Patents

Literature

1941 results about "Cyclonic spray scrubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

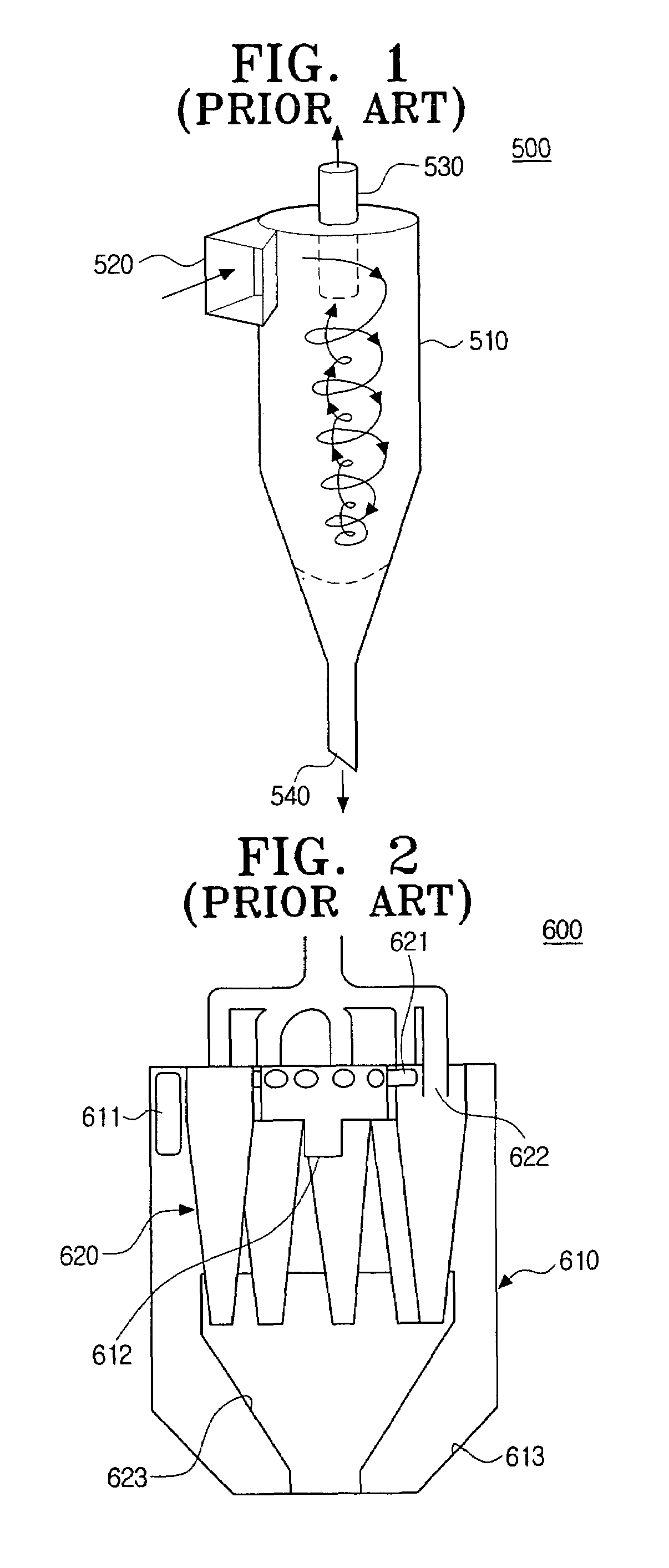

Cyclonic spray scrubbers are an air pollution control technology. They use the features of both the dry cyclone and the spray chamber to remove pollutants from gas streams. Generally, the inlet gas enters the chamber tangentially, swirls through the chamber in a corkscrew motion, and exits. At the same time, liquid is sprayed inside the chamber. As the gas swirls around the chamber, pollutants are removed when they impact on liquid droplets, are thrown to the walls, and washed back down and out.

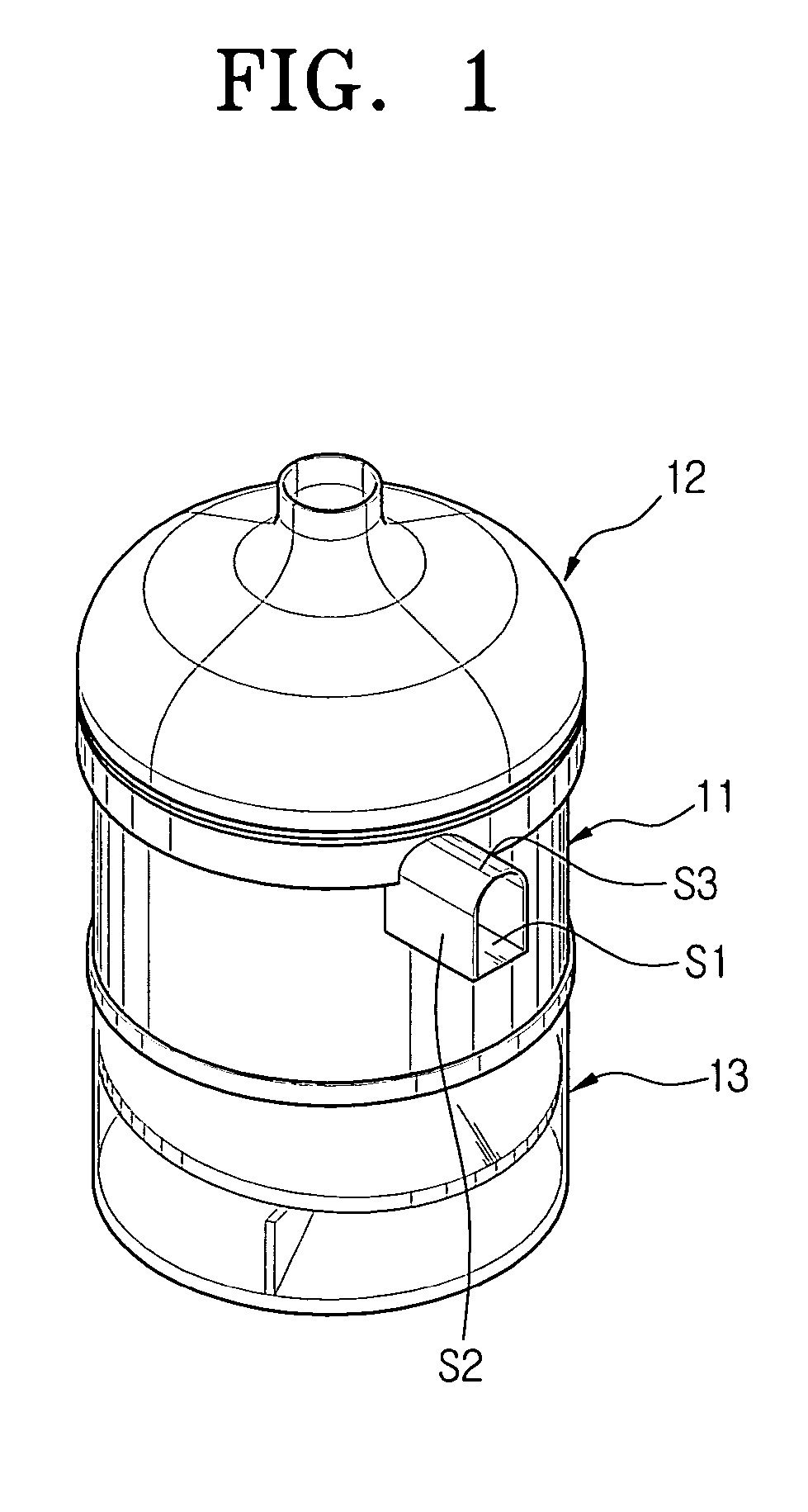

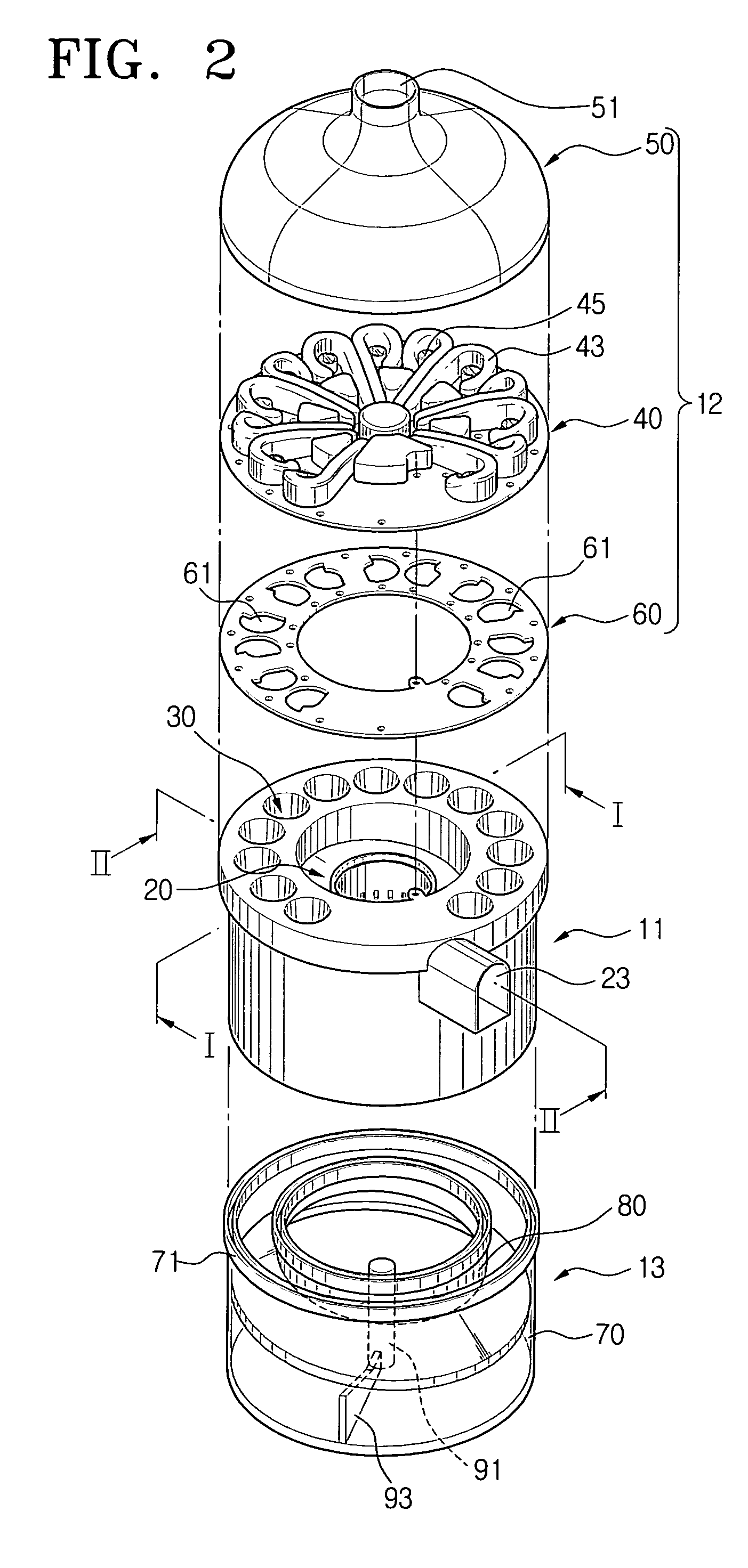

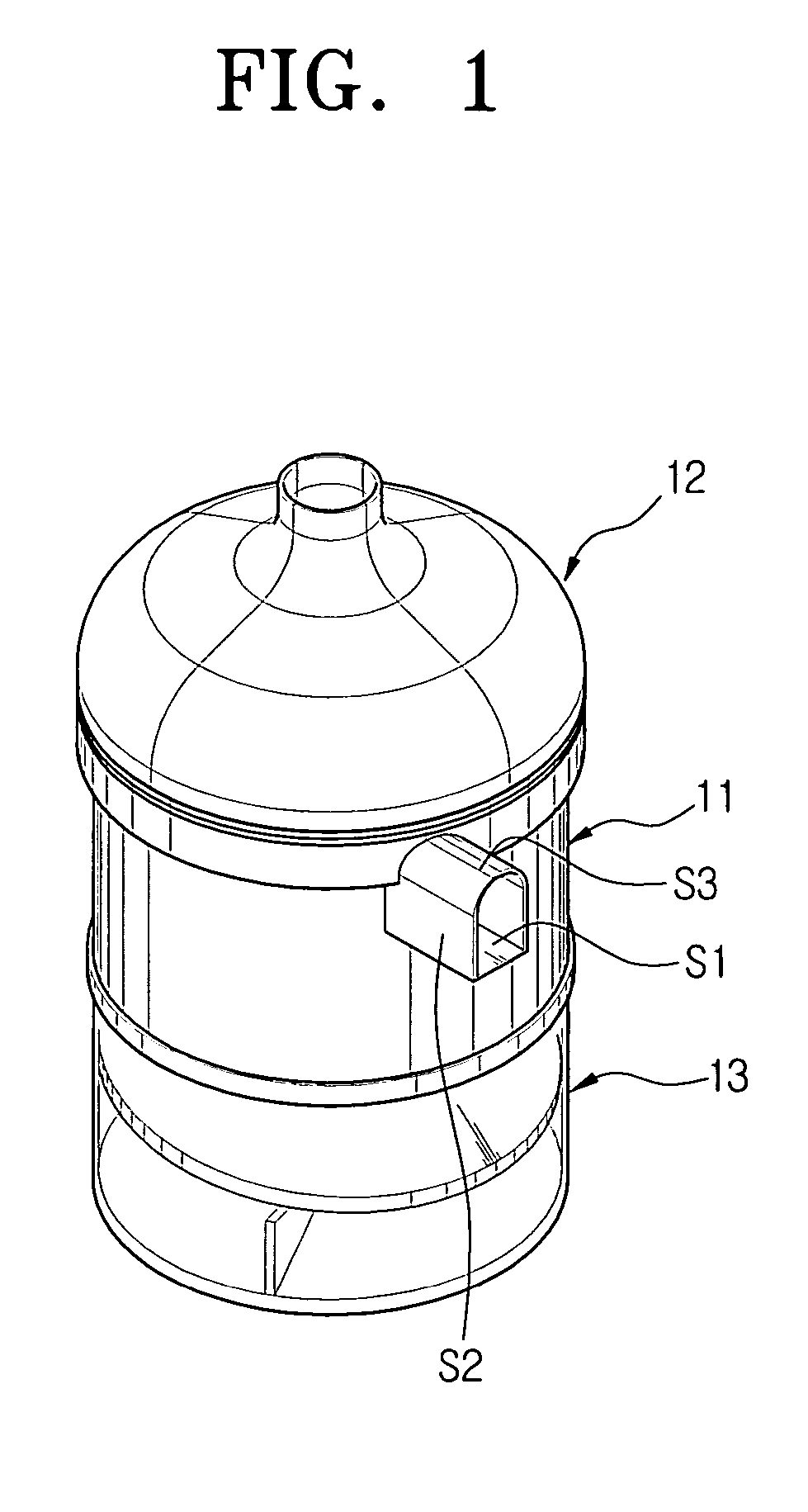

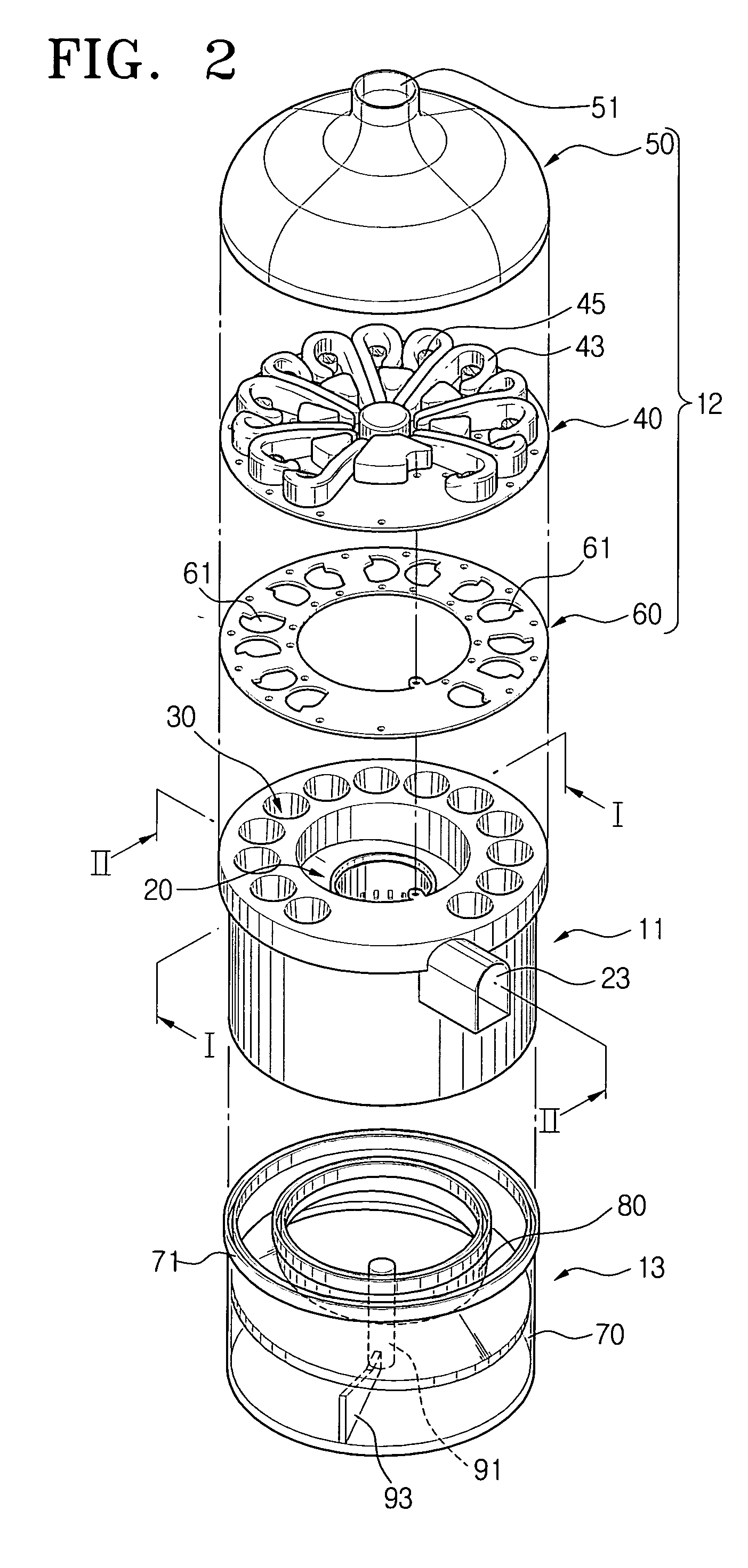

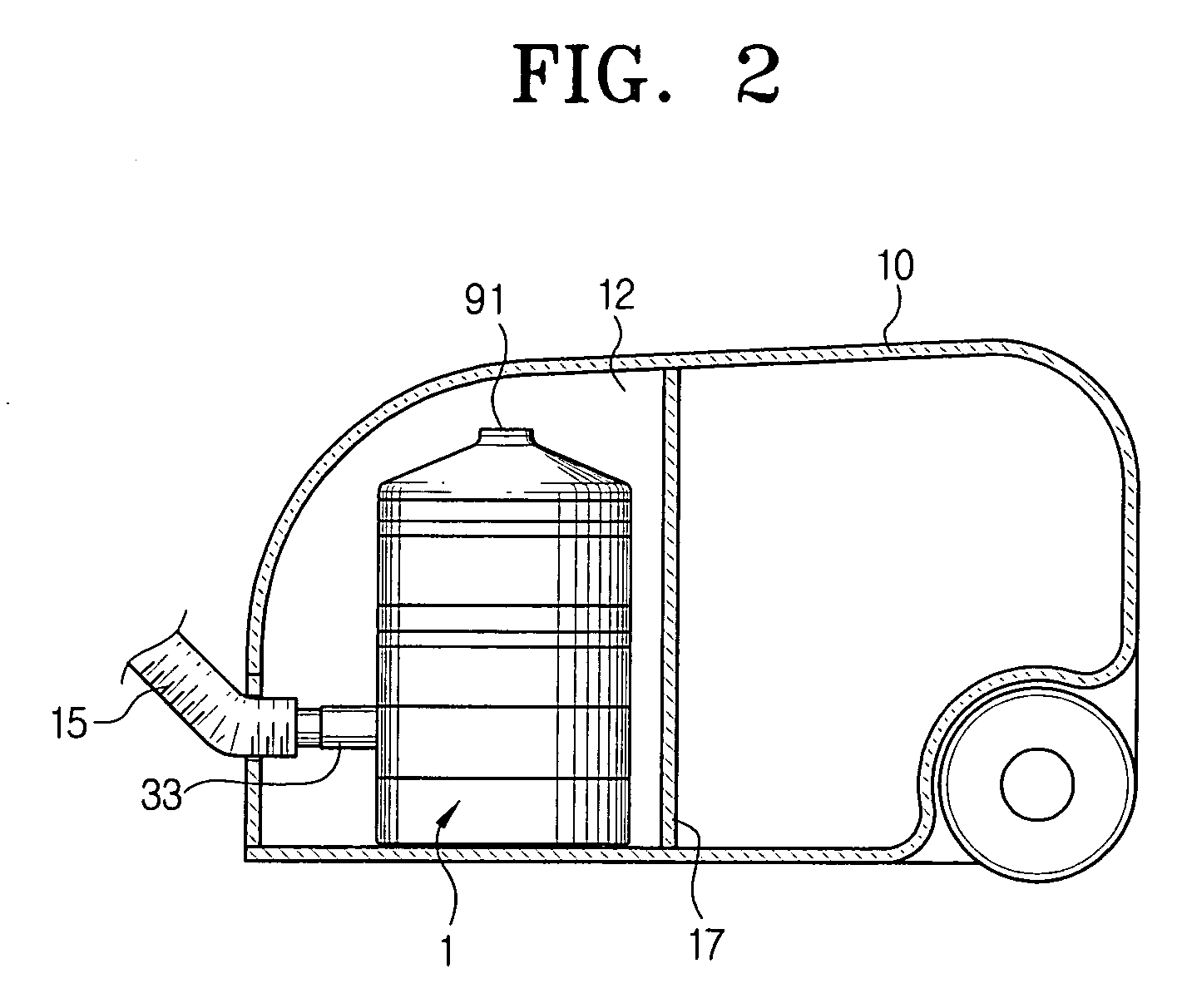

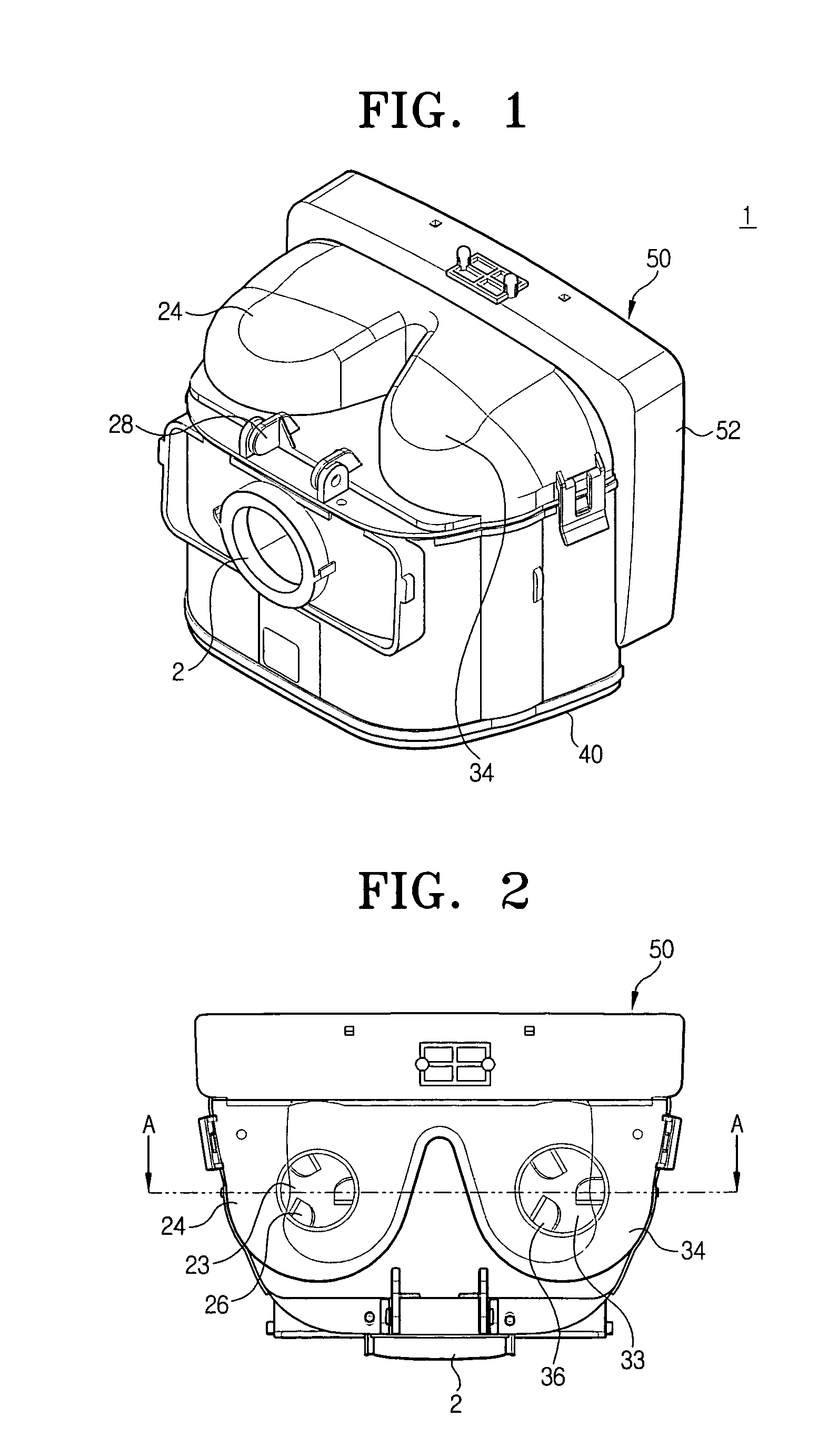

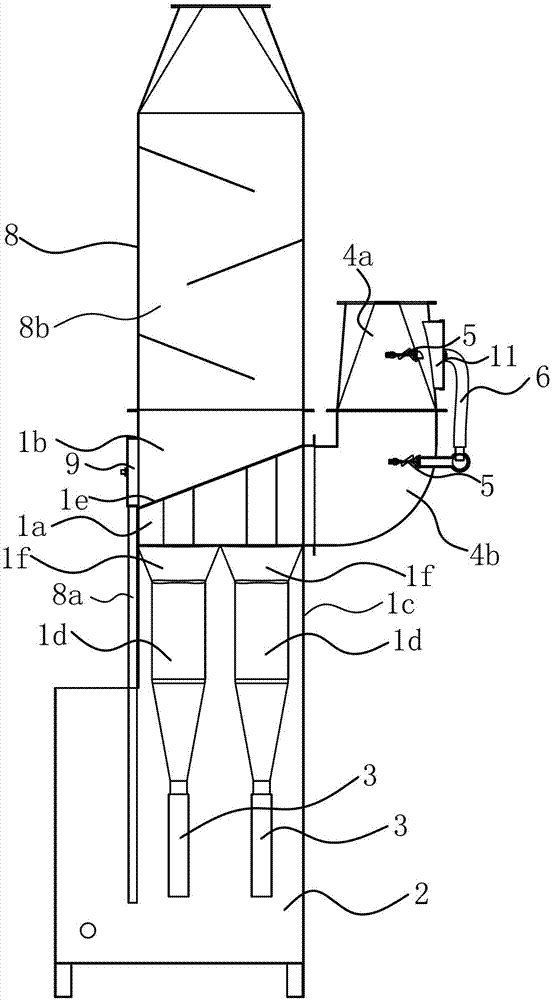

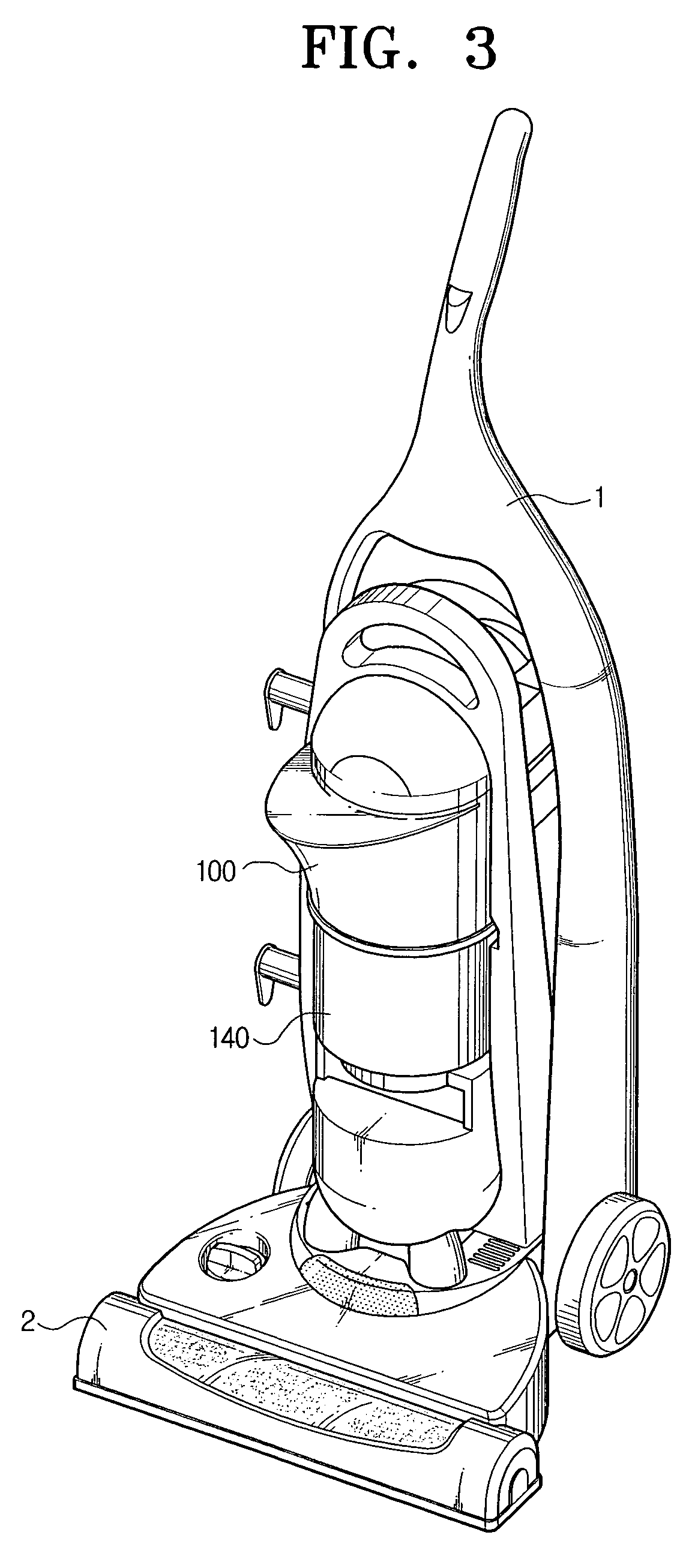

Multi-cyclone dust collector for vacuum cleaner

InactiveUS20070084160A1High contaminant collecting efficiencyMore compact structureSuction filtersDispersed particle separationCycloneEngineering

