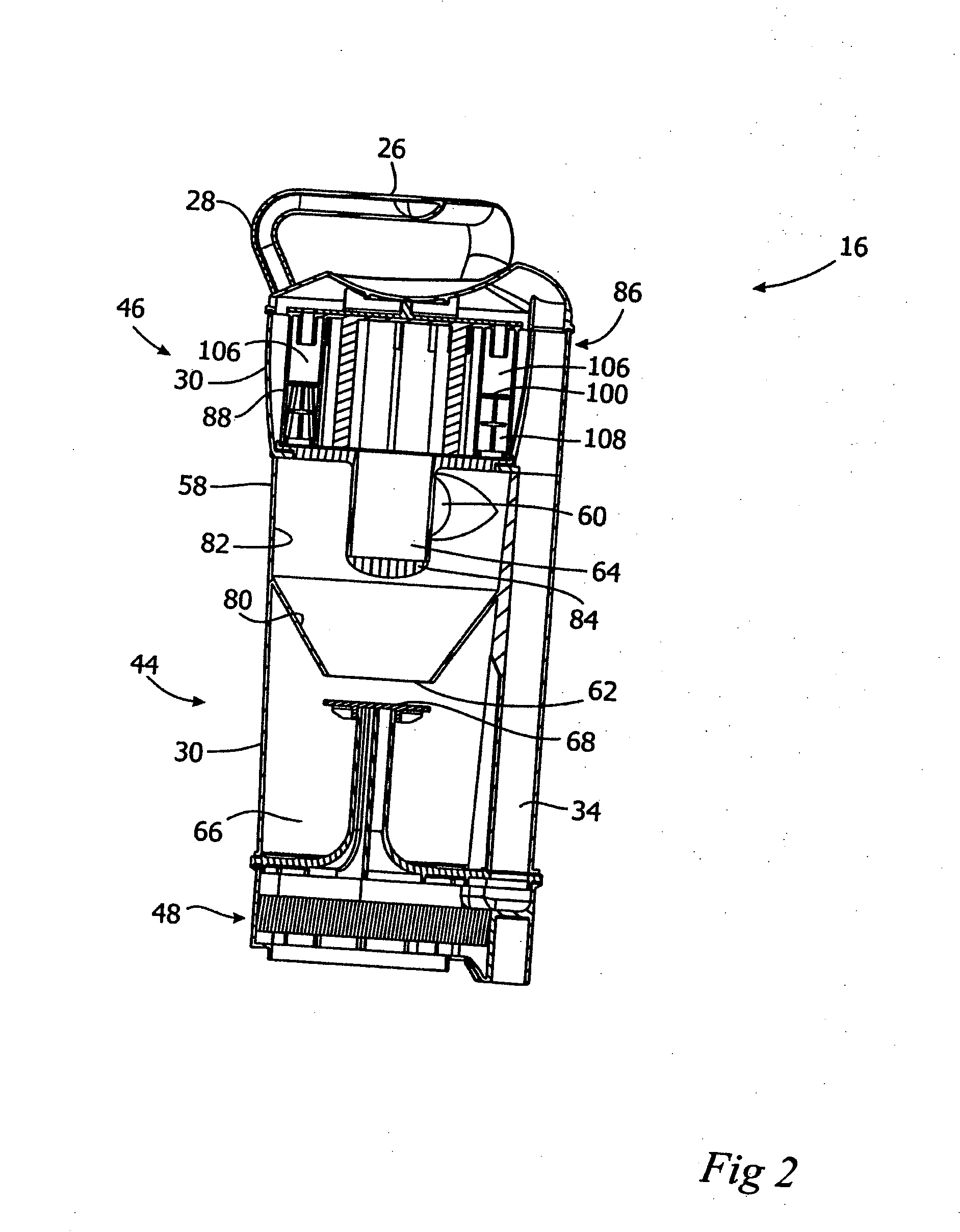

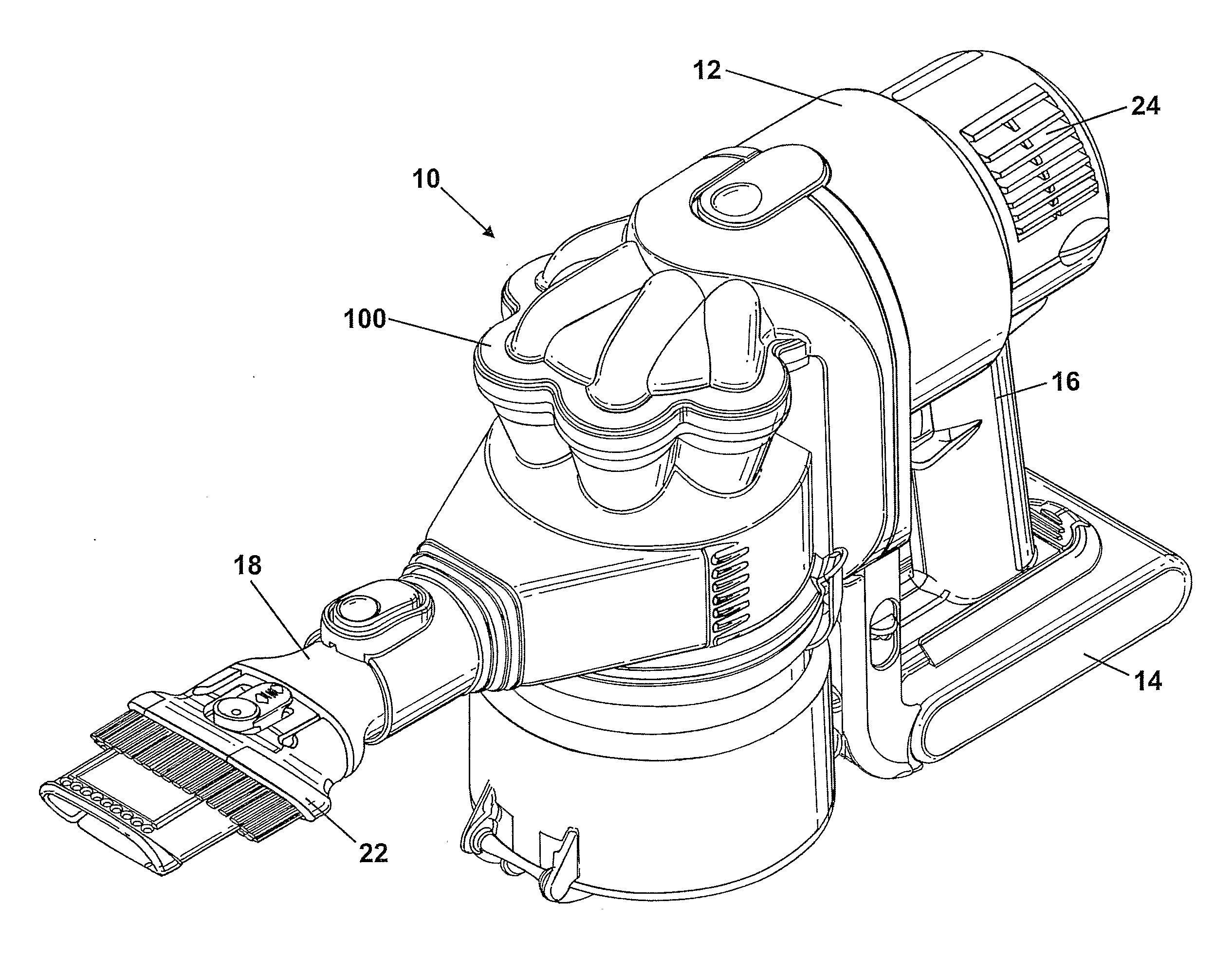

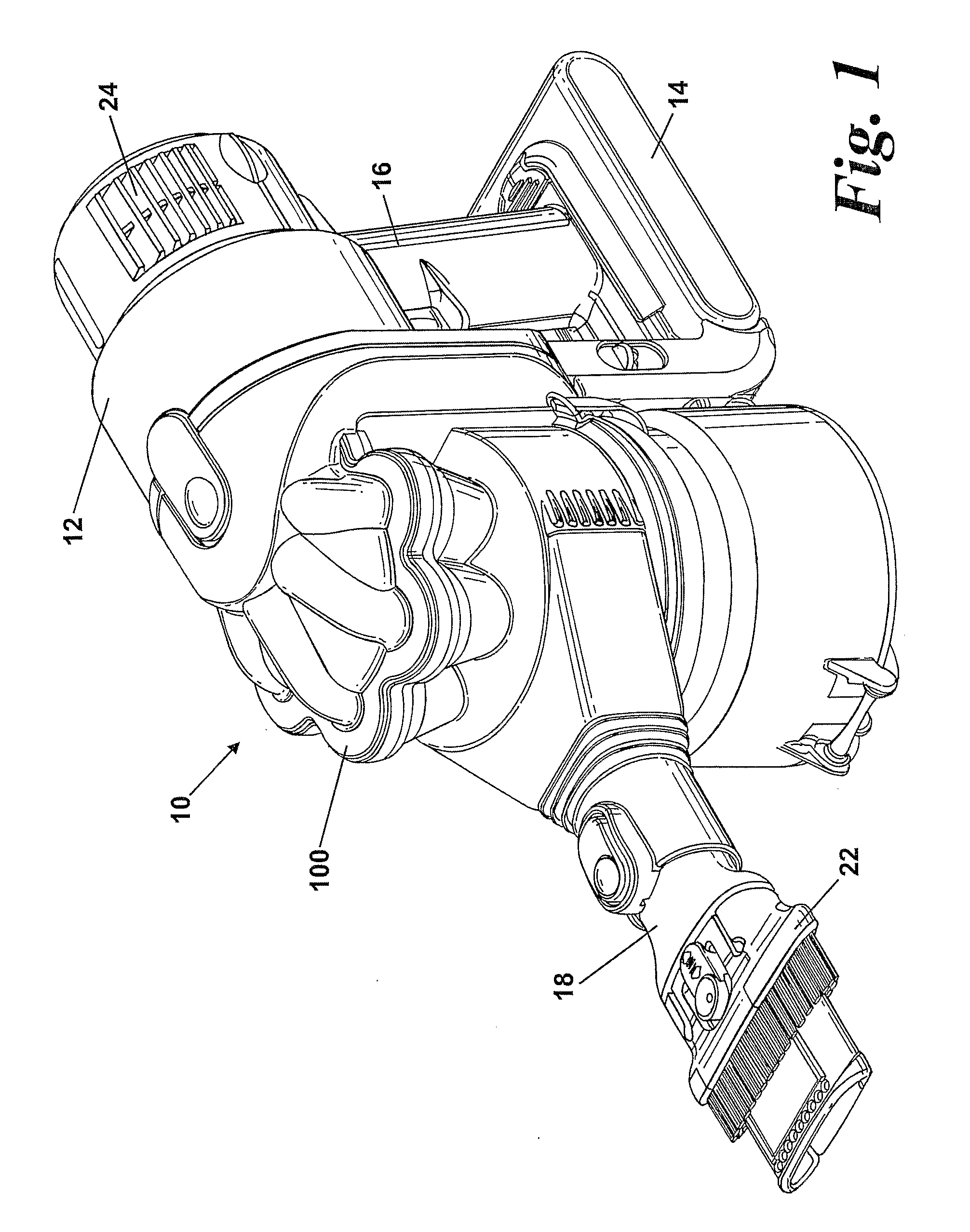

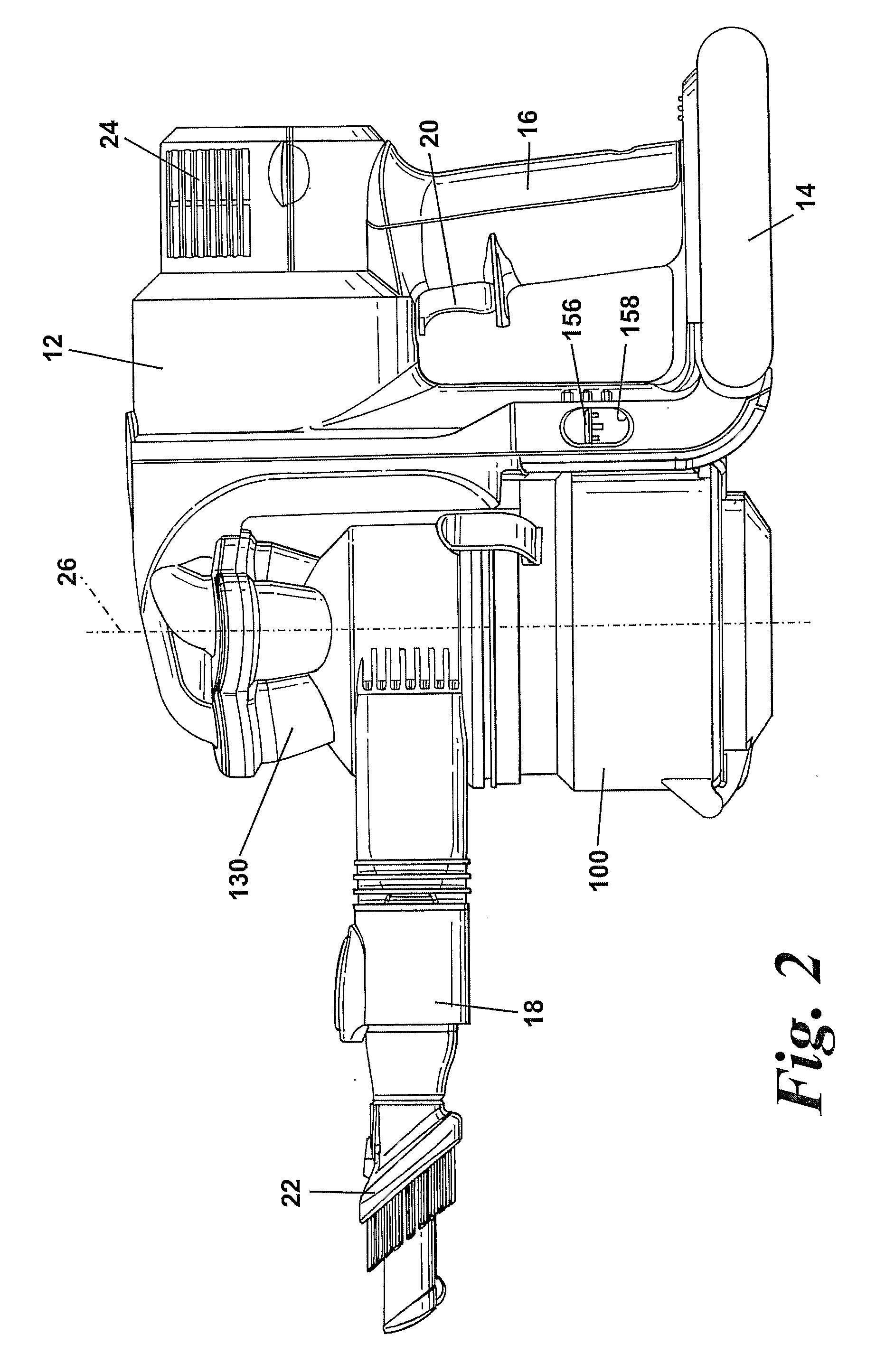

Handheld cleaning appliance

A handheld cleaning appliance includes a dirty air inlet, a clean air outlet and separating apparatus for separating dirt and dust from an airflow in an airflow path leading from the air inlet to the air outlet. The separating apparatus includes a cyclonic separator having at least one cyclone and a collector having a wall and a base member, the base member being held in a closed position by a catch and being pivotably connected to the wall. The appliance further includes a main body which incorporates an actuator for operating the catch. The actuator has a slidably mounted rod which is movable between an inoperative position and an actuating position in which the rod contacts part of the catch so as to allow the collector to be opened for emptying purposes. This arrangement allows the catch to be released without the user actually touching the collector.

