Pressure test device for pipe fittings

A technology for pressure testing and pipe fittings, which is applied in the direction of pipe components, measuring devices, pipes/pipe joints/pipe fittings, etc., which can solve the problems of heavy welding workload, difficulty, and many processing procedures, and achieve compactness of the whole machine, cost savings, and The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

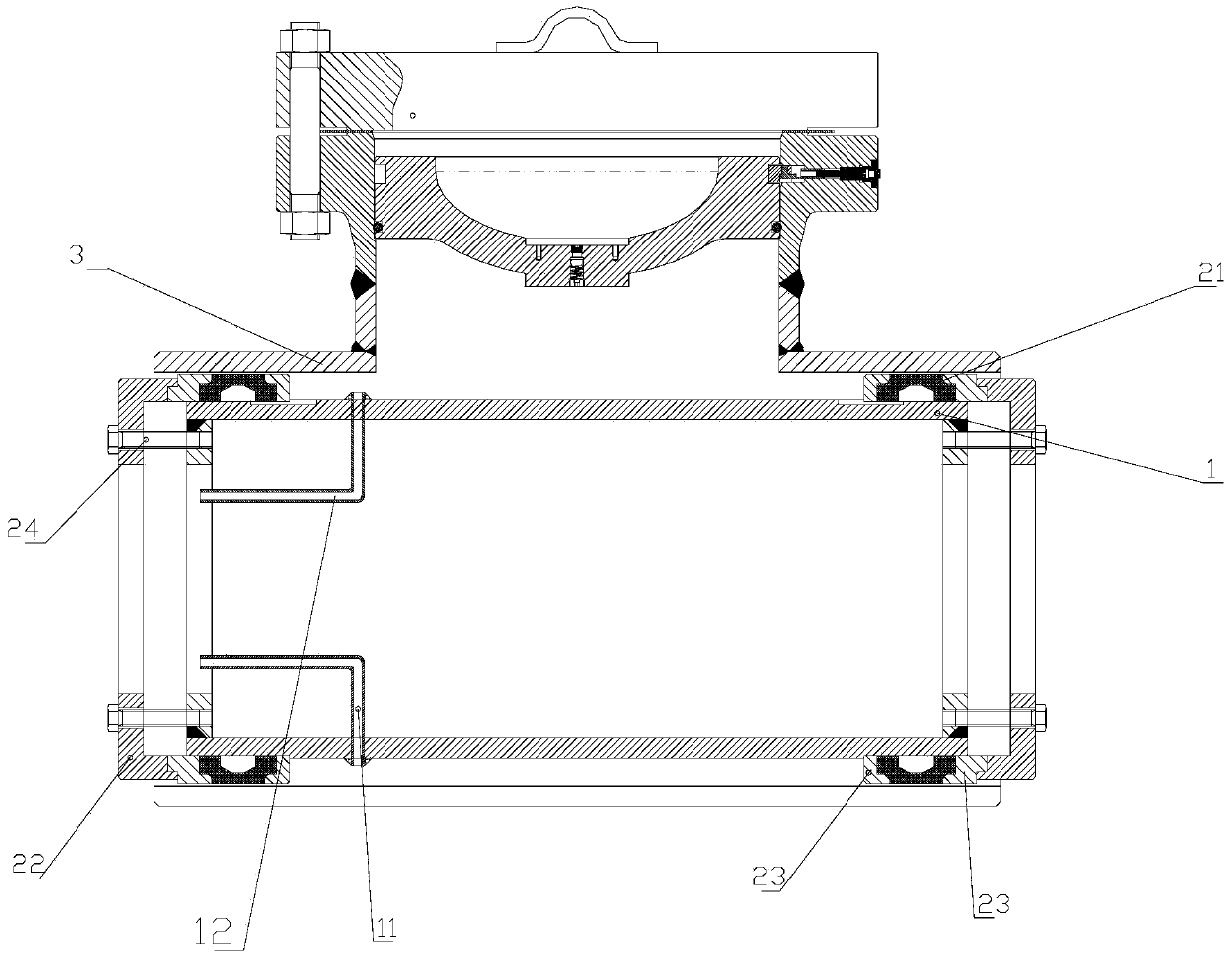

[0025] Embodiment 1 Pipe fitting pressure test device is used for tee pressure test