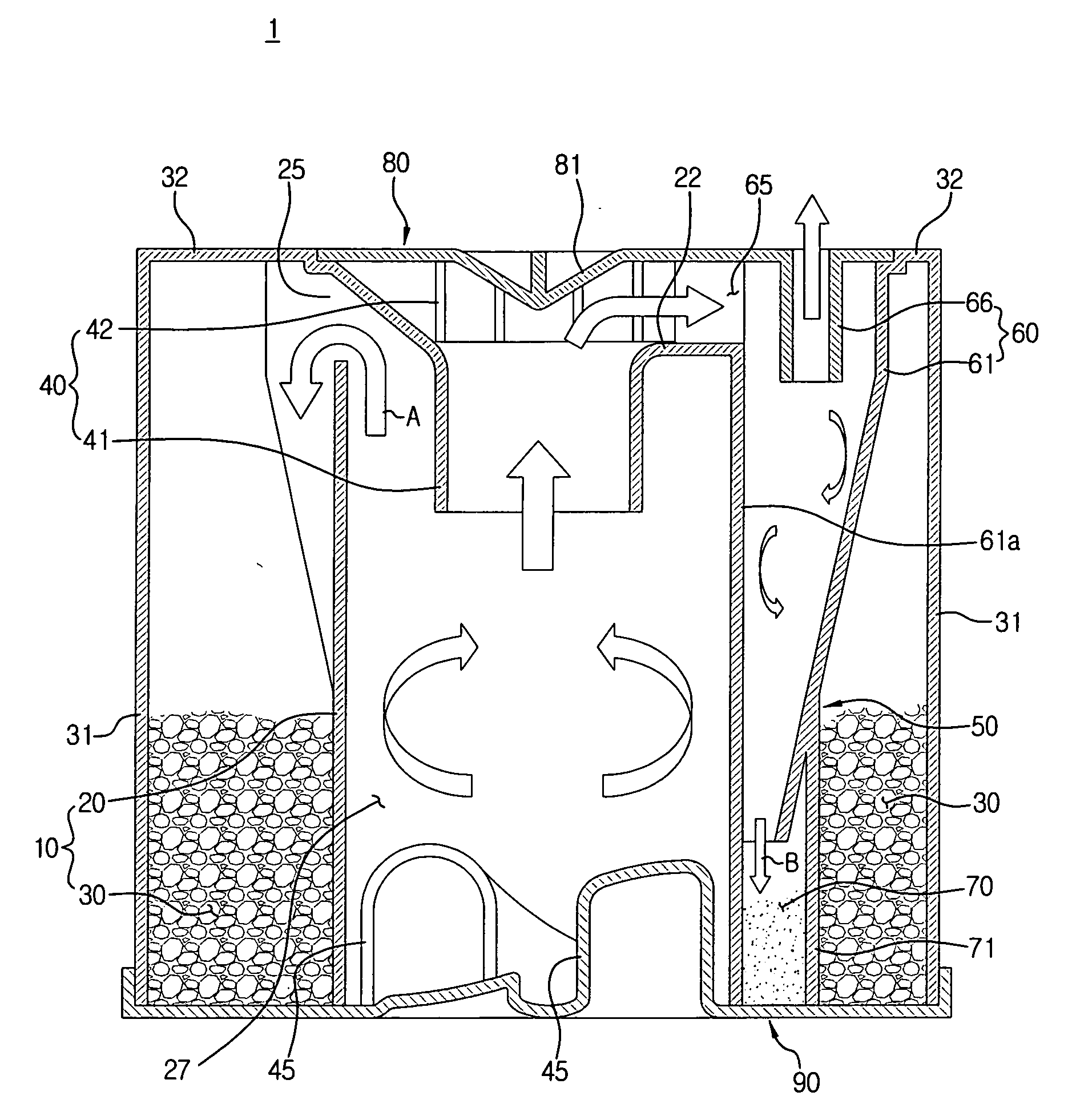

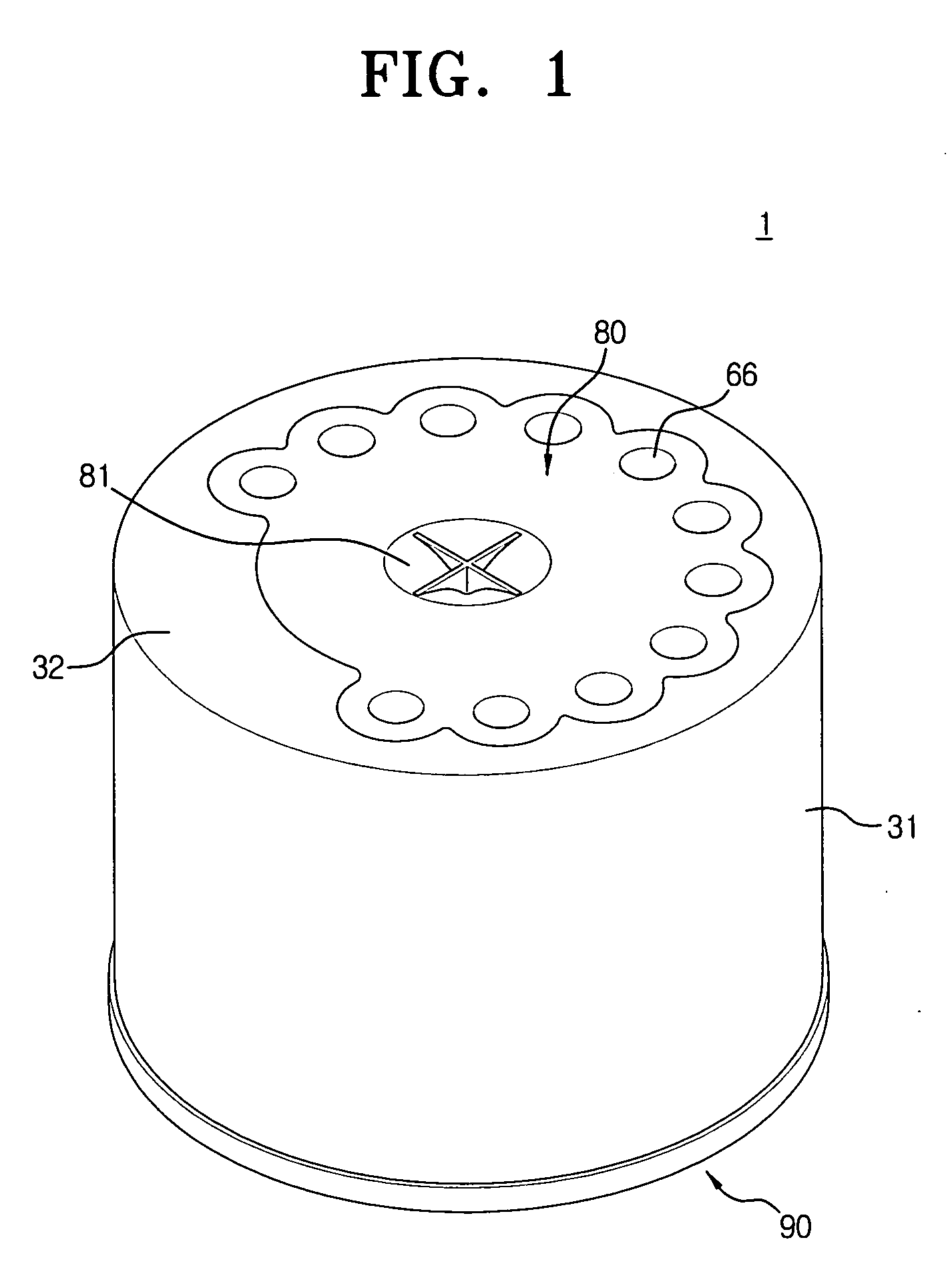

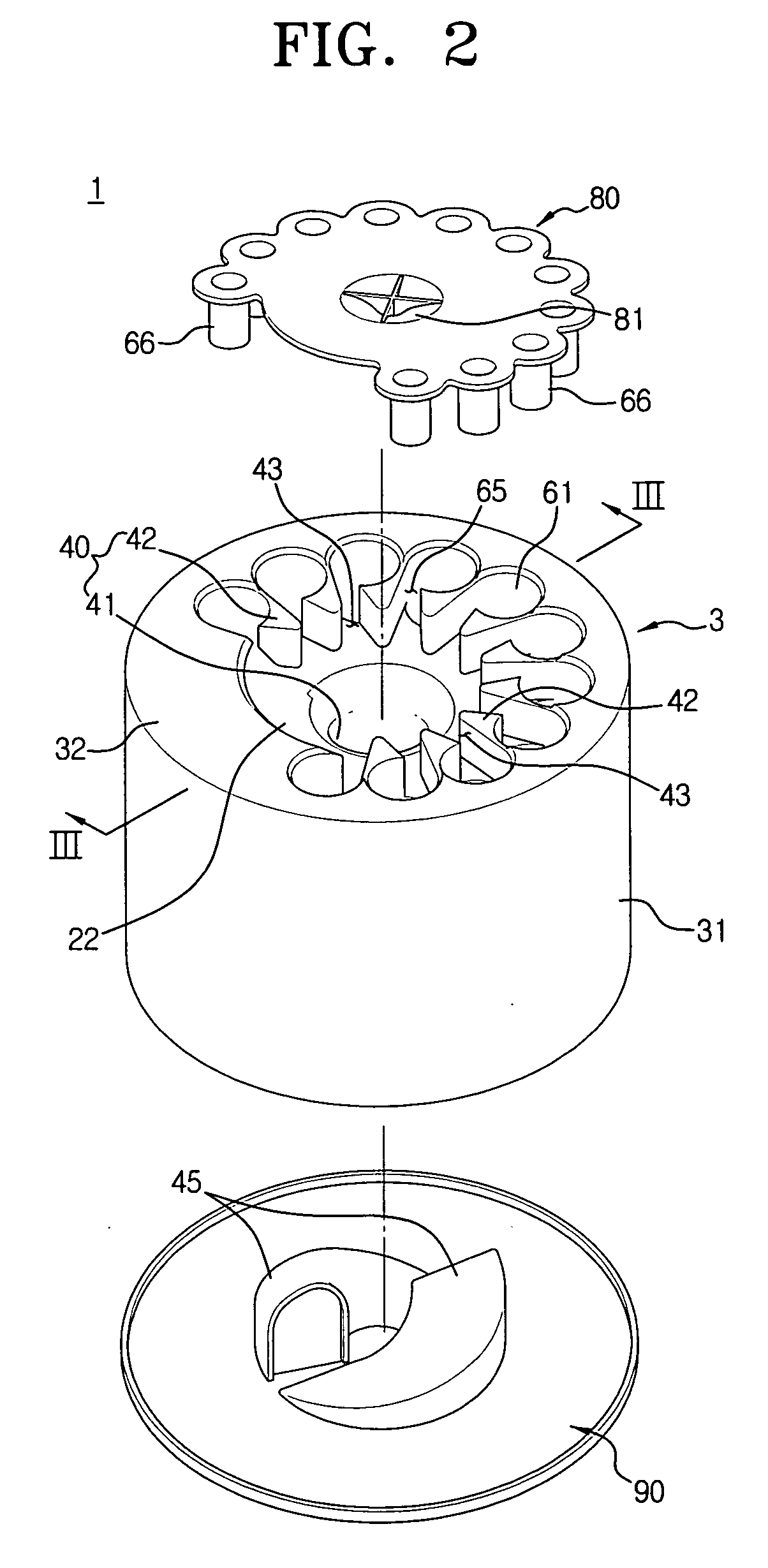

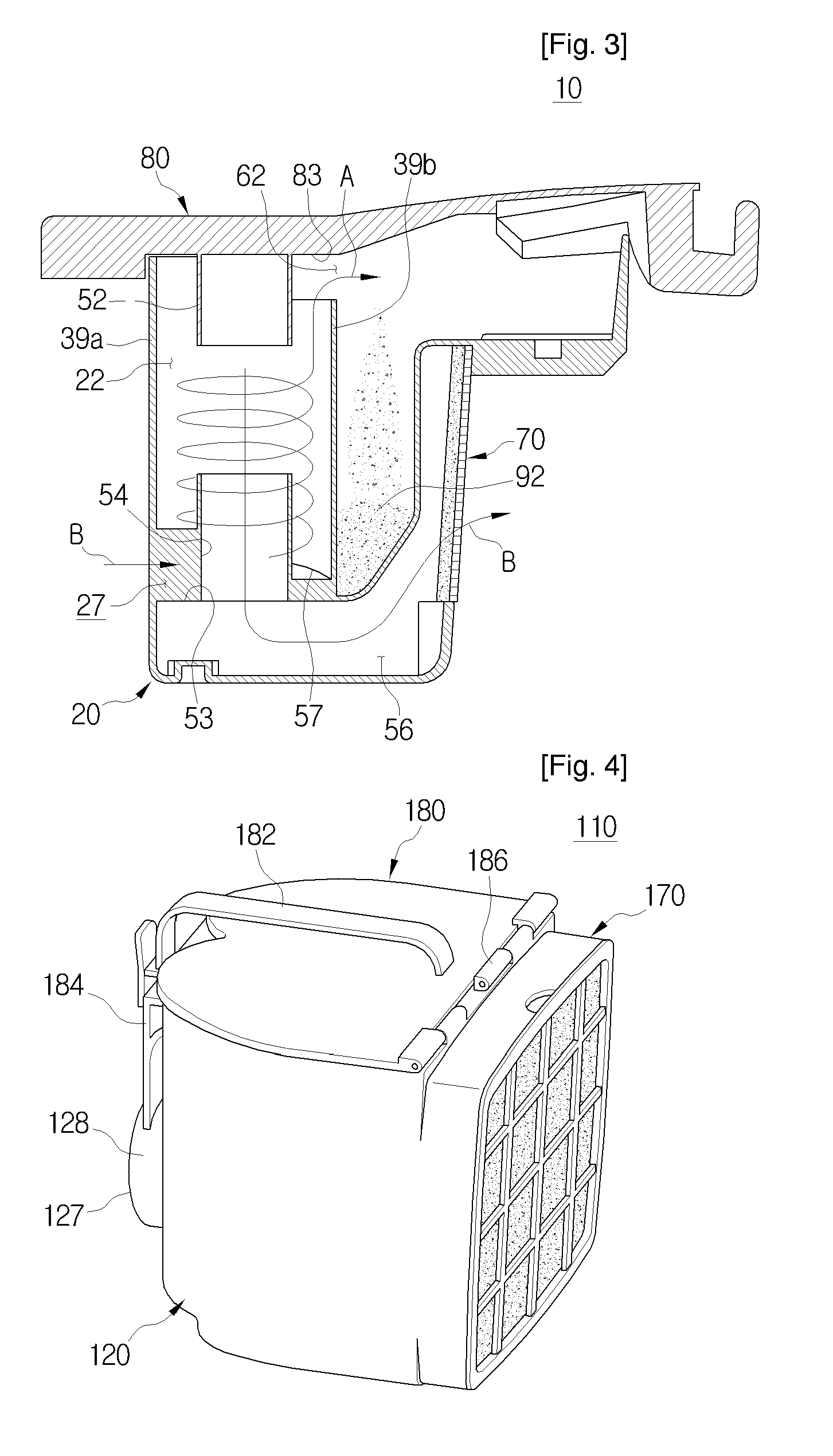

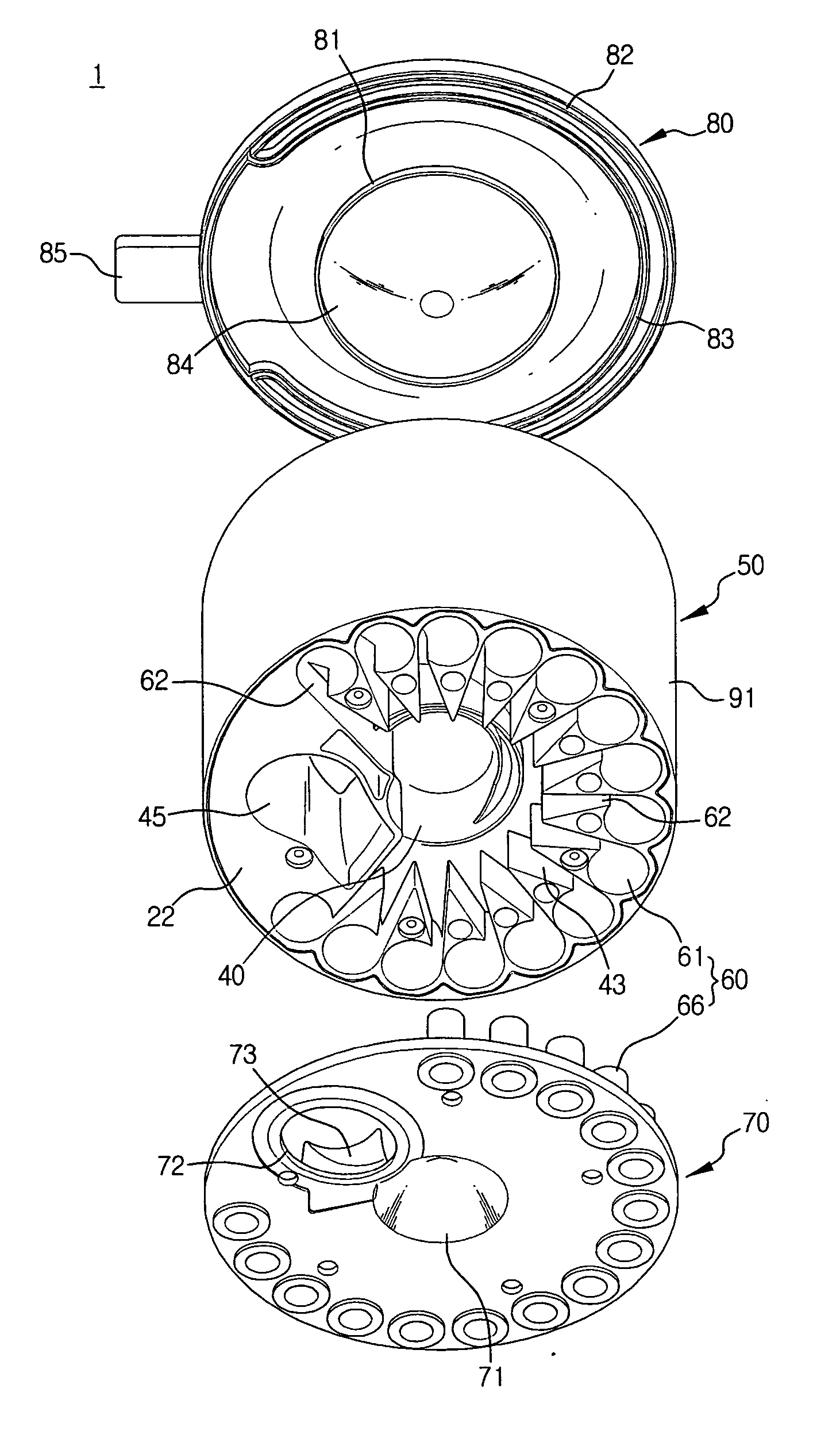

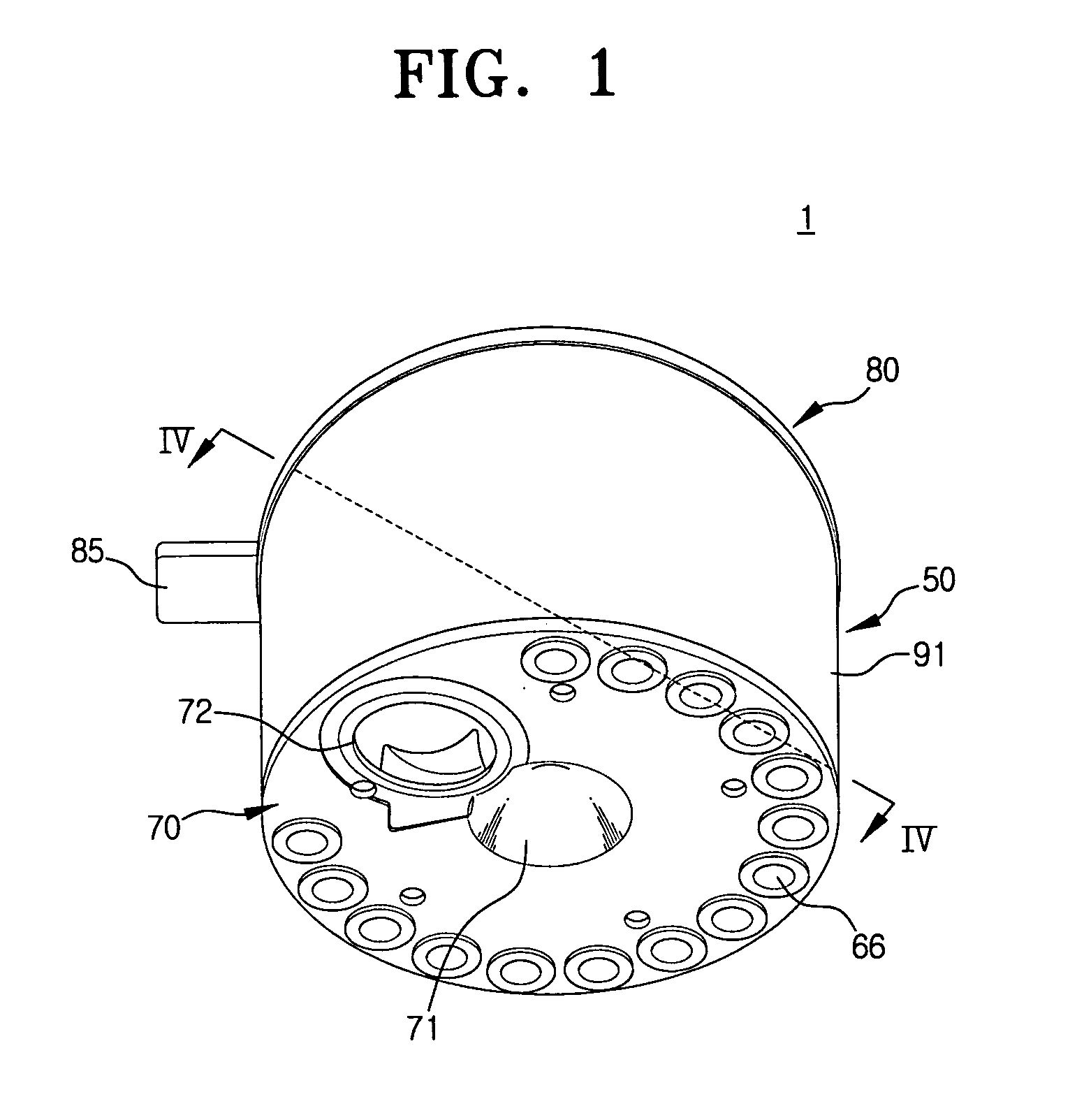

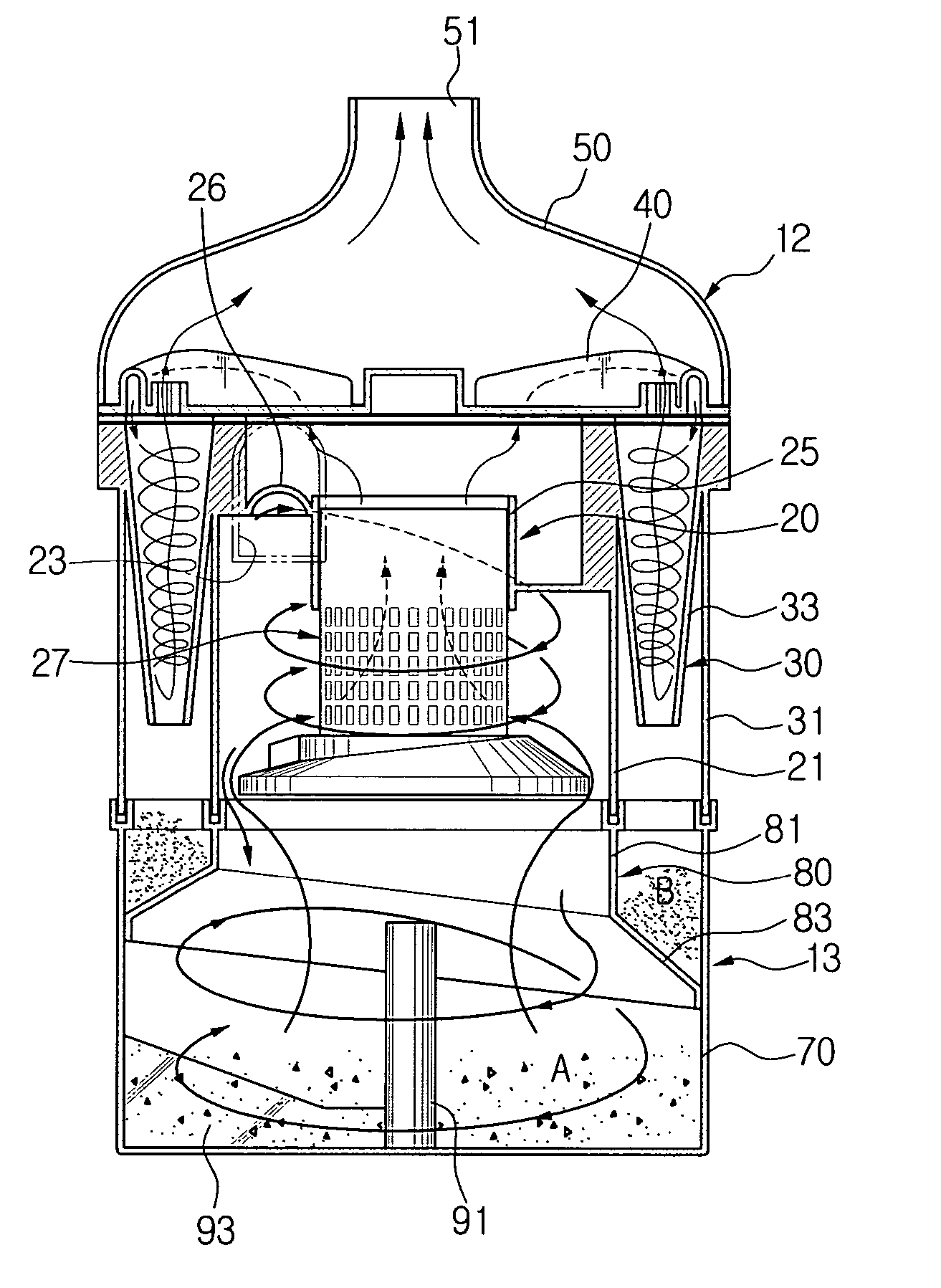

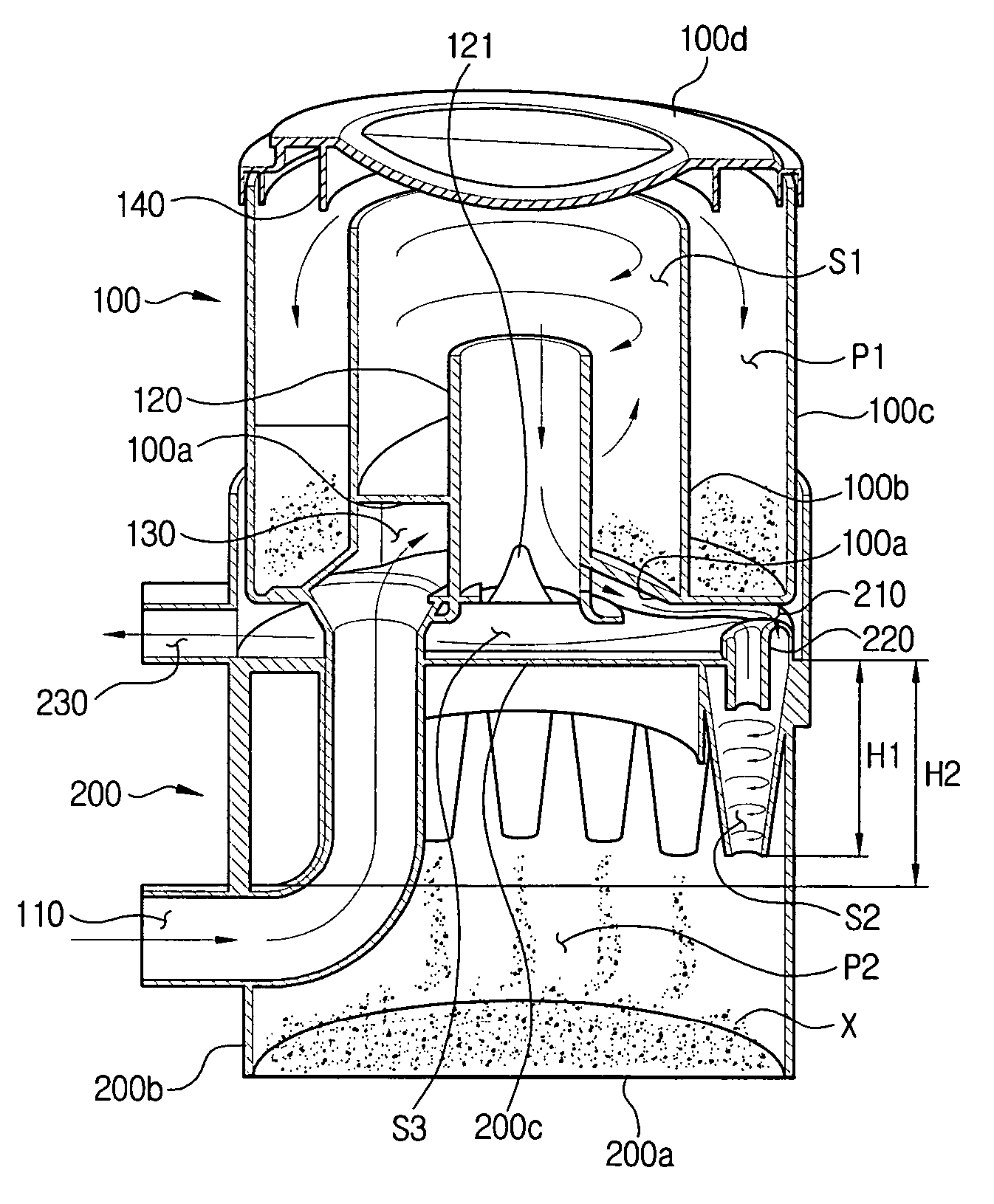

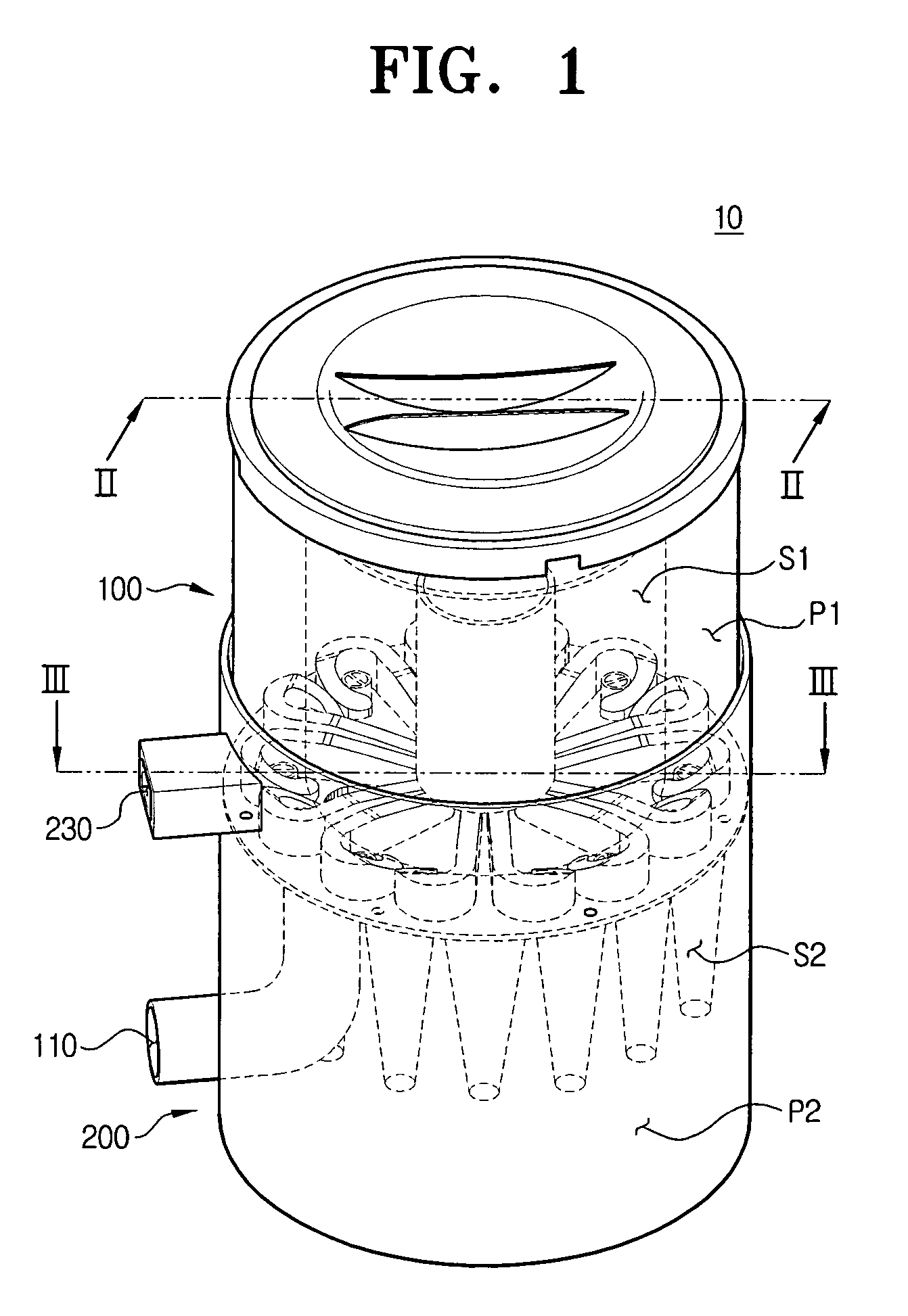

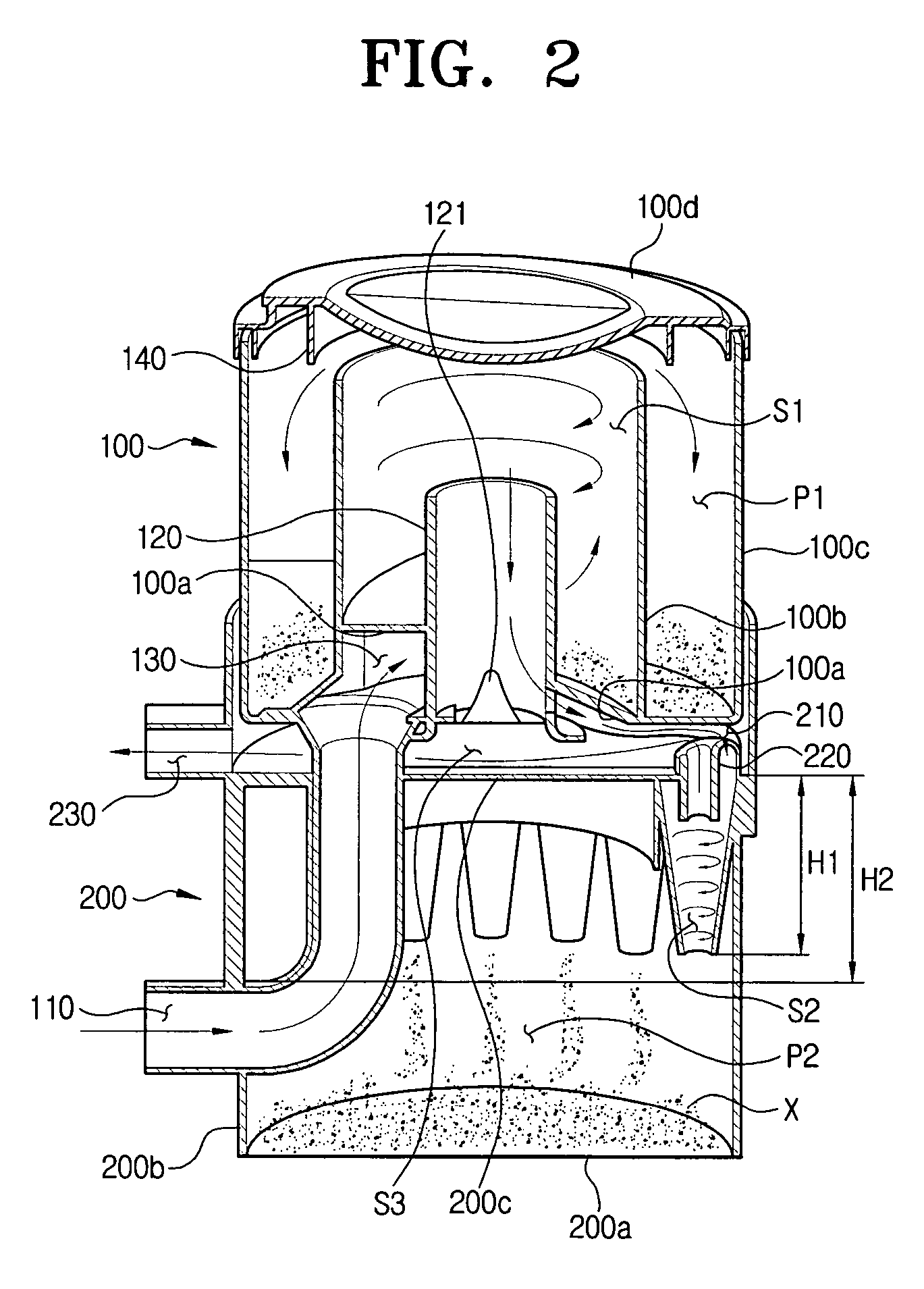

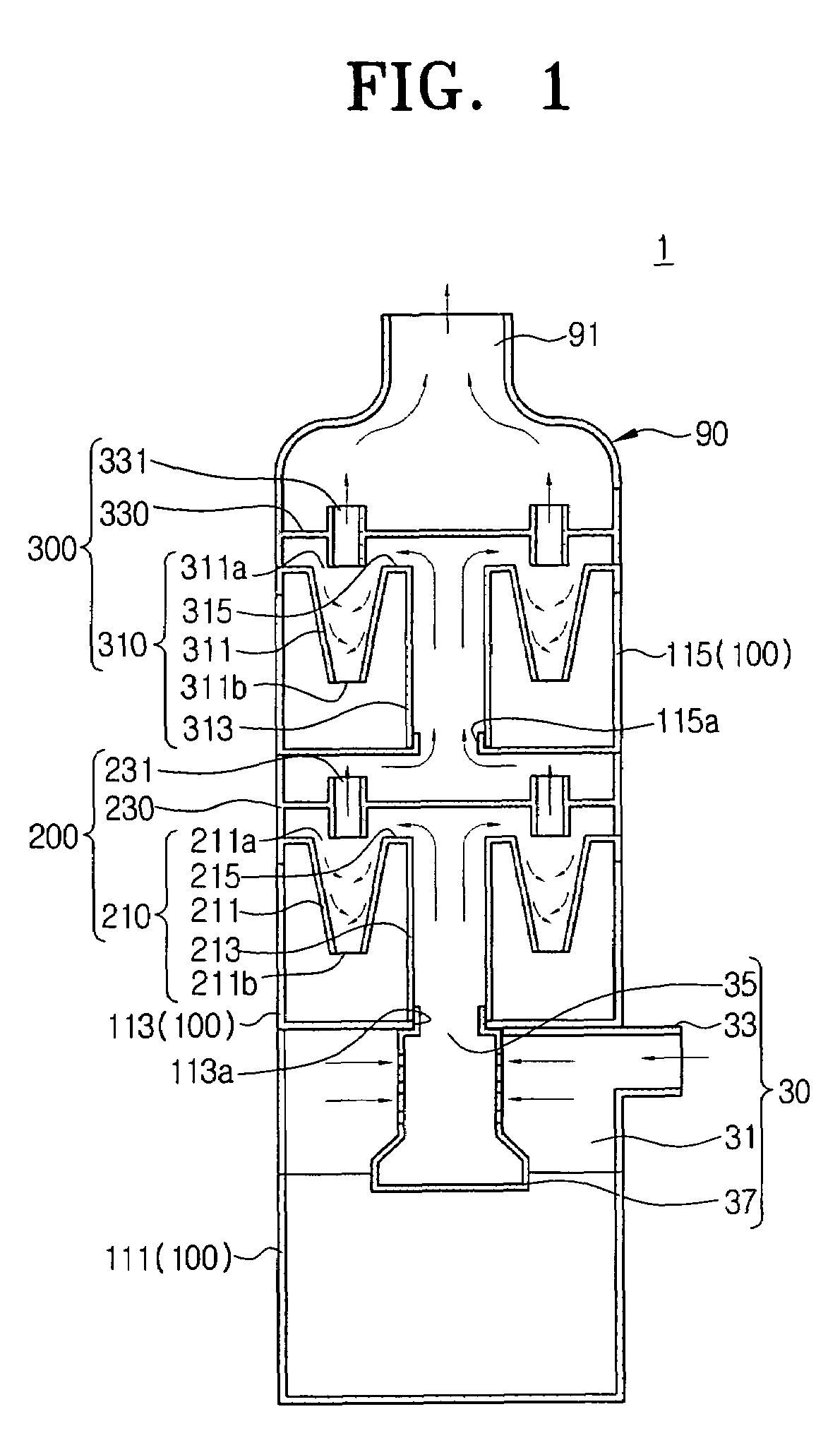

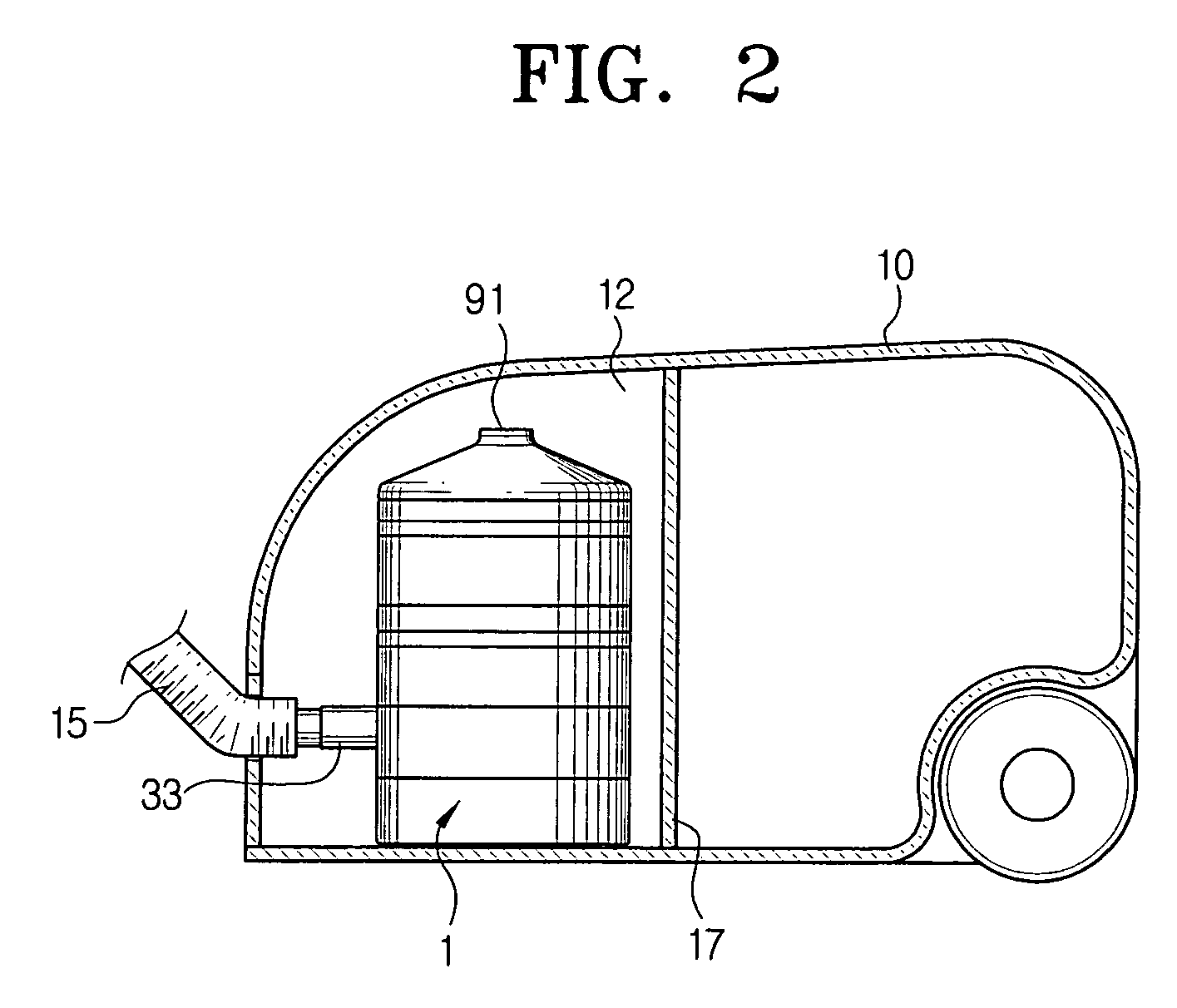

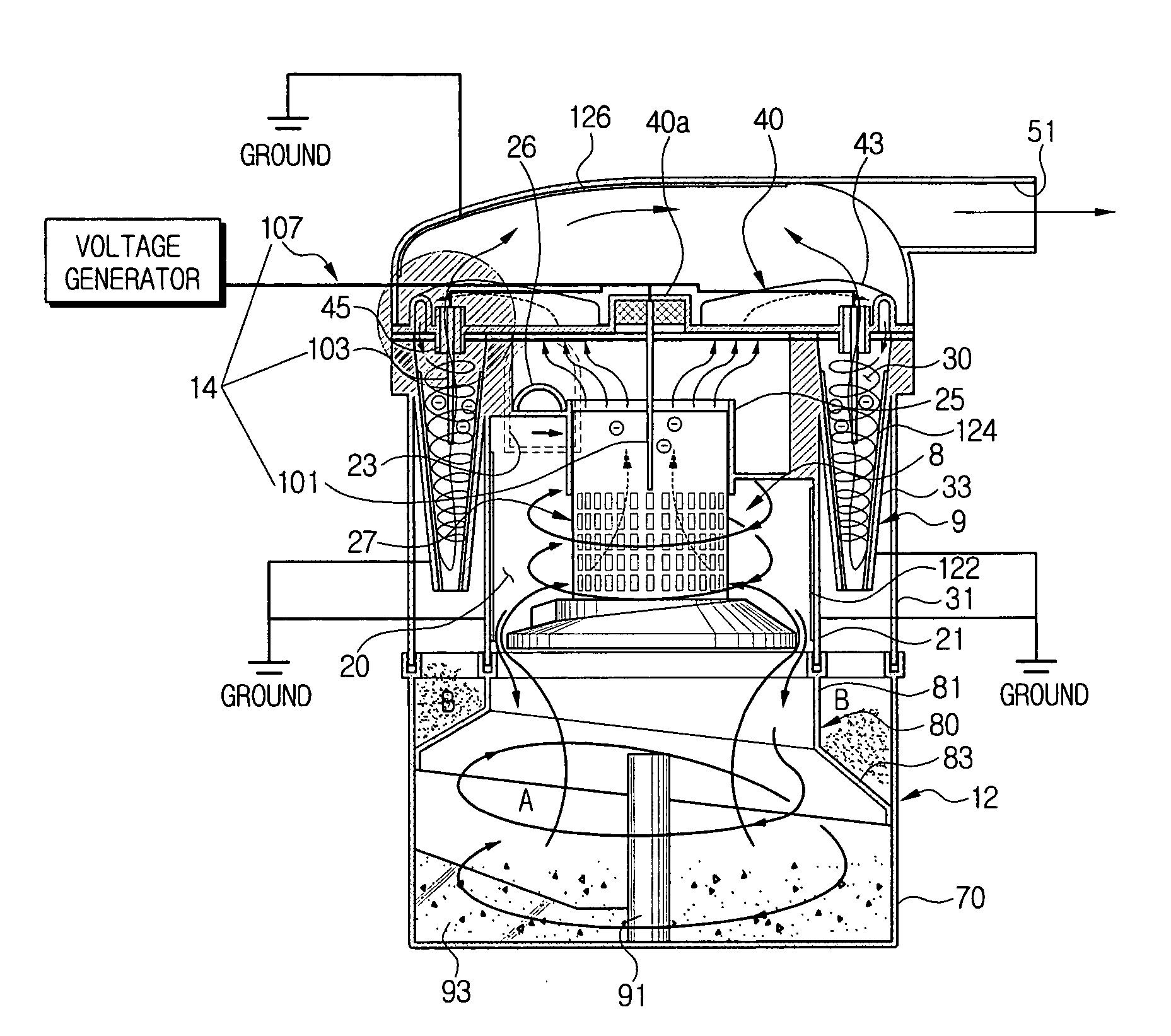

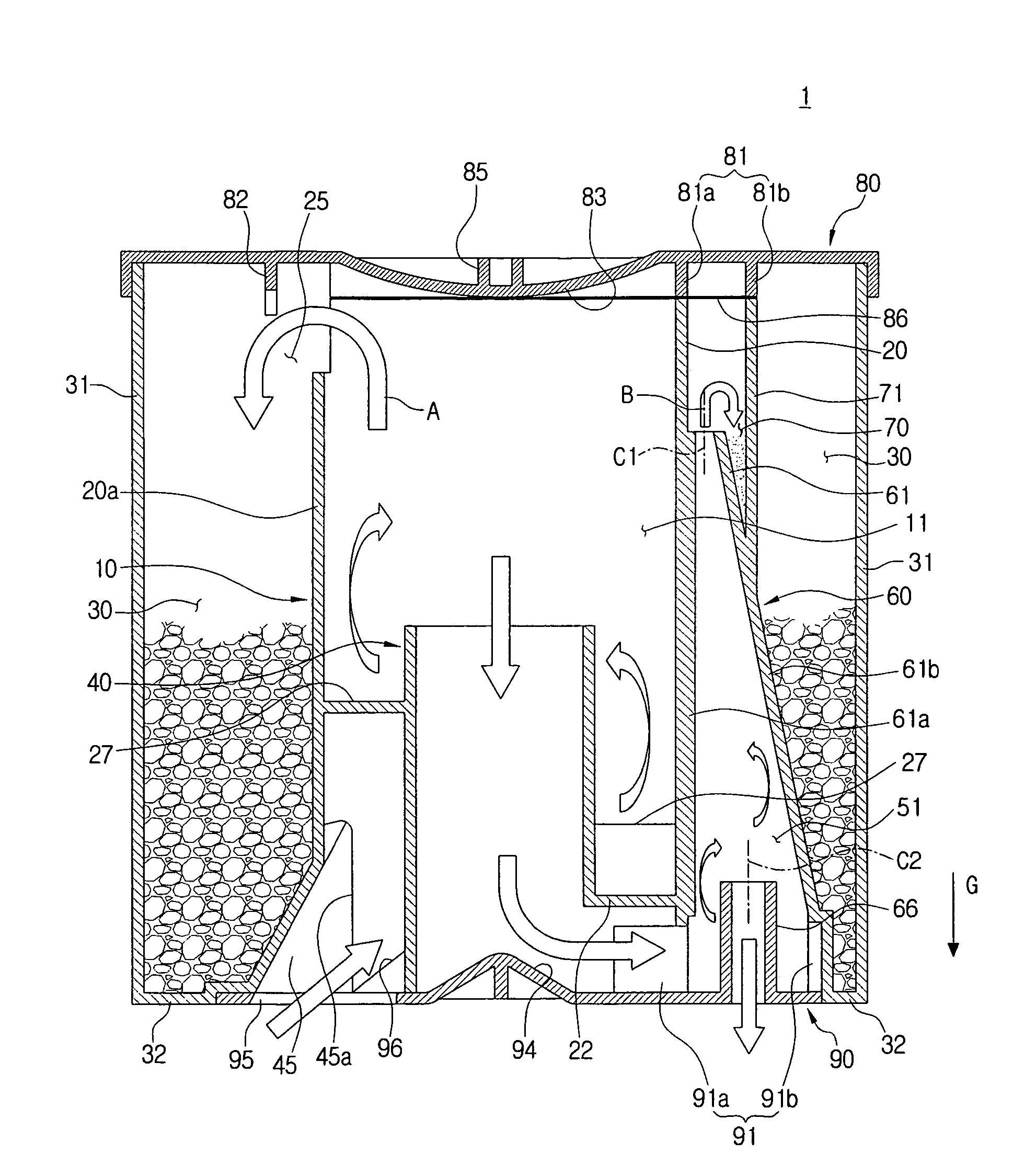

The present invention relates to a multi-cyclone dust collector for a vacuum cleaner. The multi-cyclone dust collector includes a first cyclone forcing contaminants-laden air that is drawn-in at a lower portion of the first cyclone to form an upwardly whirling air current so as to centrifugally separate contaminants therefrom air, a first contaminants chamber wrapping around a first part of the first cyclone and collecting contaminants discharged from the first cyclone, and a second cyclone unit wrapping around a second part of the first cyclone and having a plurality of second cyclones, each of the plurality of second cyclones drawing-in semi-clean air discharged from the first cyclone at an upper portion of each of the plurality of second cyclones so as to centrifugally separate fine contaminants from the semi-clean air.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

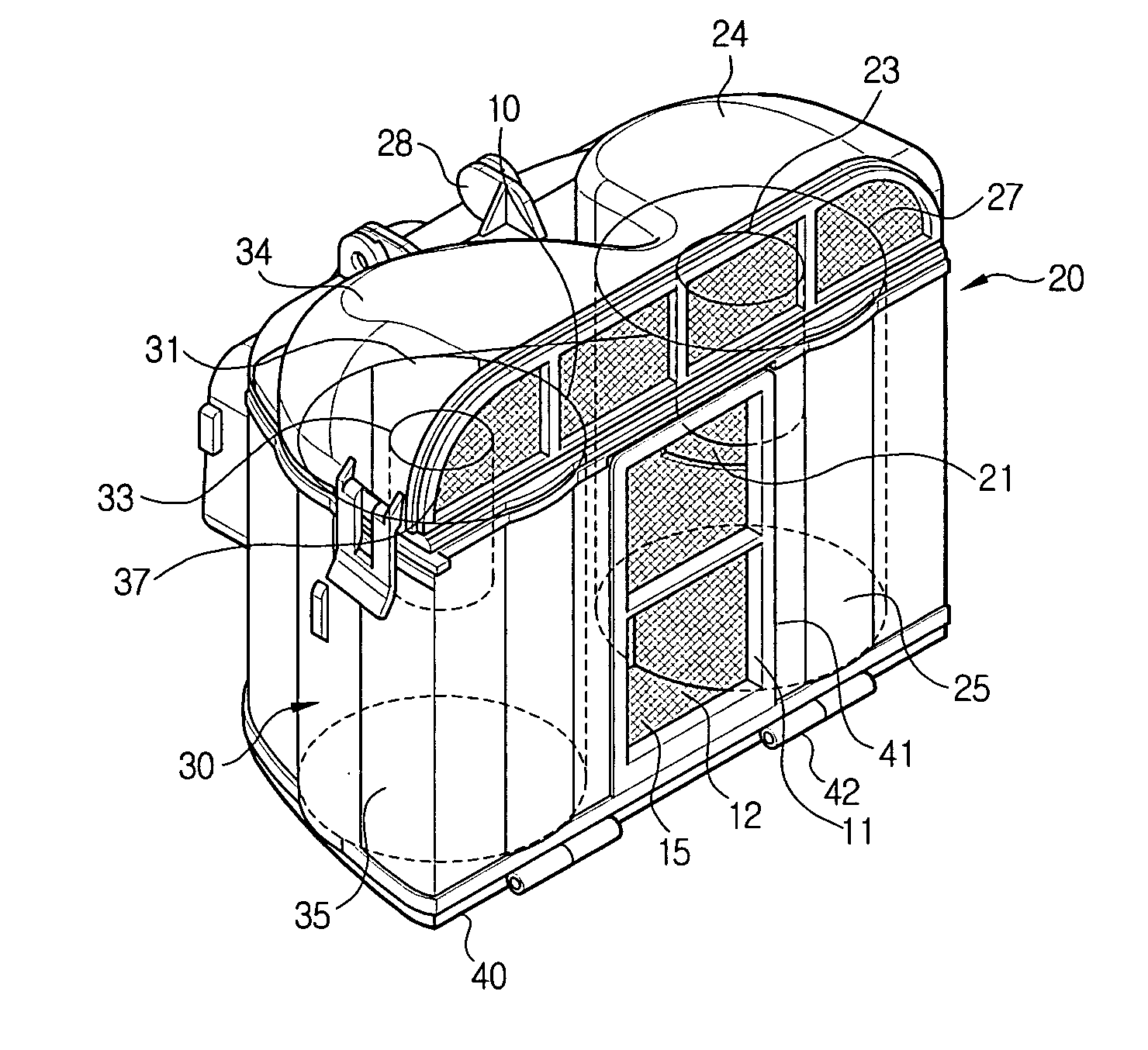

