Patents

Literature

1661 results about "Hydrocyclone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydrocyclone (often referred to by the shortened form cyclone) is a device to classify, separate or sort particles in a liquid suspension based on the ratio of their centripetal force to fluid resistance. This ratio is high for dense (where separation by density is required) and coarse (where separation by size is required) particles, and low for light and fine particles. Hydrocyclones also find application in the separation of liquids of different densities.

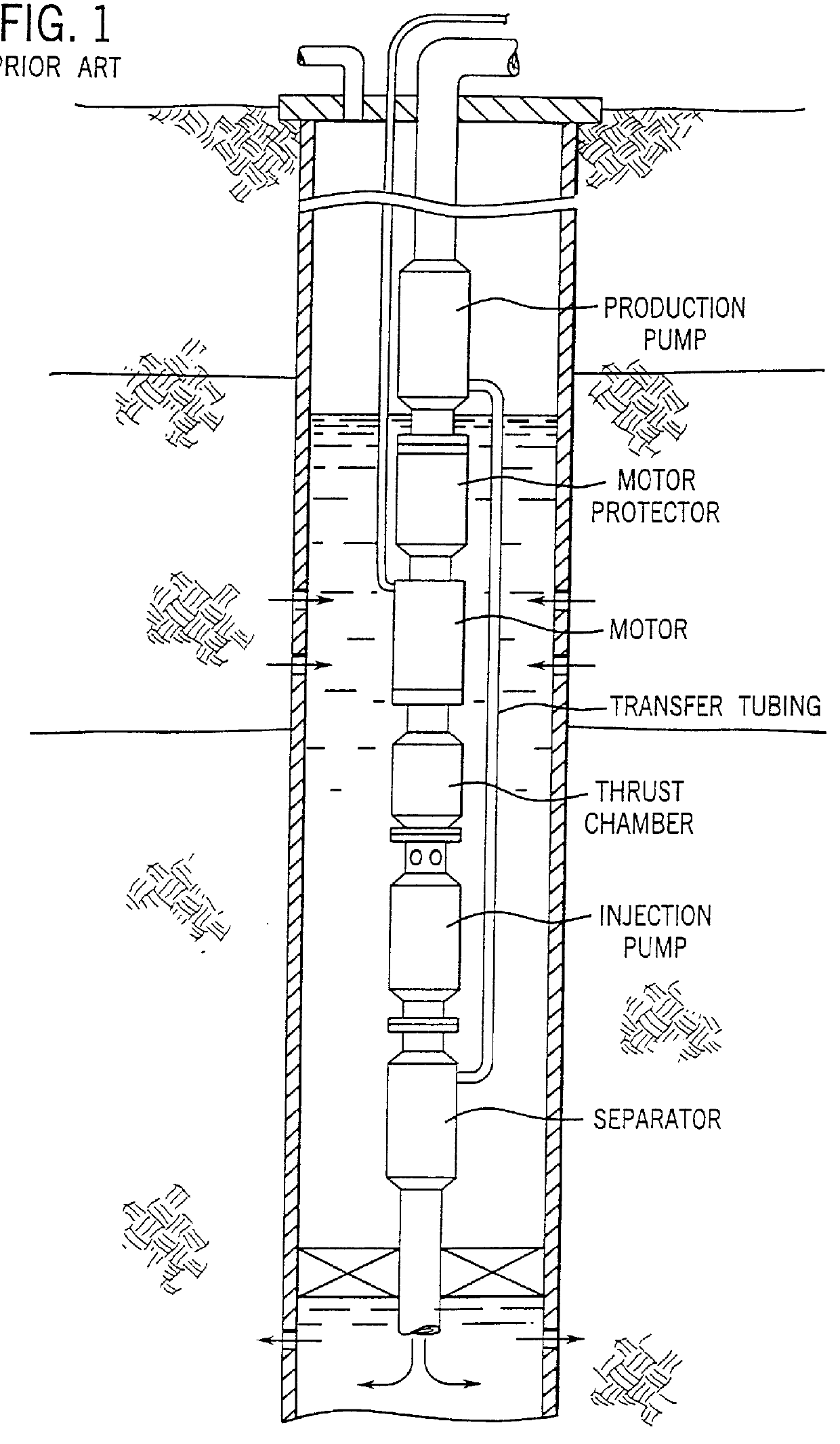

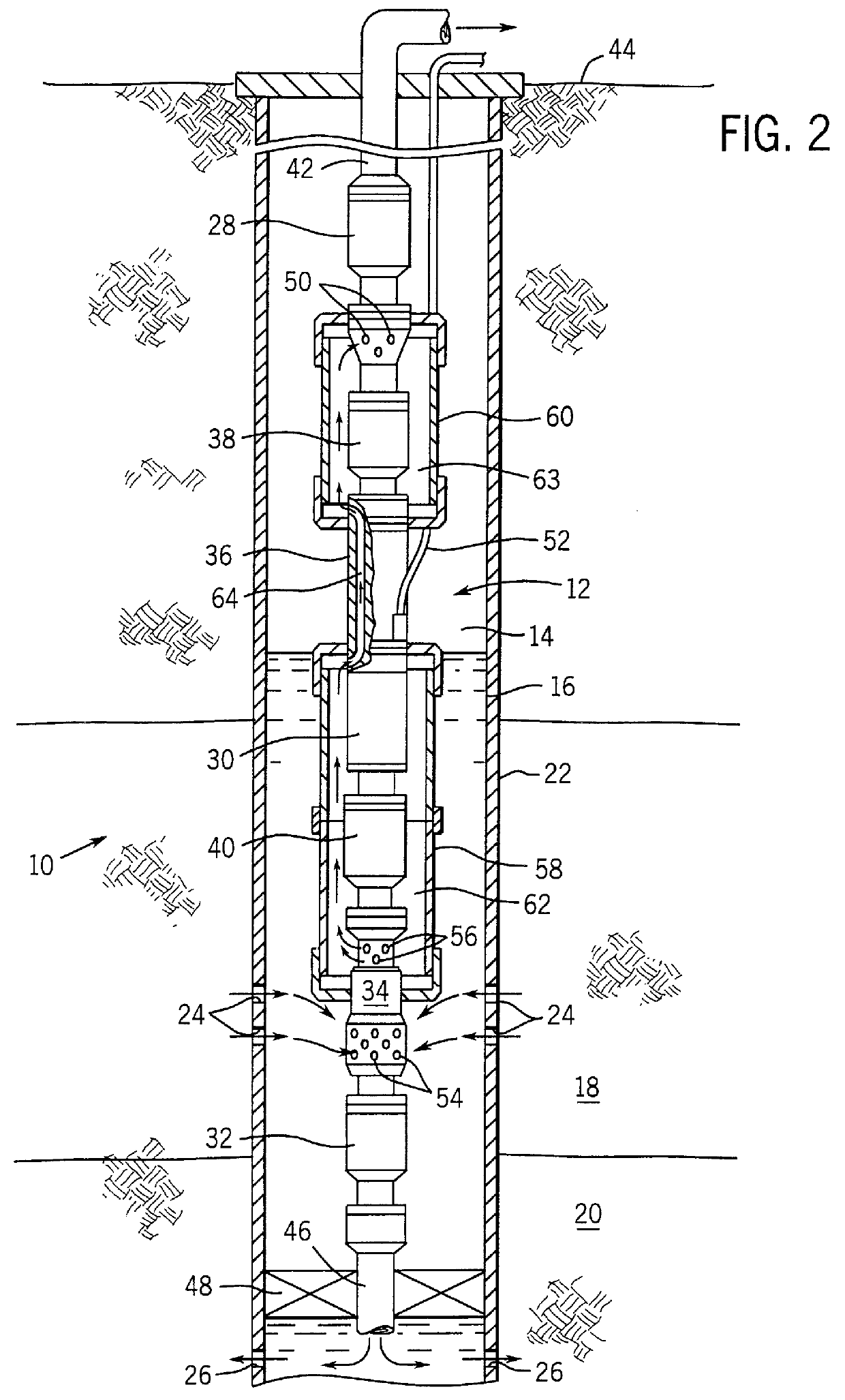

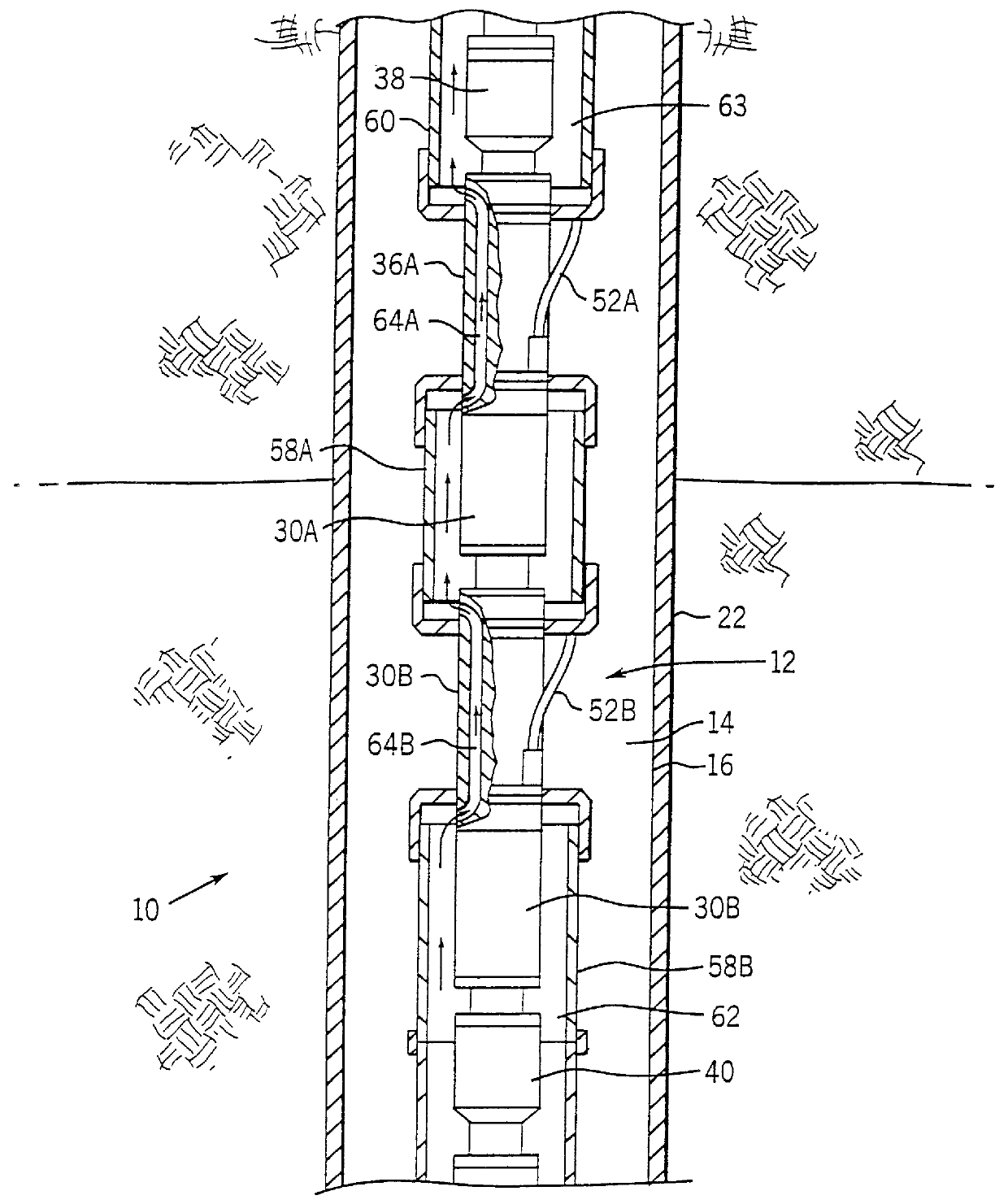

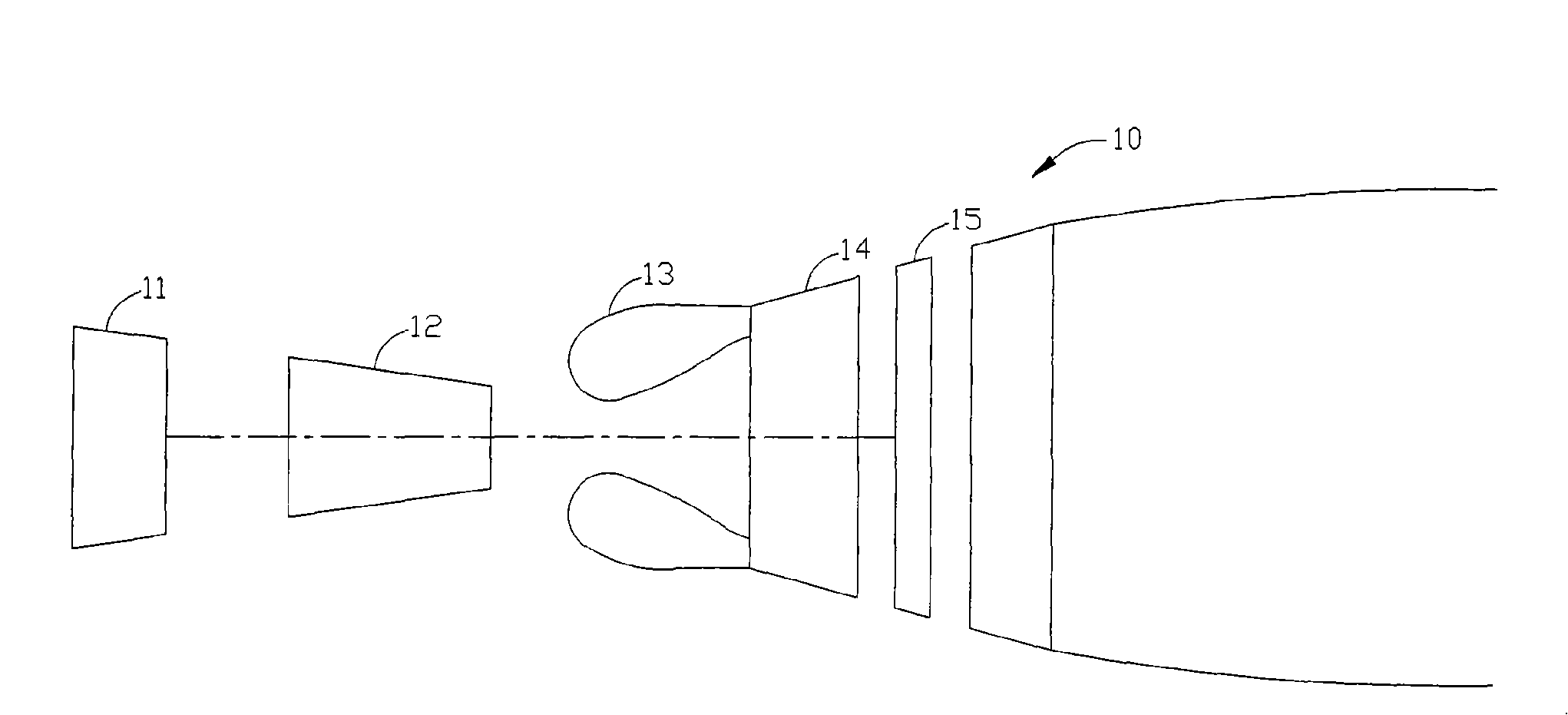

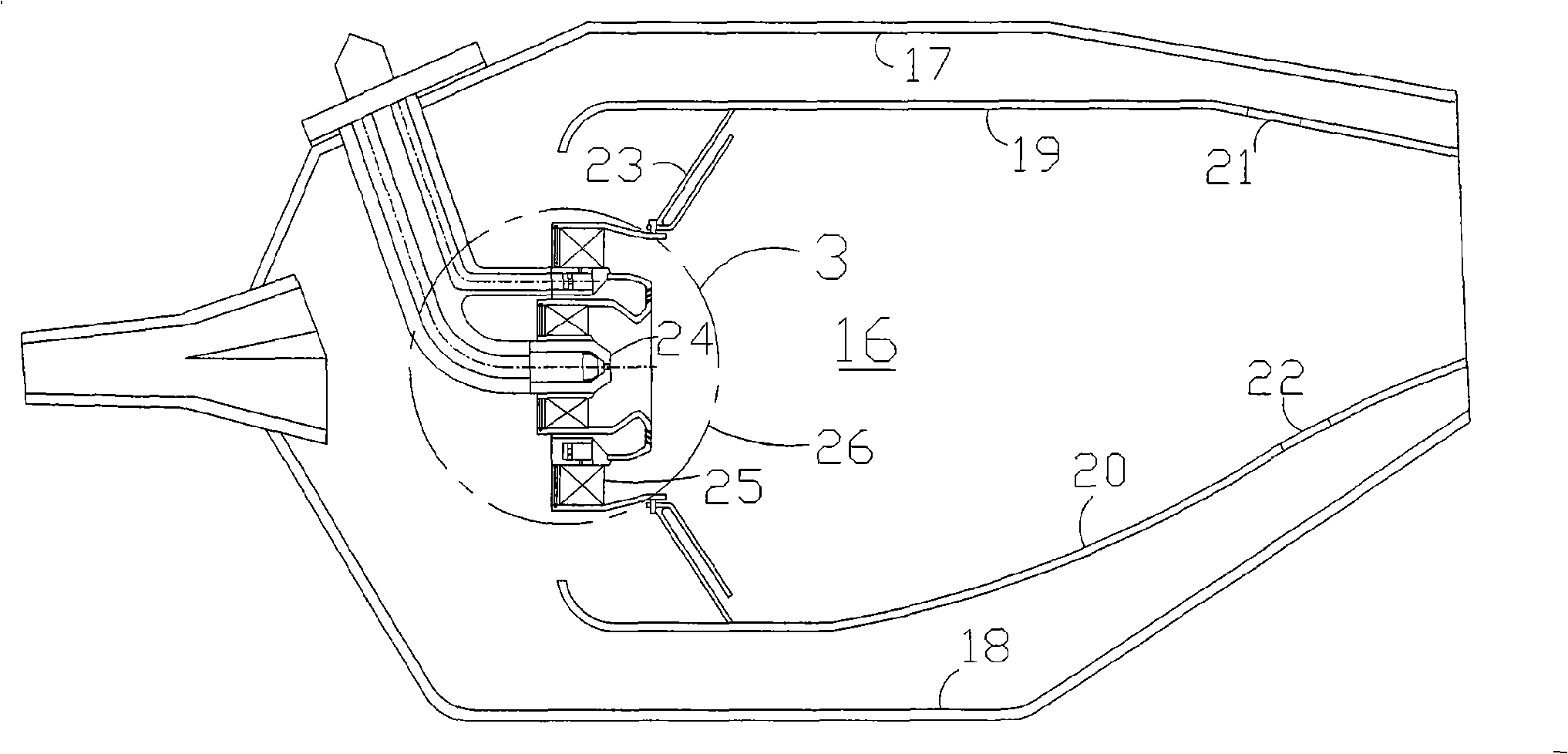

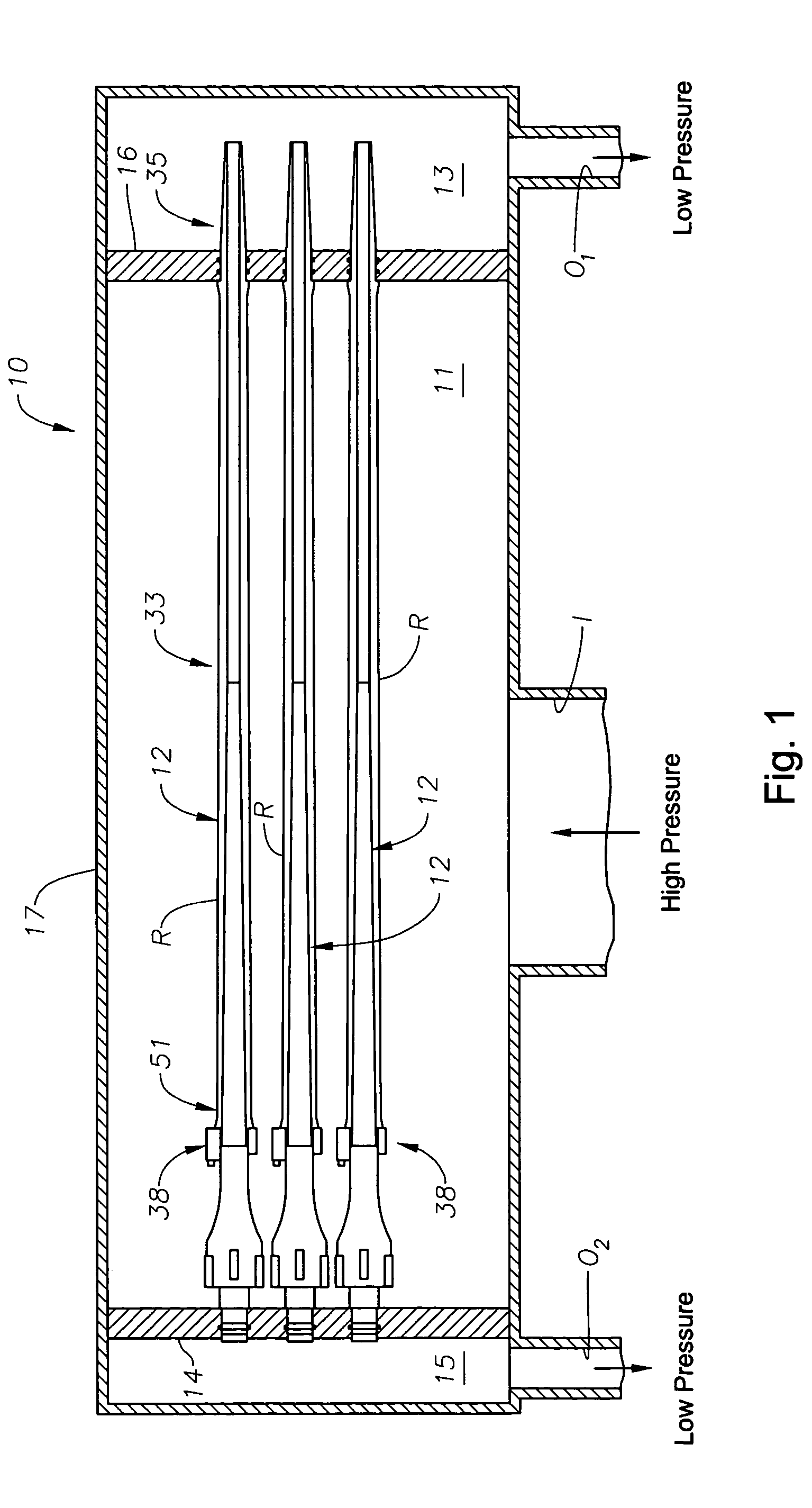

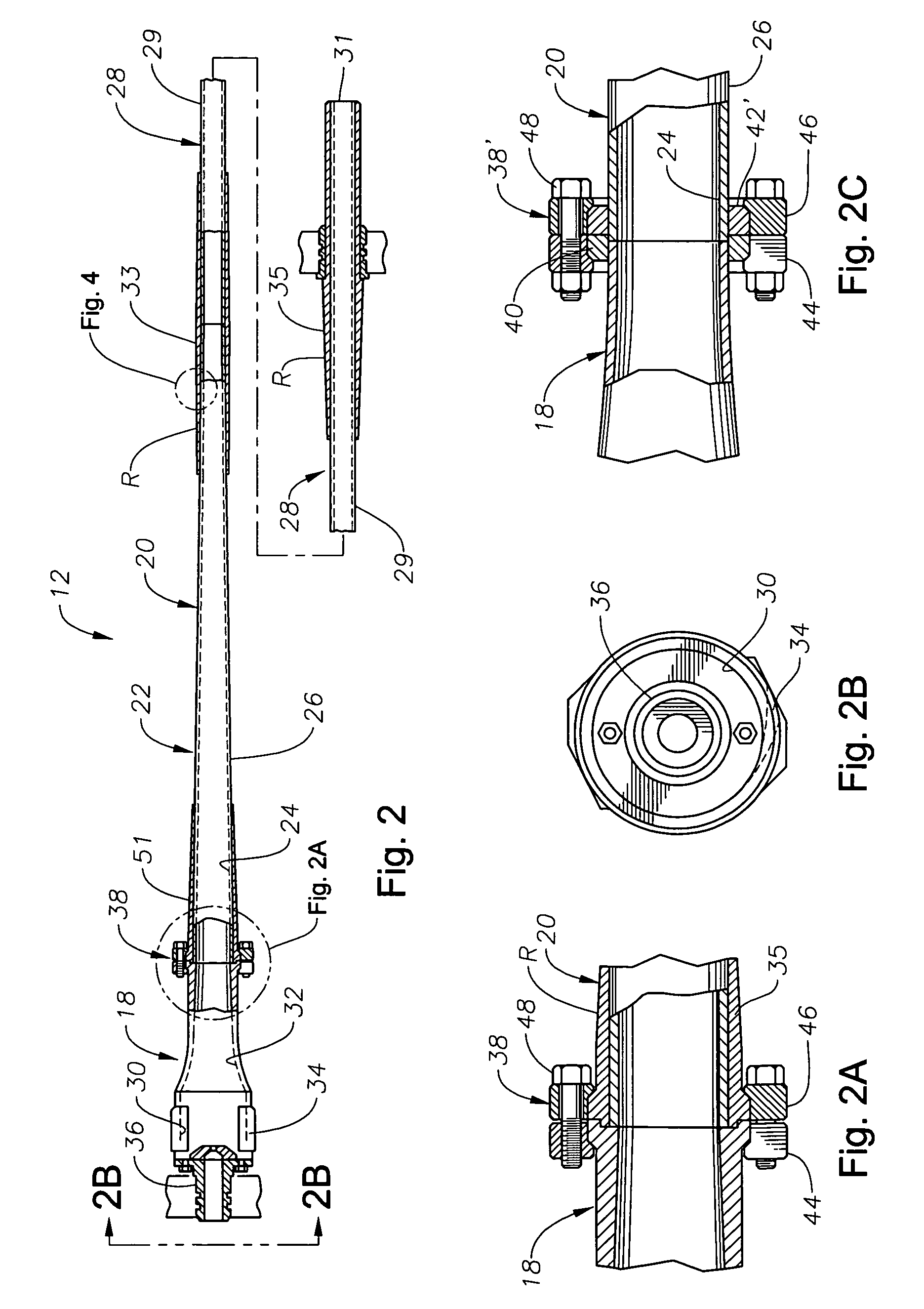

Downhole fluid separation system incorporating a drive-through separator and method for separating wellbore fluids

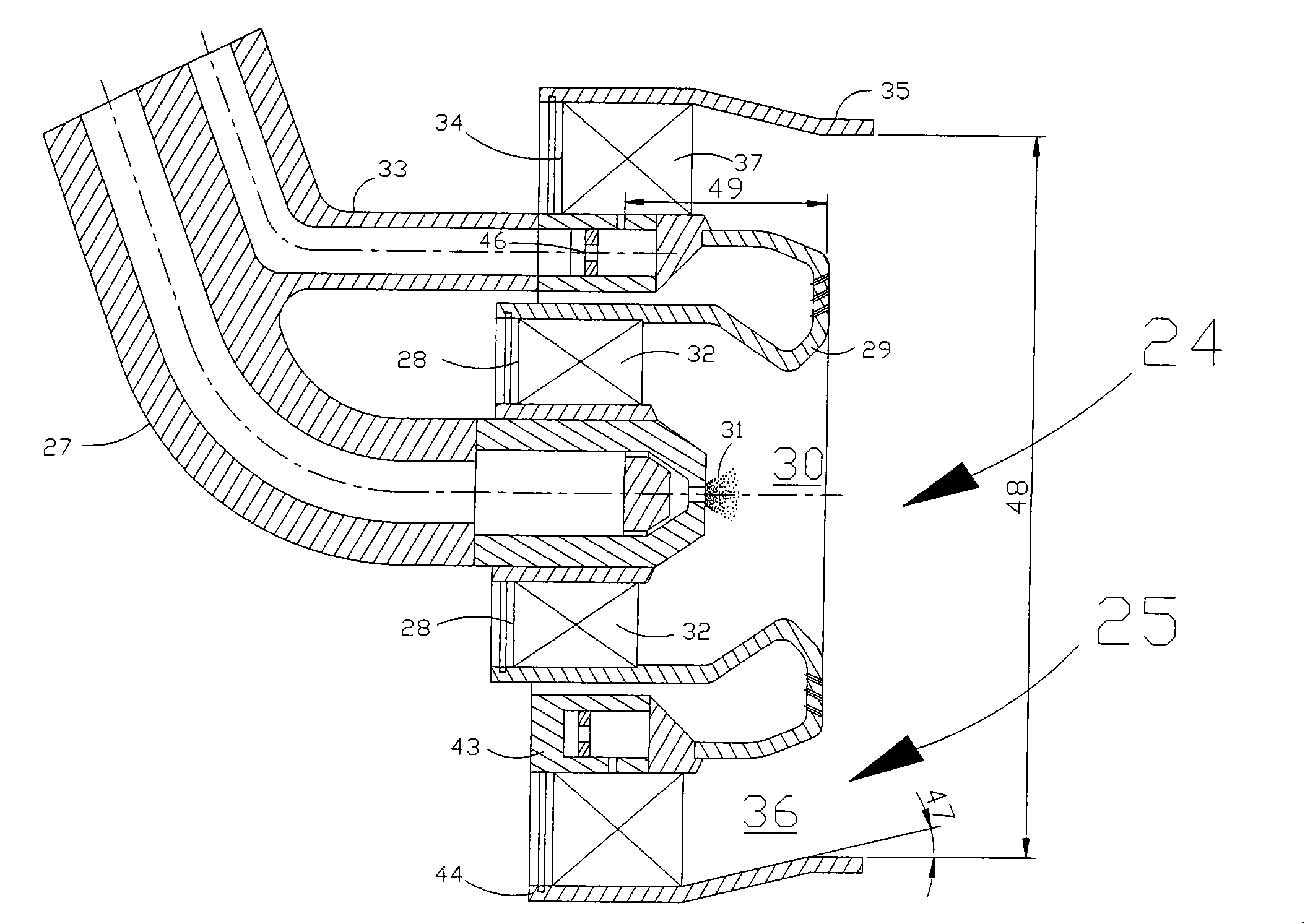

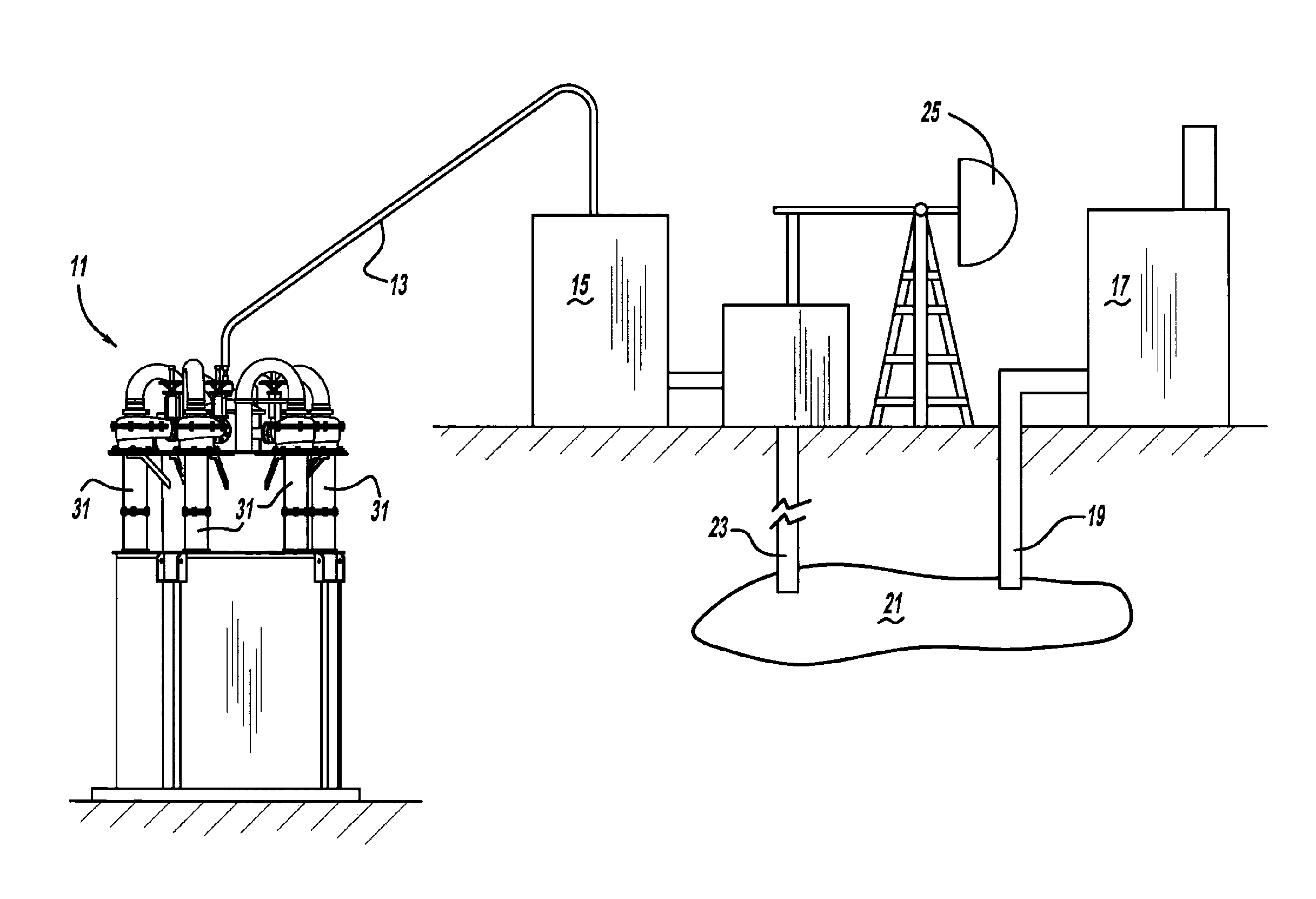

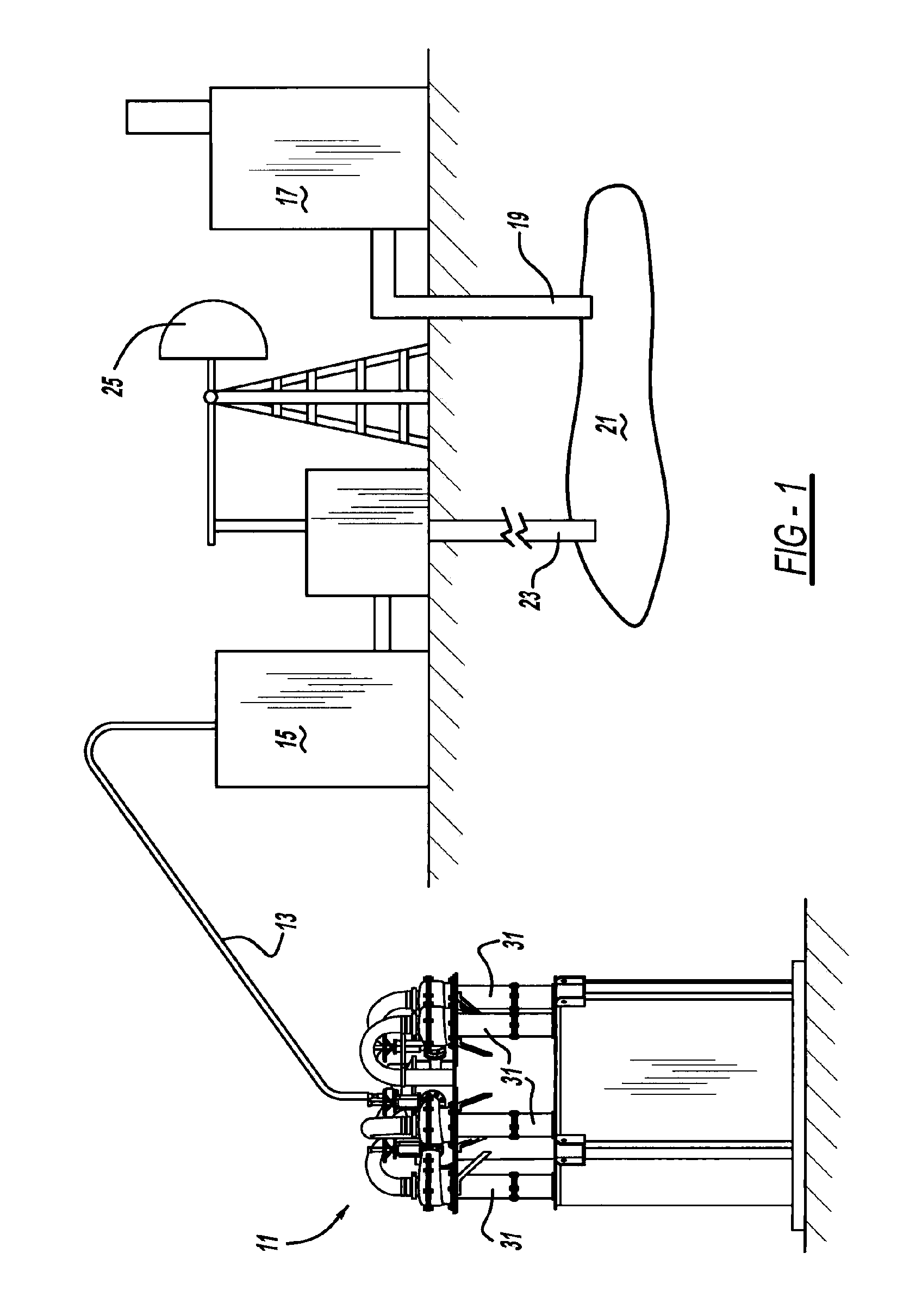

A fluid separation system is provided for separating wellbore fluids into production fluids and non-production fluids. The system includes a separator adapted for transmitting mechanical power between a drive motor and at least one pump. The separator includes one or more separation units, such as hydrocyclone separators. A drive train traversing the separator is interfaced with drive elements, such as a submergible electric motor, and driven elements such as an injection or production pump. Wellbore fluids are channeled through the separator in either a push-through or pull-through manner. Production fluids are then transferred from the separator to the production pump for removal from the well. Non-production fluids are transmitted from the separator either to the injection pump for reinjection into a subterranean discharge zone, or directly into the discharge zone from the separator. The drive train elements traversing the separator are supported by antifriction bearings in interface plates on either end of the separator. The ability to transmit mechanical power through the separator facilitates assembly of pumping system components in various configurations as well as piping fluid communication paths between the pumping system components.