Owner:DYSON TECH LTD

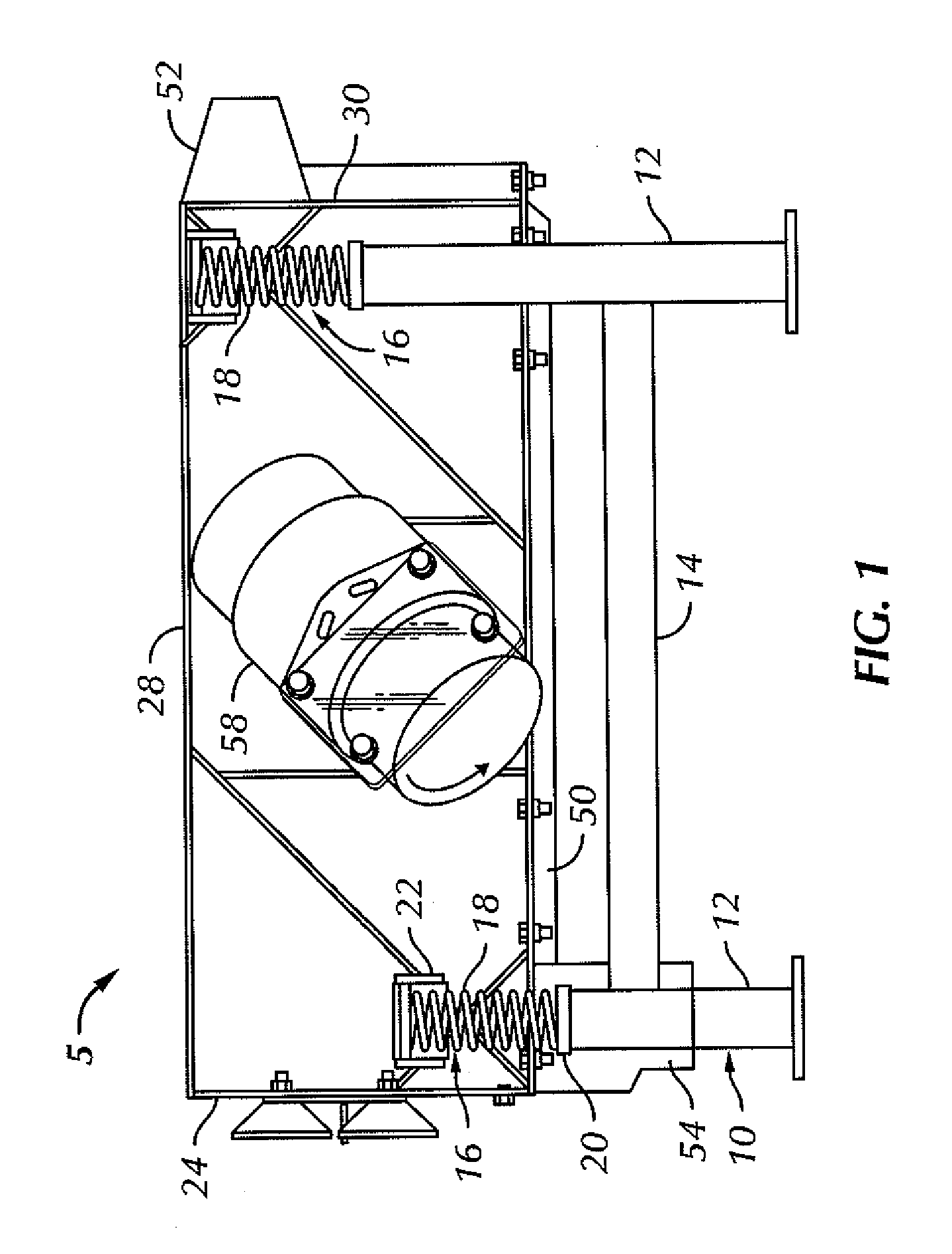

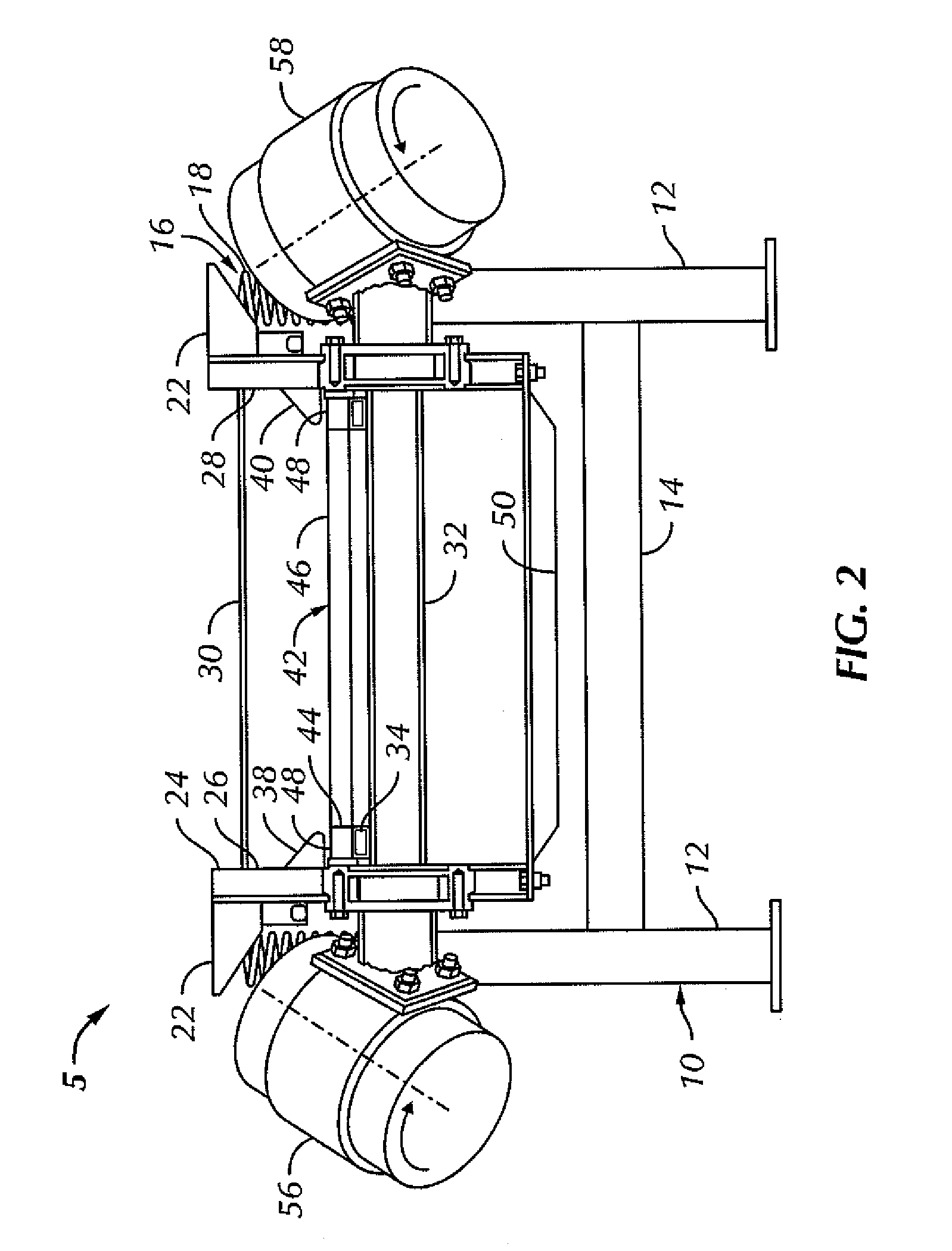

Shaker and degasser combination

A system for separating components of a slurry is disclosed, the system including a housing; a basket for holding at least one shaker screen, the basket movably mounted in the housing; at least one vibrator coupled to the basket; a sump disposed below the basket to collect at least a portion of the slurry passing through the at least one shaker screen; a pressure differential device fluidly connected to the sump for developing a pressure differential across the at least one shaker screen; and a toggling device for toggling the pressure differential across the screen. A system including a degassing chamber fluidly connected to a sump and a pressure differential device, wherein the degassing chamber is disposed between the sump and the pressure differential device, and a fluid conduit fluidly connected to the degassing chamber for recovering a degassed fluid is also disclosed.