Dual Cyclone Dust-Collecting Apparatus Vacuum Cleaner

ActiveUS20100224073A1Short heightSectional area is increasedCleaning filter meansCombination devicesCycloneEngineering

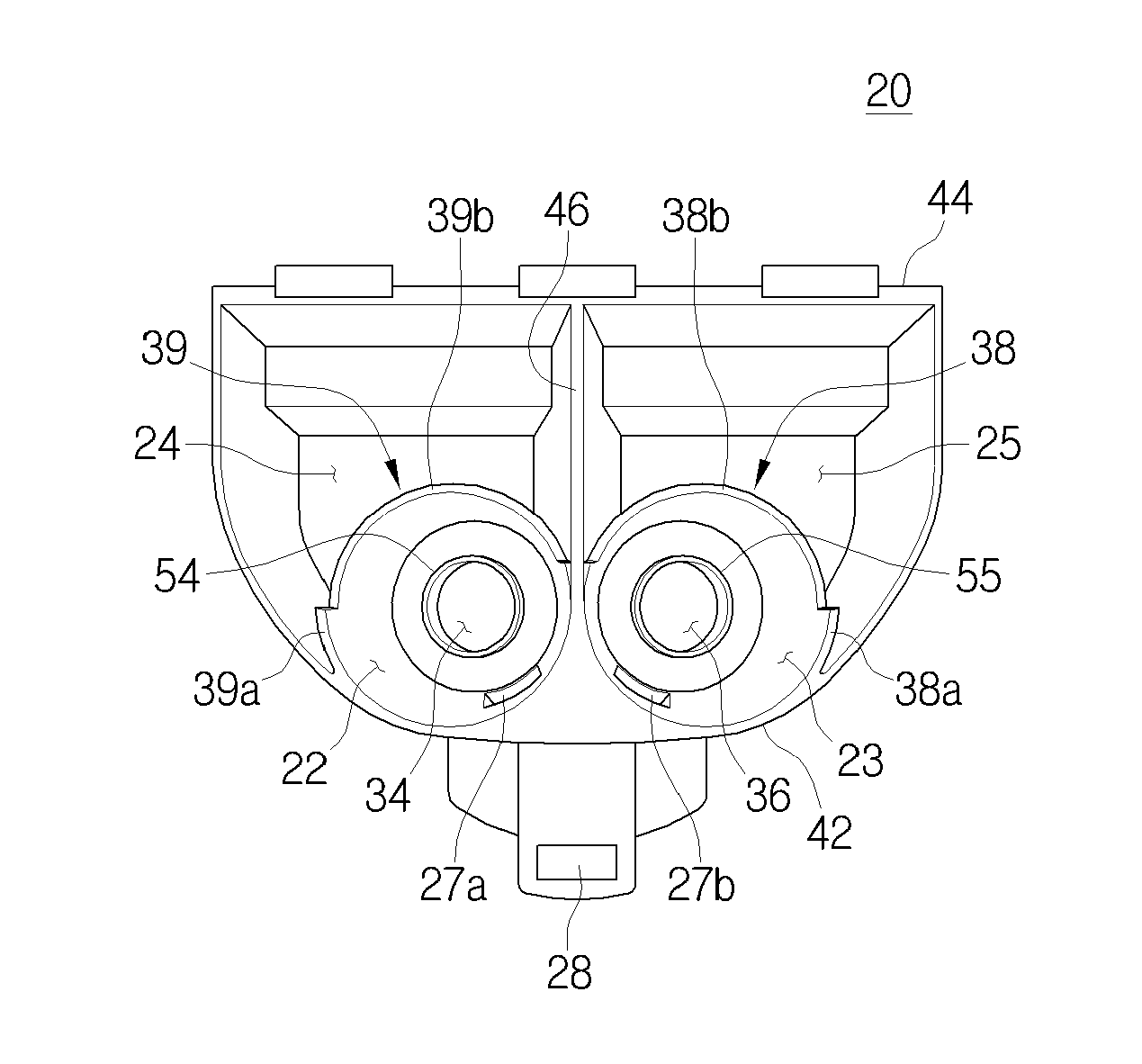

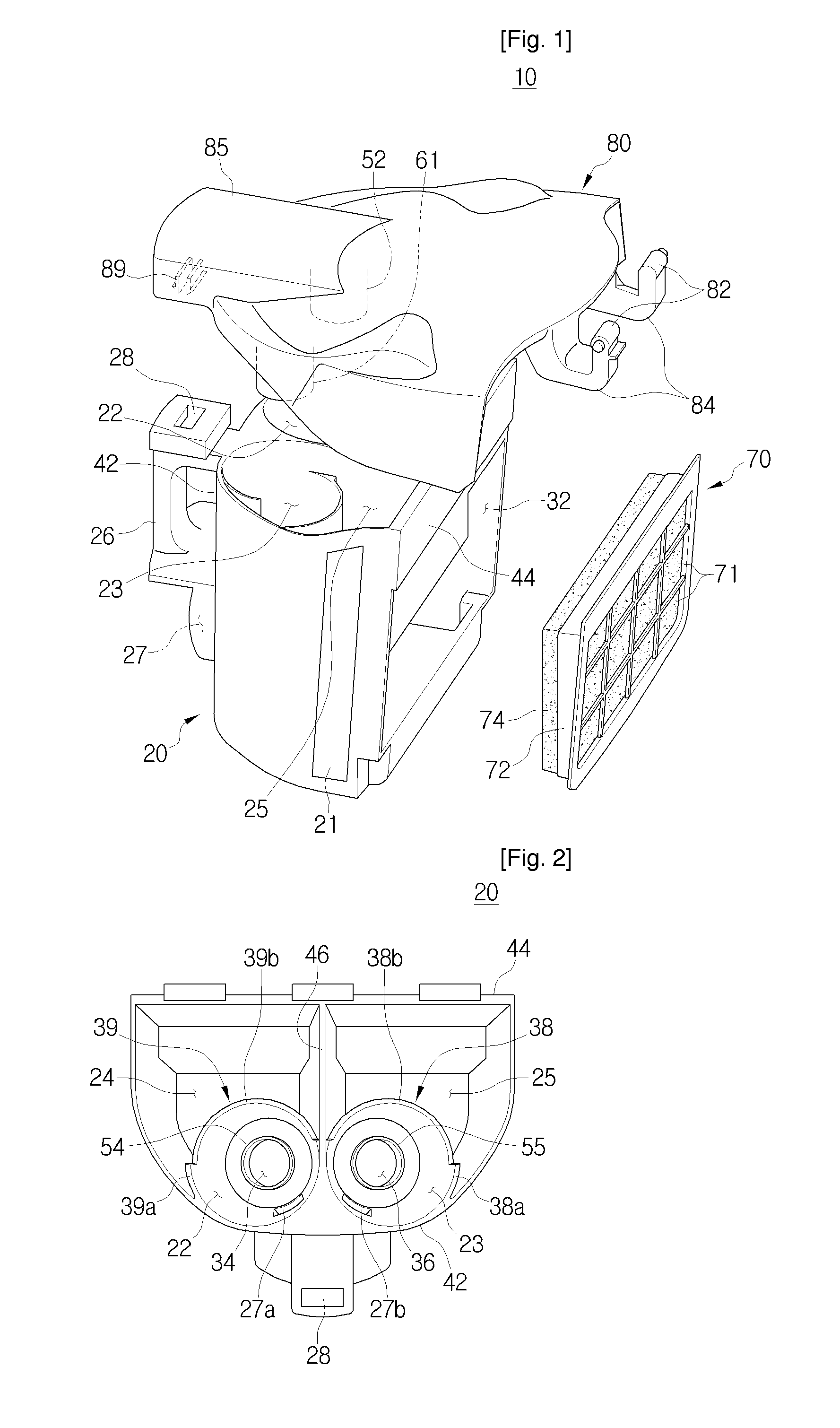

A dual cyclone dust-collecting apparatus of a vacuum cleaner is disclosed. The dust-collecting apparatus includes an air inlet through which an external air is drawn in, two cyclone chambers into which the external air drawn in through the air inlet air is drawn in, the two cyclone chamber being disposed in parallel, at least one dust-collecting chamber divided in parallel with respect to the two cyclone chambers, and two air outlets through which the external air from the two cyclone chambers is discharged. The air inlet is formed between the two cyclone chambers at a lower part of a cyclone body and the two air outlets are formed in bottom surfaces of the two cyclone chambers, respectively, so that the external air is drawn in through lower parts of one sides of the two cyclone chambers and then discharged through the bottom surfaces of the two cyclone chambers.

Owner:SAMSUNG ELECTRONICS CO LTD

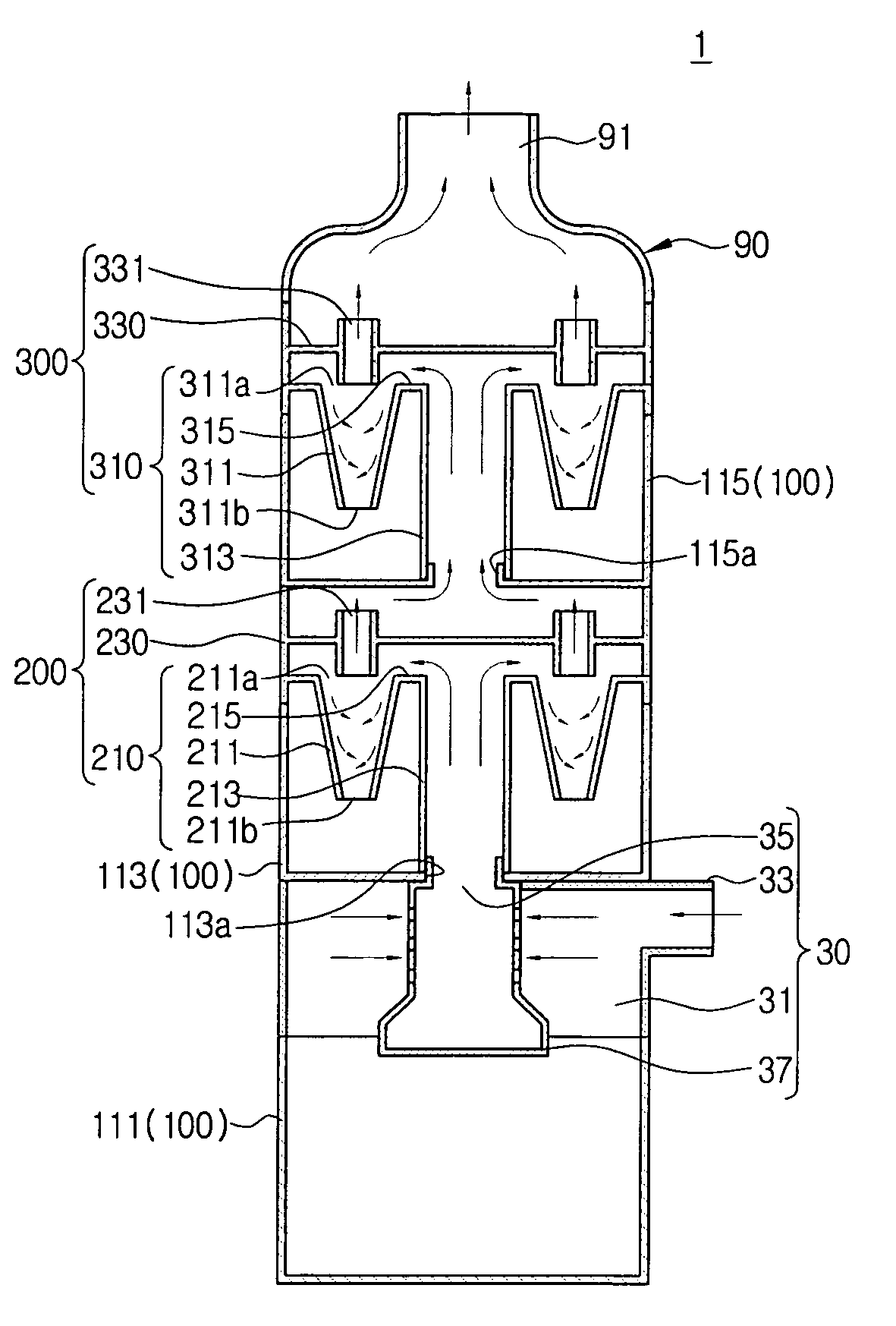

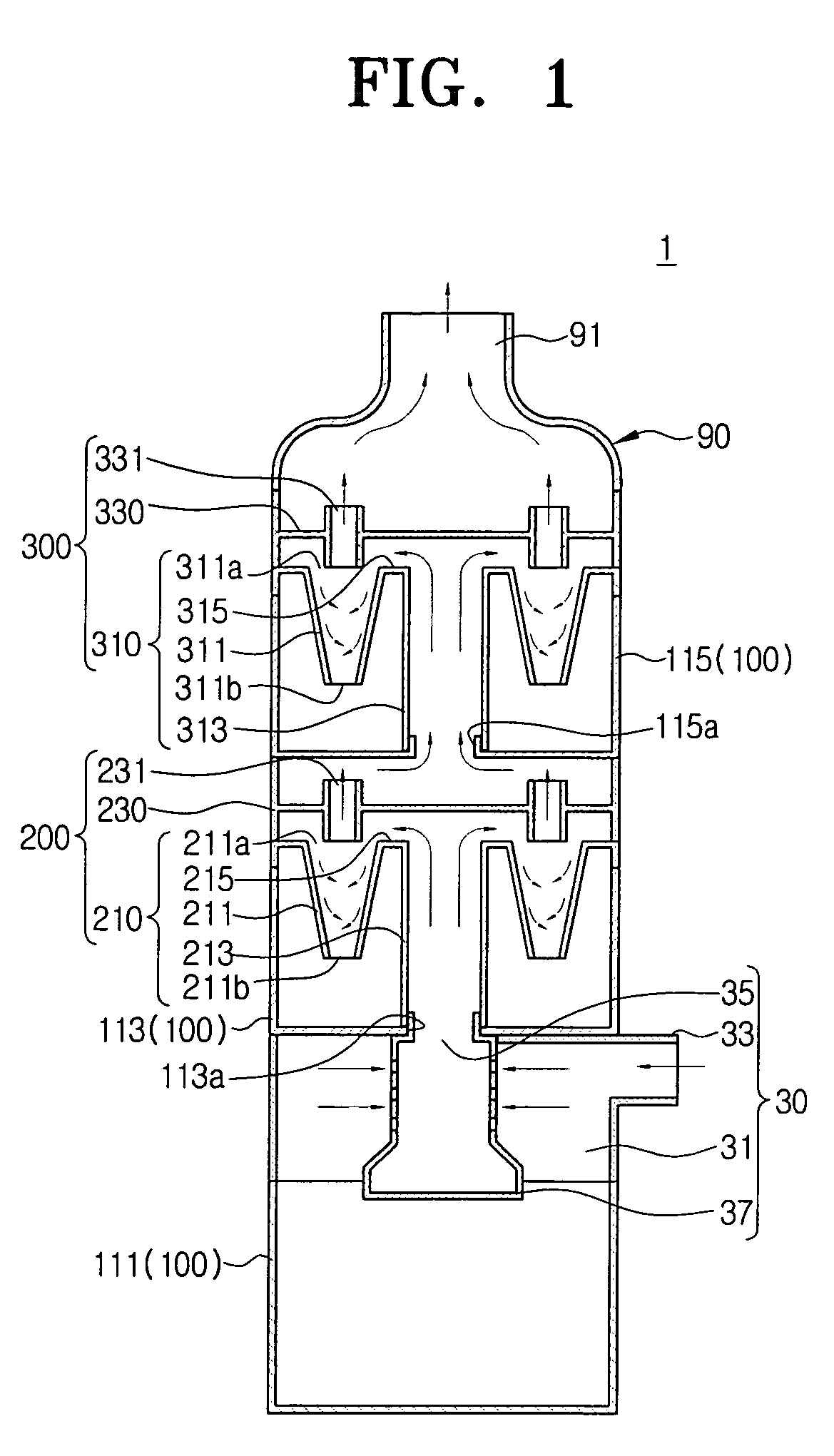

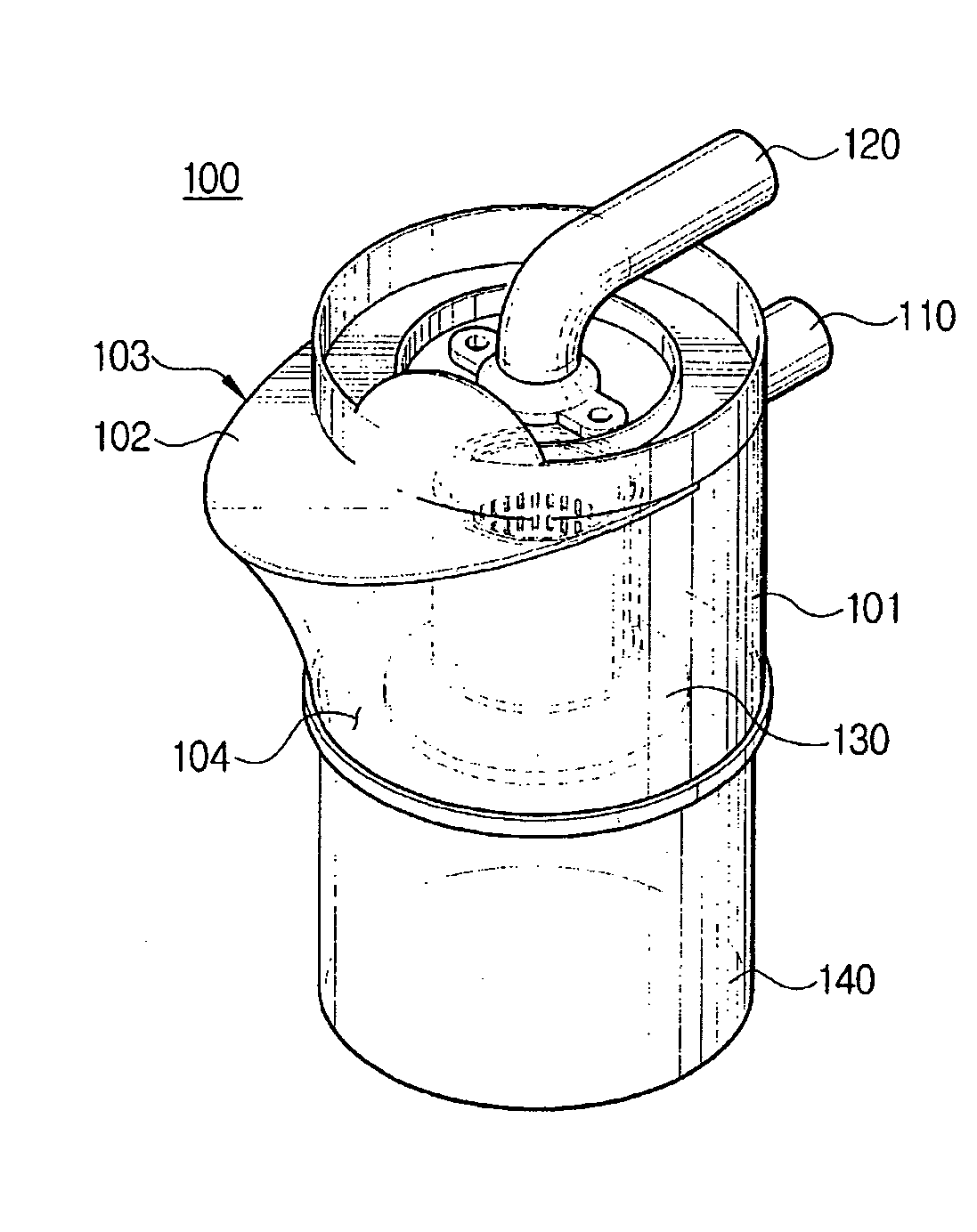

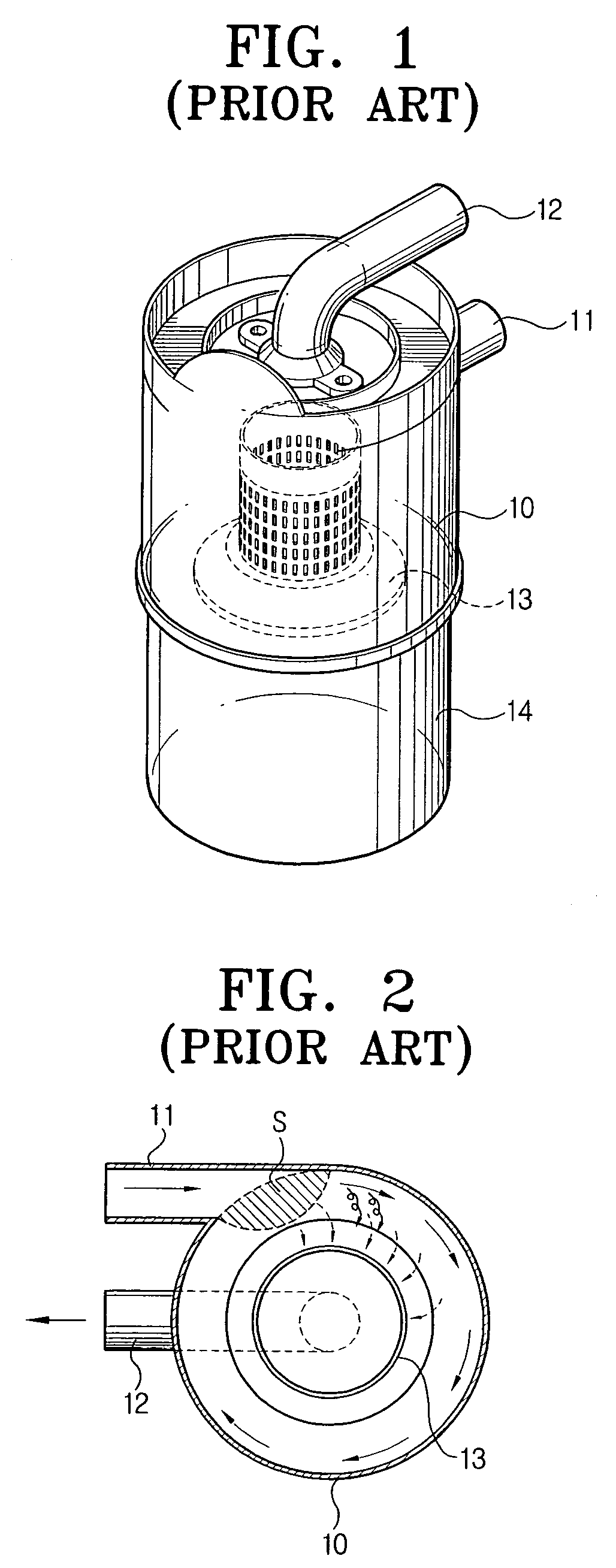

Multi-cyclone dust collector for vacuum cleaner and dust collecting method

InactiveUS20070079584A1Improve dust collection efficiencyProblem and drawbackReversed direction vortexSuction cleanersCycloneCyclonic spray scrubber