Owner:CAMCO INT

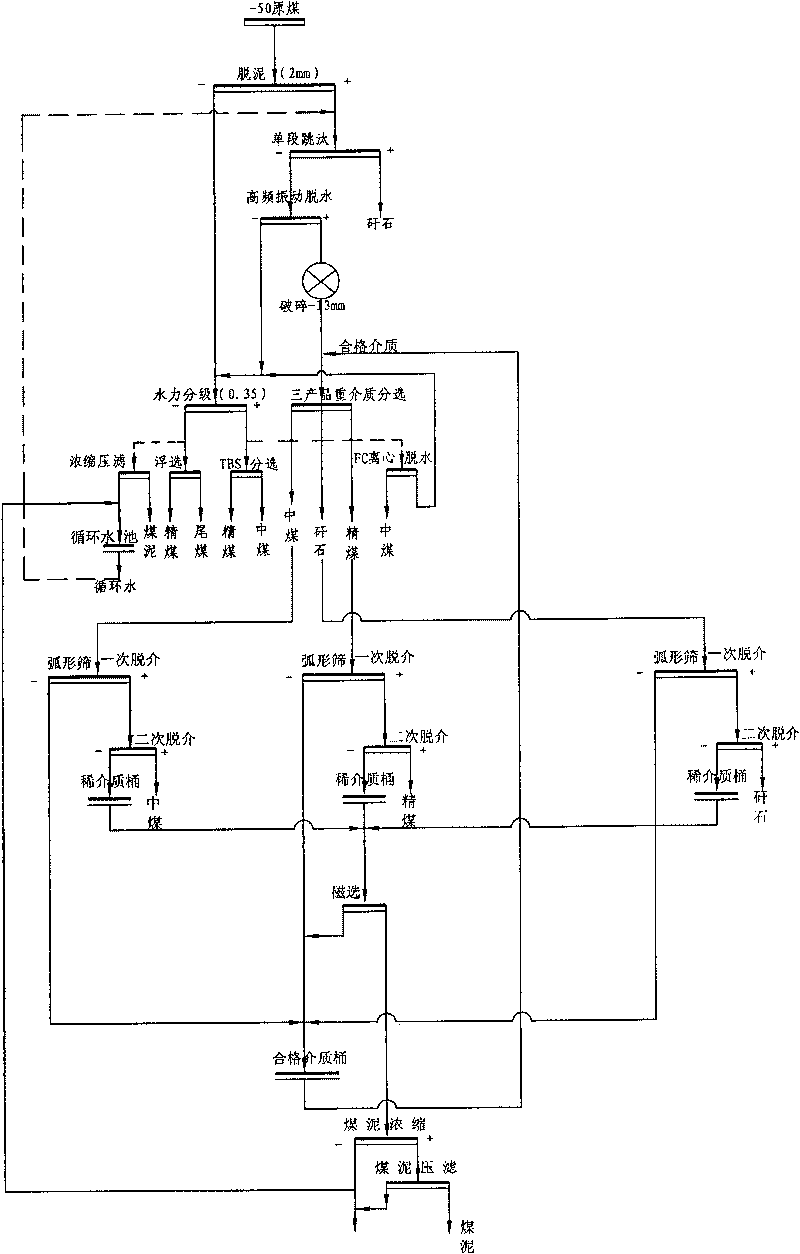

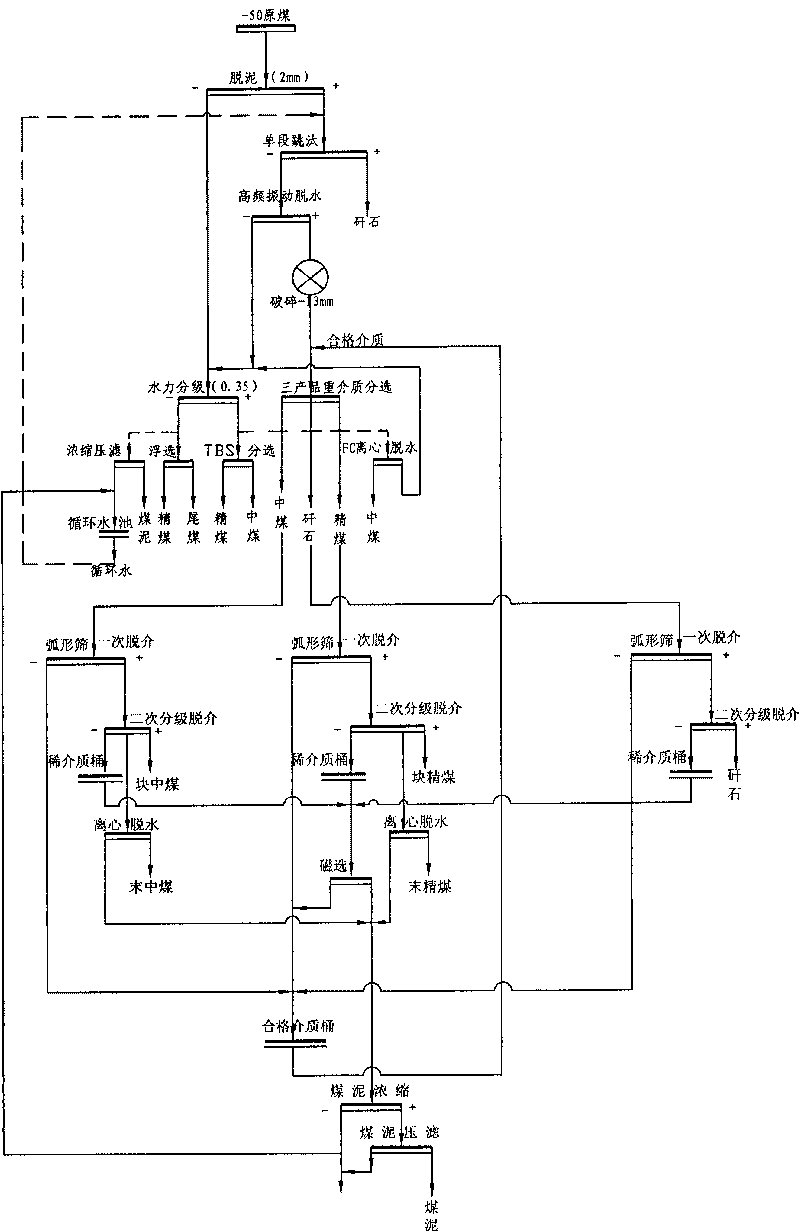

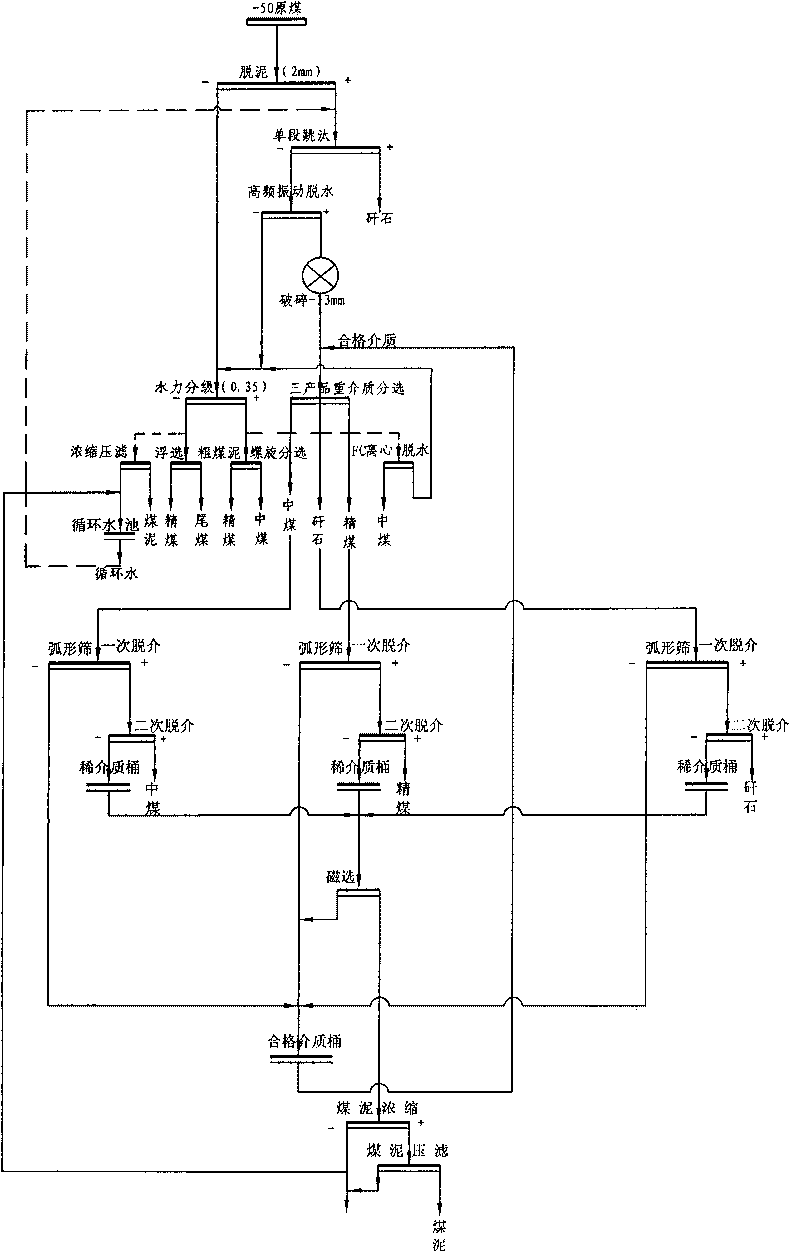

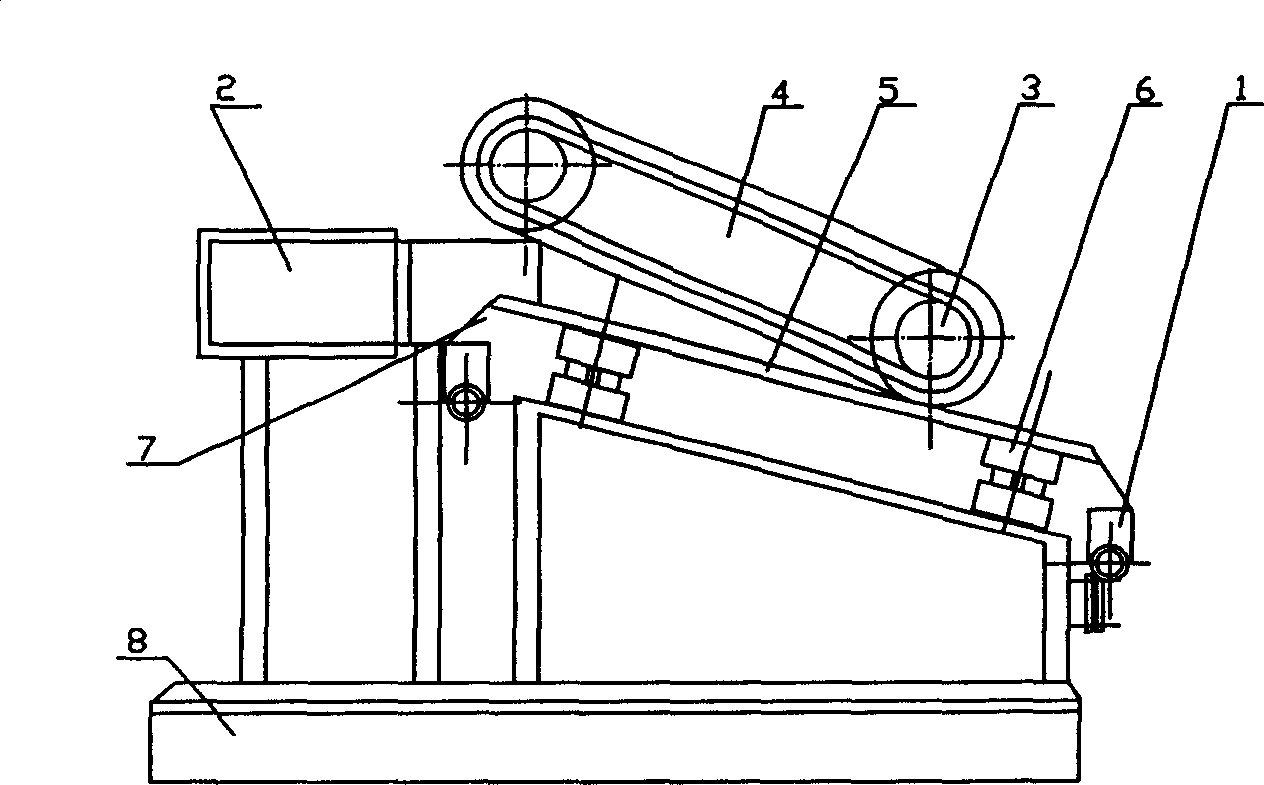

Raw coal washing process capable of realizing non-polar ash conditioning

InactiveCN101716552AReduce the amount of re-insertionReduce manufacturing costWet separationCycloneSingle stage

The invention provides a raw coal washing process capable of realizing non-polar ash conditioning. The process comprises the following steps: a, desliming and screening the part of raw coal with granularity less than 50 to 100mm; b, carrying out single stage jigging separation on screen products on a desliming screen; c, crushing lump coal obtained from the step b, namely screen products on an oscillating screen, by a crushing machine; d, feeding the crushed products from the step c into a three-product heavy medium cyclone for separation; e, respectively treating underflows and overflows obtained from a hydroclone in the step c; f, carrying out TBS separation or centrifugal dehydration treatment on the underflows of the hydroclone from the step e; g, respectively carrying out primary medium removal on clean coal, middlings coal and gangue obtained from the step d; h, respectively carrying out secondary medium removal and dehydration on the three products from the step g; and i, carrying out magnetic separation on undersize dilute medium obtained by secondary medium removal on the coal gangue in the clean coal in the step h, feeding the separated magnetite powder into a qualified medium tank, collecting residues, and carrying out coal slurry concentration.

Owner:HENAN POLYTECHNIC UNIV

Beneficiation method for removing long quarry impurities by adopting strong magnetic flotation

InactiveCN101898168AIncrease production capacityImprove grinding efficiencyFlotationMagnetic separationEngineeringBall mill

The invention relates to a beneficiation method for removing long quarry impurities by adopting strong magnetic flotation, comprising the steps of crushing, grinding, sieving, desliming, strong magnetically floating, floating, concentrating and dewatering. The concrete beneficiation method comprises the following steps of: breaking and grinding ore in a ball mill; grading ground minerals by a spiral grader and a hydraulic hydrocyclone twice; combining with the ball mill into a closed cycle; respectively mounting high-frequency linear vibration sieves in overflows graded twice; respectively removing impurities over 3 mm and 1 mm, such as mica, grass-roots bark, and the like; removing most of muddy substances from minerals through desliming equipment after the impurities are removed; removing mechanical iron, weakly magnetic iron ore, tourmaline and partial mica in a strong magnetic flotation machine; floating the minerals passing through the strong magnetic flotation machine again to remove residual iron minerals, mica and black minerals; and finally, concentrating and dewatering the minerals to form a product.

Owner:衡阳县湘雁矿业有限公司

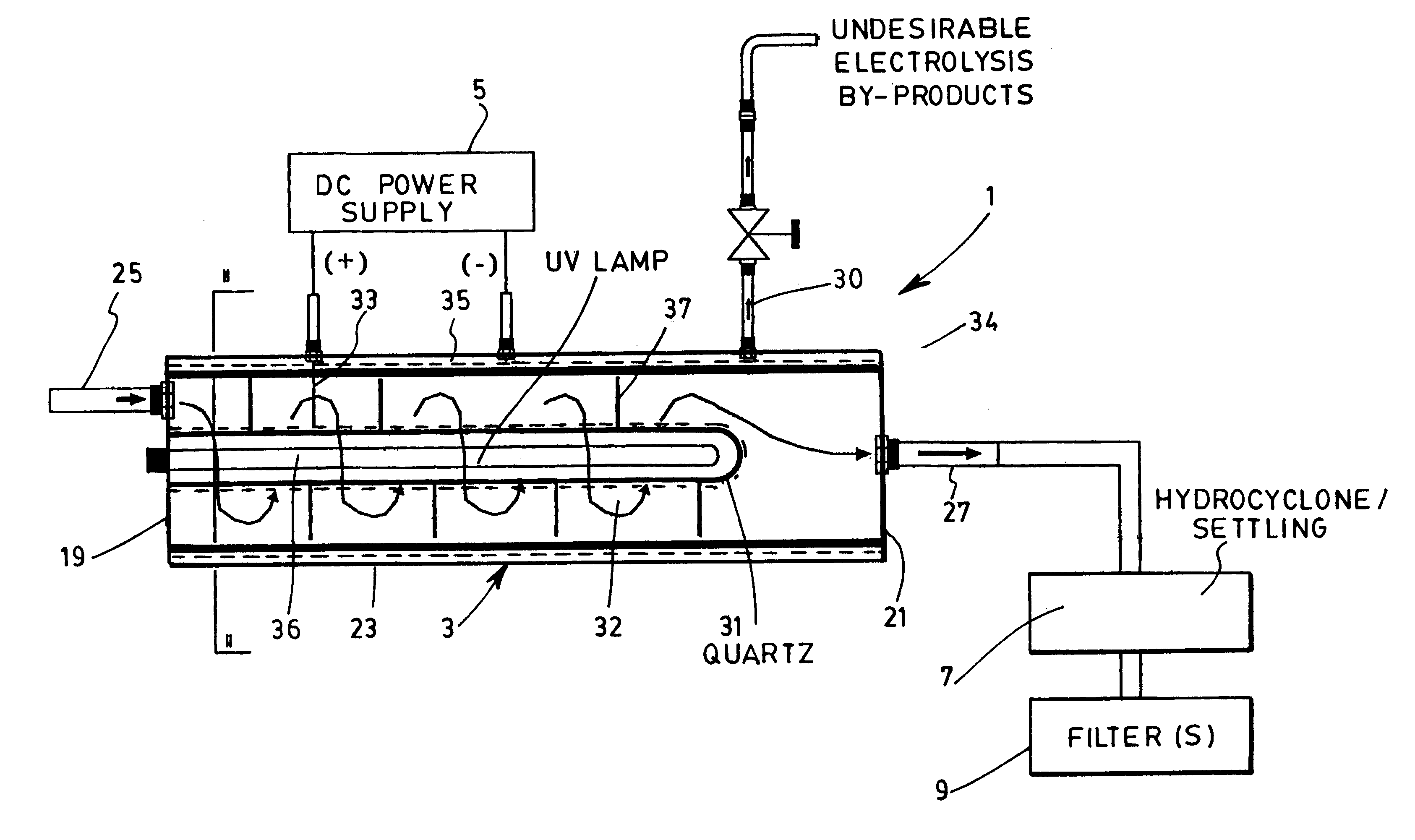

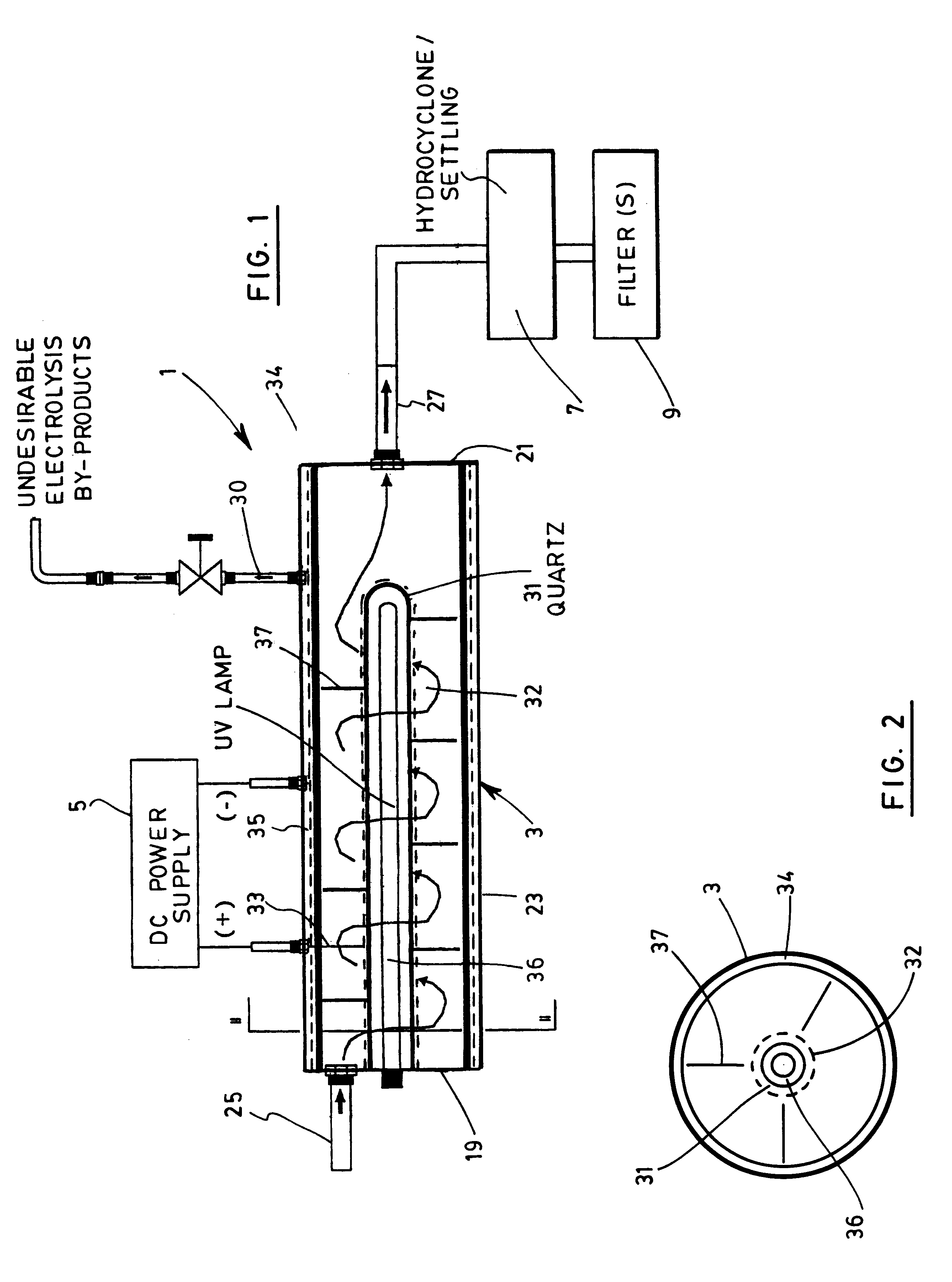

Device and method for treating water with ozone generated by water electrolysis

InactiveUS6180014B2Economical and efficient methodPhotography auxillary processesDisinfectionHigh concentrationElectrolysis

A process and a device for the treatment of water, especially for removing therefrom a large variety of pollutants, especially organic, inorganic and biological pollutants through in situ generation of ozone. Ozone is economically produced in situ at a high concentration through the interaction of electrolytically produced oxygen and UV light having a wavelength of 189 nm. The device has a set of anode and cathode for electrolytically producing nascent oxygen which reacts with UV light at a wavelength of 189 nm to produce ozone "in situ" within a vessel where the polluted water is submitted to the combinative action of ozone and other oxidation reactions. The device also has a hydrocyclone or retention tank of removing cationic pollutants such as heavy metals, free radicals as well as undesirable electrolysis byproducts such as nascent hydrogen through a secondary outlet. Oxidation by-products are subsequently removed from the exiting water stream by means of decantation, flocculation, coagulation or filtration.

Owner:SALAMA AMIR

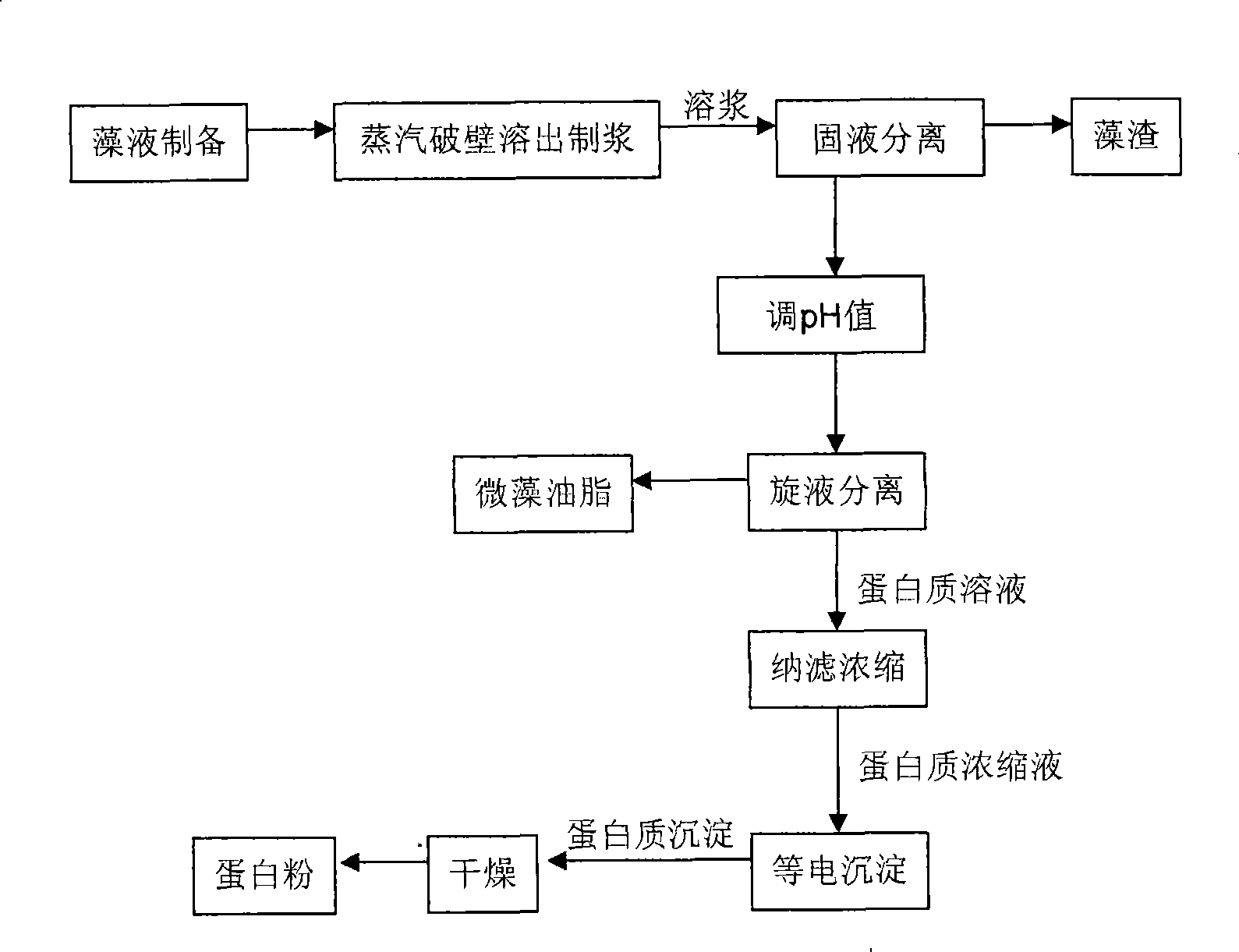

Method for simultaneously extracting lipid and protein from microalgae

ActiveCN101429467AHigh yieldPrevent drynessPeptide preparation methodsFatty-oils/fats productionOil and greaseFreeze-drying

The invention relates to a method for simultaneously extracting grease and proteins from microalgae, which takes wet algae mud as a raw material, adjusts the pH value to be alkaline or slightly alkaline, and performs wall breaking of microalgae cells and dissolution of the grease and the proteins through vapor. The method is as follows: dissolved microalgae slurry is filtered for removal of cell residue, and a mixture of the grease and the proteins is obtained; a hydrocyclone is utilized for oil-water separation, and microalgae grease is obtained; and a protein aqueous solution is subjected to nano-filtration, condensation, isoelectric precipitation and freeze drying or spray drying, and protein powder is obtained. The method utilizes the water-bearing microalgae cells as the raw material, saves the energy consumption for drying the algae cells, adopts a slightly alkaline or alkaline algae cell liquid to realize vapor wall breaking and simultaneous dissolution of the grease and the proteins, and has good wall breaking effect, high dissolution rate, low energy consumption and easily widened process. The method adopts vortex hydrocyclone separation to well solve the problem of difficult oil-water separation under the condition of low phase ratio and realize simultaneous extraction of the microalgae grease and the proteins. Moreover, the method has the advantages of simple process, economy, low energy consumption, and easy realization of industrialization.

