Multiphase separation method and system for processing oily waste water

A technology for multi-phase separation and wastewater treatment, which is applied in water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of effective separation of difficult and small oil particles, and occupies a large area , long residence time and other issues, to achieve the effects of small footprint, reduced cost input, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

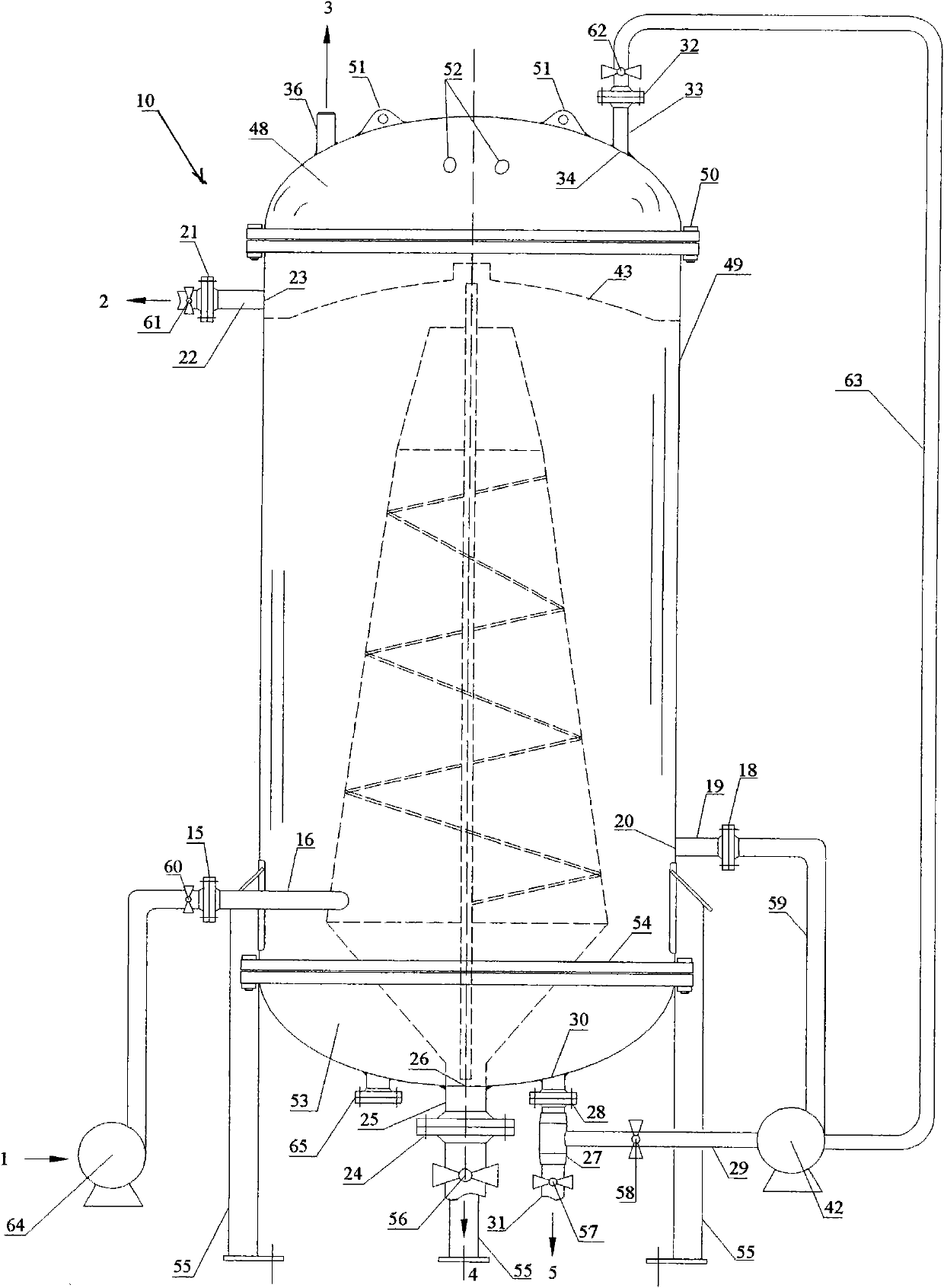

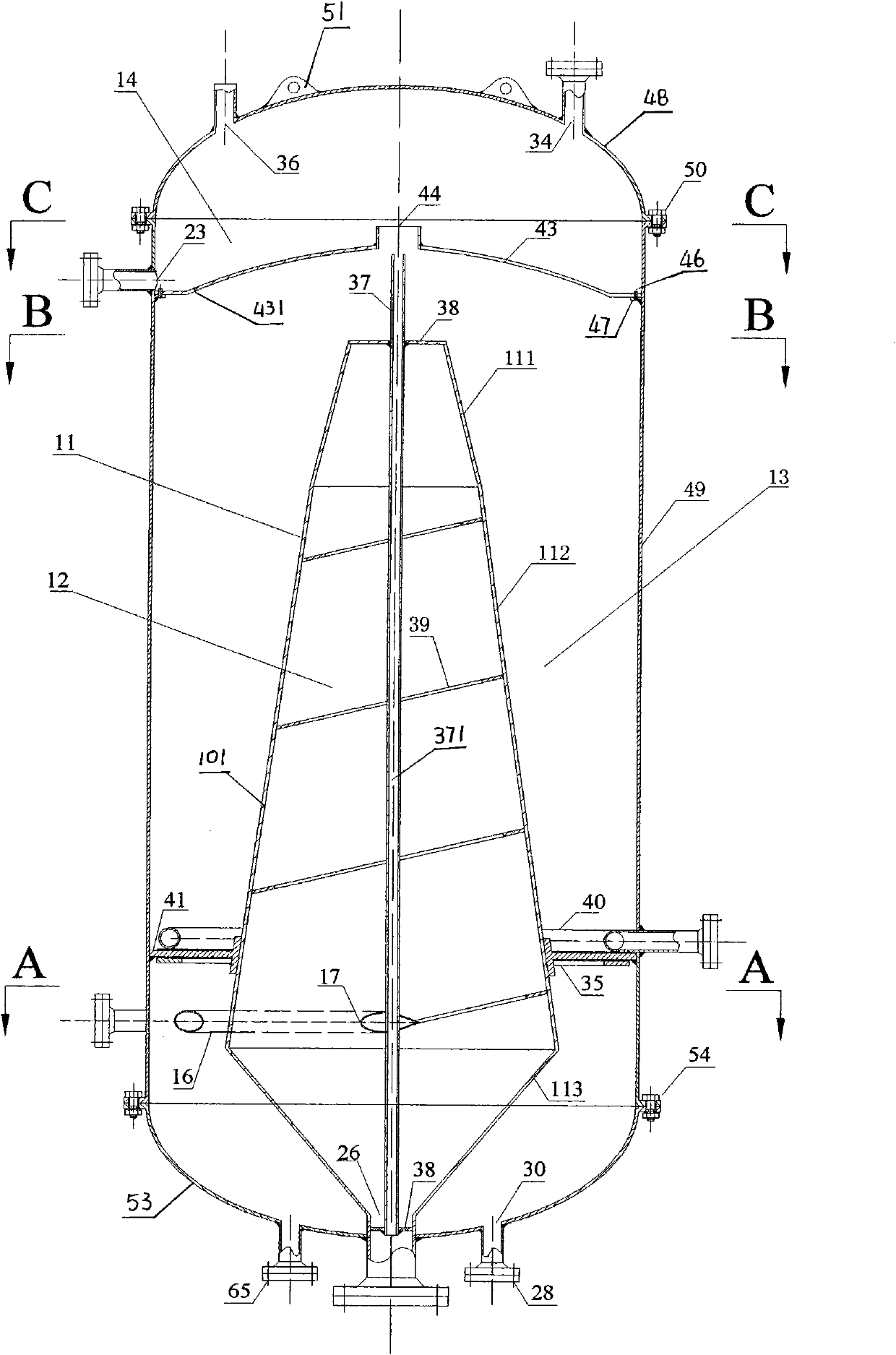