The present invention relates to a multi-cyclone dust collector for a vacuum cleaner and dust collecting chamber. The multi-cyclone dust collector includes a first cyclone unit having a first cyclone body and a first dust collecting chamber, the first cyclone body taking dust-laden air entering through an under portion thereof and forming a first upwardly whirling air current so as to separate contaminants centrifugally from the dust-laden air, the first dust collecting chamber collecting contaminants discharged from the first cyclone body; and a second cyclone unit wrapping around at least a portion of the first dust collecting chamber, sucking semi-clean air discharged from the first cyclone unit through an under portion thereof, taking the sucked semi-clean air and forming a second upwardly whirling air current so as to separate contaminants centrifugally from the semi-clean air.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

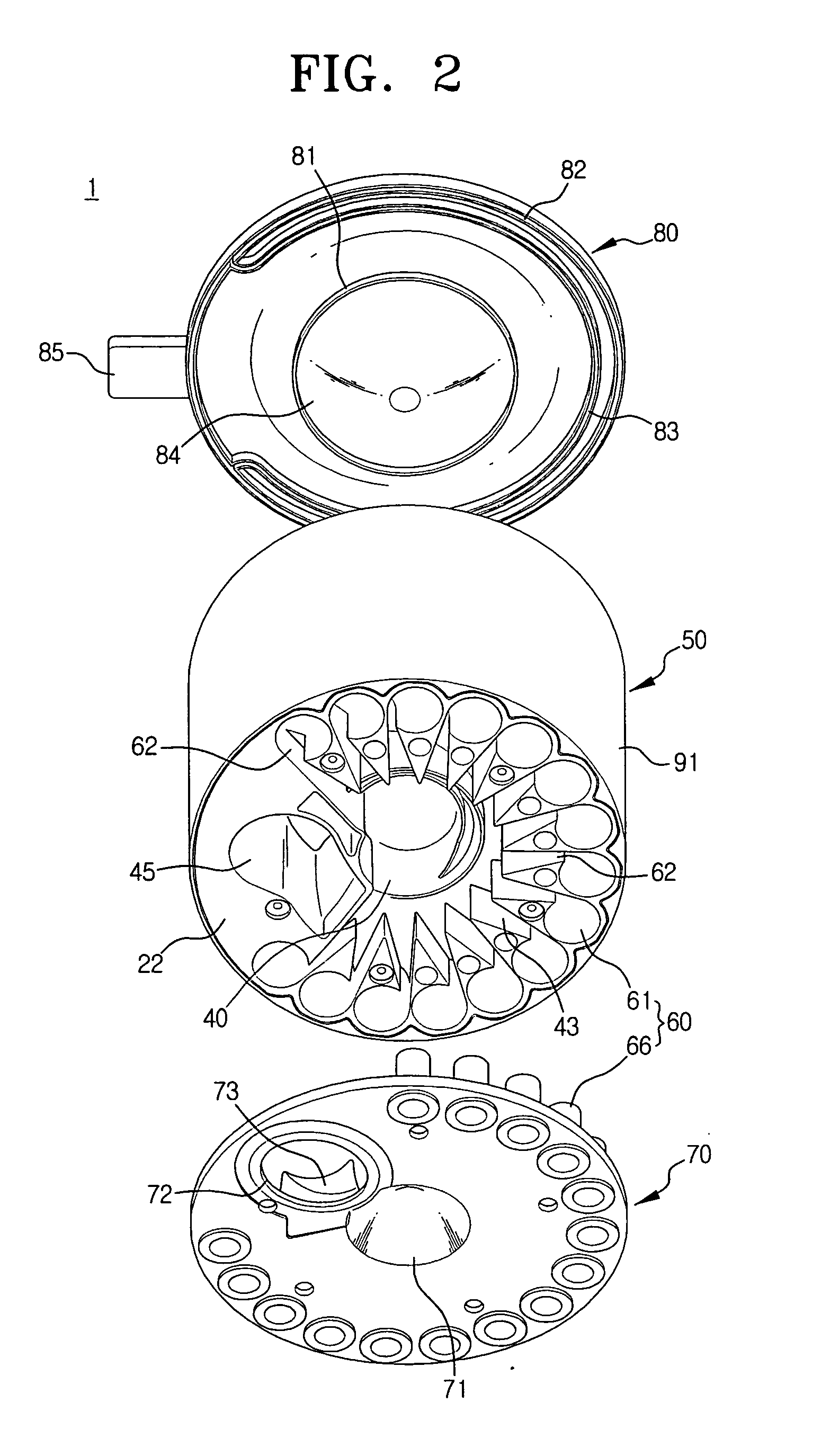

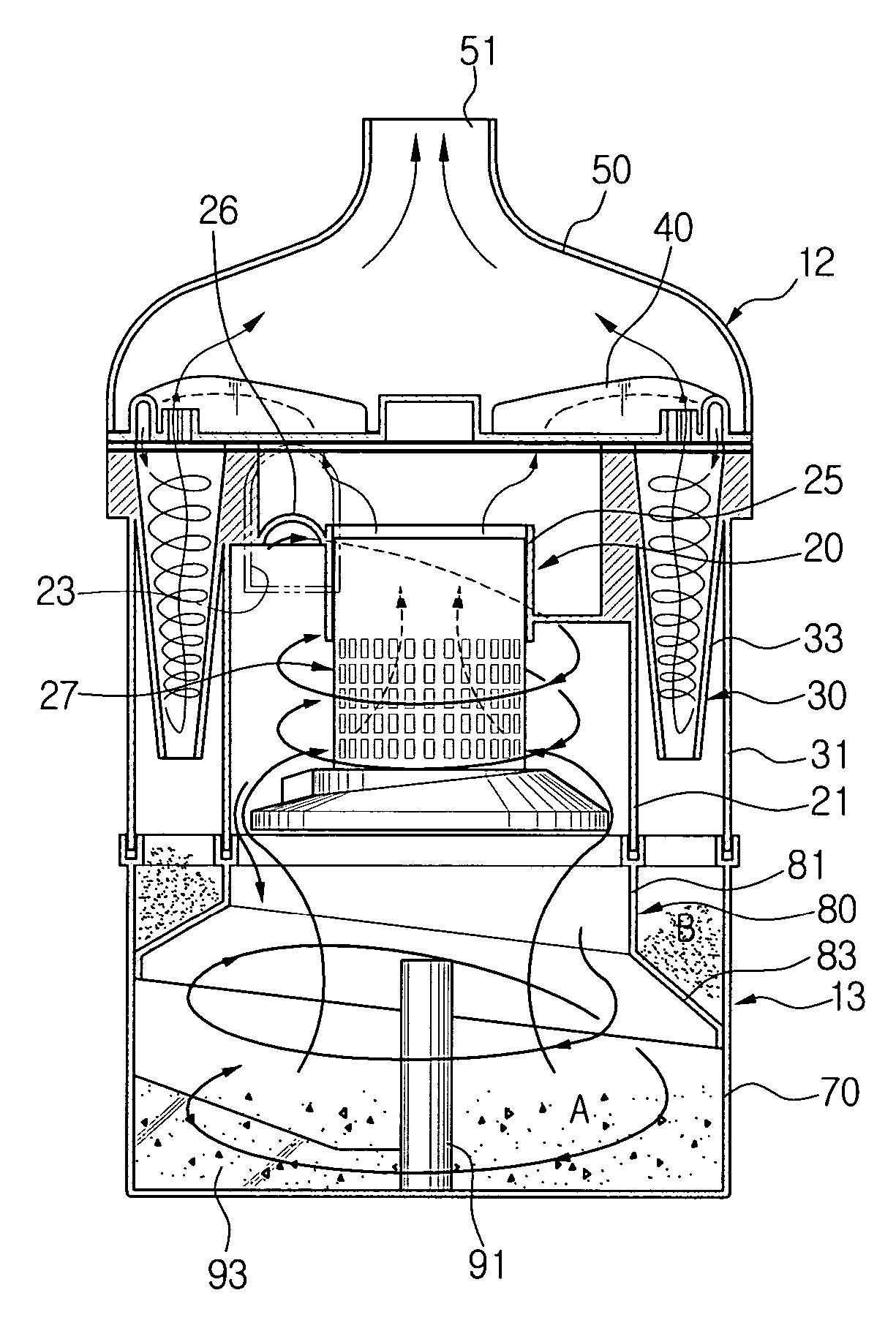

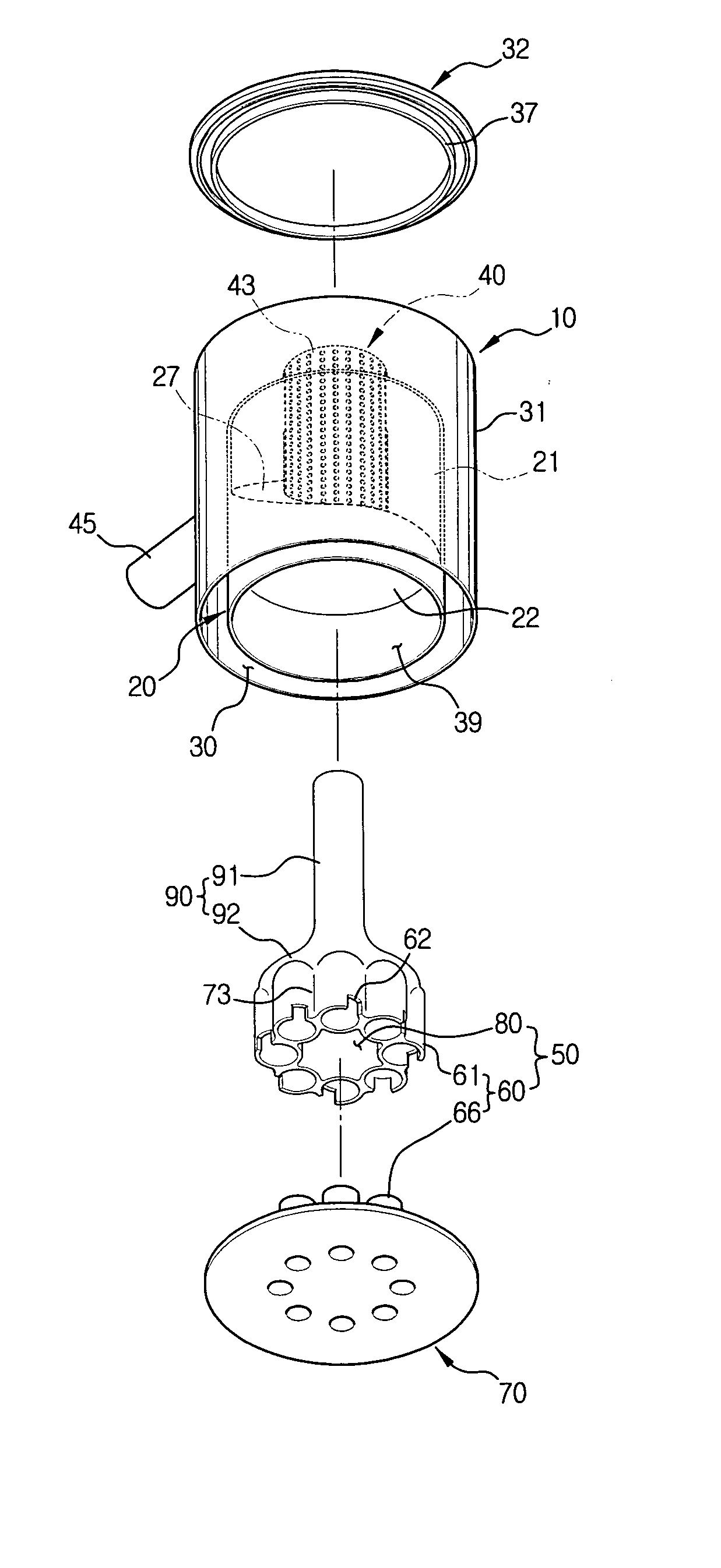

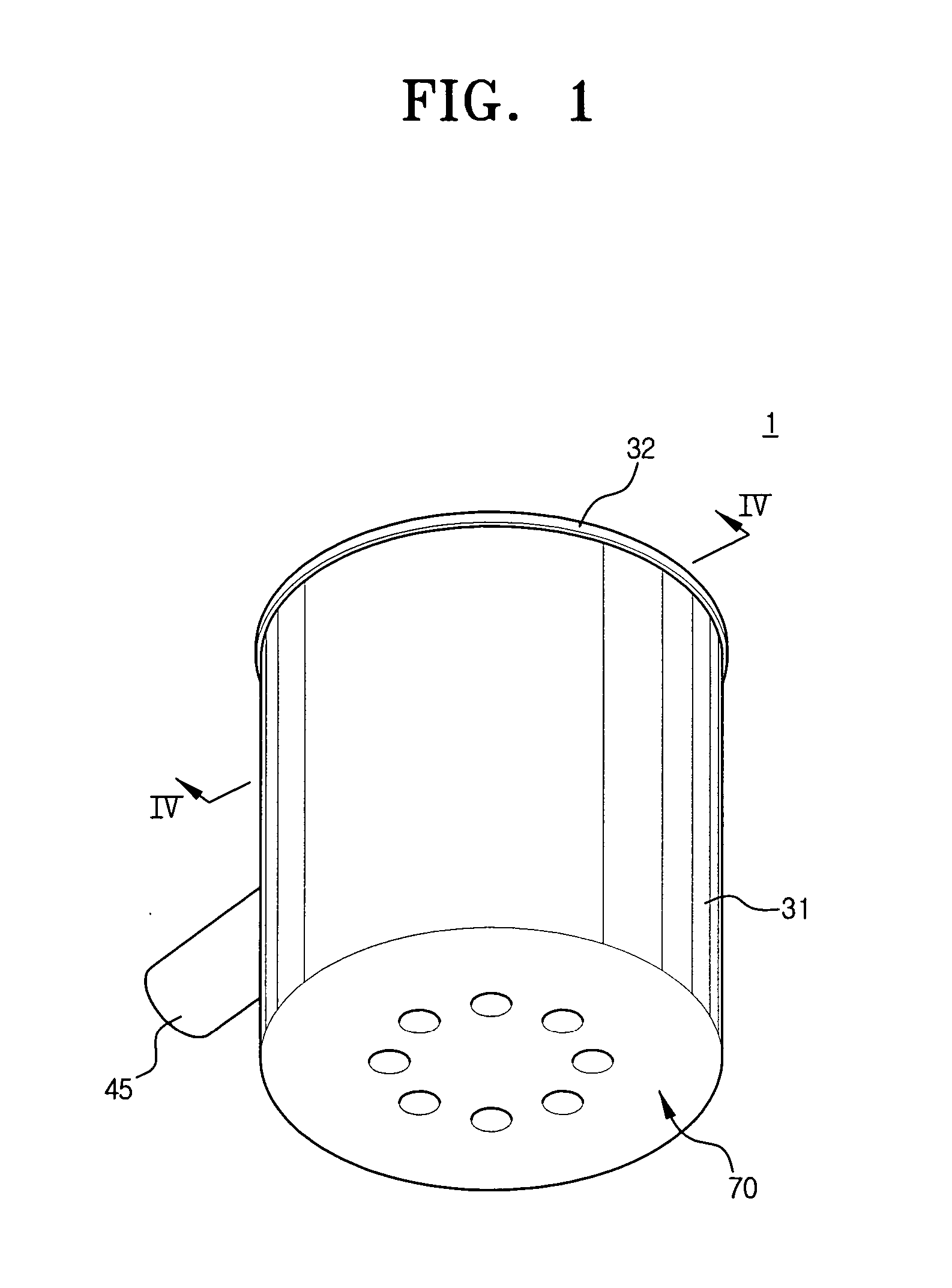

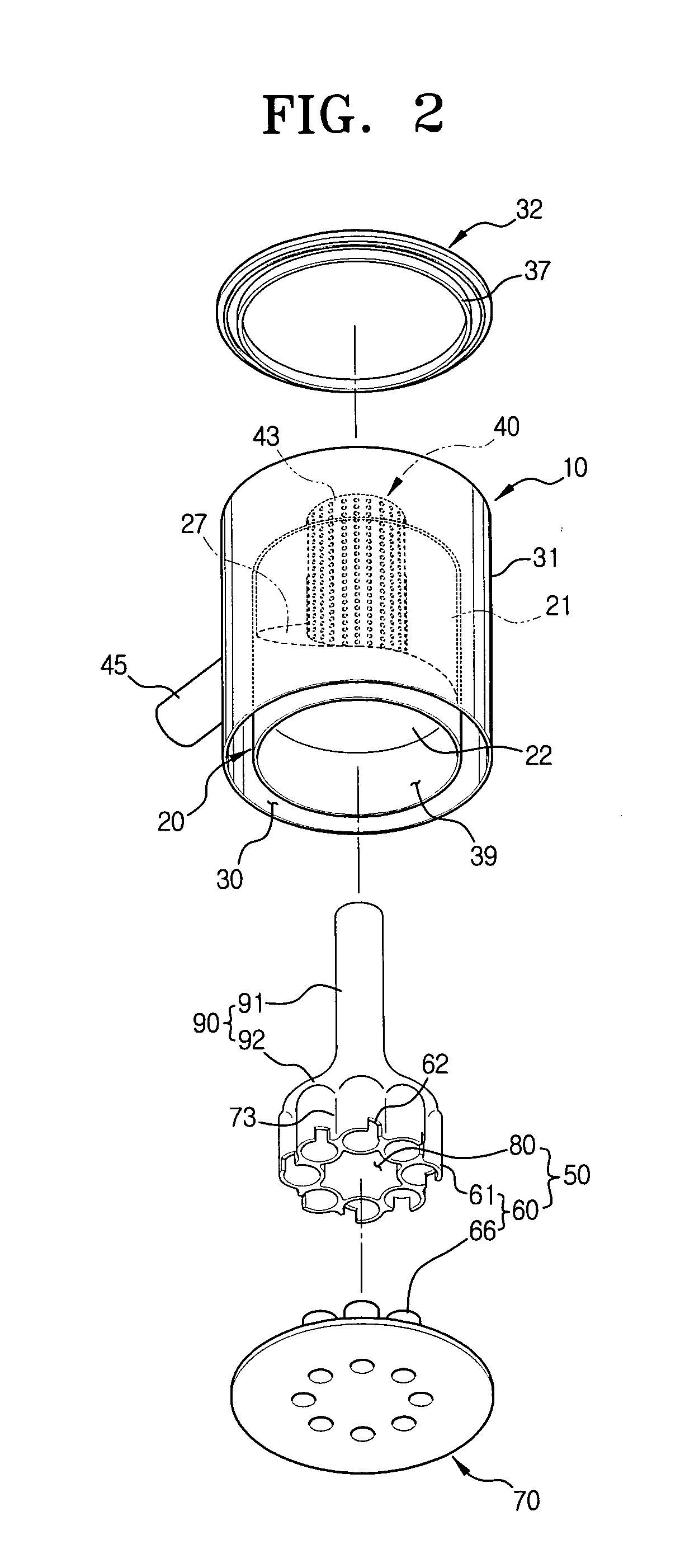

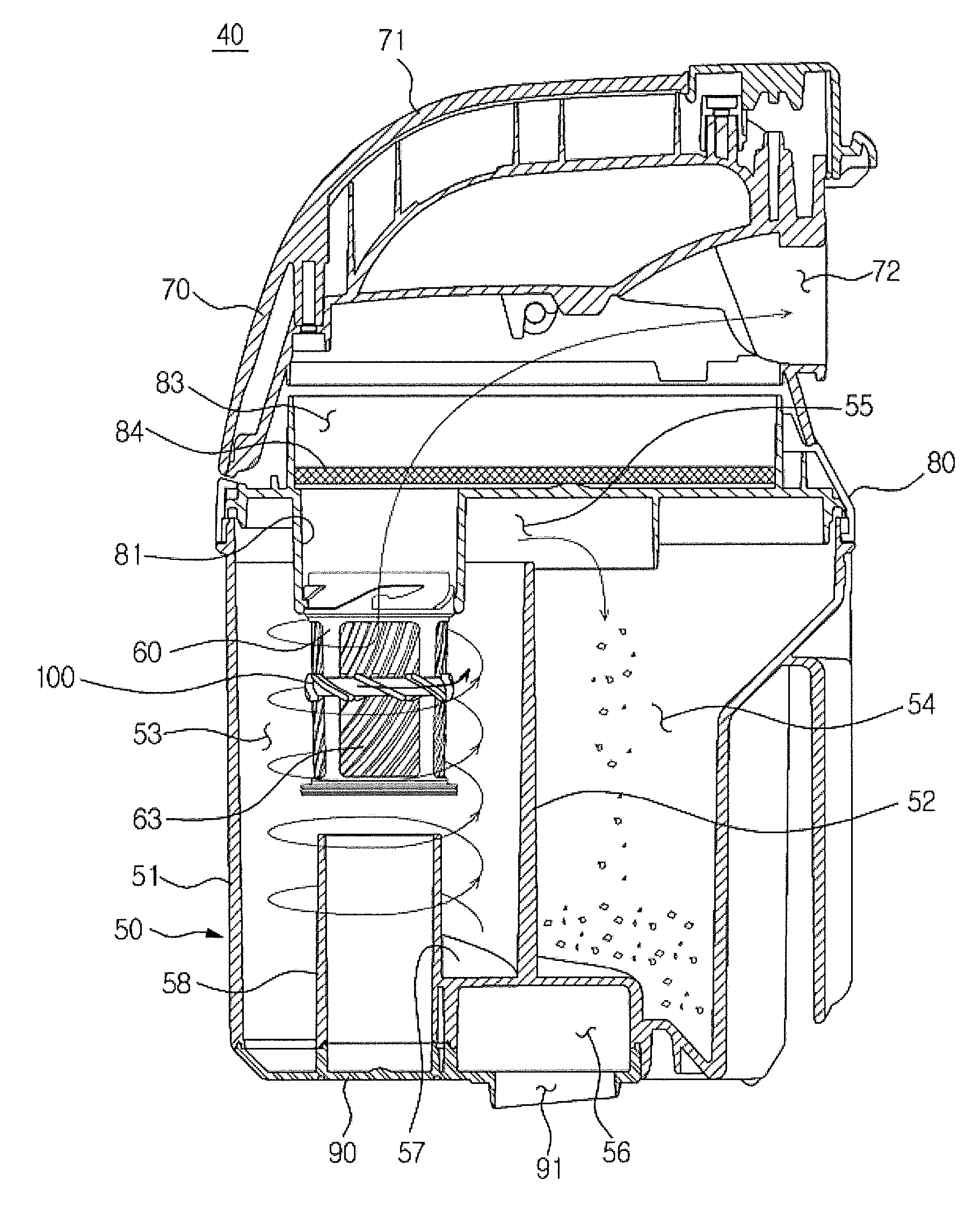

Cyclone dust-collector

ActiveUS7128770B2Efficient separationEasy constructionSuction filtersReversed direction vortexCycloneCyclonic spray scrubber

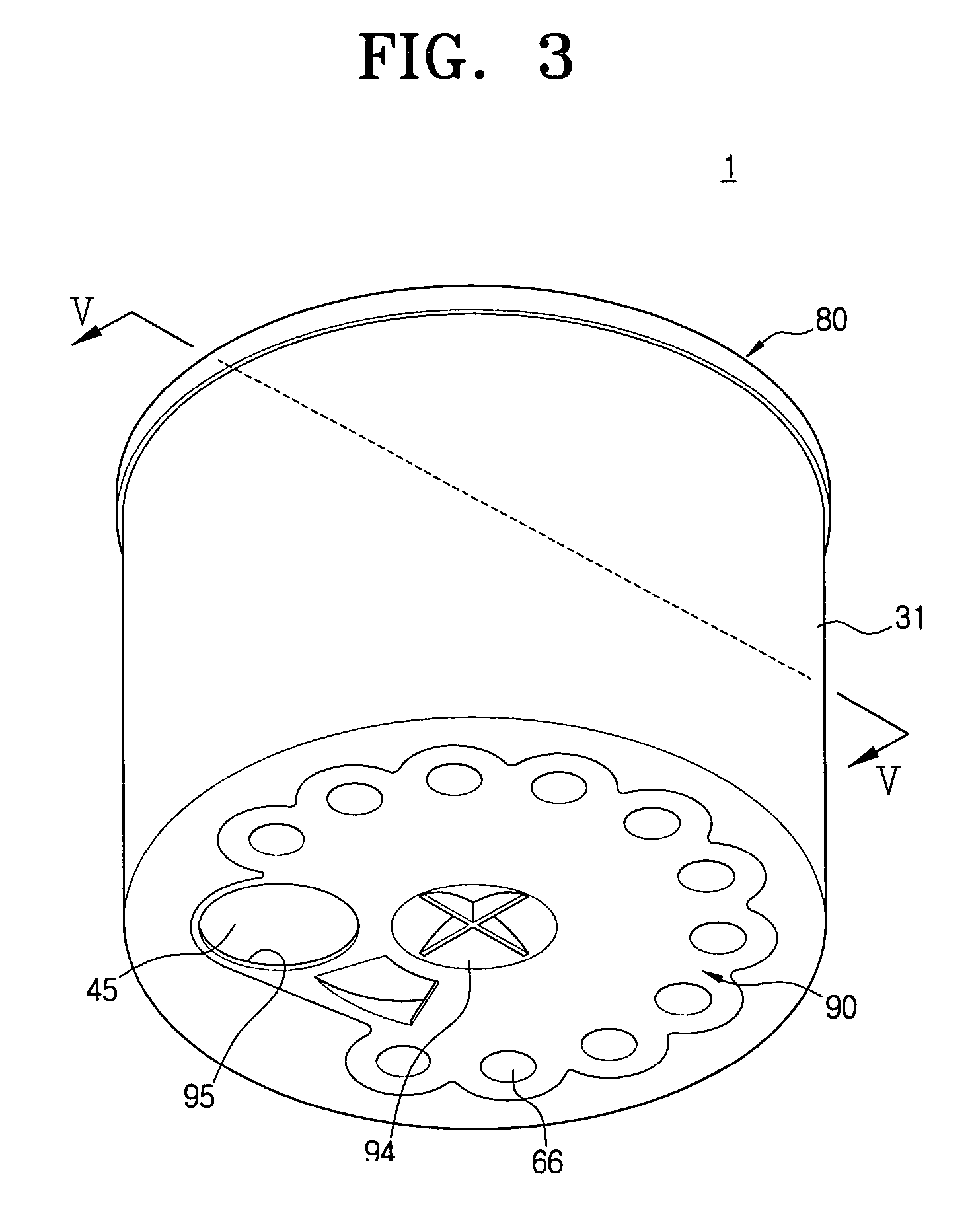

A cyclone dust-collector which filters out dust and dirt from drawn-in air at least two times, comprising a multiple cyclone unit having a first cyclone and a plurality of second cyclones arranged at the outside of the first cyclone, for centrifugally separating the dust and dirt from the drawn-in air; a cover unit connected to the upper portion of the multiple cyclone unit, for allowing the first and the second cyclones to separating communicate with each other; and a dirt-collecting unit connected to the lower portion of the multiple cyclone unit, for collecting therein the dust and dirt centrifugally separated.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