Owner:云南中科雨虹生物科技有限公司

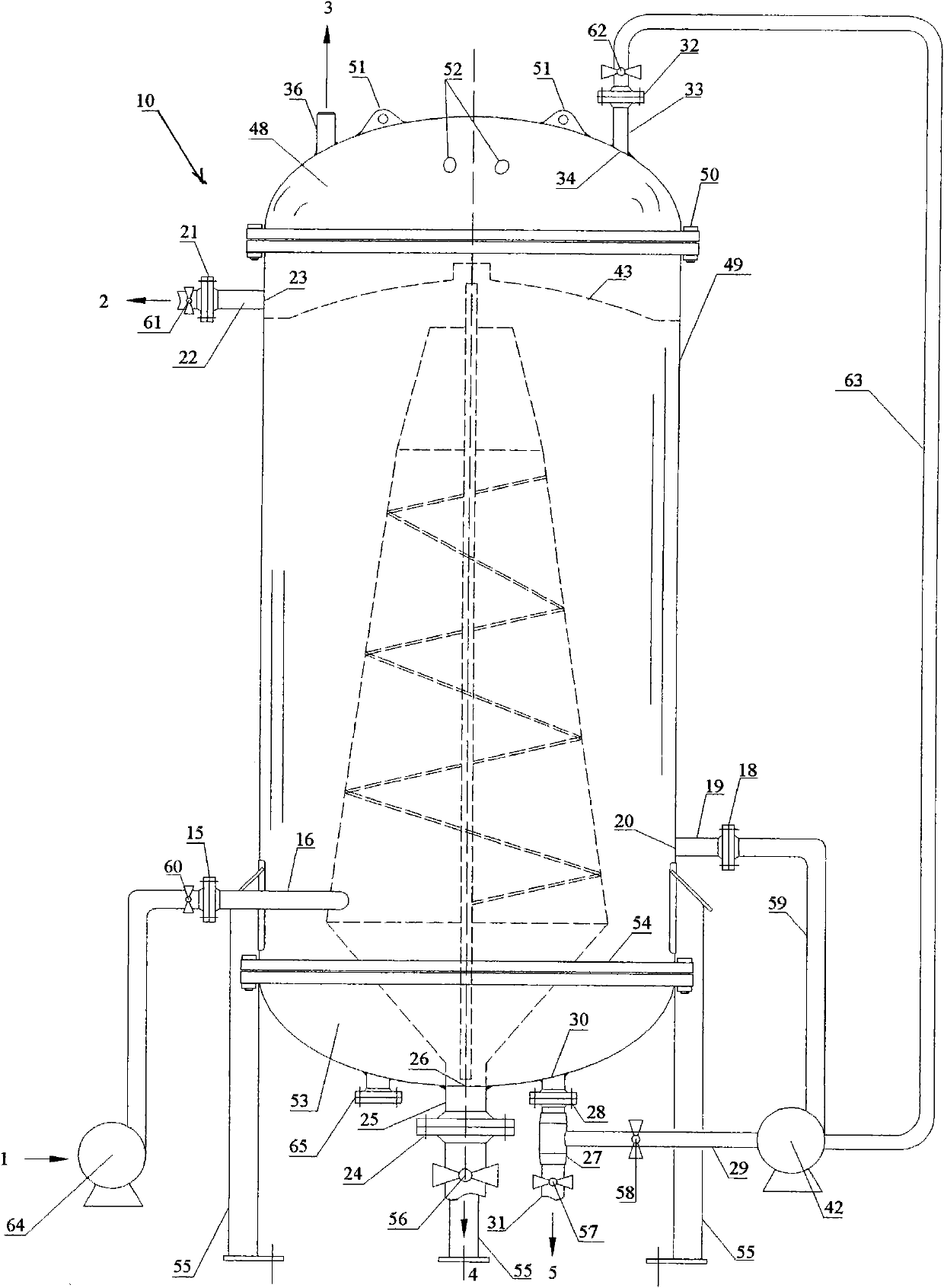

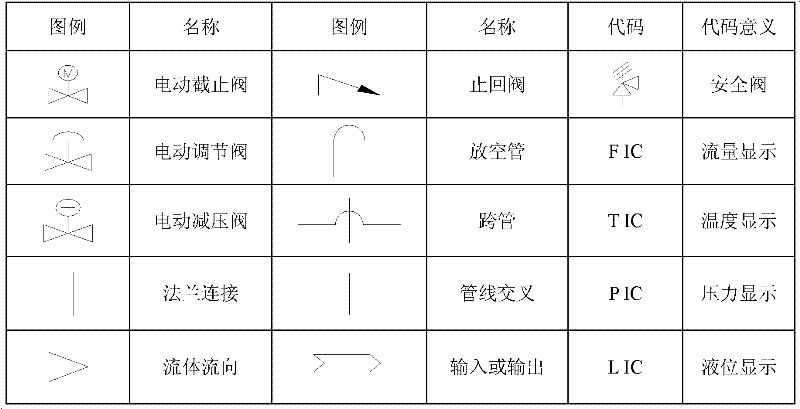

Multiphase separation method and system for processing oily waste water

InactiveCN102198984ACompactSimple appearanceWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentCycloneSolid particle

The invention discloses a multiphase separation method and a system for processing oily waste water. The multiphase separation system comprises a cyclone-air flotation integrated separator, a multiphase pump for mixing gas with liquid arranged at an oily waste water inlet, a multiphase pump for mixing pure water for circulation and backflow with circulation gas and the like. The oily waste water enters from the bottom of a tank body into a cyclone to perform a hydrocyclone separation, tiny bubbles in the waste water are released to perform a first air floatation, light substances such as bubbles with oil particles are moved to the top of the cone-shape cyclone, heavy substances such as solid particles are moved to the bottom of the cone-shape cyclone, the waste water runs over the top of the cone-shape cyclone to enter a secondary air floatation zone, the pure water for circulation and backflow and circulation gas are shear mixed in the multiphase pump, then the oily waste water is subject to a secondary air floatation by using gas-liquid mixture from water distributing apertures on an annular water-locator, and the waste water is subject to a hydrocyclone separation and two air floatation separations in a separator. The invention has the advantages of simple and compact structure, high work efficiency, and is used for the purifying process of oily waste water containing tiny dispersed oil particles.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

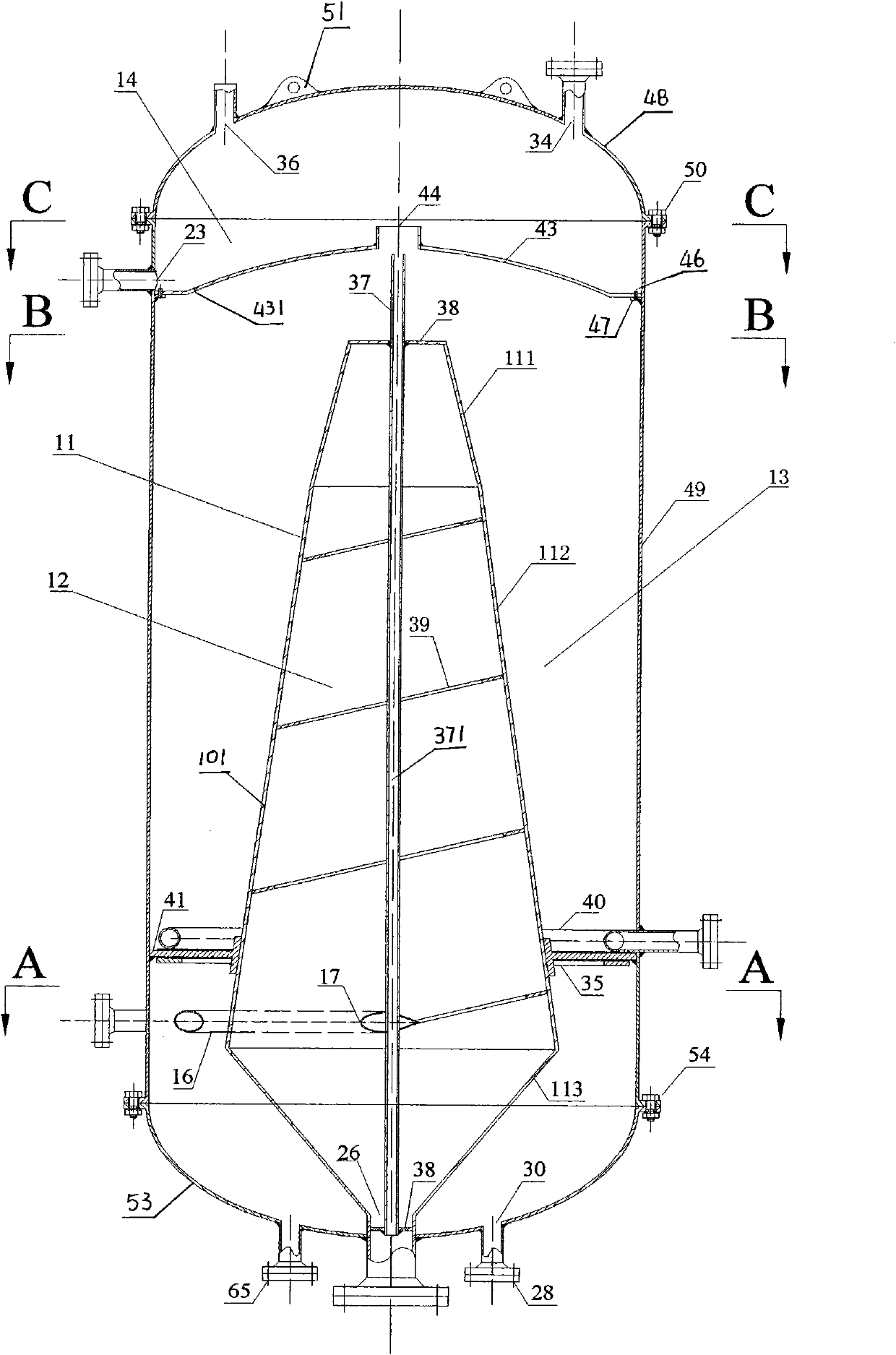

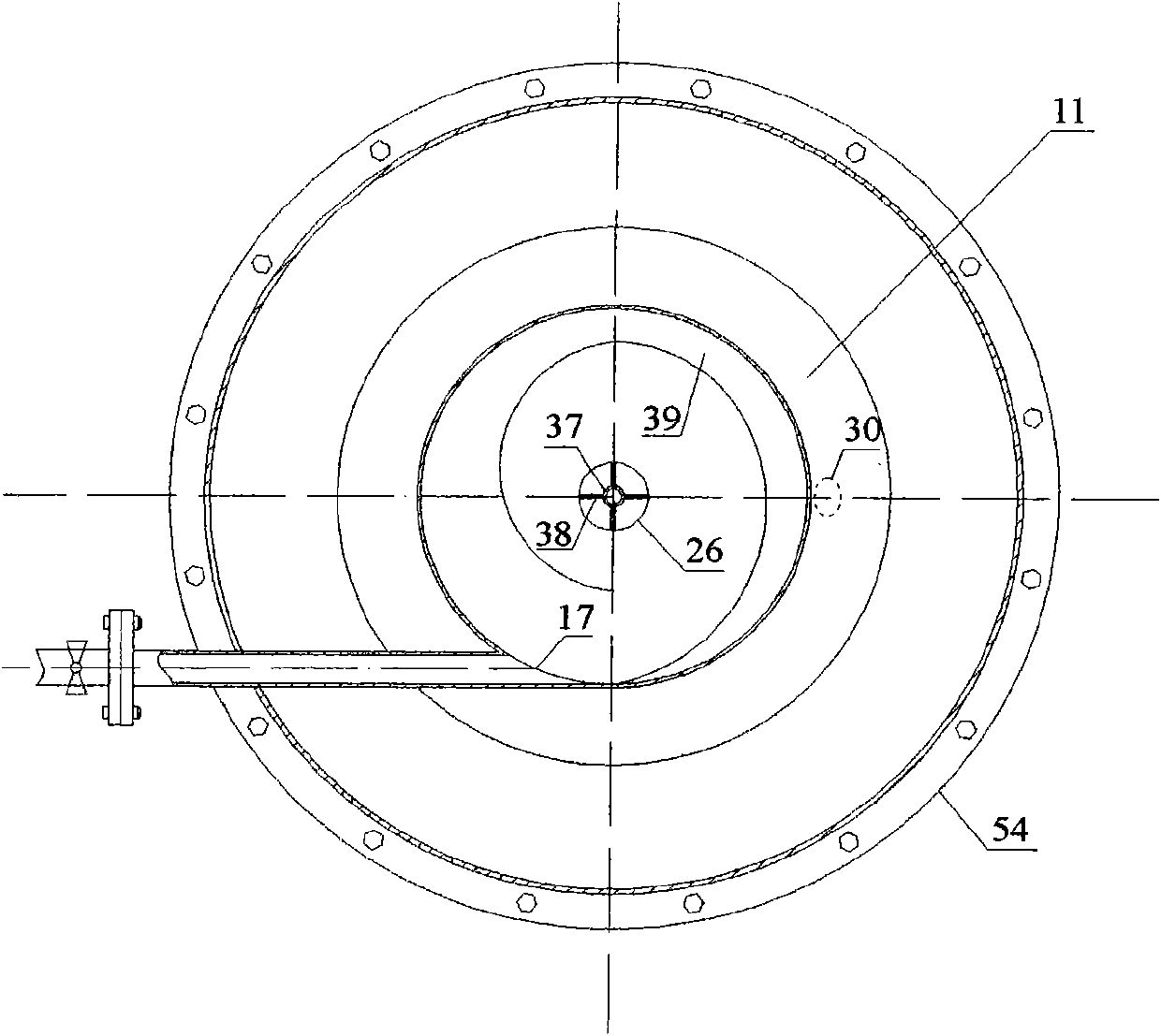

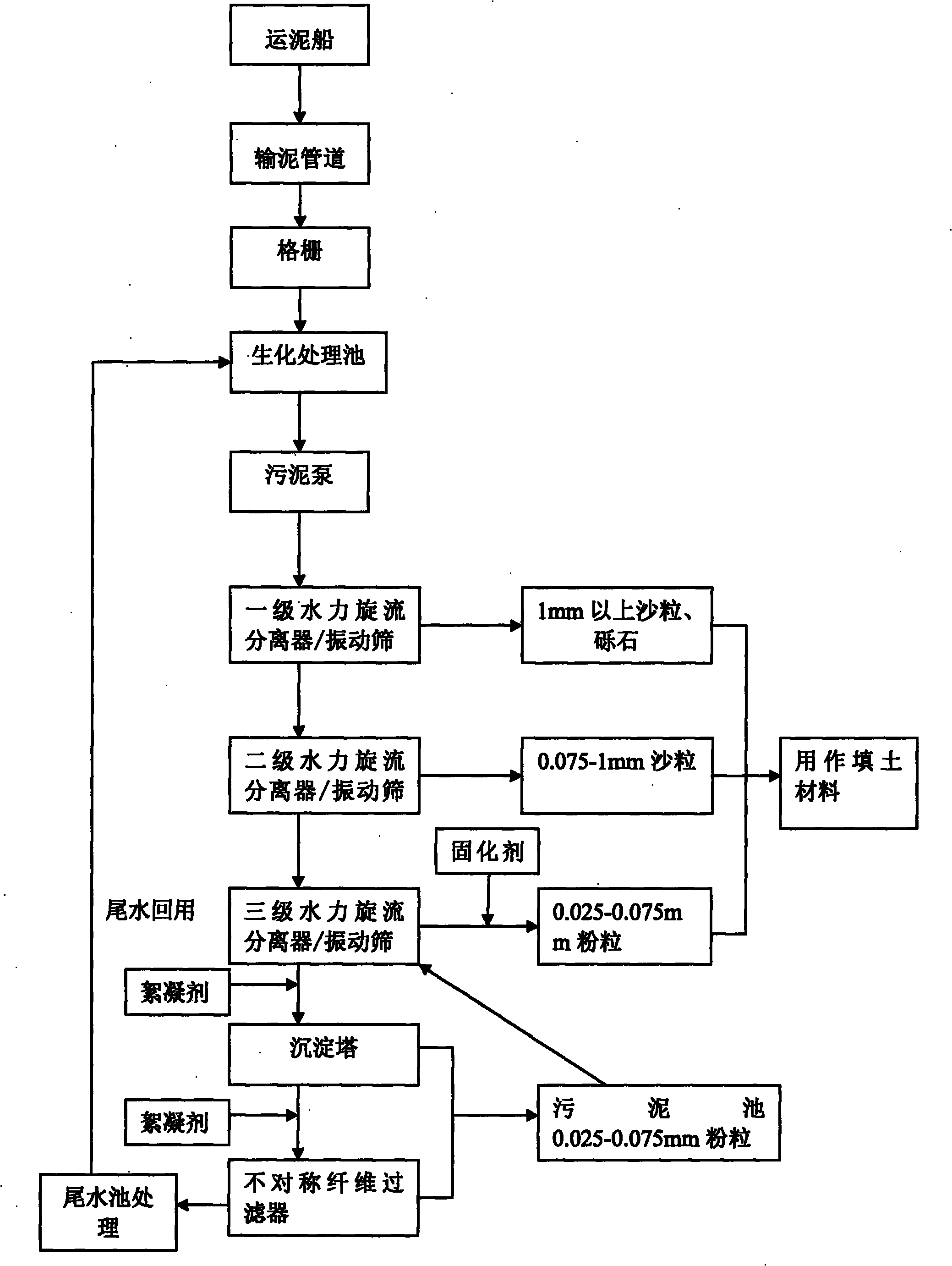

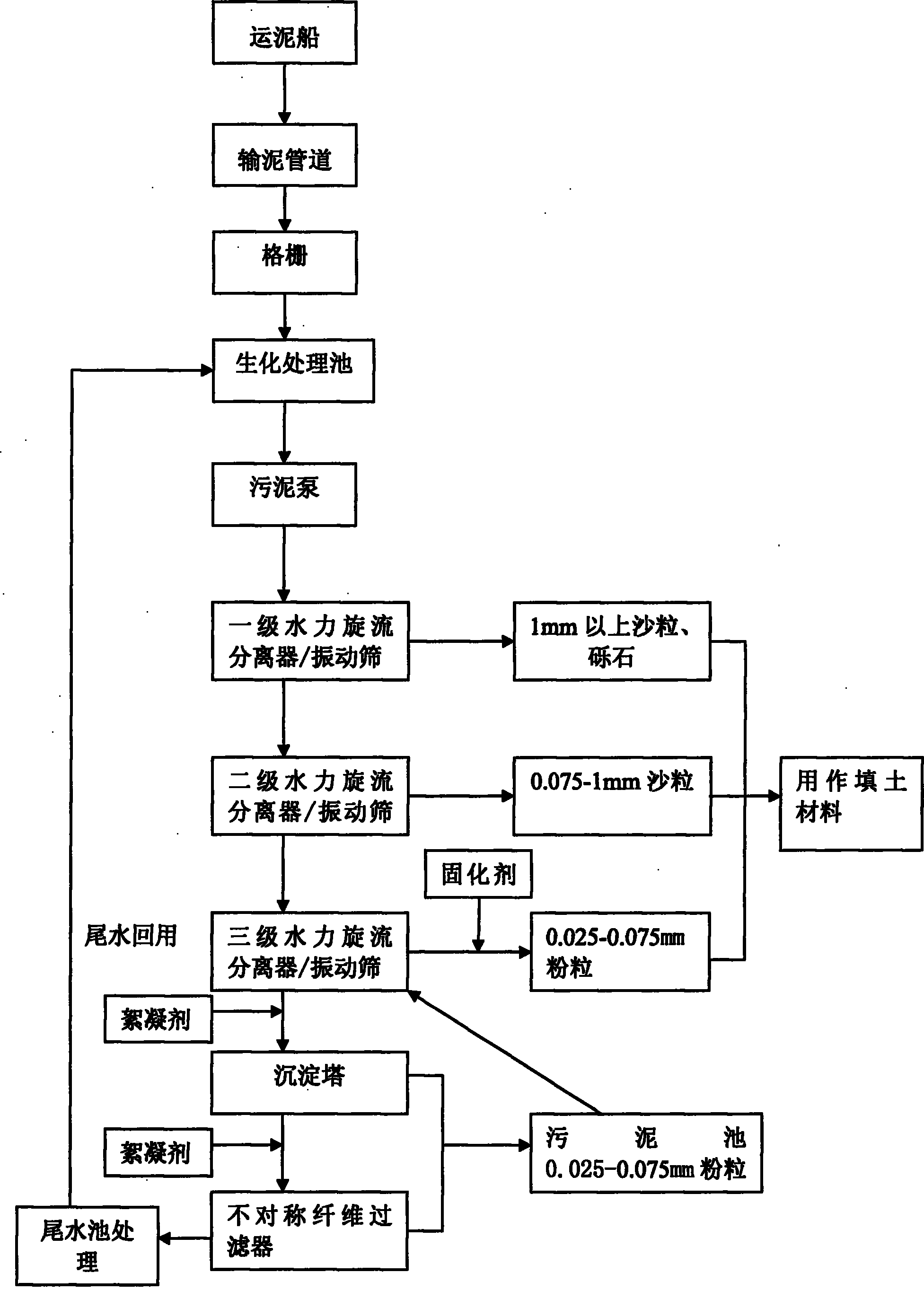

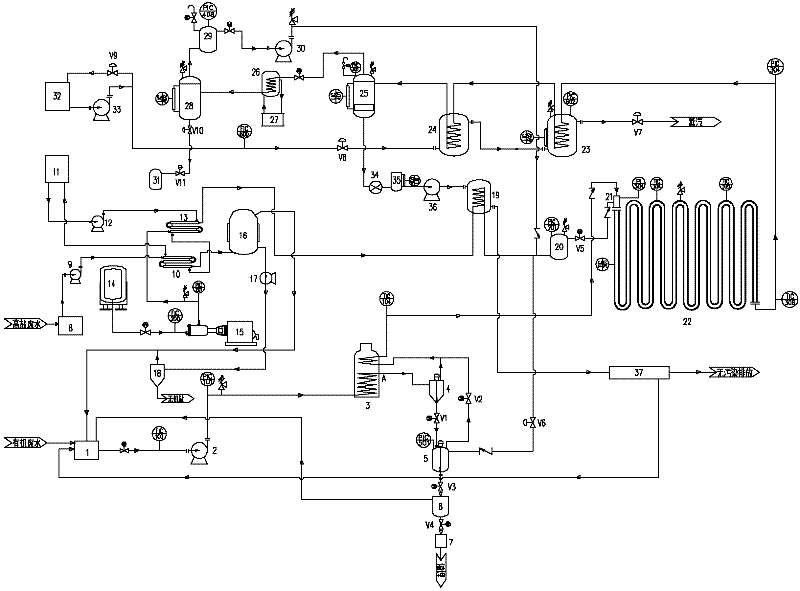

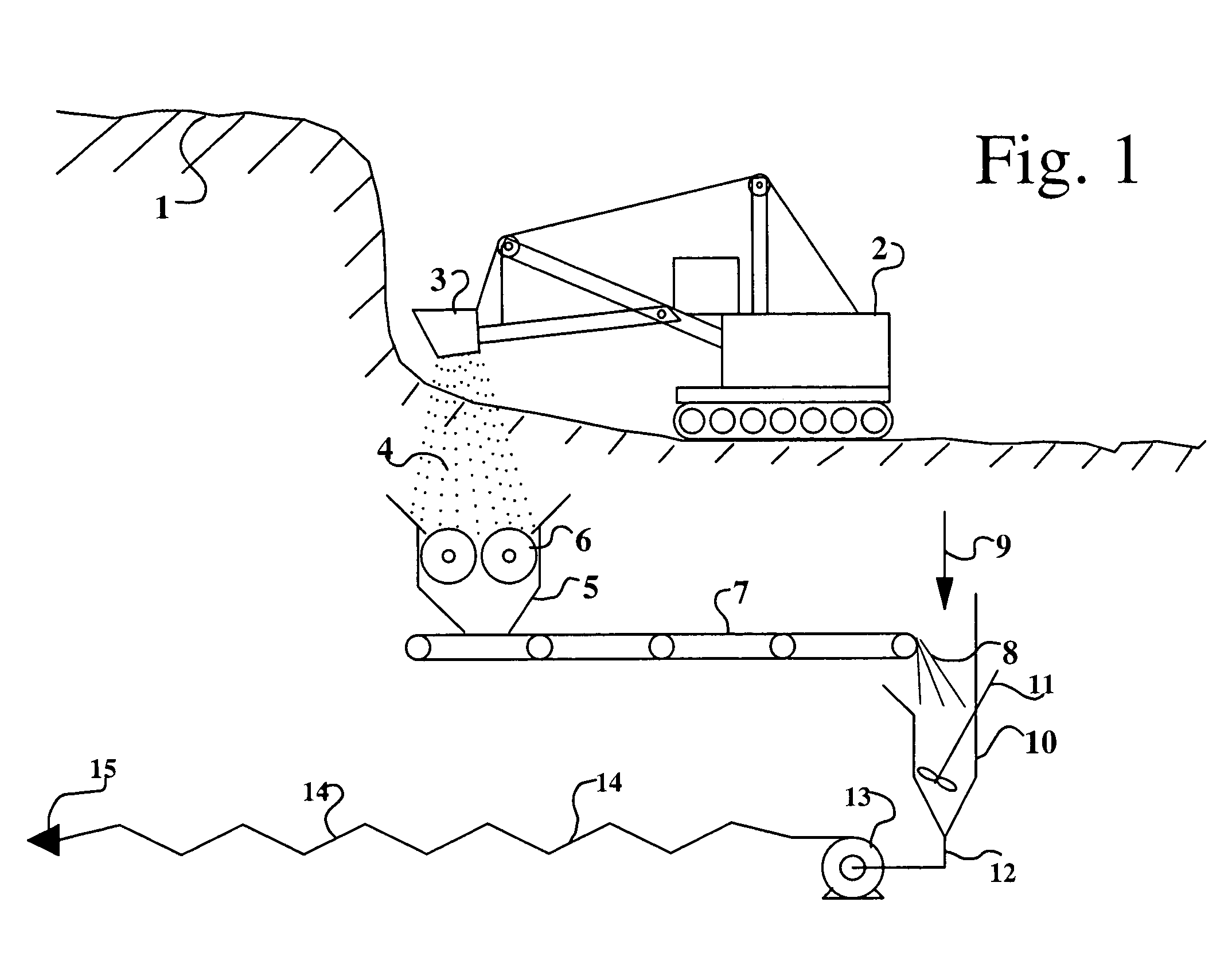

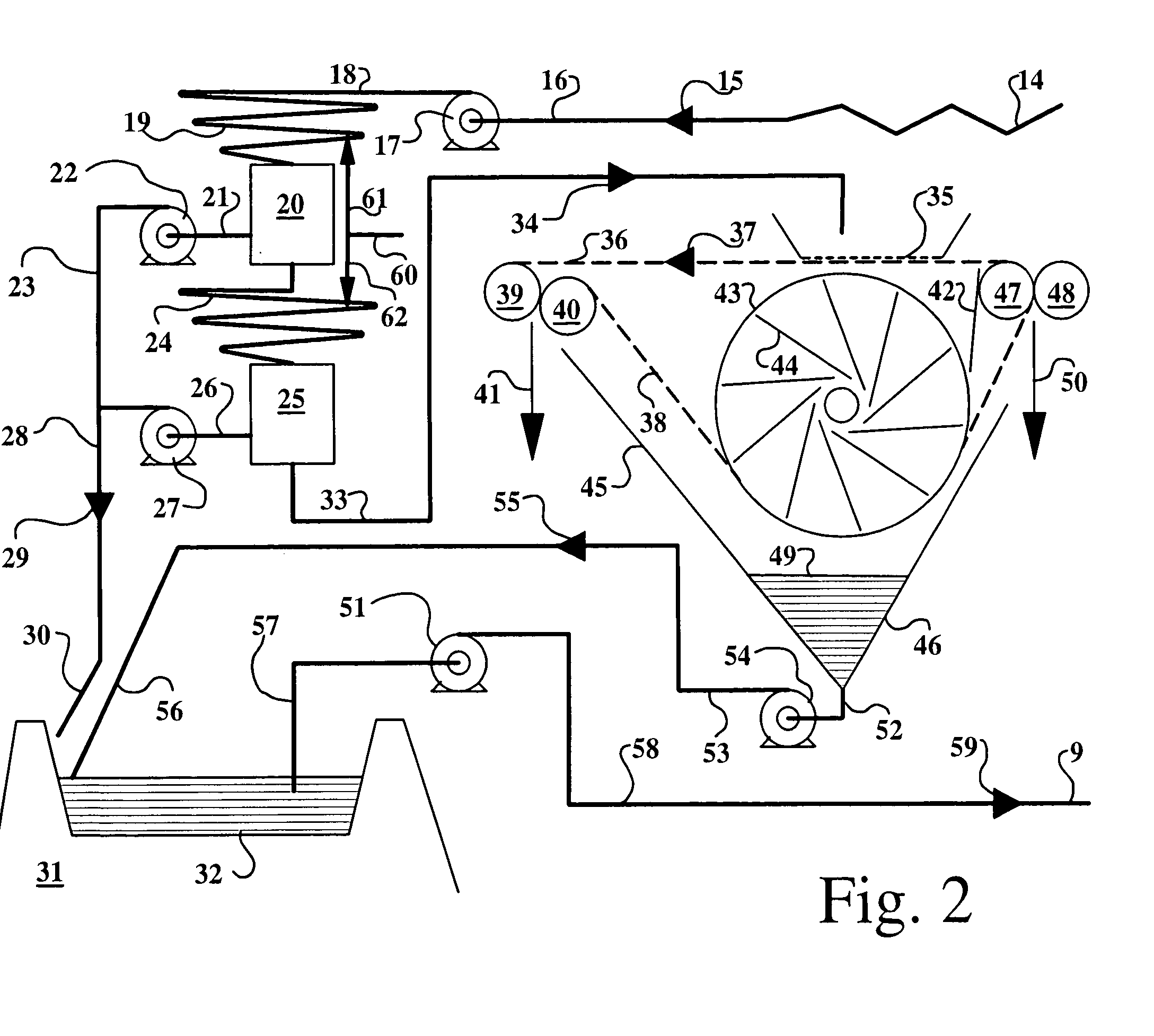

River surge silt harmless and recycling treatment method

InactiveCN101870546ALower redox potentialSmooth processSludge treatment by de-watering/drying/thickeningSolid waste managementFiberResource utilization

The invention provides a river surge silt d harmless and recycling treatment method. In the method, a dredger is utilized to suck silt, the silt is sent into a biochemical treatment pond from the ship through a silt transmission pipeline, compound enzyme is utilized to carry out bioremediation, gravels and sands with the particle size bigger than 1mm are filtered out by a primary hydrocyclone and a vibration screen, sands with the particle size of 0.075-1mm are filtered out by a secondary hydrocyclone and the vibration screen, powdery particles with the particle size of 0.025-0.075mm are filtered out by a third-level hydrocyclone and the vibration screen, powder particles are further separated out from outlet silt tail water through a sediment tower, sewage from the sediment tower is filtered by utilizing a fiber filter after flocculant is added into the sewage, and powdery particles are deposited from backflushing silt after being filtered by utilizing the sediment tower again, and the powdery particles are dehydrated by the third-level hydrocyclone and the vibration screen after entering a sludge pool and are cured by a curing agent after dehydration. The method has high resource utilization ratio, meets the requirements for the environmental protection, particularly carries out stage treatment on the silt, lowers the cost and enhances the efficiency.