Owner:MI

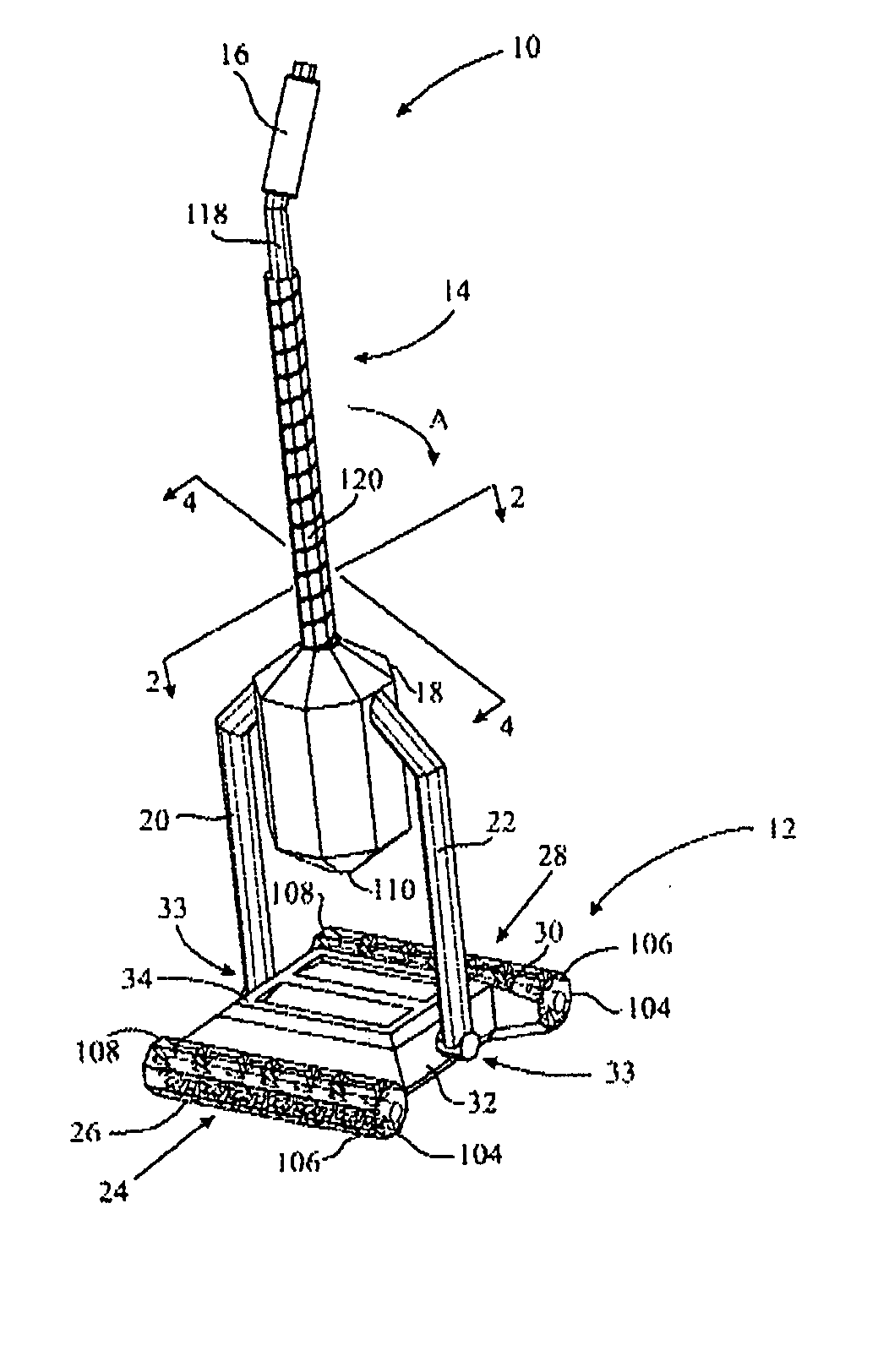

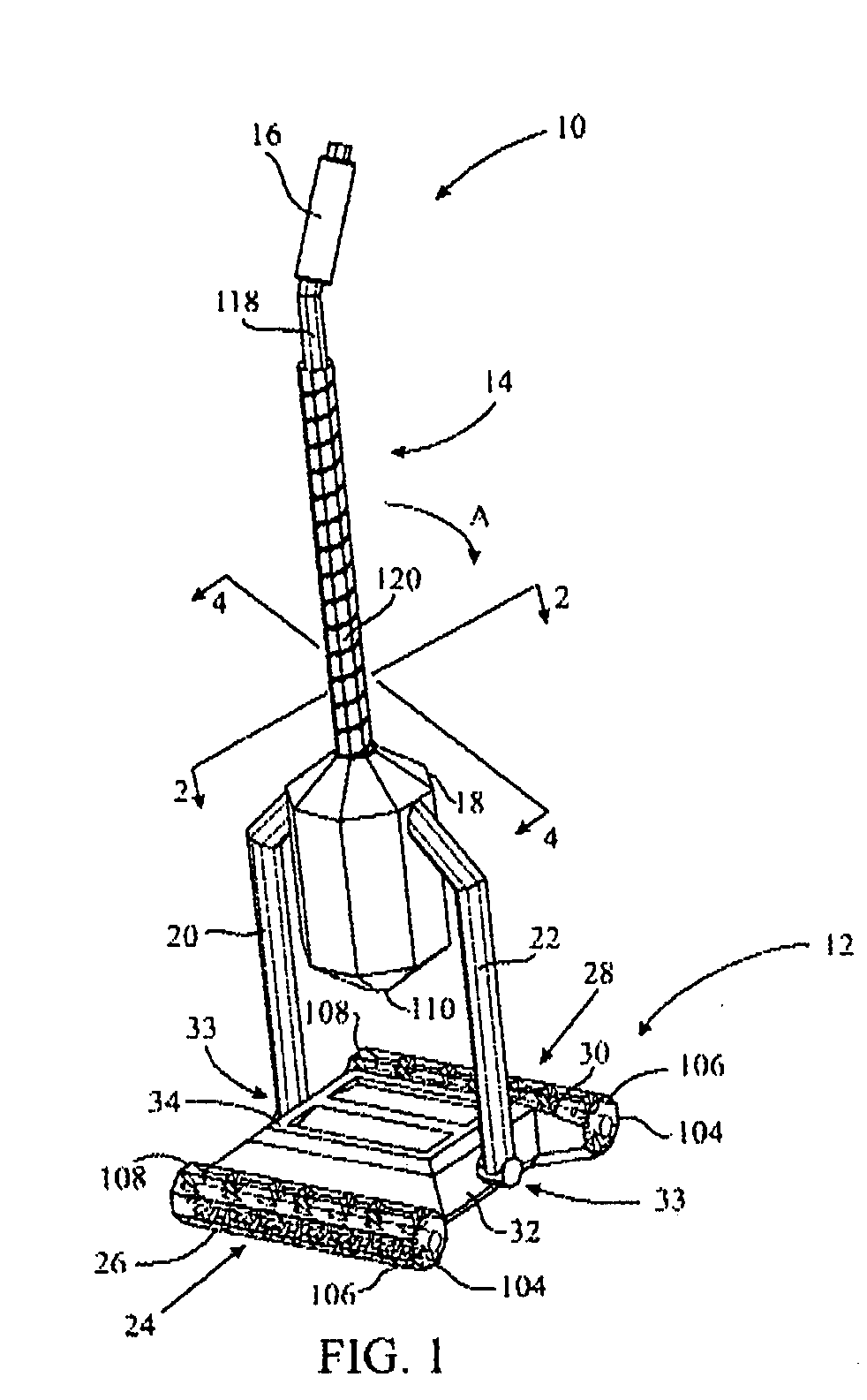

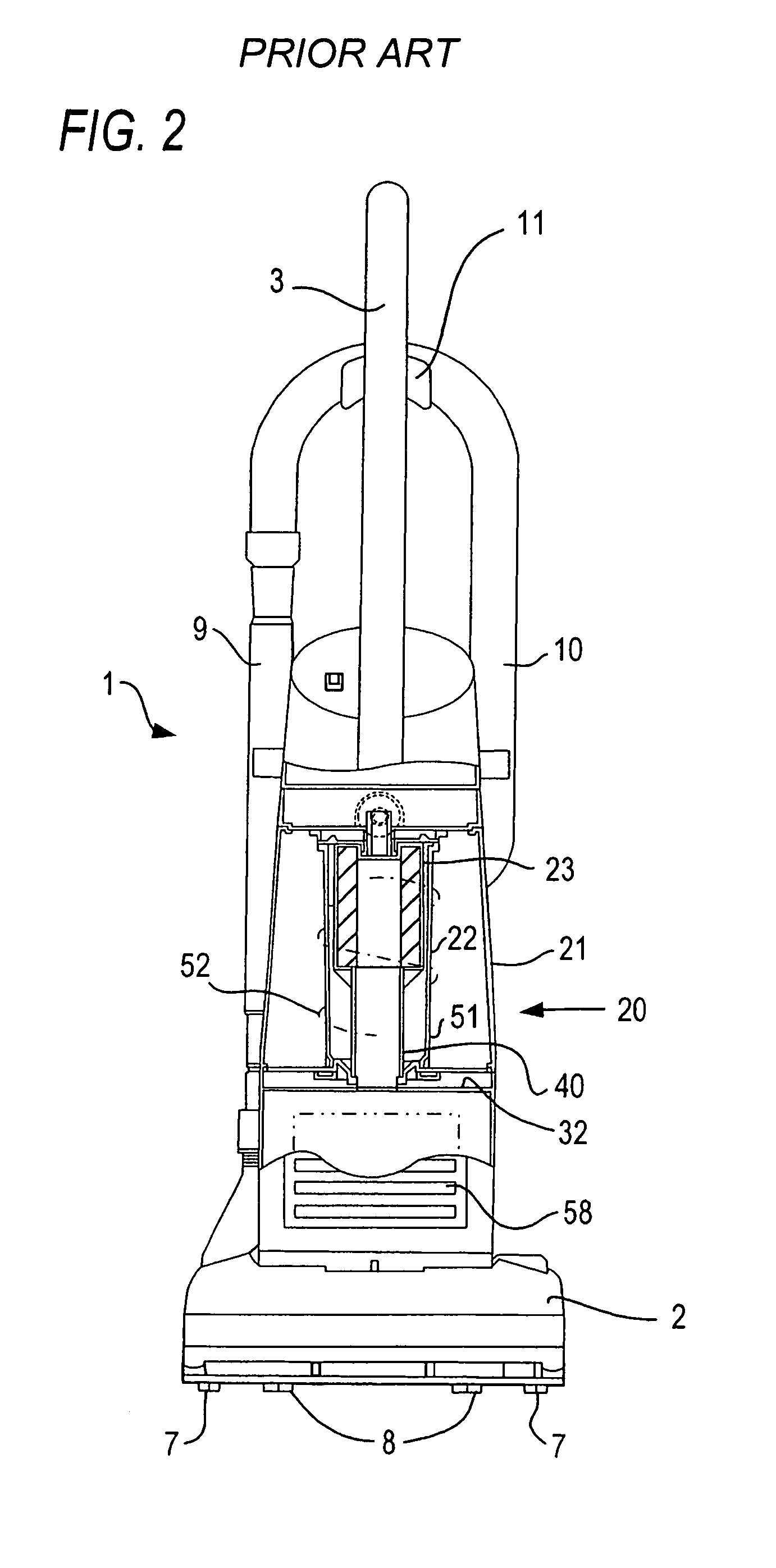

Multi cyclone vacuum cleaner

InactiveUS6840972B1Maximize capacityEasy to discardCombination devicesAuxillary pretreatmentCycloneForeign matter

The disclosure is directed to a cyclone dust collector for separating air from dusts by way of a centrifugal force and, more particularly, to a novel canister type vacuum cleaner capable of using a dual cyclone dust collector with maximized allowable dust capacity. The entire structure of the vacuum cleaner as suggested herein is configured for the user's simple manipulation in discarding various foreign matters collected in the vacuum cleaner, thereby improving reliability to the user.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com