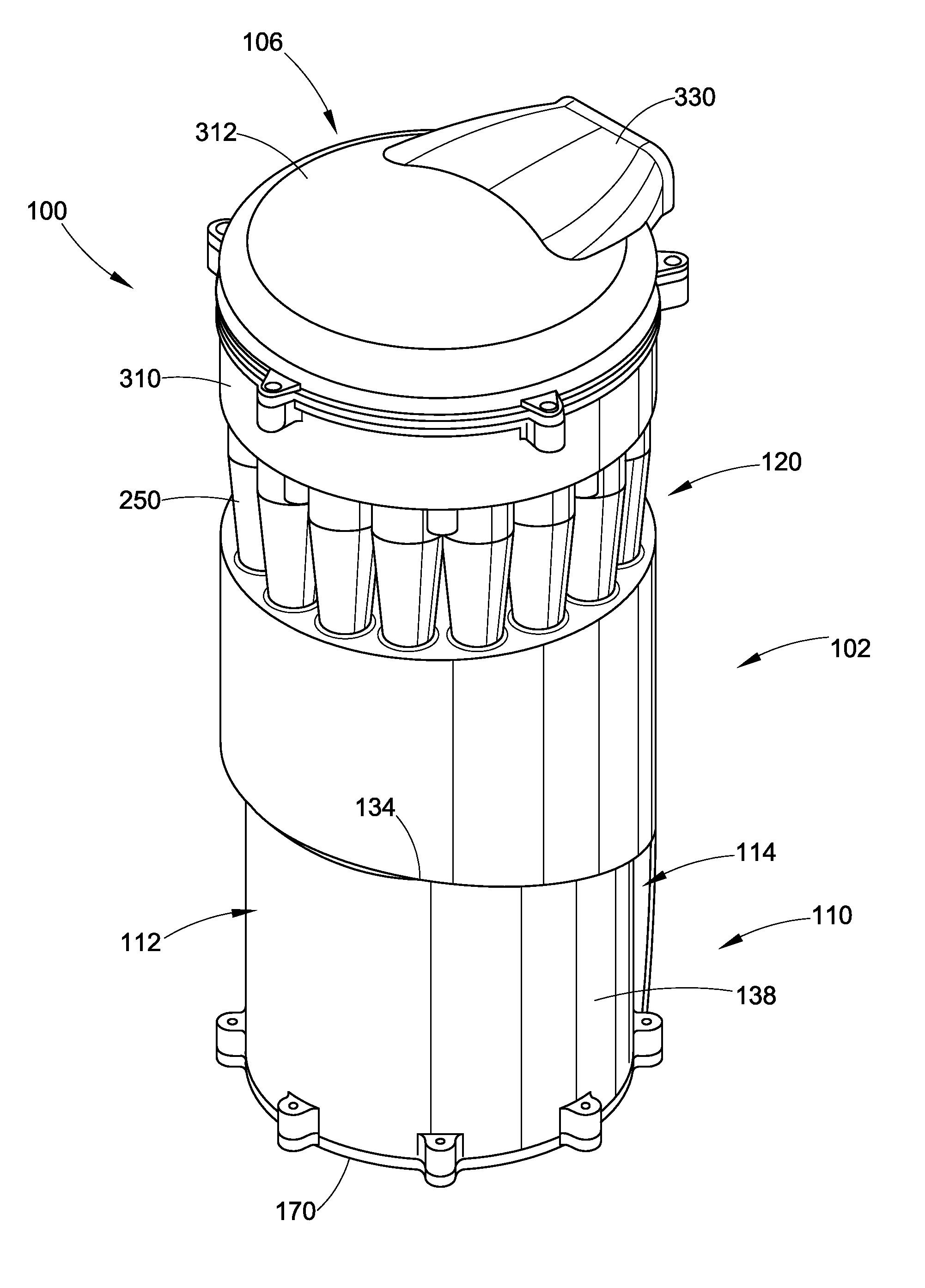

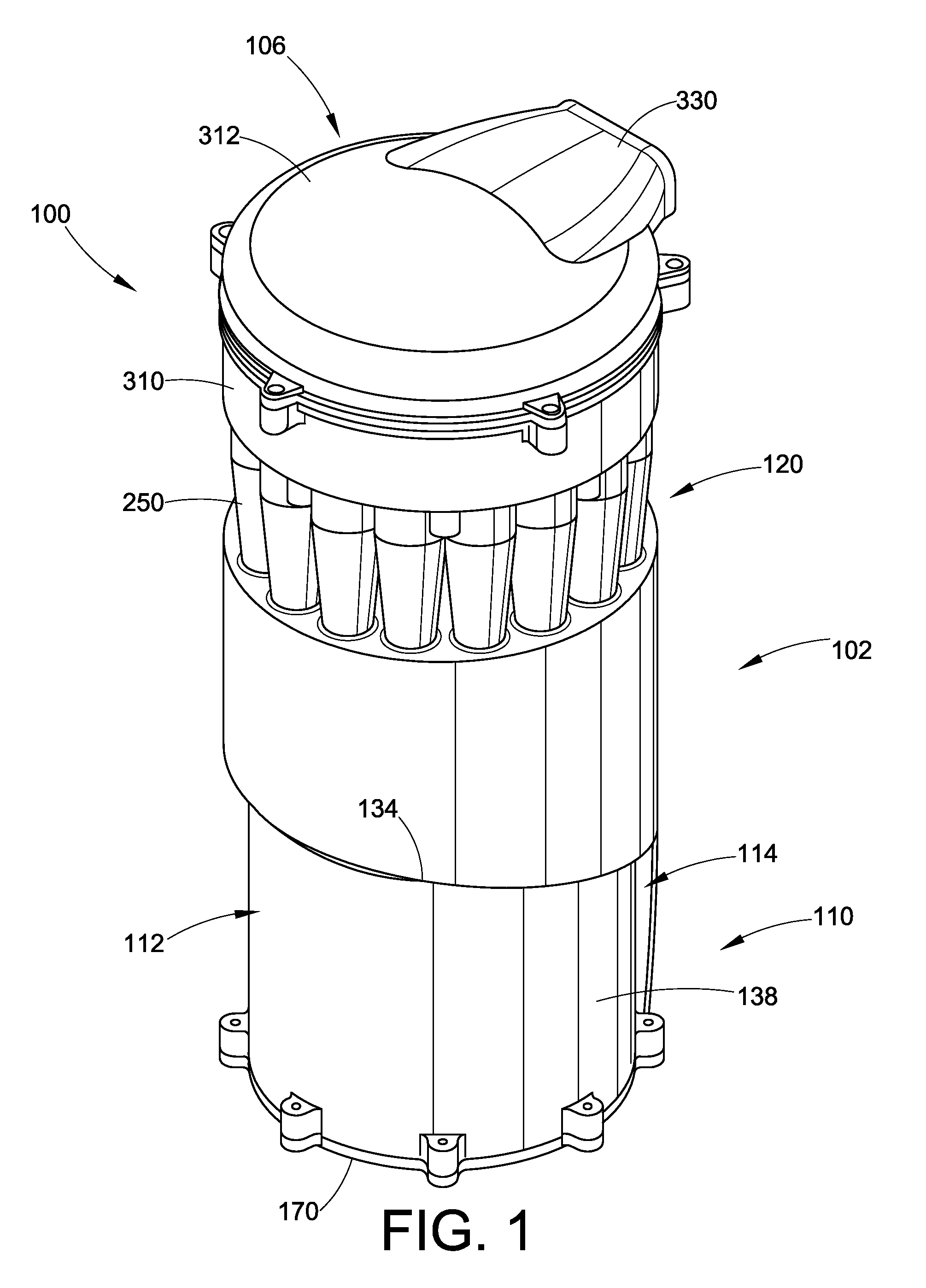

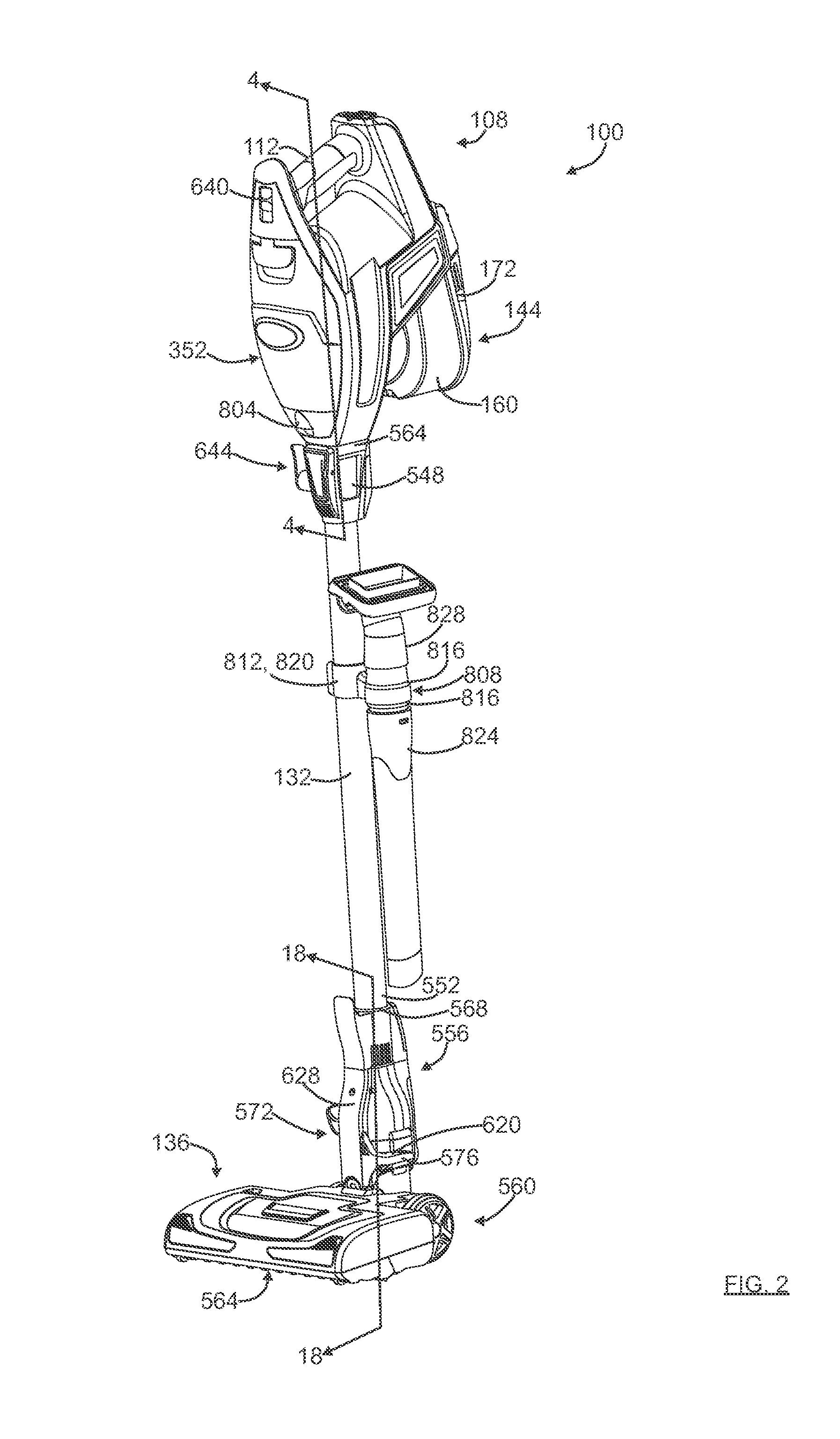

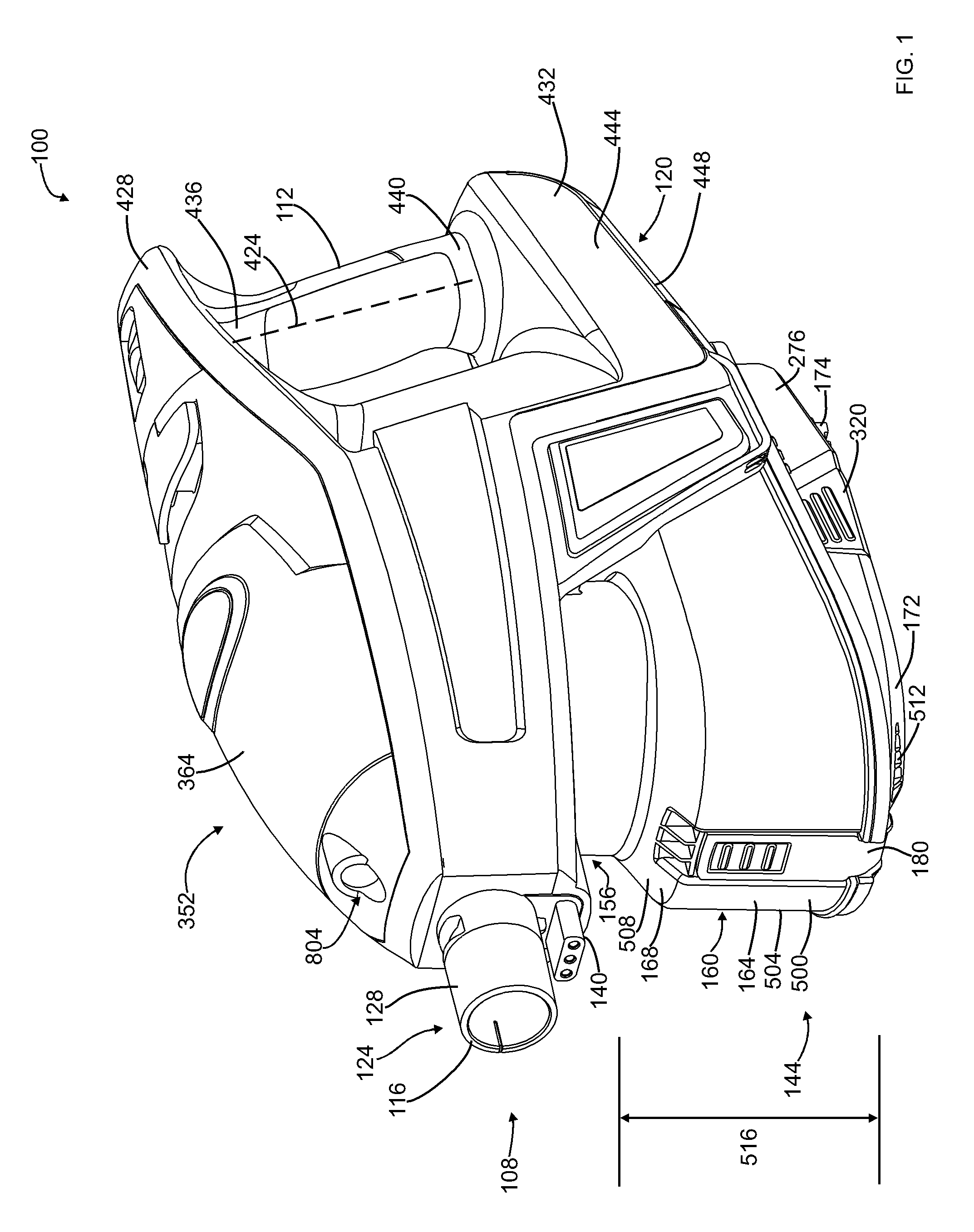

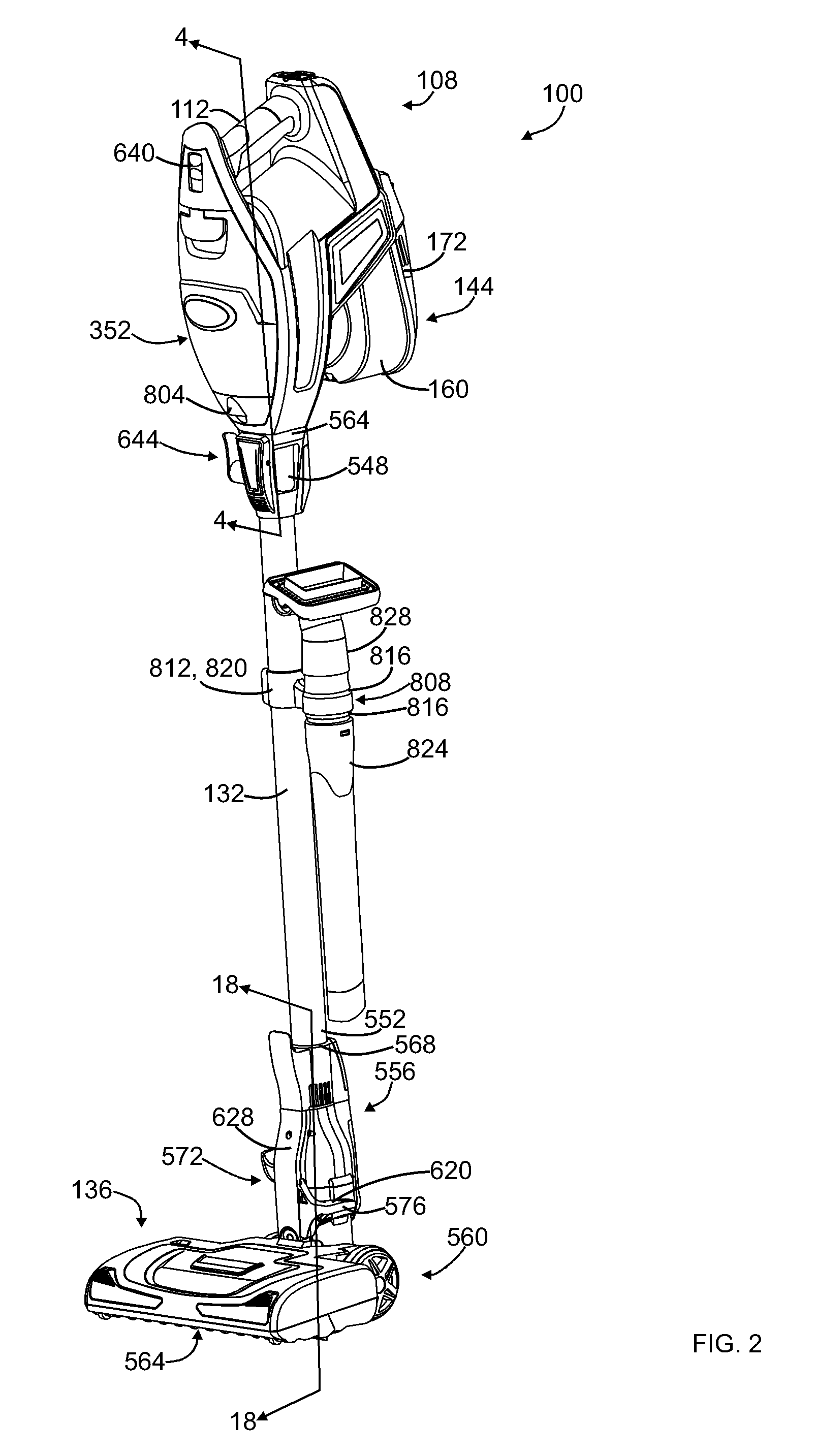

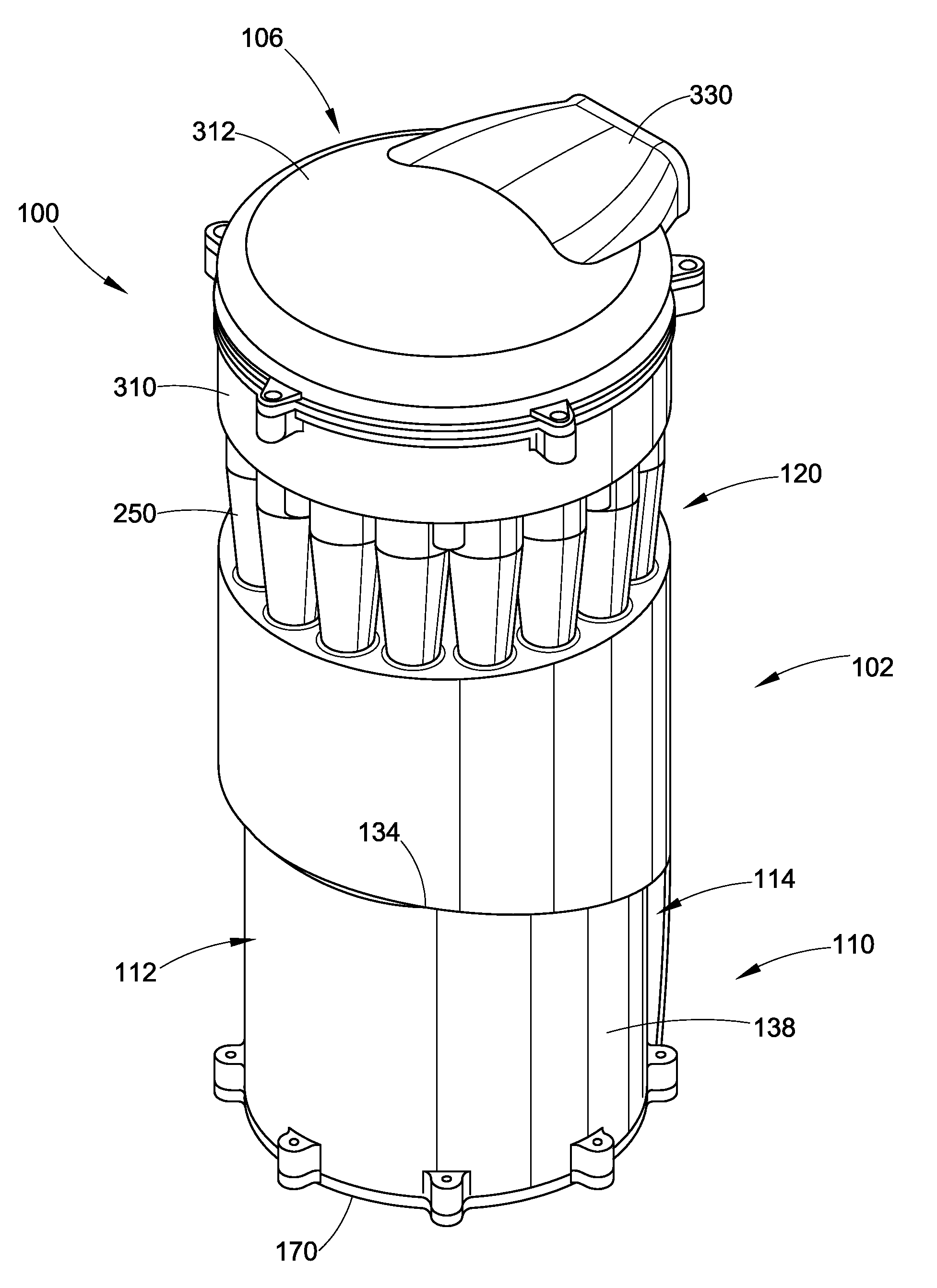

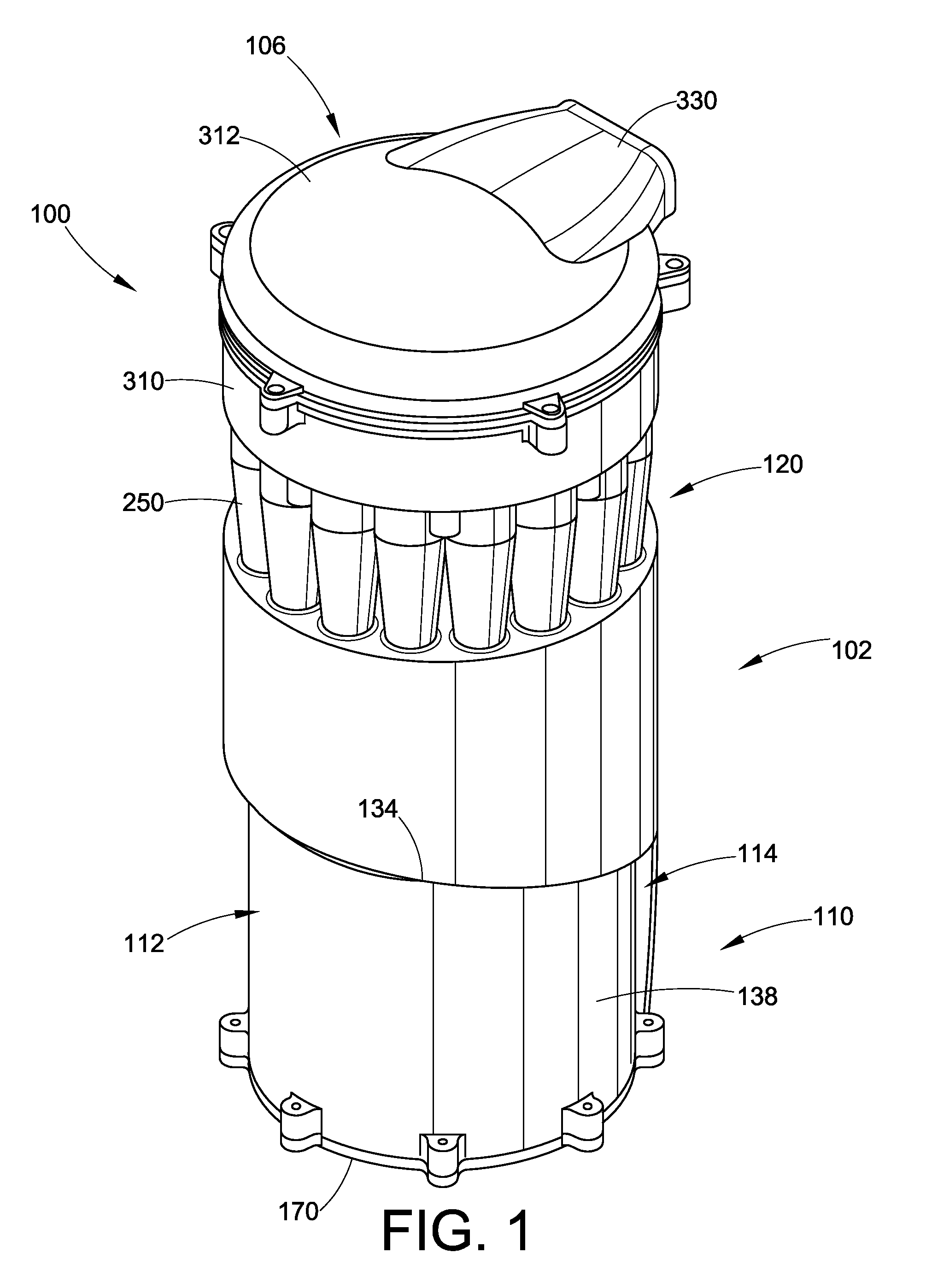

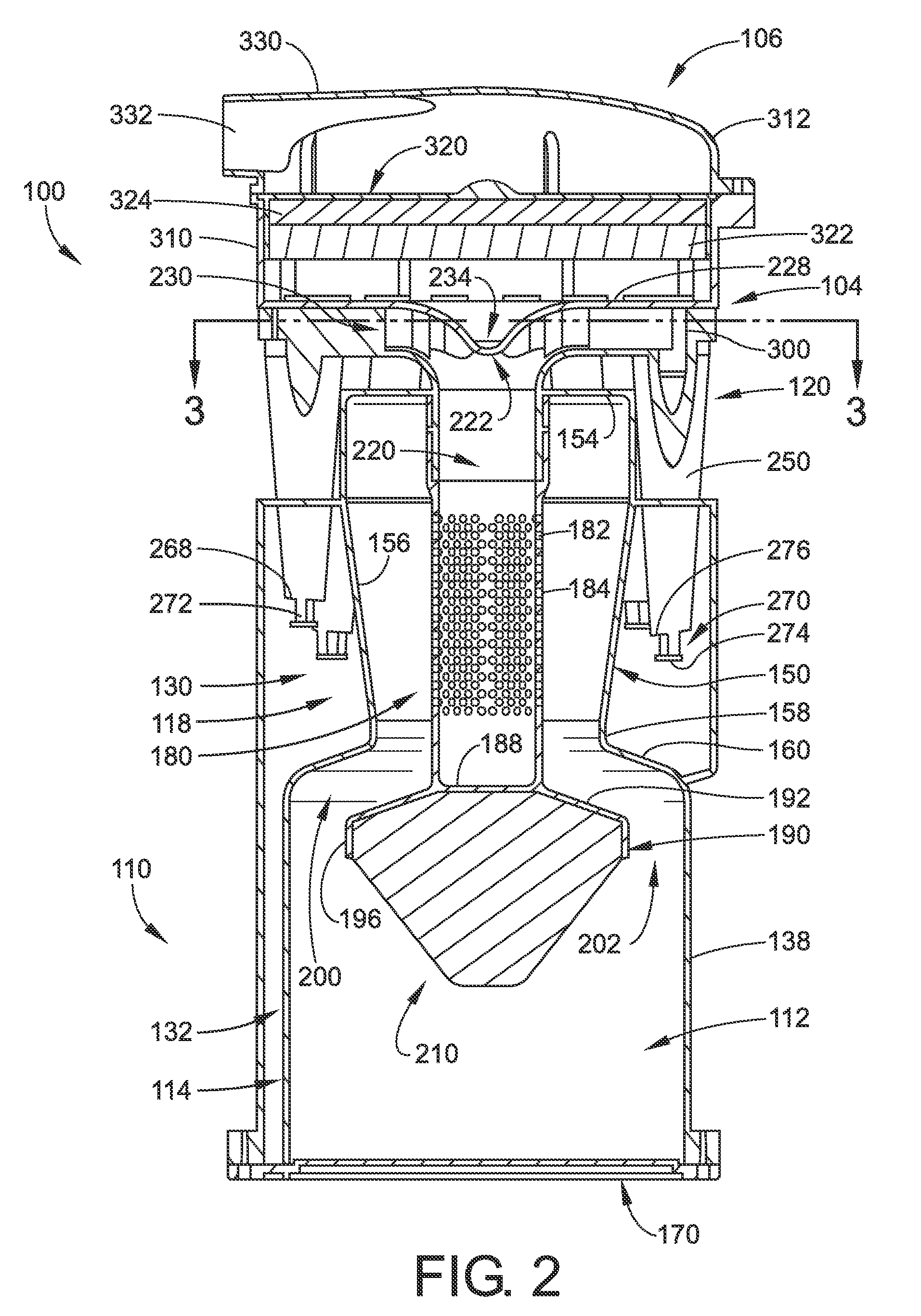

Dual Stage Cyclonic Dust Collector

A surface cleaning suction type appliance comprises a housing, an airstream suction source, a cyclone main body, and a dirt cup. The housing includes a main suction opening. The airstream suction source is mounted to the housing and includes a suction airstream inlet and a suction airstream outlet. The suction source selectively establishes and maintains a flow of air from the main suction opening, via the airstream inlet, to the airstream outlet. The cyclone main body is supported by the housing and is in communication with the main suction opening. The cyclone main body has a uniform outer circumference and includes a first stage separator, and a plurality of downstream second stage separators. The lengths of the second stage cyclonic separators are different for any number of adjacent pairs of separators from on pair up to all adjacent pairs of separators. The dirt cup is connected to the cyclone main body. The dirt cup includes a first particle collector and a second particle collector. The first particle collector communicates with the first stage separator for collecting dust particles from the first stage separator. The separate second particle collector communicates with the plurality of second stage separators for collecting dust particles from the second stage separators.

Owner:TECHTRONIC FLOOR CARE TECH LTD

Cyclone dust-collector

ActiveUS20050172584A1Efficient separationEasy constructionSuction filtersReversed direction vortexCycloneCyclonic spray scrubber

A cyclone dust-collector which filters out dust and dirt from drawn-in air at least two times, comprising a multiple cyclone unit having a first cyclone and a plurality of second cyclones arranged at the outside of the first cyclone, for centrifugally separating the dust and dirt from the drawn-in air; a cover unit connected to the upper portion of the multiple cyclone unit, for allowing the first and the second cyclones to separating communicate with each other; and a dirt-collecting unit connected to the lower portion of the multiple cyclone unit, for collecting therein the dust and dirt centrifugally separated.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

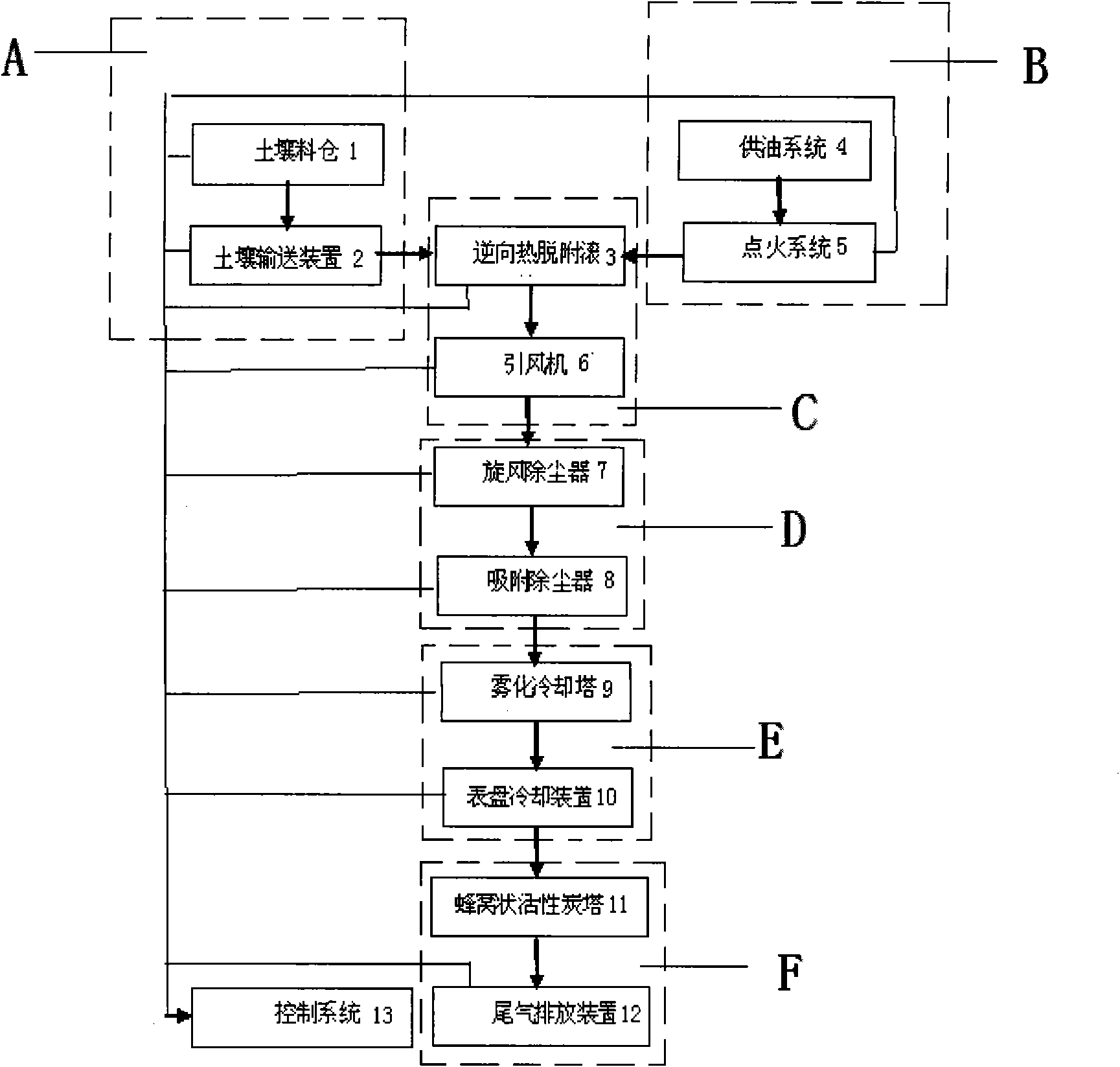

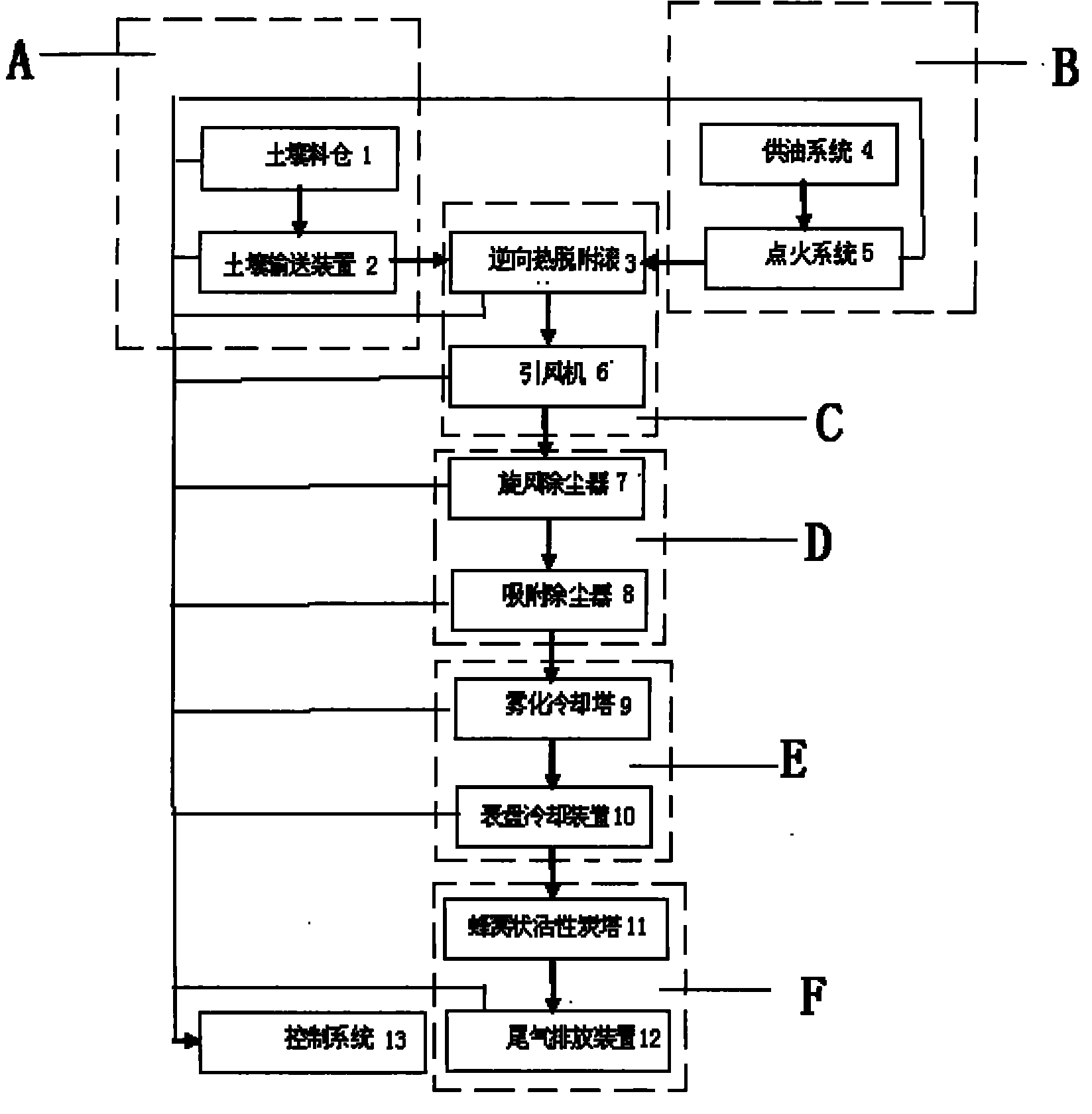

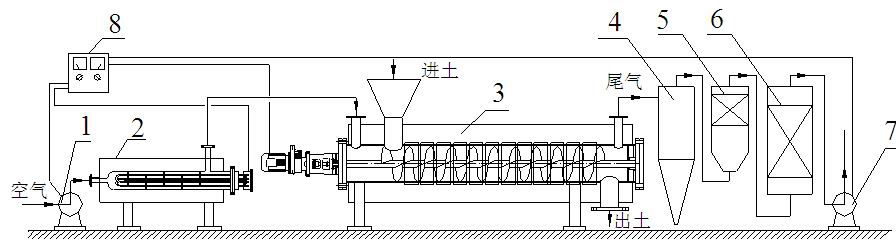

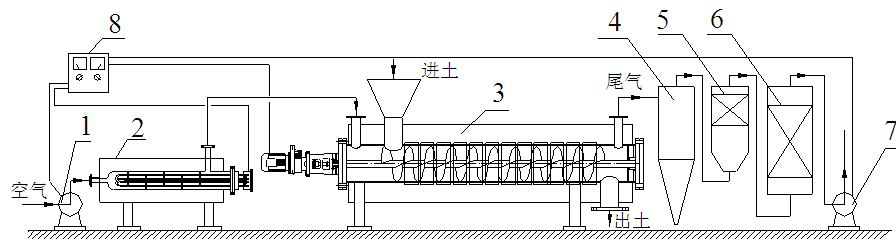

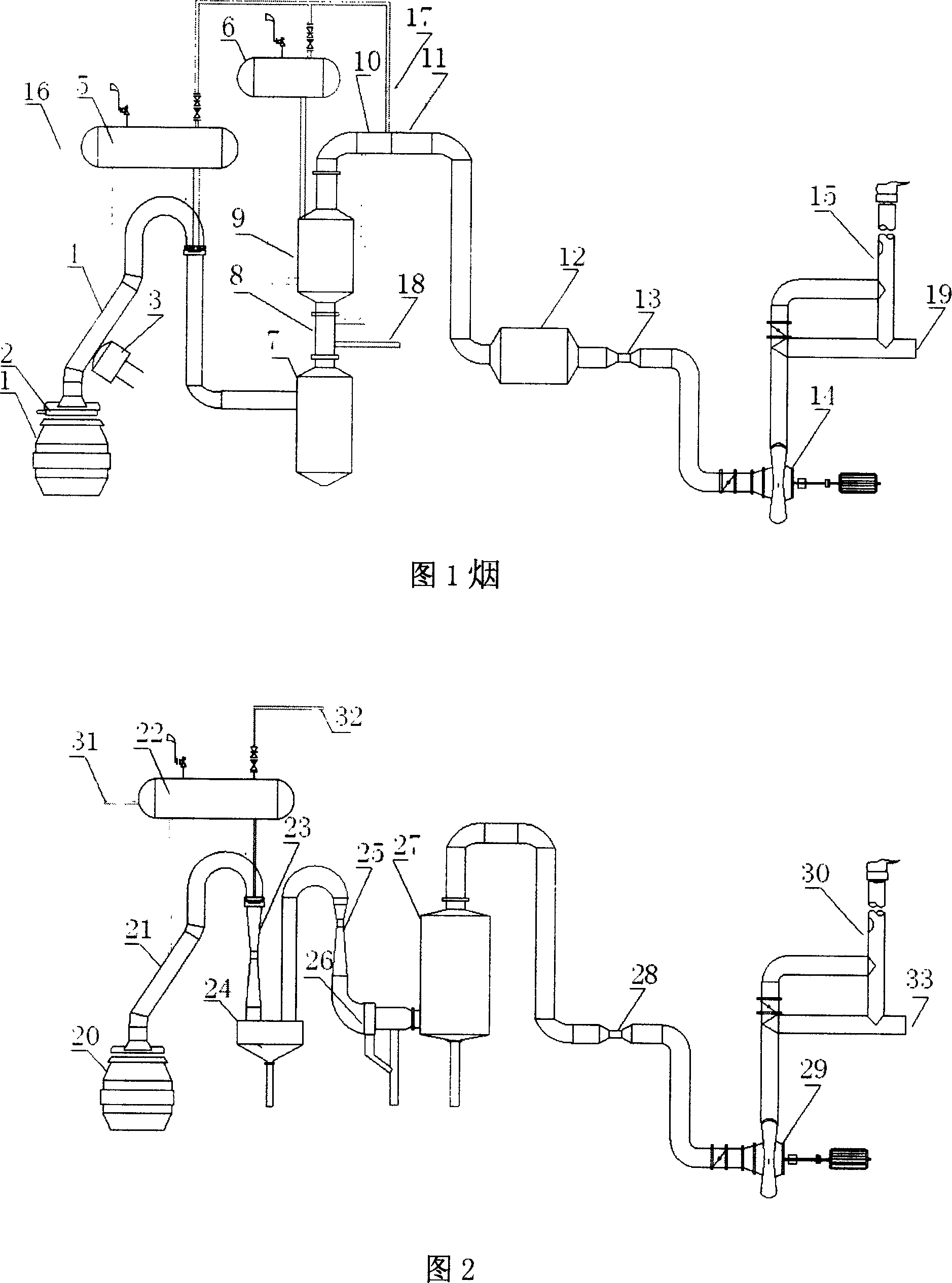

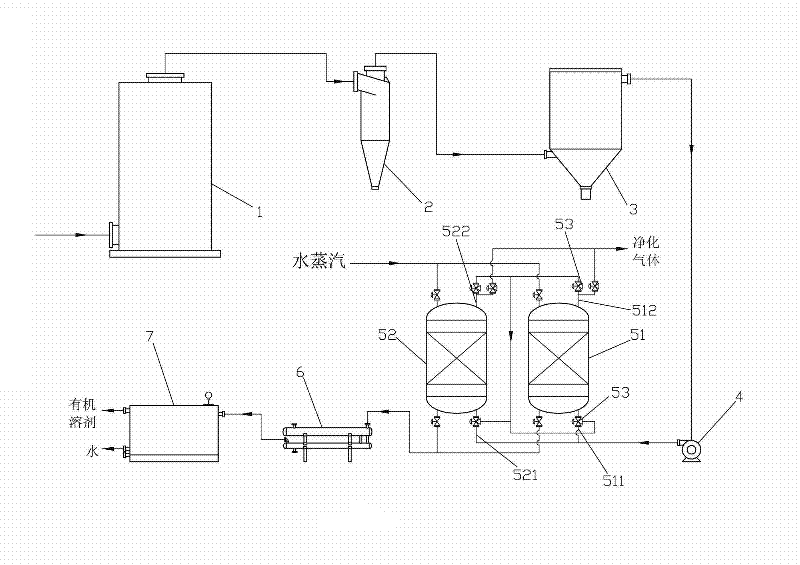

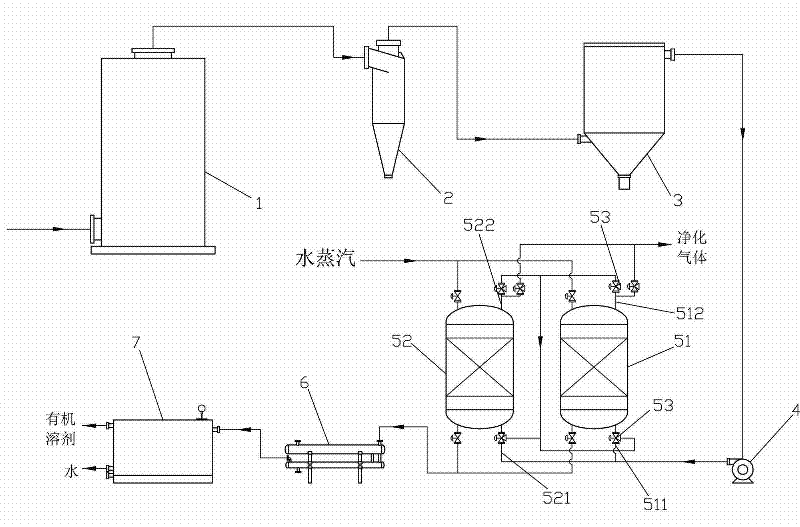

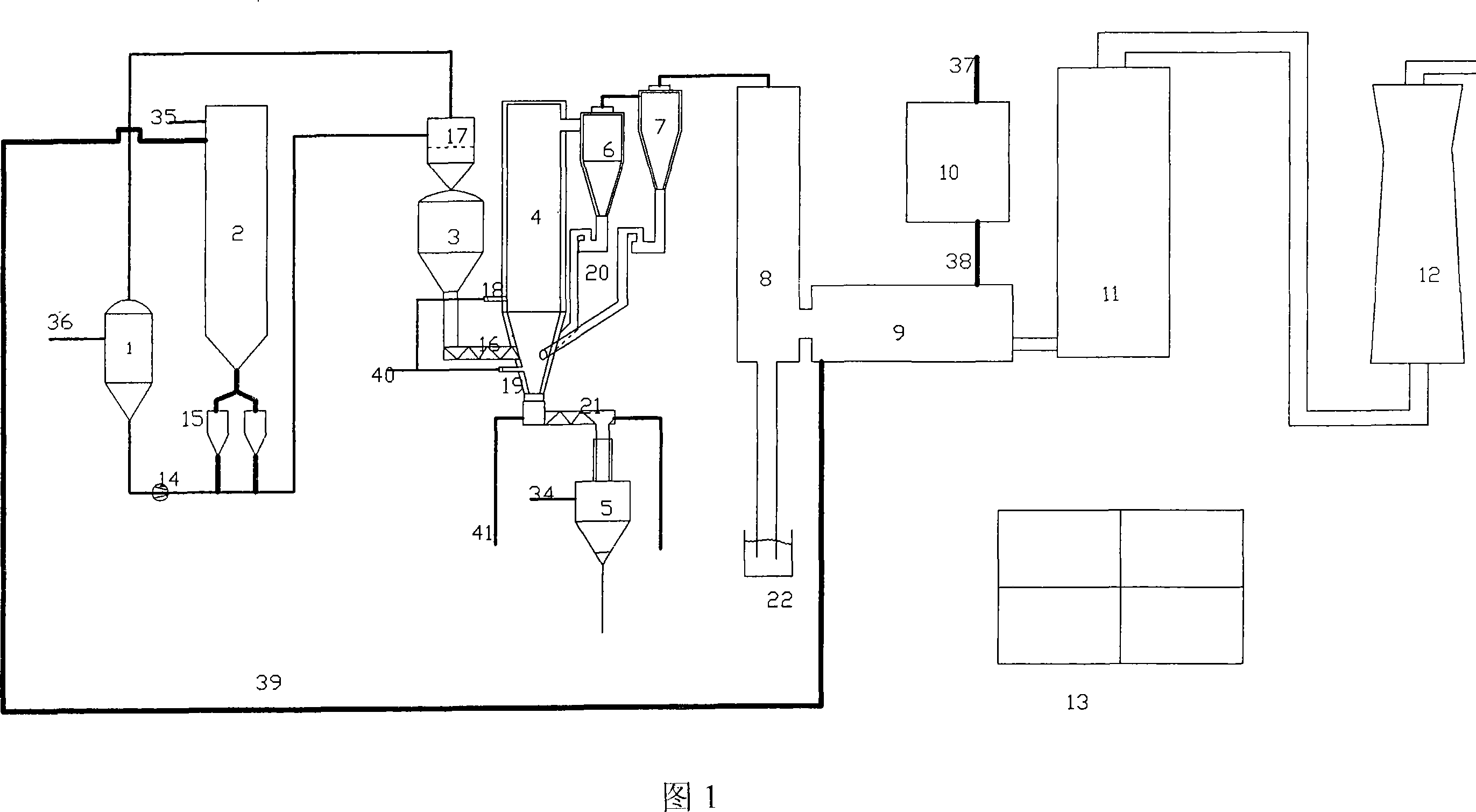

Roller-type reverse thermal desorption system for soil polluted by organic matters