[0026] The pressure test steps are as follows:

[0027] a. The pressure test tube 1 with both ends open is installed in the straight pipe of the tee 3. If the tee 3 is a tee with holes, it is necessary to block the opening without the plugging head; then press the flange 23. The sealing ring 21 and the connection plate 22 are set on the outer walls of both ends of the pressure test tube 1 according to the preset method, the bolts 24 are installed, and the bolts 24 are rotated to make the flange pressure plate 23 compress the sealing ring 21, and the sealing ring 21 deforms radially. Thereby it fits tightly with the inner wall of the tee 3, so that the outer wall of the pressure test tube 1 and the inner wall of the tee 3 form a closed cavity. (like figure 1 shown) If pre-tightening is required, a pre-tightening device must be used to set the pre-tightening before rotating the bolt 24;

[0...

Embodiment 2

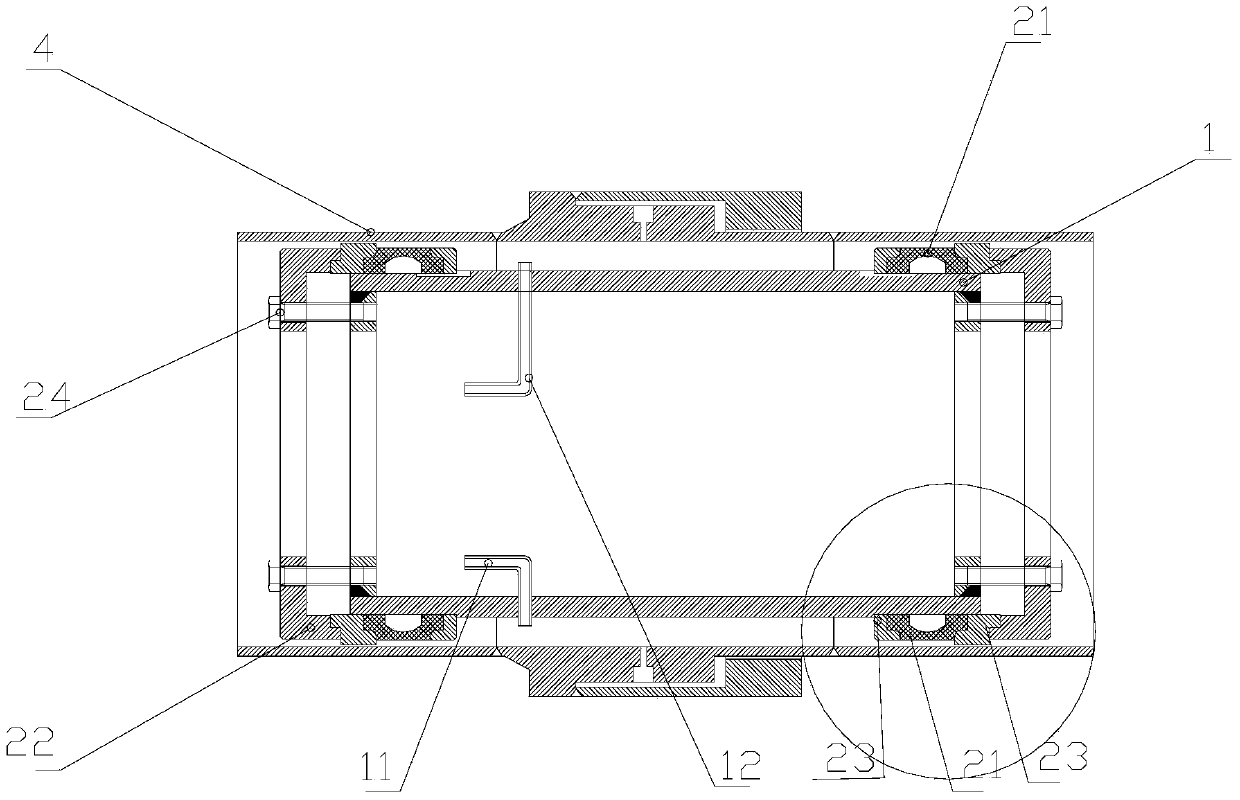

[0033] Example 2 The pipe fitting pressure test device is used for the pressure test of the insulating pup joint