Owner:GUANGZHOU BAOMINGLAI ENVIRONMENT SCI & TECH

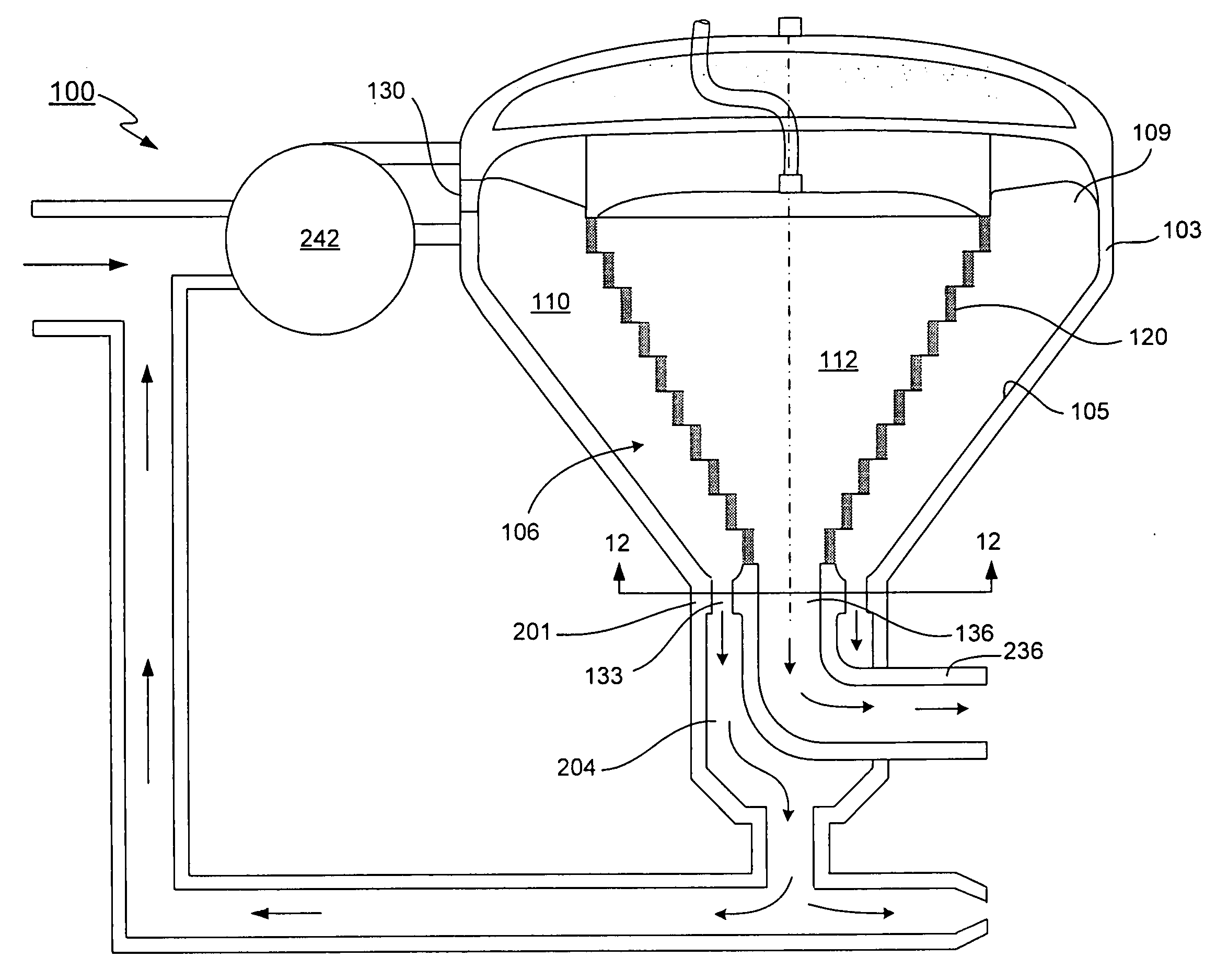

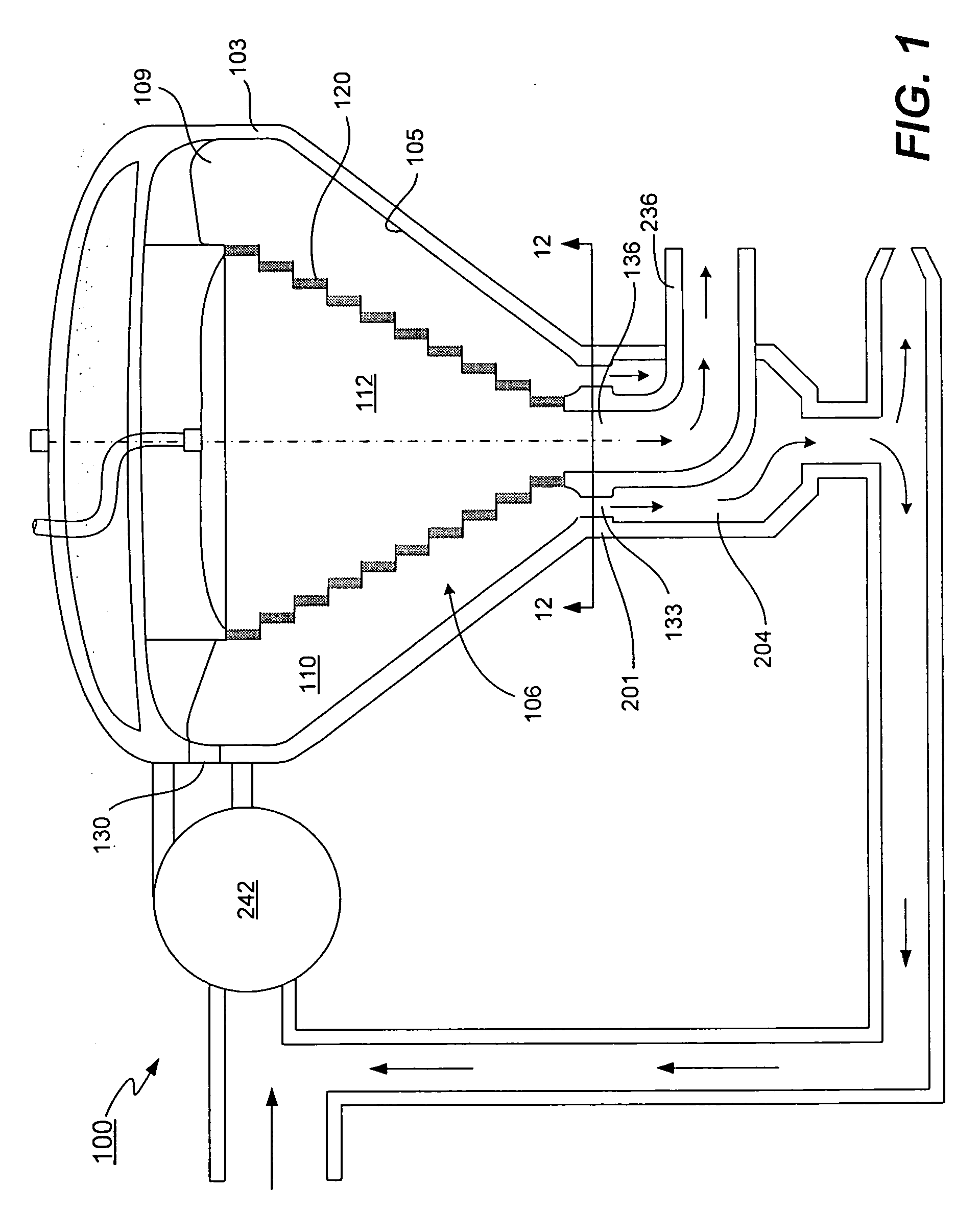

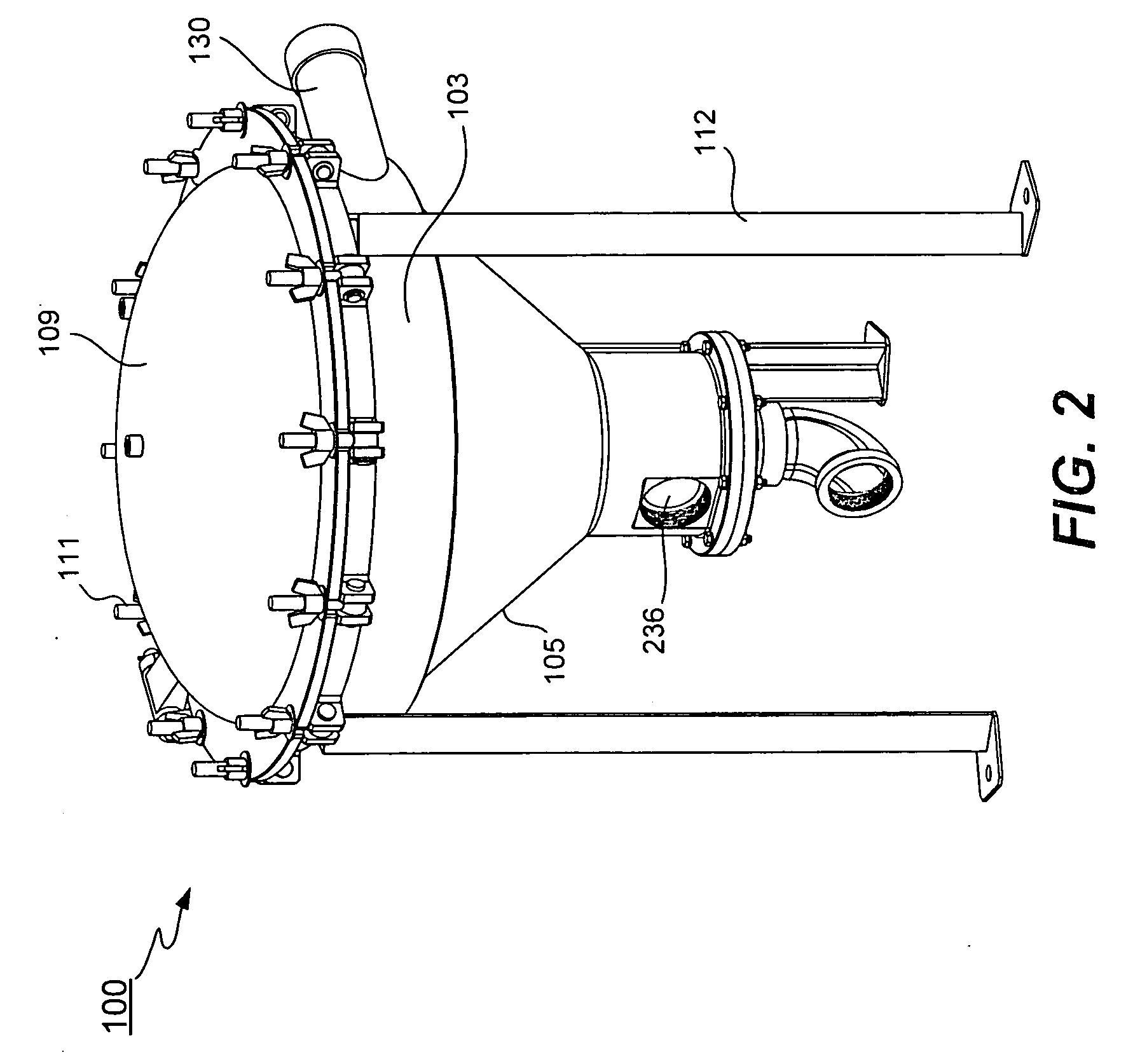

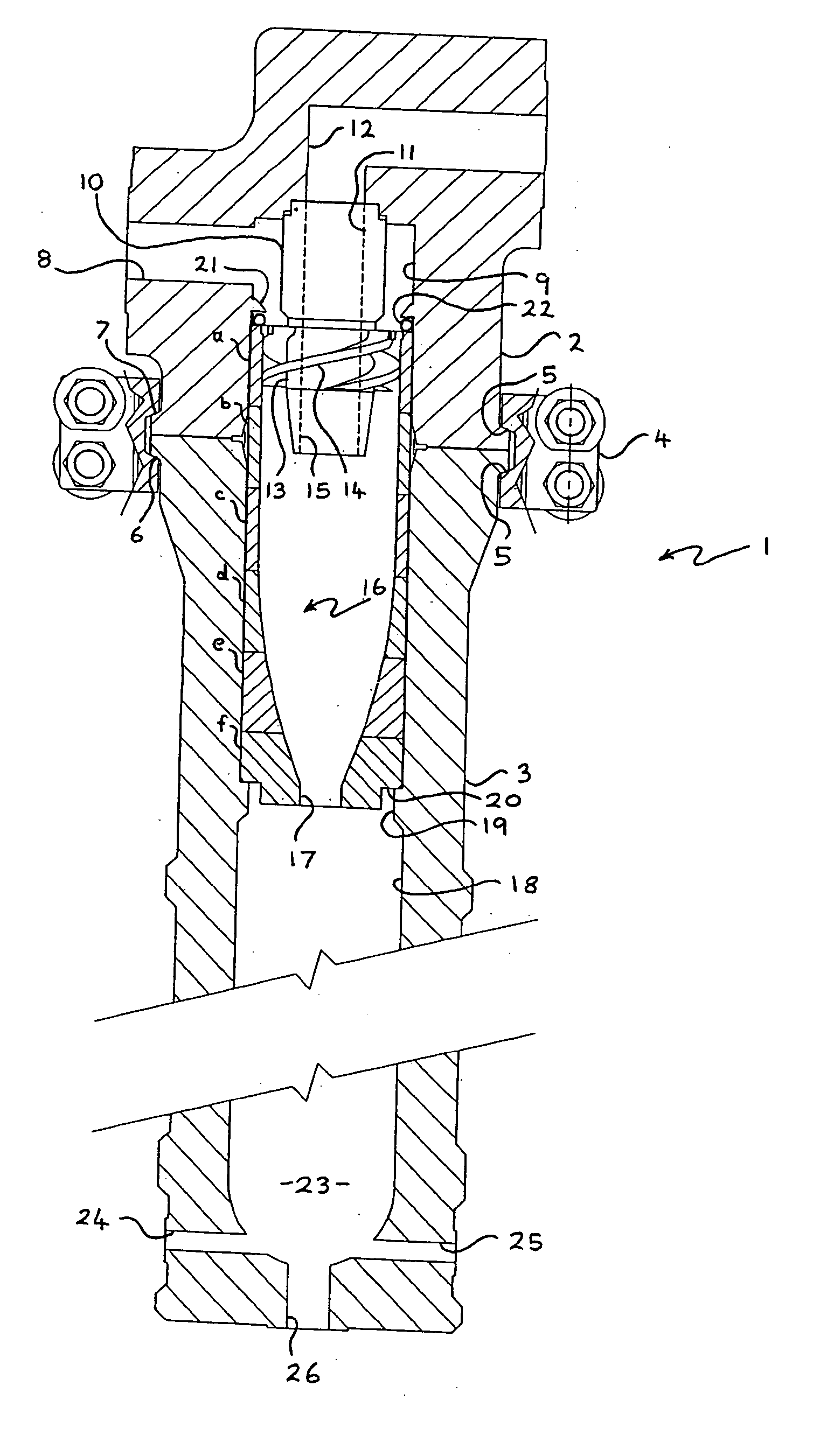

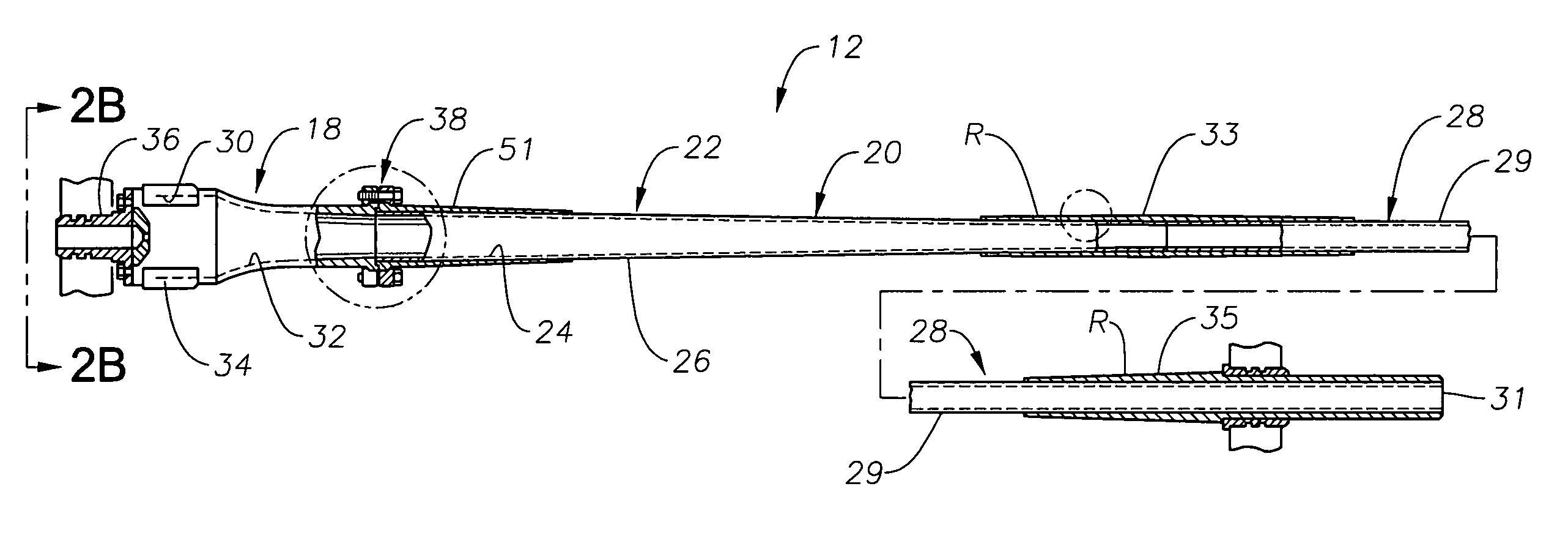

Hydroclone based fluid filtration system

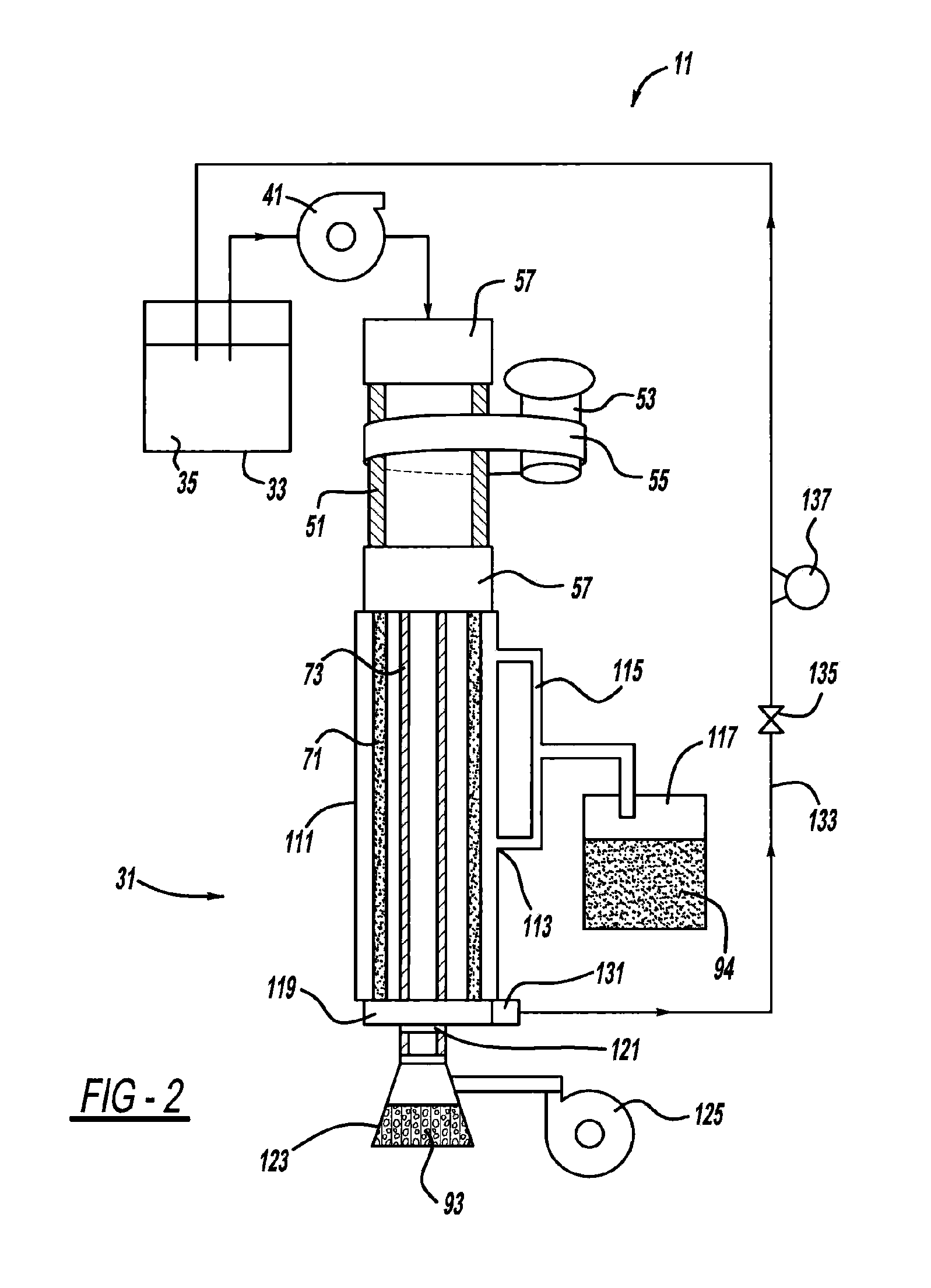

ActiveUS20070039900A1Reduce morbiditySmall diameterLiquid separation auxillary apparatusReversed direction vortexCross-flow filtrationFluid filtration

A variety of improved hydroclone based fluid filtering systems are described. The hydroclones generally include a tank having an internal chamber and a filter (preferably a surface filter) that is positioned within the internal chamber. The filter defines a filtered fluid chamber within the internal chamber of the tank. The hydroclone may be operated such that a vortex of flowing fluid is formed between the chamber wall and the filter with the filter being located in the center of the vortex. With this arrangement, the filter acts as a cross-flow filter. In one aspect of the invention, the filter is a stepped filter. In another aspect of the invention, the filter is an surface filter, as for example, an electroformed metal surface filter. In some preferred embodiments, the openings in the filter are arranged as slots that extend substantially vertically so that they are oriented substantially perpendicular to the flow path of fluid flowing in the adjacent portion of the vortex. In another aspect of the invention, a circulating cleaning assembly is provided in the hydroclone region. The cleaning assembly is arranged to help clean the filter and is driven by the vortex of flowing fluid formed in the hydroclone region of the internal chamber. In yet another aspect of the invention, improved hydroclone intake structures are described. The described hydroclones may be used to filter water and other fluids in a wide variety of applications.

Owner:ACCELERATED FILTRATION INC

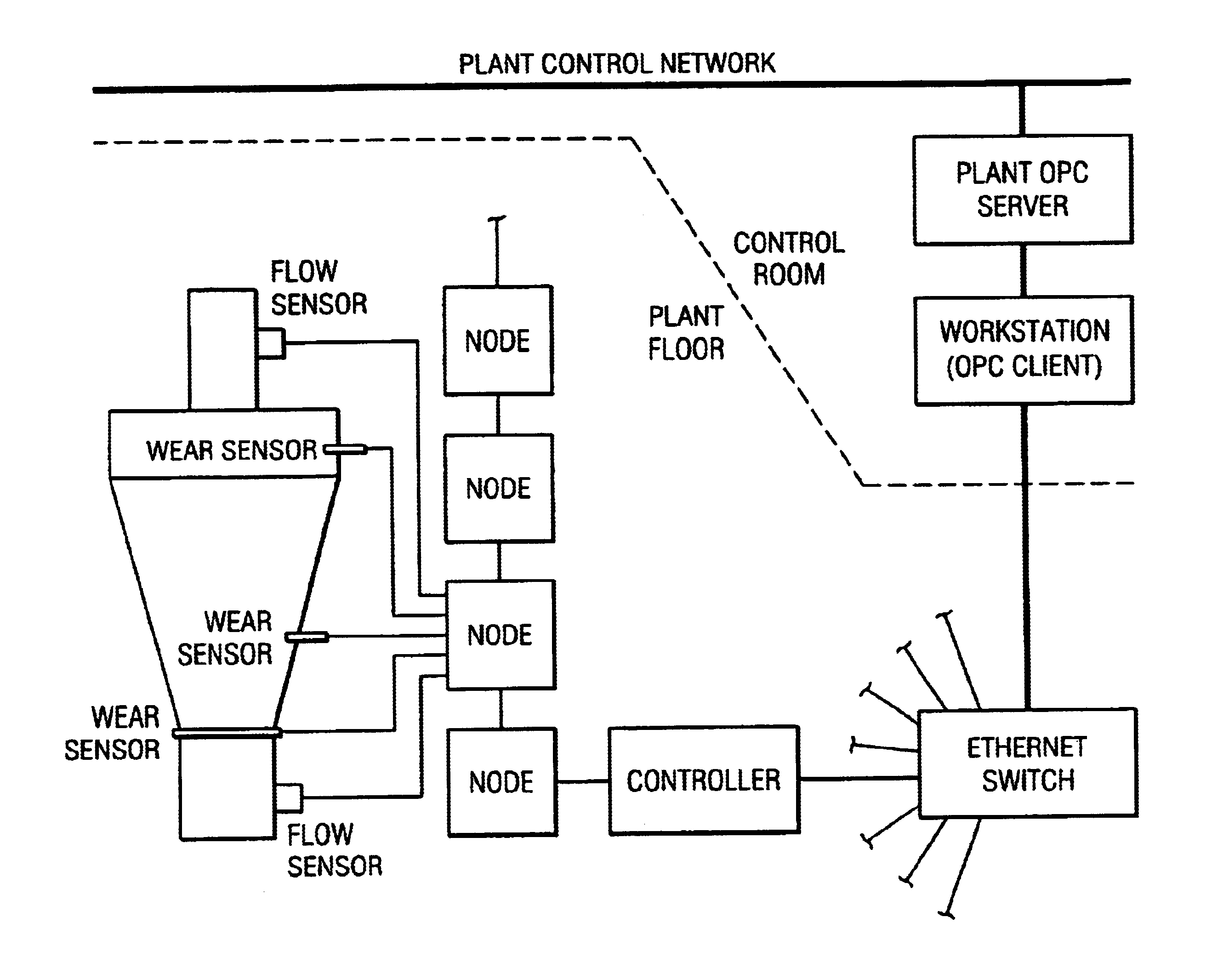

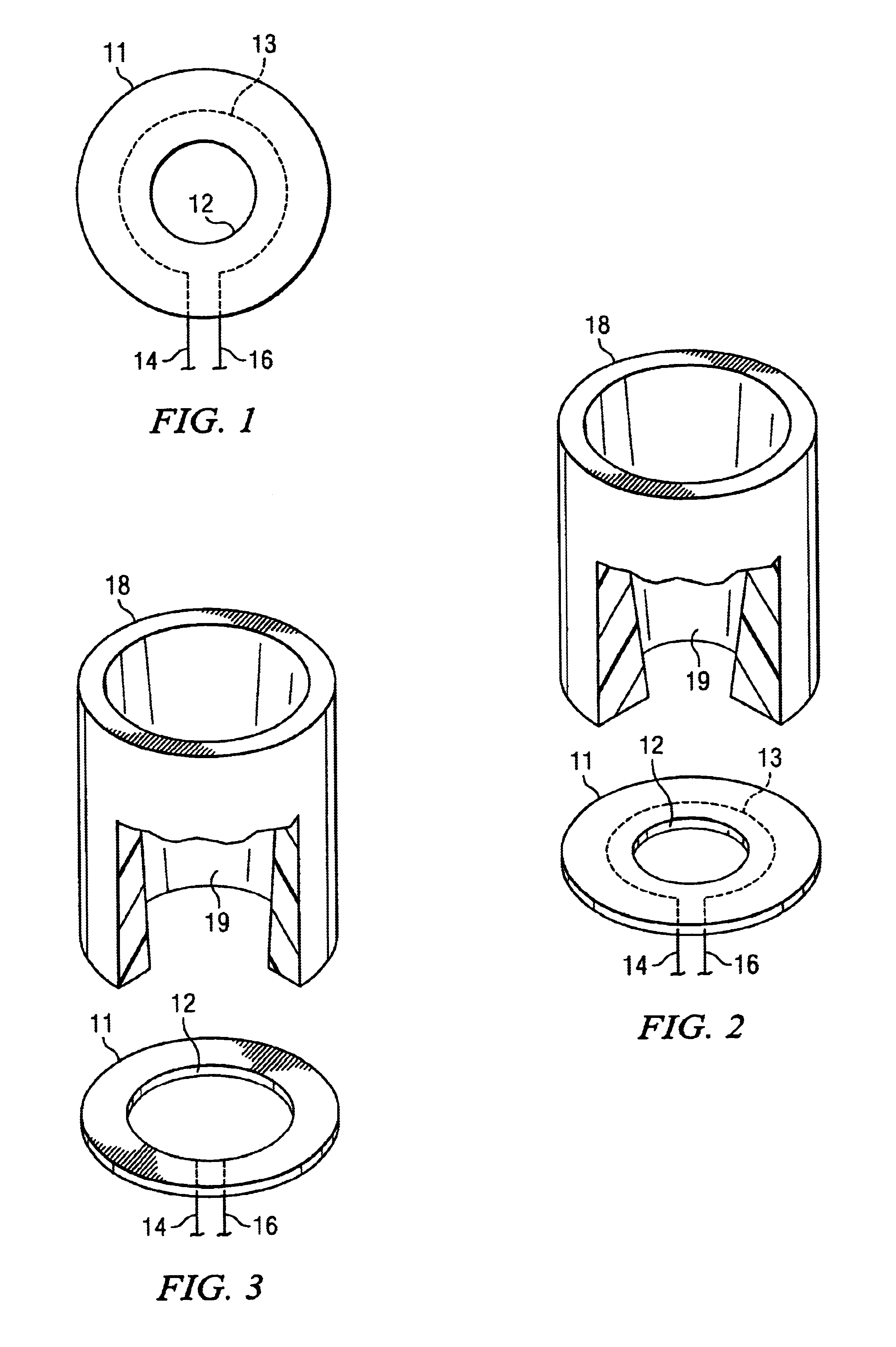

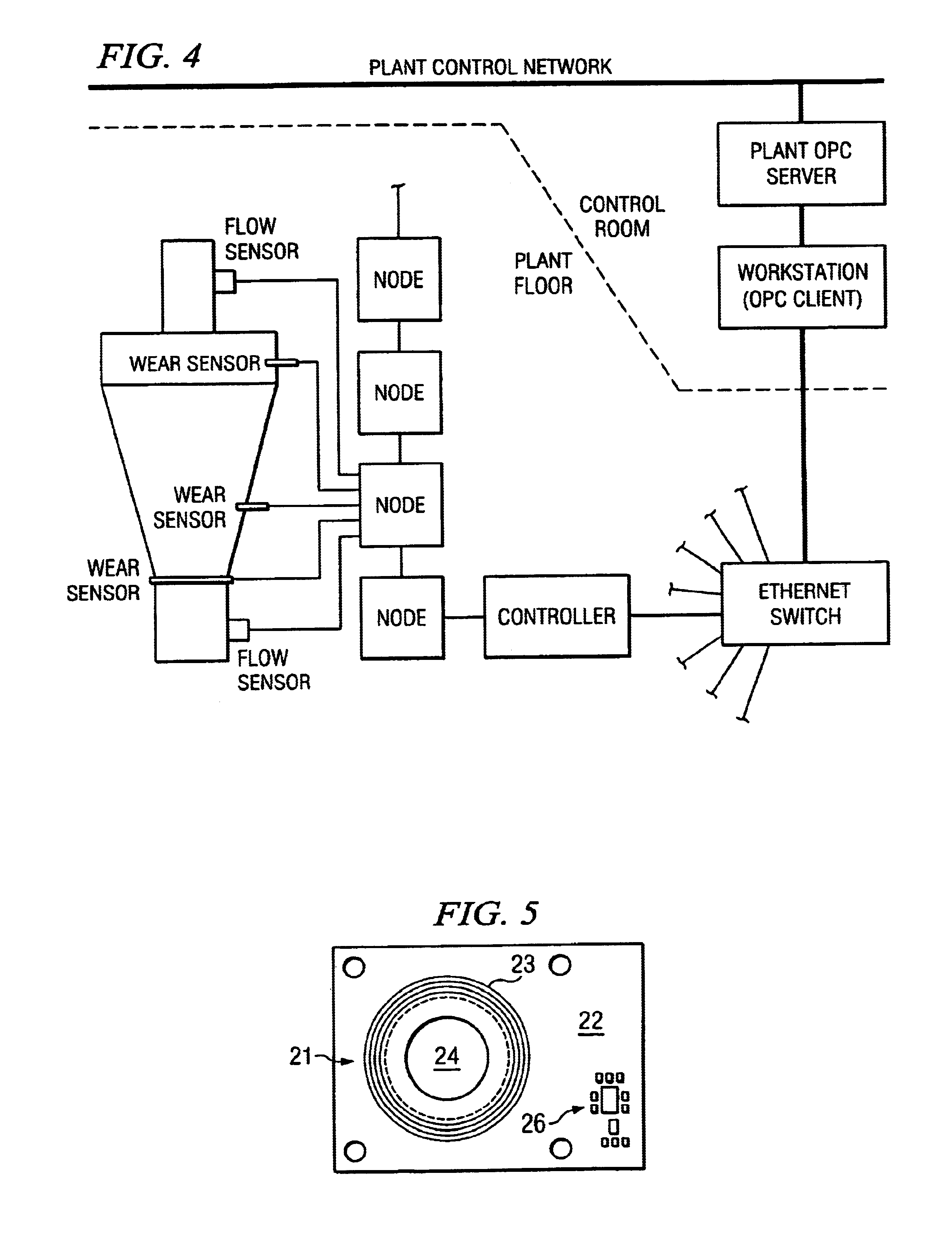

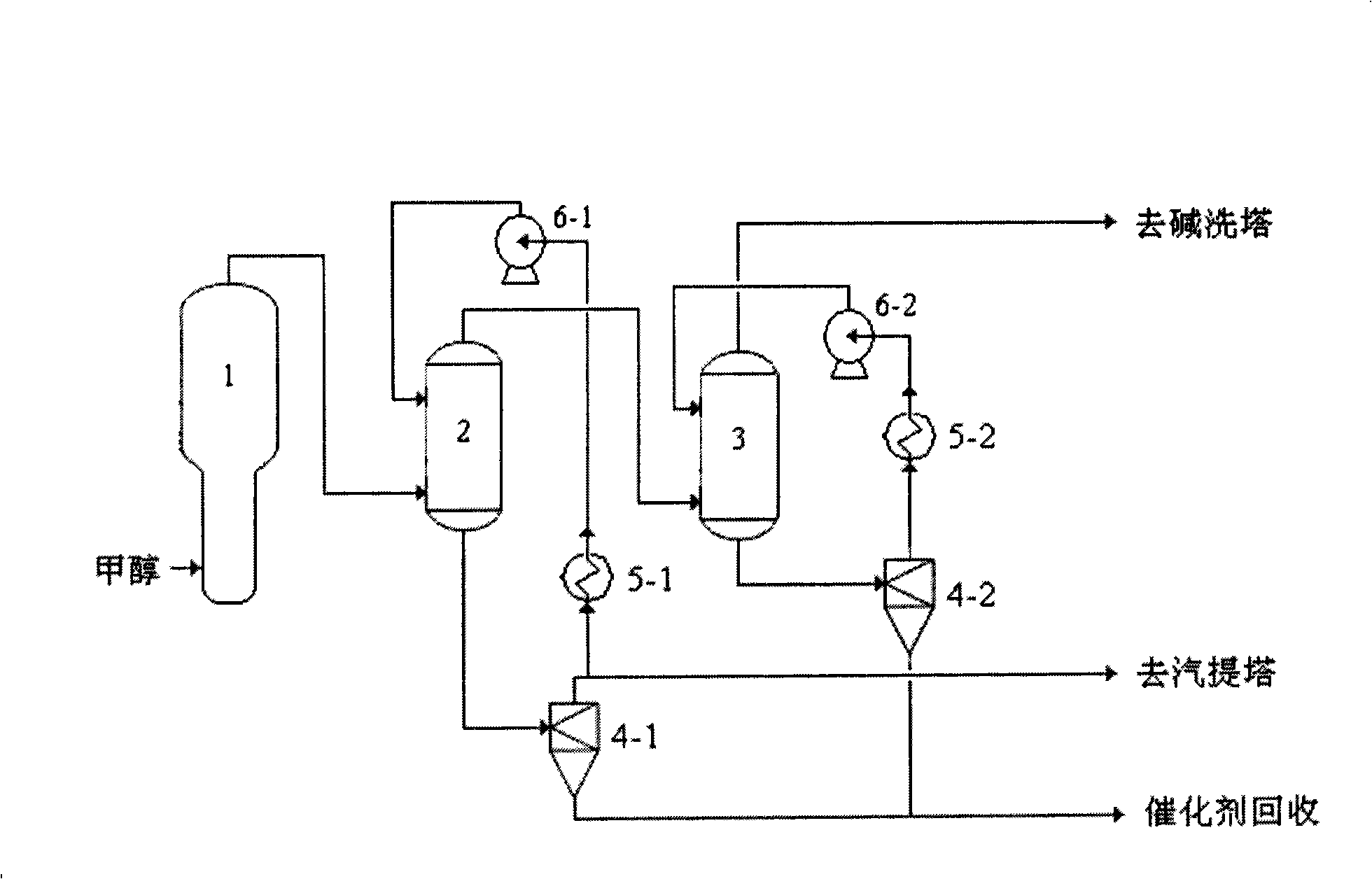

Hydrocyclone wear-detection sensor

Wear-detection sensor has a body of electrically insulating material with an opening through which a flowable substance can pass, and one or more electrical conductors surrounding the opening and adapted to undergo a discernable change in conductivity as the insulating material is worn away by the flowable substance.