ActiveCN102029287ALarge amount of processingImprove thermal desorption efficiencyContaminated soil reclamationCooling towerEngineering

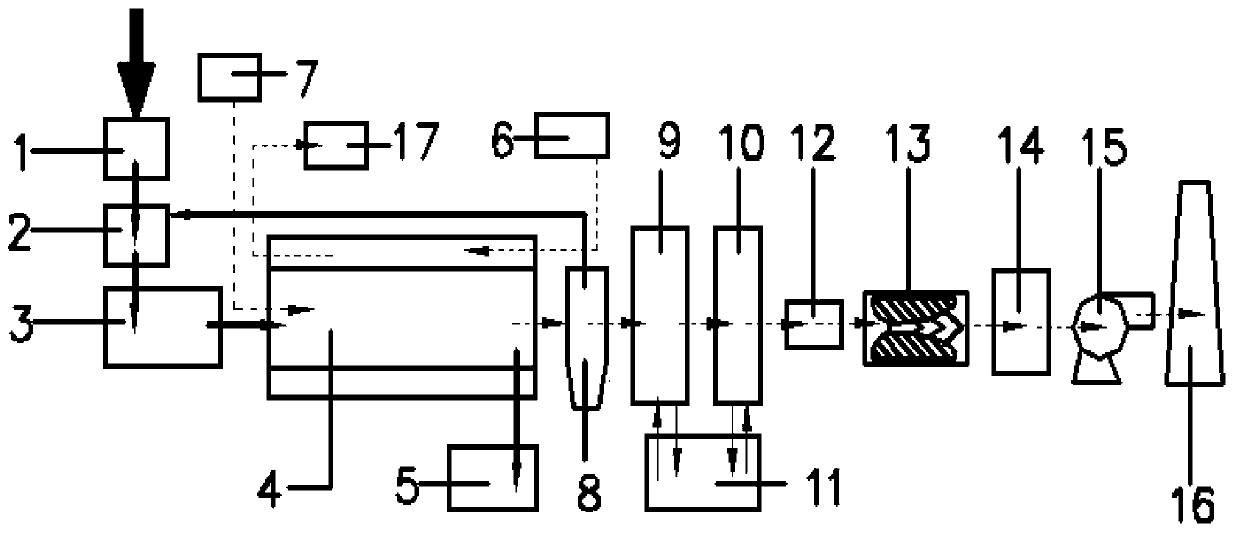

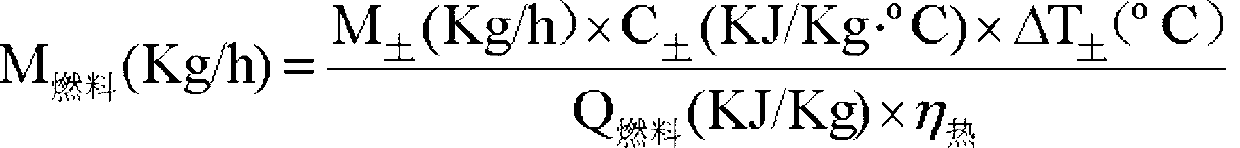

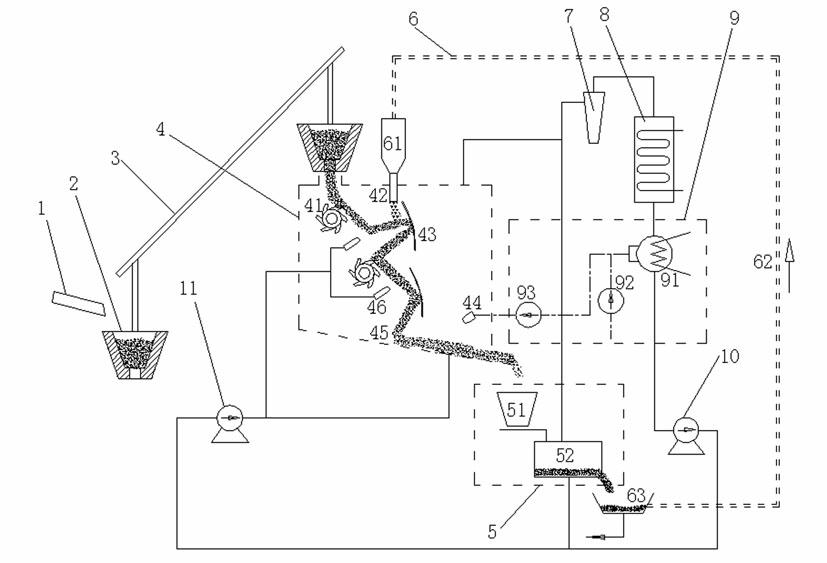

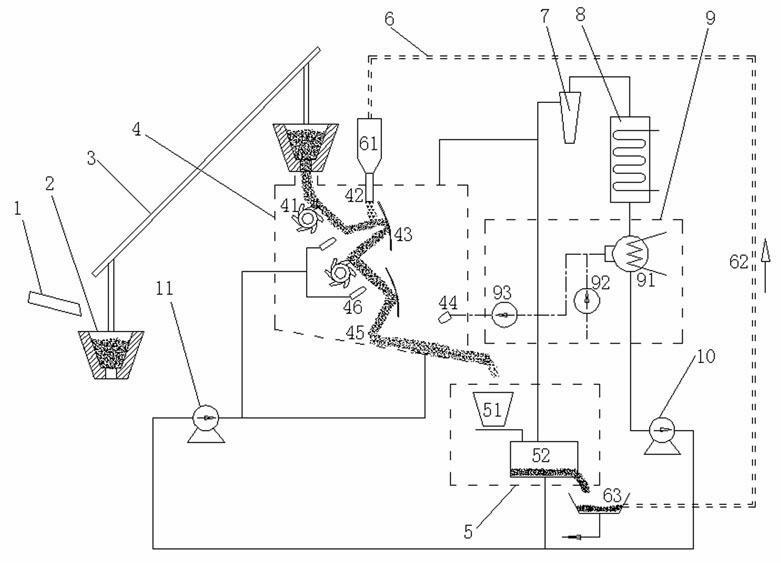

The invention relates to a roller-type reverse thermal desorption system for soil polluted by organic matters. The roller-type reverse thermal desorption system comprises a soil feeding system, wherein the soil feeding system and a heat source system are connected with a reverse thermal desorption system; the reverse thermal desorption system is connected with a dust removing system, a cooling system and an active carbon adsorption system in turn; and control ends of the soil feeding system, the heat source system, the reverse thermal desorption system, the dust removing system, the cooling system and the active carbon adsorption system are connected with a control system. In the roller-type reverse thermal desorption system, hot air is fed into a reverse thermal desorption roller by an ignition system, and polluted soil is fed into the reverse thermal desorption roller by a soil transferring device, wherein the hot air contacts the soil reversely, so that organic pollutants contained in the soil are heated and volatilized; the purified soil is used as backfill soil; and the volatilized tail gas is dedusted by a cyclone dust extractor and an adsorption dust extractor after passing through an induced draft fan, and the dedusted volatilized tail gas is absorbed by a honeycomb-shaped active carbon tower after passing through an atomization cooling tower and a dial plate cooling device, and finally is discharged by a tail gas exhaust device on the basis of meeting the national standard. Materials can be fed into the roller-type reverse thermal desorption system continuously and can be heated directly; and the hot air and the polluted soil are fully mixed, and the roller-type reverse thermal desorption system has high thermal desorption efficiency.

Owner:TSINGHUA UNIV +1

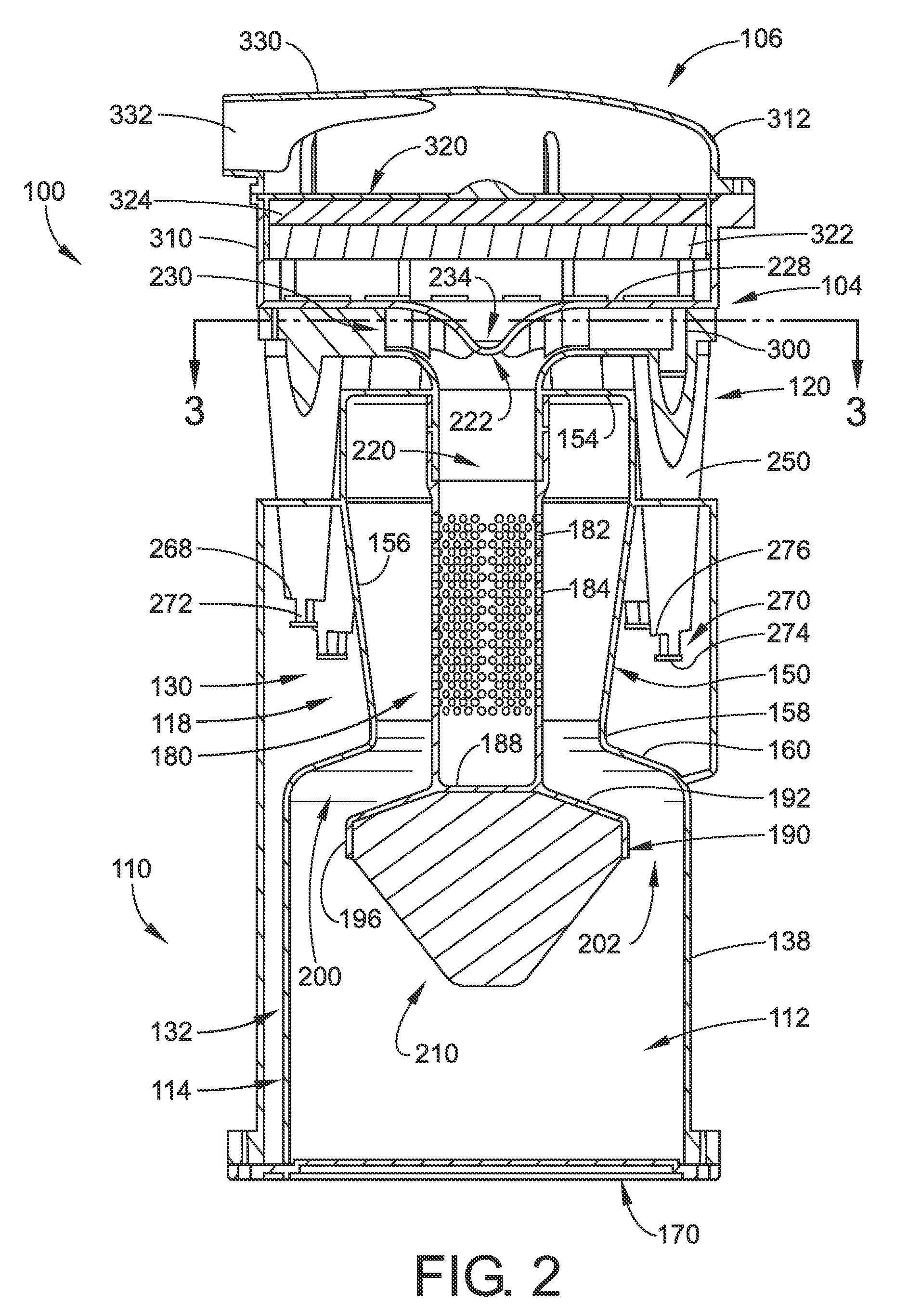

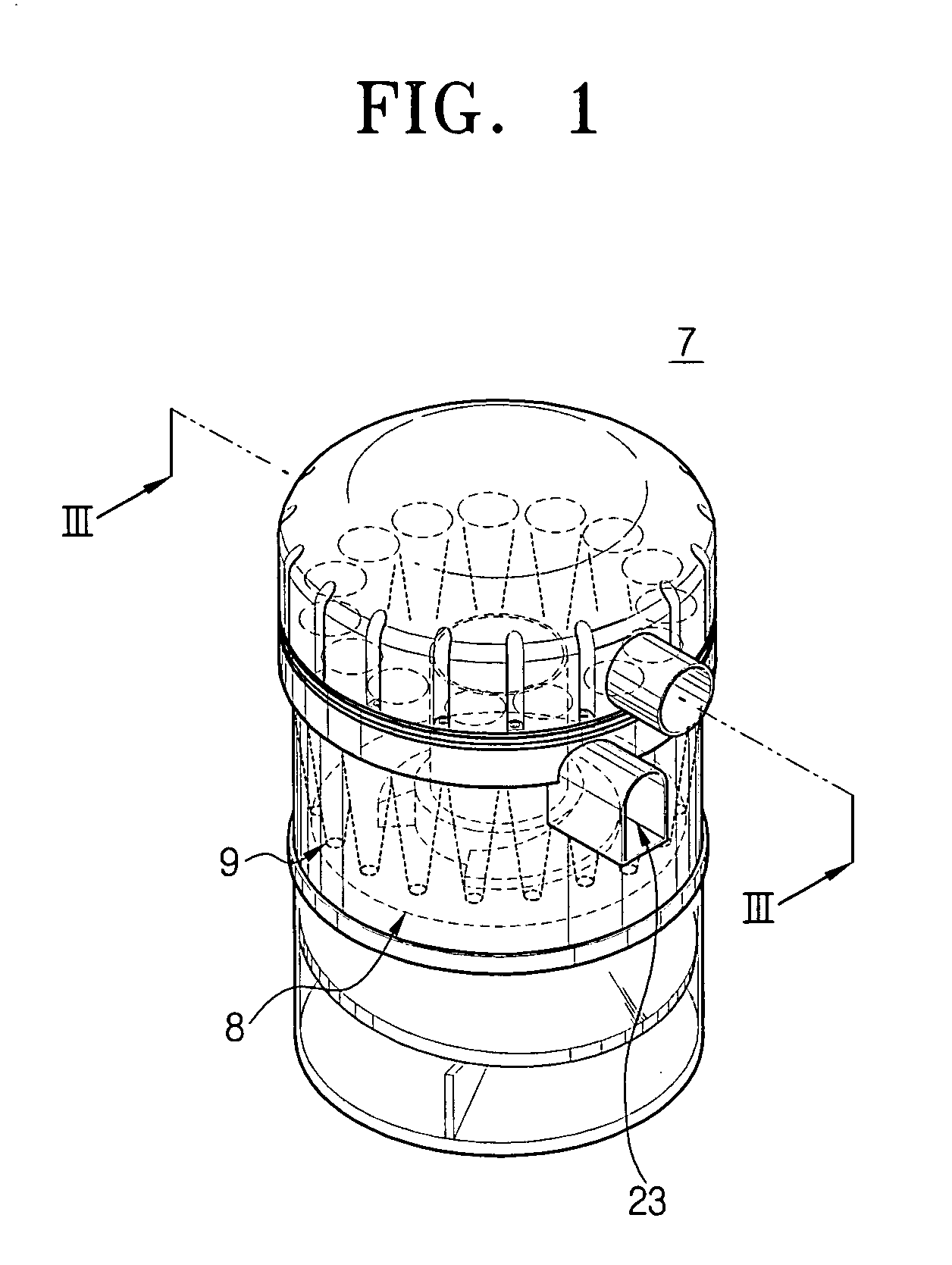

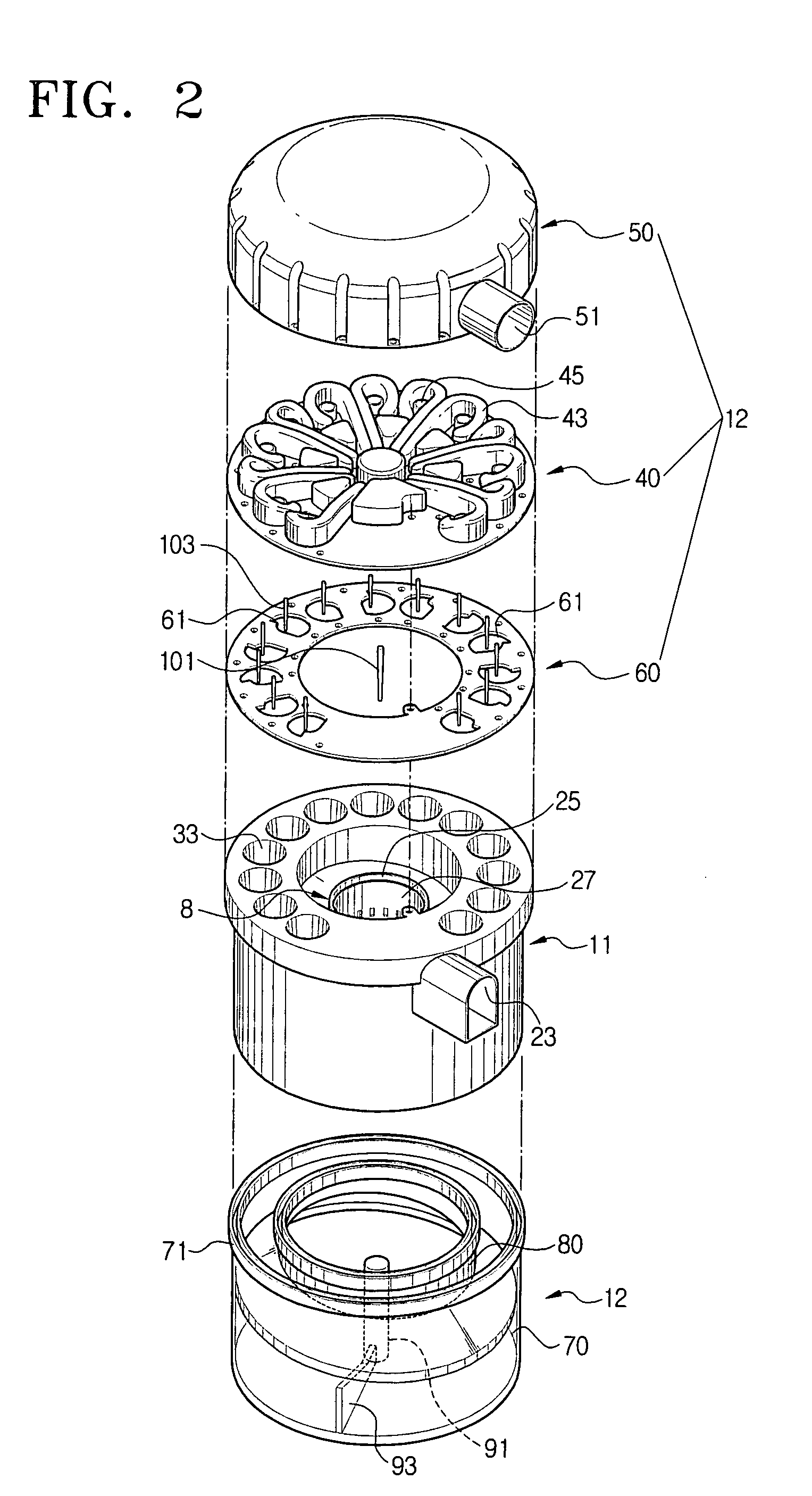

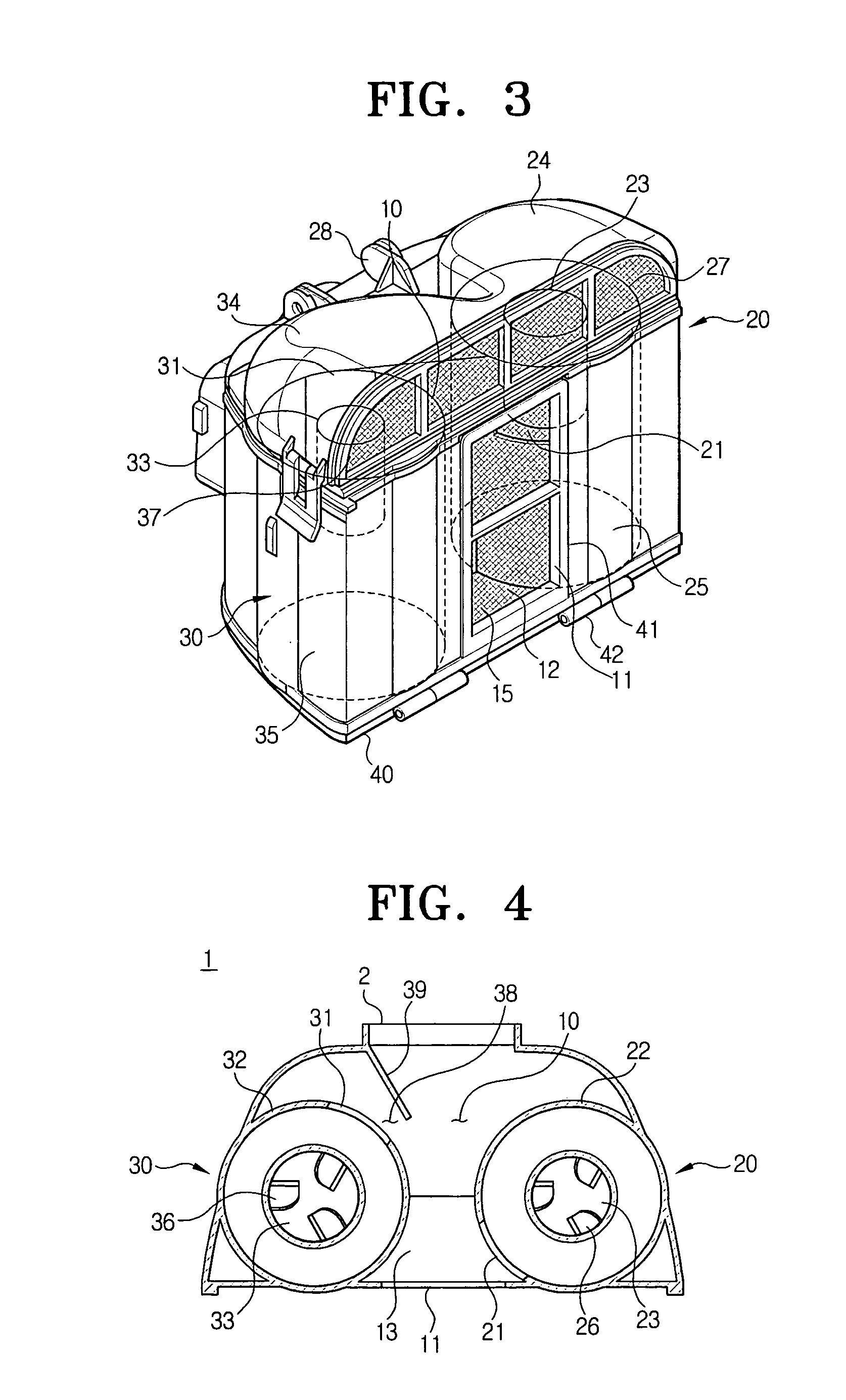

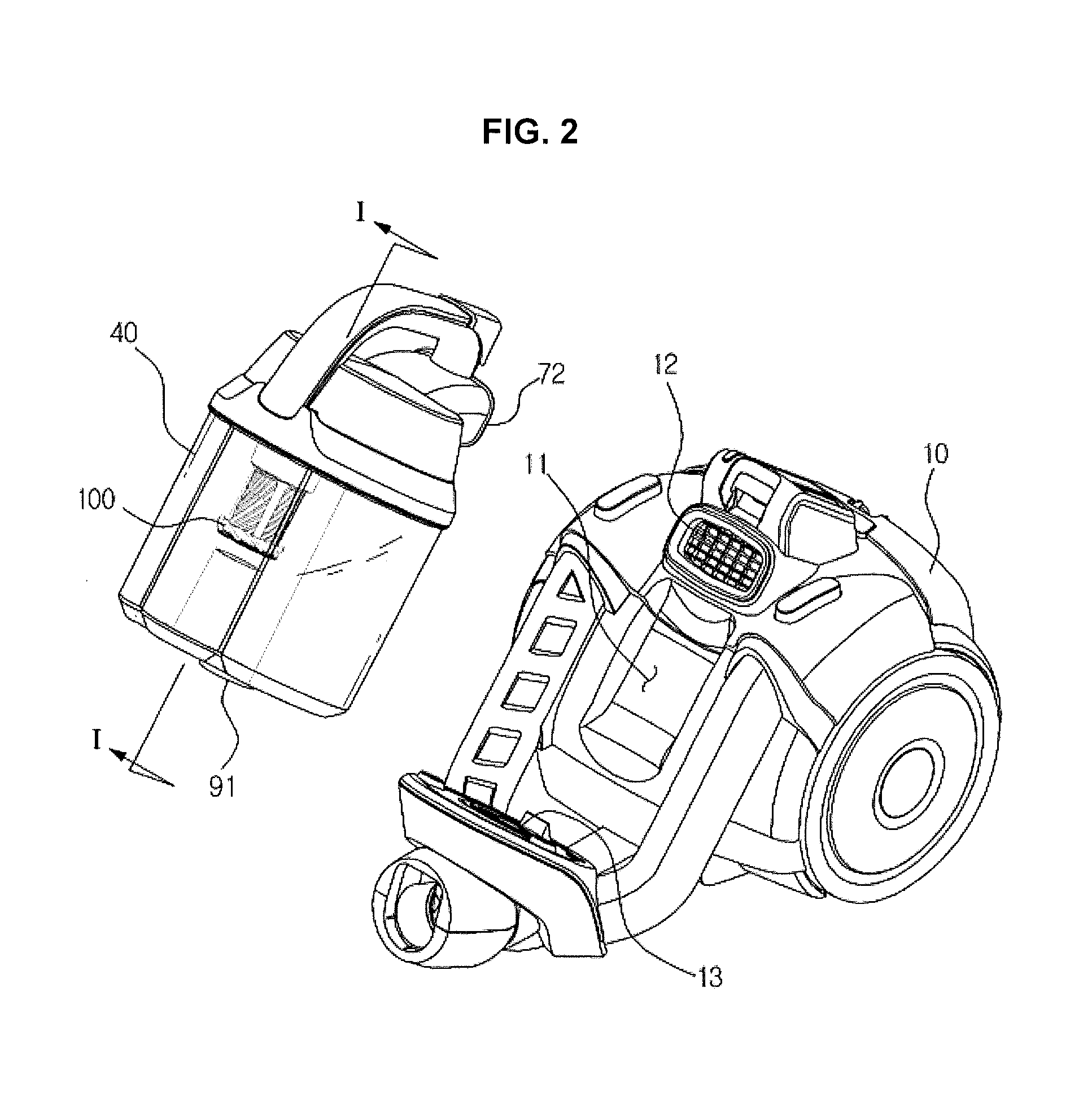

Multi-cyclone dust separator

InactiveUS7494523B2Improve efficiencyIncrease the number ofReversed direction vortexSuction cleanersCycloneEngineering

A multi-cyclone dust separator according to an embodiment of the present invention comprises a first cyclone unit having a first cyclone chamber and a first dust receptacle enclosing a circumference of the first cyclone chamber; and a second cyclone unit disposed below the first cyclone unit and having a plurality of second cyclone chambers and a second dust receptacle disposed under the second cyclone chambers to collect dust.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

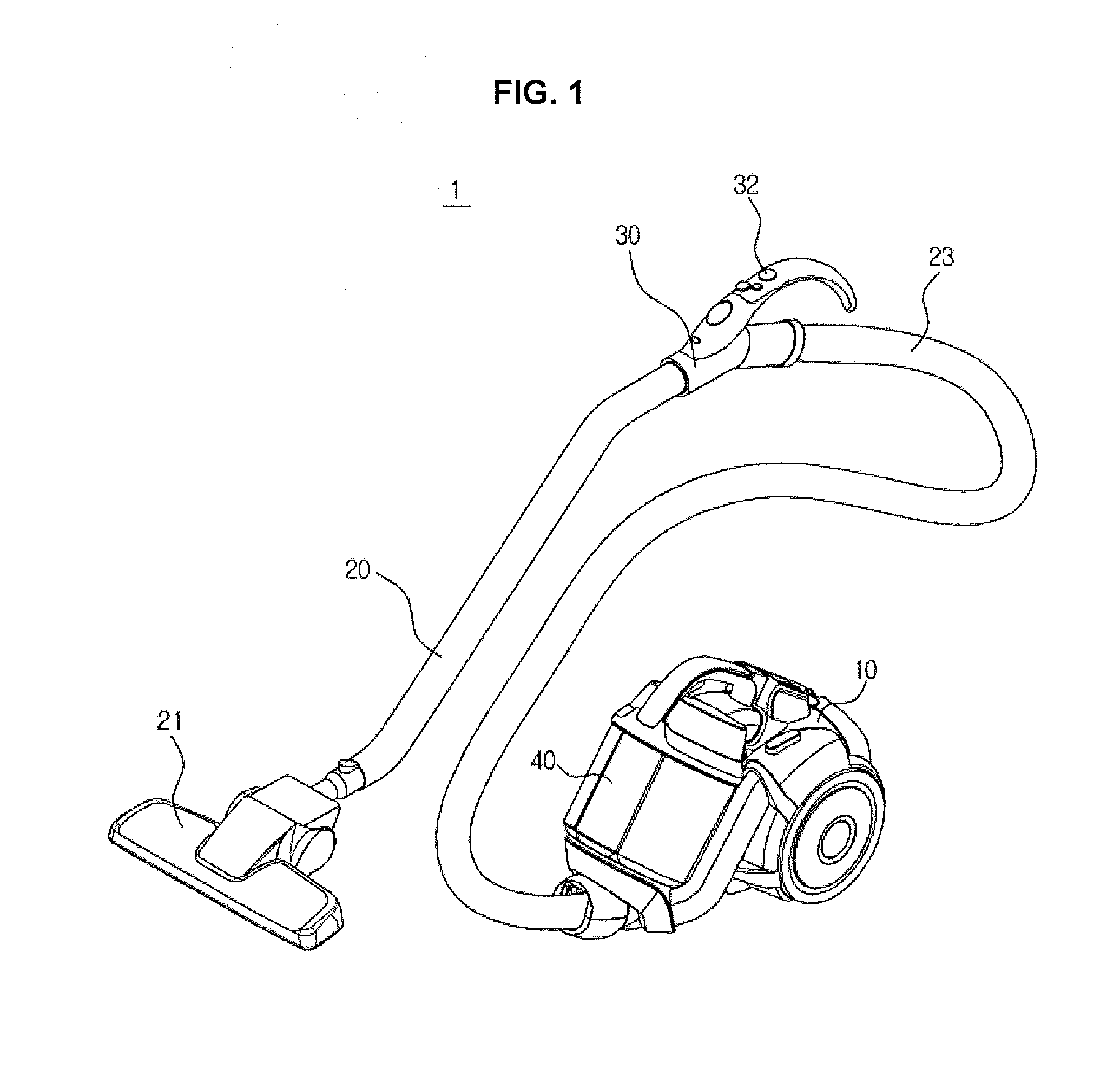

Multi-cyclone dust separator and a vacuum cleaner using the same

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Method and device for repairing contaminated soil with persistent organic pollutants

ActiveCN103272838AAvoid condensationAchieving Removal EfficiencyContaminated soil reclamationAir filterCyclonic spray scrubber

The invention relates to a method for repairing contaminated soil, and aims at providing a method and a device for repairing contaminated soil with persistent organic pollutants. The device comprises a separator, a material hopper, a material feeder and an indirect-heating thermal desorbing device which are connected with one another in sequence, wherein a soil emission device is connected to the bottom of the heating thermal desorbing device; a combustion system, a waste heat utilization device and an inert gas generator are respectively connected with the indirect-heating thermal desorbing device; the combustion system is connected with an outer barrel, and the inert gas generator is connected with an inner barrel; and a tail gas processing component comprises a cyclone dust extractor, a primary spray tower, a secondary regulating spray tower, a dehumidifier, a plasma reactor, an air filter, an induced draft fan and an exhaust barrel which are connected with one another in sequence. According to the method and the device for repairing contaminated soil with persistent organic pollutants disclosed by the invention, the amount of exhaust gas needing processing is less, water consumption is low, the persistent organic pollutants are thoroughly removed, the operation cost is reduced by 30%-60%, and the contaminated soil with persistent organic pollutants can be economically and effectively processed.