[0034]The pressure test steps are as follows:

[0035] a. Install the pressure test tube 1 with both ends open in the insulating nipple 4; then put the flange pressure plate 23, sealing ring 21, and connection plate 22 on the outer walls of the two ends of the pressure test tube 1 according to the preset method, Install the bolt 24, rotate the bolt 24 to make the flange pressure plate 23 compress the sealing ring 21, and the sealing ring 21 deforms radially, so as to fit tightly with the inner wall of the insulating nipple 4, so that the outer wall of the pressure test tube 1 and the inner wall of the insulating nipple 4 form a A closed cavity. (like figure 2 and Figure 4 shown) If pre-tightening is required, a pre-tightening device must be used to set the pre-tightening before rotating the bolt 24;

[0036] b. Connect the water injection pipe joint leading ...

Embodiment 3

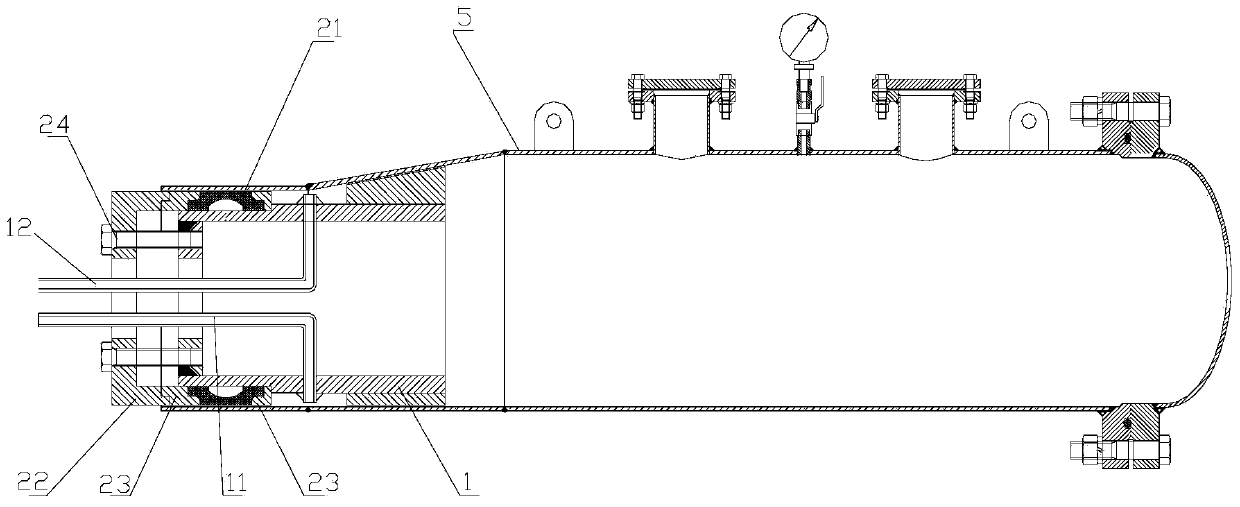

[0041] Embodiment 3 The pipe fitting pressure test device is used for the pressure test of the receiving and receiving spherical cylinder

[0042] The pressure test steps are as follows:

[0043] a. The pressure test tube 1 with one end open is installed in the receiving and receiving spherical cylinder 5, and the open end is close to the opening of the receiving and receiving spherical cylinder 5; Go out of the outlet of the receiving and receiving ball barrel 5; then put the flange pressure plate 23, the sealing ring 21, and the connection plate 22 on the outer walls of the two ends of the pressure test tube 1 according to the preset method, install the bolt 24, and rotate the bolt 24 to make the flange The pressure plate 23 compresses the sealing ring 21, and the sealing ring 21 radially deforms, thereby closely fitting with the inner wall of the receiving and receiving ball barrel 5, so that the outer wall of the pressure test tube 1 and the inner wall of the receiving and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com