Owner:KREBS ENGINEERS CORP +1

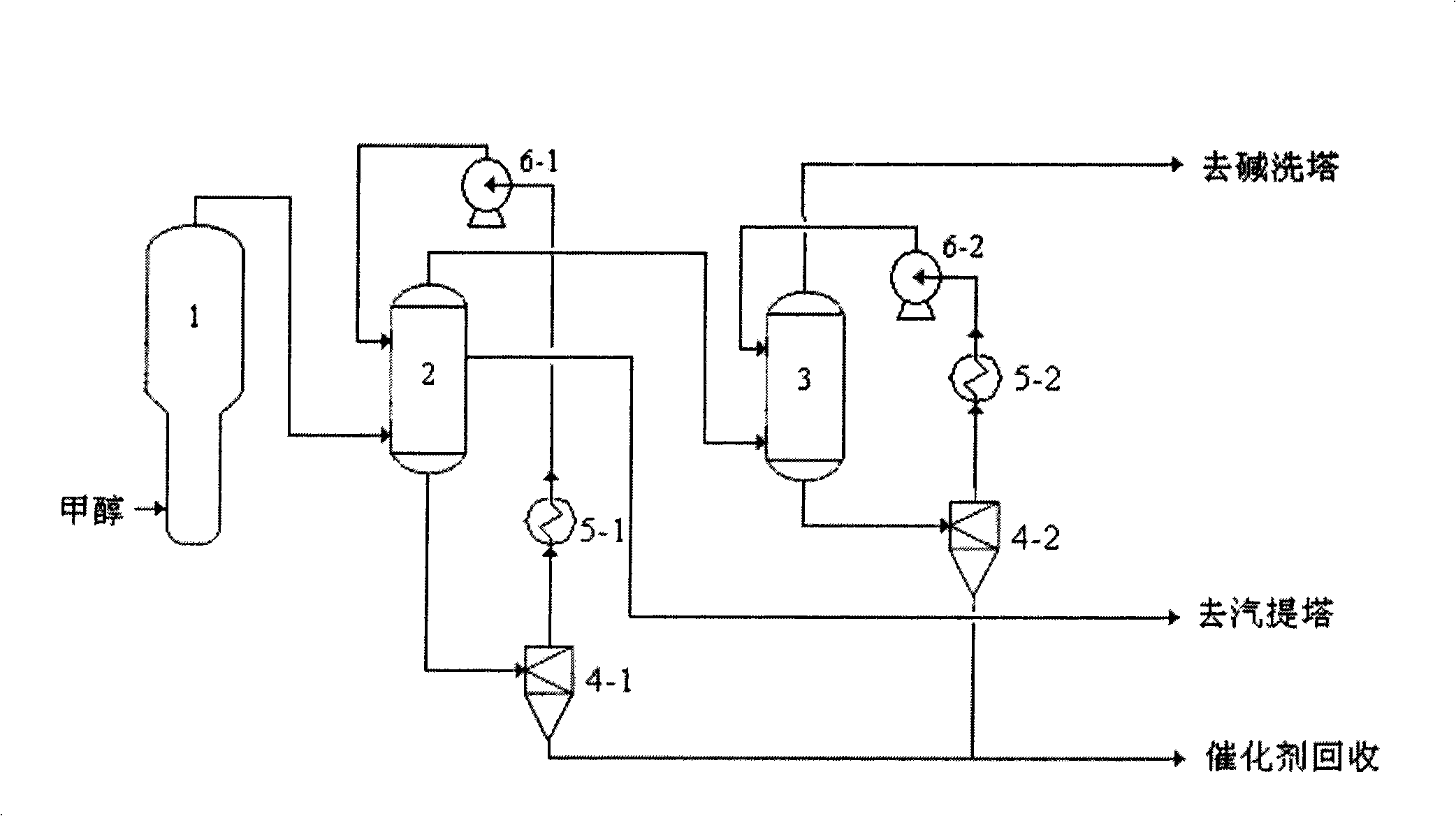

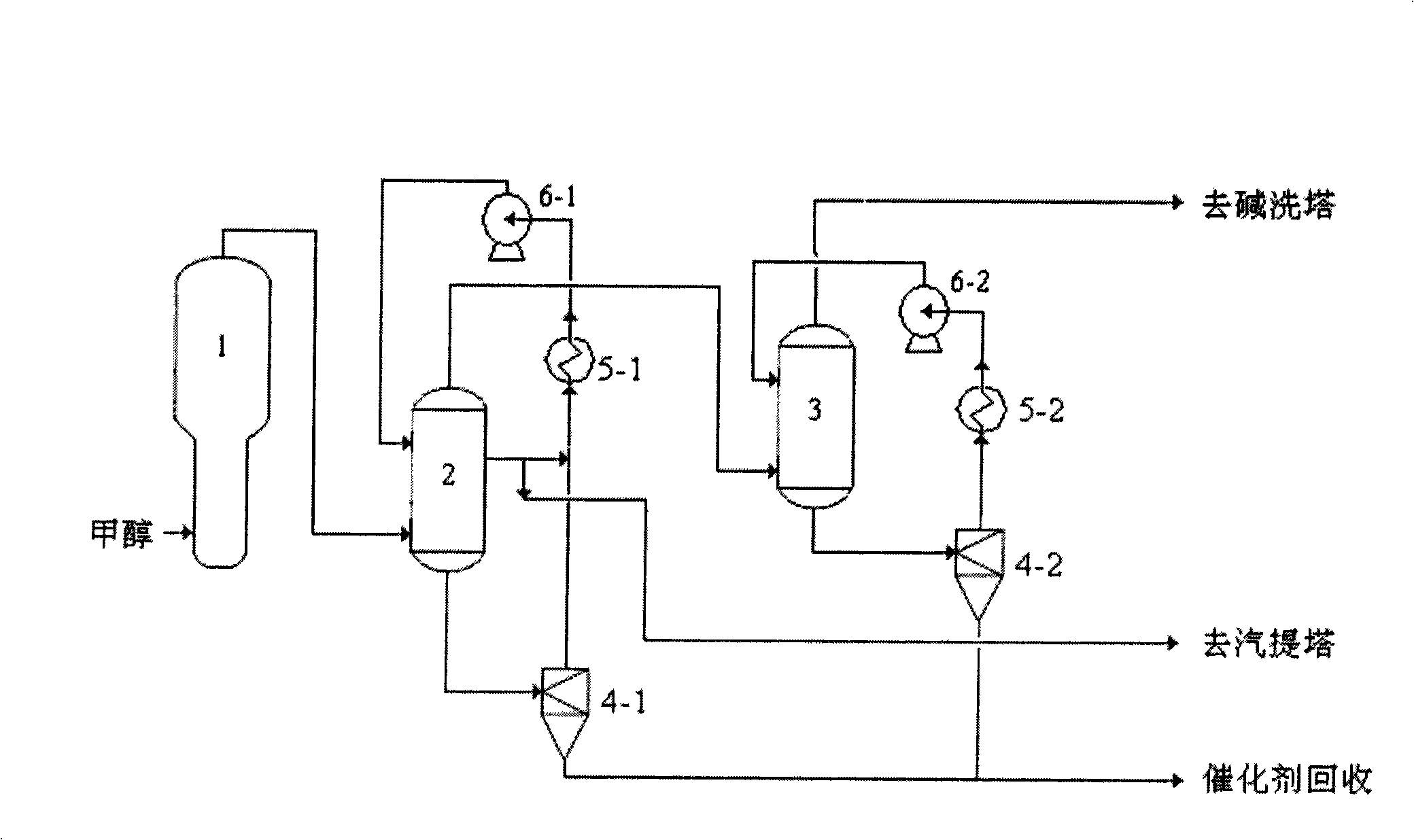

Micro hydrocyclone separation and solid removal method and apparatus of MTO quench water and water of water-washing factory

InactiveCN101352621AReversed direction vortexHydrocarbon purification/separationQuenchingPurified water

The invention provides a micro-vortex flow de-solid method used for MTO quenching water and washing water, comprising the steps as follows: the micro-vortex flow separation of the MTO quenching water is carried out so as to remove the contained catalyst grains wherein; the quenching purified water which is separated by micro-vortex flow is cooled so as to realize the circulation usage of water; the micro-vortex flow separation of the MTO washing water is carried out so as to remove the contained catalyst grains wherein, and the washing purified water separated by micro-vortex flow is cooled so as to realize the circulation usage of water. The invention also provides a micro-vortex flow de-solid device used for the MTO quenching water and washing water.

Owner:EAST CHINA UNIV OF SCI & TECH +1

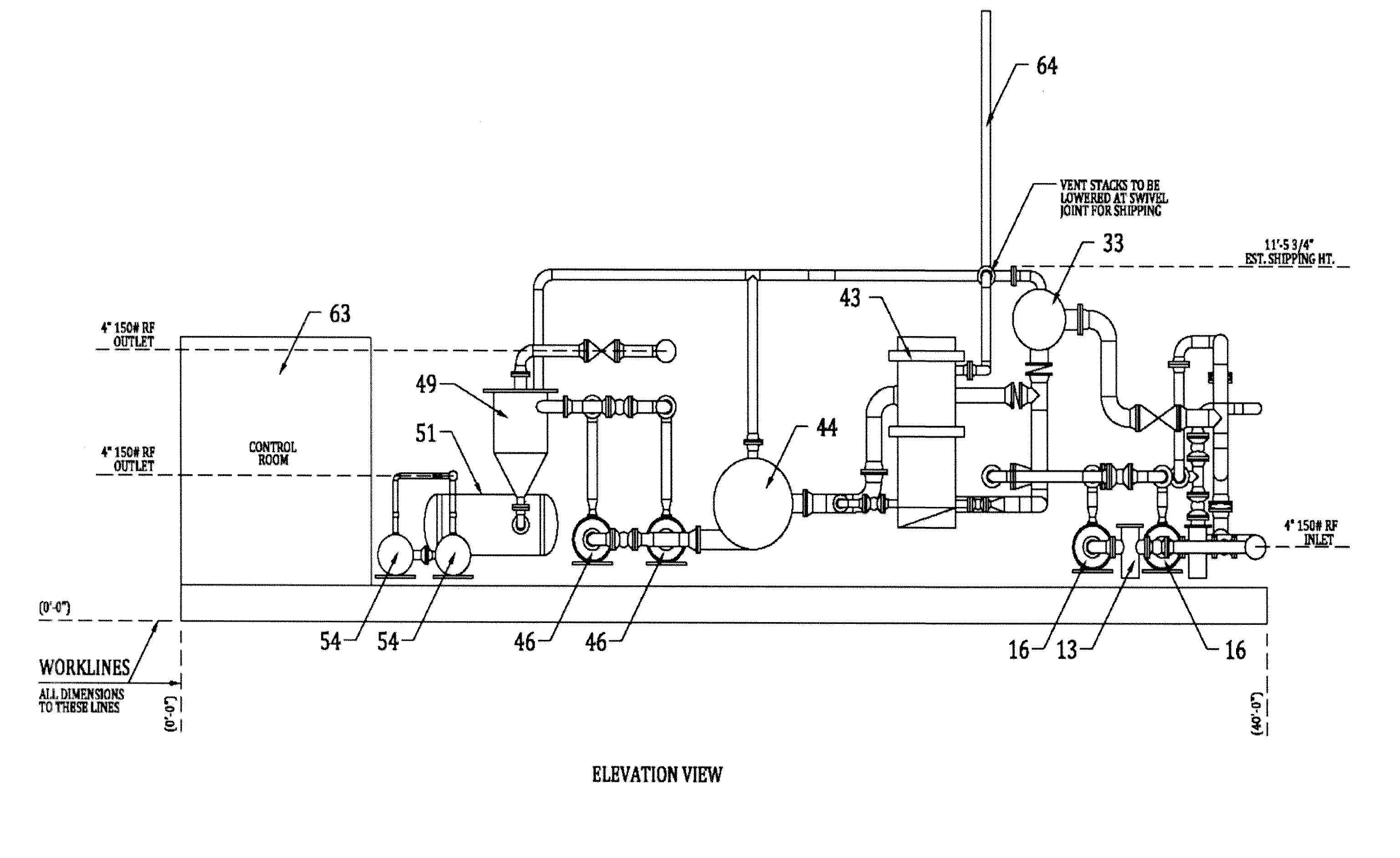

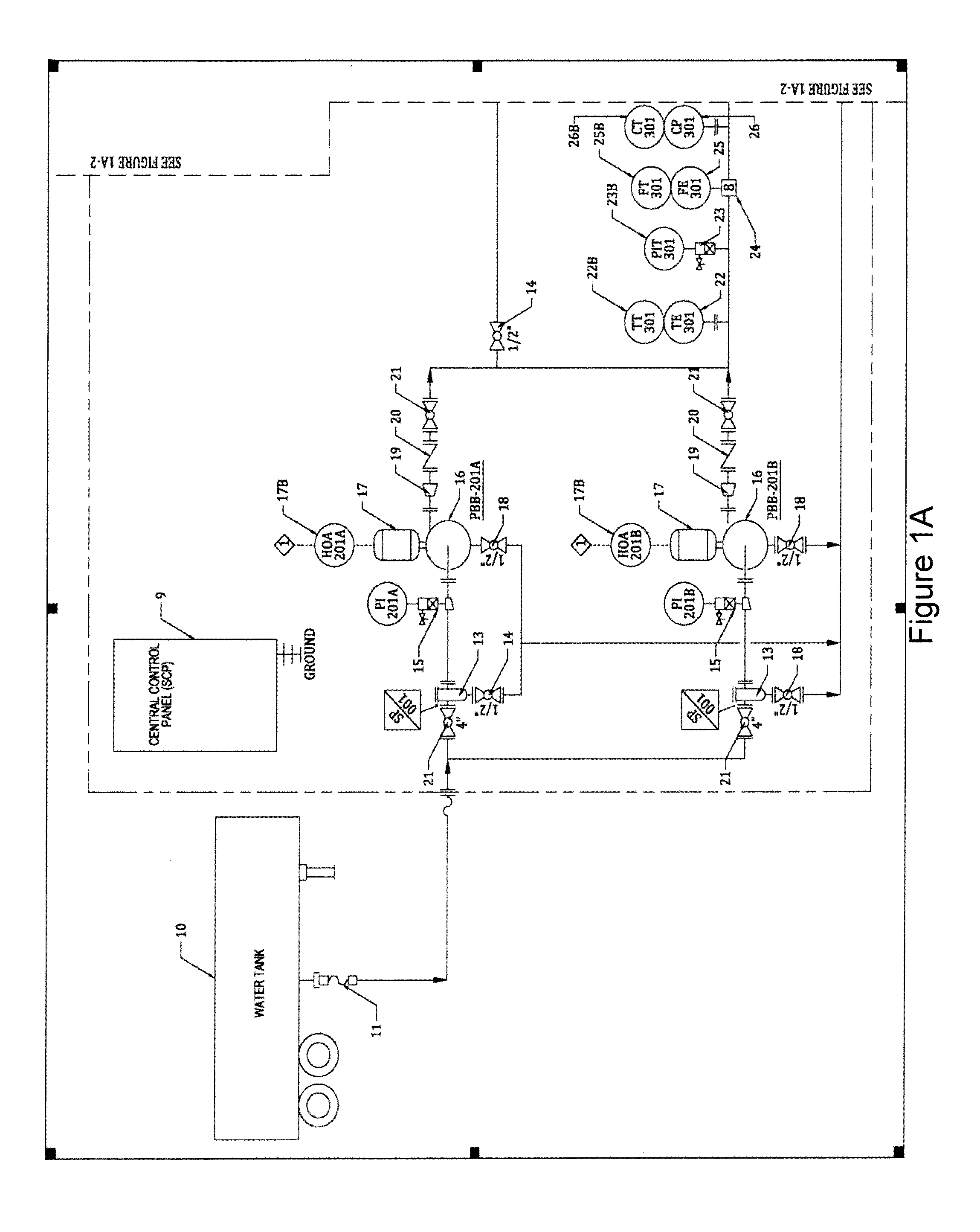

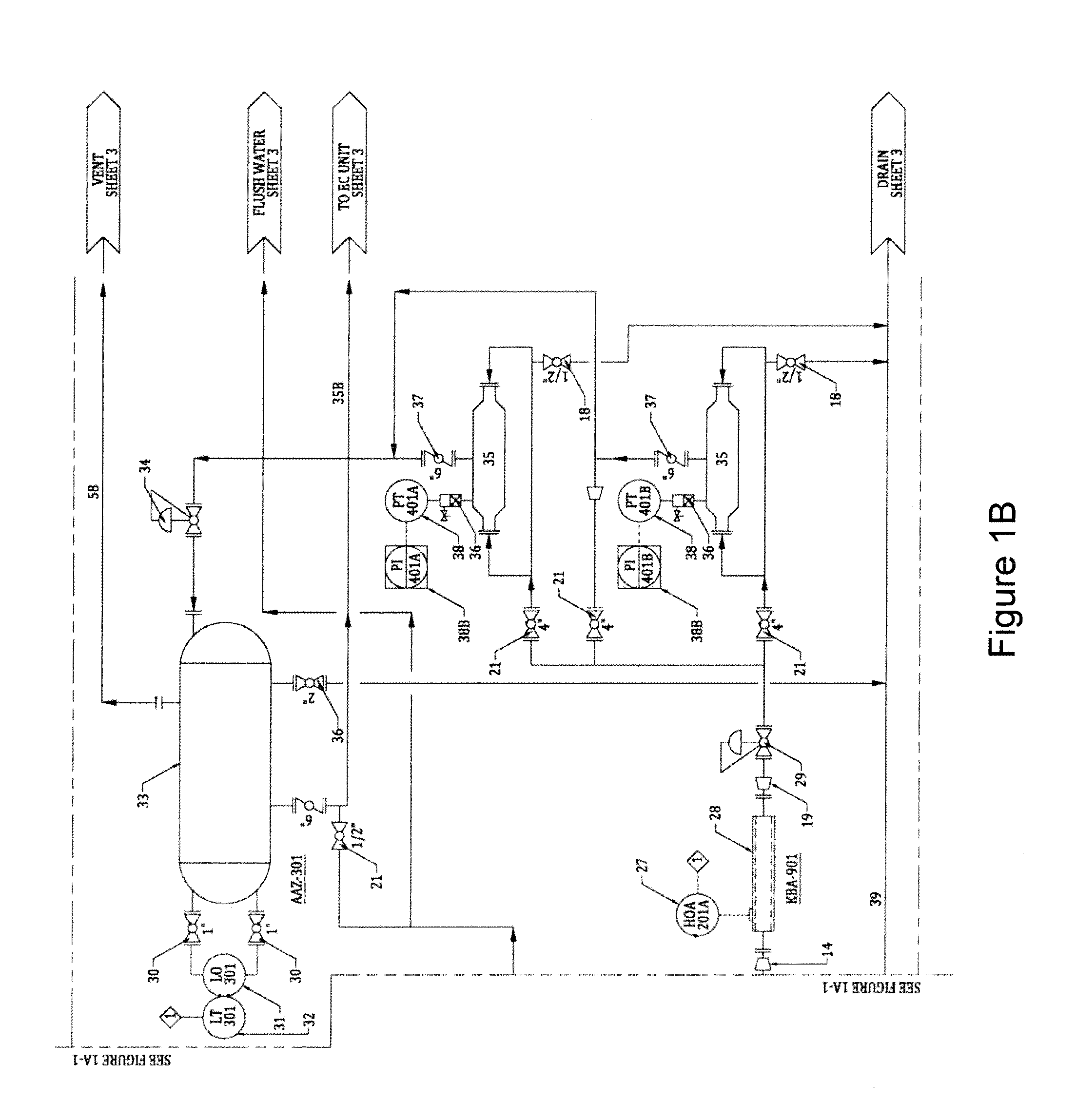

Process for single system electrocoagulation, magnetic, cavitation and flocculation (emc/f) treatment of water and wastewater

The current invention provides a novel process for the treatment and reclamation of drilling frac flowback and produced wastewater from the drilling industry. The wastewater is delivered to the EMC / F System from a frac tank or other reservoir. The wastewater is pumped into the system and is treated sequentially by passing through a mechanical hydrocavitation unit, an electromagnetic unit, an electrocoagulation unit and / or a hydrocyclone and a flocculation-sedimentation tank. Polishing of the final effluent is accomplished by passing the water through a mixed media tank.

Owner:DON E HENLEY & ASSOC

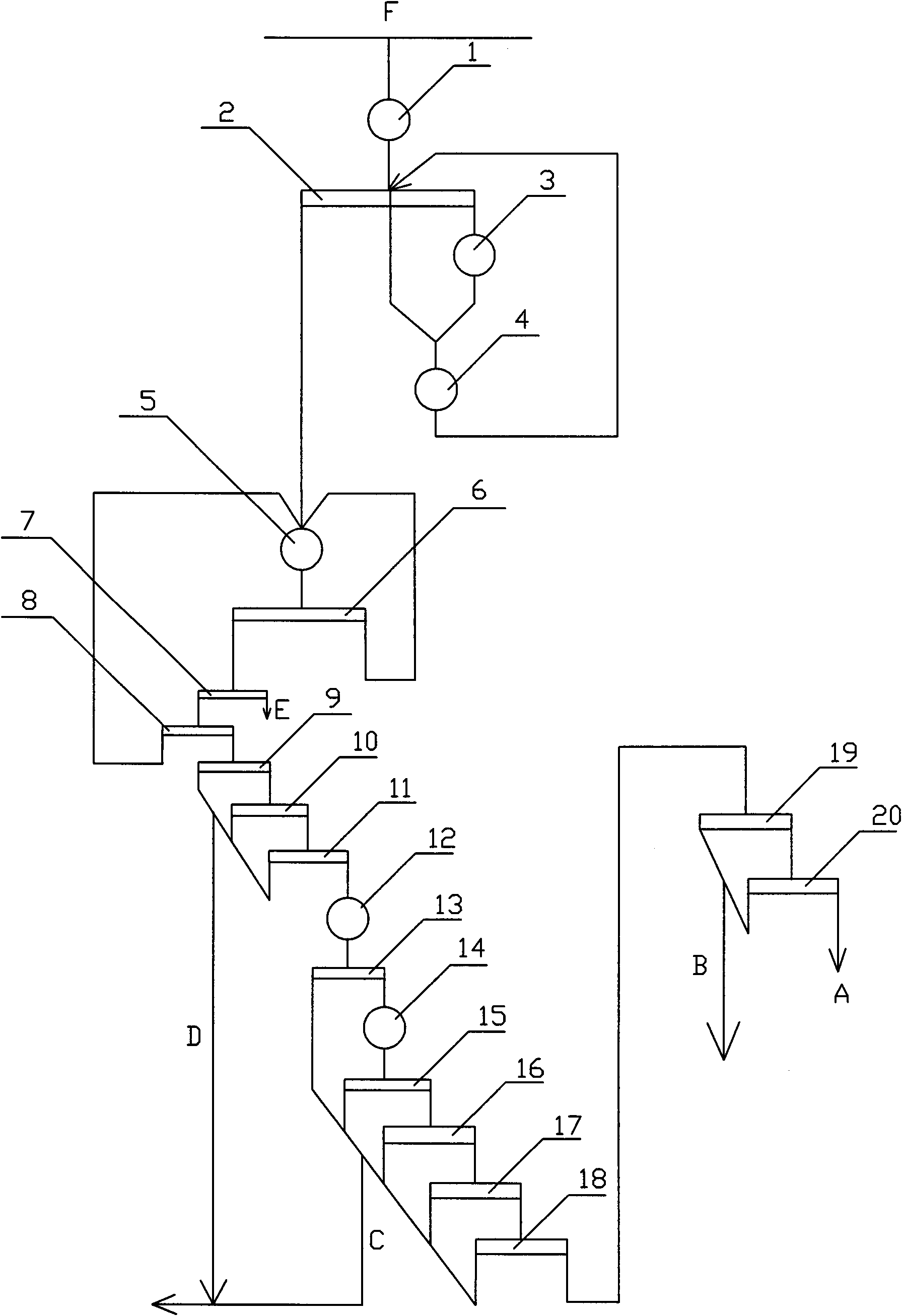

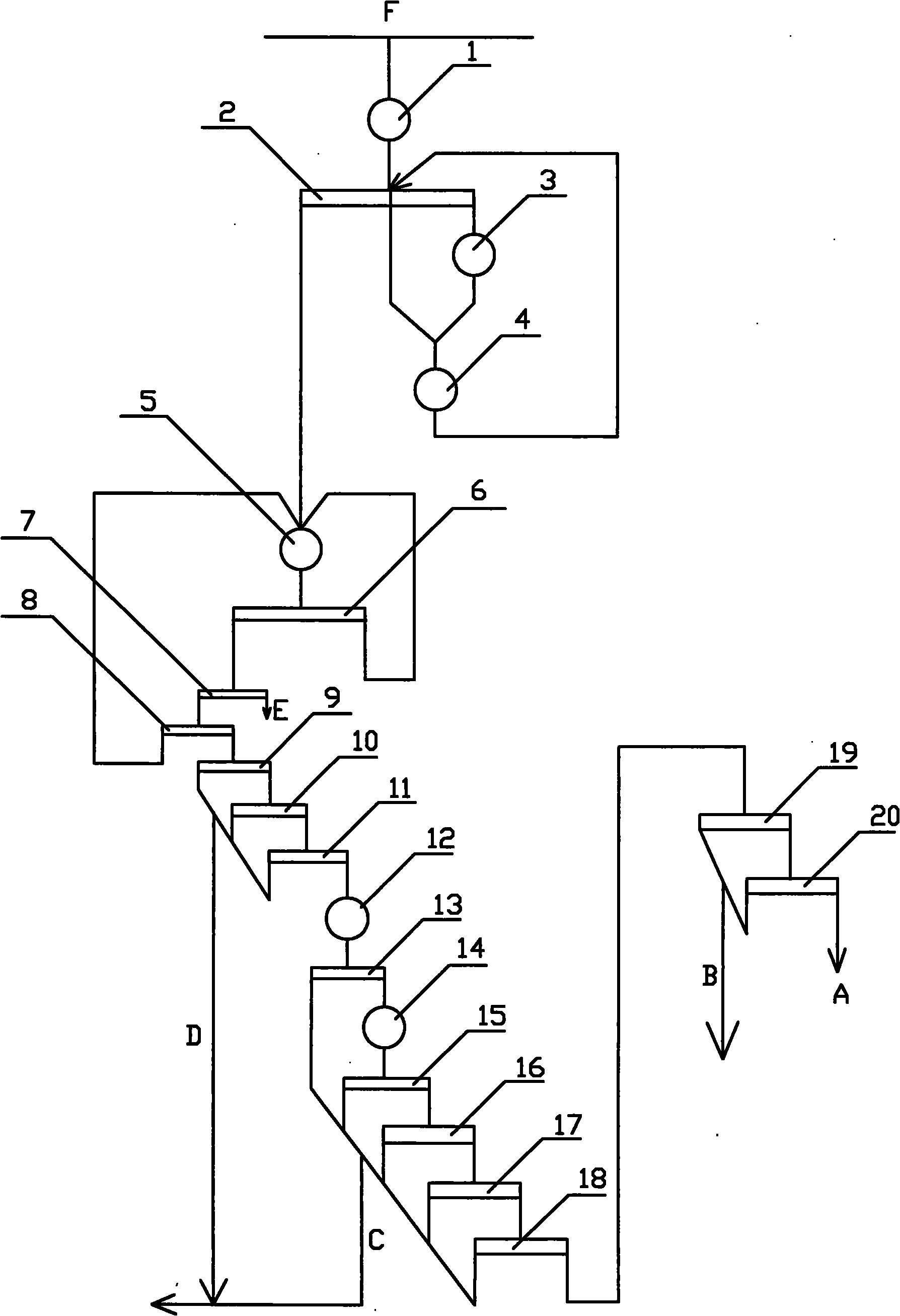

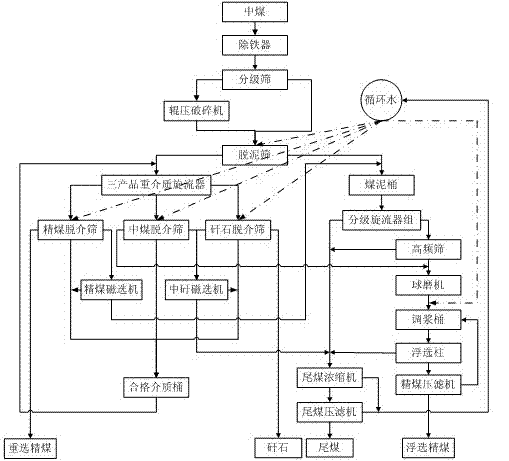

Breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking

A breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking belongs to a coal breaking dissociation flotation process. (1) coal products in a coal preparation plant serve as raw materials, and the coal which is larger than 6mm is rolled and broke into size smaller than 6mm; (2) a desliming screen is used for desliming on middings smaller than 6mm, middings which is 6-0.5mm enters a three-product dense medium cyclone, and dense medium, middings and gangue are obtained after two-stage medium separation is carried out; (3) the middings smaller than 0.5mm is mixed with clean coal magnetic separation gangue, a grading hydrocyclones group is adopted to conduct high frequency screening to obtain high ash fine silt contained slurry water, and coarse particle are mixed with middings on the midding sculping screen to enter a ball mill for wet grinding; and (4) products after grinding enter a flotation column to conduct flotation, foam clean coal and tailing are respectively concentrated, filtered and dewatered to obtain flotation clean coal and tailing products. The breaking grinding dissociation and re-flotation two-stage recovery process has the advantages that the high ash fine silt in fine fraction is pre-selected, pollution of the high ash fine silt is reduced, equipment separation particle size range is reduced, separation accuracy of equipment is improved, and scarce coking coal resources are recovered as far as possible.