Owner:ZHEJIANG UNIV

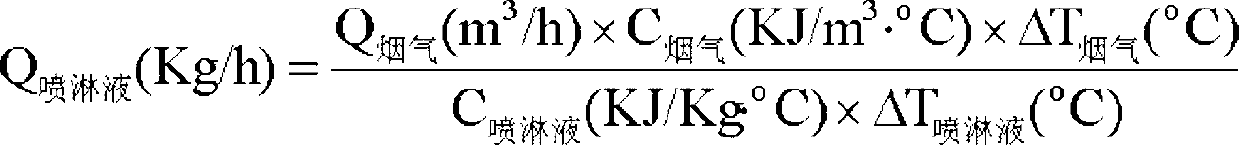

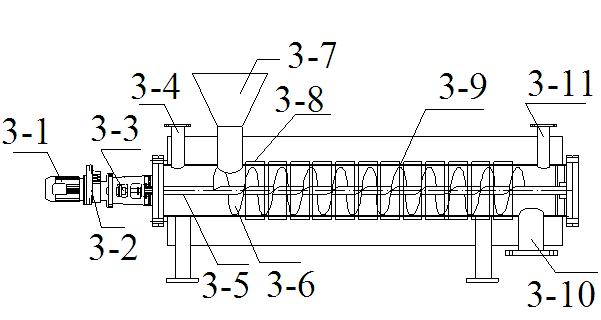

System for restoring organic contaminated soil by forced ventilation and spiral stirring thermal desorption

ActiveCN101972773AEfficient repairRemediation of organic pollution is effectiveContaminated soil reclamationAgricultural engineeringCyclonic spray scrubber

The invention provides a system for restoring organic contaminated soil by forced ventilation and spiral stirring thermal desorption, which comprises an air preheating system, a spiral stirring thermal desorption system, a tail gas treatment system and a control system, wherein the air preheating system consists of a blower and an air heater, the spiral stirring thermal desorption system consists of a spiral stirring thermal desorption device and a draft fan, the tail gas treatment system consists of a cyclone dust collector, a dehumidifier and an absorption tower, and the control system can realize the effective control of the rotation speed of a spiral stirrer, the air preheating temperature and the soil heating temperature. The system can be used for restoring soil contaminated by volatile / semi-volatile organic matters.

Owner:LIAONING HUAFU ENVIRONMENTAL ENG

Method and system for recovering high-temperature sensible heat of molten blast furnace slag

ActiveCN102162016ADoes not affect activityImprove waste heat qualityIncreasing energy efficiencyDischarge devicesSlagSlow cooling

The invention discloses a method and a system for recovering high-temperature sensible heat of molten blast furnace slag. The system comprises a blast furnace slag runner, a slag hopper, a slag hopper lifting mechanism, a quenching unit, a slow cooling unit, a cold slag particle circulation unit, a cyclone dust collector, a waste heat boiler, a condensing unit, a circulating fan, and a booster fan. The method for recovering waste heat comprises the following steps of: crushing and quickly cooling the molten blast furnace slag in the quenching unit in a composite way of a rotary crushing wheel, high-pressure cold air, a slag trap, cold slag particles and cooling water, and fully exchanging heat with solidified blast furnace slag in the slow cooling unit by using cooling air; and allowing high-temperature air which comes out of the quenching unit and the slow cooling unit to enter the waste heat boiler and performing heat exchange, transforming into steam or electric power and then outputting. The subsequent utilization of blast furnace slag and the waste heat recovery efficiency are synchronously considered, condensed water is recycled, finished slag does not contain water or only contains a small amount of water, the granulation effect of the slag is better, and the contradiction between intermittent slagging and continuous heat production of blast-furnace ironmaking is resolved.

Owner:HANGZHOU BOILER GRP CO LTD

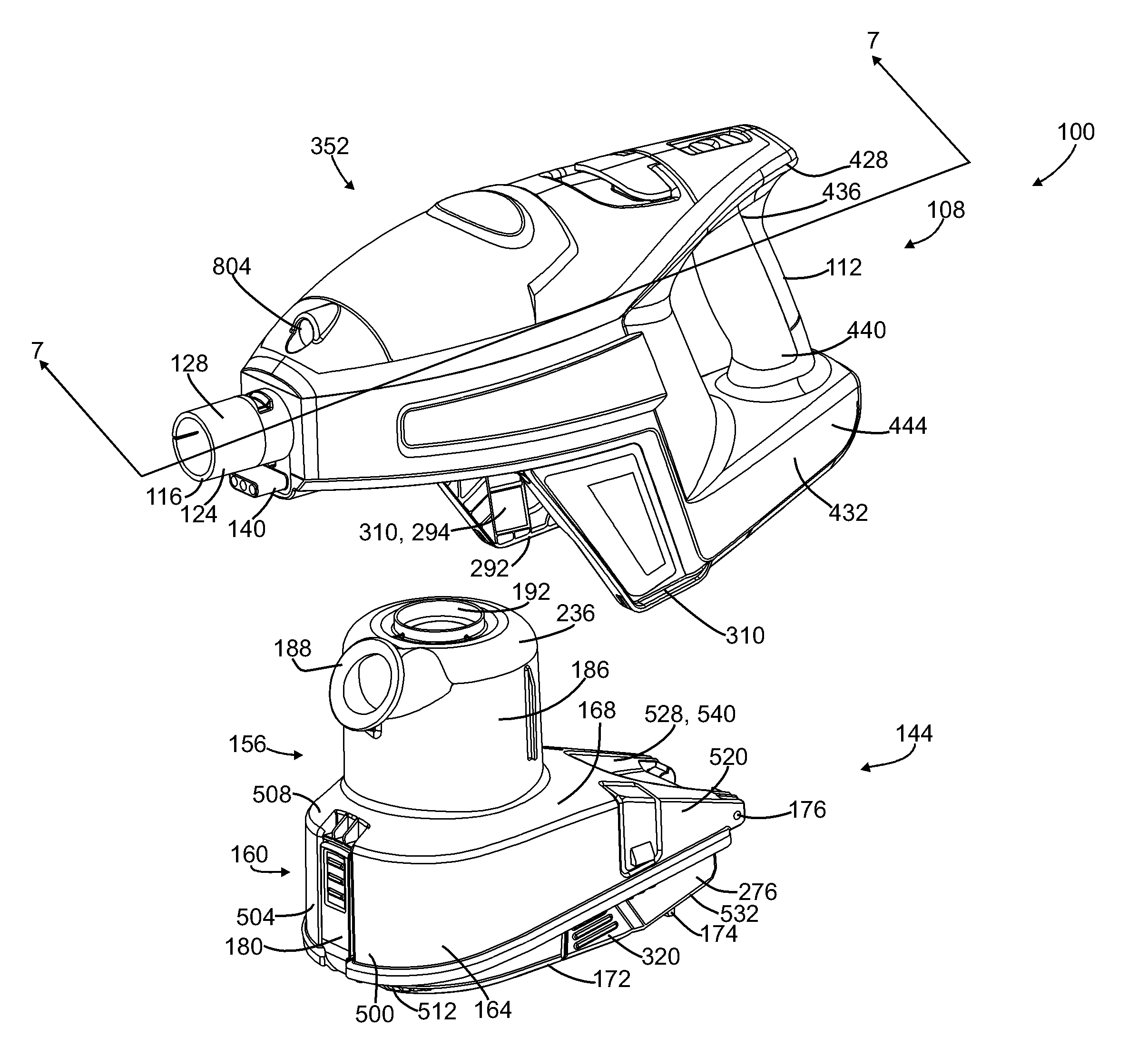

Portable surface cleaning apparatus

ActiveUS20160015230A1Lower the volumePrevent overflowSuction filtersElectric equipment installationSurface cleaningCyclonic spray scrubber

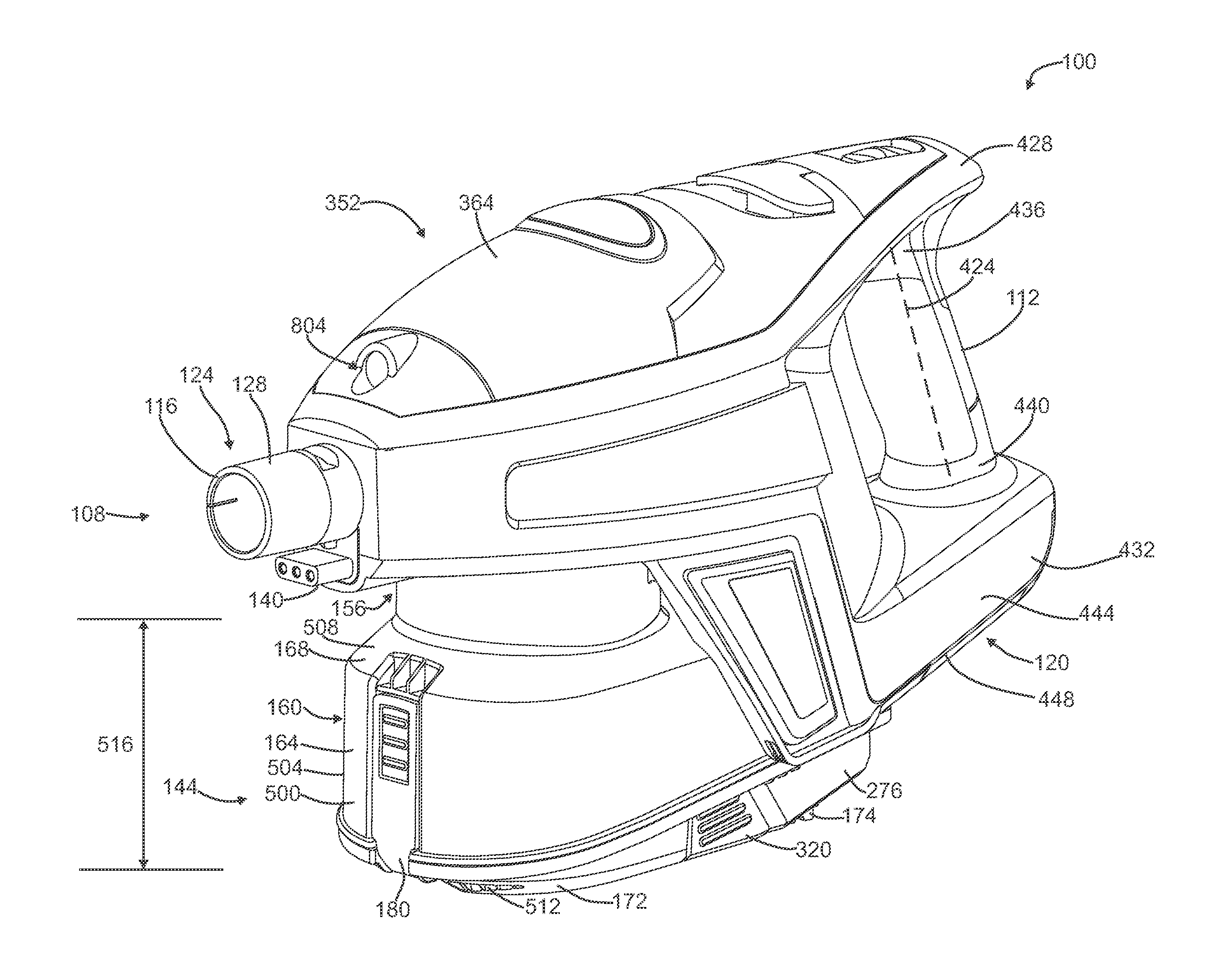

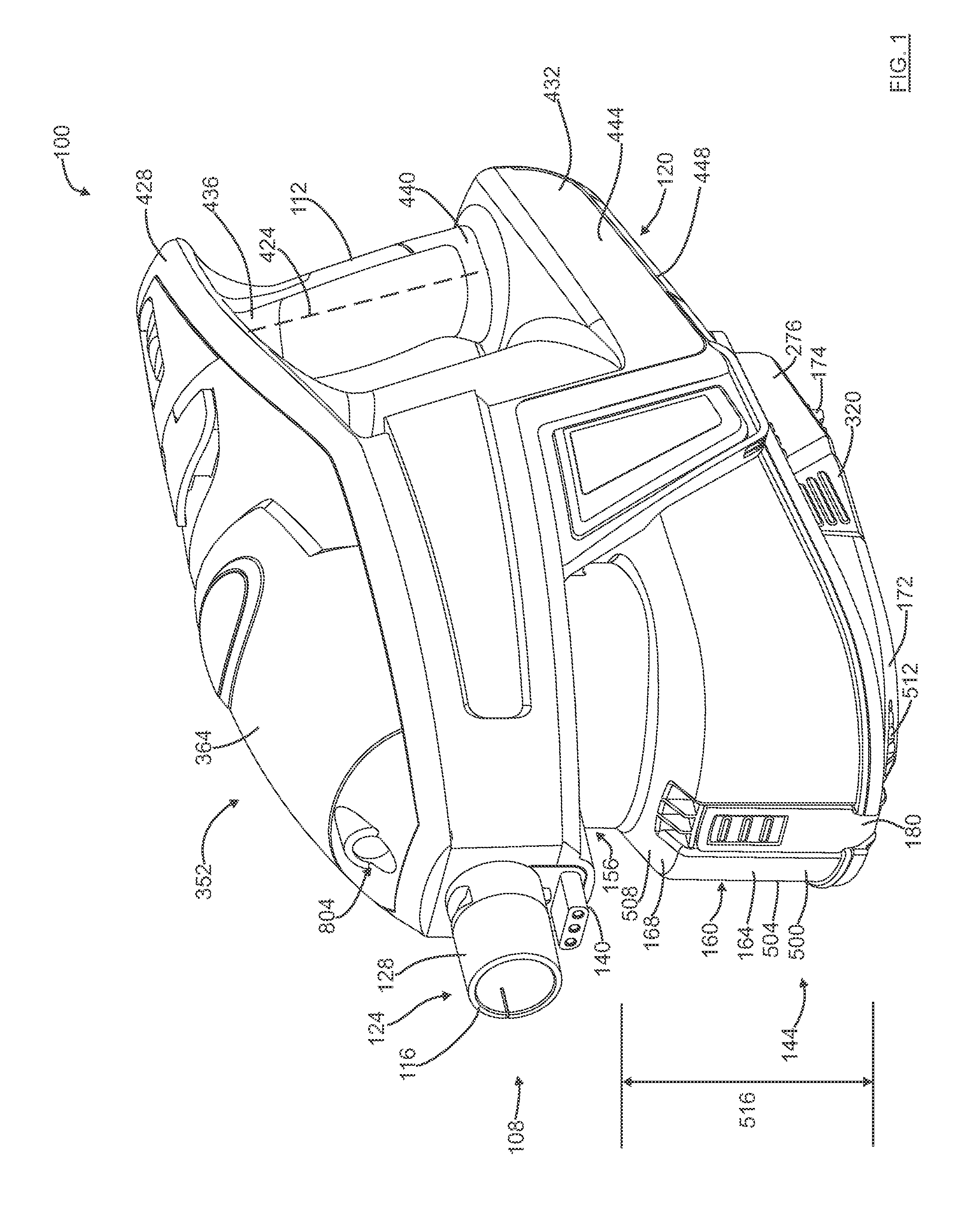

A hand carryable surface cleaning apparatus is disclosed. The apparatus comprises a main body housing a suction motor, and a cyclone bin assembly removably mounted to the main body. The cyclone bin assembly may be partially or wholly nested in the body when the cyclone bin assembly is mounted to the body. The cyclone bin assembly may be removably mounted to a lower surface of the main body. The cyclone bin assembly may be removably mounted as a sealed unit.

Owner:OMACHRON INTPROP

Cyclone dust collecting apparatus

InactiveUS20060059871A1Efficient collectionSuction filtersReversed direction vortexCycloneCyclonic spray scrubber

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Multi cyclone dust collector for a vacuum cleaner

InactiveUS7547351B2High dust collecting efficiencyLong filter maintenance cycleCombination devicesAuxillary pretreatmentCycloneEngineering

A multi-cyclone dust collector including at least one first cyclone forcing contaminants-laden air that is entered into a lower portion of the at least one first cyclone to whirl so as to centrifugally separate contaminants from the contaminants-laden air; and at least one second cyclone being disposed around the at least one first cyclone, the at least one second cyclone forcing semi-clean air that is discharged from the at least one first cyclone and is entered into a lower portion of the at least one second cyclone to whirl so as to centrifugally separate fine contaminants from the air.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

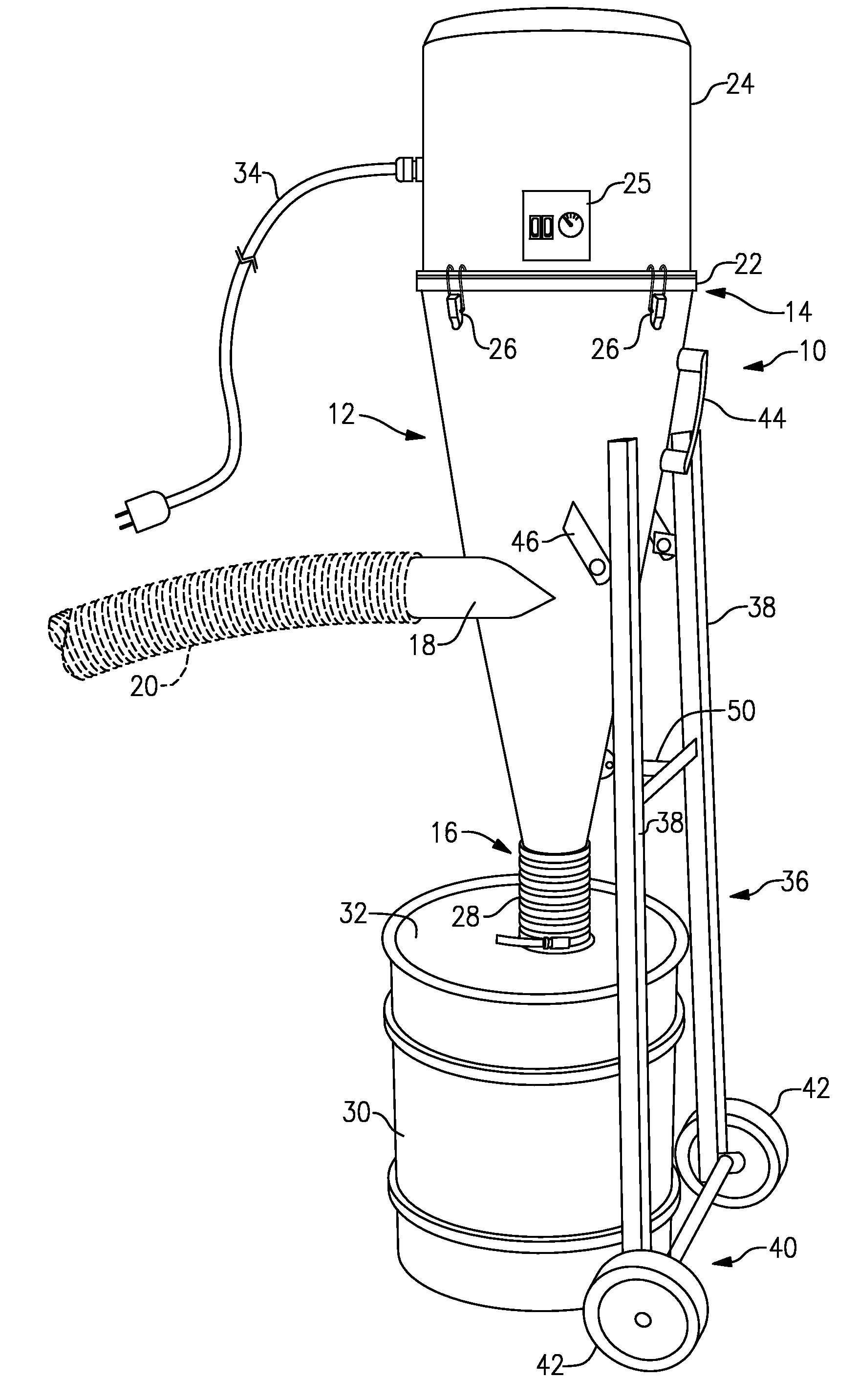

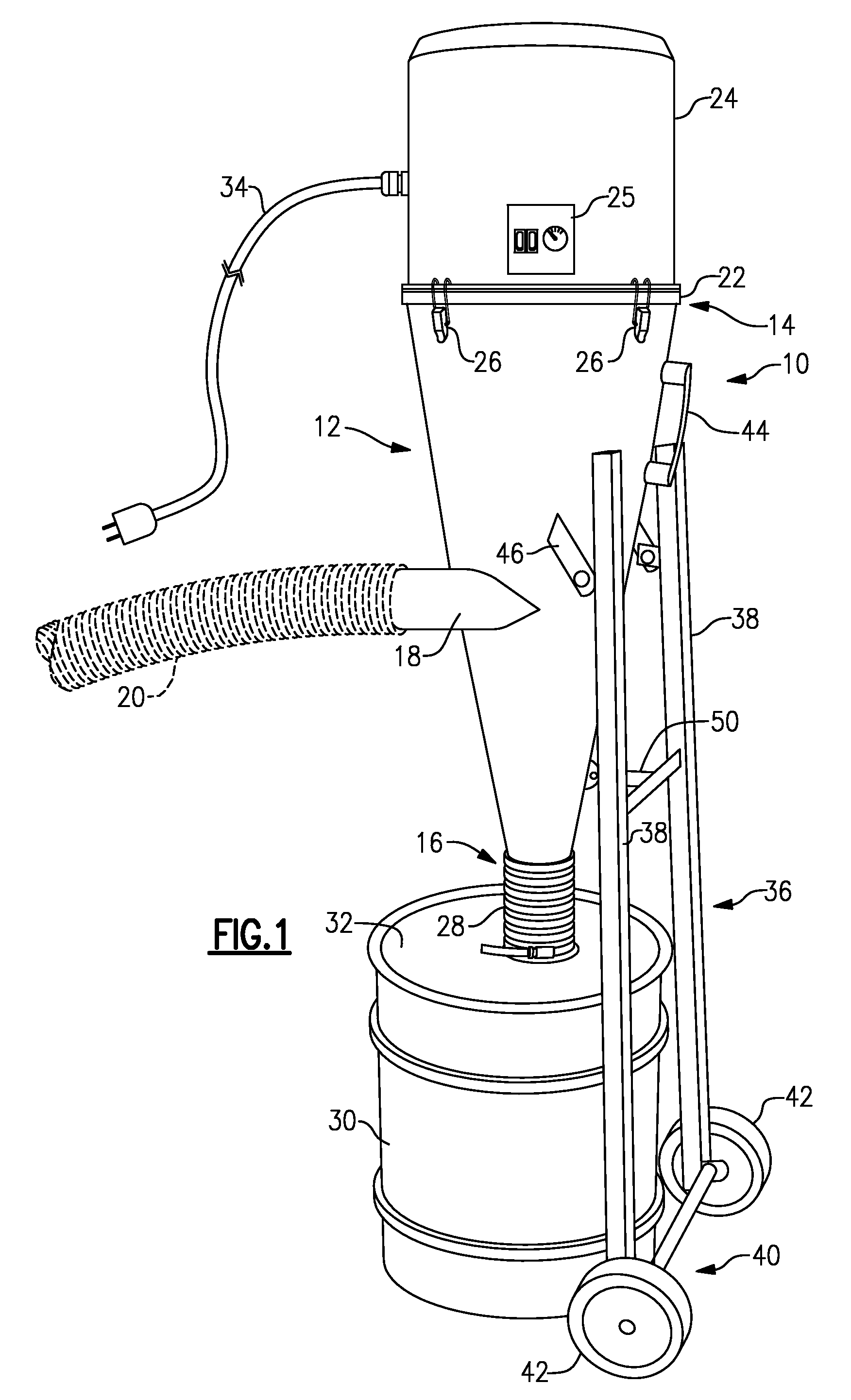

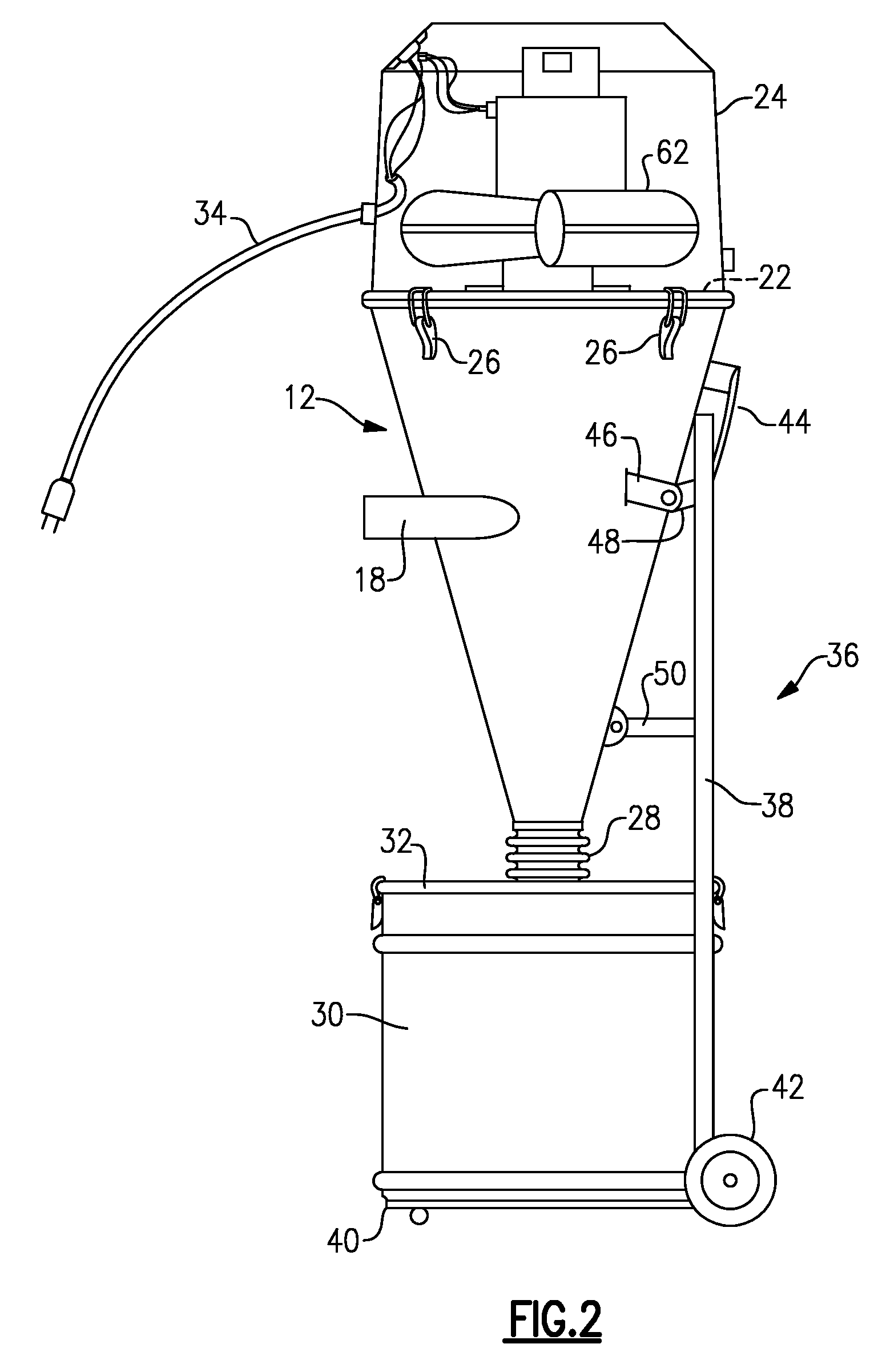

Portable Cyclonic Dust Collector/Vacuum Cleaner

ActiveUS20110094052A1Efficient but simplified designImprove energy efficiencyCleaning filter meansCombination devicesAir pumpVacuum pump

A cyclonic portable vacuum cleaner / dust collector for workshop or other use has a conic body that is supported on a hand cart or dolly. A funnel shaped divider plate within the conic body divides it into a cyclonic chamber between the divider plate and the lower nose, and a filter chamber between the divider plate and a motor plate that closes the upper mouth of the conic body. The filter chamber contains a filter cartridge. A vacuum air pump is mounted on the motor plate, and is covered by a shroud or housing. Clean, filtered air is exhausted into the ambient. Process dust settled into a dust collection drum supported beneath the nose of the conic body. A pulse cleaning arrangement serves for periodic filter cleaning. The supporting cart can be wheeled or can use a wall bracket for wall mounting.

Owner:WITTER ROBERT M

Multi-cyclone dust separator and a vacuum cleaner using the same

ActiveUS20060230719A1Improve suction efficiencyEasy to cleanCleaning filter meansSuction filtersCycloneEngineering

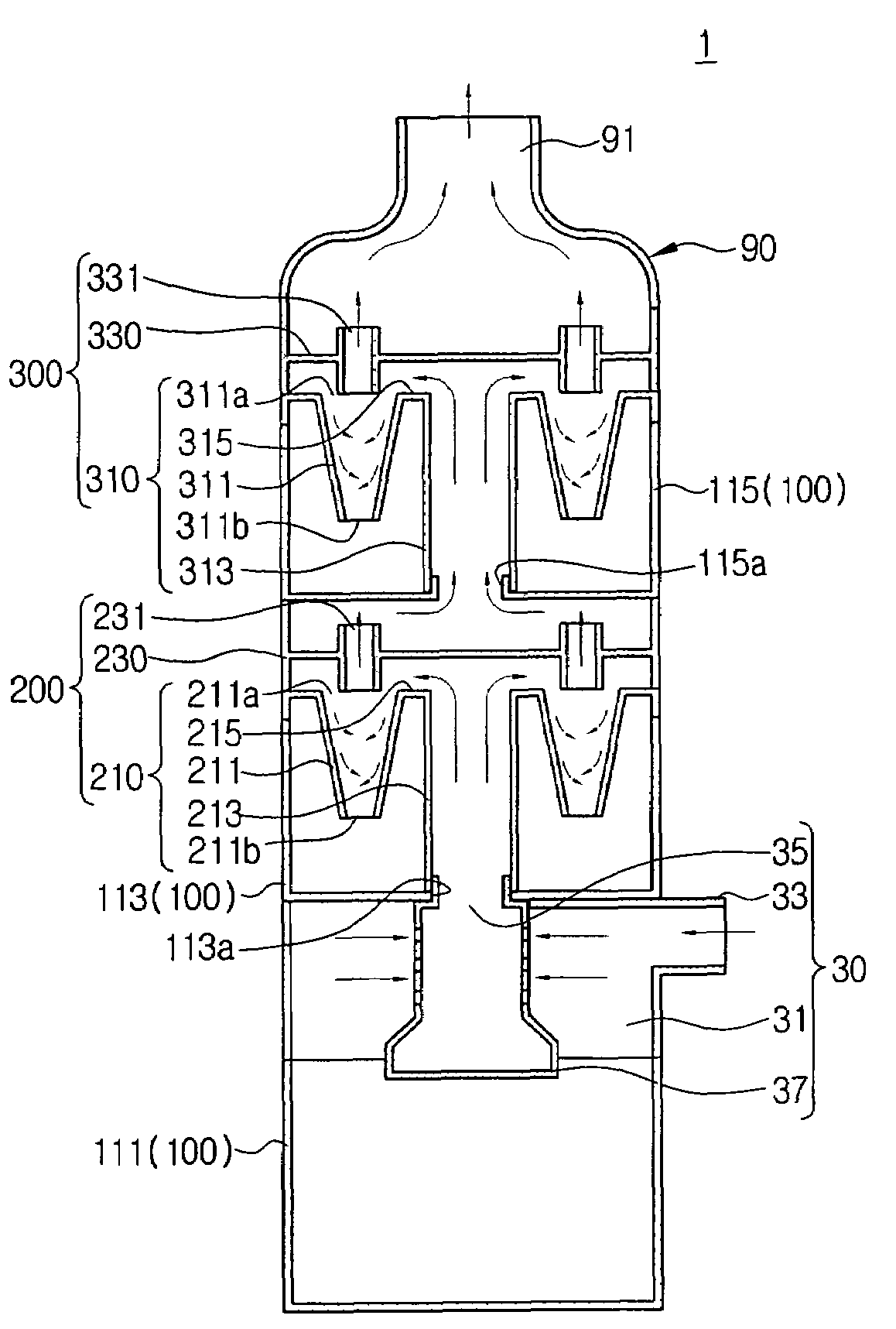

A multi-cyclone dust separator according to an embodiment of the present invention comprises at least three dust separation units for separating dust stepwise from relatively larger size. The dust separation units comprise a first dust separation unit primarily separating dust from external air drawn in; a second dust separation unit secondarily separating dust from the air primarily dust-separated by the first dust separation unit; and a third dust separation unit thirdly separating dust from the air secondarily dust-separated by the second dust separation unit. Here, the first to third dust separation units are multi-layered in a serial manner.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Multi-cyclone dust collector for vacuum cleaner

InactiveUS20070079586A1High contaminant collecting efficiencyShort heightReversed direction vortexSuction cleanersCyclonePollutant emissions

A multi-cyclone dust collector for a vacuum cleaner includes a first cyclone unit forcing contaminants-laden air to form an upwardly whirling air current so as to centrifugally separate contaminants from the contaminants-laden air, the first cyclone unit having an air communicating member; a second cyclone unit being disposed under the first cyclone unit, the second cyclone unit forcing partially cleaned air discharged through the air communicating member to be sucked into a lower portion of the second cyclone unit and to form a second upwardly whirling air current so as to centrifugally separate fine contaminants from the partially cleaned air, the second cyclone unit having a plurality of second cyclones; and a contaminants discharging member being disposed over the second cyclone unit inside the air communicating member for discharging the fine contaminants separated in the second cyclone unit to an upper side of the air communicating member.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

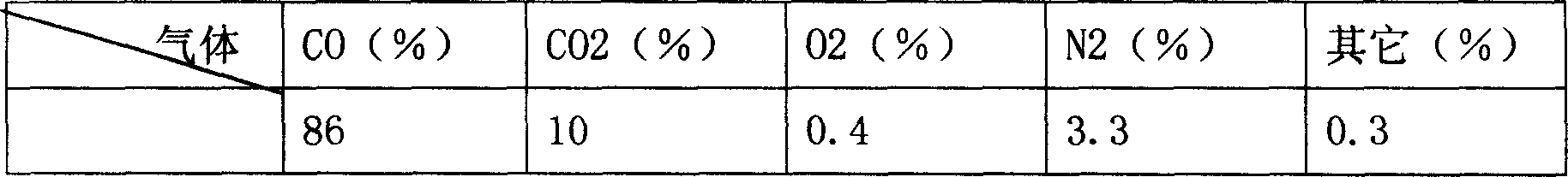

Dry-method dust collection and surplus energy recovery device for steel-smelting converter flue gas

InactiveCN1962884AExtended service lifeEnsure safetyManufacturing convertersProcess efficiency improvementCycloneBaghouse

The invention discloses a recycling device of residual heat to dedust through drying method, which is composed of steel-smelting rotary furnace, high-temperature rapid valve, mobile petticoat pipe, combusting device, vaporization cooling flue, high-temperature cyclone duster, shell-and-tube exchanger, cloth duster (or electric duster), three-way switching valve, dedusting fan, gas thruster device and gas box, wherein the gas combusting supplementing device is set in the flue after mobile smoke bell; the high-temperature vortex deduster is set behind the evaporation cooling flue; the shell-and-tube exchanger is behind the high-temperature vortex deduster, which possesses cloth deduster.