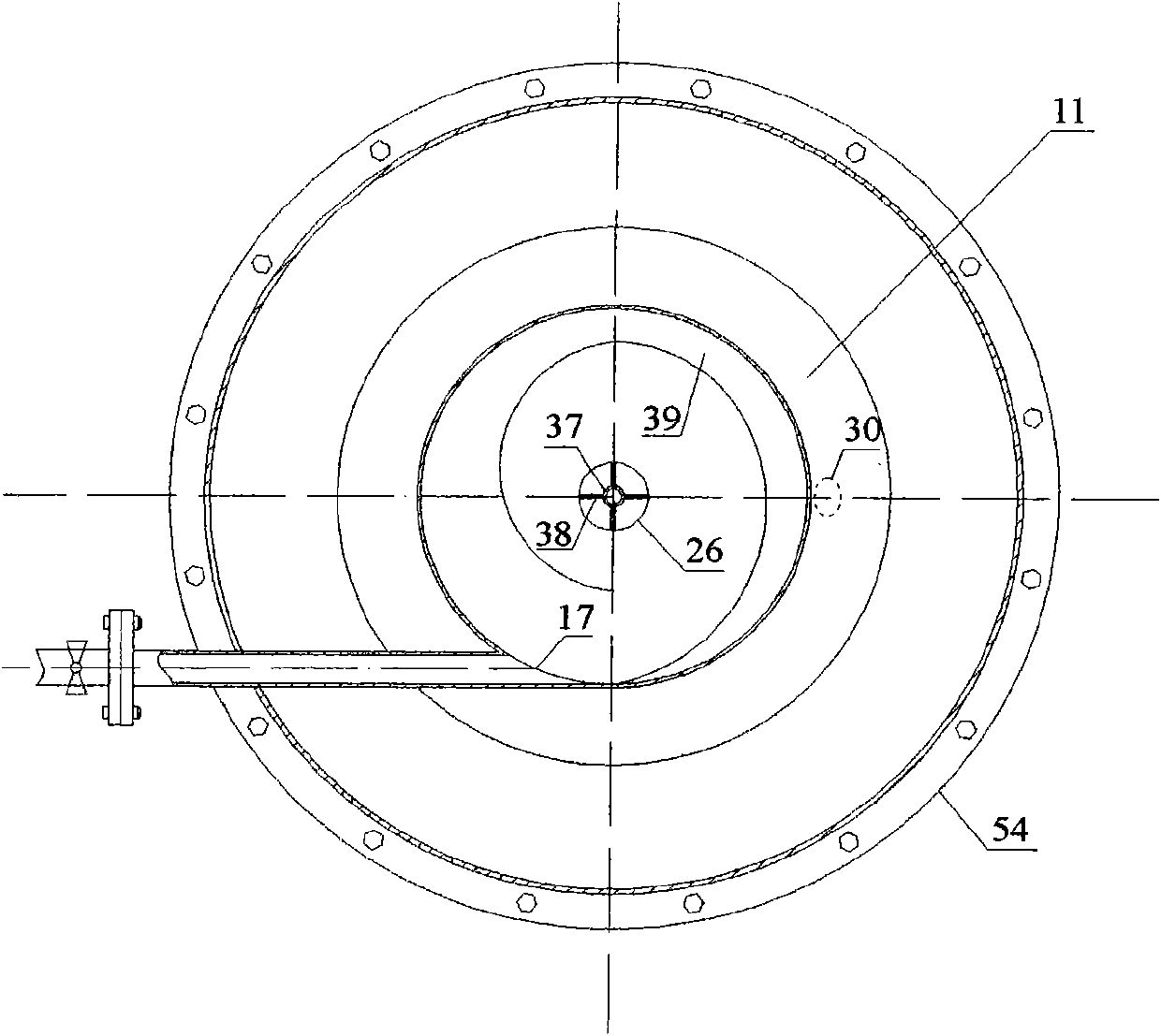

[0025] Depend on Figure 1 to Figure 6 Shown is a multiphase separation system for oily wastewater treatment, which is mainly composed of a swirling air flotation integrated separator 10, a multiphase flow pump 64 for gas-liquid mixing at the inlet of oily wastewater, and a multiphase flow pump 64 for mixing partly recirculated purified water and circulating gas. Phase flow pump 42 and necessary pipelines and valves, in which: cyclone air-flotation integrated separator 10 is fixed on the ground through three legs 55, an oval upper head 48 is set on the upper part, and a cylindrical shell 49 is set in the middle , the lower part is provided with an elliptical lower head 53, which is provided with an arc-shaped oil collection cover 43, a conical swirl tube 11, an anti-vortex air duct 37, an annular water distributor 40 and an annular baffle 35, and the arc-shaped oil collection cover 43 is located at the upper part of the separator and the annular water distributor 40 and the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com