Owner:CHINA UNIV OF MINING & TECH

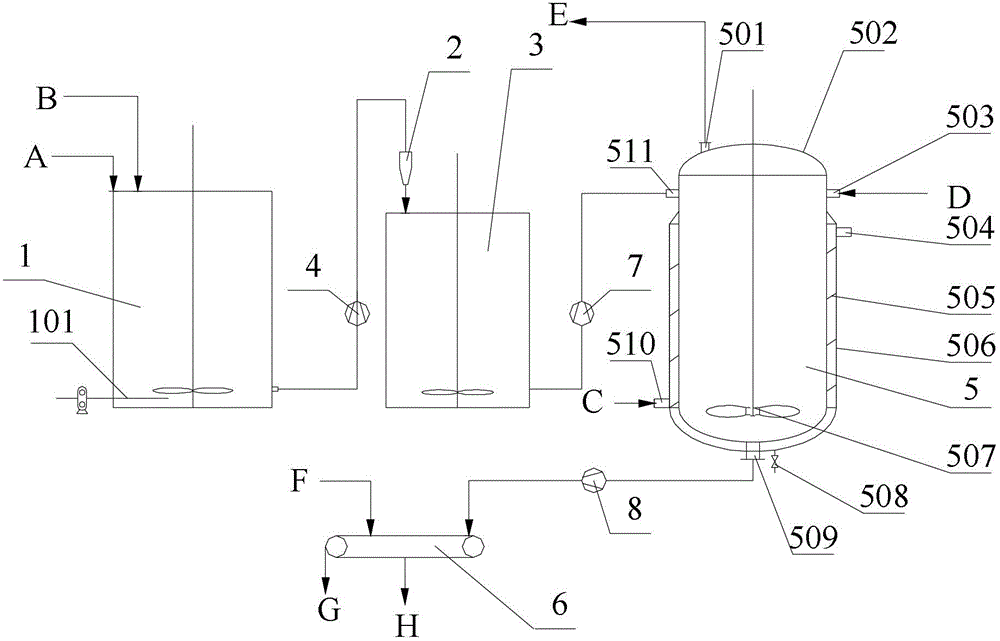

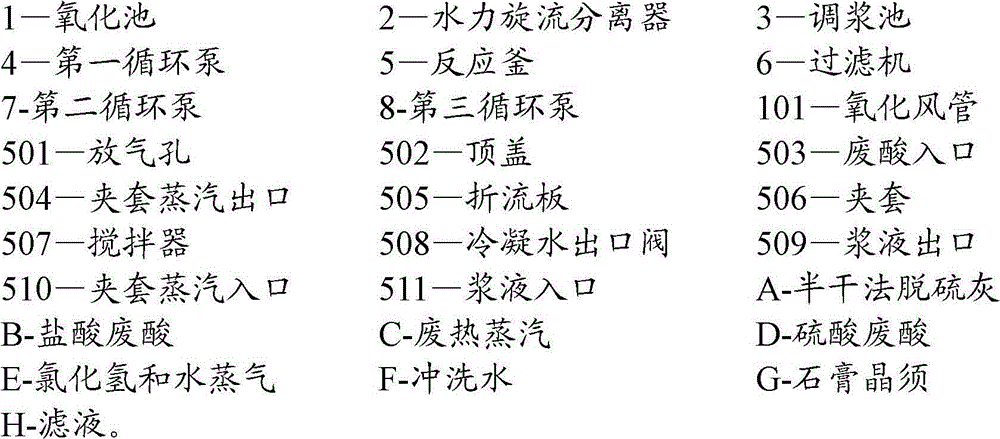

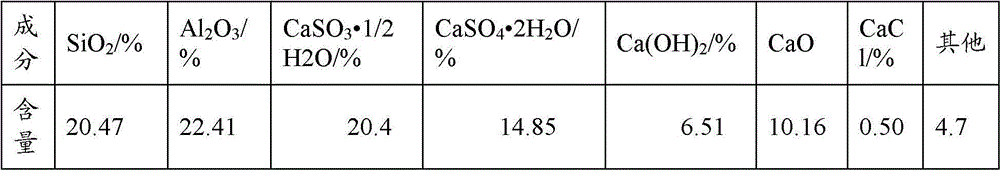

Process and device for preparing gypsum whisker by semi-dry desulfurized fly ash and waste acid

InactiveCN102912445AReduce processing difficultyPlay the role of flocculationPolycrystalline material growthFrom normal temperature solutionsSlurryToxic industrial waste

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Drilling systems

Owner:VARCO I P INC

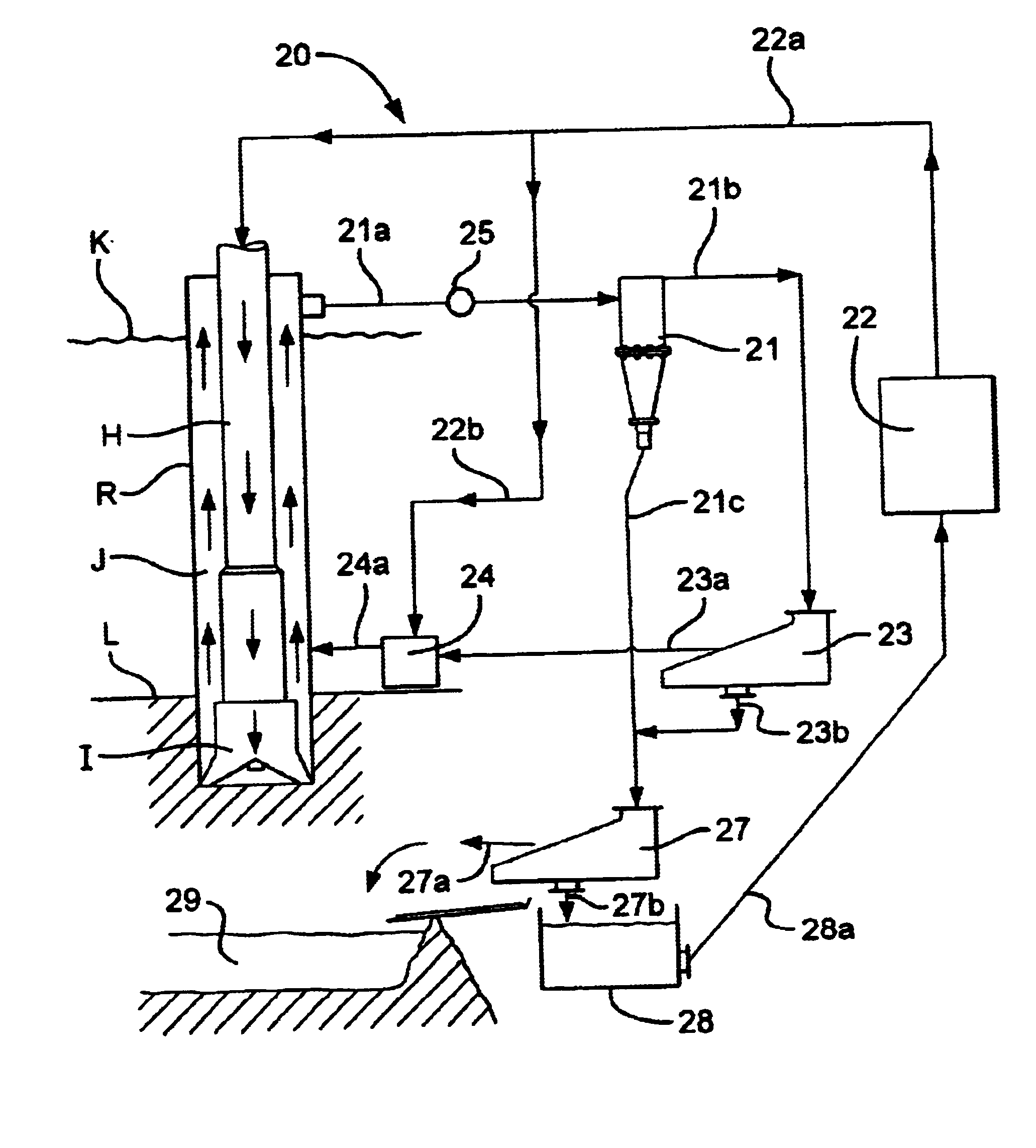

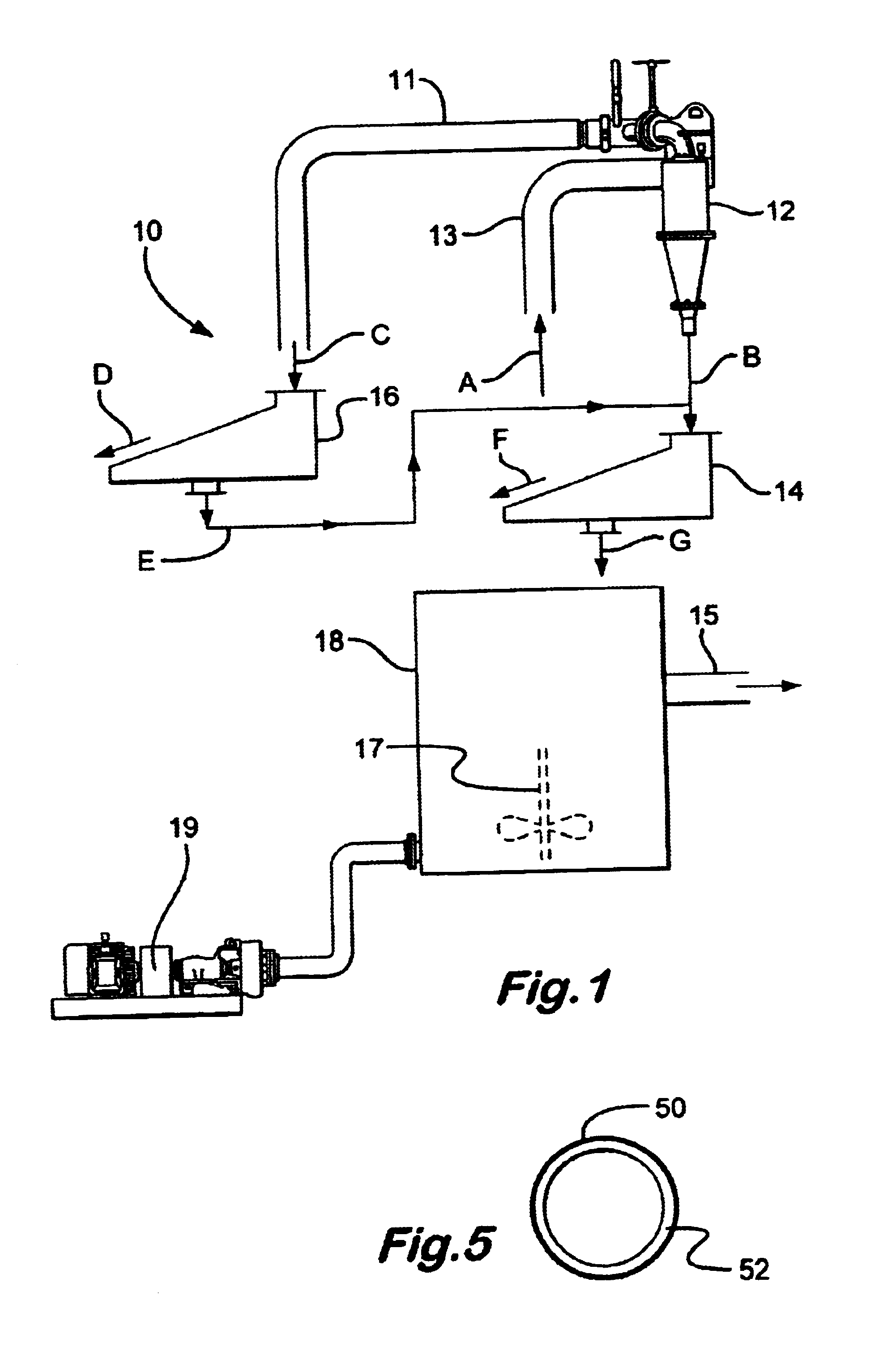

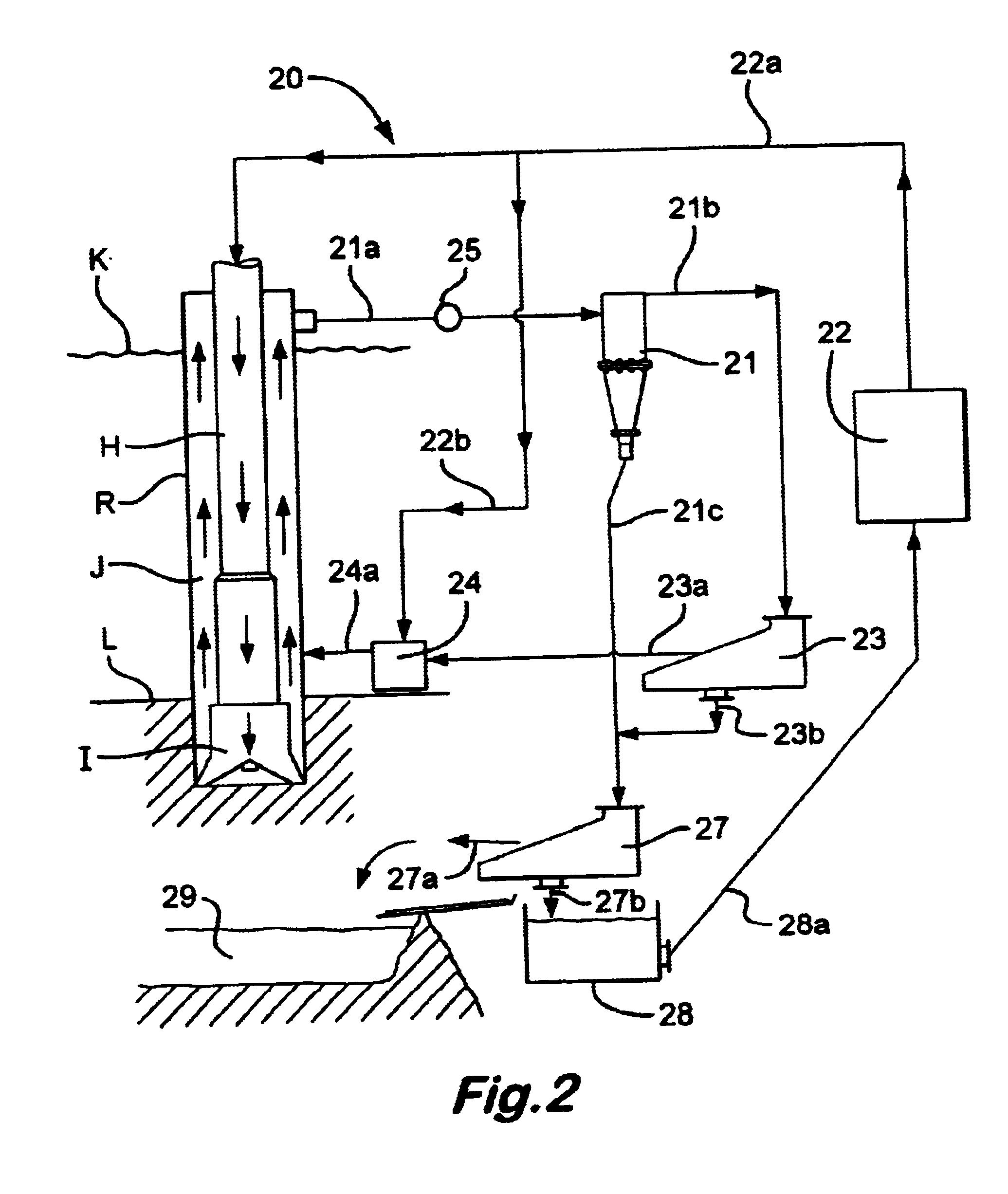

Apparatus and method for reclaiming, purifying and reutilizing boring mud

InactiveCN1803680ARealize automatic continuous operationSimple structureWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningParticulatesMicrowave oven

The invention discloses a device system to recover and re-use the drilling mud, which comprises connected by turns: a storage tank to store the waste drilling mud, a vibration screen for coarse purification, a hydrocyclone to separate the mud conveyed by a mud pump and discharge the particulate from its lower end, a first-stage centrifuge for filter and purification, a microwave oven to dry the mud, a crusher to crush the mud again, and an automatic packaging machine to pack and recover the mud. This invention is simple and convenient, has low cost and no pollution danger, and brings hundred millions economic benefits every year.

Owner:王鸿飞 +1

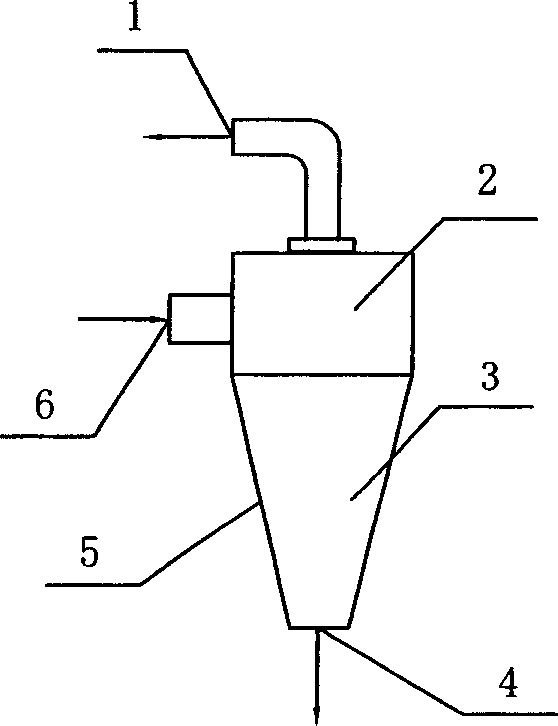

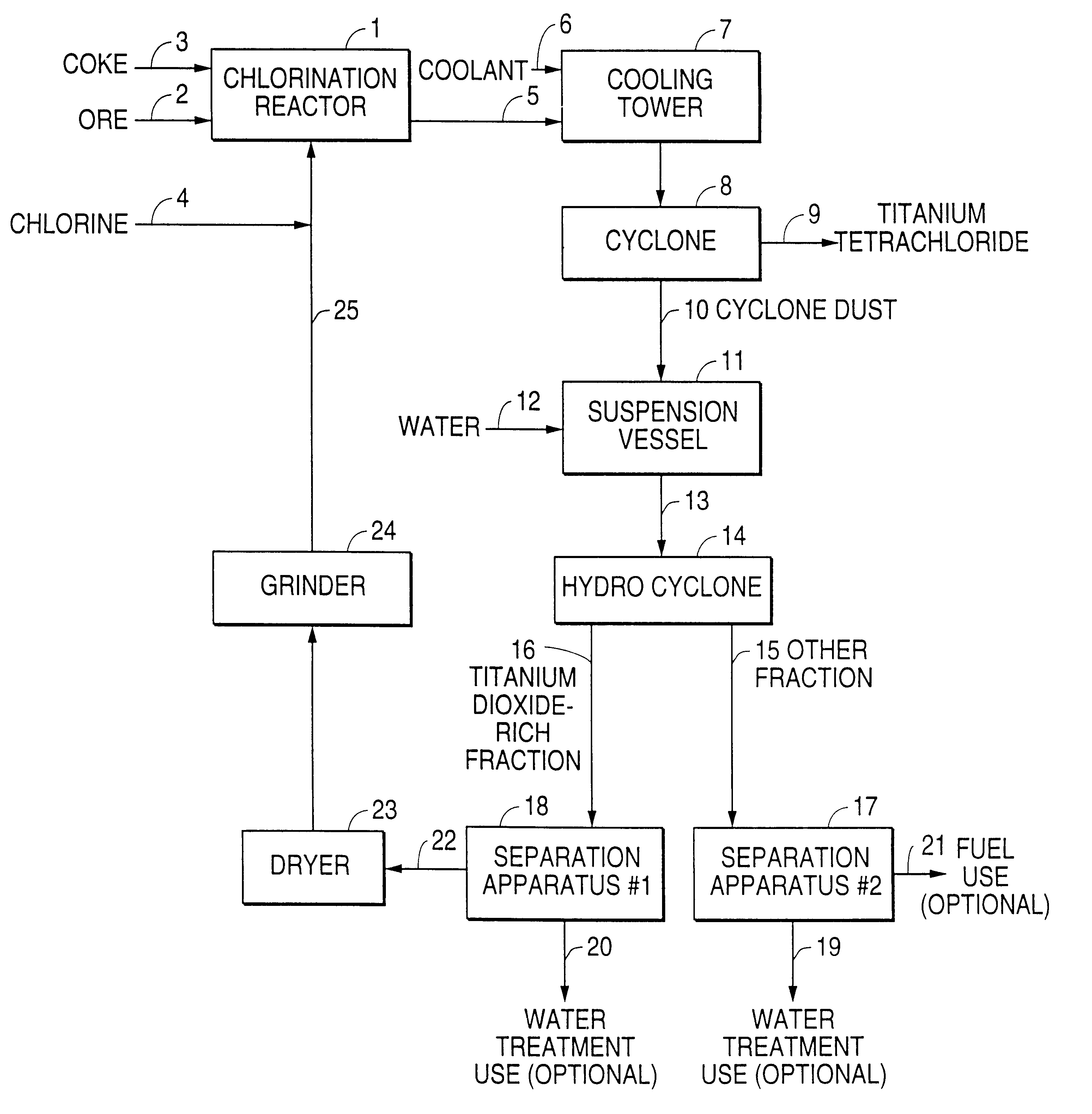

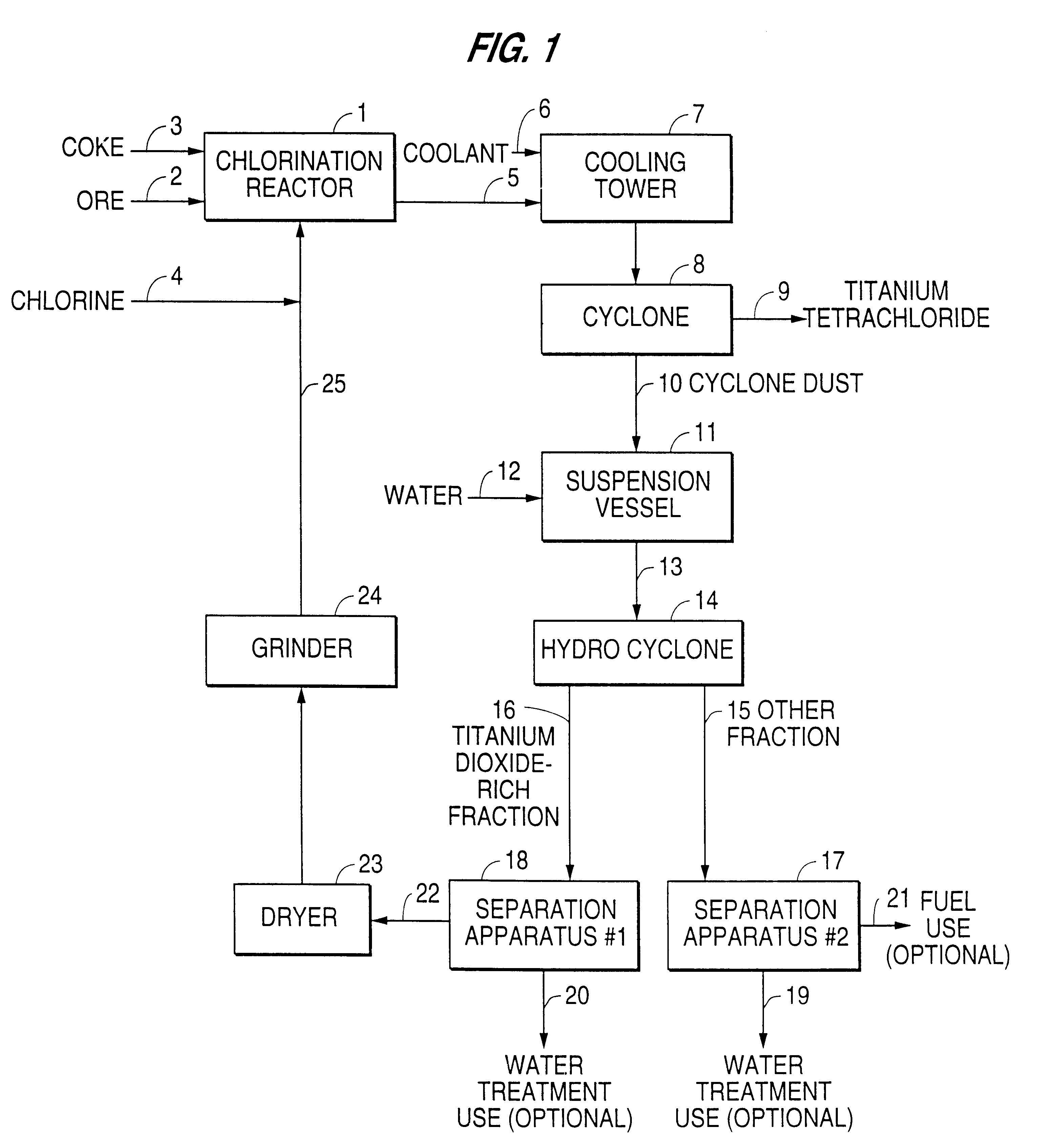

Process for increasing the yield in the manufacture of titanium dioxide by the chloride process

InactiveUS6399033B1Reduce coke contentReduced silica contentZirconium compoundsTitanium dioxideSingle stageFluidized bed

An improvement to the chloride process of making titanium dioxide. By recycling some of the cyclone dust, the yield in the chlorination of titanium-containing raw materials can be increased. In order to prevent silica accumulation in the fluidized bed, the cyclone dust is divided into two fractions. An economic solution is described of a single-stage separation of the cyclone dust in a hydrocyclone, the majority of the titanium dioxide occurring in the hydrocyclone underflow, although the separation is not sharp. By grinding and drying the solids from the hydrocyclone underflow, the titanium dioxide particles returned to the lower region of the fluidized-bed reactor are rapidly chlorinated, while the quartz and coke particles are rapidly discharged again from the fluid bed, so that no silica contamination occurs.

Owner:KRONOS INCORPORATED

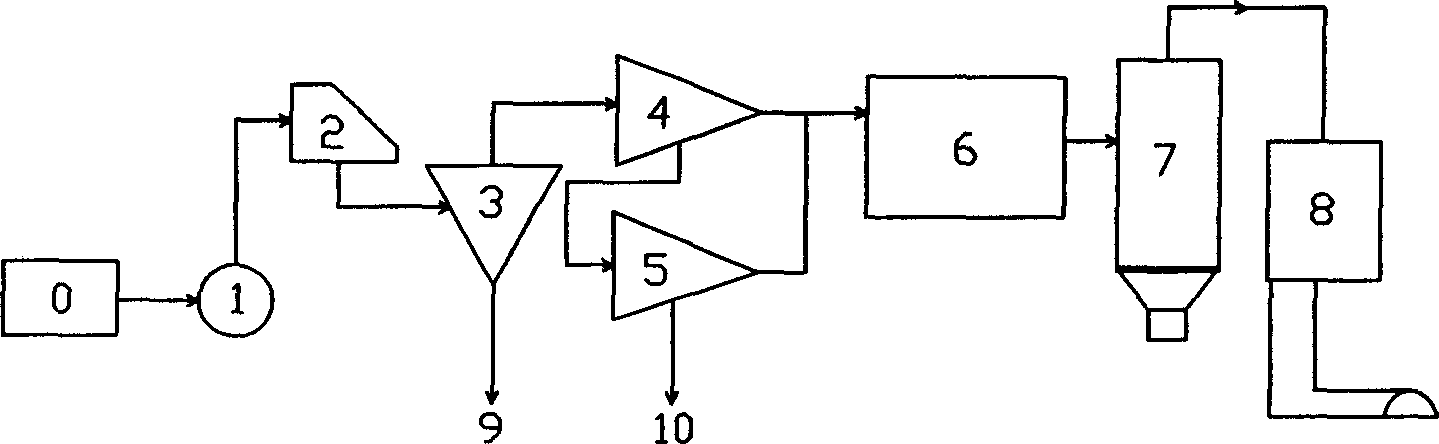

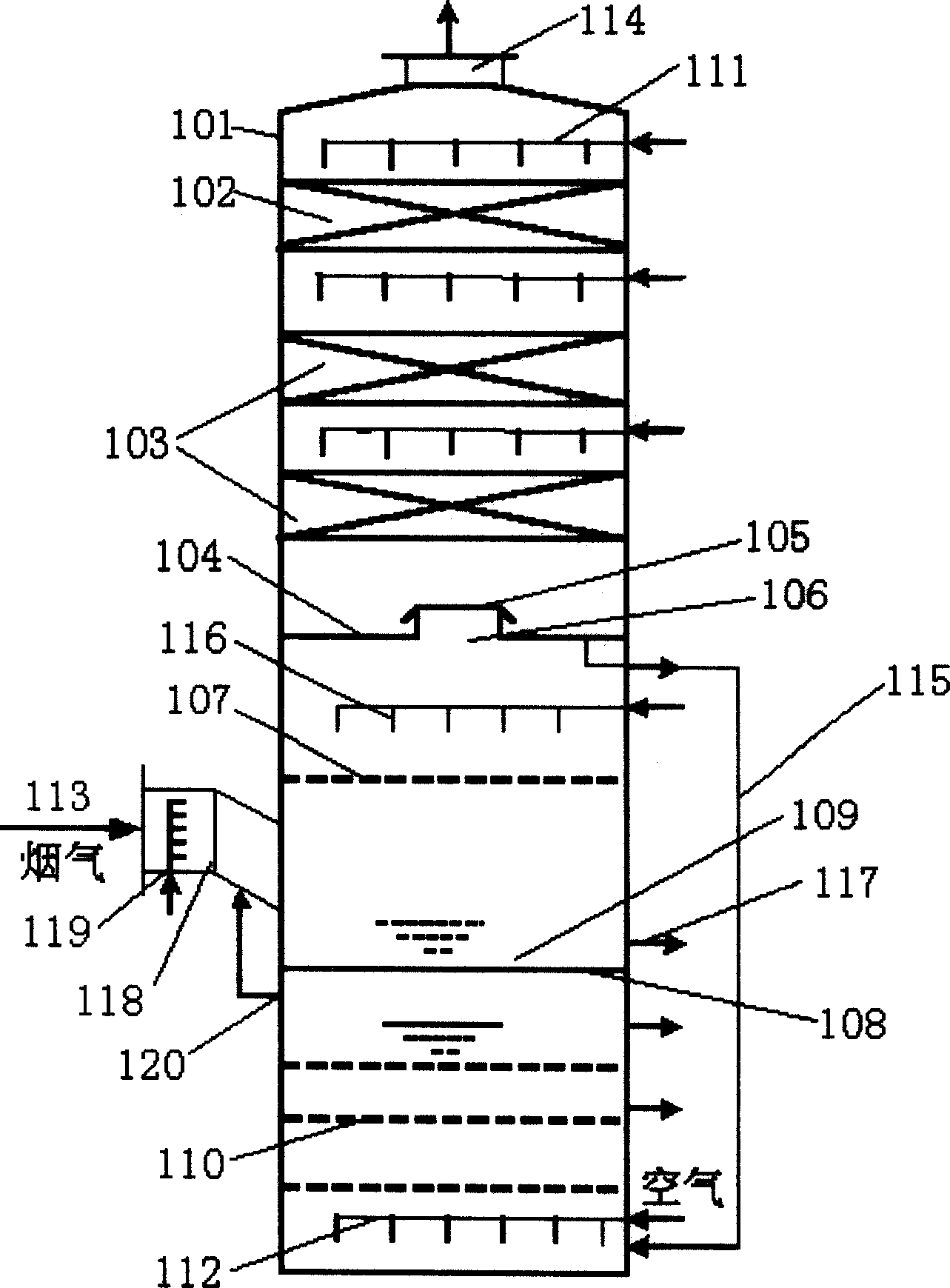

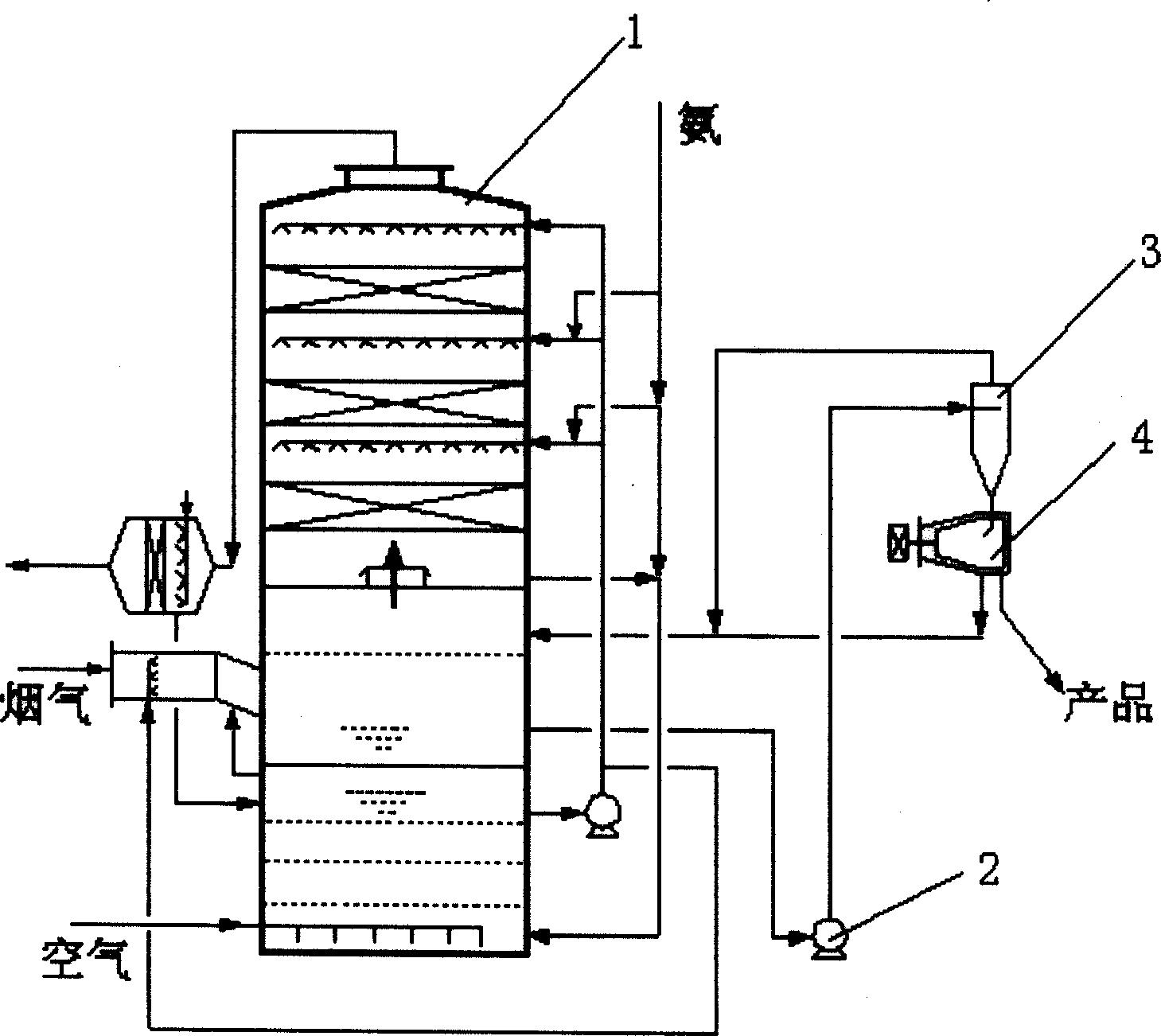

Method and device for producing thiamine from sulfur dioxide in recorered smoke

InactiveCN1648049ANo secondary pollutionDispersed particle separationAmmonium sulfatesPollutionAmmonium sulfate

The present invention discloses method and apparatus for recovering SO2 from fume to produce ammonium sulfate. The present invention has ammonia recovering section over the absorbing section to avoid loss of ammonia and independent fume cooling and humidifying section to produce ammonium sulfate crystal in a saturation and crystallization process in lowered steam energy consumption. Hydraulic staged cyclonic unit is used as effective liquid-solid separator to raise the crystallization degree of the ammonium sulfate product. The whole desulfurizing system produces no waste and has no secondary pollution. The desulfurizing tower has high eliminating efficiency of harmful SO2, SO3, NOx, HCl, HF and dust.