Owner:云南阳光基业能源管控技术股份有限公司

Portable surface cleaning apparatus

ActiveUS9451853B2The removal process is simpleSuction filtersSuction hosesSurface cleaningEngineering

Owner:OMACHRON INTPROP

Cyclone dust separator and a vacuum cleaner having the same

ActiveUS7501002B2Great suctionImprove efficiencyCombination devicesReversed direction vortexCycloneCyclonic spray scrubber

A cyclone dust separator for a vacuum cleaner, where a couple of cyclones are disposed parallel with each other and sequentially operated to separate and collect dust. The cyclone dust separator includes a bypass path guiding dust-laden air drawn in through a suction opening directly to a motor and having a first mesh that filters off dust included in drawn-in air; a first cyclone disposed at one side of the bypass path to separate the dust from the dust-laden air drawn in through the suction opening and discharge cleaned air to the motor; and a second cyclone disposed parallel with the first cyclone to separate the dust from the dust-laden air drawn in through the suction opening and discharge cleaned air to the motor. The dust included in the air is separated sequentially by the first mesh, the first cyclone and the second cyclone.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

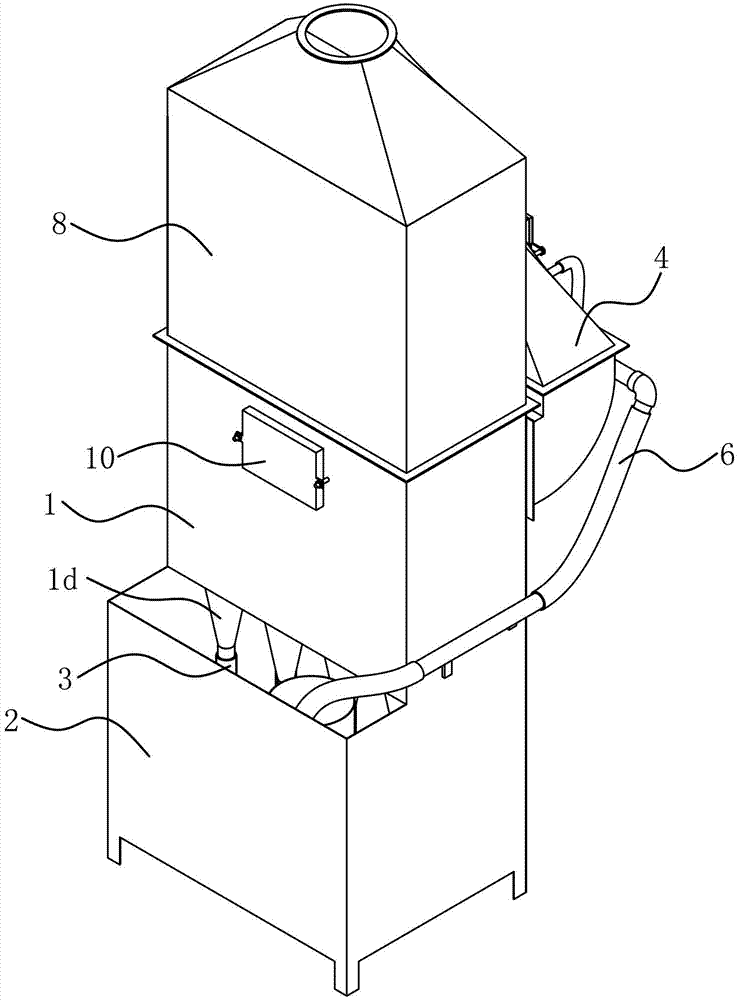

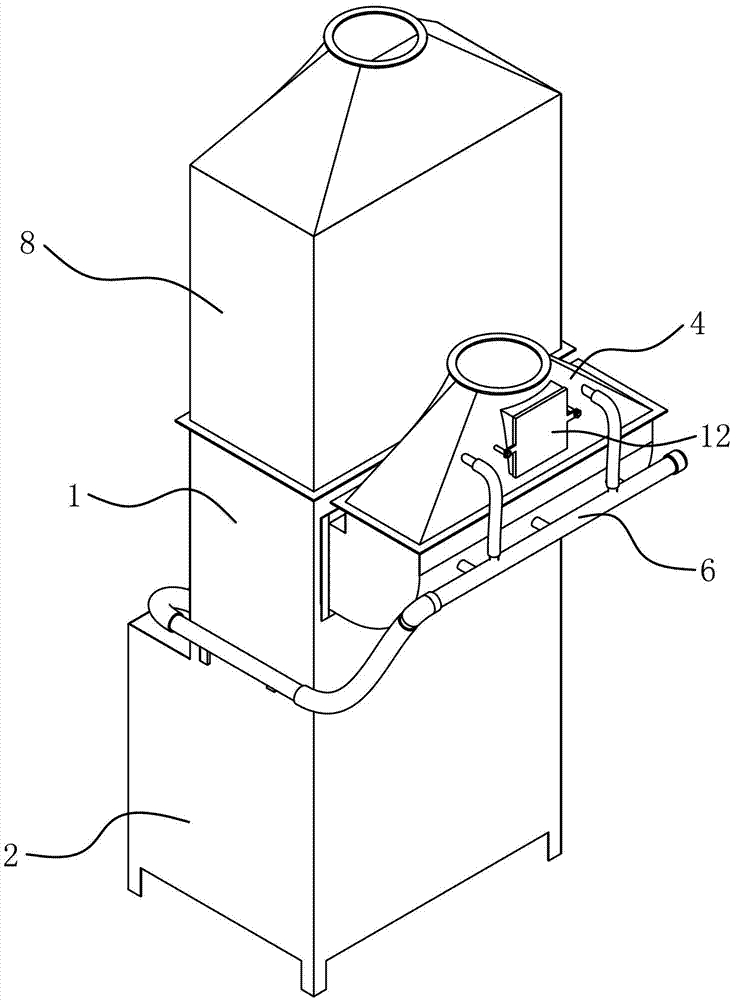

Recycling device for exhaust gas of painted organic solvent and method for recycling organic solvent

The invention discloses a recycling device for an exhaust gas of a painted organic solvent. The recycling device comprises a painting fog removing device, a fan, an absorbing jar, a condenser and an oil-water separator which are connected in turn, wherein the painting fog removing device comprises a gas collecting tank, a cyclone dust collector and a bag type dust collector; the gas collecting tank is used for temporarily storing the exhaust gas of the organic solvent; and the gas collecting tank, the cyclone dust collector and the bag type dust collector are connected in turn. All componentsof the recycling device are reasonably and compactly jointed; collection efficiency is high; and the painting fog is efficiently removed while a trouble in frequently exchanging filter cotton is avoided. The invention also discloses a method for utilizing the recycling device for the exhaust gas of the painted organic solvent to recycle the organic solvent. The method comprises the following steps: removing the painting fog; absorbing; desorbing steam; condensing; and separating oil from water, wherein the step of removing the painting fog is carried out by changing the painting fog into painting powder and then efficiently removing the painting fog. Compared with a traditional process, the method is more reasonable, compact and labor-saving.

Owner:中科天龙(厦门)环保股份有限公司

Wet type multi-pipe cyclone dust removal device and dust removal system with dust removal device

ActiveCN103157561AIncrease distanceReduce the temperatureReversed direction vortexCycloneEngineering

The invention provides a wet type multi-pipe cyclone dust removal device and a dust removal system with the dust removal device, belongs to the field of operations techniques, and solves the problem that the conventional wet type multi-cyclone dust removal device is low in dust removal efficiency. The wet type multi-pipe cyclone dust removal device comprises a multi-pipe cyclone dust removal component, and also comprises a water tank, wherein the multi-pipe cyclone dust removal component is positioned above the water tank; each cyclone dust exhaust port of the multi-pipe cyclone dust removal component is connected in series with a dust exhaust pipe; each dust exhaust pipe penetrates through the water tank; an air inlet of the multi-pipe cyclone dust removal component is connected in series with an air inlet pipe; and a spraying head capable of spraying water spray is fixedly arranged in the air inlet pipe. According to the wet type multi-pipe cyclone dust collector, the spraying is performed in the air inlet pipe, the distance between the spraying and each cyclone is increased, the water spray can be fully mixed with air, the purification effect is improved, and the temperature of high-temperature air is effectively reduced; and meanwhile, the influence of water mist flow on the stability of airflow entering the cyclones is avoided.

Owner:陈美青

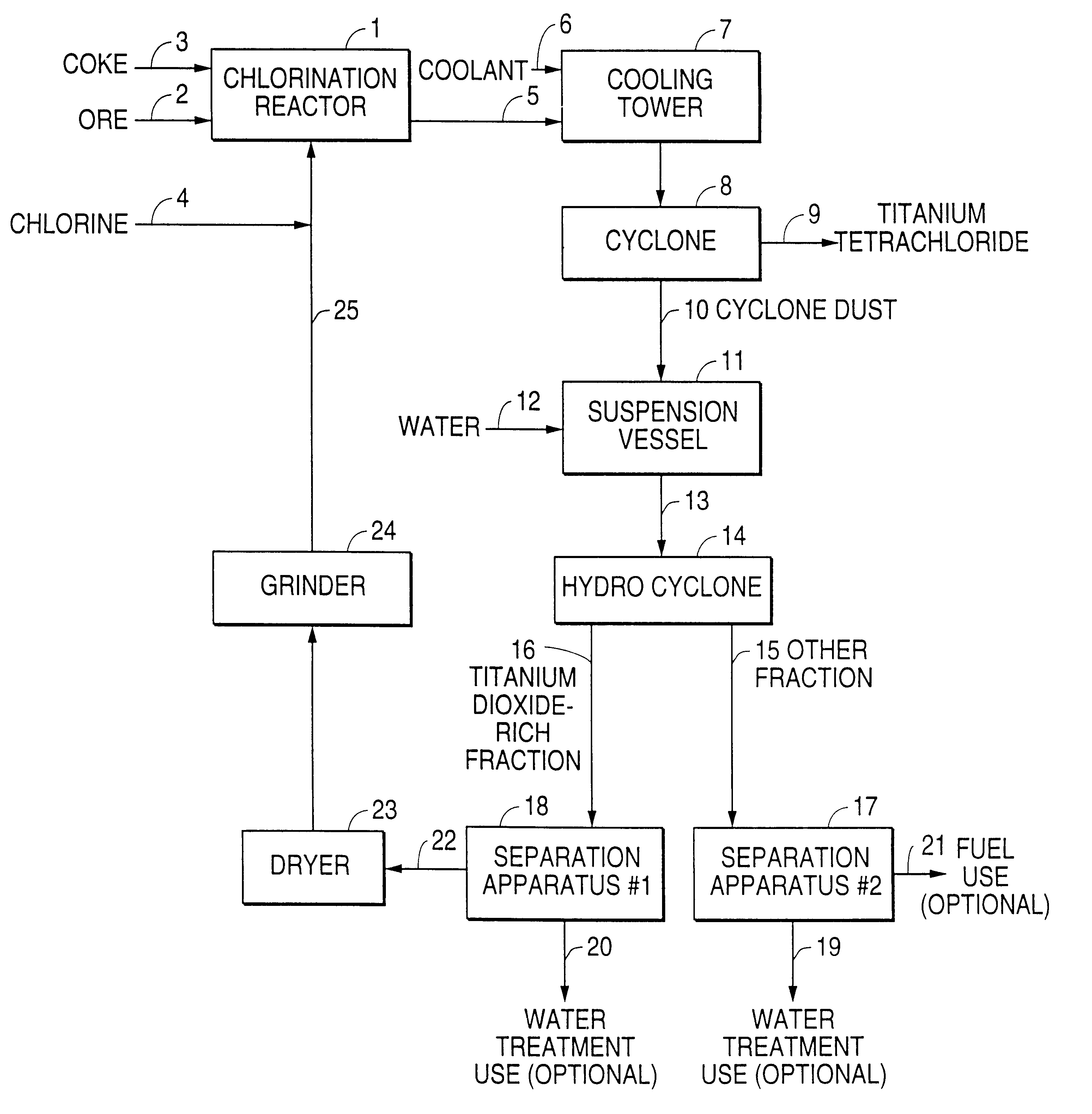

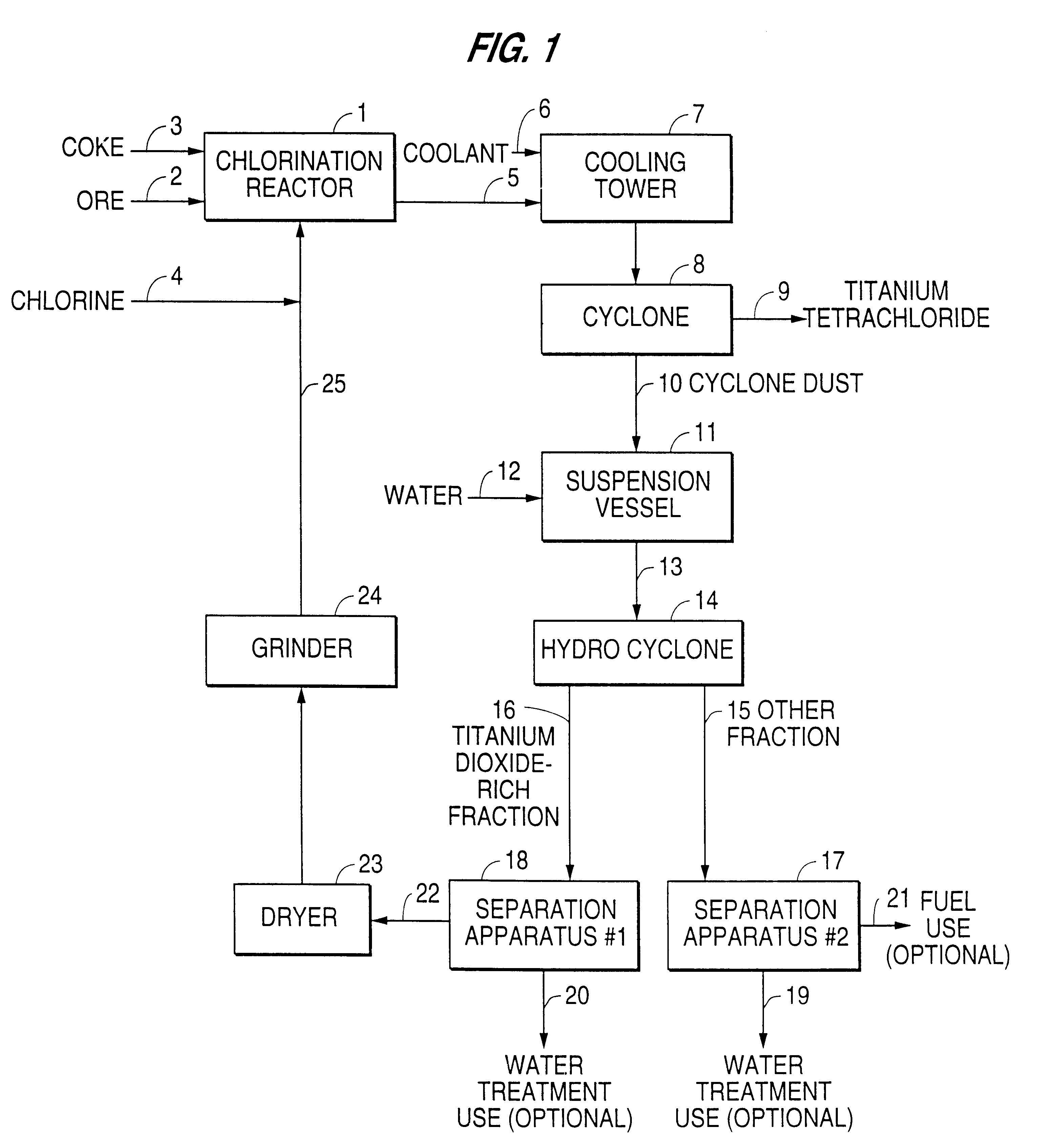

Process for increasing the yield in the manufacture of titanium dioxide by the chloride process

InactiveUS6399033B1Reduce coke contentReduced silica contentZirconium compoundsTitanium dioxideSingle stageFluidized bed

An improvement to the chloride process of making titanium dioxide. By recycling some of the cyclone dust, the yield in the chlorination of titanium-containing raw materials can be increased. In order to prevent silica accumulation in the fluidized bed, the cyclone dust is divided into two fractions. An economic solution is described of a single-stage separation of the cyclone dust in a hydrocyclone, the majority of the titanium dioxide occurring in the hydrocyclone underflow, although the separation is not sharp. By grinding and drying the solids from the hydrocyclone underflow, the titanium dioxide particles returned to the lower region of the fluidized-bed reactor are rapidly chlorinated, while the quartz and coke particles are rapidly discharged again from the fluid bed, so that no silica contamination occurs.

Owner:KRONOS INCORPORATED

Dual stage cyclonic dust collector

A surface cleaning suction type appliance comprises a housing, an airstream suction source, a cyclone main body, and a dirt cup. The housing includes a main suction opening. The airstream suction source is mounted to the housing and includes a suction airstream inlet and a suction airstream outlet. The suction source selectively establishes and maintains a flow of air from the main suction opening, via the airstream inlet, to the airstream outlet. The cyclone main body is supported by the housing and is in communication with the main suction opening. The cyclone main body has a uniform outer circumference and includes a first stage separator, and a plurality of downstream second stage separators. The lengths of the second stage cyclonic separators are different for any number of adjacent pairs of separators from on pair up to all adjacent pairs of separators. The dirt cup is connected to the cyclone main body. The dirt cup includes a first particle collector and a second particle collector. The first particle collector communicates with the first stage separator for collecting dust particles from the first stage separator. The separate second particle collector communicates with the plurality of second stage separators for collecting dust particles from the second stage separators.

Owner:TECHTRONIC FLOOR CARE TECH LTD

Cyclone dust collector and vacuum cleaner therewith

InactiveUS7291193B2Inhibition of attachmentAvoid it happening againCombination devicesSuction filtersSuspended particlesEngineering

A cyclone dust collector and a vacuum cleaner having the same. The cyclone dust collector has a cyclone body shaped to have a relatively wider upper portion and a relatively narrower lower portion and also has a suction port and a discharge port, a grill member connected to the discharge port, a dust receptacle connected to the cyclone body, and a blocking member for partially blocking the grill member. Air drawn in through the suction port moves in an increasingly wider radial path as it travels upwardly to the discharge port, increasing the centrifugal force on suspended particles as they travel toward the discharge port. The shape of the cyclone body prevents turbulent flow from being generated. Dust is prevented by the blocking member from attaching to the grill member before being centrifuged, performance of the grill member is enhanced.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Cyclone dust collector and vacuum cleaner having the same

ActiveUS20140366311A1Avoid separationCombination devicesSuction filtersCyclonic spray scrubberVacuum cleaner

A cyclone dust collector includes a cyclone chamber to centrifugally separate dust by creating rotating airflow, and a ring-shaped indicator provided to the cyclone chamber to rotate due to the rotating airflow in the cyclone chamber. The indicator visualizes the rotating airflow by rotating when the rotating airflow is created. The user may easily check condition of the rotation airflow and take proper action in the case that the cleaner malfunctions.

Owner:SAMSUNG ELECTRONICS CO LTD

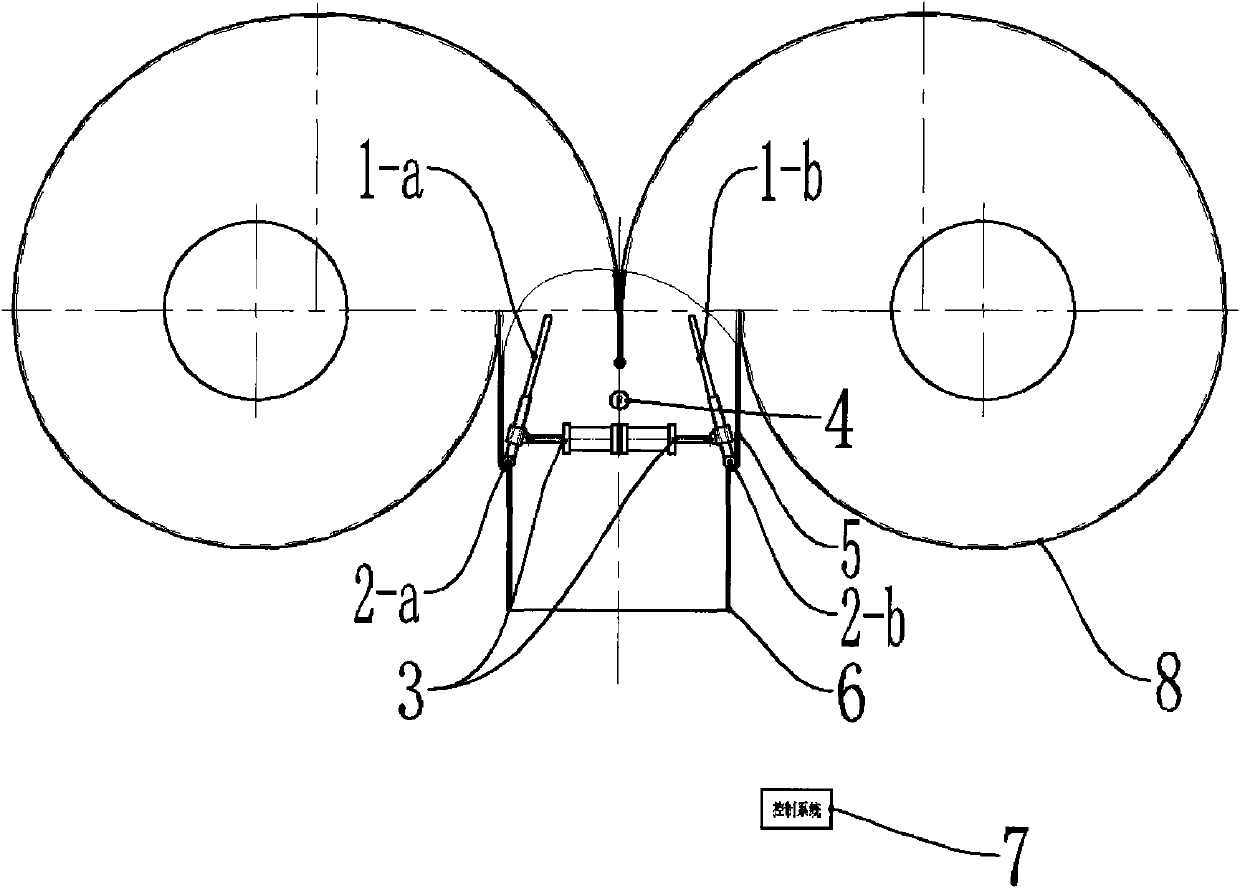

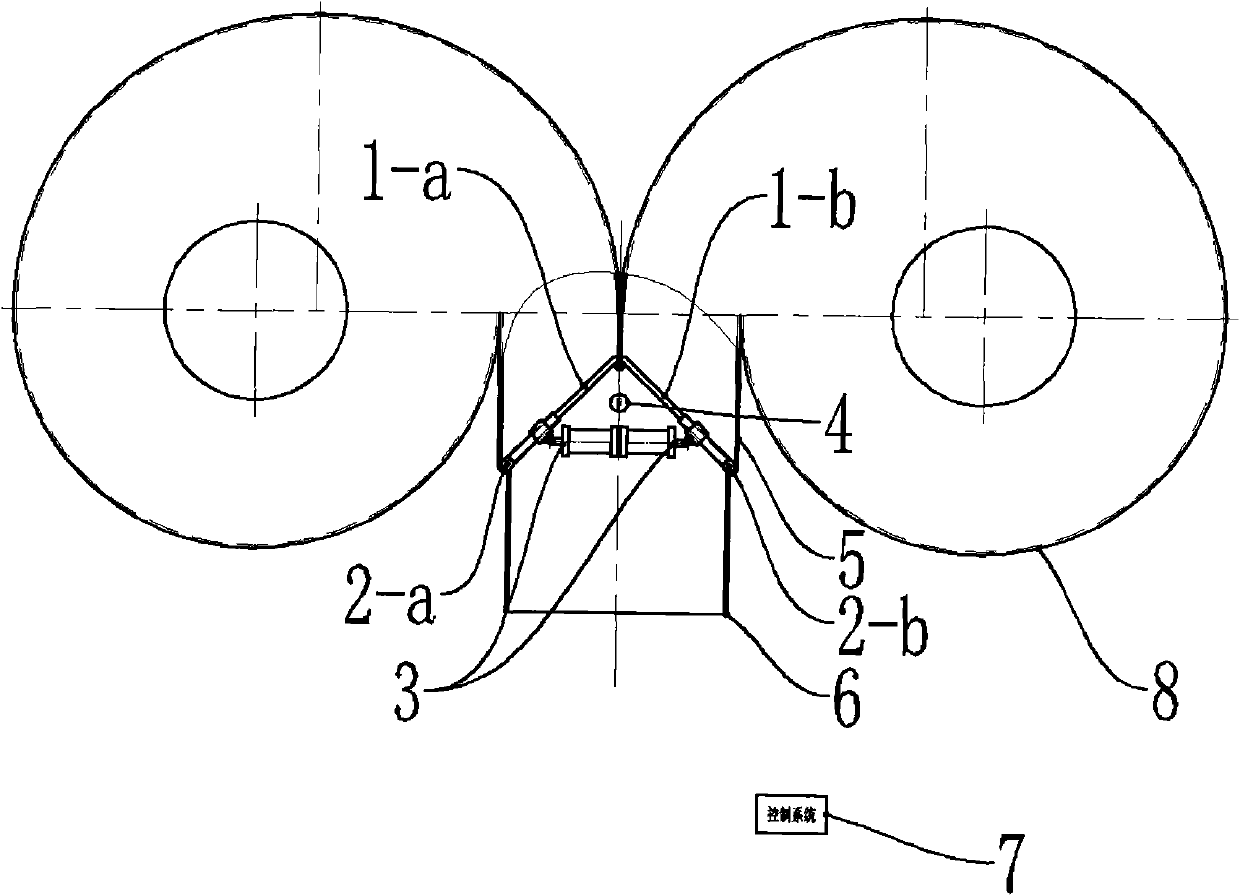

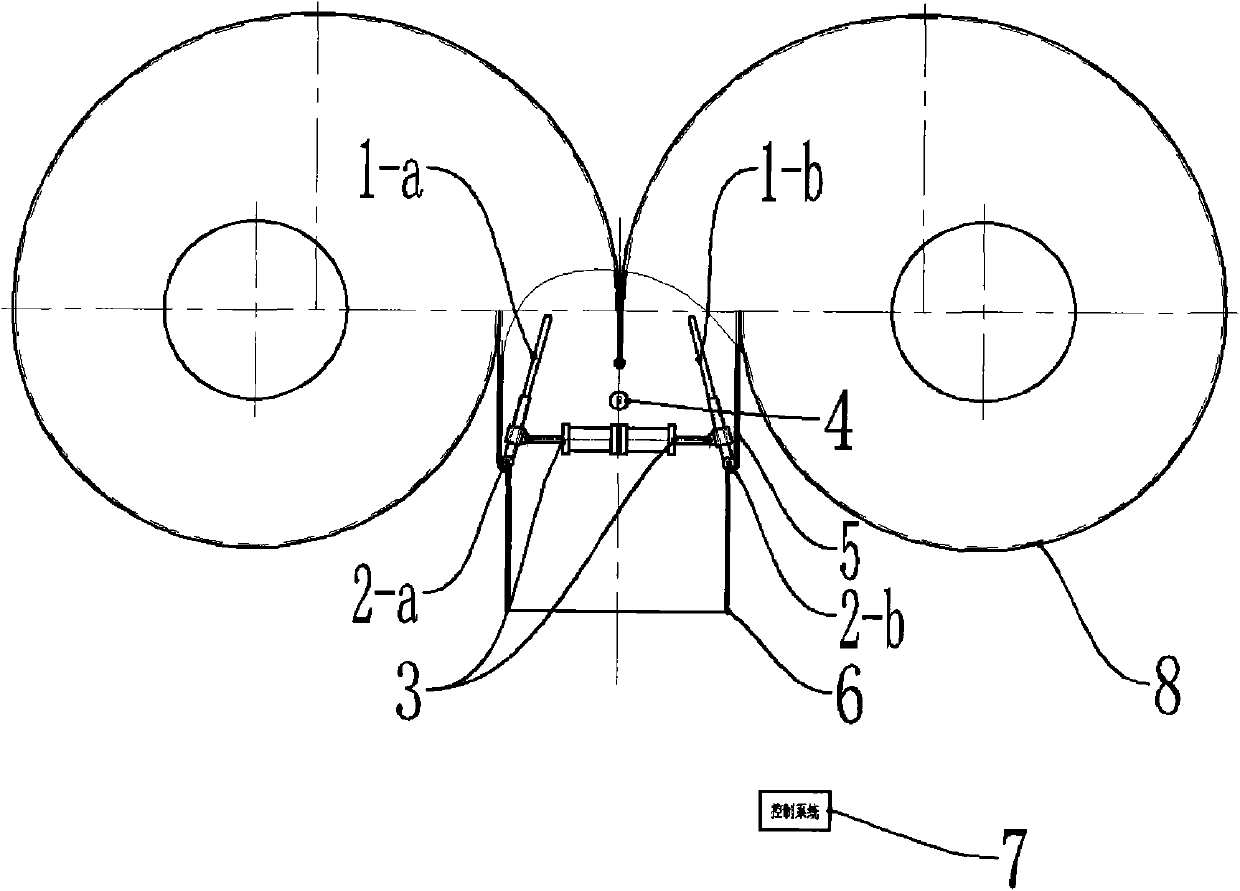

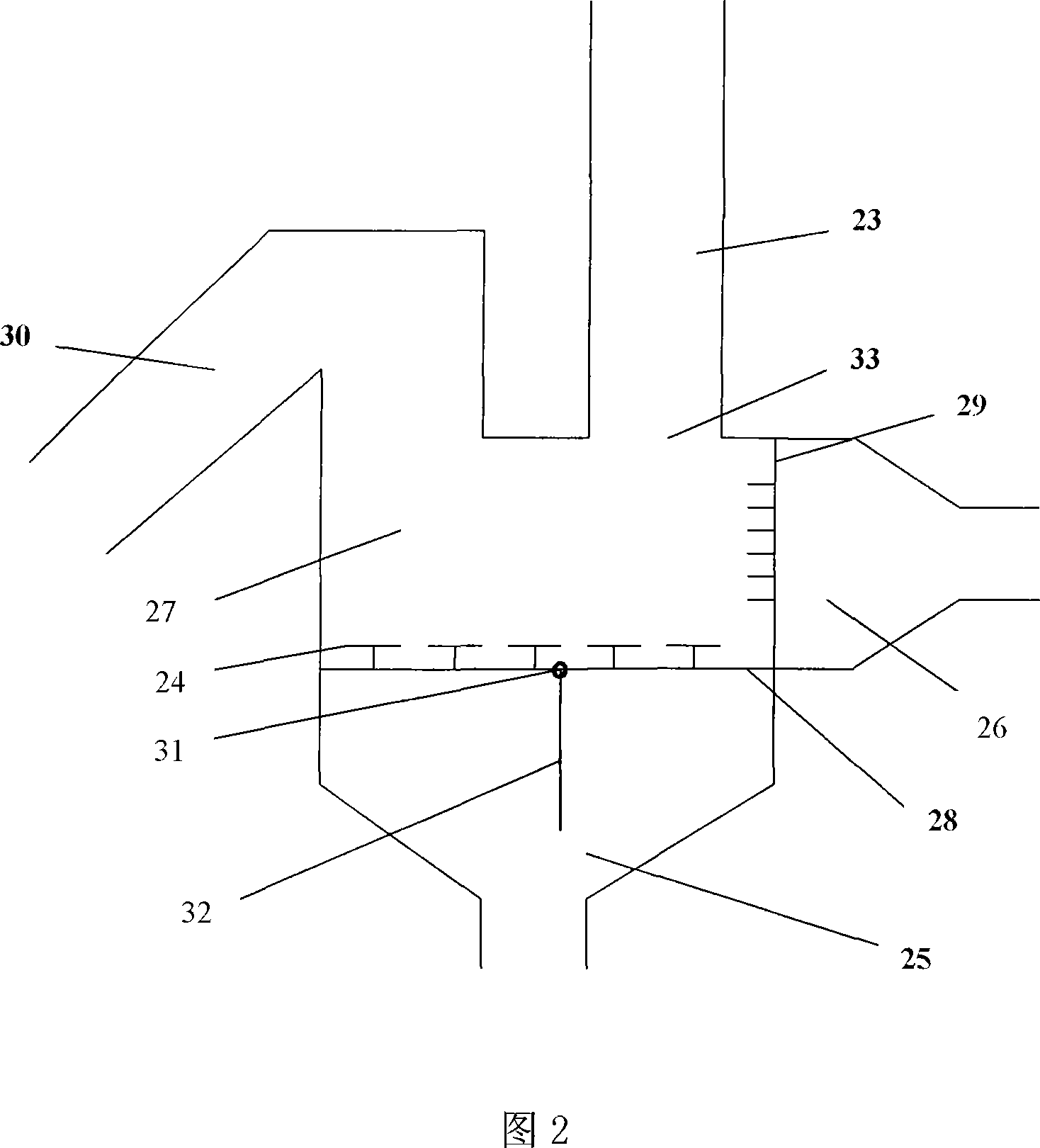

Gas inlet regulating method of double-cyclone dust collector and device thereof

InactiveCN101905196AOptimize the working conditions of the air inletReduce processing loadReversed direction vortexFlue gasControl system

The invention relates to a gas inlet regulating device of a double-cyclone dust collector. Two gas inlets of the double-cyclone dust collector are connected with a flue gas pipeline in parallel. The gas inlet regulating device is arranged at the gas inlet of the double-cyclone dust collector (8) and comprises a first valve plate (1-a), a second valve plate (1-b), a first valve plate rotating shaft (2-a), a second valve plate rotating shaft (2-b), a valve plate opening drive device (3), a gas flow rate monitoring unit (4) and a control system (7), wherein the first valve plate (1-a) and the second valve plate (1-b) are symmetrically positioned on the pipelines of the two gas inlets of the double-cyclone dust collector (8) respectively, the valve plate opening drive device (3) is used for respectively regulating the opening angles of the first valve plate (1-a) and the second valve plate (1-b) by the first valve plate rotating shaft (2-a) and the second valve plate rotating shaft (2-b), the air inlet pipeline is provided with the gas flow rate monitoring unit (4), and the valve plate opening drive device (3) and the gas flow rate monitoring unit (4) are respectively connected with the control system (7).

Owner:北京钢研新冶工程设计有限公司

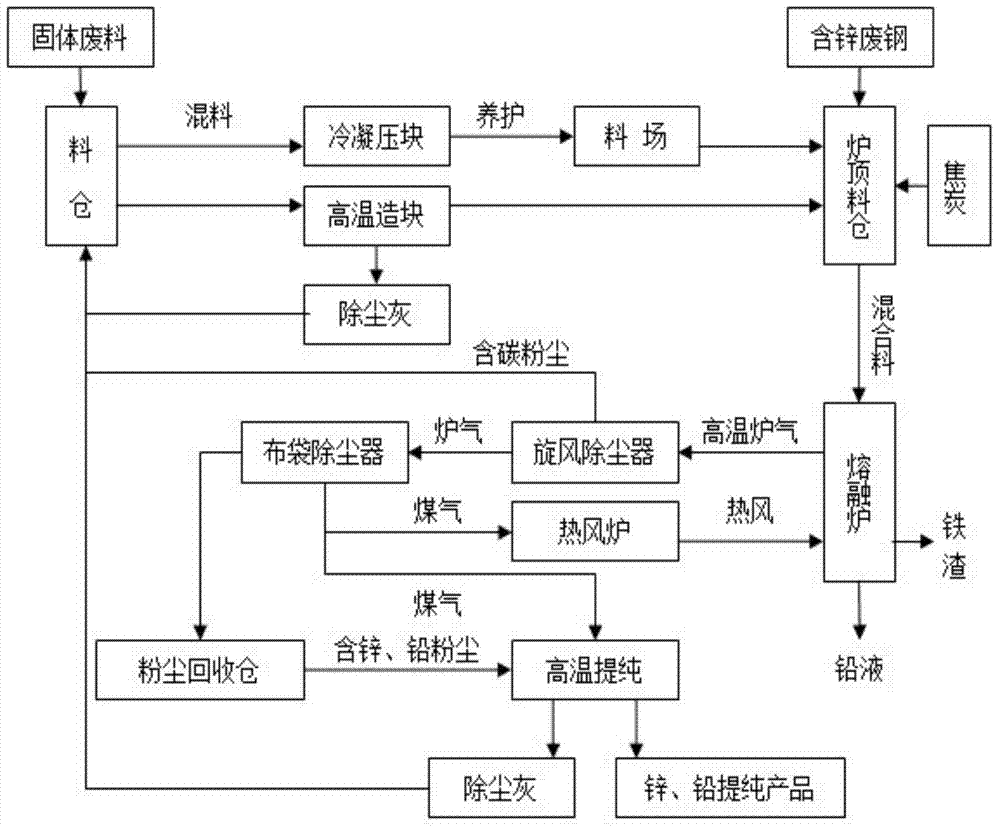

Process method for processing solid waste of steelworks by utilizing smelting furnace

The invention relates to a process method for processing iron-containing solid waste of steelworks by utilizing a smelting furnace. The process method comprises the following steps: with blast furnace dust containing zinc and lead, revolving furnace sludge, electric furnace fly ash, slag metal, waste metal and the like as principal raw materials, carrying out condensation agglomeration and high-temperature agglomeration, and carrying out operations such as maintaining or cooling and granulation so as to obtain finished agglomerates; after mixing the finished agglomerates with coke, sending the mixture into the smelting furnace to be subjected to high-temperature smelting, simultaneously adding the waste such as zinc-containing waste into the smelting furnace in a certain proportion to finally generate high-temperature mixed gas, separating elements such as carbon from the mixed gas by utilizing a cyclone dust collector at the top of the furnace, recycling carbon-containing dust again, further separating the residual mixed gas by utilizing a bag-type dust collector so as to obtain zinc-rich and lead-rich dust, and recycling the zinc-rich and lead-rich dust and applying the zinc-rich and lead-rich dust to the high-temperature agglomeration, the hot air preheating of the smelting furnace and a smelting furnace purification process; then purifying the collected zinc-rich and lead-rich dust, so as to obtain high-purity zinc and lead products; regularly opening a lead discharging hole in the bottom of the smelting furnace, and collecting lead liquid so as to simultaneously obtain wet lead and products such as molten iron and furnace slag.

Owner:卢龙宏赫废料综合利用有限公司

Coal gasification device for circulating fluidized bed and manufacturing method thereof

InactiveCN101054536AImprove gasification efficiencyReduce outputEnergy inputGranular/pulverulent flues gasificationCycloneHearth

A circulating fluidized bed coal gasification apparatus includes coal blending system, generator, cyclone dust collector, exhaust-heat boiler, water-cooling tower and Venturi scrubber, wherein the generator has up-and-down two rows of gasifying agent nozzles, helix dust collector and storage groove. The gas pipe which communicates to the cyclone dust collector is set on the top. A feed back pipe which communicates to the generator is set at the bottom of the cyclone dust collector. The cyclone dust collector communicates to the exhaust-heat boiler by gas pipe. The exhaust-heat boiler communicates to the water-cooling tower by gas pipe and communicates to the Venturi scrubber by gas pipe. The characteristics are: the feed back pipe facing to the generator hearth of the cyclone dust collector is a feed back machine with small-sized fluid bed; the cyclone dust collector is composed of at least two tandem dust collector; coal blending system has wind feeding and dust coal drier. The invention achieves the transition of the boiling bed to the circulating fluidized bed and increases the system gasification efficiency.

Owner:宋建元

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com