Owner:EAST CHINA UNIV OF SCI & TECH

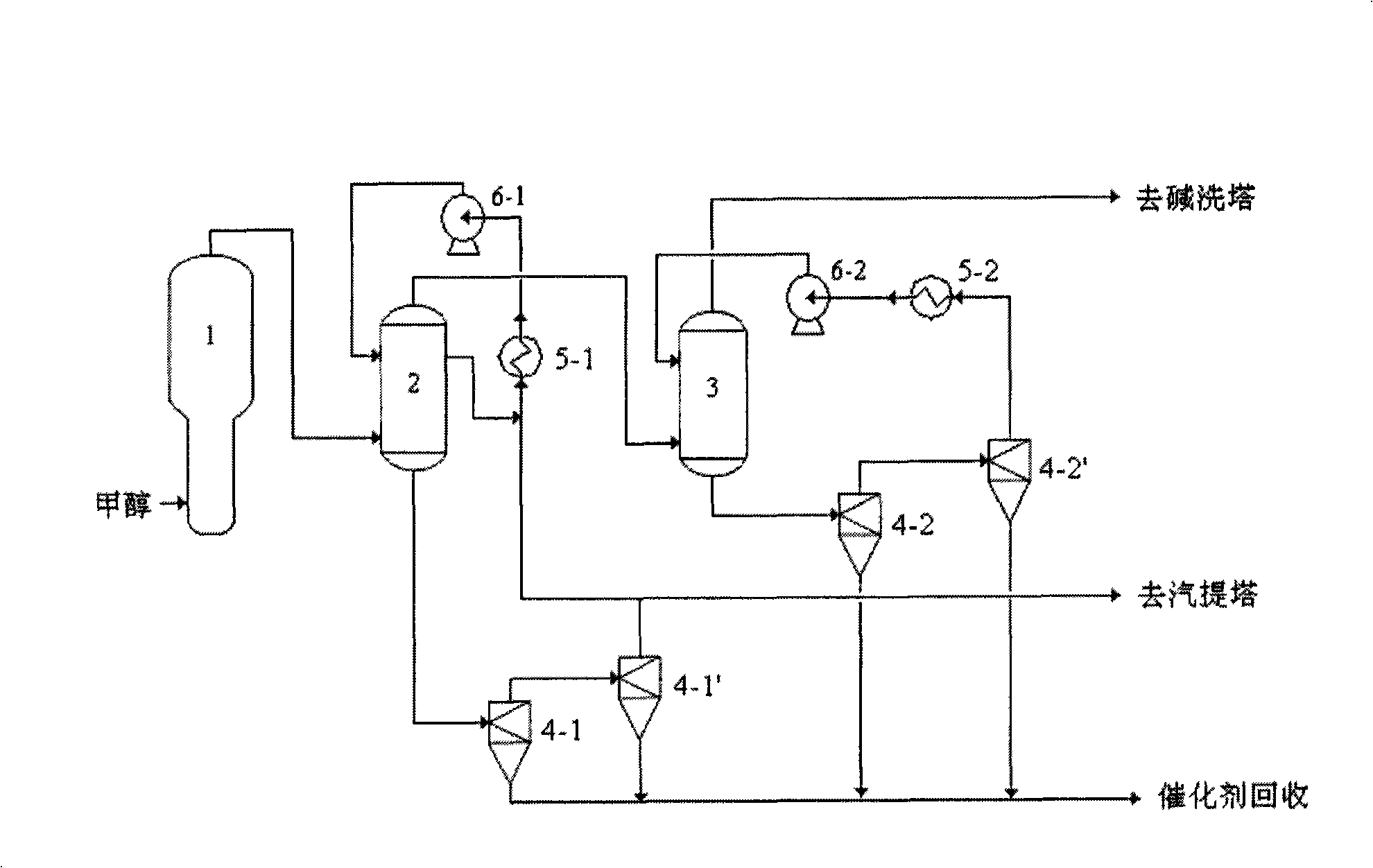

Method and apparatus for micro hydrocyclone separation of MTO quench water and water of water-washing factory, and for concentration of fine catalyst in the same

InactiveCN101352620AVortex flow apparatusCentrifugal force sediment separationEnrichment methodsQuenching

The invention provides a micro-vortex flow concentration method used for fine catalyst in MTO quenching water and washing water, comprising the steps as follows: micro-vortex flow separation of MTO quenching water is carried out so as to carry out the concentration processing on the contained catalyst and micro-vortex flow separation of MTO washing water is carried out so as to carry out the concentration processing of the contained catalyst. The invention also provides a micro-vortex flow concentration device used for the fine catalyst in the MTO quenching water and washing water.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

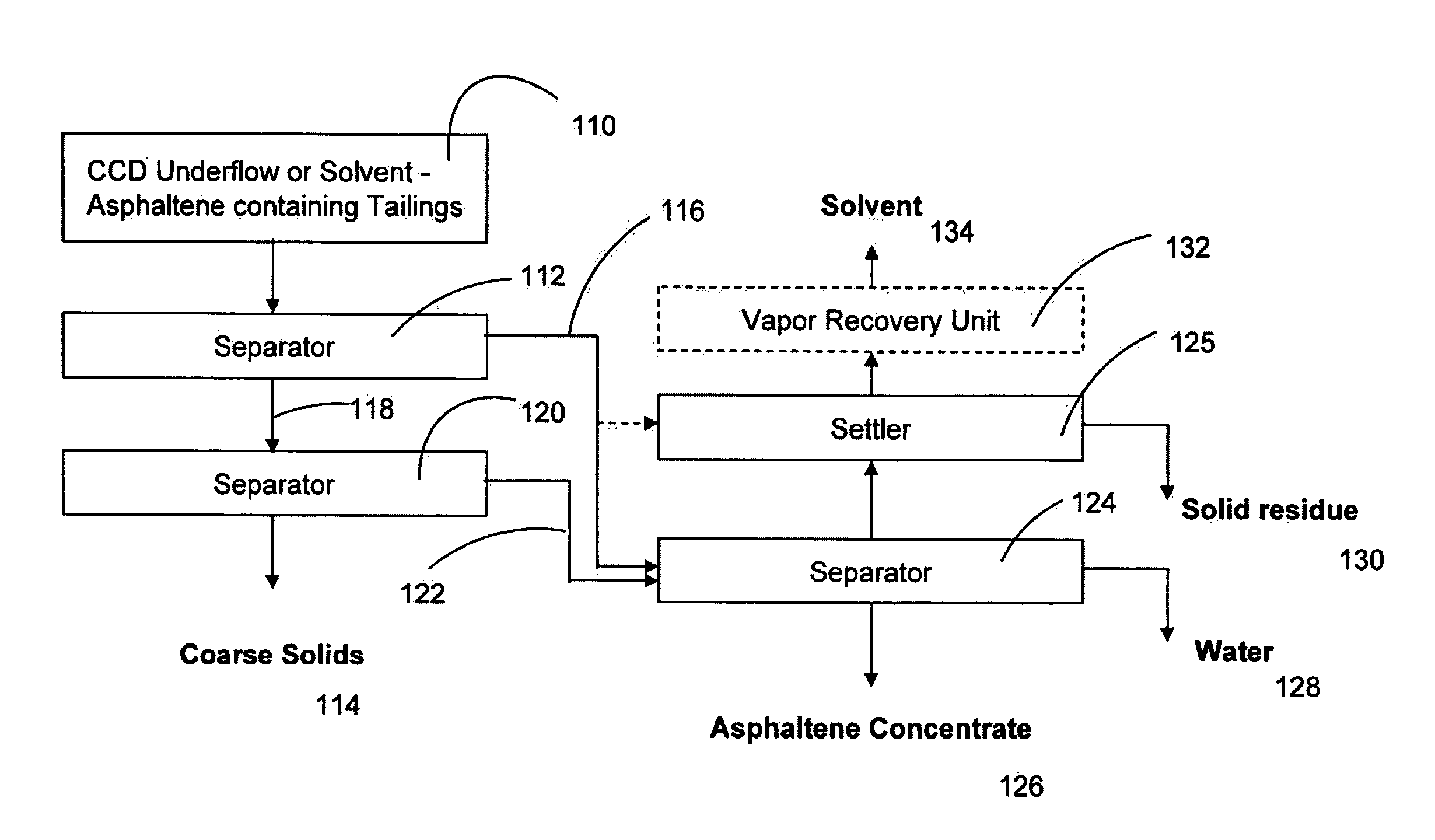

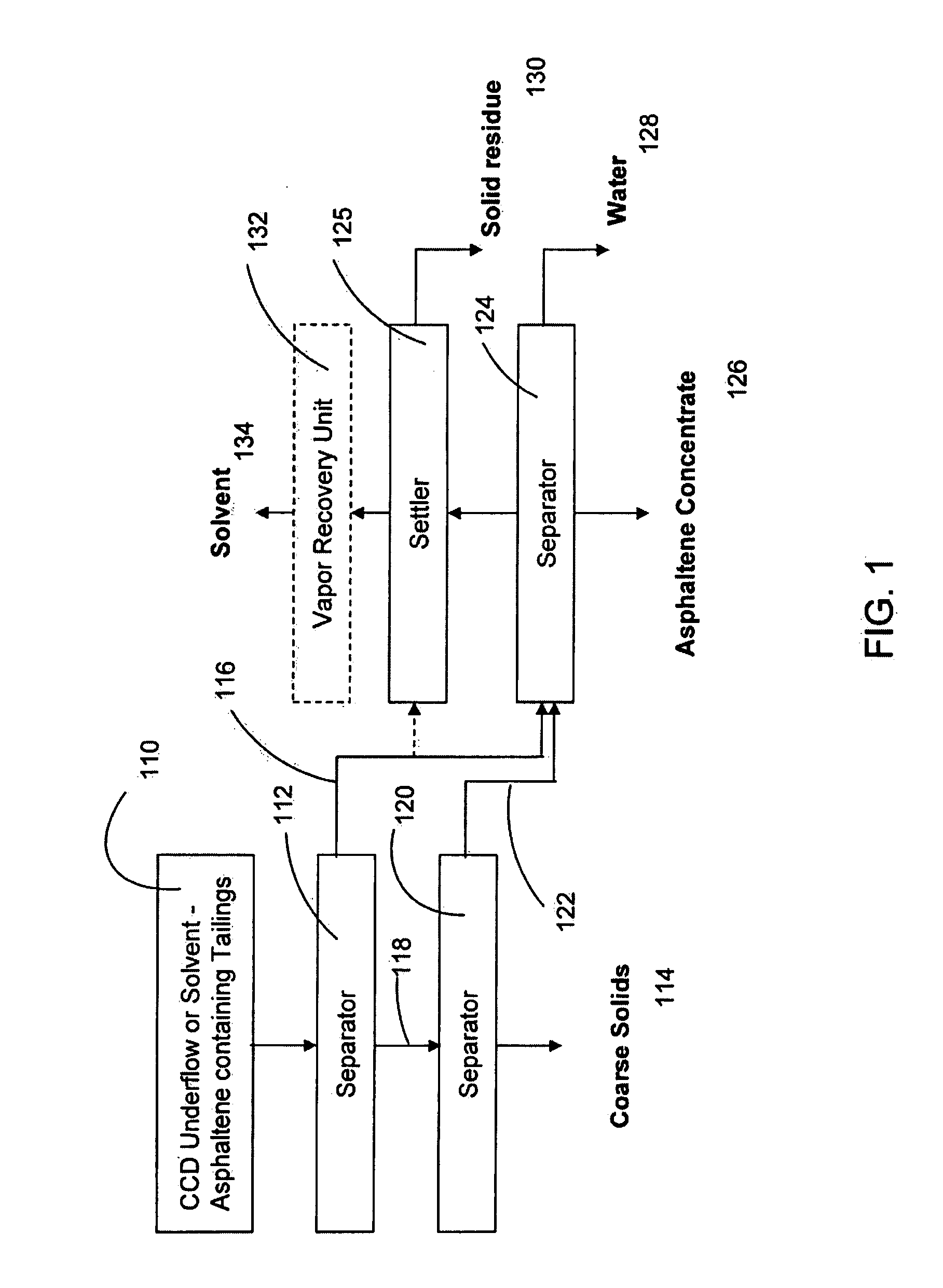

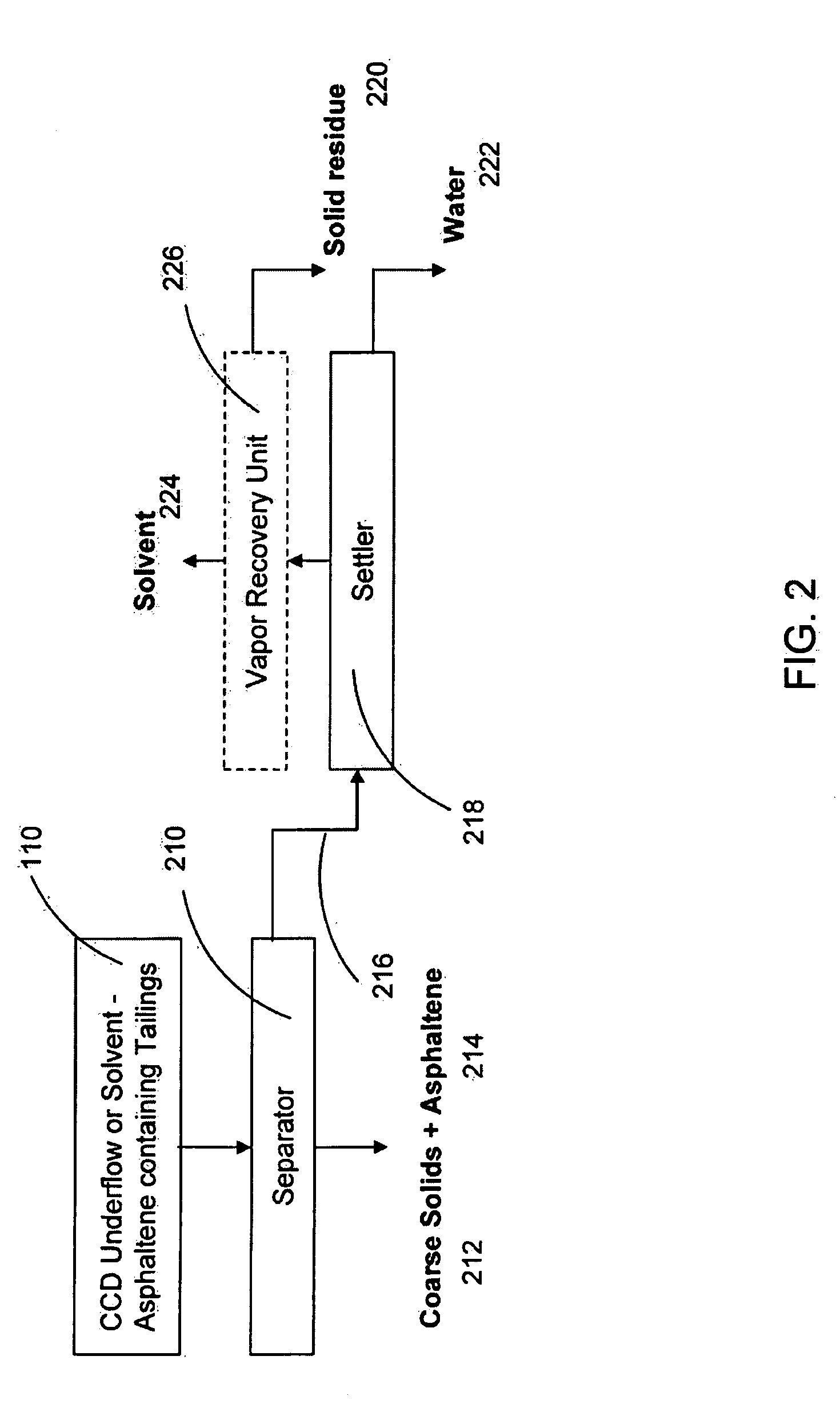

Separation of tailings that include asphaltenes

ActiveUS20080156702A1Easy and less energy intensiveSeparation easy and lessWorking-up pitch/asphalt/bitumenLiquid hydrocarbon mixture productionHydrocarbon solventsCyclonic separation

Various systems and methods are described that can be used as part of a process to separate bitumen from oil sands. The process may include adding a hydrocarbon solvent to a bitumen containing extract. The tailings from this process may contain a significant amount of solvent. The solvent may be recovered from the tailings with a tailings solvent recovery unit that utilizes negative pressure to significantly reduce the cost of the process in comparison to a conventional steam stripping unit. In one embodiment, the tailings may also separated prior to entering the tailings solvent recovery unit with a gravity separation apparatus or a cyclonic separation apparatus, such as a hydrocyclone.

Owner:CANADIAN NATURAL UPGRADING LTD +1

Integral fuel jet axial swirler pre-mixing preevaporated low pollution combustion-chamber

InactiveCN101285592AShorten the lengthReduce distanceContinuous combustion chamberCombustion chamberAtmospheric air

The invention discloses a combustion cavity of an integral fuel oil ejecting axial hydrocyclone with functions of premixing, pre-evaporation and low pollution. The combustion cavity has a single ring cavity structure, and consists of a combustion cavity head and a flame tube. The combustion cavity head comprises a precombustion stage positioned at the center and a main combustion stage positioned at the peripheral. The main combustion stage comprises a direct jet type air atomizer spray nozzle and a main combustion stage axial hydrocyclone. The technical proposal that the jetting of the main combustion stage fuel oil and the main combustion stage axial hydrocyclone are integrated is adopted. The main combustion stage fuel oil ejected by the direct jet type air atomizer spray nozzle enters into a main combustion stage axial hydrocyclone vane channel of a main combustion stage axial hydrocyclone vane, and the fuel oil is mixed with the rotary flow air of the main combustion stage axial hydrocyclone. A premixed oil-gas mixture enters into a combustion zone through a main combustion stage mixing cavity to be combusted. The combustion mode can effectively reduce pollutant emission in the combustion cavity and reduce the length of the combustion cavity. The combustion cavity is mainly used for an aerial engine combustion cavity, and also can be used for the combustion cavity of industrial gas turbines and ship gas turbines so as to reduce pollutant discharged into atmosphere.

Owner:BEIHANG UNIV

Water and oil separation system

ActiveUS20130146536A1Efficiently and completely performReduce dirtSedimentation separationLoose filtering material filtersOil separationInner membrane

A separation system includes at least a hydrocyclone and one or more membranes. In another aspect, a separation system includes a membrane having graduated and / or asymmetrical pore sizes. A further aspect of a separation system includes an inner membrane, an outer membrane and a hydrocyclonic flow between the membranes.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

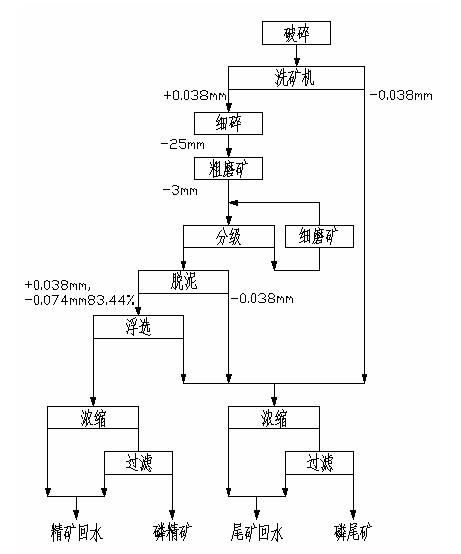

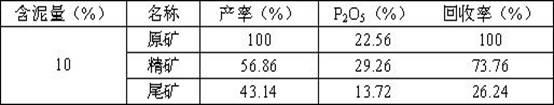

Direct and reverse flotation desliming process of collophanite

The invention discloses a flotation desliming process of collophanite. The flotation desliming process of collophanite comprises the following steps of: scrubbing collophanite crude ore; dividing the crude ore into a coarse fraction part and a fine fraction part according to different particle diameters of particles; feeding the coarse fraction part into a grinding and classification flow after getting the coarse fraction part through an ore washer; feeding into a hydraulic cyclone to deslime for the first time; feeding a settled sand part into a direct and reverse flotation flow after getting the settled sand part through the hydraulic cyclone to obtain flotation concentrate and flotation tailing; removing fine silt from the fine fraction part after getting the fine fraction part throughthe hydraulic cyclone; concentrating and filtering the flotation concentration to obtain finished products phosphate concentrate and concentrate backwater; concentrating and filtering desliming tailing of the ore washer, desliming tailing of the hydraulic cyclone and flotation tailing to obtain phosphorus tailing and tailing backwater; recycling the concentrate backwater and tailing backwater; and returning to each backwater utilization site in the ore washer or a flotation plant. According to the flotation desliming process, the flotation recovery rate and the concentrate grade can be improved, the agent consumption is reduced, and the utilization efficiency of flotation equipment is increased.

Owner:云南三明鑫疆磷业股份有限公司

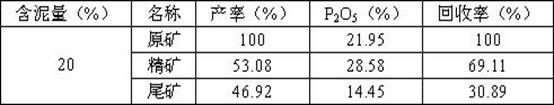

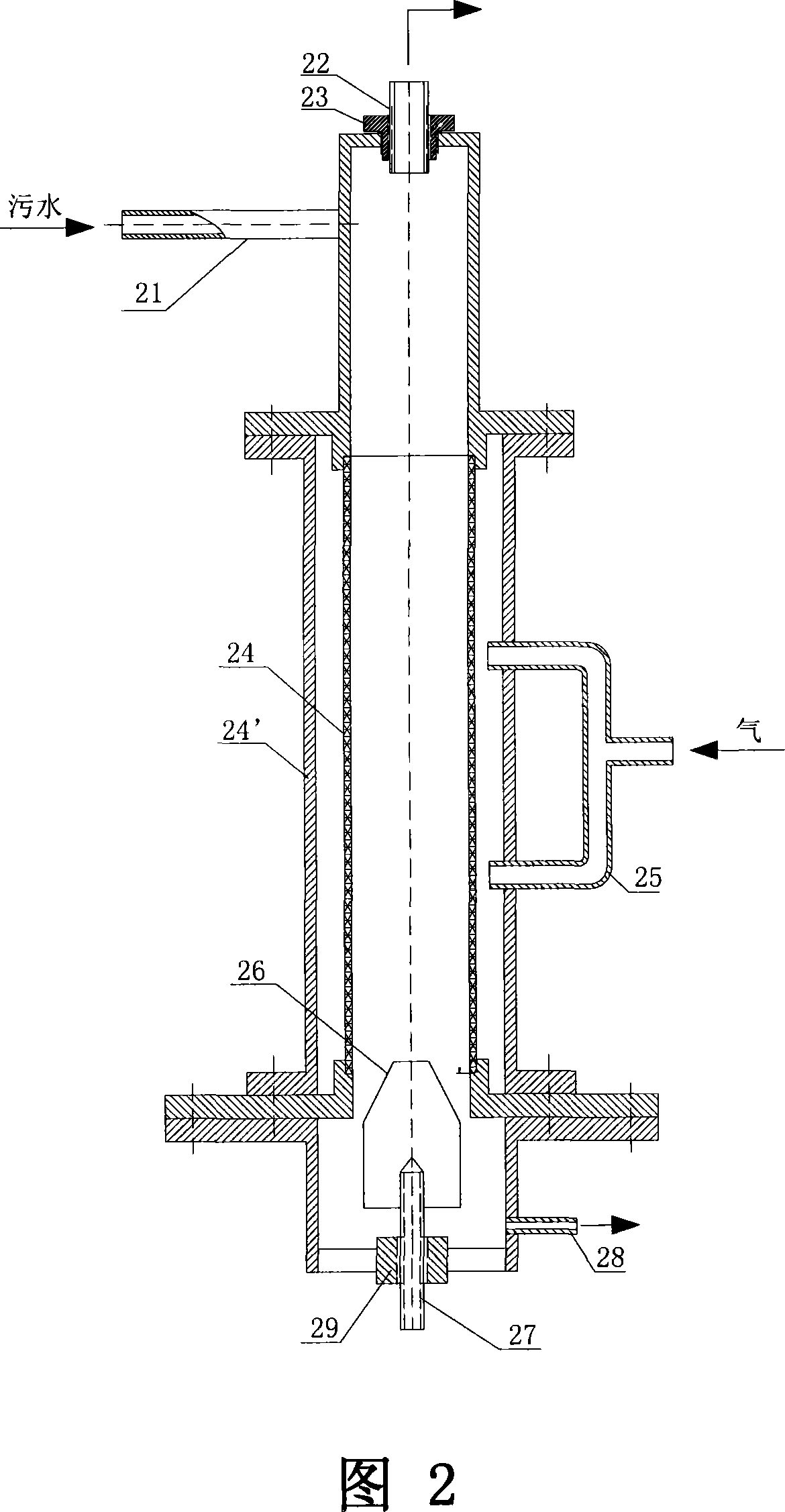

Method for treating oil refining sewage by employing multi-stage inflatable cyclonic current technology

InactiveCN101113035ADemulsification facilitates the realization ofShort stayWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesHigh concentrationEngineering

The invention provides a method for refinery waste water treatment by multi-stage air-sparged hydrocyclone technique, which can high effectively recycle floating oil, dispersed oil and emulsified oil of the refinery waste water, and eliminate most of suspension at the same time. The invention is mainly characterized in that: through setting at least two-stage air-sparged hydrocyclone, and combining the use of demulsifier, coagulant and coagulant aids, physiochemical treatment is carried out to high concentration oily waste water produced by all devices during the refinery process, and the releasing water after treatment can meet the biochemical stage water indices of normal waste water treatment field. The technique of the invention can substitute the physiochemical treatment stage (the first stage treatment) of the existing refinery waste water treatment process, and is characterized by high effect, occupying small land, and saving the investment, etc.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

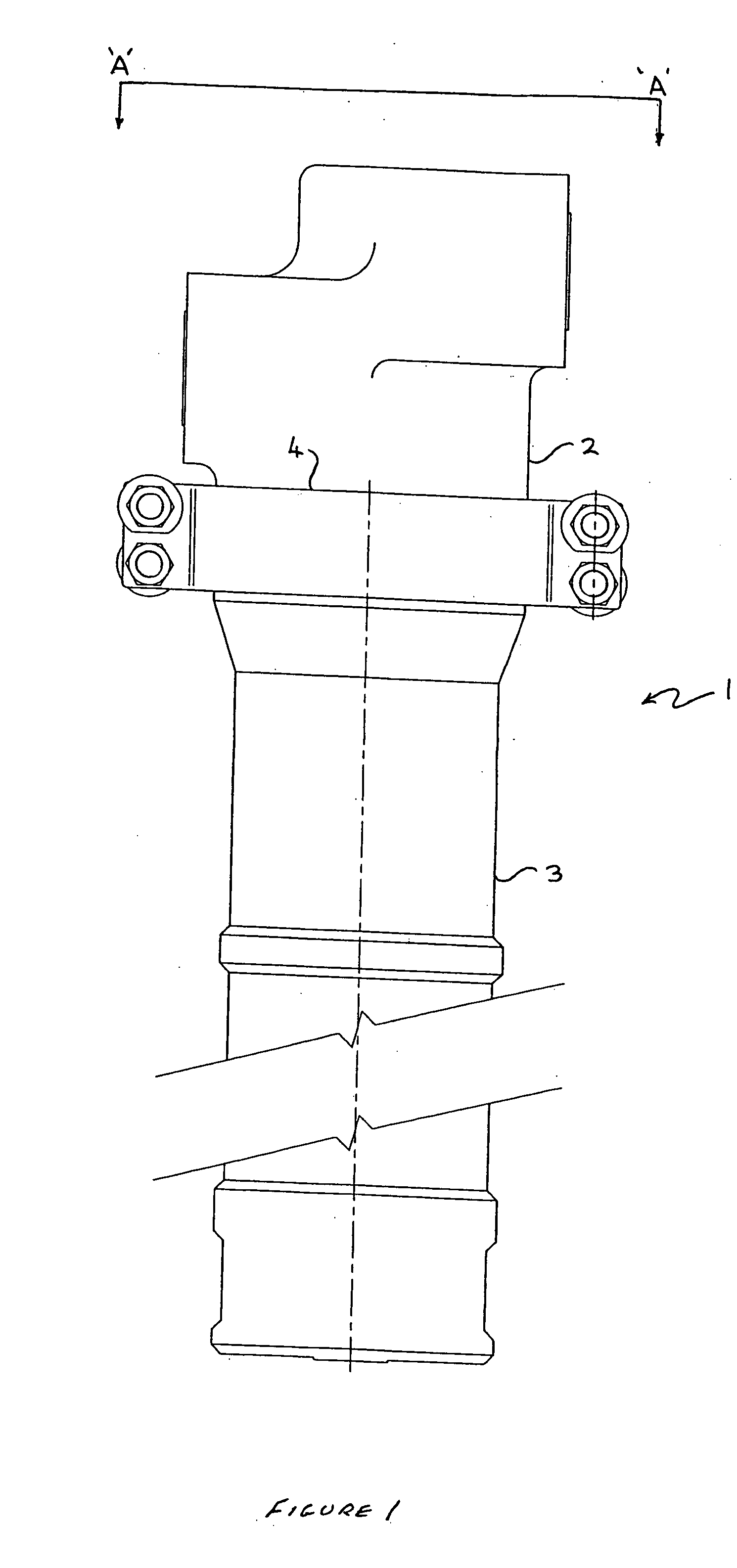

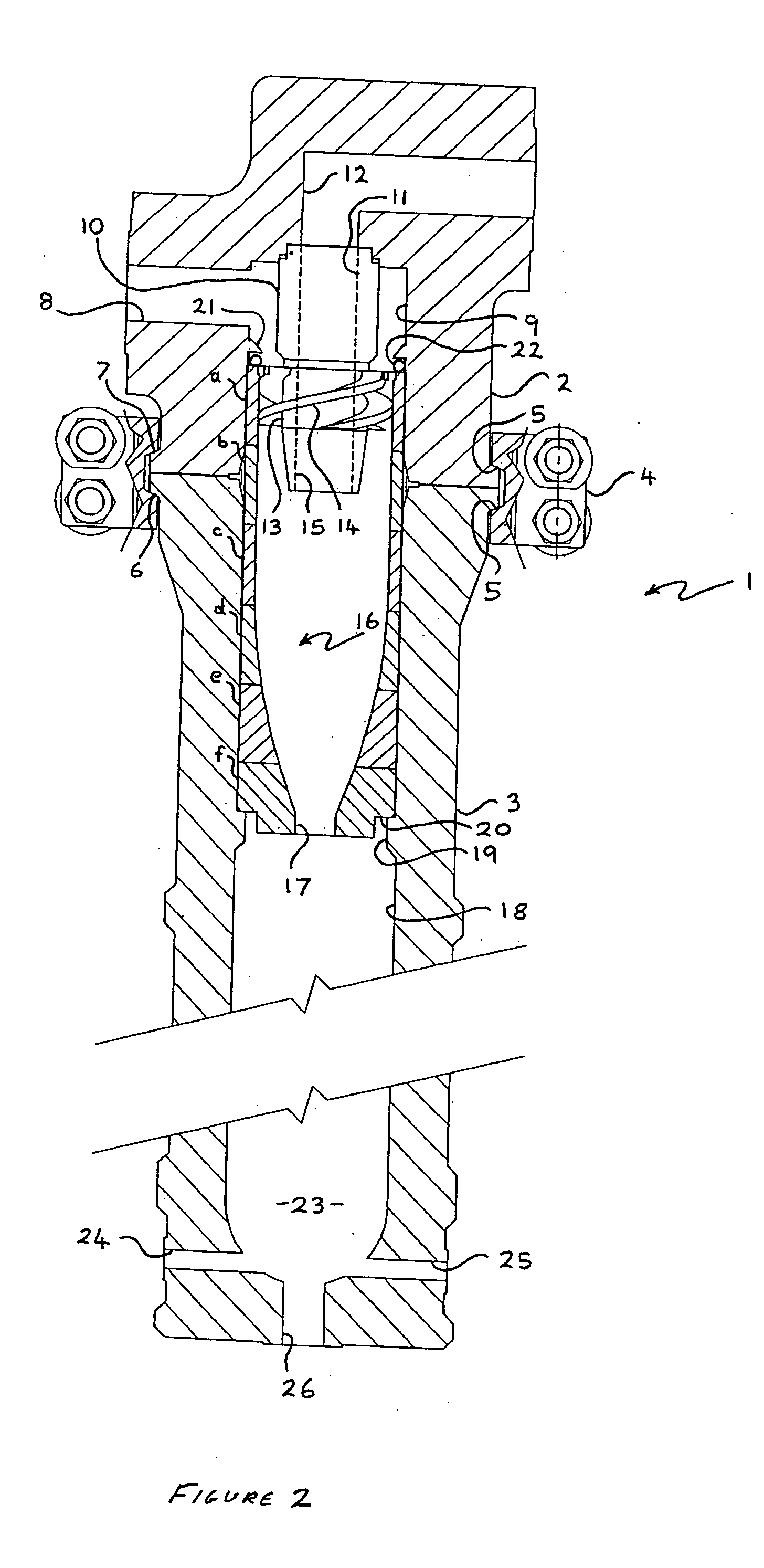

Relating to well head separators

ActiveUS20050236324A1Easy to shapeEconomising on manufacturing costWater/sewage treatment by centrifugal separationReversed direction vortexParticulatesCyclone

Well head hydrocyclone separators are typically used for separating particulates from fluids such as gas, oil and water and mixtures thereof. Well head separators are useful to prevent wear and blocking of choke valves, rupture of piping, damage to instruments and to prevent vessels from filling with particulate materials. In the present invention, the cyclone separator assembly includes an inlet, an overflow outlet and a segmented cyclone separator tube.

Owner:AXSIA SERCK BAKER

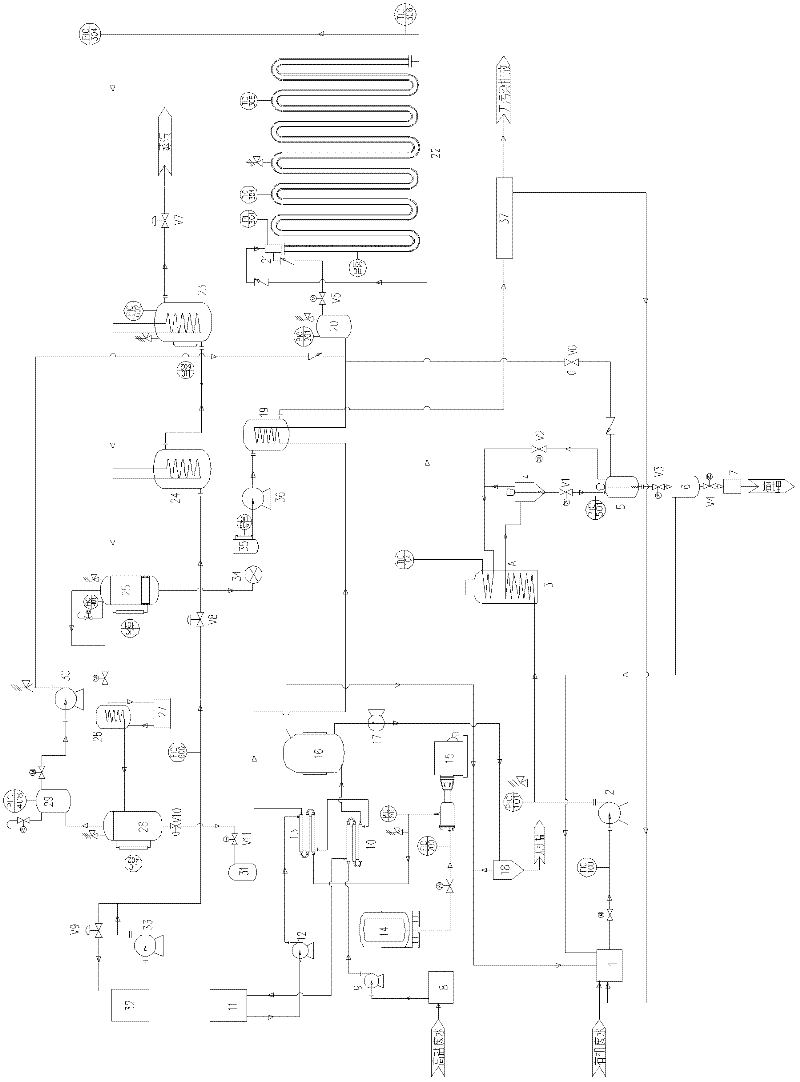

Supercritical water oxidization treatment system for high-salinity organic waste water

InactiveCN102642947AGuaranteed heat transfer coefficientAvoid cloggingSolidificationLiquefactionCycloneReaction temperature

The invention discloses a supercritical water oxidization treatment system for high-salinity organic waste water. The high-salinity waste water is subjected to cooling crystallization through cold energy of liquid oxygen to reduce mass concentration of inorganic salt in the waste water; a large amount of solid salt grains separated out from the waste water are removed by using a hydraulic cyclone device under a supercritical water condition to effectively prevent a subsequent pipeline and a reactor of the hydraulic cyclone device from plugging; and a desalting device is arranged at the lower part of the hydraulic cyclone device to continuously remove the inorganic salt from the system. In addition, excessive oxygen and CO2 product gas are recovered through a separation recovery part; the reaction time and the reaction temperature of supercritical water oxidization are reduced through arranging a simple subsequent treatment unit; and the system recovers heat energy of the reacted high-temperature fluid in a steam mode through the arrangement of a water softening device, so that the operation cost of the system is reduced. The system can be widely applied to the innocent treatment process of the high-salinity organic waste water.

Owner:XI AN JIAOTONG UNIV +1

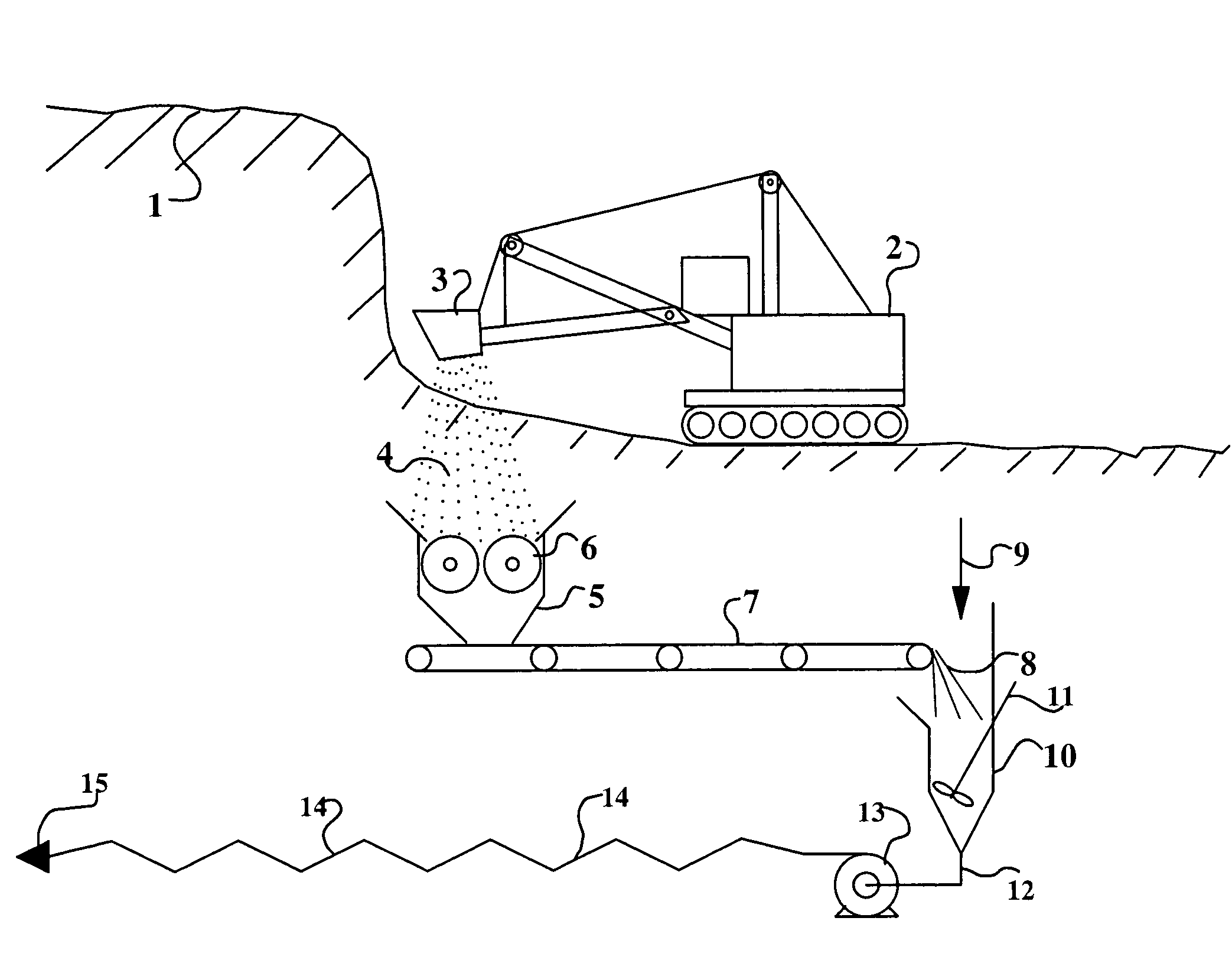

Isoelectric separation of oil sands

InactiveUS20090139906A1Reduced effectivenessReduce recoveryWater/sewage treatmentLiquid hydrocarbon mixture productionSlurryFroth flotation

A process and system for substantially isoelectric separation of an oil sand slurry is disclosed and described. The process can include mining oil sand, crushing the oil sands, forming a slurry of the oil sands, and transporting the oil sands slurry to a sinusoidal pipe. The sinusoidal pipe acts to digest the slurry from which bitumen can be separated using a hydrocyclone. Overflow from the hydrocyclone can be further treated using a revolving oleophilic device from which bitumen is recovered. Various optional further treatments can be used to dewater and / or further treat the bitumen and other process streams. The use of caustic soda, long-term tailing ponds, and froth flotation can be avoided resulting in an effective production of oil using less water than currently conventional processes.

Owner:KRUYER JAN

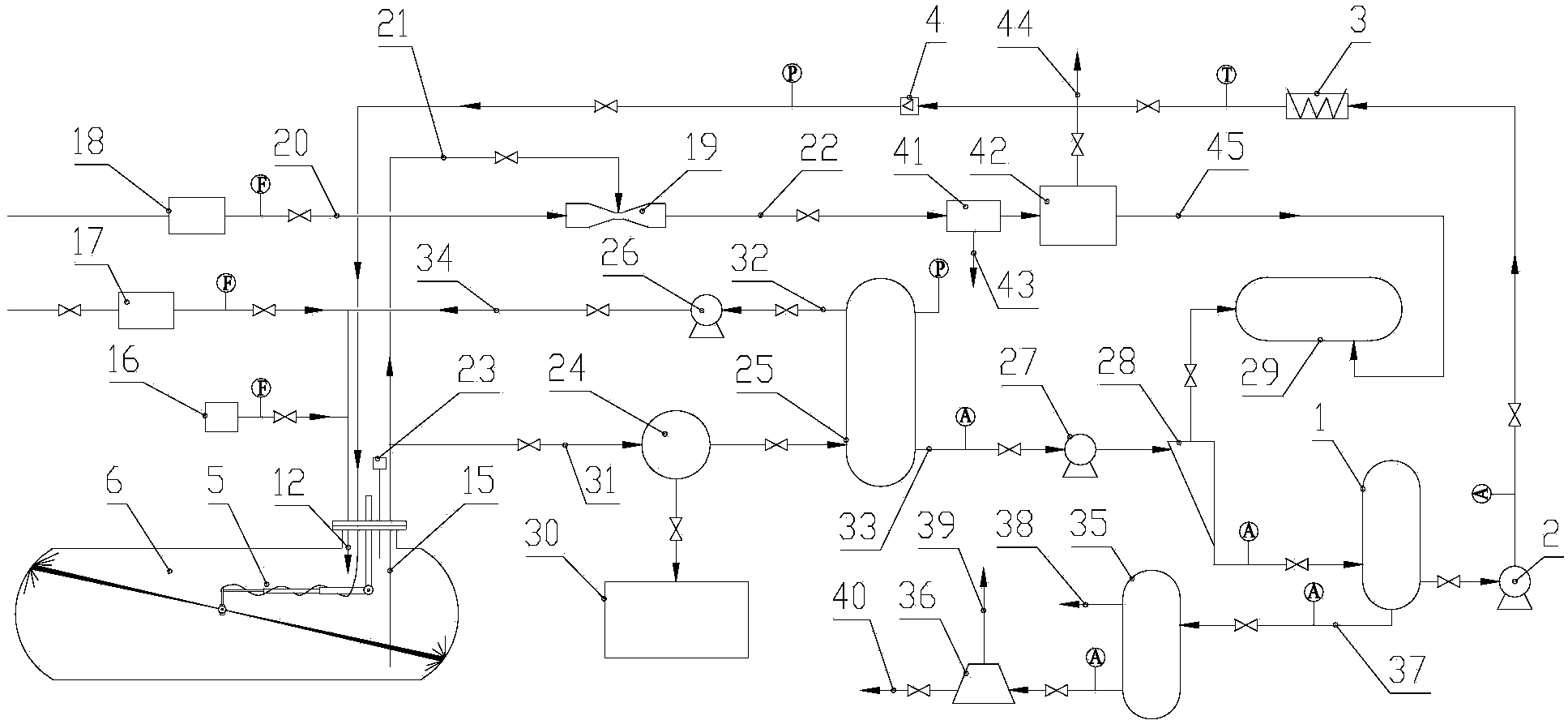

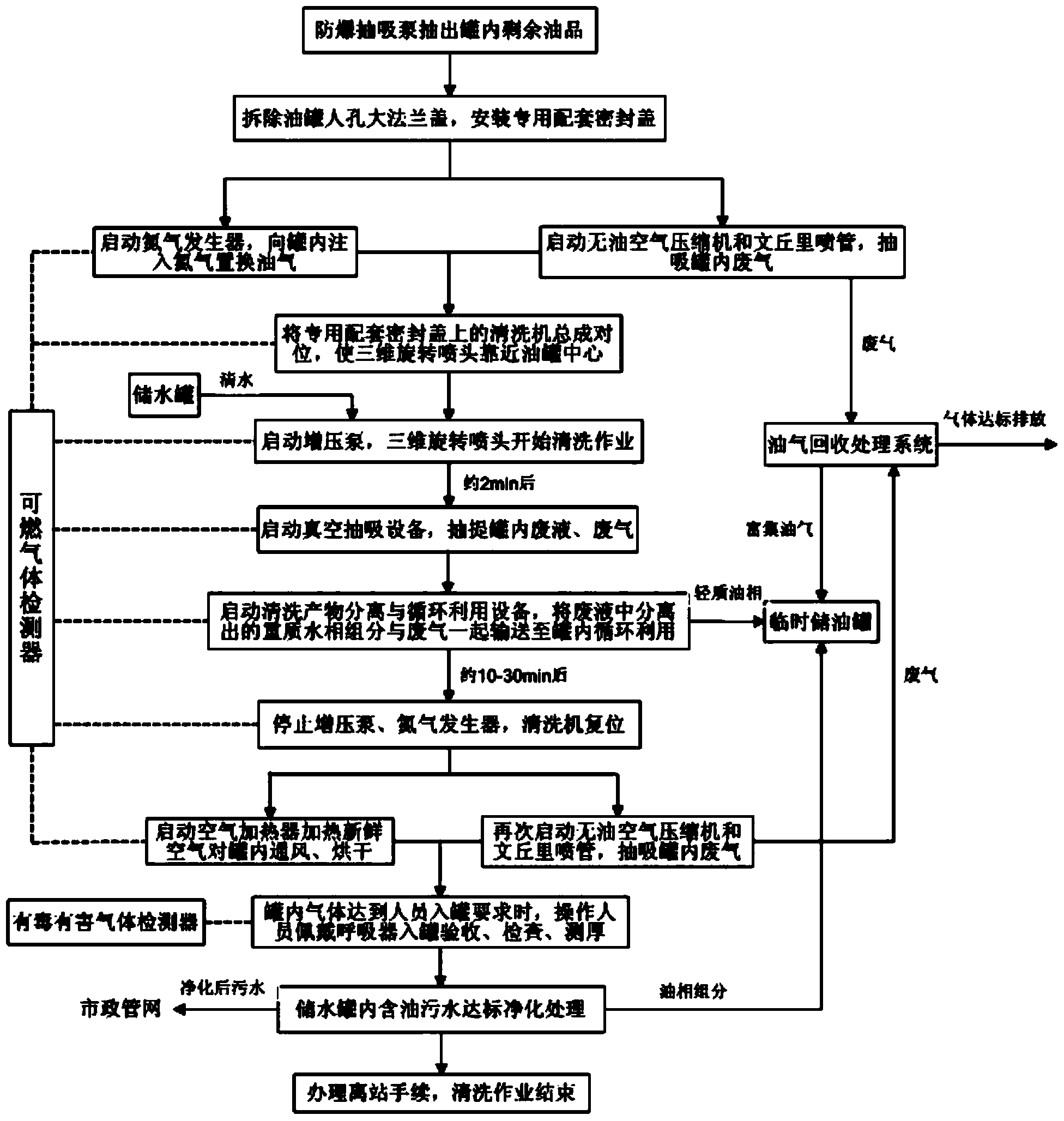

Mechanical cleaning system for underground storage tank of filling station

ActiveCN104001702ACompact structureWater/sewage treatment by centrifugal separationHollow article cleaningNitrogen generatorWater storage tank

The invention discloses a mechanical cleaning system for an underground storage tank of a filling station. The mechanical cleaning system comprises a low-pressure jet cleaning device, an air replacement device, a gas atmosphere monitoring device, a cleaned-away dirt separation and recycling device, an oily sewage discharge standardization treatment device and an oil and gas recovery treatment device. The low-pressure jet cleaning device comprises a water storage tank, a booster pump, a heater, a turbine flowmeter and a cleaning machine, wherein the water storage tank, the booster pump, the heater, the turbine flowmeter and the cleaning machine are connected in sequence through pipelines. The air replacement device comprises a nitrogen generator, an air heater and an oilless air compressor. The oil and gas recovery treatment device comprises a precooler and an activated carbon adsorption tank, wherein the precooler and the activated carbon adsorption tank are connected with each other. The cleaned-away dirt separation and recycling device comprises a filter, a vacuum suction tank, a suction pump and an axial inlet hydrocyclone. The oily sewage discharge standardization treatment device comprises a compact vertical swirling air-floatation separation tank and a disk centrifuge. The mechanical cleaning system is intrinsically safe, efficient, environmentally friendly, compact in structure and capable of meeting related discharge requirements.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

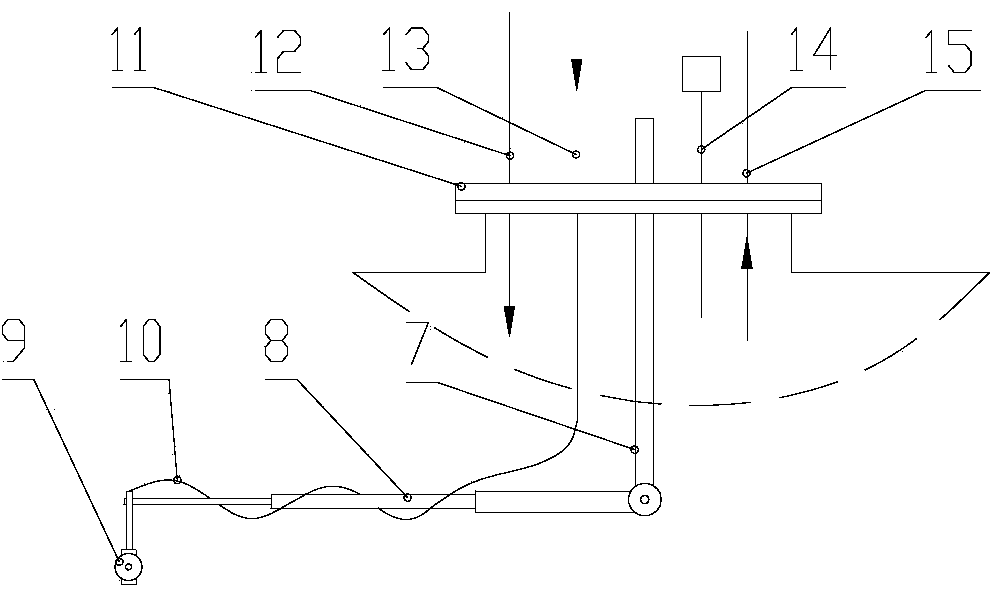

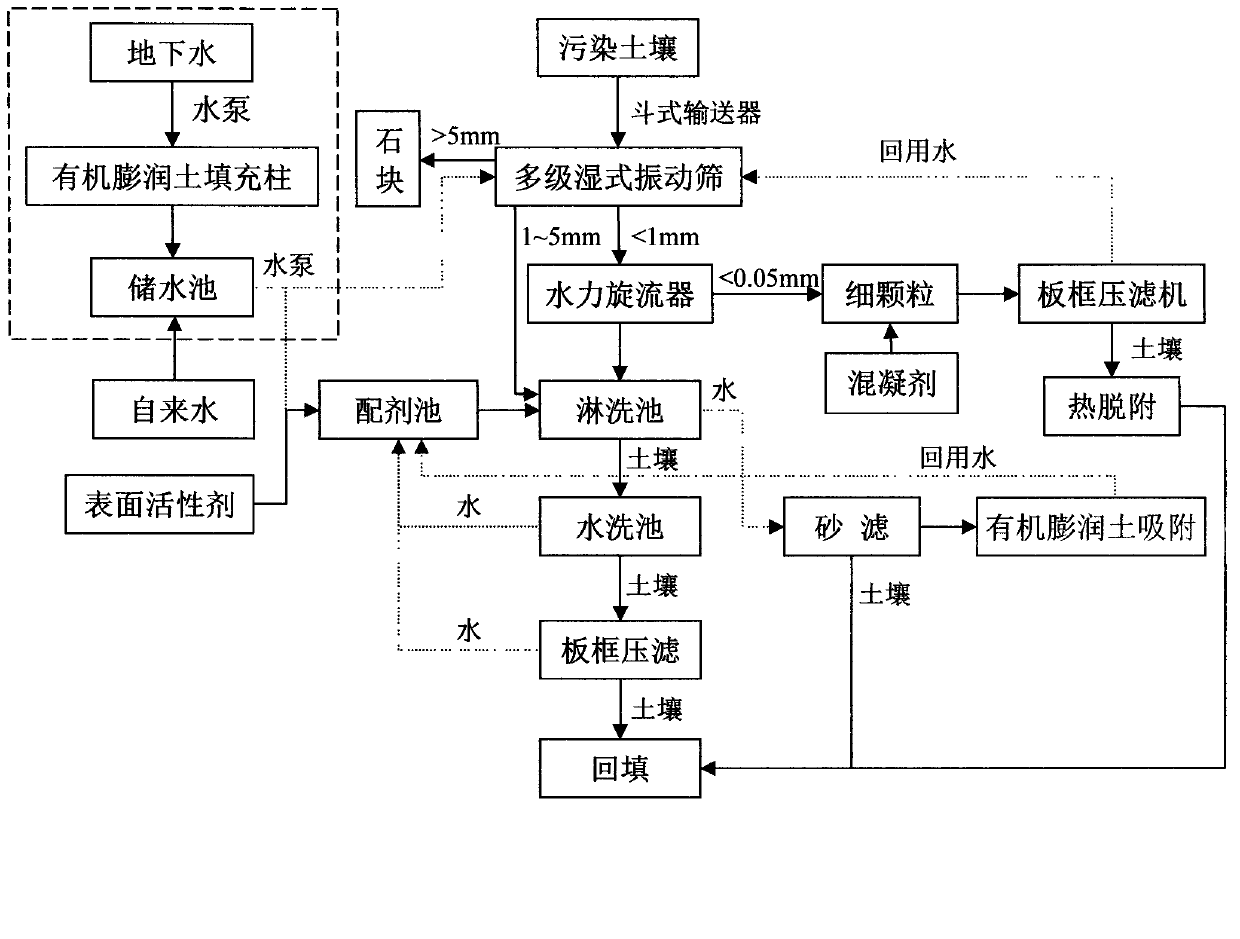

Polluted site underground water processing-soil ex-situ leaching restoration integral method

InactiveCN103230931AAdjustable dosageAdjustable stirringContaminated soil reclamationWater storage tankGroundwater remediation

The invention discloses a polluted site underground water processing-soil ex-situ leaching restoration integral method. The method comprises the steps that: extracted underground water is purified by using organic bentonite, and is discharged into a water storage tank and is used in a soil leaching process; with a multilevel wet vibration sieve, stones and coarse sand are separated from soil; a soil suspension liquid obtained by sieving enters a hydrocyclone; fine particles smaller than 0.05mm are processed and discharged into a frame filter press, and pollutants are removed with a thermal desorption method; particles larger than 0.05mm and the coarse sand are delivered into a leaching tank; a leaching liquid is a surfactant solution; stirring and ultrasonic processing are carried out, and standing sedimentation is carried out; upper-layer water phase is subjected to filtering and organic bentonite purification, and is discharged into a dispensing tank; lower-layer soil is delivered into a washing tank; stirring and ultrasonic processing are carried out, and standing sedimentation is carried out; soil phase is discharged into the frame filter press; and the soil reaches a standard and can be backfilled. With the method, underground water and soil synchronous restoration and leaching liquid recycling are realized. The method is easy to realize, and can be widely applied. The method can be used in polluted site soil and underground water restoration projects.

Owner:ZHEJIANG TAOHUAYUAN ENVIRONMENTAL PROTECTION TECH

Erosion-resistant hydrocyclone liner

ActiveUS7011219B2Less brittleReversed direction vortexSingle direction vortexComposite constructionStructure of the Earth

Erosion-resistant liquid / liquid hydrocyclone liners, wherein the weight and cost of the liners are kept within acceptable parameters through the construction of a composite hydrocyclone liner, comprised of two or more different materials. The hydrocyclone liner includes a head section that is fashioned, primarily, of a highly erosion-resistant material, such as tungsten carbide. The liner also includes a separate separation section that is primarily fashioned of a material that may be less erosion-resistant but which is less brittle and more physically durable than that used to construct the head section. As a result of this composite construction, the liner is less likely to fail mechanically during installation or use. The head and separation sections are removably affixed to one another. The separation section of the hydrocyclone liner is provided with one or more structural supports to provide mechanical strength and resistance to bending. A liner is also described having a removable involute insert of highly erosion resistant material.

Owner:PETRECO INT

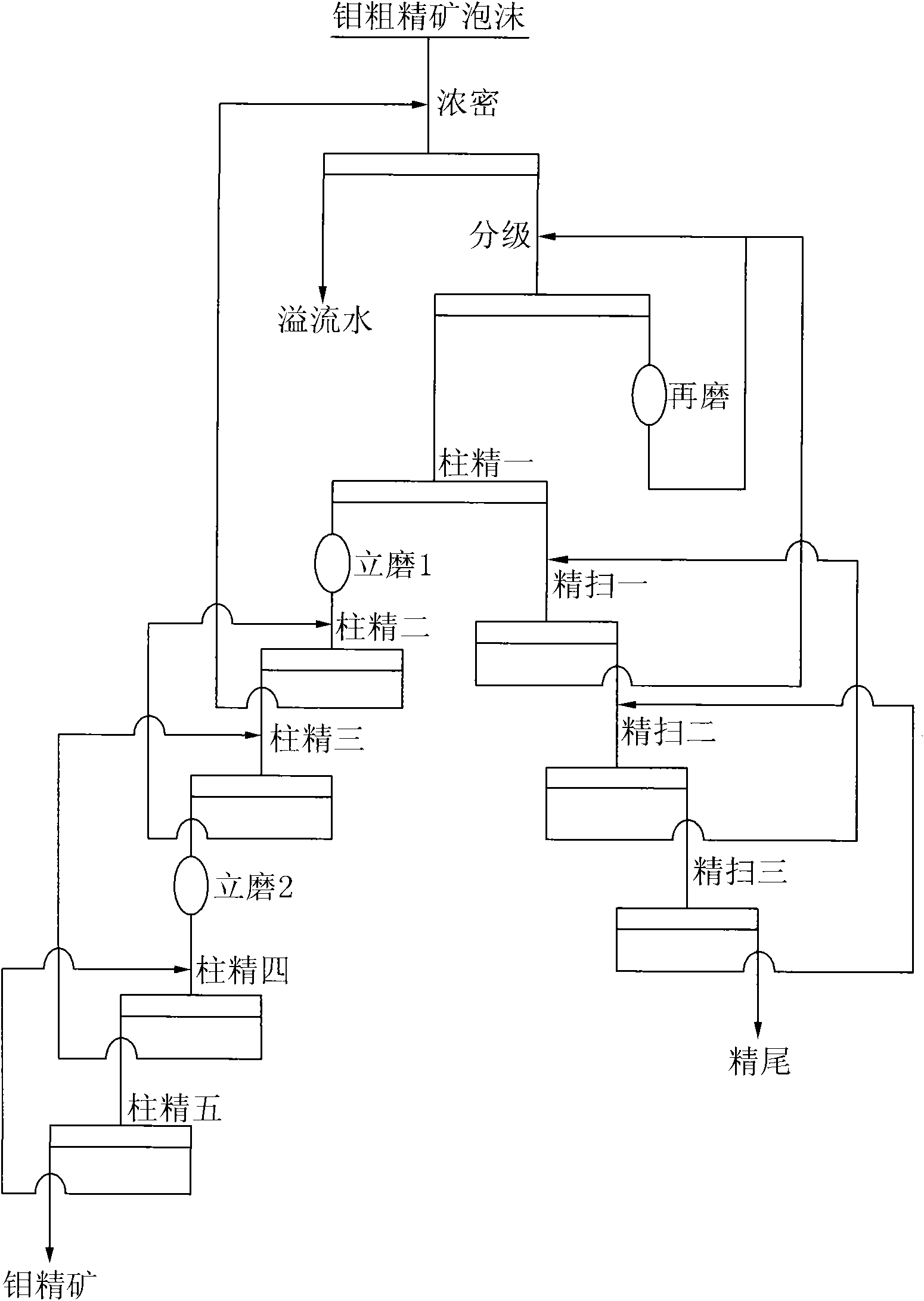

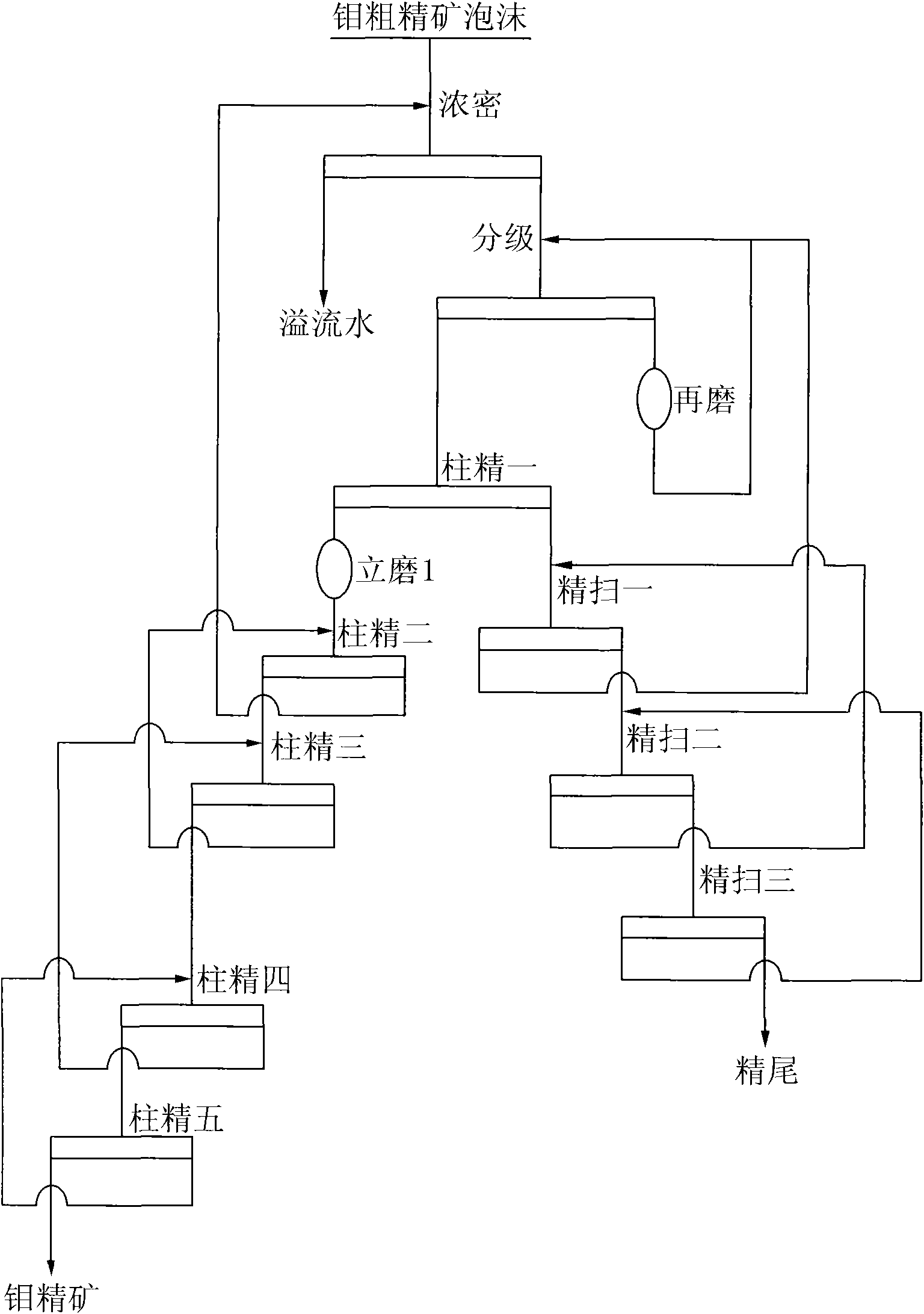

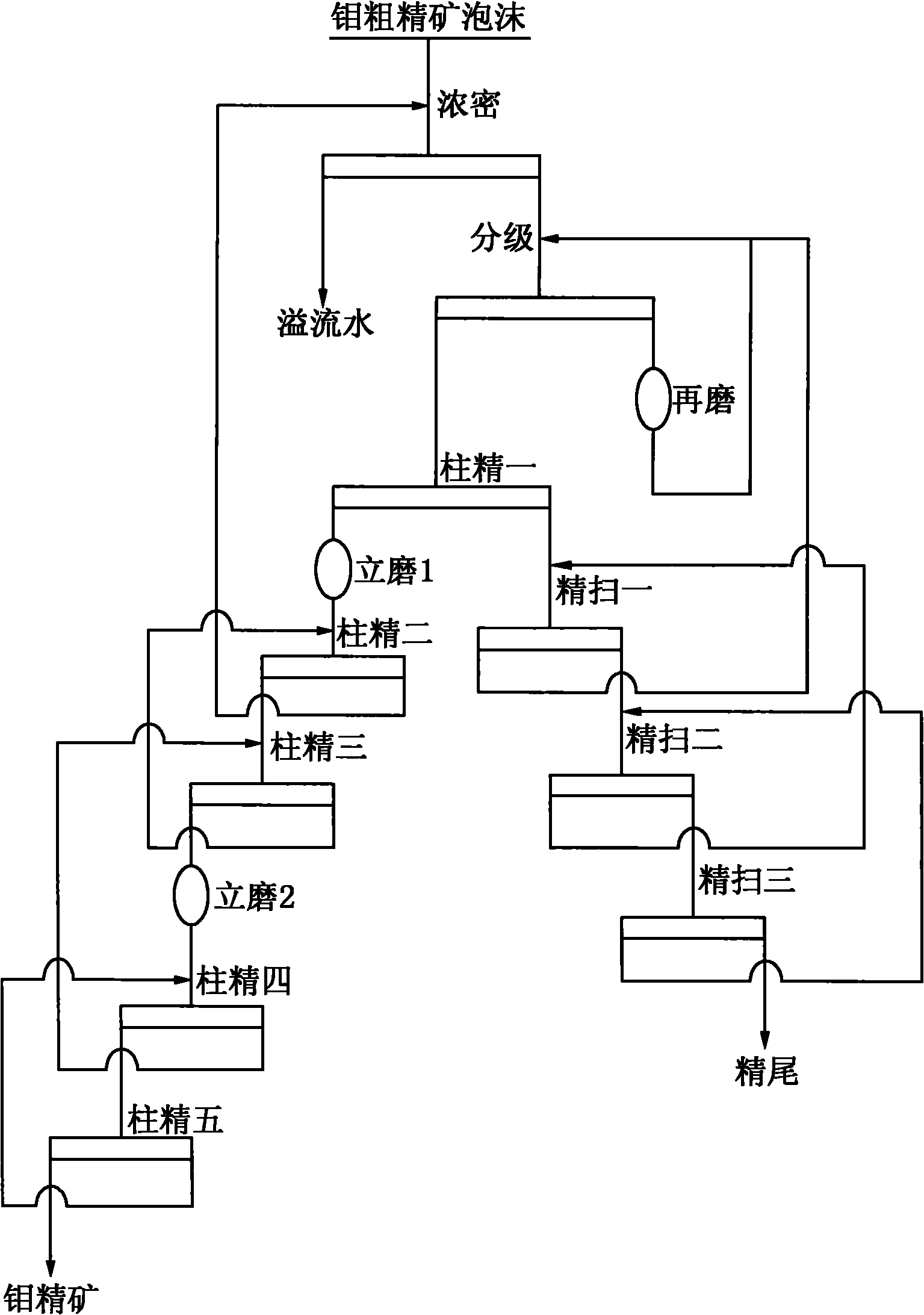

Production technology of high-grade molybdenum concentrate

ActiveCN101773871AReduce pollutionIncrease feed concentrationFlotationWet separationBall millReagent

The invention discloses a production technology of high-grade molybdenum concentrate, which comprises the following steps: rough molybdenum concentrate is obtained by roughing crude molybdenum ore, the rough molybdenum concentrate is concentrated and removed reagent through a thickener, underflow enters a hydraulic swirler to be graded previously, overflow after the grading enters a primary flotation column to be selected, the underflow after the grading enters a horizontal ball grinding mill to be reground, and after the regrinding, the ore discharge enters the hydraulic swirler to be regraded; selected concentrate from the primary flotation column is cleaned by a vertical ore mill to enter a secondary and a tertiary flotation columns to be selected, and the selected concentrate from thetertiary flotation column directly enters or enters a quartic or a quintic flotation columns to be selected after being cleaned by a second section of the vertical ore mill to obtain the high-grade molybdenum concentrate; the selected tailings from the primary flotation column is tertiary scavenged by a flotation machine, and the scavenged concentrate tailings from the tertiary scavenging enters the next procedure. The technology adopts the flotation columns and the flotation machine, so the flow is short, the agent system is simple, the adaptability of the crude ore is strong, and the molybdenum concentration ratio is high, the molybdenum concentrate has high grade, large yield and high recycling rate so as to provide excellent raw material to the following molybdenum chemical engineering and further processing.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com